Patents

Literature

143 results about "Laser coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

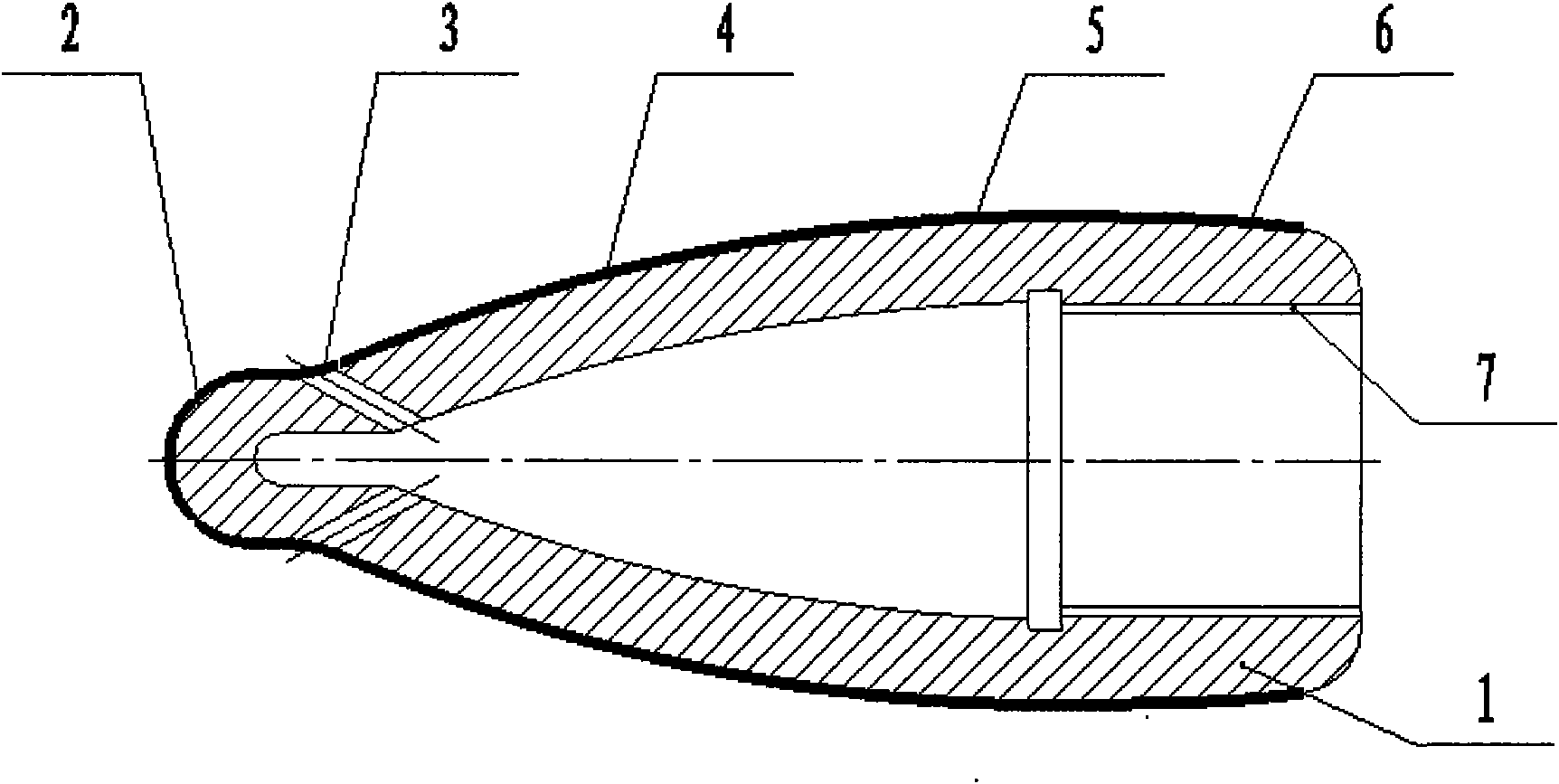

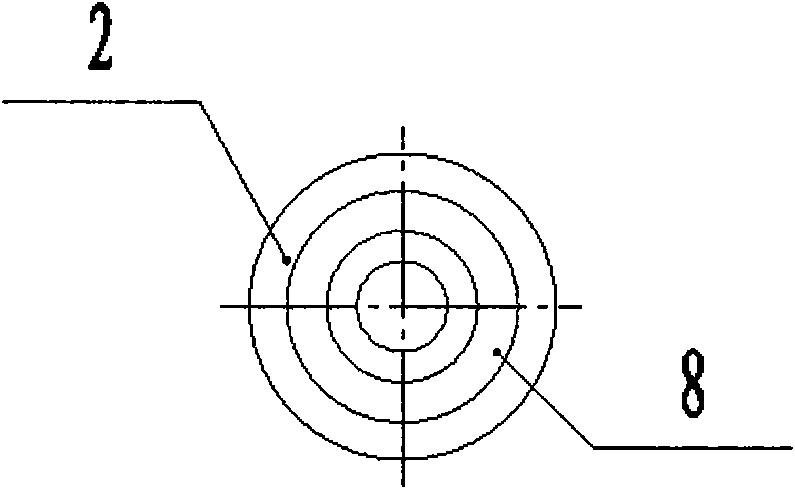

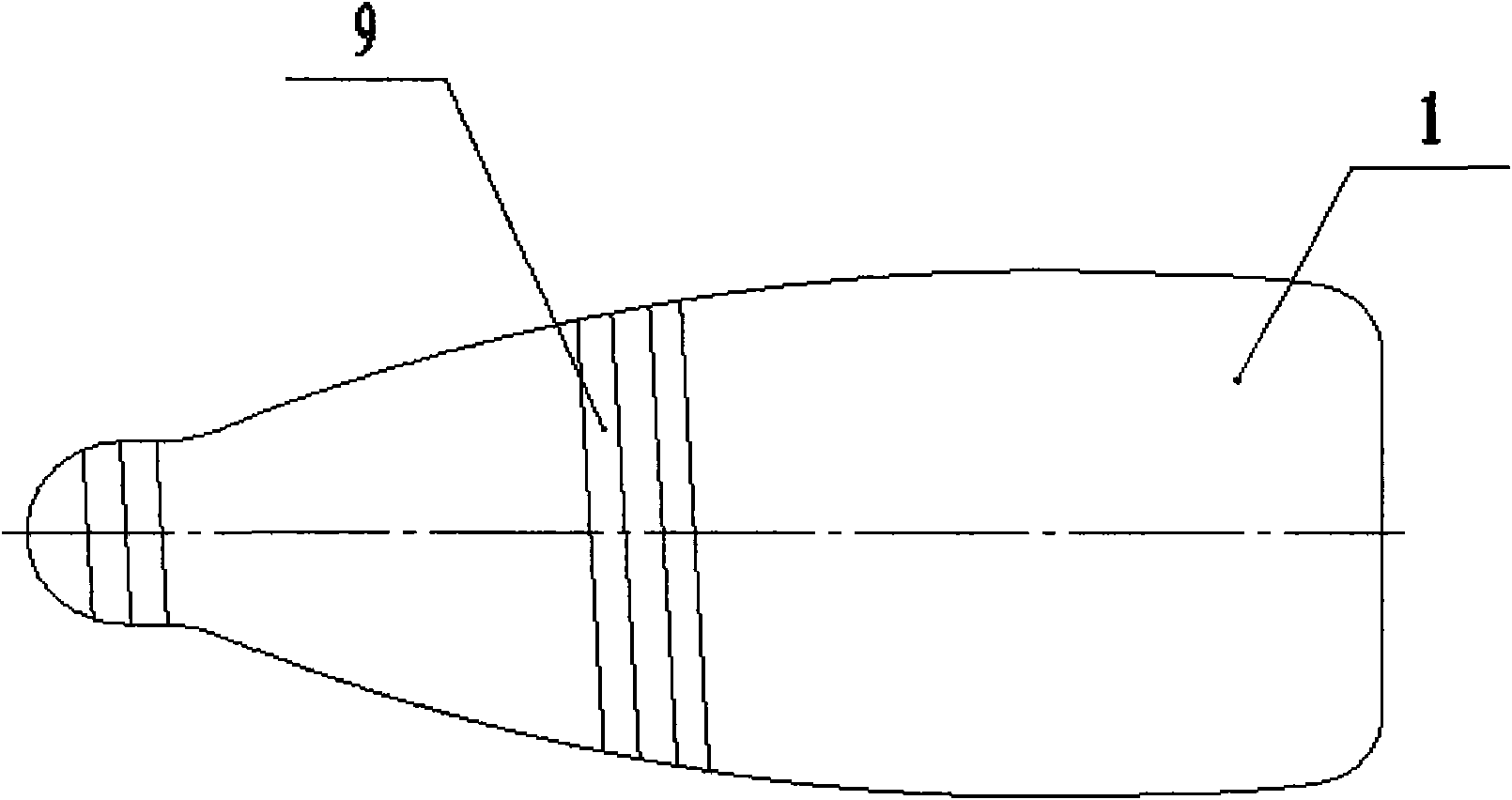

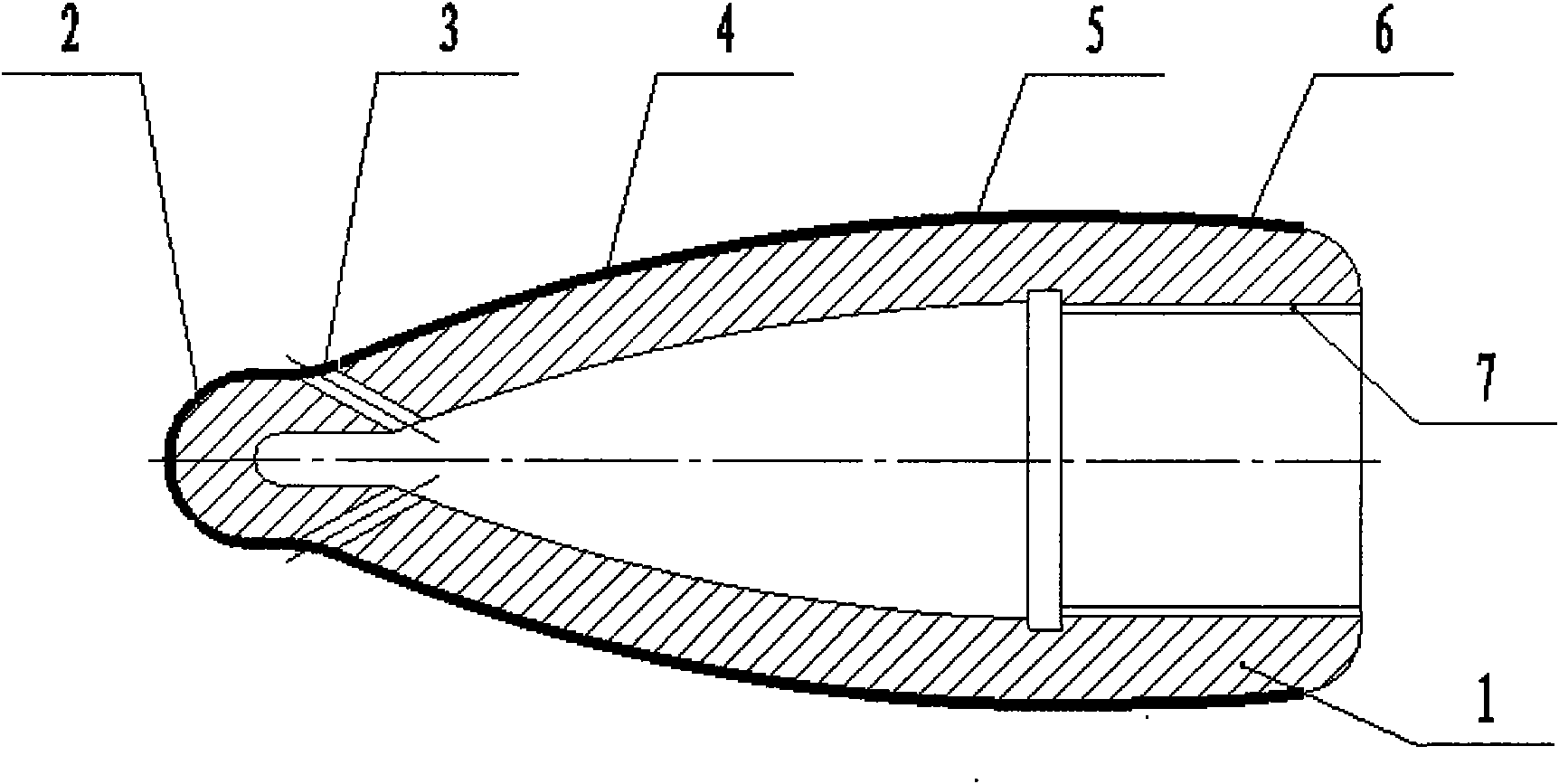

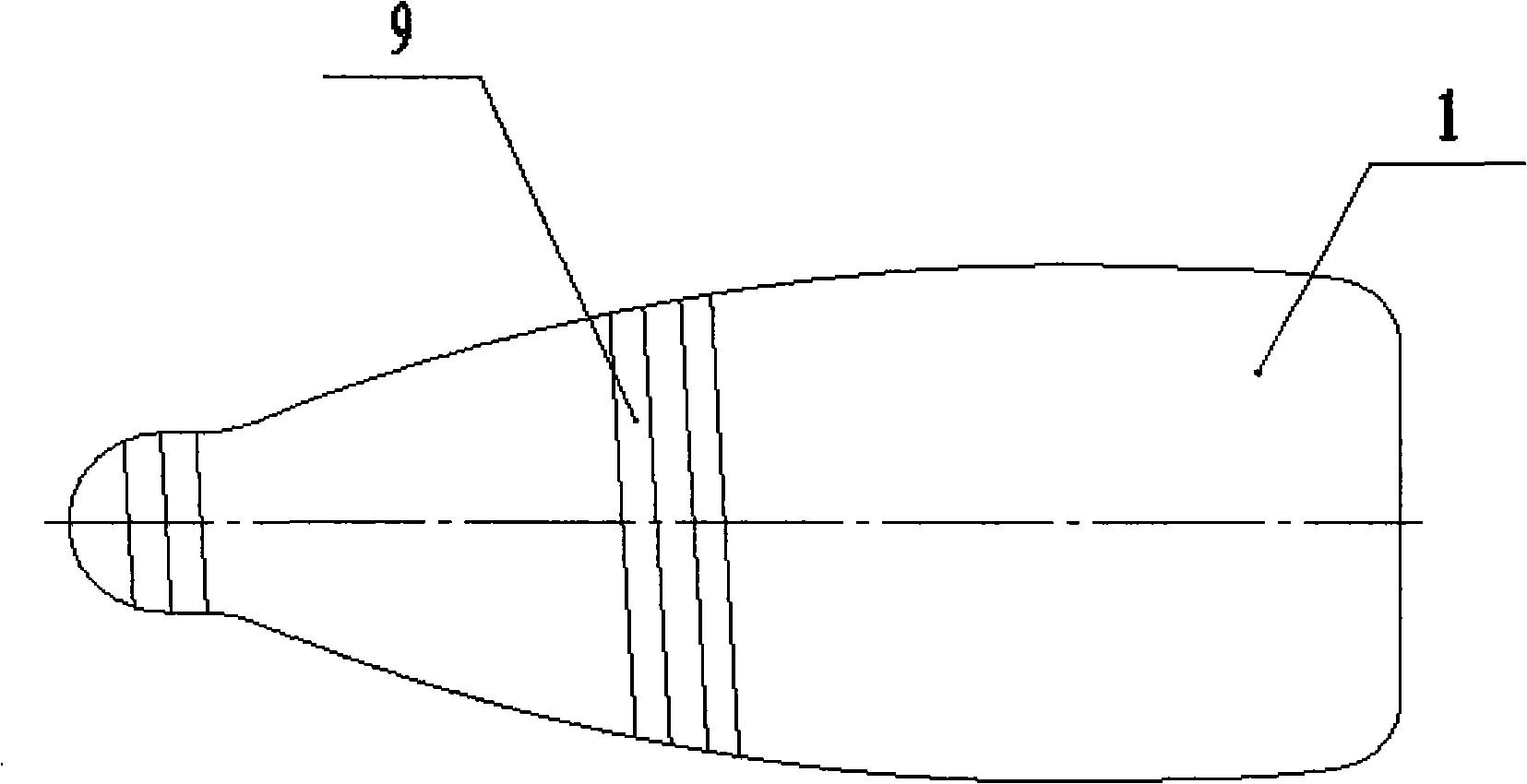

Binary alloy coating seamless steel tube top and manufacture method thereof

InactiveCN101596551AReduce stress concentrationEliminates crack-prone problemsMandrelsFurnace typesBinary alloyLaser coating

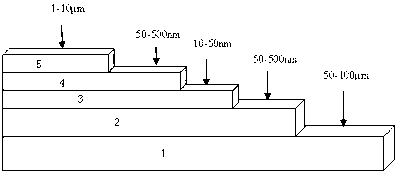

A binary alloy coating seamless steel tube top and a manufacture method belong to the field of laser processing. Aiming at solving the easy peel-off of molybdenum alloy of a molybdenum alloy top, prolonging service life and reducing cost, the invention melts and coats nickel-base or cobalt-base alloy coating at the nose or working part of the top, melts and coats iron-base alloy coating at the straightening part and the parallel part to obtain a binary alloy coating seamless steel tube top; the preparation of the top has the following steps of manufacturing the top by adopting a casting manner, performing mechanical processing on the cast top and reserving melt thickness of 1.0-3.0mm on the external surface of the top for laser melt process; using nickel-base or cobalt-base alloy to perform laser melt on the top end of the nose part; performing laser melt on the lateral of the nose part as well as the working part with nickel-base or cobalt-base alloy as melt powder, finishing laser melt on the straightening part and the parallel part with iron-base alloy incessantly; performing strain-removal treatment, namely performing mechanical processing of top nose spiracle and finishing laser coating polishing and grinding.

Owner:BEIJING UNIV OF TECH

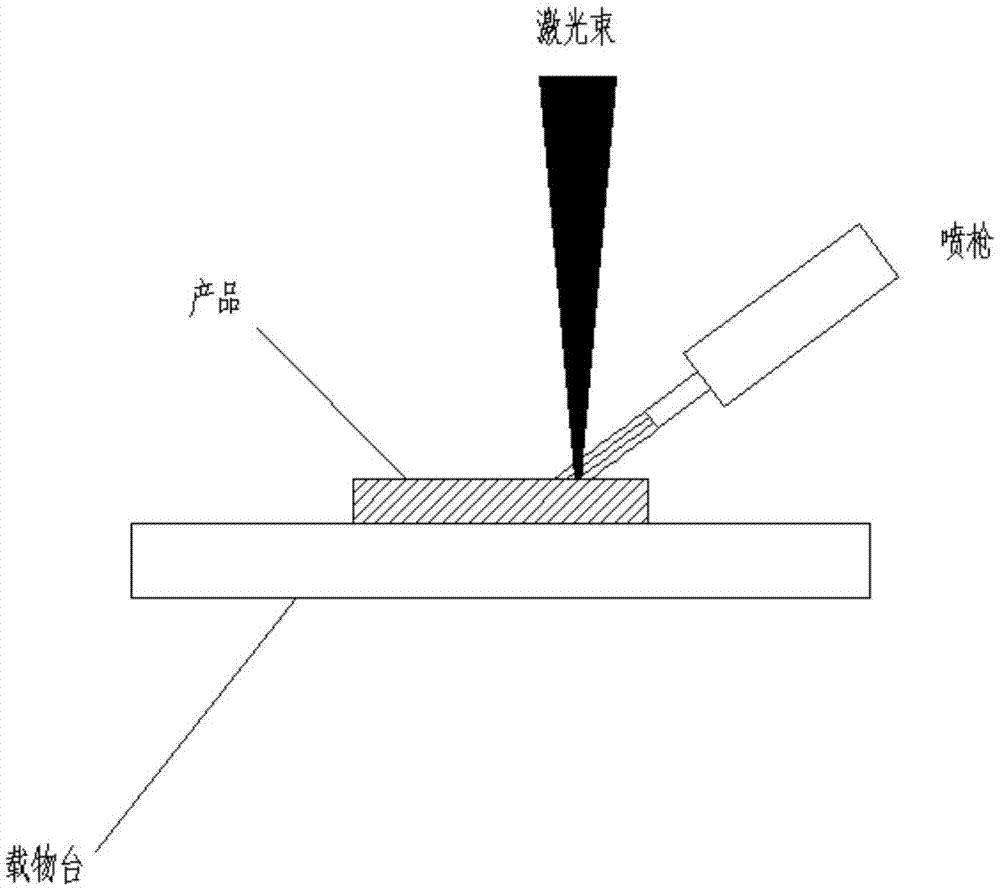

Laser stereo shaping method for preparing buccal metal prosthesis

InactiveCN1462612AMeet the requirements of personalized productionGood material performance2D-image generationLaser beam welding apparatusLaser coatingOral Prosthesis

A laser shaping method for preparing the metallic object used to repair tooth features that combination of 3D laser shaping technique with CAD and CAM to prepare said metallic object directly from metal powder includes generating a 3D CAD model of said object by computer, layering the model by a certain thickness to convert the 3D information to a series of 2D contour information, and laser coating to stacking metal powder by layer according to said contour information until the object is finished.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Method and its device for preparing cutter by laser coating composite ceramic layer

InactiveCN1554803AQuality improvementNo porosityMetallic material coating processesLaser beam welding apparatusFiberHeat-affected zone

The present invention relates to method and apparatus for making cutter with laser coated composite ceramic layer, belongs to the field of ceramic coating on metal surface, and aims at lowering cutter manufacturing cost while prolonging the service life of cutter. The cutter making process includes applying hard alloy powder to the surface of cutter base, applying mechanical pressure, preheating, and laser treating after or while applying the hard alloy powder. The cutter made may be chemical fiber cutter, milling cutter or trimming cutter. One of the cutter making apparatus includes bench, special fixture, electromagnetic coil and laser processing system. The other cutter making apparatus includes bench, chuck, powder blowing feeder and laser processing system. The present invention has high coating quality, less heat deformation, high production efficiency and other advantages.

Owner:HUAZHONG UNIV OF SCI & TECH

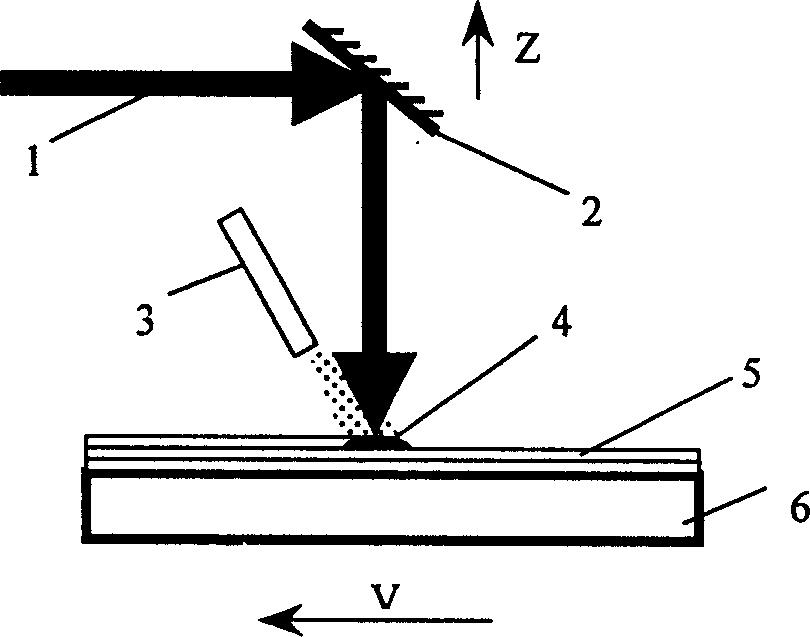

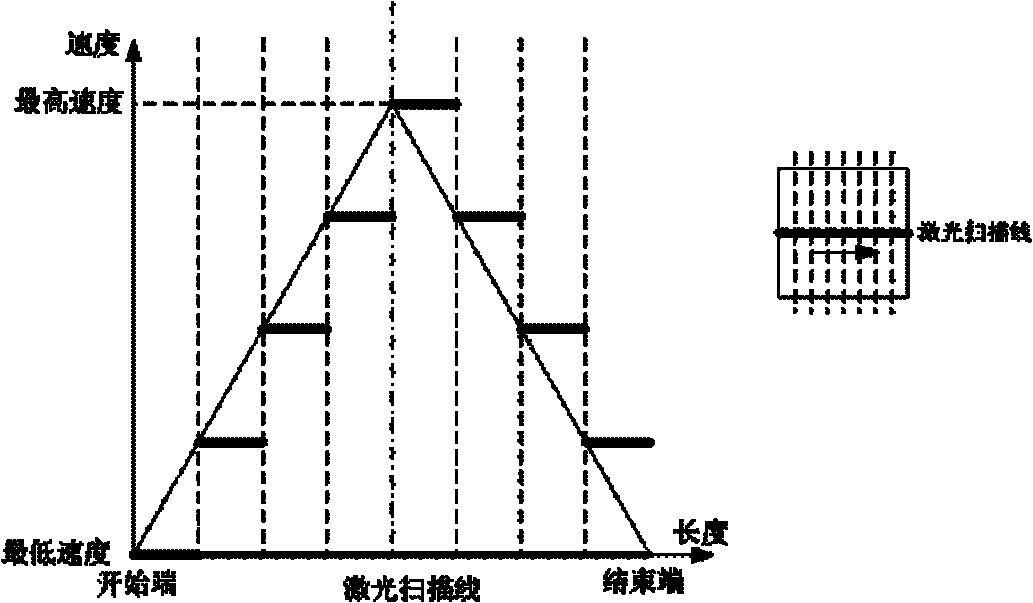

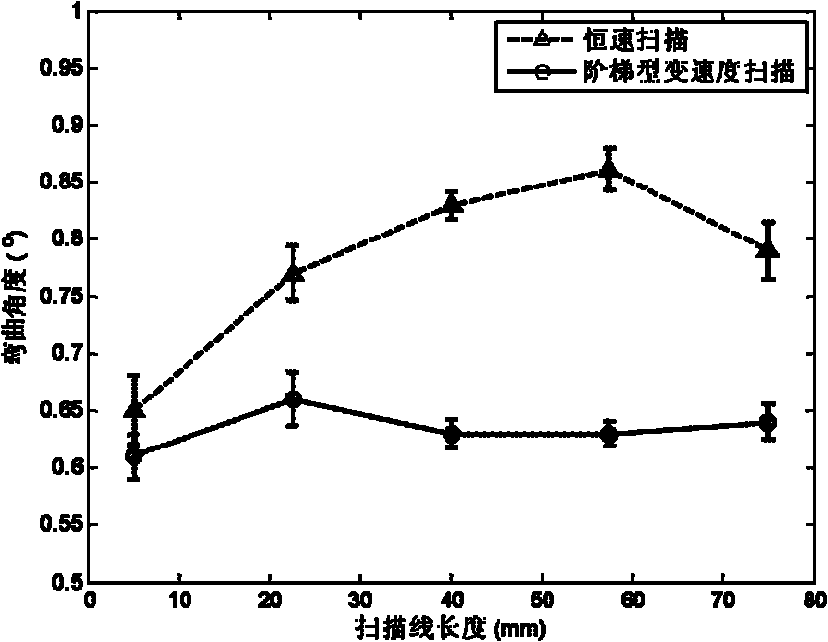

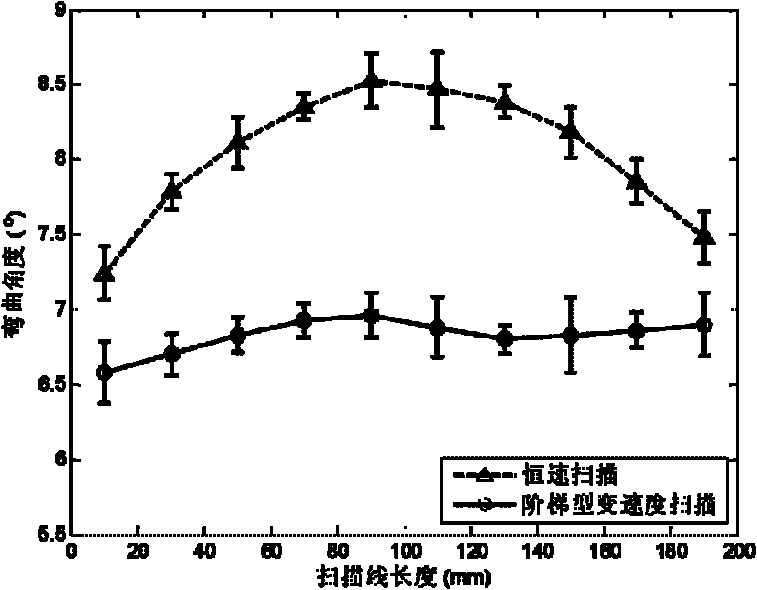

Step type variable speed scanning method for accuracy control of laser bend forming

InactiveCN101804508AAchieve bendingReduce boundary effectsLaser beam welding apparatusNumerical controlLaser coating

A step type variable speed scanning method for accuracy control of laser bend forming belongs to the technical field of plastic forming. A laser coating material is coated on the scanning area of a surface to be scanned, a sheet material to be detected is clamped on one side, the scanning speed of the scanning area is determined by the diagram method to generate the step type variable speed scanning scheme corresponding to the scanning area, and finally the sheet material to be detected is scanned and processed according to the step type variable speed scanning scheme in a laser numerical control manner. The measure and check after processing are performed after the sheet material is cooled naturally. The method of the invention can effectively reduce the phenomenon of border effect, enhance the forming accuracy of the sheet material, thereby realizing the different energy output of the different heating area to balance the geometric constraint of the sheet material and improve the border effect.

Owner:SHANGHAI JIAO TONG UNIV

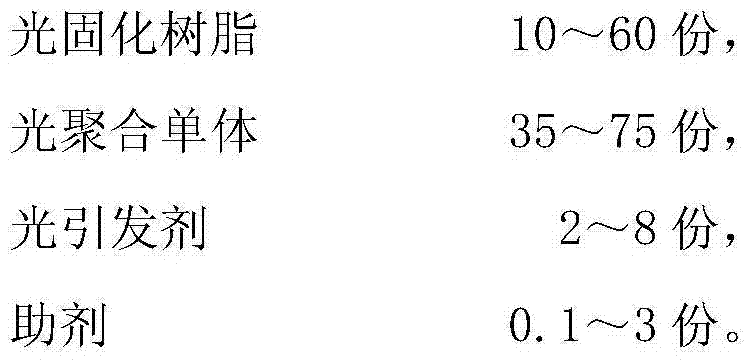

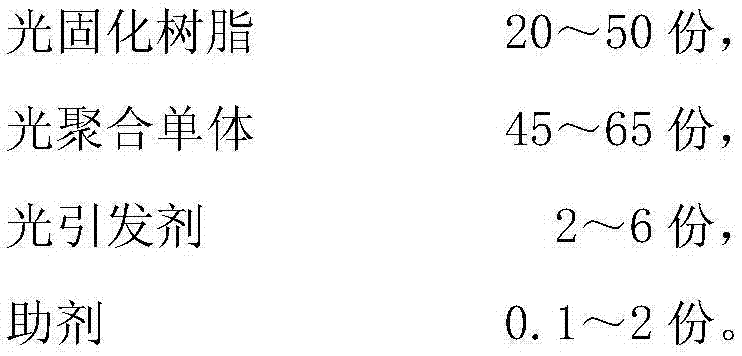

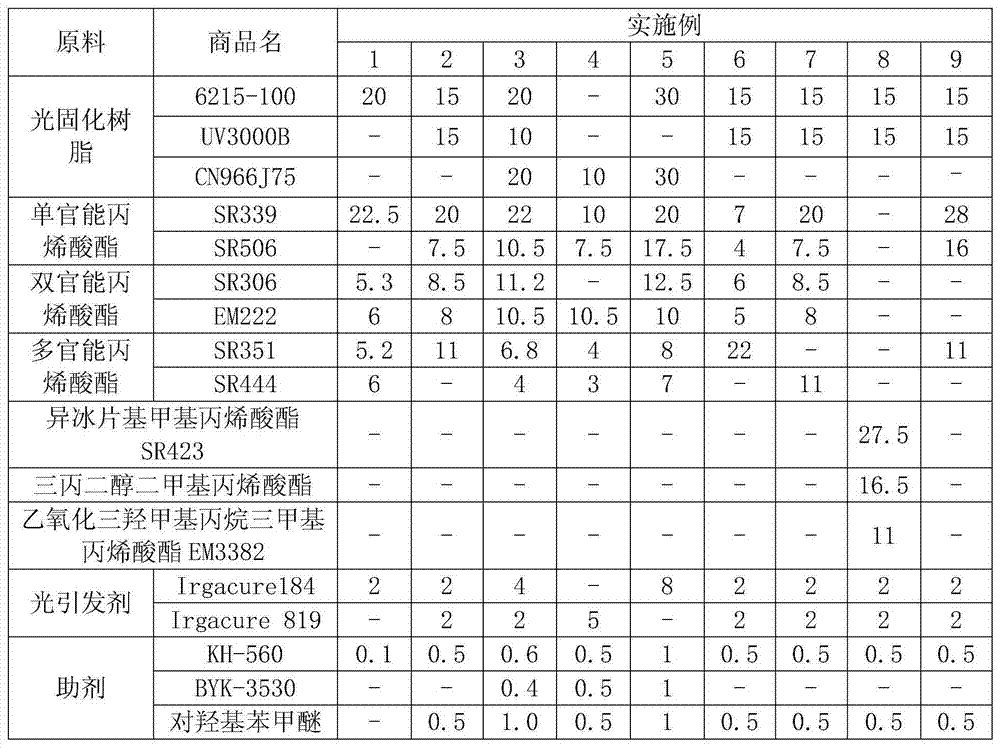

UV (Ultraviolet)-compound laser coating composition

ActiveCN103540240AReduce volatilityReduce pollutionPolyurea/polyurethane coatingsEpoxy resin coatingsLaser coatingUV curing

The invention discloses a UV (Ultraviolet)-compound laser coating composition which is a 100% UV containing coating. The composition comprises the following components in parts by weight: 10-60 parts of a light-cured resin, 35-75 parts of a photopolymerization monomer, 2-8 parts of a photoinitiator and 0-3 parts of an assistant. According to the UV-compound laser coating composition disclosed by the invention, a holographic laser effect is obtained by using mould pressing and a UV illuminating and curing process. As the mould pressing and the UV illuminating and curing process are adopted at the same time, the UV-compound laser coating composition not only can be used for obtaining the laser effect of a common shallow groove, but also can be used for making a laser pattern of a deeper groove. Compared with the prior art, the composition disclosed by the invention further has the advantages that by adopting the 100% UV containing formula which contains fewer solvents or no solvents, during use, less solvents volatilize, so that air pollution is reduced; by adopting UV curing, the energy resources are saved and the speed is fast, and the production efficiency is improved; the temperature is low during UV curing, and the influence on the base material in temperature distortion is reduced.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

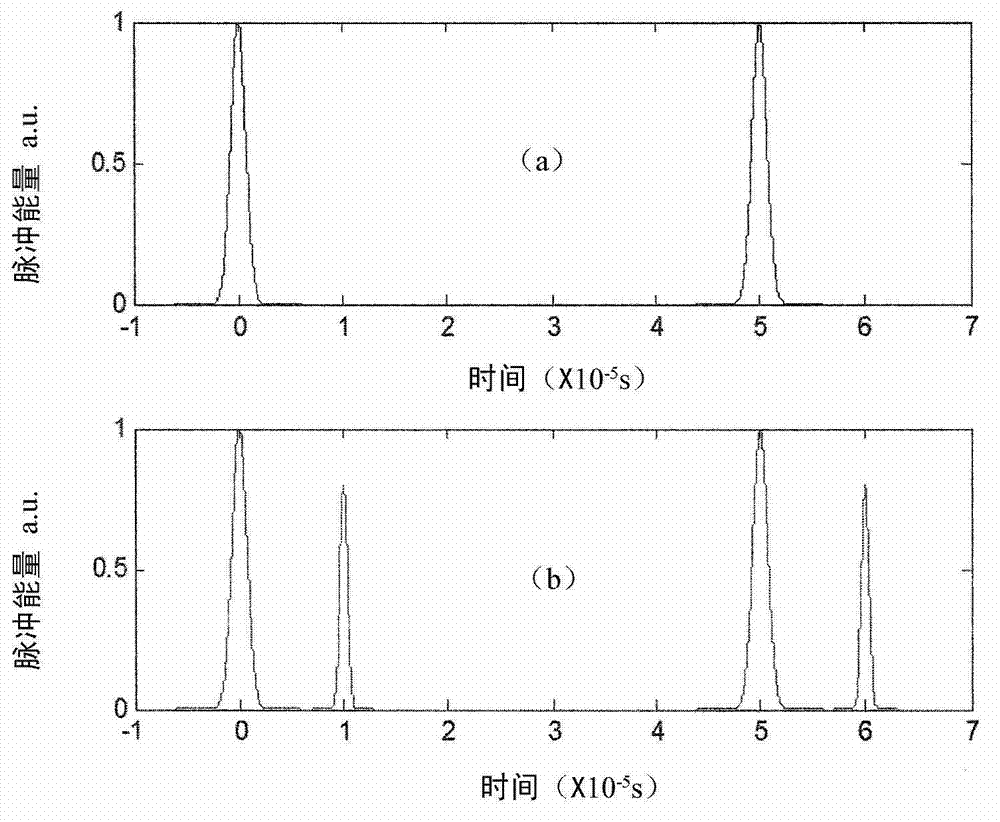

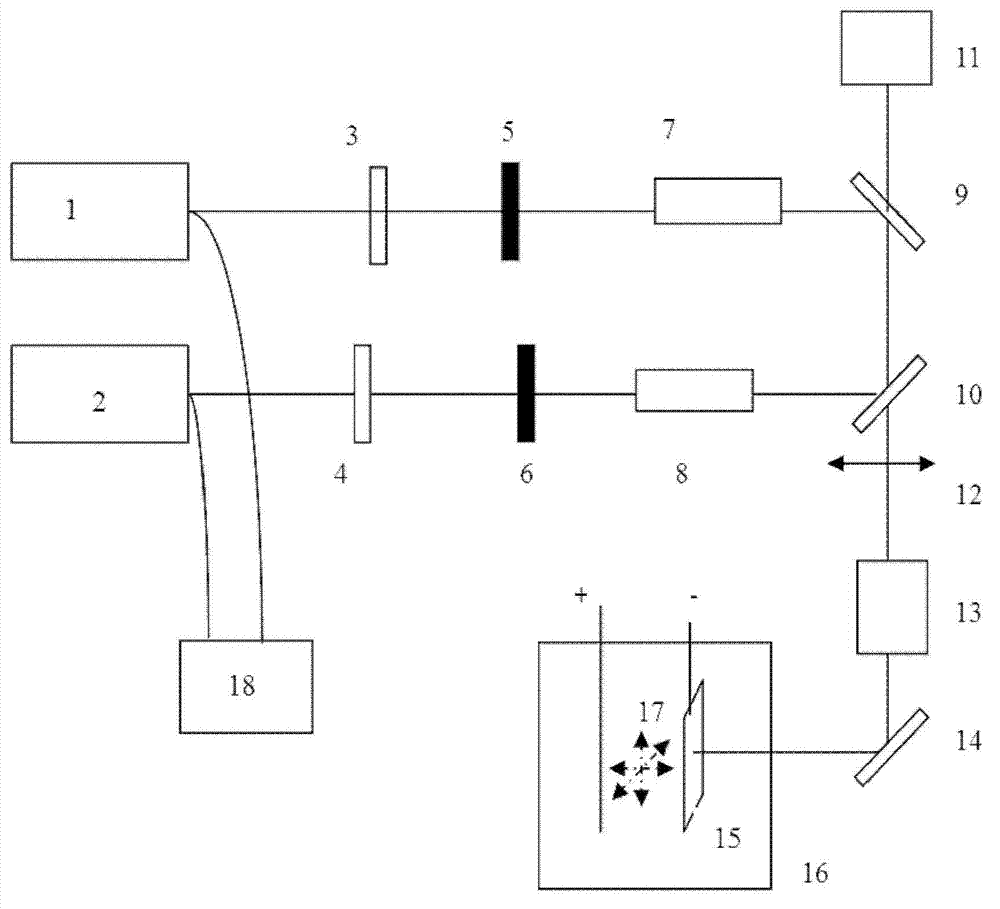

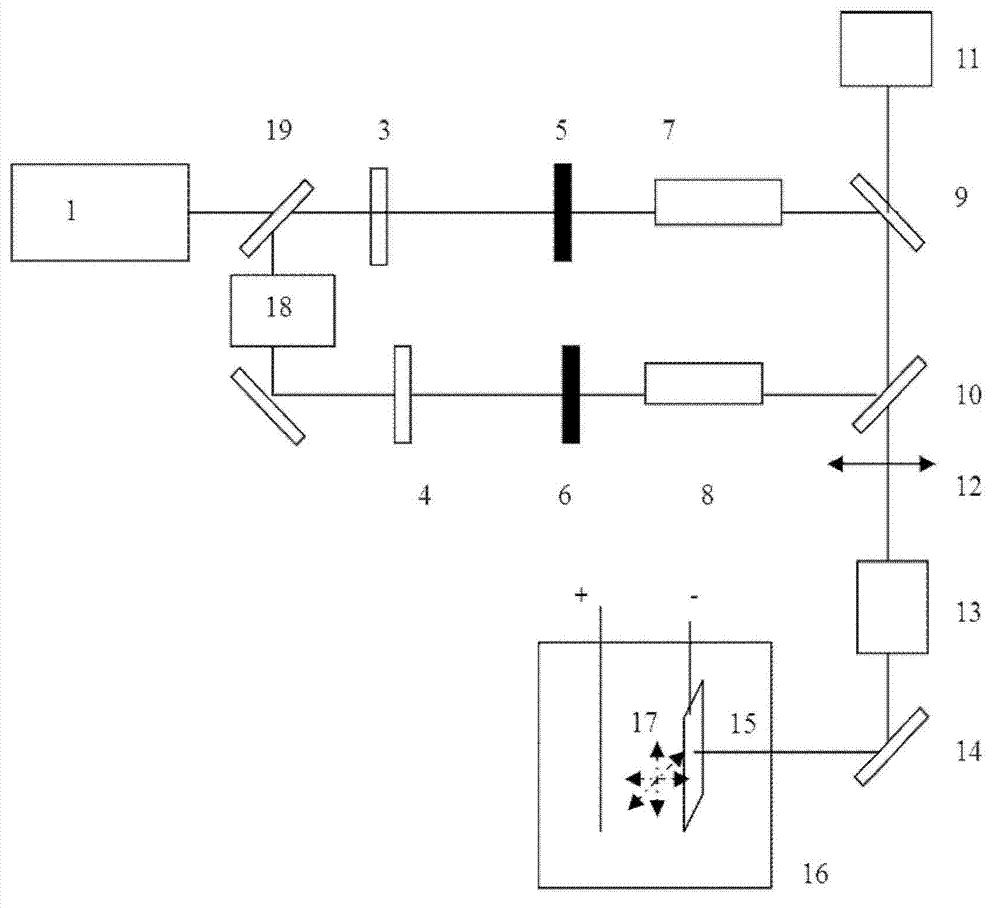

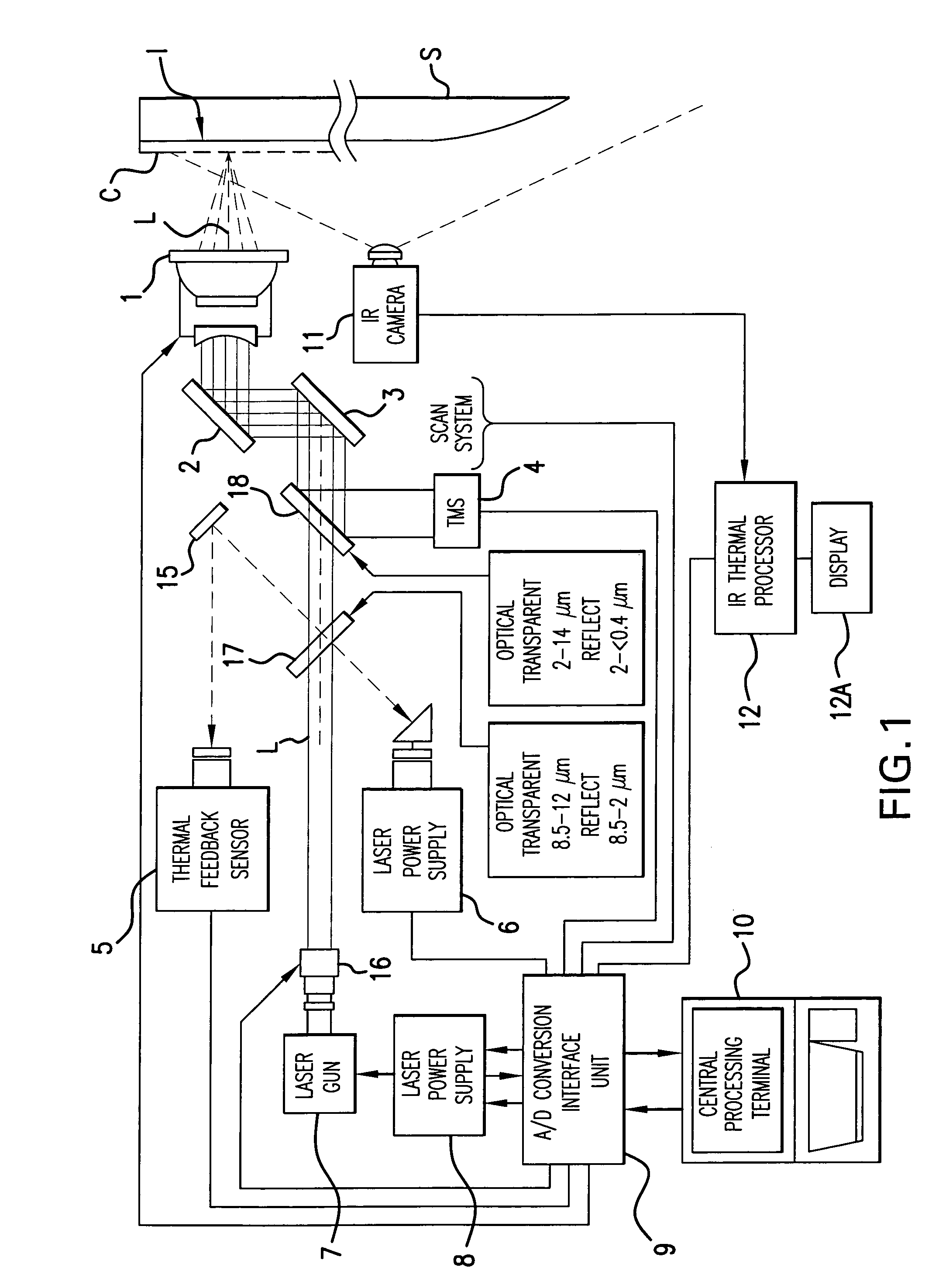

System for treating laser coating

ActiveCN102925938AFast plating speedImprove spatial resolutionLiquid/solution decomposition chemical coatingLaser beam welding apparatusChemical platingLaser coating

The invention discloses a system for treating a laser coating. The system comprises a first pulse laser (1), a second pulse laser (2), a first attenuator (3), a second attenuator (4), a first electronic shutter (5), a second electronic shutter (6), a first beam expanding lens (7), a second beam expanding lens (8), a reflector (9), a beam combiner (10), a CCD (Charge Coupled Device) real-time observation system (11), an optical galvanometer (12), a focus objective lens (13), a reflector (14), a pending sample substrate (15), an electrolytic cell (16), a three-dimensional mobile station (17) and a delay controller (18). According to the invention, a laser heat effect is fully absorbed by a material through utilizing pulse matched with the absorptive character of the material to be treated, and a laser beam of the wavelength, so that an ideal coating treatment result is obtained. The system, provided by the invention, is used for a treating process including laser electroplating, laser chemical plating, laser etching and micro laser cladding.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

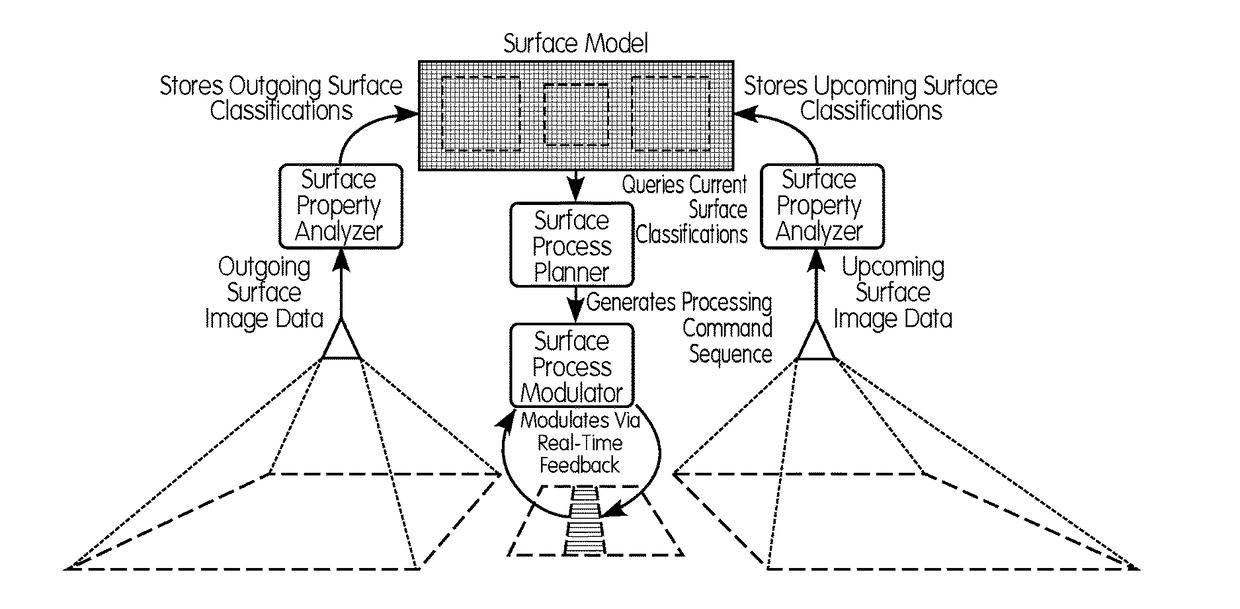

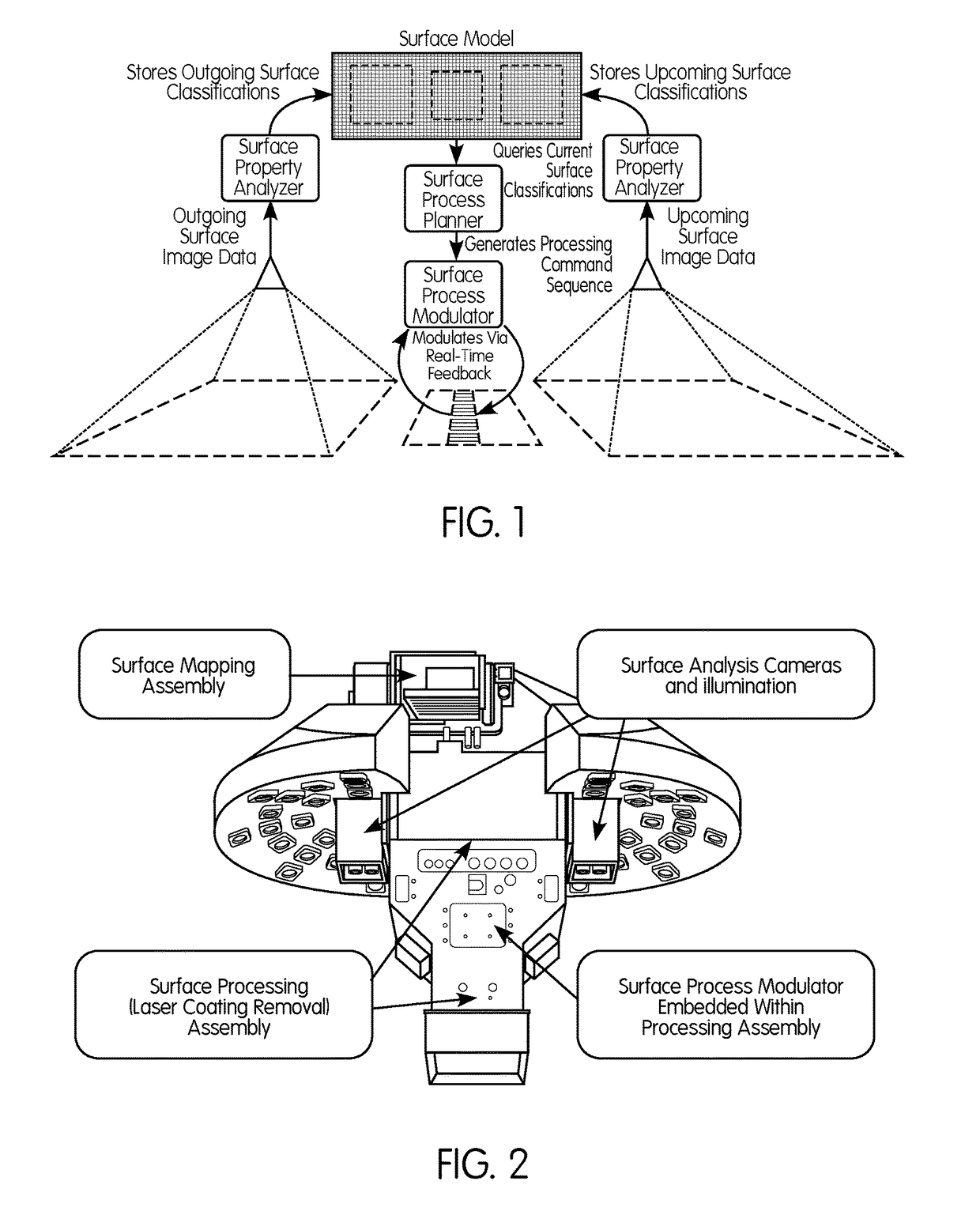

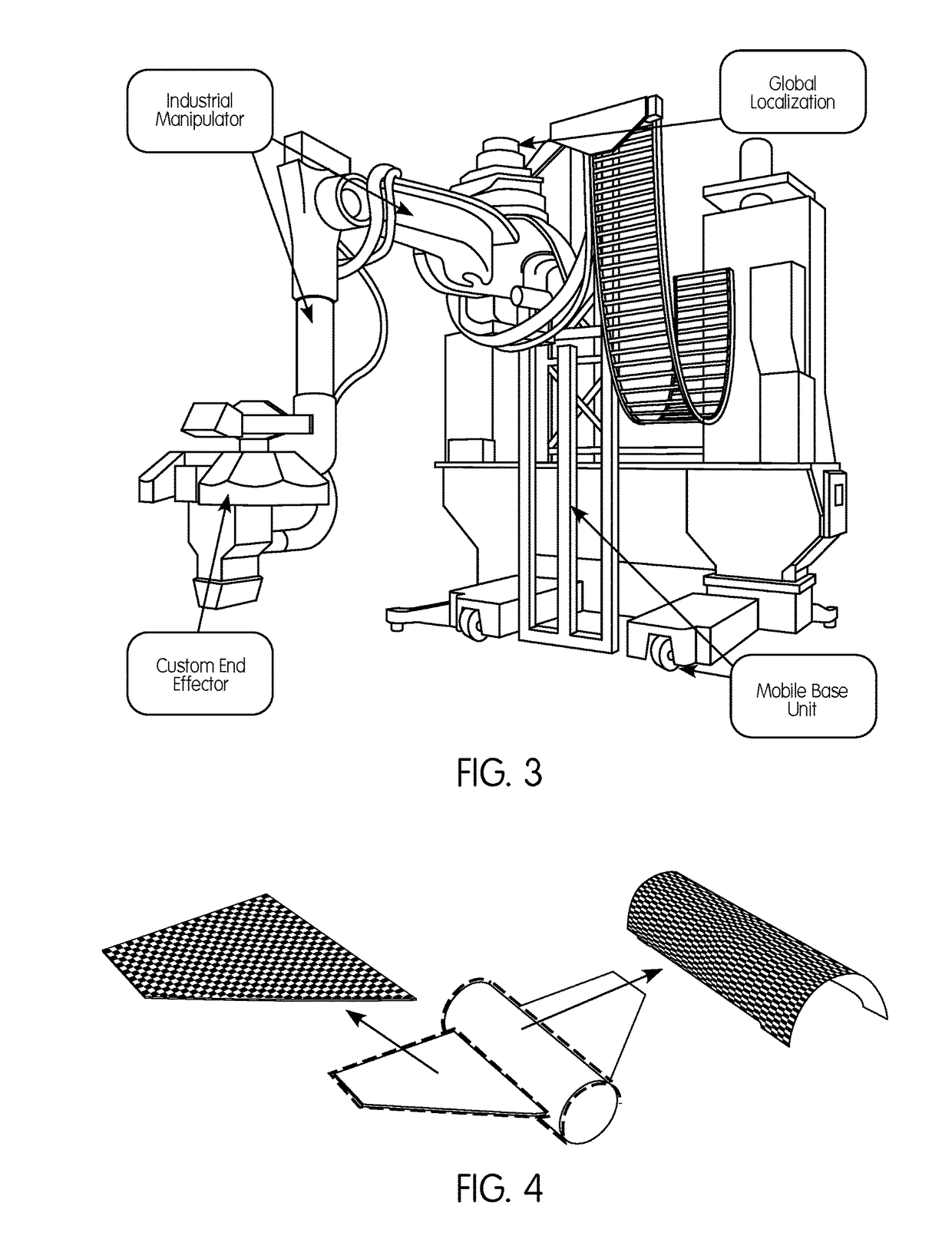

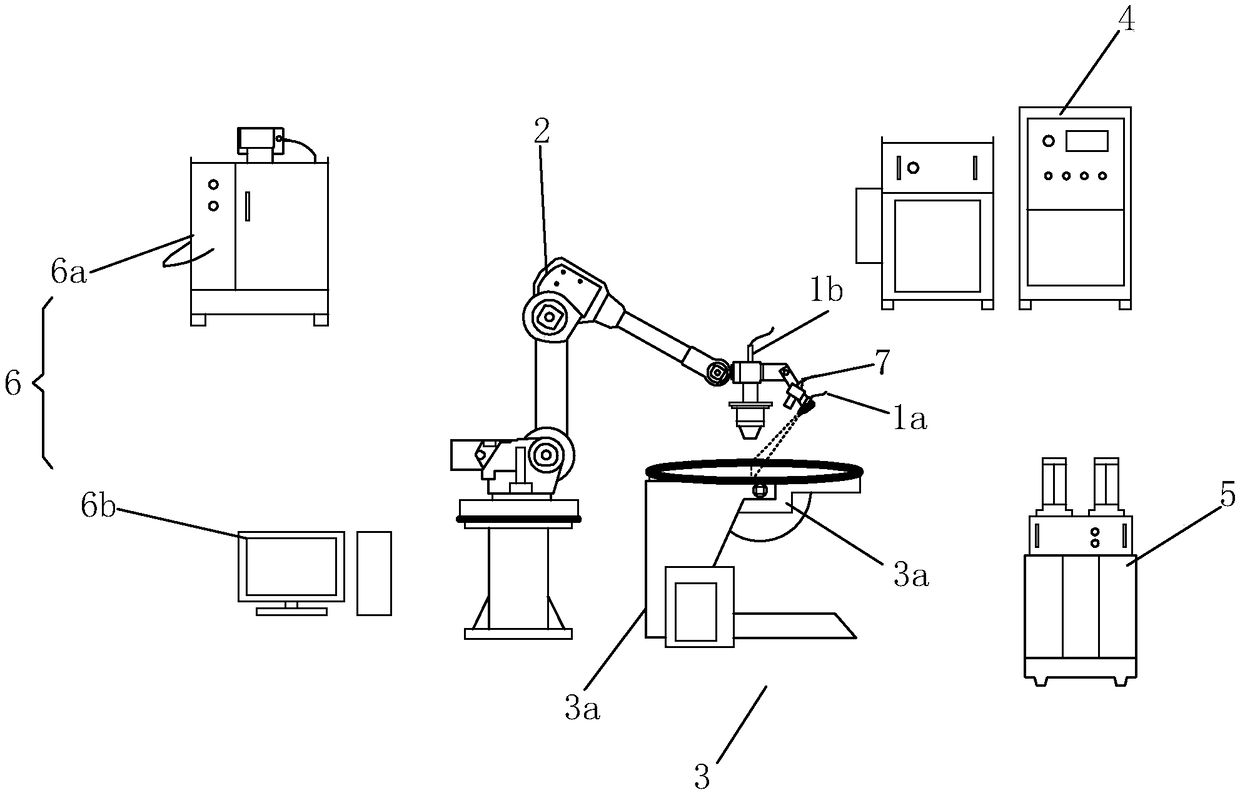

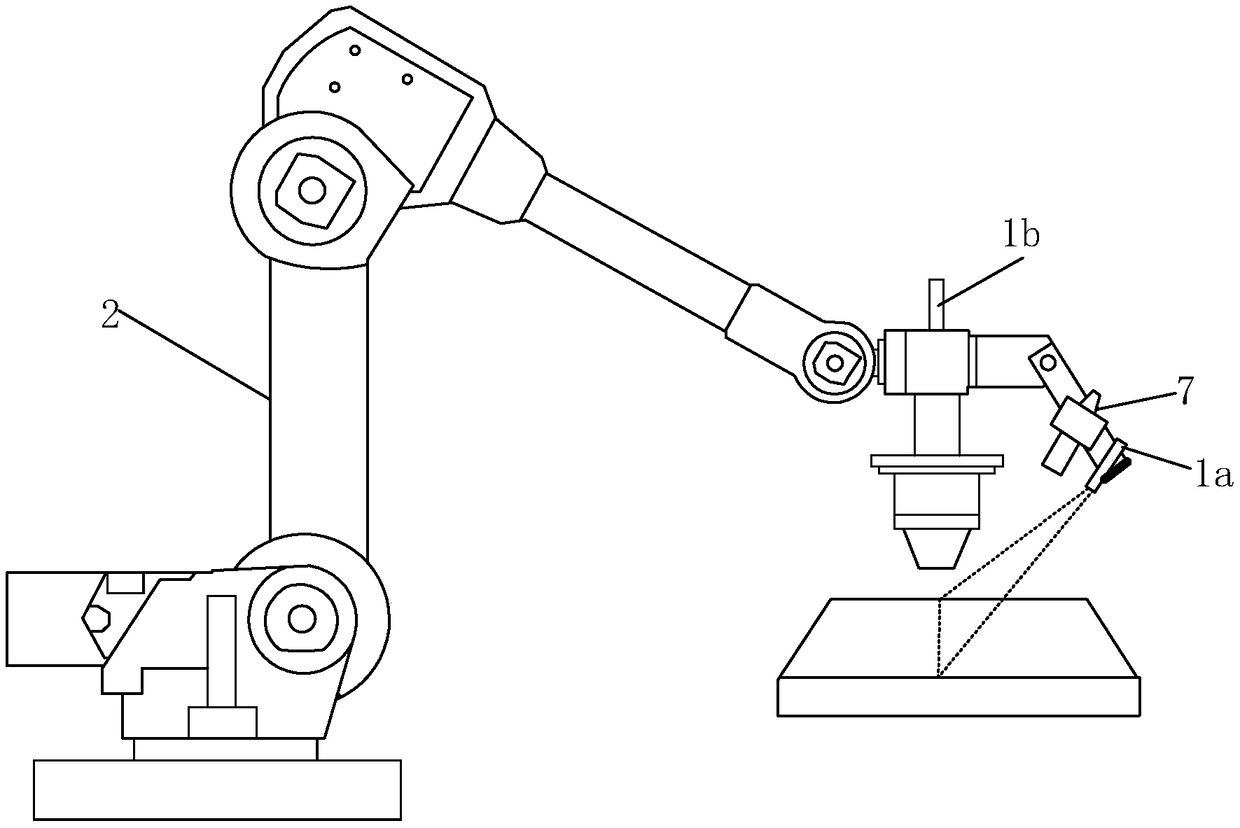

Supervised Autonomous Robotic System for Complex Surface Inspection and Processing

InactiveUS20170297198A1Accurately plan for and modulate surface processHigh-quality resultProgramme controlProgramme-controlled manipulatorRobotic systemsSystems design

The invention disclosed herein describes a supervised autonomy system designed to precisely model, inspect and process the surfaces of complex three-dimensional objects. The current application context for this system is laser coating removal of aircraft, but this invention is suitable for use in a wide variety of applications that require close, precise positioning and maneuvering of an inspection or processing tool over the entire surface of a physical object. For example, this system, in addition to laser coating removal, could also apply new coatings, perform fine-grained or gross inspection tasks, deliver and / or use manufacturing process tools or instruments, and / or verify the results of other manufacturing processes such as but not limited to welding, riveting, or the placement of various surface markings or fixtures.

Owner:CARNEGIE MELLON UNIV

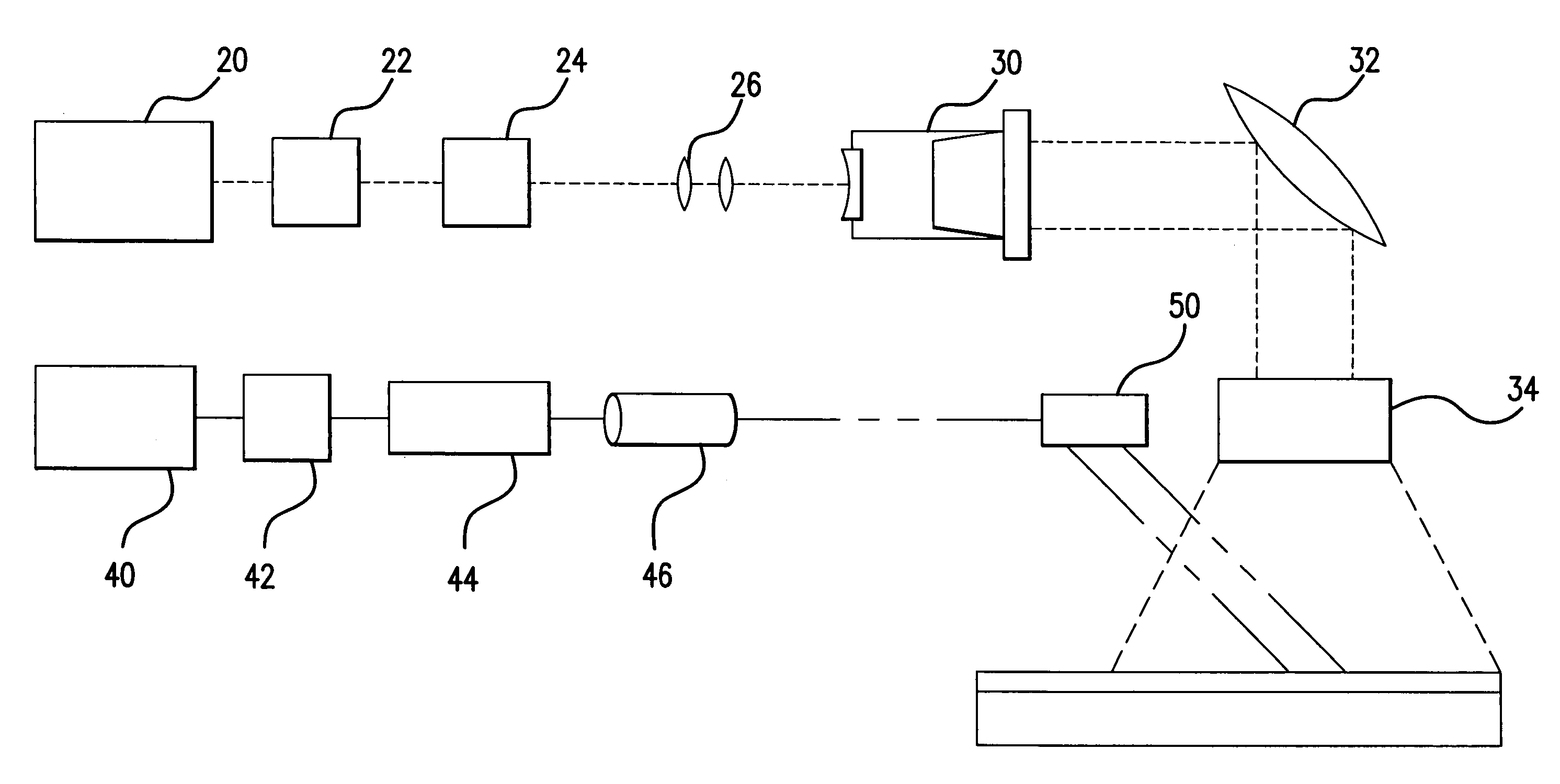

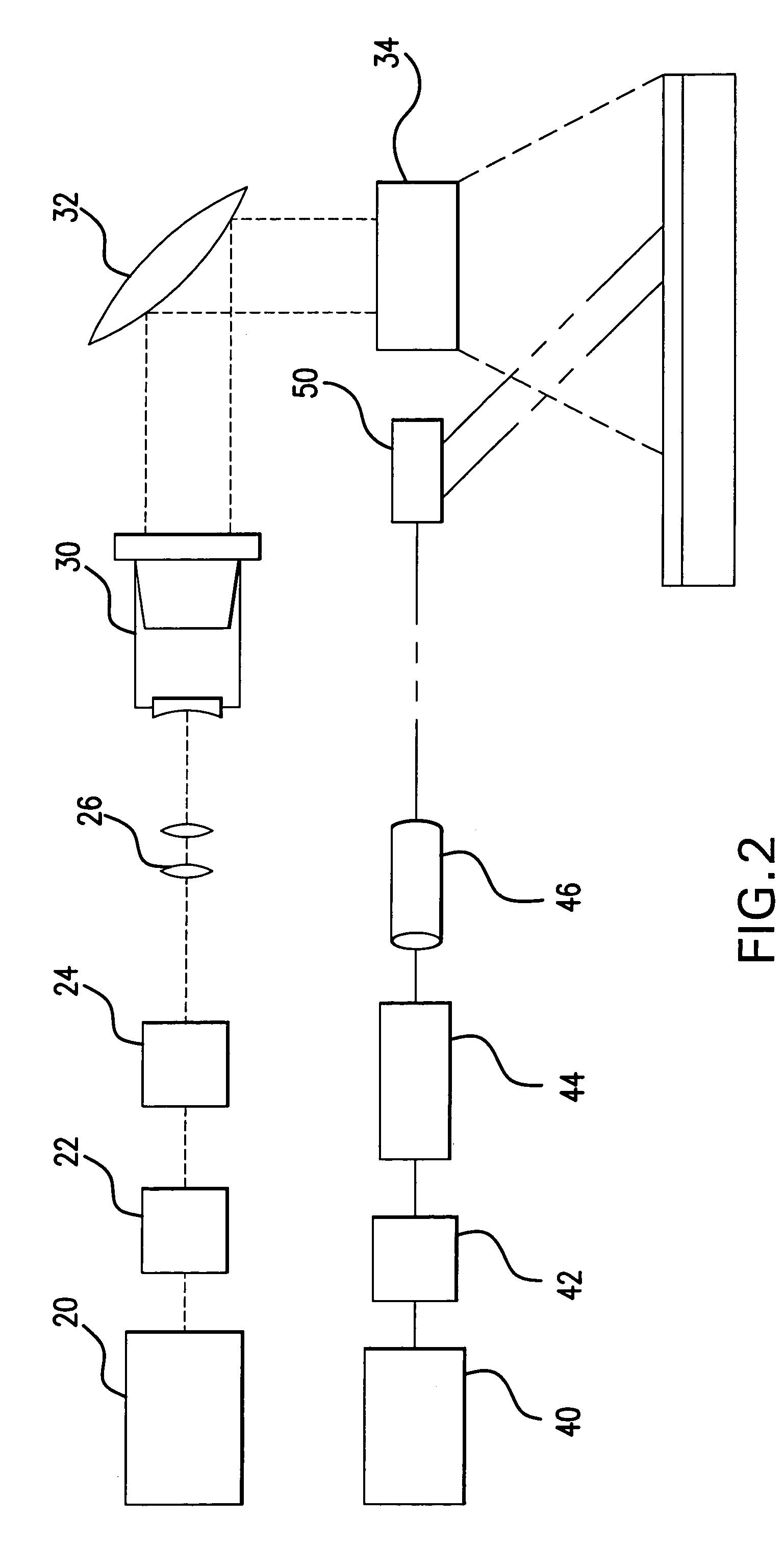

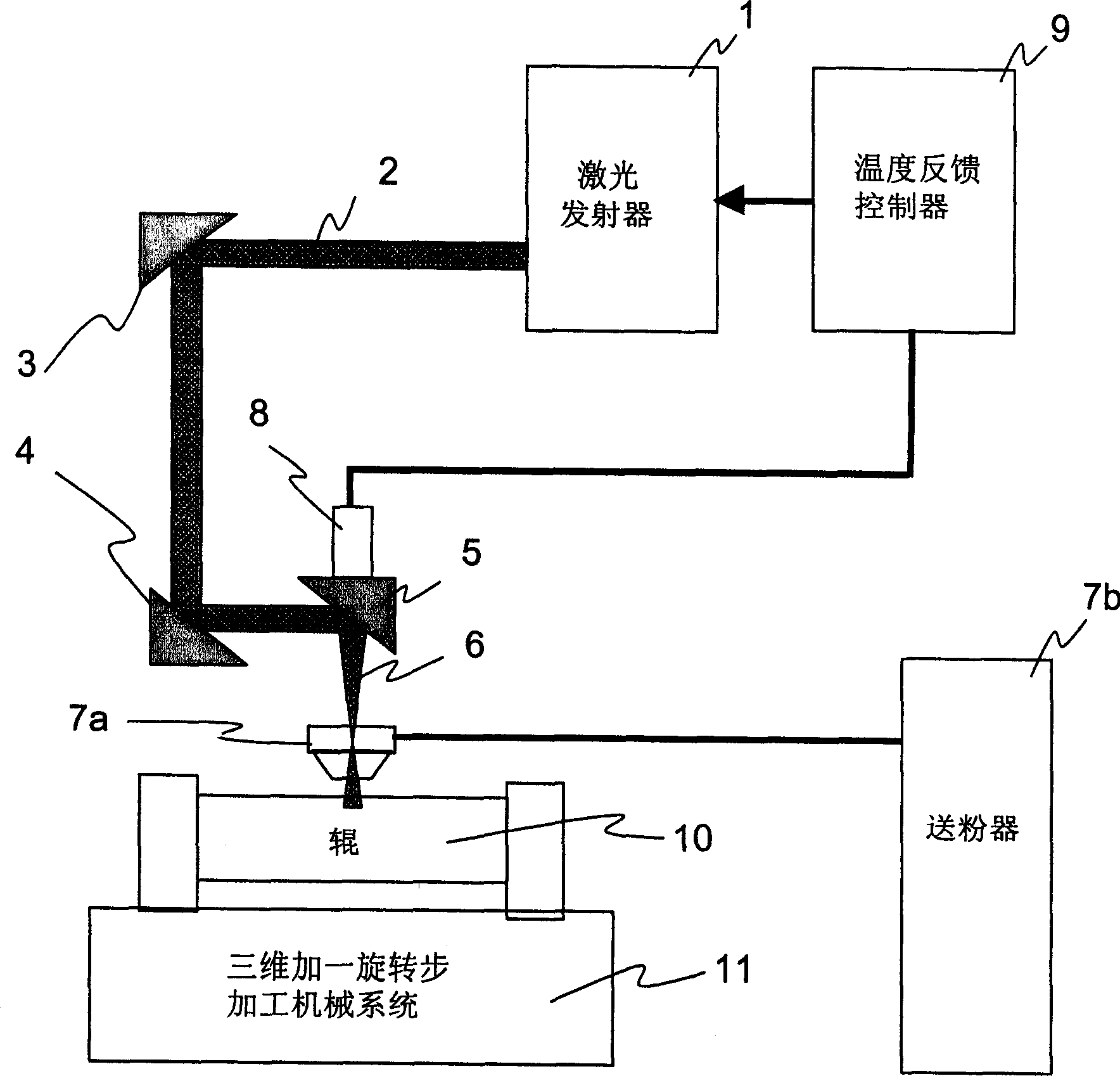

Dual laser coating apparatus and process

ActiveUS7661387B2Promote absorptionEasy temperature controlPretreated surfacesLiquid spraying apparatusTemperature controlLaser coating

An apparatus for applying and fusing a powder coating to substrates of various composition uses two lasers to accurately heat the coating to the optimum temperature. A second laser has less power and heats a smaller area than the first laser. Temperature control is enhanced by the ability to superheterodyne two lasers at separate frequencies. This allows for better absorption of certain materials being fused by the laser. Another common problem associated with laser processing occurs as the polymer heats up. During the heating process the spectral lines are Doppler broadened and slightly shifted. This can affect the absorption of a laser of a fixed wavelength. With the present invention, the optimum laser frequency can be turned to a more optimum frequency for absorption still with sufficient power for fast efficient thermal processing.

Owner:PHOTOFUSION TECH

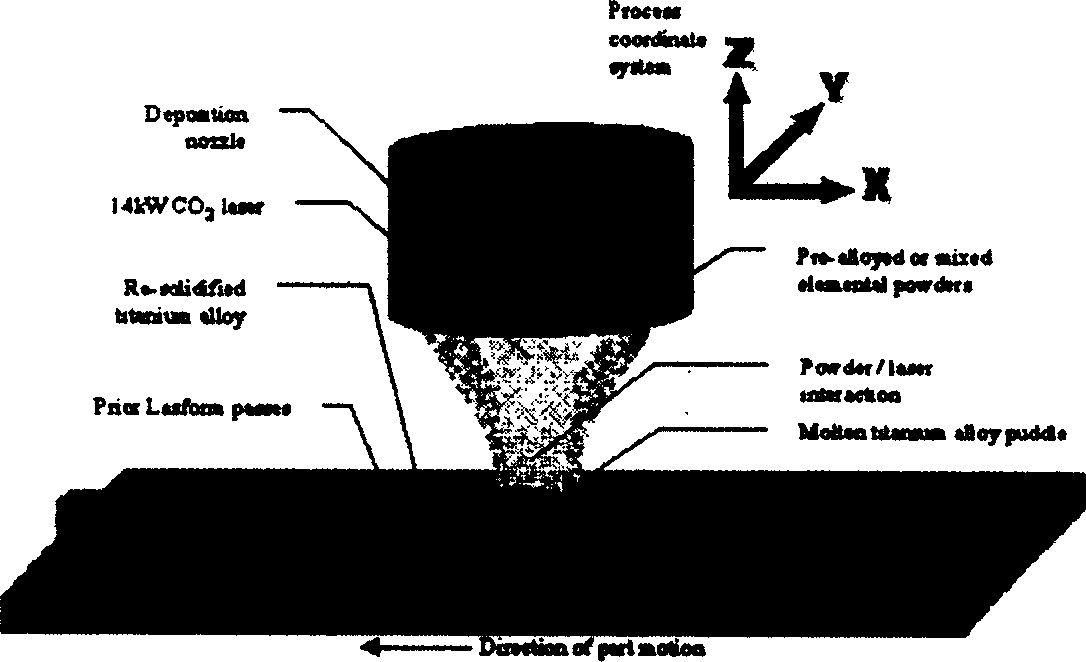

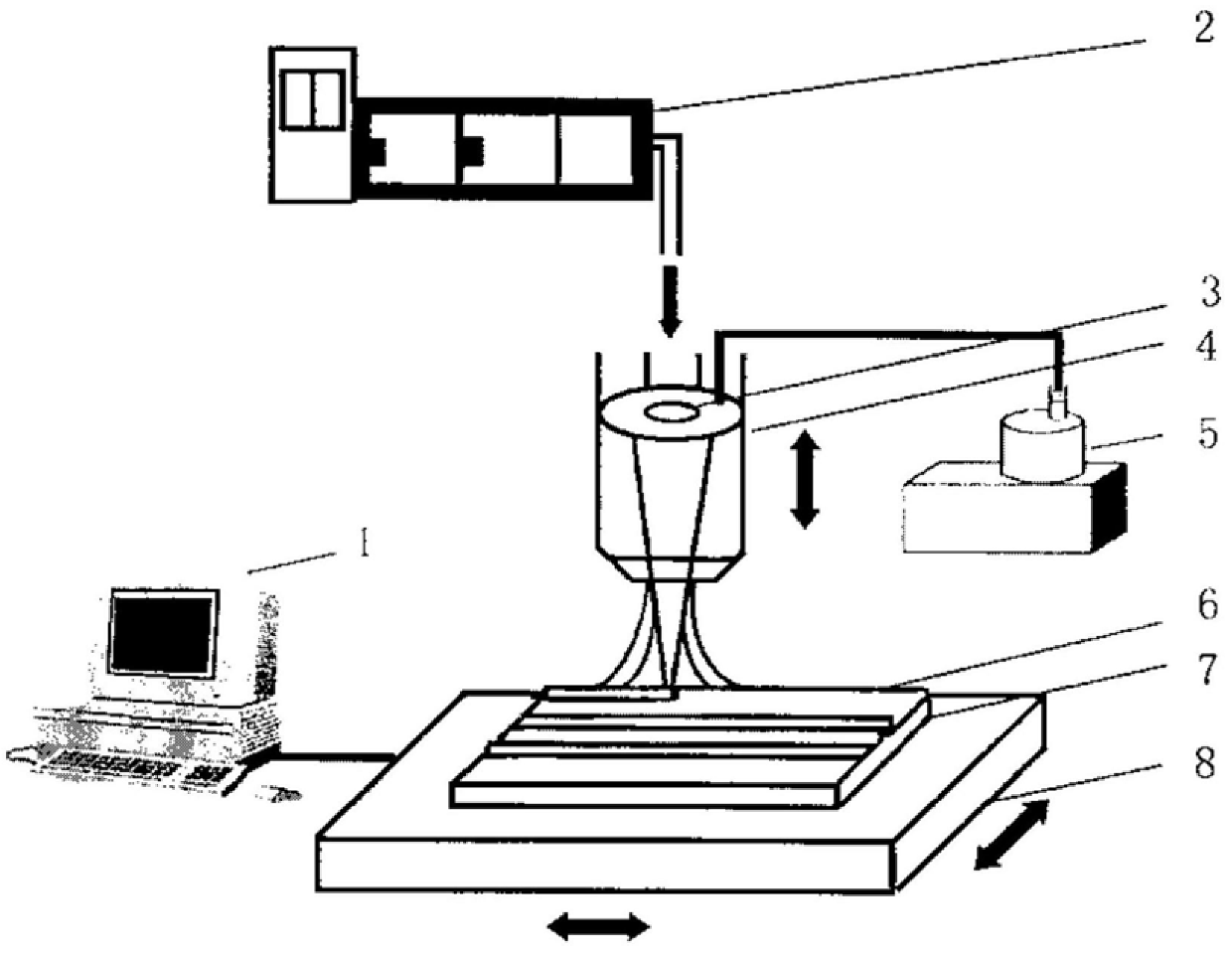

Intelligent laser remanufacturing method and system

PendingCN109487267ARealize closed-loop feedback controlJudgment time is shortMetallic material coating processesLaser coatingClosed loop feedback

The invention discloses an intelligent laser remanufacturing method and system. The intelligent laser remanufacturing method comprises the steps that a point cloud data model of a part to be repairedis obtained, and the point cloud data model is compared with a standard CAD model of the part to be repaired to distinguish an area to be repaired; a coating path is automatically generated through apath autonomous planning module, and initial process parameters are determined by using an intelligent algorithm based on a process parameter database; the defocusing amount is automatically adjusted,and an initial machining position is determined; and combined with a visual algorithm, the process parameters are adjusted in real time by monitoring the change of the shape and temperature of a molten pool, and the closed-loop feedback control of the laser cladding process is realized. The intelligent laser remanufacturing method and system have the characteristics of automation and intelligence, are suitable for the surface repair of medium and large structural parts, can reduce an operation threshold of a laser remanufacturing industry, and improve the machining quality of laser coating.

Owner:HUAQIAO UNIVERSITY

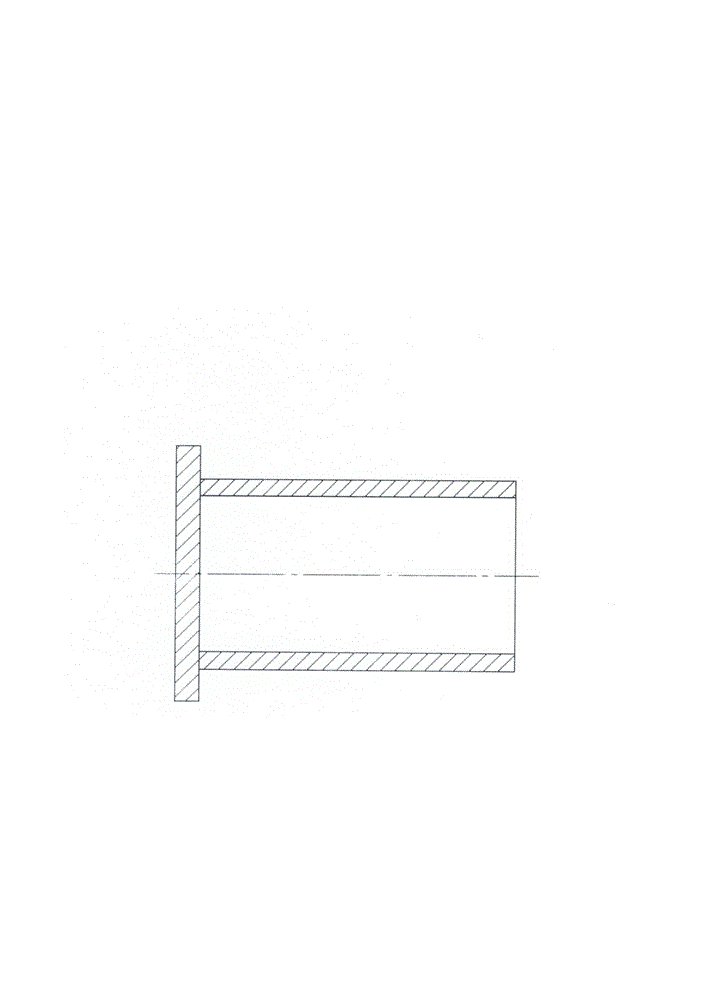

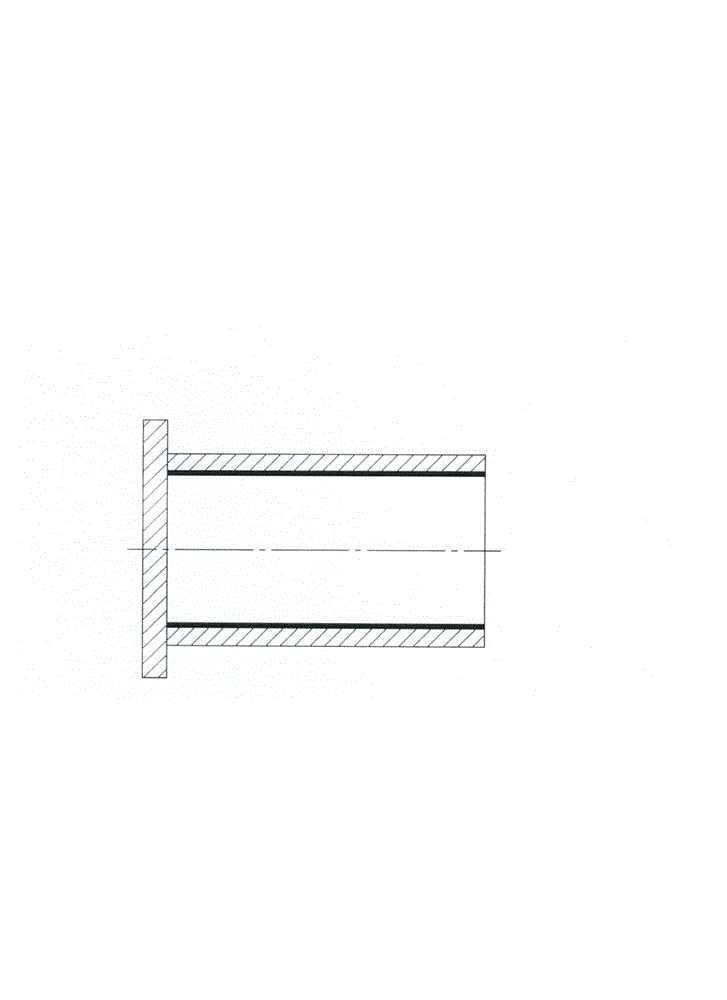

Method for restoring inner bore of gear coupling

InactiveCN102747364AExtended service lifeImprove wear resistanceMetallic material coating processesLaser coatingHigh power lasers

A method for restoring the inner bore of a gear coupling is disclosed. Dimensions of all parts of the gear coupling are measured to check whether all the dimensions satisfy laser coating restoration standards, the surface fatigue layer of the inner bore of the gear coupling is removed, Ni55 and nanometer WC powder which are prepared in proportion are fully mixed in a mechanical powder mixer through adopting a mechanical mixing method, the Ni55 and the nanometer WC powder are coated on the surface of the inner bore of the gear coupling through adopting a coaxial powder sending method and through scanning by adopting a large-power CO2 laser, and the gear coupling undergoes heat treatment and then is slowly cooled with a furnace; and the inner bore of the cooled gear coupling is machined to obtain the gear coupling with the dimensions and the surface process which satisfy requirements, the gear coupling undergoes processing precision detection, and finally the gear coupling is packaged. Compared with the prior art, the method disclosed in the invention has the advantages of continuous use, better performances and long service life of the gear coupling, simple technology, strong controllability, less energy consumption and the like.

Owner:YANSHAN UNIV

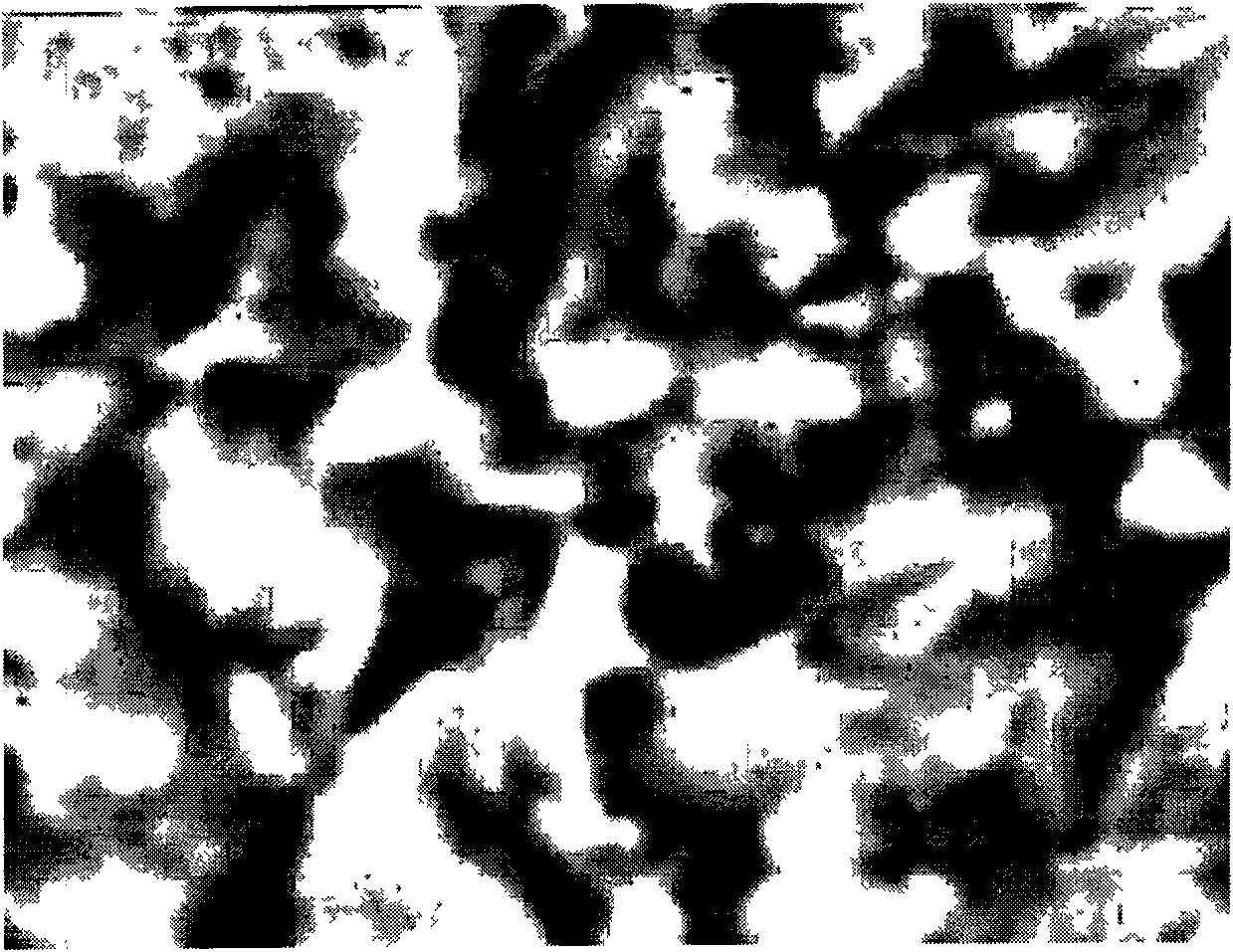

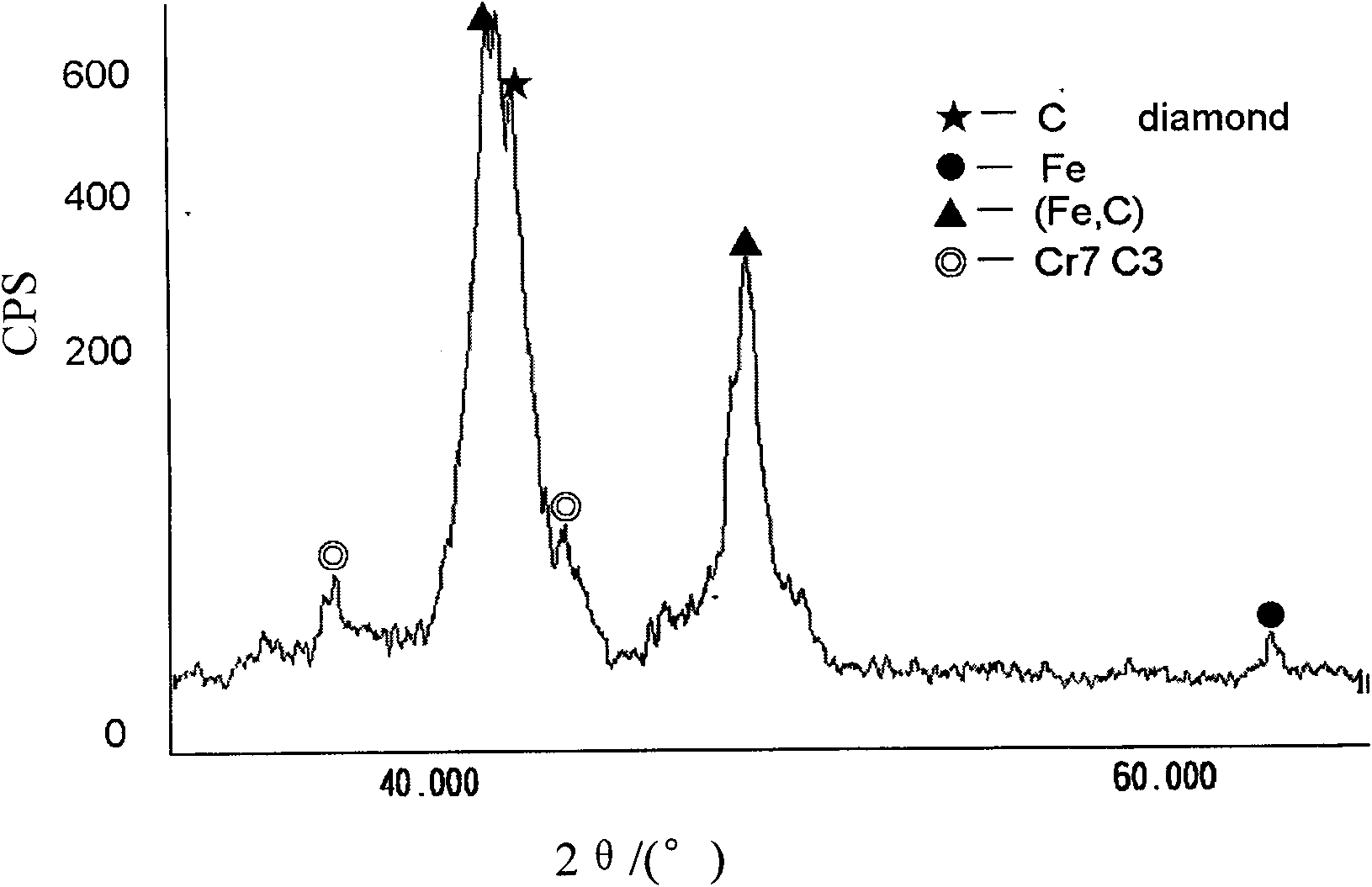

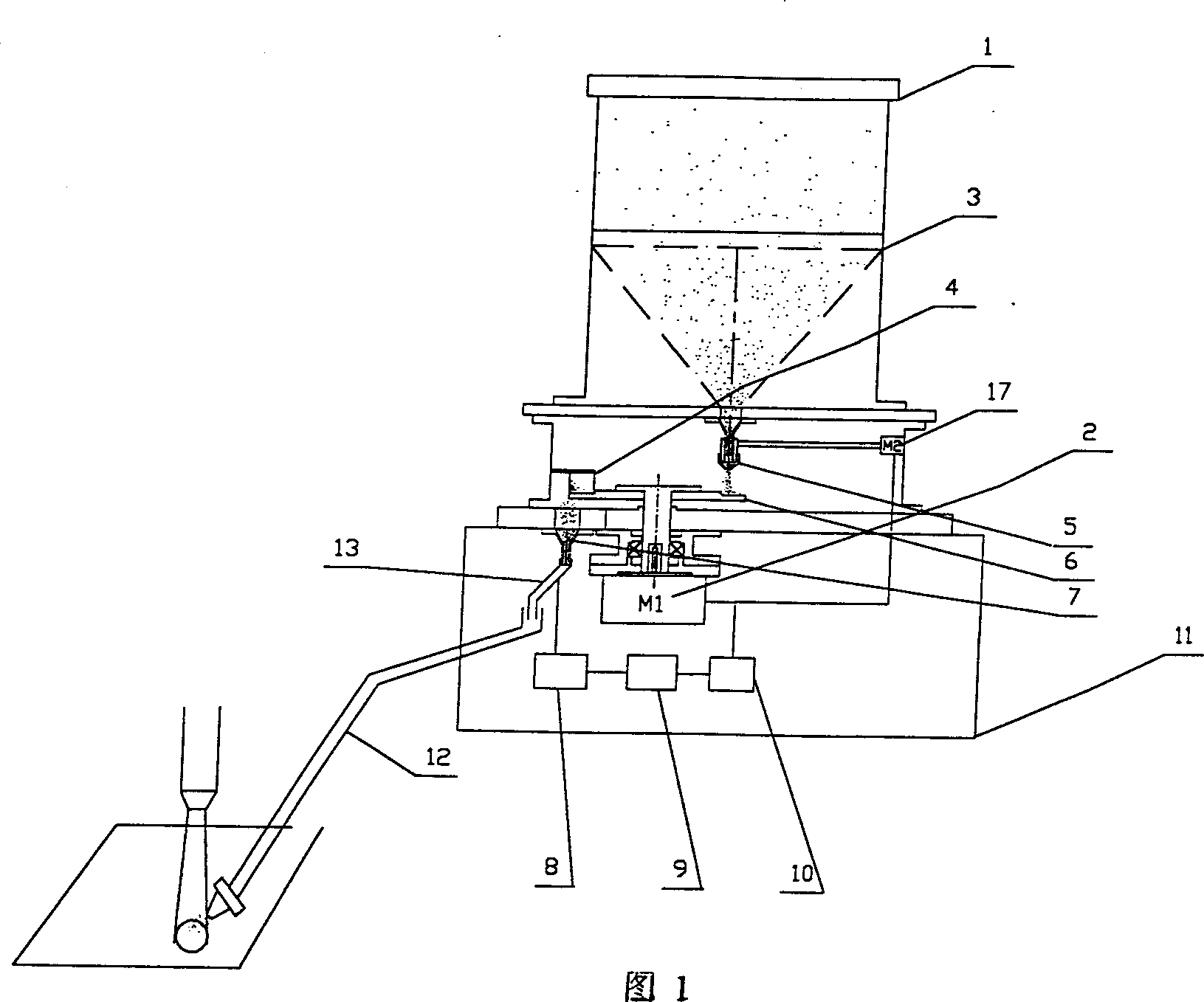

Preparation method of nano-diamond friction coat by laser coating

ActiveCN101560659ABreak molecular bondsGood composition uniformityMetallic material coating processesLaser coatingAlcohol

The invention discloses a preparation method of nano-diamond friction coat by laser coating. The preparation method comprises the steps as follows: 5%-20% of nano-diamond powder is added into alloy powder, the mixed powder is then put into alcohol and mixed by ultrasonic vibration, wherein, the ultrasound frequency is 28 / 40 kHz, the mixing time is 10 minutes, and the alcohol is vaporized; the work piece to be coated is firstly placed in a vacuum chamber and the mixed powder obtained in last step is then pre-placed on surface of the work piece to be coated by powder laying or automatic powder feeding; solid YAG pulsed laser is used to coat in the vacuum chamber by direct entering or transiting and optical fibre guiding; the laser coating power is 150W-400W, the pulse frequency is 10-30Hz, the pulse width is 3-8ms, and the vacuum degree in the vacuum chamber is not lower than 1*10Pa. The nano-diamond friction coat prepared by the method of the invention has high coating strength, compact organizational structure and excellent bonding performance with a matrix.

Owner:CSIC NO 12 RES INST

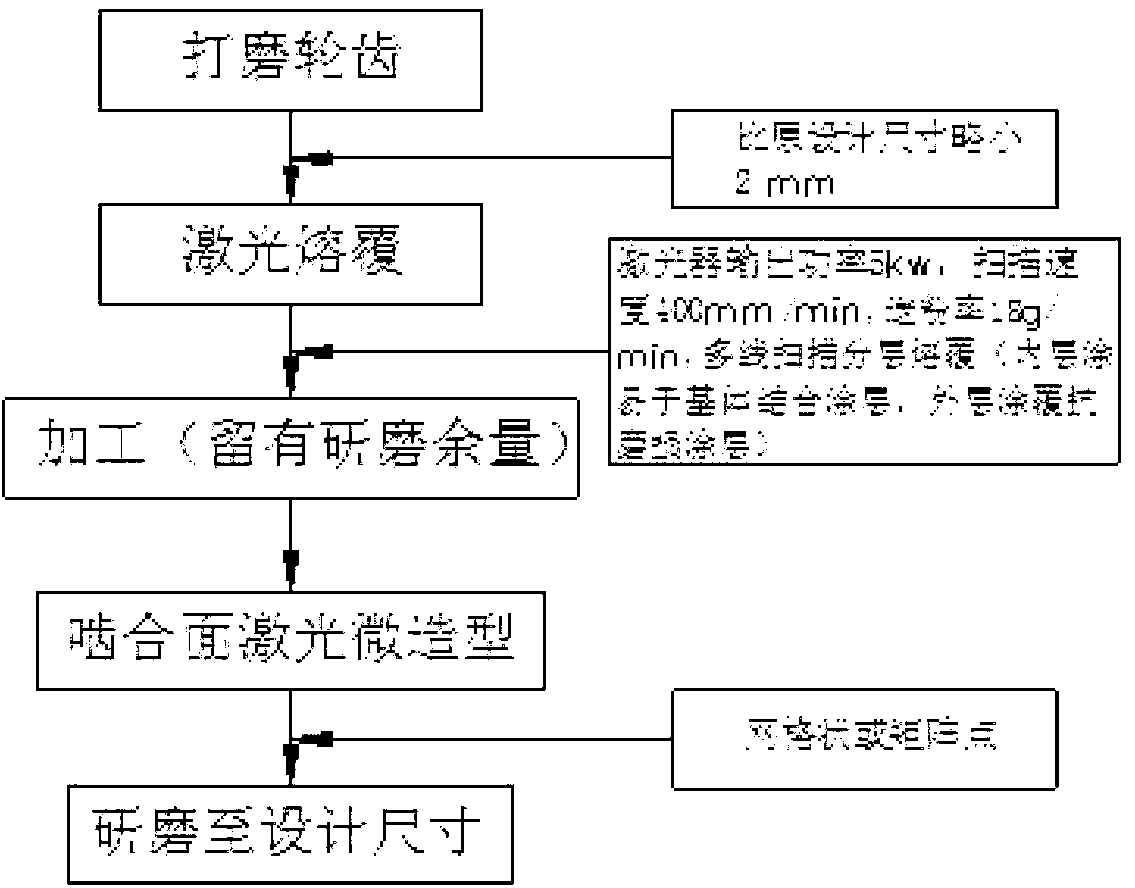

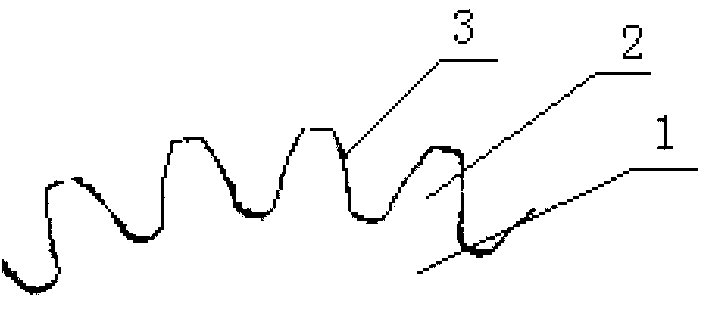

Method for repairing and strengthening gear through laser compound microtexture

InactiveCN103060796AHigh hardnessGood chemical stabilityMetallic material coating processesLaser coatingHardness

The invention provides a method for repairing and strengthening a gear through laser compound microtexture. The method comprises the following steps of (1) modeling through laser coating on a meshing surface of a gear; and (2) carrying out laser shock peening on a coating layer, so as to obtain the gear repaired and strengthened through compound microtexture. According to the method for repairing and strengthening the gear through laser compound microtexture, the gear is processed into the original size through a laser coating method, and the gear is strengthened through laser, so that the hardness and abrasion resistance of the gear are greatly improved. Through detection on the gear repaired and strengthened by the method, the wearing layer thickness is even, the distribution of hardness is uniform, the rockwell hardness of a strengthening layer is HRC65, and the abrasion resistance is three times more than that of a common gear.

Owner:WENZHOU UNIVERSITY +2

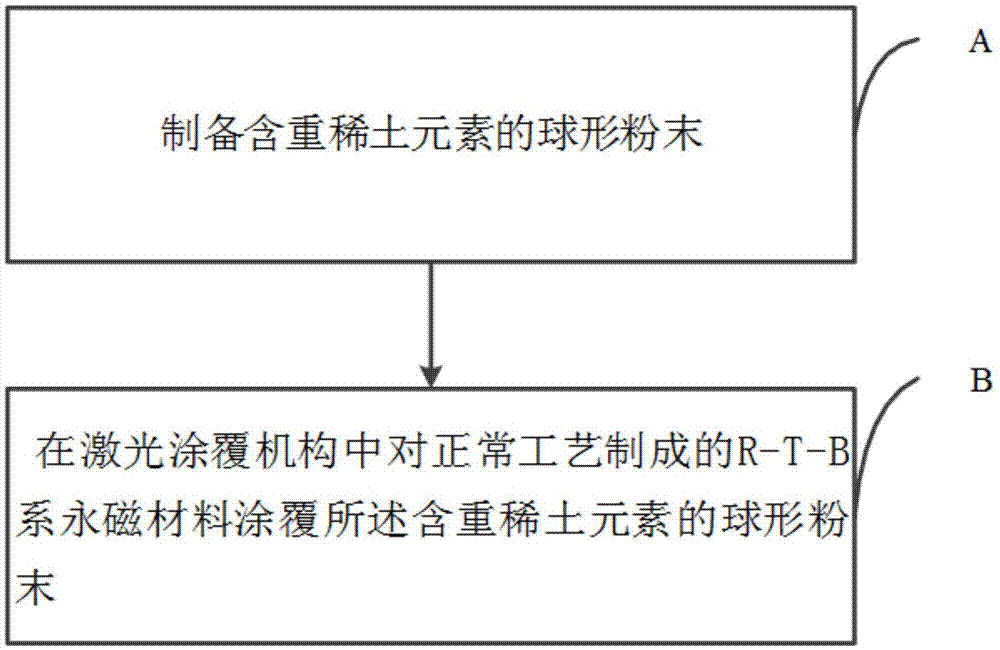

High-coercivity sintered R-T-B permanent magnet material and manufacturing method therefor

InactiveCN106920611AImprove coercive forceLow rare earth contentMolten spray coatingInorganic material magnetismRare-earth elementRemanence

The invention discloses a high-coercivity sintered R-T-B permanent magnet material and a manufacturing method therefor. The manufacturing method comprises the following steps of A, preparing spherical powder comprising heavy rare earth elements; and B, coating an R-T-B series permanent magnet material manufactured by a normal process with the spherical powder comprising heavy rare earth elements in a laser coating mechanism. By virtue of the manufacturing method for the high-coercivity R-T-B series permanent magnet material provided by the invention, the magnet coercivity can be remarkably improved without influencing remanence, and meanwhile, the usage amount of the heavy rare earth elements is obviously lowered.

Owner:NINGBO KONIT IND +1

Manufacturing method of die cutting roller, press cutting roller or indentation roller

InactiveCN1651606ASolve crackingLow costMetallic material coating processesLaser beam welding apparatusLaser coatingCarbon steel

A process for preparing the moulding-cutting roller, pressing-cutting roller or indentating roller includes making raw roller with carbon steel or alloy steel, preparing high-V alloy steel powder from V, C, Mn, Si, Cr, Mo, S and Fe, laser coating of said powder on the surface of raw roller, grinding and electrospark linear cutting to shape the cutting edges.

Owner:许正仁

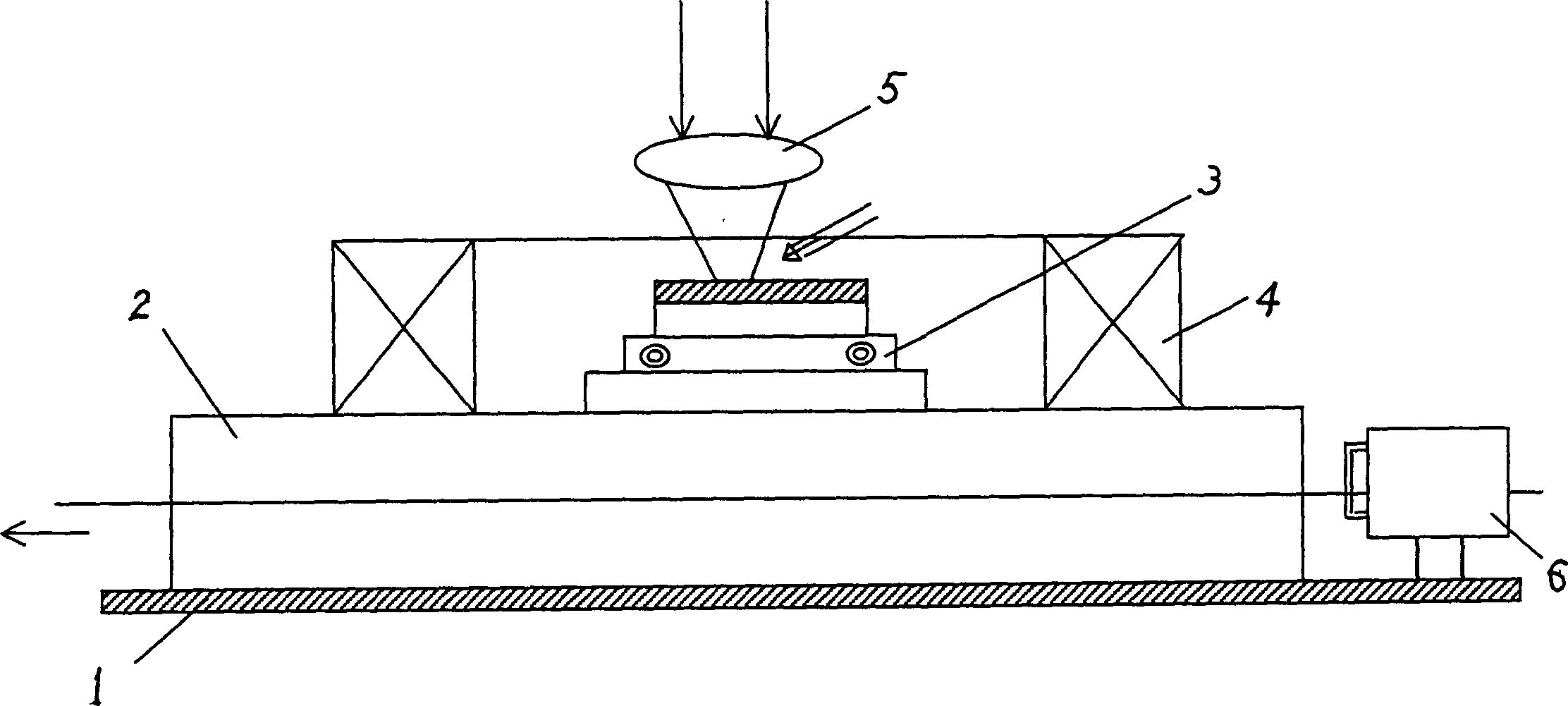

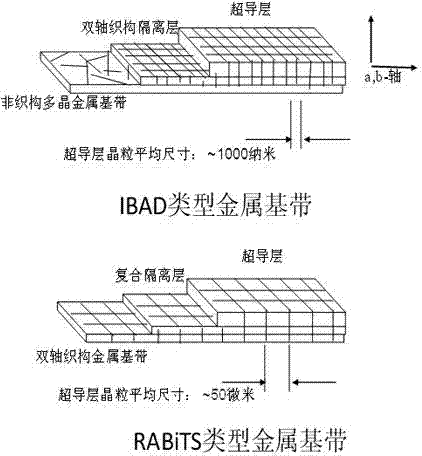

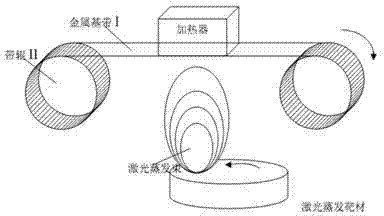

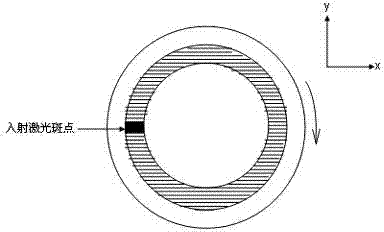

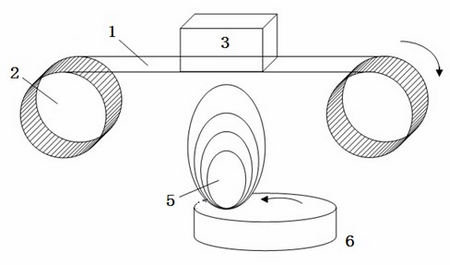

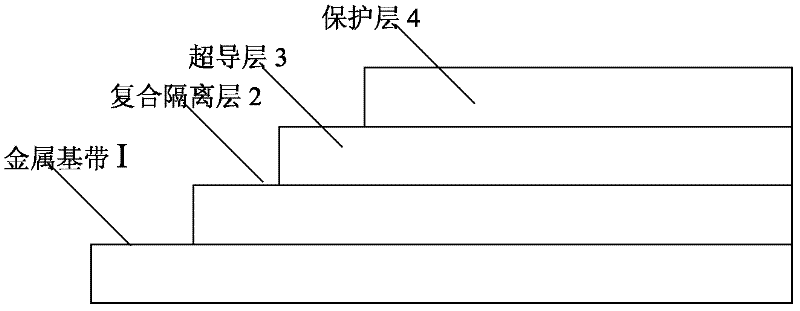

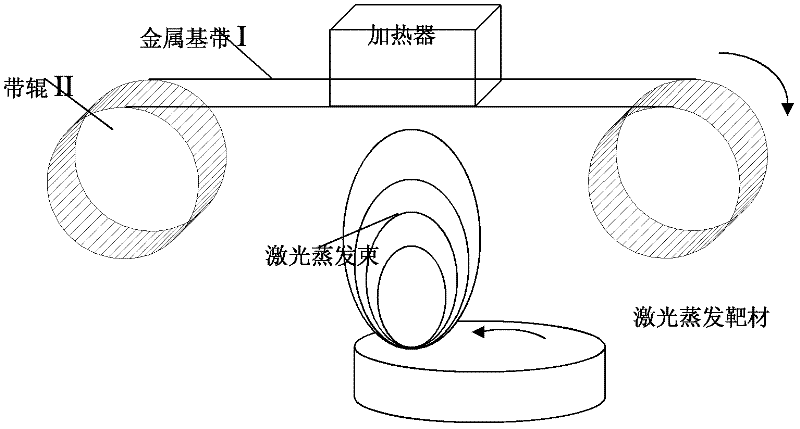

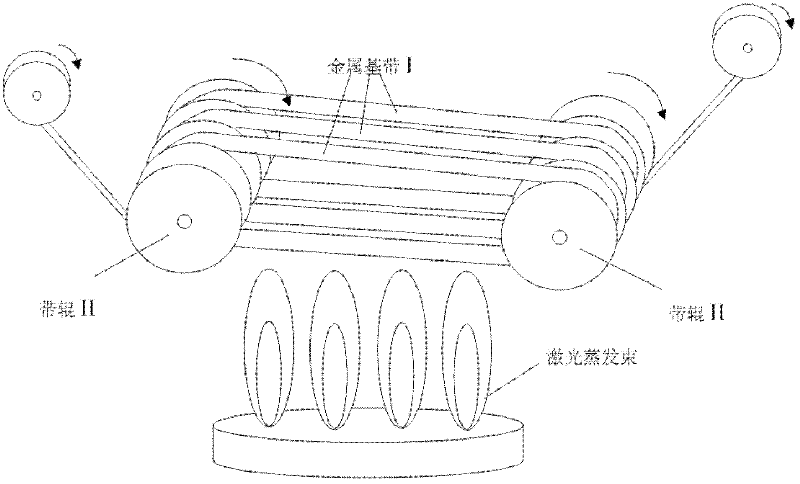

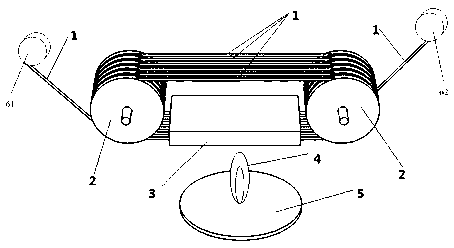

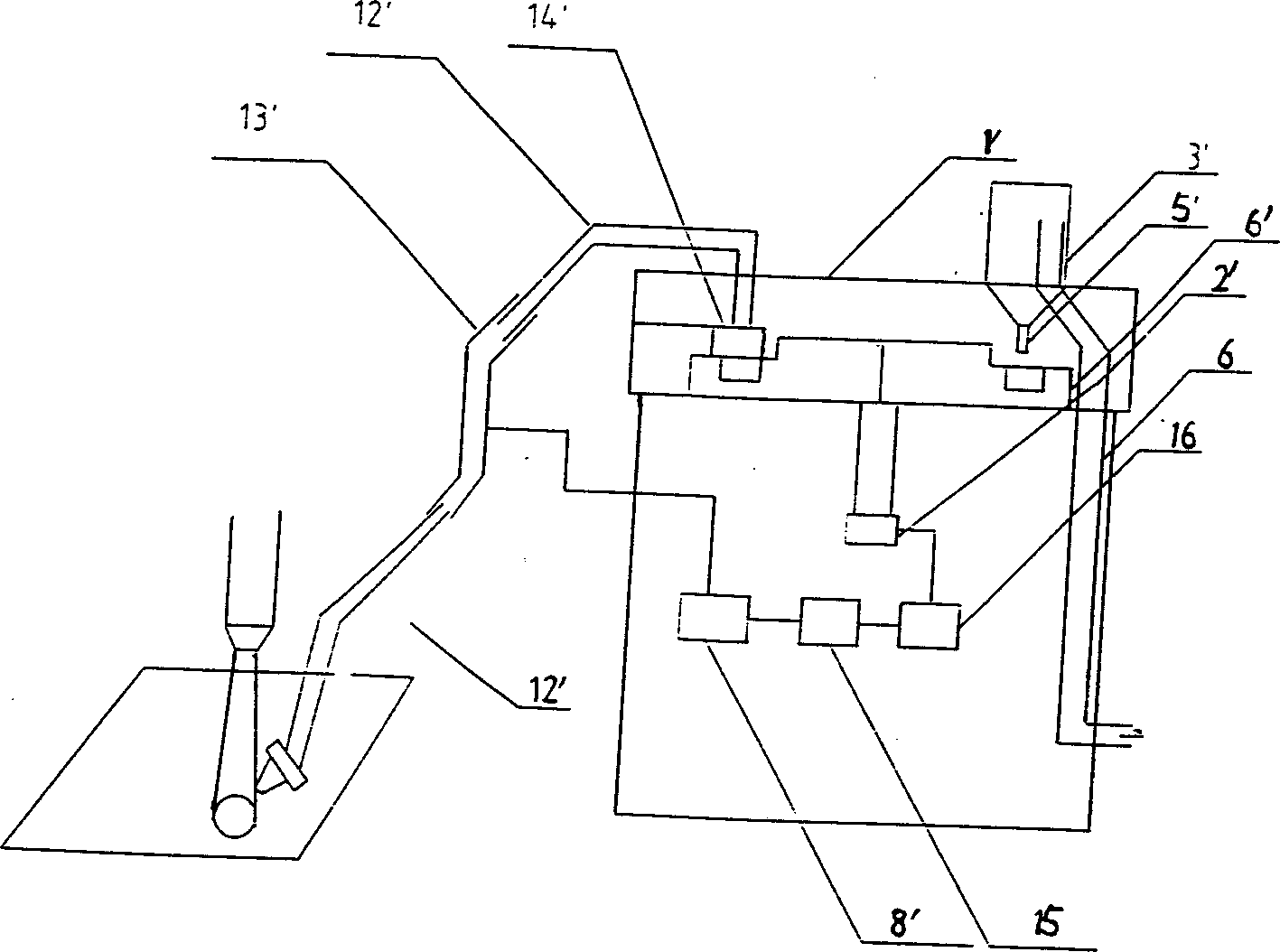

Continuous rapid laser coating method of superconducting layer in second-generation high-temperature superconducting strip

ActiveCN102409298AFast manufacturingAchieve serializationVacuum evaporation coatingSputtering coatingLaser coatingHigh temperature superconducting

The invention provides a continuous rapid laser coating method of a superconducting layer in a second-generation high-temperature superconducting strip. According to the invention, through a method of bi-dimensionally scanning a superconducting target along an x-y axle, the whole surface of the target can be utilized and a laser evaporation coating process can be stably and sustainably carried out; coating intervals are increased through a method of scanning along the motion direction of the strip by use of laser spots; and the width of the coating interval vertical to the motion direction of the strip is increased through a method of twining the strip on a belt roller above a heater multiple times. By using the method provided by the invention, evaporated substances are fully collected on a metal base band to the greatest extend, thereby effectively improving the preparation speed of the strip, increasing the utilization rates of the target and the evaporated substances, greatly improving the production efficiency and reducing the production cost of the strip. According to the method provided by the invention, the rapid coating of the second-generation high-temperature superconducting strip suitable for large-scale industrial production can be realized.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

Method for preparing reignition turbine first-stage work bladetip wear-resistant coating

InactiveCN101705487AGood room temperatureImprove wear resistanceMetallic material coating processesAutomatic controlLaser coating

The invention discloses a method for preparing a reignition turbine first-stage work bladetip wear-resistant coating, which comprises the following steps of: (1) scanning the edge of the end face of the bladetip by using an infrared scanning device of laser coating equipment to enable a scanning track program control program to record the position of a scanned point; and (2) starting a laser generator of the laser coating equipment, transferring alloy powder to the end face of the bladetip under the protection of inert gases, and melting the alloy powder with laser beams. The matrix material of the reignition turbine first-stage work blade is a nickel-based cast high-temperature alloy K488 and the alloy powder is Co-based self-fusing alloy powder. The method for preparing the coating improves the high-temperature wear resistance of the coating, also improves automatic control level and production efficiency of the coating preparation and guarantees the stability of the quality of the product.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Cold spray laser coated of iron/aluminum brake discs

InactiveUS20180180125A1Sufficient kinetic energyBraking drumsBraking discsMetal coatingLaser coating

In one aspect, a braking system is provided that comprises a part (e.g., a brake disc) with a surface that includes a metal coating applied using a cold spray laser coating. Vehicles also are provided having a part (e.g., a vehicle brake disc) with a surface that includes a metal coating that may be applied using a cold spray laser coating is provided. The part (e.g., a brake disc) has improved properties such improved resistance wear and corrosion. A metal coating may also, e.g., serve as a wear indicator for the coated part.

Owner:HYUNDAI AMERICA TECHN CENT +2

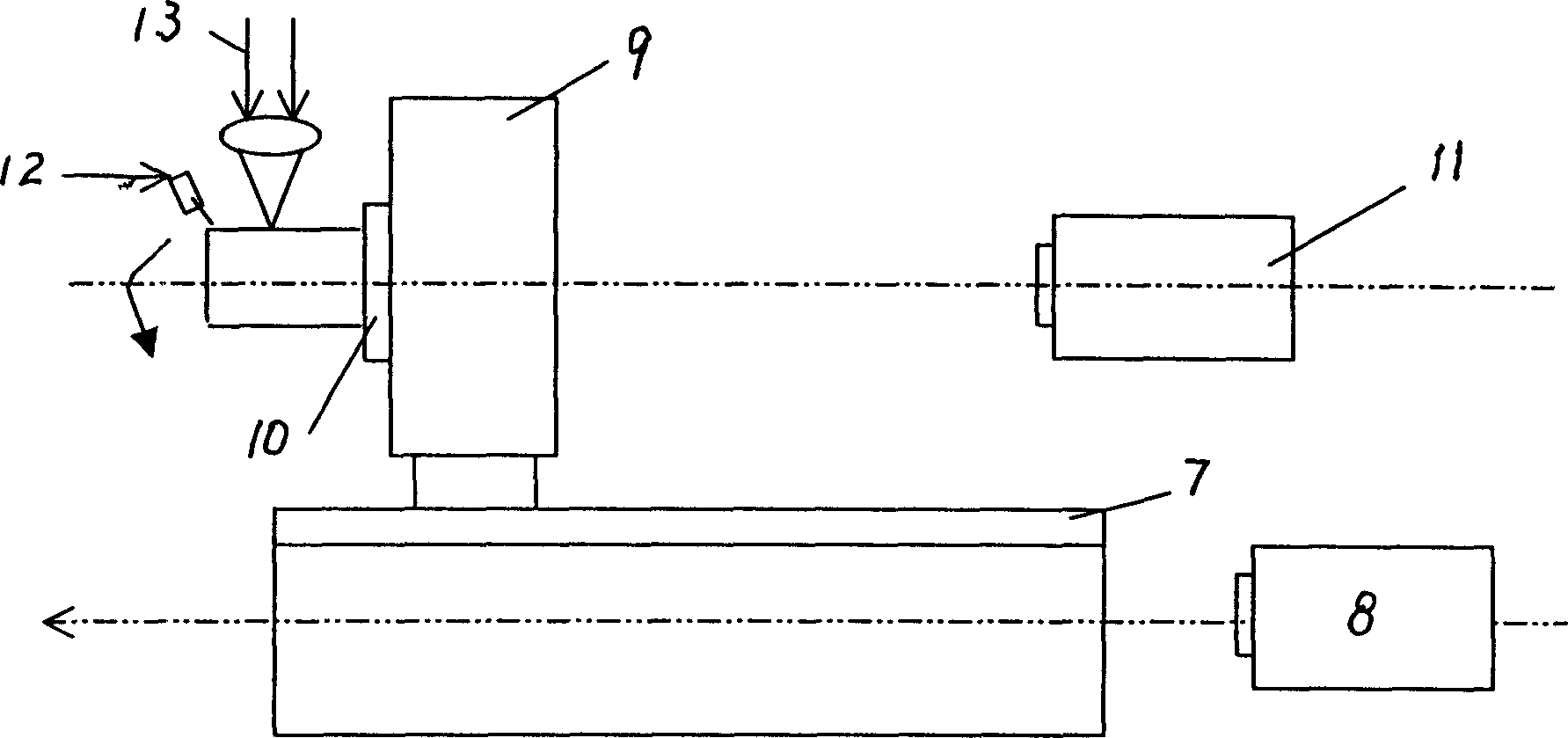

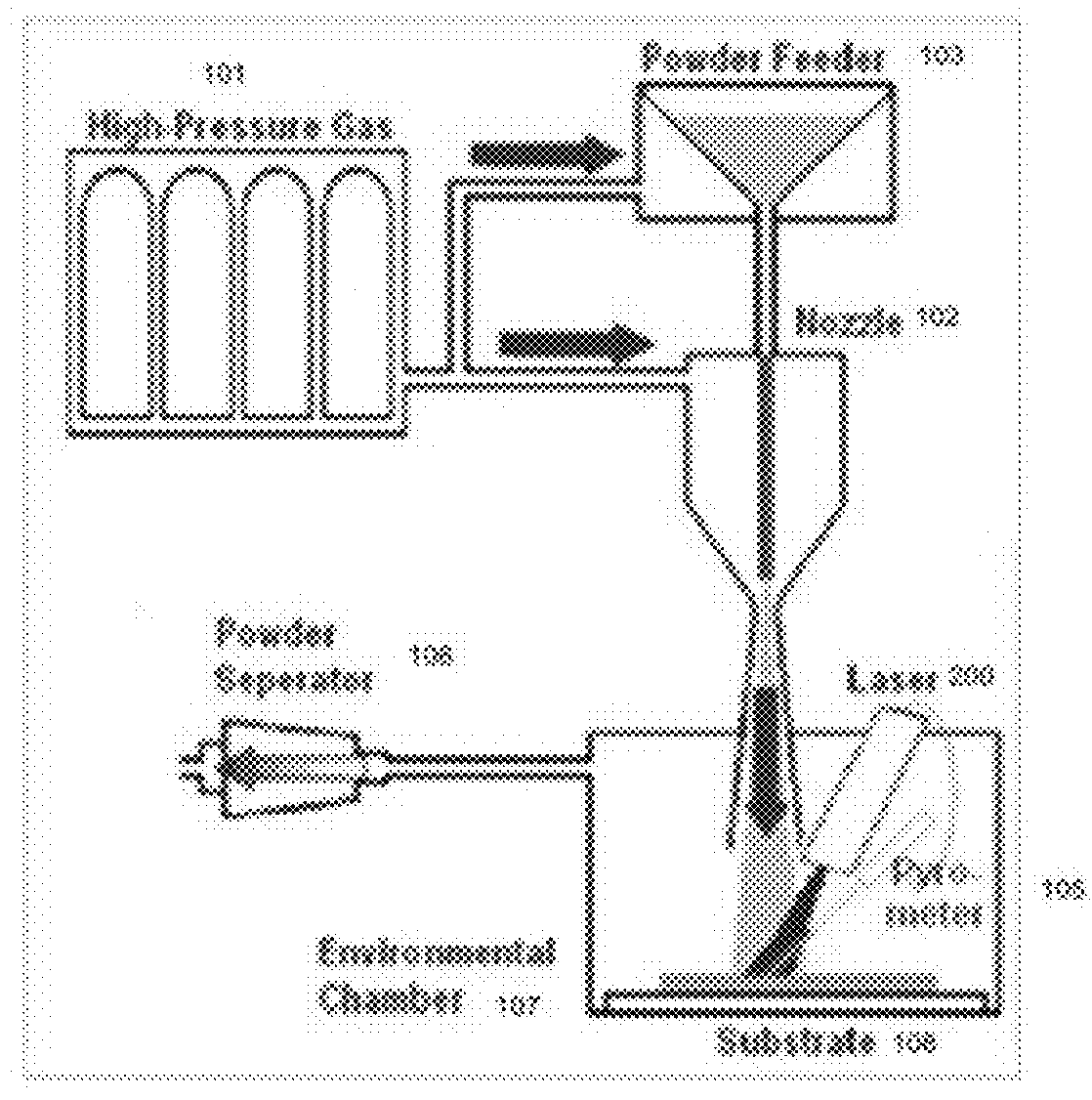

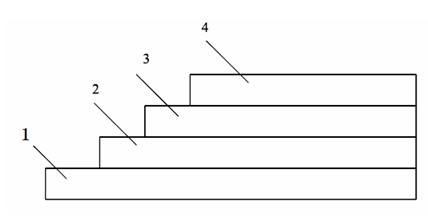

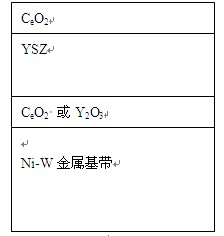

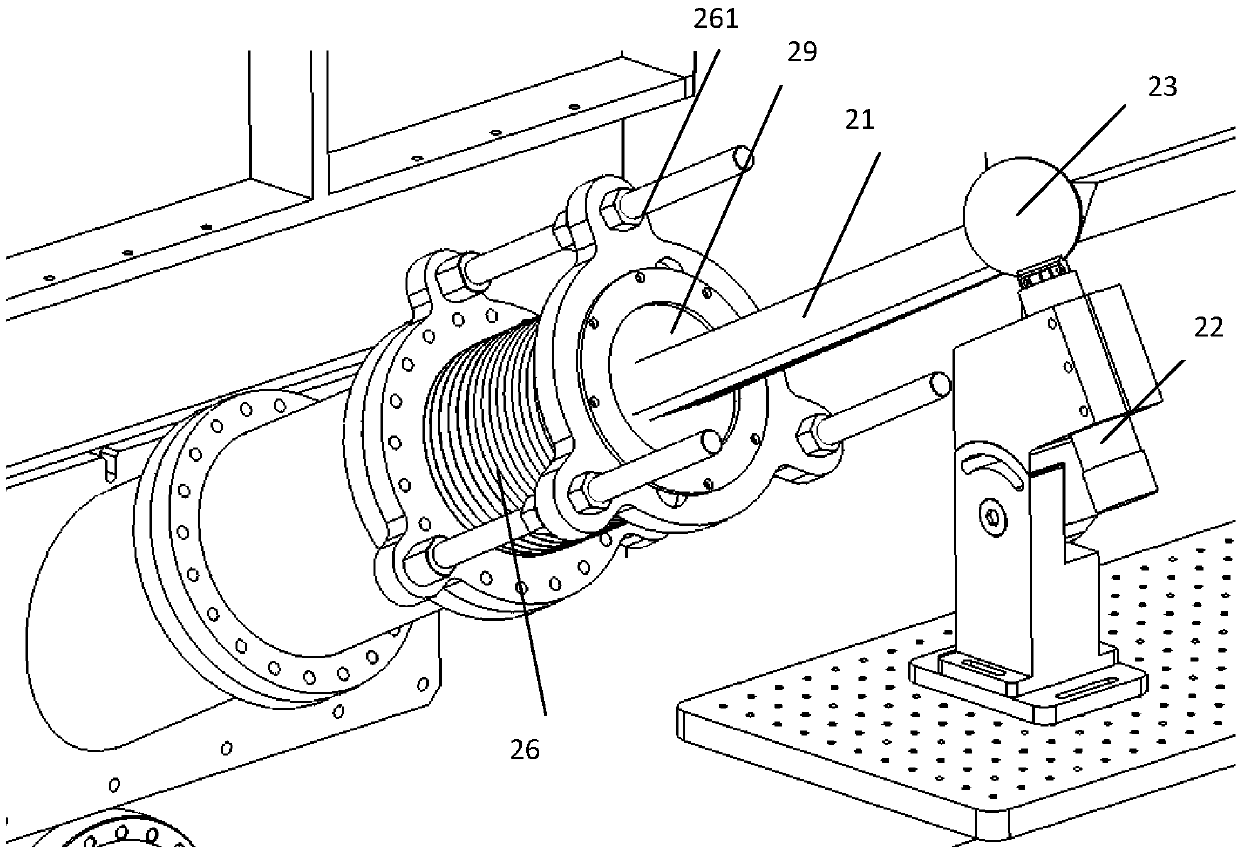

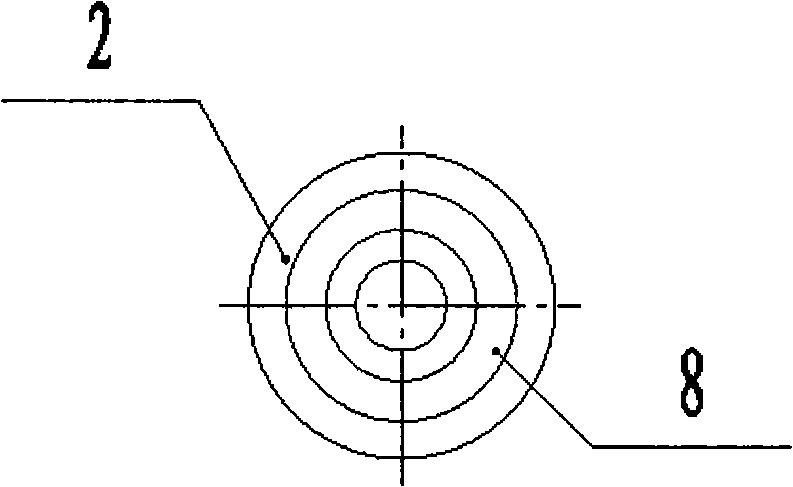

Multichannel pulsed laser deposition method for preparing YSZ buffer layer

ActiveCN102251219AOvercome the disadvantage of small coating areaPurely unidirectionalVacuum evaporation coatingSputtering coatingDeposition temperatureLaser coating

The invention discloses a multichannel pulsed laser deposition method for preparing a YSZ buffer layer, which comprises the following steps of: arranging a nickel-tungsten metal base band, a Hastelloy band, a stainless steel band or other metal base bands in a deposition cavity, winding on a band roller of a metal band transmission device of multichannel pulsed laser deposition equipment for multiple times, and raising the temperature of a heater to deposition temperature; opening an oxygen channel; starting a YSZ target manipulator and beginning the x-direction and y-direction scanning and rotation of a YSZ laser evaporation target platform; opening an optical path window of a laser, and beginning pre-evaporating the YSZ target platform; beginning depositing; and making the metal base band pass through the heater for multiple times due to multiple winding of a roll shaft of the transmission device, and finally stopping corresponding equipment. The YSZ buffer layer is prepared by the multichannel pulsed laser deposition method, so that a defect of a small deposition area of a unichannel pulsed laser deposition method is overcome, the deposition speed is greatly improved, various advantages of the pulsed laser deposition method are exerted fully, and the prepared YSZ buffer layer has single orientation, high surface quality and high crystallinity.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

Selective chemical plating process and corresponding laser coatings and preparation method thereof

InactiveCN102242354ADoes not change physical and chemical propertiesImprove processing efficiencyLiquid/solution decomposition chemical coatingEpoxy resin coatingsLaser coatingChemical plating

The invention provides a selective chemical plating process. A laser coating is coated on the external surface of a plastic workpiece, and a step of doping a catalyst into plastic matrix resin is eliminated, so that cost is reduced, the application range is broadened, and the defects of low selectivity and the like caused by non-uniform mixing of the catalyst and the resin are overcome. A plurality of laser coatings suitable for the selective chemical plating process can meet the requirement of chemical plating in processes such as a laser direct line molding technology and the like, tolerate a high temperature and a strong acidic / alkaline environment, and can meet the requirement of reflow soldering to manufacture a product suitable for a surface mount technology (SMT) process; and a preparation method is convenient and quick, and easy to operate.

Owner:TONTOP TECH

Method suitable for continuously preparing high-temperature superconductive belt material

ActiveCN102306702AFast manufacturingImprove laser utilizationSuperconductor device manufacture/treatmentSuperimposed coating processLaser coatingHigh-temperature superconductivity

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

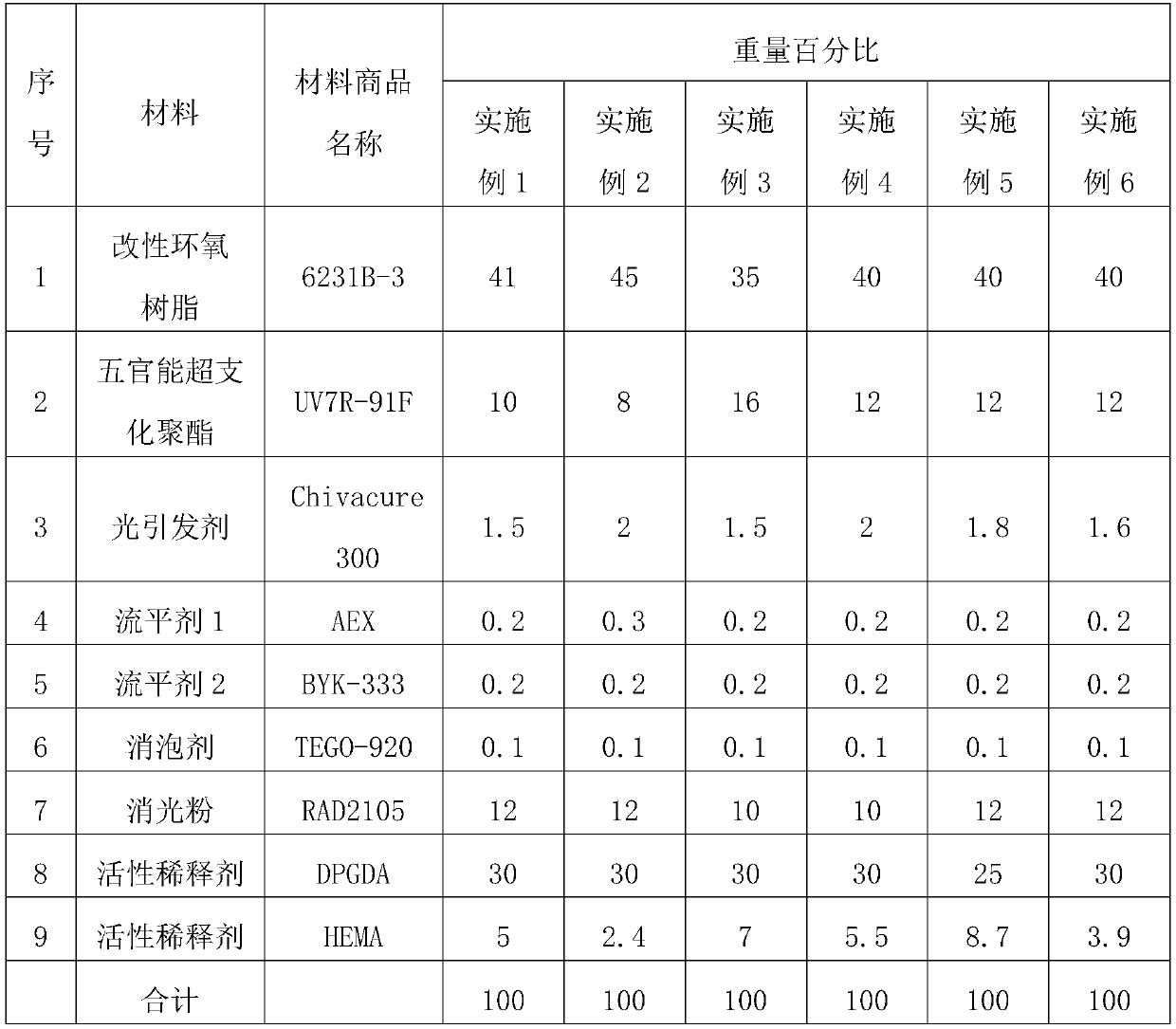

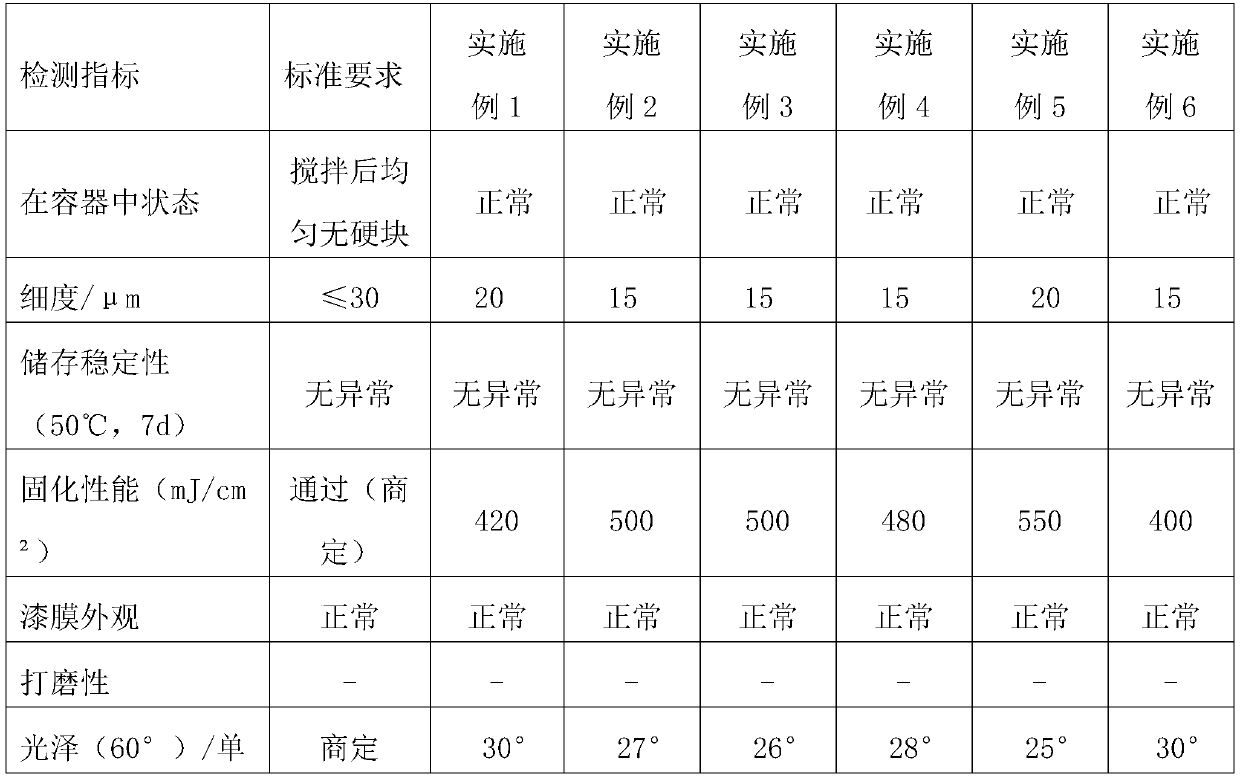

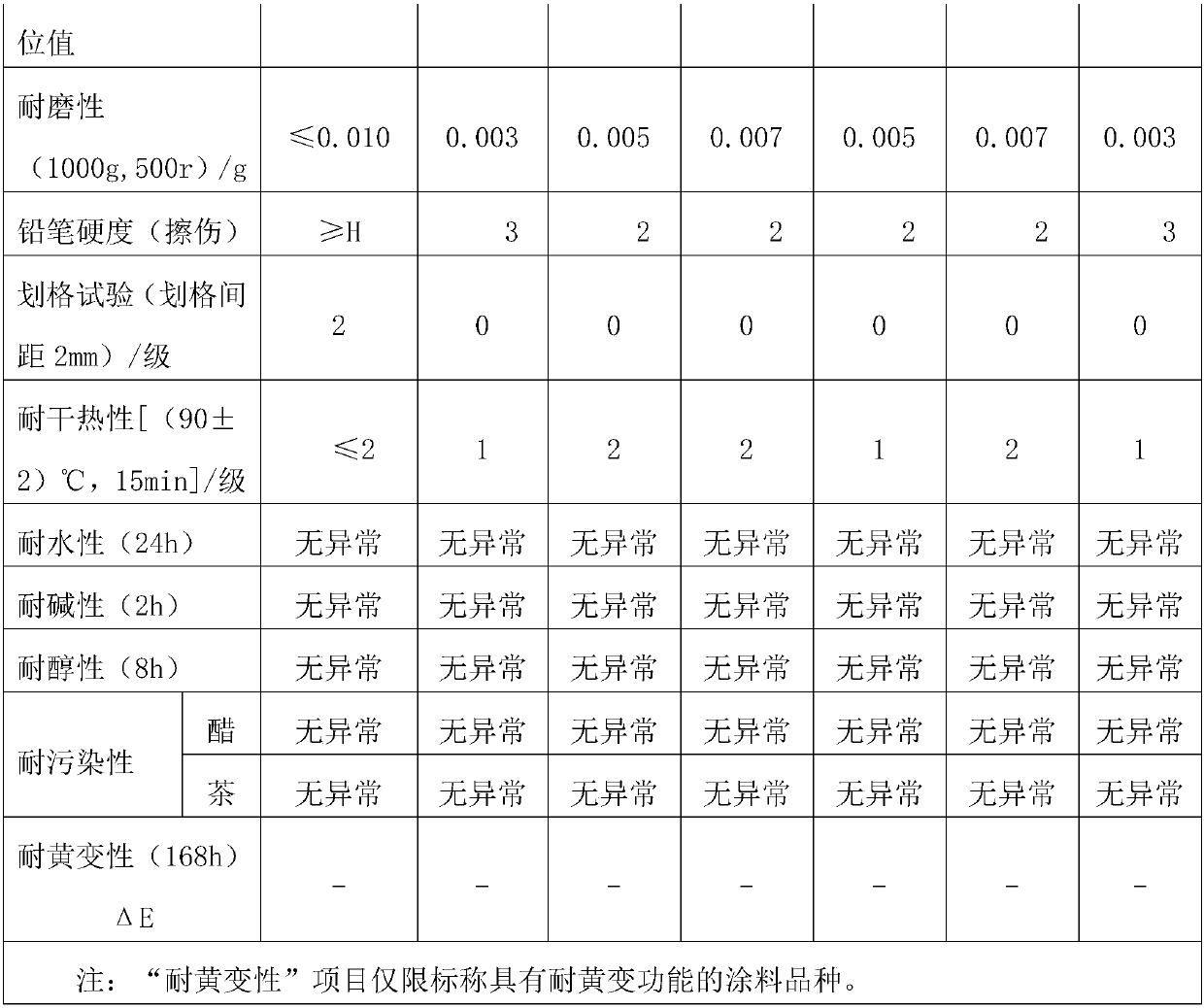

Ultraviolet-curing odorless laser-coating matt finishing paint preparation method

InactiveCN109575758AImprove curing speedImprove adhesionEpoxy resin coatingsPolyester coatingsChemical industryLaser coating

The invention belongs to the field of the chemical industry and particularly discloses ultraviolet-curing odorless laser-coating matt finishing paint and a preparation method thereof. The paint is single-component paint and prepared from, by weight, 30%-50% of epoxy acrylate resin, 5%-15% of hyperbranched polyester acrylate resin, 1%-2% of a photoinitiator, 0.3%-3% of a dispersing agent, 0.1%-0.5%of an antifoaming agent, 0.2%-0.5% of a flatting agent 1, 0.1%-0.3% of a flatting agent 2, 10%-15% of matting powder and 30%-40% of a UV active diluting agent. The ultraviolet-curing odorless laser-coating matt finishing paint is odorless, high in hardness and wear resistance, good in hand feeling and uniform and soft in gloss.

Owner:AODA KOALA PAINT HUIZHOU

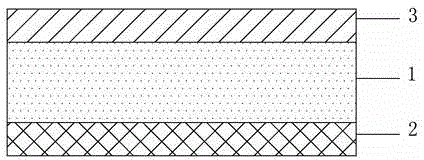

Laser medical film and preparation method thereof

The invention discloses a laser medical film and a preparation method thereof. The PET medical film is prepared directed to the laser printing demand, the film base is prepared from high temperature resistant PET plastics and is subjected to corona treatment, an anti-static layer is coated on one side of the film base and is prepared from polystyrene sulfonate, a laser ink absorption coating is coated on the other side of the film base, and the laser coating contains a nanoscale aluminum oxide powder dispersion liquid. The laser medical film provided by the invention has the advantages of fast printing speed, good imaging effect, high temperature resistance, good antistatic effect, smooth paper feeding, no jamming, applicability to doctor handwriting signing, difficult color fading, and long preservation period.

Owner:杭州健培科技有限公司

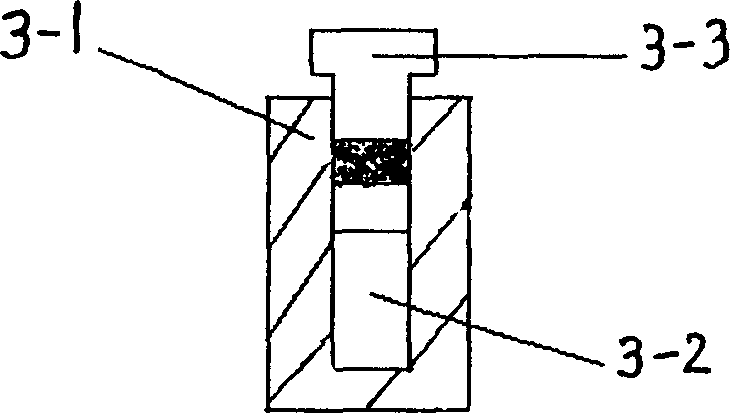

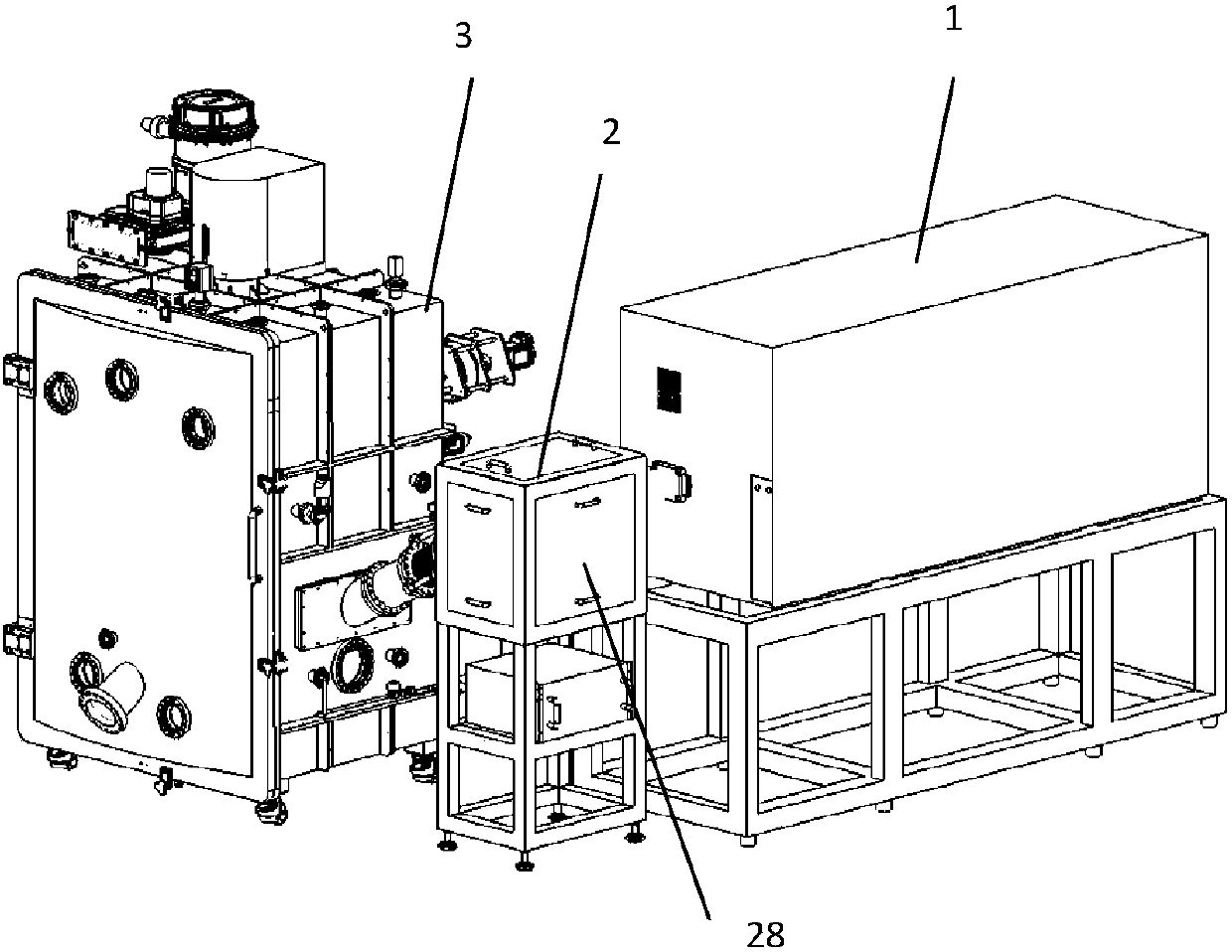

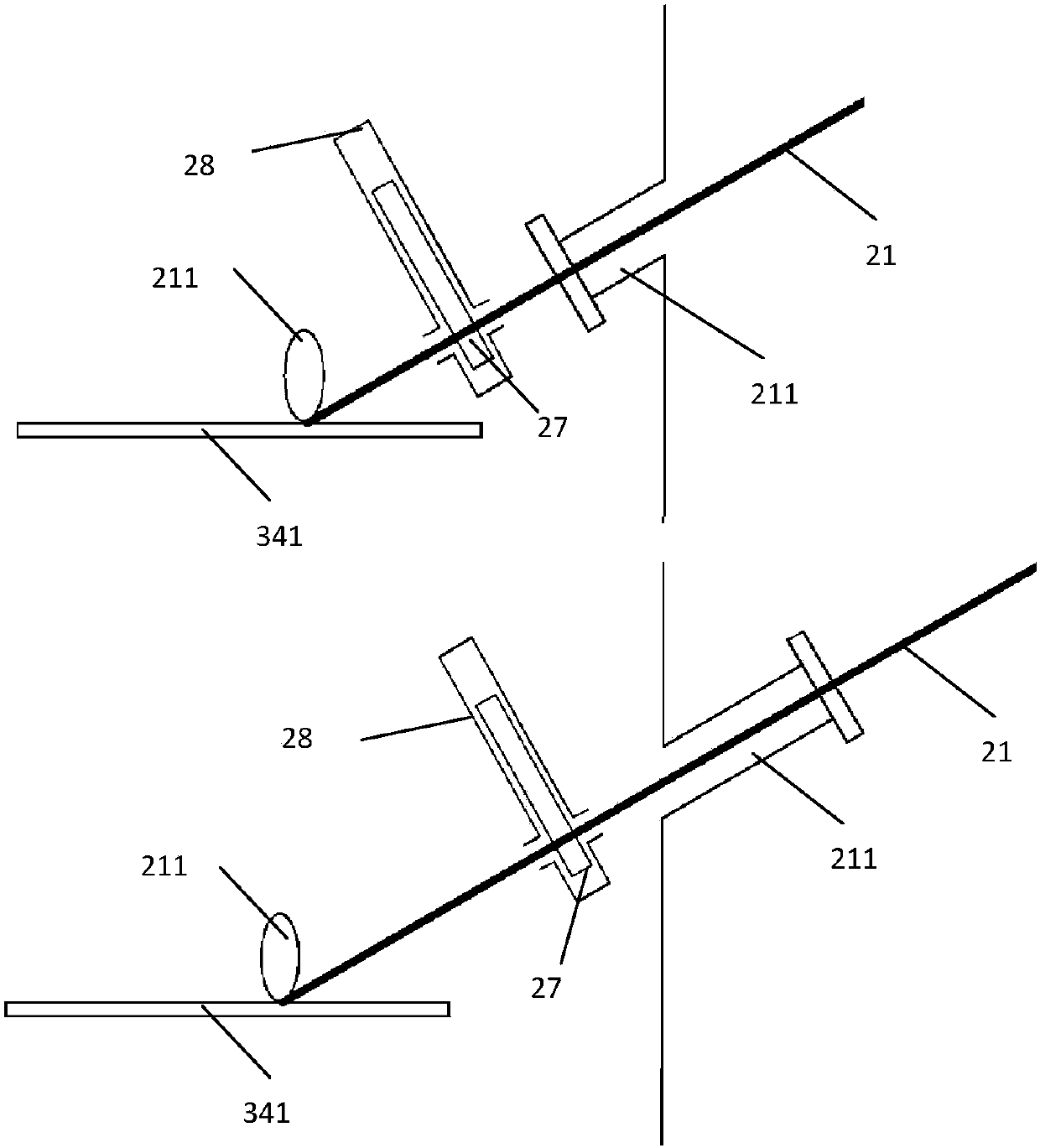

Pulse laser film coating device

ActiveCN108179386AGood qualityUniformityVacuum evaporation coatingSputtering coatingLaser coatingLight beam

The invention provides a pulse laser film coating device. The pulse laser film coating device comprises a laser (1), an optical path system (2), and a film coating cavity body (3), wherein the laser (1) produces a pulse laser beam (21); and the optical path system (2) is used for leading the pulse laser beam (21) into the film coating cavity body (3), so that plumes (211) are formed in the surfaceof a target material (341) and a material of the target material (341) is sputtered onto a base band (226) to form a superconducting layer. According to the pulse laser film coating device disclosedby the invention, the quality and the quantity of pulse laser coating films can be improved, and the use of equipment also can be improved.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

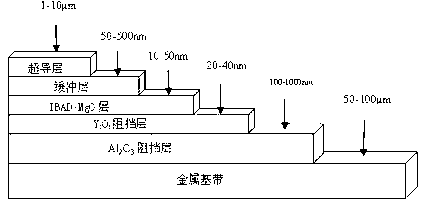

Simplified baffle layer suitable for IBAD-MgO (ion beam assisted deposition-magnesium oxide) growth on metal substrate and preparation method thereof

ActiveCN103255369AReduce the number of layersSimple preparation processVacuum evaporation coatingSputtering coatingLaser coatingManufacturing technology

The invention discloses a simplified baffle layer suitable for IBAD-MgO (ion beam assisted deposition-magnesium oxide) growth on a metal substrate and a preparation method thereof. The simplified baffle layer is arranged on the metal substrate and is a single YAlO baffle layer; and the single YAlO baffle layer is prepared by adopting a multi-channel pulse laser coating technology or a multi-channel magnetron sputtering technology. The YAlO baffle layer with a smooth surface, even surface particle size, low roughness and strong bonding strength is prepared; the YAlO baffle layer can prevent atoms of the metal substrate from diffusing to the other layers, can reduce the roughness of the metal substrate and also can be used as a nucleation layer of an IBAD-MgO layer; the surface roughness of the YAlO baffle layer is smaller than 2 nanometers; the texture degree in the surface of the prepared IBAD-MgO layer is less than 7 degrees; and a rare earth oxide superconducting layer with high performance can epitaxially grow on the baffle layer. By adopting the simplified baffle layer, the quantity of the baffle layers for IBAD-MgO is reduced; simplification, fast speed and low cost of the manufacturing technology are achieved; the simplified baffle layer has high stability, repeatability and reliability, and good application prospect in industry, and is suitable for industrial production.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

Binary alloy coating seamless steel tube top and manufacture method thereof

InactiveCN101596551BReduce stress concentrationEliminates crack-prone problemsMandrelsFurnace typesBinary alloyLaser coating

A binary alloy coating seamless steel tube top and a manufacture method belong to the field of laser processing. Aiming at solving the easy peel-off of molybdenum alloy of a molybdenum alloy top, prolonging service life and reducing cost, the invention melts and coats nickel-base or cobalt-base alloy coating at the nose or working part of the top, melts and coats iron-base alloy coating at the straightening part and the parallel part to obtain a binary alloy coating seamless steel tube top; the preparation of the top has the following steps of manufacturing the top by adopting a casting manner, performing mechanical processing on the cast top and reserving melt thickness of 1.0-3.0mm on the external surface of the top for laser melt process; using nickel-base or cobalt-base alloy to perform laser melt on the top end of the nose part; performing laser melt on the lateral of the nose part as well as the working part with nickel-base or cobalt-base alloy as melt powder, finishing laser melt on the straightening part and the parallel part with iron-base alloy incessantly; performing strain-removal treatment, namely performing mechanical processing of top nose spiracle and finishing laser coating polishing and grinding.

Owner:BEIJING UNIV OF TECH

Method for laser imprinting transfer on wrapping paper

InactiveCN101746170AEnhanced quality of laser transfer printingPattern printingPrinting after-treatmentScreen printingLaser coating

The invention discloses a method for laser imprinting transfer on wrapping paper. The main techniques of the method comprise the following steps: A. UV oil is pre-coated on the paper by a screen printing method; namely in printing, the UV oil is poured into one end of a screen printing plate, a scraper blade exerts certain pressure in the UV oil position on the screen printing plate, and at the same time the UV oil moves to the other end of the screen printing plate; the UV oil is extruded on the paper by the scraper blade from parts of oil penetrating meshes in moving; B. the coating surface of a laser film is touched with the UV oil surface on the paper, and the UV oil is stuck to the surface of the laser film with the laser coating; C. the irradiation of a UV light solidifies the UV oil; D. the laser film is stripped; and E. the dried UV oil of the laser coating on the laser film completes laser transfer on the paper. In order to overcome the defects of bad coating quality, insufficient overprinting precision and limited coating amount of the existing method for laser imprinting transfer, the invention provides the method for laser imprinting transfer with thick UV oil layer and high precision.

Owner:ZRP PRINTING GRP CO LTD

Laser coating device and method based on transparent material

InactiveCN101575695AImprove edge sharpnessLow costVacuum evaporation coatingSputtering coatingLaser coatingControl system

The invention discloses a laser coating device and a method based on a transparent material, belonging to the field of micro-machining. The device comprises a computer, a laser which is connected with the computer, a laser control system which is installed on the laser, a workstation, a transparent material plate, a target and a flat plate, wherein the laser is connected with the computer, the workstation is arranged below the laser control system, and the transparent material, the target and the flat plate are arranged on the workstation from top to bottom in sequence. When in coating, the target is arranged at the lower surface of the transparent material plate, the laser penetrates the transparent material from the upper surface and then illuminates on the target, and then the target is heated, melted and sputtered onto a close transparent substrate, later high calorie leads the transparent substrate to generate micro-melting, and thus causing a coating layer to be formed on the transparent material. The device has the advantages of simpleness, low cost, high precision and good controllability, and can coat a film with micron-level or nano-level thickness on the surface of the transparent material, wherein the film has good edge sharpness and the shape of the film can be controlled by the computer output.

Owner:BEIJING UNIV OF TECH

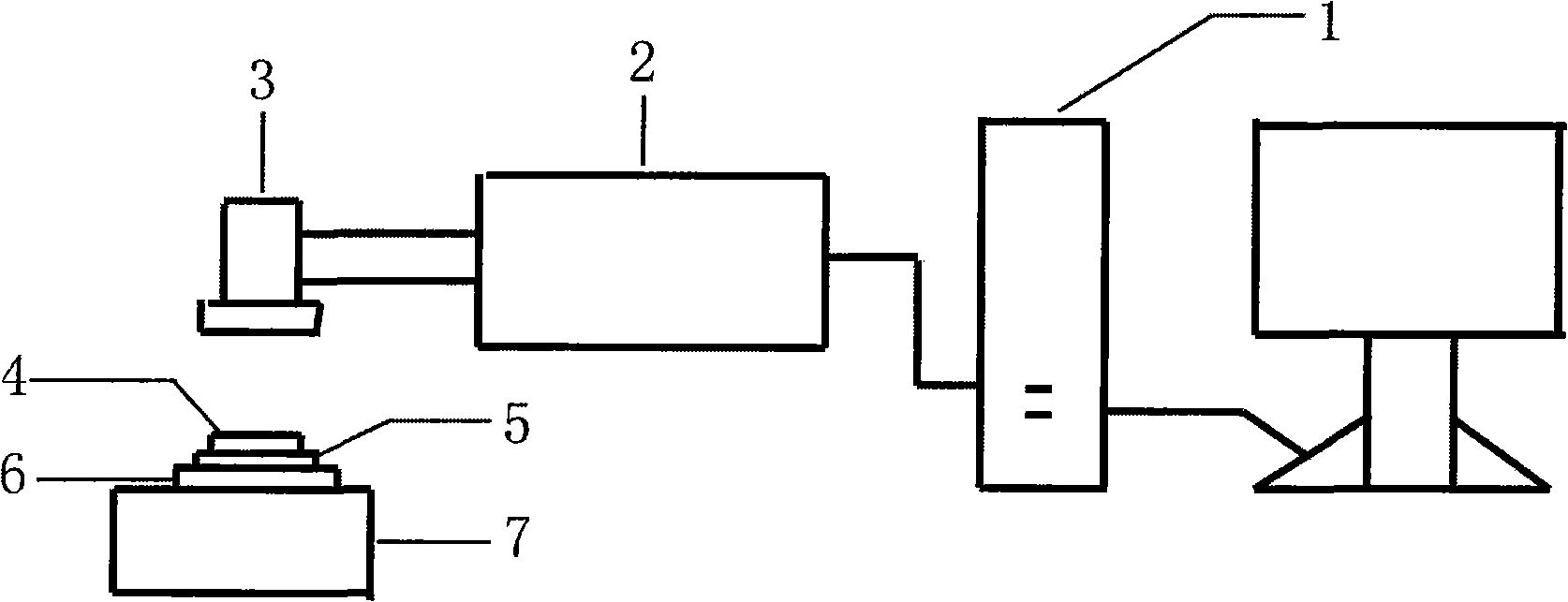

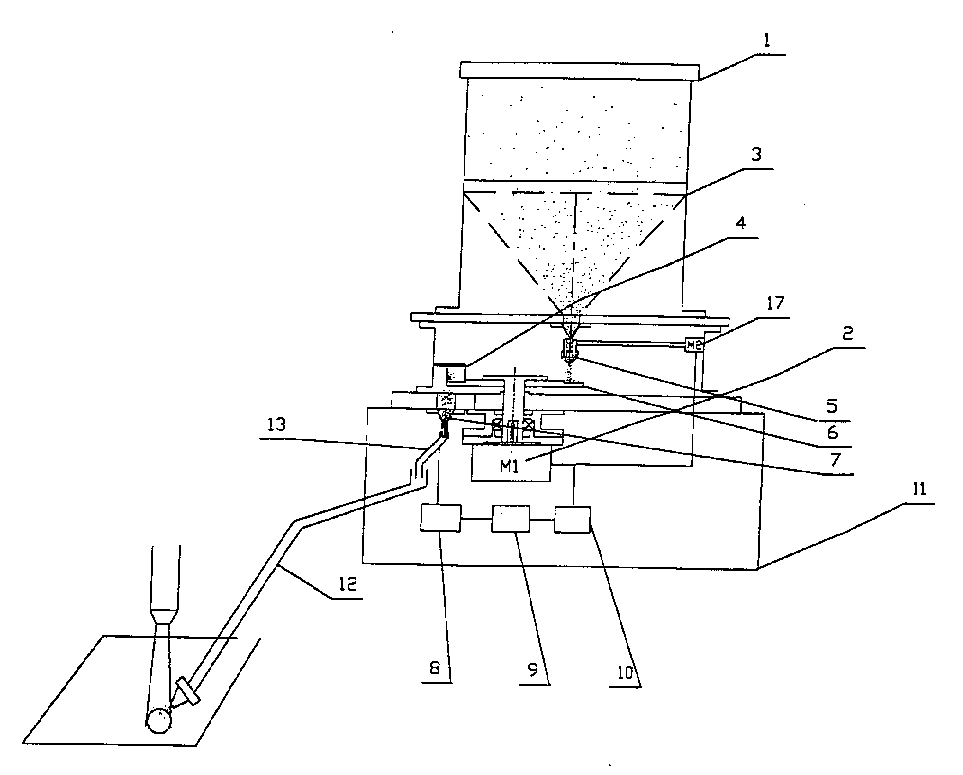

Automatic controller for laser coating and powder feeding system

InactiveCN1356608AMeet the needs of laser processingFlow control using electric meansMetallic material coating processesAutomatic controlLaser coating

An autoamtic controller for laser coating and powder-feeding system is composed of measuring pipe communicated with power-delivering pipeline, sensor, and data acquiring and processing system connected with the control motor of powder feeder and composed of amplifier, A / D converter and data processor. It can perform real-time monitor and regulation of feeded powder.

Owner:HUAZHONG UNIV OF SCI & TECH

A method of repairing parts with laser directional solidification technology

InactiveCN106342014BIntegrity guaranteedEnsure consistencyMolten casting coatingLaser beam welding apparatusNumerical controlLaser coating

The invention is a method for repairing parts by laser directional solidification technology. In order to overcome the deficiency in the prior art that the columnar crystal or single crystal structure in the repaired area is consistent with the original part structure, the present invention slices and processes the three-dimensional information of the part to be repaired into a series of two-dimensional plane data information, The CNC machine tool scans according to the scanning trajectory determined by the two-dimensional plane data. The laser beam forms a laser molten pool in the repair area of the part. Covering and stacking layer by layer, so as to realize the repair of parts by using epitaxial laser metal forming method. By adopting the technical solution of the present invention, a directionally solidified columnar crystal or single crystal repair layer can be obtained in the repair area, which is epitaxially grown from the original part tissue, which ensures the integrity and orientation consistency of the repair layer and the matrix grains, and has good applicability .

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Waterborne polyurethane emulsion for composite laser coating

The invention discloses waterborne polyurethane emulsion for a composite laser coating. The waterborne polyurethane emulsion is prepared by the following steps: performing vacuum dehydration on macromolecular polyhydric alcohol at the temperature of 120-130 DEG C for 1-1.5 hours, reducing the temperature to be 50-60 DEG C, adding diisocyanate and epoxy resin, raising the temperature to be 75-85 DEG C, and reacting for 2.5-3 hours; adding a hydrophilic chain extender and reacting for 1-2 hours; adding an alcohol chain extender and reacting for 2-3 hours, and adding acetone to reduce the viscosity during the period; adding a neutralizer, and carrying out a neutralization reaction at the temperature of 40-50 DEG C for 0.5-1 hour to obtain a neutralization product; adding the neutralization product into water in which an amine chain extender is dissolved, carrying out shearing emulsification at 30-40 DEG C for 0.5-2 hours while controlling the stirring speed to be 2000-4000rpm to obtain primary emulsion, and evaporating to remove acetone under reduced pressure to obtain the emulsion. The emulsion is a self-emulsified system and does not contain small molecular emulsifier, and an emulsifier migration phenomenon is avoided; the waterborne polyurethane emulsion is high in adhesive force with a base material, and interlayer separation is avoided; moreover, the waterborne polyurethane emulsion has high solvent resistance and paint film printability.

Owner:SHANGHAI CHENGYING NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com