Patents

Literature

67results about How to "Guarantee the quality of heat treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

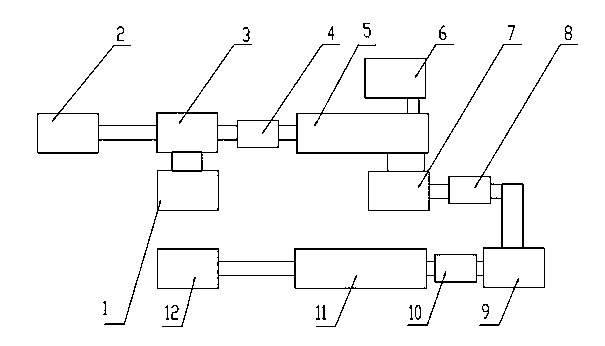

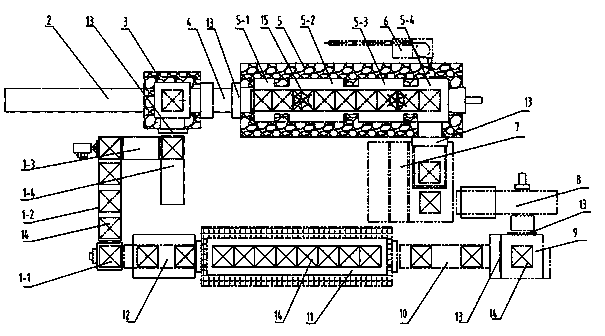

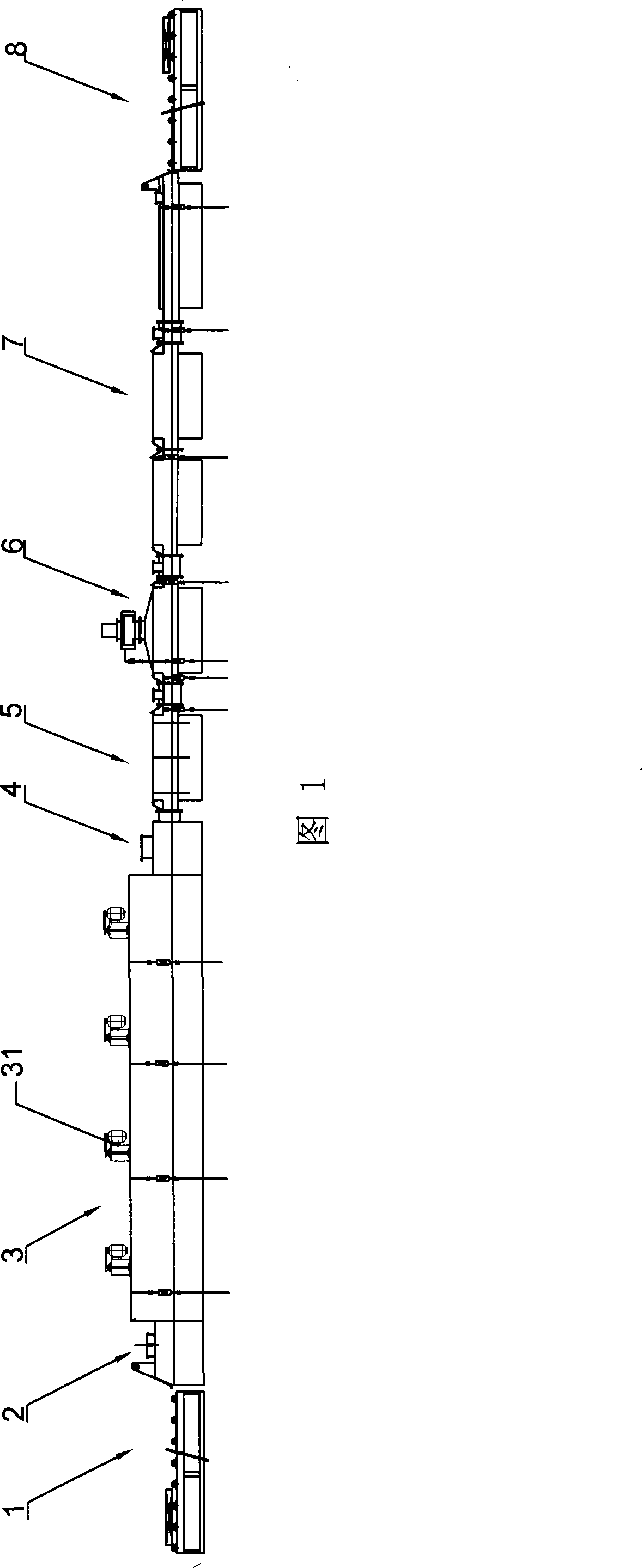

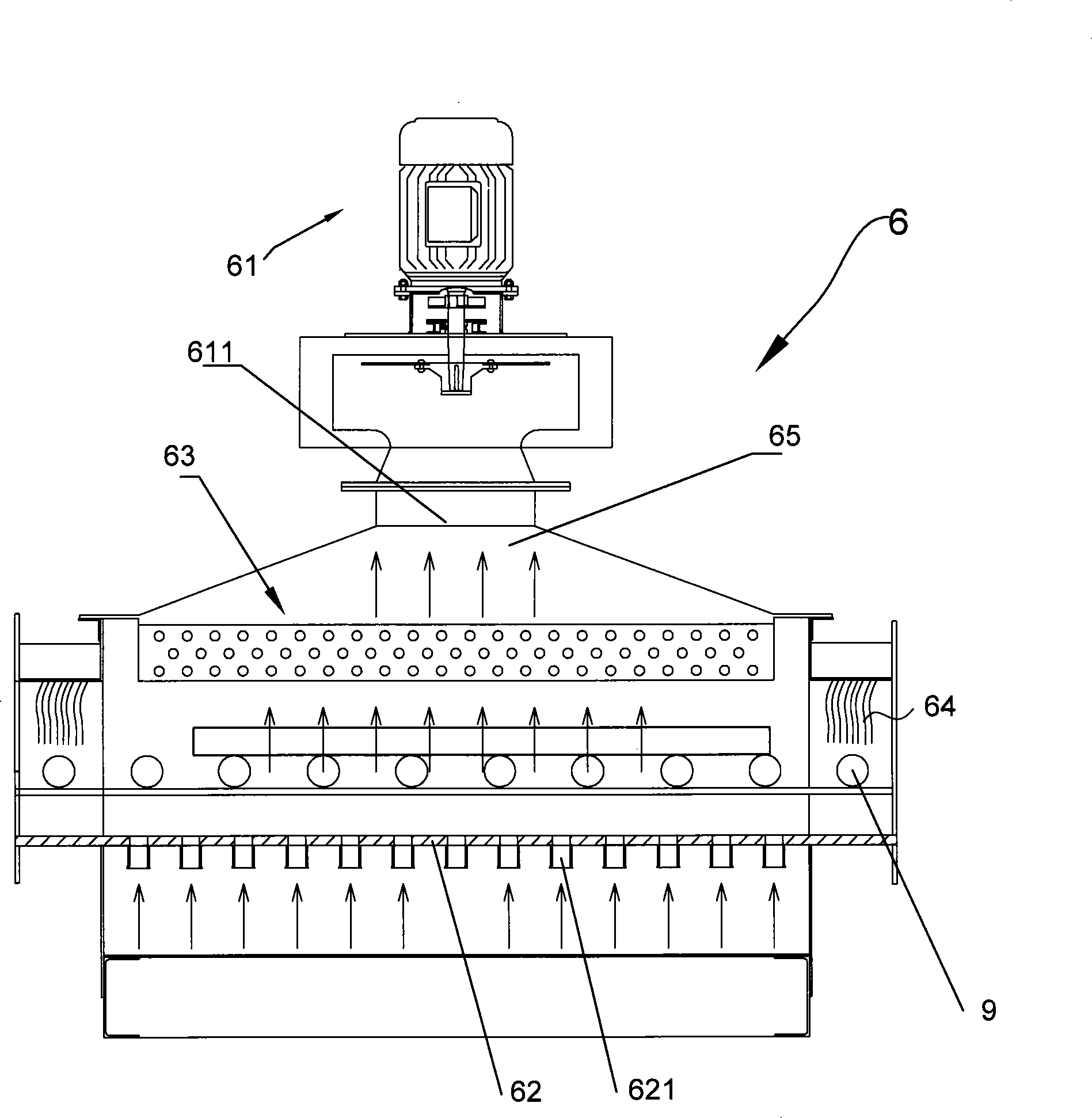

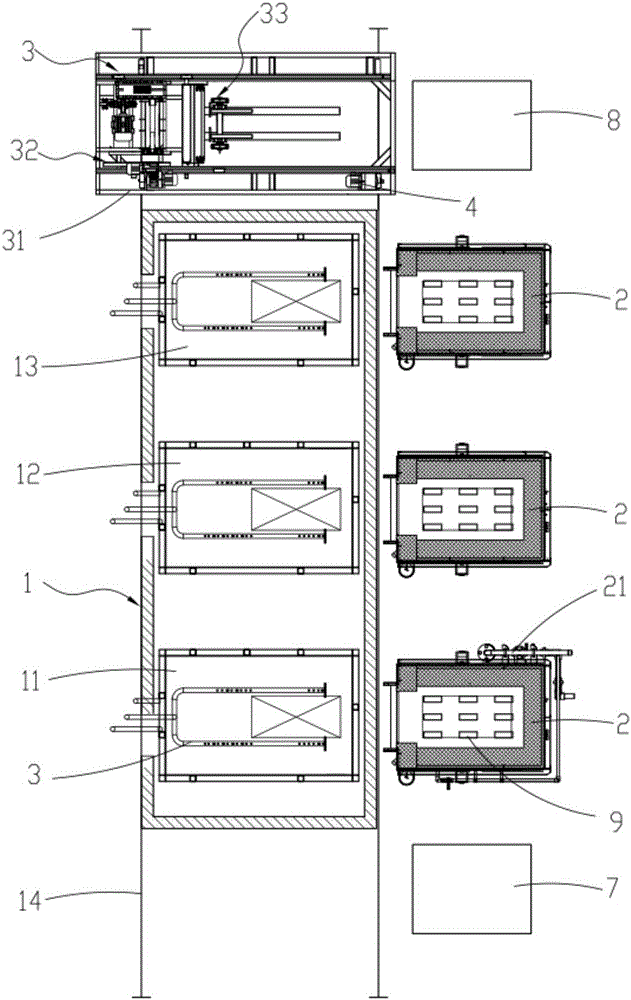

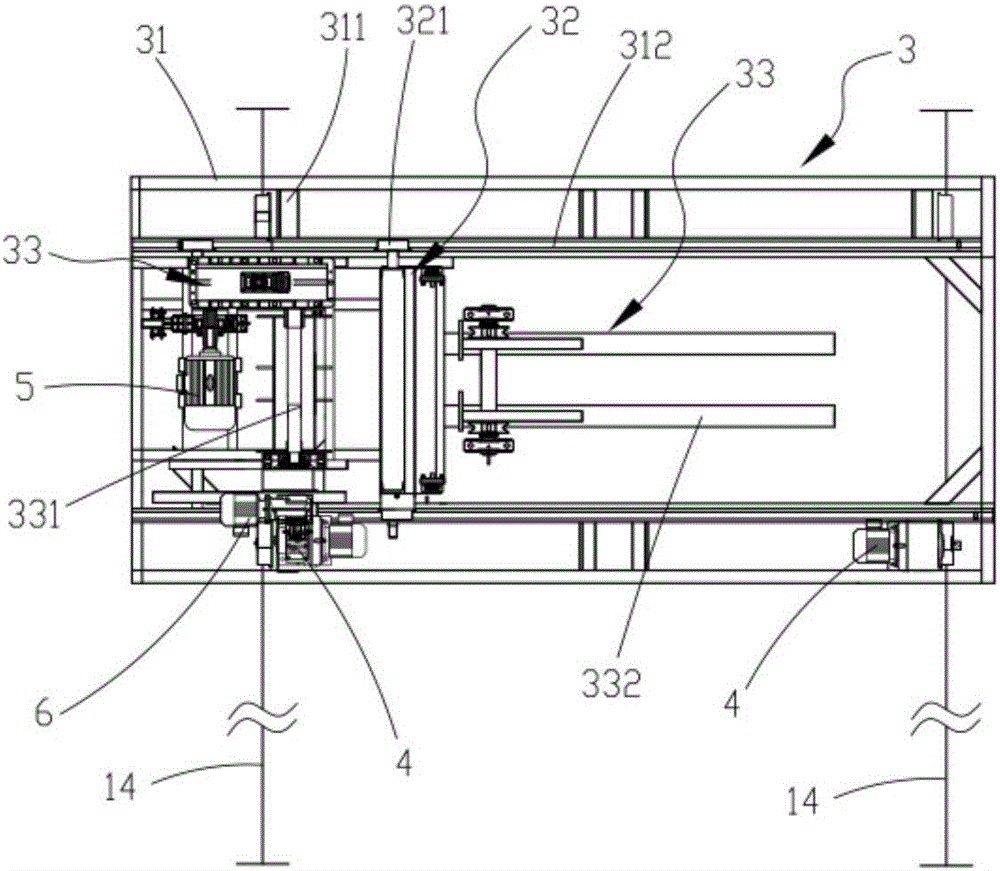

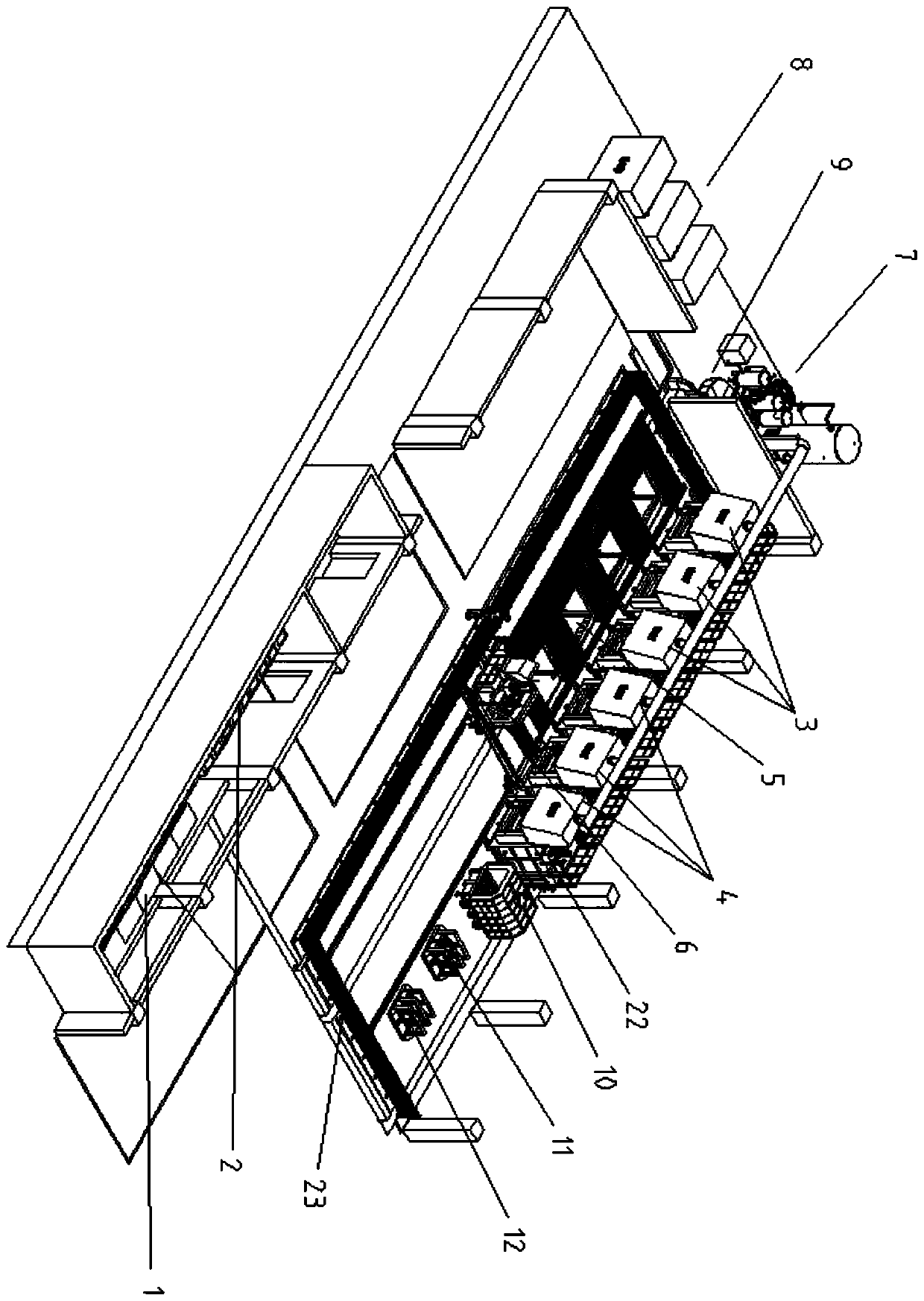

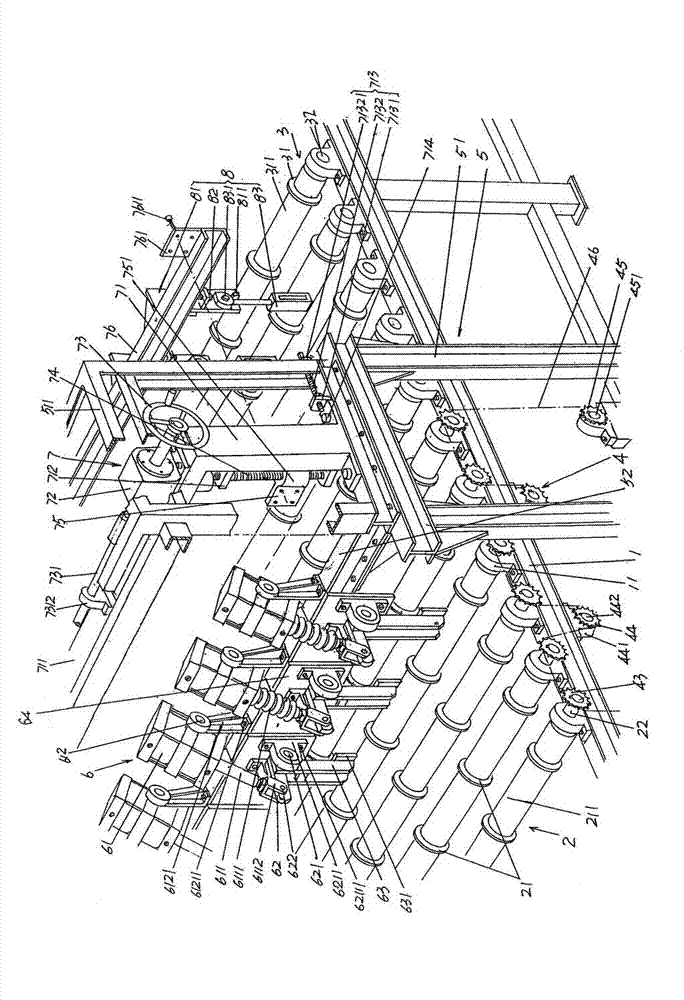

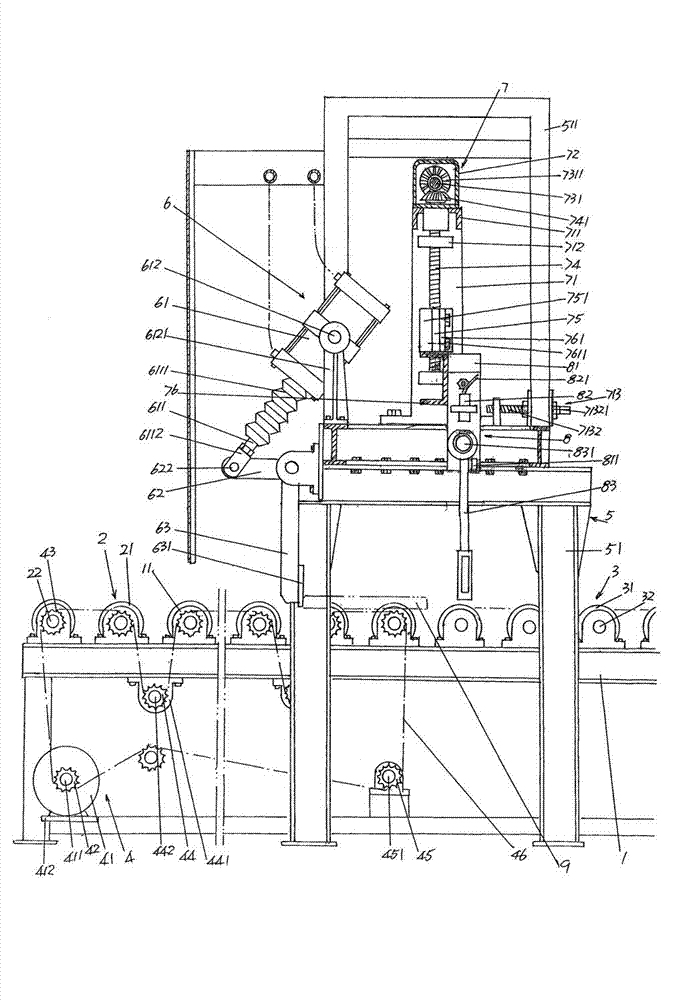

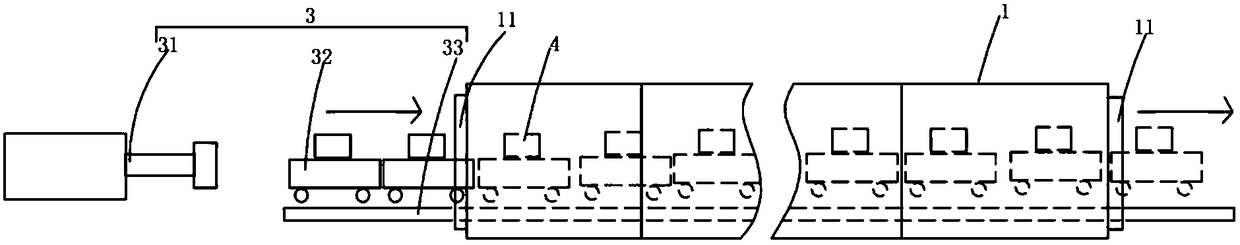

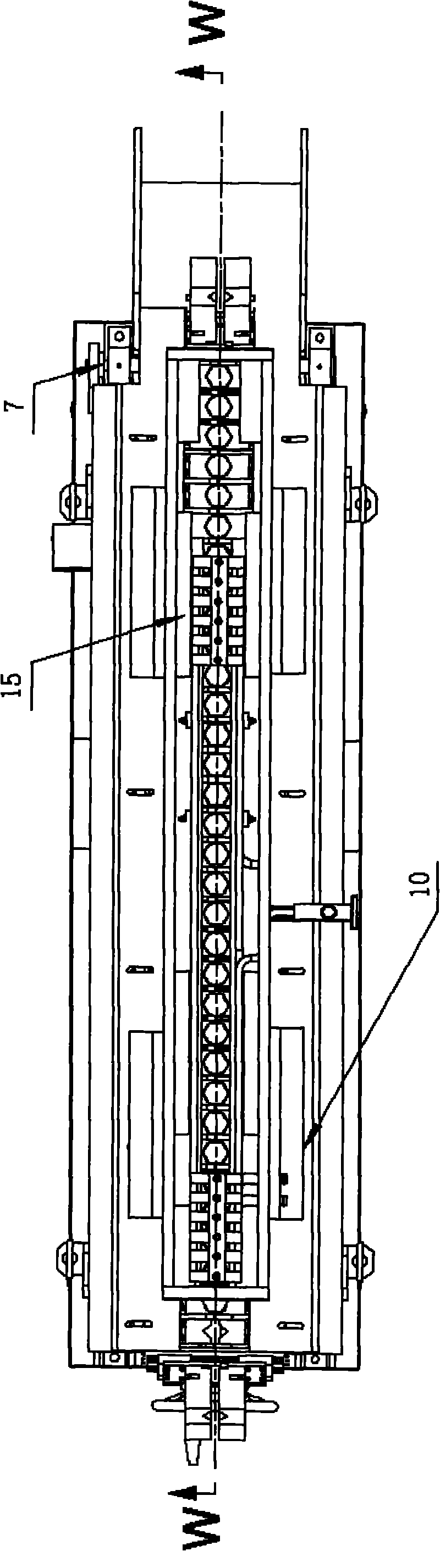

Automatic production line for saw blade heat treatment

InactiveCN103146902AGuarantee the environmentGuaranteed atmosphereFurnace typesHeat treatment furnacesProduction lineEngineering

The invention discloses an automatic production line for saw blade heat treatment, and belongs to the technical field of work piece heat treatment. The automatic production line for the saw blade heat treatment is characterized by comprising a feed mechanism, a feeding tray stepping advancing mechanism, a heat preserving furnace, a carbon-nitrogen furnace, a quenching mechanism, a cleaning machine, a tempering furnace and feeding tray conveying mechanisms, wherein the feed mechanism, the feeding tray stepping advancing mechanism, the heat preserving furnace, the carbon-nitrogen furnace, the quenching mechanism, the cleaning machine, the tempering furnace are sequentially arranged according to a manufacturing process order, and the feeding tray conveying mechanisms are arranged between each two adjacent devices. The feeding tray conveying mechanisms comprise a transition cylinder, a carbon-nitrogen furnace discharging advancing device, a quenching discharging advancing device, a tempering furnace feeding advancing device and a tempering furnace discharging advancing device, wherein the transition cylinder is arranged between the heat preserving furnace and the carbon-nitrogen furnace, the carbon-nitrogen furnace discharging advancing device is arranged on one side of the carbon-nitrogen furnace, the quenching discharging advancing device is arranged between the quenching mechanism and the cleaning machine, the tempering furnace feeding advancing device is arranged between the cleaning machine and the tempering furnace, and the tempering furnace discharging advancing device is arranged at an outlet of the tempering furnace. The automatic production line for the saw blade heat treatment has the advantages of improving production efficiency and energy use rates of the devices, ensuring heat treatment quality of saw blades due to continuous production, achieving automation operation of the whole production line and being small in number of employed workers and good in labor environment.

Owner:烟台金都锯业有限公司

Low stove pressure convection continuous roller bottom type annealing furnace and annealing technique

The invention relates to a low furnace pressure convective continuous roller hearth type annealing furnace, which comprises a charging magazine, a heating chamber, a strong cooling chamber and a roller way driving system, wherein an internal circulation draught fan and a plurality of heating elements are arranged in the heating chamber, both an air inlet and an air outlet of the internal circulation draught fan are located in a furnace body of the heating chamber, the air inlet is vertical to the plane of a roller way, the air outlet is parallel to the plane of the roller way, an external circulation draught fan, a heat exchanger and a baffle plate are arranged in the strong cooling chamber, the baffle plate is located in the middle portion of the furnace body of the strong cooling chamber, the roller way is located between the heat exchanger and the baffle plate, an upper opening and a lower opening are respectively opened on the top and the bottom of the furnace body of the strong cooling chamber, the air inlet of the external circulation draught fan is communicated with the upper opening, the air outlet of the external circulation draught fan is connected with the lower opening through a connecting pipe which is arranged outside the strong cooling chamber, the complex number of nozzles are evenly distributed on the baffle plate, and the upper portion and the lower portion of the furnace body of the strong cooling chamber are communicated only through a complex number of nozzles. The annealing furnace of the invention has the advantages of even heating, rapid cooling, high efficiency and the like.

Owner:SUZHOU ZHONGMENZI IND FURNACE TECH CO LTD

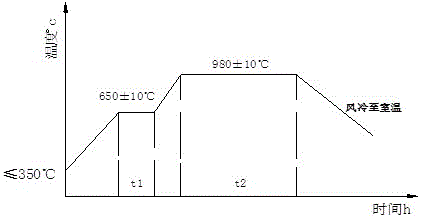

High-pressure valve material and heat treatment method thereof

InactiveCN103233165ASimple heat treatment processQuality improvementFurnace typesHeat treatment furnacesHigh pressureWater cooling

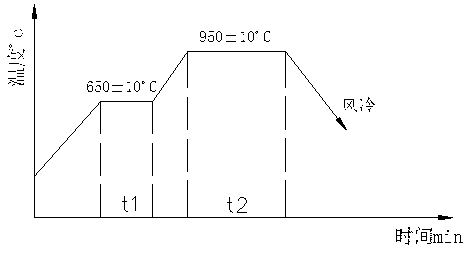

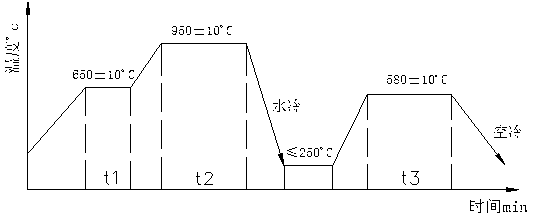

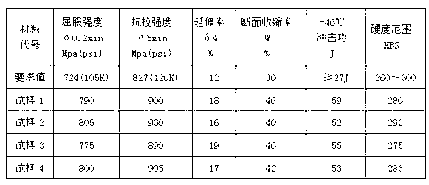

The invention discloses a high-pressure valve material and a heat treatment method thereof. The high-pressure valve material comprises the following components in percentage by mass: 0.12-0.15% of C, 0.30-0.50% of Si, 0.50-0.60% of Mn, at most 0.025% of P, at most 0.025% of S, 2.00-2.50% of Cr, 0.90-1.00% of Mo and 95.2-96.18% of Fe. The heat treatment method comprises the following steps: casting a high-pressure valve material into a valve blank according to technological requirements; preheating the valve blank to 650+ / -10 DEG C, keeping the temperature for some time, heating to 950+ / -10 DEG C, keeping the temperature for some time, discharging, and cooling in air; and preheating the valve blank subjected to normalizing treatment to 650+ / -10 DEG C, keeping the temperature for some time, continuing heating to 950+ / -10 DEG C, quenching, keeping the temperature for some time, discharging, cooling with water, heating to 580+ / -10 DEG C in furnace for tempering, keeping the temperature for some time, discharging, and cooling in air. The heat treatment method has the advantage of simple technique, enhances the mechanical properties of the treated valve to 105 K, improves the safety of the product, and lowers the production cost of the product.

Owner:JIANGSU JINSHI CASTING & FORGING

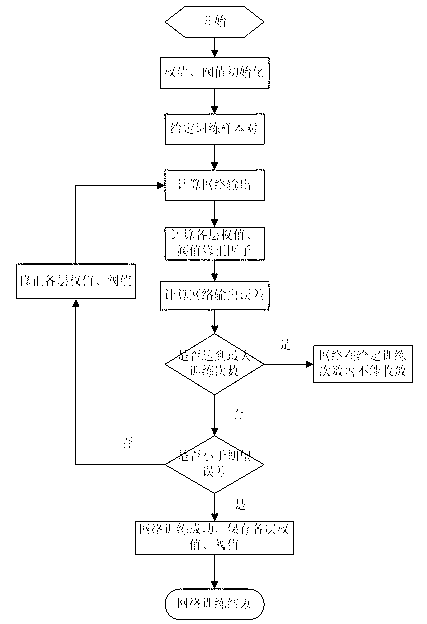

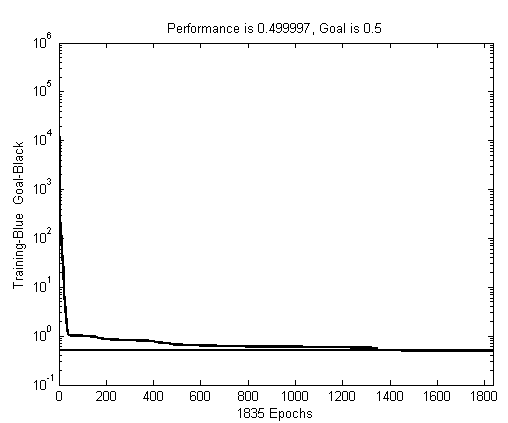

Position determining method for postweld heat treatment temperature equivalent points of inner walls of steel pipes with 9 percent of Cr

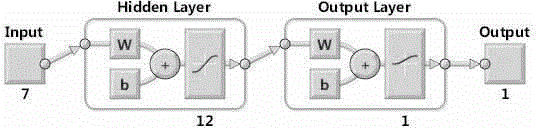

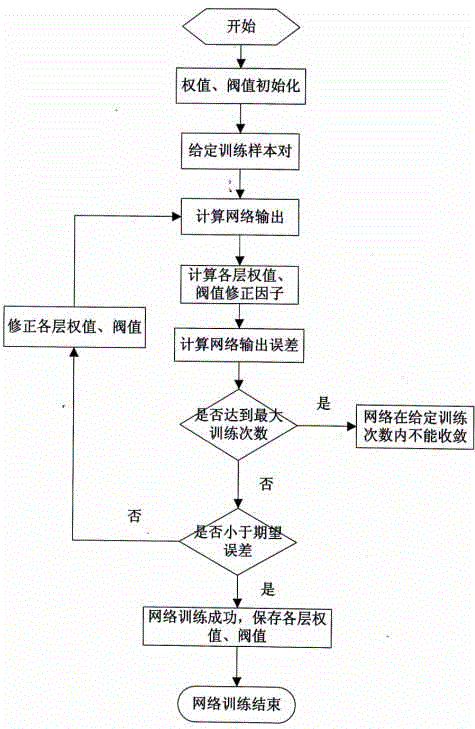

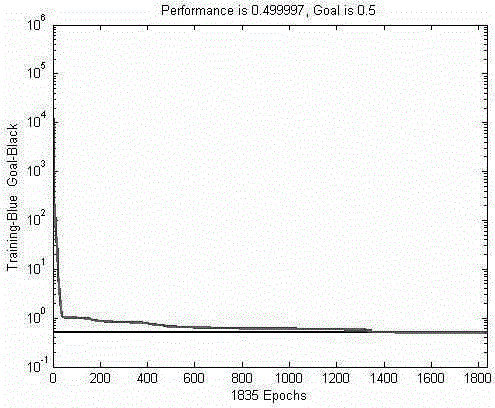

ActiveCN102816917AEasy to monitorGuarantee the quality of heat treatmentFurnace typesHeat treatment furnacesNerve networkThermodynamics

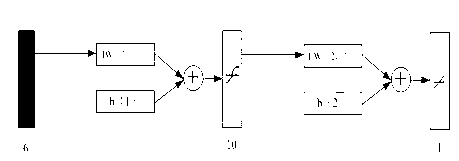

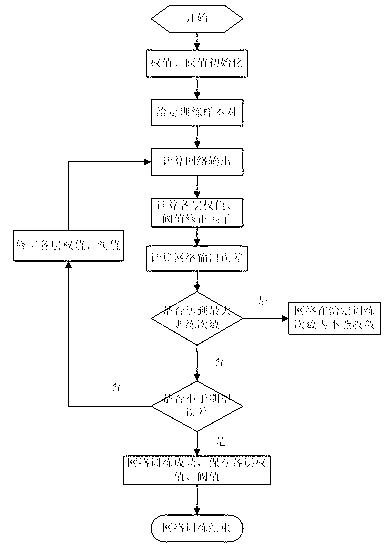

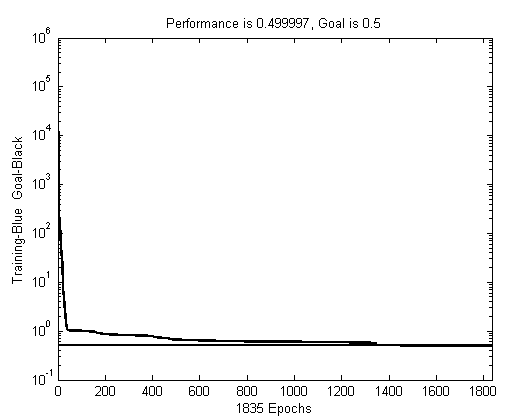

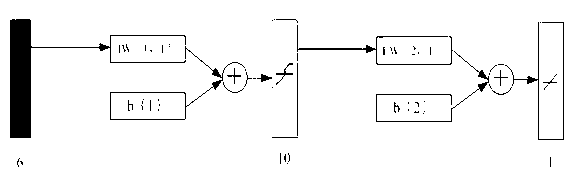

The invention relates to a position determining method for postweld heat treatment temperature equivalent points of inner walls of steel pipes with 9 percent of Cr. According to the method, T groups of data of postweld heat treatment temperature equivalent points of the inner walls of pipelines with different sizes under the conditions of different heating widths, different heat preservation widths and different heat treatment ambient temperatures are calculated, and the influences of the sizes of the pipelines, the heating widths, the heat preservation widths, the heat treatment ambient temperatures and controlled temperature on positions of the equivalent points are comprehensively considered, a nerve network based on error back propagation is built, trained and tested; and trained and tested network output thresholds are revised to obtain a method for determining postweld heat treatment temperature equivalent points of the inner walls of the novel martensite heat-resistant thick-walled steel pipelines with 9 percent of Cr according to the actual measurement data of the positions of the equivalent points. By the method, the positions of the temperature equivalent points of the inner walls can be quickly determined to help guiding and opitmizing a heat treatment process, so that the heat treatment quality is improved.

Owner:HEBEI CANGHAI PIPE FITTINGS GROUP

Forecasting method of inner and outer wall temperature difference of 9% Cr martensitic steel thick wall pipeline in heat treatment

ActiveCN102719644AGuarantee the quality of heat treatmentImprove heat treatment efficiencyFurnace typesHeat treatment process controlTemperature controlProcess engineering

The invention relates to a forecasting method of inner and outer wall temperature difference of a 9% Cr martensitic steel thick wall pipeline in heat treatment. The method comprises the following steps of: calculating to obtain inner and outer wall temperature difference data of T groups of pipelines with different dimensions in postweld heat treatment under the conditions of different heating widths, different temperature preservation widths, and different heat treatment environment temperatures and different temperature control temperatures; establishing a neural network based on an error back propagation by comprehensively considering the influence of the pipeline dimensions, the heating widths, the temperature preservation widths, the heat treatment environment temperatures and the temperature control temperatures on the inner and outer temperature difference in postweld heat treatment and training and testing the neural network; and finally, amending by combining the actual tested data to obtain a method for forecasting the inner and outer wall temperature difference of the 9% Cr novel martensitic heat-resistant steel thick wall pipeline in postweld heat treatment. The forecasting method can rapidly calculate the inner and outer wall temperature difference, can help for instructing and optimizing the heat treatment technology, and can improve the heat treatment quality.

Owner:WUHAN UNIV

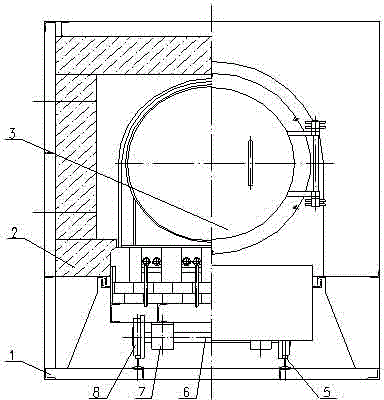

Hot workpiece fast transfer quenching system

InactiveCN105936959ASimple structureGuaranteed uptimeFurnace typesHeat treatment furnacesThermal treatmentQuenching

The invention relates to a hot workpiece fast transfer quenching system which comprises a cooling tank and at least one thermal treatment furnace, wherein the cooling tank and the thermal treatment furnaces are arranged in a split type. Each thermal treatment furnace is provided with a furnace door which can be opened or closed. A material box containing hot workpieces is arranged in each thermal treatment furnace. The hot workpiece fast transfer quenching system is characterized in that a transfer device is arranged between the cooling tank and each thermal treatment furnace and used for transferring the material box in the corresponding thermal treatment furnace into the cooling tank; the whole cooling tank is rectangular, and a water sink, an oil sink and a rinse tank are arranged inside the cooling tank side by side at intervals; and each transfer device is mounted at the upper edge of the cooling tank and reciprocates in the longitudinal direction to take in the material box of the corresponding thermal treatment furnace. By means of the transfer devices, the multiple thermal treatment furnaces are matched with the same cooling tank, the transfer time of the hot workpieces between a thermal treatment process and a cooling process is reasonably utilized, continuous quenching treatment can be conducted on the different hot workpieces, the work efficiency is improved, and energy consumption is lowered.

Owner:浙江宇清热工科技股份有限公司

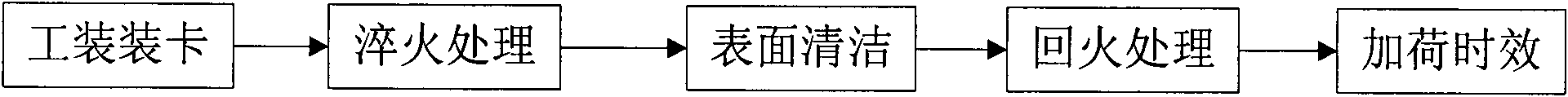

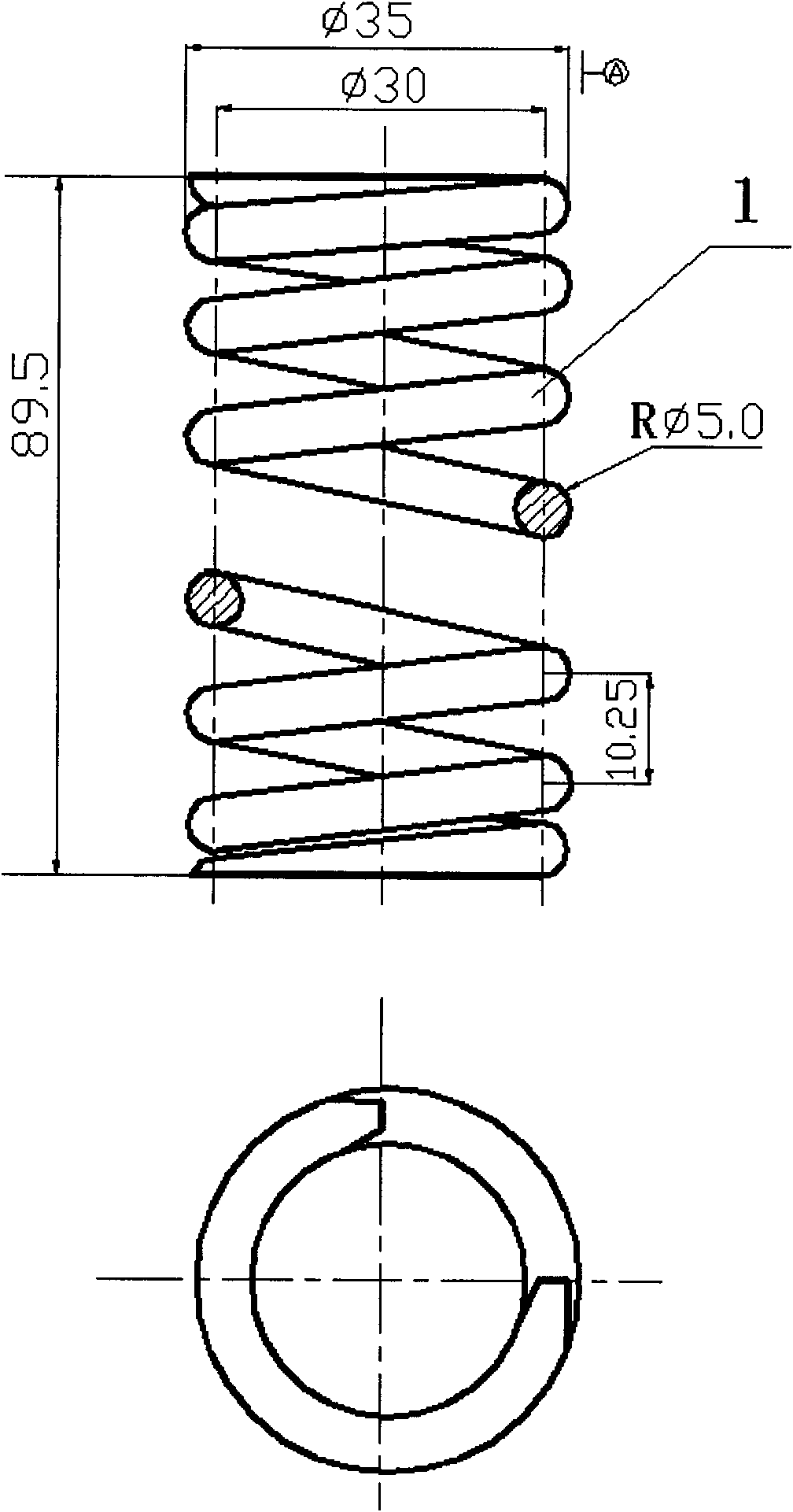

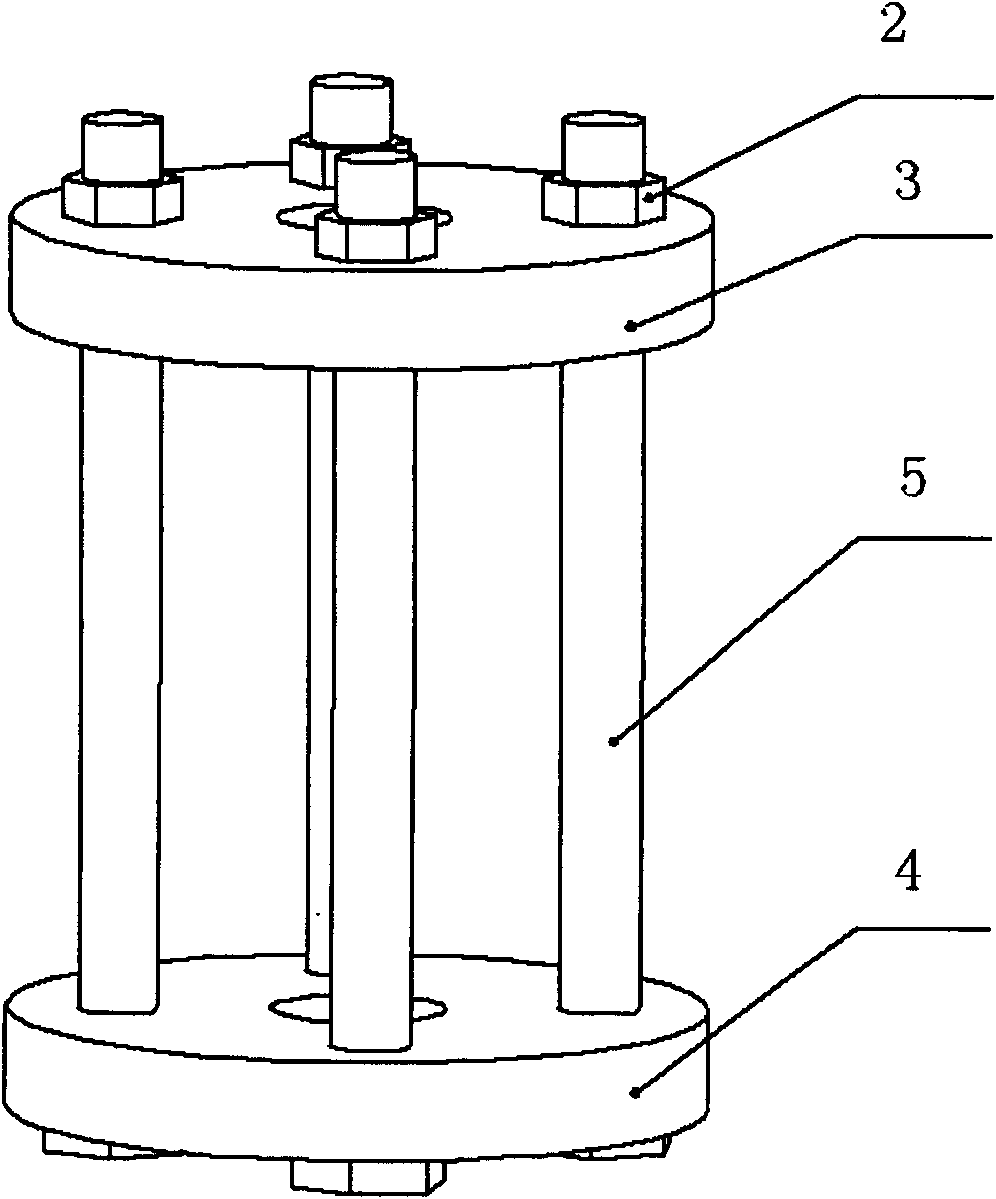

Precise heat treatment method of high-precision elastic element

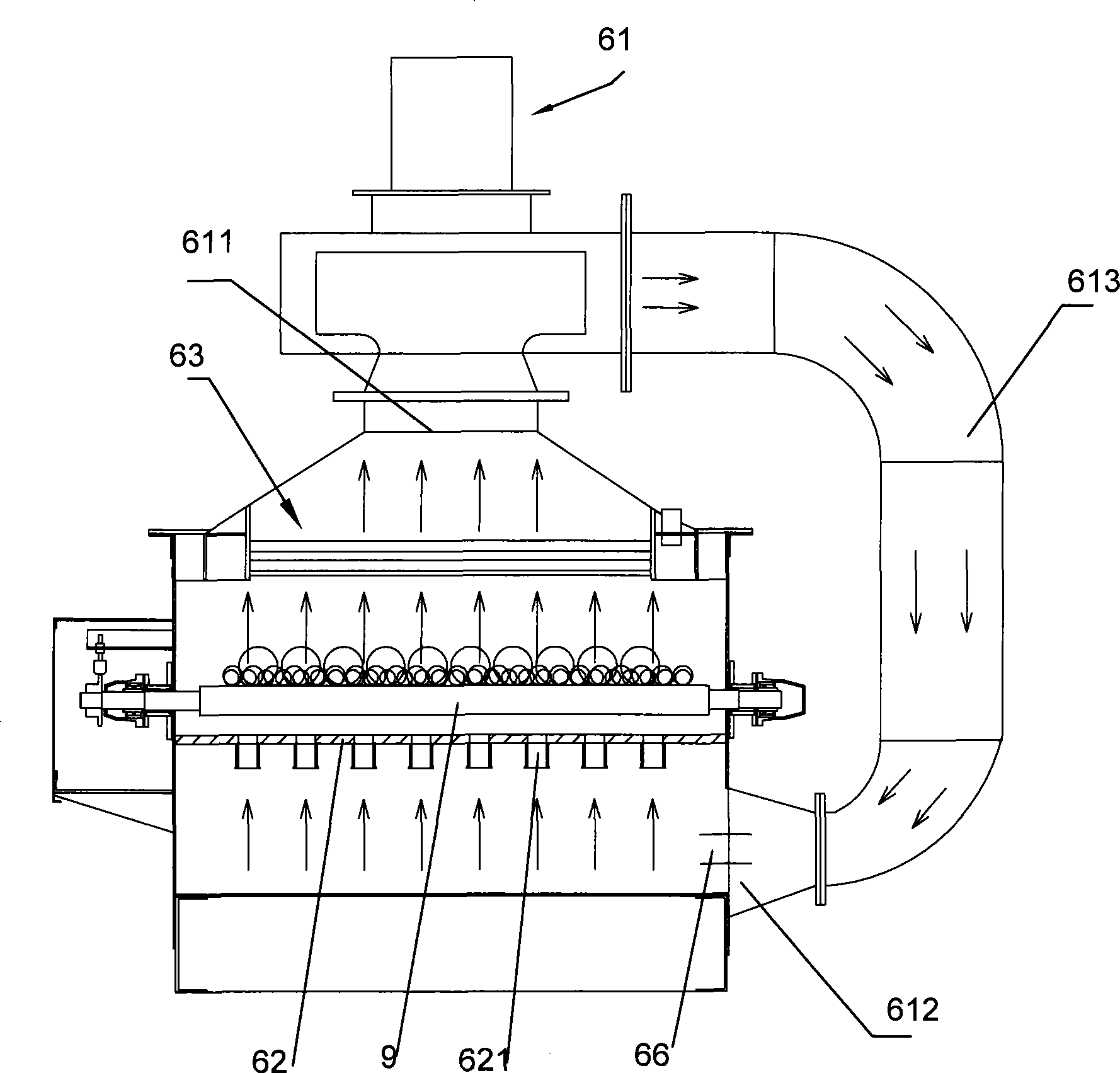

ActiveCN102134633AAchieve oxidation-free treatmentFull convectionFurnace typesHeat treatment furnacesStress relaxationGraphite particle

The invention relates to a precise heat treatment method of a high-precision elastic element. In the invention, quenching is carried out by adopting a fluidized particle furnace and elastic element quenching treatment equipment, wherein graphite particles are used as a heating medium and optimized design is carried out on the quenching temperature, the heat preservation time and the cooling manner so that the non-oxidation quenching treatment of the high-precision elastic element is realized and the surface quality and the size precision of the high-precision elastic element are improved; according to the quenching rigidity of the high-precision elastic element, proper technological parameters are selected to carry out tempering treatment; and loading ageing treatment is conducted to the element by adopting elastic element loading treatment equipment so that the stress relaxation property of the elastic element is improved, the stress in the winding process is reduced and the micro-yield strength is effectively improved. Through the heat treatment method of the invention, the high-precision elastic element is free of oxidation on the surface, free of deformation on the size and stable in mechanical property after the quenching, and the reliability and the quality of the heat treatment of the high-precision elastic element are improved.

Owner:BEIJING SATELLITE MFG FACTORY

Intelligent heat treatment production line

PendingCN110747325AReasonable locationSmall footprintFurnace typesHeat treatment process controlProduction lineCooling tower

The invention discloses an intelligent heat treatment production line. The intelligent heat treatment production line comprises an operation control center, a control cabinet system, a plurality of quenching furnaces and tempering furnaces, an automatic lifting type quenching tank, a transferring forklift, a nitrogen generation system, a cooling system, a waste gas purification system, a normalizing table, a feeding station and a discharging station, wherein the quenching furnaces, the tempering furnaces, the normalizing table, the feeding station and the discharging station are sequentially arranged in the same straight line; the automatic lifting type quenching tank is a sinking type quenching tank and is parallel to the quenching furnaces; the transferring forklift runs above the automatic lifting type quenching tank in the path parallel to the quenching furnaces and the tempering furnaces; the nitrogen generation system communicates with the quenching furnaces through pipelines; the cooling system comprises a plurality of cooling towers communicating with the automatic lifting type quenching tank through pipelines; the waste gas purification system communicates with the quenching furnaces, the tempering furnaces and the automatic lifting type quenching tank through waste gas collecting ducts; and the operation control center and the control cabinet system are used for controlling operation of the whole heat treatment production line.

Owner:武汉电炉有限公司

Heat treatment of cam shaft for diesel engine

InactiveCN1940095AAvoid pollutionImprove distributionFurnace typesIncreasing energy efficiencyInductorEngineering

Treatment of diesel engine cam shaft is carried out by high-frequency heating for cam gear, bearing gear and gear, spraying cooling liquid, quenching, taking water as cooling liquid, coating magnetic-conductive powder onto surface of inductor, stopping cooling at 160degree, controlling temper temperature and time and eliminating heat stress. It's cheap, has no crack and environmental pollution.

Owner:YANGDONG CO LTD

Quenching cooling monitoring system

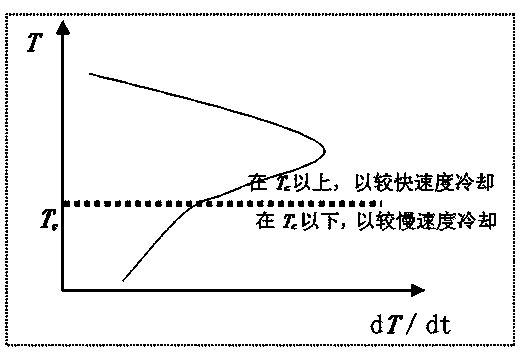

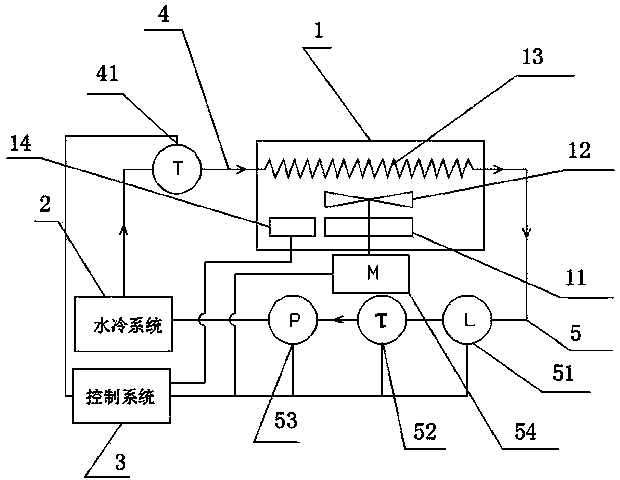

ActiveCN103849758ACooling Capacity AdjustmentEasy to understandHeat treatment process controlControl signalEngineering

The invention discloses a quenching cooling monitoring system, comprising a water-cooling system, a heat exchange system, a control system, a cold delivery pipe, a heat delivery pipe, a cold end temperature measuring meter, a flow meter, a hot end temperature measuring meter and a water pump, wherein a plenum gauge is arranged inside the heat exchange system; the monitoring system calculates and records according to the real-time measurement information fed back by the cold end temperature measuring meter, the flow meter, the hot end temperature measuring meter and the plenum gauge. Thus, the online monitoring function of the cooling process is achieved; the monitoring data can be used as a foundation for quality judgment; the monitoring system also can emit a corresponding real-time control signal according to the actual cooling condition according to the preset and the actual cooling condition; the rotating speeds of a convection fan blade motor and a water-cooling system motor and gas pressure inside the heat exchange system are controlled to achieve the target of adjusting the cooling speed. The implementation of the quenching cooling monitoring system also can be used as equipment for detecting the cooling capacity of a vacuum furnace at regular intervals, and also can be used as an effective tool for a research design of the vacuum furnace. Thus, the energy-efficient target is achieved, and the trend of development of the technology at present is accorded.

Owner:东莞市禾盛金属科技有限公司 +2

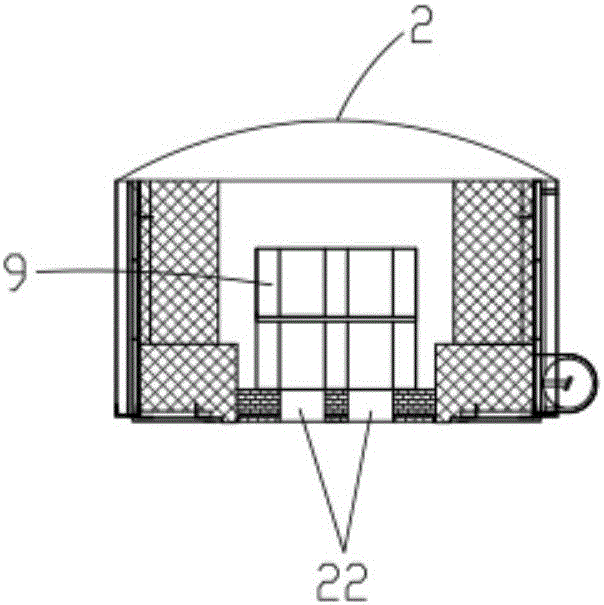

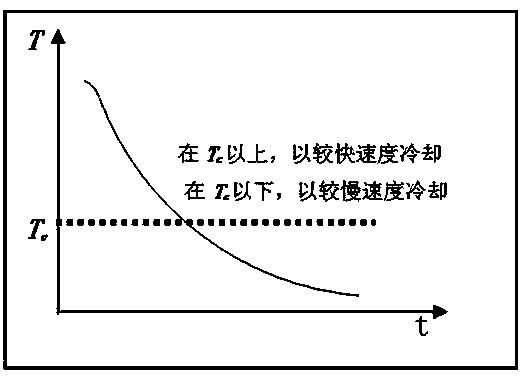

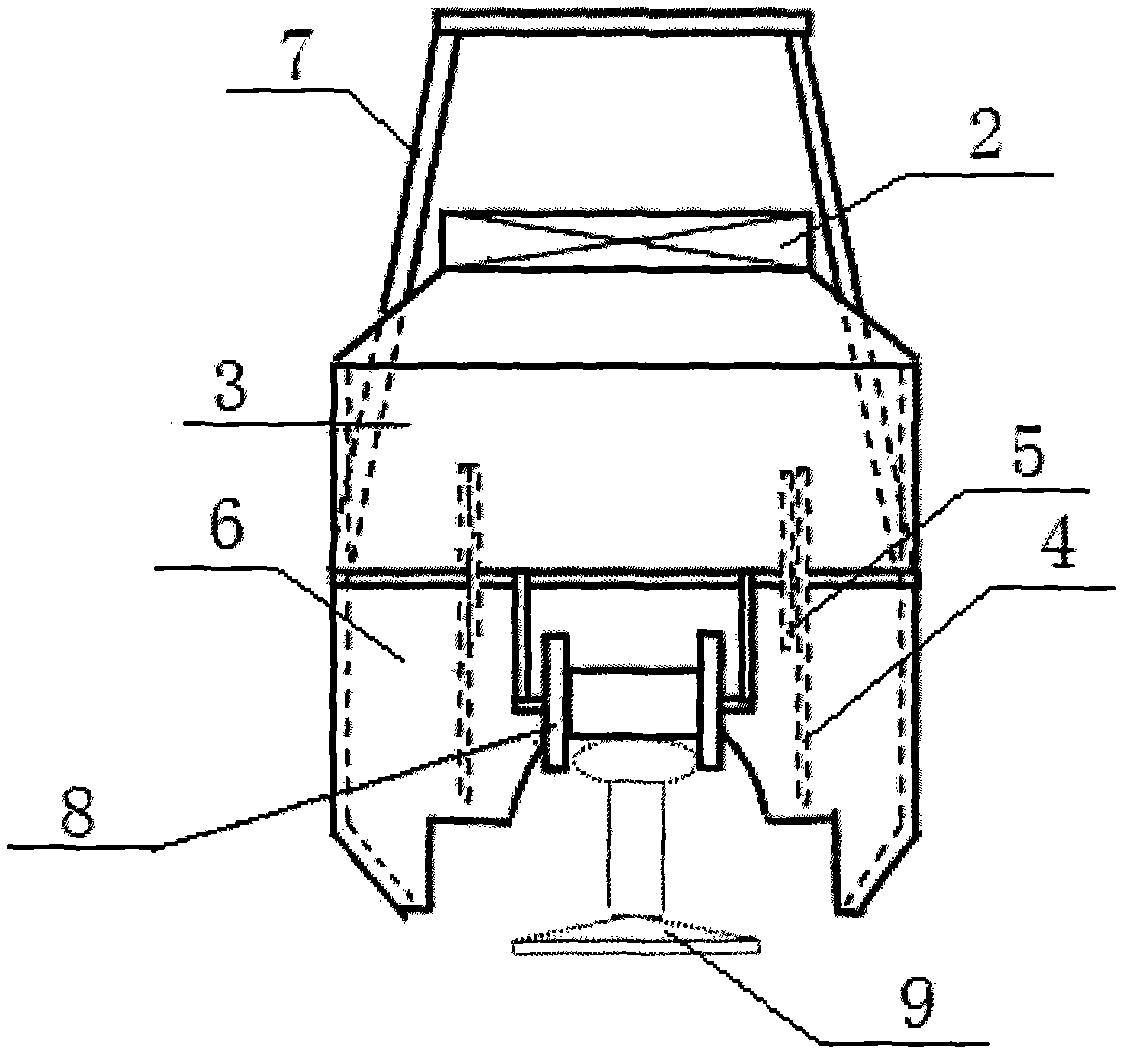

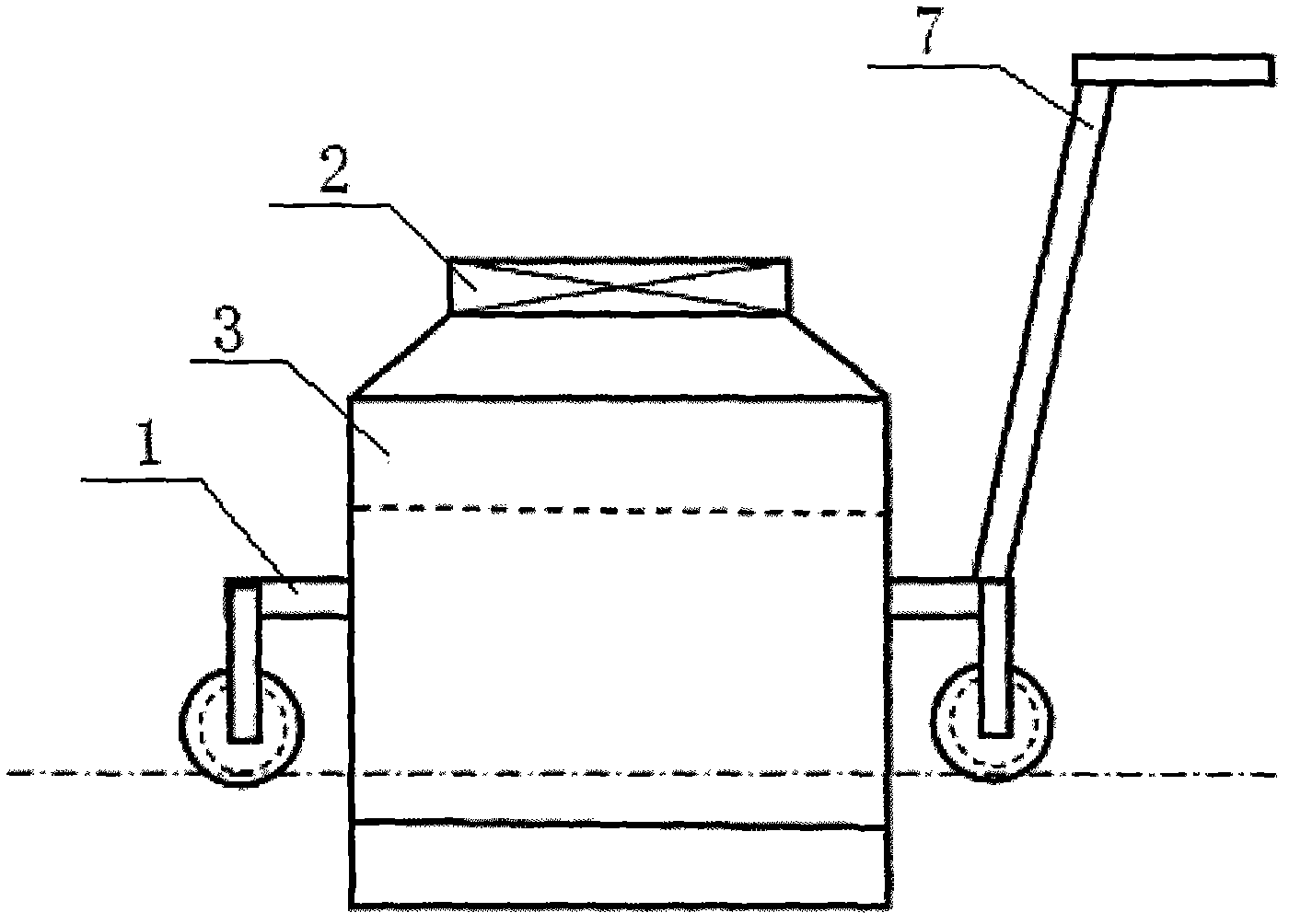

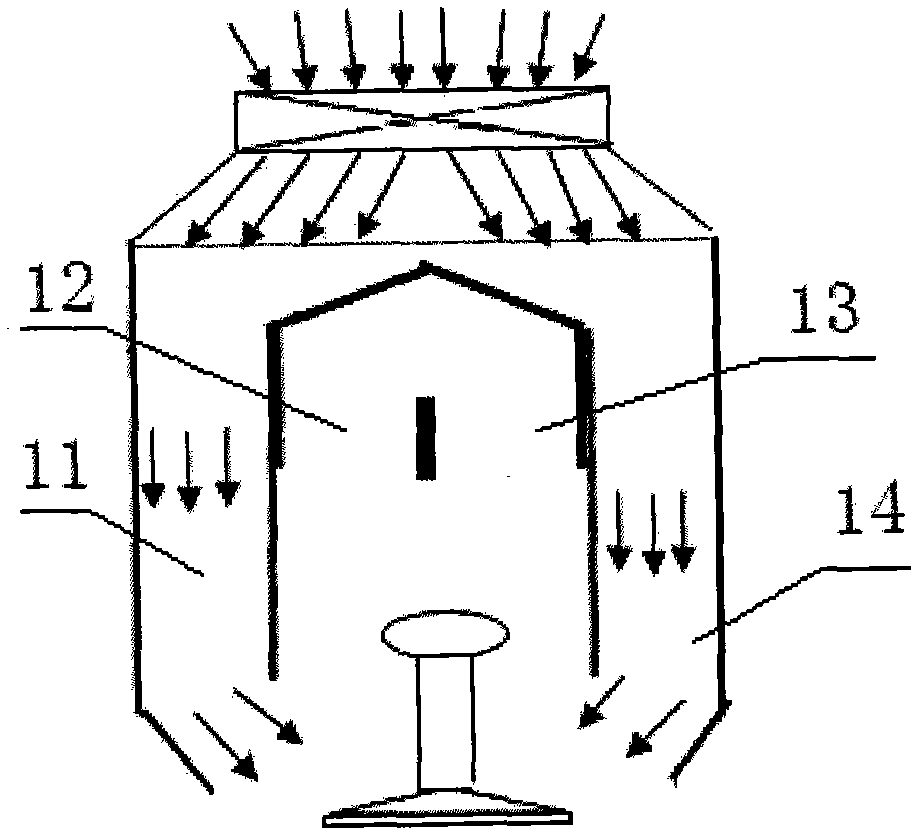

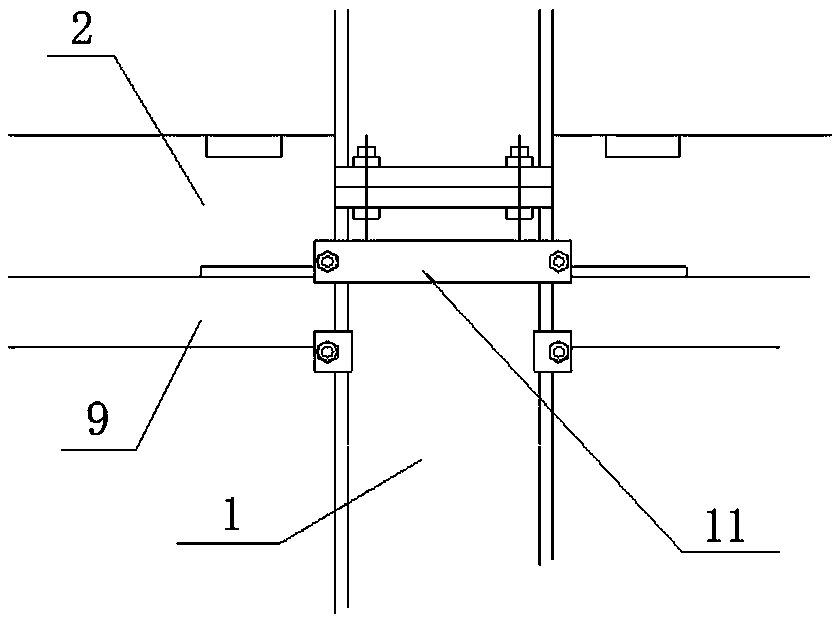

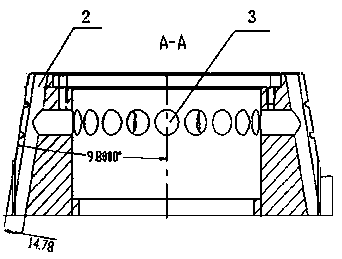

Cooler for cooling on-site welded joint of long steel rail and using method for cooler

InactiveCN102409585AGuarantee welding qualityGuarantee the quality of heat treatmentRailway track constructionAir volumeThermal deformation

The invention discloses a cooler for cooling an on-site welded joint of a long steel rail and a using method for the cooler. The cooler is characterized by comprising a walking support, a cooling fan and a cooling wind path distributing device, wherein the cooling wind path distributing device is fixed on the walking support; the cooling fan is arranged on the top of the cooling wind path distributing device; the cooling wind path distributing device has a bottomless empty tank shape; the lower part of the tank body is inwardly folded; wind path partitioning boards and a wind path switch are arranged in the tank; the wind path partitioning boards partition the tank body into a plurality of vertical spaces; and the tops of the wind path partitioning boards are moveably connected with the wind path switch. The using method comprises the following steps of: pushing the cooling wind path distributing device which is connected with an external power supply along the steel rail to a position above the on-site welded joint; turning on a switch of the cooling fan; distributing wind generated by the cooling fan to a part required to be cooled according to a certain sequence and a certain wind amount; and making the center of the cooling wind path distributing device uniformly swing within a range of 10cm around the welded joint so as to fulfill the aim of uniform cooling. The appearance of the welded joint is corrected by using a rule of thermal deformation in the cooling process, so that the appearance qualification rate of the welded joint is improved, the appearance polishing workload is reduced, and the product quality is improved.

Owner:中铁二十二局集团第二工程有限公司 +1

Large-diameter thick walled pipe postweld heat treatment method

ActiveCN107641702AGuarantee the quality of heat treatmentGuaranteed one-time successFurnace typesHeat treatment furnacesEconomic benefitsTemperature difference

The invention provides a large-diameter thick walled pipe postweld heat treatment method. By adopting the large-diameter thick walled pipe postweld heat treatment method provided by the invention, insulating temperature is determined according to a hardness range of a base material in the postweld heat treatment process, simultaneous heating of an inner wall and an outer wall is adopted, a heatingwidth is determined according to a formula, a power of a heater is determined according to a formula, and thus the heat treatment quality of a weld crater is effectively ensured, a temperature difference between the inner wall and the outer wall of the weld crater in postweld heat treatment is lowered to meet the standard requirement or a higher standard to avoid the phenomenon of base material overburning or difference between the weld crater properties of the inner wall and the outer wall caused by a temperature deviation, weld crater heat treatment can be ensured to mold at a time at the same time to avoid the phenomenon of heat treatment again, the heat treatment effect is improved, and the economic benefit is very considerable.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

Method for calculating position of highest temperature point of postweld heat treatment of 9-12% Cr martensitic heat-resistant steel vertical arrangement pipeline

InactiveCN103602802AQuick calculationImprove reliabilityFurnace typesHeat treatment process controlElement analysisComputational model

The invention relates to a method for calculating position of highest temperature point of postweld heat treatment of a 9-12% Cr martensitic heat-resistant steel vertical arrangement pipeline. The method provided by the invention is characterized by comprising the following steps that 1, a theoretical highest temperature point calculation module is used for establishing T groups of calculation models of postweld heat treatment temperature fields of the 9-12% Cr martensitic heat-resistant steel vertical arrangement pipelines with different sizes under different heating widths, different heat preservation widths, different heat treatment environment temperatures and different heat treatment temperatures on the basis of a heat transfer theory, and calculating the position of the highest temperature point of heat treatment under corresponding conditions through a finite element analysis method; 2, a BP neural network model module; 3, a prediction model creating module; 4, a model correcting module; 5, a highest temperature point determining module. The method provided by the invention can be used for conveniently and quickly calculating the position of the highest temperature point of the post weld heat treatment of the 9-12% Cr martensitic heat-resistant steel vertical arrangement pipeline.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

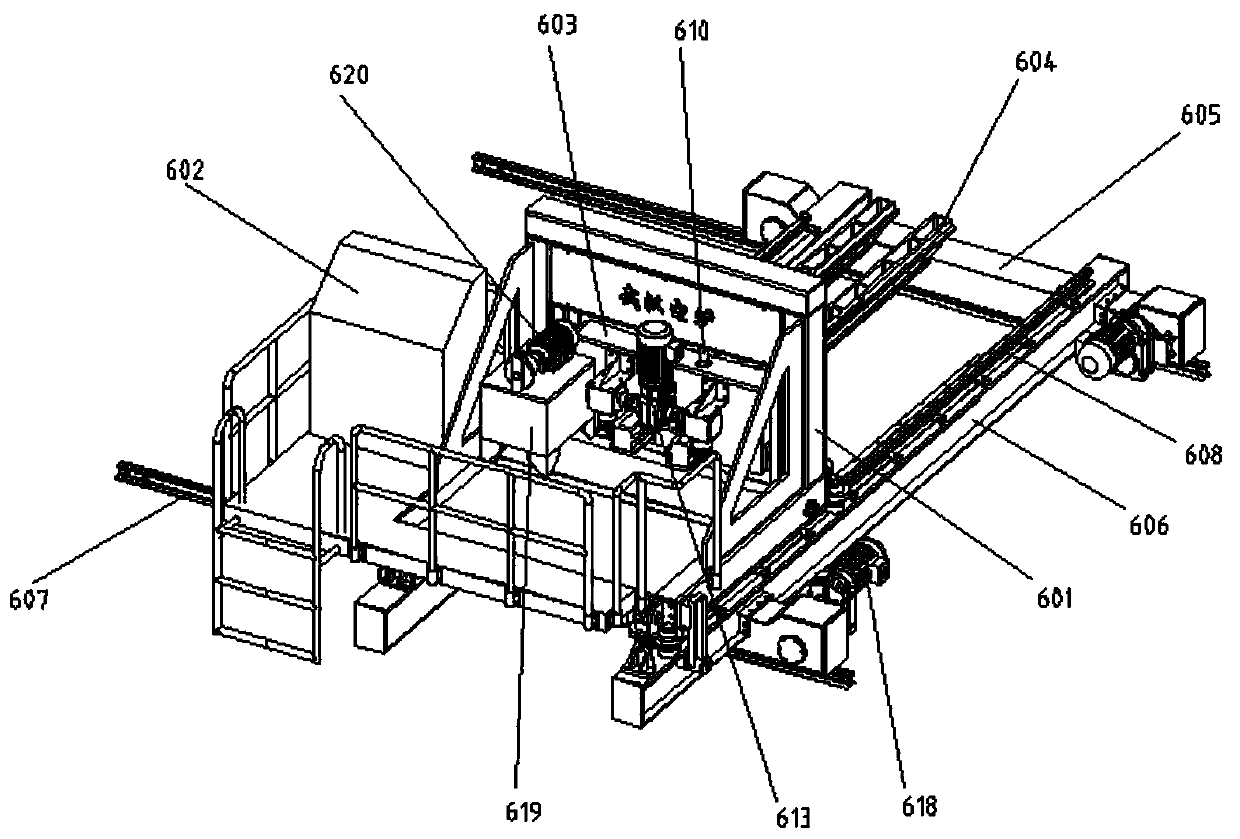

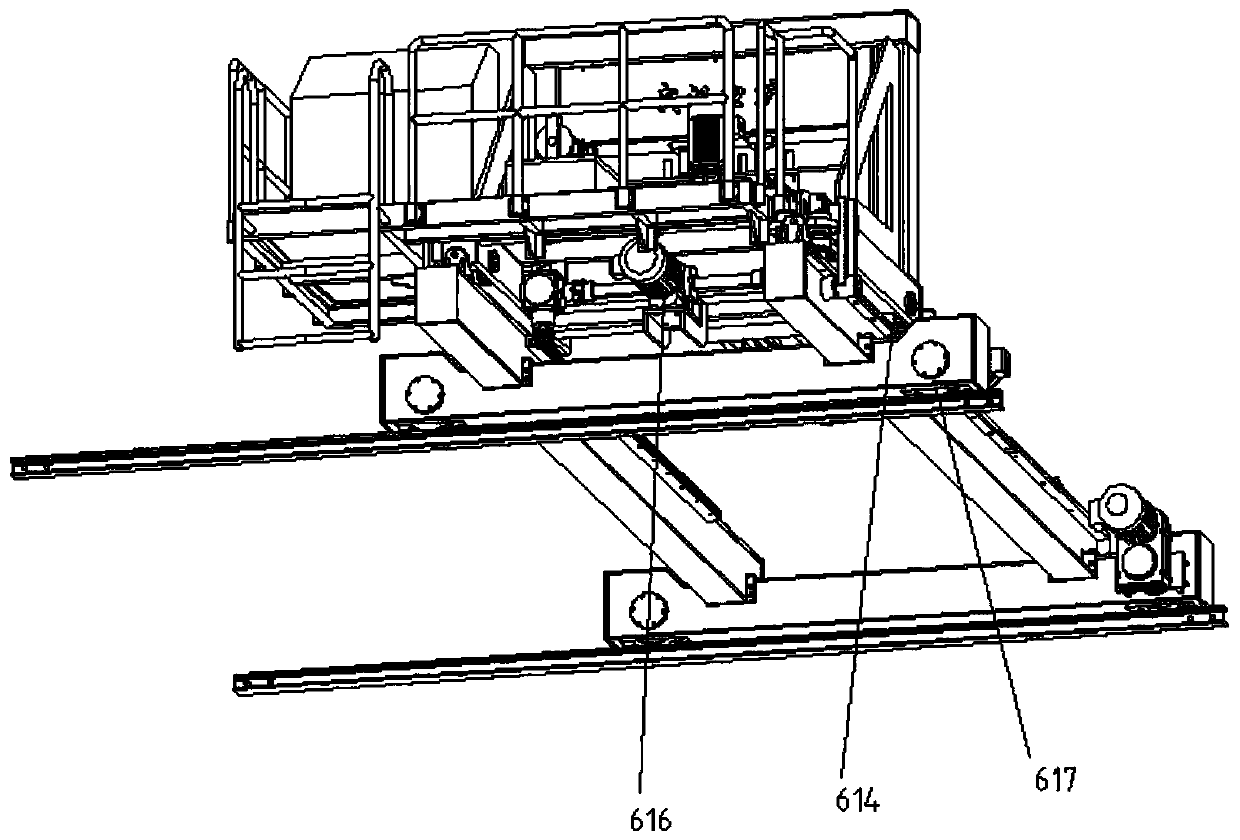

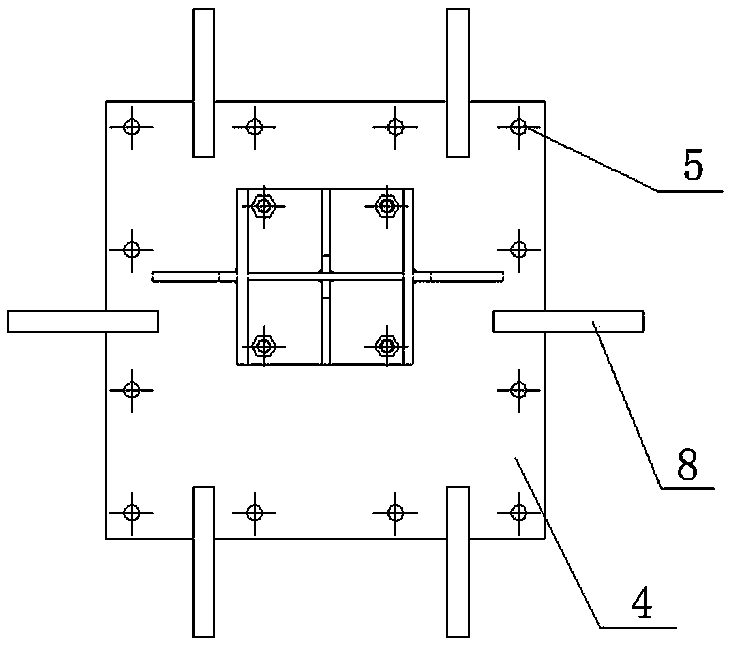

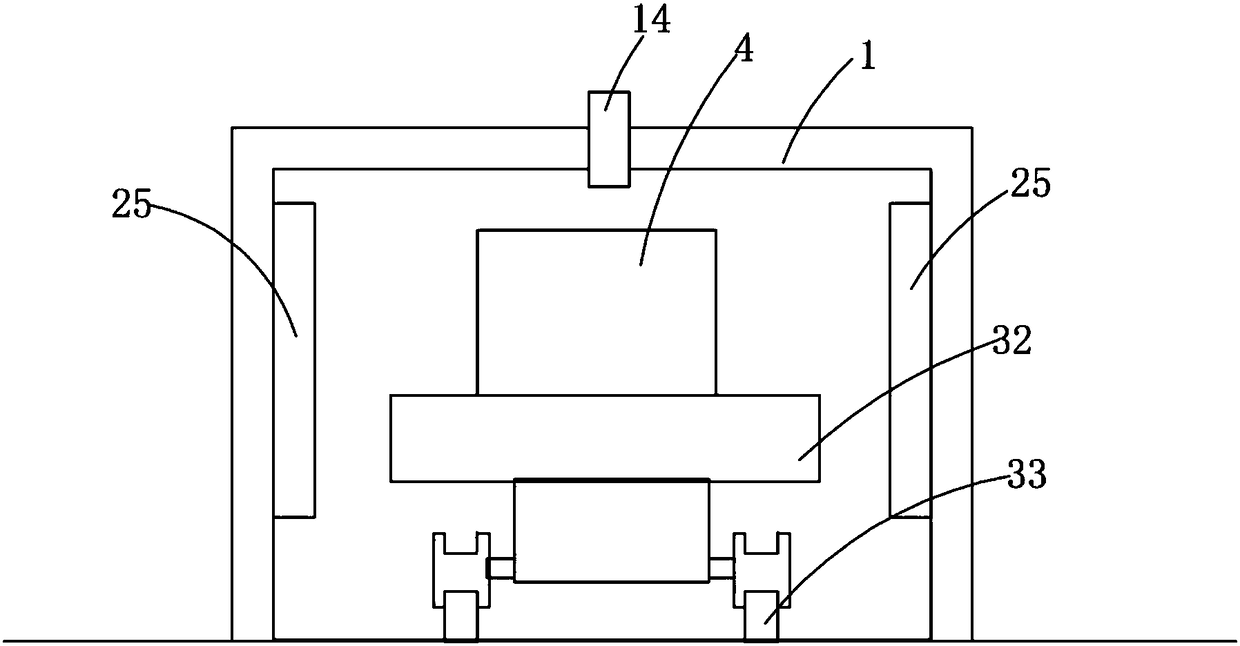

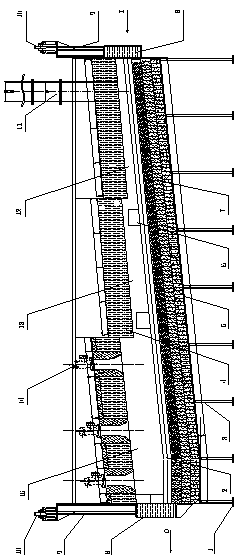

Automatic feeding mechanism for furnace

InactiveCN102767963AGuarantee the quality of heat treatmentAvoid getting togetherCharge manipulationPortal frameSignal acquisition

The invention discloses an automatic feeding mechanism for a furnace and belongs to the field of furnace facilities. The automatic feeding mechanism comprises a feeding roller rack, a feeding roller, a transition roller and a feeding roller driving device and also comprises an overhead frame, a workpiece channel opening / closing device, a workpiece signal acquisition unit adjusting device and a workpiece signal acquisition device, wherein the overhead frame comprises a pair of portal frames and a crossbeam; a workpiece channel opening / closing device is arranged along the length direction of the crossbeam; the workpiece signal acquisition unit adjusting device is fixed on the top of the pair of portal frames; the workpiece signal acquisition device is arranged on the workpiece signal acquisition unit adjusting device; a feeding roller workpiece isolating flange ring is arranged in the length direction of the feeding roller; a transition roller workpiece isolating flange ring is arranged in the length direction of the transition roller; a workpiece signal acquisition device is correspondingly arranged above a workpiece lead-in channel; and the transition roller is in transmission connection with the transition roller driving device. The working efficiency is guaranteed, the quality is ensured, the energy is saved, and the labor intensity is lightened.

Owner:SUZHOU HUIKE EQUIP CO LTD

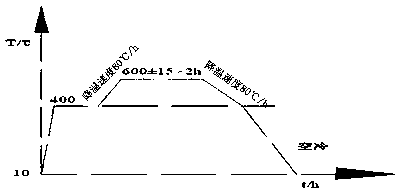

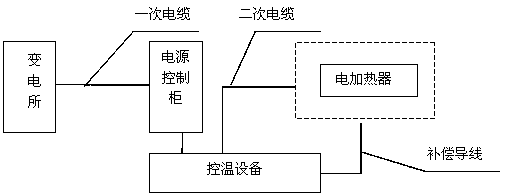

Movable assembly type heating furnace capable of carrying out electric heating in furnace to eliminate stress and construction method thereof

The invention relates to a movable assembly type heating furnace capable of carrying out electric heating in the furnace to eliminate stress and a construction method thereof. The heating furnace comprises ground beams, stand columns, a furnace cover, furnace body plates, a temperature measuring device, an electric heating device and a component support. A plurality of ground beams are spliced toform a plane furnace bottom. Base anchors are welded to the bottoms of the stand columns. The stand columns and the ground beams are vertically connected by the adoption of bolts. A plurality of furnace body plates are laid between the stand columns and on the inner side of the furnace cover. The temperature measuring device comprises a plurality of thermocouples and temperature recorders. The electric heating device comprises temperature control cabinets and a plurality of electric heating plates. The temperature control cabinets and the thermocouples are connected by the adoption of compensating lead wires. According to the heating furnace, in the process of centralized overall heat treatment of an installing and welding framework of a steel structure framework, centralized heat treatment of all the processes of heat treatment can be completed at a time; compared with a traditional electric heating fin tying method adopting local heat treatment, the heating furnace has the characteristics that construction is convenient, the stress eliminating effect is good, the recycling rate of a heat preserving material is high, consumed labor time is short, the cost is low, and efficiency ishigh; the heat treatment quality is ensured, the first-pass yield of heat treatment is increased greatly, the site installing efficiency is improved greatly, all joints can be assembled and disassembled rapidly, and recycling is convenient.

Owner:CHINA CHEM ENG SECOND CONSTR

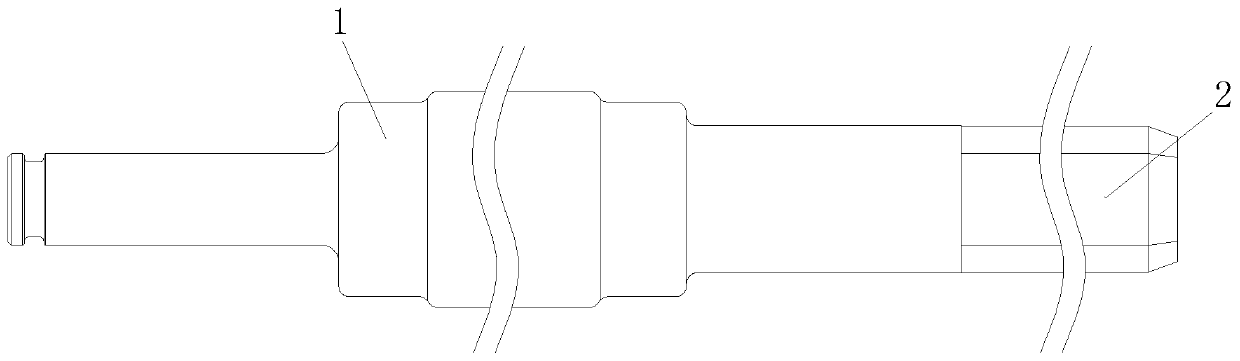

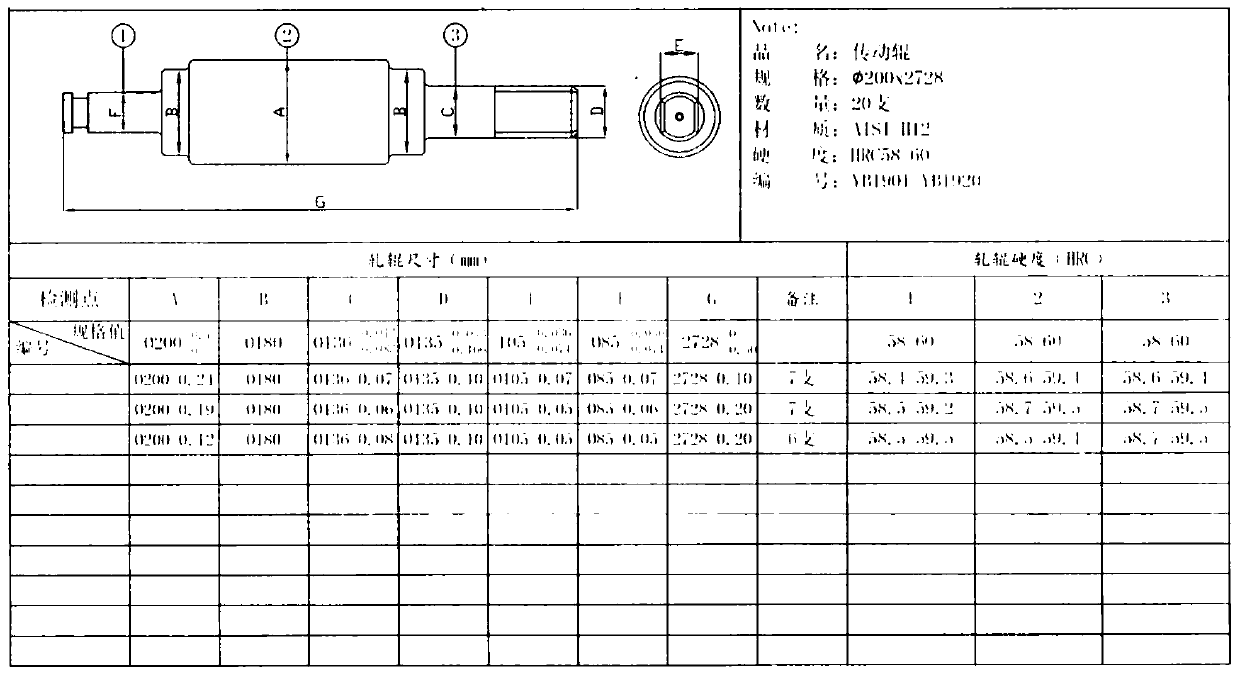

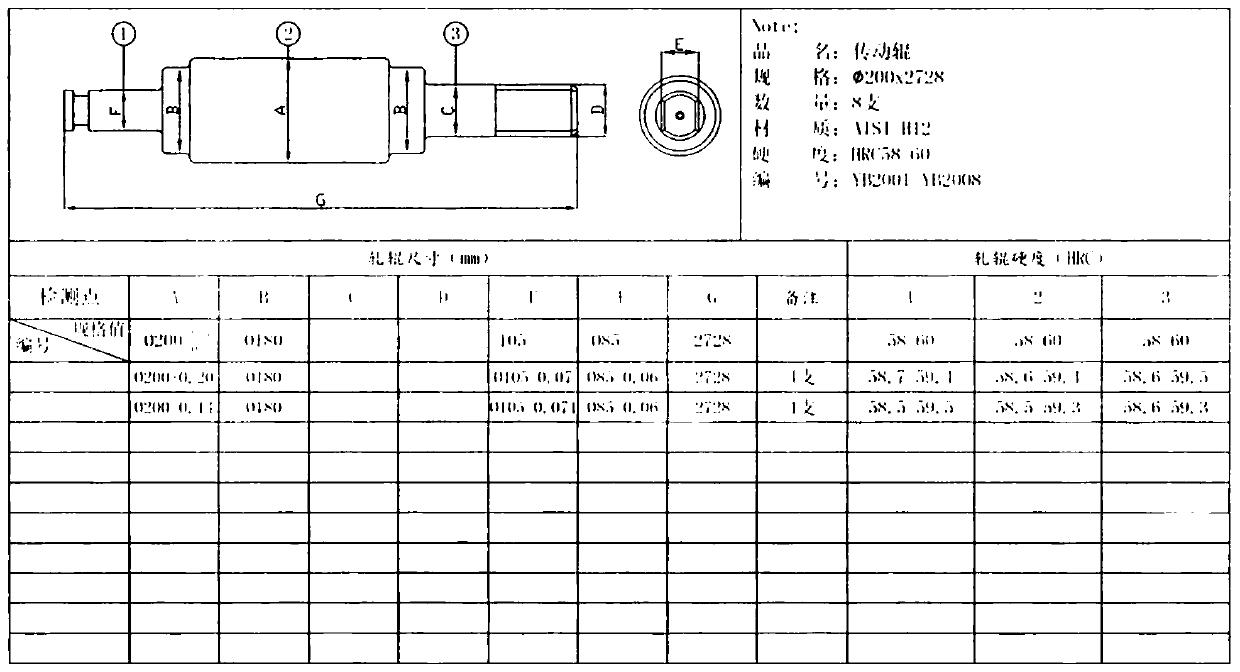

Novel cold rolled driving roller heat treatment process

PendingCN111549205AHigh hardnessReduce deformationFurnace typesHeat treatment furnacesTemperingEngineering

The invention relates to the technical field of cold rolled driving roller heat treatment, and discloses a novel cold rolled driving roller heat treatment process. According to the process, a workpiece and a driving side end are included, wherein the driving side end is located at one end of the workpiece, the workpiece and the driving side end are firstly subjected to preheating treatment, and then is subjected to heating, a heated workpiece is subjected to constant-temperature quenching, the quenched workpiece and the driving side end are cooled, then low-temperature tempering is carried out, after low-temperature tempering is conducted, heating and preheating are carried out, then two-time high-temperature tempering is carried out, and a cold rolled driving roller is preheated after subjected to high-temperature tempering and cooling, high-temperature tempering is performed on the driving side end separately and then cooling is conducted. According to the novel cold rolled driving roller heat treatment process, residual austenite can be converted into martensite, after secondary high-temperature tempering, the residual austenite accounts about 8%-10%, the residual austenite is converted into the martensite, the wear resistance and the service life of the cold rolled driving roller are effectively increased and prolonged, the crack condition is effectively solved during rolling by a customer, and the service life of a roller is prolonged.

Owner:WUXI YIBAO MACHINERY EQUIP CO LTD

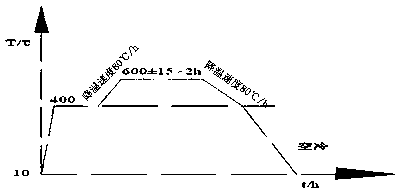

Product heat treatment process

InactiveCN108106419AImprove consistencyRealize continuous deliveryFurnace typesEngineeringHeat treated

The invention provides a product heat treatment process for solving the problem of generation of cracks in products, nonuniform density and low heat treatment efficiency in the prior art. The productheat treatment process comprises the following steps: (S1) products are positioned in a first temperature environment for preheating; (S2) the products are positioned in a second temperature environment for roasting or insulation; and (S3) the products are positioned in a third temperature environment for cooling; the first temperature environment and / or the third temperature environment are constant temperatures; the second temperature environment is a constant temperature; and the temperature of the second temperature environment is higher than the temperatures of the first temperature environment and the third temperature environment. The products are transited in the heating and cooling process, so that the condition of extreme cooling and extreme heating is prevented, and the qualityof the products is improved.

Owner:CISDI ENG CO LTD +1

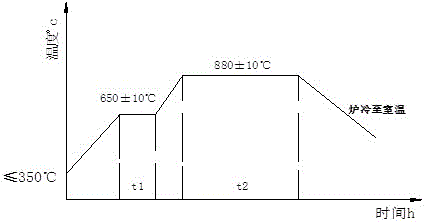

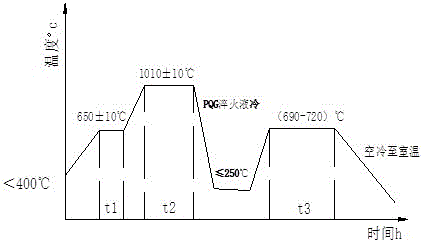

High-performance and high-corrosion-resistant mandrel hanger material and heat treatment method thereof

ActiveCN106011682ASimple heat treatment processQuality improvementFurnace typesHeat treatment furnacesRoom temperatureHardness

The invention discloses a high-performance and high-corrosion-resistant mandrel hanger material and a heat treatment method thereof. The material is prepared from the following components in percentage by mass: 0.10-0.15% of C, 0.20-0.40% of Si, 0.60-0.70% of Mn, less than or equal to 0.025% of P, less than or equal to 0.025% of S, 12.50-13.50% of Cr, 0.20-0.30% of Mo, less than or equal to 0.2% of Cu, 0.50-0.60% of Ni, less than or equal to 0.1% of V, 0.10-0.25% of Sn, less than or equal to 0.1% of other microelements and the balance of Fe. The heat treatment method comprises the steps of forging a mandrel hanger blank by using a mandrel hanger material according to a process requirement; preheating the mandrel hanger blank to 650+ / -10 DEG C and preserving the heat, then, heating the mandrel hanger blank to 880+ / -10 DEG C and preserving the heat, and then, carrying out furnace cooling to the room temperature; and after annealing, preheating the mandrel hanger blank to 650+ / -10 DEG C and preserving the heat, then, heating the mandrel hanger blank to 1010+ / -10 DEG C, quenching and preserving the heat, then, taking the mandrel hanger blank out of a furnace, carrying out oil cooling, heating the mandrel hanger blank to 700+ / -10 DEG C, tempering and preserving the heat, then, taking the mandrel hanger blank out of the furnace, carrying out air cooling. A mandrel hanger disclosed by the invention has the mechanical property of 75K, the impact property of 35J (60 DEG C below zero) and the hardness of 220+ / -2HB and is improved in corrosion stability and high in product safety.

Owner:JIANGSU JINSHI CASTING & FORGING

Non-strengthening heat treatment construction technology for over-sized device aerial strength weld

InactiveCN107043849AGuarantee the quality of heat treatmentGuaranteed feasibilityFurnace typesHeat treatment process controlTemperature stressPetrochemical

The invention relates to a non-strengthening heat treatment construction technology for an over-sized device aerial strength weld. Along with the fast development of maximization, modularization and automation of a petrochemical device, compared with an overall lifting technology, an over-sized device aerial assembling technology can relieve the pressure of field plane arrangement and can also reduce the parameter grade of a crane; however, high-temperature stress will be certainly generated at the weld position to cause cylinder deformation when the aerial weld is affected by the factors such as the heating temperature, the constant-temperature time, the weld upper portion device weight and the wind load during heat treatment. By means of the non-strengthening heat treatment construction technology for the over-sized device aerial strength weld, targeted safety technological measures are implemented through data mastered through a material high-temperature test under the premise that the device aerial heat treatment weld is not strengthened, the heat treatment quality of the weld is ensured, feasibility of the technology is forcefully verified, and the non-strengthening heat treatment construction technology is worthy of being applied and popularized in the same industry.

Owner:陕西化建工程有限责任公司

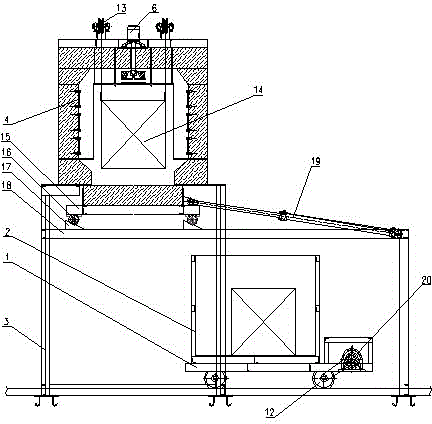

Non-oxidation energy saving ageing furnace of nonferrous metal

InactiveCN105695903ANo damage to the structureNovel ideaFurnace typesHeat treatment furnacesElectricityFurnace temperature

A non-oxidation energy saving ageing furnace of nonferrous metal comprises a furnace frame and a pusher, the upper portion of the furnace frame is fixedly provided with a heat insulation fiber module, the lower portion of the furnace frame is fixedly provided with a track, a track pedestal is provided with wheels and a motor, the motor is connected with the wheels through a driving belt, the pusher pedestal is also fixedly provided with a heat insulation fiber modulus, an electric heating element and a stainless steel inner container, he opening of the inner container is covered with a furnace cover, a sealing ring is arranged between the inner container opening and the furnace cover, the inner container opening and the furnace cover are fixed, sealed and locked through a compacting device, the furnace cover is fixedly provided with a preliminary vacuum pumping tube and a protection gas inlet tube which are introduced to the inner container, the heat insulation fiber module of the pusher abuts on the heat insulation fiber module of the furnace rack to form a closed hearth, and the inner container and the electric heating element are fixedly placed in the hearth. The furnace has the advantages of novel conception and reasonable design, allows gas flow in the hearth to be repeatedly cycled, and also allows a workpiece to be indirectly heated by using heat convection in order to avoid damages to the structure of the workpiece and maximally guarantee furnace temperature uniformity.

Owner:潘亚辉

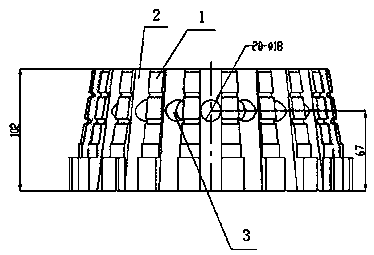

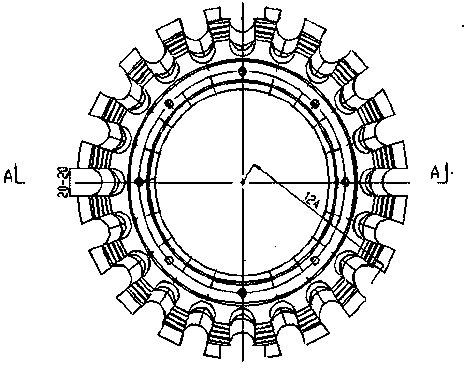

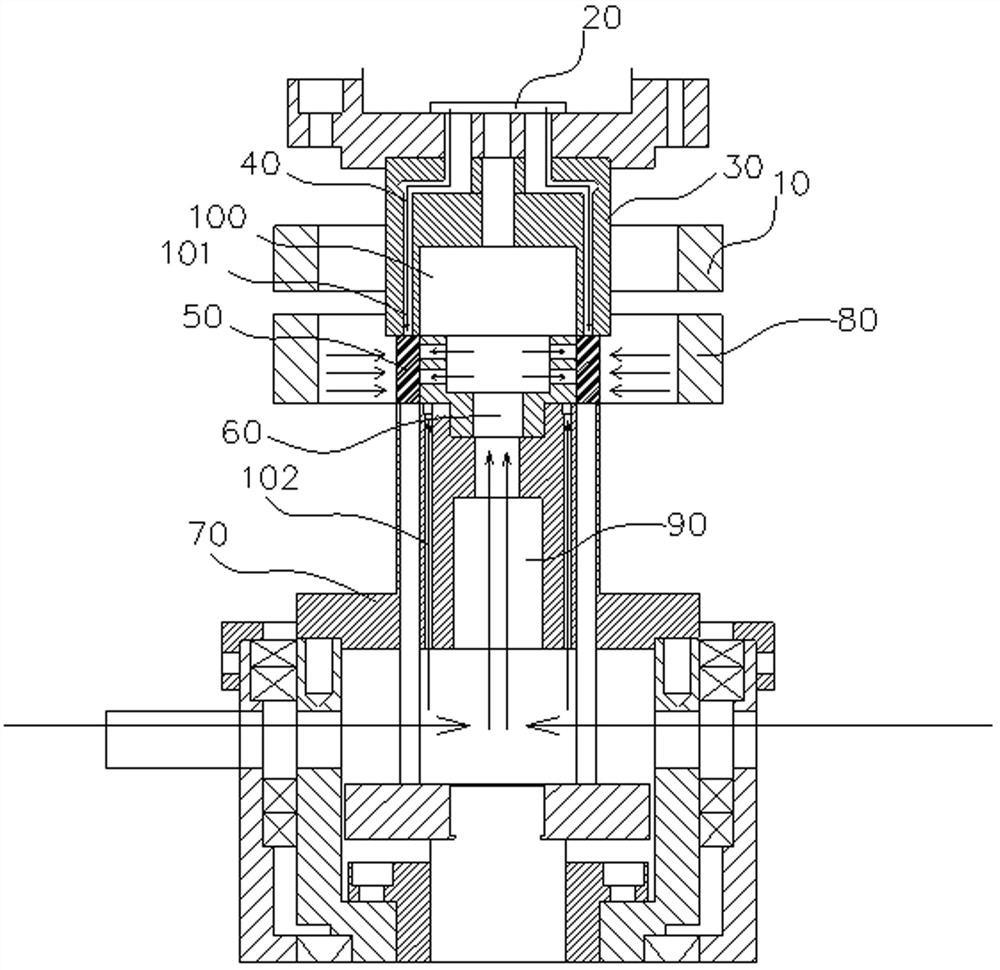

Carburizing steel bearing quenching mold

PendingCN109338057AImprove quenching and cooling capacityHigh hardnessFurnace typesHeat treatment furnacesCooling capacityQuenching

The invention relates to a bearing quenching mold, in particular to a carburizing steel bearing quenching mold in the heat treatment process of a wagon and belongs to the technical field of bearings.An upper mold and a lower mold are included; the lower mold is of a cone frustum structure; the circumferential side wall of the lower mold is uniformly provided with a plurality of oil passing grooves in the longitudinal direction, and each oil passing groove is provided with an oil passing hole; a transverse oil passing hole is added for the mold, quenching oil is circulated both inside and outside the quenching mold, and the quenching cooling capacity is improved; the oil grooves for oil passing of the mold are widened, the oil passing amount is large, the mold quenching and cooling capacity is further improved, the carburizing steel bearing core hardness is improved, and therefore the heat treatment quality and the service life of the wagon bearing are guaranteed; and the carburizing steel bearing quenching mold after being optimized thoroughly solves the problem that core hardness is low.

Owner:WAFANGDIAN BEARING GRP STATE BEARING ENG TECH RES CENT CO LTD

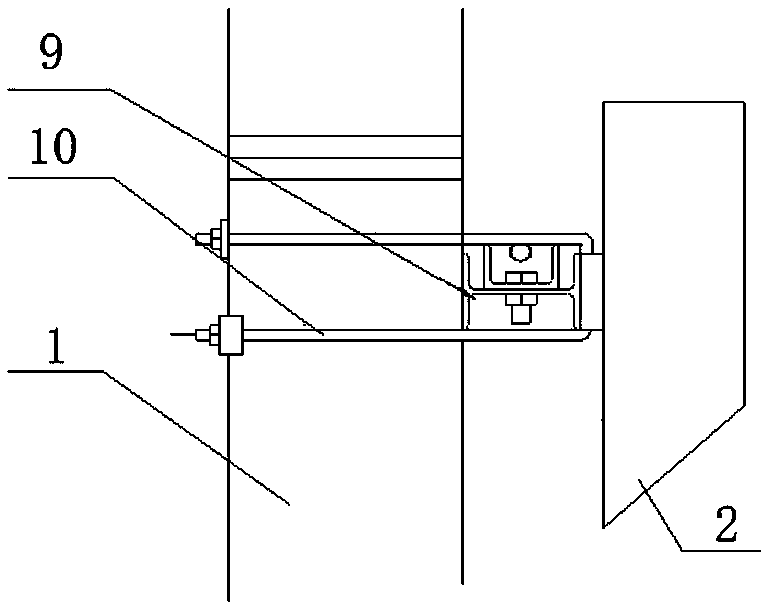

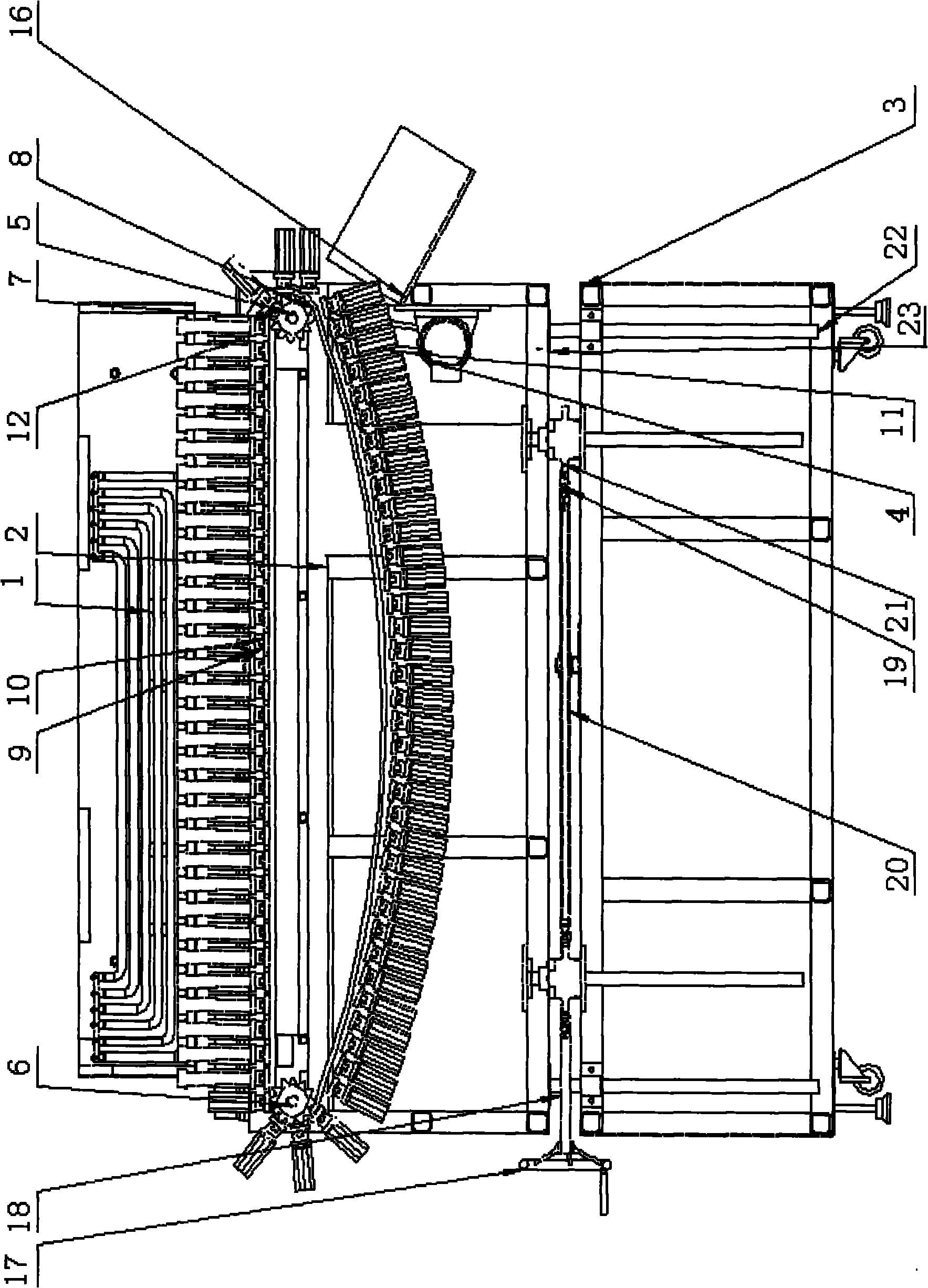

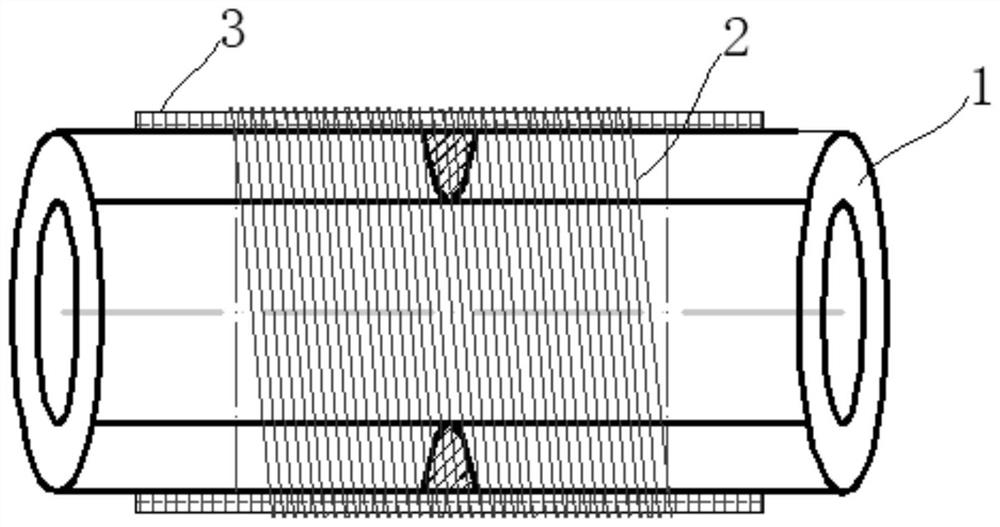

End induction heating device

InactiveCN101864513AGuarantee the quality of heat treatmentSimple structureIncreasing energy efficiencyFurnace typesHeating timeEngineering

The invention discloses an end induction heating device comprising a U-shaped heating furnace with a reverse cross section and a vertical-type conveyer. The heating furnace is located on the upper part of the vertical-type conveyer; a U-shaped port of the heating furnace corresponds to a chucking port of the vertical-type conveyer; besides, the vertical-type conveyer comprises a transmission device, a conveying device, a lifting device, a positioning and guiding device, a stand and a lift rack, wherein the lifting device is arranged on the lifting rack; the transmission device, the conveying device and the positioning and guiding device are arranged on the stand; and the stand is located on the upper part of the lifting rack. The invention has simple structure, is easy to operate, ensures that workpieces are arranged sequentially in the heating process under the coactions of a conveying chain and a V-shaped block and can successfully enter the U-shaped heating furnace, can control the heating time and the heating surface favorably, ensures the thermal treatment quality of the workpieces, and can be used for heating the step sections of ladder cylindrical or square materials and other materials that can be clamped by a V shape.

Owner:FIVE POWER ELECTRICAL TECHKUNSHAN

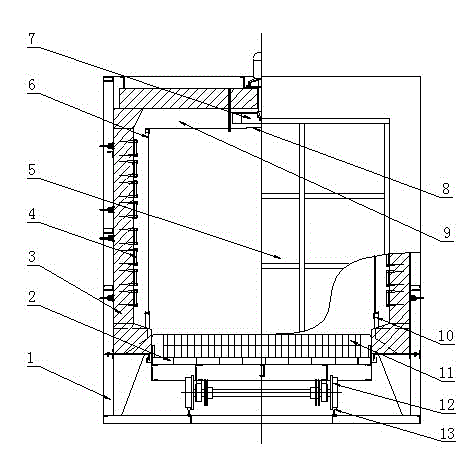

Rapid quenching furnace

A rapid quenching furnace is composed of a furnace body, a bogie, a rapid joint, a movable furnace door, a flue and a closed device, the furnace body is arranged on the bogie, the flue is arranged at the top of the furnace body, one side of the furnace body is provided with the movable door, a workpiece is arranged in the furnace body, the flue is composed of a main flue and a branch flue, and the branch flue is provided with the closed device. The rapid quenching furnace has the advantages of novel conception and reasonable design; the opening of the furnace is downward, the furnace body is inversely arranged on a steel structure furnace rack, and the furnace door rolls along a track from a cylinder to complete opening and closing motion, so the opening time is greatly shortened; and the workpeice inversely suspends in a hearth through a hoisting chain and undergoes heating treatment, then the furnace door is rapidly opened, the workpiece rapidly downslides through the hoisting chain, falls into a water tank of a water tank vehicle, and undergoes solid solution treatment, so the whole solid solution process is completed in a shortest time, and the heat treatment quality is ensured.

Owner:潘亚辉

Shaft oxidation annealing furnace

InactiveCN105695681AReduce heat lossGuarantee the quality of heat treatmentTreatment qualityElectric heating

A shaft oxidation annealing furnace comprises a furnace body, the furnace body is composed of a baking area and a drying area, a conveying chain traverses through the furnace body and enters the drying area and the drying area, and a furnace body inlet, an electric heating wire, the conveying chain, a sprocket wheel and a drying furnace connecting plate form the drying area; a baking furnace connecting plate, a baking heating resistance rod, a conveying chain transmission roller and a furnace body discharge opening form the baking area; and the baking area is seamlessly abutted to the drying area through the baking furnace connecting plate and the drying furnace connecting plate. The baking area and the drying area are adopted to substitute heat insulation materials of fireproof bricks or common fibers of old products, so the heat loss is greatly reduced; and a furnace door outlet is sealed and locked, and a direct current blower is arranged in a hearth to realize uniform involution of heat in the furnace, so oxidation-free generation of workpieces of in the processing process is maintained to ensure the heat treatment quality.

Owner:徐艳

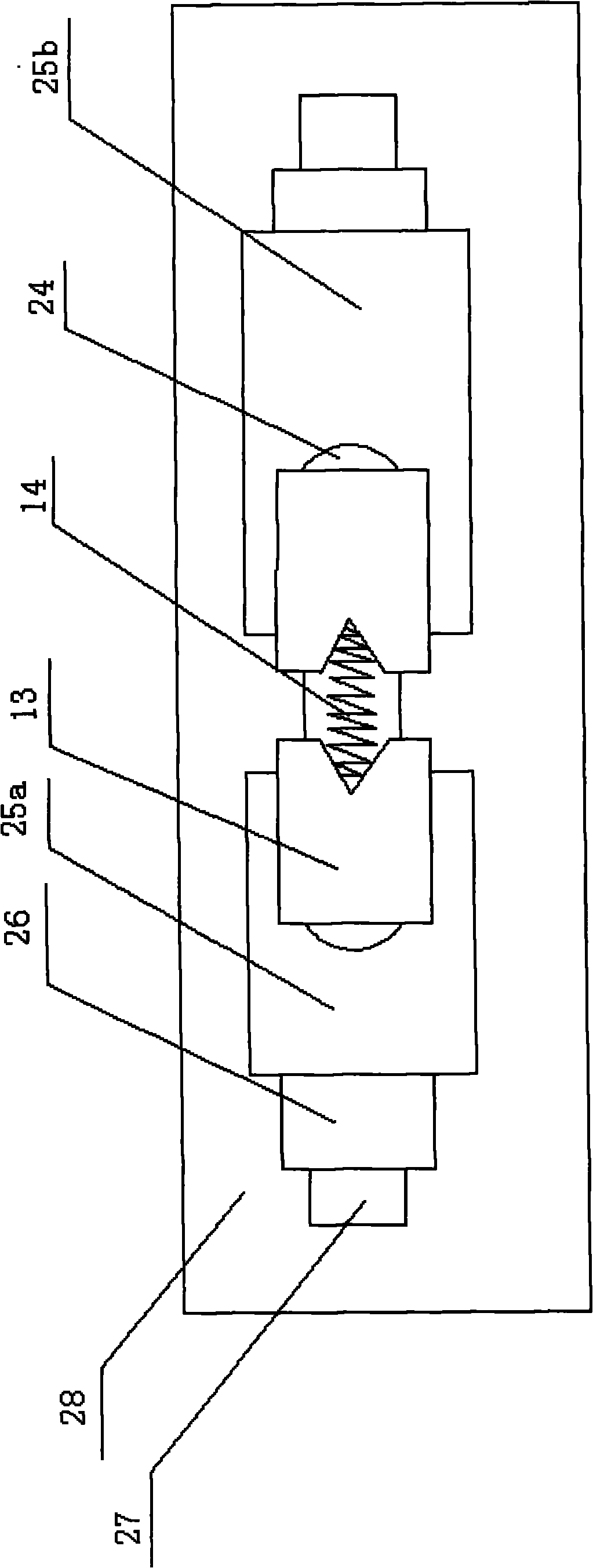

Quick quenching furnace

The invention discloses a quick quenching furnace, relating to the technical field of heat treatment furnaces. The quick quenching furnace comprises a furnace frame (3), a furnace body (21), a furnace door (15), an air cylinder (19), a track (18), a water tank car and a track (9). The quick quenching furnace is characterized in that the furnace body (21) is built by insulated materials and is mounted above the furnace frame (3); a furnace opening faces down; a water tank (2), a motor (20) and wheels (12) are fixed on the water tank car; the motor (20) is connected with the wheels (12) through a belt; the water tank car is arranged on the track (9) through the wheels (12). According to the quick quenching furnace, the furnace opening faces down, the furnace body is mounted on the furnace frame adopting the steel structure upside down, the furnace door rolls along the tracks under the action of the air cylinder to finish opening and closing actions, the opening time is greatly shortened, a workpiece is hung in a hearth upside down through a lifting chain and is subjected to heat treatment, the furnace door is quickly opened after the workpiece is heated, the whole solid solution process is finished within the shortest time, and the heat treatment quality is ensured.

Owner:江苏华烨炉业有限公司

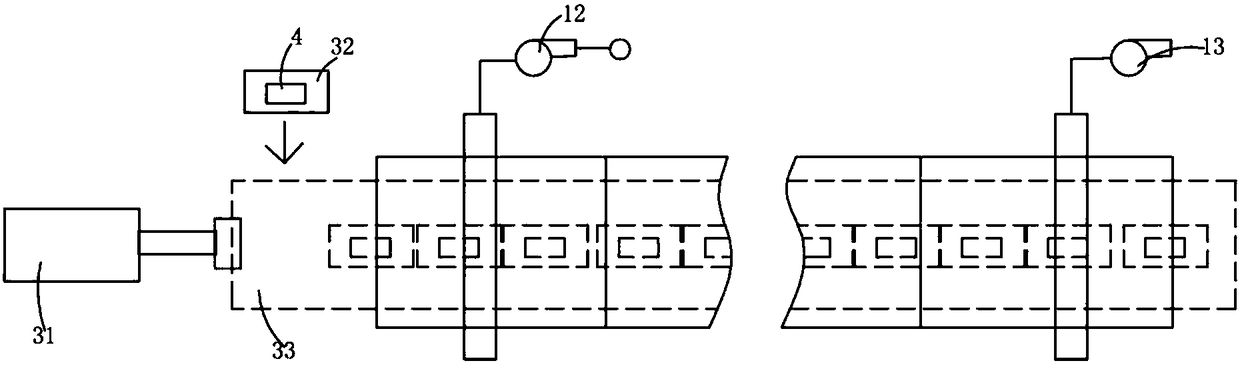

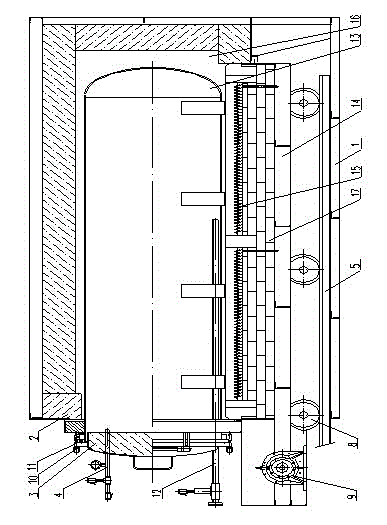

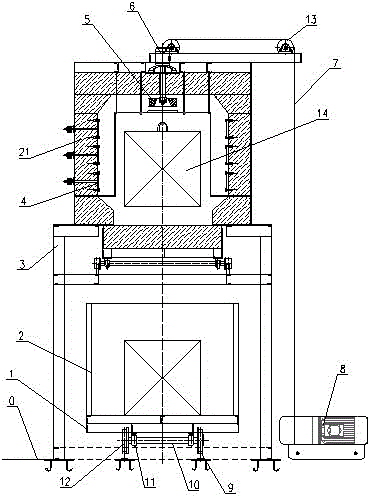

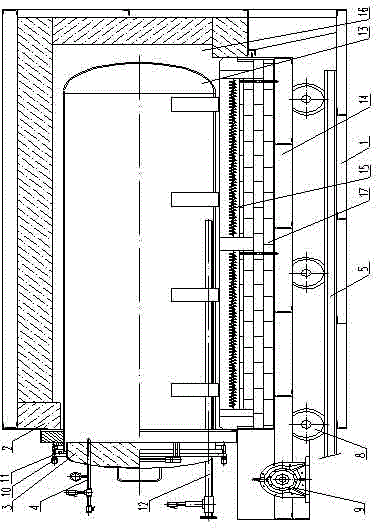

Non-oxidation vacuum annealing furnace for nonferrous metal

The invention discloses a non-oxidation vacuum annealing furnace for nonferrous metal. The vacuum annealing furnace comprises a furnace frame (1) and a trolley (14), wherein an insulated fiber module (2) is fixed at the upper part of the furnace frame (1); a track (5) is fixed at the lower part of the furnace frame (1); and wheels (8) and a motor (9) are mounted on a base of the trolley (14). The vacuum annealing furnace is characterized in that a pre-vacuumizing pipe (4) and a protection gas inlet pipe (12) are fixed on a furnace cover (3) and are communicated to an inner container (13); the insulated fiber module (17) of the trolley (14) is against an insulated fiber module (2) of the furnace frame (1) to form a closed hearth (16); and the inner container (13) and an electrical heating element are arranged in the hearth (16). According to the vacuum annealing furnace, high-quality high-aluminum fiber cotton and the 321 stainless steel inner container are adopted, the outlet of a furnace door is sealed and locked, a direct-current fan is mounted in the hearth, and the pre-vacuumizing pipe is added to the furnace cover to ensure non-oxidation and heat treatment quality of workpieces in a treatment process.

Owner:江苏华烨炉业有限公司

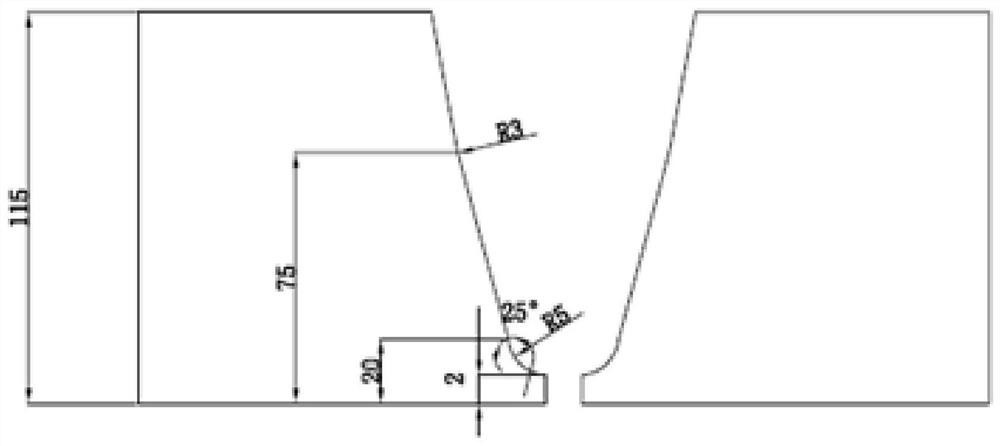

Welding and assembling thermal treatment method for martensite heat-resistant steel G115 large-diameter thick-wall pipeline

InactiveCN111992855ASolve Welding ProblemsSolve process problemsWelding accessoriesThick wallThermal treatment

The invention relates to the technical field of G115 large-diameter thick-wall pipelines, in particular to a novel welding and assembling thermal treatment method for martensite heat-resistant steel G115 large-diameter thick-wall pipeline. In order to solve the problem that quality defect is liable to generate in a novel welding process for the martensite heat-resistant steel G115 large-diameter thick-wall pipeline, a groove design form and a weld bead distribution design are optimized, parameter selection of welding and thermal treatment processes is clear, welding and thermal treatment quality is guaranteed, and the problem that the novel welding and thermal treatment method for the martensite heat-resistant steel G115 large-diameter thick-wall pipeline is unclear is solved.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

Rapid demolding method after press quenching of synchronous ring and synchronous ring press quenching device thereof

PendingCN114457231AWon't strainEasy to demouldFurnace typesIncreasing energy efficiencyTransformerInductor

The invention discloses a rapid demolding method for a synchronous ring after pressure quenching and a synchronous ring pressure quenching device thereof. The synchronous ring pressure quenching device comprises a lower mold, an upper mold and a quenching core mold, the upper die and the lower die are oppositely arranged, the upper die is installed on the upper pressing die connecting base, a core die is arranged at the bottom of the upper die, the upper die is provided with a cooling water channel, an inductor electrically connected with a power supply transformer is arranged on the periphery of the end, close to the core die, of the upper die, and a water spraying ring is arranged on the periphery of the core die and comprises an inner ring and an outer ring. The inner ring and the outer ring form an annular quenching spraying cavity, and the water spraying flow speed and the water spraying time of the water spraying ring are controlled by a controller. A lower die, an upper die and a quenching core die are arranged; the inductor is arranged on the periphery of the end, close to the core mold, of the upper mold, so that a product on the quenched core mold is preheated, demolding is facilitated, and the mold and a workpiece cannot be strained.

Owner:株洲市湘宁高中频设备有限责任公司

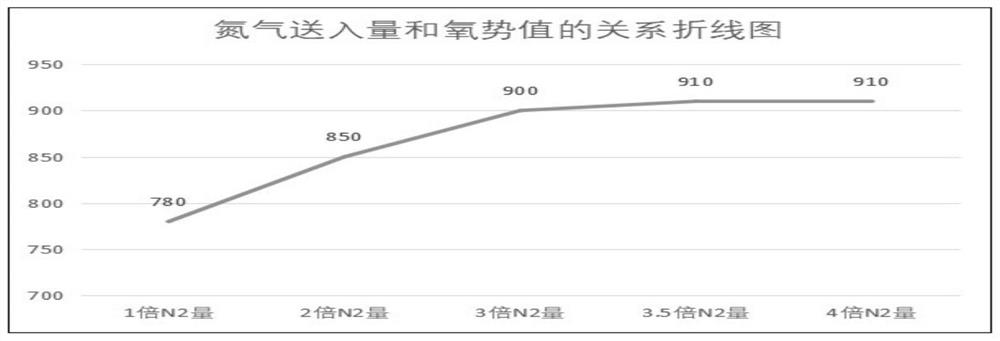

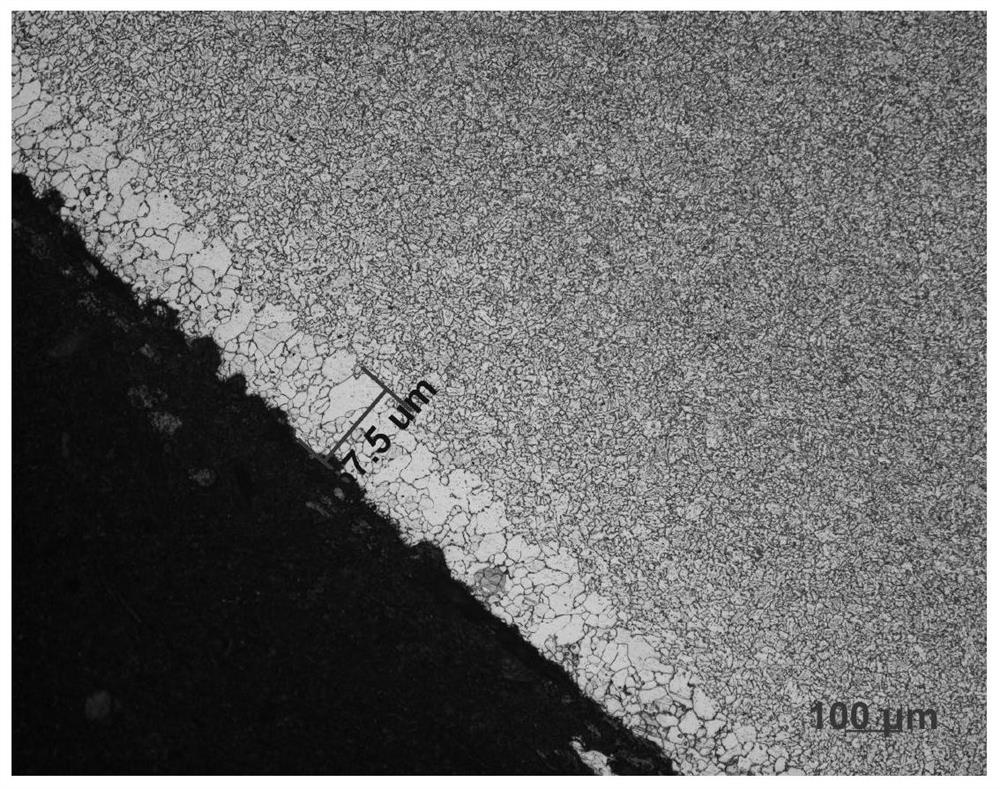

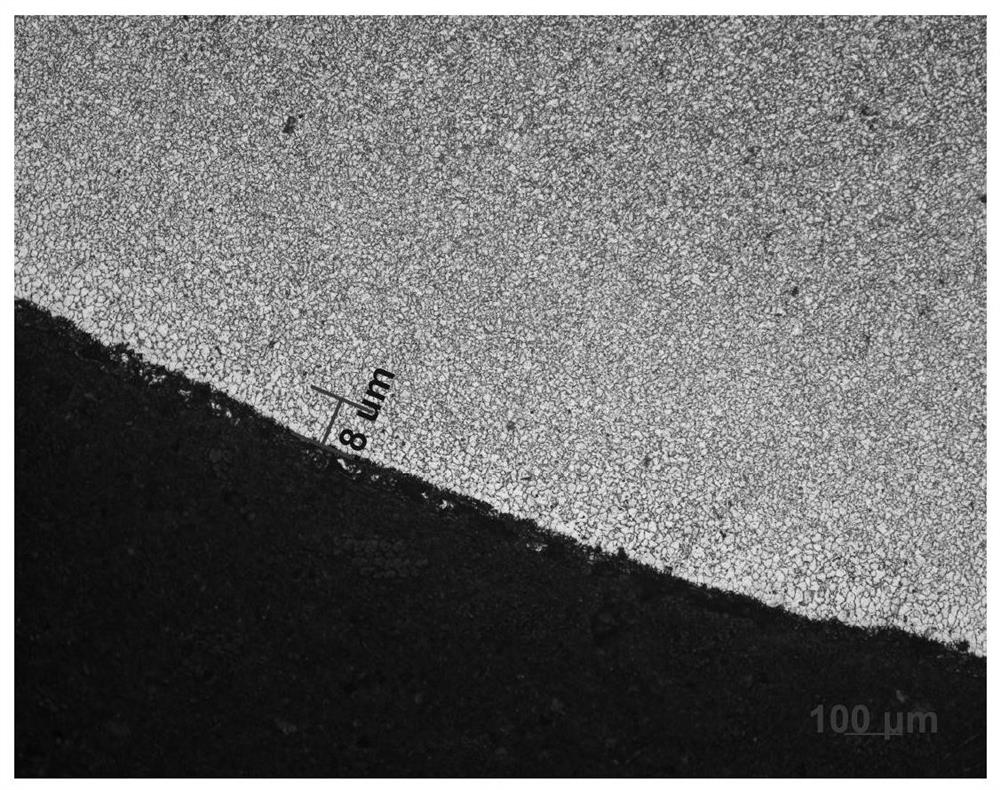

Decarburization and recarburization prevented atmosphere protection heat treatment process

ActiveCN113981186APrevent decarbonizationGuarantee the quality of heat treatmentHeat treatment process controlProcess efficiency improvementHeat conservationOxygen potential

A decarburization and recarburization prevented atmosphere protection heat treatment process mainly comprises the following steps that N2 with the volume 3-4 times that of a heat treatment furnace is introduced, and air in the heat treatment furnace is exhausted; protective atmosphere is introduced into the heat treatment furnace, the oxygen potential value in the heat treatment furnace is monitored, and the protective atmosphere comprises, by volume, 20.7% of CO2, 19.27% of CO, 42.47% of CH and 77.56% of H2; when the oxygen potential value in the heat treatment furnace reaches 1050, the protective atmosphere is continuously introduced, meanwhile, N2 is introduced for pressure maintaining, the temperature of the heat treatment furnace is controlled to be kept at 750-770 DEG C, and the heat preservation time is 10-12 h; and after the heat preservation time is over, the heat treatment furnace is controlled to be cooled, introduction of the protective atmosphere is stopped, N2 is continuously introduced, the protective atmosphere in the heat treatment furnace is discharged till the heat treatment furnace is cooled to 540-560 DEG C or below, the steel is taken out, and the heat treatment process is completed. The condition of unstable protective atmosphere components is avoided, decarburization and recarburization are avoided, and the heat treatment quality of the steel is guaranteed.

Owner:浙商中拓集团浙江新材料科技有限公司

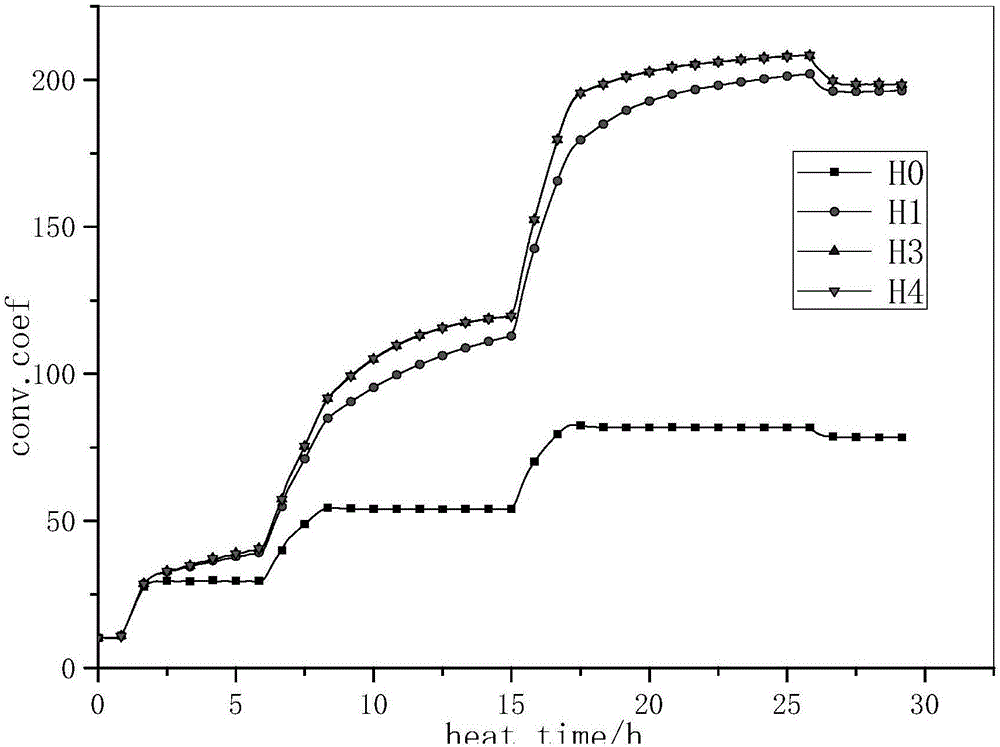

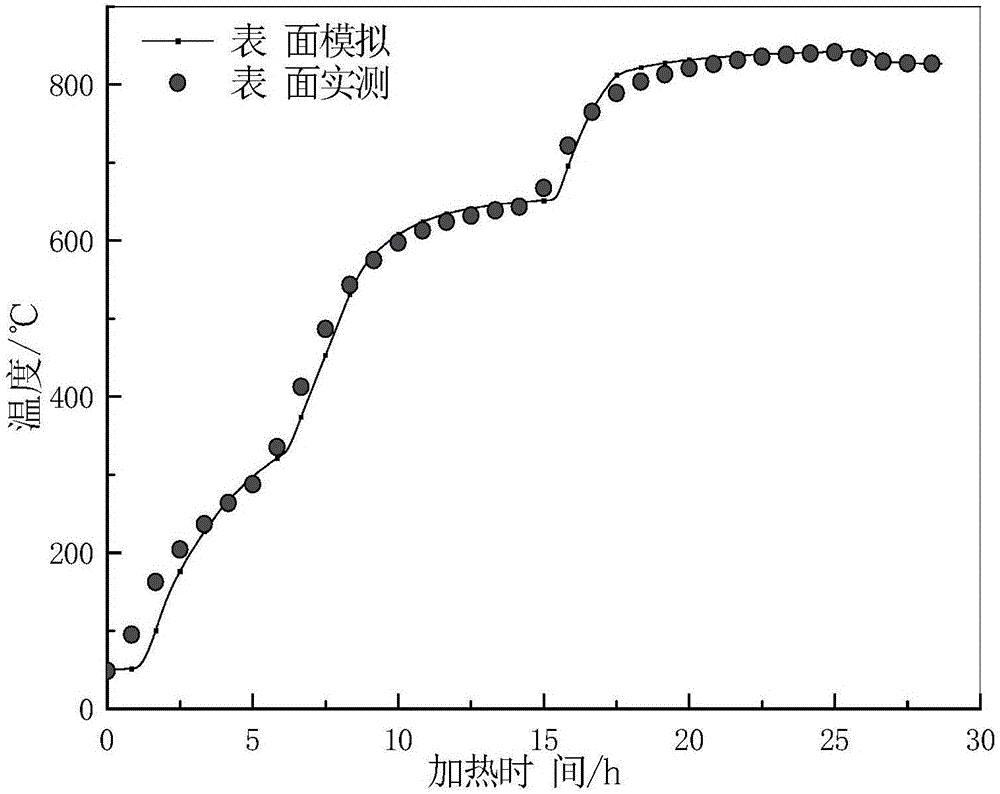

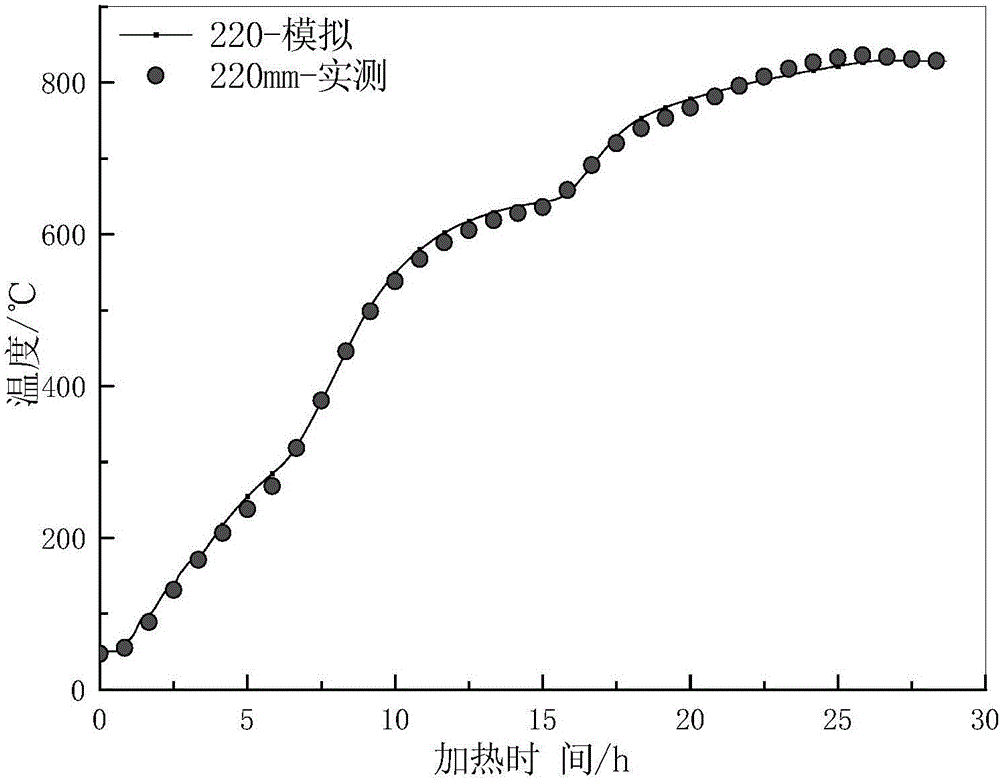

Workpiece temperature field determination method and heat treatment parameter determination method

InactiveCN106676254AGuarantee the quality of heat treatmentReduce energy consumptionDesign optimisation/simulationHeat treatment process controlThree dimensional modelElement analysis

The invention relates to a workpiece temperature field determination method. The workpiece temperature field determination method comprises the steps of establishing a three-dimensional model of a workpiece; and conducting iterative computation for multiple times through a workpiece air-cooled surface heat exchange coefficient fitting formula and finite element analysis and simulation software. Surface temperature functions close to true values are obtained, and subsequently a temperature field of the workpiece can be calculated. After the temperature filed is determined through the method, a proper heat treatment process can be determined; efficiency of the heat treatment procedure is improved; and product quality is guaranteed.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com