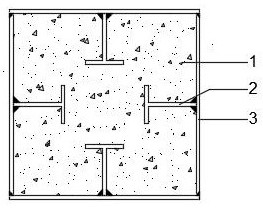

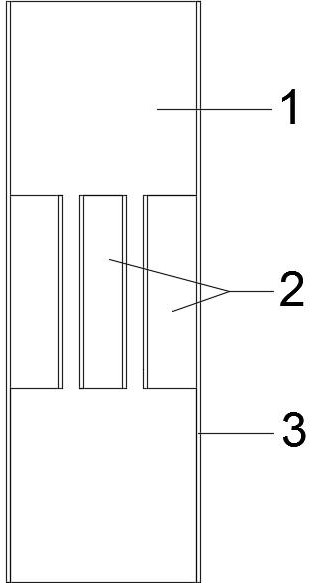

Concrete-filled steel tube column with T-shaped stiffening ribs on inner side of steel tube

A concrete column and stiffening type technology, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of square concrete-filled steel tube structure bearing capacity, low ductility, buckling of pipe walls, and reduction of component bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention provides a steel pipe with T-shaped stiffening ribs on the inner side of the concrete-filled steel pipe column. The present invention will be further described through the description of the drawings and specific implementation methods below.

[0020] When making square steel pipes with T-shaped stiffening ribs, four steel plates for making pipe walls are cut according to the predetermined size, then T-shaped stiffening ribs are welded at their predetermined positions in the longitudinal direction, and then welded into steel pipes. Due to the thinner steel plates, penetration fillet welds are used for tailor welding of steel plates. All the welding work in the production process of the test piece is welded by carbon dioxide shielded welding, and the quality of the weld seam is guaranteed to reduce the influence of welding residual stress and residual deformation on the test results. Two square steel plates with a plate thickness of 10mm are process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com