Patents

Literature

607 results about "Compressive load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compressive strength is defined as the maximum compressive load a body can bear prior to failure, divided by its cross sectional area. Ceramics typically have good tensile strengths and are used under compression e.g. concrete.

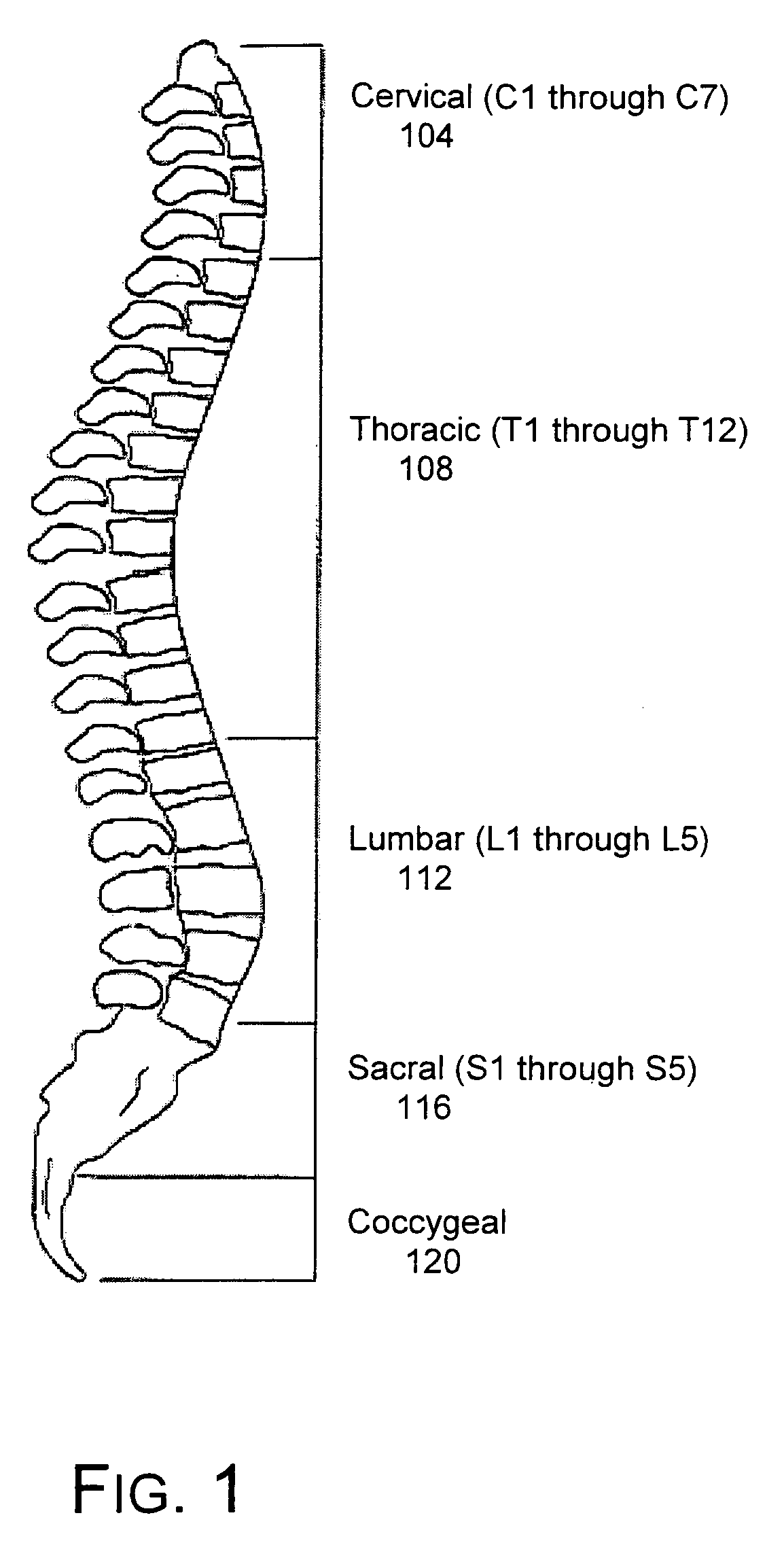

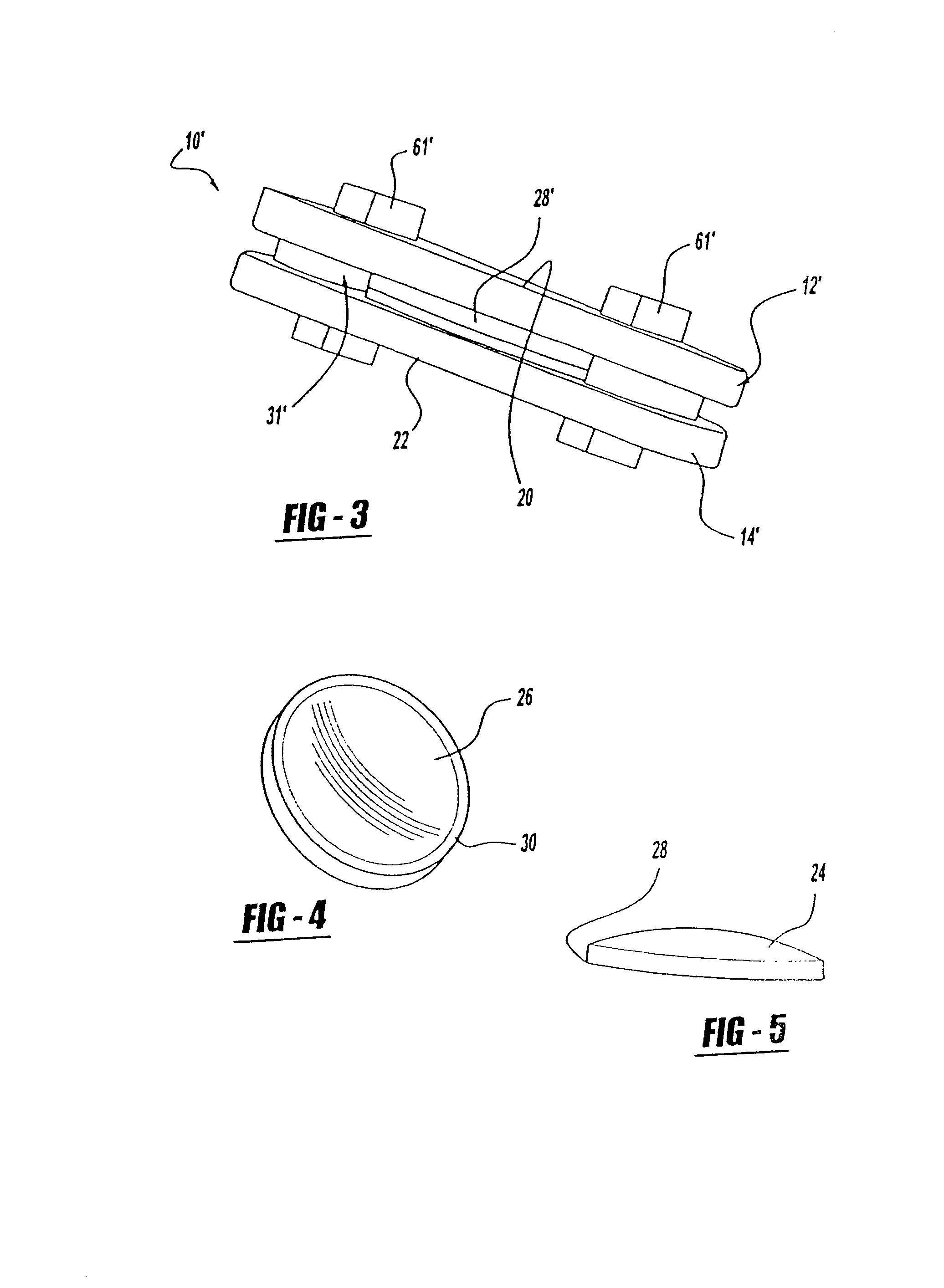

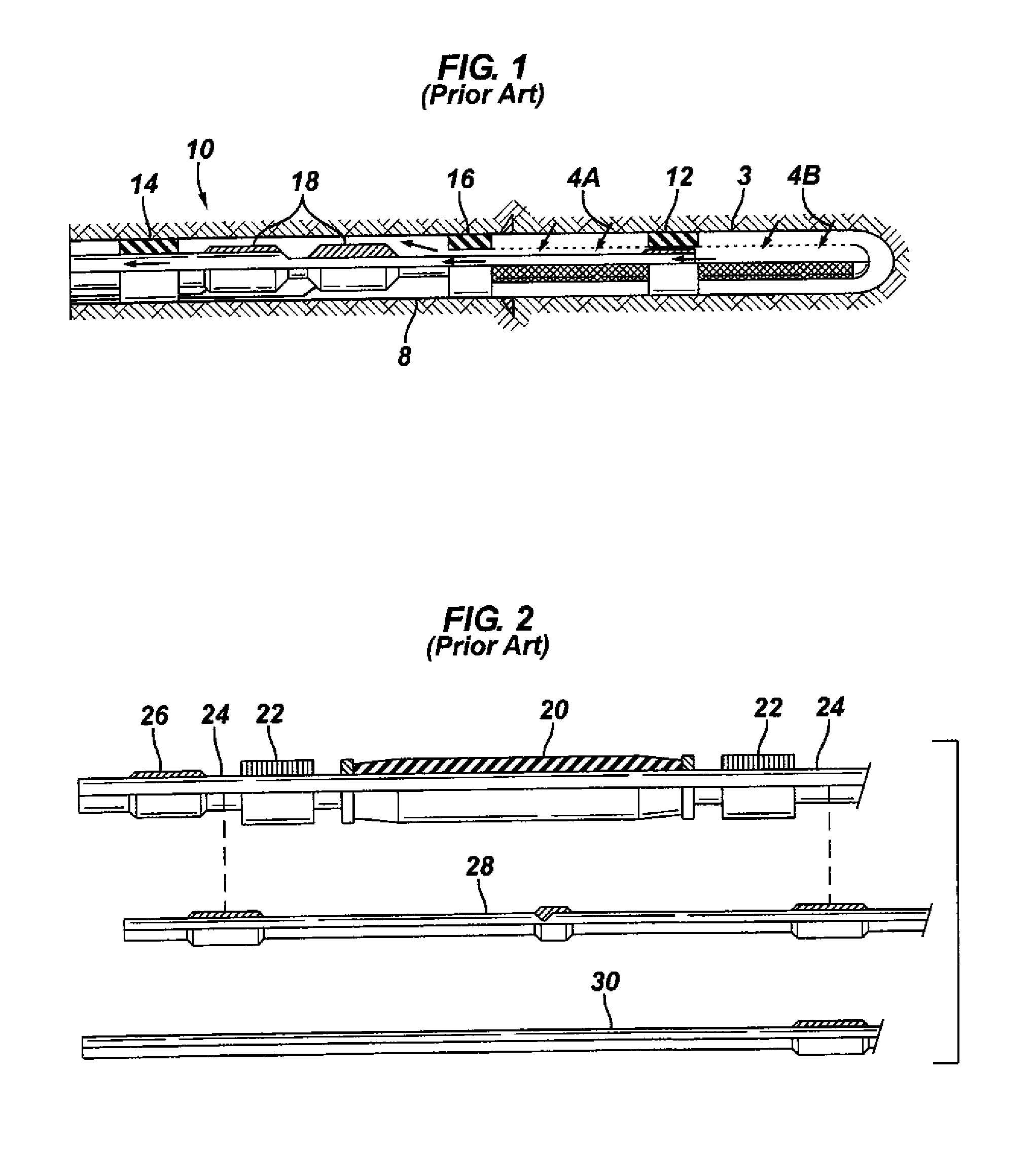

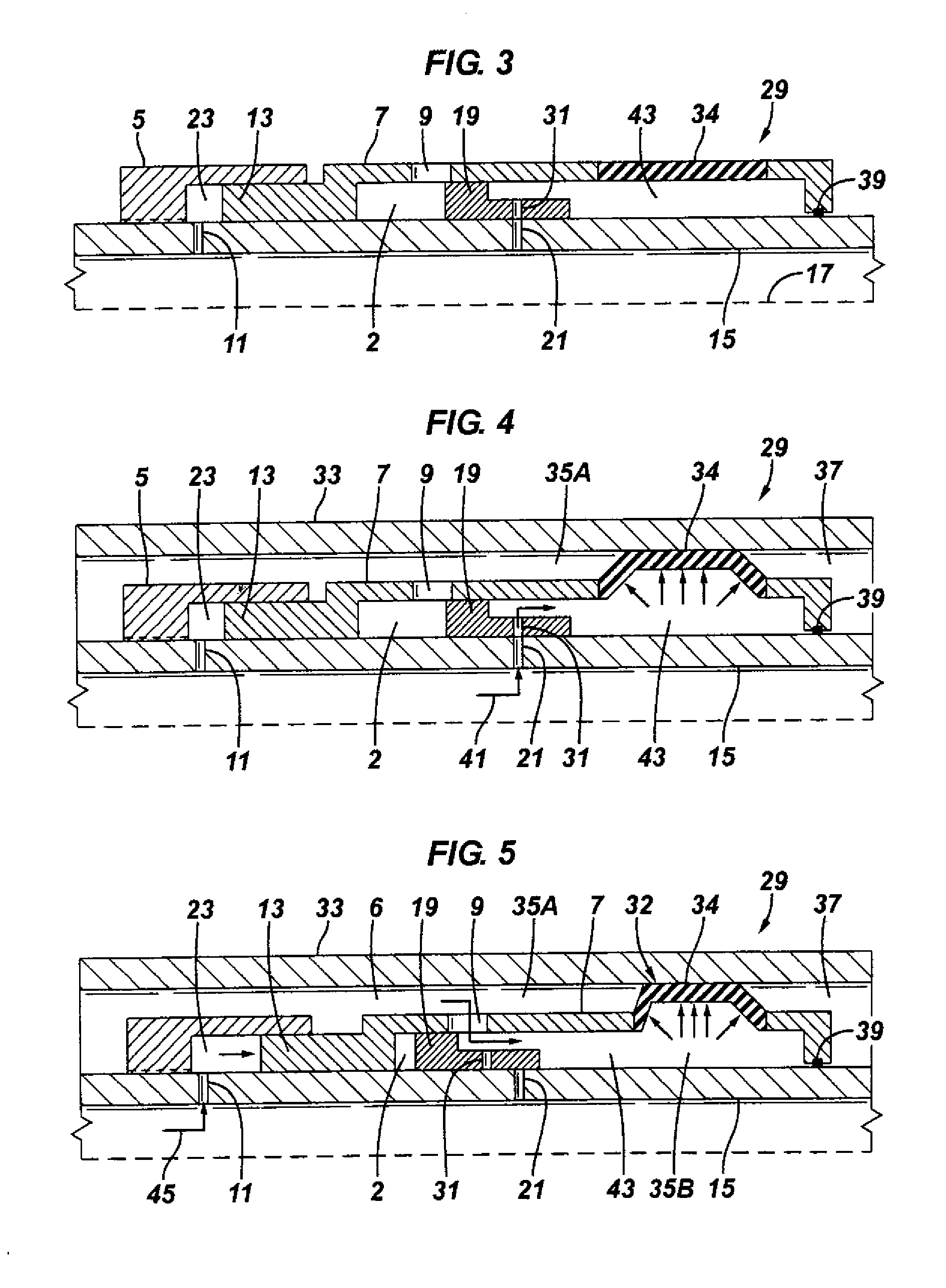

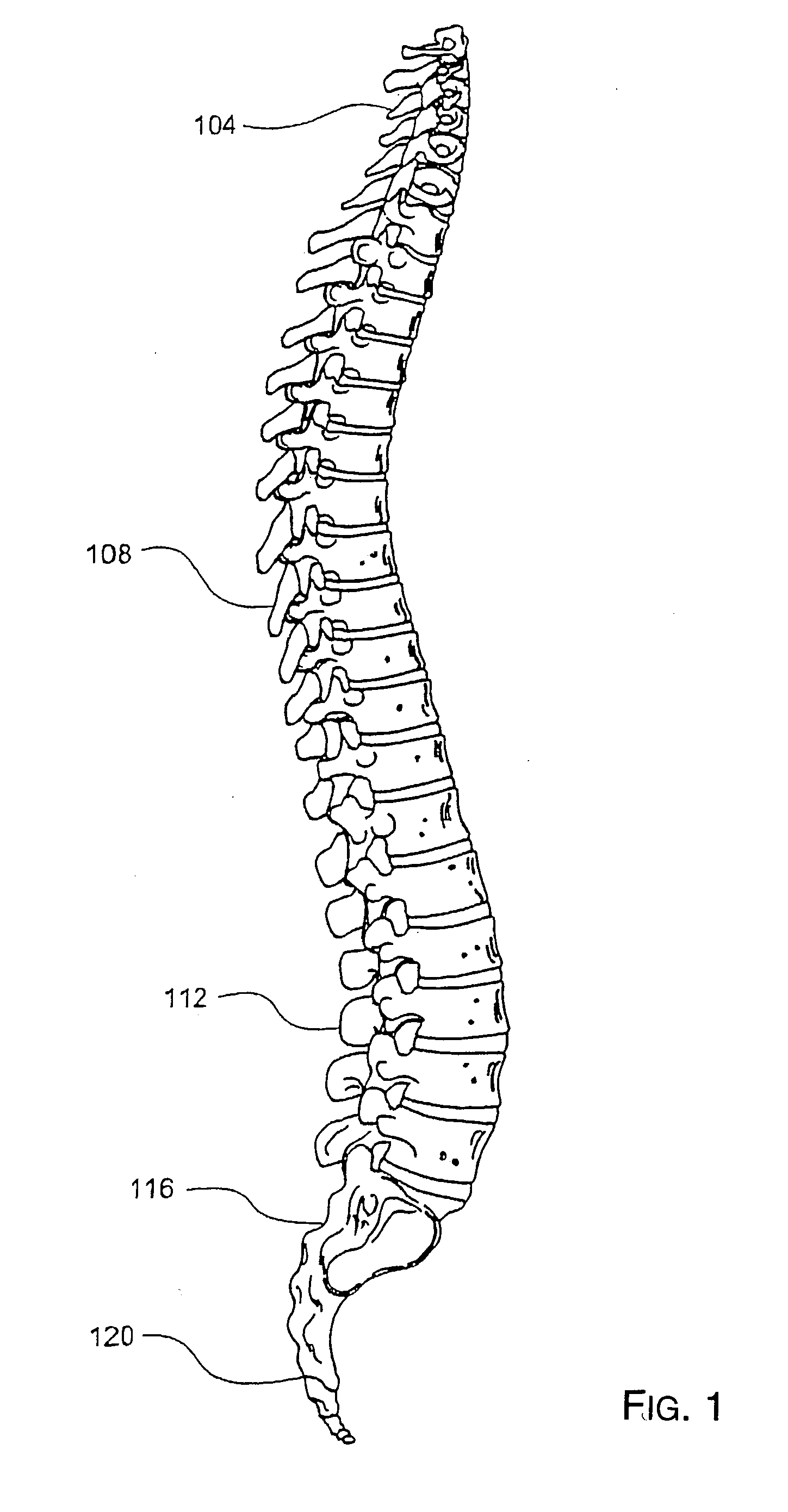

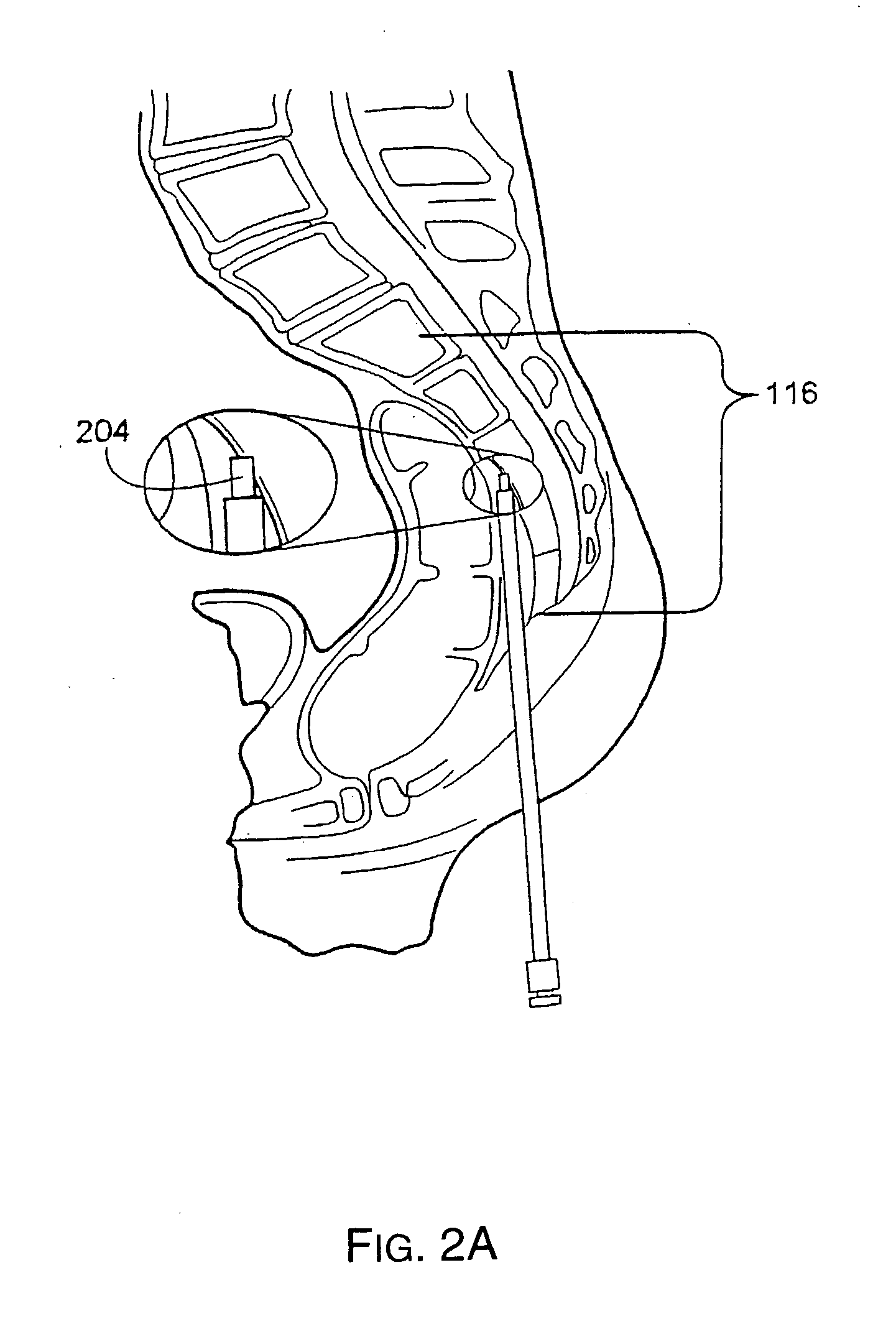

Spinal motion preservation assemblies

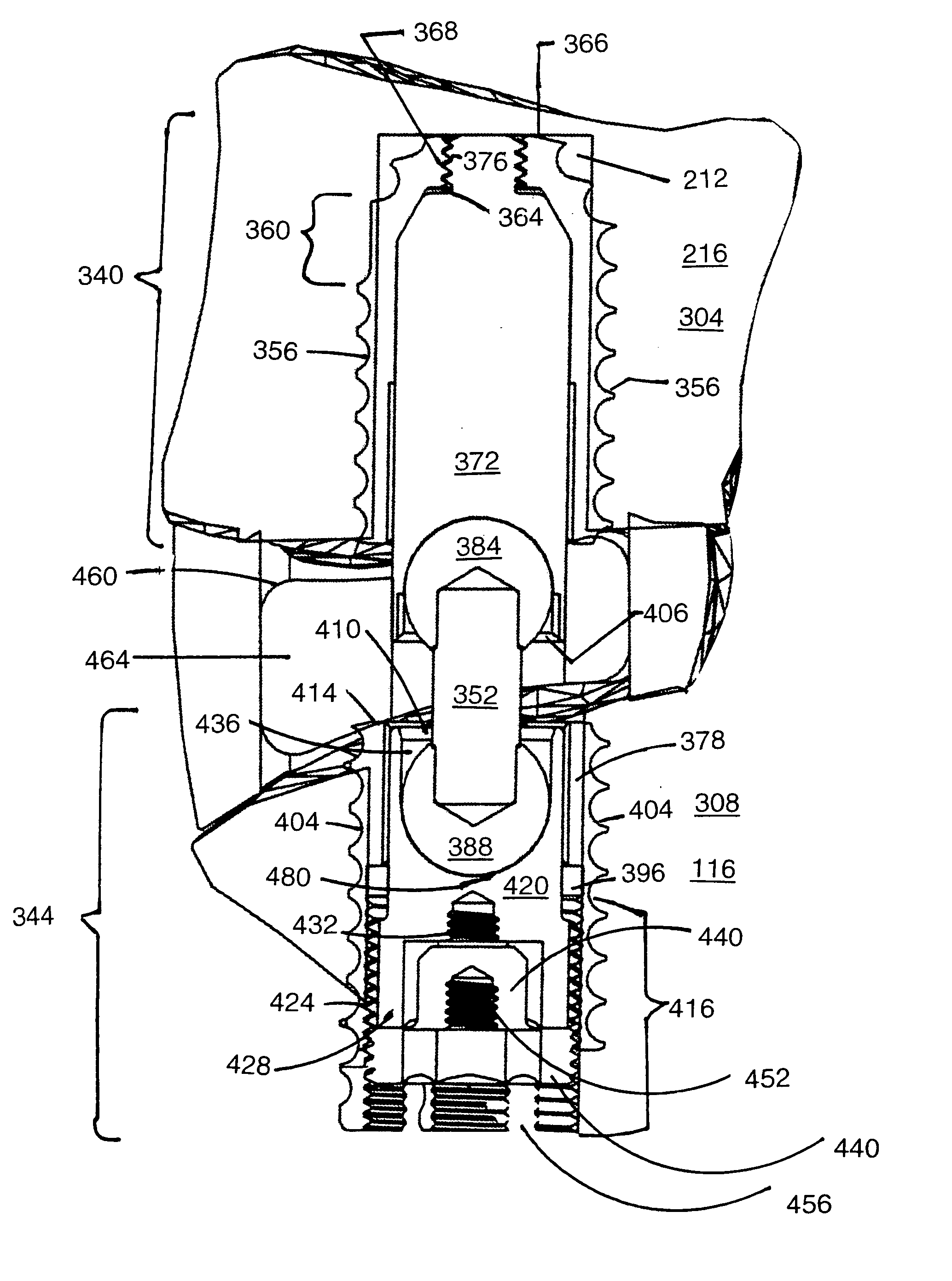

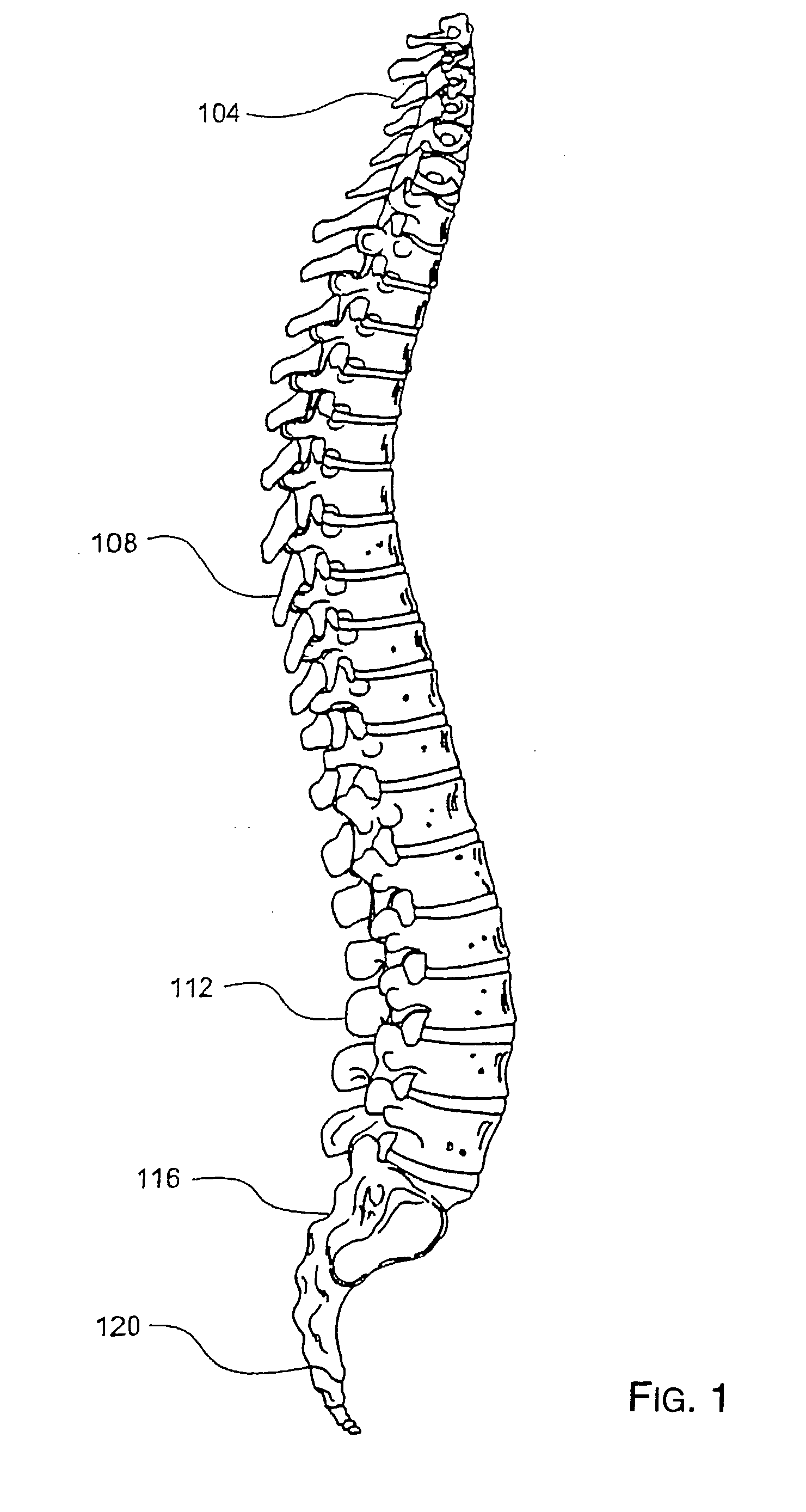

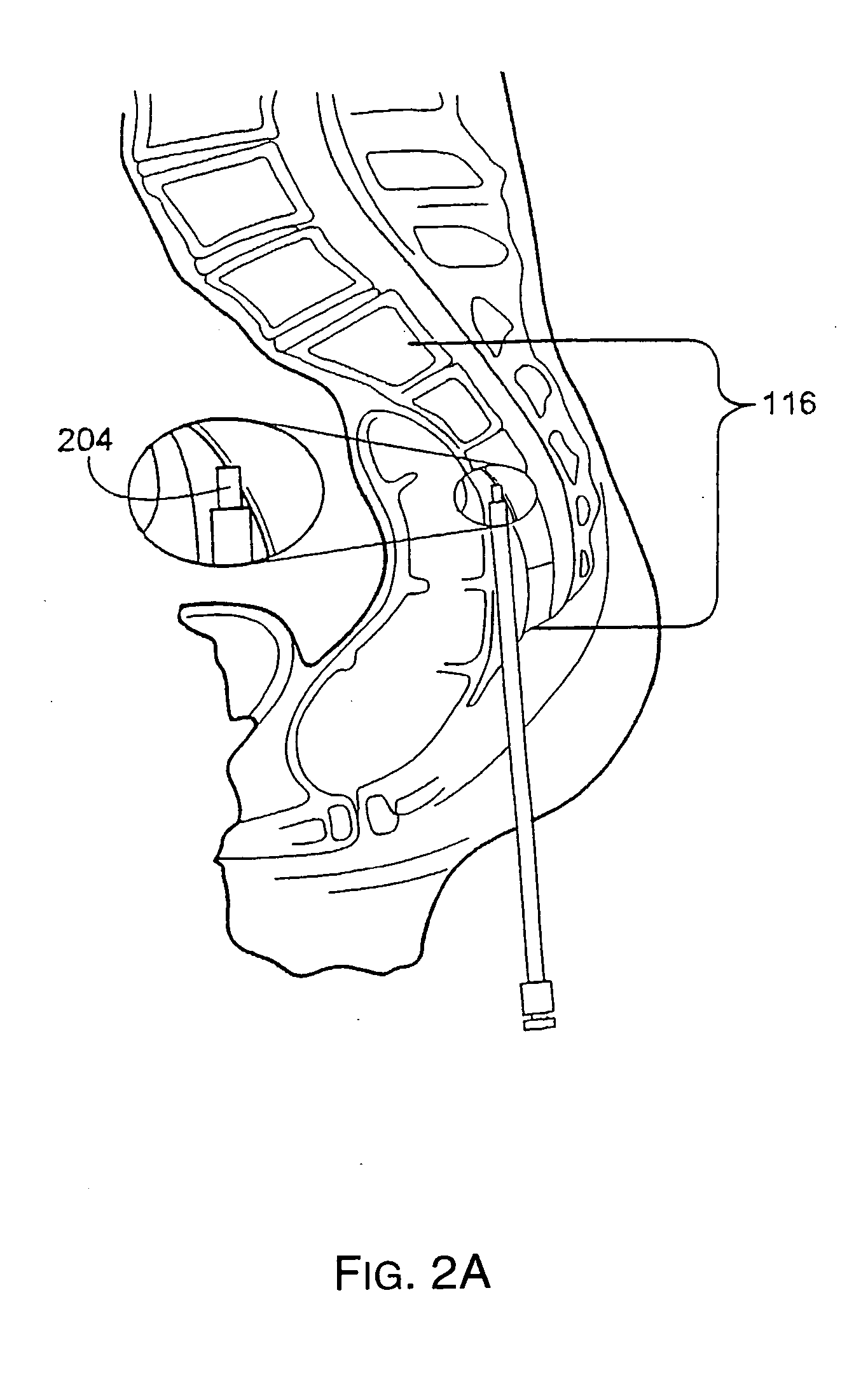

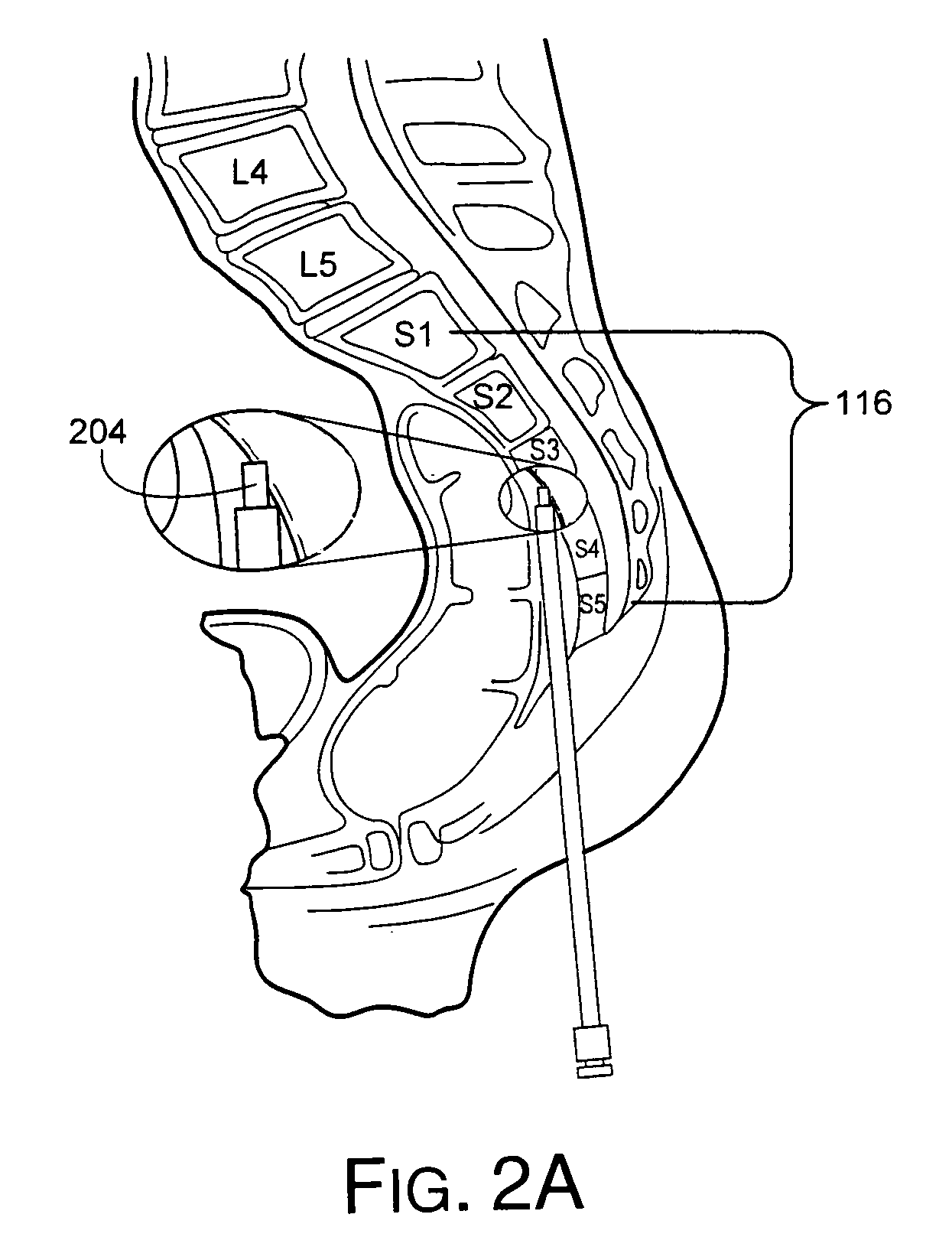

InactiveUS20070168036A1Maintain normal physiological functionReduce riskInternal osteosythesisCannulasSpinal columnAnesthesia

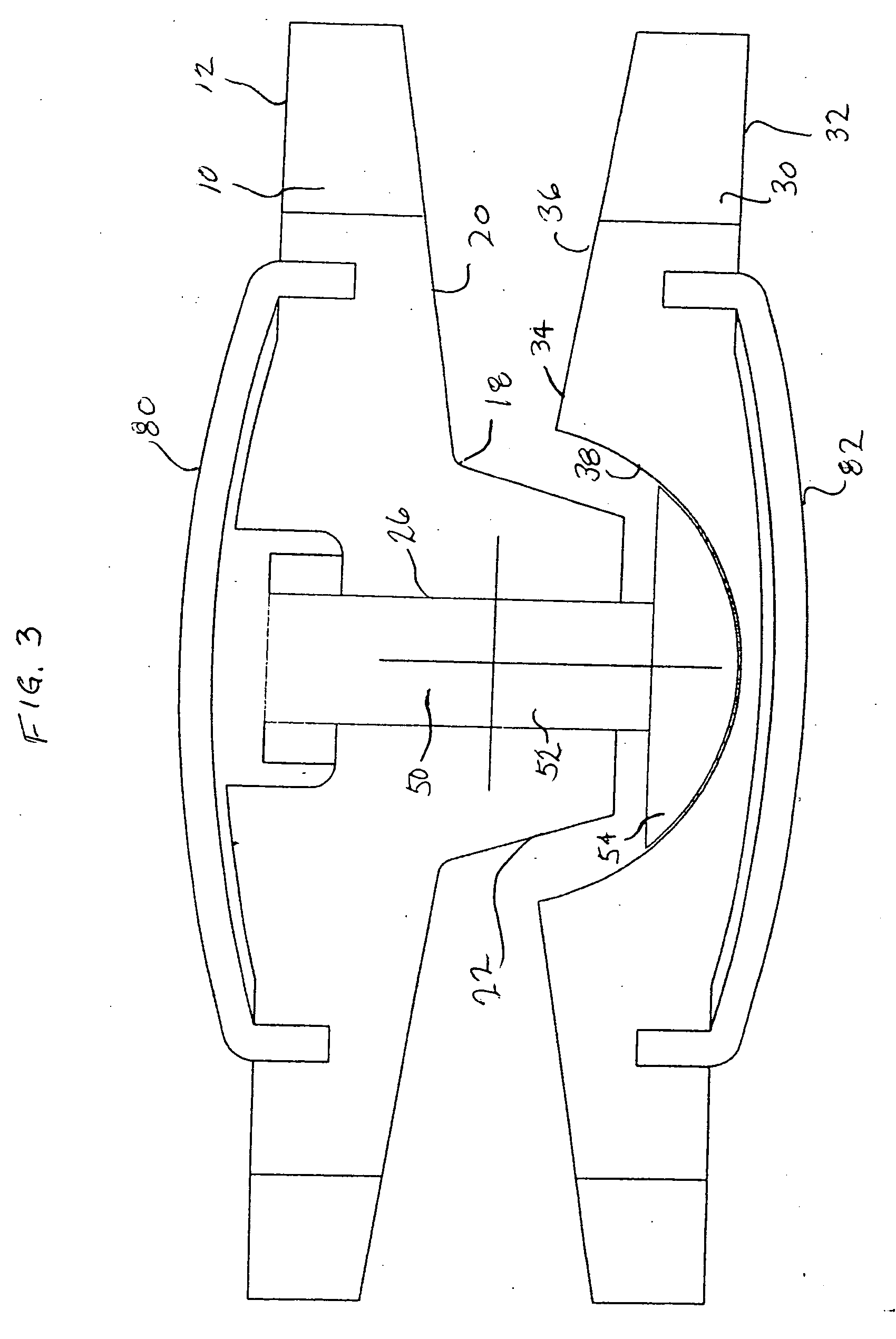

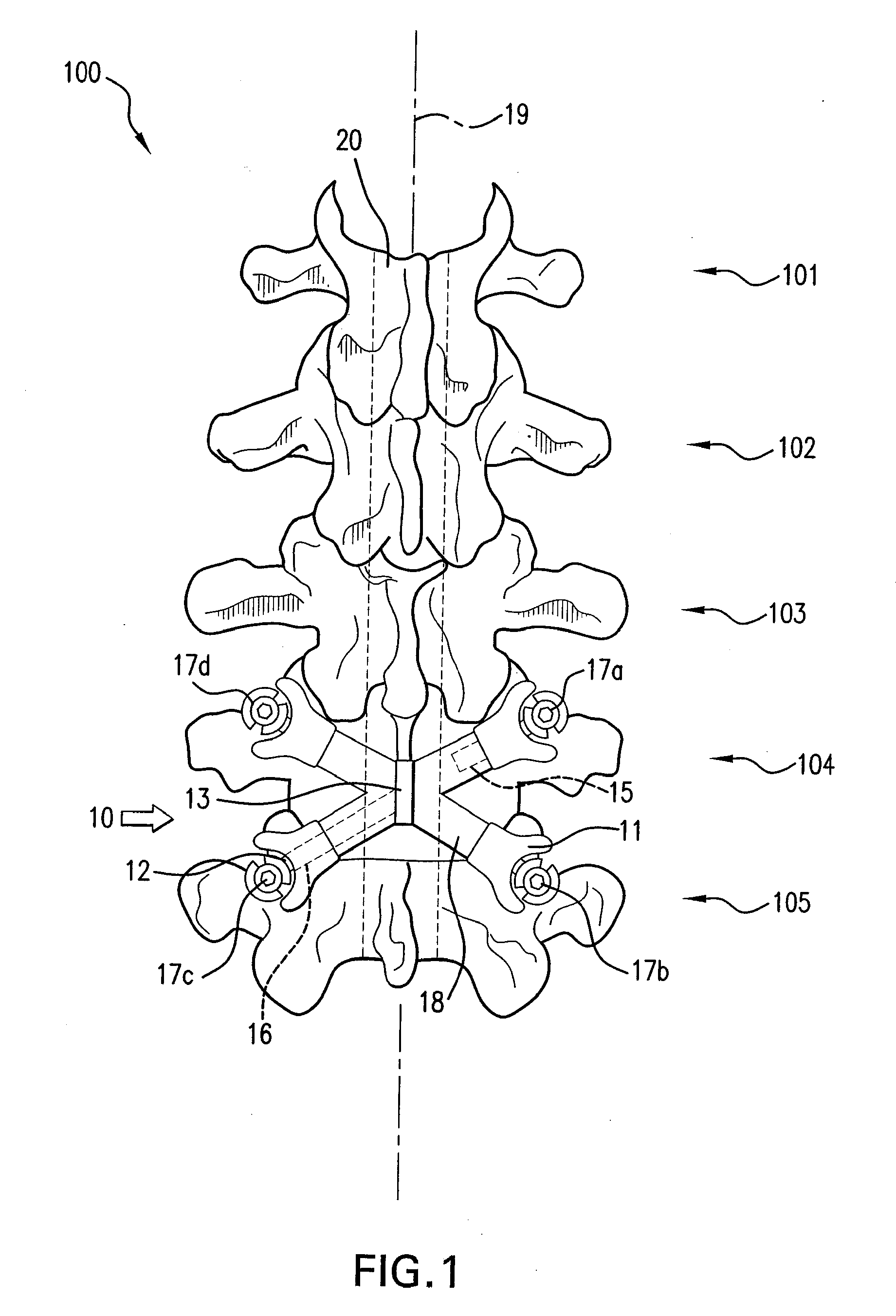

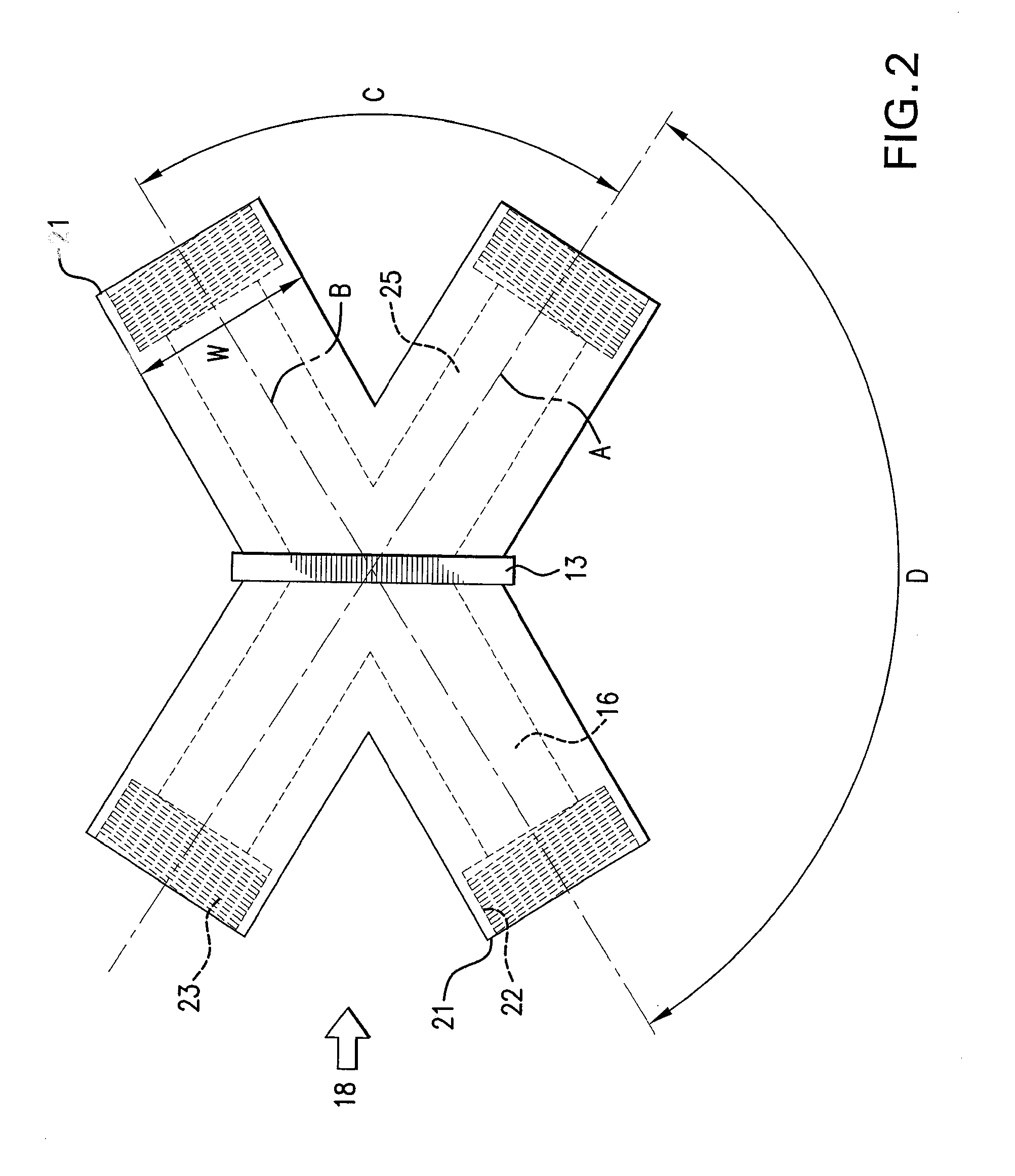

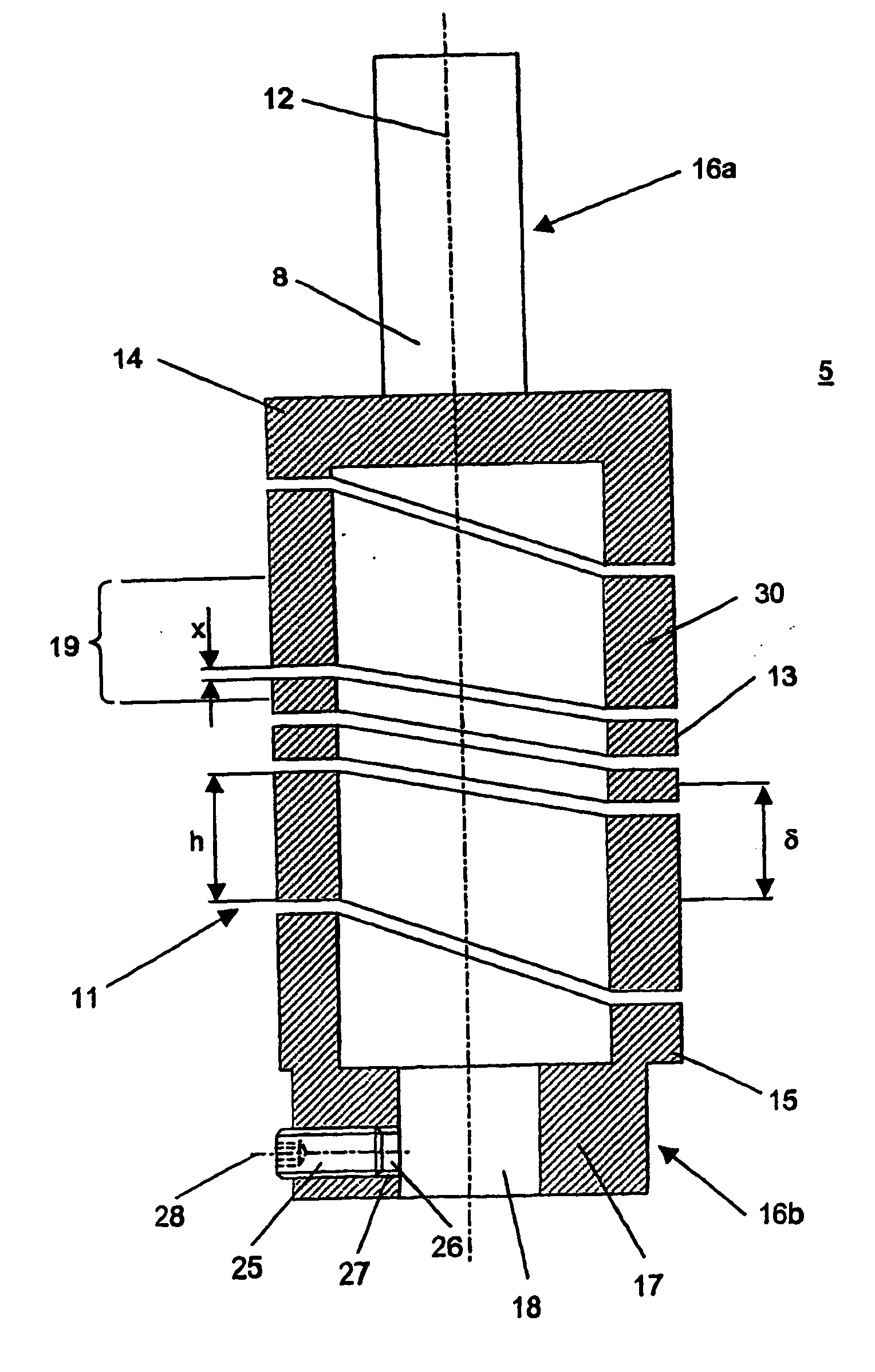

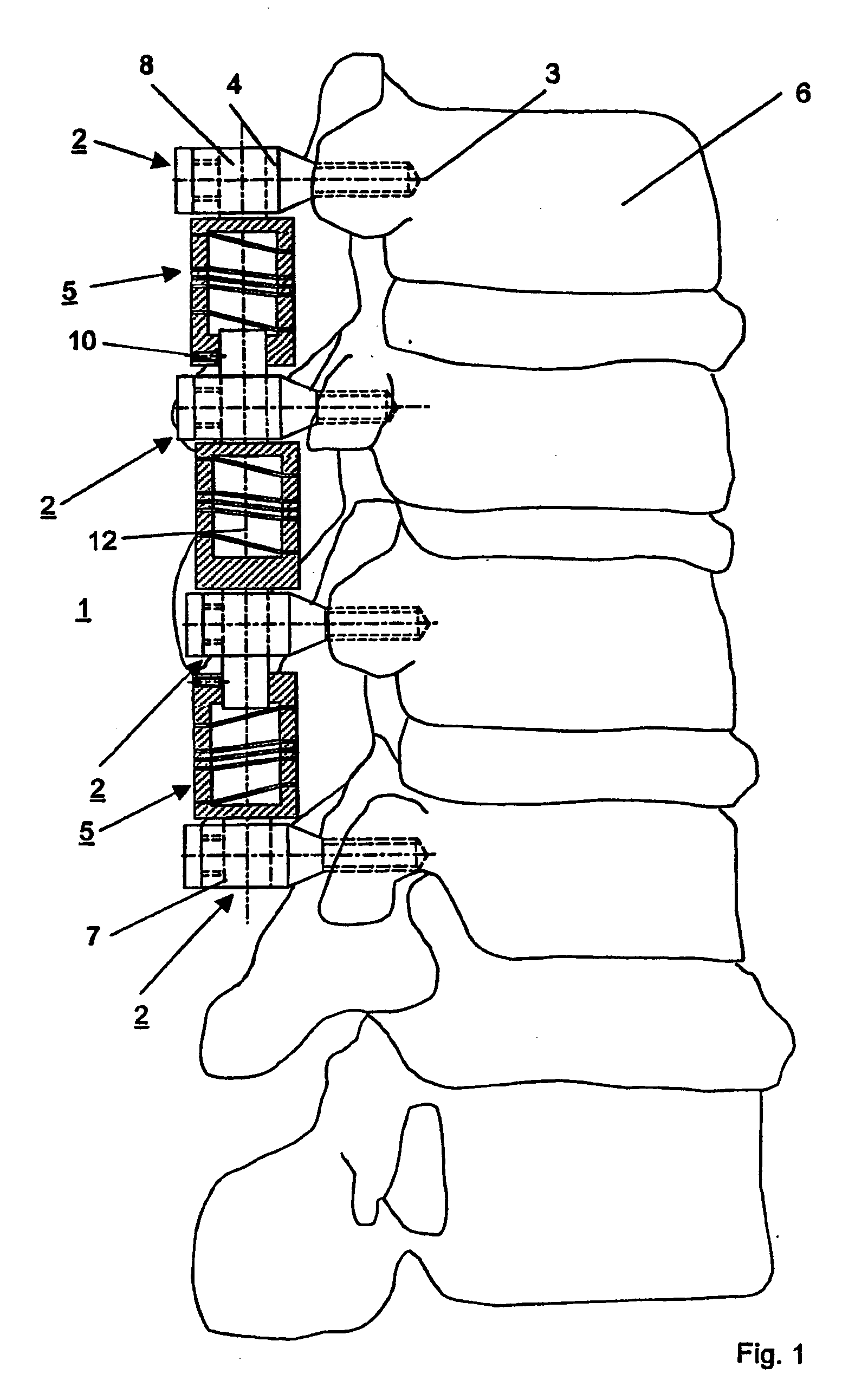

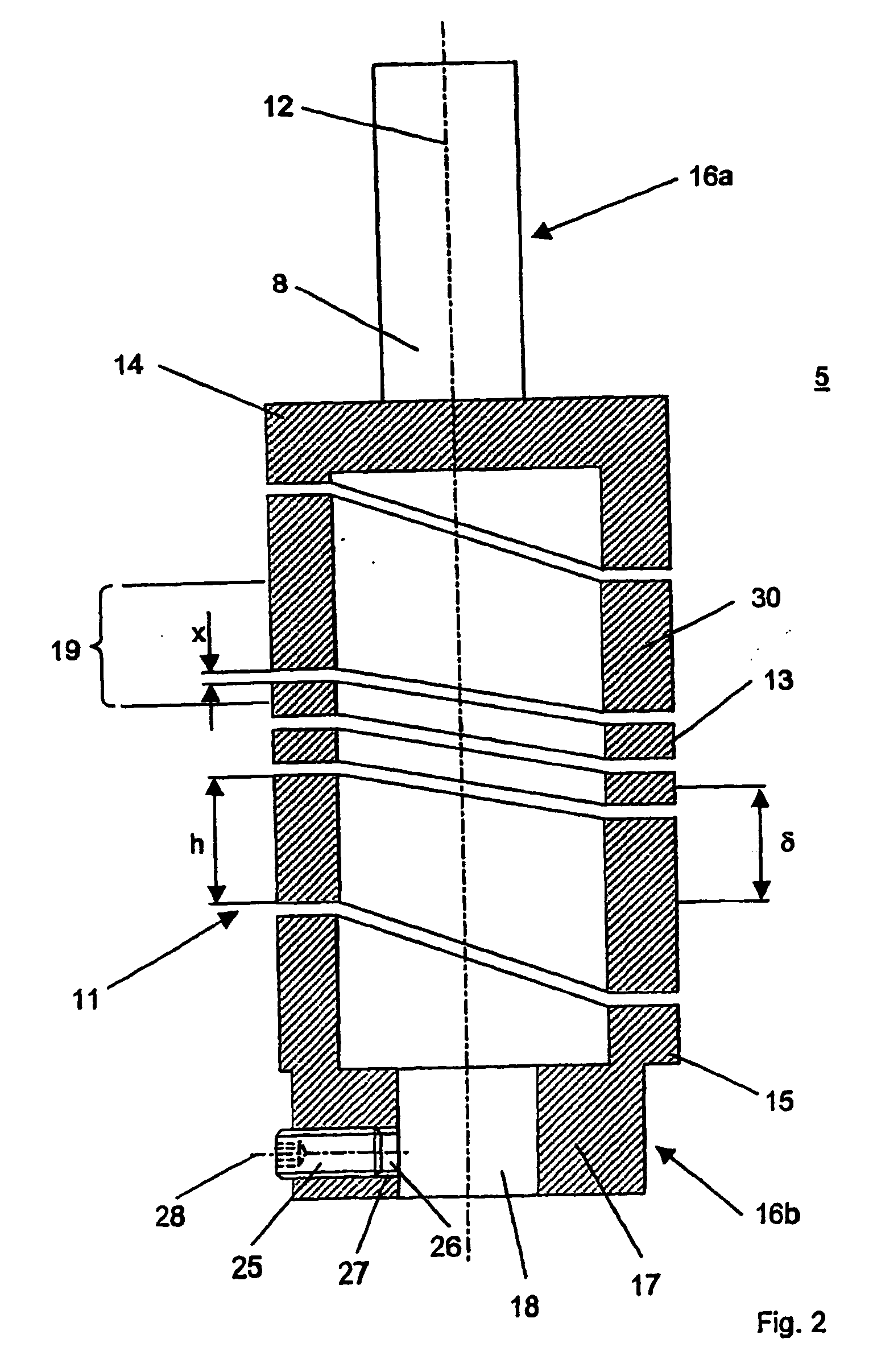

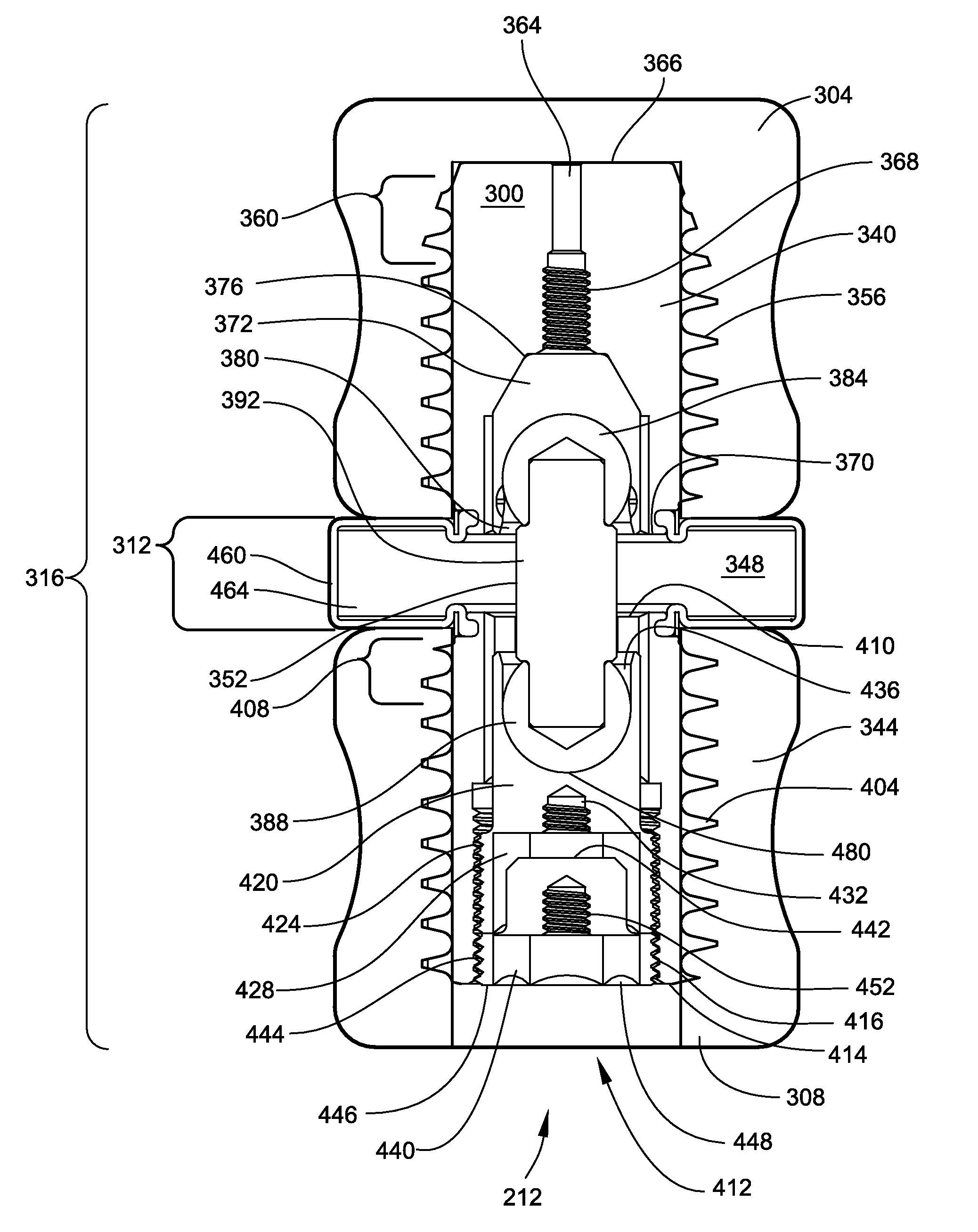

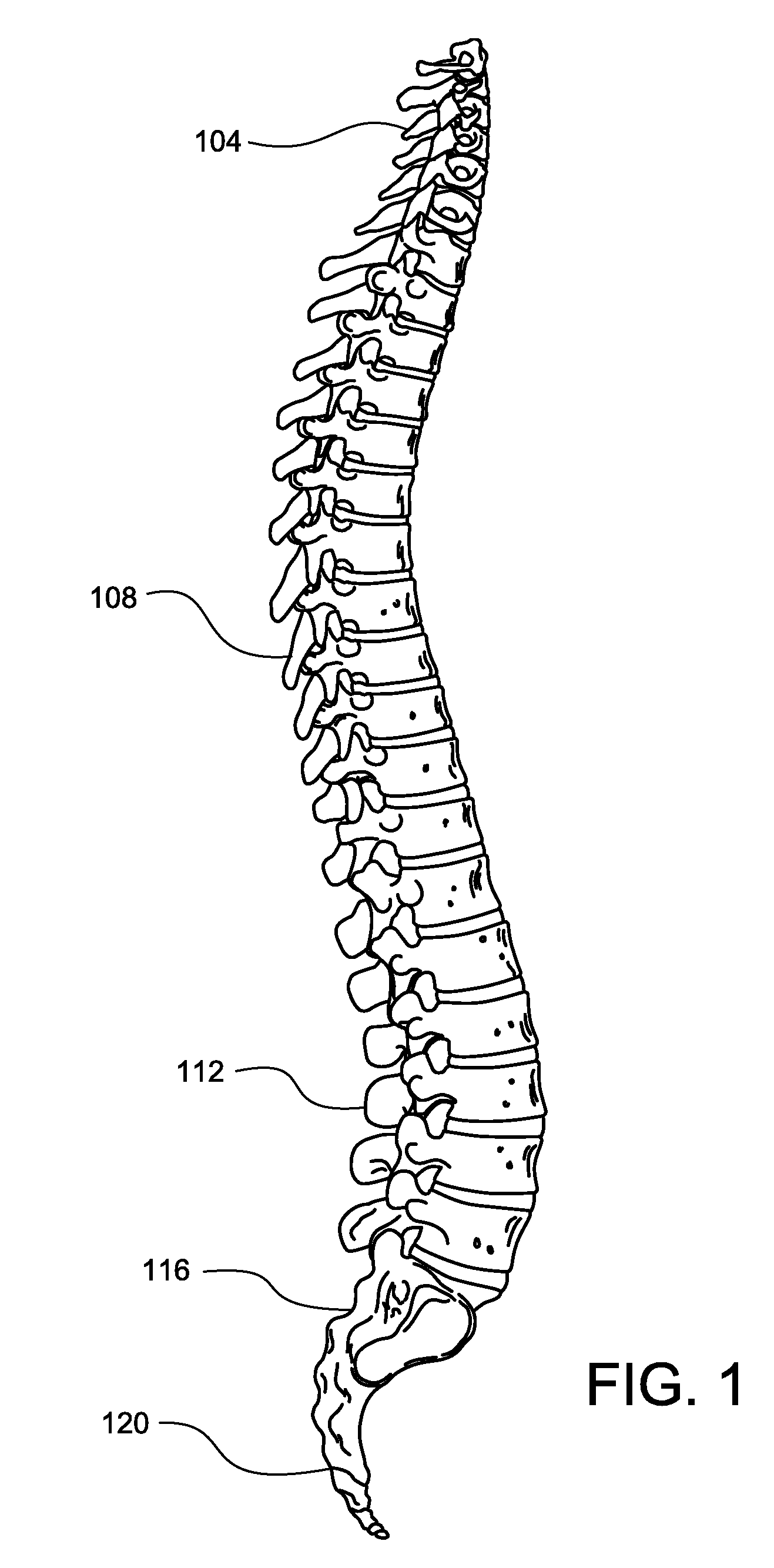

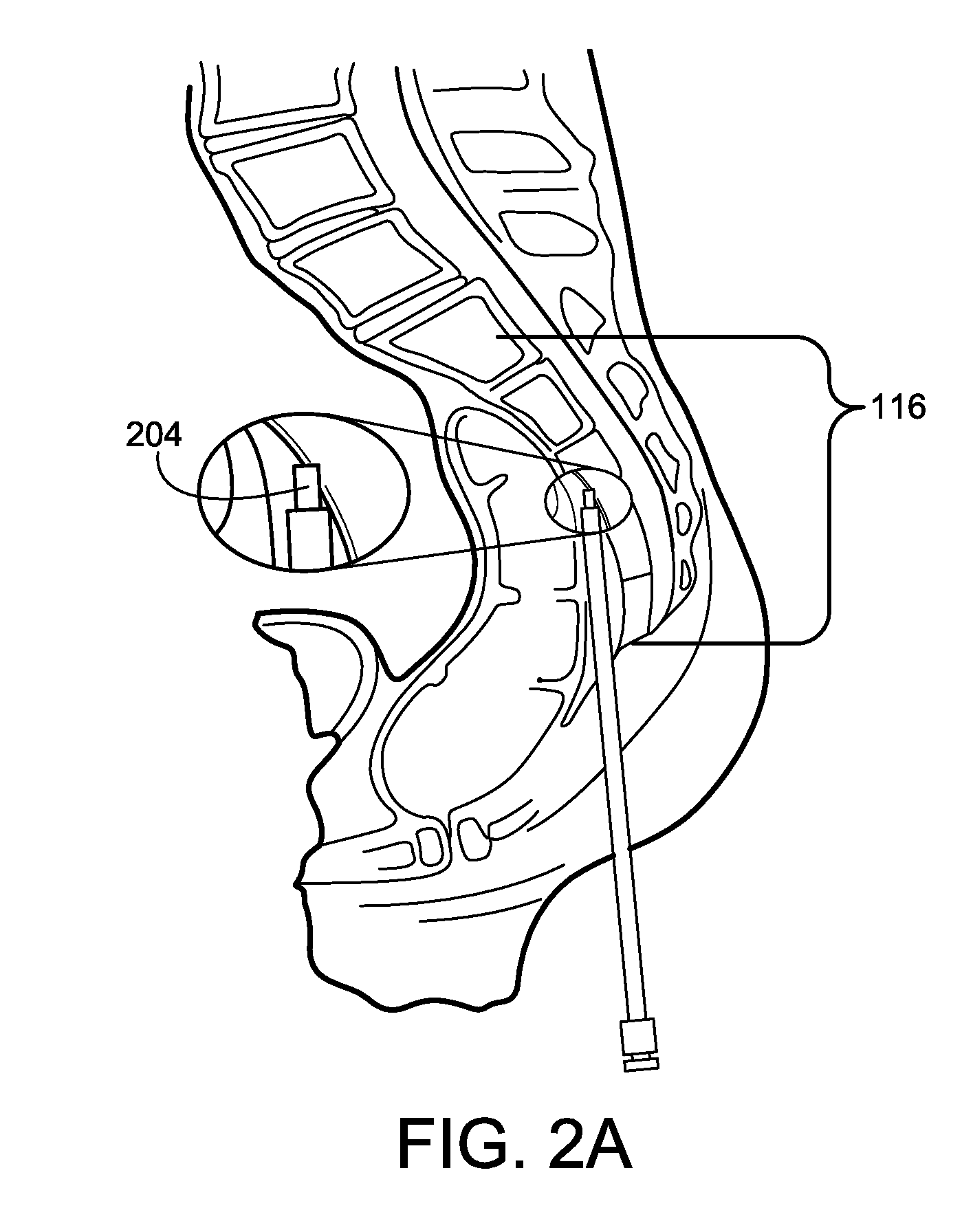

Spinal motion preservation assemblies adapted for use in a spinal motion segment are disclosed including the process for delivering and assembling the spinal motion preservation assemblies in the spinal motion segment via an axial channel created with a trans-sacral approach. Many of the spinal motion preservation assemblies make use of a dual pivot. A number of different embodiments of spinal motion preservation assemblies are disclosed which include at least one component adapted for elastic deformation under compressive loads. The disclosed mobility preservation assemblies provide for dynamic stabilization of the spinal motion segment. Other variations and implementations of the teachings are disclosed, including the sheathed delivery of membranes in order to protect the membranes before and during deployment.

Owner:MIS IP HLDG LLC

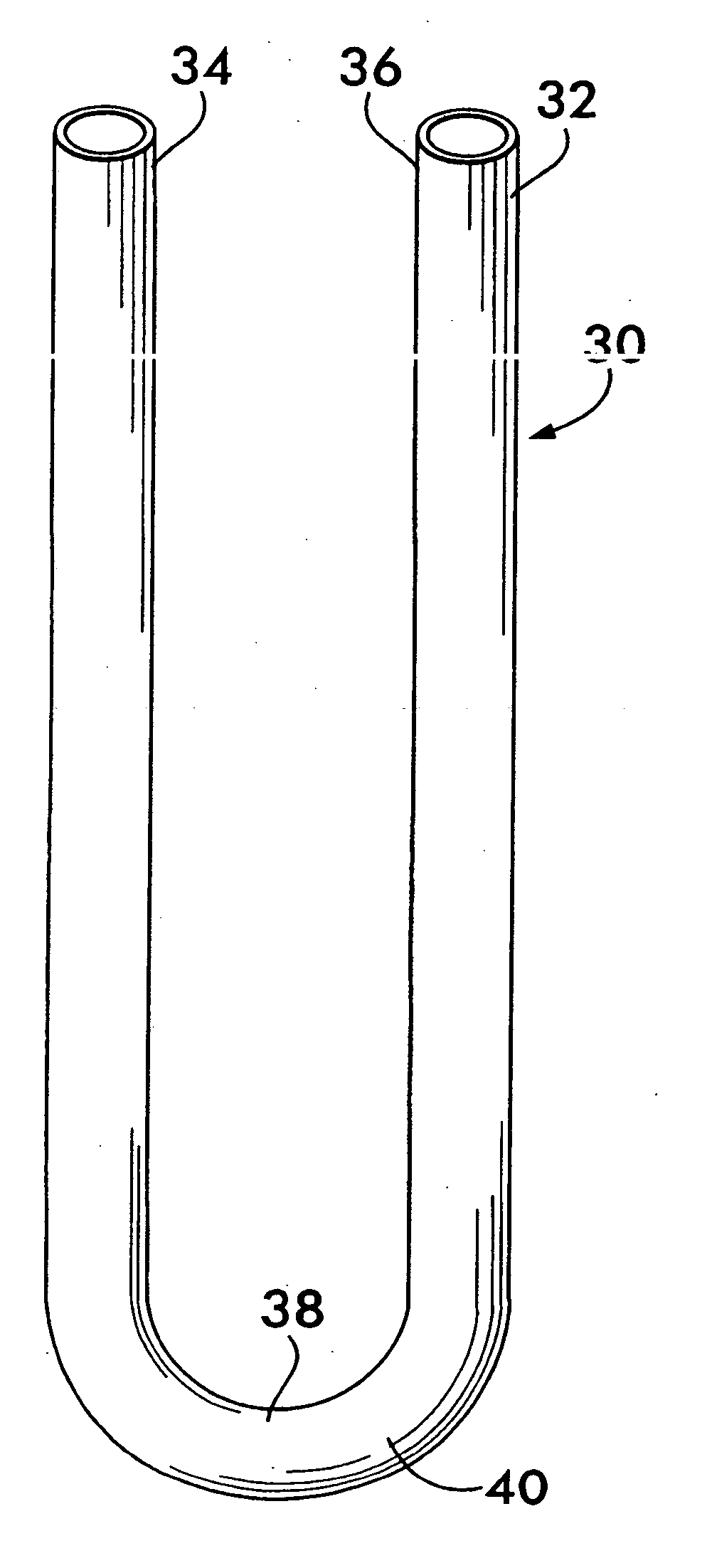

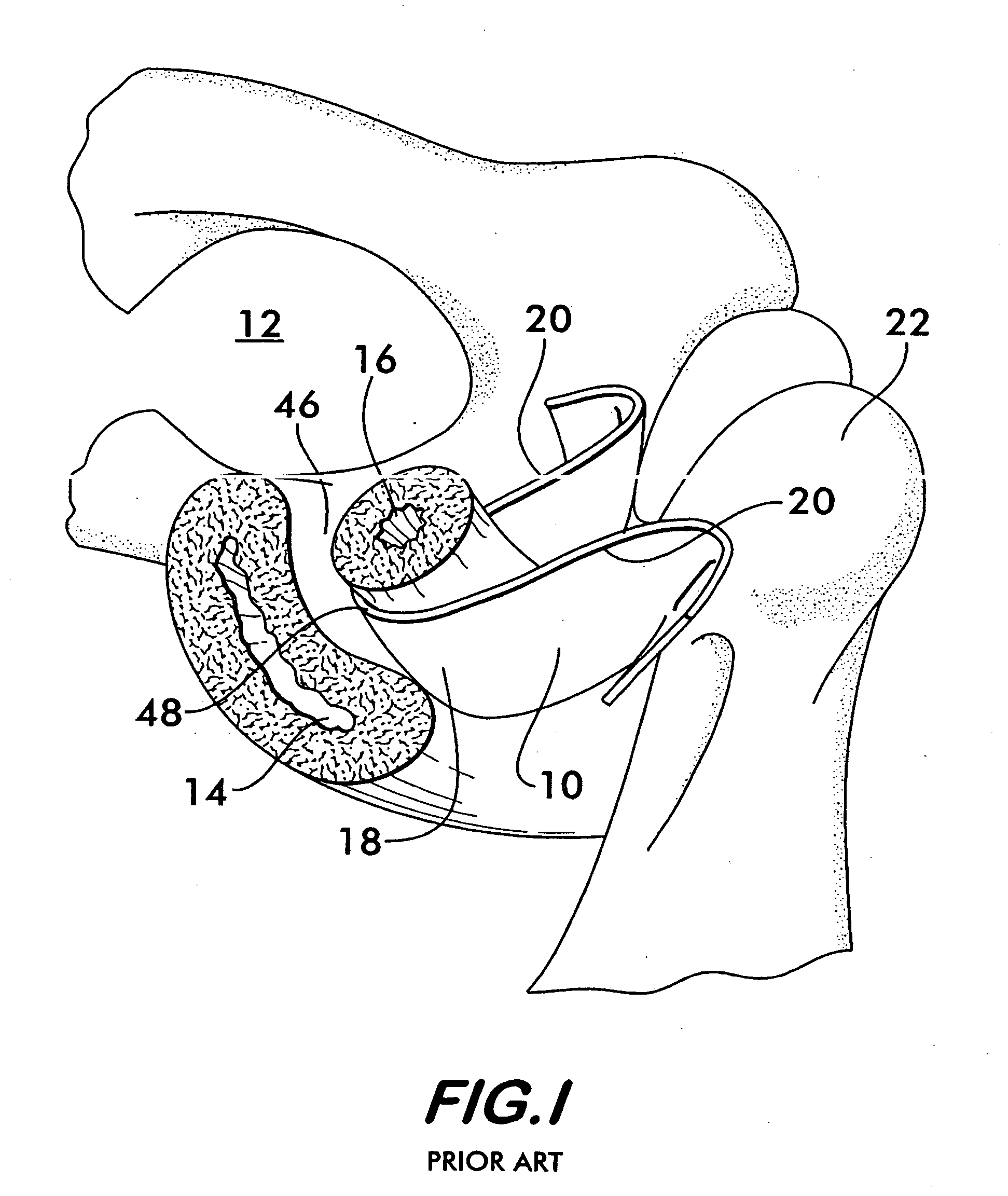

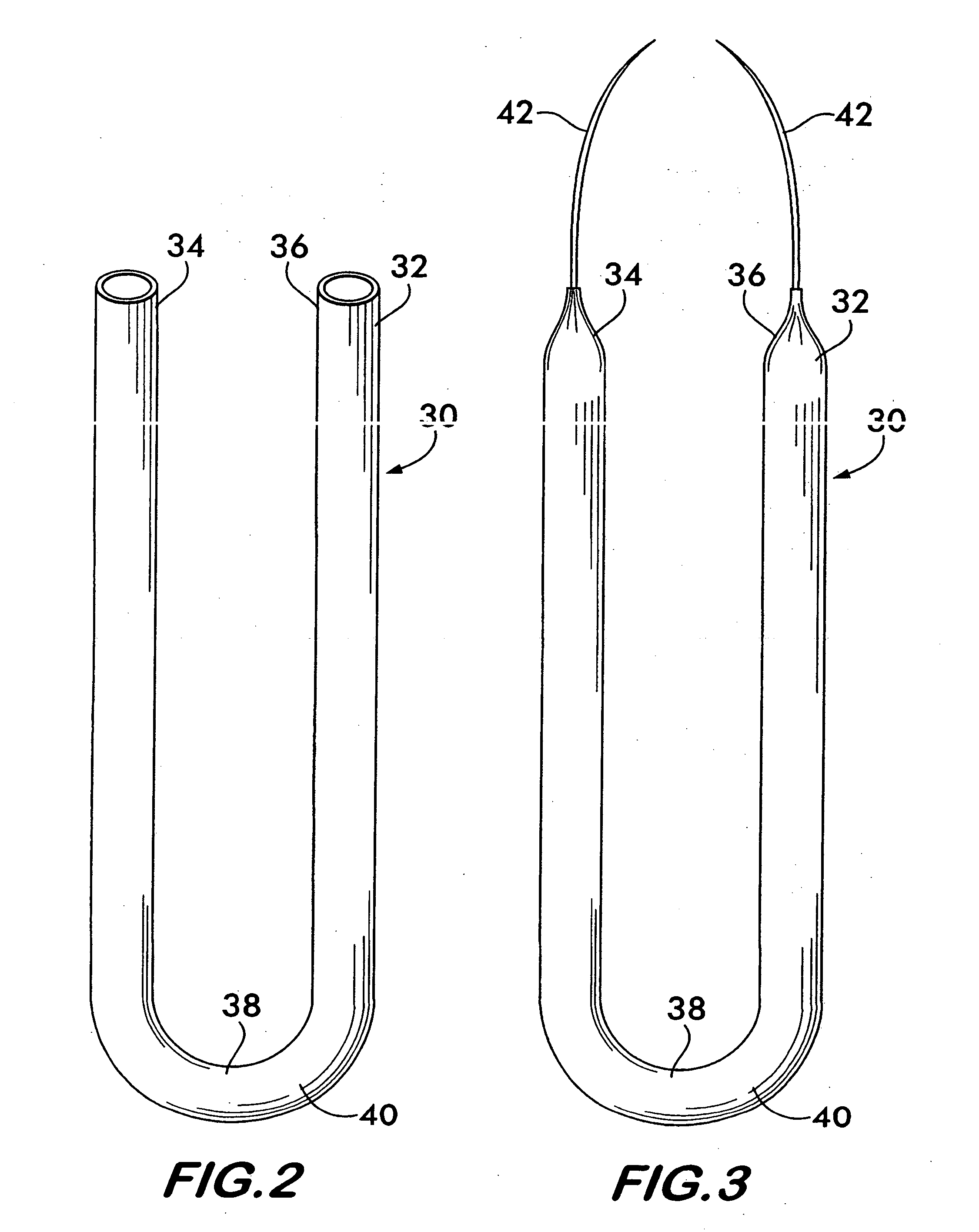

Incontinence sling

A sling for controlling urinary incontinence is disclosed. The sling is formed from a tube having substantially lengthwise inextensible end portions and an elastically lengthwise extensible intermediate portion between the end portions. The intermediate portion has a U-shape which cradles the urethra. The end portions extend through the abdominal tissue to anchor the intermediate portion in position. The sling places the urethra under a transverse compressive load to hold it closed and prevent inadvertent urination. The tube is formed from interlaced filamentary members. Interlacing may be by warp knitting, weaving using a leno weave or braiding using a tri-axial braid structure. The end portions have a rough texture to facilitate anchoring in the tissue of the abdominal wall. The intermediate portion is smooth and soft to prevent tissue erosion.

Owner:STOUT MEDICAL GROUP

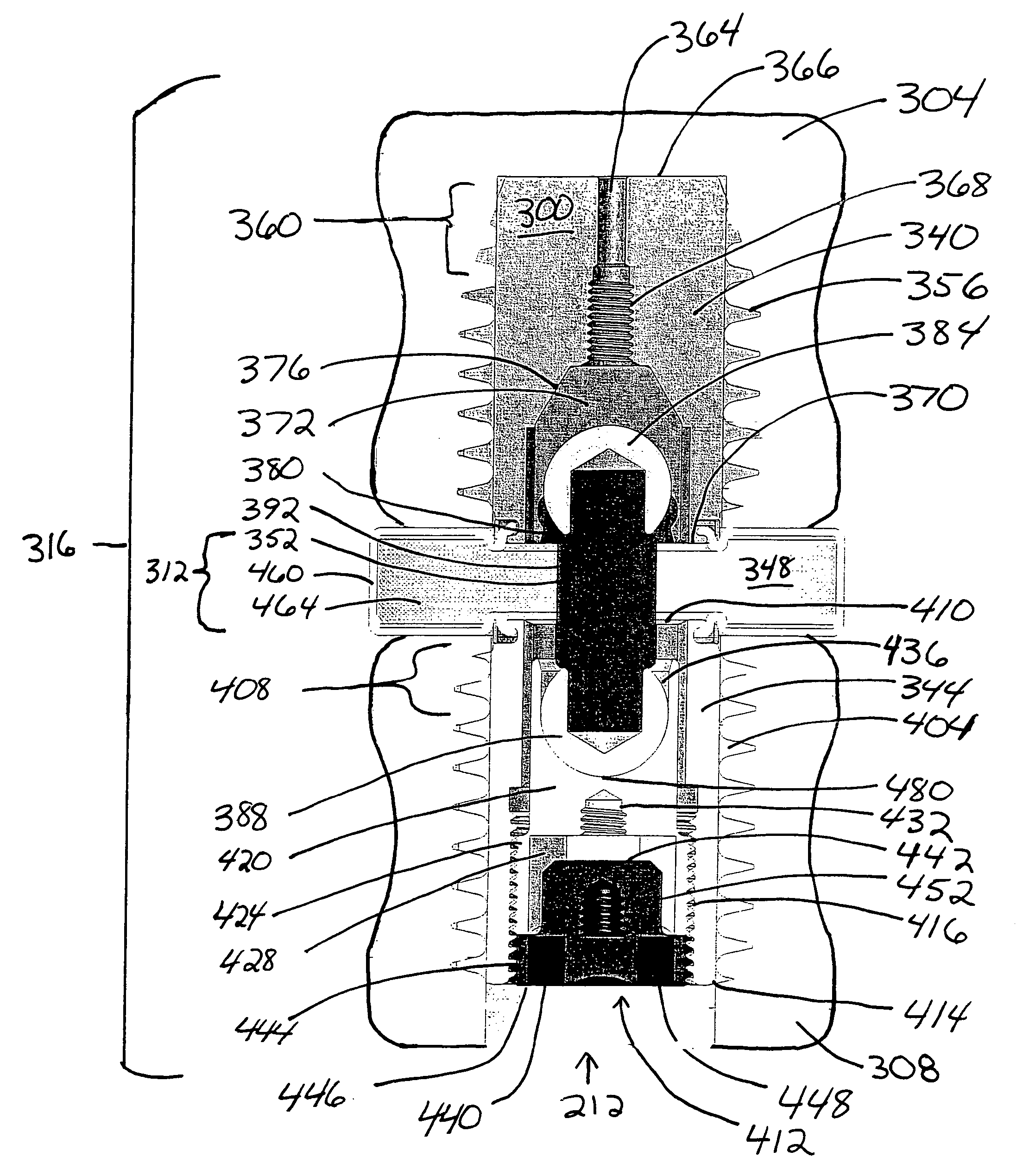

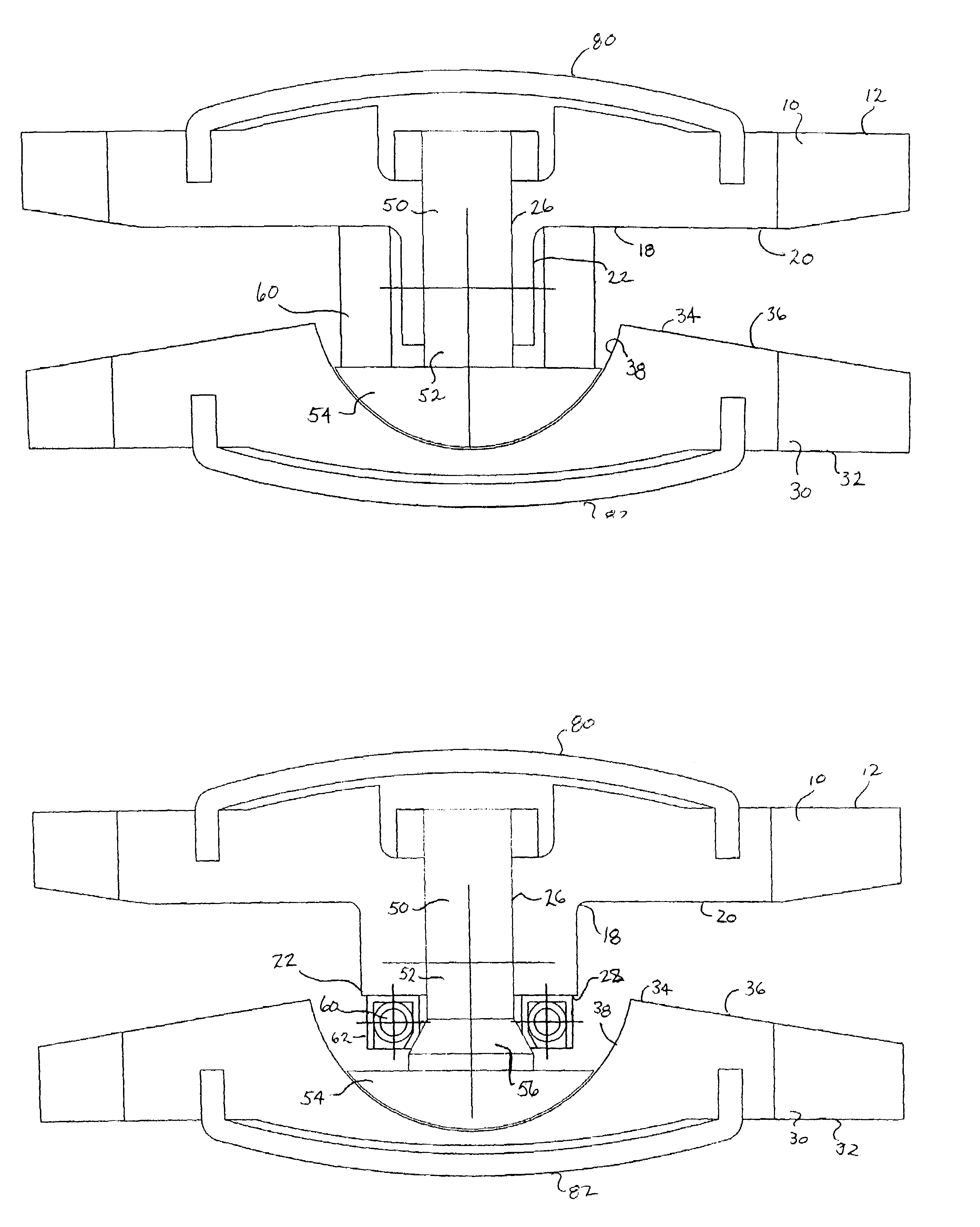

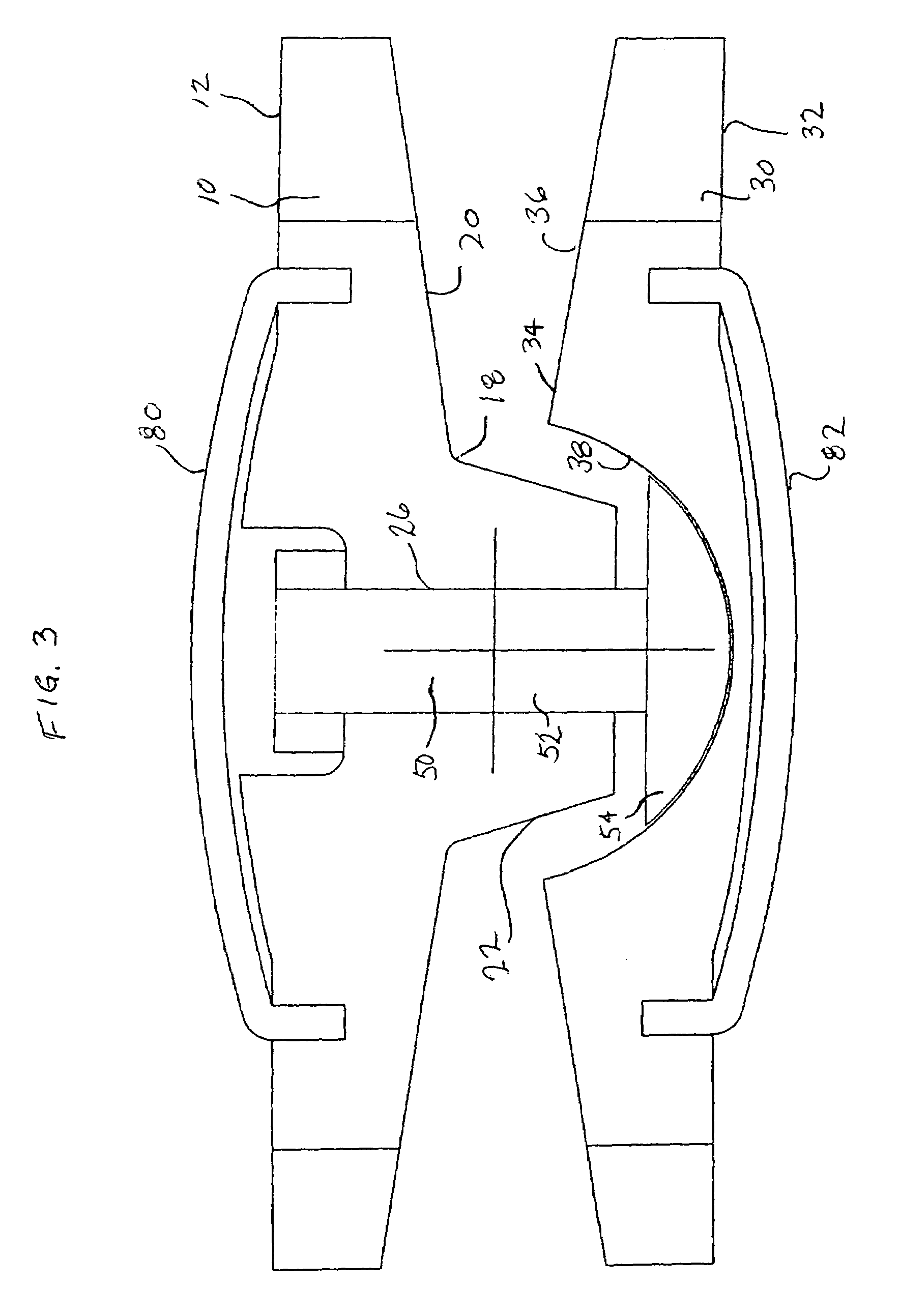

Spinal motion preservation assemblies

InactiveUS20060079898A1Maintain normal physiological functionReduce riskInternal osteosythesisJoint implantsAnesthesiaSpinal locomotion

Spinal motion preservation assemblies adapted for use in a spinal motion segment are disclosed including the process for delivering and assembling the spinal motion preservation assemblies in the spinal motion segment via an axial channel created with a trans-sacral approach. The spinal motion preservation assemblies make use of a dual pivot. A number of different embodiments of spinal motion preservation assemblies are disclosed which include at least one component adapted for elastic deformation under compressive loads. The disclosed mobility preservation assemblies provide for dynamic stabilization (DS) of the spinal motion segment.

Owner:MIS IP HLDG LLC

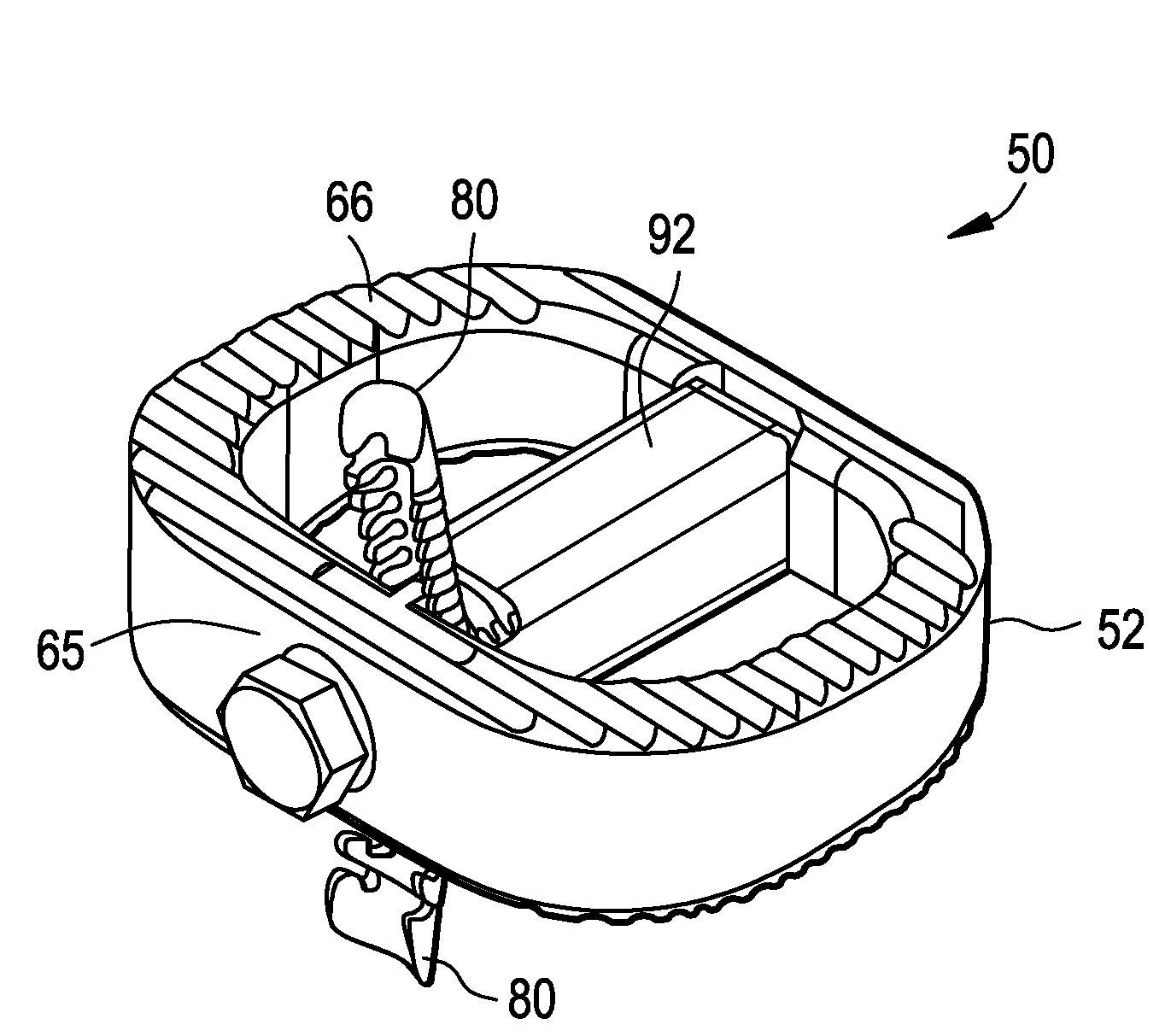

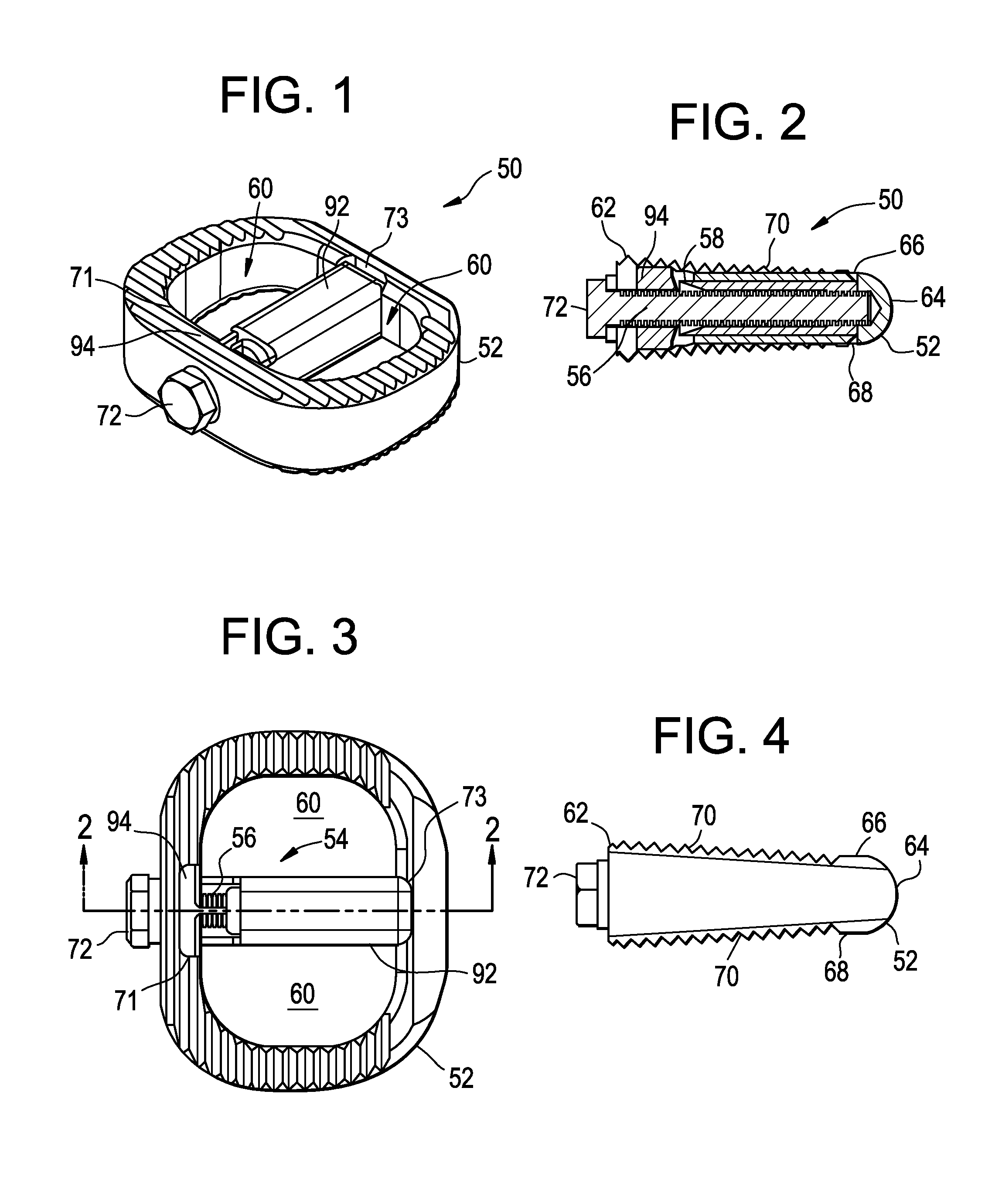

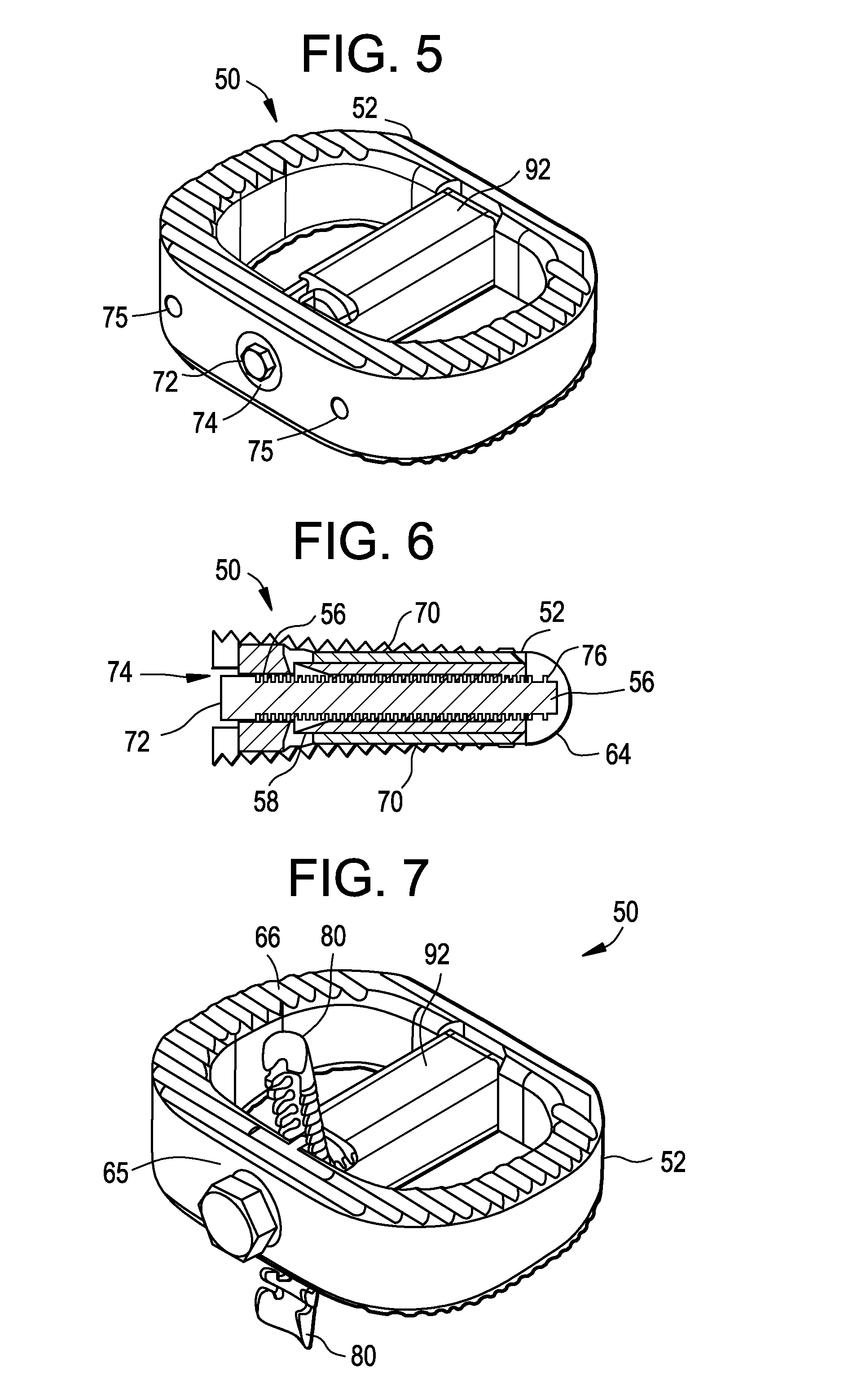

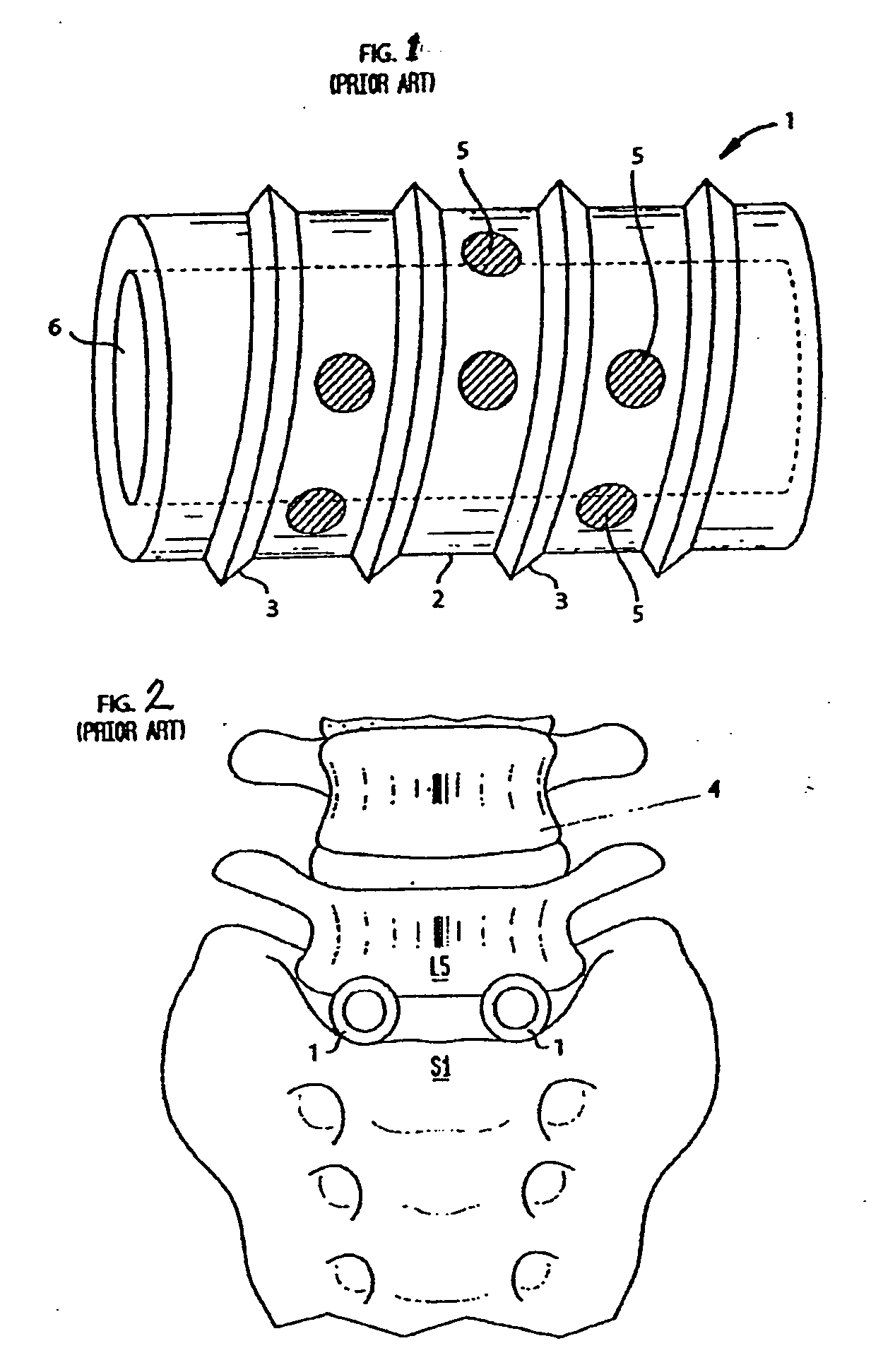

Interbody fusion device and method of operation

An interbody fusion device is provided that includes an interbody cage, a fixation system and an actuation mechanism to deploy one or more blades. The cage acts as an intervertebral spacer and provides resistance to the compressive loads in the spinal column. The fixation system includes an anchor and a ramp. These components could be manufactured from various medical grade materials.

Owner:INCITE INNOVATION

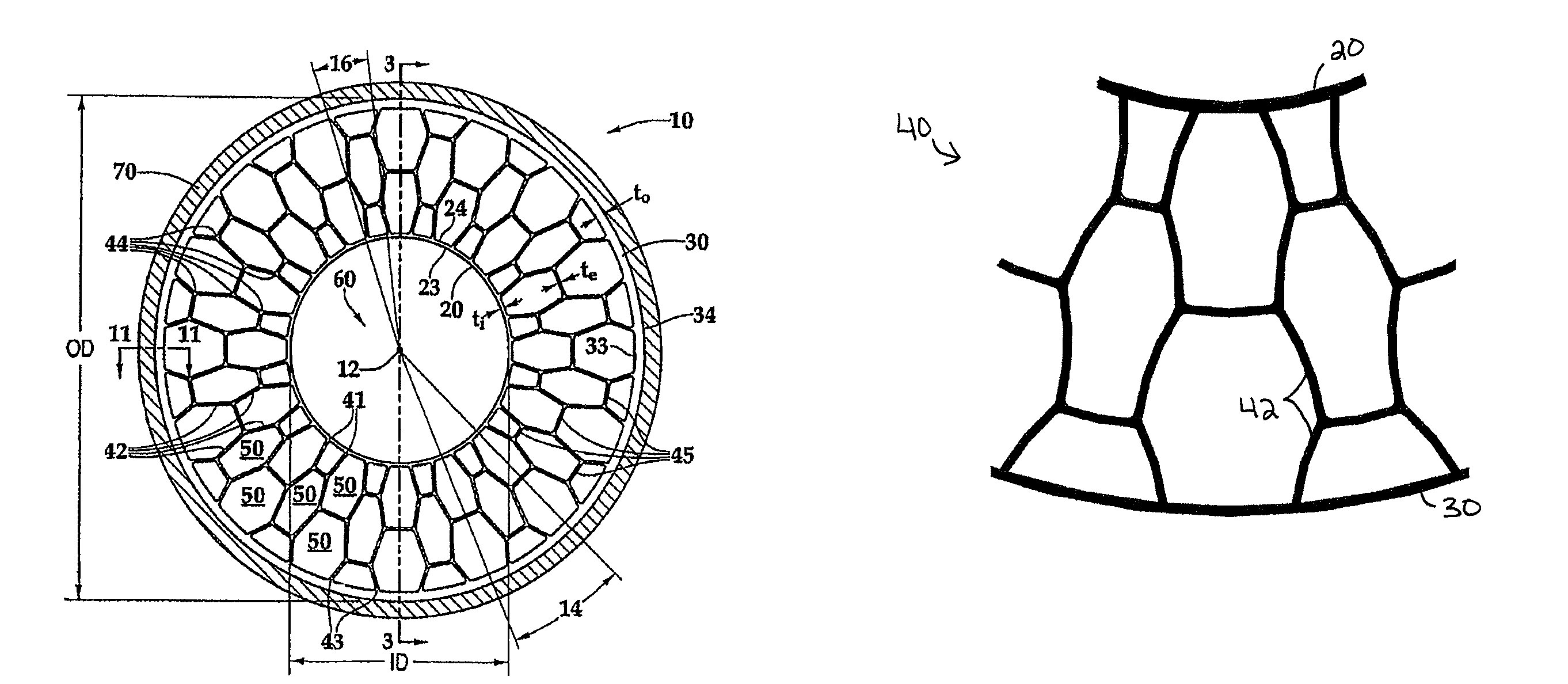

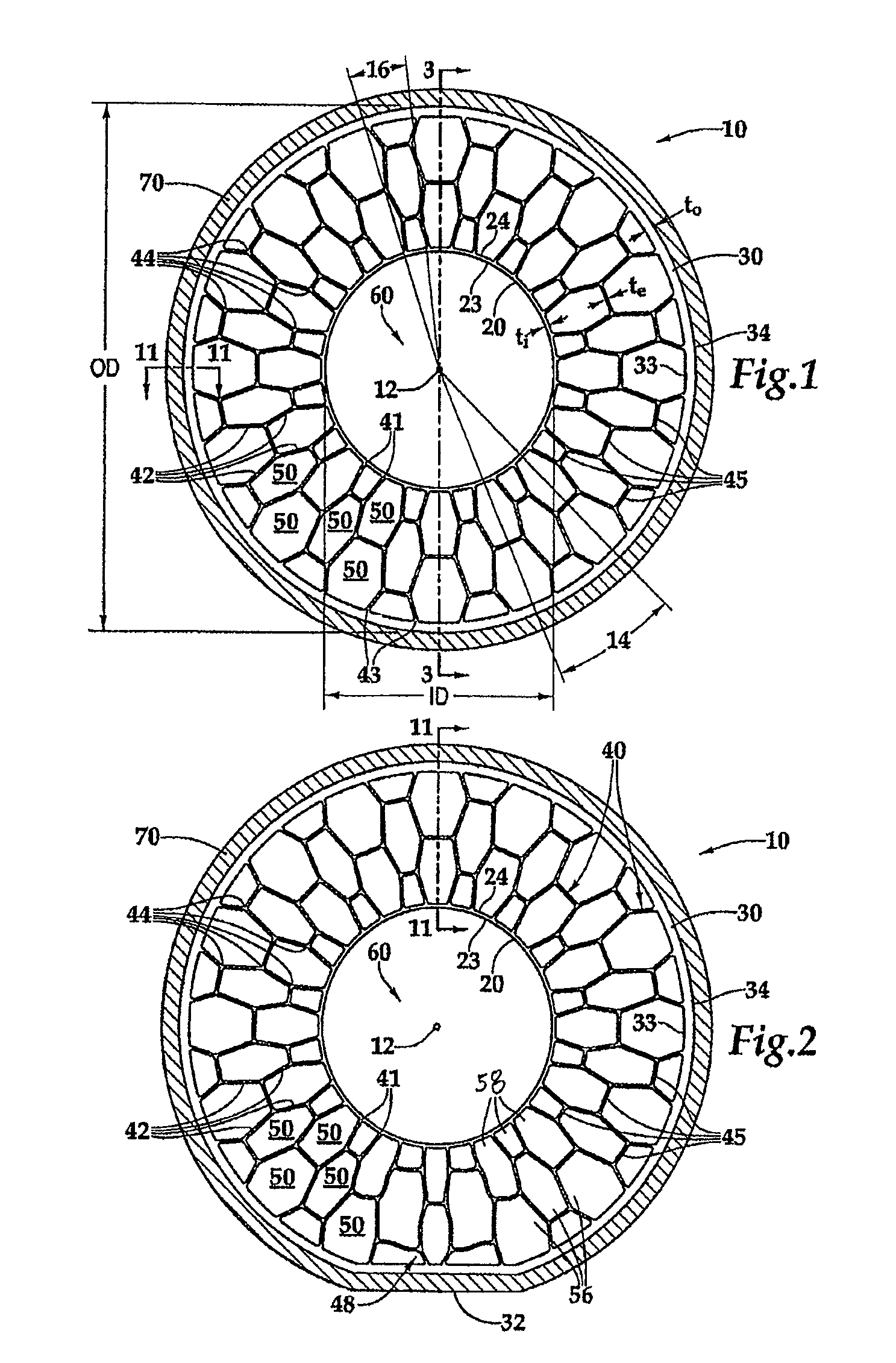

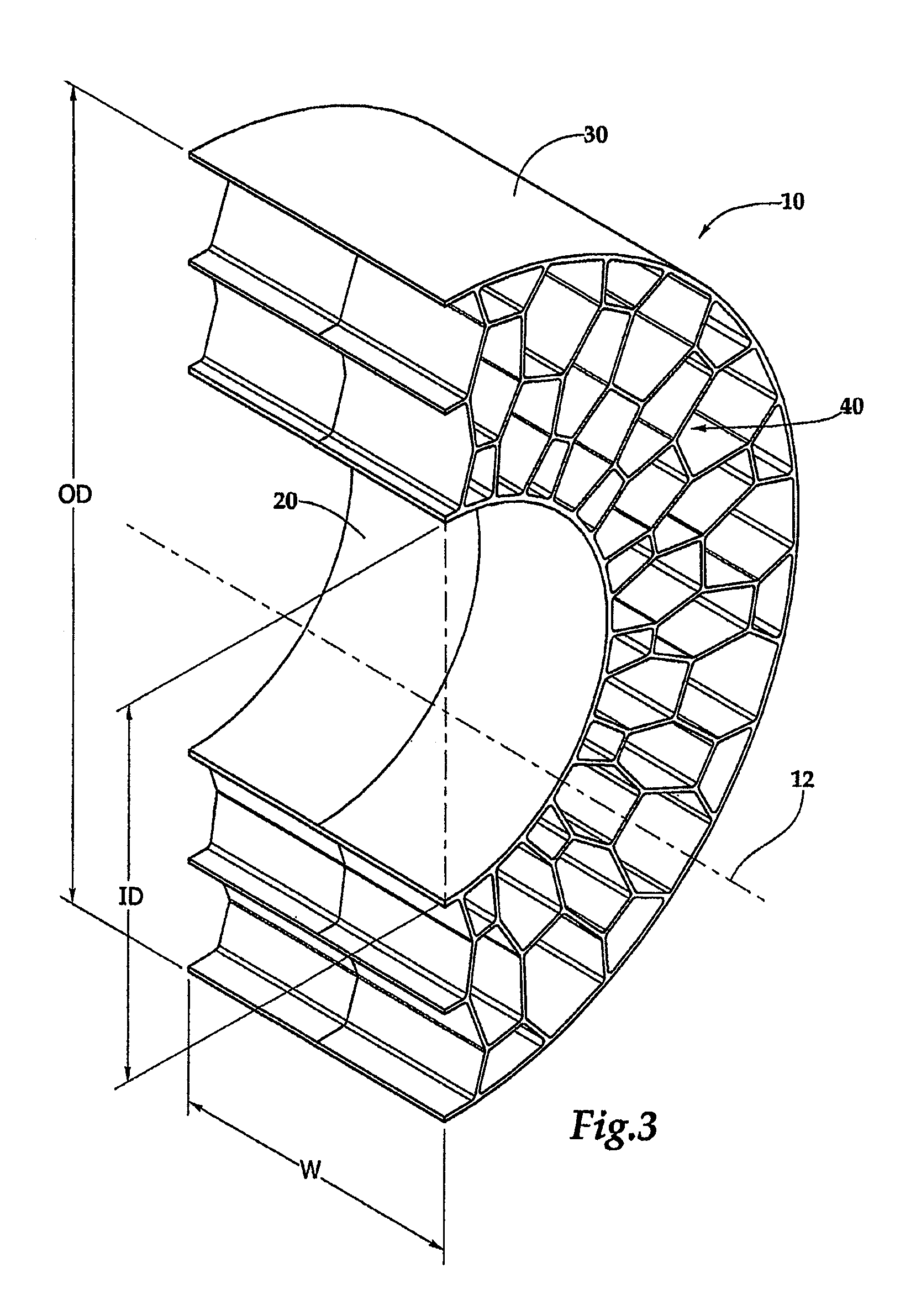

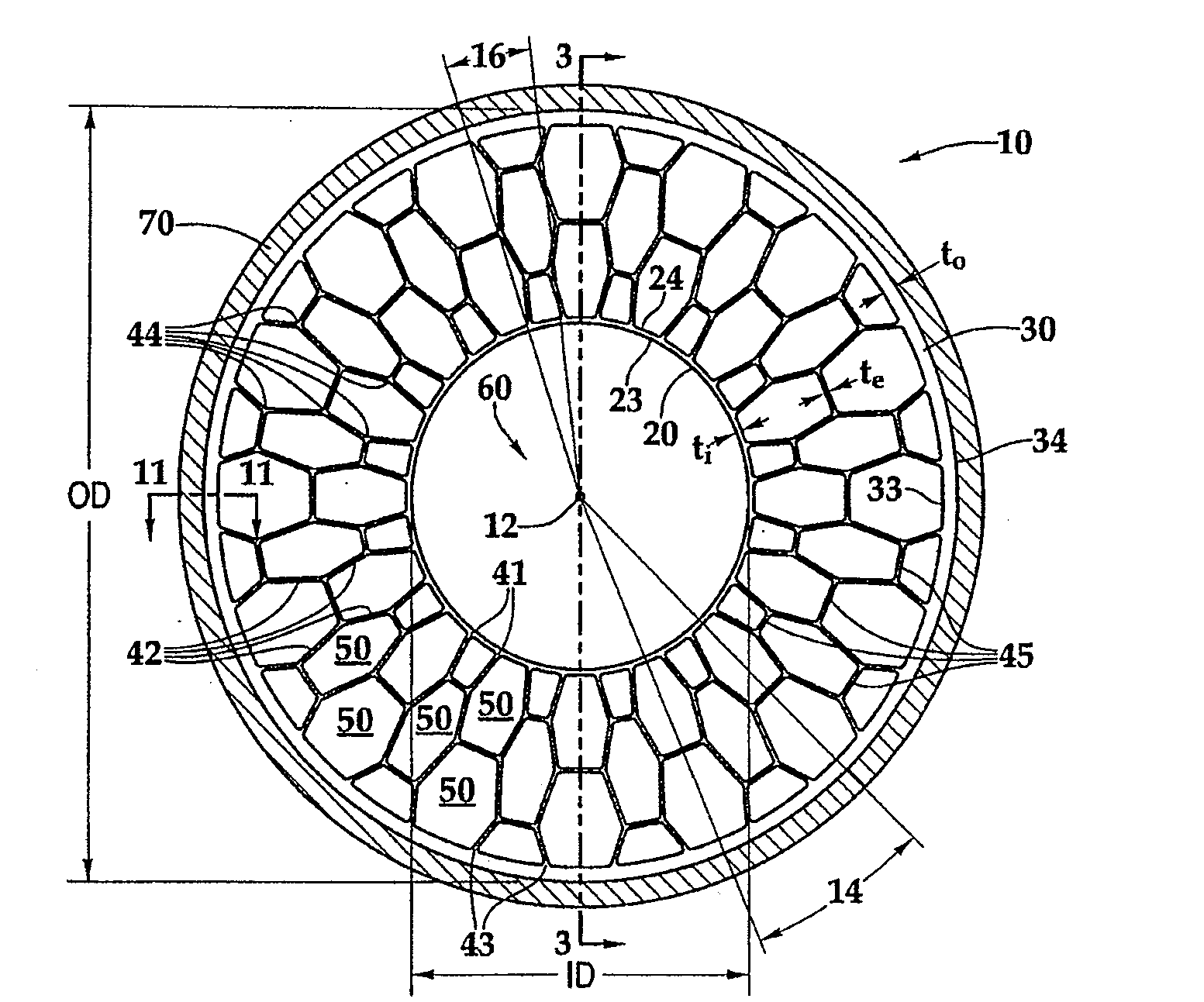

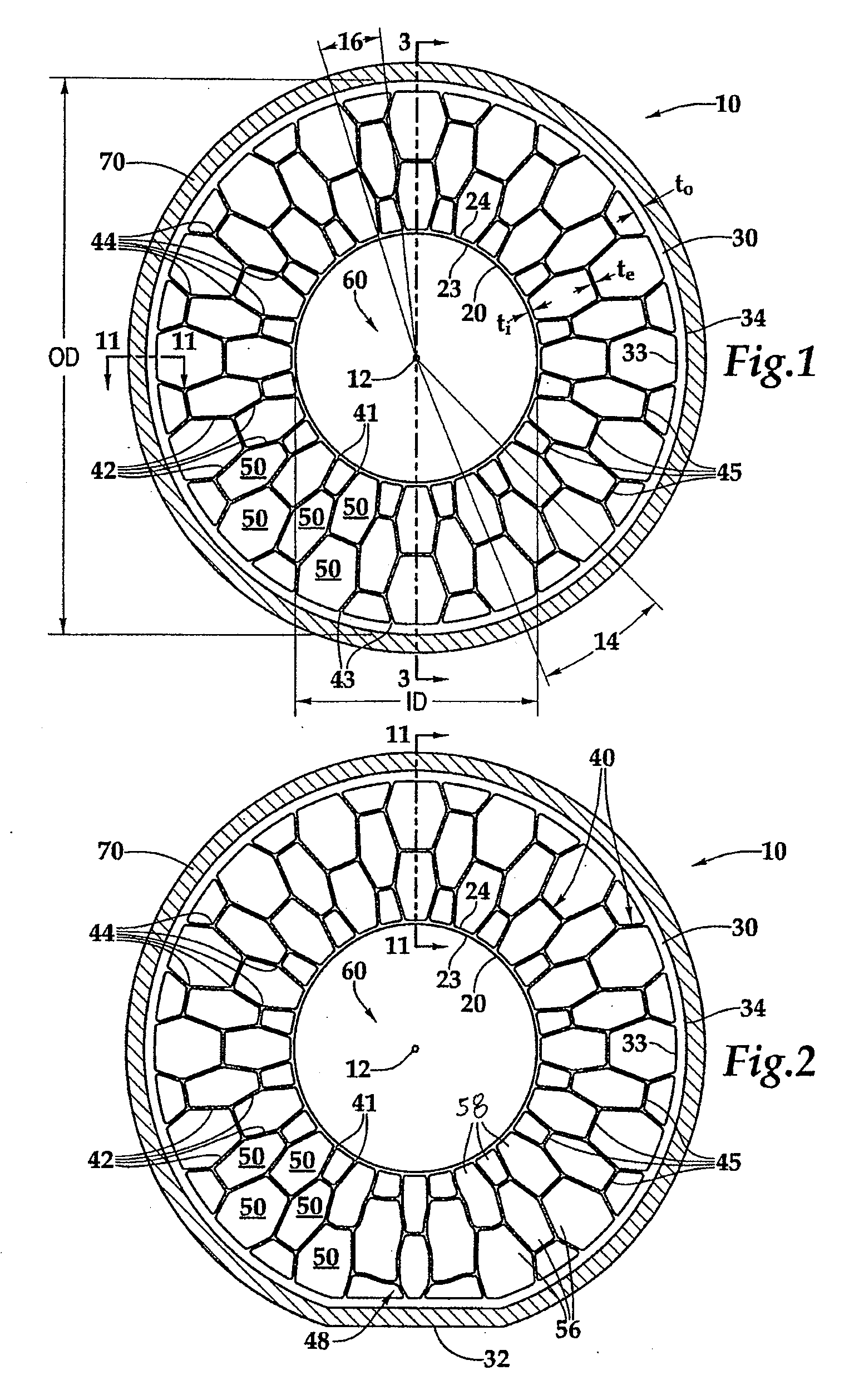

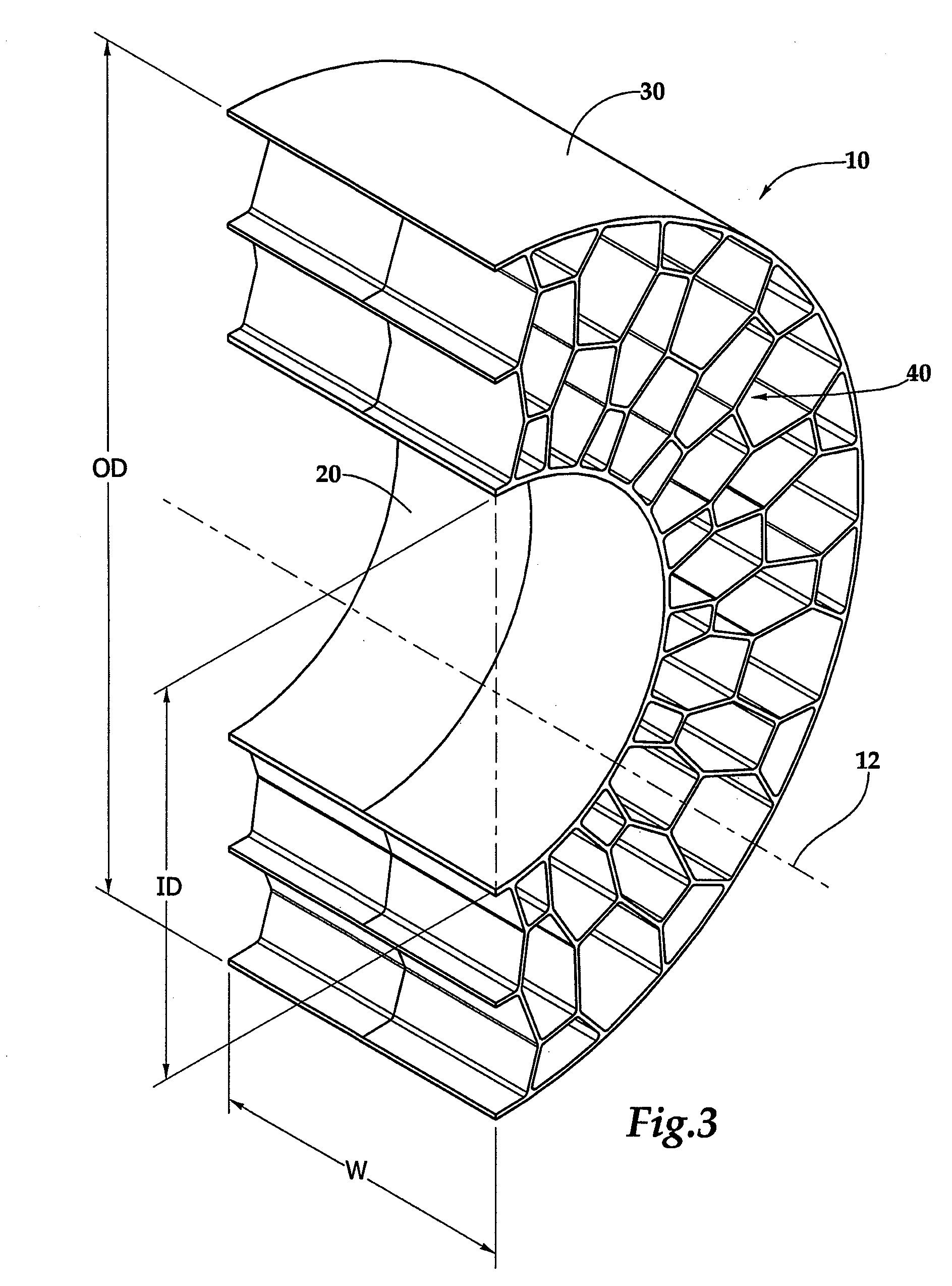

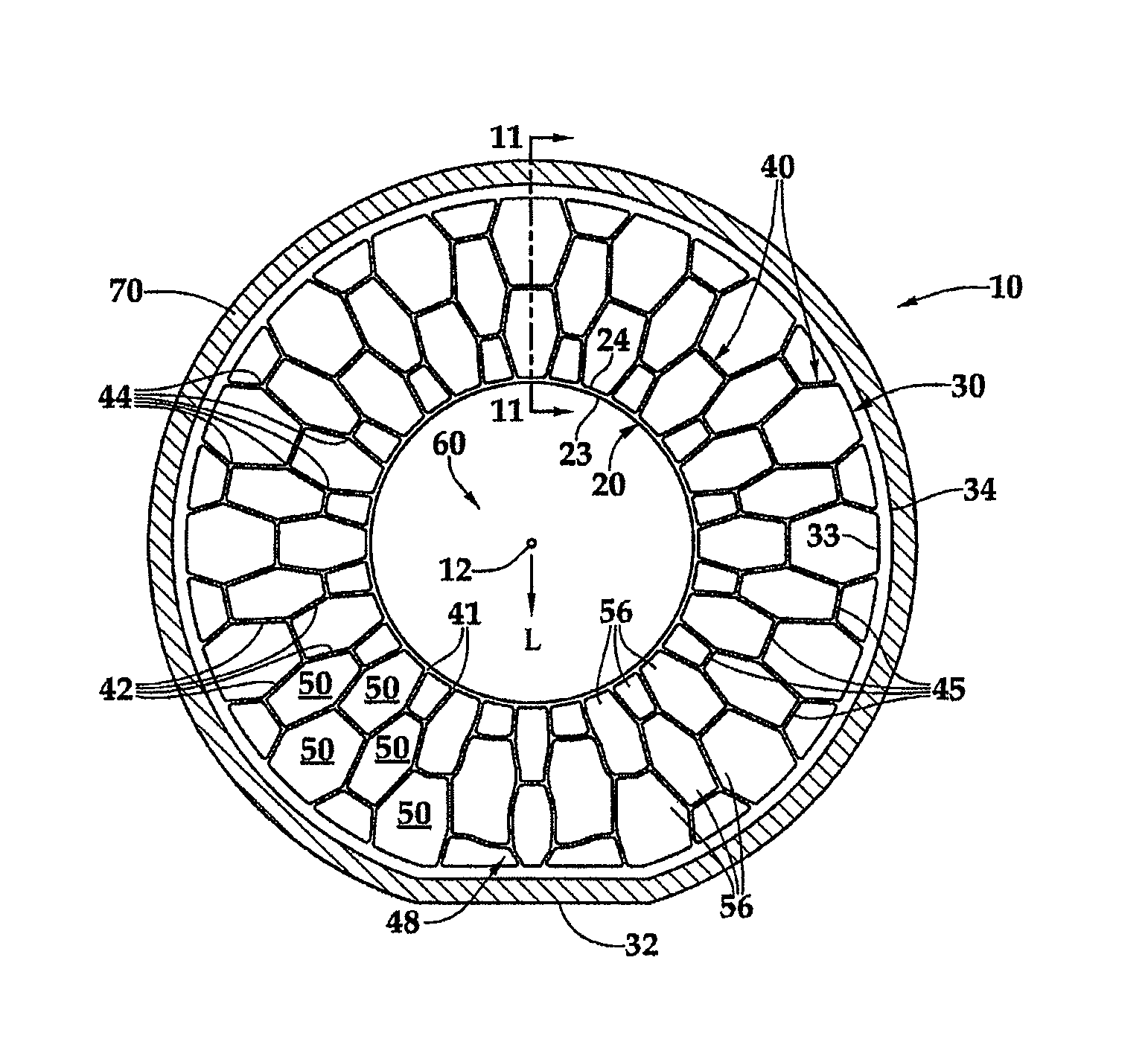

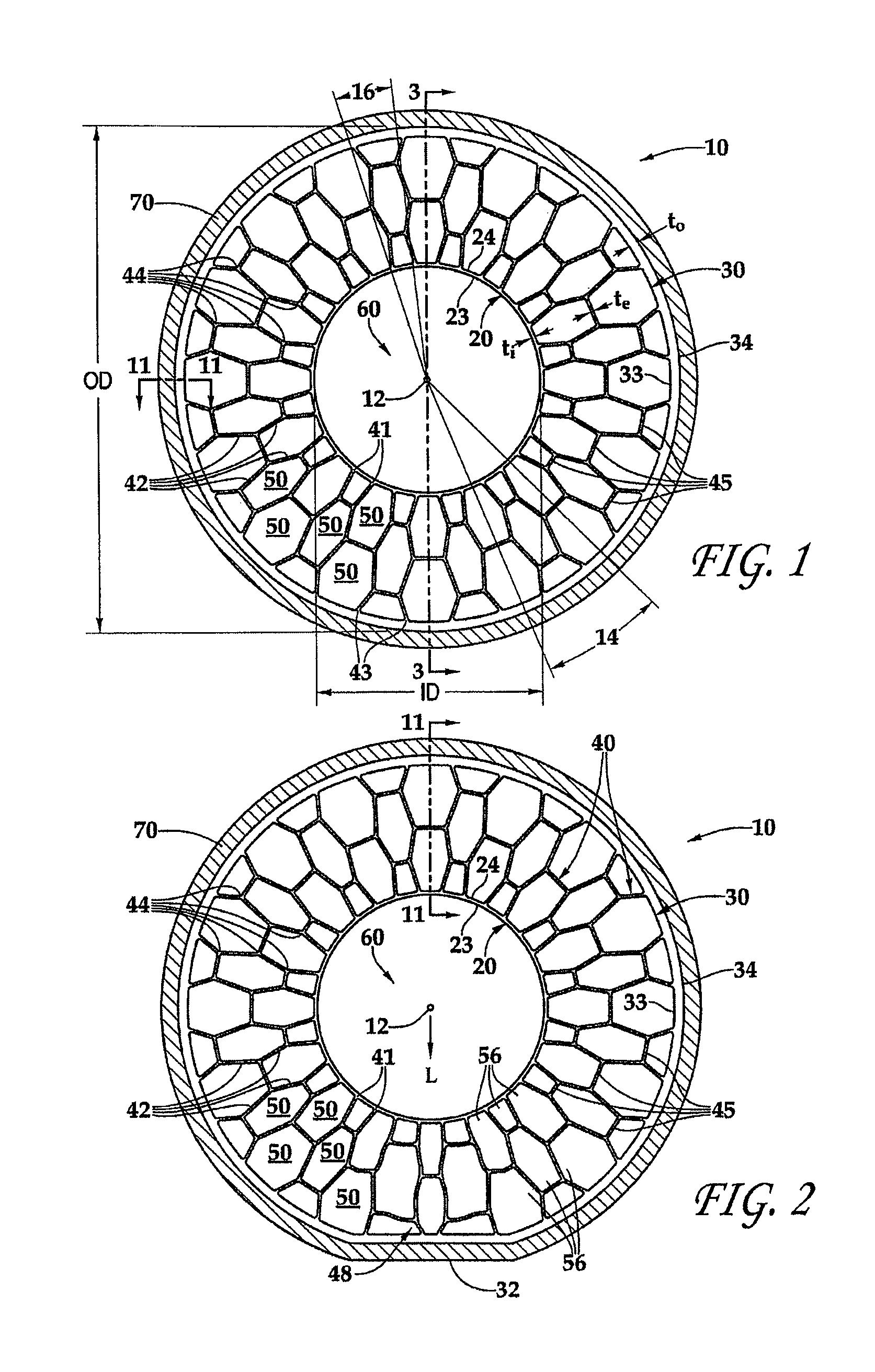

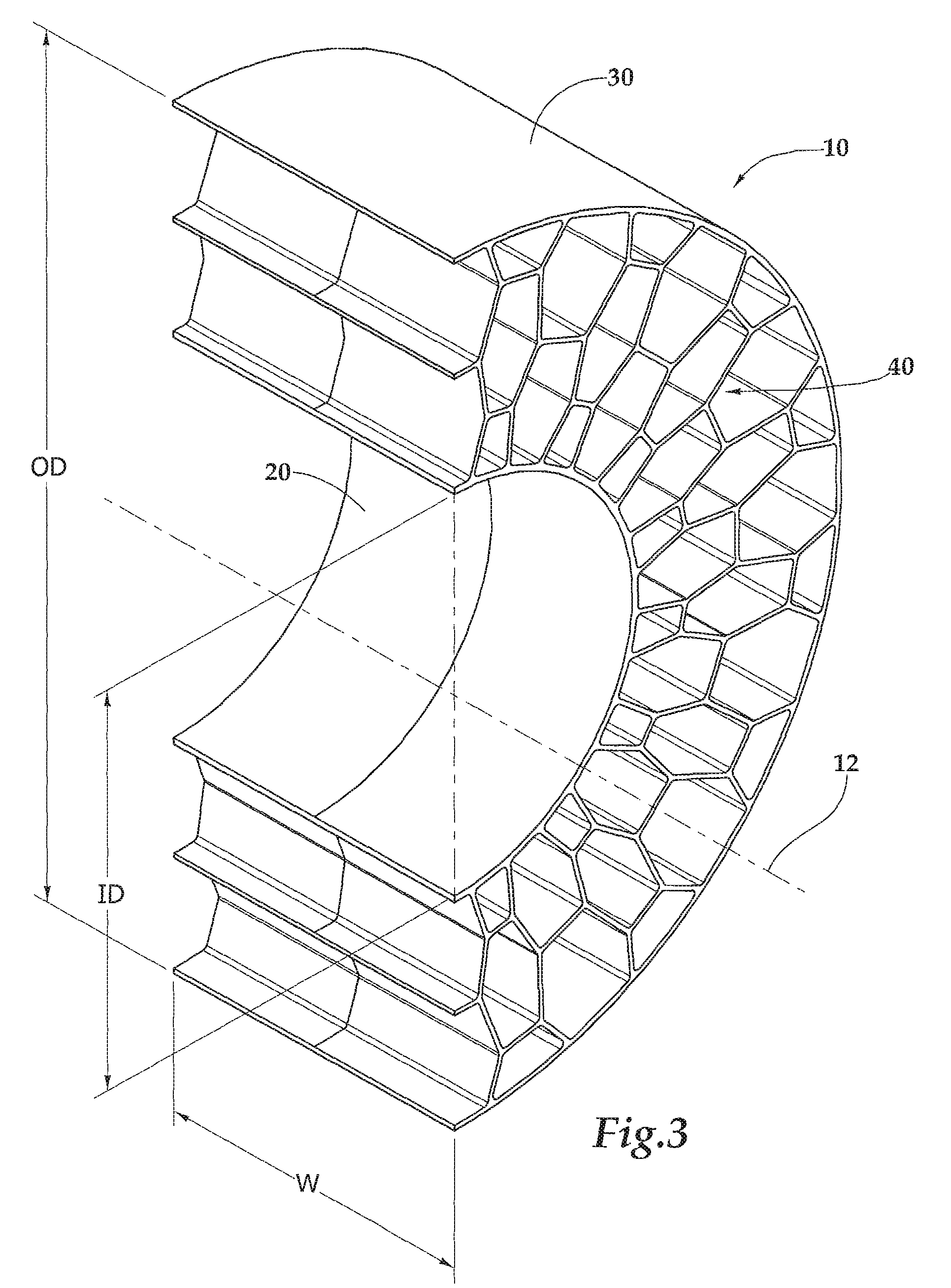

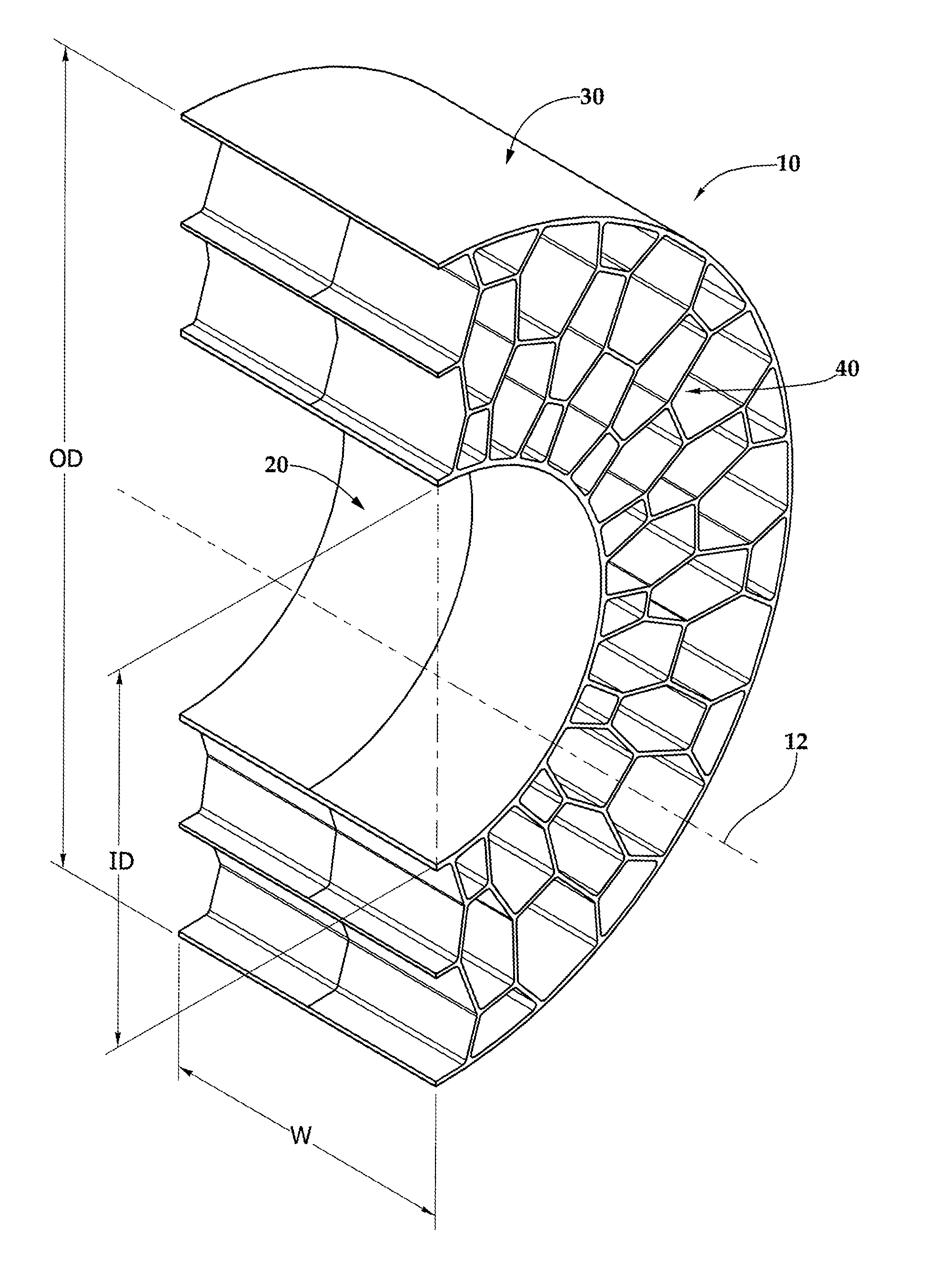

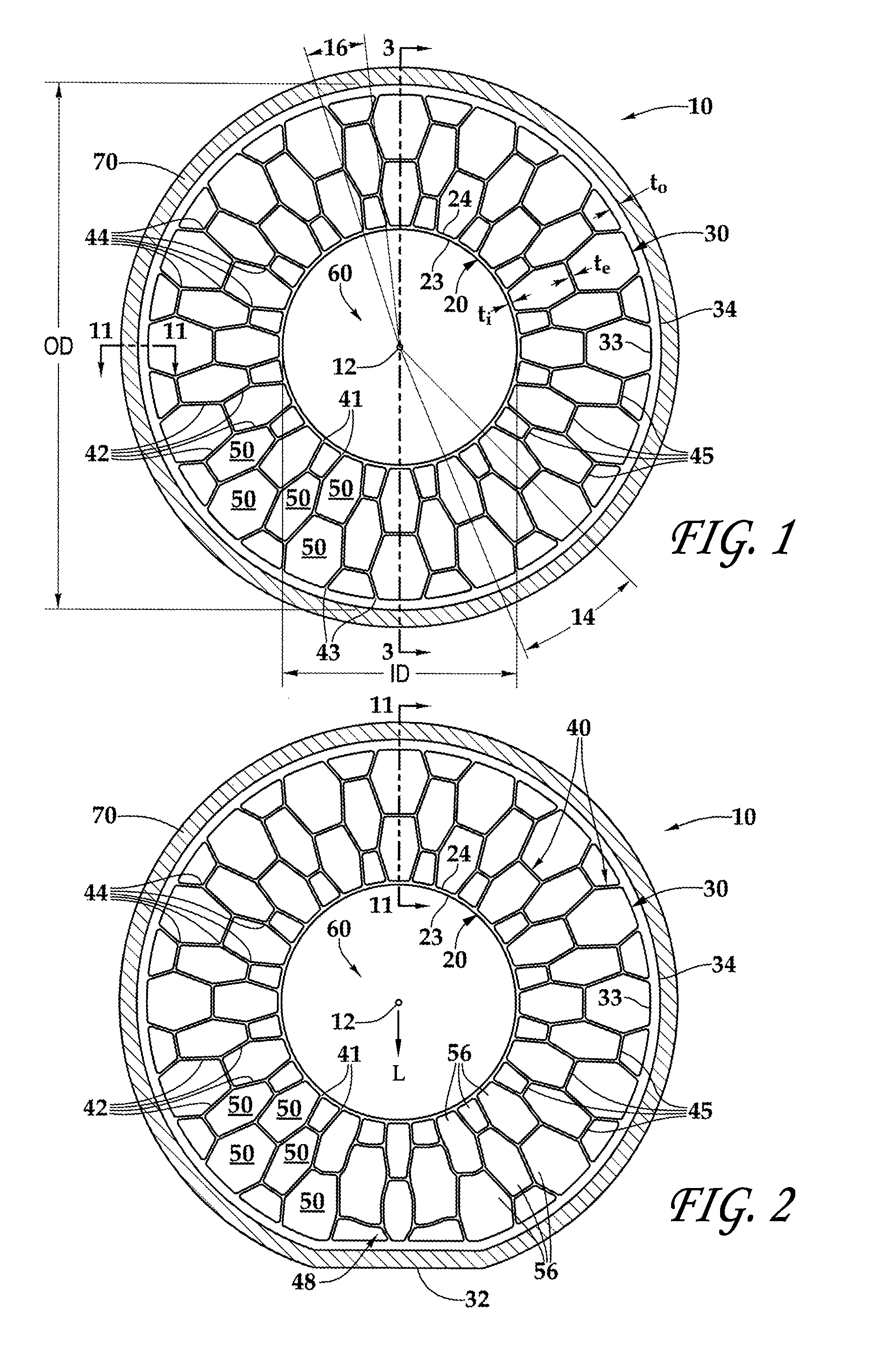

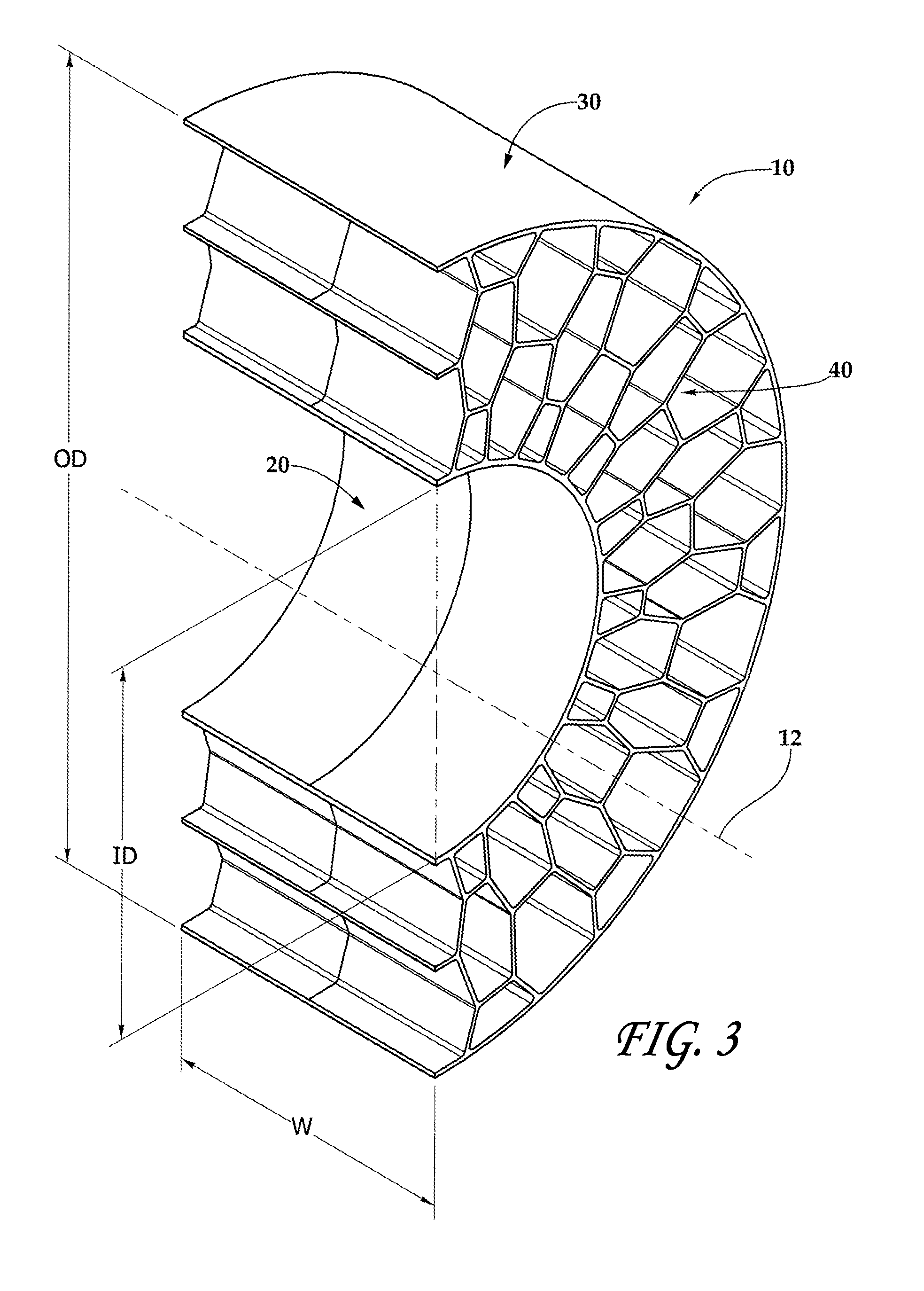

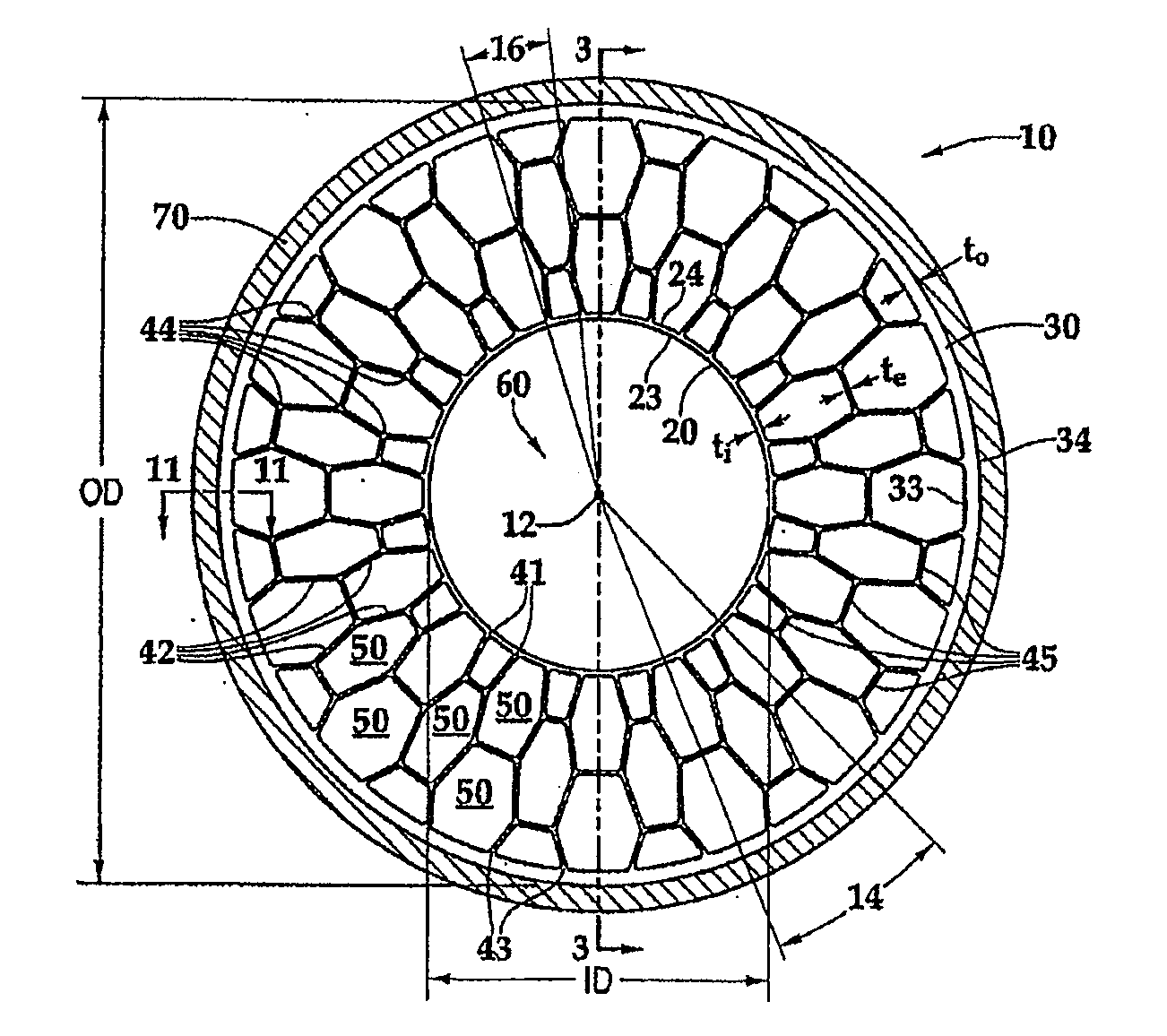

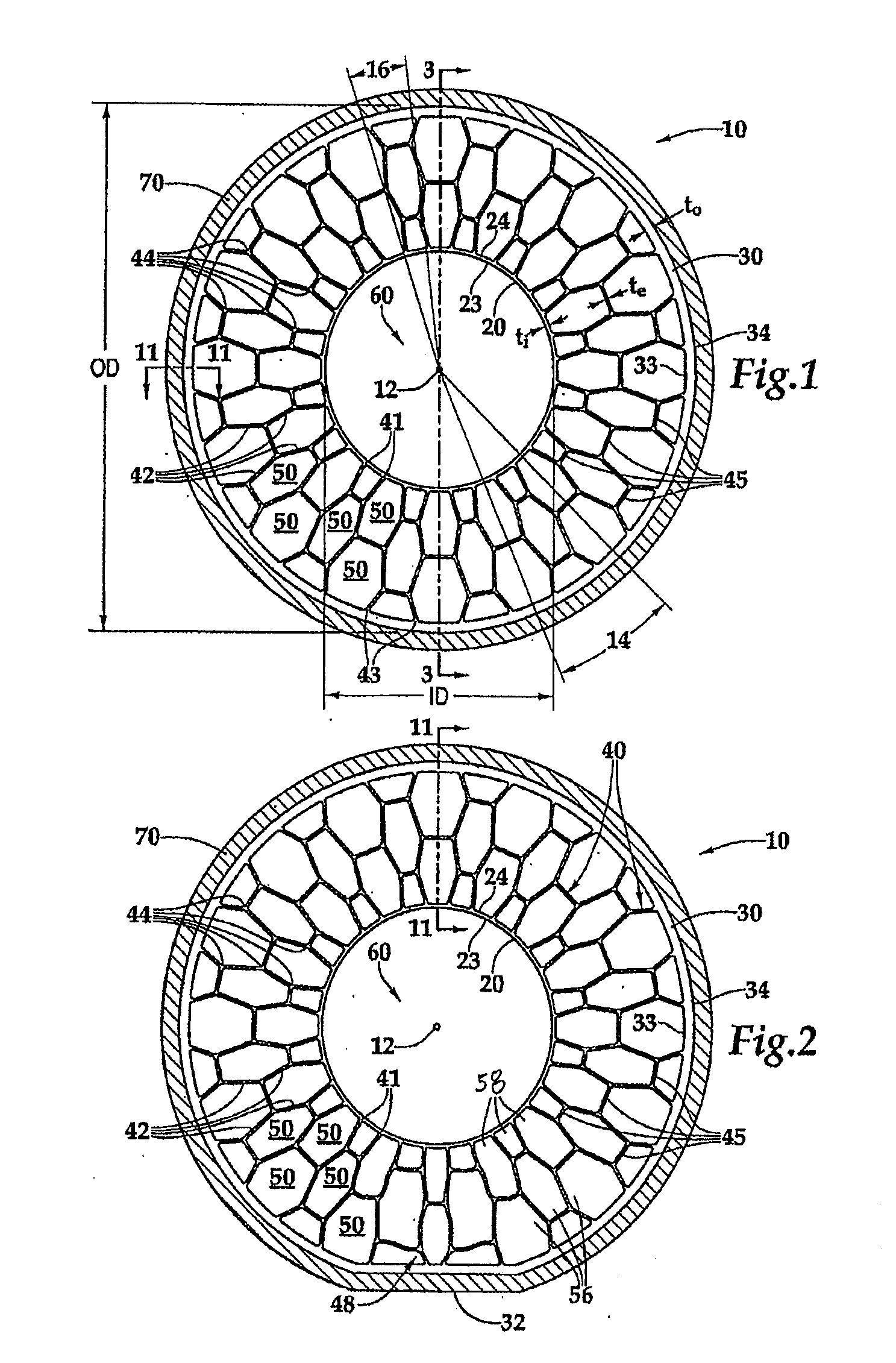

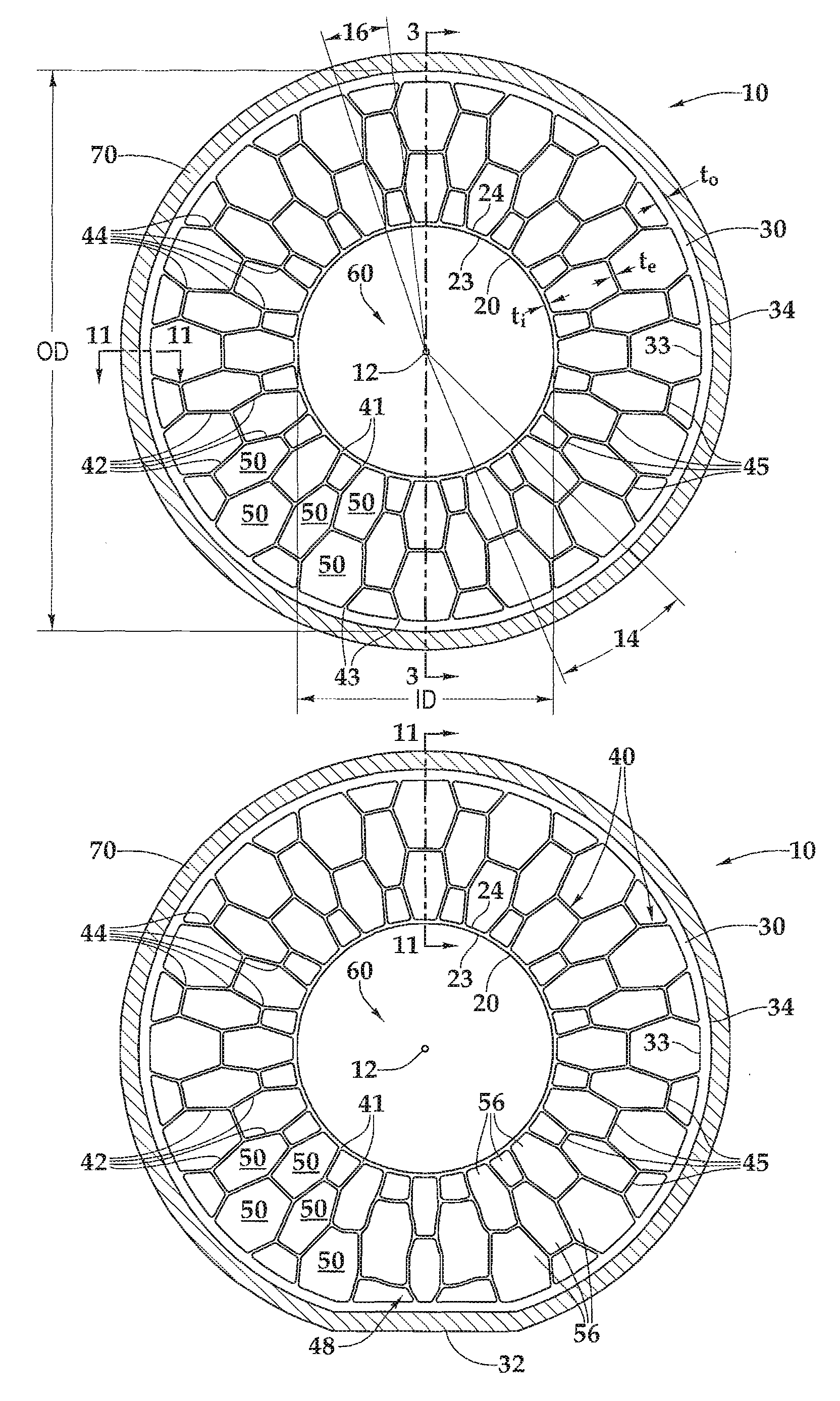

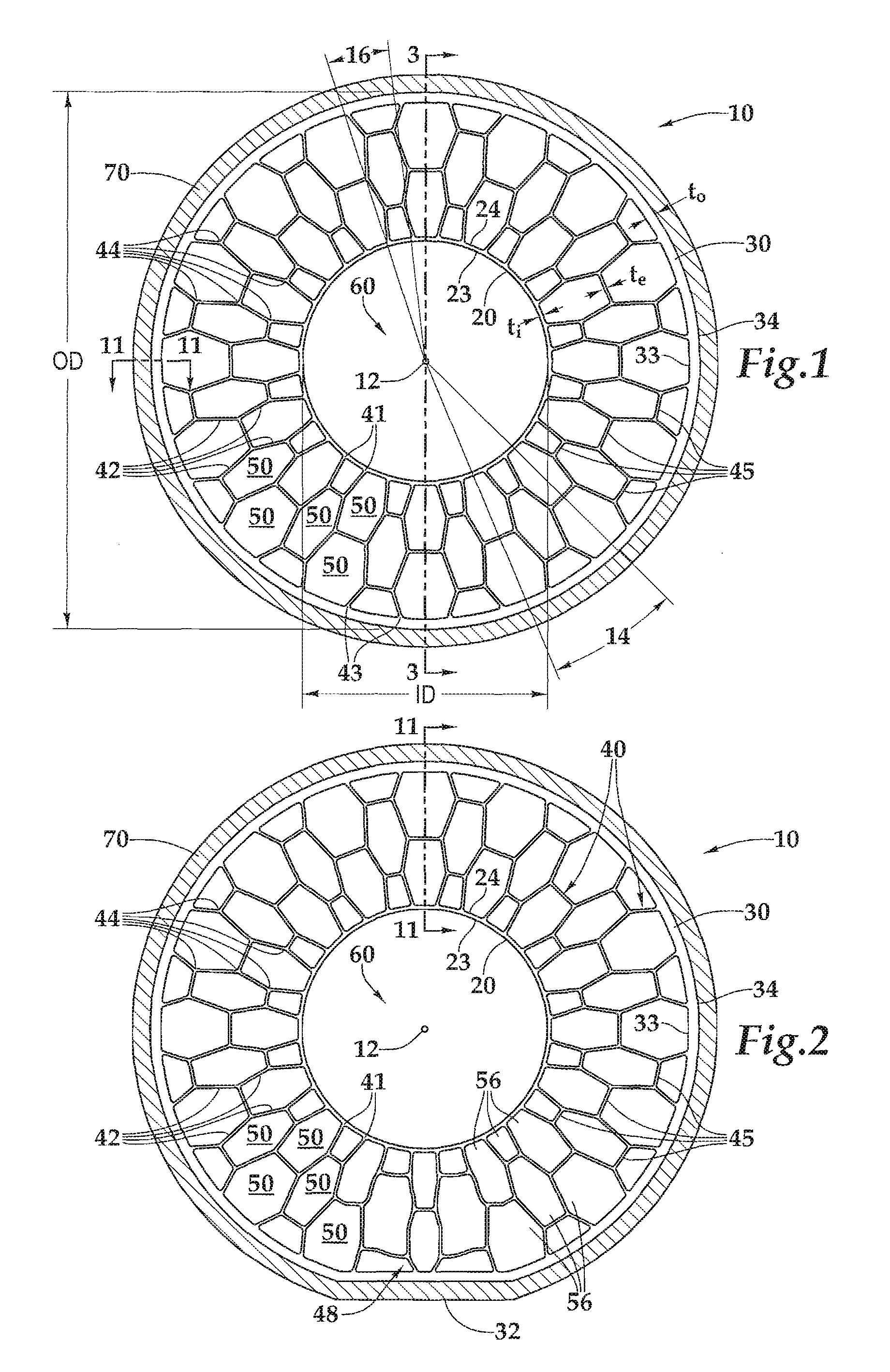

Tension-based non-pneumatic tire

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner ring, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, curved, oriented, and comprised of varying thicknesses of material which facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a wheel and a footprint region where the tire contacts a surface can assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

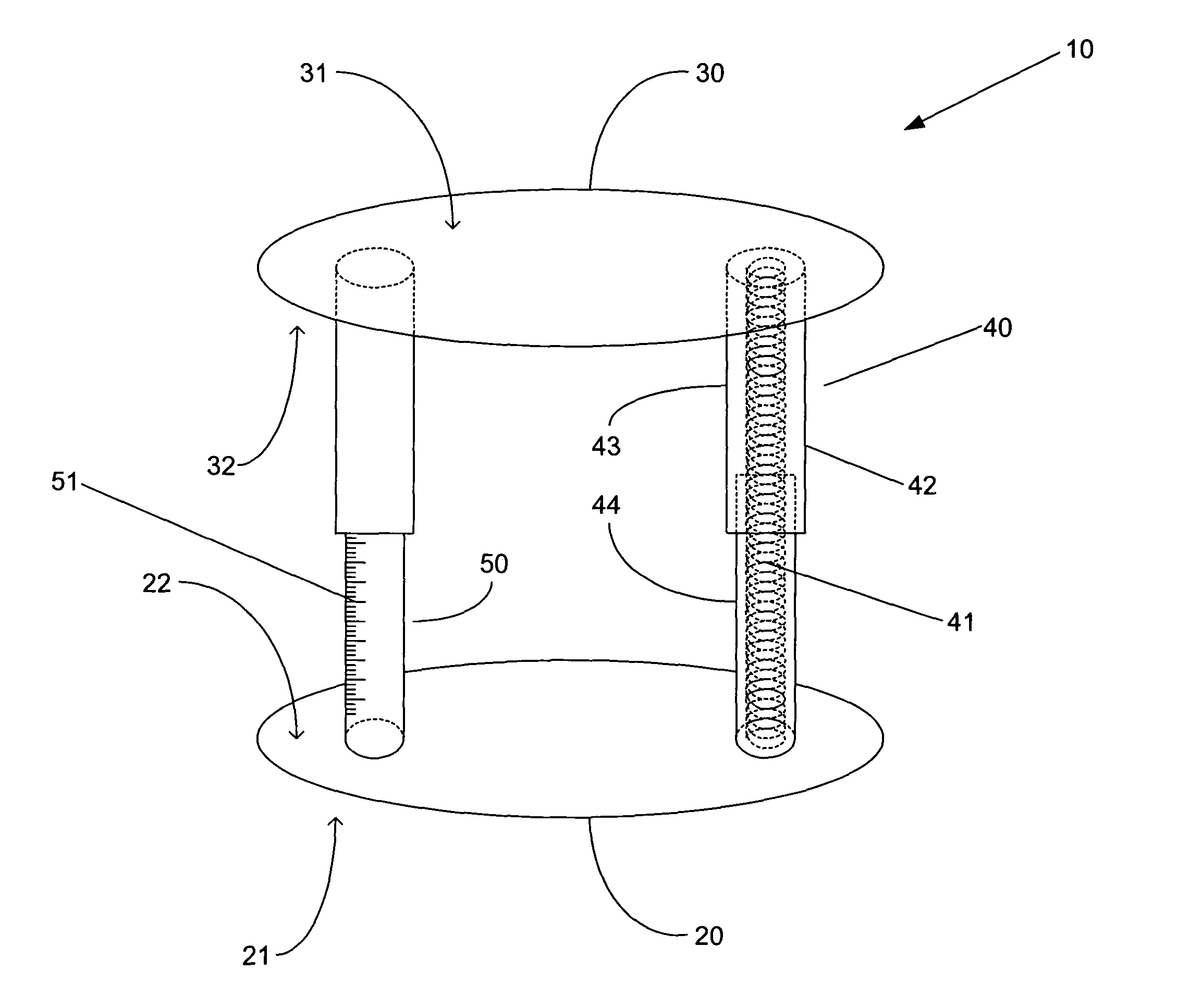

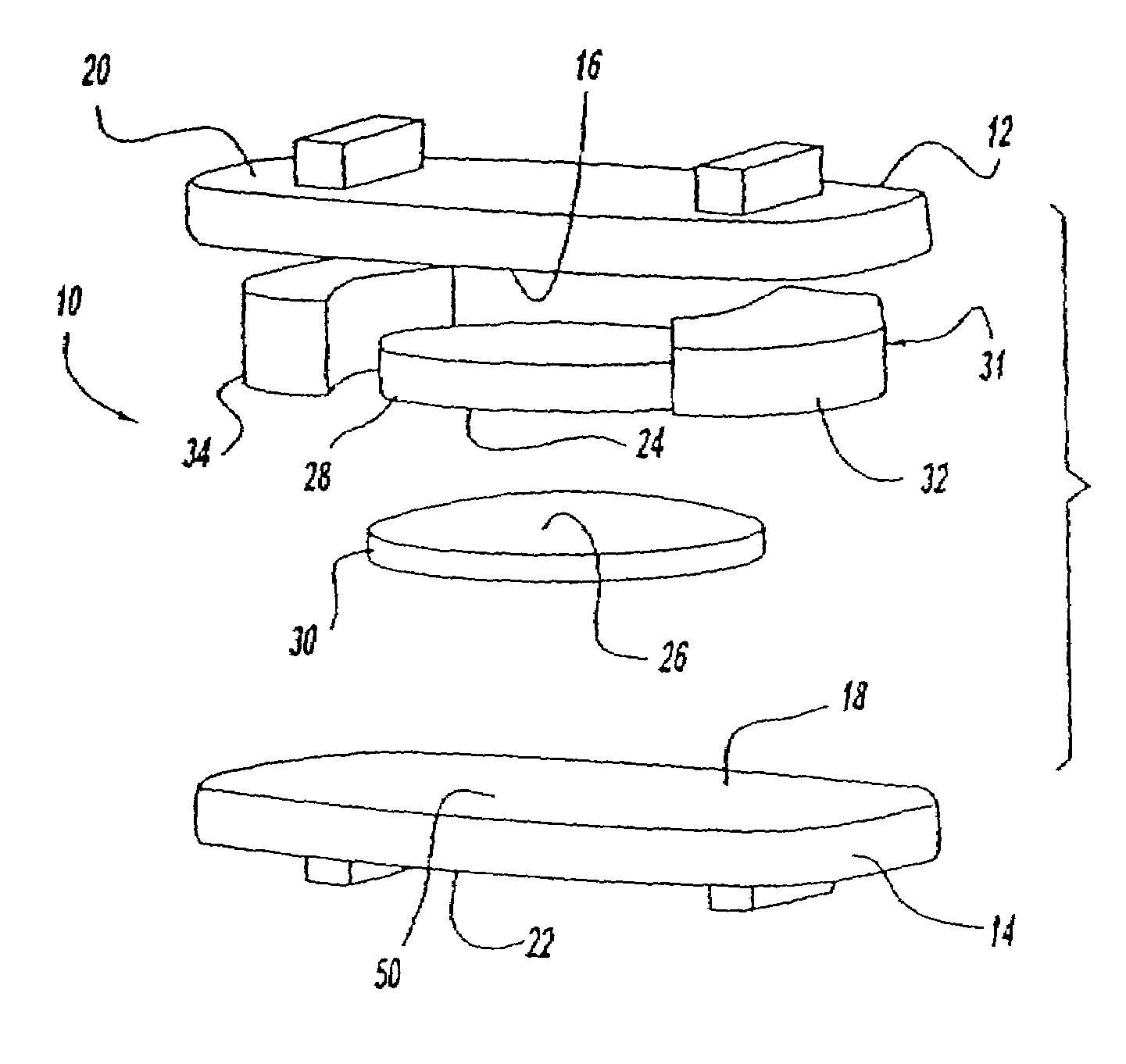

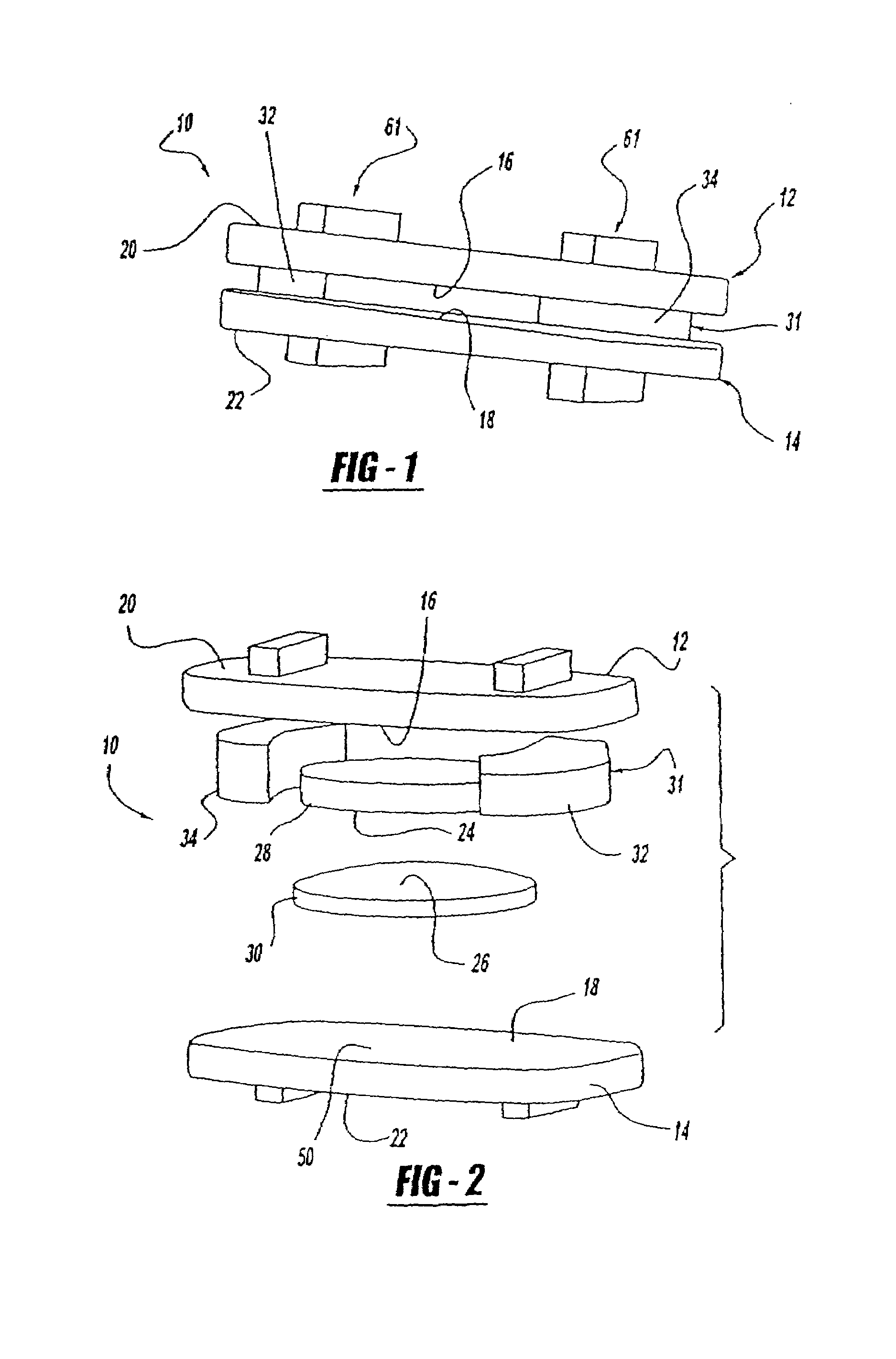

Dynamic spacer for total knee arthroplasty

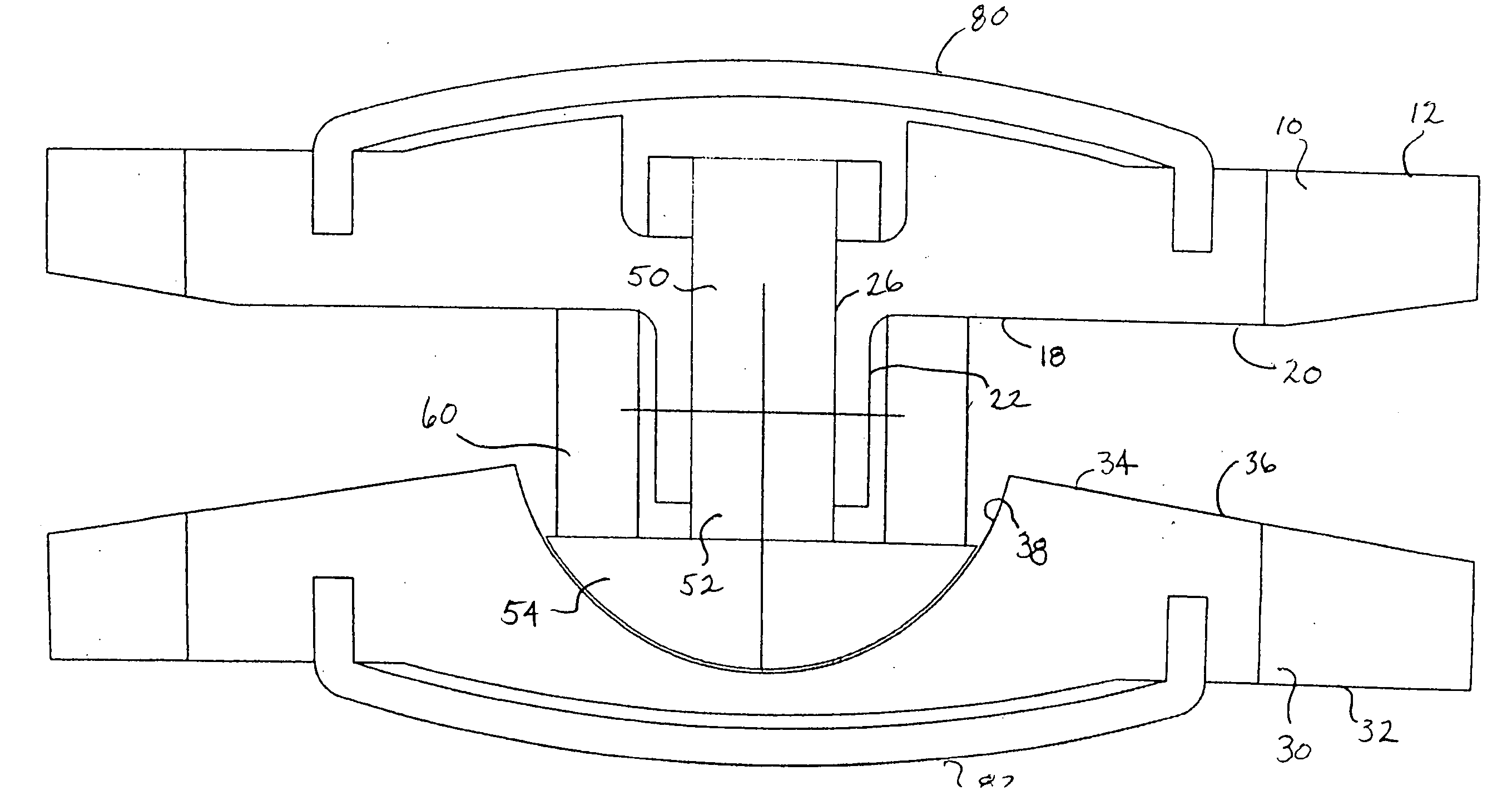

InactiveUS20050020941A1Easy to useEasy constructionSurgeryPerson identificationPhysical medicine and rehabilitationSurgical instrumentation

A dynamic spacer is provided for measuring flexion-extension gap during total knee arthroplasty. The dynamic spacer is an improved surgical instrumentation system that it easy to use, simple in construction, and accurately measures flexion-extension gaps under repeatable soft tissue tension. The dynamic spacer generally comprises a first planar member having a lower tissue engaging surface, a second planar member having an upper tissue engaging surface. A tensioner is disposed between the first planar member and the second planar member for applying a tensile force acting upon the first and second planar members. The tensioner is fixedly attached to the first and second planar members, such that the first planar member is held substantially parallel to the second planar member in the absence of compressive load. The dynamic spacer allows for accurately measuring flexion-extension gaps and angular deviation in flexion indicating the appropriateness of femoral rotation.

Owner:TARABICHI SAMIH

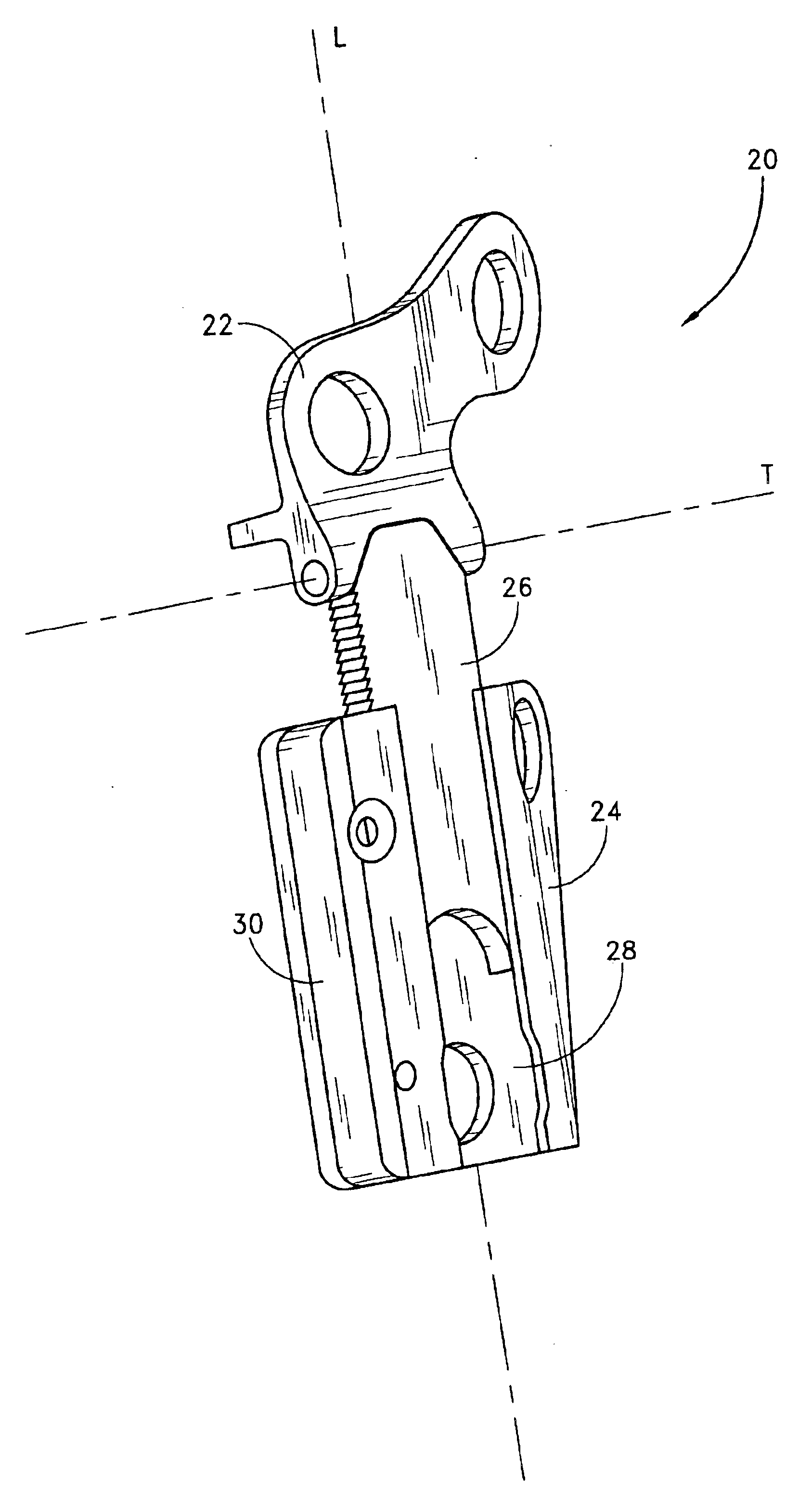

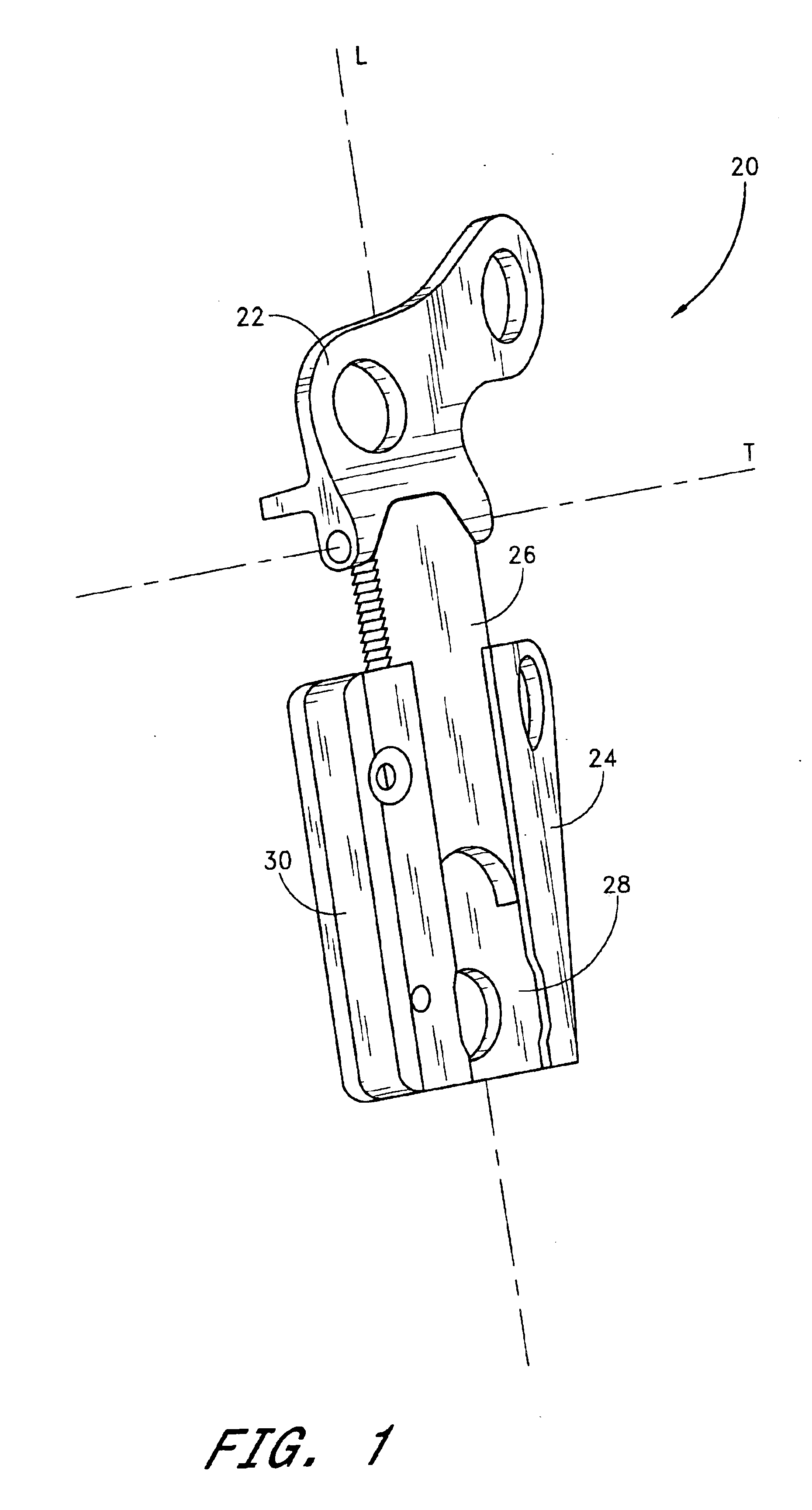

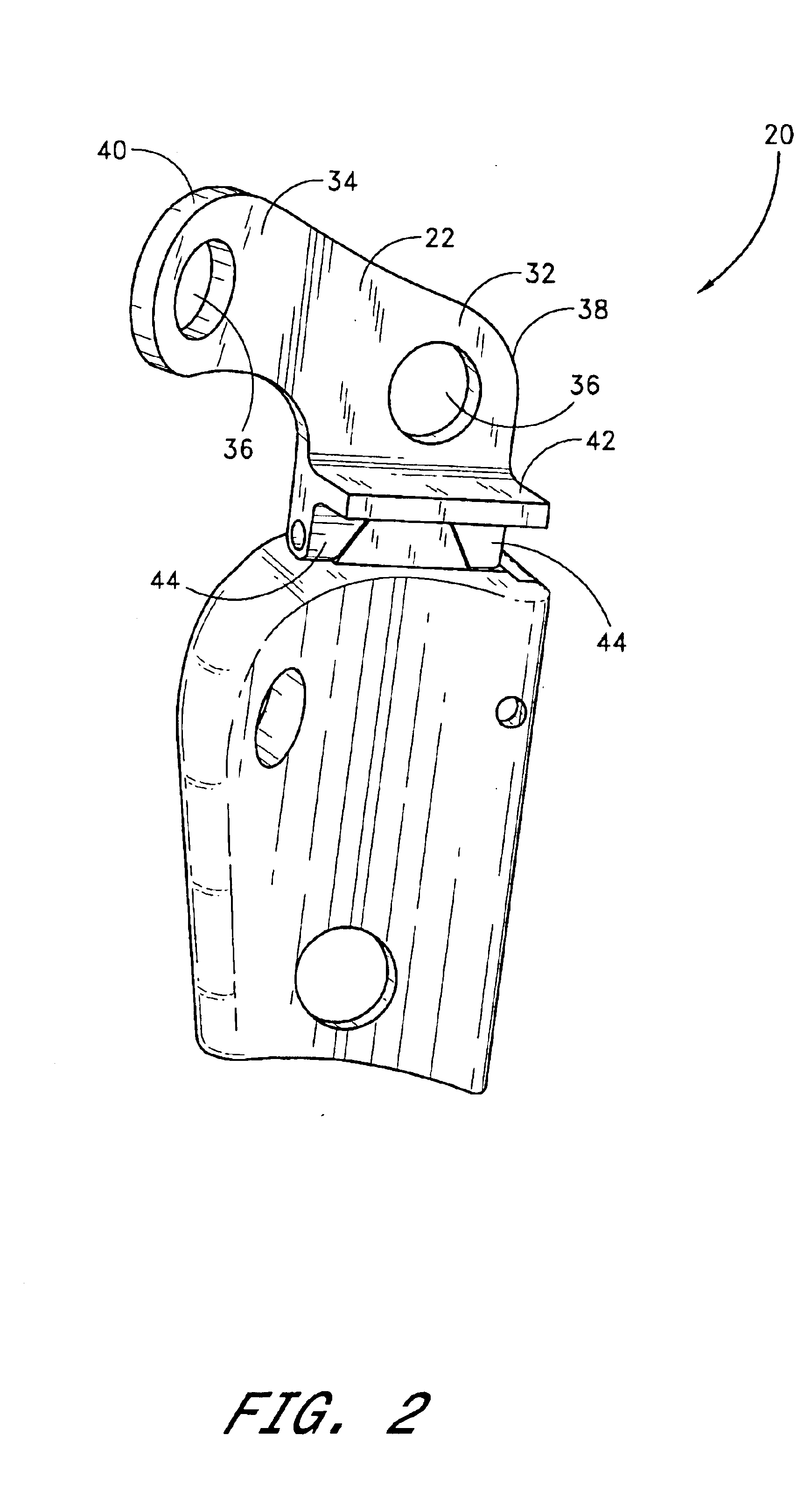

Internal osteotomy fixation device

InactiveUS6852113B2Flexibility in initially fittingLow profileInternal osteosythesisJoint implantsImplanted deviceConstant stress

An internal osteotomy fixation apparatus is provided. The device comprises a distal plate including a channel. A slide is slidably received within the channel such that the slide is translatable with respect to the distal plate along a first axis. A proximal plate is hingedly connected to the slide, such that the proximal plate has two degrees of freedom relative to the distal plate. A ledge protruding from a first portion of the proximal plate is configured to support a proximal bone segment when the device is implanted. The slide includes ratchet teeth. A ratchet arm including teeth is attached to the distal plate, and configured to engage the slide ratchet teeth. A cross-section of the ratchet arm is configured to maintain a constant stress level along a flexed portion of the arm. The distal plate includes a shelf upon which the ratchet arm rests. Compressive loads borne by the device are translated through the shelf to the distal plate. A minimum length of the device is related to the longer of the ratchet arm or the segment of teeth on the slide. The distal plate includes a hole through which a release mechanism is accessible.

Owner:ORTHOPAEDIC DESIGNS

Artificial intervertebral disc having an articulating joint

InactiveUS7214244B2Improve securityInhibition of translationJoint implantsSpinal implantsIntervertebral discSacroiliac joint

Owner:HOWMEDICA OSTEONICS CORP

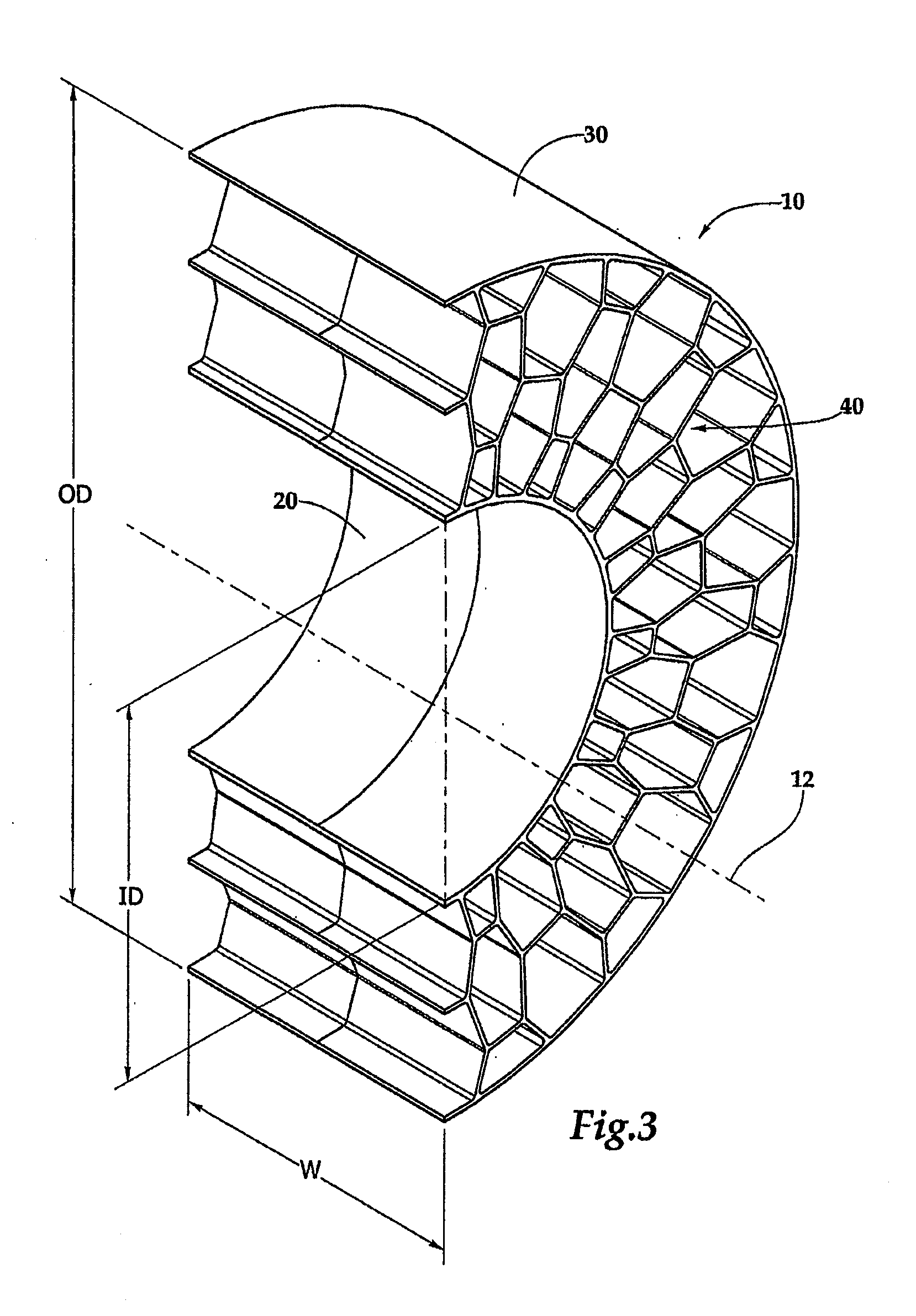

Tension-based non-pneumatic tire

ActiveUS20080314486A1Increase stiffnessEasy to disassembleNon-inflatable tyresHigh resiliency wheelsEngineeringMechanical engineering

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner ring, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, oriented and comprised of a material that facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a wheel and a footprint region where the tire contacts a surface can assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Tension-based non-pneumatic tire

ActiveUS8104524B2Extend tire lifeLess susceptible to shock and vibrationNon-inflatable tyresHigh resiliency wheelsMechanical engineeringFlat tire

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner surface, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, oriented and comprised of a material that facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a hub and a footprint region where the tire contacts a surface may assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load. Since the tire is non-pneumatic, it may be easier to maintain and may have a longer life than standard pneumatic tires since it eliminates the possibility of blowouts, flat tires, or tires operating with low air pressure. By virtue of the portion of the tire in the footprint region not bearing a significant portion of the load, non-pneumatic tire may also exhibit a more comfortable ride subject to less noise and vibration and improved handling capabilities.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

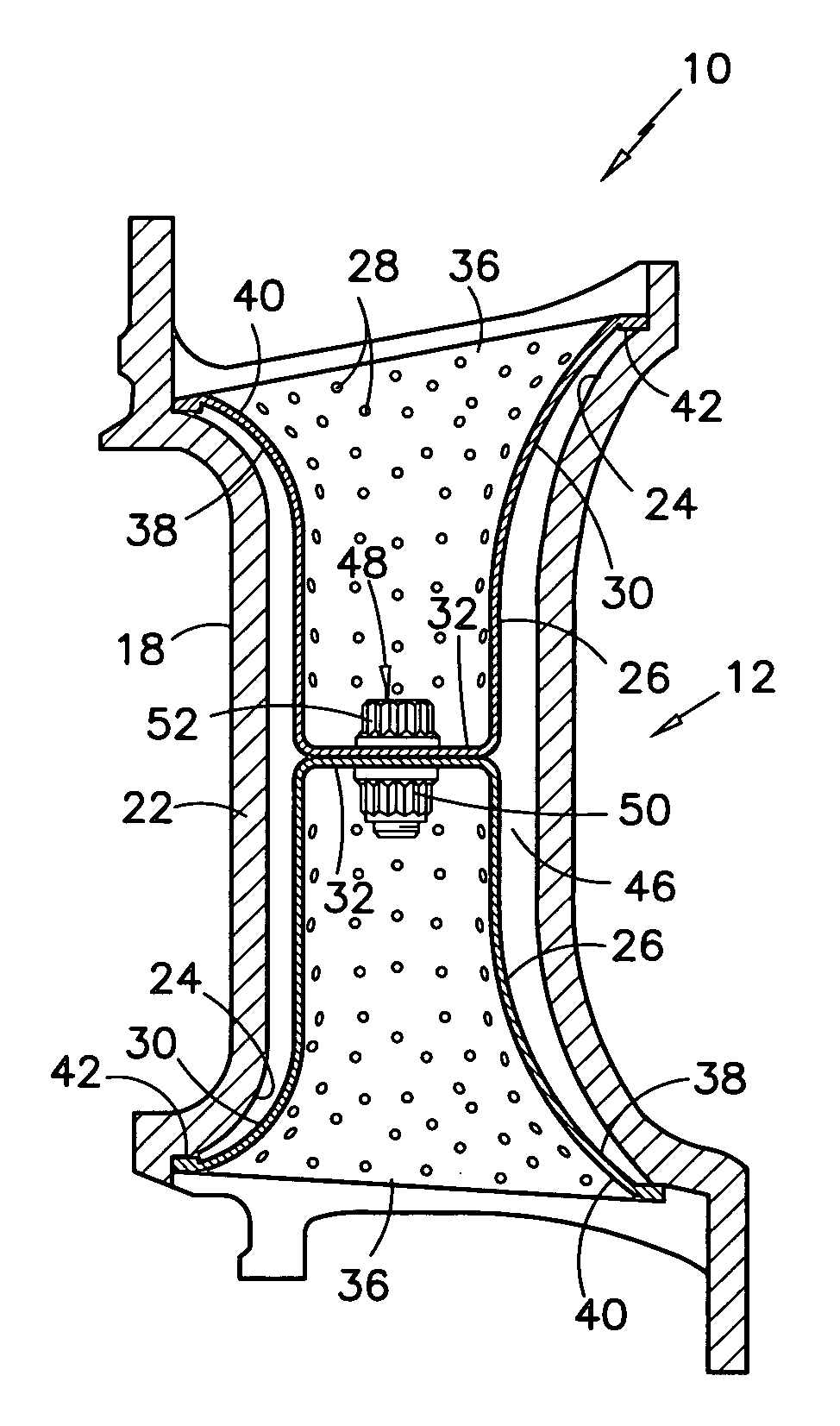

Artificial intervertebral disc

An artificial intervertebral disc including housing members including spaced inner surfaces facing each other and oppositely facing outer surfaces for engaging spaced apart intervertebral surfaces; self-adjusting bearing mechanisms operatively disposed between the inner surfaces for moving relative to the housing members to adjust and compensate for vertebral disc motion; and positioning ring for controlling motion and position of the bearing mechanisms and for absorption of compressive loads. An artificial intervertebral disc including housing members having an oval recess on the inner surfaces; oval bearing mechanisms operatively disposed within the oval recess between the inner surfaces for moving relative to the housing members to adjust and compensate for vertebral disc motion; and oval positioning ring. A spring member for an artificial intervertebral disc including a substantially annular body having an axially extended bore therethrough defining a passageway.

Owner:AESCULAP IMPLANT SYST

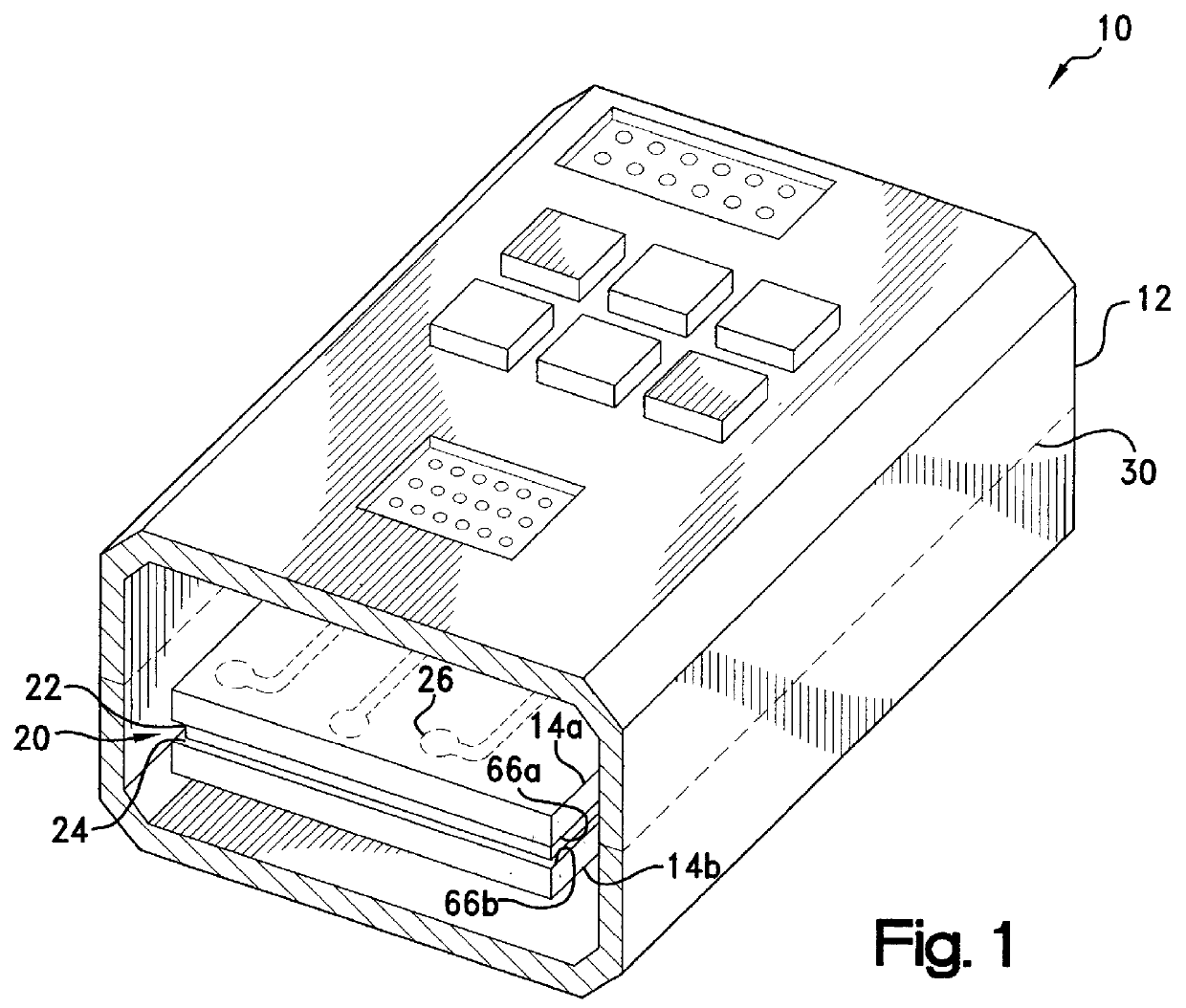

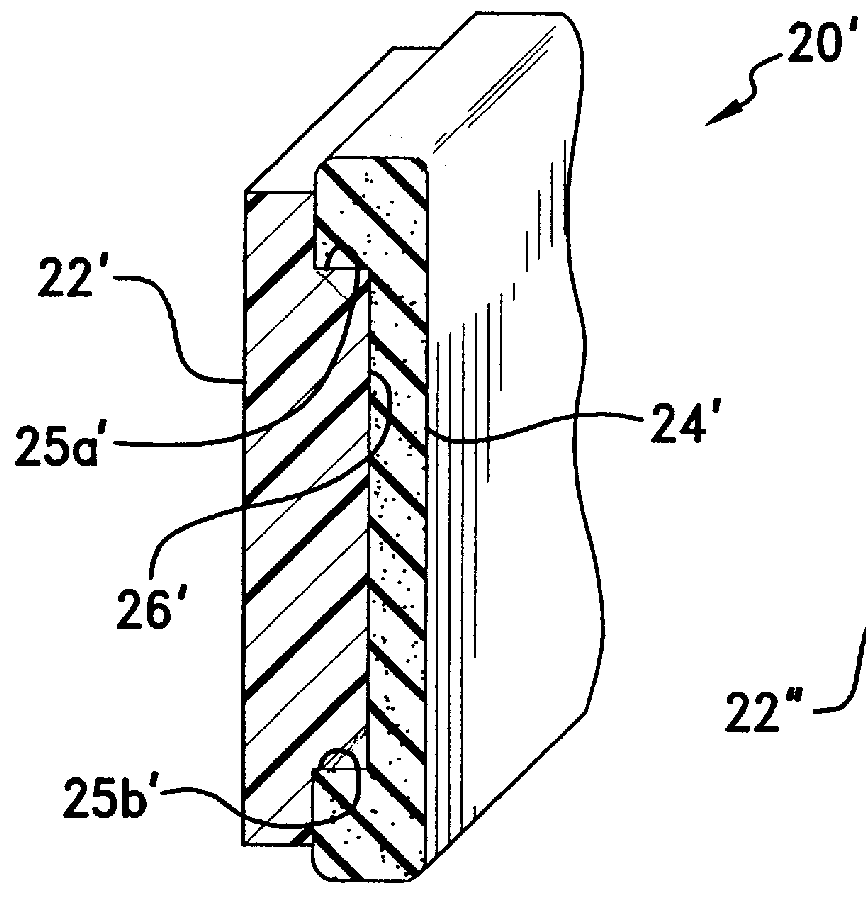

Low closure force EMI shielding spacer gasket

InactiveUS6121545AEnhance the imageEnsure electrical continuityEngine sealsScreening gaskets/sealsEdge surfaceBending moment

An EMI shielding spacer gasket assembly for interposition under a predetermined compressive load within an electronics enclosure between a first surface and an oppositely-disposed second surface of the enclosure. The assembly includes a frame member and an electrically conductive, elastomeric member extending along at least a portion of the perimeter of the frame member as retained on a corresponding peripheral edge surface thereof. The elastomeric member has an outboard side which is compressible axially under the compressive load for providing an electrically conductive pathway between the surfaces of the enclosure. In an uncompressed orientation, the outboard side of the elastomeric member exhibits elongate upper and lower bearing portions which are disposed at a spaced-apart radial distance from the frame member to define a corresponding bending moment arm. Each of the bearing portions is angularly deflectable relative to the moment arm to effect the compression of the elastomeric member under a relatively low compressive load.

Owner:PARKER INTANGIBLES LLC

Artificial intervertebral disc having an articulating joint

InactiveUS20050192670A1Improve securityInhibition of translationJoint implantsSpinal implantsIntervertebral discSacroiliac joint

Owner:HOWMEDICA OSTEONICS CORP

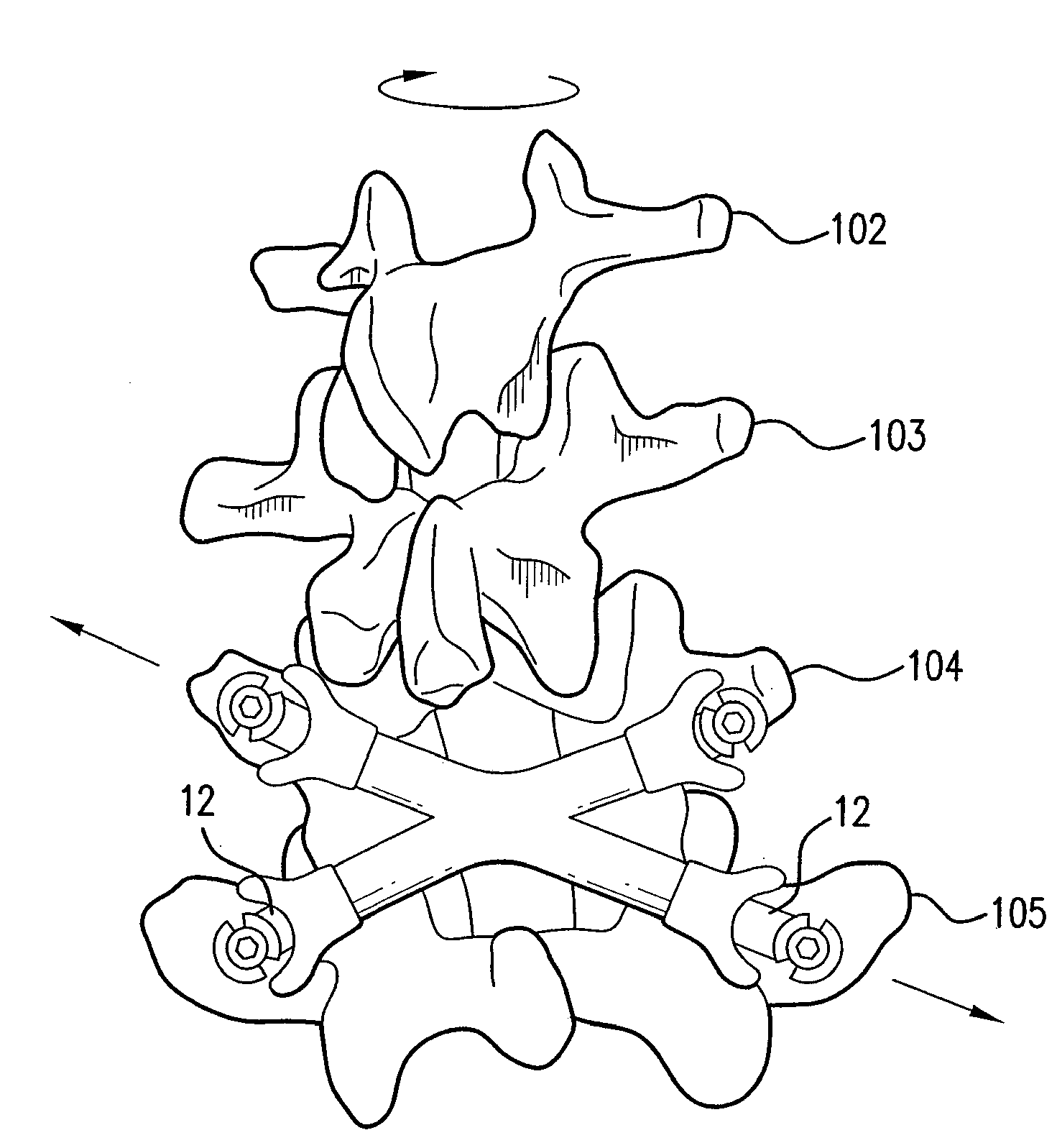

Dynamic spinal stabilization device

InactiveUS20080033433A1Stabilize vertebraPreserve physiological spinal movementInternal osteosythesisJoint implantsSpinal columnCross connection

The present invention regards linking spinal vertebrae to provide support and alignment of one or more vertebrae. The various systems, methods, devices and kits that embody the invention may employ a vertebrae crossover connector to link or otherwise connect one or more vertebrae in a column of vertebrae. These connectors may be positioned between anchors added to the vertebrae and may span the center of the spinal column when the connectors are positioned between the anchors. In certain embodiments each crossover connector may include one or more stretchable couplings that can stretch and resist tensile loads placed on them when the spinal column is stationary and in various ranges of motion. The crossover connector may also include a main body that may resist compressive loads placed on the crossover connector when the spinal column is in various ranges of motion in certain positions.

Owner:IMPLICITO DANTE

Tension-based non-pneumatic tire

ActiveUS8109308B2Increase stiffnessEasy to disassembleNon-inflatable tyresHigh resiliency wheelsMechanical engineeringCompressive load

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Device for elastically stabilizing vertebral bodies

ActiveUS20060260483A1Great elastic yieldingIncrease dampingInternal osteosythesisJoint implantsMetallic materialsEngineering

Owner:SYNTHES USA

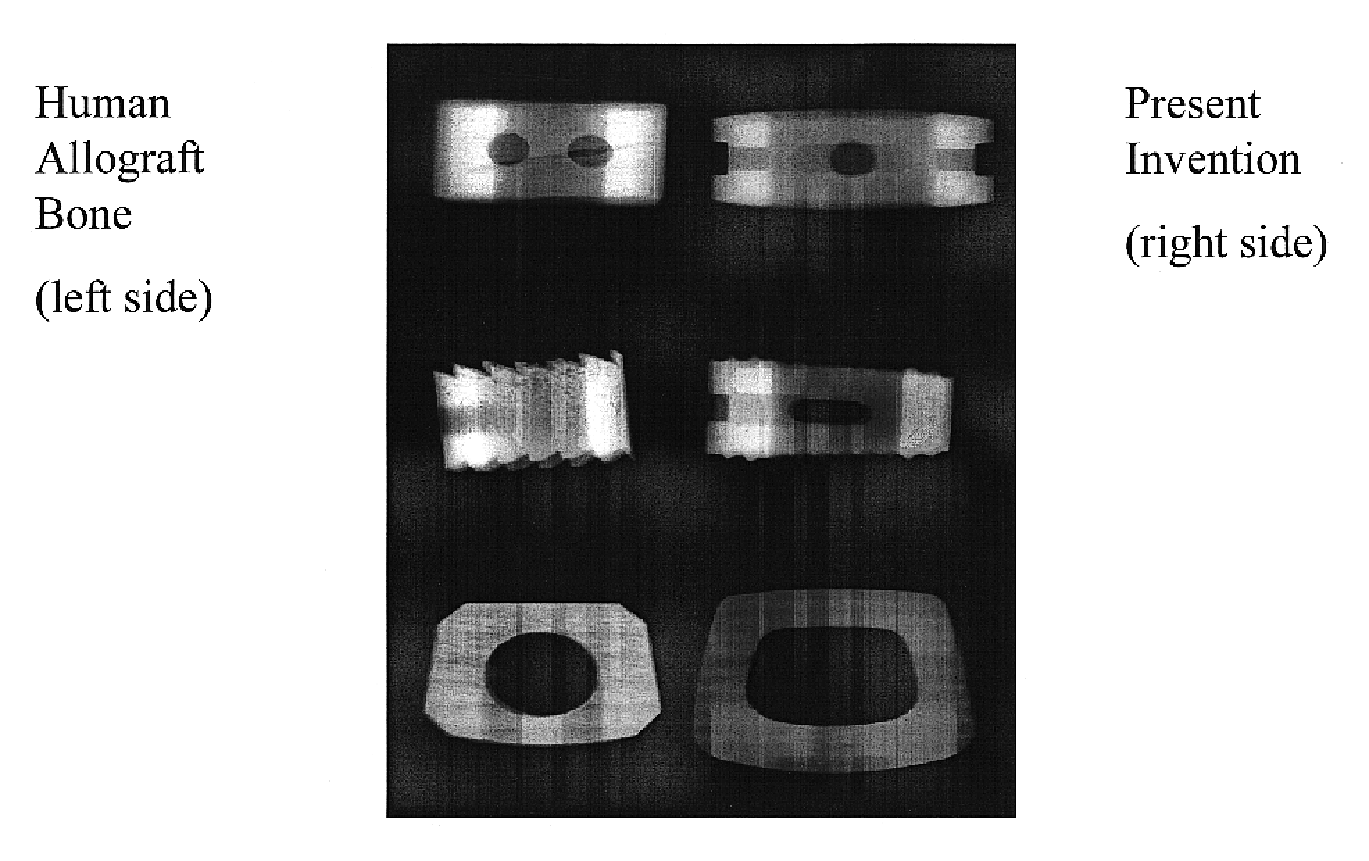

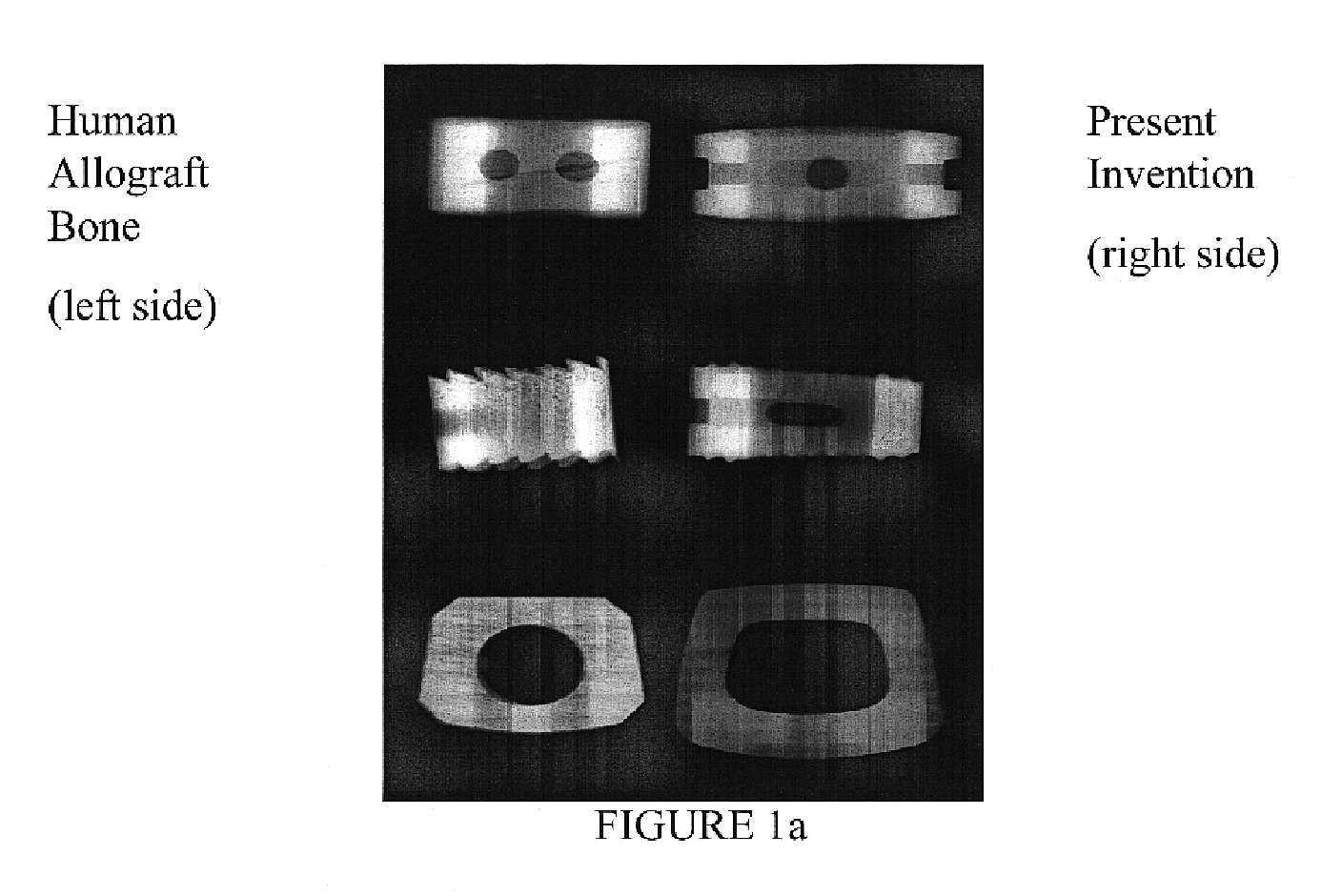

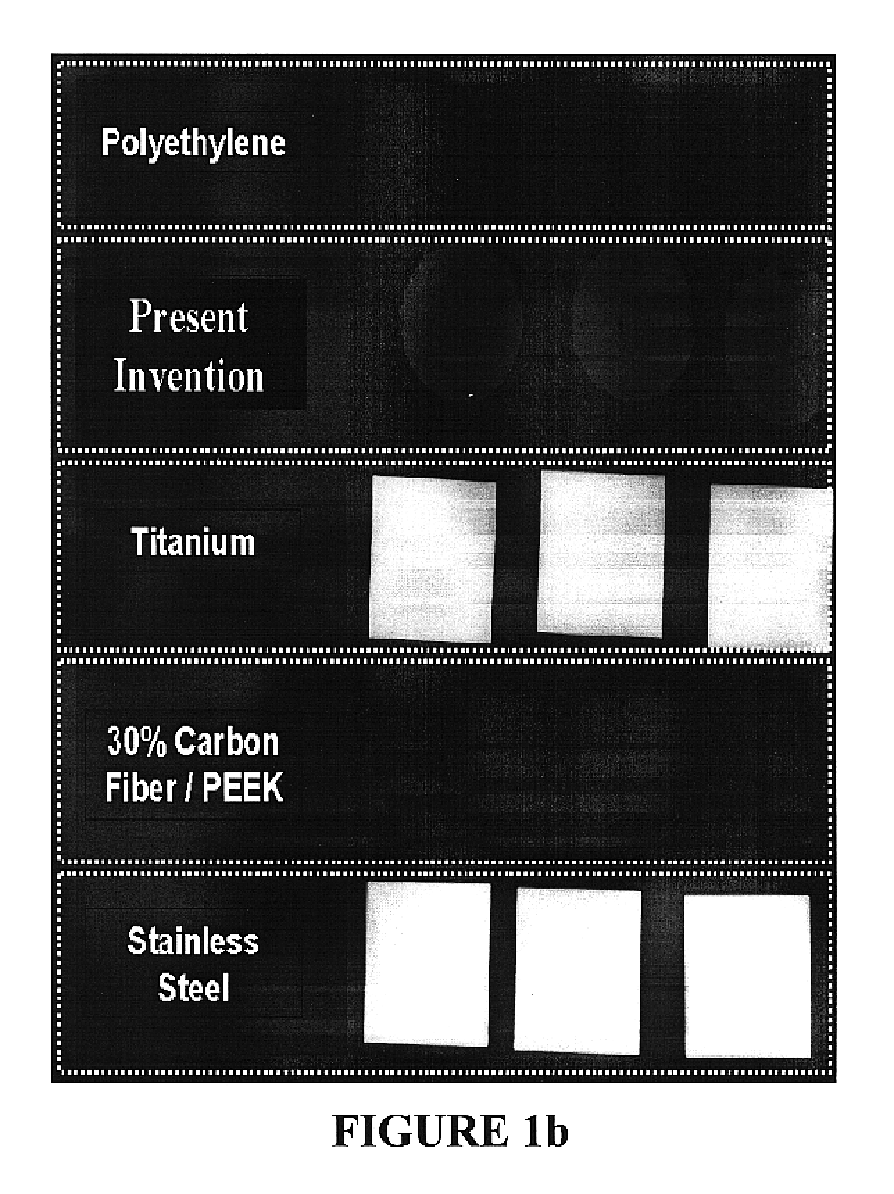

Bioactive spinal implant material and method of manufacture thereof

InactiveUS6987136B2High strengthGreat advantageImpression capsSurgical adhesivesMedicineSpinal implant

Bioactive spinal implant materials having optimized radiopacity, stiffness, and bioactivity properties for formulation of shaped bodies capable of withstanding large dynamic, compressive loads are provided. The invention also provides methods of making the optimized implant materials.

Owner:ORTHOVITA INC

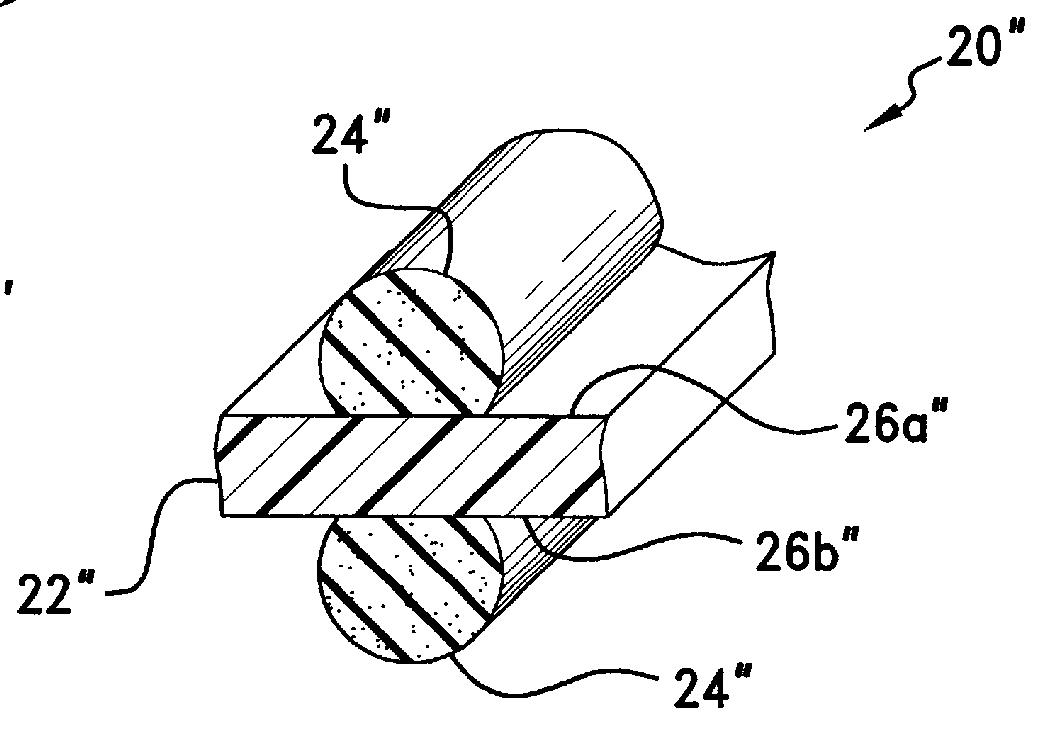

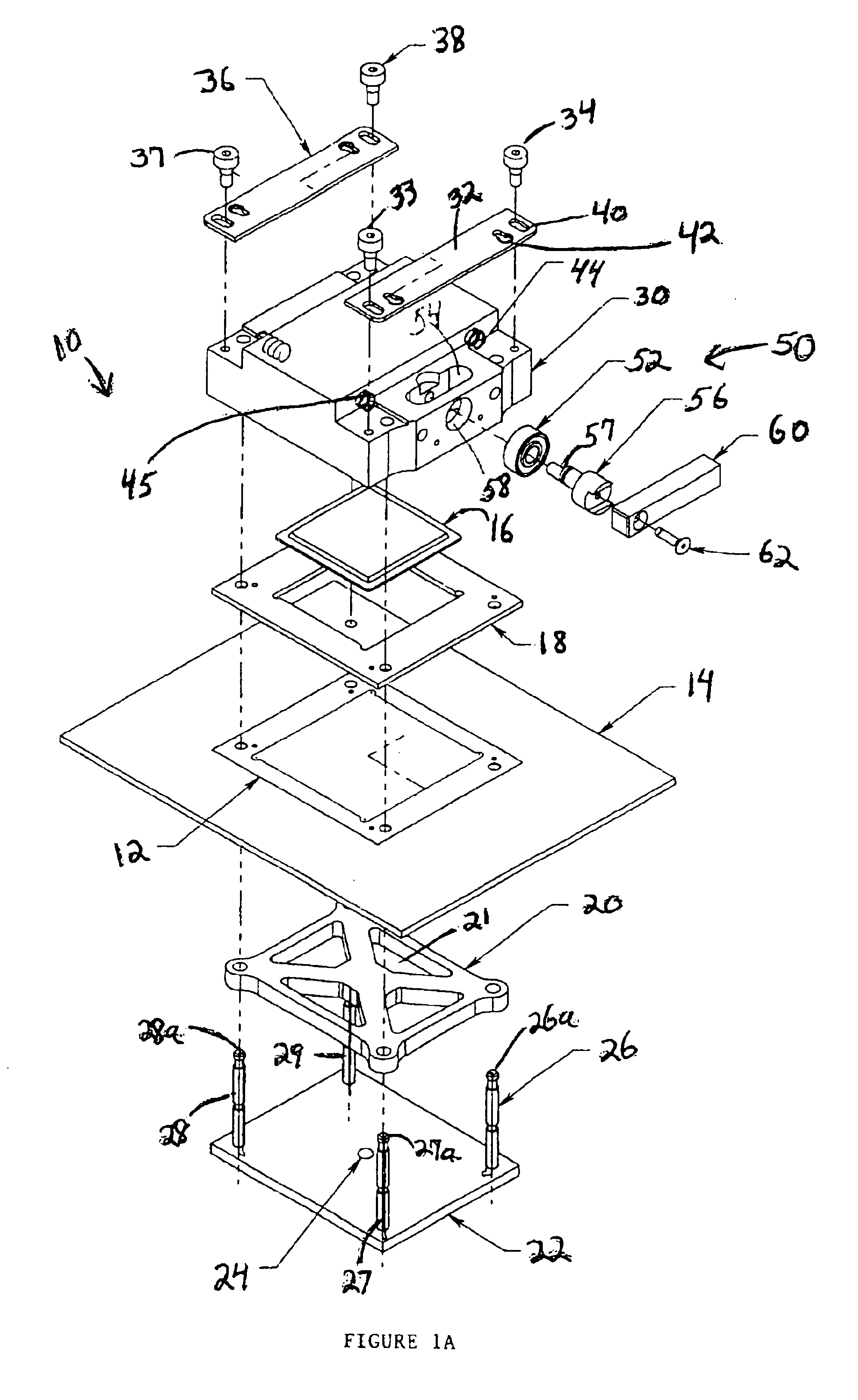

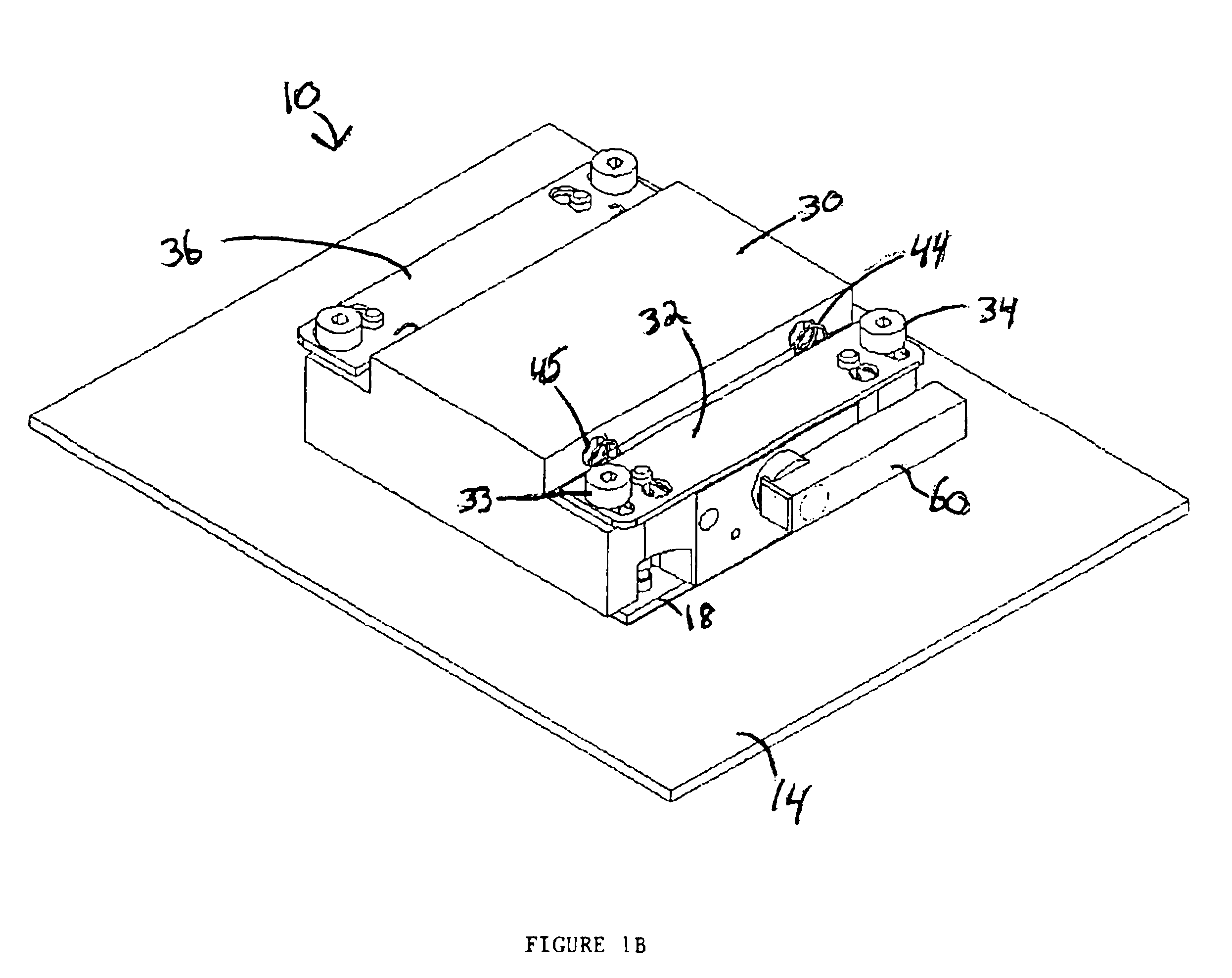

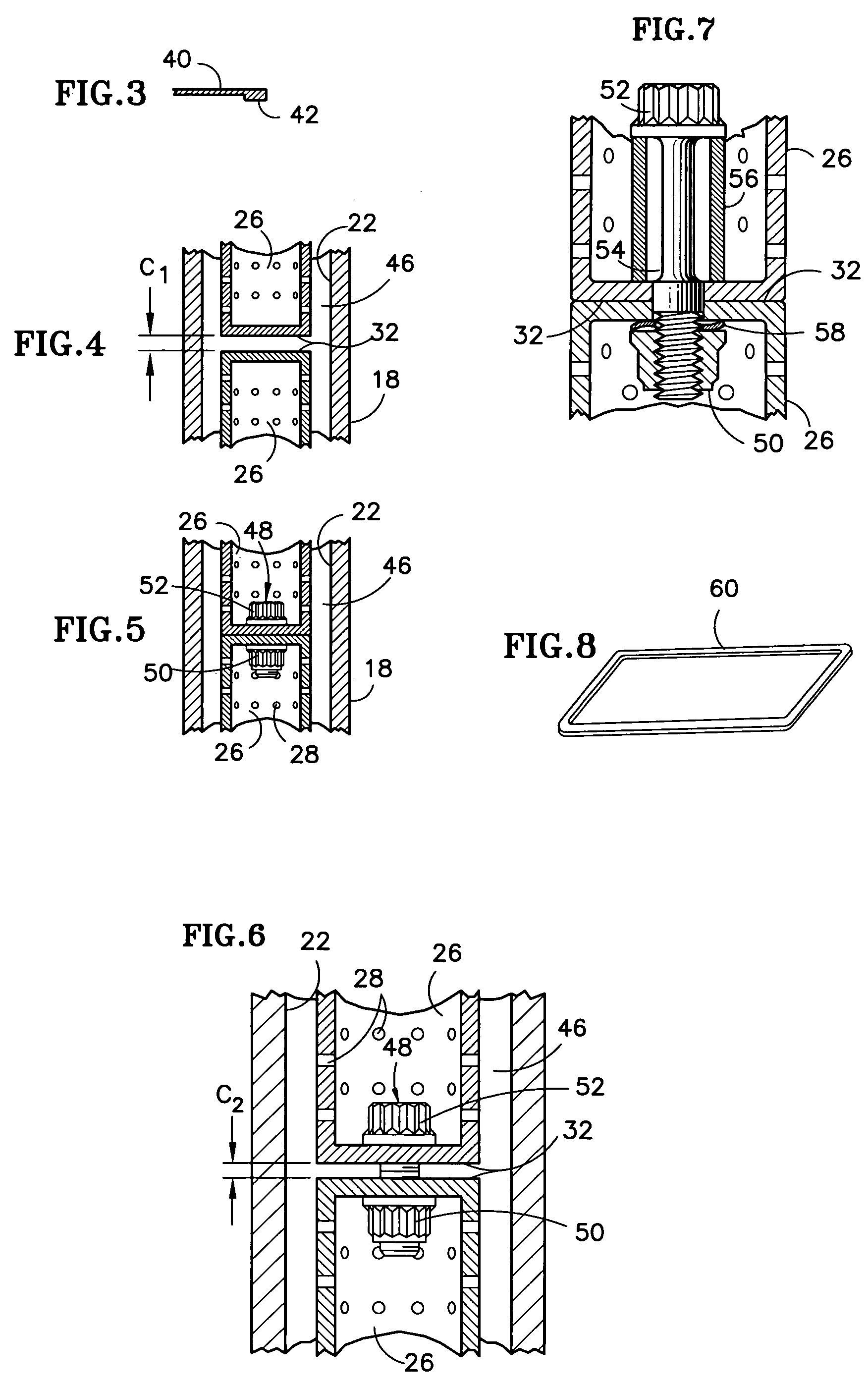

Apparatus for applying a mechanically-releasable balanced compressive load to an assembly such as a compliant anisotropic conductive elastomer electrical connector

InactiveUS6929484B2Quick releaseImprove electrical performanceCoupling contact membersPrinted circuitsElastomerElectrical connection

An apparatus for applying a mechanically-releasable balanced compressive load to an assembly such as a compliant electrical connector that electrically connects an electrical device to a first side of a two-sided substrate. The apparatus includes a backup plate coupled to the second side of the substrate, a rocker plate behind the backup plate, the rocker plate touching the backup plate at only one location, and a rigid member coupled to the first side of the substrate. There are three or more pins mechanically coupled to the rocker plate and the rigid member. When there are four or more pins, a rocker member is mechanically coupled to two of the pins, and in contact with the rocker plate at a single pivot. A compressible spring, mechanically coupled to a pin, applies a force, coupled through the pin, to urge the backup plate and rigid member together and thereby compress the compliant electrical connector between the electrical device and the substrate to make the separable electrical connection.

Owner:PARICON TECH

Tension-based non-pneumatic tire

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner ring, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, curved, oriented, and comprised of varying thicknesses of material which facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a wheel and a footprint region where the tire contacts a surface can assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

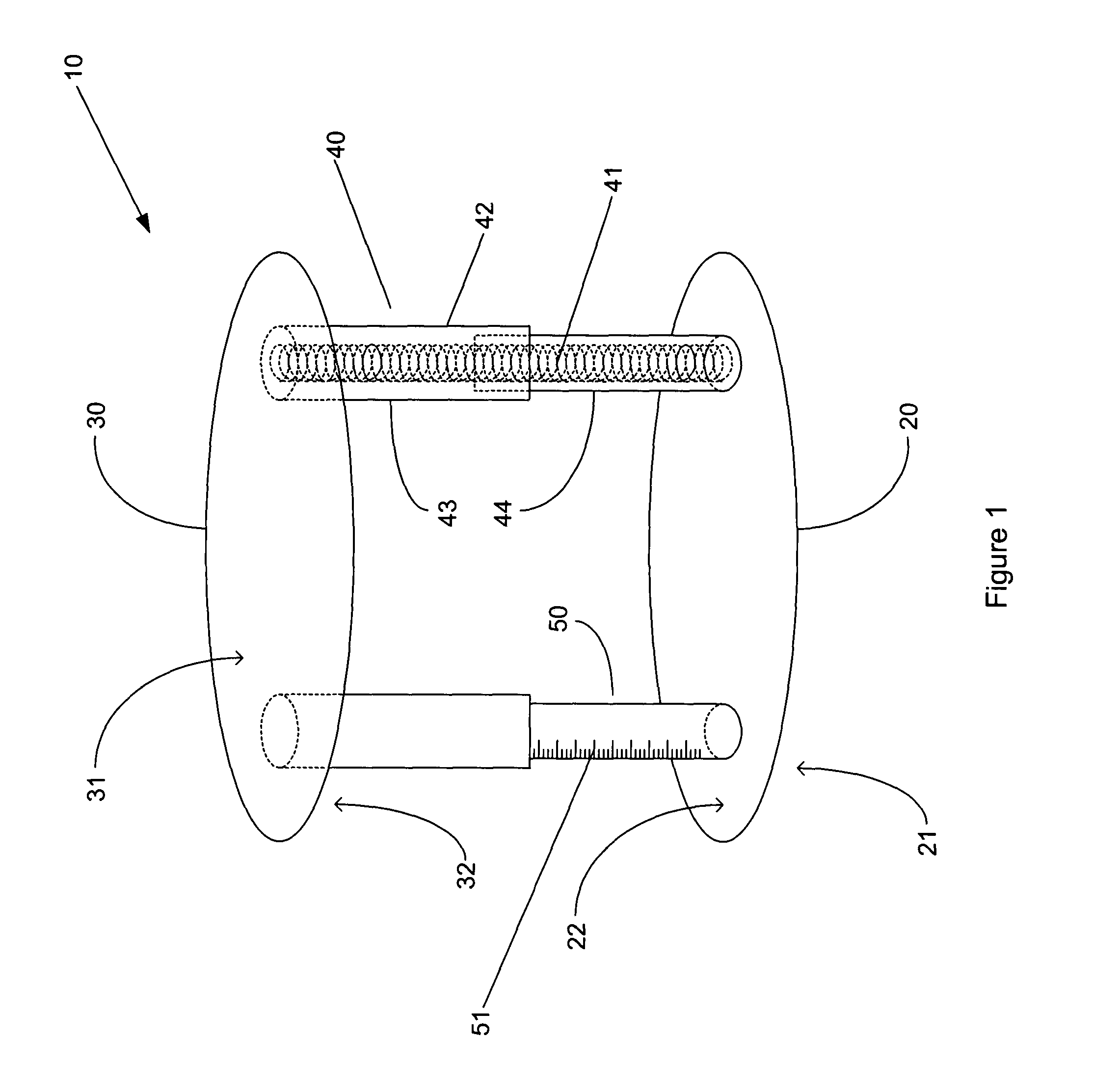

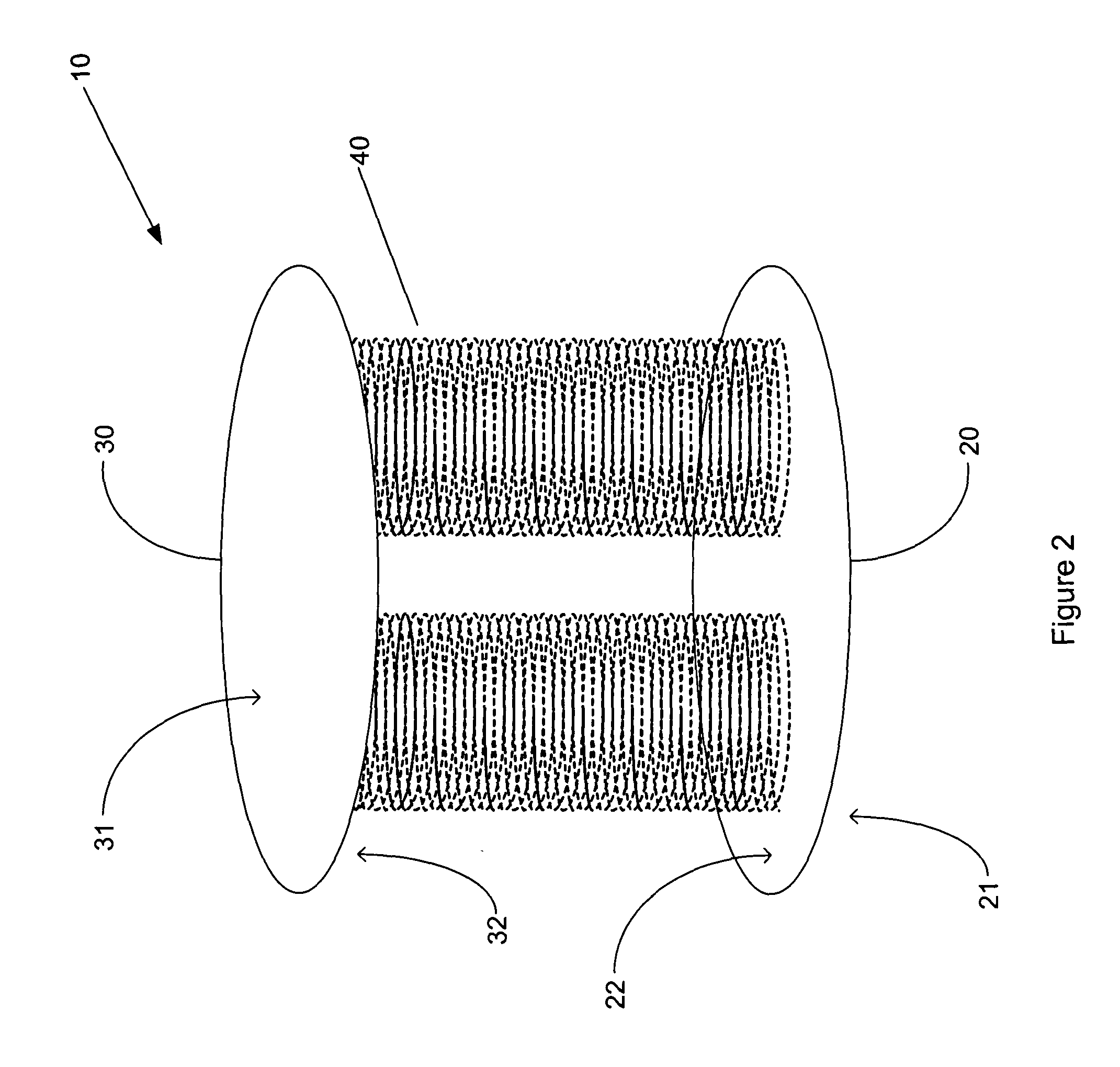

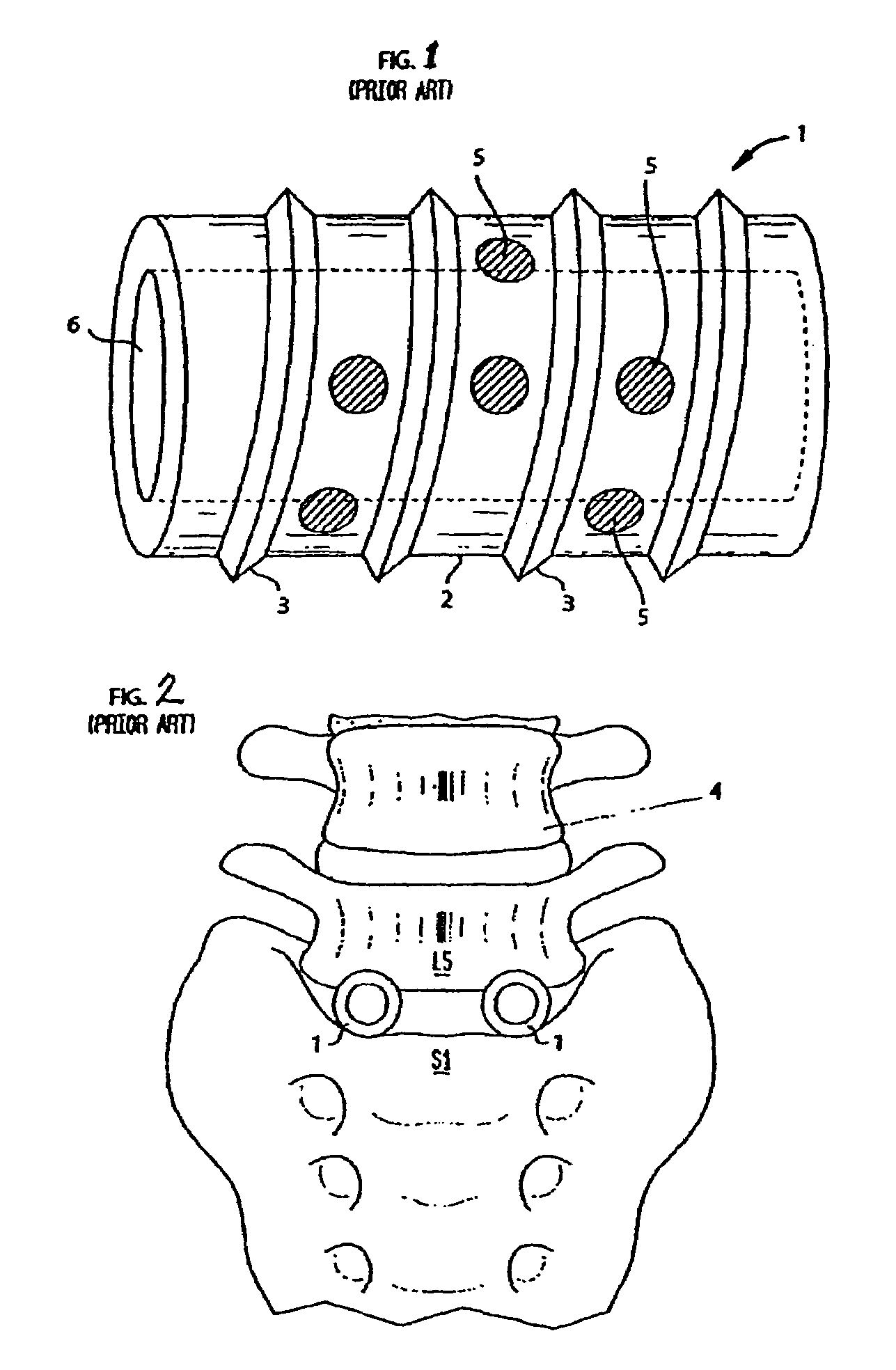

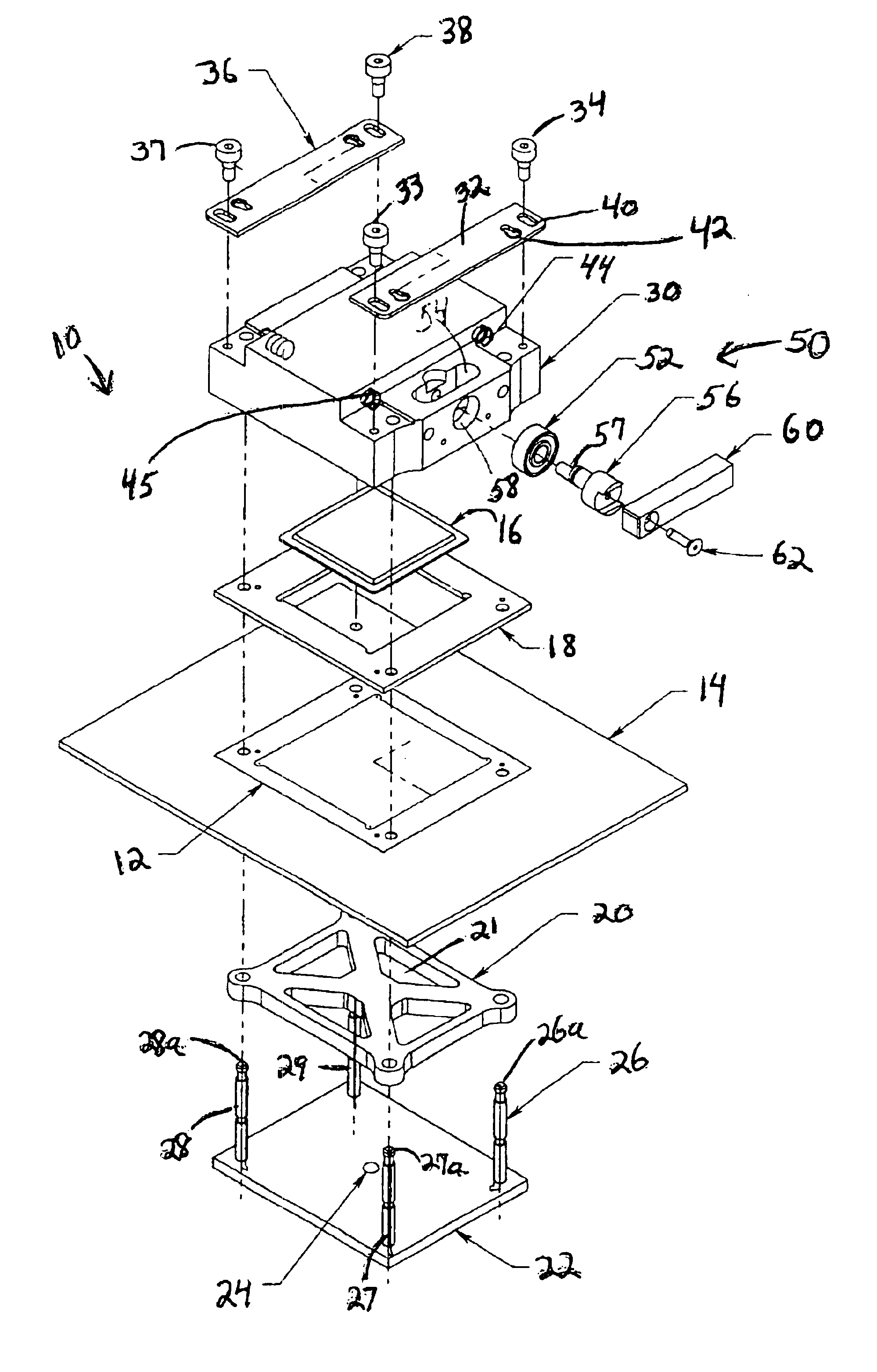

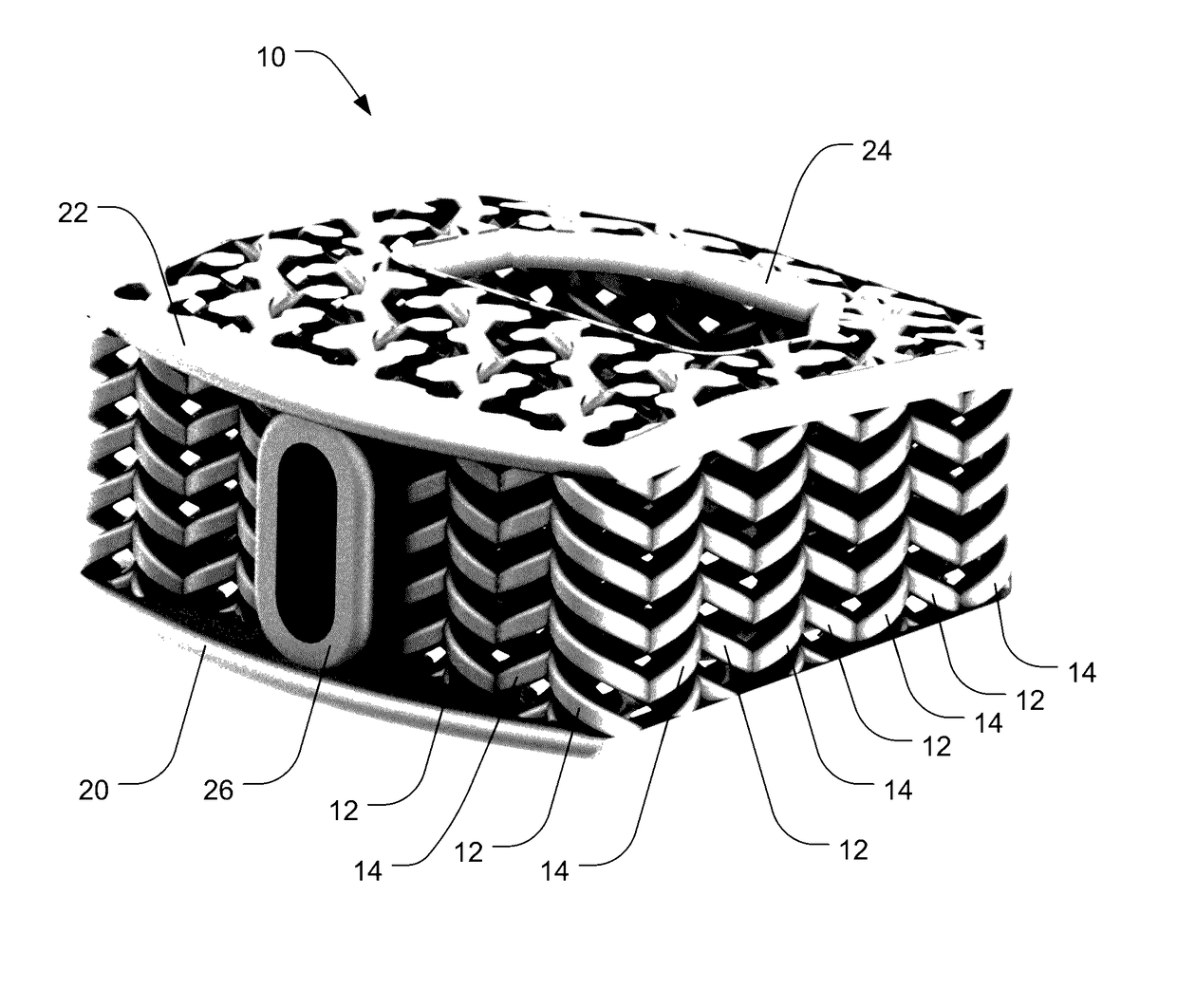

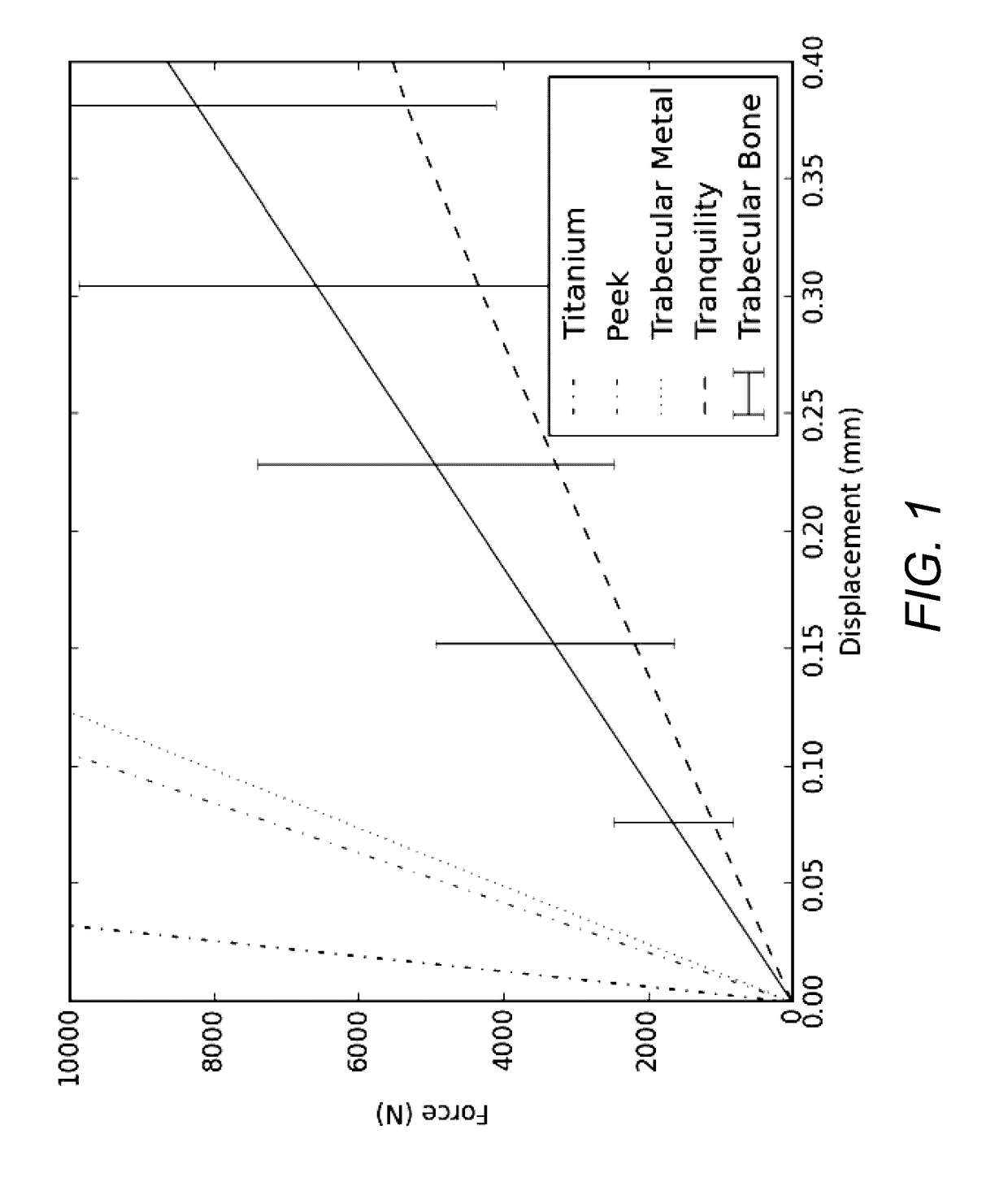

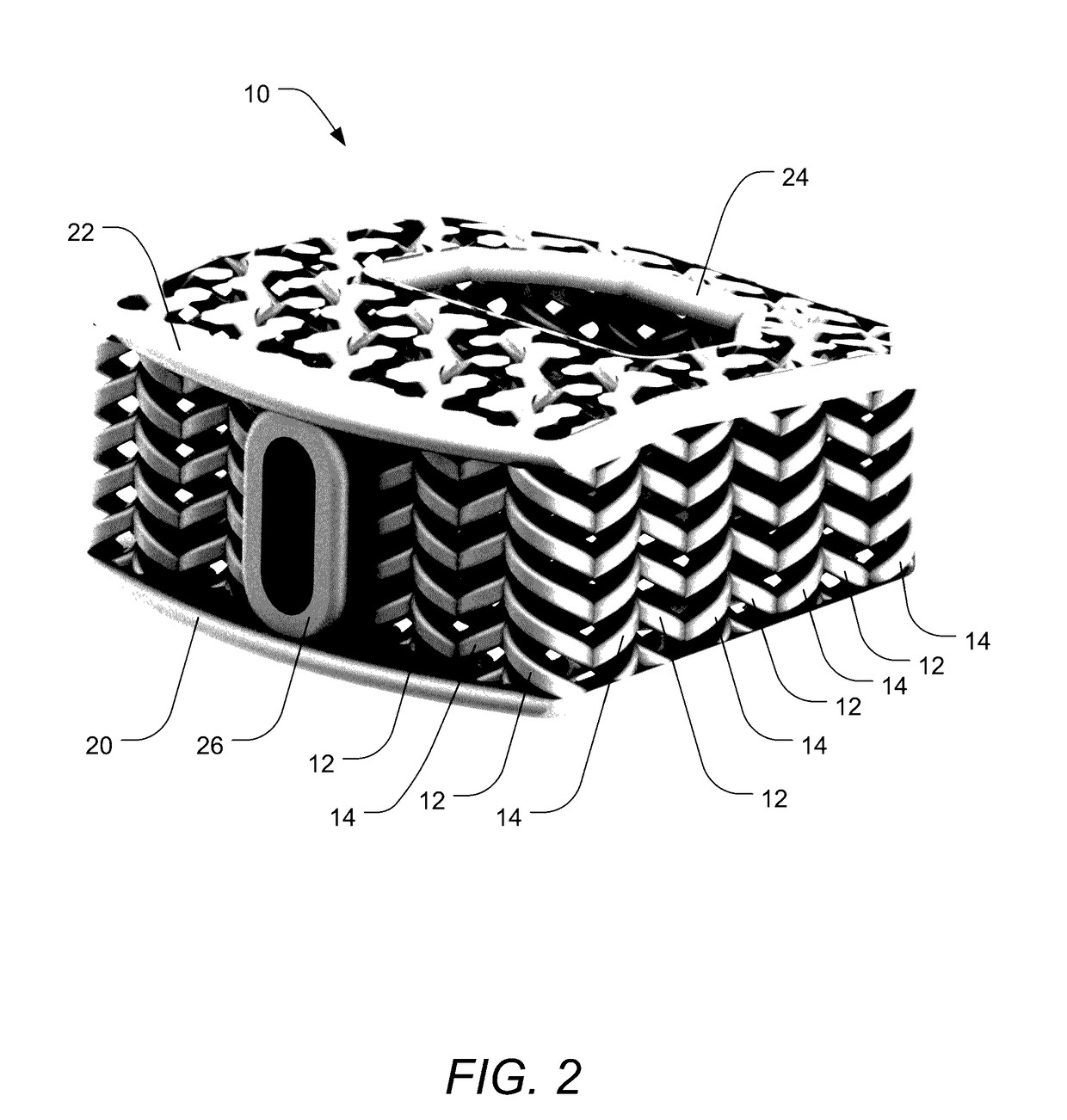

Porous Interbody Spacer

Orthopedic implants, particularly interbody spacers, have a combination of correct pore size and stiffness / flexibility. When the implants have the proper pore size and stiffness, osteocytes are able to properly bridge the pores of the implant and then experience a proper compressive load to stimulate the bone cells to form bone within the pores. An implant includes a body formed of an osteoconductive material and having a stiffness of between 400 megapascals (MPa) and 1,200 MPa. Additionally, the body includes a plurality of pores having an average size of between 150 microns and 600 microns. The pores permit the growth of bone therein. The body is formed of packs of coils which may be formed using an additive manufacturing process and using traditional orthopedic implant materials such as titanium and titanium alloys while still achieving desired stiffness and pore sizes of the implants.

Owner:NEXUS SPINE L L C

Methods for Deploying Spinal Motion Preservation Assemblies

InactiveUS20080195156A1Dampen compressionMaintain normal physiological functionInternal osteosythesisEar treatmentAnesthesiaSpinal locomotion

Spinal motion preservation assemblies adapted for use in a spinal motion segment are disclosed including the process for delivering and assembling the spinal motion preservation assemblies in the spinal motion segment via an axial channel created with a trans-sacral approach. The spinal motion preservation assemblies make use of a dual pivot. A number of different embodiments of spinal motion preservation assemblies are disclosed which include at least one component adapted for elastic deformation under compressive loads. The disclosed mobility preservation assemblies provide for dynamic stabilization (DS) of the spinal motion segment.

Owner:TRANS1

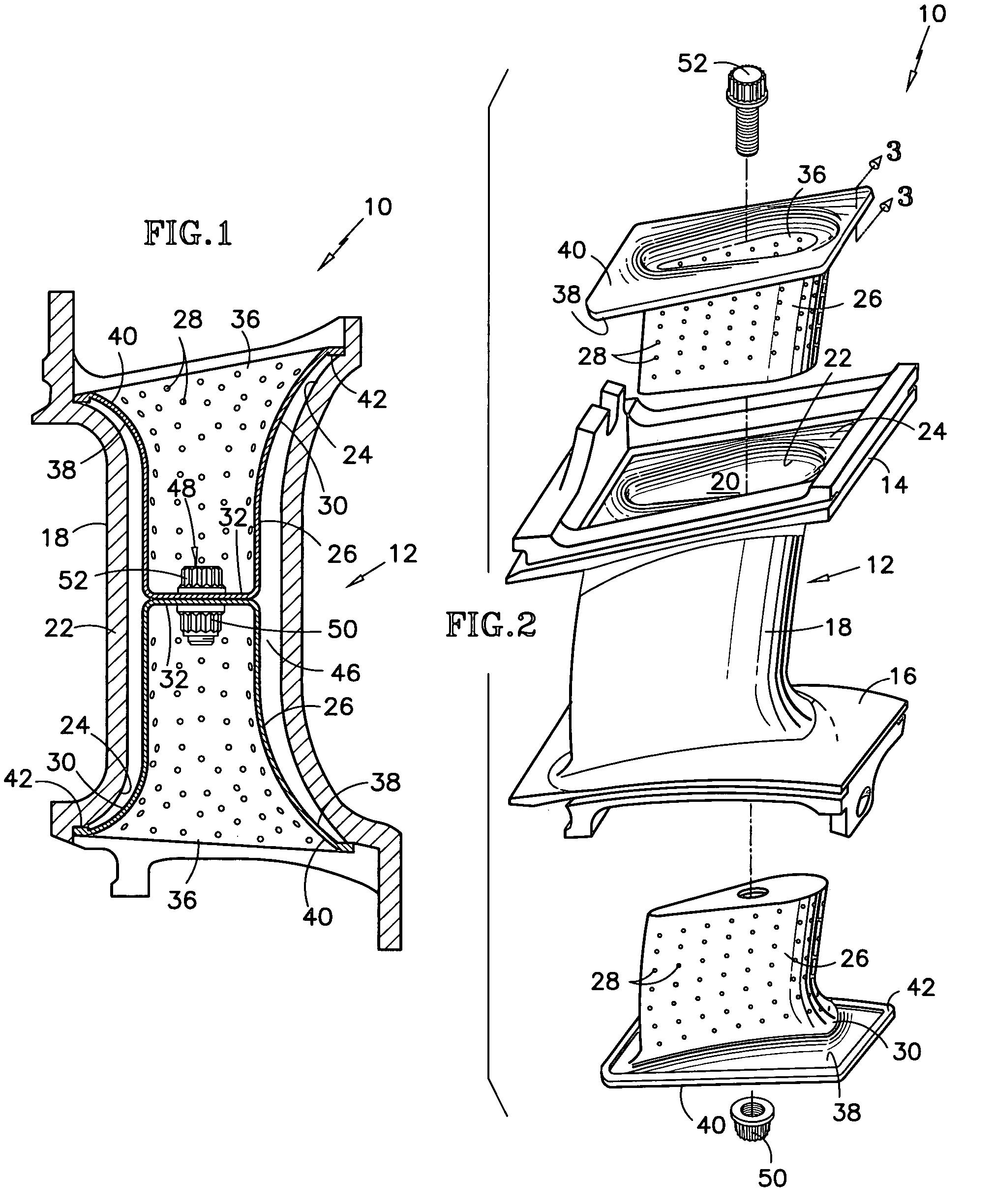

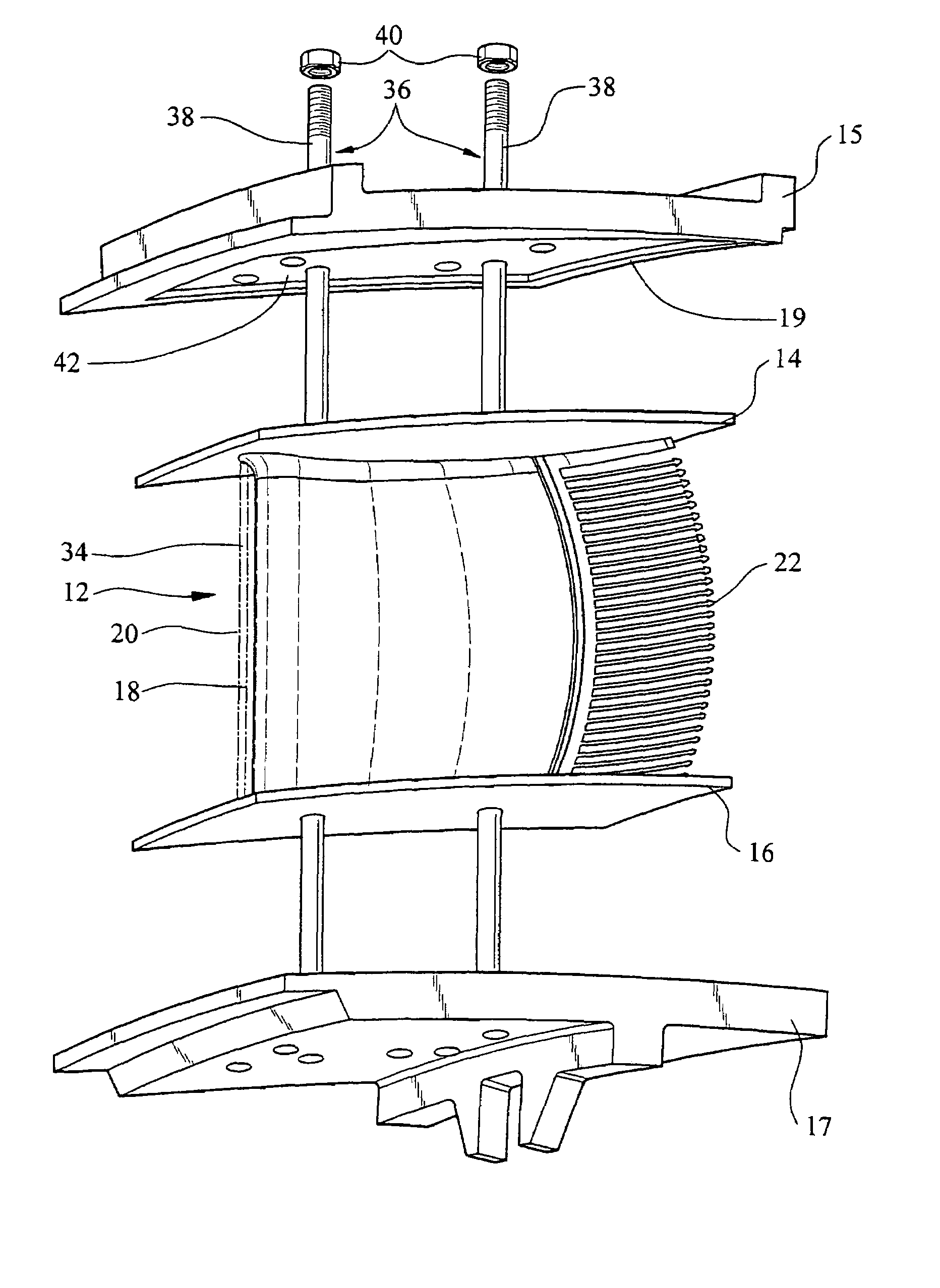

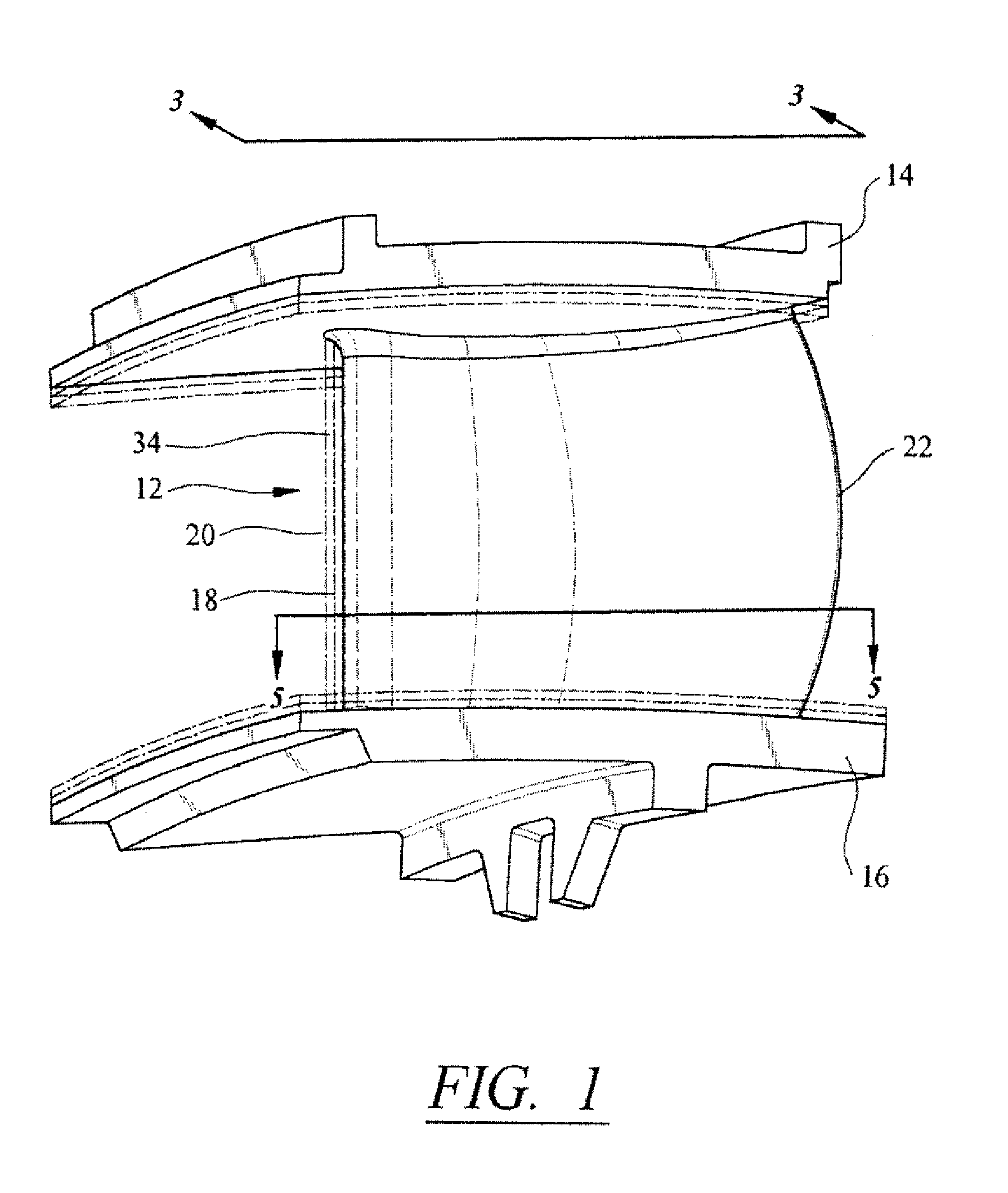

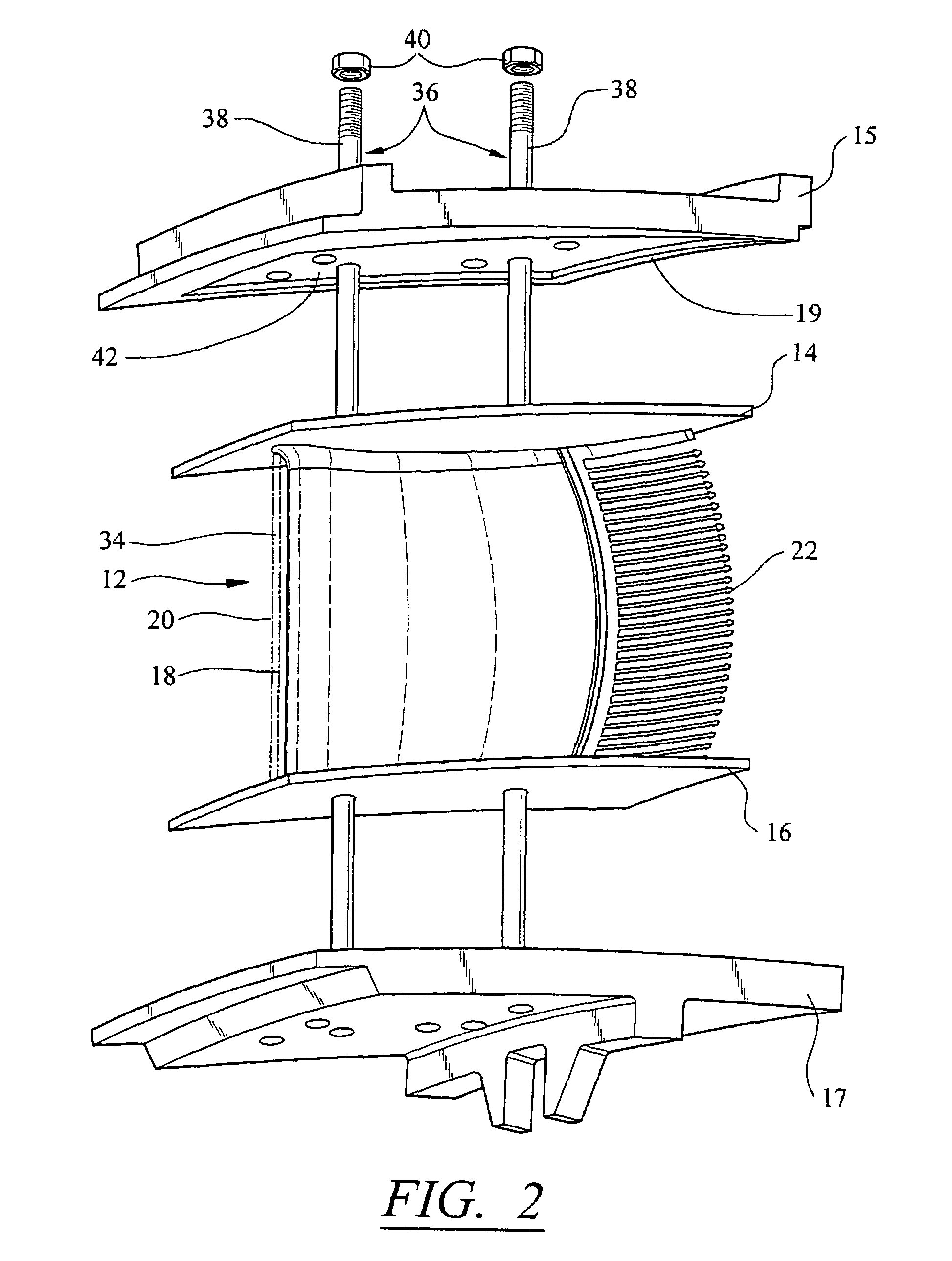

Temperature tolerant vane assembly

A vane assembly 10 suitable for a turbine engine features a refractory vane 12 with an internal cavity 20 and a pair of flexible metallic baffles 26 extending into the cavity from spanwisely opposite ends of the vane. A rigid fastener 48, such as a nut and bolt assembly applies a tensile load to the baffles. The tensile load is reacted out as a compressive load applied to the vane. In another embodiment, the baffle is relatively rigid but the fastener is flexible. The compressive loading exerted on the vane counteracts the brittleness customarily exhibited by refractory materials and imparts damage tolerance to the vane. The arrangement also allows the use of a metal baffle that can be easily secured to the vane and dispenses with any need for a potentially troublesome seal between the baffles and the spanwise extremities of the vane.

Owner:RTX CORP

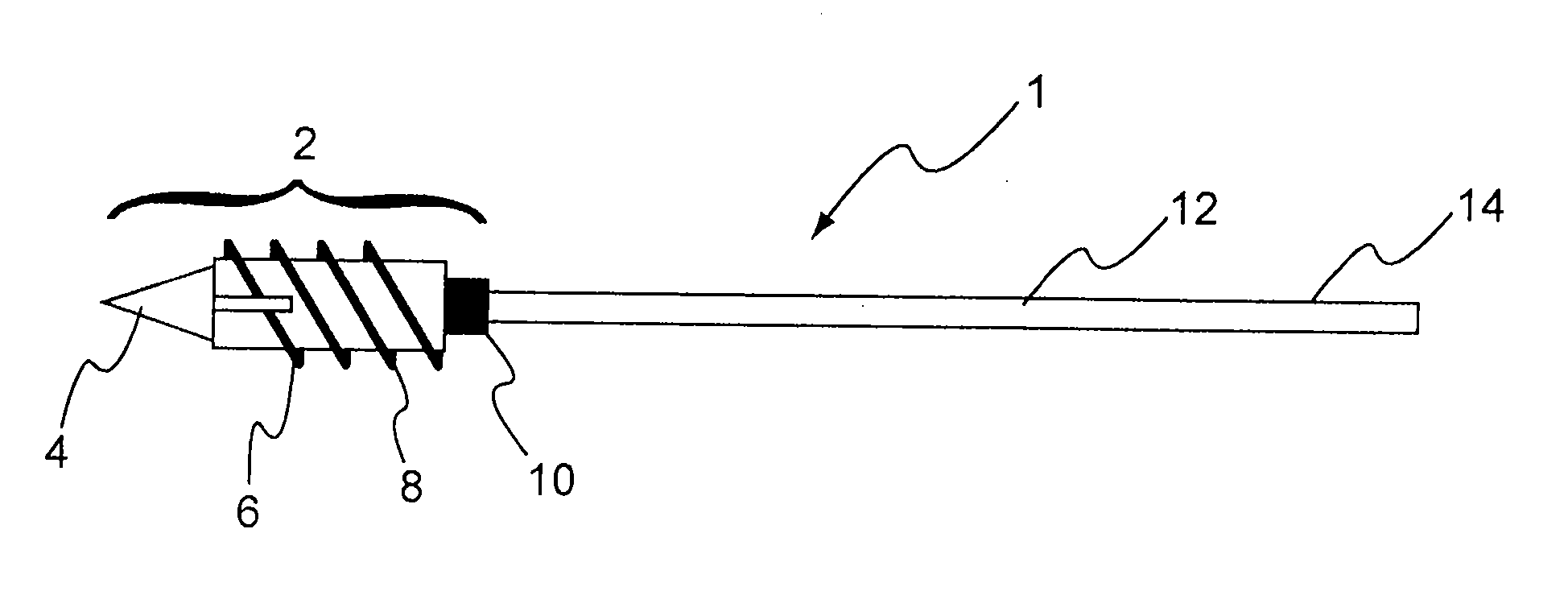

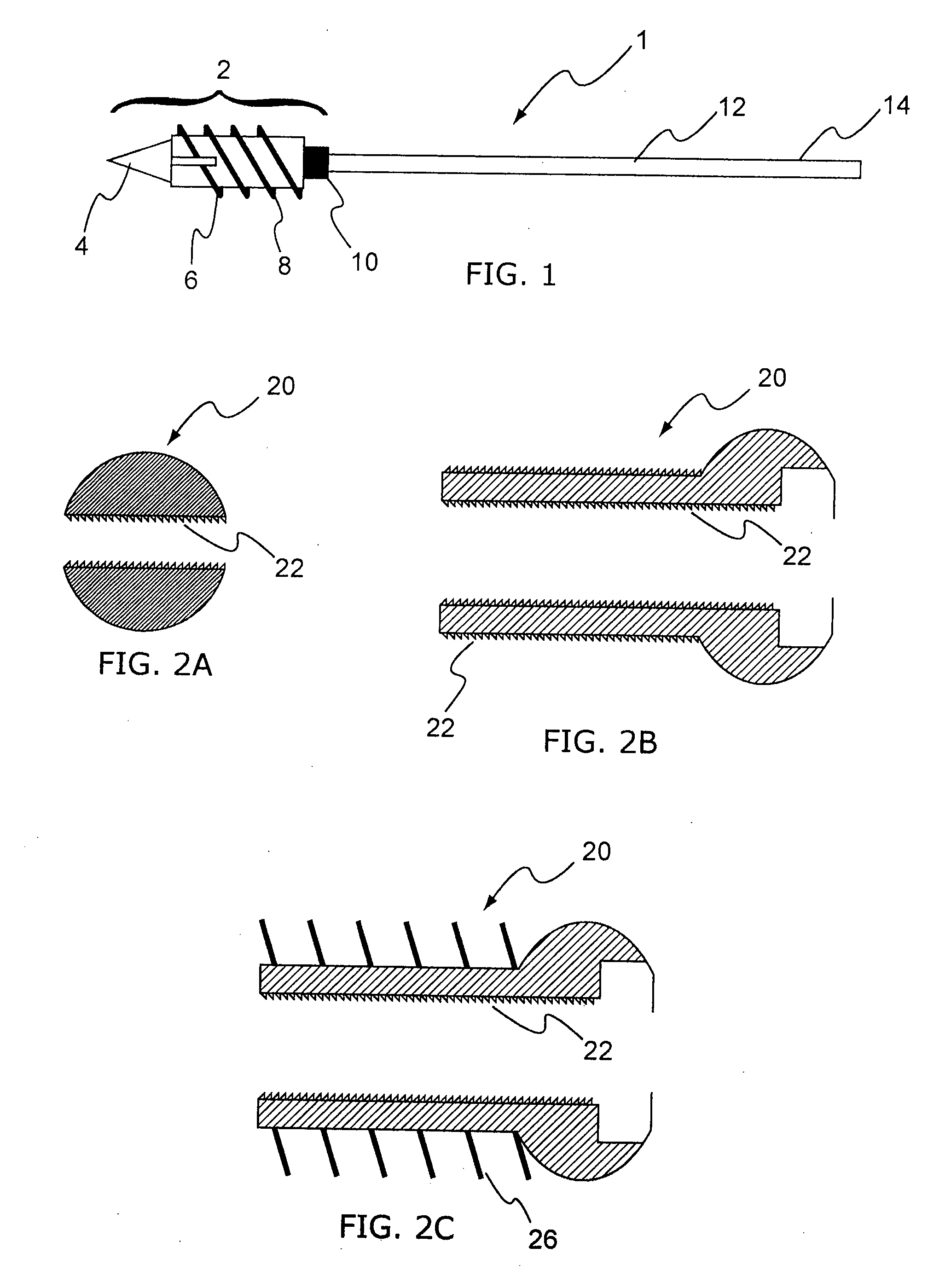

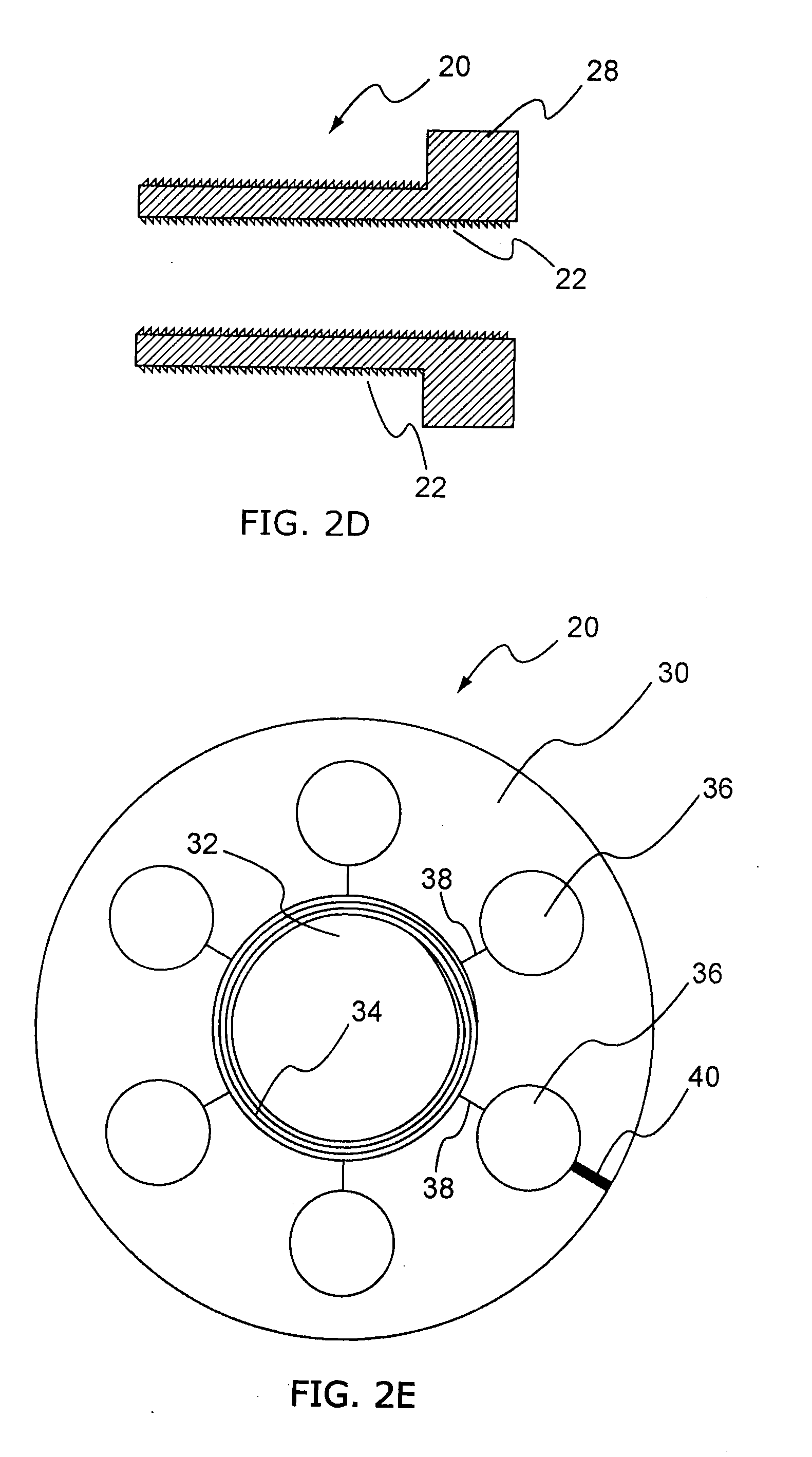

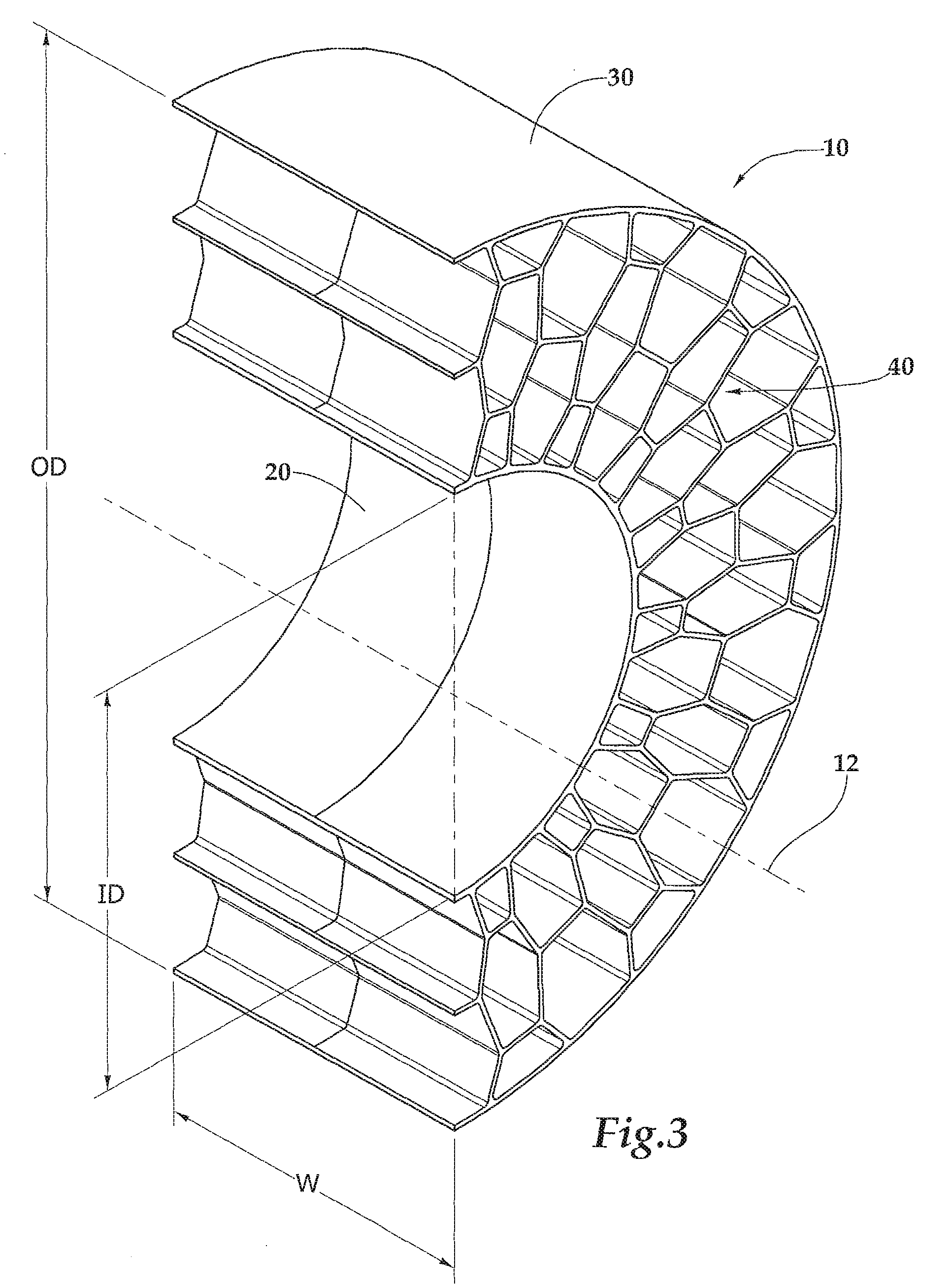

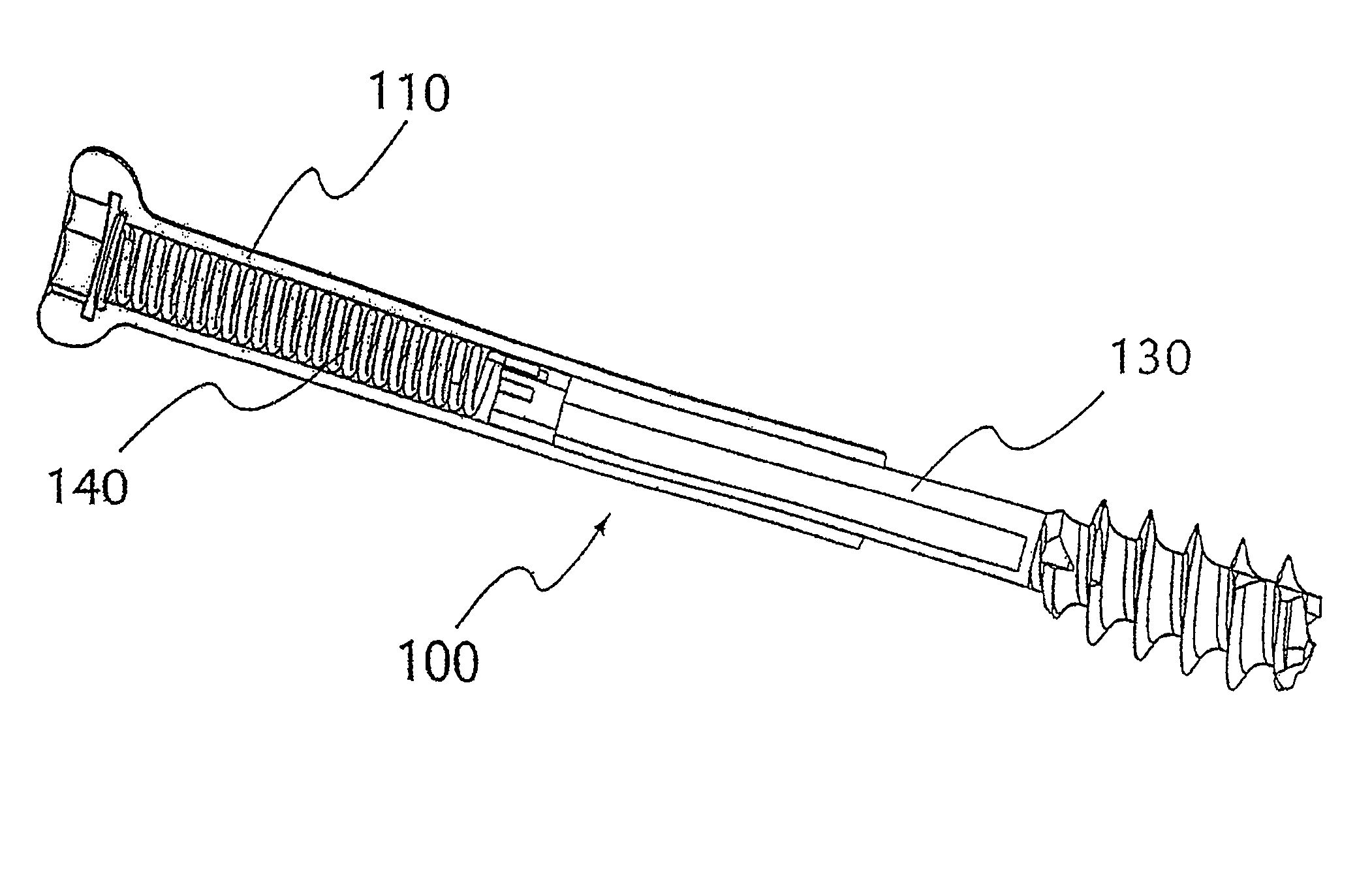

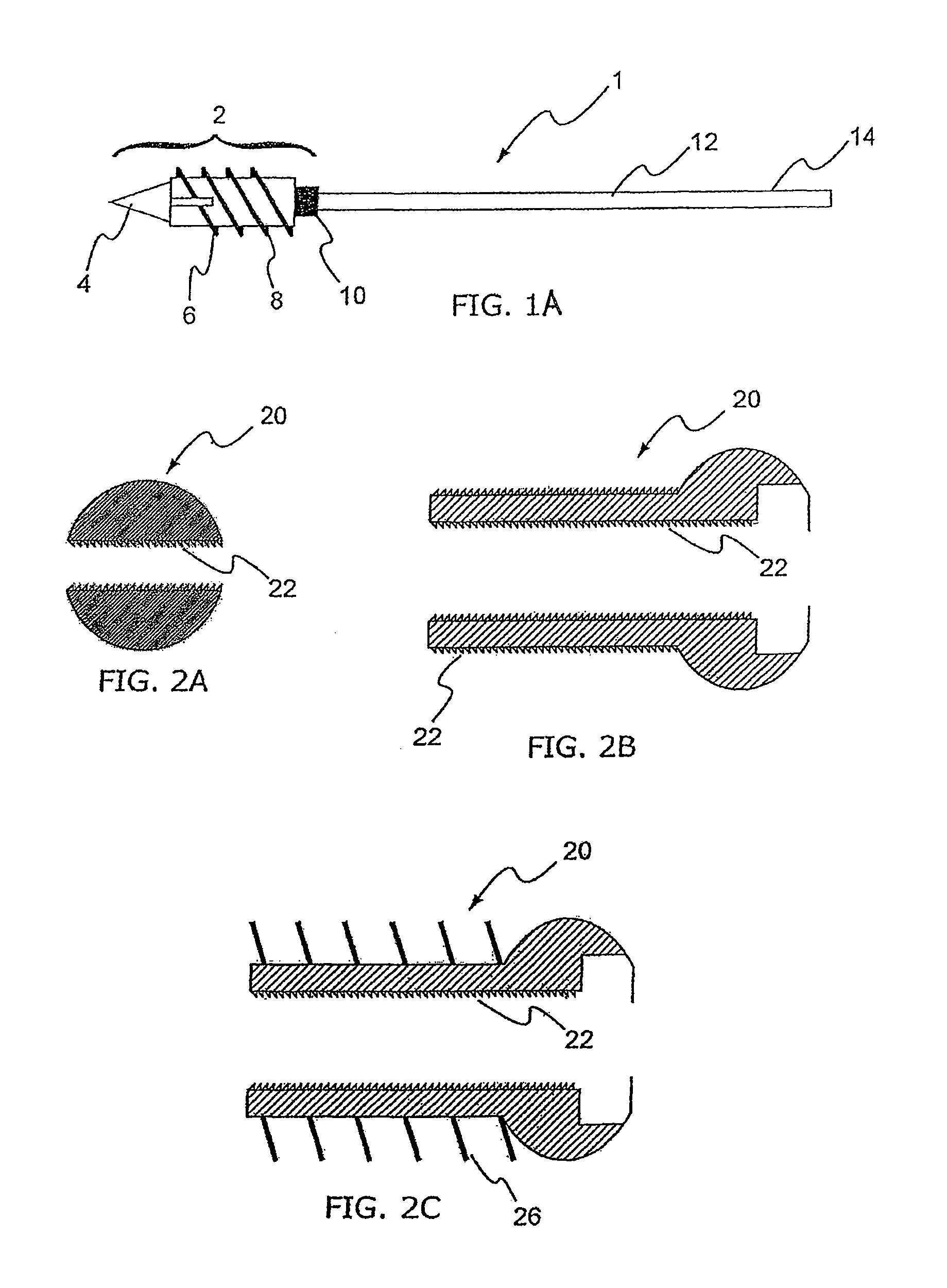

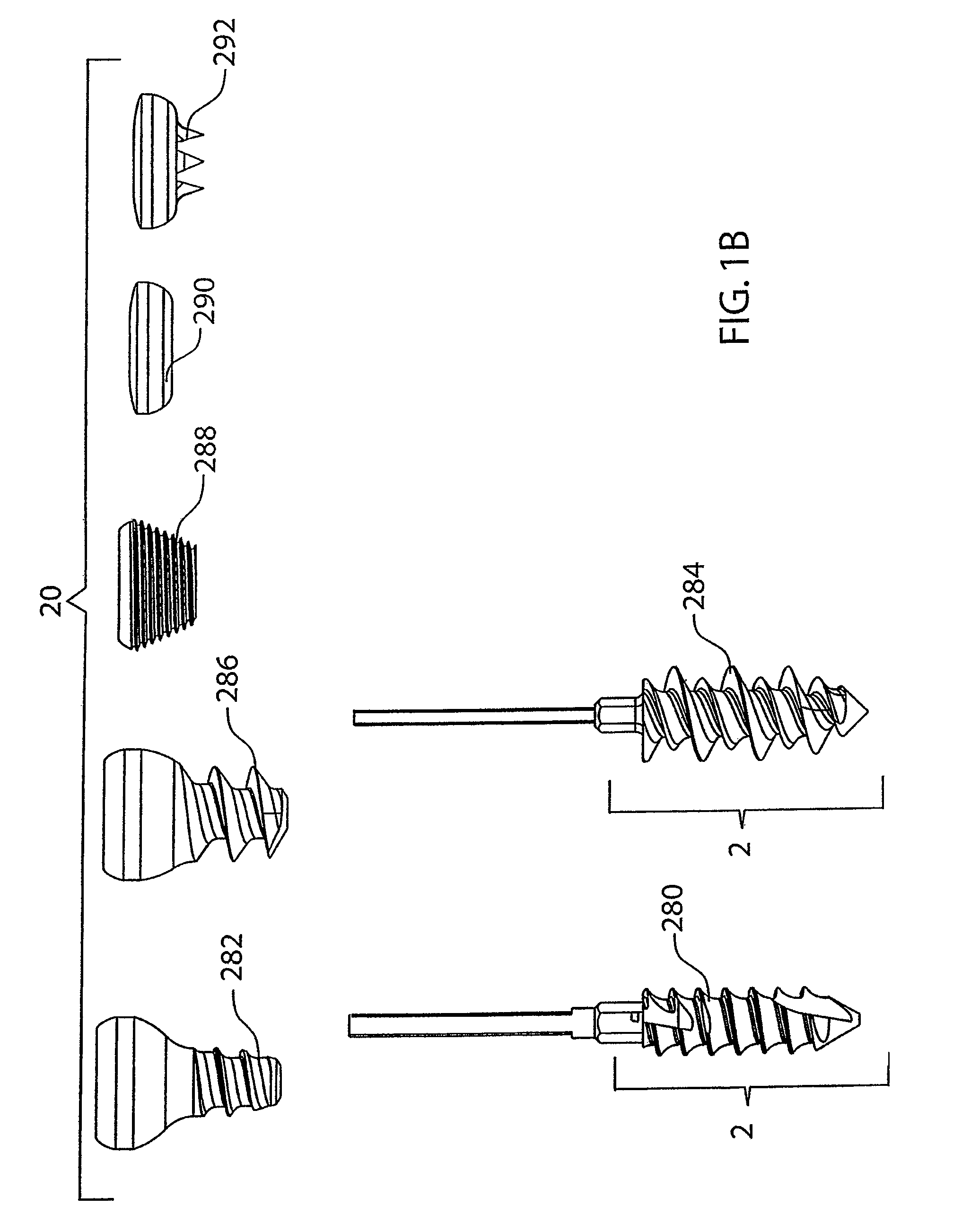

Cannulated bone screw system and method

ActiveUS20070260248A1Preventing and minimizingLittle strengthInternal osteosythesisJoint implantsDistal portionIliac screw

An improved bone screw is disclosed which includes a shaft with distal portion having a threaded surface thereon, a sleeve having an opening which receives the shaft such that the shaft is able to move within the sleeve without moving the sleeve. A compressive device may be incorporated between the sleeve and the proximal portion of the shaft such that the compressive device forces the shaft and sleeve towards each other, thereby maintaining the compressive load at the union of the fracture. As additional compression is exerted on the load from weight bearing, the force may be reduced, but the head of the sleeve is still substantially maintained against the lateral cortex.

Owner:ORTHOIP

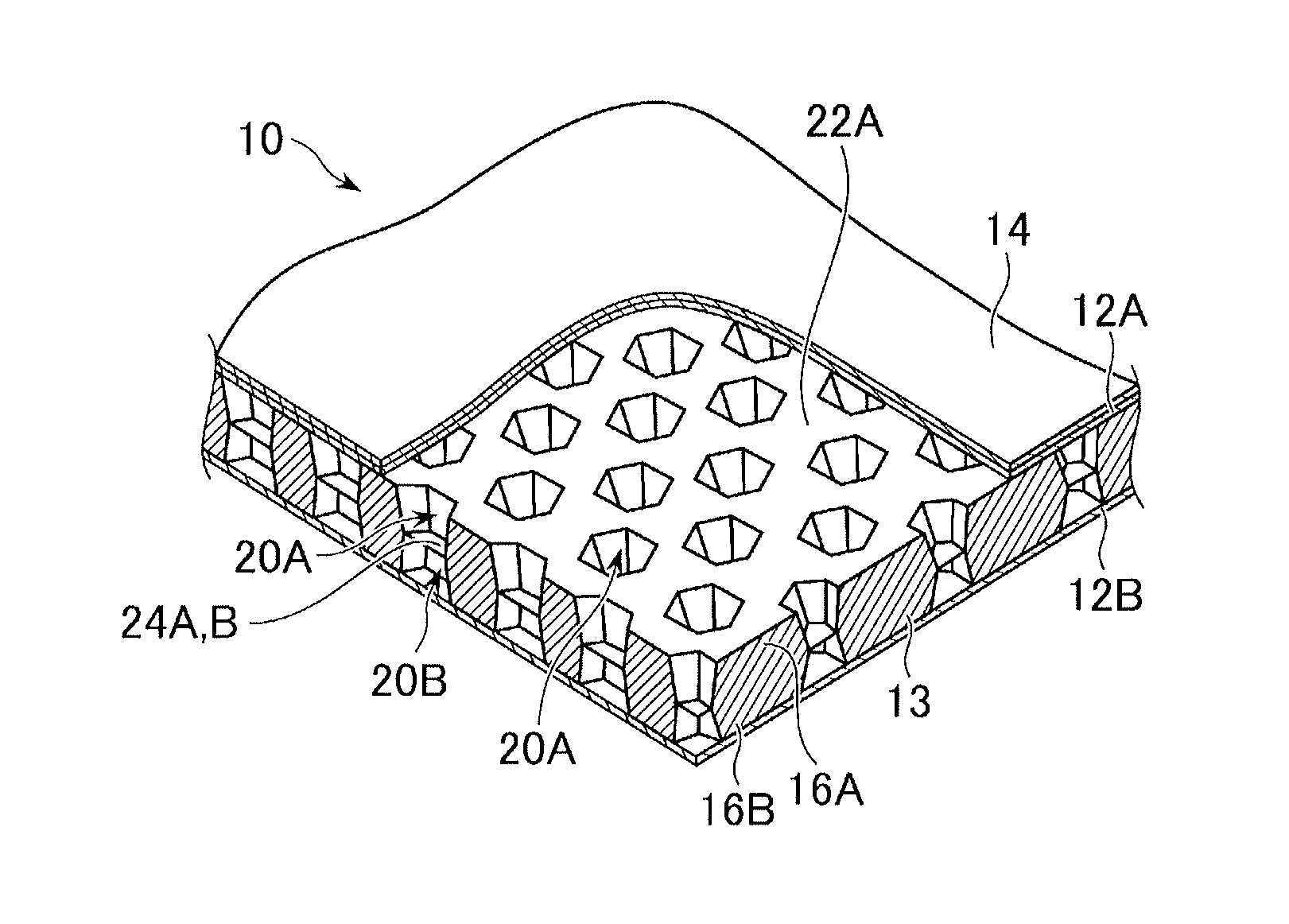

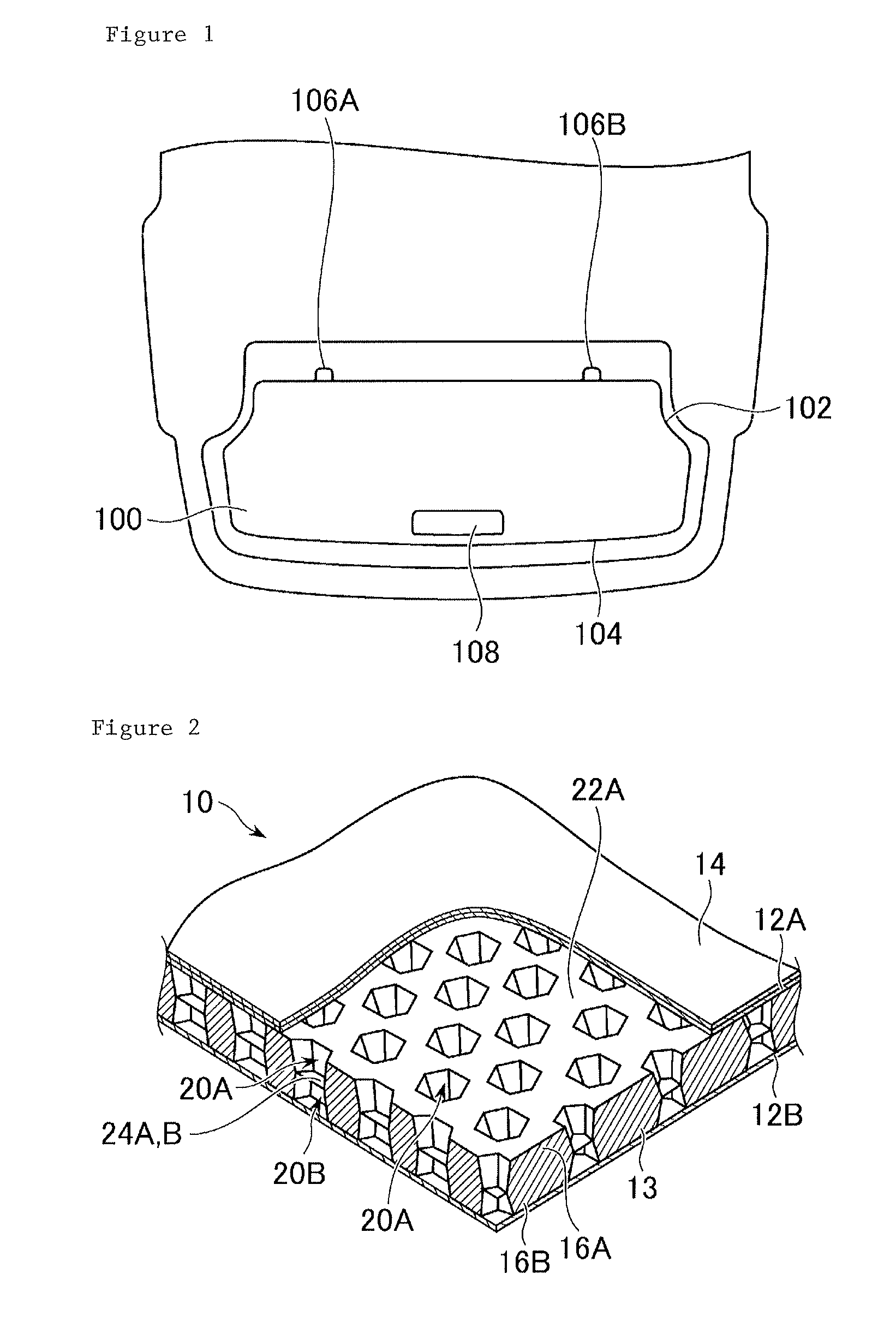

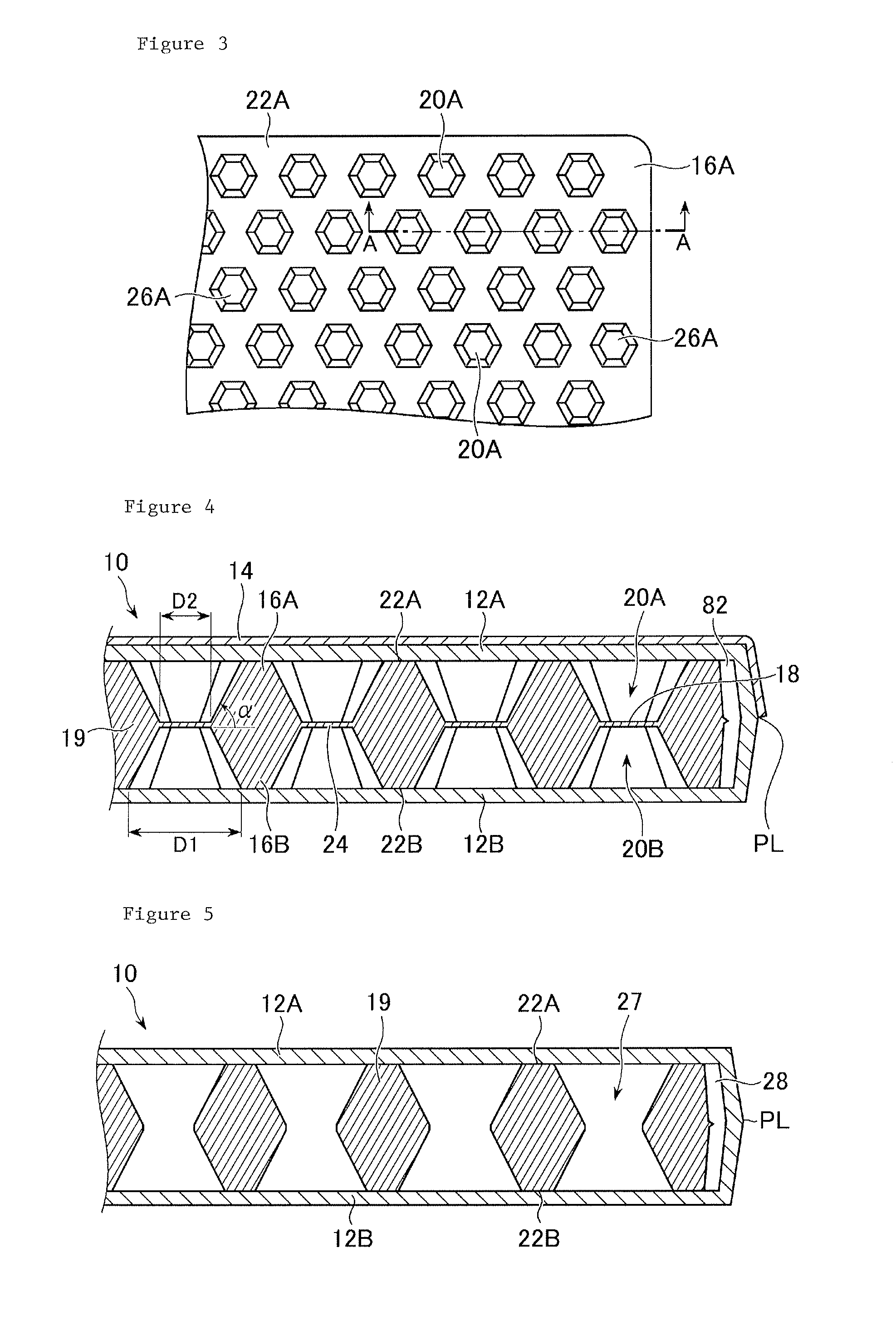

Sandwich panel, method of forming core material for sandwich panel, and method of forming sandwich panel

ActiveUS20110250384A1Increase weightLamination ancillary operationsSynthetic resin layered productsEngineeringSandwich panel

Owner:KYORAKU CO LTD

Tension-based non-pneumatic tire

ActiveUS20090283185A1Eliminating flat tireExtend tire lifeNon-inflatable tyresHigh resiliency wheelsEngineeringMechanical engineering

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner surface, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, oriented and comprised of a material that facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a hub and a footprint region where the tire contacts a surface may assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load. Since the tire is non-pneumatic, it may be easier to maintain and may have a longer life than standard pneumatic tires since it eliminates the possibility of blowouts, flat tires, or tires operating with low air pressure. By virtue of the portion of the tire in the footprint region not bearing a significant portion of the load, non-pneumatic tire may also exhibit a more comfortable ride subject to less noise and vibration and improved handling capabilities.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Bone screw system and method

ActiveUS8828067B2Easy to fixPreventing and minimizingSuture equipmentsInternal osteosythesisDistal portionEngineering

An improved bone screw is disclosed which includes a shaft with distal portion having a threaded surface thereon, a sleeve having an opening which receives the shaft such that the shaft is able to move within the sleeve without moving the sleeve. A compressive device may be incorporated between the sleeve and the proximal portion of the shaft such that the compressive device forces the shaft and sleeve towards at least a portion each other, thereby maintaining the compressive load at the union of the fracture. As additional compression is exerted on the load from weight bearing, the force may be reduced, but the head of the sleeve is still substantially maintained against the lateral cortex.

Owner:ORTHOIP

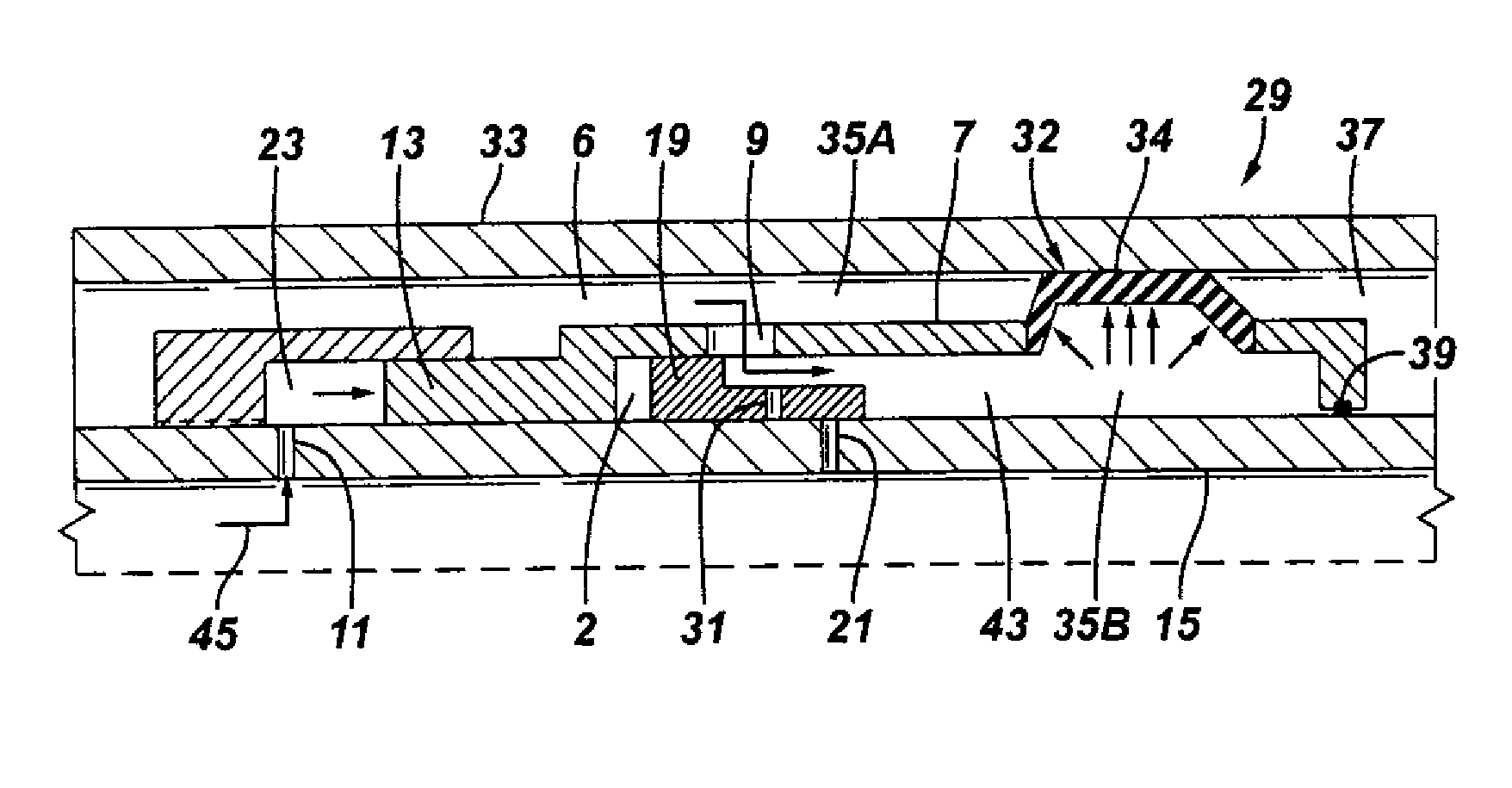

Zonal isolation tools and methods of use

Zonal isolation tools and methods of using same are described. The zonal isolation tools include a wellbore sealing member expandable by fluid pressure to contact a wellbore over an initial contact area, an inflation valve open during expansion of the sealing member to the initial contact area and closed upon the fluid pressure reaching a predetermined setting, a vent between the sealing member and a wellbore annulus adapted to open after the inflation valve is closed, and a compressive load imparted to the sealing member via a linear piston to achieve a sealing point at the leading edge of the sealing member. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:SCHLUMBERGER TECH CORP

Support system for a composite airfoil in a turbine engine

ActiveUS7326030B2Improve abilitiesLess likely can be damagedPropellersPump componentsSupporting systemTurbine

A turbine airfoil support system for coupling together a turbine airfoil formed from two or more components, wherein the support system is particularly suited for use with a composite airfoil. In at least one embodiment, the turbine airfoil support system may be configured to attach shrouds to both ends of an airfoil and to maintain a compressive load on those shrouds while the airfoil is positioned in a turbine engine. Application of the compressive load to the airfoil increases the airfoil's ability to withstand tensile forces encountered during turbine engine operation.

Owner:SIEMENS ENERGY INC

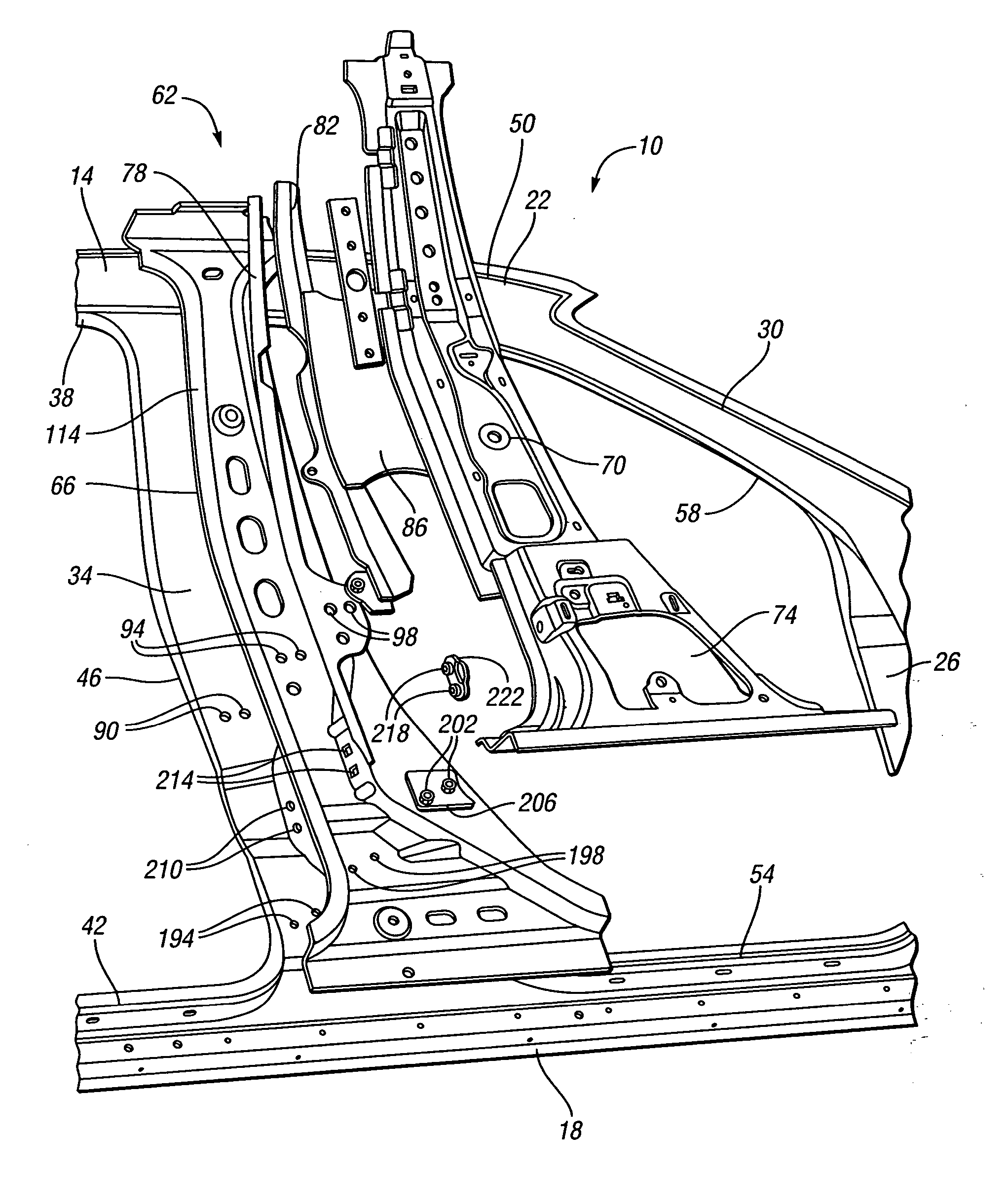

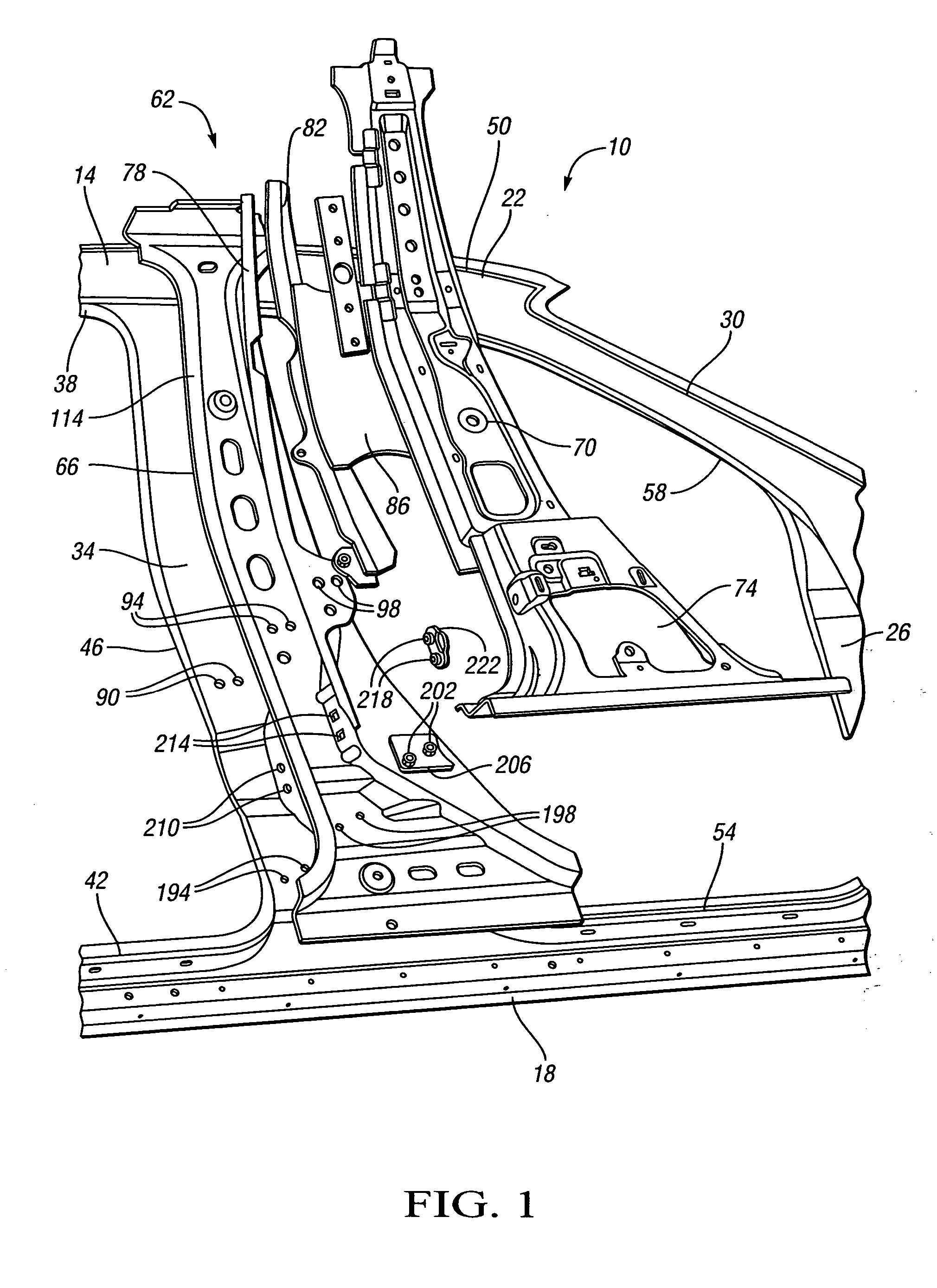

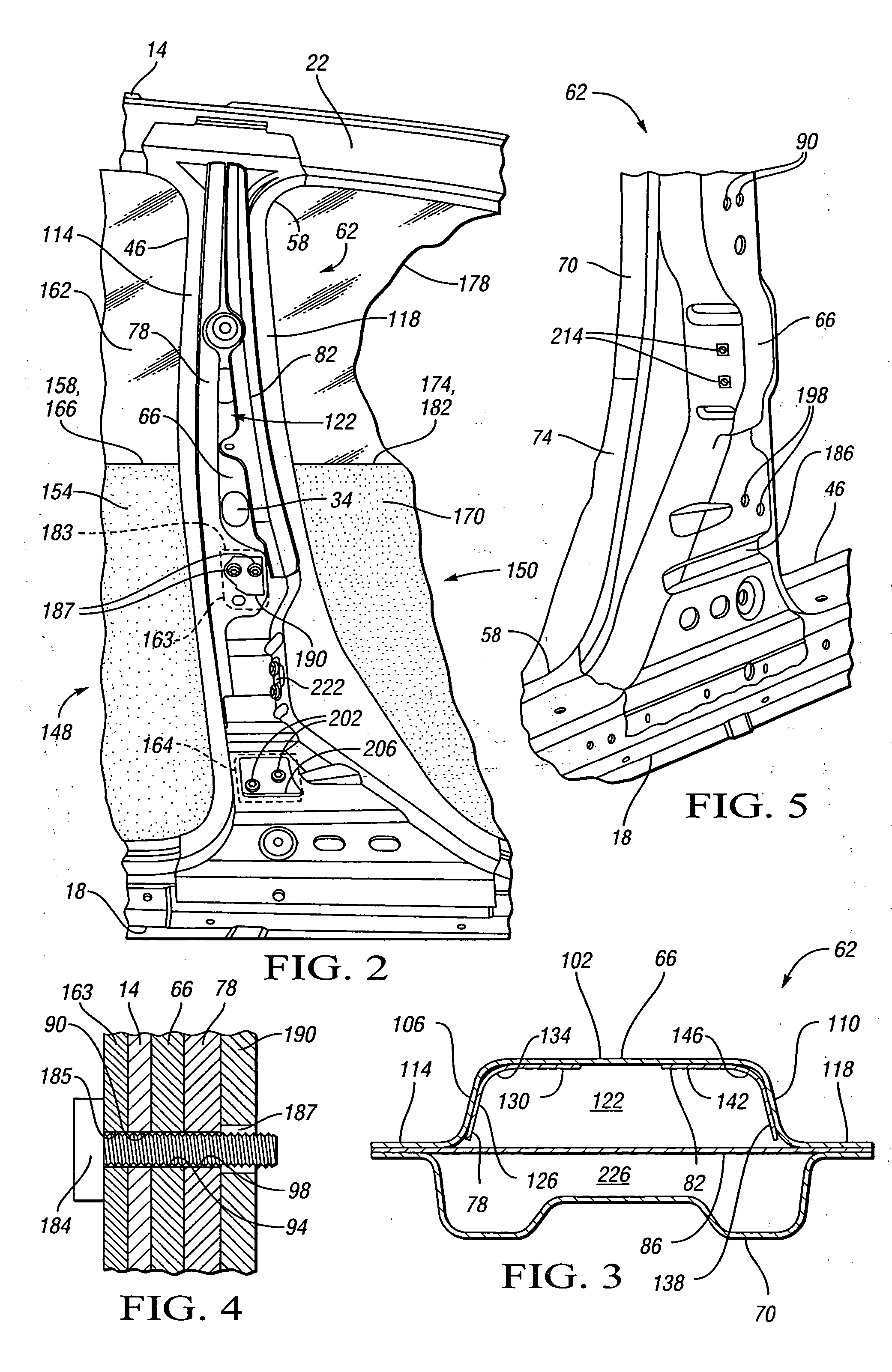

Vehicle center pillar structure

Owner:GM GLOBAL TECH OPERATIONS LLC

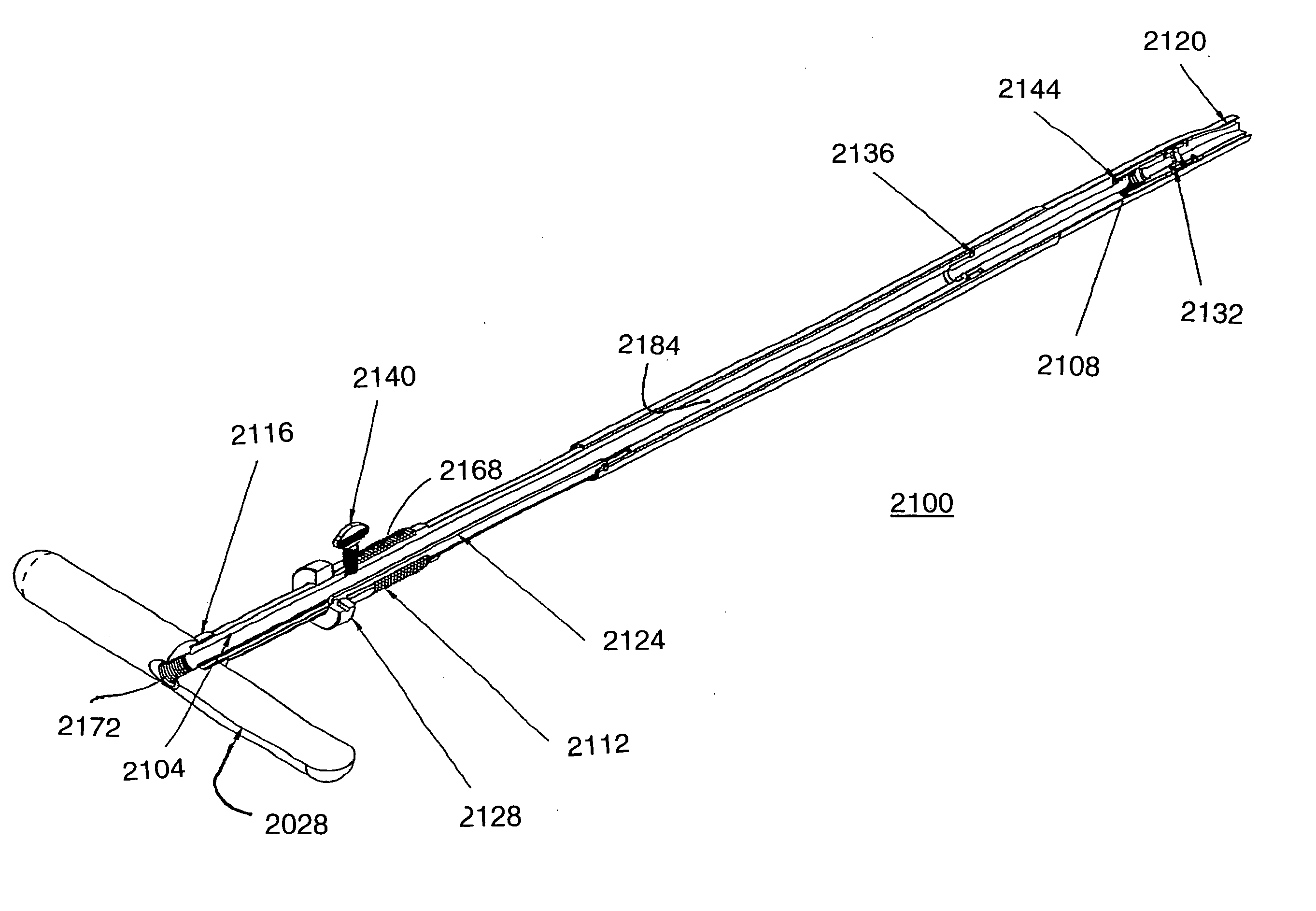

Methods and tools for delivery of spinal motion preservation assemblies

InactiveUS20070167951A1Dampen compressionImprove distributionInternal osteosythesisCannulasAnesthesiaMembrane configuration

Spinal motion preservation assemblies adapted for use in a spinal motion segment are disclosed including the process for delivering and assembling the spinal motion preservation assemblies in the spinal motion segment via an axial channel created with a trans-sacral approach. Many of the spinal motion preservation assemblies make use of a dual pivot. A number of different embodiments of spinal motion preservation assemblies are disclosed which include at least one component adapted for elastic deformation under compressive loads. The disclosed mobility preservation assemblies provide for dynamic stabilization of the spinal motion segment. Other variations and implementations of the teachings are disclosed, including the sheathed delivery of membranes in order to protect the membranes before and during deployment.

Owner:MIS IP HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com