Patents

Literature

1849results about "Non-inflatable tyres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

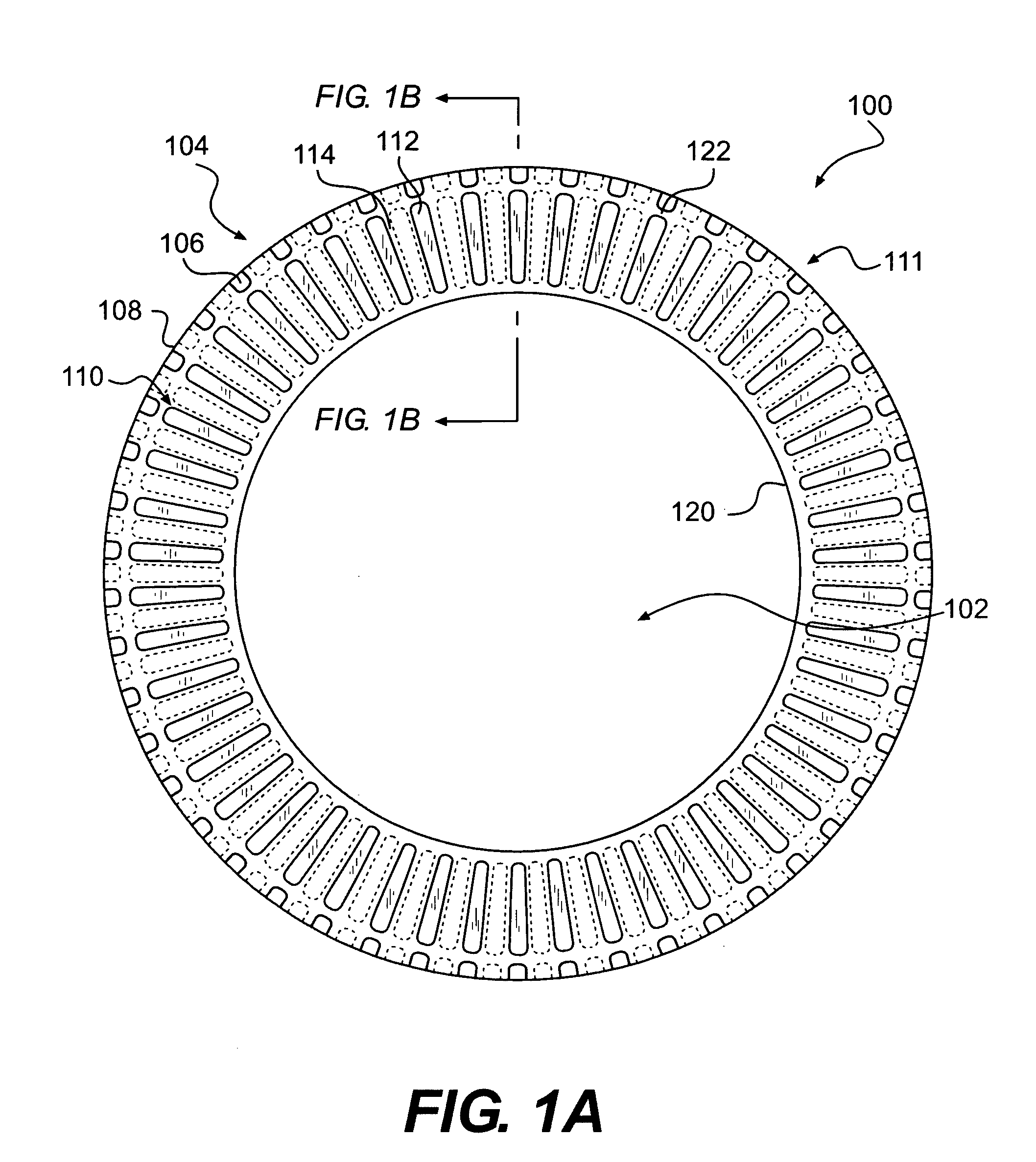

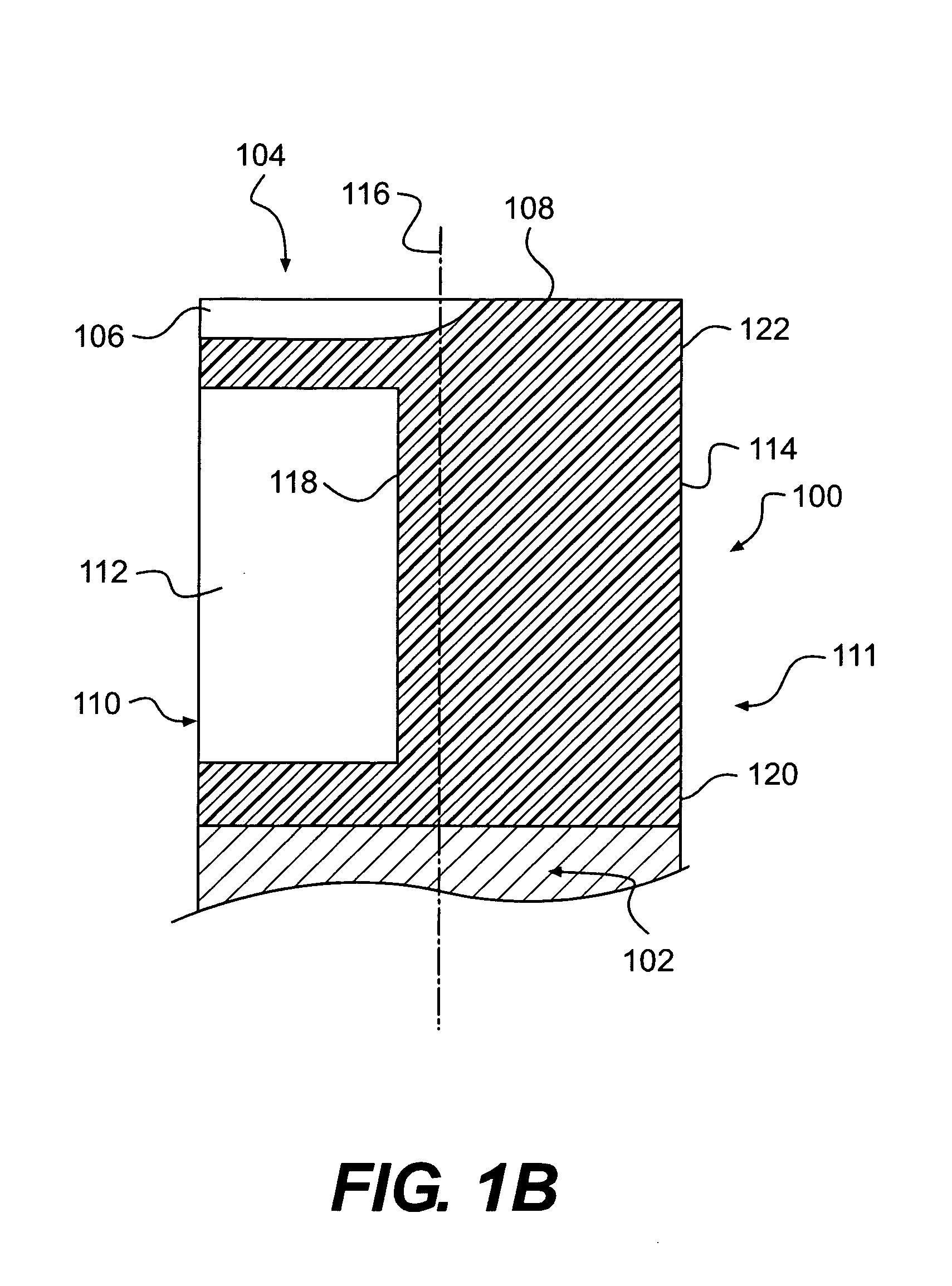

Non-pneumatic tire

InactiveUS7201194B2Supporting massHigh effective radial stiffness in tensionNon-inflatable tyresPneumatic tyre reinforcementsElastomerShear modulus

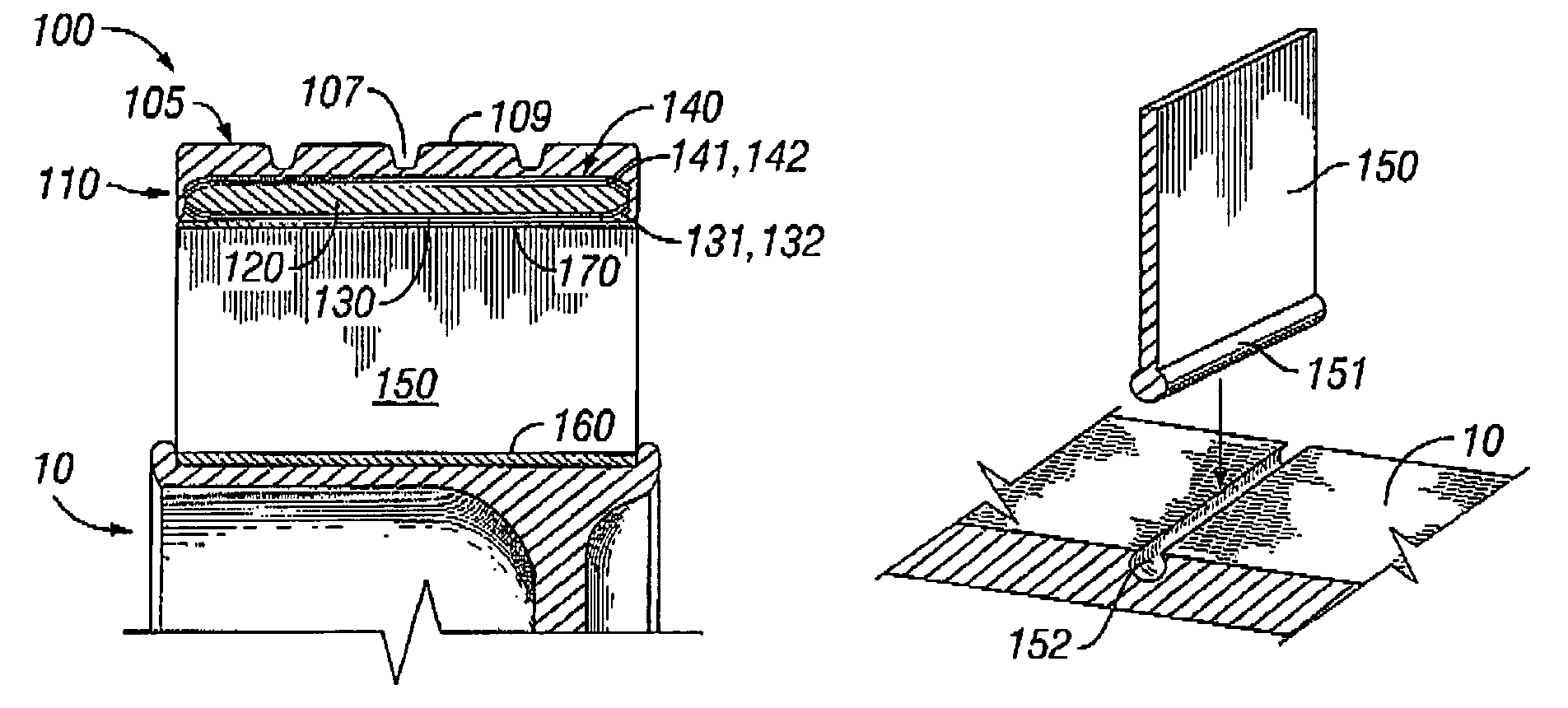

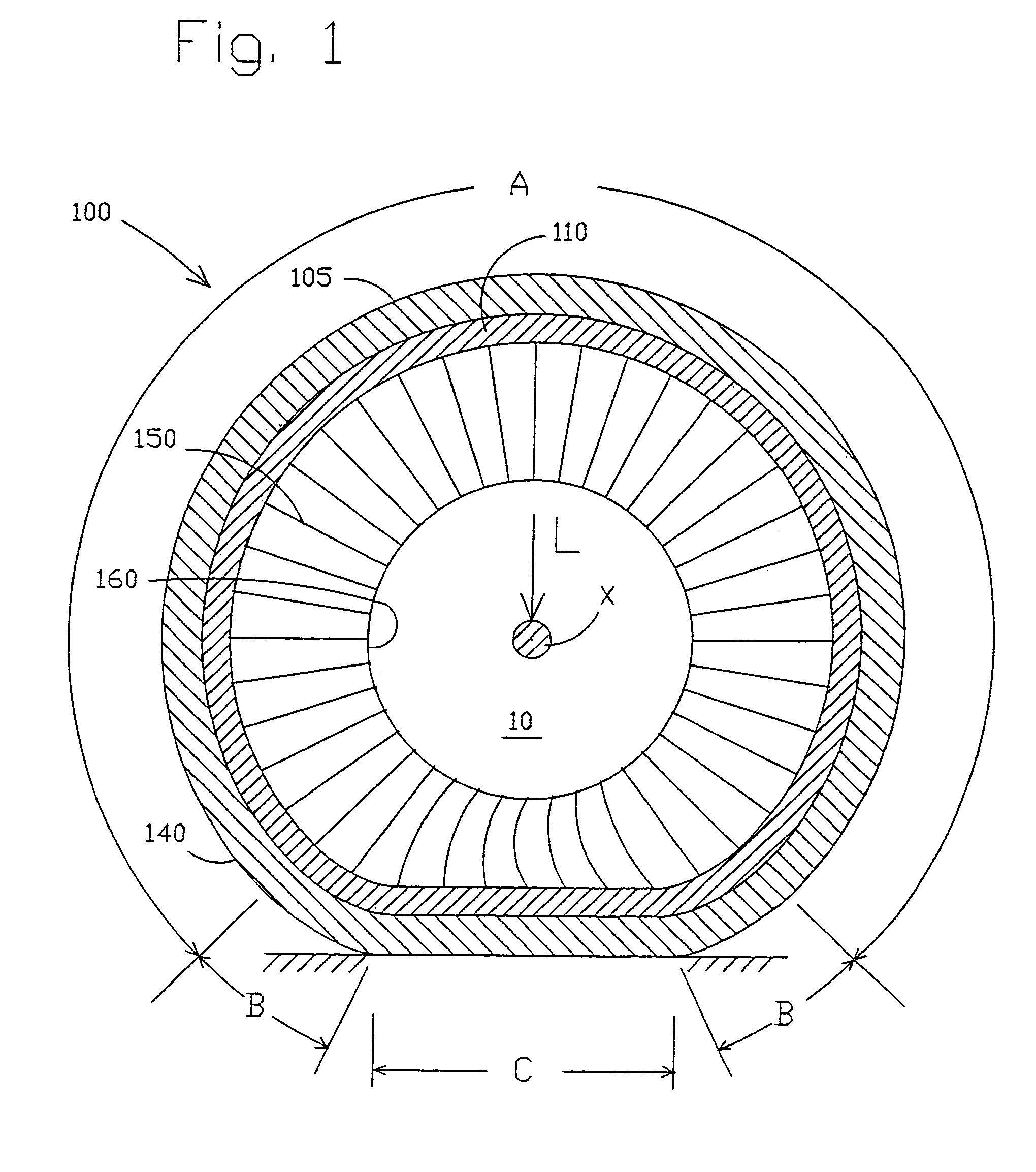

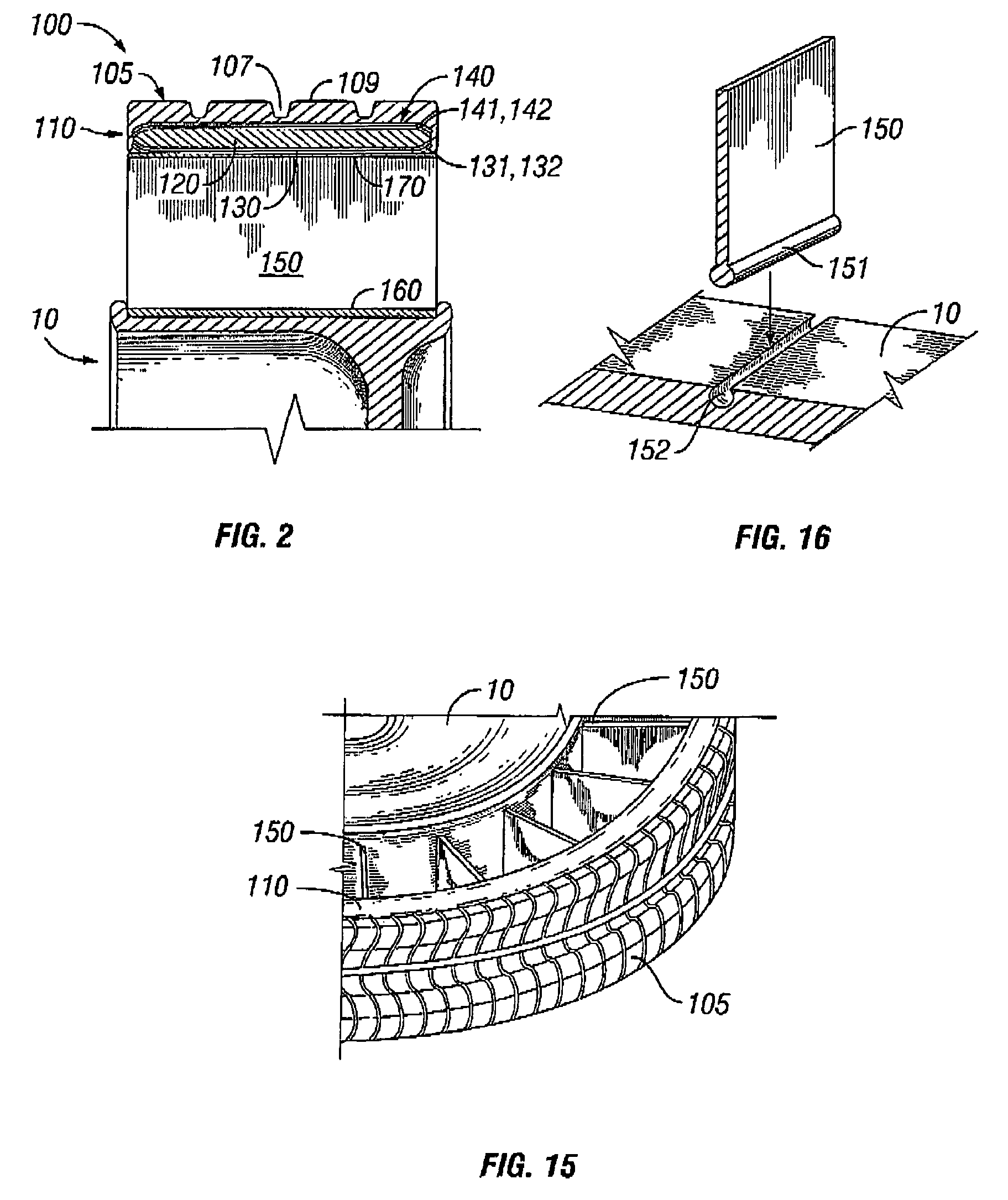

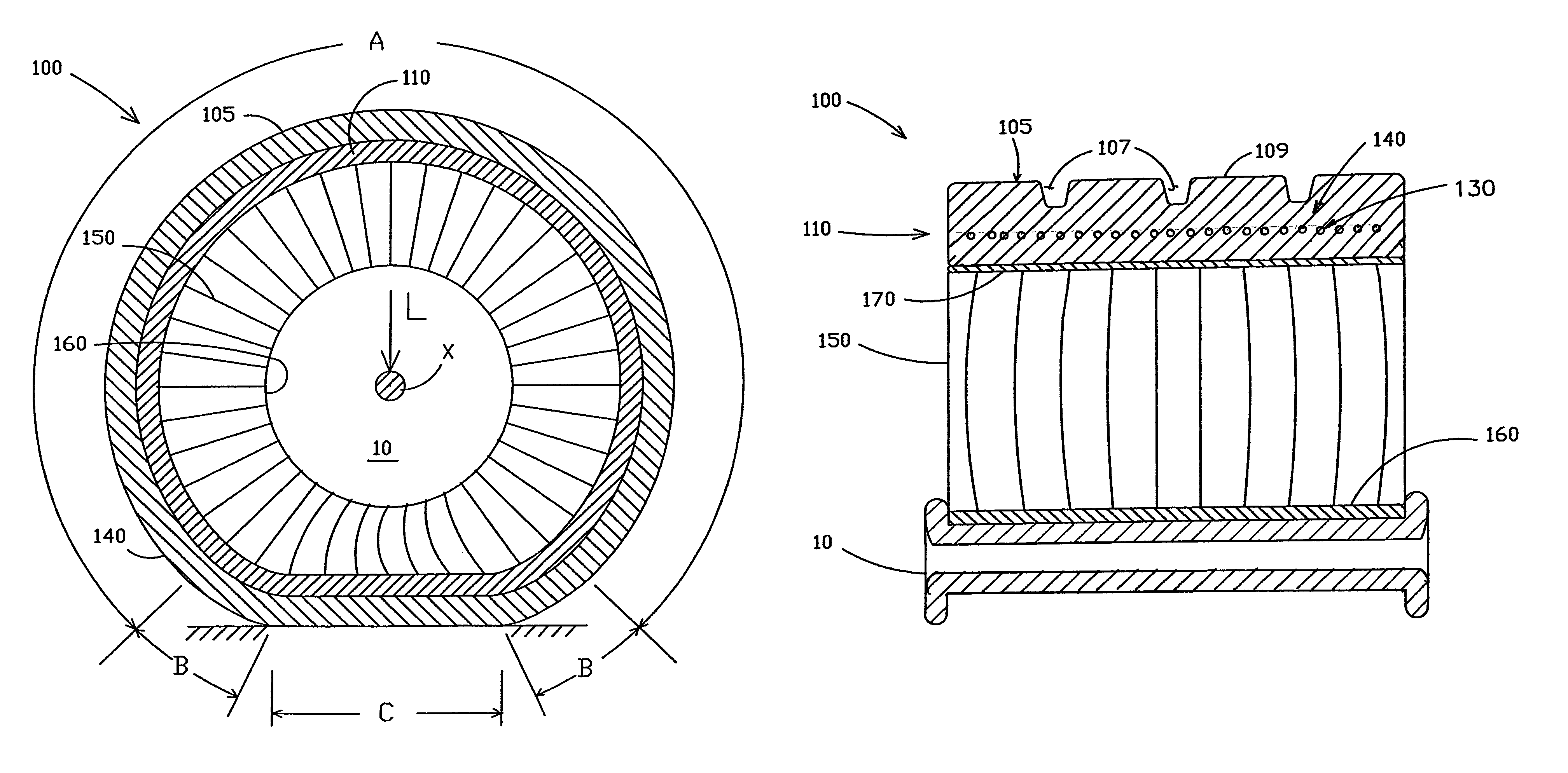

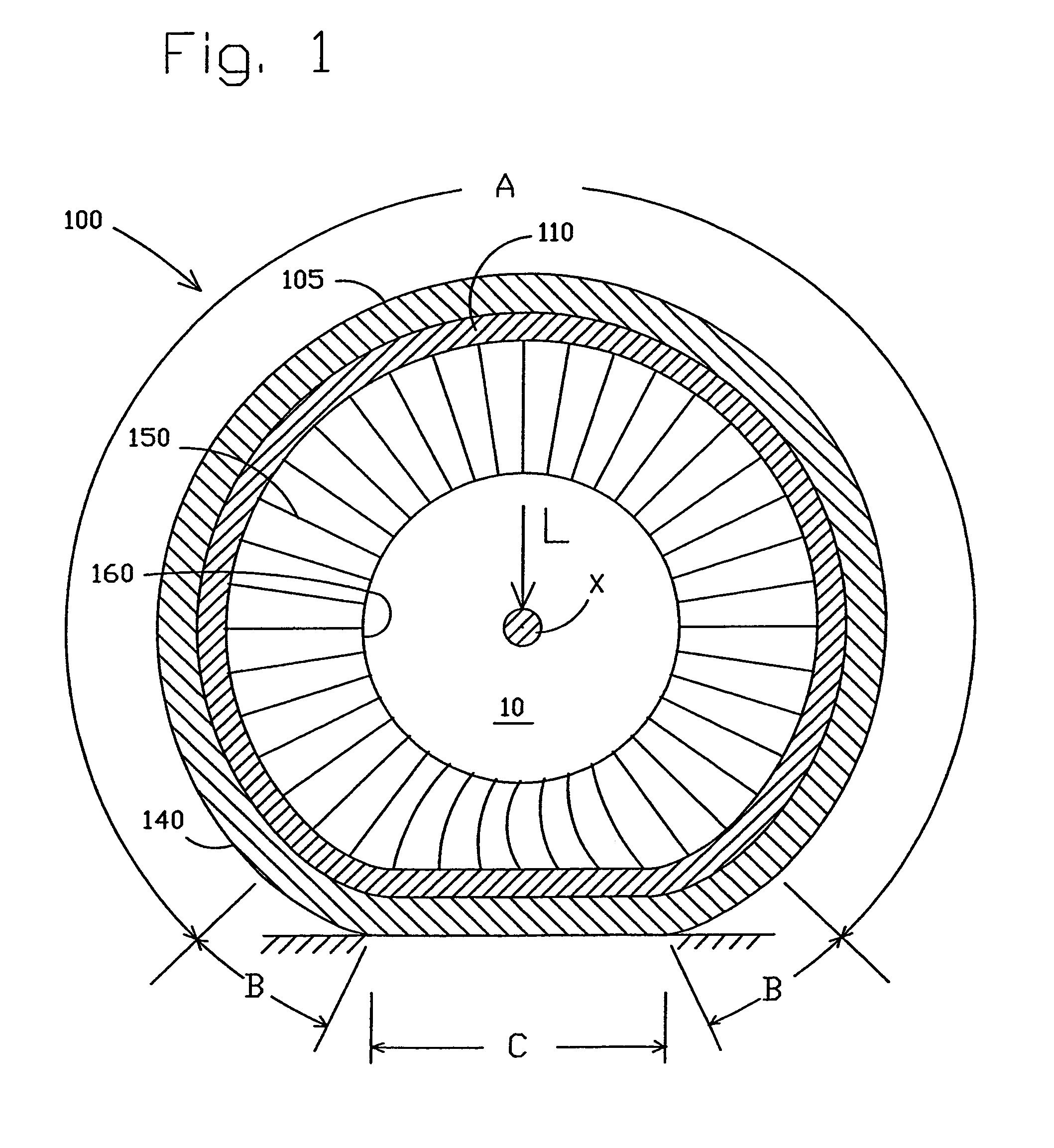

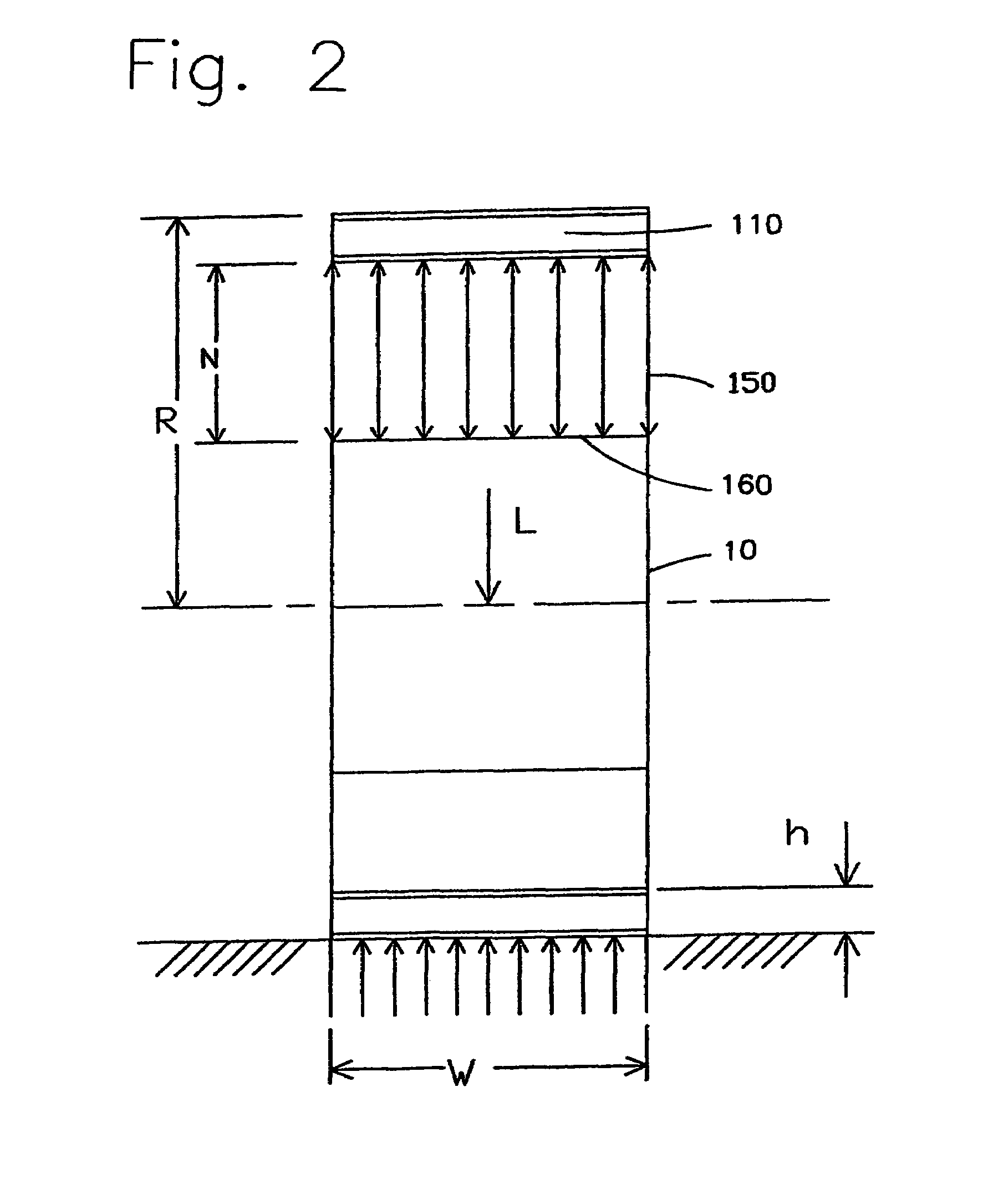

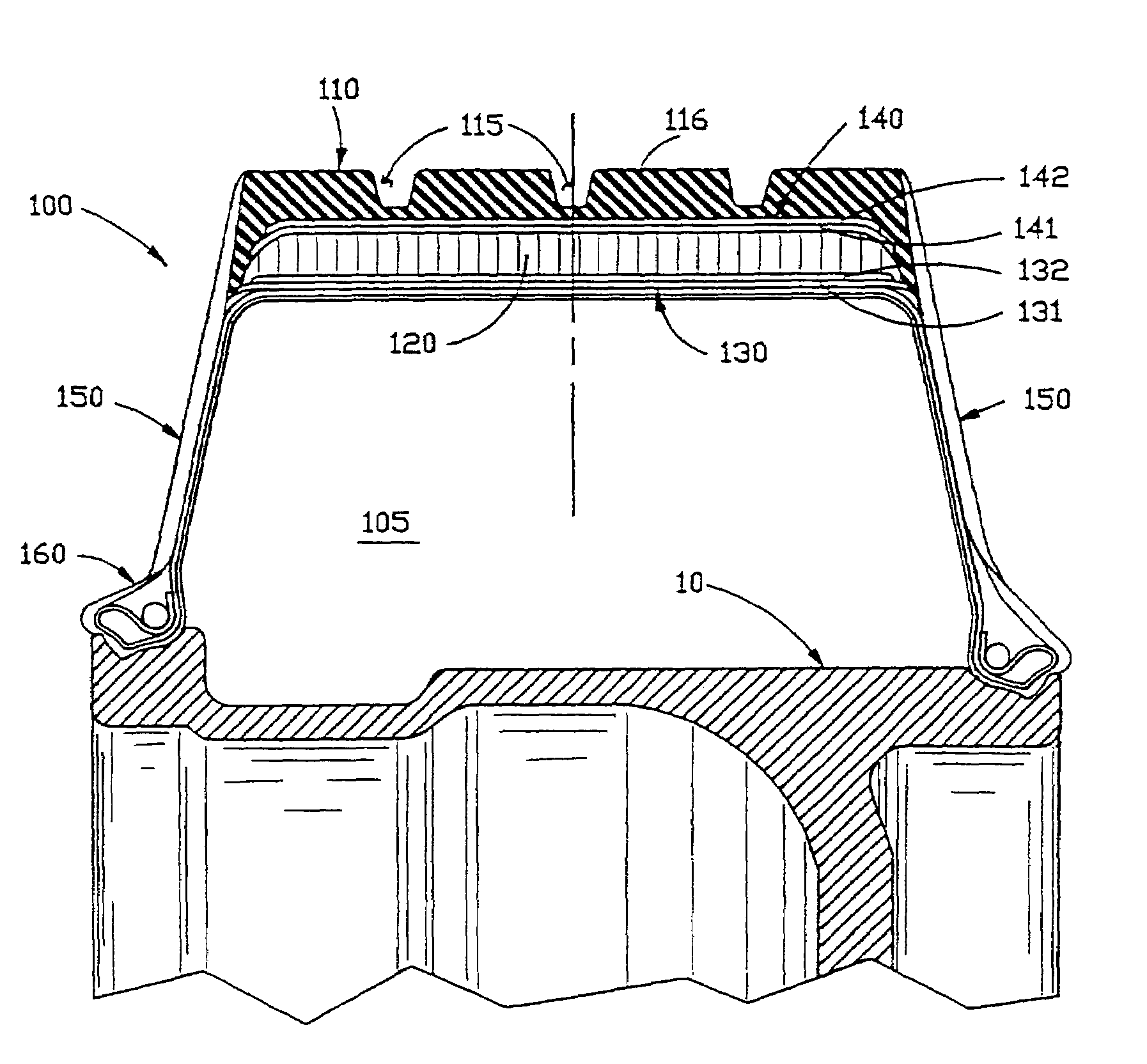

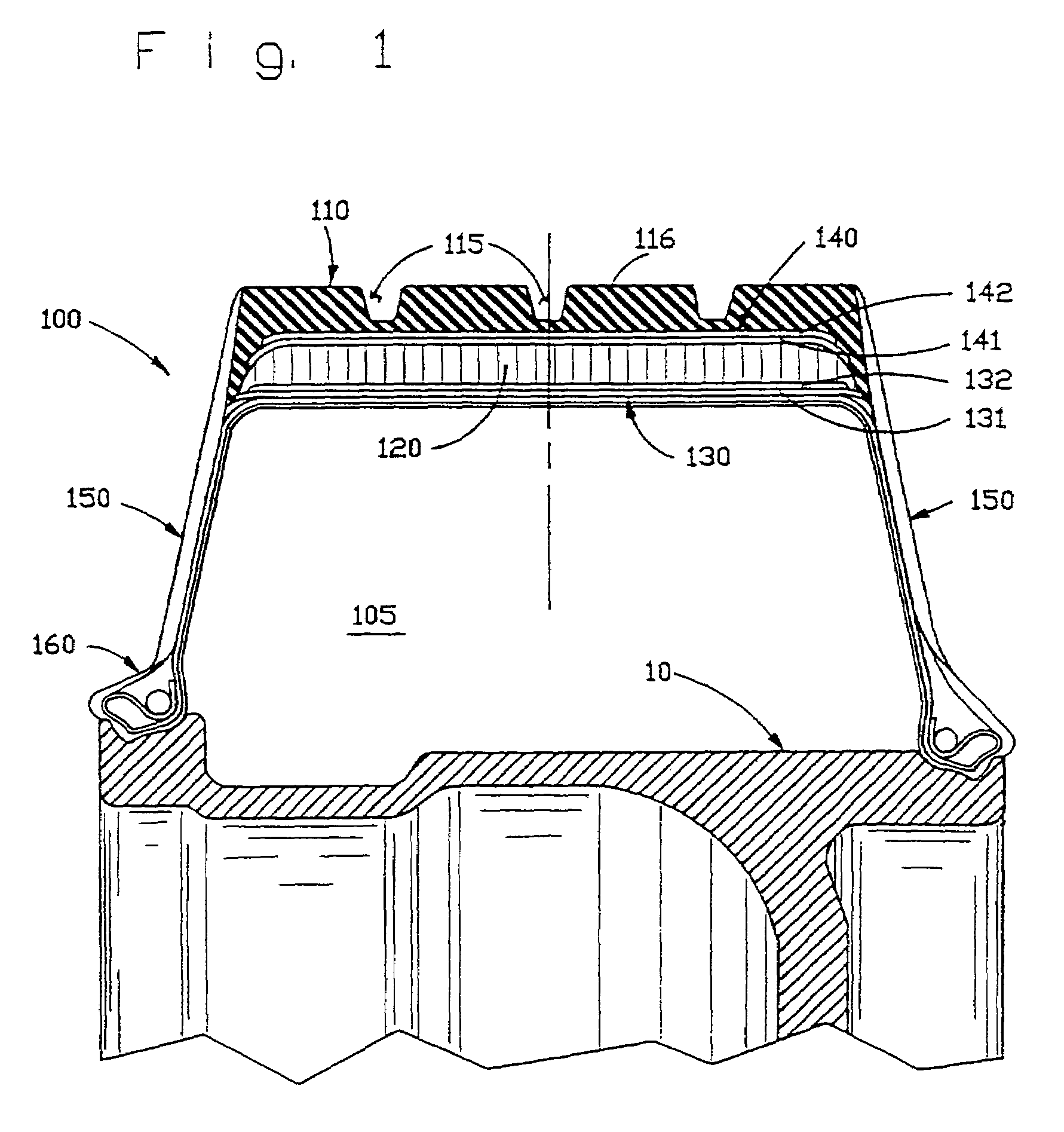

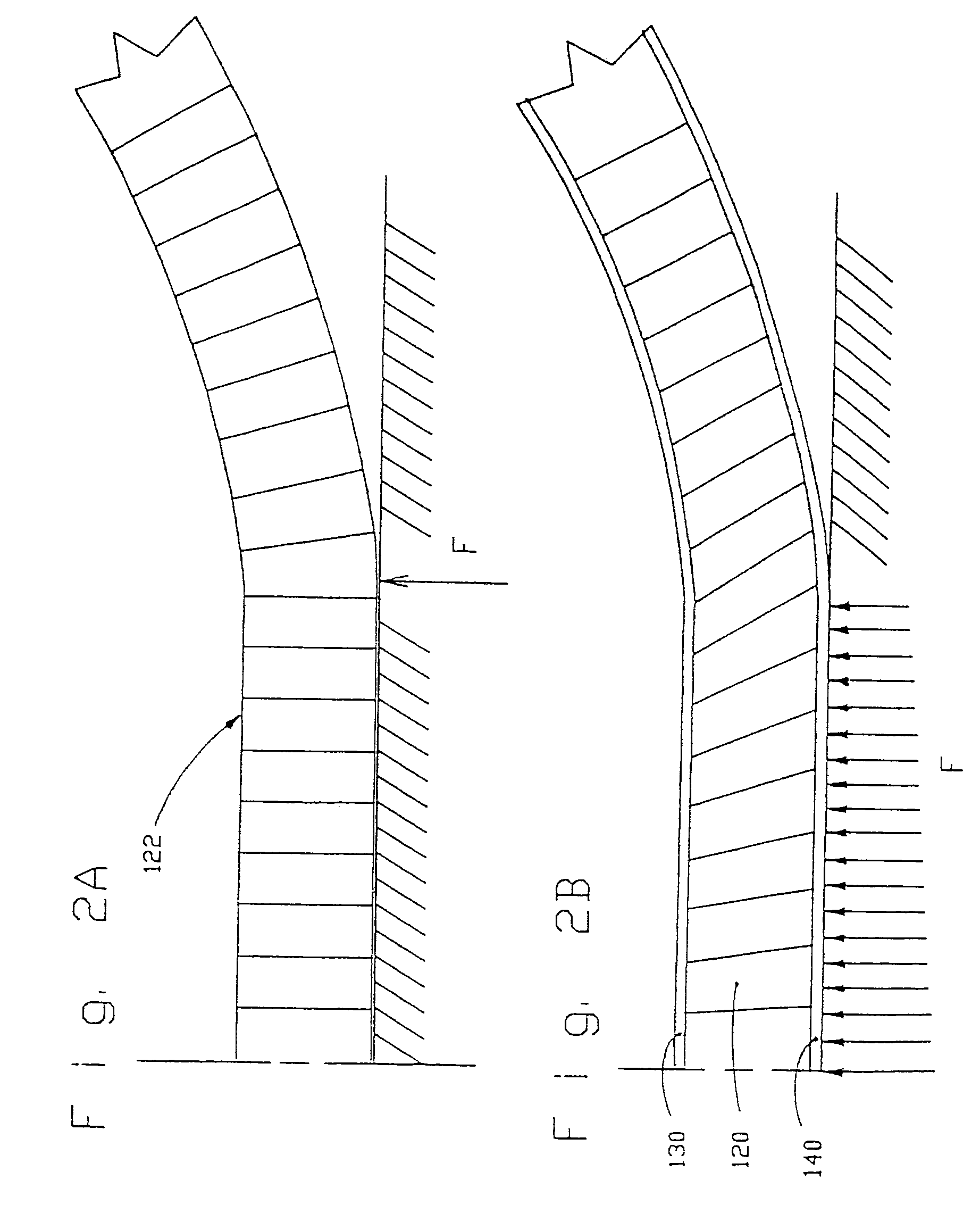

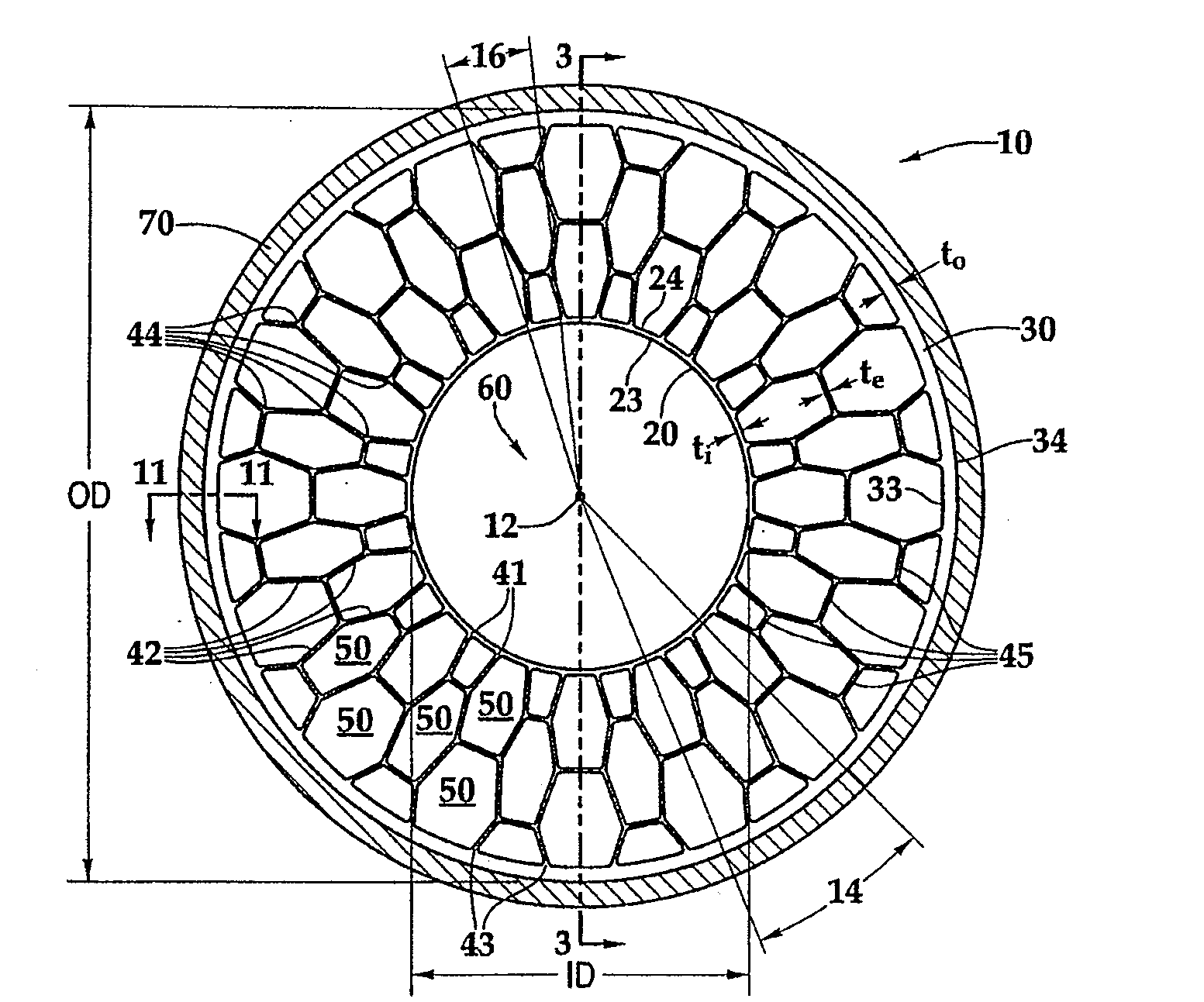

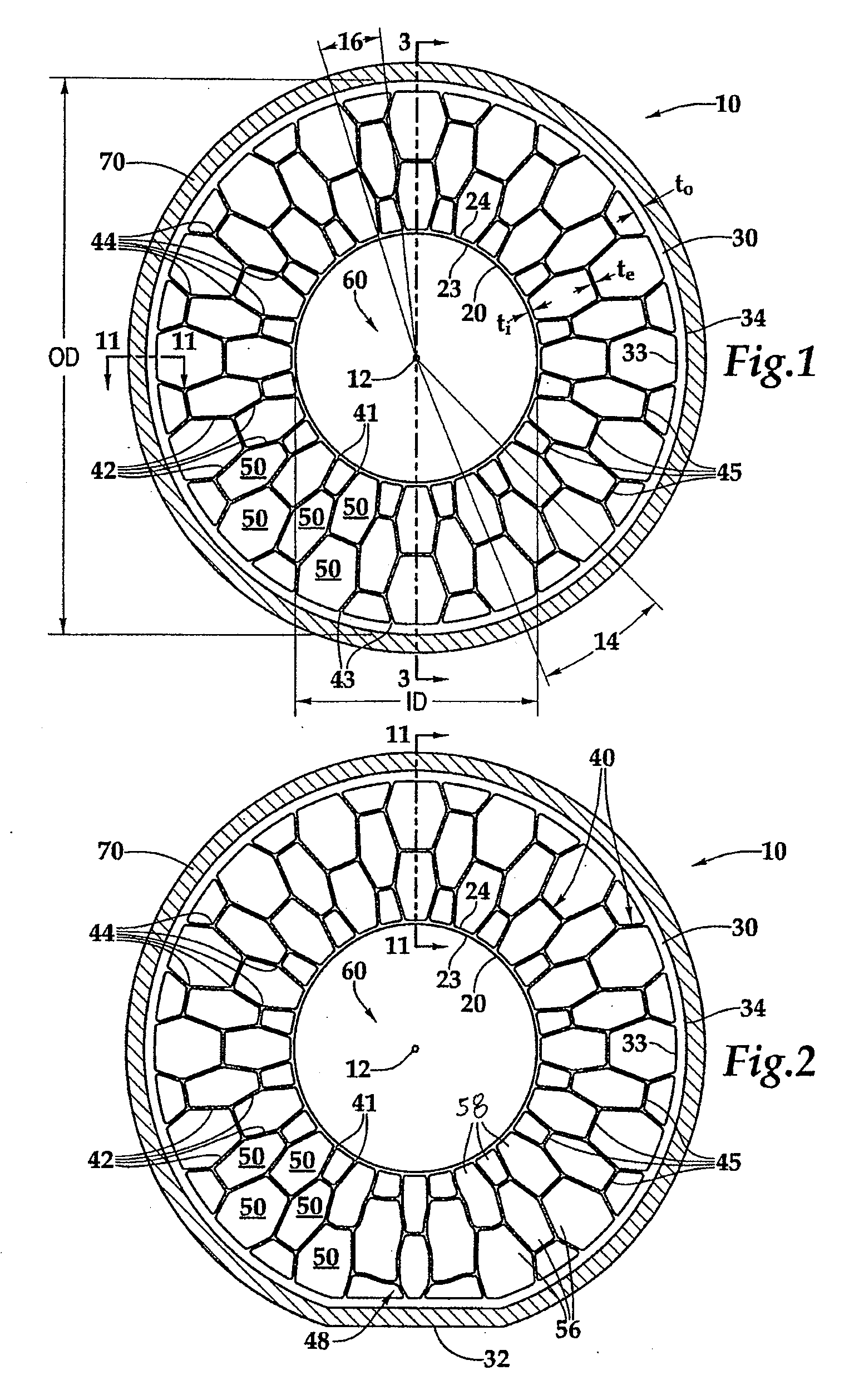

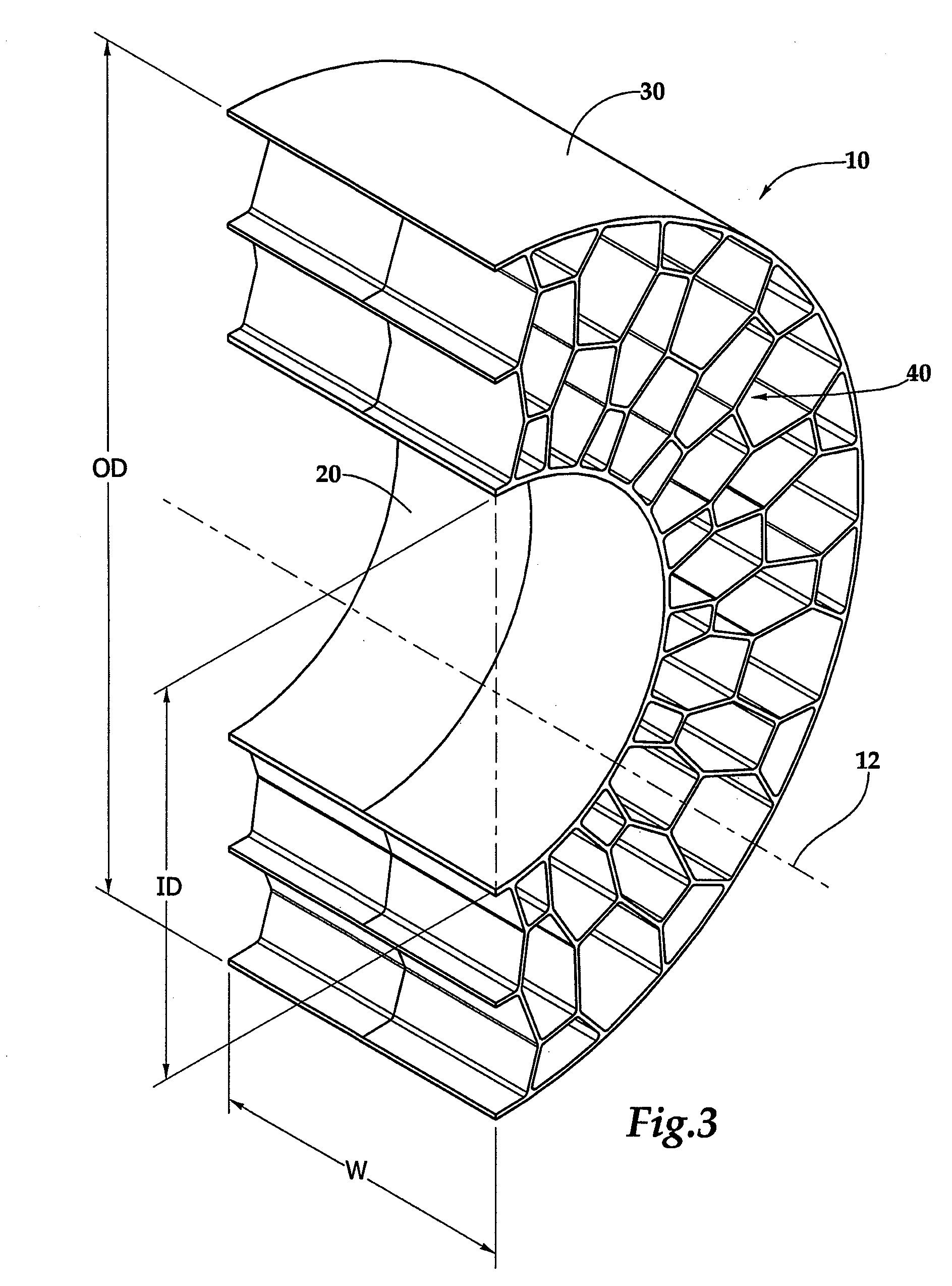

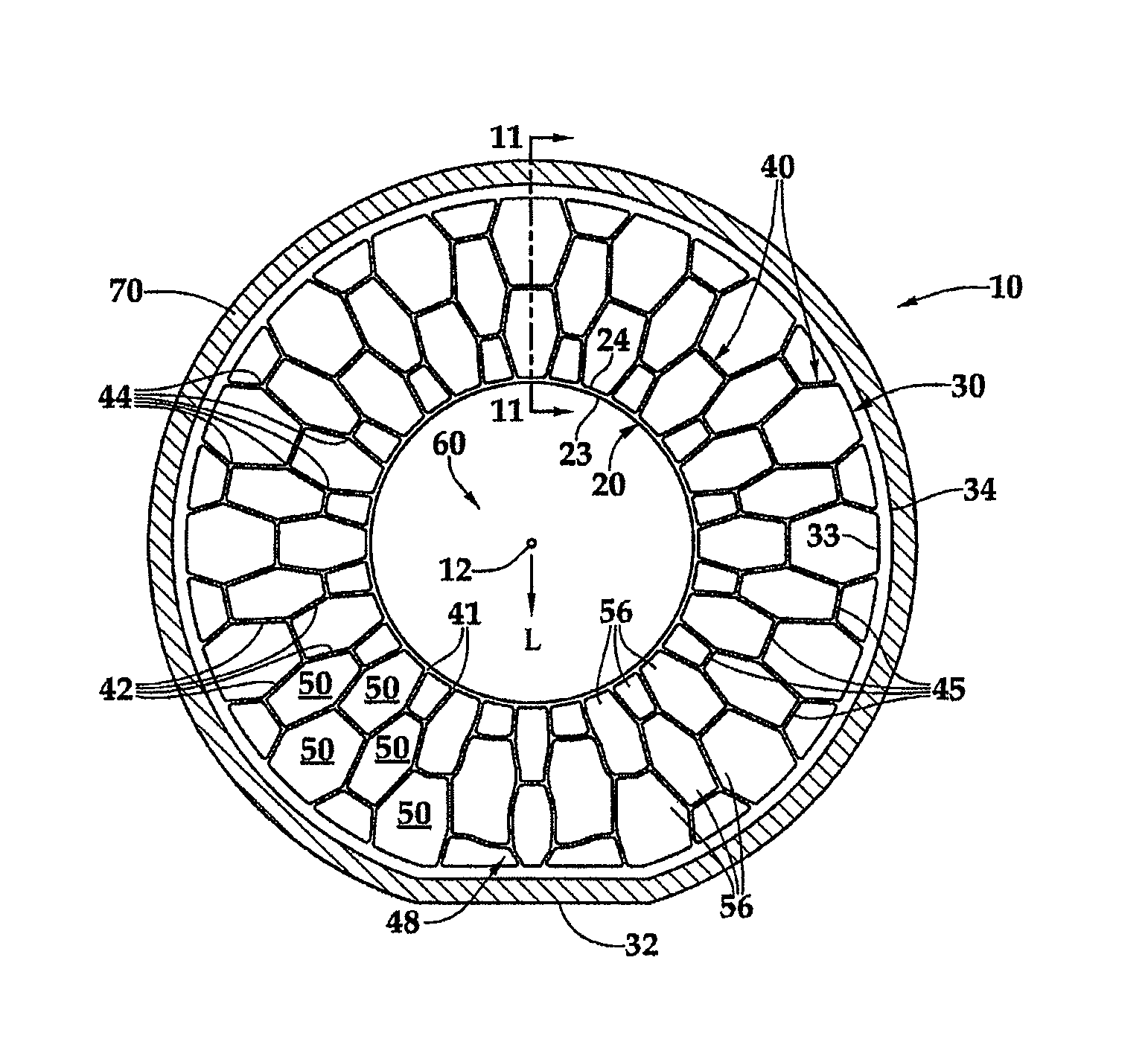

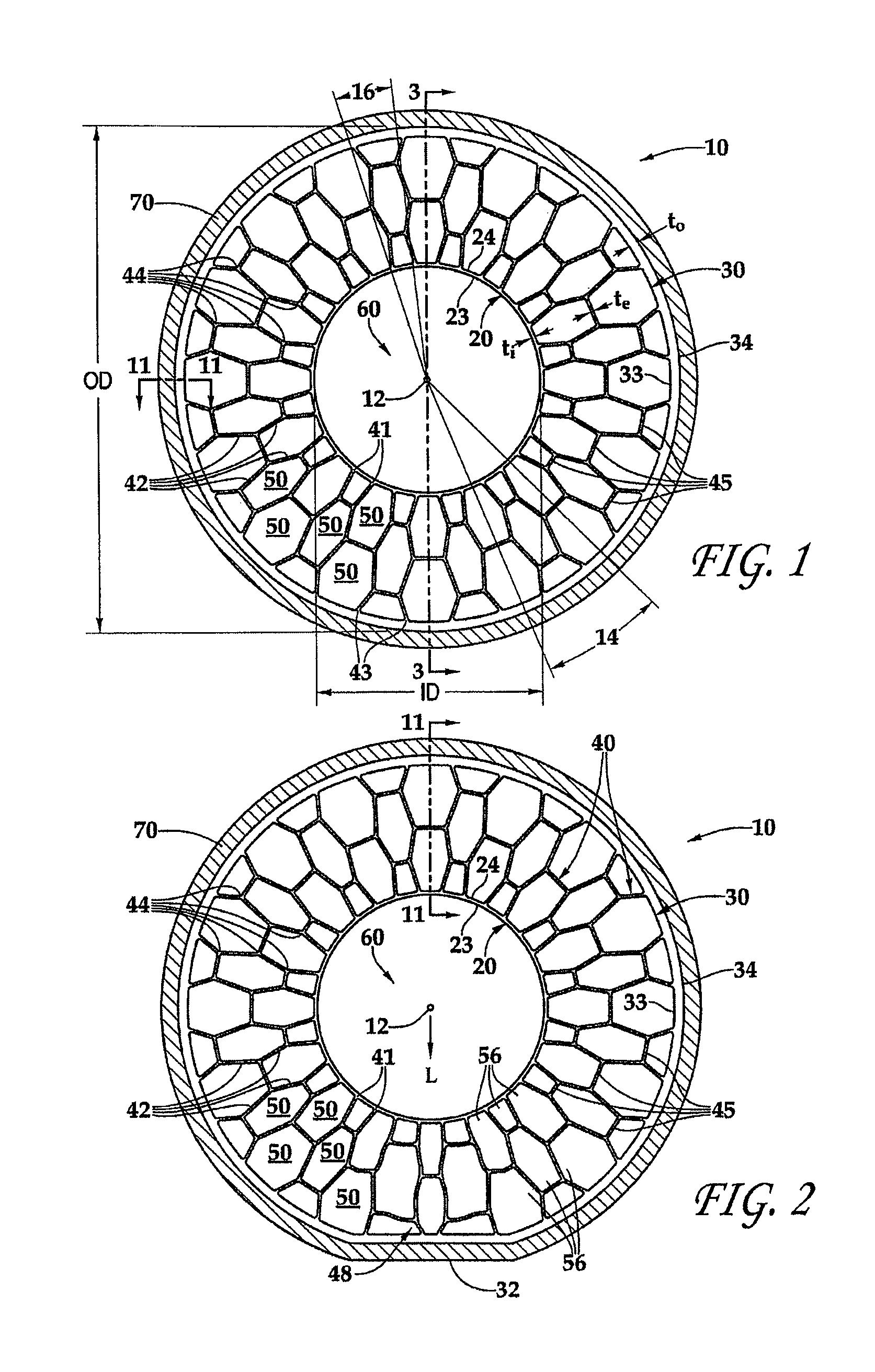

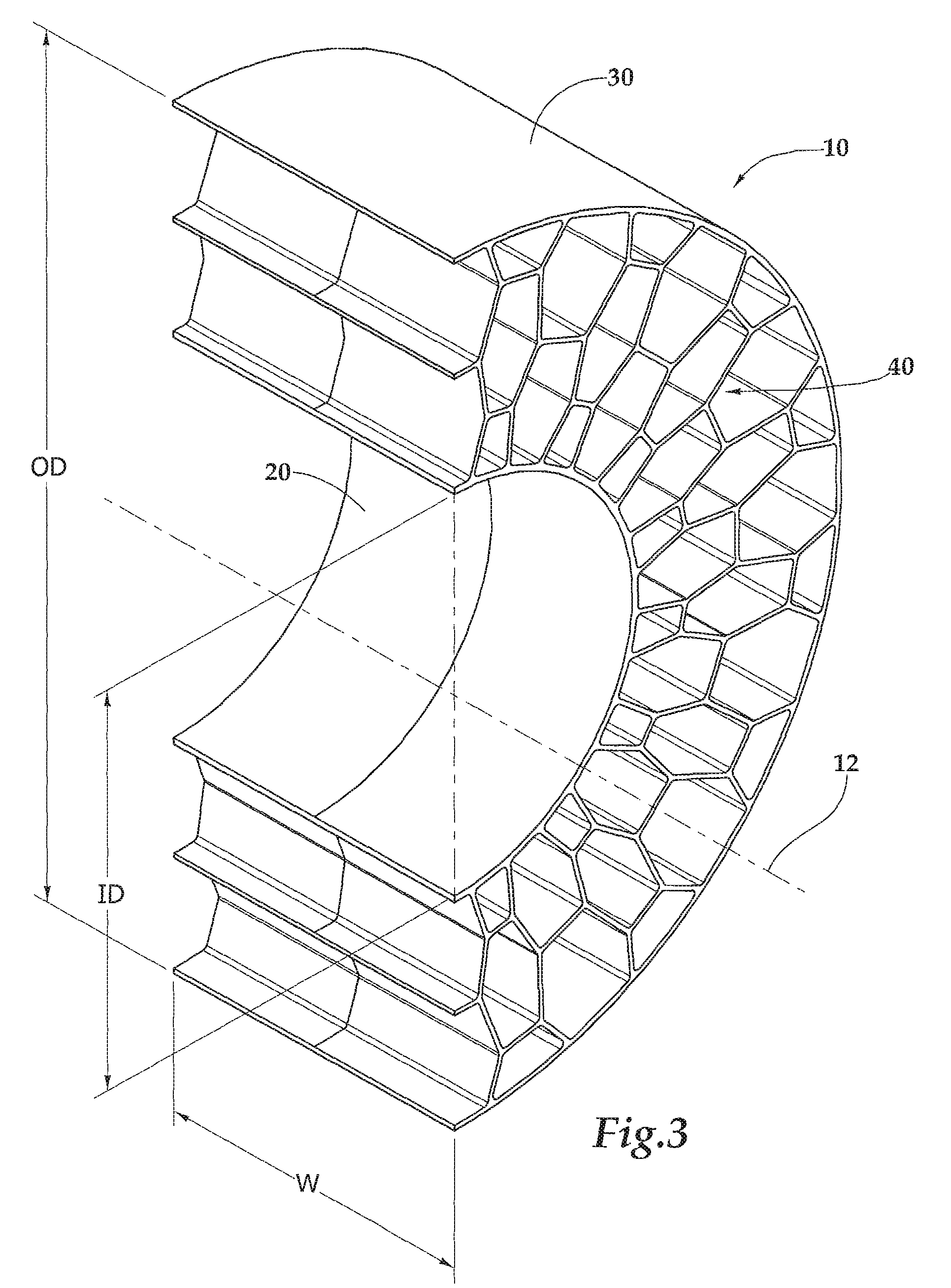

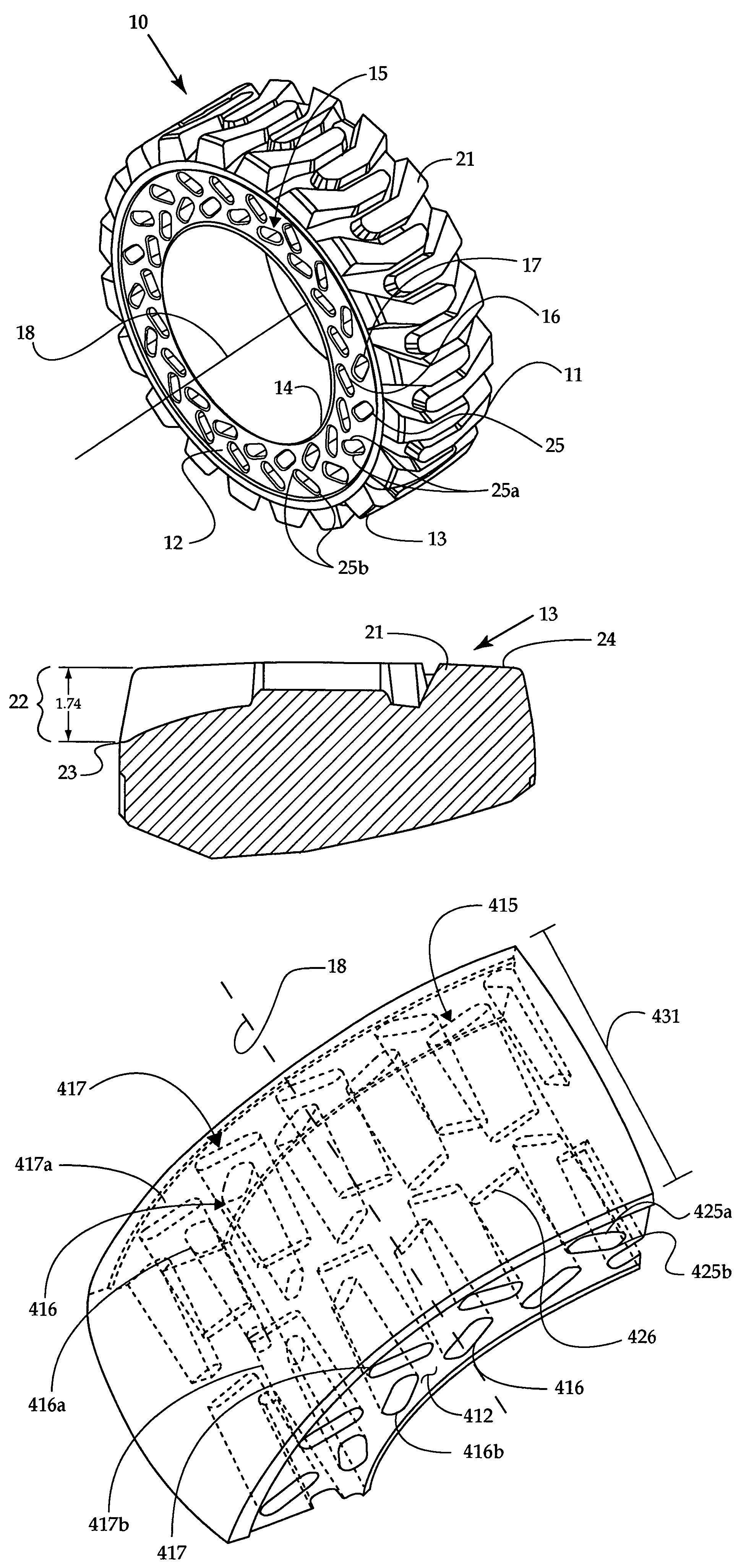

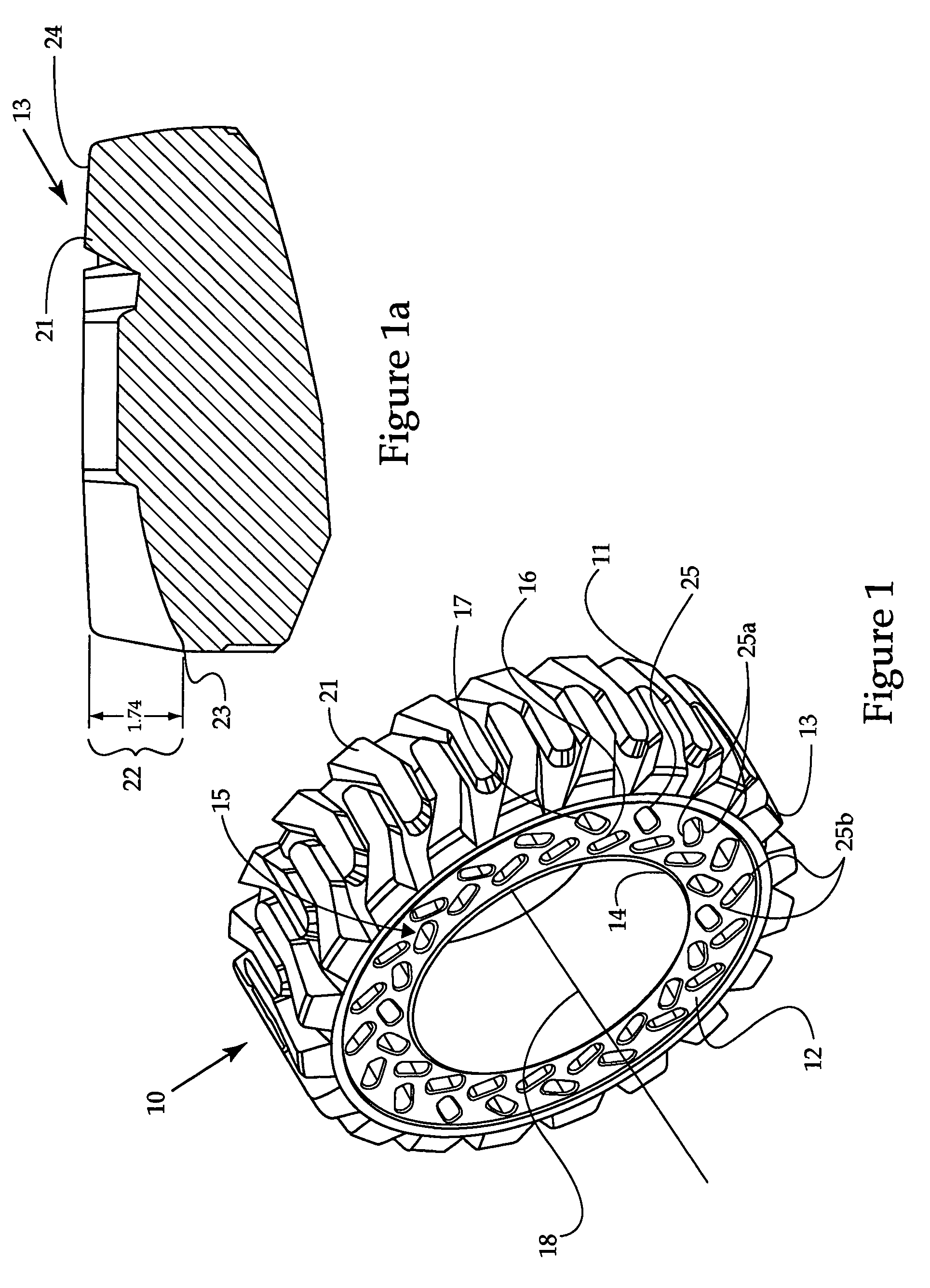

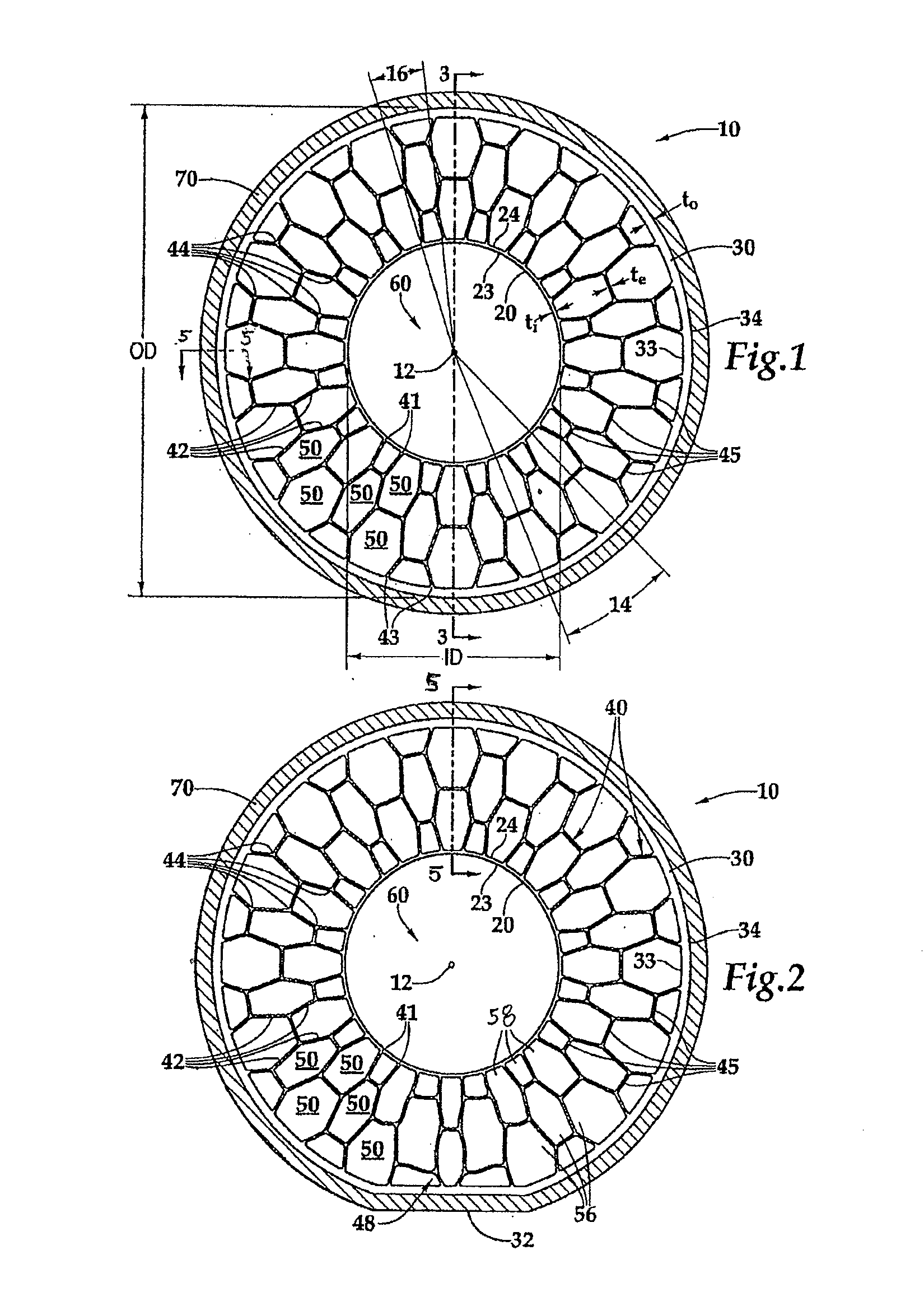

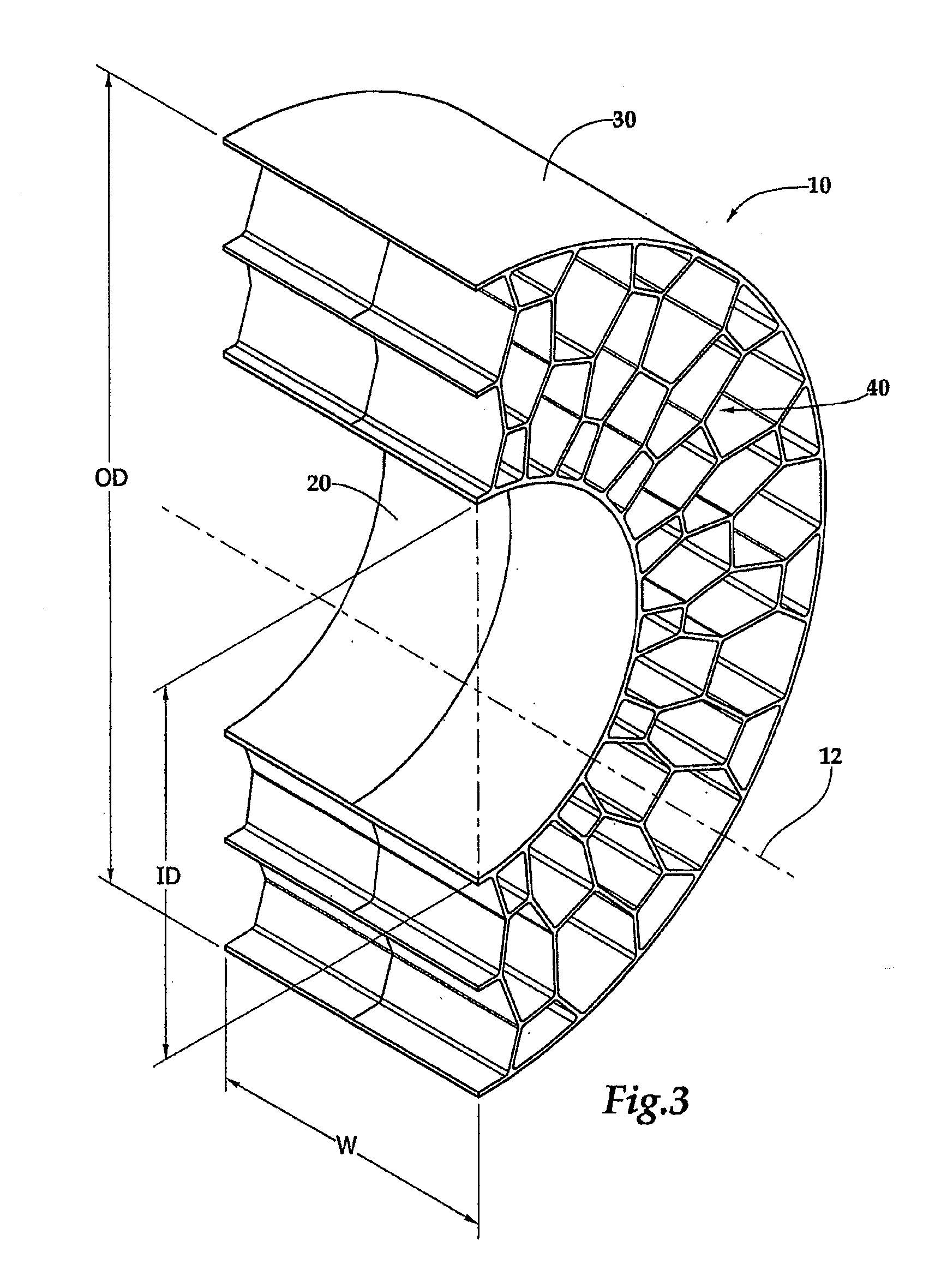

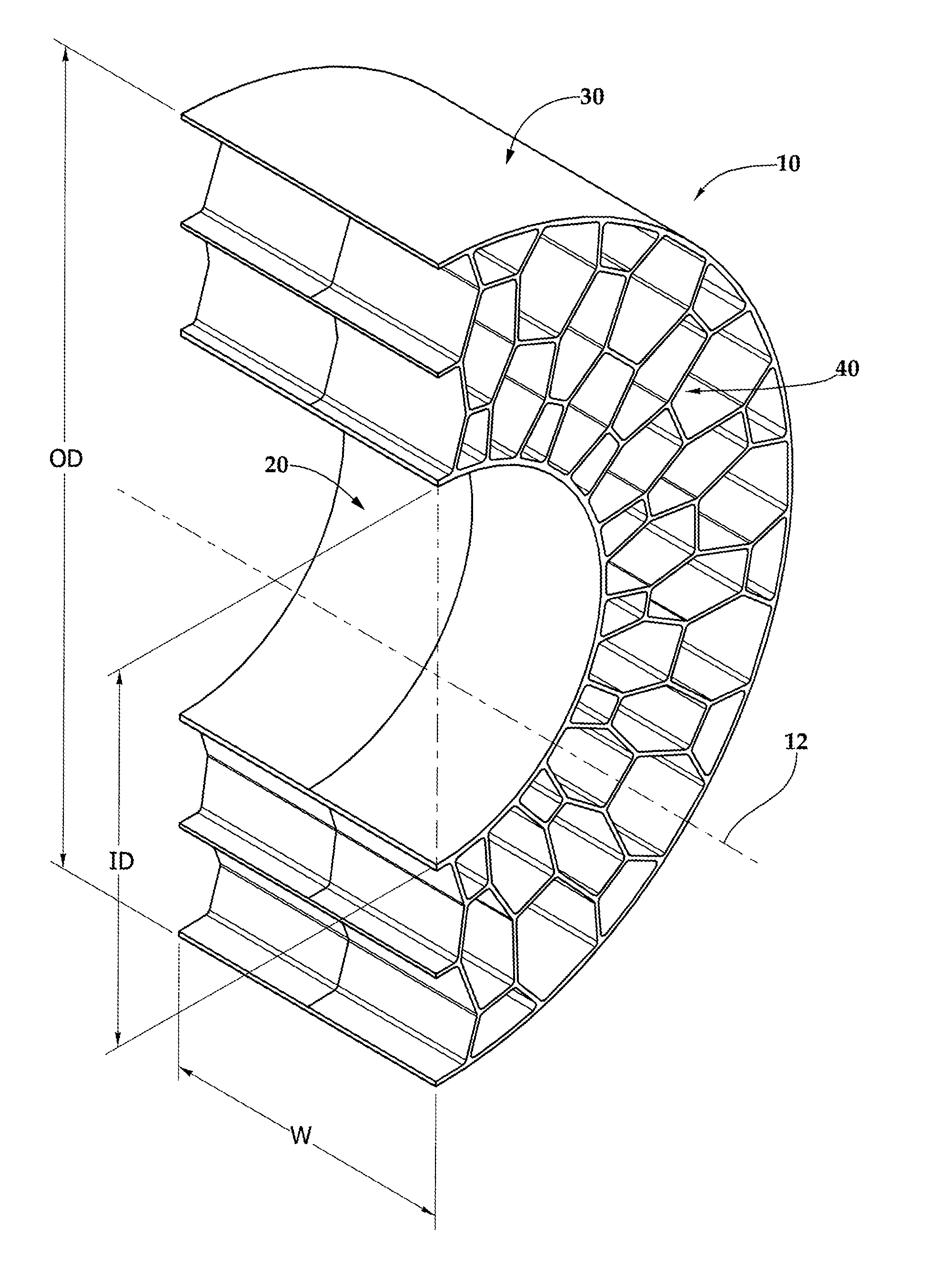

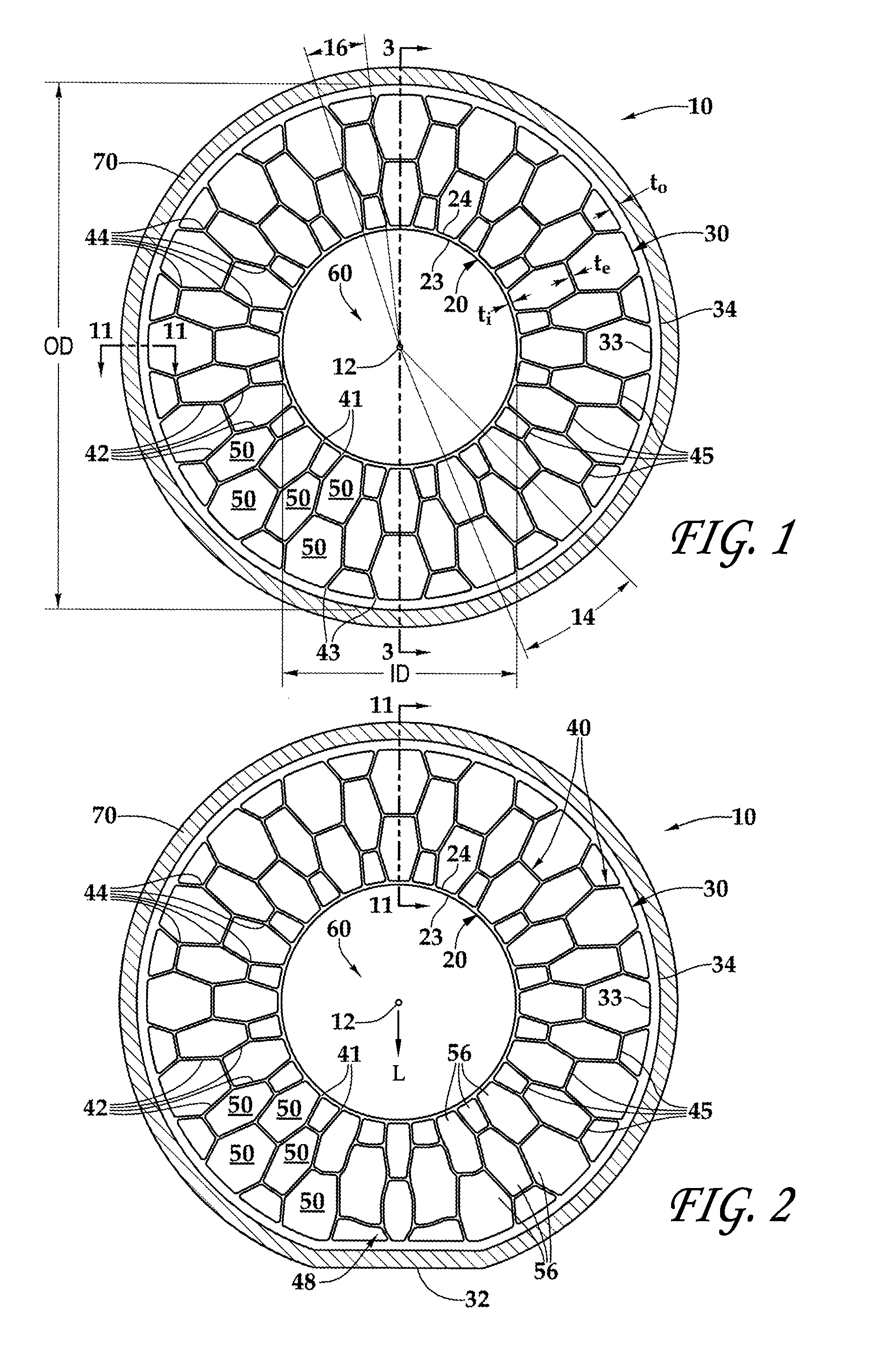

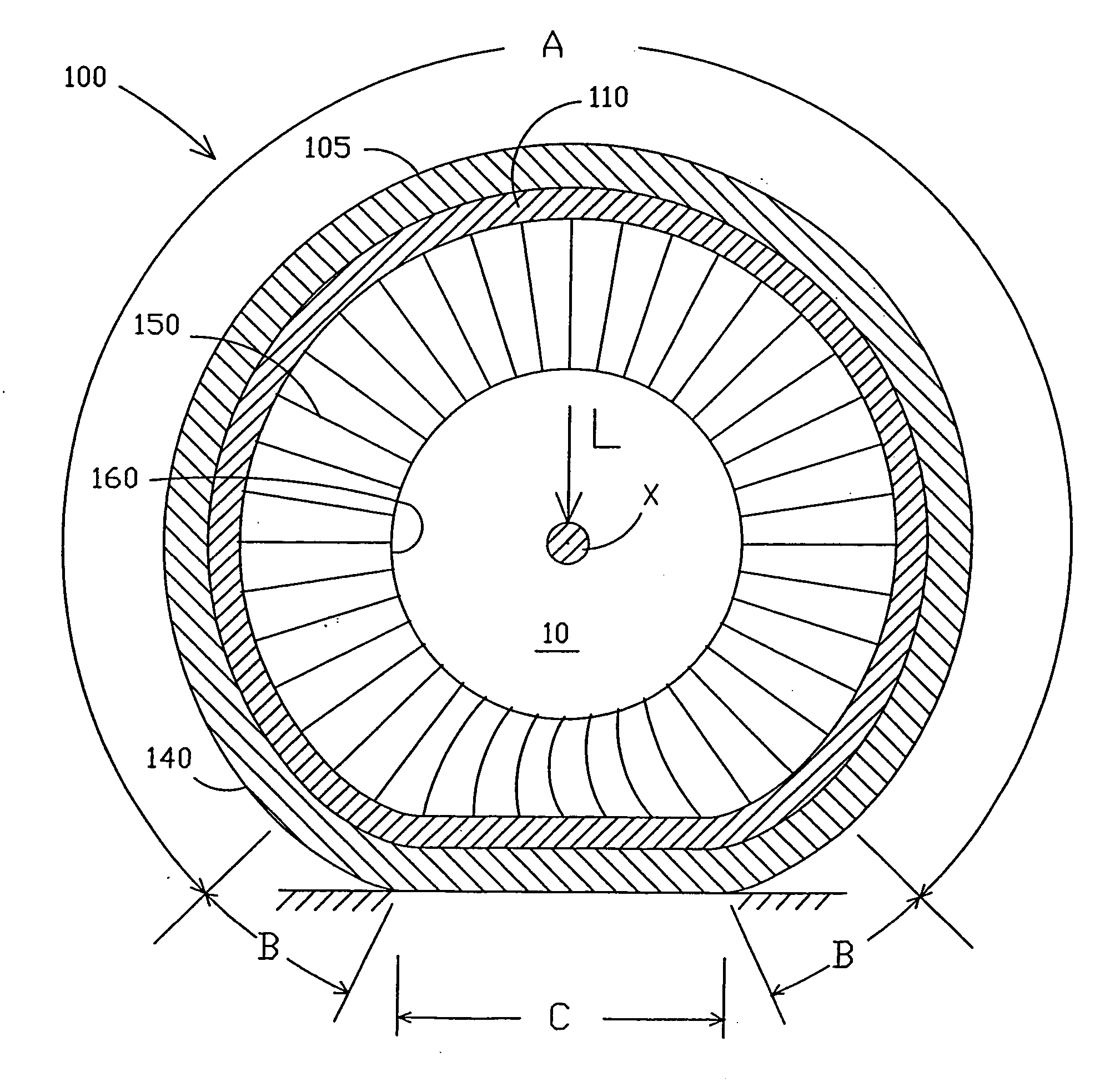

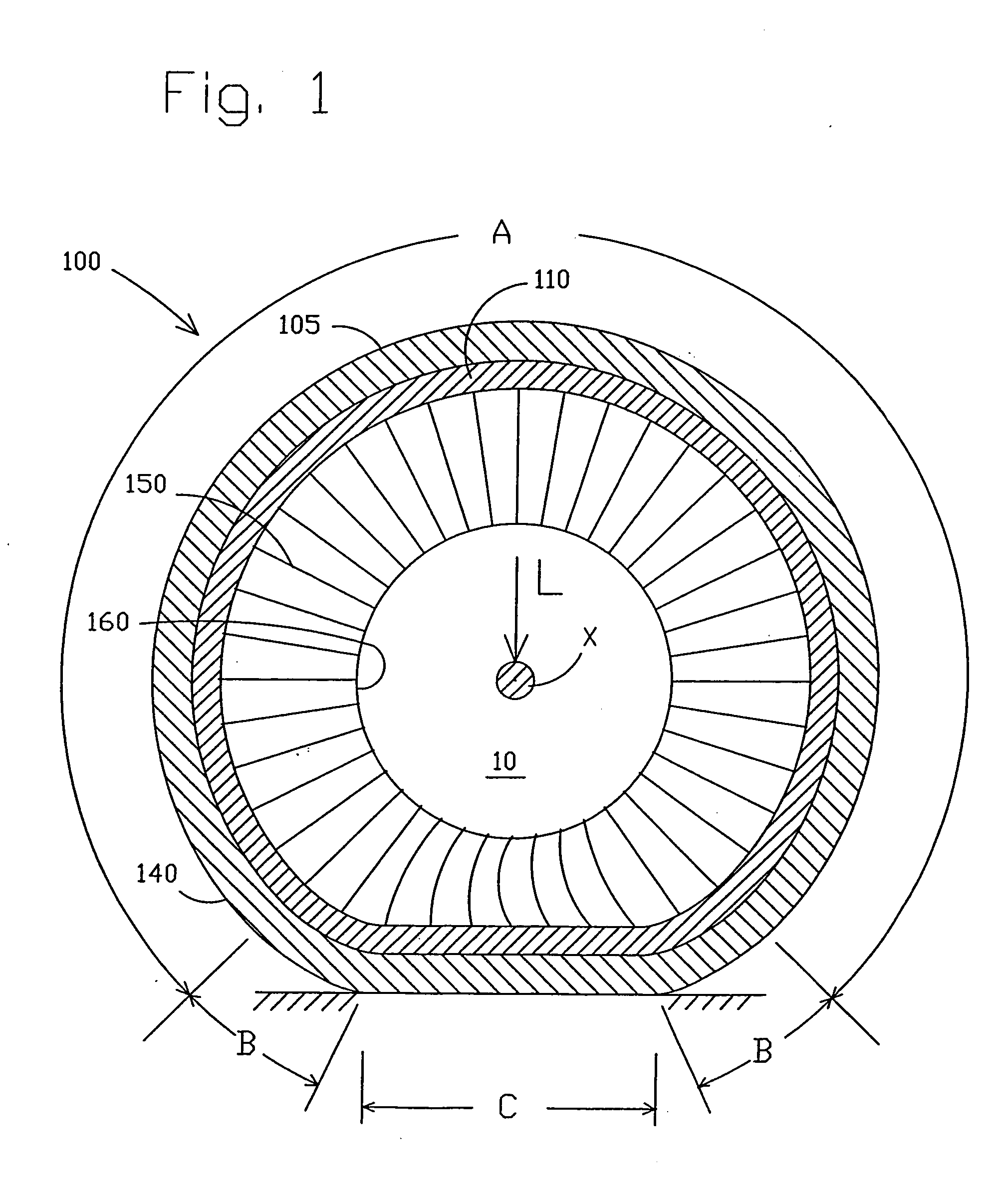

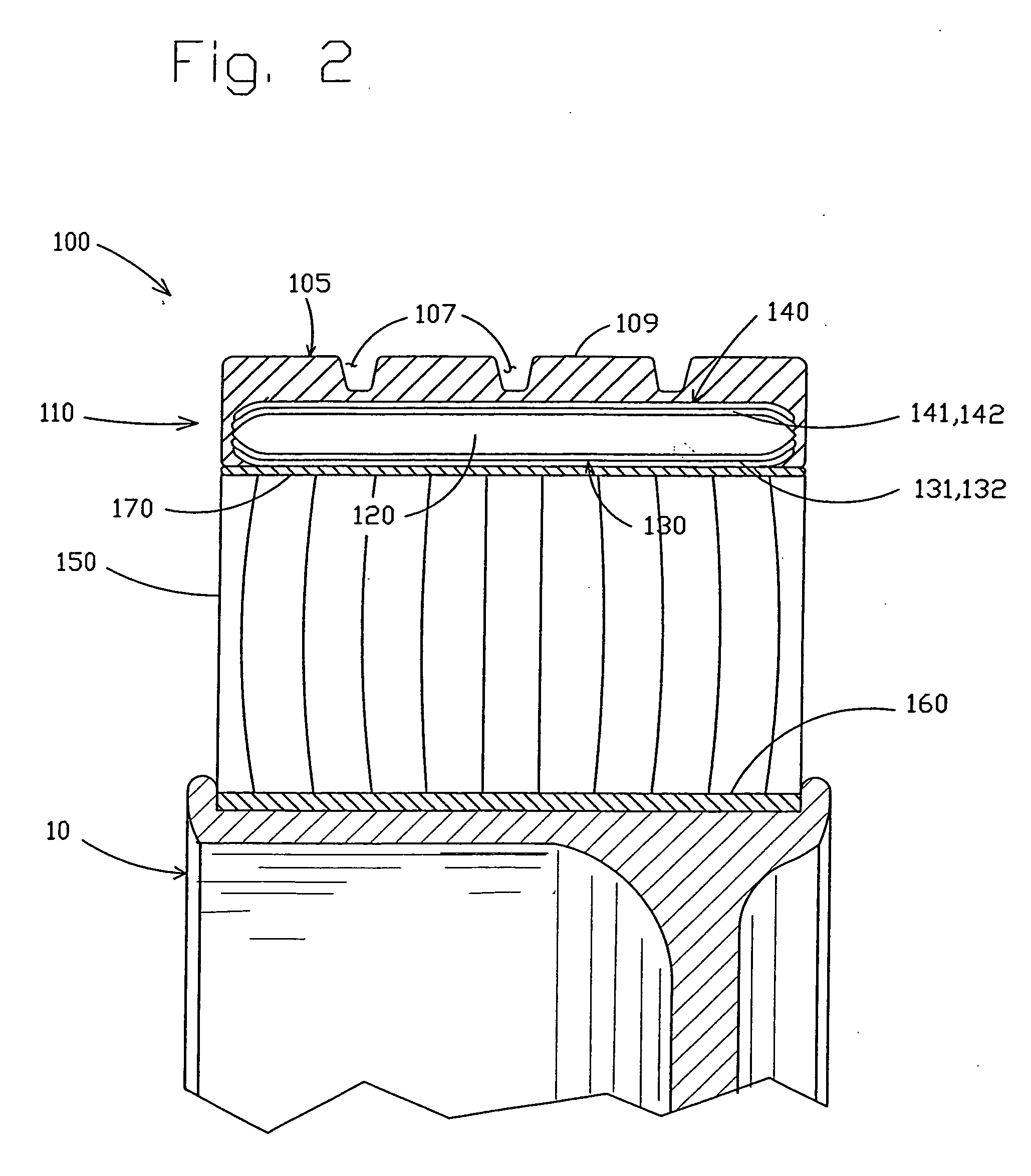

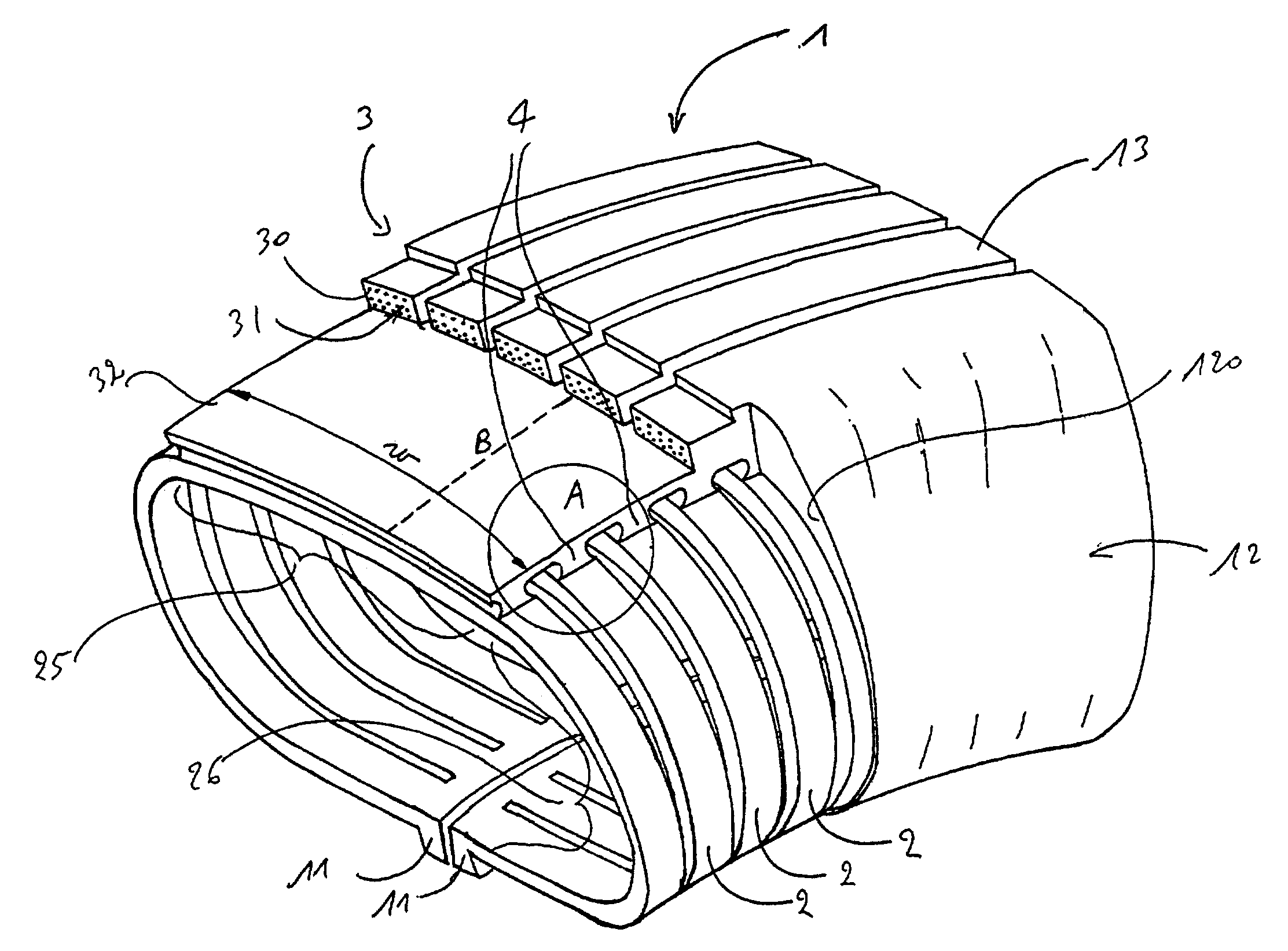

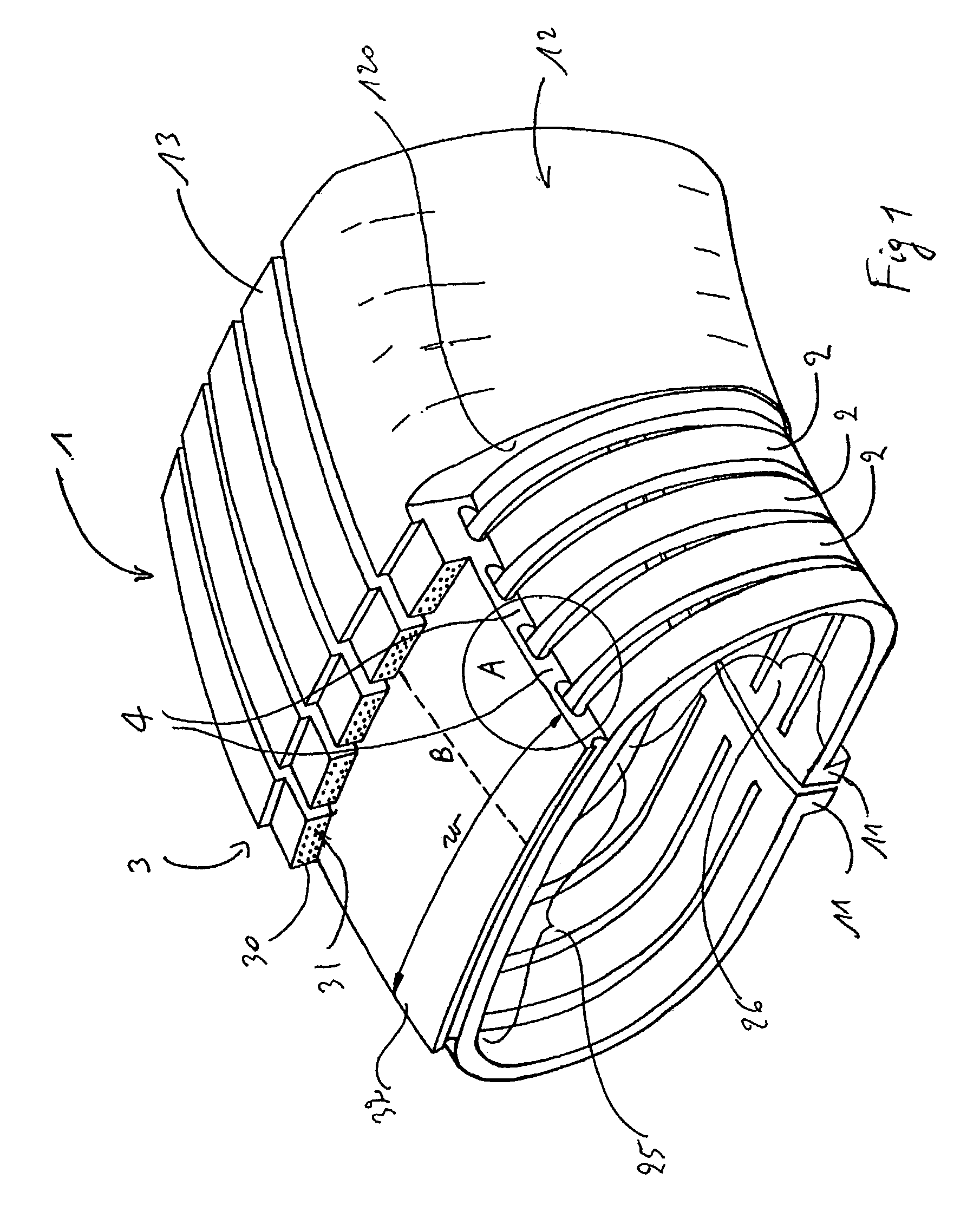

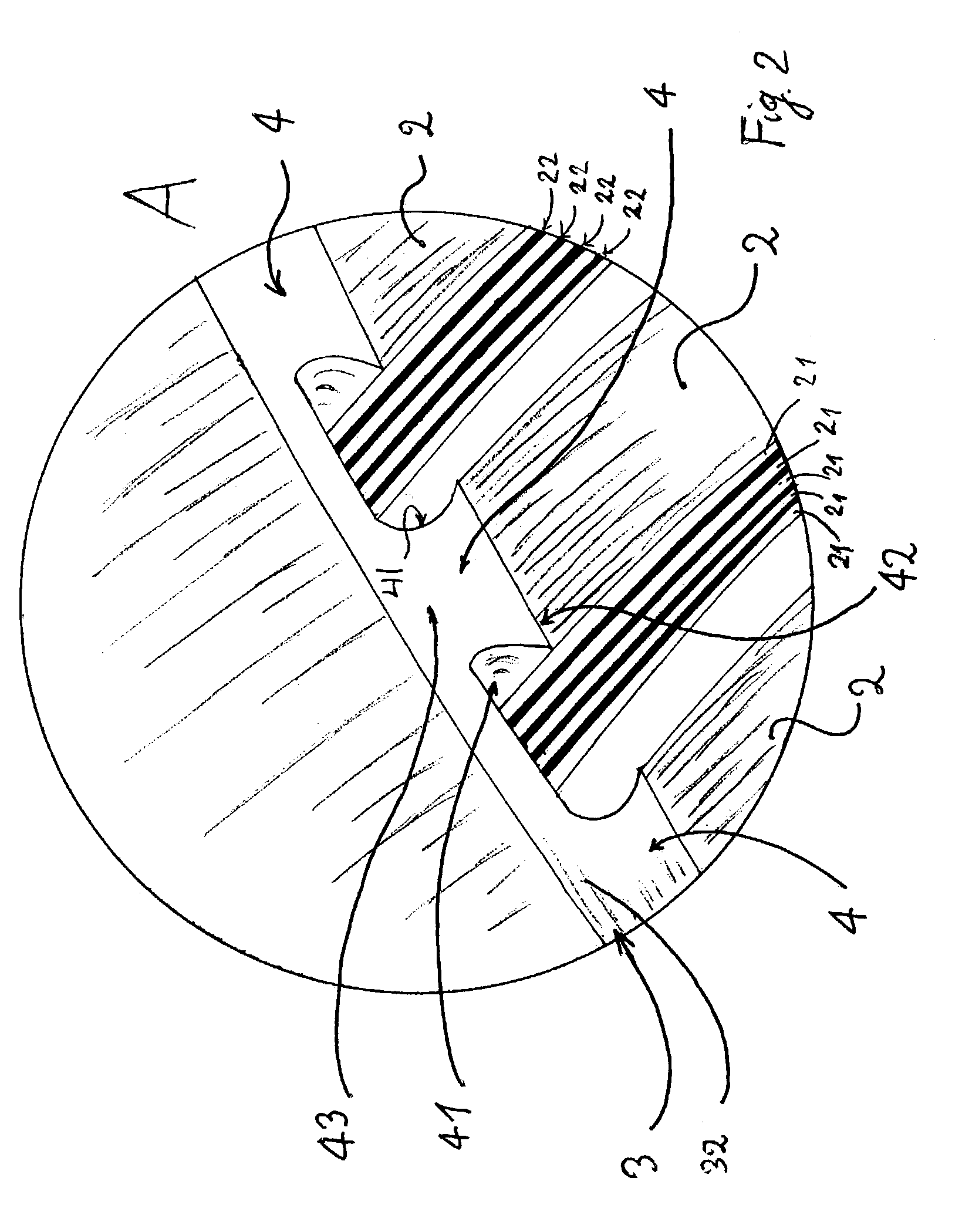

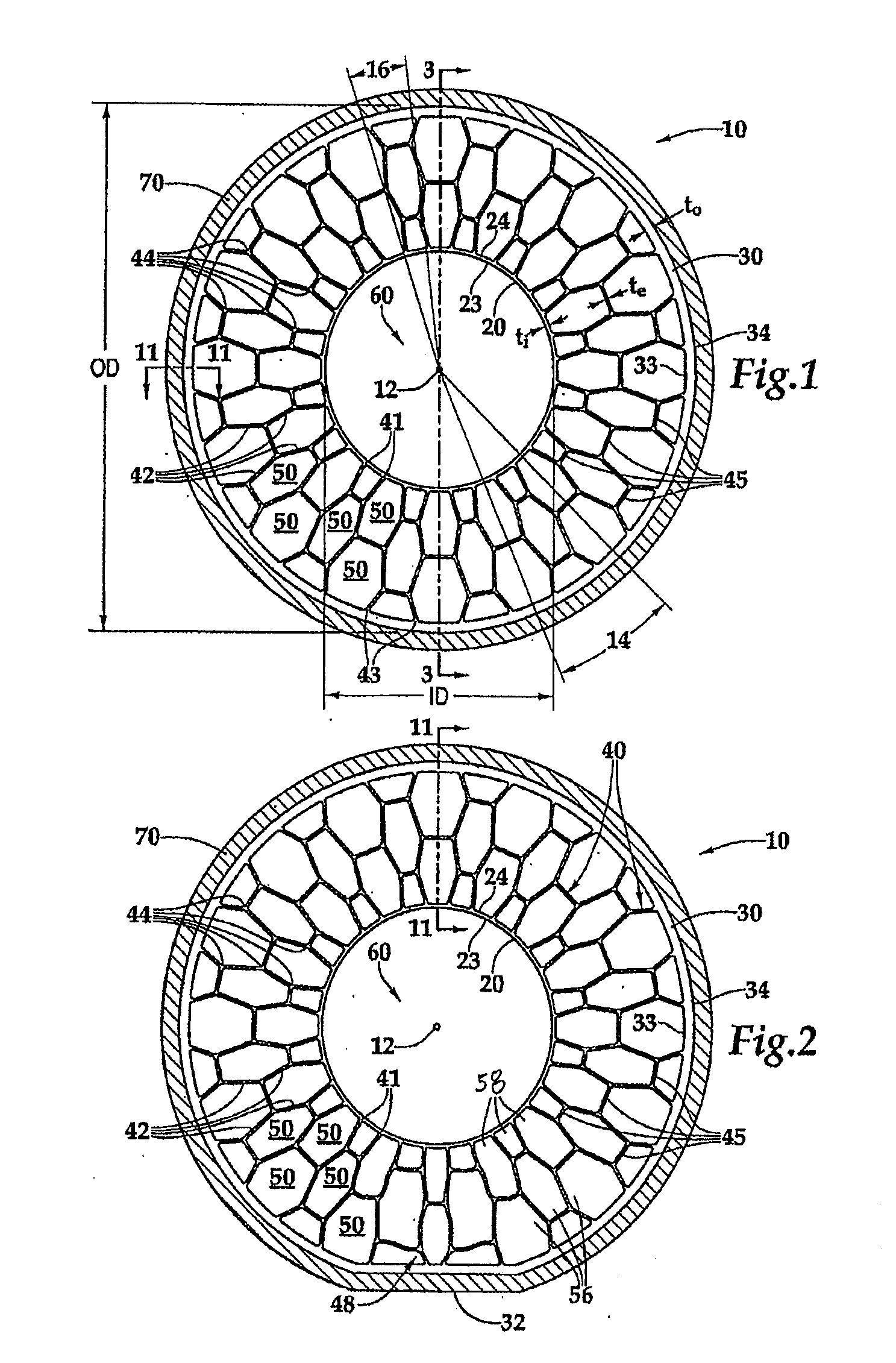

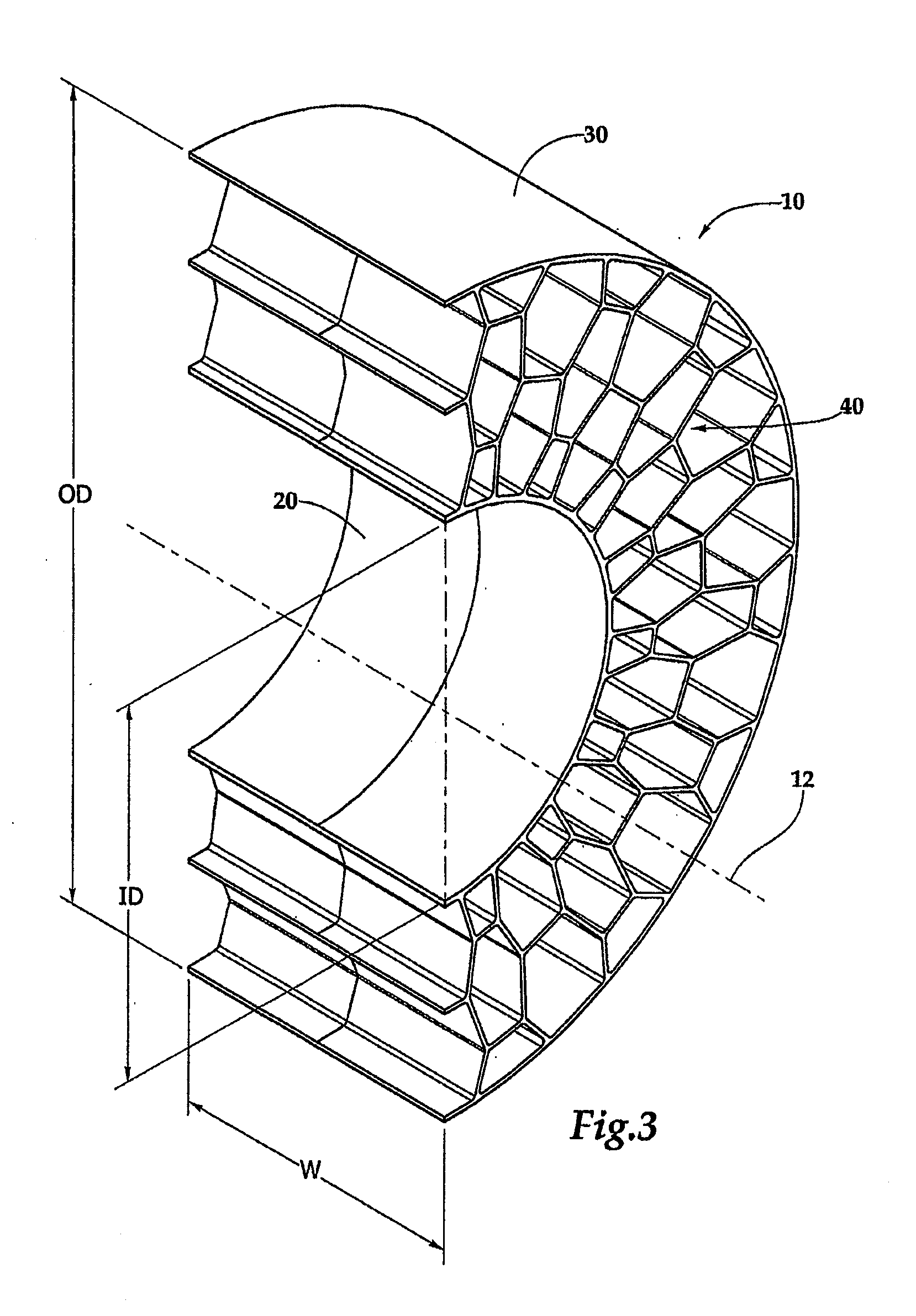

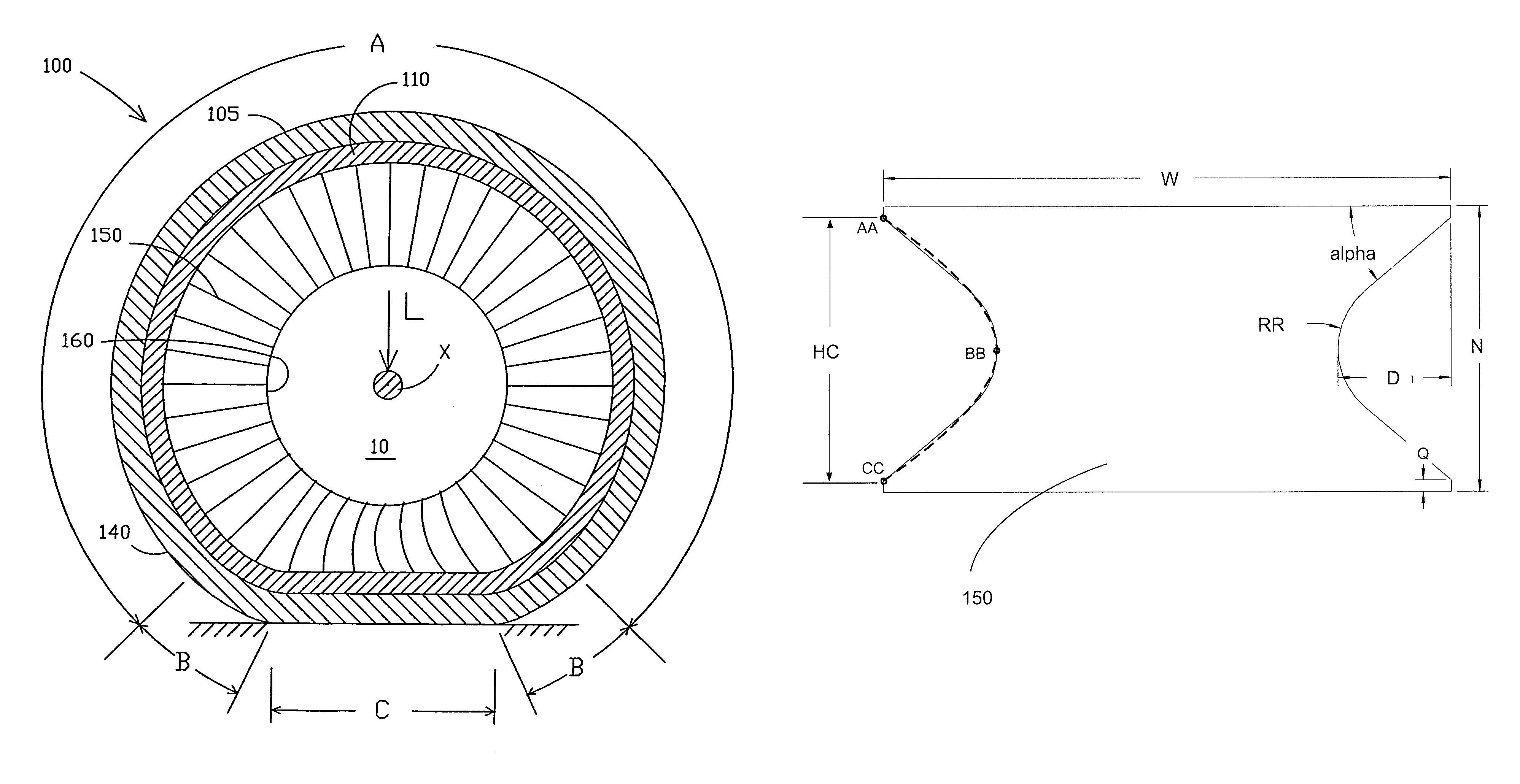

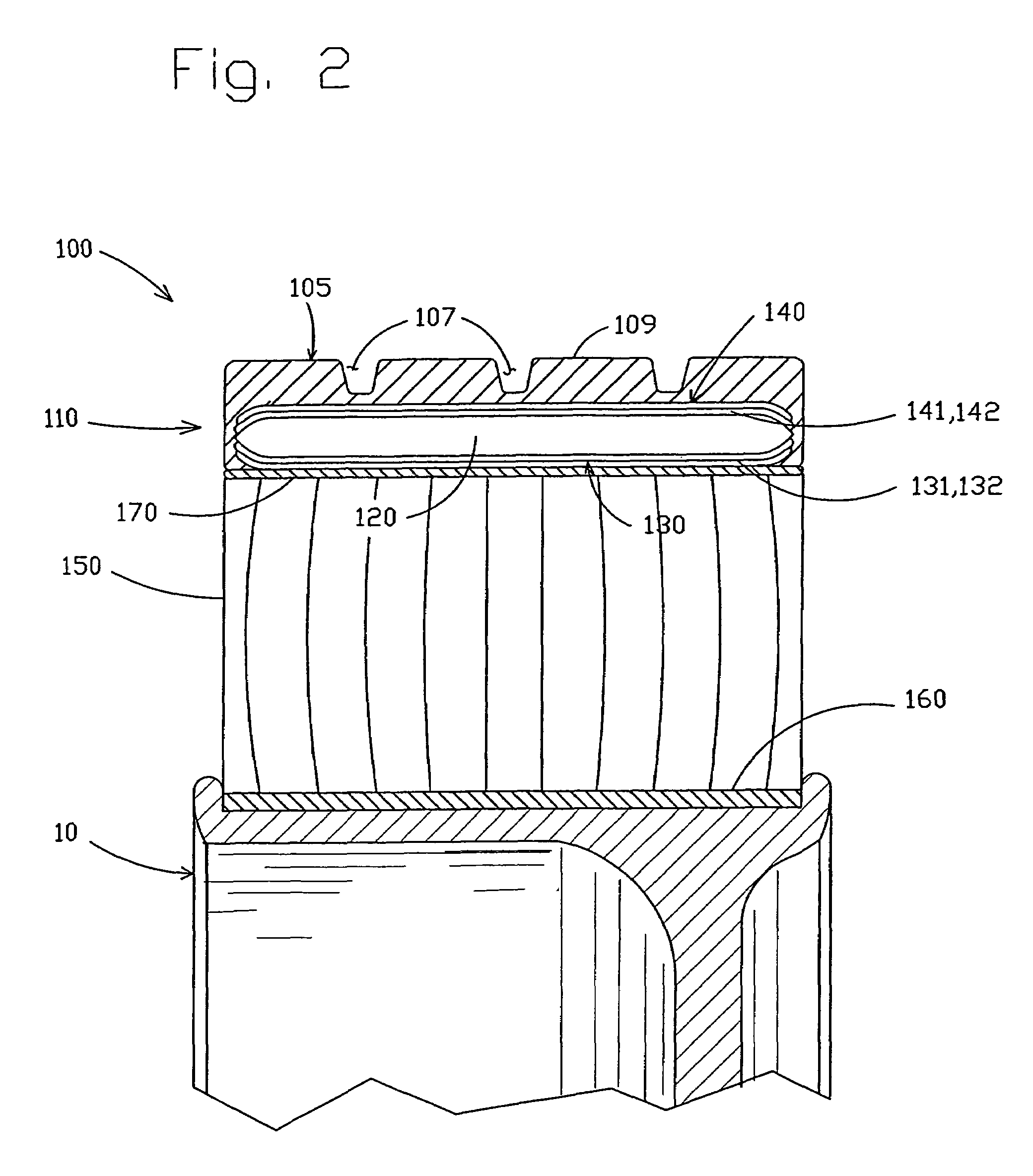

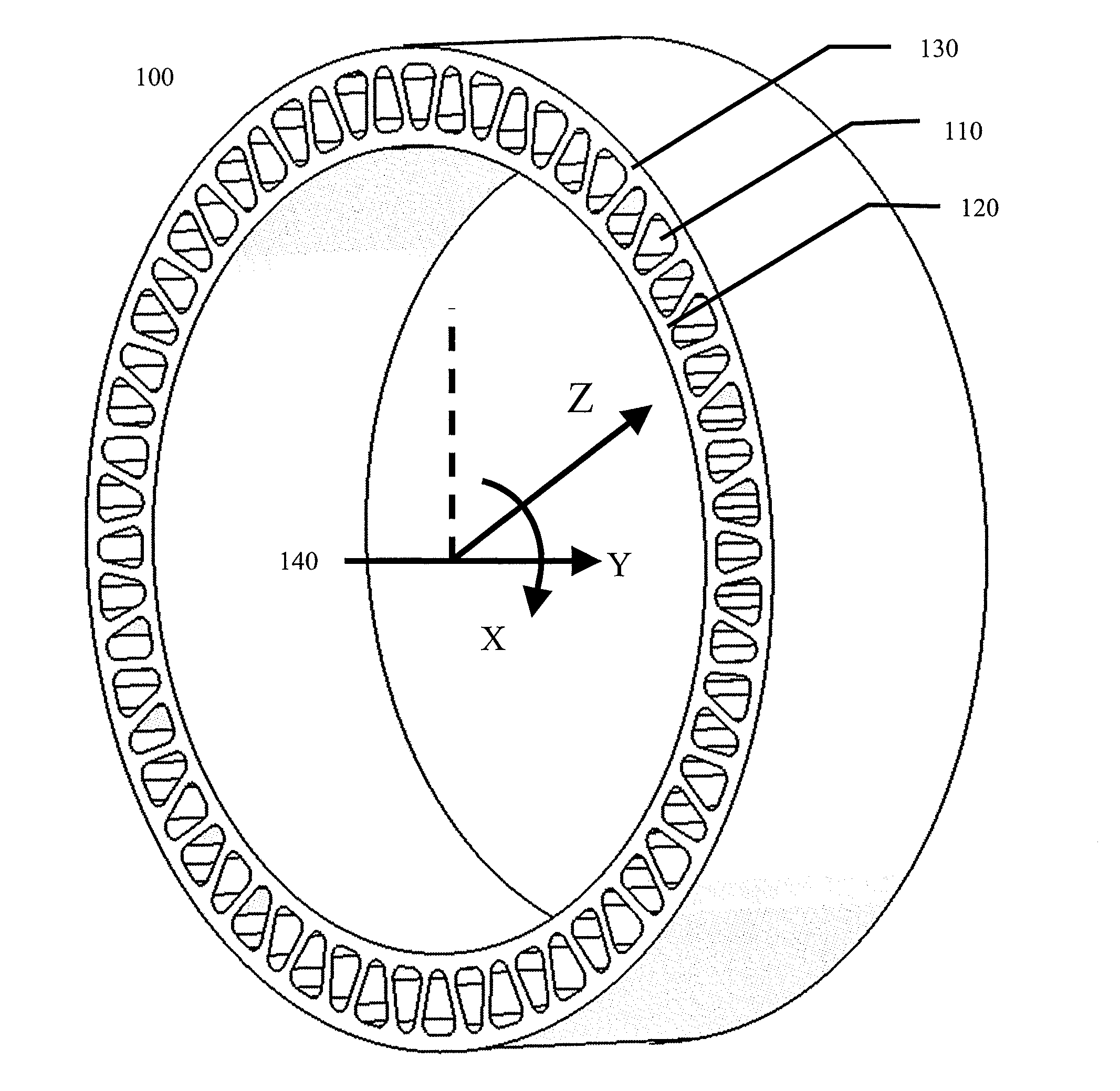

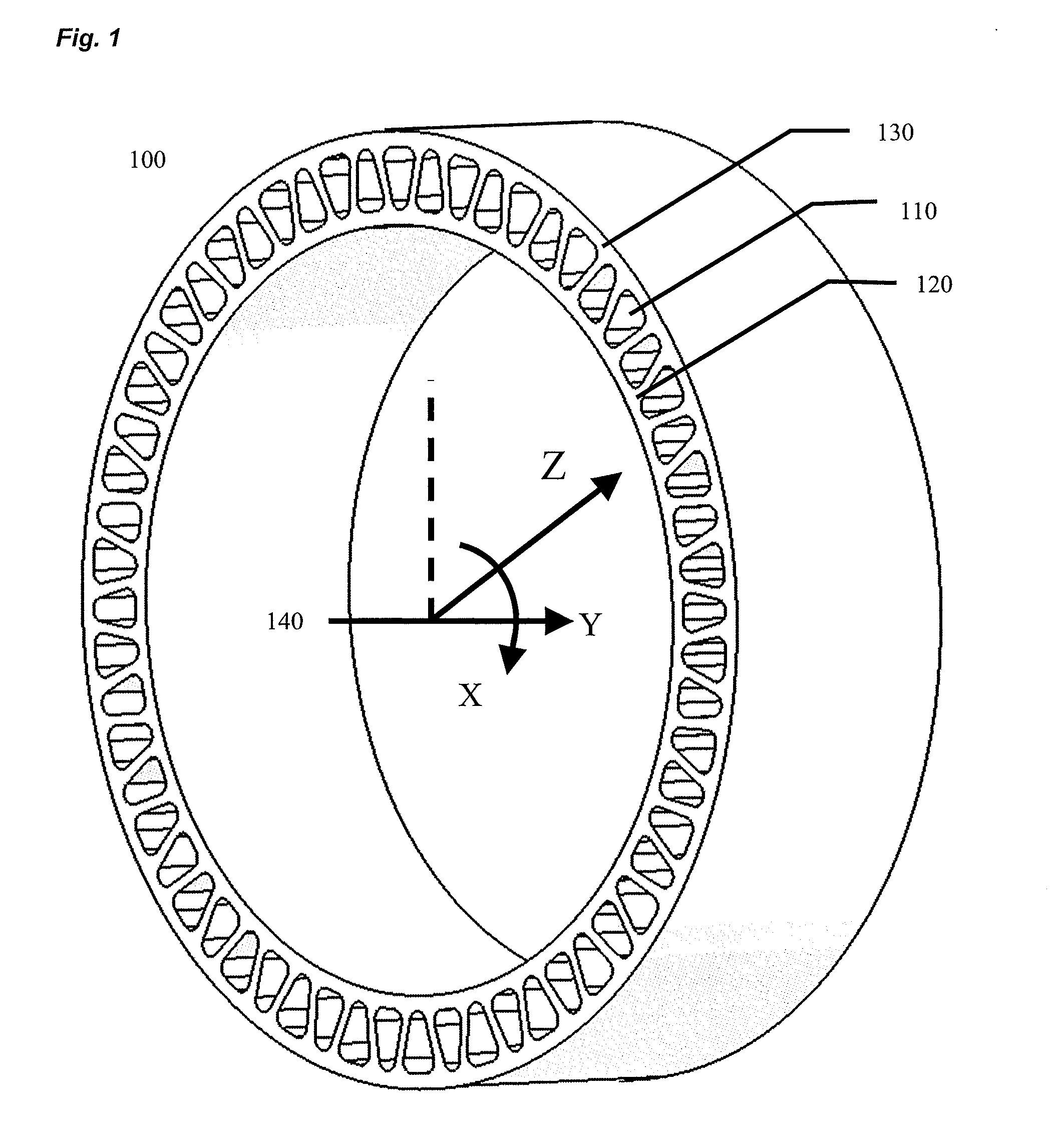

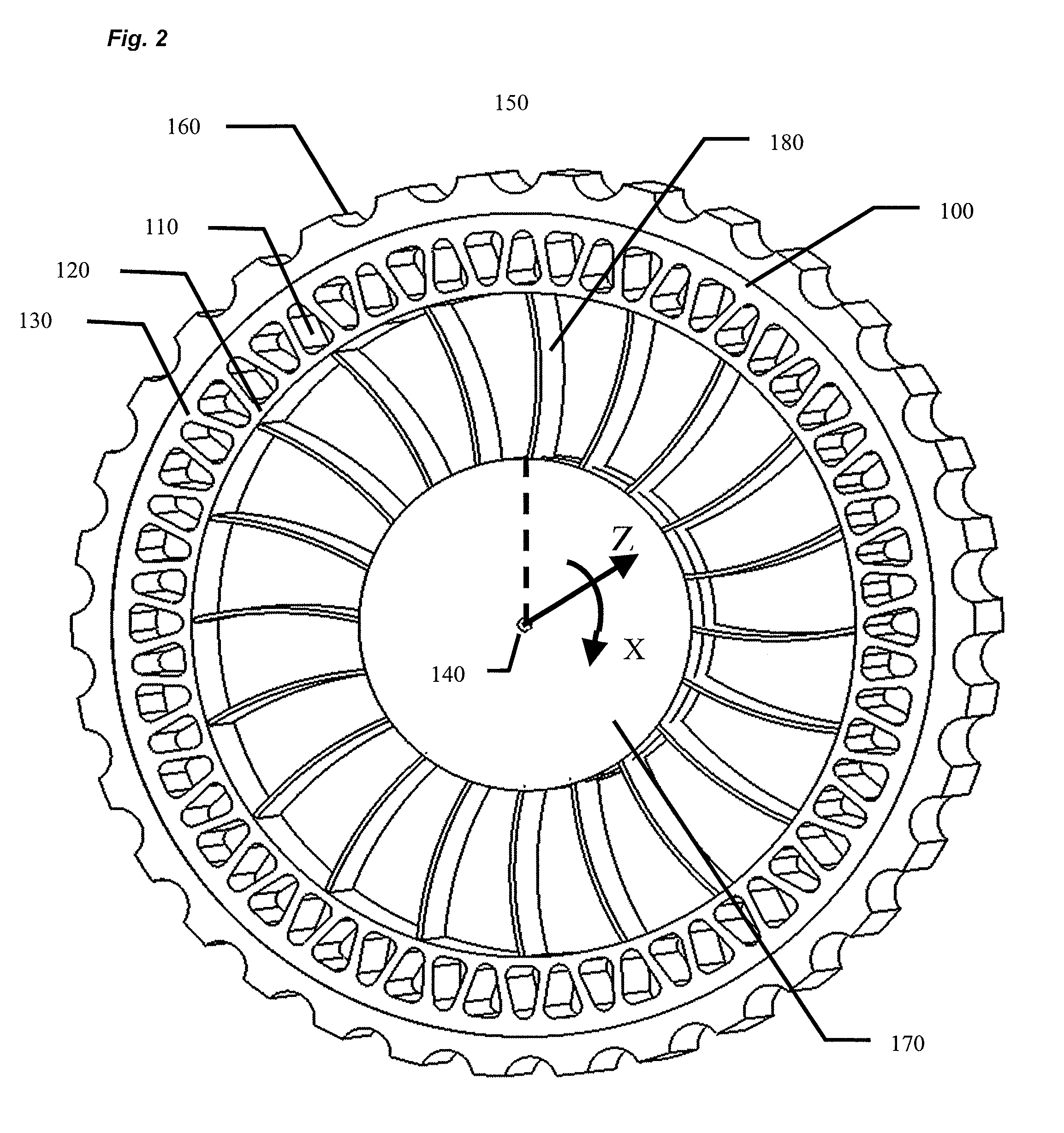

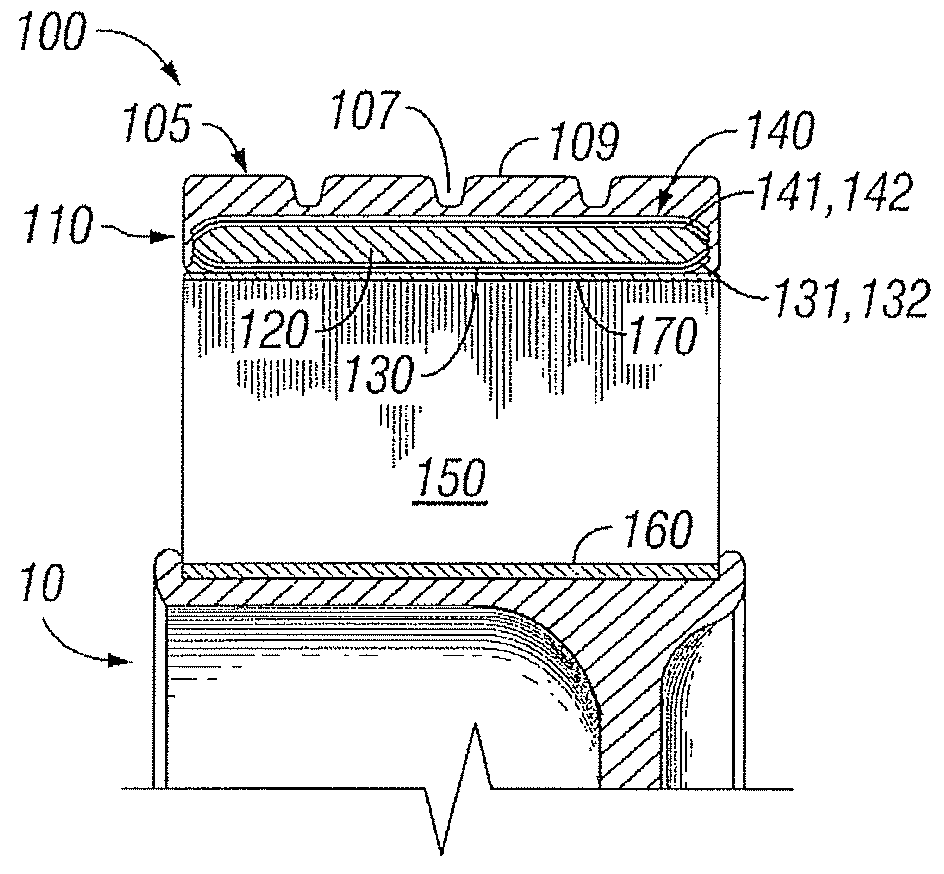

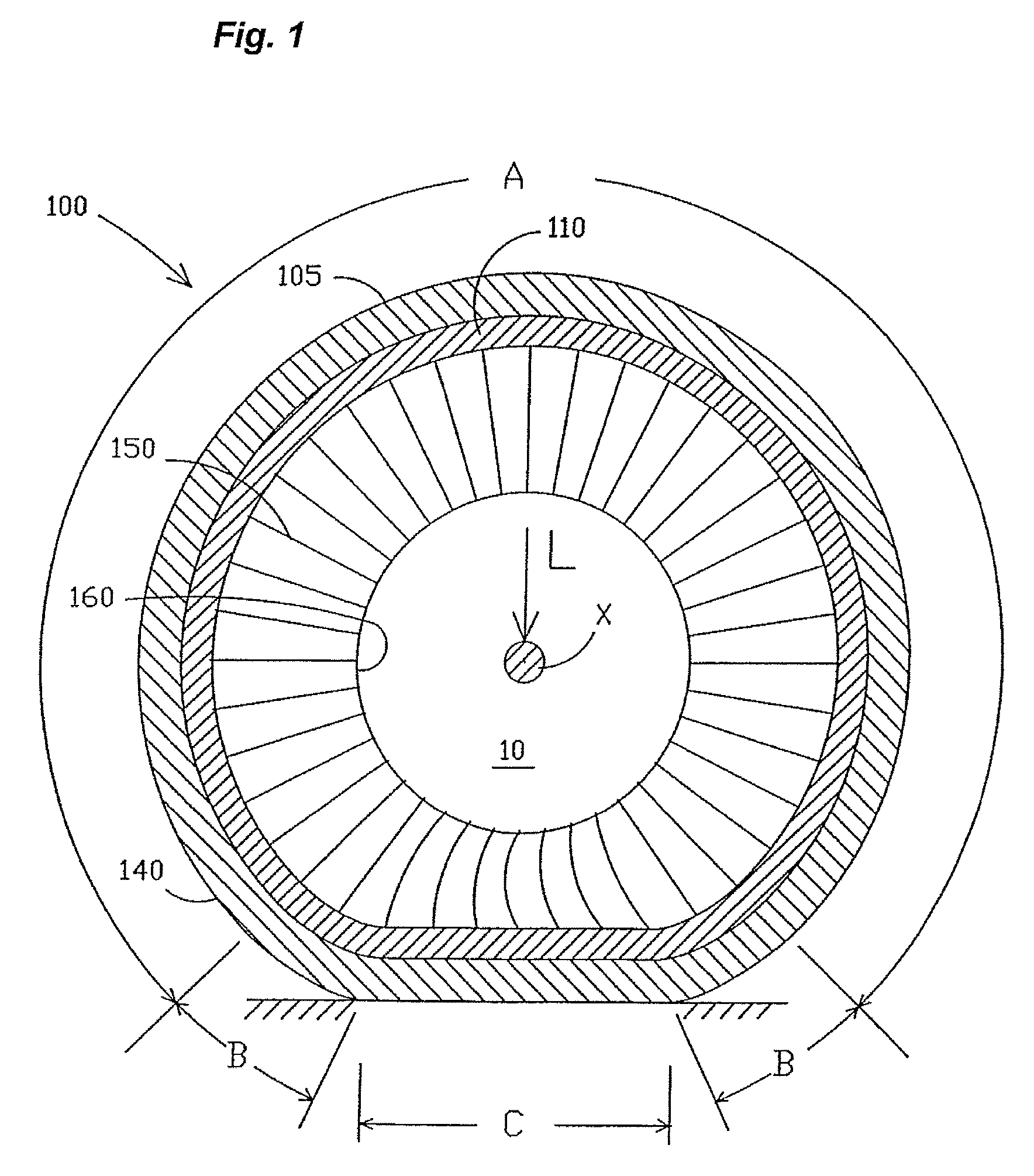

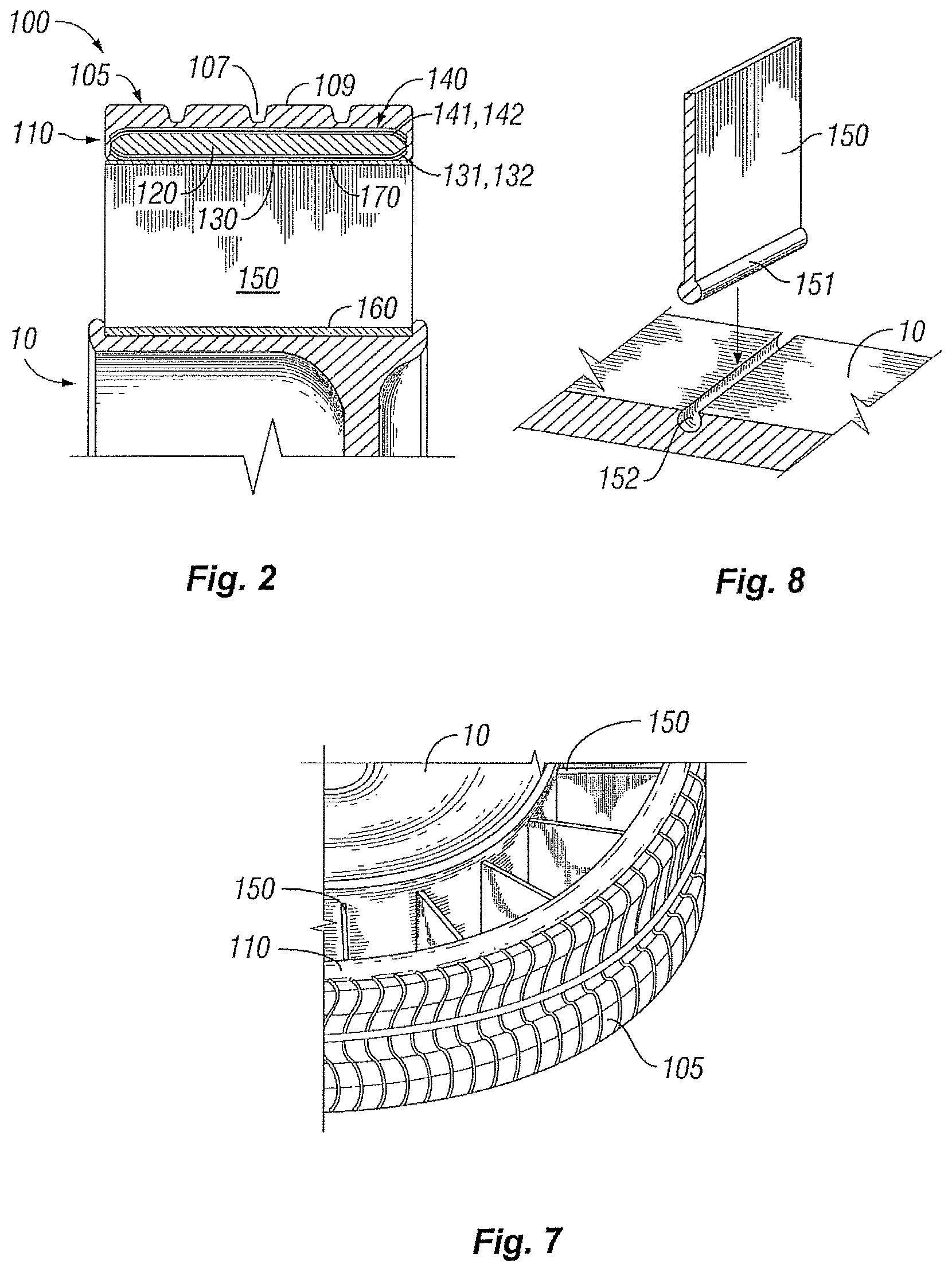

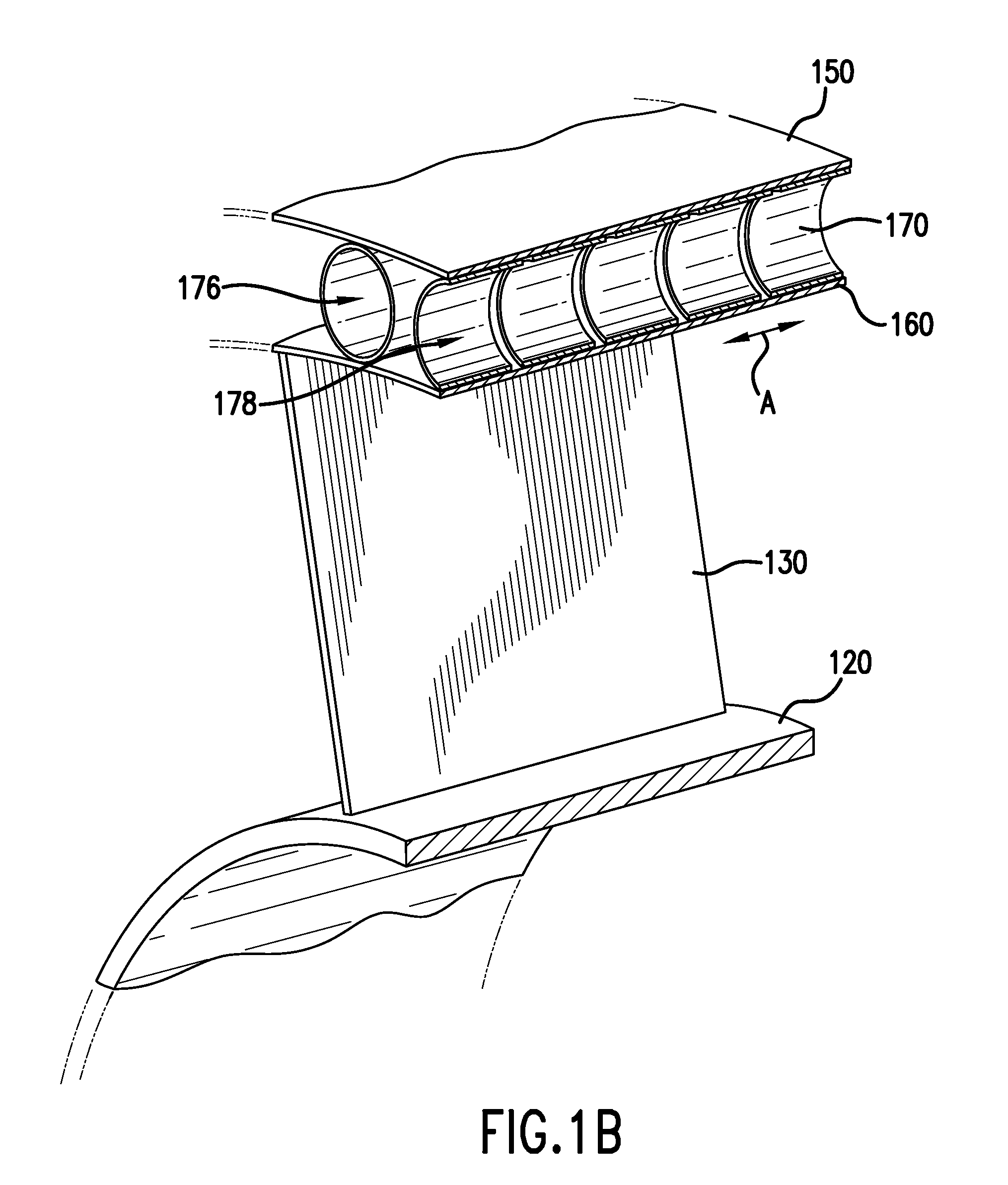

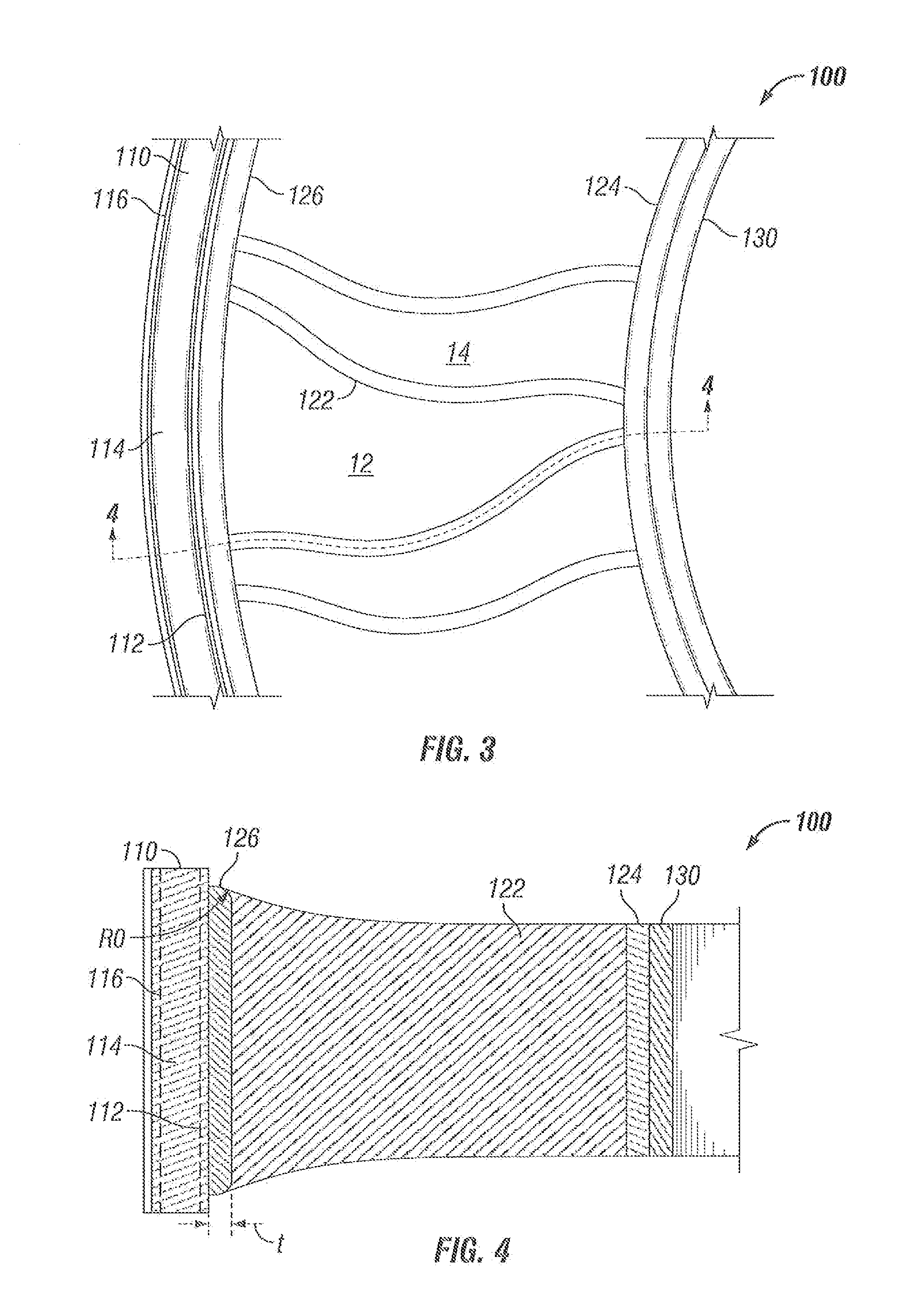

A structurally supported tire includes a ground contacting tread portion, a reinforced annular band disposed radially inward of the tread portion, and a plurality of web spokes extending transversely across and radially inward from the reinforced annular band and anchored in a wheel or hub. The reinforced annular band comprises an elastomeric shear layer, at least a first membrane adhered to the radially inward extent of the elastomeric shear layer and at least a second membrane adhered to the radially outward extent of the elastomeric shear layer. Each of the membranes has a longitudinal tensile modulus sufficiently greater than the shear modulus of the shear layer so that when under load the ground contacting portion of the tire deforms to a flat contact region through shear strain in the shear layer while maintaining constant the length of the membranes, the web spokes transmitting load forces between the annular band and the hub through tension in the web spokes not connected to the ground contacting portion of the tire.

Owner:MICHELIN RECH & TECH SA

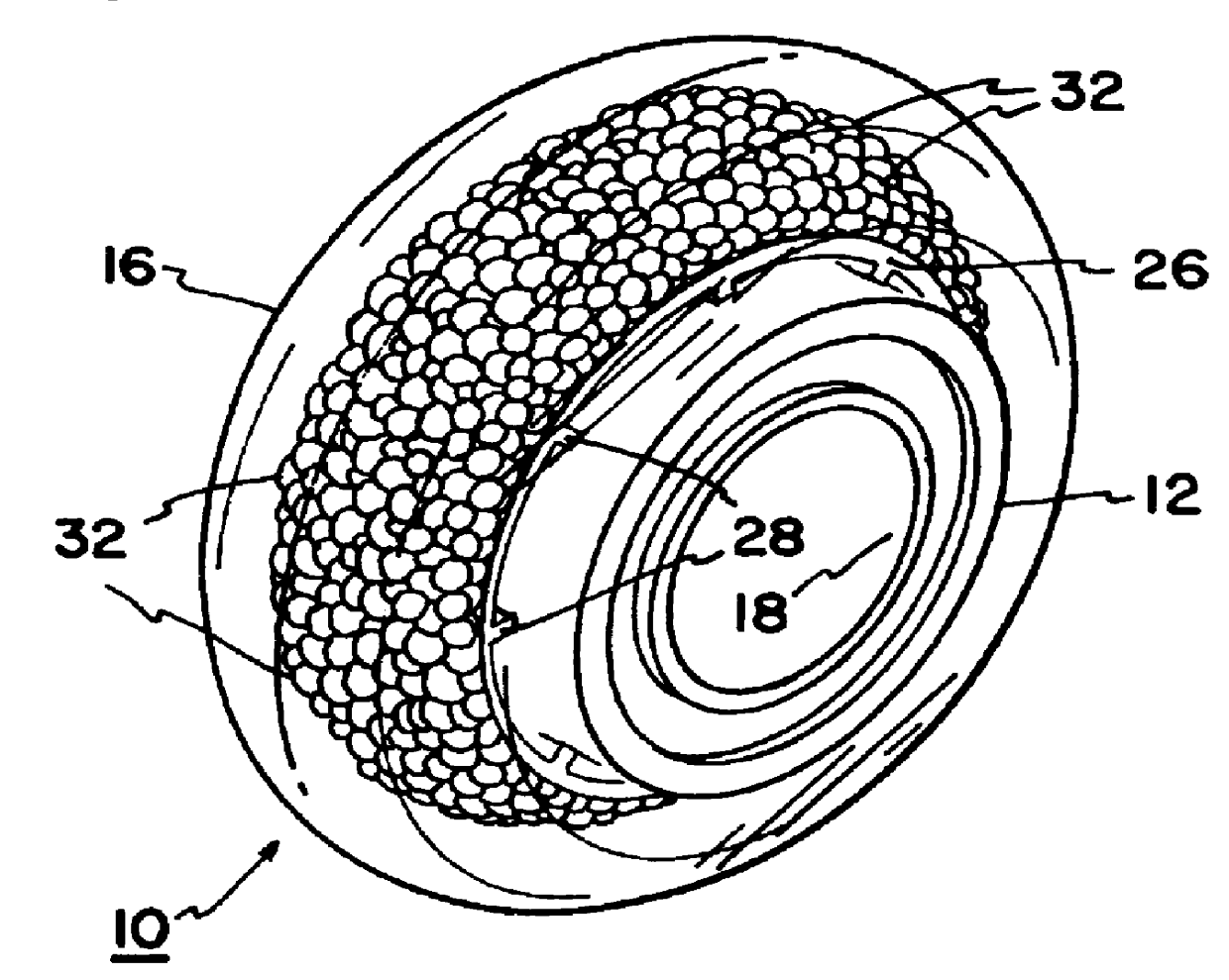

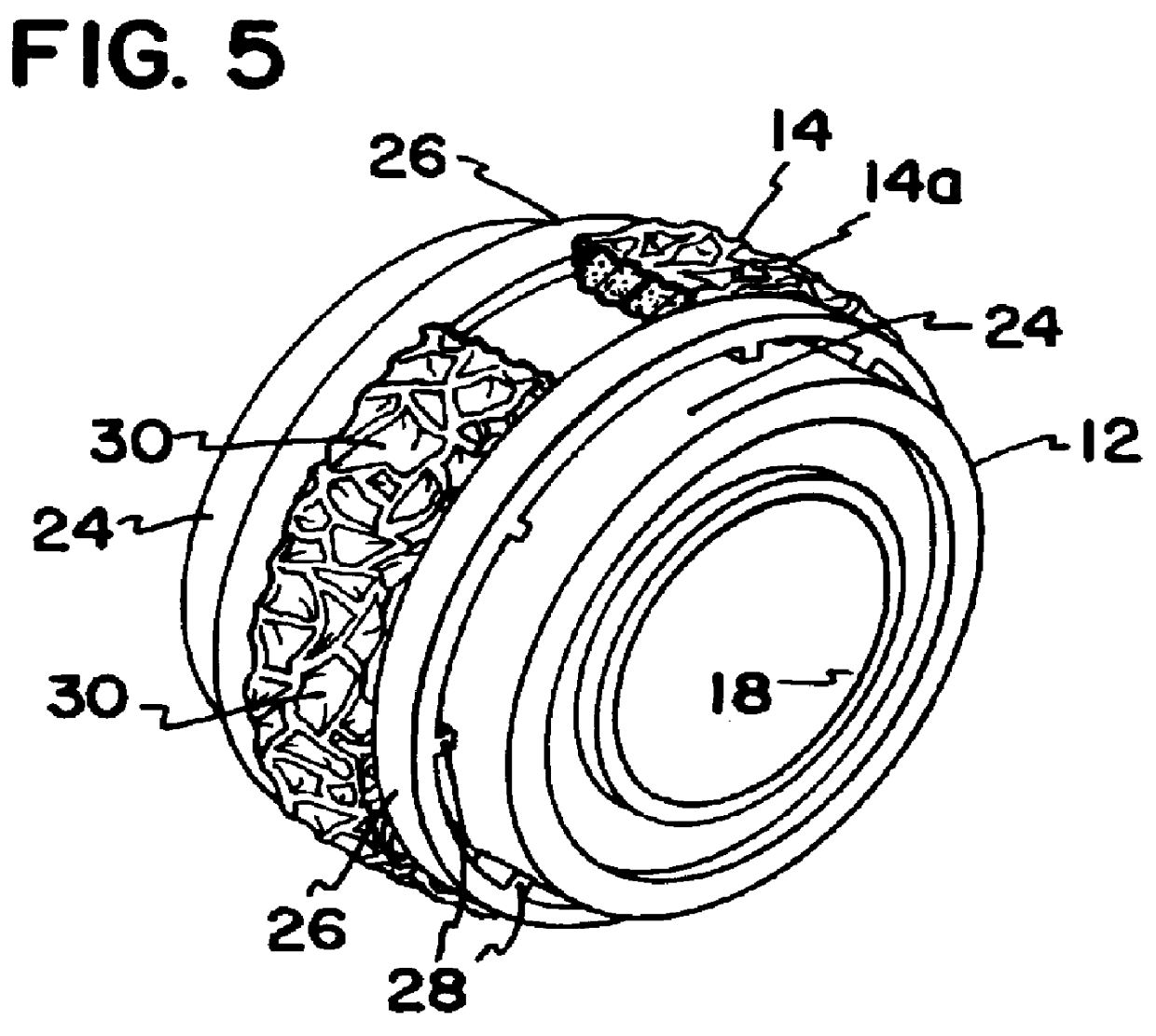

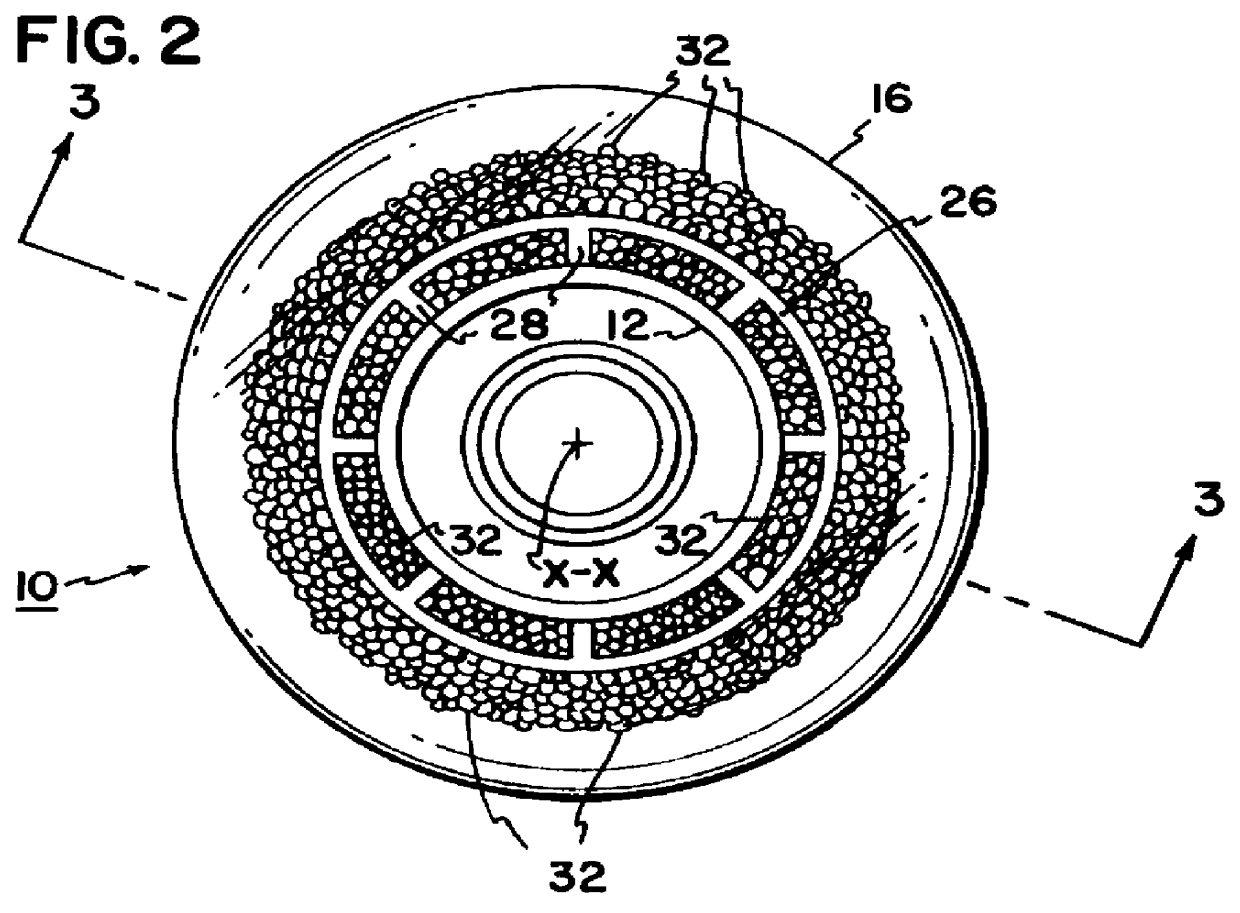

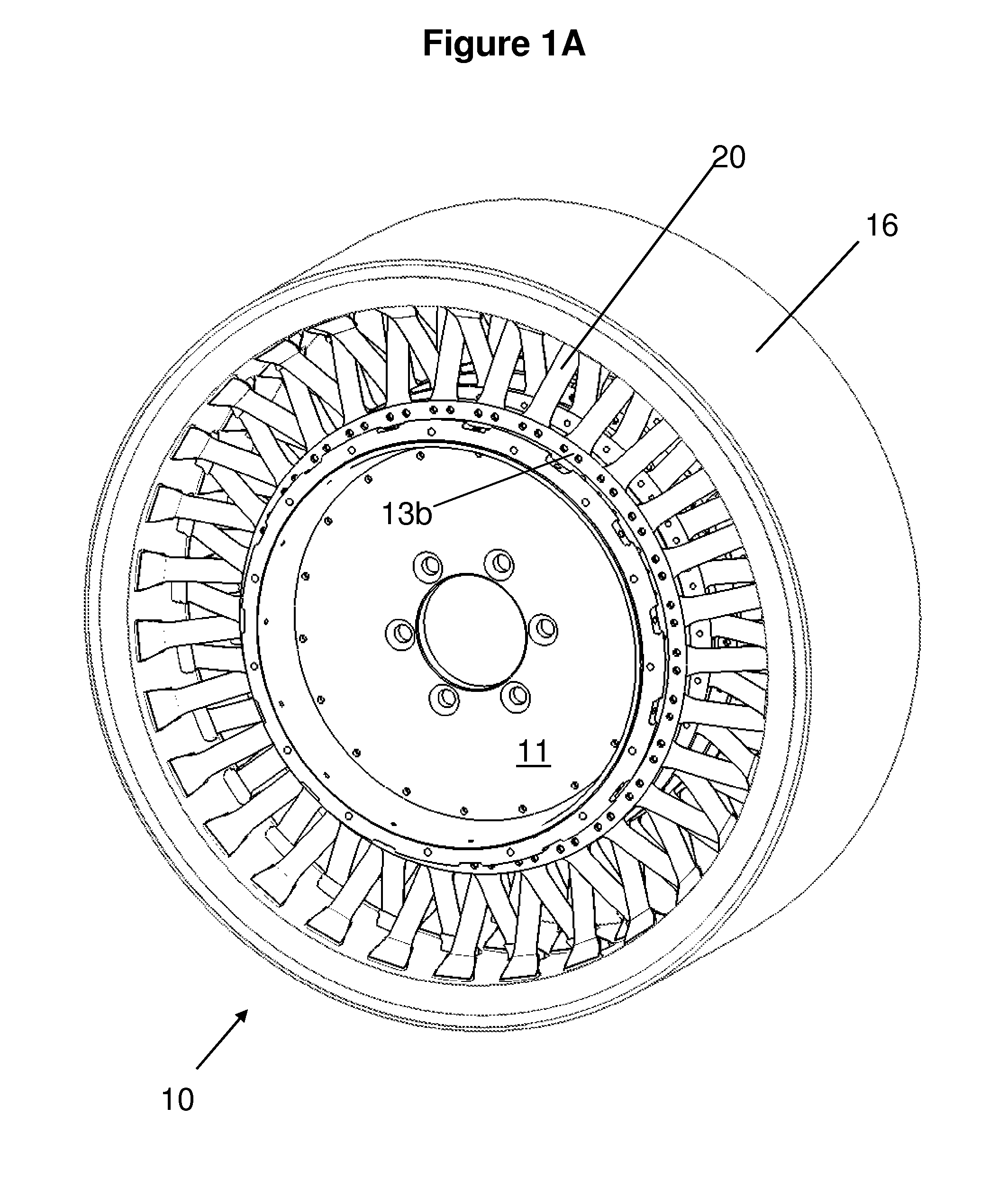

Compliant wheel

InactiveUS7013939B2High effective stiffness in tensionLow effective stiffness in compressionNon-inflatable tyresWheel manufactureBand bendingGround contact

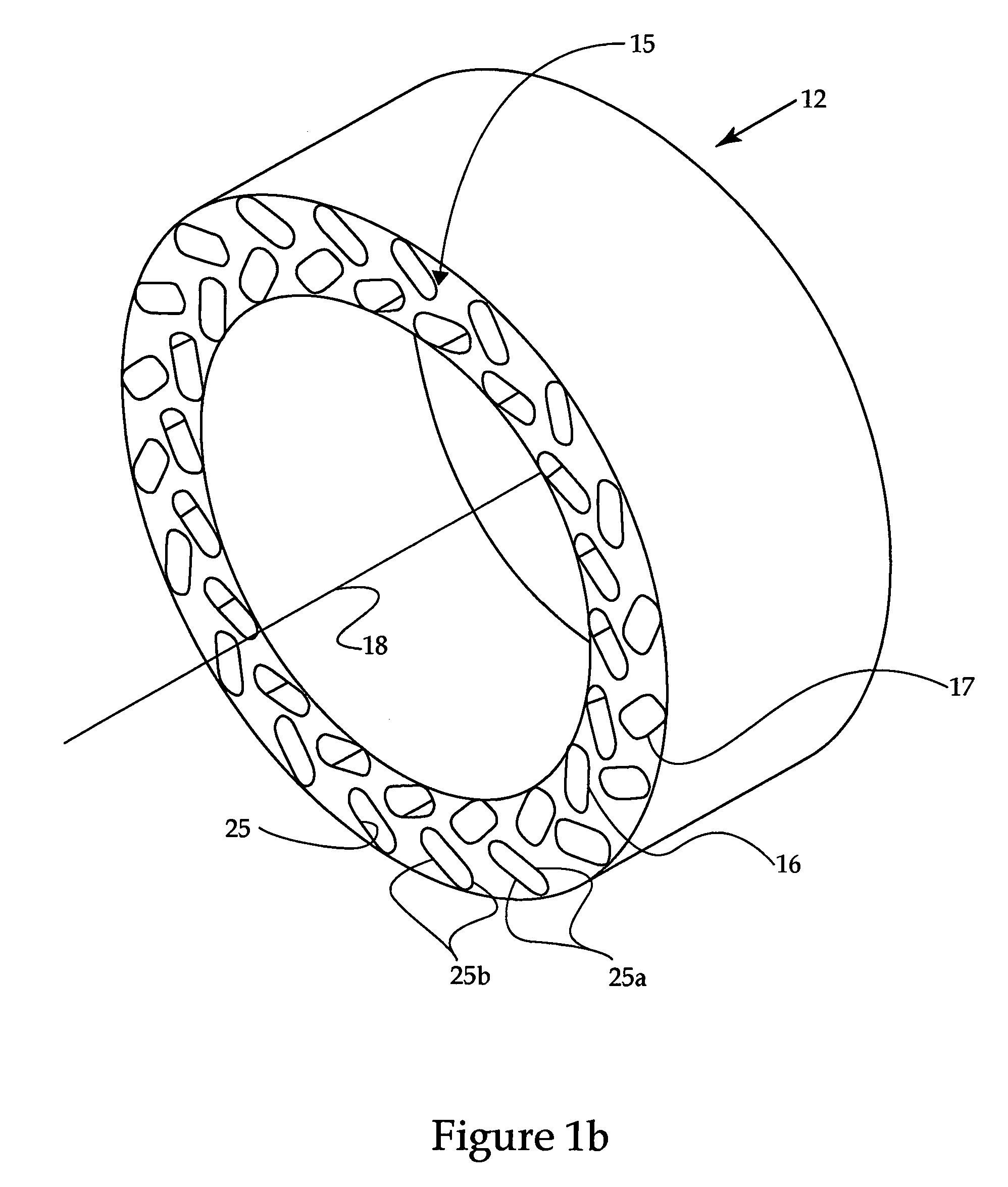

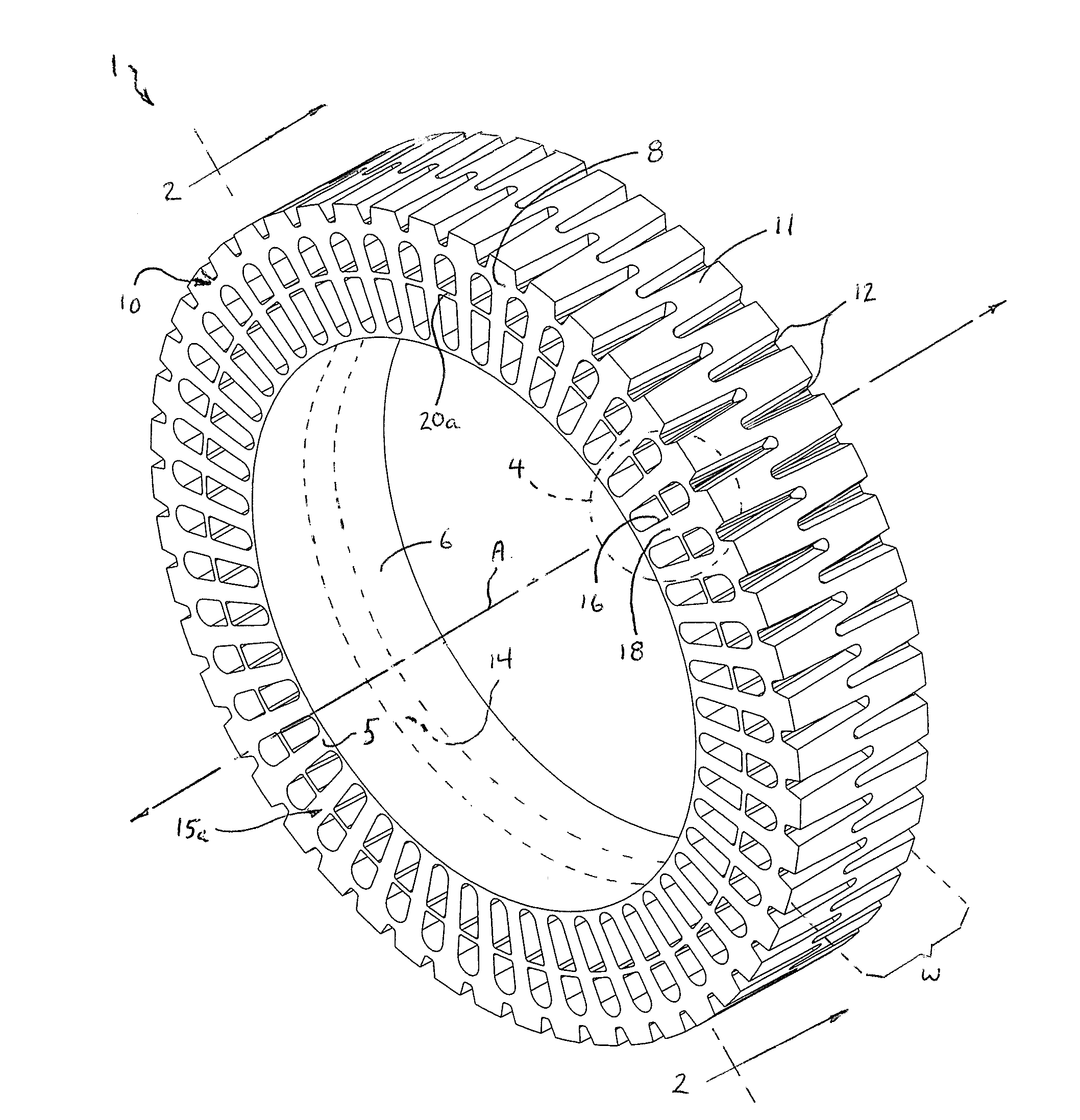

A compliant wheel includes a compliant band and a plurality of web spokes extending transversely across and inward from the reinforced compliant band for attachment to a hub. The compliant band bends to comply with a contact surface and to envelope obstacles. The web spokes transmit load forces between the compliant band and the hub through tension in the web spokes not connected to the ground contacting portion of the wheel. The outer surface of the compliant band may be formed to include a tread, or a separate tread band may be attached.

Owner:MICHELIN RECH & TECH SA

Structurally supported resilient tire and materials

The invention comprises an improved non-pneumatic tire, and particularly a shear layer for a non-pneumatic tire wherein the shear layer comprises an elastomeric composition that includes a metal salt of a carboxylic acid. The shear layer preferably comprises a dienic elastomeric composition that includes a metal salt of a carboxylic acid. In one embodiment of the invention, the metal salt of the carboxylic acid is zinc diacrylate or zinc dimethacrylate. In one embodiment of the invention, the metal salt of the carboxylic acid is zinc diacrylate or zinc dimethacrylate, and a peroxide curative agent is employed.

Owner:MICHELIN RECH & TECH SA

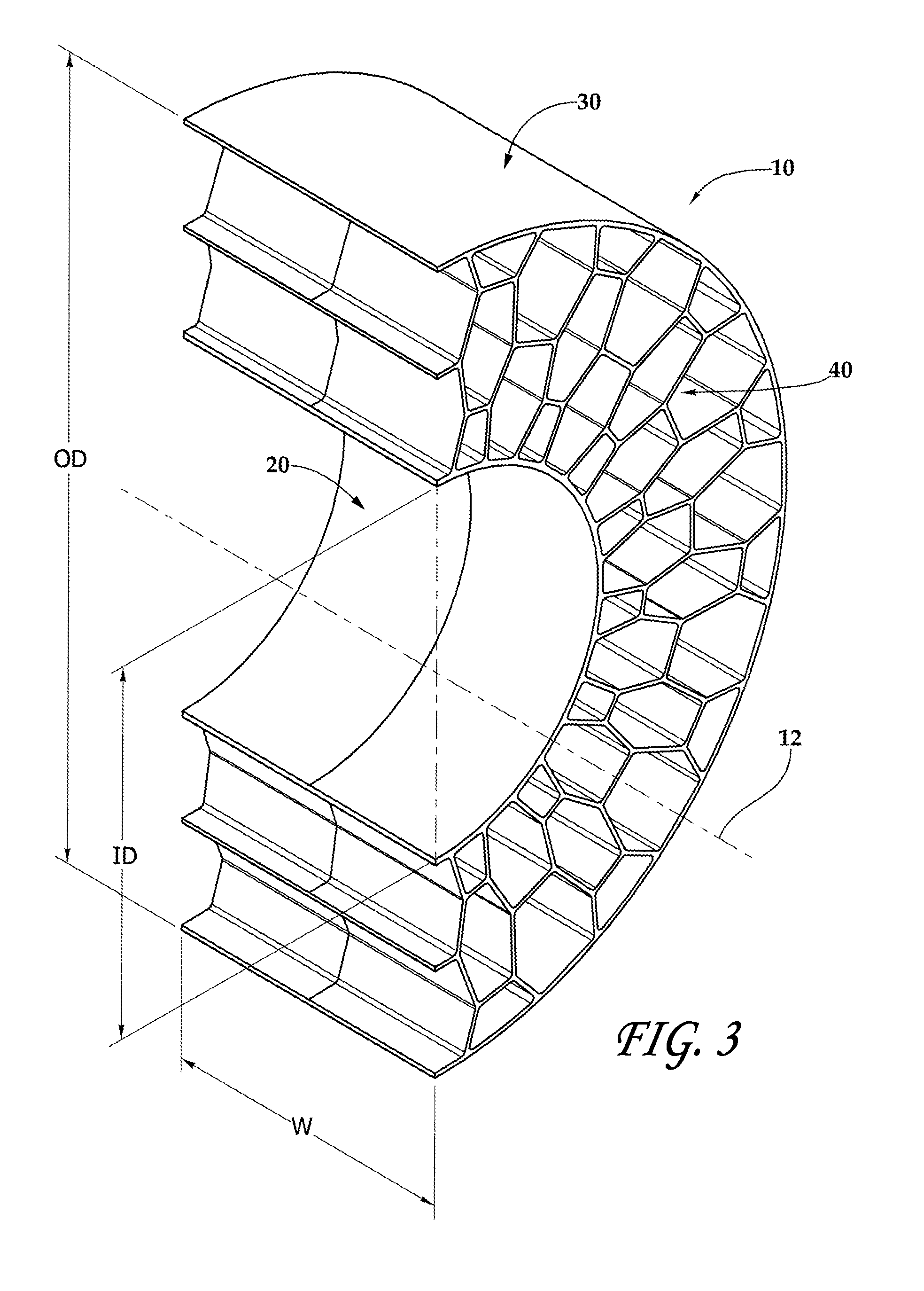

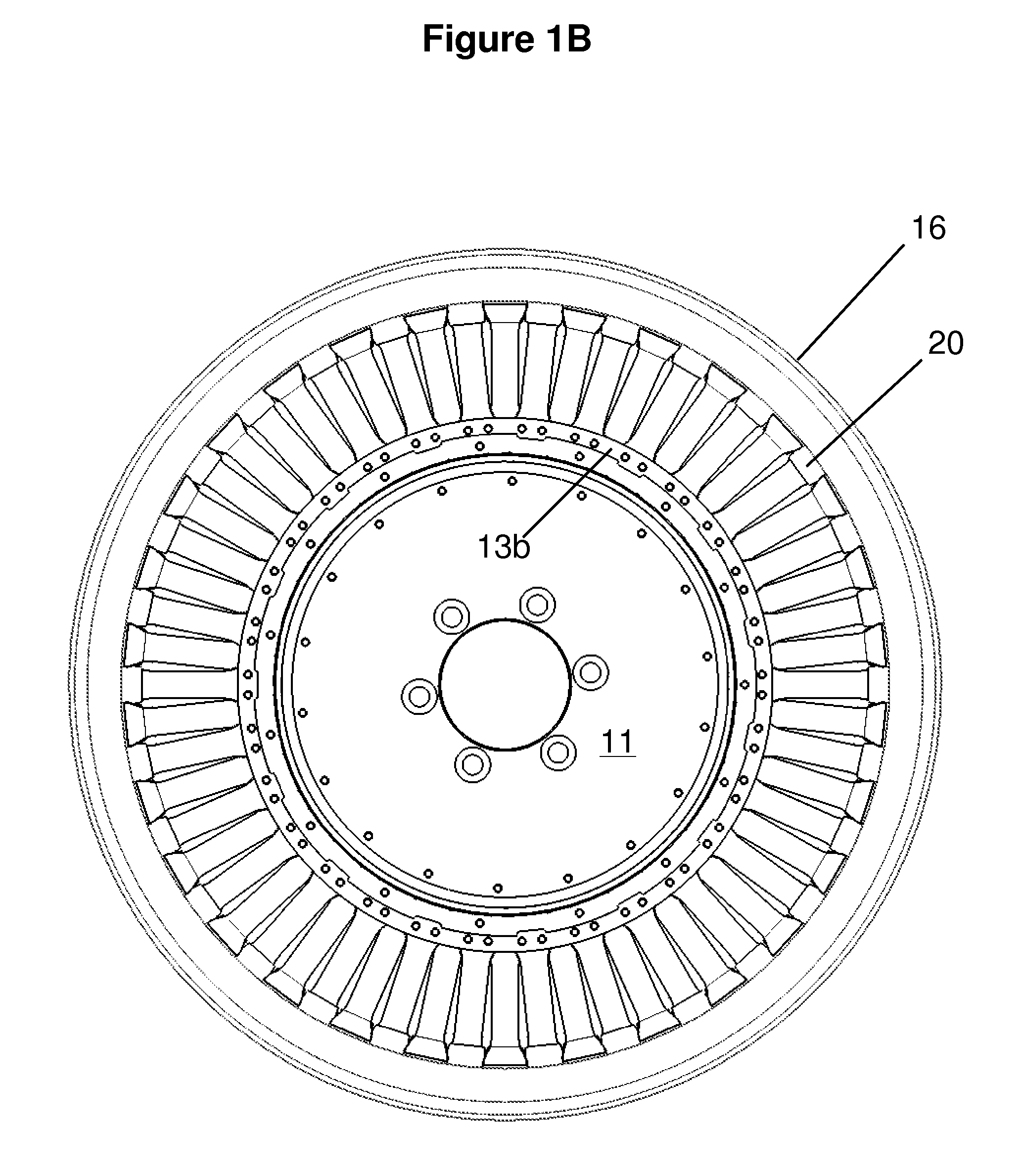

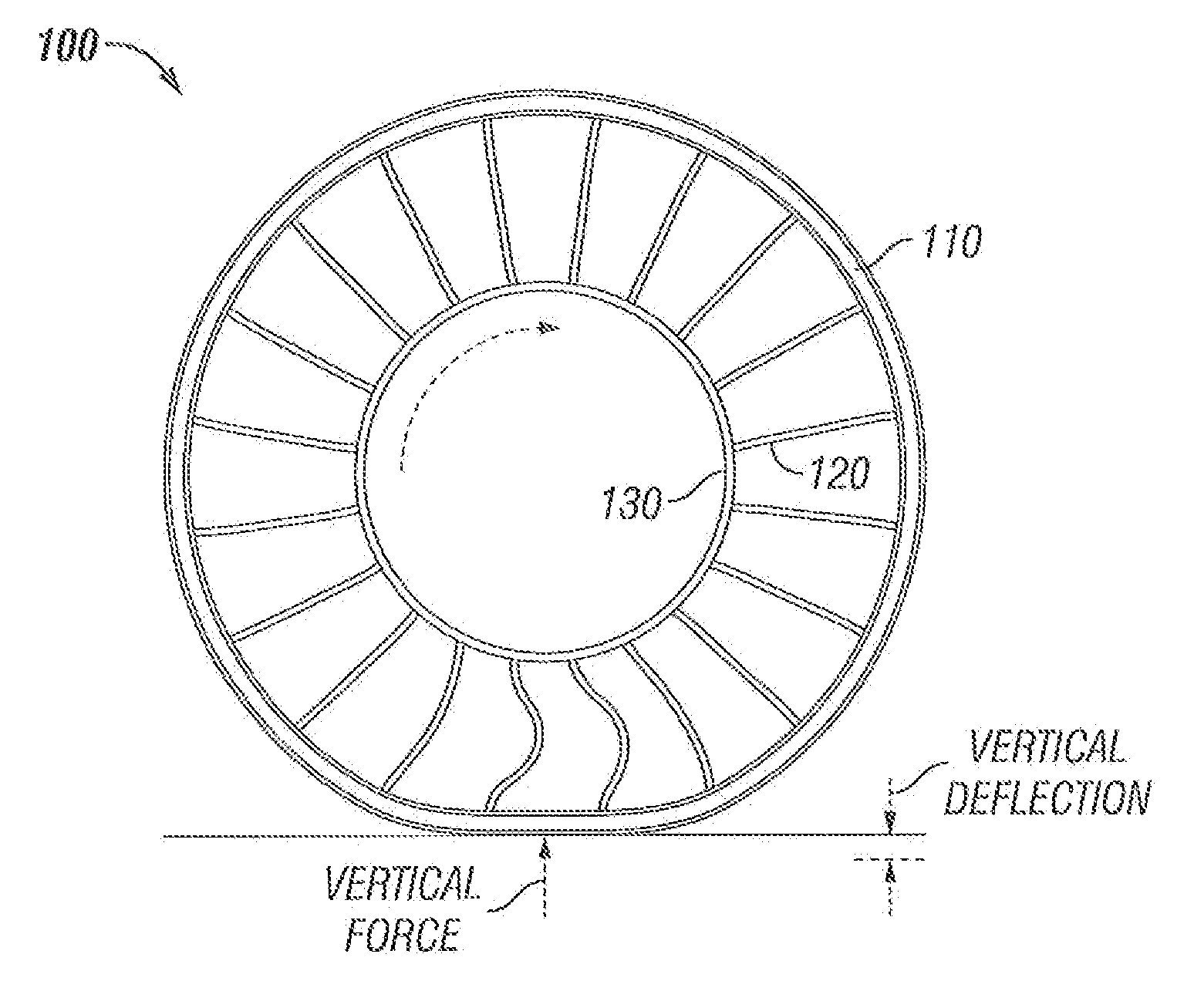

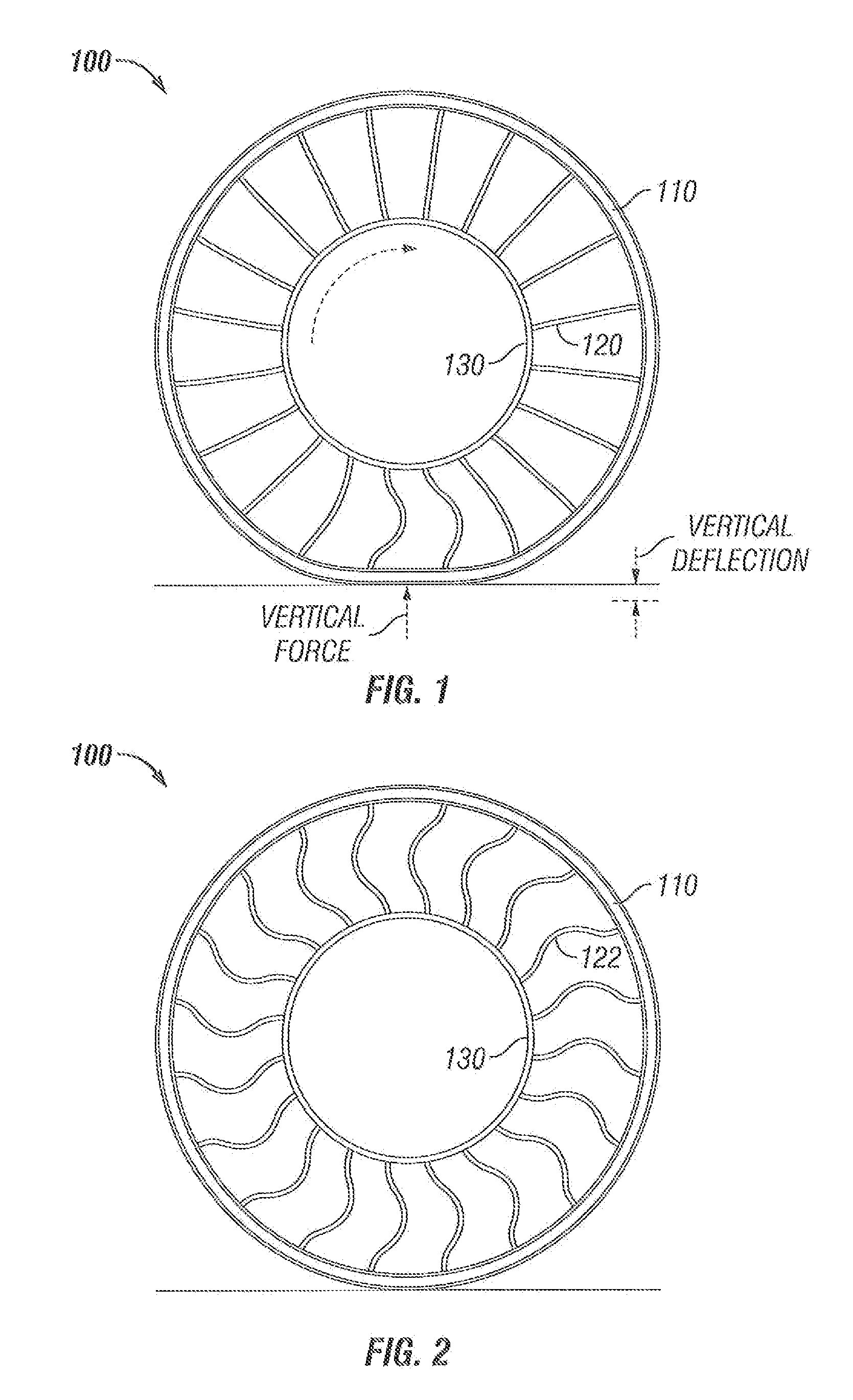

Tension-based non-pneumatic tire

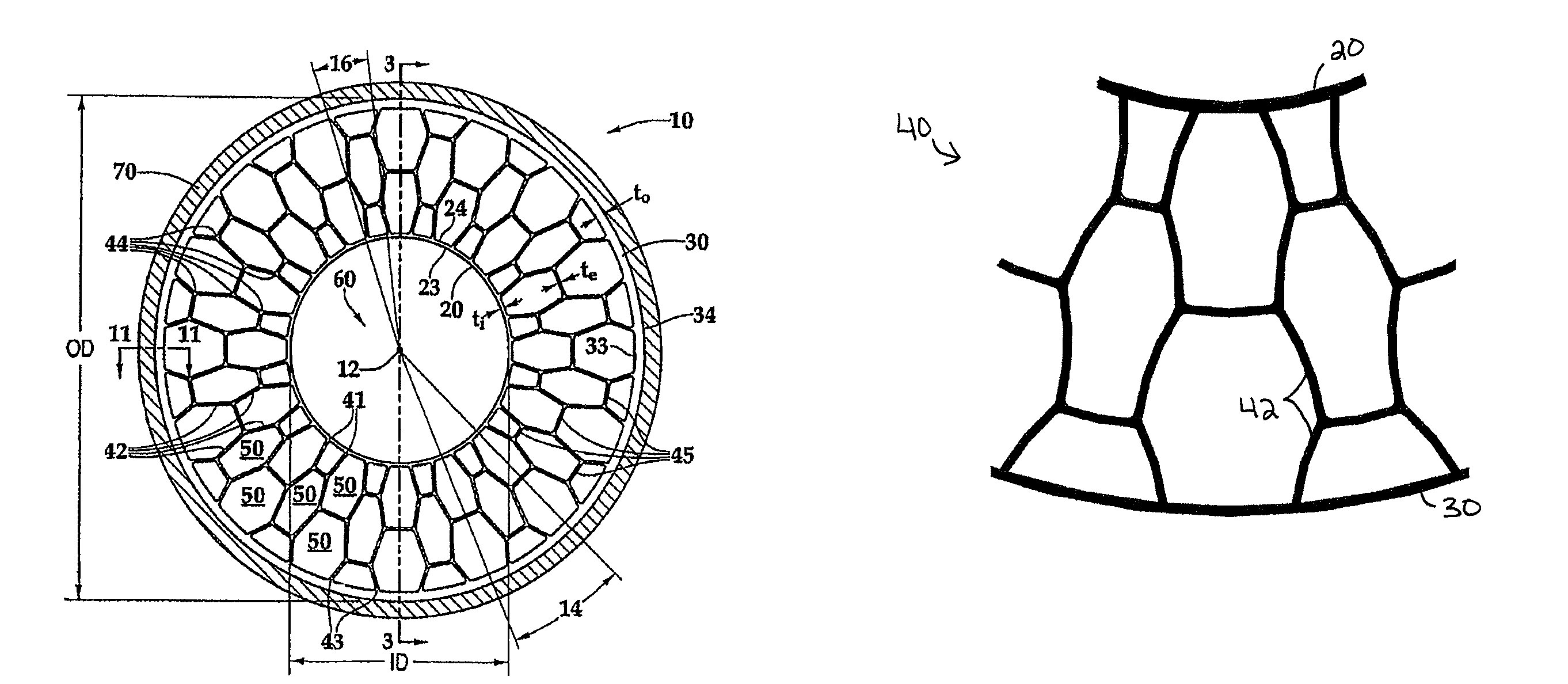

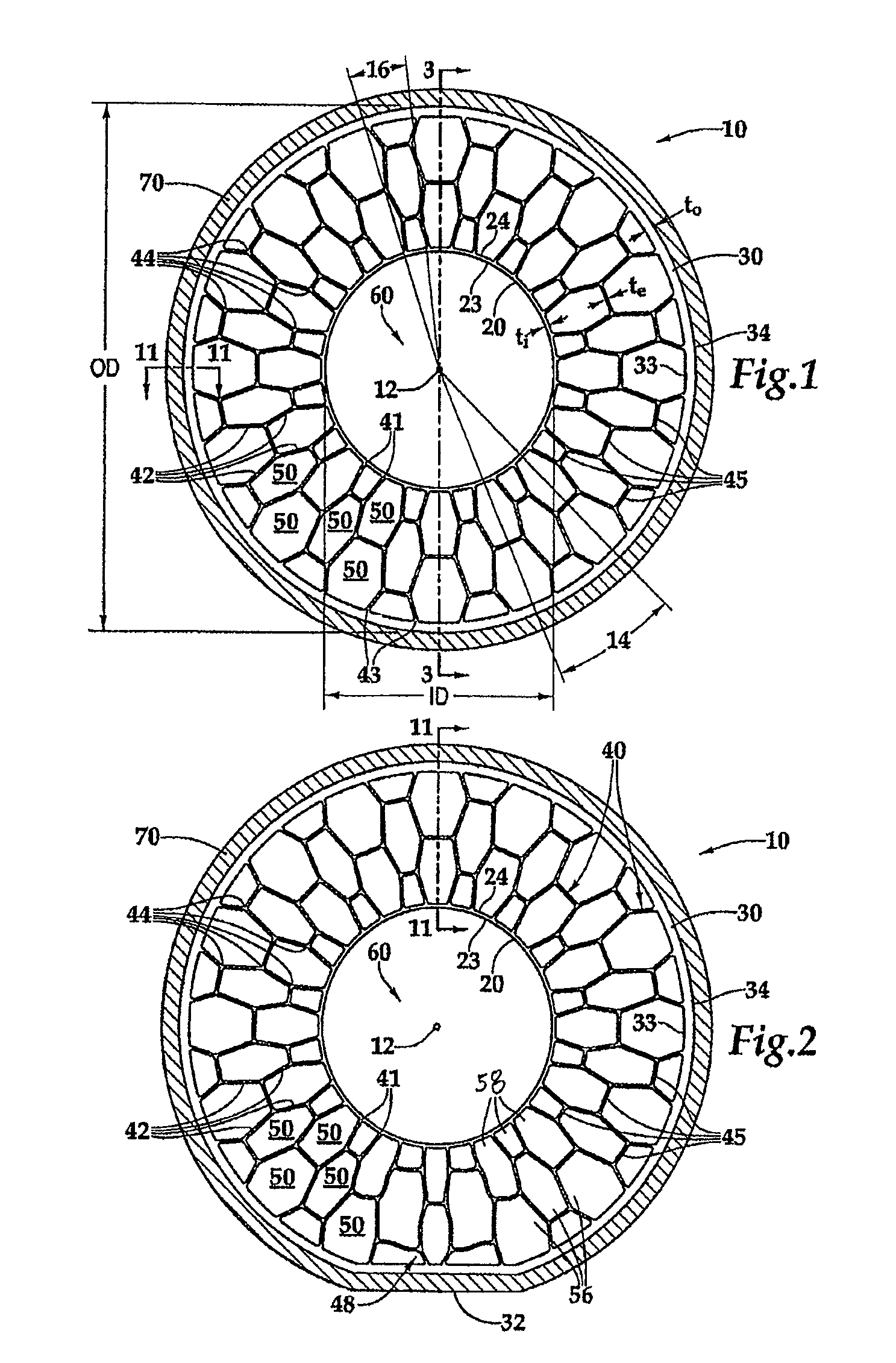

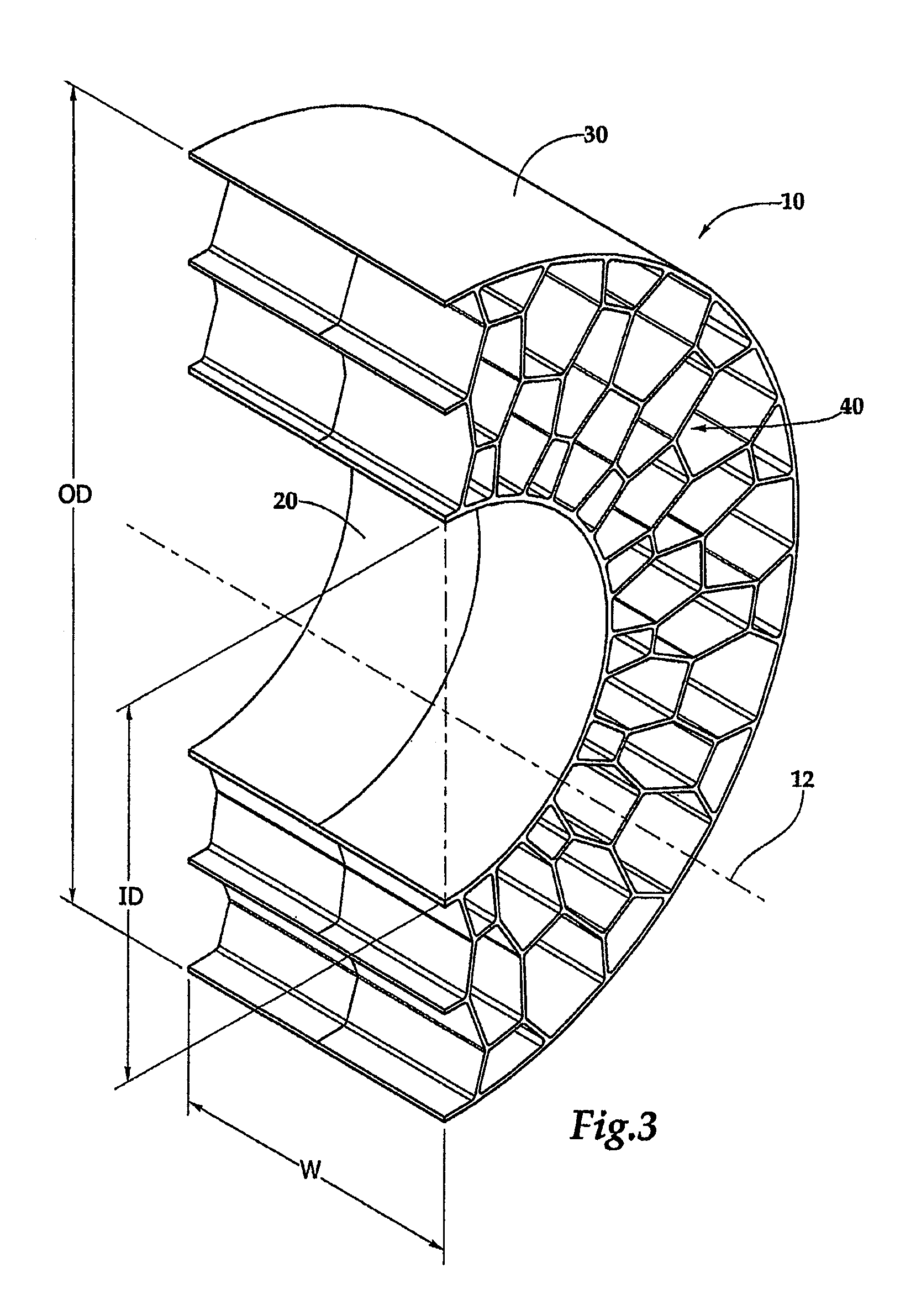

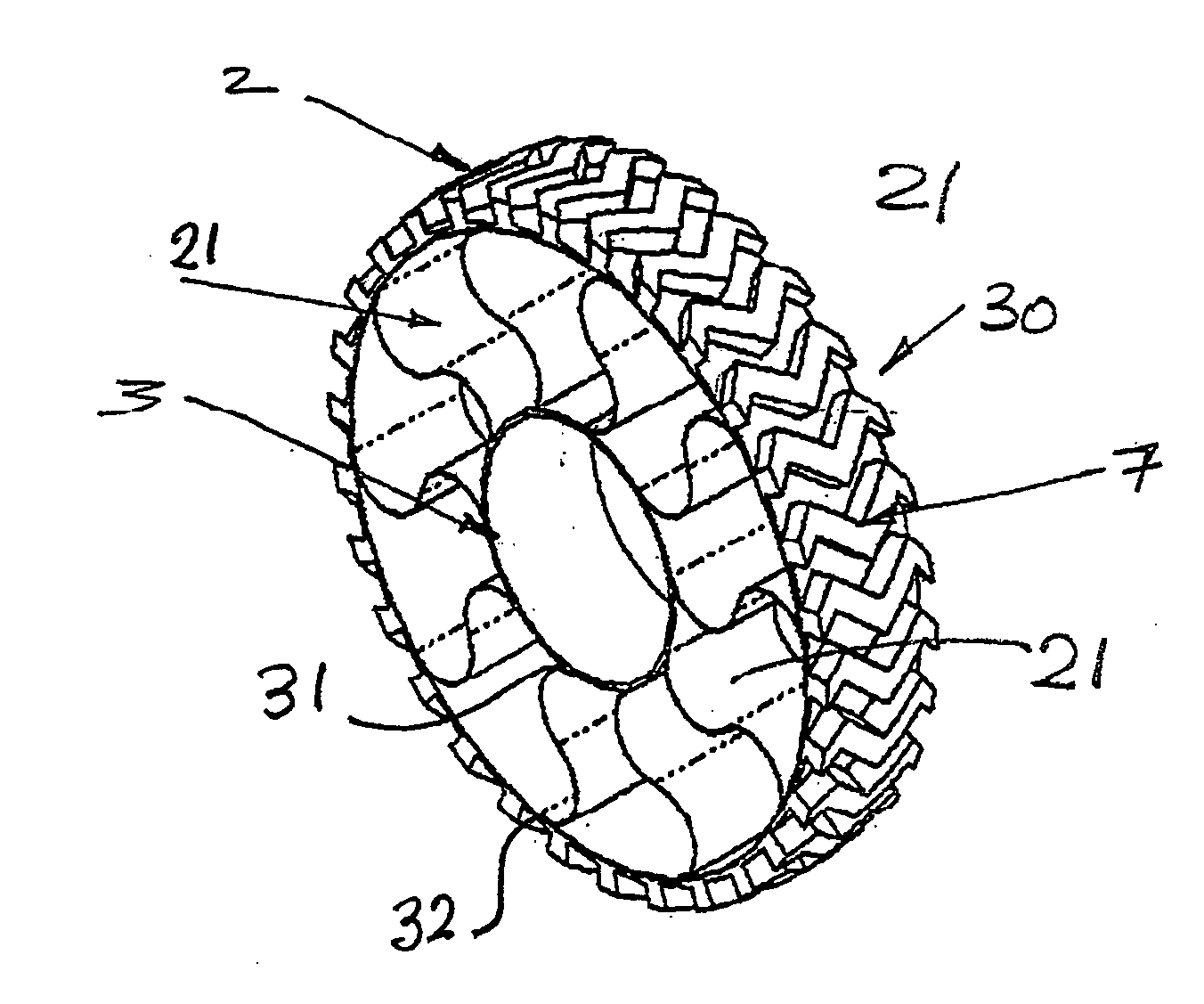

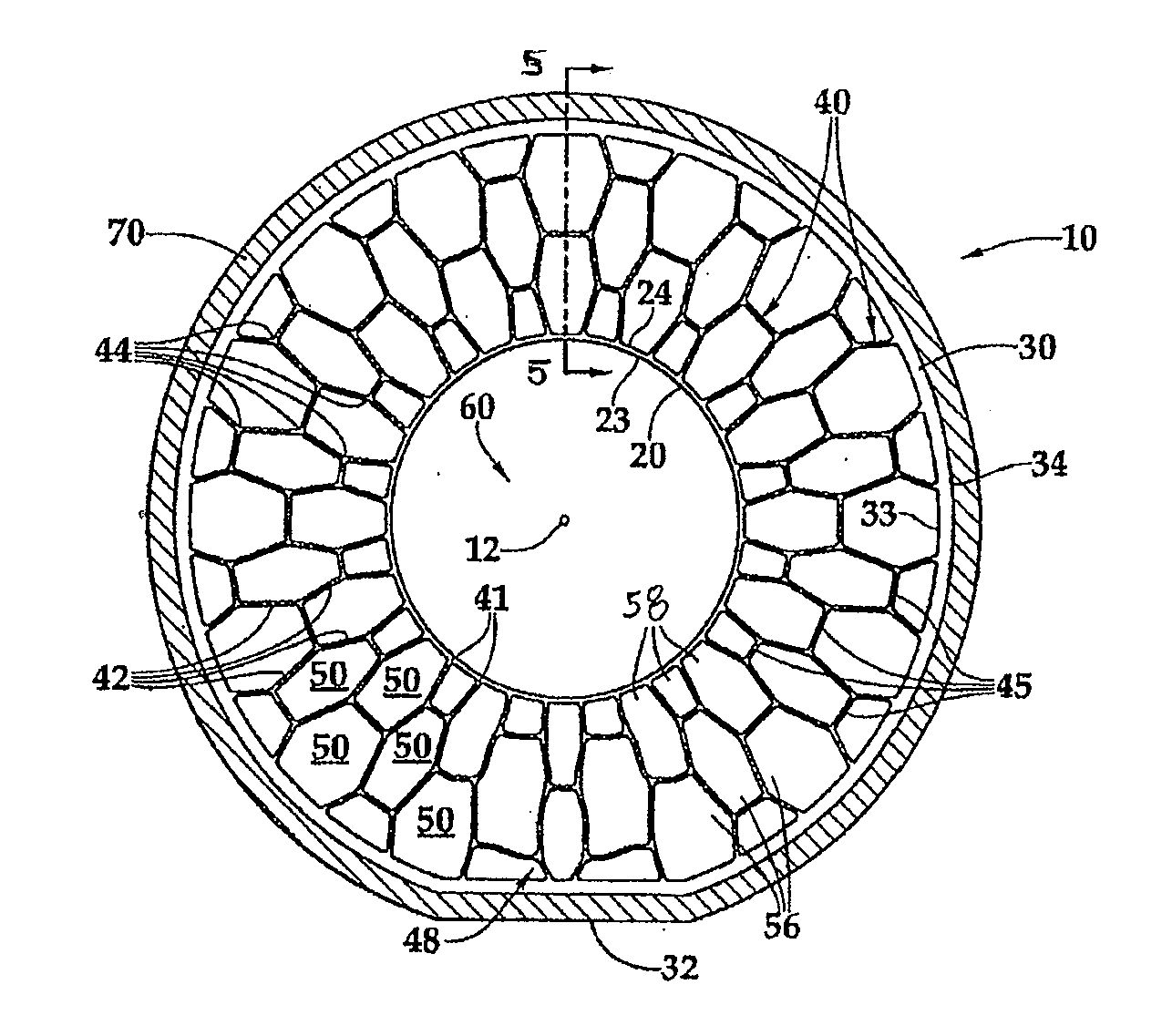

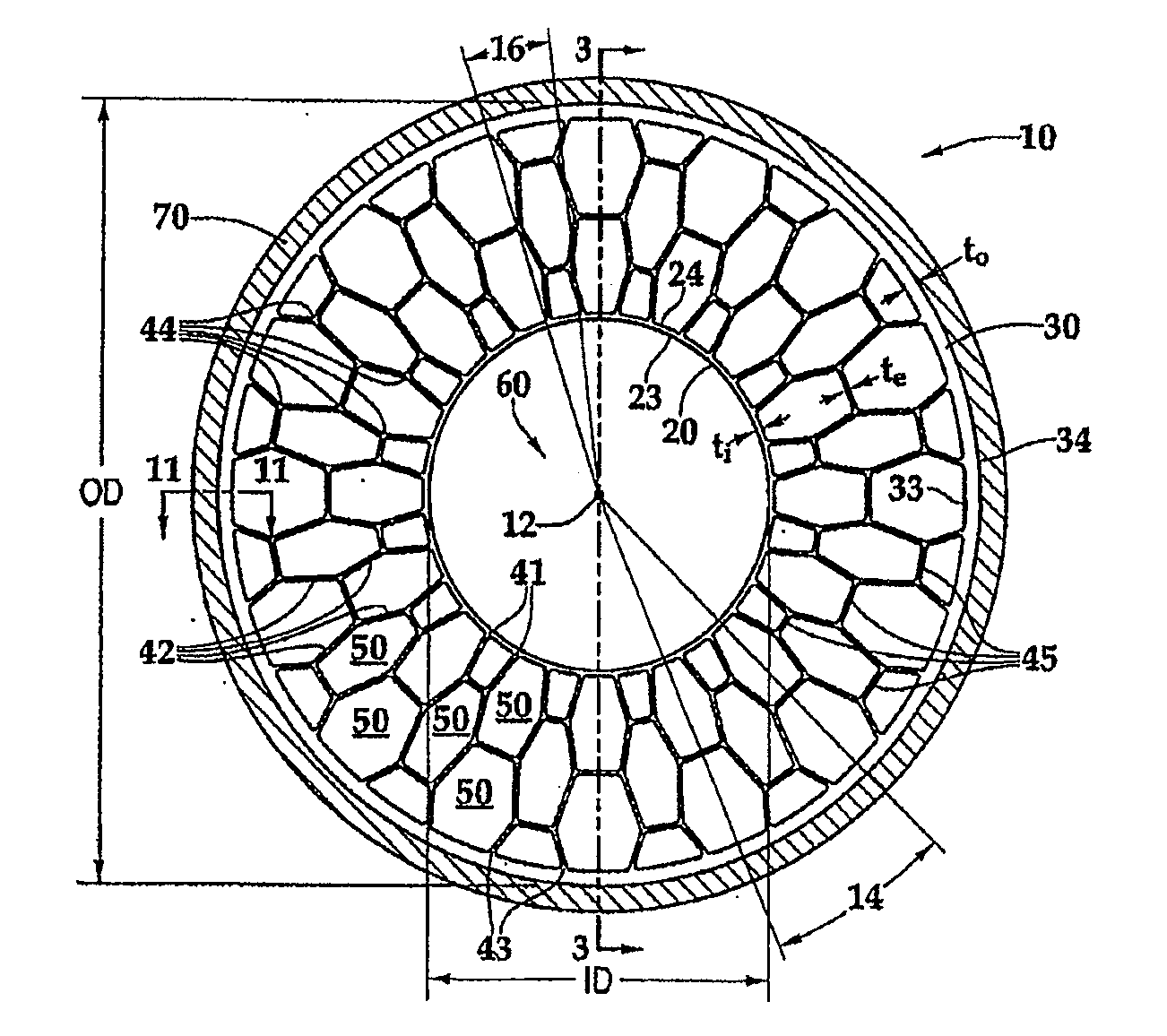

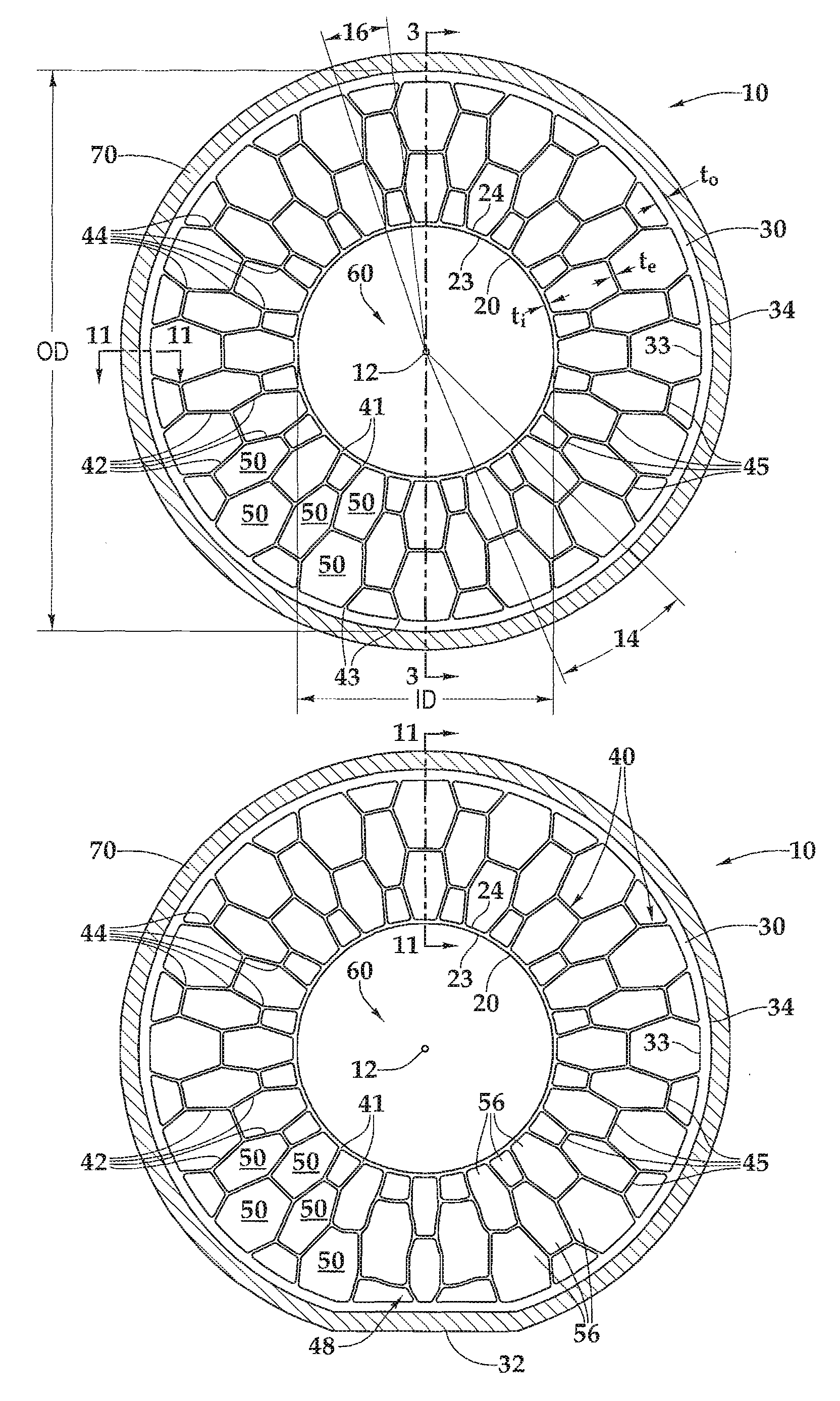

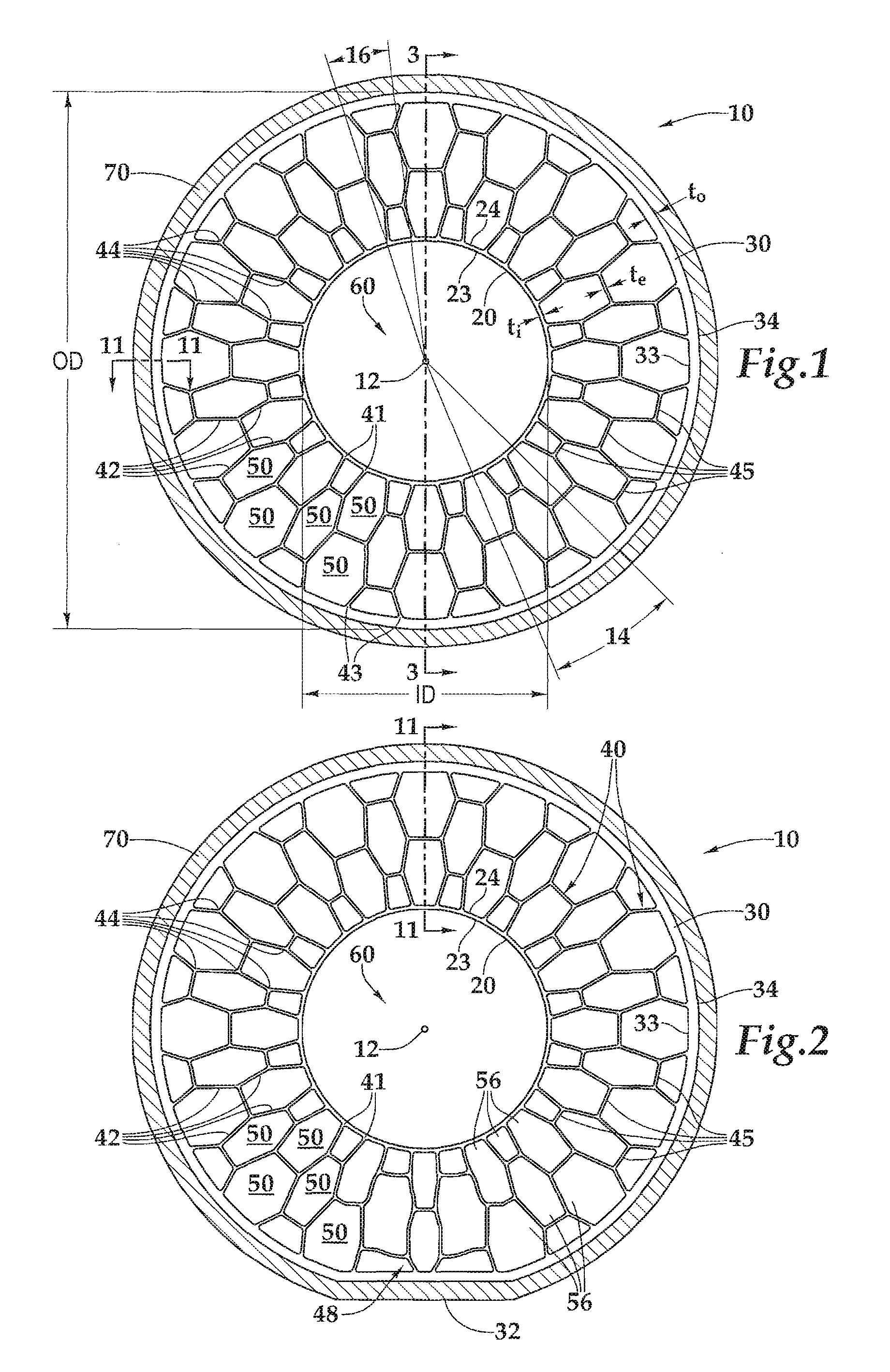

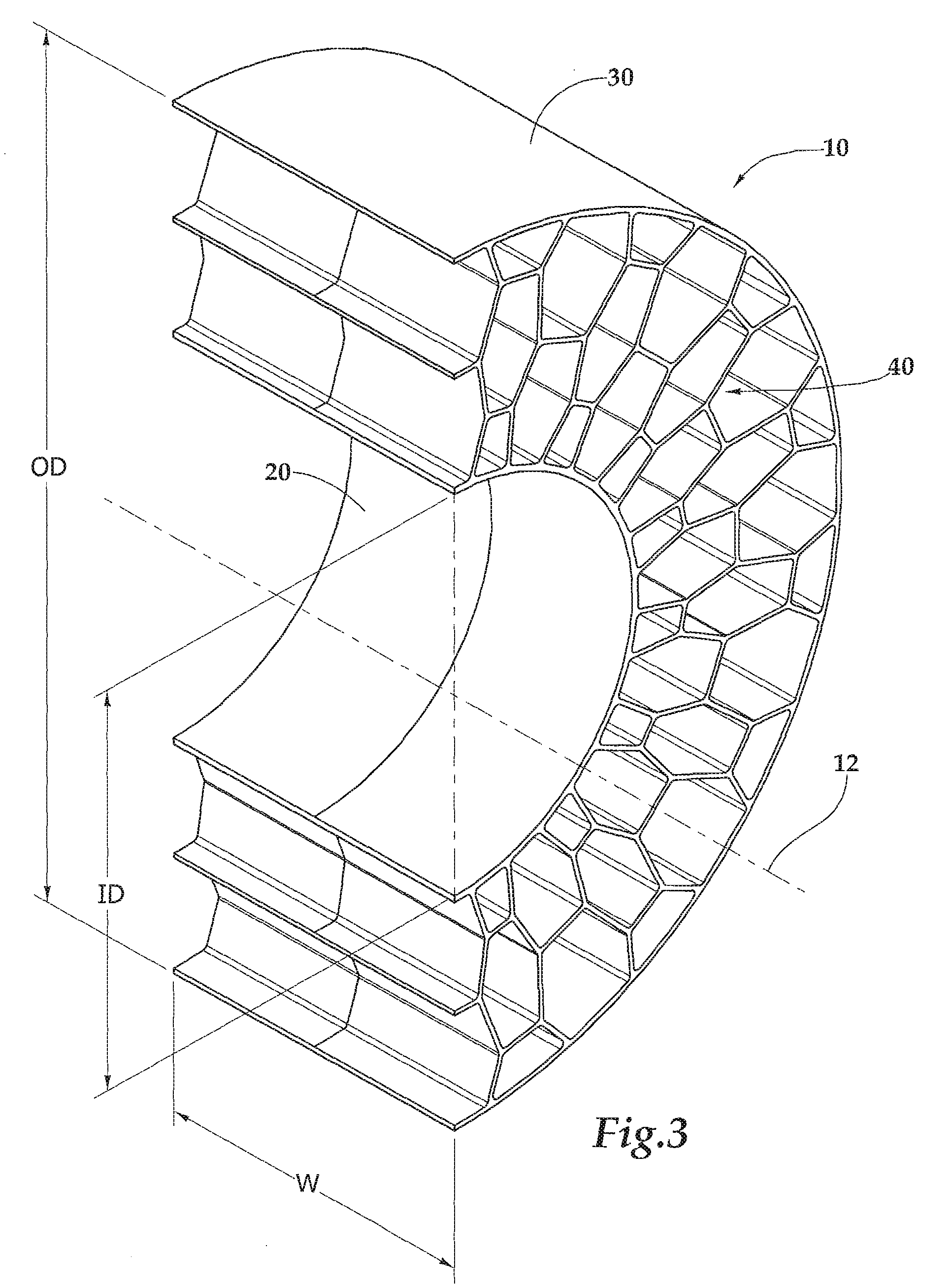

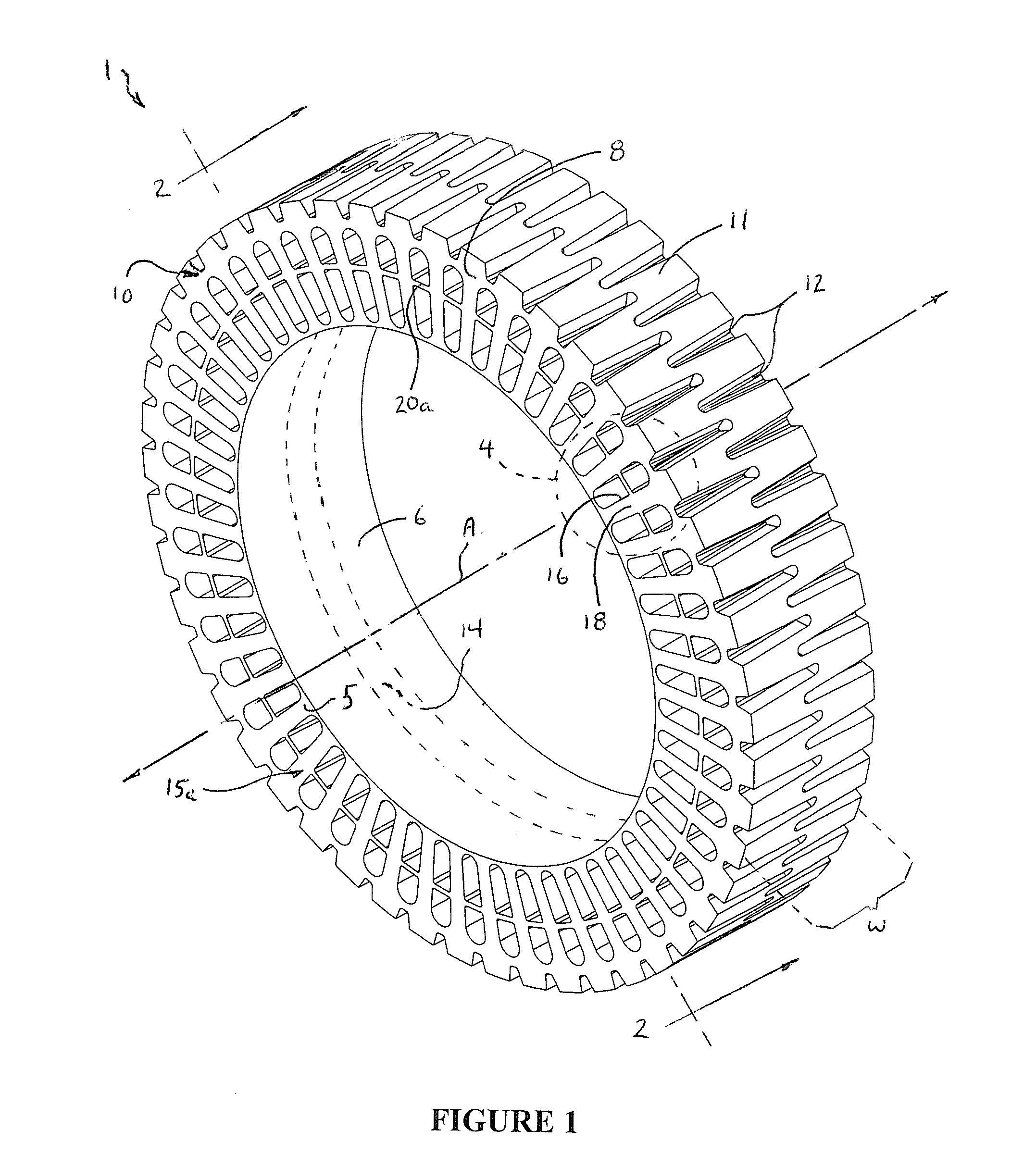

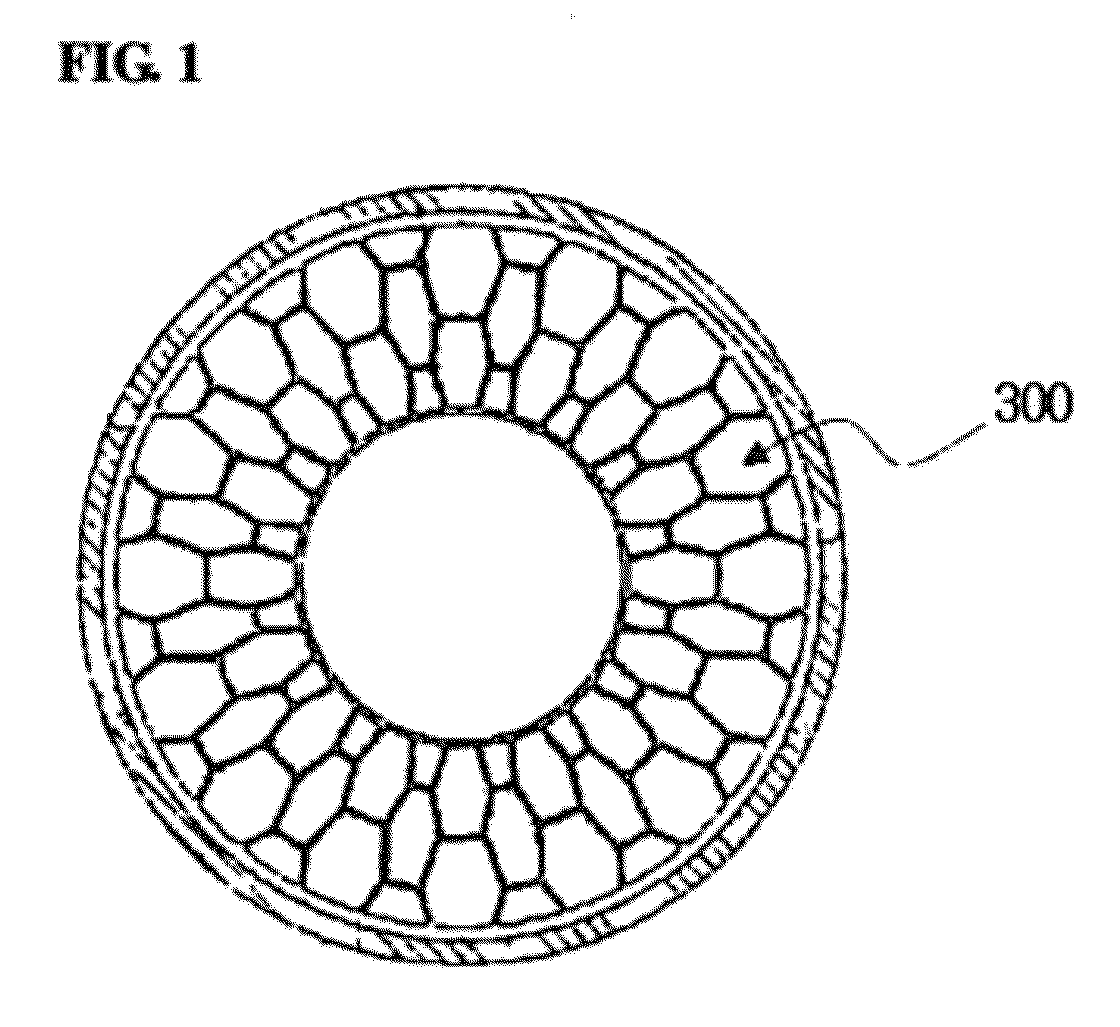

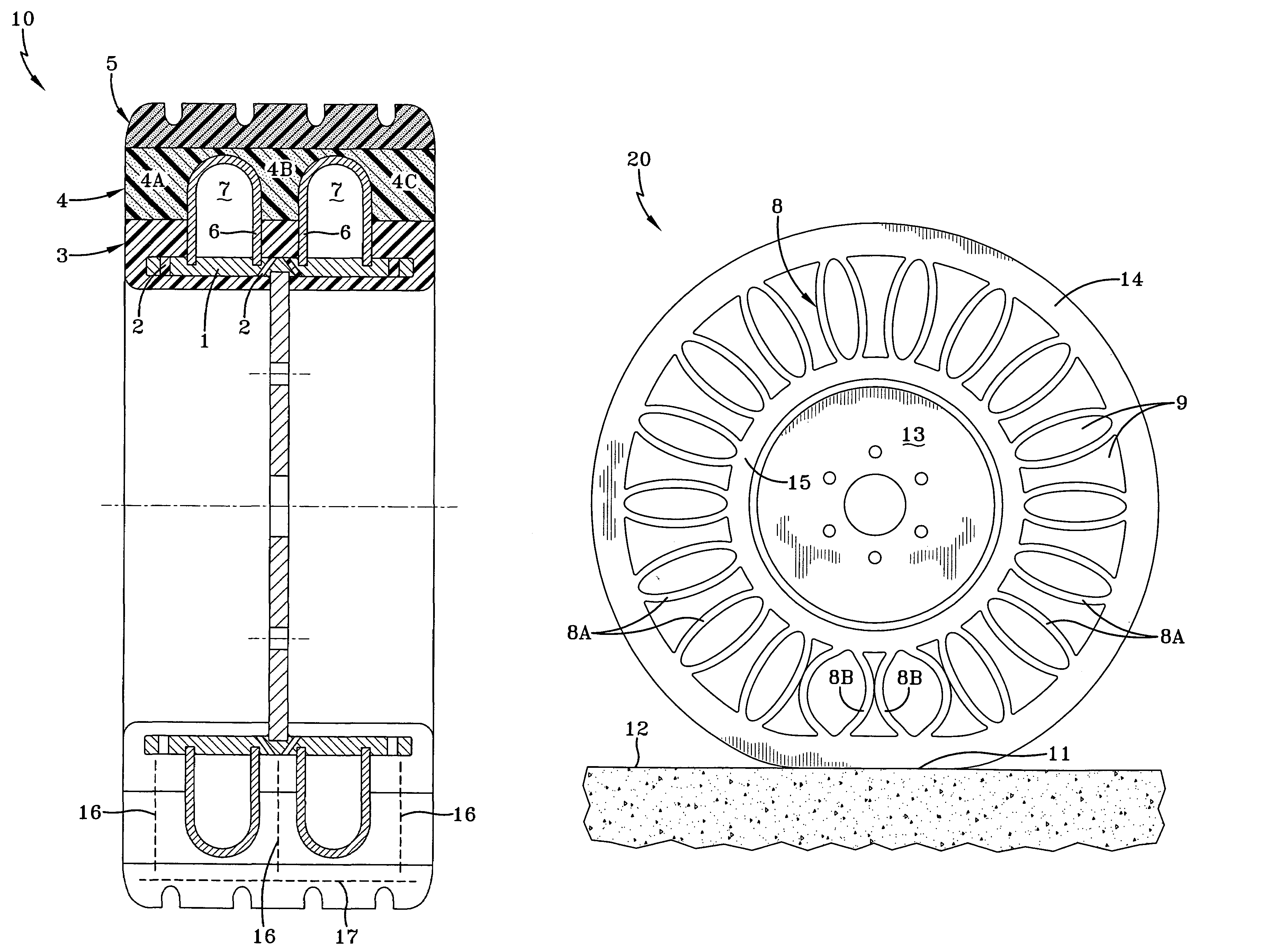

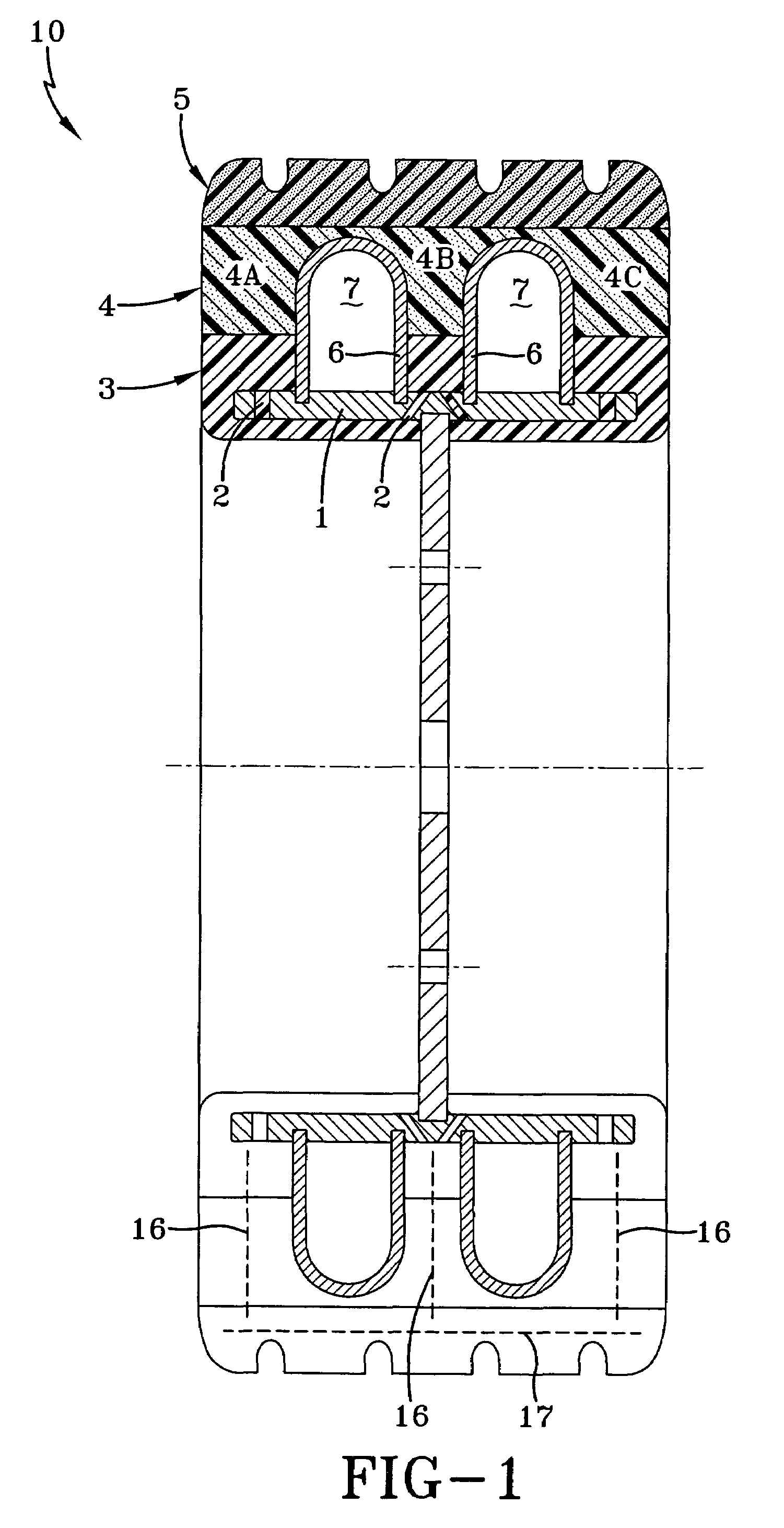

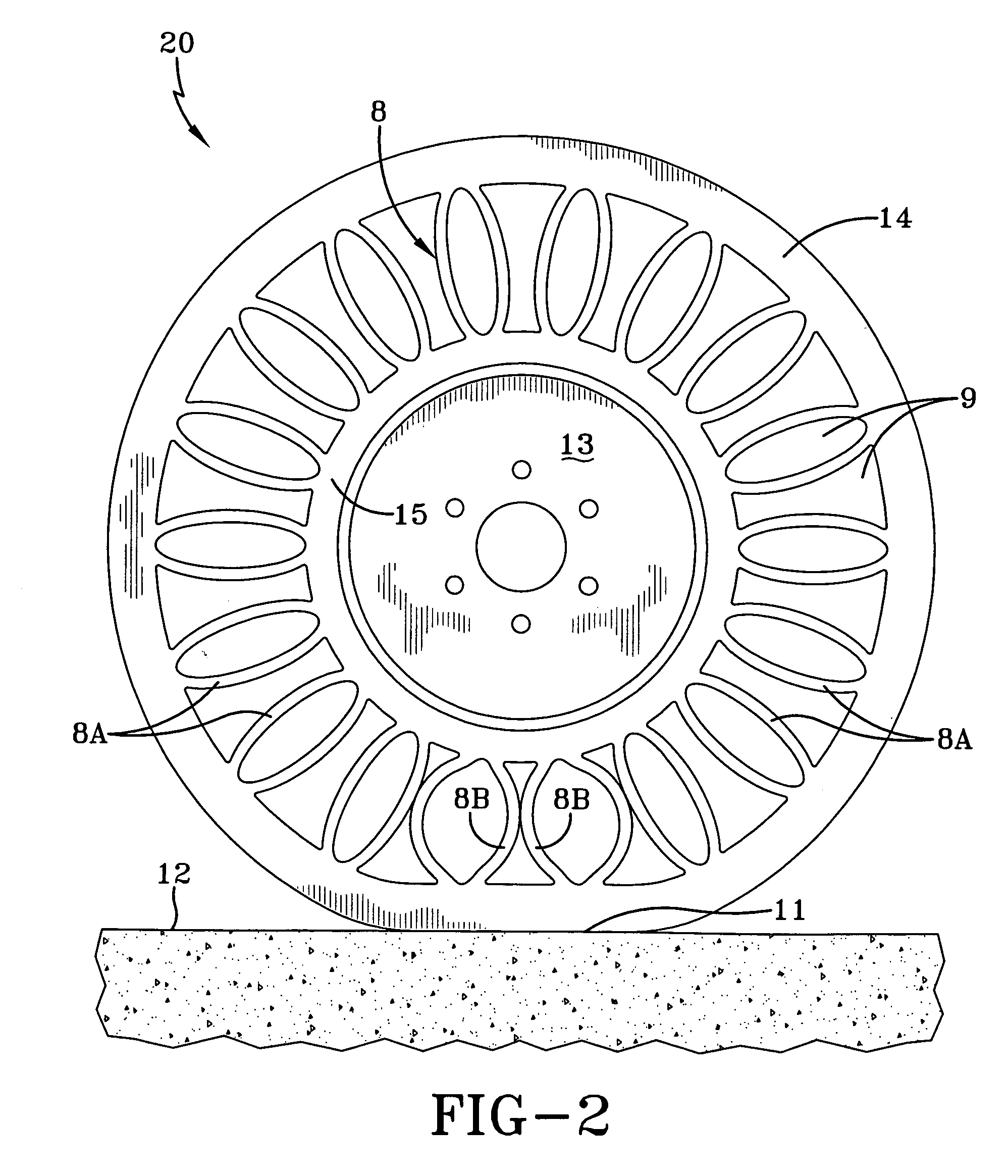

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner ring, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, curved, oriented, and comprised of varying thicknesses of material which facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a wheel and a footprint region where the tire contacts a surface can assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Tension-based non-pneumatic tire

ActiveUS20080314486A1Increase stiffnessEasy to disassembleNon-inflatable tyresHigh resiliency wheelsEngineeringMechanical engineering

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner ring, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, oriented and comprised of a material that facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a wheel and a footprint region where the tire contacts a surface can assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Tension-based non-pneumatic tire

ActiveUS8104524B2Extend tire lifeLess susceptible to shock and vibrationNon-inflatable tyresHigh resiliency wheelsMechanical engineeringFlat tire

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner surface, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, oriented and comprised of a material that facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a hub and a footprint region where the tire contacts a surface may assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load. Since the tire is non-pneumatic, it may be easier to maintain and may have a longer life than standard pneumatic tires since it eliminates the possibility of blowouts, flat tires, or tires operating with low air pressure. By virtue of the portion of the tire in the footprint region not bearing a significant portion of the load, non-pneumatic tire may also exhibit a more comfortable ride subject to less noise and vibration and improved handling capabilities.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Wheel

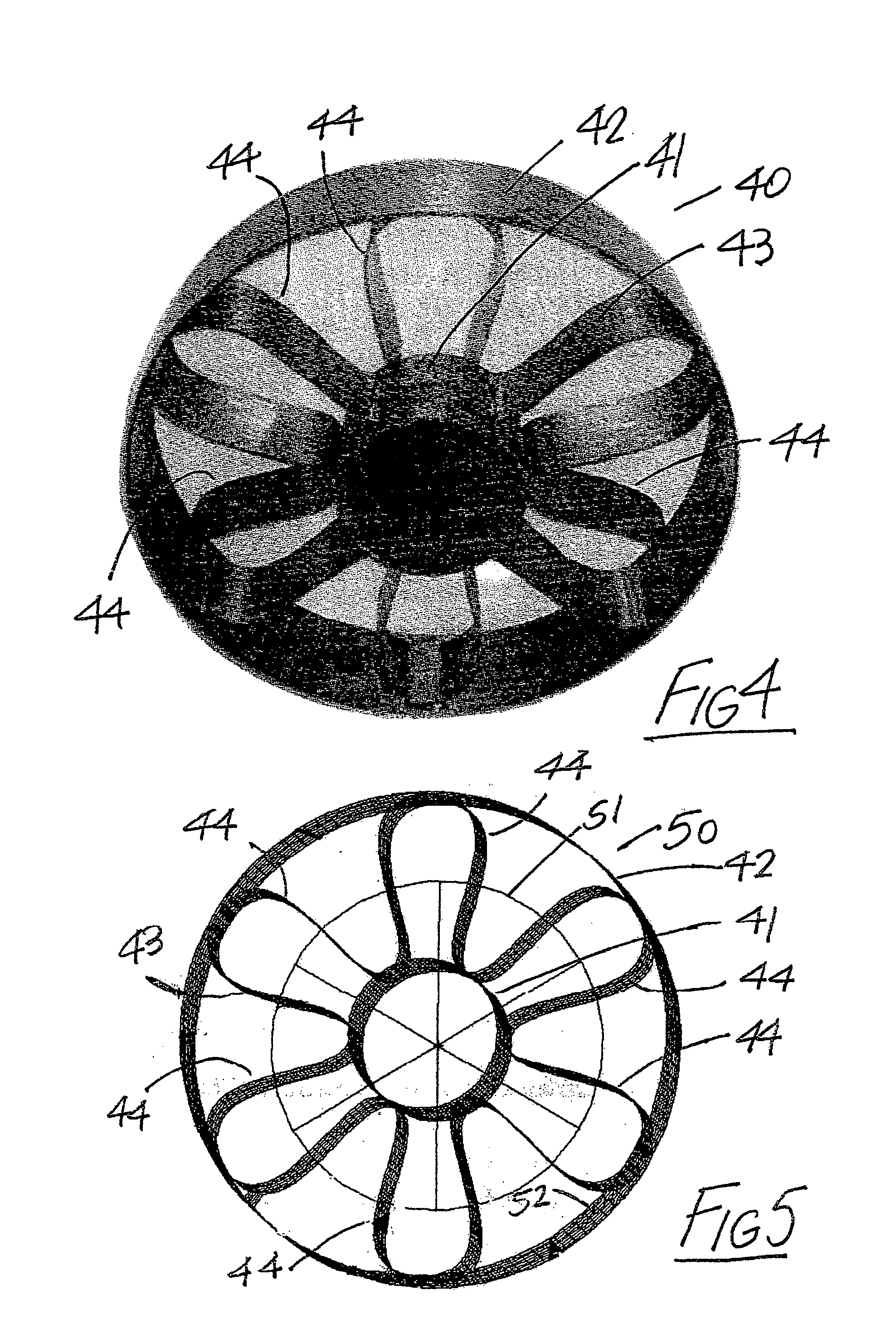

InactiveUS20040069385A1Improve gripGreat tractionNon-inflatable tyresHigh resiliency wheelsCarbon fibersMechanical engineering

A lightweight wheel is constructed of titanium or a composite material such as carbon fibre reinforced nylon material. The wheel has a central hub and a circular rim which are interconnected by sprig elements such as may be formed by a looped spring band having a number of radial loops extending between the hub and rim. A tyre strip may be mounted around an outer circumferential face of the rim.

Owner:TECH INVESTMENTS

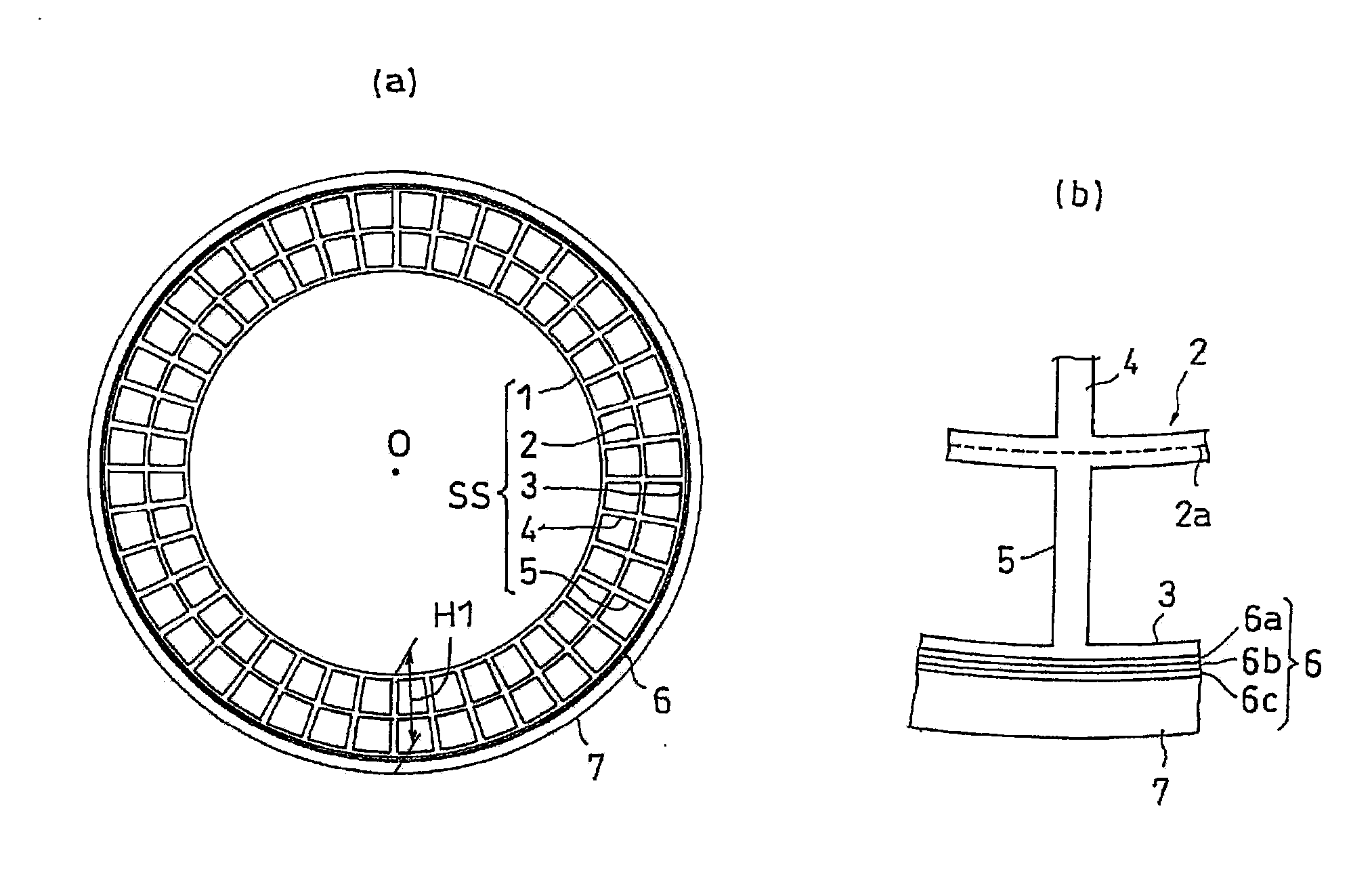

Non-pneumatic tire and its manufacturing method

InactiveUS20100200131A1Increased durabilityRigidity fluctuation is hardNon-inflatable tyresTyresCouplingEngineering

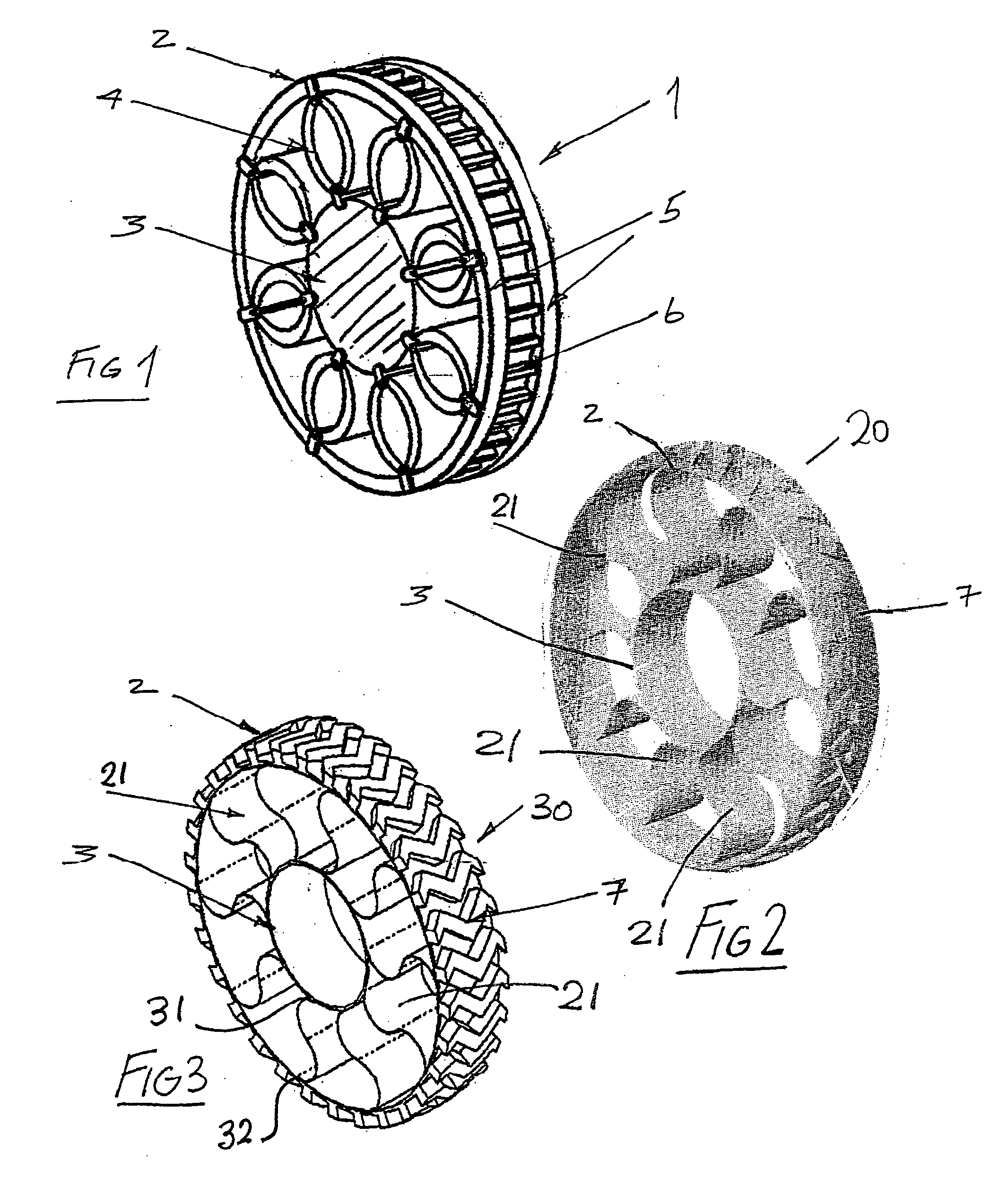

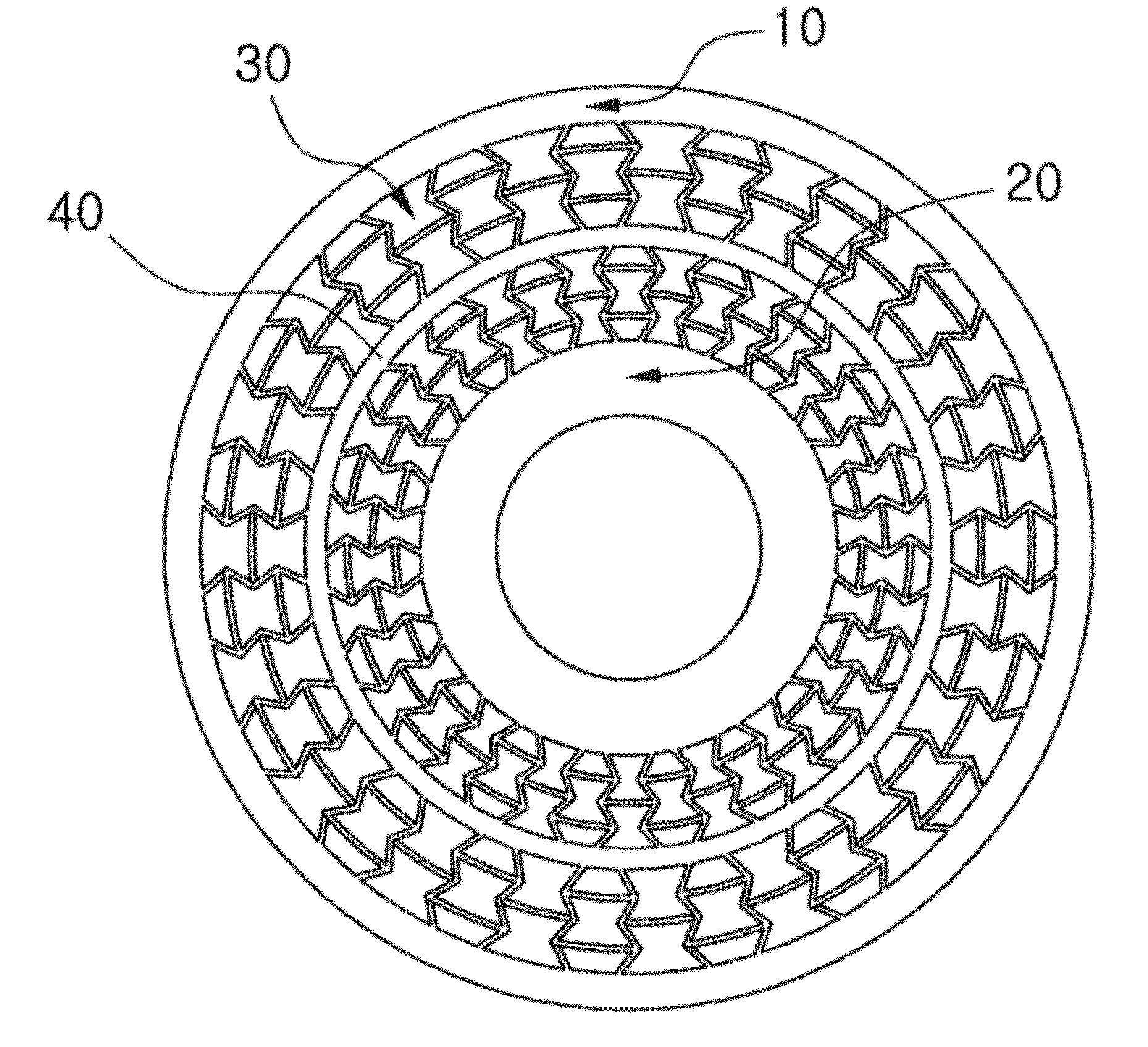

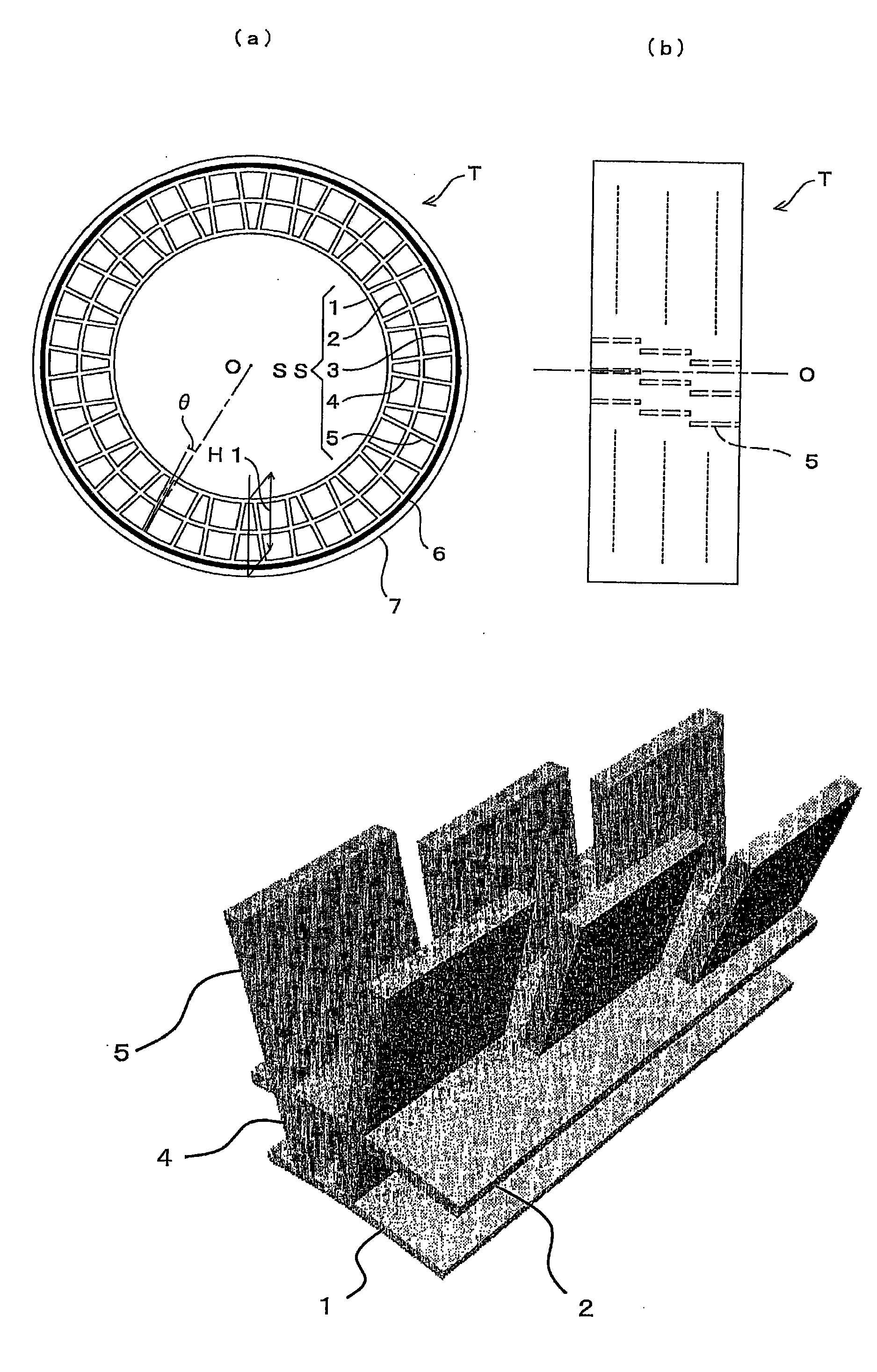

In a non-pneumatic tire having a support structure body supporting a load from a vehicle, the support structure body (SS) comprises an inner annular portion (1) an intermediate annular portion (2) provided concentrically in an outer side of the inner annular portion (1), an outer annular portion (3) provided concentrically in an outer side of the intermediate annular portion (2), a plurality of inner coupling portions (4) coupling the inner annular portion (1) and the intermediate annular portion (2) and being independent in a circumferential direction, and a plurality of outer coupling portions (5) coupling the outer annular portion (3) and the intermediate annular portion (2) and being independent in a circumferential direction.

Owner:TOYO TIRE & RUBBER CO LTD

Solid suspended work machine tire

Owner:CATERPILLAR INC

Tension-based non-pneumatic tire

ActiveUS20110024008A1Easy to disassembleLow stiffnessNon-inflatable tyresTyresEngineeringMechanical engineering

A non-pneumatic tire for supporting a load by working in tension. The tire can comprise a generally annular inner ring, a generally annular outer ring, and a web having a plurality of web elements. The tire can further comprise a layer or layers fabric material acting as a bonding agent to bond tire components together.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Tension-based non-pneumatic tire

ActiveUS8109308B2Increase stiffnessEasy to disassembleNon-inflatable tyresHigh resiliency wheelsMechanical engineeringCompressive load

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Non-pneumatic tire

InactiveUS20060113016A1Supporting massHigh effective radial stiffness in tensionNon-inflatable tyresPneumatic tyre reinforcementsMaximum depthEngineering

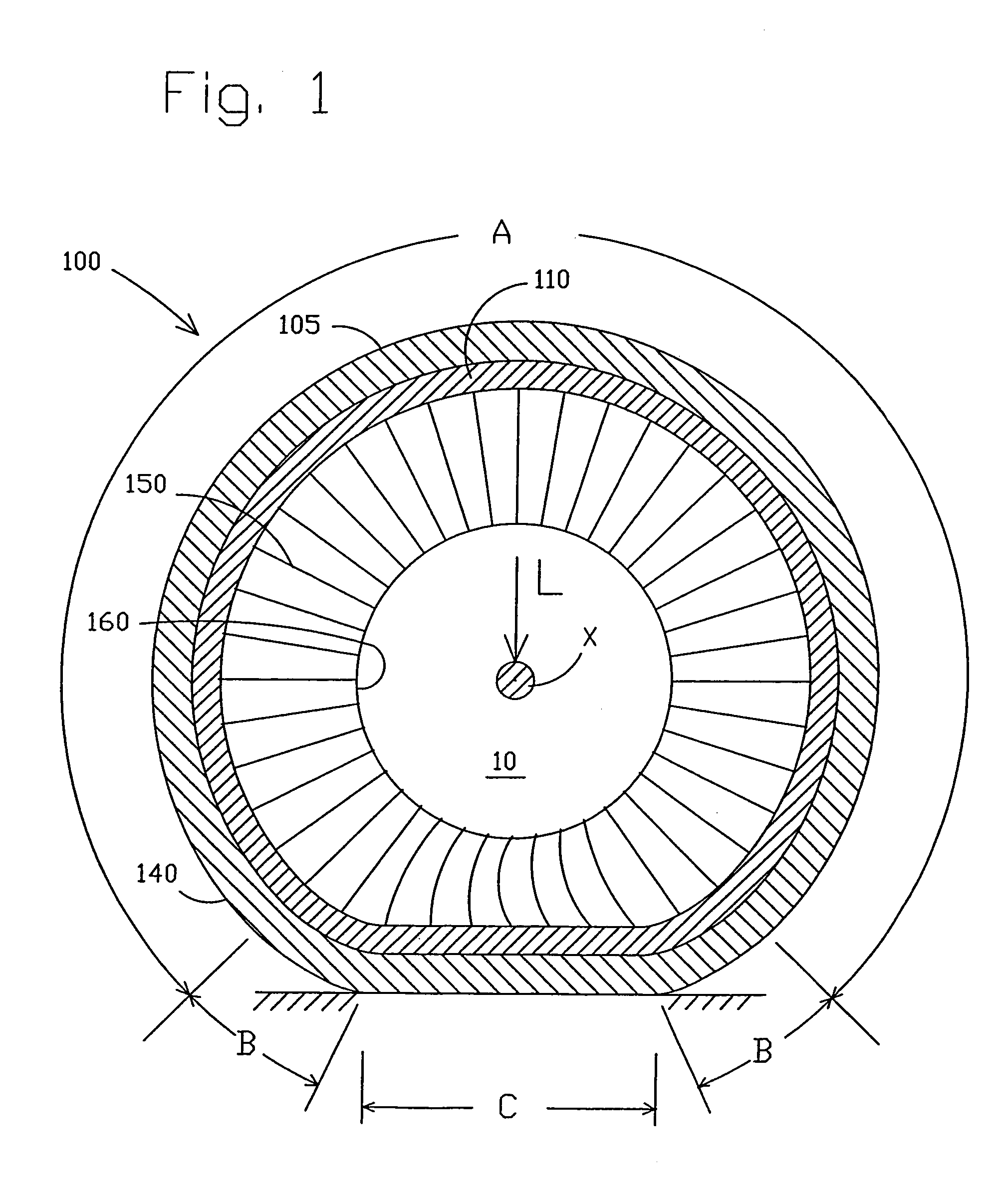

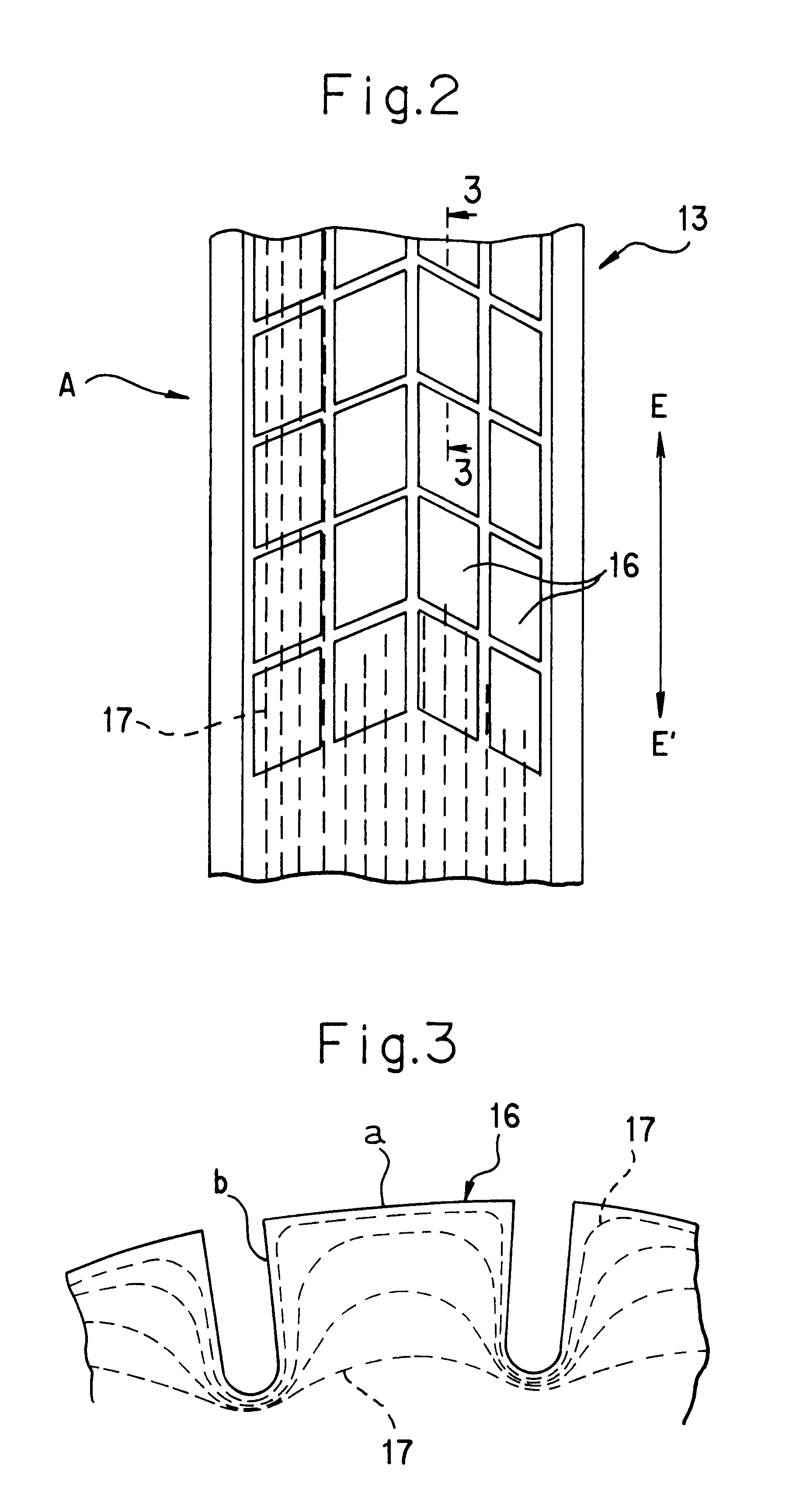

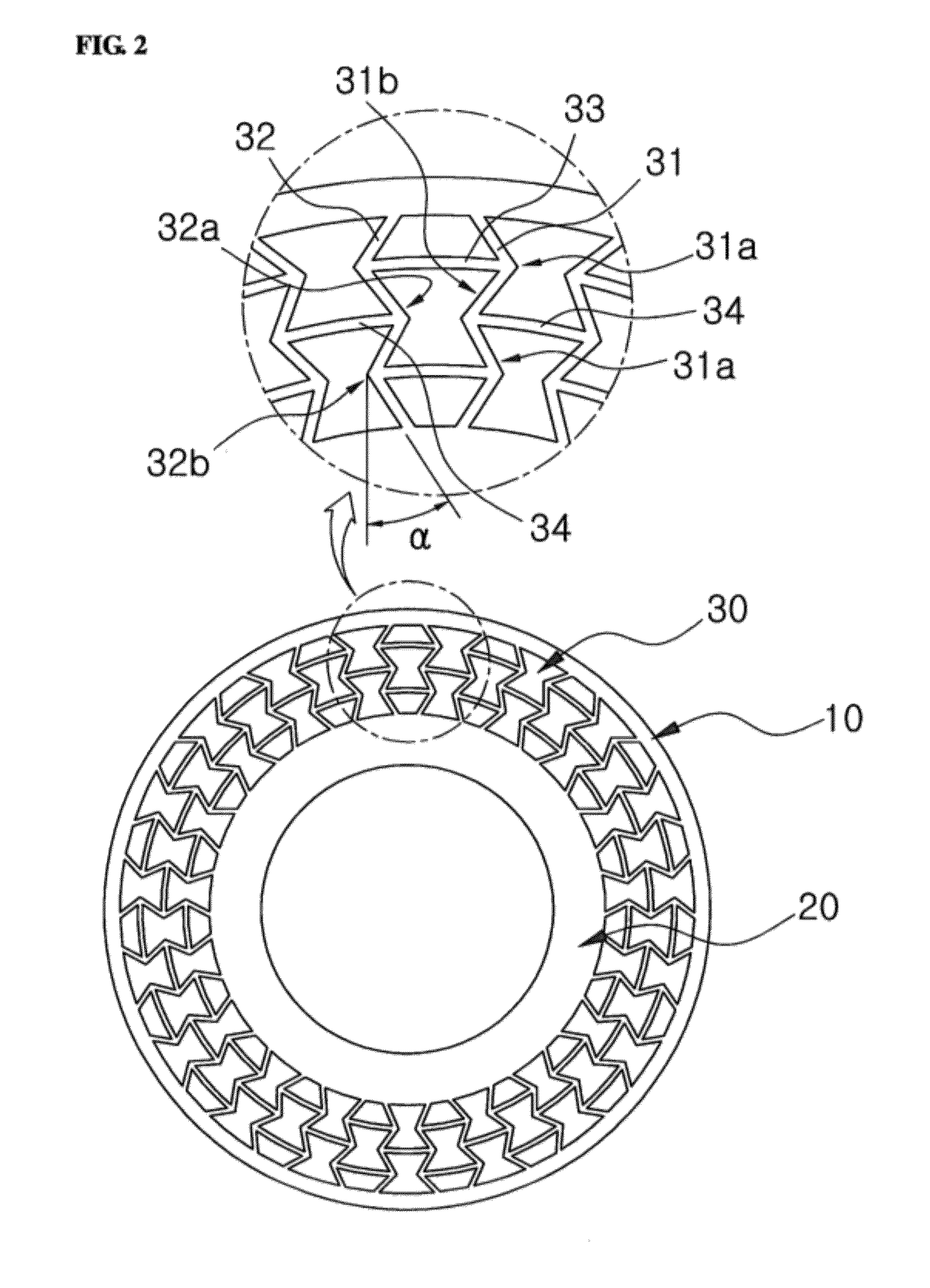

A structurally supported tire includes an outer annular band, and a plurality of web spokes extending transversely across and radially inward from the annular band and anchored in a wheel or hub. The annular band may further comprise a shear layer, at least a first membrane adhered to the radially inward extent of the shear layer, and at least a second membrane adhered to the radially outward extent of the shear layer. A preferred web spoke has a cutaway section transverse to the annular band. The cutaway section has a profile formed by straight line segments joined by a blending radius. The profile of the cutaway comprises a height and a maximum depth greater than five percent of the height and less than thirty percent of the maximum width. The profile has an angle alpha formed by a line tangent to the profile relative to the horizontal at least equal to ten degrees at the radially outermost and radially innermost extent of said profile. The minimum radius of curvature of the profile is at least equal to twenty percent of the height of the cutaway section.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Flexible non-pneumatic tire

InactiveUS6994135B2Easy to operateImprove staminaNon-inflatable tyresPneumatic tyre reinforcementsInterconnectionMechanical engineering

A non-pneumatic tire comprises circumferentially-spaced support elements joined together by an interconnection structure with the interposition of flexible joints, so as to ensure good overall operation.

Owner:CONCEPTION & DEV MICHELIN SA

Tension-based non-pneumatic tire

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner ring, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, curved, oriented, and comprised of varying thicknesses of material which facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a wheel and a footprint region where the tire contacts a surface can assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Non-pneumatic tire

InactiveUS7418988B2High effective radial stiffness in tensionLow effective radial stiffnessNon-inflatable tyresPneumatic tyre reinforcementsMaximum depthEngineering

A structurally supported tire includes an outer annular band, and a plurality of web spokes extending transversely across and radially inward from the annular band and anchored in a wheel or hub. The annular band may further comprise a shear layer, at least a first membrane adhered to the radially inward extent of the shear layer, and at least a second membrane adhered to the radially outward extent of the shear layer. A preferred web spoke has a cutaway section transverse to the annular band. The cutaway section has a profile formed by straight line segments joined by a blending radius. The profile of the cutaway comprises a height and a maximum depth greater than five percent of the height and less than thirty percent of the maximum width. The profile has an angle alpha formed by a line tangent to the profile relative to the horizontal at least equal to ten degrees at the radially outermost and radially innermost extent of said profile. The minimum radius of curvature of the profile is at least equal to twenty percent of the height of the cutaway section.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Tension-based non-pneumatic tire

ActiveUS20090283185A1Eliminating flat tireExtend tire lifeNon-inflatable tyresHigh resiliency wheelsEngineeringMechanical engineering

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner surface, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, oriented and comprised of a material that facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a hub and a footprint region where the tire contacts a surface may assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load. Since the tire is non-pneumatic, it may be easier to maintain and may have a longer life than standard pneumatic tires since it eliminates the possibility of blowouts, flat tires, or tires operating with low air pressure. By virtue of the portion of the tire in the footprint region not bearing a significant portion of the load, non-pneumatic tire may also exhibit a more comfortable ride subject to less noise and vibration and improved handling capabilities.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Annular ring and non-pneumatic tire

The present invention provides an annular beam of monolithic construction of one homogeneous material and a related efficient, low-cost non-pneumatic tire. Specific geometric design, combined with nonlinear elastomer physical properties, enable the suppression of all reinforcing belts, continuous fibers, or other strengthening layers in the annular beam. The annular beam consists of at least two bands that are continuous in the circumferential direction and connected by a web geometry. The non-pneumatic tire consists of the annular beam, a ground contacting portion, a central wheel, and a plurality of web spokes that connect the wheel and beam. When the tire is loaded to a design load against a flat surface over a design contact length, a contact area of essentially uniform pressure is produced, while the load is transmitted from the beam to the hub via tension in the web spokes. The tire can be economically manufactured.

Owner:CAMOPLASY INC

Non-pneumatic tire

A non-pneumatic tire comprising side cavities that are staggered with respect to laterally opposing side cavities, and laterally extending tread grooves that are in substantial radial alignment with the cavities. In another embodiment, the invention is to a tire comprising side ribs that are staggered with respect to laterally opposing side ribs, and laterally extending tread grooves that are substantially offset relative to the side ribs. Also provided are processes for making such tires and to off-the-road (OTR) vehicles employing such tires.

Owner:LANXESS SOLUTIONS US INC

Non-pneumatic tire having web spokes

InactiveUS7650919B2High effective radial stiffness in tensionLow effective radial stiffnessNon-inflatable tyresPneumatic tyre reinforcementsGround contactElastomer

Owner:MICHELIN RECH & TECH SA

Non-pneumatic tire with annular spoke reinforcing web

InactiveUS20120234444A1Increased bending stiffnessIncrease the maximum loadNon-inflatable tyresLoad carryingEngineering

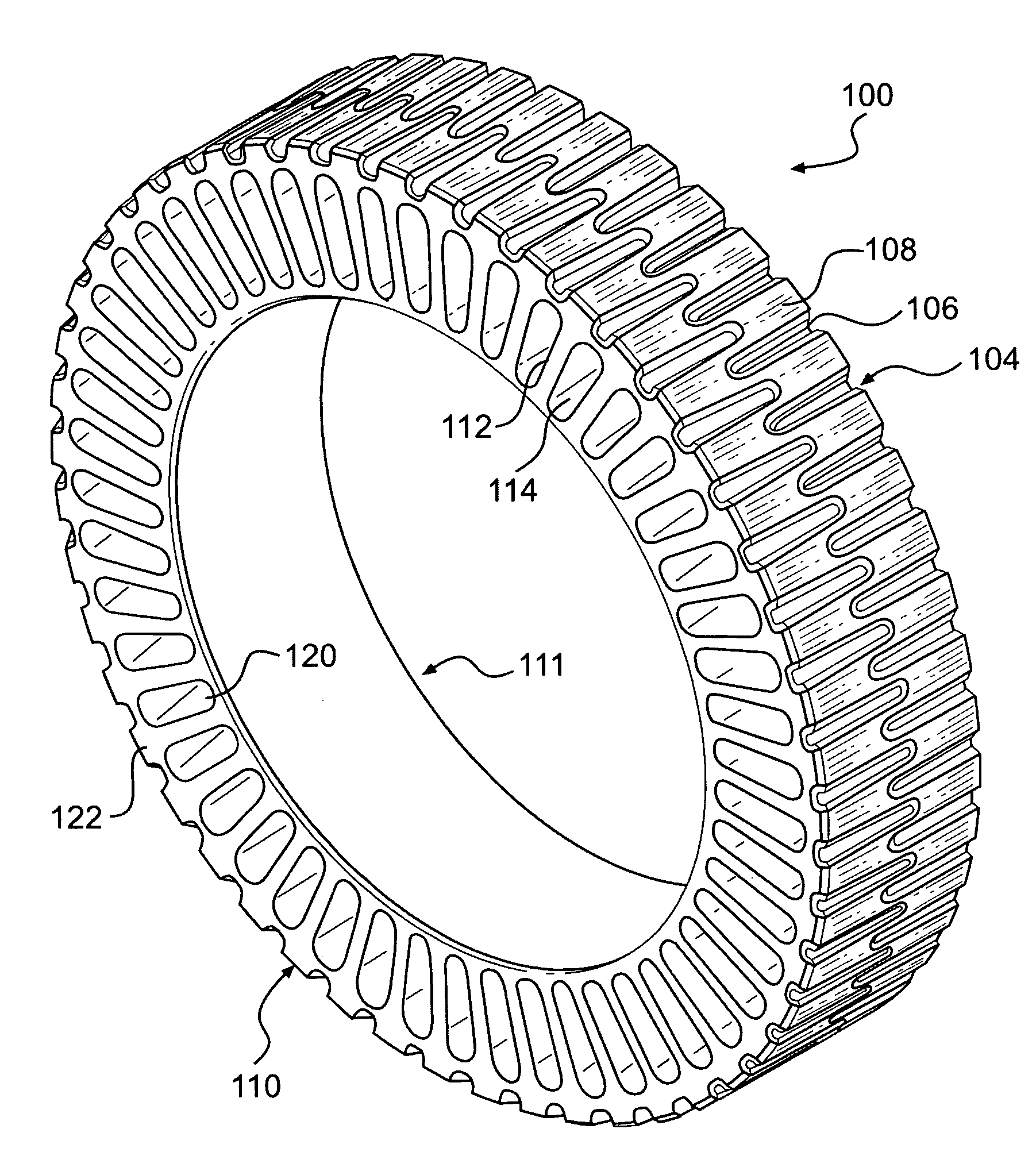

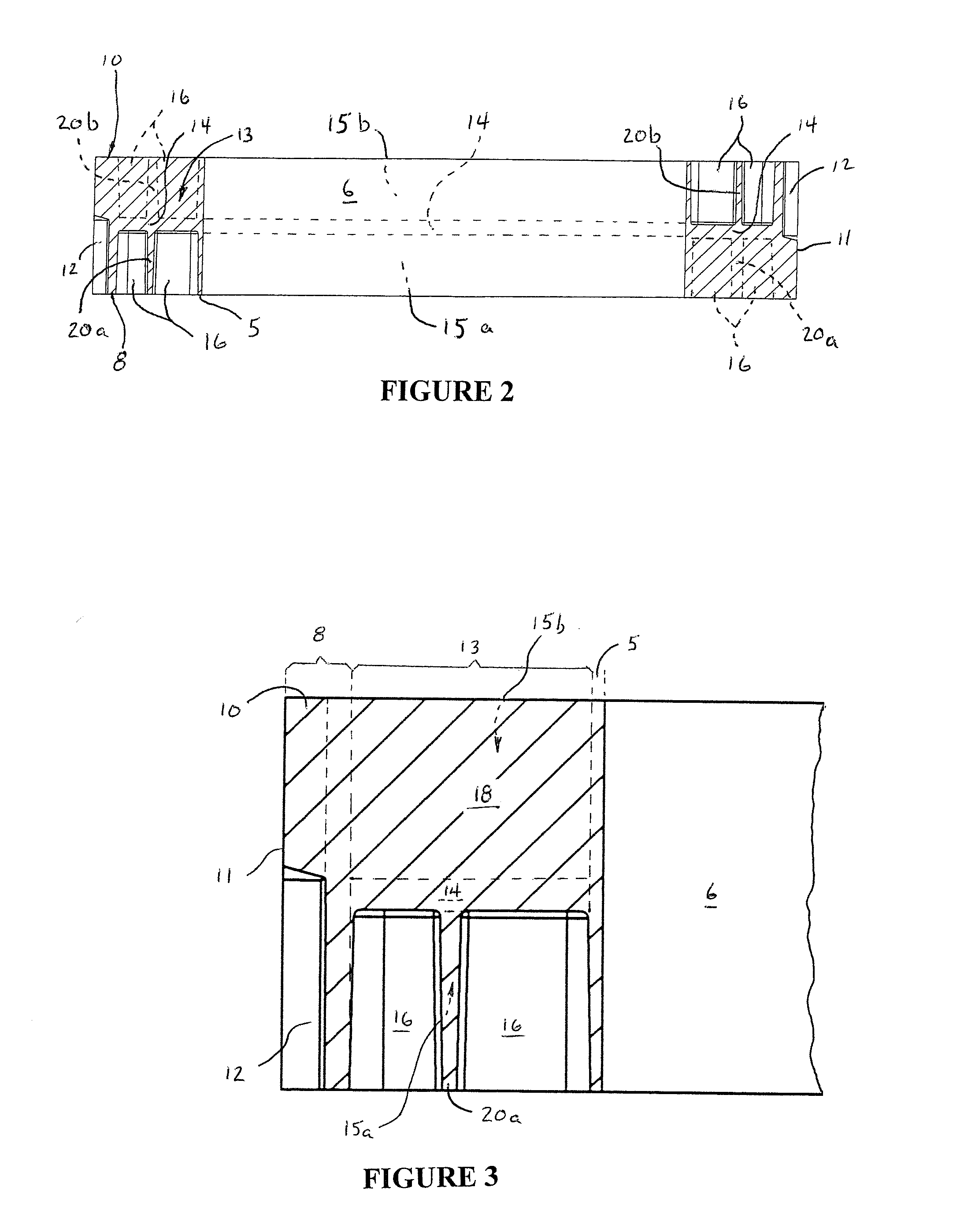

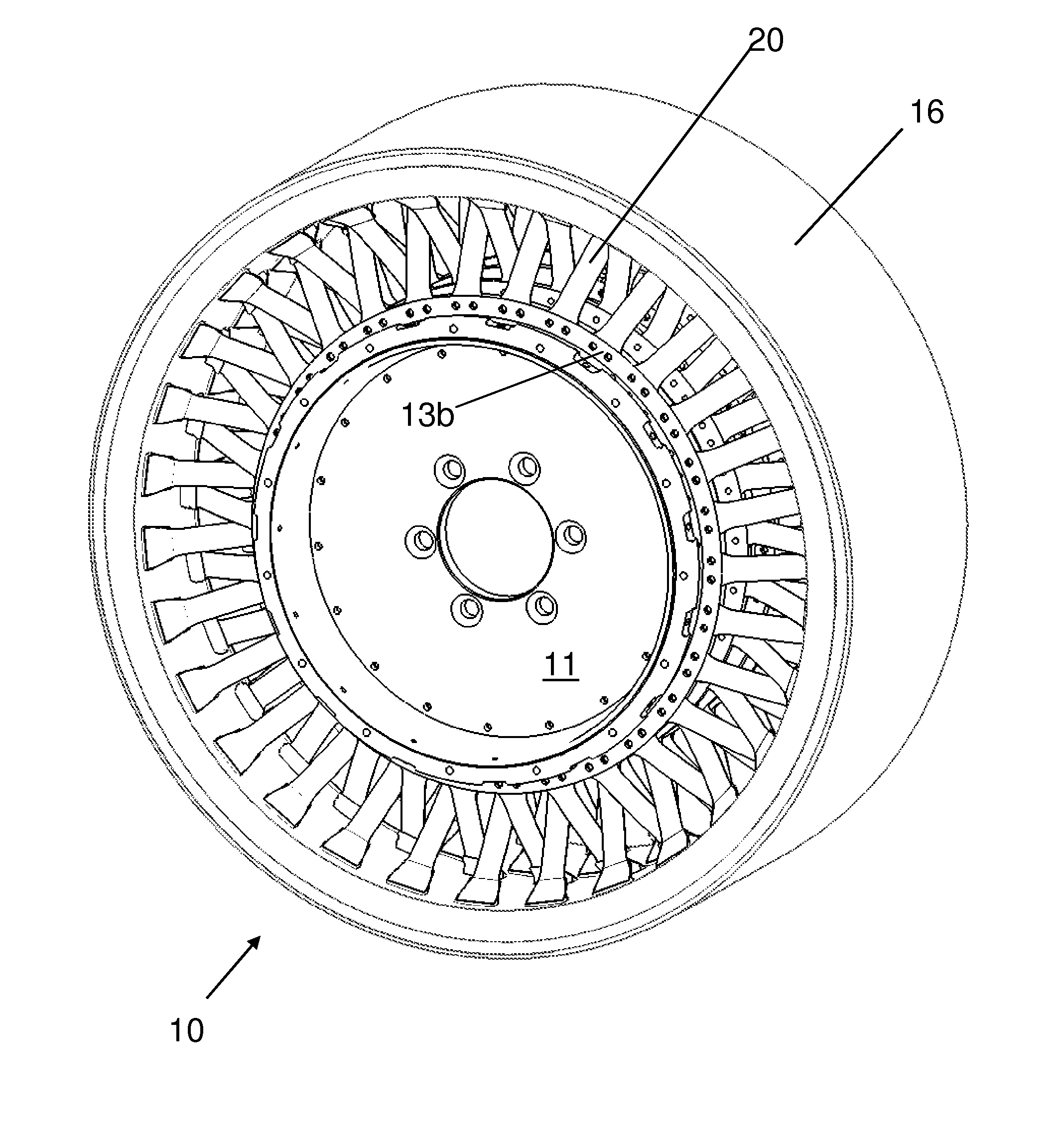

A non-pneumatic tire is provided with an annular reinforcing web that reduces the bending of compression spokes formed in the tire and reduces stresses and strains in the tire. The non-pneumatic tire includes an inner hoop member having an inner surface that defines the inner diameter of the tire, and an outer hoop member having a tread groove region that defines the outer diameter of the tire. A disc-shaped central web portion connects the inner and outer hoop members. A plurality of elongated, radially aligned cavities on either side of the central web defines integrally-formed compression spokes which connect the inner and outer hoop members. The annular reinforcing web is located on and affixed to either side of the central web portion and interconnects a mid portion of each spoke to a mid portion of the spokes on either side of it. Preferably, the annular reinforcing web is reinforced with fiber webbings on its outer side for added strength. The annular reinforcing web allows the tire to be made with less polyurethane material with no reduction in load carrying capability.

Owner:CATERPILLAR INC

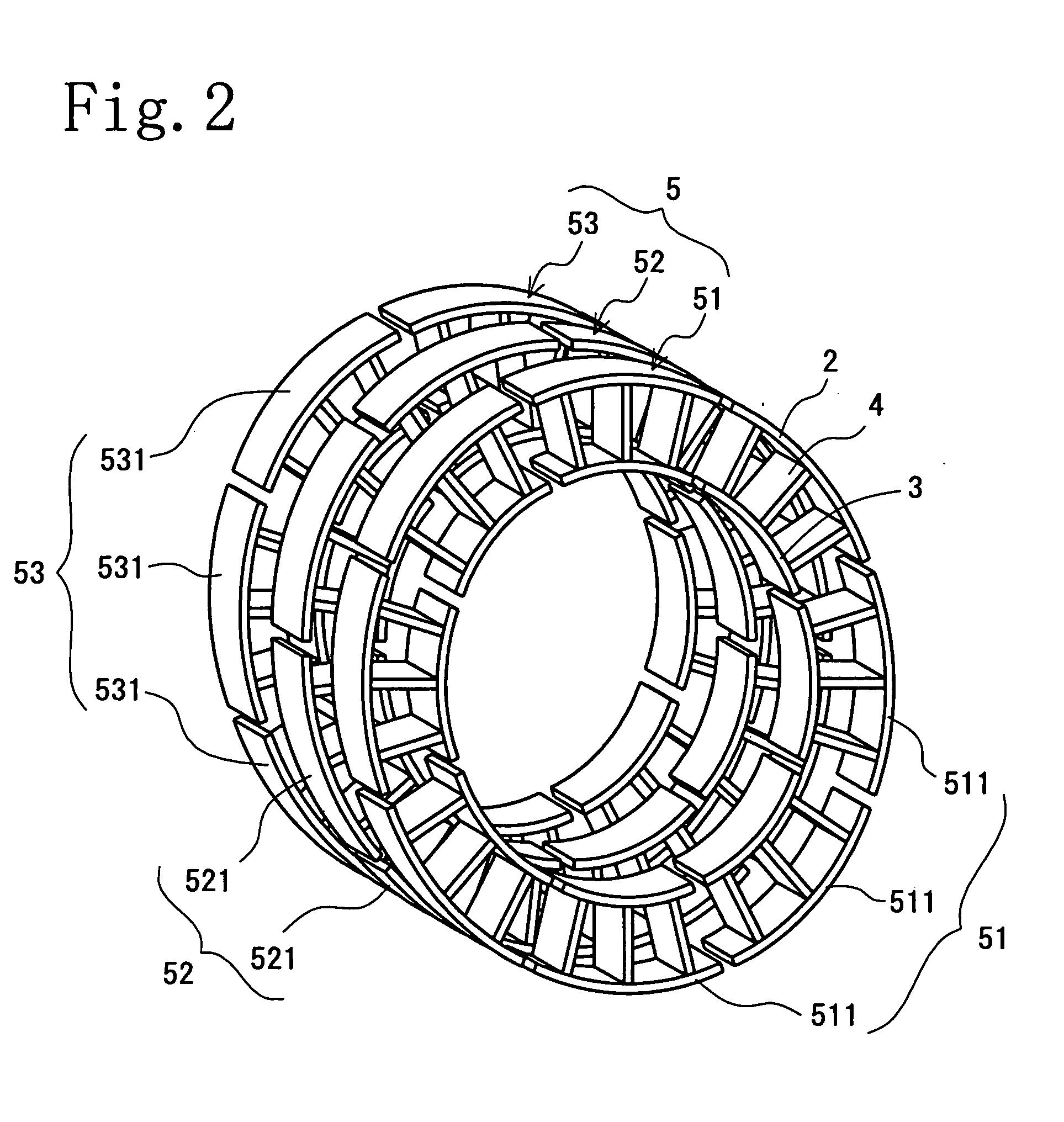

Non-pneumatic tire and method of manufacturing same

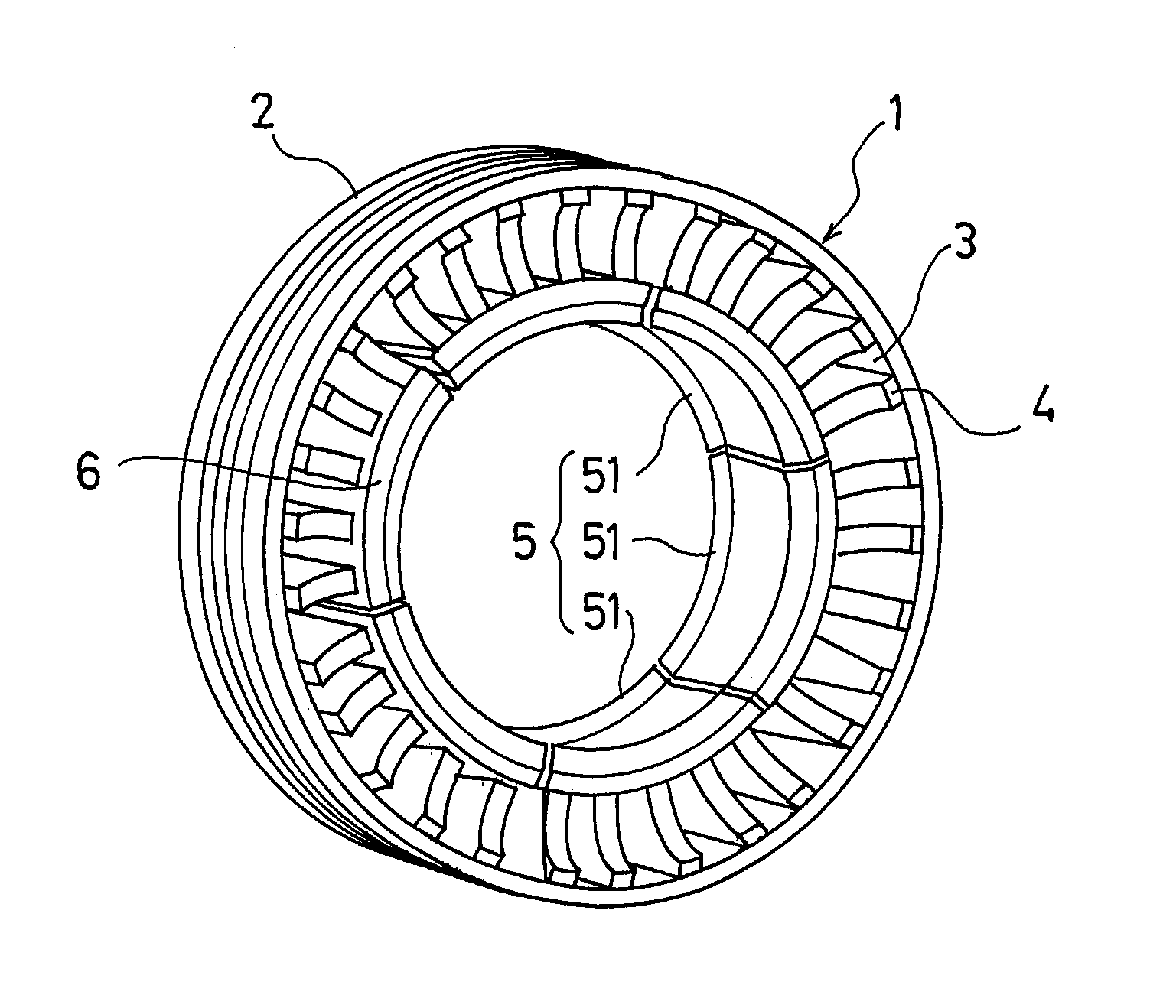

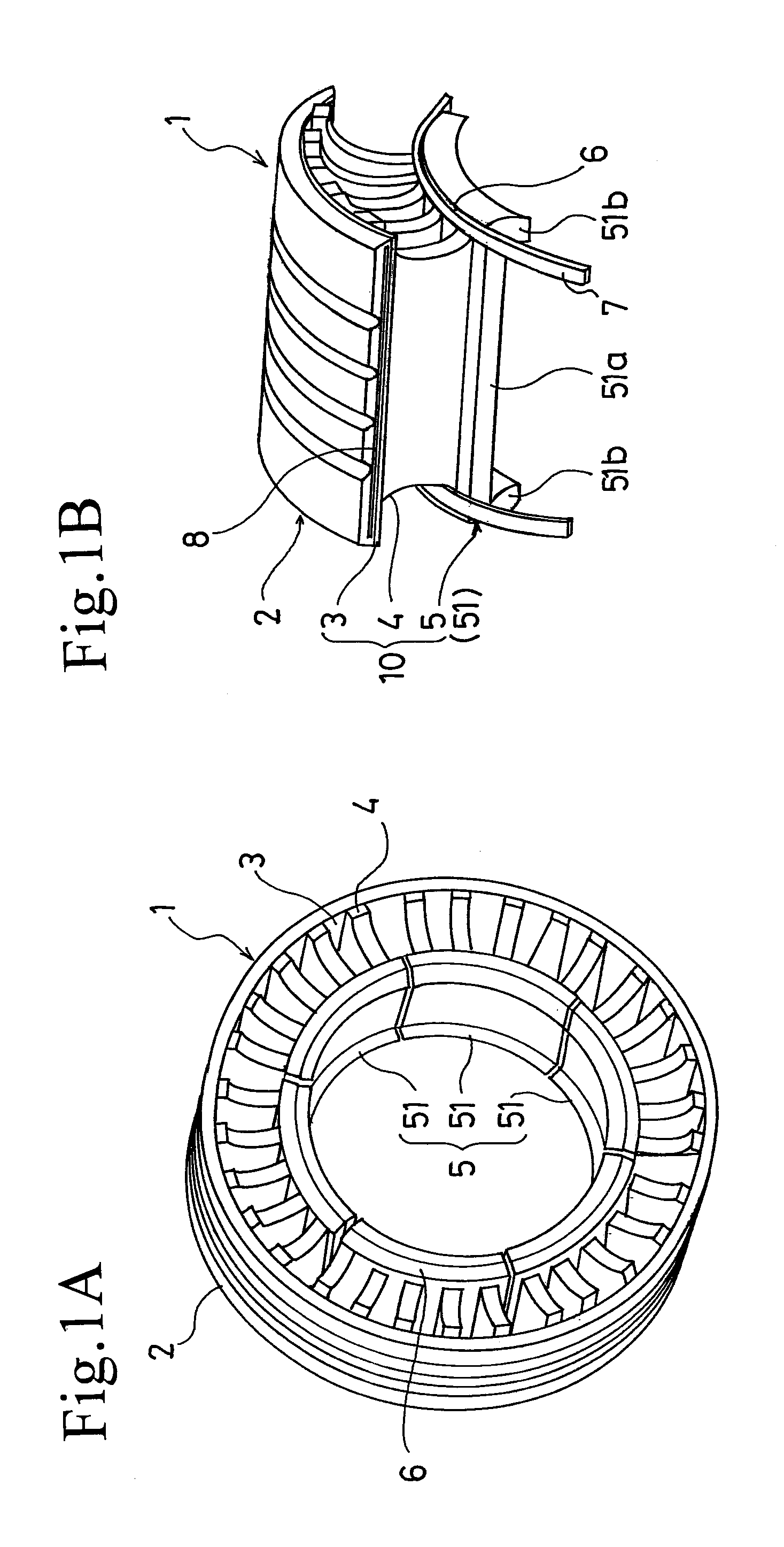

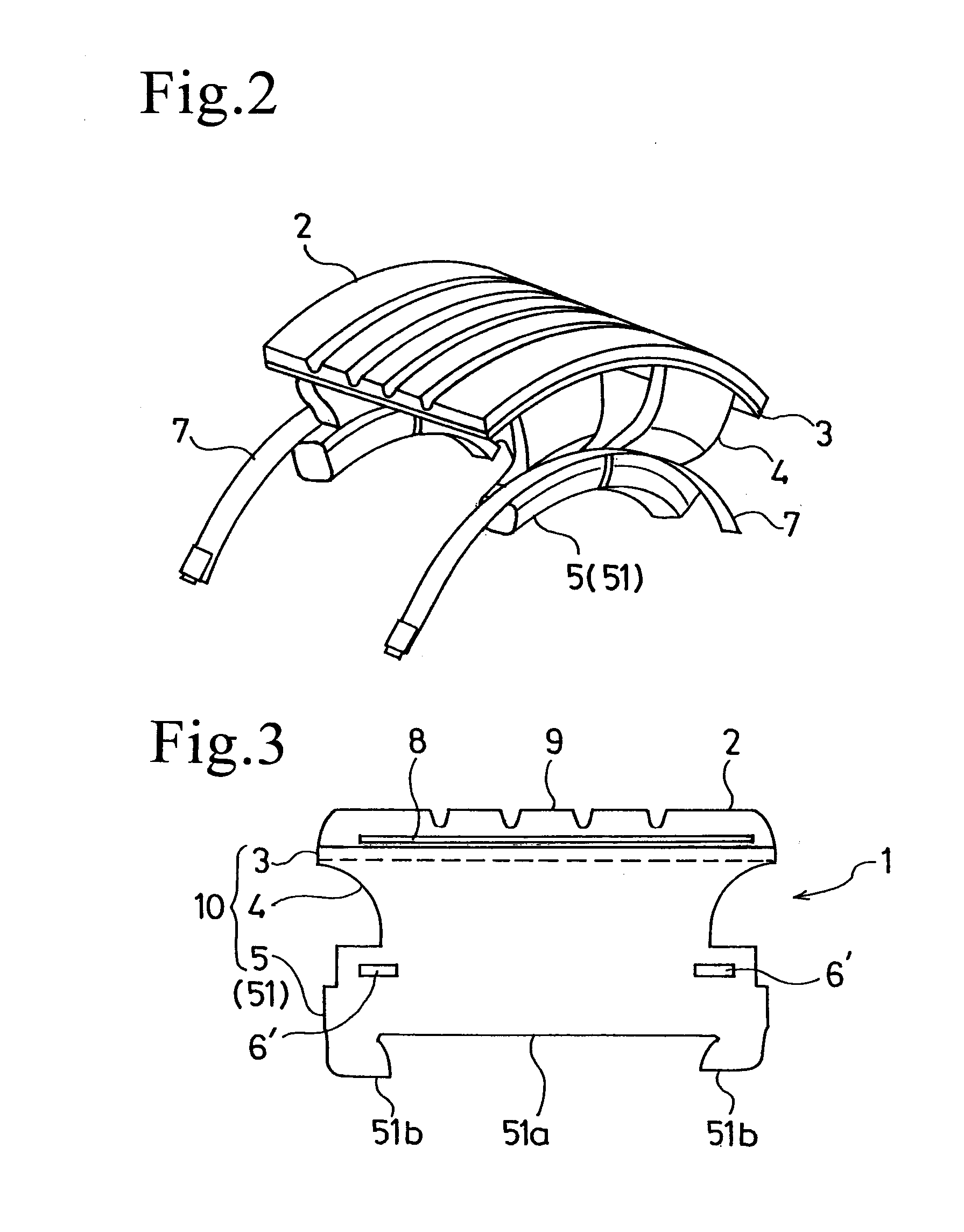

A non-pneumatic tire with spokes easily mountable on and dismountable from a wheel. In the non-pneumatic tire (1), a spoke structure (10) including an annular outer peripheral member (3) and an inner peripheral member (5) connected to each other by a plurality of spokes (4) is joined to the inner peripheral side of a tread ring (2). The non-pneumatic tire is characterized in that the inner peripheral member (5) is divided into independent members (51) in the circumferential direction of the tire.

Owner:THE YOKOHAMA RUBBER CO LTD

Rubber composition for tire tread having high performance on ice and pneumatic tire using the same

InactiveUS6550508B1Good physical propertiesReduce hardnessNon-inflatable tyresSpecial tyresFiberVulcanization

Owner:YOKOHAMA RUBBER CO LTD

In-line skate wheel

An in-line skate wheel includes an polyethylene closed cell foam ring surrounding the outer cylindrical surface of a hard plastic hub. Polyurethane is molded onto the outer cylindrical surface of the hub and surrounding the polyethylene ring. The polyethylene ring is provided with a substantially lower density than the density of the polyurethane.

Owner:ROLLERBLADE

Airless tire

Disclosed herein is an airless are which absorbs shock and holds pressure applied to the tire through an auxetic spoke buffer without using air pressure. The airless tire includes a cylindrical tread being in contact with the ground, an axle fixing section having a smaller circumference than the tread and disposed inside the tread, and an auxetic spoke buffer connecting the tread and the axle fixing section and providing a buffering function. Accordingly, the airless tire is transformed only to an extent to properly function as a fire when the spoke buffer is transformed by pressure or impact and fully returns to an original shape when pressure or impact is removed.

Owner:HANKOOK TIRE WORLDWIDE

Non-pneumatic tire

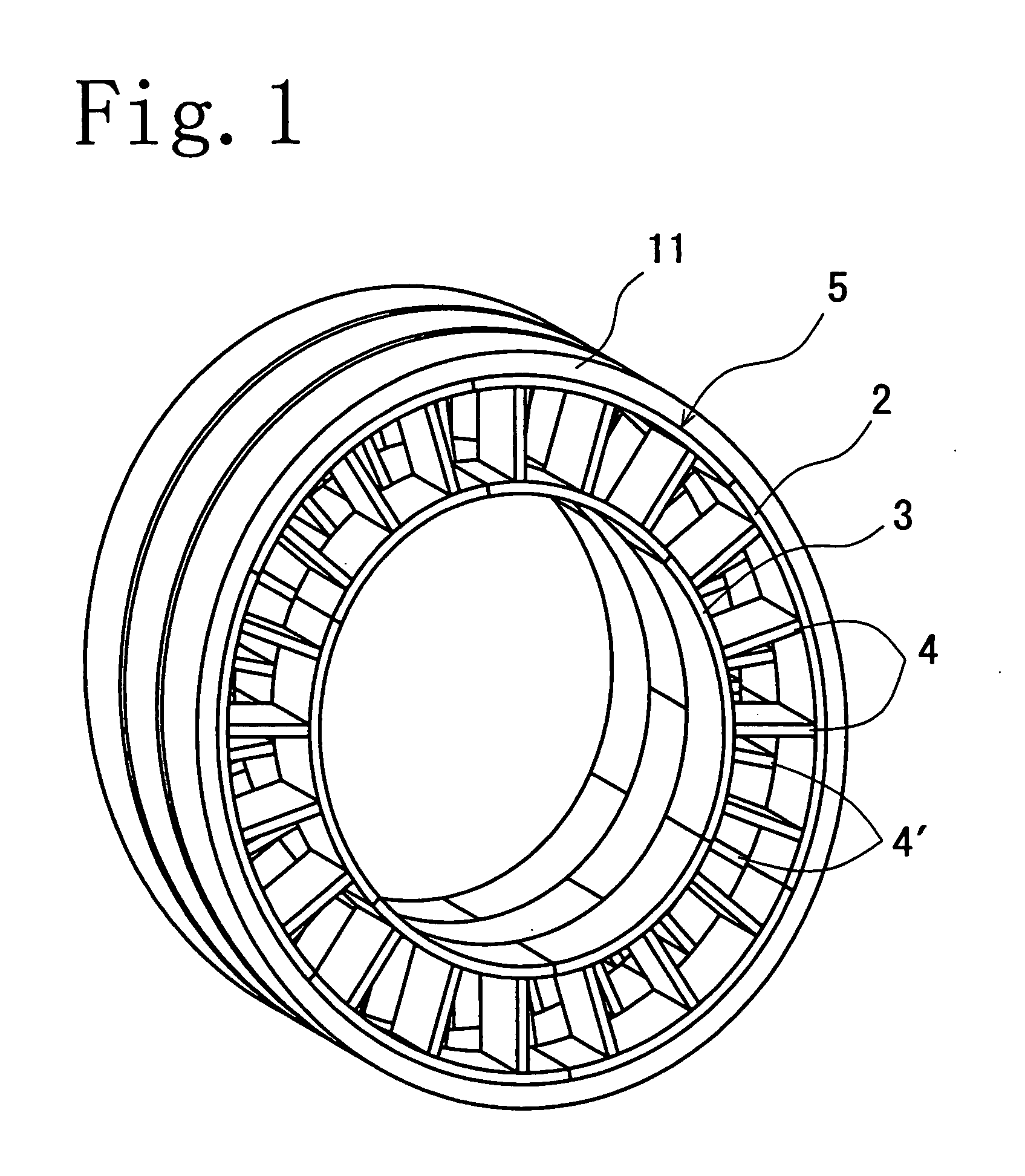

InactiveUS20080053586A1Easy to installIncreased durabilityNon-inflatable tyresWheelsEngineeringSpoke

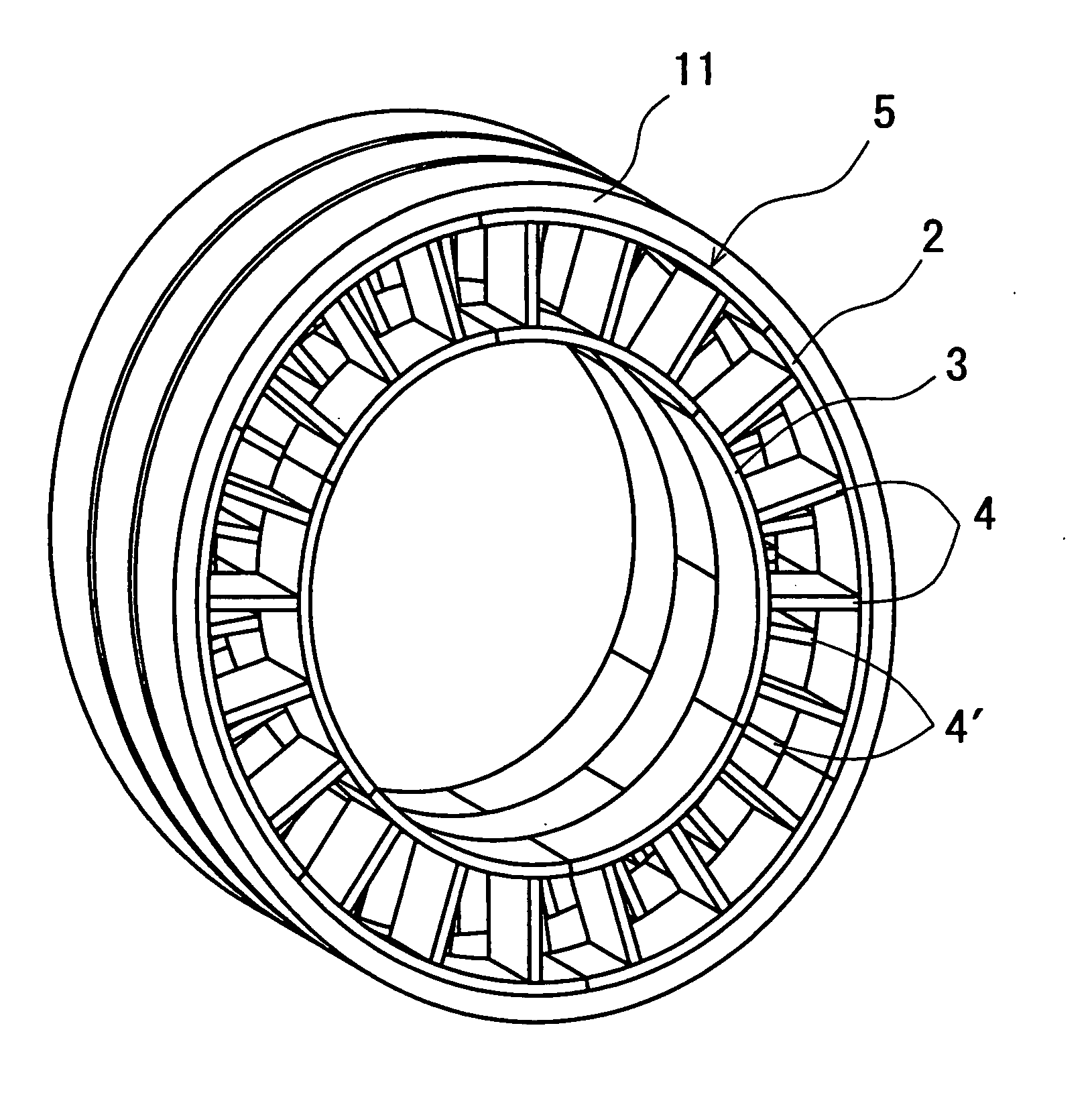

To provide a non-pneumatic tire, including a spoke structure, which can be easily mounted on a rim of a wheel. In addition, to provide a non-pneumatic tire whose durability is improved by suppressing the buckling of a spoke structure.[Solving Means] Provided is a non-pneumatic tire including a spoke structure (5) and a tread ring (11). The spoke structure (5) includes a cylindrical outer member (2) and a cylindrical inner member (3) which are concentrically arranged, and which are connected to each other with a plurality of fins (4, 4′) arranged in between at intervals in the circumferential direction. The tread ring (11) is fitted onto the outer periphery of the spoke structure (5). In the pneumatic tire, the spoke structure (5) is divided in the tire circumferential direction into at least two circumferential-direction separate structures (511, 521, 531).

Owner:THE YOKOHAMA RUBBER CO LTD

Elastic shear band with cylindrical elements

A shear band that may be used as part of a structurally supported wheel is provided. More particularly, a shear band constructed from resilient, cylindrical elements attached between inextensible members is described. In certain embodiments, the shear band may be constructed entirely or substantially without elastomeric or polymer-based materials. Multiple embodiments are available including various arrangements of the cylindrical elements between the members as well as differing geometries for the cylindrical elements.

Owner:MICHELIN RECH & TECH SA

Airless tire

ActiveUS7143797B2Low hysterisis elastomersImprove performanceNon-inflatable tyresHigh resiliency wheelsElastomerEngineering

This invention pertains to a tire which supports load by means of compressing the tire's elastomeric structure and requires no internal inflation pressure. The preferred embodiments utilize circumferential ribs or radially oriented ribs of elastomer to support the load.

Owner:VANNAN FREDERICK F

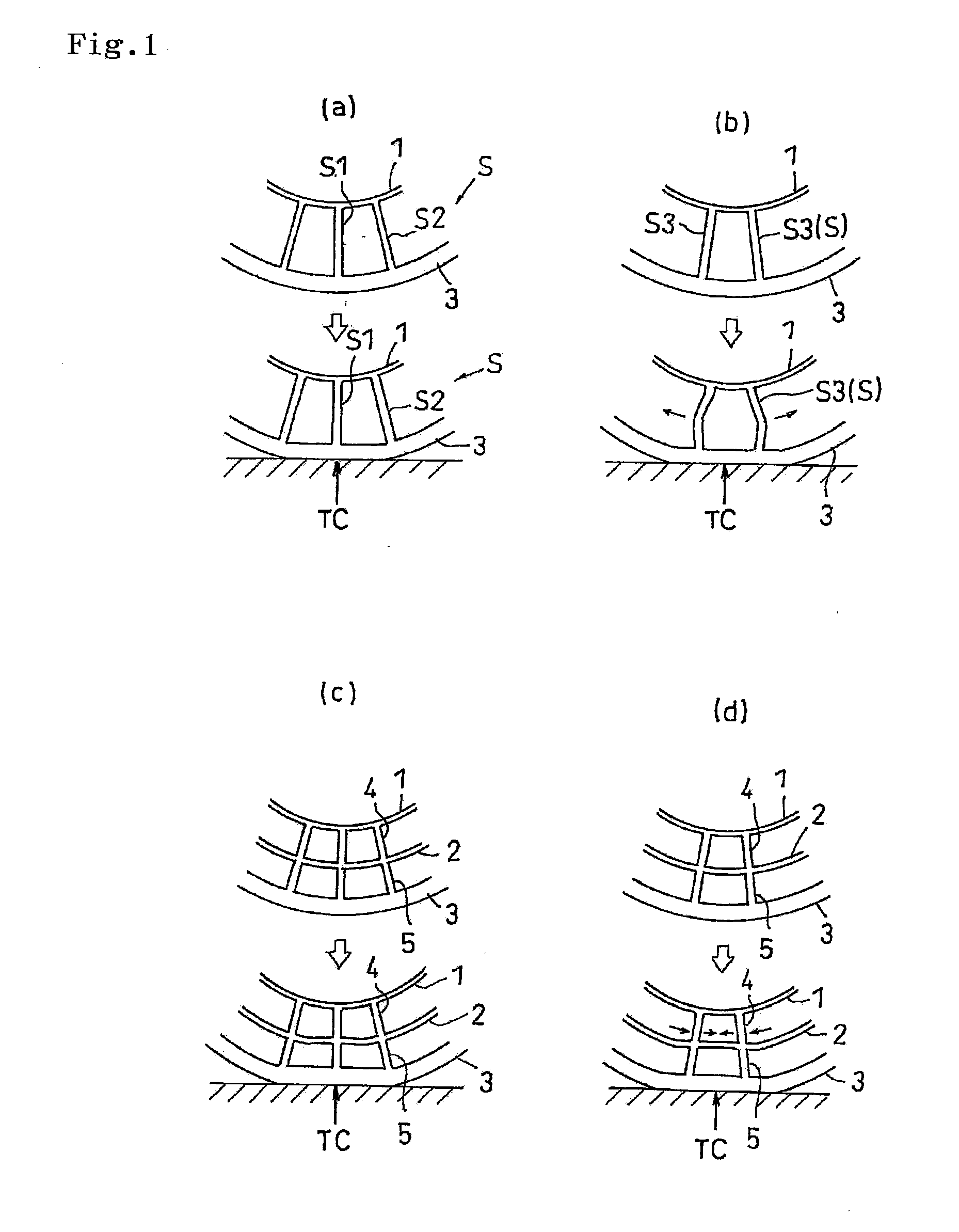

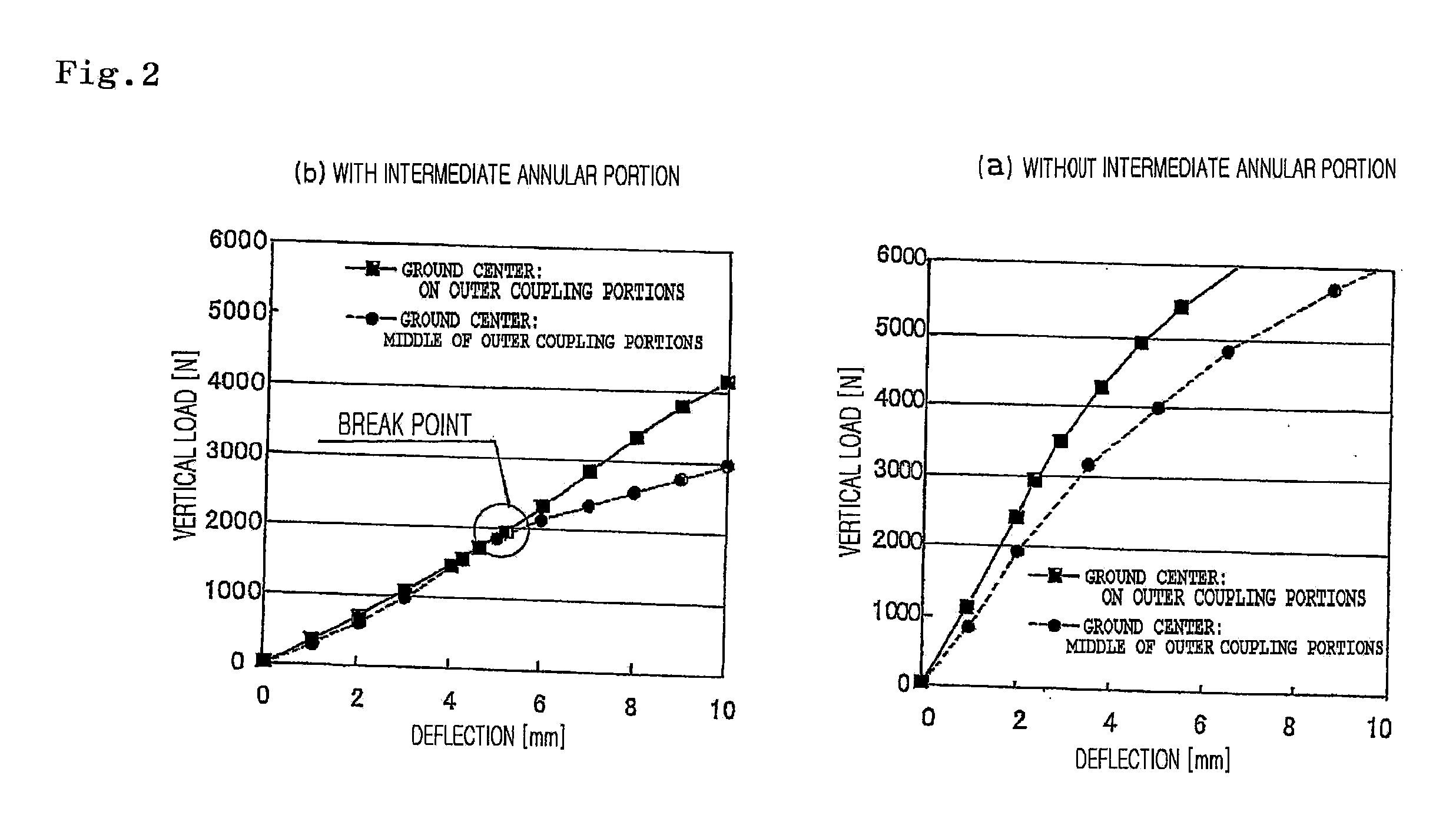

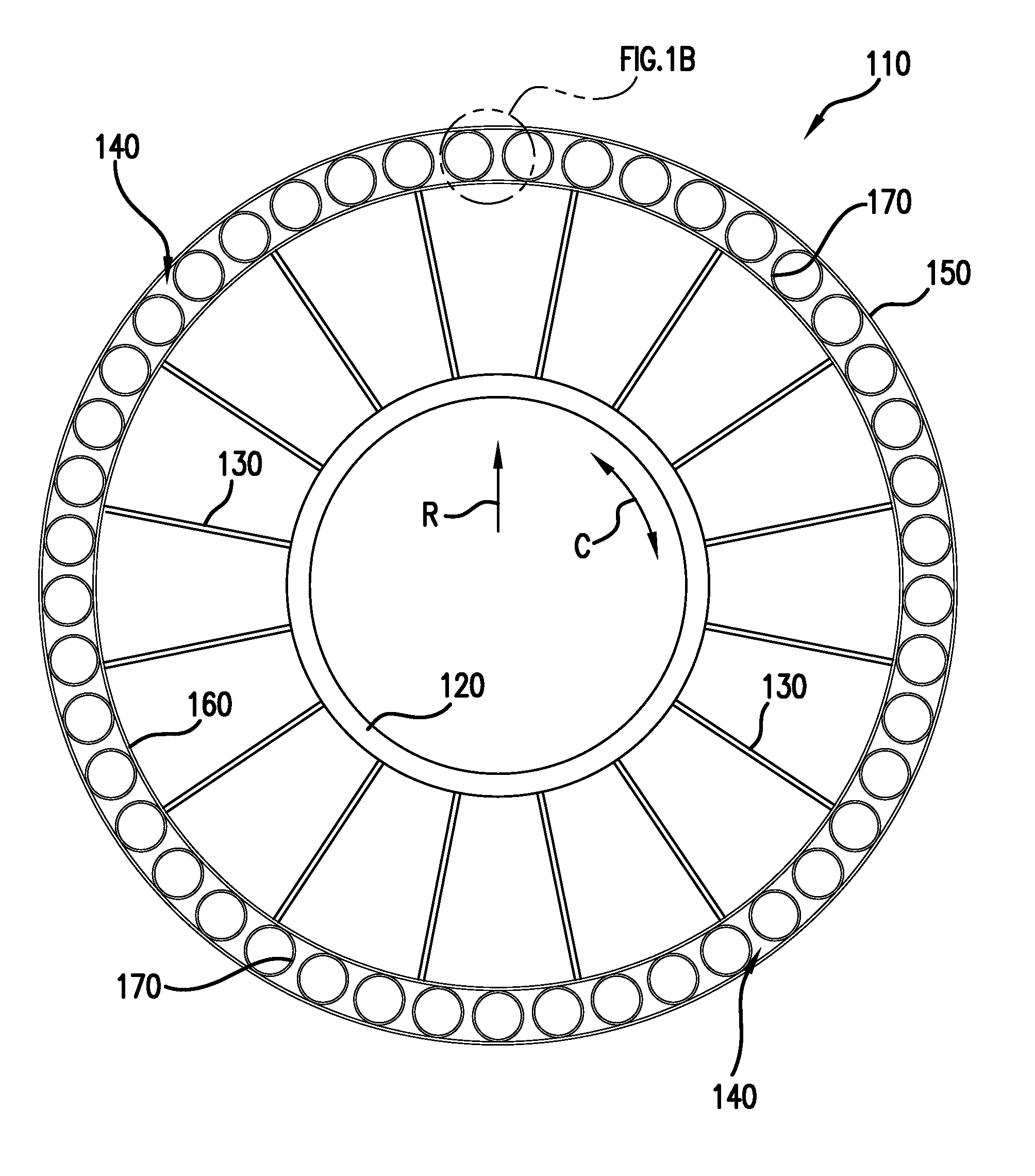

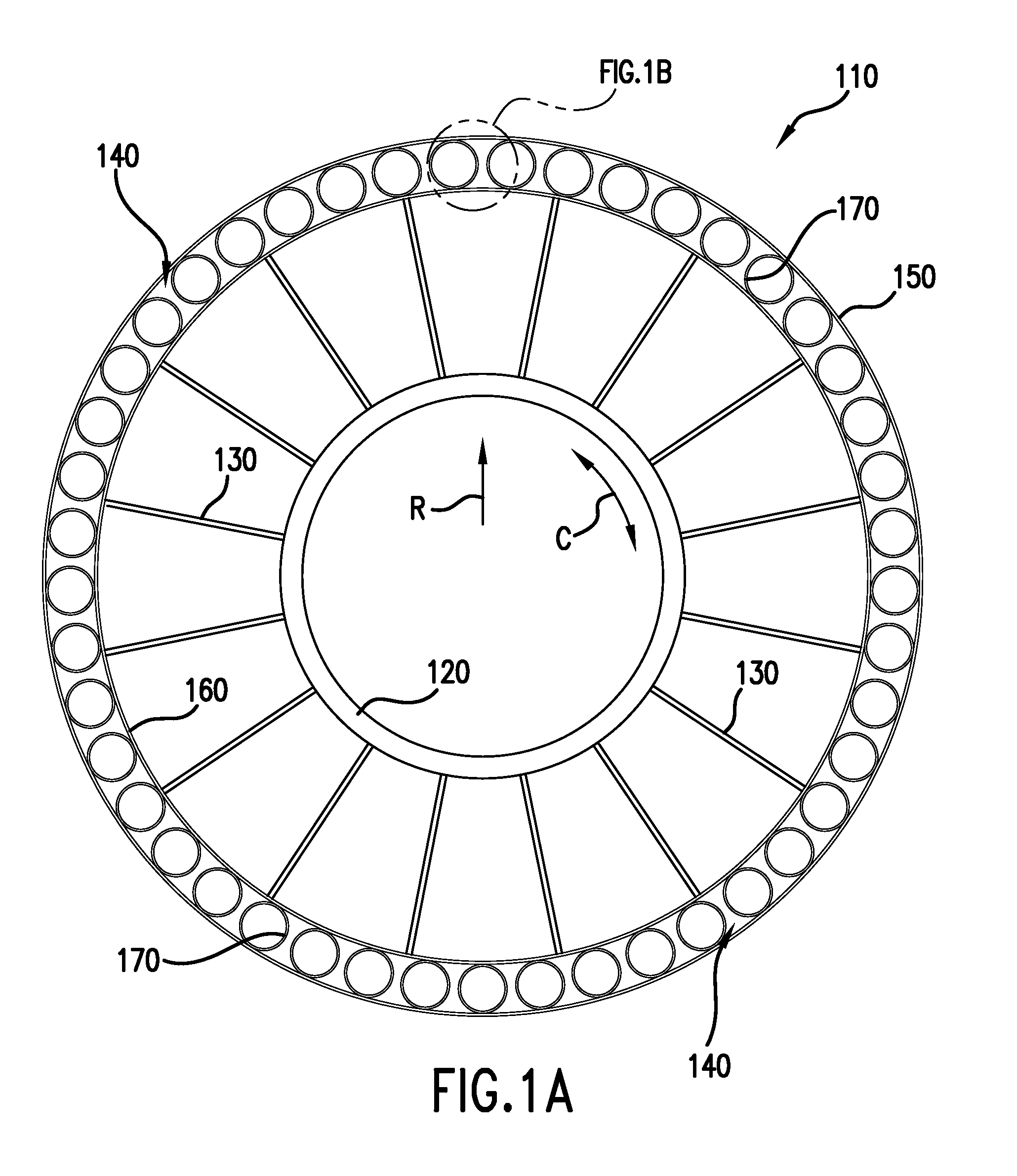

Non-Pneumatic Tire

InactiveUS20100132865A1Buckling of a ground portionBuckling suppressionNon-inflatable tyresWheelsCouplingEngineering

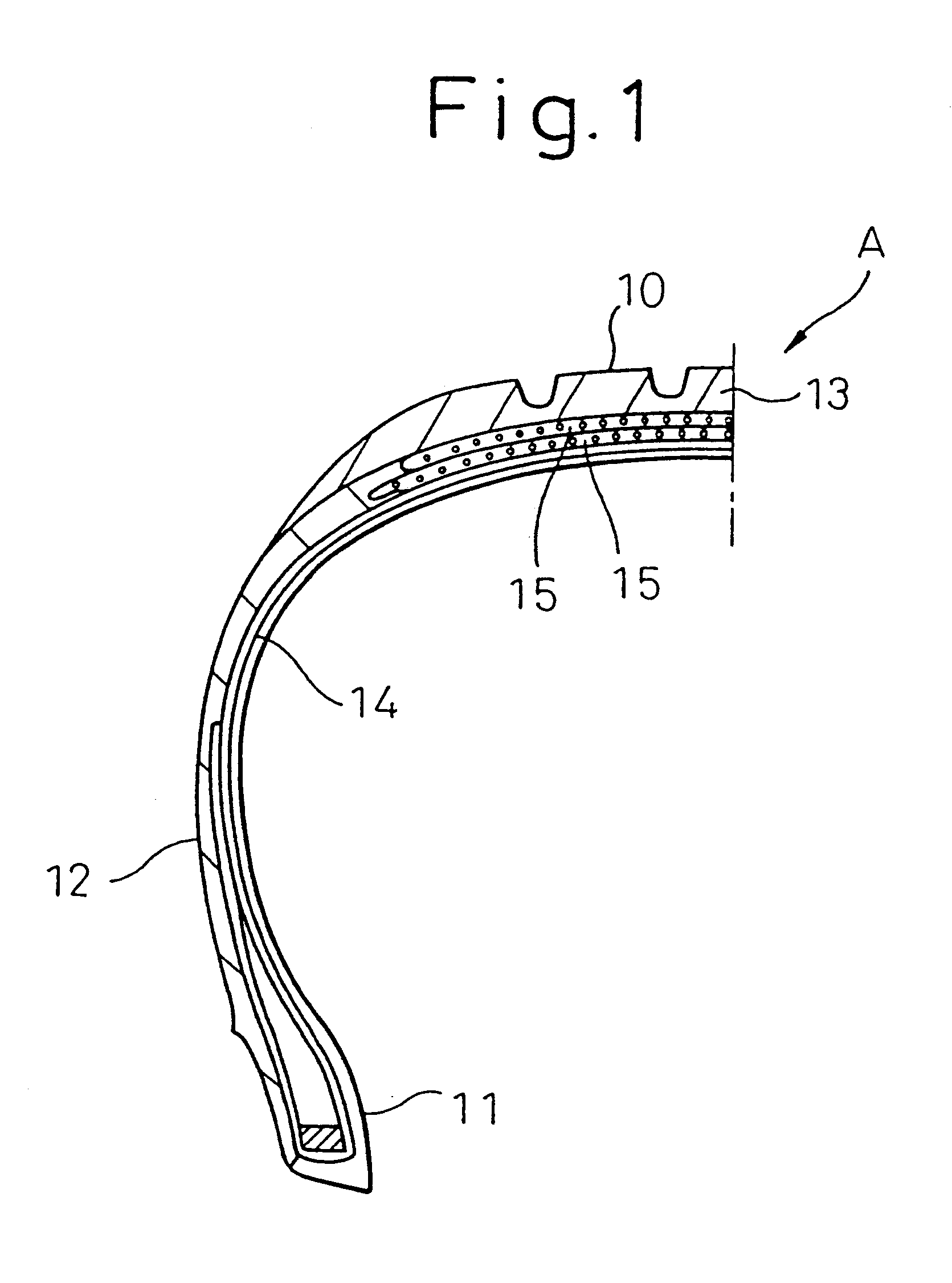

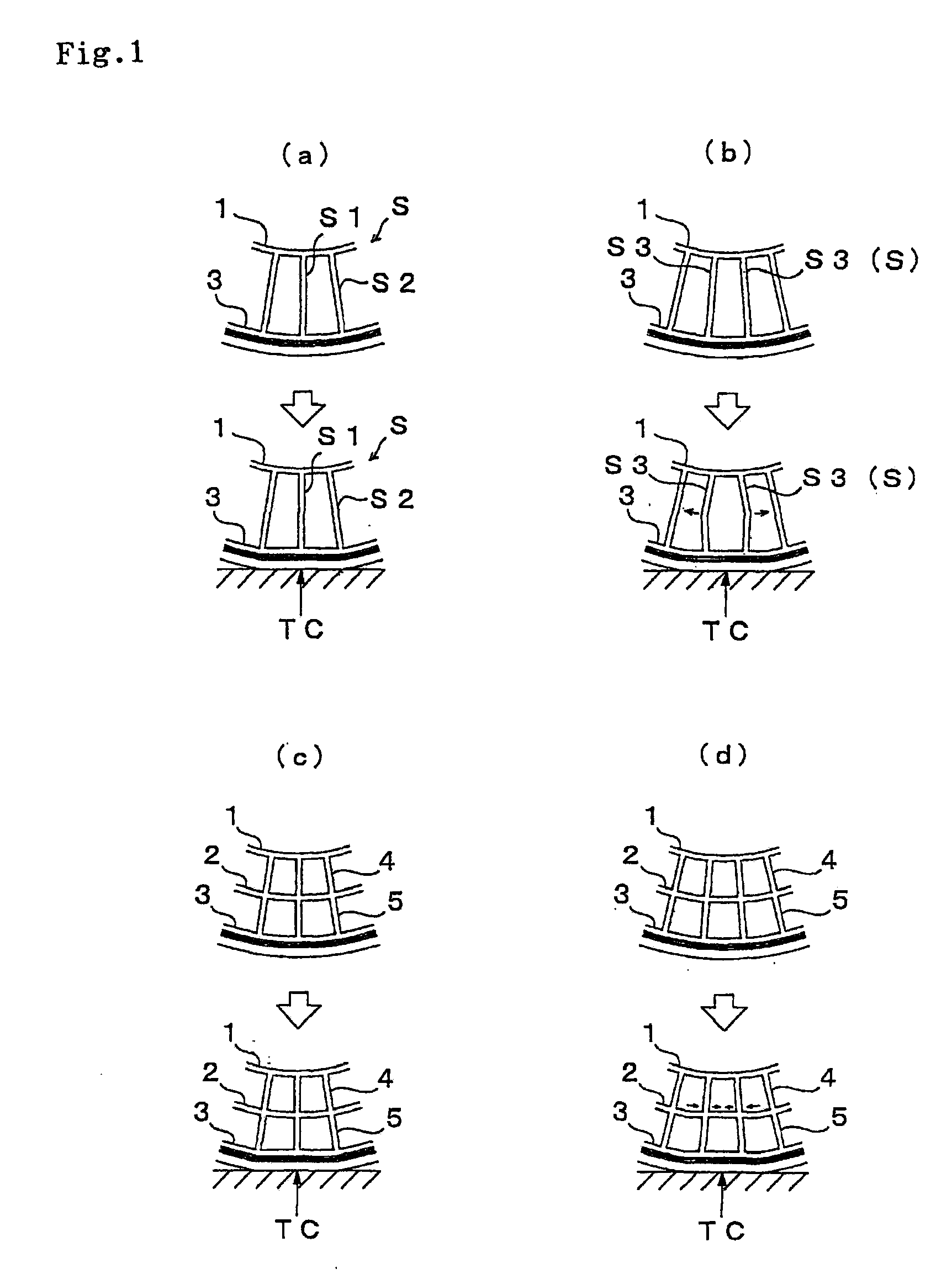

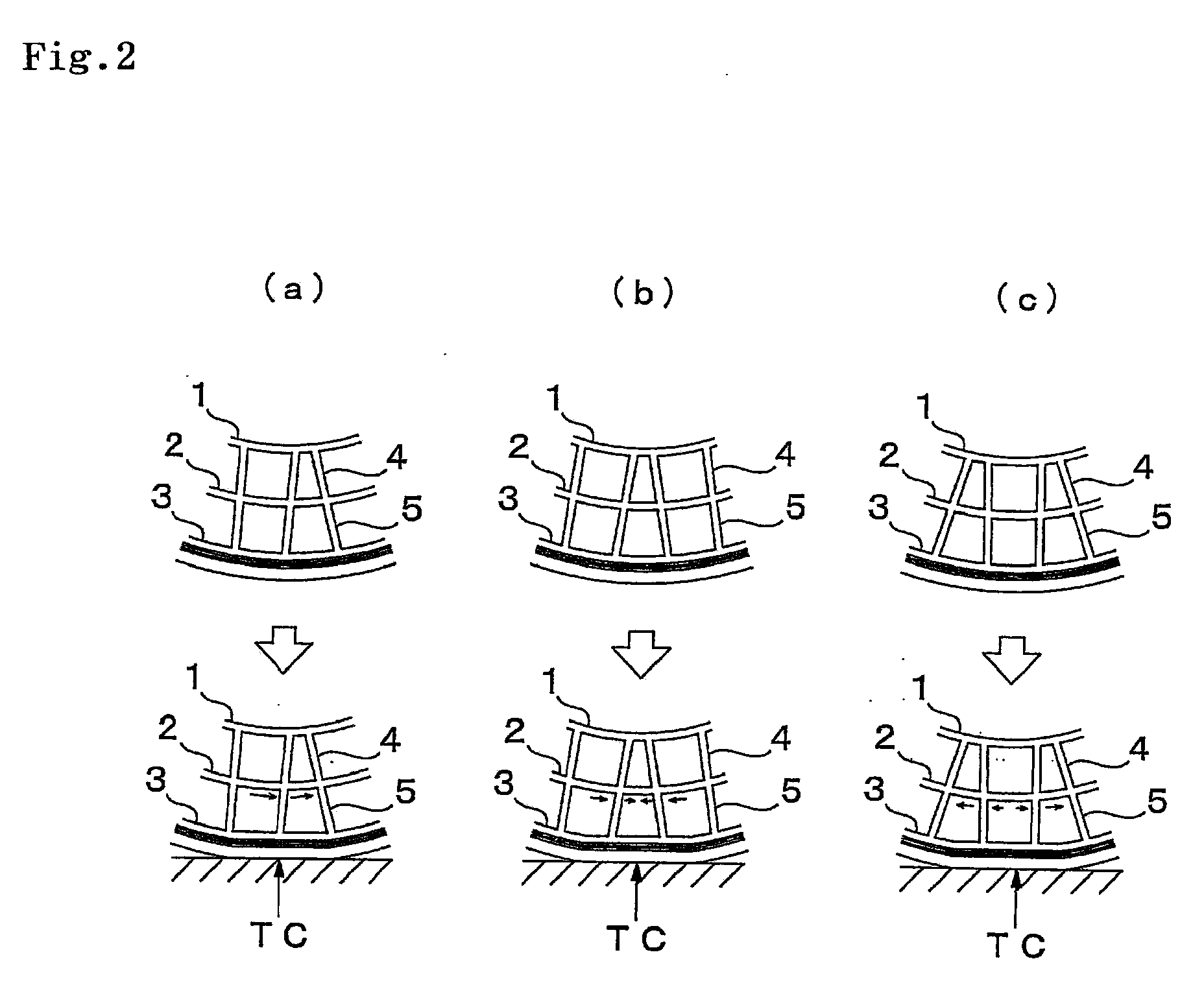

The invention provides a non-pneumatic tire in which a fluctuation in a circumferential direction of tire rigidity is hard to be generated by a positional relationship between a spoke position and a center position of a ground surface, and a buckling of a ground portion between the spokes can be sufficiently suppressed. In a non-pneumatic tire T comprising a support structure body SS supporting a load from a vehicle, the support structure body SS includes an inner annular portion 1, an intermediate annular portion 2 concentrically provided in an outer side of the inner annular portion 1, an outer annular portion 3 concentrically provided in an outer side of the intermediate annular portion 2, a plurality of inner coupling portions 4 coupling the inner annular portion 1 and the intermediate annular portion 2, and a plurality of outer coupling portions 5 coupling the outer annular portion 3 and the intermediate annular portion 2, wherein the inner coupling portions 4 and the outer coupling portions 5 are divided in a tire width direction, are independent in a tire circumferential direction, and are provided so as to be shifted from each other in the tire circumferential direction per zones which are divided in the tire width direction.

Owner:TOYO TIRE & RUBBER CO LTD

Variable Compliance Wheel

ActiveUS20110272254A1Improve lateral performanceReduce wasteShaft and bearingsNon-inflatable tyresEngineeringMechanical engineering

A system for adjusting the compliance of a wheel is provided. In one embodiment, wheel segments are adjusted, causing the stiffness of the wheel to change. Such adjustments can be made while the wheel is rotating, allowing the wheel compliance to be changed while a vehicle is in motion.

Owner:MILLENWORKS

Molded article and venting assembly for a rotating mold

A molded article comprises an outer interface element, an inner interface element, and a plurality of web spokes positioned therebetween. The common surfaces of the inner and outer interface elements and a pair of adjacent web spokes form a void space. The surface of at least a portion of an interface element common to one of the voids has an edge radius with a variation from a maximum radius at a circumferential location corresponding to a mid point between a pair of adjacent web spokes to a minimum radius at a circumferential location corresponding to the intersection of the interface element with the web spoke.

Owner:MICHELIN RECH & TECH SA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com