Decarburization and recarburization prevented atmosphere protection heat treatment process

A technology of anti-decarburization and heat treatment furnace, applied in the field of heat treatment, can solve the problems of product scrap, insufficient methanol cracking, decarburization of material surface, etc., to avoid unstable components and ensure the effect of heat treatment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An atmosphere protection heat treatment process for preventing decarburization and increasing carbon, comprising the following steps:

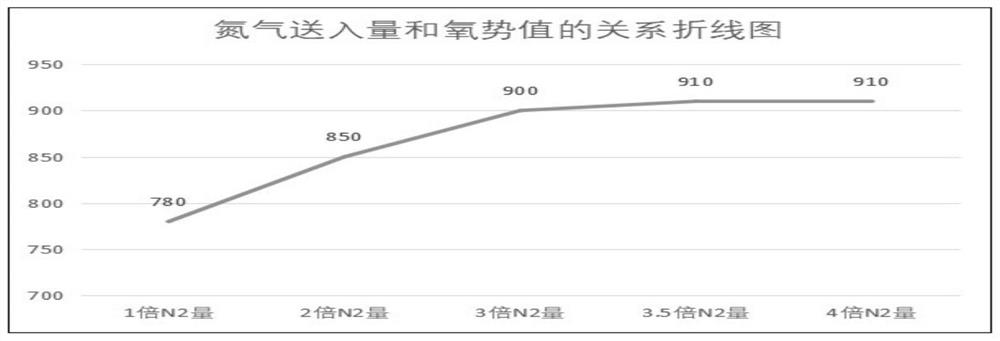

[0041] S100, put the steel into the heat treatment furnace, control the temperature rise of the heat treatment furnace, and at the same time pass into the heat treatment furnace 3 times the volume of the heat treatment furnace. 2 , and monitor the oxygen potential value in the heat treatment furnace through the detection probe;

[0042] S200, when the oxygen potential value in the heat treatment furnace reaches a value of 900, a protective atmosphere is passed into the heat treatment furnace, and the oxygen potential value in the heat treatment furnace is monitored through a detection probe, wherein, by volume percentage, the protective atmosphere includes CO 2 0.7%, CO 19.27%, CH 4 2.47% and H 2 77.56%.

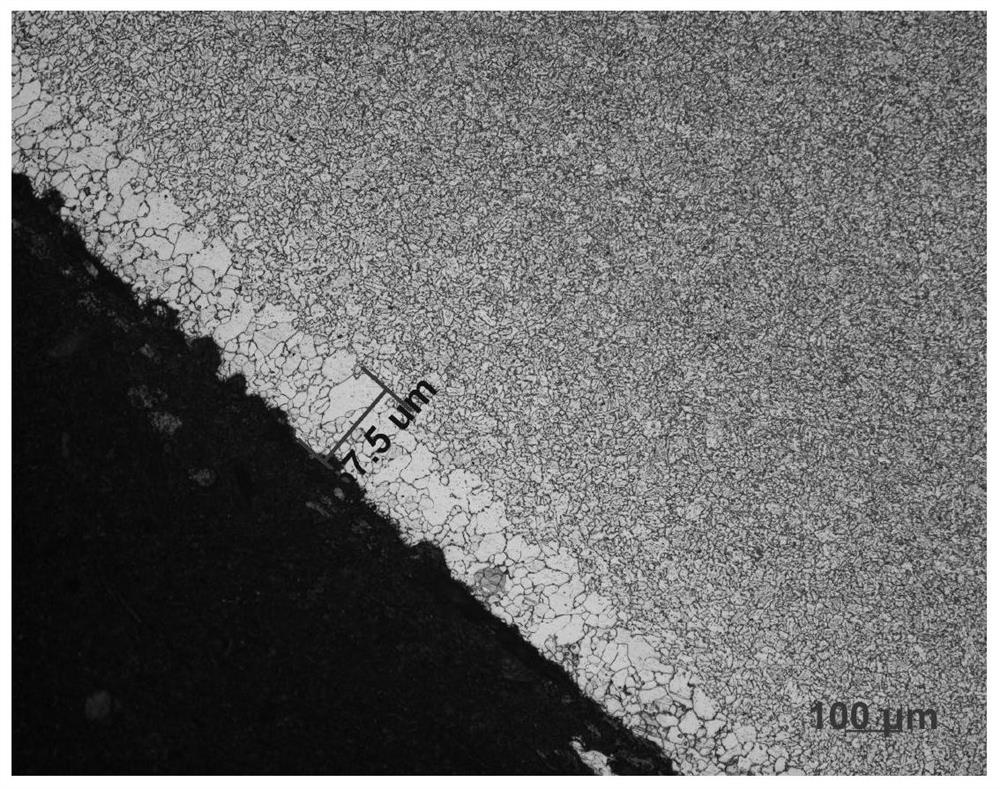

[0043] S300, when the oxygen potential value in the heat treatment furnace reaches 1050, the protective atmosphere is continuo...

Embodiment 2

[0046] An atmosphere protection heat treatment process for preventing decarburization and increasing carbon, comprising the following steps:

[0047] S100, put the steel into the heat treatment furnace, control the temperature rise of the heat treatment furnace, and at the same time pass into the heat treatment furnace 3 times the volume of the heat treatment furnace. 2 , and monitor the oxygen potential value in the heat treatment furnace through the detection probe;

[0048] S200, when the oxygen potential value in the heat treatment furnace reaches a value of 900, a protective atmosphere is passed into the heat treatment furnace, and the oxygen potential value in the heat treatment furnace is monitored through a detection probe, wherein, by volume percentage, the protective atmosphere includes CO 2 0.7%, CO 19.27%, CH 4 2.47% and H 2 77.56%.

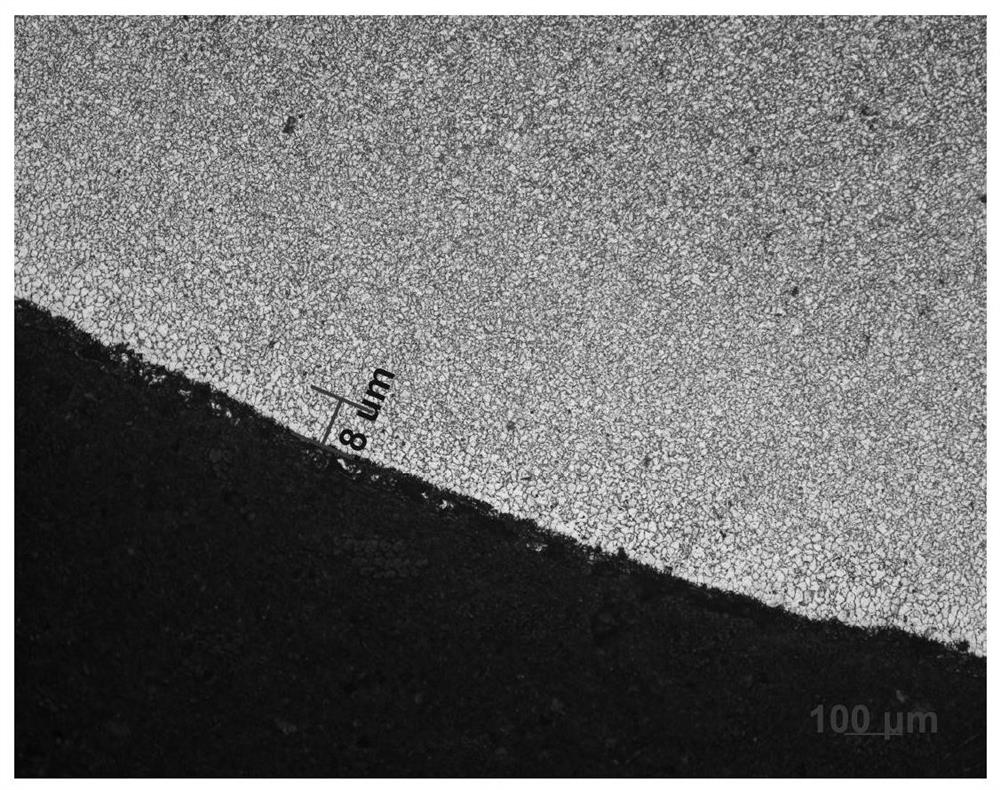

[0049] S300, when the oxygen potential value in the heat treatment furnace reaches 1050, the protective atmosphere is continuo...

Embodiment 3

[0052] An atmosphere protection heat treatment process for preventing decarburization and increasing carbon, comprising the following steps:

[0053] S100, put the steel into the heat treatment furnace, control the temperature rise of the heat treatment furnace, and at the same time pass into the heat treatment furnace 3 times the volume of the heat treatment furnace. 2 , and monitor the oxygen potential value in the heat treatment furnace through the detection probe;

[0054] S200, when the oxygen potential value in the heat treatment furnace reaches a value of 910, pass a protective atmosphere into the heat treatment furnace, and monitor the oxygen potential value in the heat treatment furnace through a detection probe, wherein, by volume percentage, the protective atmosphere includes CO 2 0.7%, CO 19.27%, CH 4 2.47% and H 2 77.56%.

[0055] S300, when the oxygen potential value in the heat treatment furnace reaches 1050, the protective atmosphere is continuously intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com