High-coercivity sintered R-T-B permanent magnet material and manufacturing method therefor

An R-T-B, permanent magnet material technology, applied in the direction of magnetic material, inorganic material magnetism, metal material coating process, etc., can solve the problems of high process cost, low effective utilization rate of rare earth elements, etc., and achieve the effect of low rare earth content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

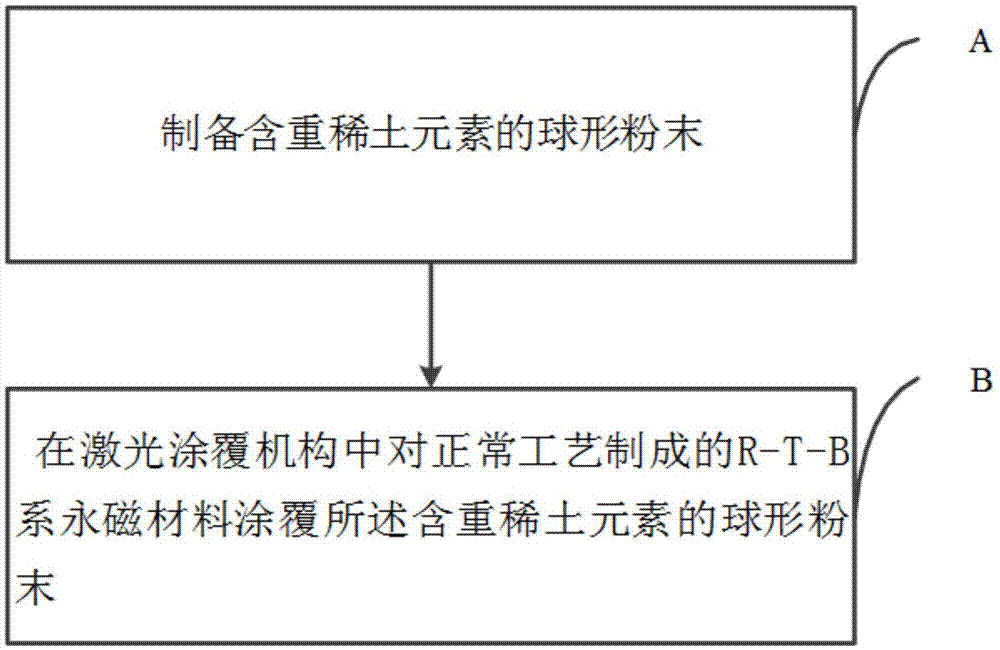

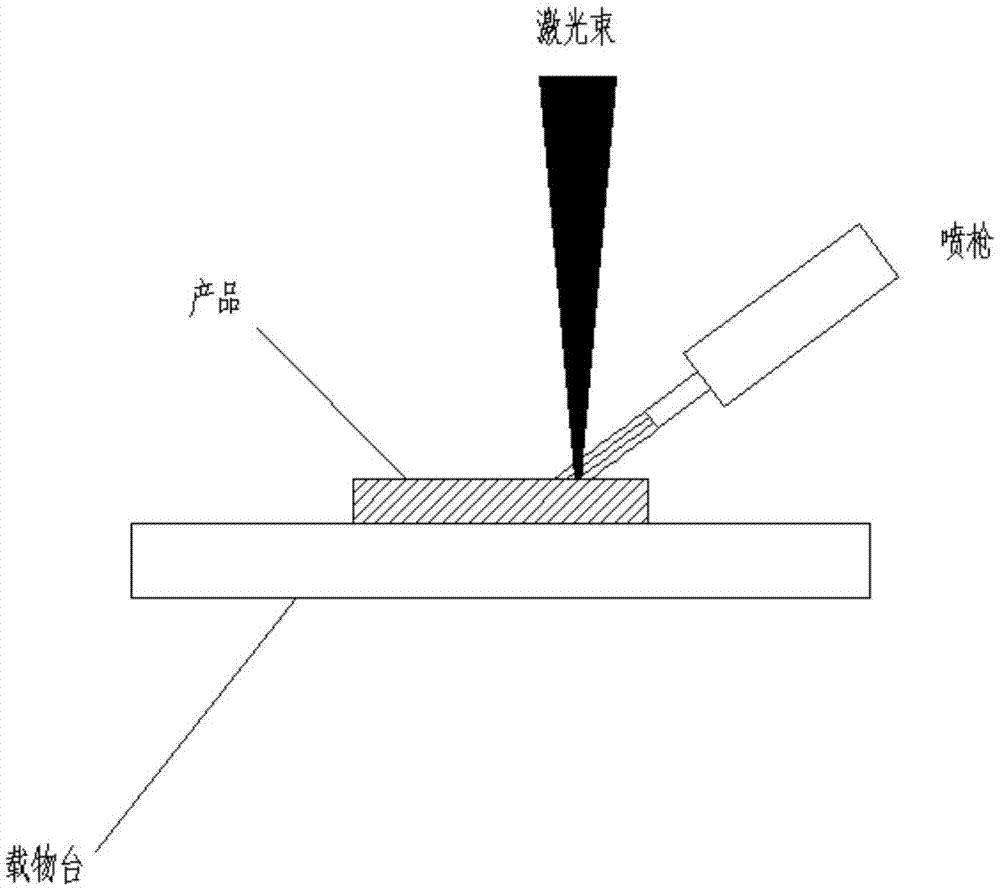

Method used

Image

Examples

Embodiment 3

[0055] Experiment 3 Utilizes the method provided by the present invention to make a magnet sample containing Dy, except for steps A, B, and C, the equipment and experimental conditions used are the same as those of Comparative Examples 1 and 2, and the specific steps are as follows:

[0056] Firstly, the Nd-Fe-B alloy was made by strip-spinning process, and its composition ratio was 31.0% Nd, 65.7% Fe, 1.0% Co, 0.1% Cu, 0.1% Al, 0.1% Zr, 1.0% B;

[0057] Then, the alloy is subjected to hydrogen explosion treatment, and about 0.1% lubricant is added to the obtained coarse powder and mixed;

[0058] Then, the above coarse powder is pulverized with a jet mill to obtain a fine powder whose average particle size is 3.0 μm;

[0059] Then, the fine powder is subjected to orientation compression molding under a magnetic field of 1.9T;

[0060] Then, the formed blank is placed in a high vacuum sintering furnace, sintered at a temperature of 1080°C, and then aged at 900°C and 500°C res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com