Patents

Literature

5010 results about "Sliding contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sliding Contact¶. The sliding contact is a special type of contact which allows dispacement tangential to the contact surface but no relative movement along the normal direction.

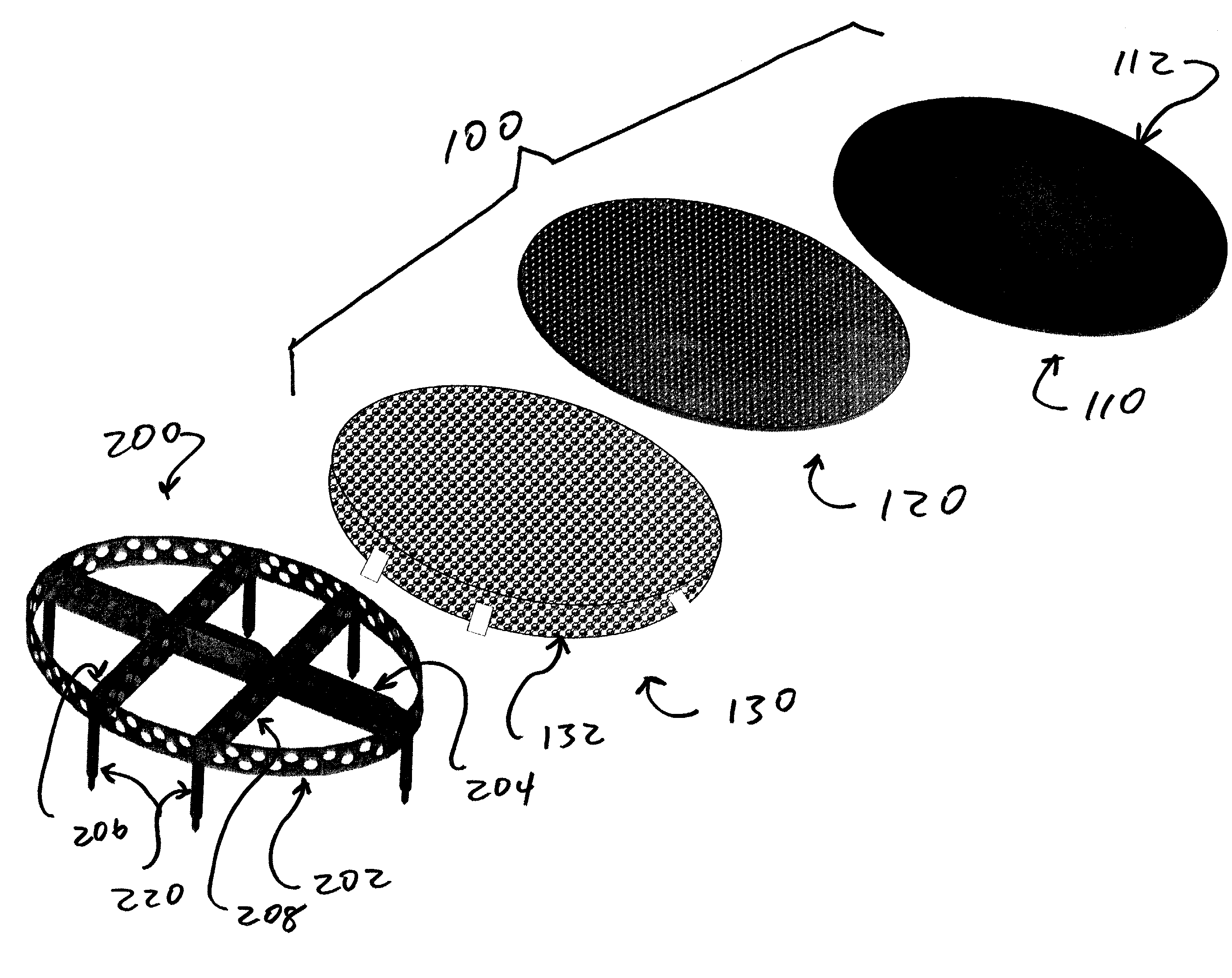

Cartilage repair implant with soft bearing surface and flexible anchoring device

InactiveUS9050192B2Strong and more permanent fixationSoft and bendableJoint implantsHip jointsCartilage repairSurgical implant

A surgical implant for replacing hyaline cartilage in a knee or other articulating synovial joint has an anchoring side on one side of the implant adapted for fixing the implant to one of the bones in the joint, and a bearing surface on the opposite side of the implant for lubricious rubbing and sliding contact with another bone in the joint. The anchoring side can be configured with an irregular surface for tissue ingrowth. The bearing side can include hydrogel. The implant can be rolled up from an original shape and surgically inserted by arthroscopic means, and opens into its original shape when released inside the joint.

Owner:FORMAE

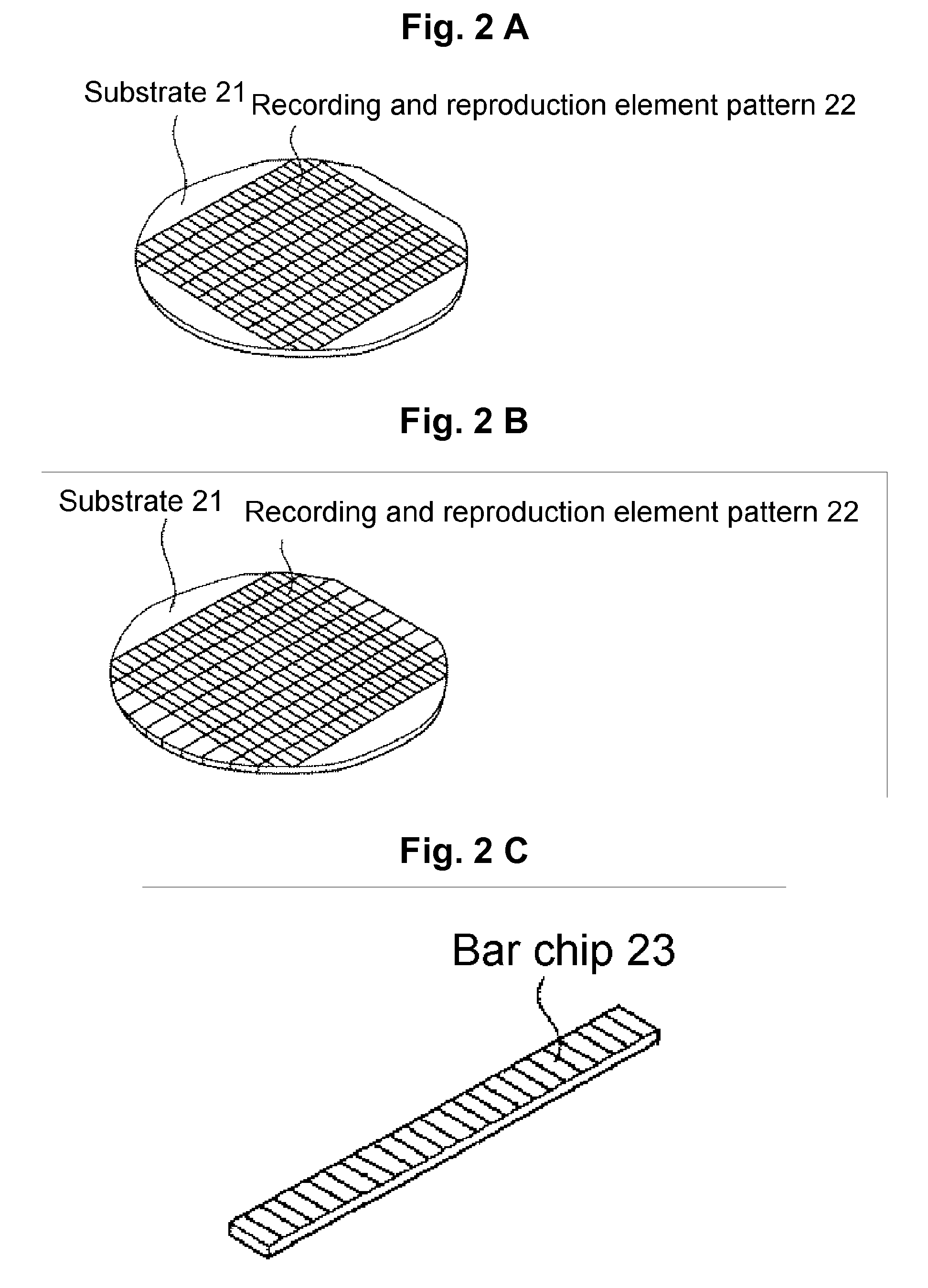

Magnetic signal reproduction system and magnetic signal reproduction method

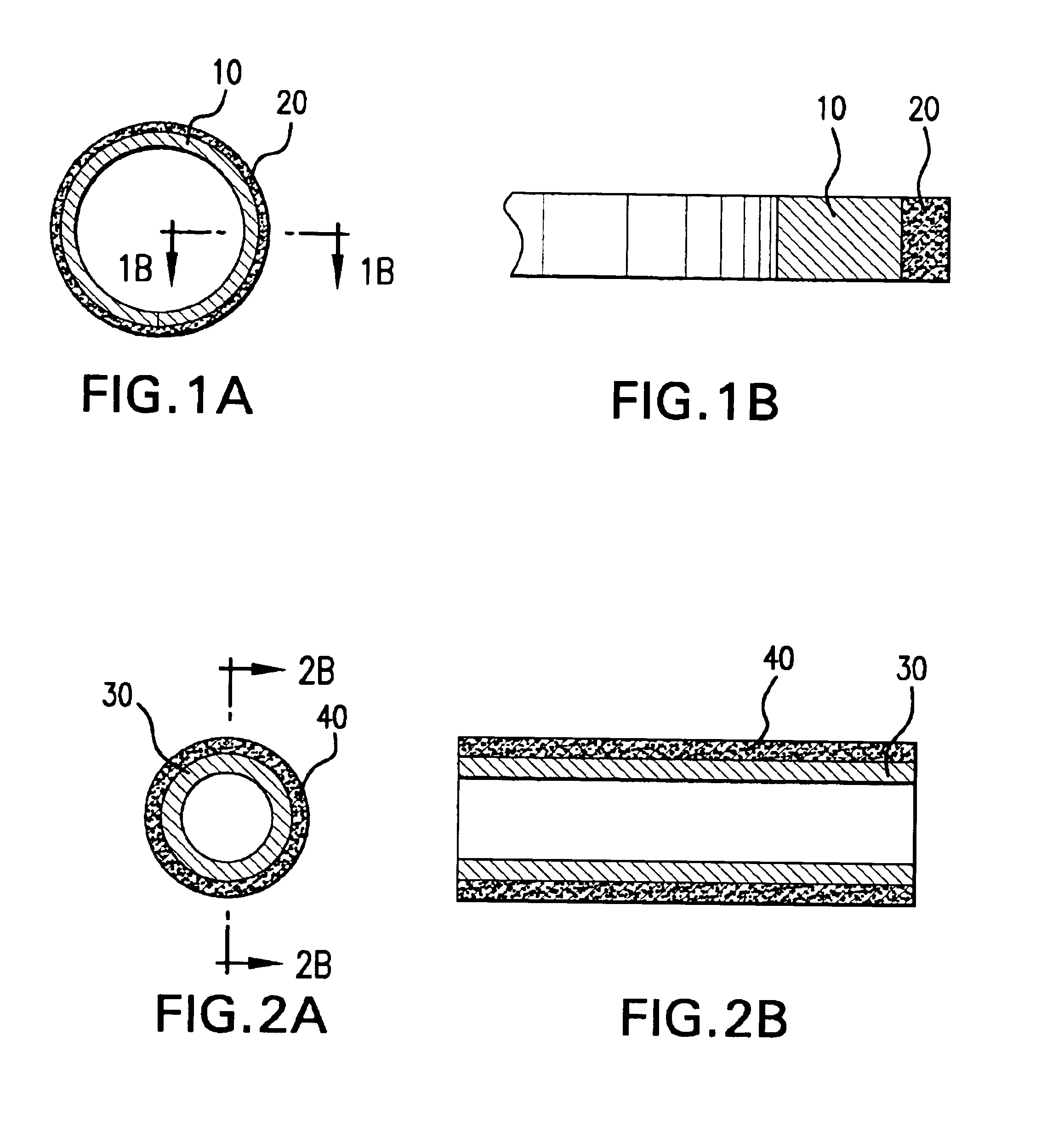

InactiveUS20090027812A1Stable reproduction propertyDeterioration of reproduction propertyManufacture unitary devices of plural headsRecord information storageIridiumAlloy

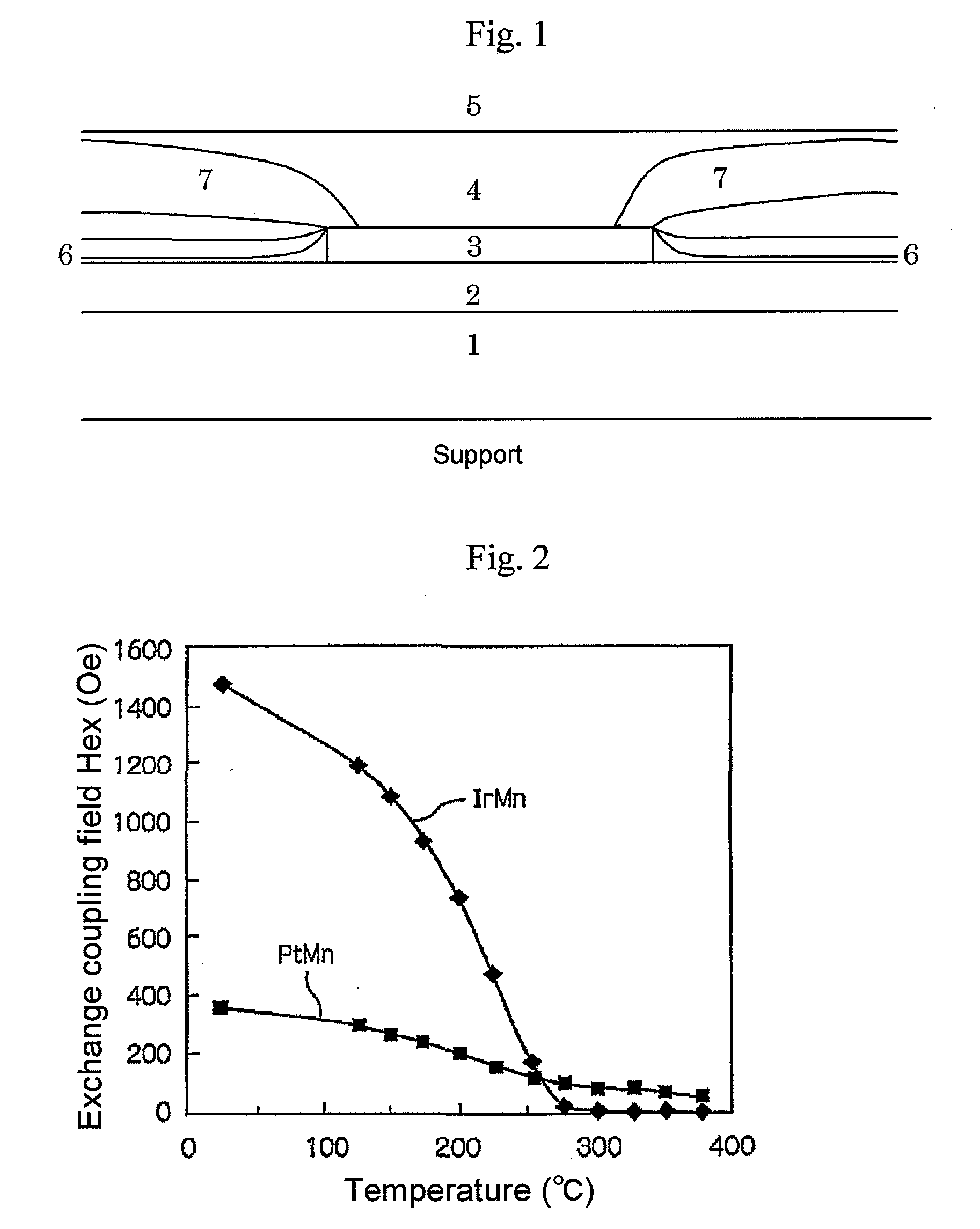

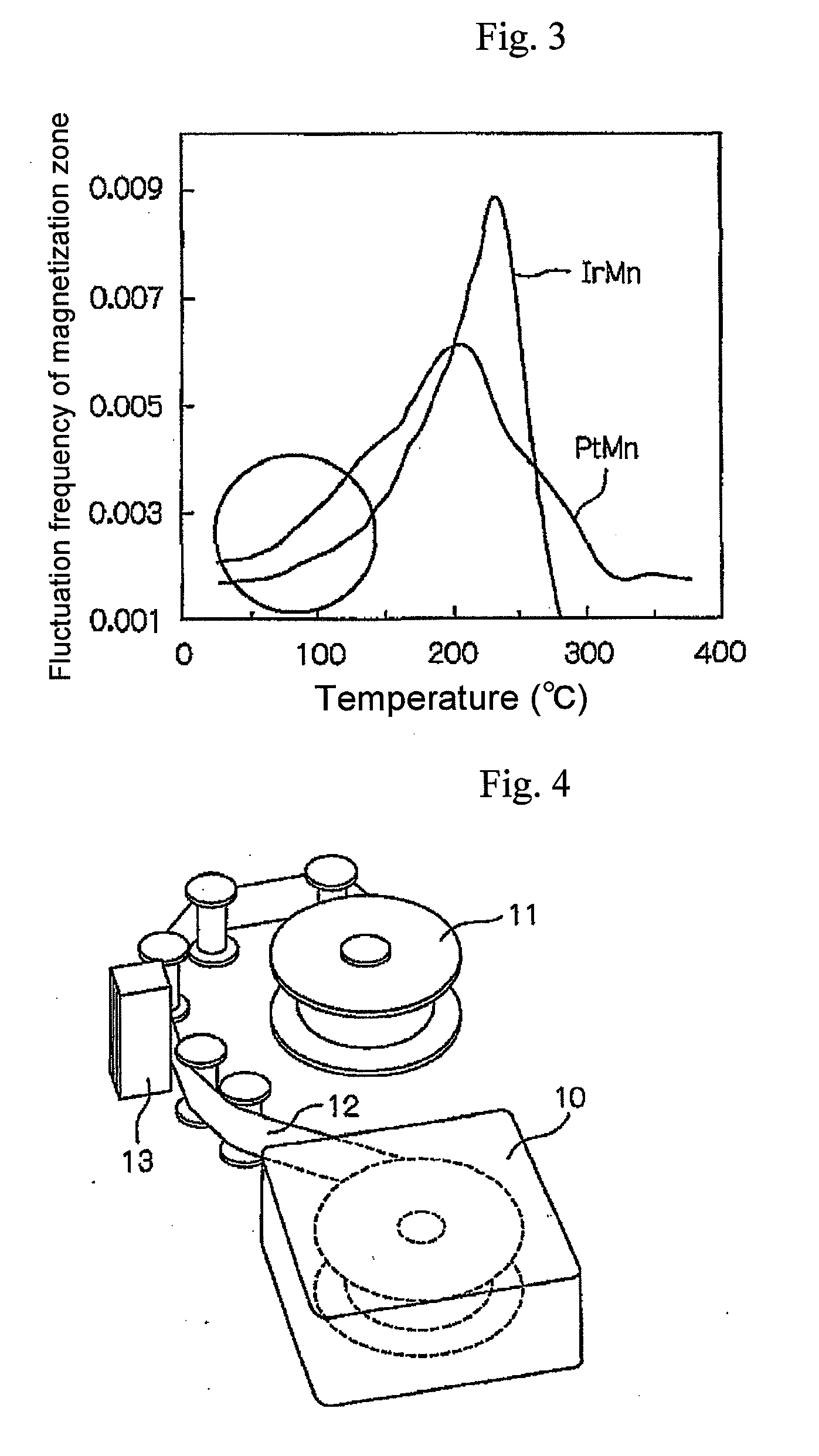

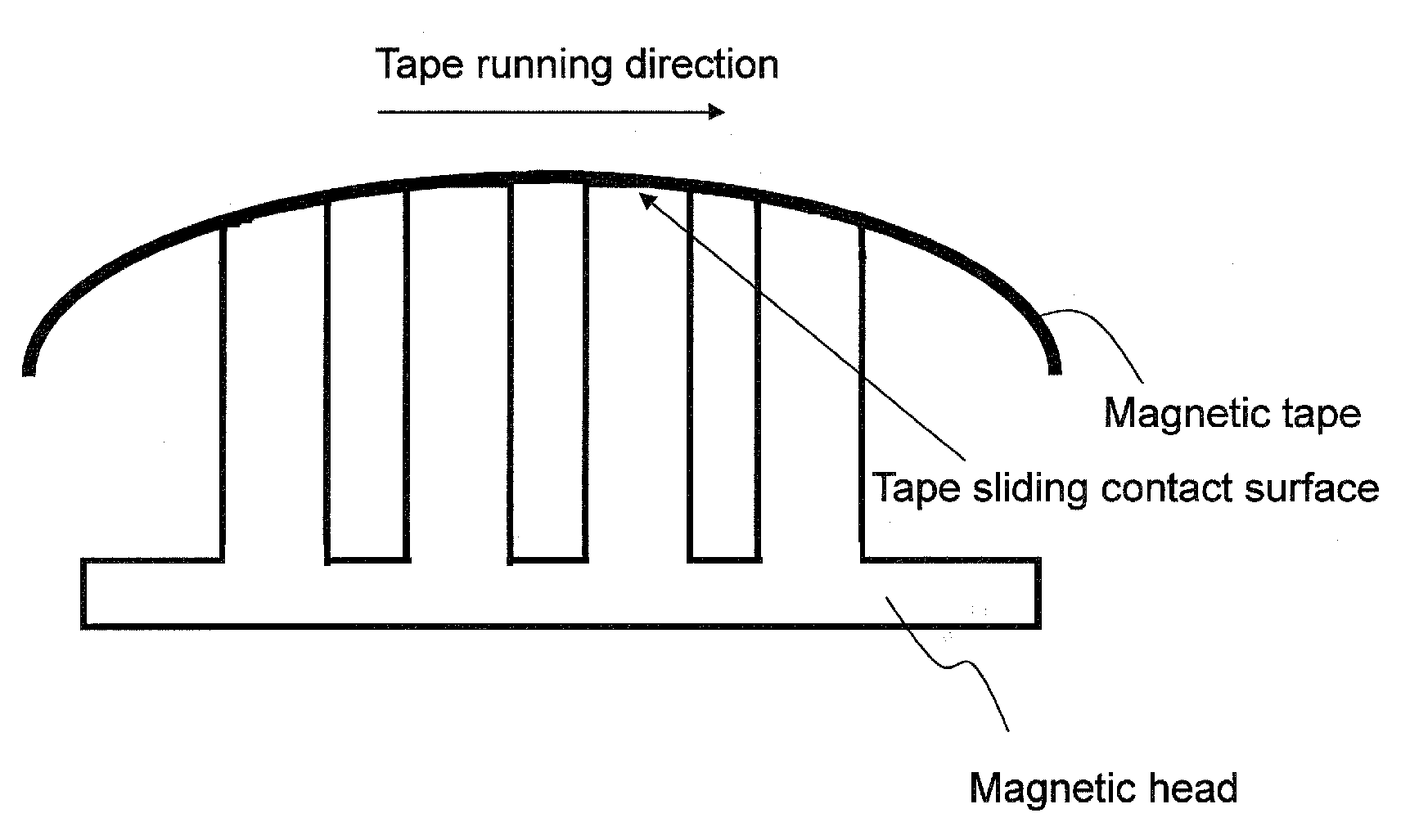

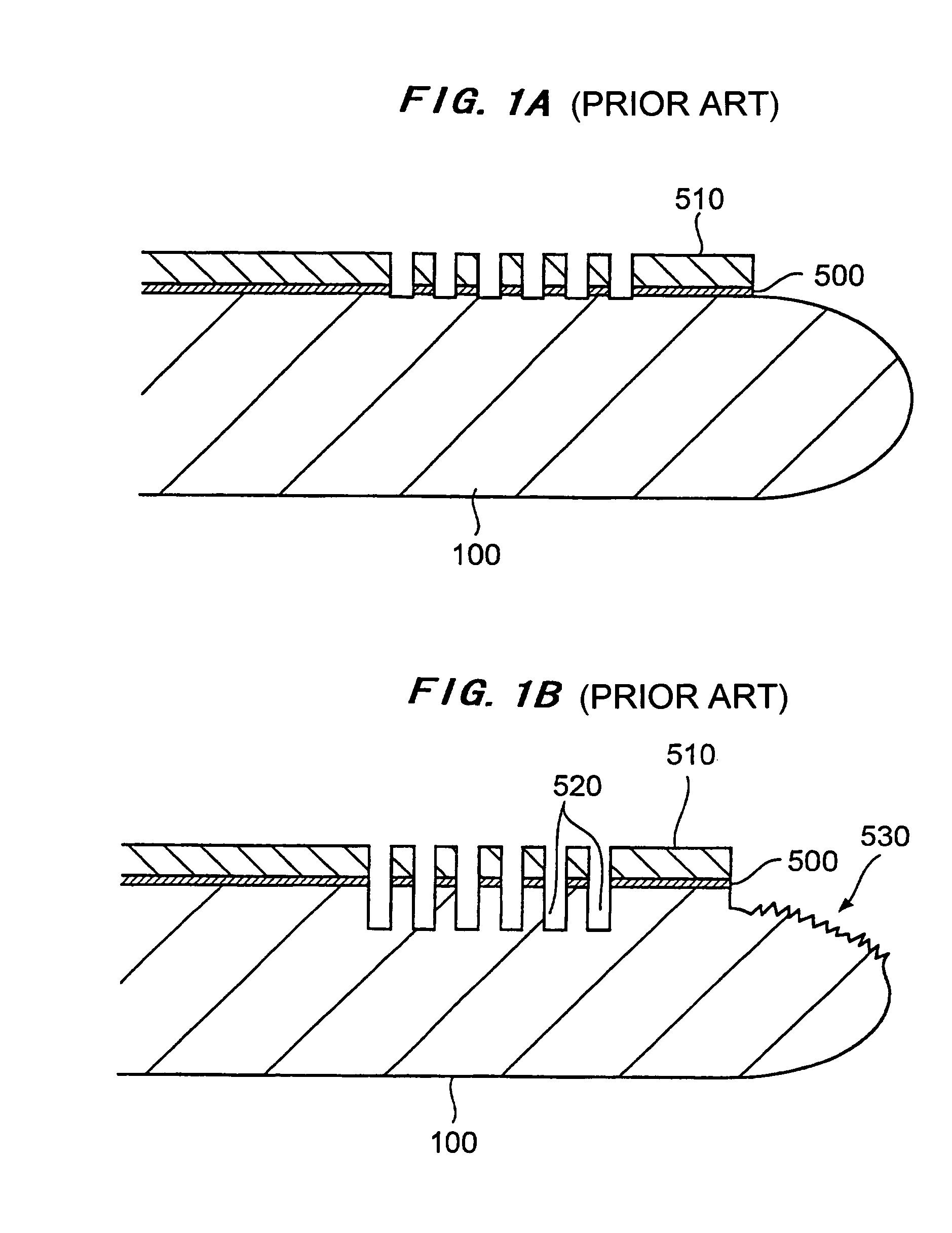

The magnetic signal reproduction system comprises a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support and a reproduction head, wherein a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 2500 / 10,000 μm2, a quantity of lubricant on the magnetic layer surface, denoted as a surface lubricant index, ranges from 0.5 to 5.0, a surface abrasive occupancy of the magnetic layer ranges from 2 to 20 percent, the reproduction head is a magnetoresistive magnetic head comprising a spin-valve layer, the spin-valve layer comprises a magnetization free layer, a magnetization pinned layer and an antiferromagnetic layer, and the antiferromagnetic layer is comprised of alloy comprising iridium and manganese, and the reproduction head comes in sliding contact with the magnetic recording medium during signal reproduction.

Owner:FUJIFILM CORP +1

Magnetic head and method of manufacturing the same, linear tape drive apparatus, and magnetic recording and reproduction method

InactiveUS20100073816A1Excellent characteristicsImprove stabilityElectrical transducersRecord information storageMagnetic tapeImage View

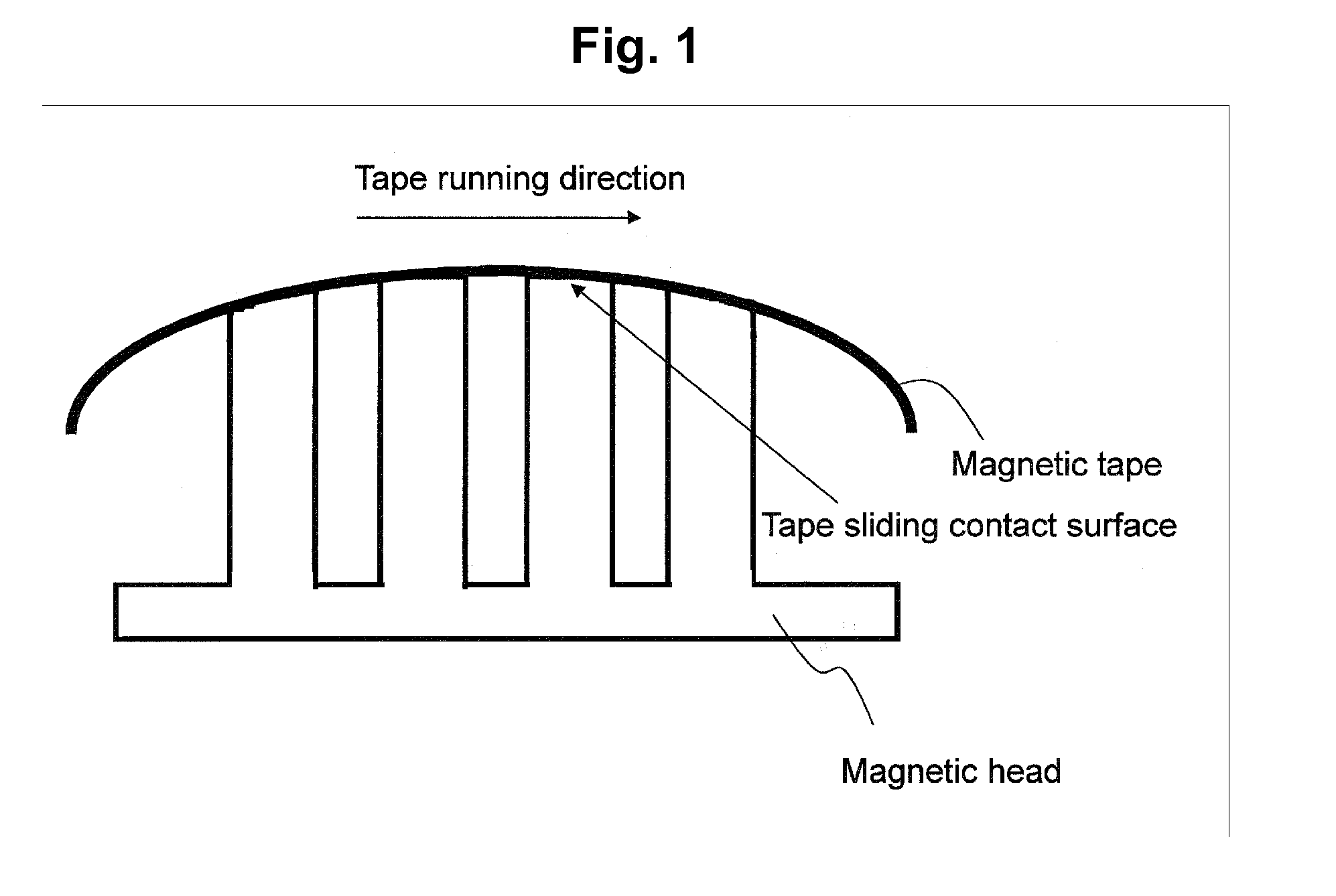

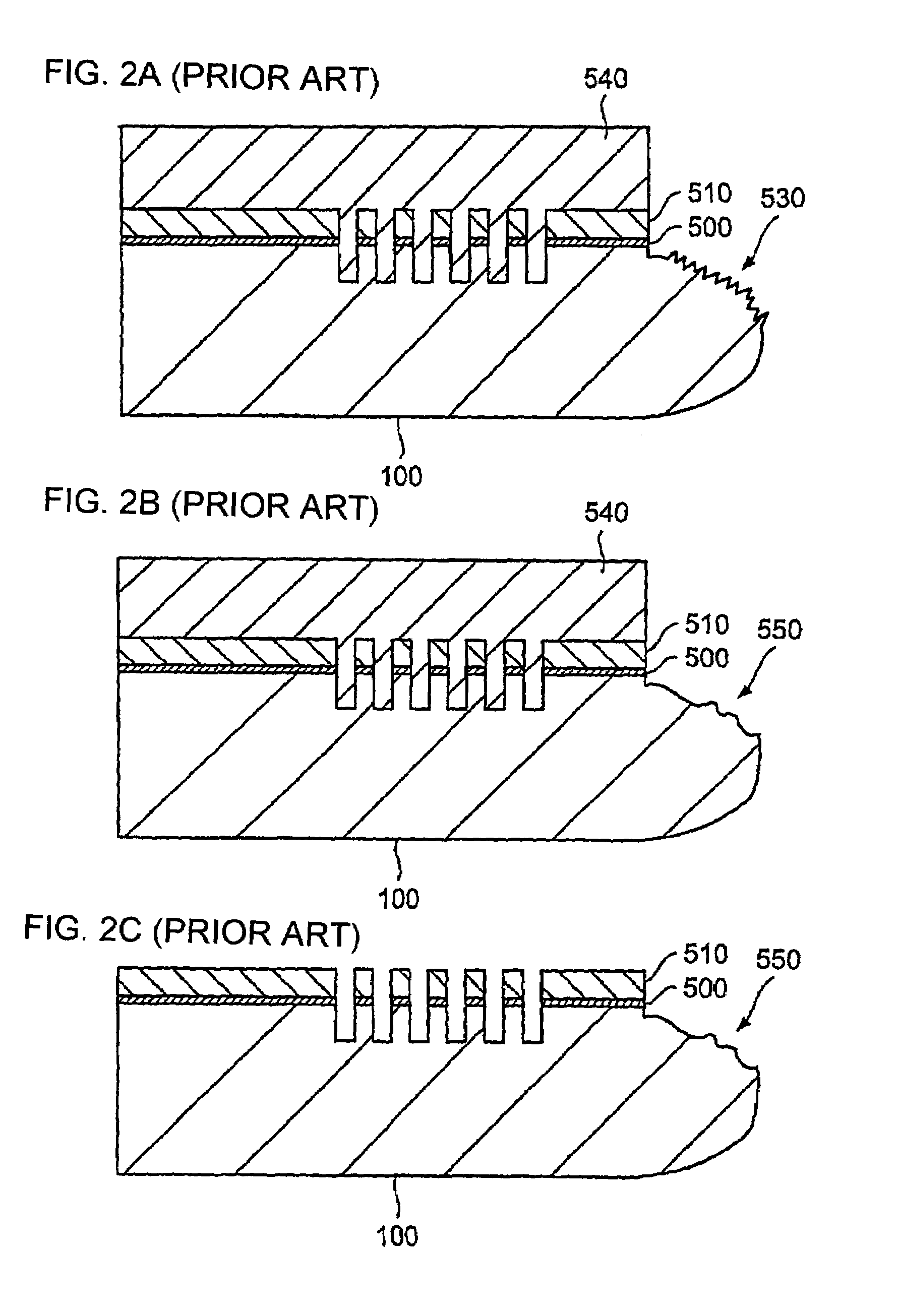

An aspect of the present invention relates to a magnetic head employed in a linear tape drive in the form of a sliding-contact linear tape drive. The magnetic head comprises multiple indentations that are observed in a surface topographic image viewed by a scanning probe microscope on a surface (sliding contact surface) of sliding contact with a magnetic tape, and the multiple indentations satisfy (1) to (4) below:(1) an average area of the indentations in the sliding contact surface ranges from about 0.2 μm2 to about 1.0 μm2;(2) a standard deviation of an area of the indentations ranges from about 0.5 μm2 to about 2.0 μm2;(3) an area ratio of the indentations in the sliding contact surface ranges from about 20 percent to about 50 percent; and(4) an average depth of the indentations is equal to or greater than about 15 nm.

Owner:FUJIFILM CORP

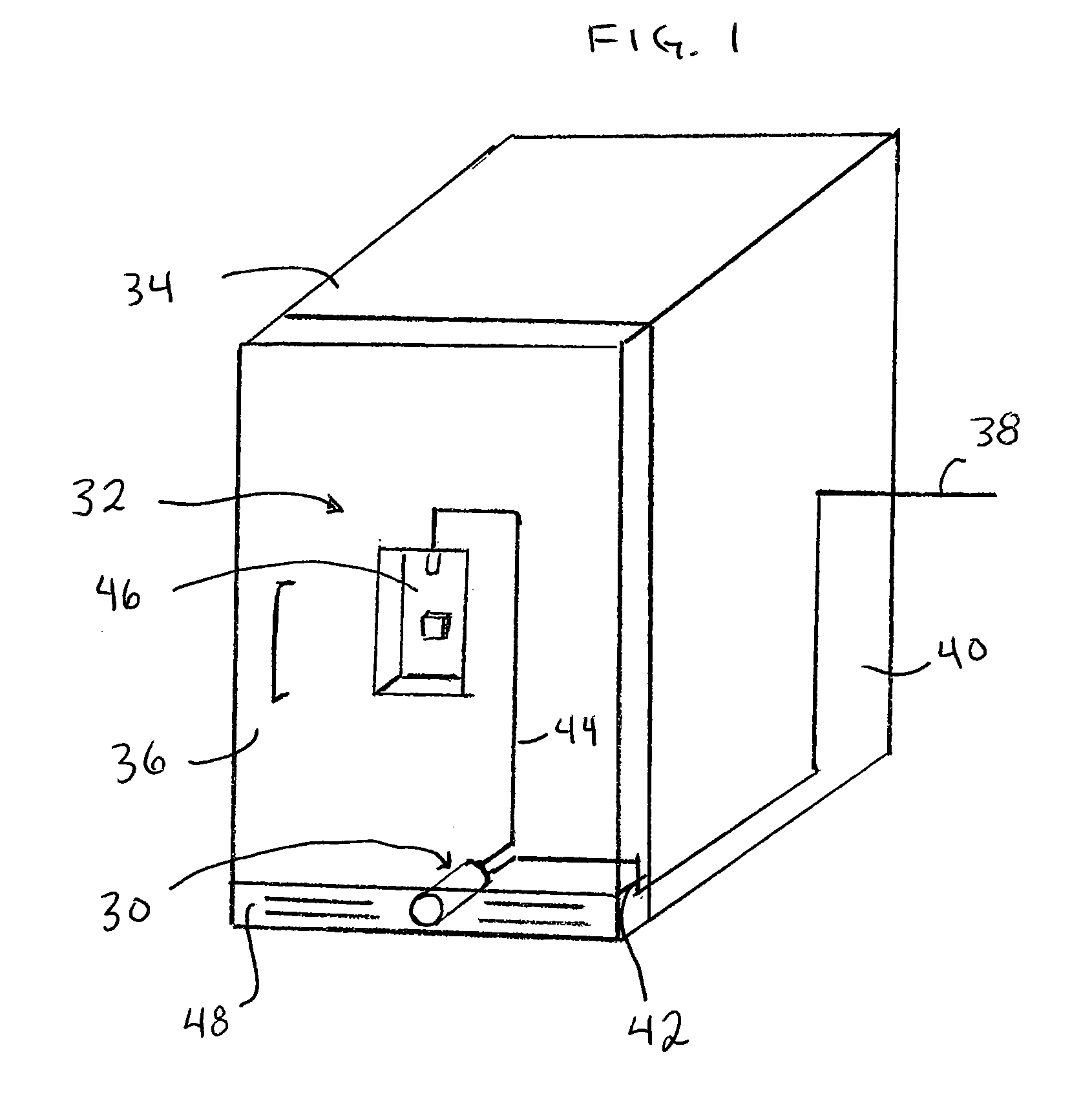

Water Filter Cartridge and Valve with Autobypass Feature

InactiveUS20080000820A1Avoid communicationSemi-permeable membranesOperating means/releasing devices for valvesWater filterValve actuator

A liquid filter cartridge system includes a housing, a valve body, a valve actuator, a filter, an inlet passage having a portion extending through each of the valve body and the valve actuator and into the filter, and an outlet passage having a portion leading out of the filter, and extending through each of the valve actuator and the valve body. An interface is located between the inlet passage portions in the valve actuator and the filter and an interface is located between the outlet passage portions in the valve actuator and the filter. The inlet passage interface and the outlet passage interface may lie in the same plane as each other. They may each comprise a face seal comprising an axial seal between the valve actuator and the filter. They may each comprise a seal between the valve actuator and the filter, wherein the two seals are sealed via compression and not via sliding contact.

Owner:WHIRLPOOL CORP

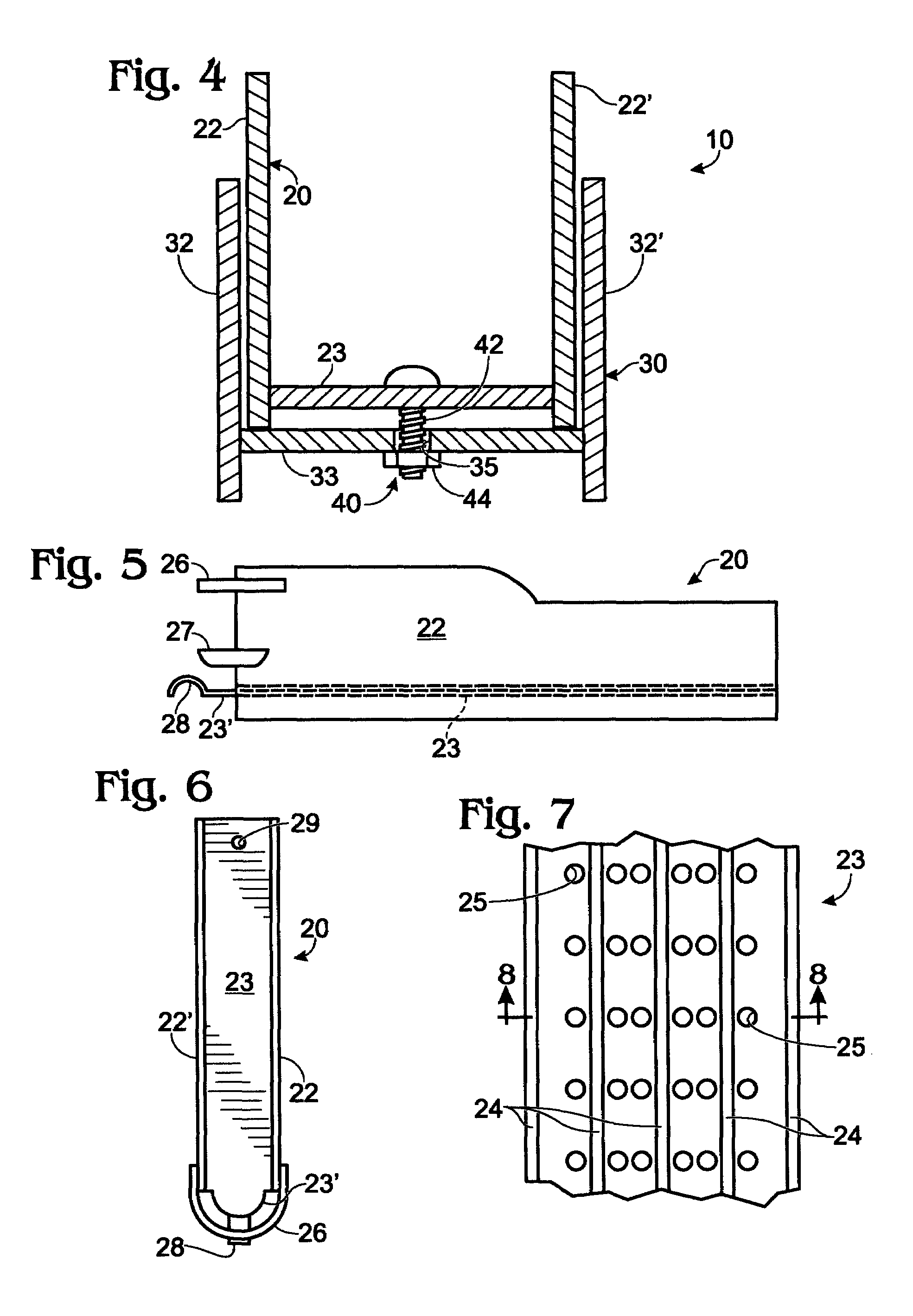

Display tray and rack assembly

A tray and rack assembly for beverage containers. The assembly includes a rack subassembly and a tray subassembly slidingly engaging said rack member. The tray subassembly includes a pair of substantially parallel tray sidewalls, a tray floor extending between the lower edges of the tray sidewalls, at least one beverage container stop member extending at least partially between the outer ends of the tray sidewalls, and a tray pull member extending from the outer end of the tray. The rack subassembly includes a pair of substantially parallel rack sidewalls, and a rack floor extending between the lower edges of the rack sidewalls. Sliding attachment means are adapted to hold the tray subassembly in sliding contact with the rack subassembly and permit the tray subassembly to be extended from and inserted into the rack subassembly.

Owner:KIM CHANG S

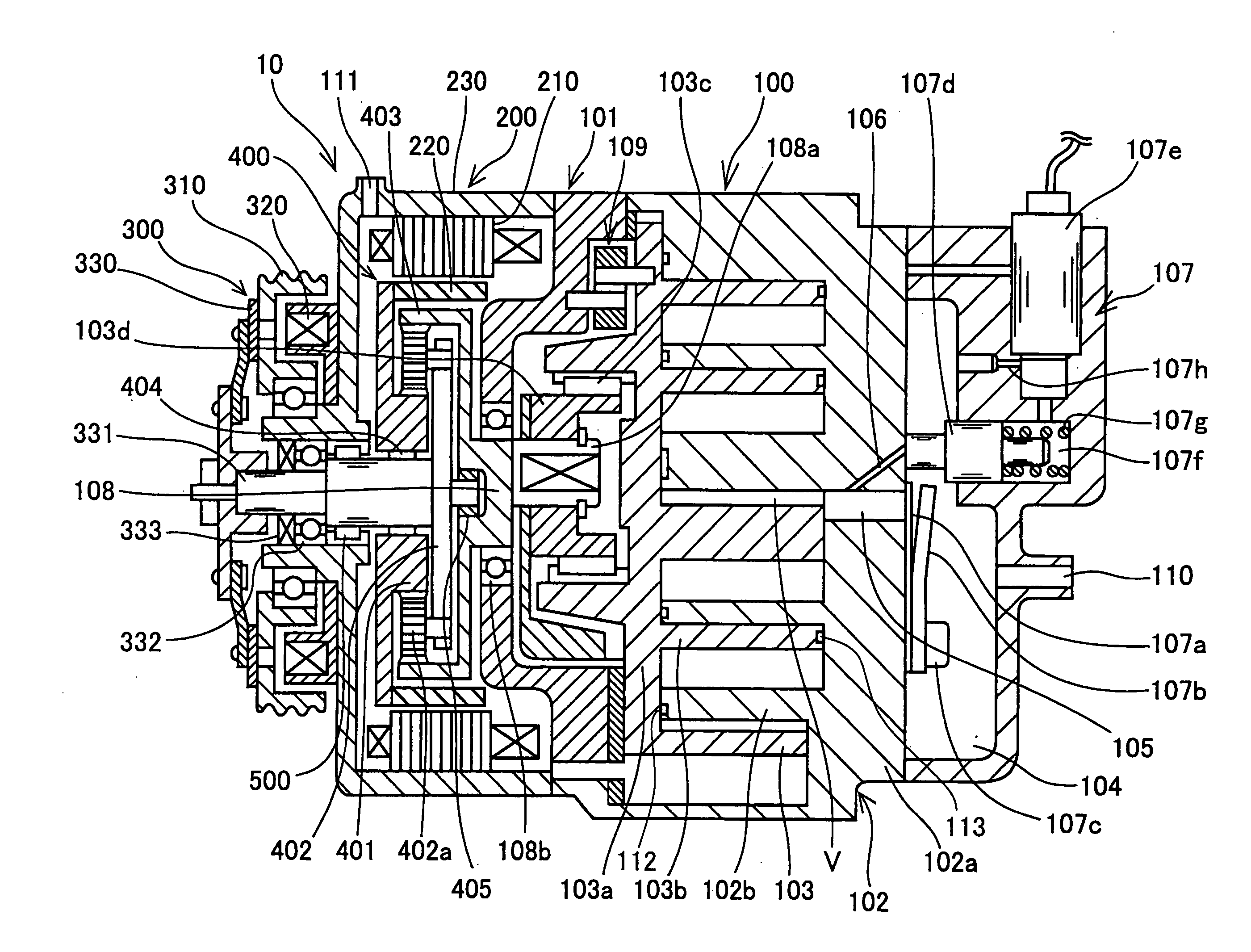

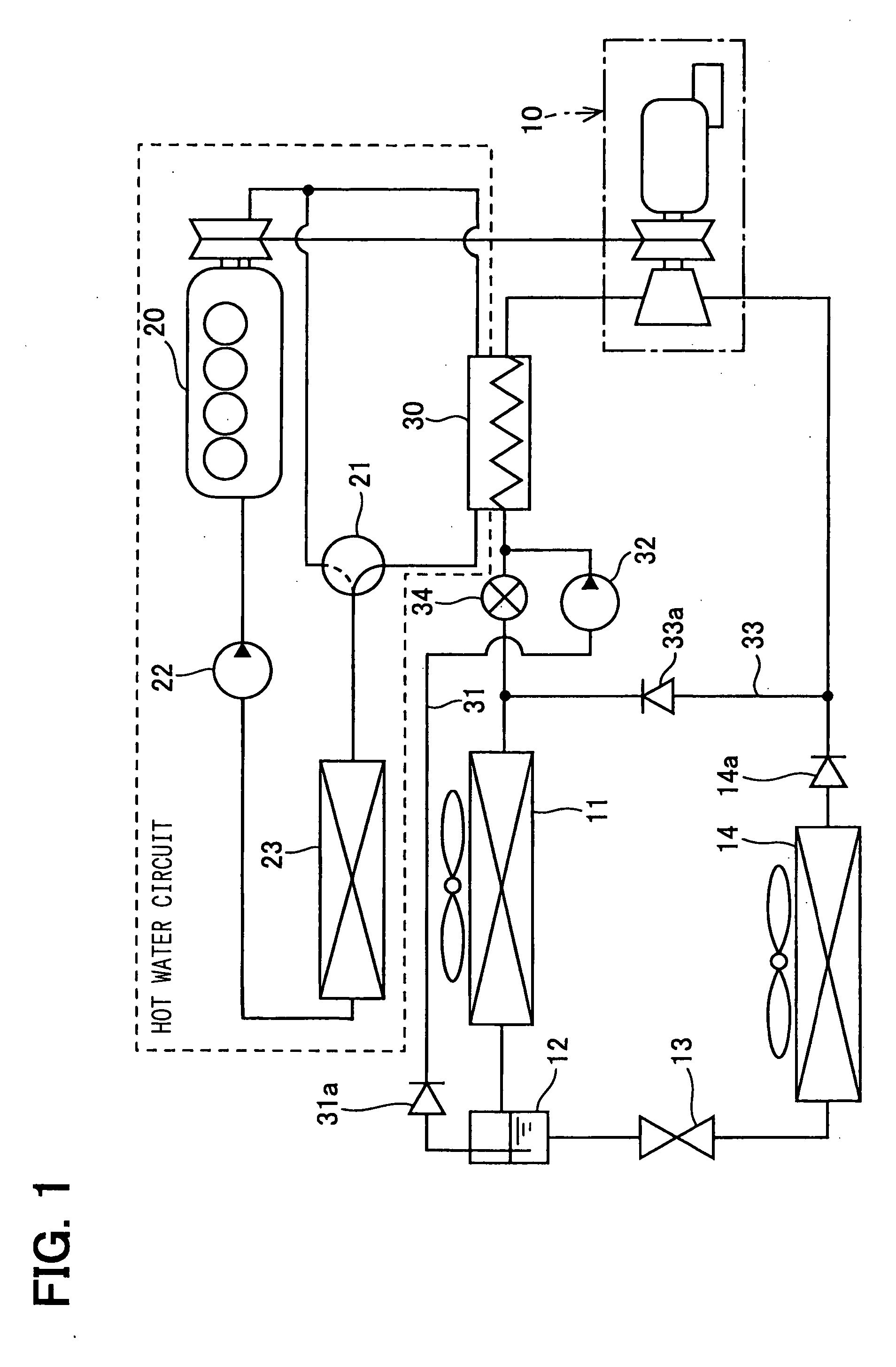

Fluid machine

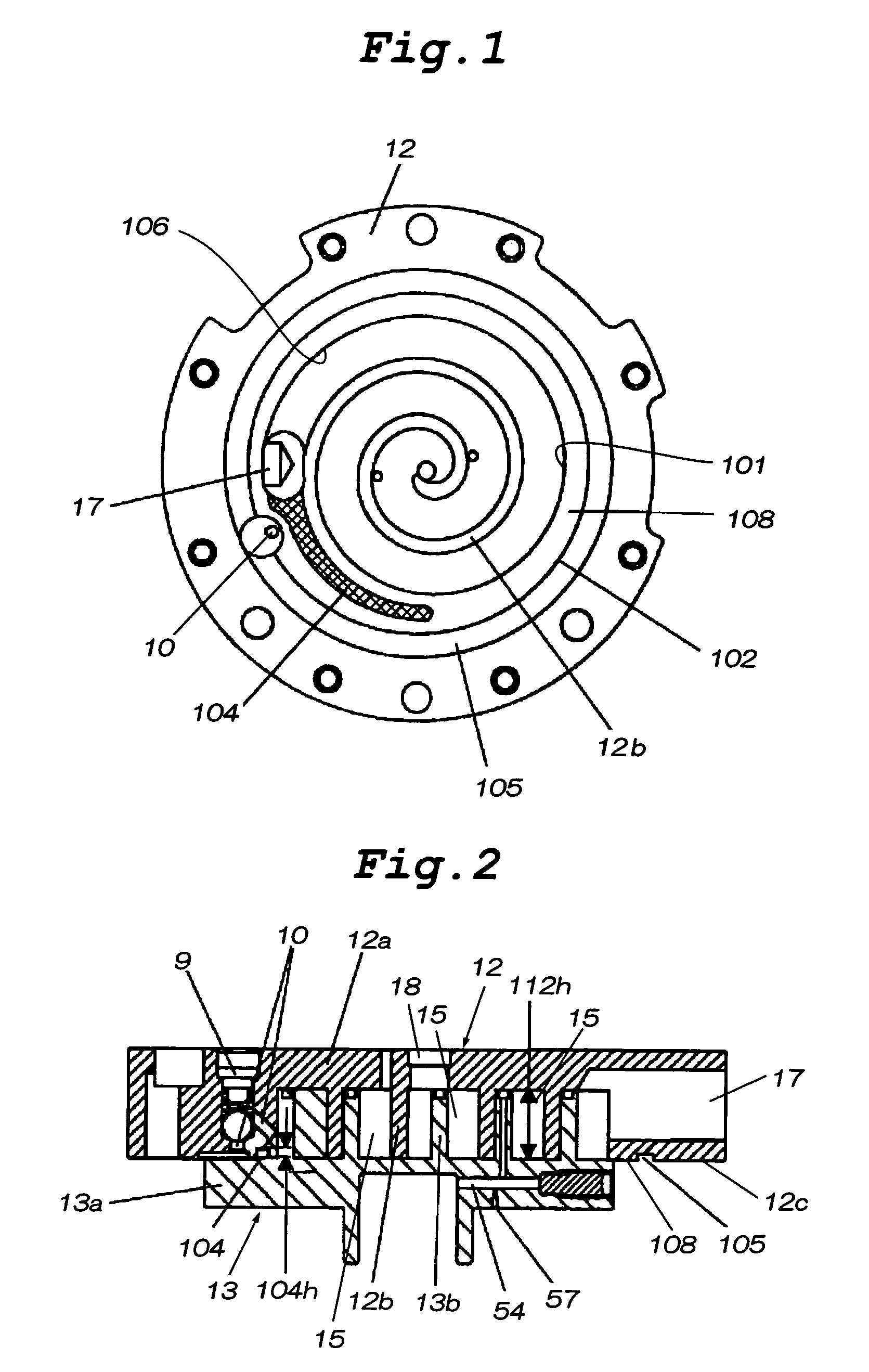

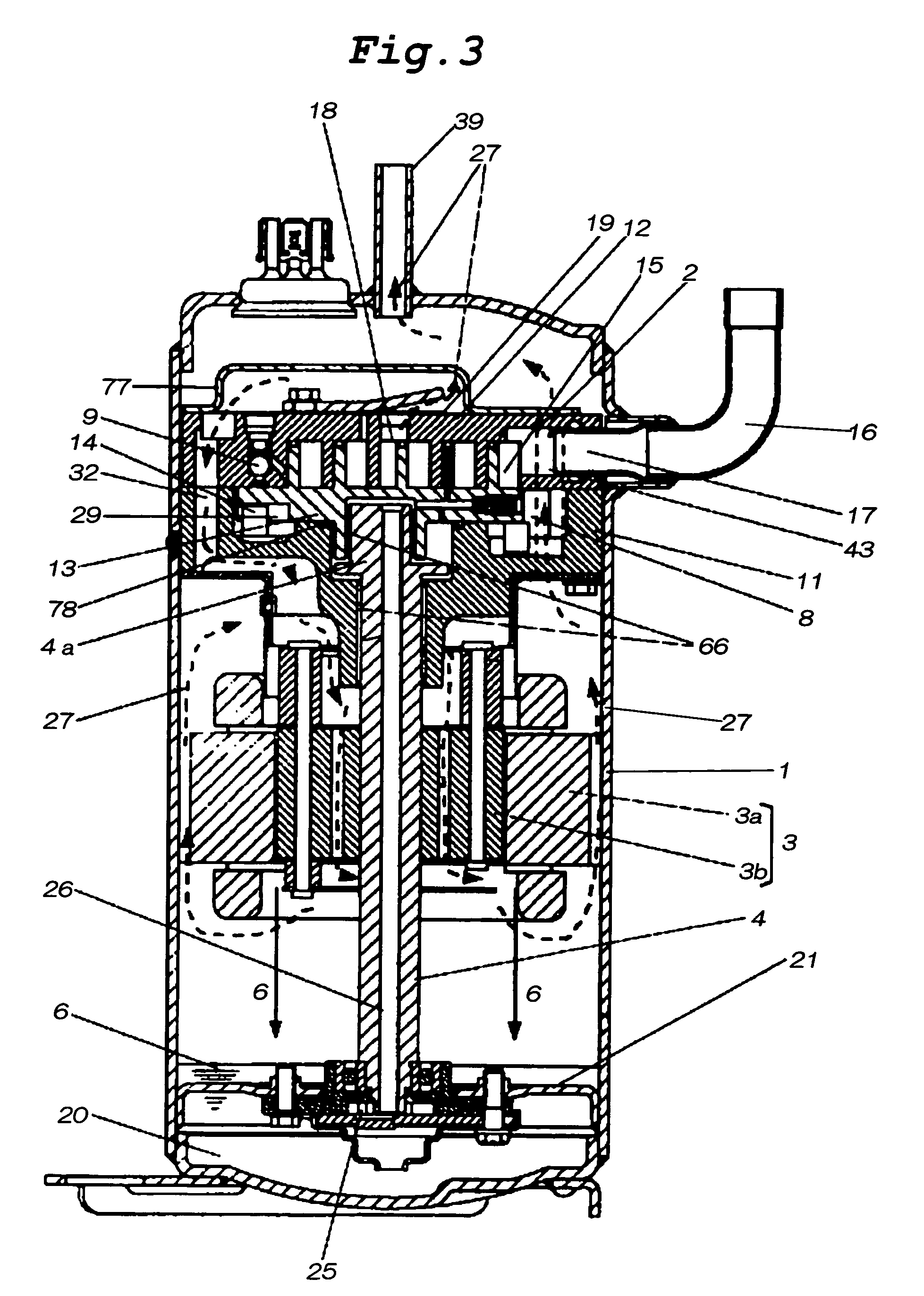

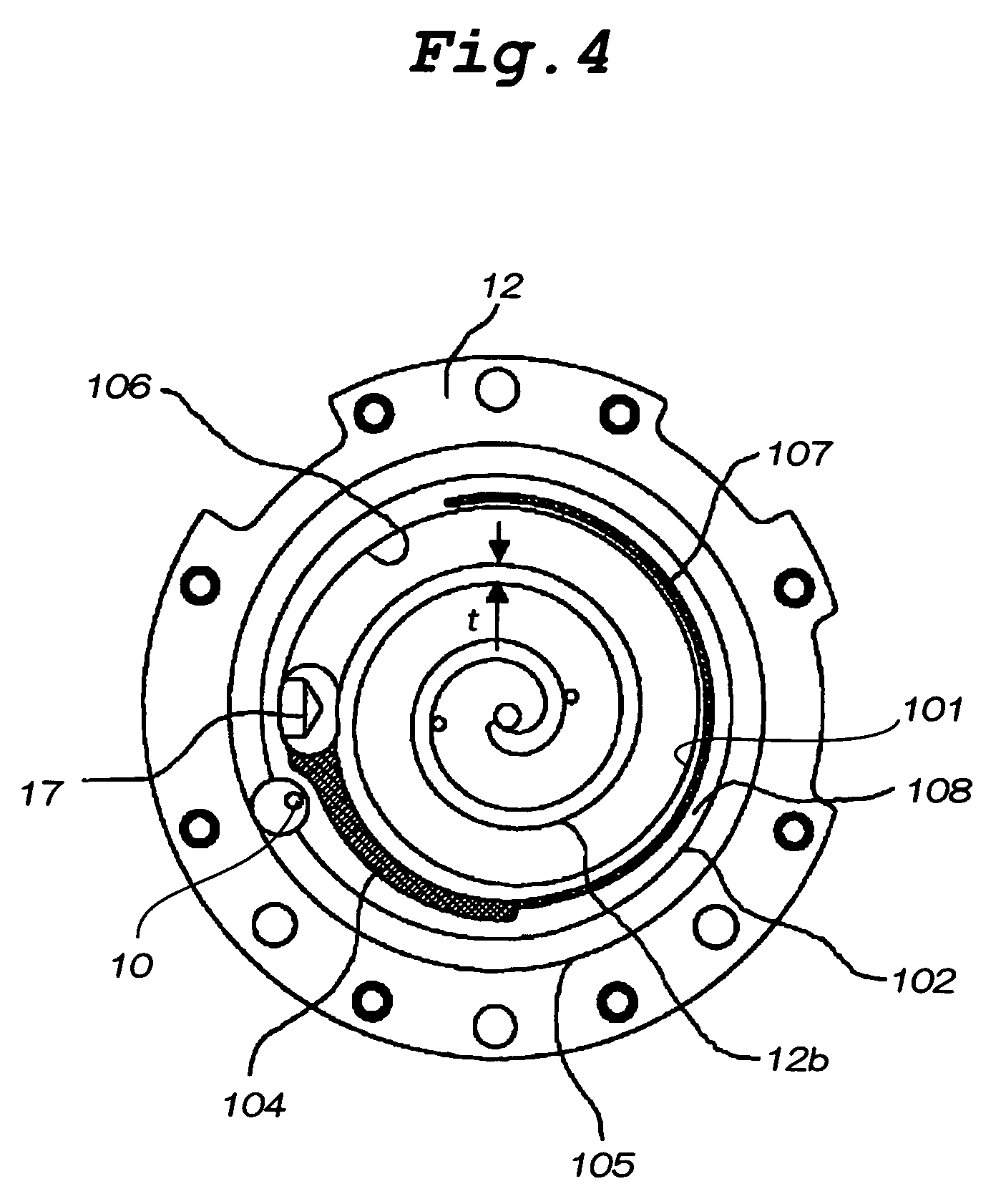

InactiveUS20050214148A1Improve sealingSmall sizeCompressorEngine of arcuate-engagement typeEngineeringSliding contact

An outer end of a seal element for a fixed scroll is extended to a position close to an end of an inside spiral wall of the fixed scroll, and an outwardly extended portion is formed at an outer periphery of a disc-shaped base plate of a movable scroll, so that a bottom surface of the movable scroll is always kept in a sliding contact entirely with the seal element during the orbital movement of the movable scroll. A thickness of the outwardly extended portion formed at the outer periphery of the disc-shaped base plate is made smaller than that of the disc-shaped base plate, so that the weight of the fluid machine can be smaller.

Owner:NIPPON SOKEN +1

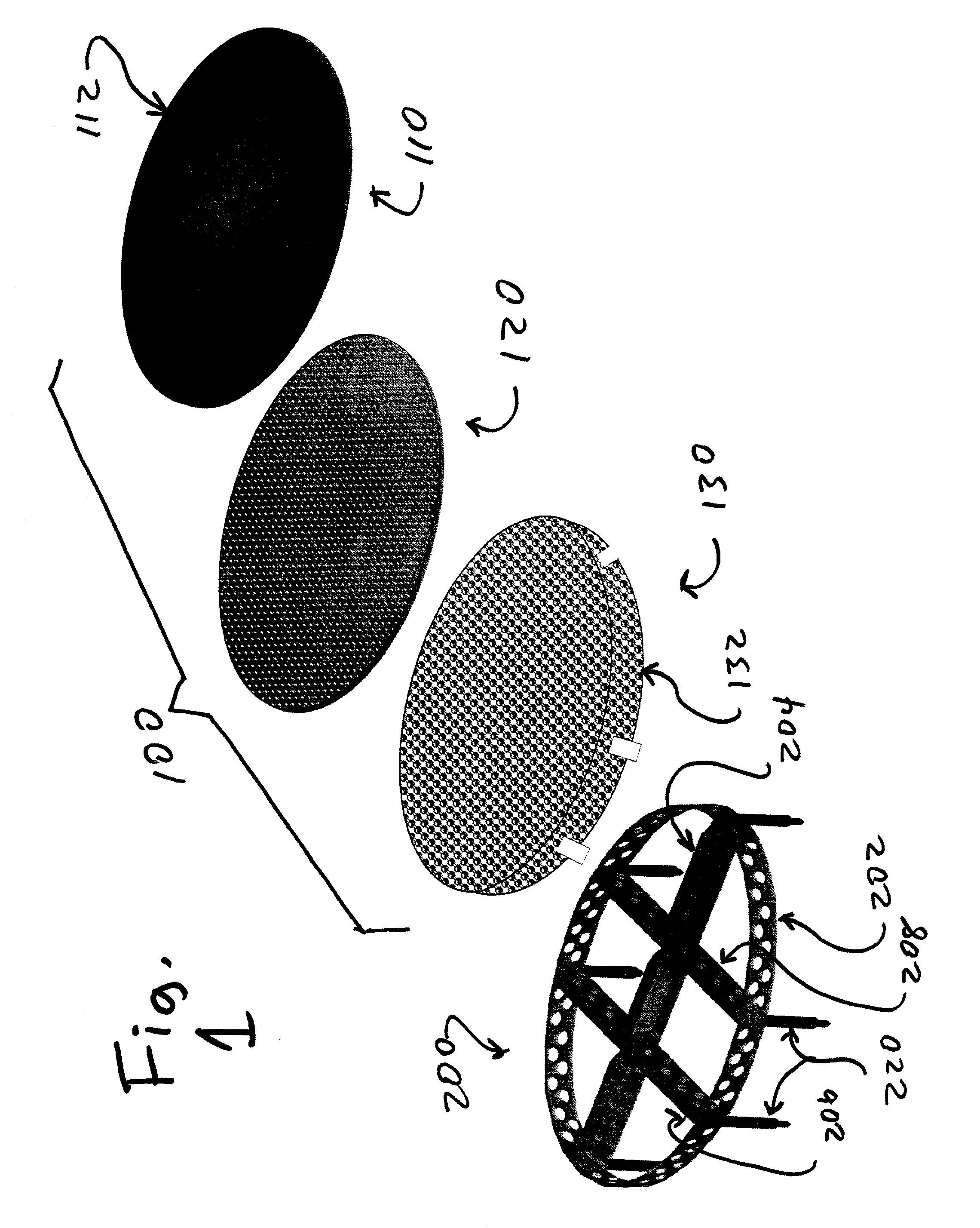

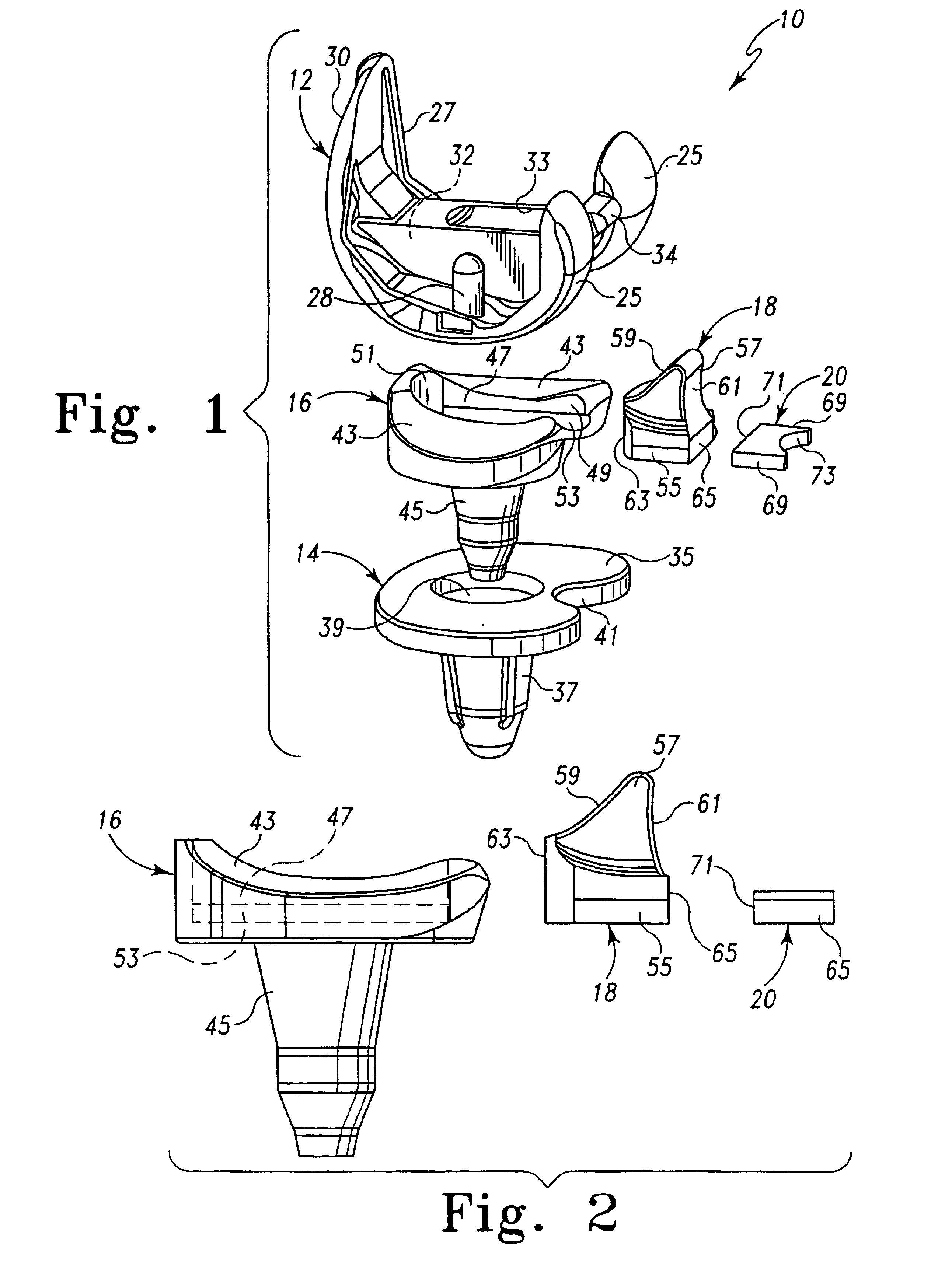

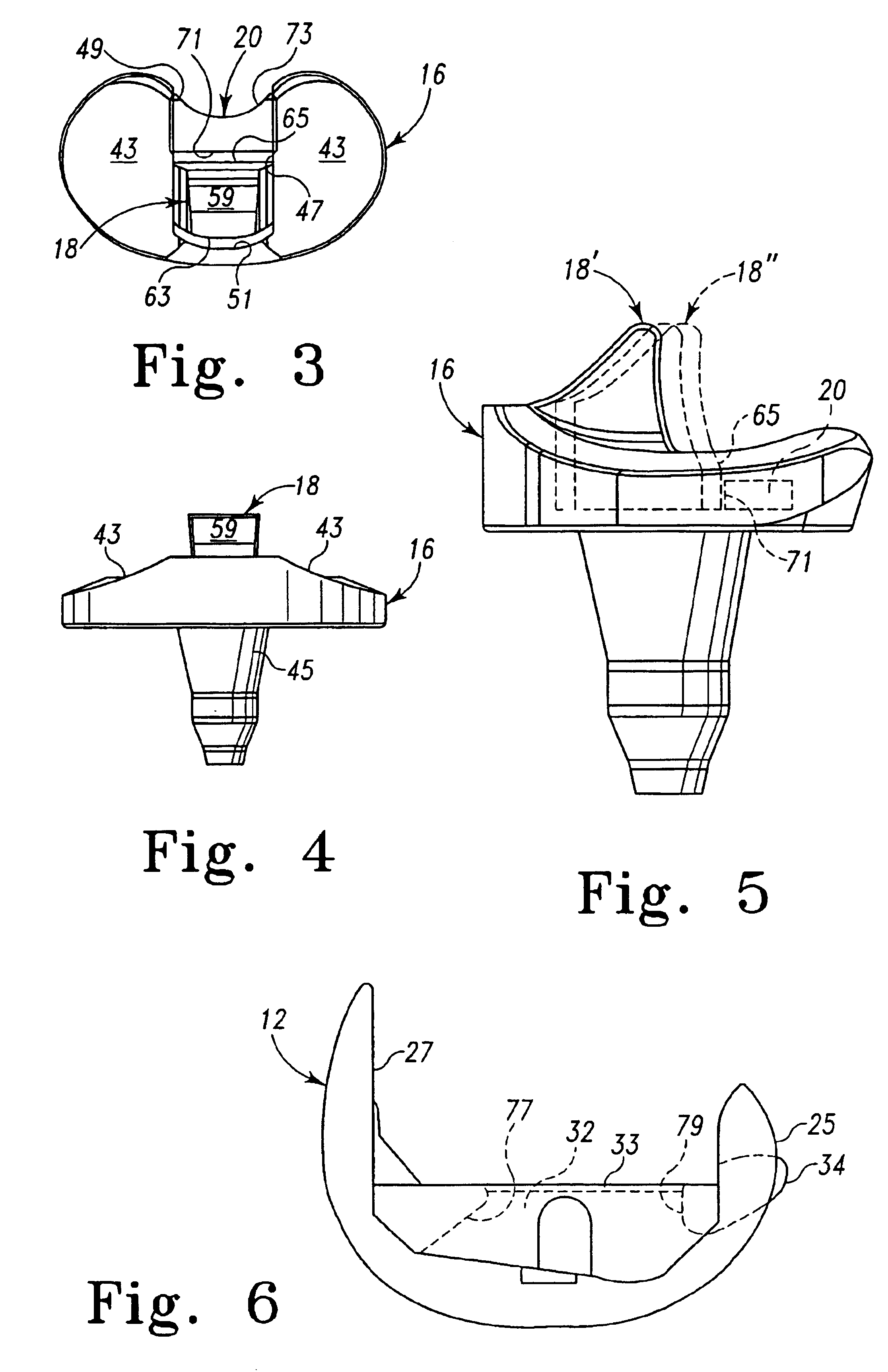

Modular knee joint prosthesis

A knee joint prosthesis includes a femoral component for engaging the femur having an articular surface and a recess within the articular surface, and a tibial component for engaging the tibia with a bore, and a meniscal component comprising a rotation pin configured for rotatable mounting within the bore of the tibial component. The meniscal component also includes a bearing surface for sliding contact with the articular surface of the femoral component and an elongated channel defined amid the bearing surface. A stabilizing post is provided that includes a base slidably mounted with the elongated channel and a spine post projecting from the base through the channel and into the recess when the articular surface is in contact with said bearing surface. The stabilizing post thus slides within the channel when contacted by the interior of the recess in the femoral component.

Owner:DEPUY ORTHOPAEDICS INC

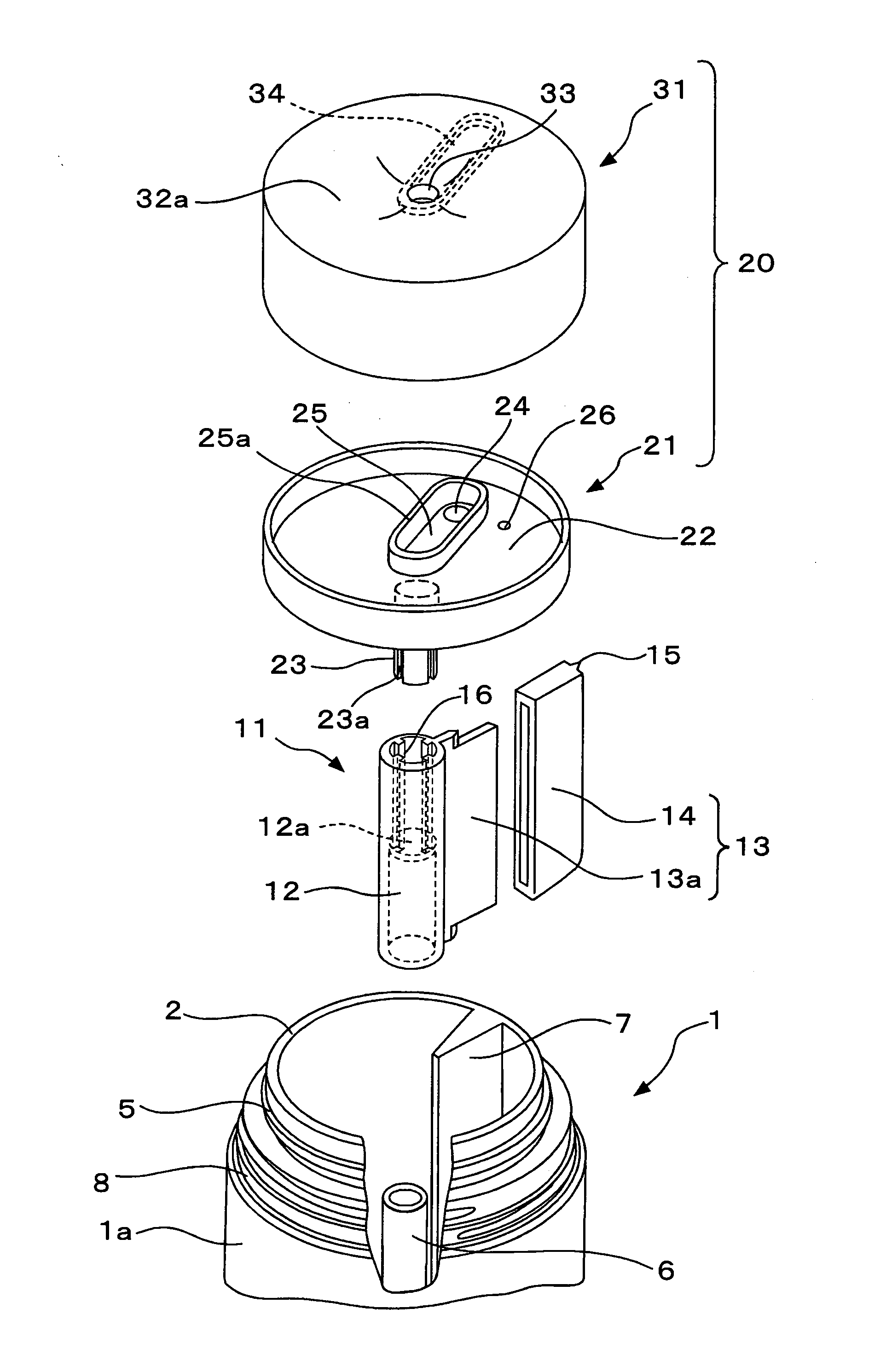

Discharge Container

InactiveUS20070205226A1Little resistanceGuaranteed uptimeVolume measurement and fluid deliveryLarge containersEngineeringSoft materials

A discharge container includes a cylindrical container body with a bottom which includes a support extending upward from a bottom wall along a center axis, and a fixed partitioning plate extending from a region from a peripheral wall to a bottom wall as a base end to partition the inside of the container body in a radial direction; a rotor which includes a cylindrical shaft piece rotatably engaging with the outer surface of the support, and a rotatable partitioning plate extending from the cylindrical shaft piece as a base end to be arranged in a radial direction along with the fixed partitioning plate; and a cylindrical lid with a top which has a top wall having a saucer-shaped upper surface, and a downwardly extending shaft extending downwardly from the lower surface of the top wall and engaging with the cylindrical shaft piece from above such that the downwardly extending shaft cannot rotate therein, the lid covering the cylindrical opening as a lid and rotatably engaging with the cylindrical opening, wherein the edge of the fixed partitioning plate is brought into sliding contact with the cylindrical shaft piece; the edge of the rotatable partitioning plate is formed by a spatula-shaped sliding member made of soft material and is brought into sliding and linear contact with an area from the peripheral wall to the bottom wall of the container body; the lower surface of the top wall is brought into sliding contact with the upper end surfaces of the cylindrical opening and the fixed partitioning plate and brought into contact with the upper end surface of the rotatable partitioning plate; and contents are pressed by relative rotation between the container body and the lid and are discharged through a discharge opening provided on the top wall.

Owner:THE PROCTER & GAMBLE COMPANY +1

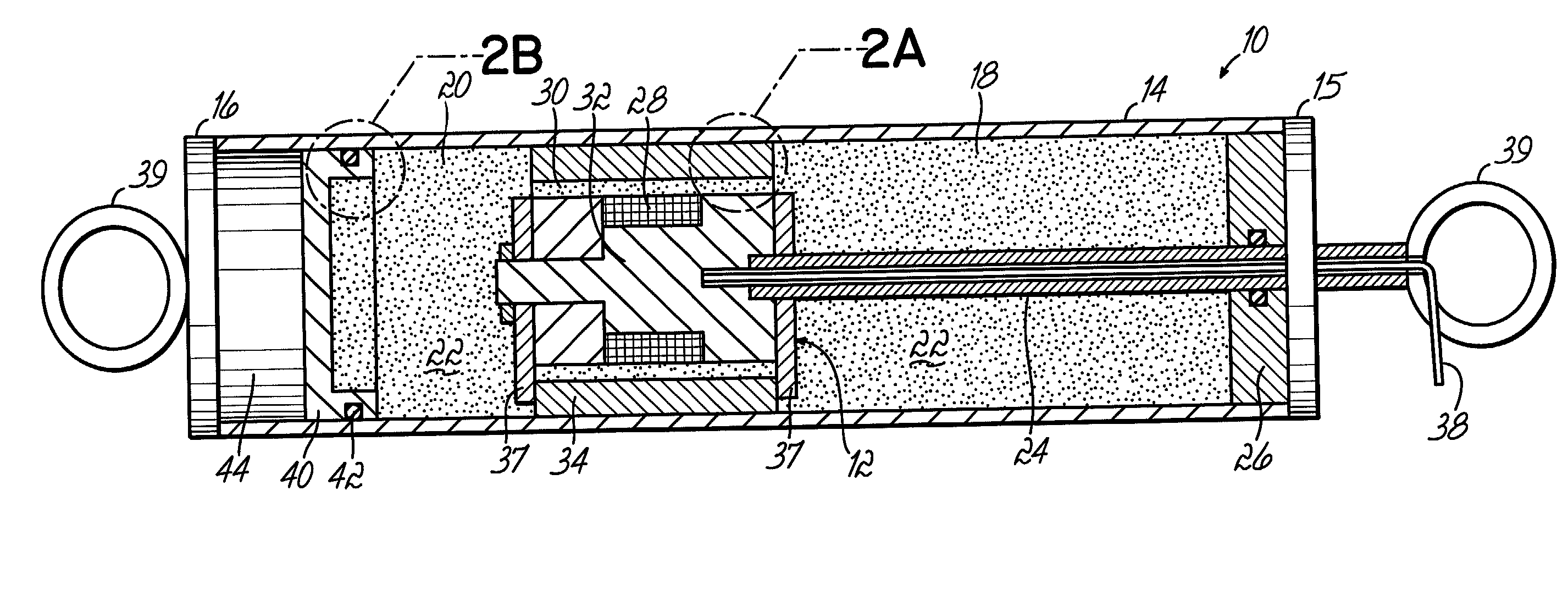

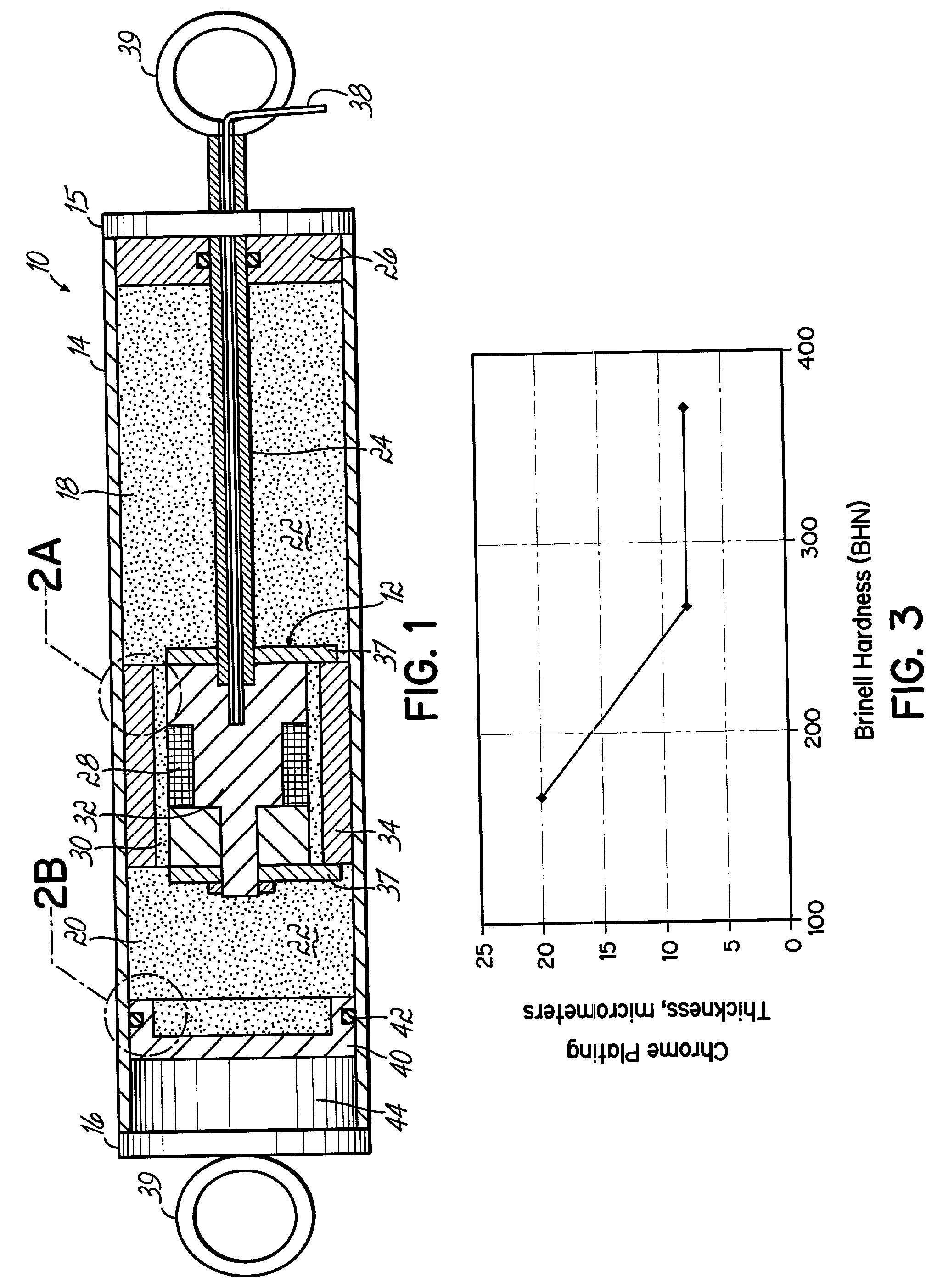

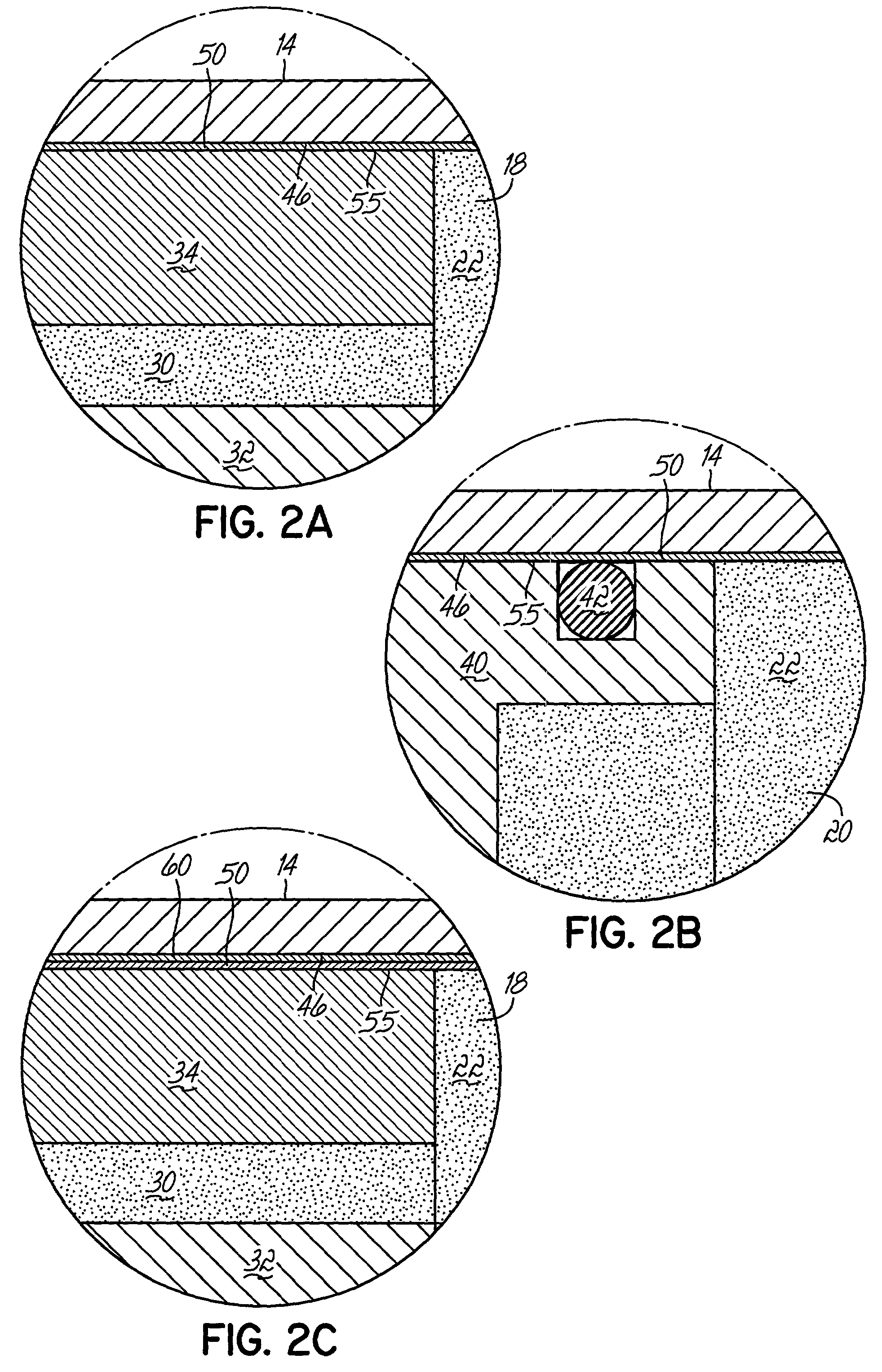

Magnetorheological dampers with improved wear resistance

InactiveUS20020130003A1Improve wear resistanceIncrease effective viscositySpringsNon-rotating vibration suppressionEngineeringHardness

A damper body for a magnetorheological (MR) damper and associated methods of forming the damper body. The damper body is formed of a base material, such as a steel, and is coated with an abrasion-resistant layer comprising chromium. The layer of chromium provides a sliding wear surface for sliding contact with a reciprocating piston. To avoid high-stress abrasive wear over the expected service life of the magnetorheological damper, the layer of chromium has a minimum thickness greater than or equal to a minimum thickness of about 8 .mu.m. In other embodiments, be fore applying the abrasion-resistant layer of chromium, the damper body is coated with a layer of a hard coating material having a hardness greater than the hardness of the base material. The effective hardness of the damper body is a composite of the respective hardnesses of the base material comprising the damper body and the layer of hard coating material. The thickness of abrasion-resistant layer of chromium is chosen in direct relation to the effective hardness.

Owner:BWI CO LTD SA +1

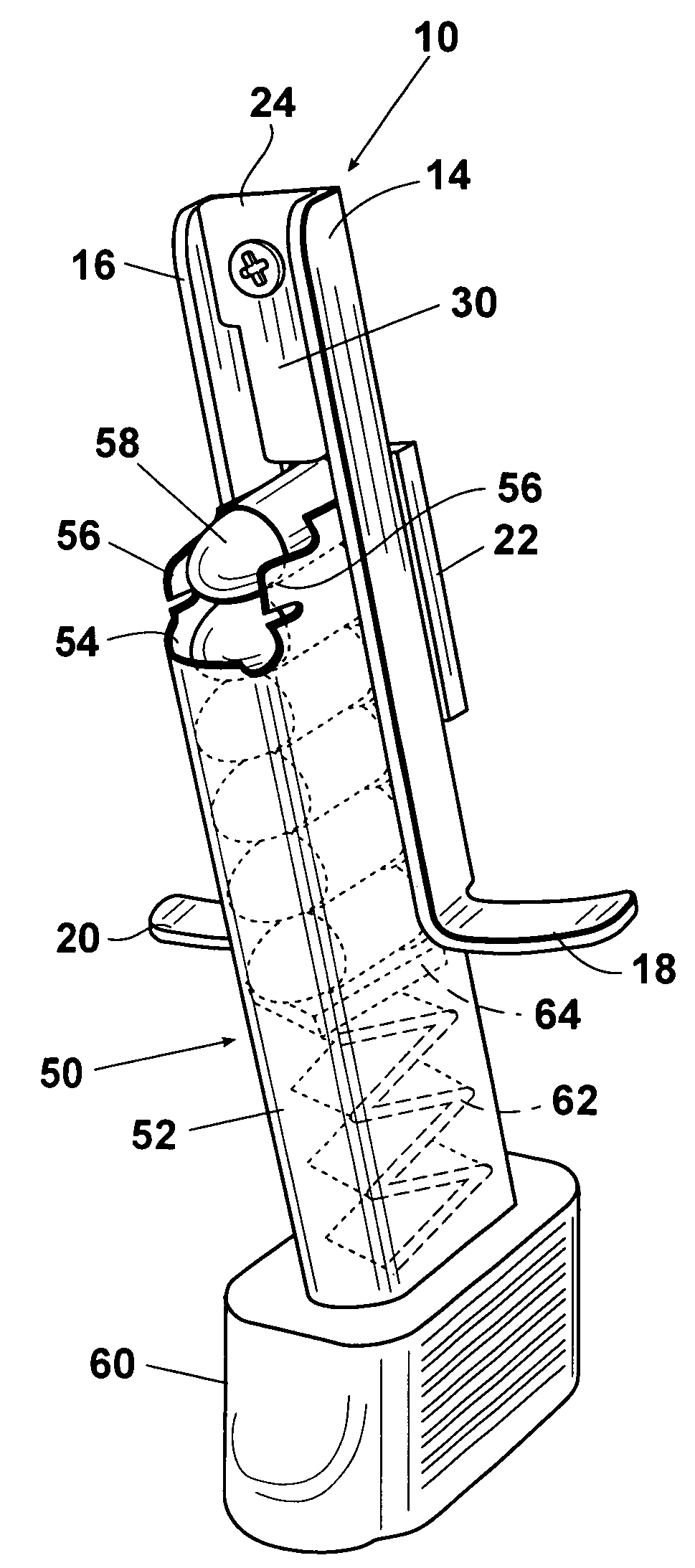

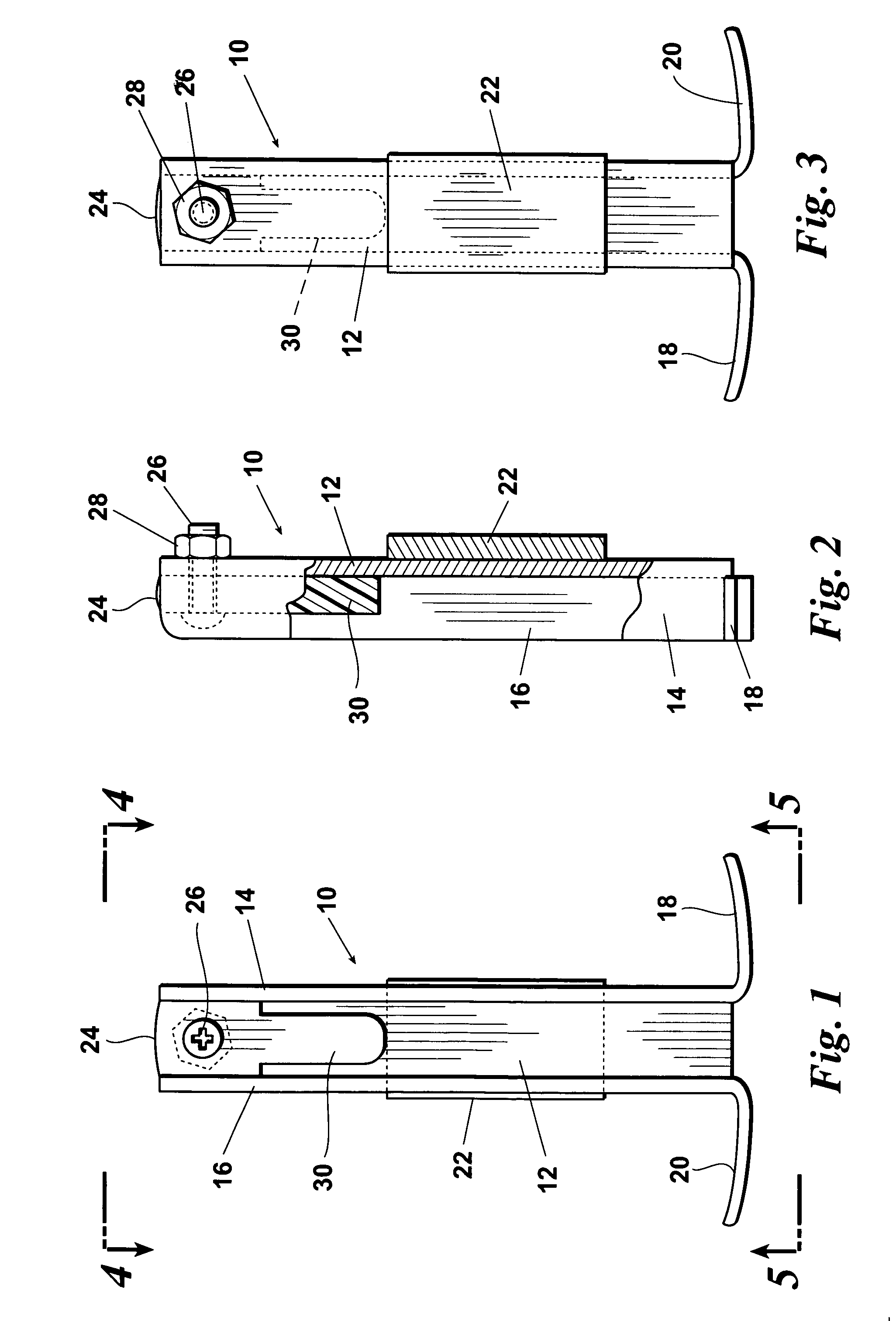

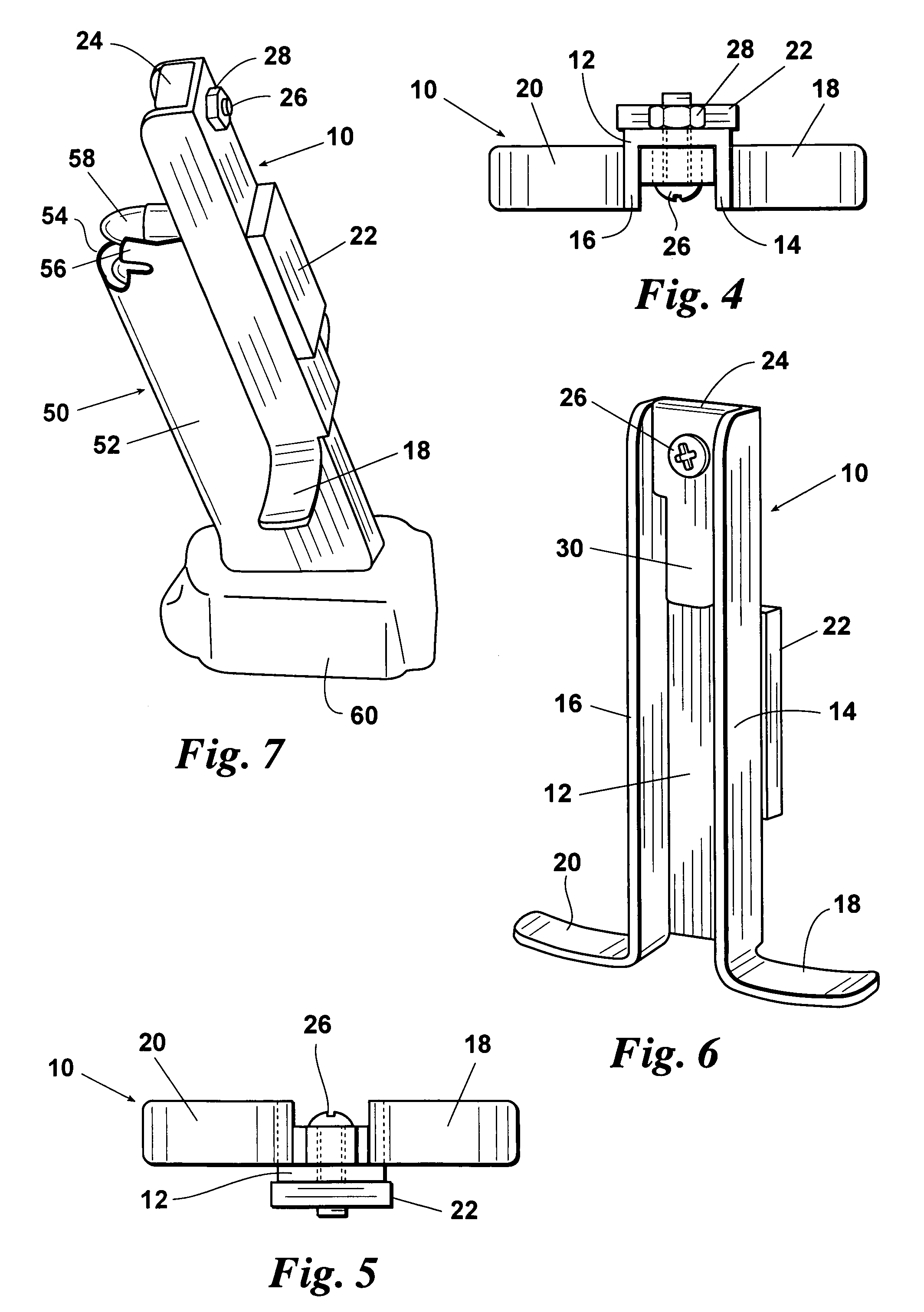

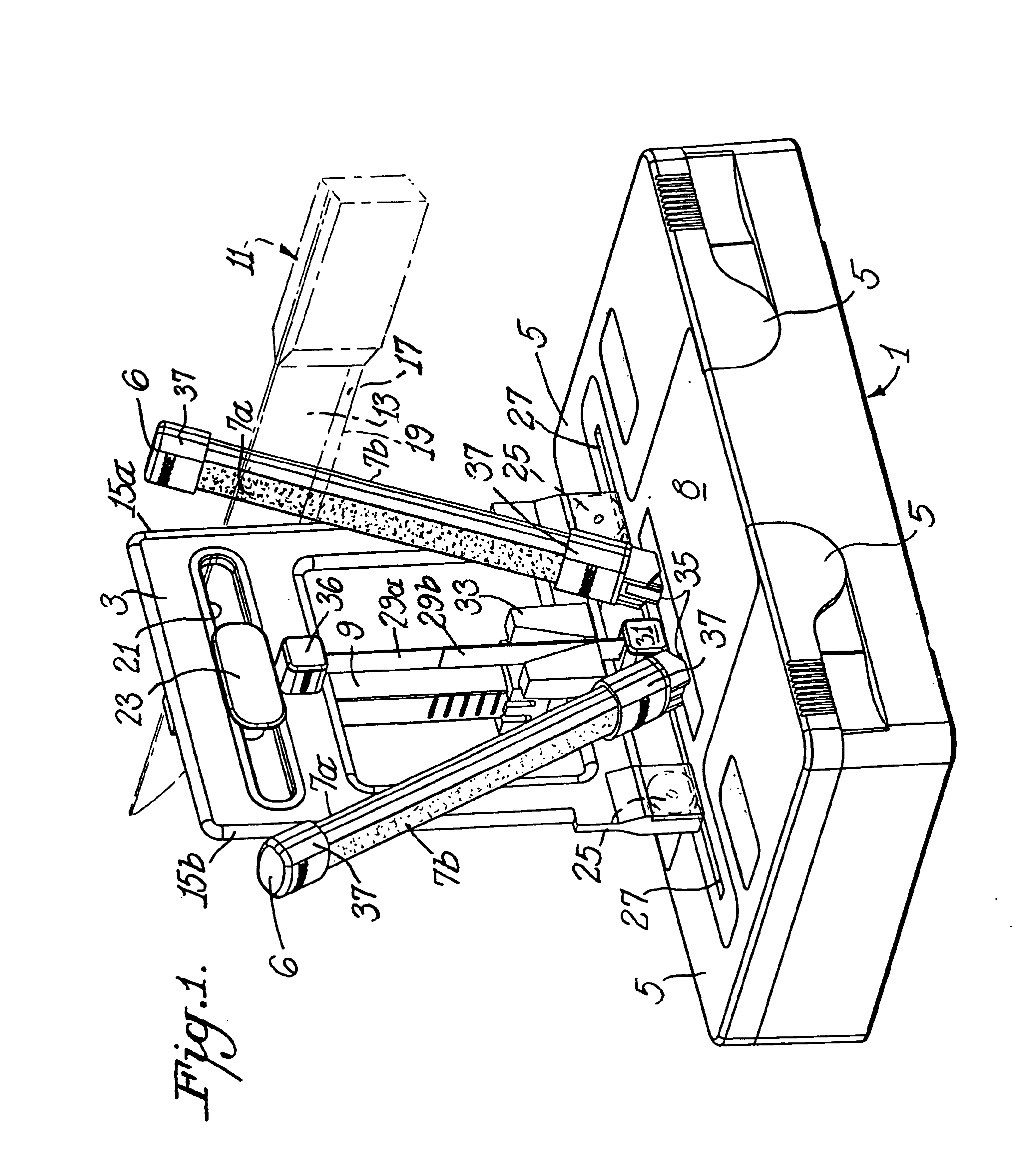

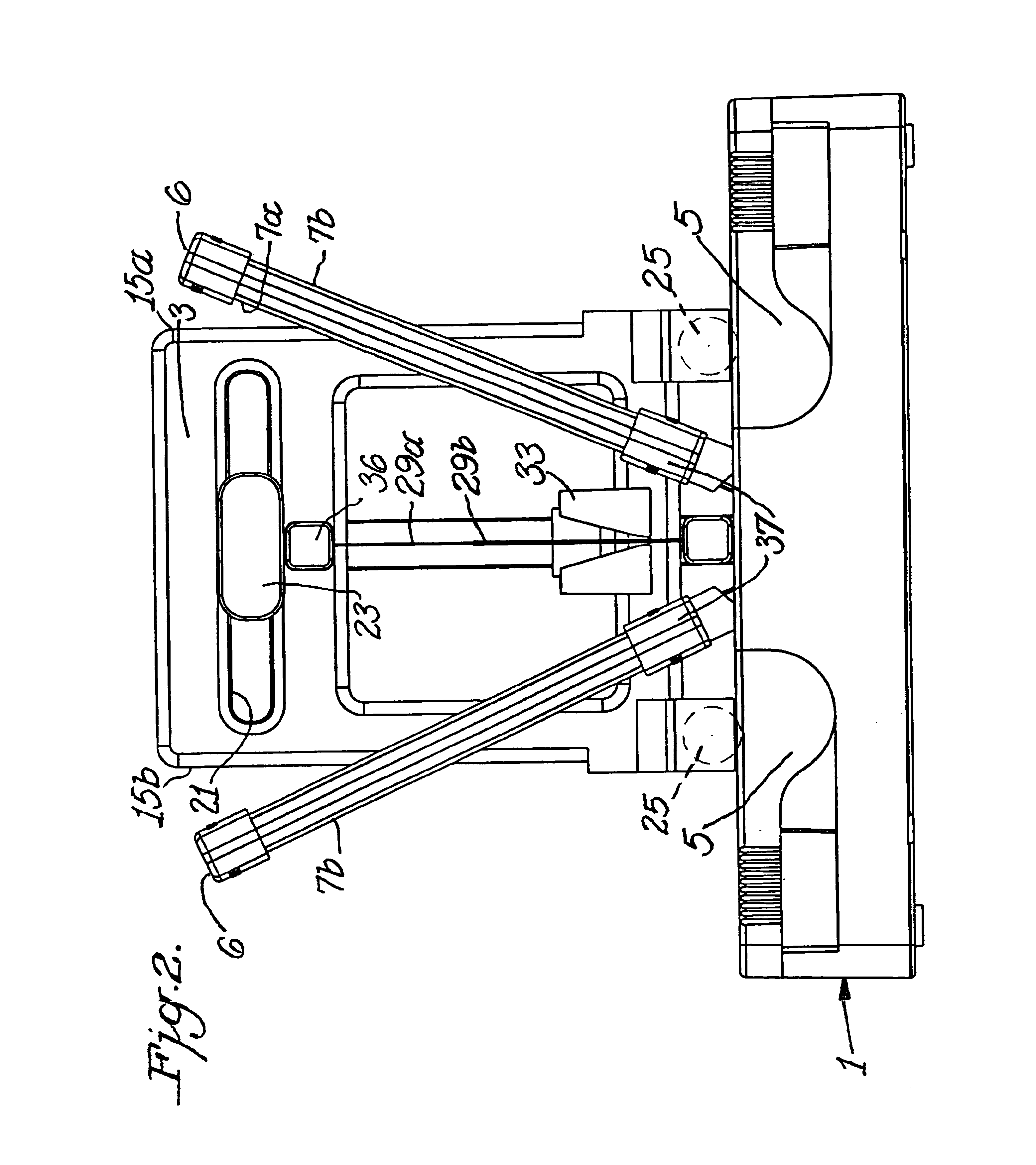

Magazine loader

A loader for a magazine having an upper open end, a lower closed end, a forward vertical side edge and a rear vertical flat side edge, loader having a vertical channel for receiving therein the rear flat edge of the cartridge, the channel being formed by a pair of flat vertical side members spaced apart in parallel relation and having a rear flat edge where it slidably engages the rear flat edge of the magazine, the magazine being made of ferrous metal and the loader being made of non-ferrous material. A vertically extending tab is mounted in the upper portion of the channel and is provided with a downwardly vertically extending plunger mounted at the lower end of the tab for engaging the edge of an uppermost bullet mounted within the magazine. A pair of outwardly and horizontally extending arms are mounted at the lower ends of the flat vertical sides of the loader, the magazine being adapted to receive a plurality of vertically stacked bullets therein, a spring mounted internally in the magazine for urging the bullets upwardly towards the open end of the magazine and against a retaining means which holds the bullets within the magazine whereby, when the user's fingers engage the arms on the loader and urge the loader downwardly against the action of the spring within the magazine, the uppermost bullet is urged away from the retaining means at the top of the magazine and whereby an additional bullet can be inserted into the magazine above the then uppermost bullet after which the loader can be slid upwardly so that the plunger is completely above the last added bullet to permit the last added bullet to be pushed in by hand against the inner flat edge of the magazine, the loader being maintained in sliding contact within the magazine by virtue of a magnet mounted on the rear of the loader.

Owner:FARLEY II ALLEN D

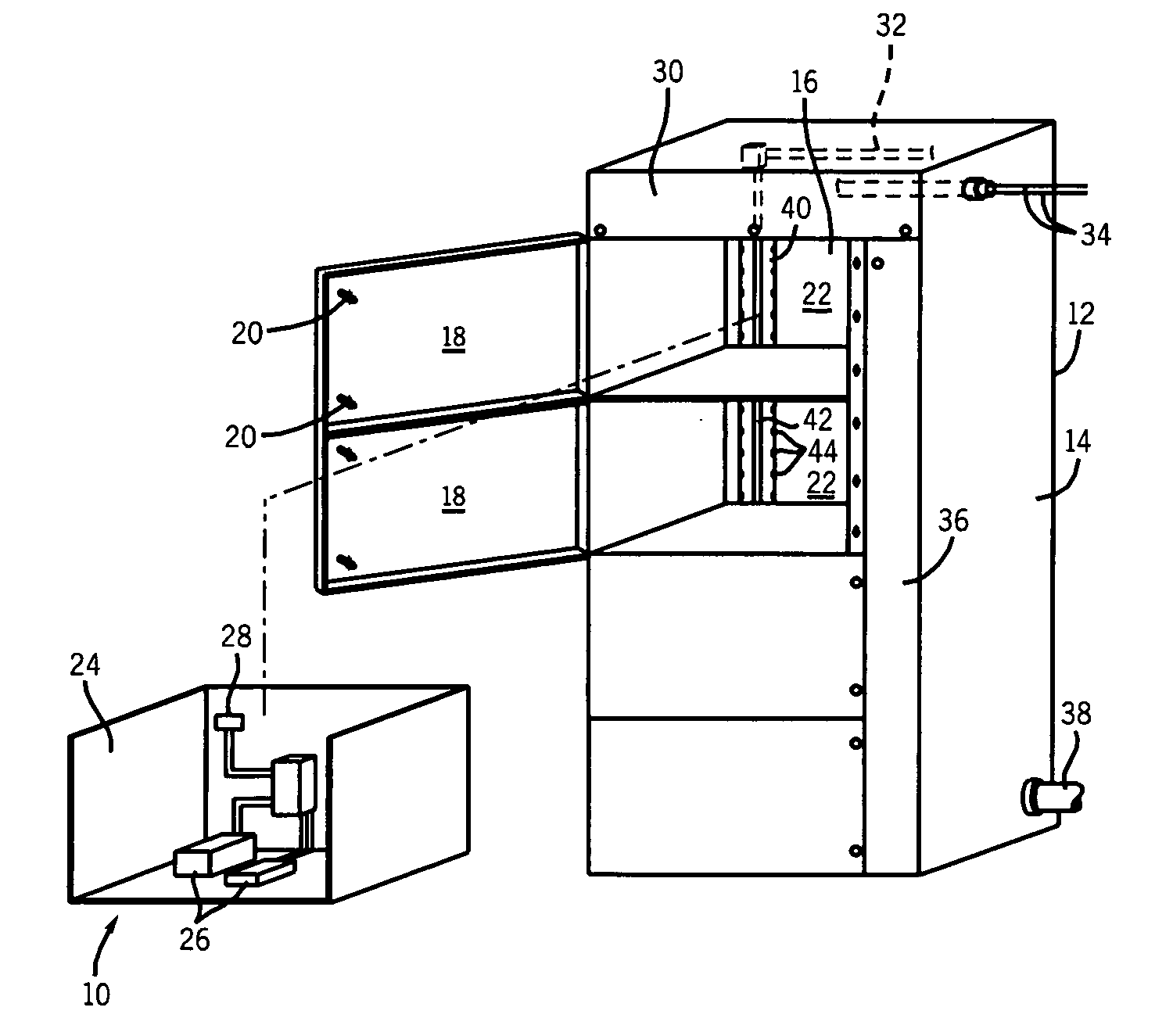

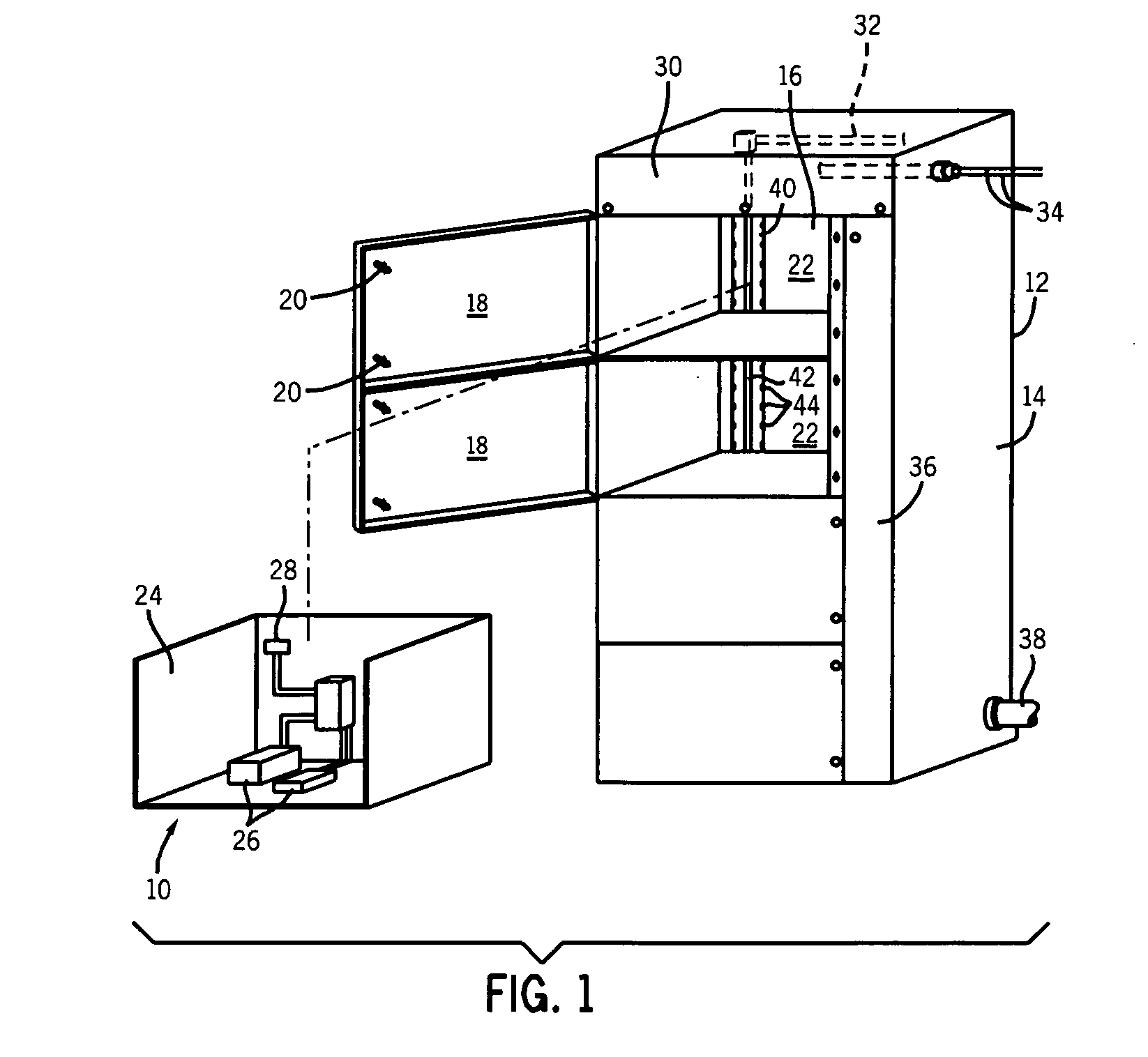

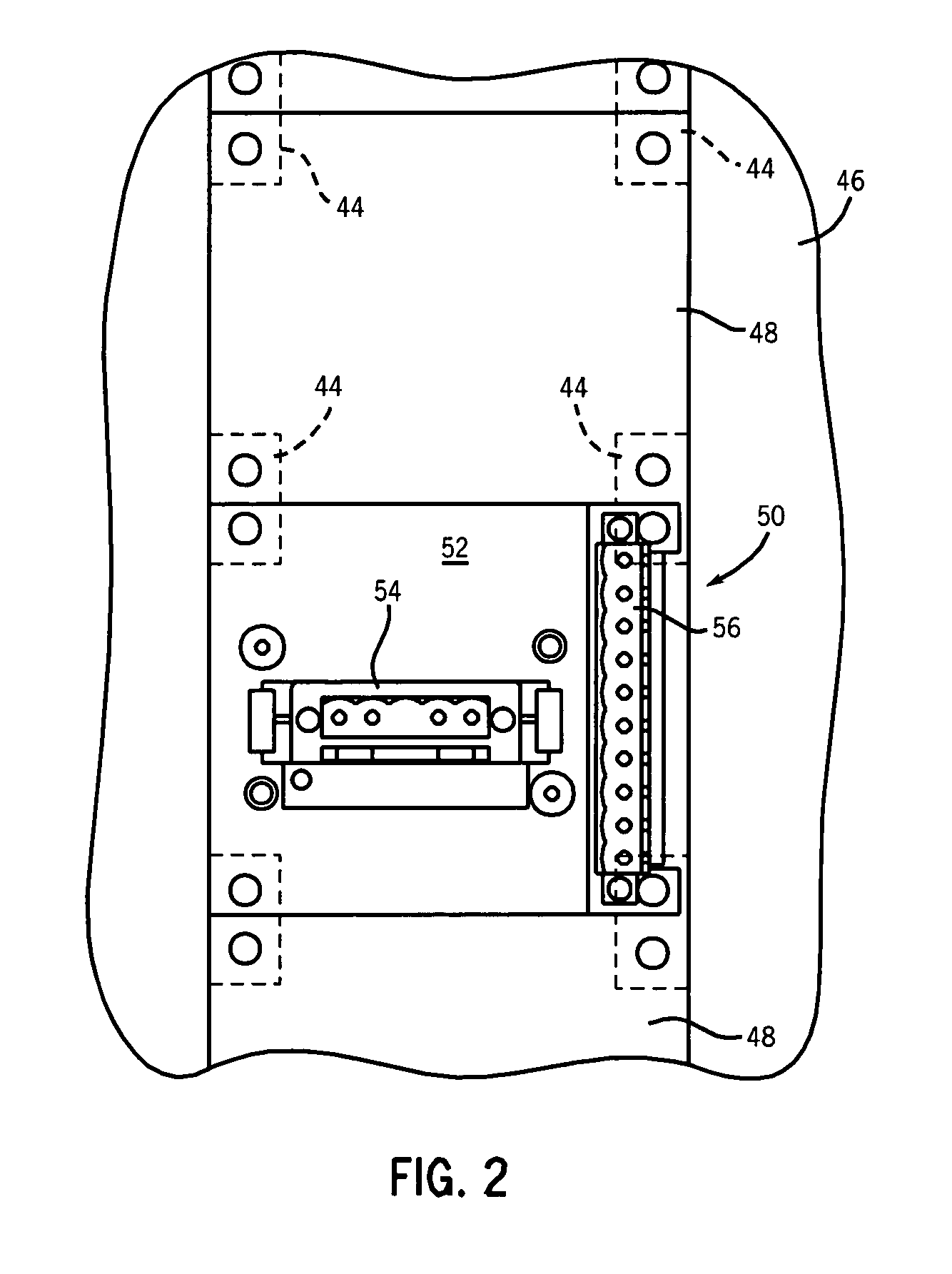

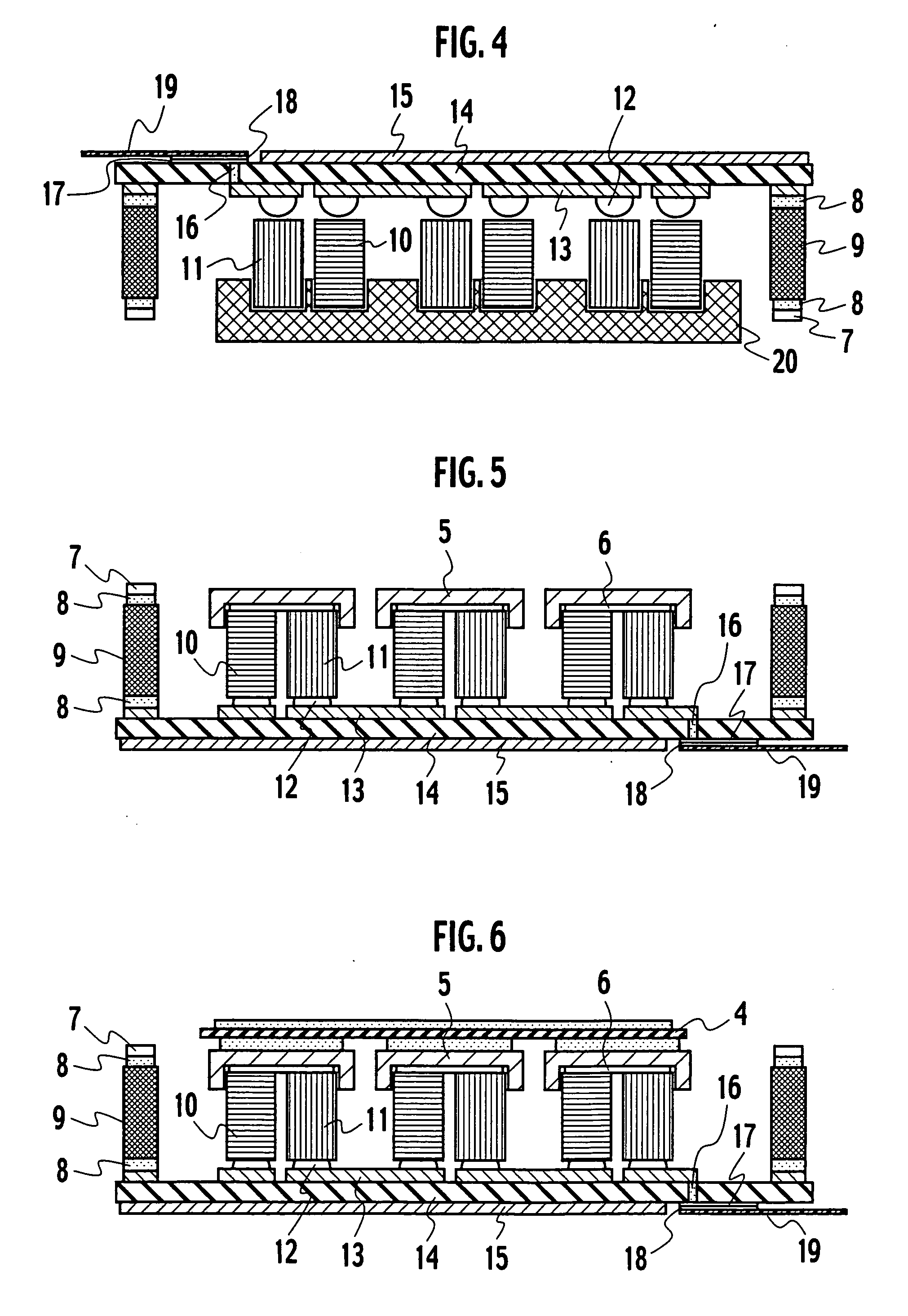

Electrical system having withdrawable unit with maintained control and communication connection

ActiveUS20070111575A1Firmly connectedSubstation/switching arrangement detailsIncorrect coupling preventionControl powerNetwork connection

A connector arrangement is provided for packaged electrical systems, such as motor control centers. The connector arrangement provides for a component connector assembly mounted to component supports for providing network signals and control power to components on the support. A mating prewired connector assembly is provided in the enclosure and forced to mate with the component connector assembly when the component support is fully engaged within the enclosure. Thereafter, the component support may be partially withdrawn from the enclosure to disconnect main power from the component support, while leaving network connections and control power connections by virtue of the mated connectors. The connectors provide for non-sliding contact both when fully engaged and when the components are partially withdrawn from the enclosure.

Owner:ROCKWELL AUTOMATION TECH

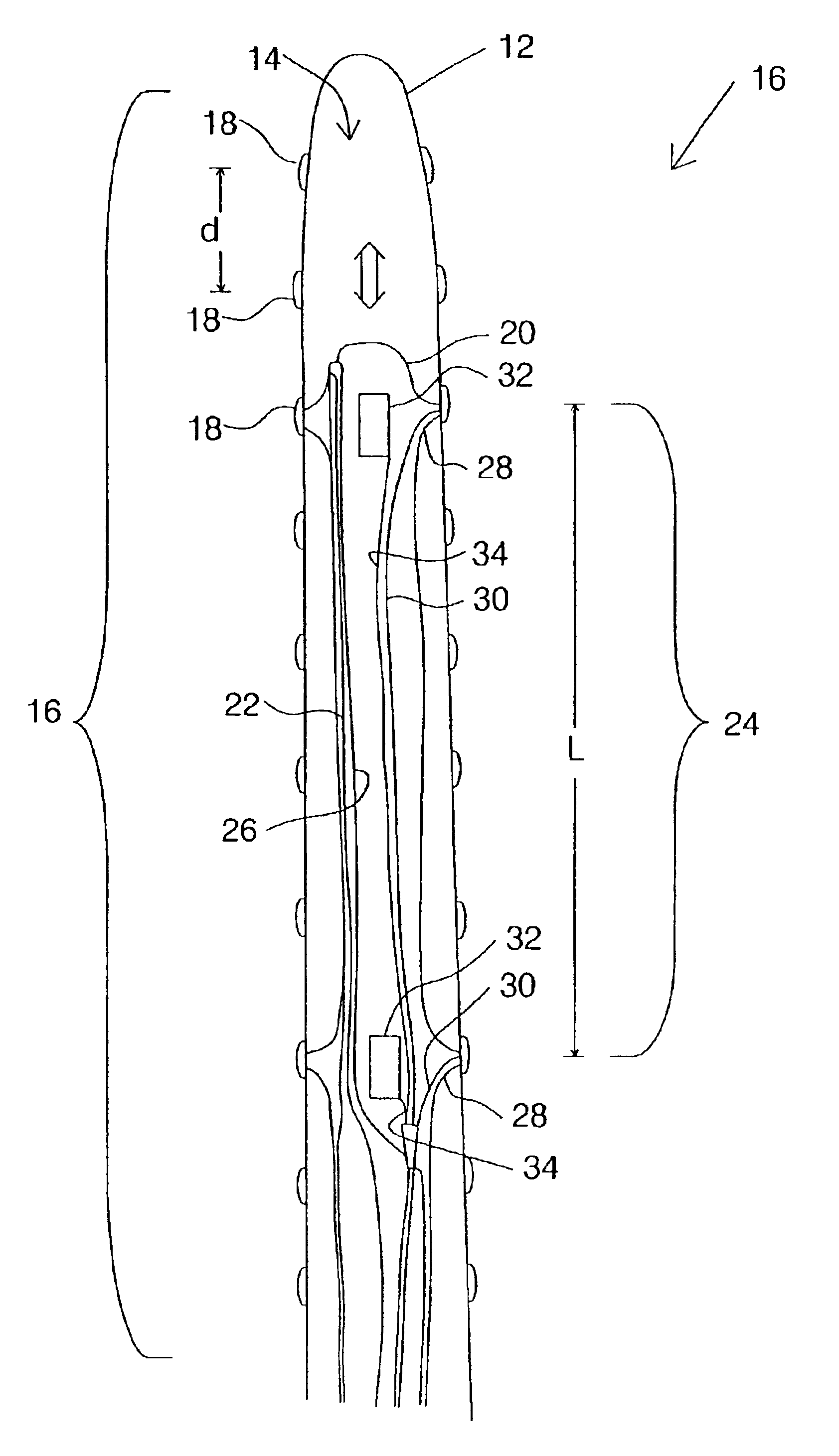

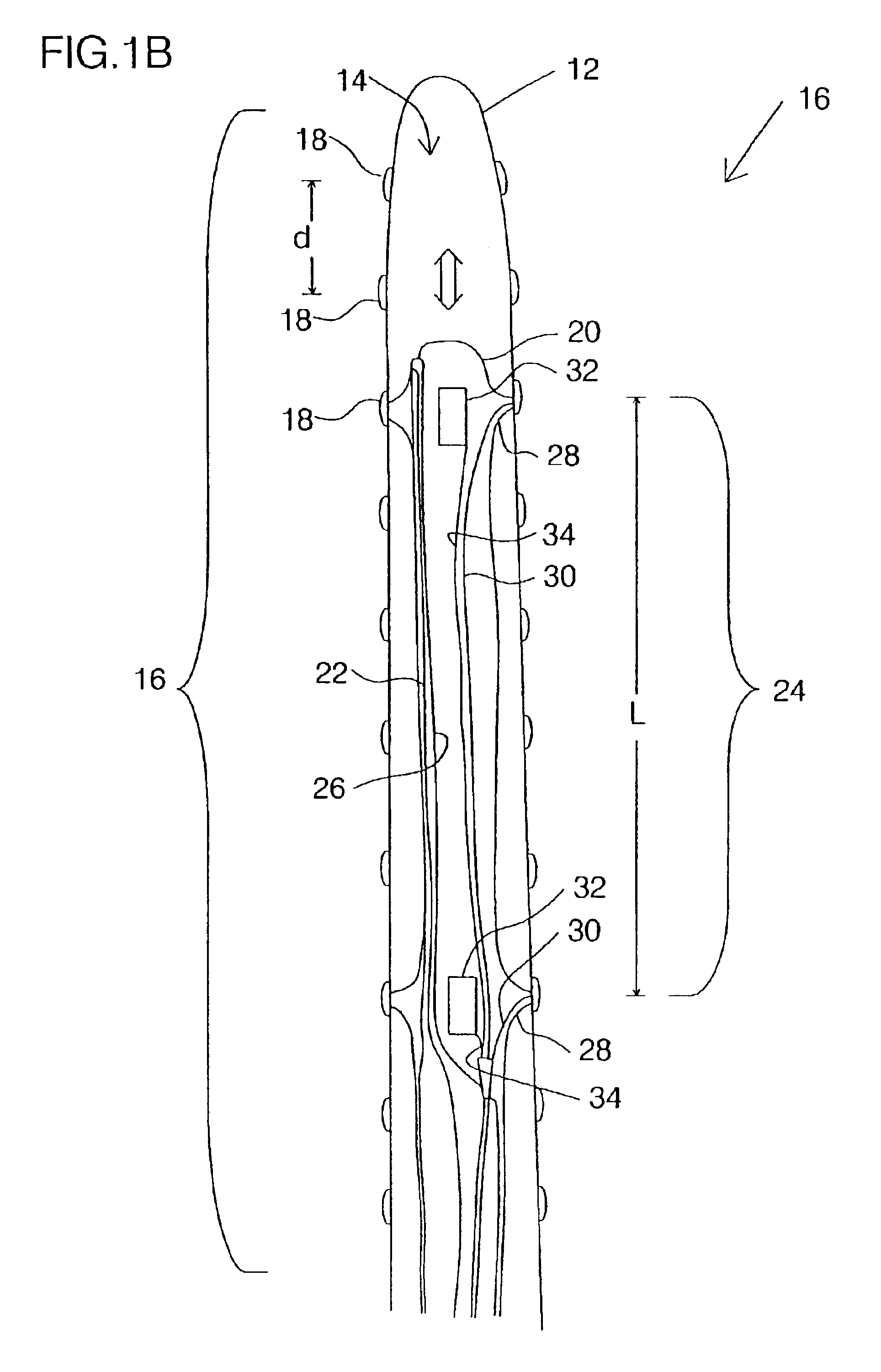

Multiple-electrode catheter assembly and method of operating such a catheter assembly

A multiple-electrode catheter assembly includes a hollow catheter having an internal elongated channel and a flexible distal portion. A number of electrodes are spaced along the flexible distal portion. An inner element, slidingly engaged within the elongated channel, has a steering mechanism configured for selectively deflecting a steerable distal portion of the inner element. According to additional, or alternative, features, the inner element includes sliding contacts for forming electrical connections with the electrodes, and displaceable locating elements for determining the position of an electrode during operation. Also provided is a method for operating such a catheter.

Owner:TYCO HEALTHCARE GRP LP

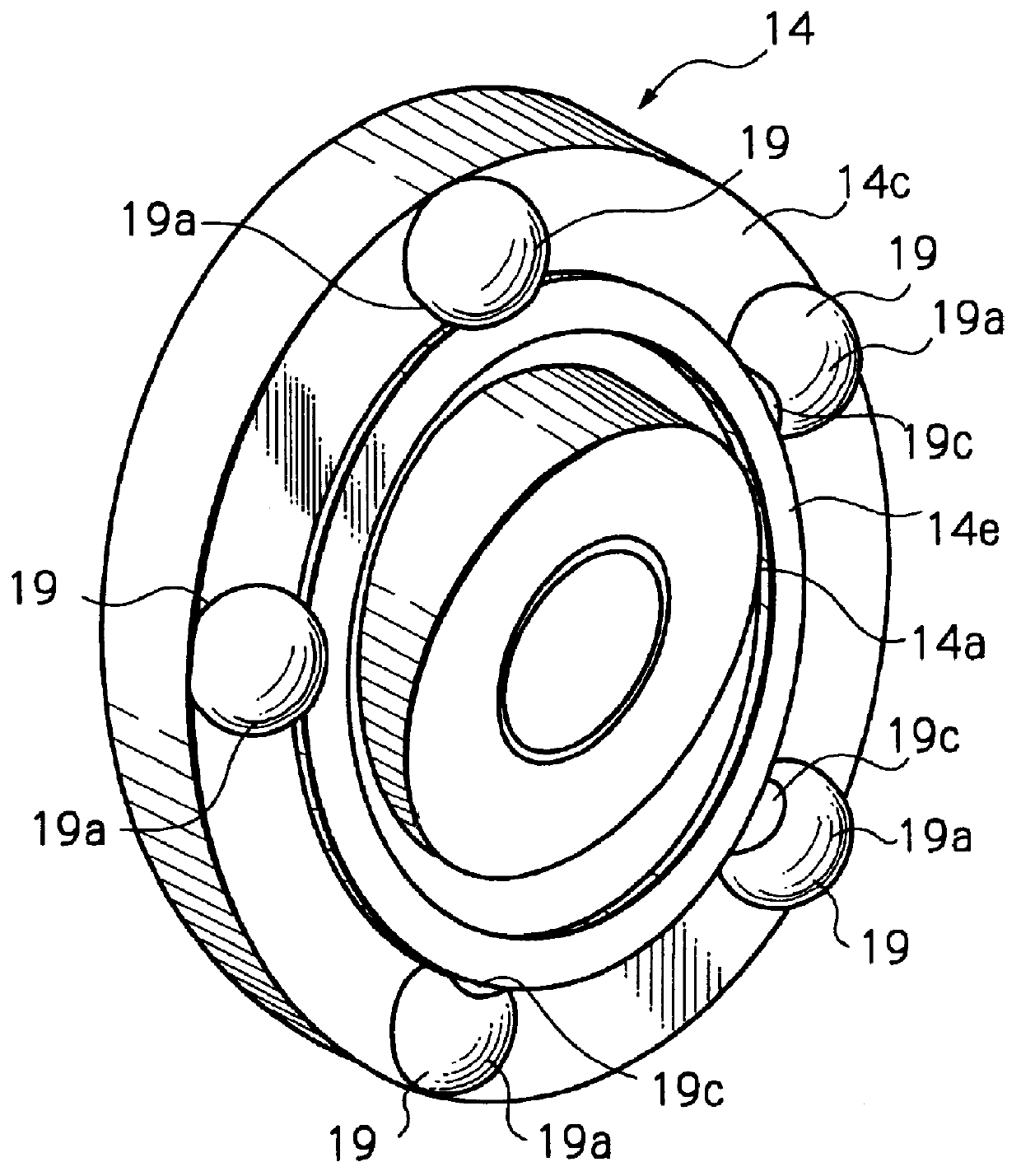

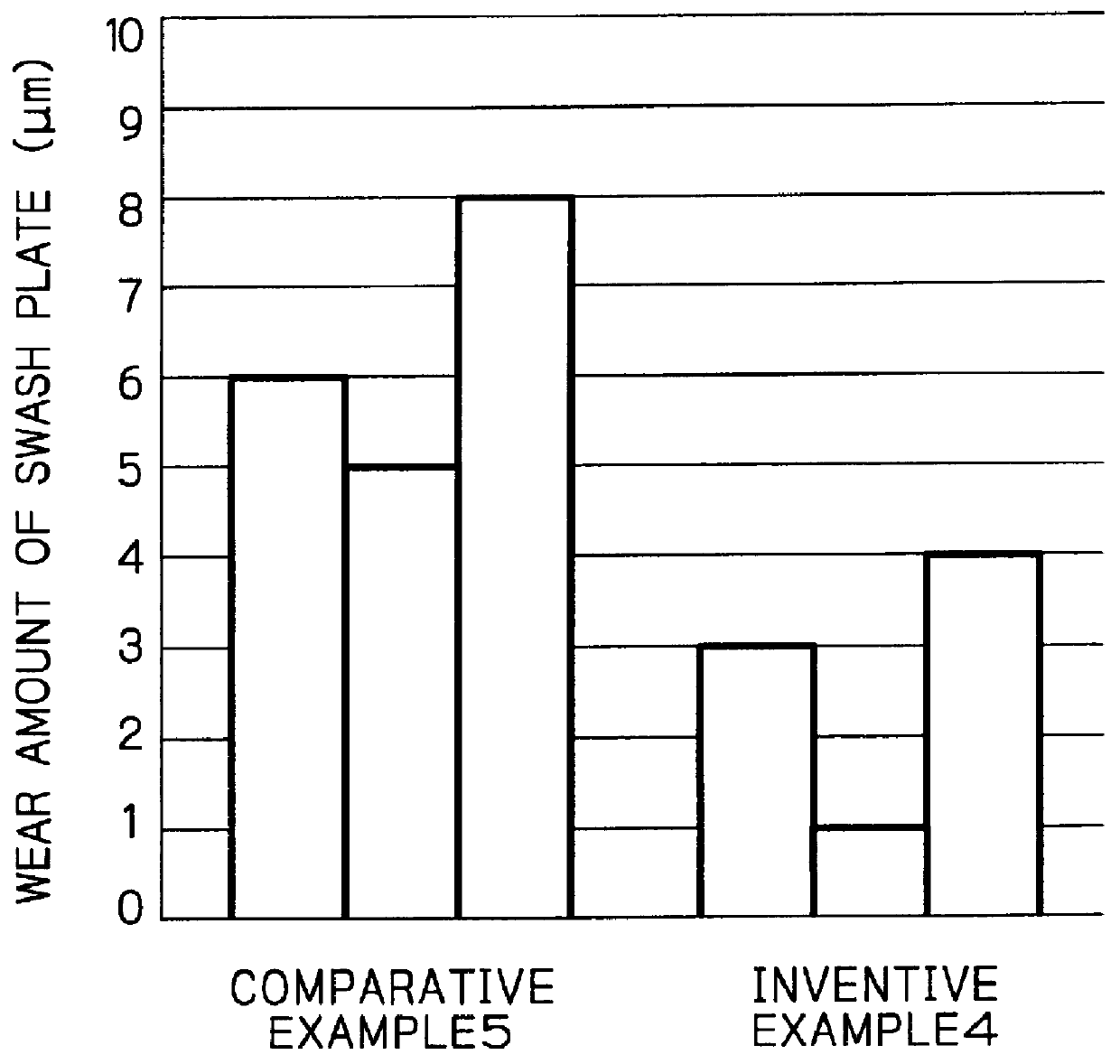

Swash plate of swash-plate compressor

InactiveUS6123009AReduce coating thicknessReduce loadPositive displacement pump componentsAdditivesGas compressorGraphite

A swash plate of a swash-plate compressor is subjected to sliding on shoes and is required to have excellent seizure resistance and wear resistance under the dry lubricating condition. The swash plate according to the present invention is provided with the surface-treated layer, i,e., the intermediate layer consisting of Cu, Sn or metal phosphate, and a sliding contact layer consisting of MoS2 and / or graphite and thermosetting resin.

Owner:TAIHO INDUSTRIES CO LTD +1

Sliding structure for automotive engine

InactiveUS6886521B2Preventing cracking and separationReduce coefficient of frictionPiston ringsMolten spray coatingCarbon filmPiston ring

A sliding structure for an automotive engine includes a sliding member with a sliding portion and a lubricant applied to the sliding portion so that the sliding portion can make sliding contact with a counterpart member via the lubricant. The sliding member is either of a piston ring, a piston pin, a cam lobe, a cam journal, a plain bearing, a rotary vane and a timing chain. The sliding portion has a base made of a steel or aluminum material and a hard carbon film formed on the base to coat the sliding portion. The hard carbon film has a thickness of 0.3 to 2.0 mum, a Knoop hardness of 1500 to 4500 kg / mm2, a surface roughness Ry (mum) satisfying the following equation: Ry<{(0.75-Hk / 8000)xh+0.07 / 0.8}, where h is the thickness (mum) of the film; and Hk is the Knoop hardness (kg / mm2) of the film.

Owner:NISSAN MOTOR CO LTD

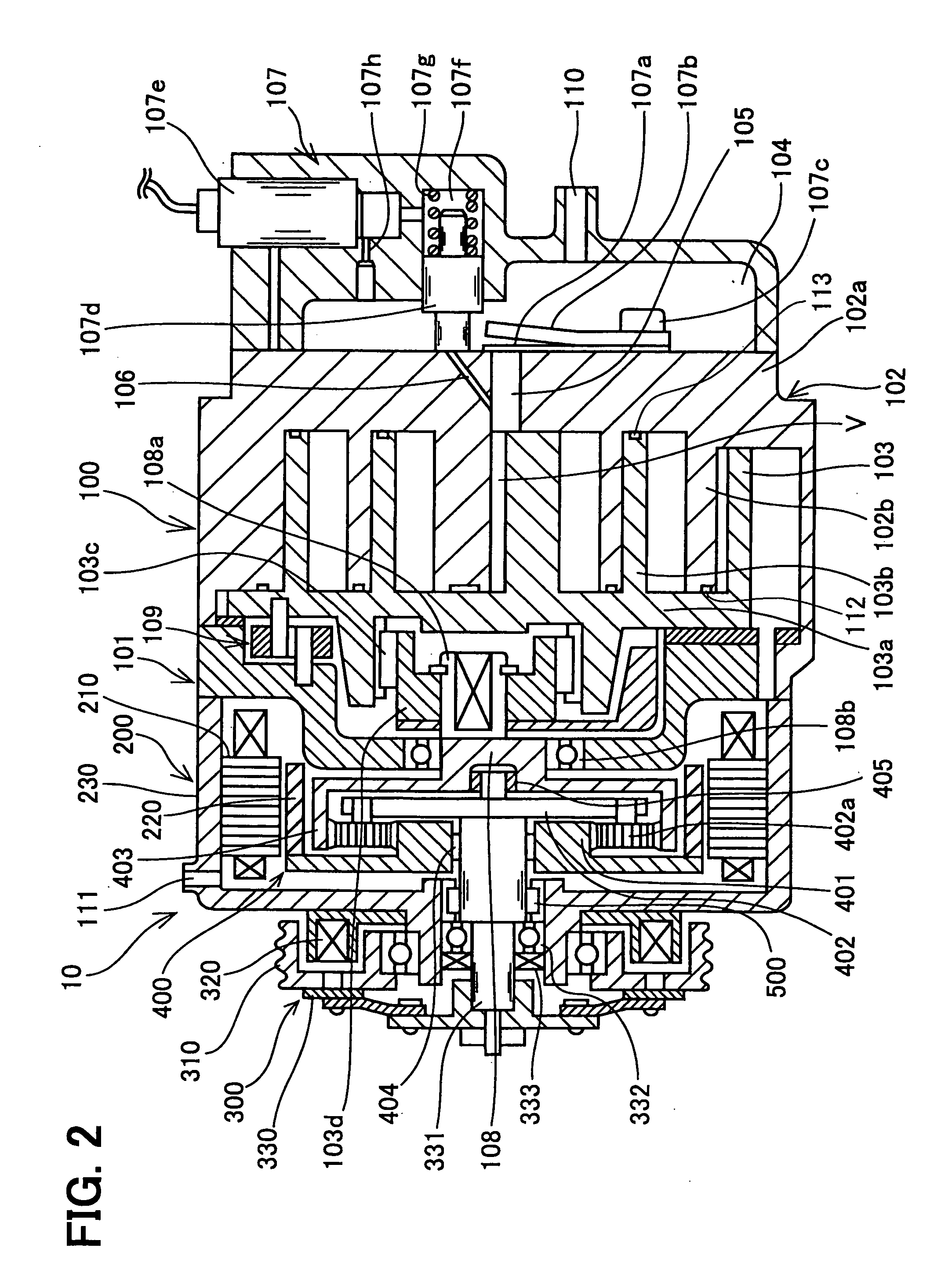

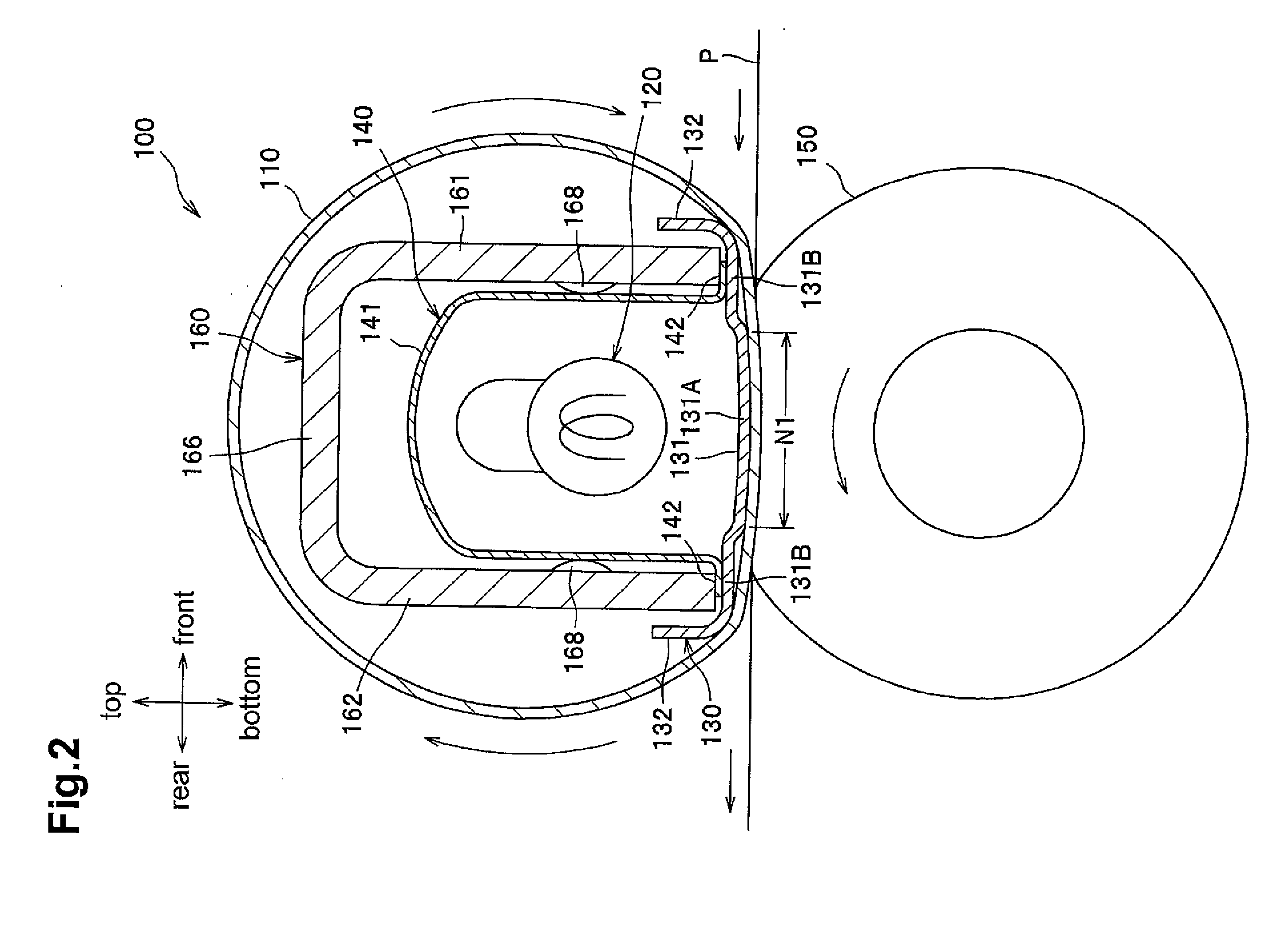

Scroll compressor having an annular recess located outside an annular seal portion and another recess communicating with suction port of fixed scroll

ActiveUS7229261B2Reduce back pressureSliding loss can be reducedEngine of arcuate-engagement typeOscillating piston enginesEngineeringSliding contact

A surface of a fixed scroll which is opposed to a end plate of an orbiting scroll existing outside of a lap of the fixed scroll is formed with: a substantially annular seal portion which extends such as to have an outer wall surface of the fixed scroll outwardly extending from an inner wall surface of outermost periphery of the lap substantially along the inner wall surface, and which comes into slide contact with the end plate of the orbiting scroll; a substantially annular recess located outside of the substantially annular seal portion; and a recess which is brought into communication with an intake port of the fixed scroll independently from the substantially annular recess. With this, back pressure of the orbiting scroll is increased, and turning-over phenomenon of the orbiting scroll can be suppressed.

Owner:PANASONIC CORP

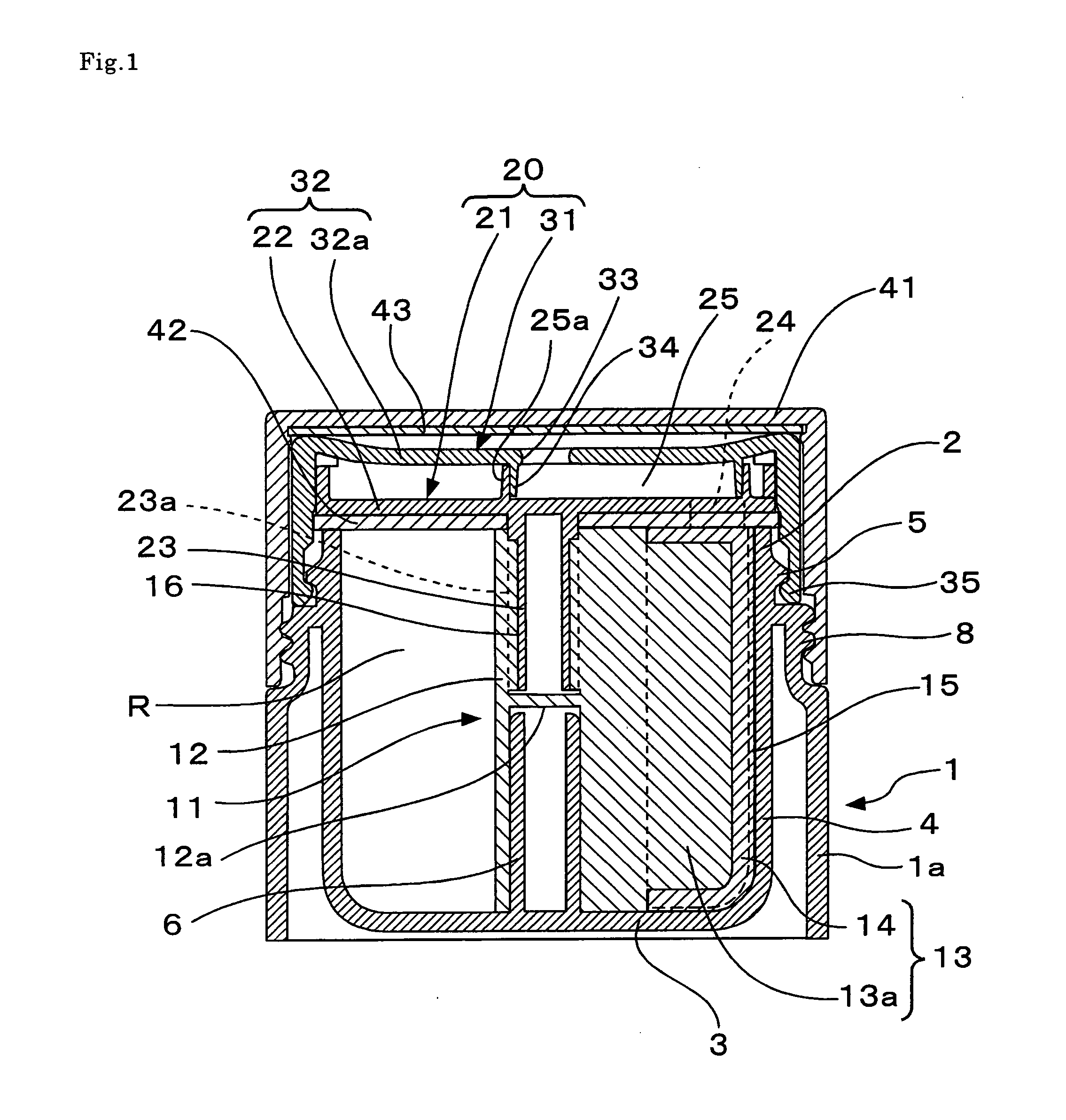

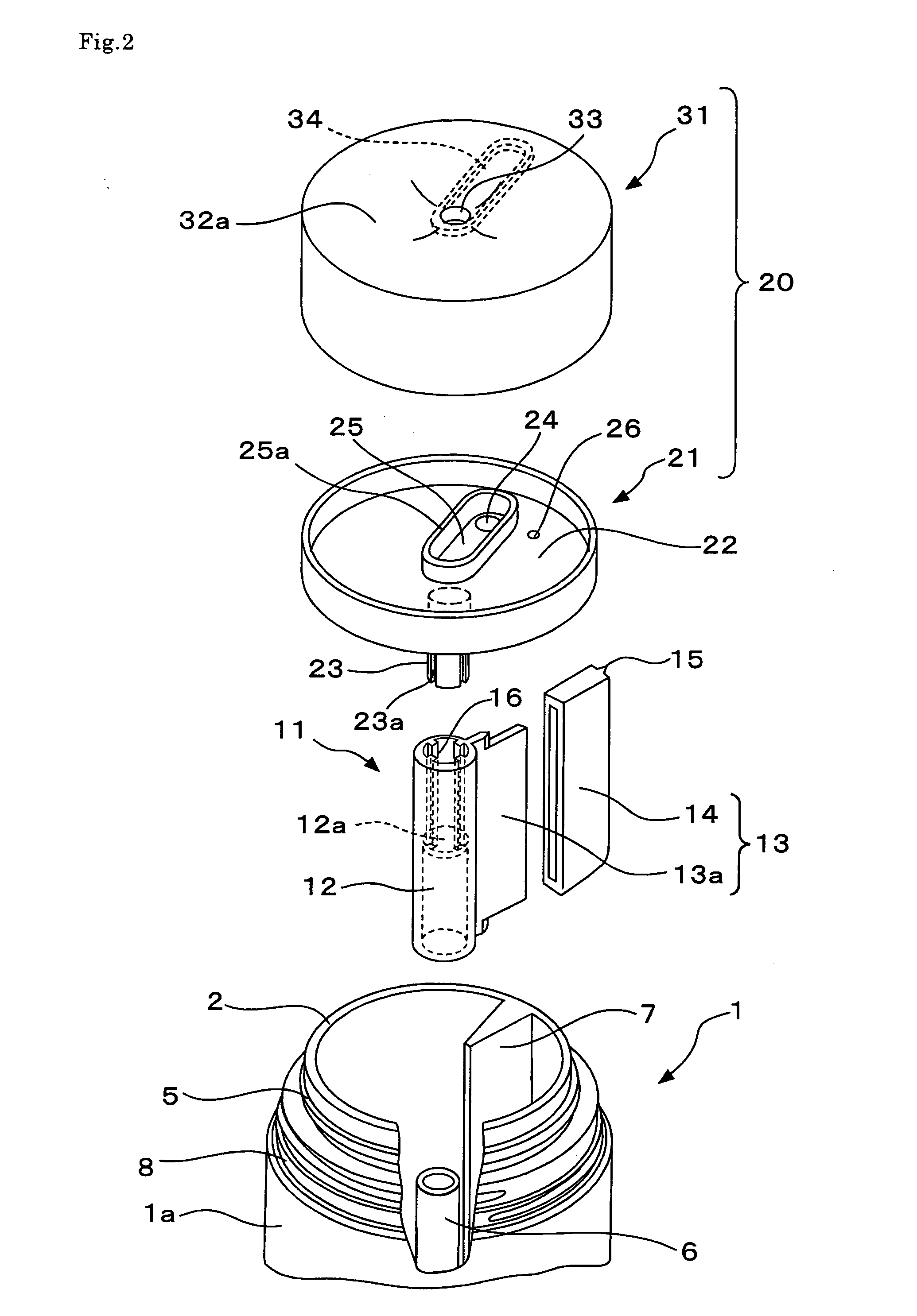

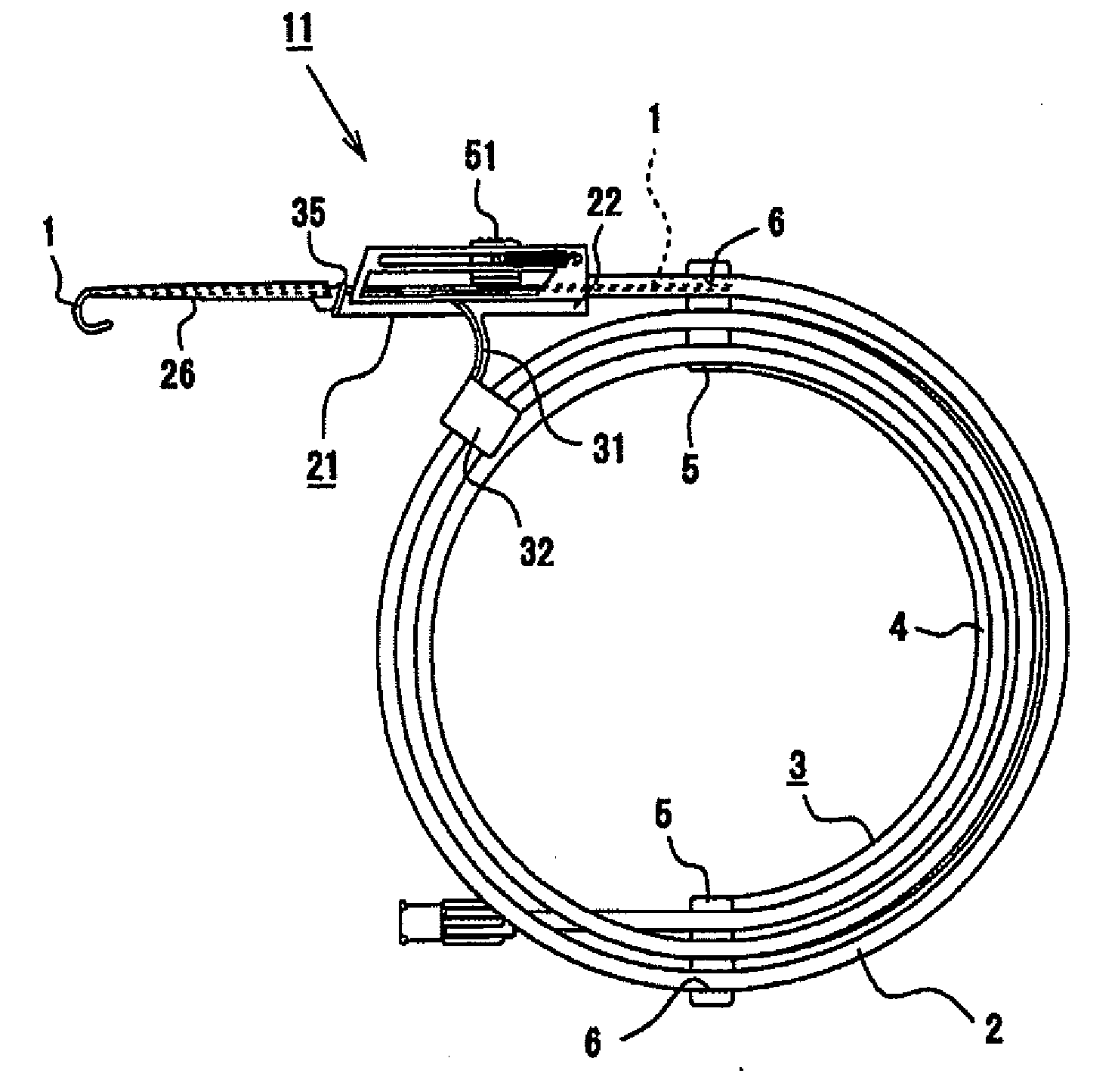

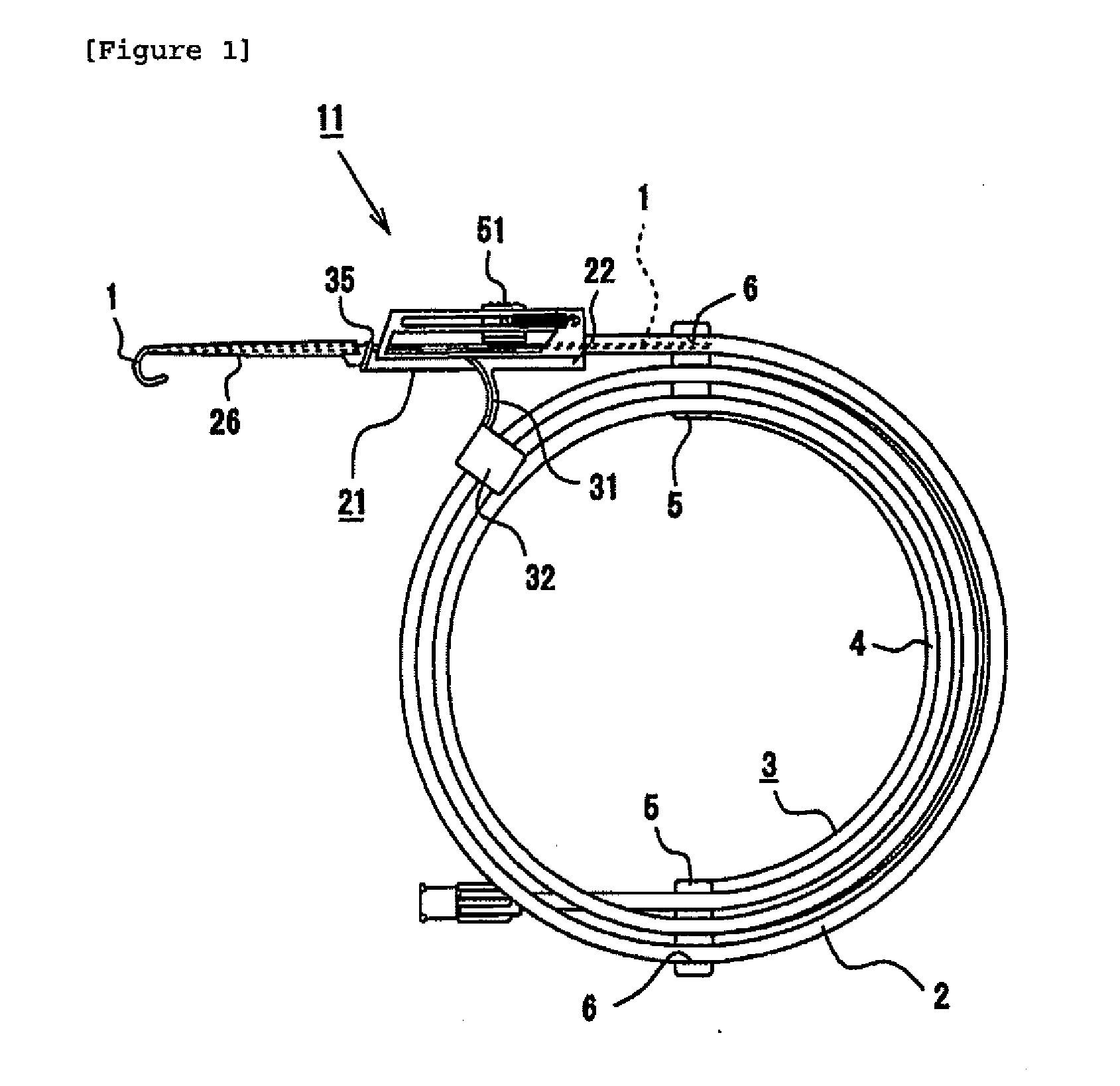

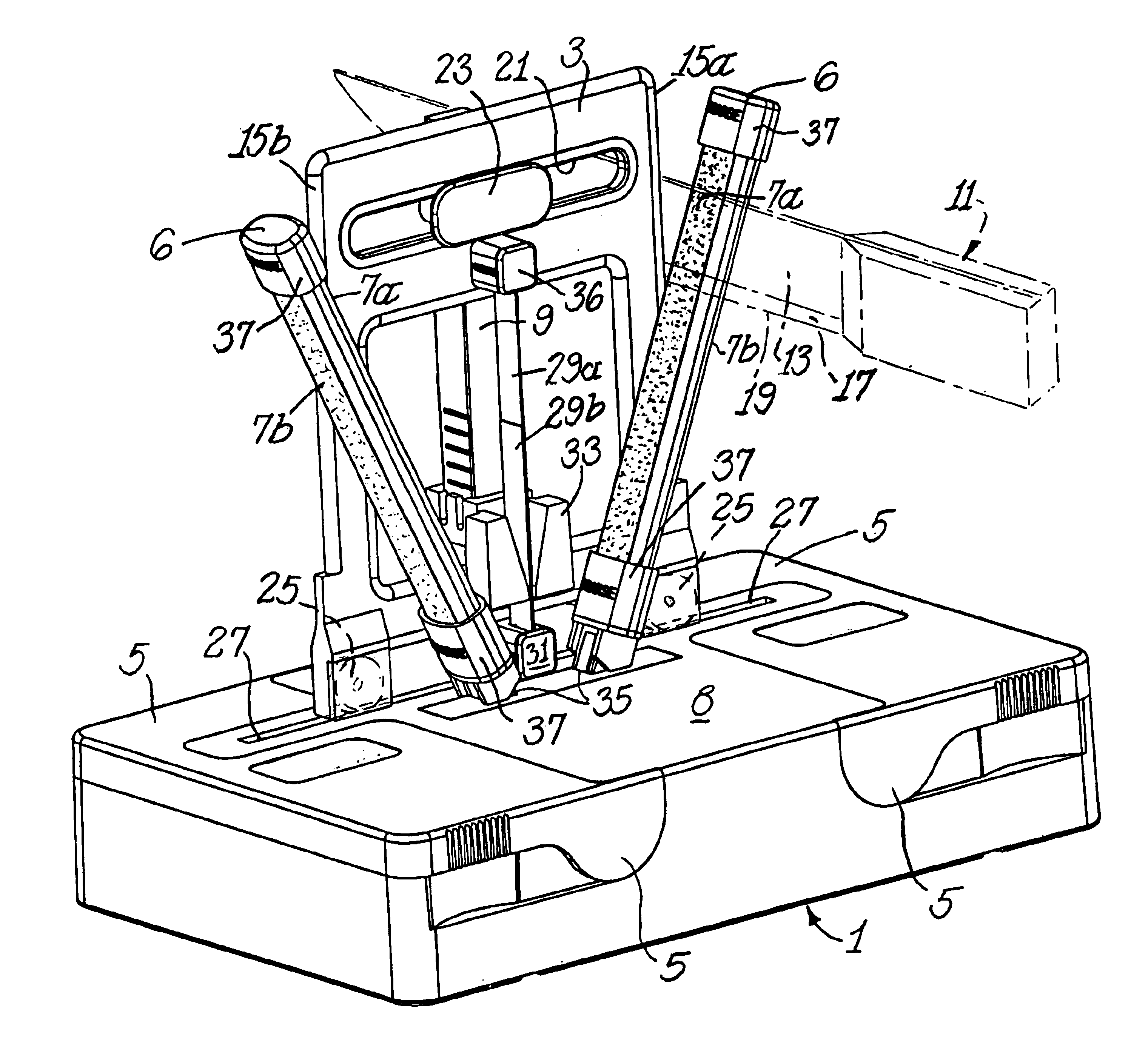

Guidewire insertion aid

ActiveUS9011351B2Easy to operateEasily fed outGuide wiresDiagnostic recording/measuringMedical equipmentSliding contact

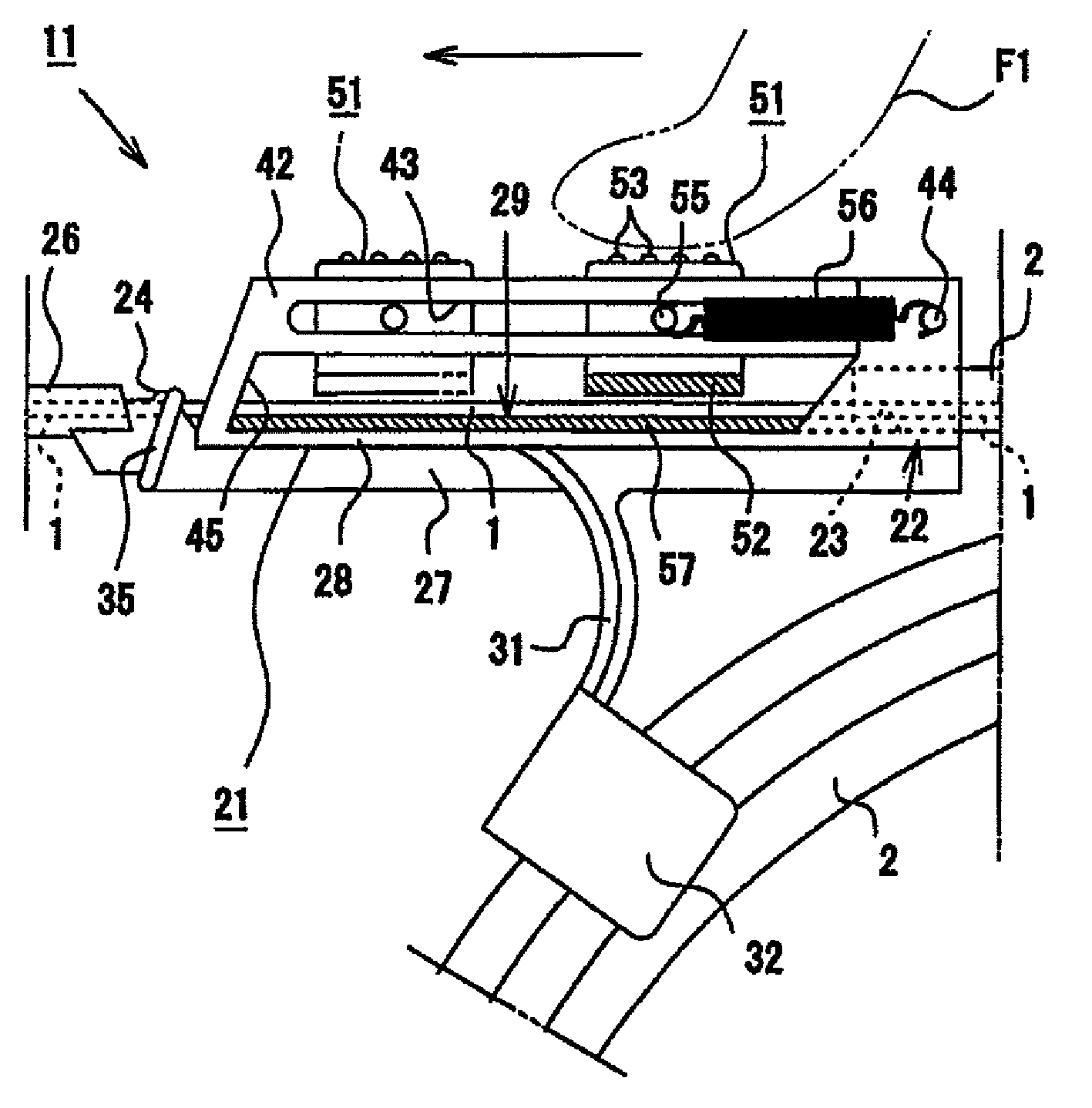

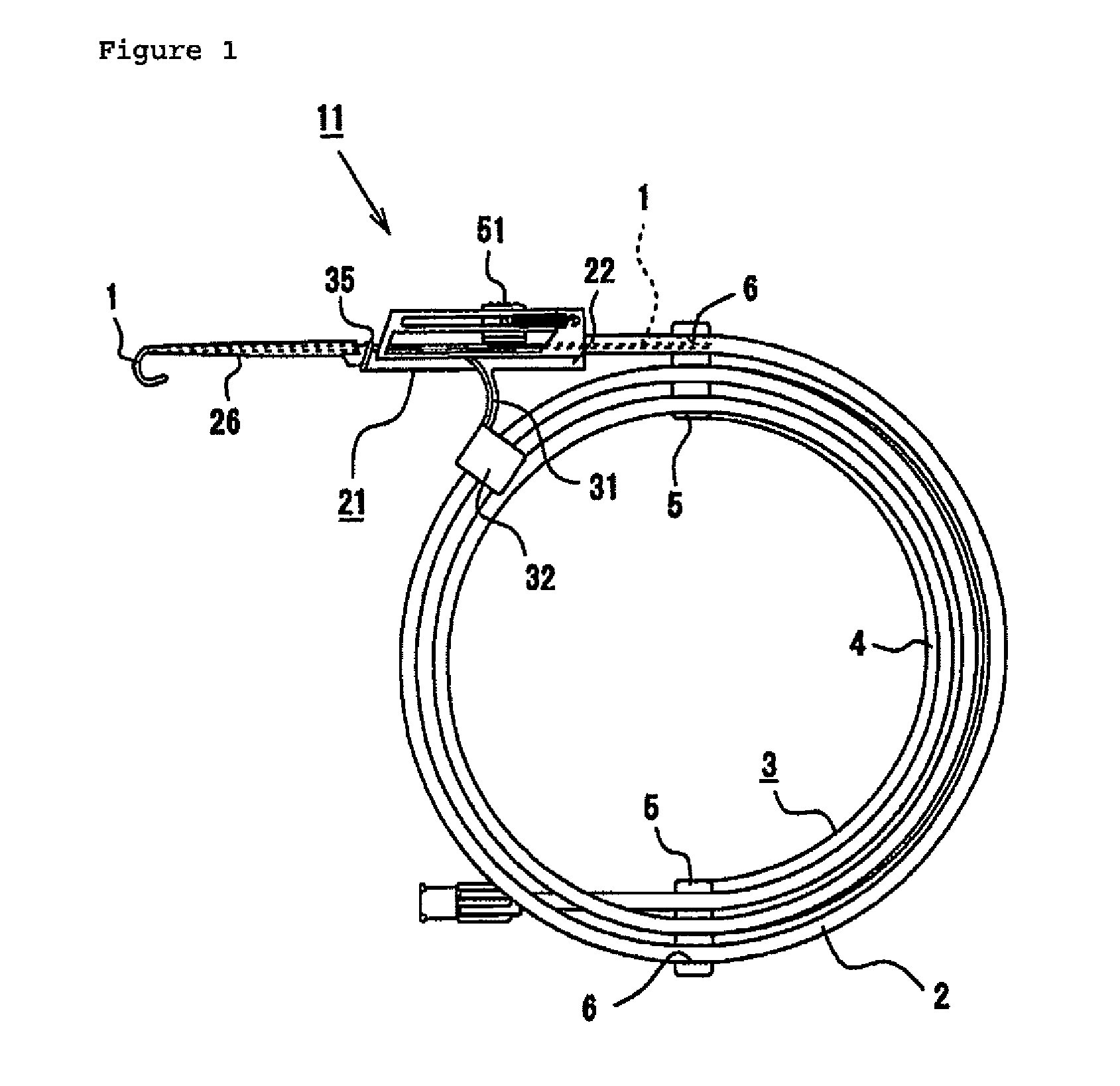

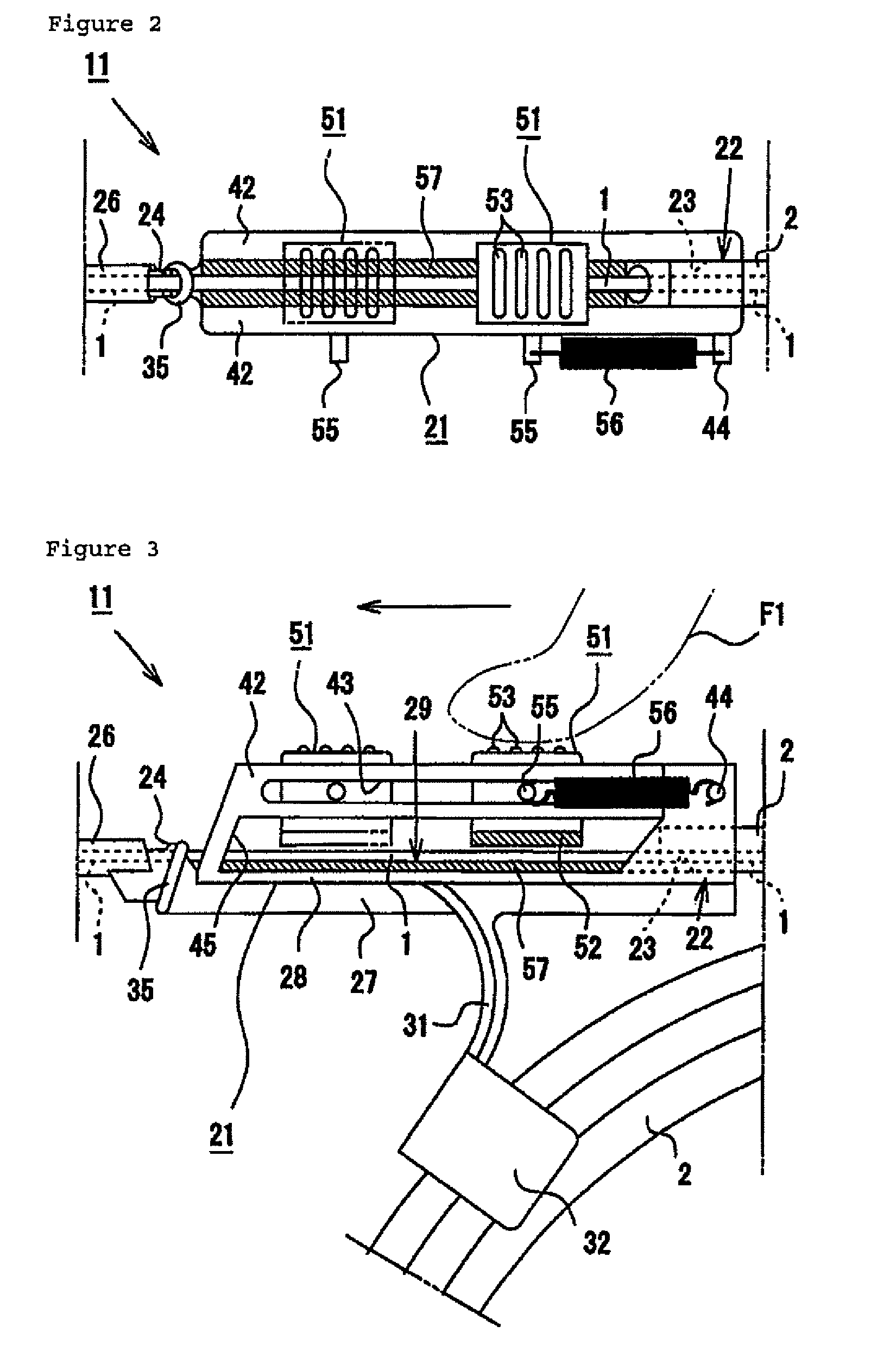

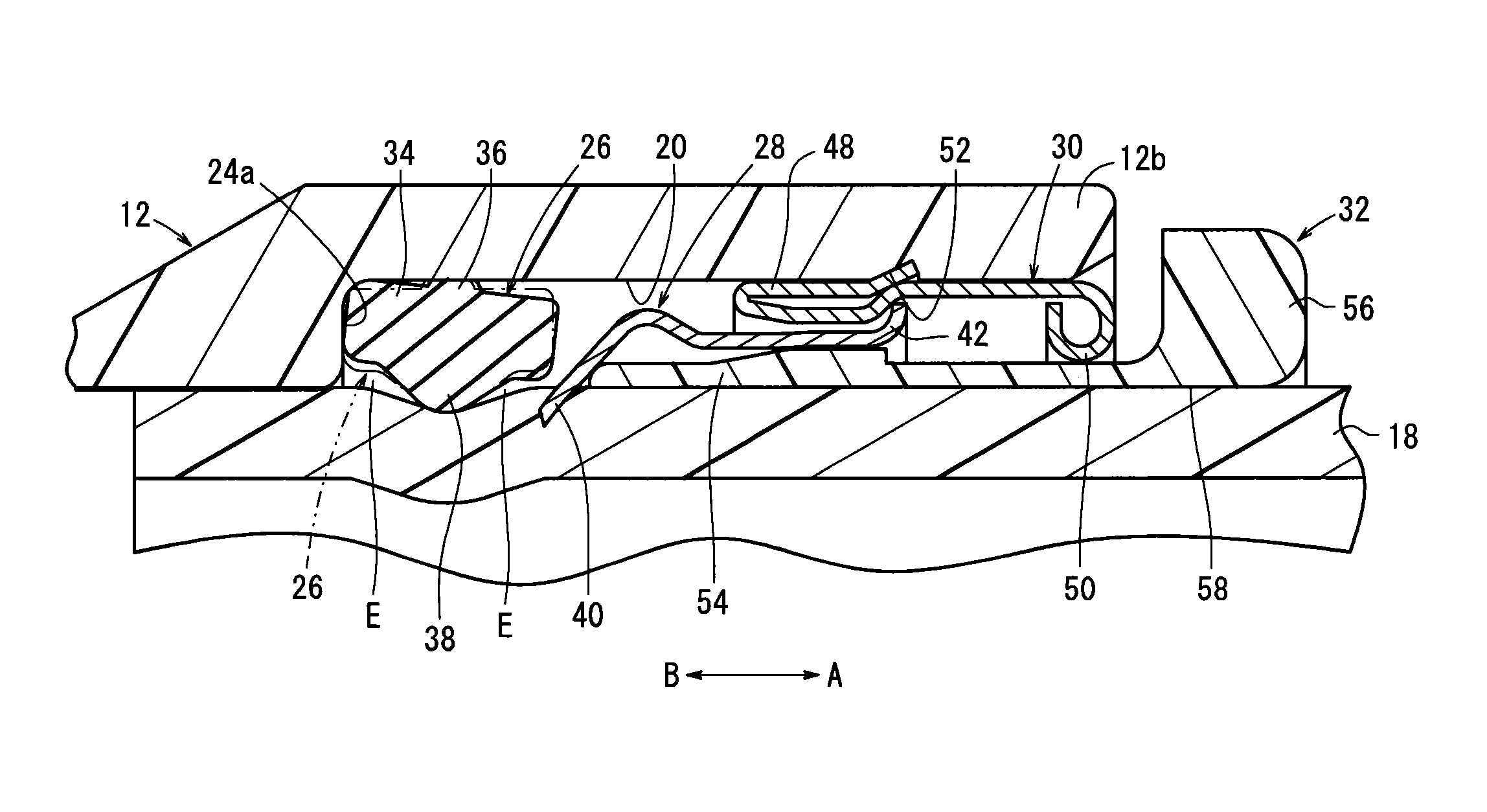

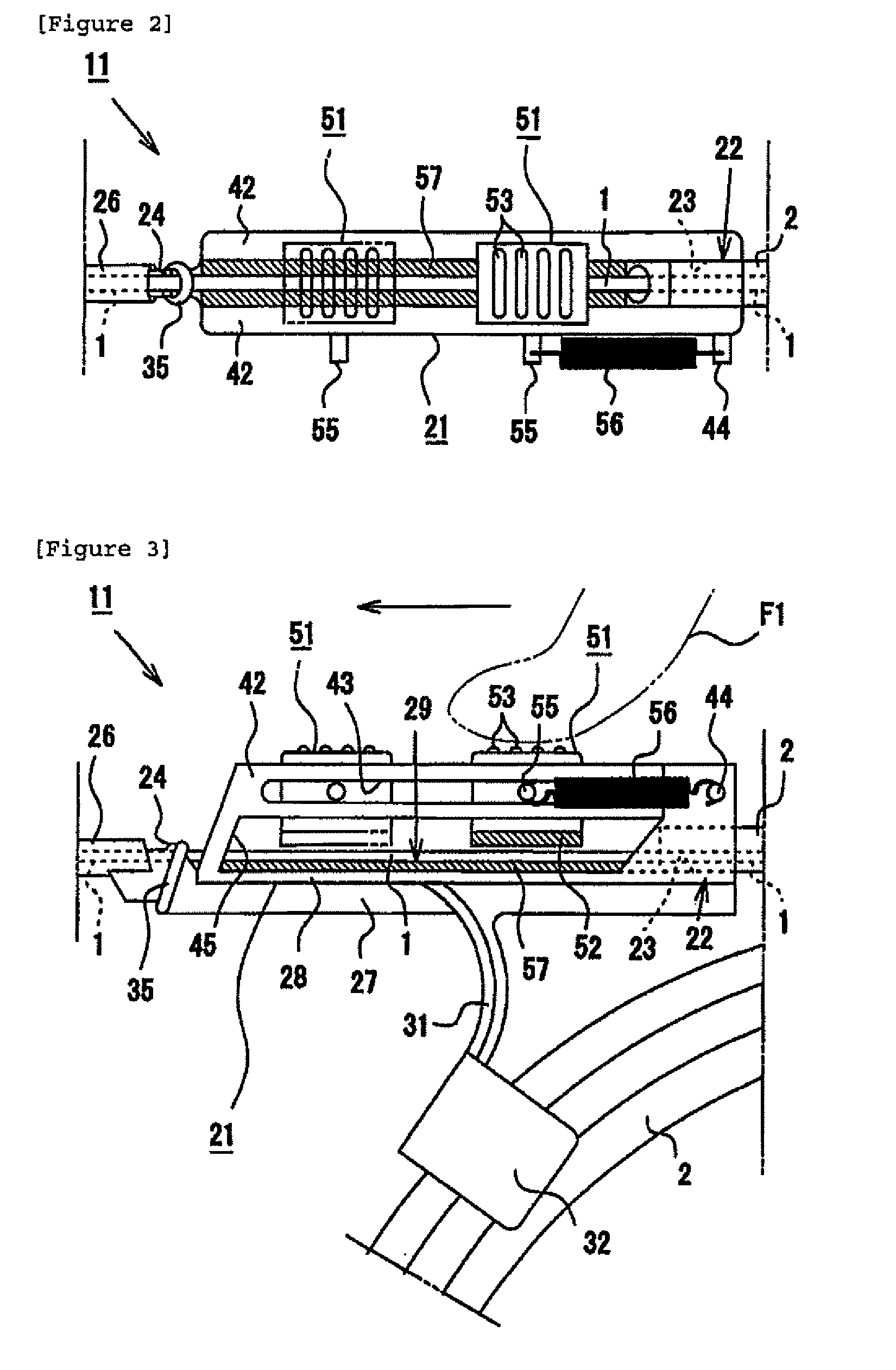

[Issue] To provide a guidewire insertion aid which is very easy to operate because a lubricated guidewire can be easily fed out.[Means of Resolution] A guidewire insertion aid 11 according to the present invention is used for feeding out a guidewire 1 inserted in a housing 2 in order to insert said guidewire into the lumen of a piece of medical equipment. The insertion aid 11 comprises: a main body 21, a housing support part 22 and a guidewire support part 26. A sliding contact part 28 is disposed between the housing support part 22 and the guidewire support part 26. The sliding contact part 28 extends in the lengthwise direction of the main body and has a sliding contact surface 28 for the guidewire 1. A feed-out member 51 is provided on the main body 21 and has a water-retentive water-retention member 52. The feed-out member 51 is disposed with the water-retention member 52 side thereof facing towards the sliding contact surface 29. The feed-out member 51 can be displaced while the guidewire 1 is held between said feed-out member and the sliding contact part 28.

Owner:TYCO HEALTHCARE GRP LP

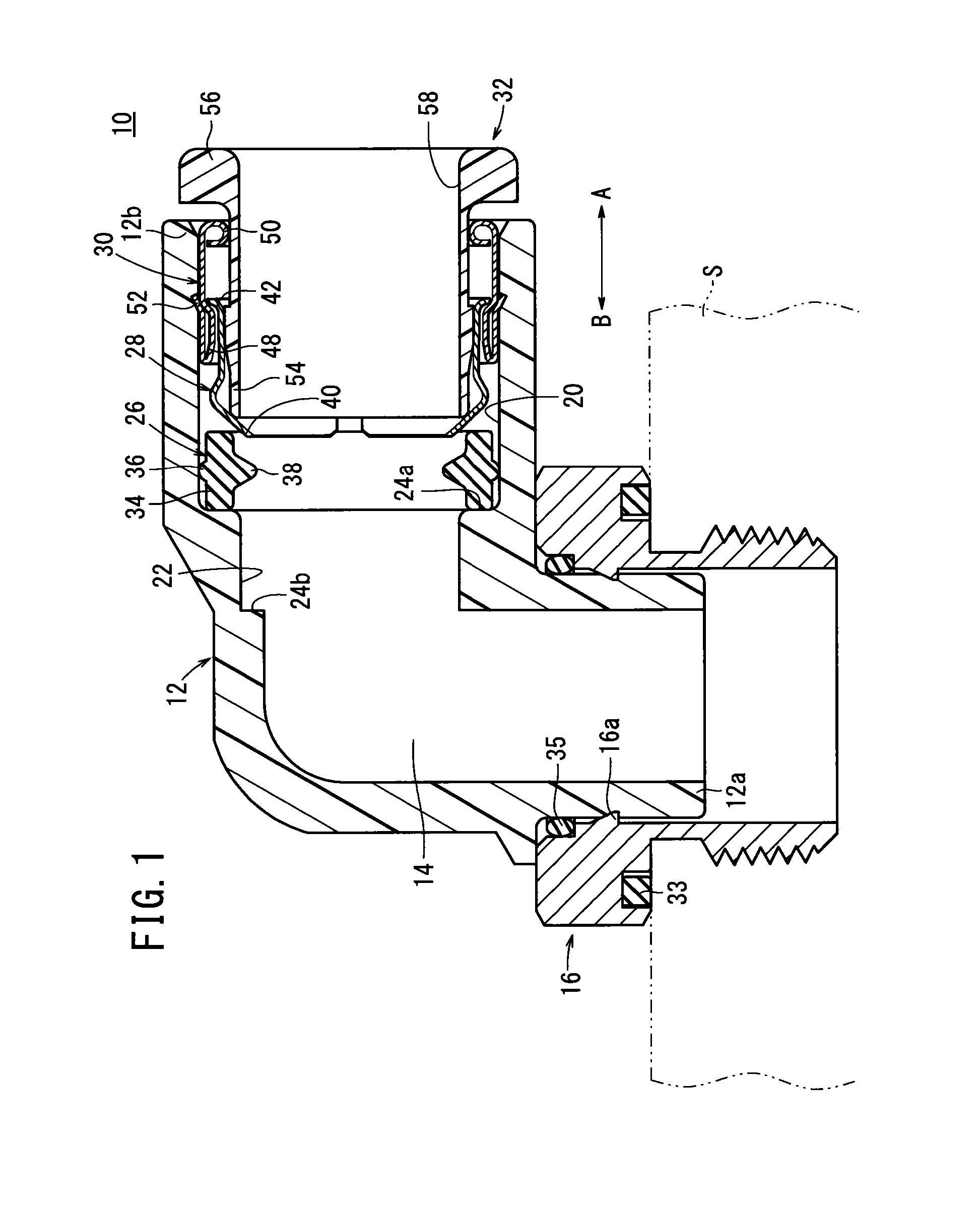

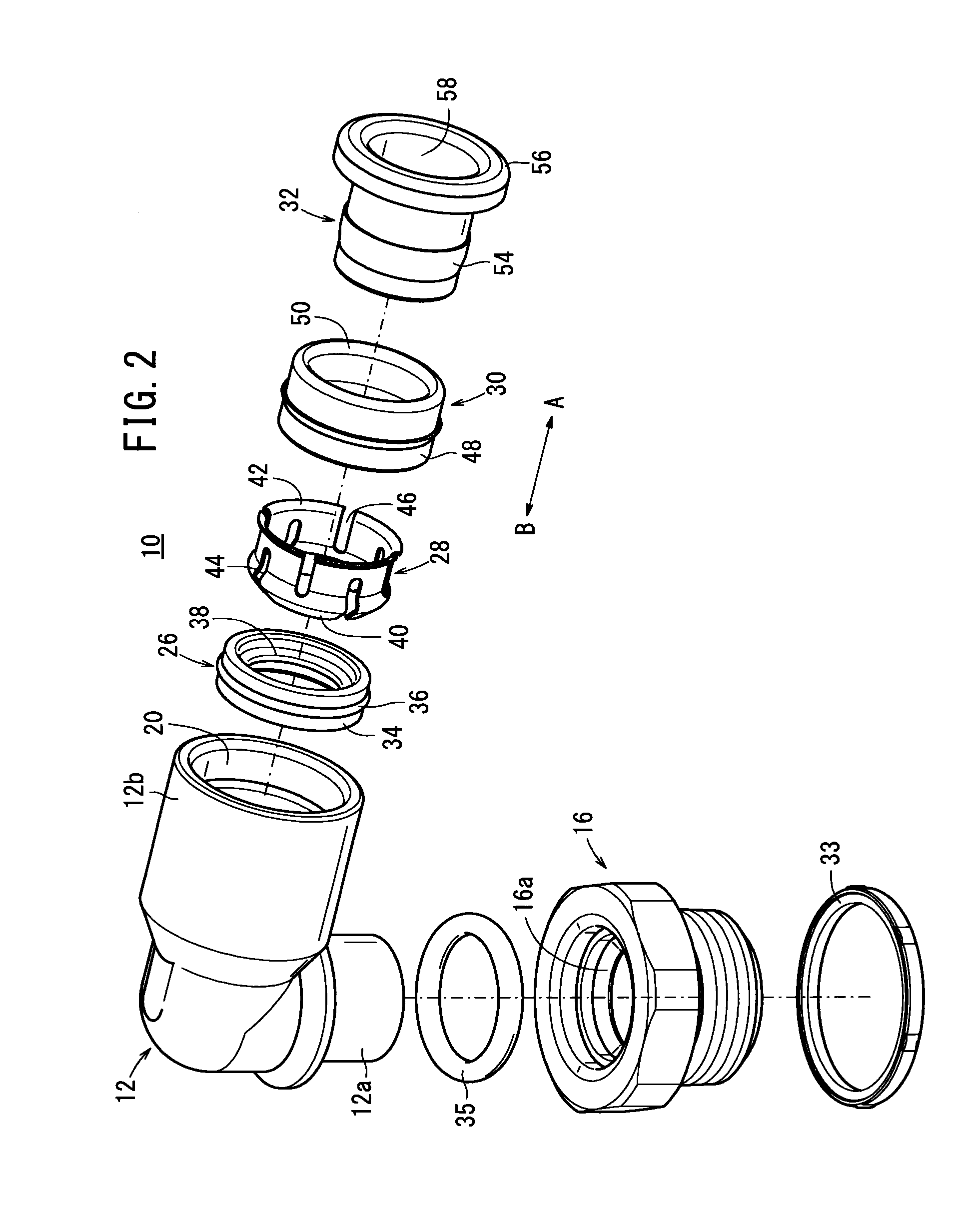

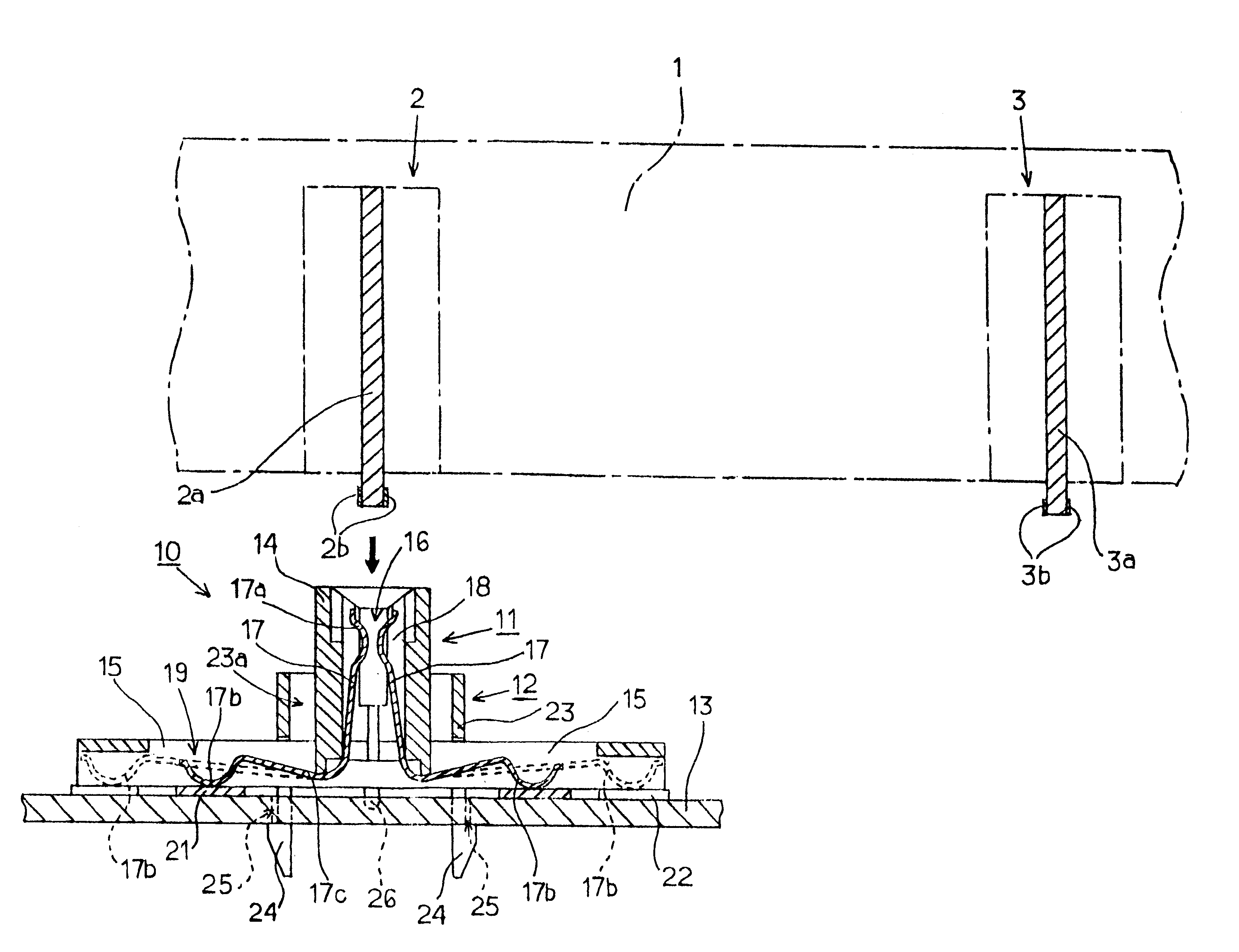

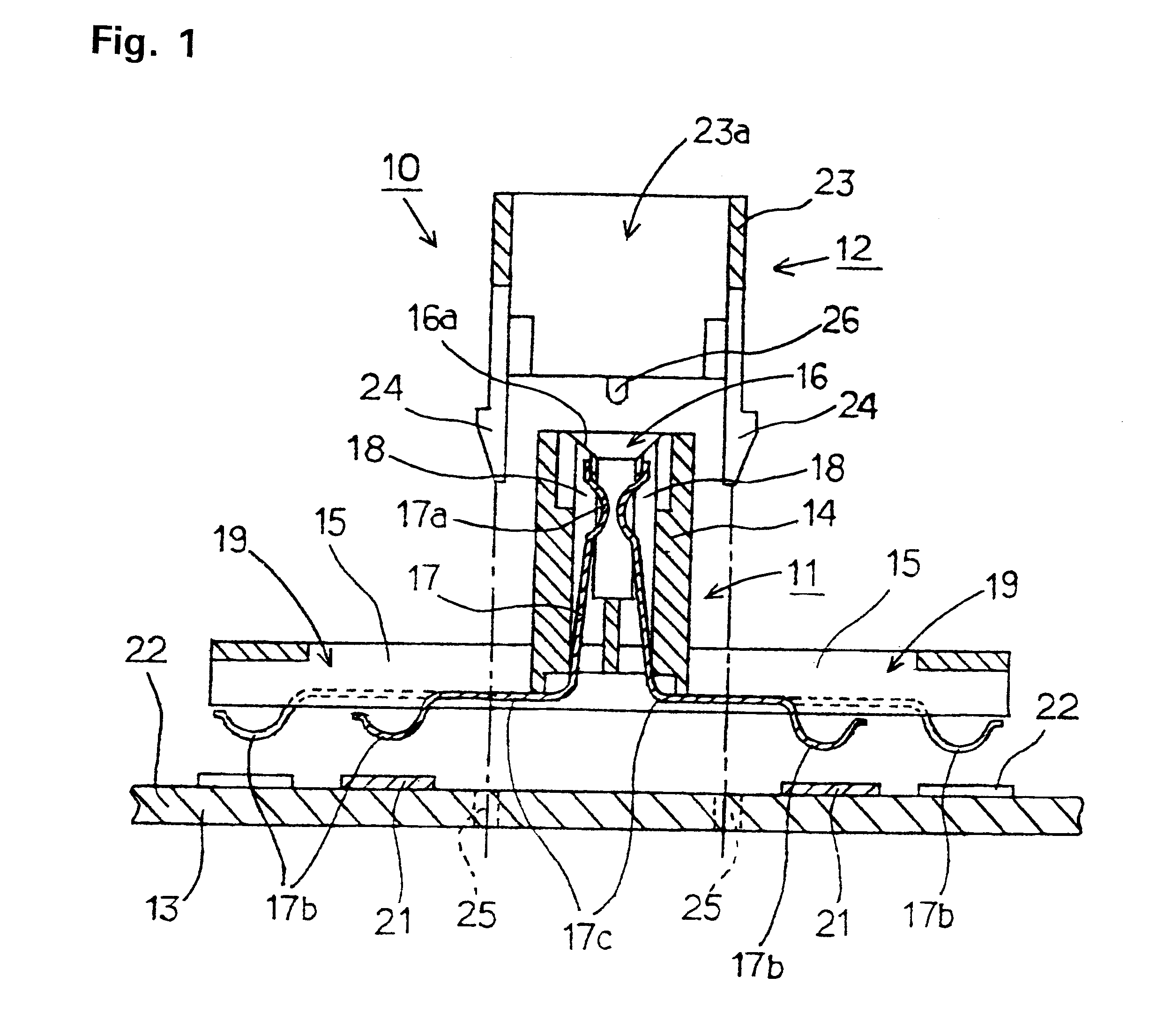

Pipe joint

ActiveUS9556991B2Easy to operateImprove sealing propertiesSleeve/socket jointsFluid pressure sealed jointsEngineeringSliding contact

A pipe joint has a body, and an annular packing is mounted to the opening of the body into which a fluid tube is inserted. The packing is provided with: a body section having a substantially rectangular cross-sectional shape; and a seal section protruding in the radial direction from the inner peripheral surface of the body section. The seal section is formed at substantially the center of the body section in the widthwise direction thereof and is formed in a triangular cross-sectional shape tapering to the inner peripheral side. When the fluid tube is inserted in the opening, the seal section of the packing makes sliding contact with the outer peripheral surface of the fluid tube.

Owner:SMC CORP

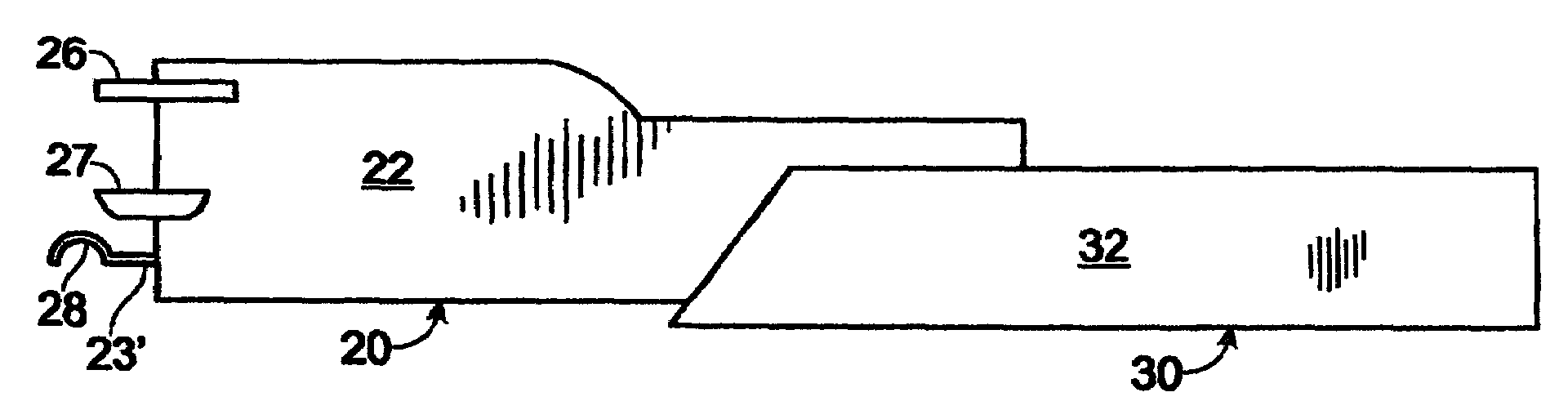

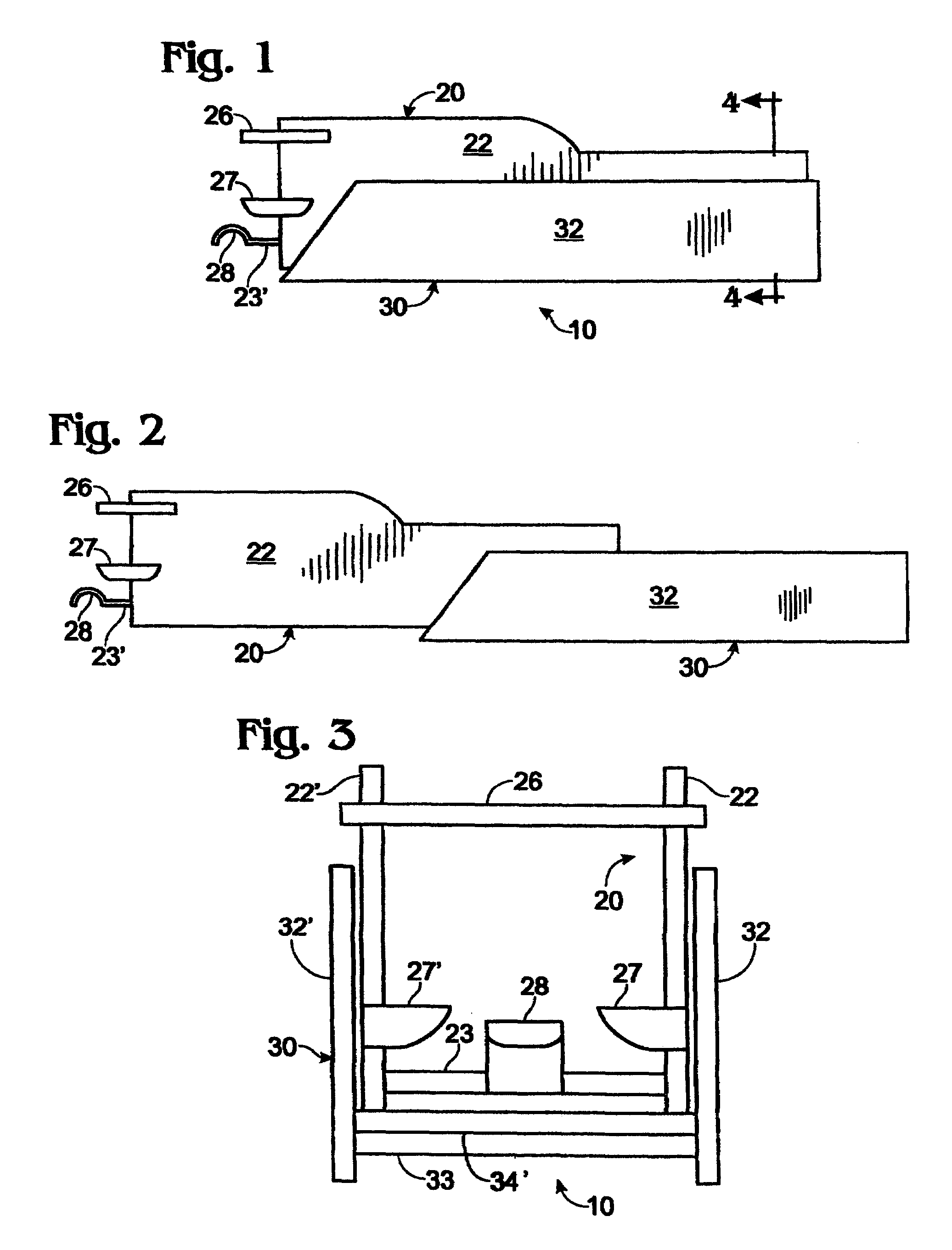

Guidewire Insertion Aid

[Issue] To provide a guidewire insertion aid which is very easy to operate because a lubricated guidewire can be easily fed out.[Means of Resolution] A guidewire insertion aid 11 according to the present invention is used for feeding out a guidewire 1 inserted in a housing 2 in order to insert said guidewire into the lumen of a piece of medical equipment. The insertion aid 11 comprises: a main body 21, a housing support part 22 and a guidewire support part 26. A sliding contact part 28 is disposed between the housing support part 22 and the guidewire support part 26. The sliding contact part 28 extends in the lengthwise direction of the main body and has a sliding contact surface 28 for the guidewire 1. A feed-out member 51 is provided on the main body 21 and has a water-retentive water-retention member 52. The feed-out member 51 is disposed with the water-retention member side thereof facing towards the sliding contact surface 29. The feed-out member 51 can be displaced while the guidewire 1 is held between said feed-out member and the sliding contact part 28.

Owner:TYCO HEALTHCARE GRP LP

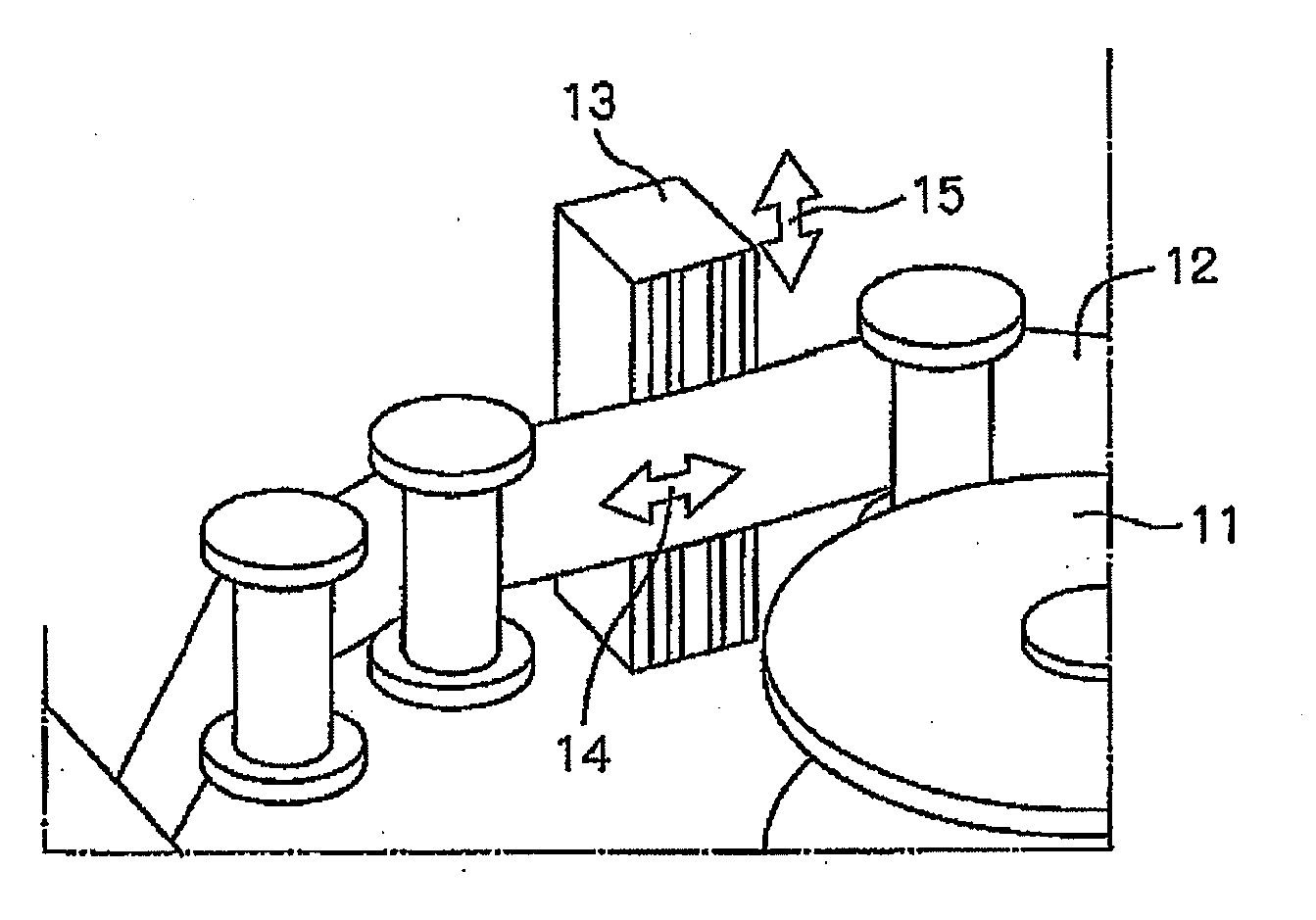

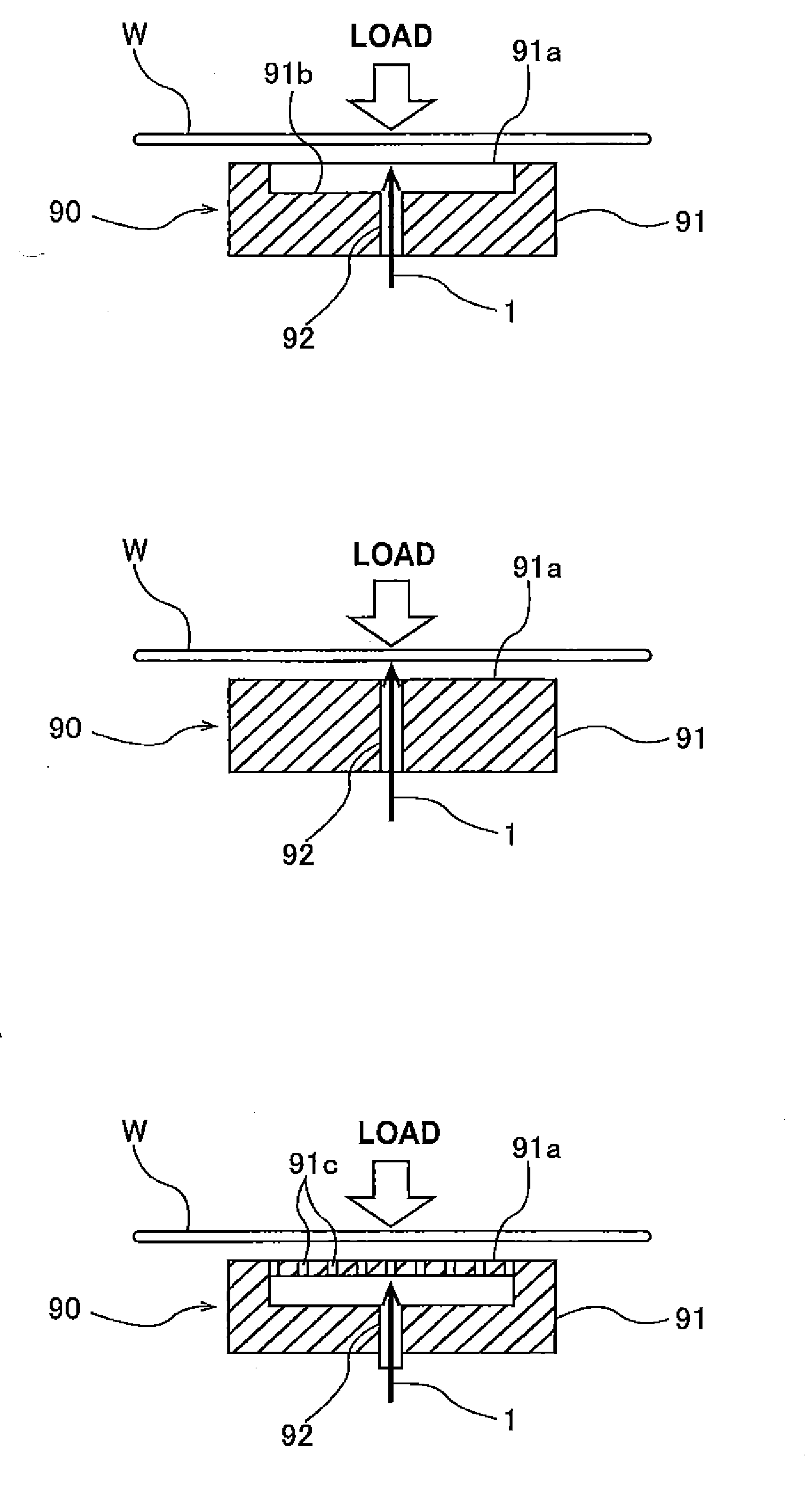

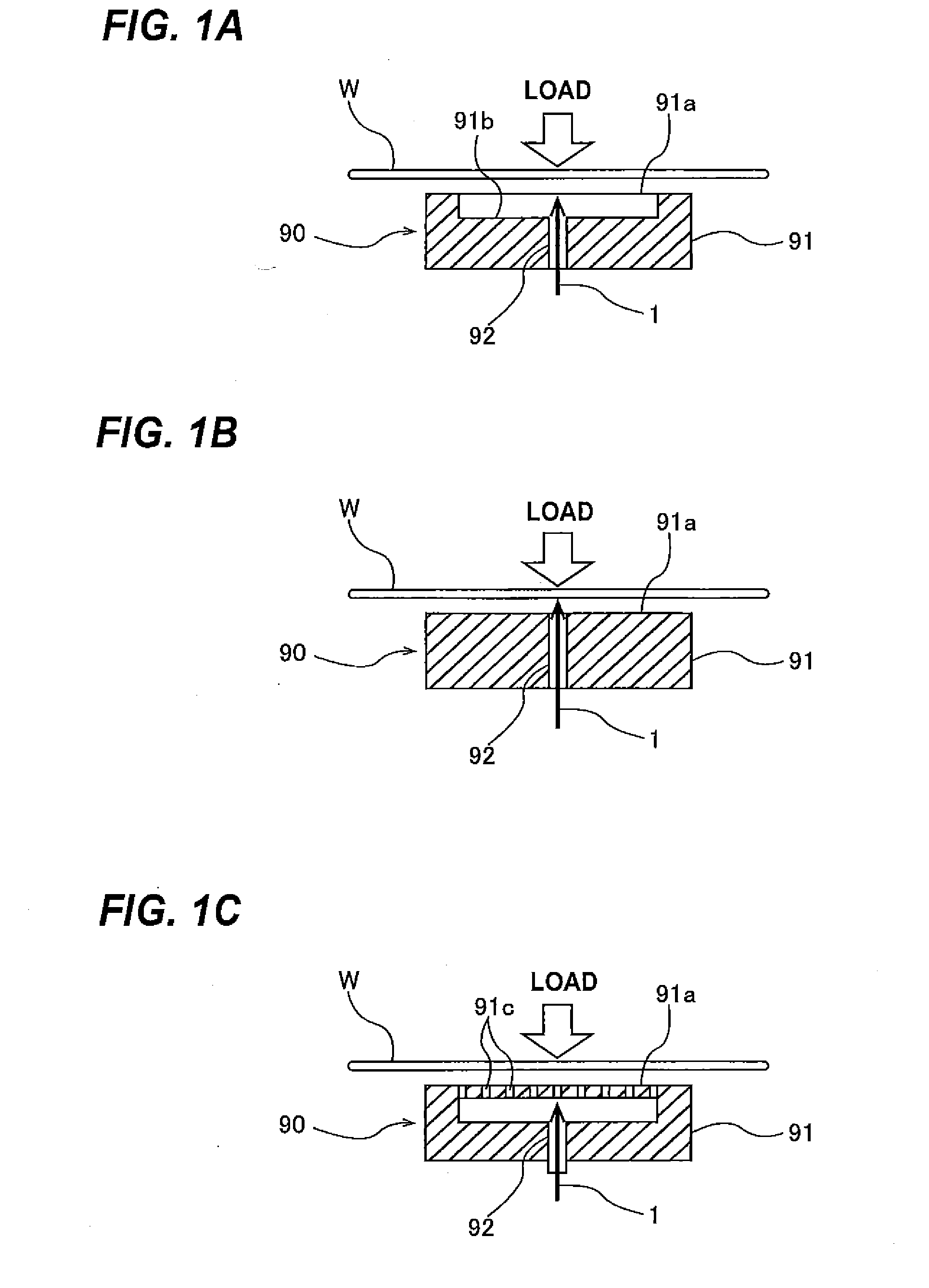

Substrate processing apparatus

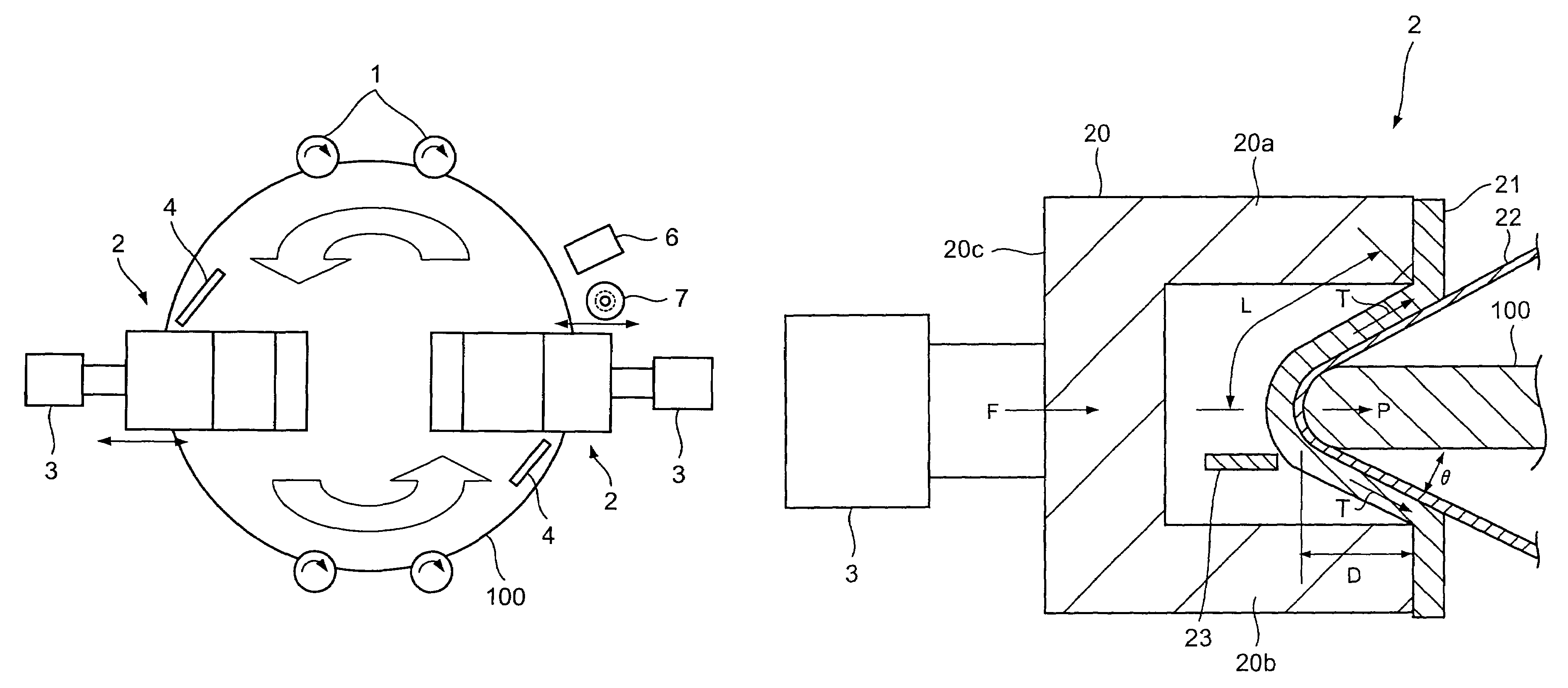

InactiveUS7367873B2Eliminate surface roughnessShort timeEdge grinding machinesRevolution surface grinding machinesConstant forceEngineering

A substrate processing apparatus has a polishing tape and a polishing head for pressing the polishing tape against a peripheral portion of a semiconductor wafer. The substrate processing apparatus polishes the wafer due to sliding contact of the polishing tape and the wafer. The polishing head has an elastic body for supporting the polishing tape. The substrate processing apparatus has an air cylinder for pressing the polishing head so that the elastic body of the polishing head presses the polishing tape against the predetermined portion of the wafer under a constant force.

Owner:EBARA CORP +1

Floating connector

InactiveUS6347950B1Prevent plastic(not elastic) deformationMinimum shapeIncorrect coupling preventionPrinted circuitsElectricityElectrical connection

The present invention provides a floating connector, used for electrical connection between electrical components and a circuit board. Multiple embodiments include a plurality of elastic contacts retained between the circuit board and an insulated housing movable laterally and orthogonally in a fixed range to accommodate misalignment. The contacts are in sliding contact with the circuit board to ensure a reliable connection without solder. The embodiments employ guiding slits to maintain electrical separation between the contacts during adjustment. Each embodiment accommodates movement in multiple directions, requires no solder, and provides for secure flexible electrical connection between an electronic component and the circuit board.

Owner:SMK CORP

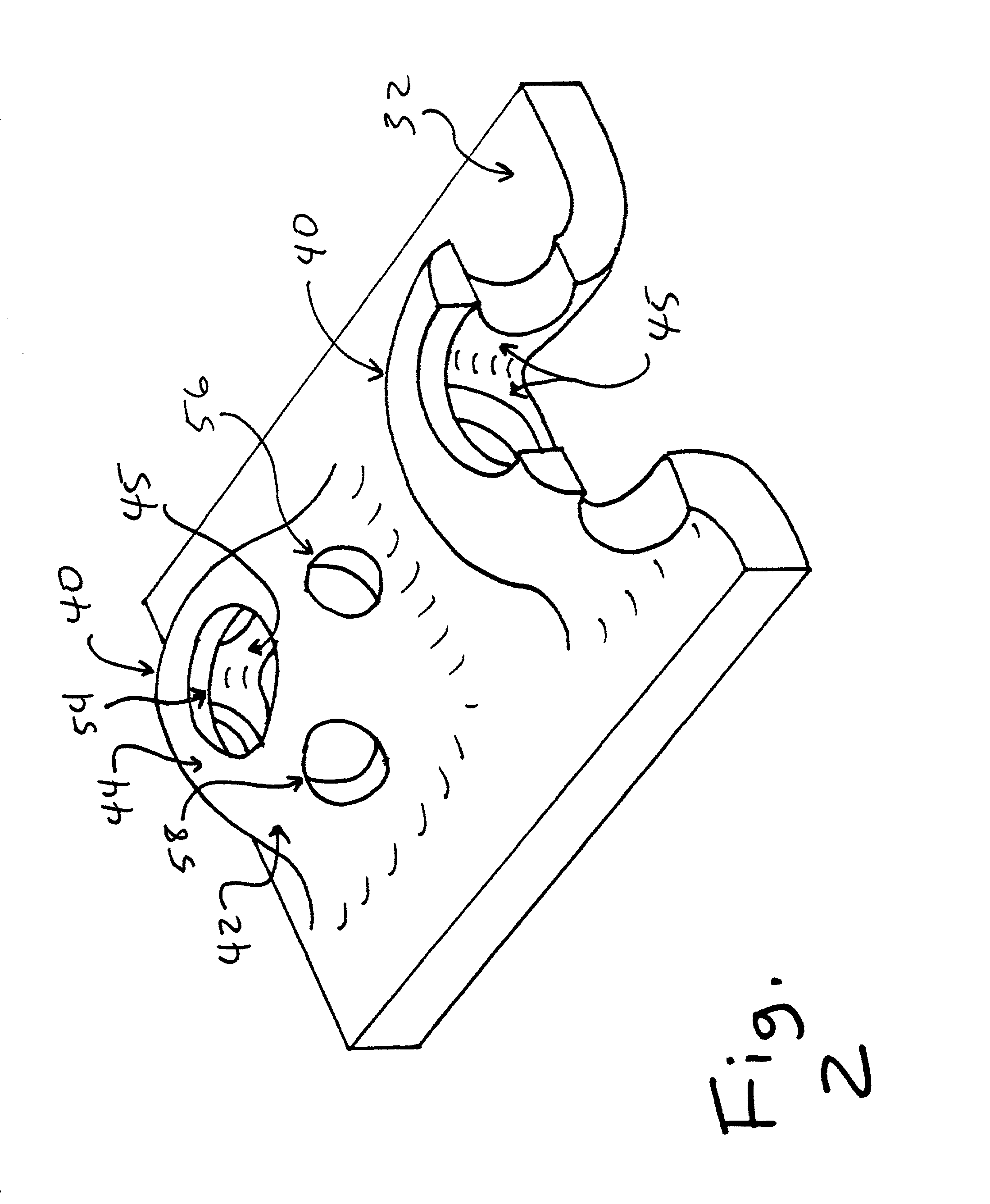

Manual knife sharpener with angle control

InactiveUS6881137B2Ease of useImprove portabilityEdge grinding machinesRevolution surface grinding machinesKnife sharpenerEngineering

A sharpener for blades comprises a physical structure supporting at least one abrasive surface. A displaceable guiding plate having an integral linear structural feature of the support is disposed toward one side of the abrasive surface. The linear structural feature provides sliding contact with a face of the blade to establish the relative angle of the plane of the edge facet of the blade with the plane of the abrasive surface at the point of mutual contact as the facet is guided into contact with the abrasive surface.

Owner:EDGECRAFT

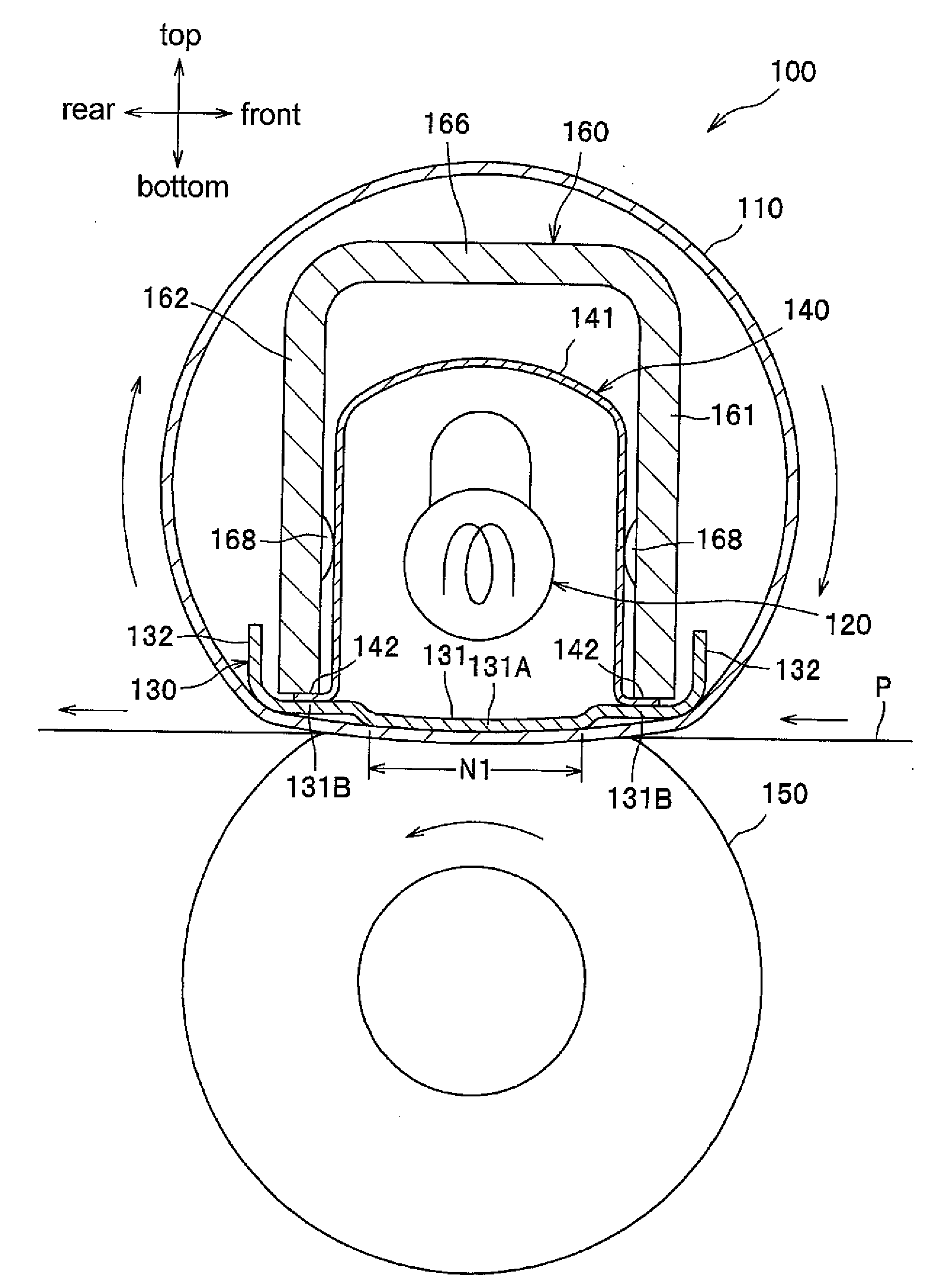

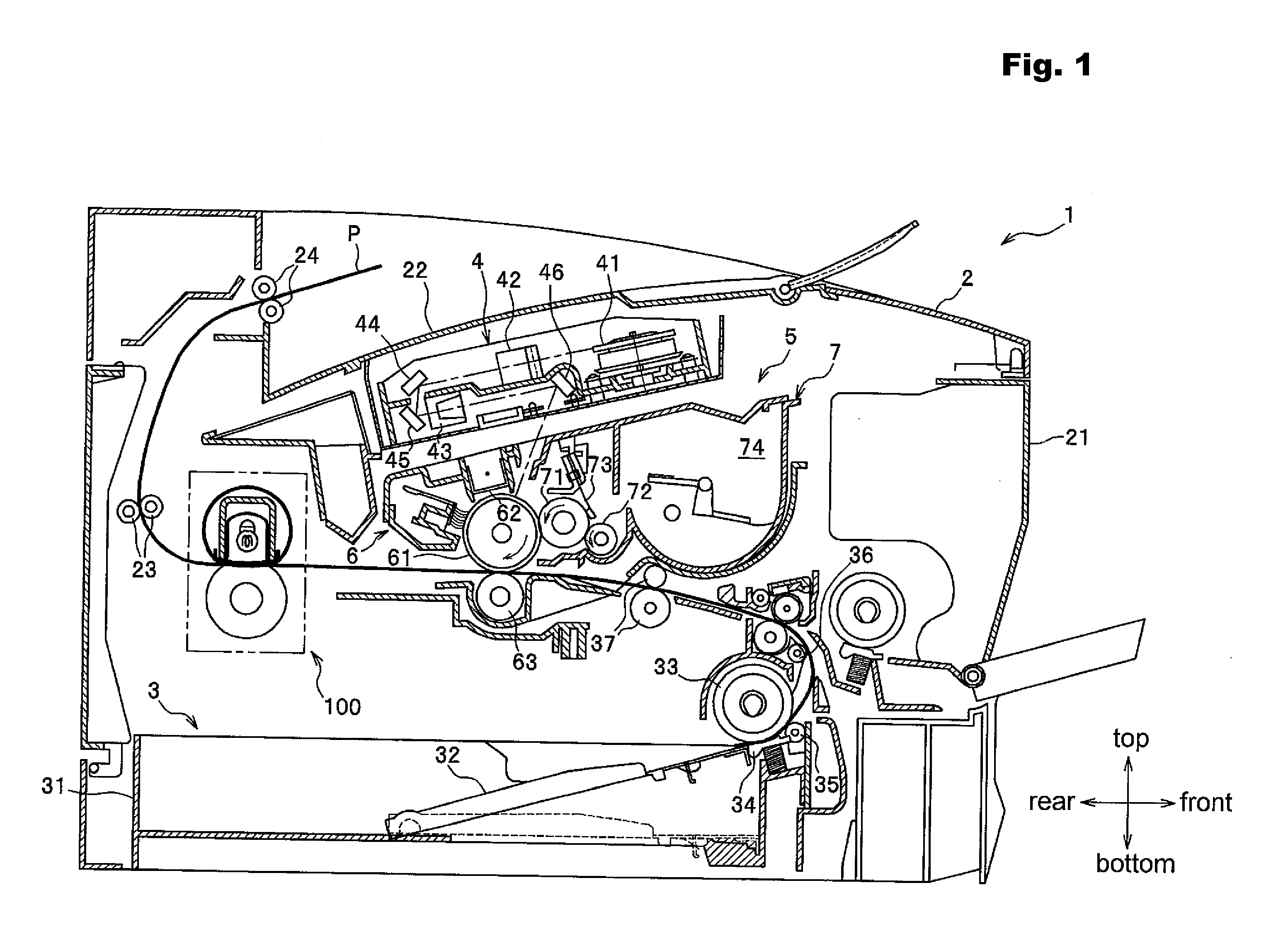

Fixing Device

A fixing device includes a tubular fusing film, a heater, a nip member, a backup member, a backup member, first supporting member, and a second supporting member. The heater may be disposed inside the tubular shape of the fusing film. The nip member may be disposed so as to be in sliding contact with the inner surface of the fusing film and heated by the heater. The backup member may form a nip portion between the backup member and the fusing film with the fusing film between the backup member and the nip member. The first supporting member may be configured to integrally support the heater and the nip member. The second supporting member may be configured to movably support the first supporting member so that the nip member moves relative to the backup member.

Owner:BROTHER KOGYO KK

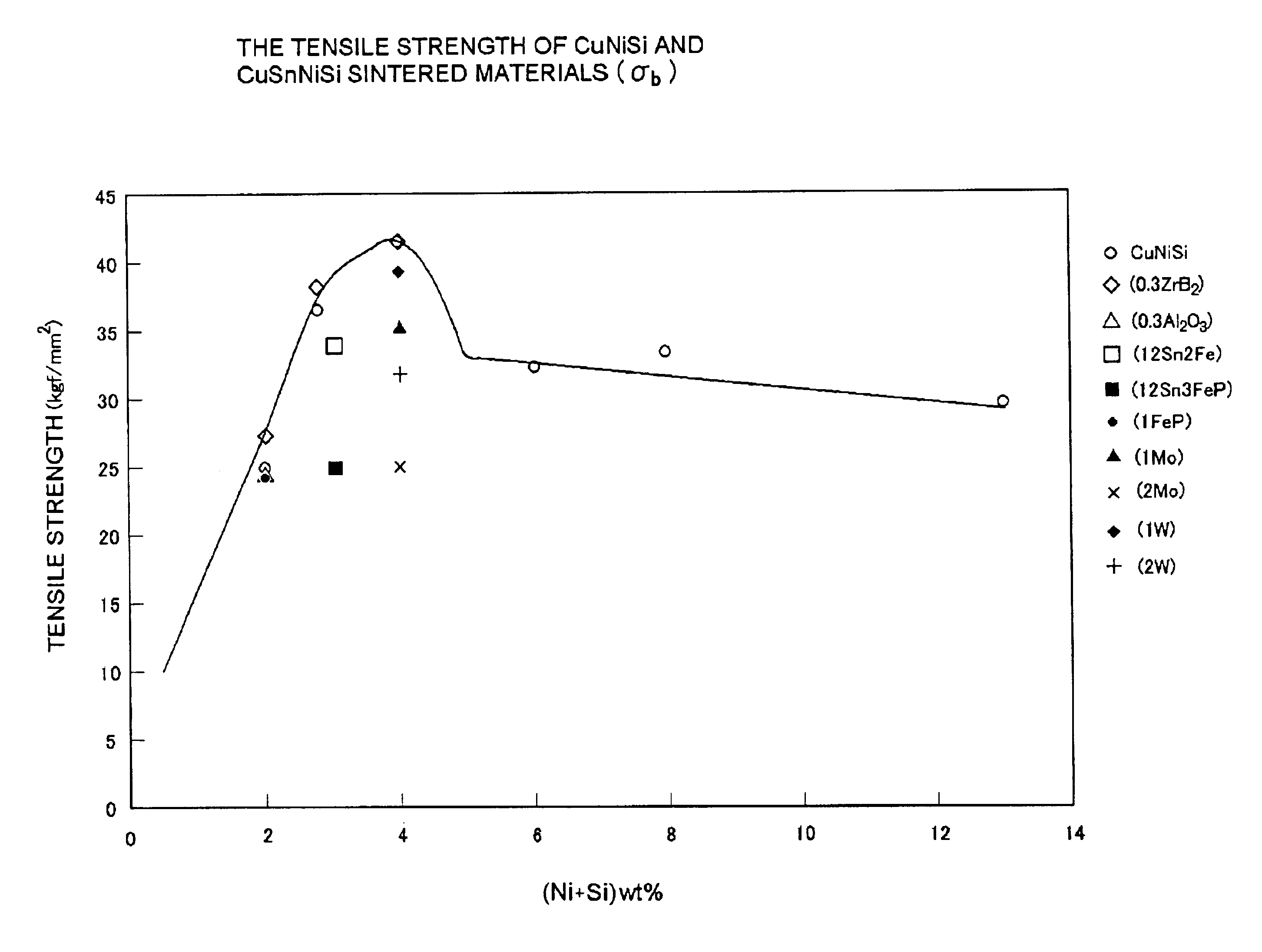

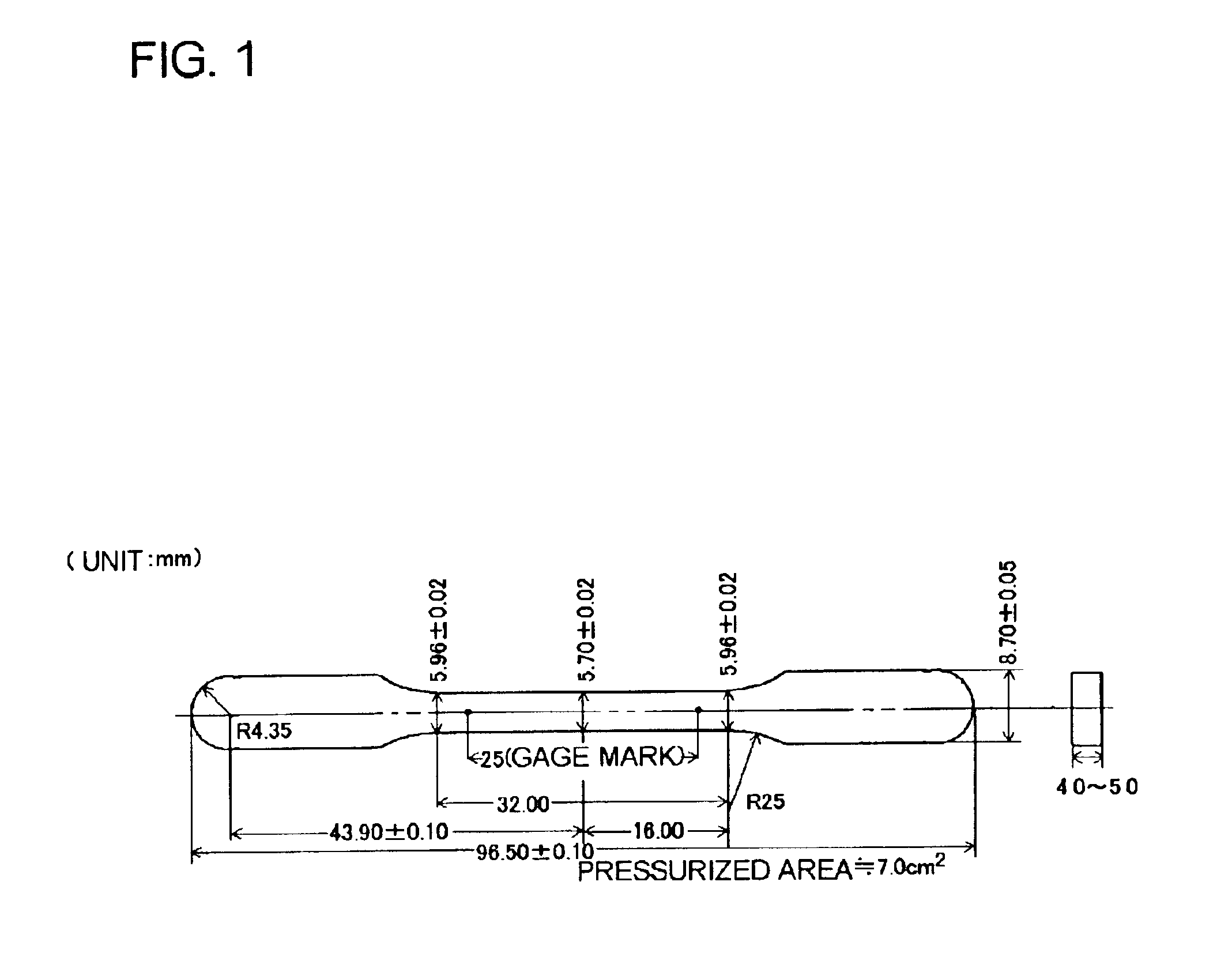

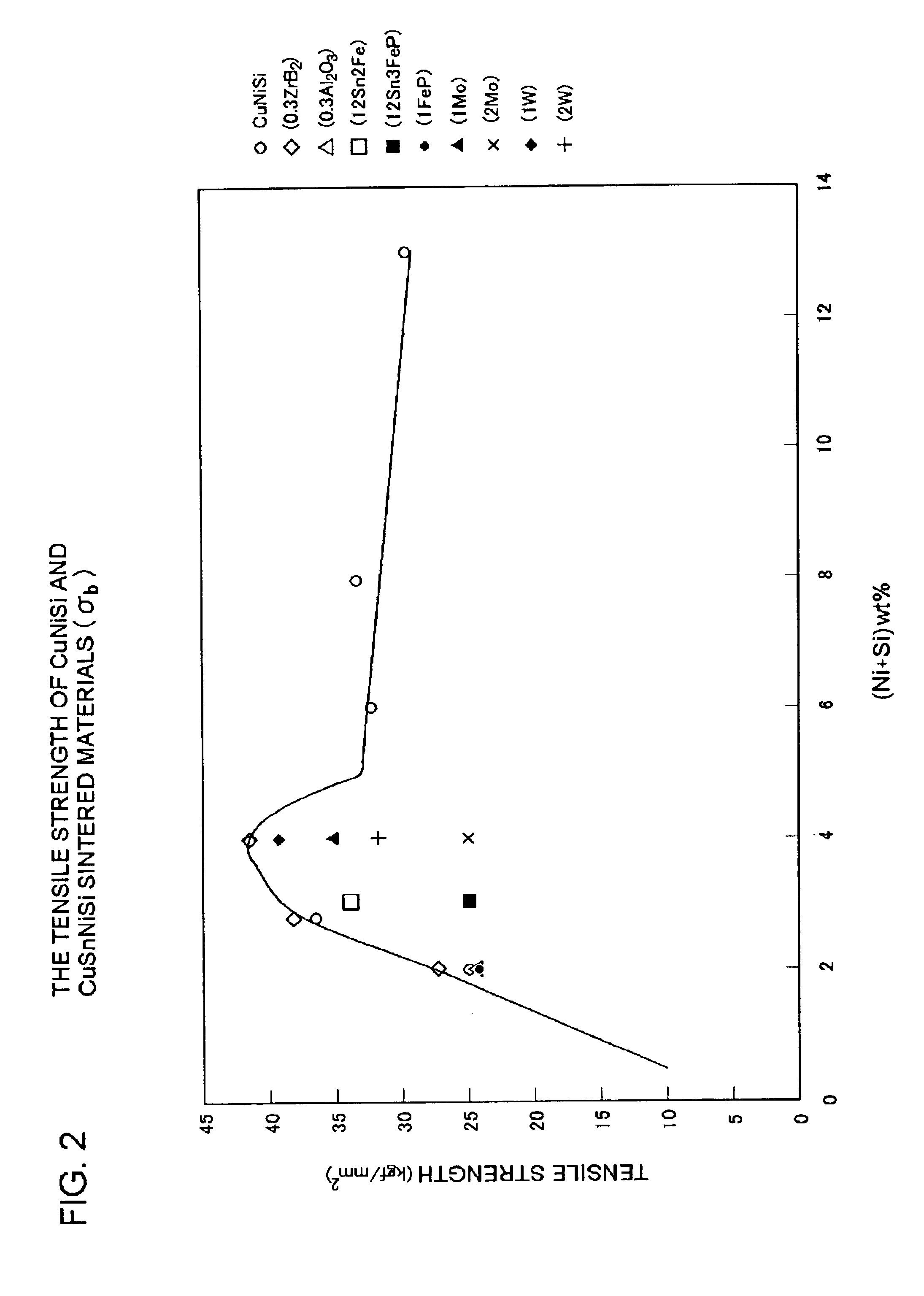

Copper based sintered contact material and double-layered sintered contact member

With the objectives of alleviating the property of attacking on the mating member by scratching-off of local agglutinates on the sliding contact surface, achieving improved wear resistance, and achieving improved seizure resistance through restraint of frictional heat generation by a hard phase, a copper based sintered contact material contains shock-resistant ceramics in an amount of 0.05 to less than 0.5 wt % as non-metallic particles composed of one or more substances selected from pulverized oxides, carbides and nitrides. The shock-resistant ceramics are comprised of SiO2 and / or two or more substances selected from SiO2, Al2O3, LiO2, TiO2 and MgO.

Owner:KOMATSU LTD

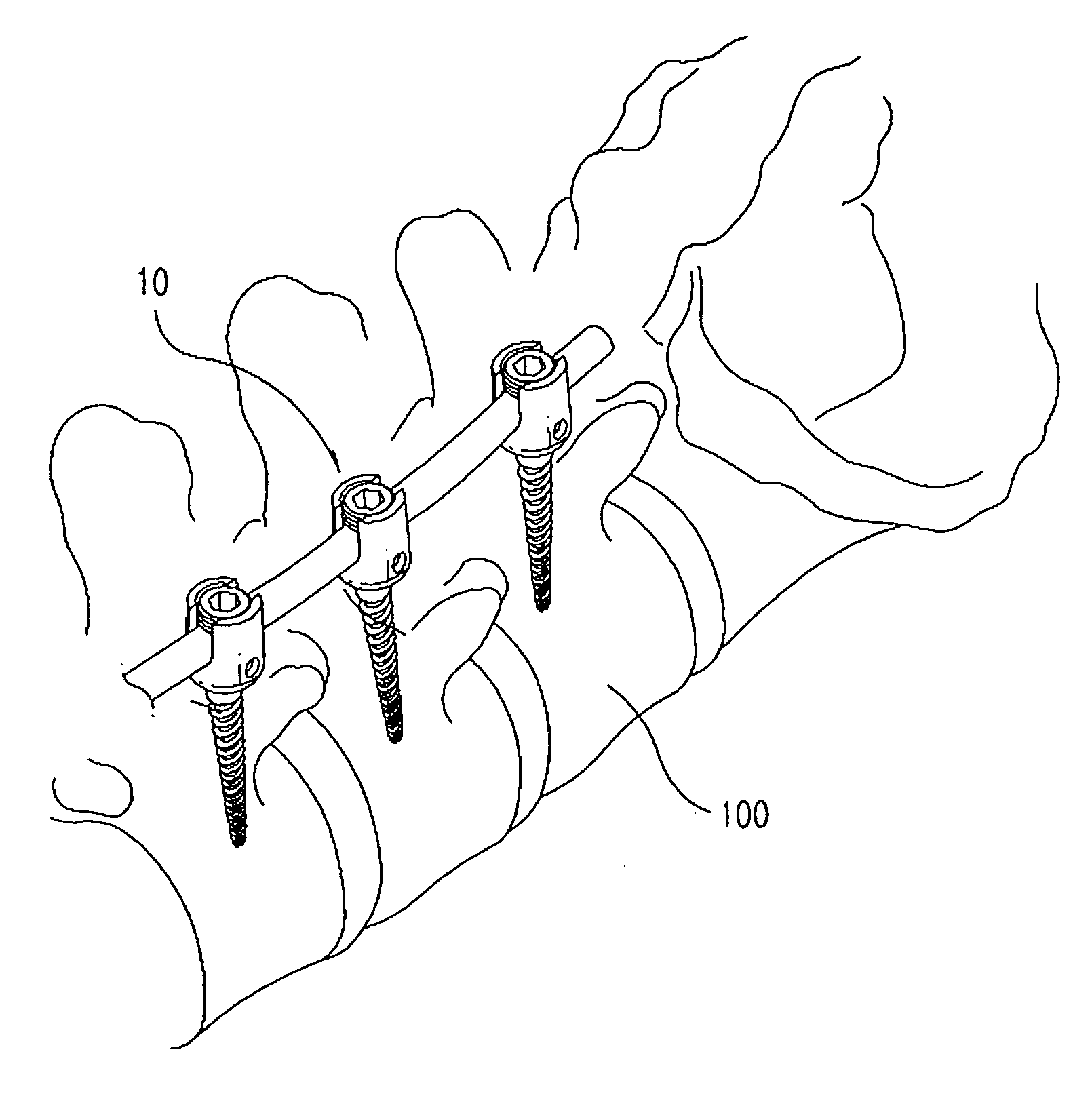

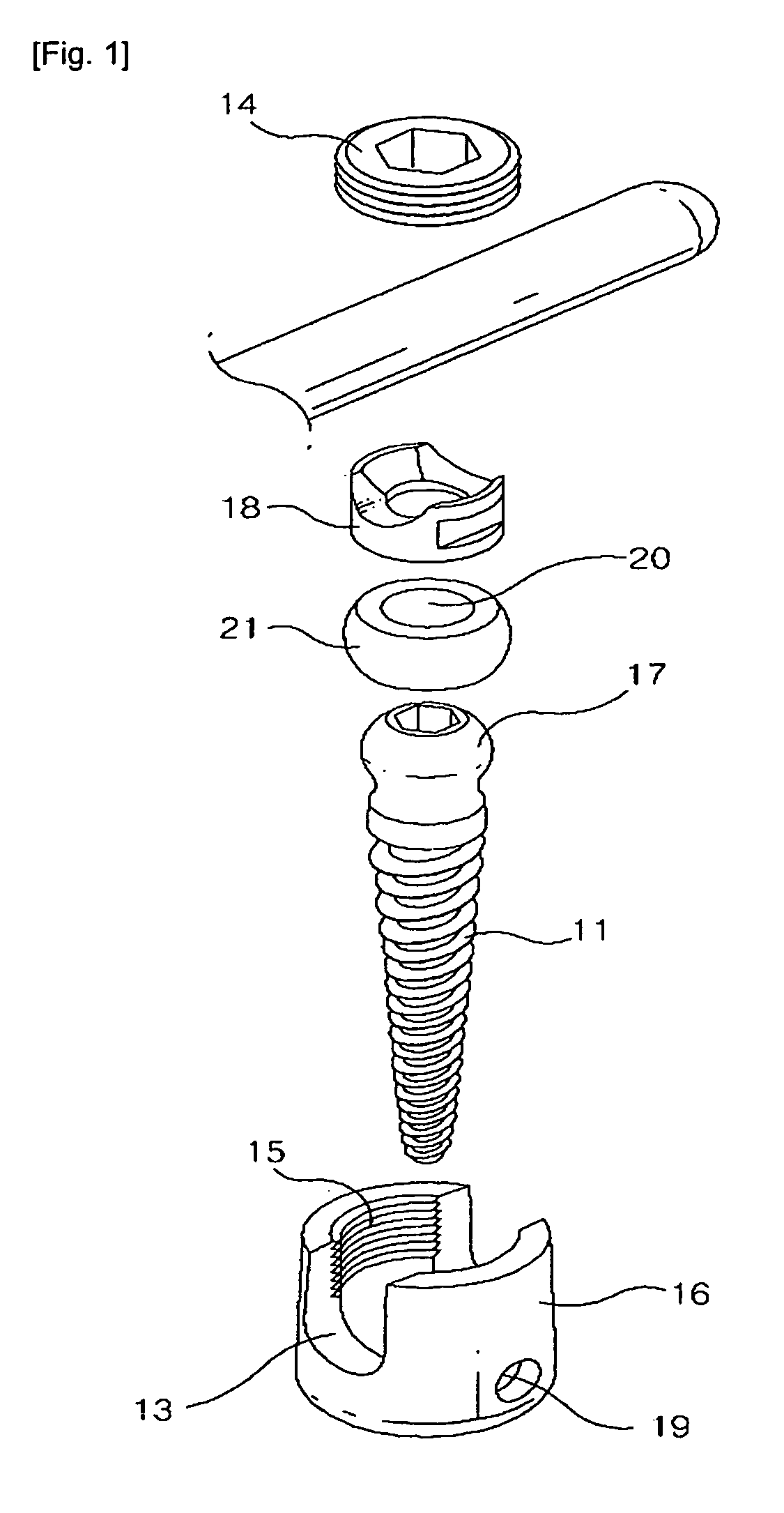

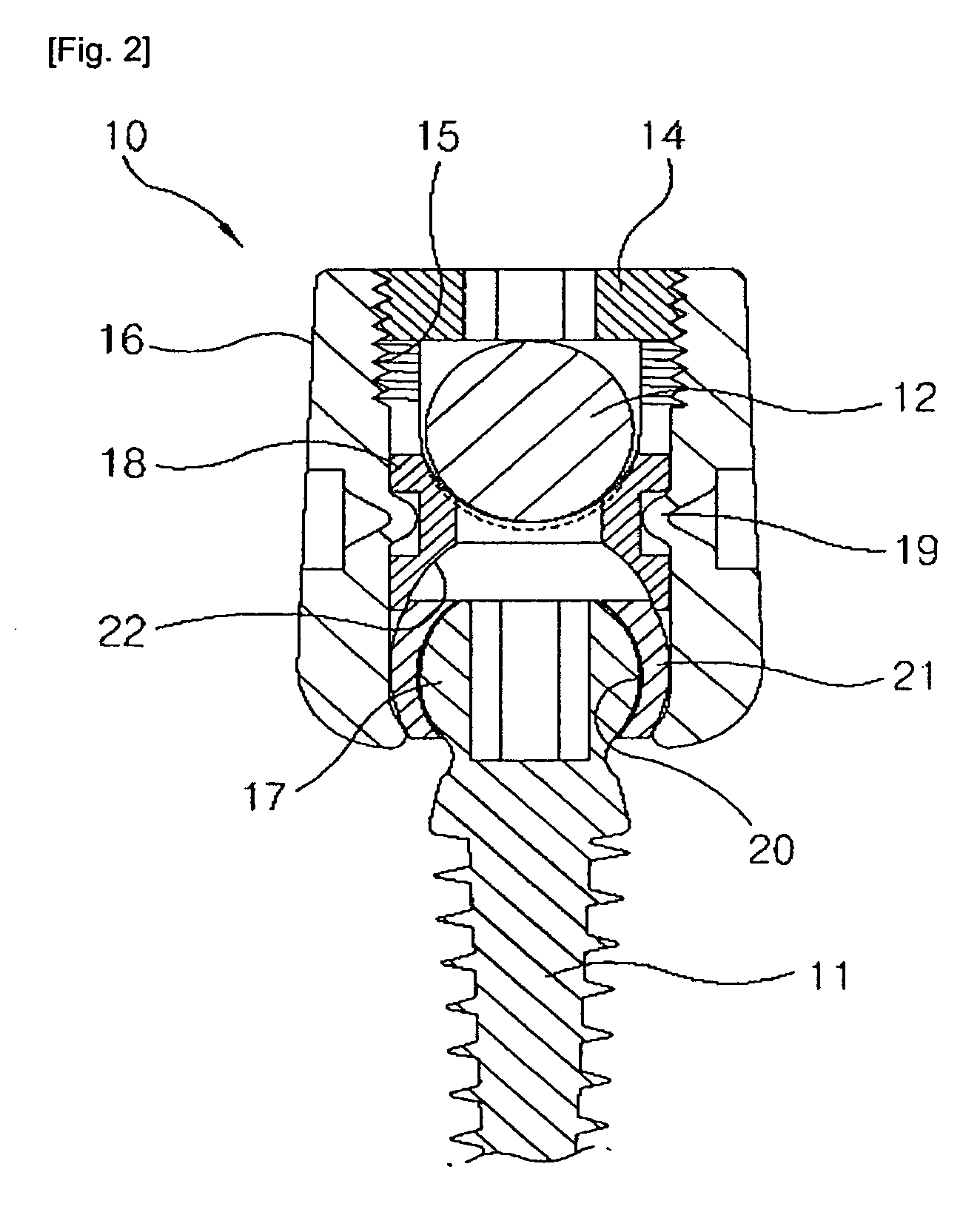

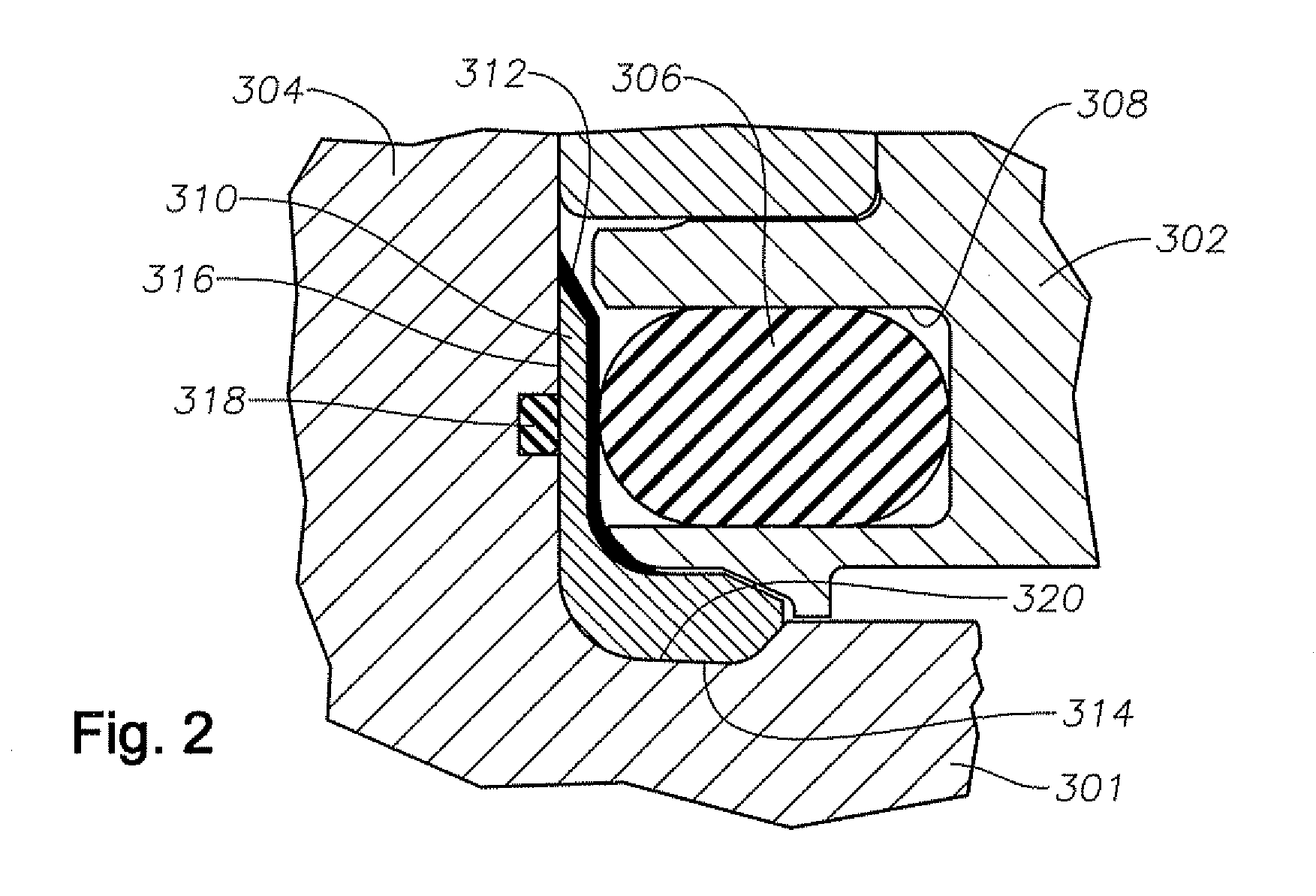

Buffer type vertebral pedicle screw

InactiveUS20090240290A1Avoid vibrationPainSuture equipmentsInternal osteosythesisEngineeringVertebral pedicle

A vertebral pedicle screw includes a screw body driven into a vertebral pedicle, a housing assembled to an upperend of the screw body and having grooves for seating a rod and a threaded portion for locking a fastening bolt, the fastening bolt pressing the rod positioned thereunder as it is threaded downward, and a fastening ring inserted into the housing. The vertebral pedicle screw further includes an insert placed on an outer surface of a screw head of the screw body in the housing, installed to be partially come into contact with the fastening ring on an upper portion thereof, and accommodating the screw head ofthe screw body on a curved inner surface thereof such that the insert and the screw head are brought into sliding contact with each other, whereby an entire rod-side assembly can be slidingly moved in all directions with respect to the screw body.

Owner:CHOI GIL WOON

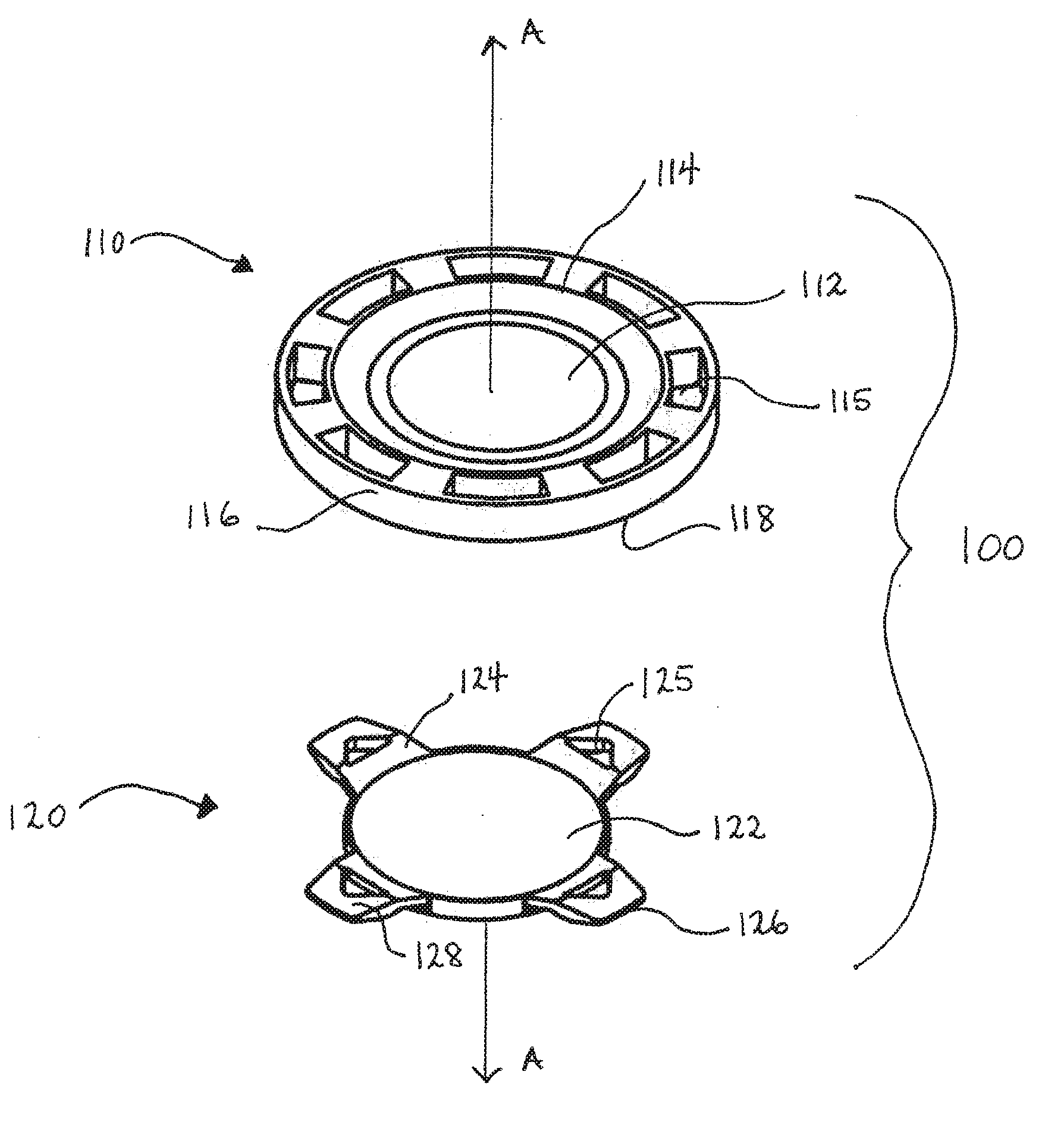

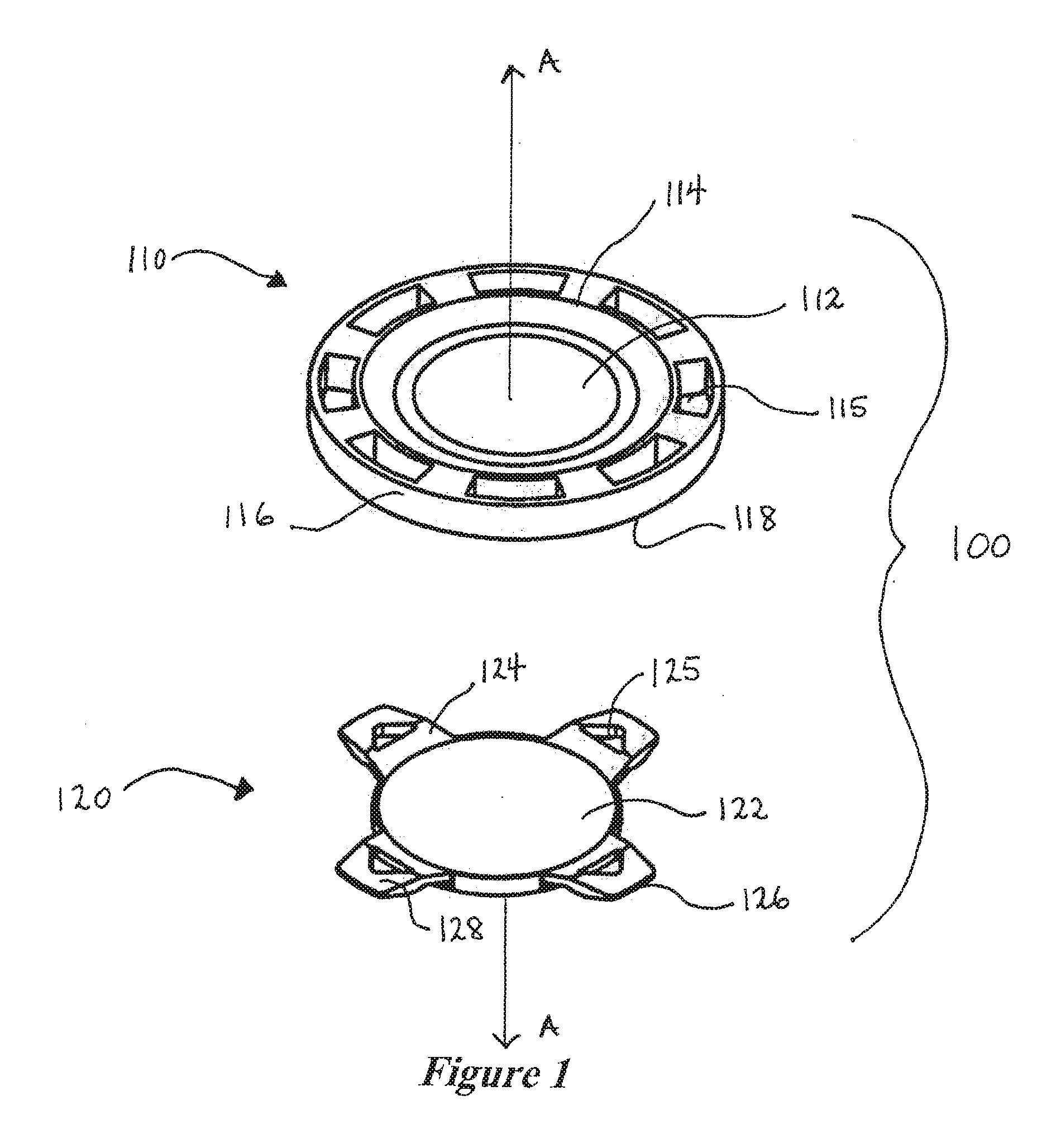

Two-part accommodating intraocular lens device

ActiveUS20160317286A1Reduce incision sizeReduced delivery profileDiagnosticsSurgeryIntraocular lensCentration

A two-part accommodating intraocular lens (IOL) device for implantation in a capsular bag of a patient's eye. The IOL device includes a primary lens assembly and a power changing lens. The primary lens assembly includes a fixed lens and a peripherally disposed centration member. The centration member has a circumferential distal edge and a first coupling surface adjacent the circumferential distal edge. The power changing lens has an enclosed, fluid- or gel-filled lens cavity and haptic system disposed peripherally of the lens cavity. The haptic system has a peripheral engaging edge configured to contact the capsular bag and a second coupling surface. The first and second coupling surfaces are in sliding contact with one another to permit movement of the power changing lens relative to the primary lens assembly and also to maintain a spaced relationship between the fixed lens and the lens cavity during radial compression of the power changing lens.

Owner:LENSGEN INC

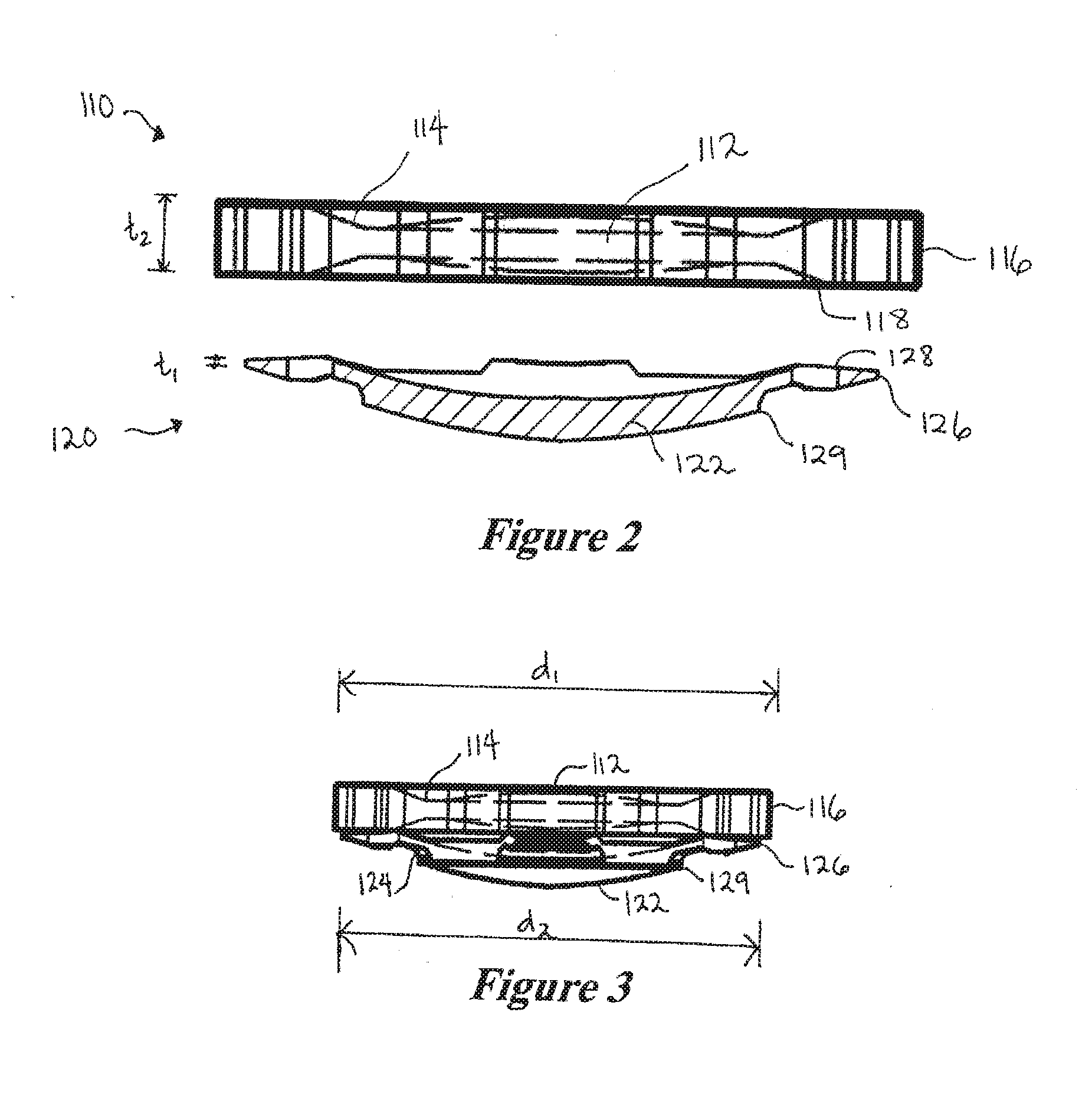

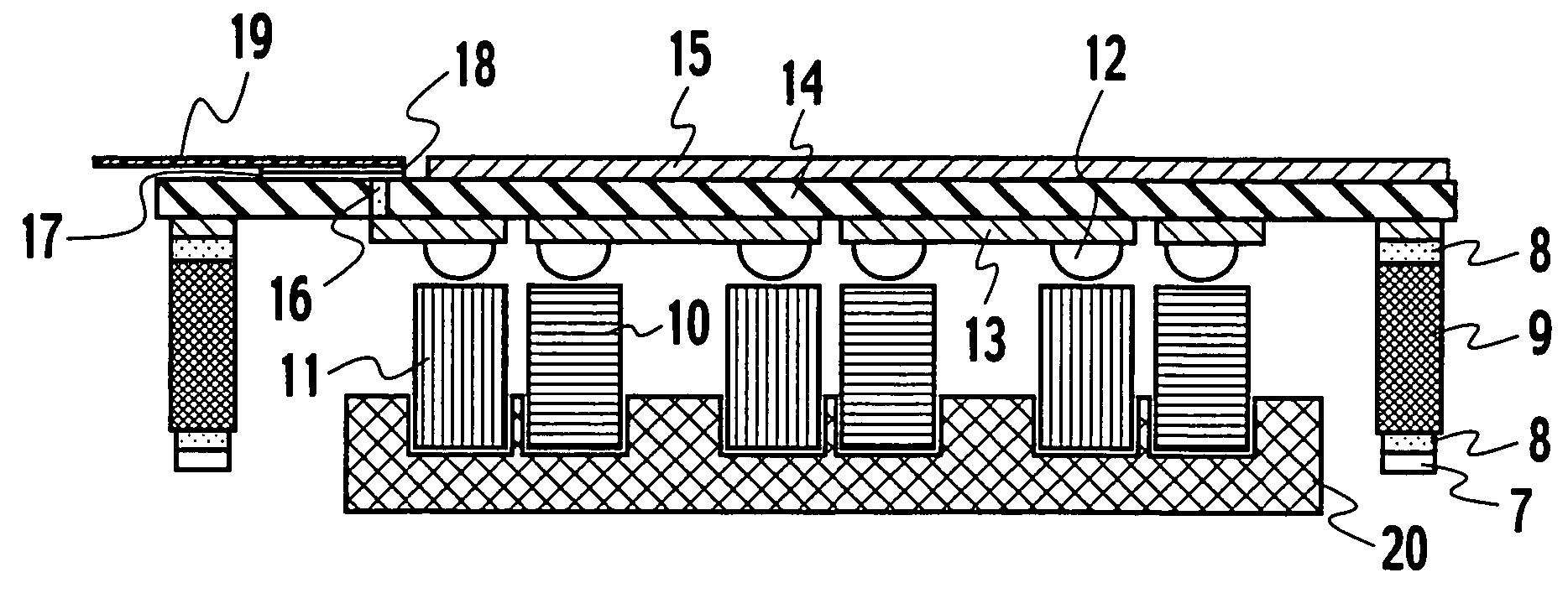

Thermoelectric device

ActiveUS20050016183A1Improve reliabilityNot easy to damageThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric elementSliding contact

In order to provide a highly reliable thermoelectric device, in a thermoelectric device, a plurality of heat-radiating-side electrodes, arranged in accordance with positions where respective thermoelectric elements are to be arranged, are arrayed in an array fashion on a planer surface of a heat-radiating-side board. Heat-radiating-side end surfaces of the plurality of p-type thermoelectric elements and n-type thermoelectric elements and the heat-radiating-side electrodes are joined together by solders. Heat-absorbing-side electrodes are brought into sliding contact with heat-absorbing-side end surfaces of these thermoelectric elements.

Owner:KK TOSHIBA

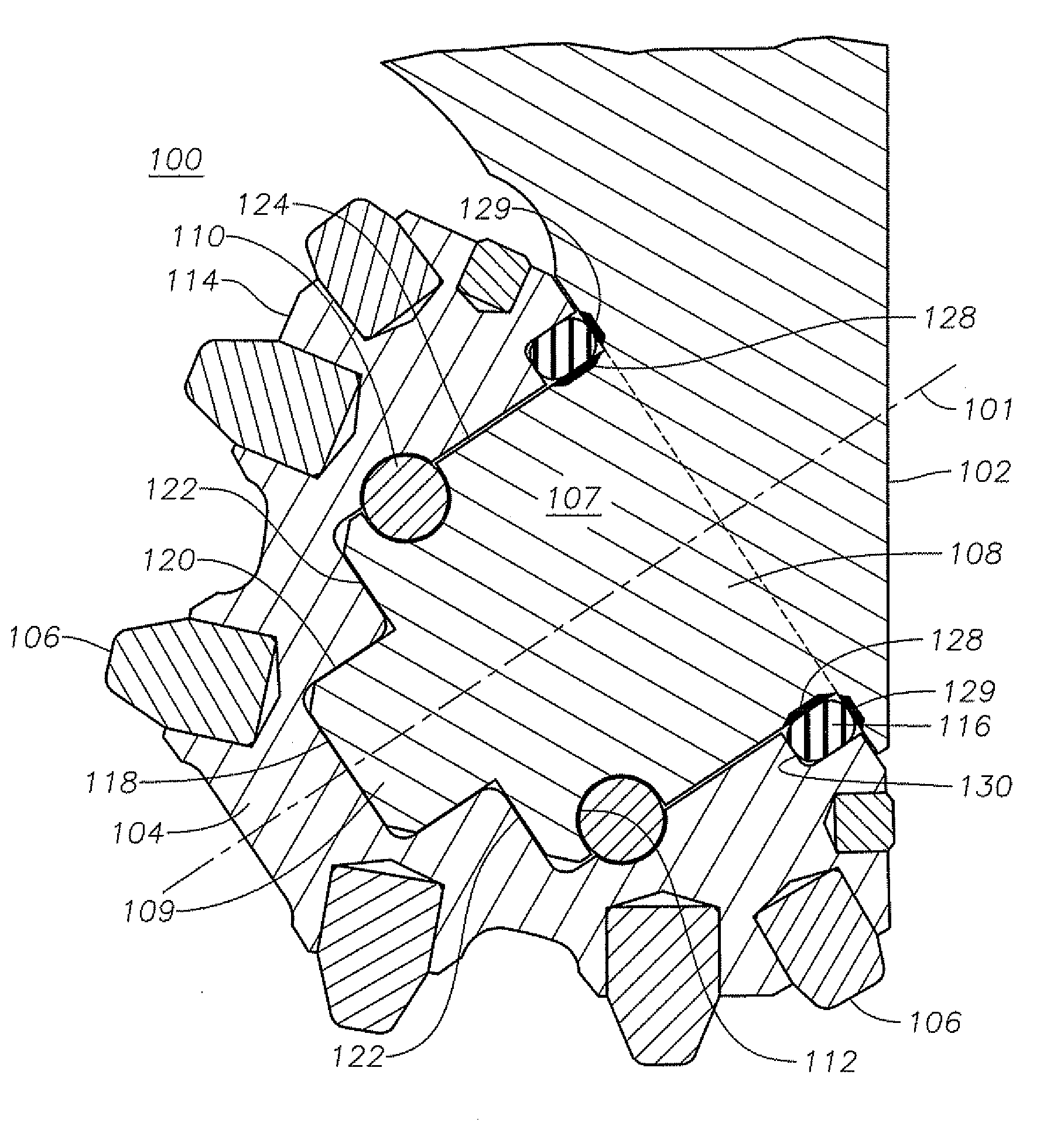

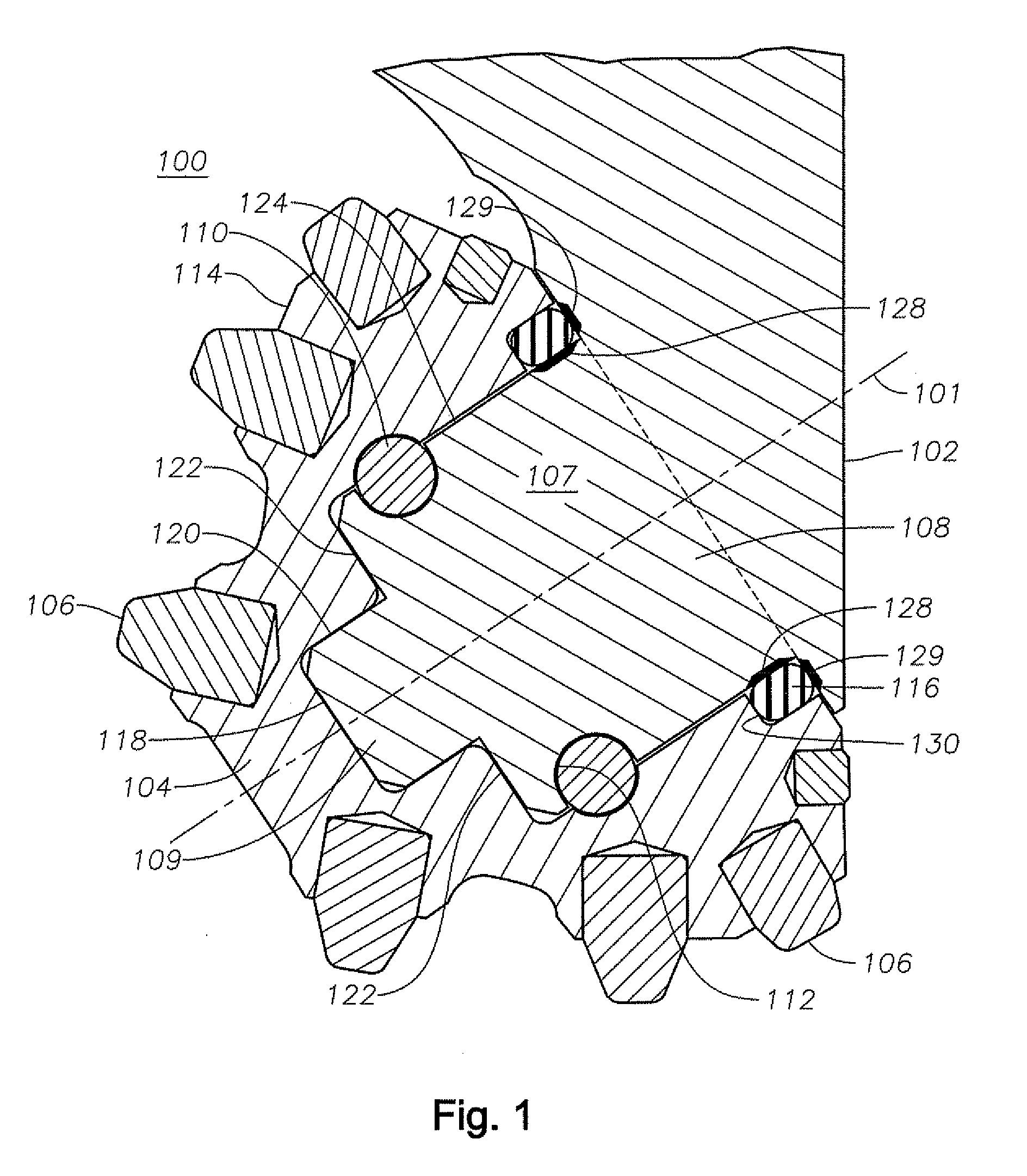

Earth Boring Bit with DLC Coated Bearing and Seal

A roller cone bit is provided that includes a wear resistant diamond-like carbon coating applied to a bearing shaft, where it is in sliding contact with the bearing seal. The wear resistant diamond-like carbon coating reduces wear and corrosion of the head bearing shaft sealing surface and provides extended life to the bearing seal.

Owner:BAKER HUGHES INC

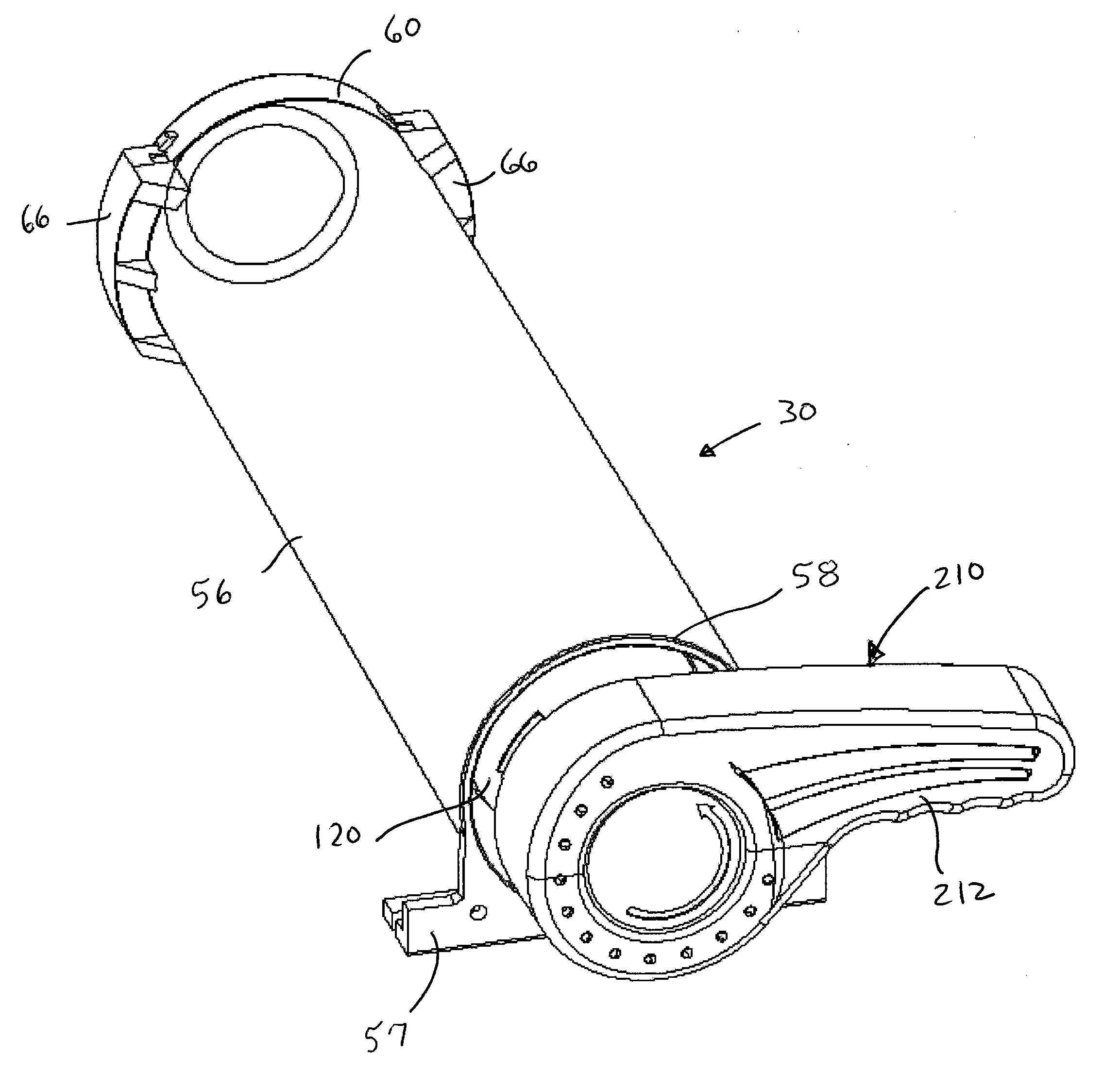

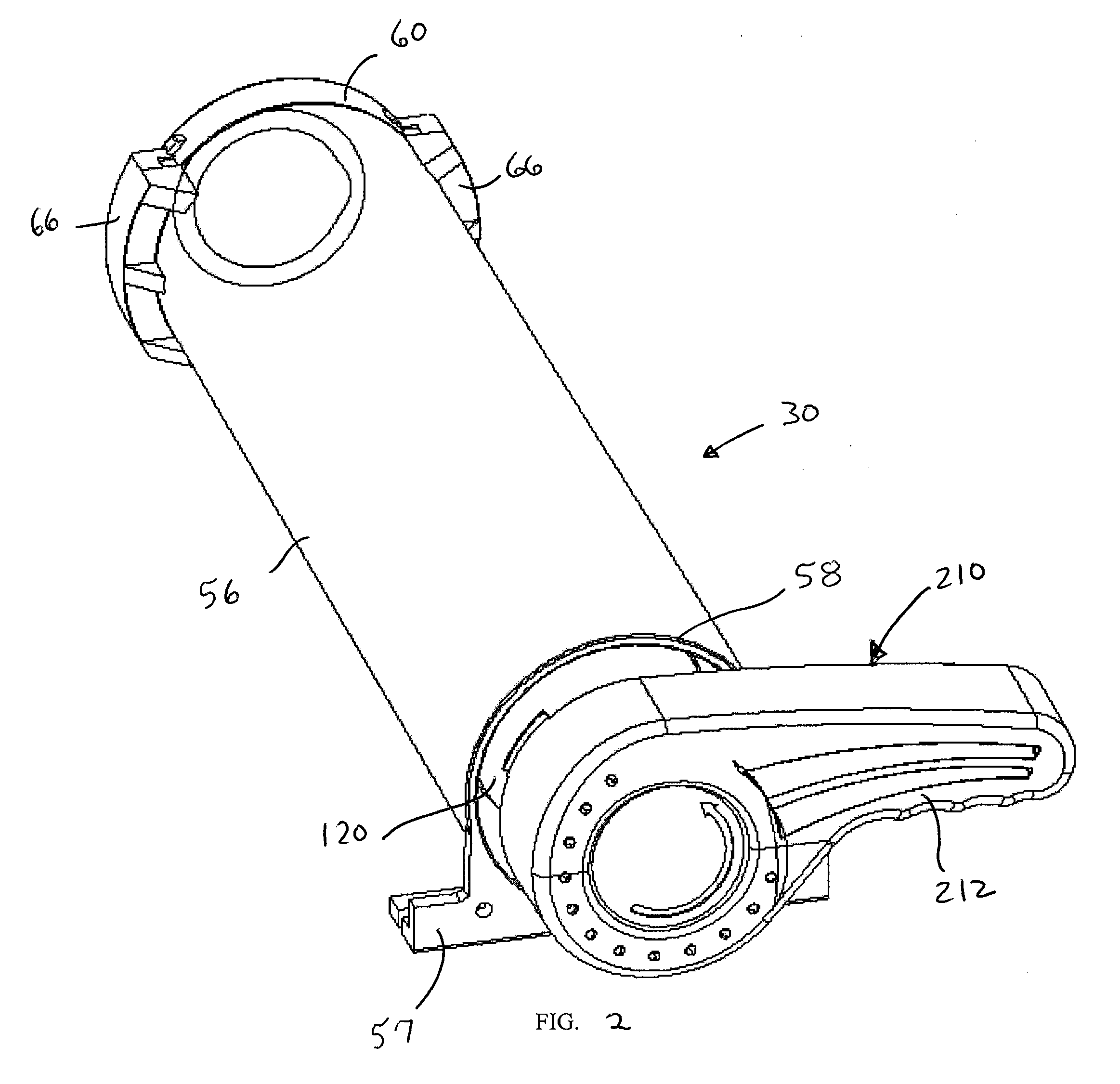

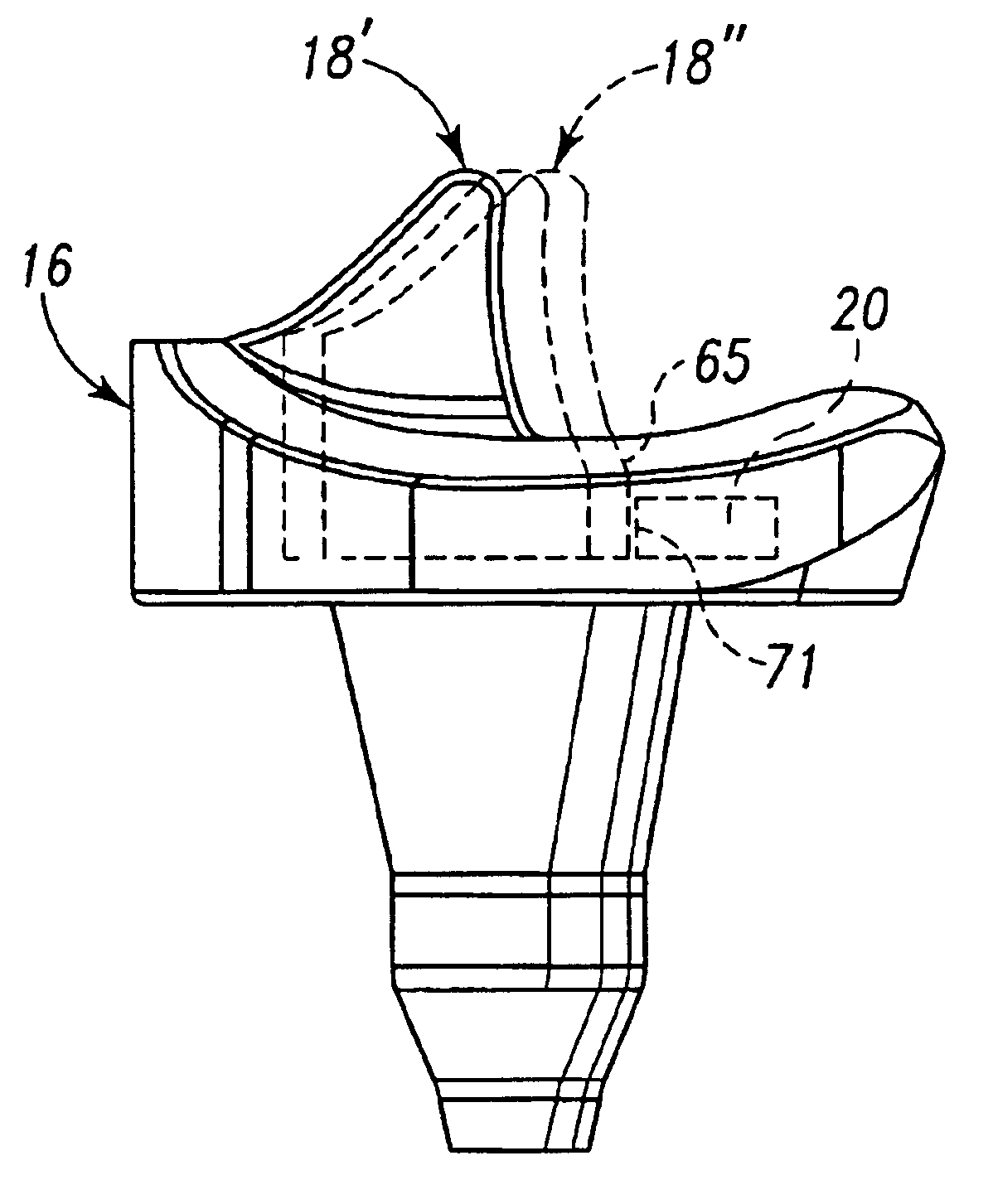

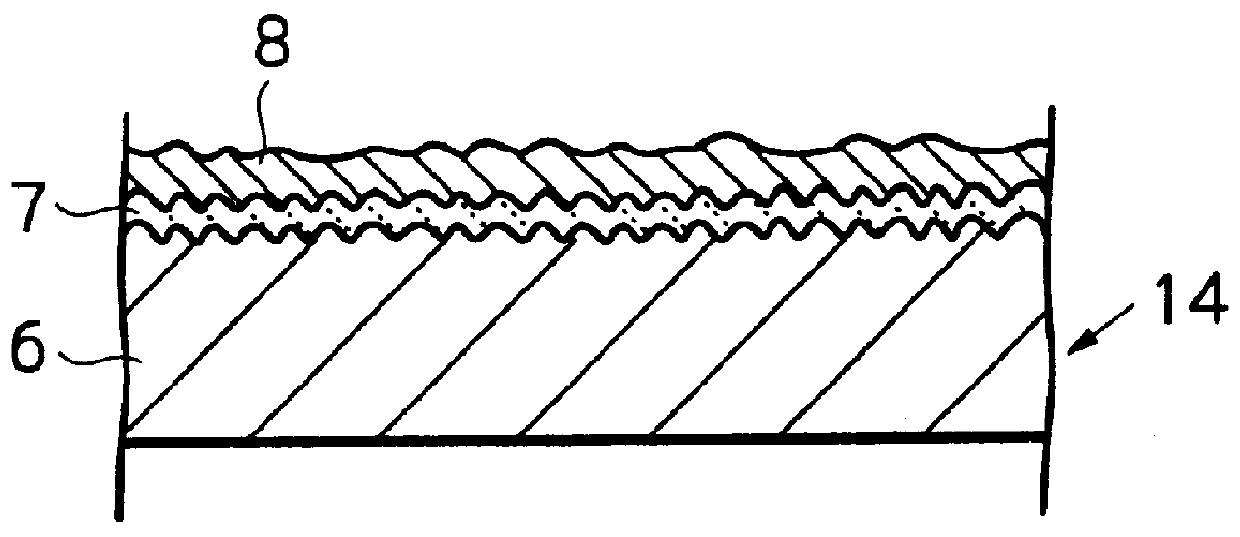

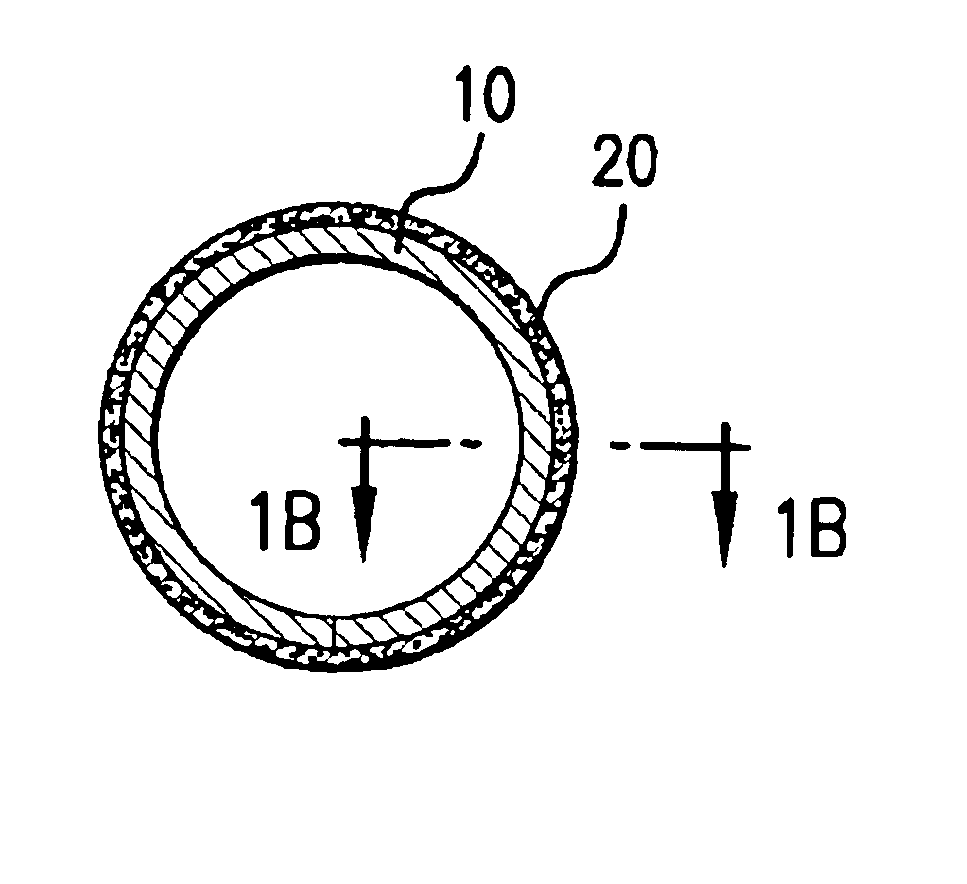

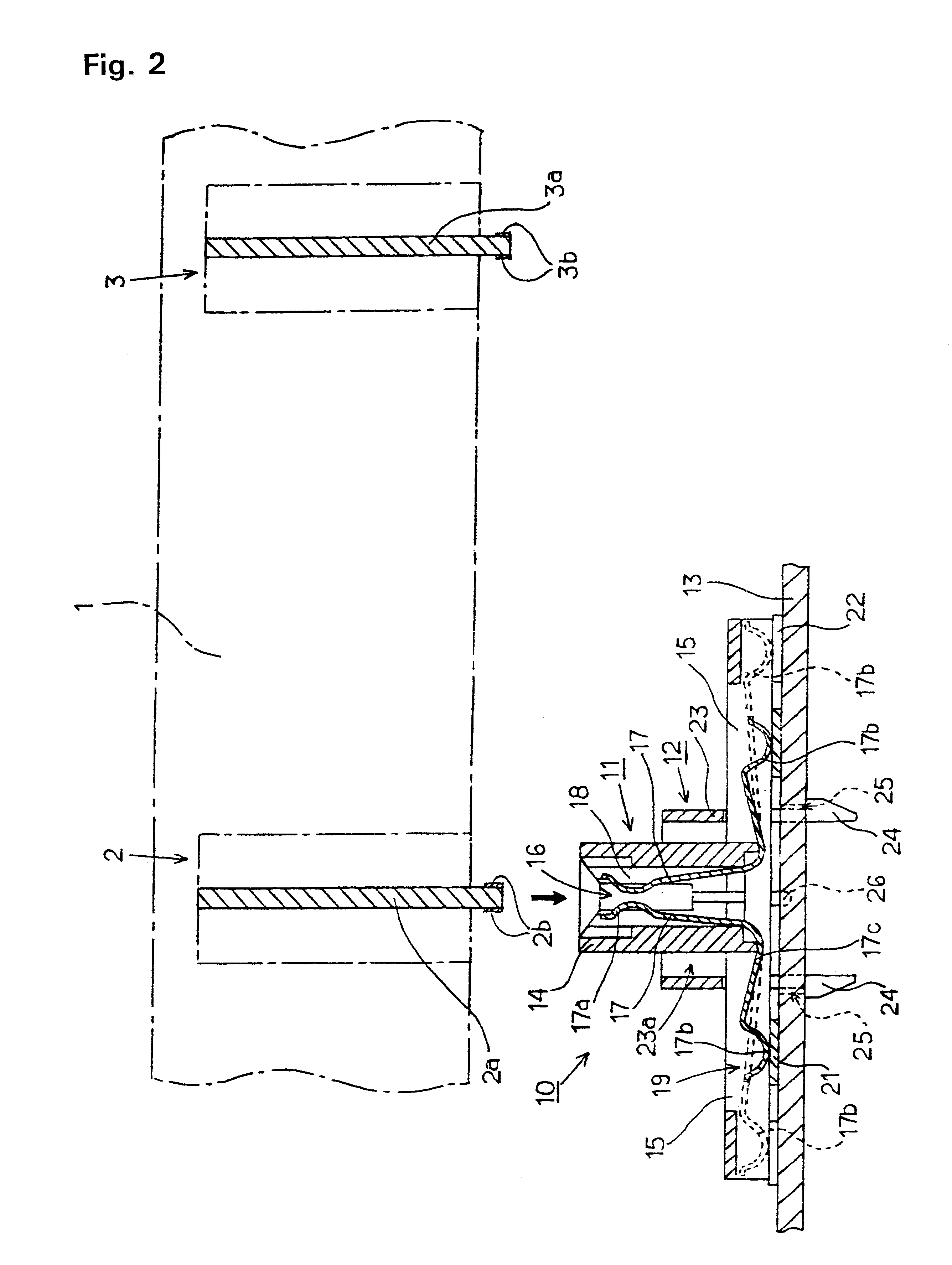

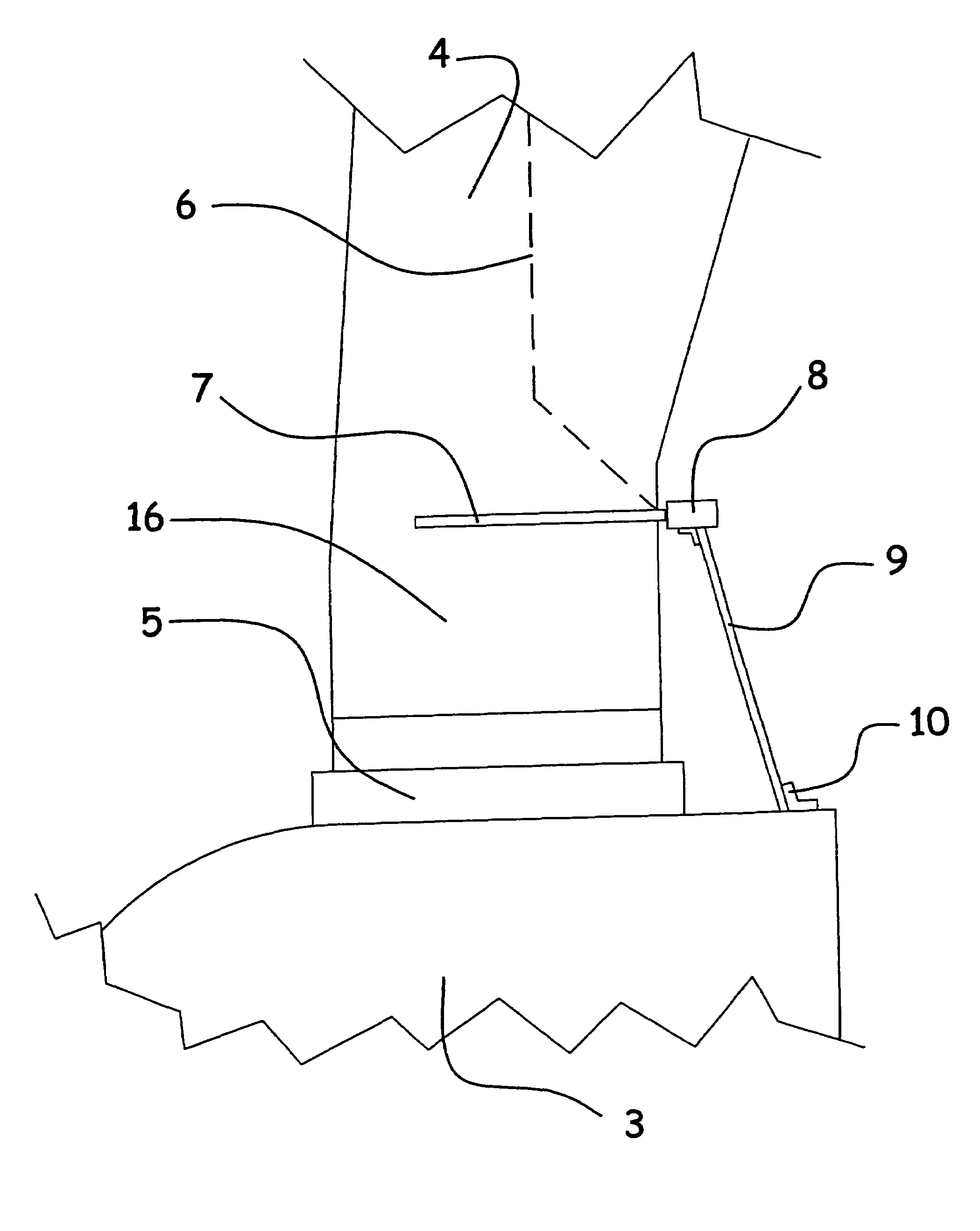

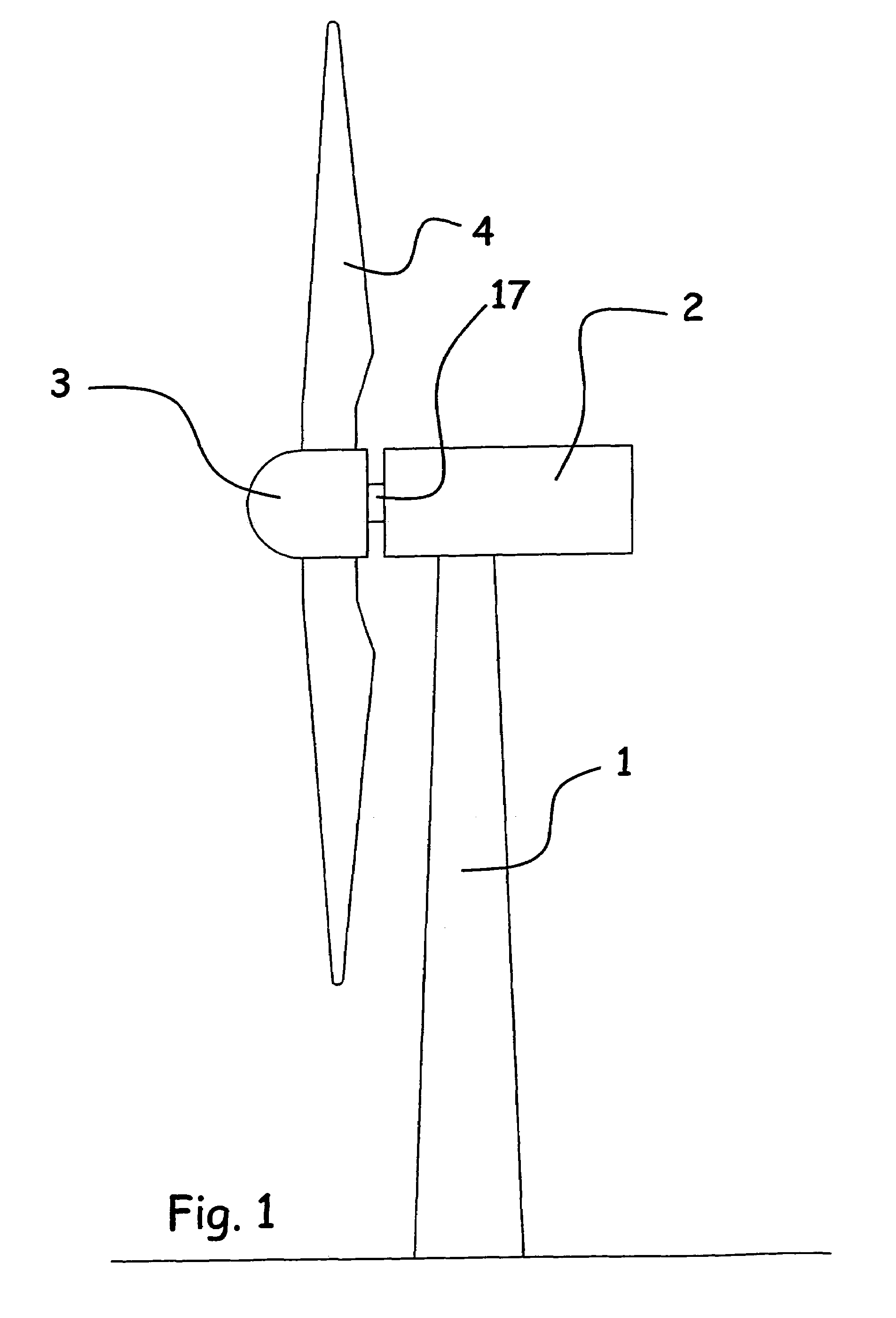

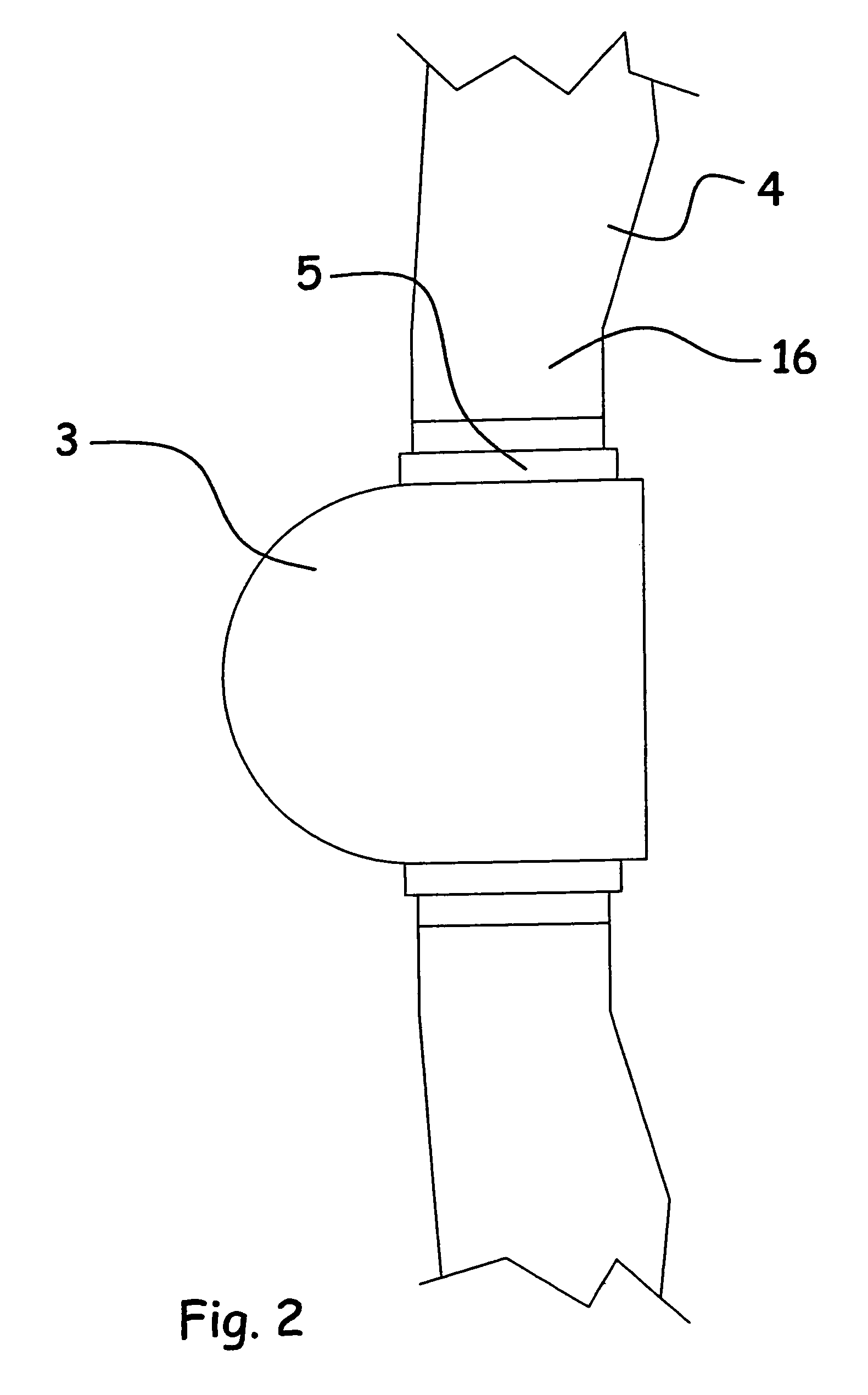

Lightning protection of a pitch-controlled wind turbine blade

ActiveUS7390169B2Current protectionReduce resistancePropellersPump componentsTurbine bladeBlade pitch

A wind turbine rotor including a rotor hub (3) and a plurality of blades (4), and where each blade root (16) is connected to said rotor hub through a pitch bearing (5) in such a manner that the pitch angle of the blade is adjustable by a turning of the blade about its longitudinal axis relative to the rotor hub. The blade is provided with at least one electrically conducting lightening down-conductor (6) extending in the longitudinal direction of the blade to the blade root and being electrically isolated from the pitch bearing (5). A spark gap (15) is provided between the lightning down-conductor and the rotor hub, said spark gap (15) being adapted to conduct a lightning current passing through the lightning down-conductor. A sliding contact connection (7, 12) is provided parallel to the spark gap (15) between the lightning down-conductor (6) and the rotor hub (3), said sliding contact connection ensuring electrical contact between said lightening down-conductor (6) and said rotor hub (3) irrespective of the pitch angle of the blade. The invention also relates to a wind turbine including such a rotor.

Owner:LM GLASSFIBER

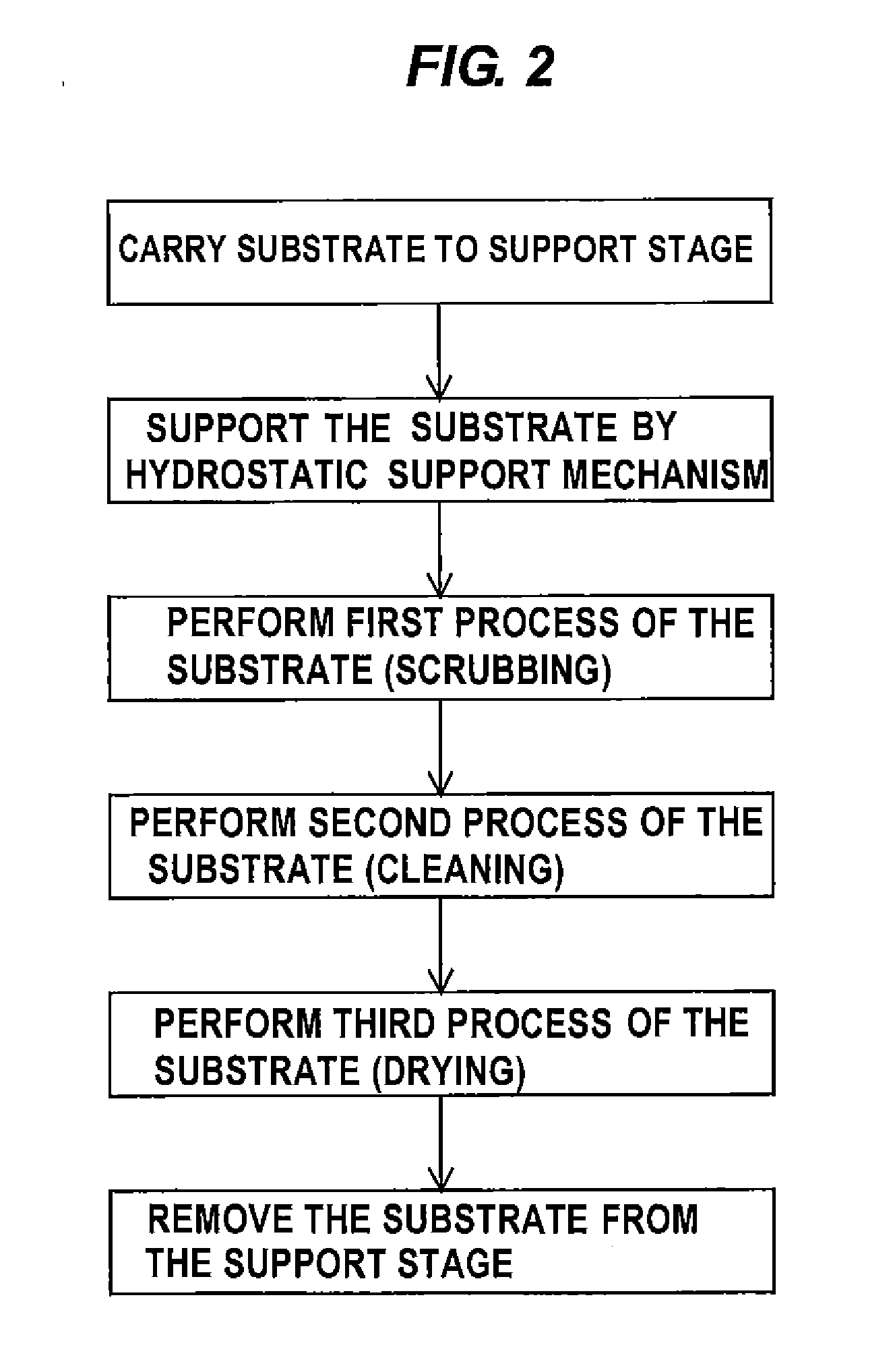

Substrate processing apparatus and substrate processing method

ActiveUS20130213437A1Improve removal efficiencyIncrease loadLiquid processingCarpet cleanersForeign matterEngineering

A substrate processing apparatus removes foreign substances from a substrate at high removal efficiency. The substrate processing apparatus includes: a scrubber to perform surface processing of the substrate by bringing a scrubbing member into sliding contact with a first surface of the substrate, a hydrostatic support mechanism for supporting a second surface of the substrate via fluid pressure without contacting the substrate, the second surface being an opposite surface of the first surface, a cleaner to clean the processed substrate, and a dryer to dry the cleaned substrate. The scrubber brings the scrubbing member into sliding contact with the first surface while rotating the scrubbing member about a central axis of the scrubber.

Owner:KIOXIA CORP +1

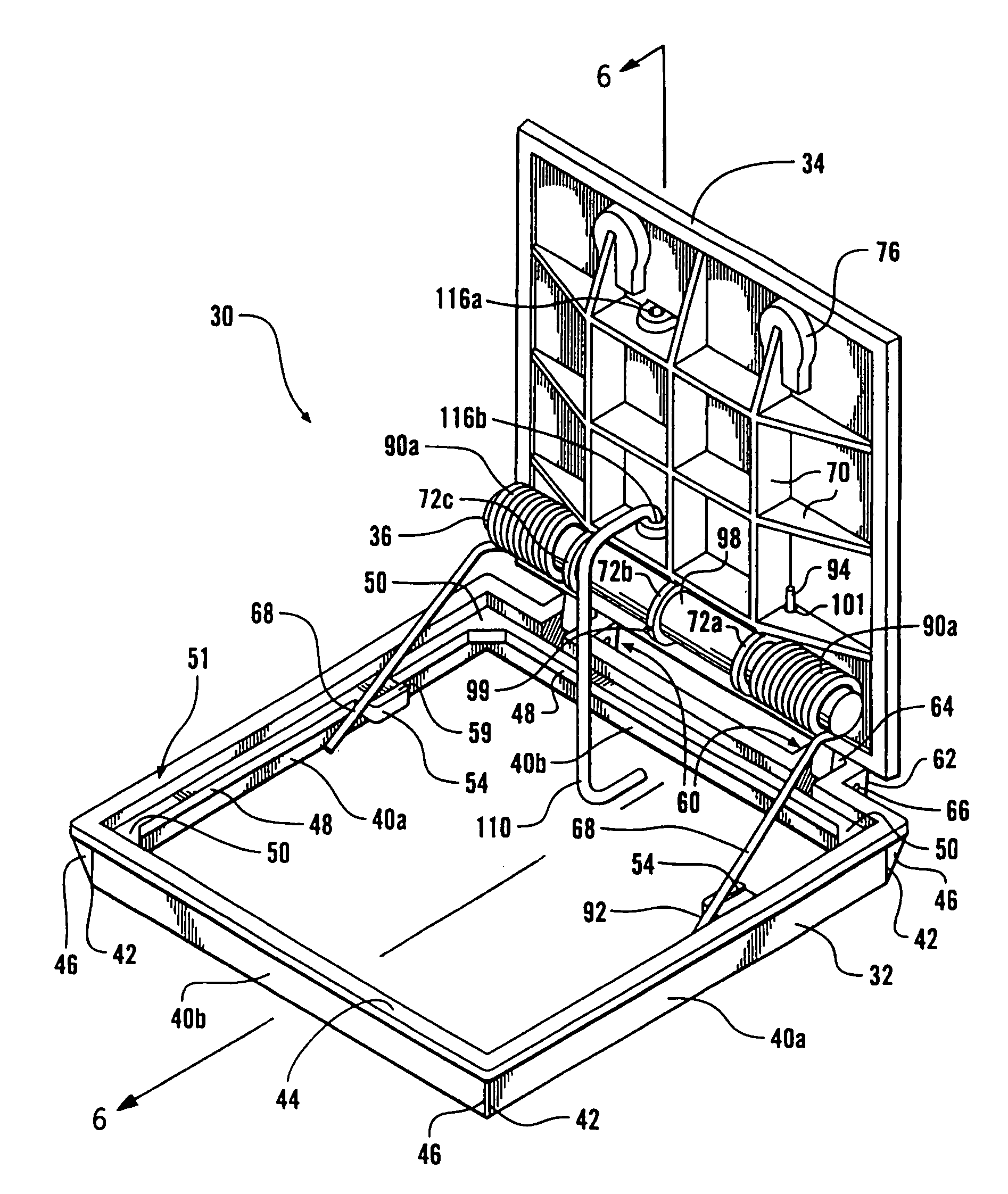

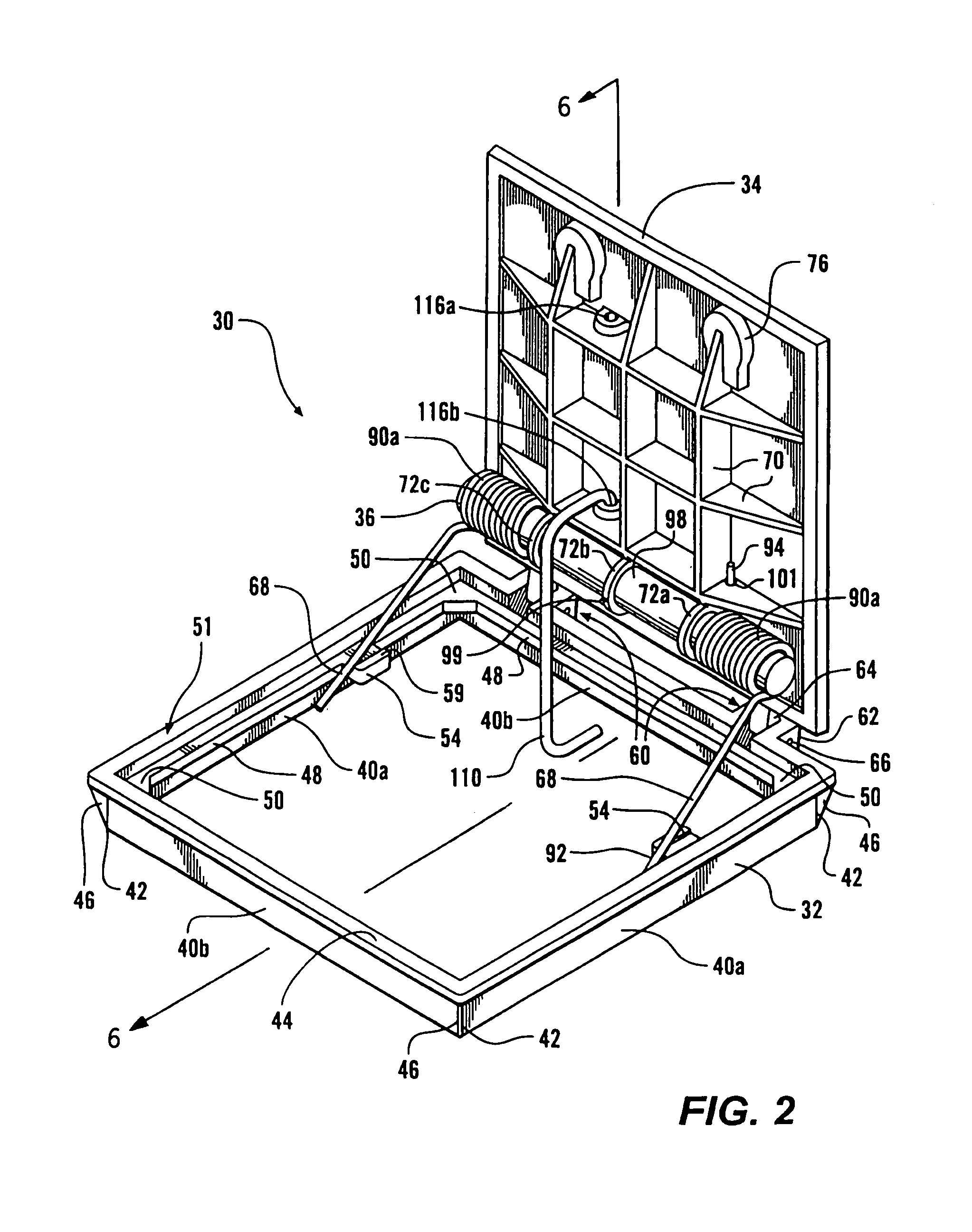

Access hatch cover assembly with lift-assist assembly and method therefor

ActiveUS7216459B1Cost-effectiveSolve the real problemArtificial islandsUnderwater structuresEngineeringTorsion spring

A hatch cover with spring assembly to assist in lifting open the hatch cover lid. The lid is hinged to a frame so it can be rotated about the hinge to an open position. A spring or a pair of springs are attached to the underside of the lid. Each spring is a torsion spring having one arm selectively attached to the lid, and another arm in sliding contact with the frame. For ease of repair or replacement, the spring is attached only to the lid. In addition, attaching the spring to the lid allows the spring to retract when the lid is opened. The method for assembling the hatch includes the step of selectively attaching the spring to the lid underside. This step may be performed when the lid is detached from the frame.

Owner:NEENAH FOUNDRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com