Patents

Literature

2248results about How to "Improve creep resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

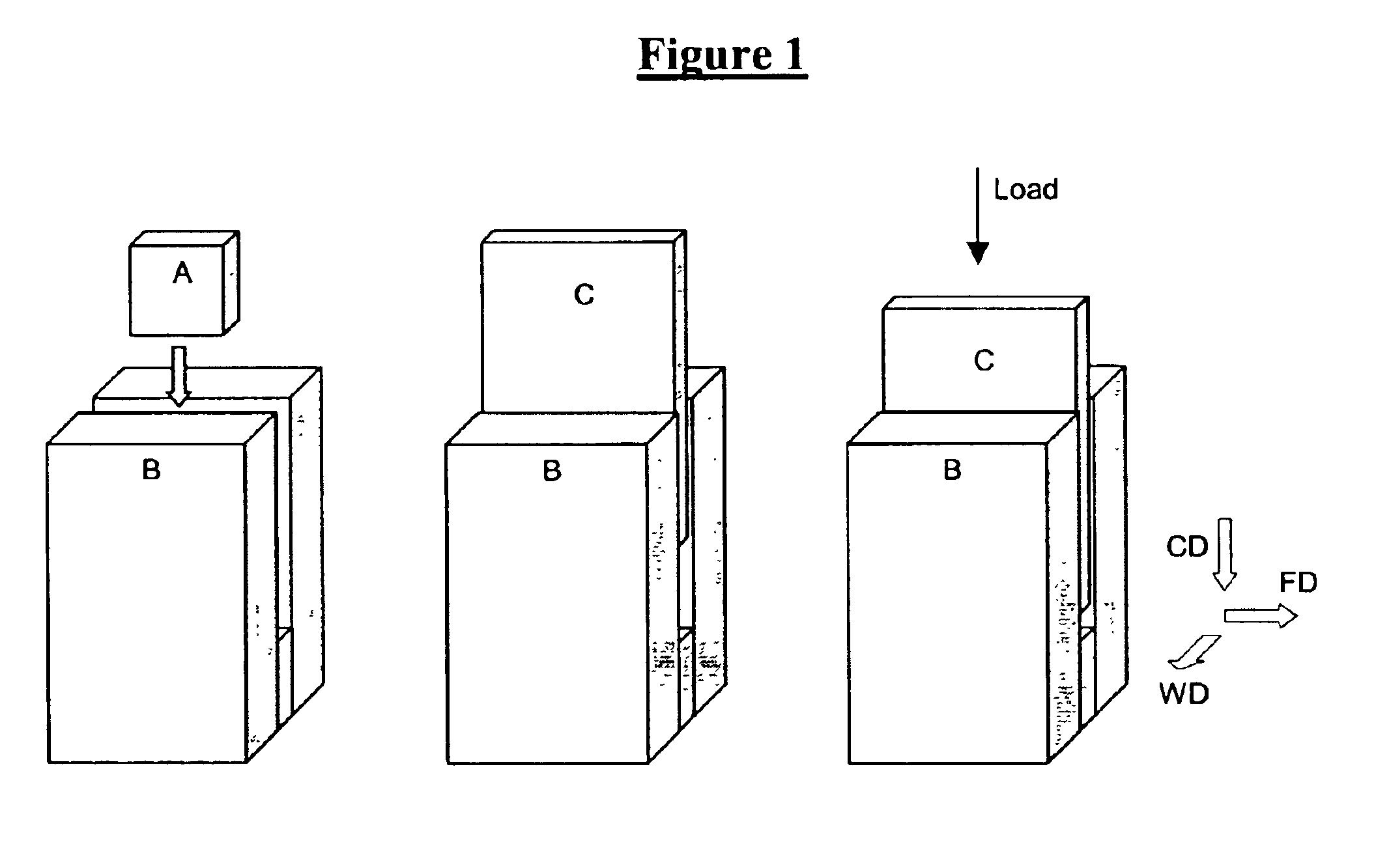

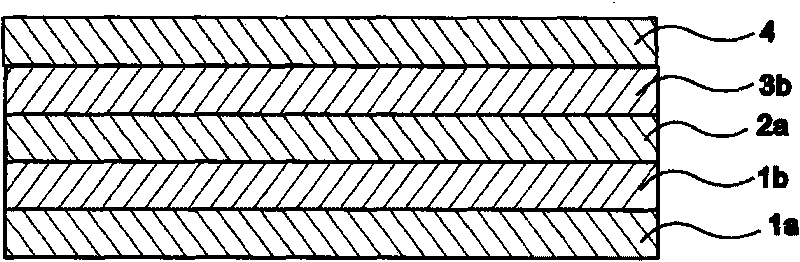

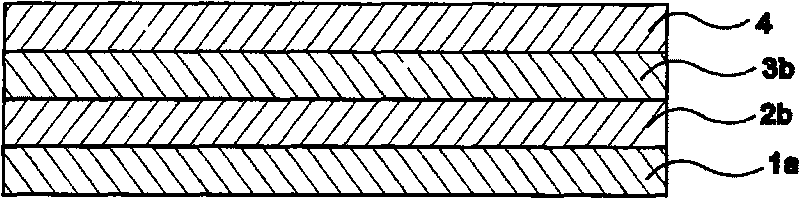

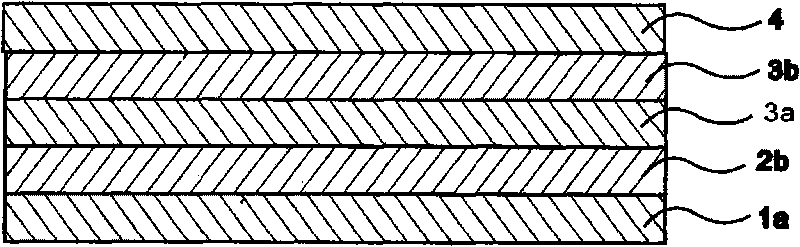

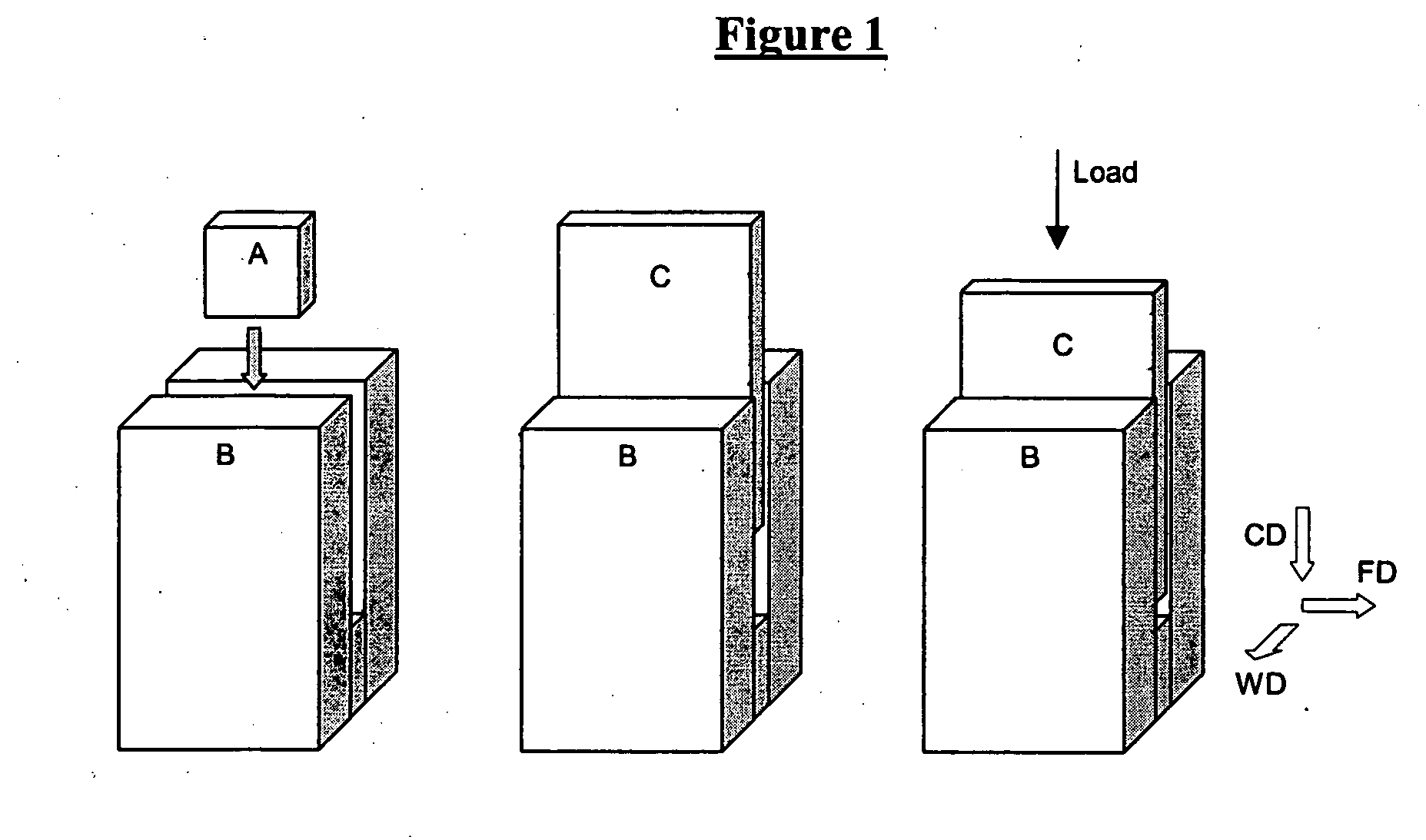

Polymer-bioceramic composite for orthopaedic applications and method of manufacture thereof

InactiveUS20040002770A1Promote ingrowthImprove toughnessBone implantJoint implantsCompression moldingPolymer science

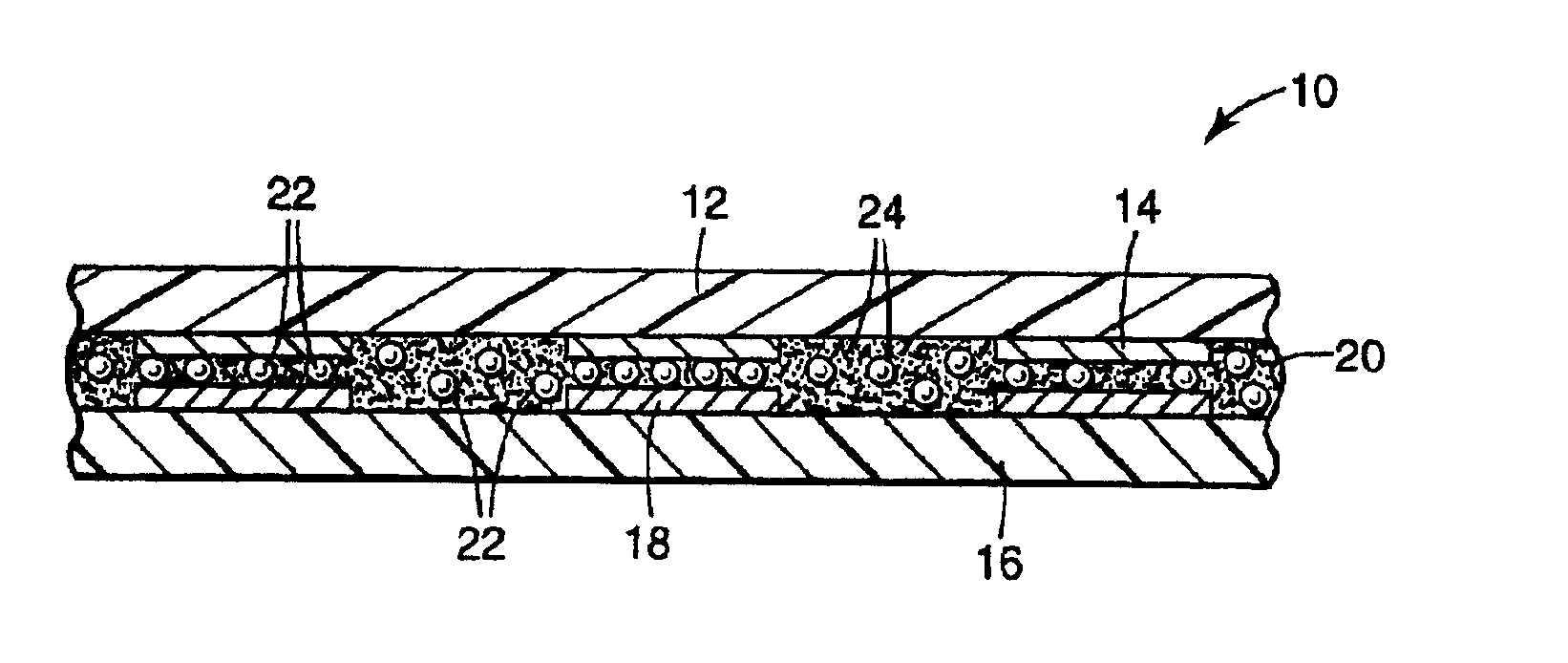

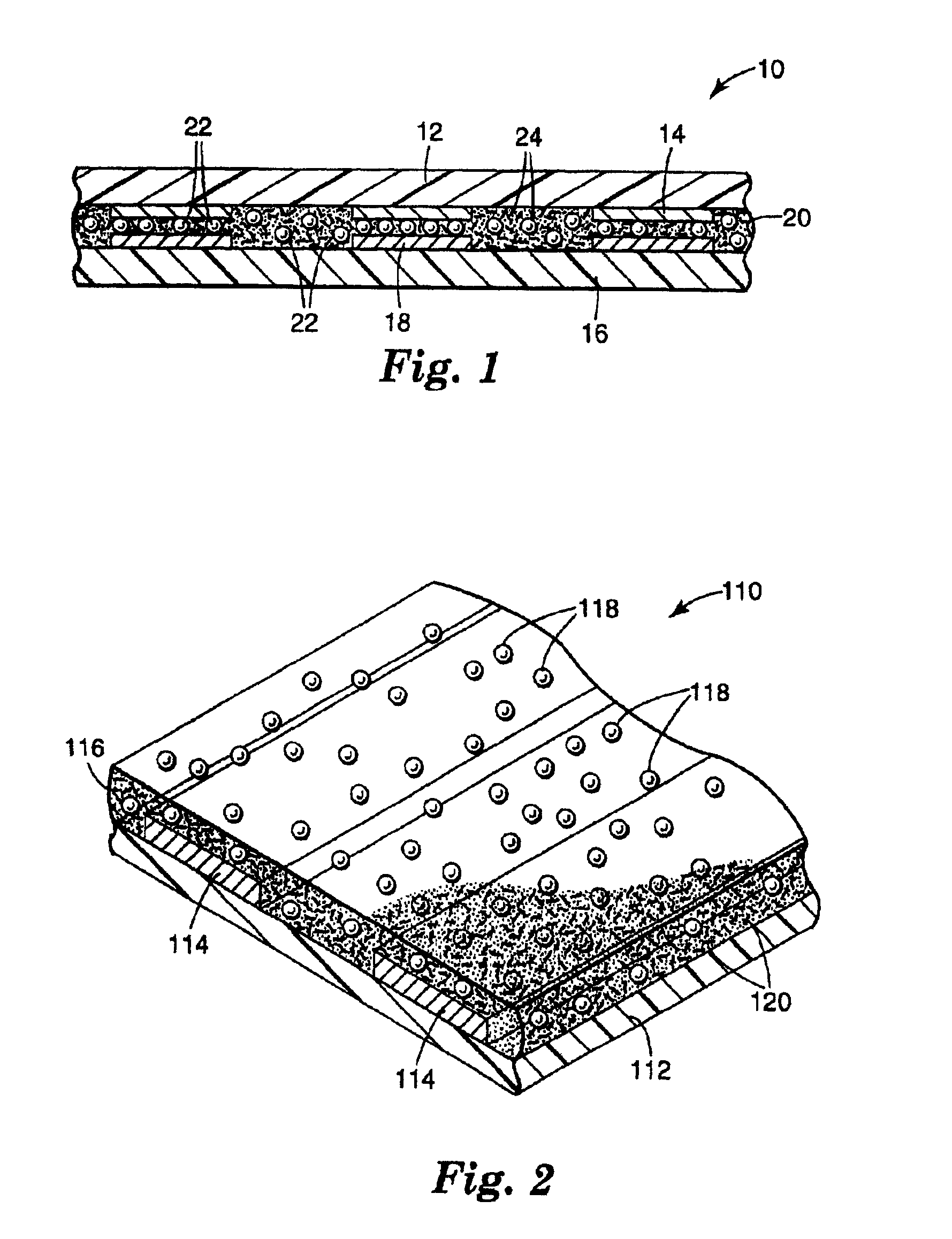

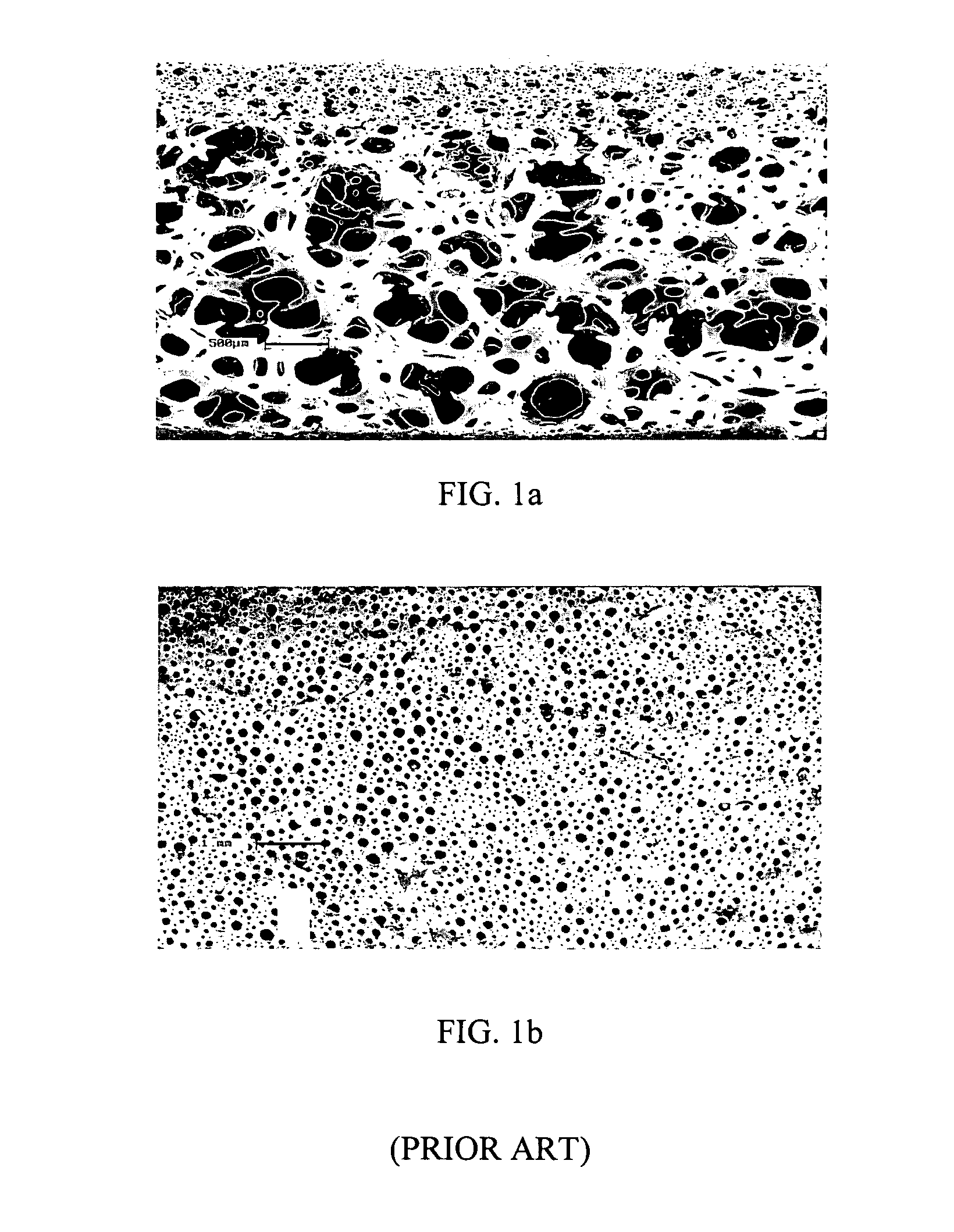

Polymer-bioceramic structures are described for use in the repair of bone defects. The composites of the present disclosure are characterized by a polymer disposed in a porous bioceramic matrix. Processes for preparing the composites of the present invention by compression molding are described, including compression molding to induce orientation of the polymer is multiple directions. The composites of the present invention are also useful as drug delivery vehicles to facilitate the repair of bone defects.

Owner:DEPUY SYNTHES PROD INC

High melt strength polypropylene

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / l0 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

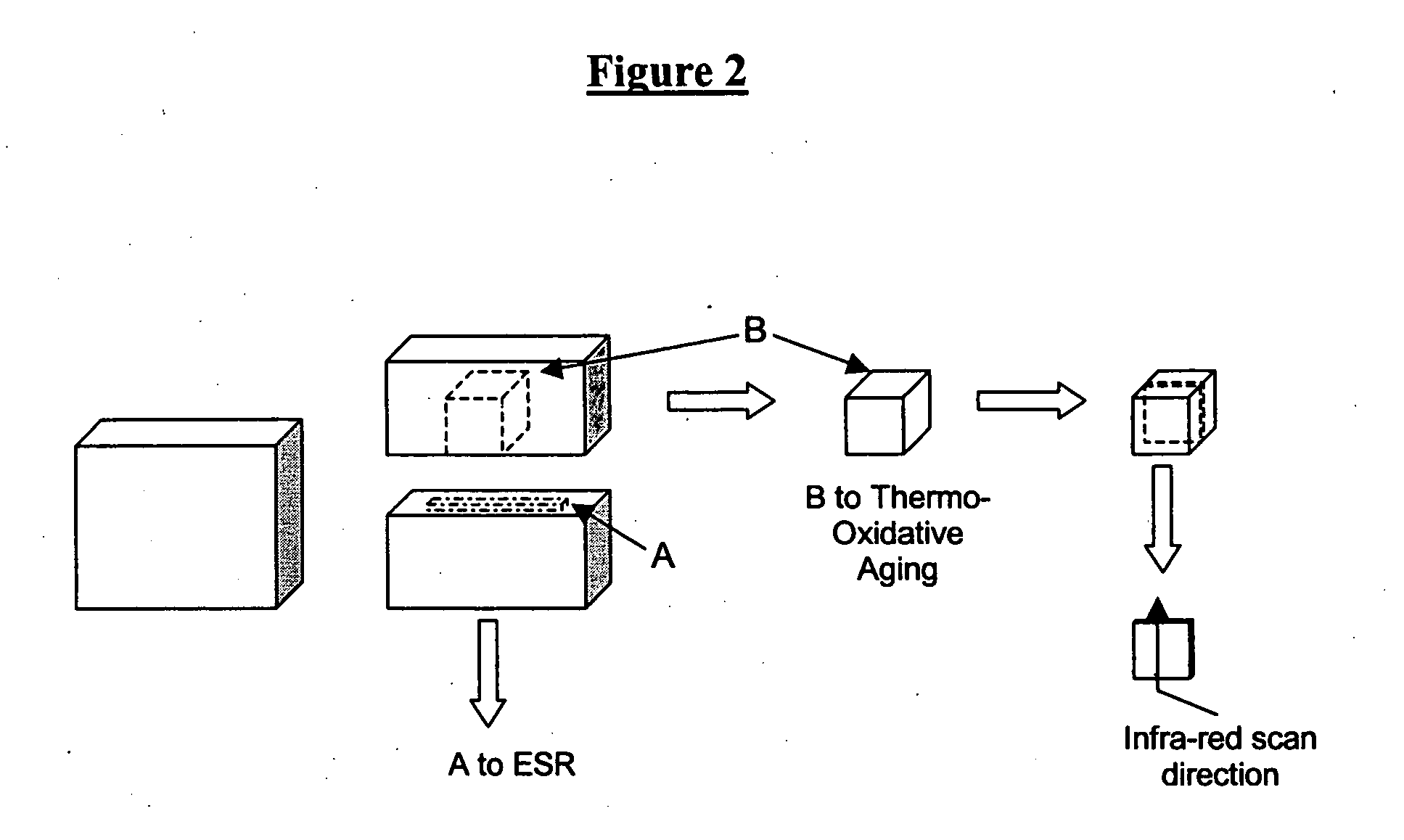

High modulus crosslinked polyethylene with reduced residual free radical concentration prepared below the melt

InactiveUS6852772B2Improve diffusivityHigh-frequency sonicationImpression capsAnkle jointsPolymer scienceCross-linked polyethylene

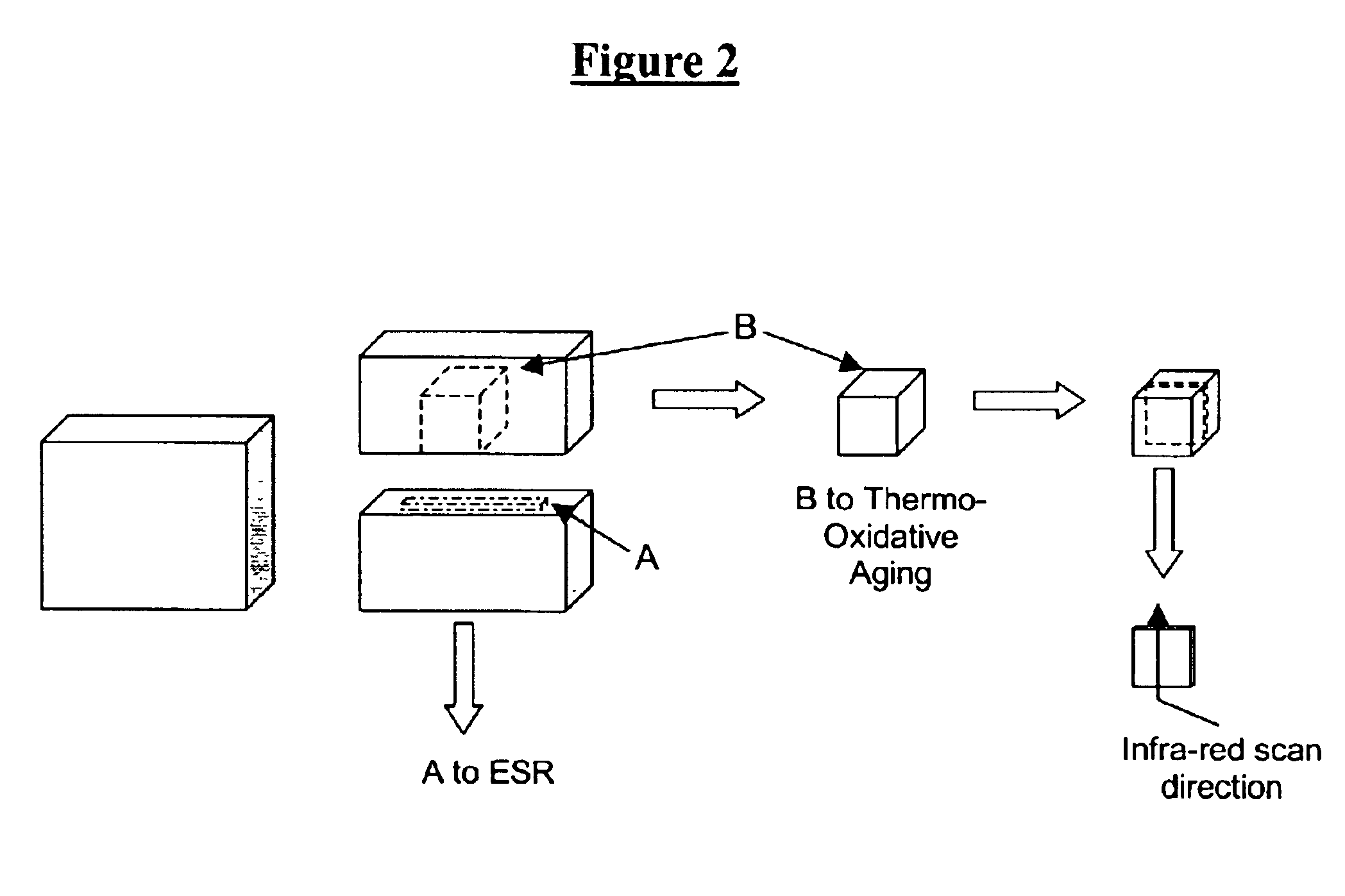

The present invention provides an irradiated crosslinked polyethylene containing reduced free radicals, preferably containing substantially no residual free radical. Disclosed is a process of making irradiated crosslinked polyethylene by irradiating the polyethylene in contact with a sensitizing environment at an elevated temperature that is below the melting point, in order to reduce the concentration of residual free radicals to an undetectable level. A process of making irradiated crosslinked polyethylene composition having reduced free radical content, preferably containing substantially no residual free radicals, by mechanically deforming the polyethylene at a temperature that is below the melting point of the polyethylene, optionally in a sensitizing environment, is also disclosed herein.

Owner:THE GENERAL HOSPITAL CORP +1

Devices, compositions, and methods incorporating adhesives whose performance is enhanced by organophilic clay constituents

InactiveUS6884833B2Faster build-upImprove adhesionPrinted circuit assemblingNon-insulated conductorsOrganoclayHot melt

Incorporating organophilic clay into hot melt adhesive compositions, particularly those comprising semi-crystalline, thermoplastic polymers, greatly improves the adhesive properties in many respects. Some of these improvements are particularly beneficial to the specific use of hot melt adhesives filled with electrically conductive particles for use as electrically conductive adhesives.

Owner:3M INNOVATIVE PROPERTIES CO

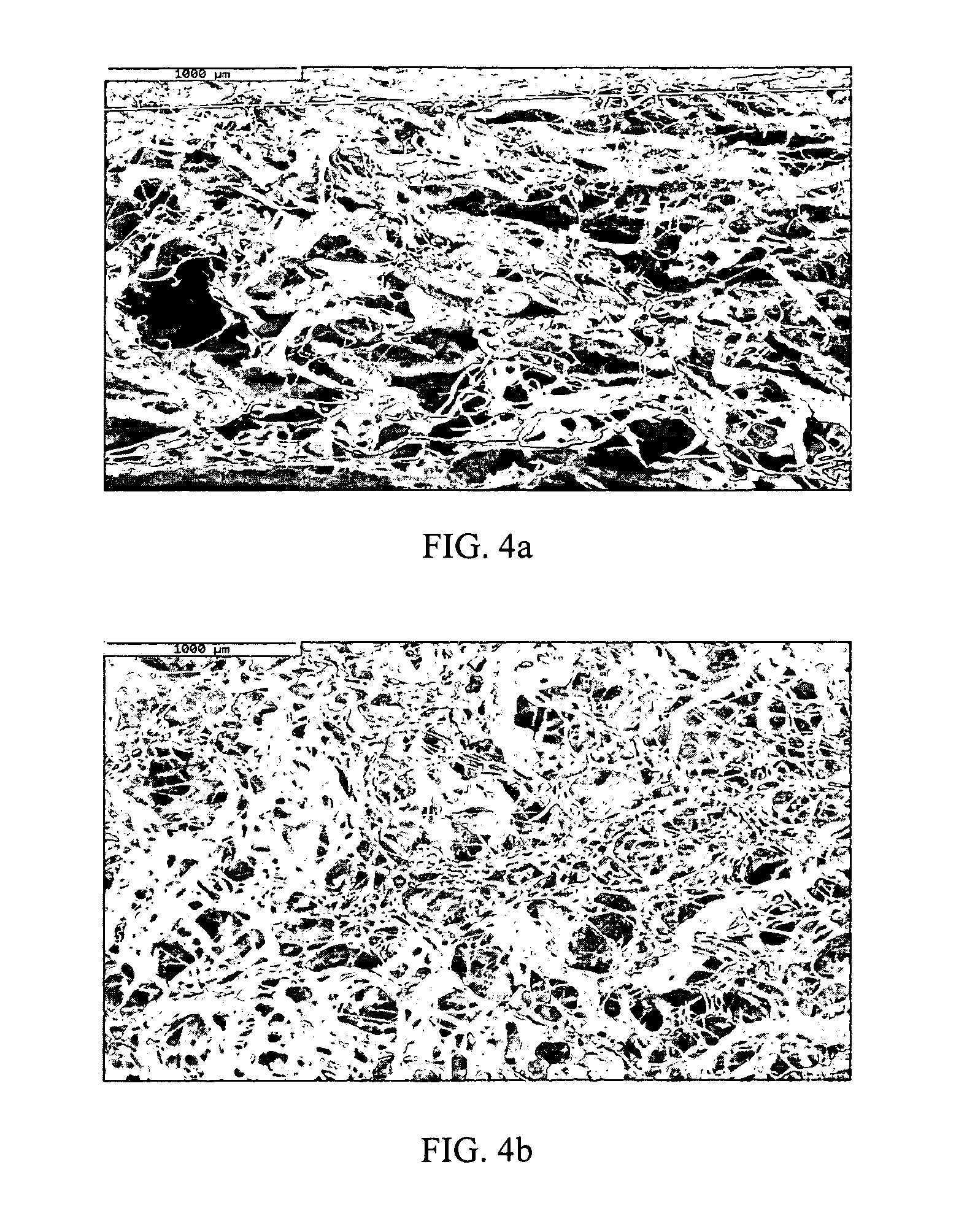

Fibrillated polyolefin foam

ActiveUS20080076844A1Improve heat resistanceLow compression setAbsorbent padsBandagesThermoplasticFiber

A method for generating a thermoplastic foam from an aqueous dispersion, the aqueous dispersion comprising a thermoplastic resin, water, and a dispersion stabilizing agent, the method including: adding at least one froth stabilizing surfactant to the aqueous dispersion to form a mixture; adding a fiber to the mixture; and frothing the mixture to create a froth, removing at least a portion of the water in the froth to create a foam, wherein the foam generated has a non-cellular fibrillated morphology. In another aspect, embodiments disclosed herein relate to a foam having a thermoplastic-based, fibrillated, non-cellular structure, wherein the foam has an average density of about 0.02 g / cm3 to about 0.07 g / cm3. In certain embodiments, the foam may be used in an absorbent article.

Owner:DOW GLOBAL TECH LLC

Rare earth-containing high strength heat resisting magnesium alloy and preparation thereof

The invention relates to a high strength heat-resistant magnesium alloy containing rare earths of the technical field of metallic materials and a preparation method thereof. The magnesium alloy comprises the following components according to the mass percent: Y with more than or equal to 3% and less than or equal to 16%, Gd with more than or equal to 0% and less than or equal to 10%, Ca with more than or equal to 0.3% and less than or equal to 5%, Zr with more than or equal to 0.1% and less than or equal to 1.5%, and one or a plurality of Nd, Si, Sb, Ti, Sn, Sr, Bi, Cd, Nd with more than or equal to 0% and less than or equal to 5%, Si with more than or equal to 0% and less than or equal to 5%, Sb with more than or equal to 0% and less than or equal to 5%, Ti with more than or equal to 0% and less than or equal to 5%, Sn with more than or equal to 0% and less than or equal to 5%, Sr with more than or equal to 0% and less than or equal to 5%, Bi with more than or equal to 0% and less than or equal to 5%, Cd with with more than or equal to 0% and less than or equal to 5%, and the rest is Mg and impurities. The magnesium alloy is obtained by using melting and the subsequent heat treatment. The magnesium alloy not only can serve as casting magnesium alloy but also can serve as the deformation magnesium alloy and has better predominant mechanical property compared with the WE series commercial magnesium alloy.

Owner:SHANGHAI JIAO TONG UNIV

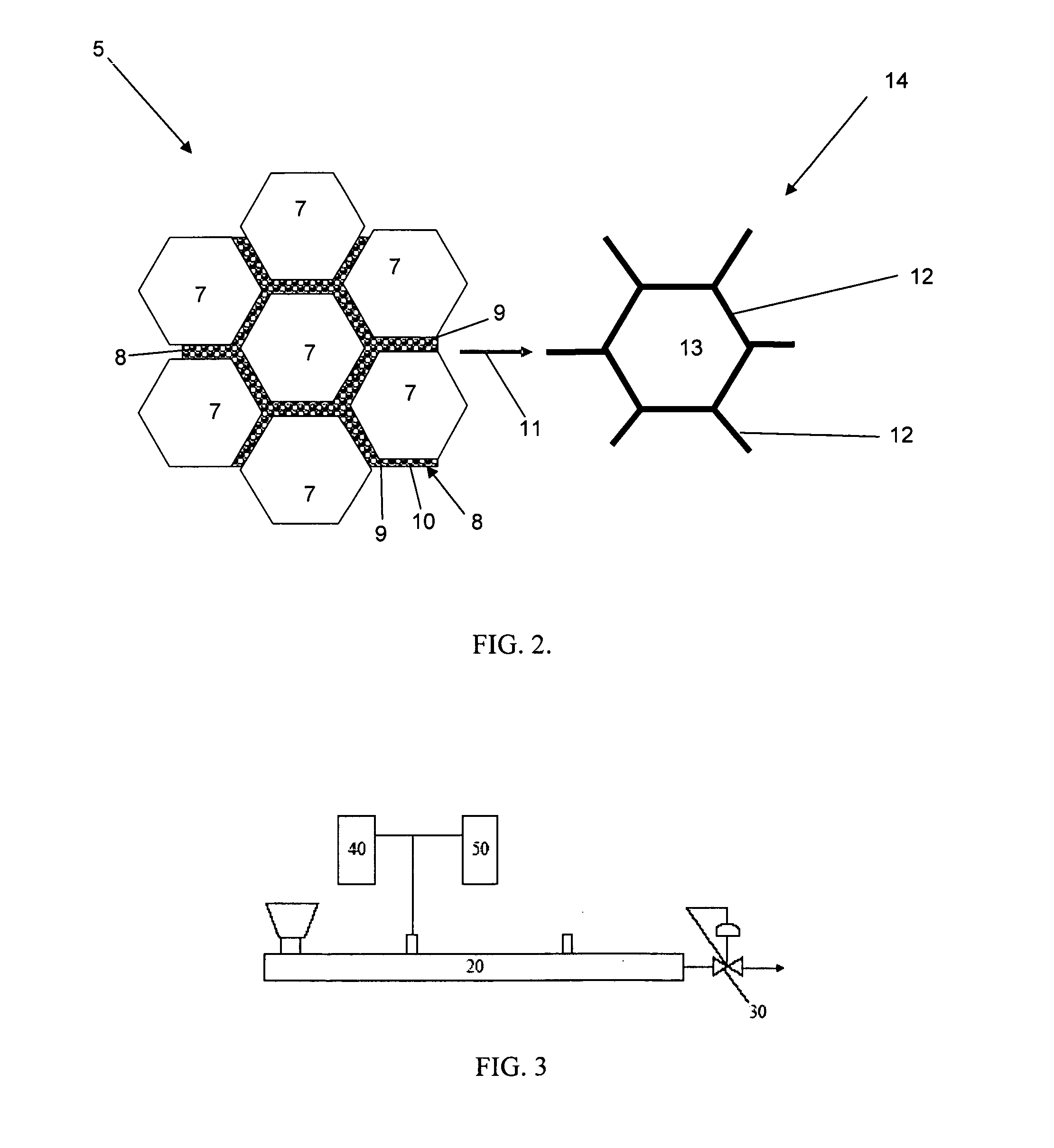

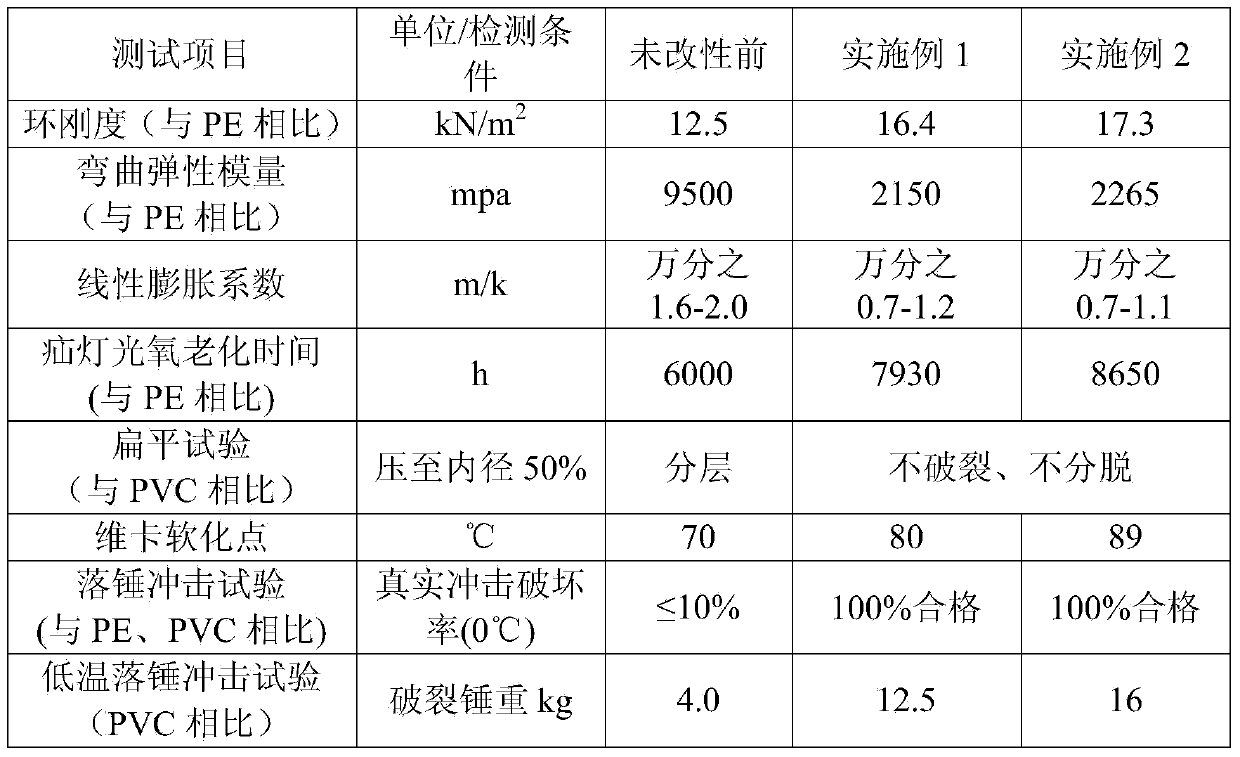

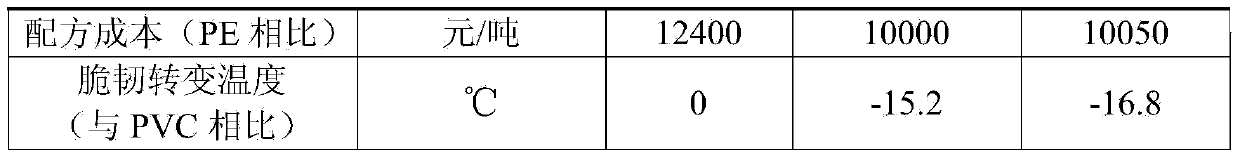

Polyethylene-polyvinyl chloride blend-modified tube and preparation method thereof

The invention belongs to the field of drainage tubes, and particularly relates to a polyethylene-polyvinyl chloride blend-modified tube and a preparation method thereof. The polyethylene-polyvinyl chloride blend-modified tube aims to solve the technical problems of poor shock strength, high sensitivity to temperature, poor ring stiffness, higher cost and short service life in the existing tube. In order to solve the technical problems, the invention provides a polyethylene-polyvinyl chloride blend-modified tube which comprises the following components in parts by weight: 50-150 parts of polyethylene resin, 50-150 parts of polyvinyl chloride resin, 10-30 parts of nano material, 0.5-5 parts of pigment, 2-20 parts of leadless stabilizer, 1-20 parts of processing assistant, 1-5 parts of lubricant, 0.5-5 parts of antioxidant, 0.5-2 parts of photostabilizer, 1-25 parts of solubilizer, 1-15 parts of impact-resistant modifier, 1-15 parts of enhancer and 0.5-10 parts of coupling agent. The polyethylene-polyvinyl chloride blend-modified tube has the advantages of higher ring stiffness, favorable toughness, aging resistance and greatly higher shock strength.

Owner:KANGTAI PLASTIC SCI & TECH GRP

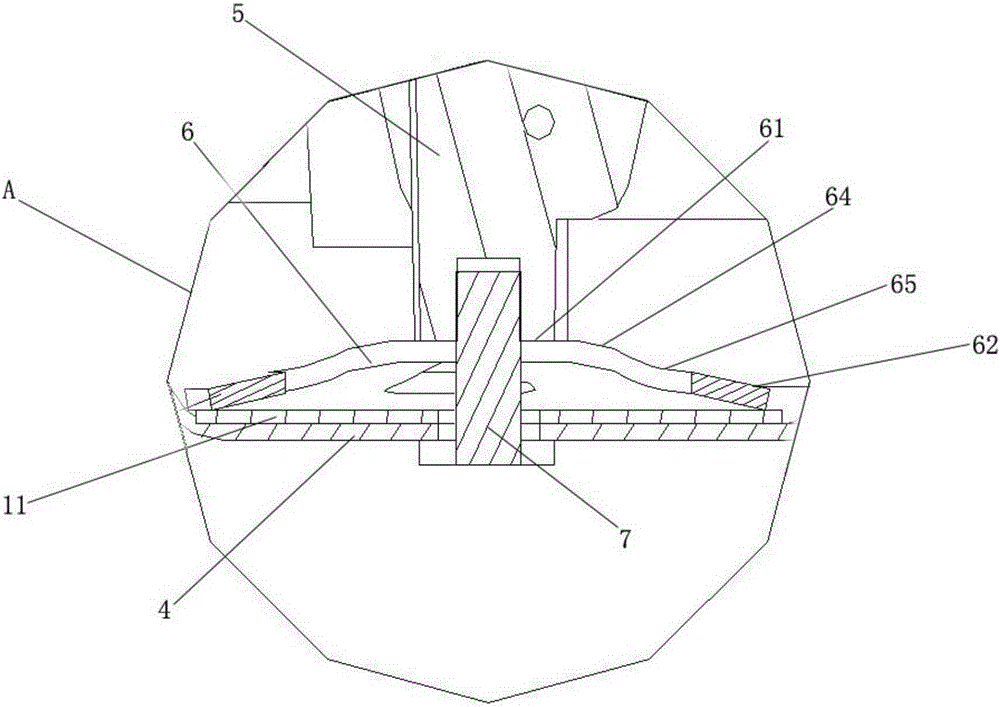

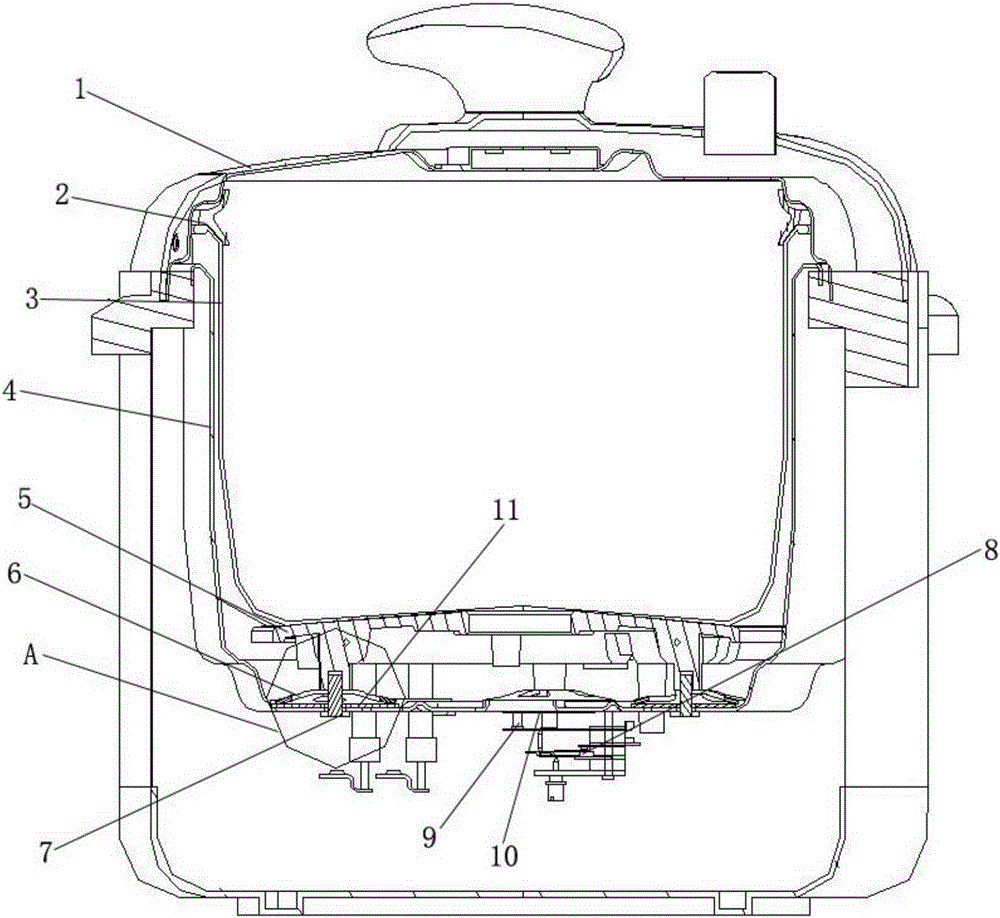

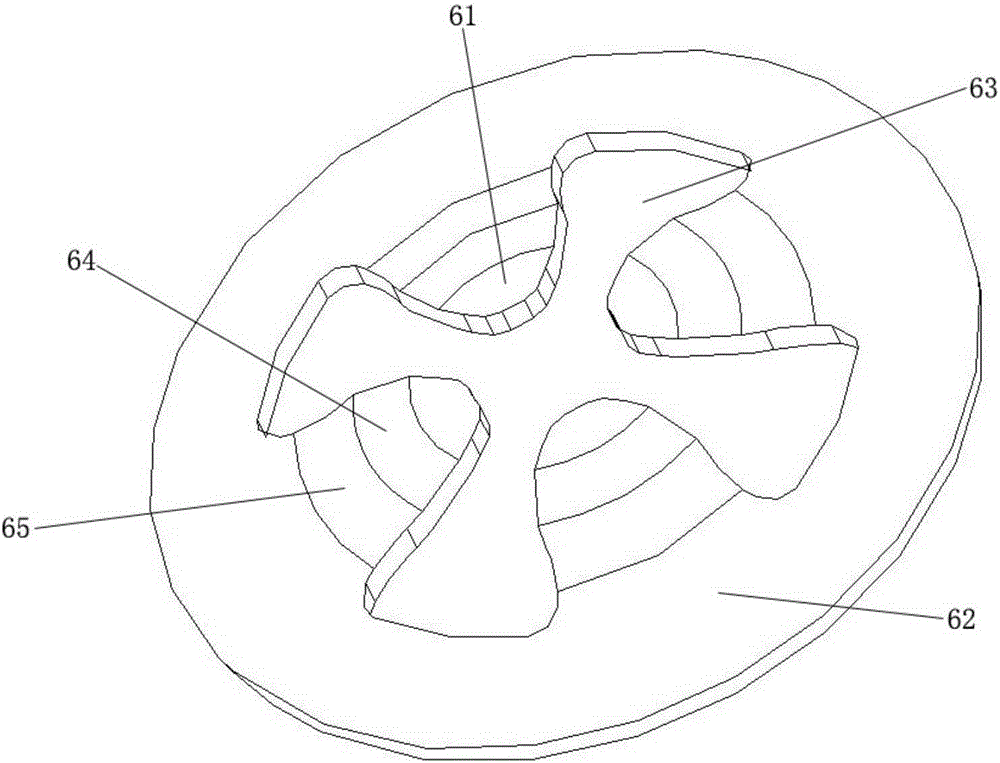

Pressure-control type electric pressure cooker

ActiveCN105286498AImprove stability and securitySimple structurePressure-cookersEngineeringPressure controlled ventilation

The invention discloses a pressure-control type electric pressure cooker. A sealed body is formed by sequentially connecting a pot cover, a seal ring, an inner pot and an outer pot; a plurality of belleville springs, which are provided with opening grooves, are arranged between a heating plate and the outer pot; upper supporting rings are formed by horizontally flanging the small-diameter ends of the belleville springs towards inner sides, and lower supporting rings are formed by the big-diameter ends of the belleville springs; an elastic deformation area is formed by a conical wall parts between each of the upper supporting rings and each of the lower supporting rings; the elastic deformation areas penetrate through the upper supporting rings in a radial direction and extend to conical body parts, and the opening grooves that contour lines projected on a horizontal plane are in a cross form are formed; the opening grooves are of gradually expanded structures with upsides smaller than downsides from openings to bottoms; the lower supporting rings are supported on the bottom of the outer pot; the upper supporting rings are propped against supporting legs of the heating plate; and the supporting legs and the belleville springs are integrally positioned with and connected to the outer pot by virtue of fixed screws. The amount of elastic deformation of the electric pressure cooker is effectively improved by virtue of the belleville springs, and the change in induction pressure of a pressure detection device is more conveniently to be detected, so that the precision and the safety stability of pressure control are improved.

Owner:HANGZHOU YONGYAO TECH

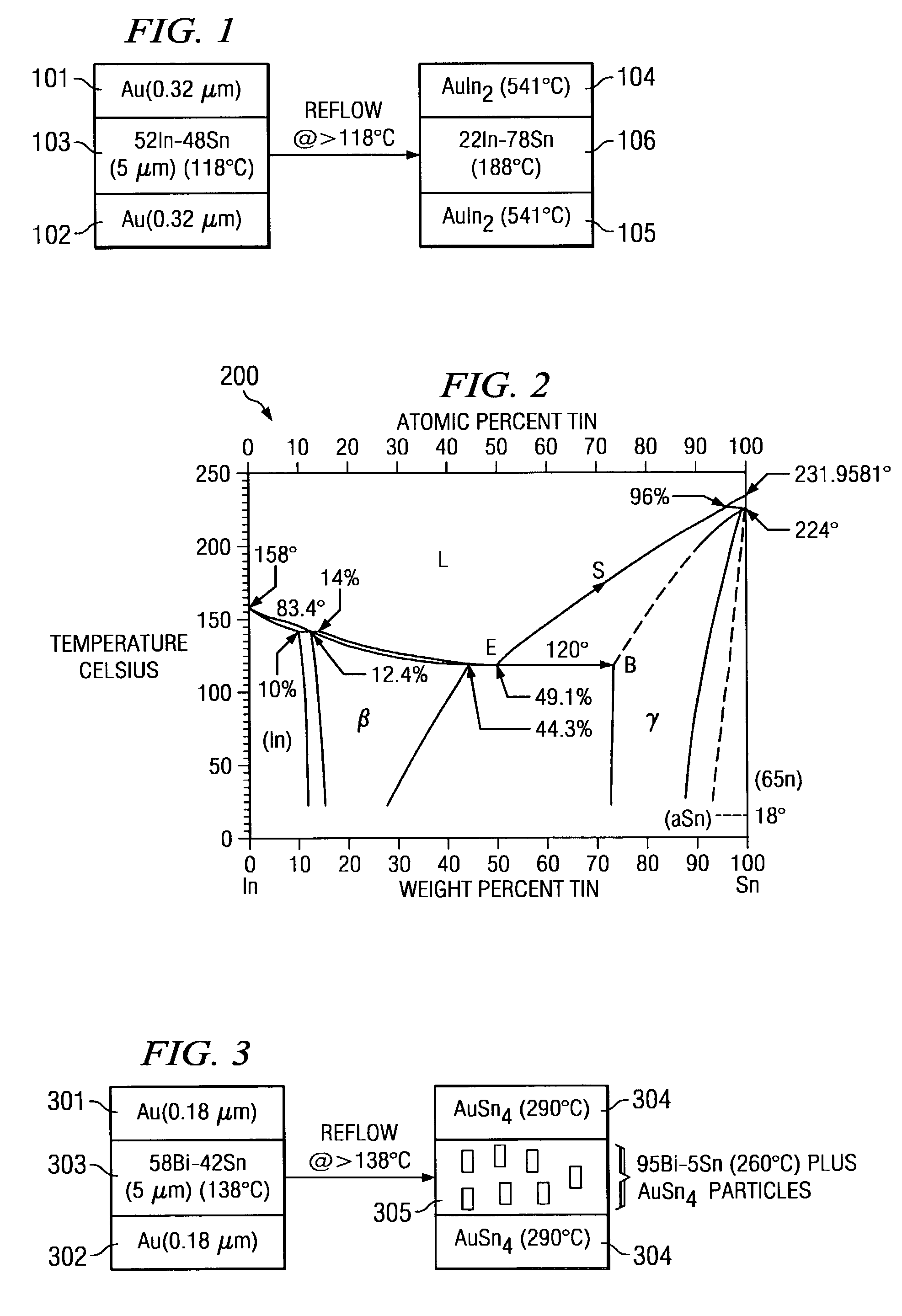

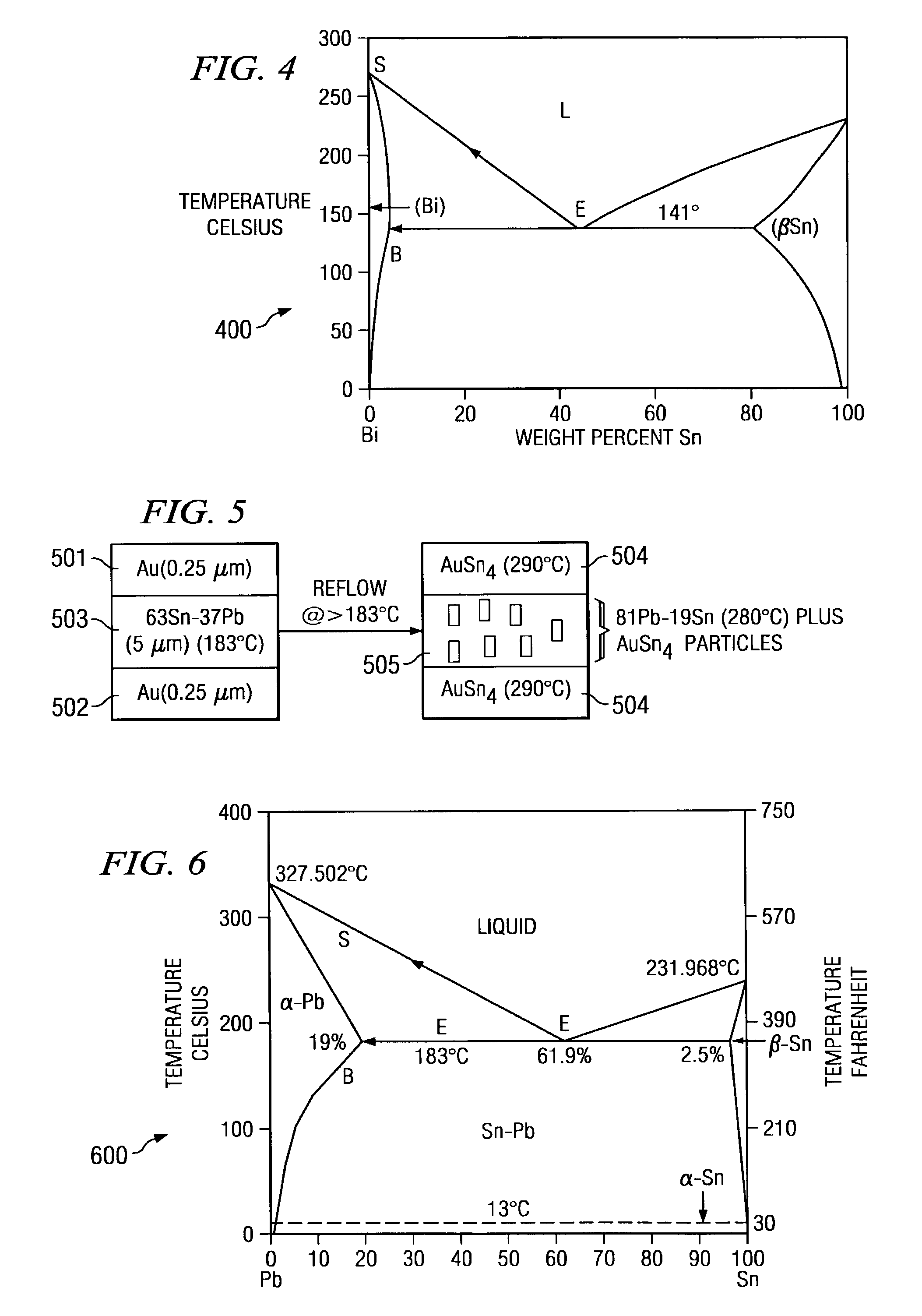

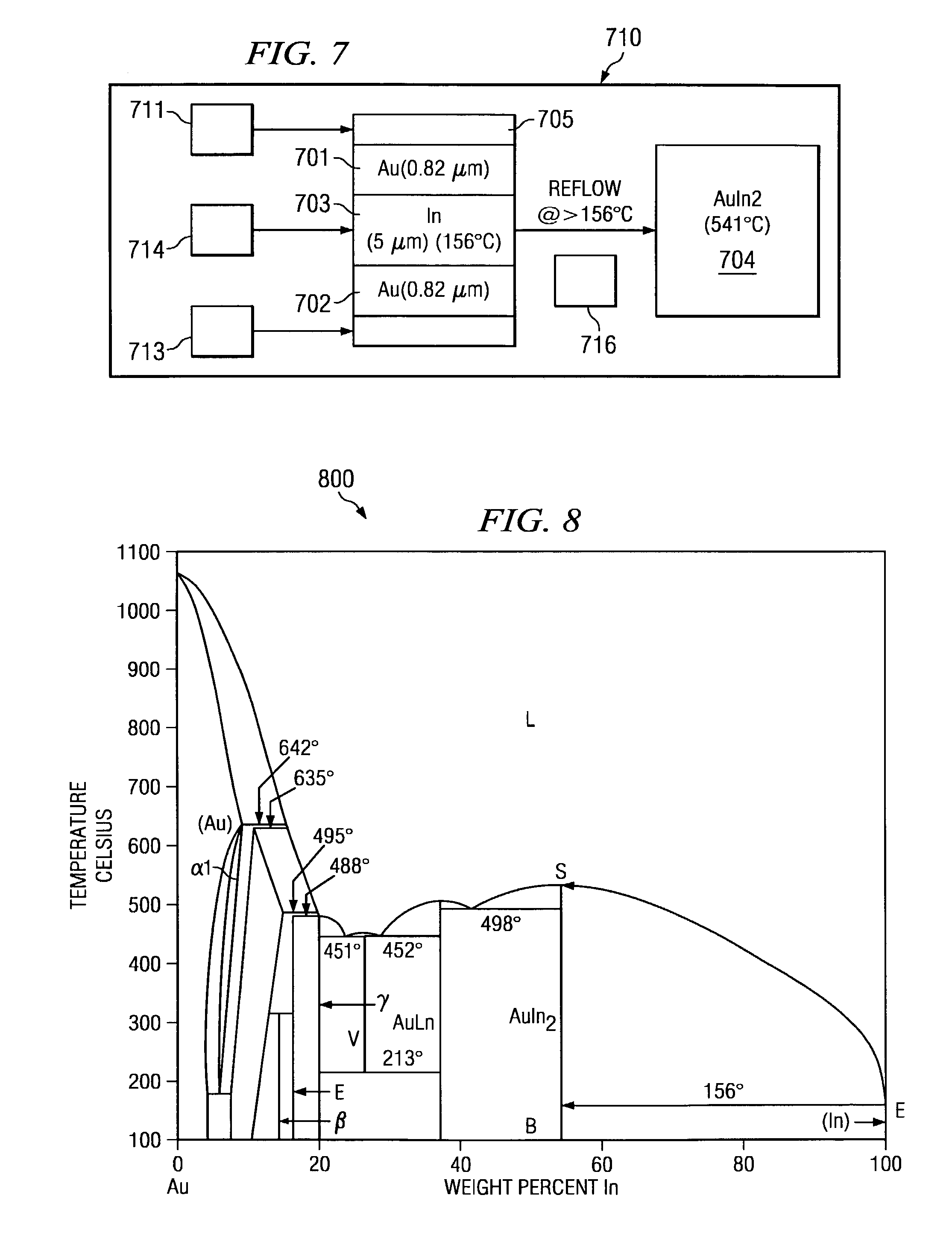

System and method for hermetic seal formation

InactiveUS7168608B2High melting temperatureMinimize thermal induced warpageEngine sealsSolid-state devicesMetallurgyHermetic seal

System and method for formation of a hermetic seal with an significantly greater melting temperature than the melting temperature of the solder employed. The hermetic seal is formed from a solder with a low melting point and a metal having a predetermined thickness that corresponds to the solder. The solder and metal combination undergoes reflow for a period of time relative to the solder thickness. The resultant seal has a melting point at a temperature significantly greater than the melting temperature of the solder.

Owner:AVAGO TECH INT SALES PTE LTD

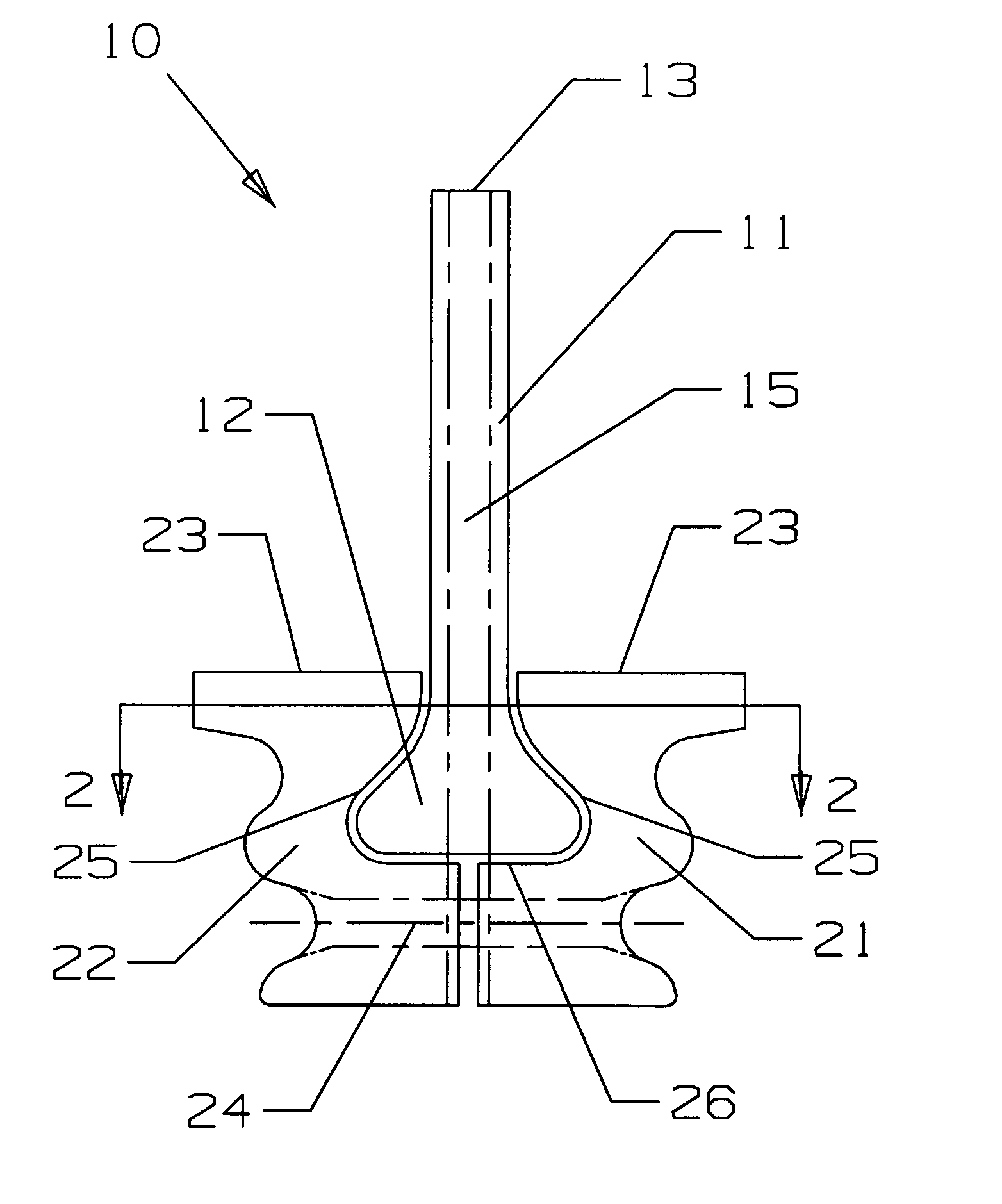

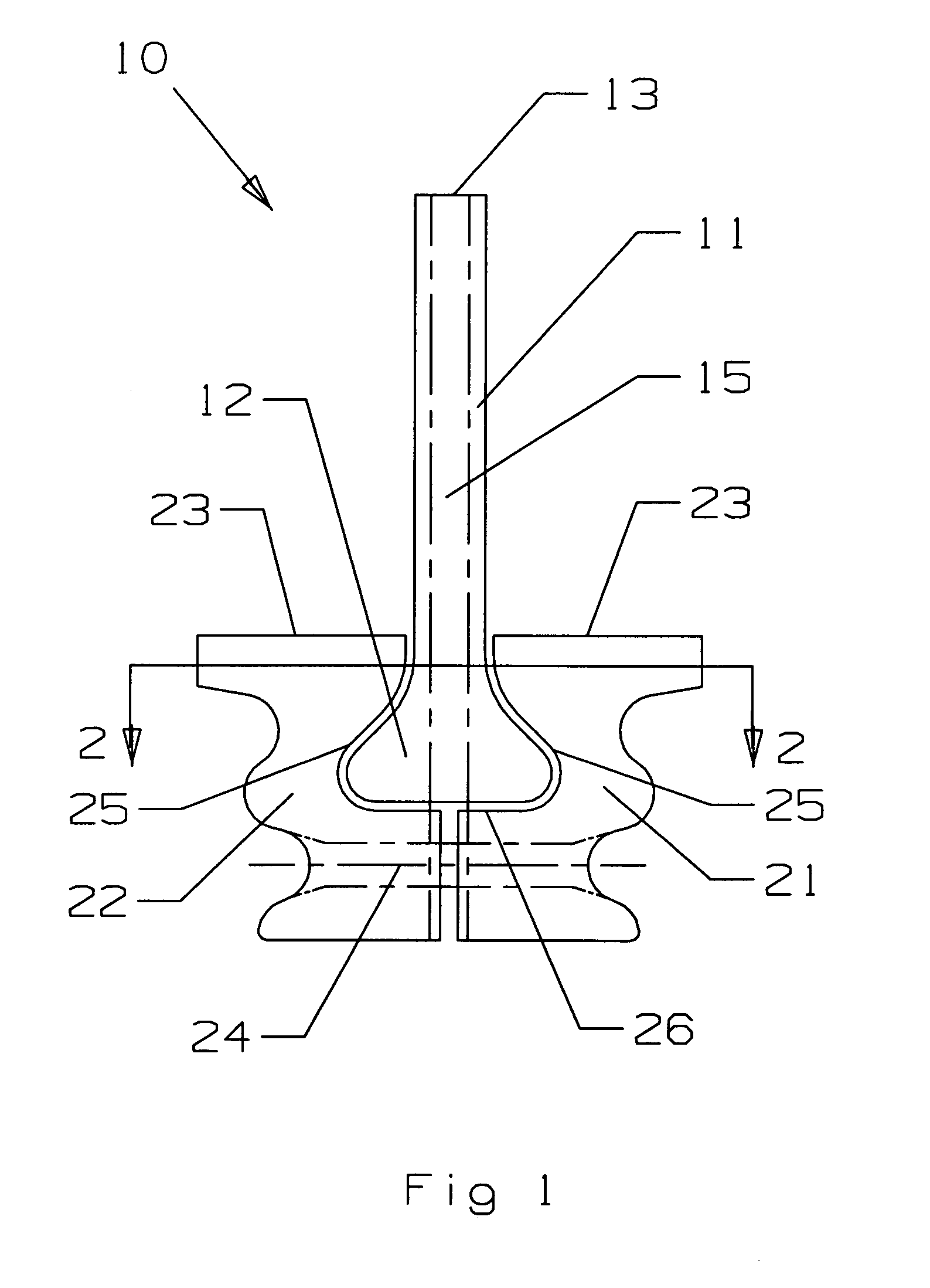

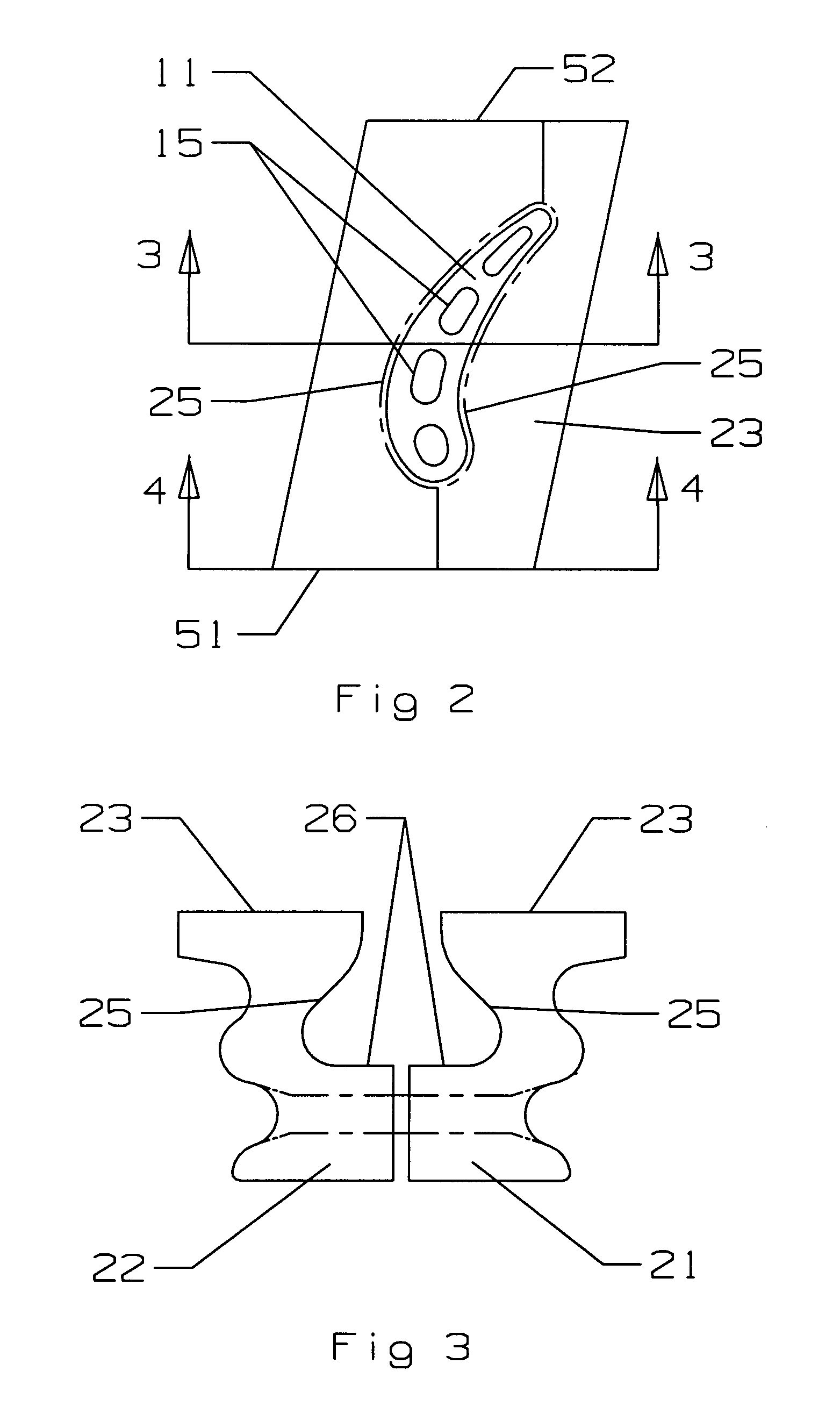

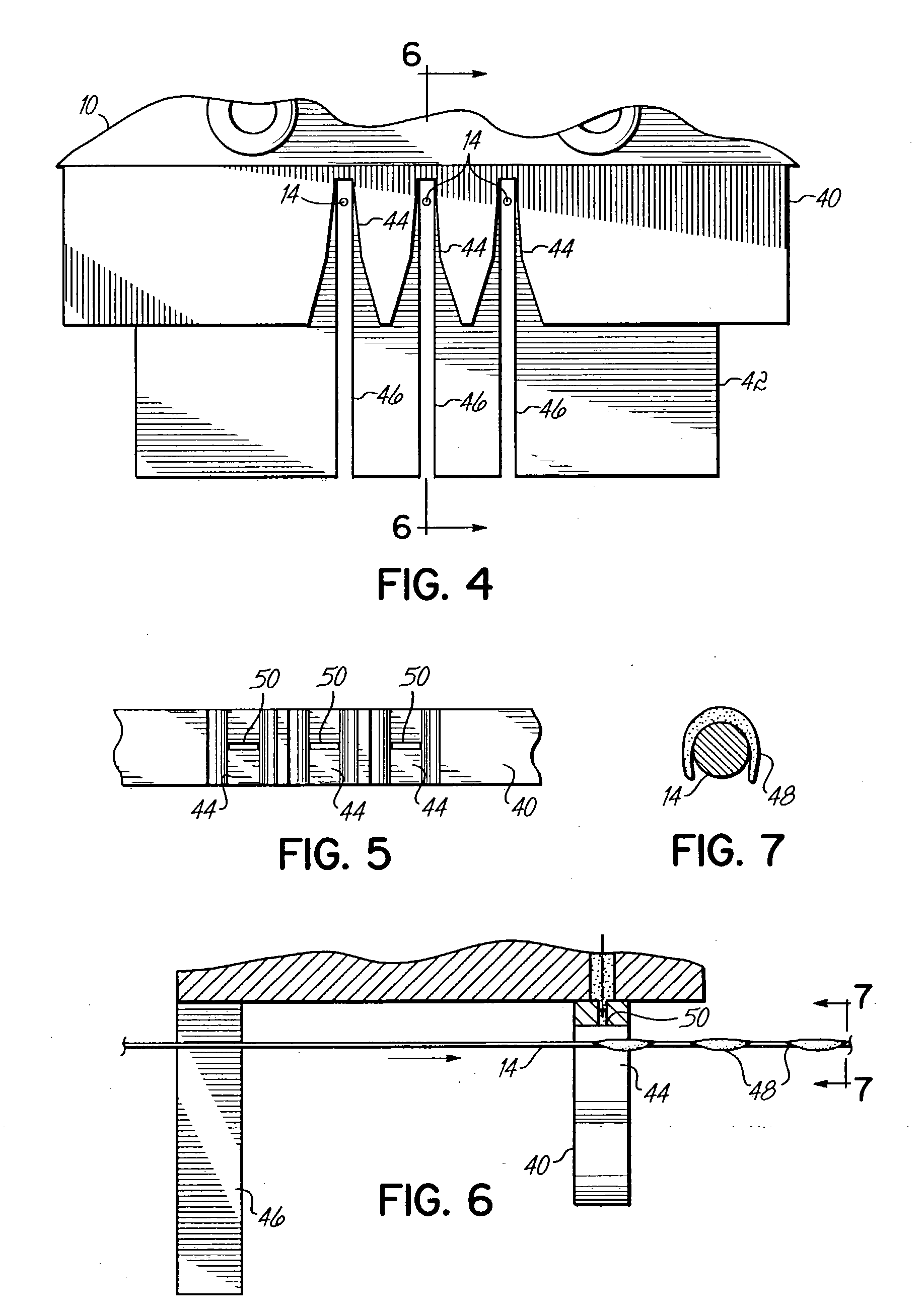

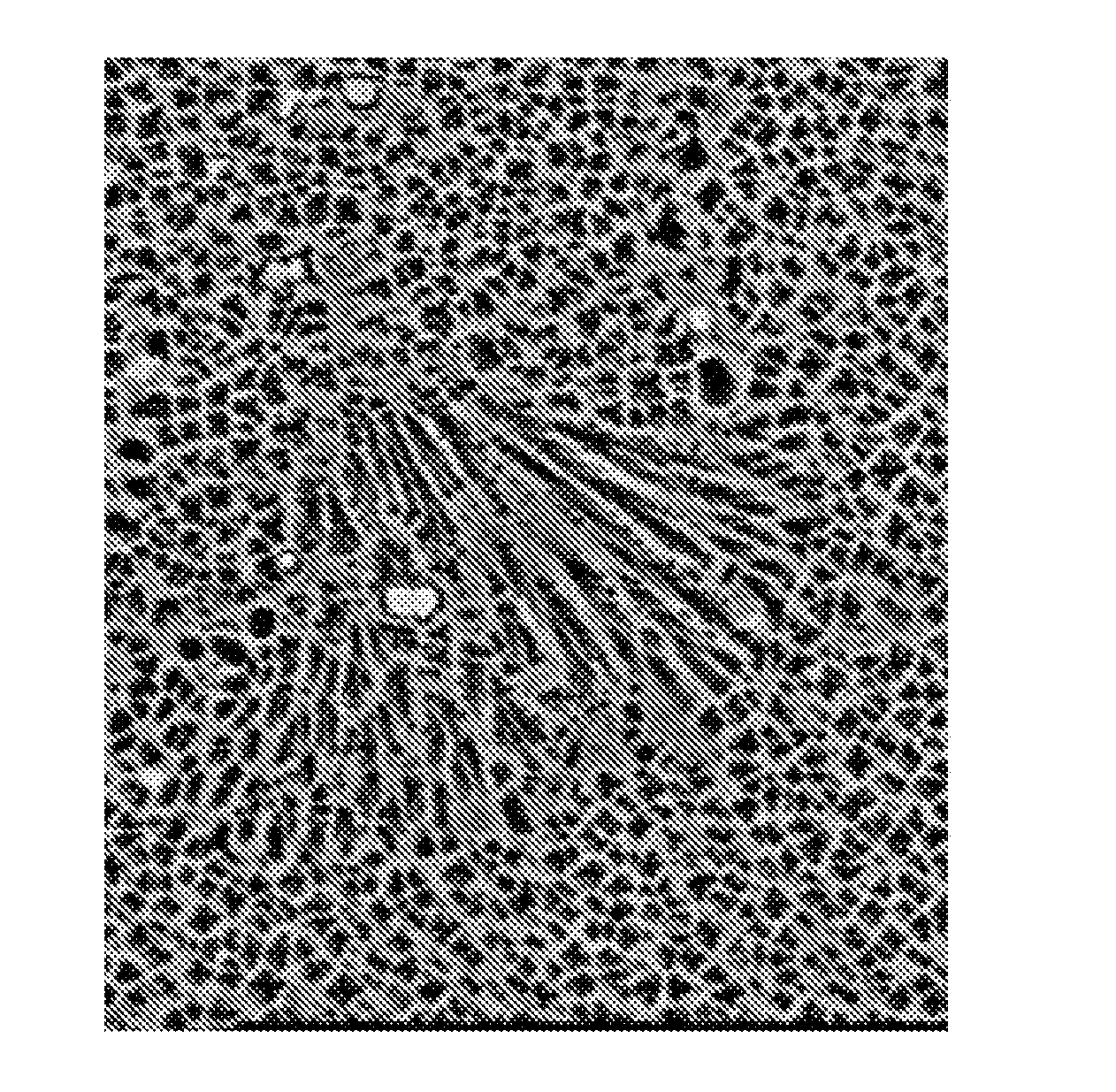

Integral turbine blade and platform

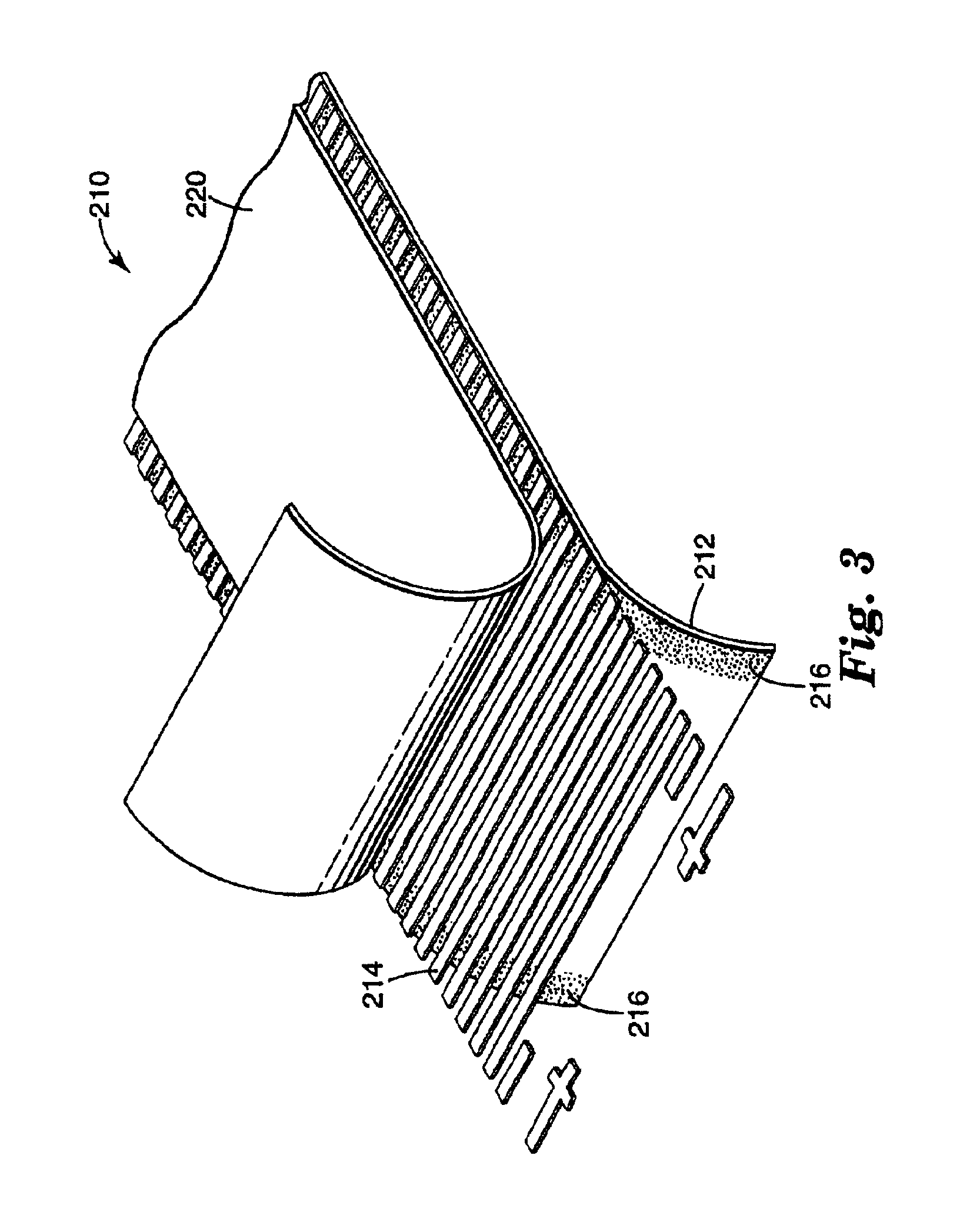

InactiveUS7972113B1Reduce defective castingIncrease mechanical fatiguePropellersRotary propellersTurbine bladeSingle crystal

A turbine blade for a gas turbine engine, in which the turbine blade includes an airfoil portion with a root having a dovetail shape, and two platform halves that include a dovetail shaped opening within the platform halves to secure the blade root within the platform halves when fastened together. The platform halves have an outer fir tree shaped surface so that the blade assembly can be inserted into a slot within a rotor disk. the blade is uncoupled from the platform in the invention so that the airfoil can be made from a single crystal material with low casting defects because the platform is not cast with the airfoil. the two platform halves include the openings with side walls that are curved to follow the contour of the airfoil root so that the airfoil is secured within the platform halves against all directions of movement. An annular groove extends around the platform opening to provide for a seal to produce a seal between the high pressure cooling air supply passage within the platform and the lower pressure hot gas flow passing through the blade.

Owner:FLORIDA TURBINE TECH

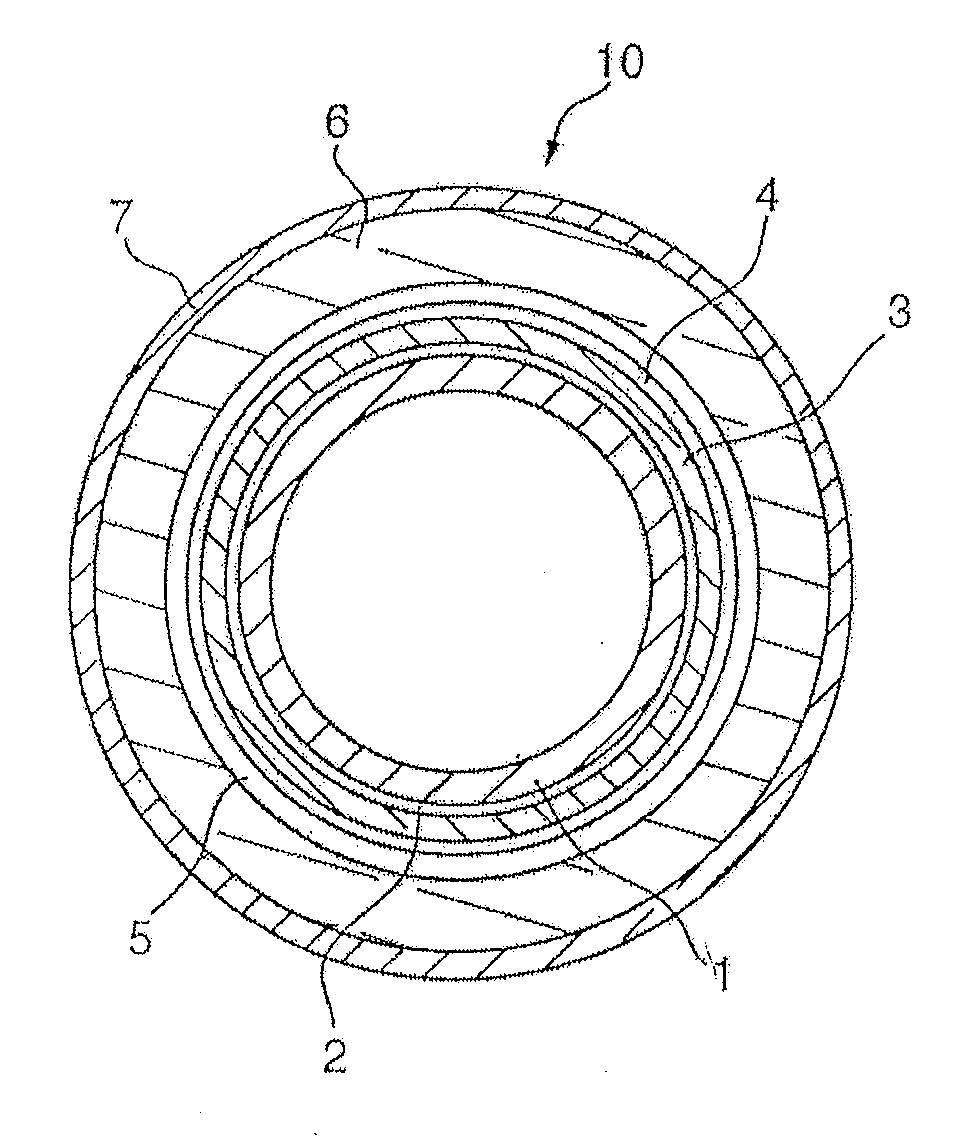

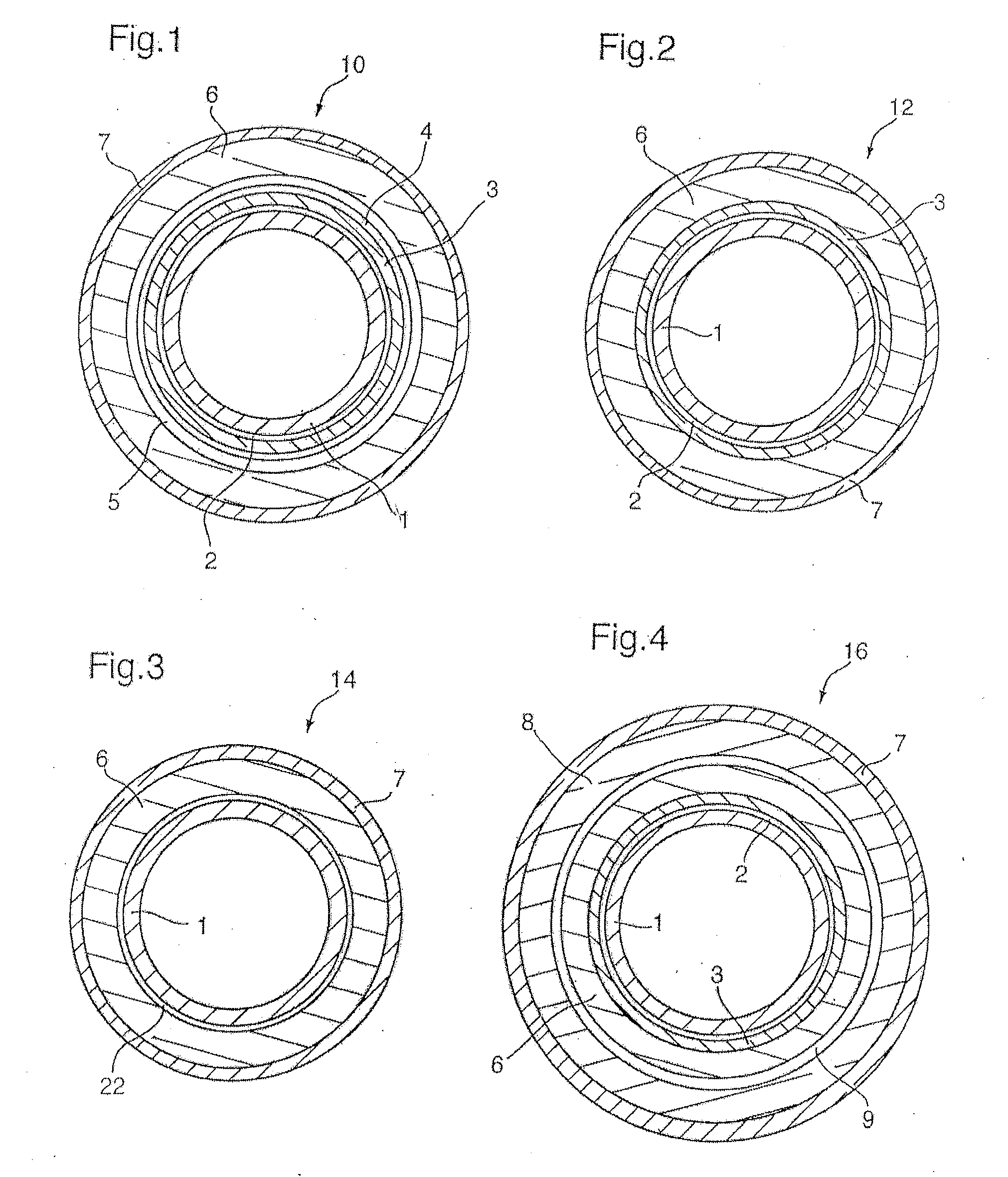

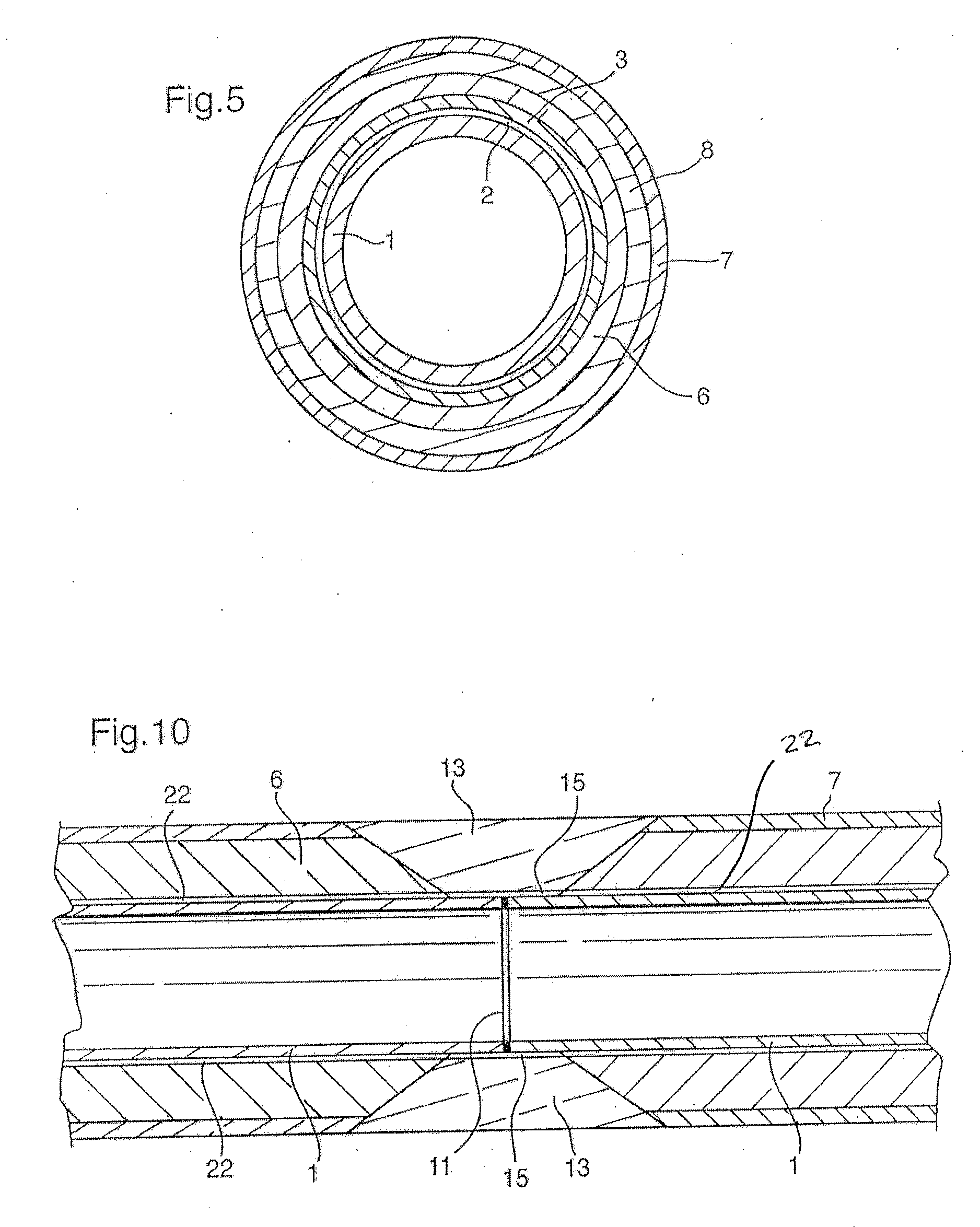

High temperature resistant insulation for pipe

ActiveUS20100043906A1Low thermal conductivityImprove thermal stabilityThermal insulationSynthetic resin layered productsBisphenol-A-polycarbonatePolyetherimide

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130° C. or higher in water depths above 1,000 metres. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

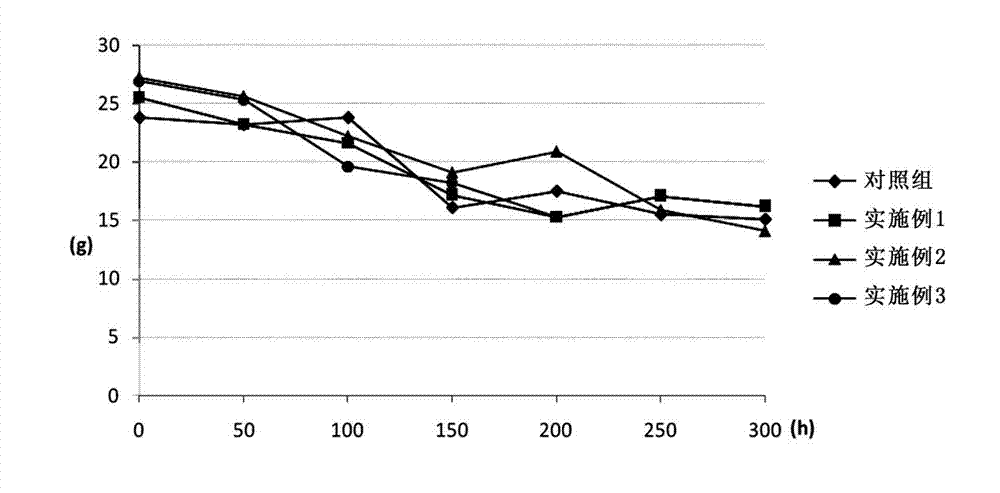

Method for improving creep resistant performance of ultra-high molecular weight polyethylene fiber

ActiveCN102493168AHigh surfaceIncrease internal cross-link pointsPhysical treatmentFibre typesFiberPolymer science

The invention relates to a method for improving the creep resistant performance of an ultra-high molecular weight polyethylene fiber; and the method is characterized by jointly triggering crosslinking by using a photosensitizer and a thermal initiating agent, thereby crosslinking points of the surface and interior of the ultra-high molecular weight polyethylene fiber are increased, the crosslinking efficiency of a cross-linking agent is improved, the relative slippage among molecules of the ultra-high molecular weight polyethylene fiber is effectively impeded and the creep resistant performance of the fiber is increased.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Method for manufacturing heat-resistant aluminum alloy wire for power cable

InactiveCN101604563AImprove creep resistanceGuaranteed stabilityOther manufacturing equipments/toolsMetal/alloy conductorsElectrical connectionCerium

The invention discloses a method for manufacturing a heat-resistant aluminum alloy wire for a power cable, and belongs to the technical field of design and manufacture of power transmission lines. The aluminum alloy wire uses magnesium, copper, iron, silicon, boron, cerium-rich rare earth, zirconium, yttrium, cobalt and the like as alloying elements. The manufacturing process for the aluminum alloy wire comprises the following steps: adding the alloying elements into fused aluminum of a shaft furnace, casting the mixture after smelting into a cast strip and thermally rolling the cast strip, then performing cold-drawing processing, annealing in the cold-drawing process, adopting recrystallization and thermal treatment before final cold-drawing, and later performing trace cold-drawing processing. The aluminum alloy wire not only has good bending resistant performance and forming performance, but also has high conductivity and good heat resistance (comprising high-temperature creep resistance), and can ensure the stability of electrical connection under both normal temperature and high temperature.

Owner:ZHENGZHOU CABLE +1

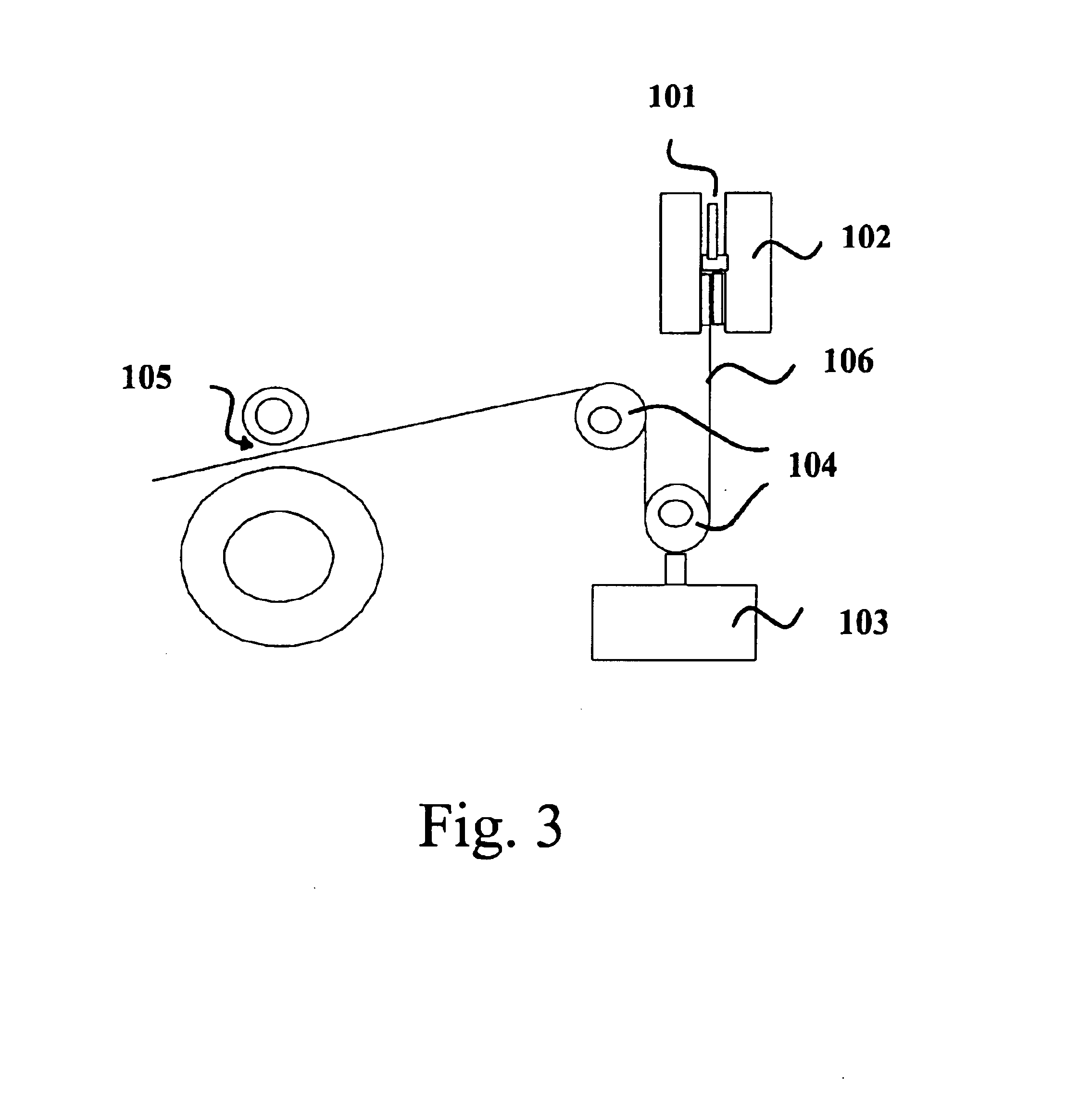

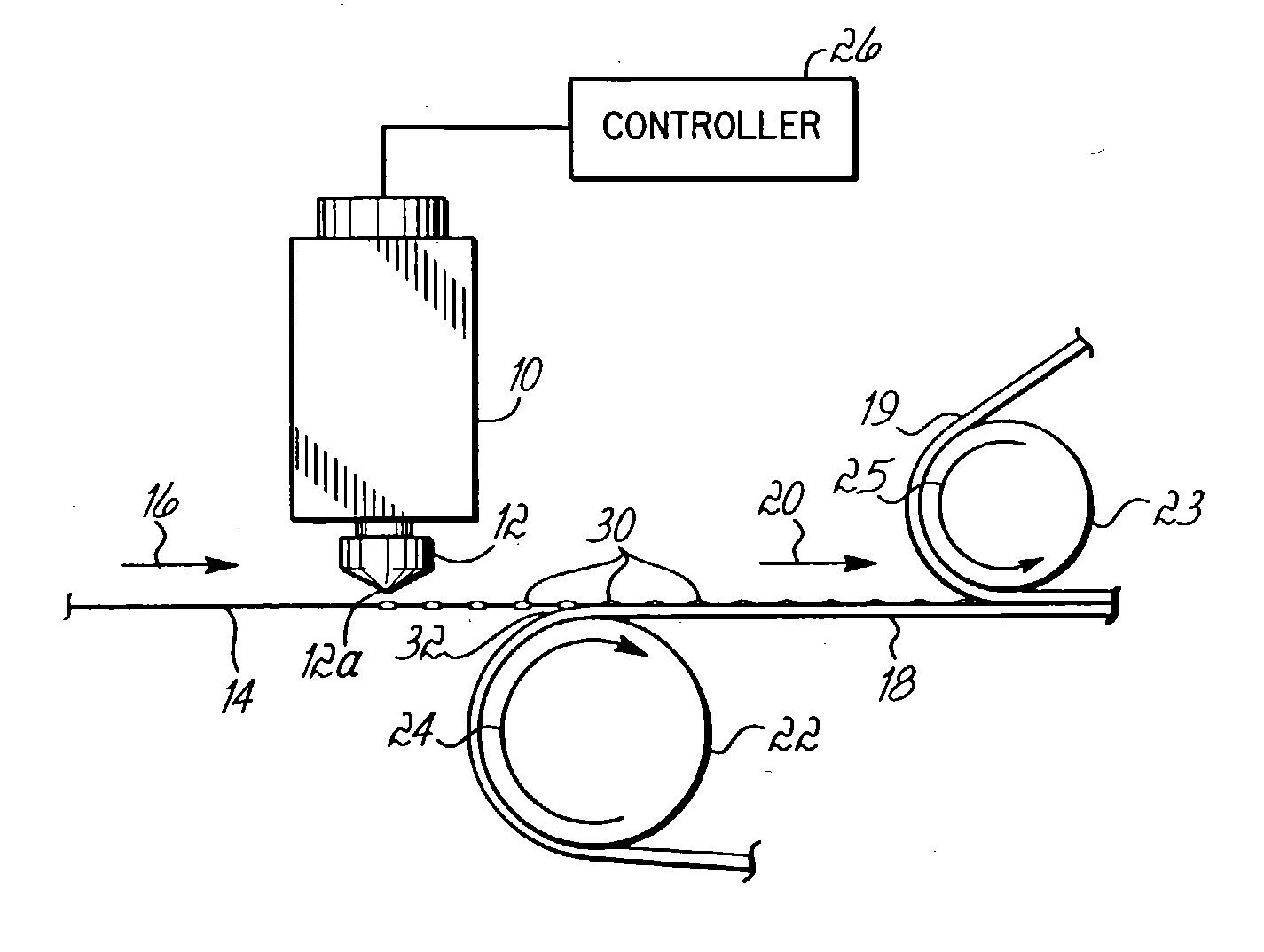

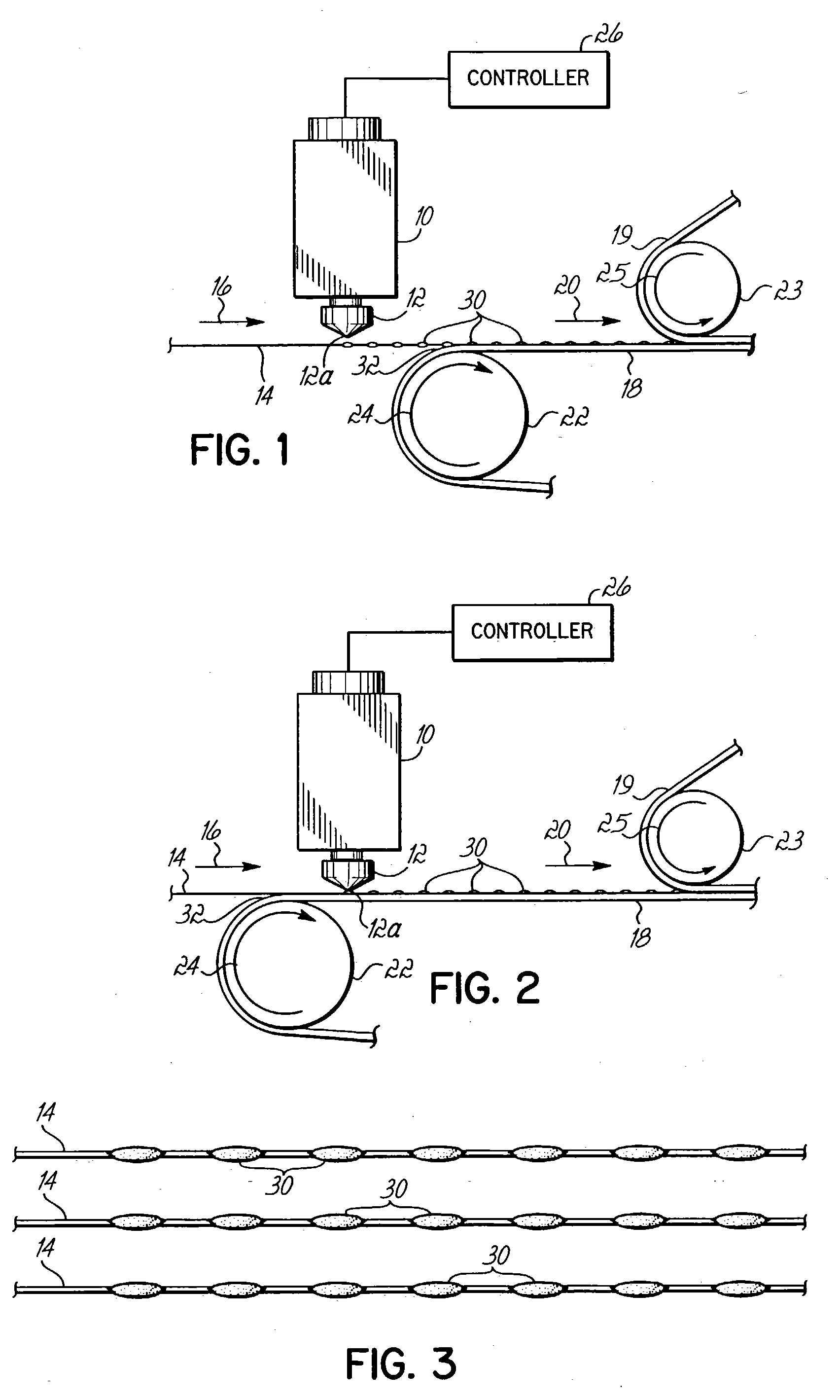

Method of securing elastic strands to flat substrates and products produced by the method

PendingUS20050013975A1Cost reductionIncrease creep resistanceLiquid surface applicatorsPersonal careEngineeringAdhesive

A method of securing an elastic strand to a sheet of material includes moving the elastic strand and the sheet in a converging manner from a position in which the elastic strand is spaced from the sheet to another position in which the elastic strand contacts one surface of the sheet. Discrete elongate segments of adhesive are intermittently applied to the strand. The elongate segments of adhesive secure the strand to the sheet. Various articles of manufacture may be formed using the method, including hygienic articles such as diapers.

Owner:NORDSON CORP

High-elongation aluminum alloy material and preparation method thereof

ActiveCN101525709AHigh strengthImprove creep resistanceTemperature control deviceMetal rolling arrangementsRare-earth elementElectrical conductor

The invention relates to a high-elongation aluminum alloy material and a preparation method thereof. The high-elongation aluminum alloy material contains 0.30-1.20% of iron, 0.03-0.10% of silicon, 0.01-0.30% of rare earth elements, and aluminum and inevitable impurities in weight percentage. The aluminum alloy is made from materials according to a fusion casting process and half-annealing treatment. An aluminum alloy conductor made by the method has high elongation and good safety and stability in use.

Owner:ANHUI JOY SENSE CABLE

Method and device for printing pictures and texts on surface of irregular object

InactiveCN101734030ASimple color printingEfficient Color PrintingDecorative surface effectsDuplicating/marking methodsPlastic moldingElectrical and Electronics engineering

The invention relates to a method and a device for printing pictures and texts, particularly to a method and a device for printing fine pictures and texts on the surface of an irregular object, which comprises the following steps of: a. manufacturing a compound transfer printing film; b. pre-deforming the compound transfer printing film; c. placing the deformed compound transfer printing film in a plastic hollow blow molding mould, realizing transfer printing in the plastic molding process, or clinging the deformed compound transfer printing film to a printing undertaking object, and sharing through one or more modes of heating, infrared illumination, ultraviolet illumination and pressurization to realize transfer printing; and d. removing a substrate layer and a stripping layer. The invention has the advantages that the printing of fine pictures and texts can be carried out on the surfaces of a regular object and the irregular object, pictures and texts are continuous, whether the local surface or the entire surface can be printed once through the invention, and the invention has a good solution particularly for an object with a complicated surface.

Owner:赵东林

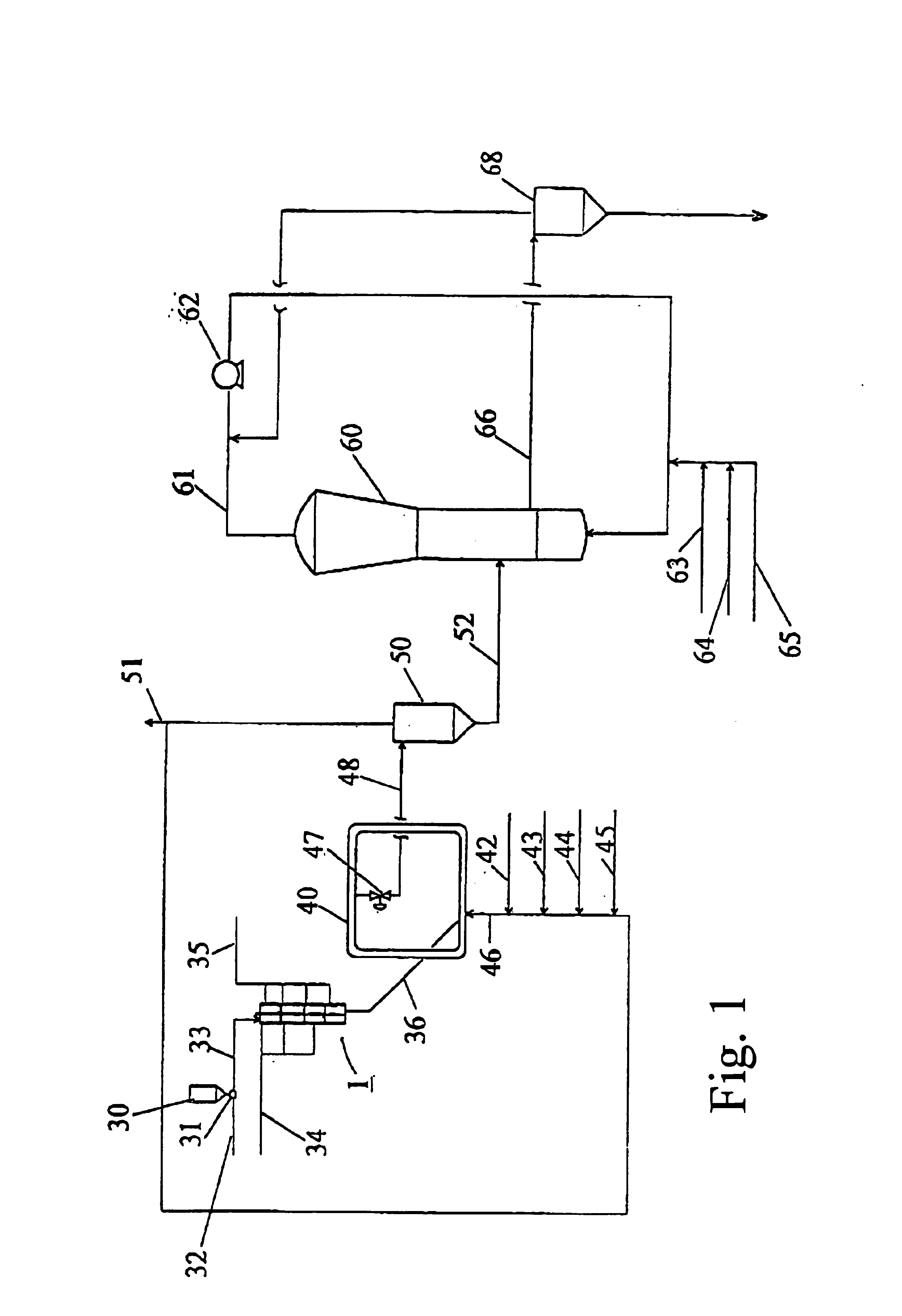

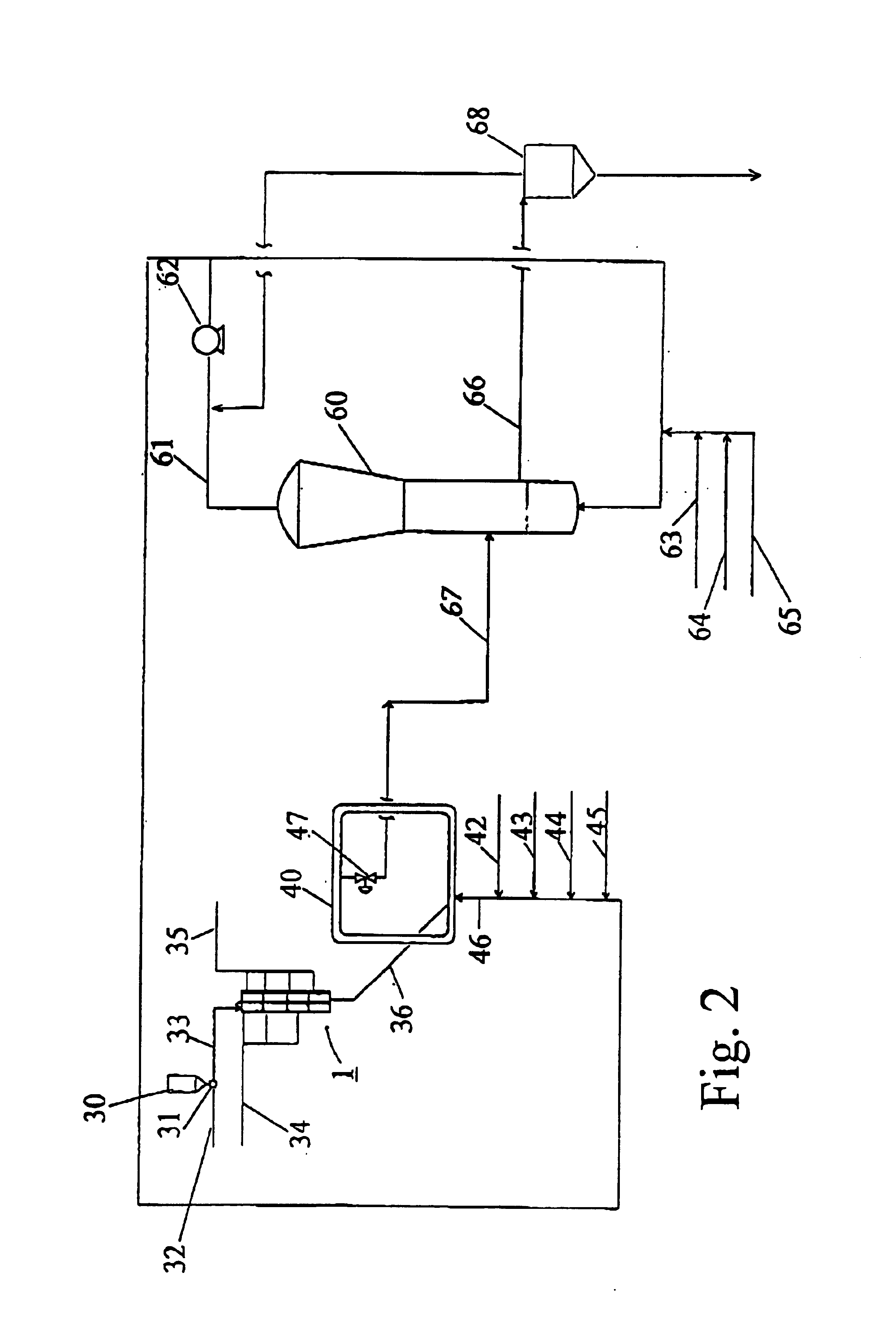

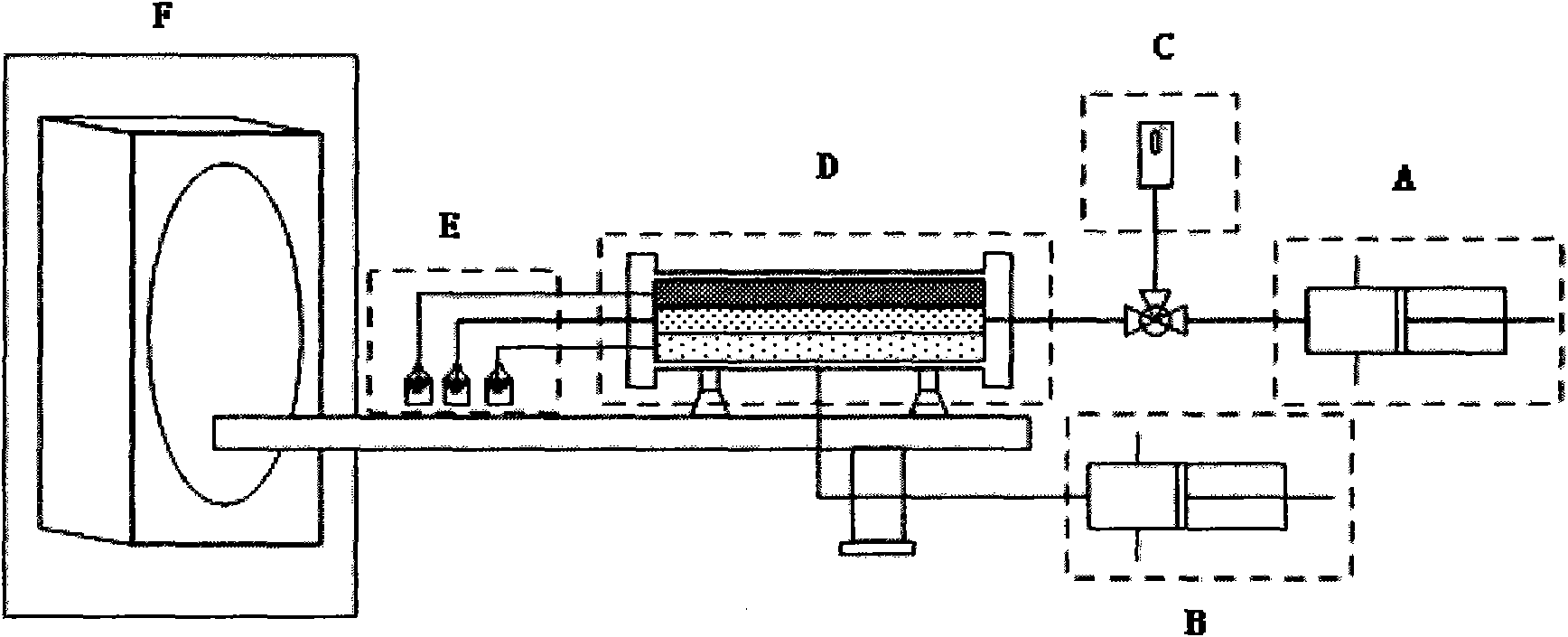

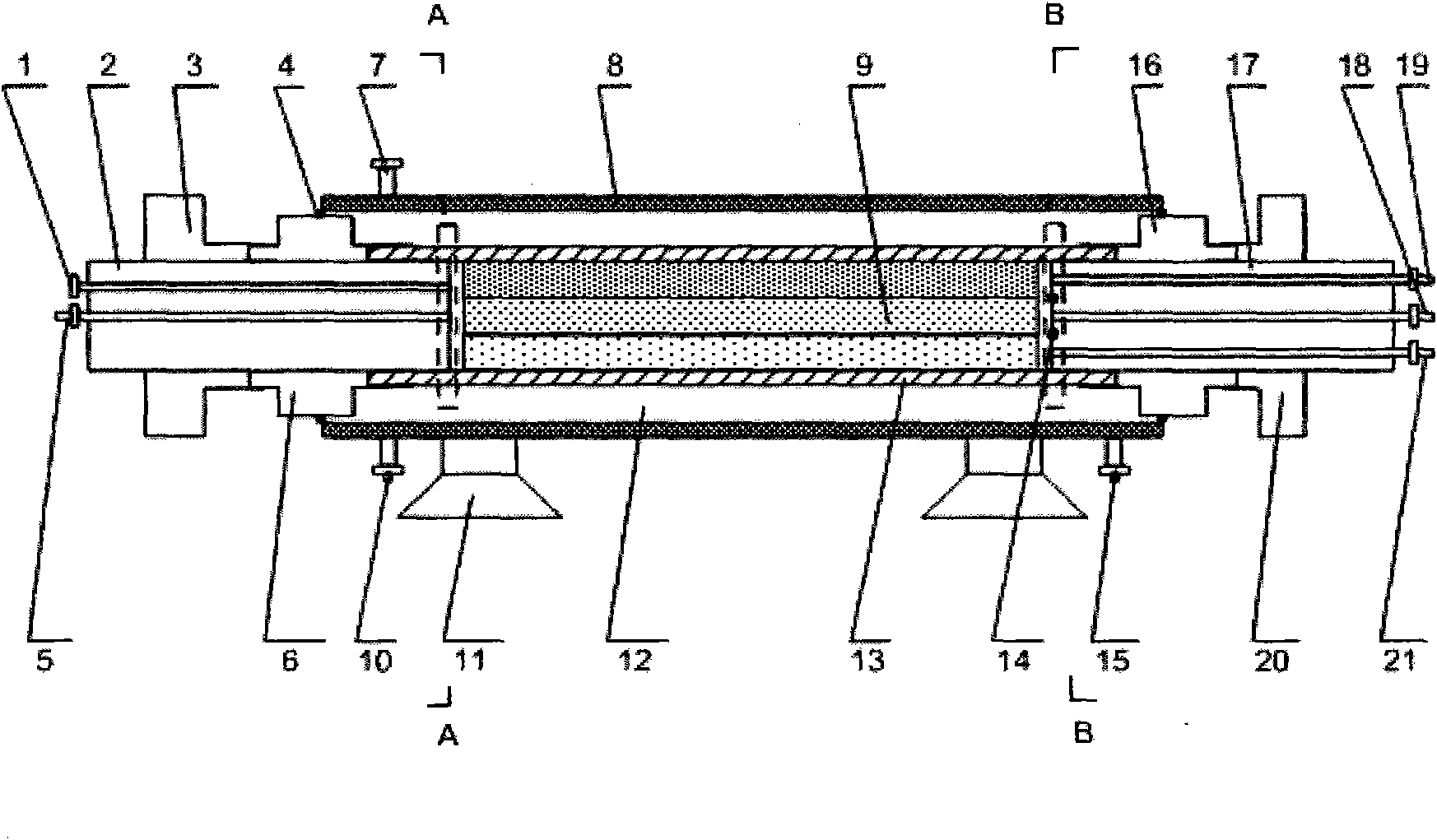

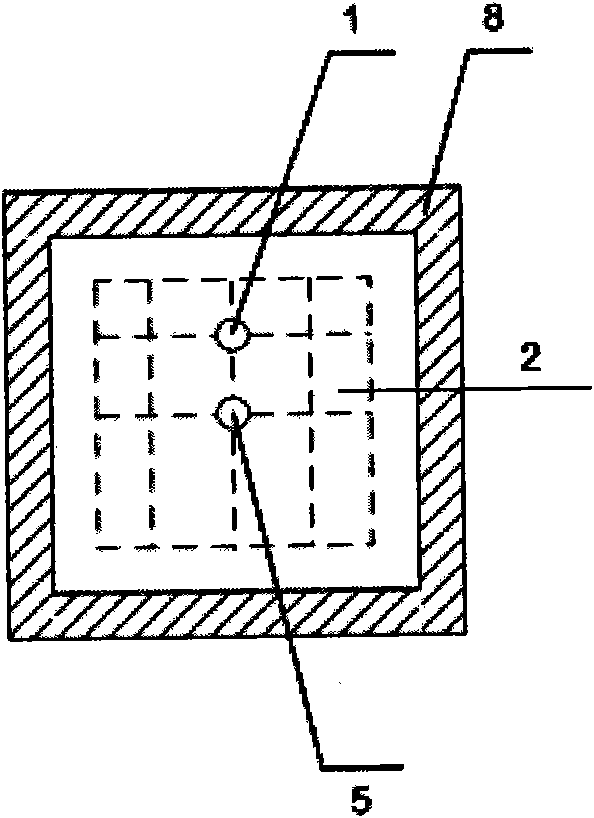

Computed tomography (CT) scanning heterogeneous model testing system

ActiveCN102095740AImprove mechanical propertiesPeel-resistantPermeability/surface area analysisMaterial analysis by transmitting radiationFluid saturationComputed tomography

The invention relates to a computed tomography (CT) scanning heterogeneous model testing system. The system comprises a CT scanning system, a displacement system, an overburden pressure system, a pressure measurement system, a heterogeneous multilayer core clamp holder and a metering system, wherein the heterogeneous multilayer core clamp holder consists of a shell, a rubber cylinder, a core left plug, a core right plug, a left fixing sleeve, a right fixing sleeve, a left fastening sleeve, a right fastening sleeve and a fixed bracket; the core right plug is provided with a plurality of liquid outlets; each liquid outlet is respectively aligned with one layer of core model; and a strip liquid outlet sealing gasket is formed on the core right plug, which correspond to a seam between two adjacent layers of core models, so that liquid flow passing through each layer of core model flows out from the corresponding liquid outlet of each layer of core model, and thus, intraformational heterogeneous water displacing oil layered measurement is realized. By the CT scanning system, the real-time on-line monitoring of the on-way distribution of saturation of fluid on each layer section in a heterosphere is realized so as to observe the interlayer communication phenomenon.

Owner:PETROCHINA CO LTD

Low cost heat-resistant magnesium alloy containing rare earth, and prepartion method

This invention discloses a method for preparing low-cost heat-resistant Mg alloy containing rare earth, which is prepared by: adding Mg / rare earth intermediate alloy into molten AZ91D, AM50B or AM60B Mg alloy, and die-casting. The rare earth content of the heat-resistant Mg alloy is 0.1-3.0 wt.%, and the rare earth is one of La, Pr, Sm, Eu, Tb, Ho, Er, Tm, Dy, Gd, Ce, Y, Ce-rich mixed rare earths and Nd-rich mixed rare earths. The method comprises: smelting Mg / rare earth intermediate alloy ingot (rare earth content = 10-60 wt.%), pressing into wire or rod, melting AZ91D, AM50B or AM60B Mg alloy, cutting Mg / rare earth intermediate alloy wire or rod, preheating, adding into molten AZ91D, AM50B or AM60B Mg alloy, and die-casting into heat-resistant Mg alloy. The heat-resistant Mg alloy has largely increased creep resistance at 120-200 deg.C, and can be used in cylinder body, automatic gear box, oil pump and crankcase.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

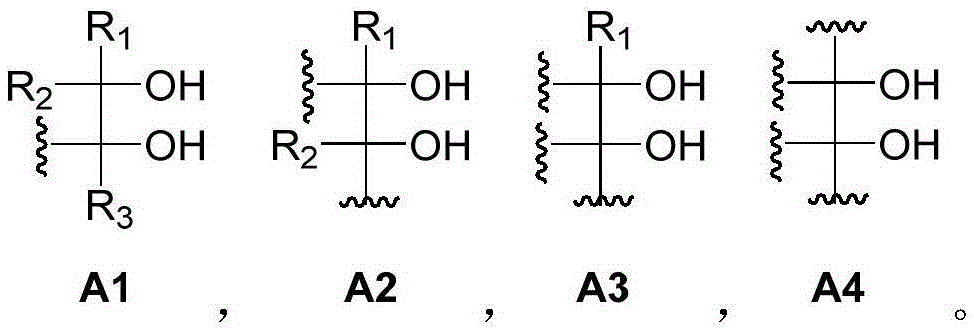

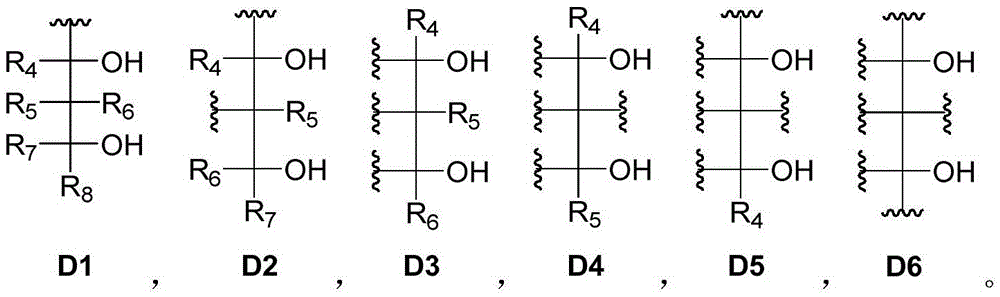

Dynamic polymer material

InactiveCN105646872ADynamic responsivenessMild reaction conditionsCoatingsPhenylboronic acidCross-link

The invention discloses a dynamic polymer material. The dynamic polymer material comprises a product obtained through reaction of the following components: at least one polyol compound containing two or more 1,2-diol motifs or 1,3-diol motifs as well as at least one phenylboronic acid compound containing two or more phenylboronic acid motifs provided with aminomethyl groups in ortho-positions. Dynamic reversible phenylborate bonds are formed through the reaction of the components and then constitute a dynamic cross-linked polymer. The polymer material has reusability and recoverability because of the dynamic reversibility of the special phenylborate bonds; besides, when the polymer material adopting a specific formula receives external force, dynamic bonds break preferentially to have energy dissipation and stress elimination functions, so that the material has good toughness. The material has broad application prospect in the fields of military space equipment, functional paint and coatings, biomimetic materials, biomedical materials and the like.

Owner:翁秋梅

Creep-resistant polypropylene composition and preparation method and application thereof

ActiveCN102344609AIncrease the interfacial bonding areaPerfect crystallinityElastomerPolymer science

The invention belongs to the field of material engineering and discloses a creep-resistant polypropylene composition and a preparation method and application thereof. The creep-resistant polypropylene composition is prepared from 40-80 percent by weight of polypropylene resin, 5-30 percent by weight of elastomer, 10-40 percent by weight of high-aspect-ratio (HAR) inorganic filler and 0.01-0.5 percent by weight of nucleating agent, wherein the nucleating agent is an alpha-crystal nucleating agent. In the invention, the polypropylene composition modified by the HAR inorganic filler and the alpha-crystal nucleating agent has high creep resistance; and an injection molding piece prepared from the polypropylene composition has stable size and small deformation under practical use conditions, and can fully meet the using requirements of relevant industries such as automobiles, home appliances and the like.

Owner:KINGFA SCI & TECH CO LTD +2

Silylated thermoplastic vulcanizate compositions

InactiveUS20060235156A1Improve creep resistanceEasy to condenseGraft polymer adhesivesElastomerSilanes

A process for making a thermoplastic vulcanizate includes blending a thermoplastic first polymer, an elastomeric second polymer, a carboxylic anhydride, a free radical generator, and a tackifier to provide a tacky first blend containing the thermoplastic first polymer and grafted elastomeric second polymer with the tackifier dispersed therein; then, reacting the first blend with a silane to provide a non-tacky thermoplastic vulcanizate product.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

High modulus crosslinked polyethylene with reduced residual free radical concentration prepared below the melt

InactiveUS20050124718A1Reduced free radical concentrationReduced residual free radical contentSurgical adhesivesAnkle jointsPolymer scienceCross-linked polyethylene

The present invention provides an irradiated crosslinked polyethylene containing reduced free radicals, preferably containing substantially no residual free radical. Disclosed is a process of making irradiated crosslinked polyethylene by irradiating the polyethylene in contact with a sensitizing environment at an elevated temperature that is below the melting point, in order to reduce the concentration of residual free radicals to an undetectable level. A process of making irradiated crosslinked polyethylene composition having reduced free radical content, preferably containing substantially no residual free radicals, by mechanically deforming the polyethylene at a temperature that is below the melting point of the polyethylene, optionally in a sensitizing environment, is also disclosed herein.

Owner:THE GENERAL HOSPITAL CORP +1

Cement-based grouting material and preparation method thereof

The invention relates to a cement-based grouting material and a preparation method thereof. The cement-based grouting material comprises a component A, a component B and a component C, wherein the component A comprises the following components by weight part: 80 to 90 parts of epoxy resin, 1 to 10 parts of diluents, 0 to 1 part of defoaming agent and 1 to 5 parts of coupling agent; the component B comprises a water-soluble amine curing agent with an emulsification function; the component C comprises the following components by weight part: 30 to 50 parts of cement, 2 to 4 parts of ultrafine mineral powder, 0 to 1 part of silica micropowder, 2 to 4 parts of expanding agent, 0 to 1 part of water-reducing agent and 40 to 60 parts of river sand; and the weight ratio among the component A, the component B and the component C is (60 to 100) : (90 to 150) : (400 to 800). Mechanical indexes, such as compressive strength, breaking strength and the like, of the cement-based water-soluble epoxy resin grouting material are far more excellent than those of the common cement grouting material.

Owner:天津天盈新型建材有限公司

Halogen-free flame-retardant long glass fiber reinforced polypropylene material and preparation method thereof

The invention relates to a halogen-free flame-retardant long glass fiber reinforced polypropylene material, which comprises the following raw materials in percentage by weight: 49 to 88.8 percent of polypropylene, 0.1 to 0.5 percent of thermal stabilizer, 0.1 to 0.5 percent of lubricating agent, 5 to 20 percent of halogen-free flame retardant, 1 to 5 percent of glass fiber compatilizer and 5 to 25 percent of long glass fiber, wherein the polypropylene is high fluidity polypropylene. The invention also relates to a preparation method for the polypropylene material. The preparation method comprises the following steps of: preparing a long glass fiber master batch and a halogen-free flame-retardant master batch, mixing the two master batches uniformly, and thus obtaining the polypropylene material, wherein when the polypropylene material is used, the polypropylene material is directly used for injection molding of parts. The polypropylene material has excellent flame-retardant property and dimensional stability, high mechanical strength, low shrinkage rate and good creep resistance and thermal oxidation resistance, is suitable for injection molding of thin-wall large pieces and automotive part products with complex structures such as automotive engine bottom guard plates, front-end modules, instrument panel frameworks and the like, saves the automobile manufacturing cost, and is environment-friendly.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Silver alloy wire and preparation method thereof

The invention relates to a silver alloy wire and a preparation method thereof. The silver alloy wire is prepared from the following components of 0.5-10 percent of Au, 0-1 percent of Pt, 1-6 percent of Pd, 0-1 percent of Rh, 0-1 percent of Cu, 0-500ppm of Ln, 0-200ppm of Ce, 0-0.5 percent of Al, 0.7-3 percent of Ti, 0-0.2 percent of Si, 0-0.3 percent of Zn, 0-1 percent of Sn, 0-10 percent of Be and the balance of Ag. A directional continuous casting process is adopted. The prepared silver alloy wire overcomes the problem that the bonded silver wire is easily subjected to sulfur corrosion in the prior art, and has a series of other excellent characteristics.

Owner:YANTAI YINUO SEMICON MATERIAL CO LTD

Mn-containing creep-resisting rolled zinc alloy belt material and preparation method thereof

InactiveCN101906555AOutstanding advantagesHighlight positive effectsRoll mill control devicesMetal rolling arrangementsRare-earth elementManganese

The invention relates to a Mn-containing creep-resisting rolled zinc alloy belt material. The material comprises the following components in percentage by weight: 0.5 to 3.0 percent of copper, 0.01 to 2.0 percent of manganese, 0.05 to 0.3 percent of titanium and the balance of zinc and less than 0.05 percent of impurities. An alloy component can also contain the following component in percentage by mass: 0.01 to 0.5 percent of X, wherein the X is at least one of aluminum and rare earth elements (Ce+La). A method for preparing the material comprises the following steps of: smelting by a protective covering method and adding alloy elements in the forms of pure zinc, Zn-Cu, Zn-Ti, Cu-Mn, pure aluminum and Ce+La composite rare earth, wherein a smelting temperature is between 650 and 740 DEG C; pouring at the temperature of between 420 and 480 DEG C; uniformly annealing cast ingots at the temperature of between 350 and 380 DEG C for 6 to 10 hours; performing hot rolling for multiple times at the temperature of between 220 and 280 DEG C, wherein total deformation is between 60 and 95 percent; performing cold rolling, wherein the total deformation is between 50 and 80 percent; and after rolling, annealing at the temperature of between 180 and 200 DEG C for 2 to 3 hours. The alloy of the invention has high creep resistance, hot processing performance and mechanical property and is suitable for the fields of building decoration, transportation, instruments, meters and the like.

Owner:CENT SOUTH UNIV

Coupling agents for natural fiber-filled polyolefins

InactiveUS20070208110A1Increased durabilityLow water absorptionVegetal fibresPolyolefinPolymer science

The invention is a coupling agent, which is made from a polyolefin composition and is for wetting a cellulosic fiber. The coupling agent desirably includes a polyolefin resin having a melt flow index at 190° C. and 2.16 kg of about 0.5 to 100 (g / 10 min). The polyolefin resin is combined with 1.6 to 4.0 weight percent maleic anhydride, and the composition has less than 1,500 ppm of free maleic anhydride. The coupling agent has a yellowness index of 20 to 70. A cellulosic composite can be made from the coupling agent by combining the coupling agent with cellulosic fiber and at least one thermoplastic polymer.

Owner:CHEMTURA CORP

Nickel-base alloy, processing therefor, and components formed thereof

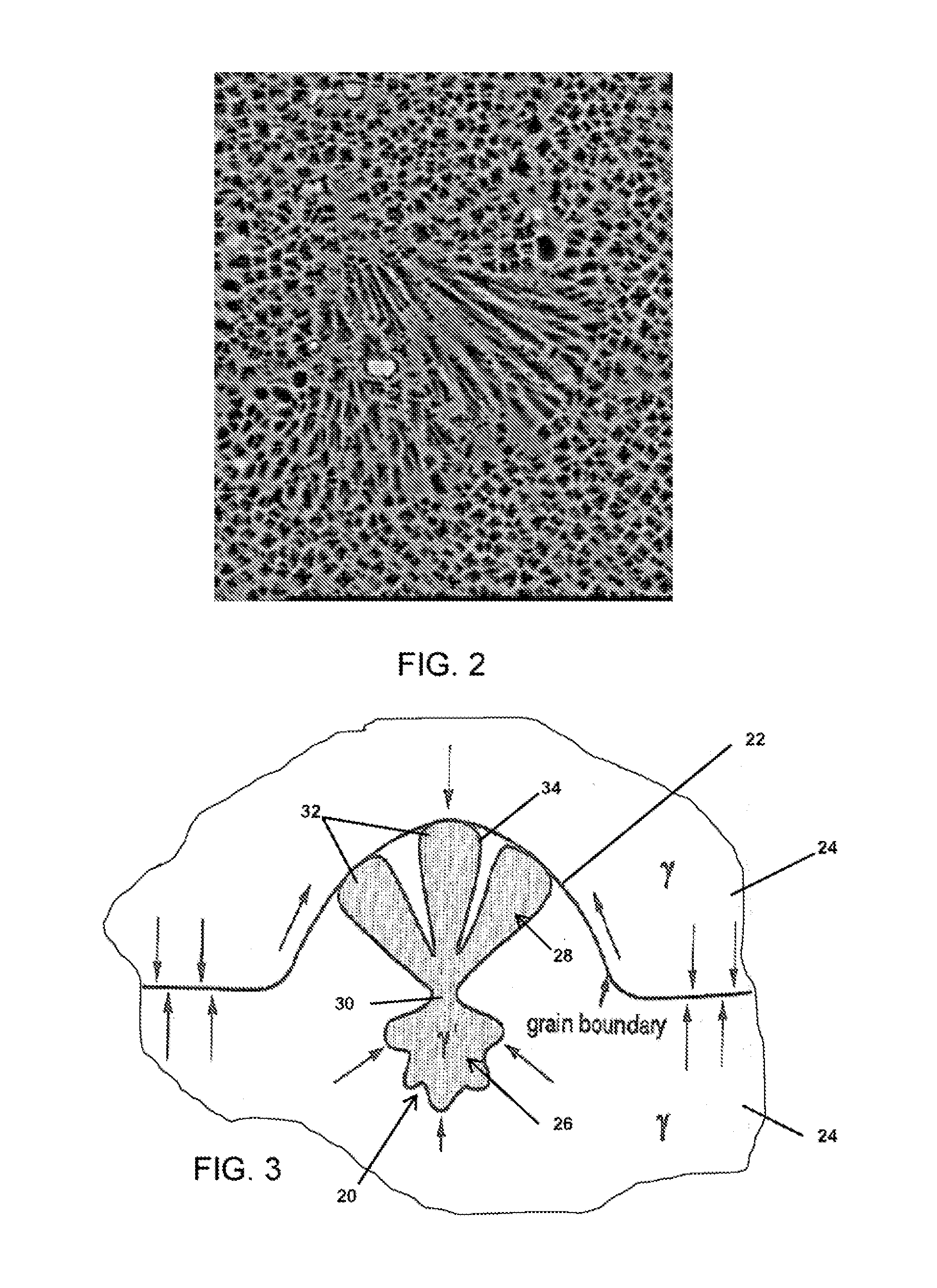

A gamma prime nickel-base superalloy and components formed therefrom that exhibit improved high-temperature dwell capabilities, including creep and dwell fatigue crack growth behavior. The superalloy contains, by weight, 10.00 to 22.0% cobalt, 10.0 to 14.0% chromium, 4.0 to 6.0% tantalum, 2.0 to 4.0% aluminum, 2.0 to 6.0% titanium, 1.5 to 5.0% tungsten, 1.5 to 5.0% molybdenum, 1.0 to 3.5% niobium, 0.05 to 0.6% hafnium, 0.02 to 0.10% carbon, 0.01 to 0.40% boron, 0.02 to 0.10% zirconium, the balance essentially nickel and impurities, wherein the titanium:aluminum weight ratio is 0.7 to 1.5. The superalloy is hot worked and heat treated to contain cellular gamma prime precipitates that distort grain boundaries, creating tortuous grain boundary fracture paths that are believed to promote the fatigue crack growth resistance of the superalloy.

Owner:GENERAL ELECTRIC CO

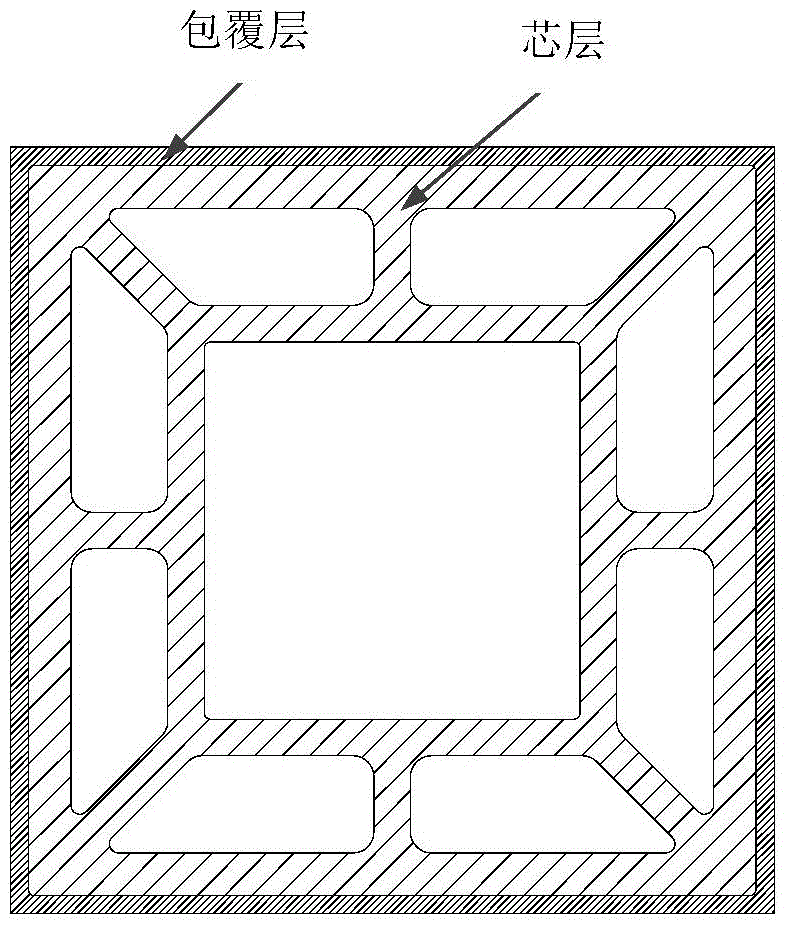

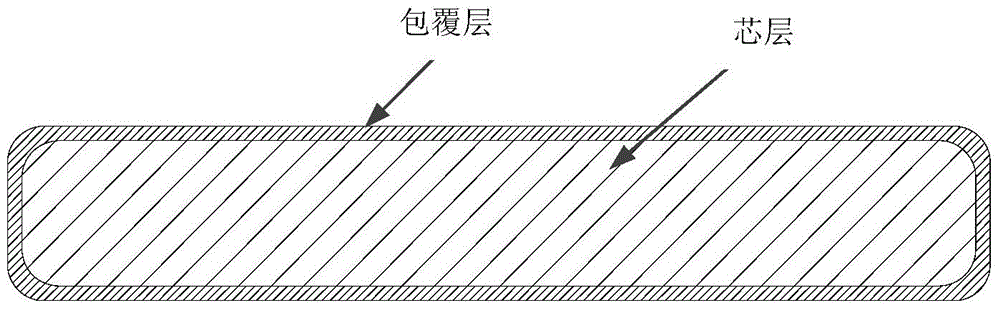

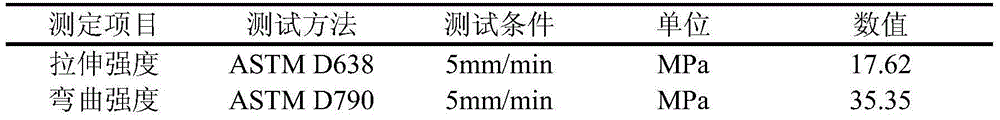

High strength wood-plastic coated coextruded composite material and preparation method thereof

InactiveCN105644074APlay the role of "filling"Improve mechanical propertiesSynthetic resin layered productsLaminationFiberDiameter ratio

The invention provides a high strength wood-plastic coated coextruded composite material. The material is composed of a core layer and a coating layer. The coating layer coats the surface of the core layer through a co-extrusion technology, biomass powder in the core layer is improved to a biomass fiber material, because of a large length-diameter ratio, the biomass fiber material not only plays a "filling" role in a wood-plastic composite material, but also plays a "reinforcing" role, greatly improves the mechanical properties of the composite material, especially improves the impact resistance, creep resistance and other properties, thereby broadening the application scope of the wood-plastic composite material. In addition, the coating layer involved in the invention preferably contains ethylene-methyl acrylate copolymer resin, ethylene-vinyl alcohol copolymer resin and high strength fiber, thus being conducive to further enhancing the mechanical properties of the composite material and the binding force with the core layer.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High adhesion leadless soldering tin grease

InactiveCN1569383AStrong adhesionImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaSolventBenzimidazole

The invention discloses a leadless solder paste with high adhesion force for electron product surface pasting. The leadless solder paste contains a Sn-Ag-Cu-Bi-Ni base leadless solder powder blended with solder agent. The solder agent is made up of 35-50wt% of resin (such as modified abietic resin and waterless malic acid resin), 1-10wt% of thixotrope(such as modified hydro castor oil, fatty glyceride), 35-55%wt% of solvent (undercanol, dimethyl hexanediol), 1.5-5wt%of activator (succinic acid, tetrabutyl amine hydrobromic acid). The solder agent may also include 0.01-0.9wt% copper inhibitor made up of one or several of benzothiazole, benzotrinitrogenazole, and benzimidazole.

Owner:郴州金箭焊料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com