Patents

Literature

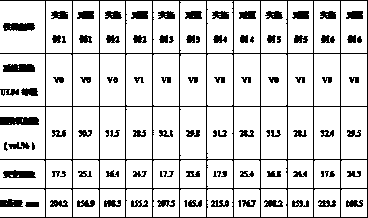

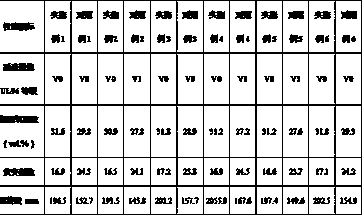

63results about How to "Little loss of mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite flame retardant containing microcapsule-coated intumescent flame retardant and preparation method

InactiveCN103724666AHigh flame retardant efficiencyOvercome moisture absorptionPolymer scienceHindered amine light stabilizers

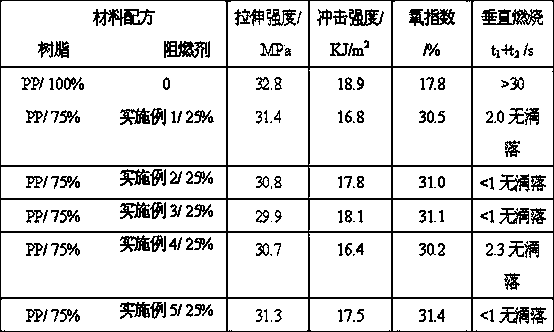

The invention belongs to the field of flame retardant materials, and particularly relates to a composite flame retardant containing a microcapsule-coated intumescent flame retardant and a preparation method. The composite flame retardant containing the microcapsule-coated intumescent flame retardant consists of the following components in percentage by mass: 60-94 percent of microcapsule intumescent flame retardant, 5-25 percent of flame-retardant synergist, 0.9-10 percent of smoke suppressant and 0.1-5 percent of hindered amine light stabilizer. The preparation method comprises the following steps: preparing the microcapsule-coated intumescent flame retardant; placing the microcapsule-coated intumescent flame retardant, the flame-retardant synergist, the smoke suppressant and the hindered amine light stabilizer into a high-speed mixer for mixing uniformly, and discharging to obtain the composite flame retardant containing the microcapsule-coated intumescent flame retardant. Multiple components in the composite flame retardant can play roles in retarding flame in a synergetic way, so that the flame retardance of a high polymer material is improved remarkably, the production of toxic and harmful smog in a burning process can be suppressed, and the flame retarding efficiency is increased greatly.

Owner:LIAONING TECHNICAL UNIVERSITY

Efficient halogen-free intumescent flame-retardant polypropylene material

The invention discloses an efficient halogen-free intumescent flame-retardant polypropylene material. At present, the flame-retardant modification of polypropylene is mainly realized by introducing an additive flame retardant, and the flame retardant used for polypropylene mainly comprises a halogenated flame retardant and a halogen-free flame retardant. The efficient halogen-free intumescent flame-retardant polypropylene material is a blend comprising the following components in percentage by mass: 72-85% of PP (polypropylene) resin, 12-23% of an intumescent flame retardant, 0.5-3% of a carbon-forming catalyst, 0.5-1% of an antioxidant and 0.5-2% of a coupling agent. The flame retardant efficiency of the blend is improved, the dosage of an intumescent flame retardant system is reduced and the flame retardant performance is improved by using the carbon-forming catalyst to accelerate an esterification reaction of a carbon source and between the carbon source and an acid source; and on the premise of obtaining the same flame retardant performance, the dosage of the flame retardant is reduced, and the lose of mechanical properties of the material is reduced.

Owner:慈溪金岛塑化有限公司

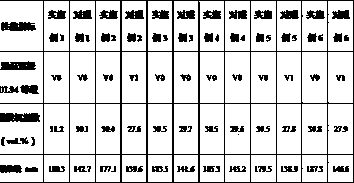

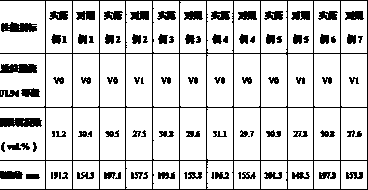

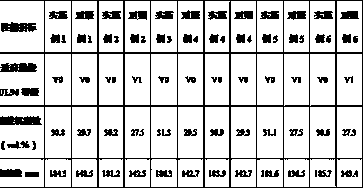

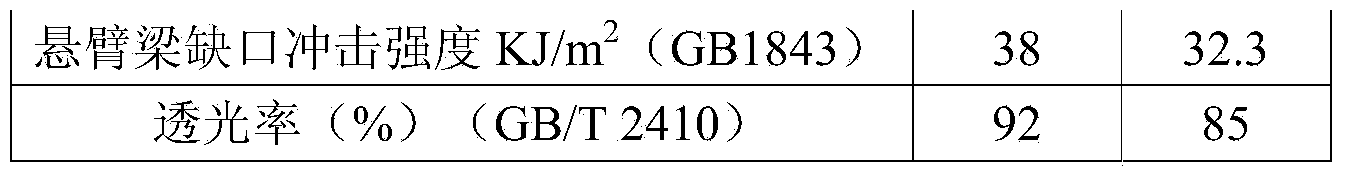

Flame retardant polypropylene material

InactiveCN102040775ALow shrinkageImprove toughnessCell component detailsHeat resistanceFire retardant

The invention discloses a flame retardant polypropylene material, relating to the technical field of high molecule plastics. The flame retardant polypropylene material comprises the following compositions in percentage by weight: 25-50 percent of high fluidity homo polypropylene, 25-50 percent of high fluidity propylene copolymer, 10-33 percent of flame retardant, 5-30 percent of inorganic strengthening agent, 1-10 percent of barrier additive, 0.1-3 percent of heat resistance strengthening agent, 0.1-4 percent of antioxygen and nucleating agent, 0.1-3 percent of compound pigment and 1-5 percent of internal and external lubricant. The flame retardant polypropylene material reaches V0 grade flame retardation property without lowering the mechanical performance of the material and has good heat resistance and good anti-seep performance.

Owner:LUOYANG CITY HEZHIYANG MACROMOLECULE MATERIAL

Hydrophilic modification method of polymer separation membrane

ActiveCN106492643ANot easy to loseGood hydrophilic stabilitySemi-permeable membranesHydrophilizationHydrophilic polymers

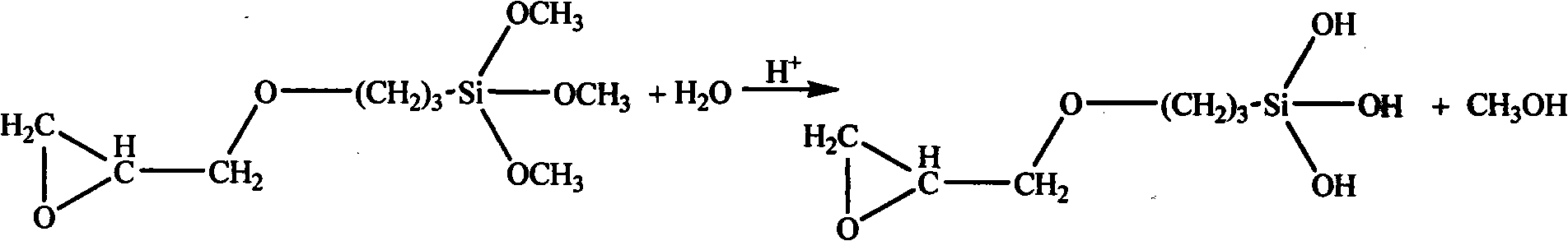

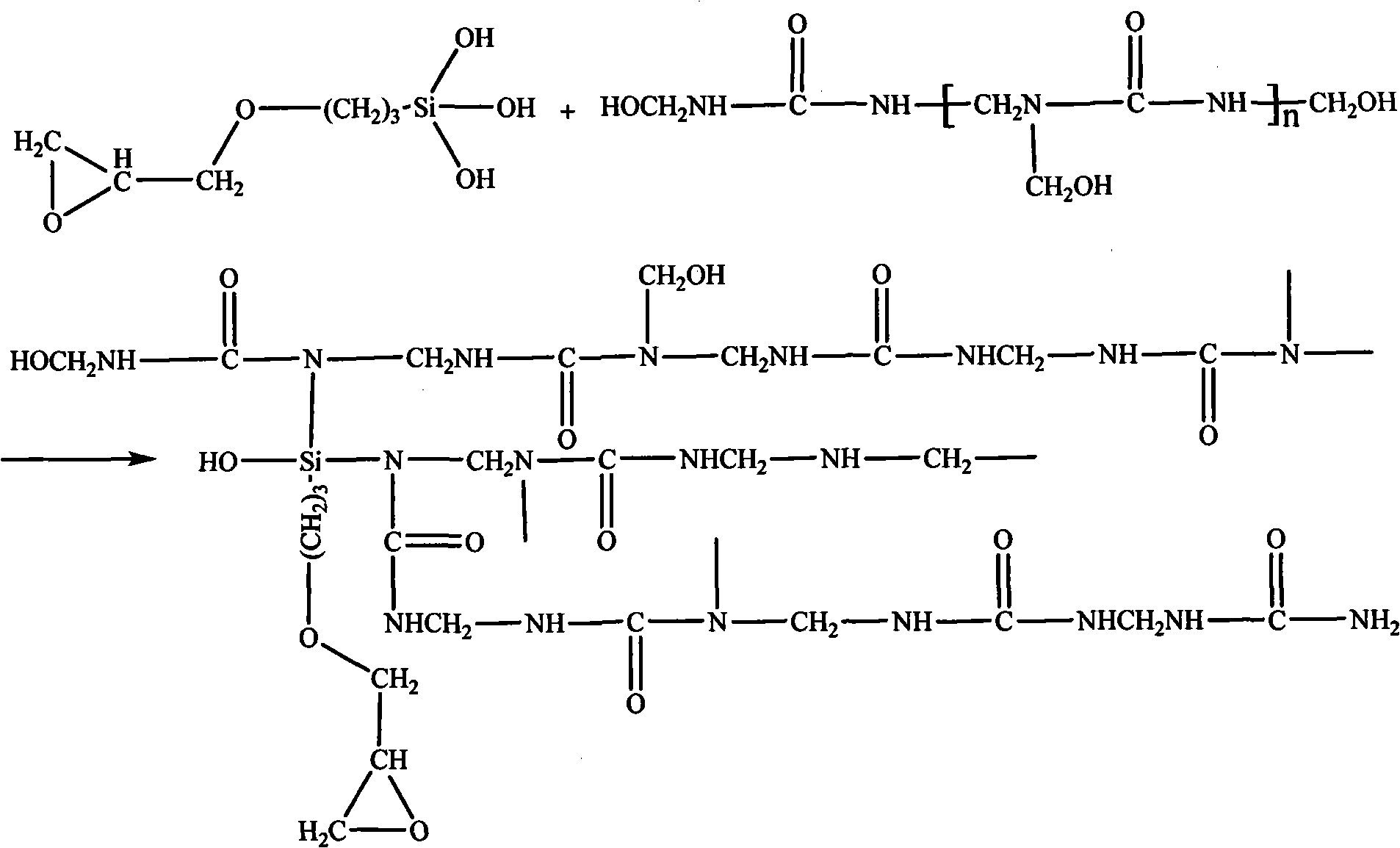

The invention discloses a hydrophilic modification method of a polymer separation membrane. The method includes the following steps: (1) preparing hydrophilic agent solution containing silane coupling agent; (2) soaking treatment of the to-be-modified membrane, adding diluent-diluted soak solution into the hydrophilic agent solution containing silane coupling agent, and soaking the to-be-modified polymer separation membrane into the soak solution for soaking treatment; (3) coupled reaction, taking out the soaked polymer separation membrane from the soak solution, and soaking the soaked polymer separation membrane into aqueous solution for further coupling reaction to obtain the hydrophilic polymer separation membrane with the surface coated with a hydrophilic polymer coupling layer. The hydrophilic polymer is firmly fixed to the surface of the membrane by the aid of coupling effect of the coupling agent without drain easily, hydrophilic stability is good, mechanical performance loss of the membrane is small as the hydrophilic polymer is fixed to the surface of the membrane, and mechanical property of the polymer separation membrane in use is guaranteed.

Owner:NINGBO SHUIYI FILM TECH DEV CO LTD

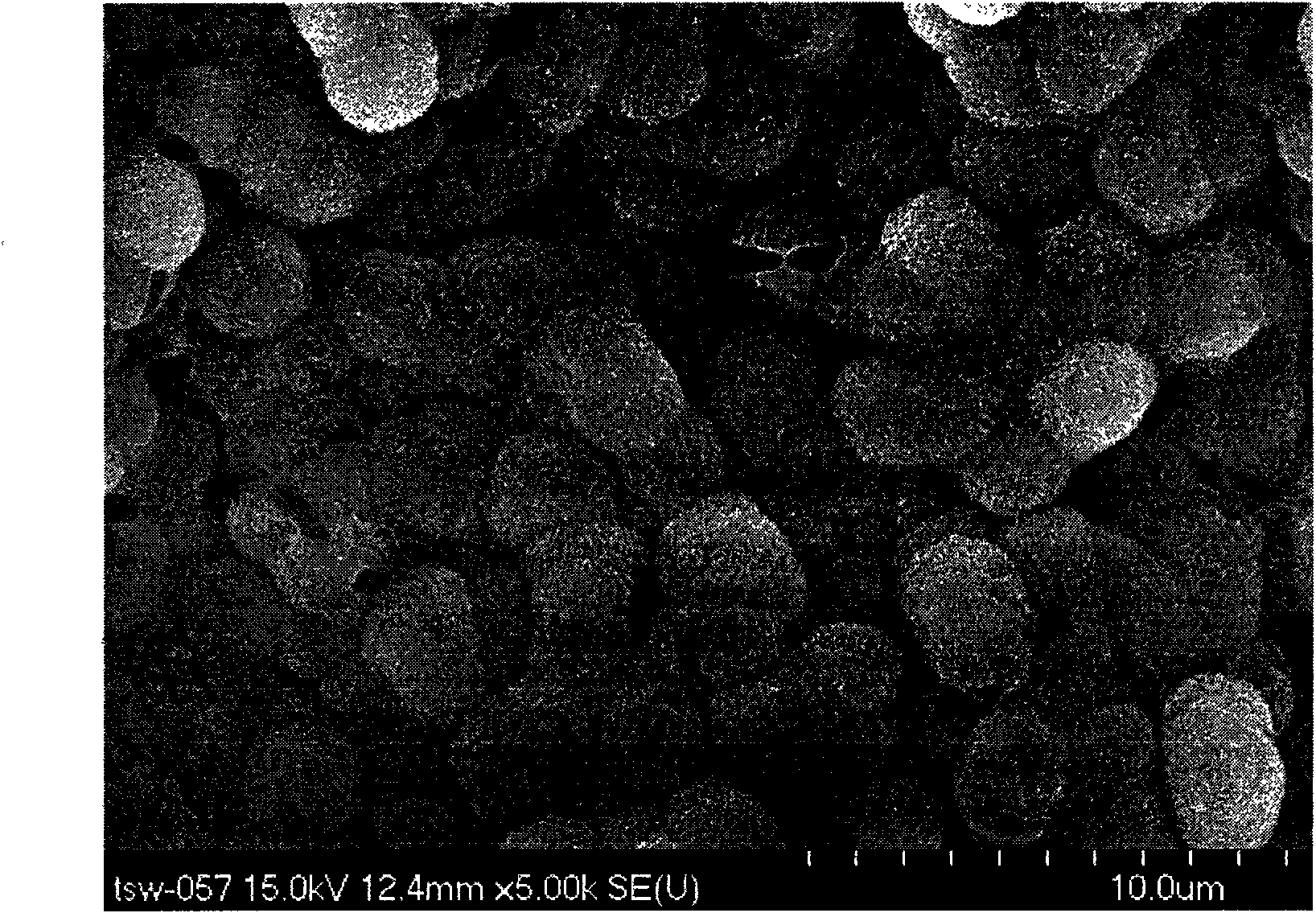

Polymer group composite material self-repairing nano-scale capsule and preparation method thereof

InactiveCN101269311ALittle loss of mechanical propertiesExtended service lifeMicroballoon preparationMicrocapsule preparationMicroemulsionPrepolymer

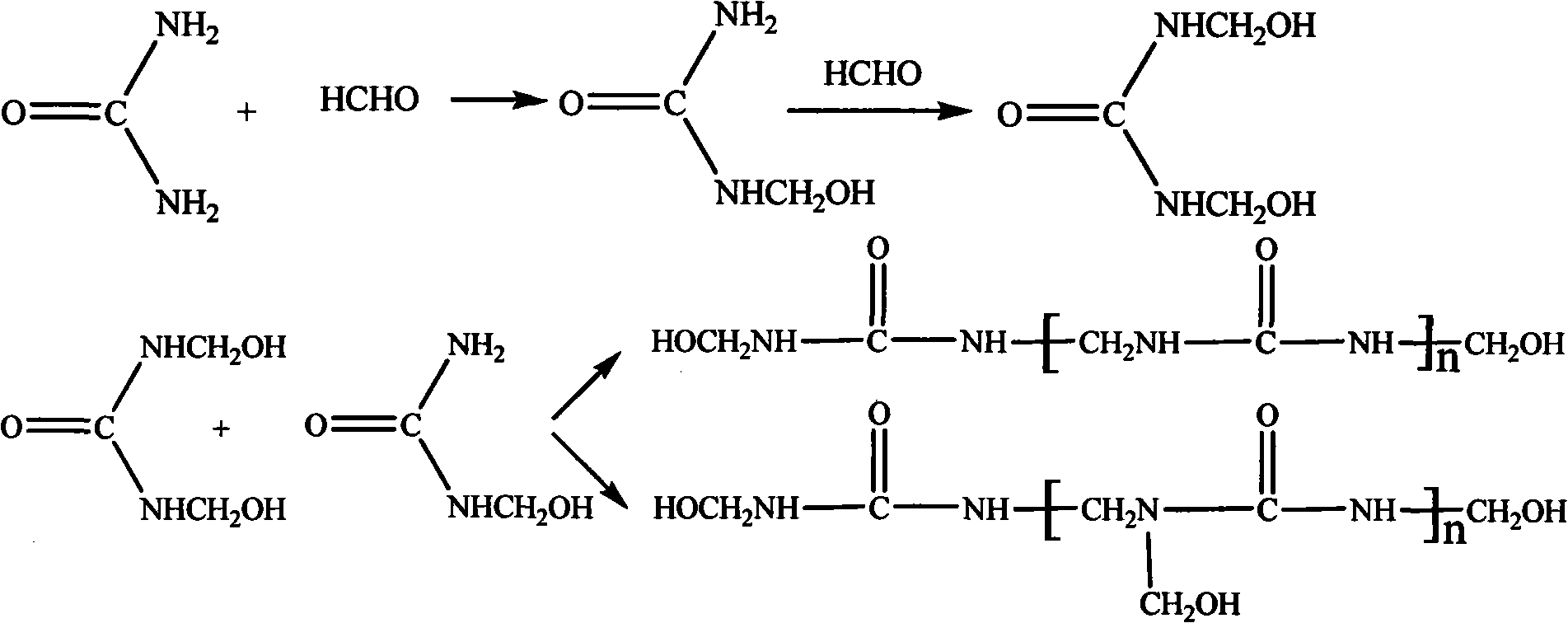

The invention discloses a polymer based composite material self-repairing nanometer class capsule and the preparation method thereof, relating to a composite material self-repairing capsule and the preparation method. The invention solves the problems that the prior self-repairing capsule is large in size, cannot bring the self-repairing function into play at the early stage of a crack occurrence. The nanometer class capsule is made by carbamide, formaldehyde solution, dicyclopentadiene, sodium dodecyl benzene sulfonate, resorcinol, normal butanol, octane, KH-560 and deionized water. The preparation method is that: 1. preparing prepolymer of Lauxite; 2. preparing microemulsion; 3. performing polymerization reaction; 4. cleaning, filtering and drying. The grain size of the self-repairing nanometer class capsule is 100 to 800 nm and the capsule can self-repair the nanometer class microcracks which occur on polymer based composite material, preventing the extension of the cracks, reducing the damage of mechanical performance of the polymer based composite material and prolonging the service life. The polymer based composite material self-repairing nanometer class capsule has the advantages of easy preparation, convenient operation, low requirement for the equipment performance and easy promotion.

Owner:HARBIN INST OF TECH

Special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and preparation method of halogen-free flame-retardant synergistic masterbatch

ActiveCN110591341AEffective protectionImprove thermal protection performanceAcrylonitrilePolytetrafluoroethylene

The invention relates to the technical field of modification and processing of plastics, in particular to special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and a preparation method of the halogen-free flame-retardant synergistic masterbatch. Multiple-compounded coated aluminum diethylphosphinate is adopted as a phosphorous-based flame retardant of the functional masterbatch, and the functional masterbatch comprises the compositions: in percent by mass, 55.0-65.0% of multiple-compounded coated aluminum diethylphosphinate, 20.0-30.0% of anhydrous zinc borate, 8.0-10.0% of nylon 6 resin, 3.0-5.0% of star-shaped nylon, 0.5-1.0% of styrene-acrylonitrile copolymer-coated polytetrafluoroethylene, 0.5-1.0% of a dispersant and 0.3-0.5% of a lubricant. Whenthe prepared functional masterbatch is compared with traditional flame-retardant functional masterbatch, the heat resistance and thermal stability of aluminum diethylphosphinate are improved significantly, aluminum diethylphosphinate is adaptive to a high processing temperature of nylon resin, so that the flame retardant effect of aluminum diethylphophinate on nylon resin is improved more effectively.

Owner:江苏万纳普新材料科技有限公司

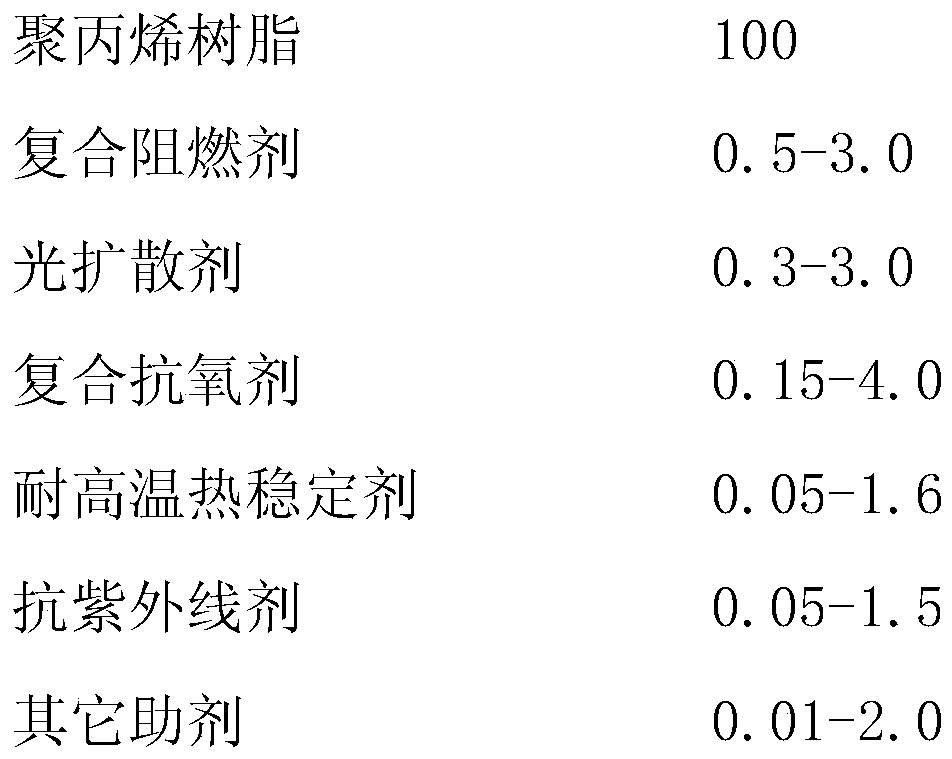

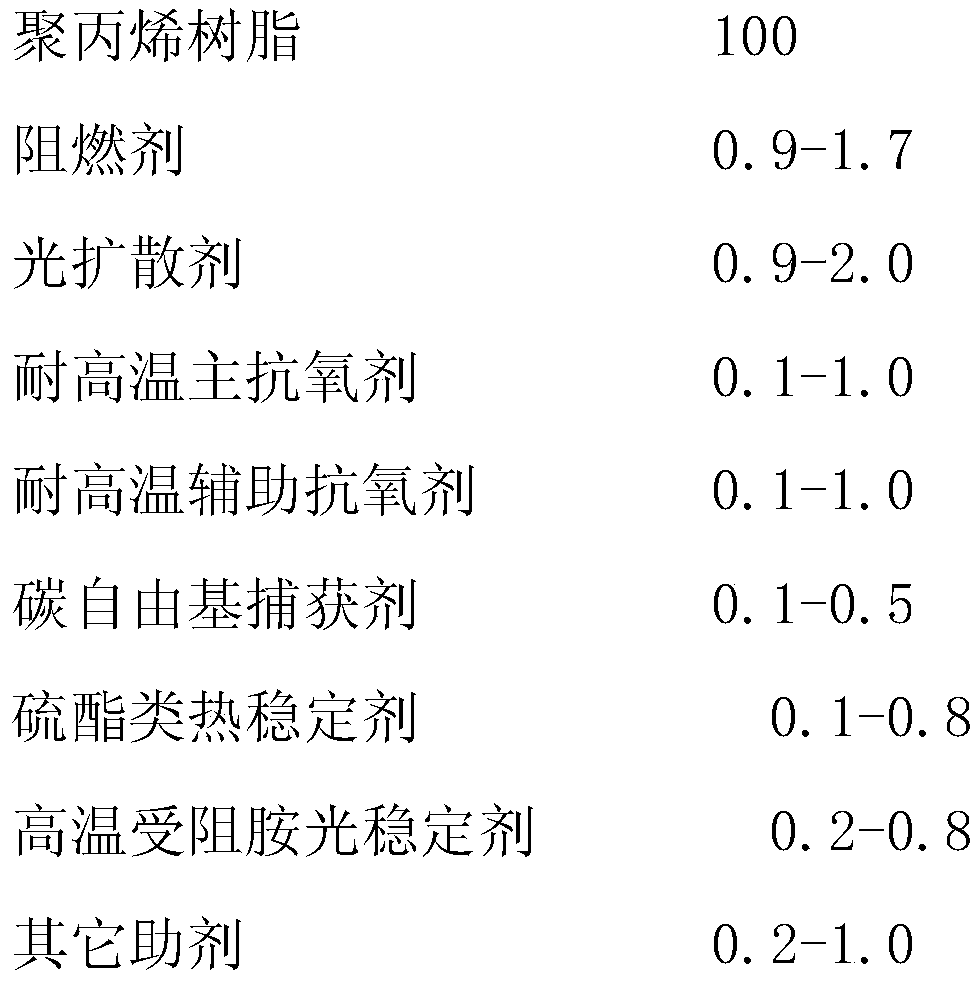

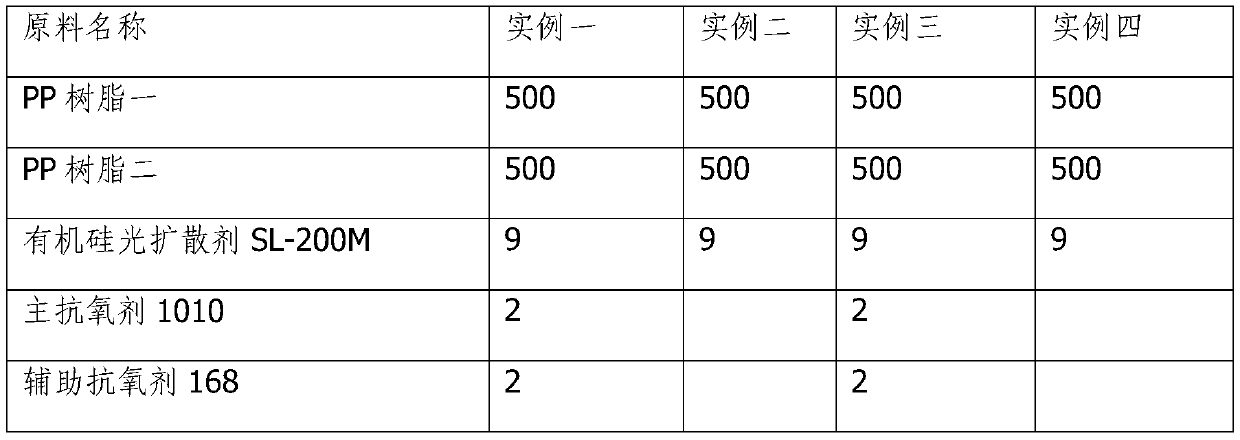

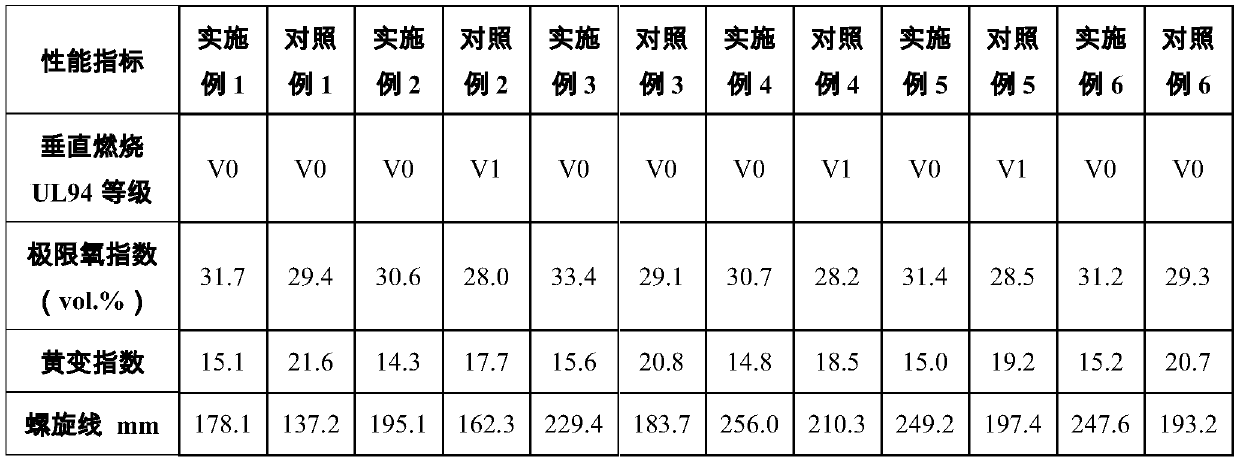

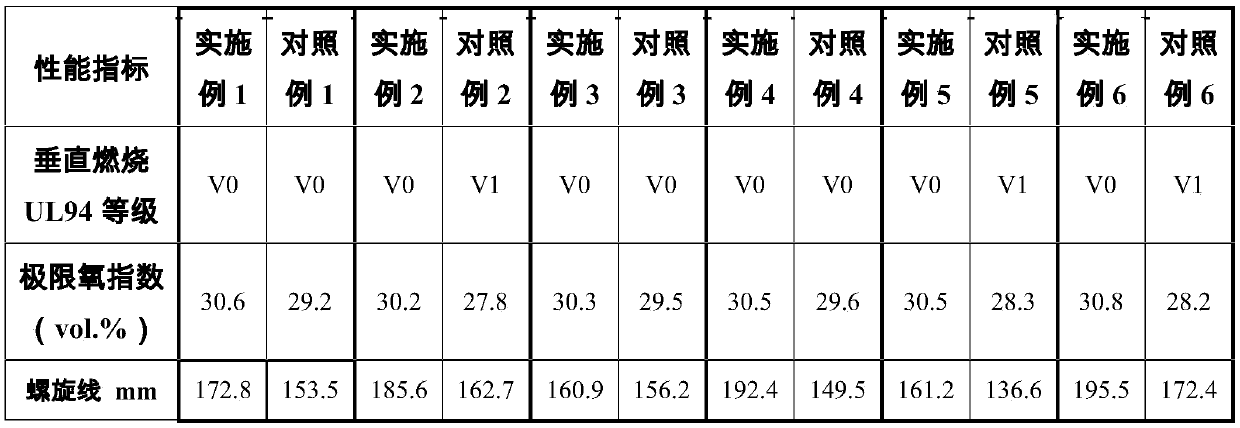

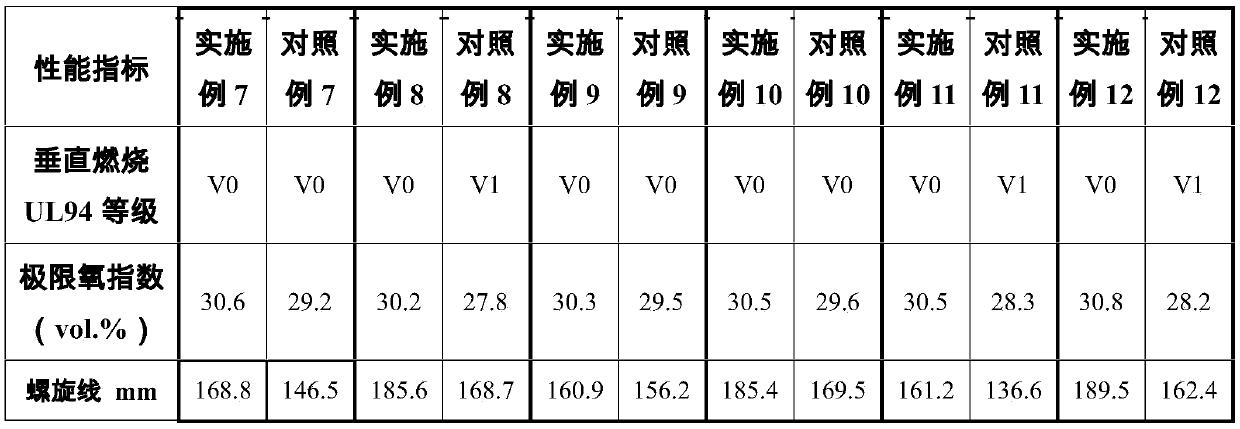

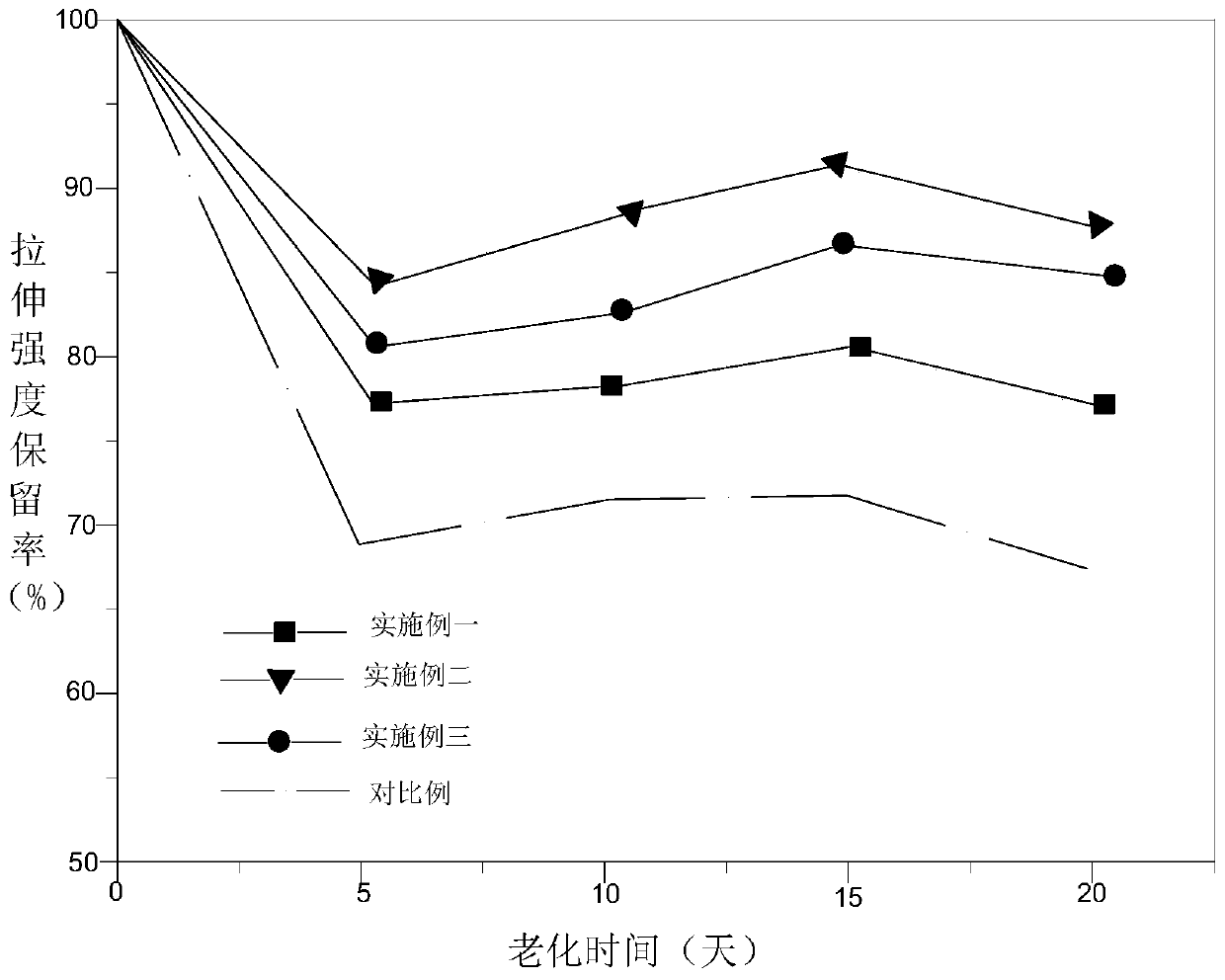

Flame-retardant light-diffusing PP material with thermal-oxidative aging resistant function and preparation method thereof

The invention discloses a flame-retardant light-diffusing PP material with the thermal-oxidative aging resistant function and a preparation method thereof. The PP material comprises a polypropylene resin, a composite flame retardant, a light diffusing agent, a composite antioxidant, a high temperature resistant heat stabilizer, an anti-ultraviolet agent, and other auxiliary agents. The prepared flame-retardant light-diffusing PP material has the characteristics of high luminous flux, good flame retardancy, no precipitation of the flame retardant during the use, long service life, and the like.

Owner:NANTONG DONGFANG PLASTIC CO LTD +1

Degumming method applicable to green fluorescent protein-containing bave

ActiveCN104389032AStrong fluorescent propertiesLittle loss of mechanical propertiesDe-gumming silkAlkaline proteaseFluorescence

The invention discloses a degumming method applicable to green fluorescent protein-containing bave. The degumming method comprises the following steps: drying the bave to be constant-weight, soaking the bave in a pretreating solution in a bath ratio of 1: 50, degumming for 30-120 minutes under the conditions that the concentration of alkaline protease is 0.5-3g / L and the temperature is 40-60 DEG C, washing by water, and drying to obtain the degummed bave, wherein the pretreating solution is a solution with pH of 10 and containing 1g / L sodium carbonate and 0.5g / L penetrant JFC. The degumming method is suitable for degumming the green fluorescent protein-containing bave; by the degumming method, the degumming rate is high and the fluorescent characteristic of the bave can be retained to the maximum extent; after the bave is degummed through the degumming method, the bave has relatively small mechanical performance loss, soft hand feel and good mercerization; through the degumming method, a requirement on degumming of transgenic green bave can be met.

Owner:SOUTHWEST UNIVERSITY

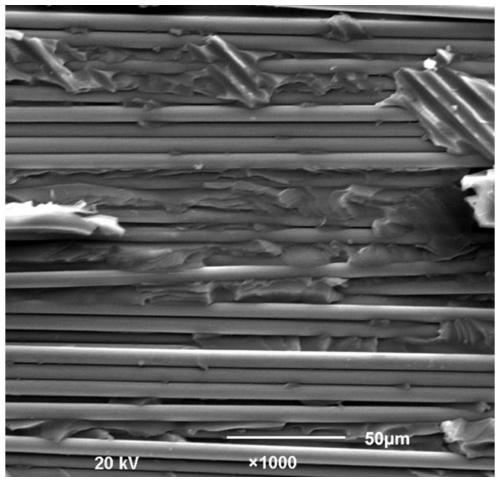

Fiber extending method for carbon fibers through supersonic wave

InactiveCN103343444AEnhanced fiber spreading effectImprove mechanical propertiesPhysical treatmentYarnChemical solution

The invention relates to a fiber extending method for carbon fibers through supersonic wave, belonging to a field of weaving processing and weaving machinery. A technical scheme comprises guiding the carbon fiber bundles into a container filled with a supersonic generator and a chemical solution through yarn guide rollers, and the carbon fiber bundles are subjected to drawing effects of two or more tangent yarn guide rollers. By using the technical scheme provided by the invention, the carbon fiber bundles can be obviously extended to be relatively wide and relatively thin, meanwhile, a strength loss of the carbon fibers is small and quality is reliable.

Owner:JIANGNAN UNIV

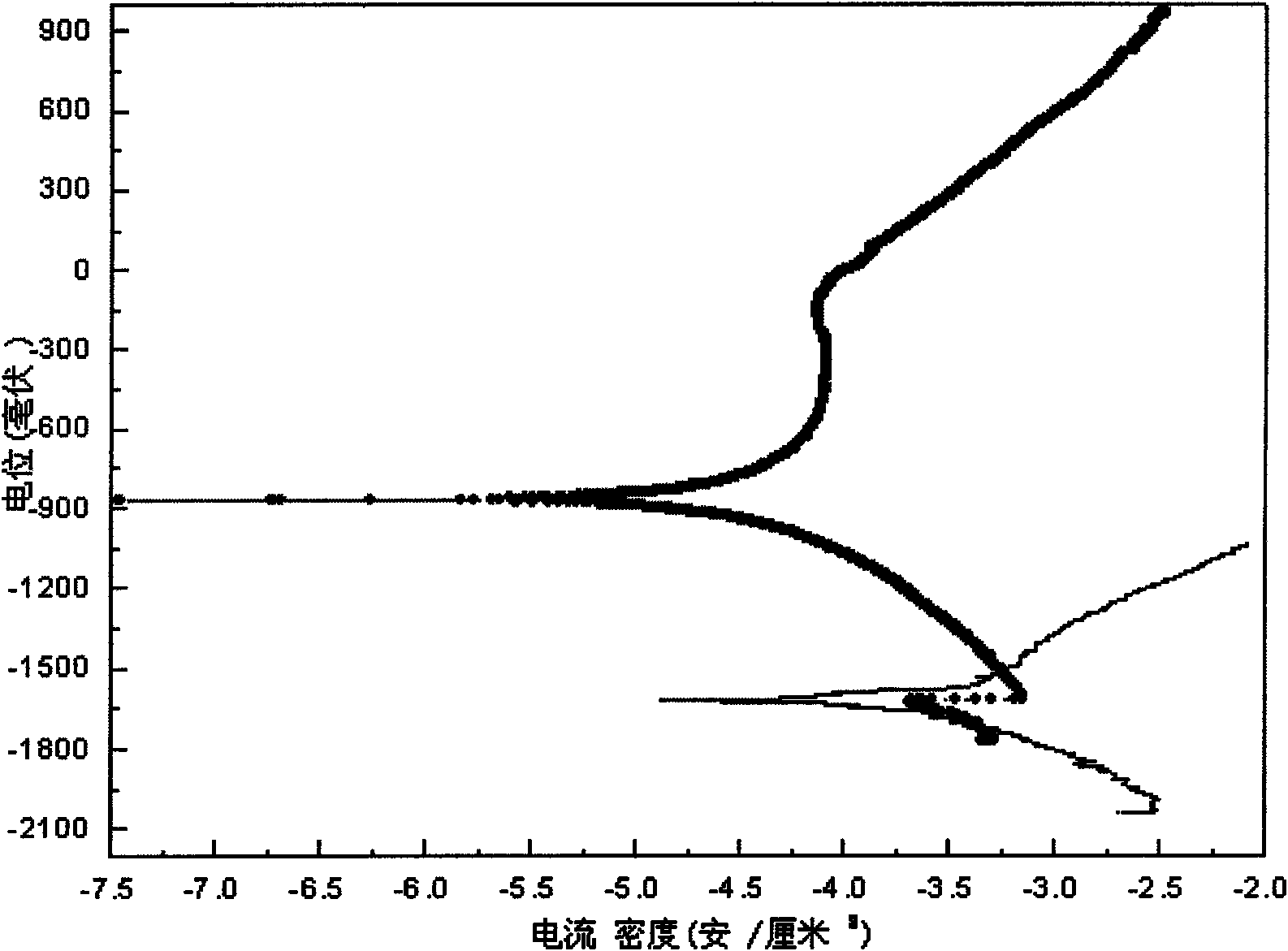

Treatment method of magnesium or magnesium alloy surface

InactiveCN101565825AImprove corrosion resistanceReduce corrosionMetallic material coating processesPhosphateApatite

A treatment method of magnesium or magnesium alloy surface relates to the treatment method of metal material surface and solves the problems of the existing magnesium or magnesium alloy in application, such as severe mechanical property loss, excessive degradation speed and local pH value increase caused by the generation of large numbers of hydrogen bubbles accompanied with the degradation process. The method comprises the steps of: firstly, washing and drying parent metal; secondly, using NaOH solution for treating the parent metal after washing; and thirdly, forming a dicalcium phosphate dehydrate layer on the surface of the parent metal. Adopting the NaOH solution for treatment, the method can adjust the magnesium or magnesium alloy surface state and transplants parent material for forming hydroxylapatite into a human body, the mechanical property loss is reduced, the degradation speed is slowed, and the pH value is not changed basically; and the method has simple technique and can form uniform hydroxylapatite on the surface of the parent material, without the falling-off phenomenon.

Owner:HARBIN INST OF TECH

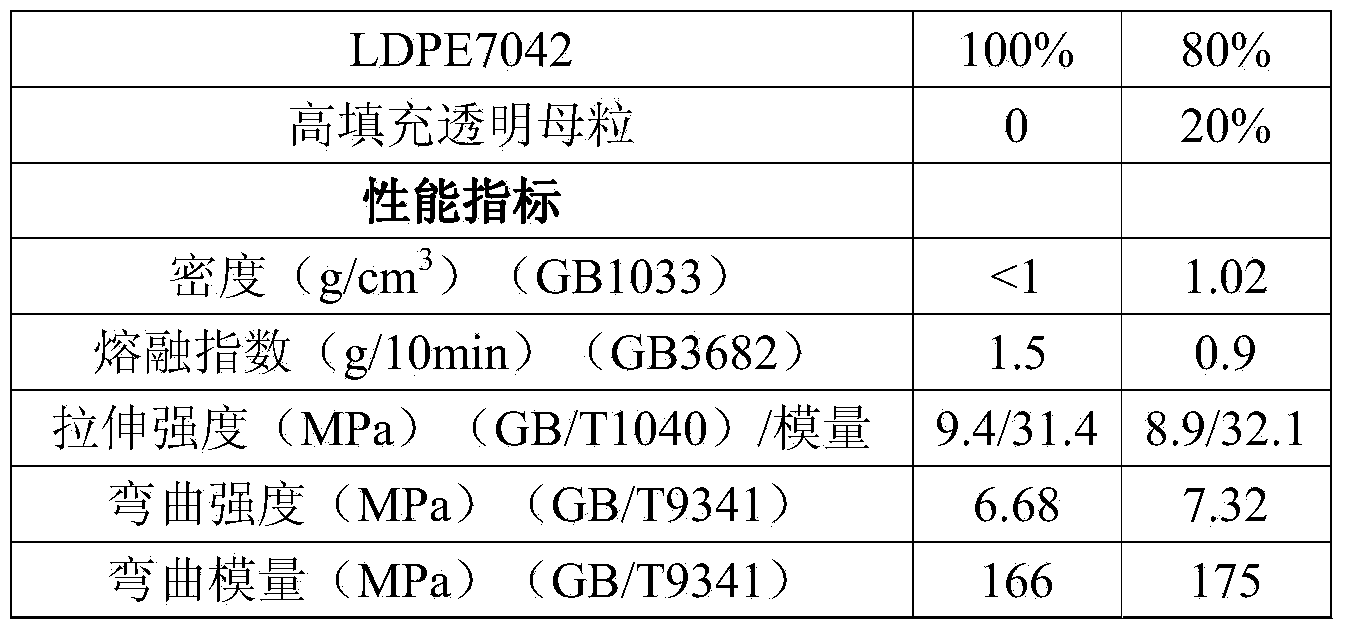

High-transparency filling material as well as preparation method and application of high-transparency filling material

InactiveCN104292641AHigh transparencyMeet the mechanical performance requirementsPolyolefinFilling materials

The invention discloses a high-transparency filling material prepared from the following raw materials in parts by weight: 100 parts of transparent polyolefin resin, 60-600 parts of sodium sulfate, 0-200 parts of starch and 1-50 parts of surface treating agent. The high-transparency filling material is suitable for high-transparency filling master batches of transparent or semitransparent packing films or packing bags, and by adopting the high-transparency filling material, the problems that the currently used filling materials are poor in transparency and have great influence on the transparency of the packing films are solved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Special nylon resin modification flame-retardant synergetic functional master batch and preparation method thereof

InactiveCN110591243AImprove thermal stabilityImprove thermal protection performanceAcrylonitrilePolystyrene

The invention relates to the technical field of plastic modification processing and in particular discloses a special nylon resin modification flame-retardant synergetic functional master batch and apreparation method thereof. The functional master batch adopts multiple composite coated brominated polystyrene as main body flame retardant, and comprises the following components in percentage by mass: 55.0-70.0wt.% of multiple composite coated brominated polystyrene, 15.0-30.0wt.% of anhydrous zinc borate, 8.0-10.0wt.% of nylon 6 resin, 2.0-3.0wt.% of starlike nylon, 0.5-1.0wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0wt.% of a dispersant and 0.3-0.5wt.% of a lubricant. Compared with a conventional plastic flame-retardant functional master batch, the flame-retardant synergetic functional master batch disclosed by the invention is capable of improving the thermal stability and the flowing dispersibility of domestic brominated flame retardant, so that theflame retardance efficiency can be improved, a flame retardance effect identical to that of a conventional flame-retardant functional master batch can be achieved with a less master batch addition amount, and in addition, the mechanical performance loss of a modified high-temperature-resistant nylon resin composite material can be effectively reduced.

Owner:江苏万纳普新材料科技有限公司

Antistatic polypropylene composite material capable of being used in explosion-proof environment and preparation method thereof

InactiveCN111073204AOvercome compatibilityOvercoming heat resistancePolypropylene compositesPolymer science

The invention discloses an antistatic polypropylene composite material capable of being used for an explosion-proof container and a preparation method of the antistatic polypropylene composite material. The polypropylene composite material is prepared from the following raw materials in percentage by weight: 68 to 90 percent of polypropylene, 10 to 25 percent of an antistatic agent, 0.1 to 2 percent of a stabilizer and 0 to 5 percent of other additives. Through the synergistic effect of various antistatic agents, the antistatic polypropylene composite material with the surface resistivity of 10 <5>-10 <8> ohm is obtained, and the antistatic polypropylene composite material is suitable for various injection-molded or blow-molded containers or other products with explosion-proof requirements.

Owner:SHANGHAI PRET COMPOSITES +3

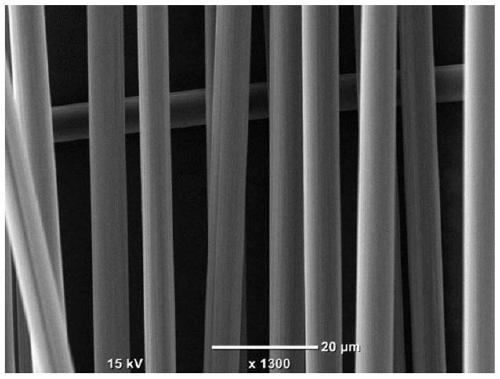

Method for quickly and efficiently recycling high-performance resin-based carbon fiber composite material

ActiveCN110172177AImprove surface topographyHigh retention rate of mechanical propertiesAcetic acidPotassium hydroxide

The invention discloses a method for quickly and efficiently recycling a high-performance resin-based carbon fiber composite material. The method is used for solving the technical problem of poor practicability of an existing method for recycling the carbon fiber reinforcement resin-based composite material. According to the technical scheme, the method comprises the steps that a waste carbon fiber reinforcement resin-based composite material is put into glacial acetic acid and pretreated for 30-40 minutes at 108-112 DEG C. The pretreated waste carbon fiber reinforcement resin-based compositematerial is put into a drying oven of 90-95 DEG C for being dried, then put into a mixed solution degradation system with dimethyl sulfoxide and potassium hydroxide and degraded for 40-70 minutes at 150-180 DEG C, and the solid product after degradation is separated, cleaned through deionized water and dried. The dried solid product is weighed, and the degradation rate is calculated. According tothe method, the recycle efficiency is high, the conditions are mild, the surface appearance of recycled carbon fibers is good, and the retention rate for the mechanical properties is high.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Flame-retardant synergistic functional master batch special for polyethylene modification and preparation method thereof

PendingCN110643098AImprove flame retardant effectReduce usageBrominated flame retardantPolytetrafluoroethylene

The invention relates to the technical field of plastic modification processing, in particular to a flame-retardant synergistic functional master batch special for polyethylene modification and a preparation method thereof. The functional master batch takes multi-composite coated decabromodiphenylethane as a main flame retardant, and the functional master batch comprises the following components by mass percentage: 55.0-70.0 wt.% of multi-composite coated decabromodiphenylethane, 15.0-30.0 wt.% of antimony trioxide, 9.0-13.0 wt.% of an ethylene-octene copolymer, 1.0-2.0 wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0 wt.% of a dispersant, and 0.3-0.5 wt.% of a lubricant. Compared with traditional flame-retardant functional master batch, the functional masterbatch prepared by the invention significantly improves the thermal stability of brominated flame retardants, effectively reduces the material yellowing phenomenon in the thermal machining process, and enhances the flame-retardant effect of domestic brominated flame retardants on polyethylene.

Owner:江苏万纳普新材料科技有限公司

Special halogen-free flame-retardant synergistic functional masterbatch for polyolefin resin modification and preparation method thereof

The invention relates to the technical field of plastic modification processing, in particular to special halogen-free flame-retardant synergistic functional masterbatch for polyolefin resin modification and a preparation method thereof. According to the functional masterbatch, multiple composite coated ammonium polyphosphate is used as a phosphorus-based flame retardant; the functional masterbatch is prepared from the following components in percentage by mass: 55.0-65.0 wt.% of the multiple composite coated ammonium polyphosphate, 25.0-35.0 wt.% of a nitrogen flame retardant, 7.0-11.0 wt.% of carrier resin, 0.5-1.0 wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0 wt.% of a dispersing agent and 0.3-0.5 wt.% of a lubricating agent. Compared with the traditional flame-retardant functional masterbatch, the functional masterbatch prepared by the invention has the advantages that the thermal stability of ammonium polyphosphate is remarkably improved, and thewater resistance of the ammonium polyphosphate is enhanced, so that the flame-retardant effect of the ammonium polyphosphate on polyolefin resin is more effectively improved.

Owner:江苏万纳普新材料科技有限公司

Thermoplastic styrene-butadiene rubber used in medical treatment field and preparation method of thermoplastic styrene-butadiene rubber

InactiveCN104312076AImprove temperature resistanceGood weather resistanceThermoplasticPolymer science

The invention discloses thermoplastic styrene-butadiene rubber used in the medical treatment field. The rubber is prepared from the following components in percentage by weight: 10-40 percent of styrene-butadiene-styrene segmented copolymer, 20-50 percent of naphthenic oil 4006, 0.5-10 percent of n-butyllithium, 1-6 percent of tetrahydrofuran, 0.1-3 percent of titanocene dichloride, 0.1-5 percent of antioxygen, 0.2-3 percent of UL327 and 0.1-0.5 percent of vinyl bistearic amide, the sum of the weight percentage of all components being 100 percent. The thermoplastic styrene-butadiene rubber has the advantages of high temperature tolerance, weather resistance and ultraviolet (UV) resistance, and is free of toxicity, good in flexibility, low in compression deformation and high in sealing performance; 120-DEG C steam sterilization and X-ray irradiation can be borne; the food and drug administration standard of elastic characteristics of styrene type thermoplastic elastomer is met so that the rubber conforms to the food and drug administration (FDA) and can be used for making medical rubber products such as injectors and transfusion instruments.

Owner:NINGBO JENIUS PLASTIC

Flame-retardant styrene butadiene rubber

InactiveCN104592594ALittle loss of mechanical propertiesImprove flame retardant performanceSulfurHydrotalcite

The invention discloses a flame-retardant styrene butadiene rubber, which includes the following raw materials by weight: 100 parts of styrene butadiene rubber-1500, 1 part of stearic acid, 3 parts of sulfur, 5 parts of zinc oxide, 1 part of an accelerator NOBS, 1 part of an antioxidant 4010NA, 10 parts of carbon black N330, 40 parts of white carbon black, 80 parts of hydrotalcite, 10 parts of microencapsulated red phosphorus and 10 parts of tricresyl phosphate. The flame retardant styrene butadiene rubber provided by the invention has the advantages of little mechanical performance loss and obvious flame retardant effect, meets the requirements for industrial production and daily use.

Owner:QINGDAO WANGYU RUBBER

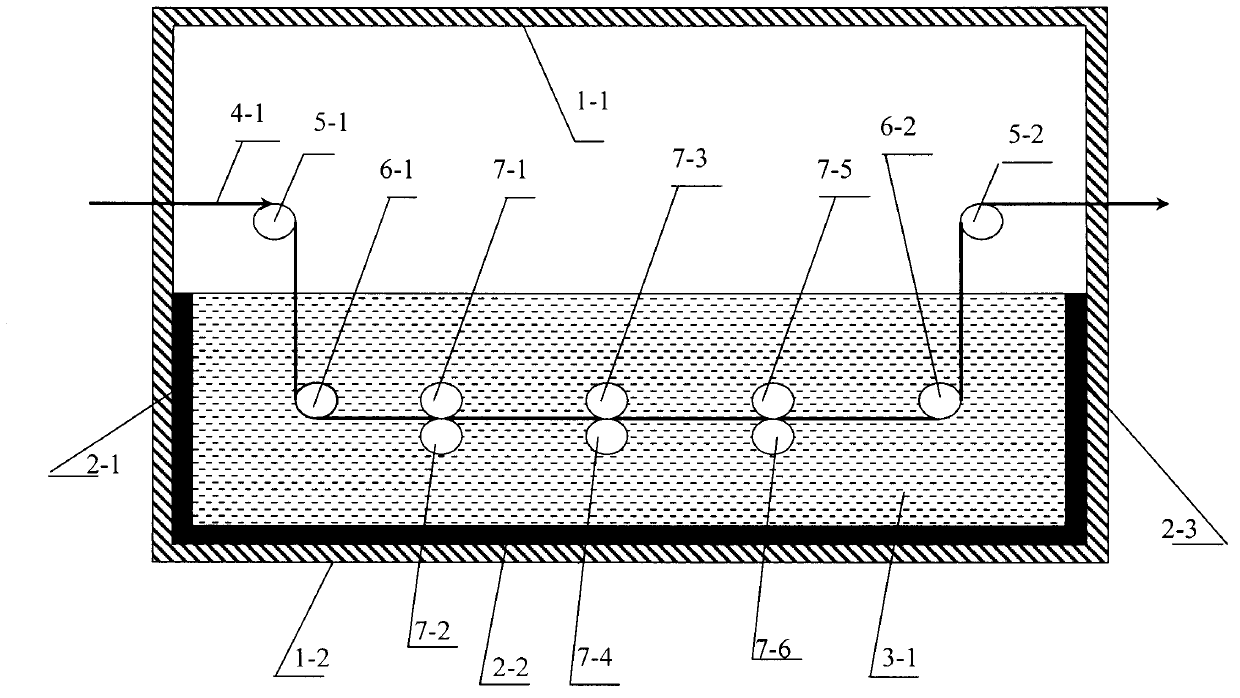

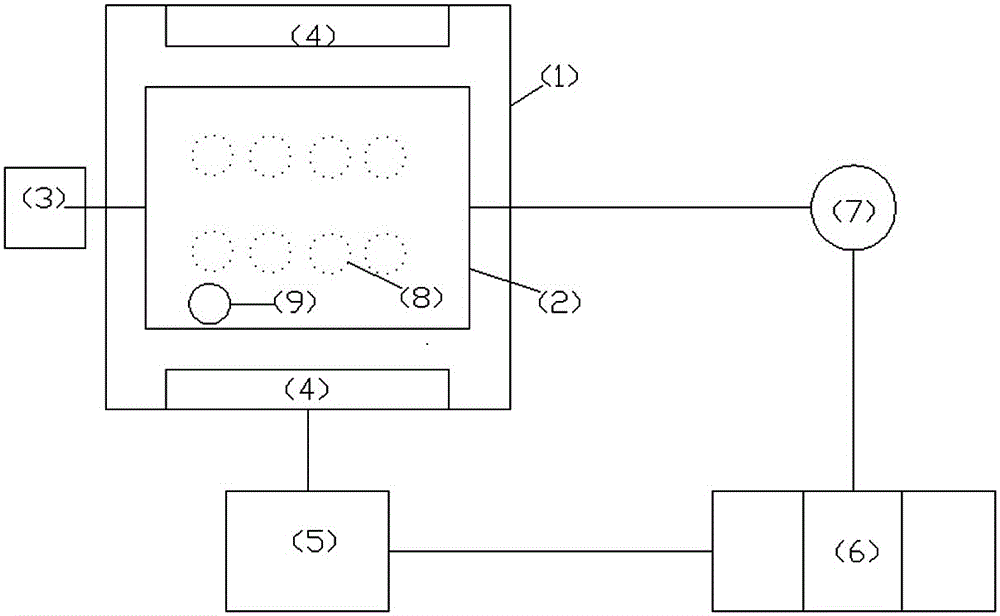

A cleaning method and device for regeneration of waste denitrification catalyst

ActiveCN104069900BComplete structureIncrease contentCatalyst regeneration/reactivationPunchingEngineering

The invention relates to a cleaning method and device for regenerating of a waste denitration catalyst. The cleaning method comprises the following steps: putting a waste denitration catalyst module in a module rotating box, carrying out first-time positioned punching and cleaning on pore channels of the catalyst module by using a movable high-pressure water gun; introducing steam into an aeration pipe to heat water in a cleaning box body till the temperature is 60-80 DEG C; introducing compressed air into the aeration pipe to carry out water-steam cleaning operation; rotating the module rotating box till the pore channels of the catalyst module are in the horizontal direction by using a speed reducing motor, and starting an ultrasonic vibrating plate to carry out ultrasonic cleaning on the pore channels of the catalyst module; and after ultrasonic cleaning, discharging cleaning water in a cleaning box into a sedimentation basin, rotating the module rotating box till the pore channels of the module catalyst are in the vertical direction by using the speed reducing motor, and carrying out second-time positioned punching and cleaning on the pore channels of the catalyst module by using the movable high-pressure water gun. The device integrates the functions of heating cleaning, water-steam cleaning, high-pressure water cleaning, ultrasonic cleaning, rotating and disturbing cleaning and waste-water treatment and the like, and is simple in structure, convenient to operate, and green and energy-saving.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

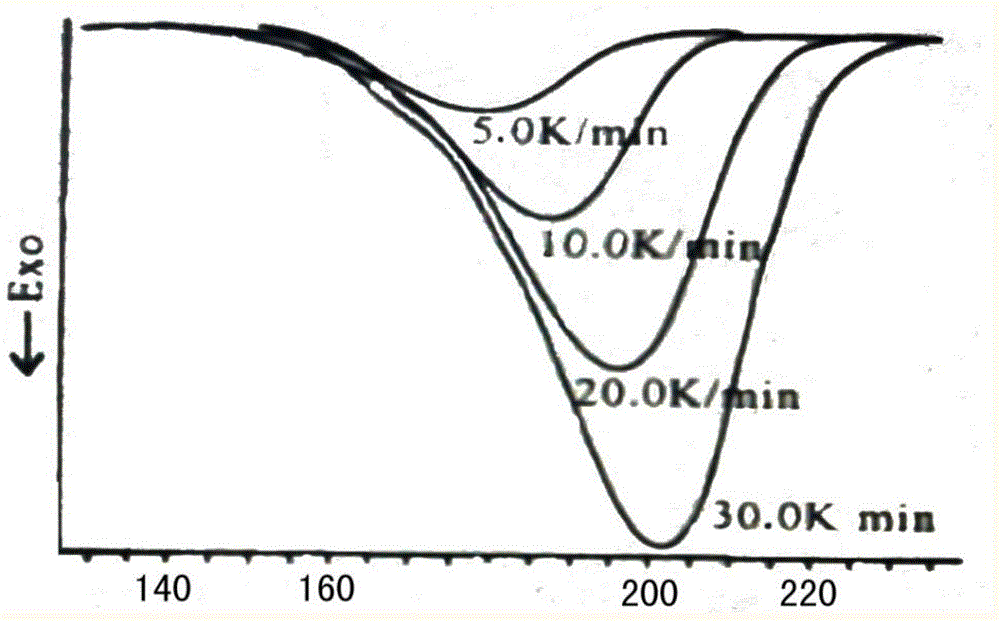

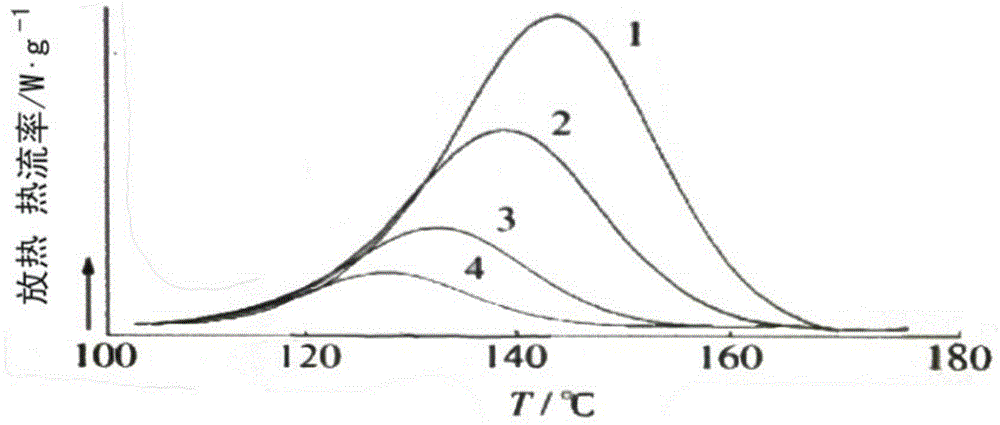

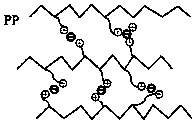

Reversible micro-crosslinking high melt strength polypropylene and preparation method thereof

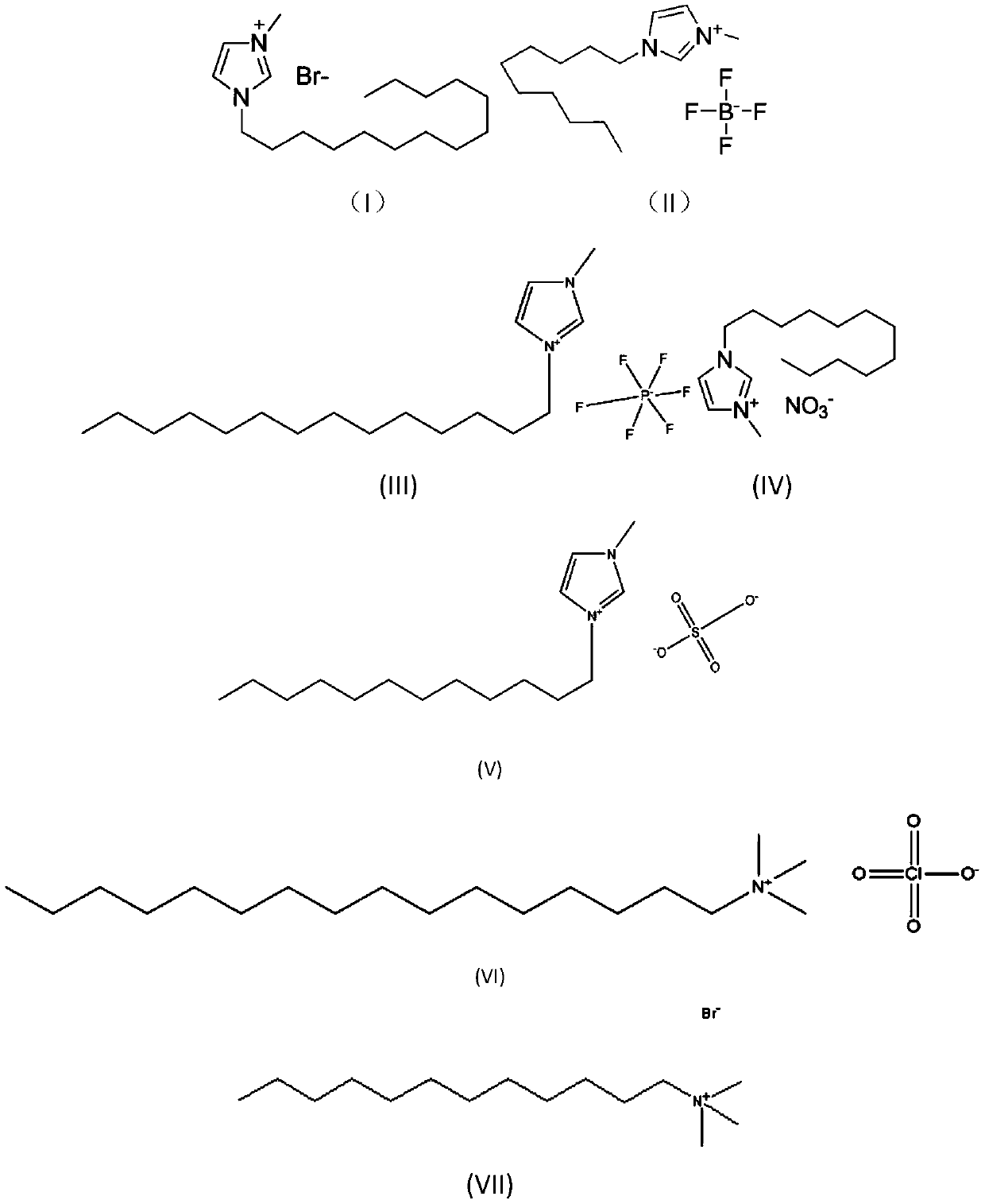

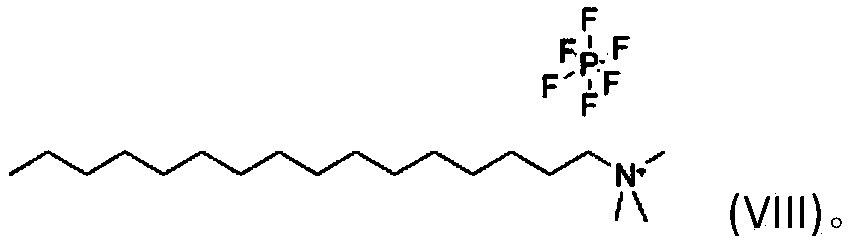

The invention discloses a reversible micro-crosslinking high melt strength polypropylene and a preparation method thereof. To prepare the reversible micro-crosslinking high melt strength polypropylene, the reaction of polypropylene, initiator, free radical stabilizer and active crosslinking agents is carried out, and then antioxidants are added to terminate the reaction to obtain the reversible micro-crosslinking high melt strength polypropylene, wherein the active crosslinking agents are selected from one or more of the ionic liquid with a C5-C30 long hydrocarbon chain. The preparation methodof the reversible micro-crosslinking high melt strength polypropylene includes the steps of evenly mixing the polypropylene, initiator, free radical stabilizer and active crosslinking agents in proportion in a high speed mixer, adding the mixed material to a twin-screw extruder for melt extrusion reaction, and then adding antioxidant masterbatch from side feed to terminate the reaction. The preparation method of the reversible micro-crosslinking high melt strength polypropylene has the advantages of effectively improving the melt strength and mechanical properties of polypropylene materials,and guaranteeing small material performance loss after repeated processing.

Owner:WANHUA CHEM GRP CO LTD +1

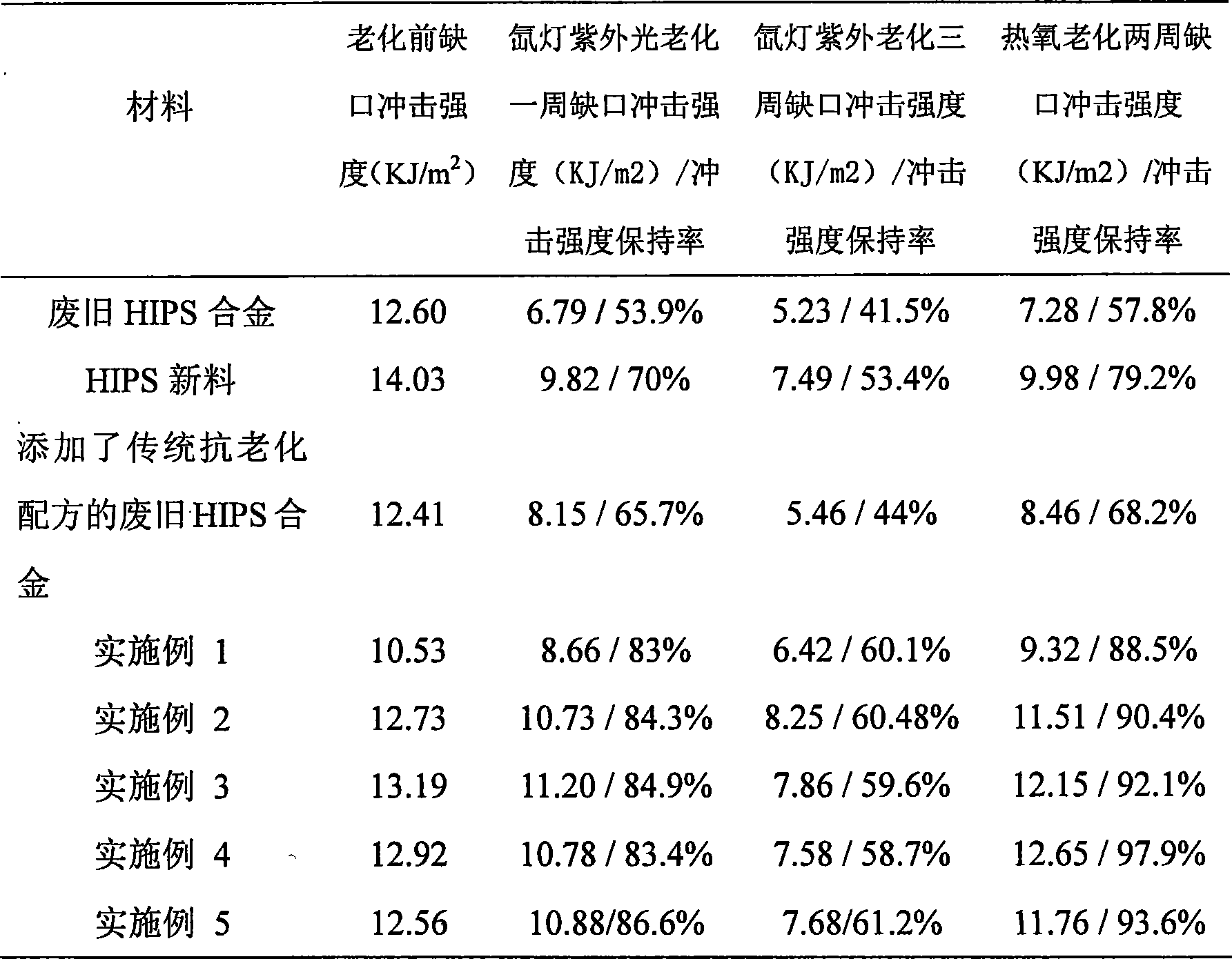

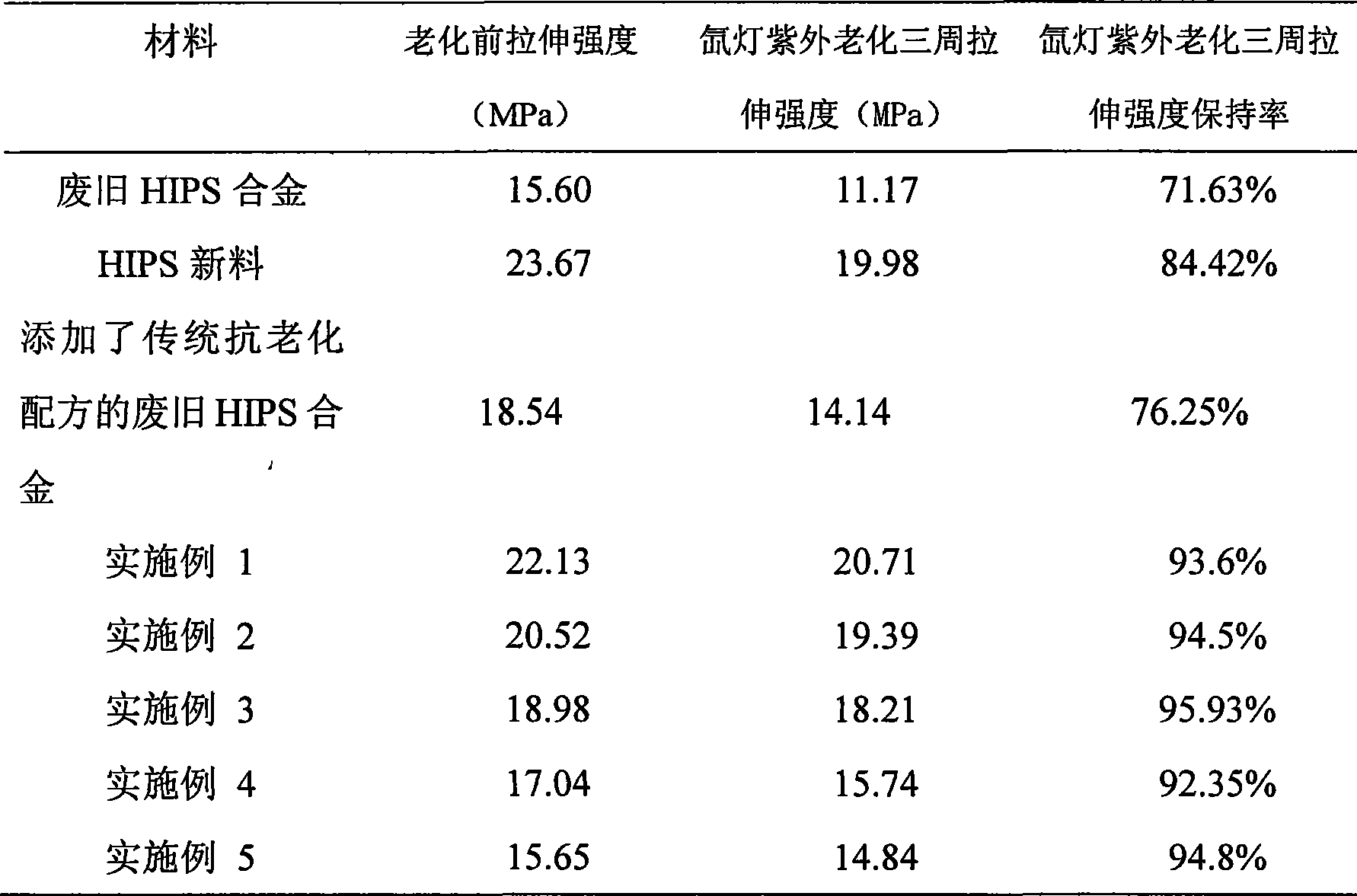

Modified waste high impact polystyrene anti-aging master batch

InactiveCN101407569BGood anti-aging performanceImprove toughnessElastomerLinear low-density polyethylene

The invention discloses an improved disposed high impact-resistant polystyrene antiageing master batch. The master batch is prepared by the following steps: 75 to 95 parts by weight of disposed high impact-resistant polystyrene, 5 to 25 parts by weight of elastomer, 5 to 10 parts by weight of linearity low density polythene, 0.25 to1.0 part by weight of ultraviolet screening agent or / and chemicalinhibitor are added into a high speed mixer for mixing, and then into a double-screw extruder, and simultaneously 5-10 parts of styrene with 0.07 to 0.70 part of dissolved evocating agent and resin acceptor with the weight ratio being 1:1 are added from the glass fiber hole of the double-screw extruder, and then fusion and mixing are carried out at the temperature of 150 to 210 DEG C. The gap impacting intensity of the master batch is greatly increased, and the mechanics performance expense after aging experiment is lower than disposed HIPS alloy without ultraviolet screening agent or compound chemical inhibitor, and antiageing performance is ever better than that of HIPS new material, thus being used in producing office supplies, electron and electric, household electrical appliances, casing and the like, with apparent economic and social benefits.

Owner:SICHUAN UNIV

High-voltage cable production method

InactiveCN107622834ALittle loss of mechanical propertiesGuaranteed performanceInsulating conductors/cablesWarm waterEngineering

The invention discloses a high-voltage cable production method. The high-voltage cable production method specifically comprises the following steps of 1, winding a pay-off rack with a cable core wire;2, starting the pay-off rack and conveying the core wire to a preheater to be preheated; 3, conveying the preheated cable core wire to three extruders in sequence; 4, conveying a cable plated with athird insulating layer to a movable warm water tank and a fixed water tank to be cooled and shaped; 5, enabling the shaped cable to pass through a ranging appliance, a dual-wheel traction machine anda metering apparatus to be conveyed to a wire storage frame; and 6, conveying the cable on the wire storage frame to a dual-shaft take-up machine to be wound into a coil. By virtue of the high-voltagecable production method, the problems of low cable quantity and easy damage caused in the existing method can be solved.

Owner:BAOJI CHANGDA ELECTRICAL TECH

Special thermoplastic polyurethane modification flame-retardant synergetic functional master batch and preparation method thereof

ActiveCN110591336AGood heat protectionHigh thermal decomposition temperatureBromineBrominated flame retardant

The invention relates to the technical field of plastic modification processing and in particular to a special thermoplastic polyurethane modification flame-retardant synergetic functional master batch and a preparation method thereof. The functional master batch adopts multiple composite coated ethylene di(tetrabromo phthalic diamide) as main body flame retardant, and comprises the following components in percentage by mass: 60.0-75.0wt.% of multiple composite coated ethylene di(tetrabromo phthalic diamide), 10.0-25.0wt.% of zinc phosphate, 9.0-13.0wt.% of thermoplastic polyurethane, 1.0-2.0wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0wt.% of a dispersant and 0.3-0.5wt.% of a lubricant. Compared with a conventional flame-retardant functional master batch,the functional master batch disclosed by the invention is capable of remarkably improving the thermal stability of brominated flame retardant, a material yellowing phenomenon in a thermal mechanicalprocessing process can be effectively reduced, and the flame retardant effect of domestic brominated flame retardant on the thermoplastic polyurethane can be improved.

Owner:江苏万纳普新材料科技有限公司

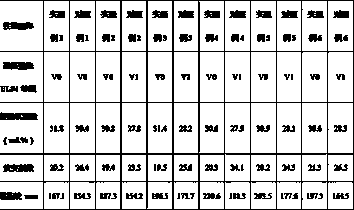

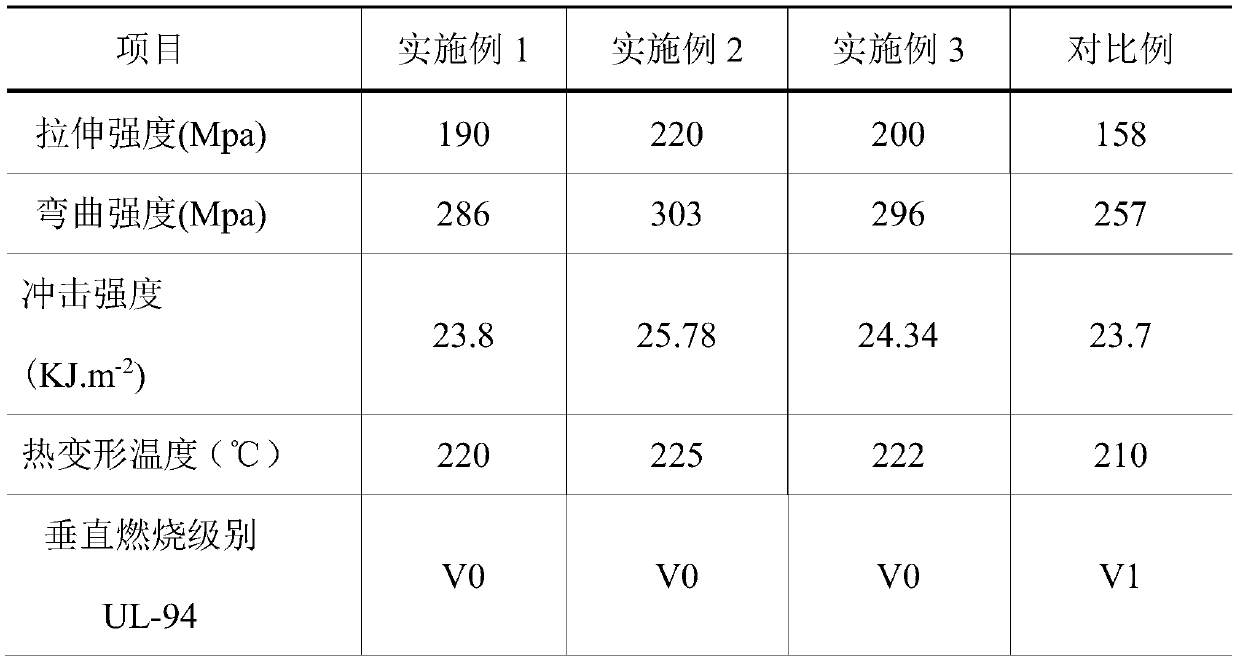

High-temperature-resistant humidity-resistant glass fiber reinforced nylon composite material and preparation method thereof

InactiveCN110283455AEnhancement effect is goodImprove mechanical propertiesPolymer scienceEngineering plastic

The invention discloses a high-temperature humidity-resistant glass fiber reinforced nylon composite material , wherein the preparation raw material comprises the following components in mass percentage: 30% to 40% of nylon 66, 15% to 25% of polyphthalamide resin, 10% to 20% of long glass fiber, 5% to 10% of polycarbonate, 5% to 15% of an inorganic filler, 3% to 7% of modified sepiolite, 1% to 5% of a compatibilizer, 0. 5% to 1.5% of a lubricant, 0.5% to 2.5% of an impact modifier, and 0.5% to 3.5% of a flame retardant. The invention also discloses a preparation method of the high-temperature-resistant moisture-resistant glass fiber reinforced nylon composite material. The glass fiber reinforced nylon composite material has excellent mechanical properties, impact resistance and flame retardancy, and can maintain high mechanical strength under high temperature and high humidity environment, ensuring dimensional stability and good processability. Surface roughness and warpage are not easy to appear, high use demand is met, and wide application in the field of engineering plastics can be realized.

Owner:SUZHOU HECHANG POLYMERIC MATERIALS

Continuous production process for enabling gold metal to be firmly attached to aromatic special fiber filaments

ActiveCN113529409AGuaranteed StrengthGuaranteed adhesionFibre typesUltrasonic/sonic fibre treatmentAviationPolymer science

The invention discloses a continuous production process for enabling gold metal to be firmly attached to aromatic special fiber filaments, belongs to the technical field of metallization of special fibers, and relates to a method for continuously and uninterruptedly producing gold-plated aromatic special fibers such as aramid fibers, PBO fibers and polyimide fibers for 24 hours. Firstly, the problems that high-strength fiber metallization cannot leave a laboratory, and stable long fibers with consistent parameters cannot be produced, for example, more than thousands of meters of long fibers cannot be produced at a time are solved; and meanwhile, due to the controllability of the production speed and various electroplating parameters, the technical problems that the fibers are the same in length, different in required conductivity and different in plating layer thickness are solved, and different specifications can be customized according to the special requirements of space flight and aviation.

Owner:铜陵蔚屹新材料有限公司

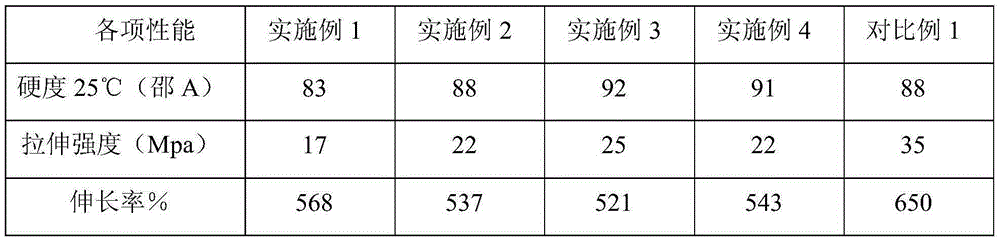

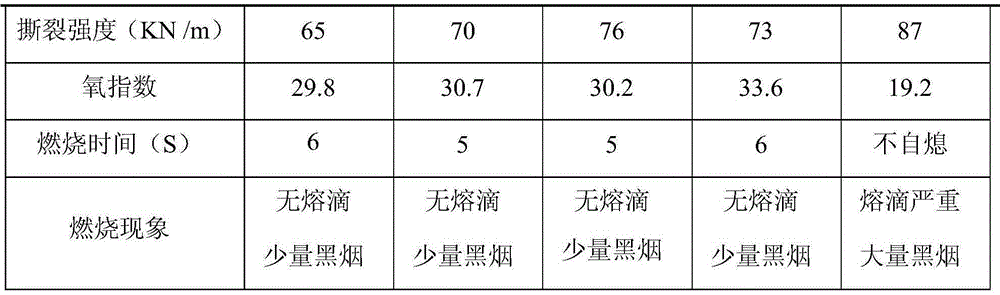

Preparation method of highly flame-retardant and environment-friendly thermoplastic polyurethane elastomer

Owner:SHANDONG INOV POLYURETHANE

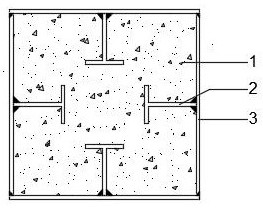

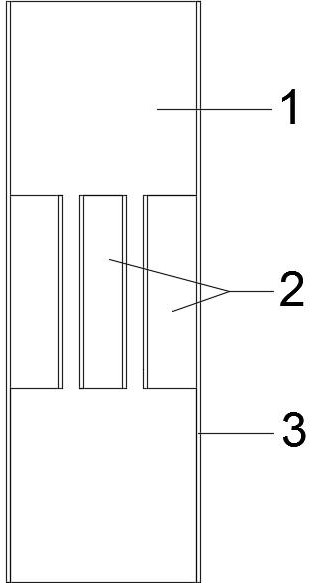

Concrete-filled steel tube column with T-shaped stiffening ribs on inner side of steel tube

PendingCN113530084AReduce binding forceReduce the difficulty of repairStrutsPillarsSteel tubeCivil engineering

The invention discloses a concrete-filled steel tube column with T-shaped stiffening ribs on the inner side of a steel tube. The concrete-filled steel tube column with the T-shaped stiffening ribs on the inner side of the steel tube comprises the steel tube and a T-shaped stiffening rib. The steel tube is a square steel tube and filled with concrete, The T-shaped stiffening ribs are embedded in the square steel tube and extend in the height direction of the steel tube. According to the concrete-filled steel tube column with the T-shaped stiffening ribs on the inner side of the steel tube, the longitudinal T-shaped stiffening ribs are arranged on the inner side of the steel tube wall along each side, the concrete-filled square steel tube column with the stiffening ribs is formed, local buckling of the tube wall is delayed, constraint of the tube wall on the concrete is enhanced, the bearing capacity and the deformation performance of a component are improved, and the performance of two materials of steel and the concrete can be brought into play easily.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Method for manufacturing coaxial cables

InactiveCN103440933AImprove heat resistanceGood resistance to chemical attackManufacturing co-axial cablesElastomerPolyester

The invention relates to the technical field of cables and the manufacturing technique thereof, in particular to a method for manufacturing non-halogen coaxial cables. The method comprises the following steps that, firstly, core wires are prepared, the metal core wires are combined to form a set, and an insulation layer is wrapped on the outer layer of the core wire set through extruding equipment, wherein high density polyethylene materials are adopted in the insulation layer; then a metal braiding layer wrapping the insulation layer is formed outside the insulation layer through a braiding machine; a coating wraps outside the braiding layer through extruding equipment, and thermoplastic polyester elastomer (TPEE) is adopted in the coating; finally; irradiation treatment is carried out on wires coated with the coating to obtain finished products. Through the adoption of the technical scheme, manufactured products have good engineering characteristic, and the performance of high temperature resistance, erosion resistance and aging resistance of the products are improved. Meanwhile, the method for manufacturing the coaxial cables can further simplify production procedures, and reduce production cost.

Owner:龚余粮

Special polypropylene modified flame-retardant synergetic functional master batch and preparation method thereof

PendingCN110591228AImprove thermal protection performanceEffective protectionPolymer scienceTetrabromobisphenol A

The invention relates to the technical field of plastic modification processing and in particular relates to a special polypropylene modified flame-retardant synergetic functional master batch and a preparation method thereof. The functional master batch adopts tetrabromobisphenol A di(2,3-dibromopropyl) ether in multiple composite coating as main body flame retardant, and comprises the followingcomponents in percentage by mass: 55.0-70.0wt.% of tetrabromobisphenol A di(2,3-dibromopropyl) ether in multiple composite coating, 15.0-30.0wt.% of antimonous oxide, 7.0-10.0wt.% of high-flowabilitypolypropylene, 2.0-4.0wt.% of atactic polypropylene, 1.0-2.0wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0wt.% of a dispersant and 0.3-0.5wt.% of a lubricant. Comparedwith a conventional flame-retardant functional master batch, the functional master batch provided by the invention is capable of remarkably improving the thermal stability of brominated flame retardant, effectively reducing material yellowing phenomena in the thermal mechanical processing process, and improving the flame retardance effect of domestic brominated flame retardant on polypropylene.

Owner:江苏万纳普新材料科技有限公司

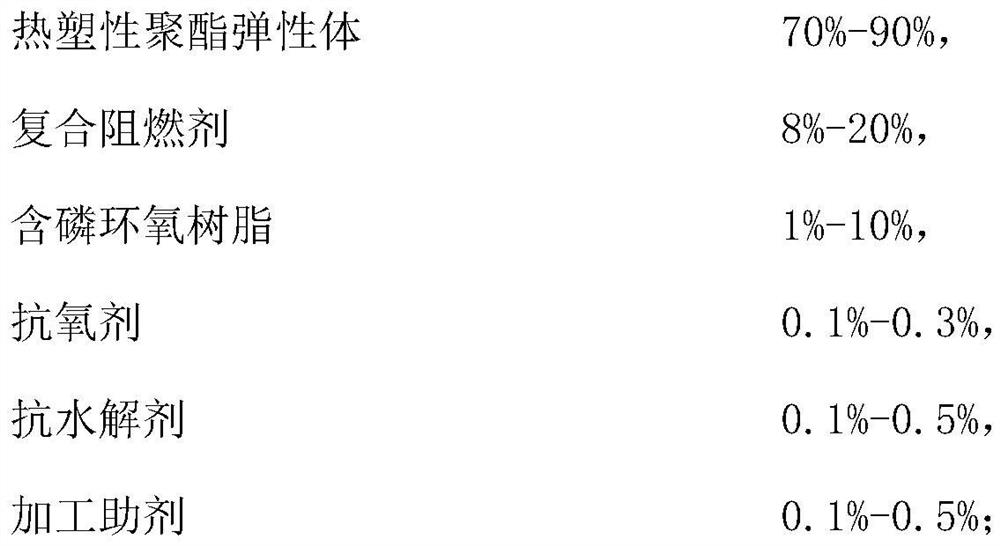

Thermoplastic polyester elastomer composite material and preparation method thereof

PendingCN113683867AImprove flame retardant performanceLittle loss of mechanical propertiesEpoxyPolyester

The invention discloses a thermoplastic polyester elastomer composite material and a preparation method thereof. The thermoplastic polyester elastomer composite material is prepared from 70%-90% by mass of a thermoplastic polyester elastomer, 8%-20% by mass of a composite flame retardant, 1%-10% by mass of phosphorus-containing epoxy resin, 0.1%-0.3% by mass of an antioxidant, 0.1%-0.5% by mass of an anti-hydrolysis agent and 0.1%-0.5% by mass of a processing aid; wherein the composite flame retardant is a compound of a phosphorus flame retardant, a nitrogen flame retardant, a silane coupling agent, an anti-dripping agent and montmorillonite. The thermoplastic polyester elastomer composite material has the advantages of excellent flame retardant property, small mechanical property loss, favorable processability and excellent comprehensive properties.

Owner:会通新材料(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com