Halogen-free flame-retardant long glass fiber reinforced polypropylene material and preparation method thereof

A technology of polypropylene material and long glass fiber, which is applied in front-end modules, manufacturing automobile engine bottom guard, instrument panel frame, halogen-free flame-retardant long glass fiber reinforced polypropylene material and its preparation field, which can solve the problem of non-compliant automobile parts Modularization requirements, low degree of manufacturing integration, insufficient design freedom, etc., to achieve excellent dimensional stability, good heat and oxygen aging resistance, and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

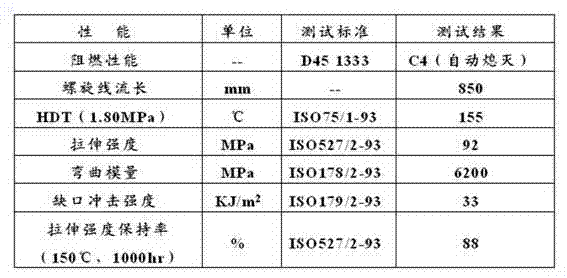

Embodiment 1

[0032] (1) Plasticize 4kg of polypropylene with a melt flow rate of 50g / 10min and 1kg of glass fiber compatibilizer through a single-screw extruder, and transport them through a die to a temperature set between 280°C and 380°C Then add 5 kg of alkali-free continuous long glass fibers into the high-temperature melt tank and melt and blend with the above-mentioned raw materials, so that the obtained materials are pulled out from the high-temperature melt tank, and then cut Pelletizing by a granulator to obtain long glass fiber masterbatches with a length of 12mm and a mass content of long glass fibers of 50%;

[0033] (2), 84.8 kg of polypropylene same as step (1), 0.1 kg of heat stabilizer Irganox 1010 (CIBA company), 0.1 kg of lubricant EBS (ie N, N-ethylene bis stearamide) from The main feeding port located at one end of the screw extruder is fed into the screw extruder for melt blending; make 5 kg of halogen-free flame retardant FP-2200 (a kind of phosphorus suitable for...

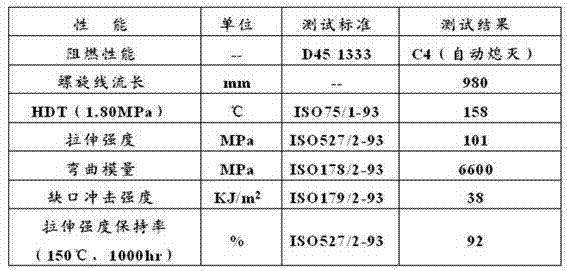

Embodiment 2

[0038] (1) Plasticize 8kg of polypropylene with a melt flow rate of 100g / 10min and 2kg of glass fiber compatibilizer through a single-screw extruder, and transport them through a die to a temperature set between 280°C and 380°C Then add 10 kg of alkali-free continuous long glass fibers into the high-temperature melt tank and melt and blend with the above-mentioned raw materials, so that the obtained material is pulled out from the high-temperature melt tank and then cut Pelletizing by a granulator to obtain long glass fiber masterbatches with a length of 12mm and a mass content of long glass fibers of 50%;

[0039] (2), 69.6 kg of polypropylene same as step (1), 0.2 kg of heat stabilizer Irganox 1010 (CIBA company), 0.2 kg of lubricant EBS (ie N, N-ethylene bis stearamide) from The main feeding port located at one end of the screw extruder is fed into the screw extruder for melt blending; make 10 kg of halogen-free flame retardant FP-2200 (a kind of phosphorus suitable for...

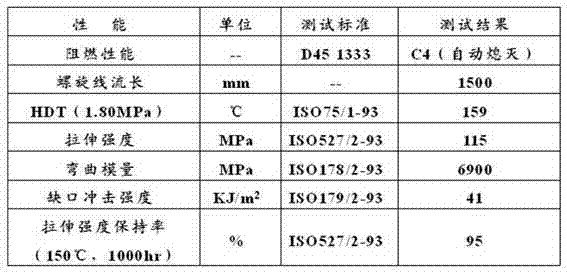

Embodiment 3

[0044] (1) Plasticize 12kg of polypropylene with a melt flow rate of 180g / 10min and 3kg of glass fiber compatibilizer through a single-screw extruder, and convey it through a die to a temperature set between 280°C and 380°C Then add 15 kg of alkali-free continuous long glass fibers into the high-temperature melt tank and melt and blend with the above-mentioned raw materials, so that the obtained materials are pulled out from the high-temperature melt tank, and then cut Pelletizing by a granulator to obtain long glass fiber masterbatches with a length of 12mm and a mass content of long glass fibers of 50%;

[0045] (2), 54.4 kg of polypropylene same as step (1), 0.3 kg of heat stabilizer Irganox 1010 (CIBA company), 0.3 kg of lubricant EBS (ie N, N-ethylene bis stearamide) from The main feed port located at one end of the screw extruder is fed into the screw extruder for melt blending; make 15 kg of halogen-free flame retardant FP-2200 (a kind of phosphorus suitable for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com