Unsprung third rail collector beam support for a swing arm primary suspension railway truck

A technology for railway wagons and collector rings, which is applied to railway vehicles, electric tracks, locomotives, etc., and can solve problems such as insufficient beam elastic pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

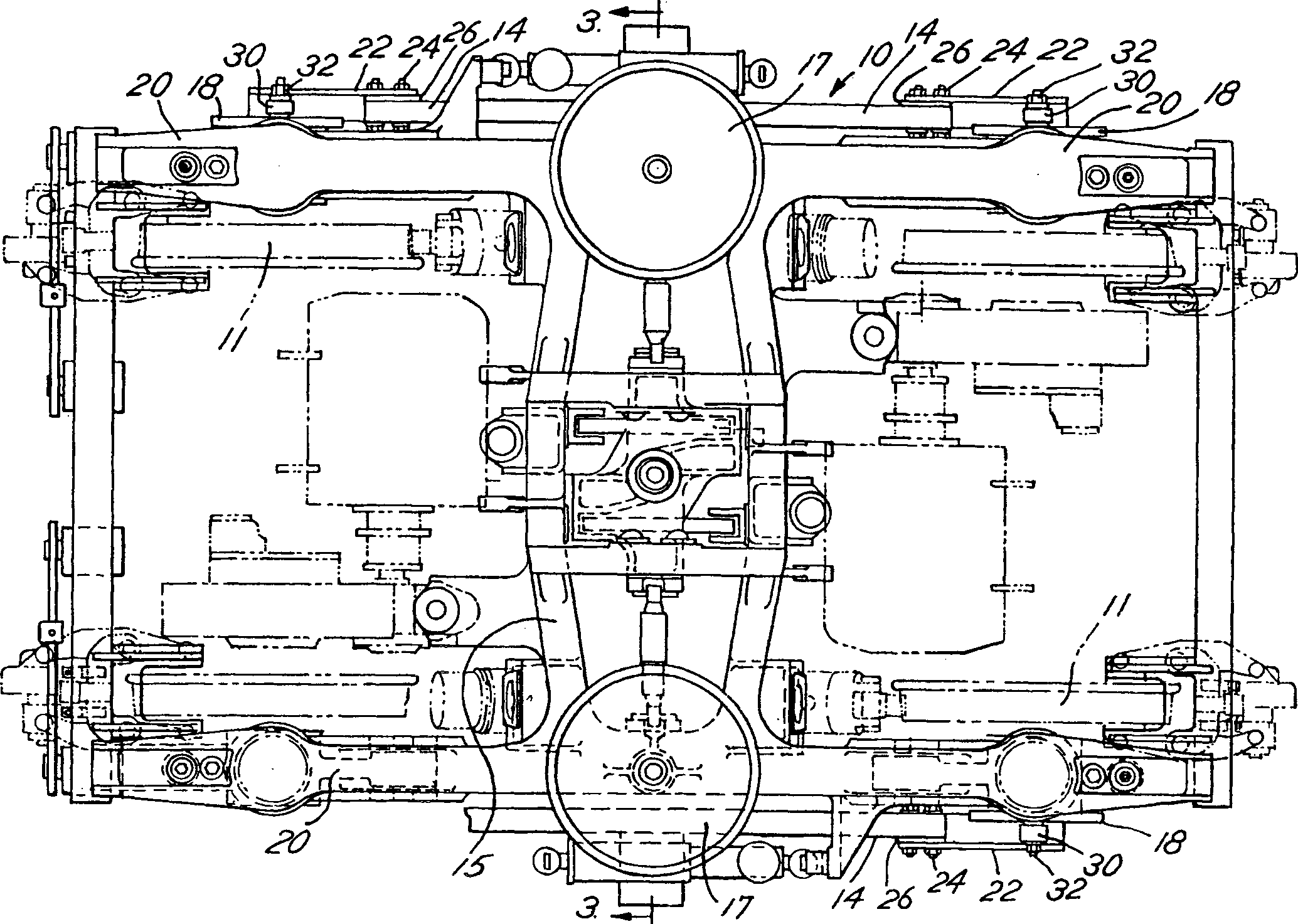

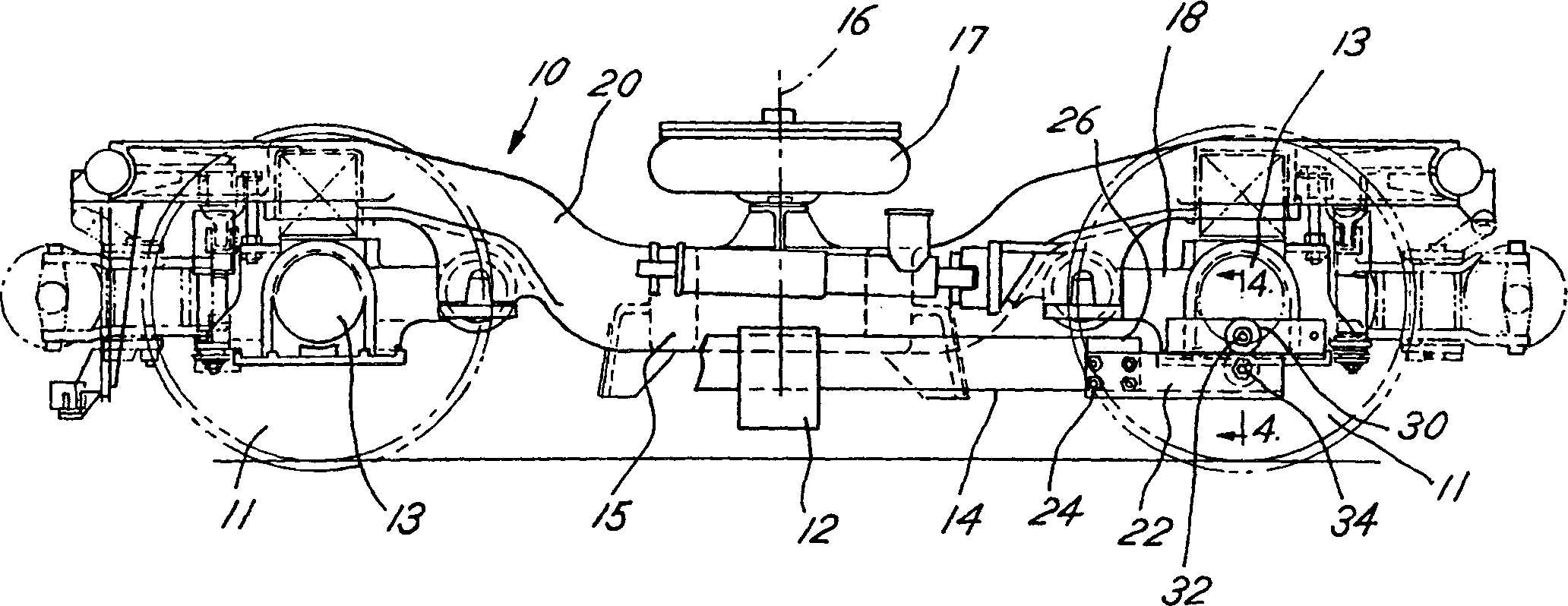

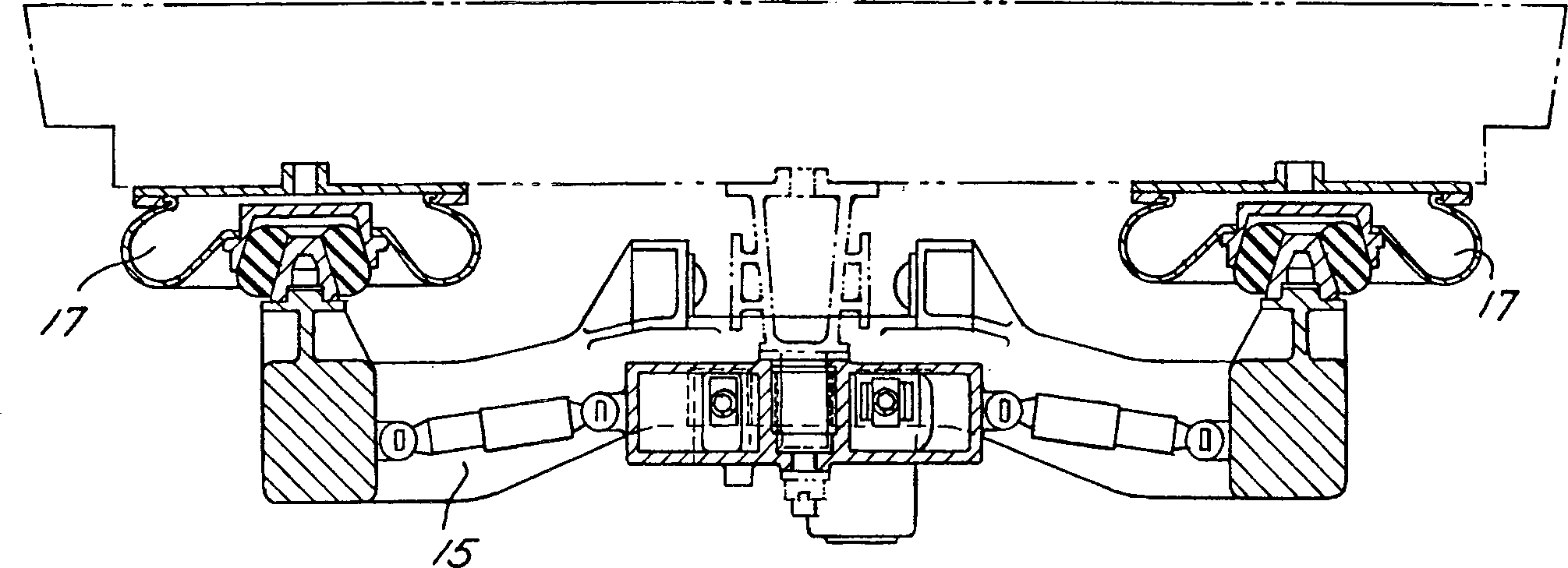

[0016] refer to Figure 1-3 , shows a preferred embodiment of the electric railway wagon underframe of the present invention equipped with a preferred third rail collector beam support, as conventional, the electric wagon underframe 10 includes the wheelsets, It comprises two wheels 11 spaced transversely from each other and connected by a transversely extending axle 13 . Supported on each wheel set is the truck underframe frame 20 on which the secondary suspension 17 is mounted.

[0017] The preferred electric truck chassis 10 also includes a slip ring 12 , shown generally, mounted on a non-conductive slip ring beam 14 at or near a truck bed centerline 16 . A slip ring 12 is mounted on each side of the truck chassis 10 . Slip ring 12 is typically a brake shoe or plate that runs against the charged third along-line track and receives current from the charged track. The slip ring beam 14 extends longitudinally from the truck underframe centerline 16 to adjacent the swing arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com