Patents

Literature

332results about How to "Low compression set" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

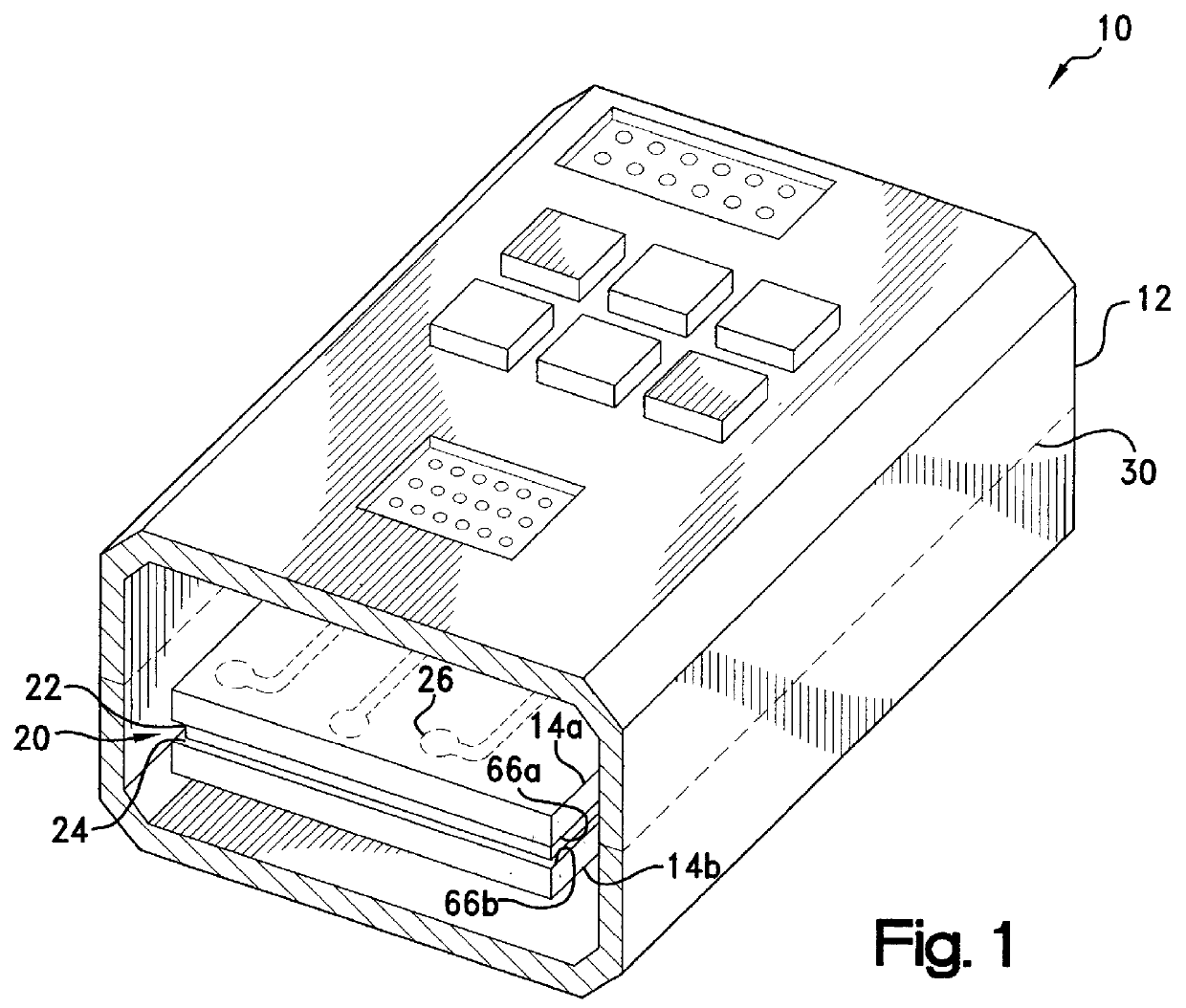

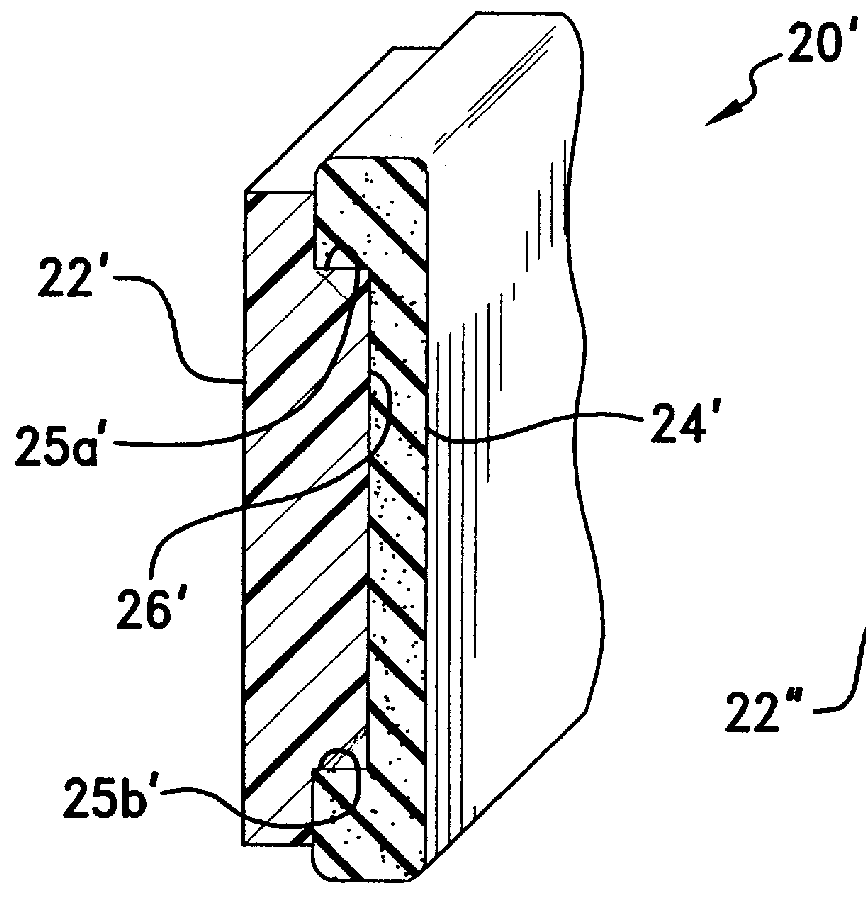

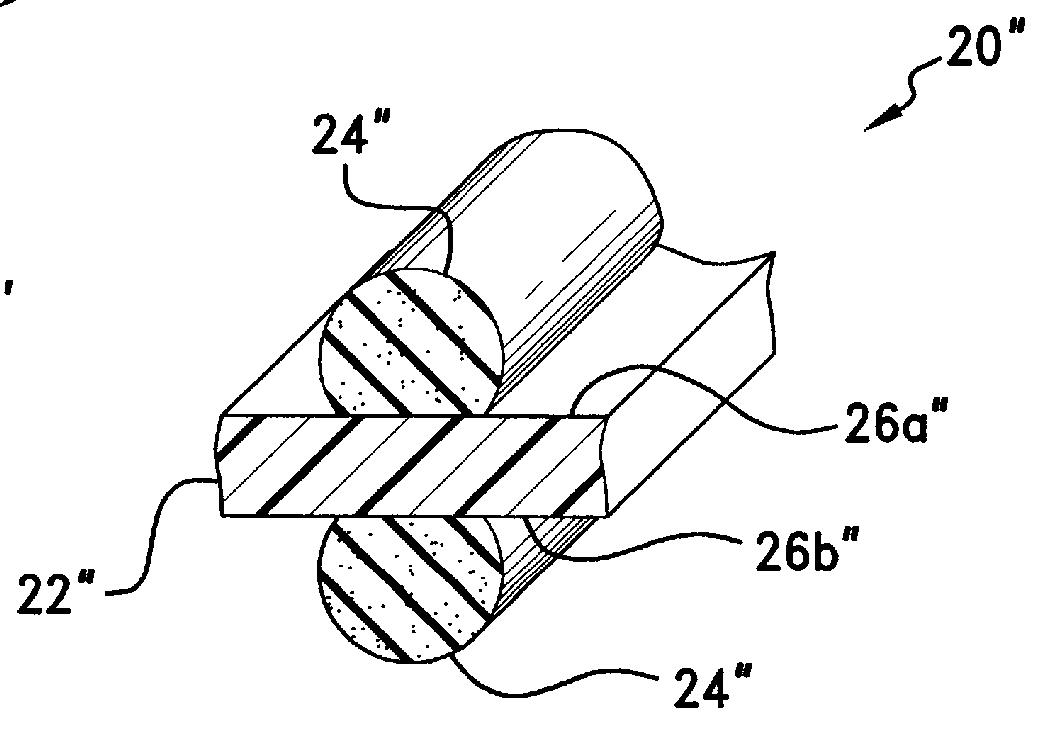

Low closure force EMI shielding spacer gasket

InactiveUS6121545AEnhance the imageEnsure electrical continuityEngine sealsScreening gaskets/sealsEdge surfaceBending moment

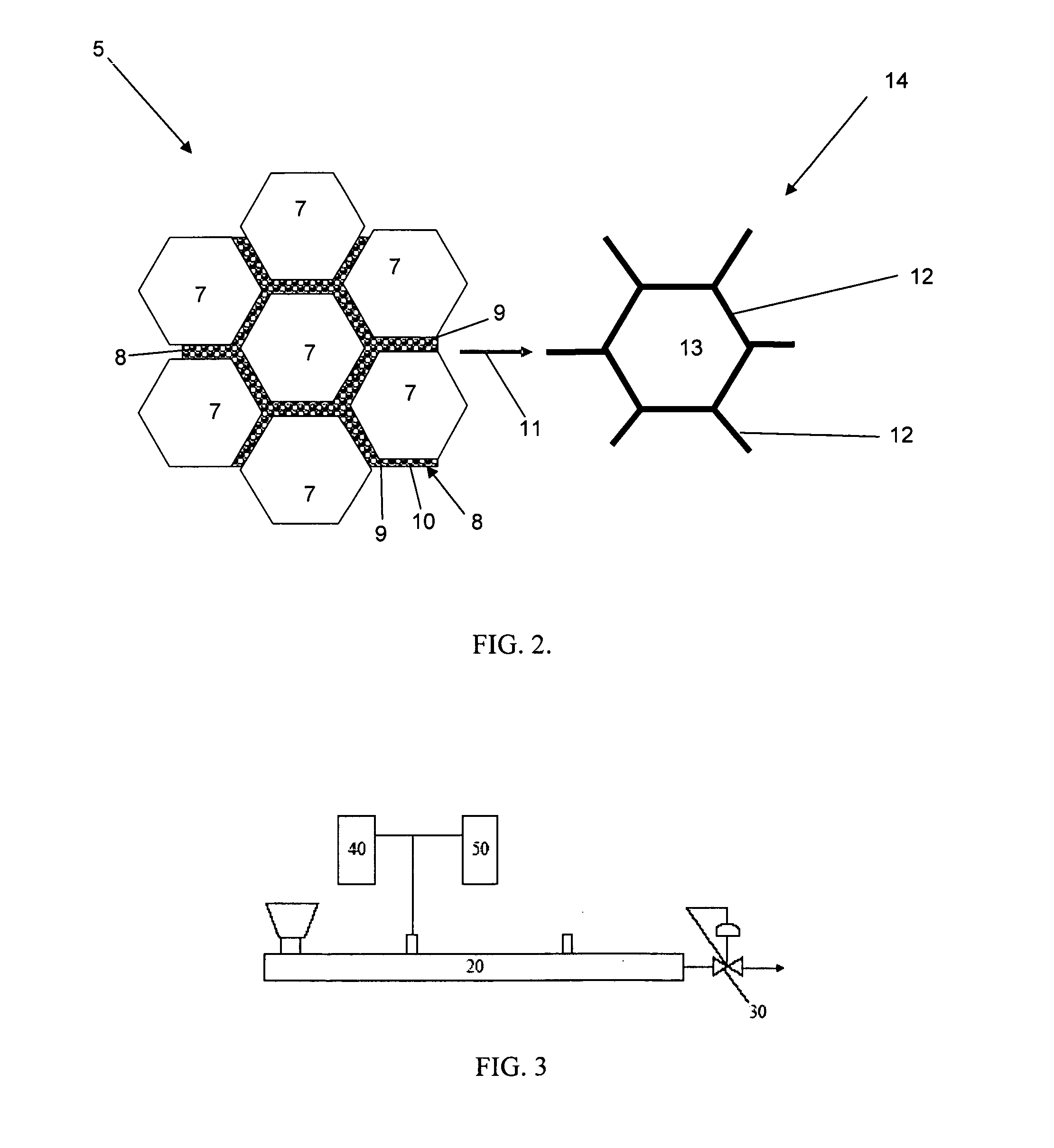

An EMI shielding spacer gasket assembly for interposition under a predetermined compressive load within an electronics enclosure between a first surface and an oppositely-disposed second surface of the enclosure. The assembly includes a frame member and an electrically conductive, elastomeric member extending along at least a portion of the perimeter of the frame member as retained on a corresponding peripheral edge surface thereof. The elastomeric member has an outboard side which is compressible axially under the compressive load for providing an electrically conductive pathway between the surfaces of the enclosure. In an uncompressed orientation, the outboard side of the elastomeric member exhibits elongate upper and lower bearing portions which are disposed at a spaced-apart radial distance from the frame member to define a corresponding bending moment arm. Each of the bearing portions is angularly deflectable relative to the moment arm to effect the compression of the elastomeric member under a relatively low compressive load.

Owner:PARKER INTANGIBLES LLC

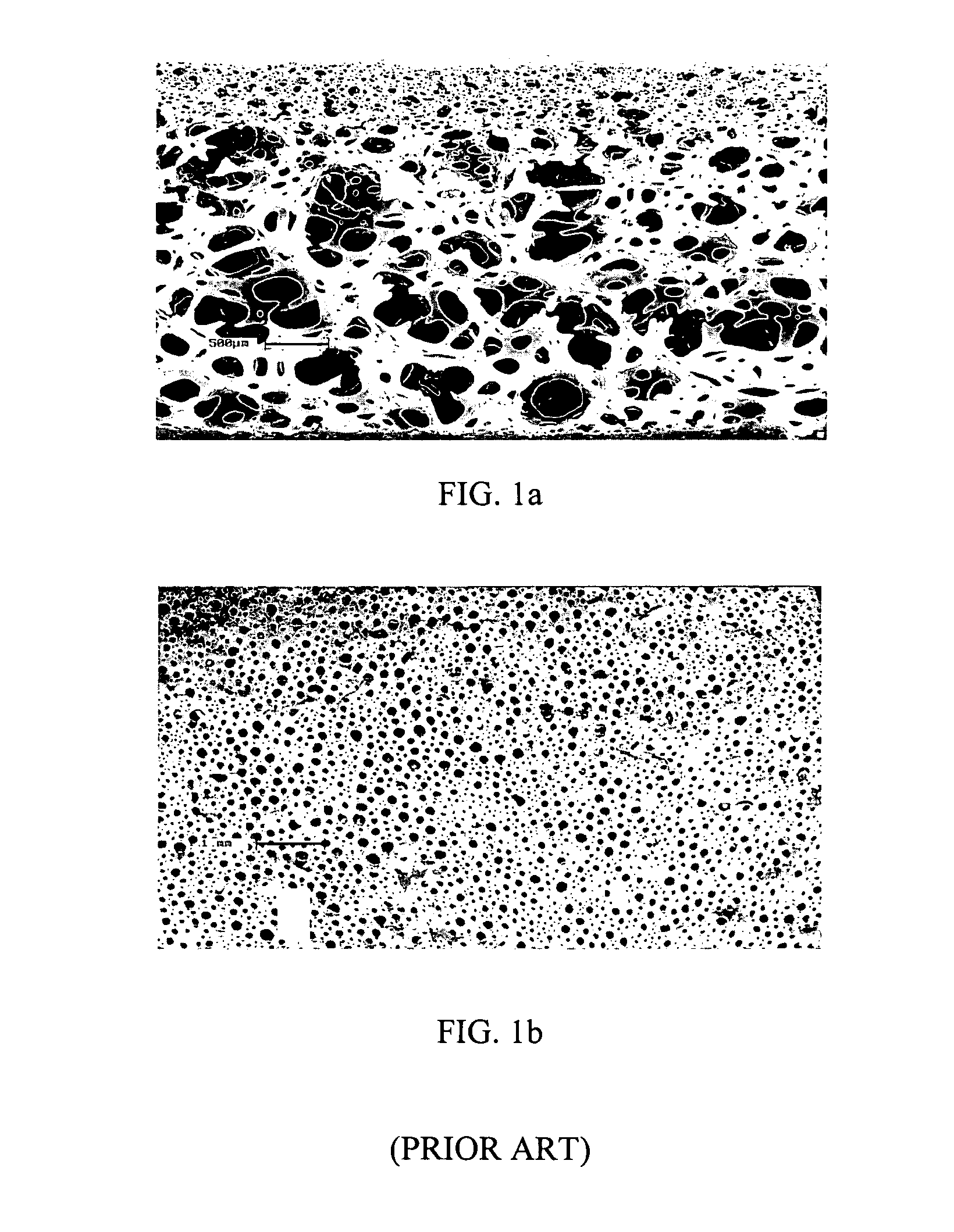

Fibrillated polyolefin foam

ActiveUS20080076844A1Improve heat resistanceLow compression setAbsorbent padsBandagesThermoplasticFiber

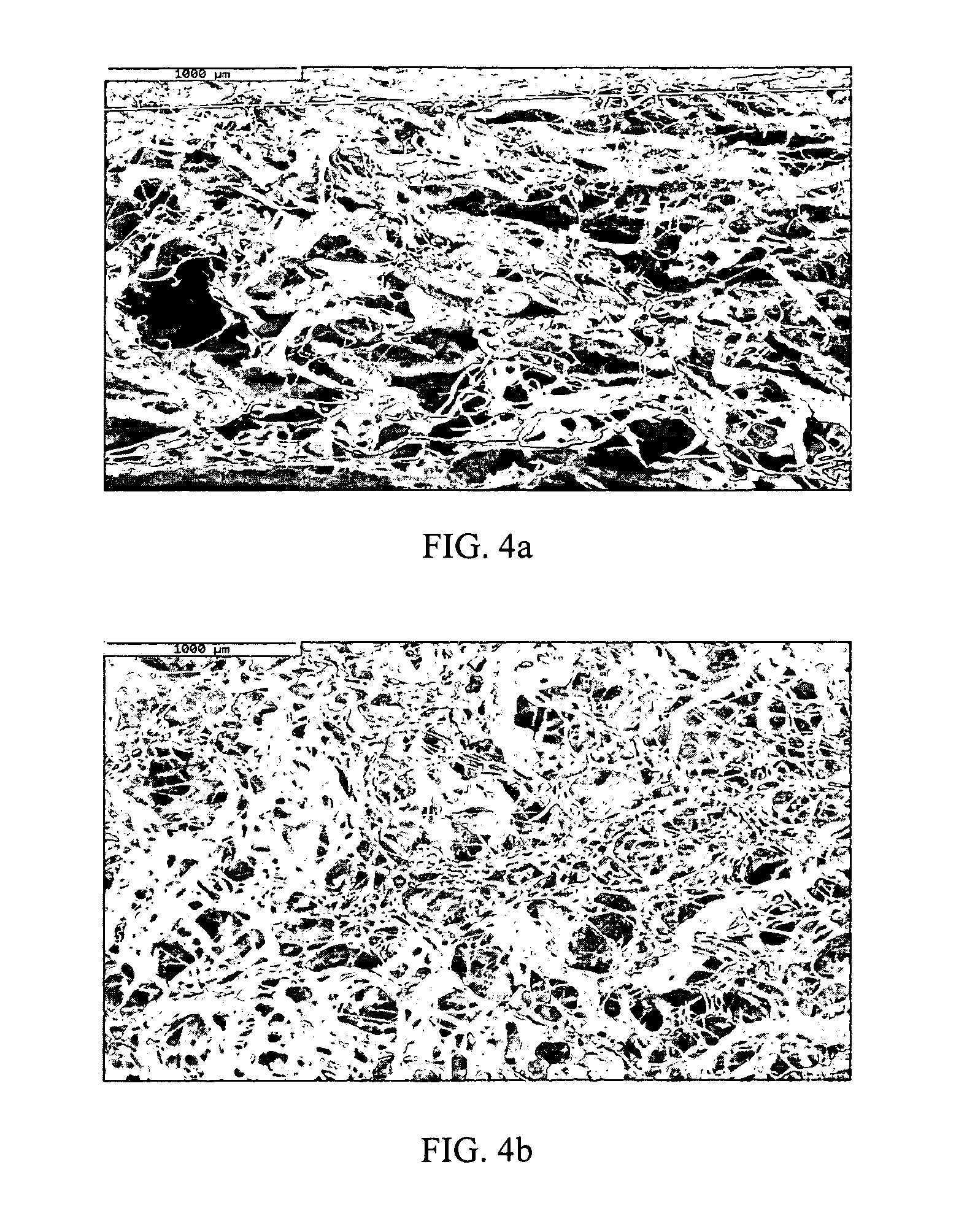

A method for generating a thermoplastic foam from an aqueous dispersion, the aqueous dispersion comprising a thermoplastic resin, water, and a dispersion stabilizing agent, the method including: adding at least one froth stabilizing surfactant to the aqueous dispersion to form a mixture; adding a fiber to the mixture; and frothing the mixture to create a froth, removing at least a portion of the water in the froth to create a foam, wherein the foam generated has a non-cellular fibrillated morphology. In another aspect, embodiments disclosed herein relate to a foam having a thermoplastic-based, fibrillated, non-cellular structure, wherein the foam has an average density of about 0.02 g / cm3 to about 0.07 g / cm3. In certain embodiments, the foam may be used in an absorbent article.

Owner:DOW GLOBAL TECH LLC

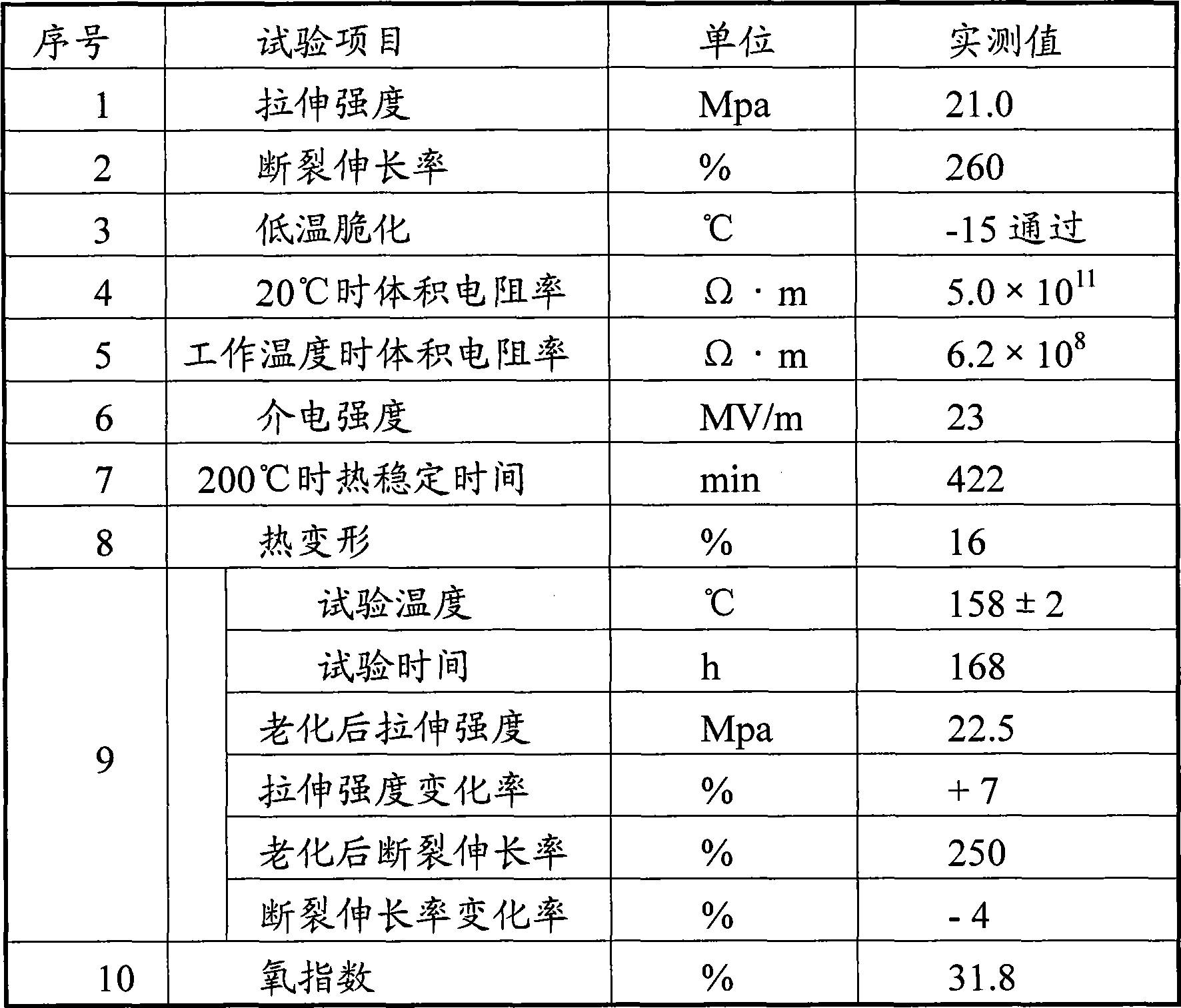

High temperature resistant environment-protective polychloroethylene material for electric wire and cable

InactiveCN101412834AImprove mechanical propertiesImprove insulation performancePlastic/resin/waxes insulatorsInsulated cablesPolyesterPolyvinyl chloride

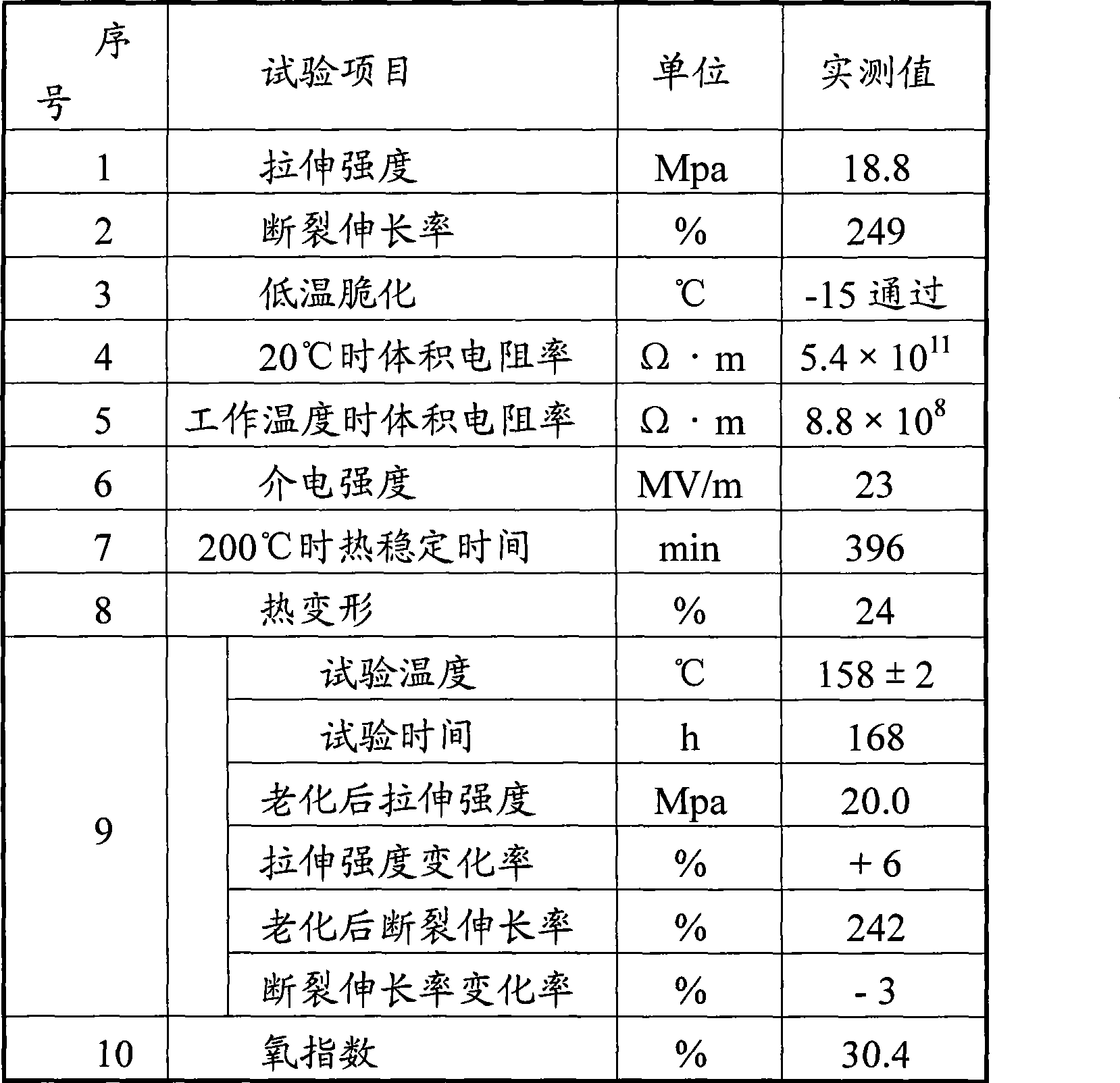

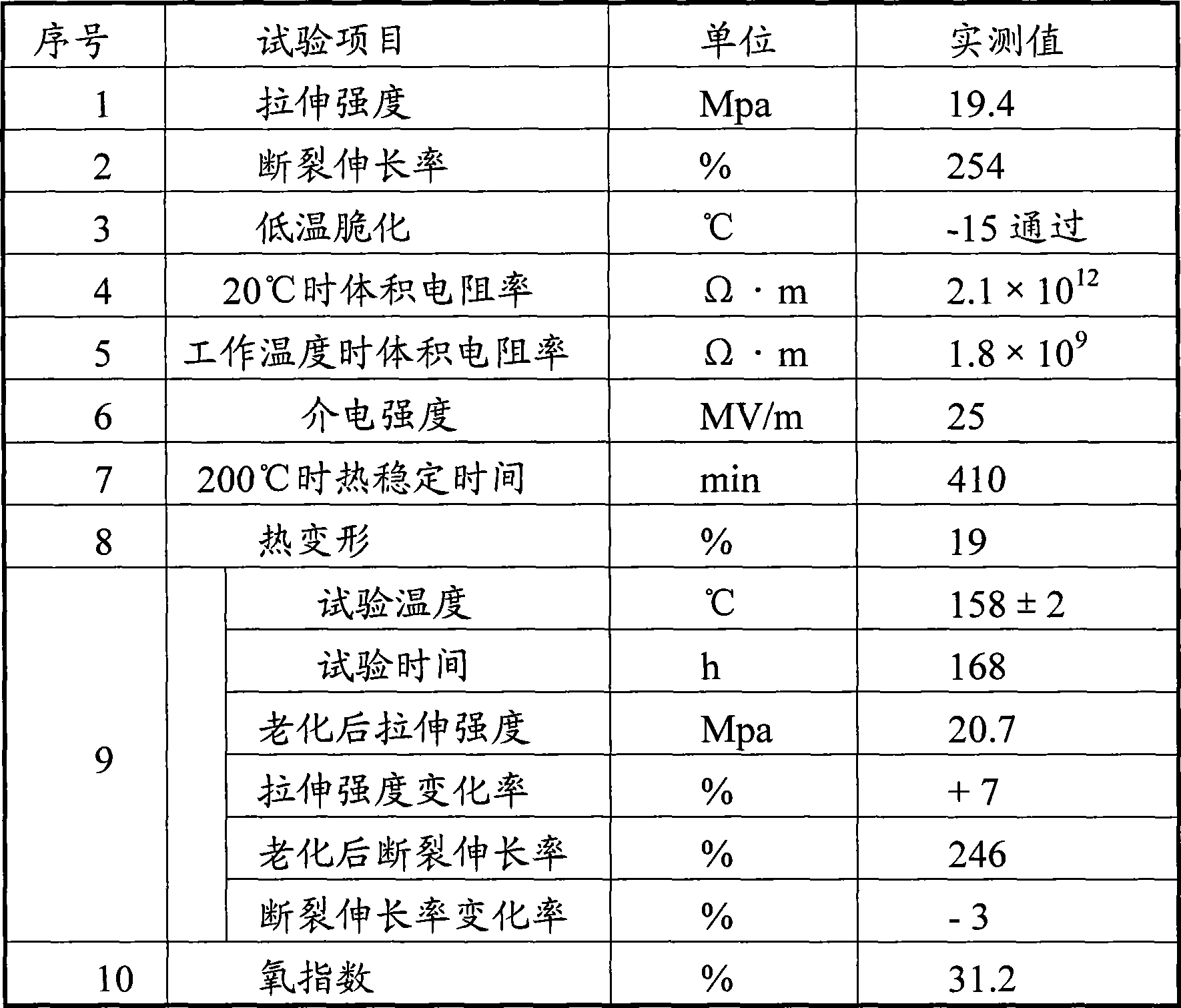

The invention provides a high-temperature resistant environment-friendly polyvinyl chloride material for wires and cables. A raw material formulation mainly comprises the following materials in weight portion: 80 to 120 portions of loose-type polyvinyl chloride resin, 20 to 55 portions of tetraoctyl pyromellitate, 5 to 35 portions of polyester plasticizer and 12 to 18 portions of calcium-zinc stabilizer, wherein the polymerization degree of the loose-type polyvinyl chloride resin is between 2,000 and 3,000; in the calcium-zinc stabilizer, the total content of lead, cadmium, mercury and hexavalent chromium is less than or equal to 10 ppm of the total weight of the calcium-zinc stabilizer; the polyester plasticizer is polypropylene-1, 2-glycol adipate or polypropylene-1, 3-butylene terephthalate; and the molecular weight of the polyester plasticizer is between 3,000 and 4,000. After the material is aged in a hot-air oven for 168 hours at 158 DEG C, the retention rate of tensile strength is up to 106 percent; the retention rate of elongation at break is 97 percent; and the material is good in mechanical physical properties and insulating property. Therefore, the material meets the temperature-resistant requirement on long-term operating temperature at 125 DEG C in UL1581.

Owner:中广核三角洲(江苏)塑化有限公司

Polyurethane foam, process for producing the same, and foam forming composition

InactiveUS6455606B1Improve mechanical propertiesLow compression setPeptide preparation methodsCushioningFoaming agent

A polyurethane foam which is obtained by reacting an addition-polymerizable active hydrogen component comprising a compound having a group containing active hydrogen and an addition-polymerizable functional group or comprising both this compound and a compound containing at least 2.5 groups (on the average) containing active hydrogen and not containing addition-polymerizable functional groups with an organic polyisocyanate in the presence or absence of at least one auxiliary selected from the group consisting of foaming agents and additives to polymerize the addition-polymerizable functional group and simultaneously form a polyurethane, and which has a structure in which the chains formed by the addition polymerization have been cross-linked to the polyurethane chains. The polyurethane foam is useful as a rigid polyurethane foam excellent in hardness, dimensional stability, etc. and usable as a heat insulator, shock-absorbing material, synthetic wood, etc., or is useful as a soft polyurethane foam reduced in compression set and usable as a cushioning material, shock-absorbing material, sound insulating / absorbing material, etc.

Owner:SANYO CHEM IND LTD

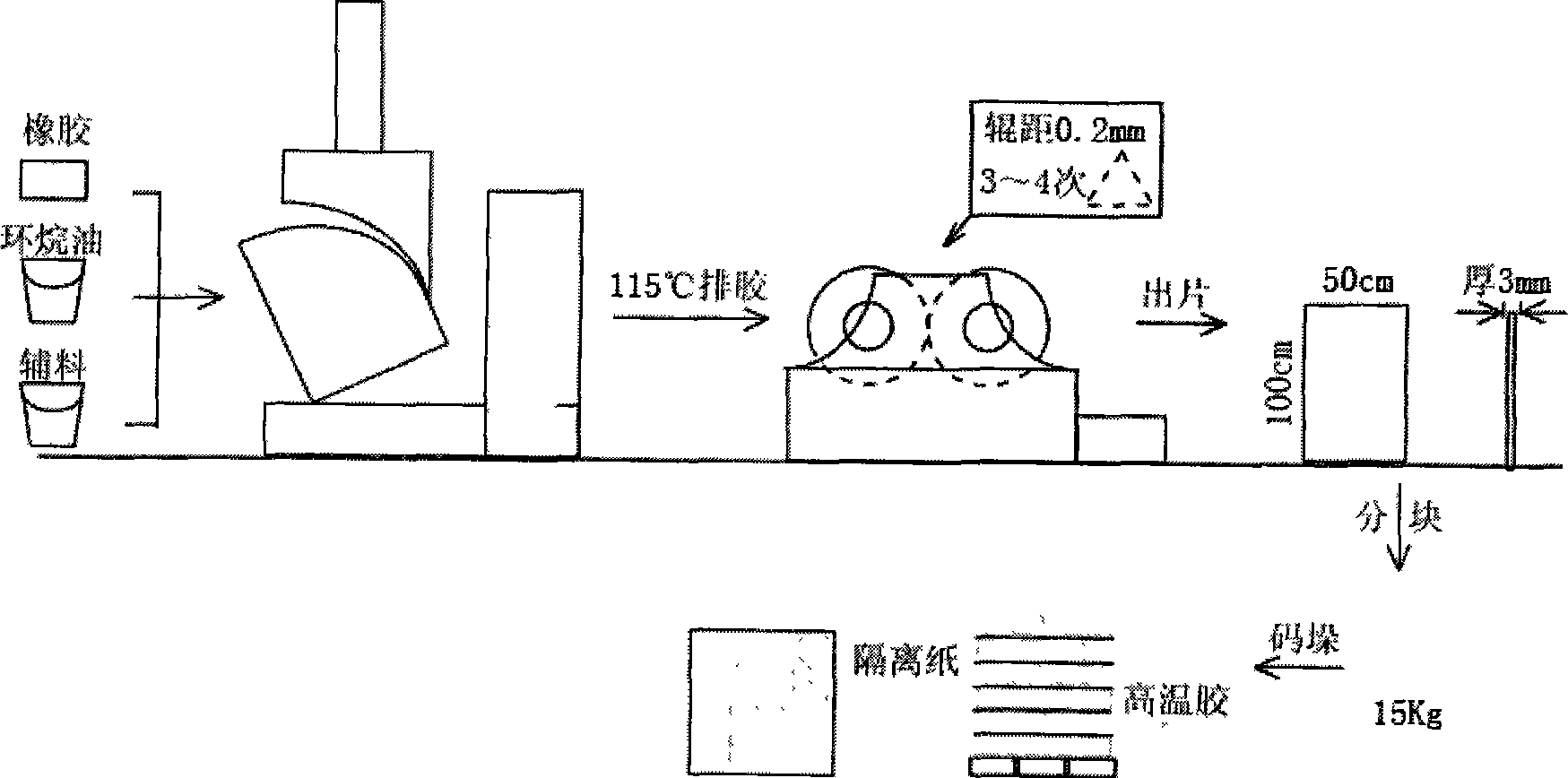

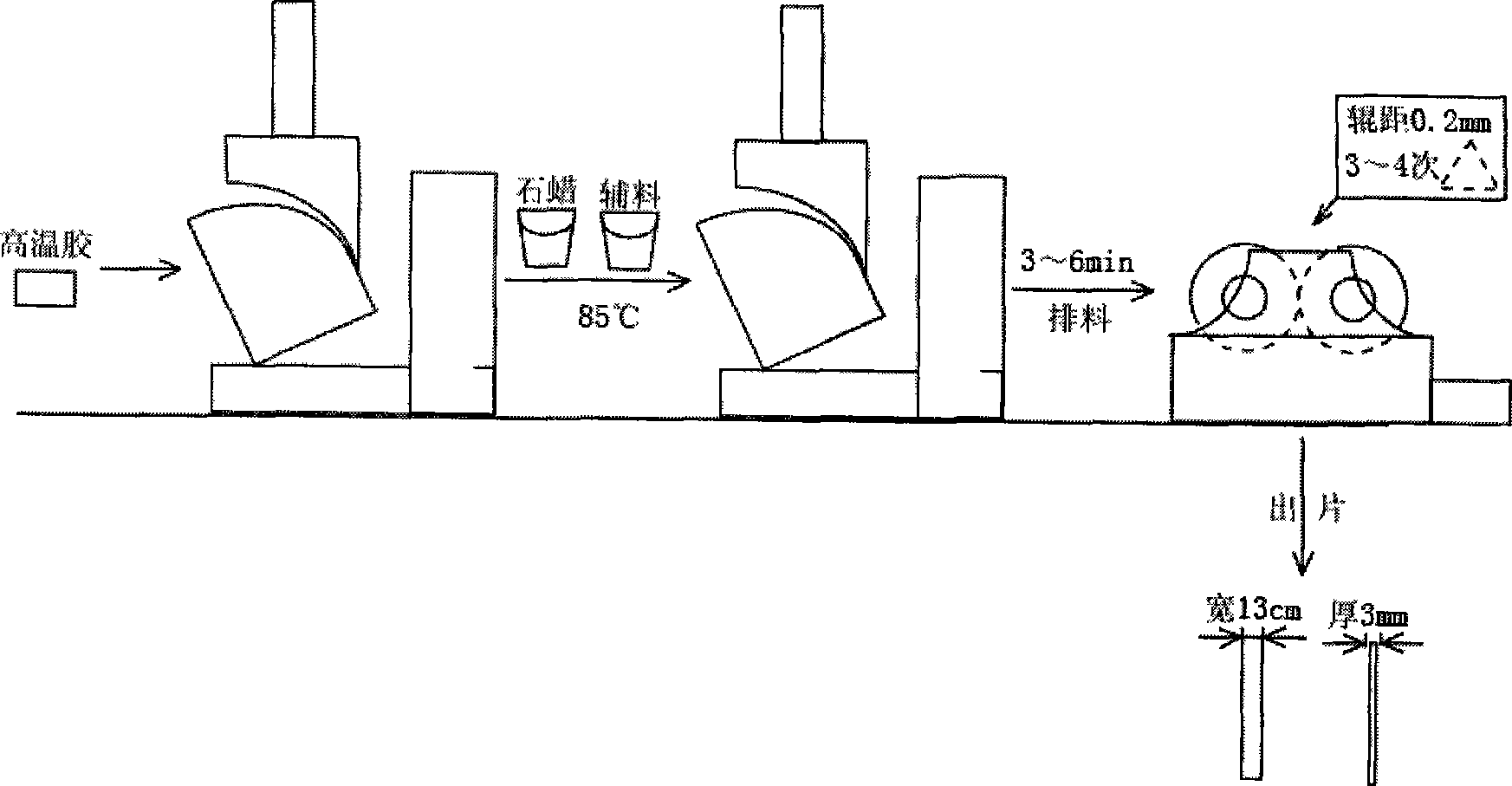

Thermoplastic elastomer and its production method

The invention provides a high elasticity thermal plasticity elastic body and the method to make. The weight proportion of the elastic body includes: plasticity ingredient styrene-butadiene-styrene block copolymer 100, filling naphthenic oil or white oil 40-60, modification agent 0-110, stabilizing agent 2-10, lubricant 2-65, and other bulk agent 10-300. The invention has advantages of low compression deformation, strong flexing resistance and good resilience.

Owner:闫俊龙

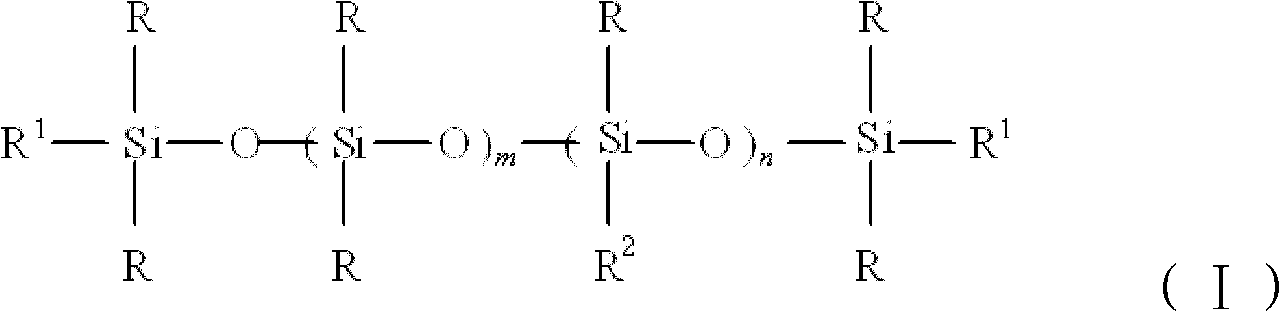

Liquid silicon rubber composition and preparation method thereof

The invention relates to a liquid silicon rubber composition which comprises the following components in parts by mass: 100 parts of polydimethylsiloxane with vinyl as an end group, 1-400 parts of inorganic reinforcing agent, 1-20 parts of low-viscosity polydimethylsiloxane with a vinyl-containing side group, 0.01-10 parts of cross-linking agent, 1-30 parts of polydimethylsiloxane with hydroxyl as an end group, and a platinum catalyst capable of curing the liquid silicon rubber composition. The invention further relates to a preparation method of the liquid silicon rubber composition. The liquid silicon rubber composition has low viscosity and good fluidity before being cured and is applicable to injection molding; and the composition has excellent resilience and low compression deformation ratio after being cured. The liquid silicon rubber composition can be applied to an elastomer, a pressure roll and an image heating and fixing device in a copier and a laser printer as well as certain silicon rubber products in need of the properties.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

Polyurethane foam, process for producing the same, and foam forming composition

InactiveUS20020052425A1Improve mechanical propertiesLow compression setPeptide preparation methodsCushioningHydrogen

A polyurethane foam which is obtained by reacting an addition-polymerizable active hydrogen component comprising a compound having a group containing active hydrogen and an addition-polymerizable functional group or comprising both this compound and a compound containing at least 2.5 groups (on the average) containing active hydrogen and not containing addition-polymerizable functional groups with an organic polyisocyanate in the presence or absence of at least one auxiliary selected from the group consisting of foaming agents and additives to polymerize the addition-polymerizable functional group and simultaneously form a polyurethane, and which has a structure in which the chains formed by the addition polymerization have been cross-linked to the polyurethane chains. The polyurethane foam is useful as a rigid polyurethane foam excellent in hardness, dimensional stability, etc. and usable as a heat insulator, shock-absorbing material, synthetic wood, etc., or is useful as a soft polyurethane foam reduced in compression set and usable as a cushioning material, shock-absorbing material, sound insulating / absorbing material, etc.

Owner:SANYO CHEM IND LTD

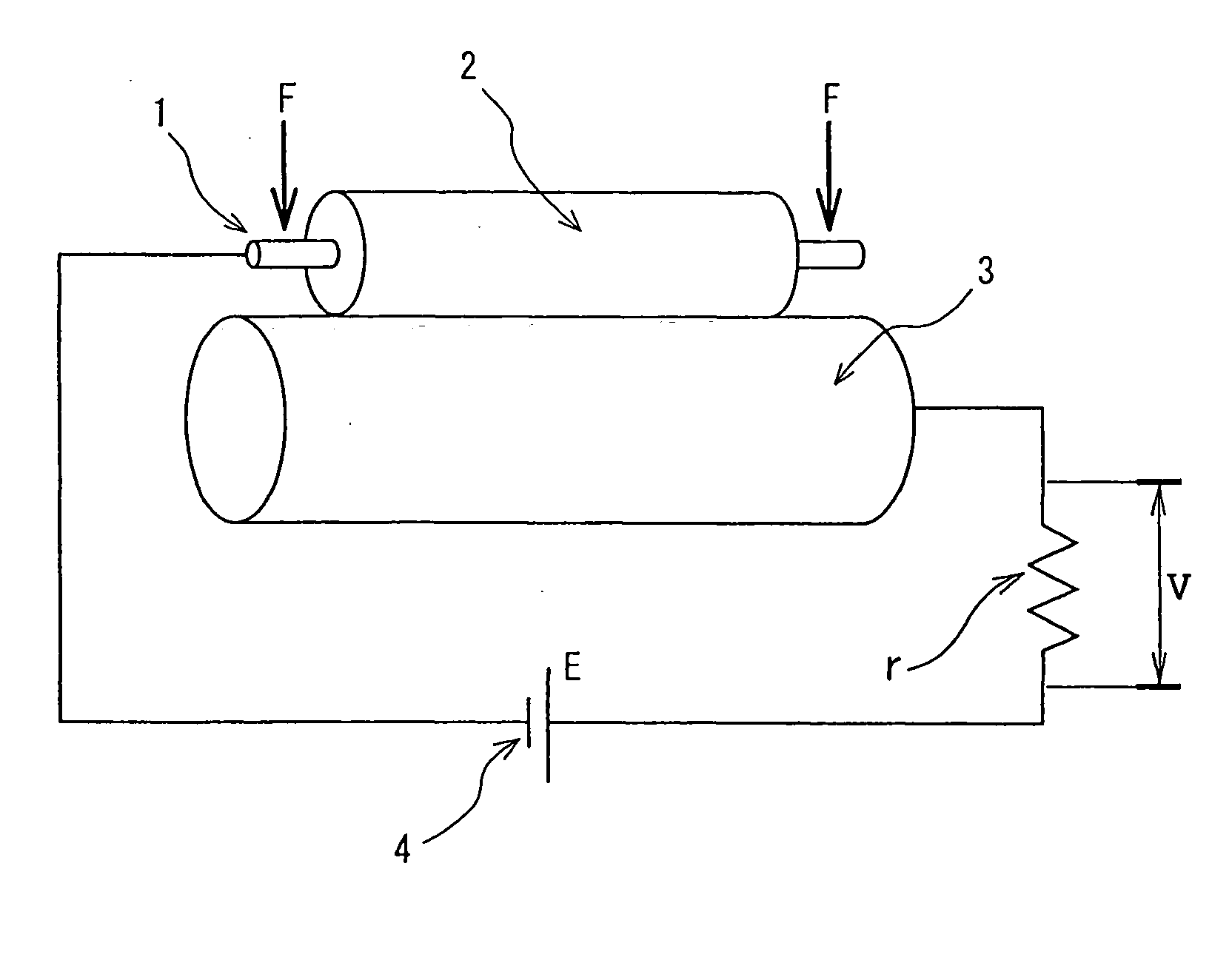

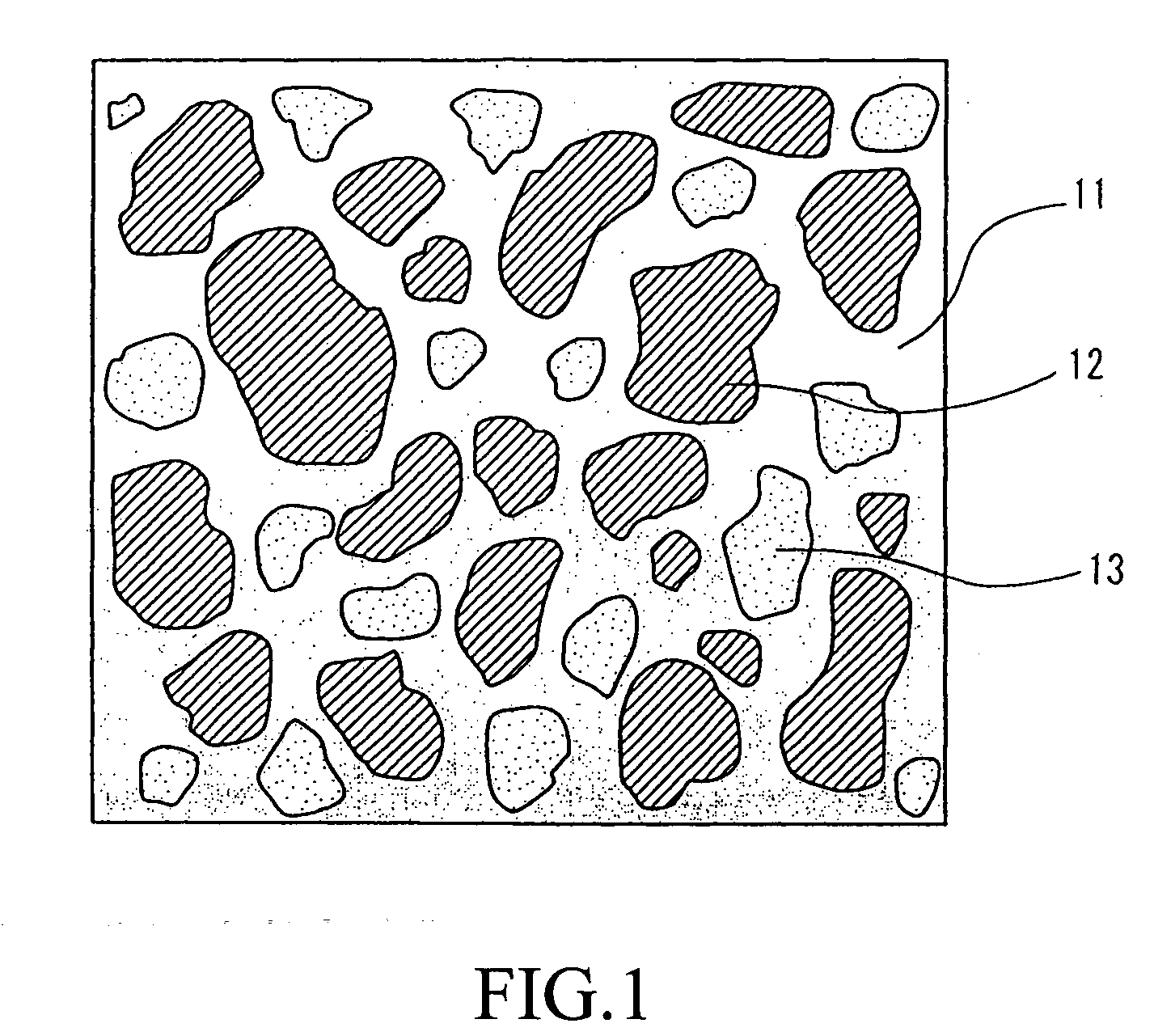

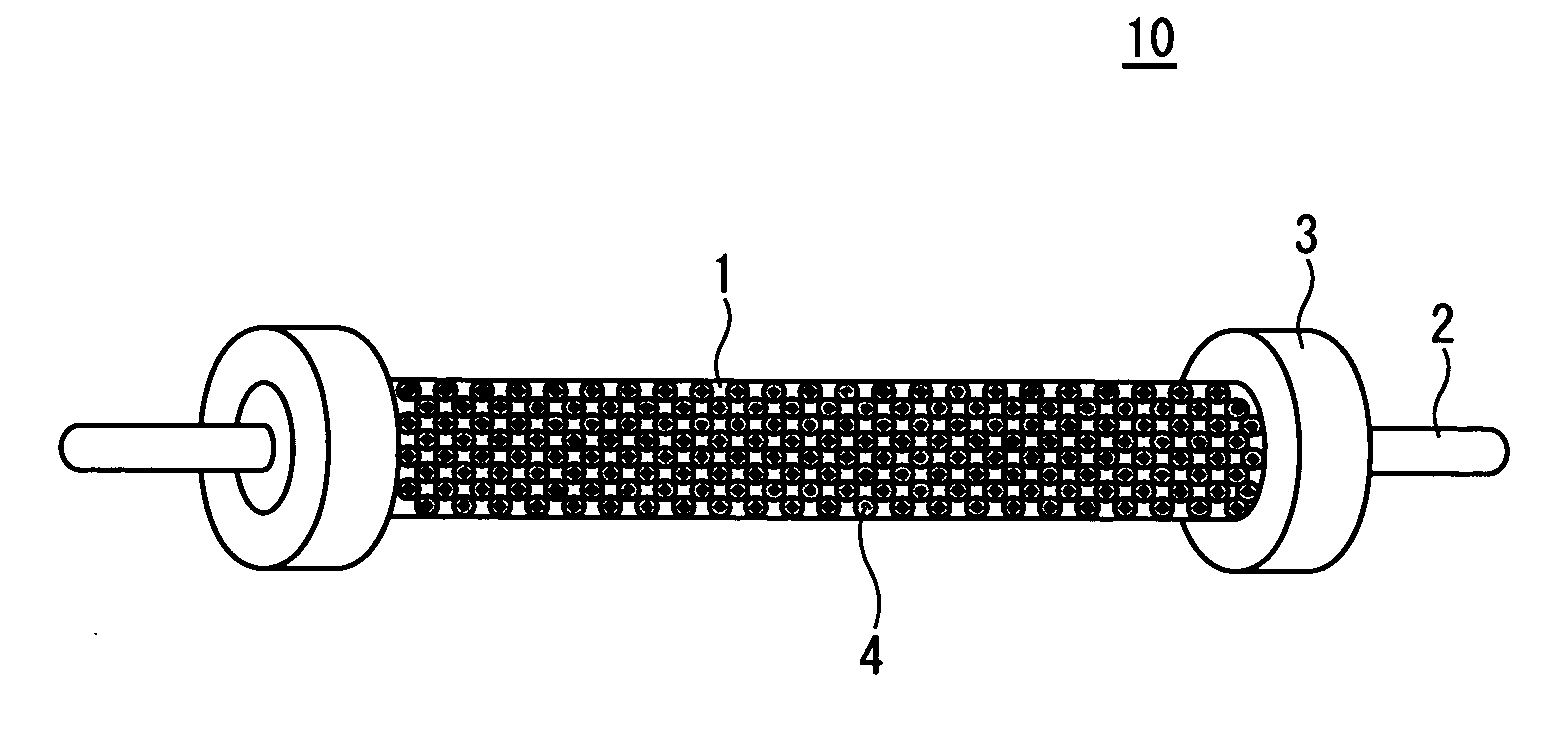

Method for producing conductive thermoplastic elastomer composition and conductive roller composed of same

InactiveUS20080315159A1Low compression setDecreasing variation of electric resistanceShaft and bearingsConductive materialElastomerPolymer science

A conductive thermoplastic elastomer composition including a continuous phase and first and second uncontinuous phases. The continuous phase and the first and second uncontinuous phases form a sea-island structure; and the first and second uncontinuous phases independently forming island structures. In this structure, the continuous phase contains a composition (A) which is a mixture of a thermoplastic elastomer and a thermoplastic resin; the first continuous phase contains a rubber component (B) containing at least one of diene rubber and ethylene-propylene-diene rubber; and the second continuous phase contains an ethylene oxide-propylene oxide-allyl glycidyl ether copolymer containing an anion-containing salt having a fluoro group and a sulfonyl group (component (C)).

Owner:SUMITOMO RUBBER IND LTD

Foams and methods for making the same

InactiveUS6713520B2Low compression setReduce loadLayered productsThin material handlingPolymer chemistryCopolymer

A foam profile prepared by a process comprising the steps of foaming a thermoplastic vulcanizate, where the thermoplastic vulcanizate is prepared by a process comprising the step of dynamically vulcanizing a rubber within a mixture that includes from about 15 to about 95 percent by weight of the rubber and from about 5 to about 85 percent by weight of a thermoplastic component based upon the total weight the rubber and thermoplastic component combined, where the thermoplastic component includes from about 65 to about 90 percent by weight of a conventional thermoplastic resin and from about 10 to about 35 percent by weight of a random propylene copolymer based upon the total weight of the thermoplastic component.

Owner:ADVANCED ELASTOMER SYST LP

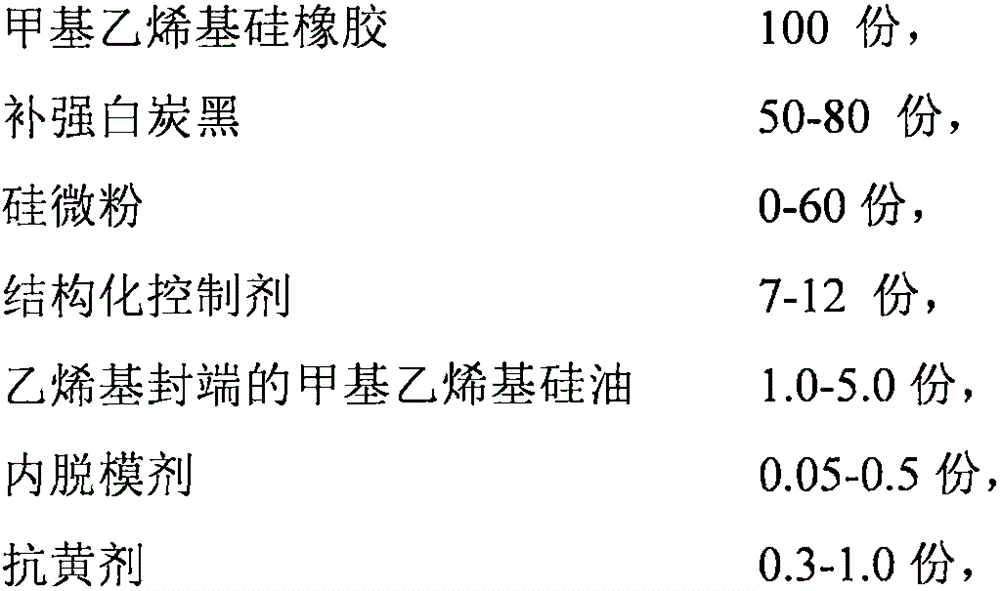

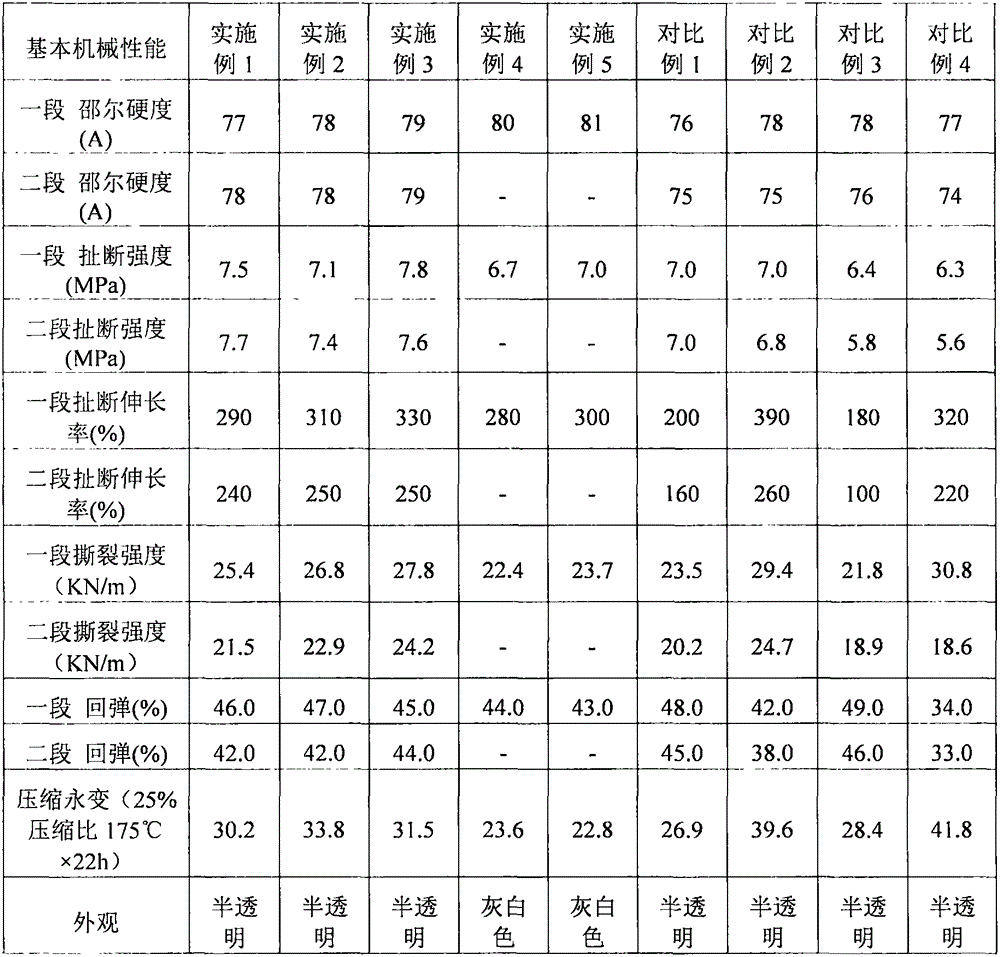

High-hardness extruded silicone rubber composition and preparation method thereof

The invention provides high-hardness extruded silicone rubber composition. The silicone rubber takes methyl vinyl siloxane with the average molecular weight of 0.55-0.75 million and the average vinyl molar content of 0.4-0.55% as rubber master batch, and reinforced white carbon black, silica powder, a structurized control agent, vinyl-terminated methyl vinyl silicone oil, an internal releasing agent, an anti-yellowing agent, magnesium oxide and cerium oxide are added. The prepared silicone rubber has high hardness, high resilience, relatively high elongation and high tear resistance after high temperature vulcanization and can be applicable to silicone products such as an industrial rubber-covered roller, a pressing wheel, a sealing ring and a sealing element.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

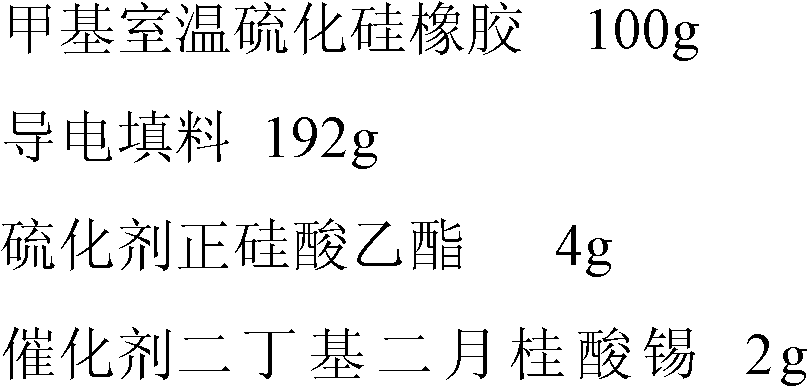

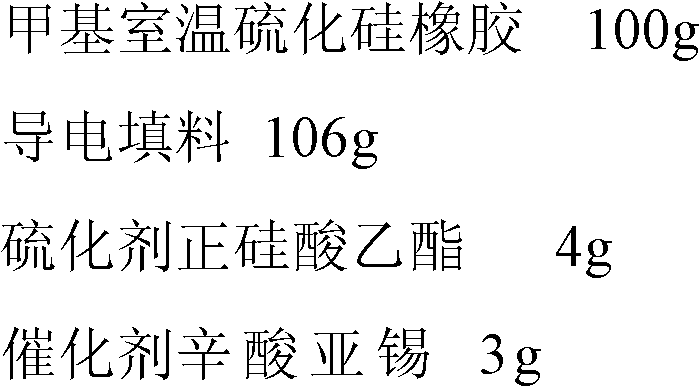

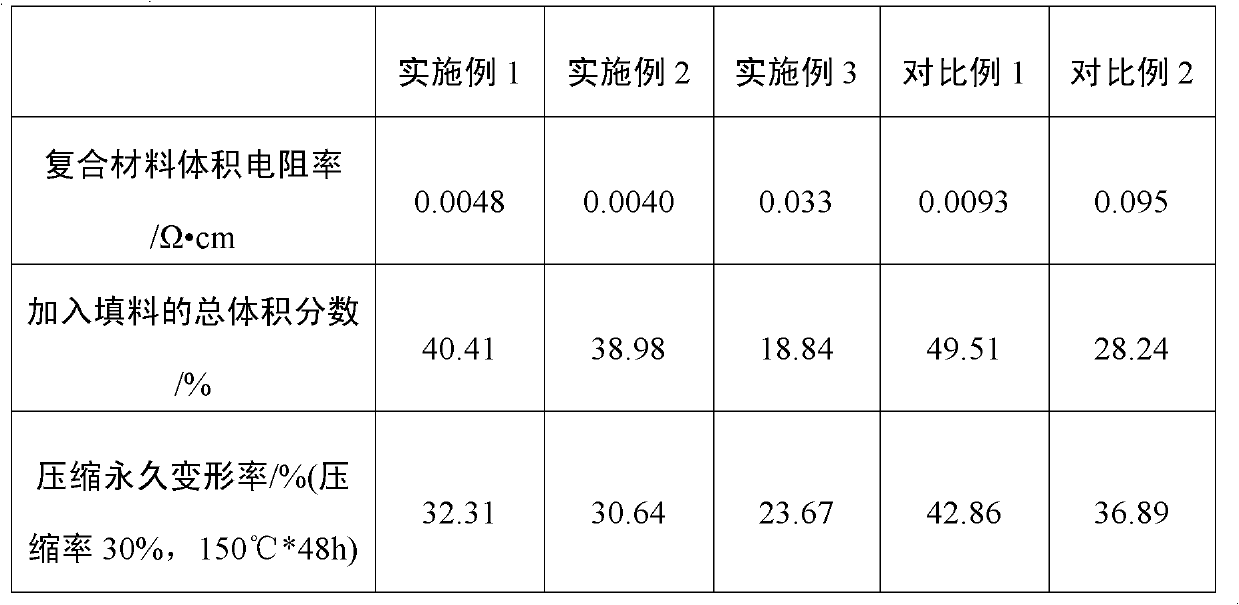

Low-compressive-deformation and high-conductivity rubber composite material and preparation method thereof

The invention relates to a low-compressive-deformation and high-conductivity rubber composite material and a preparation method thereof. The low-compressive-deformation and high-conductivity rubber composite material is prepared by the following steps of: taking silicon rubber as a base body and utilizing modified grain-shaped and fiber-shaped metal-plating conductive fillers containing a reactive double-bond silane coupling agent under a CO2 supercritical state to prepare low-compressive-deformation and high-conductivity rubber composite material. Under the condition of guaranteeing the high conductivity, the use amount of the conductive fillers is reduced and the composite material has low compressive deformation and high conductive property.

Owner:BEIJING UNIV OF CHEM TECH +1

Car door-window straight-line part gland strip and preparation method

InactiveCN102516673AIncrease elasticityImprove aging resistanceOther chemical processesGeneral purposeSulfur

The invention relates to a car door-window straight-line part gland strip and a preparation method, which iare used for solving the problem that the compression permanent deformation rate of the present car door-window straight-line part gland strip is high, and adopts the technical scheme that: the gland strip is prepared by the following substances in part by weight: 22 to 27 ethylene propylenediene rubber 9090M, 6 to 10 ethylene propylene diene rubber 3072EM, 1 to 3 active zinc oxide, 0.4 to 0.8 stearic acid, 0.4 to 1.0 dispersant L-24, 0.7 to 1.1 polyethyleneglycol, 25 to 30 general purpose furnace black (GPF)-grade carbon black N650, 10 to 14 heavy calcium carbonate, 16 to 20 paraffin oil, 1 to 3 calcium oxide, 1.3 to 1.7 accelerator, 0.05 to 0.08 antiscorching agent, 0.2 to 0.6 sulfur and 0.8 to 1.2 p,p'-Oxybis(benzenesulfonyl hydrazide) N8000W. The car door-window straight-line part gland strip has good elasticity, good aging resistance, excellent ozone property, good low-temperature application property and appropriate apparent density.

Owner:GREAT WALL MOTOR CO LTD

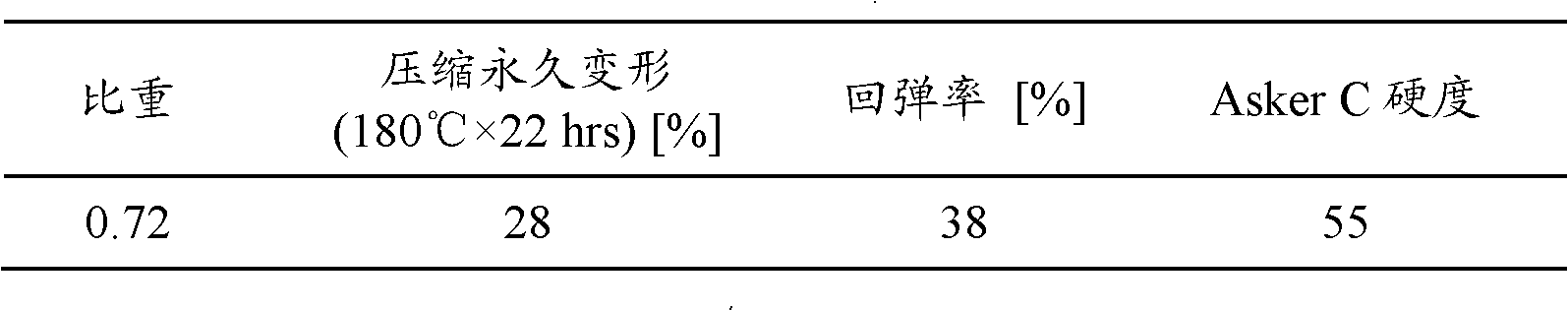

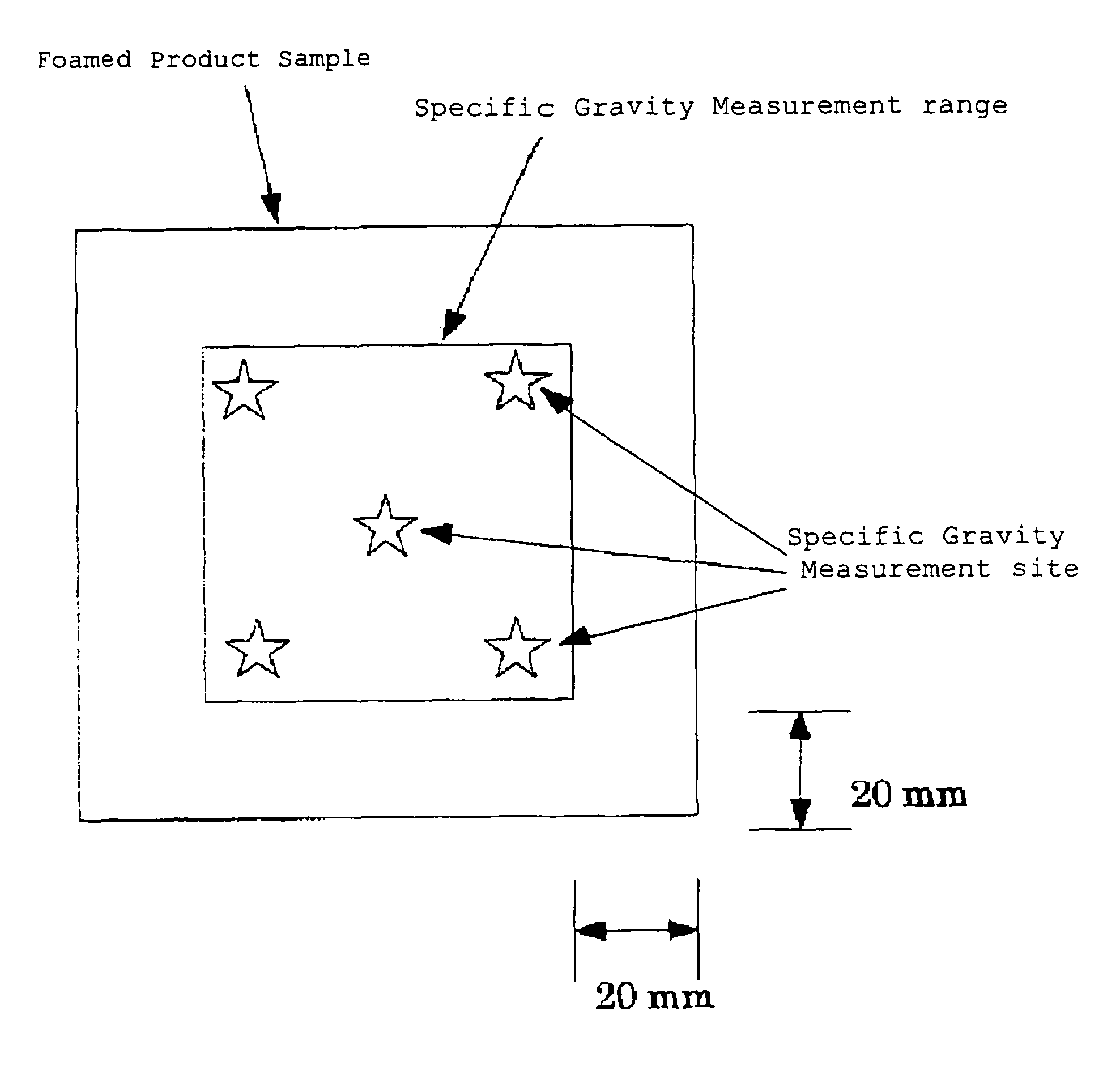

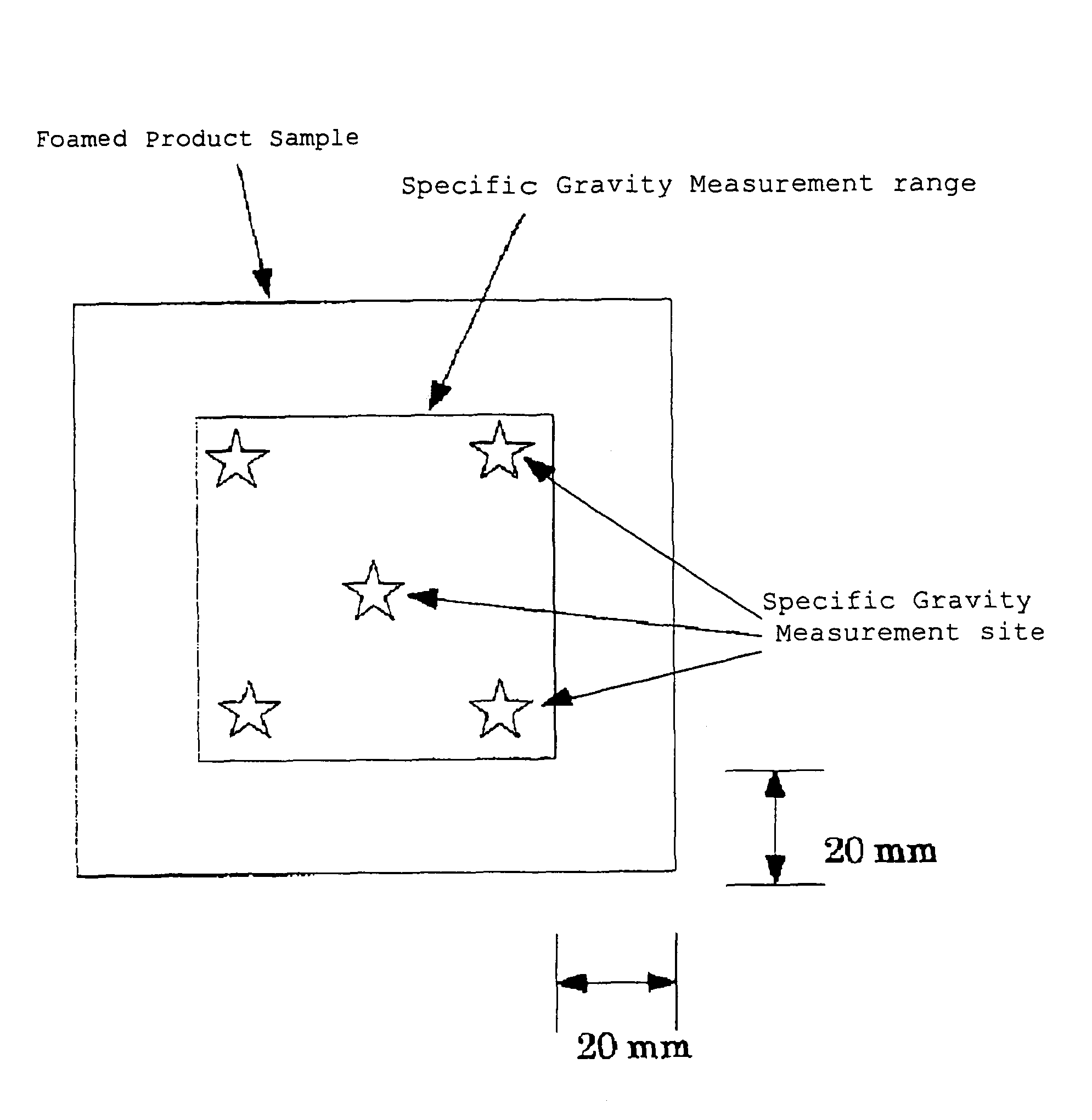

Crosslinked olefin elastomer foam and elastomer composition therefor

A crosslinked olefin elastomer foam has a specific gravity of 0.05 to 0.2, an expansion ratio of 8 to 15, a compression set of 30 to 60% and a tear strength of 1.5 to 2.5 kg / cm. The crosslinked foam is obtained by heating an elastomer composition comprising a specific ethylene / alpha-olefin copolymer, an organic peroxide, a crosslinking auxiliary and a foaming agent. The crosslinked foam has a high expansion ratio, is free from surface roughening attributed to defoaming, realizes a soft touch, exhibits a low compression set and is excellent in mechanical strength (particularly tear strength) and heat resistance.

Owner:MITSUI CHEM INC

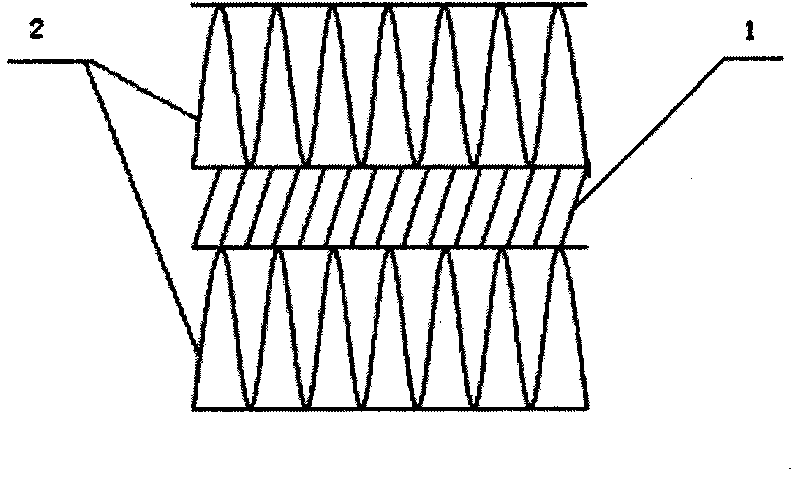

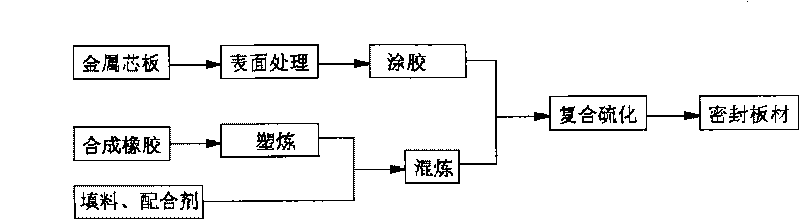

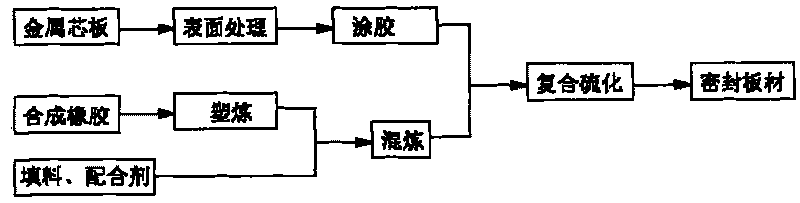

Composite sealing material and manufacturing method thereof

InactiveCN101747862AGood compression and rebound performanceGood long-term pressure resistance and sealing performanceOther chemical processesSurface finishingElastic membrane

The invention discloses a novel sealing material, which consists of a core plate and elastic membrane layers compounded on two sides of the core plate, wherein the core plate a metal or non-metal core plate after surface treatment; the elastic membrane layers are prepared from elastic foaming materials or non-foaming materials which are compounded on the surfaces of the core plate in a mechanical or chemical mode to form the membrane layers. The sealing material has the advantages of simple structure, excellent compression resilience, wonderful long-term pressurization sealability, very low creep relaxation performance, long service life and wonderful conformability with a sealing surface.

Owner:上海骏焱化工材料有限公司

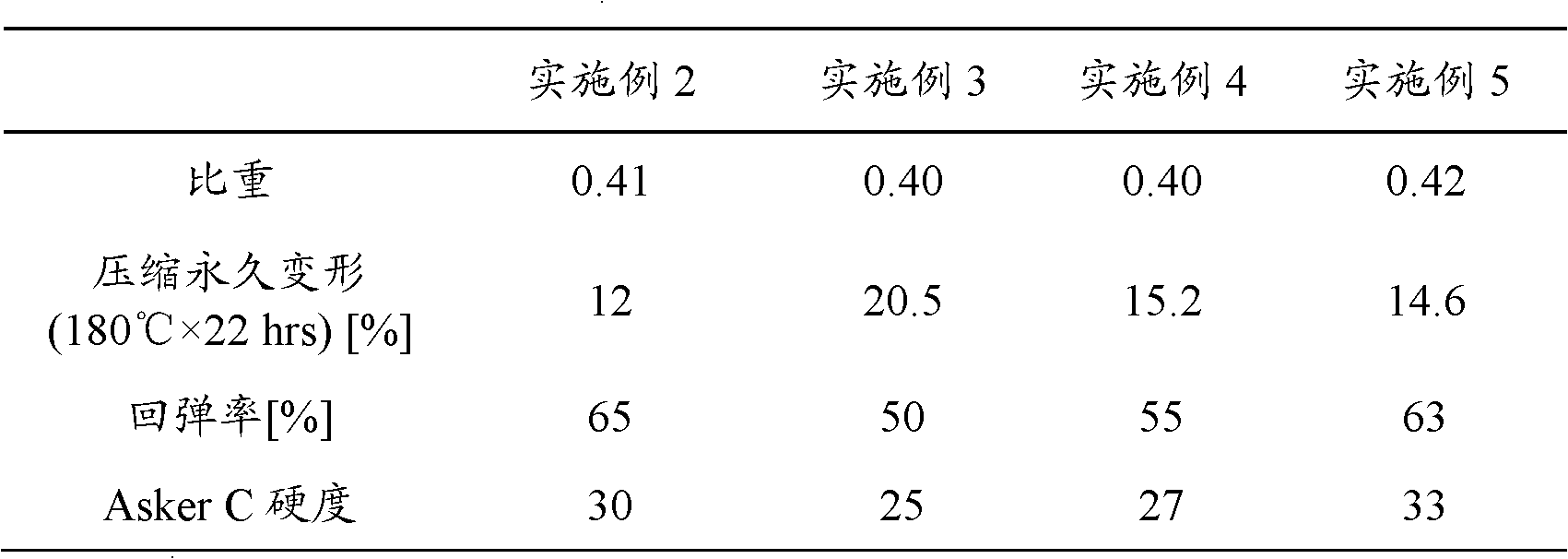

Molded Foam Article, Foamed Sole, and Shoe

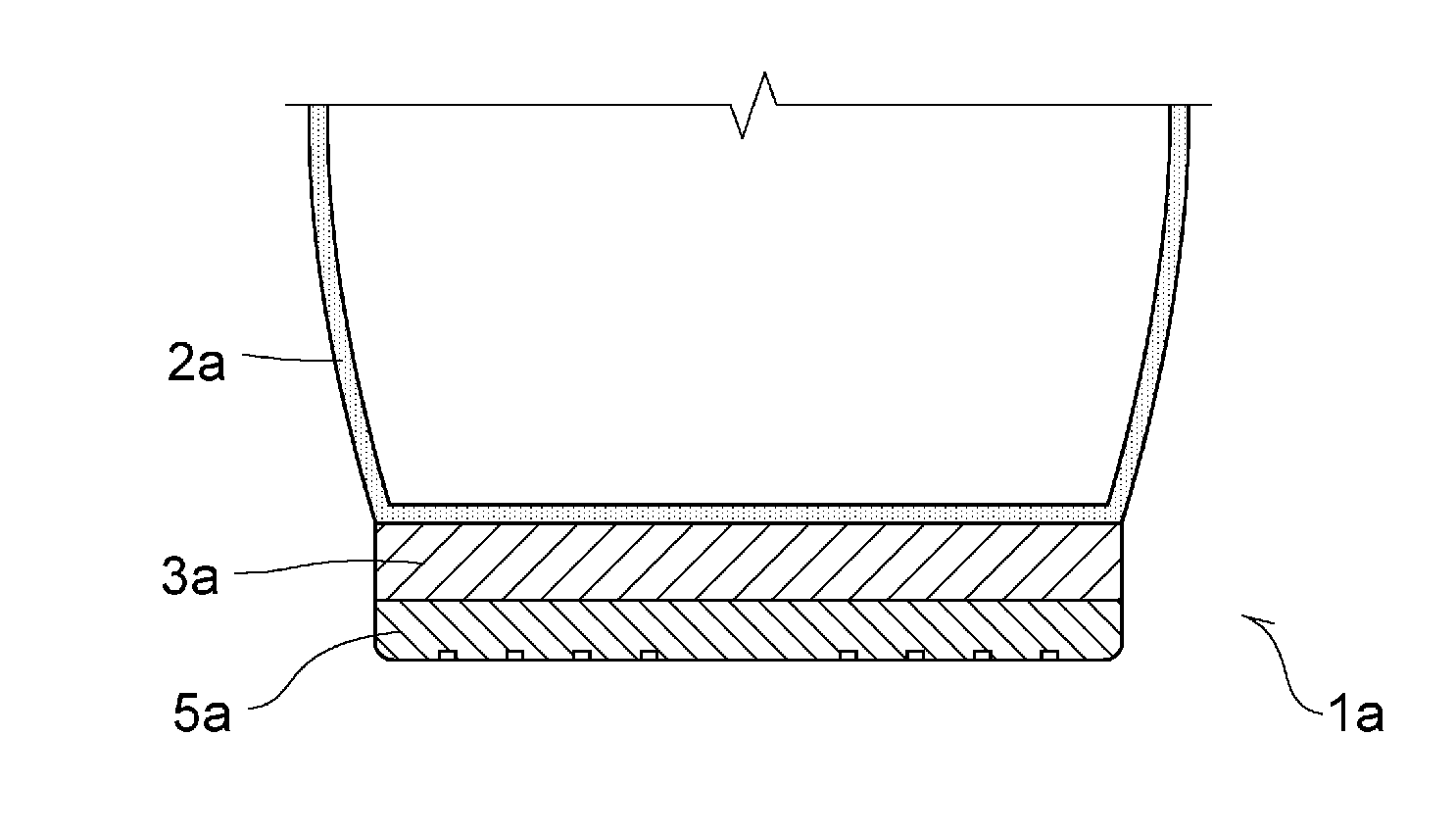

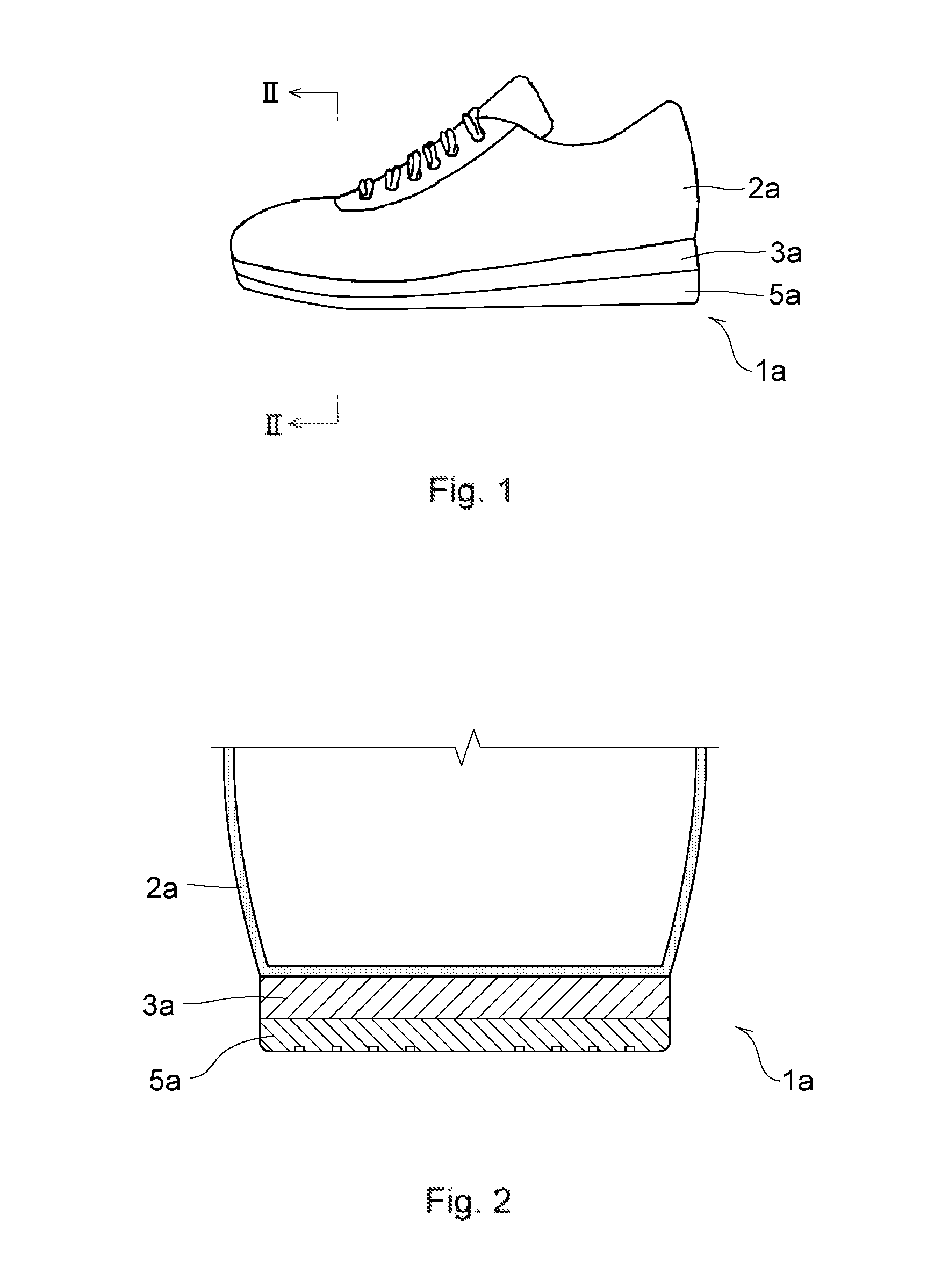

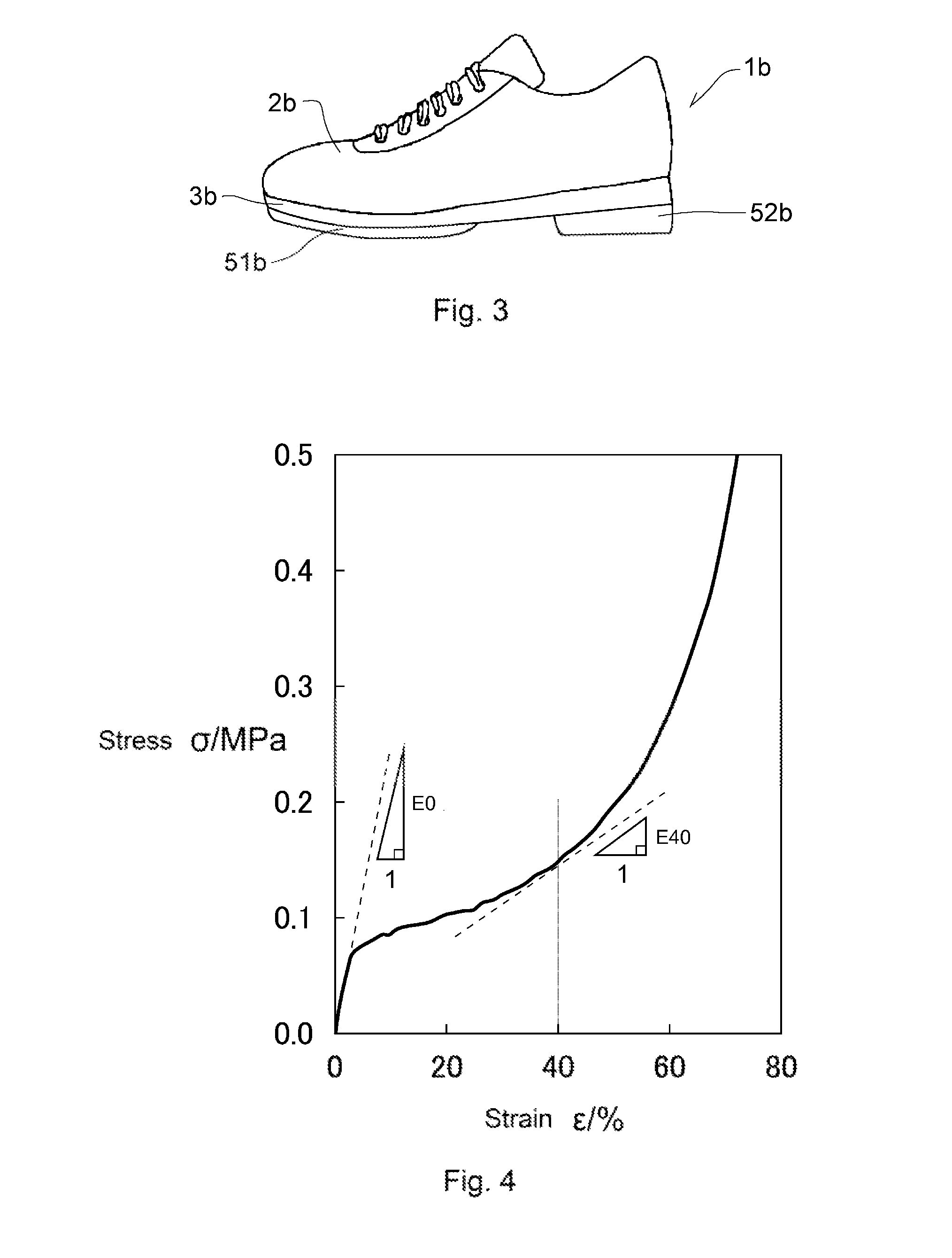

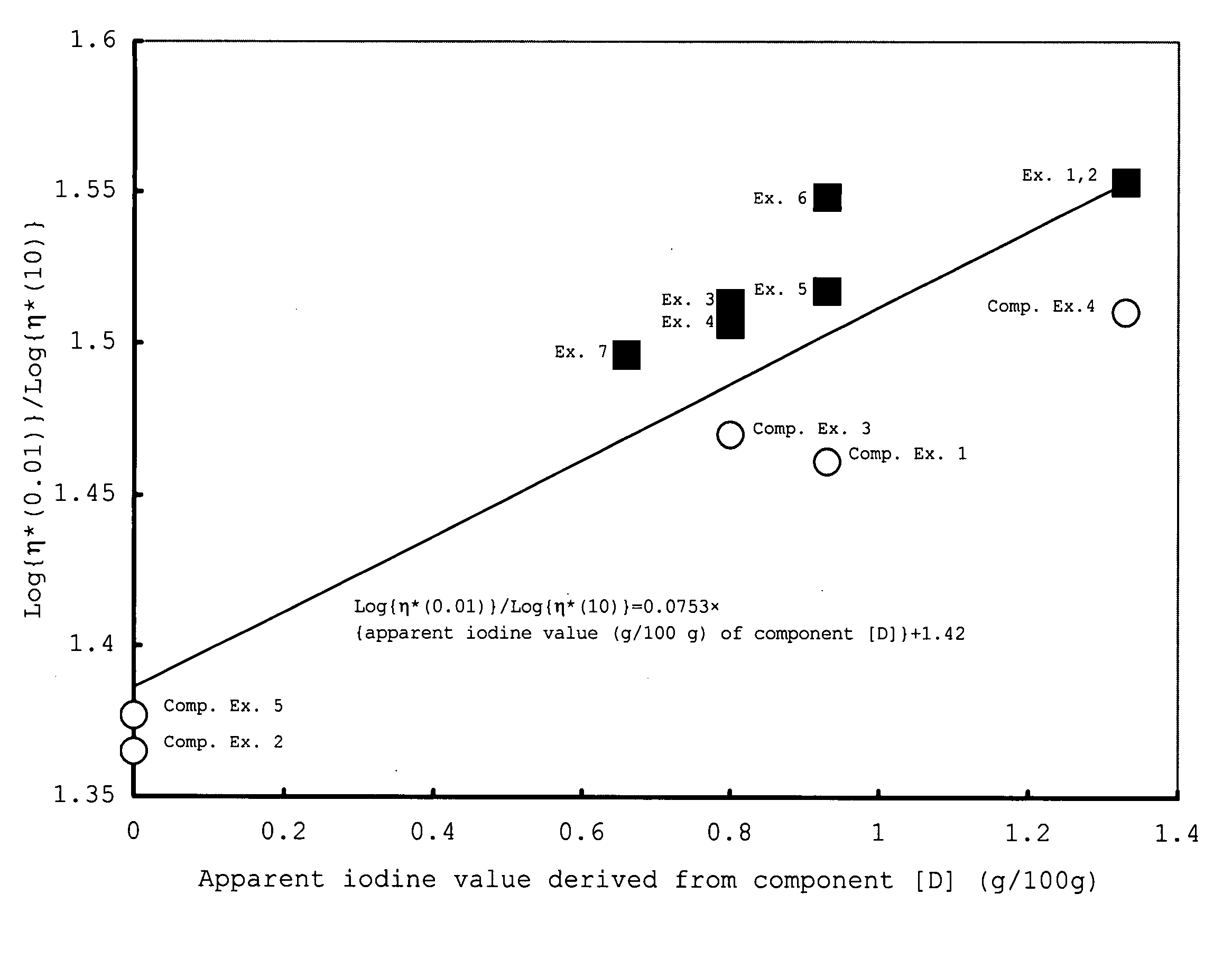

ActiveUS20150143723A1Little change in hardnessKeep elasticSolesAbsorbent padsCompressive deformationComposite material

There is provided a molded foam article including a foam obtained by foaming a formation material wherein the formation material contains a resin component, an Asker C hardness of the foam is 10 degrees or more, and a ratio E40 / E0 of the foam is 0.5 or more, the ratio E40 / E0 being a ratio of an elastic coefficient E40 at a strain of 40% in relation to an elastic coefficient E0 at a strain of 0% of the foam.The molded foam article has appropriate softness with a small change in hardness under compressive deformation.

Owner:ASICS CORP

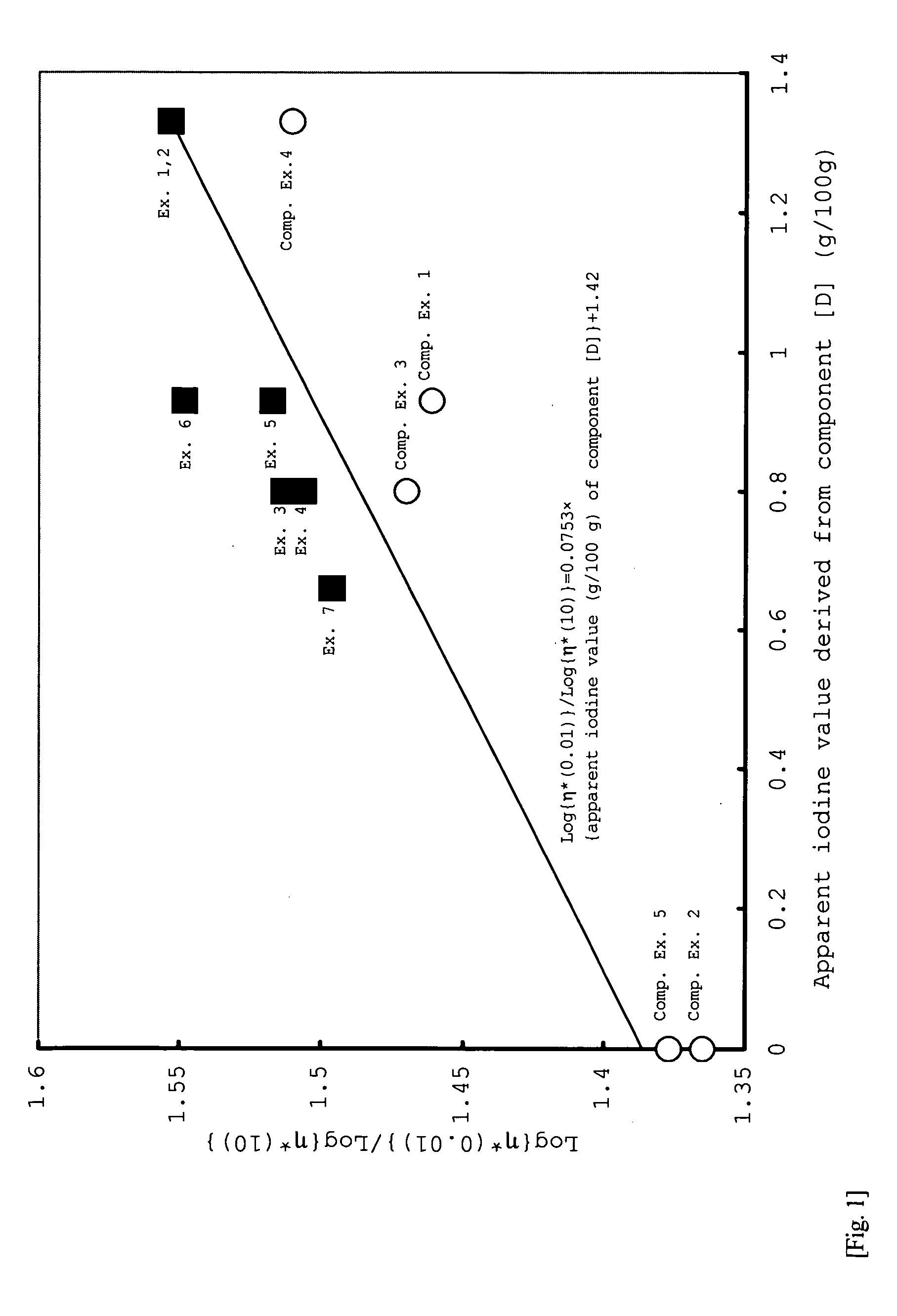

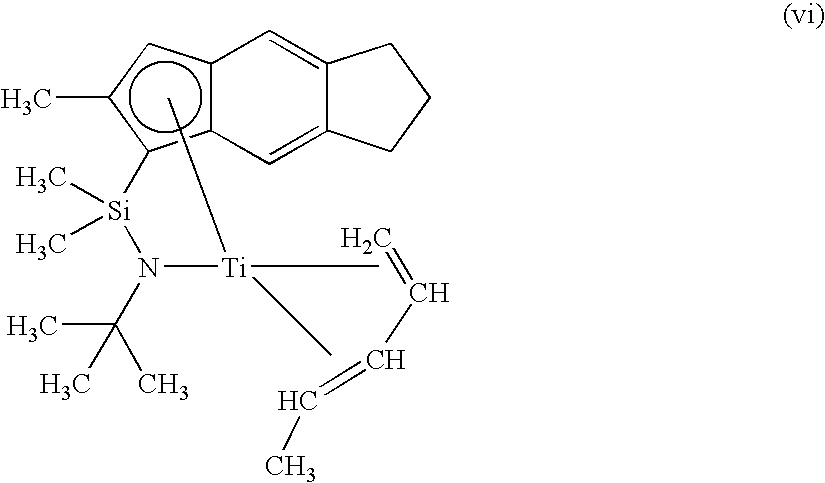

Copolymer rubber, rubber composition and rubber molding

The present invention provides a copolymer rubber which contains only small amounts of impurities and is excellent in kneading processability, extrusion processability and retention of shape and a rubber composition containing the copolymer rubber, and further provides a rubber molded product which is obtained from the rubber composition, is excellent in surface appearance, strength properties, heat aging resistance and weathering resistance and has a low compression set. The copolymer rubber of the present invention comprises structural units derived from [A]ethylene, [B] an α-olefin of 3 to 20 carbon atoms, [C] a non-conjugated polyene having one double bond between adjacent carbon atoms in one molecule, said double bond being capable of polymerization by a metallocene catalyst, and [D] a non-conjugated polyene having two of the above double bonds in one molecule, and the copolymer rubber satisfies specific requirements (1) to (5).

Owner:MITSUI CHEM INC

Semiconductor rubber composition and semicondctive rubber roller

InactiveUS20060284142A1Easy to oxidizeLower energy requirementsClosuresLayered productsPolymer scienceEthylene oxide

A semiconductive rubber composition contains copolymerized rubber containing ethylene oxide; chloroprene rubber; and acrylonitrile-butadiene rubber. A conductive rubber roller has a conductive rubber layer composed of the semiconductive rubber composition on an outermost layer thereof.

Owner:SUMITOMO RUBBER IND LTD

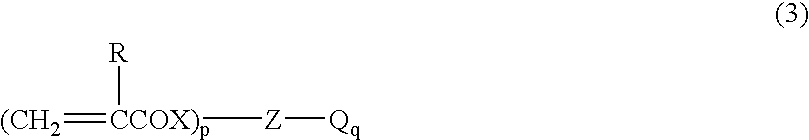

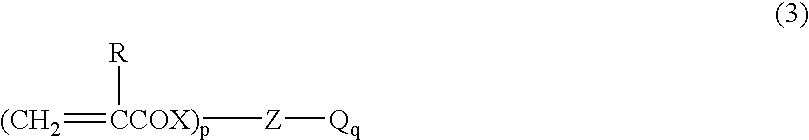

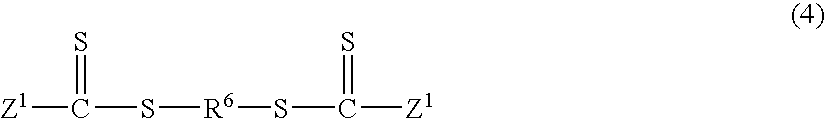

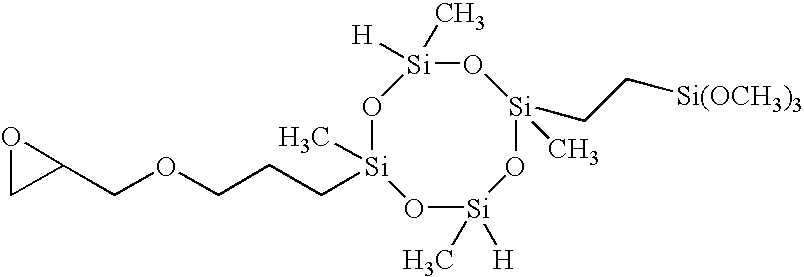

Curable composition

InactiveUS20050004318A1Low dyeabilityLow compression setReversible addition−fragmentation chain-transfer polymerizationPolymer chemistry

The present invention provides a curable composition that comprises a polymer (A) containing a cross-linkable silyl group and a condensation catalyst (B). The polymer (A) containing a cross-linkable silyl group is obtained by a process comprising the steps of conducting a radical polymerizable monomer in the presence of a thiocarbonylthio compound. For example, the polymer (A) is obtained by (i) initiating a reversible addition-fragmentation chain transfer polymerization of a radical polymerizable monomer in the presence of a thiocarbonylthio compound, and (ii) adding an unsaturated compound containing a cross-linkable silyl group for copolymerization when a consumed amount of the radical polymerizable monomer by the polymerization has reached a level of 80% or more.

Owner:OHSHIRO NOBUAKI +2

Conductive elastomer composition, conductive roller, and conductive belt

InactiveUS7291663B2Lower the resistance valuePreferable mechanical propertyGroup 4/14 element organic compoundsShaft and bearingsElastomerEthylene oxide

A conductive roller or a conductive belt is composed of a conductive elastomer composition including a polymer composition having a plurality of carbon-to-carbon double bonds and containing not less than 40 mol % of ethylene oxide; an organometallic salt containing a fluoro group or / and a sulfonyl group; and an elastomer having a plurality of carbon-to-carbon double bonds.

Owner:SUMITOMO RUBBER IND LTD

Low-compressive-deformation fluororubber material of high-temperature-resistant lubricating oil and preparation method of low-compressive-deformation fluororubber material

The invention discloses a low-compressive-deformation fluororubber material of high-temperature-resistant lubricating oil and a preparation method of the low-compressive-deformation fluororubber material. The low-compressive-deformation fluororubber material comprises the following components in parts by weight: 100 parts of fluororubber, 4-6 parts of magnesium oxide, 3-10 parts of calcium hydroxide, 2-3 parts of a processing auxiliary agent, 15-25 parts of a reinforcing agent, 5-10 parts of a pigment and 2.2-3 parts of a vulcanizing agent. The low-compressive-deformation fluororubber material prepared by using the method disclosed by the invention has excellent resistance and tolerance to mineral oil such as the high-temperature lubricating oil with the temperature of 200 DEG C and hydraulic oil, and also has extremely low compression permanent deformation performance. By adopting the low-compressive-deformation fluororubber material disclosed by the invention, the problems that existing fluororubber is easily subjected to swelling corrosion by the high-temperature lubricating oil to cause sealing leakage and the like can be solved; and meanwhile, because the low-compressive-deformation fluororubber material is extremely low in compression permanent deformation performance, the service life of a sealed product can be greatly prolonged, and the maintenance cost caused by frequent replacement can be reduced.

Owner:宁波精科机械密封件制造有限公司

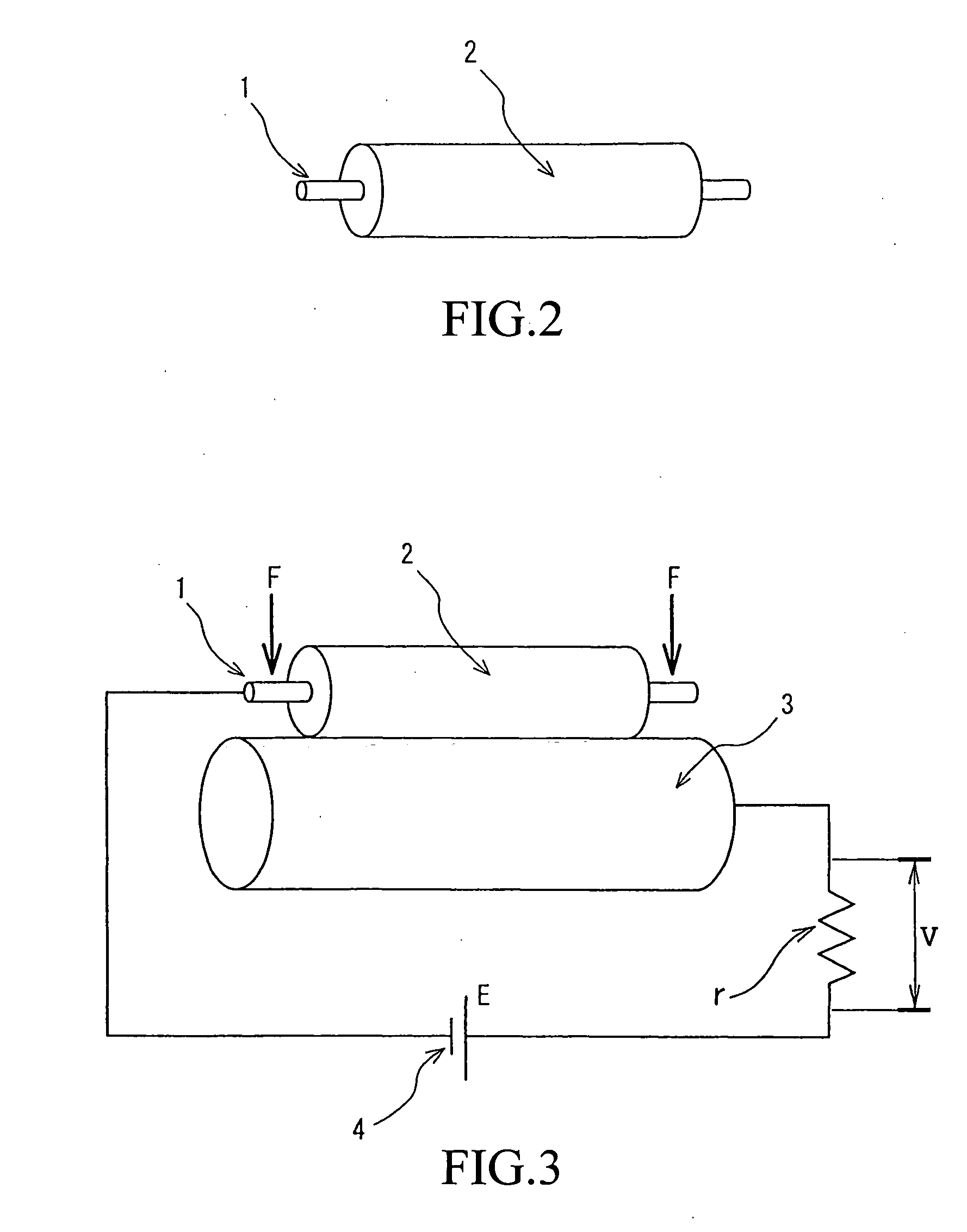

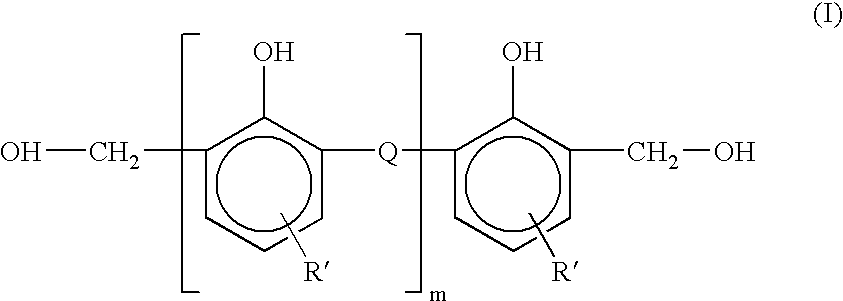

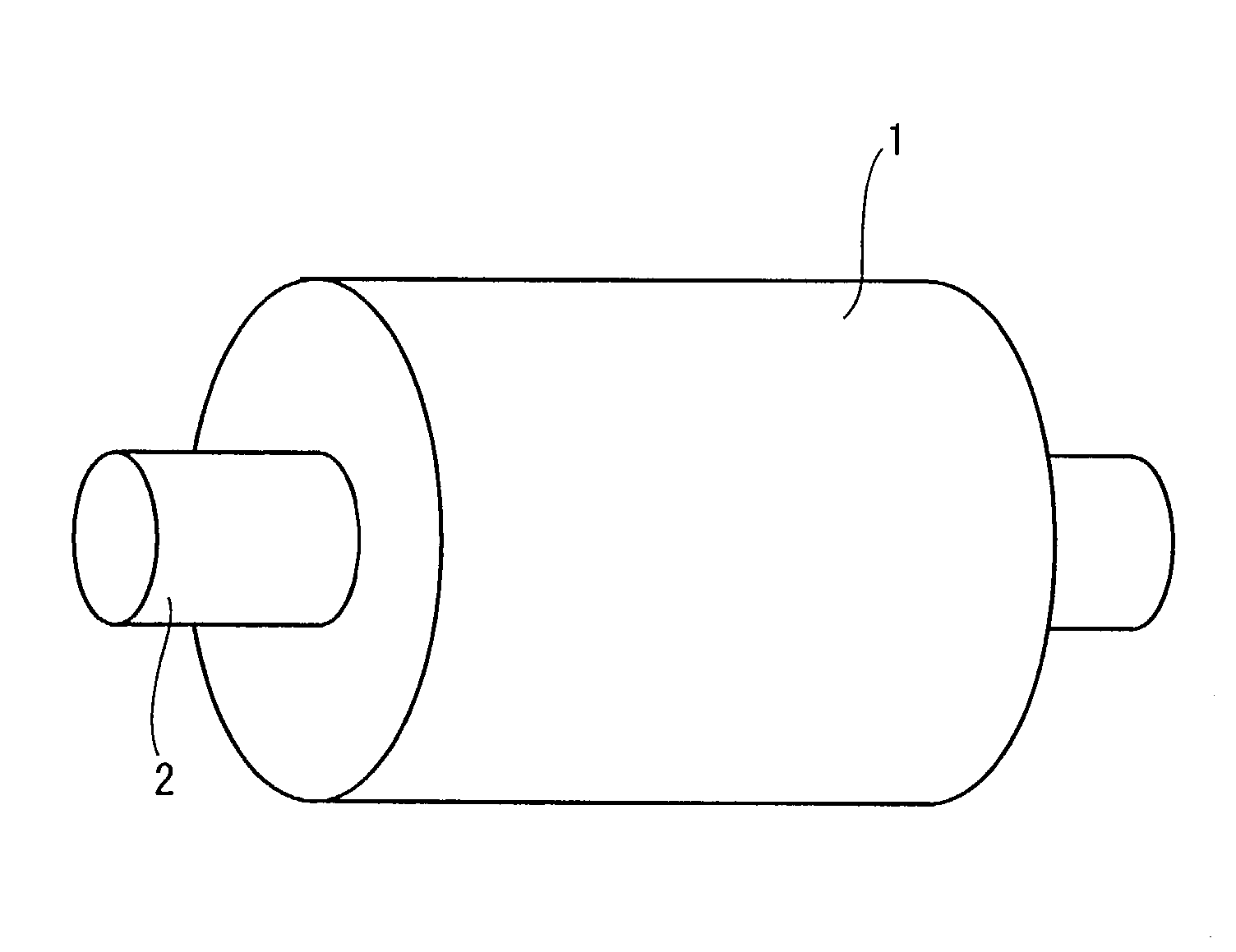

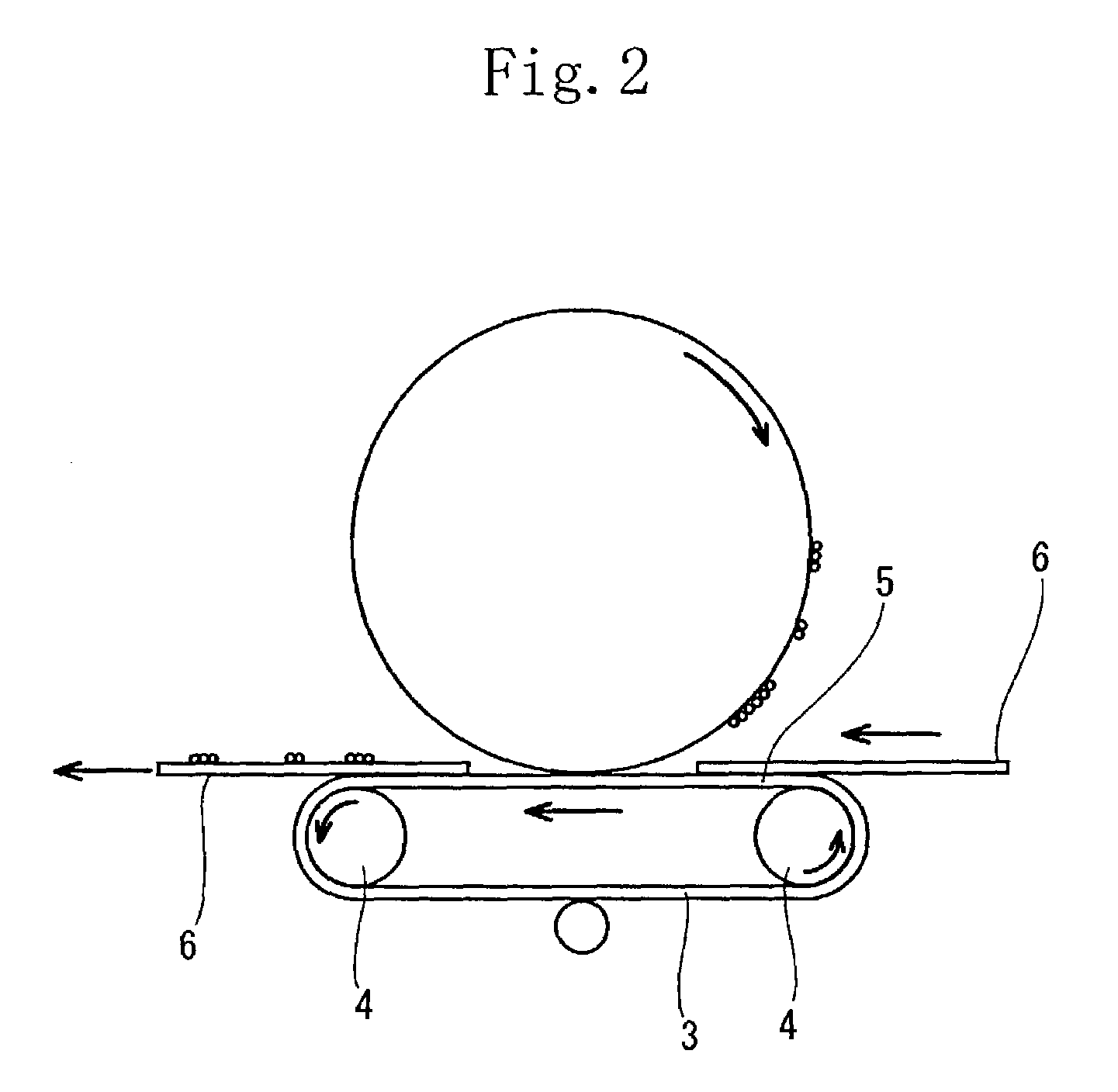

Heat fixing roll and fixing belt

ActiveUS20070135555A1Overcome lack of heat resistanceAdequate modulusShaft and bearingsSynthetic resin layered productsPolymer scienceSilicon

A heat fixing roll or belt having a silicone rubber layer which is formed by curing a silicone rubber composition comprising (A) 100 pbw of an organopolysiloxane having at least two silicon-bonded alkenyl radicals in a molecule, (B) 20-500 pbw of a metallic silicon powder having an average particle size of up to 100 μm, and (C) an effective amount of a curing agent. The silicone rubber layer has a high heat conductivity and long-term temperature durability.

Owner:SHIN ETSU CHEM IND CO LTD

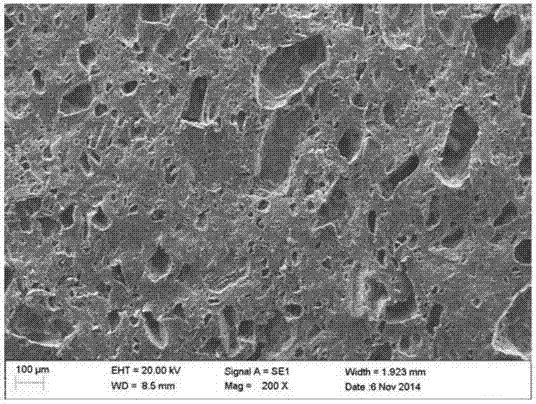

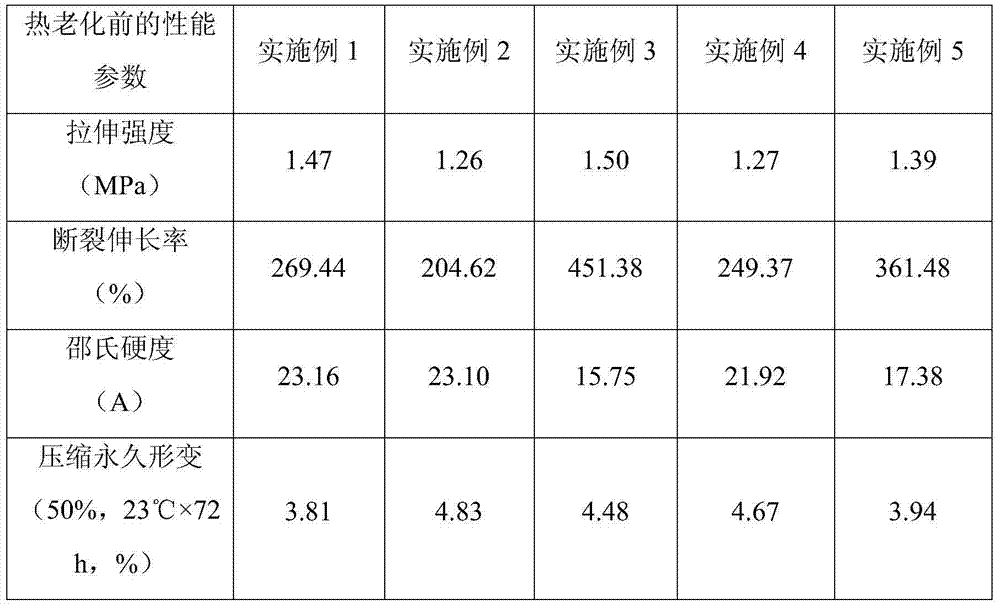

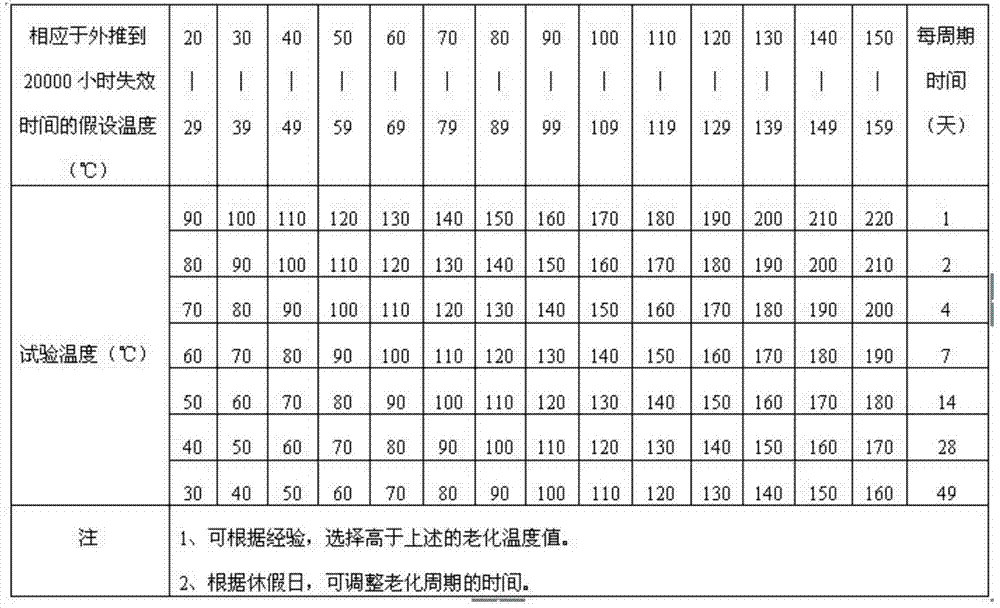

High-temperature-resistant silicone rubber foam material and preparation method thereof

The invention discloses a high-temperature-resistant silicone rubber foam material and a preparation method thereof. The preparation method of the high-temperature-resistant silicone rubber foam material is characterized by comprising the following steps: mixing 100 parts of silicone rubber base stock, 20-35 parts of a reinforcing agent, 2-3 parts of a structure controlling agent, 0-0.2 part of colour master batch, 60-150 parts of a pore-forming agent and 4-5 parts of a radiation sensitizer, moulding, crosslinking through gamma ray radiation, forming pores through subsection dissolving-out, and drying, so that the silicone rubber foam material which is resistant to high temperature of 250 DEG C and still maintains excellent performance after equivalent time of 20000 hours can be obtained. The preparation method of the high-temperature-resistant silicone rubber foam material has the advantages that radiation crosslinking and dissolving-out pore forming are combined, so that crosslinking is uniform, control is easy, energy conservation and environmental protection are realized, a technology is concise, reproducibility is good, and production efficiency is high; the high-temperature-resistant silicone rubber foam material still maintains high tensile strength, high weight loss, low longitudinal deformation and low surface hardness after the equivalent time of 20000 hours at the temperature of 250 DEG C, permanent compressive deformation is slightly increased, the high-temperature-resistant silicone rubber foam material does not become brittle or hard, and the high-temperature-resistant silicone rubber foam material can serve as filling and positioning, sealing cushion, cable insulation as well as buffer and vibration-absorptive materials or parts which are used in high-temperature environment.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Ethylenic copolymer, composition containing the copolymer and use thereof

ActiveUS8329848B2High vinyl-group contentGood cross-linking effectDomestic footwearFootwearAlpha-olefinCompression set

An object of the present invention is to provide a novel ethylene-α-olefin copolymer excellent in crosslinking properties; a foamed molded article having a low specific gravity and a low compression set (CS) and a composition capable of producing the foamed molded article, footwear parts composed of a foamed molded article; an ethylenic copolymer composition excellent in balance between weather resistance and mechanical strength, and an electric wire coating material and an electric wire sheath using the ethylenic copolymer composition; and a thermoplastic elastomer capable of producing a molded article excellent in balance between mechanical strength and toughness. The ethylenic copolymer (A) of the present invention is a copolymer composed of only ethylene and an α-olefin having 3 to 20 carbon atoms, and is characterized in that vinyl-group content (a) per 1000 carbon atoms as measured by infrared absorption spectroscopy, MFR10 / MFR2.16 (b), and the specific gravity (c) are within a specific range.

Owner:MITSUI CHEM INC

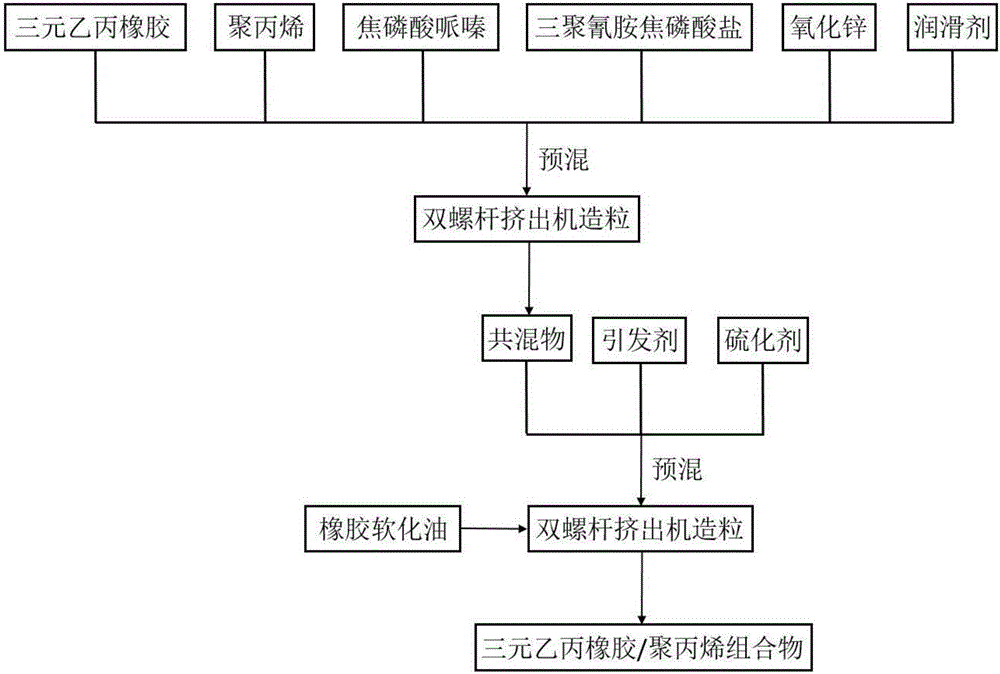

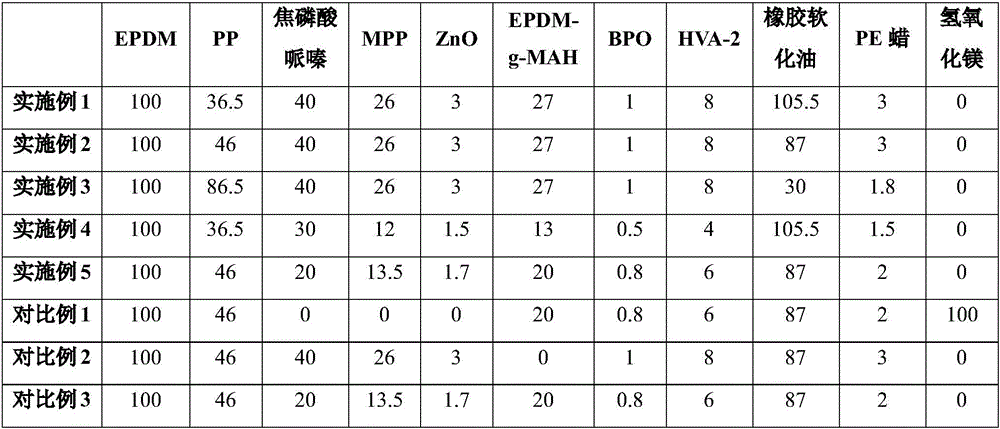

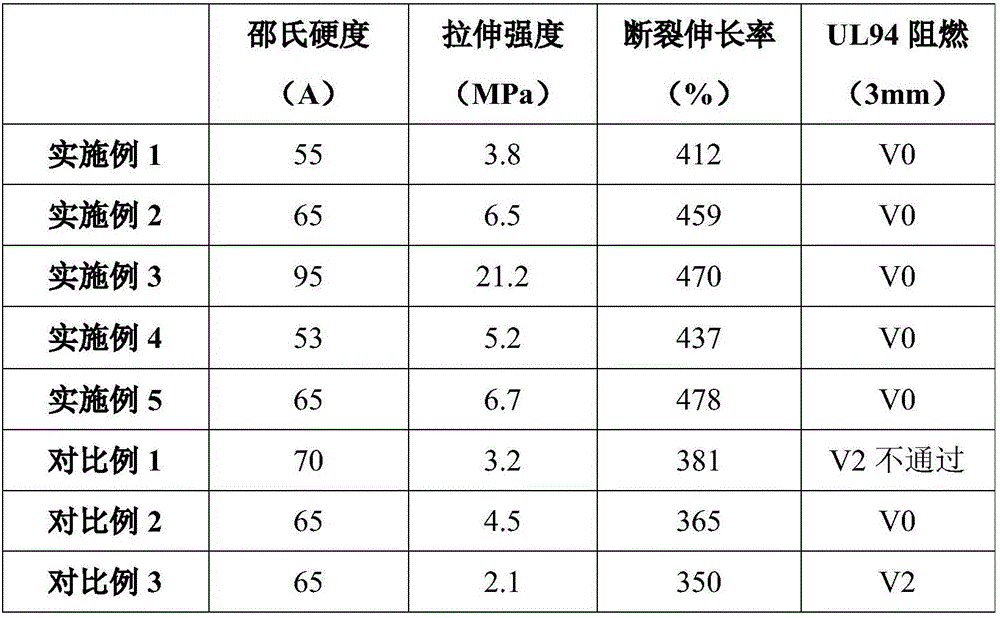

Halogen-free flame-retardation thermoplastic dynamic sulfurated ethylene-propylene-diene monomer rubber/polypropylene composition and preparation method thereof

The invention discloses a halogen-free flame-retardation thermoplastic dynamic sulfurated ethylene-propylene-diene monomer rubber / polypropylene composition and a preparation method thereof. The ethylene-propylene-diene monomer rubber / polypropylene composition is prepared by ethylene-propylene-diene monomer rubber, polypropylene, coked piperazine phosphate, melamine pyrophosphate, zinc oxide, ethylene-propylene-diene-grafted maleic anhydride, an initiator, a vulcanizing agent, rubber softening oil and a lubricant. The preparation method comprises the following steps: 1) mixing EPDM, PP, coked piperazine phosphate, MPP, ZnO, EPDM-g-MAH and the lubricant, and dispersing the materials; 2) performing melt extrusion on a premix obtained in the step 1) and performing granulation on the premix; and 3) mixing the premix, the initiator, the vulcanizing agent and the rubber softening oil, extruding a mixture, and granulating the mixture. The ethylene-propylene-diene monomer rubber / polypropylene composition has the advantages of heat resistance, aging resistance, excellent mechanical property and flame resistance performance, enables thermoplastic processing, has a production process, and can be widely used for wire and cable compounds with high flame-resistance requirements.

Owner:广东省石油化工研究院

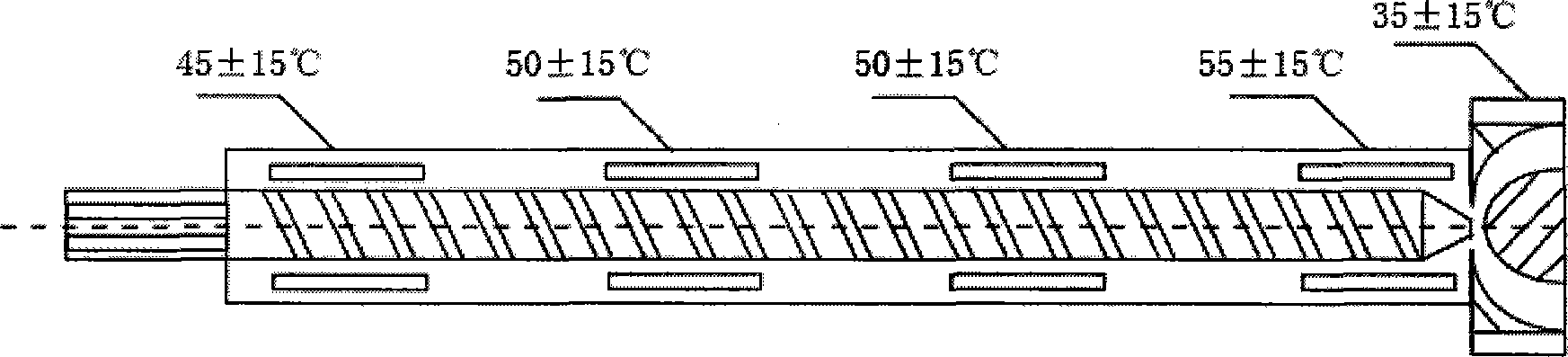

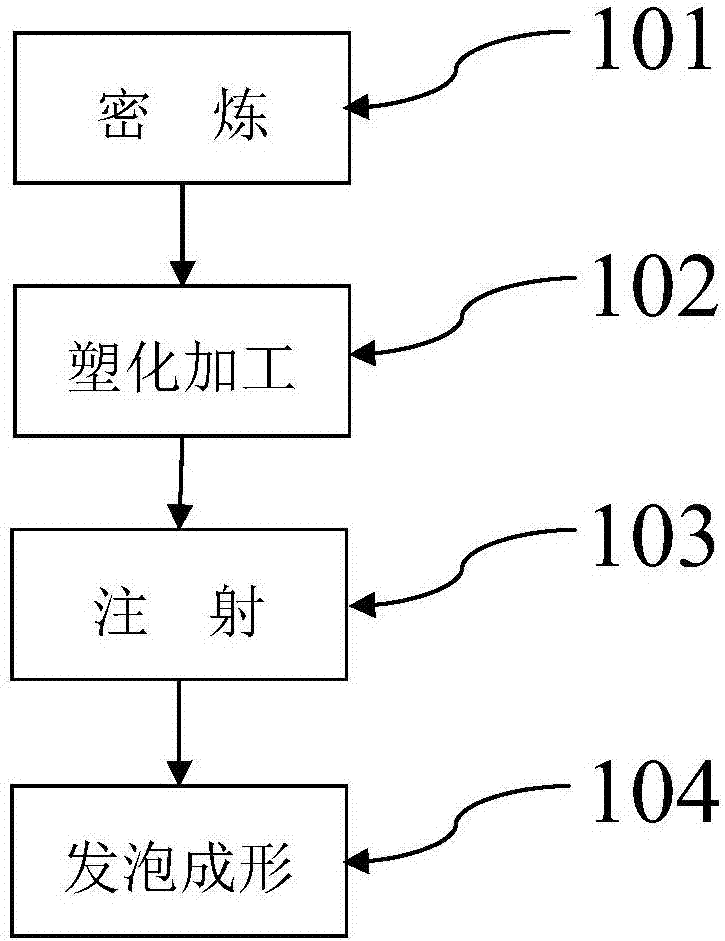

Foam material and moulding method thereof

InactiveCN101497721AUniform foamingLow compression setPolymer scienceEthylene-propylene-diene-monomer

The invention relates to a foaming material and a molding method thereof, in particular to an ethylene propylene diene monomer (EPDM) and chlorinated polyethylene (CPE) foaming material and a molding method thereof. The material is prepared in the following steps that: firstly, high-temperature mixed rubber containing ethylene propylene diene monomer (EPDM) and chlorinated polyethylene (CPE) is mixed in an internal mixer according to a formula; after piece output and placing, high-temperature mixed rubber is mixed into low-temperature rubber according to a mixture radio; after the low-temperature rubber is cut into pieces, foaming is extruded on an extruding machine; and secondary sulfuration and shaping are carried out in a drying tunnel after the extruding so as to manufacture the foaming material. The invention has the characteristics of favorable season durability, temperature durability, aging durability, damping seal, and the like, and can be applied to the fields of heat insulation of a central air conditioner and a pipeline of a refrigeration set, buffer pad, sound absorption, voice reduction, and the like.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Footwear Compositions Comprising Propylene-Based Elastomers

Disclosed are footwear compositions comprising a propylene-based elastomer. The presence of the propylene-based elastomer provides the footwear sole with a well-balanced combination of desired properties, including low density, low compression set, and weldability.

Owner:EXXONMOBIL CHEM PAT INC

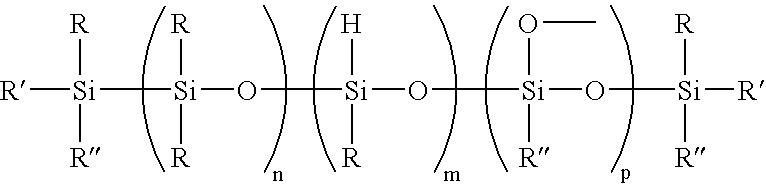

Two-part curable silicone composition

InactiveUS20060040116A1Low compression setExcellent curabilityThin material handlingRubber layered productsPolymer scienceNitrogen

Provided is a two-part curable silicone composition including: (A) 100 parts by mass of an organopolysiloxane containing at least two alkenyl groups bonded to silicon atoms, (B) an organohydrogenpolysiloxane containing at least two SiH groups, in sufficient quantity to provide from 0.5 to 5.0 mols of SiH groups within the component (B) for every 1 mol of alkenyl groups within the entire composition, (C) an effective quantity of a hydrosilylation reaction catalyst, and (D) from 0.0001 to 1 part by mass of a nitrogen-containing compound (a triazole-based compound and / or an imidazole-based compound), which is prepared in two separate parts, in which the components (A) through (C) do not exist within one part, and the component (D) exists in a different part from that of the component (C). Also provided are a method of curing the composition and a cured product obtained by the method. Further provided are a method for potting an electrical and electronic component using the composition and a method for producing a silicone rubber molded product using the composition. The composition is capable of stably maintaining favorable curability and a high level of flame retardancy or a low compression set, and is useful for silicone rubber potting materials and silicone rubber molded products.

Owner:SHIN ETSU CHEM IND CO LTD

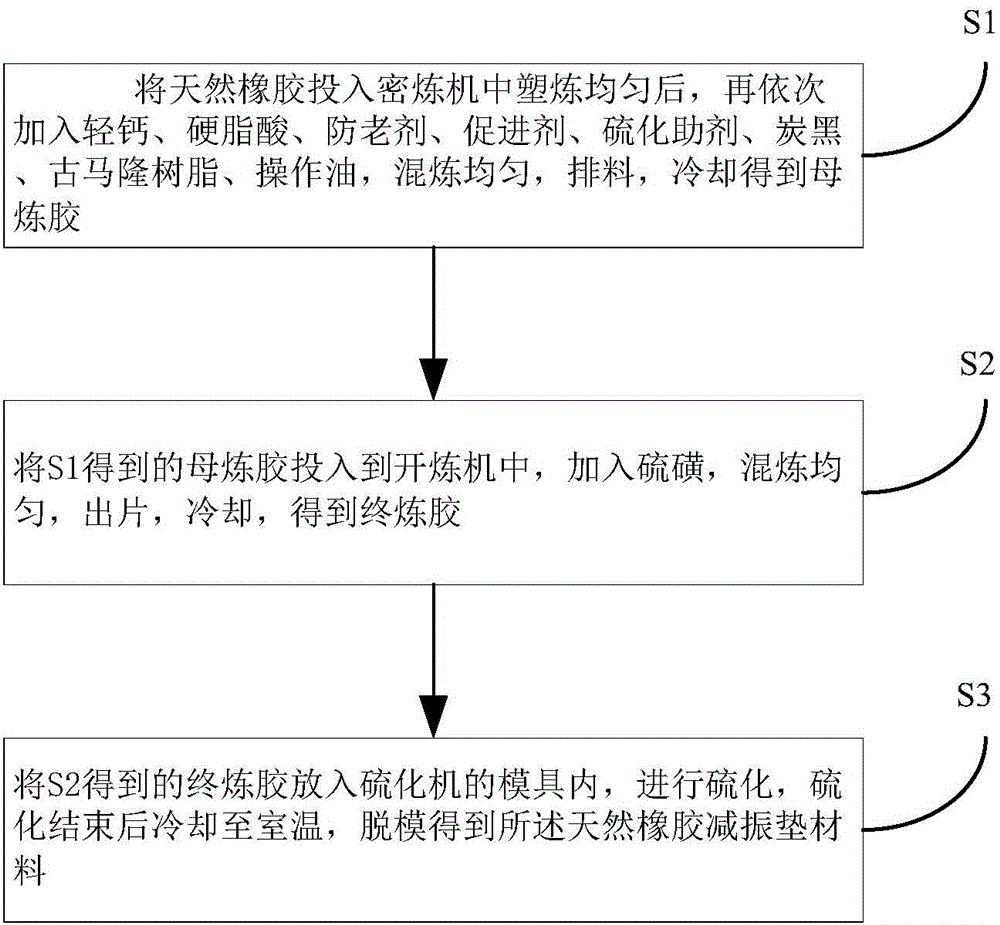

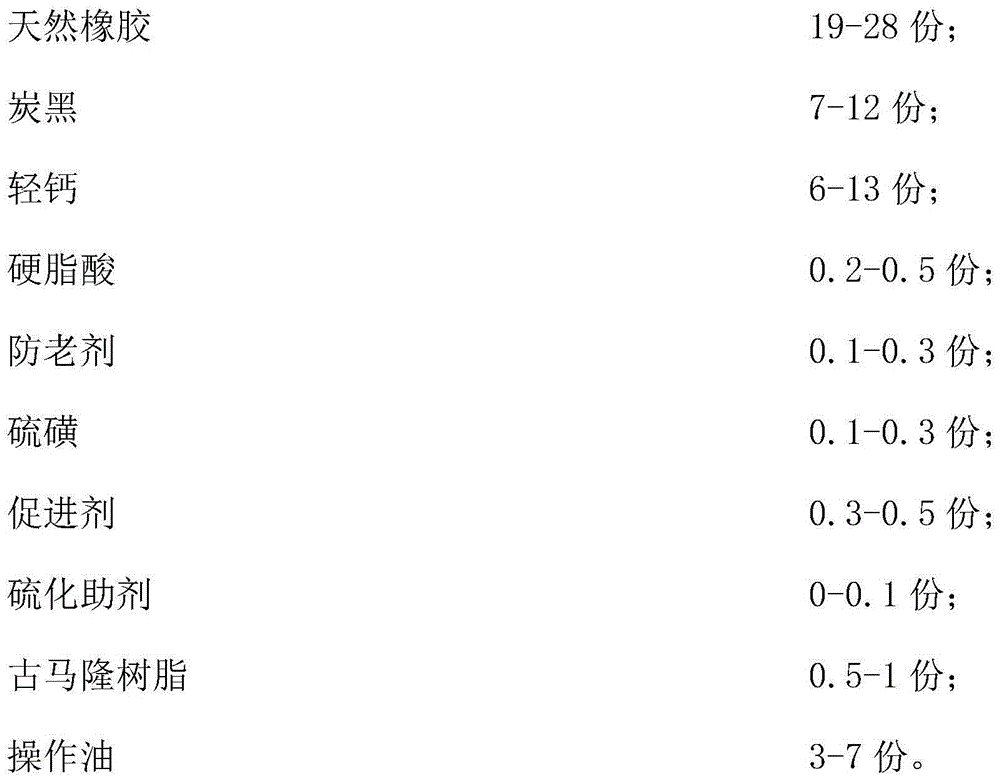

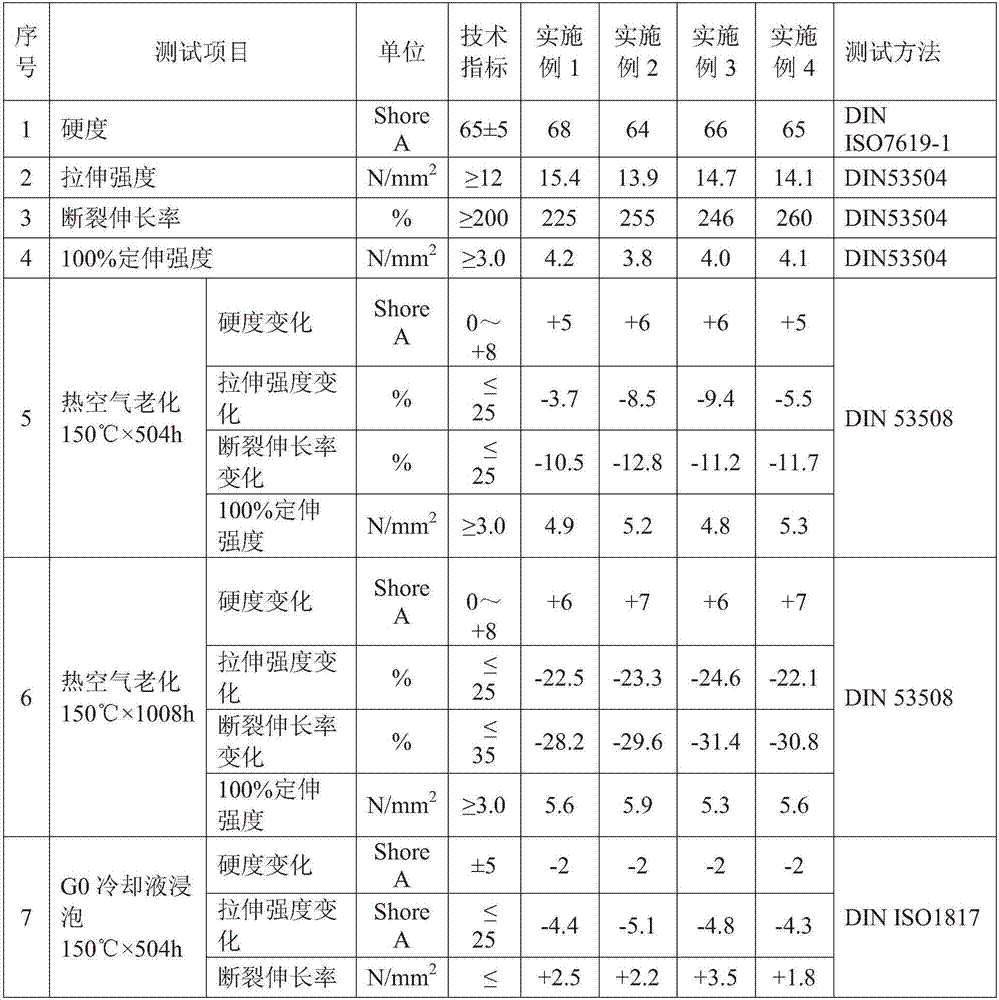

Natural rubber anti-vibration pad material and preparation method thereof

The invention discloses a natural rubber vibration damping pad material. The raw materials include: natural rubber, 19-28 parts; carbon black, 7-12 parts; light calcium, 6-13 parts; stearic acid, 0.2-13 parts by weight. 0.5 part; anti-aging agent, 0.1‑0.3 part; sulfur, 0.1‑0.3 part; accelerator, 0.3‑0.5 part; vulcanization aid, 0‑0.1 part; coumarone resin, 0.5‑1 part; process oil, 3‑ 7 servings. The natural rubber vibration-damping pad material has good vibration-damping effect and excellent weather resistance, and at the same time has high radial strength, moderate hardness, good elasticity and long service life. The invention also discloses a preparation method of the natural rubber damping pad material.

Owner:安徽华润仪表线缆有限公司

Ethylene propylene rubber material for sealing part of automobile heat dissipation system and production method of ethylene propylene rubber material

InactiveCN107090133AImprove high temperature resistanceLow temperature resistanceCross-linkRubber material

The invention discloses an ethylene propylene rubber material for a sealing part of an automobile heat dissipation system and a production method of the ethylene propylene rubber material and belongs to the technical field of rubber. The rubber material is prepared from the following components in parts by weight: 100 parts of raw ethylene propylene rubber, 5 parts of zinc oxide, 0.5 to 1.5 parts of stearic acid, 3 to 6 parts of an anti-ageing agent, 20 to 30 parts of fast extruding carbon black N550, 10 to 20 parts of semi-reinforced carbon black N774, 3.5 to 7 parts of a cross-linking auxiliary agent Ricon 153D and 5 to 8.5 parts of a vulcanizing agent Perkadox 14-40B-GR. The rubber material disclosed by the invention has excellent high-temperature-resisting performance and can be used for a long time under the condition that the temperature is -50 DEG C to 150 DEG C; meanwhile, the rubber material has remarkable advantages of low temperature resistance and low-compression permanent deformation.

Owner:南京金三力高分子科技有限公司

Production formula and preparation method for elastic rotator

The invention discloses a production formula and a preparation method for an elastic rotator, which belong to the technical field of road transportation equipment. The formula comprises the following specific components: 10 to 20 percent of ethylene-octene copolymer (POE), 40 to 60 percent of EVA (ethylene-vinyl acetate copolymer), 10 to 20 percent of ethylene-propylene-diene monomer, 5 to 10 percent of anti-shrinking agent, 1 to 3 percent of filler, 0.6 to 1.6 percent of dispersed lubricant, 1 to 2 percent of zinc oxide, 0.7 to 1.2 percent of cross-linking agent, 1.5 to 2.5 percent of foaming agent, 1.5 to 2.5 percent of flowable agent and 2 to 4 percent of color masterbatch pigment, and the total weight is 100 percent. The POE, the ethylene-propylene-diene monomer and the EVA are mixed and refined, and are added with a variety of additives, so that the three types of materials keep respective properties and complement one another, the elasticity of the prepared elastic rotator is high, moreover, after foaming, the texture is dense, the weight is light, the good anti-aging property of the elastic rotator is ensured, the elastic rotator cannot be easily cracked when receiving impact force, and the service life of the elastic rotator is effectively prolonged.

Owner:江苏恪铭智慧交通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com