Patents

Literature

6101 results about "Automotive engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

As of 2013, there were a wide variety of propulsion systems available or potentially available for automobiles and other vehicles. Options included internal combustion engines fueled by petrol, diesel, propane, or natural gas; hybrid vehicles, plug-in hybrids, fuel cell vehicles fueled by hydrogen and all electric cars. Fueled vehicles seem to have the advantage due to the limited range and high cost of batteries. Some options required construction of a network of fueling or charging stations. With no compelling advantage for any particular option car makers pursued parallel development tracks using a variety of options. Reducing the weight of vehicles was one strategy being employed.

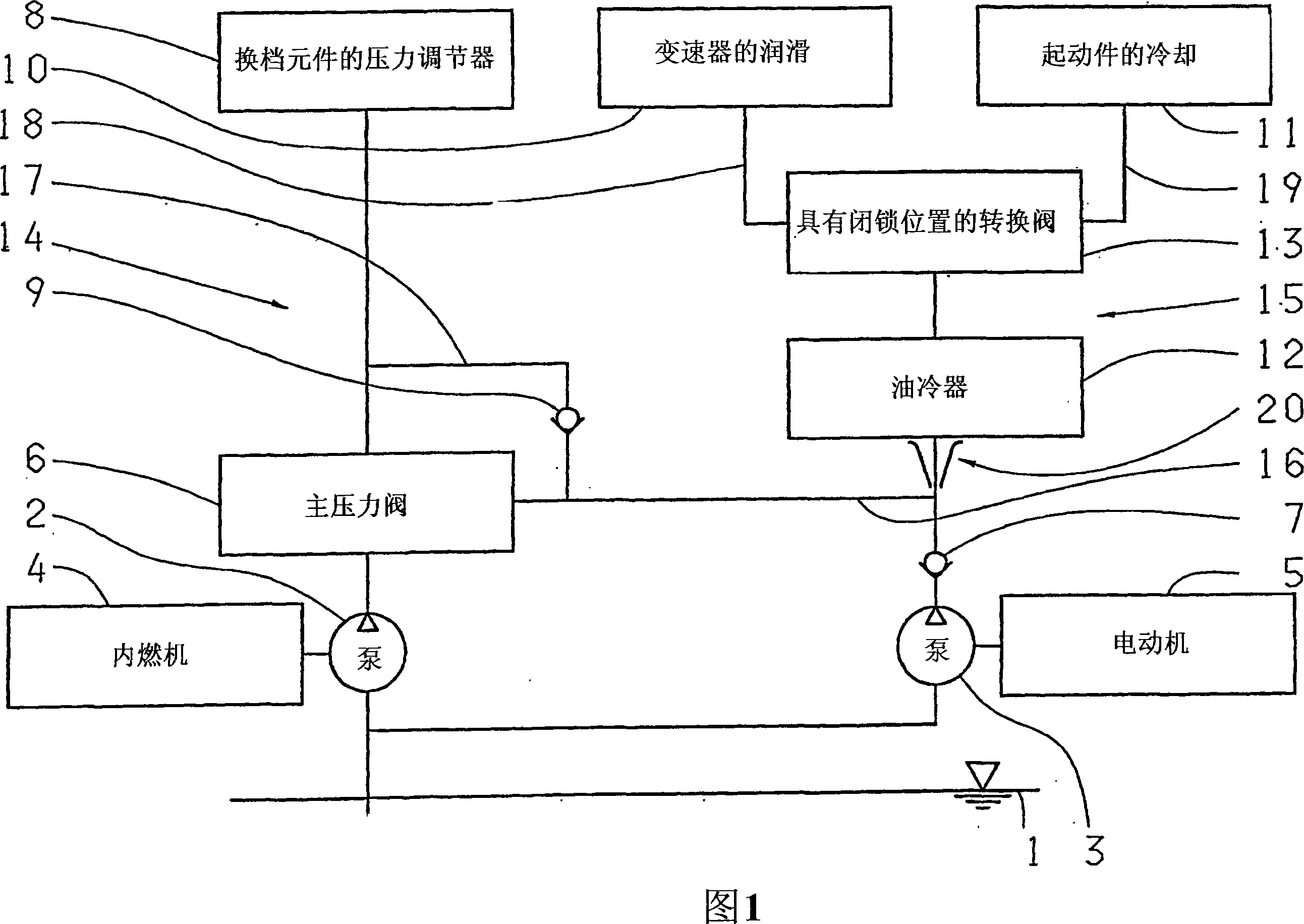

Method and device for controlling the oil supply of an automatic gearbox and a starting element

InactiveCN101147014AAvoid emissionsSave fuelGear lubrication/coolingGearing controlHydraulic control unitAutomatic transmission

A method and a device for controlling the oil supply of an automatic transmission (gearbox) and to a starting element. The method can guarantee a sufficient supply of oil to a hydraulic control unit of the automatic transmission and / or the starting element, in particular an oil-cooled friction clutch, both during the operation of the internal combustion engine (4) and when the latter is at a standstill with the aid of an oil pump (2) that can be mechanically driven by the internal combustion engine (4) and a second oil pump (3) that can be electrically driven. In addition, the cooling oil supply of the starting element is guaranteed by the provision of a low-pressure oil by way of the electrically driven oil pump (3), at least during the starting operation, the stream cooling the starting element (11).

Owner:ZF FRIEDRICHSHAFEN AG

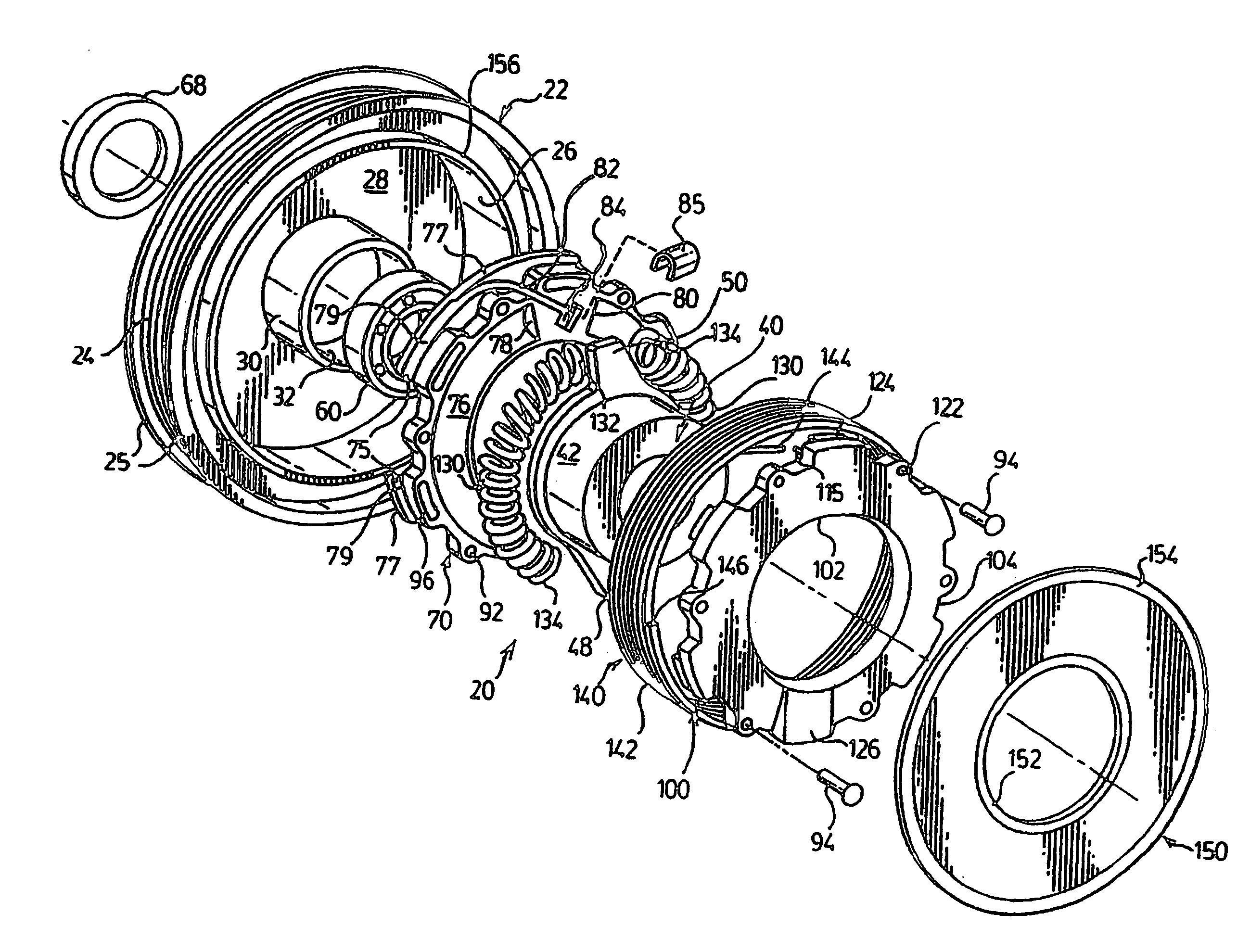

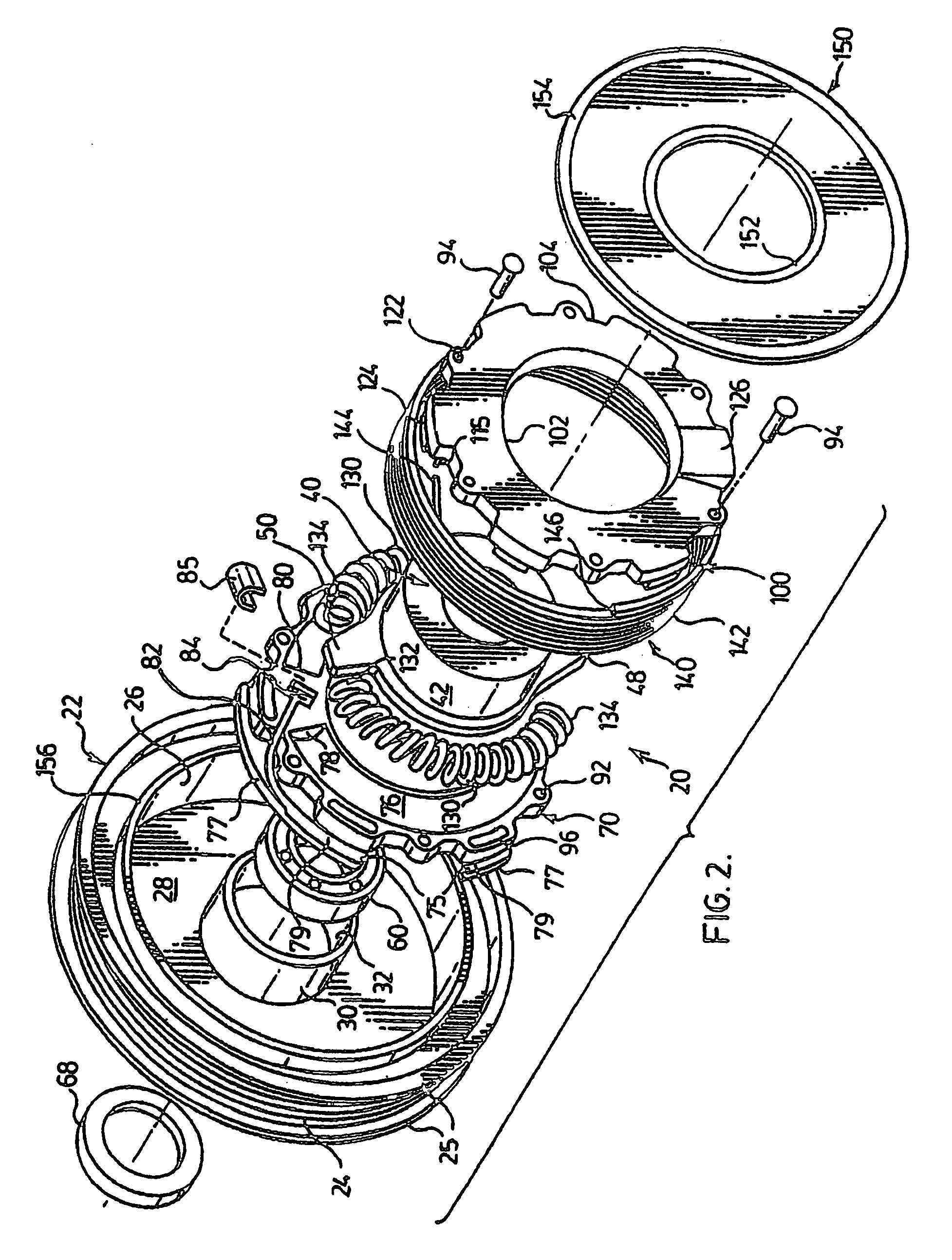

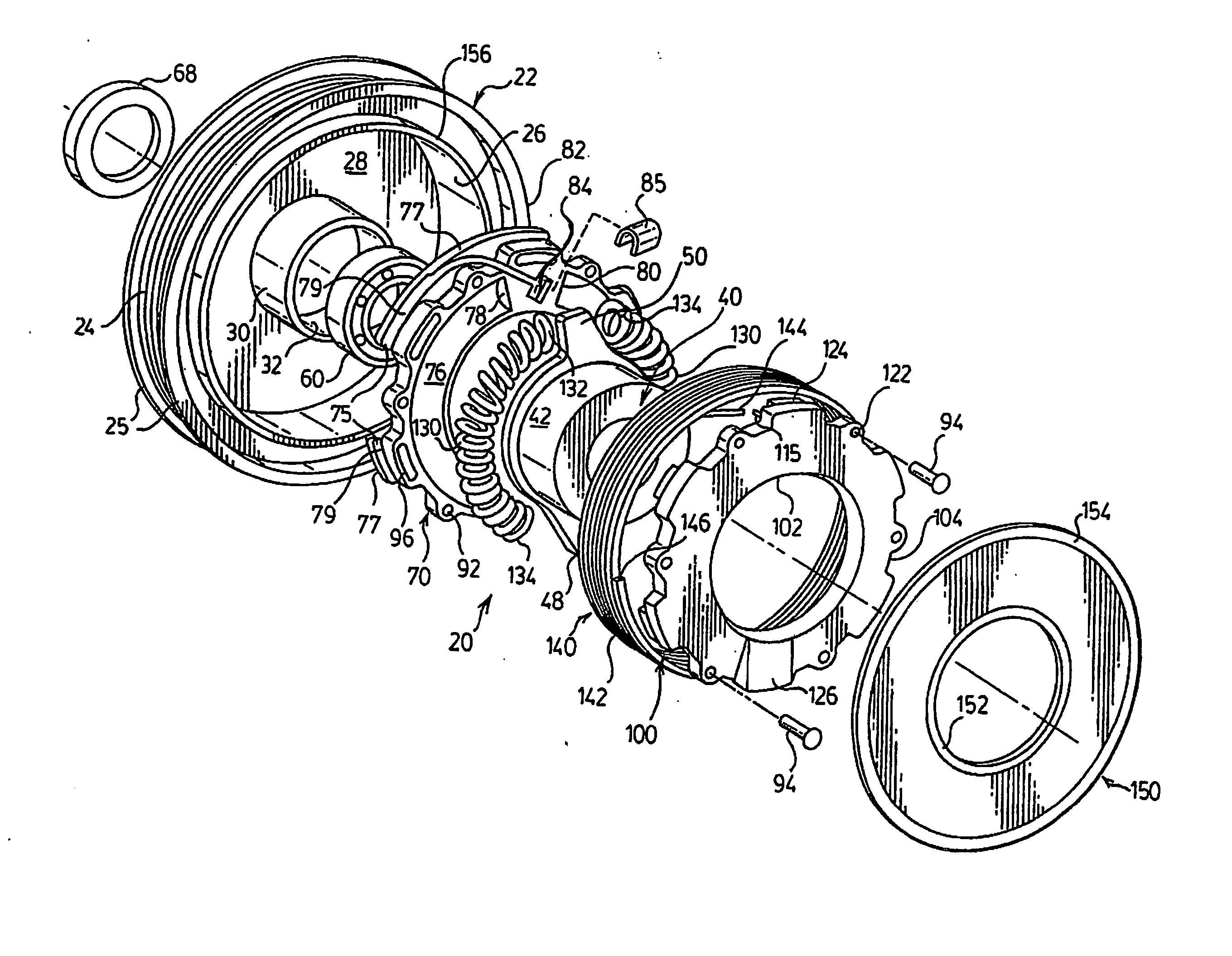

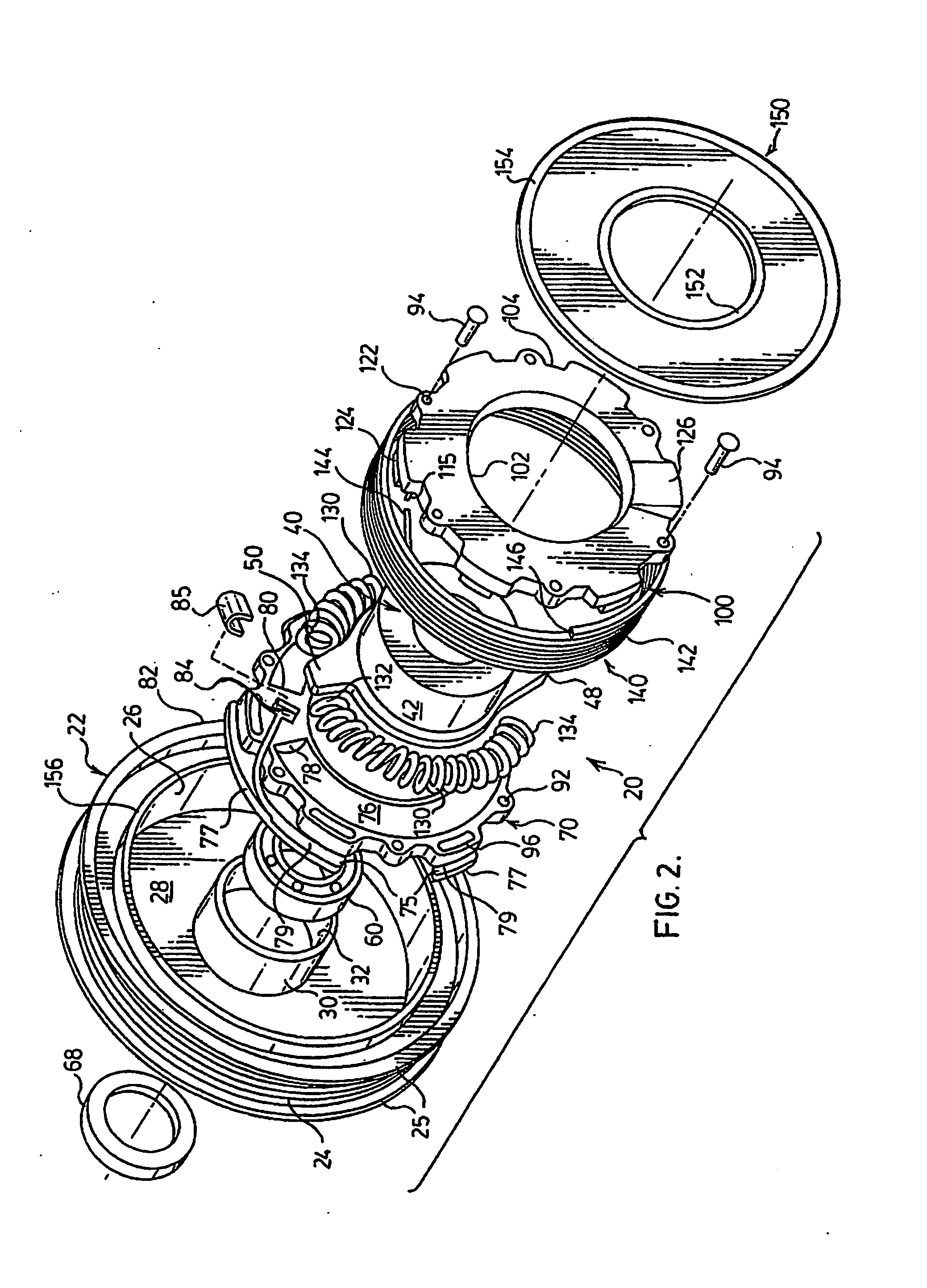

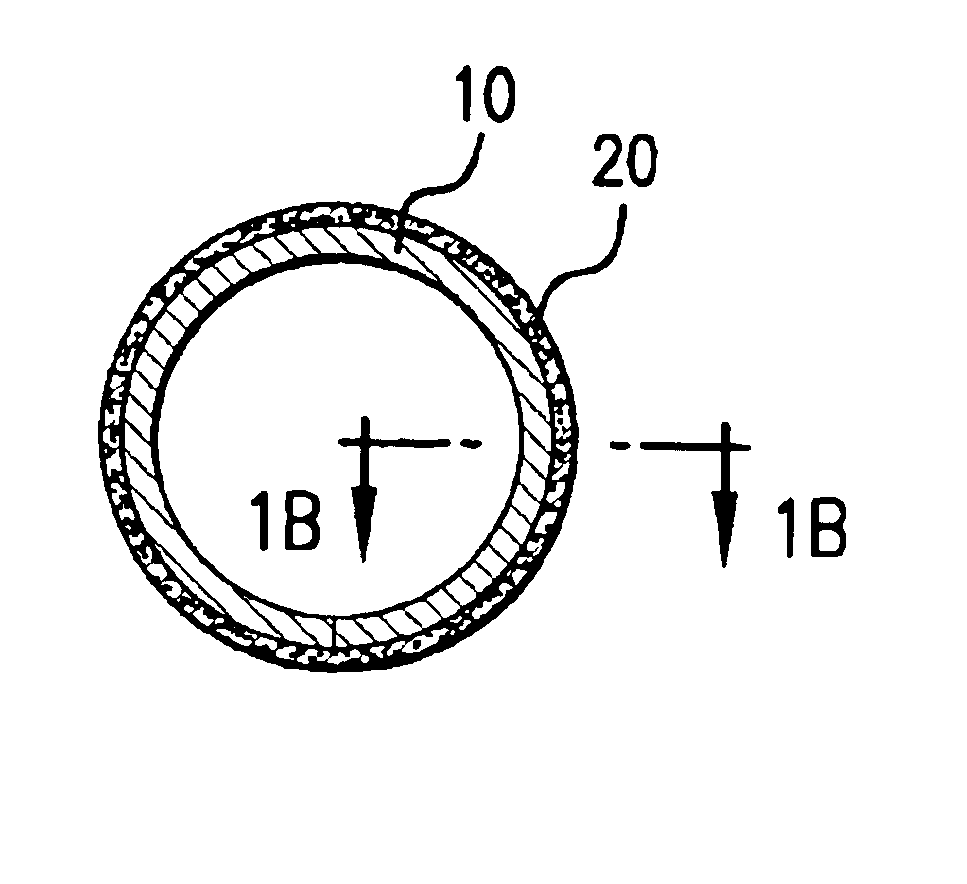

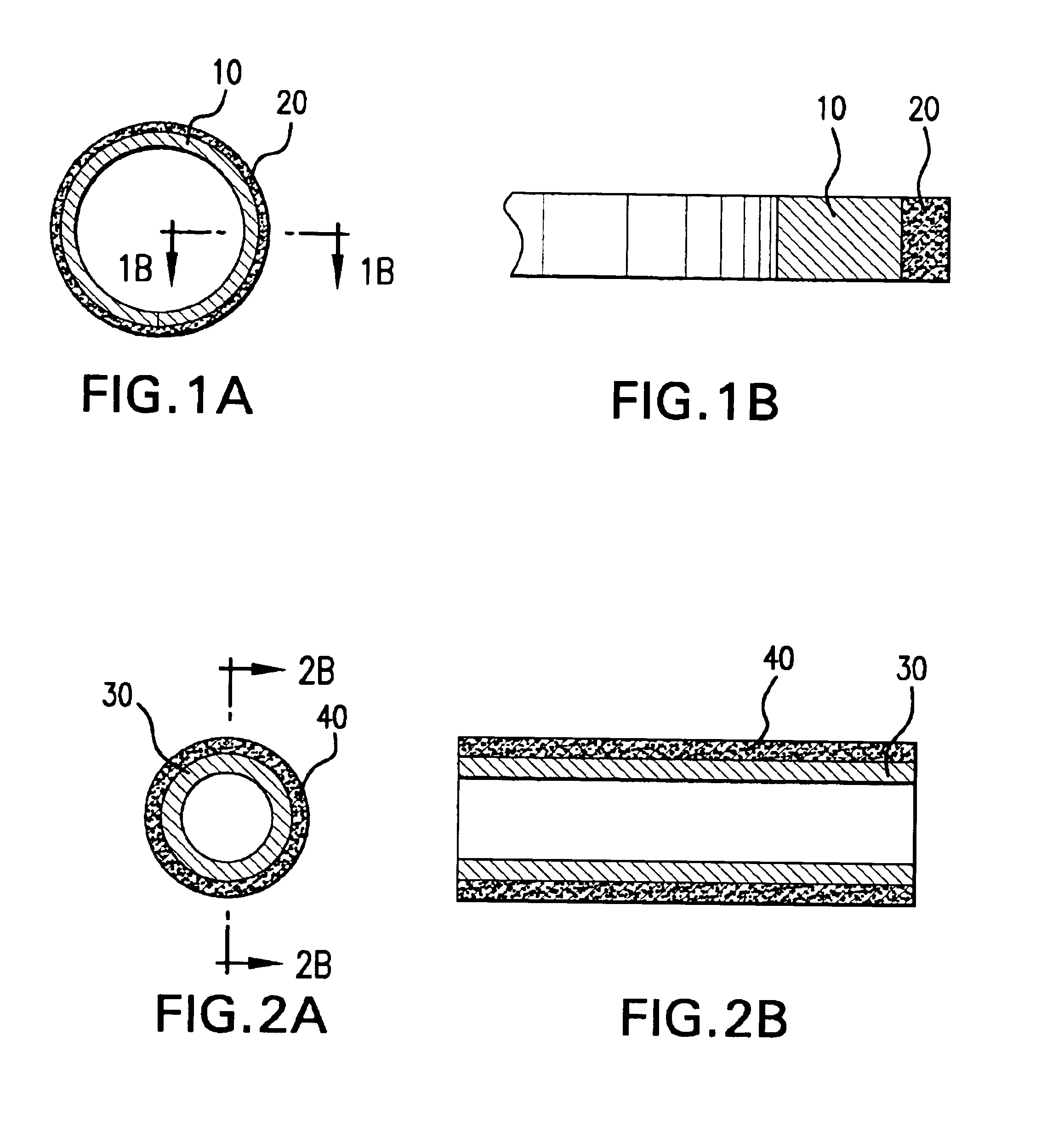

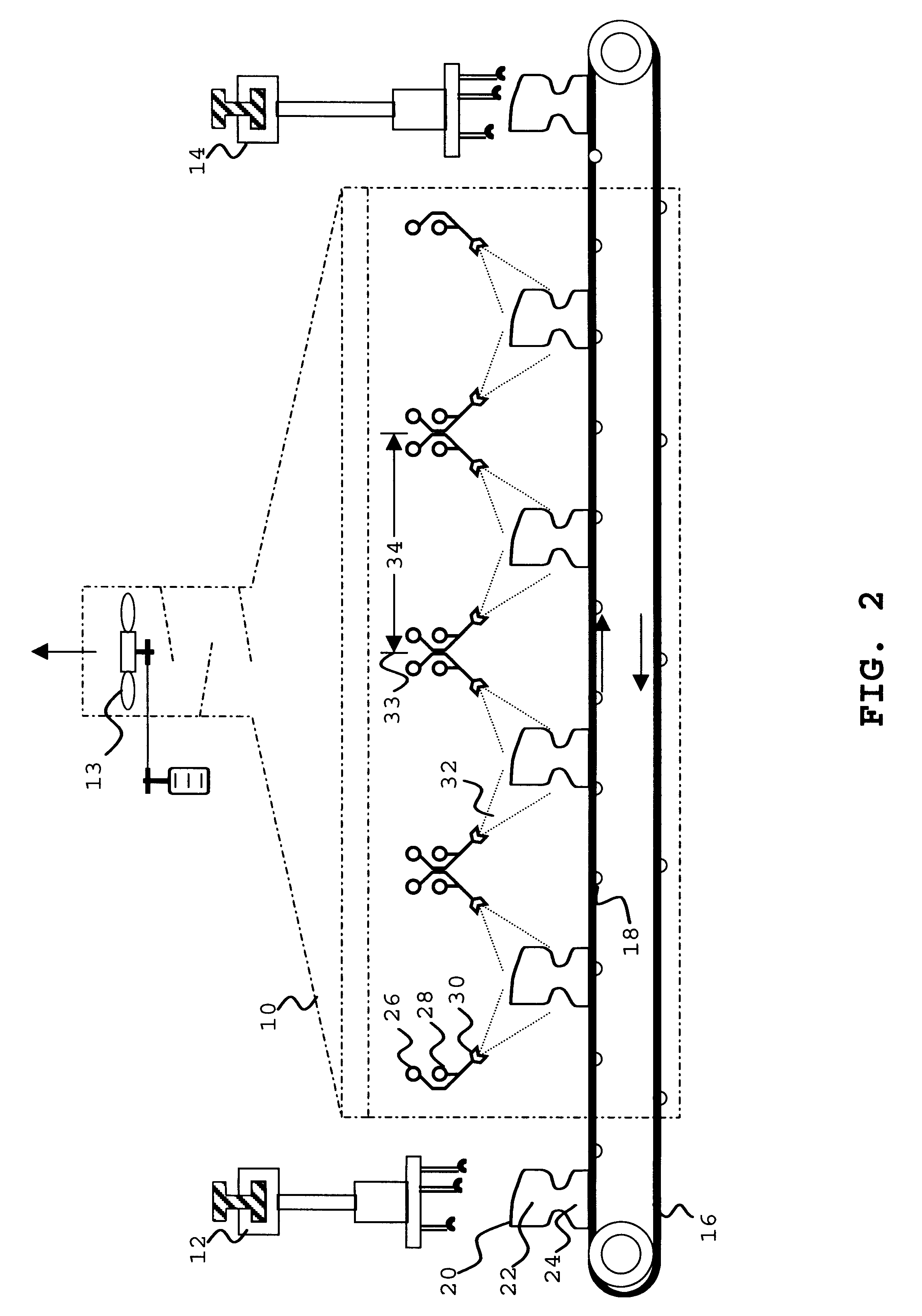

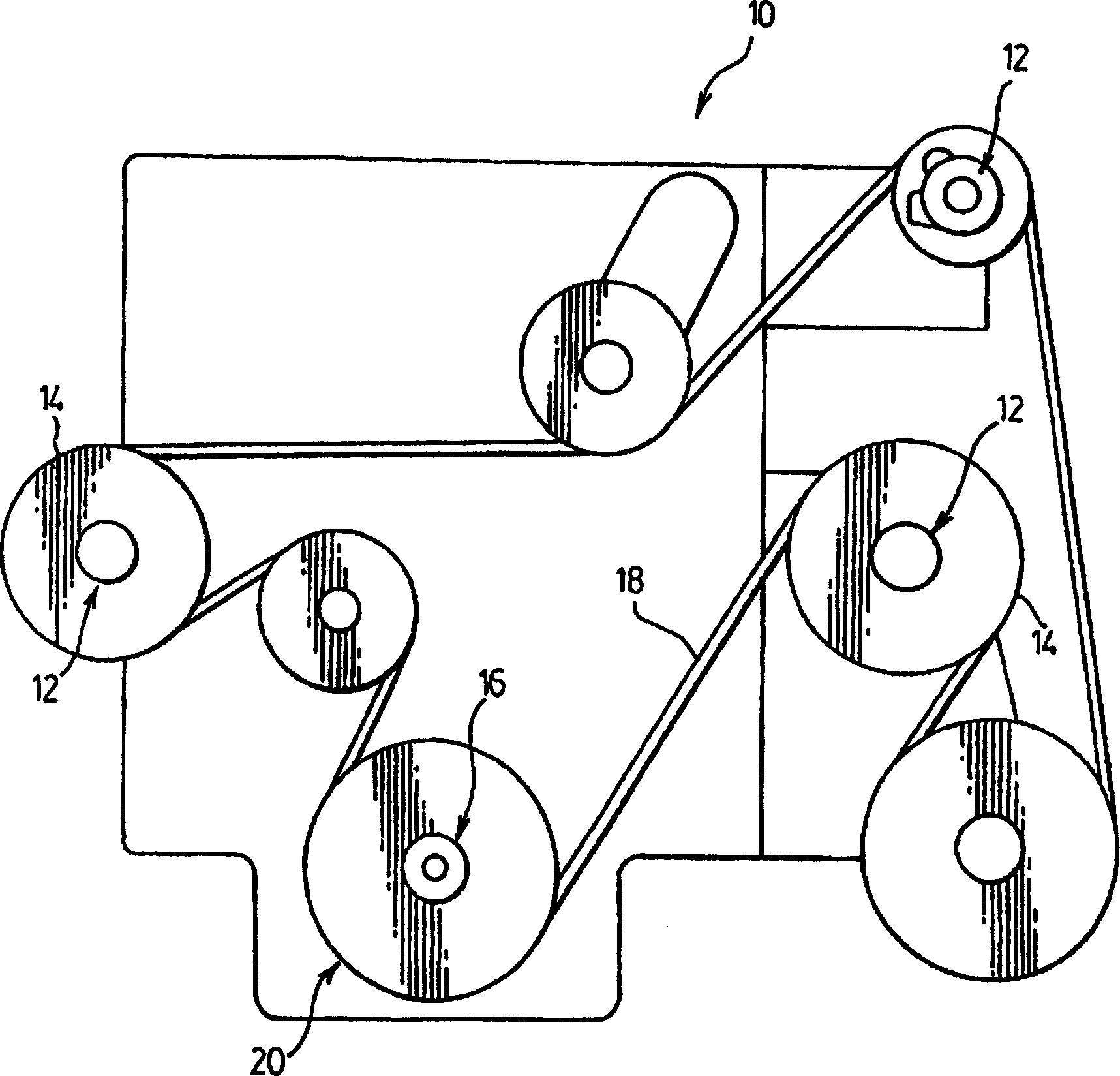

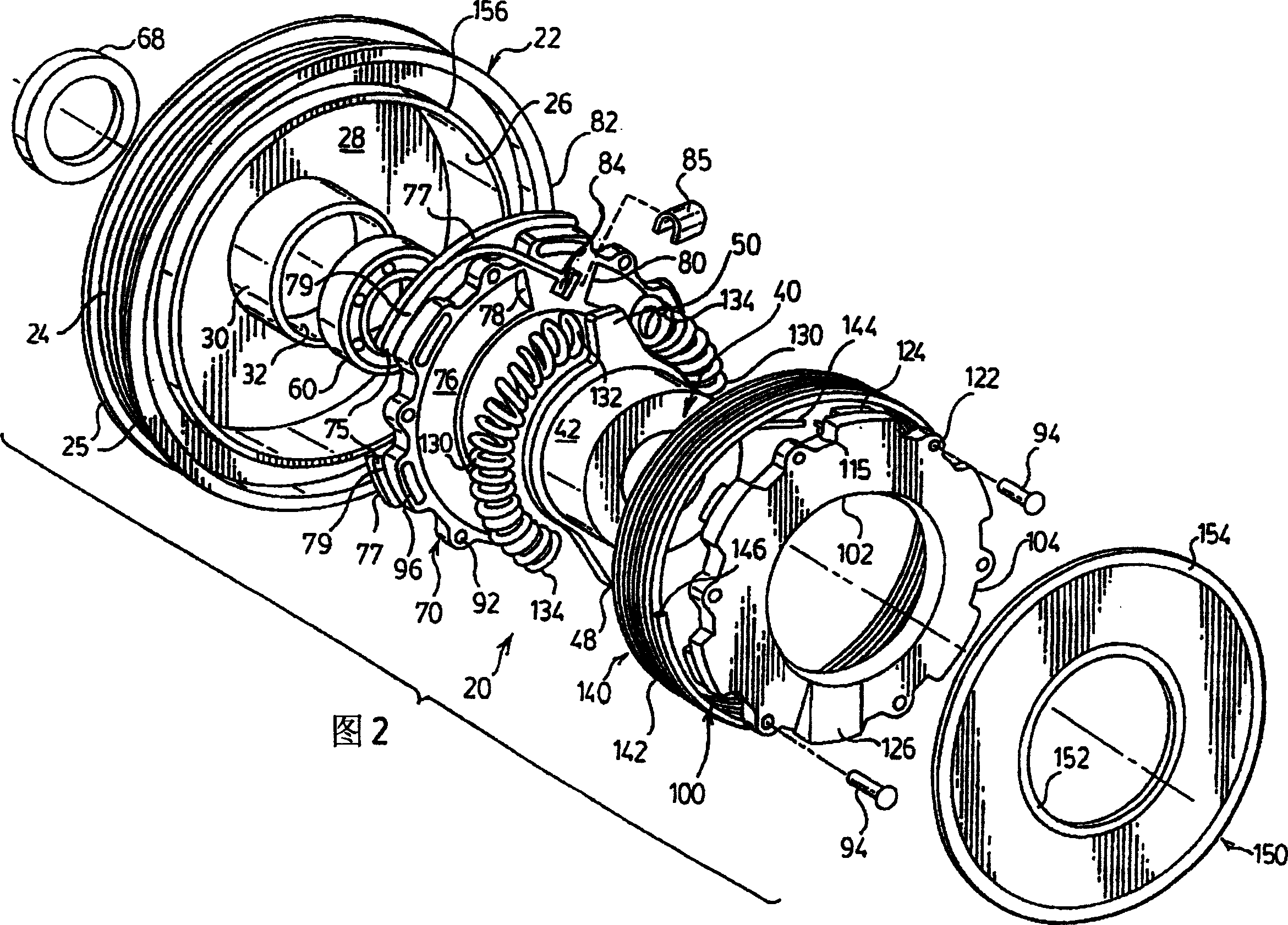

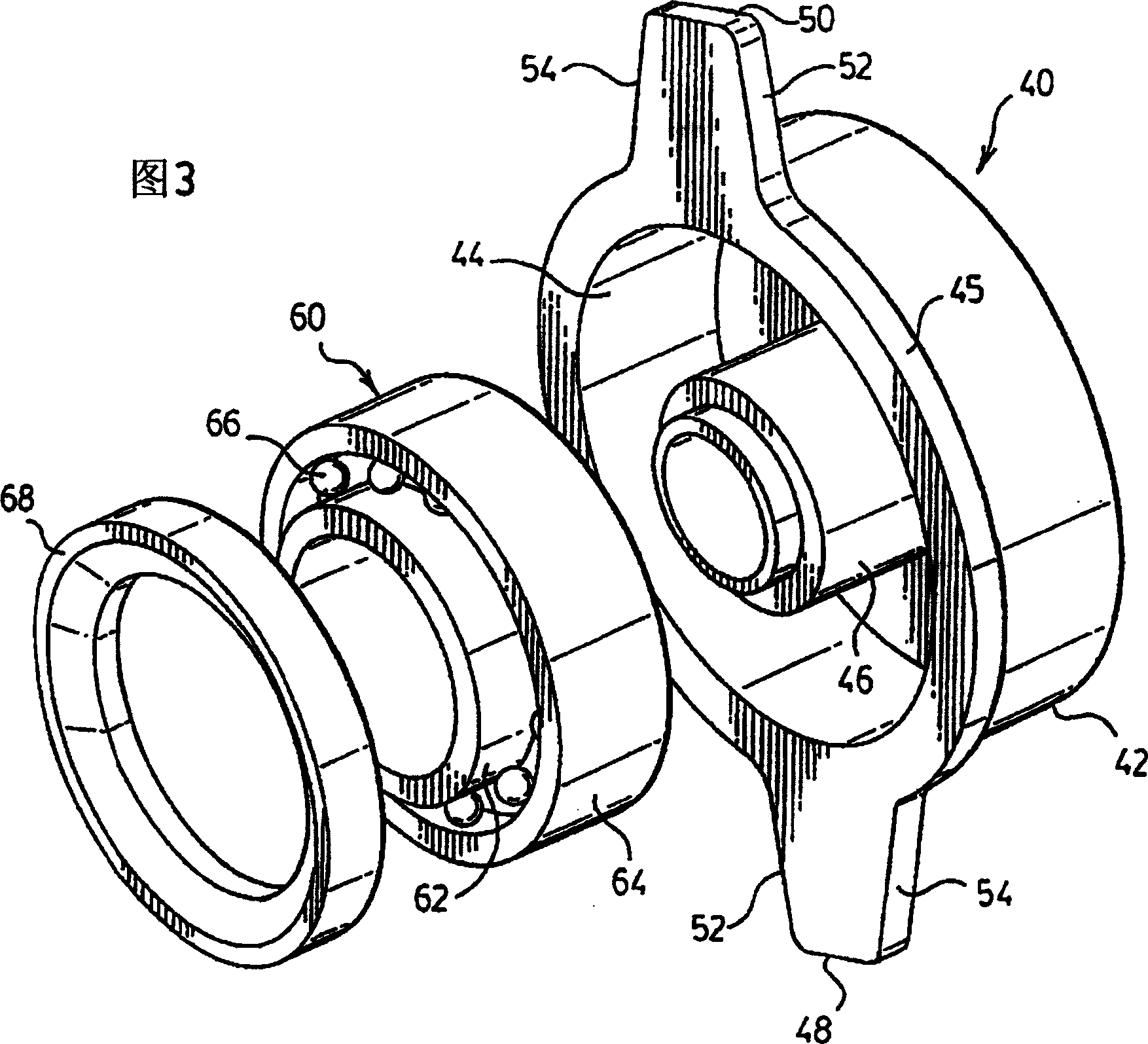

Crankshaft decoupler

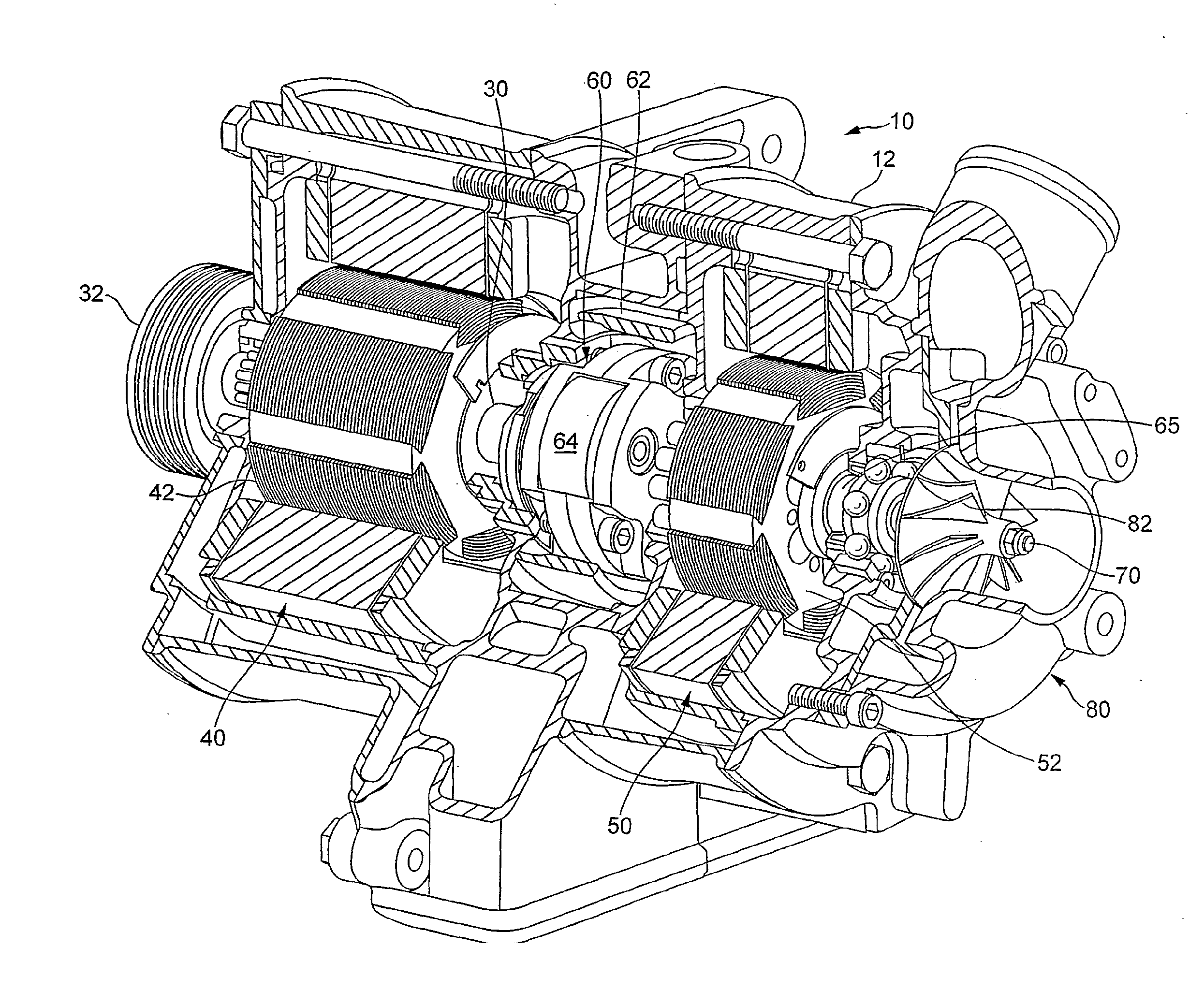

A decoupler assembly (20) is provided for transferring rotational torque between a drive shaft (16) and a drive belt (18) of an automotive engine. The decoupler assembly includes a drive hub (40) configured to be fixedly secured to the drive shaft. A pulley (22) is rotatably coupled to the drive hub (40) and adapted to be drivingly engaged with the belt (18). A spring shell (70, 100) is operatively coupled between the drive hub and the pulley for selective rotation therewith and a biasing member (130) is operatively coupled between the spring shell and the drive hub for isolating oscillatory vibrations between the drive hub and the pulley caused by rotation of the drive shaft. A clutch element (140) is seated between the spring shell (70, 100) and the pulley (22) for selectively transferring rotational torque from the drive hub to the pulley. The pulley (22) includes an inner clutch surface (26) and the clutch element includes a plurality of coils in frictional engagement with the inner clutch surface and an end coupled to the spring shell for expanding the coils against the inner clutch surface upon rotation of the spring shell with the drive hub to selectively transfer torque between the drive hub (40) and the pulley (22).

Owner:LITENS AUTOMOTIVE INC

Crankshaft decoupler

A decoupler assembly (20) is provided for transferring rotational torque between a drive shaft (16) and a drive belt (18) of an automotive engine. The decoupler assembly includes a drive hub (40) configured to be fixedly secured to the drive shaft. A pulley (22) is rotatably coupled to the drive hub (40) and adapted to be drivingly engaged with the belt (18). A spring shell (70, 100) is operatively coupled between the drive hub and the pulley for selective rotation therewith and a biasing member (130) is operatively coupled between the spring shell and the drive hub for isolating oscillatory vibrations between the drive hub and the pulley caused by rotation of the drive shaft. A clutch element (140) is seated between the spring shell (70, 100) and the pulley (22) for selectively transferring rotational torque from the drive hub to the pulley. The pulley (22) includes an inner clutch surface (26) and the clutch element includes a plurality of coils in frictional engagement with the inner clutch surface and an end coupled to the spring shell for expanding the coils against the inner clutch surface upon rotation of the spring shell with the drive hub to selectively transfer torque between the drive hub (40) and the pulley (22).

Owner:LITENS AUTOMOTIVE INC

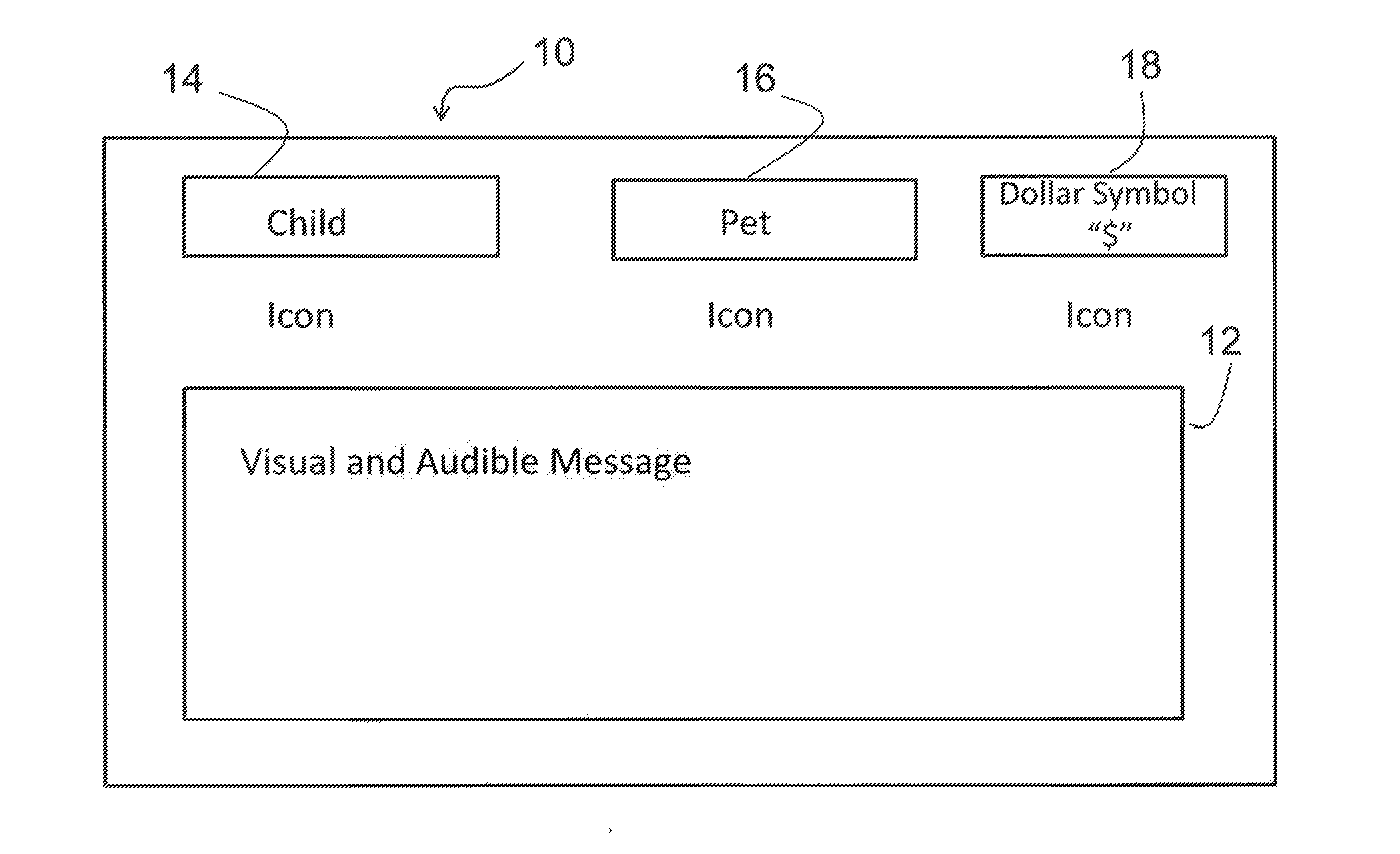

Auto Reminder

Apparatus for warning a driver of a car that a child, pet or valuable is still in the car when an attempt is made by the driver to lock the car doors after the car is parked and the engine is turned off comprising a keyless remote entry device having a door unlocking button and a door locking button; at least one button on the keyless remote entry device which, when first pressed, shows that a child, pet or valuable is being placed in the car; a control circuit coupled to the keyless remote entry device; and an alarm circuit controlled by the control circuit; wherein the keyless remote entry device cannot be used to lock the car doors when a child, pet or valuable is still in the car after the car engine is turned off and the button has not been pressed a second time to alert the remote entry device that the child, pet or valuable has been removed from the car.

Owner:LAFFEY SR JOSEPH FRANCIS +1

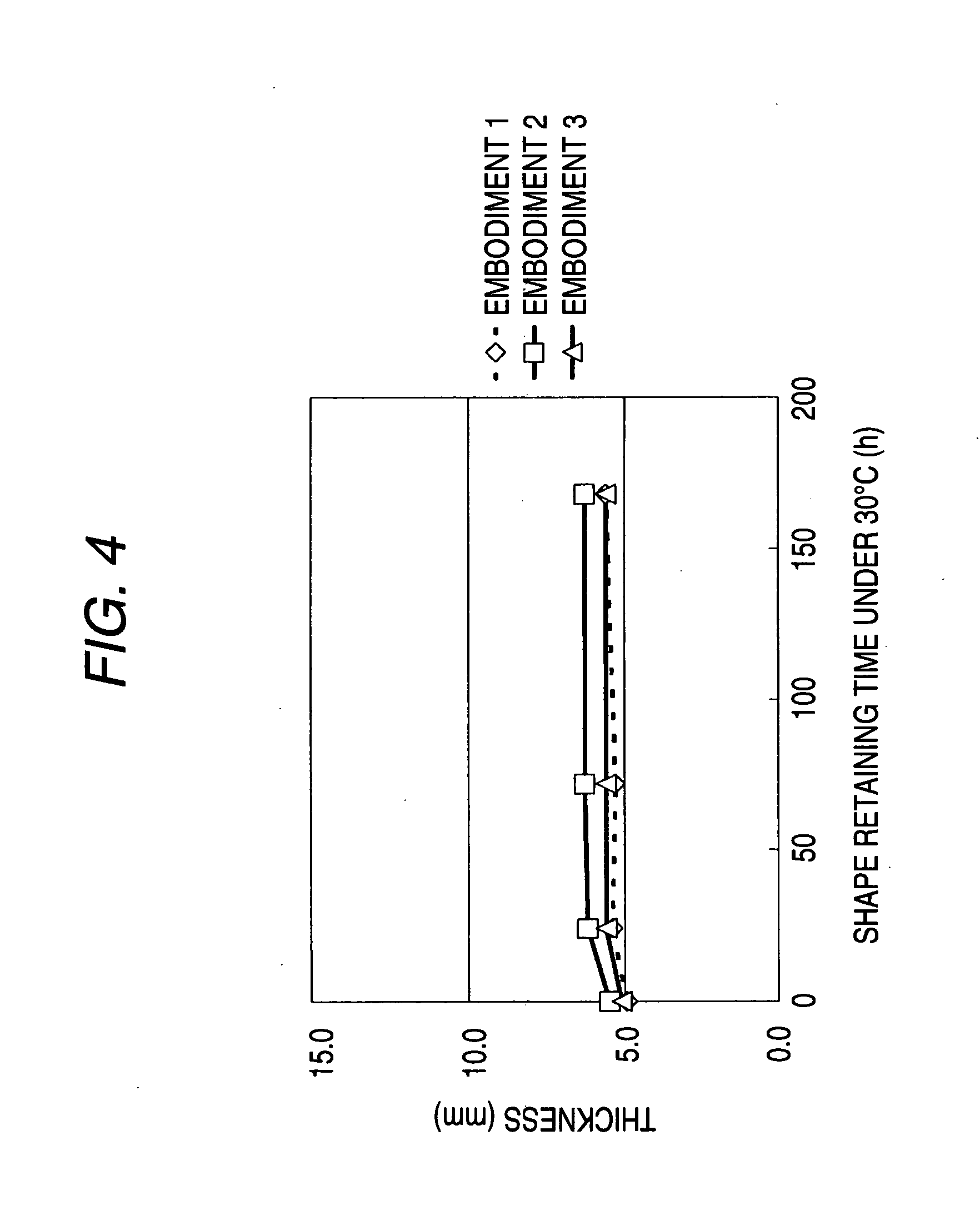

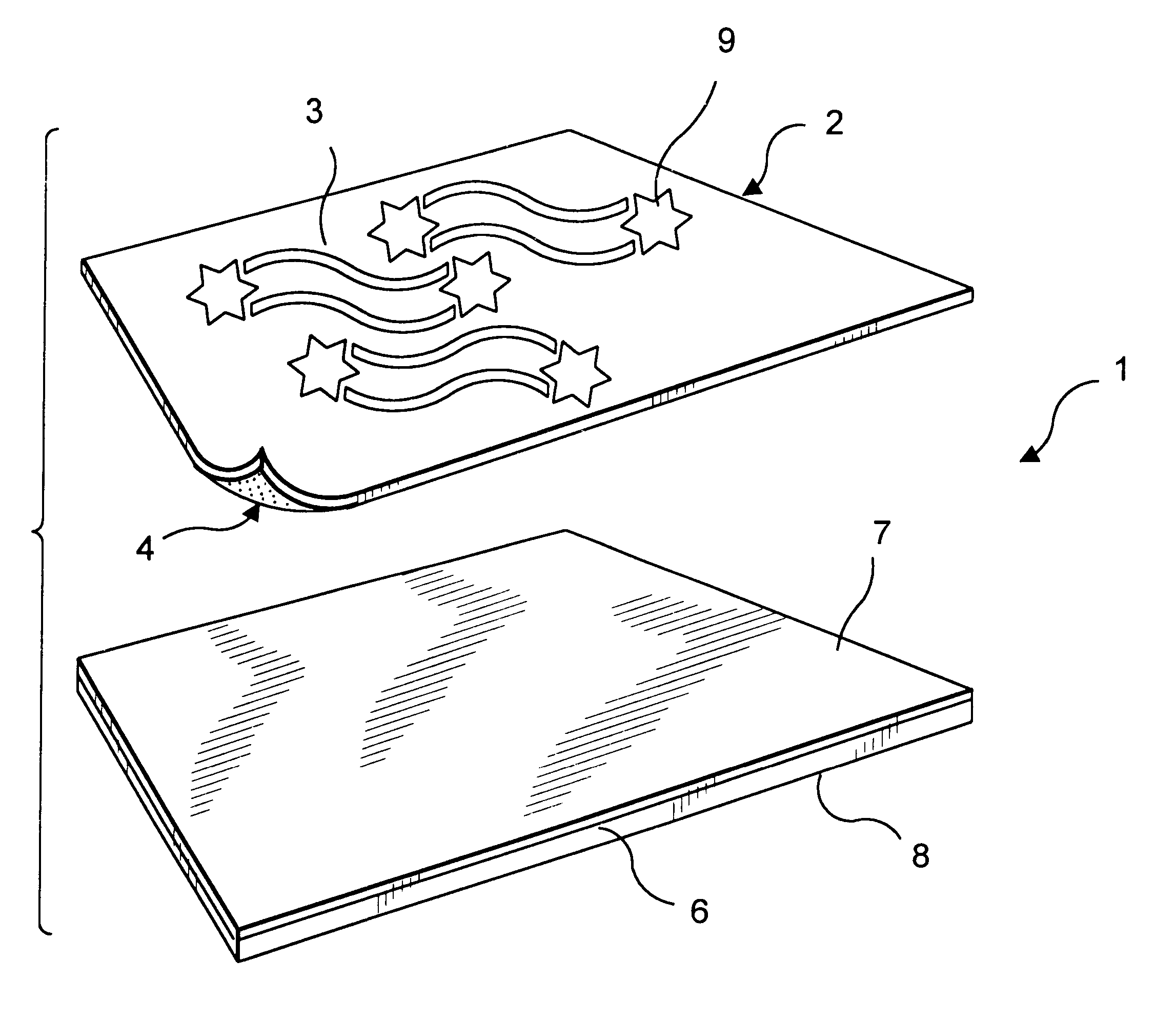

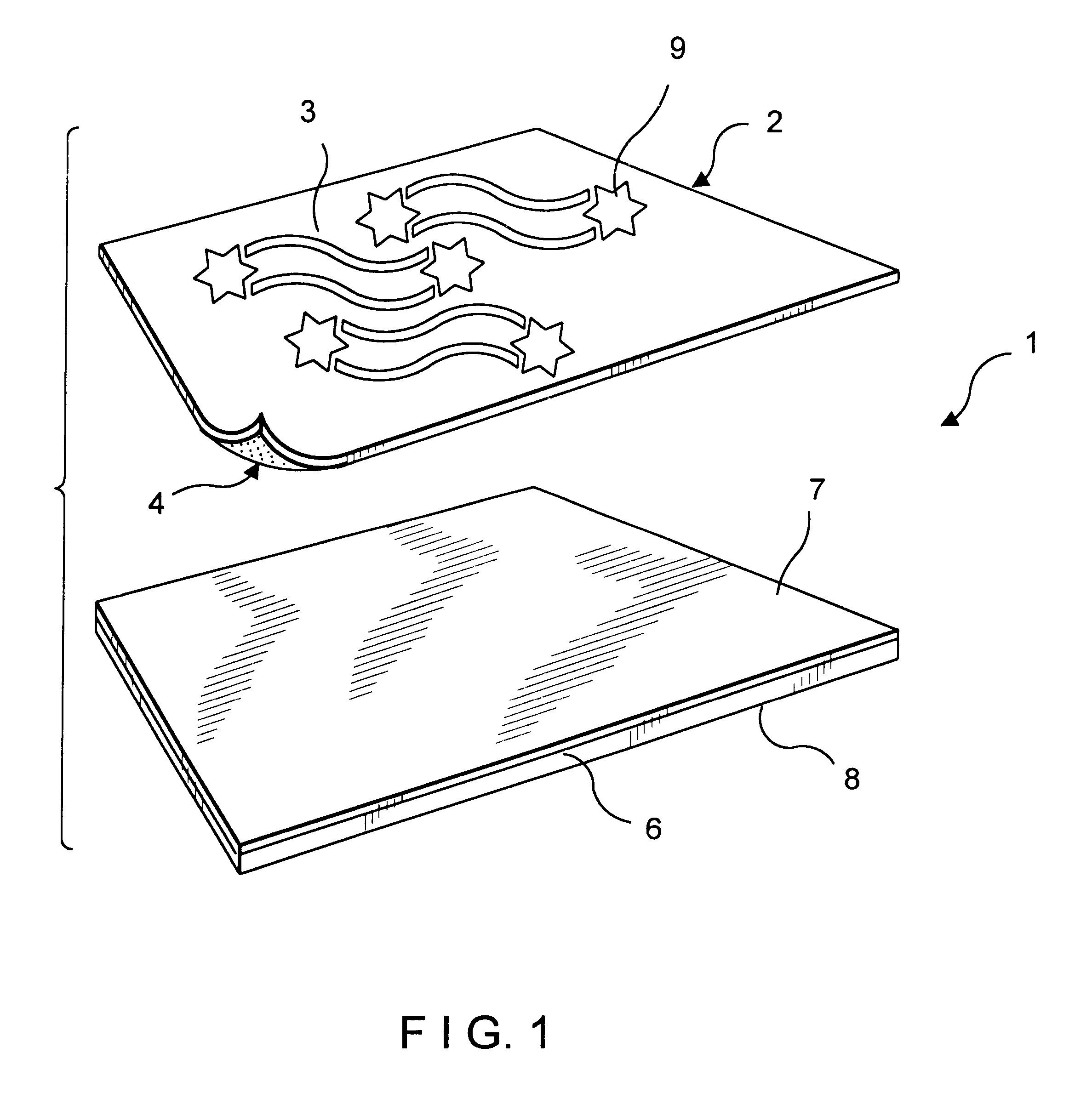

Shape memory foam material

InactiveUS20040164499A1Excellent mounting property and soundproof performanceImprove insulation effectEngine sealsMachines/enginesSurface layerRoom temperature

A shape memory foam material is obtained by impregnating a base foam material in a thermoplastic substance, heating and compressing the same at a temperature the same as or higher than the softening temperature of a thermoplastic substance as well as less than the softening temperature of the base foam material, cooling down while retaining the compressed state, and releasing the pressure after the cooling operation. The compressed state of the shape memory foam material is retained in a room temperature by a hardened product of a thermoplastic substance existing at least in the surface layer part thereof. The compressed state is released by softening the hardened product by heating. Moreover, a soundproof cover for an automobile engine is obtained using this shape memory foam.

Owner:NICHIAS CORP

Solar selective coating having higher thermal stability useful for harnessing solar energy and a process for the preparation thereof

InactiveUS20070196670A1Easy to optimizeImprove thermal stabilitySolar heat devicesVacuum evaporation coatingAbsorptanceEngineering

The present invention provides an improved solar selective multilayer coating having higher thermal stability and a process for the preparation thereof. Solar selective coatings having higher thermal stability are useful in solar steam generation, solar steam turbines to produce electricity and also on automobile engine components. In the present invention, a tandem stack of three layers of TiAlN, TiAlON and Si3N4 is deposited on metal and non-metal substrates at room temperature using a planar reactive direct current magnetron sputtering process. The first two layers function as the absorber and the third antireflection layer further enhances the coating's absorptance. The solar selective coatings were annealed in air and vacuum to test the thermal stability at different temperatures and durations. The coatings of the present invention deposited on copper substrates are stable in air up to a temperature of 625° C. for a duration of 2 hours and exhibit higher solar selectivity in the order of 9-10 and these coating also show no change in the absorptance and the emittance values even after vacuum annealing at 600° C. for 3 hours. Coatings deposited on copper substrates showed no significant degradation in the optical properties even after continuous heating in air at 525° C. for 50 hours. The solar selective coatings of the present invention exhibit high hardness, high oxidation resistance, chemical inertness and stable microstructure.

Owner:COUNCIL OF SCI & IND RES

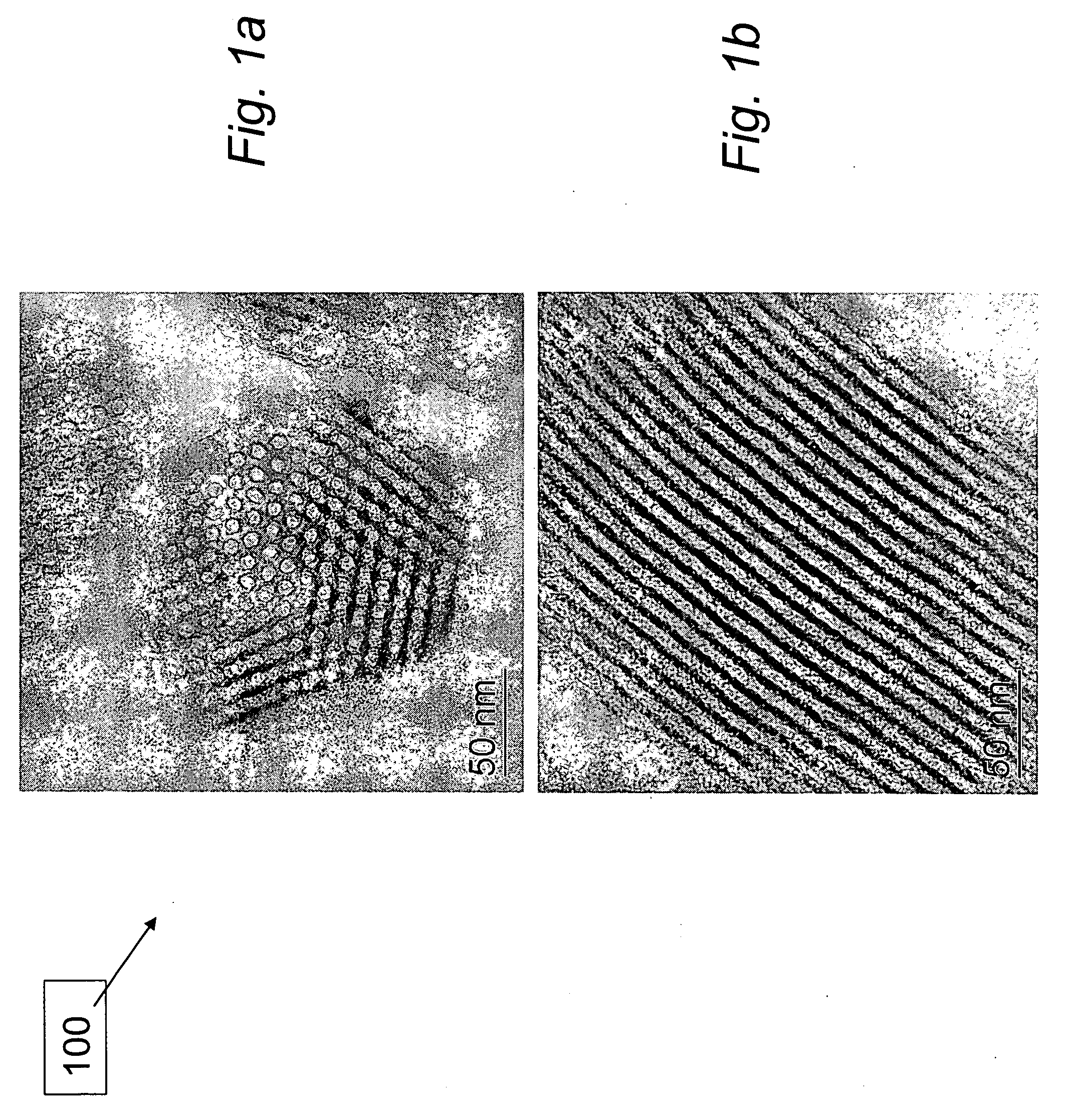

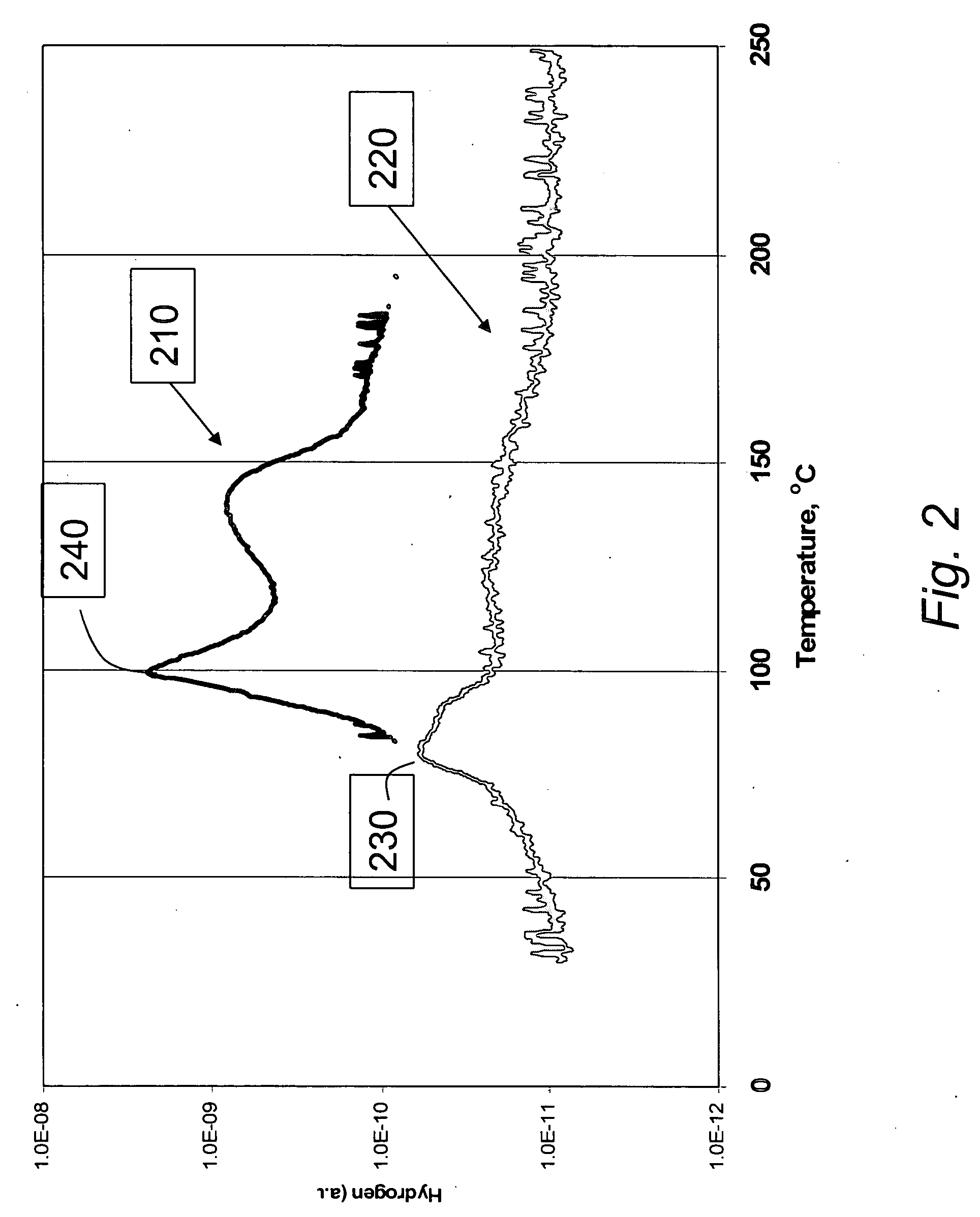

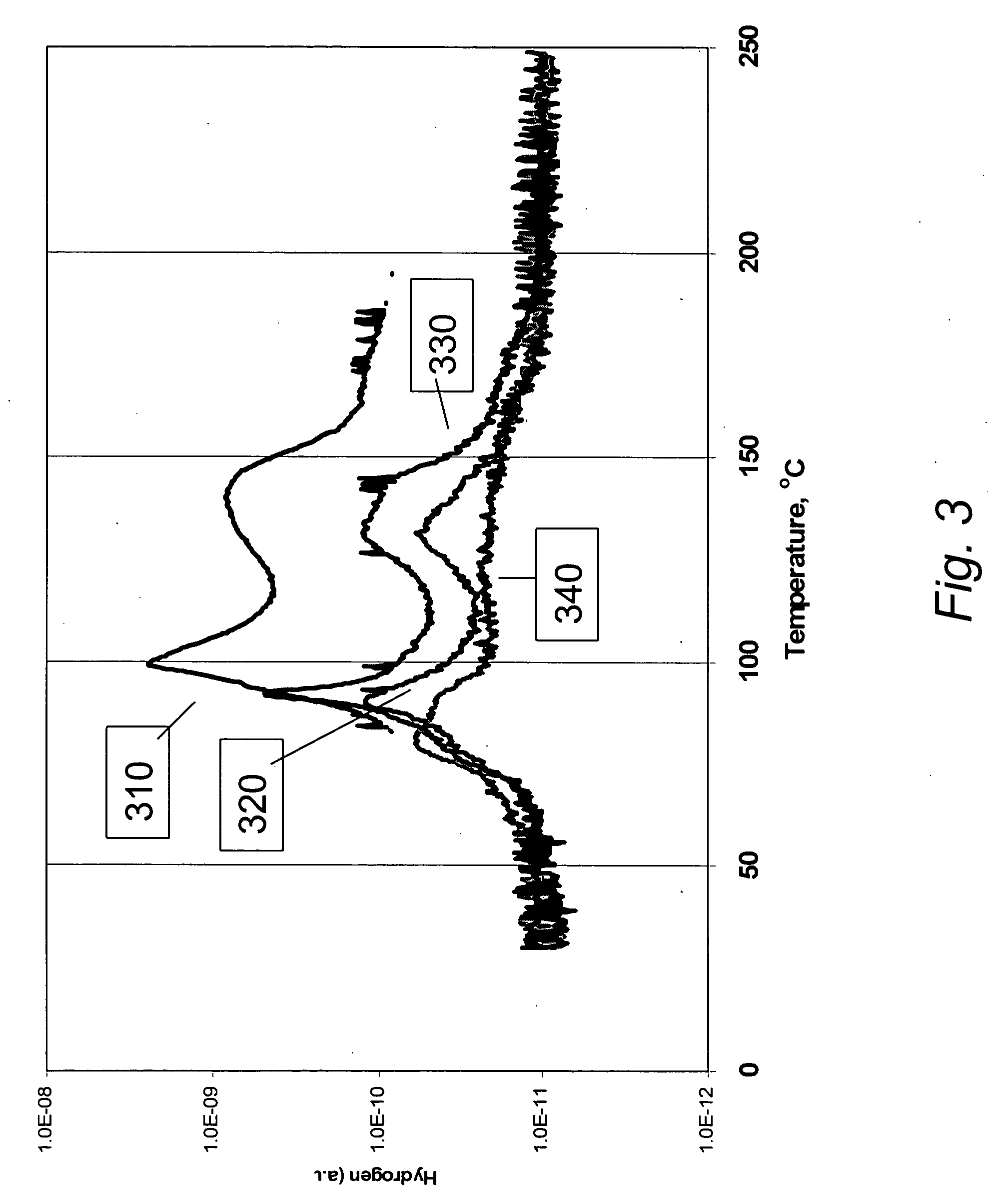

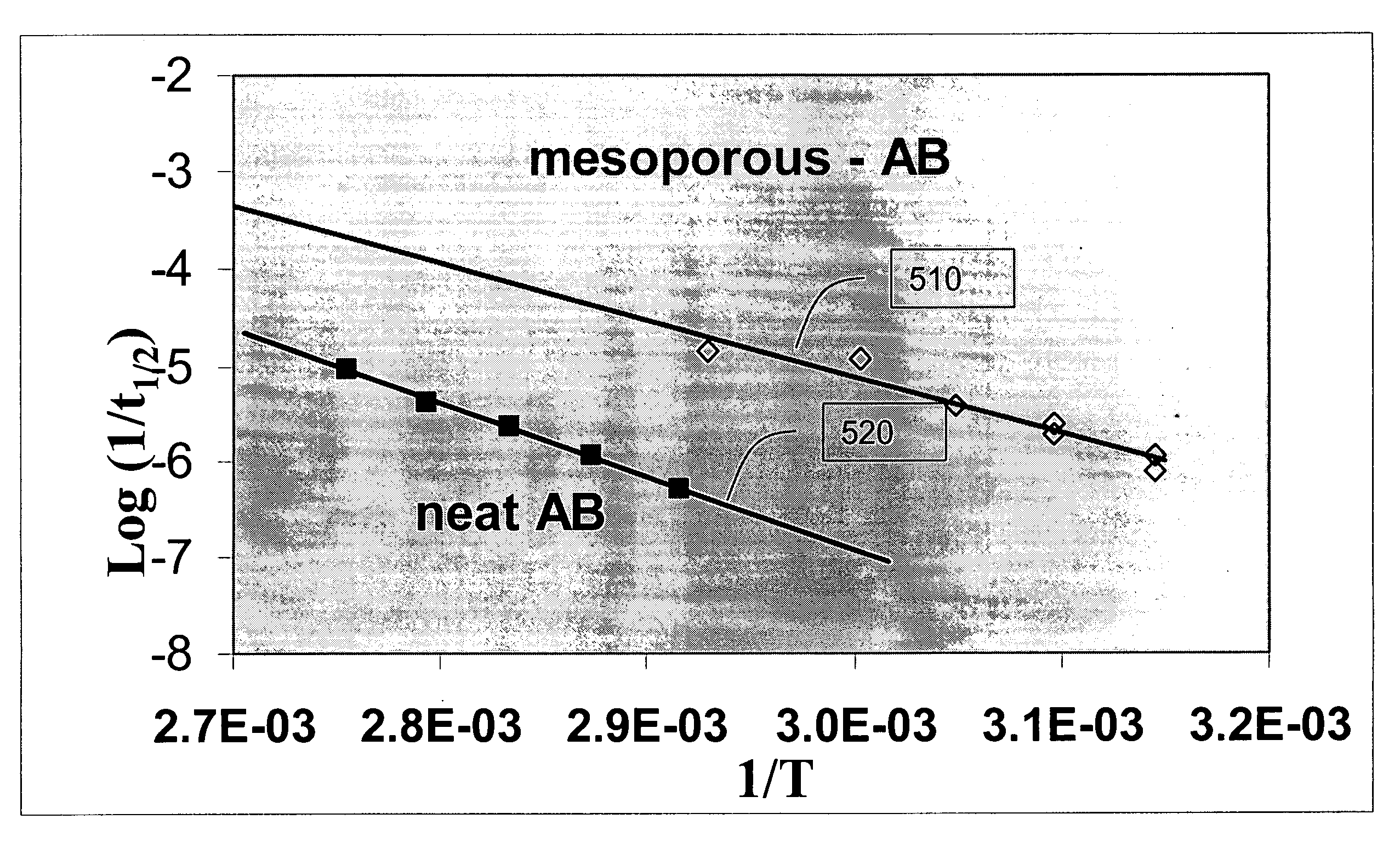

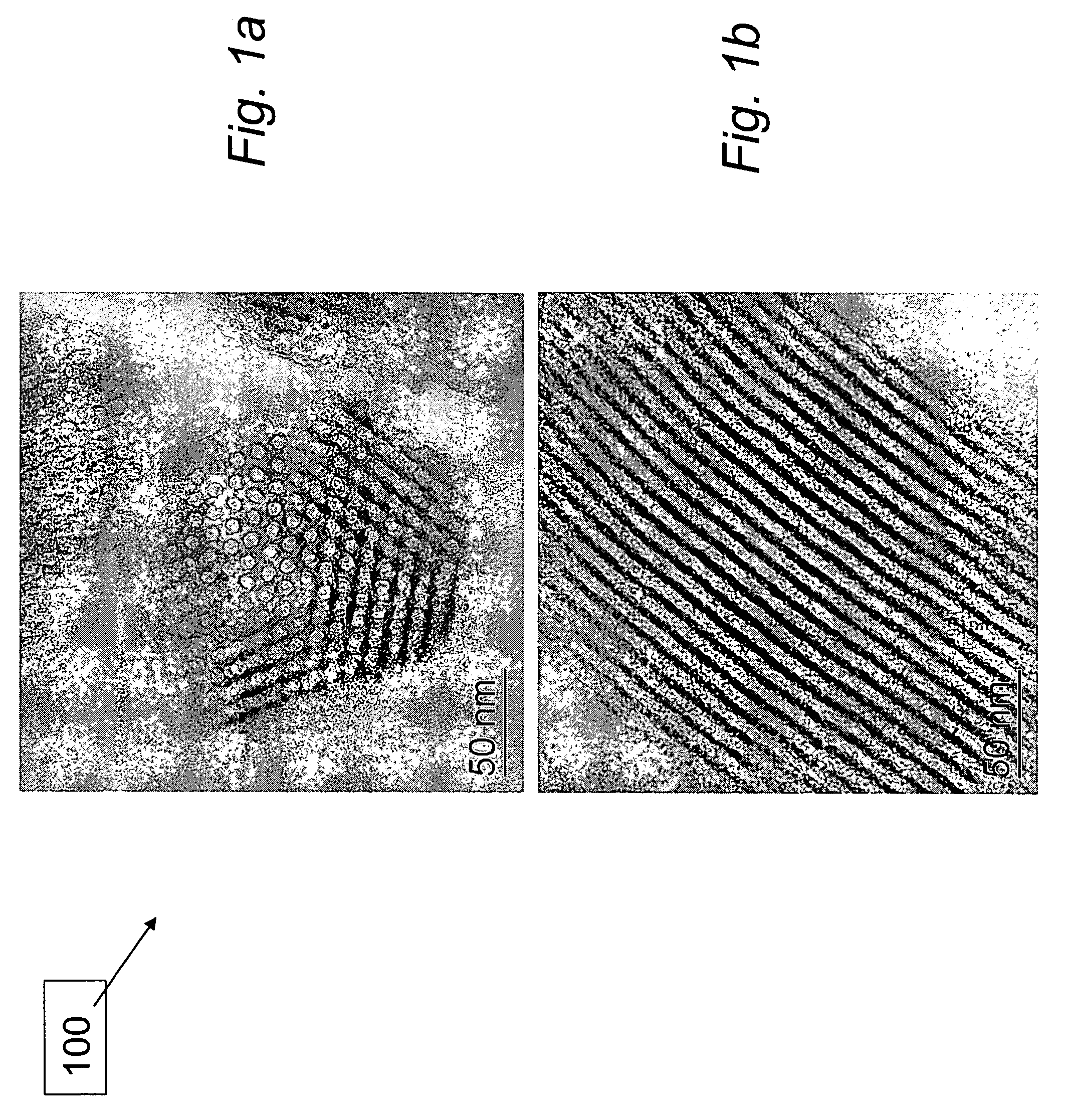

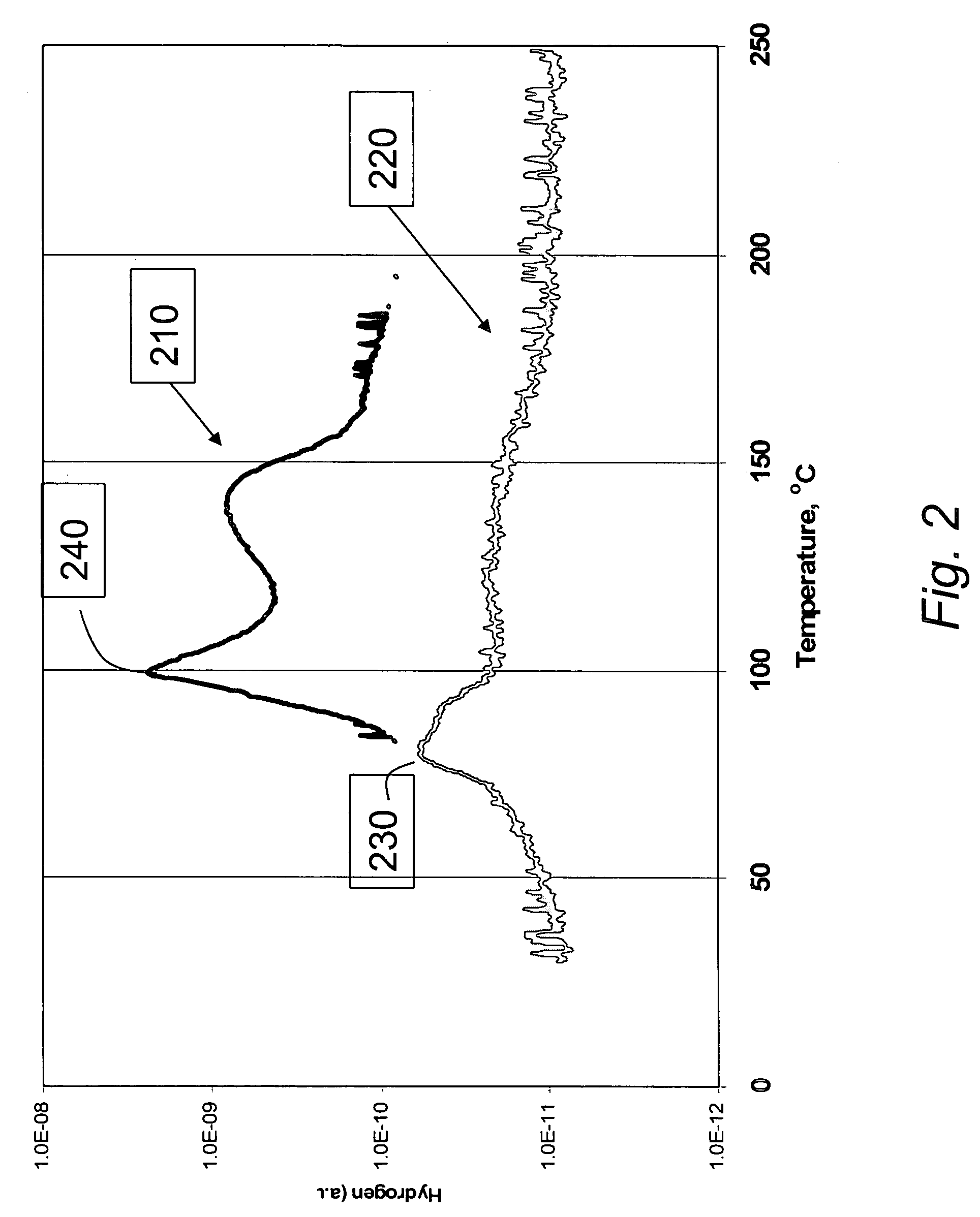

Materials for hydrogen storage and methods for preparing and using same

ActiveUS20050180916A1Reduce the temperatureImprove rate for hydrogen releaseAlkali/alkaline-earth/beryllium/magnesium hydridesMultiple metal hydridesFast releaseAutomotive engine

The invention relates to materials for storing and releasing hydrogen and methods for preparing and using same. The materials exhibit fast release rates at low release temperatures and are suitable as fuel and / or hydrogen sources for a variety of applications such as automobile engines.

Owner:BATTELLE MEMORIAL INST

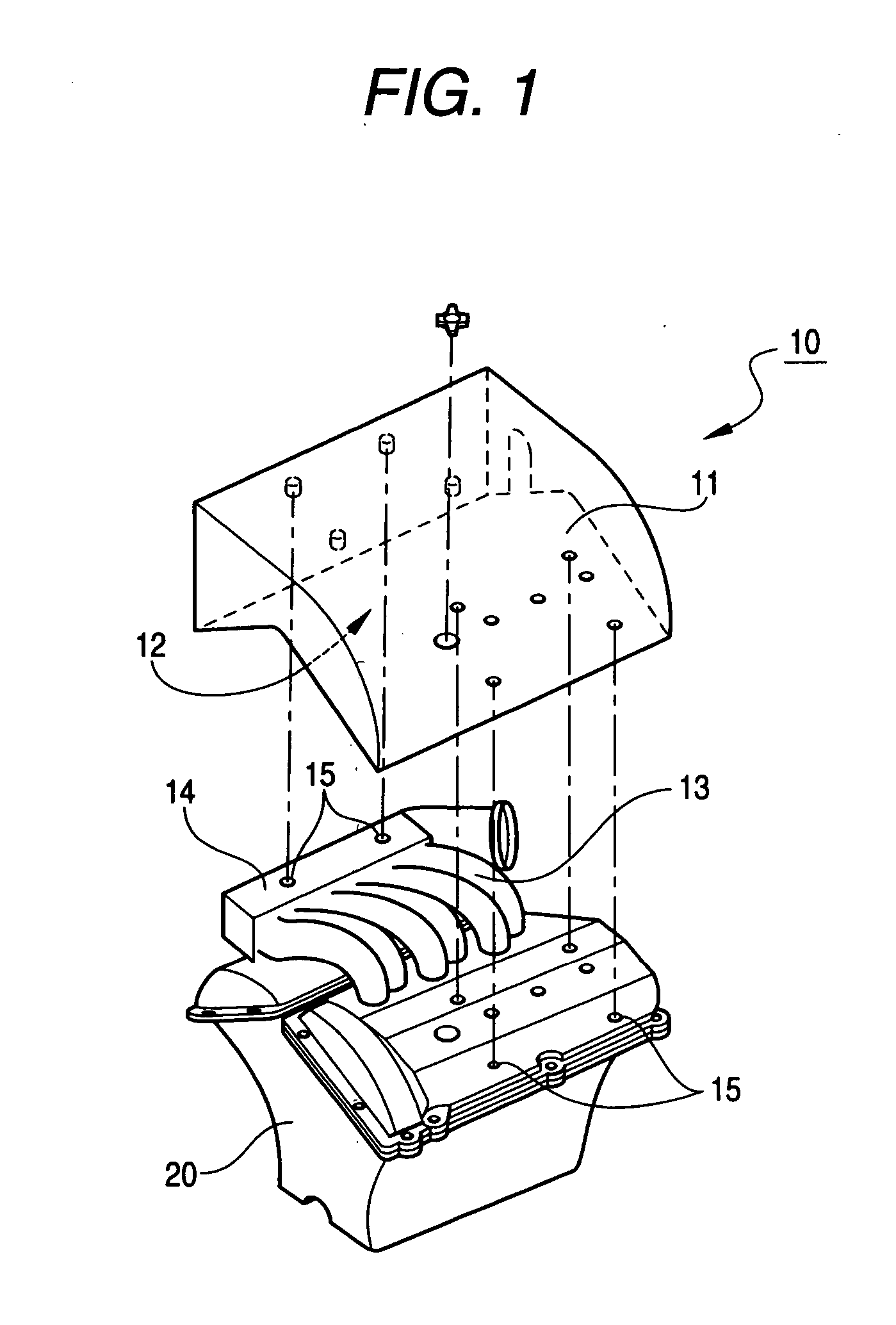

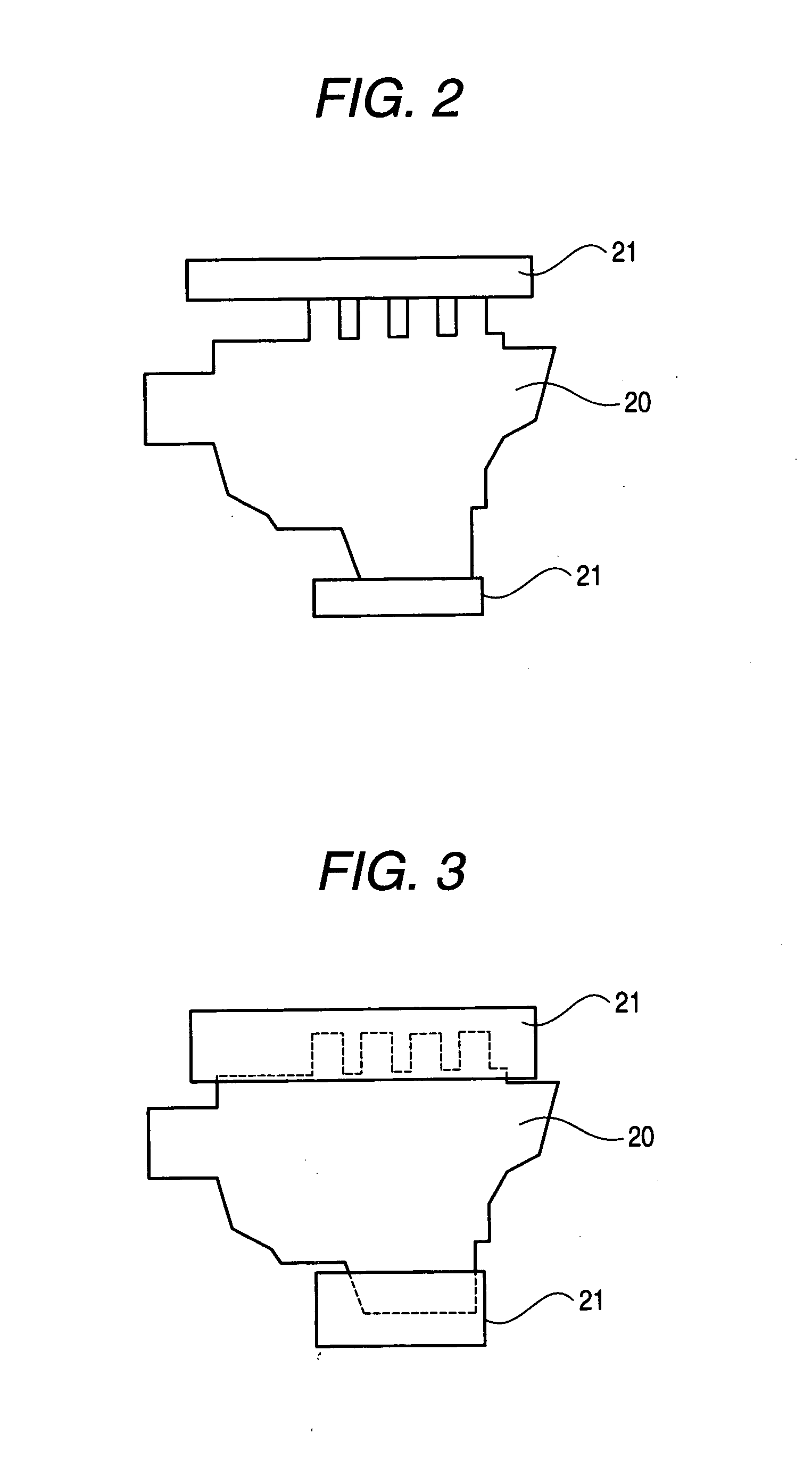

Sliding structure for automotive engine

InactiveUS6886521B2Preventing cracking and separationReduce coefficient of frictionPiston ringsMolten spray coatingCarbon filmPiston ring

A sliding structure for an automotive engine includes a sliding member with a sliding portion and a lubricant applied to the sliding portion so that the sliding portion can make sliding contact with a counterpart member via the lubricant. The sliding member is either of a piston ring, a piston pin, a cam lobe, a cam journal, a plain bearing, a rotary vane and a timing chain. The sliding portion has a base made of a steel or aluminum material and a hard carbon film formed on the base to coat the sliding portion. The hard carbon film has a thickness of 0.3 to 2.0 mum, a Knoop hardness of 1500 to 4500 kg / mm2, a surface roughness Ry (mum) satisfying the following equation: Ry<{(0.75-Hk / 8000)xh+0.07 / 0.8}, where h is the thickness (mum) of the film; and Hk is the Knoop hardness (kg / mm2) of the film.

Owner:NISSAN MOTOR CO LTD

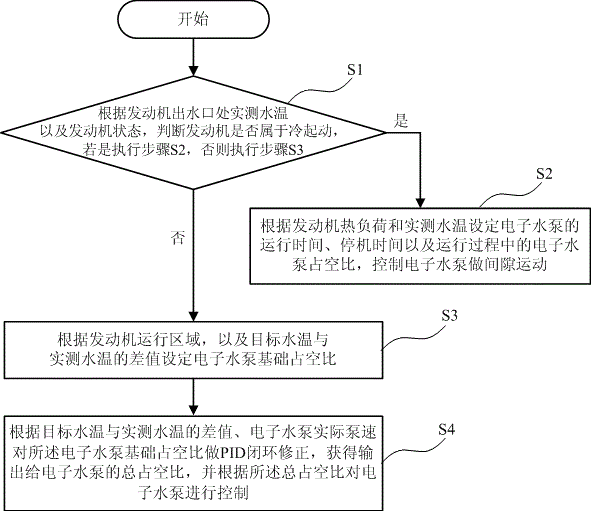

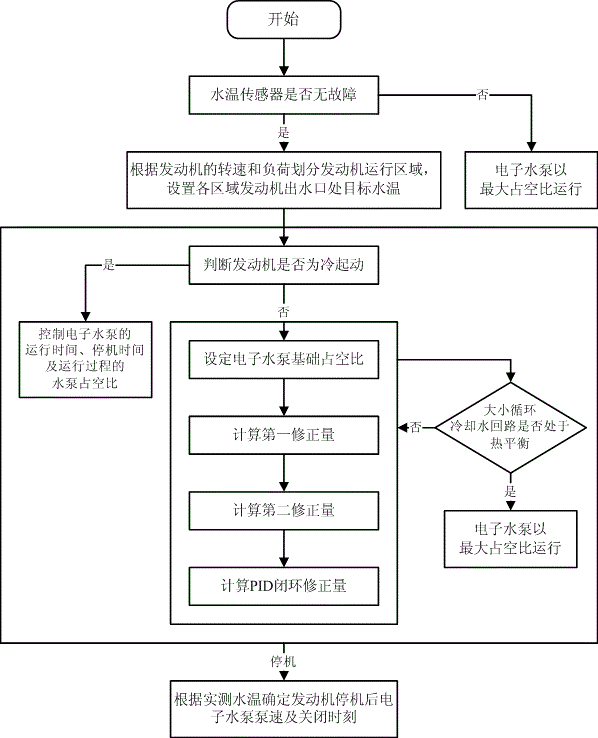

Method and device for controlling electronic water pump of water-cooling system of automobile engine

ActiveCN106246328ALower working temperatureEasy to controlCoolant flow controlMeasurement deviceIntermittent motionStop time

The invention provides a method and device for controlling an electronic water pump of a water-cooling system of an automobile engine. The method comprises the following steps: step S1, judging whether the engine is in a cold start state or not according to actually measured water temperature at a water outlet of the engine and the state of the engine, if the engine is in the cold start state, carrying out step S2, and if the engine is not in the cold start state, carrying out step S3; step S2, setting running time and stopping time of the electronic water pump according to the thermal load and the actually measured water temperature of the engine and duty ratio of the electronic water pump in a running process, and controlling the electronic water pump to carry out intermittent motion; step S3, setting a basic duty ratio of the electronic water pump according to a running region of the engine and difference between target water temperature and the actually measured water temperature; and step S4, carrying out PID closed-cycle correction on the basic duty ratio of the electronic water pump according to the difference between the target water temperature and the actually measured water temperature and actual pump speed of the electronic water pump to obtain total duty ratio output to the electronic water pump, and controlling the electronic water pump according to the total duty ratio. By the method and device for controlling the electronic water pump of the water-cooling system of the automobile engine, warming time can be shortened, and the water temperature control effect is improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Ornamental device for hood of a car

Owner:BLYDEN IRA +1

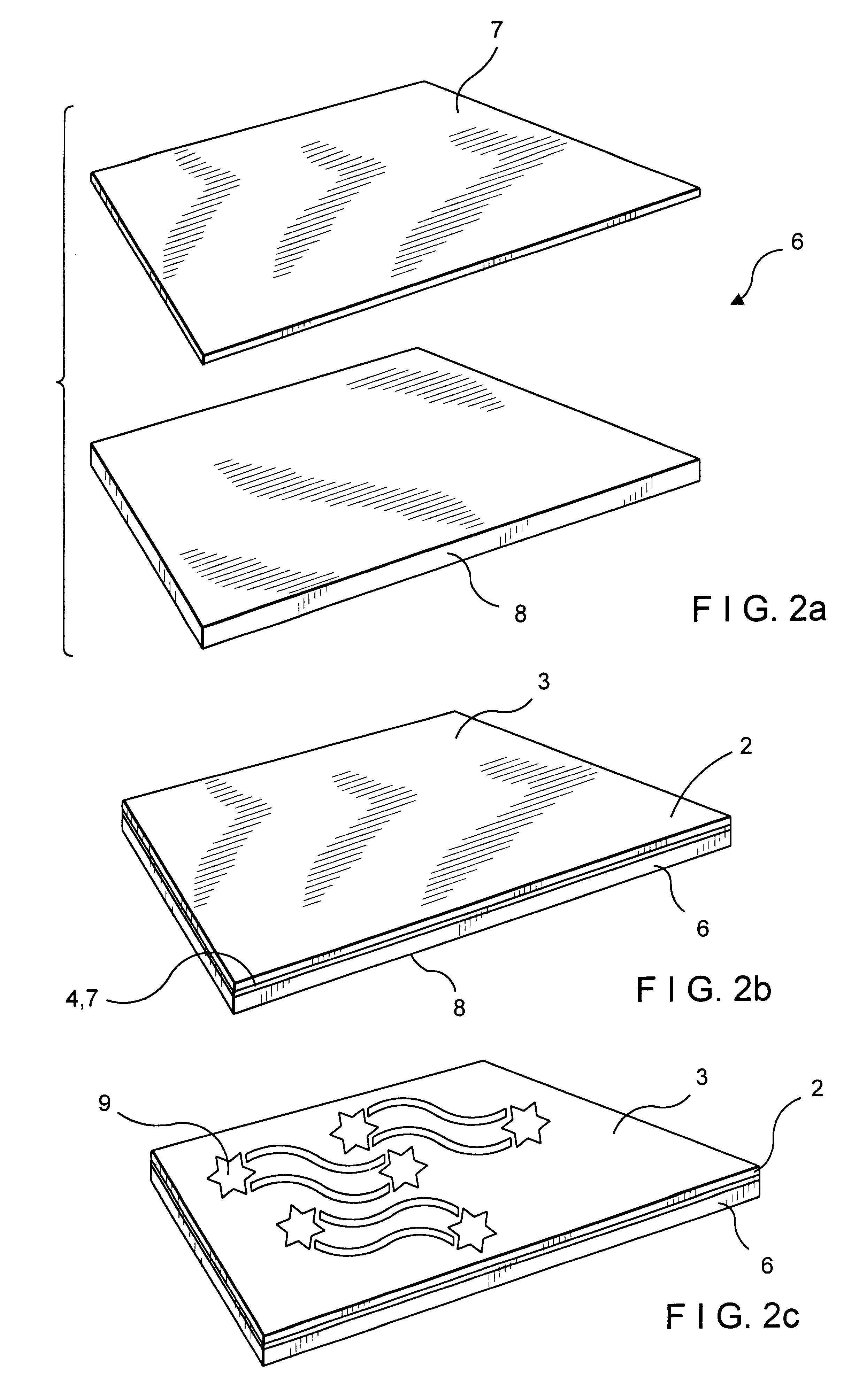

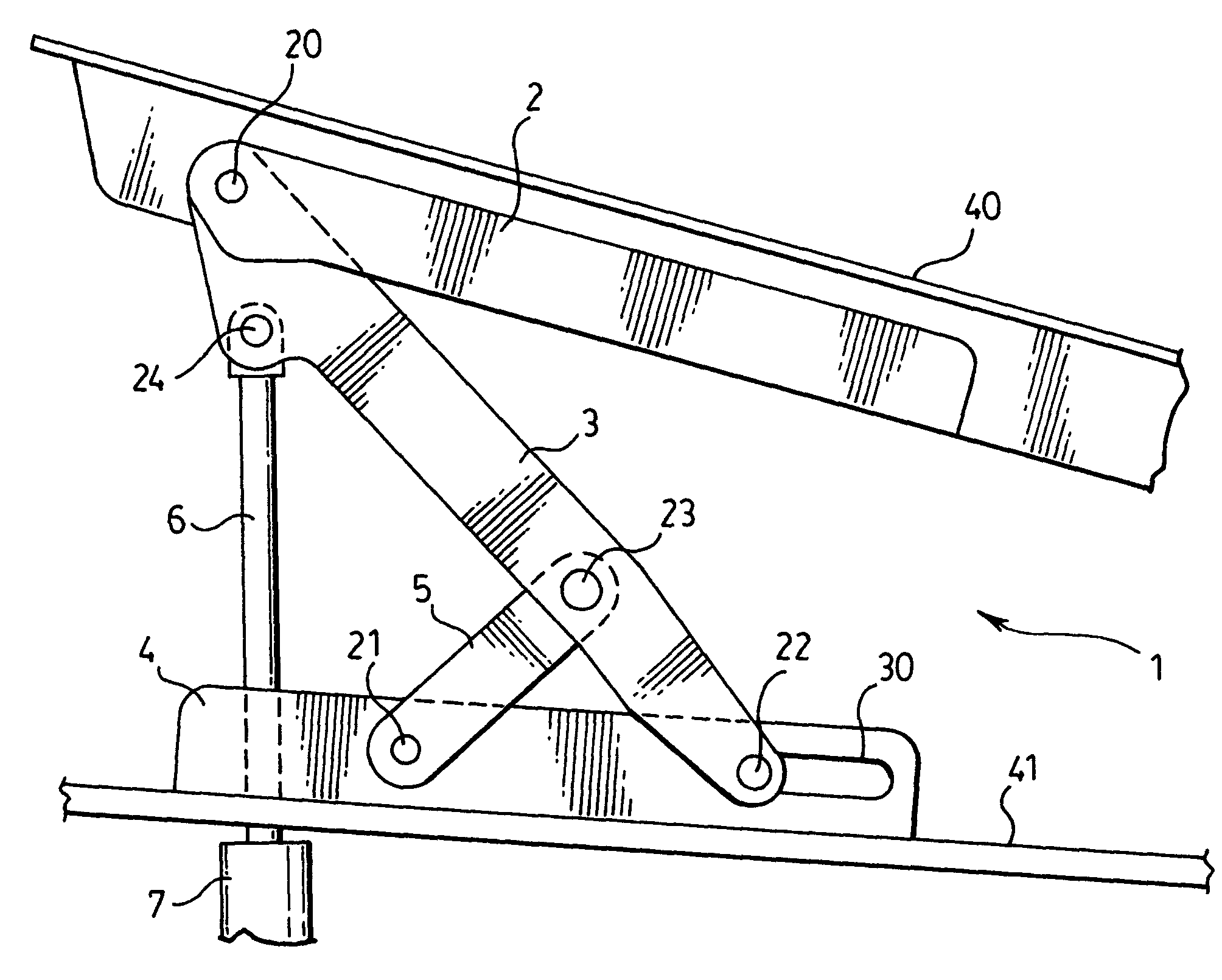

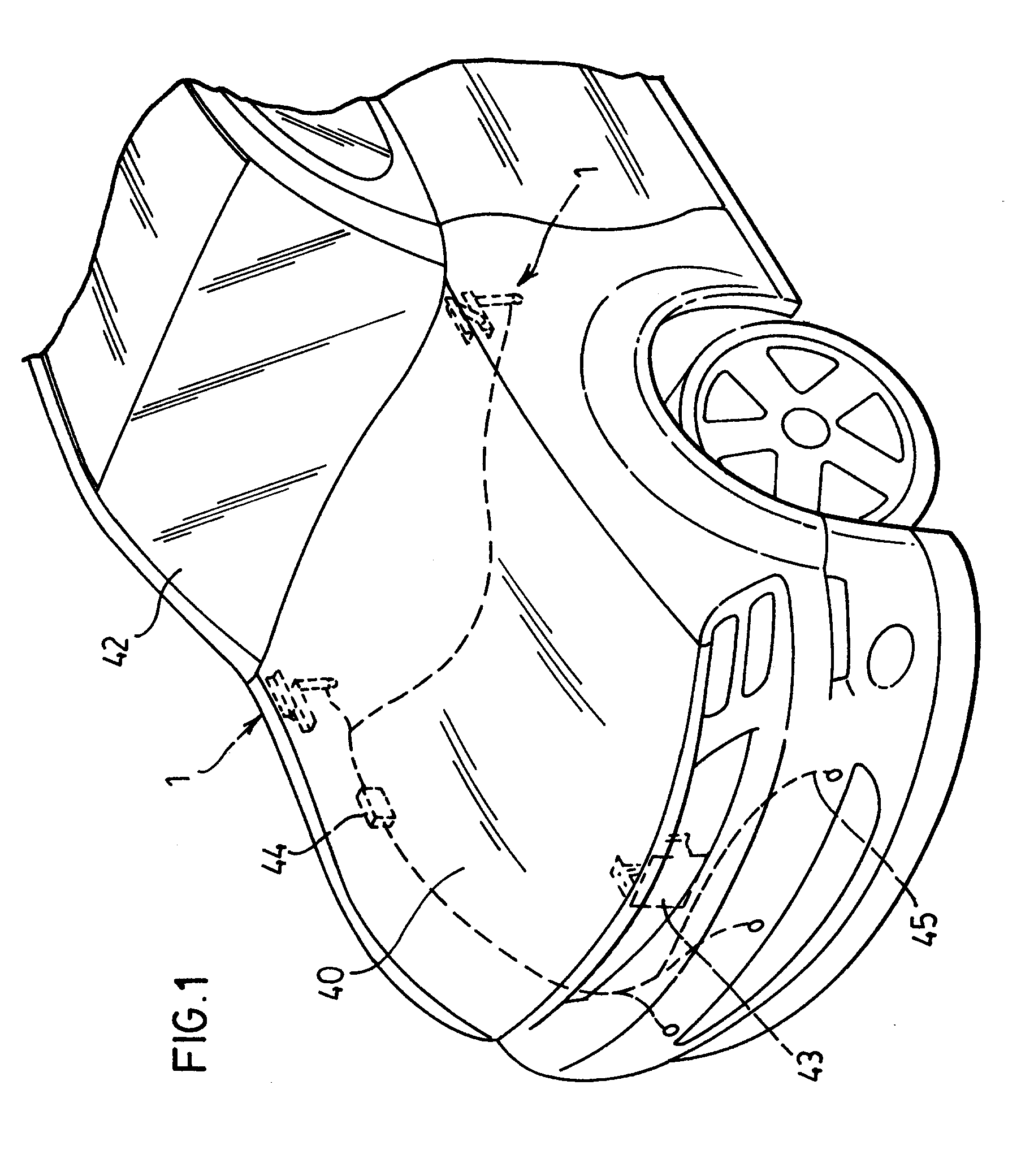

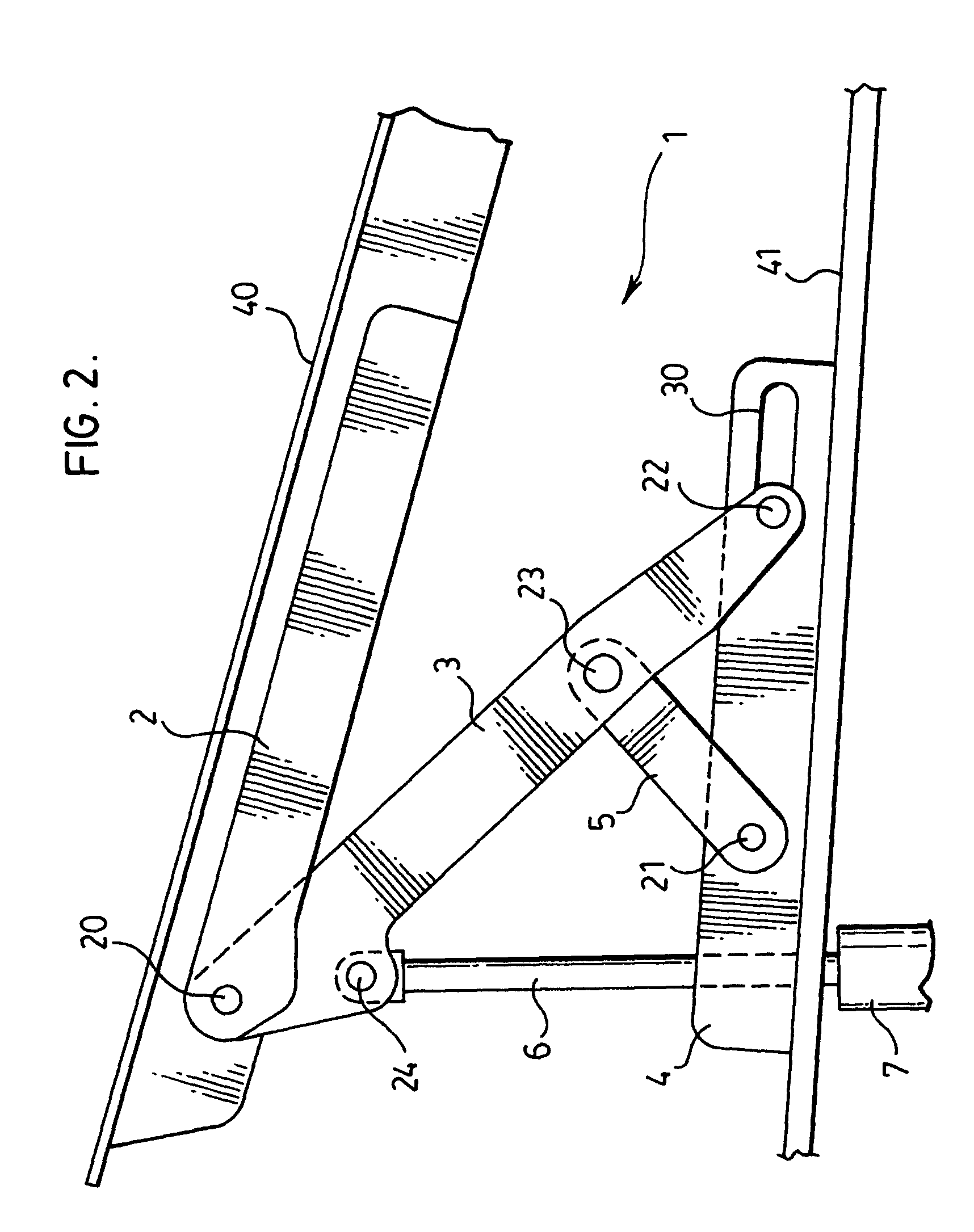

Pedestrian protection automotive hood hinge assembly

ActiveUS7506716B1Simple and intuitiveEfficiently dissipatedVehicle seatsPedestrian/occupant safety arrangementEngineeringActuator

An automotive hood hinge assembly is adapted to act as a safety device in the event of a collision with a pedestrian. The hood hinge assembly is constructed from a series of linkages and an energy storage actuator that is configured to raise the rear of a vehicle hood in response to a pedestrian collision. The deployed system forms a rigid structure that restrains rearward movement of the hood while providing a vertical motion path and resistive force capable of efficiently dissipating the energy imparted by the pedestrian and therefore significantly lowering injury levels. The linkages are configured to provide conventional rotary opening and closing motion of the hood when the system is in the retracted position and also provide a reset function so that a simple opening and closing motion of the hood when the system is in the deployed position resets it to the retracted position.

Owner:MULTIMATIC INC

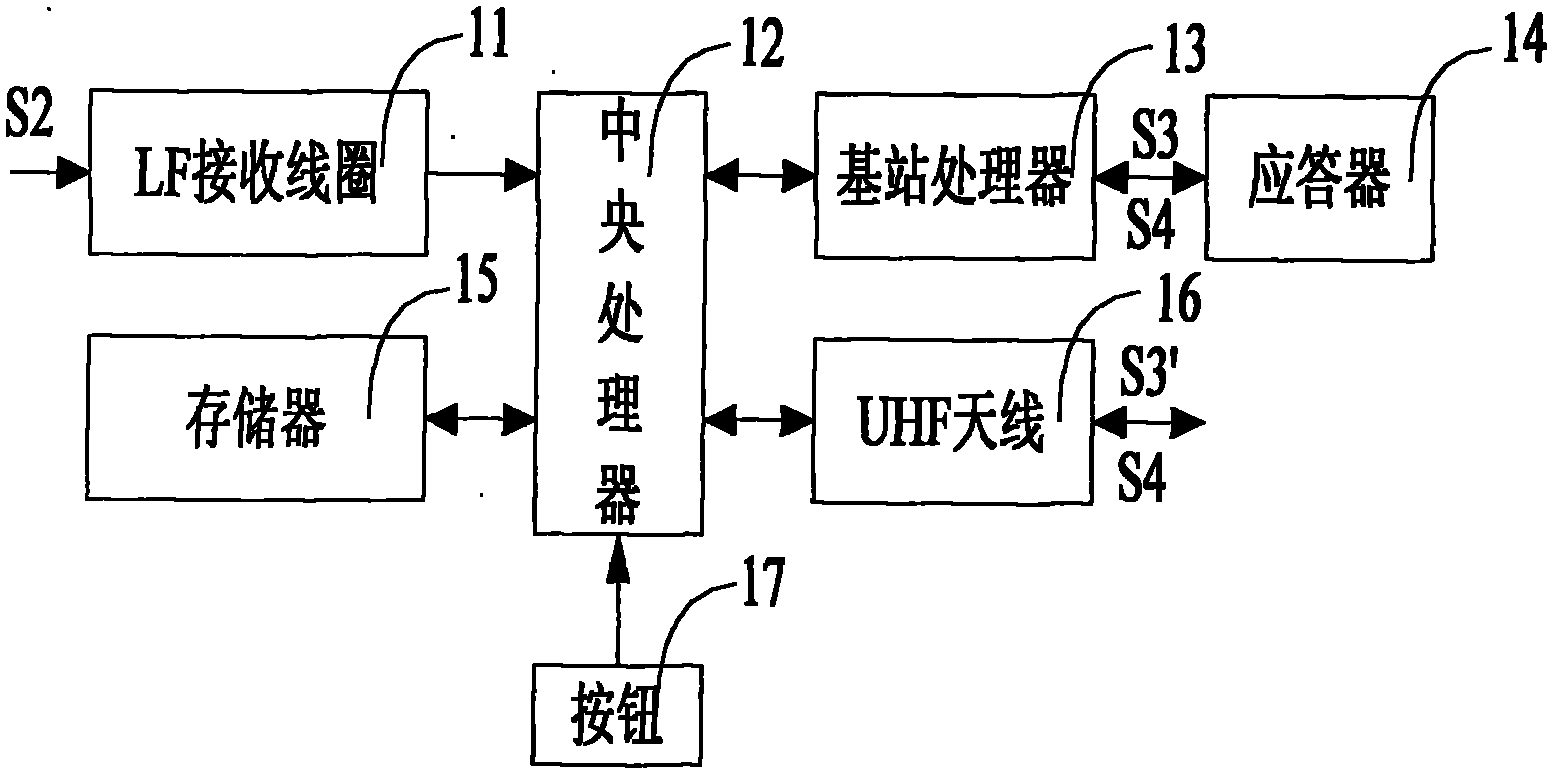

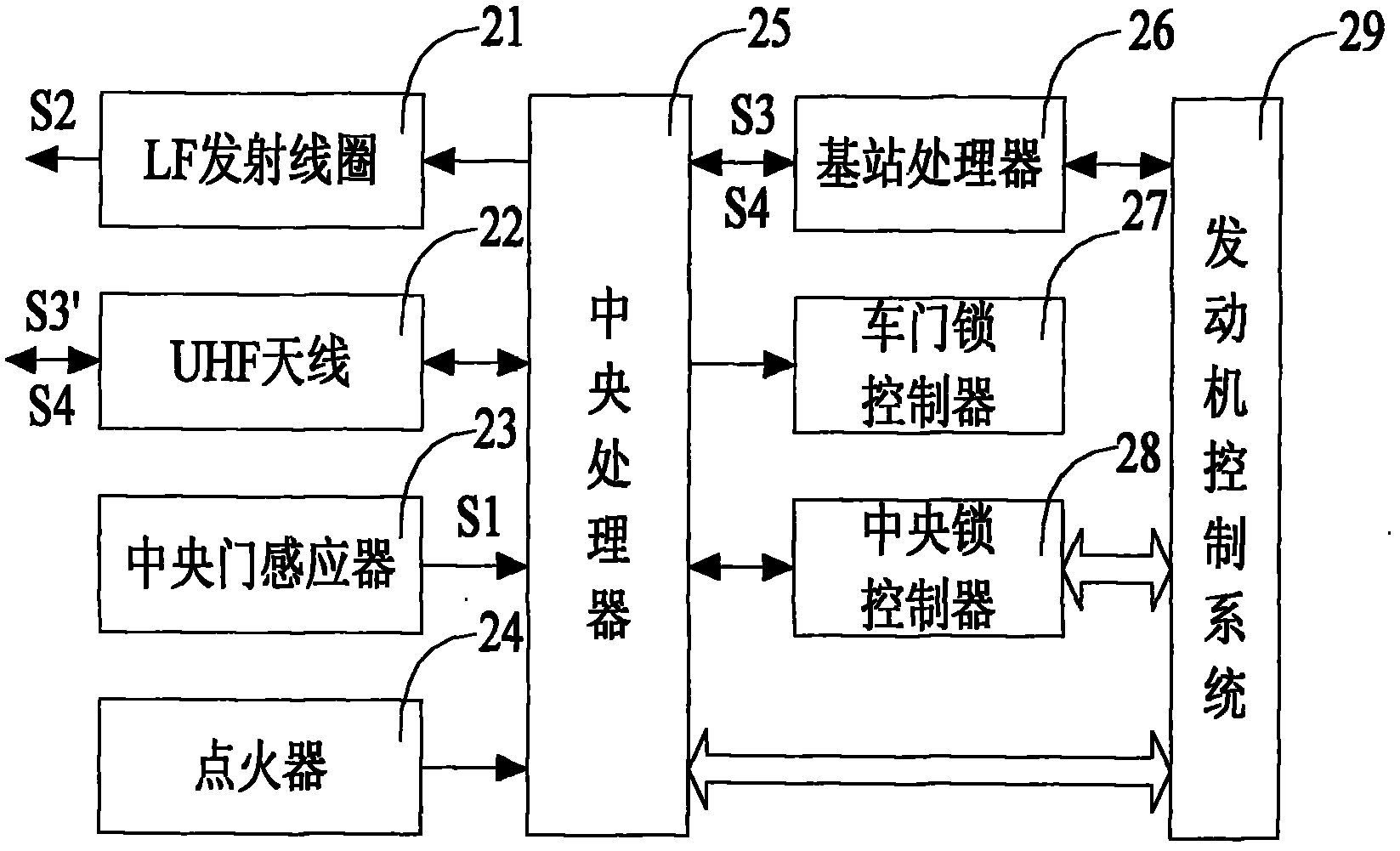

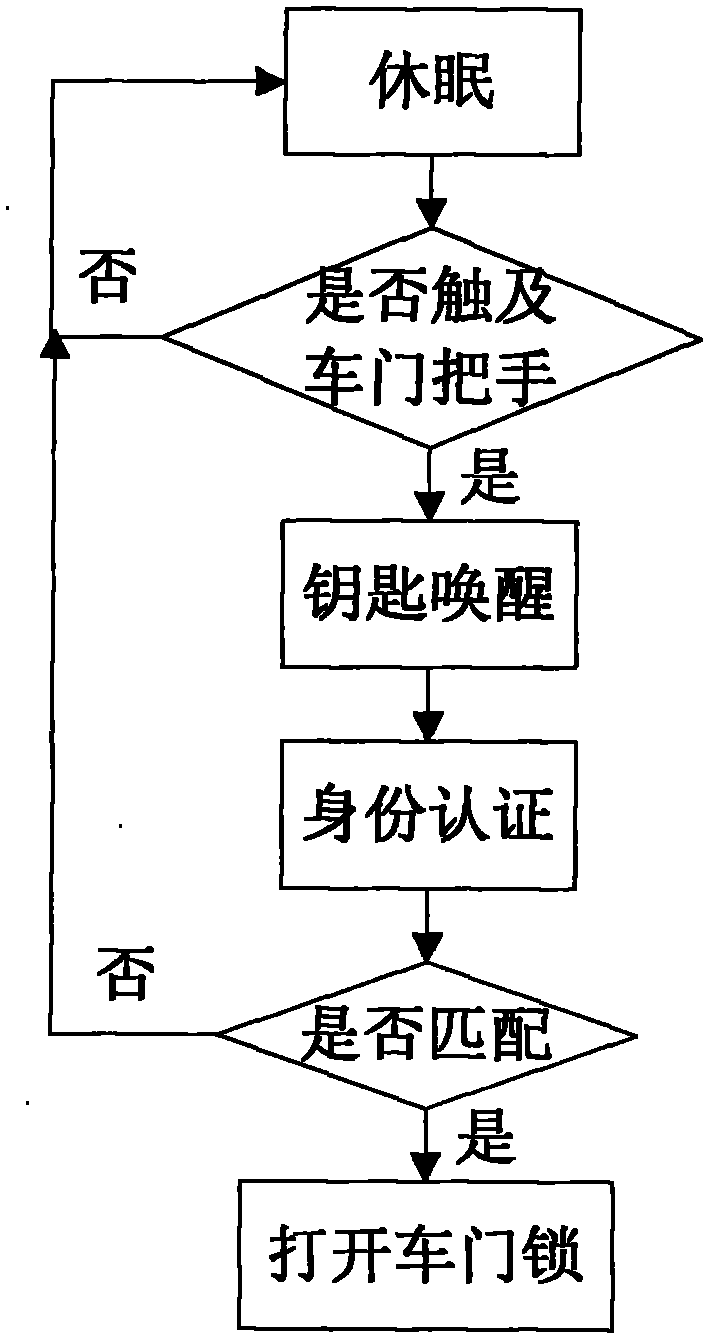

Remote-control no-key system for automobile and data processing method thereof

InactiveCN102096956ASecure transmissionImplement ignition controlAnti-theft devicesIndividual entry/exit registersTelecommunications linkCommunication link

The invention discloses a remote-control no-key system for automobiles and a data processing method thereof. The system is composed of an induction key system and a vehicle-mounted control system and is characterized in that the induction key system is composed of an LF (lower frequency) receiving coil, a key central processor, a key base station processor, a transponder, a storage and a UHF (ultra high frequency) key antenna module; the vehicle-mounted control system is composed of an LF emission coil, a UHF vehicle-mounted antenna module, a central door inductor, an igniter, a vehicle-mounted central processor, a vehicle-mounted base station processor, a door lock controller, a central lock controller and an engine control system. When data is processed, a communication link for identity authentication is is required to be built between the vehicle-mounted control system and the induction key system to open the door lock and ignite the engine. Even if people break into the vehicle, the vehicle engine can not be ignited without the key, so that the burglar-proof performance of the vehicle is greatly improved, and the automobile also has the function of one-button starting.

Owner:王翔

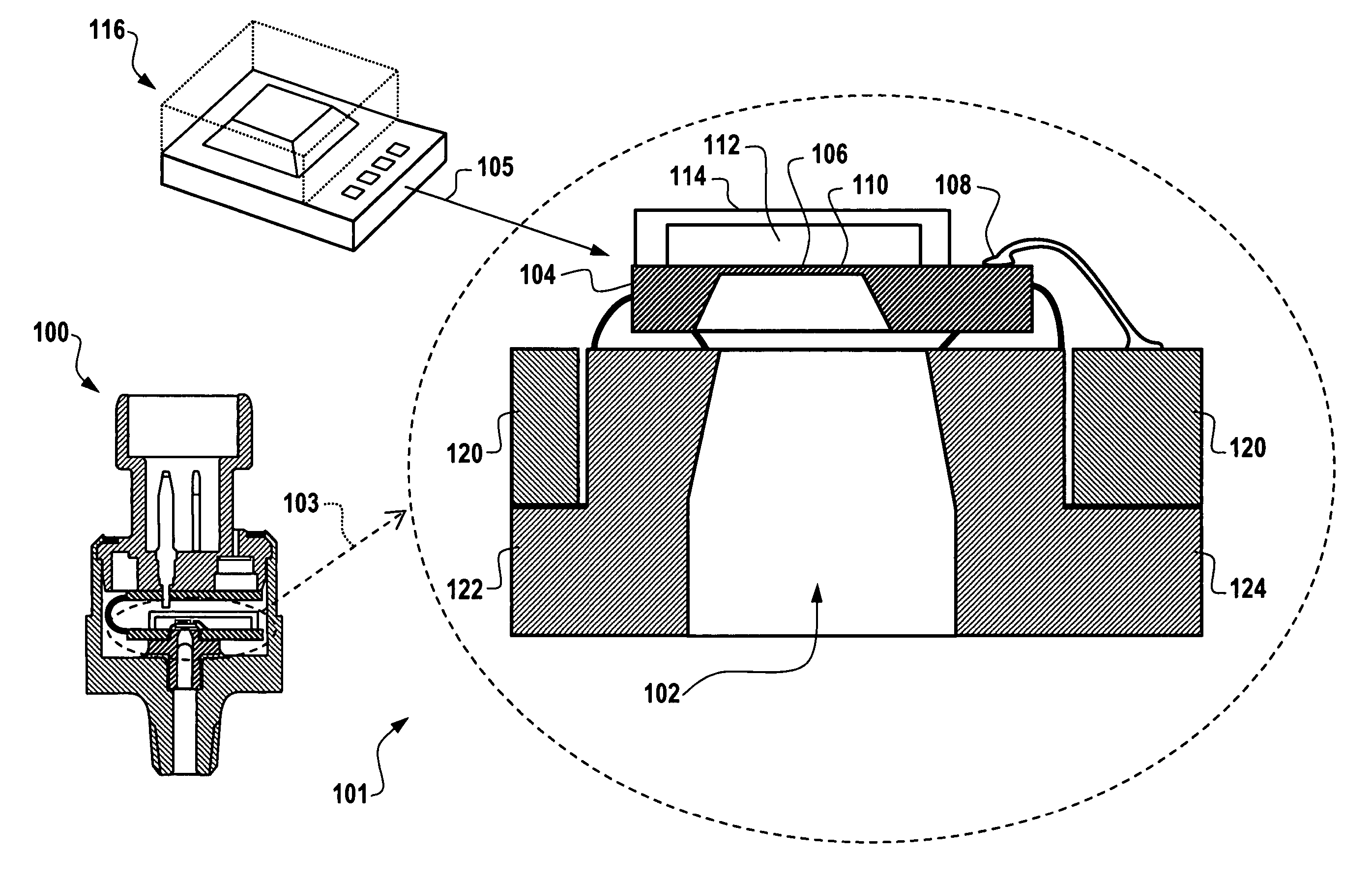

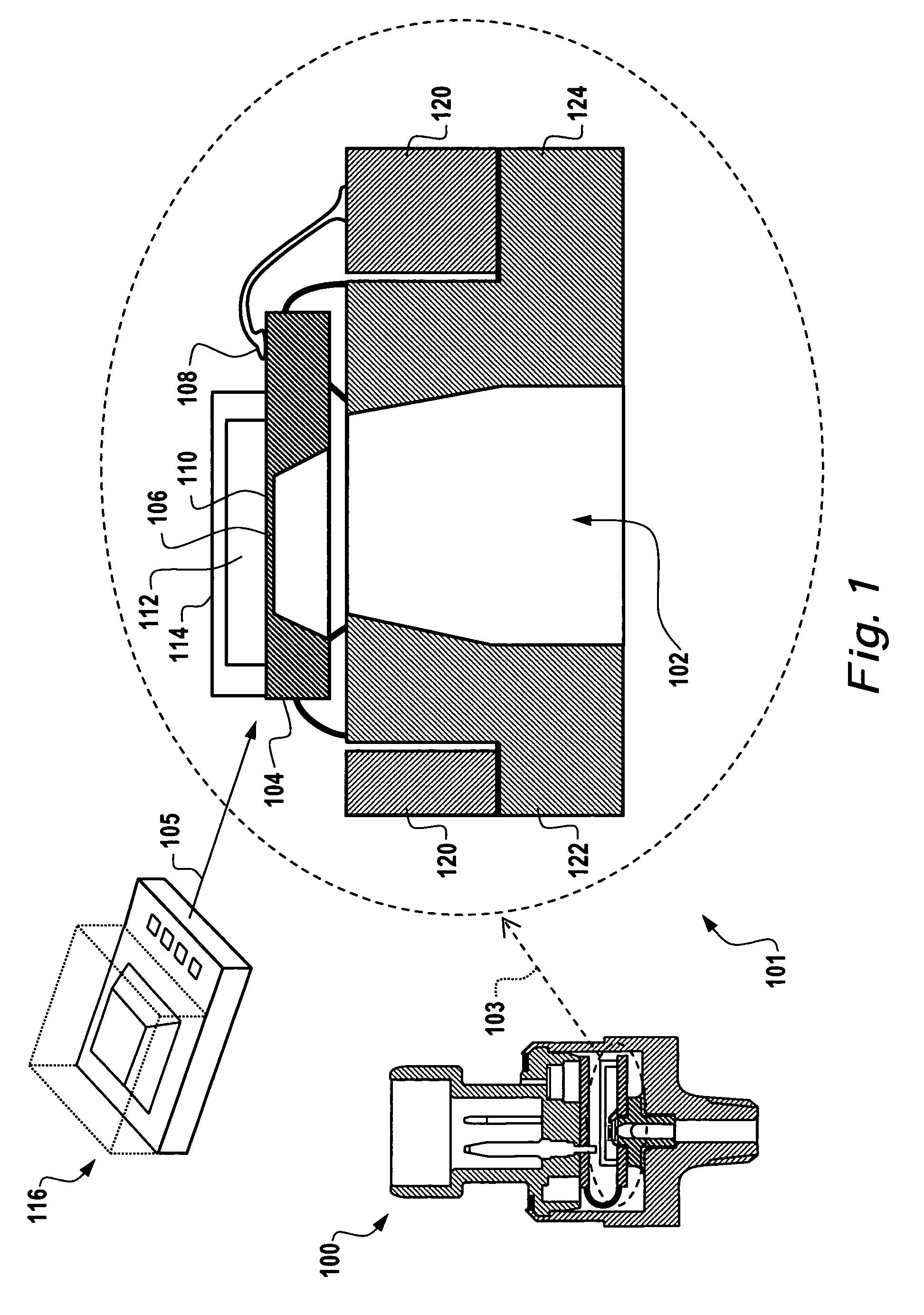

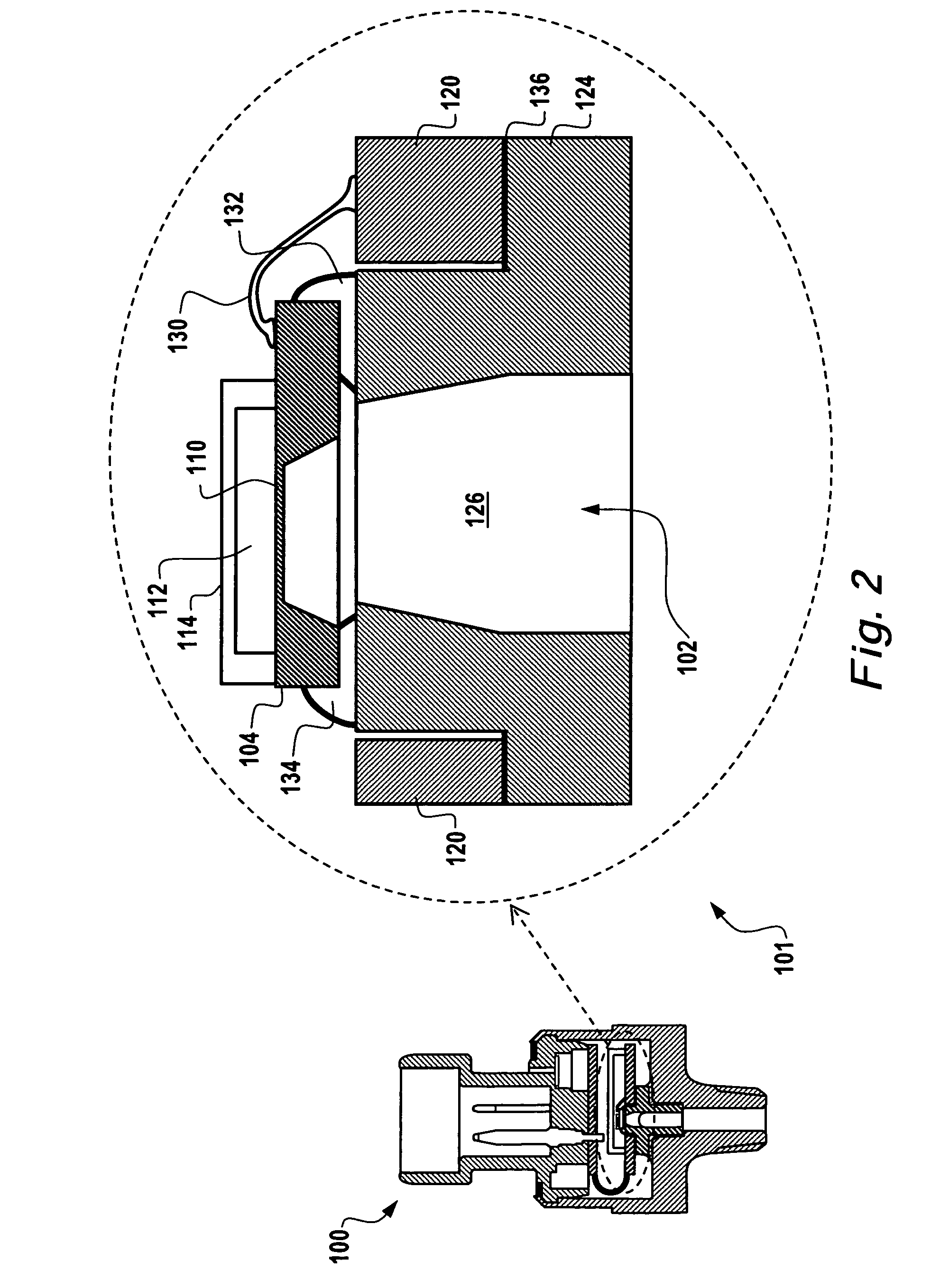

Exhaust back pressure sensor using absolute micromachined pressure sense die

ActiveUS7073375B2Internal combustion piston enginesExhaust apparatusDifferential pressurePressure sense

Sensor systems and methods are disclosed, which generally incorporate isolation between the sensor's electronics and the sensed media. The sensor's electronic circuit can incorporate one or more application specific integrated circuit (ASIC) that processes and outputs the signal for both absolute and differential measurements. Such a sensor can be adapted for use in exhaust gas re-circulation (EGR) systems utilized with automotive gasoline engines. Such a sensor can also be utilized for measuring differential pressure across diesel particular filters and / or applications in which differential pressure is required for system control and / or monitoring purposes. The absolute pressure sensor disclosed herein can therefore sense the exhaust pressure on automotive engines and other mechanical and / or electromechanical devices and machines.

Owner:HONEYWELL INT INC

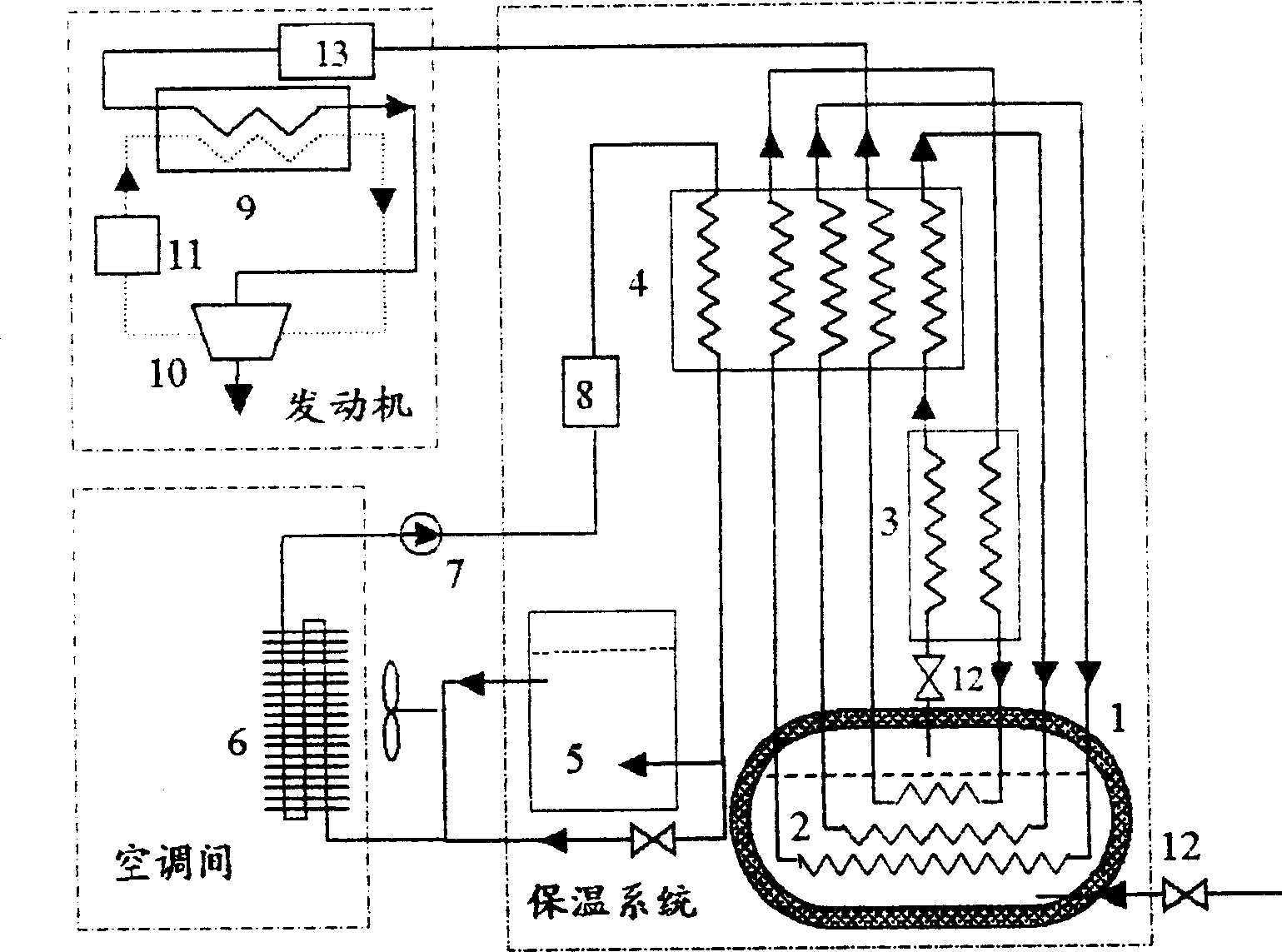

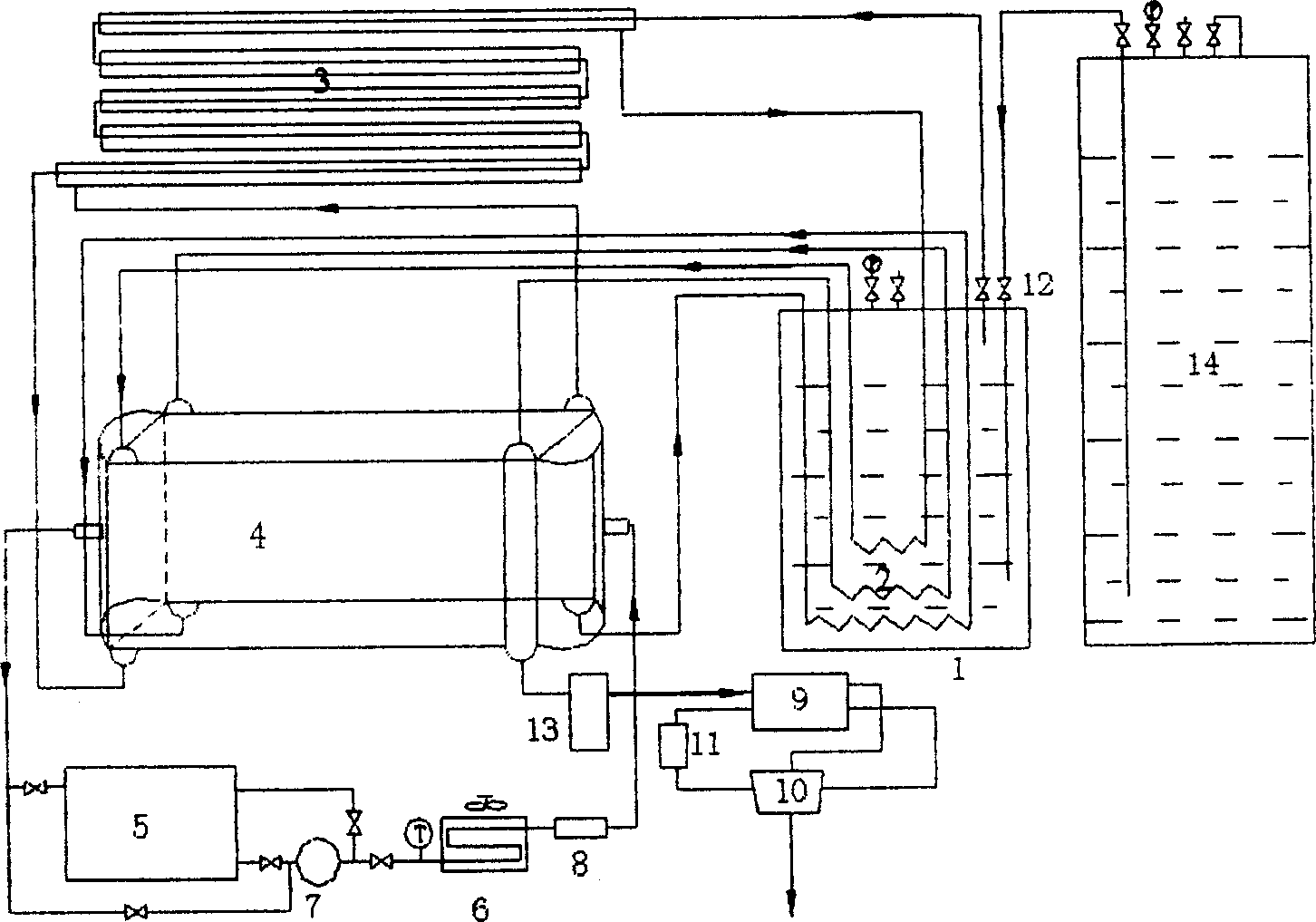

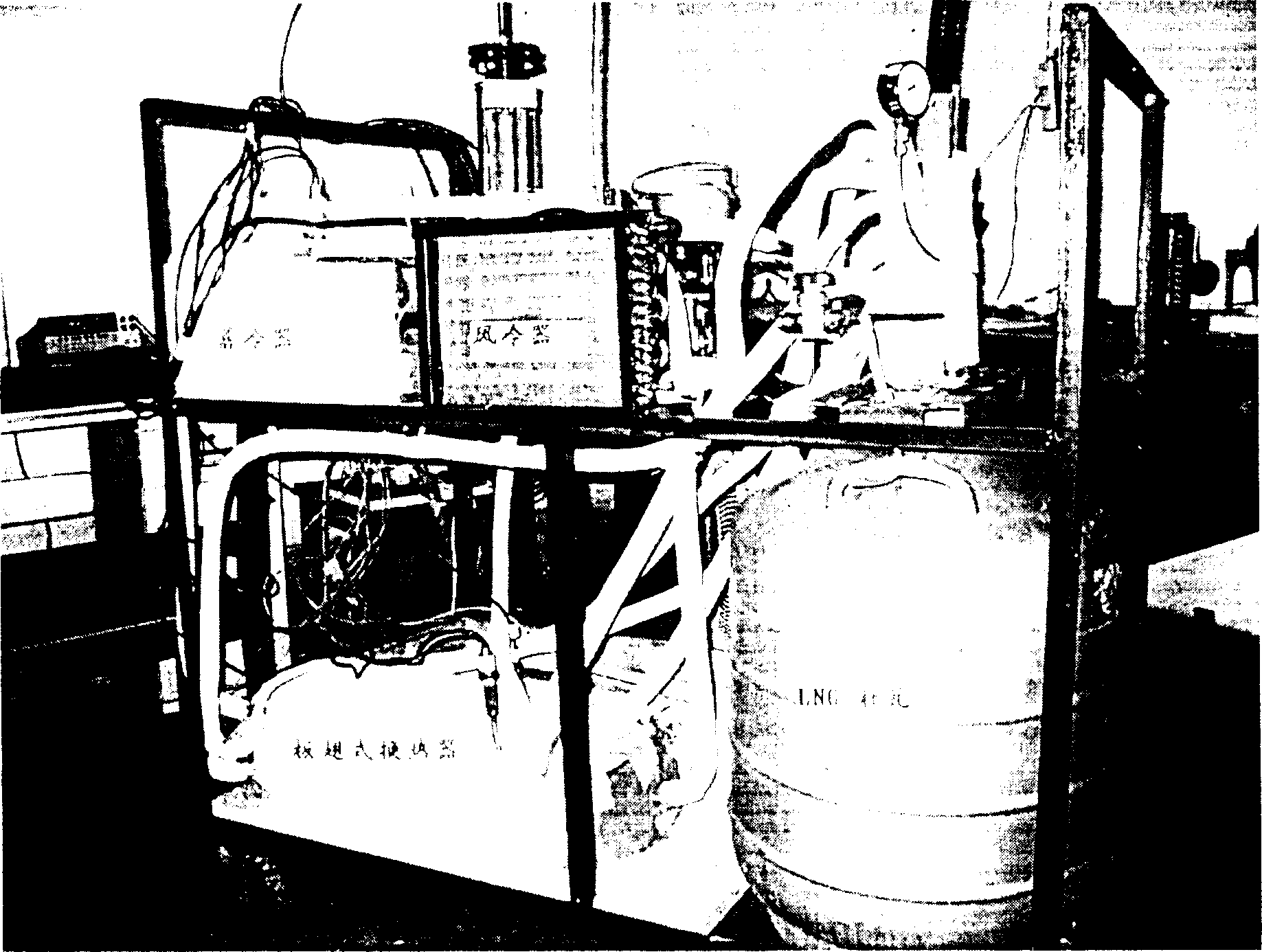

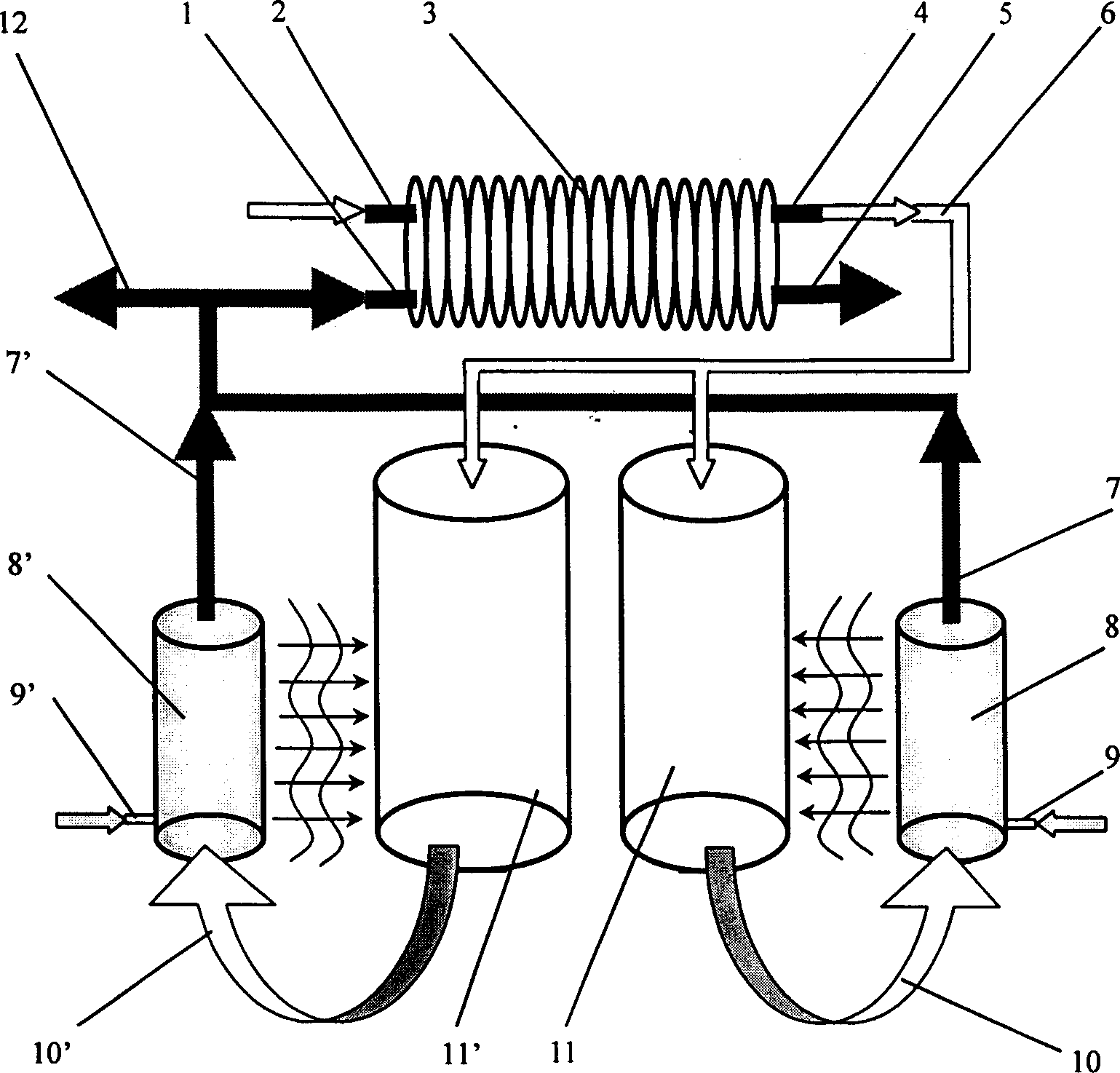

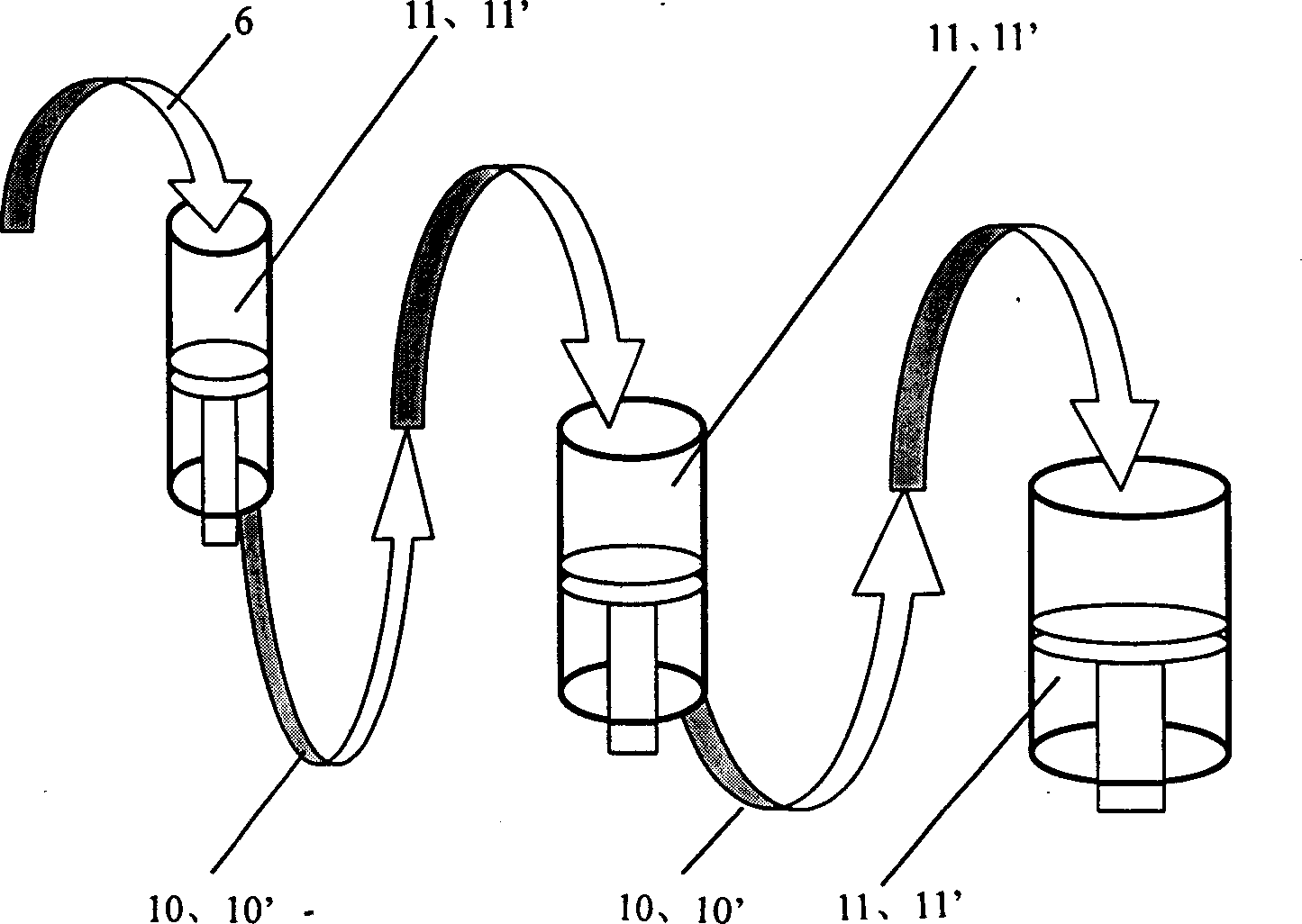

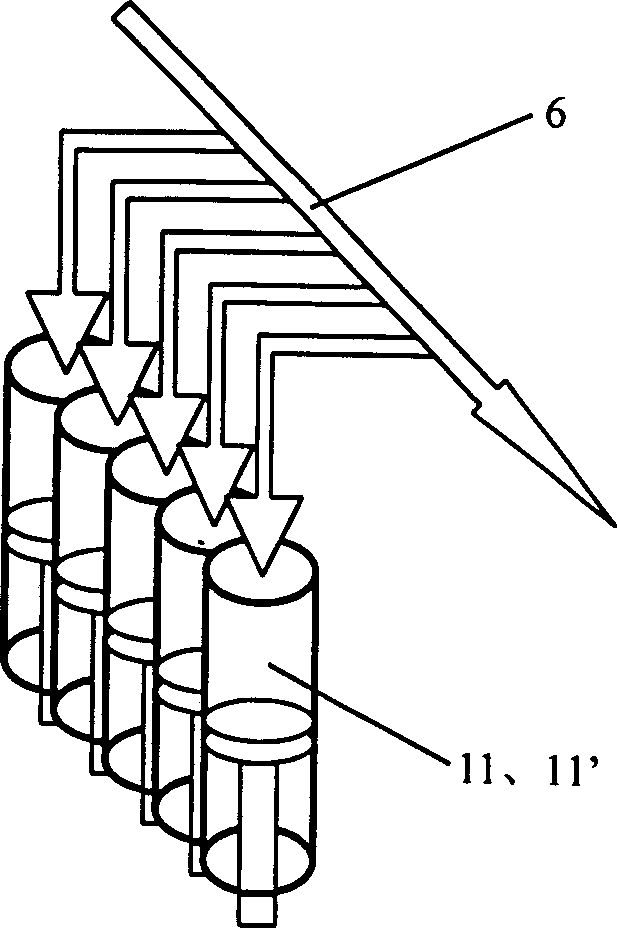

Car air conditioner making use of quantity of cold of liquefied natural gas

InactiveCN1431107AImprove balanceGood adjustment functionAir-treating devicesDomestic cooling apparatusAutomobile air conditioningProcess engineering

An air conditioner using the cold of liquefied natural gas for automobile is composed of liquefied natural gas cylinder, coiled-tube beat exchanger arranged in said cylinder, sleeve-tube heat exchanger, finned heat exchanger, cold-accumulating ethanediol box, air cooling heat exchanger and liquid pump, which are communicated. The said fined heat exchanger is communicated with engine via low-pressure gas accumulator and condenser. The cooling water of engine is cooled by heat exchanger and then used to cool engine. Its advantages are better transient and steady-state performance and better cold balancing and regulating function.

Owner:XI AN JIAOTONG UNIV

Materials for storage and release of hydrogen and methods for preparing and using same

ActiveUS7316788B2Minimize undesirableHigh purityAlkali/alkaline-earth/beryllium/magnesium hydridesOther chemical processesHydrogenFast release

The invention relates to materials for storing and releasing hydrogen and methods for preparing and using same. The materials exhibit fast release rates at low release temperatures and are suitable as fuel and / or hydrogen sources for a variety of applications such as automobile engines.

Owner:BATTELLE MEMORIAL INST

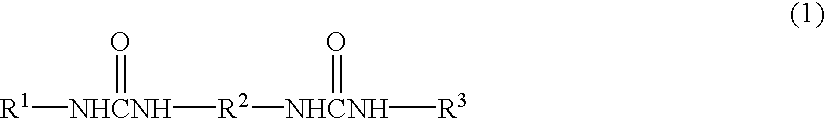

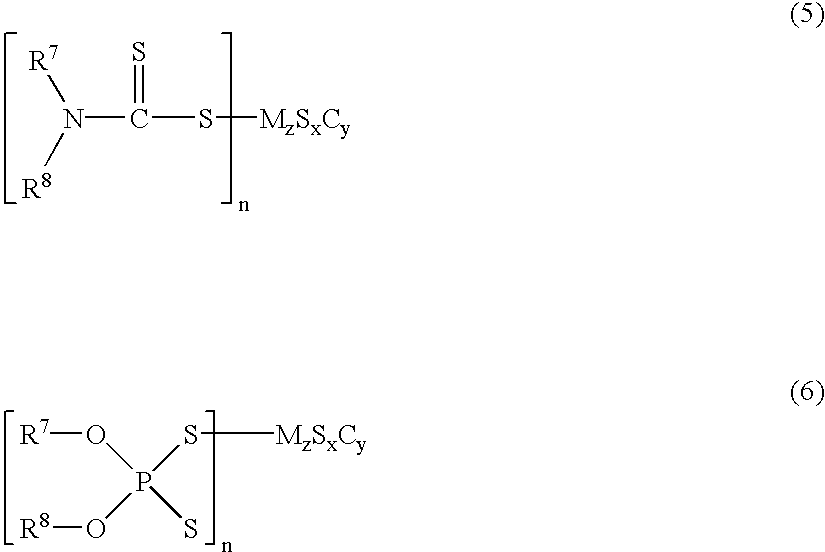

Rolling bearing

InactiveUS20030040442A1Reaction can be suppressedImprove fatigue strengthLiquid carbonaceous fuelsThickenersAlternatorRolling-element bearing

The invention aims to provide a rolling bearing that secures a sufficient bearing life economically even when used under such conditions that water from the outside or water formed by moisture condensation may seep into the lubricant or the bearing is affected by the vibrations, and particularly a rolling bearing suited to the electric parts and accessaries of au automobile engine, such as an alternator. To accomplish the object, the hydrogen ion exponent pH of the grease sealed into the inside of the bearing is adjusted in a range of from 7 to 13. For the same purpose, the hydrogen ion exponent pH of the grease is adjusted in a range of from 5 to 13 where a prescribed amount of an organic metal salt or ADTC is added to the grease, where a prescribed amount of an inorganic compound having an average particle size of 2 squarem or smaller is added to the grease, or where a diurea compound containing an aromatic amine or a mixture of the diurea compound is added to the grease as a thickener.

Owner:NSK LTD

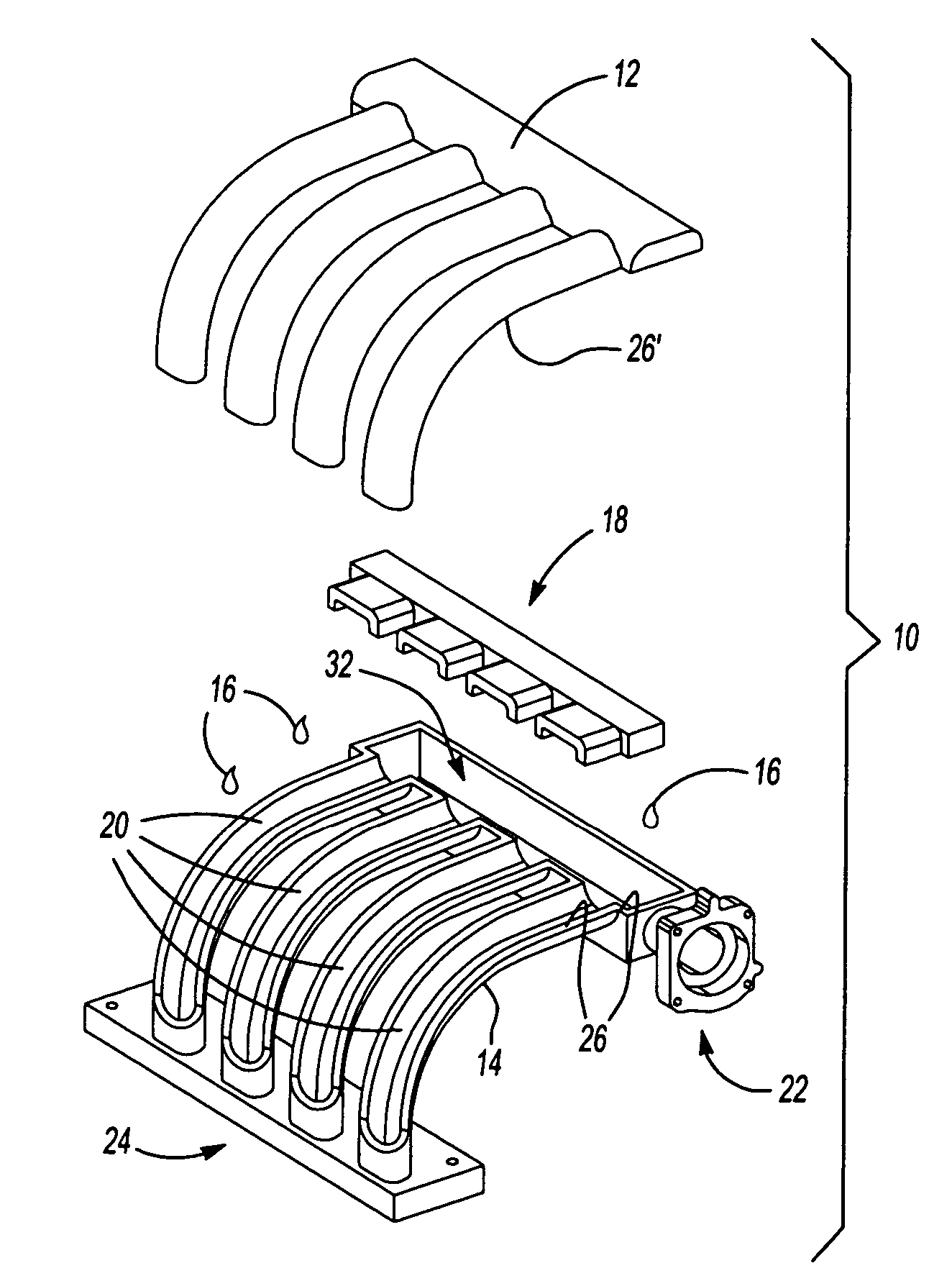

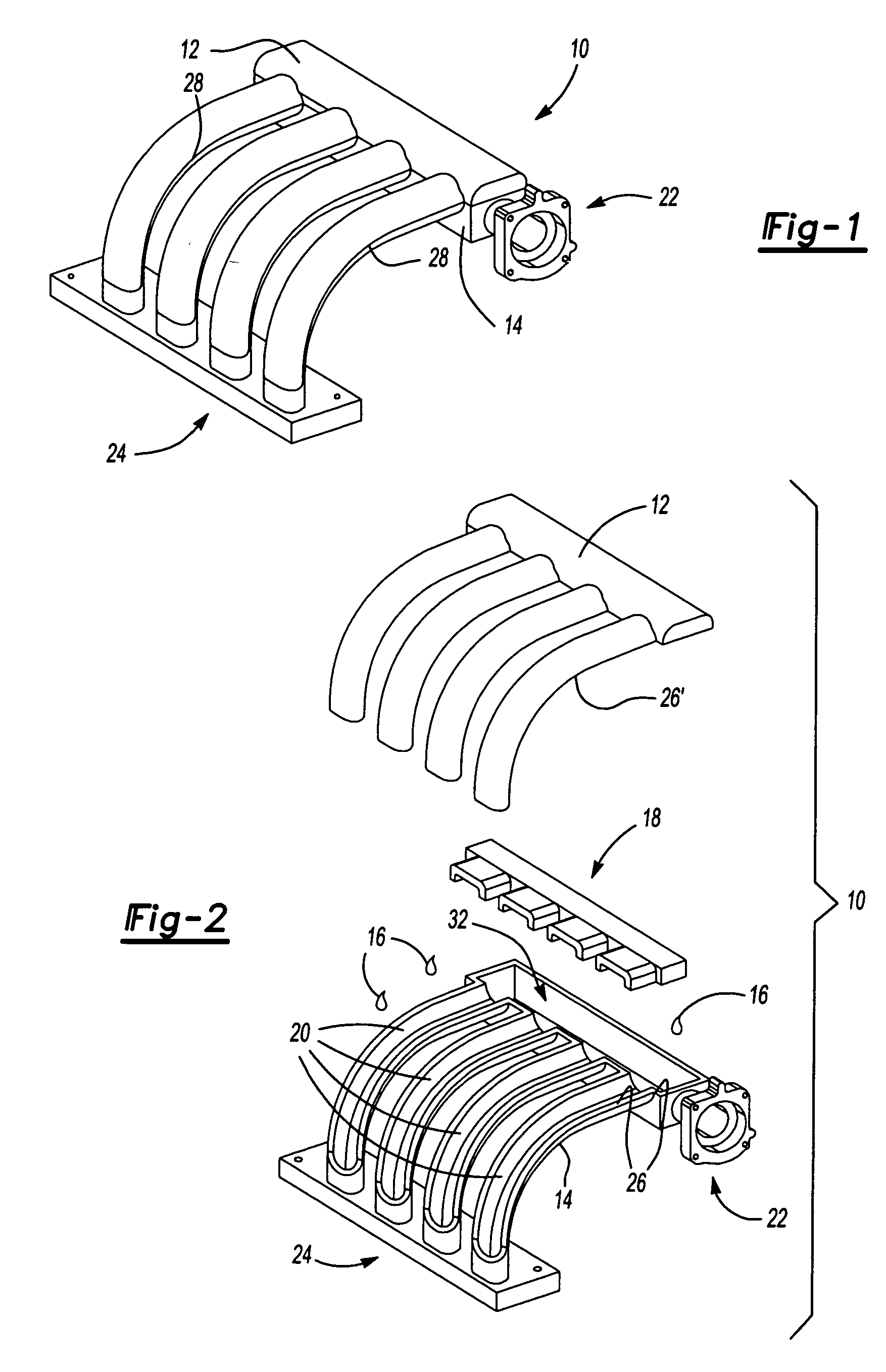

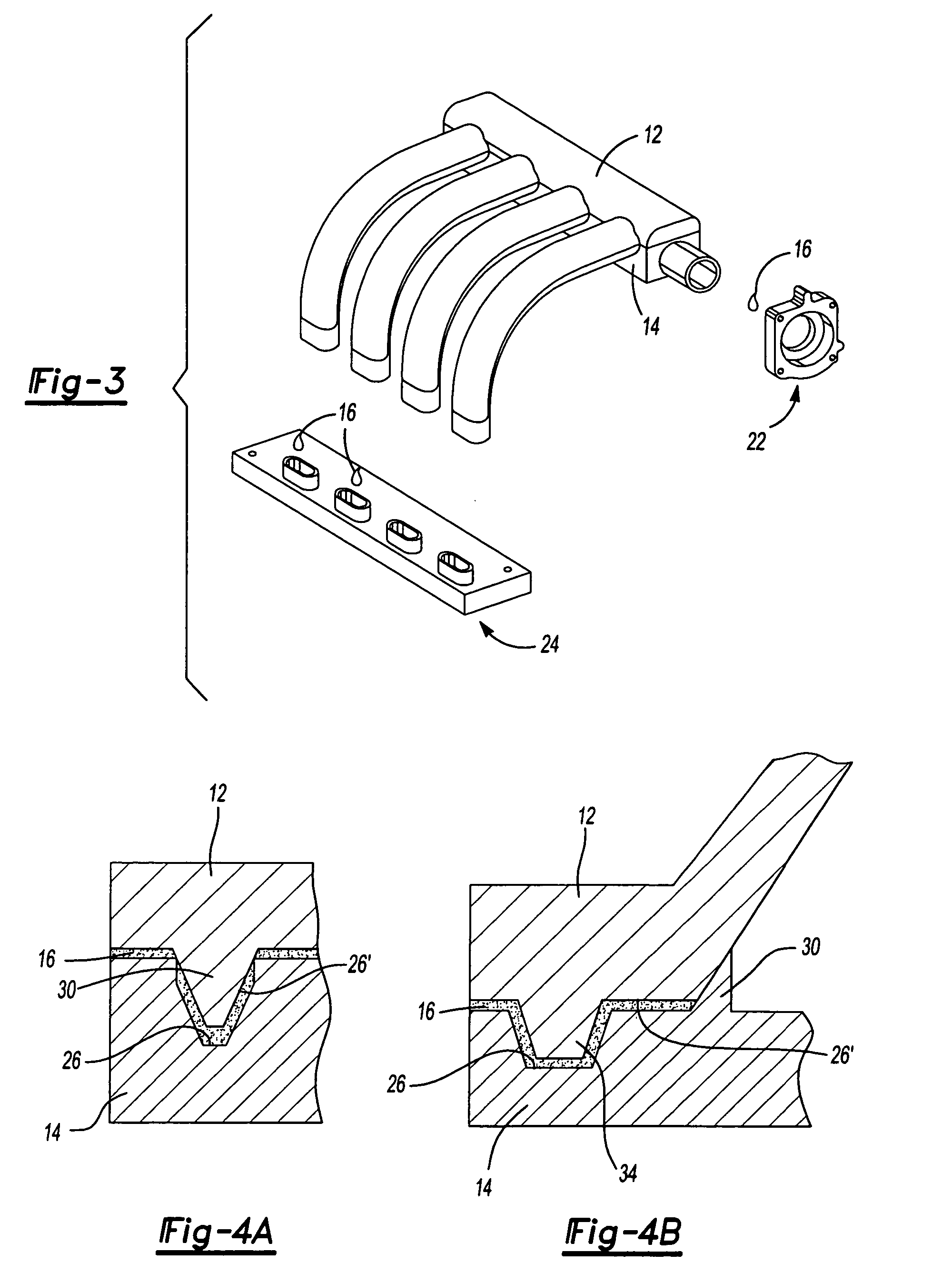

Engine intake manifold assembly

An engine intake manifold assembly including a first portion configured with a first material and a second portion configured with a second material, wherein the first and second portions are adhesively bonded together. Preferably, the intake manifold assembly is additionally configured with a cylinder head flange, for mounting the same to an automotive engine component, and a throttle body attachment for attachment of a throttle body component. The cylinder head flange and throttle body attachment may be an integral component of the first or second portions or attached to the same during or after assembly of the first and second portions. Optionally, an insert is located between the assembled first and second portion to create one or more plenums thereby creating one or more air flow paths through the intake manifold assembly.

Owner:DOW GLOBAL TECH LLC

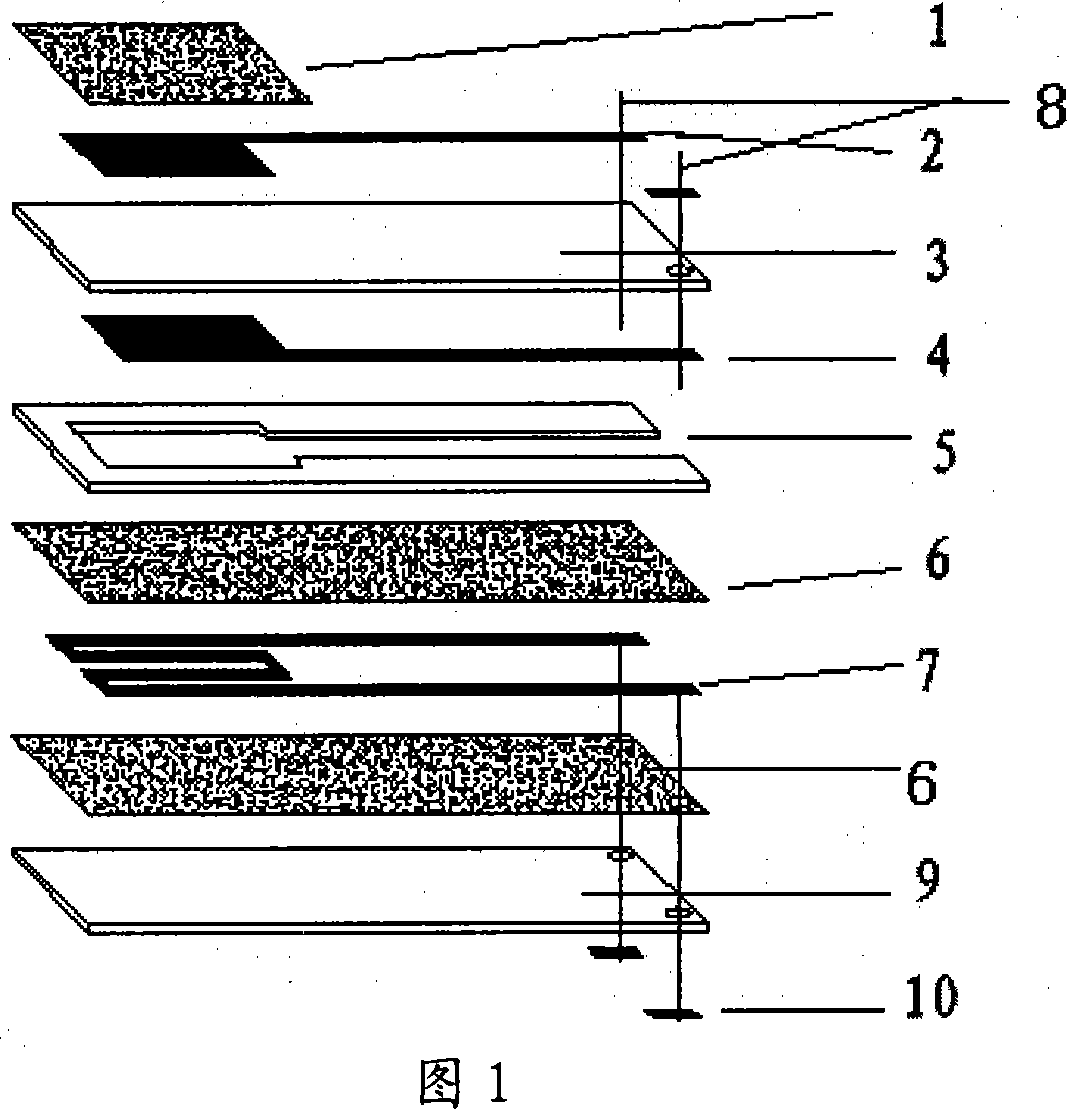

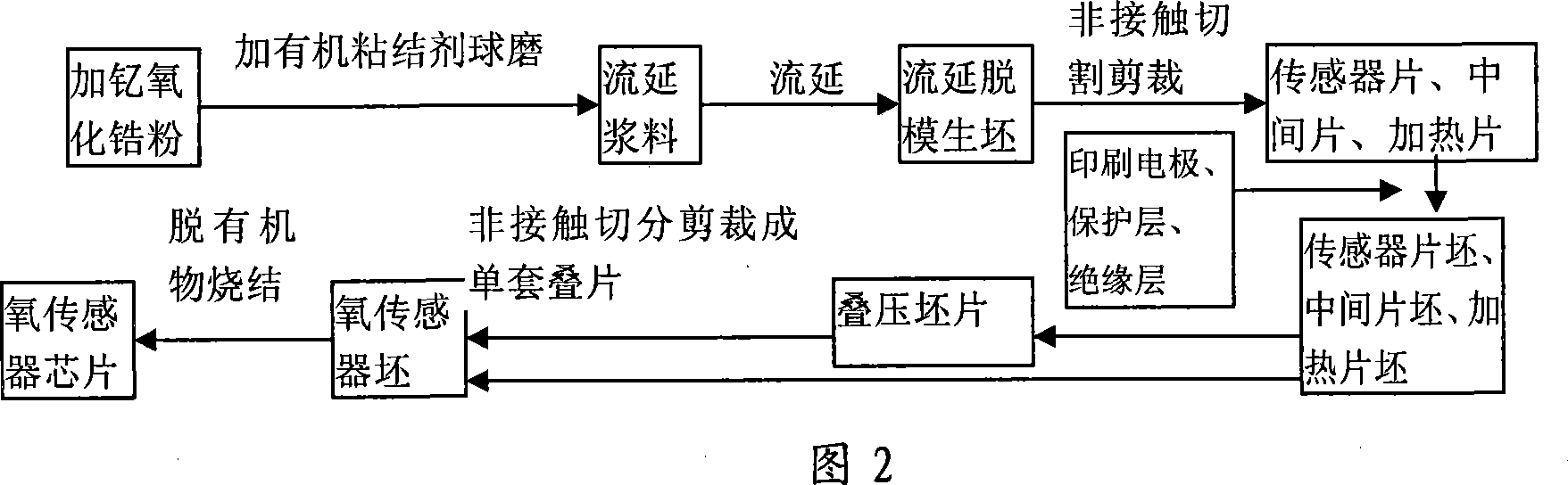

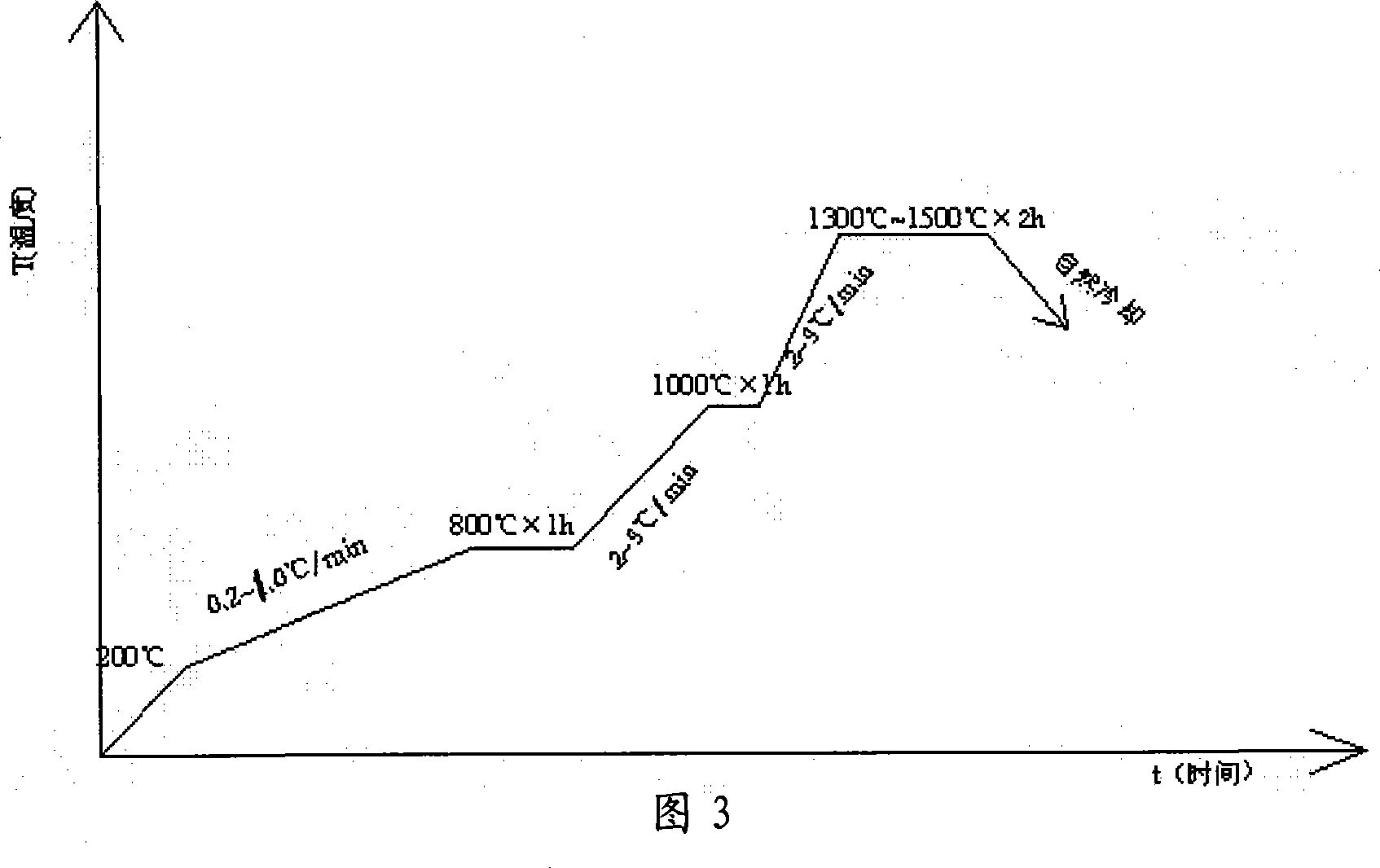

Manufacturing method of plate type oxygen sensor chip

This invention relates to one process method to control cargo motor hollow burst plane oxygen sensor chip, which comprises the following steps: processing flow paste on zircite ceramics powder mixed with yttrium and processing bright and complete film through flow and then cutting into relative sensor slices, heating slice and middle slices by non-contact cut machine; printing electrode inside sensor slice and heating resistance on heating slices; then using overlap heating type to integrate three slices into plane sensor load to remove organism under temperature of 1300 to 1500 degrees.

Owner:ZHENJIANG NERNST AUTOMOTIVE TECH

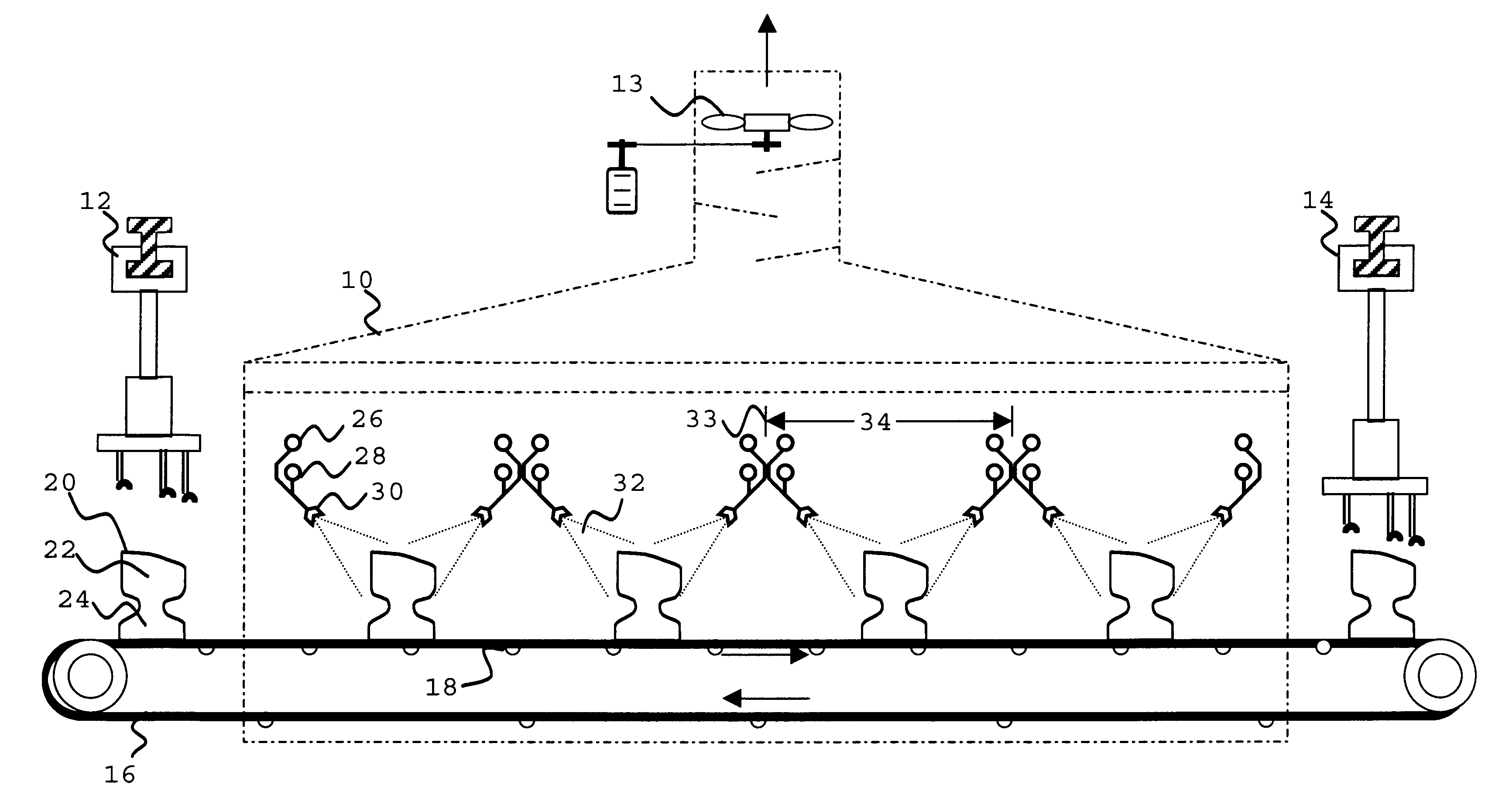

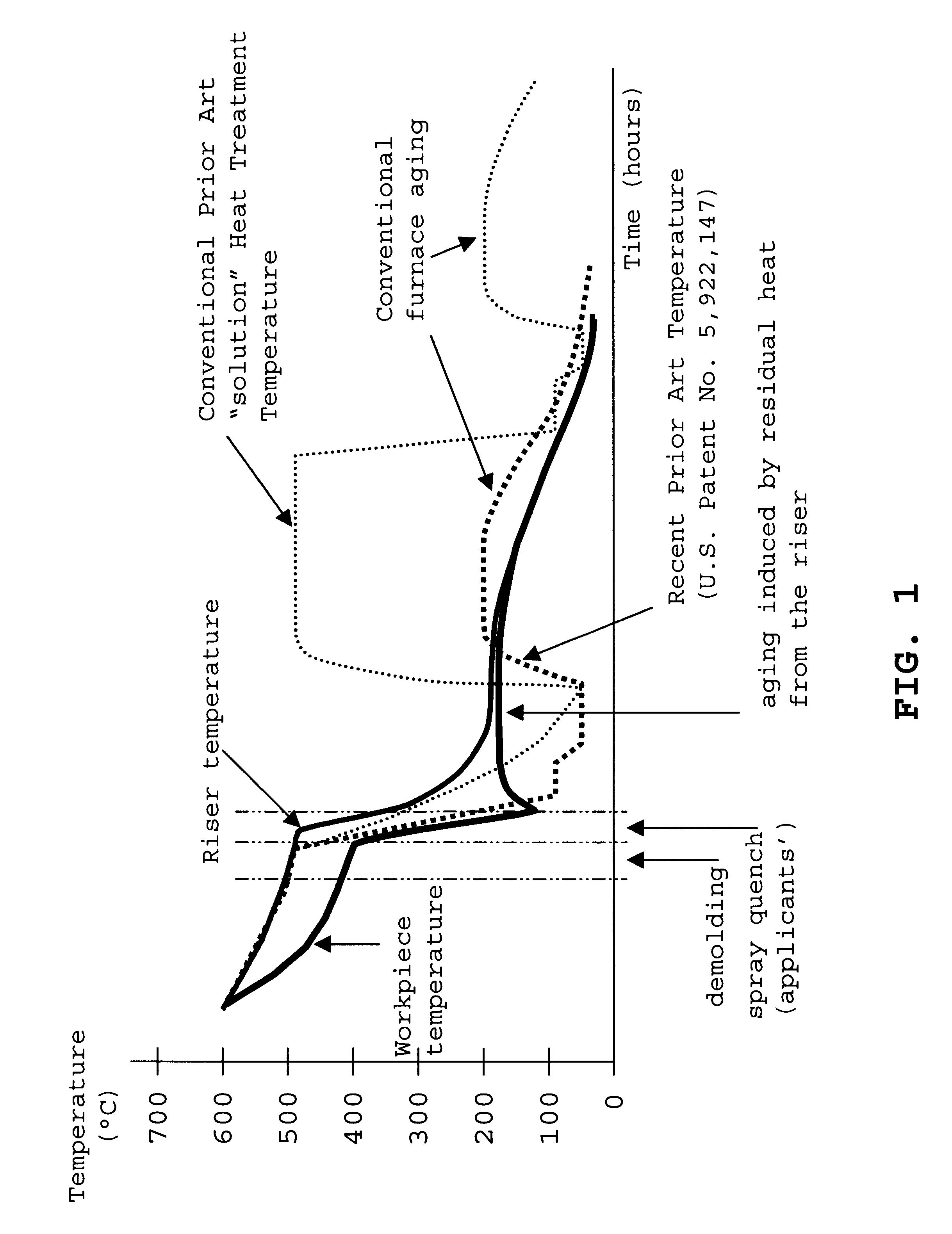

Method and apparatus for simplified production of heat treatable aluminum alloy castings with artificial self-aging

InactiveUS6224693B1Simplifying even further the overall heat-treatmentProducing the casting in a considerably shorter timeCylinder headFree cooling

Simplified heat-treatment in making aluminum alloys castings of the type improved by aging, especially for automotive engine cylinder heads and motor blocks. The castings, after solidification and extraction from their molds, each have an end product (workpiece) portion and a riser portion (the latter being ultimately cut off as waste). The workpiece portion of the casting is selectively quenched from solution temperatures down to about 120° C. by spraying water or other appropriate liquid preferably as a gas driven mist onto the surfaces of the workpiece while maintaining the riser portion of the casting essentially unsprayed at relatively significantly higher temperatures. After the quench, the residual reservoir of heat thus retained by said riser portion, by internal heat conduction, reheats the workpiece portion and maintains such workpiece portion for an effective time period within the temperature range for artificial aging, thus obviating any need for the aging furnace used by the prior art. Preferably, the quench is immediately after the casting mold extraction (without the standard natural cooling, reheating, and solution heat-treatment, all prior to quenching), thus obviating also the need for a solution heat-treatment furnace, required by the conventional prior art.

Owner:TENEDORA NEMAK SA DE CV

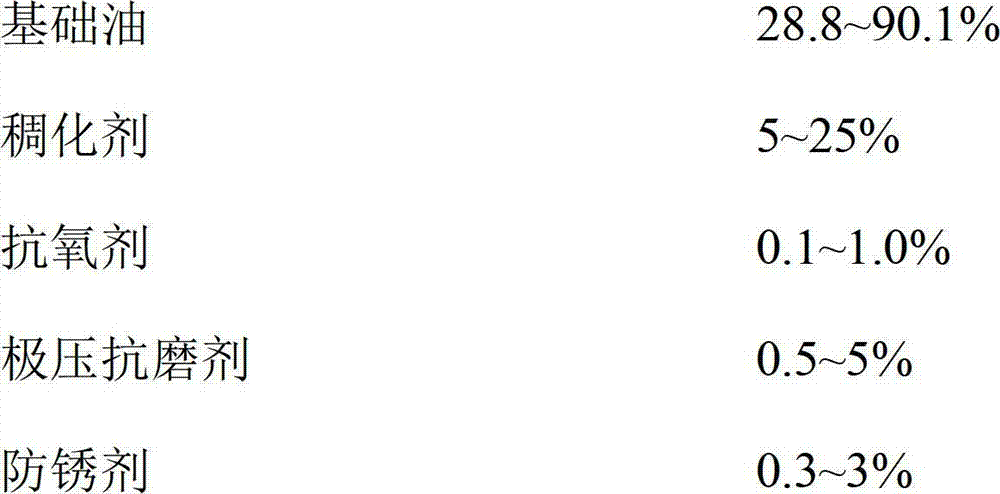

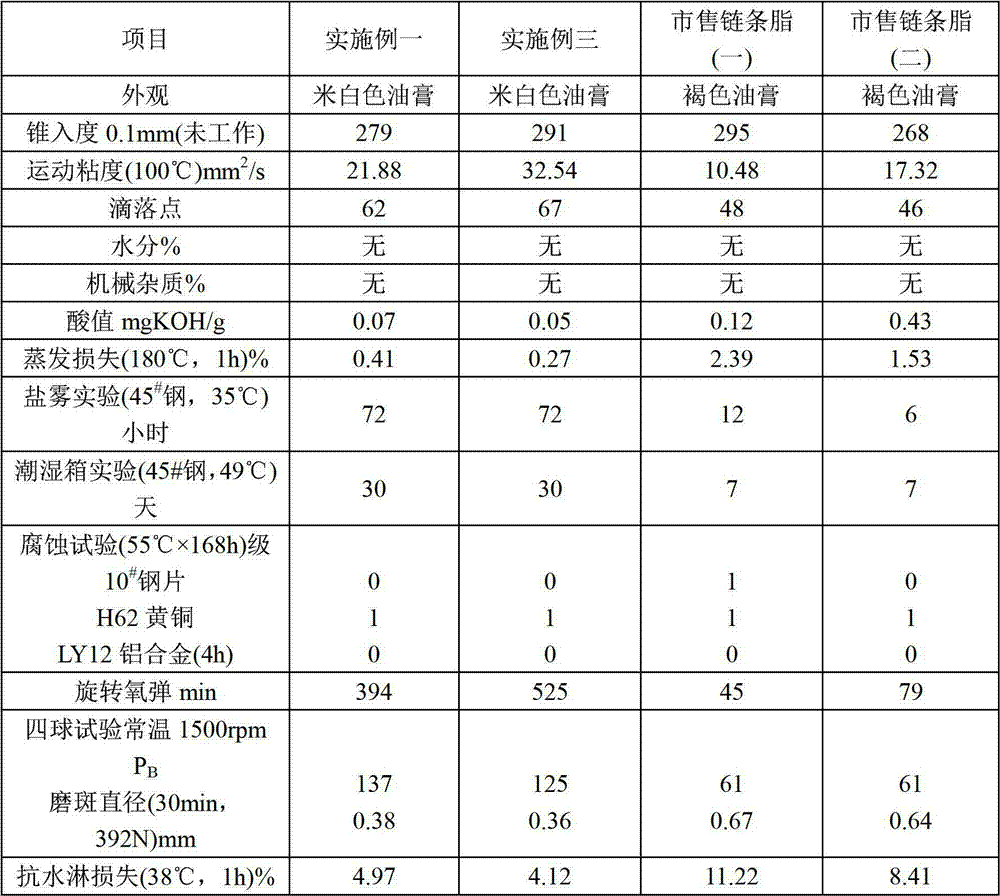

High-speed chain lubricating grease and preparation method thereof

ActiveCN102965178AExcellent anti-wear extreme pressure agentGood high and low temperature performanceLubricant compositionAntioxidantBase oil

The invention provides a high-speed chain lubricating grease, comprising the following components by weight: 28.8-90.1% of base oil, 5-25% of thickening agent, 0.1-1.0% of antioxidant, 0.5-5% of anti-wear reagent at extreme pressure, 0.3-3% of an anti-rust agent, 0.02-0.2% of a metal passivating agent, 2-20% of a solid lubricant and 2-20% of a tackifier. The invention also provides a preparation method of the high-speed chain lubricating grease. The high-speed chain grease provided by the invention is suitable for high-speed motorcycle chain, automobile engine chain and industrial chain. The high-speed chain lubricating grease provided by the invention adopts compound of the anti-wear reagent at extreme pressure and the solid lubricant, has excellent rust resistance, high temperature resistance, antifriction performance, water resistance, antiwear performance at extreme pressure and long-term anti-wear effect maintenance, and can be used in chains of extremely harsh speed racing car (motorcycle and automobile engine); and the chain has elongation less than 2 mm, and service life reaching up to 10000 kilometers.

Owner:武汉博达特种润滑技术有限公司

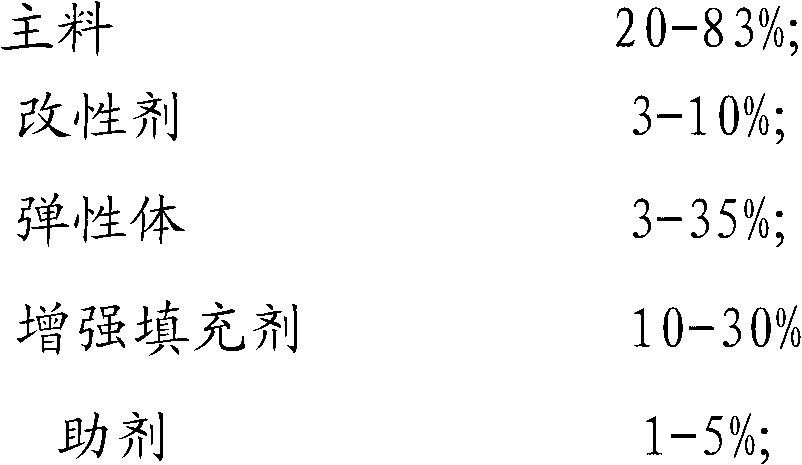

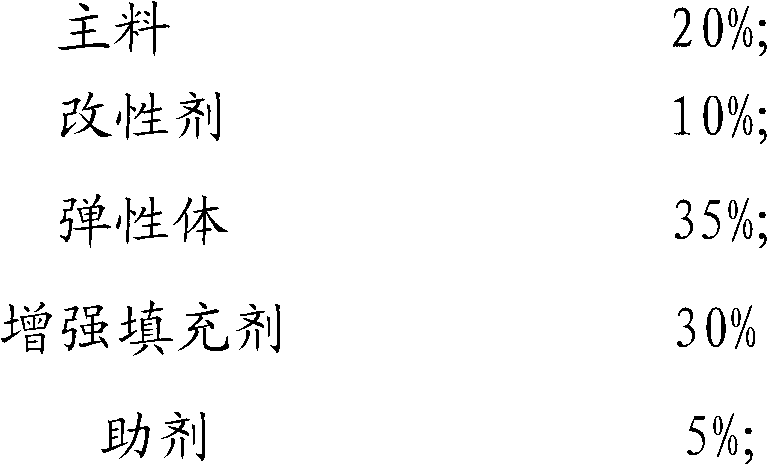

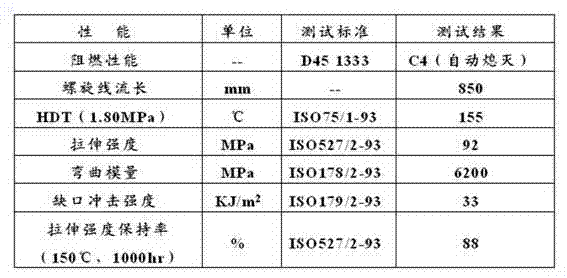

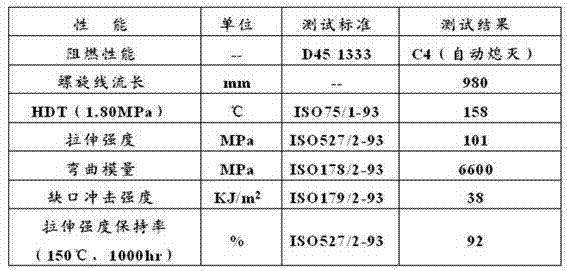

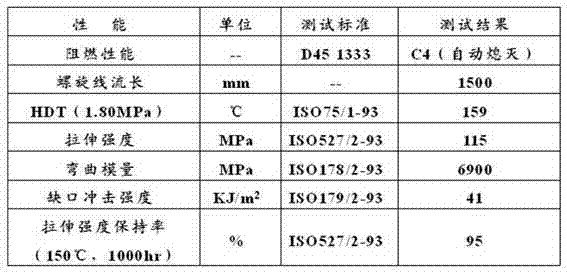

Composite material special for blow molding of reinforced nylon air inlet pipe and preparation method thereof

The invention provides a composite material special for blow molding of a reinforced nylon air inlet pipe. The composite material comprises the following components in percentage by mass: 20-83 percent of main material, 3-10 percent of modifier, 3-35 percent of elastomer, 10-30 percent of enhancing filler and 1-5 percent of auxiliary agent. The composite material special for blow molding of the reinforced nylon air inlet pipe can be used in blow molded products of air inlet pipelines, oil paths or cooling system pipelines at the peripheries of automobile engines. The composite material contains the reinforcing filler; the strength and the high temperature resistance performance of the composite material are improved; and the composite material is rich and cheap in raw materials and is suitable for promotion and application.

Owner:辰东意普万新材料(广东)有限公司

Halogen-free flame-retardant long glass fiber reinforced polypropylene material and preparation method thereof

The invention relates to a halogen-free flame-retardant long glass fiber reinforced polypropylene material, which comprises the following raw materials in percentage by weight: 49 to 88.8 percent of polypropylene, 0.1 to 0.5 percent of thermal stabilizer, 0.1 to 0.5 percent of lubricating agent, 5 to 20 percent of halogen-free flame retardant, 1 to 5 percent of glass fiber compatilizer and 5 to 25 percent of long glass fiber, wherein the polypropylene is high fluidity polypropylene. The invention also relates to a preparation method for the polypropylene material. The preparation method comprises the following steps of: preparing a long glass fiber master batch and a halogen-free flame-retardant master batch, mixing the two master batches uniformly, and thus obtaining the polypropylene material, wherein when the polypropylene material is used, the polypropylene material is directly used for injection molding of parts. The polypropylene material has excellent flame-retardant property and dimensional stability, high mechanical strength, low shrinkage rate and good creep resistance and thermal oxidation resistance, is suitable for injection molding of thin-wall large pieces and automotive part products with complex structures such as automotive engine bottom guard plates, front-end modules, instrument panel frameworks and the like, saves the automobile manufacturing cost, and is environment-friendly.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

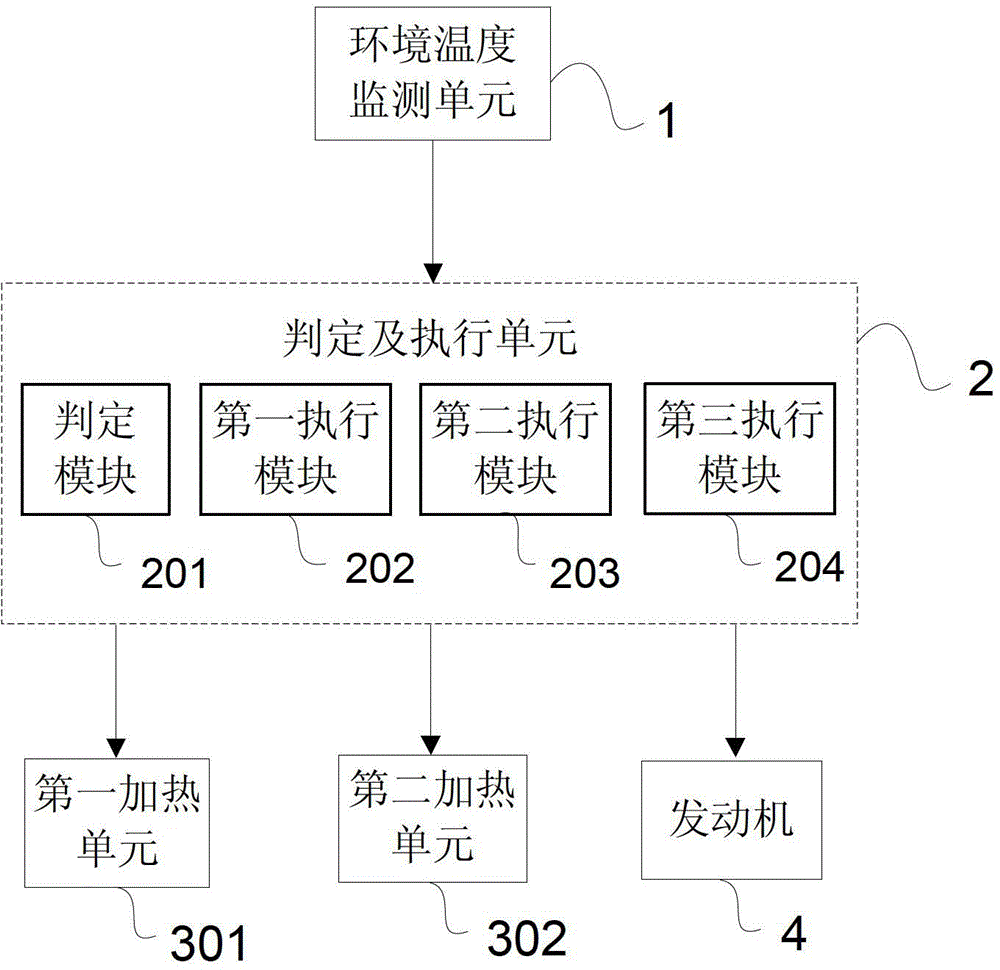

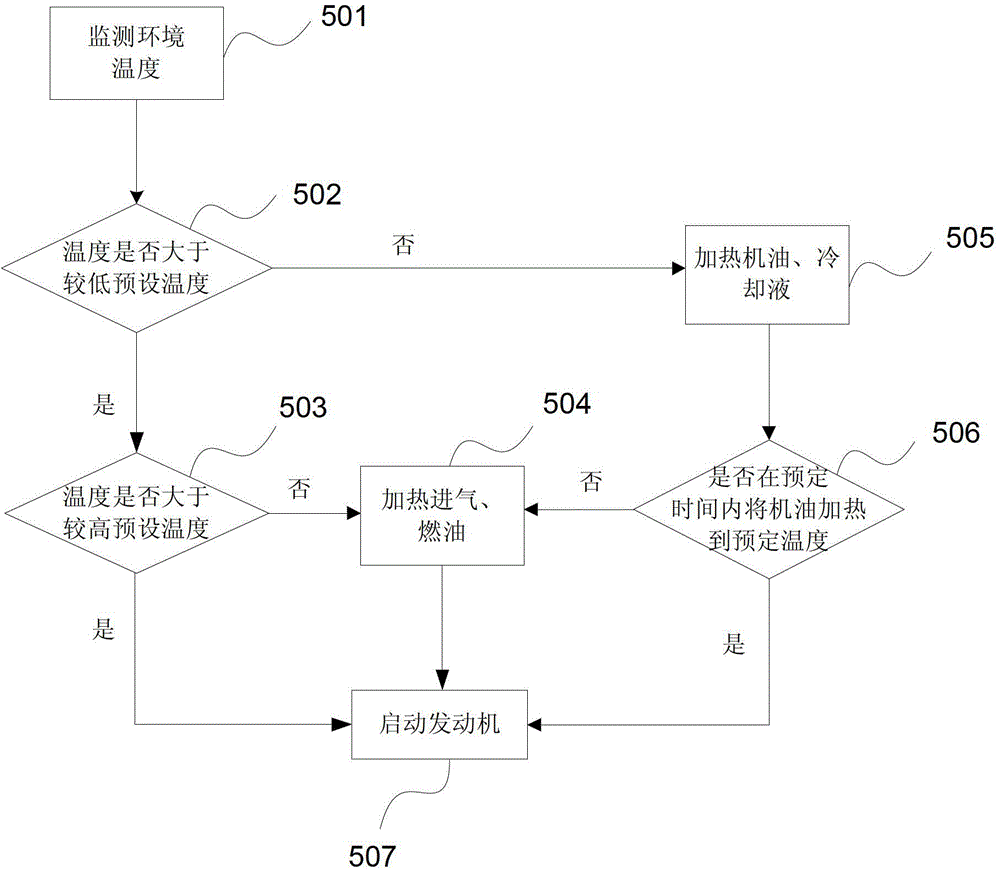

Preheating method and preheating system for cold start of engine

ActiveCN103147897AFast heatingHigh heating efficiency and safetyMachines/enginesEngine startersWorking environmentAutomotive engine

The invention discloses a preheating method and a preheating system for the cold start of an engine. The preheating method includes the steps of monitoring the external work environment temperature of an automobile engine in real time, and comparing the external work environment temperature with a lower preset temperature value and a higher preset temperature value; if the external work environment temperature is larger than the higher preset temperature value, starting the engine directly; if the external work environment temperature is smaller than or equal to the higher preset temperature value and larger than the lower preset temperature value, heating intake air and fuel oil of the engine for second scheduled time and then starting the engine; and if the external work environment temperature is smaller than or equal to the lower preset temperature value, heating engine oil and a coolant liquid of the engine for first scheduled time, and determining whether the engine oil temperature is larger than or equal to an engine oil expected value, if yes, starting the engine, or otherwise, heating the intake air and the fuel oil of the engine for the second scheduled time and then starting the engine. The preheating system is simple in structure and high in heating efficiency.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

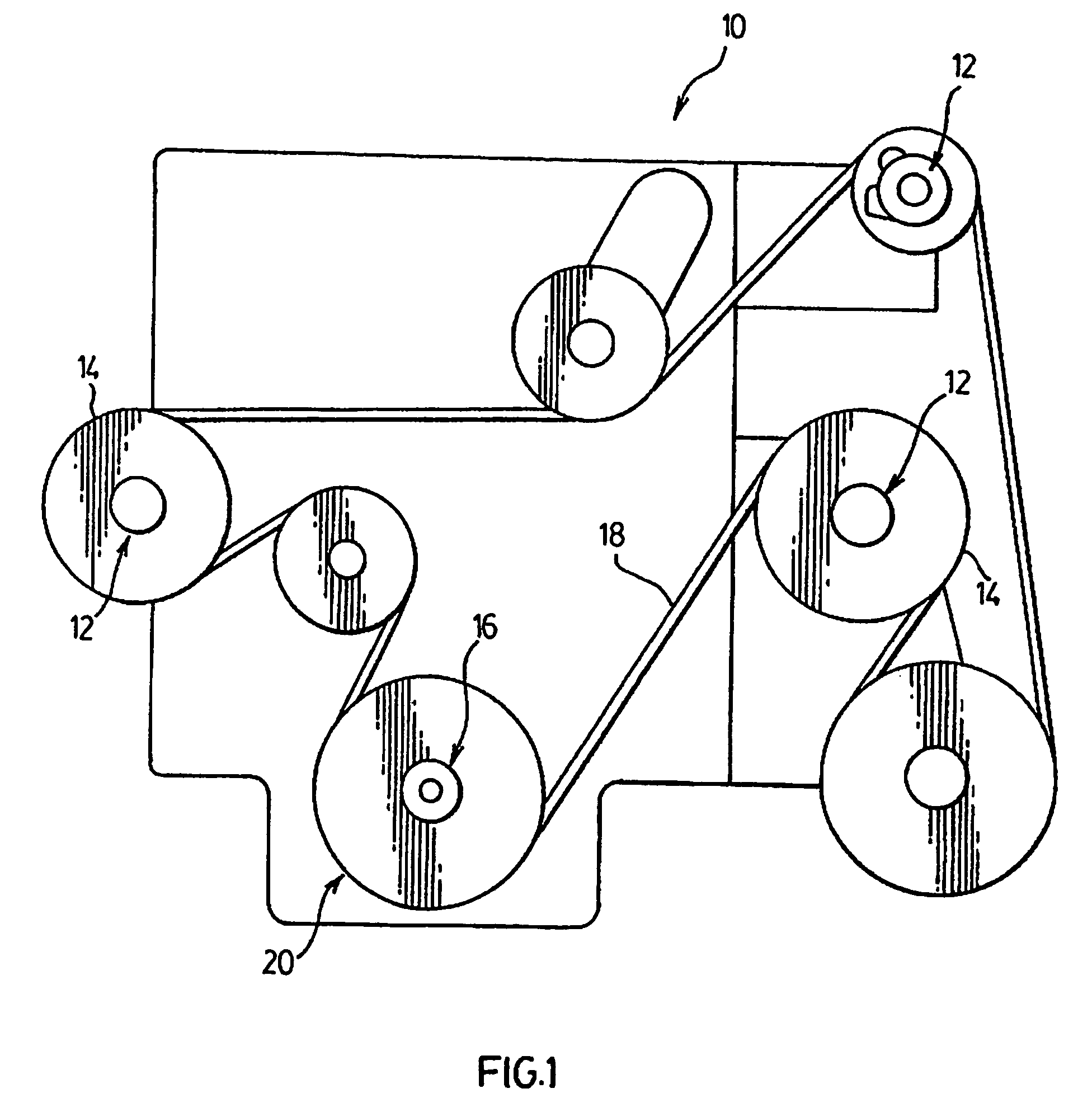

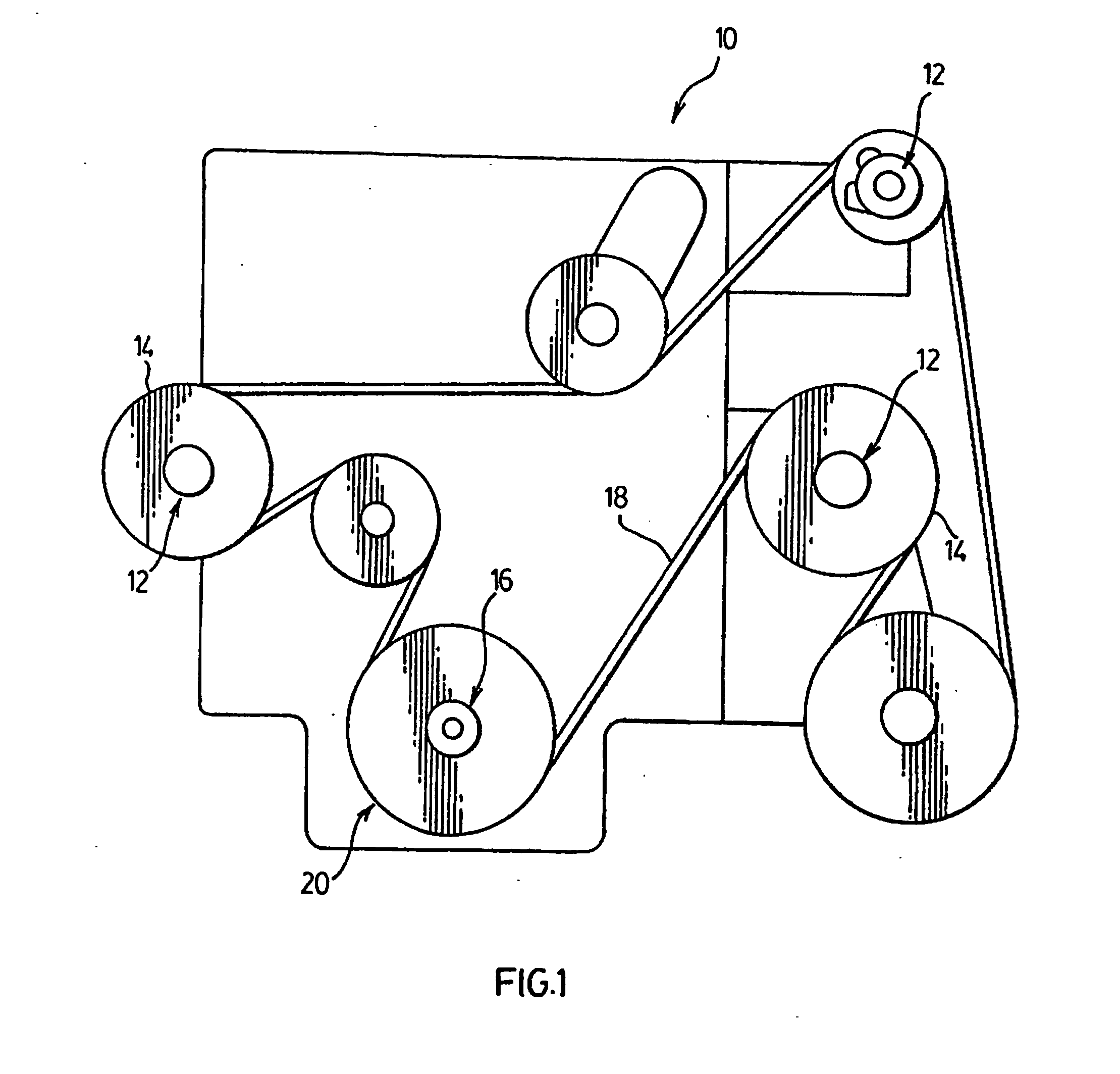

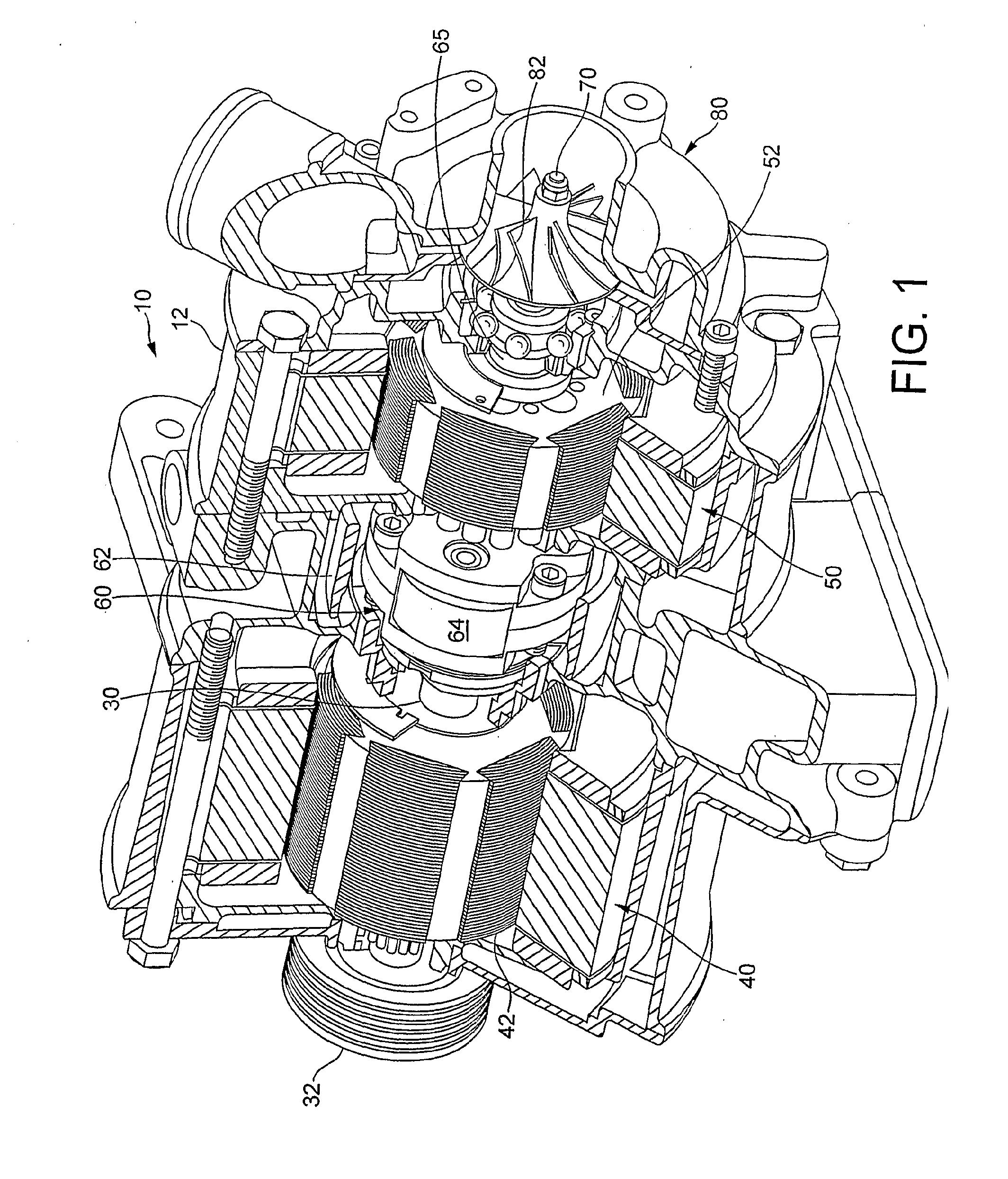

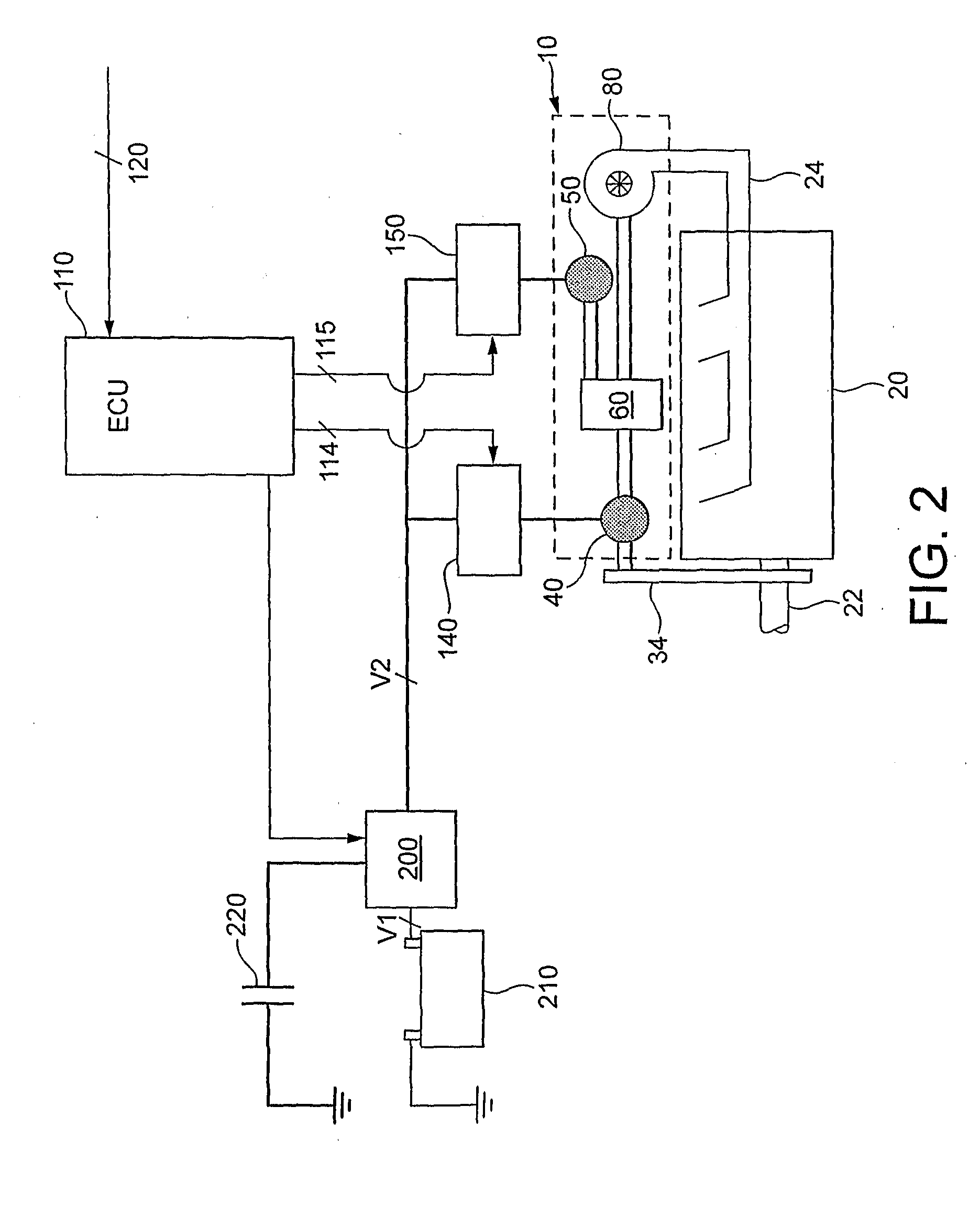

Method of operating a supercharger

ActiveUS20100275890A1Constant speedReduce cycle variationCombustion enginesPlural diverse prime-mover propulsion mountingCrankshaftElectric generator

A method of operating a supercharger (10) for an automotive engine (20) is disclosed. A supercharger (10) has an input shaft (30) for coupling to a crank shaft (22) of the engine and also for coupling to the rotor of a first electrical machine (40) and the annulus of an epicyclic gear train (60). An output shaft (70) is connected to a compressor (80) and a sun gear of the epicyclic gear train (60). A carrier carrying planet gears of the epicyclic gear train (60) is connected to the rotor of a second electrical machine (50). The first electrical machine (40) is selectively operable to supply electrical energy to the second electrical machine (50). The second electrical machine (50) is selectively operable as a motor or a generator to accelerate or decelerate the compressor (80), thereby tending to increase or decrease the power output of the engine. The first electrical machine (40) is selectively operable as a motor or a generator to control the torque transmitted from the input shaft (30) back to the crank shaft (22) caused by operation of the second electrical machine (50).

Owner:NEXXTDRIVE LTD +1

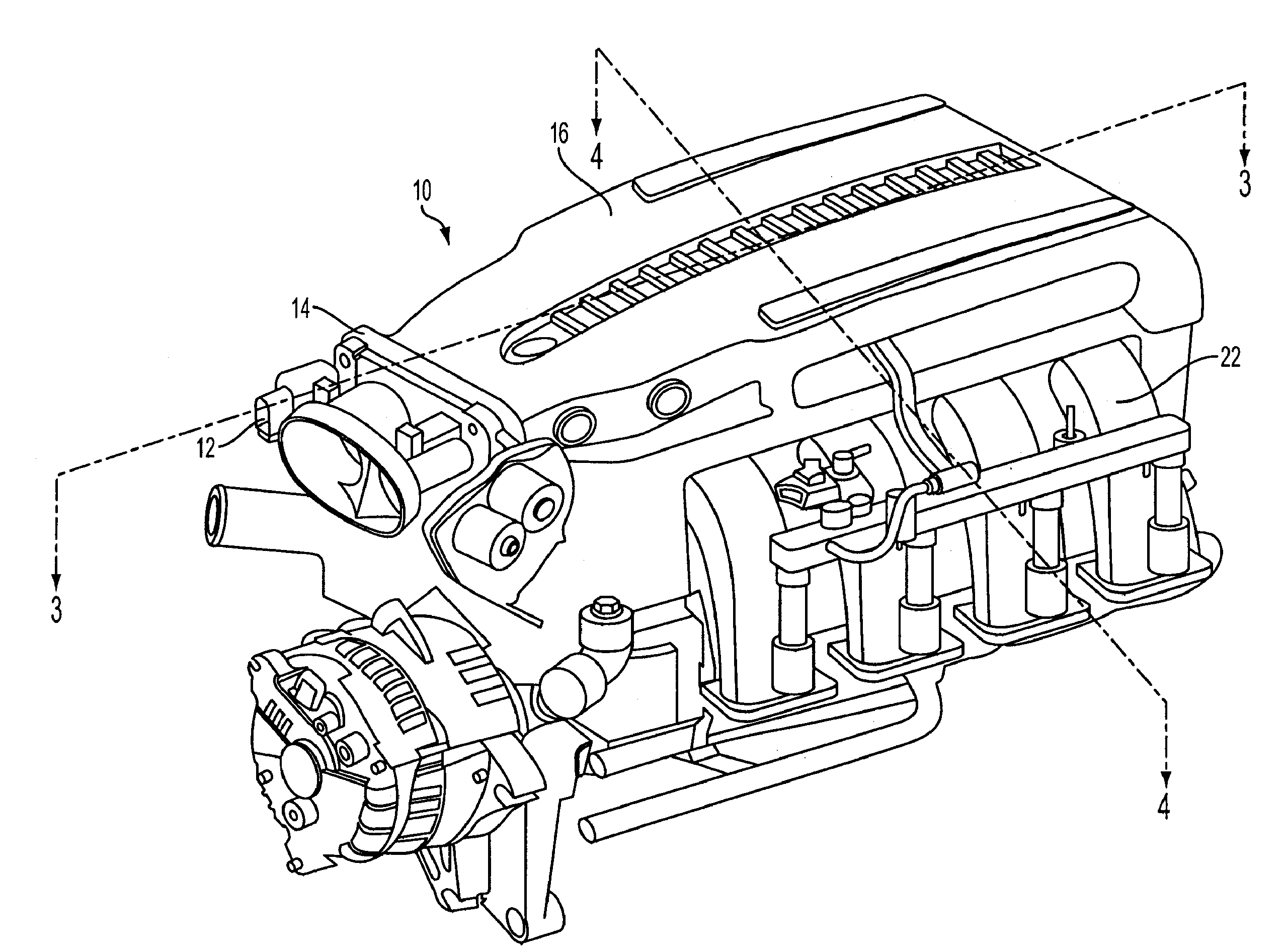

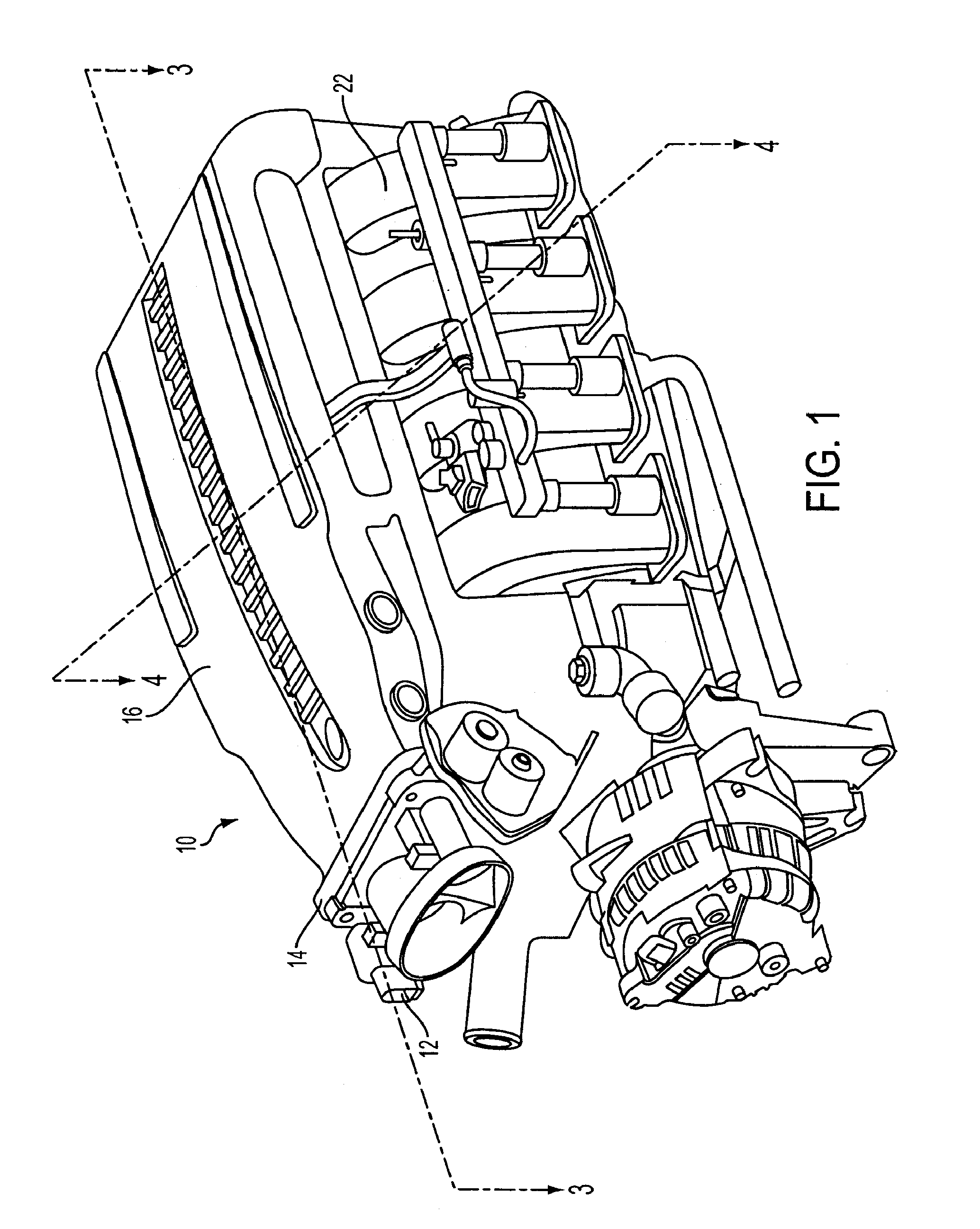

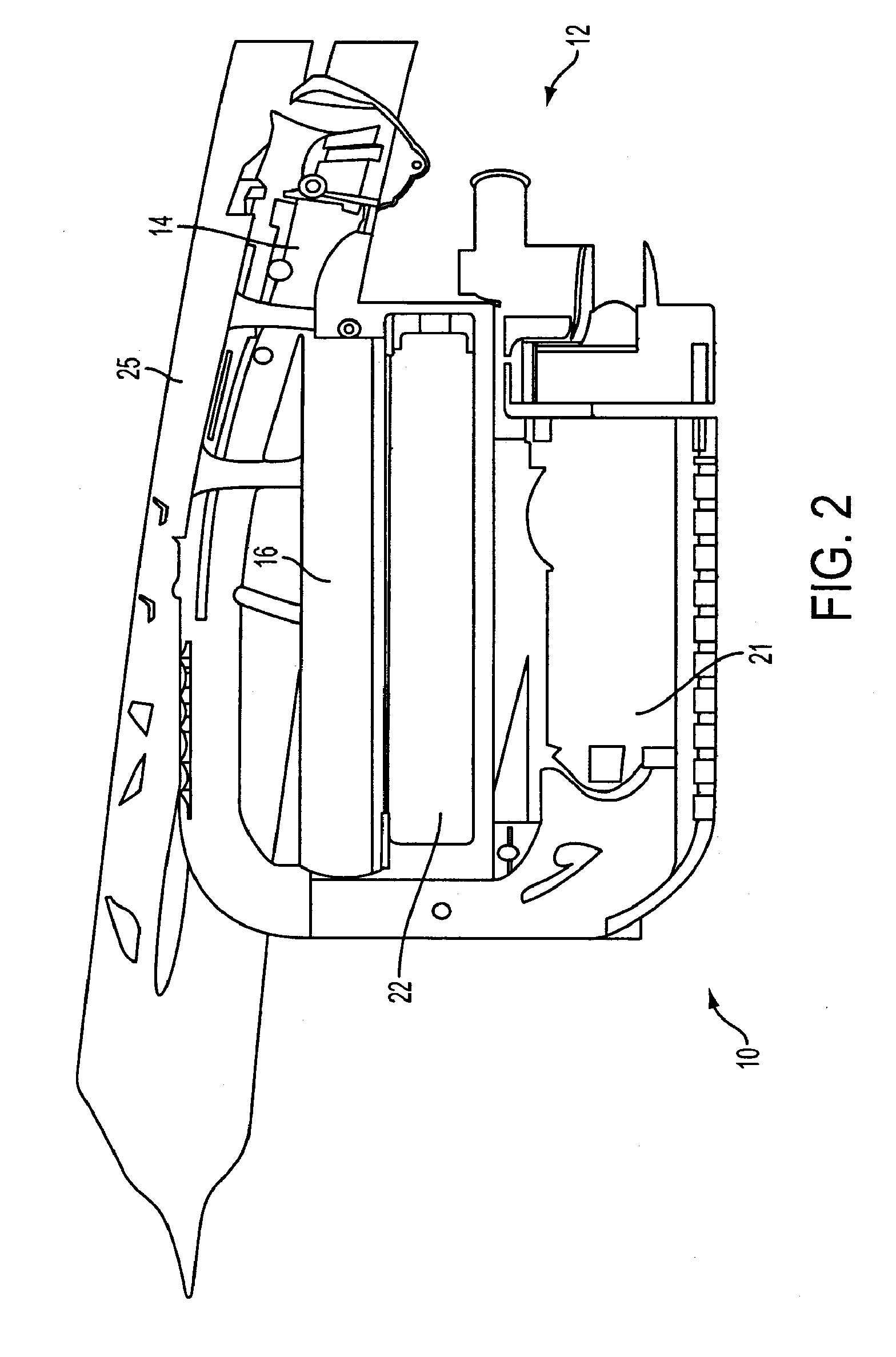

Apparatus and method for boosting engine performance

InactiveUS20070175456A1Internal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringIntercooler

A supercharger (10) is positioned in the valley of an automobile engine (60) so that it fits under the engine hood (25). The supercharger (10) has a low profile air inlet (14) at the top that passes air to an inlet tube (16). The height of the inlet tube (16) decreases and its width expands as the inlet tube (16) extends away from the air inlet (14) to keep a low profile while minimizing restrictions to airflow. The inlet tube (16) supplies air to a compressor (18) at the bottom. The pressurized air flows through a large and thin intercooler (24) directly above the compressor (18). The cooled air is fed to long and straight intake manifold runners (28) positioned above the engine heads (61, 62) of the engine (60). The supercharger (10) provides a large volume of low pressure and low temperature air charge to the engine (60).

Owner:MJ ACQUISITIONS

Crankshaft decoupler

A decoupler assembly (20) is provided for transferring rotational torque between a drive shaft (16) and a drive belt (18) of an automotive engine. The decoupler assembly includes a drive hub (40) configured to be fixedly secured to the drive shaft. A pulley (22) is rotatably coupled to the drive hub (40) and adapted to be drivingly engaged with the belt (18). A spring shell (70, 100) is operatively coupled between the drive hub and the pulley for selective rotation therewith and a biasing member (130) is operatively coupled between the spring shell and the drive hub for isolating oscillatory vibrations between the drive hub and the pulley caused by rotation of the drive shaft. A clutch element (140) is seated between the spring shell (70, 100) and the pulley (22) for selectively transferring rotational torque from the drive hub to the pulley. The pulley (22) includes an inner clutch surface (26) and the clutch element includes a plurality of coils in frictional engagement with the inner clutch surface and an end coupled to the spring shell for expanding the coils against the inner clutch surface upon rotation of the spring shell with the drive hub to selectively transfer torque between the drive hub (40) and the pulley (22).

Owner:LITENS AUTOMOTIVE INC

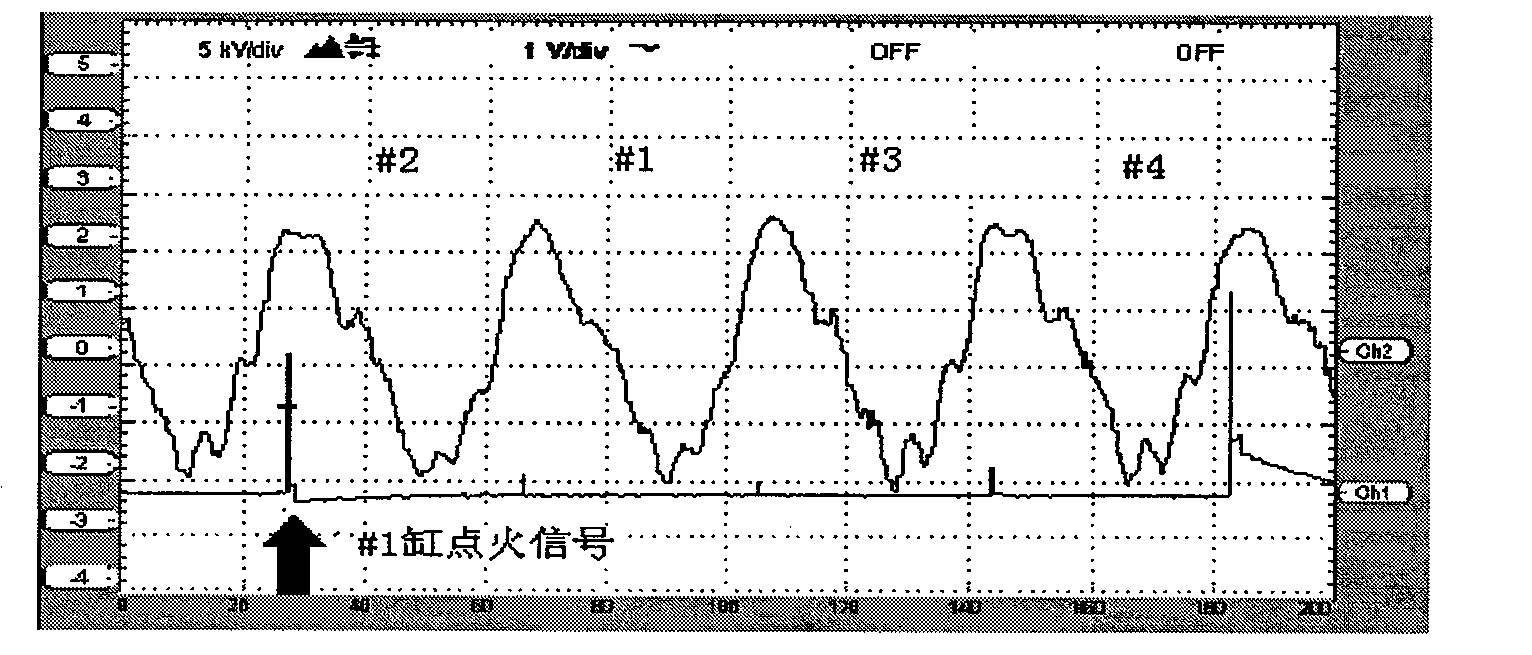

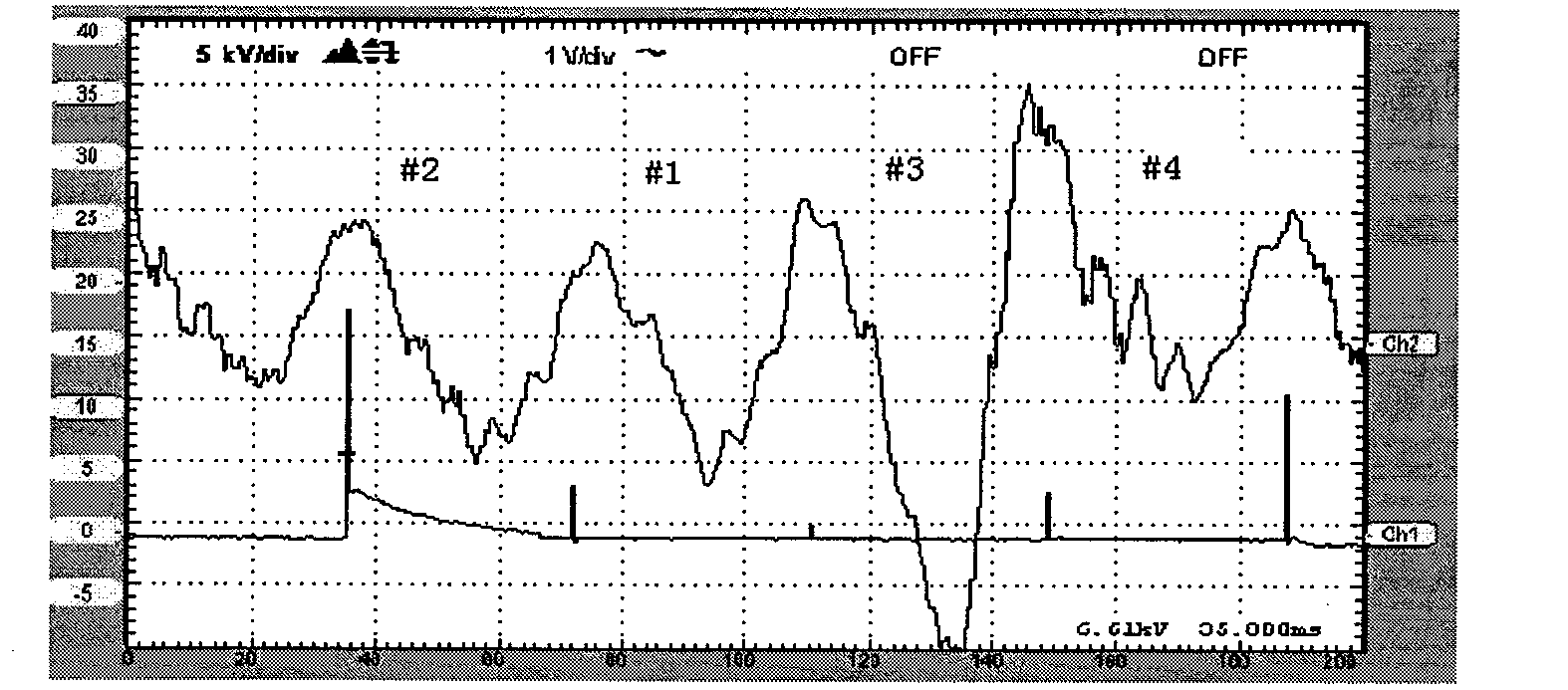

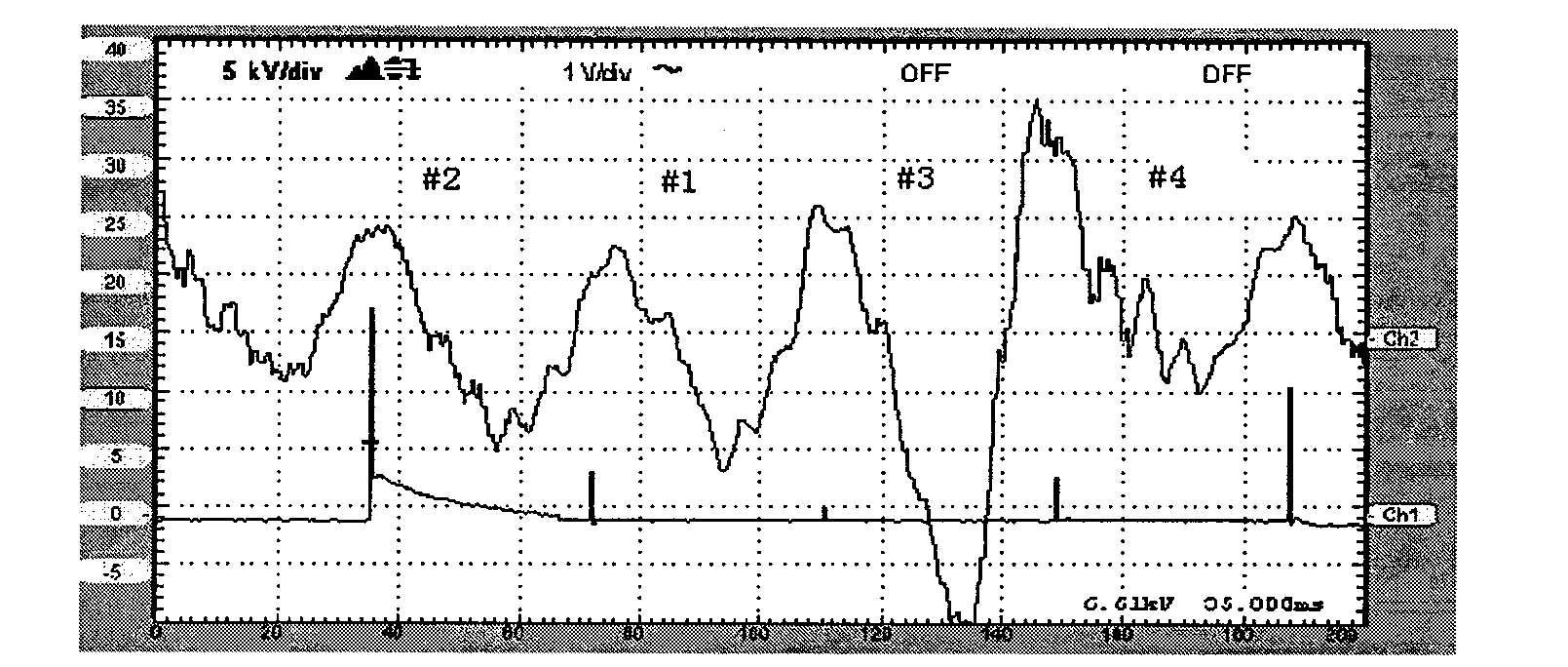

Method and system for on-line monitoring car engine state

The invention relates to an automobile engine state on-line monitoring method and a system thereof. Through analyzing the form and transmission of exhaust fluctuation in an exhaust system of an engine, an exhaust fluctuation signal is researched, such as the relation between an exhaust pressure fluctuation signal and engine operation; on the basis of recording and analyzing the fluctuation of the exhaust system, the automobile engine state on-line monitoring method and the system thereof which can accurately realize the on-line monitoring of the automobile engine are obtained by adopting a few detection projects. The system can acquire general engine working conditions by less detection amount, detect and diagnose the fault of the automobile engine, thereby realizing the on-line monitoring of the automobile engine. The intelligent fluctuation detection system can be used as a powerful tool for the optimal control of the engine and has long-term application prospect in terms of the fault diagnosis of an internal-combustion engine and the optimal control and the noise control of the automobile engine.

Owner:GUILIN UNIV OF ELECTRONIC TECH

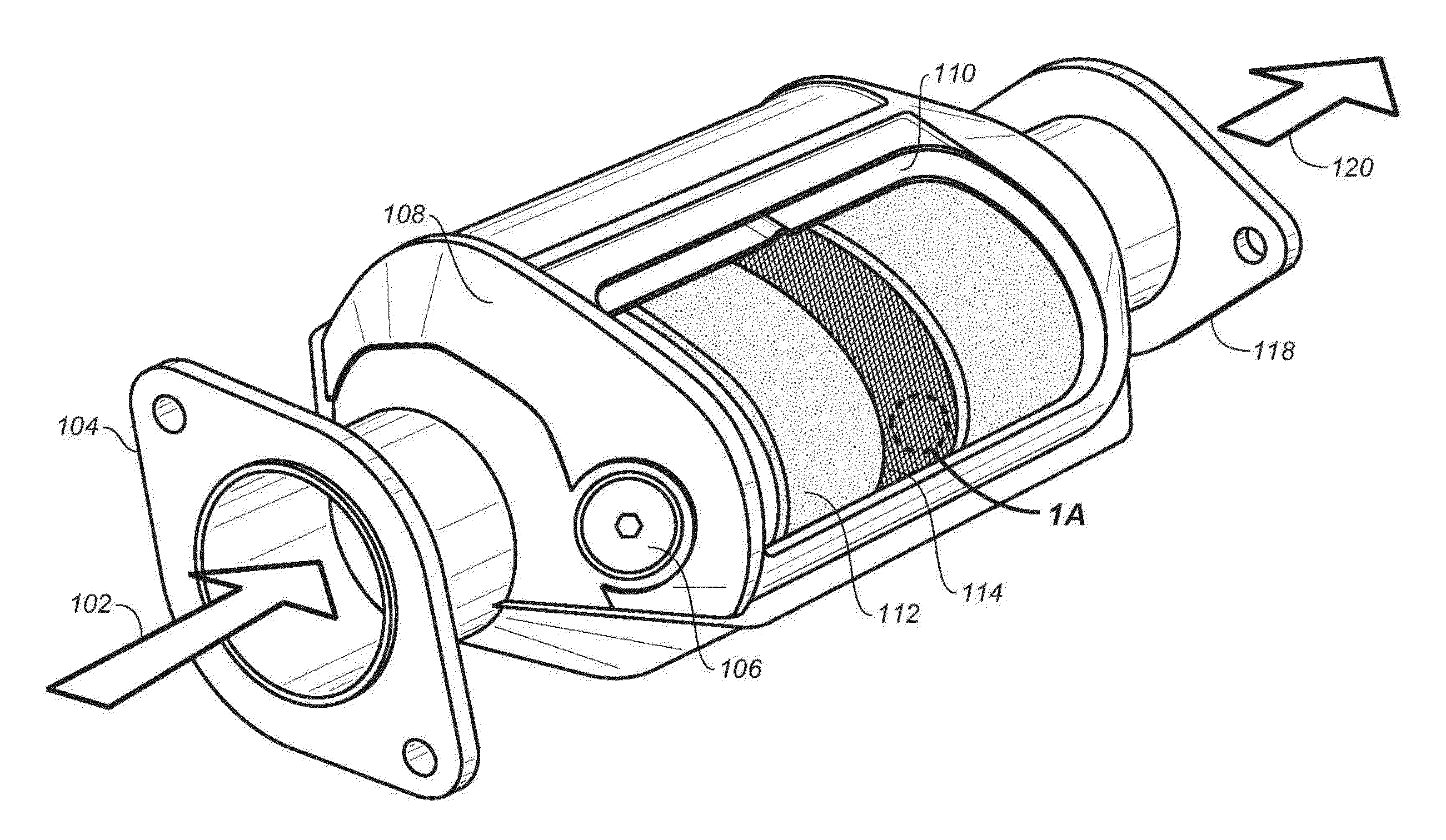

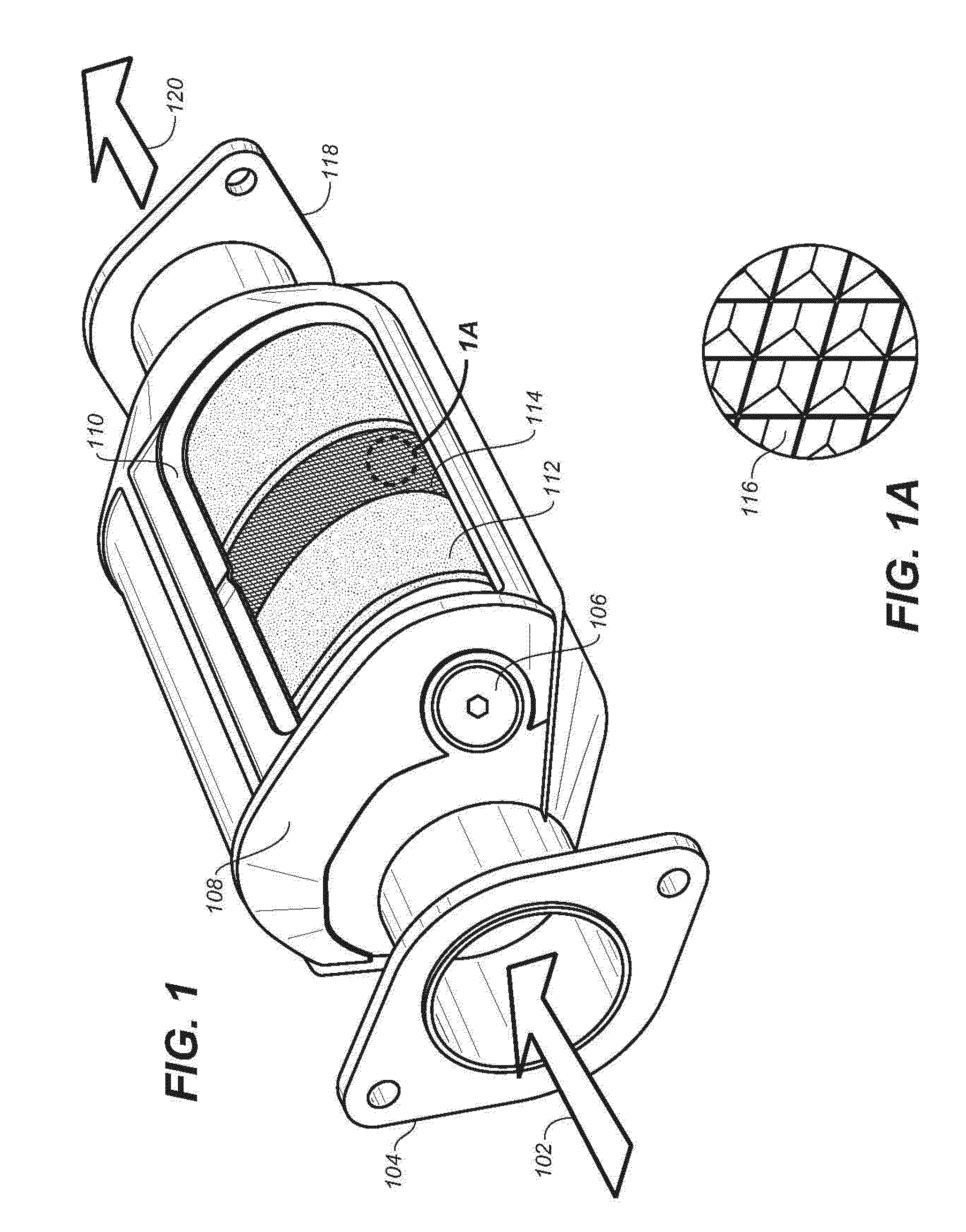

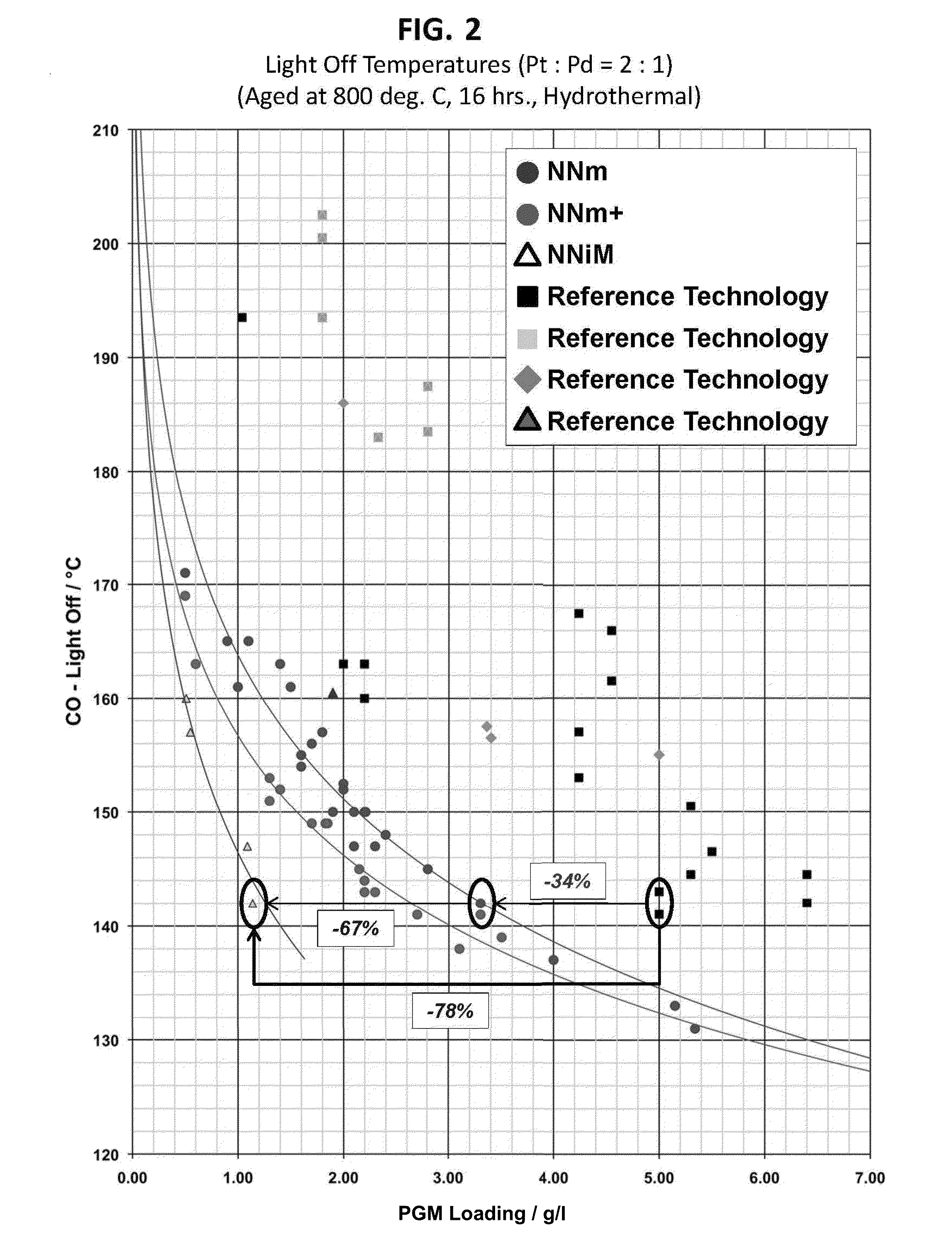

High surface area catalyst

InactiveUS20150140317A1High catalytic efficiencyReduce impactMolecular sieve catalystsLayered productsPorosityNanoparticle

The present invention relates to the field of catalysts, and more specifically to nanoparticle catalysts. Materials with high porosity which contain nanoparticles can be created by various methods, such as sol-gel synthesis. The invention provides catalytic materials with very high catalytically active surface area, and methods of making and using the same. Applications include, but are not limited to, catalytic converters for treatment of automotive engine exhaust.

Owner:SDC MATERIALS

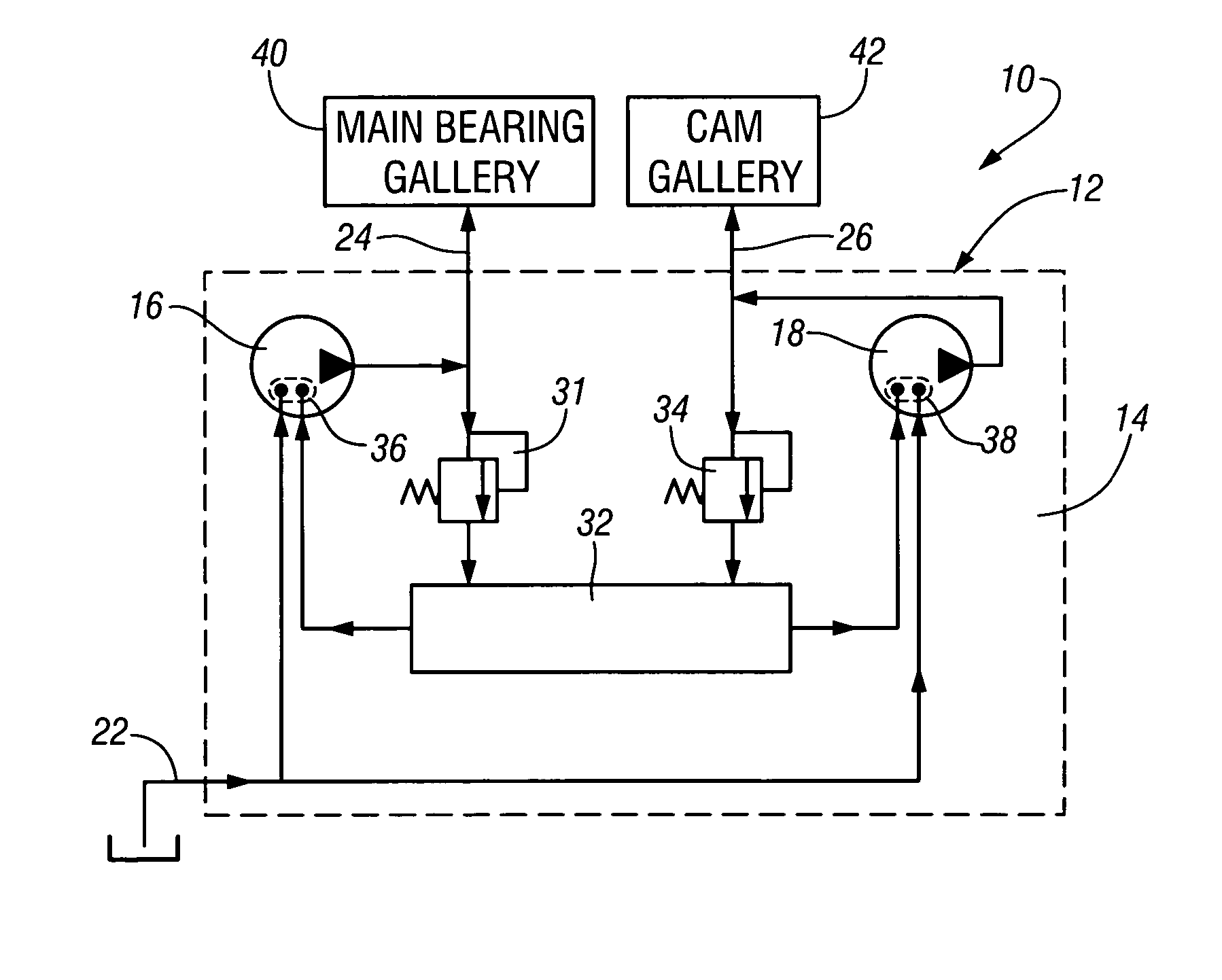

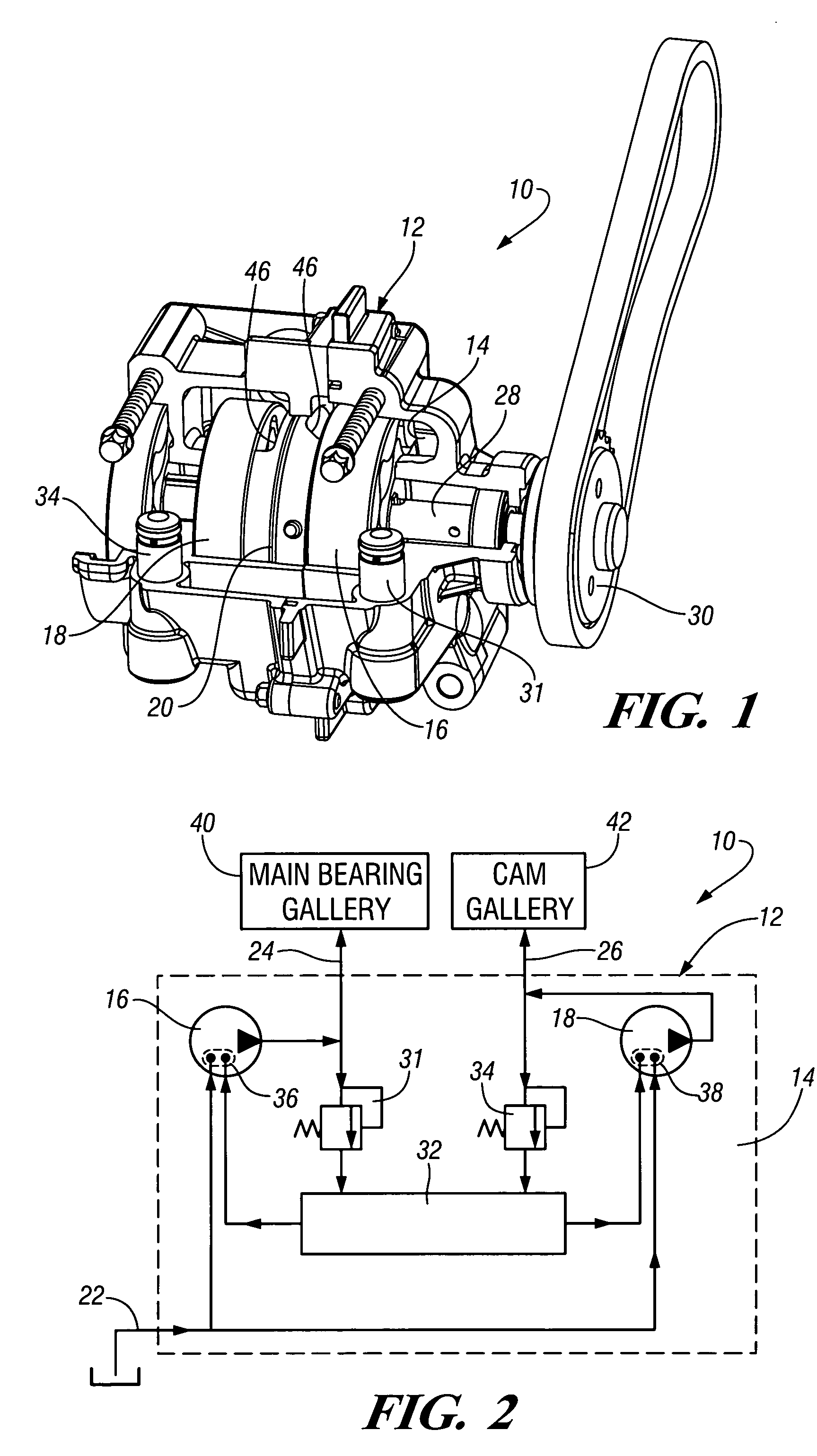

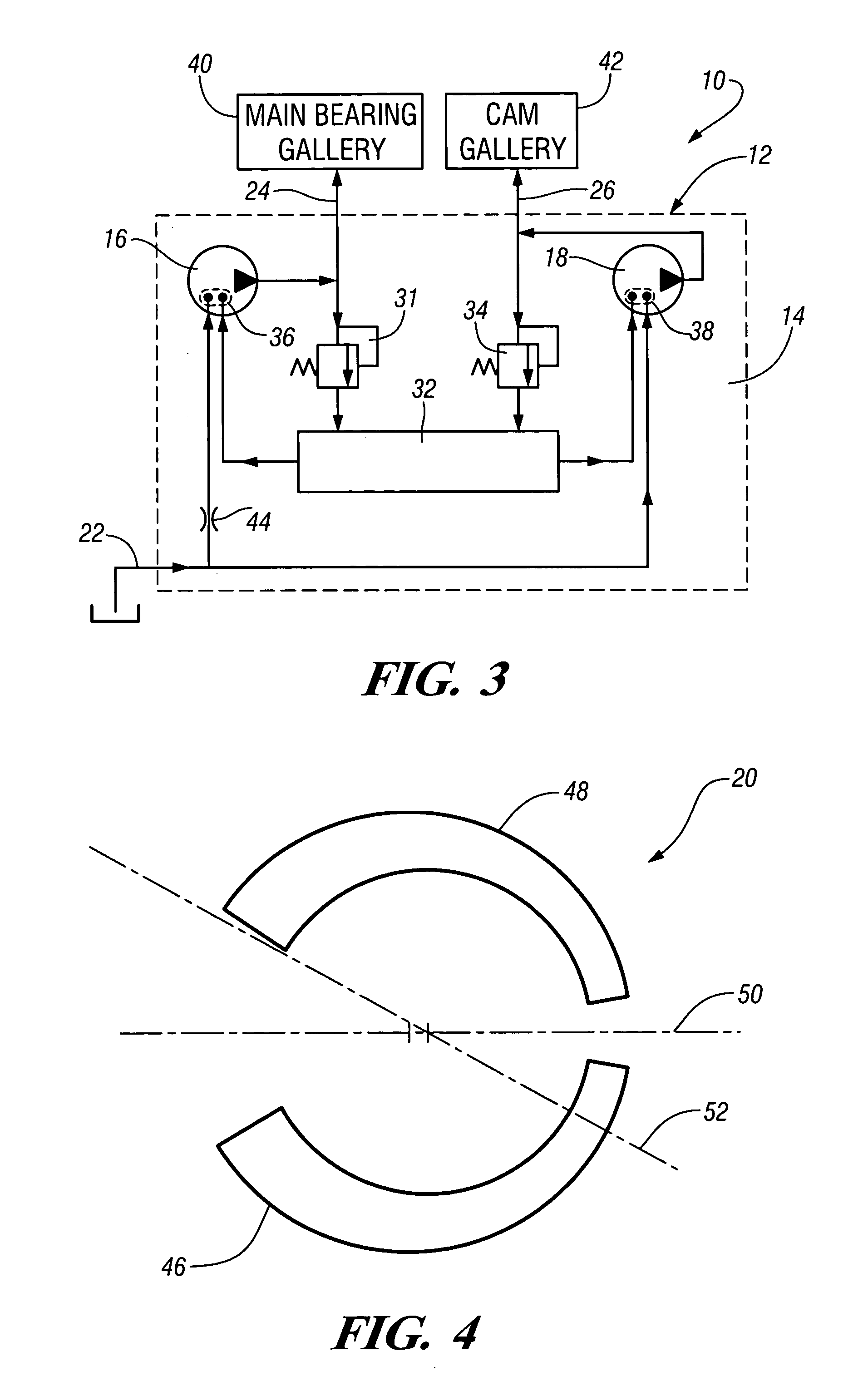

Dual oil supply pump

InactiveUS20050180870A1Maximizing packing efficiencyReduces flow pulsationPositive displacement pump componentsRotary piston pumpsCavitationEngineering

An automotive engine oil pump assembly having first and second pump mechanisms contained within a common housing. A shaft rotatably supported in the housing drives the pump mechanisms in a conventional manner. The pump mechanisms are offset in phase to reduce flow pulsations through the housing and limit pump noise and vibration. The first pump mechanism communicates with a common inlet and first outlet of the housing. The second pump mechanism communicates with the common inlet and second outlet of the housing. A common reservoir connected to inlets of the first and second oil pump mechanisms provides a supplemental oil source to balance oil pressures at the pump inlets to prevent pump cavitation and further reduce pump noise and vibration.

Owner:GM GLOBAL TECH OPERATIONS LLC

Car engine using mixture of comprssed air and fuel oil or fuel gas

InactiveCN1382901AEasy accessPlay the role of air intake boostInternal combustion piston enginesFuel oilInternal combustion engine

A car engine using compressed air and fuel oil / gas as power source has more cylinders, Part of then uses compressed air as power source and other are IC engien unit whose exhausted gas is used to heat the input air of said non-IC unit via heat exchanger. The exhausted gas of said non-IC unit is used as the input gas of IC engine unit for boosting the input gas. Its advantages are reasonable structure, high efficiency and low environmental pollution.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com