Patents

Literature

279results about "Wheels with spade lugs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

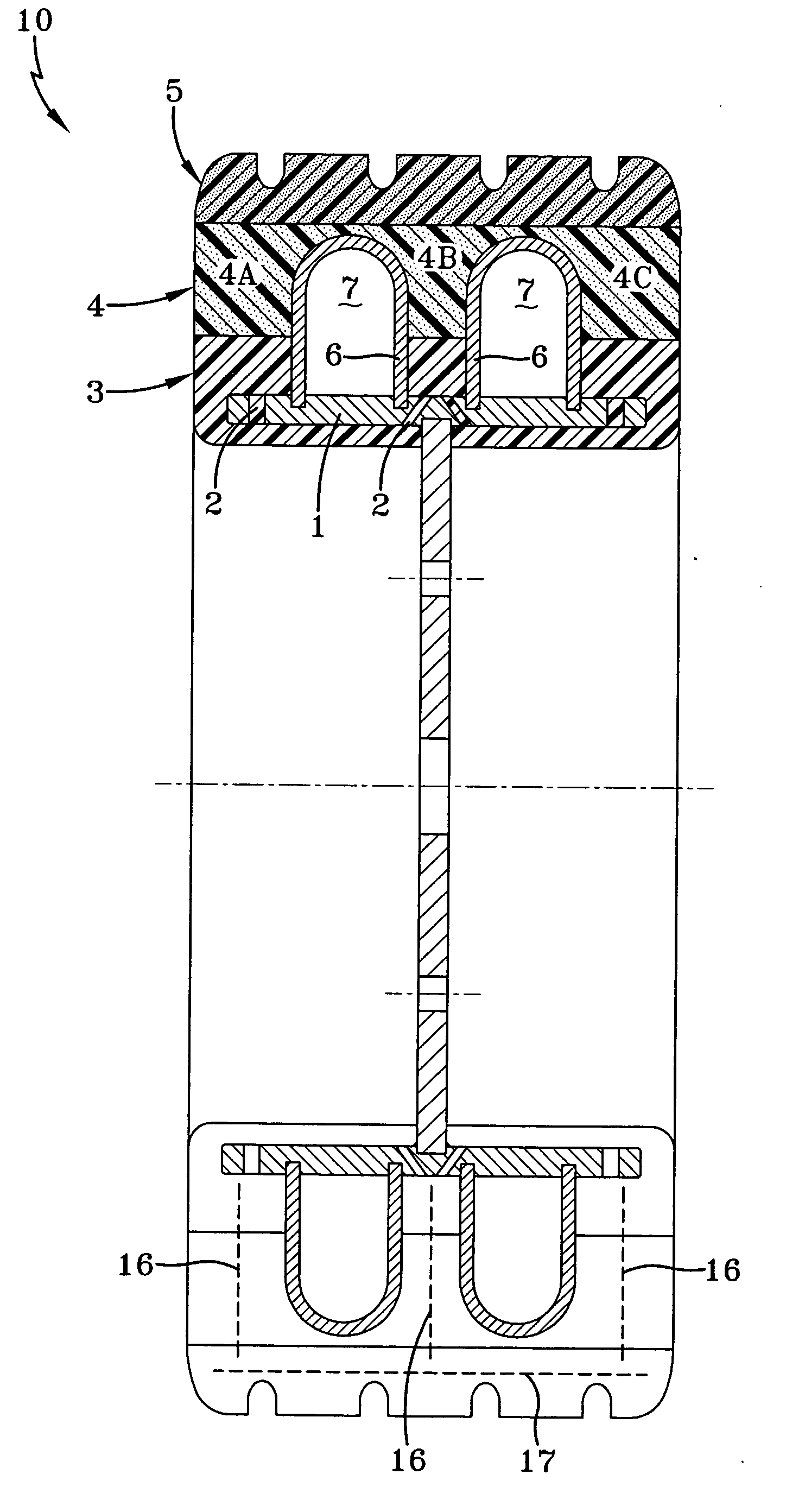

Non-pneumatic tire

InactiveUS7201194B2Supporting massHigh effective radial stiffness in tensionNon-inflatable tyresPneumatic tyre reinforcementsElastomerShear modulus

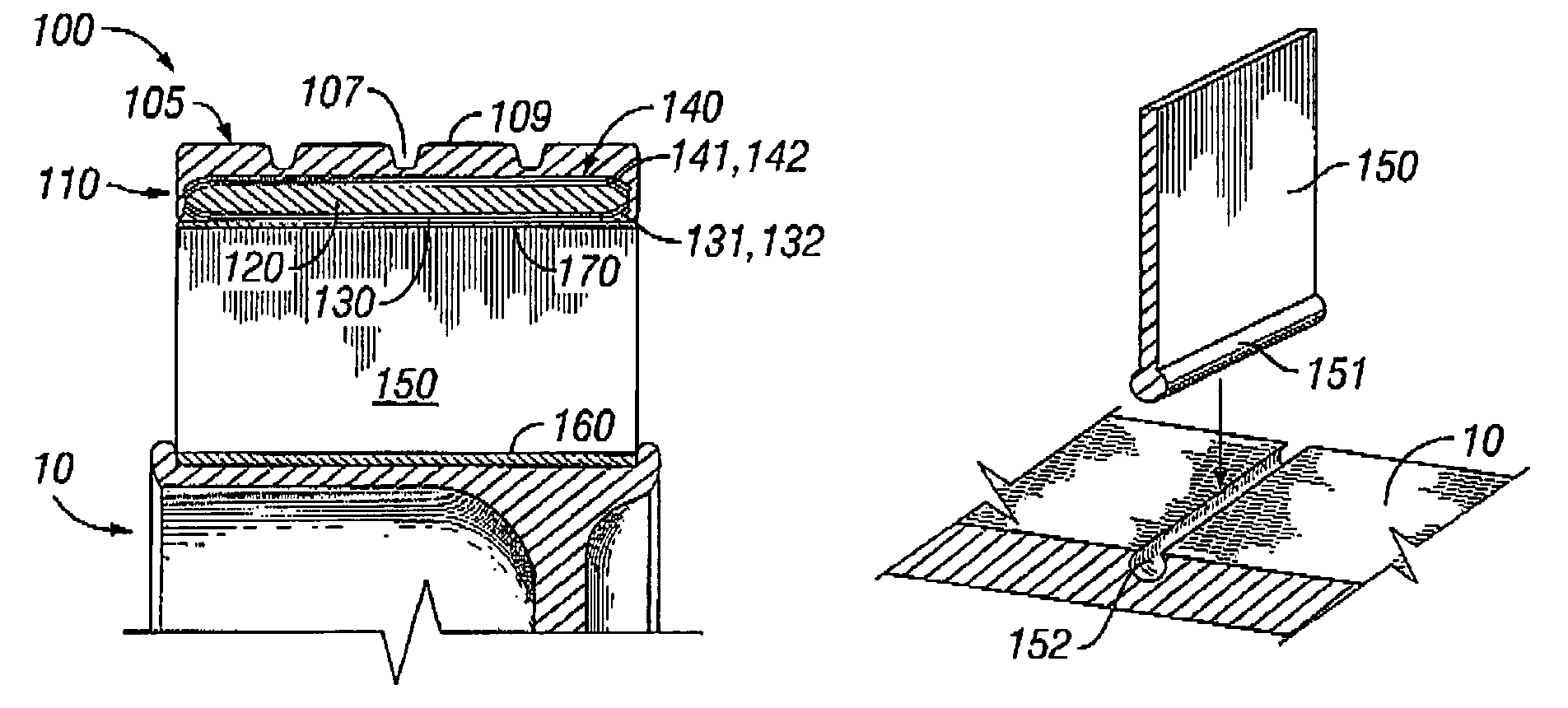

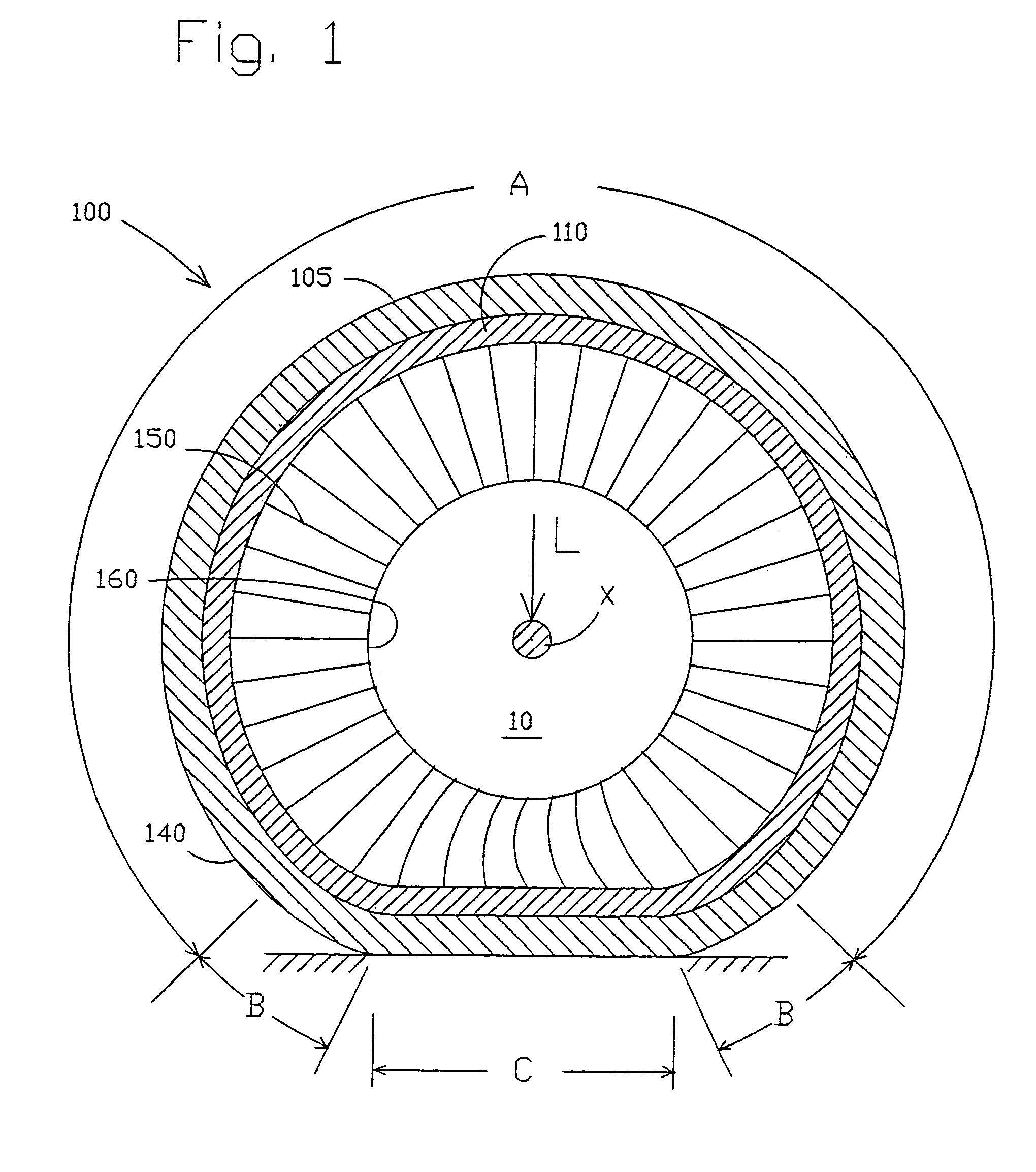

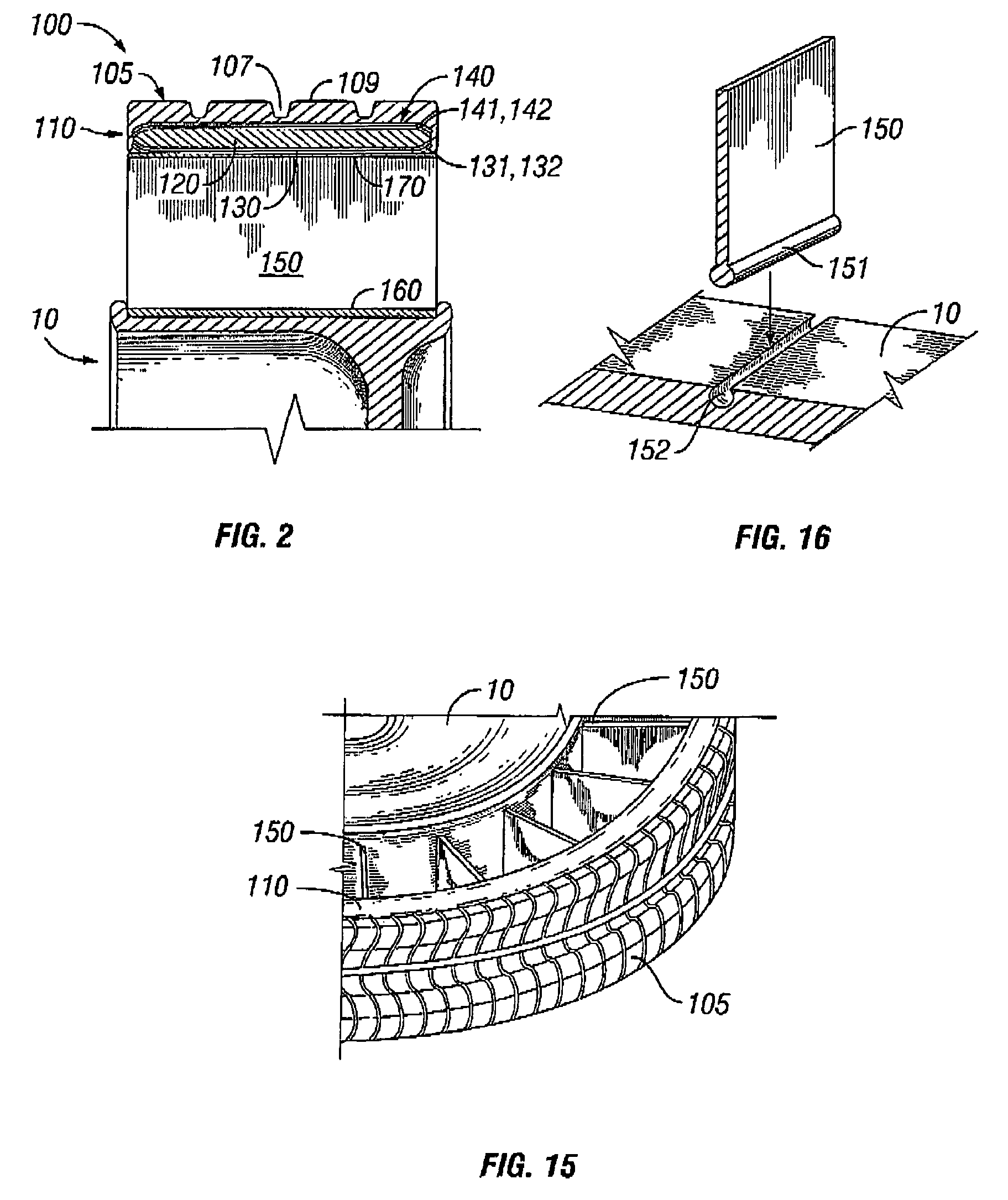

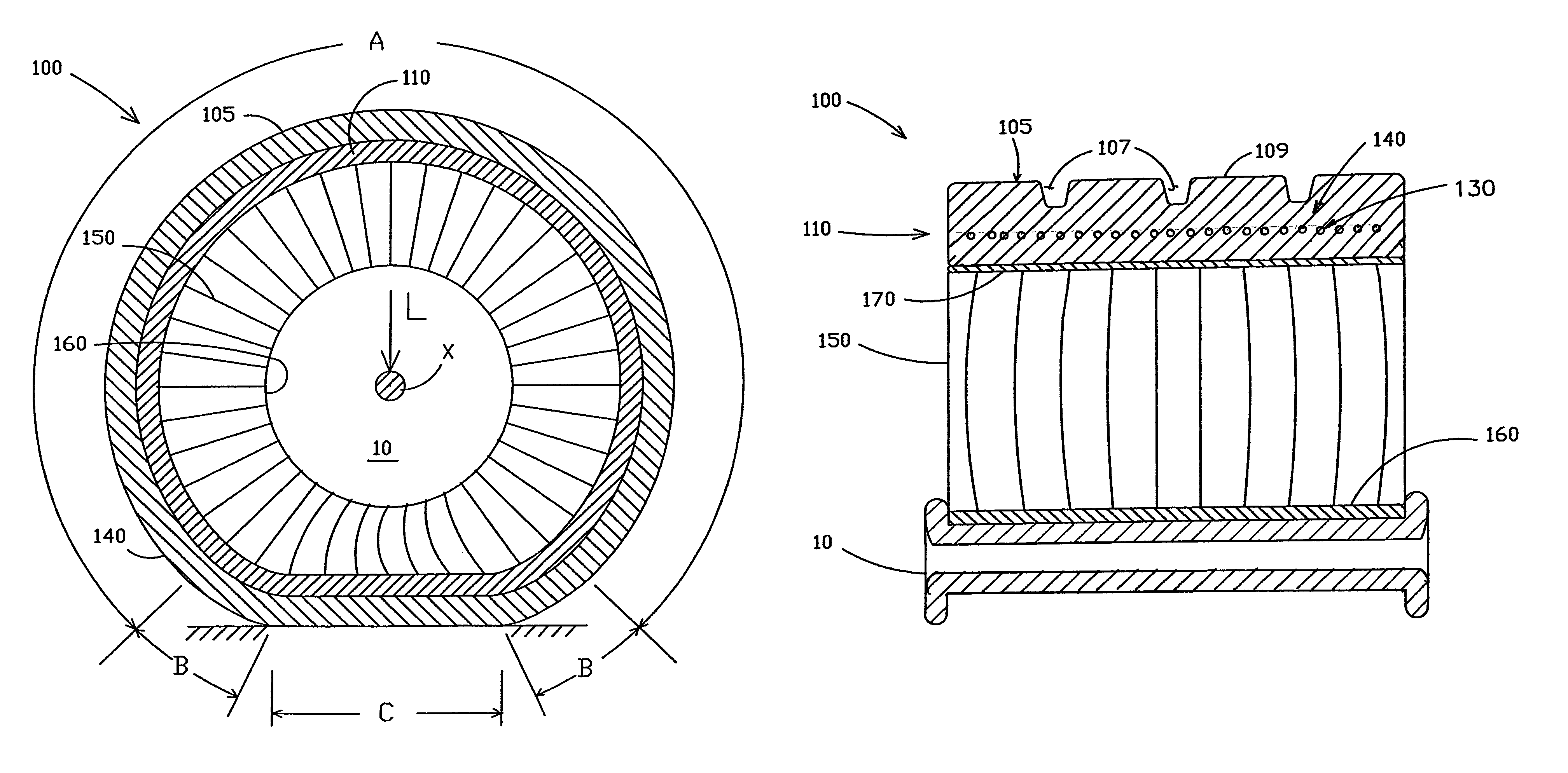

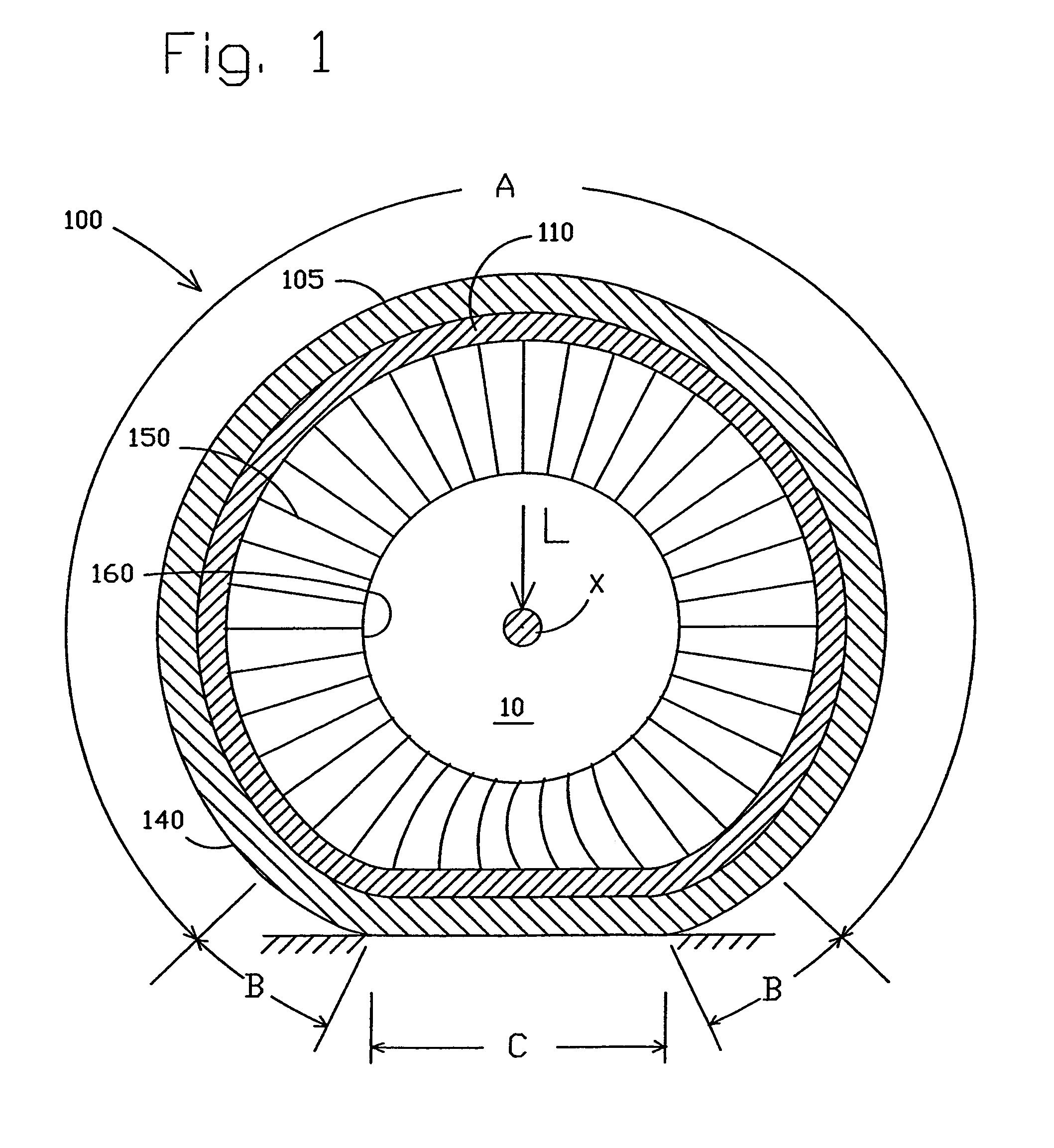

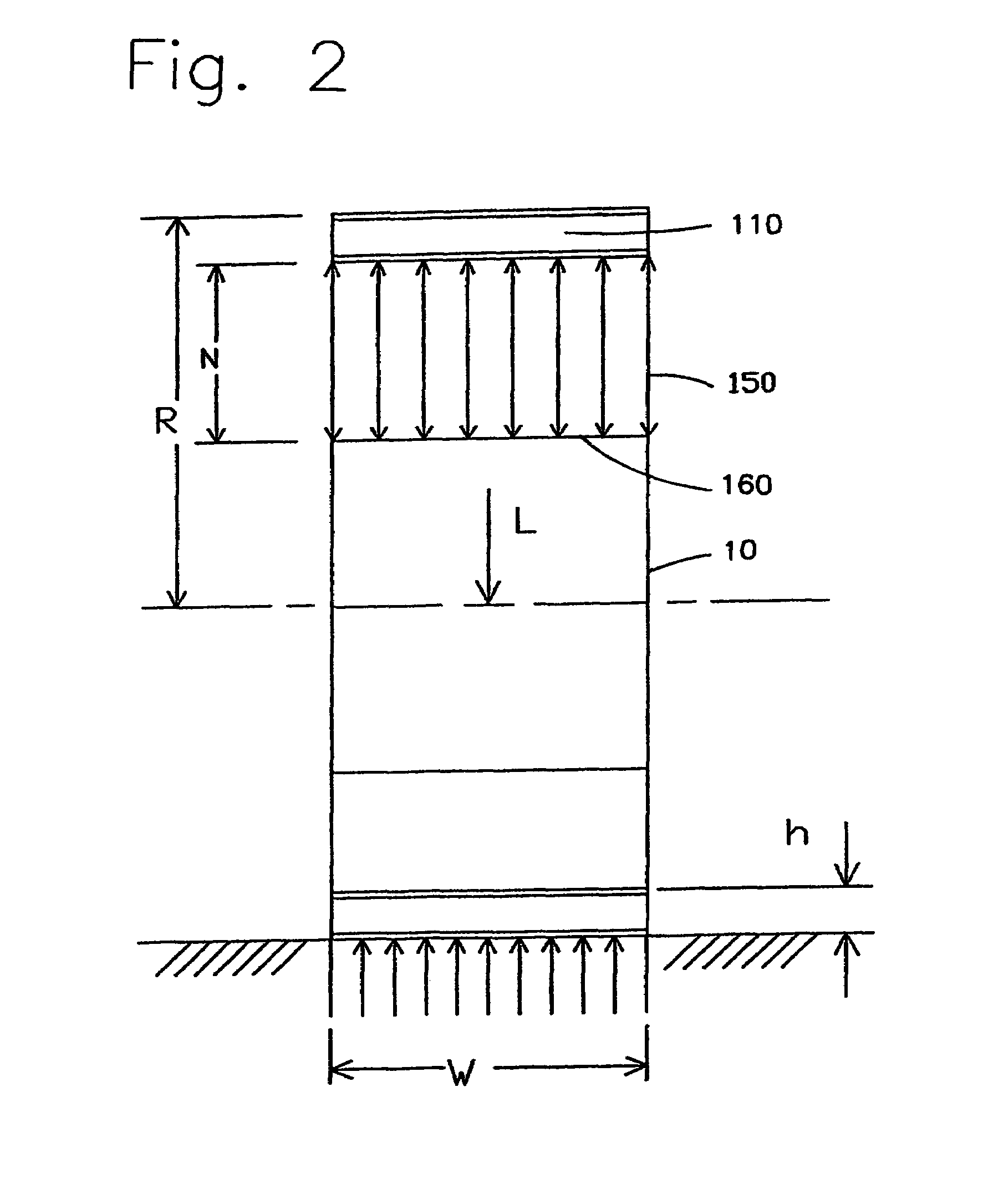

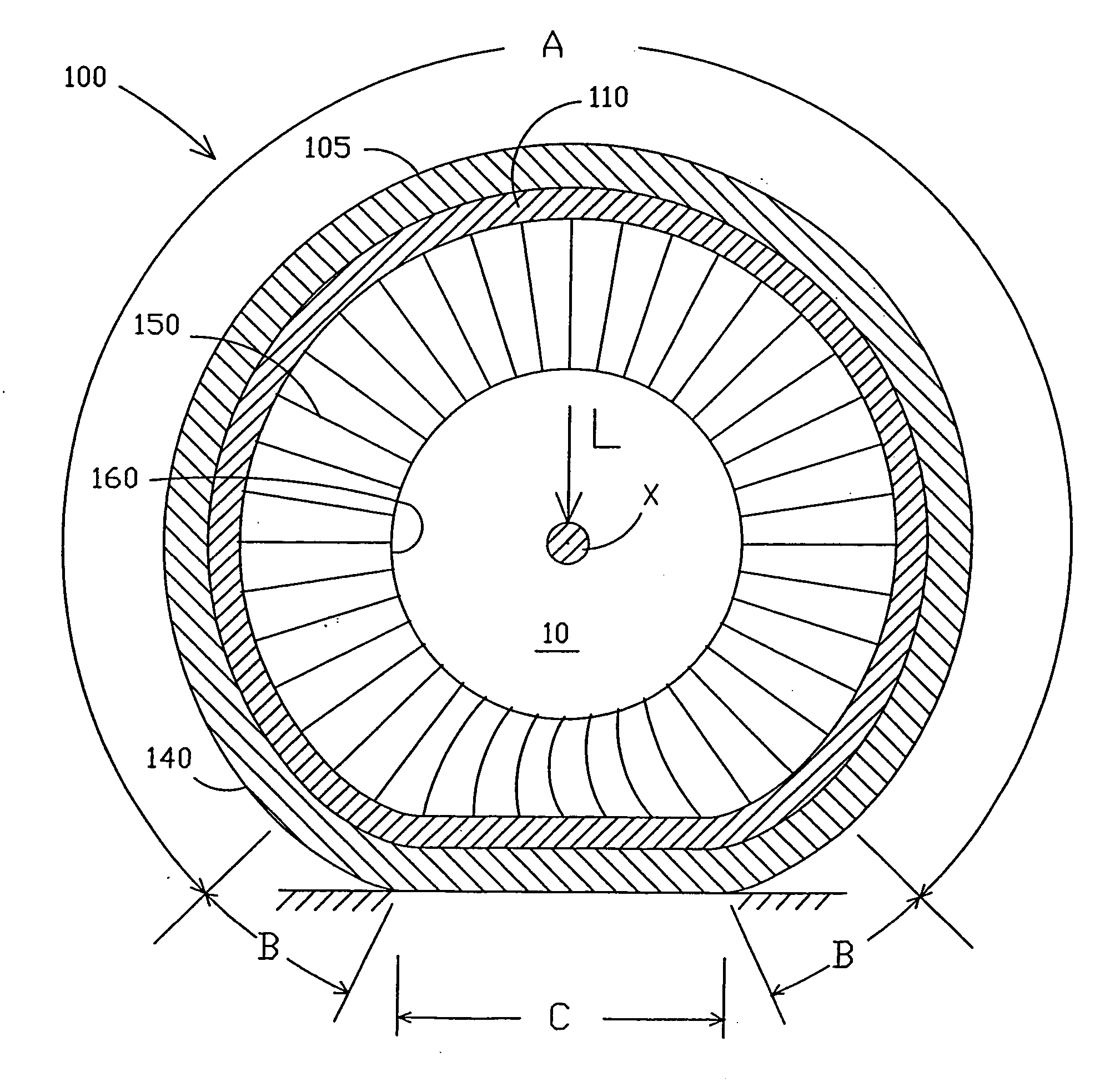

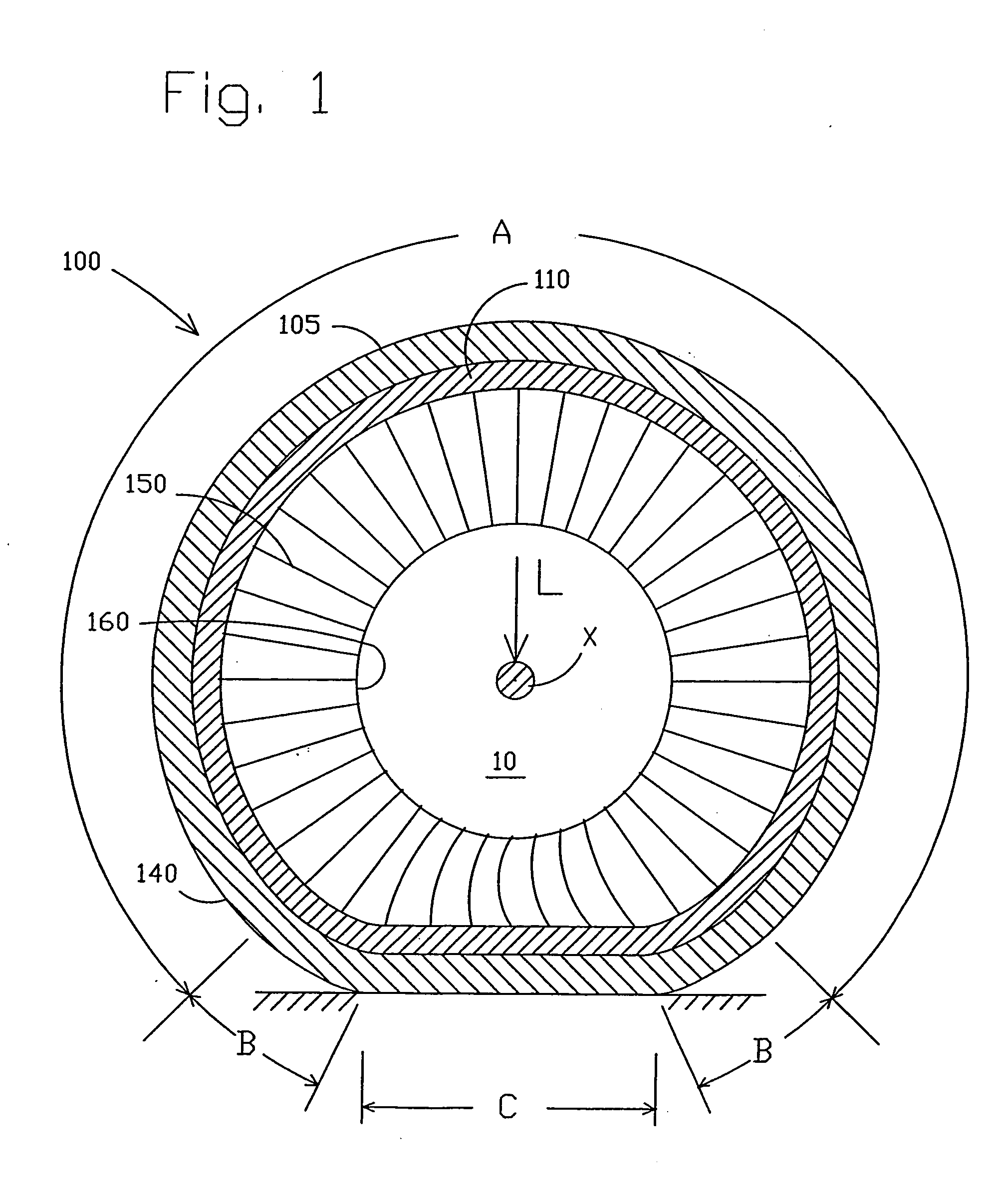

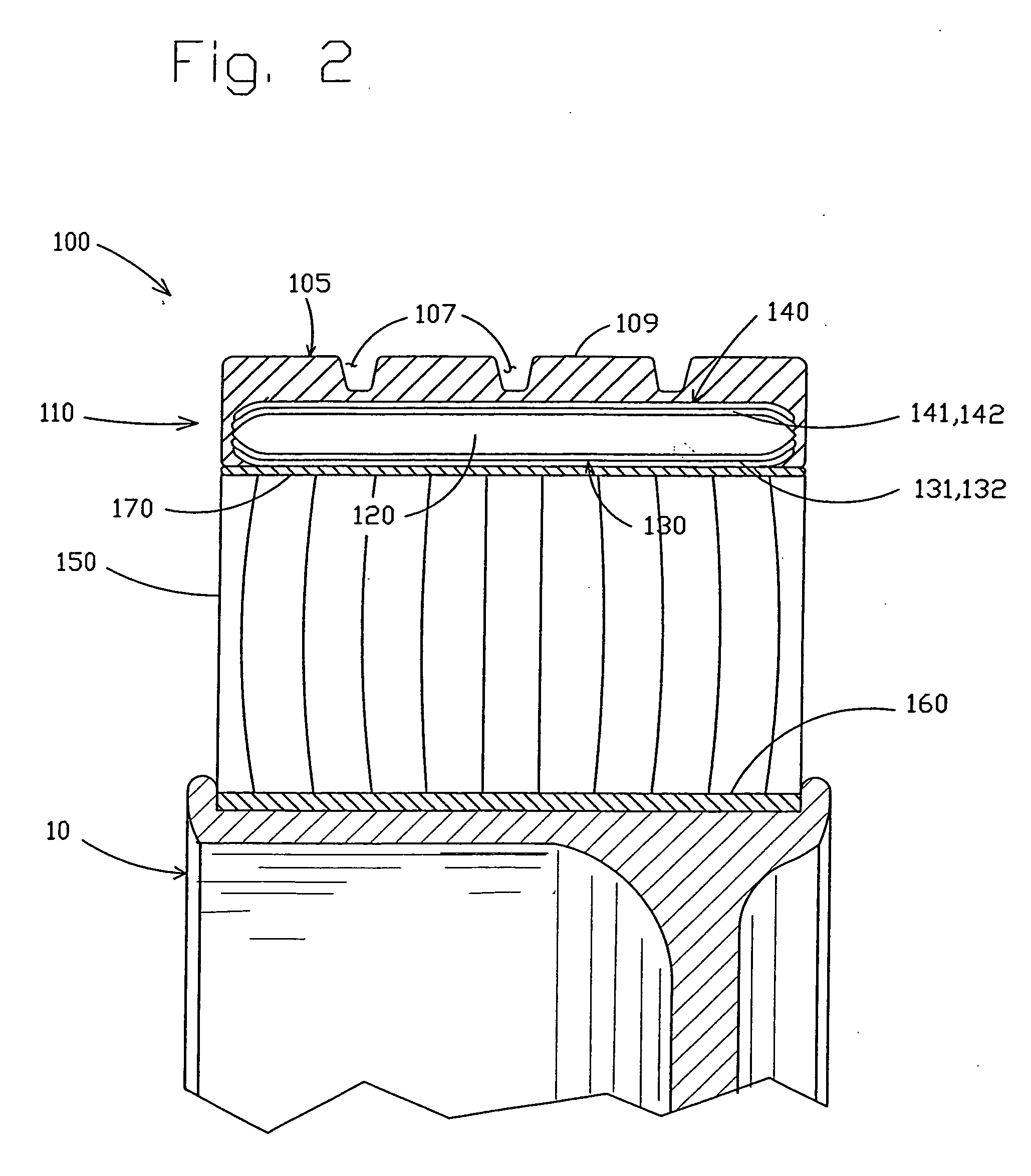

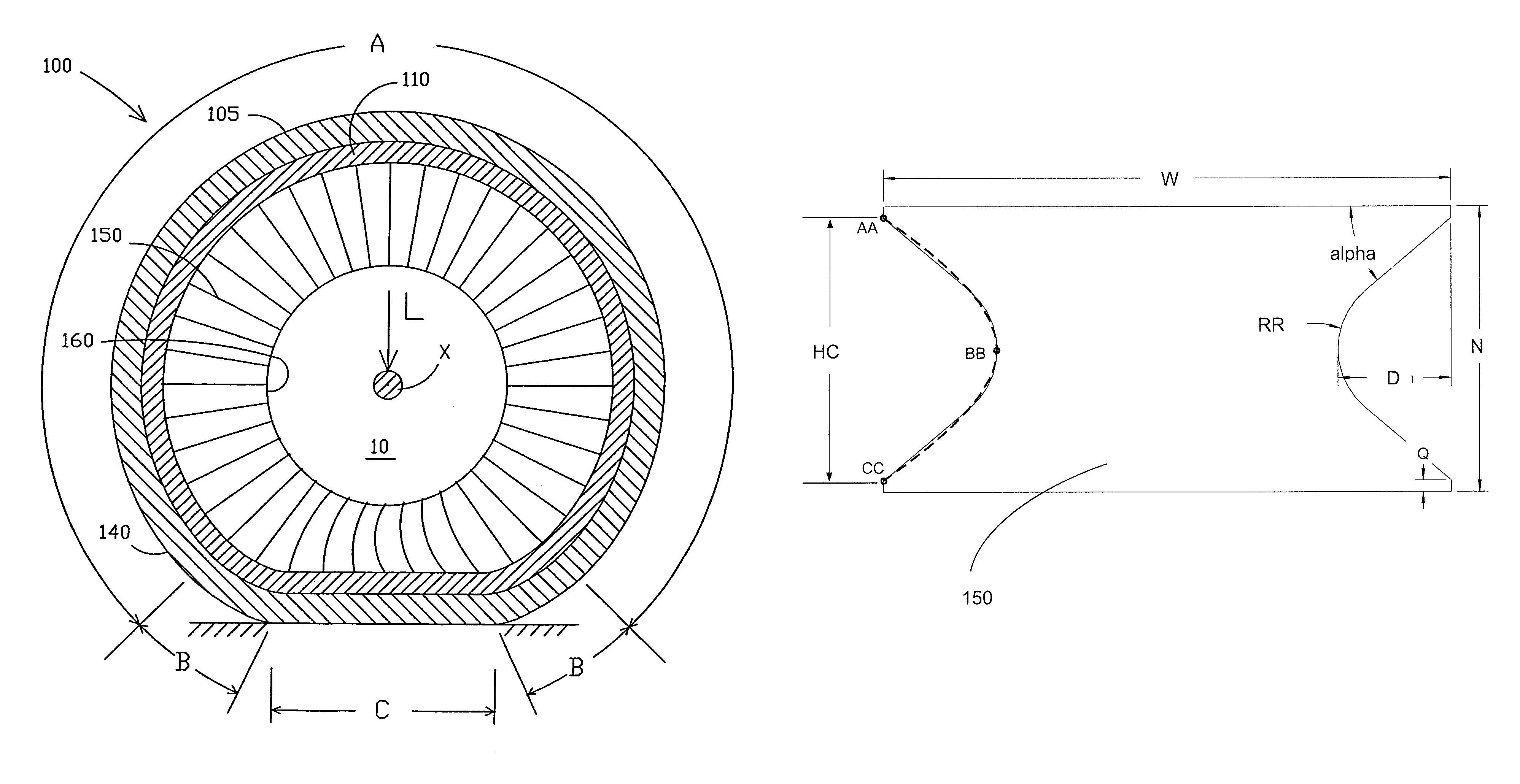

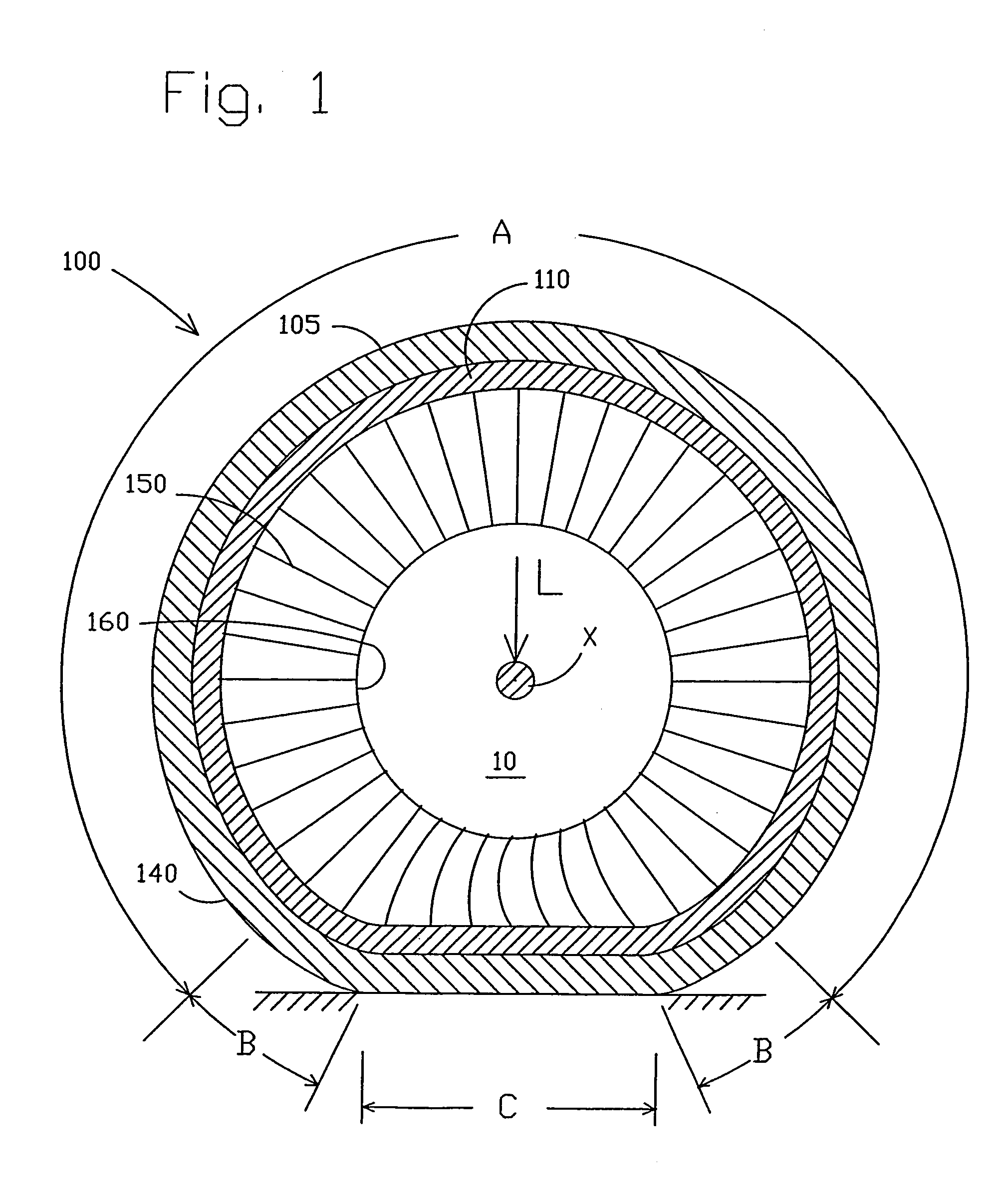

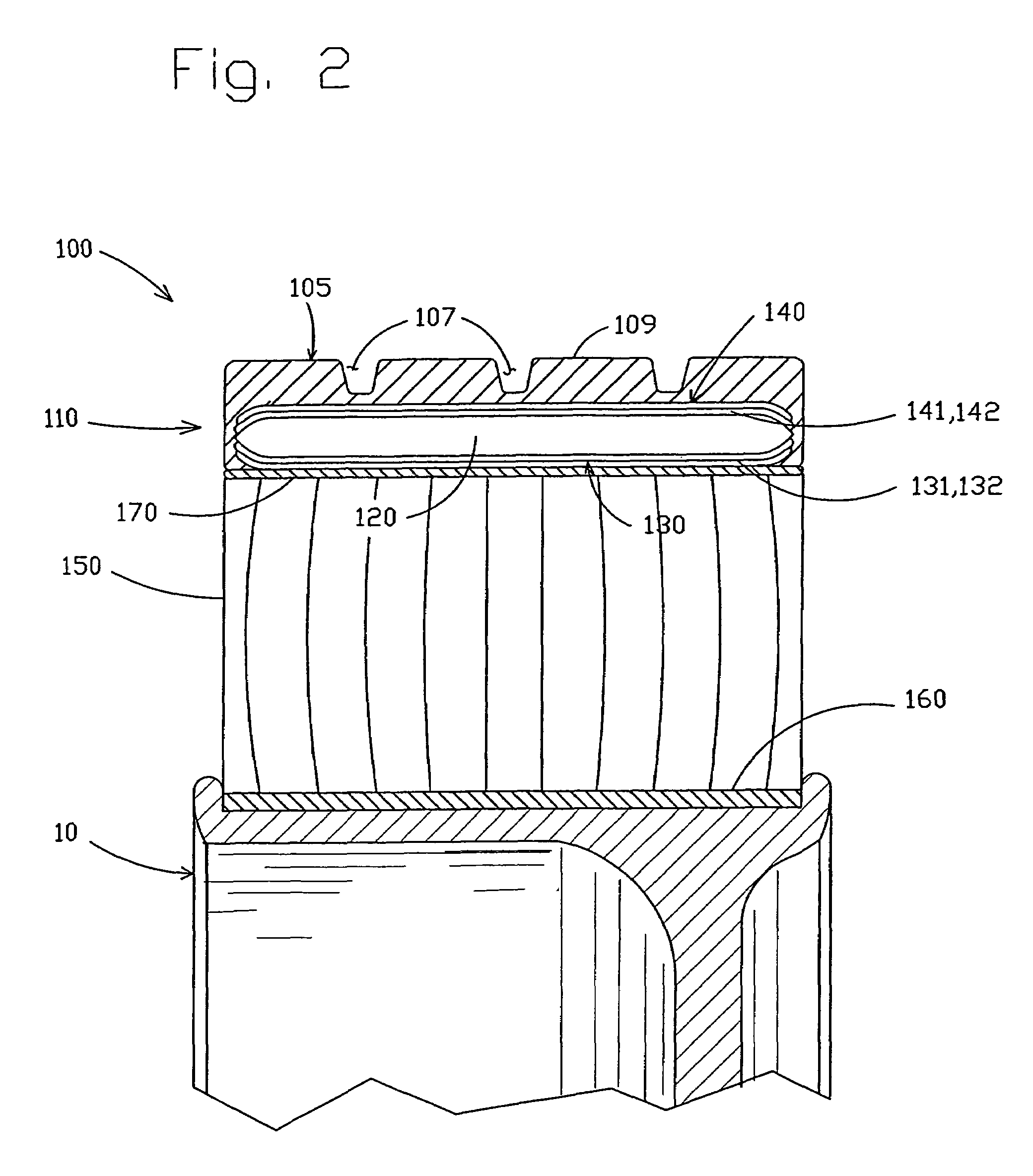

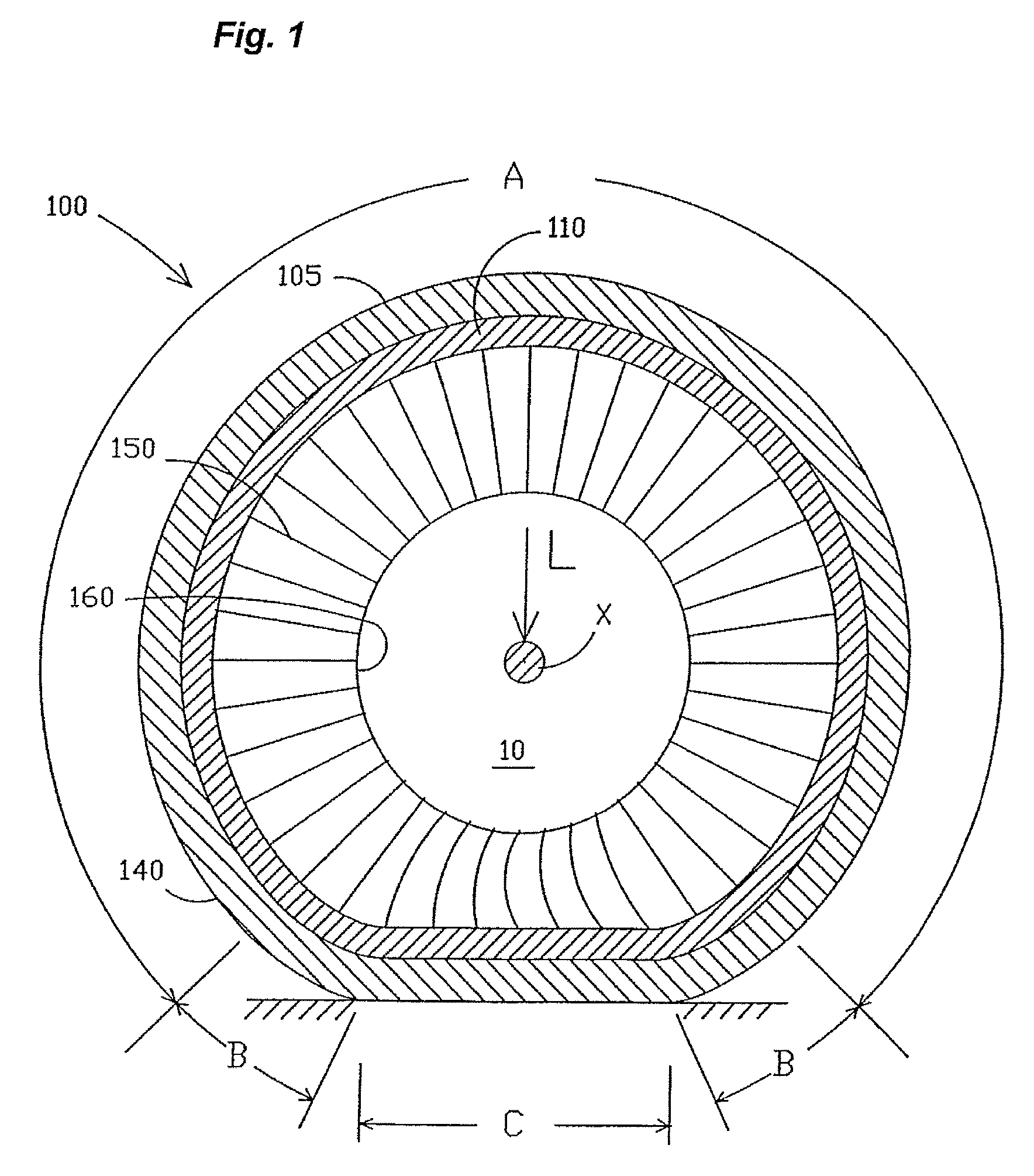

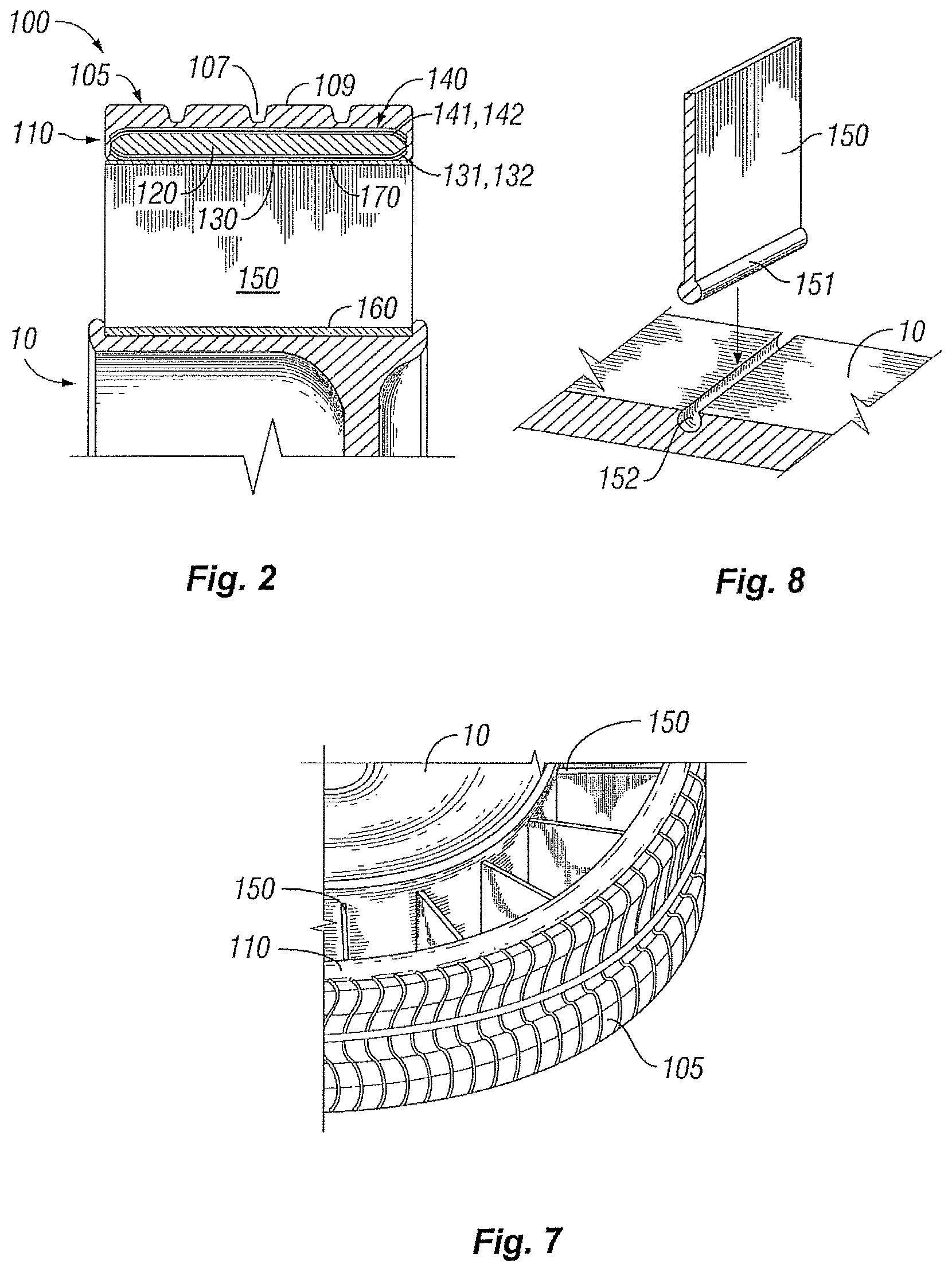

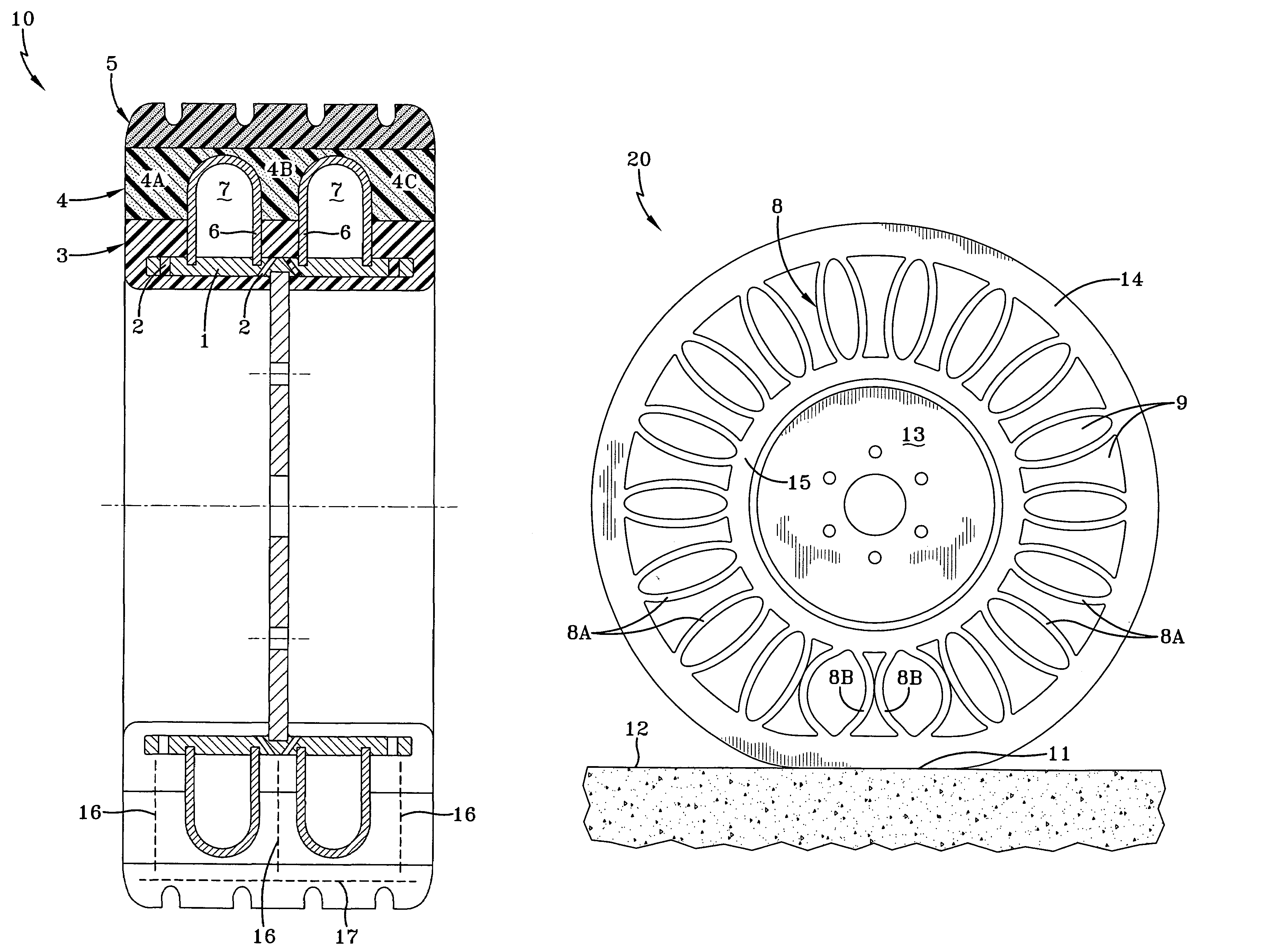

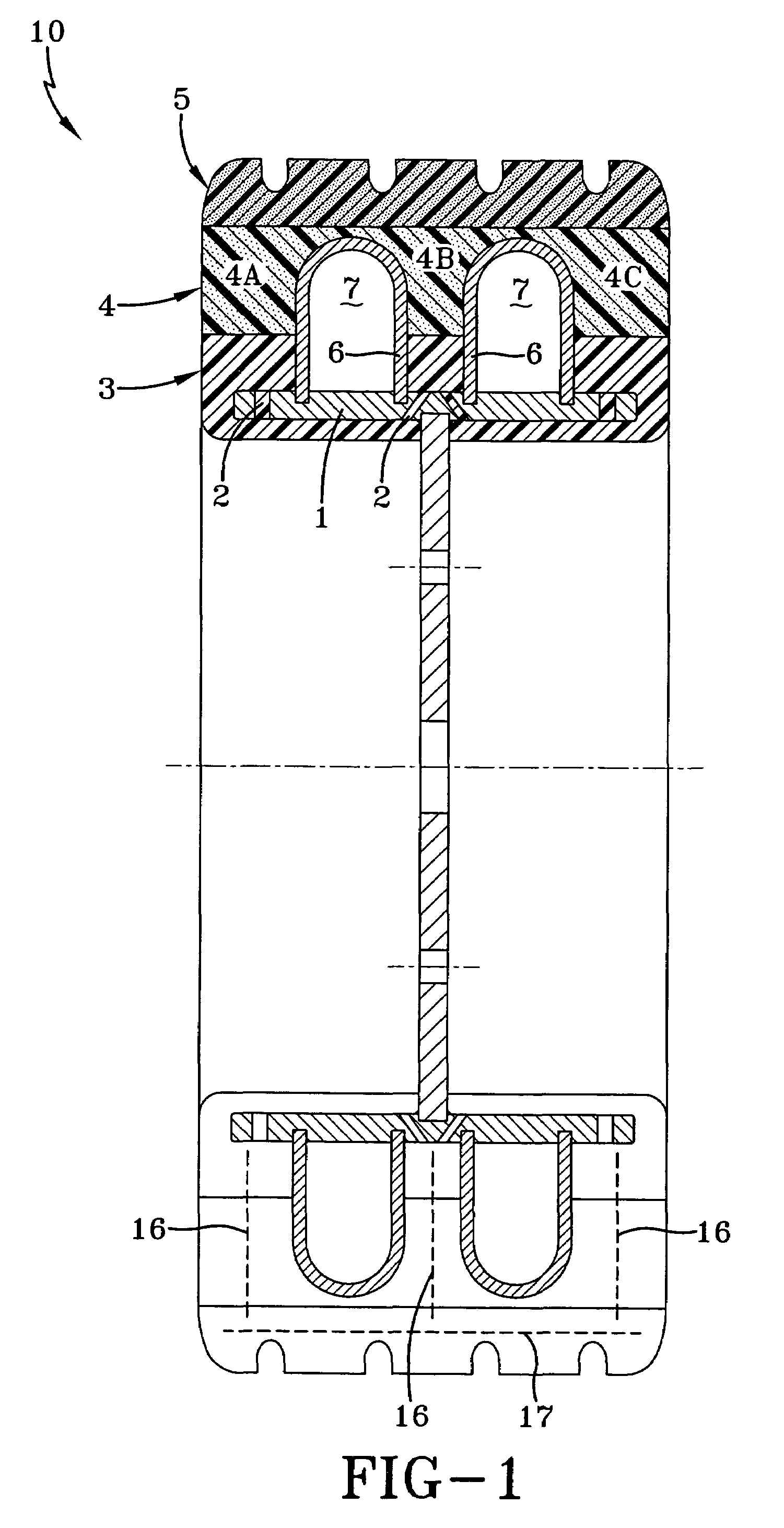

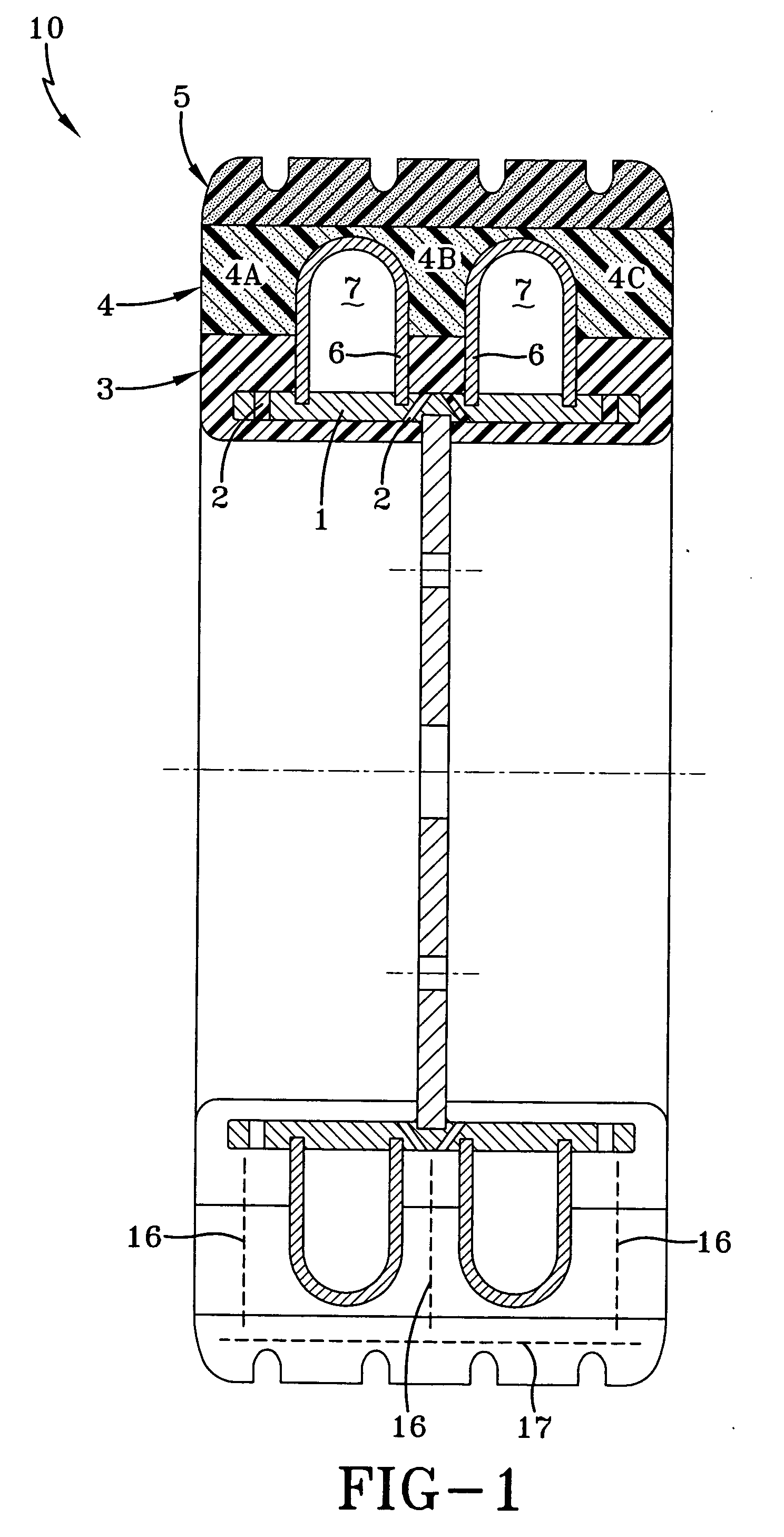

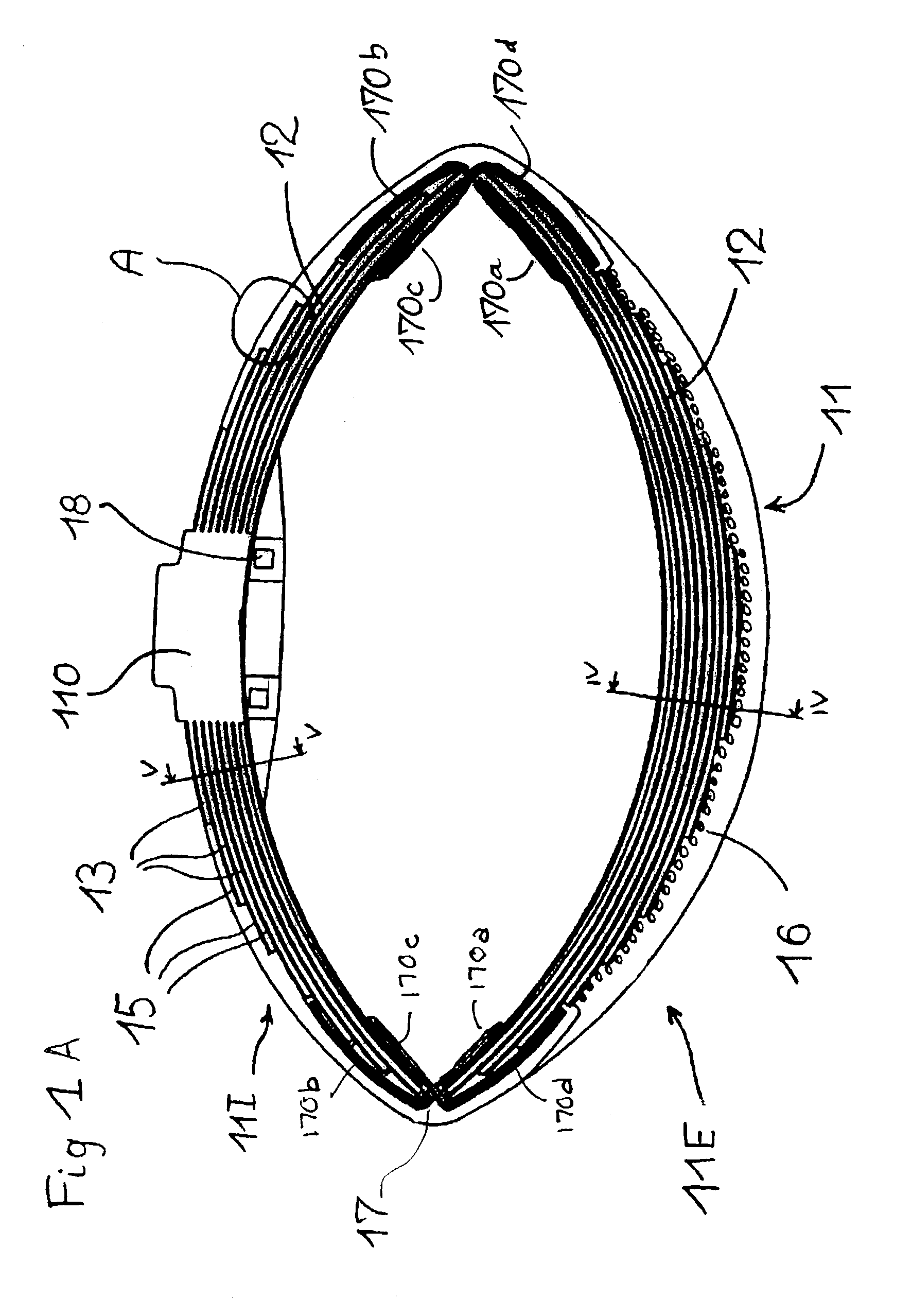

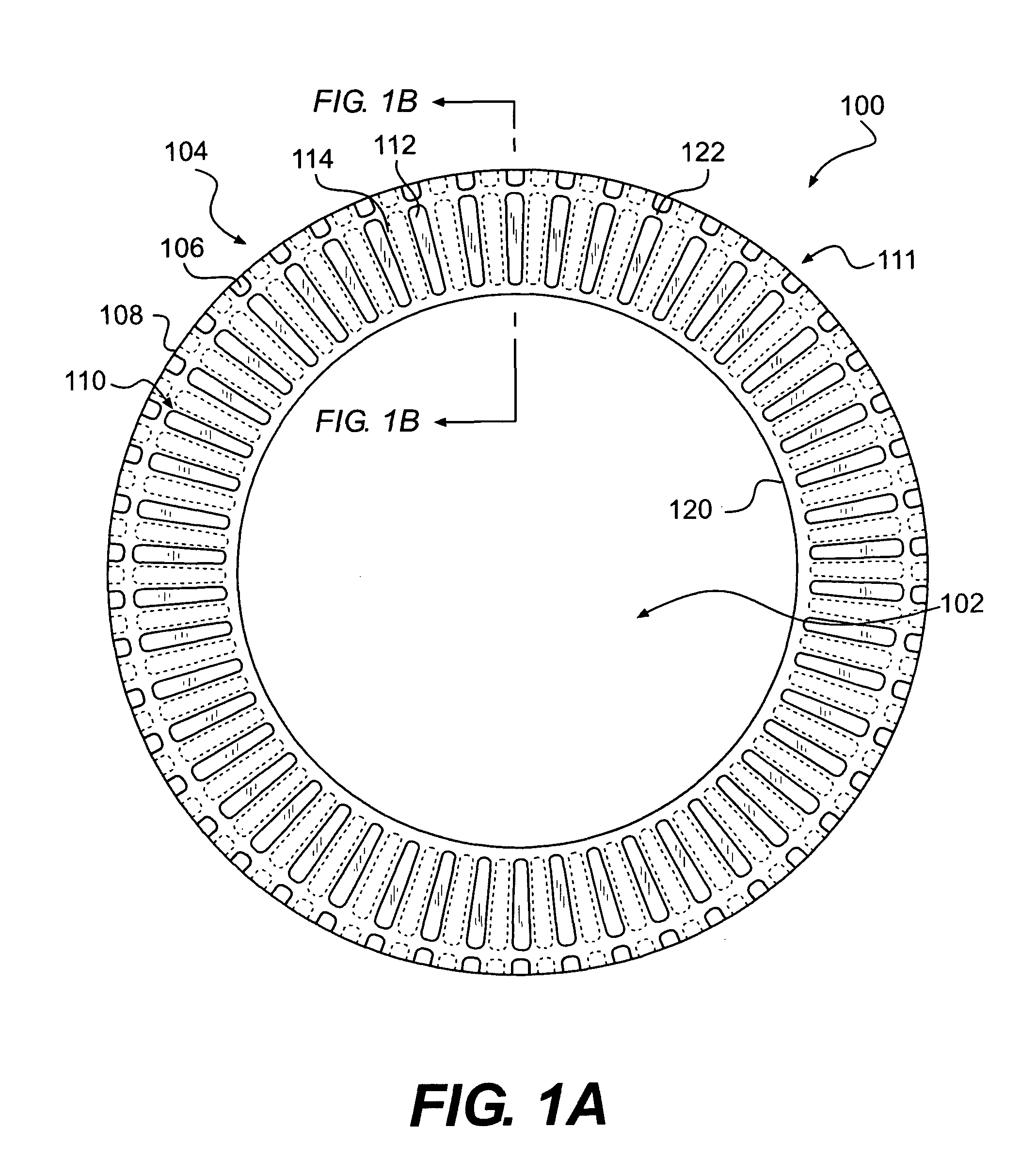

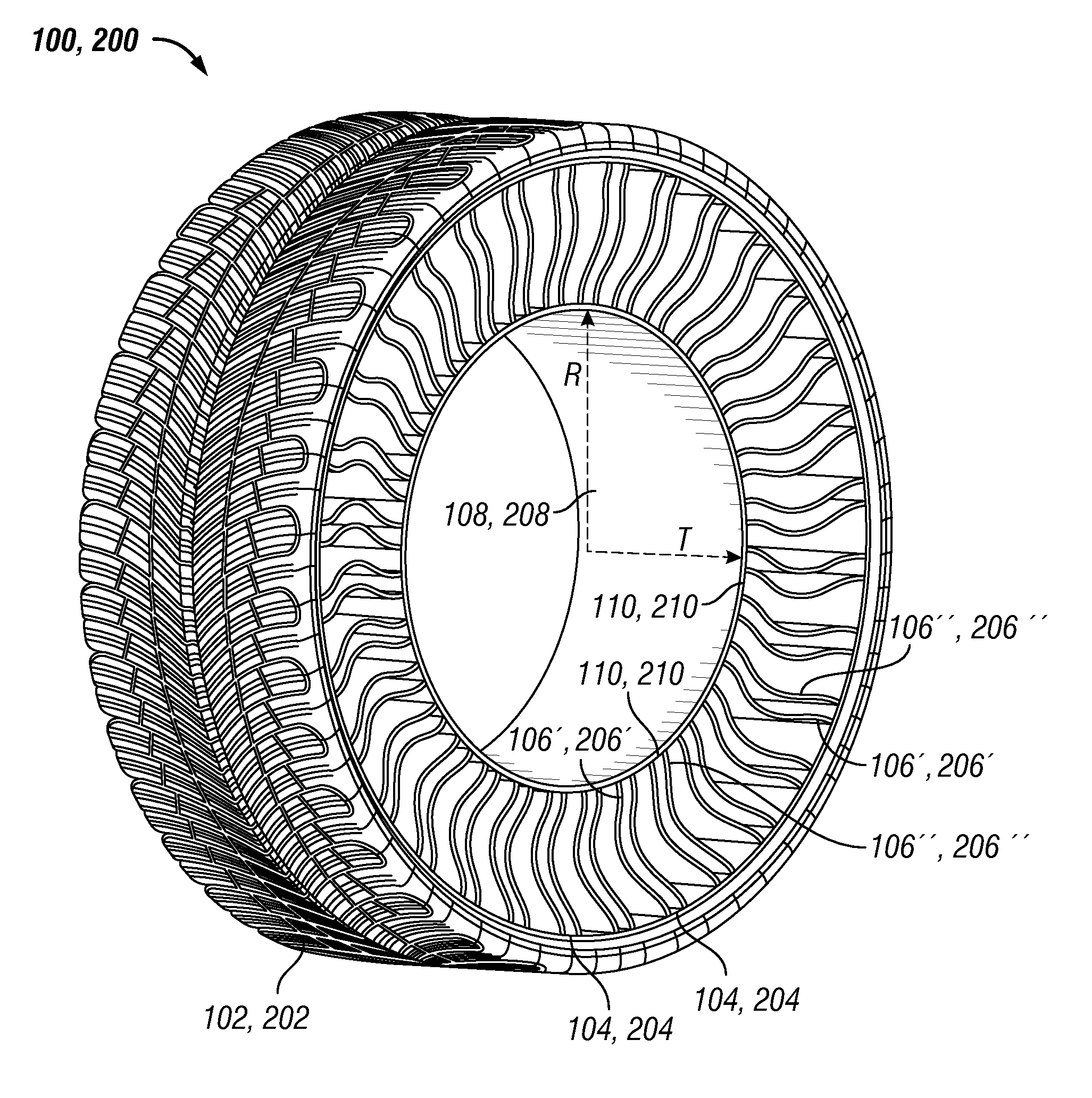

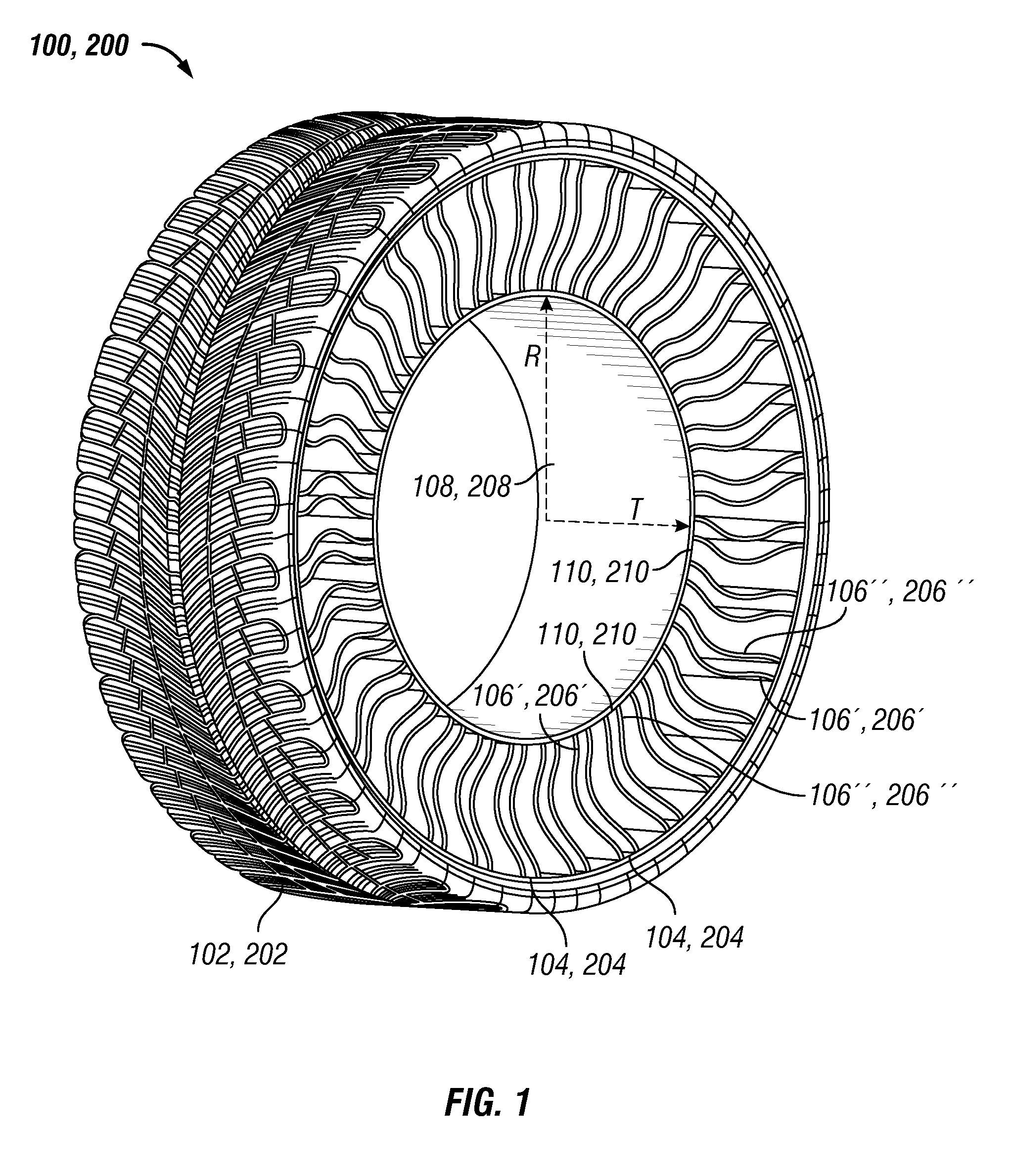

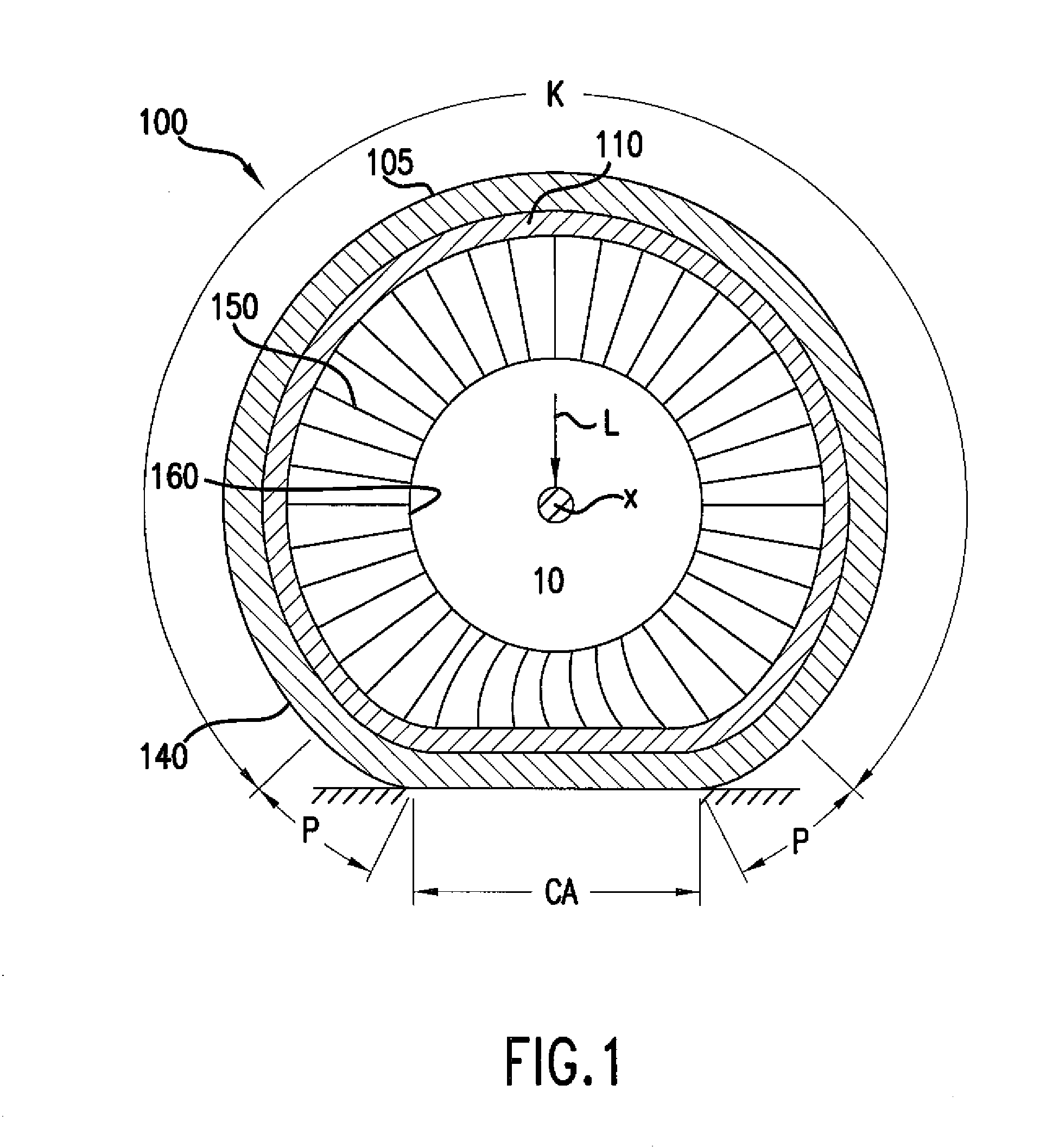

A structurally supported tire includes a ground contacting tread portion, a reinforced annular band disposed radially inward of the tread portion, and a plurality of web spokes extending transversely across and radially inward from the reinforced annular band and anchored in a wheel or hub. The reinforced annular band comprises an elastomeric shear layer, at least a first membrane adhered to the radially inward extent of the elastomeric shear layer and at least a second membrane adhered to the radially outward extent of the elastomeric shear layer. Each of the membranes has a longitudinal tensile modulus sufficiently greater than the shear modulus of the shear layer so that when under load the ground contacting portion of the tire deforms to a flat contact region through shear strain in the shear layer while maintaining constant the length of the membranes, the web spokes transmitting load forces between the annular band and the hub through tension in the web spokes not connected to the ground contacting portion of the tire.

Owner:MICHELIN RECH & TECH SA

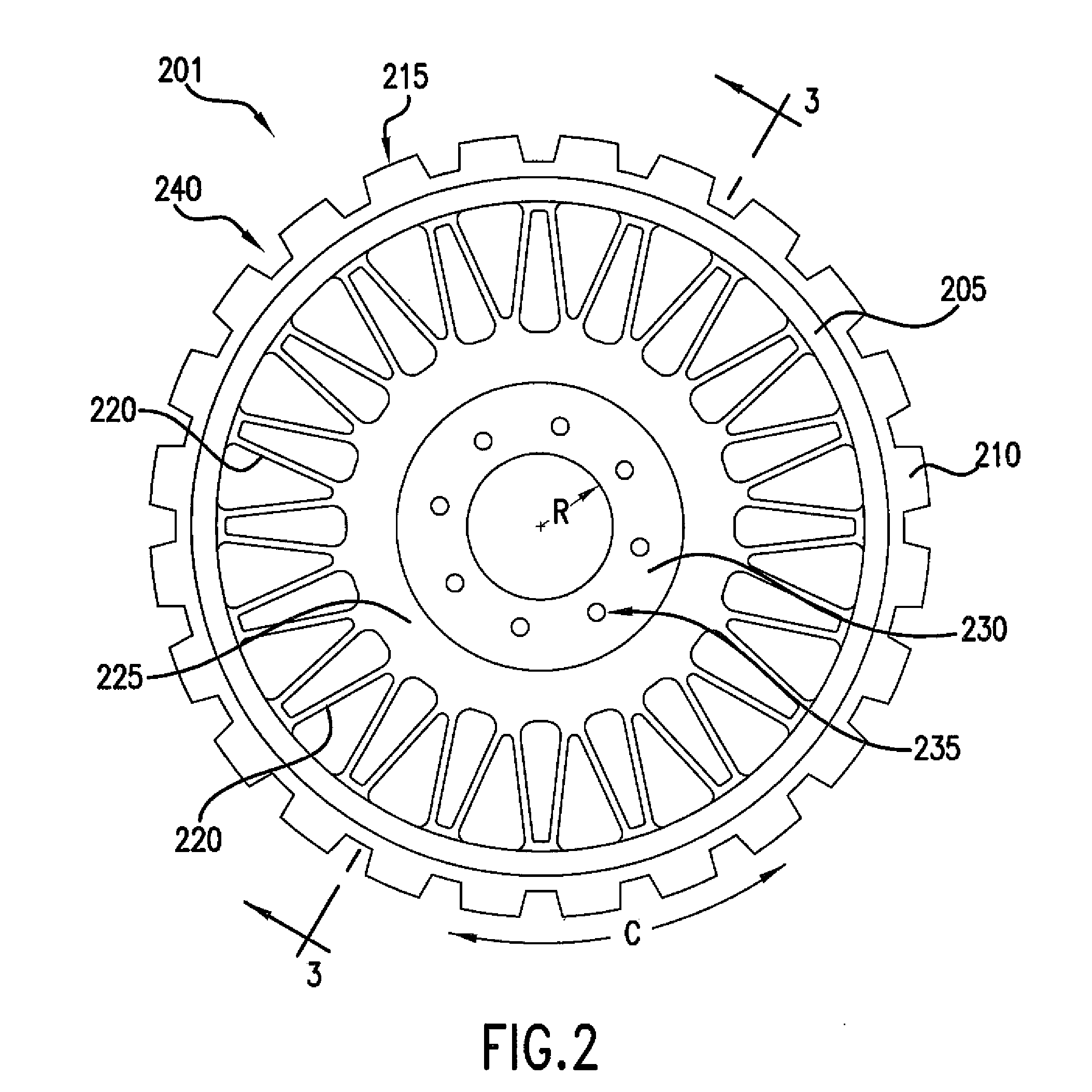

Compliant wheel

InactiveUS7013939B2High effective stiffness in tensionLow effective stiffness in compressionNon-inflatable tyresWheel manufactureBand bendingGround contact

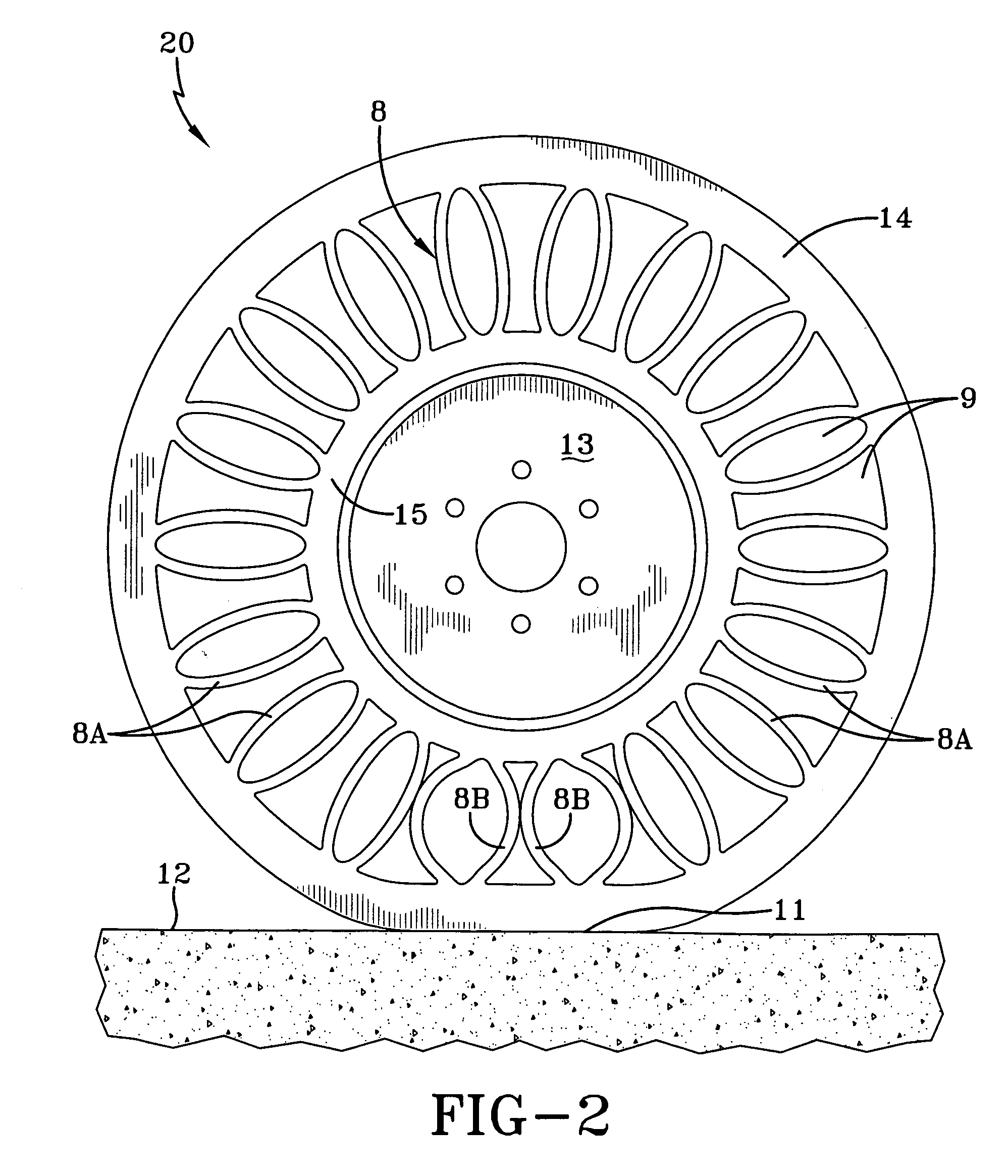

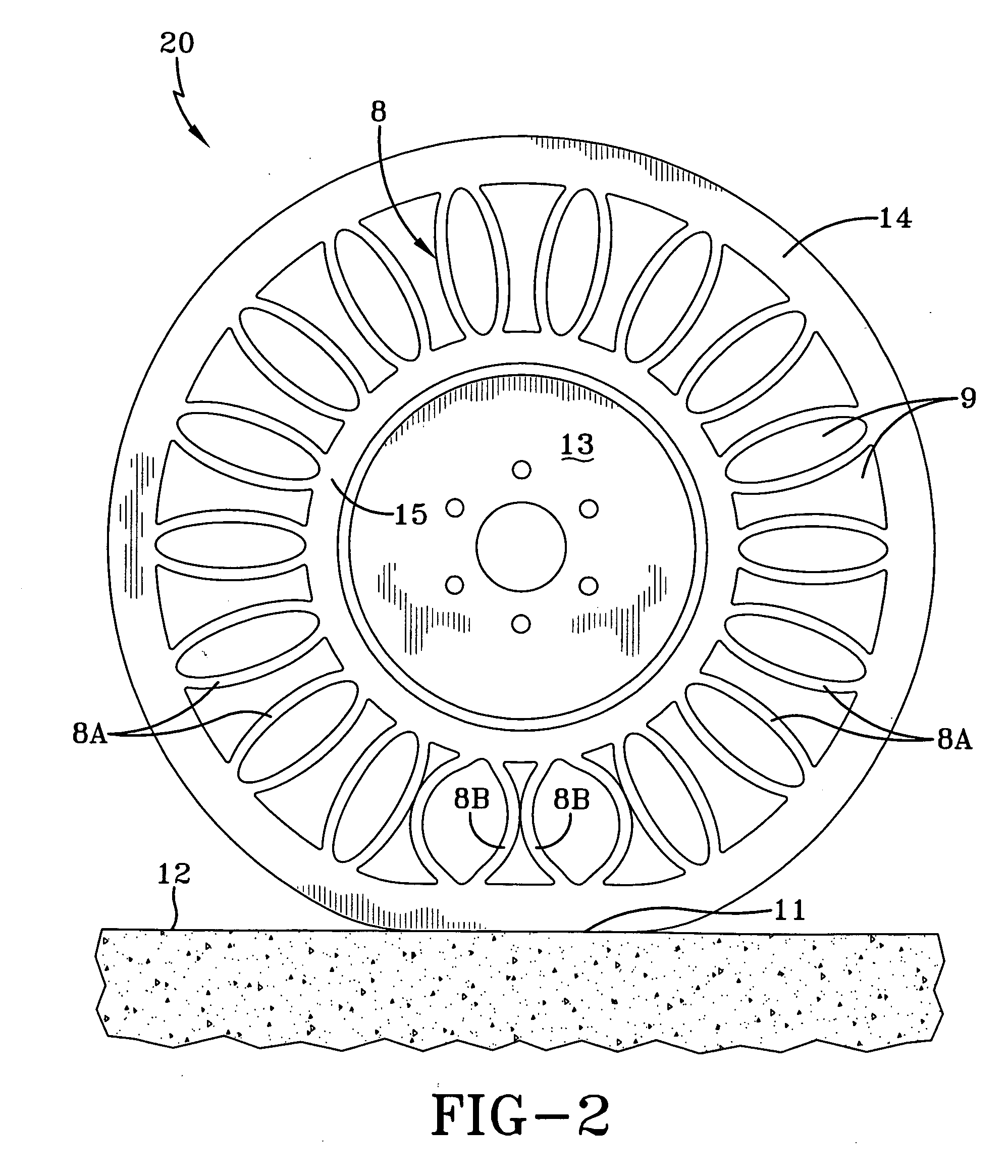

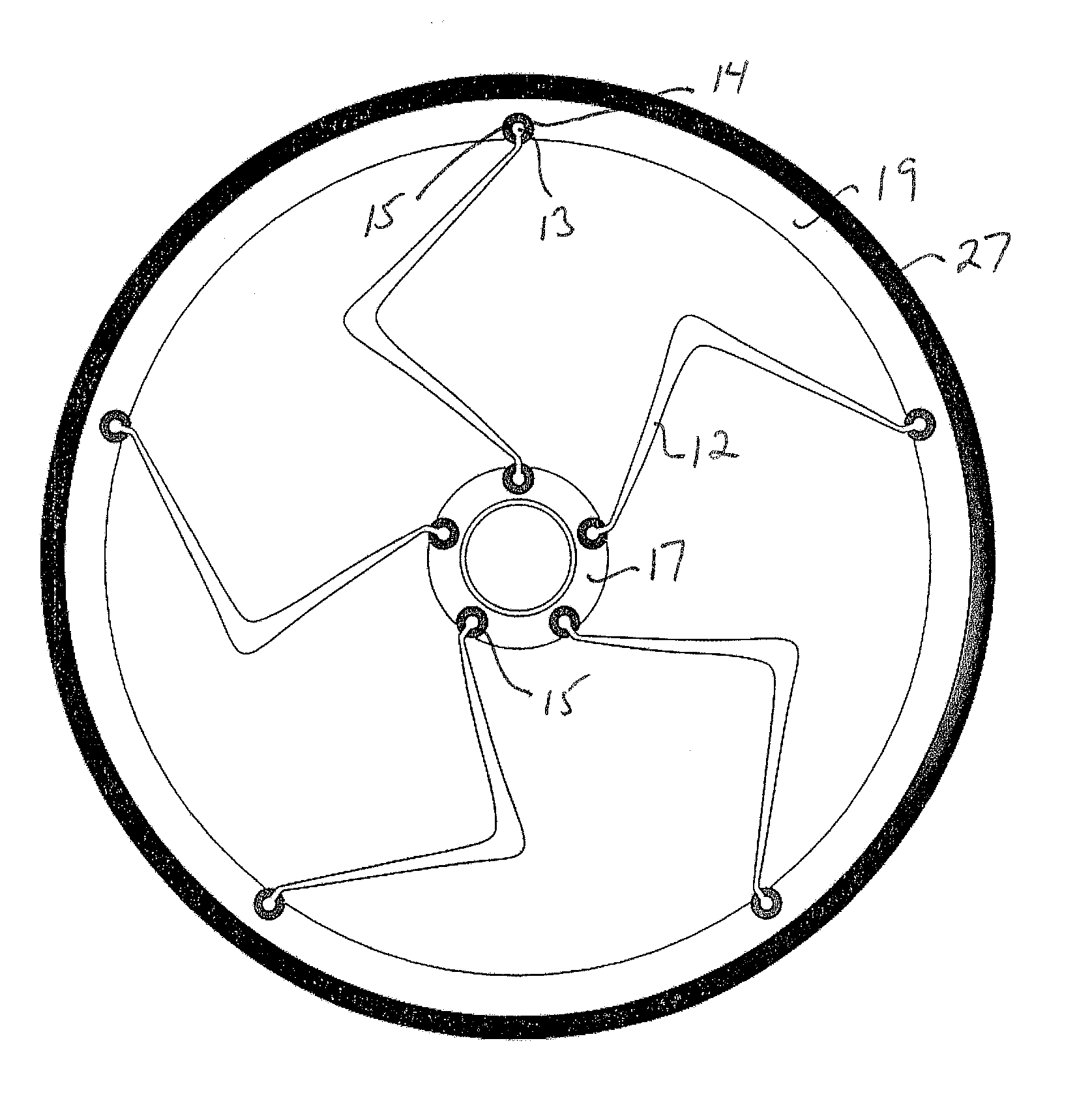

A compliant wheel includes a compliant band and a plurality of web spokes extending transversely across and inward from the reinforced compliant band for attachment to a hub. The compliant band bends to comply with a contact surface and to envelope obstacles. The web spokes transmit load forces between the compliant band and the hub through tension in the web spokes not connected to the ground contacting portion of the wheel. The outer surface of the compliant band may be formed to include a tread, or a separate tread band may be attached.

Owner:MICHELIN RECH & TECH SA

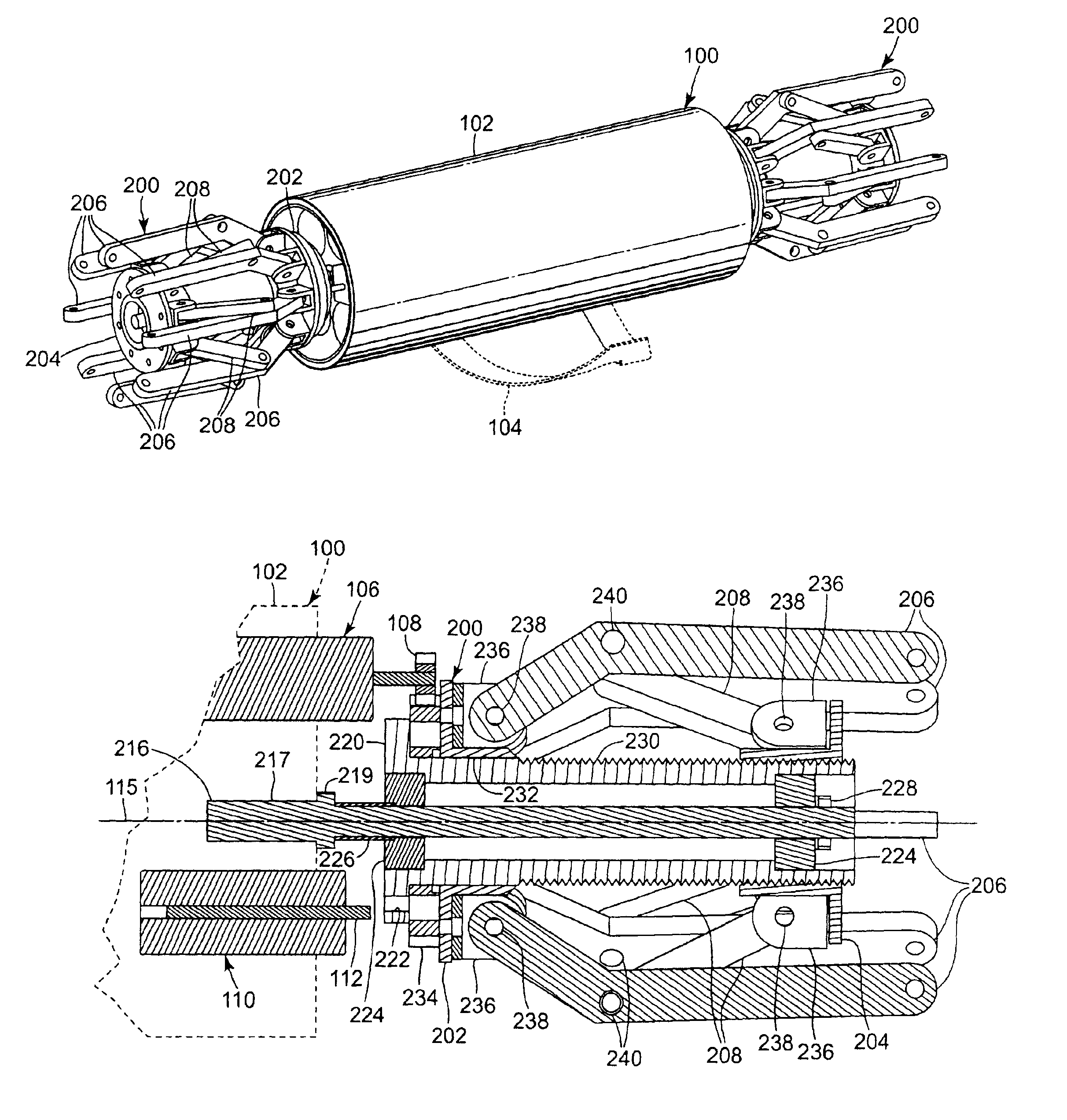

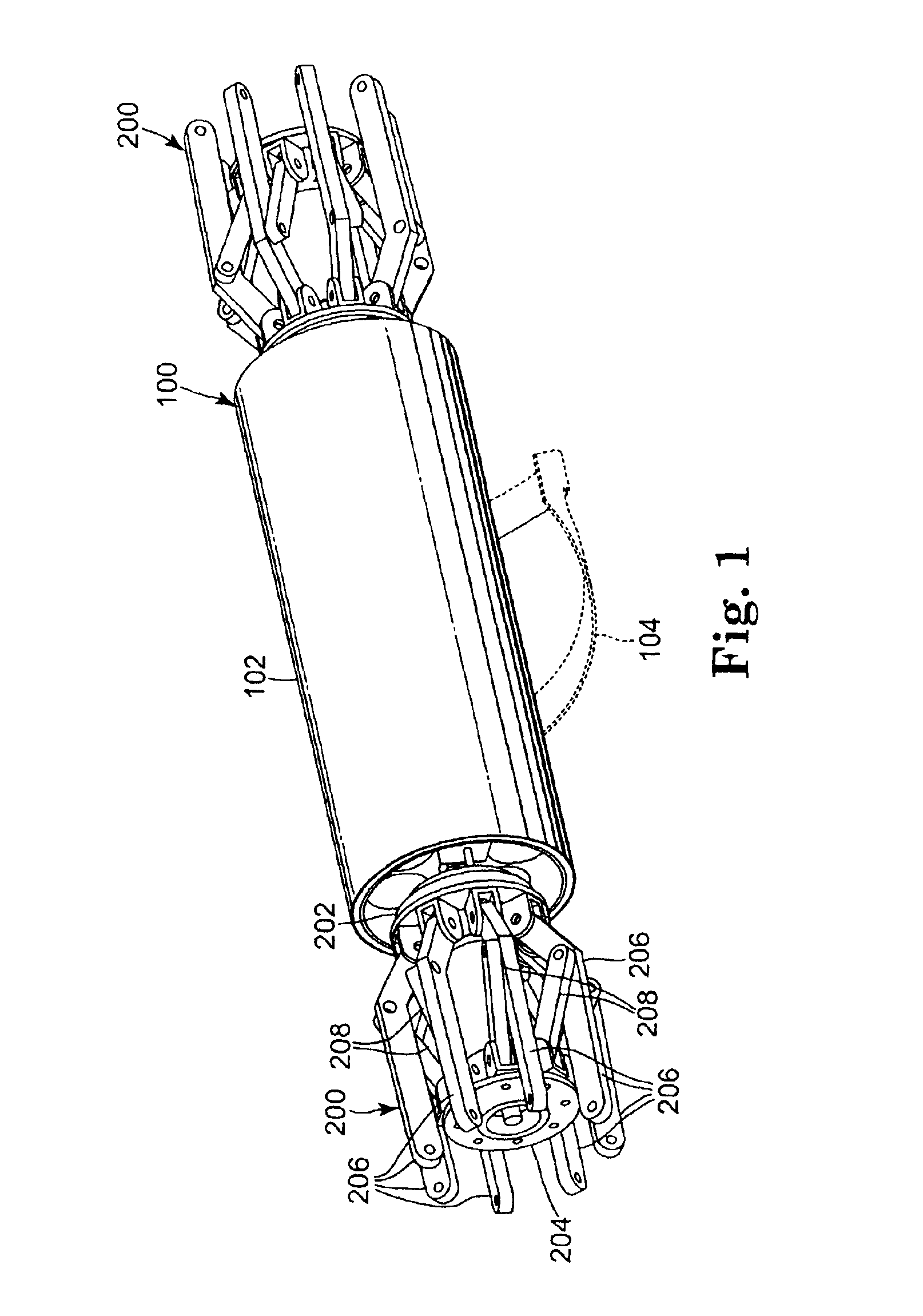

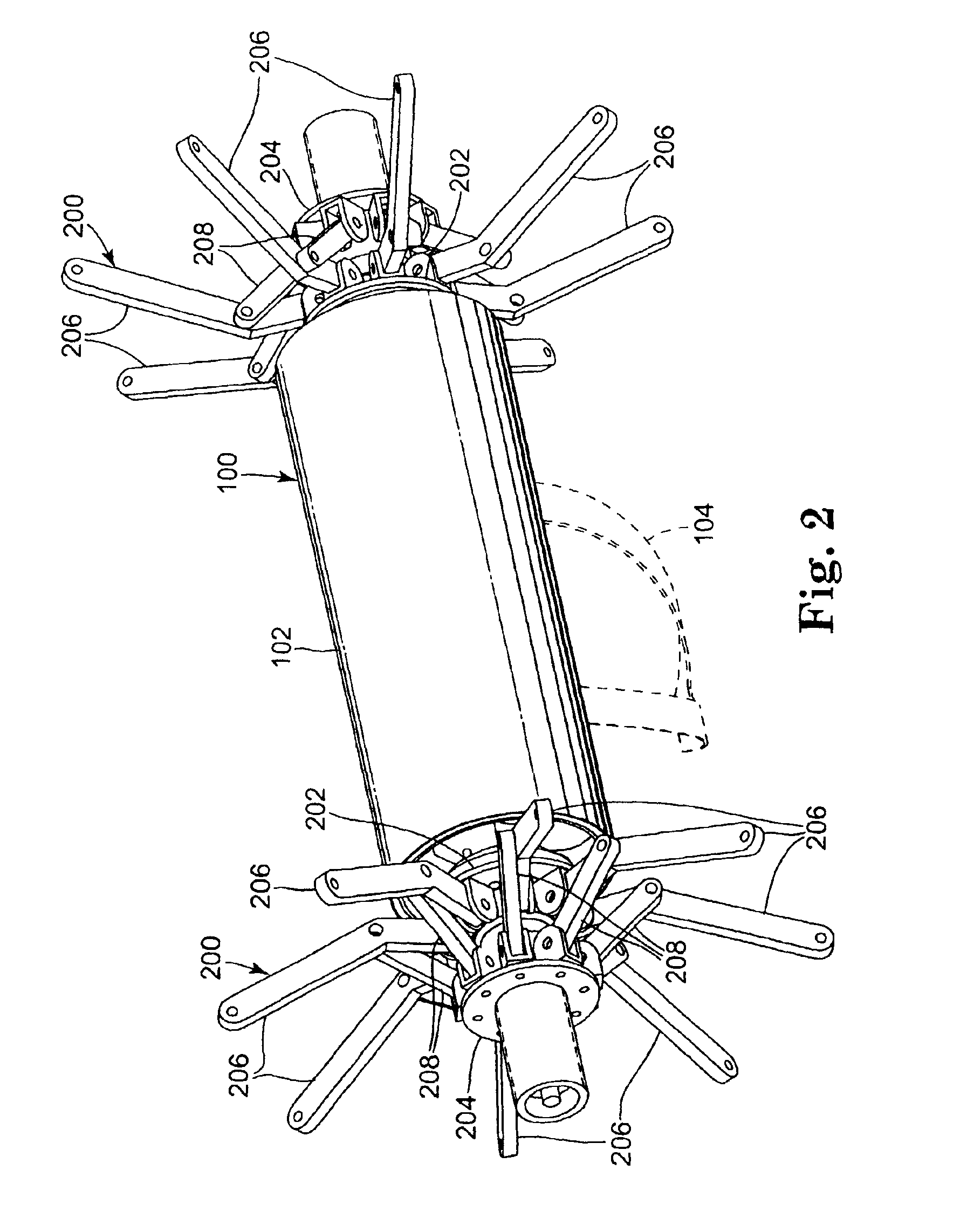

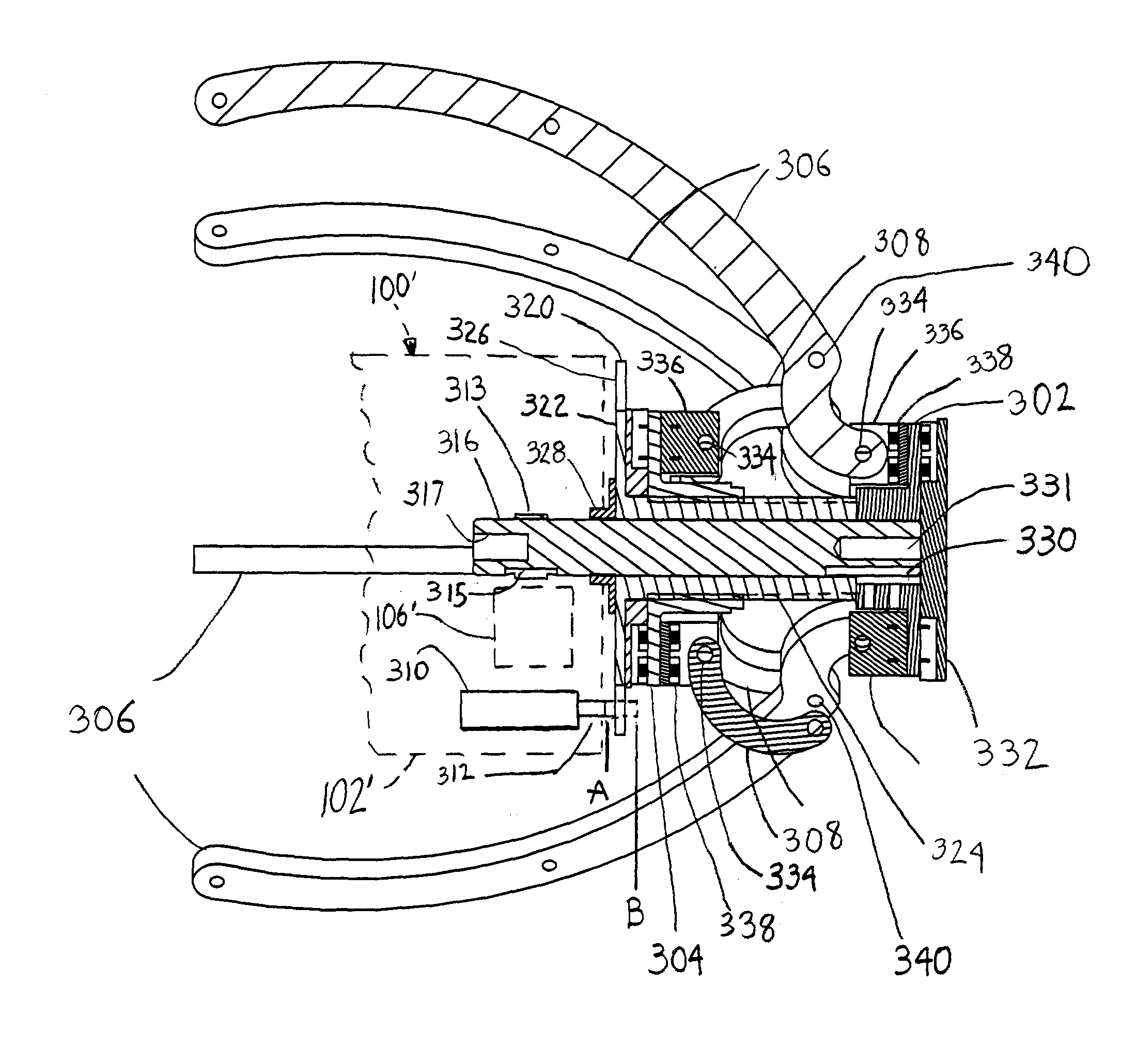

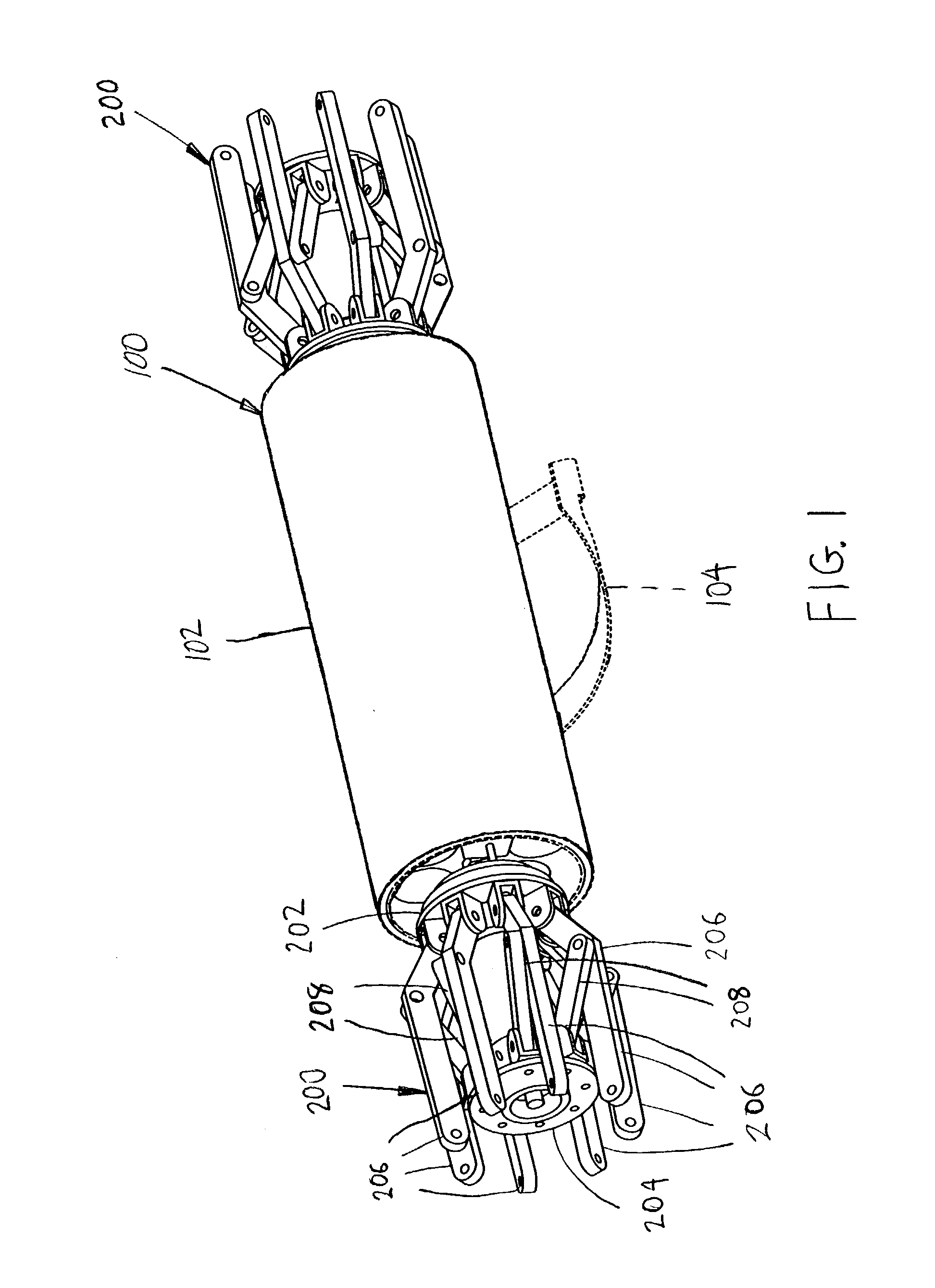

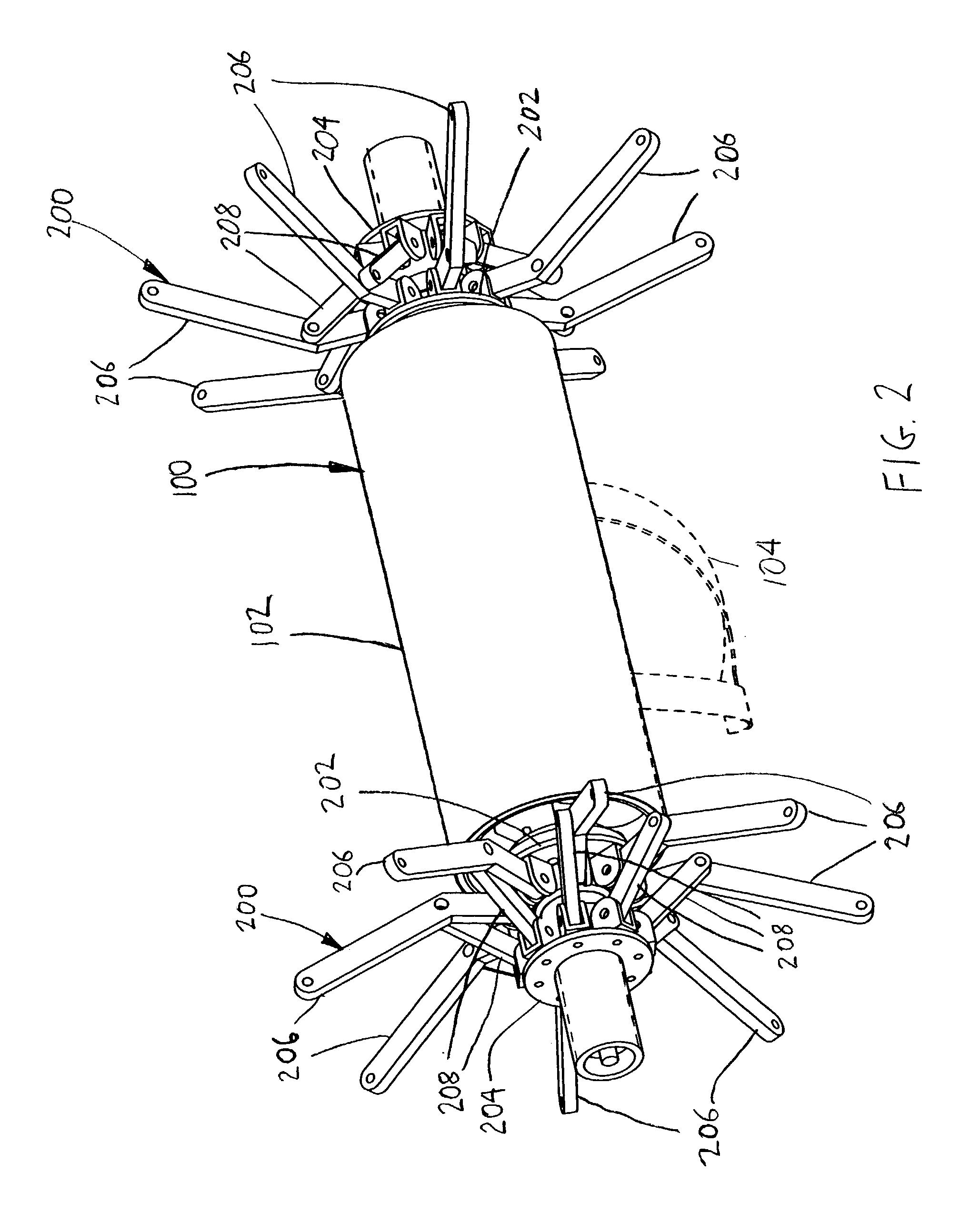

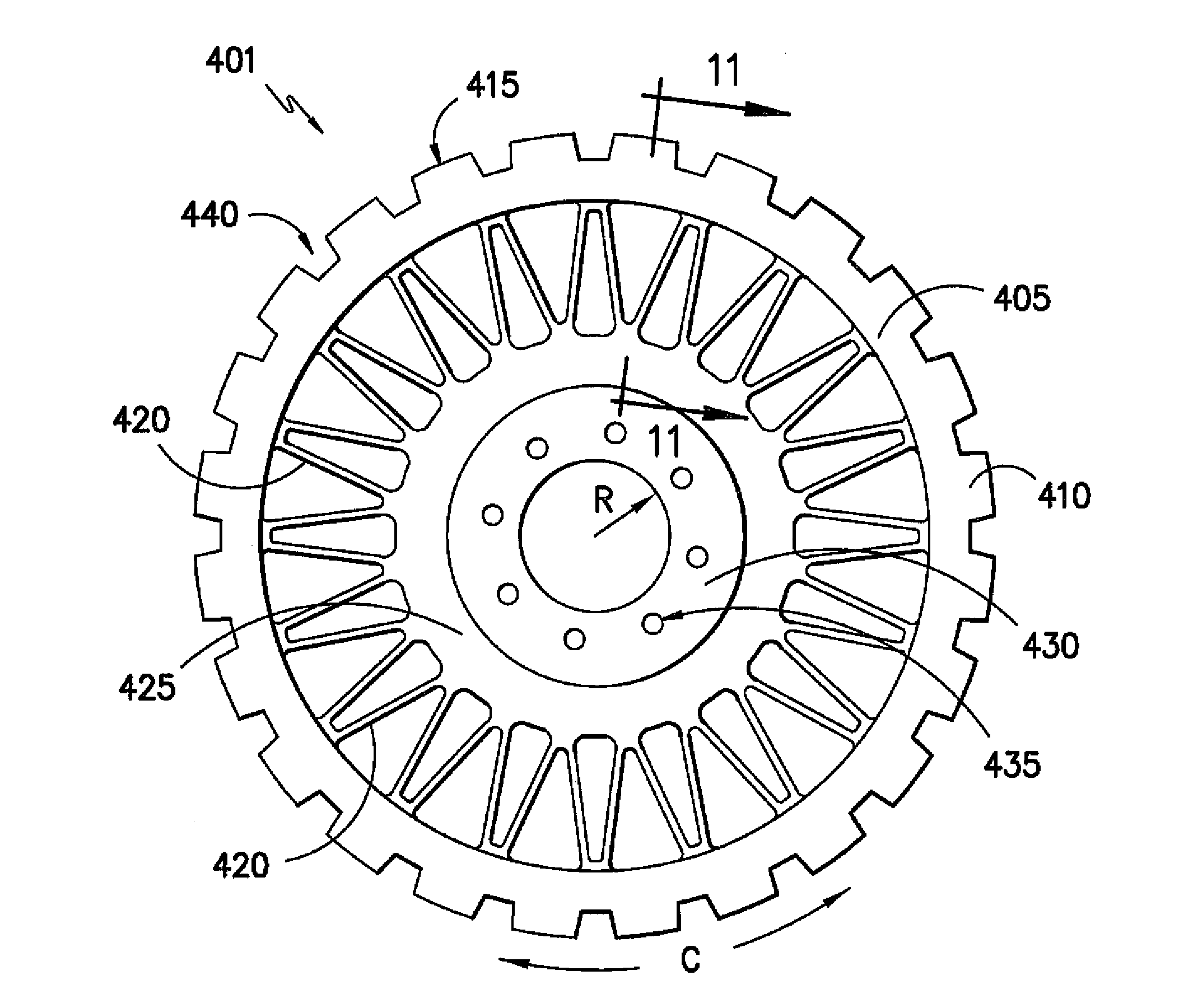

Adjustable diameter wheel assembly, and methods and vehicles using same

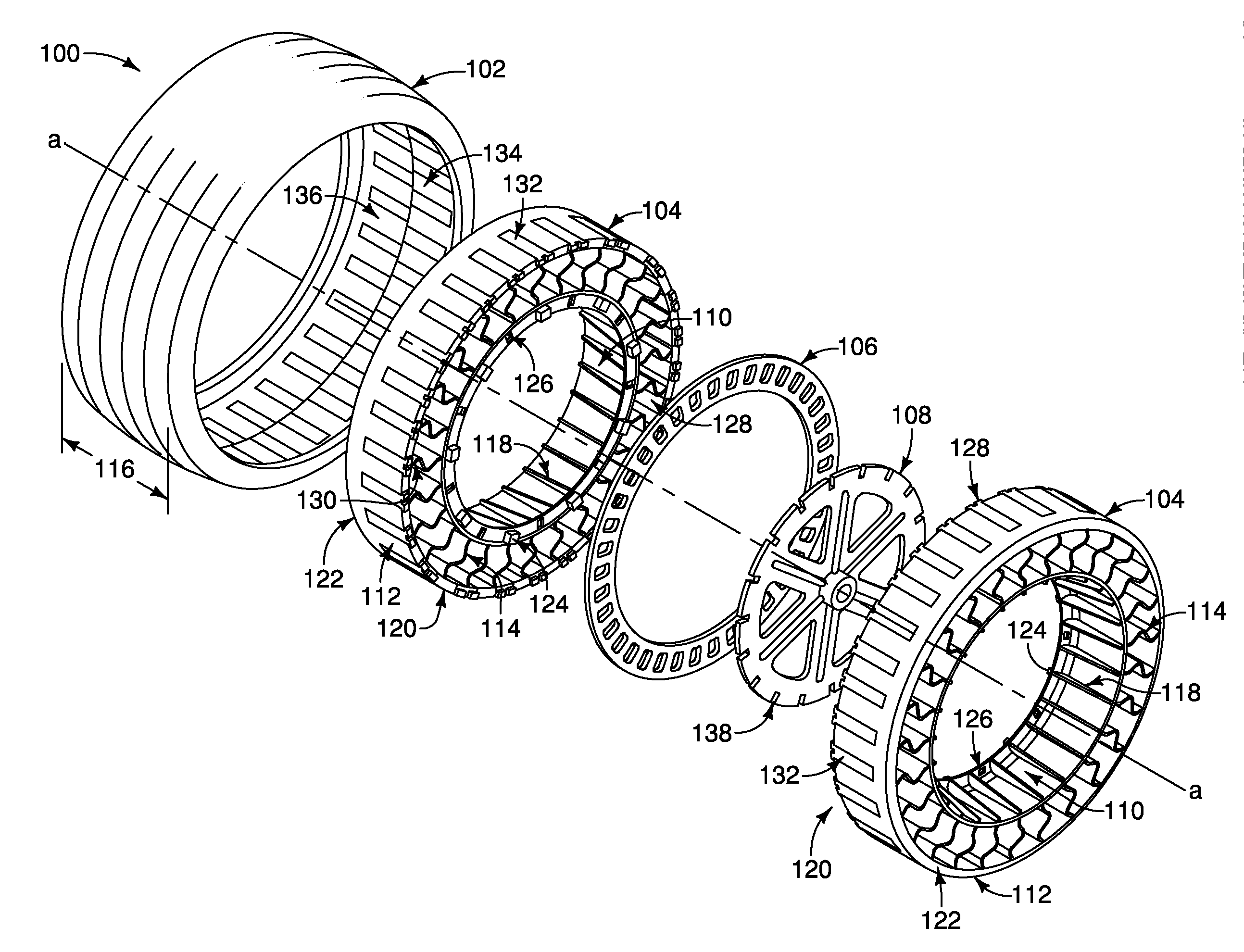

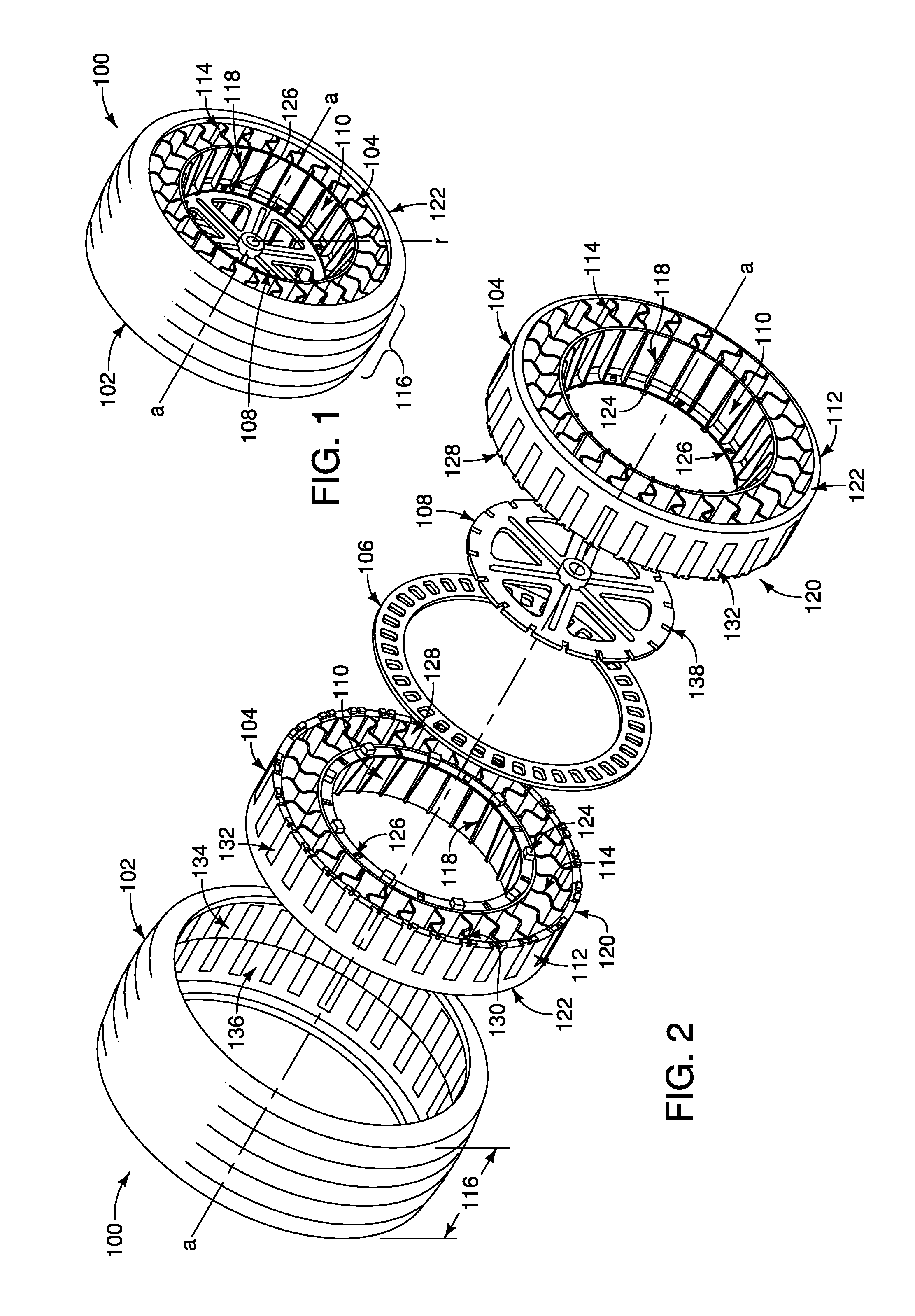

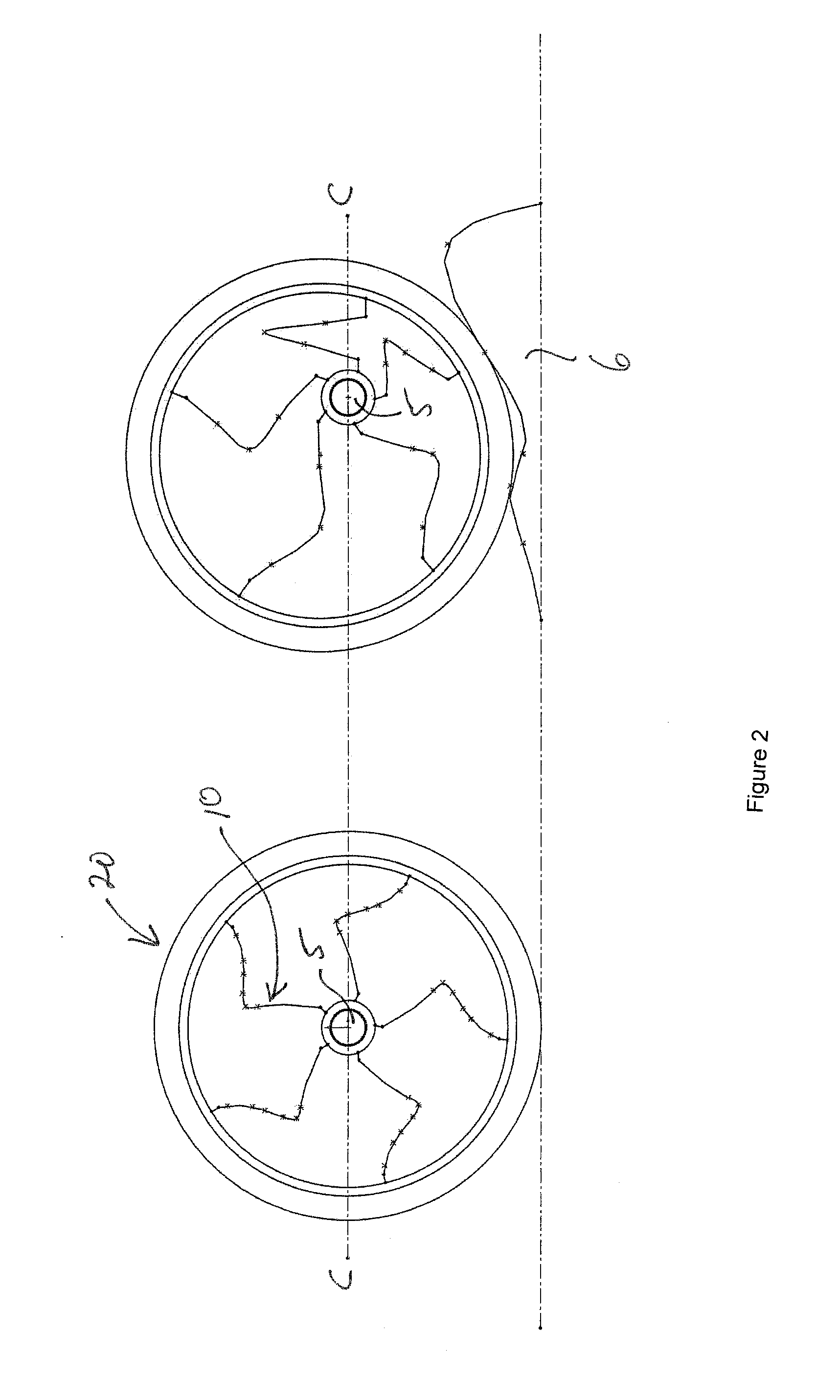

A powered wheel assembly, and method and ground-engaging vehicle (e.g., a robotic vehicle) using the same, are provided. The vehicle incorporates at least one of the wheel assemblies on its chassis body. In addition to its ability to propel the vehicle across a surface, the wheel assembly is reconfigurable between a retracted configuration, wherein the wheel assembly has a first rolling diameter, and an expanded configuration, wherein the wheel assembly has a second rolling diameter greater than the first rolling diameter. A drive motor assembly may both rotate the wheel assembly, e.g., propel the vehicle across a surface, and selectively actuate the wheel assembly from the first rolling diameter to the second rolling diameter, or to any intermediate rolling diameter.

Owner:MINNESOTA RGT UNIV OF A CORP OF MN

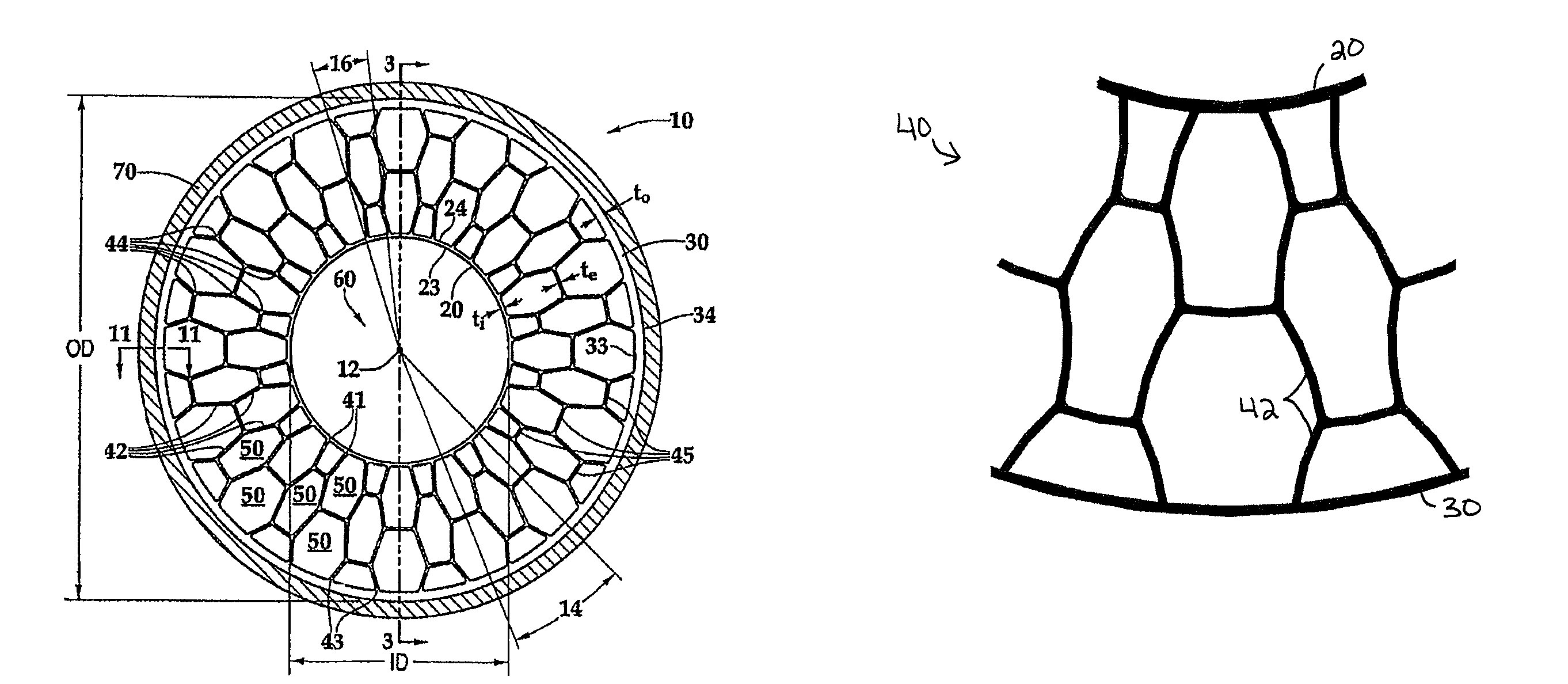

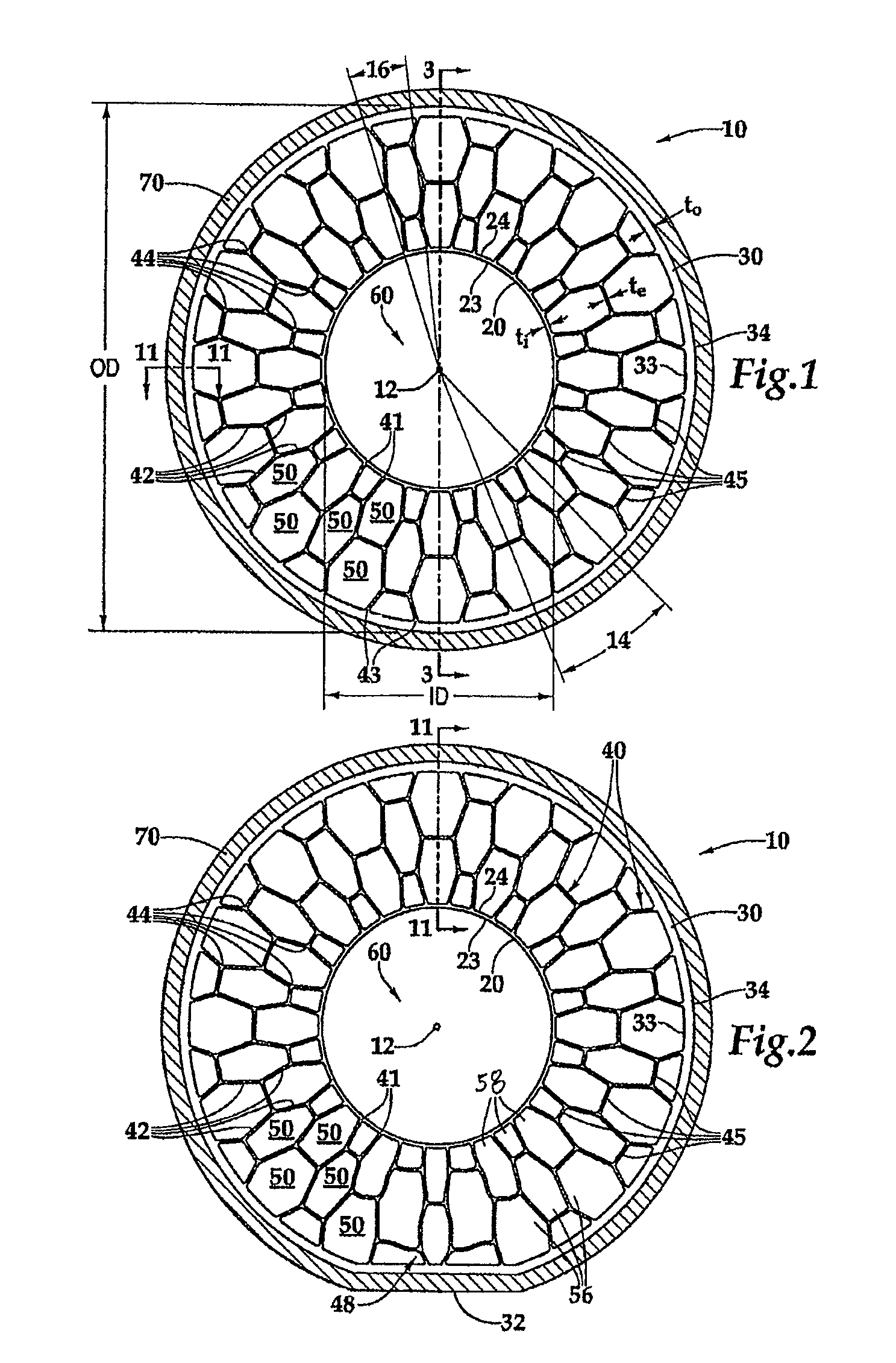

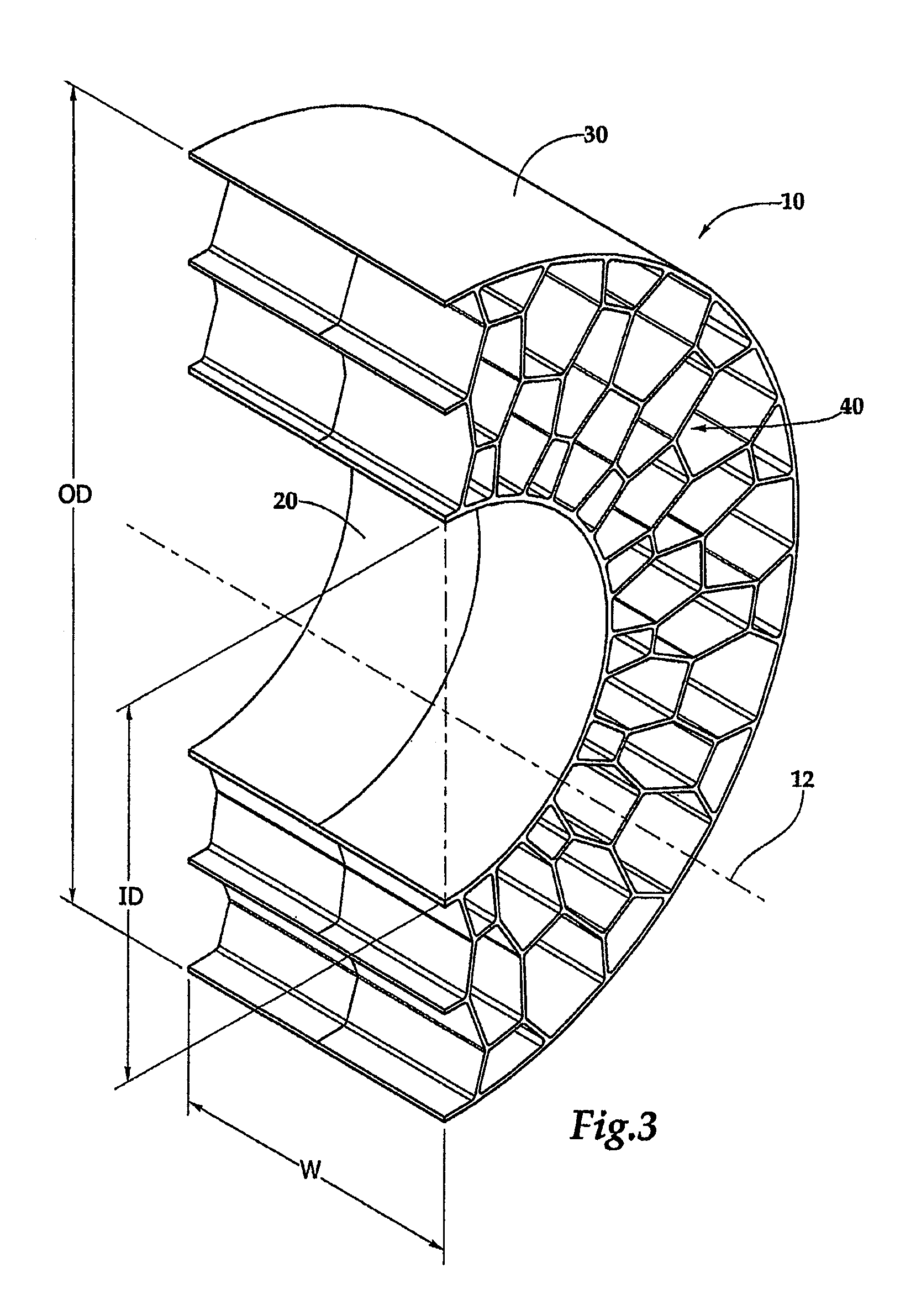

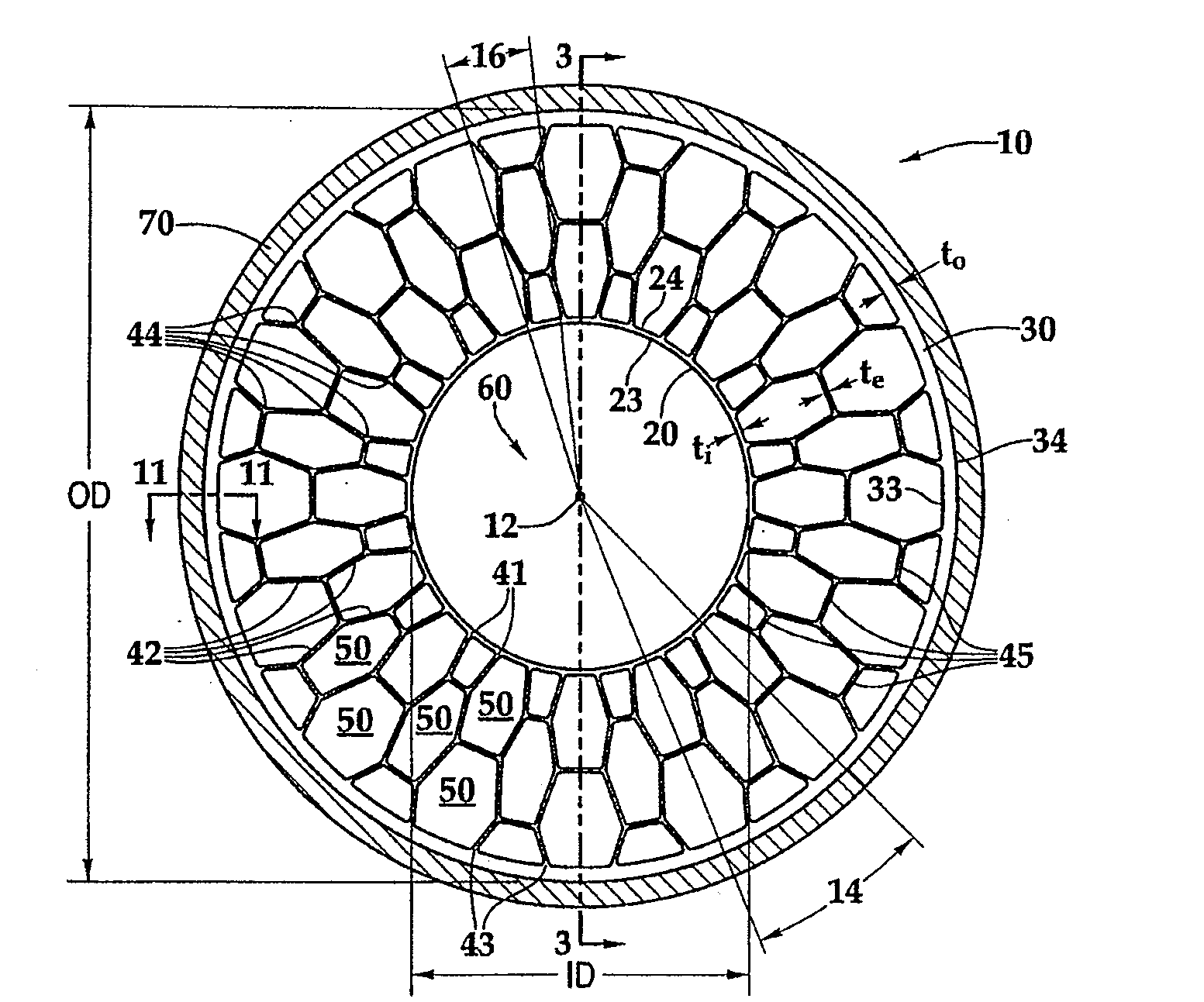

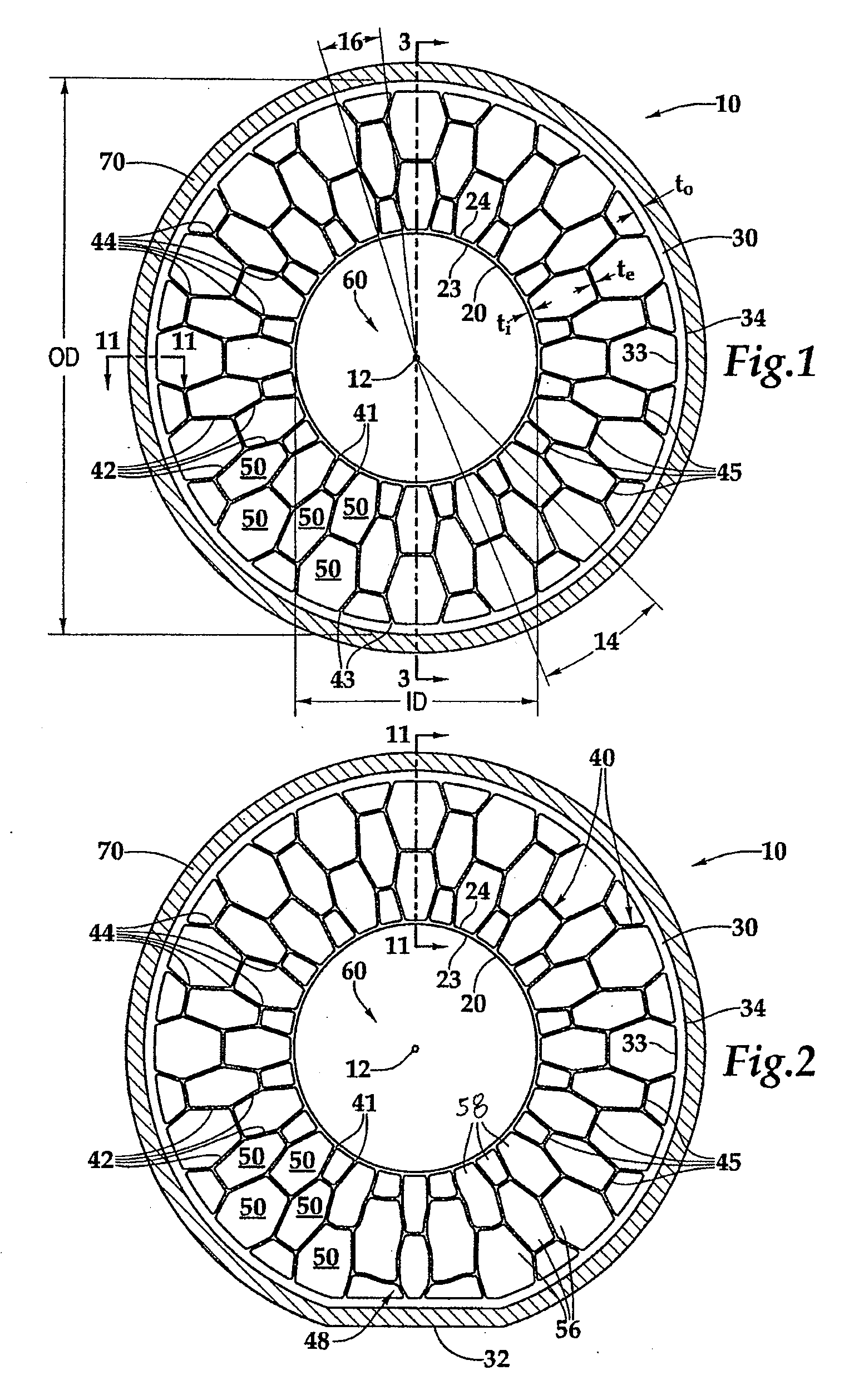

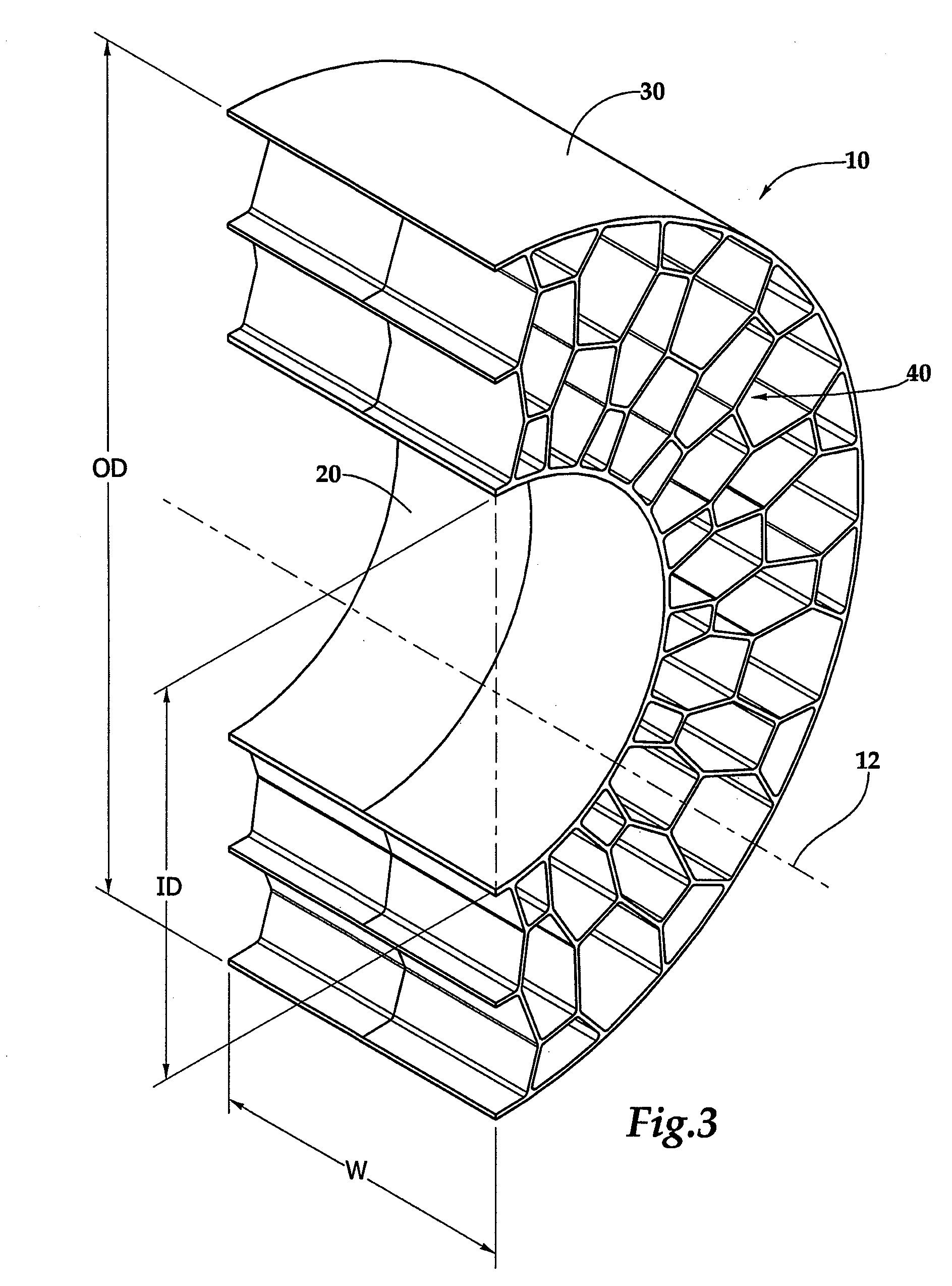

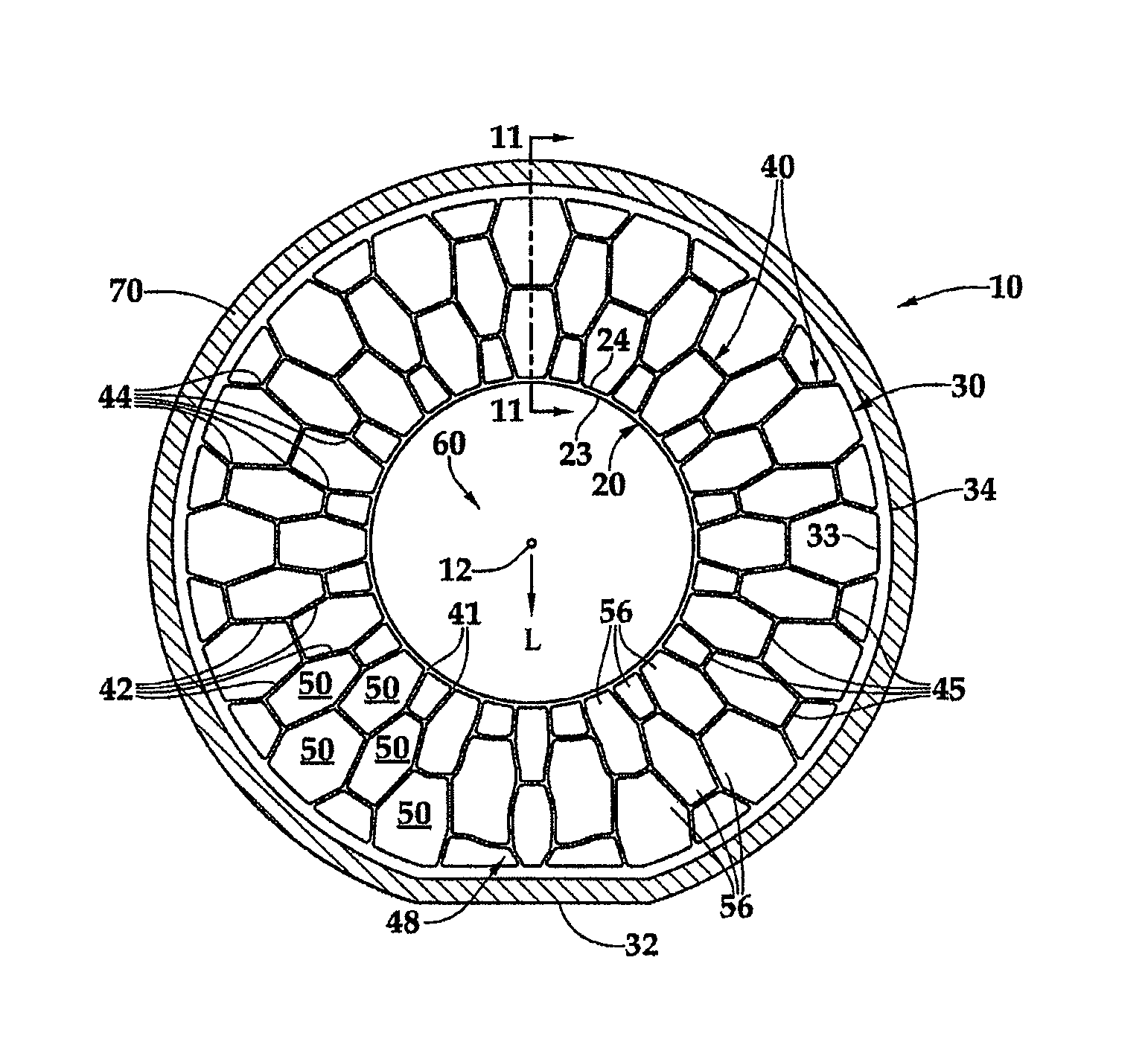

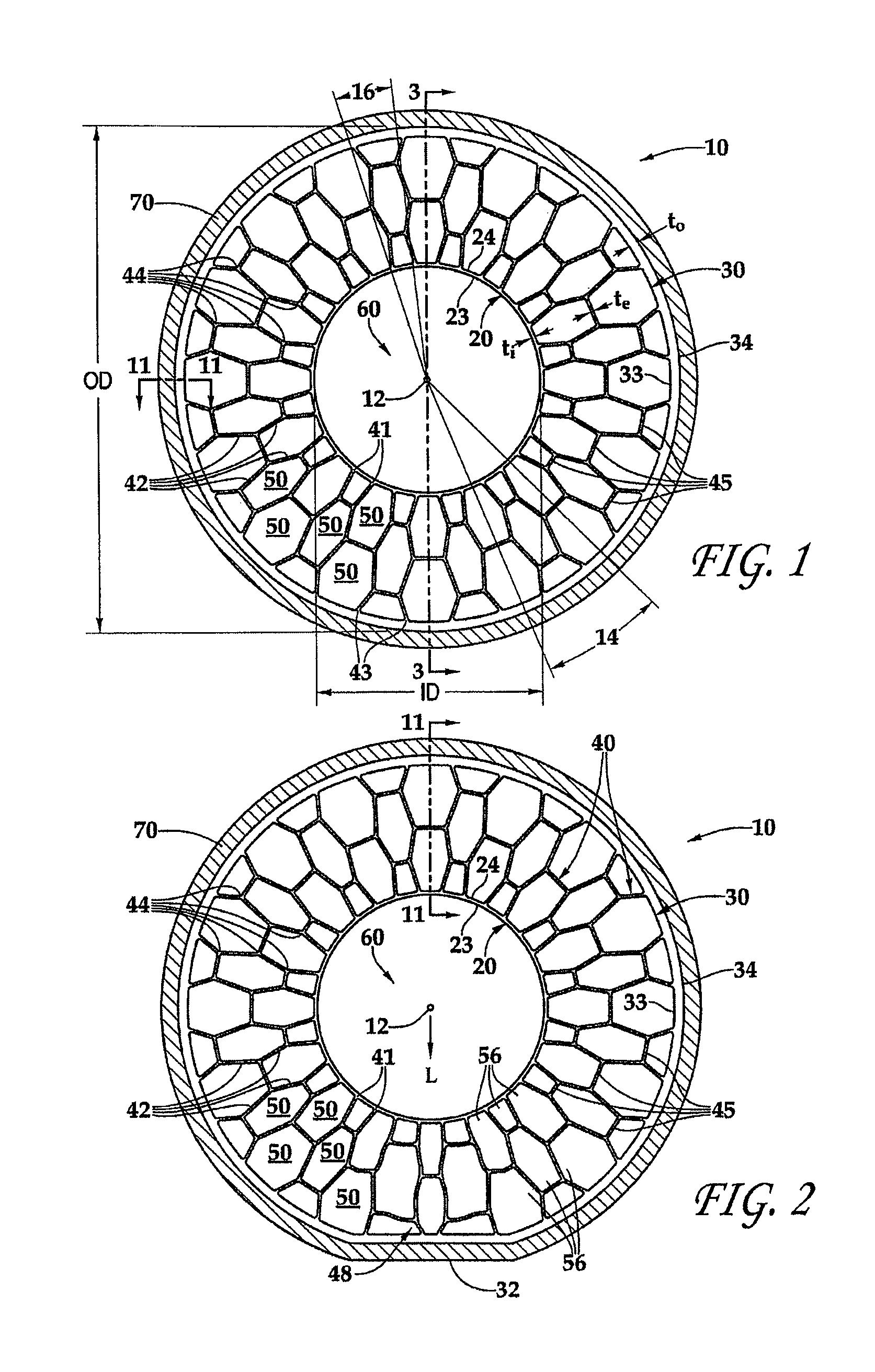

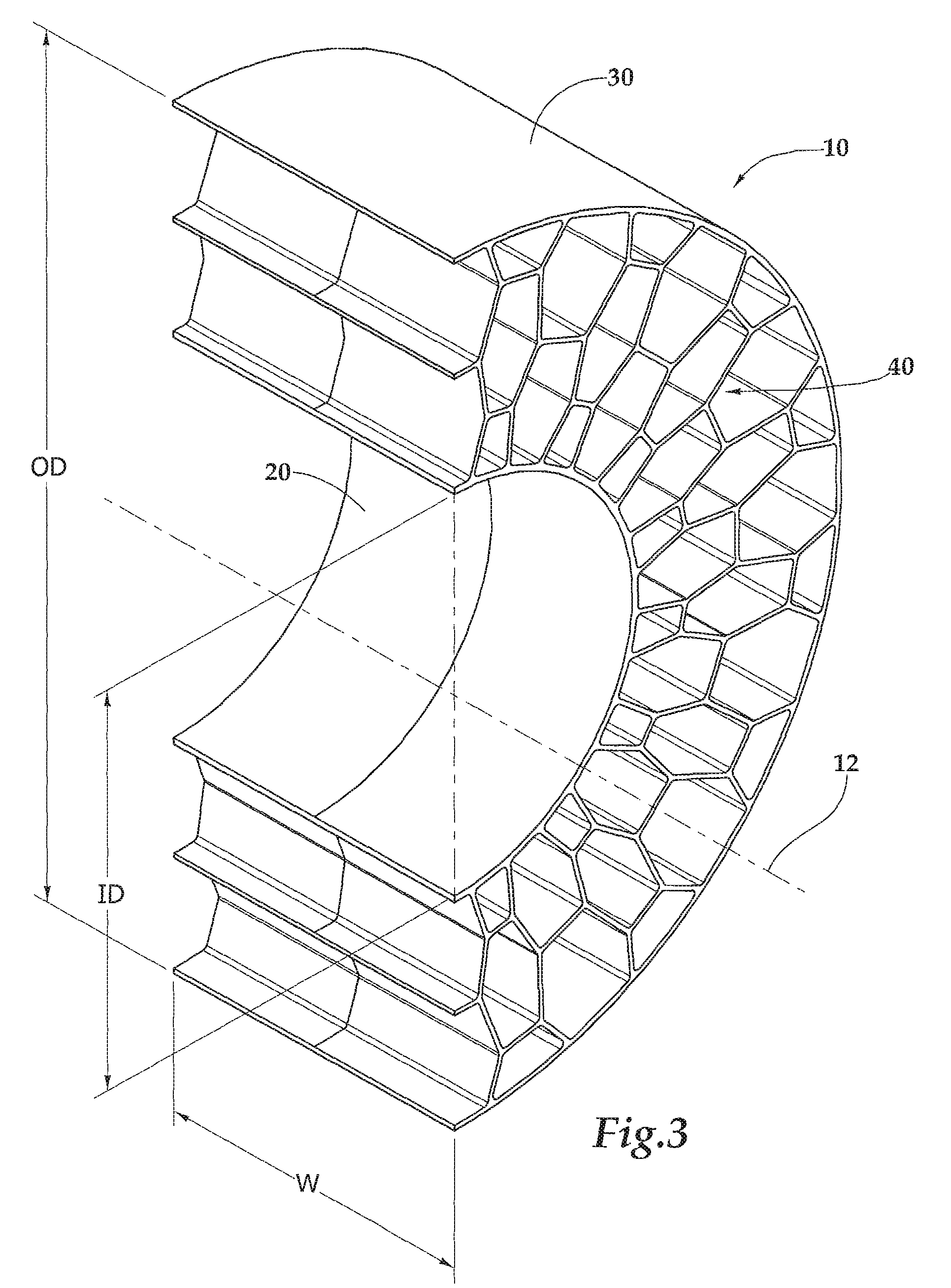

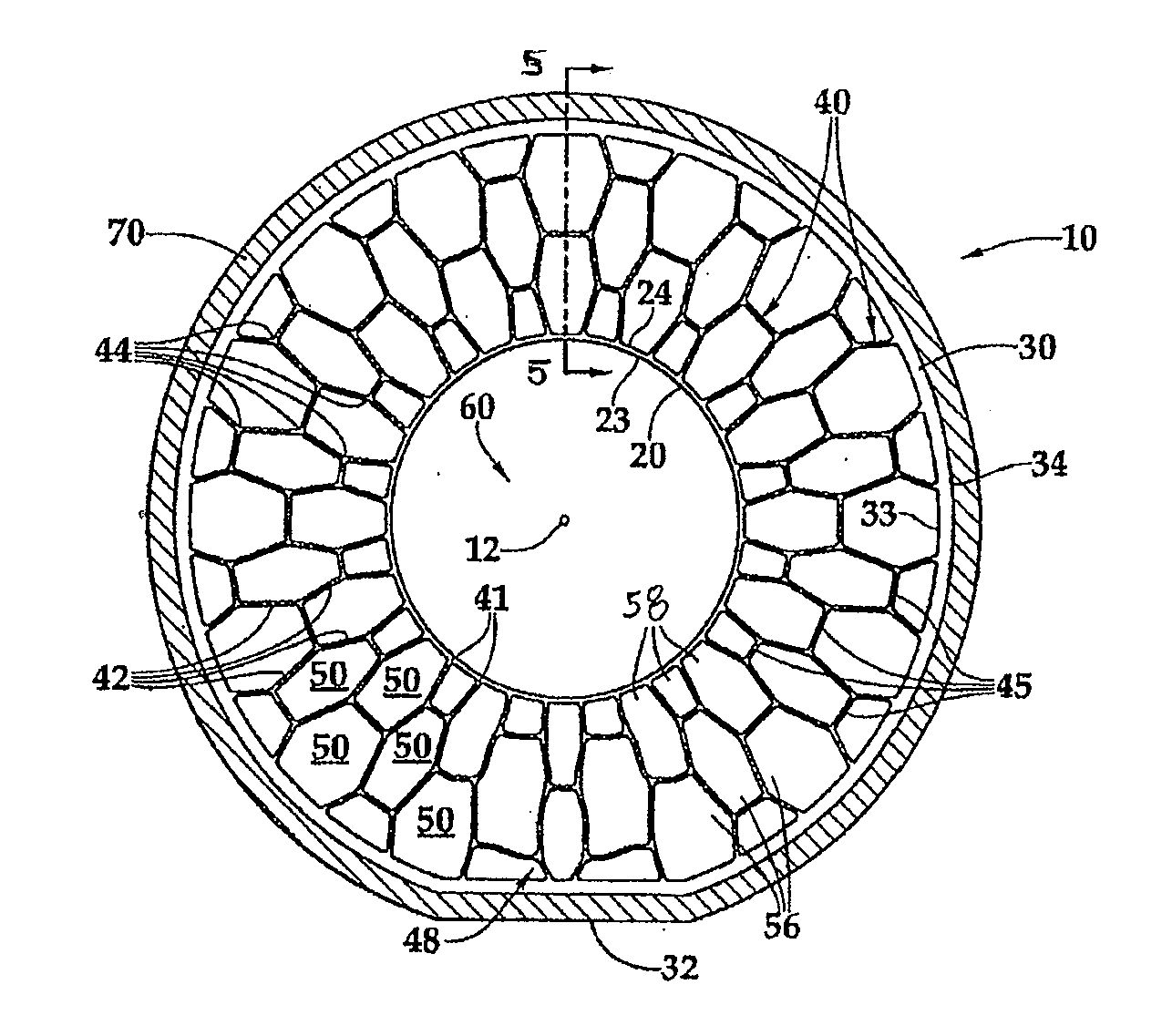

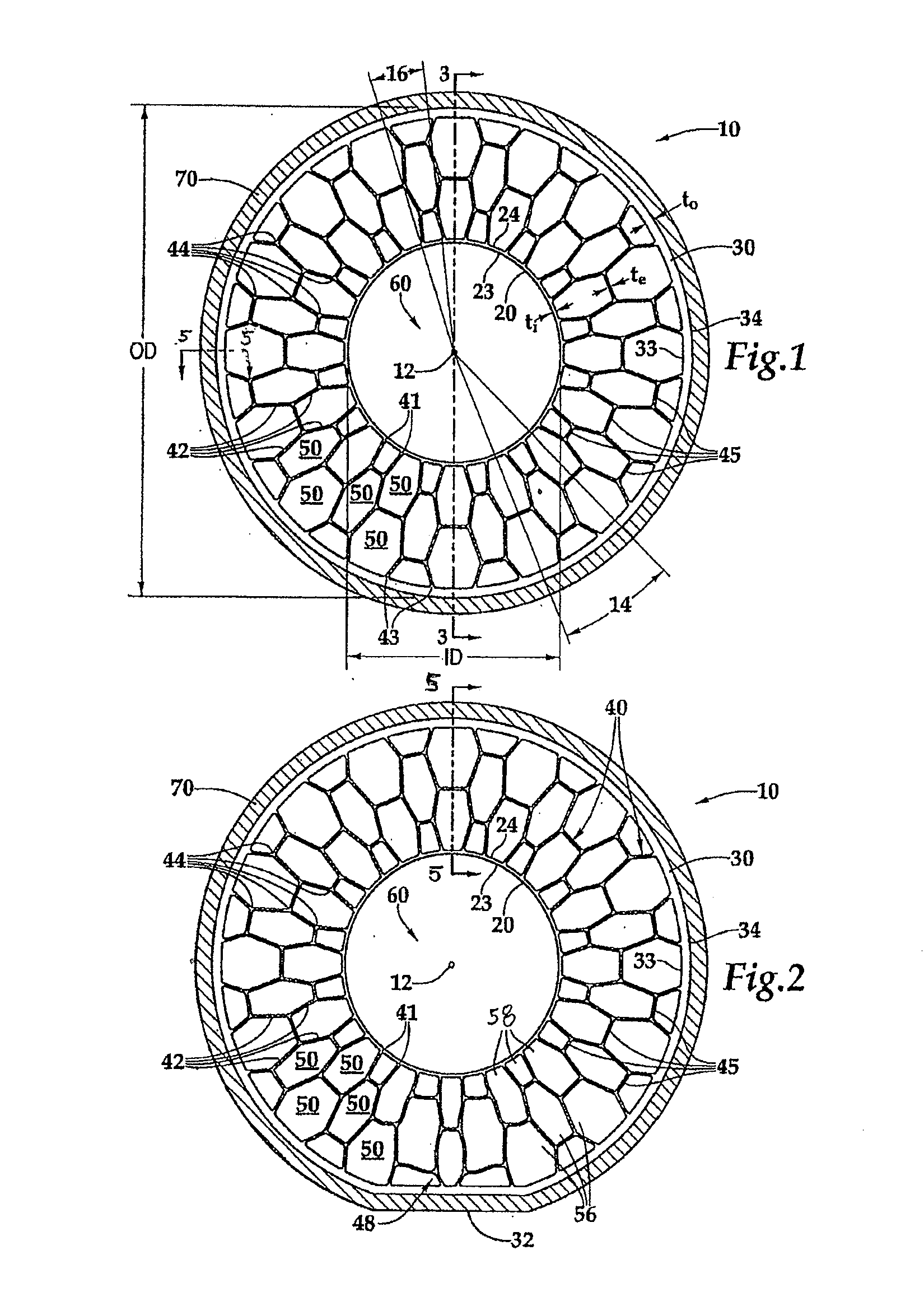

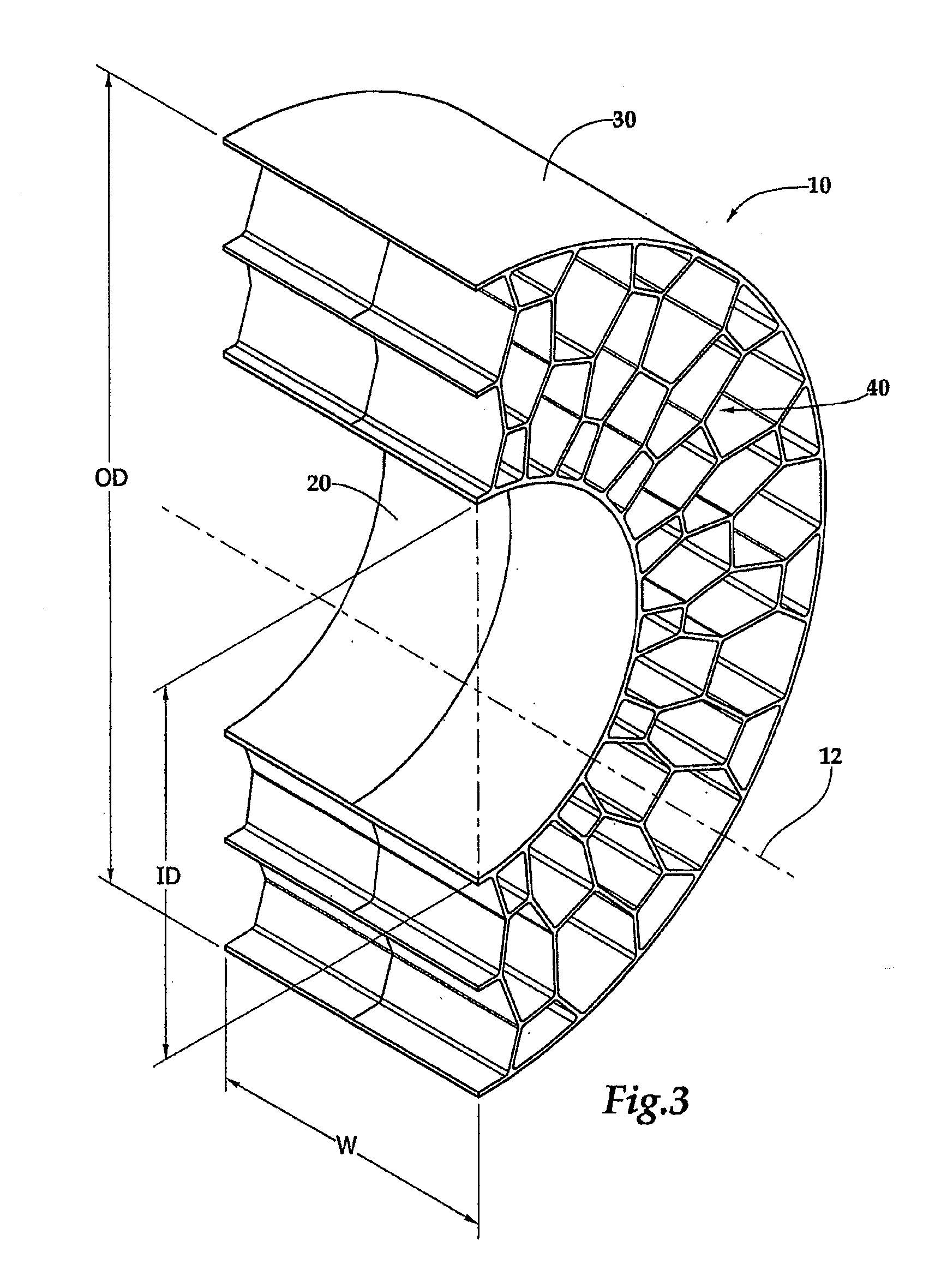

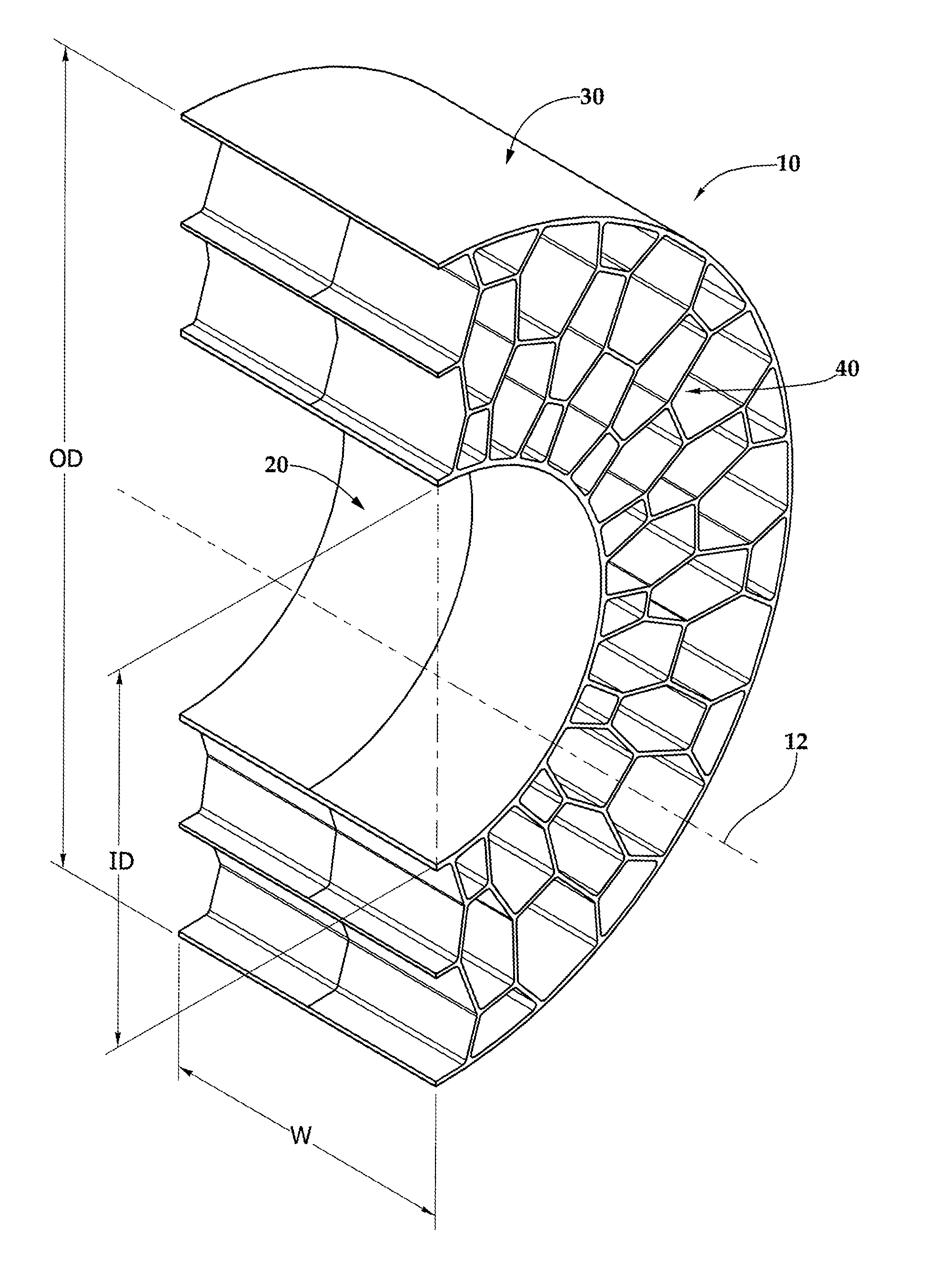

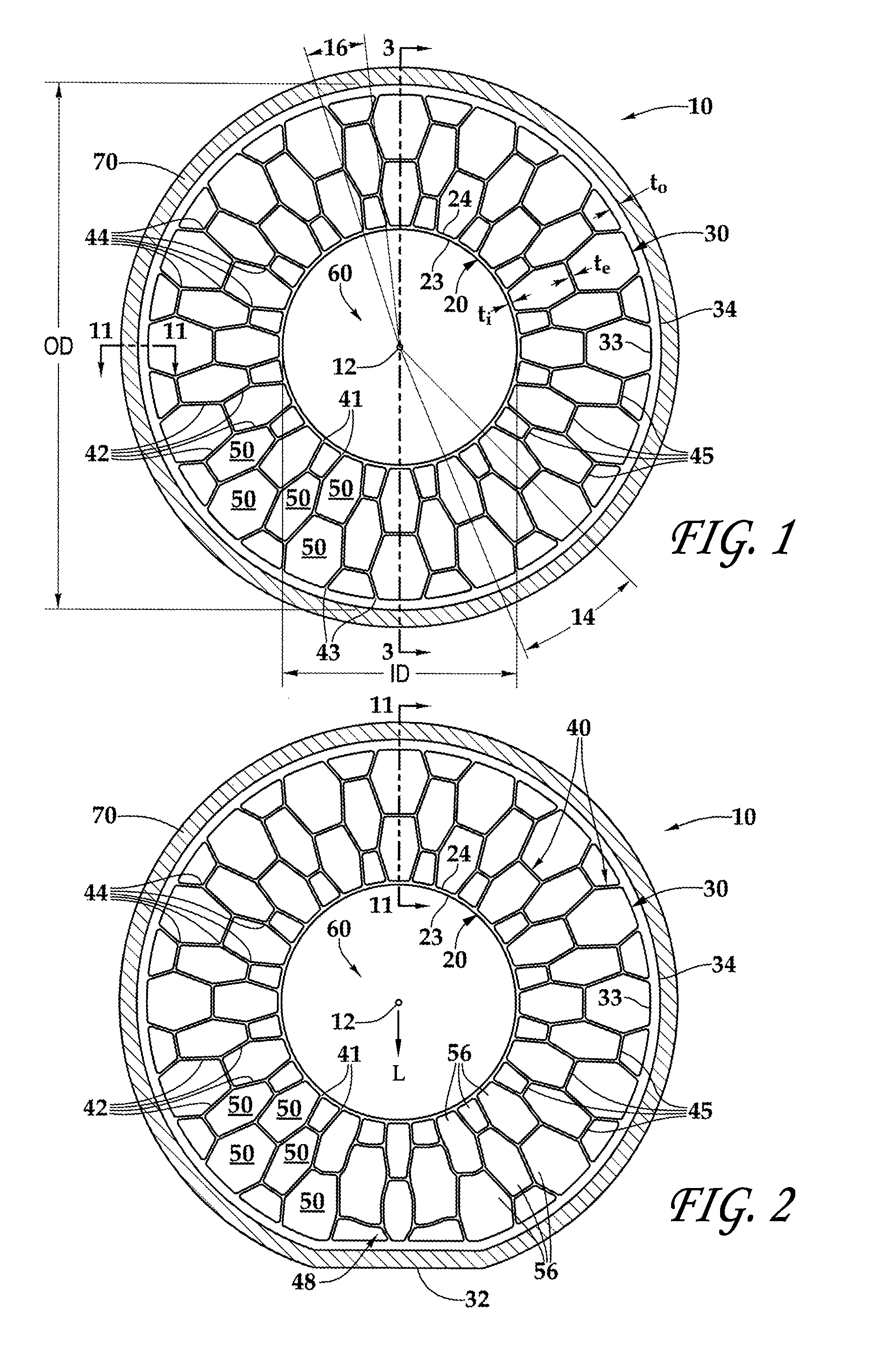

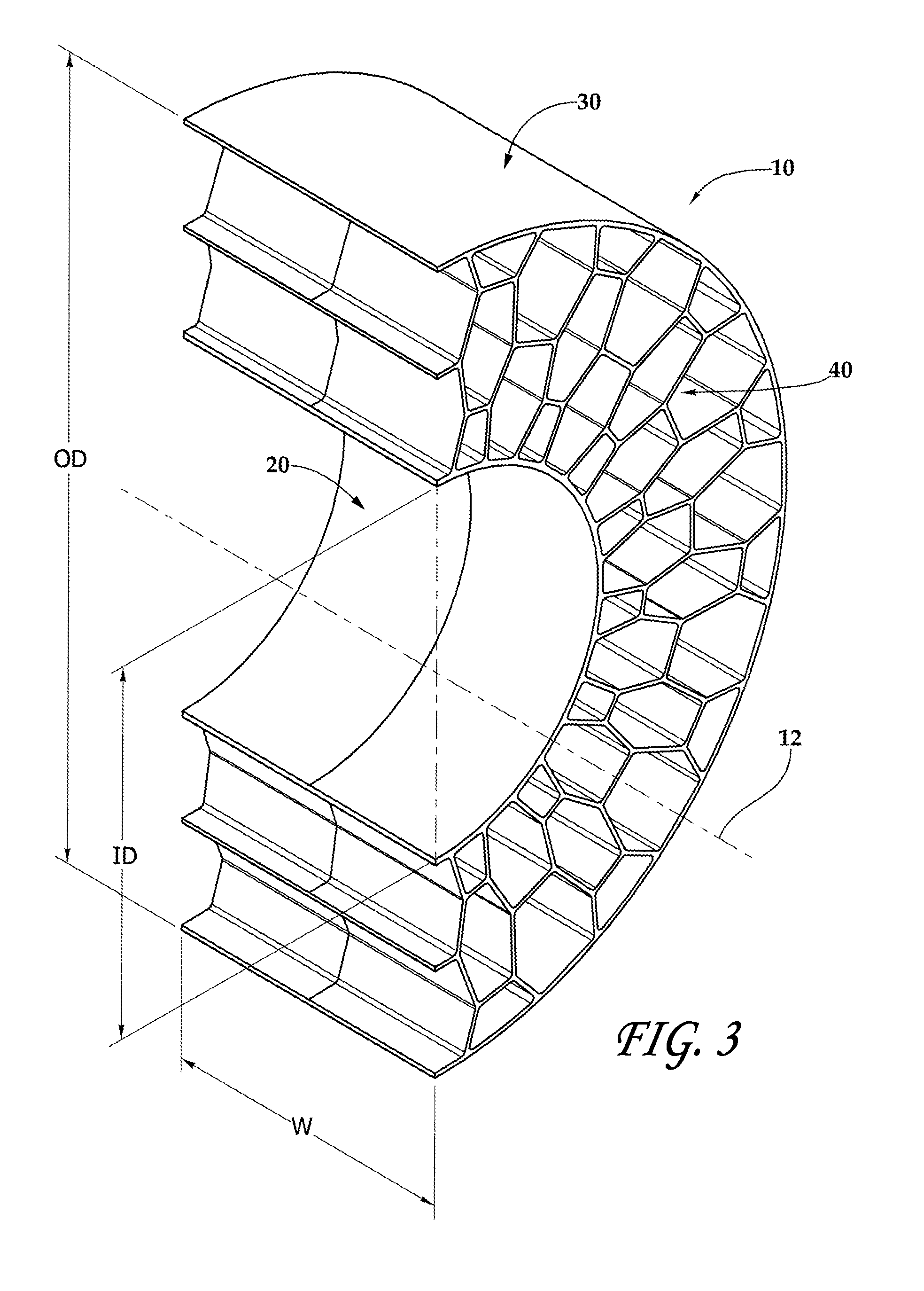

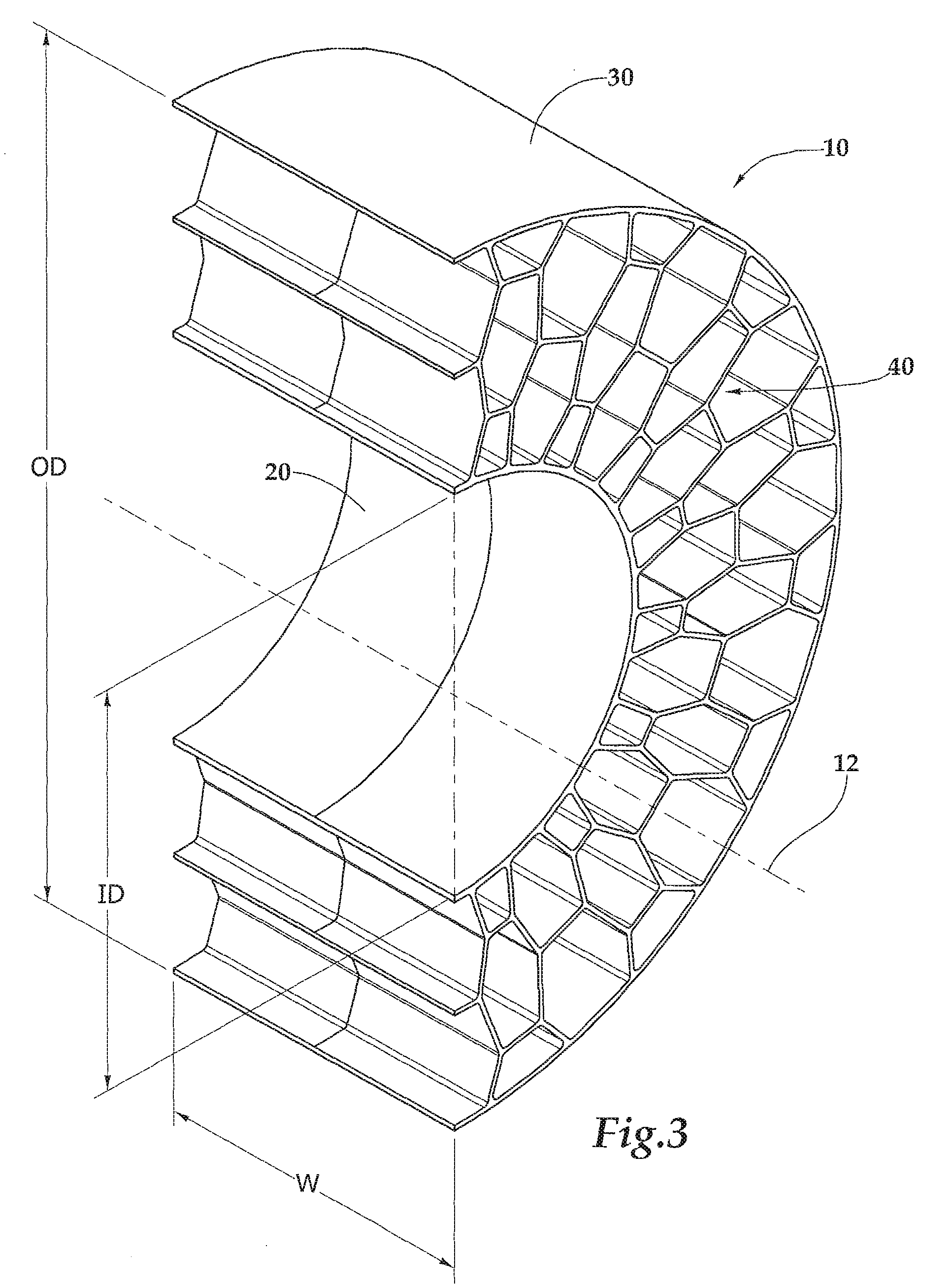

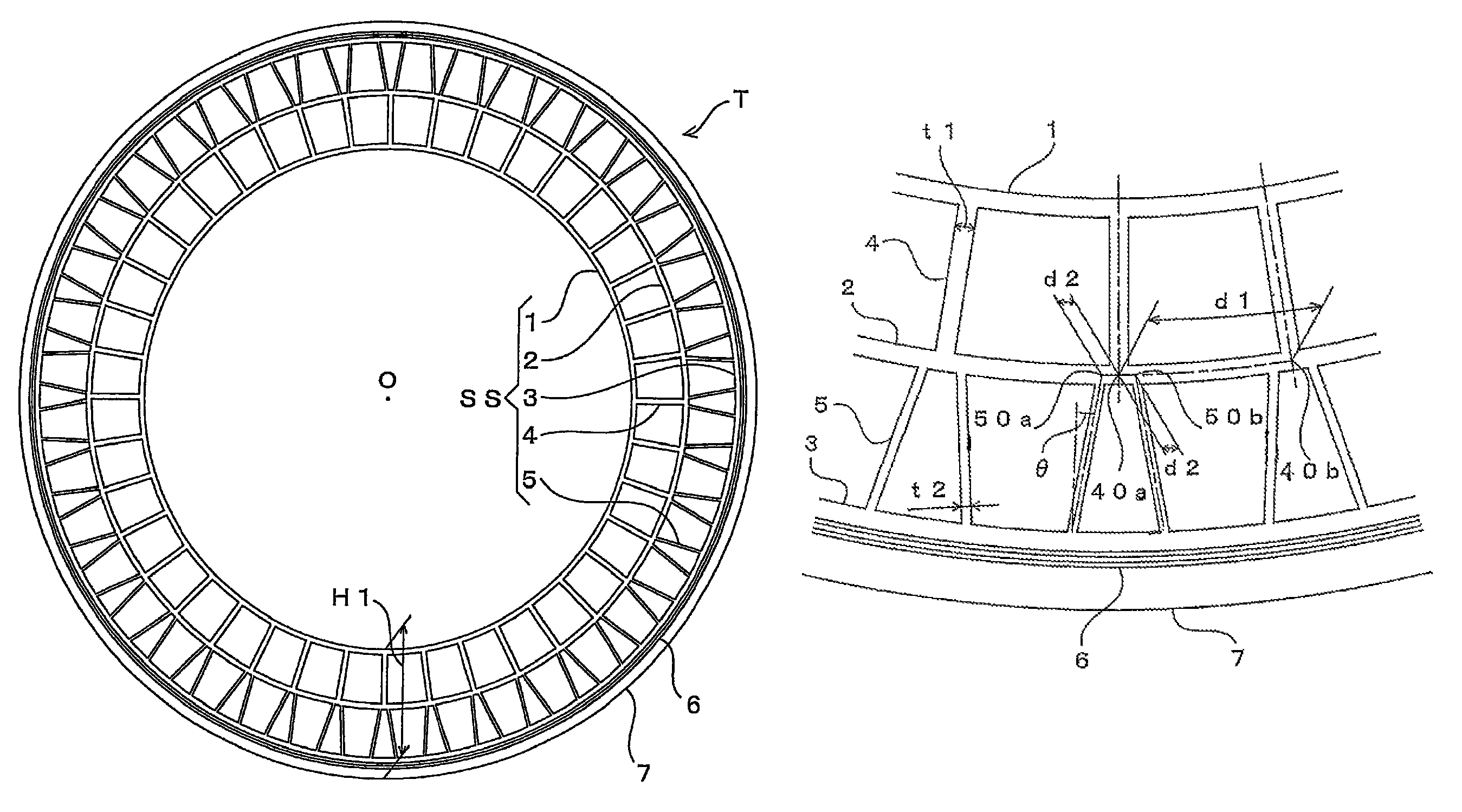

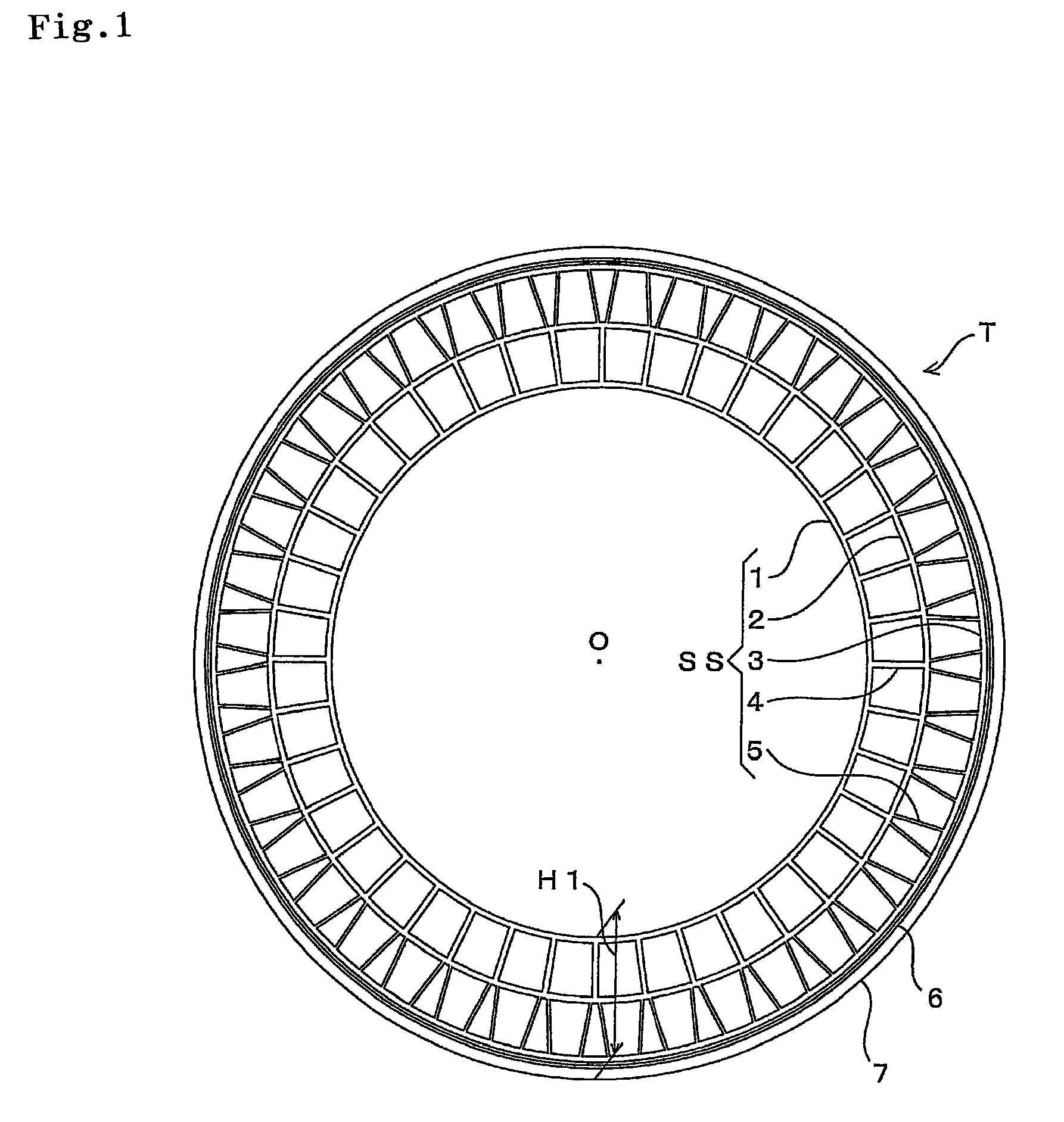

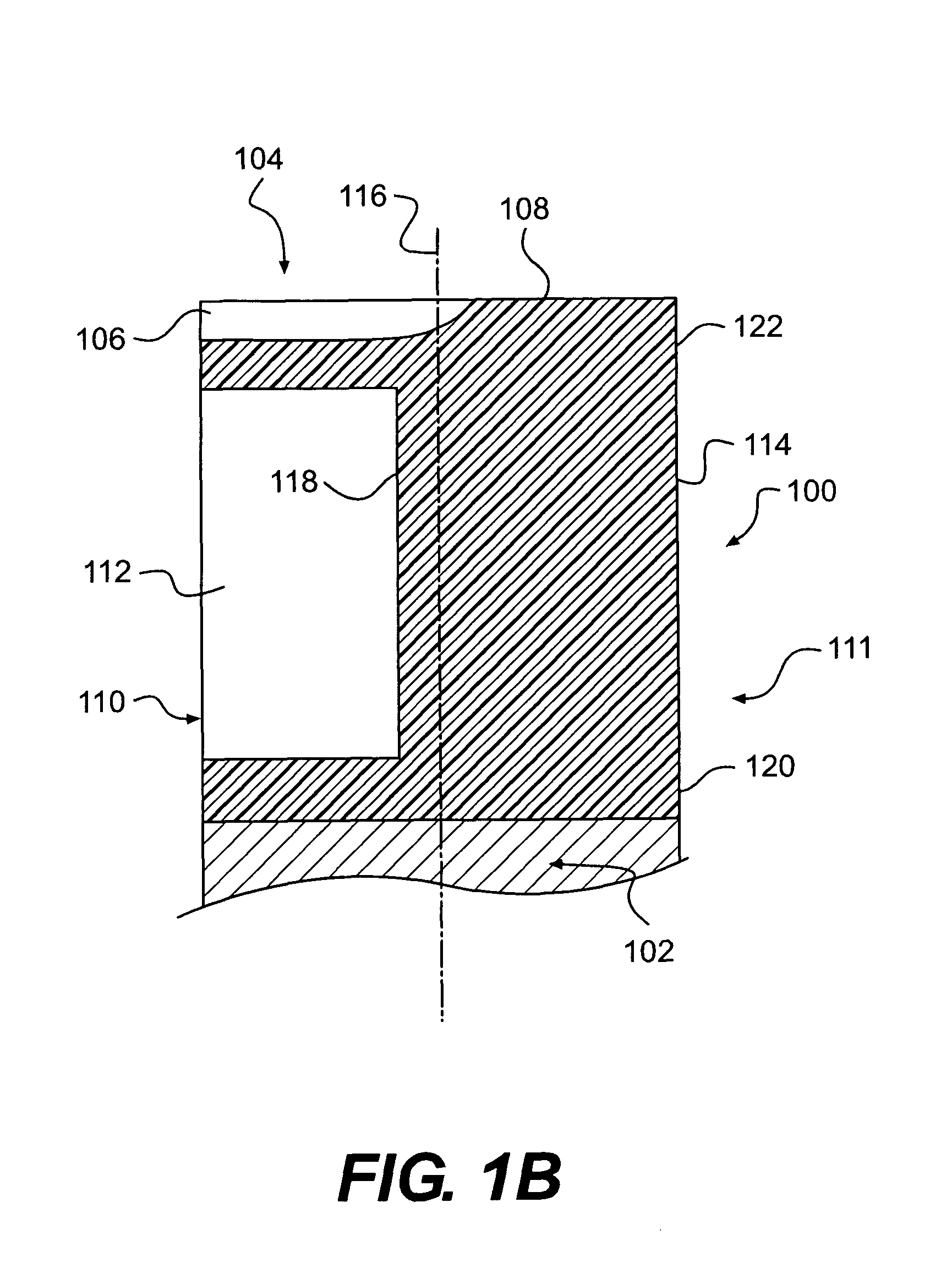

Tension-based non-pneumatic tire

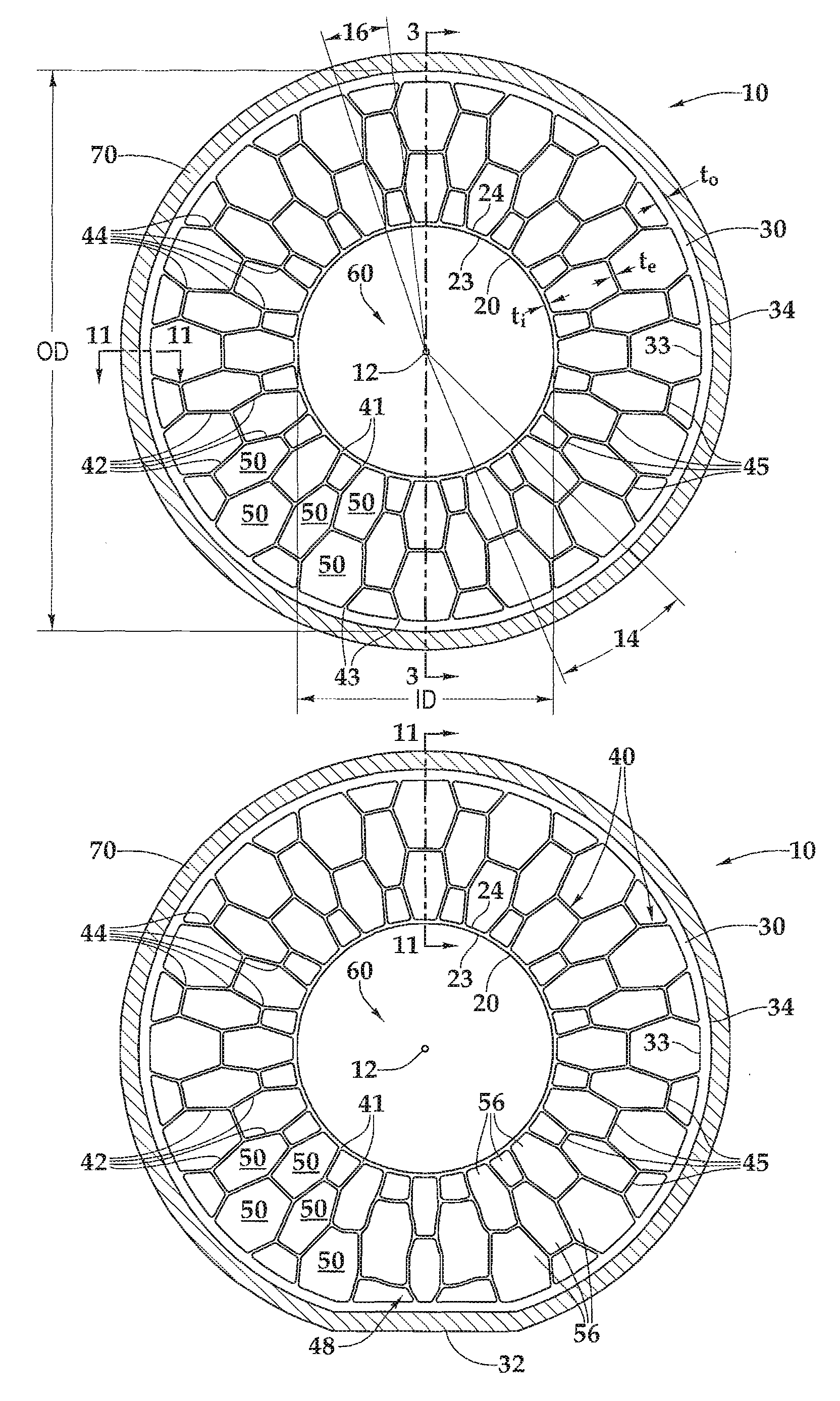

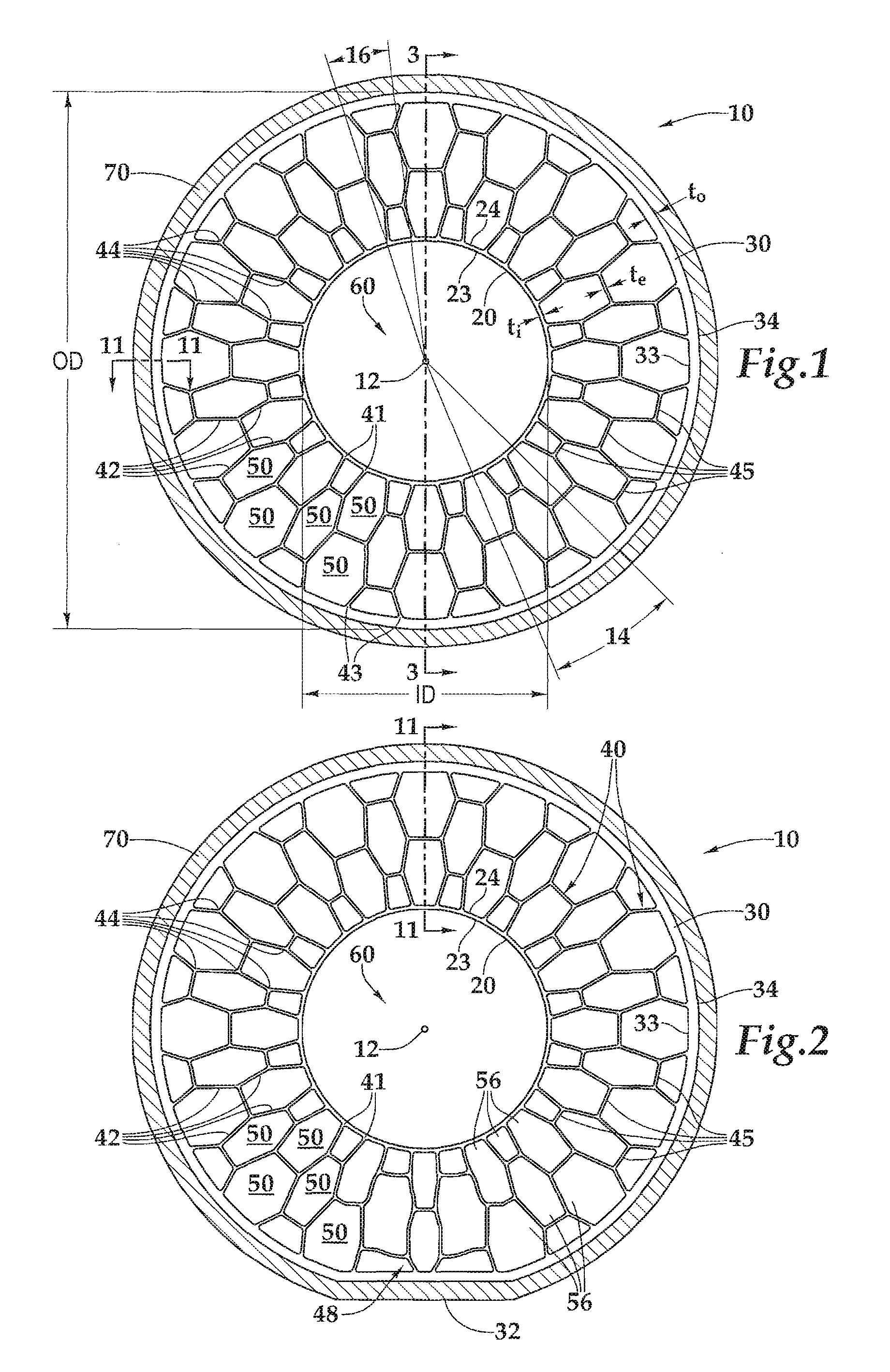

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner ring, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, curved, oriented, and comprised of varying thicknesses of material which facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a wheel and a footprint region where the tire contacts a surface can assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Tension-based non-pneumatic tire

ActiveUS20080314486A1Increase stiffnessEasy to disassembleNon-inflatable tyresHigh resiliency wheelsEngineeringMechanical engineering

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner ring, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, oriented and comprised of a material that facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a wheel and a footprint region where the tire contacts a surface can assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Tension-based non-pneumatic tire

ActiveUS8104524B2Extend tire lifeLess susceptible to shock and vibrationNon-inflatable tyresHigh resiliency wheelsMechanical engineeringFlat tire

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner surface, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, oriented and comprised of a material that facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a hub and a footprint region where the tire contacts a surface may assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load. Since the tire is non-pneumatic, it may be easier to maintain and may have a longer life than standard pneumatic tires since it eliminates the possibility of blowouts, flat tires, or tires operating with low air pressure. By virtue of the portion of the tire in the footprint region not bearing a significant portion of the load, non-pneumatic tire may also exhibit a more comfortable ride subject to less noise and vibration and improved handling capabilities.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Tension-based non-pneumatic tire

ActiveUS20110024008A1Easy to disassembleLow stiffnessNon-inflatable tyresTyresEngineeringMechanical engineering

A non-pneumatic tire for supporting a load by working in tension. The tire can comprise a generally annular inner ring, a generally annular outer ring, and a web having a plurality of web elements. The tire can further comprise a layer or layers fabric material acting as a bonding agent to bond tire components together.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Tension-based non-pneumatic tire

ActiveUS8109308B2Increase stiffnessEasy to disassembleNon-inflatable tyresHigh resiliency wheelsMechanical engineeringCompressive load

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Non-pneumatic tire

InactiveUS20060113016A1Supporting massHigh effective radial stiffness in tensionNon-inflatable tyresPneumatic tyre reinforcementsMaximum depthEngineering

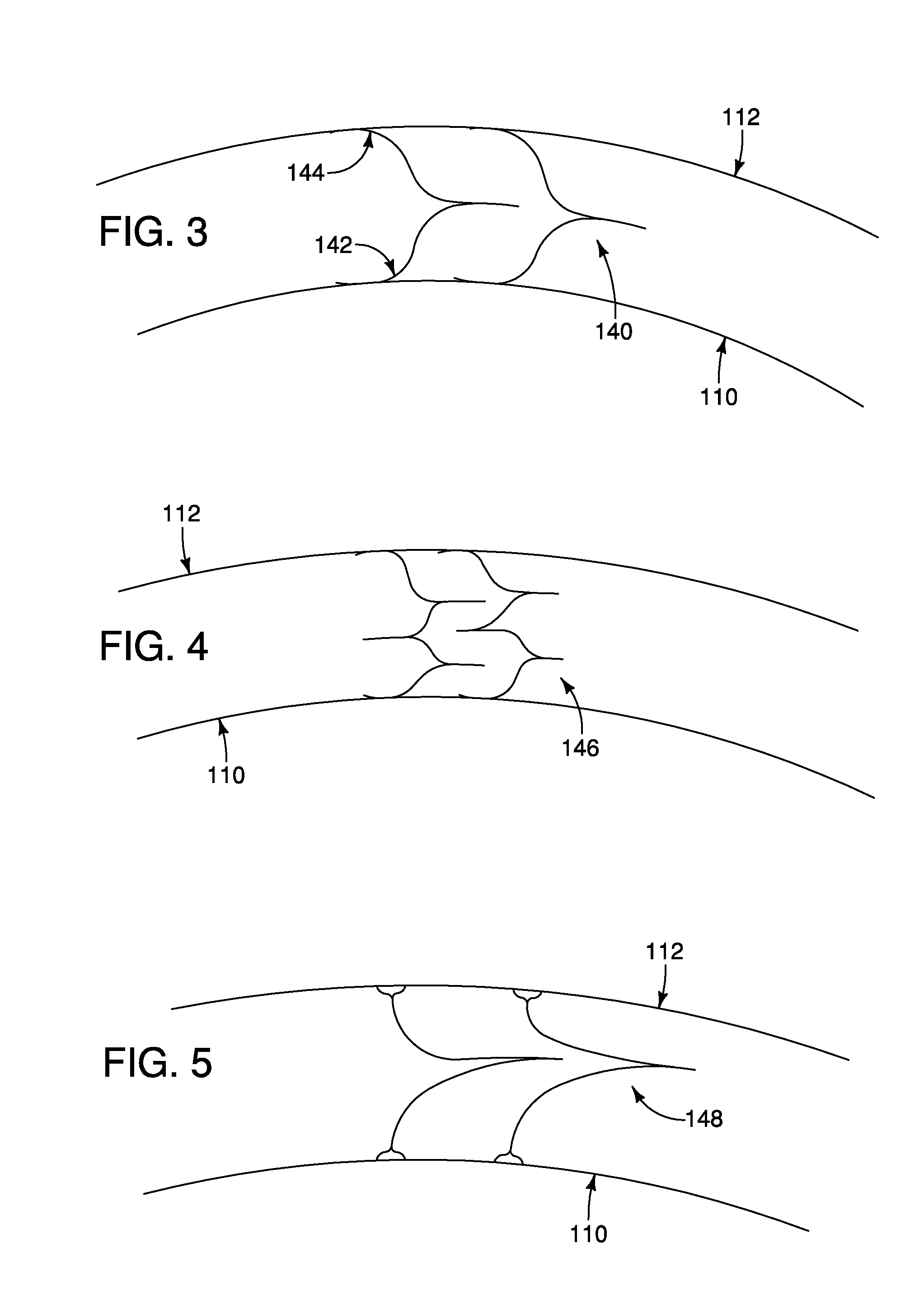

A structurally supported tire includes an outer annular band, and a plurality of web spokes extending transversely across and radially inward from the annular band and anchored in a wheel or hub. The annular band may further comprise a shear layer, at least a first membrane adhered to the radially inward extent of the shear layer, and at least a second membrane adhered to the radially outward extent of the shear layer. A preferred web spoke has a cutaway section transverse to the annular band. The cutaway section has a profile formed by straight line segments joined by a blending radius. The profile of the cutaway comprises a height and a maximum depth greater than five percent of the height and less than thirty percent of the maximum width. The profile has an angle alpha formed by a line tangent to the profile relative to the horizontal at least equal to ten degrees at the radially outermost and radially innermost extent of said profile. The minimum radius of curvature of the profile is at least equal to twenty percent of the height of the cutaway section.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Non-pneumatic tire

InactiveUS7418988B2High effective radial stiffness in tensionLow effective radial stiffnessNon-inflatable tyresPneumatic tyre reinforcementsMaximum depthEngineering

A structurally supported tire includes an outer annular band, and a plurality of web spokes extending transversely across and radially inward from the annular band and anchored in a wheel or hub. The annular band may further comprise a shear layer, at least a first membrane adhered to the radially inward extent of the shear layer, and at least a second membrane adhered to the radially outward extent of the shear layer. A preferred web spoke has a cutaway section transverse to the annular band. The cutaway section has a profile formed by straight line segments joined by a blending radius. The profile of the cutaway comprises a height and a maximum depth greater than five percent of the height and less than thirty percent of the maximum width. The profile has an angle alpha formed by a line tangent to the profile relative to the horizontal at least equal to ten degrees at the radially outermost and radially innermost extent of said profile. The minimum radius of curvature of the profile is at least equal to twenty percent of the height of the cutaway section.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Tension-based non-pneumatic tire

ActiveUS20090283185A1Eliminating flat tireExtend tire lifeNon-inflatable tyresHigh resiliency wheelsEngineeringMechanical engineering

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner surface, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, oriented and comprised of a material that facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a hub and a footprint region where the tire contacts a surface may assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load. Since the tire is non-pneumatic, it may be easier to maintain and may have a longer life than standard pneumatic tires since it eliminates the possibility of blowouts, flat tires, or tires operating with low air pressure. By virtue of the portion of the tire in the footprint region not bearing a significant portion of the load, non-pneumatic tire may also exhibit a more comfortable ride subject to less noise and vibration and improved handling capabilities.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Adjustable diameter wheel assembly, and methods and vehicles using same

A powered wheel assembly, and method and ground-engaging vehicle (e.g., a robotic vehicle) using the same, are provided. The vehicle incorporates at least one of the wheel assemblies on its chassis body. In addition to its ability to propel the vehicle across a surface, the wheel assembly is reconfigurable between a retracted configuration, wherein the wheel assembly has a first rolling diameter, and an expanded configuration, wherein the wheel assembly has a second rolling diameter greater than the first rolling diameter. A drive motor assembly may both rotate the wheel assembly, e.g., propel the vehicle across a surface, and selectively actuate the wheel assembly from the first rolling diameter to the second rolling diameter, or to any intermediate rolling diameter.

Owner:MINNESOTA RGT UNIV OF A CORP OF MN

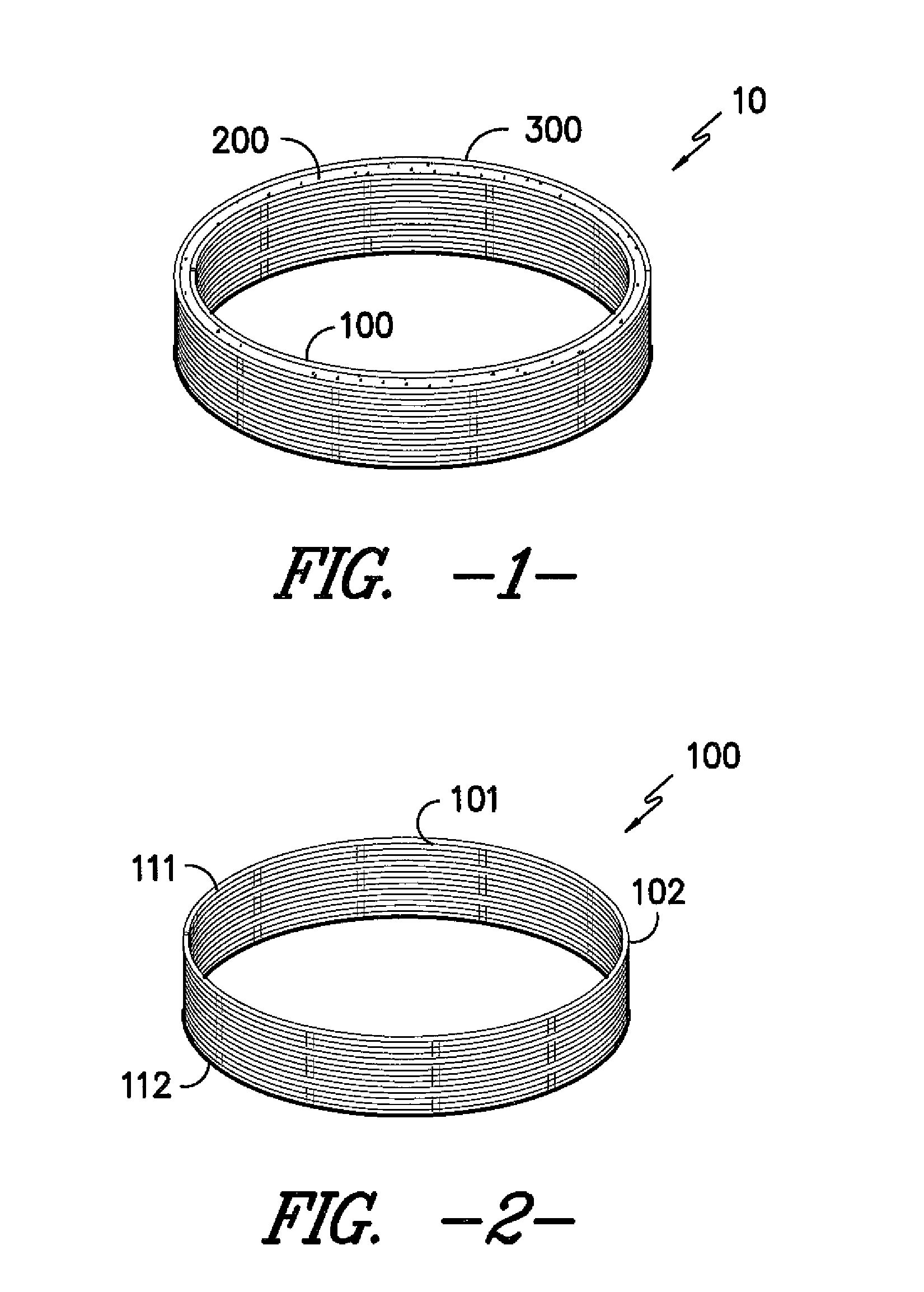

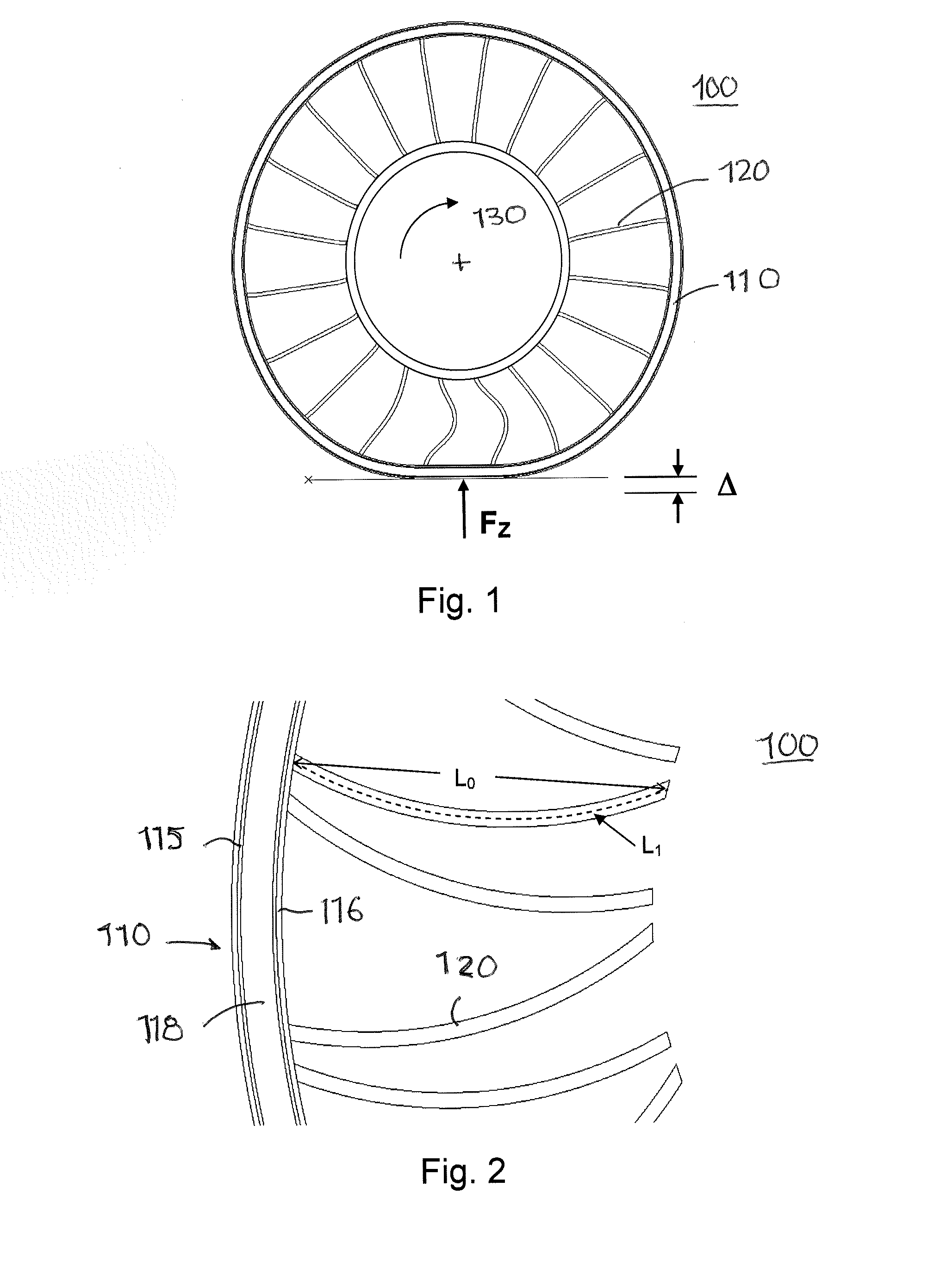

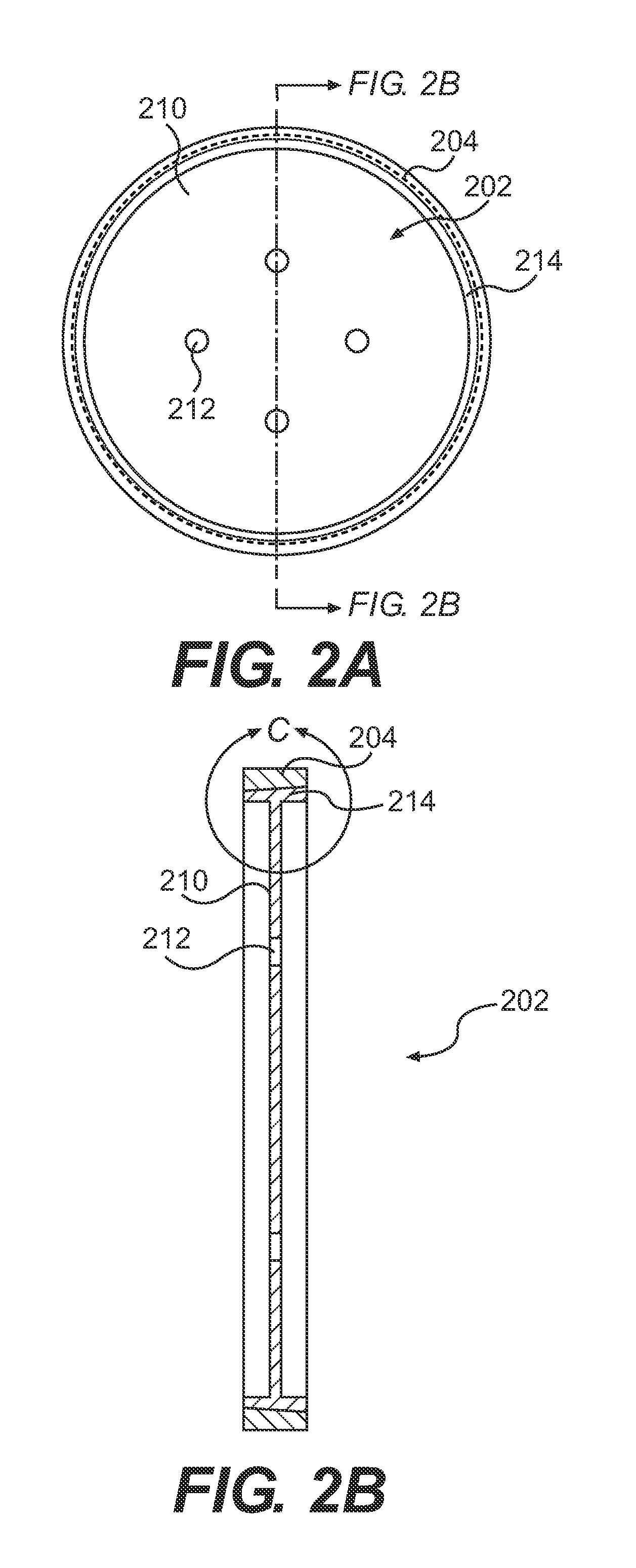

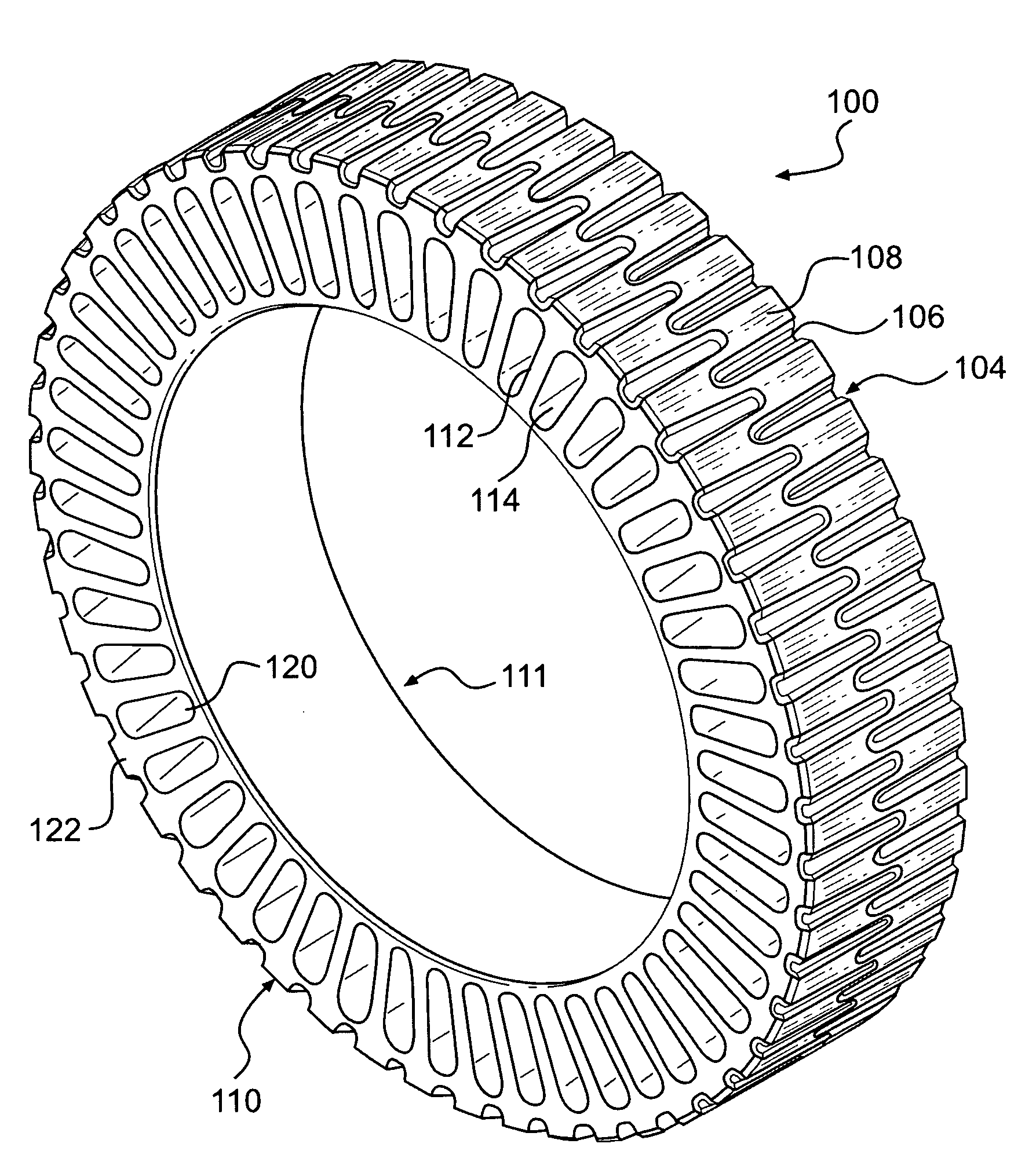

Annular ring and non-pneumatic tire

The present invention provides an annular beam of monolithic construction of one homogeneous material and a related efficient, low-cost non-pneumatic tire. Specific geometric design, combined with nonlinear elastomer physical properties, enable the suppression of all reinforcing belts, continuous fibers, or other strengthening layers in the annular beam. The annular beam consists of at least two bands that are continuous in the circumferential direction and connected by a web geometry. The non-pneumatic tire consists of the annular beam, a ground contacting portion, a central wheel, and a plurality of web spokes that connect the wheel and beam. When the tire is loaded to a design load against a flat surface over a design contact length, a contact area of essentially uniform pressure is produced, while the load is transmitted from the beam to the hub via tension in the web spokes. The tire can be economically manufactured.

Owner:CAMOPLASY INC

Non-pneumatic tire having web spokes

InactiveUS7650919B2High effective radial stiffness in tensionLow effective radial stiffnessNon-inflatable tyresPneumatic tyre reinforcementsGround contactElastomer

Owner:MICHELIN RECH & TECH SA

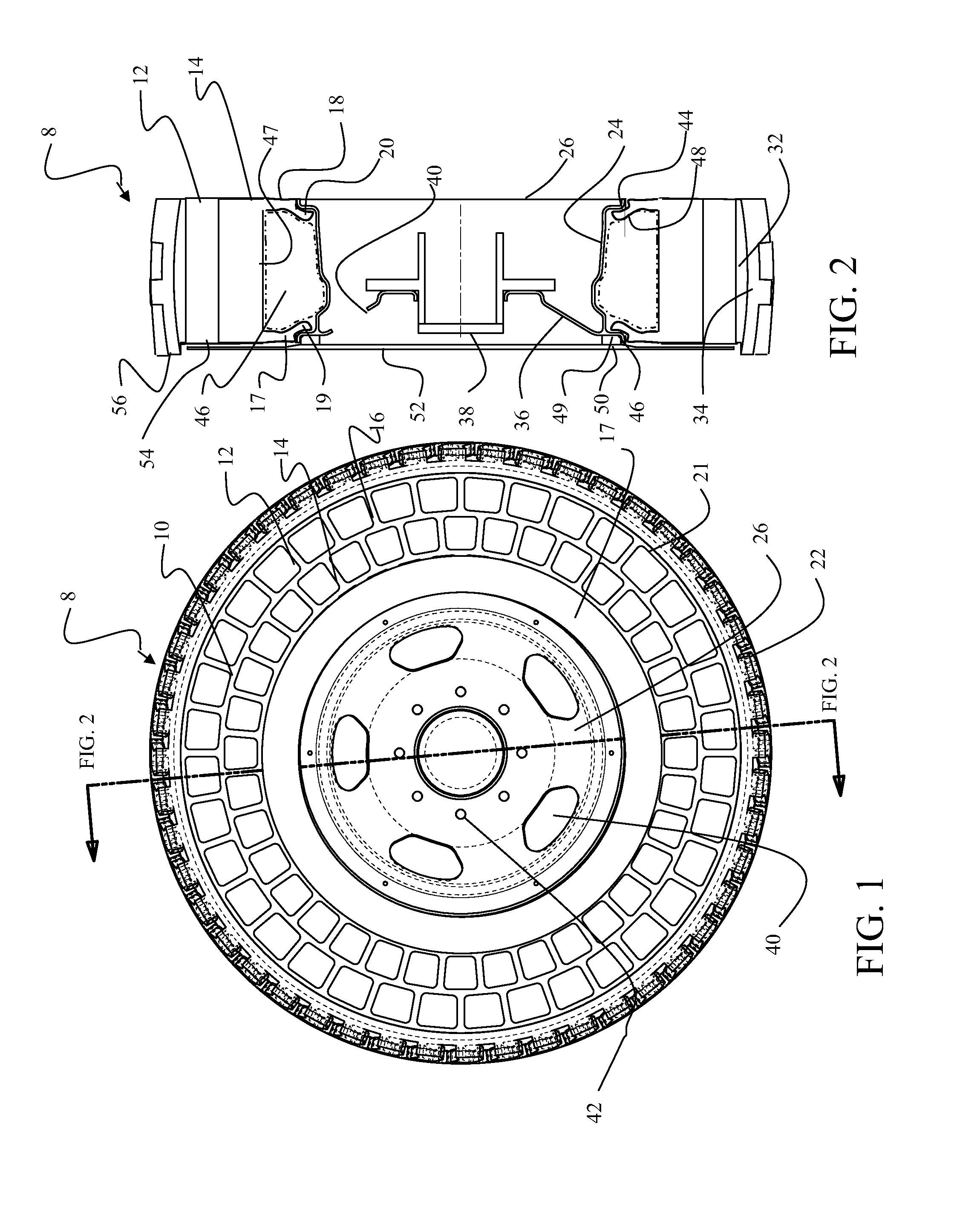

Non-pneumatic tire

ActiveUS20140083581A1Improve ride characteristicQuality improvementAgricultural vehiclesHigh resiliency wheelsGround contactEngineering

A non-pneumatic tire with at least one annular band having an inner ring and a deformable outer ring, a plurality of generally flexible web-spokes connecting the inner ring to the outer ring and a ground contacting tread cap affixed to the annular band.

Owner:MTD PRODUCTS

Airless tire

ActiveUS7143797B2Low hysterisis elastomersImprove performanceNon-inflatable tyresHigh resiliency wheelsElastomerEngineering

This invention pertains to a tire which supports load by means of compressing the tire's elastomeric structure and requires no internal inflation pressure. The preferred embodiments utilize circumferential ribs or radially oriented ribs of elastomer to support the load.

Owner:VANNAN FREDERICK F

Non-pneumatic tire

ActiveUS8113253B2Improve performanceQuality improvementNon-inflatable tyresHigh resiliency wheelsCouplingEngineering

Owner:TOYO TIRE & RUBBER CO LTD

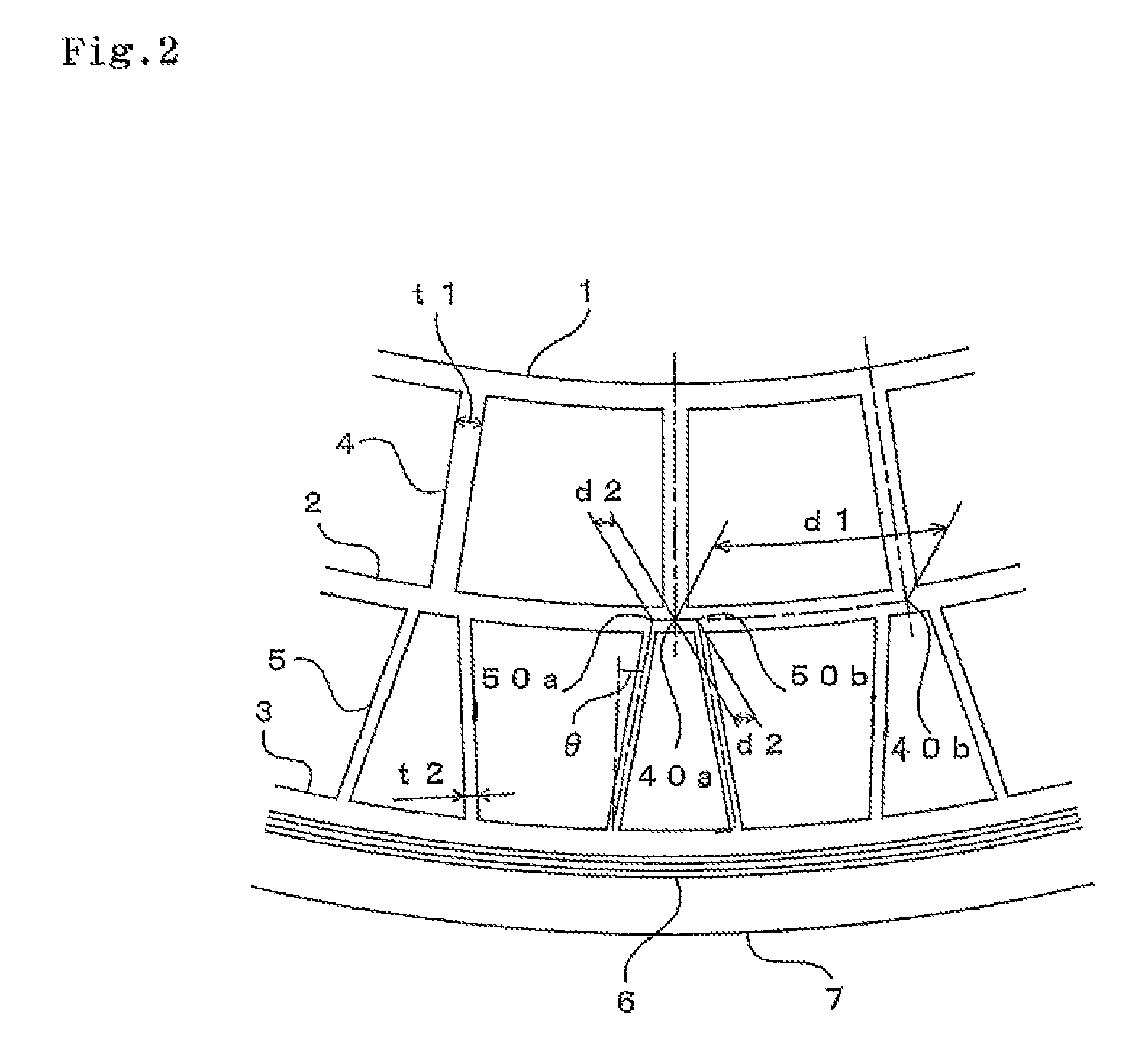

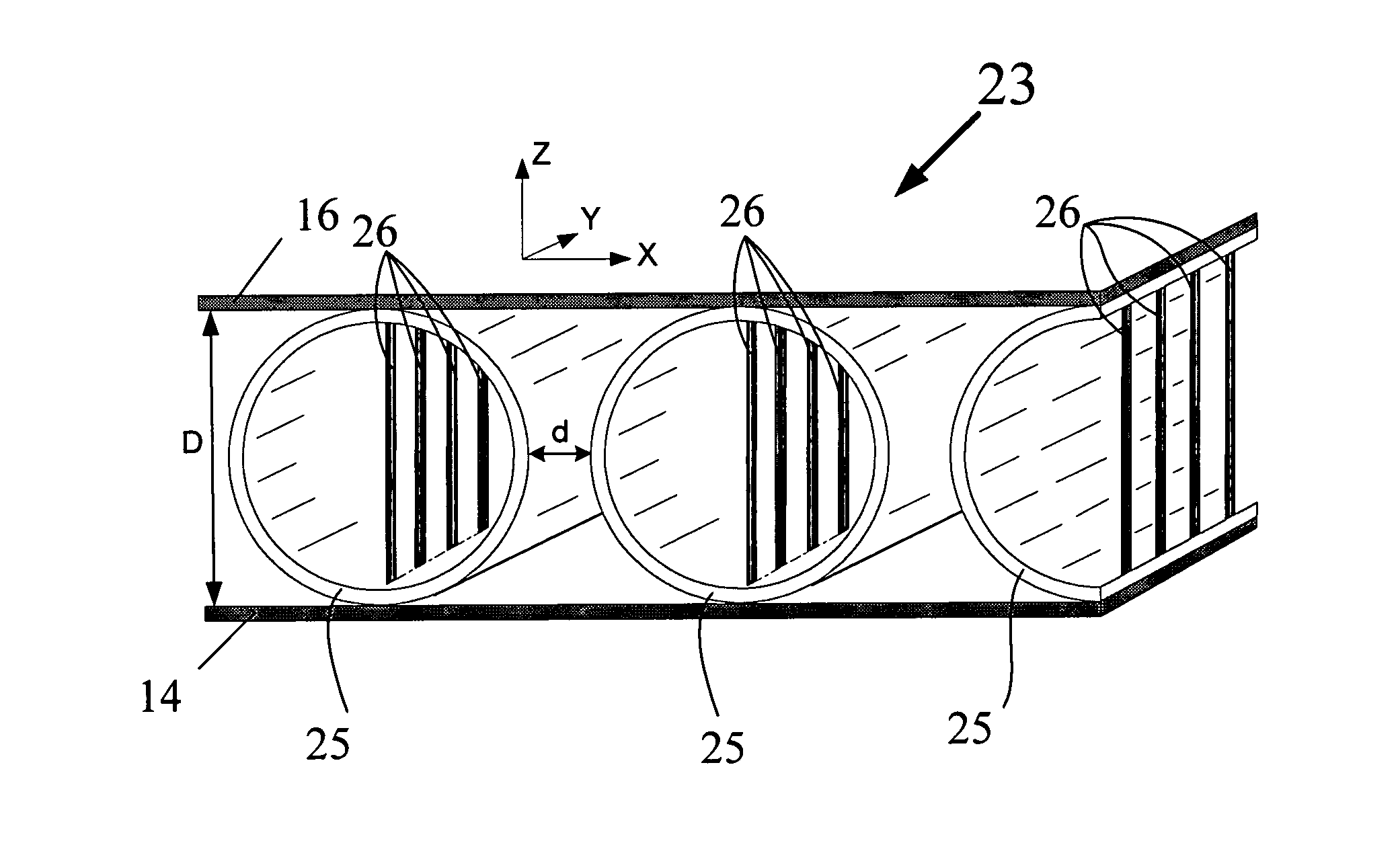

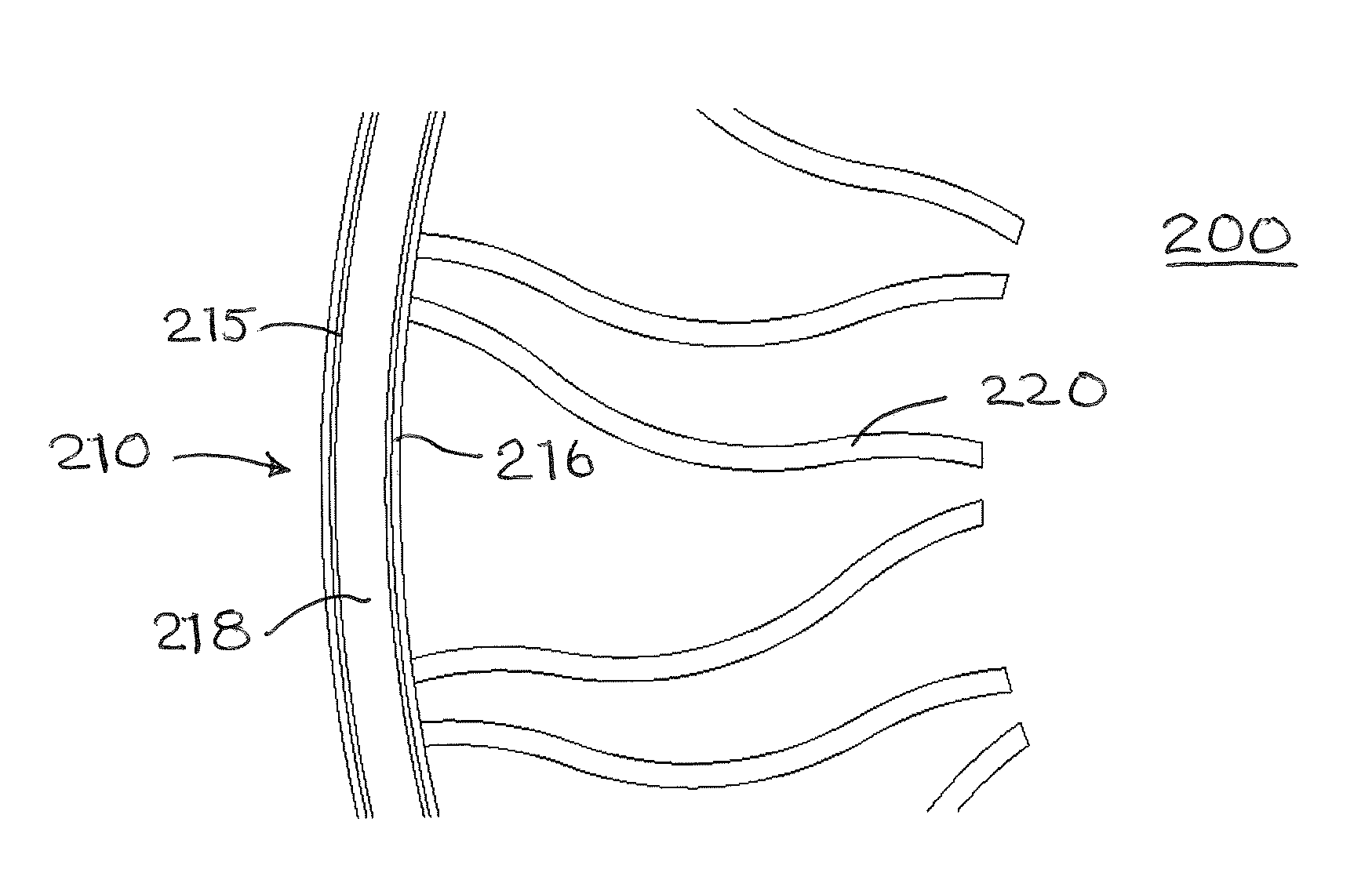

Non-Pneumatic Elastic Wheel

ActiveUS20100307653A1Improve staminaIncrease resistanceNon-inflatable tyresNon-metallic wheel bodyFiberResin matrix

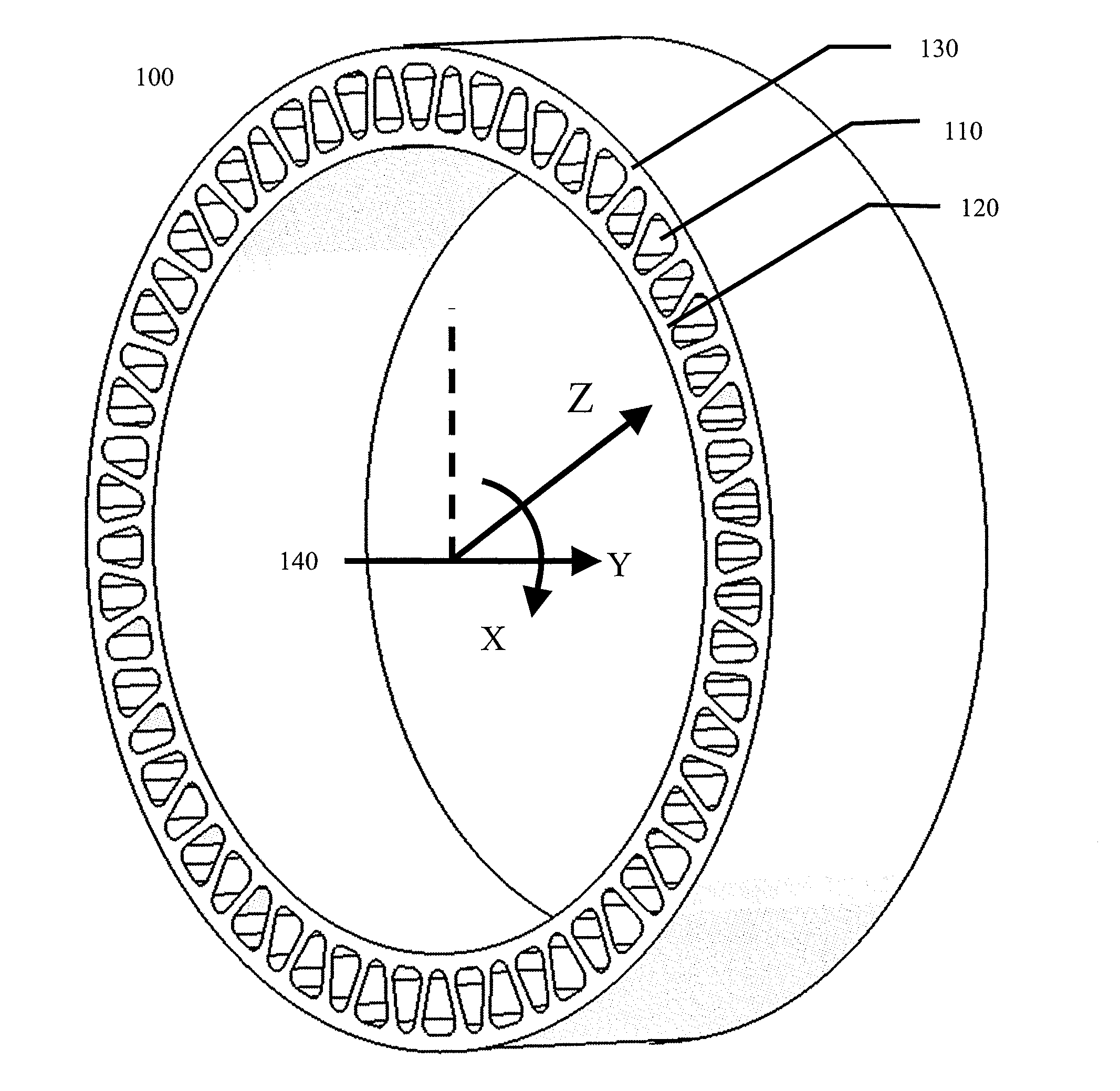

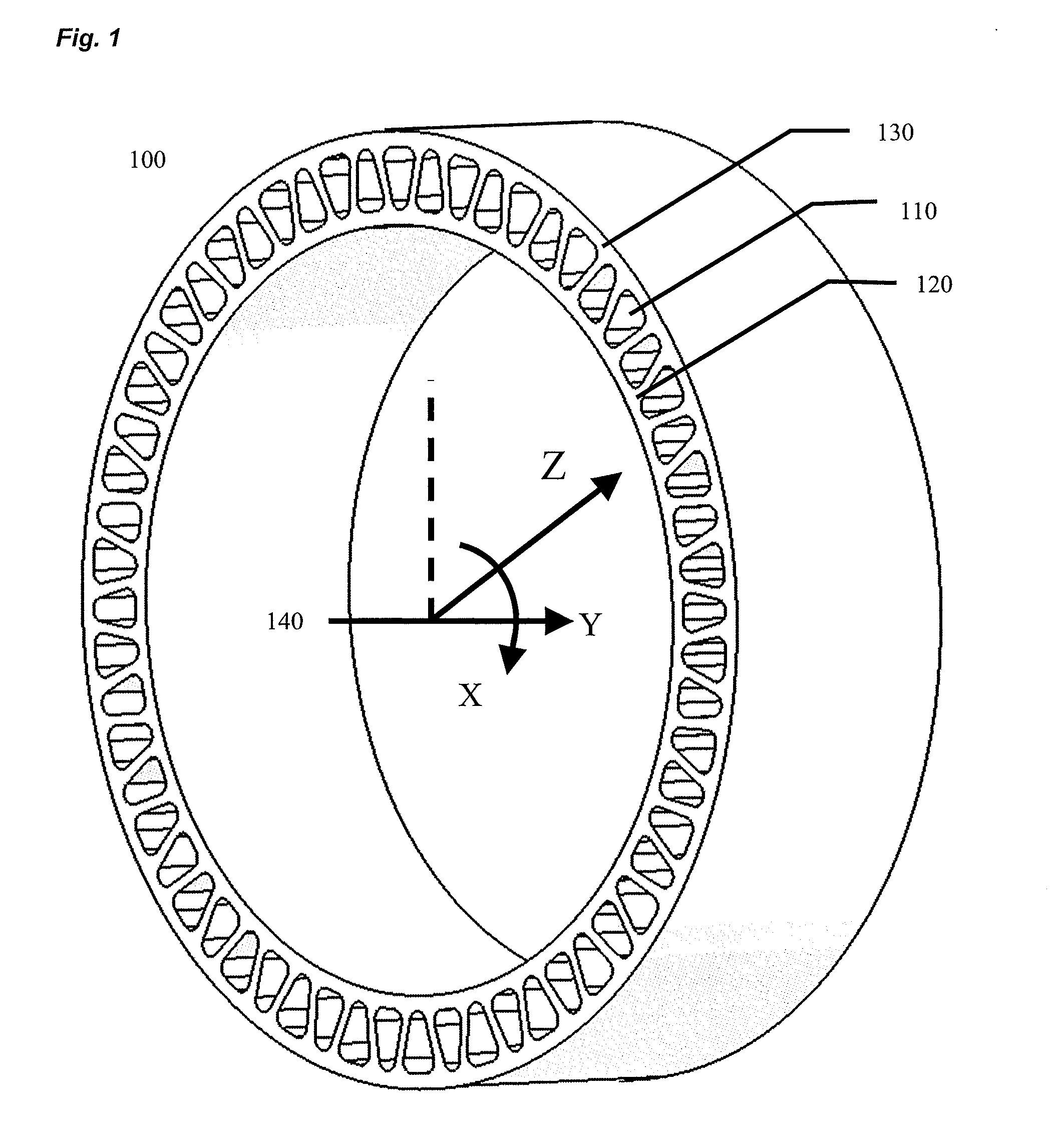

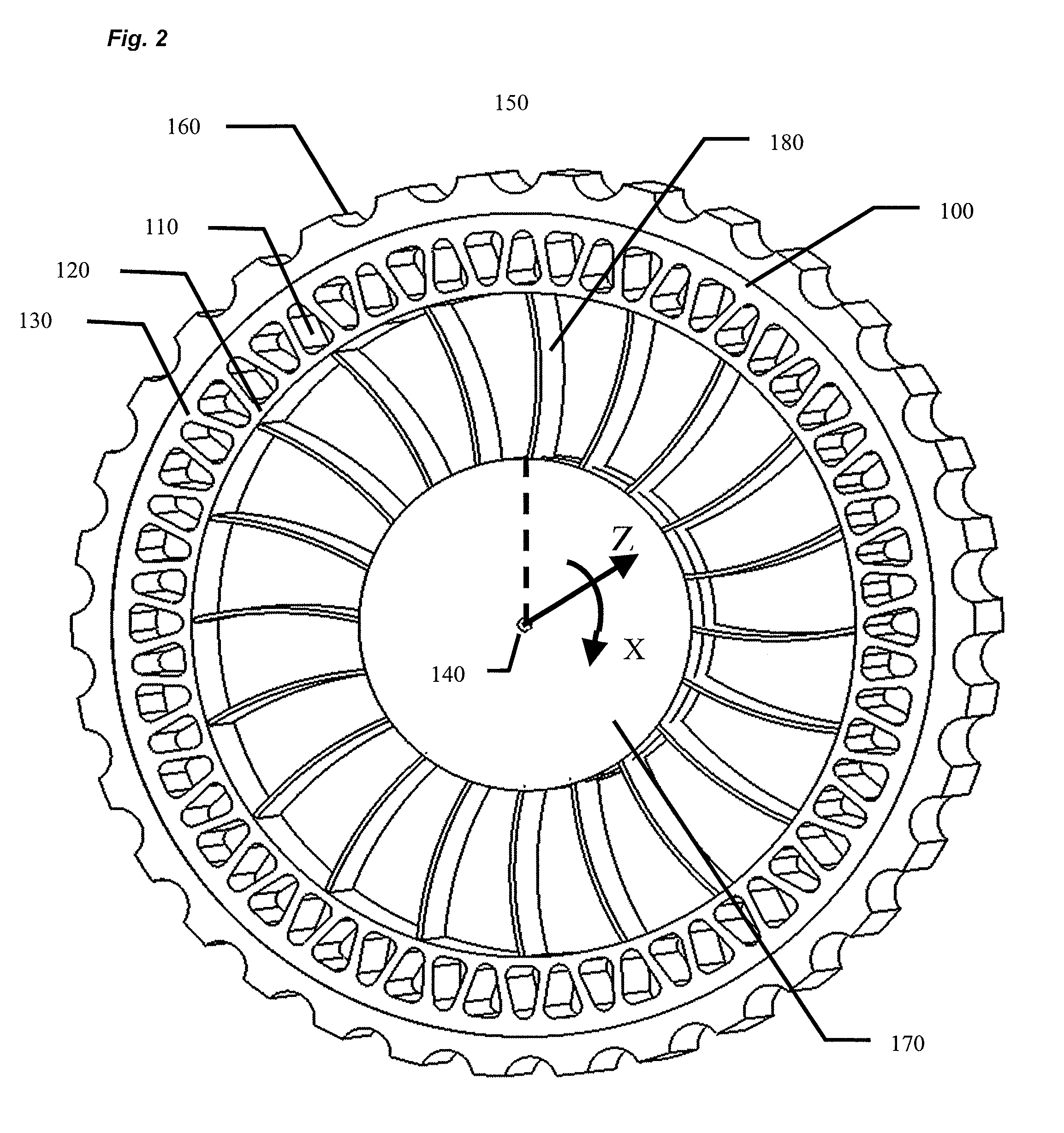

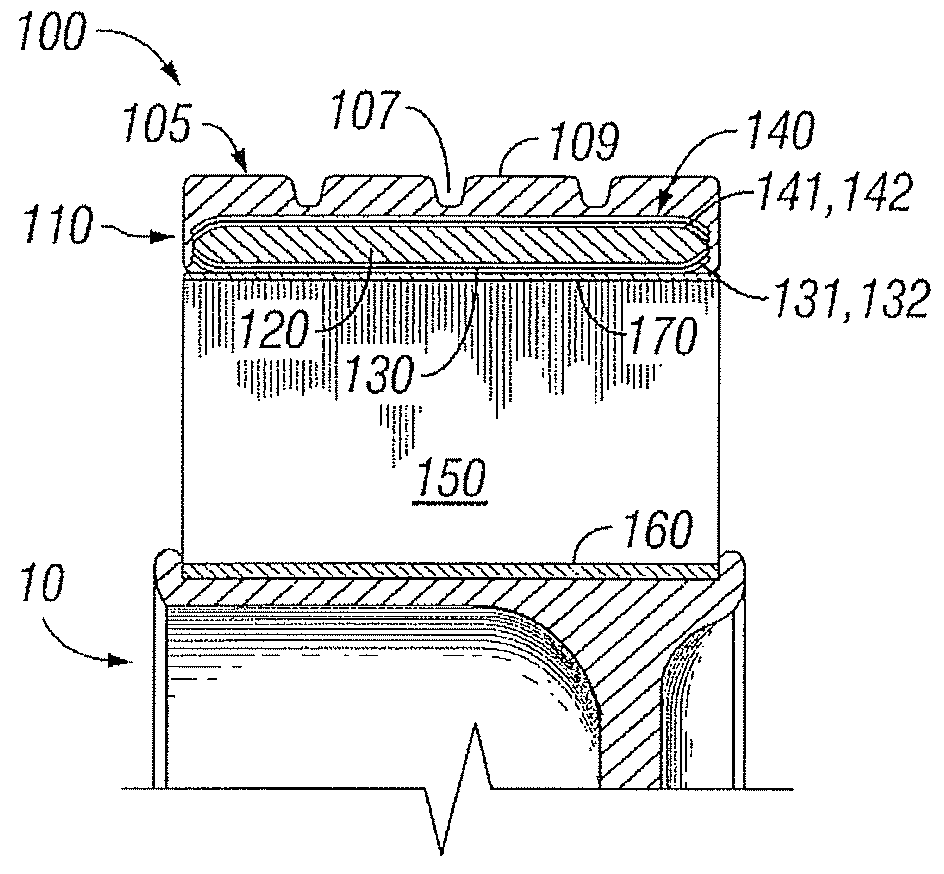

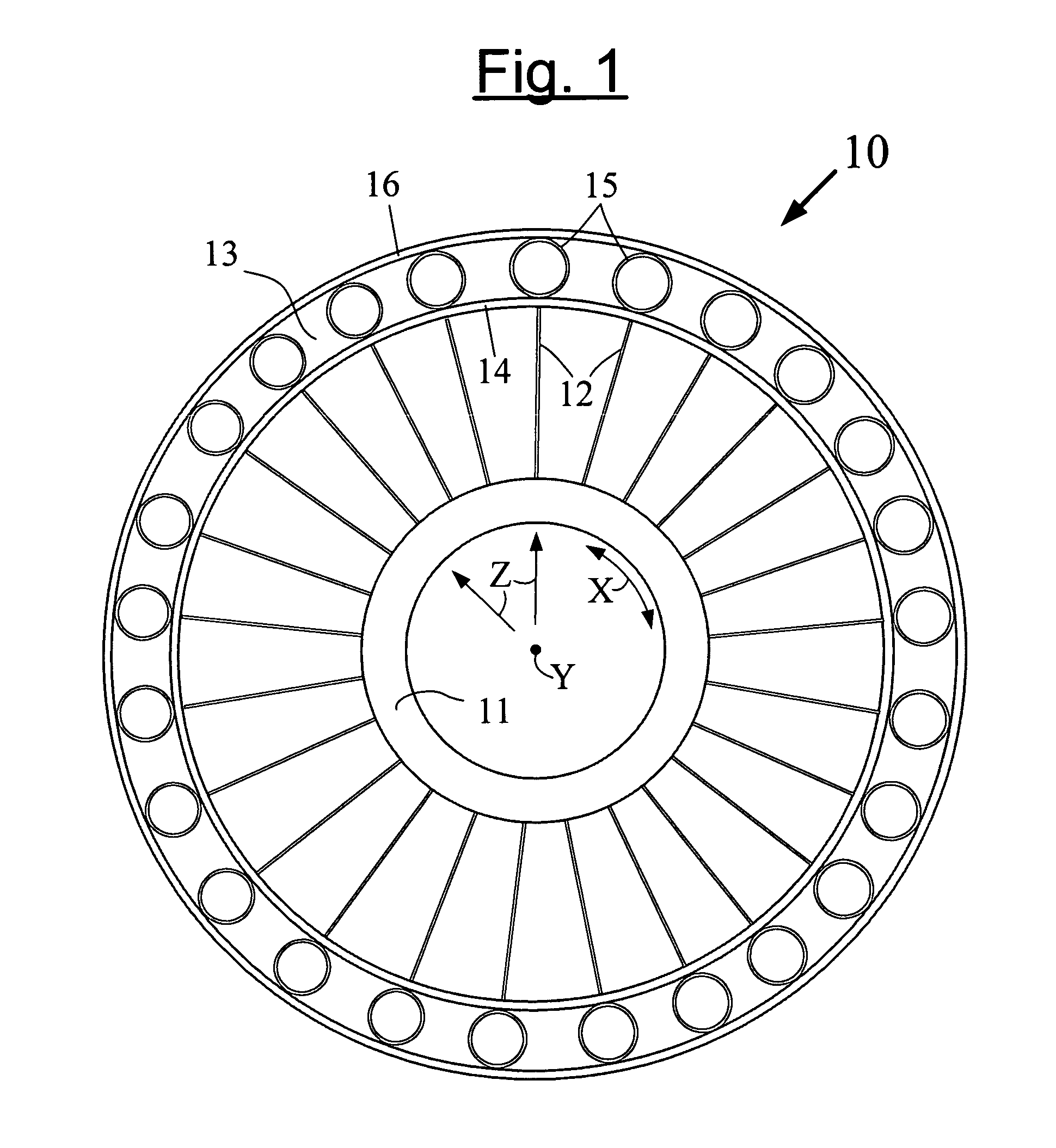

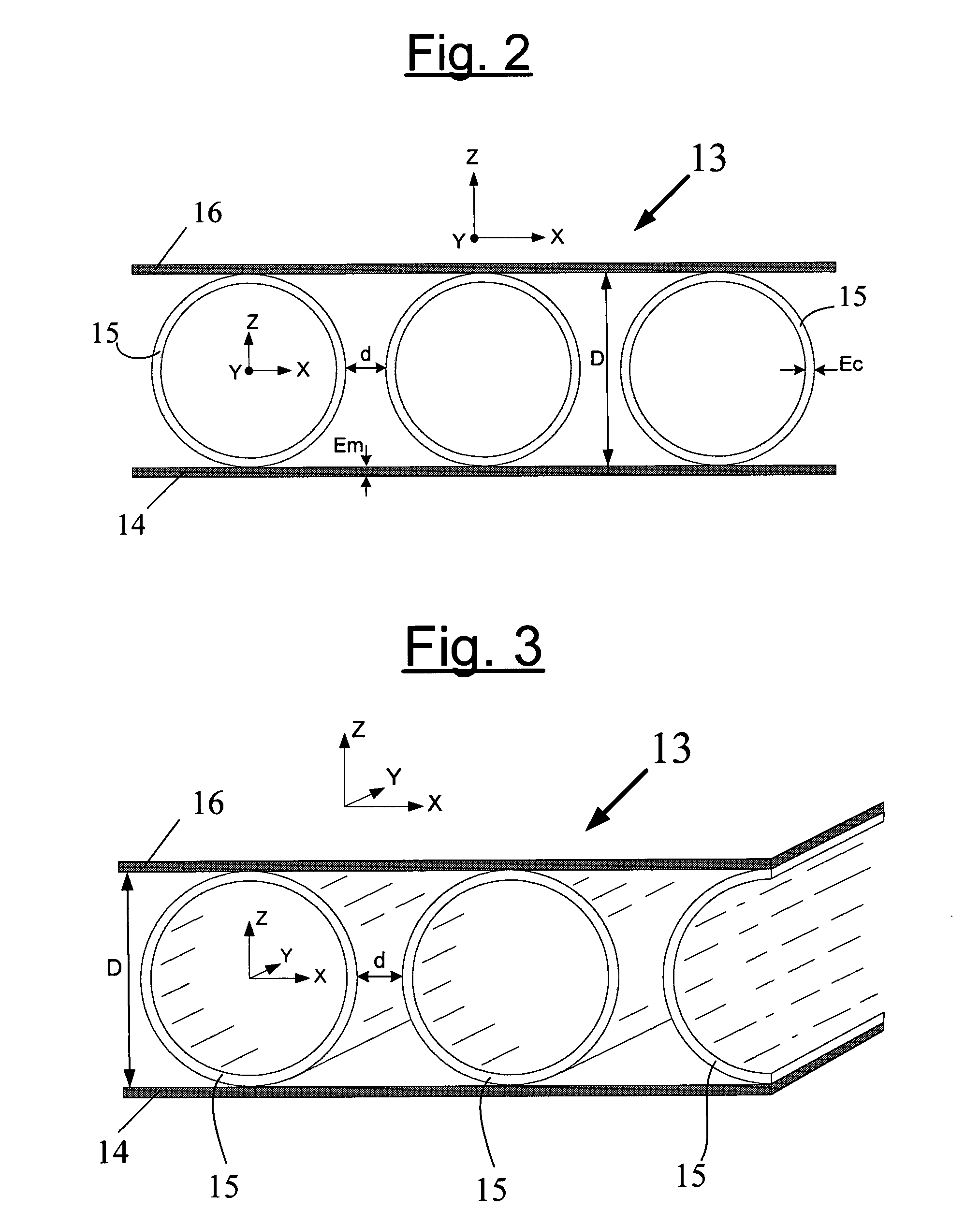

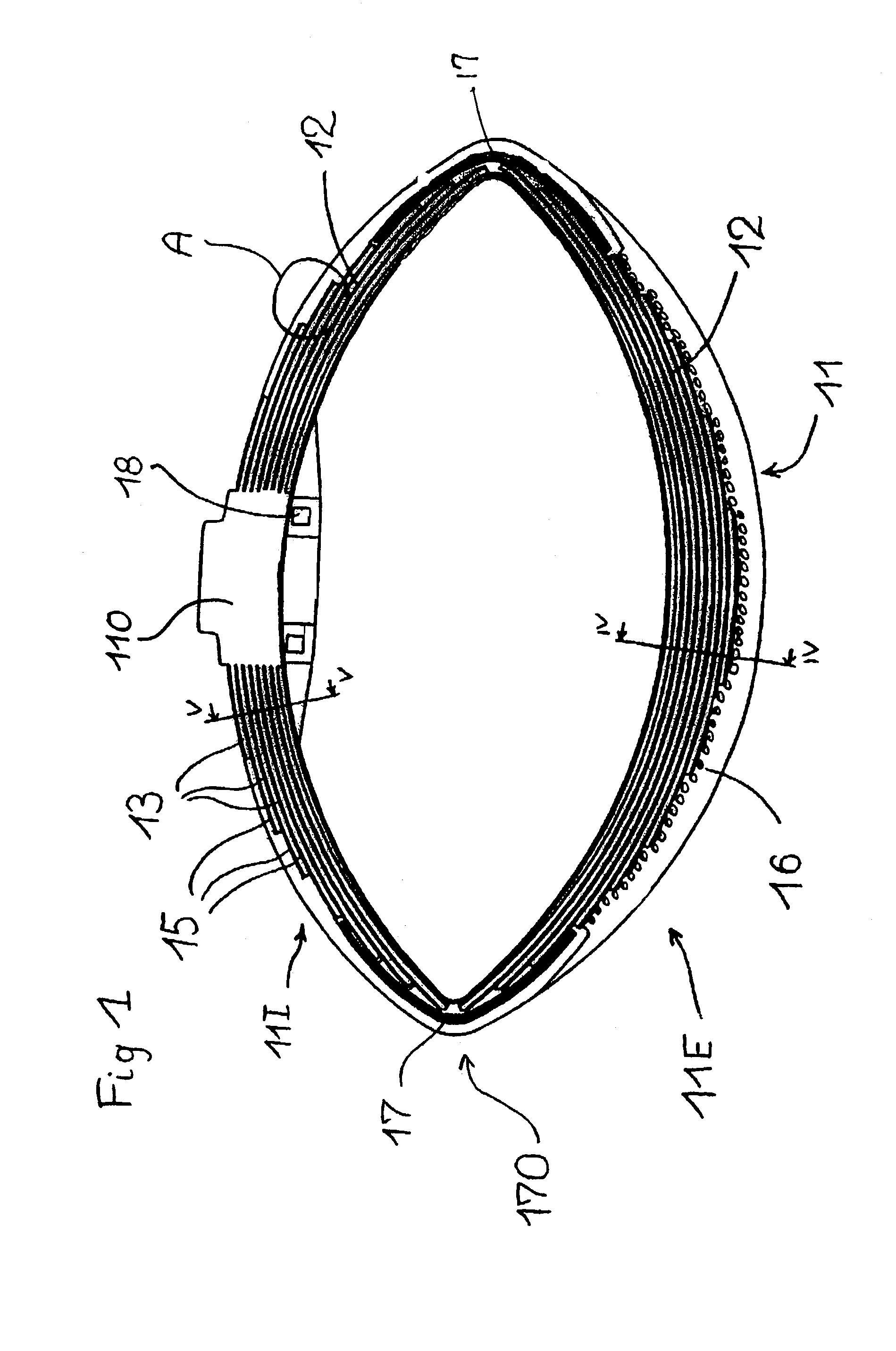

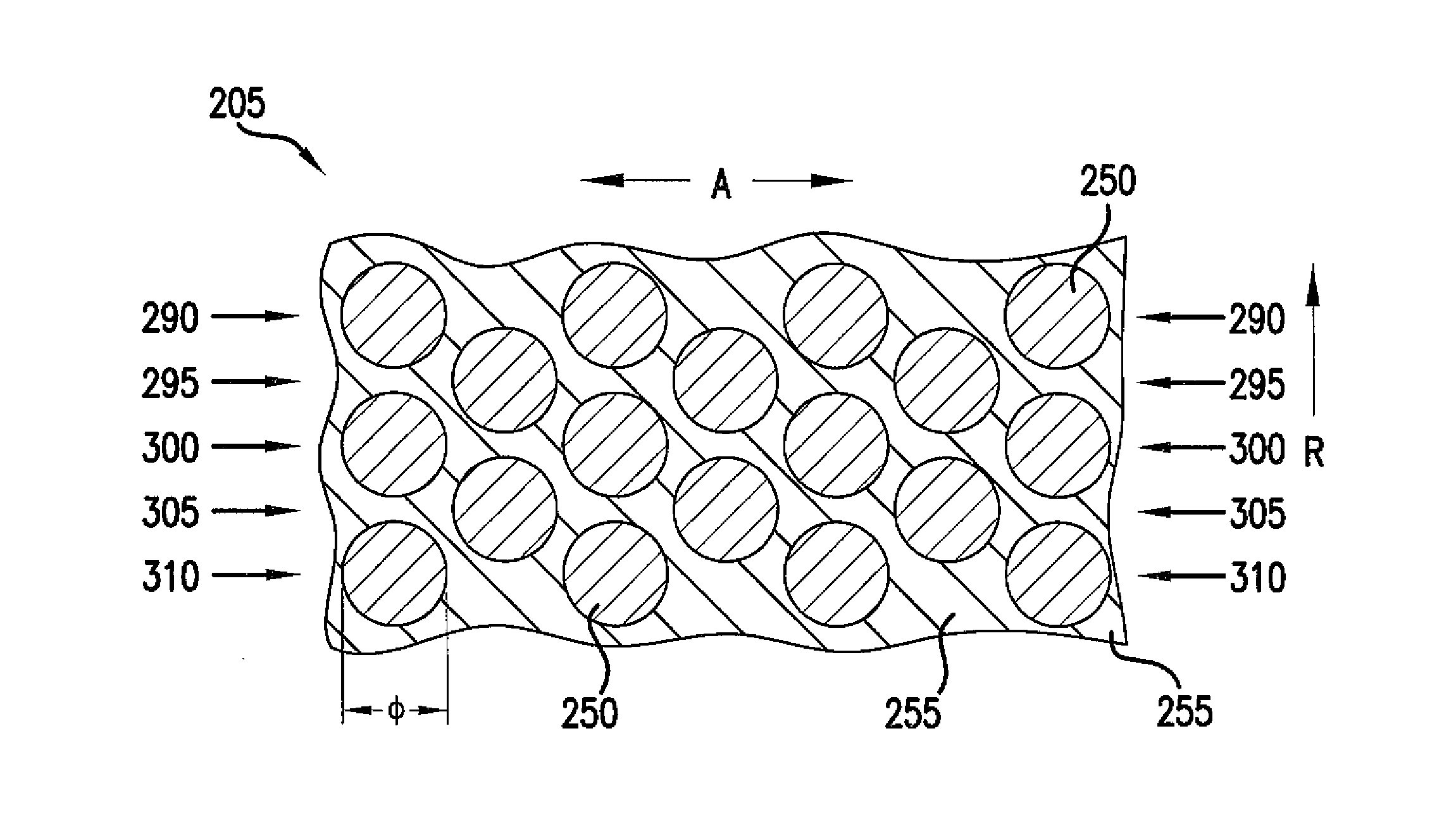

Non-pneumatic resilient wheel (10), that is supported structurally and defines three perpendicular directions, circumferential (X), axial (Y) and radial (Z), this wheel comprising: a hub (11); an annular band referred to as a shear band (13) comprising at least one inner circumferential membrane (14) and one outer circumferential membrane (16) that are oriented in the circumferential direction X; and a plurality of support elements (12) that connect the hub (11) to the inner circumferential membrane (14)U. The two membranes (14, 16) are connected to one another by means of a series, that extends in the circumferential direction (X), of cylinders (15) referred to as connection cylinders, said connection cylinders (15) being non-touching in the circumferential direction X and having their generatrix oriented in the axial direction Y. The connection cylinders (15) are composite cylinders comprising fibres embedded in a resin matrix.

Owner:MICHELIN RECH & TECH SA +1

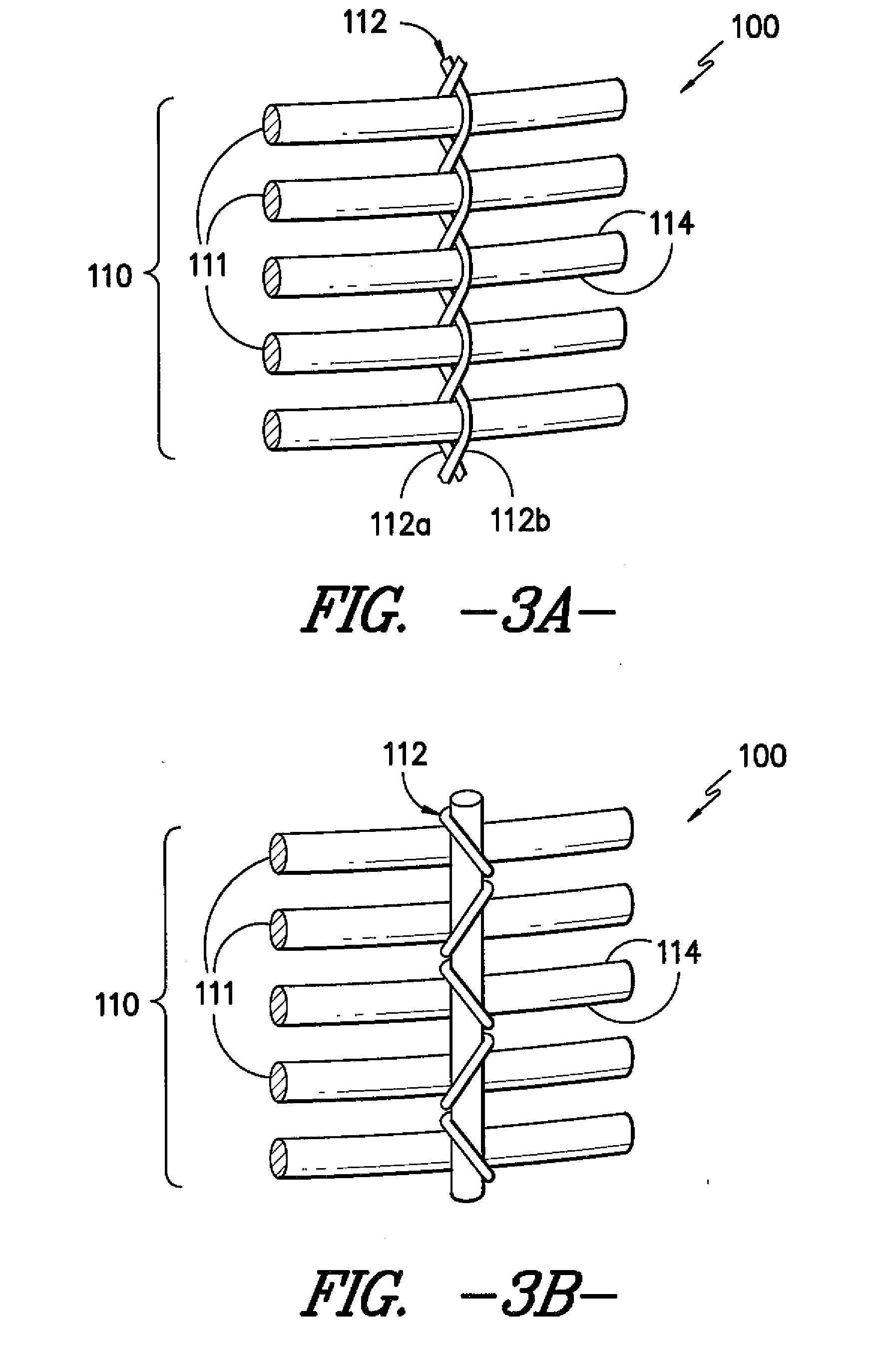

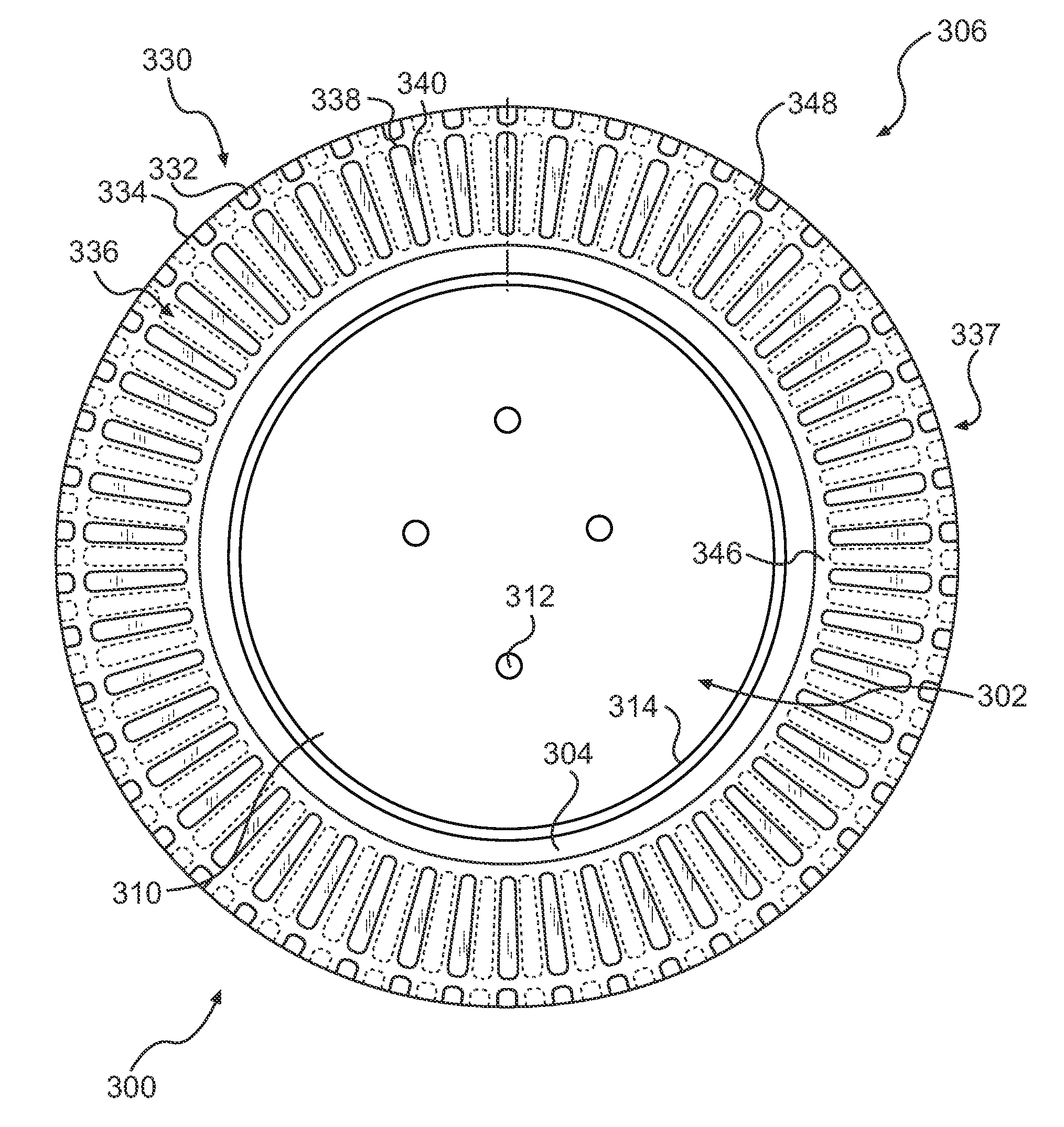

Structurally supported, non-pneumatic wheel with continuous loop reinforcement assembly

ActiveUS20120318417A1Maintain integrityIncrease stiffnessNon-inflatable tyresPneumatic tyre reinforcementsEngineeringReceipt

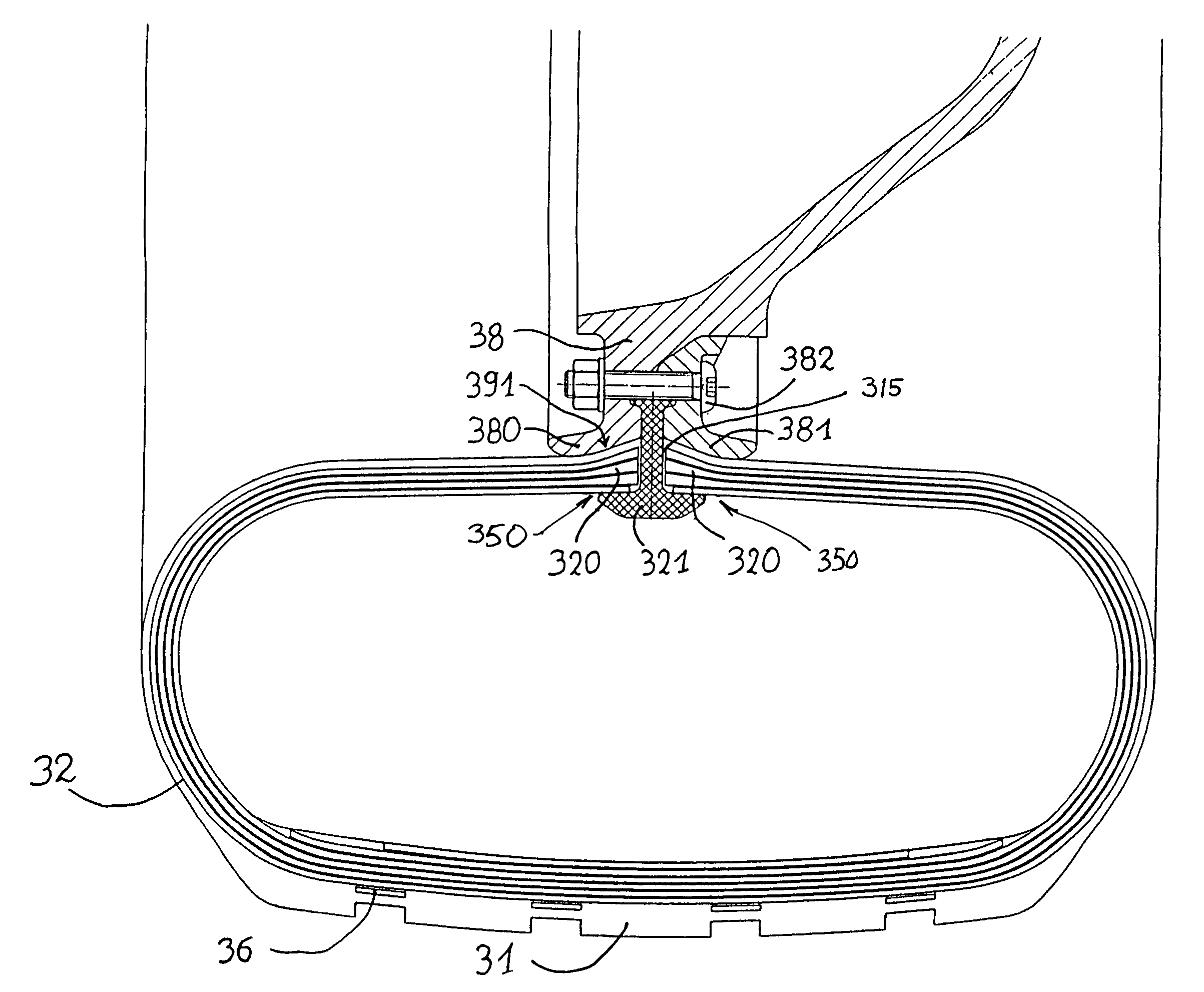

A non-pneumatic wheel is provided having a continuous loop reinforcement assembly that can support a load and have performance similar to pneumatic tires. Various configurations of a non-pneumatic wheel, including variations of the continuous loop reinforcement assembly, are provided. One or more resilient spacers can be positioned with the continuous loop reinforcement assembly and can be configured for the receipt of a matrix material.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

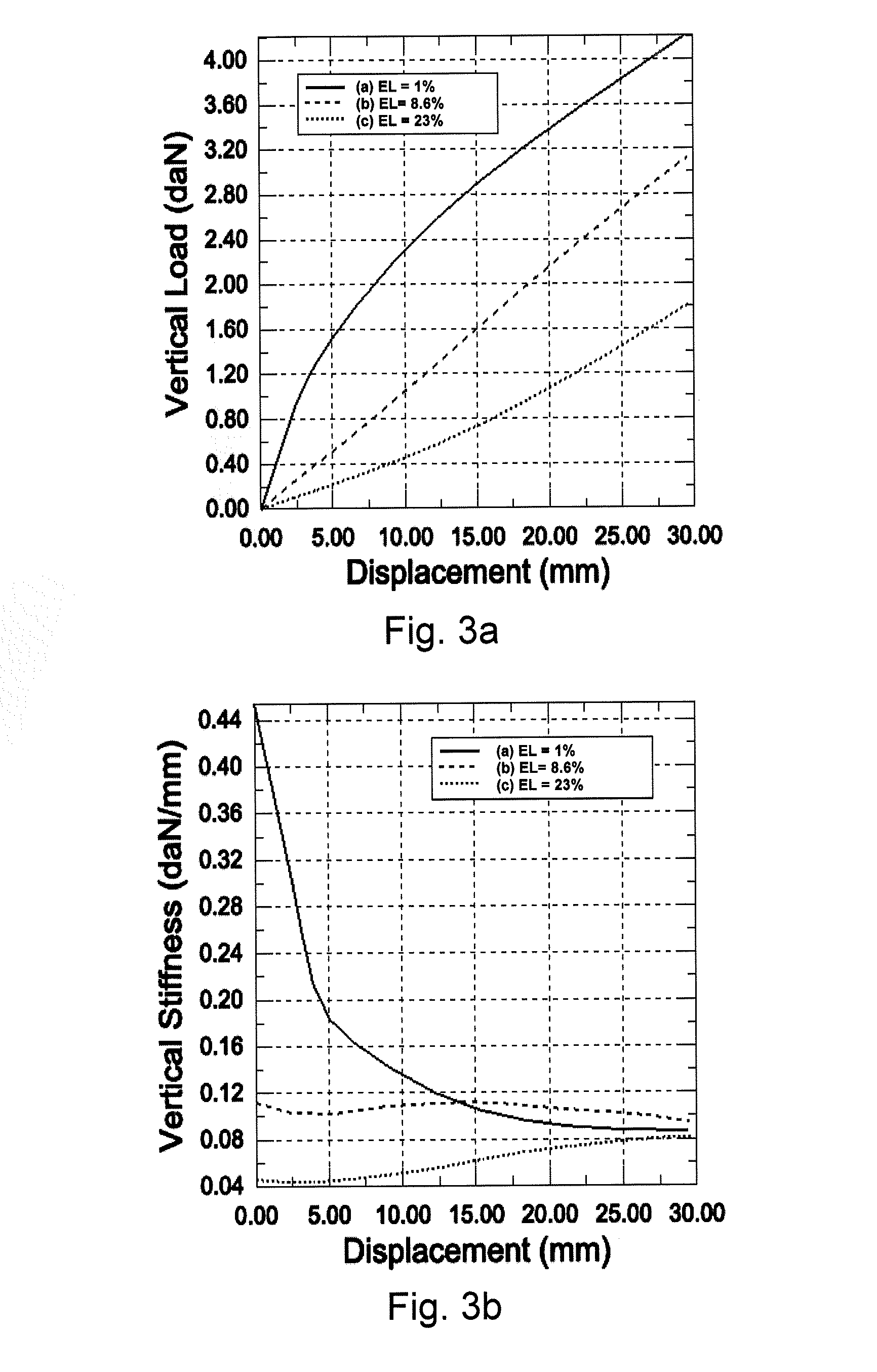

Variable Stiffness Spoke For a Non-Pneumatic Assembly

InactiveUS20090294000A1Reduce stress concentrationNon-inflatable tyresHigh resiliency wheelsVariable stiffnessEngineering

The invention described herein provides a non-pneumatic deformable structure having a variable stiffness spoke assembly that provides a method of adjusting the vertical stiffness. The structure comprises an outer annular band having a predetermined stiffness, a set of spoke elements having an outer end and an inner end, where the outer end is connected to the outer band, with the spoke element extending inward and having its inner end connected to a hub, the hub being configured to attach the structure to a vehicle axle or other apparatus capable of rotation about an axis. Each of the spoke elements has a curvilinear length greater than the length of a straight line segment extending from a point of connection of the outer end of the spoke element with the outer annular band to a point of connection of the inner end of the spoke element to the hub. The outer end of said spoke element is tangent to the straight line segment, and the inner end of said spoke element is tangent to the straight line segment.

Owner:MICHELIN RECH & TECH SA +1

Tire and tire rim assembly

Owner:CHEMTURA CORP

Airless tire

ActiveUS20060144488A1Low hysterisis elastomersImprove performanceNon-inflatable tyresHigh resiliency wheelsElastomerEngineering

This invention pertains to a tire which supports load by means of compressing the tire's elastomeric structure and requires no internal inflation pressure. The preferred embodiments utilize circumferential ribs or radially oriented ribs of elastomer to support the load.

Owner:VANNAN FREDERICK F

Non-pneumatic resilient tire

InactiveUS7032634B2Improve comfortImprove adhesionNon-inflatable tyresSpecial tyresEngineeringMechanical engineering

Owner:CONCEPTION & DEV MICHELIN SA

Reactive planar suspension for a wheel

InactiveUS20110126948A1Sacrificing comfort and performanceLow profileHigh resiliency wheelsWheels with plate-like shoesEngineeringHorizontal and vertical

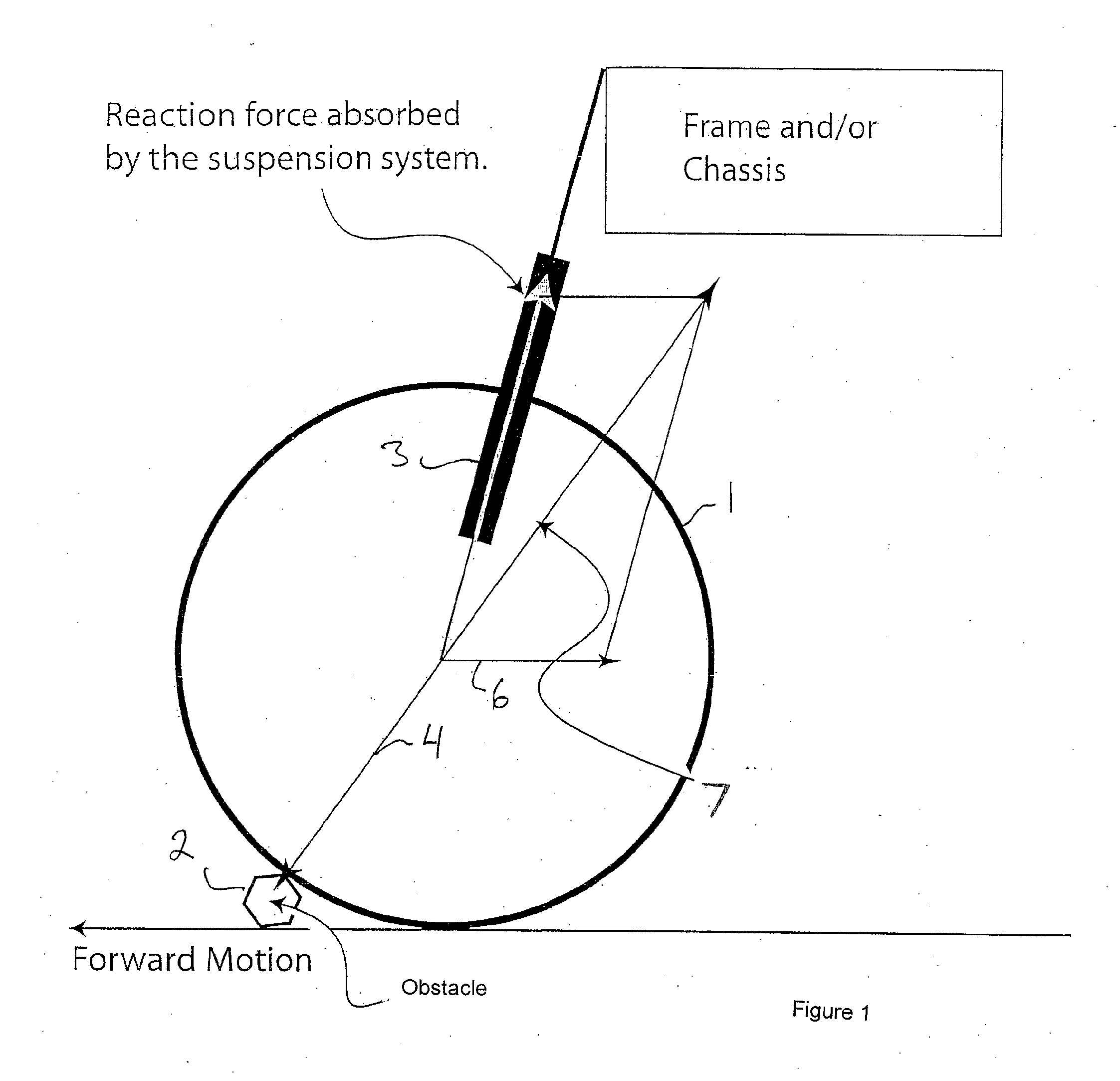

There is described a suspension wheel comprising a substantially rigid rim, a substantially rigid hub disposed concentrically within the rim to define an annular space between the rim and the hub, the hub being adapted for connection to an axle for the wheel, and suspension members disposed in the annular space and connected to the rim and the hub to allow the rim to move in one or both of the horizontal and vertical directions relative to the hub in response to an input to the rim.

Owner:MINDMATTER INNOVATES

Process for creating expandable tire chamber

InactiveUS6905564B1Improve gripTelevision system scanning detailsAuxillary traction increasing equipmentRoad surfaceEngineering

A process for producing a tire having an expandable chamber utilized for extending and retracting studs provided in the periphery of the tire. In one embodiment, a non-stick film is strategically positioned between the casing and the tread prior to curing the tread onto the casing. The interface at either side of the film forms the sides of an expandable chamber. The tread side of the chamber is inset and studs are affixed thereto. Expansion of the chamber extends the studs out of the inset and into engagement with a road surface. Alternative processes provide a channel in the tread and the expansion chamber formed in the channel.

Owner:Q TIRES

Non-pneumatic tire

A non-pneumatic tire comprising side cavities that are staggered with respect to laterally opposing side cavities, and laterally extending tread grooves that are in substantial radial alignment with the cavities. In another embodiment, the invention is to a tire comprising side ribs that are staggered with respect to laterally opposing side ribs, and laterally extending tread grooves that are substantially offset relative to the side ribs. Also provided are processes for making such tires and to off-the-road (OTR) vehicles employing such tires.

Owner:LANXESS SOLUTIONS US INC

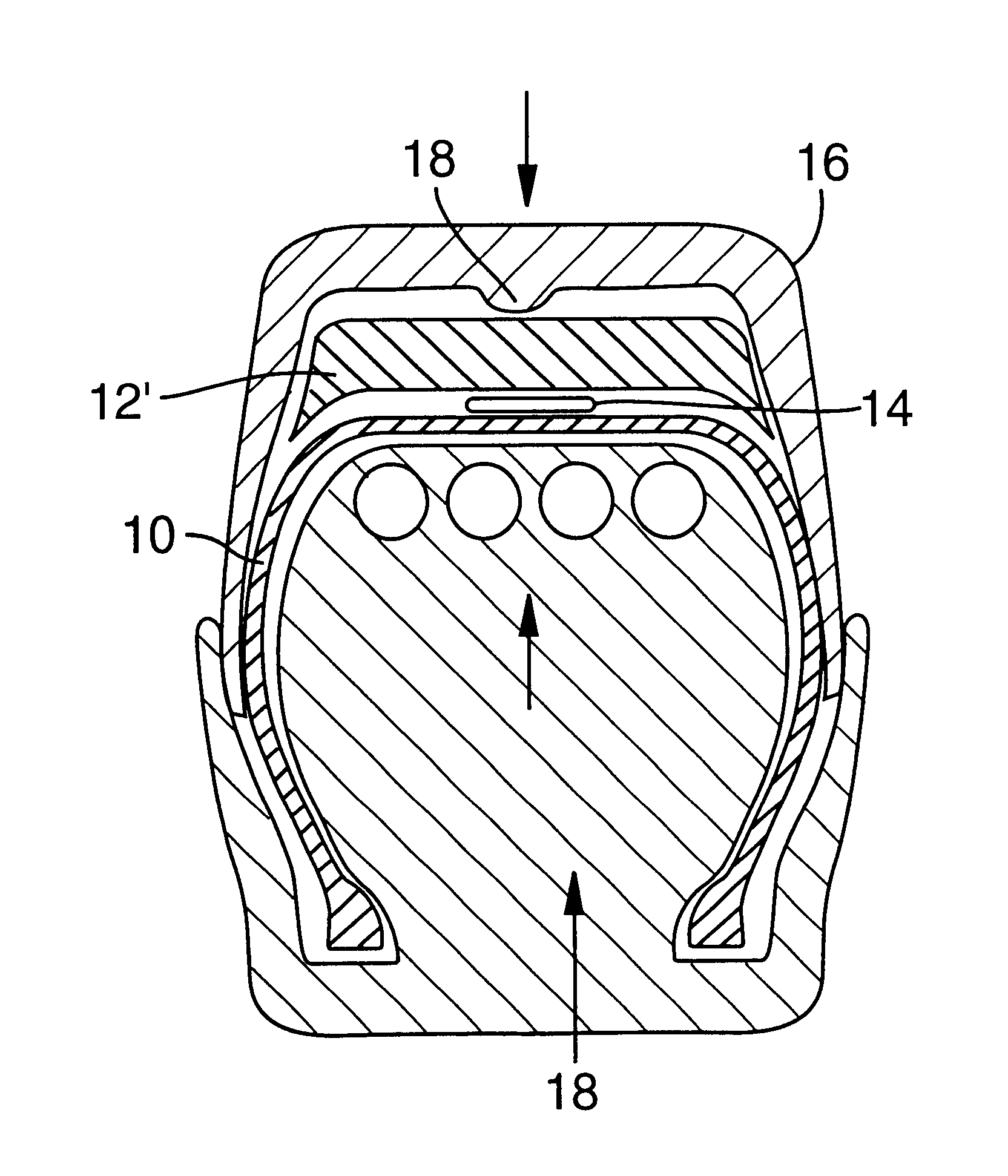

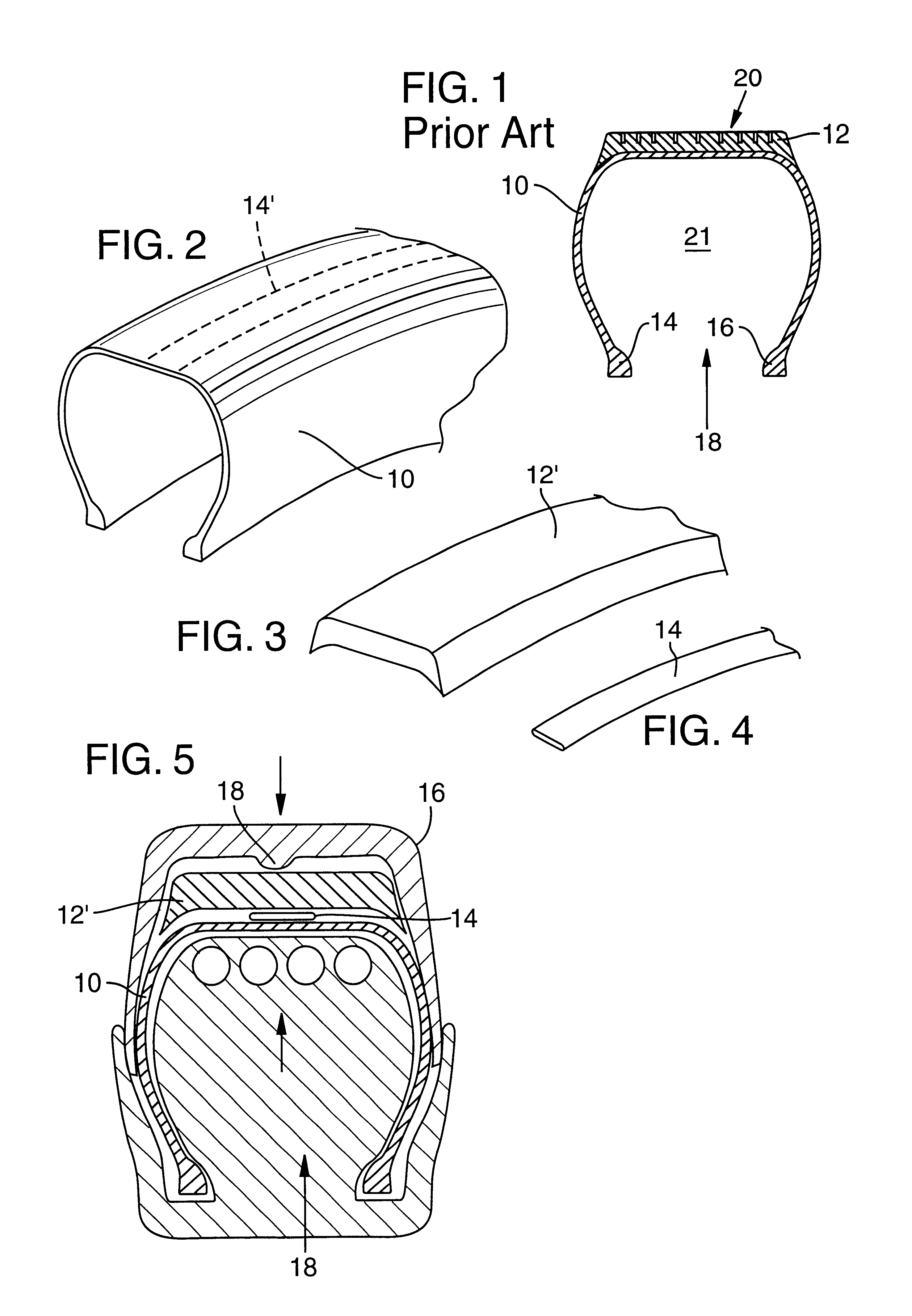

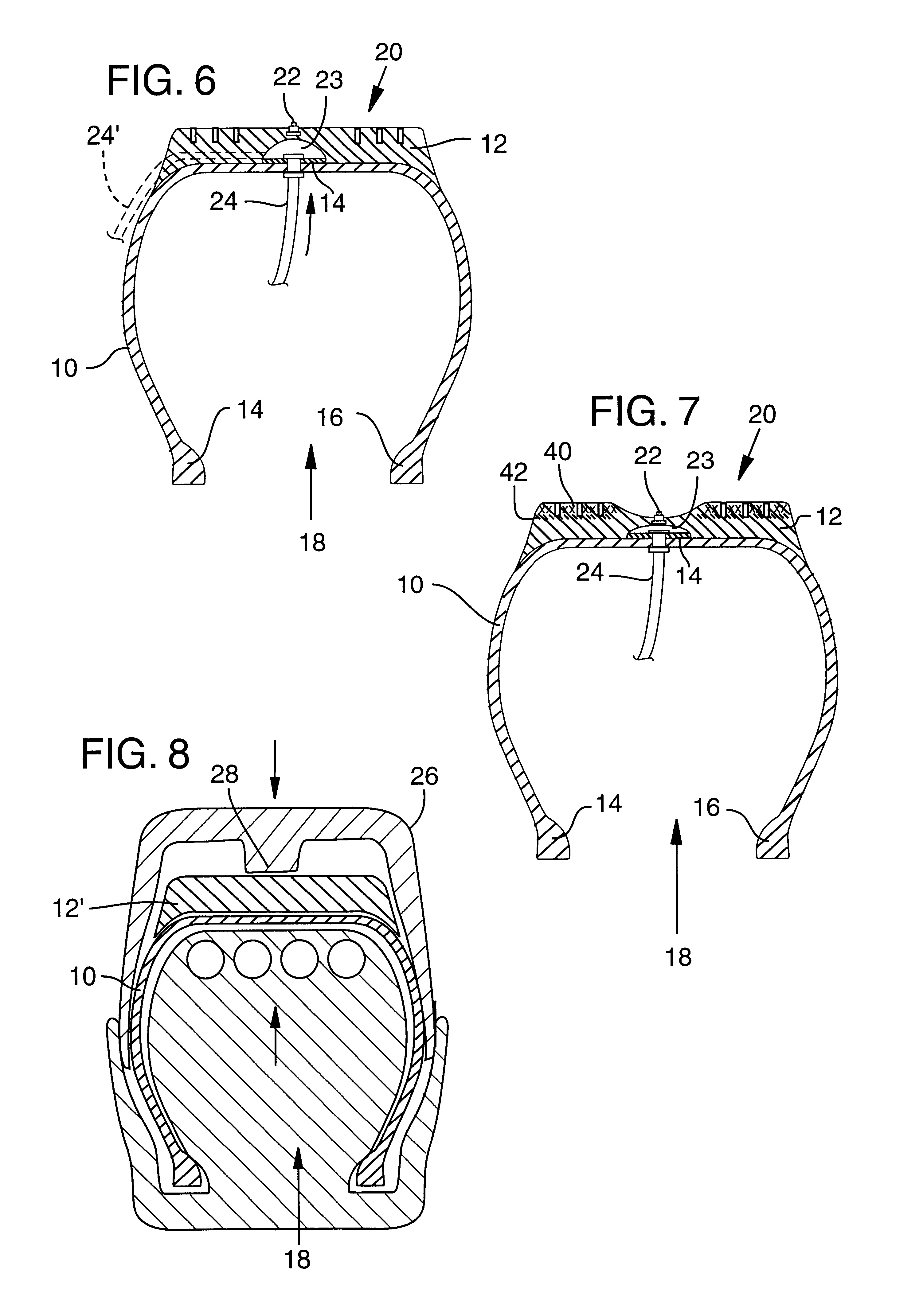

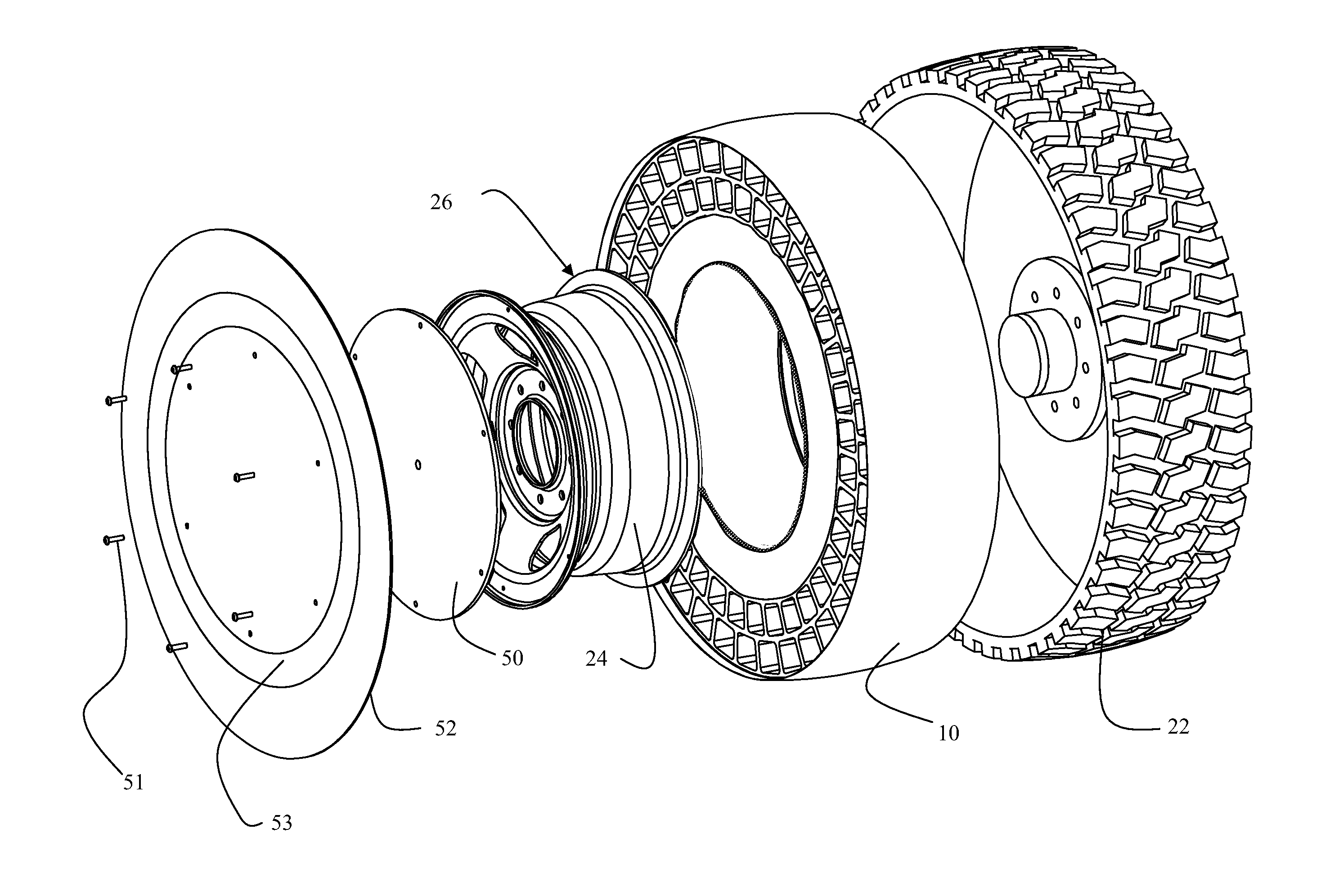

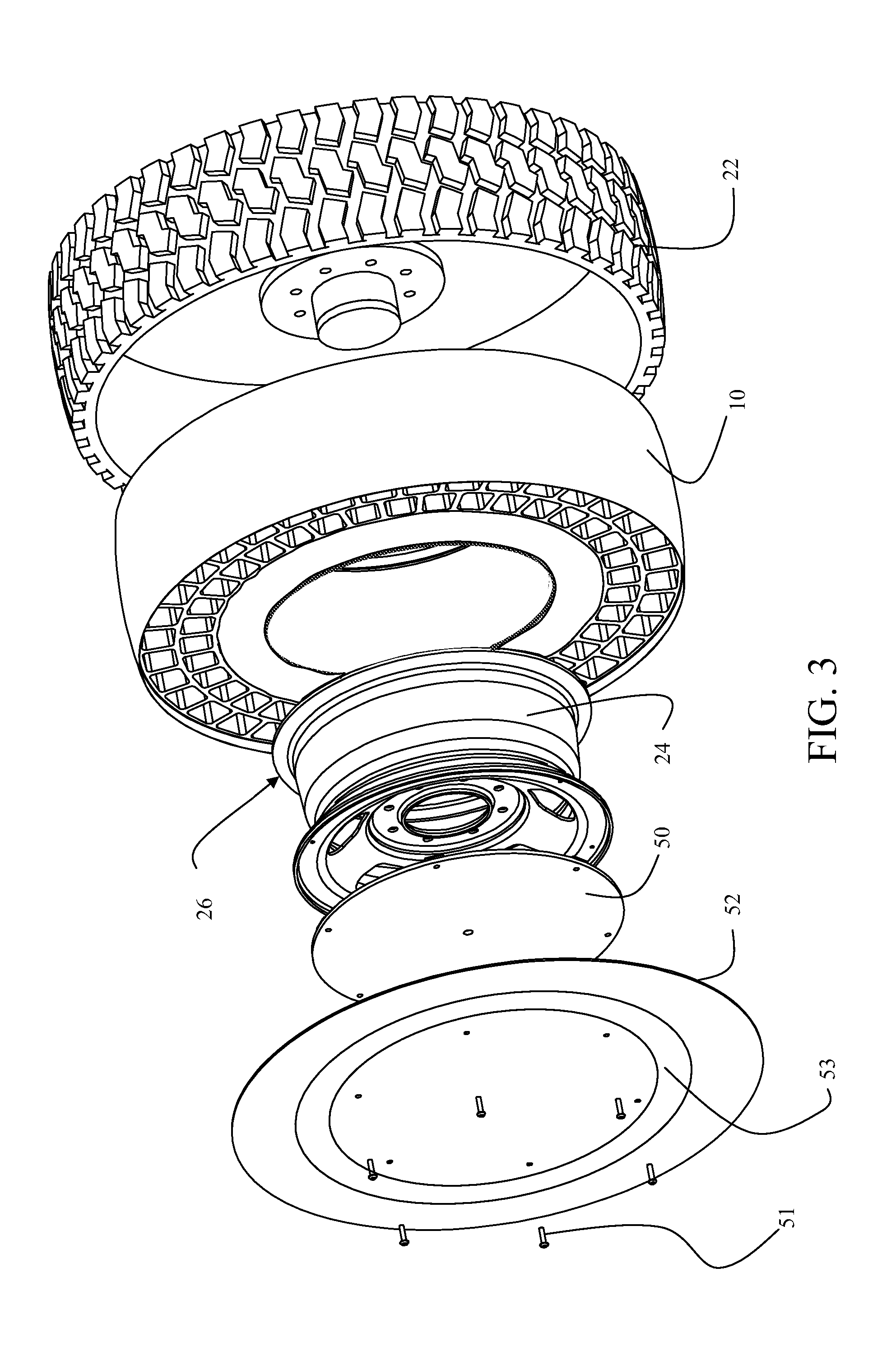

Non-pneumatic survivable tire mounting system for conventional wheels

A non-pneumatic tire and wheel assembly incorporates a tire tread and a conventional vehicle wheel with an elastomer tire body element and integral wall elements extending radially inward from the tire body element for sealing engagement with the wheel. The tire body element includes multiple concentric layers with alternating spokes. A bonded multilayer cover may be employed which is received within a recess in an outer surface of the tire body element from the tire tread. An attachment plate is engaged to the cover and attached to the wheel.

Owner:THE BOEING CO

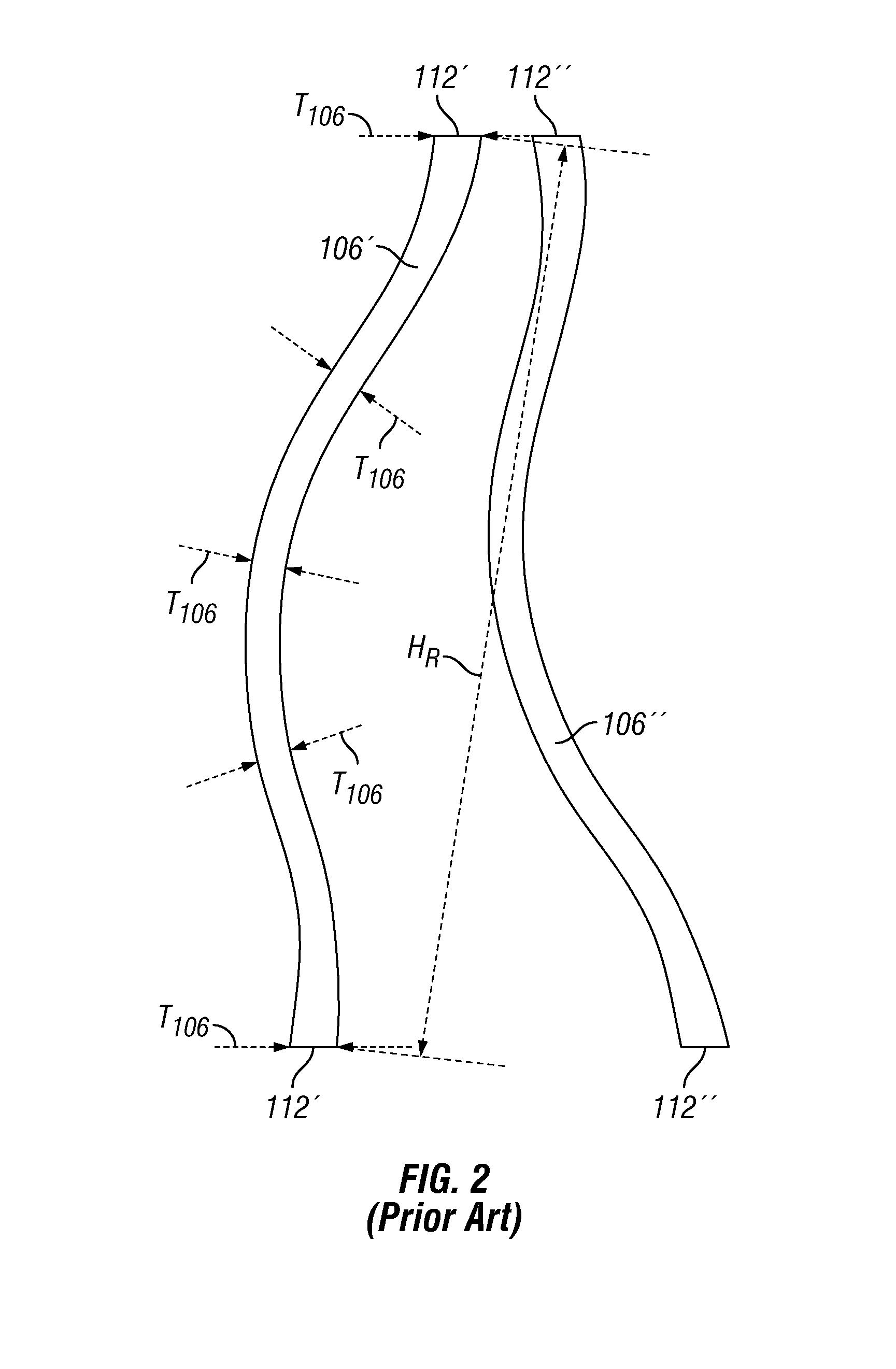

Spoke for a tire with optimized thickness for improved durability

ActiveUS20150174953A1Non-inflatable tyresNon-metallic wheel bodyStrain energyVolumetric Mass Density

The present invention provides spoke geometry for a non-pneumatic tire that is less prone to fatigue when used. In particular, the spoke geometry is provided with an optimized thickness profile over the length of the spoke. This optimization results in a reduction in the peak strain energy density levels in the spoke, thereby reducing the likelihood of crack initiation and propagation which in turn enhances the durability of the spoke and tire.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

Shear band with interlaced reinforcements

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

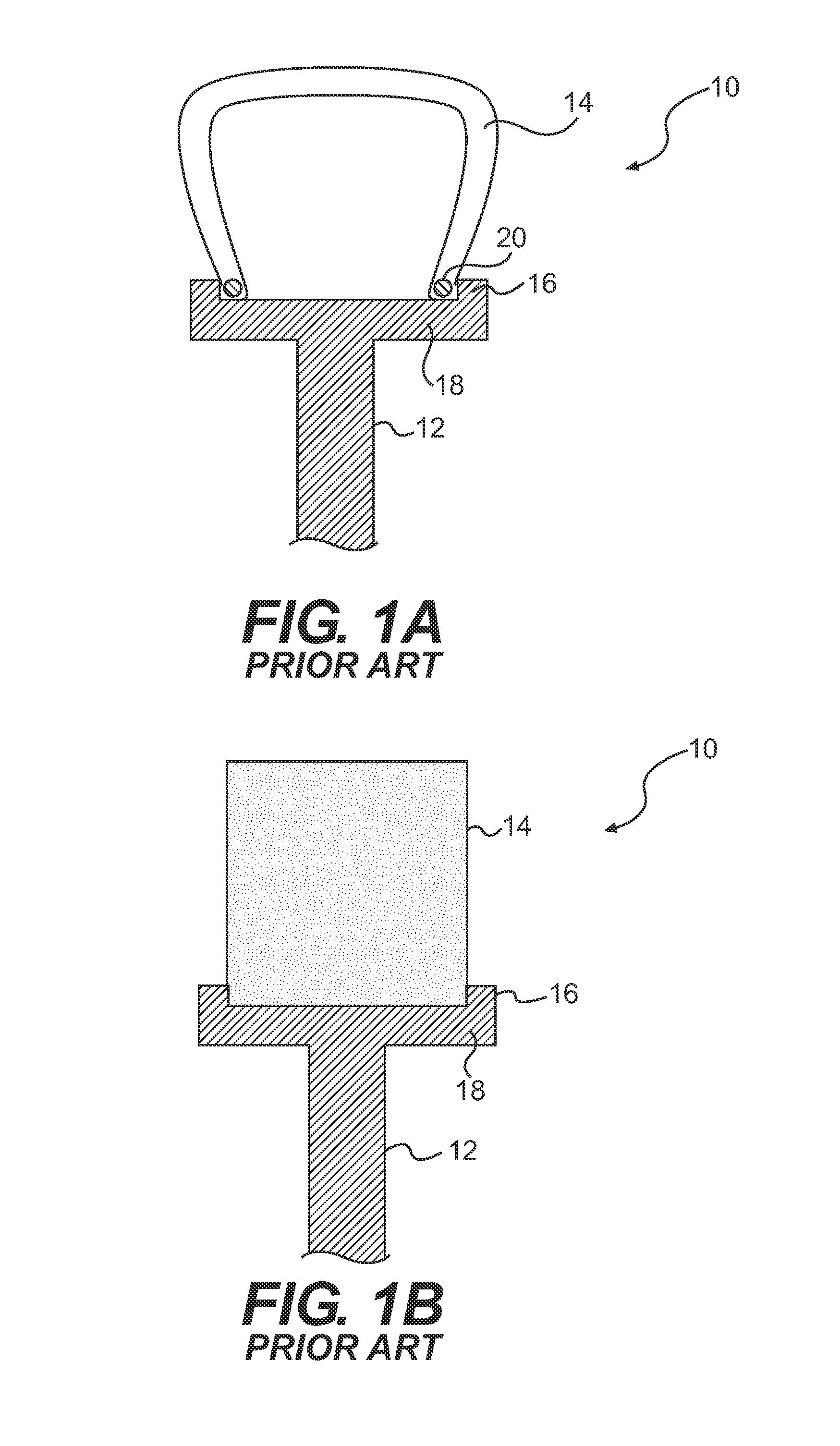

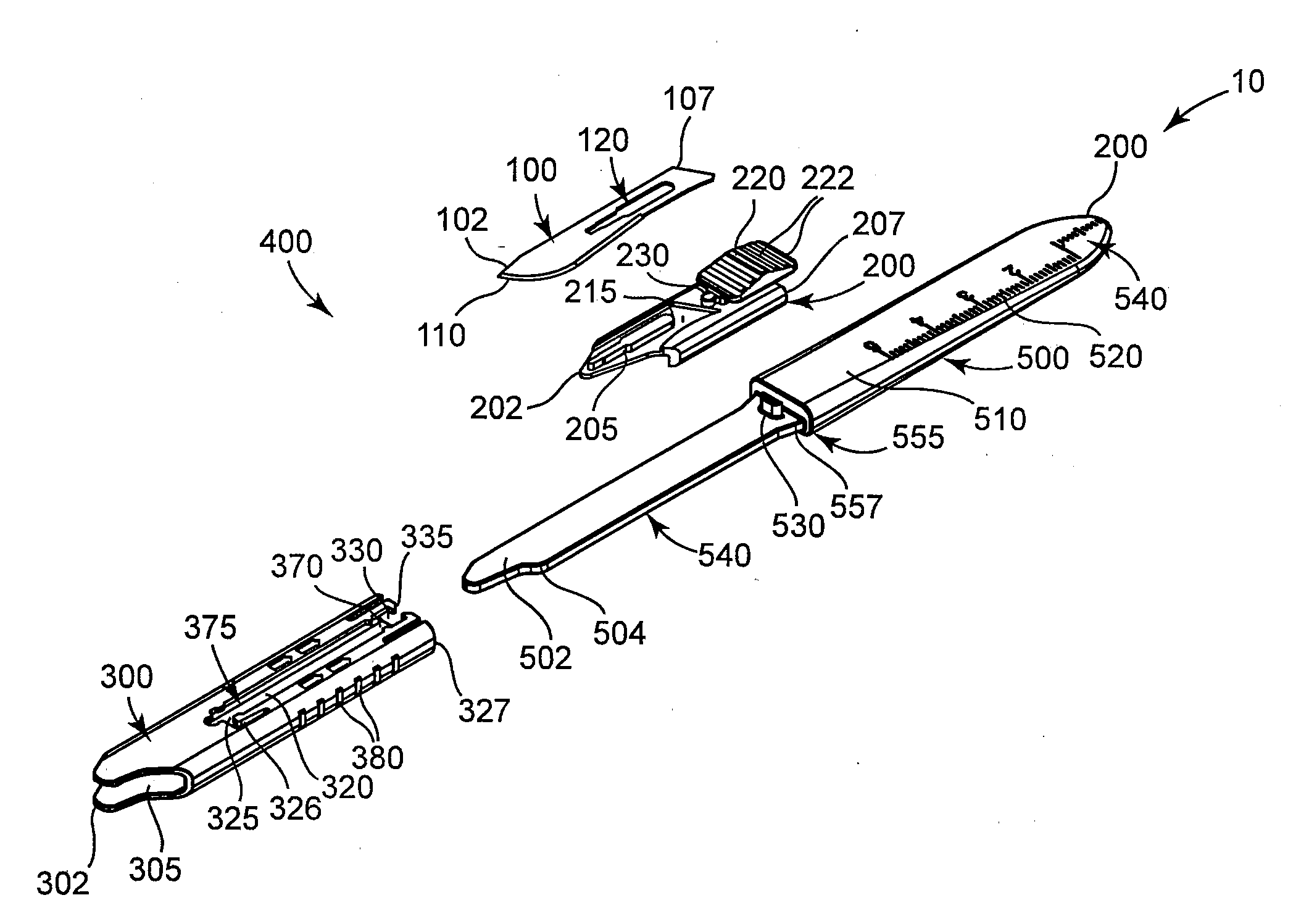

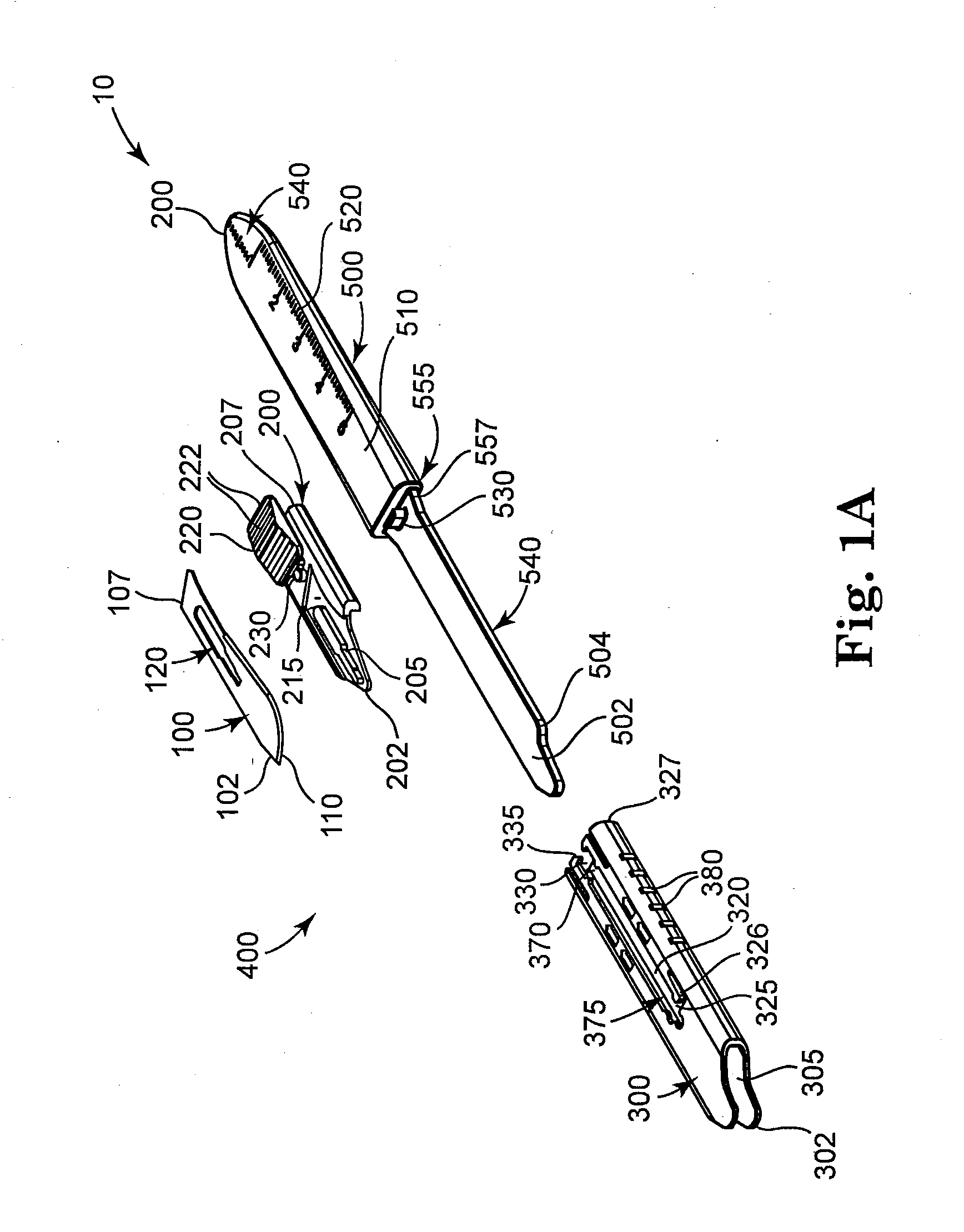

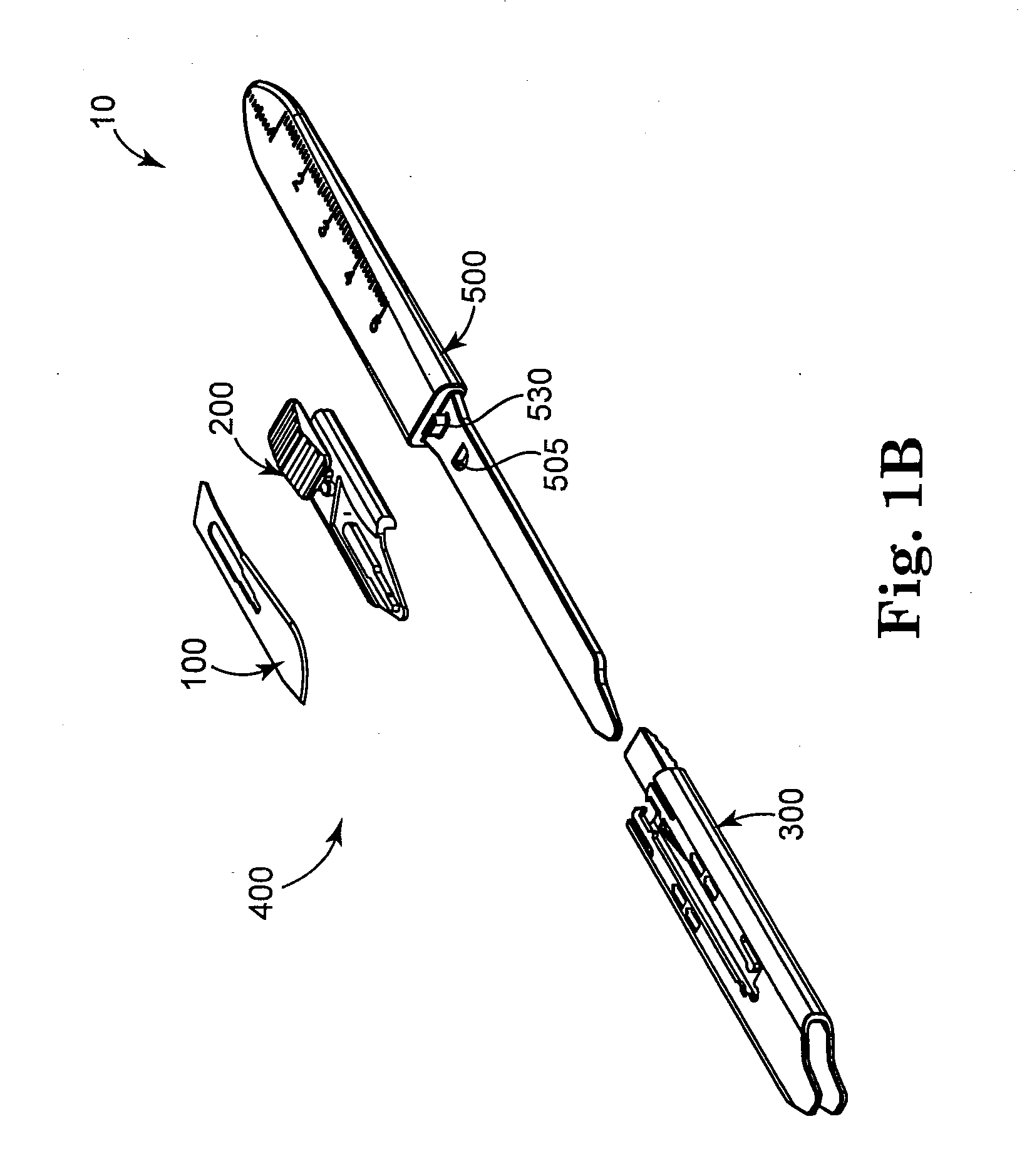

Safety scalpel

A safety scalpel that incorporates a reusable metal scalpel handle similar in shape and feel to the conventional metal handle preferred by most surgeons, and a disposable blade cartridge that covers the blade before, during and after use, and is easily mounted and released from the scalpel handle. The blade cartridge includes a blade with similar cutting profiles as standard surgical blades, a blade holder that is permanently fixed to the blade, and a blade guard that covers the blade and within which the blade holder is able to slide. The scalpel handle is reusable, while the blade cartridge is disposable. The blade cartridge is attachable and detachable from the scalpel handle.

Owner:MEDIPURPOSE PTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com