Patents

Literature

585 results about "Spin valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

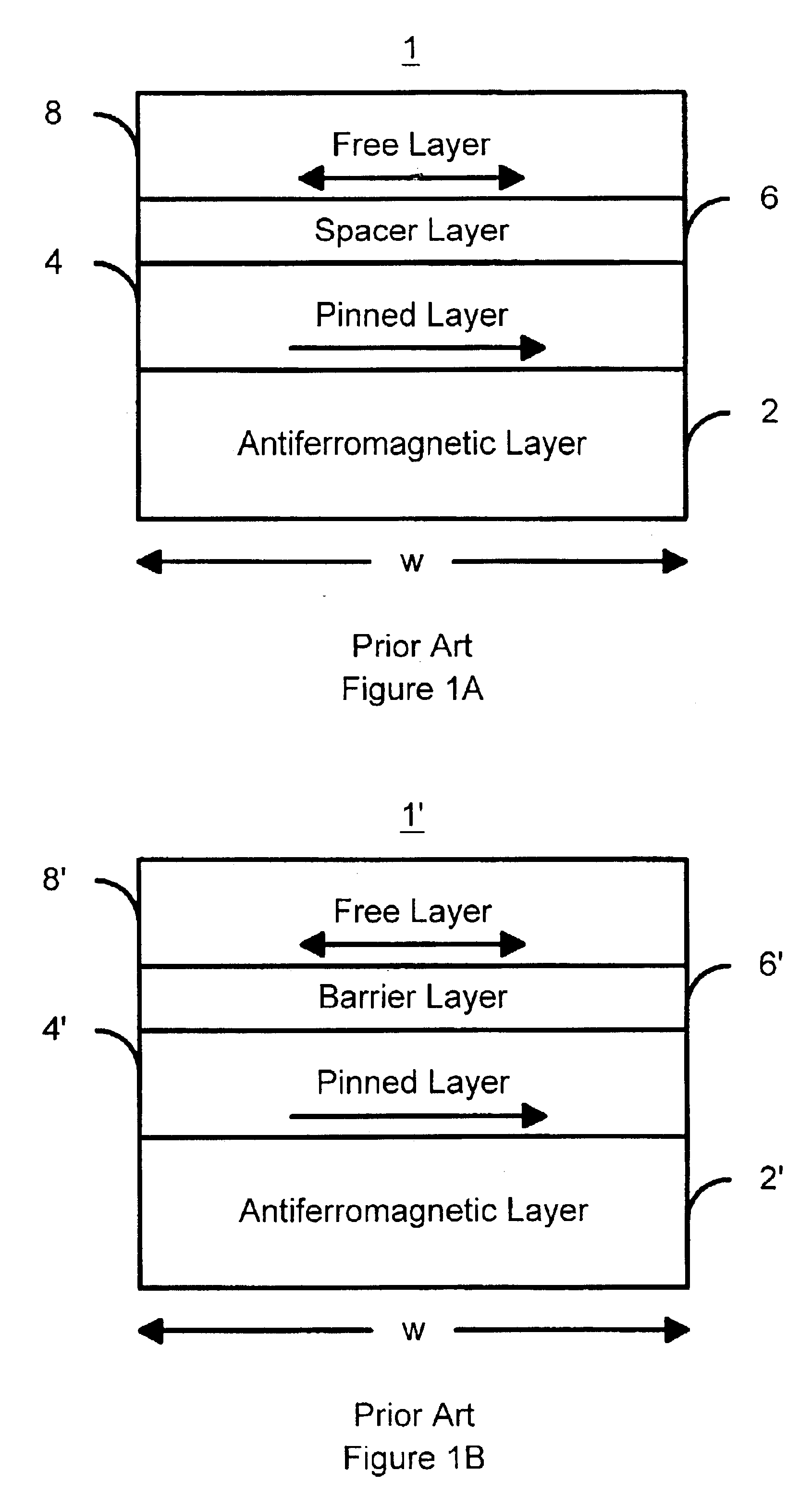

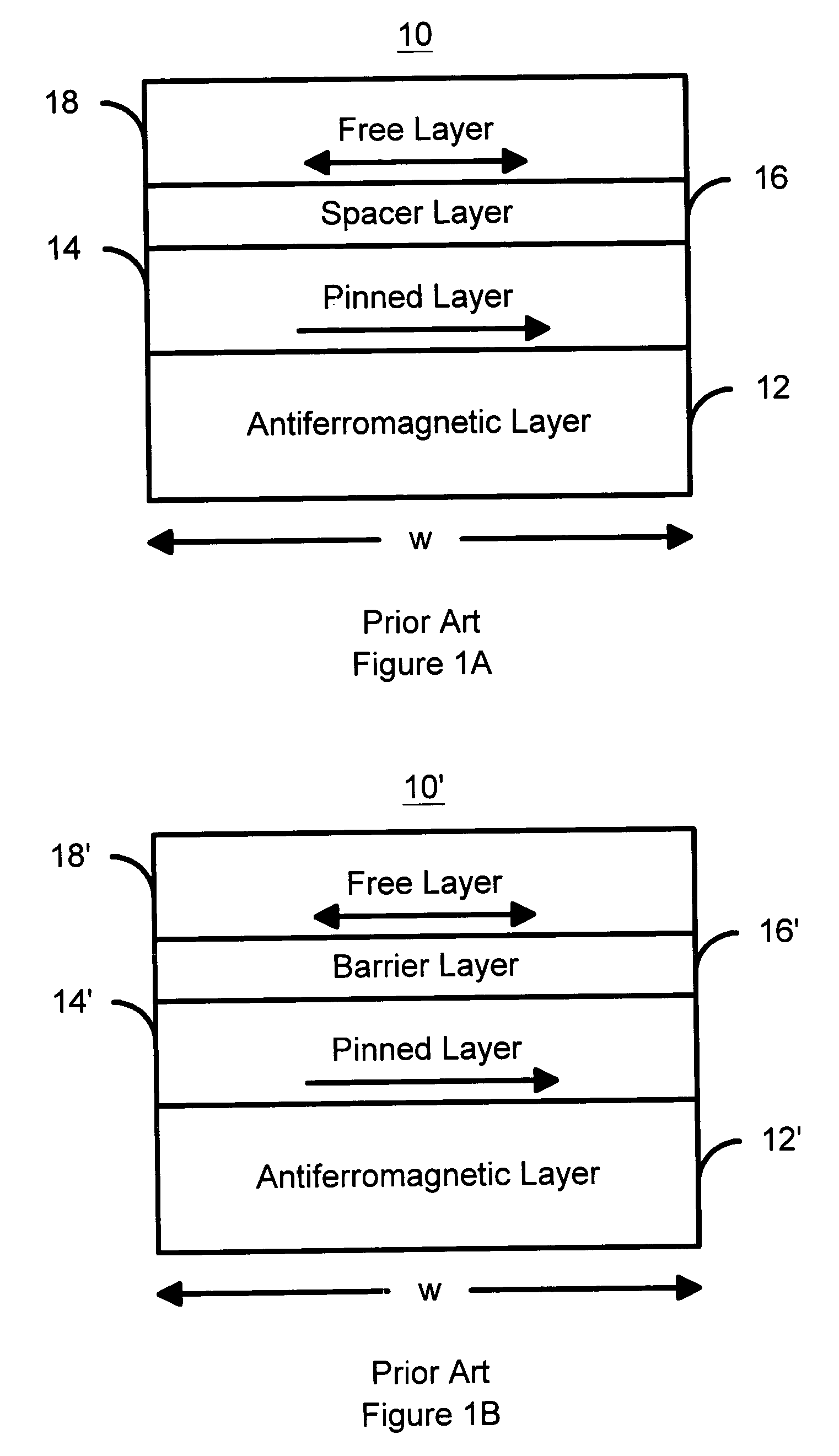

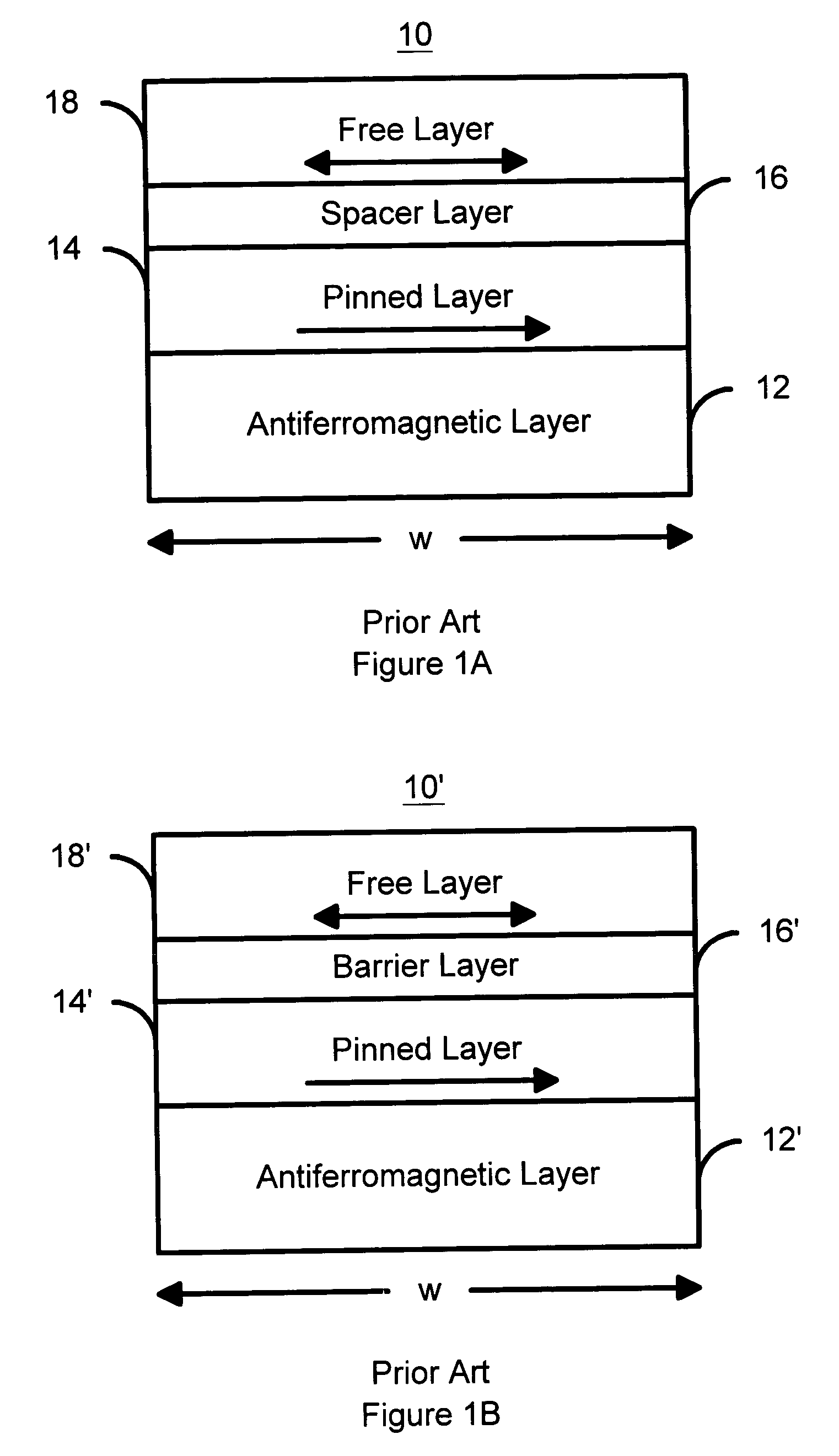

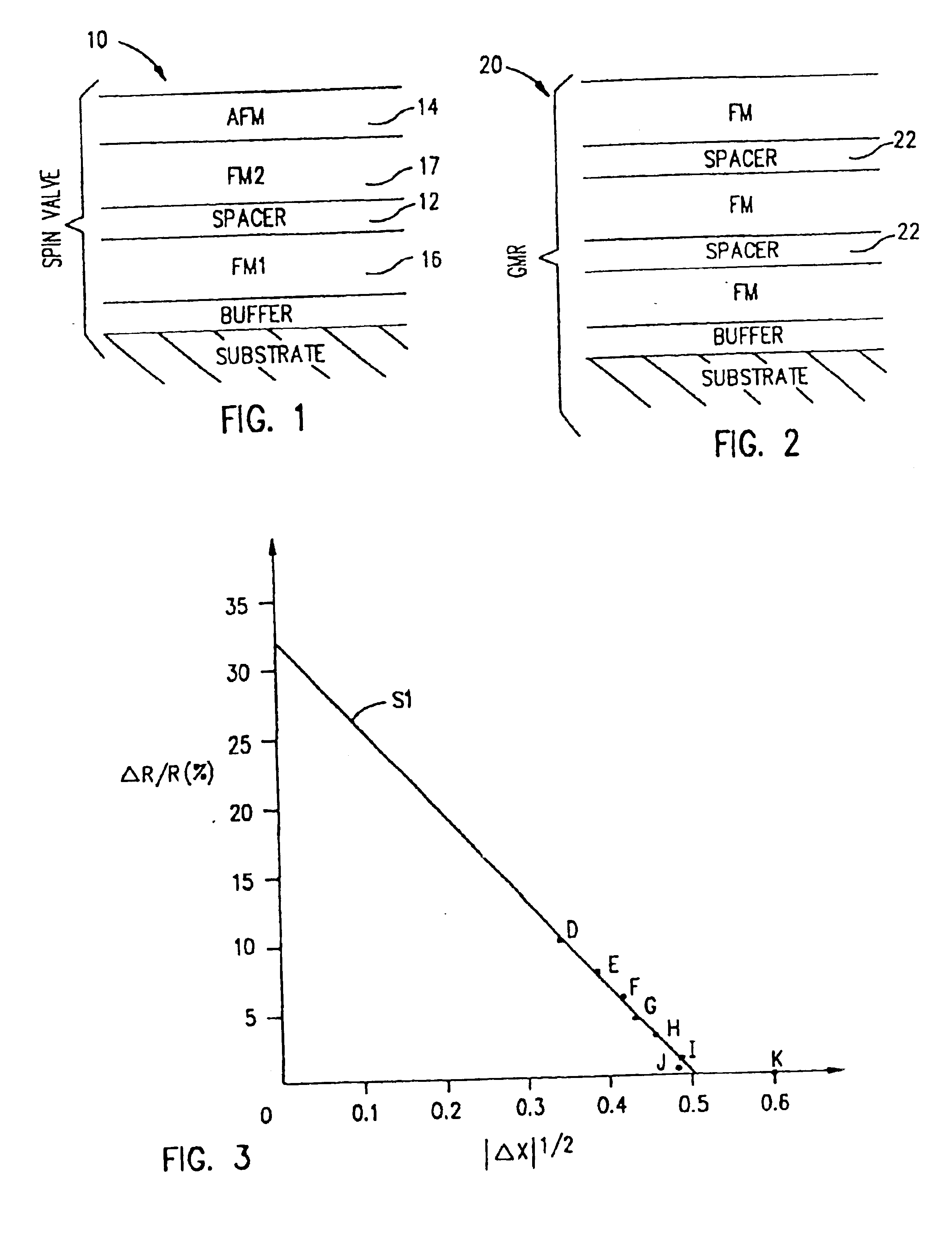

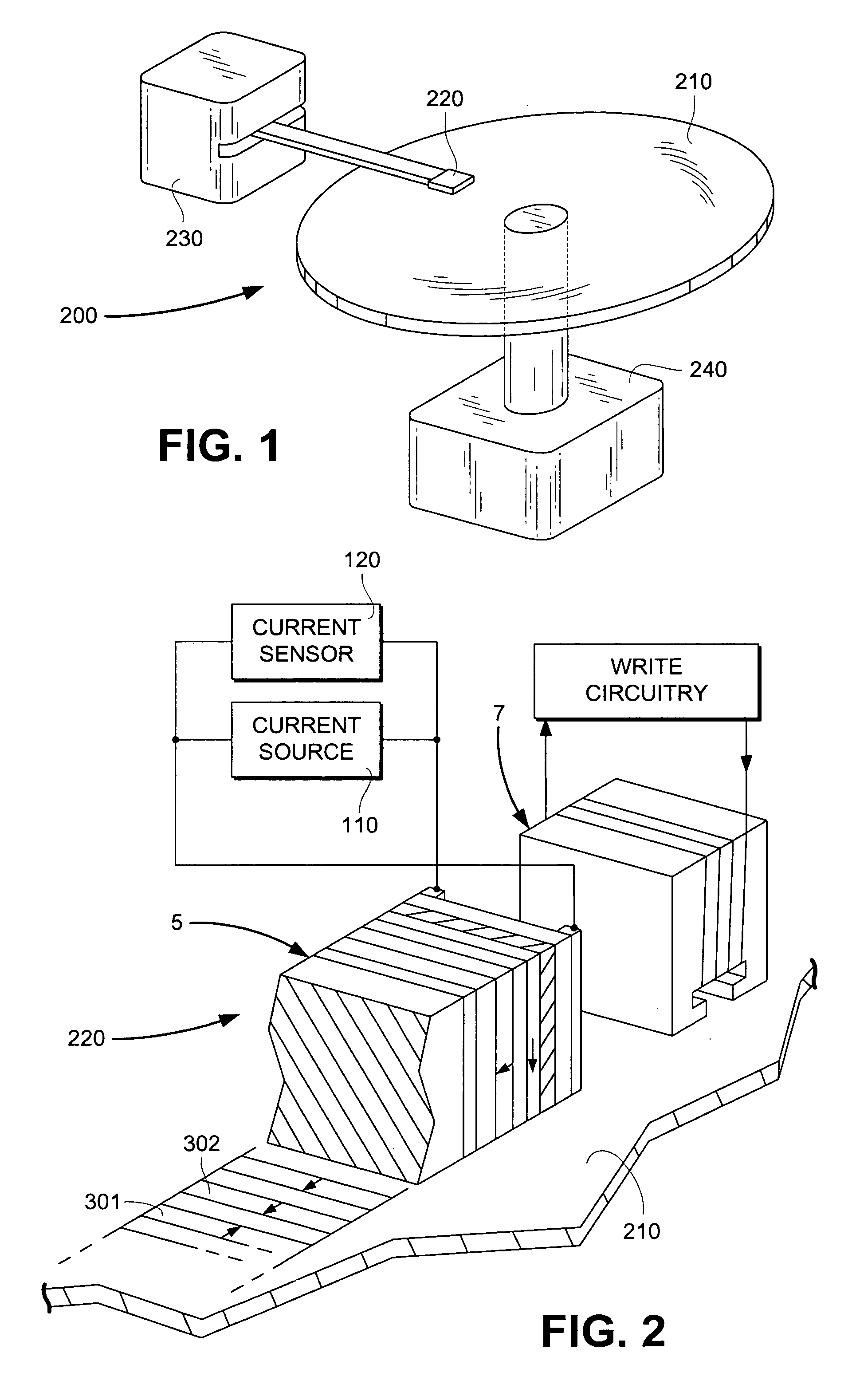

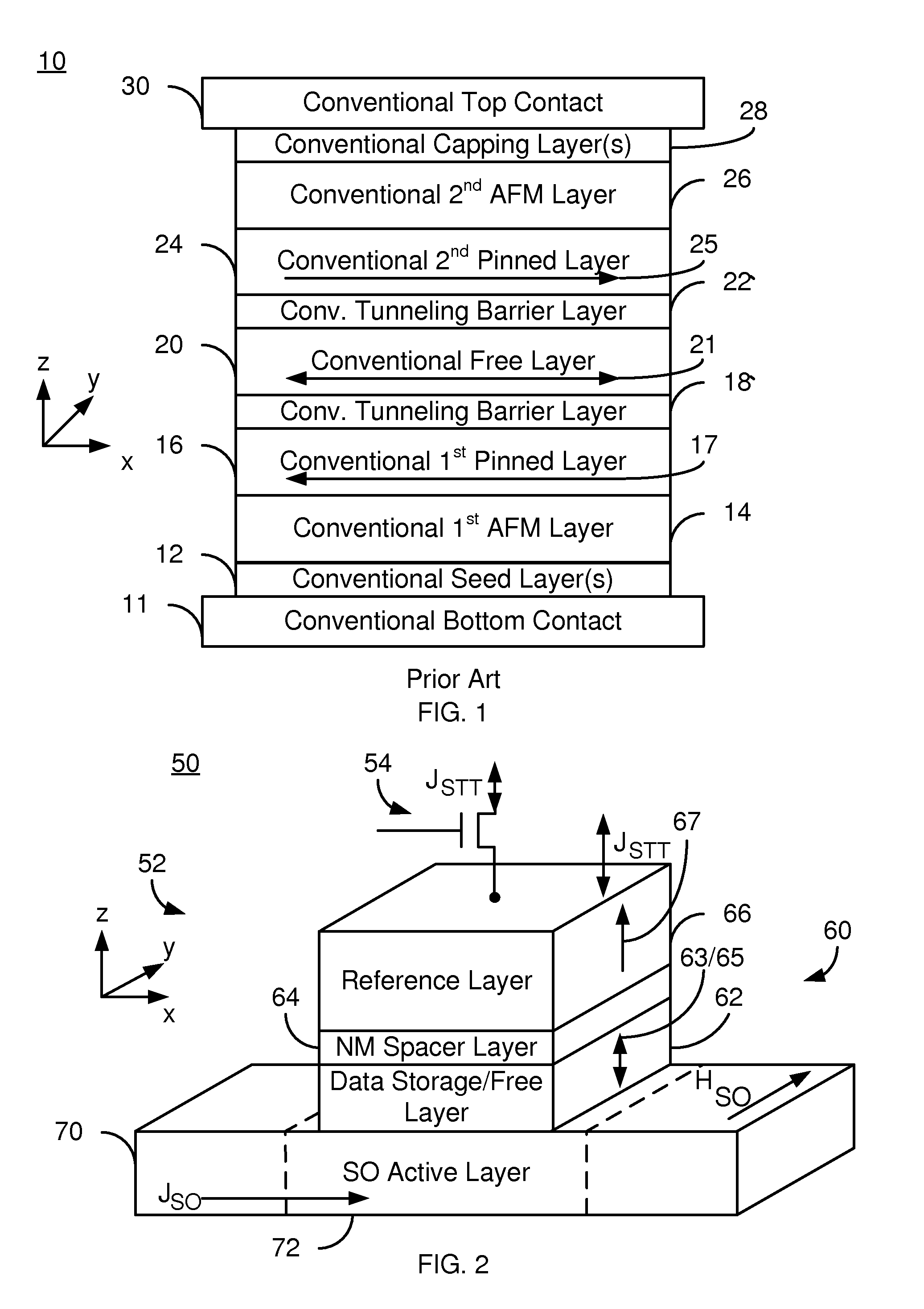

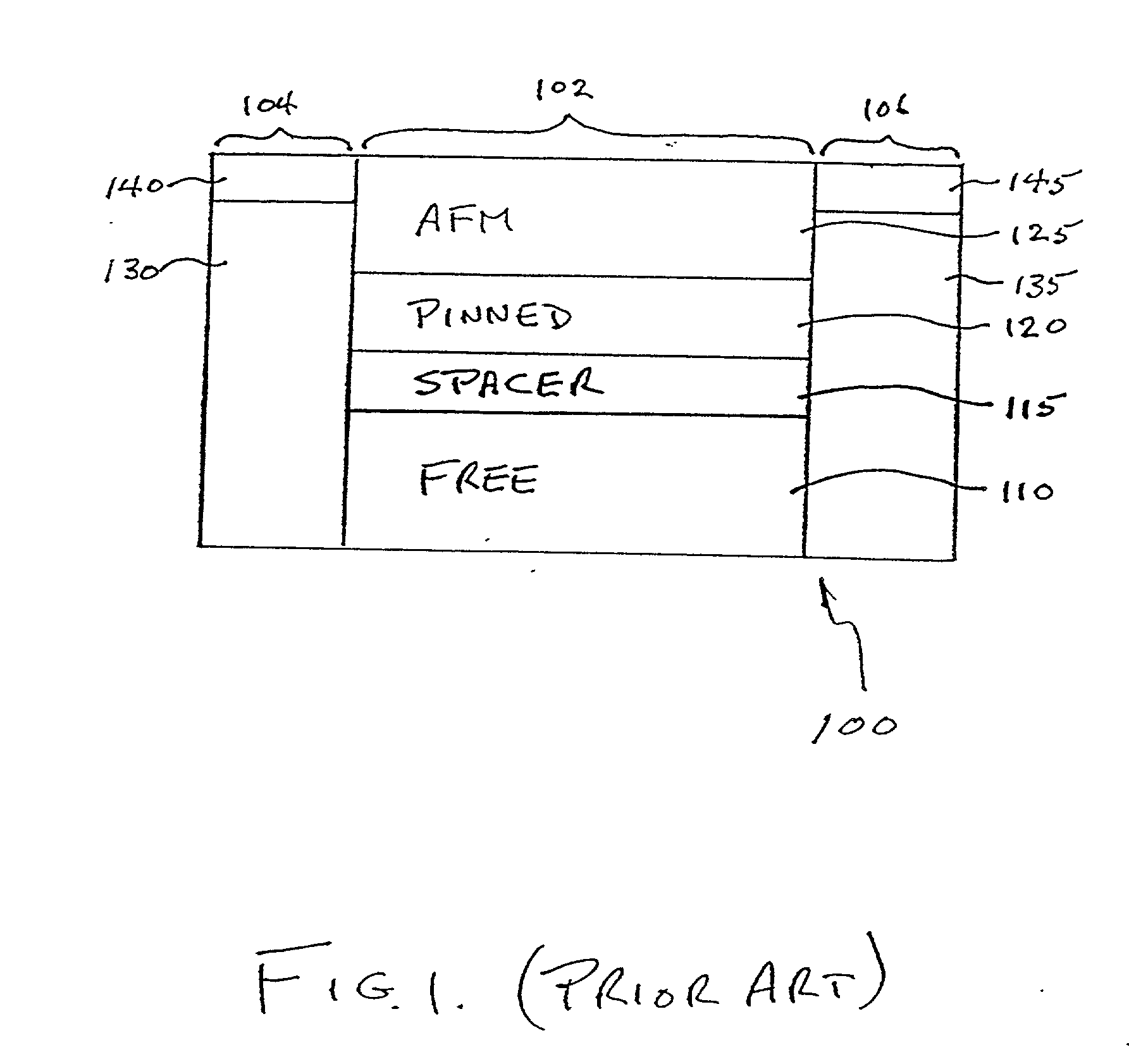

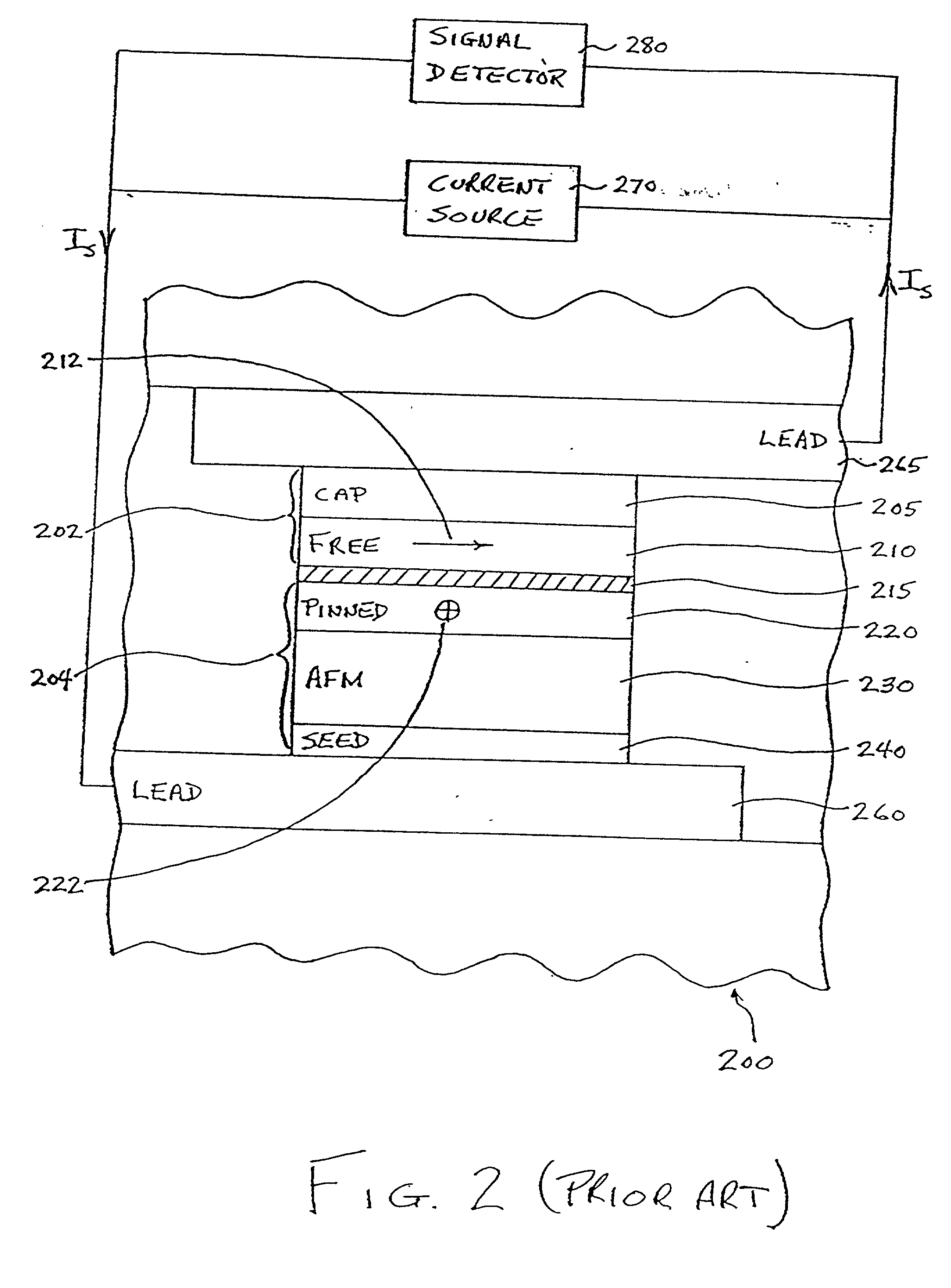

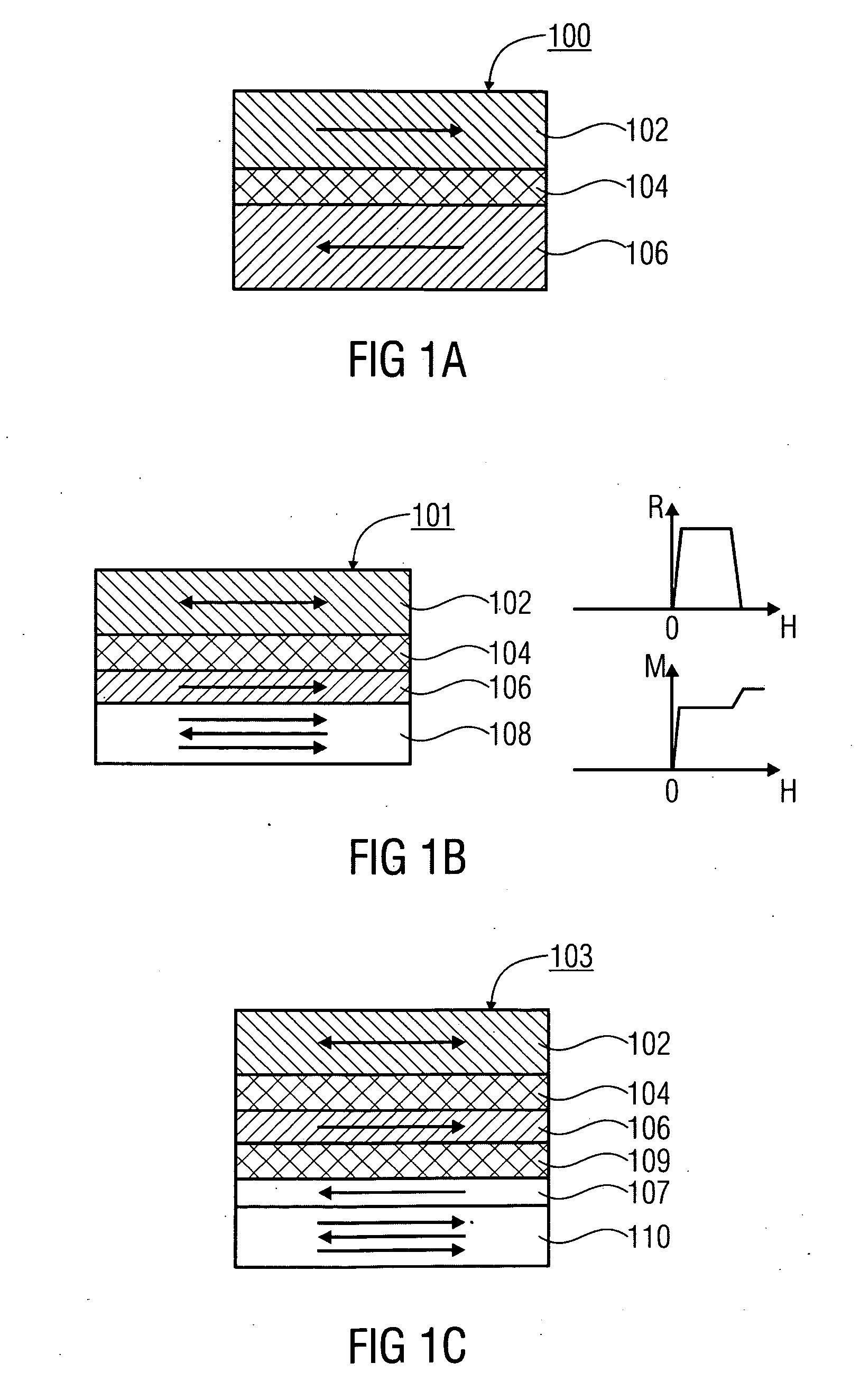

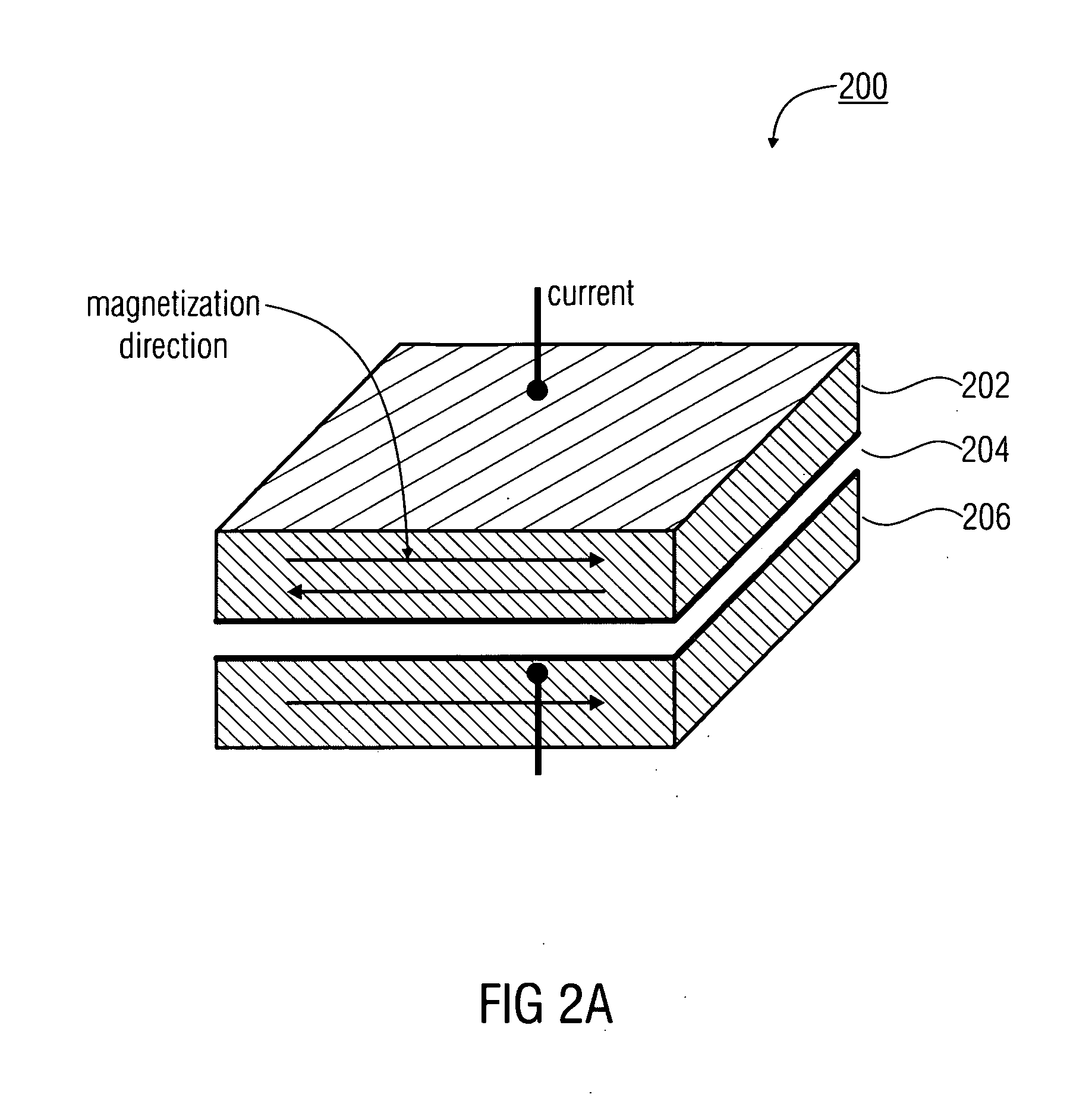

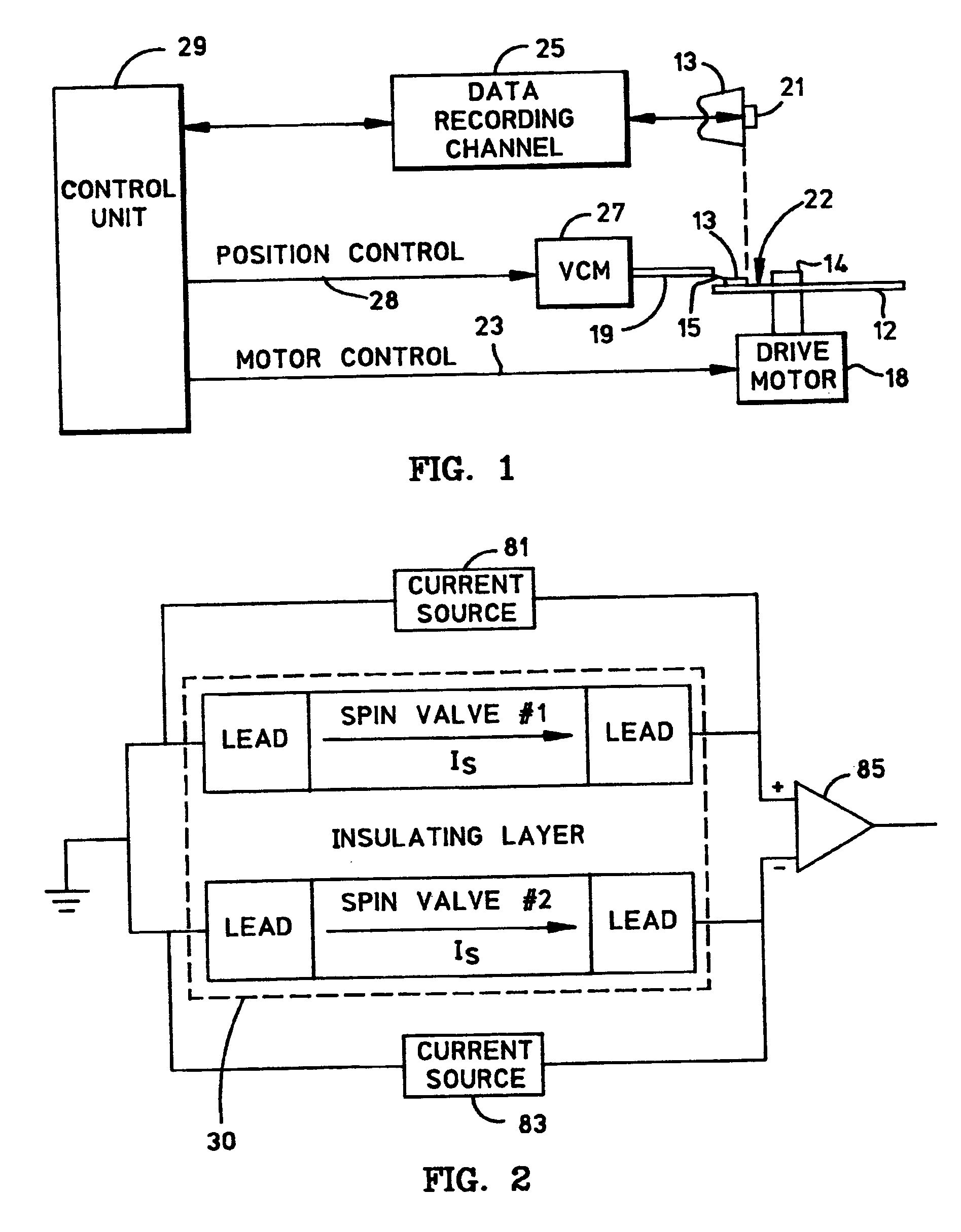

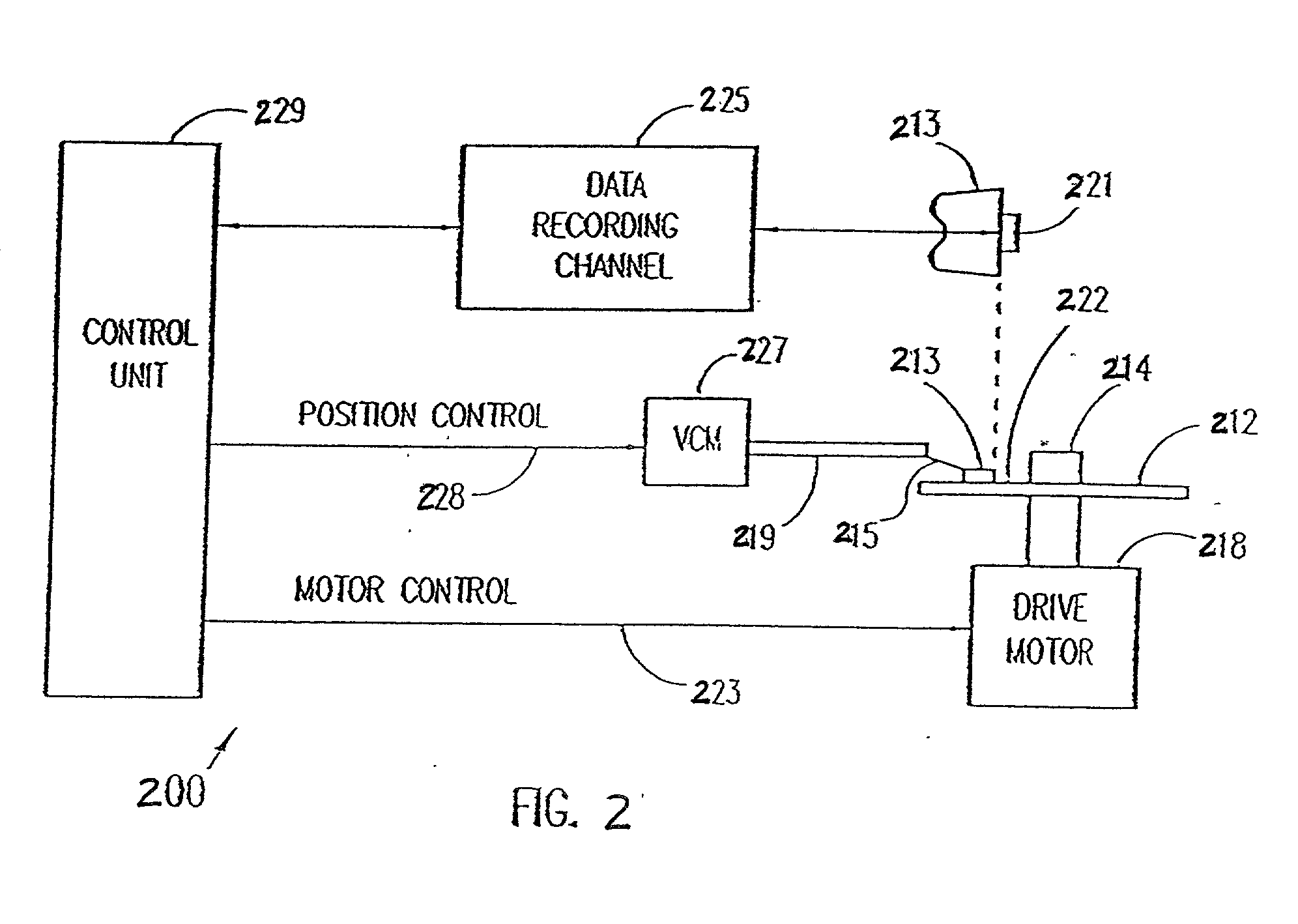

A spin valve is a device, consisting of two or more conducting magnetic materials, whose electrical resistance can change between two values depending on the relative alignment of the magnetization in the layers. The resistance change is a result of the giant magnetoresistive effect. The magnetic layers of the device align "up" or "down" depending on an external magnetic field. In the simplest case, a spin valve consists of a non-magnetic material sandwiched between two ferromagnets, one of which is fixed (pinned) by an antiferromagnet which acts to raise its magnetic coercivity and behaves as a "hard" layer, while the other is free (unpinned) and behaves as a "soft" layer. Due to the difference in coercivity, the soft layer changes polarity at lower applied magnetic field strength than the hard one. Upon application of a magnetic field of appropriate strength, the soft layer switches polarity, producing two distinct states: a parallel, low-resistance state, and an antiparallel, high-resistance state.

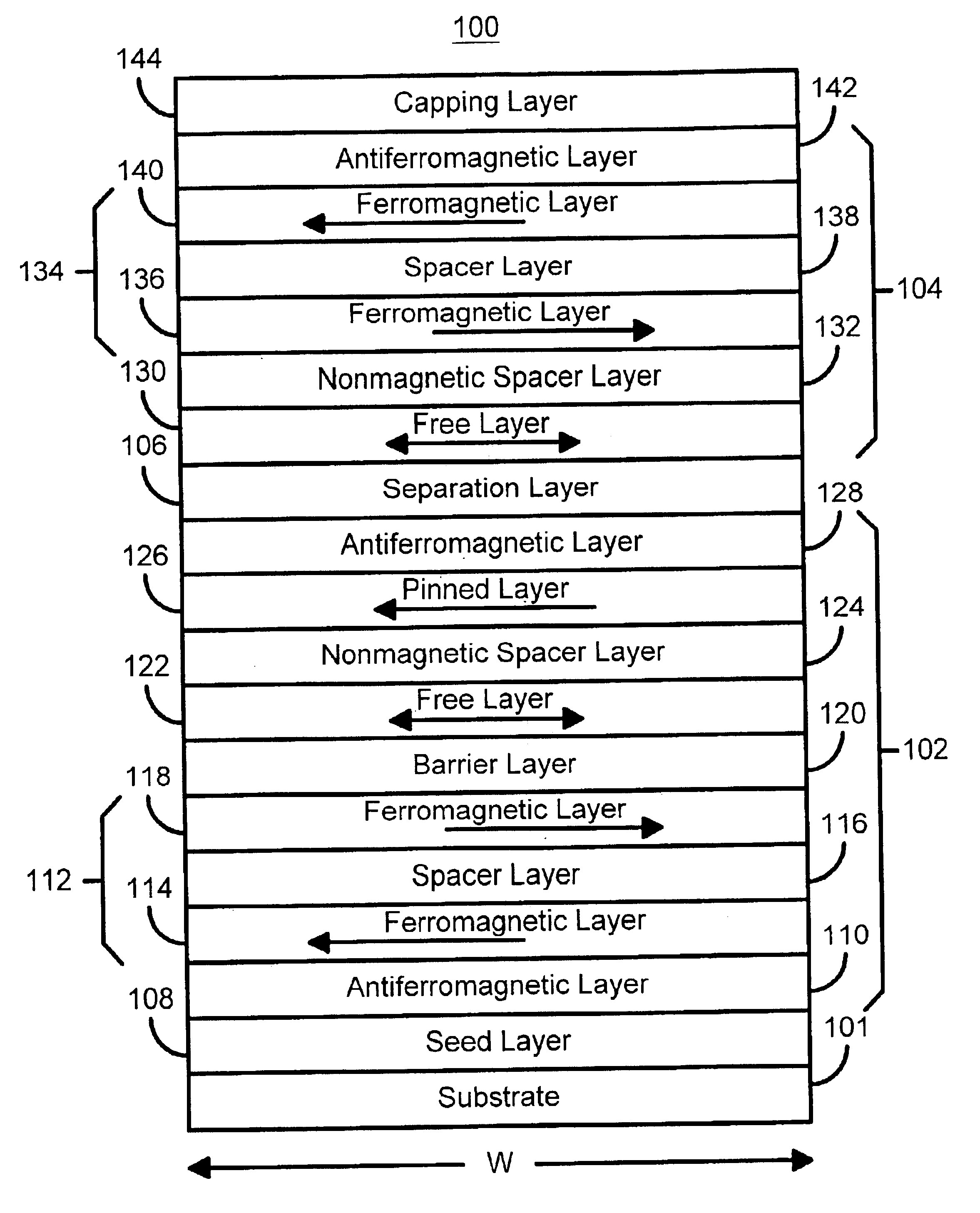

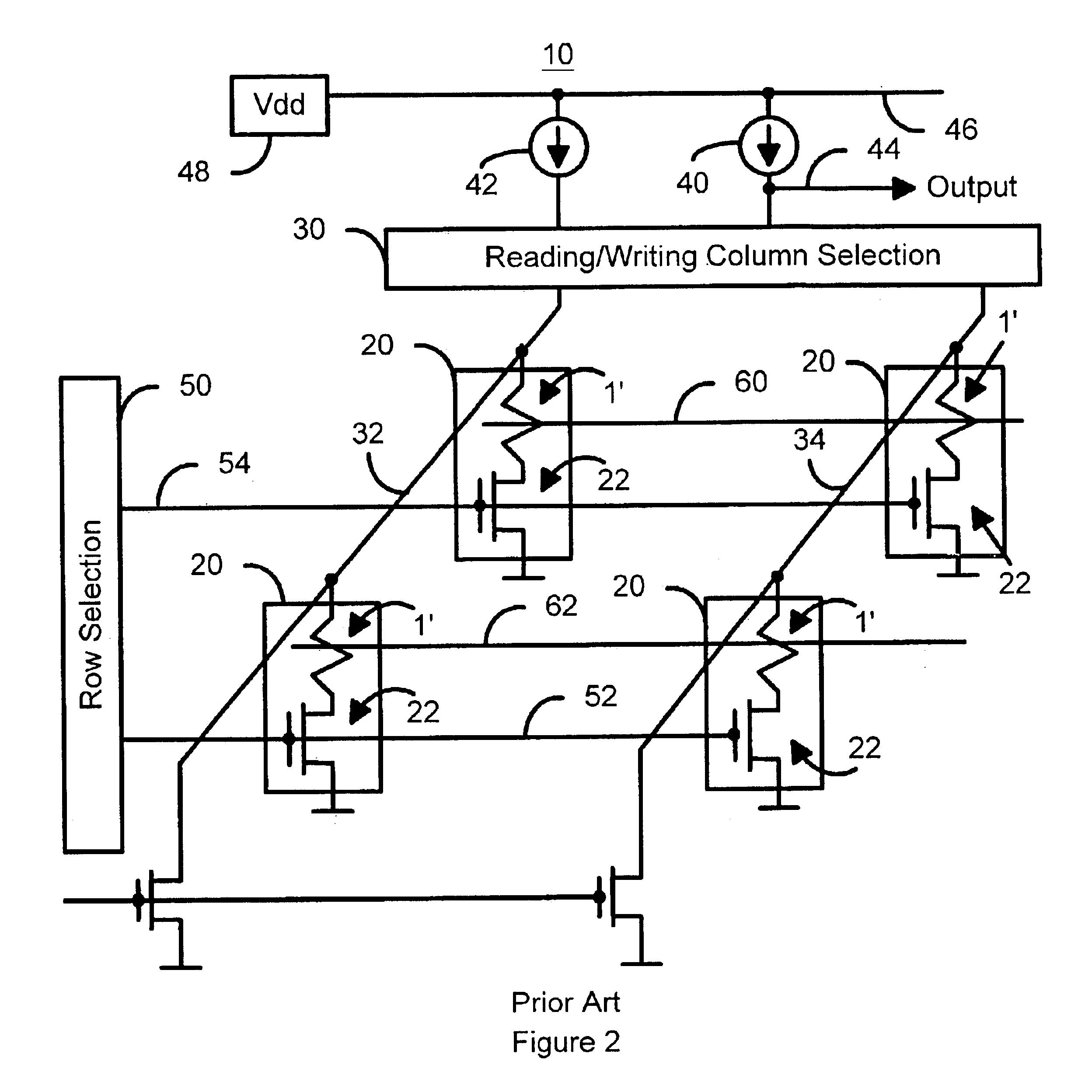

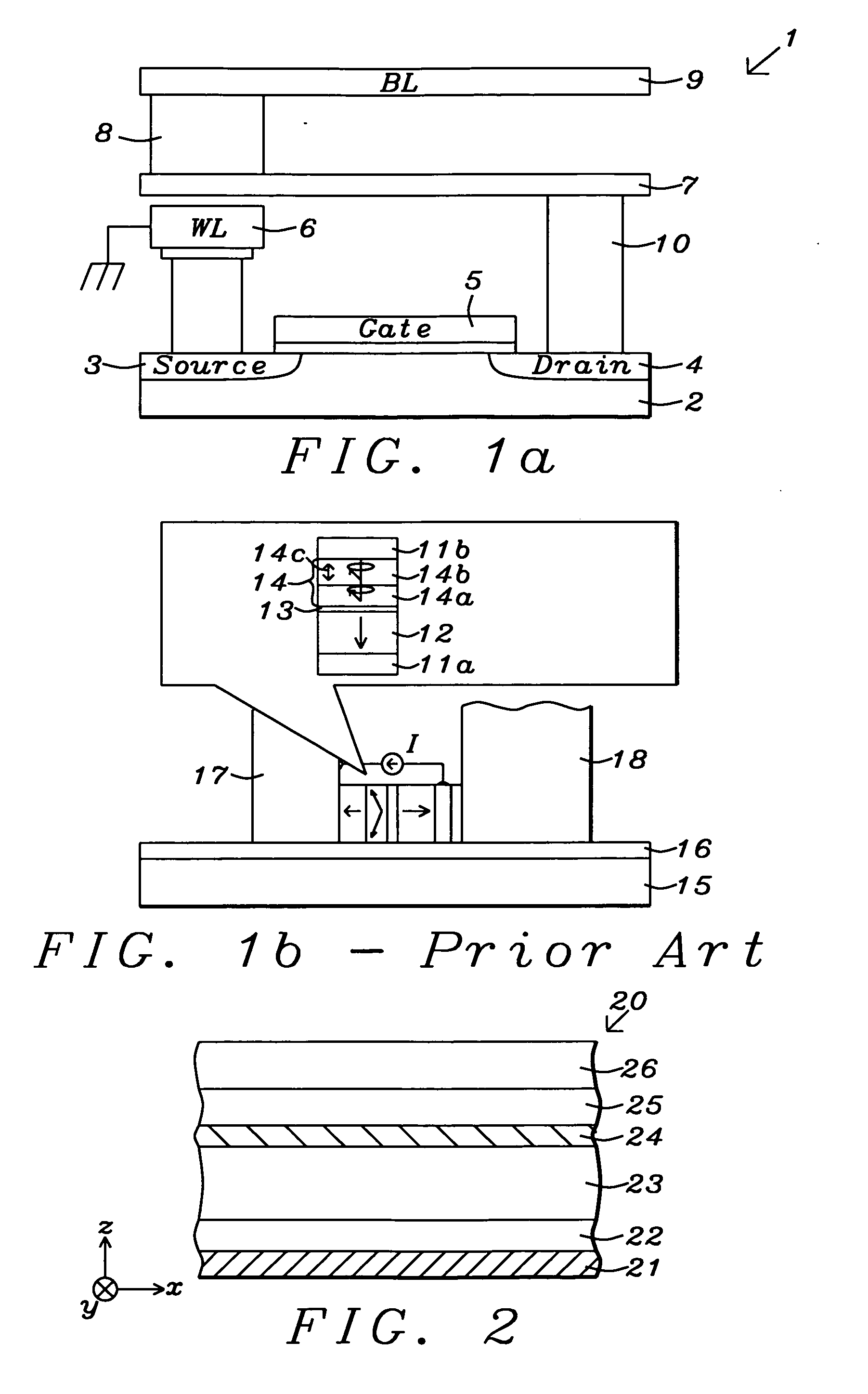

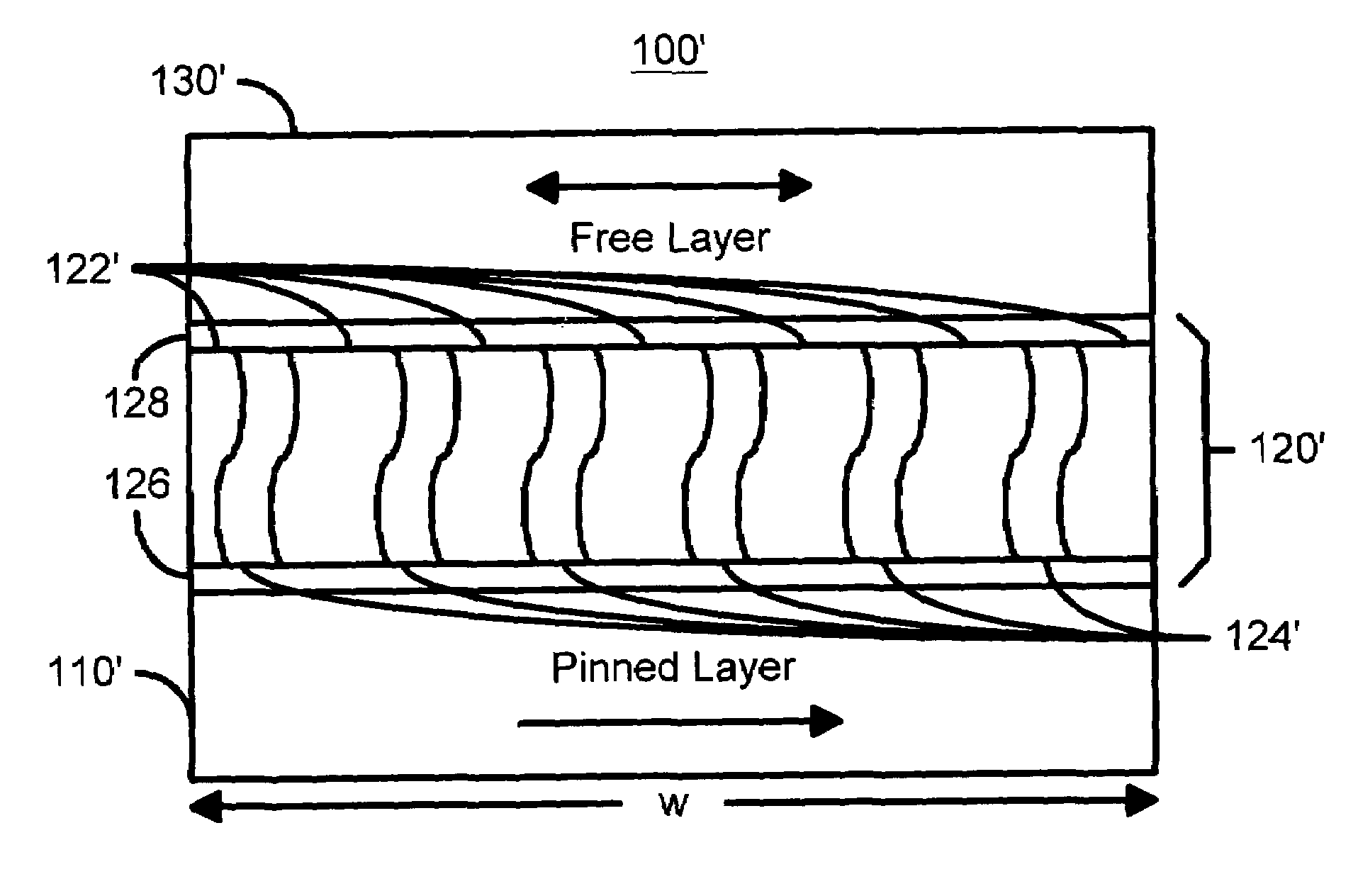

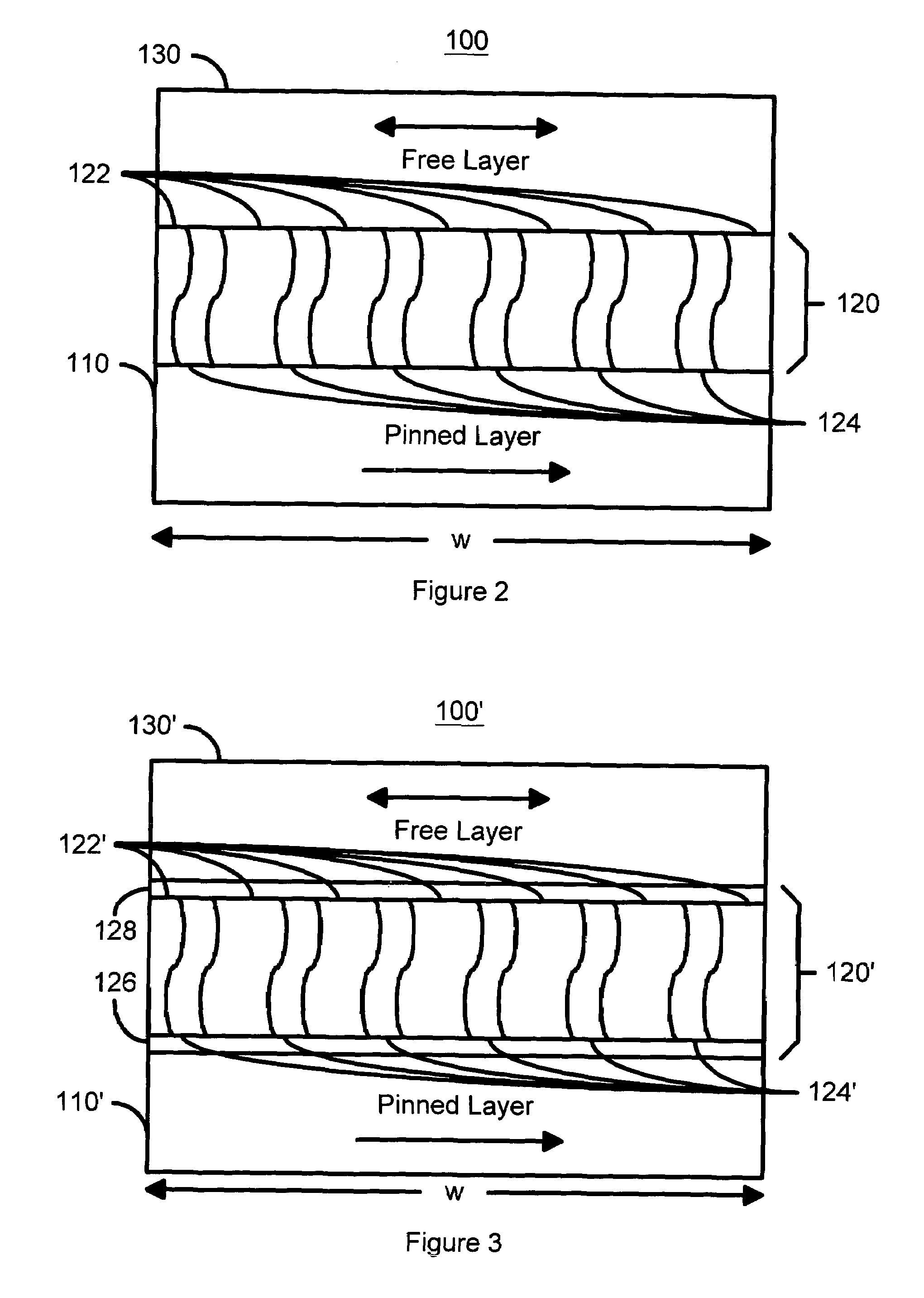

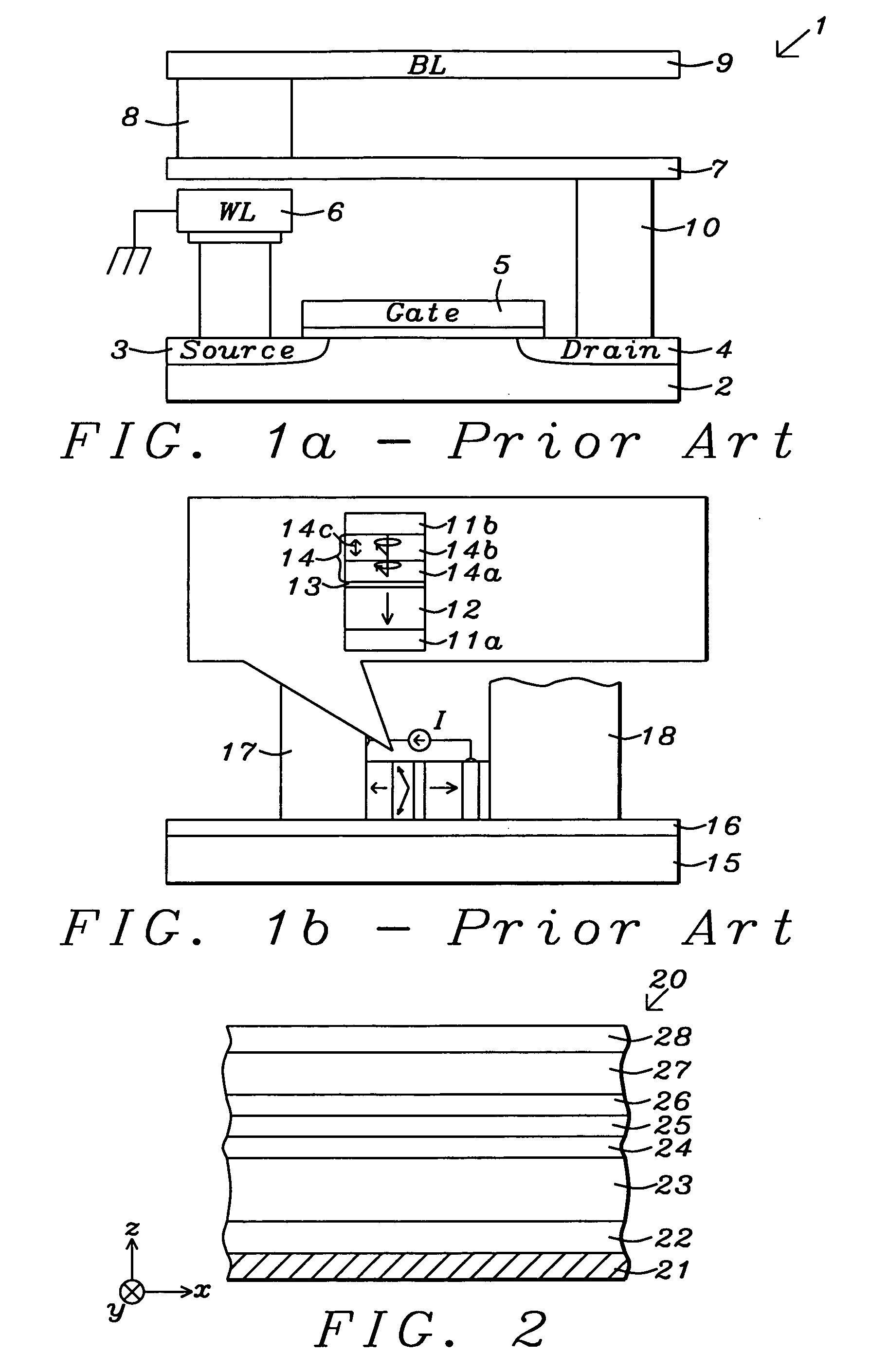

Magnetostatically coupled magnetic elements utilizing spin transfer and an MRAM device using the magnetic element

A method and system for providing a magnetic element and a corresponding memory are disclosed. In one aspect, the method and system include providing a dual spin tunnel / valve structure and at least one spin valve. The dual spin tunnel / valve structure includes a nonmagnetic spacer layer between a pinned layer and a free layer, another pinned layer and a barrier layer between the free layer and the other pinned layer. The free layers of the dual spin tunnel / valve structure and the spin valve are magnetostatically coupled. In one embodiment a separation layer resides between the dual spin tunnel / valve structure and the spin valve. In another aspect, the method and system include providing two dual spin valves, a spin tunneling junction there between and, in one embodiment, the separation layer. In both aspects, the magnetic element is configured to write to the free layers using spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

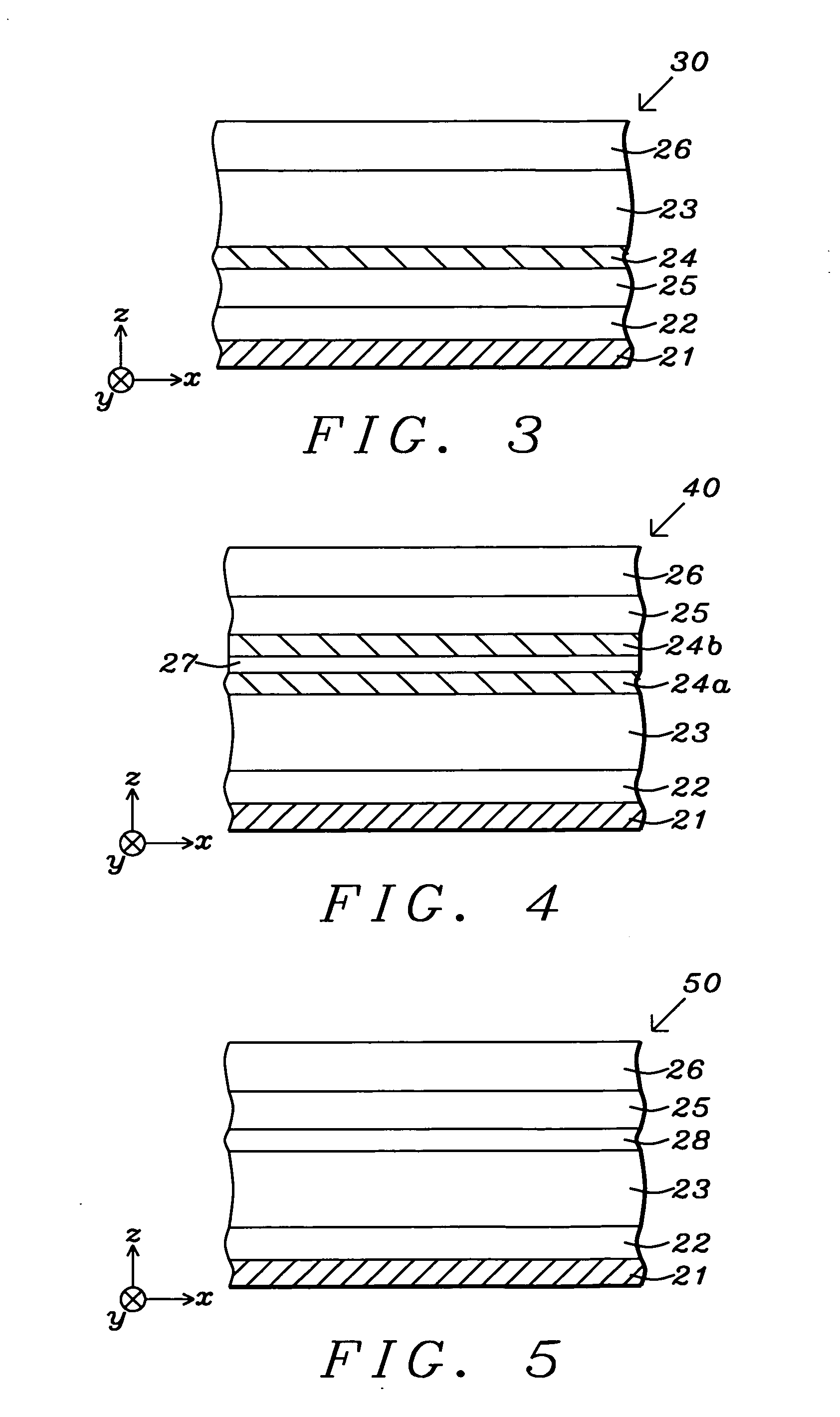

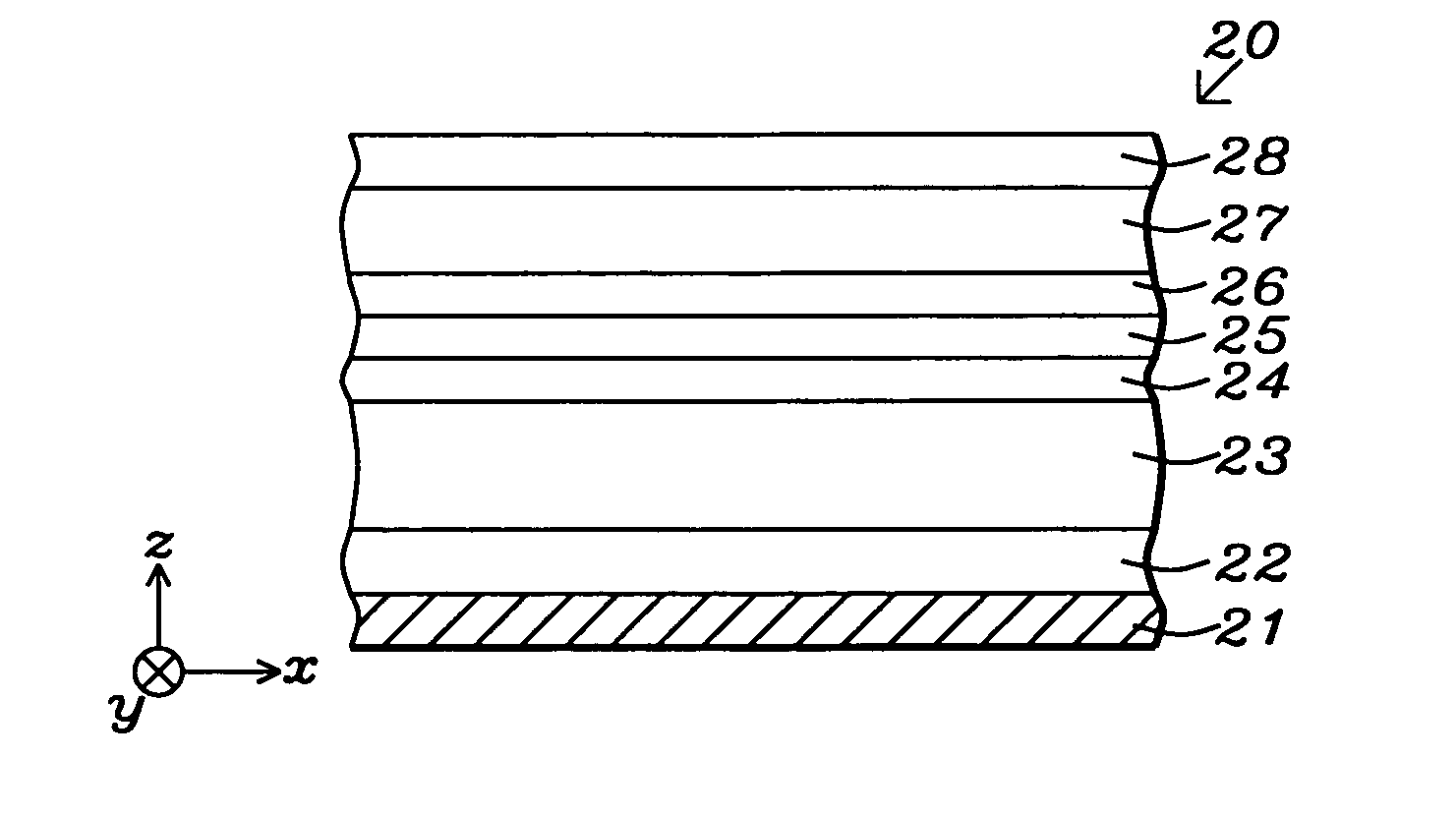

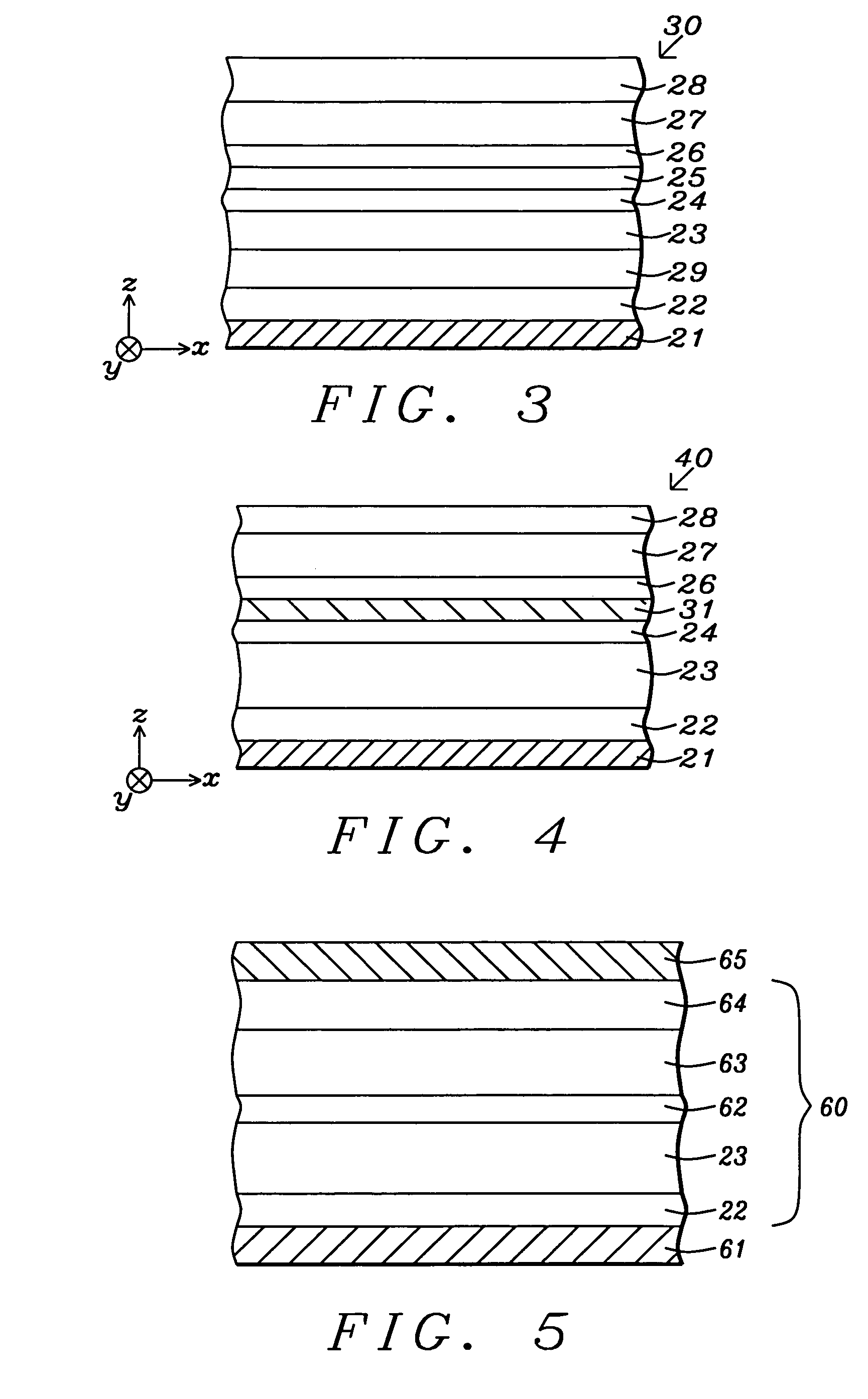

Thin seeded Co/Ni multilayer film with perpendicular anisotropy for spintronic device applications

ActiveUS20090257151A1Raise the ratioNot to damageMagnetic measurementsVacuum evaporation coatingPerpendicular anisotropySpins

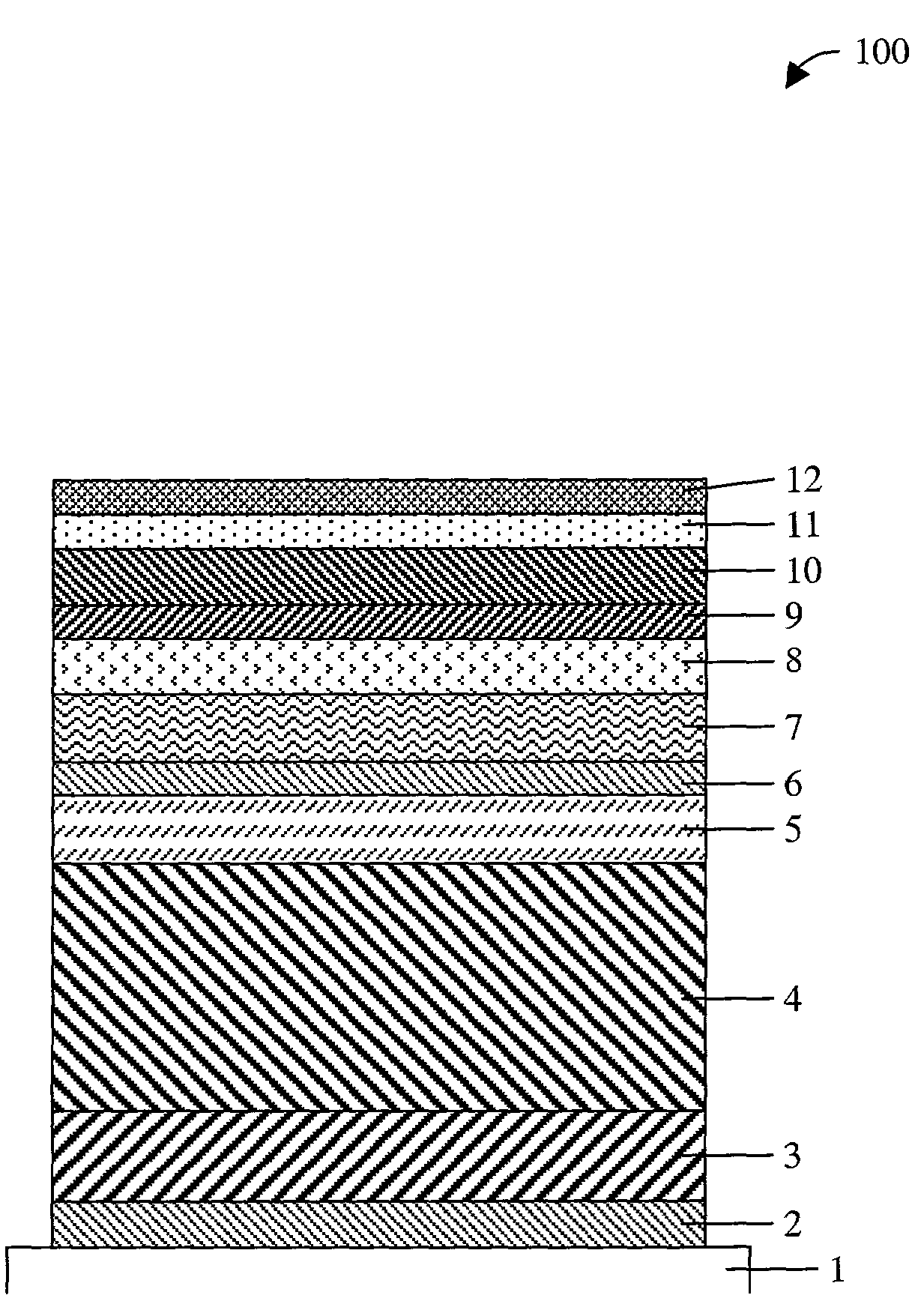

A spin valve structure for a spintronic device is disclosed and includes a composite seed layer made of at least Ta and a metal layer having a fcc(111) or hcp(001) texture to enhance perpendicular magnetic anisotropy (PMA) in an overlying (Co / Ni)x multilayer. The (Co / Ni)x multilayer is deposited by a low power and high Ar pressure process to avoid damaging Co / Ni interfaces and thereby preserving PMA. As a result, only a thin seed layer is required. PMA is maintained even after annealing at 220° C. for 10 hours. Examples of GMR and TMR spin valves are described and may be incorporated in spin transfer oscillators and spin transfer MRAMs. The free layer is preferably made of a FeCo alloy including at least one of Al, Ge, Si, Ga, B, C, Se, Sn, or a Heusler alloy, or a half Heusler alloy to provide high spin polarization and a low magnetic damping coefficient.

Owner:TDK CORPARATION +1

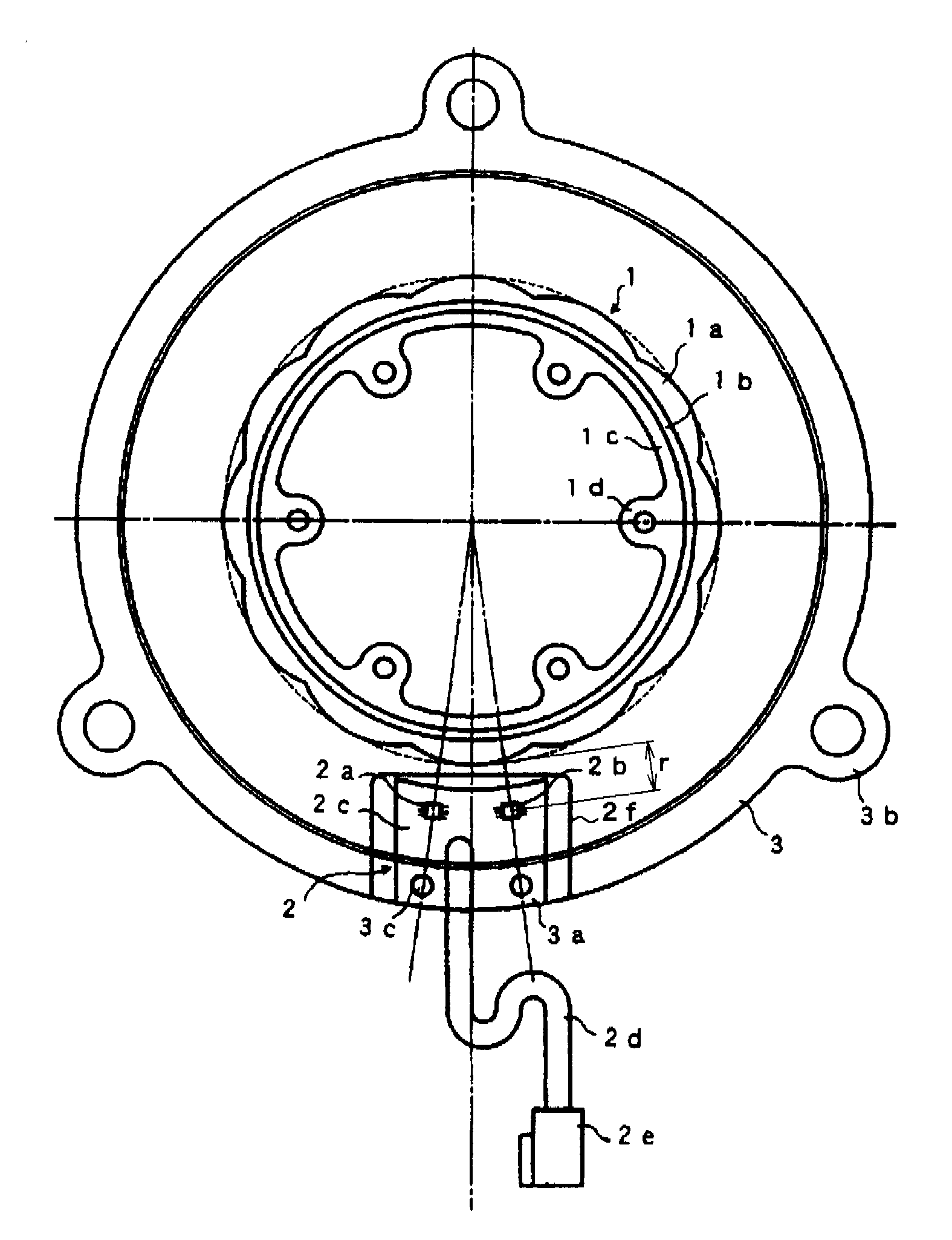

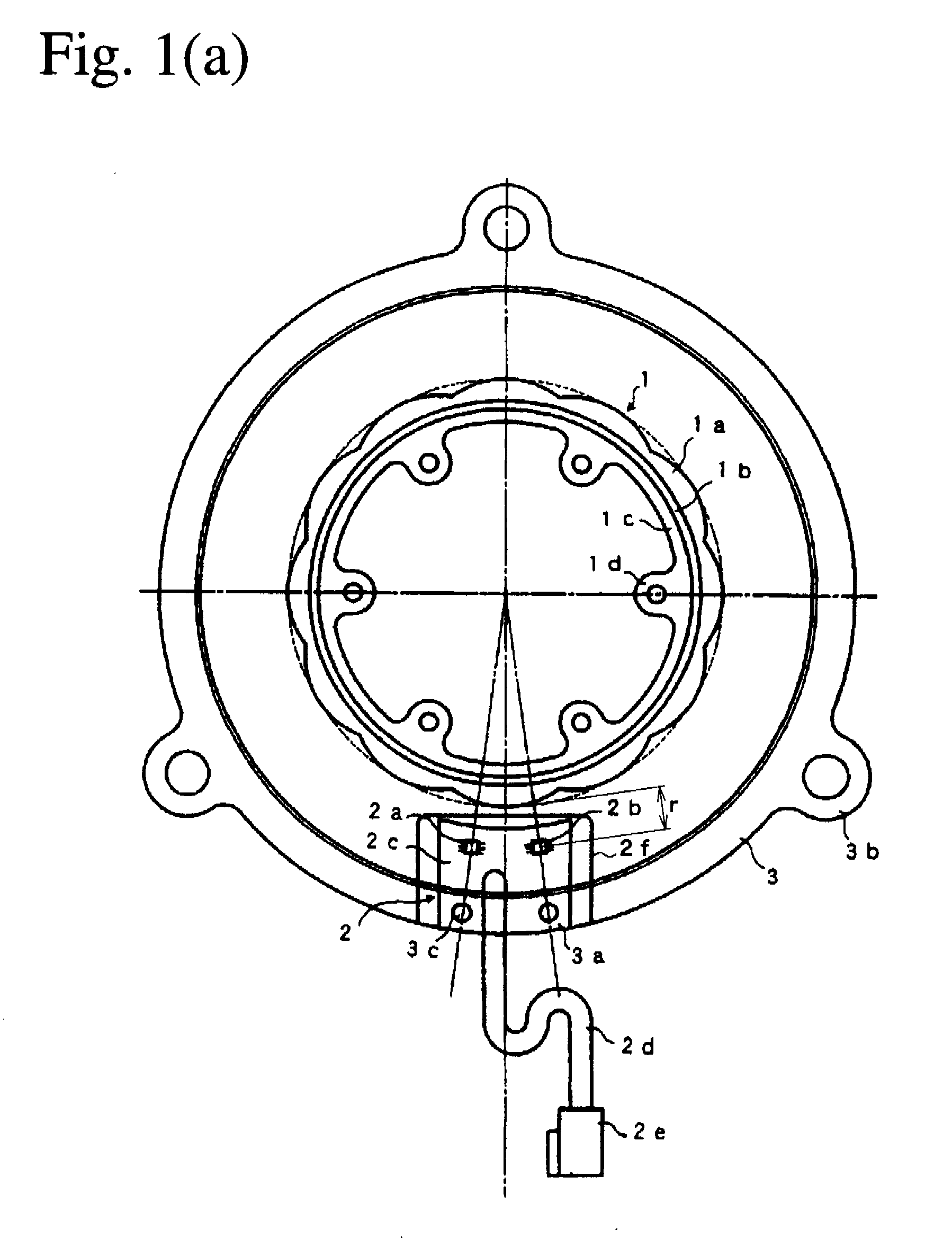

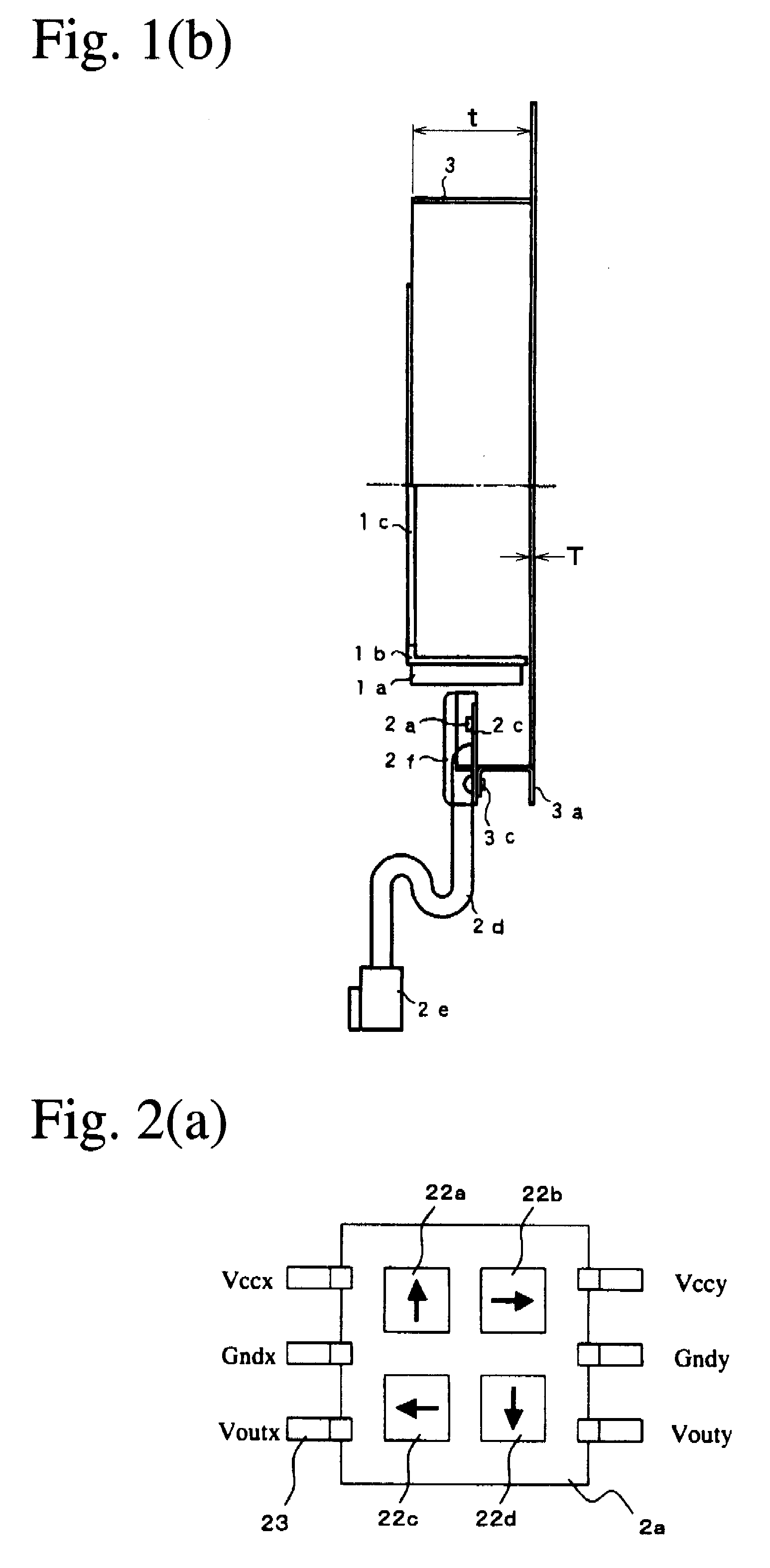

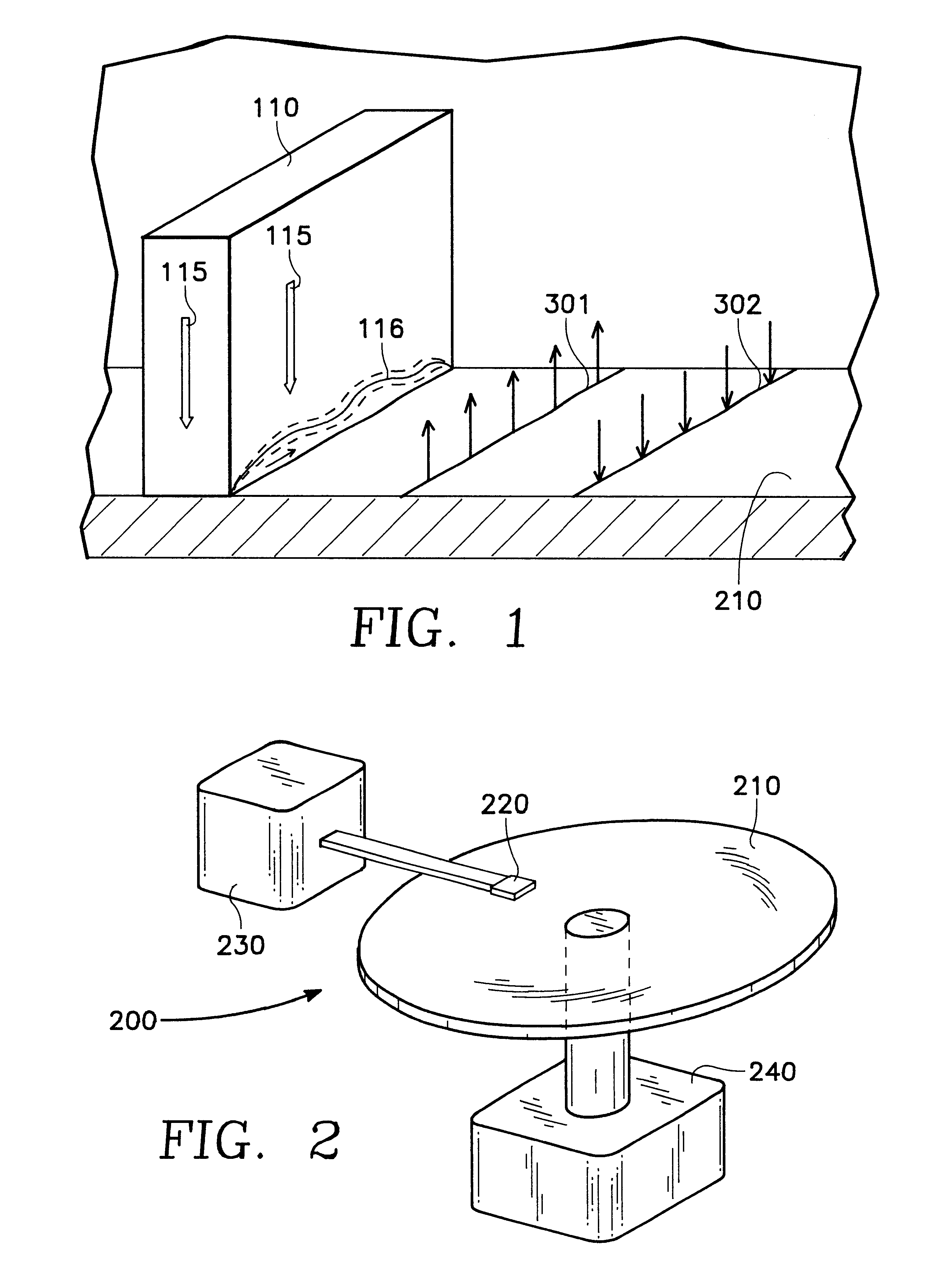

Rotation-angle-detecting apparatus, rotating machine, and rotation-angle-detecting method

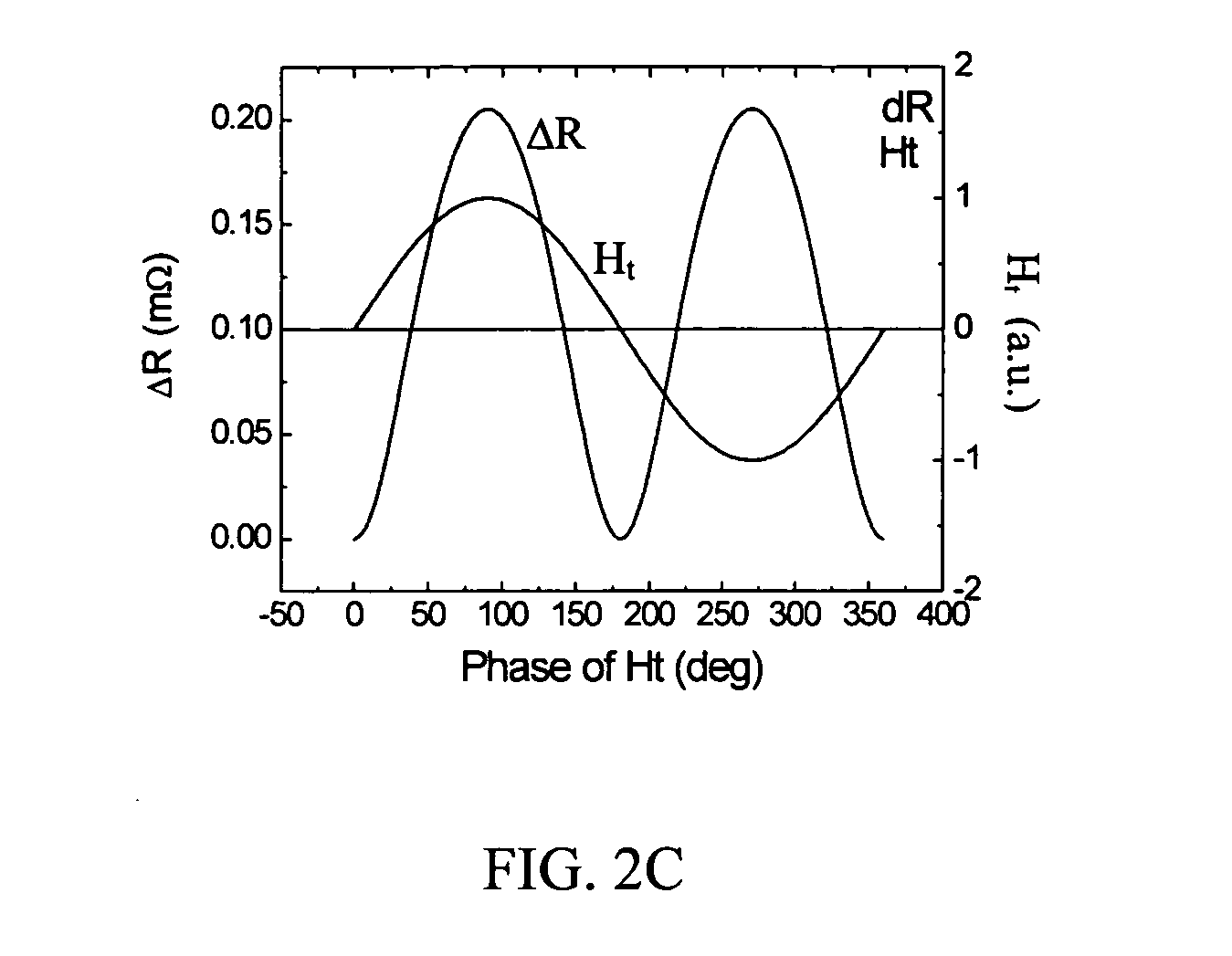

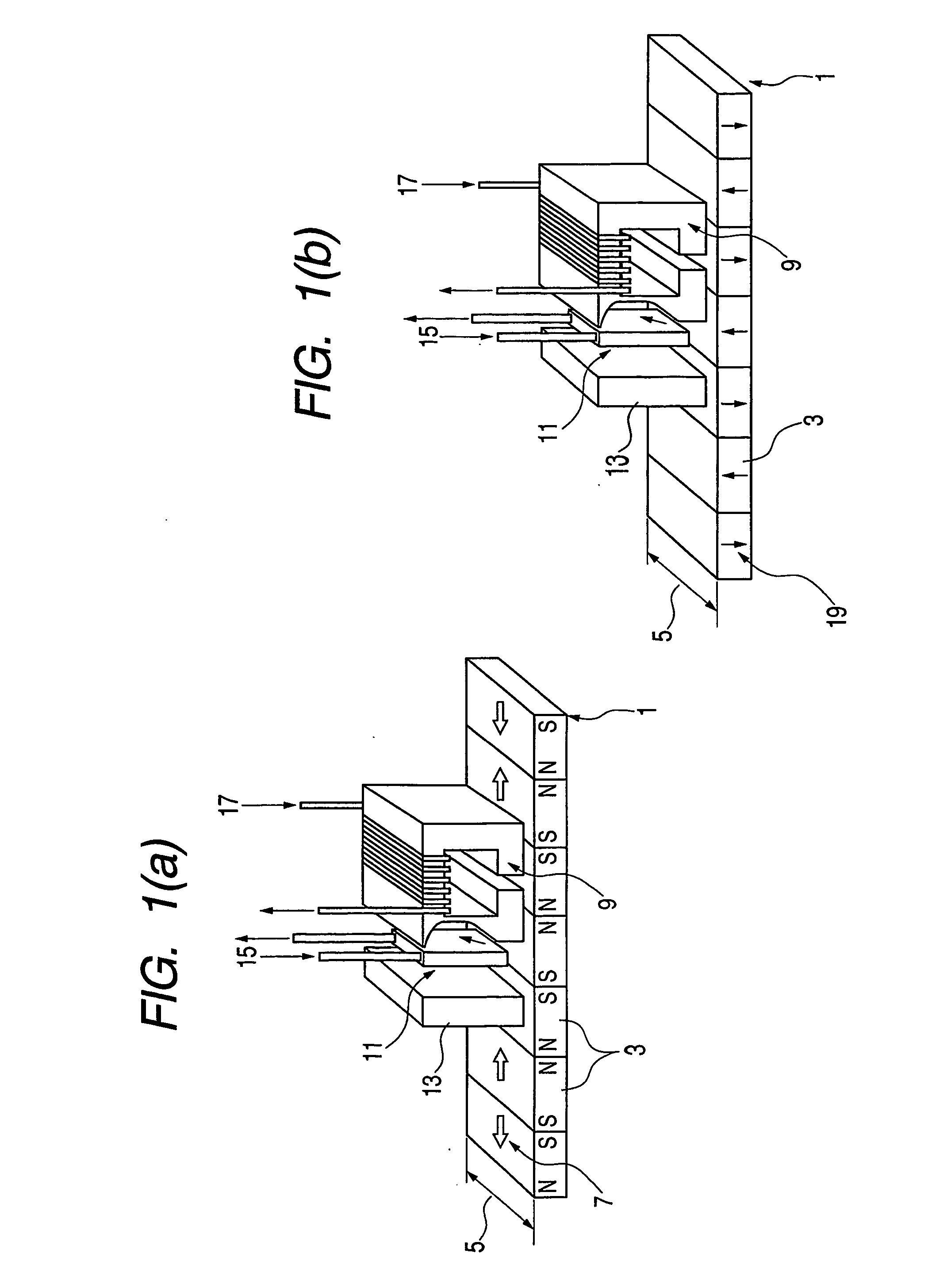

ActiveUS20090206827A1High resolutionAccurate measurementUsing electrical meansConverting sensor outputMagnetic polesSpin valve

A rotation-angle-detecting apparatus comprising a magnet rotor having 4 or more magnetic poles on the surface, and sensor device for detecting magnetic flux from the magnet rotor, and an electronic circuit for outputting a signal representing the rotation angle of the magnet rotor using pluralities of signals obtained from the sensor device, the sensor device having pluralities of spin-valve, giant-magnetoresistive devices for outputting two or more different phase signals from a rotating magnetic field near the rotating magnet, each spin-valve, giant-magnetoresistive device having a pinned layer and a free layer, the magnetization direction of the pinned layer being fixed, and the magnetization direction of the free layer rotating depending on a magnetic field direction, pluralities of the spin-valve, giant-magnetoresistive devices comprising a first spin-valve, giant-magnetoresistive device having a reference magnetic-field-sensing direction, and a second spin-valve, giant-magnetoresistive device having a magnetic-field-sensing direction different from that of the first spin-valve, giant-magnetoresistive device.

Owner:HITACHI METALS LTD

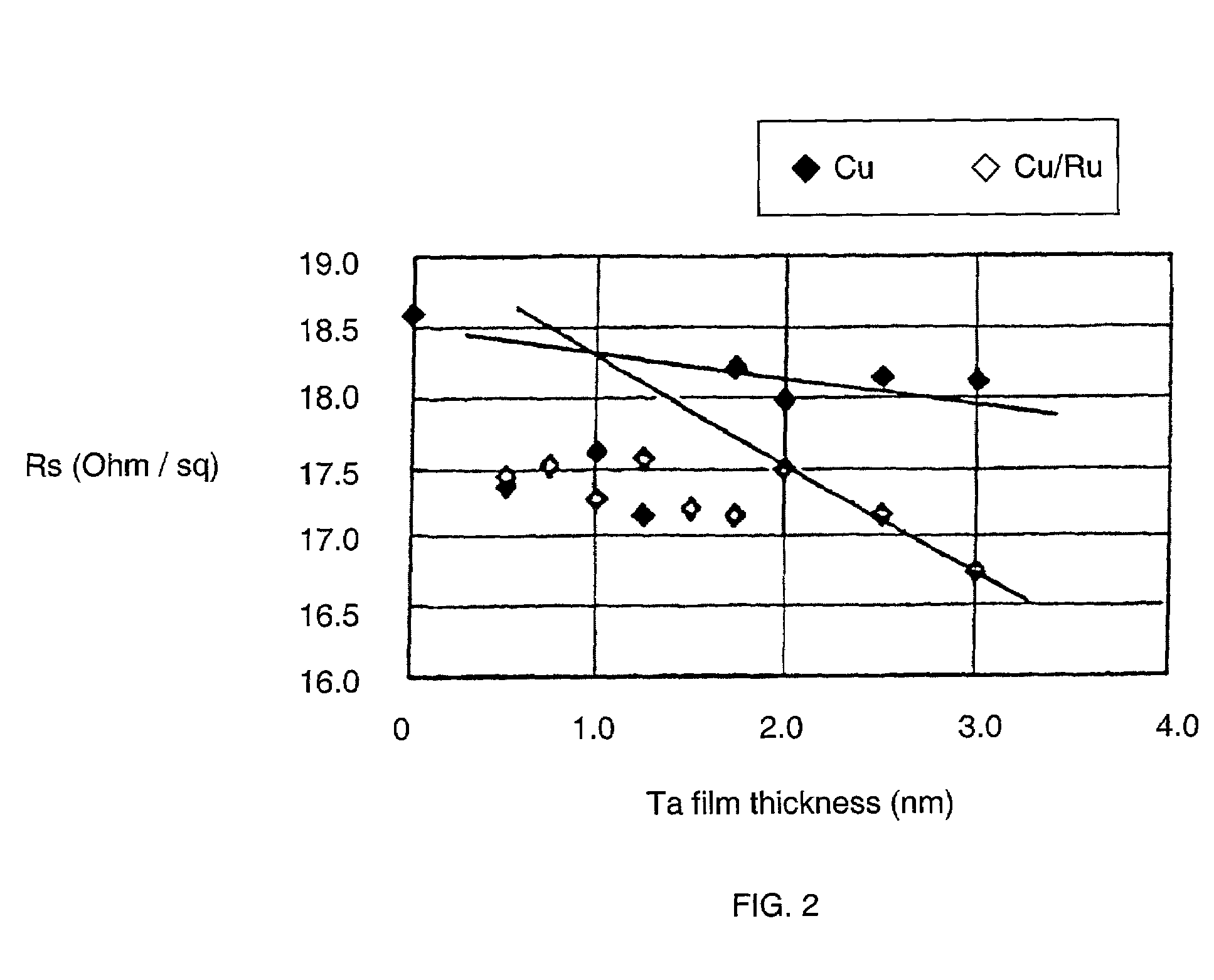

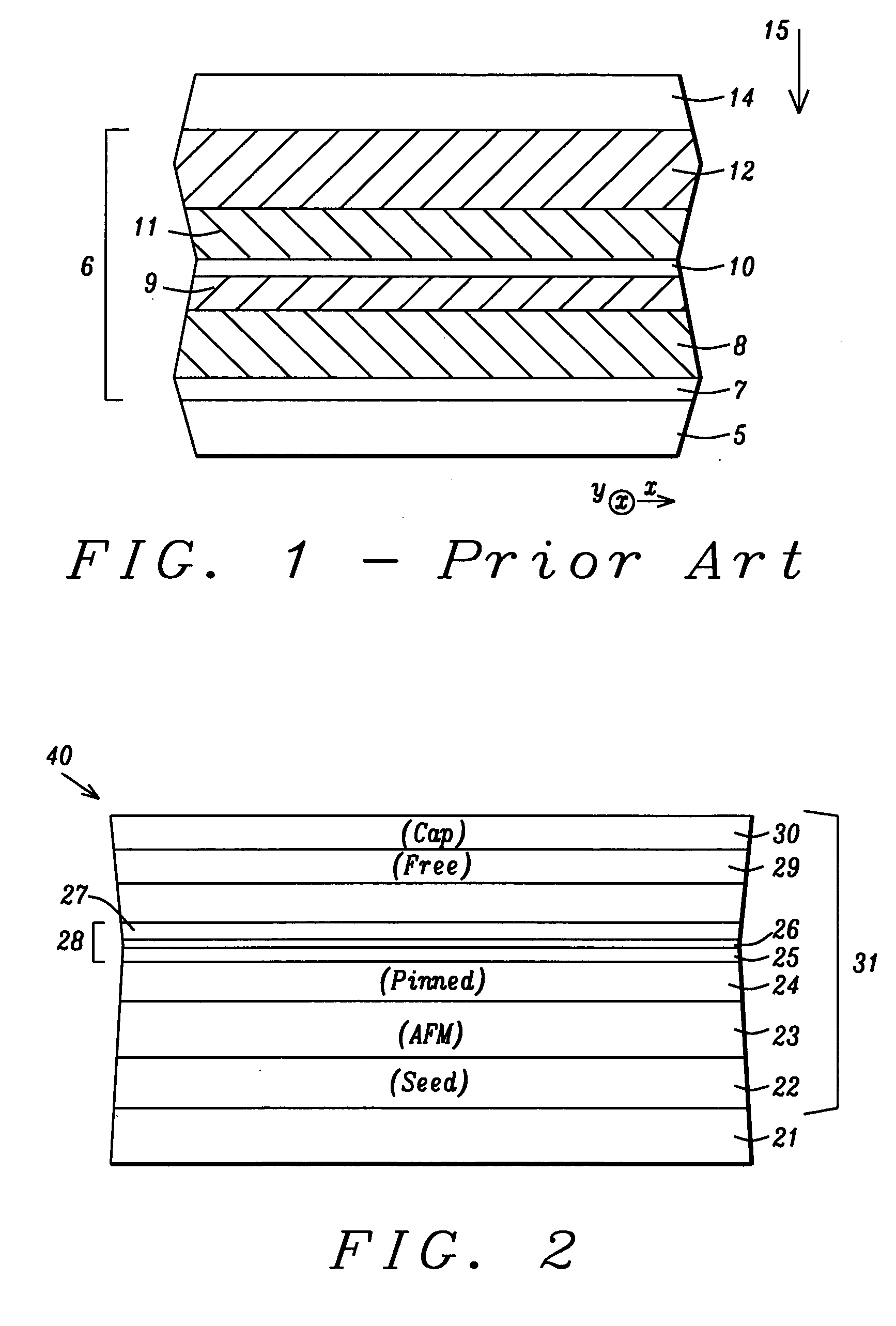

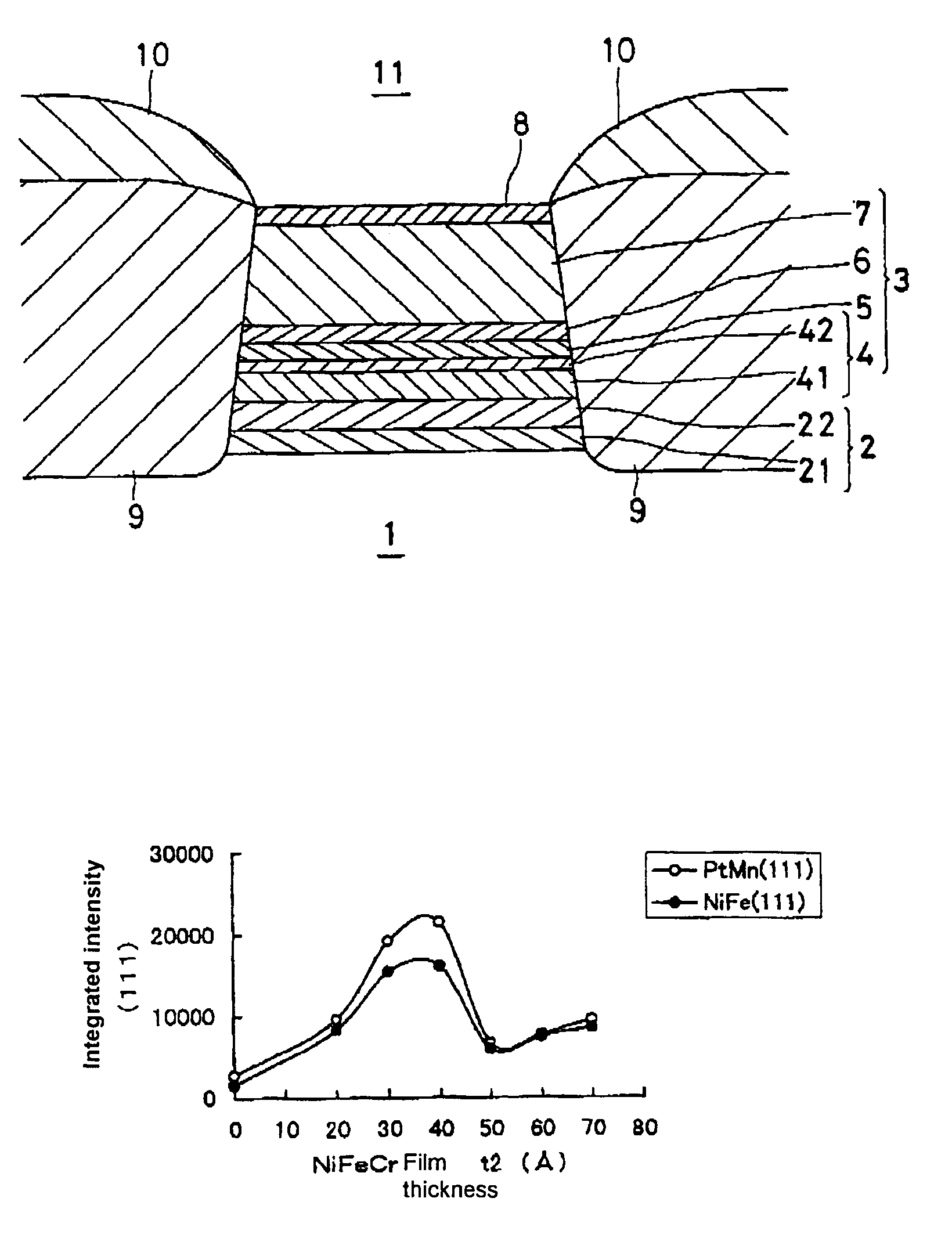

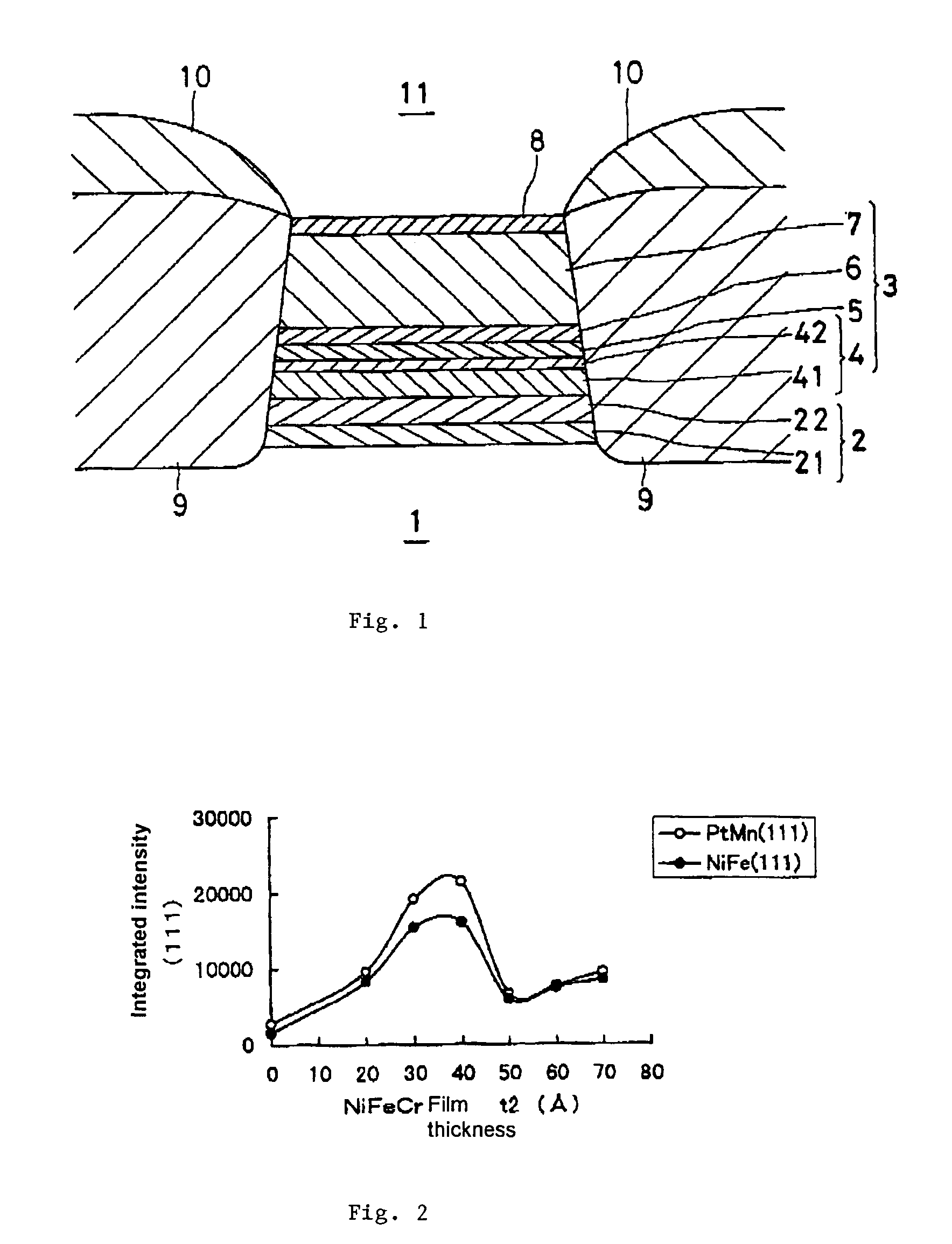

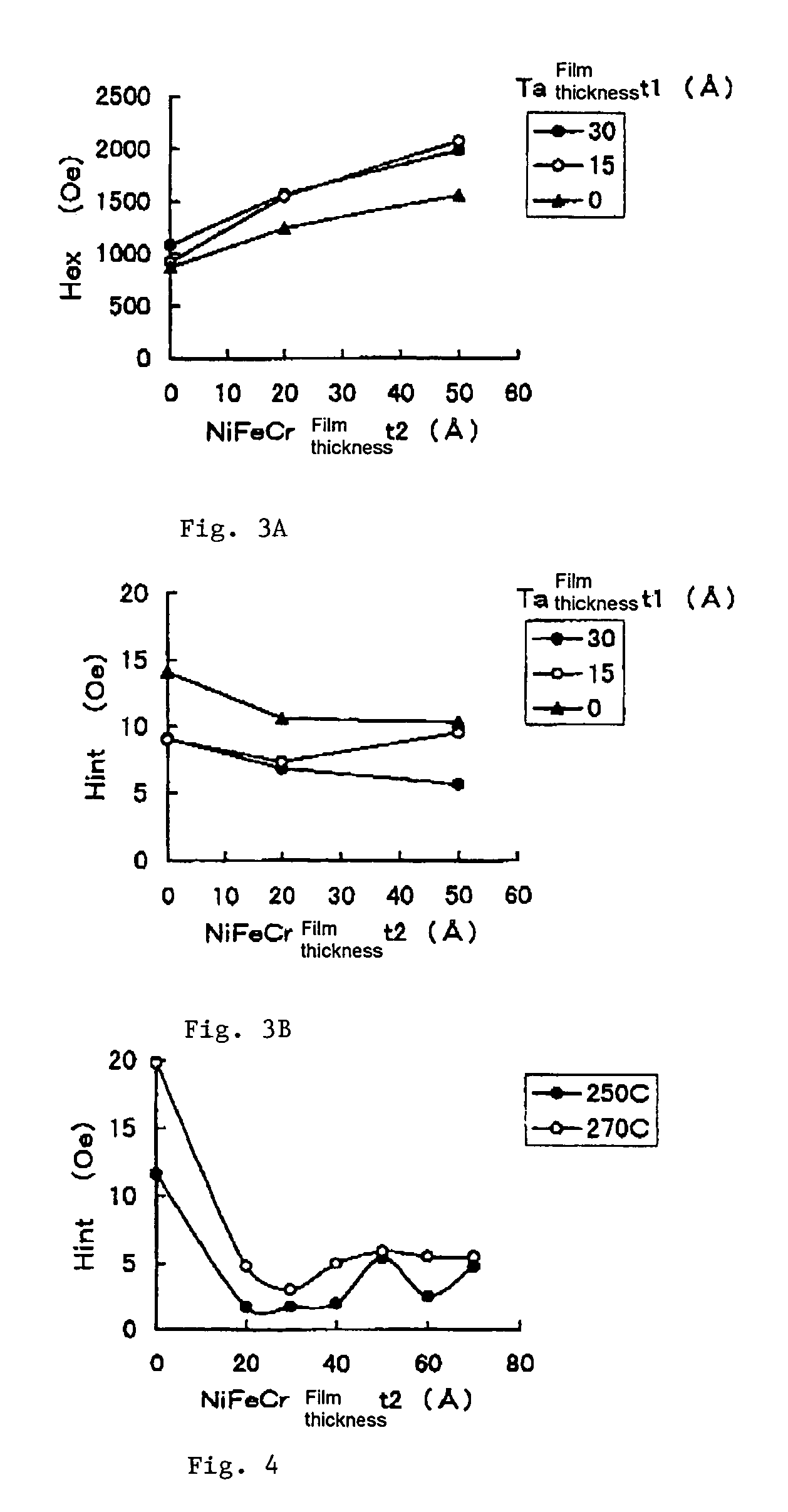

Top spin valve with improved seed layer

InactiveUS6687098B1Improved exchange bias fieldNanostructure applicationNanomagnetismEngineeringHigh resistivity

The present invention provides an improved top spin valve and method of fabrication. In the preferred embodiment of the top spin valve of the present invention, a seed layer is formed of non-magnetic material having the elements Ni and Cr. In the preferred embodiments, the seed layer material has an ion milling rate comparable to that of the free layer material. This allows free layer sidewalls to be formed with shorter tails, improving free layer-to-magnetic bias layer junction, thus improving free layer domain structure and track width. In one embodiment, the seed layer may have NiFeCr, with Cr from about 20% to 50%. In another embodiment, the seed layer may have NiCr, with about 40%. Some embodiments may have the seed layer formed on an optional Ta pre-seed layer. Such embodiments provide an improved fcc (111) texture particularly for NiFe and for NiFe / CoFe free layers grown on a seed layer improving spin valve performance, and especially in embodiments having very thin NiFe free layers, ultra thin NiFe free layers, and free layers without NiFe, such as a free layer of CoFe. Such a seed layer can improve AFM pinning layer texture to improve the exchange bias, thus providing better thermal stability. Such a seed layer also provides high resistivity and can improve the magnetostriction of adjacent NiFe free layer material or improve the soft properties of an adjacent CoFe free layer.

Owner:WESTERN DIGITAL TECH INC

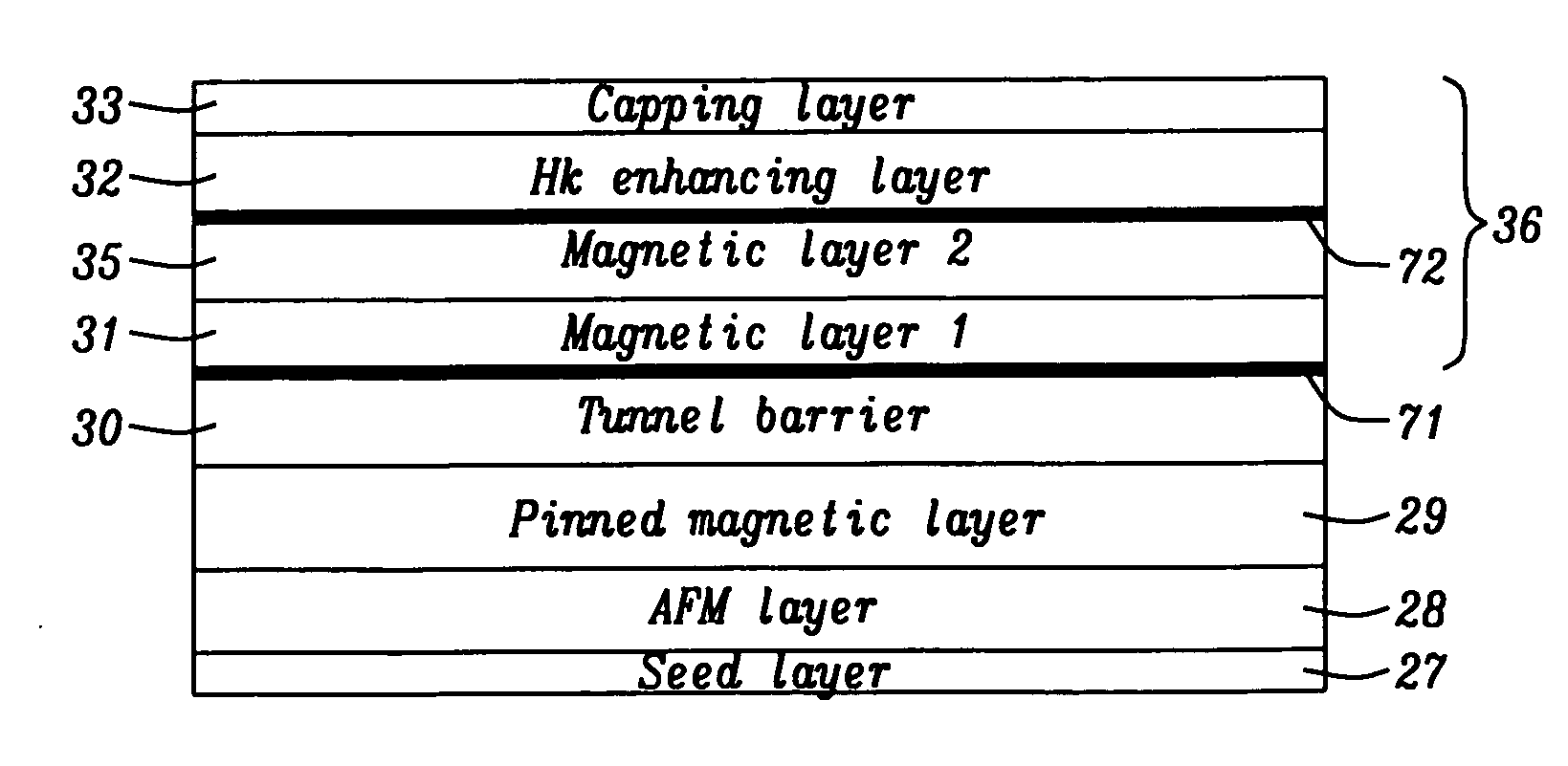

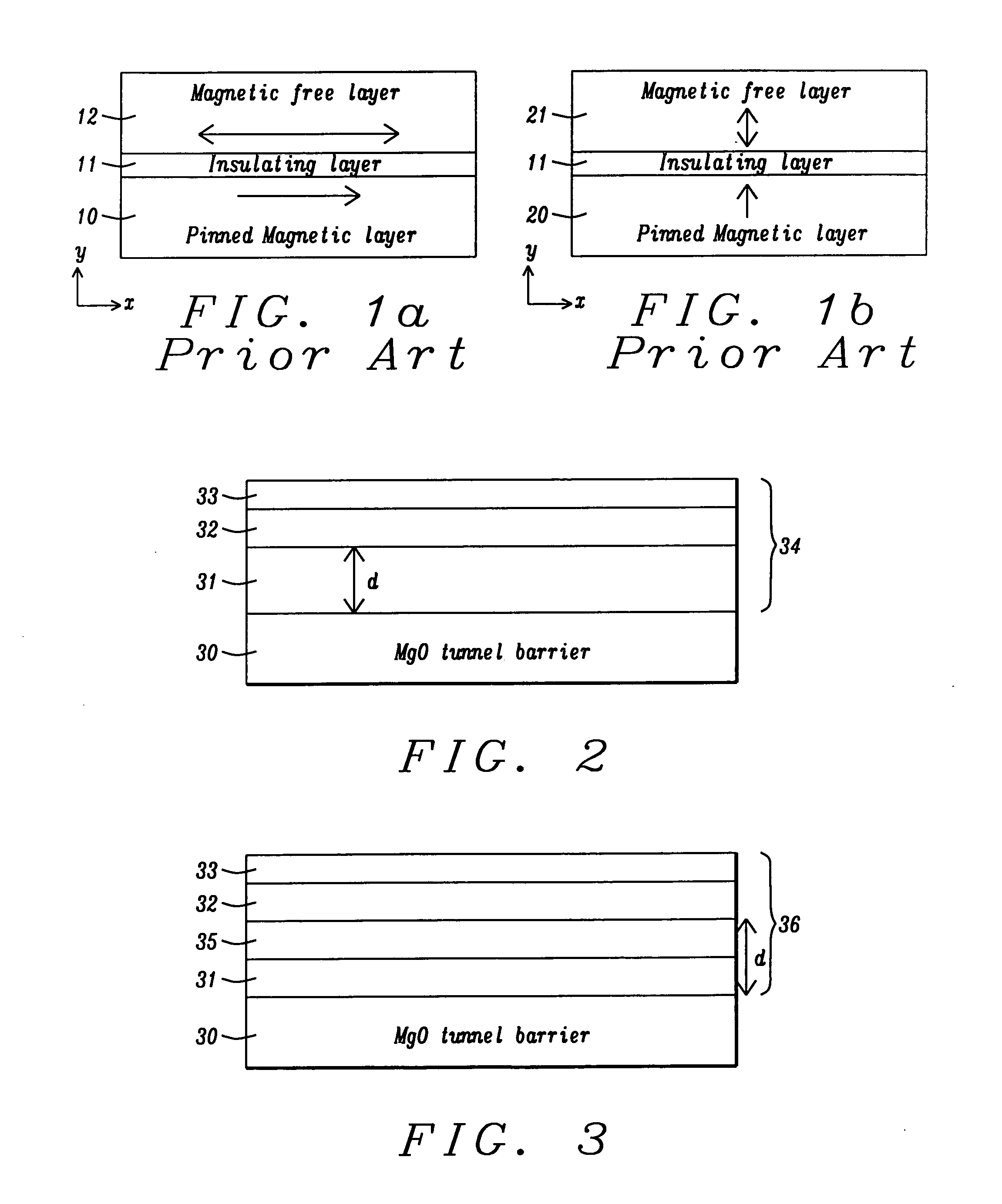

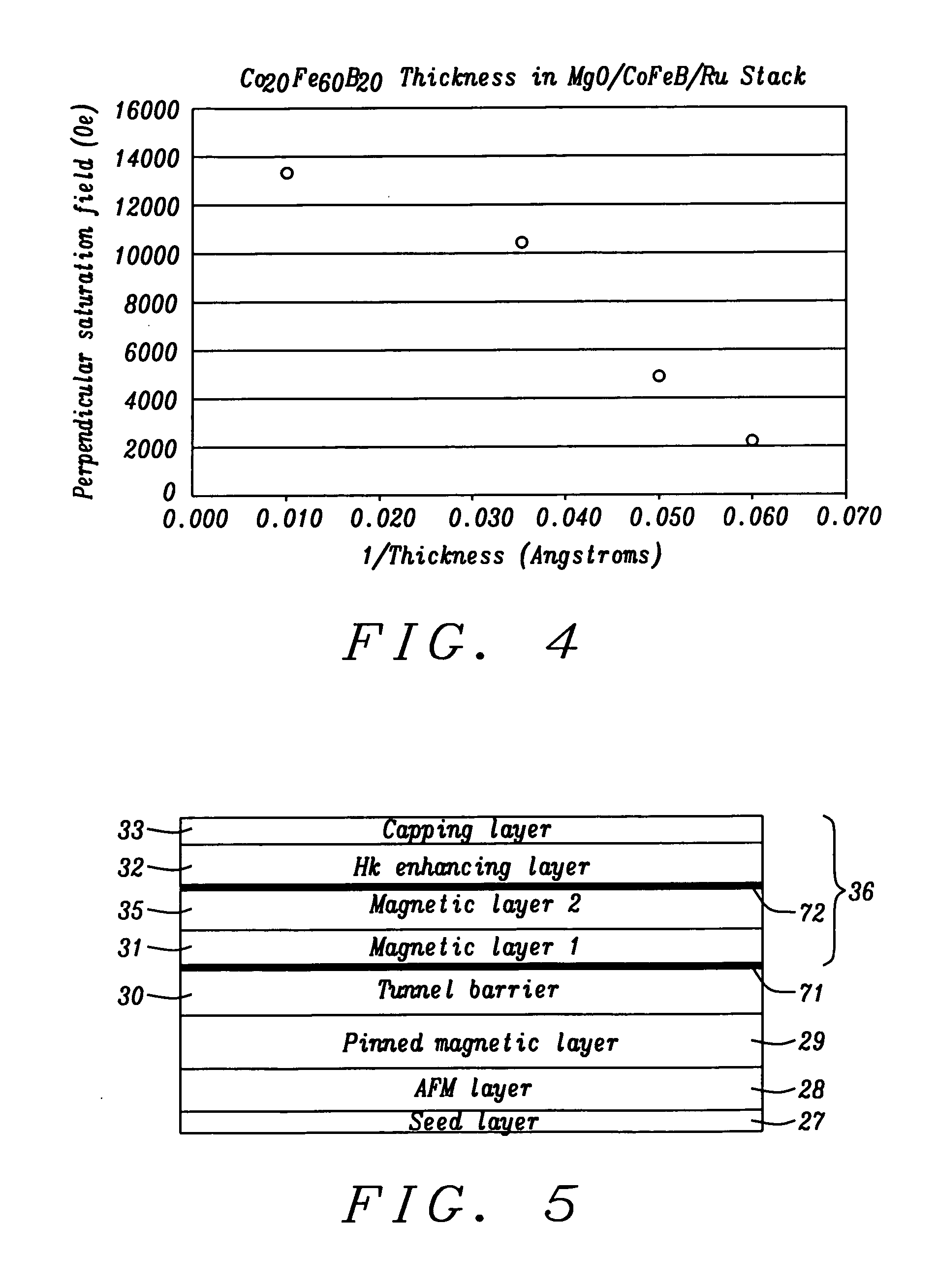

Magnetic element with improved out-of-plane anisotropy for spintronic applications

ActiveUS20120205758A1Without degrading thermal stability and MR ratioEnhanced interfacial perpendicular anisotropyMagnetic-field-controlled resistorsGalvano-magnetic material selectionPerpendicular anisotropyAlloy

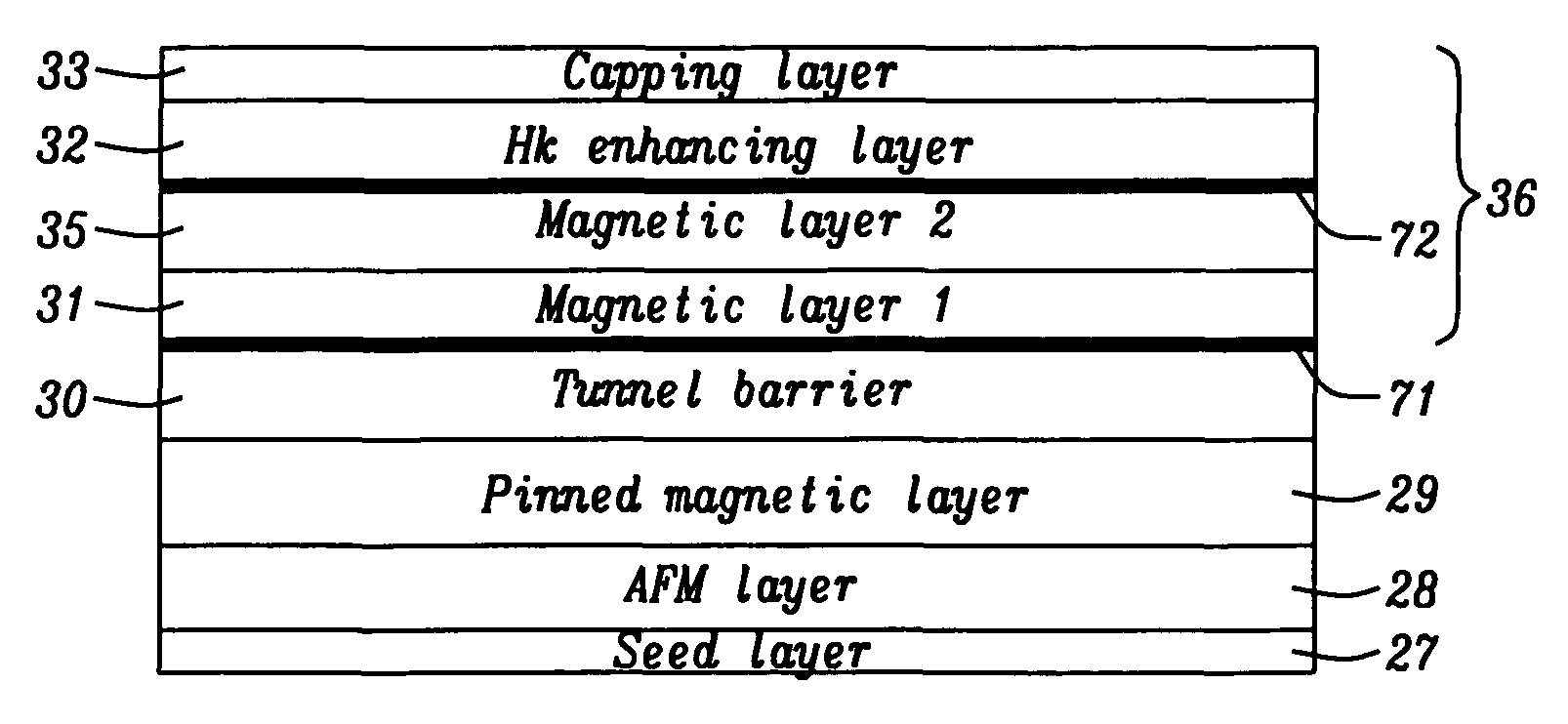

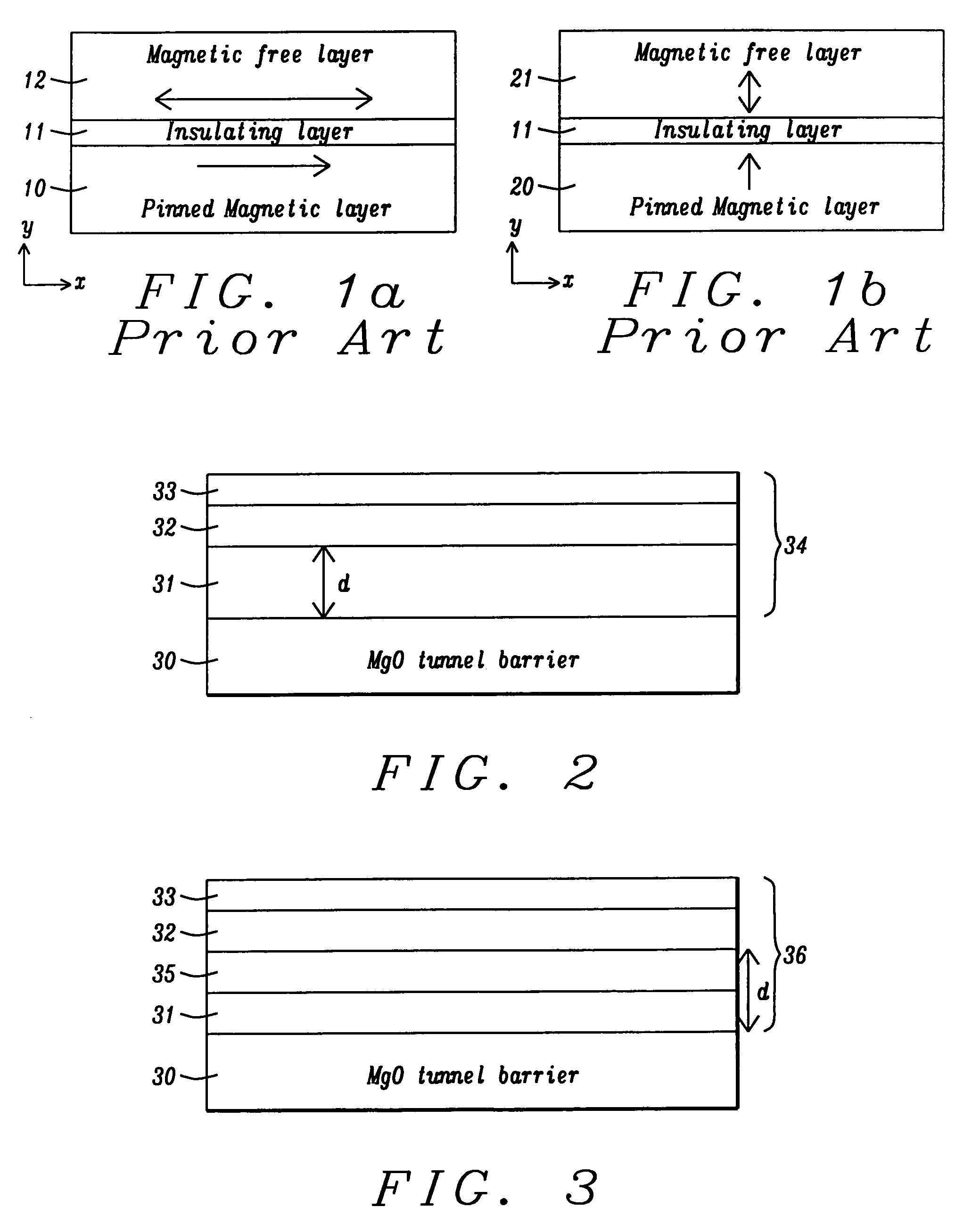

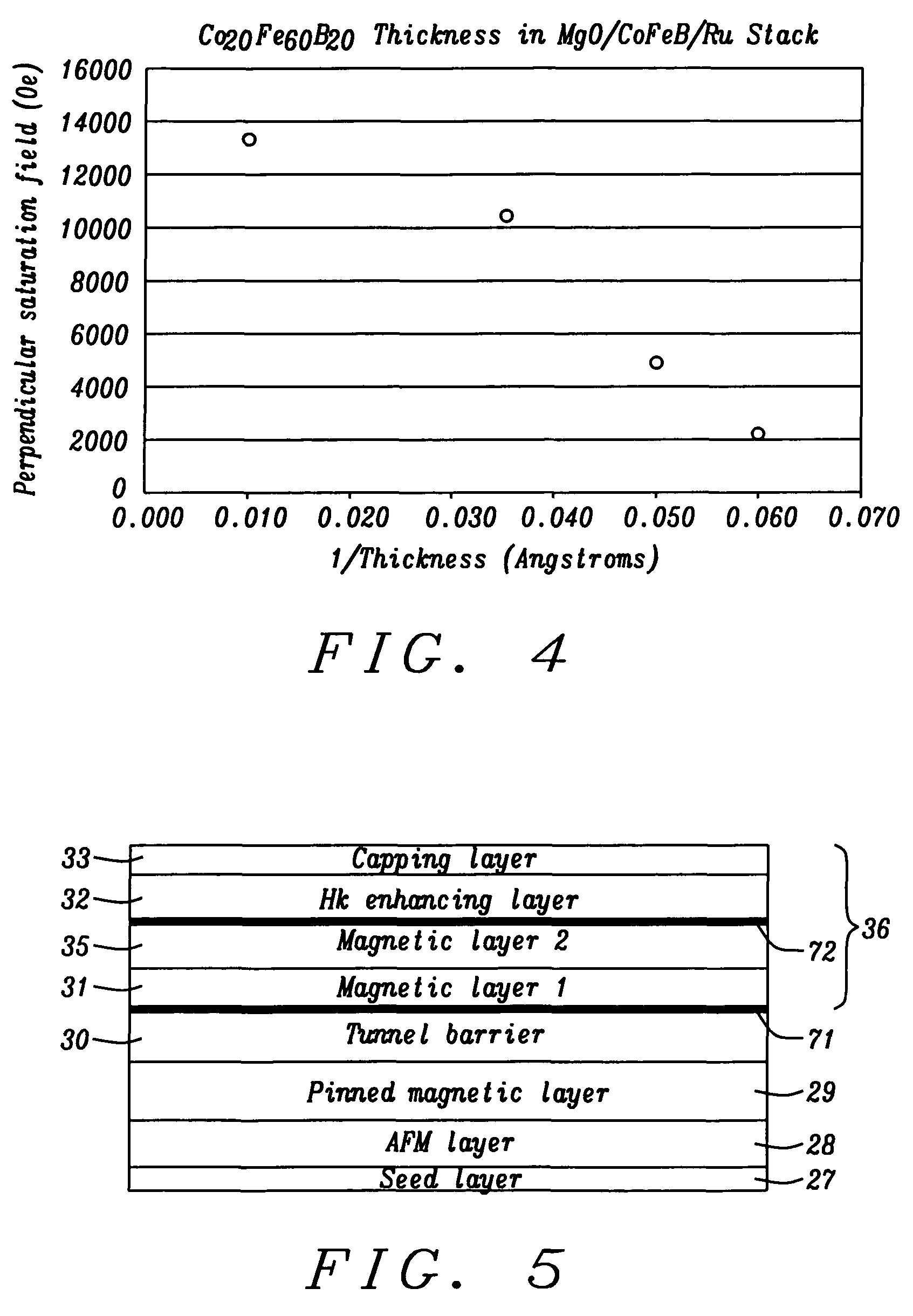

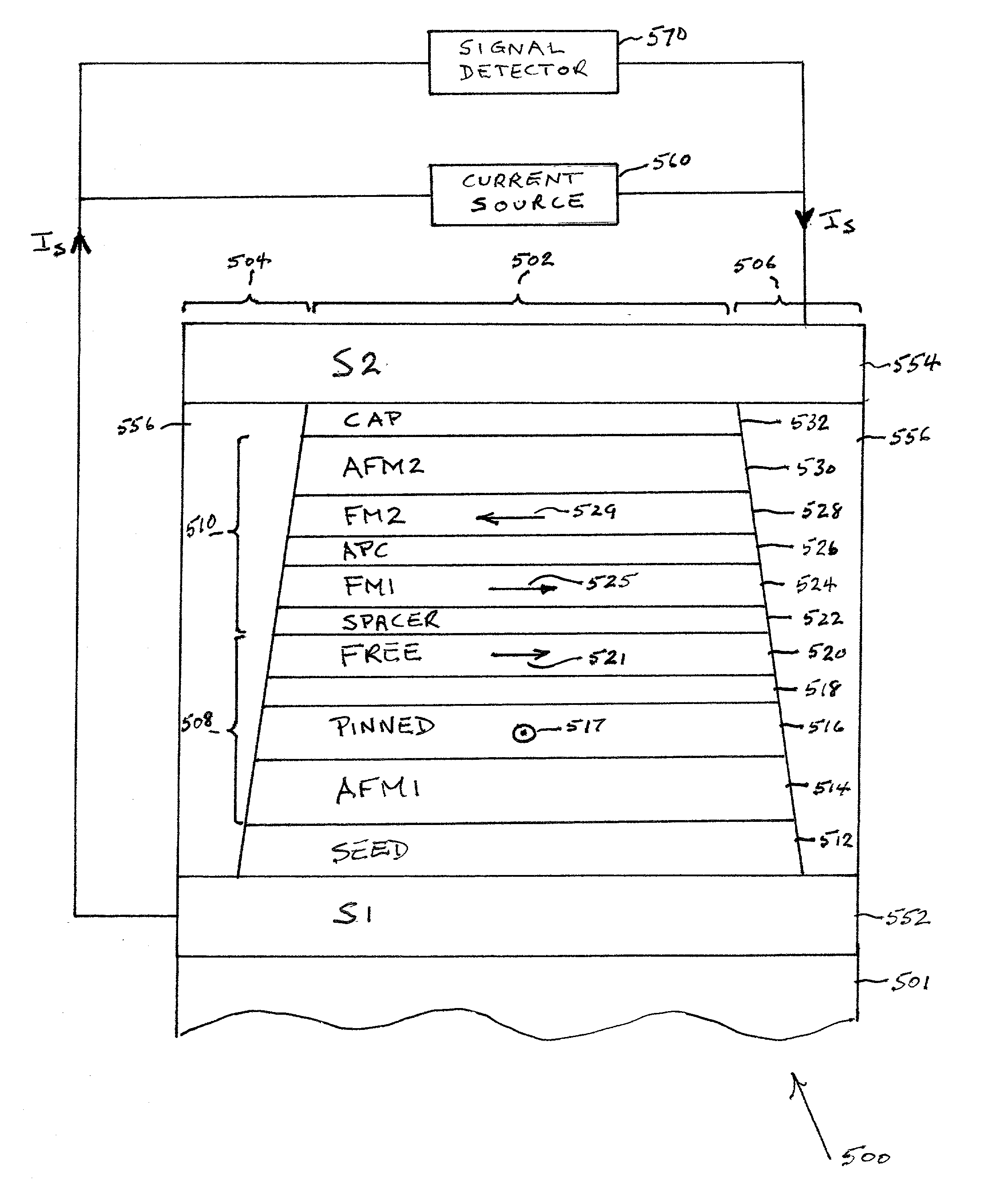

A magnetic element is disclosed wherein first and second interfaces of a free layer with a Hk enhancing layer and tunnel barrier, respectively, produce enhanced surface perpendicular anisotropy to lower switching current or increase thermal stability in a magnetic tunnel junction (MTJ). In a MTJ with a bottom spin valve configuration where the Hk enhancing layer is an oxide, the capping layer contacting the Hk enhancing layer is selected to have a free energy of oxide formation substantially greater than that of the oxide. The free layer may be a single layer or composite comprised of an Fe rich alloy such as Co20Fe60B20. With a thin free layer, the interfacial perpendicular anisotropy may dominate the shape anisotropy to generate a magnetization perpendicular to the planes of the layers. The magnetic element may be part of a spintronic device or serve as a propagation medium in a domain wall motion device.

Owner:TAIWAN SEMICON MFG CO LTD

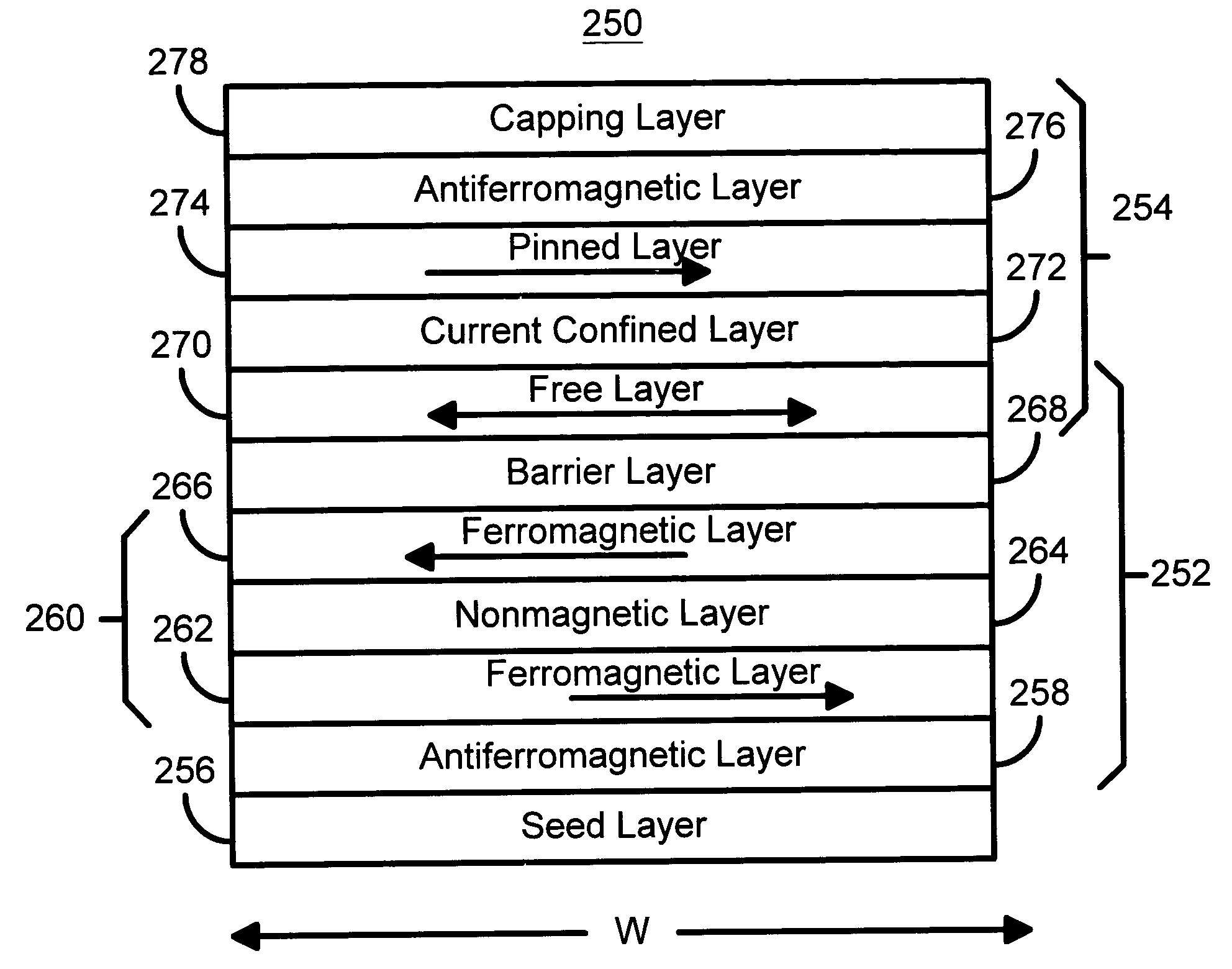

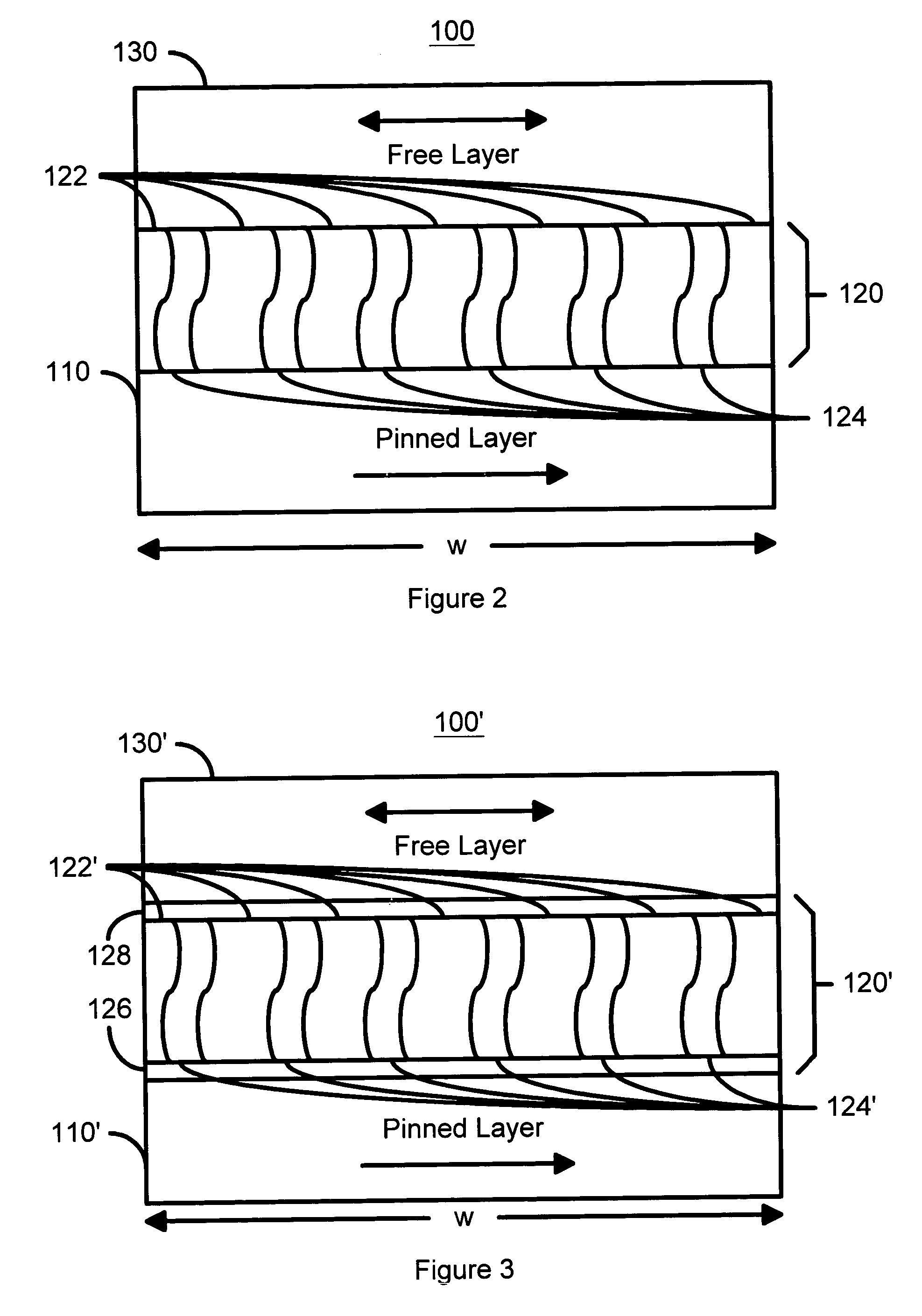

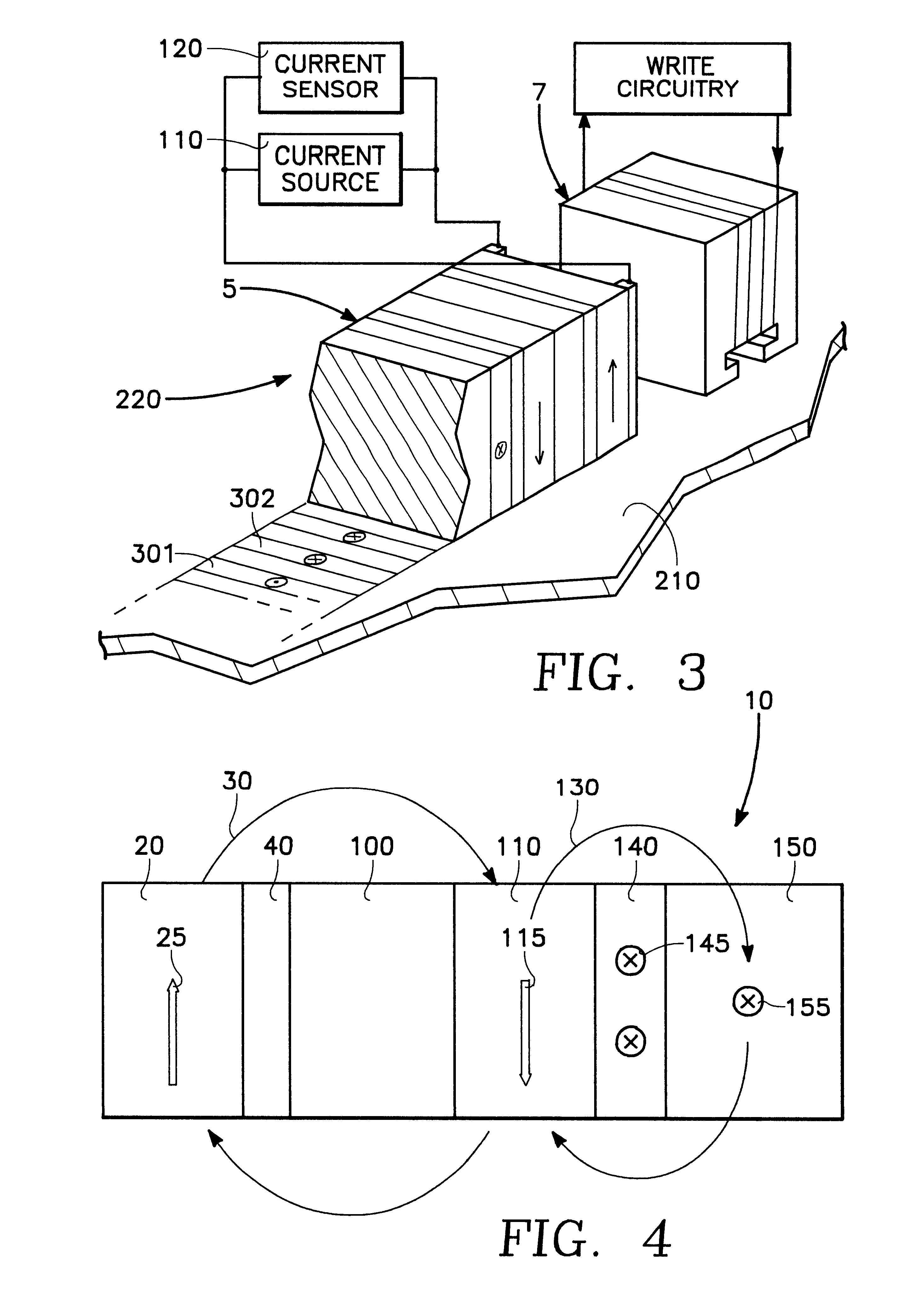

Current confined pass layer for magnetic elements utilizing spin-transfer and an MRAM device using such magnetic elements

ActiveUS20050063222A1Total current dropFunction increaseDigital storageCurrent limitingSpin tunneling

A method and system for providing and magnetic element is disclosed. In one aspect, the magnetic element includes at least a pinned layer, a free layer, and a current confined layer residing between the pinned layer and the free layer. The pinned layer is ferromagnetic and has a first magnetization. The current confined layer has at least one channel in an insulating matrix. The channel(s) are conductive and extend through the current confined layer. The free layer is ferromagnetic and has a second magnetization. The pinned layer, the free layer, and the current confined layer are configured to allow the magnetization of the free layer to be switched using spin transfer. The magnetic element may also include other layers, including layers for spin valve(s), spin tunneling junction(s), dual spin valve(s), dual spin tunneling junction(s), and dual spin valve / tunnel structure(s).

Owner:SAMSUNG SEMICON

Spin valve device with improved thermal stability

The present invention provides spin valve with a magnetic compensation field which couples to the pinned layer and counteracts sensing current induced magnetic field. The spin valve sensor of the present invention may be formed having a structure comprising: a free layer, a first spacer layer, a pinned layer, a pinning layer, a second spacer layer, and a compensation layer. The compensation layer may be formed of ferromagnetic material with its magnetization set so that the compensation field oriented in a reinforcing relationship with the magnetization of the pinned layer. Current through the compensation layer and the spacer layer may add to the compensation field. The spacer layer may be formed of a nonmagnetic material of sufficient thickness to prevent interaction between the pinning layer and the compensation layer while providing a sufficiently small distance to allow sufficient magnetic coupling to the pinned layer. The present invention may be used to improve thermal stability and reduce Barkhausen noise while not impacting output symmetry.

Owner:WESTERN DIGITAL TECH INC

Current confined pass layer for magnetic elements utilizing spin-transfer and an MRAM device using such magnetic elements

Owner:SAMSUNG SEMICON

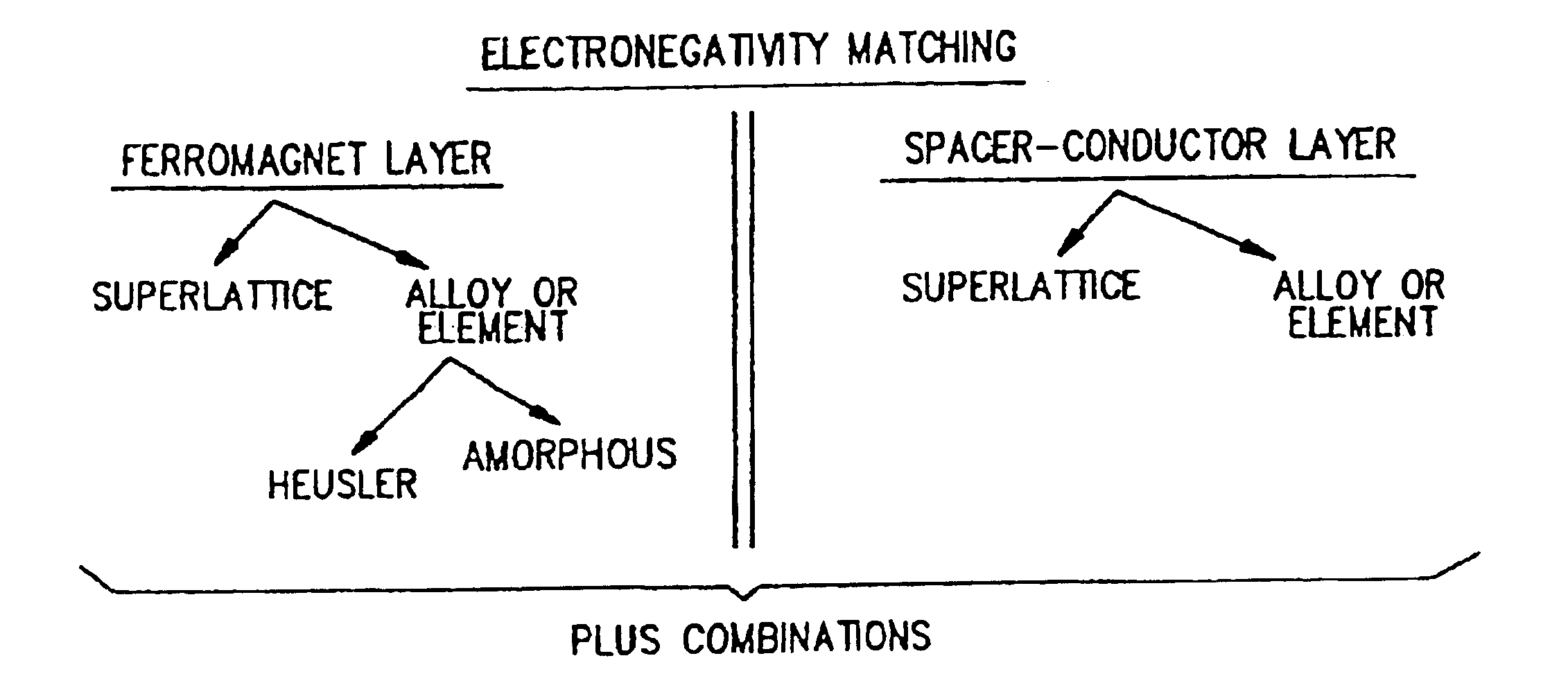

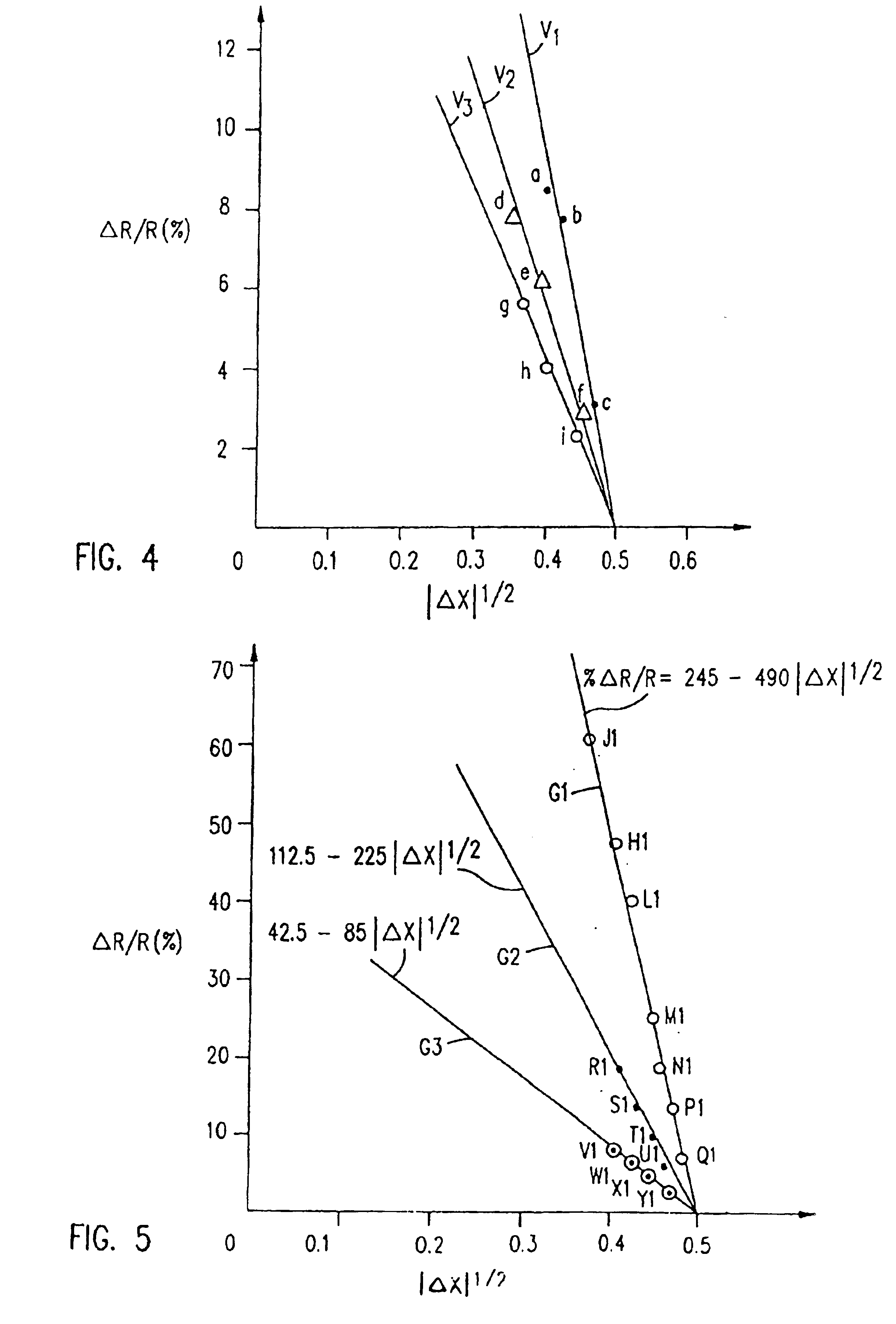

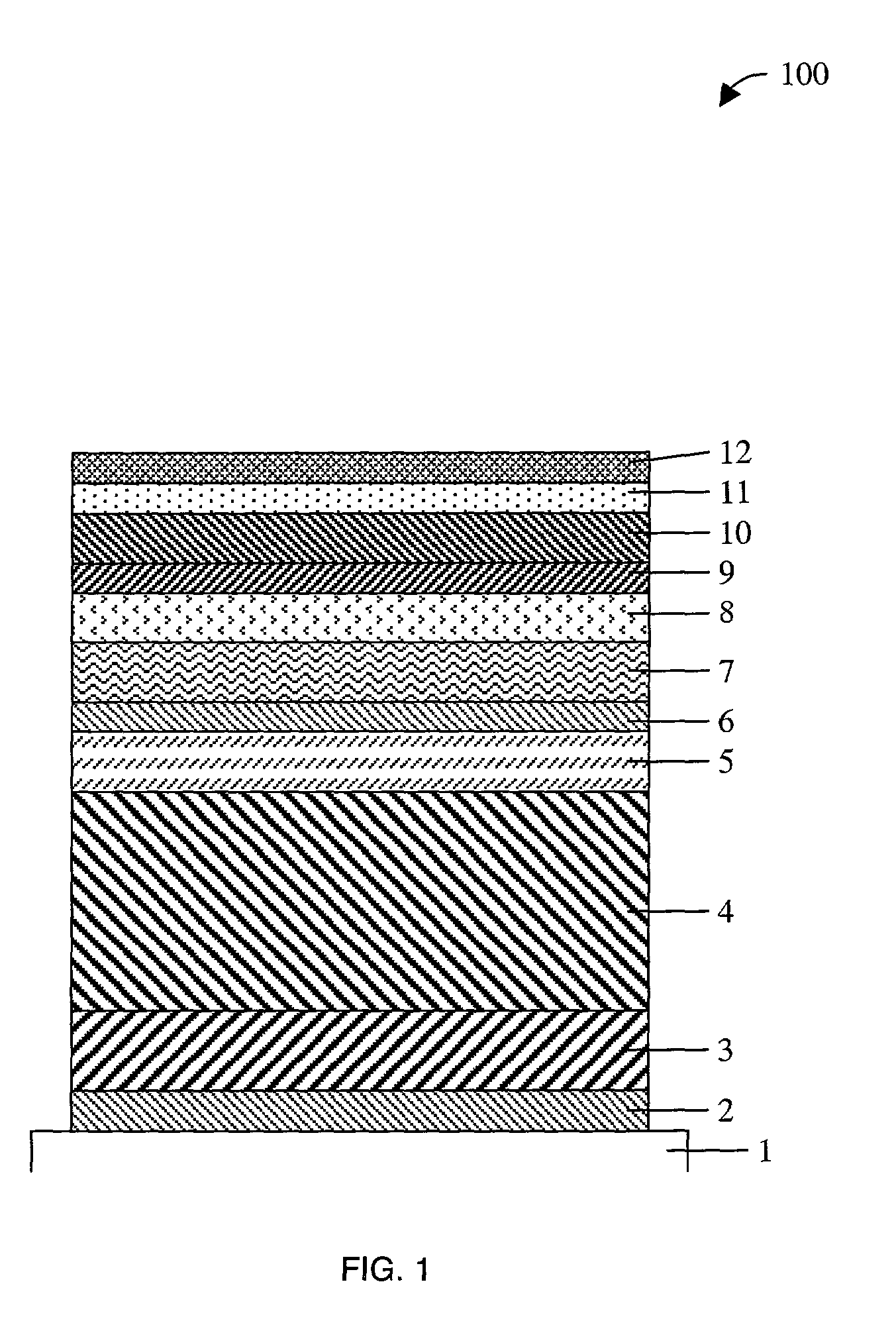

Methods and compositions for optimizing interfacial properties of magnetoresistive sensors

InactiveUS6828897B1Minimize electromigrationExtended service lifeNanomagnetismFixed microstructural devicesMean free pathElectronegativity

A method for maximizing the interfacial properties of magnetoresistive sensors, such as spin valve and GMR sensors used in storage devices, comprises selecting the materials for ferromagnetic layers and for electrically conductive spacers that are interposed between the ferromagnetic layers. The electronegativities of the selected materials are substantially matched so that an absolute value of the differences in electronegativities is minimized. The conductive spacer material provides a relatively low resistivity and a large mean free path. The sensors experience greater chemical and thermal stability, are corrosion resistant, and realize an increased signal output.

Owner:WESTERN DIGITAL TECH INC

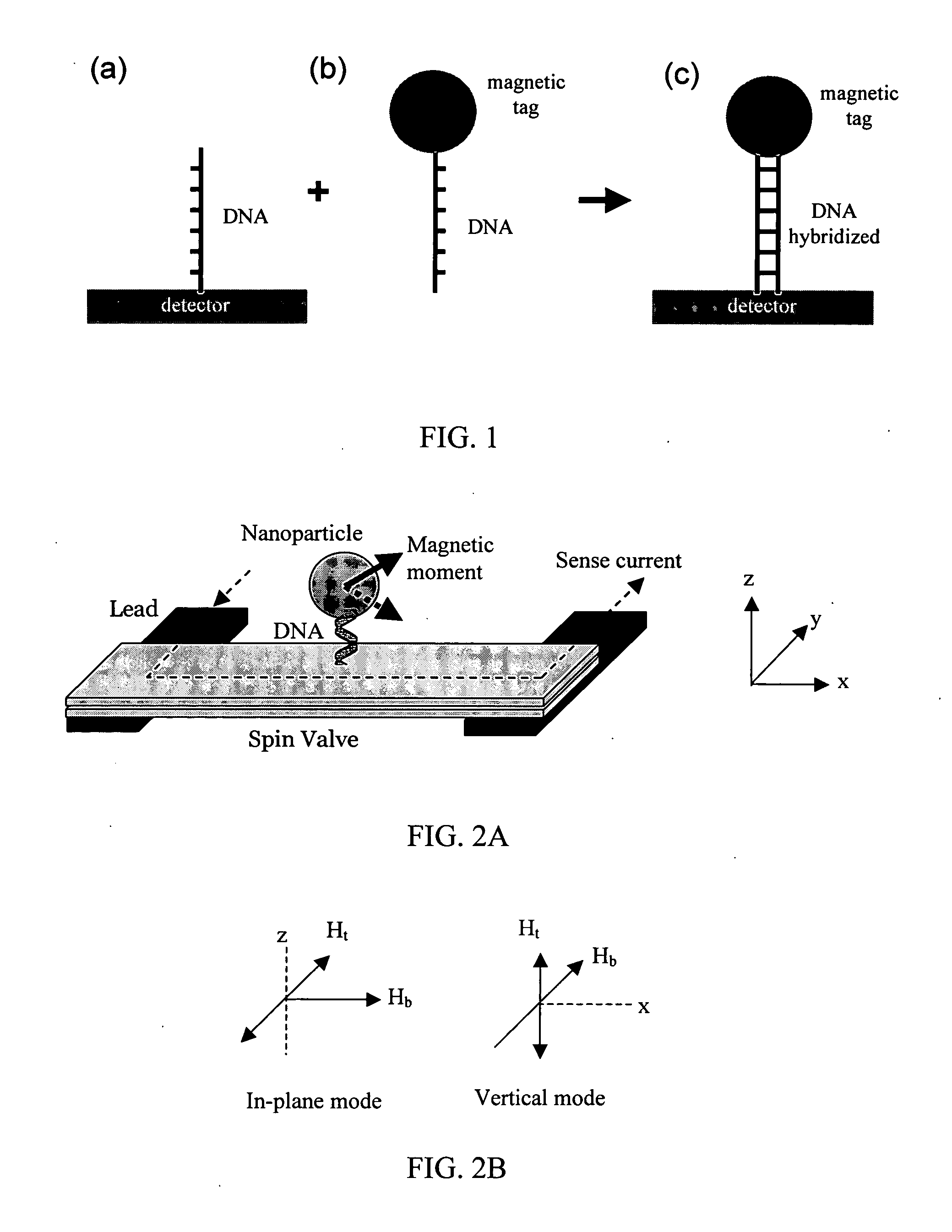

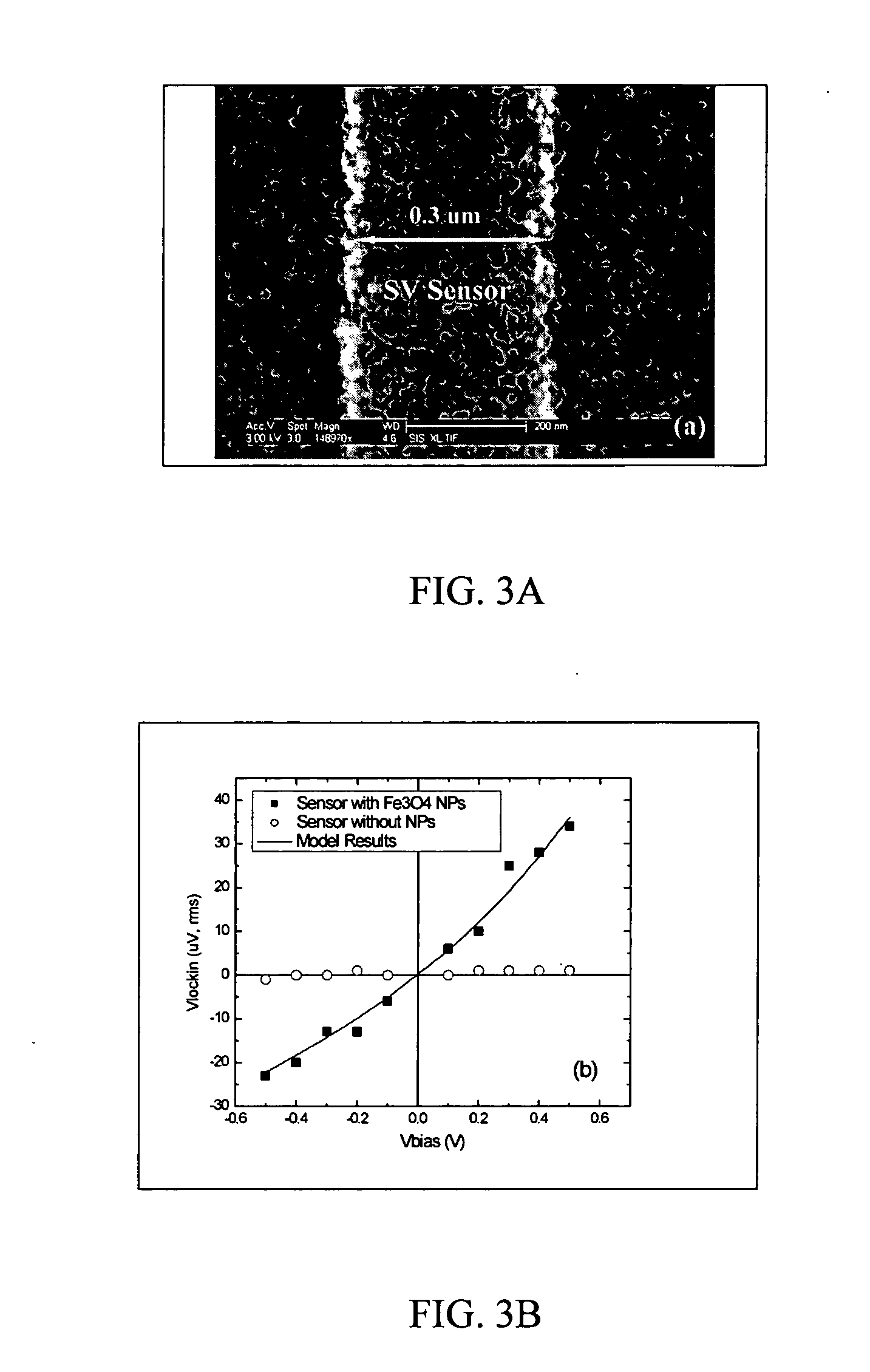

Magnetic nanoparticles, magnetic detector arrays, and methods for their use in detecting biological molecules

Magnetic nanoparticles and methods for their use in detecting biological molecules are disclosed. The magnetic nanoparticles can be attached to nucleic acid molecules, which are then captured by a complementary sequence attached to a detector, such as a spin valve detector or a magnetic tunnel junction detector. The detection of the bound magnetic nanoparticle can be achieved with high specificity and sensitivity.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

MTJ incorporating CoFe/Ni multilayer film with perpendicular magnetic anisotropy for MRAM application

ActiveUS20110096443A1Minimize impinging ion energyMaximize PMA propertyMagnetic measurementsVacuum evaporation coatingSpin transferSpin valve

A MTJ for a spintronic device is disclosed and includes a thin composite seed layer made of at least Ta and a metal layer having fcc(111) or hcp(001) texture as in Ta / Ti / Cu to enhance perpendicular magnetic anisotropy (PMA) in an overlying laminated layer with a (CoFe / Ni)X, (Co / NiFe)X, (Co / NiCo)X, (CoFe / NiFe)X, or (CoFe / NiCo)X composition where x is from 5 to 30. In one embodiment, a CPP-TMR spin valve has one or both of a laminated free layer and laminated reference layer with the aforementioned compositions. The MTJ includes an interfacial layer made of CoFeB, CoFeB / CoFe, or CoFe / CoFeB between each laminated structure and the tunnel barrier. The laminated layers are deposited by a low power and high Ar pressure process to avoid damaging interfaces between adjoining layers. Annealing occurs at 220° C. to 400° C. A laminated layer with high PMA may also be included in one or more layers of a spin transfer oscillator.

Owner:TAIWAN SEMICON MFG CO LTD

Magnetoresistive read sensor with reduced effective shield-to-shield spacing

Owner:WESTERN DIGITAL TECH INC

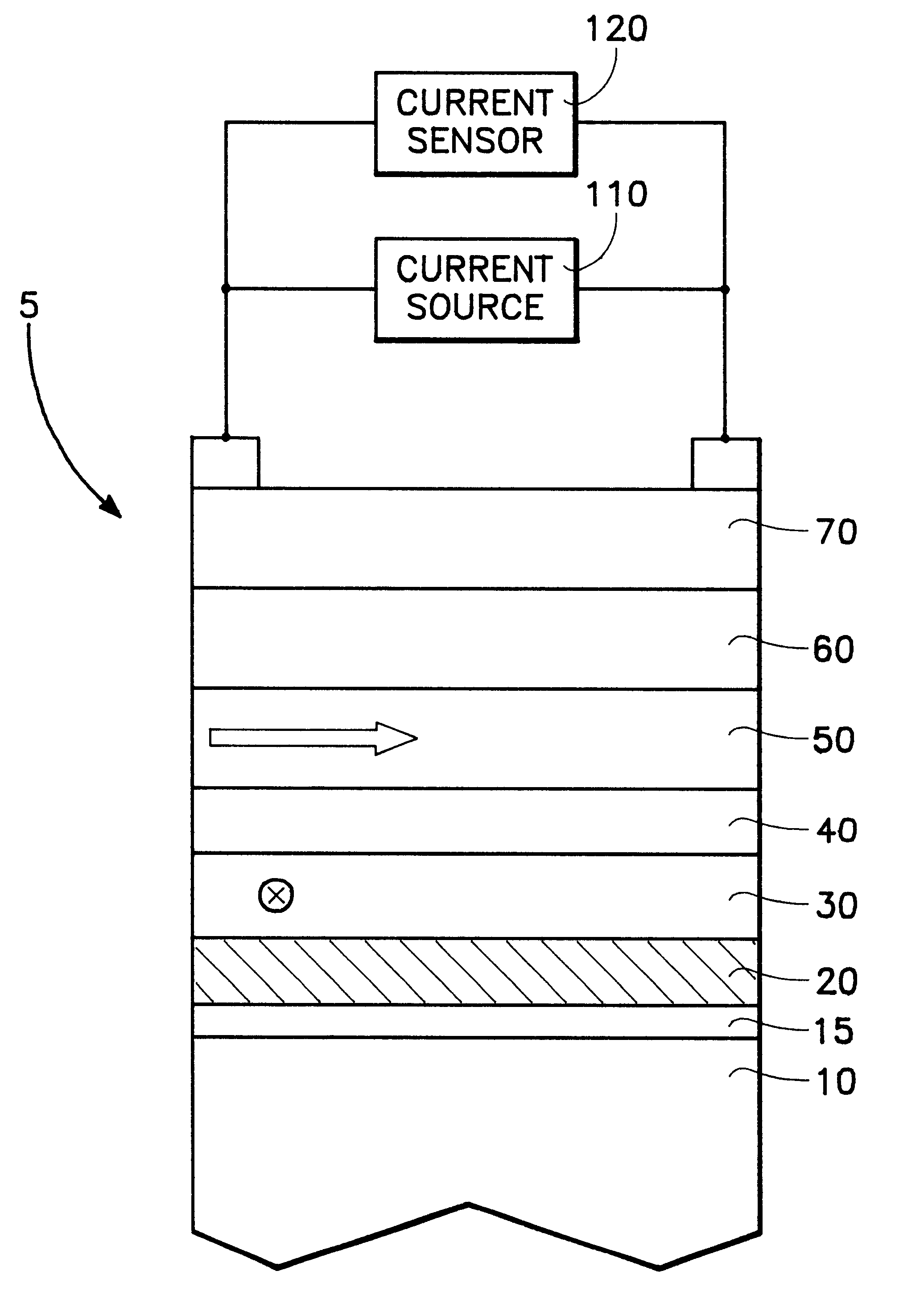

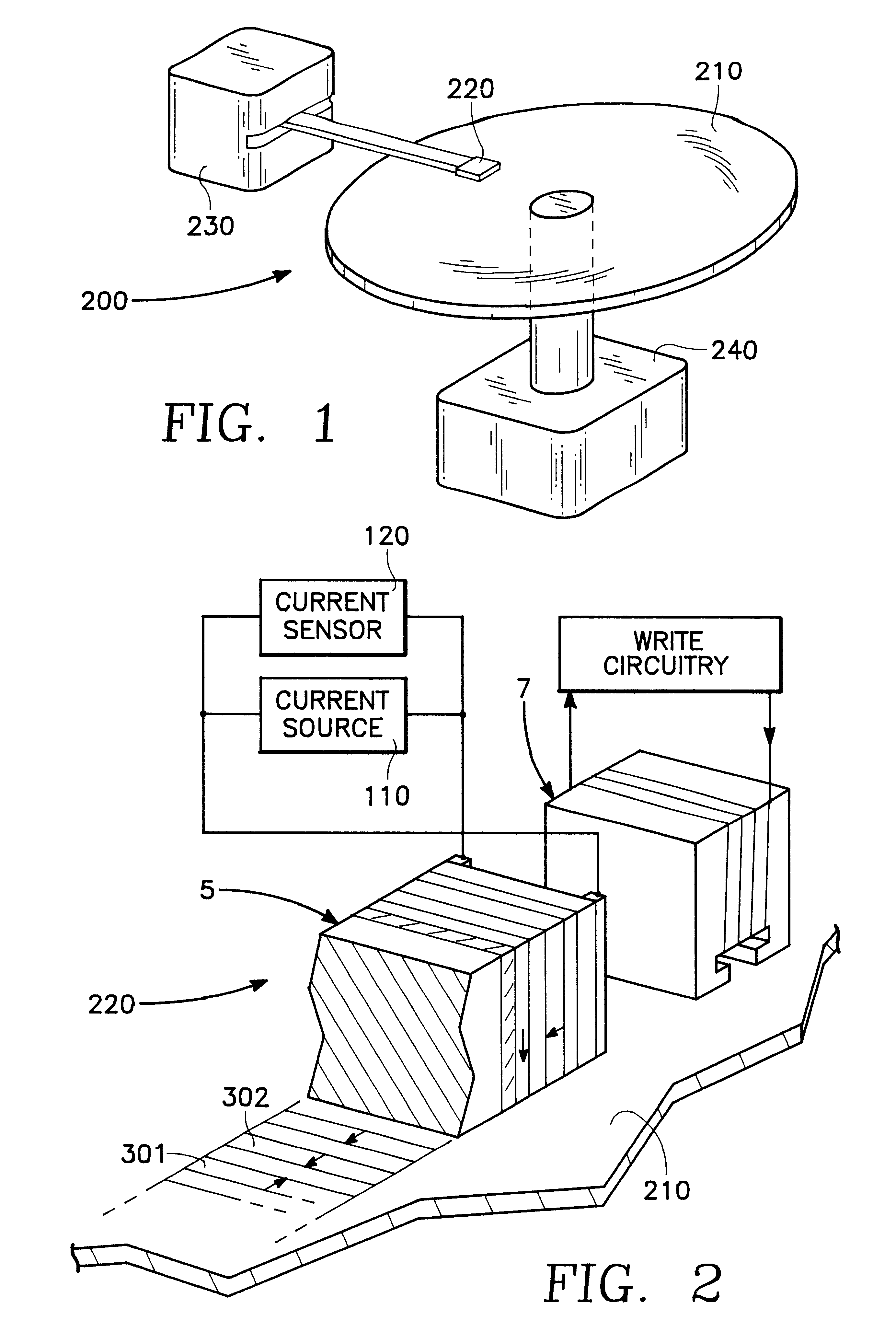

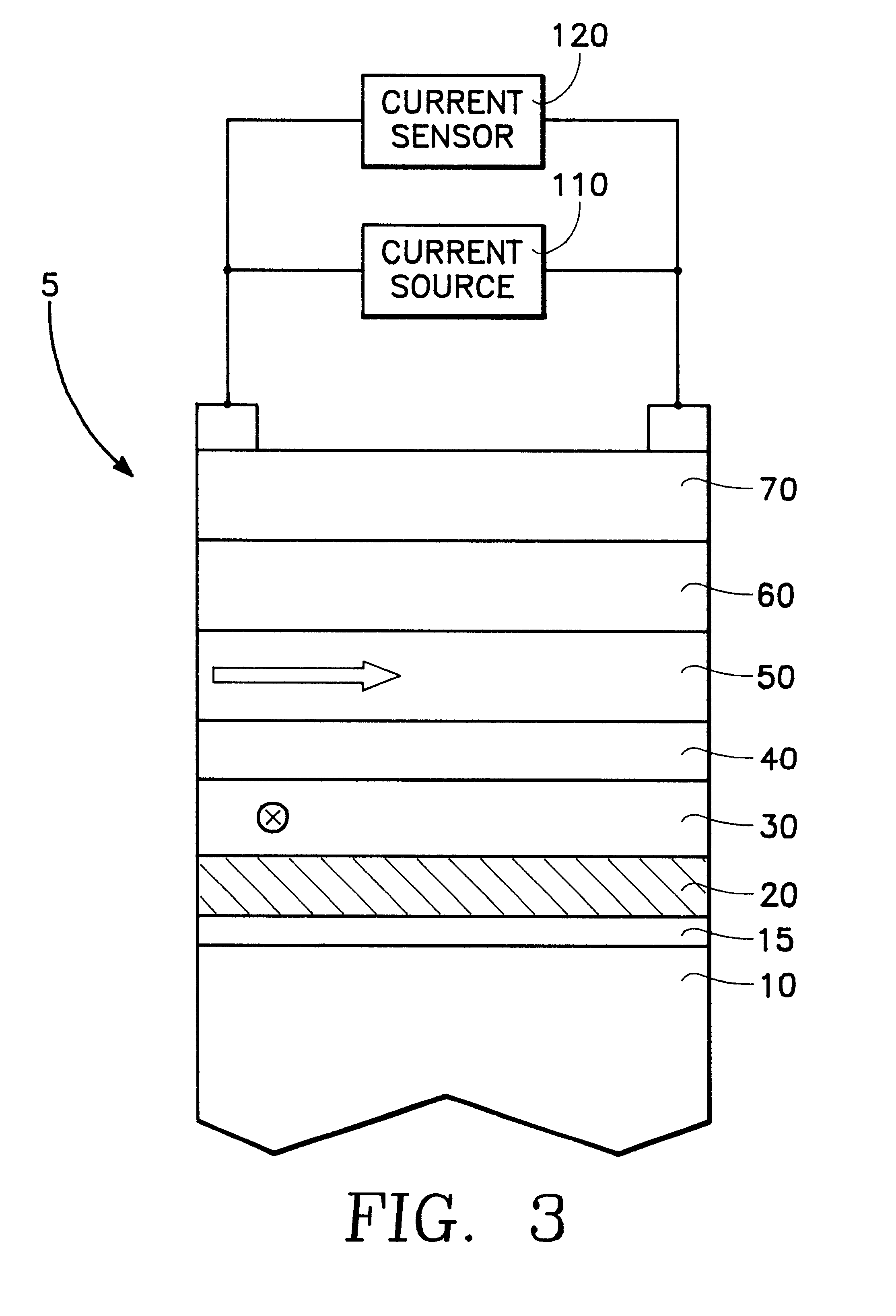

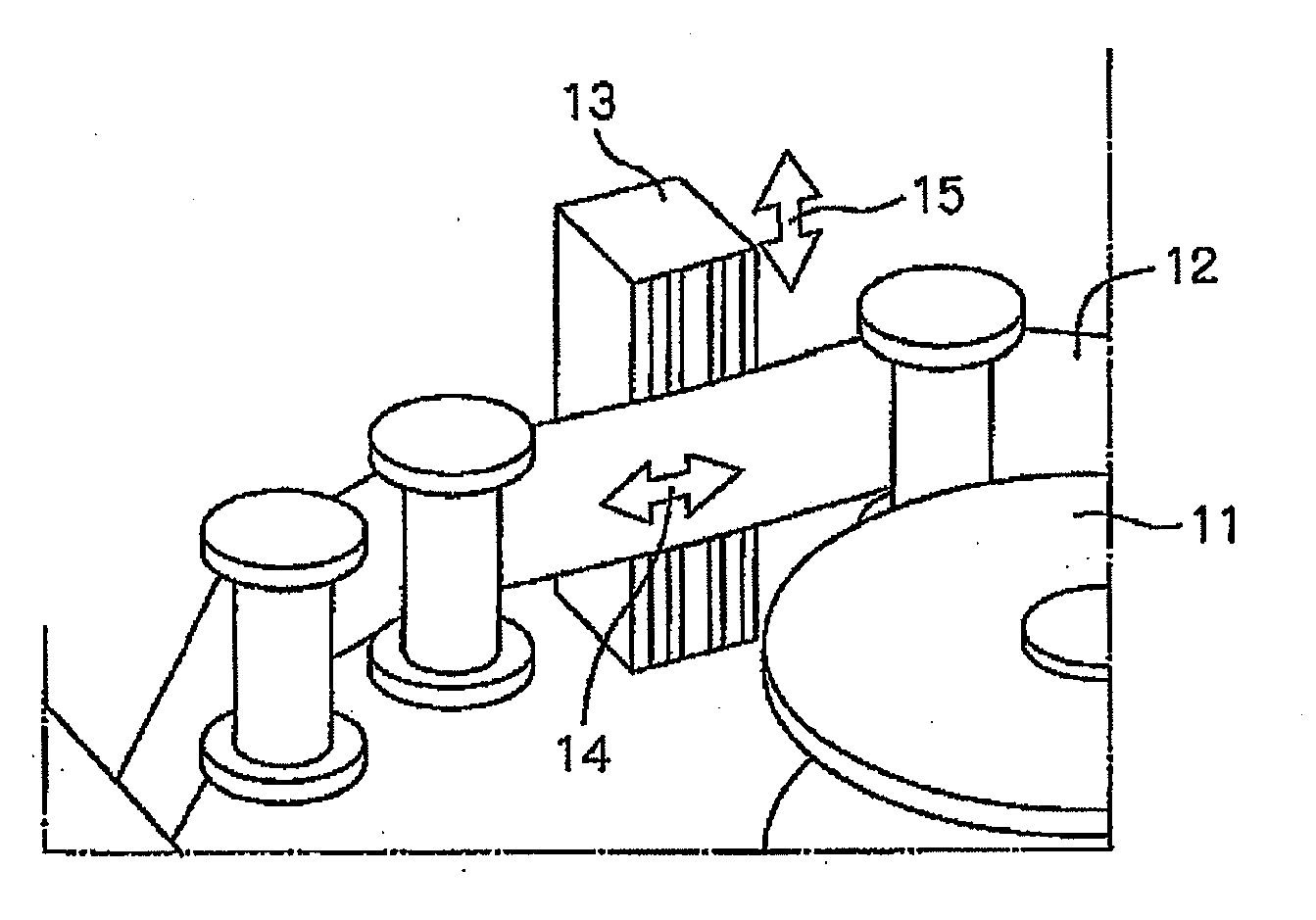

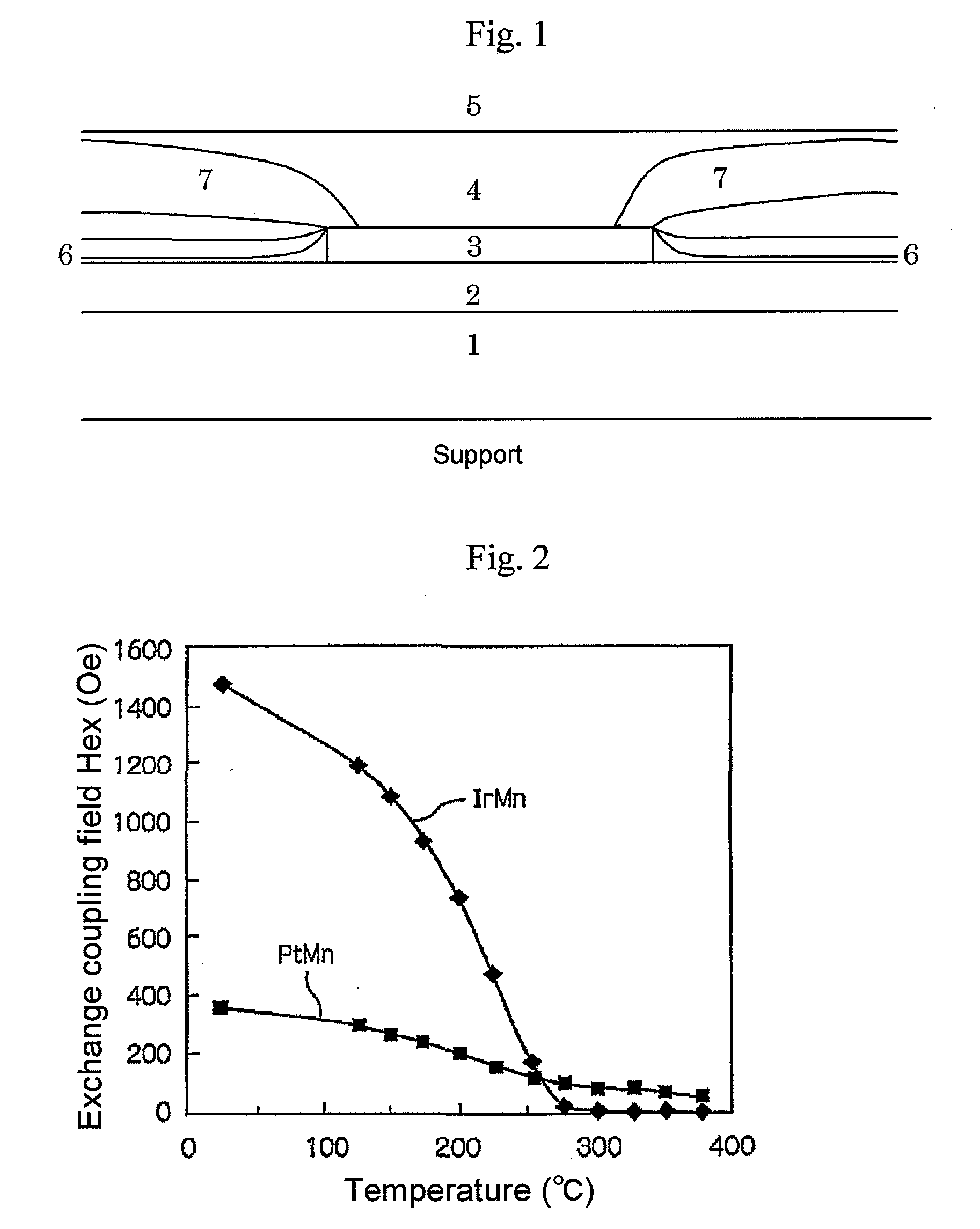

Spin-valve type magnetoresistance sensor and thin-film magnetic head

A method and apparatus of a spin-type magnetoresistance sensor having a free and pinned magnetic layer stacked with a non-magnetic interposed layer are disclosed. Specifically, the spin-valve type magnetoresistance sensor of the present invention is equipped with a free ferromagnetic layer, a pinned ferromagnetic layer, a non-magnetic spacer layer which is sandwiched between the aforementioned ferromagnetic layers, an anti-ferromagnetic layer which is disposed adjacent to the aforementioned pinned ferromagnetic layer and which is used to pin the direction of magnetization of said pinned ferromagnetic layer, a non-magnetic back layer which is disposed adjacent to the aforementioned free ferromagnetic layer and which is stacked on the opposite side the free ferromagnetic layer from the aforementioned nonmagnetic spacer layer, and an electron-reflective layer which is disposed adjacent to the aforementioned back layer and which is stacked on the opposite side of the back layer from the aforementioned free ferromagnetic layer.

Owner:WESTERN DIGITAL TECH INC

Spin valve sensor having a nonmagnetic enhancement layer adjacent an ultra thin free layer

InactiveUS7196880B1Effective bias point controlReduce thicknessNanomagnetismMagnetic measurementsMean free pathElectronic properties

A spin valve device includes a non-magnetic enhancement layer adjacent an ultra thin free layer. The thickness of the free layer may be less than the mean free path of a conduction electron through the free layer. The GMR ratio is significantly improved for free layer thicknesses below 50 Å. The enhancement layer allows electrons to travel longer in their spin state before encountering scattering sites. The electronic properties of the enhancement layer material can be matched with the adjacent free layer without creating a low resistance shunt path. Because the free layer may be made ultra thin and the enhancement layer is formed of a nonmagnetic material, less magnetic field is required to align the free layer, allowing for improved data density. Also, the enhancement layer allows for effective bias point control by shifting sensor current density distribution.

Owner:WESTERN DIGITAL TECH INC

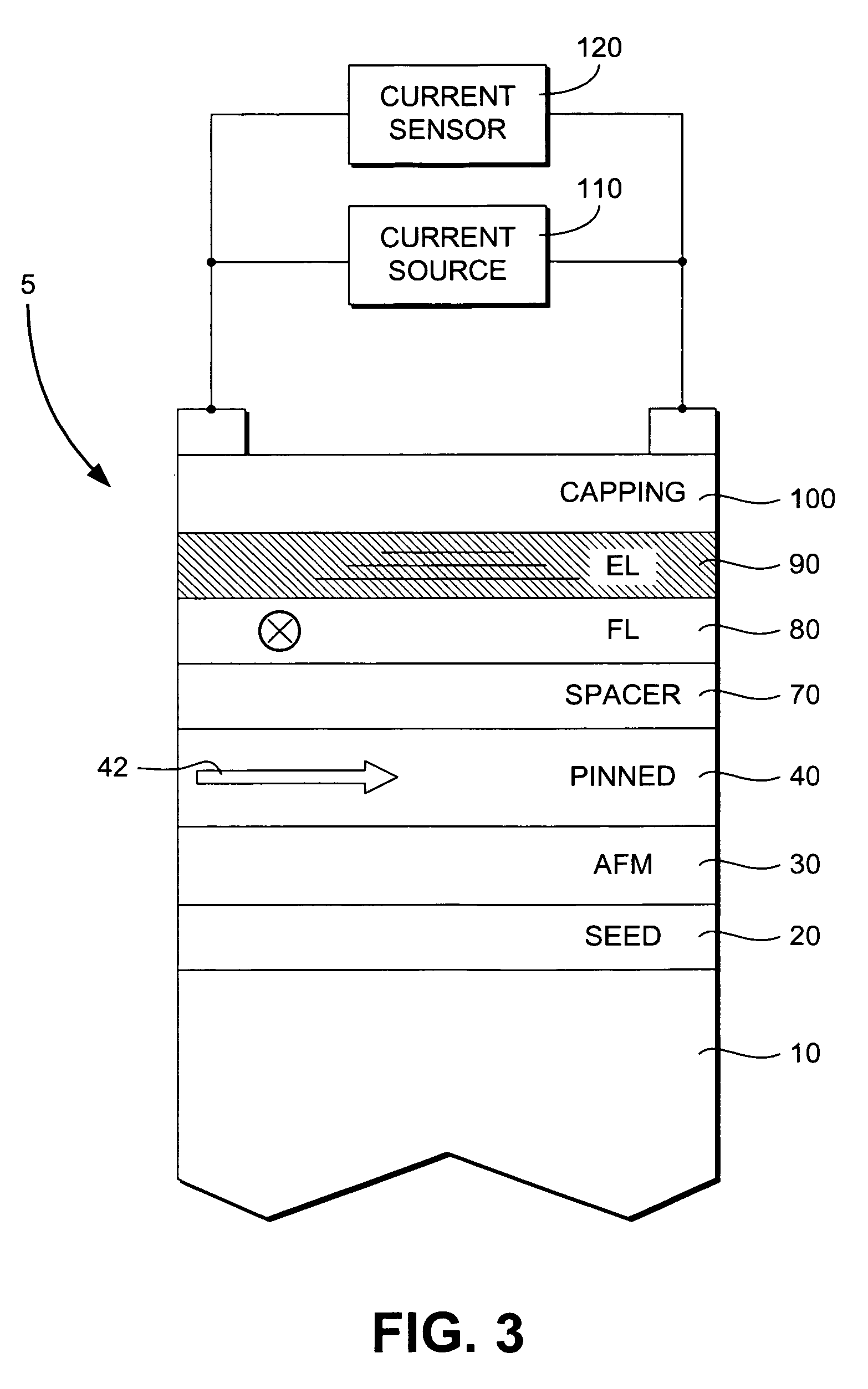

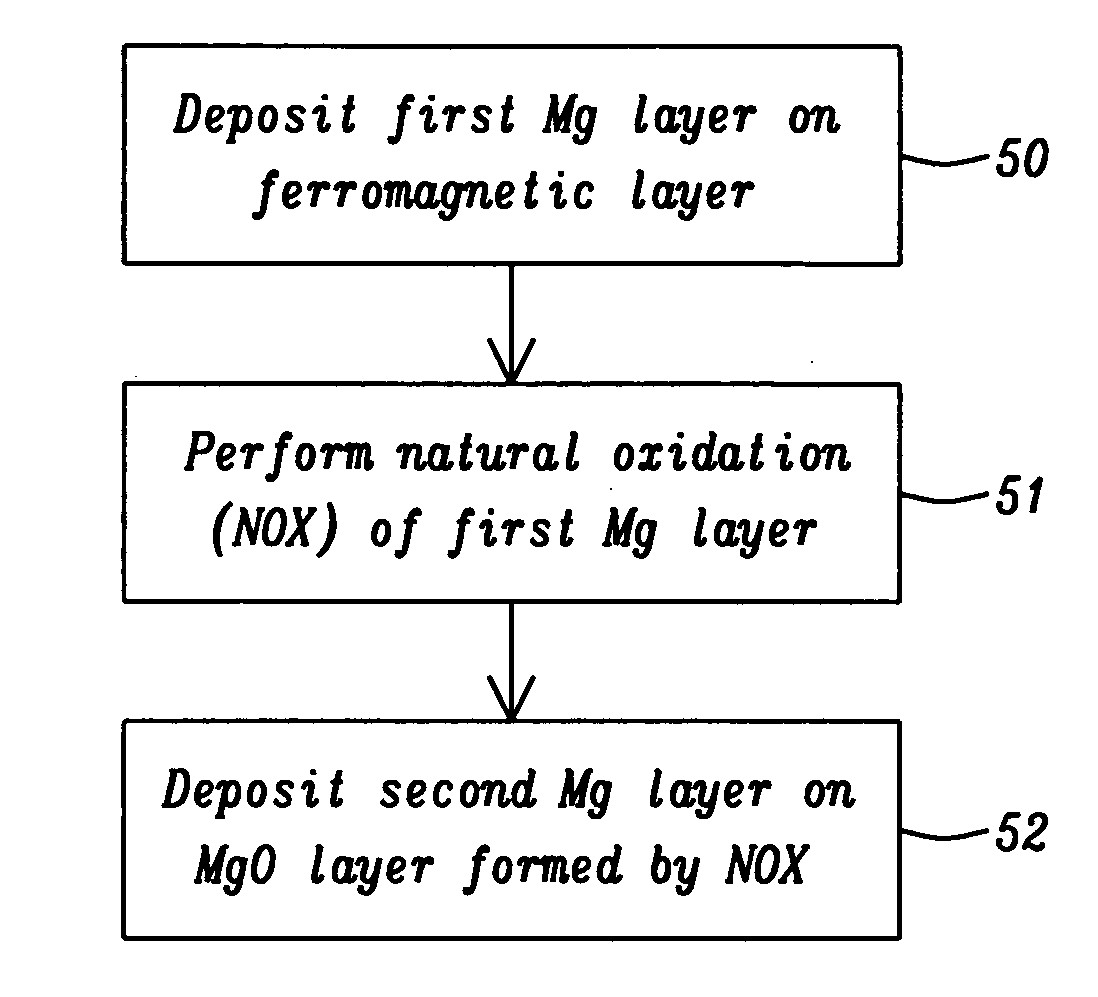

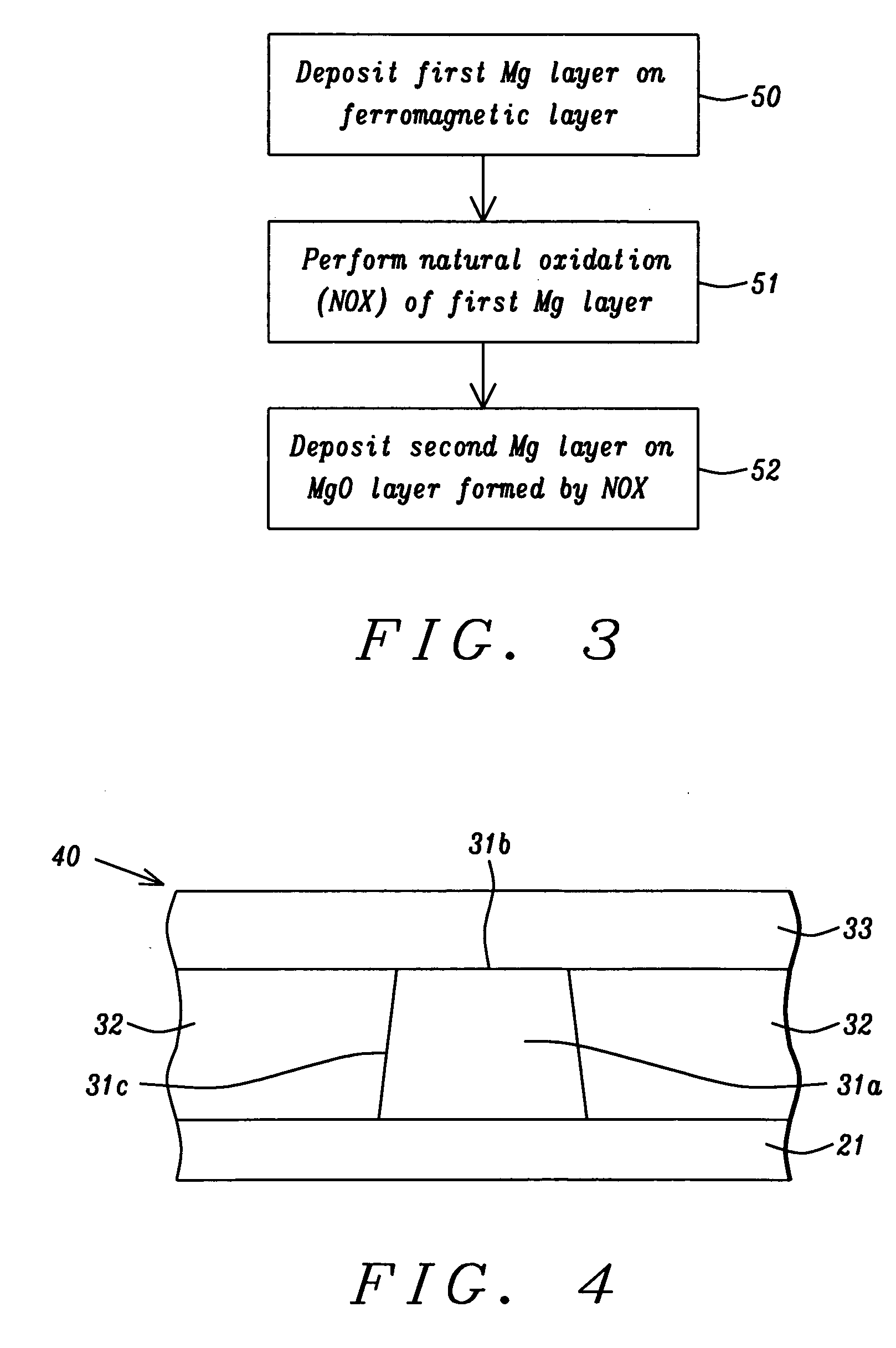

Low resistance tunneling magnetoresistive sensor with natural oxidized double MgO barrier

ActiveUS20070111332A1Improve uniformityHigh MR ratioNanomagnetismMagnetic measurementsSpin valveMaterials science

A high performance TMR sensor is fabricated by incorporating a tunnel barrier having a Mg / MgO / Mg configuration. The 4 to 14 Angstroms thick lower Mg layer and 2 to 8 Angstroms thick upper Mg layer are deposited by a DC sputtering method while the MgO layer is formed by a NOX process involving oxygen pressure from 0.1 mTorr to 1 Torr for 15 to 300 seconds. NOX time and pressure may be varied to achieve a MR ratio of at least 34% and a RA value of 2.1 ohm-um2. The NOX process provides a more uniform MgO layer than sputtering methods. The second Mg layer is employed to prevent oxidation of an adjacent ferromagnetic layer. In a bottom spin valve configuration, a Ta / Ru seed layer, IrMn AFM layer, CoFe / Ru / CoFeB pinned layer, Mg / MgO / Mg barrier, CoFe / NiFe free layer, and a cap layer are sequentially formed on a bottom shield in a read head.

Owner:HEADWAY TECH INC

Spin valve magnetoresistance sensor and thin film magnetic head

A spin valve magnetoresistance sensor of a thin film magnetic head. In one embodiment, a spin valve magnetoresistance sensor is provided with a spin valve film, in which a base layer including a first base film of Ta or some other nonmagnetic metal and, on top of this, a second base film of an alloy represented by NiFeX (where X is at least one element selected from among Cr, Nb, Rh) is formed on a substrate, and on top of this are formed by layering a free magnetic layer and pinned magnetic layer arranged to enclose a nonmagnetic conductive layer, as well as an antiferromagnetic layer, the second base film has an fcc (face-centered cubic) structure and also has a (111) orientation.

Owner:WESTERN DIGITAL TECH INC

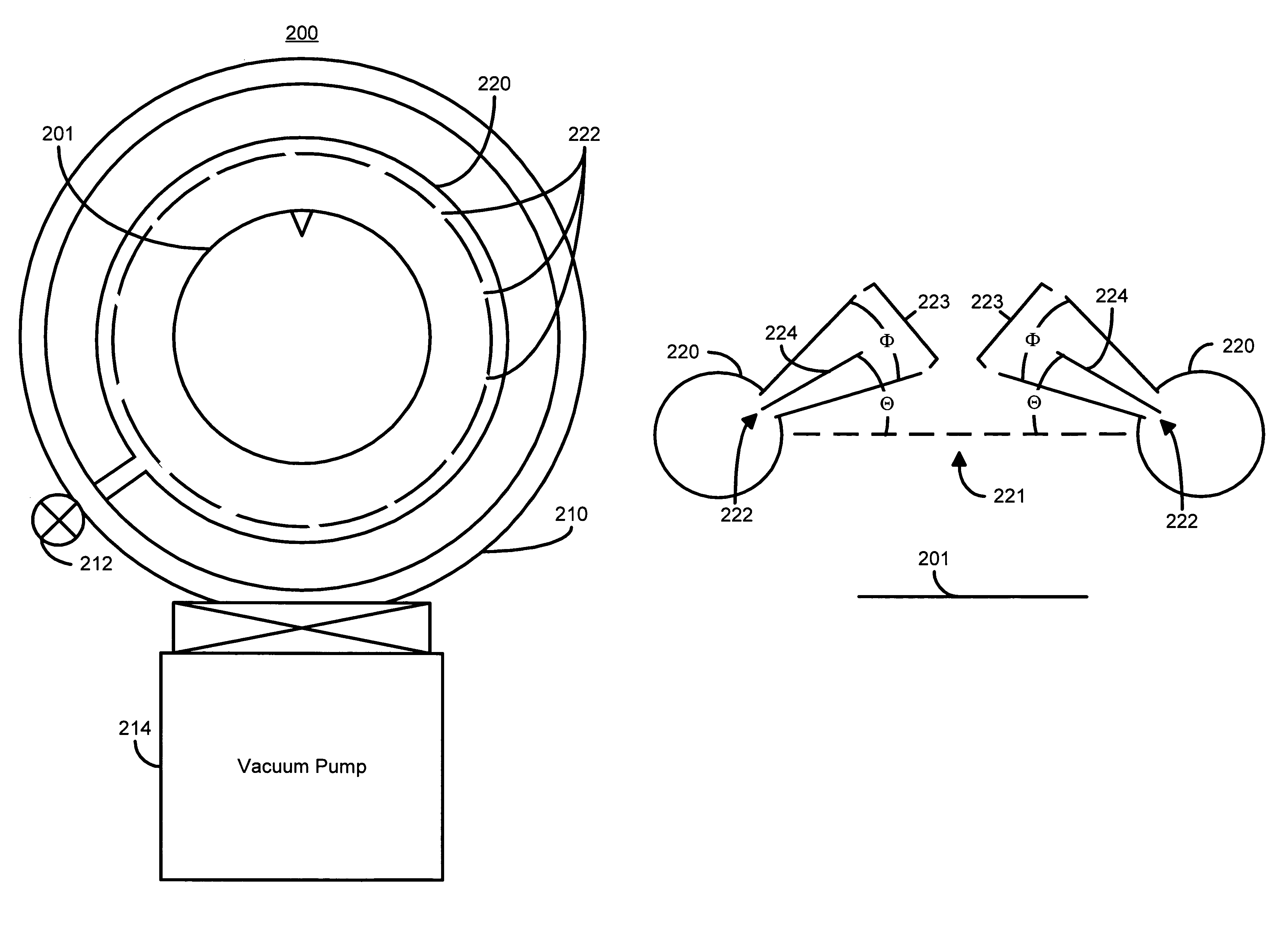

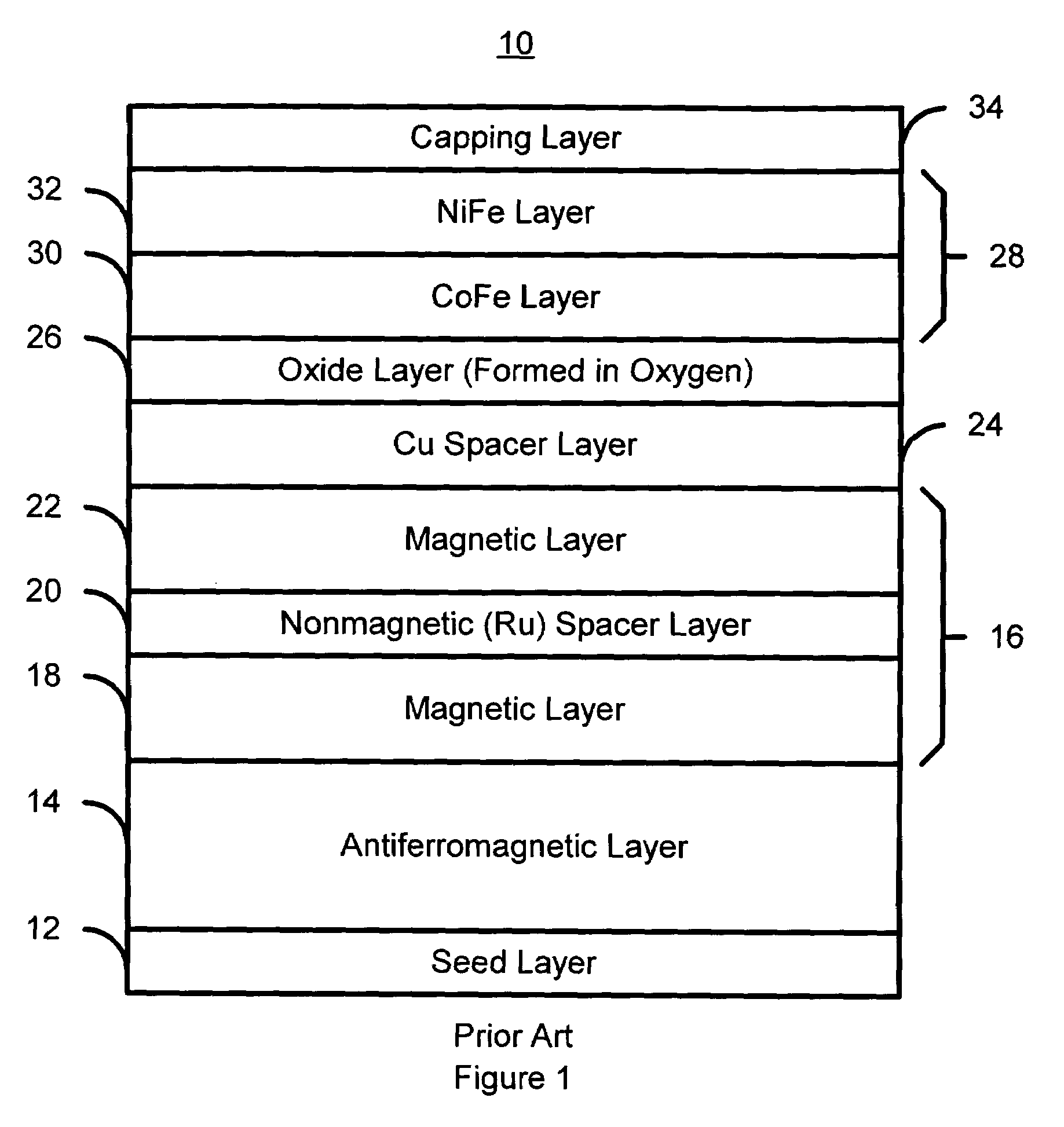

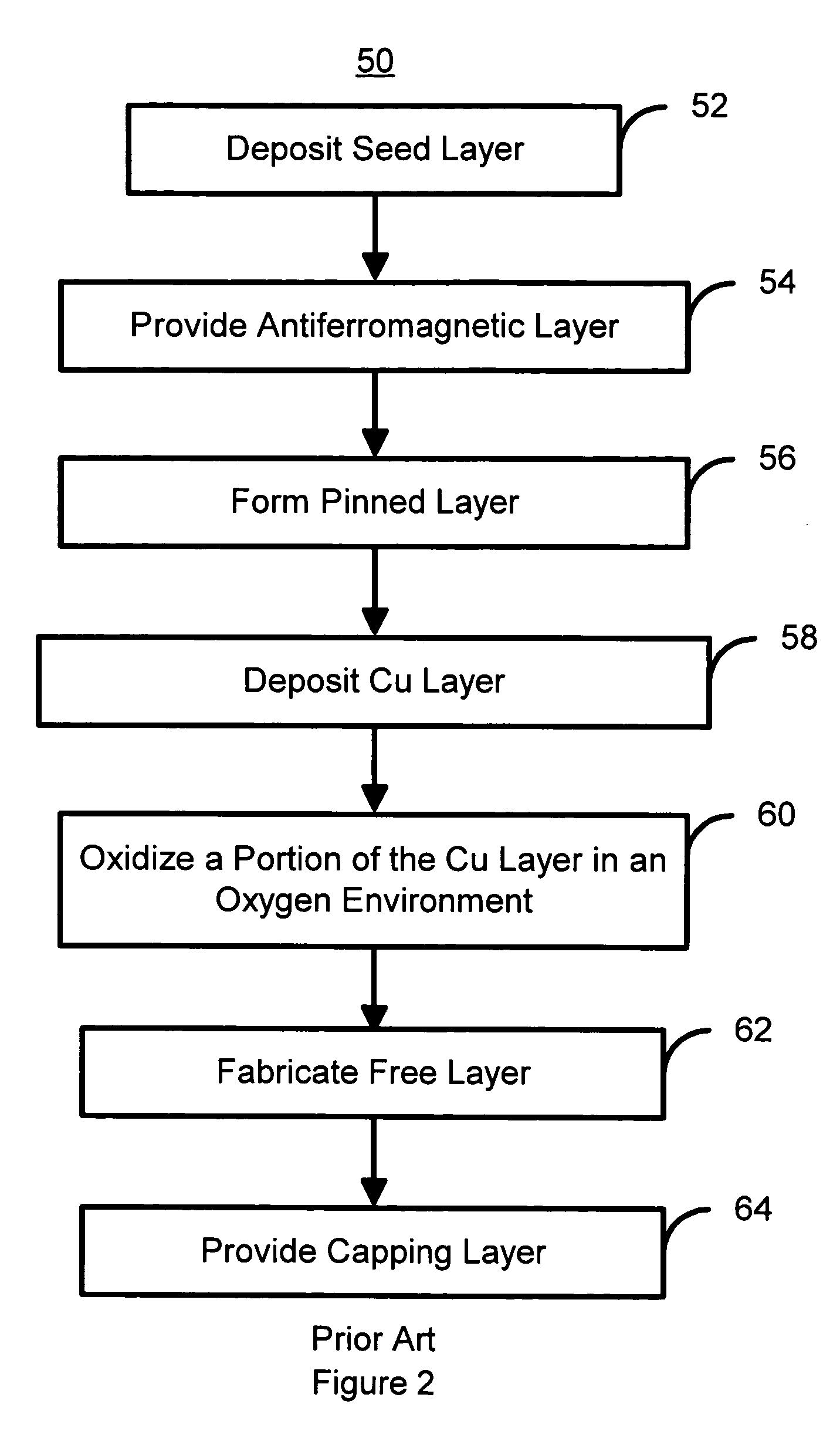

Method and apparatus for controlling magnetostriction in a spin valve sensor

A method and system for providing a magnetic element are described. The method and system include providing a pinned layer, fabricating a metallic spacer layer and oxidizing a portion of the spacer layer in an environment including at least oxygen and a gas inert with respect to the spacer layer to provide an oxide layer. The method and system also include creating a free layer. The oxide layer is between a remaining metallic portion of the spacer layer and the free layer. In one aspect, the system includes a chamber and a gas diffusion apparatus within the chamber. The gas diffusion apparatus includes a plurality of nozzles and defines a plane. The gas exits each of the plurality of nozzles in a cone having an apex angle. The nozzles are directed at a nozzle tilt angle of at least half of the apex angle from the plane and the spacer layer.

Owner:WESTERN DIGITAL TECH INC

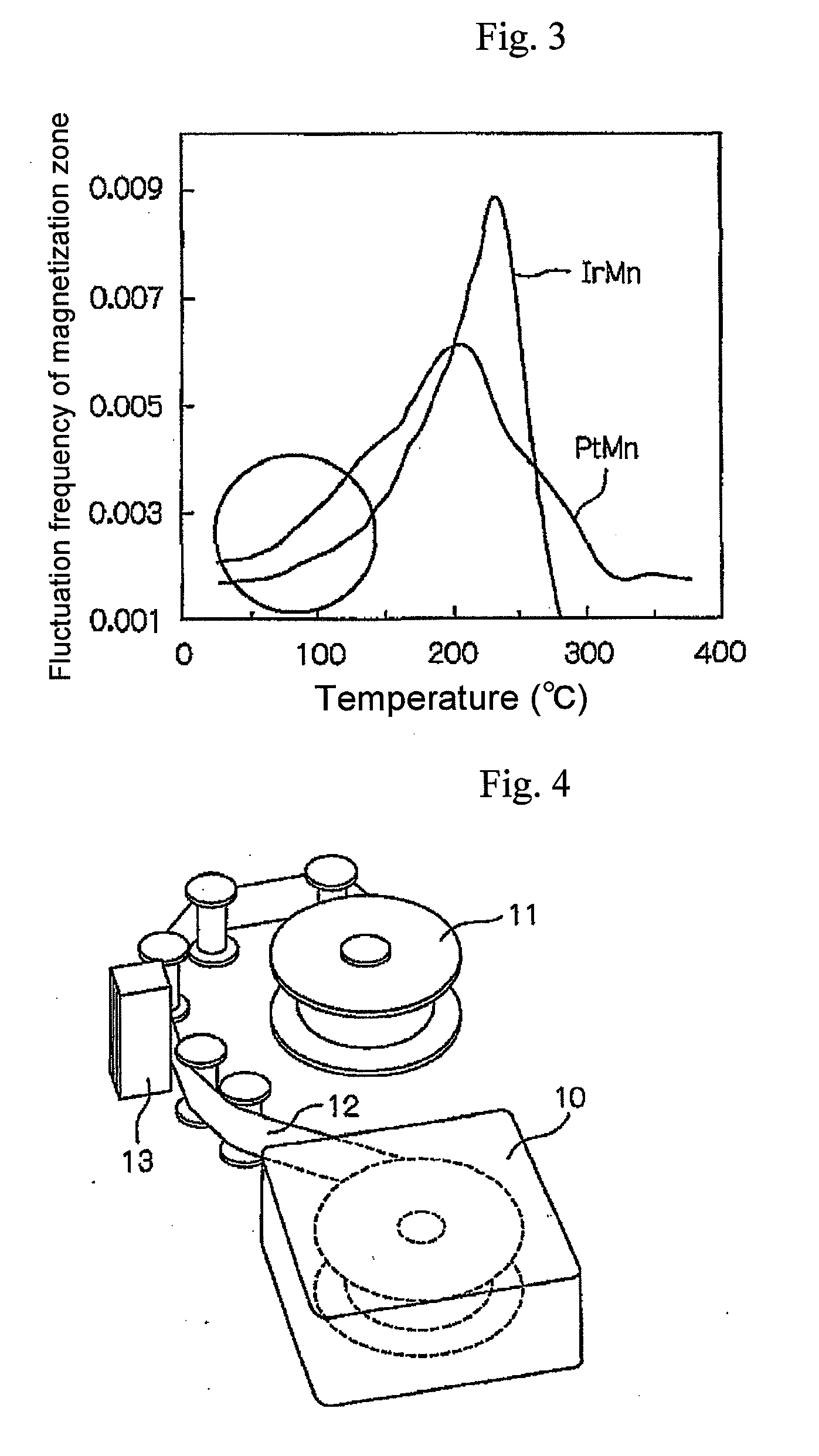

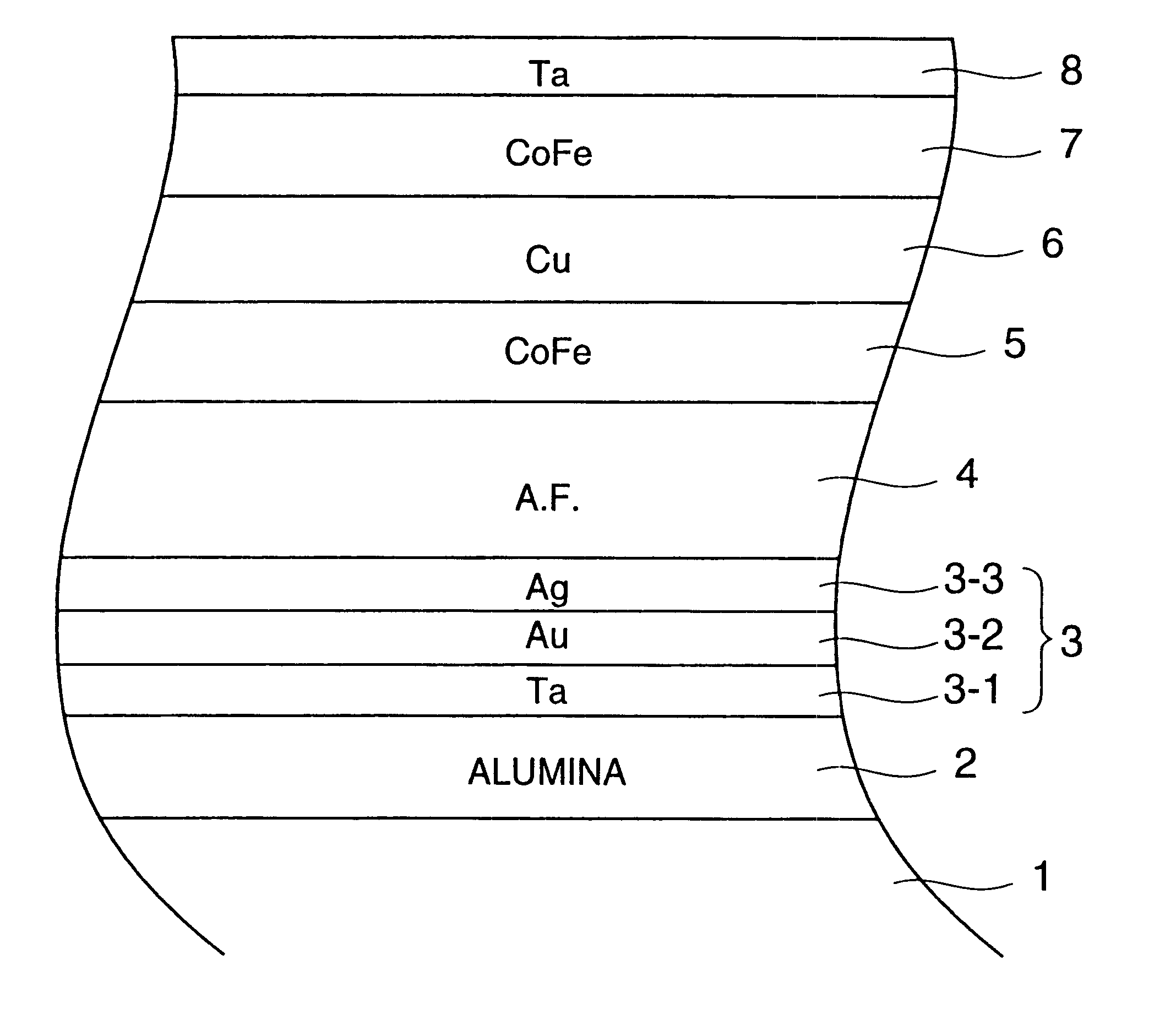

Magnetic signal reproduction system and magnetic signal reproduction method

InactiveUS20090027812A1Stable reproduction propertyDeterioration of reproduction propertyManufacture unitary devices of plural headsRecord information storageIridiumAlloy

The magnetic signal reproduction system comprises a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support and a reproduction head, wherein a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 2500 / 10,000 μm2, a quantity of lubricant on the magnetic layer surface, denoted as a surface lubricant index, ranges from 0.5 to 5.0, a surface abrasive occupancy of the magnetic layer ranges from 2 to 20 percent, the reproduction head is a magnetoresistive magnetic head comprising a spin-valve layer, the spin-valve layer comprises a magnetization free layer, a magnetization pinned layer and an antiferromagnetic layer, and the antiferromagnetic layer is comprised of alloy comprising iridium and manganese, and the reproduction head comes in sliding contact with the magnetic recording medium during signal reproduction.

Owner:FUJIFILM CORP +1

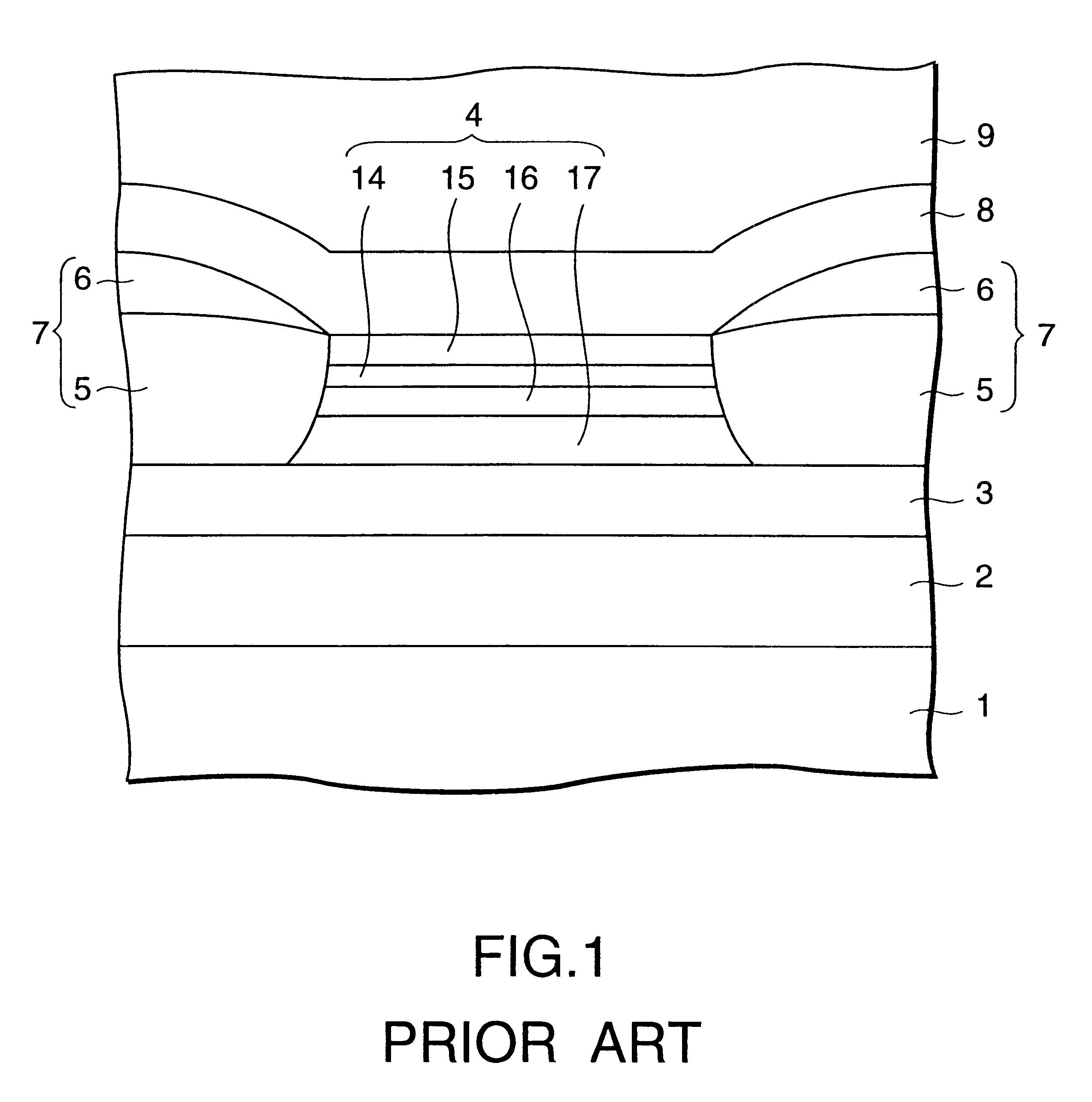

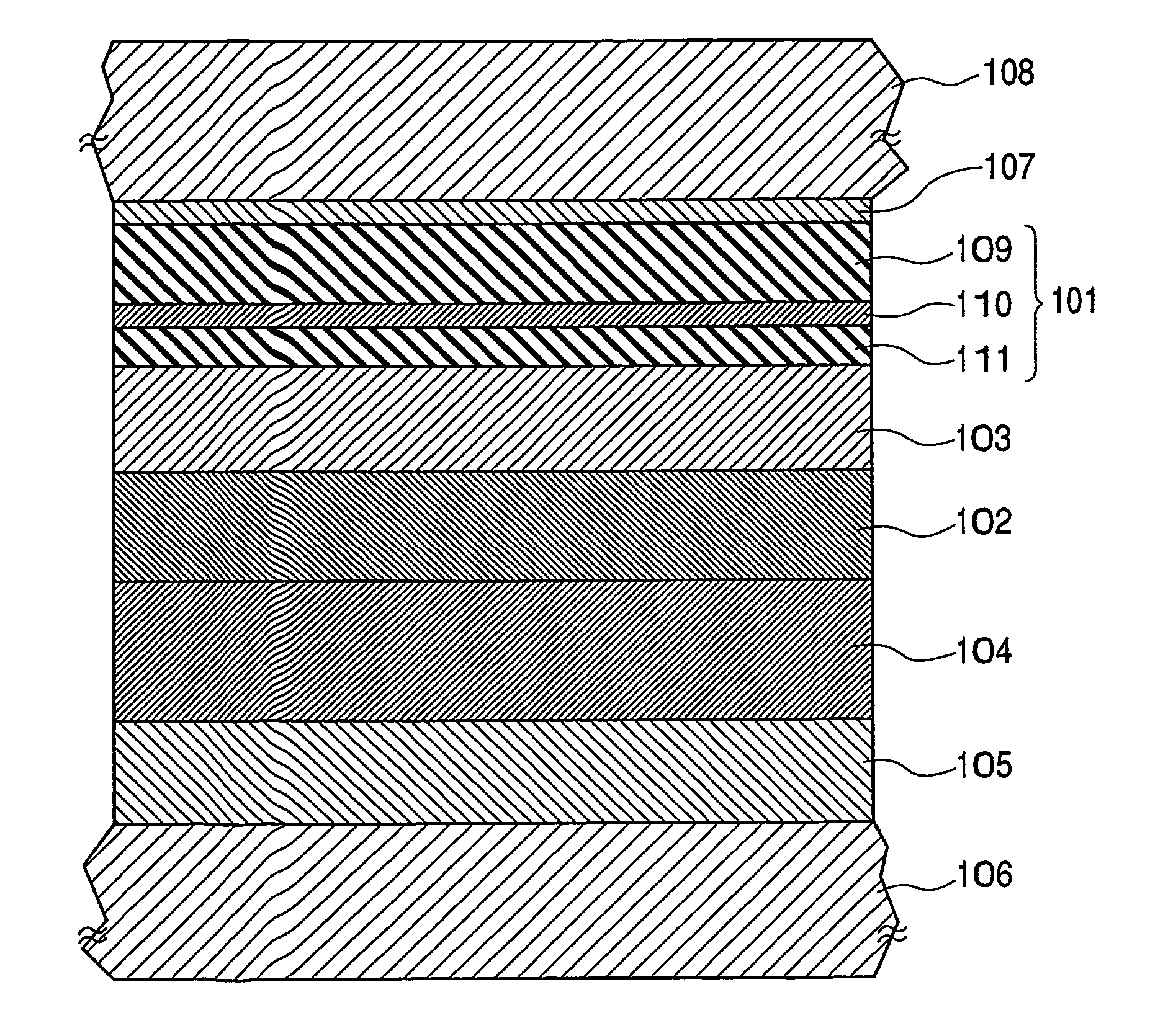

Laminated magnetorestrictive element of an exchange coupling film, an antiferromagnetic film and a ferromagnetic film and a magnetic disk drive using same

InactiveUS6313973B1Stable output voltageRaise the ratioNanomagnetismNanoinformaticsGiant magnetoresistanceCoupling

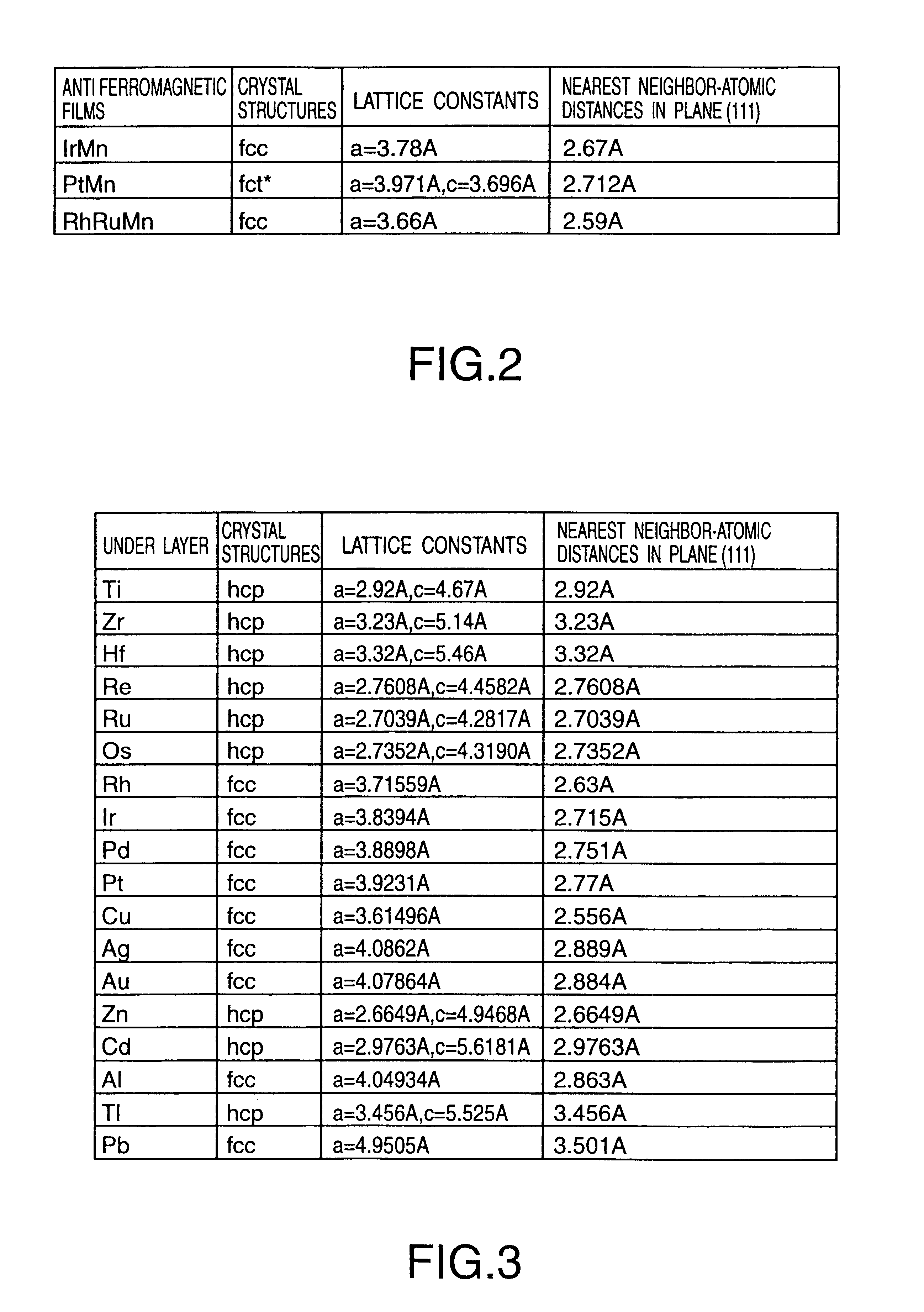

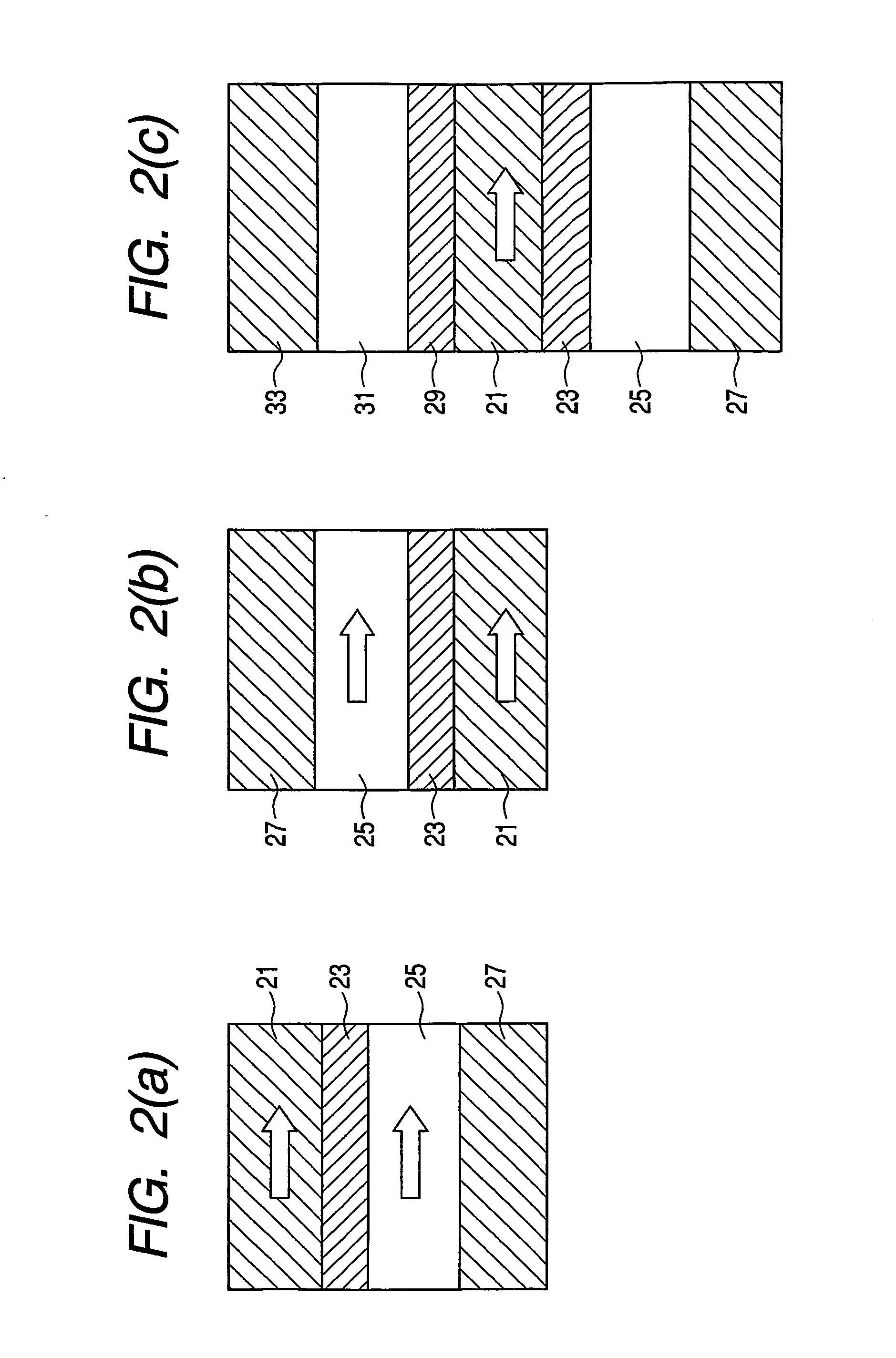

A magnetoresistive element comprises an exchange coupling film having a under layer, an antiferromagnetic film and a ferromagnetic film, which are laminated in that order, the under layer including a metal having a face centered cubic crystal structure or hexagonal closest packing crystal structure which have a longer nearest neighbor atomic distance than that of the antiferromagnetic film. With this construction, it is possible to improve the exchange coupling field and to satisfy a stable output over a long period of time. A magnetoresistive element having a dual spin valve structure has a magnetization adjusting layer, which is antiferromagnetically connected to a pinned layer via an anti-parallel connection layer, to adjust the value of the product of the saturation magnetization of each of the magnetization adjusting layer and the pinned layer by the thickness thereof. Moreover, a magnetoresistance head use a giant magnetoresistance effect, and has at least one pair of pinned layer and free layer arranged via a non-magnetic spacer layer. The pinned layer has a pair of ferromagnetic layers which have different compositions and different coercive forces and which are antiferromagnetically connected to each other via a connection layer, so that the effective exchange coupling field of the pinned layer is 200 Oe or more.

Owner:KK TOSHIBA

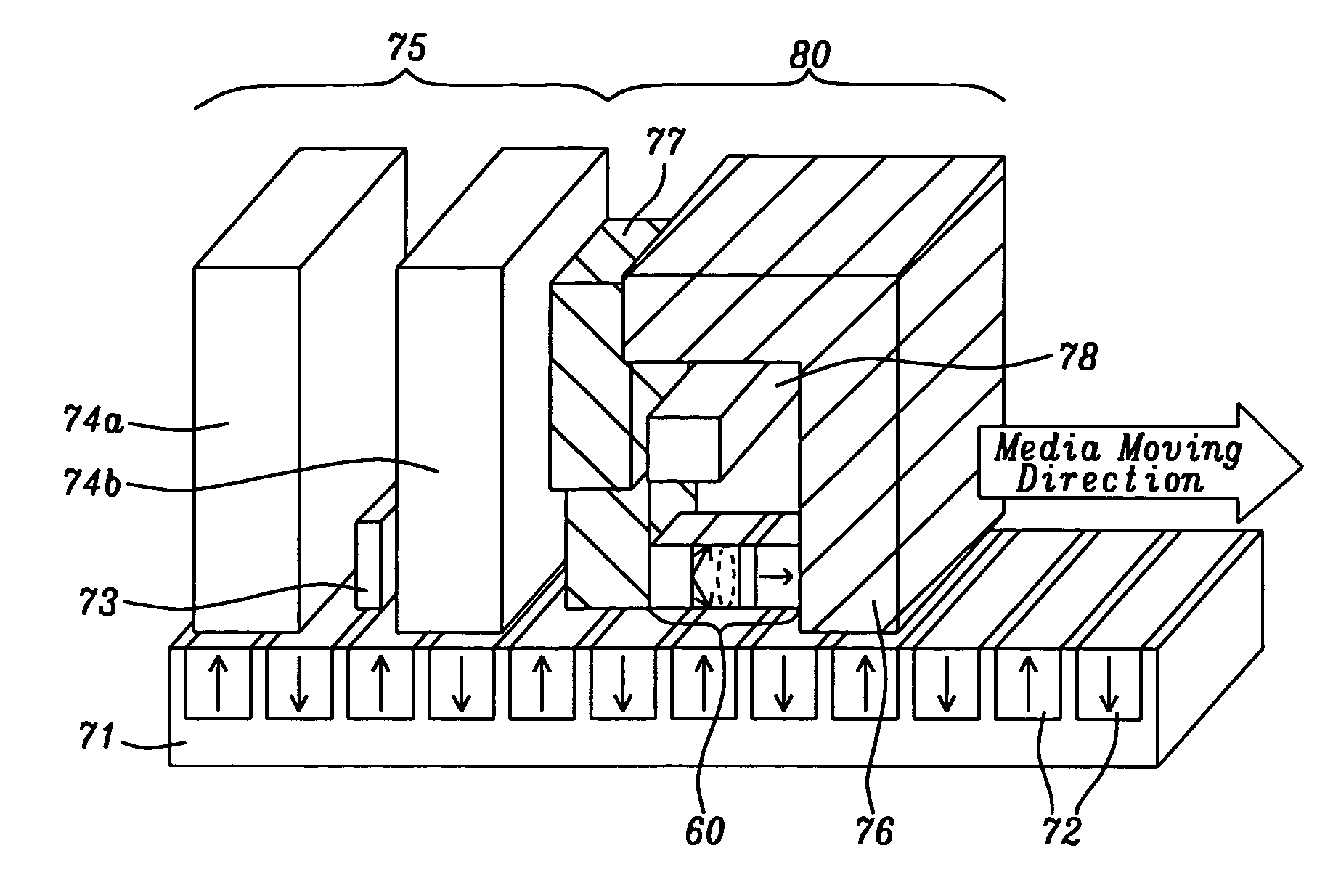

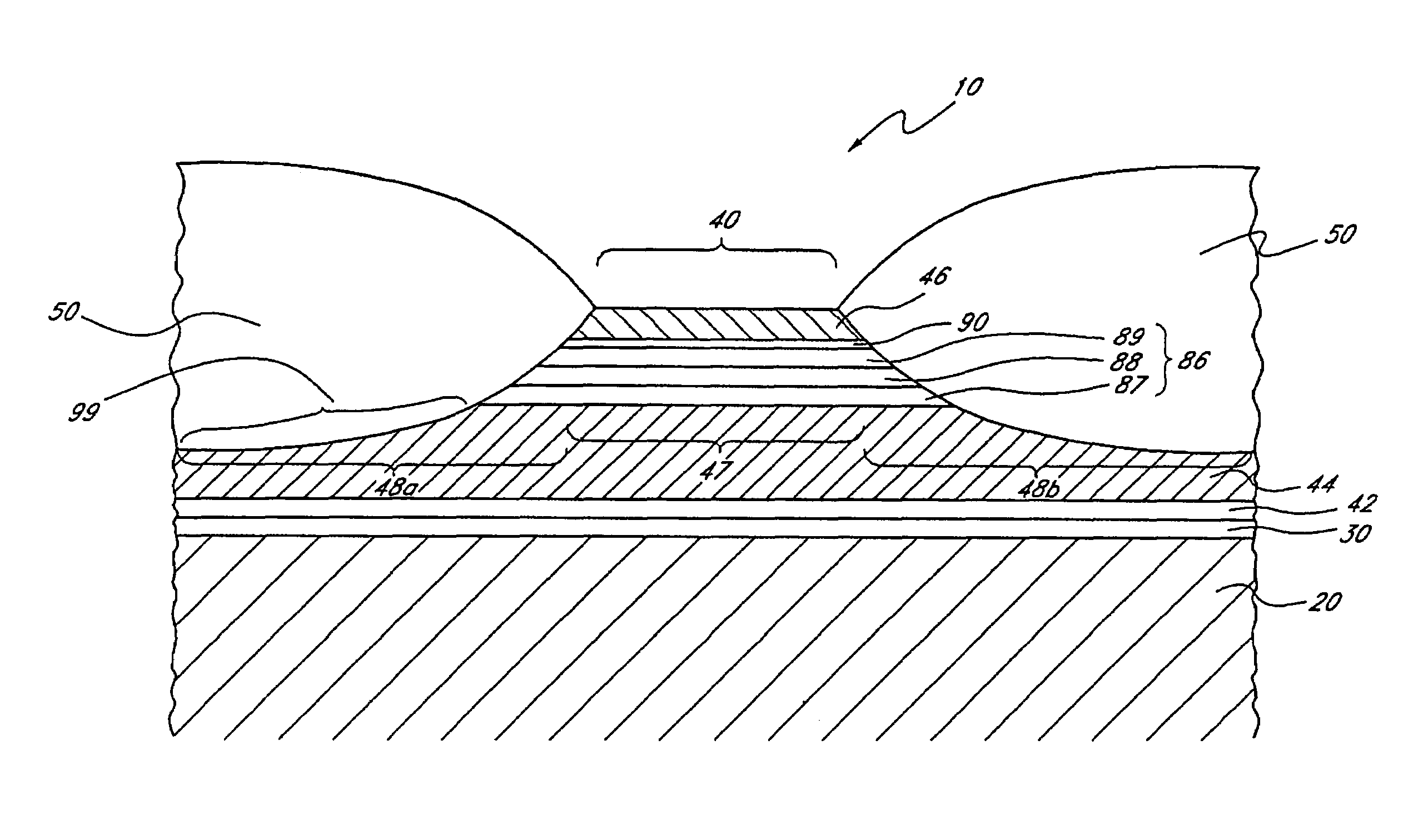

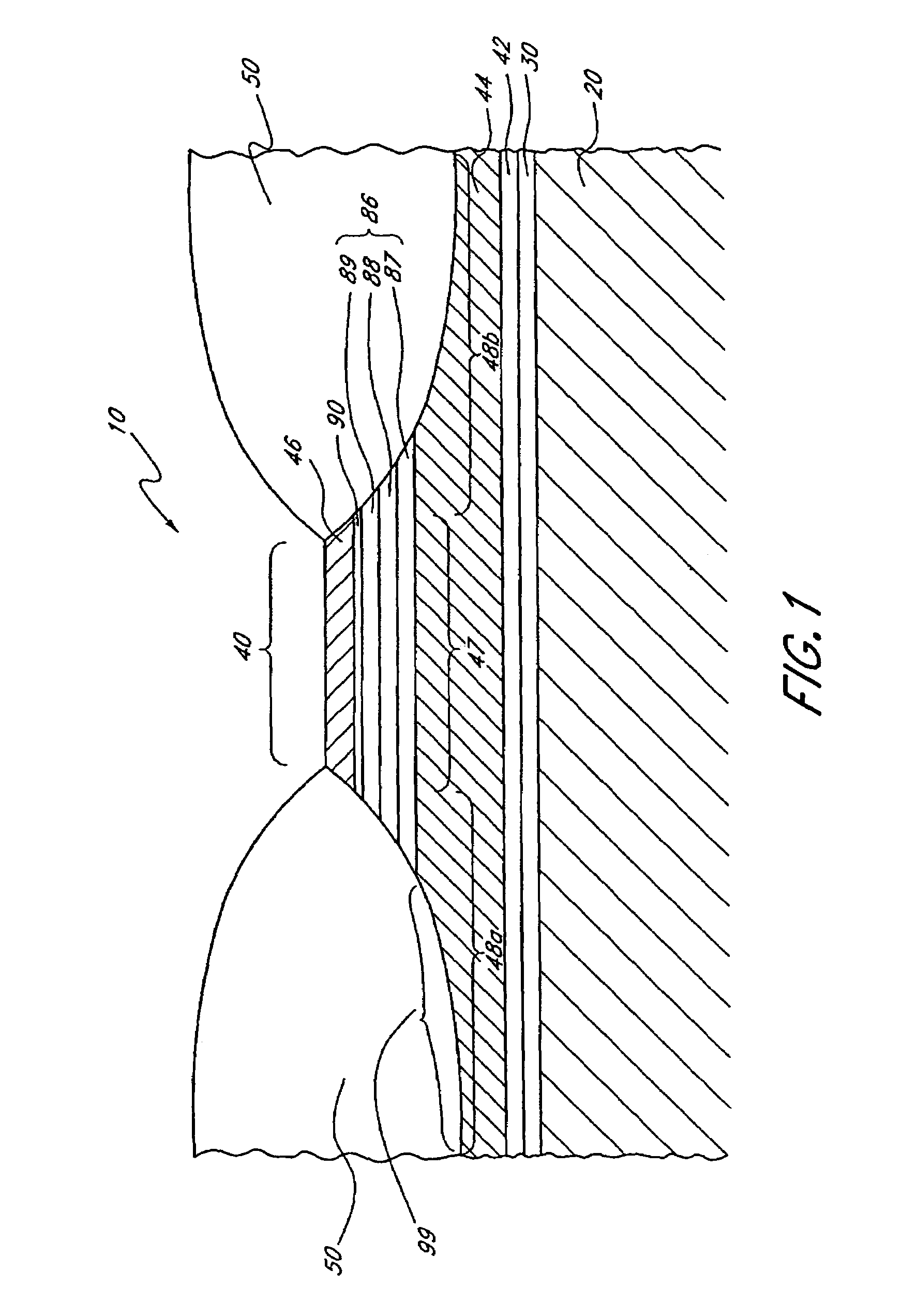

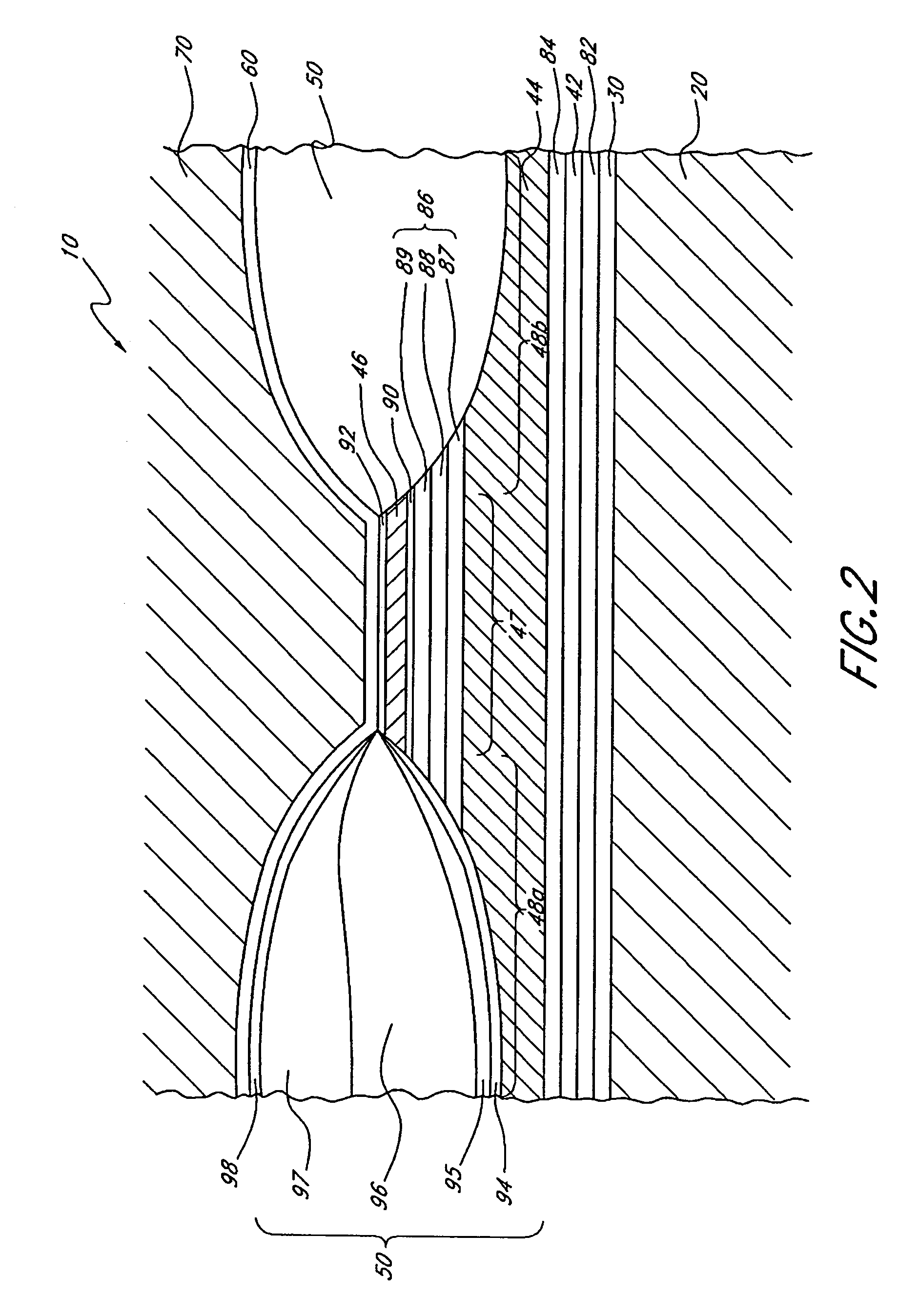

Adjacent track readers

ActiveUS7755863B2Record information storageManufacture of flux-sensitive headsMagnetic storageEngineering

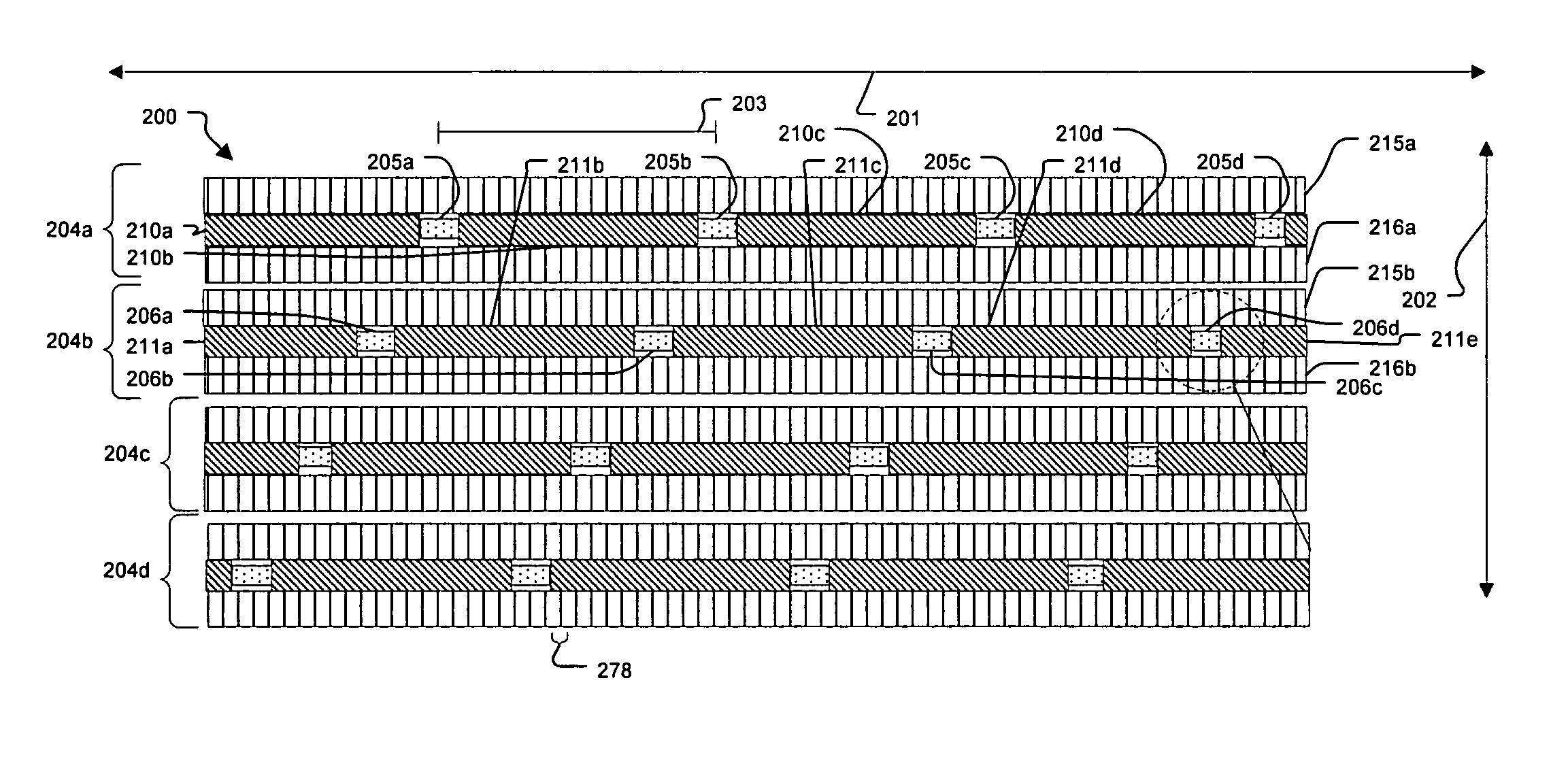

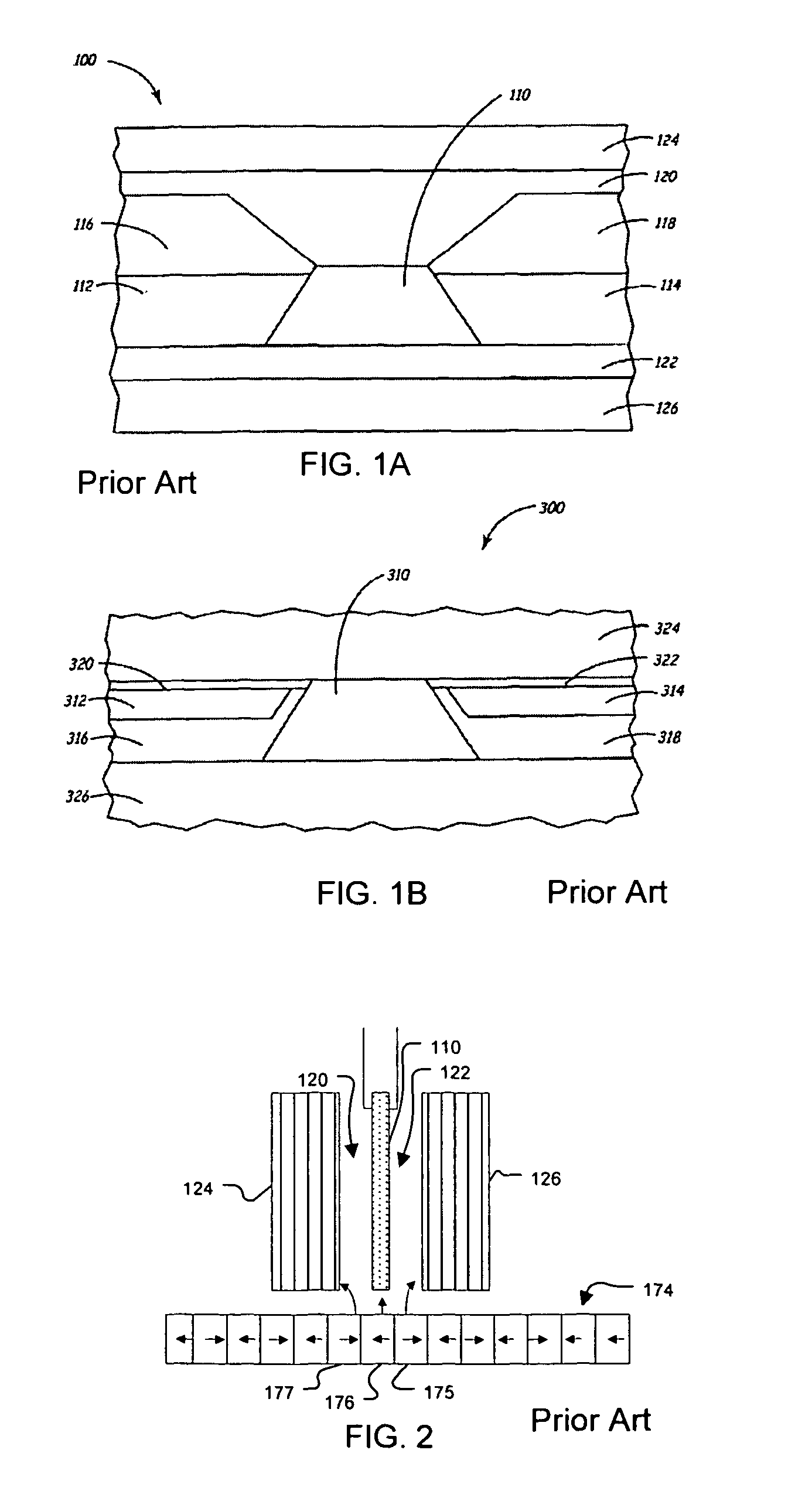

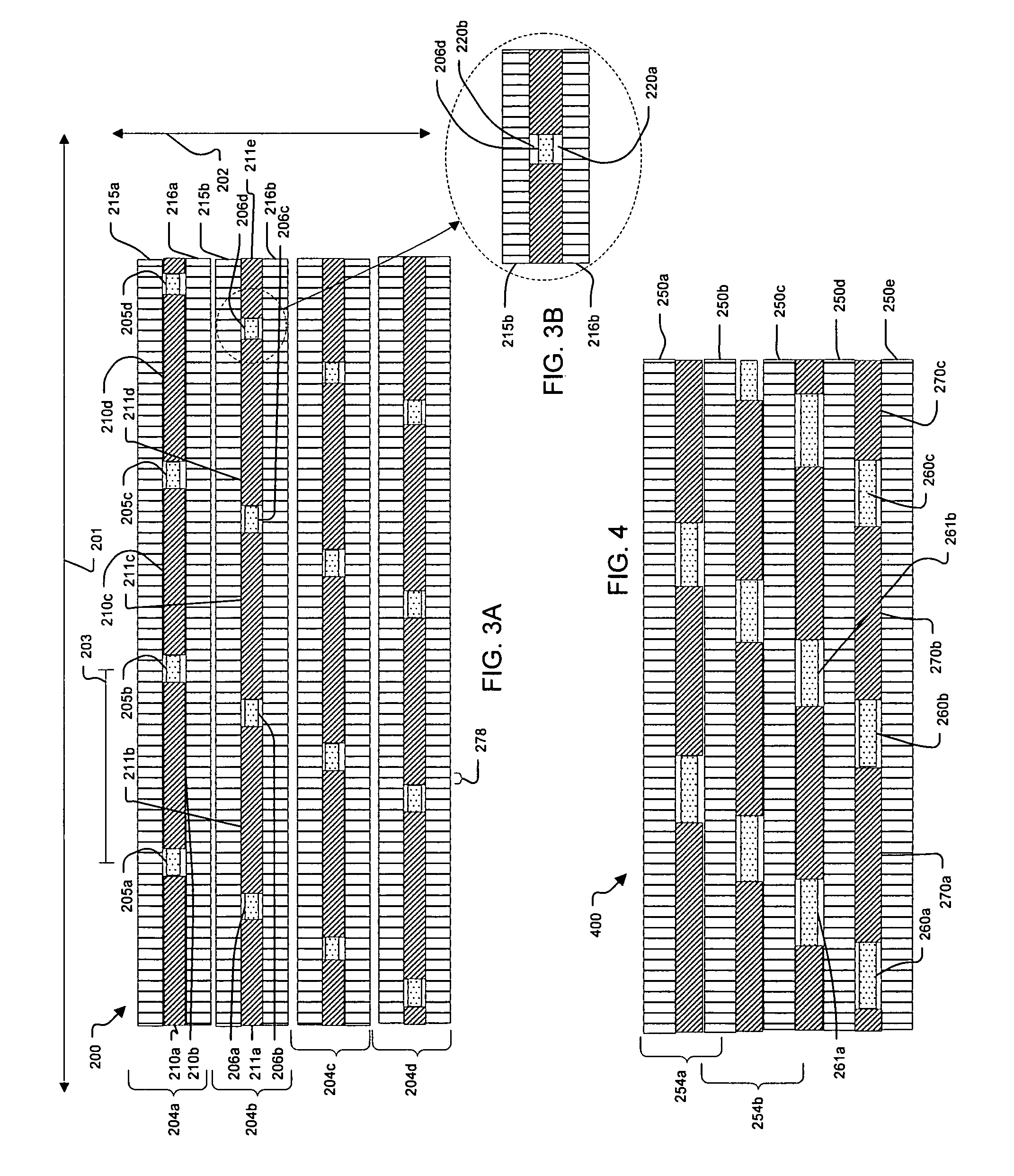

Aspects include readers for magnetic storage media. Each reader is operable to read multiple tracks from the storage media simultaneously by using a plurality of active regions, each active region for reading a different track. The active regions may be disposed in rows of columns, and between rows, each active region in a row may be separated from other active regions in that row to prevent interference between those active regions. Active regions of different rows may be offset from each other such that no active region overlaps with another active region over the same data track. Active regions may share shielding and / or sense current conductors. Active regions may comprise AMR, CIP GMR, CPP GMR, including spin valve and tunneling varieties of flux sensors. Multiple active regions in a row may be defined from a single MR element by spaced apart voltage tabs. Readers may be integrally fabricated in layers.

Owner:QUANTUM CORP

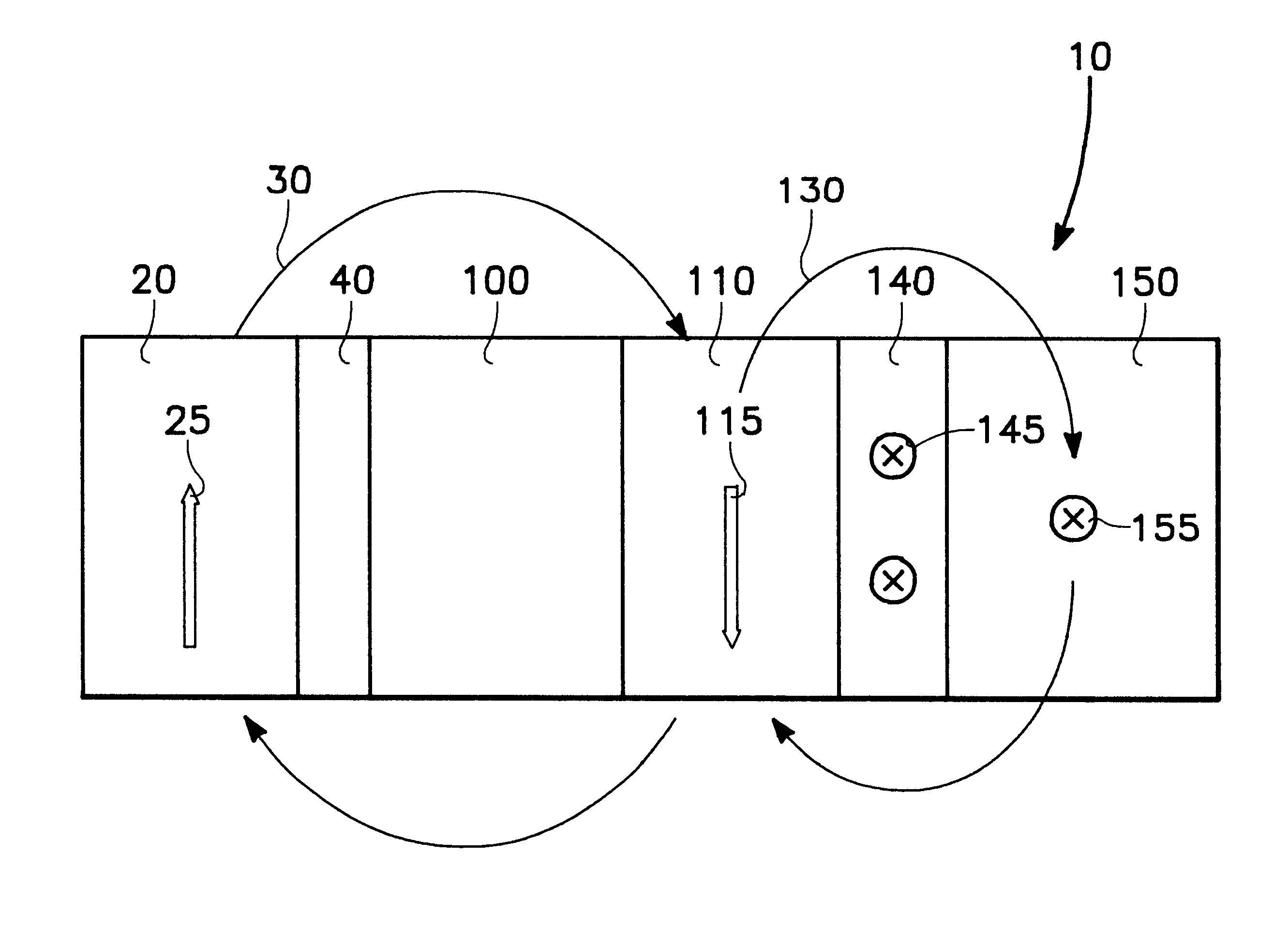

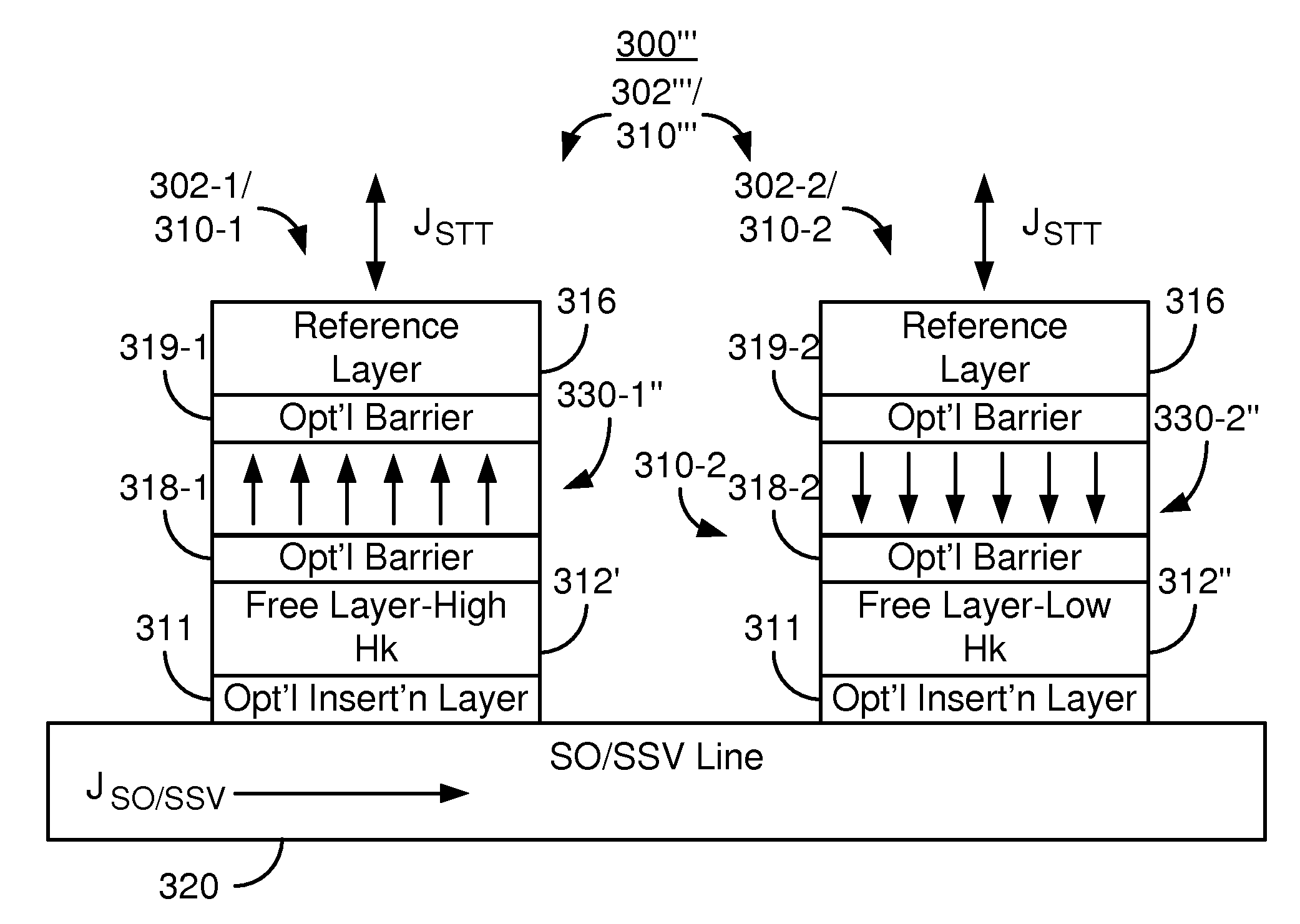

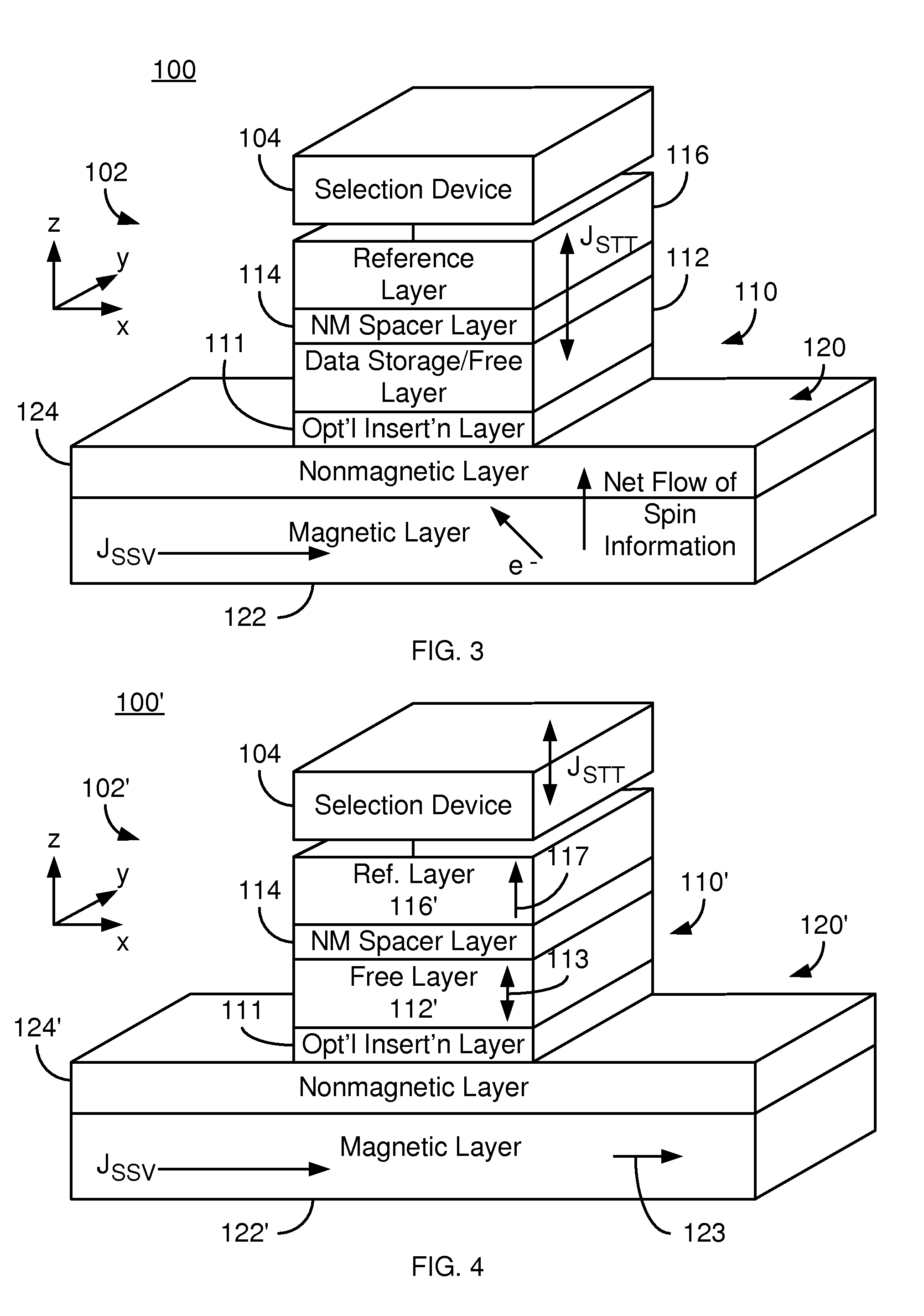

Method and system for providing magnetic memories switchable using spin accumulation and selectable using magnetoelectric devices

A magnetic memory is described. In one aspect, the magnetic memory includes magnetic junctions and at least one semi-spin valve (SSV) line adjacent to the magnetic junctions. Each magnetic junction includes a magnetic free layer. The SSV line(s) include a ferromagnetic layer and a nonmagnetic layer between the ferromagnetic layer and the magnetic junctions. The SSV line(s) are configured to exert a spin accumulation induced torque on at least a portion of the magnetic junctions due to an accumulation of spin polarized current carriers from a current that is substantially in-plane. The free layer is configured to be written using at least the spin accumulation induced torque. In another aspect, the magnetic memory includes magnetic memory cells and at least one spin torque (ST) line that is analogous to the SSV line. Each magnetic memory cell includes magnetic junction(s) analogous to those above and magnetoelectric selection device(s).

Owner:SAMSUNG ELECTRONICS CO LTD

Composed free layer for stabilizing magnetoresistive head having low magnetostriction

A magnetoresistive read head includes a spin valve having at least one free layer spaced apart from at least one pinned layer by a spacer. The free layer includes a thin CoFeOx lamination layer in the CoFe, and an optional Cu layer. The amount of oxygen is below 10% of total gas. The pinned layer is a single layer, or a synthetic multi-layered structure having a spacer between sub-layers, and may have the foregoing low-magnetostriction material. As a result, low magnetostriction is obtained to improve read quality and / or improve the pinned field of the pinned layer. Other parameters are not adversely affected.

Owner:TDK CORPARATION

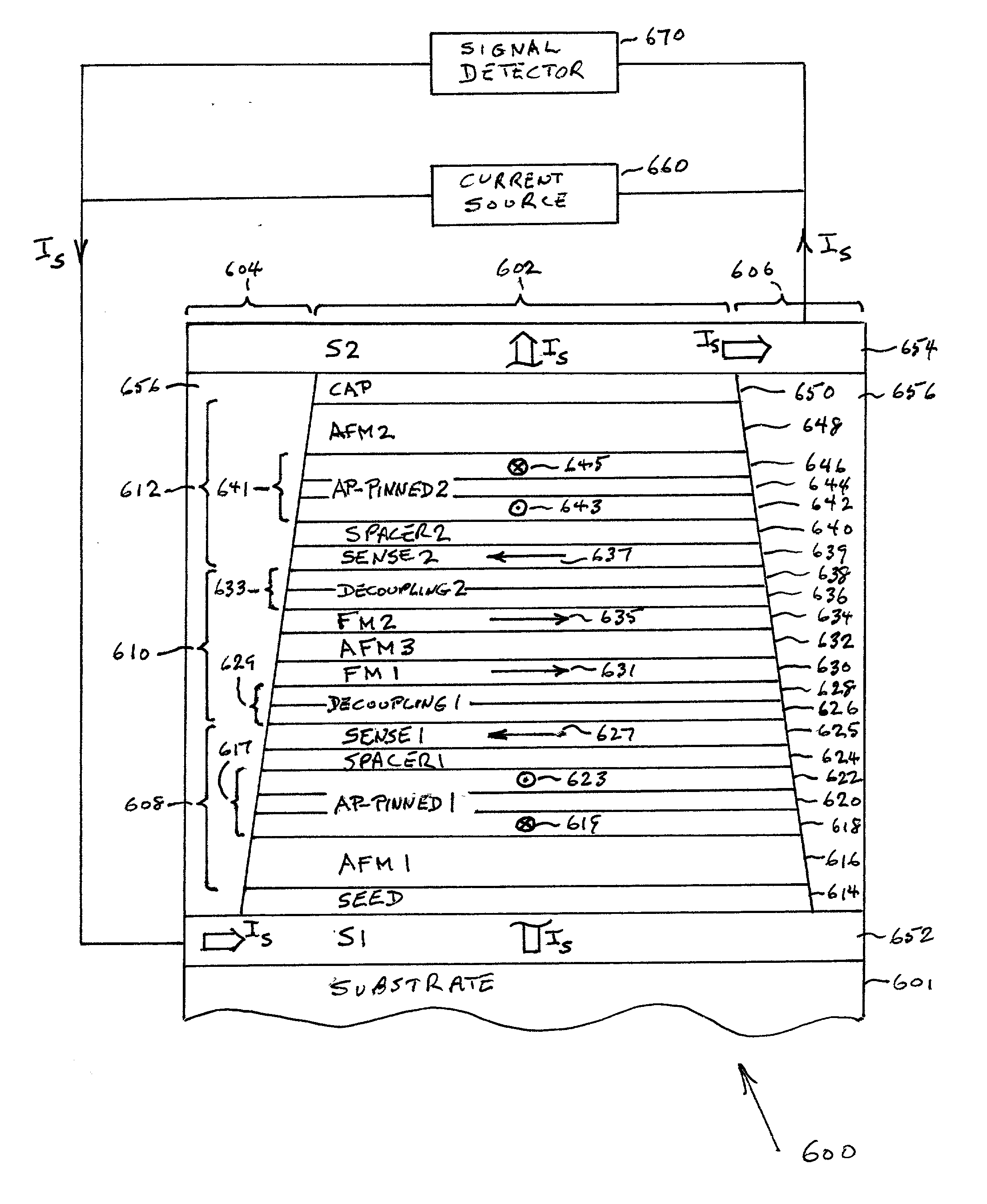

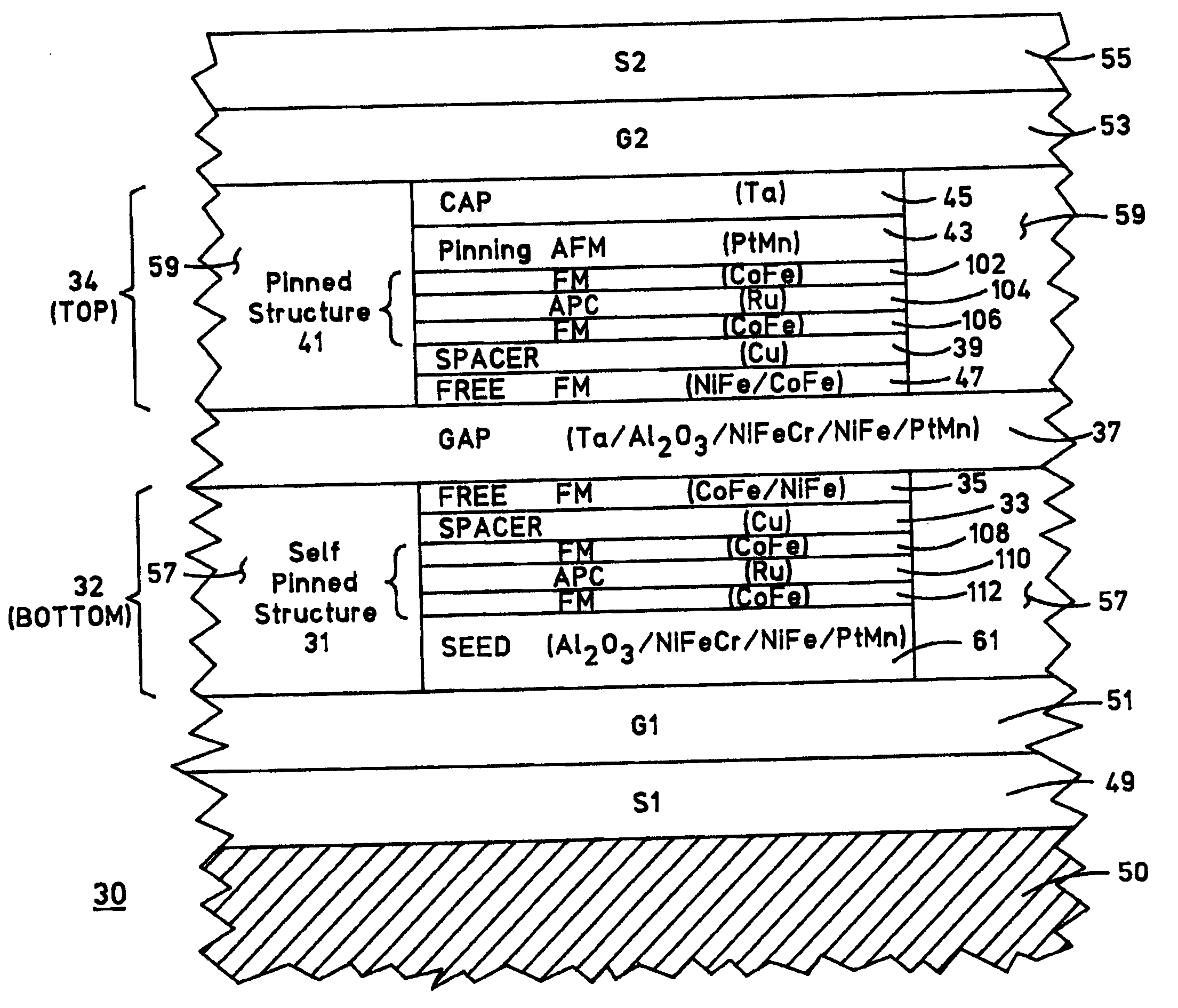

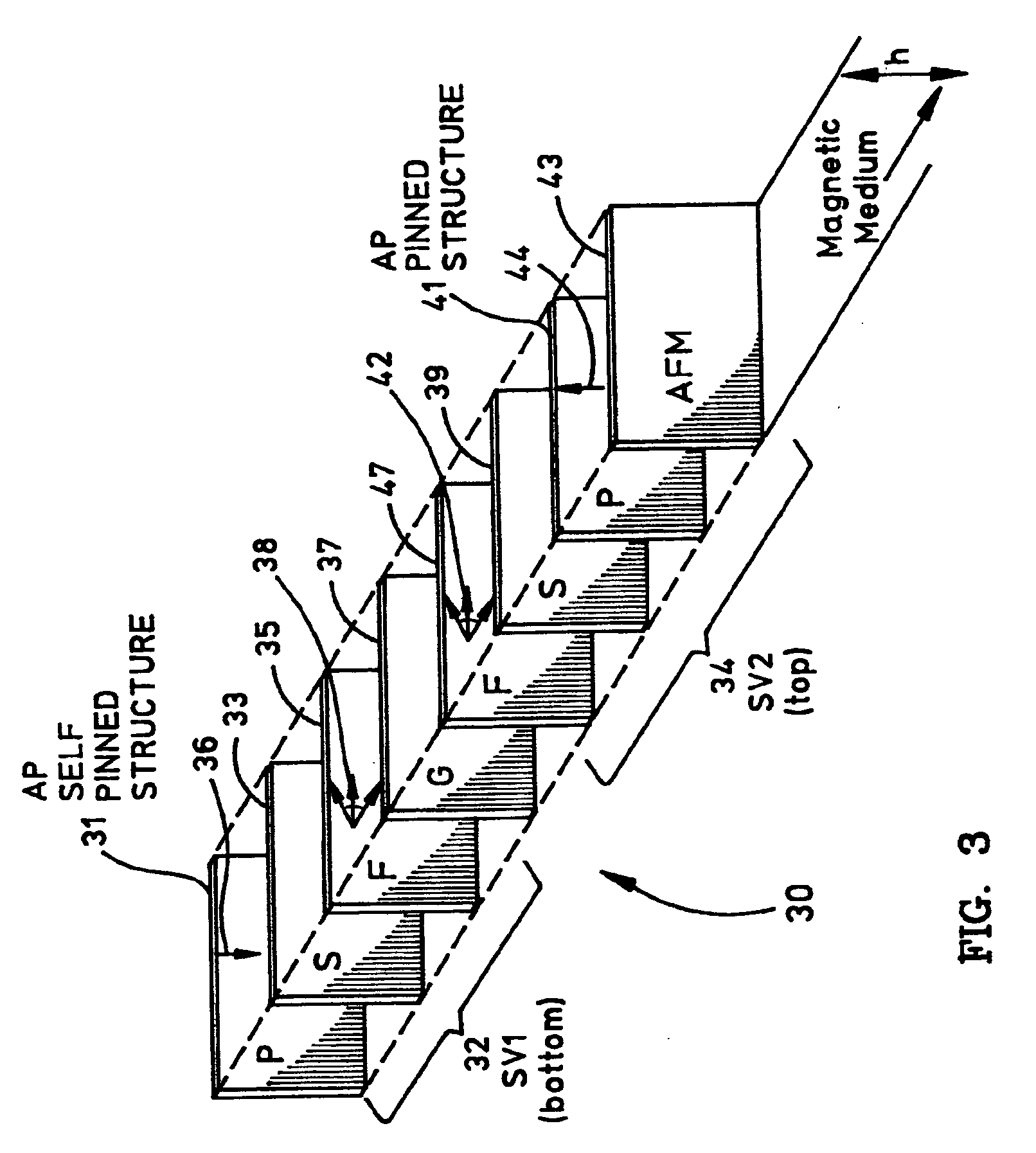

Dual spin valve sensor with a longitudinal bias stack

A dual spin valve (SV) sensor is provided with a longitudinal bias stack sandwiched between a first SV stack and a second SV stack. The longitudinal bias stack comprises an antiferromagnetic (AFM) layer sandwiched between first and second ferromagnetic layers. The first and second SV stacks comprise antiparallel (AP)-pinned layers pinned by AFM layers made of an AFM material having a higher blocking temperature than the AFM material of the bias stack allowing the AP-pinned layers to be pinned in a transverse direction and the bias stack to be pinned in a longitudinal direction. The demagnetizing fields of the two AP-pinned layers cancel each other and the bias stack provides flux closures for the sense layers of the first and second SV stacks.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

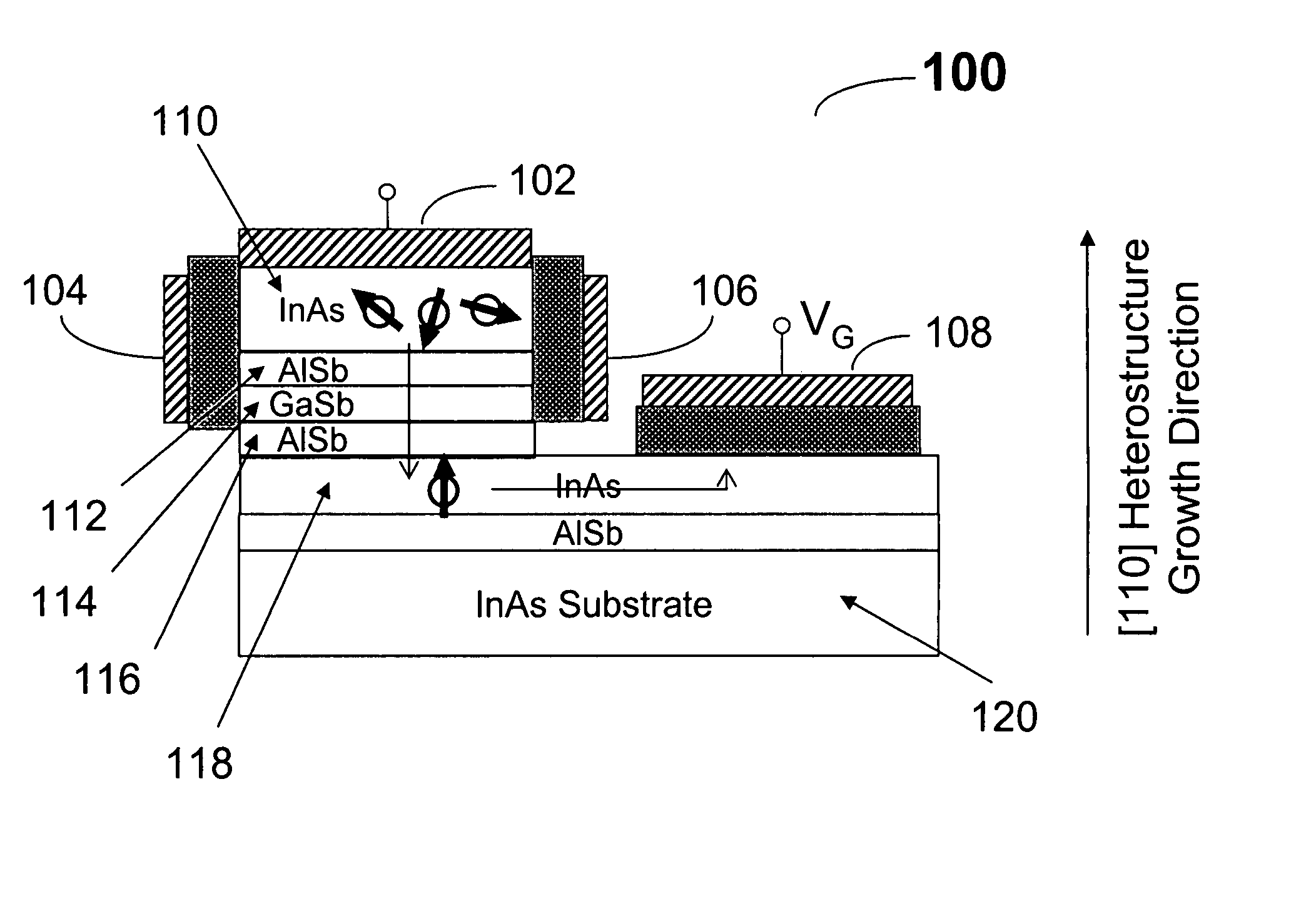

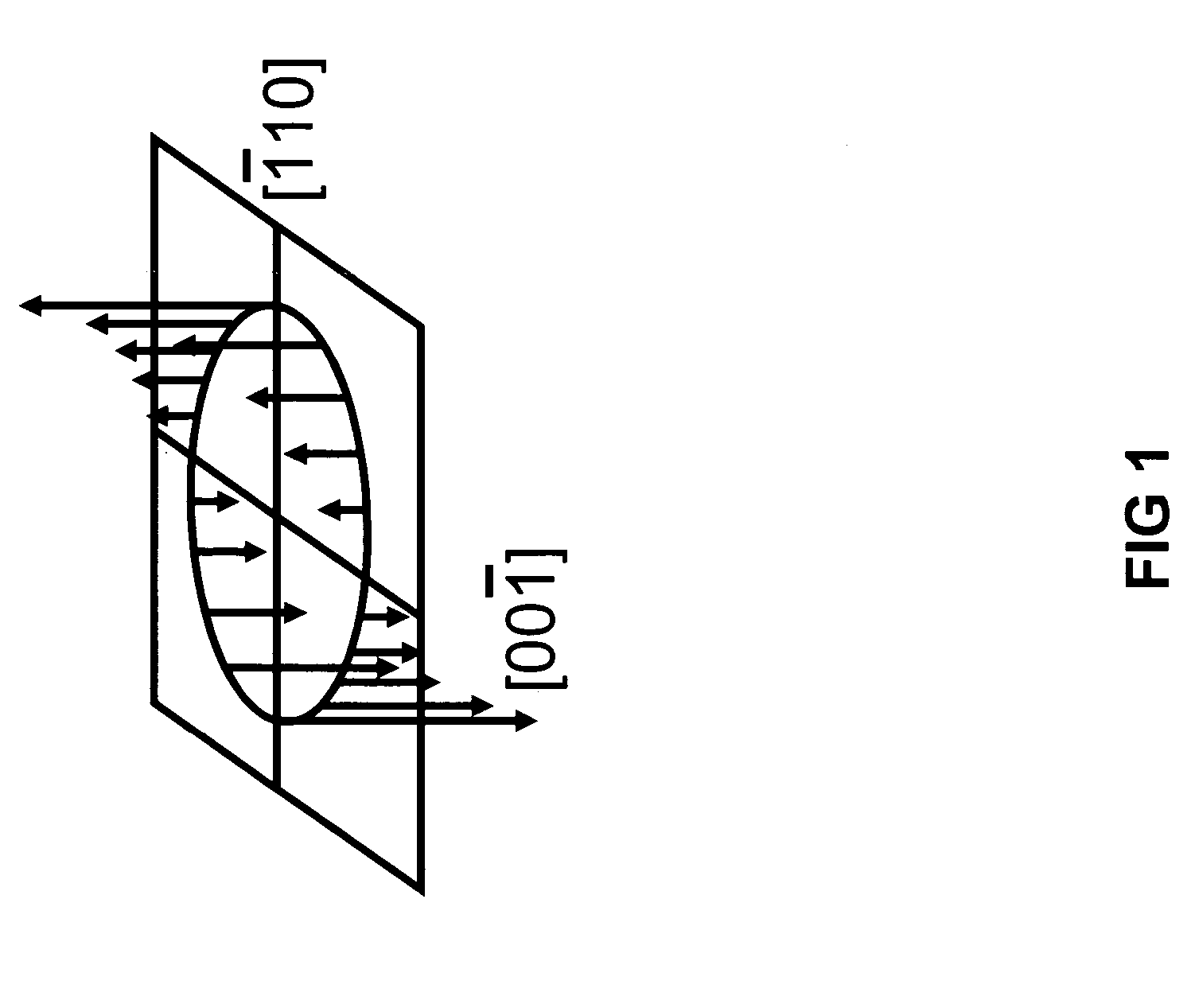

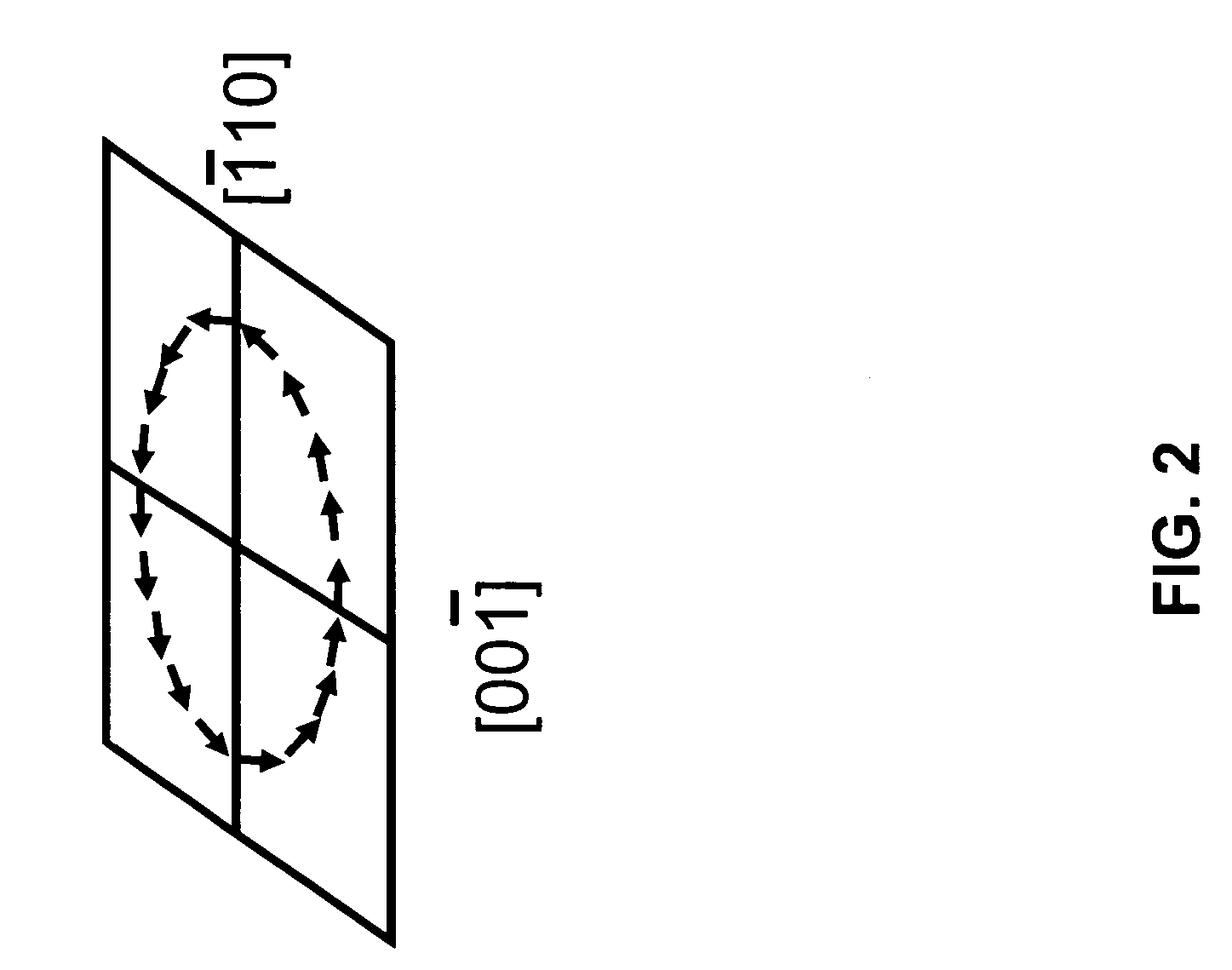

Non-magnetic semiconductor spin transistor

InactiveUS20050263751A1High sensitivityNanoinformaticsSolid-state devicesTunnel diodeDevice material

A nonmagnetic semiconductor device which may be utilized as a spin resonant tunnel diode (spin RTD) and spin transistor, in which low applied voltages and / or magnetic fields are used to control the characteristics of spin-polarized current flow. The nonmagnetic semiconductor device exploits the properties of bulk inversion asymmetry (BIA) in (110)-oriented quantum wells. The nonmagnetic semiconductor device may also be used as a nonmagnetic semiconductor spin valve and a magnetic field sensor. The spin transistor and spin valve may be applied to low-power and / or high-density and / or high-speed logic technologies. The magnetic field sensor may be applied to high-speed hard disk read heads. The spin RTD of the present invention would be useful for a plurality of semiconductor spintronic devices for spin injection and / or spin detection.

Owner:UNIV OF IOWA RES FOUND

Magnetoresistive Magnetic Field Sensor Structure

A magnetic field sensor structure including a first magnetoresistive element in a spin-valve arrangement with a first reference layer structure with a first reference magnetization direction and a second magnetoresistive element in a spin-valve arrangement with a second reference layer structure with a second reference magnetization direction, wherein the first and second magnetoresistive elements are arranged in a layer vertically above each other and galvanically isolated from each other by an intermediate layer, and wherein the first and second reference magnetization directions are different.

Owner:INFINEON TECH AG

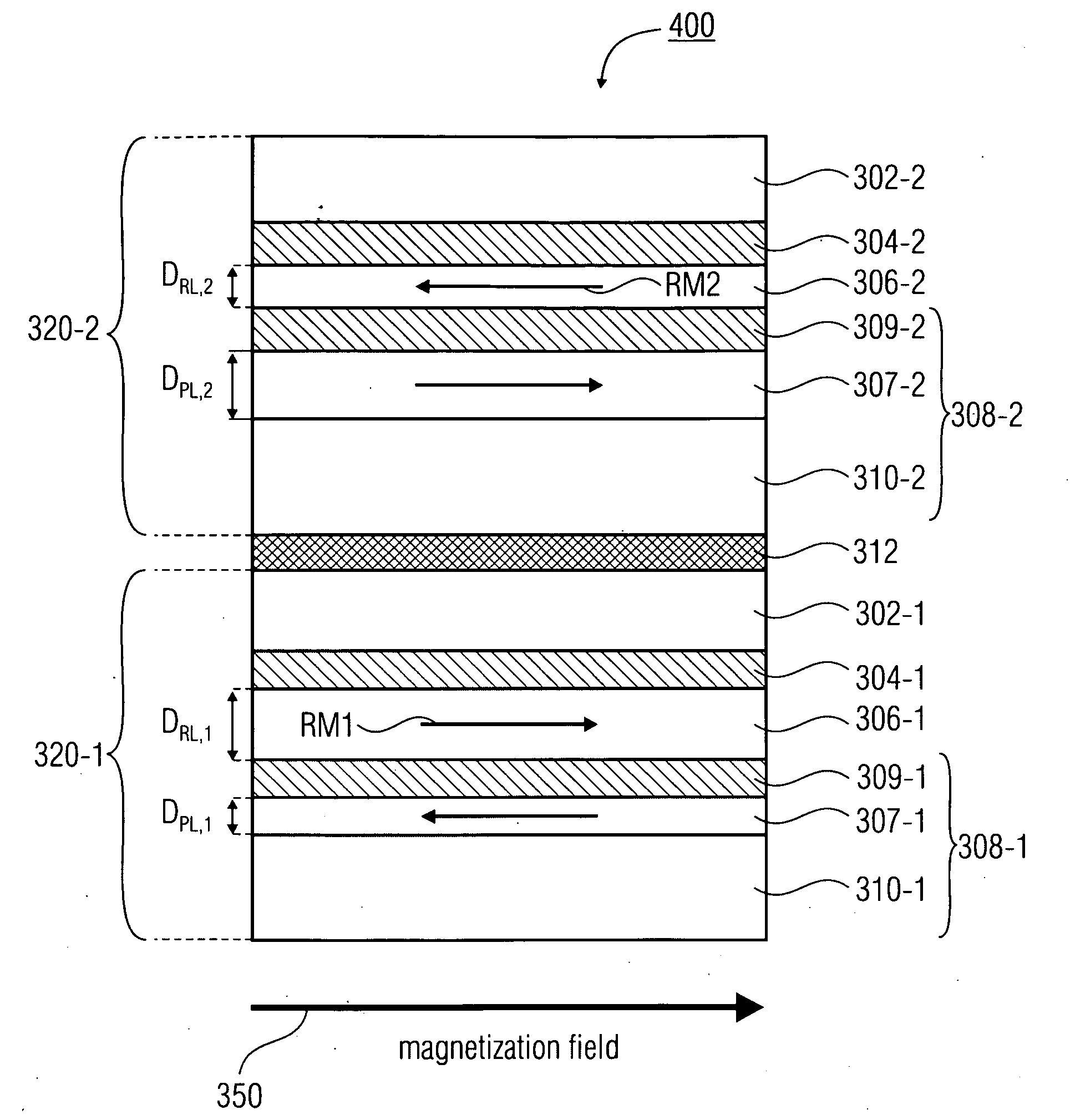

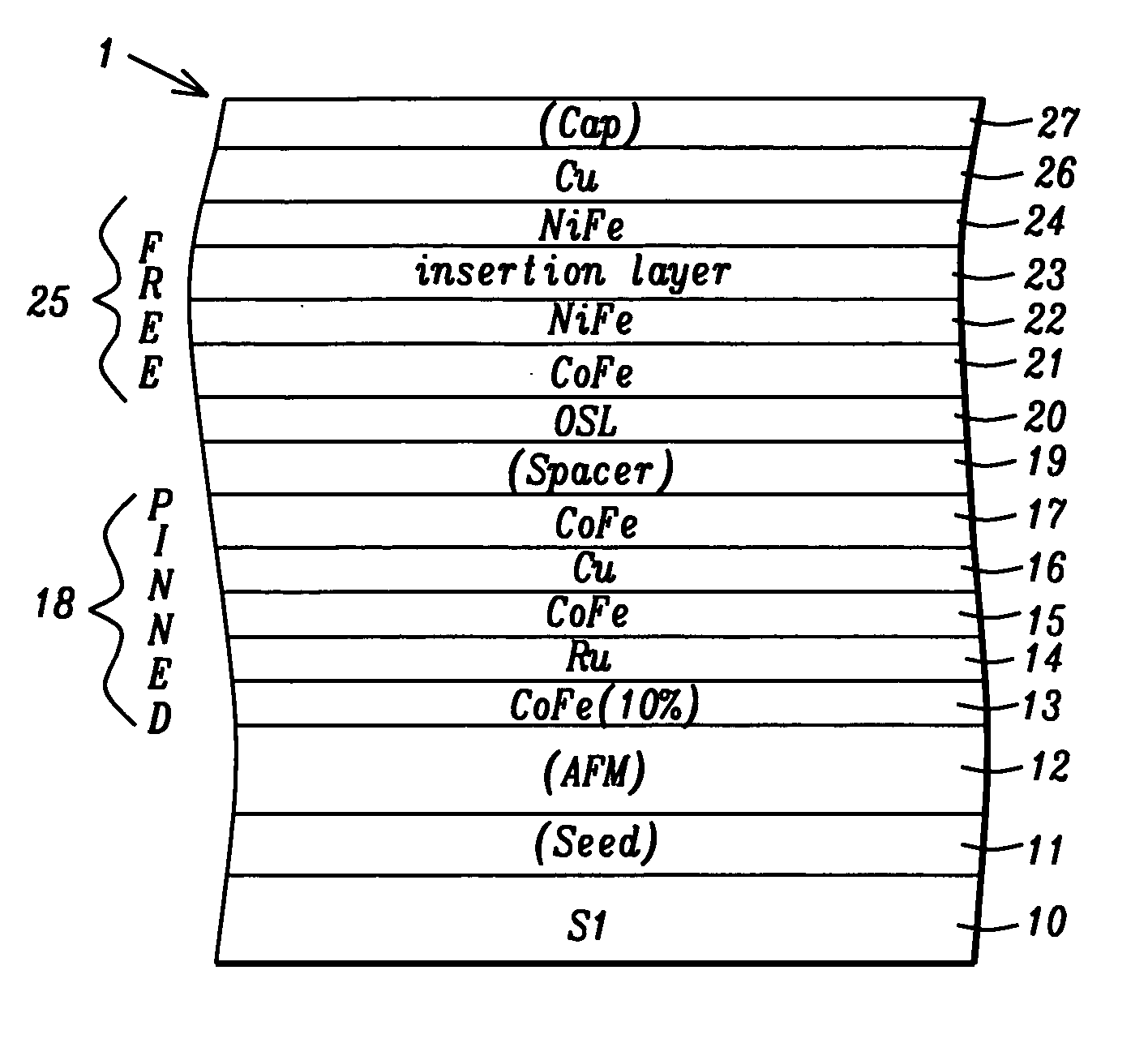

Differential spin valve sensor having both pinned and self-pinned structures

InactiveUS20050068684A1Common mode noiseHigh resolutionRecord information storageManufacture of flux-sensitive headsElectrical polaritySpin valve

A dual / differential spin valve sensor of a magnetic head includes a first spin valve having an antiparallel (AP) “pinned” layer structure and a second spin valve having an AP “self-pinned” layer structure. The AP pinned layer structure has a magnetization direction which is fixed by an adjacent antiferromagnetic (AFM) layer, whereas the AP self-pinned layer structure has a magnetization direction which is fixed by magnetostriction as well as air bearing surface (ABS) stress. The magnetization direction of the AP pinned layer structure is fixed in a direction antiparallel to the magnetization direction of the AP self-pinned layer structure. The dual / differential spin valve sensor may be configured to have either a top AP pinned layer structure and a bottom AP self-pinned layer structure, or a top AP self-pinned layer structure and a bottom AP pinned layer structure. Advantageously, the dual / differential spin valve sensor is relatively thin and overcomes the difficulties of the AFM polarity setting process when two AP pinned layer structures are utilized.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

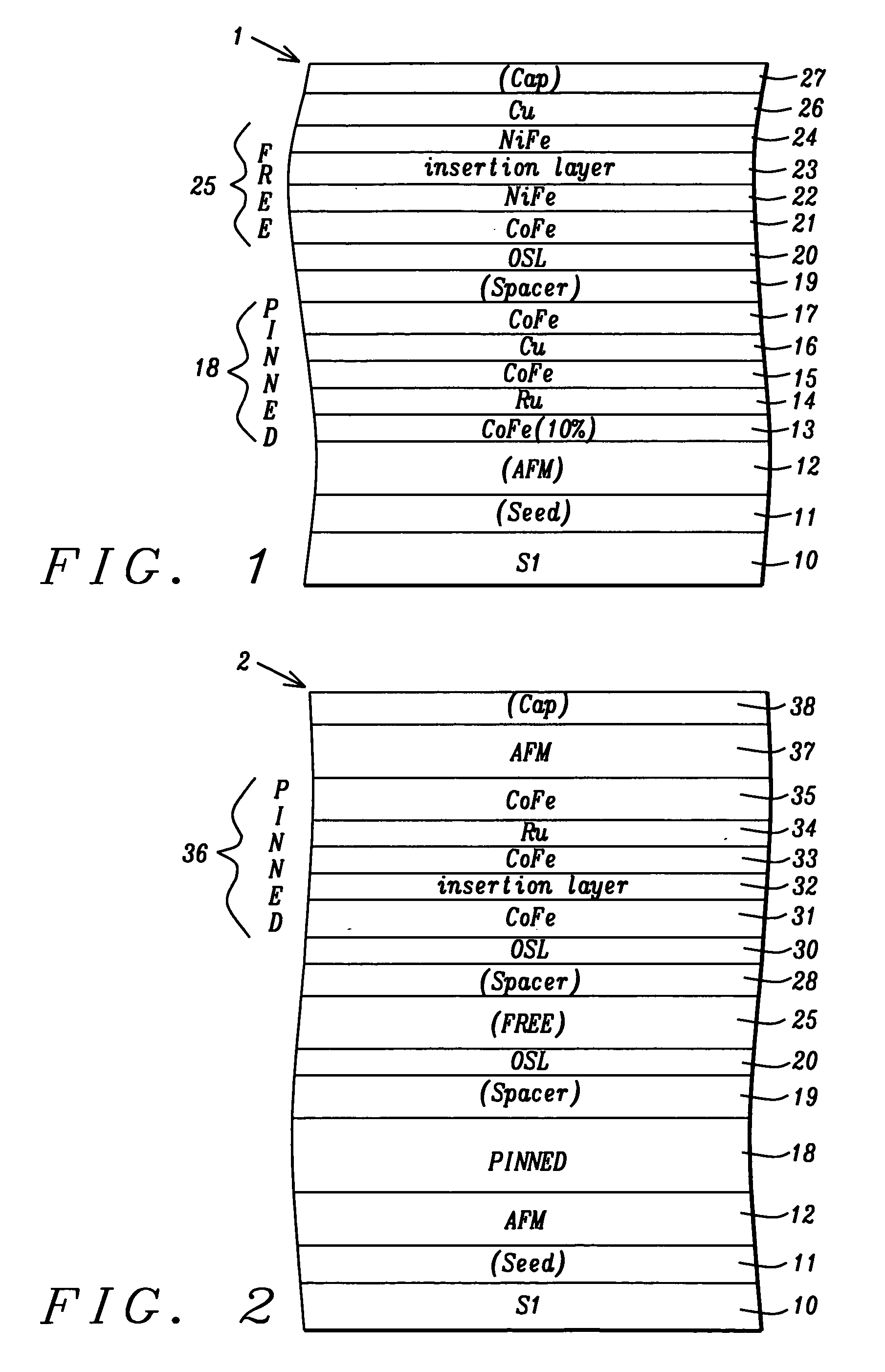

Novel process and structure to fabricate CPP spin valve heads for ultra-hing recording density

InactiveUS20050201022A1Enhanced Specular ReflectionIncrease bulk scatteringNanostructure applicationNanomagnetismDopantSpins

A CPP-GMR spin value sensor structure with an improved MR ratio and increased resistance is disclosed. All layers except certain pinned layers, copper spacers, and a Ta capping layer are oxygen doped by adding a partial O2 pressure to the Ar sputtering gas during deposition. Oxygen doped CoFe free and pinned layers are made slightly thicker to offset a small decrease in magnetic moment caused by the oxygen dopant. Incorporating oxygen in the MnPt AFM layer enhances the exchange bias strength. An insertion layer such as a nano-oxide layer is included in one or more of the free, pinned, and spacer layers to increase interfacial scattering. The thickness of all layers except the copper spacer may be increased to enhance bulk scattering. A CPP-GMR single or dual spin valve of the present invention has up to a threefold increase in resistance and a 2 to 3% increase in MR ratio.

Owner:HEADWAY TECH INC

Novel CPP device with an enhanced dR/R ratio

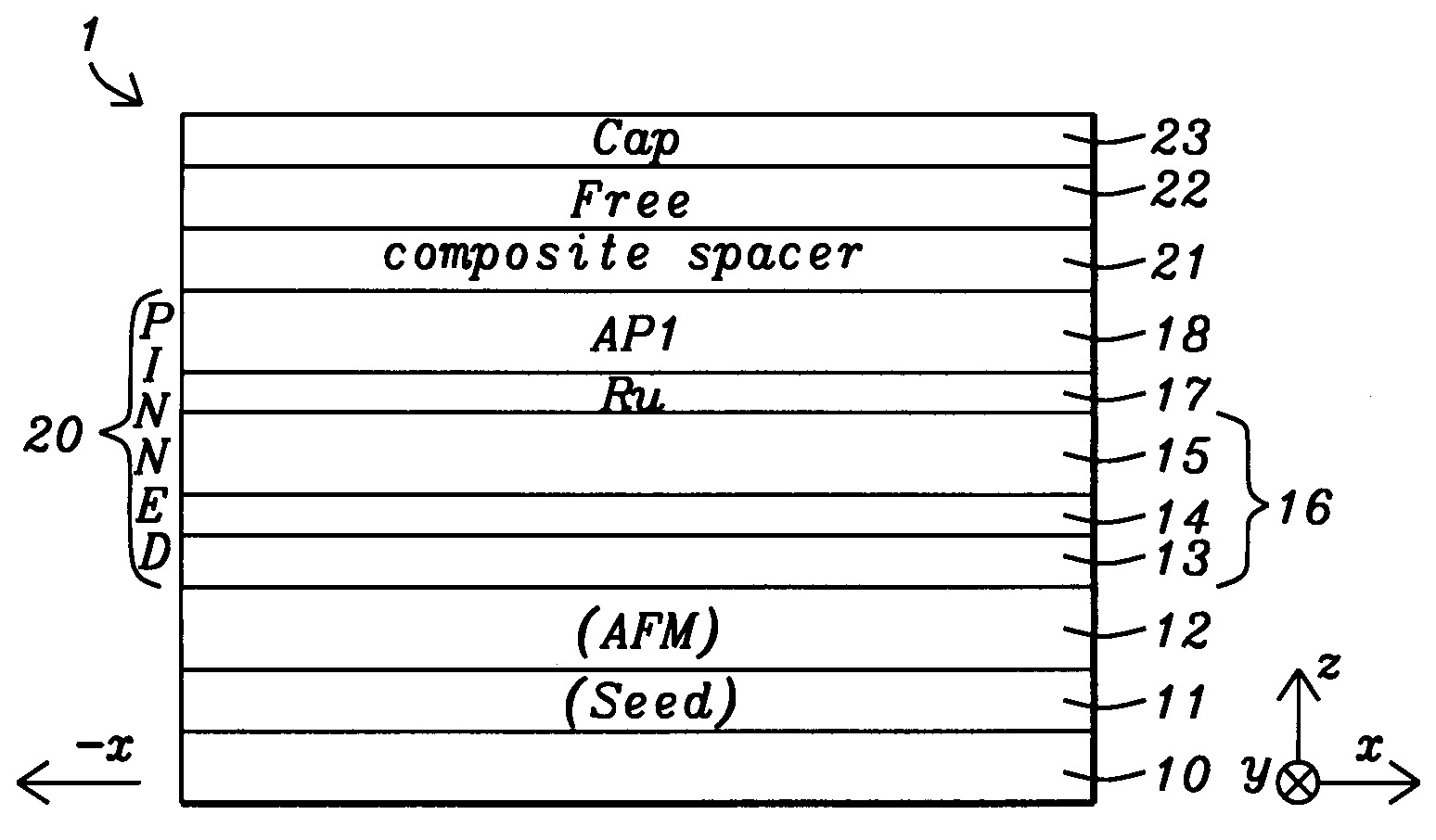

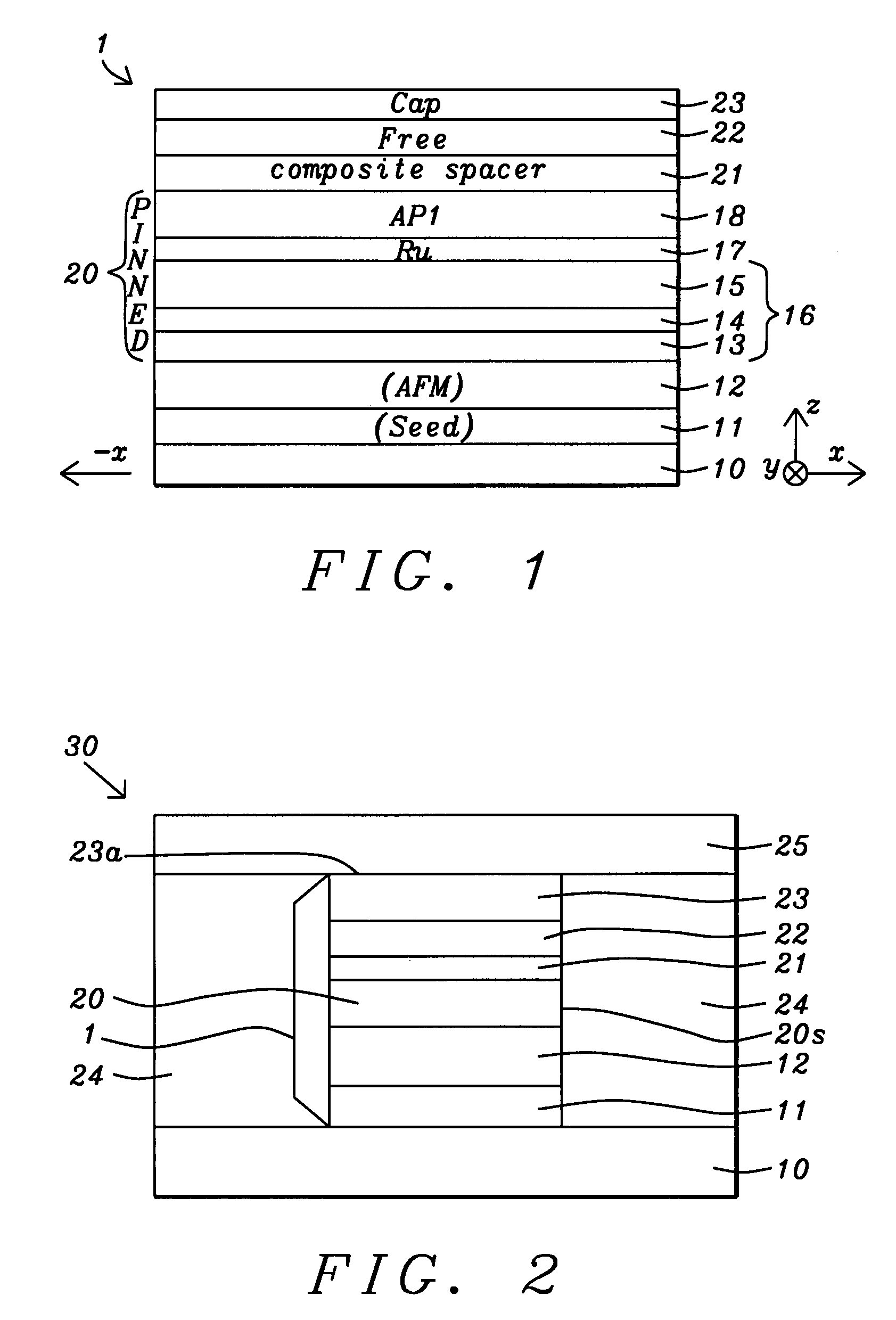

ActiveUS20080278864A1Prevent undesirable Barkhausen noiseRaise the ratioNanomagnetismNanoinformaticsCouplingSpin valve

A CPP-GMR spin valve having a composite spacer layer comprised of at least one metal (M) layer and at least one semiconductor or semi-metal (S) layer is disclosed. The composite spacer may have a M / S, S / M, M / S / M, S / M / S, M / S / M / S / M, or a multilayer (M / S / M)n configuration where n is an integer ≧1. The pinned layer preferably has an AP2 / coupling / AP1 configuration wherein the AP2 portion is a FCC trilayer represented by CoZFe(100-Z) / FeYCo(100-Y) / CoZFe(100-Z) where y is 0 to 60 atomic %, and z is 75 to 100 atomic %. In one embodiment, M is Cu with a thickness from 0.5 to 50 Angstroms and S is ZnO with a thickness of 1 to 50 Angstroms. The S layer may be doped with one or more elements. The dR / R ratio of the spin valve is increased to 10% or greater while maintaining acceptable EM and RA performance.

Owner:HEADWAY TECH INC

Magnetic element with improved out-of-plane anisotropy for spintronic applications

ActiveUS9006704B2Enhanced interfacial perpendicular anisotropyImprove thermal stabilityNanostructure applicationMagnetic-field-controlled resistorsPerpendicular anisotropyAlloy

A magnetic element is disclosed wherein first and second interfaces of a free layer with a Hk enhancing layer and tunnel barrier, respectively, produce enhanced surface perpendicular anisotropy to lower switching current or increase thermal stability in a magnetic tunnel junction (MTJ). In a MTJ with a bottom spin valve configuration where the Hk enhancing layer is an oxide, the capping layer contacting the Hk enhancing layer is selected to have a free energy of oxide formation substantially greater than that of the oxide. The free layer may be a single layer or composite comprised of an Fe rich alloy such as Co20Fe60B20. With a thin free layer, the interfacial perpendicular anisotropy may dominate the shape anisotropy to generate a magnetization perpendicular to the planes of the layers. The magnetic element may be part of a spintronic device or serve as a propagation medium in a domain wall motion device.

Owner:TAIWAN SEMICON MFG CO LTD

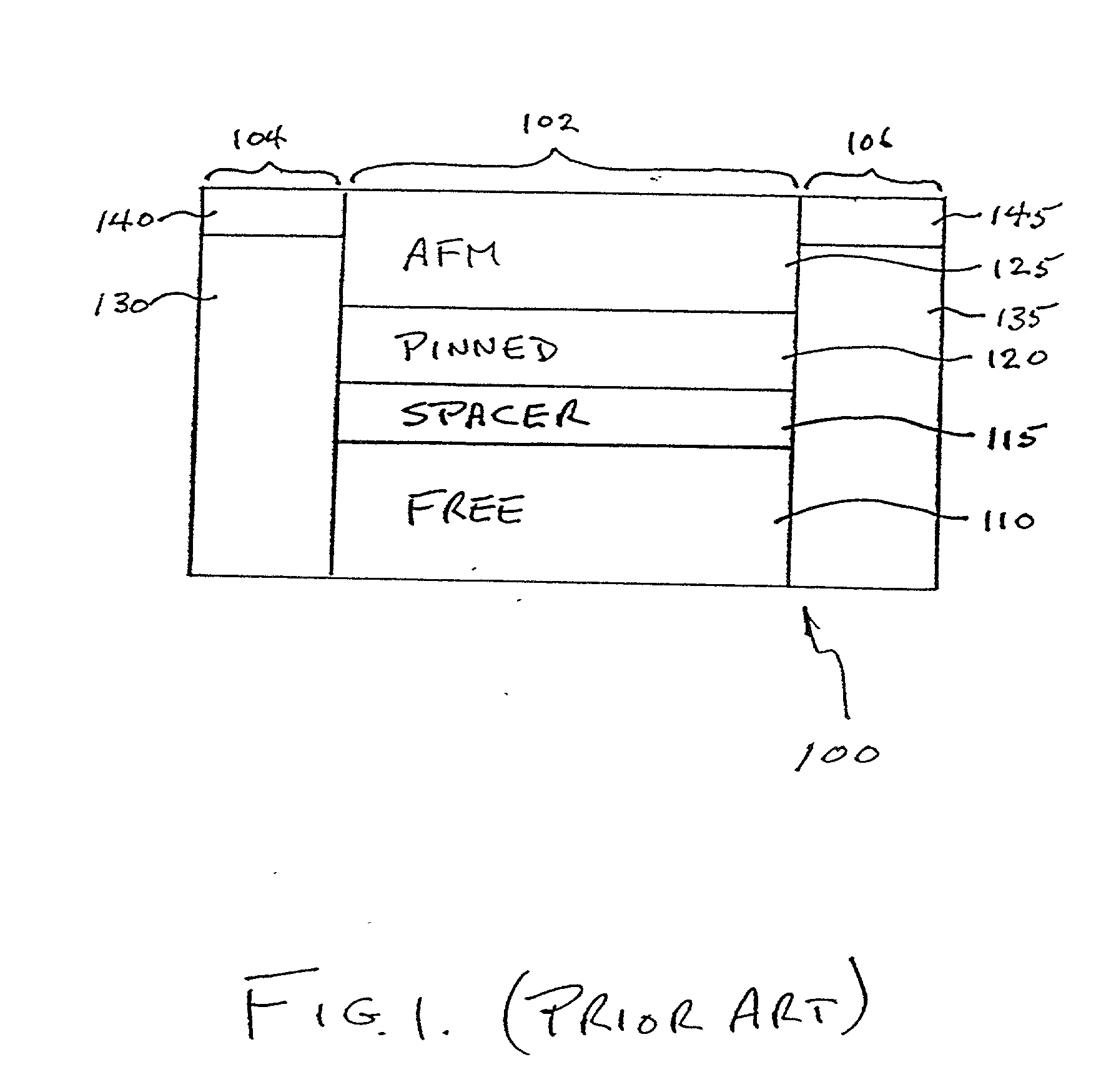

Stabilization structures for CPP sensor

Current-perpendicular-to-plane (CPP) spin valve (SV) and magnetic tunnel junction (MTJ) sensors are provided having an antiparallel (AP)-coupled longitudinal bias stack for instack biasing to stabilize the free layer. A CPP sensor comprises a longitudinal bias stack adjacent to and in contact with a free (sense) layer of the sensor. The bias stack comprises an antiparallel (AP)-pinned layer including FM1 and FM2 layers separated by an antiparallel coupling (APC) layer. The FM1 layer is separated from the free layer of the sensor by a nonmagnetic spacer layer. By choosing the relative thicknesses of the FM1 and FM2 layers, the bias field HB from the AP-pinned layer and the ferromagnetic coupling field HFC between the FM1 layer and the free layer is made additive at the free layer for either positive or negative coupling. By ensuring that the bias field adds to the coupling field, the stability of the free layer by in-stack longitudinal biasing is improved.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com