Patents

Literature

579 results about "Crack initiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical scoring and separation of strengthened glass

ActiveUS20110226832A1Secure clean sheet separationEasy to adaptFine working devicesGlass severing apparatusLine tubingEngineering

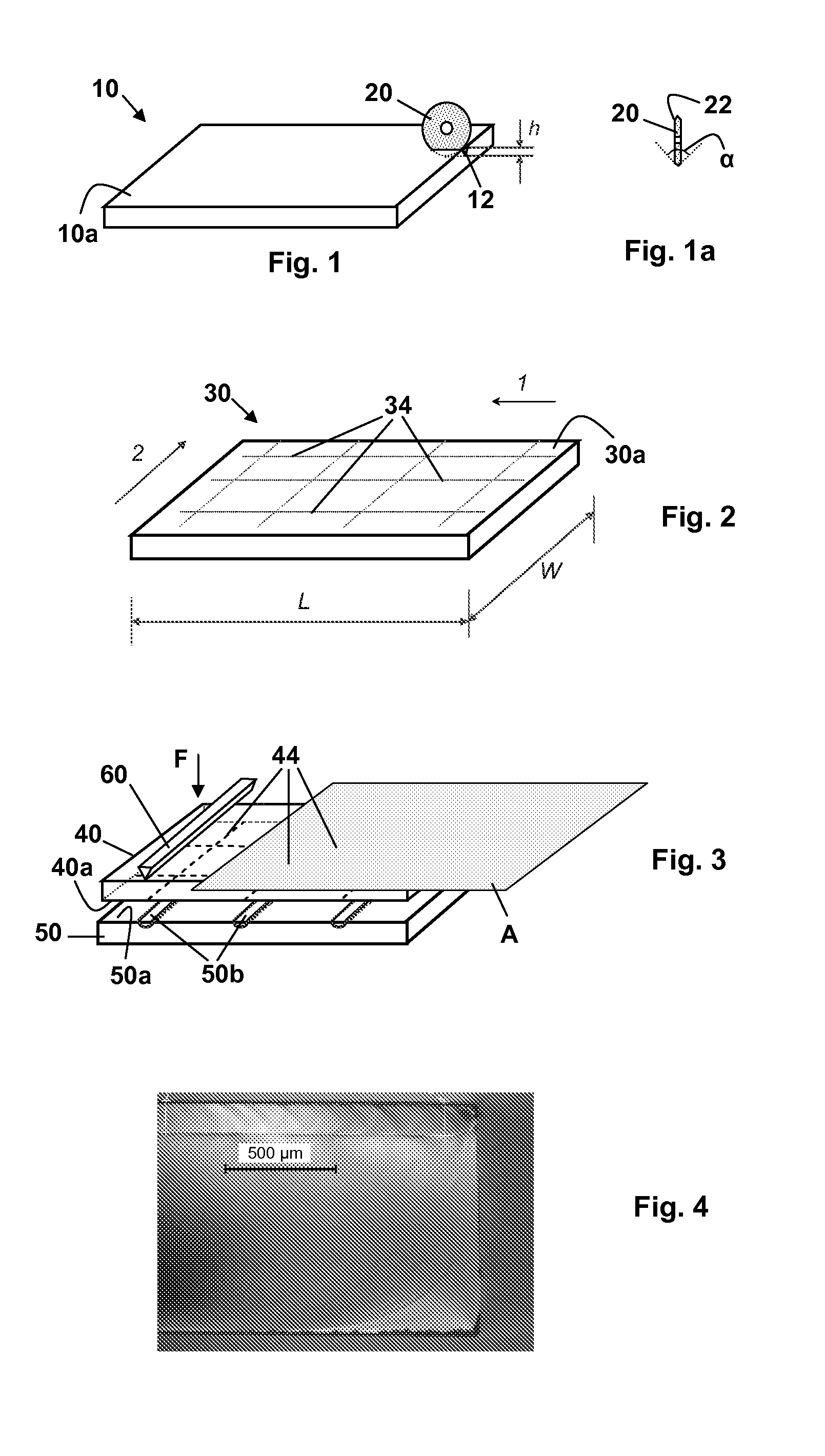

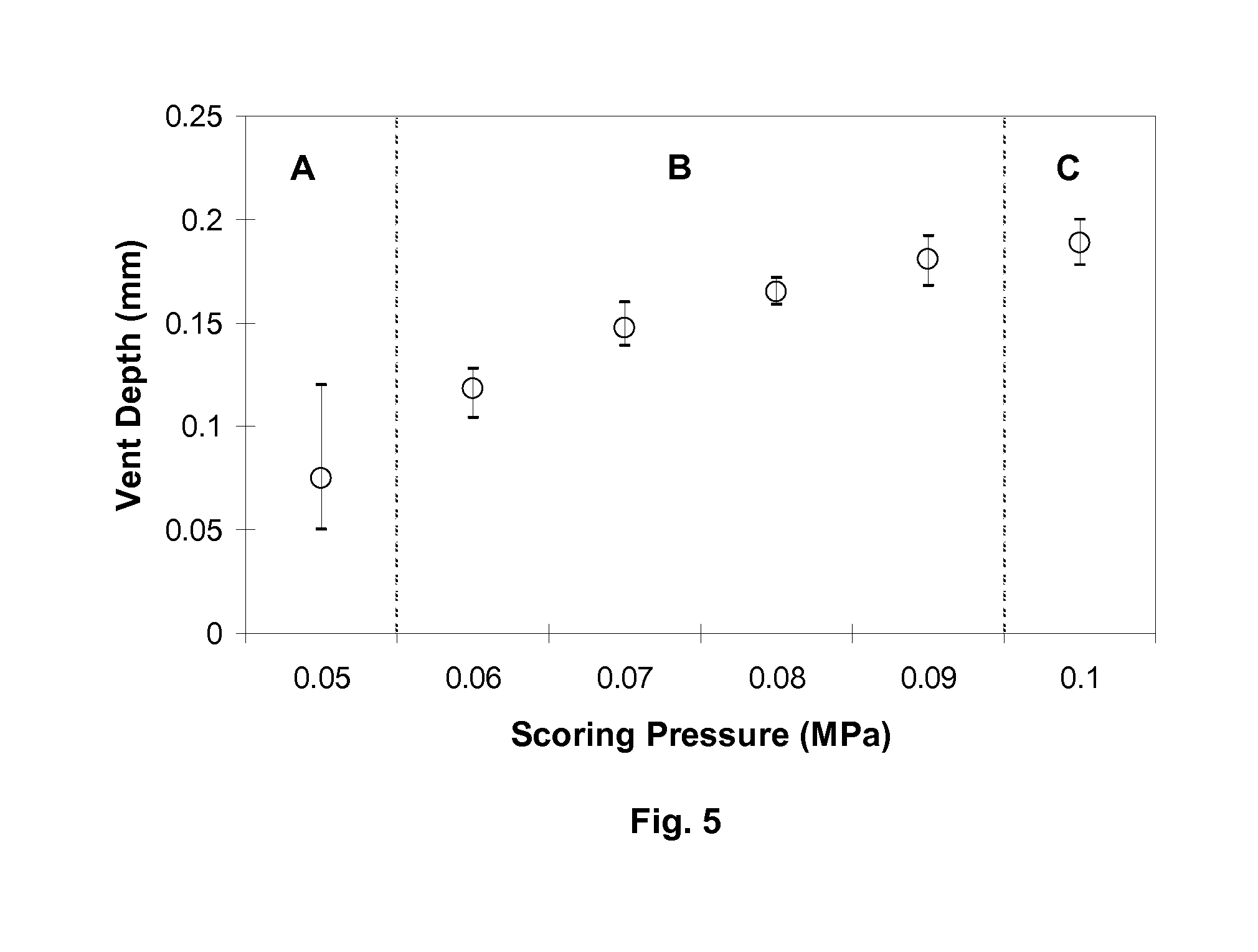

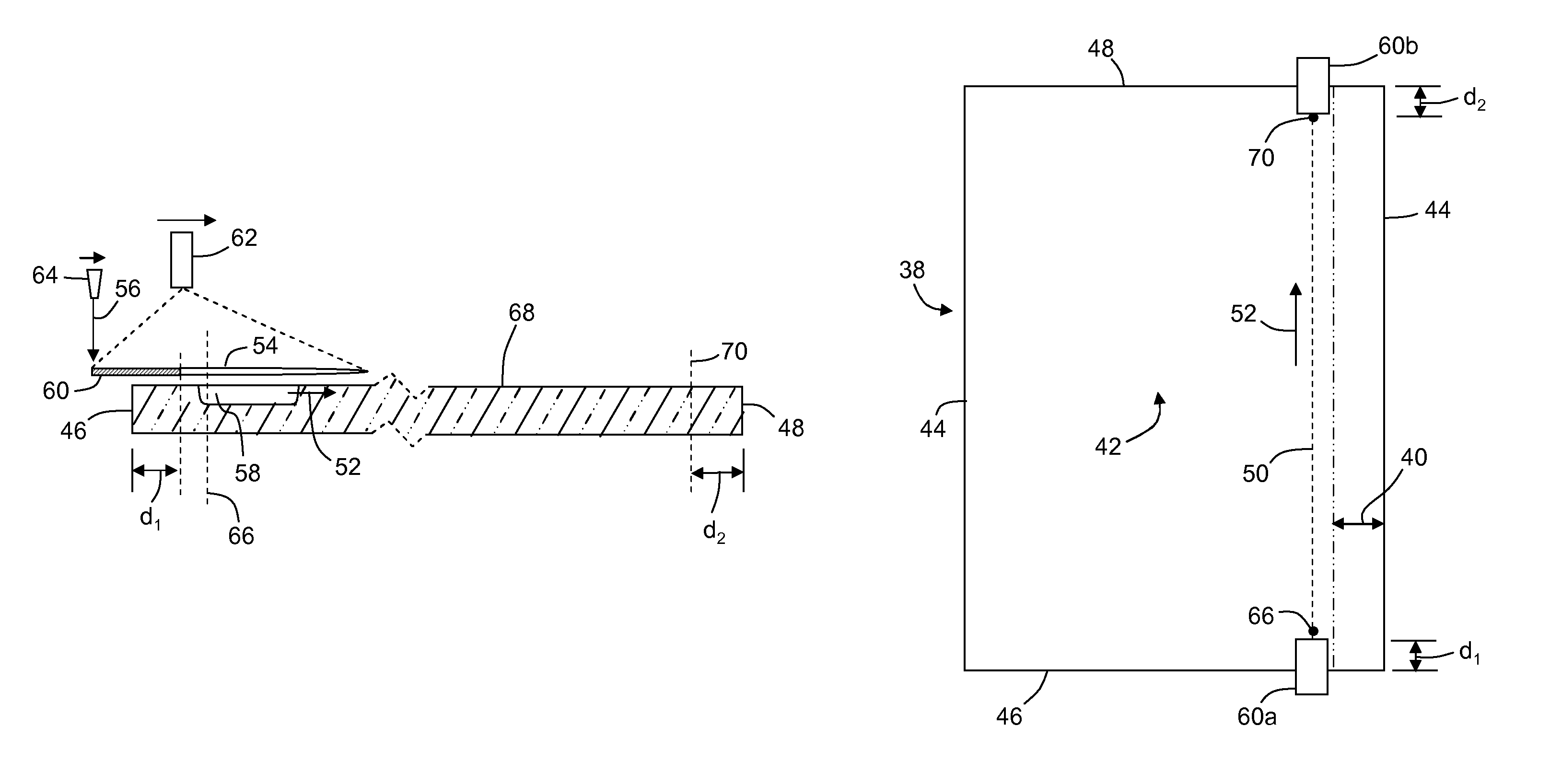

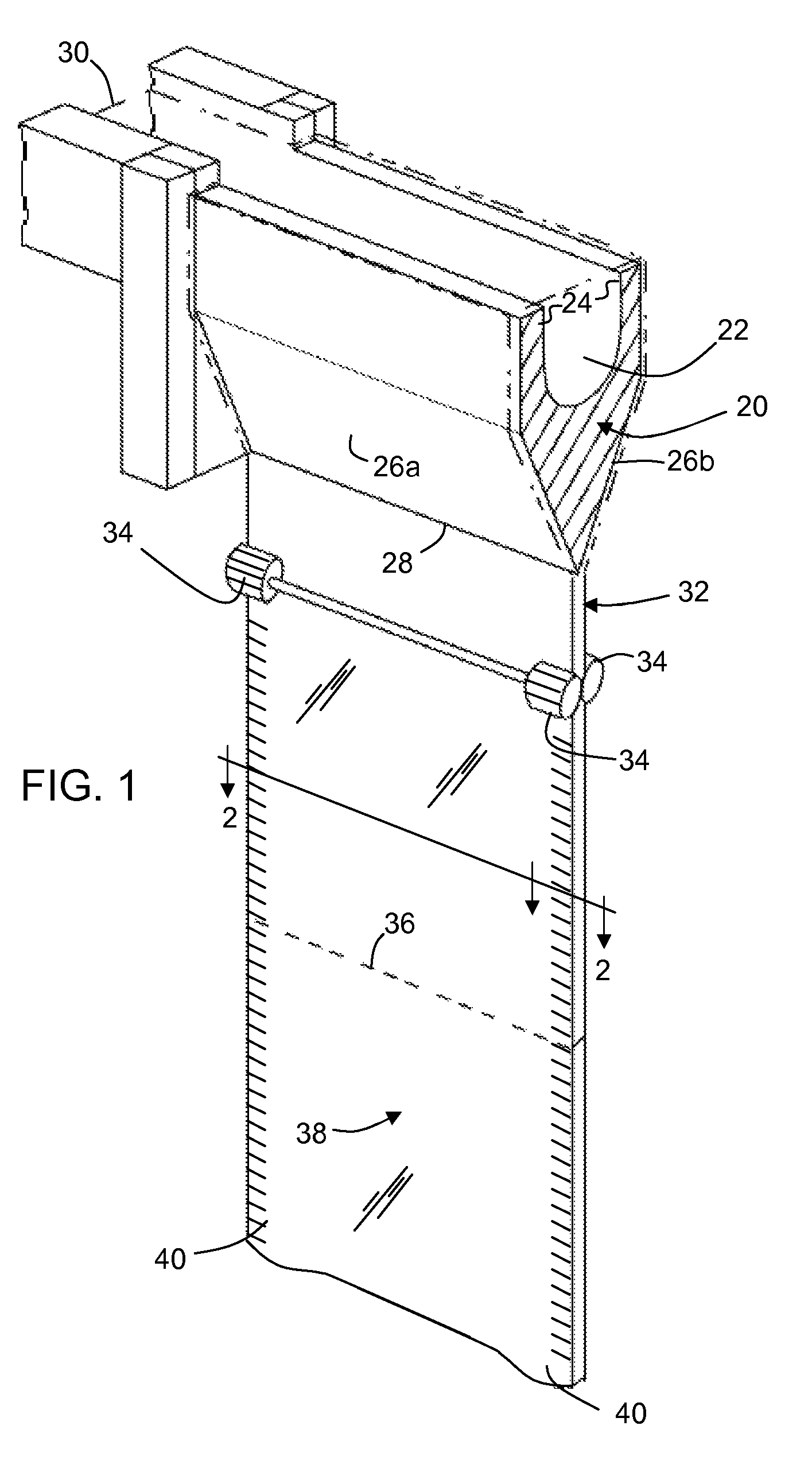

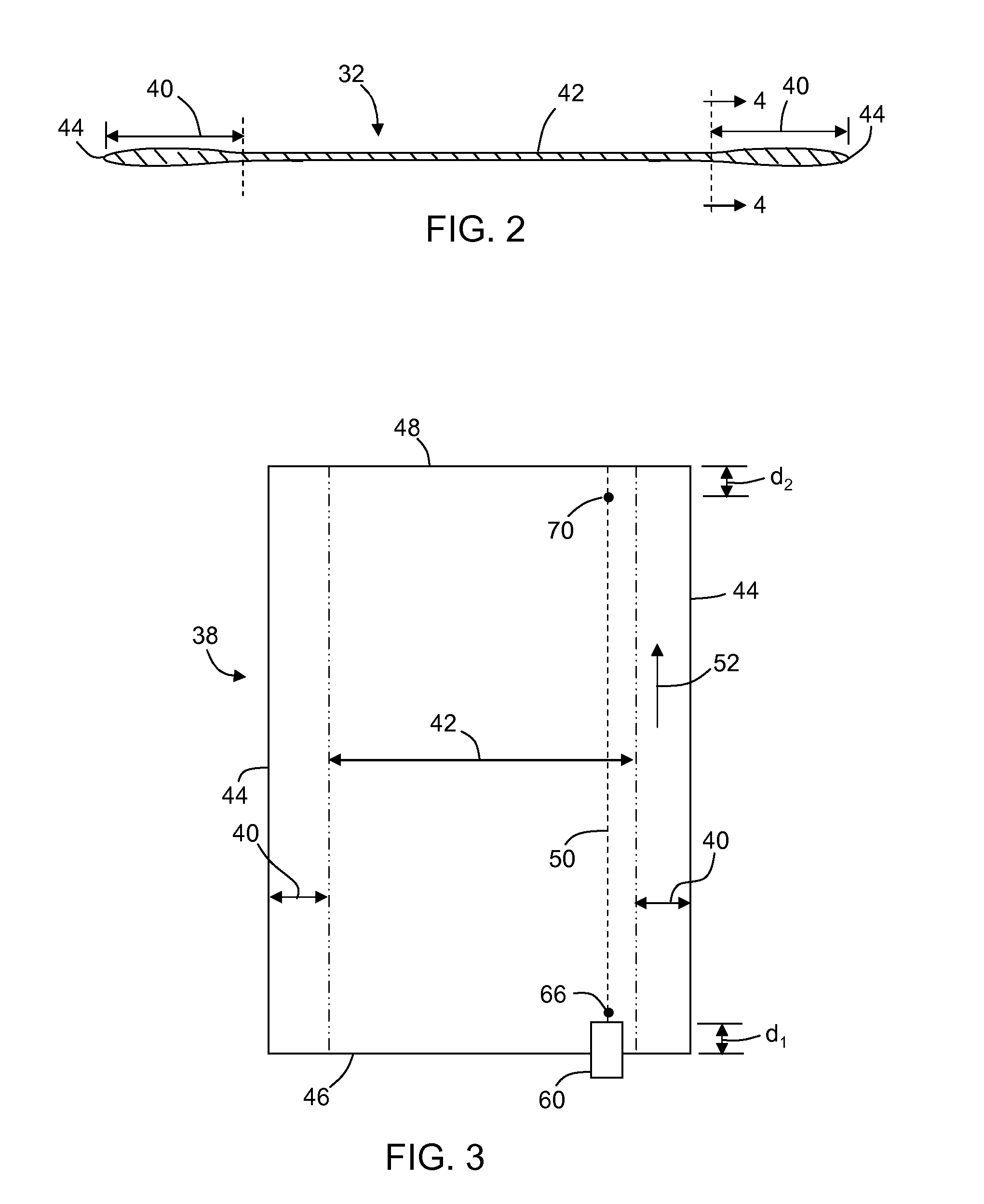

A strengthened glass sheet is separated into undamaged sheet segments by mechanically scribing one or more vent lines of controlled depth into the sheet surface, the depths of the scribed lines being insufficient to effect sheet separation, and then applying a uniform bending moment across the vent lines to effect separation into multiple sheet segments, the vent lines being scribed from crack initiation sites comprising surface indentations formed proximate to the edges of the glass sheet.

Owner:CORNING INC

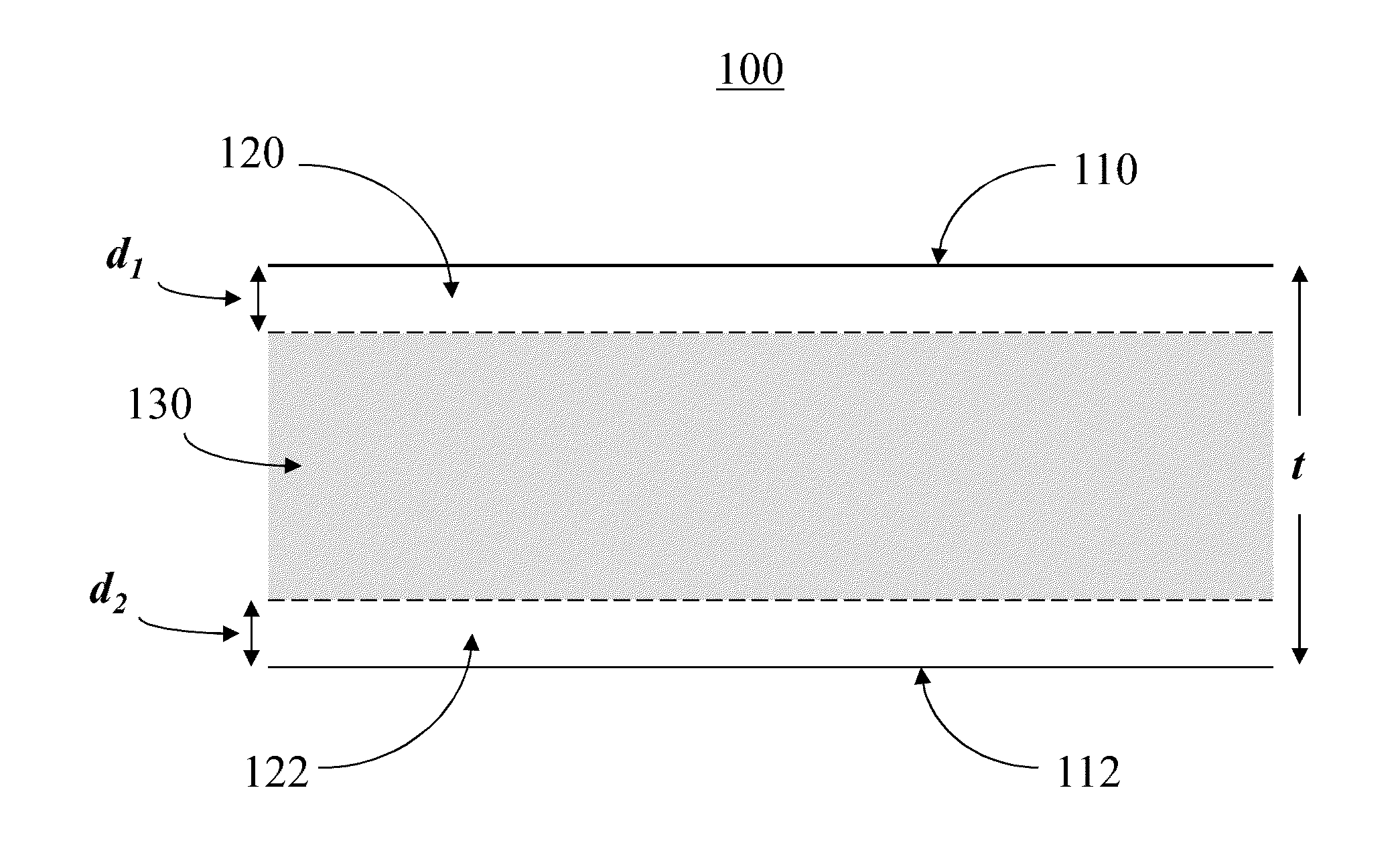

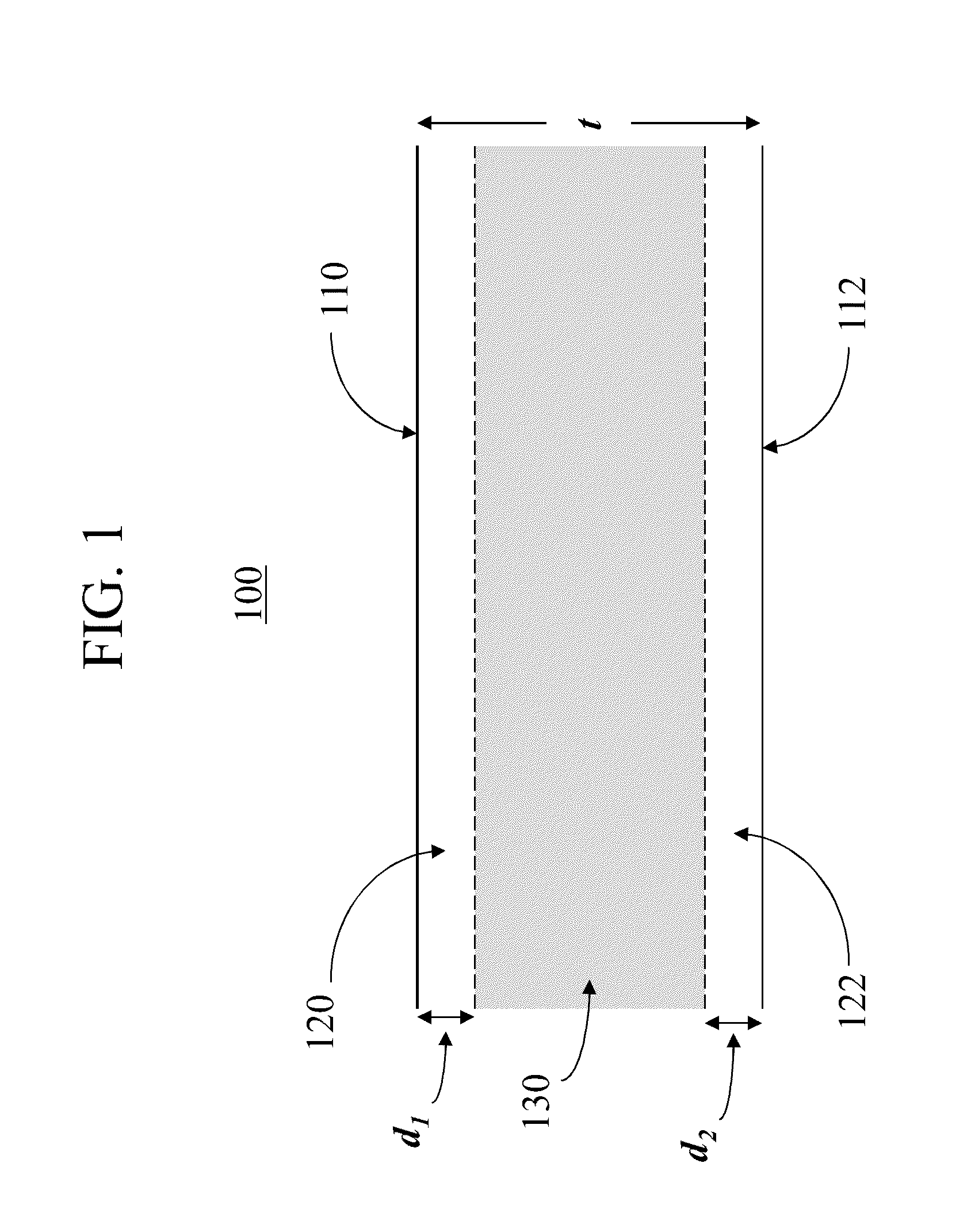

Durable glass housings/enclosures for electronic devices

The invention relates to glass articles suitable for use as electronic device housing / enclosure or protective cover which comprise a glass material. Particularly, a housing / enclosure / cover comprising an ion-exchanged glass exhibits the following attributes: (1) radio, and microwave frequency transparency, as defined by a loss tangent of less than 0.03 and at a frequency range of between 15 MHz to 3.0 GHz; (2) infrared transparency; (3) a fracture toughness of greater than 0.6 MPa*m<1 / 2>; (4) a 4-point bend strength of greater than 350 MPa; (5) a Vickers hardness of at least 450 kgf / mm<2> and a Vickers median / radial crack initiation threshold of at least 5 kgf; (6) a Young's Modulus ranging between about 50 to 100 GPa; (7) a thermal conductivity of less than 2.0 W / m DEG C; and (9) at least one of the following attributes: (i) a compressive surface layer having a depth of layer (DOL) greater and a compressive stress greater than 400 MPa, or, (ii) a central tension of more than 20 MPa.

Owner:CORNING INC

Zircon compatible, ion exchangeable glass with high damage resistance

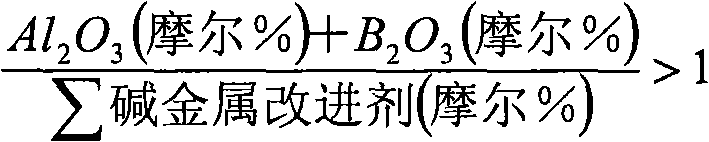

An ion exchangeable glass having a high degree of resistance to damage caused by abrasion, scratching, indentation, and the like. The glass comprises alumina, B2O3, and alkali metal oxides, and contains boron cations having three-fold coordination. The glass, when ion exchanged, has a Vickers crack initiation threshold of at least 10 kilogram force (kgf).

Owner:CORNING INC

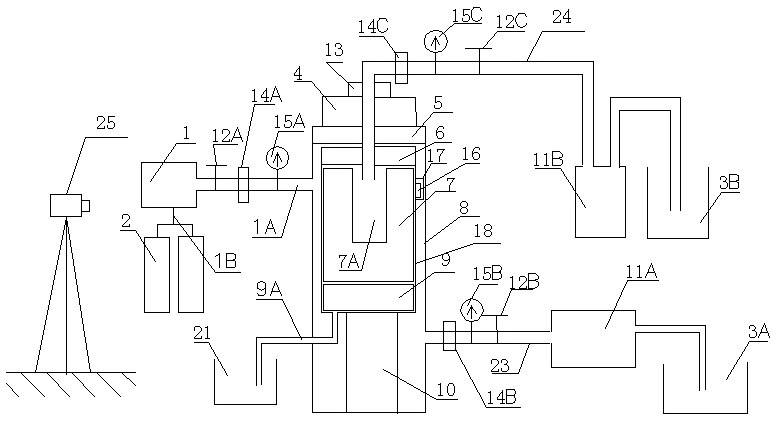

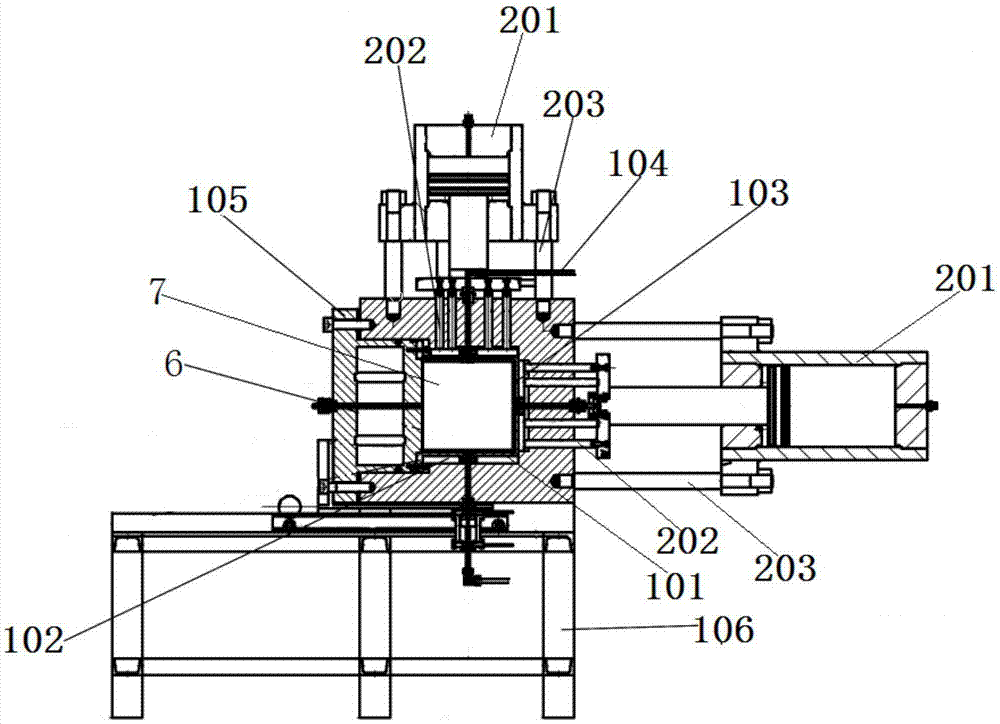

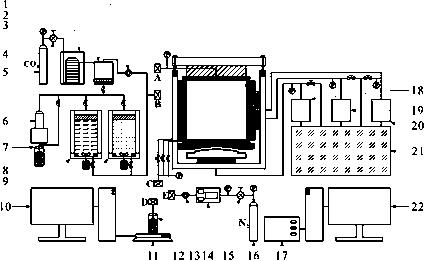

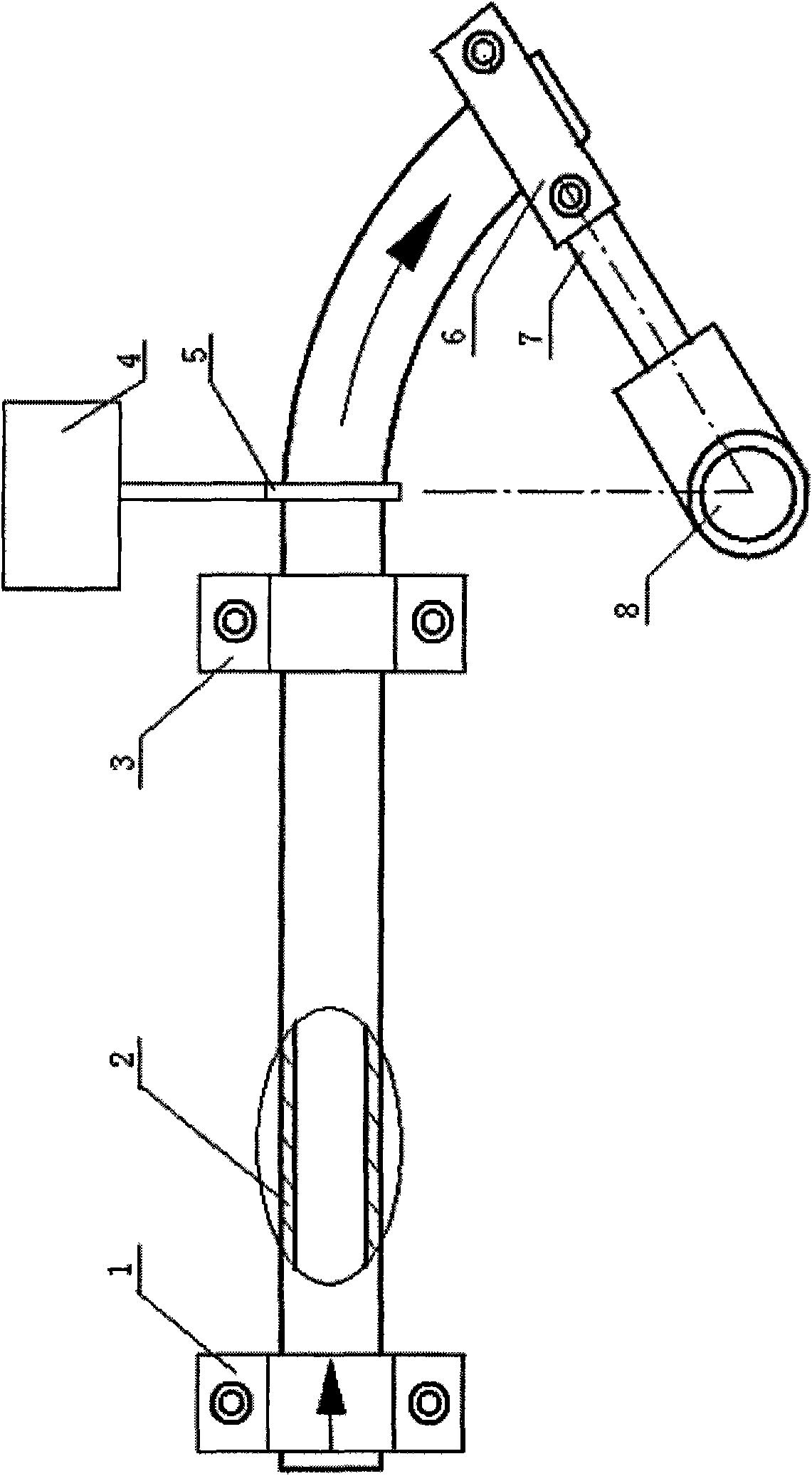

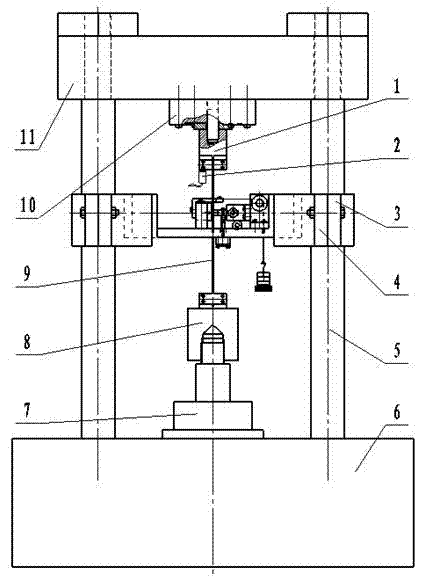

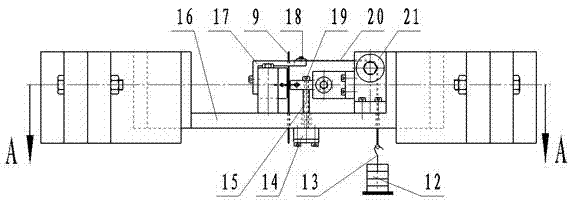

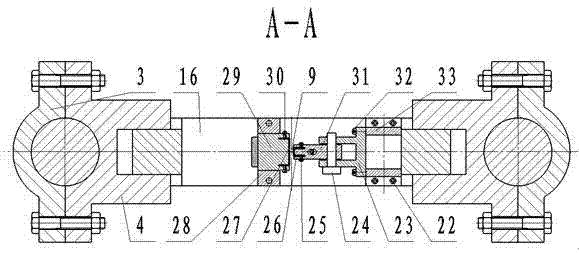

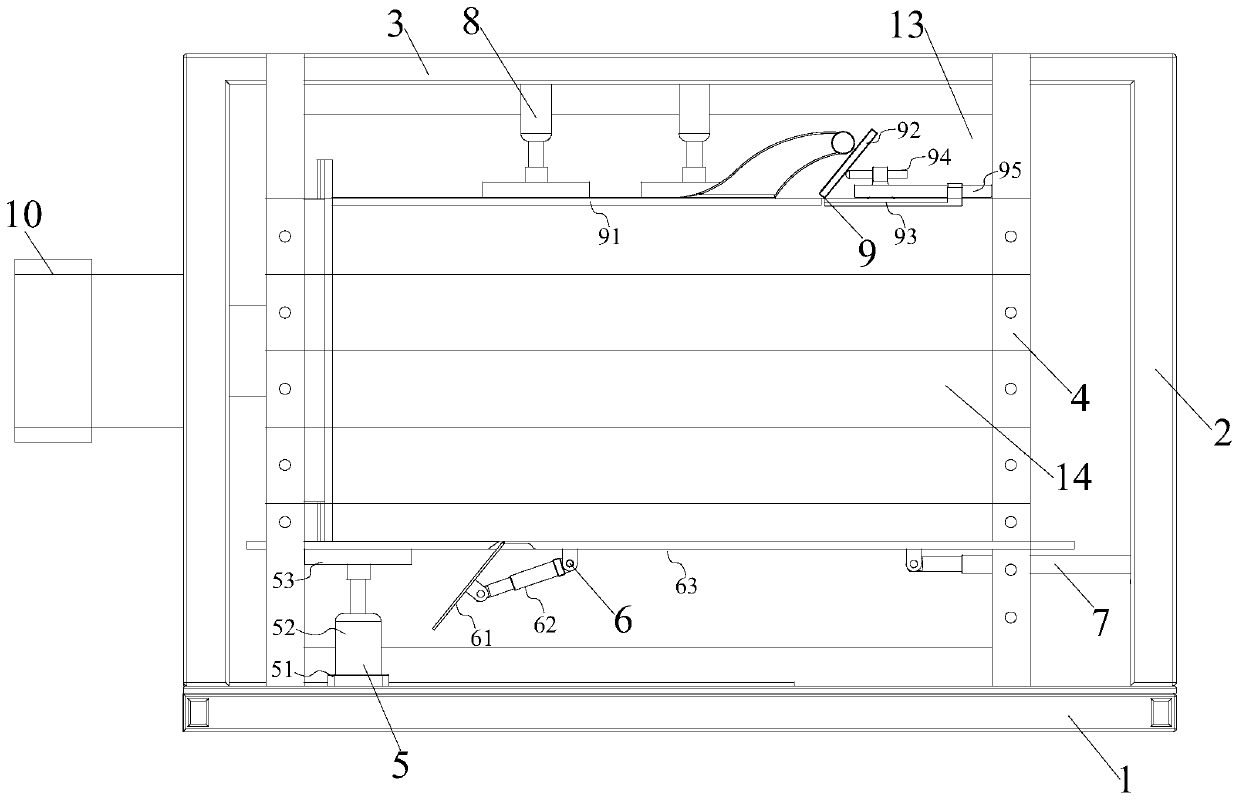

Type of testing equipment for detecting the failure process of thermal barrier coating in a simulted working environment

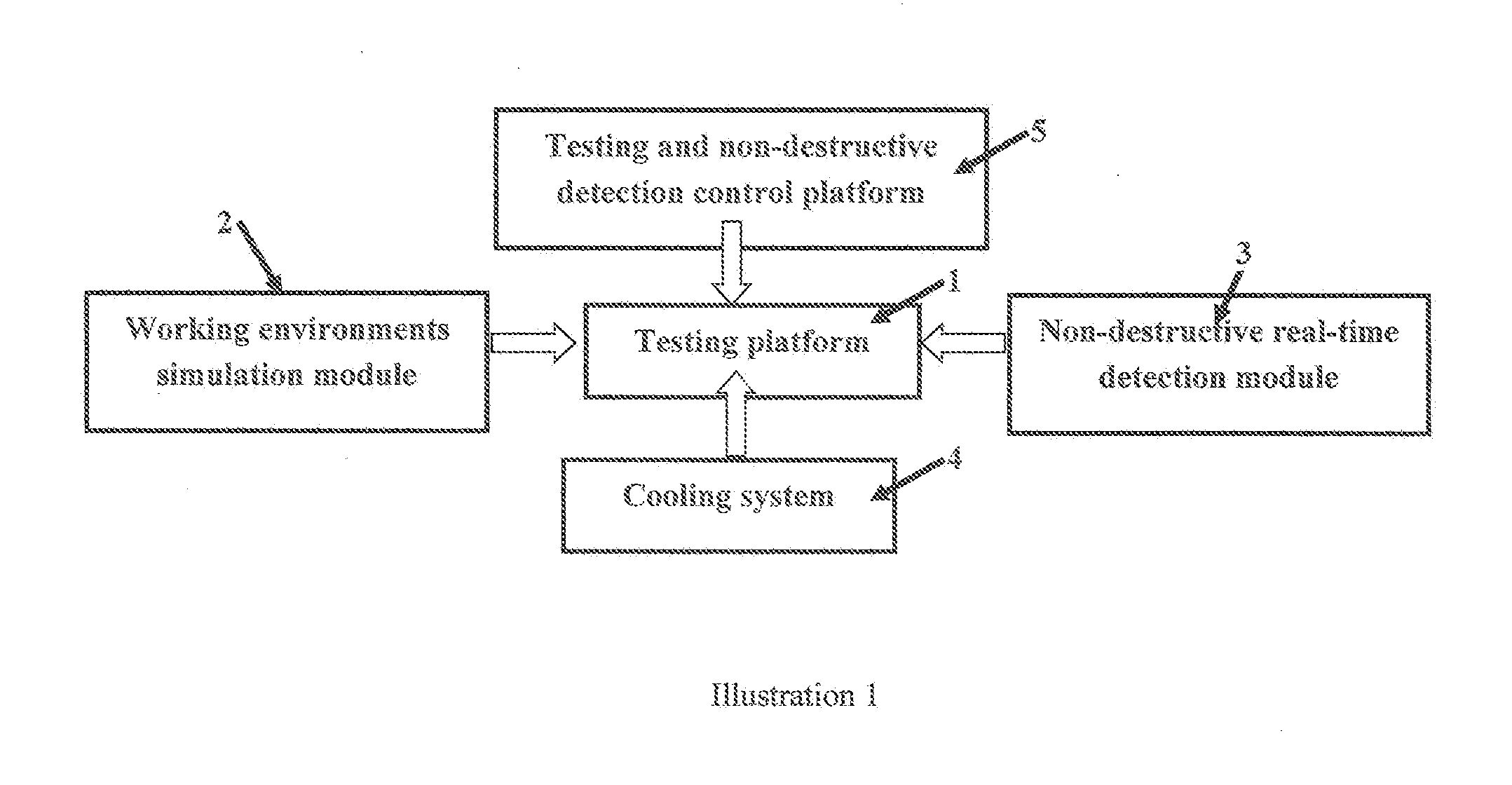

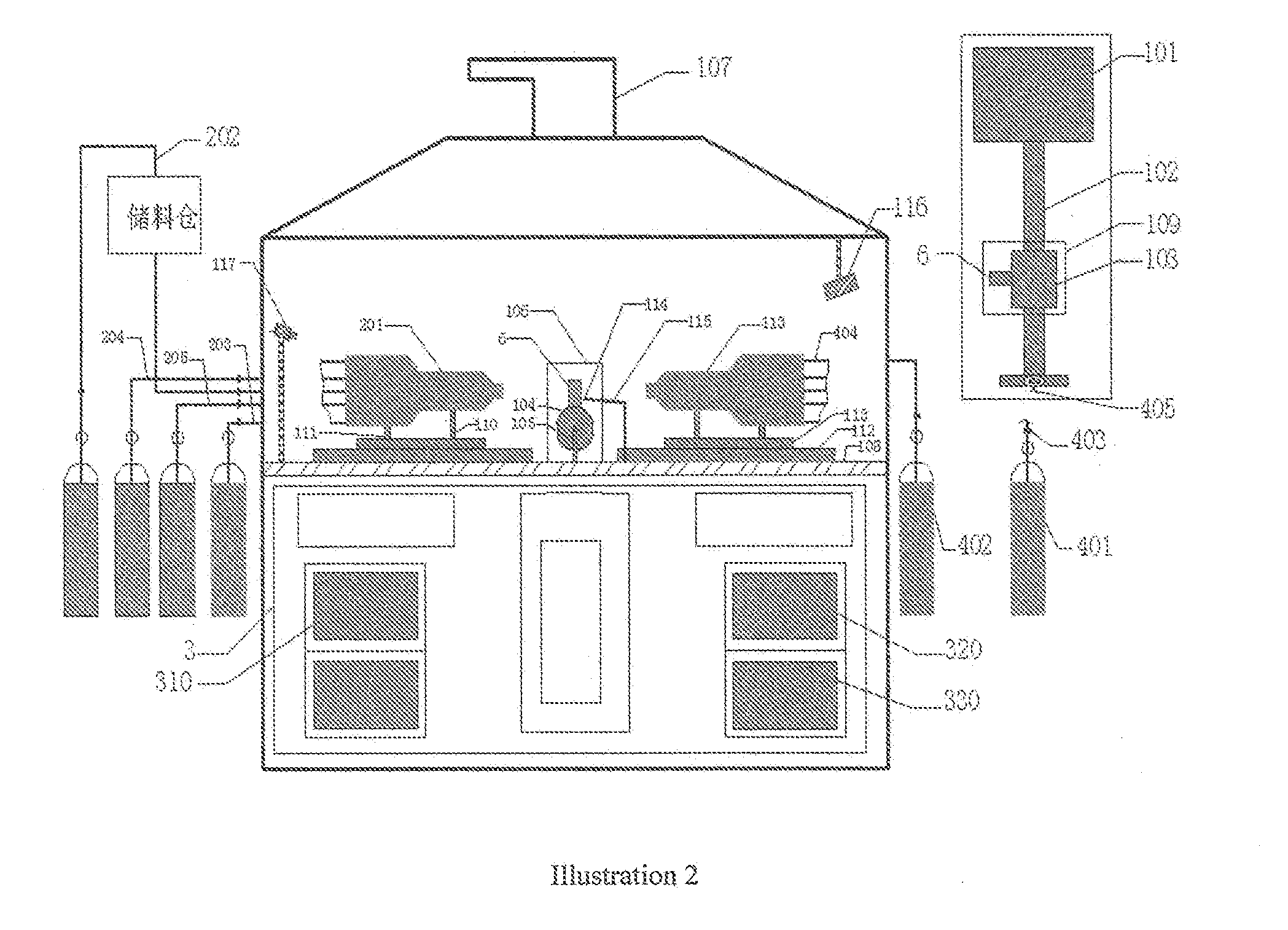

ActiveUS20150355074A1Better understandingReliable assessmentWeather/light/corrosion resistanceEngine testingSurface oxidationTurbine blade

A type of testing equipment for detecting the failure process of thermal barrier coating in a simulated working environment; it belongs to the field of simulated special working environment equipment. Testing equipment includes testing platform equipped with static or dynamic specimen holding apparatus, simulated module of working environment, real-time detection module, control panel. This invention is capable of simulating a high temperature, erosive, corrosive working environment for thermal barrier coated turbine blade of aero-engines; simulate high speed spinning working environment for thermal coated blade, simulate static working environment for guiding blade; perform real-time testing of temperature field, 3-D displacement field, crack initiation and expansion, surface oxidation, etc. This invention has achieved complete integration of high temperature, erosive, corrosive working environment for thermal barrier coating and complete integration static or dynamic working environment, complete integration of simulated working environment and real-time testing, thus providing a crucial testing platform and reference data to properly understand the failure mechanism of thermal barrier coated blade and to improve relevant designs; strong applicability.

Owner:XIANGTAN UNIV

Method for scoring a sheet of brittle material

InactiveUS8245540B2Increase pressureImprove scoreGlass reforming apparatusGlass severing apparatusCutting glassMaterials science

A method of cutting glass that prevents uncontrolled crack propagation when high background stress is present, either in the form of thermal residual stress, external mechanical stress or a combination thereof. The method includes masking an edge of the glass by blocking the beam using highly reflective or absorptive material located near the glass surface, or deposited on the surface in a form of a thin film (or highly reflective paint) to prevent uncontrolled crack initiation and propagation starting from the glass edge. The initiation of the laser scoring is located at a predetermined distance from the glass edge. Yet another aspect of the invention embodies stopping propagation of the vent at the exiting end of the score line.

Owner:CORNING INC

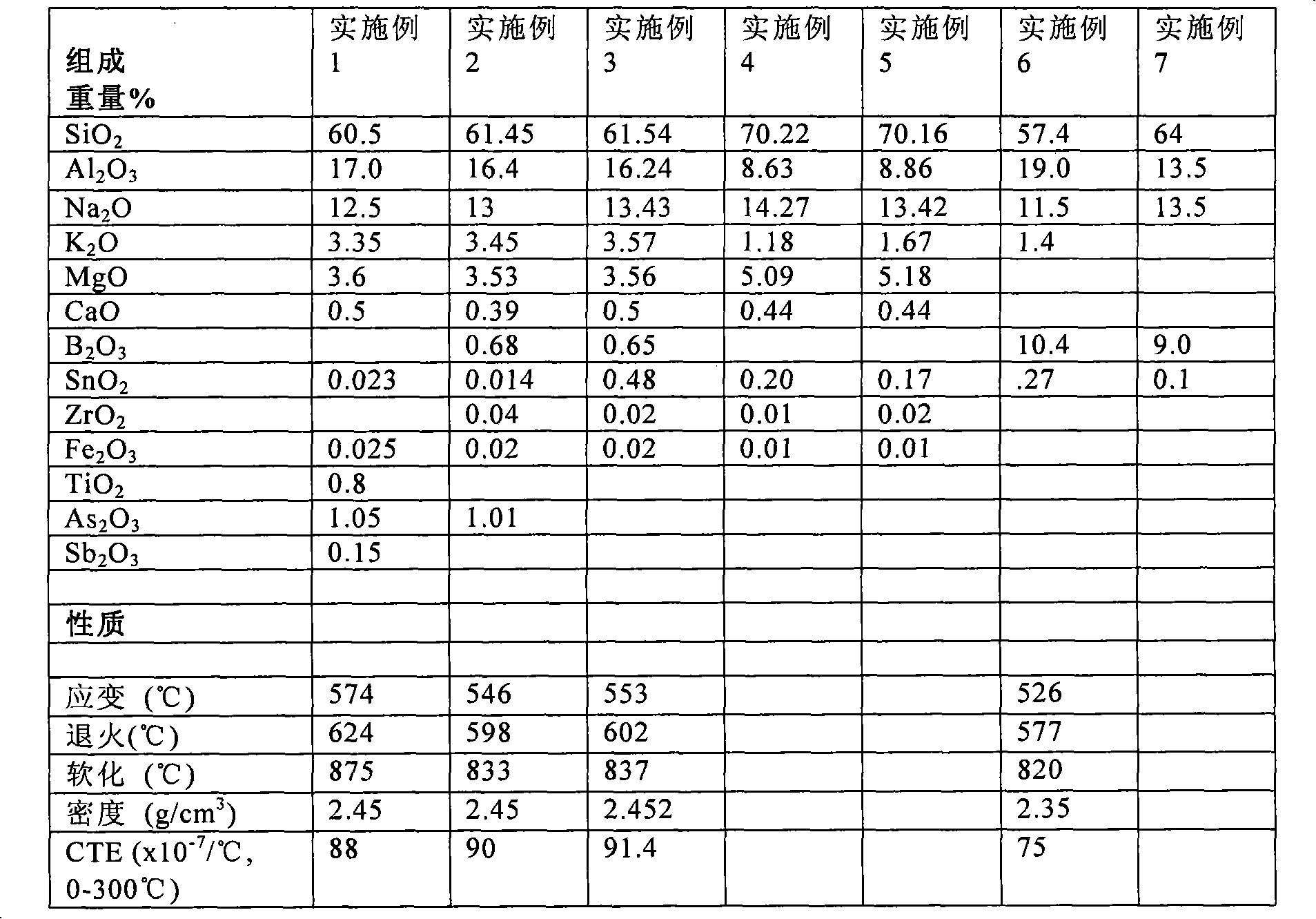

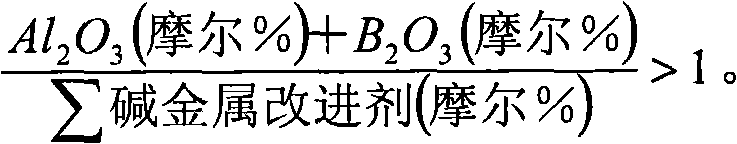

Damage resistant glass with high coefficient of thermal expansion

ActiveUS20150064472A1Fast ion exchangeGlass/slag layered productsThin material handlingIon exchangeThermal expansion

Ion exchangeable glasses having coefficients of thermal expansion (CTE) at least about 90×10−7 ° C.−1. The glasses undergo rapid ion exchange, for example, in a molten KNO3 salt bath to a depth of layer of greater than 30 microns in less than 2 hours at temperatures of 370° C. to 390° C. When ion-exchanged to a depth of layer between 30 to 50 microns, the glasses exhibit a Vickers median / radial crack initiation threshold exceeding 30 kilograms force (kgf). The glasses are fusion formable and, in some embodiments, compatible with zircon.

Owner:CORNING INC

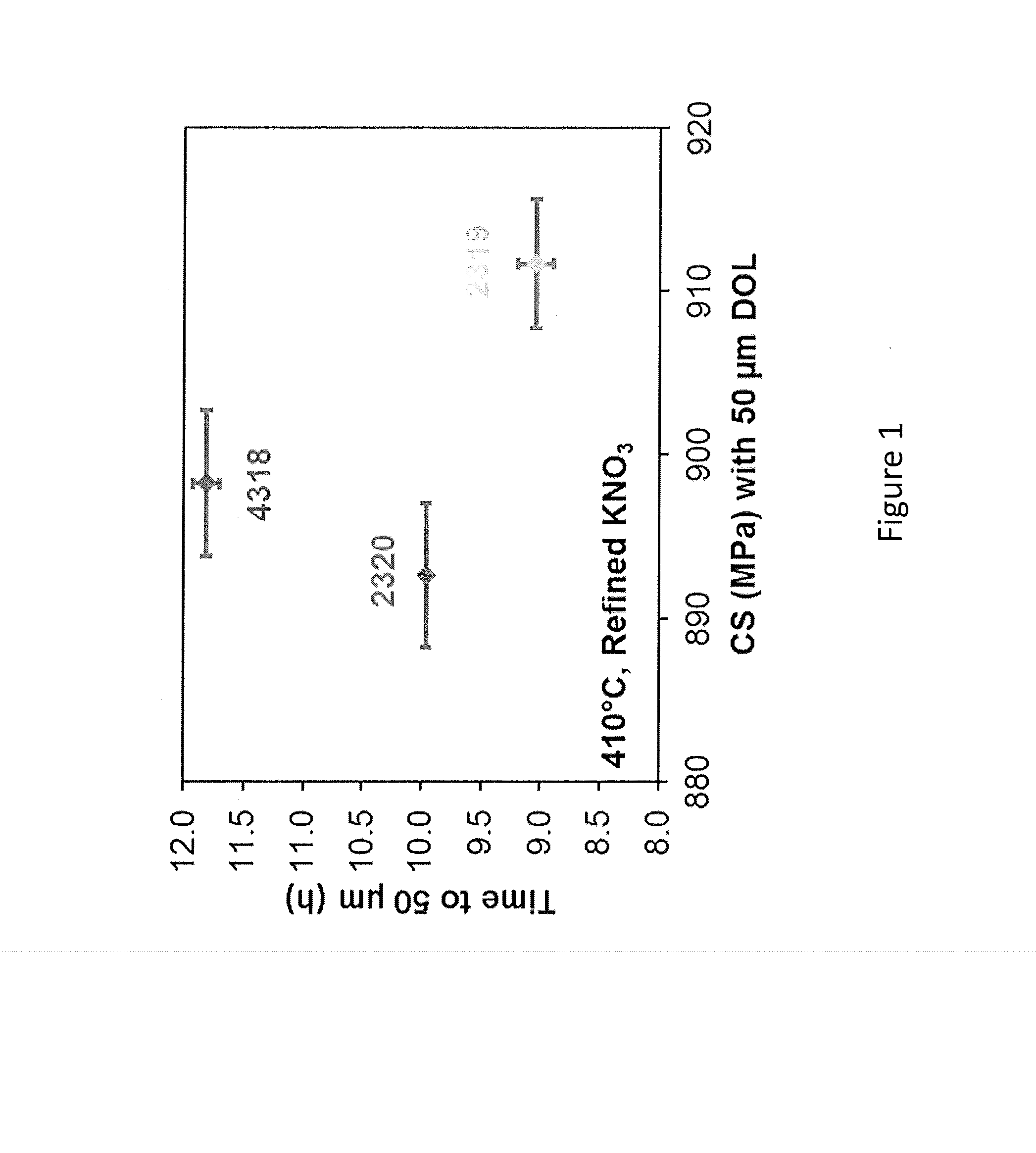

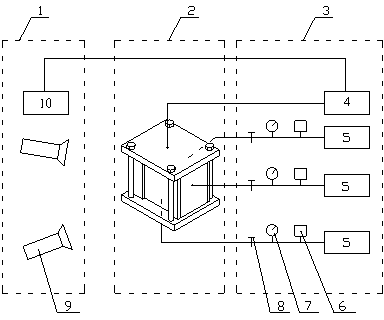

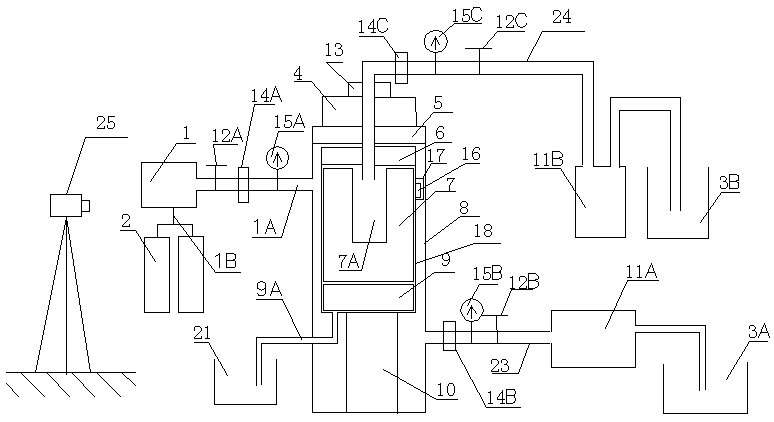

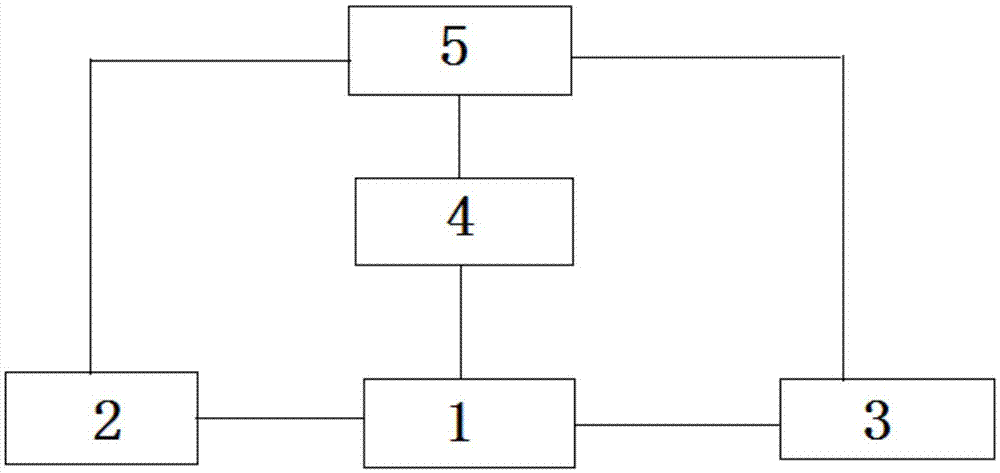

System and method for visualization fracturing simulation experiment

The invention relates to a system and method for a visualization fracturing simulation experiment. According to the technical scheme, the system comprises a visualization fracturing simulation experiment device, a pressure control module and a data acquisition module, wherein the visualization fracturing simulation experiment device is a square container, the pressure control module comprises a servo control injection pump, a confining pressure pump and the like, and the data acquisition module comprises a pressure data recorder and a high-definition high-frequency vidicon. Through combination of the visualization fracturing simulation experiment device and transparent specimens, crack initiation characteristics and expanding dynamic states of hydraulic fractures in interiors of the experiment specimens can be clearly known by researchers, and study of crack initiation mechanisms and expanding rules of the hydraulic fractures are deepened. According to the experiment method, crack initiation and expanding dynamic state videos of the fractures can be obtained, crack initiation and the expanding rules of the fractures can be clearly showed, storage of video data is simple, spreading is convenient, and the method can help the researchers to exchange experiment achievements across regions.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

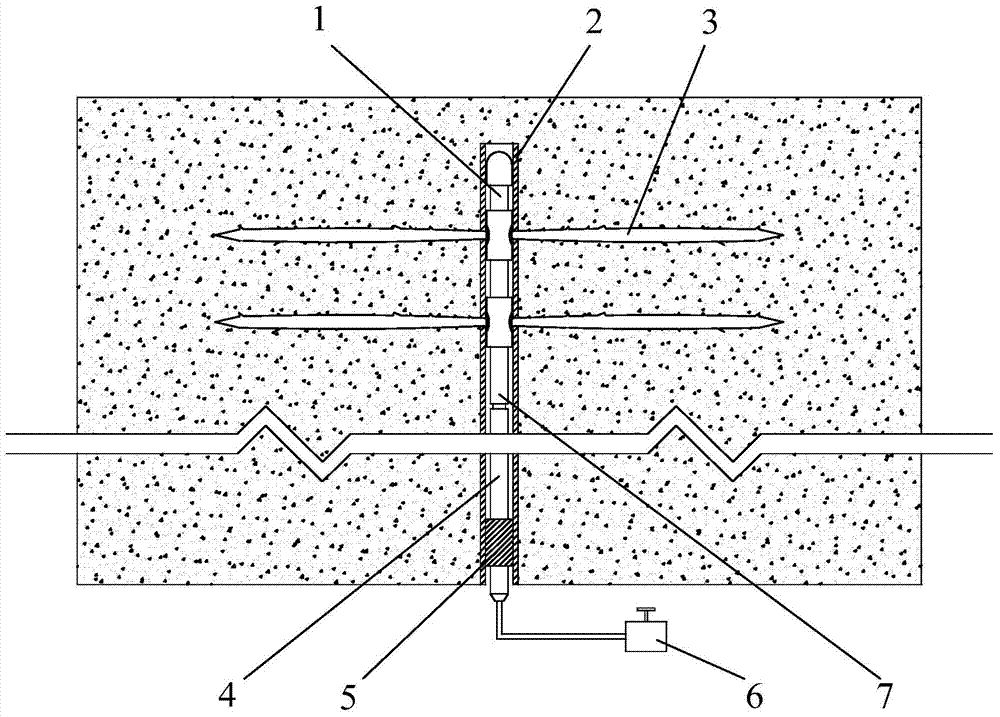

Coal and rock bore hydraulic fracture experimental apparatus

InactiveCN102031954AImprove fracturing effectEasy to take pictures and recordEarth material testingFluid removalPressure systemAcoustic emission

The invention discloses a coal and rock bore hydraulic fracture experimental apparatus, which comprises a sample device system, a confining pressure system, a fracture system, a sealing system and a monitoring system, wherein the sample device system comprises a sample cylinder, the bottom in the sample cylinder is provided with a screen drum of which the bottom is provided with a water outlet pipe, a sample is accommodated in the sample cylinder above the screen drum, and a simulated bore is formed in the sample; the confining pressure system comprises an air filling subsystem and a water filling subsystem; the fracture system comprises a fracture high-pressure water pump of which a water outlet is communicated with the simulated bore through a fracture pipeline; the sealing system comprises a sample cylinder sealing device and an experimental cylinder sealing device; and the monitoring system comprises an acoustic emission sensor arranged on an external wall of the sample cylinder. By the coal and rock bore hydraulic fracture experimental apparatus, a simulated experiment can be performed in a laboratory to investigate the change rules of crack initiation, expansion and extension in the hydraulic fracture process of a coal mine underground coal seam bore, and know a crack extending direction so as to guide field fracture; therefore, the fracture effect is greatly improved.

Owner:HENAN POLYTECHNIC UNIV

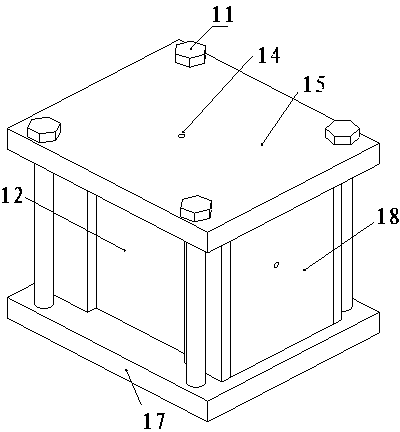

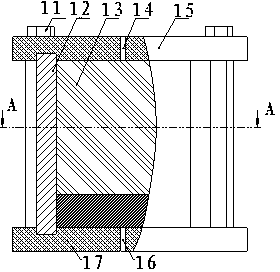

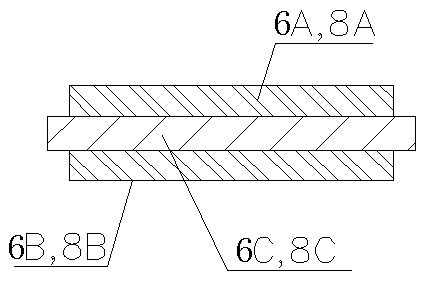

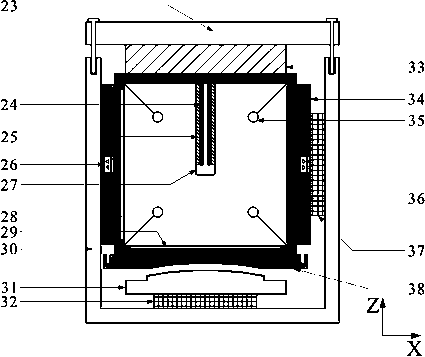

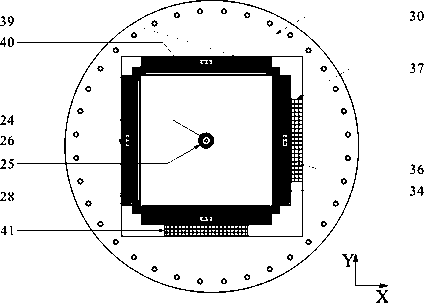

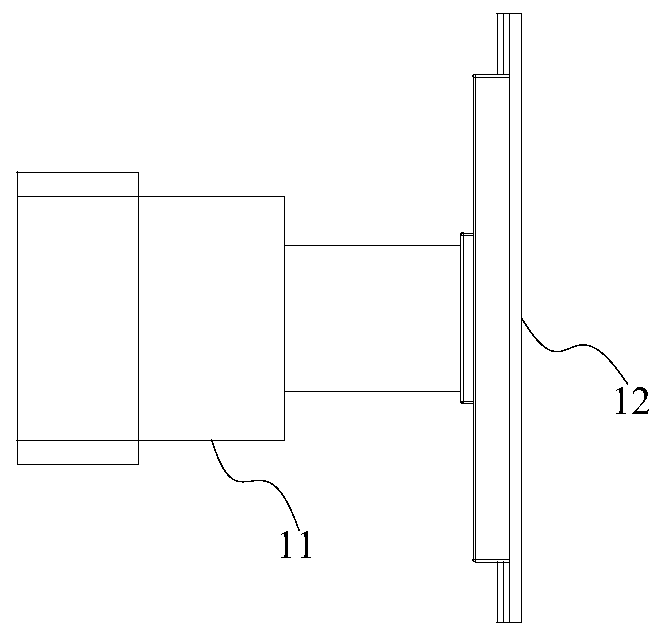

Device for simulating crack initiation and evaluating fissured flow under true triaxial stress

ActiveCN106896043ASimulation results are accurateThe test result is accurateMaterial strength using tensile/compressive forcesPermeability/surface area analysisSaline waterRock core

The invention discloses a device for simulating crack initiation and evaluating fissured flow under true triaxial stress and belongs to the field of fracture acidizing. The device disclosed by the invention comprises a rock core clamping system, a true triaxial stress loading system, an acid liquor and fracturing fluid injection system, a filtration capacity measuring system and a fracturing data acquisition and processing system, wherein the rock core clamping system is used for clamping a cubic rock core sample which has the side length of 100-300mm and a simulation wellbore is embedded inside the rock core sample; the true triaxial stress loading system is used for applying stresses on the rock core sample in an X axis direction, a Y axis direction and a Z axis direction, so as to simulate a true triaxial stress state of the rock core sample; the acid liquor and fracturing fluid injection system is used for injecting acid liquor and fracturing liquid into the simulation wellbore of the rock core sample, so that crack initiation is carried out on the rock core sample and a fracture extends to simulate the fracture acidizing process of the rock core sample; the filtration capacity measuring system is used for injecting saline water into the rock sample subjected to crack initiation, thus data representing filtration capacity of the fracture of the rock core sample are measured; and the fracturing data acquisition and processing system is used for acquiring data representing a simulated crack initiation process in the rock core sample and data representing the filtration capacity of the fracture in the rock core sample, processing the data and outputting a processing result.

Owner:PETROCHINA CO LTD

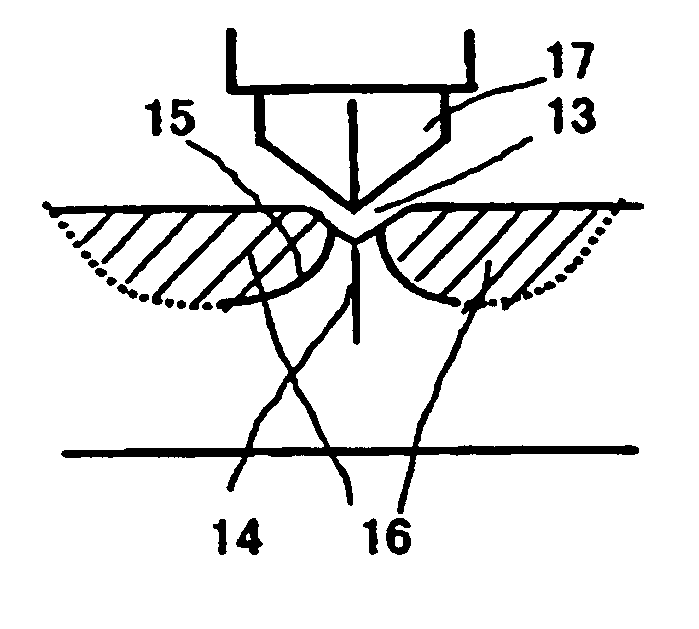

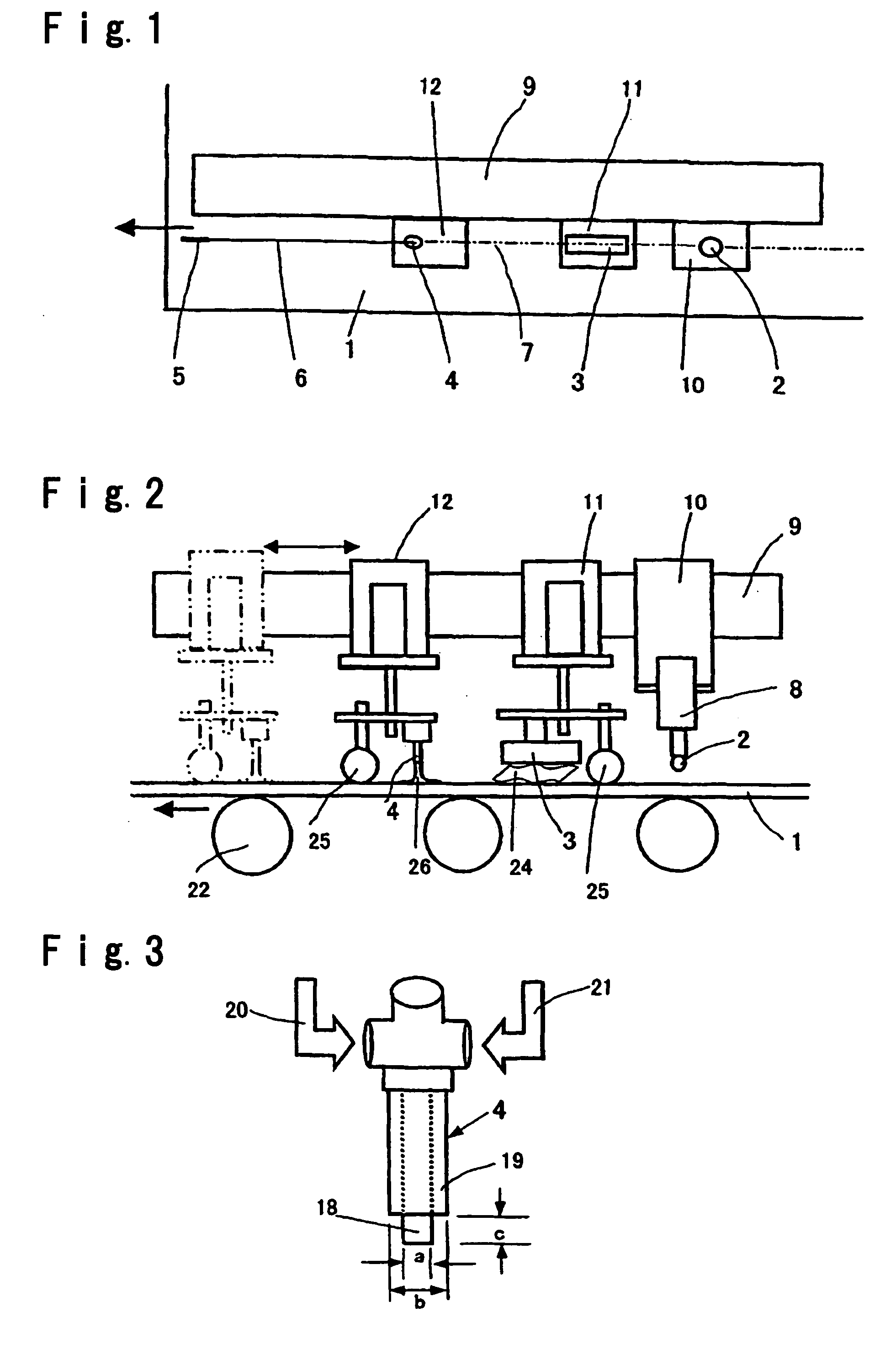

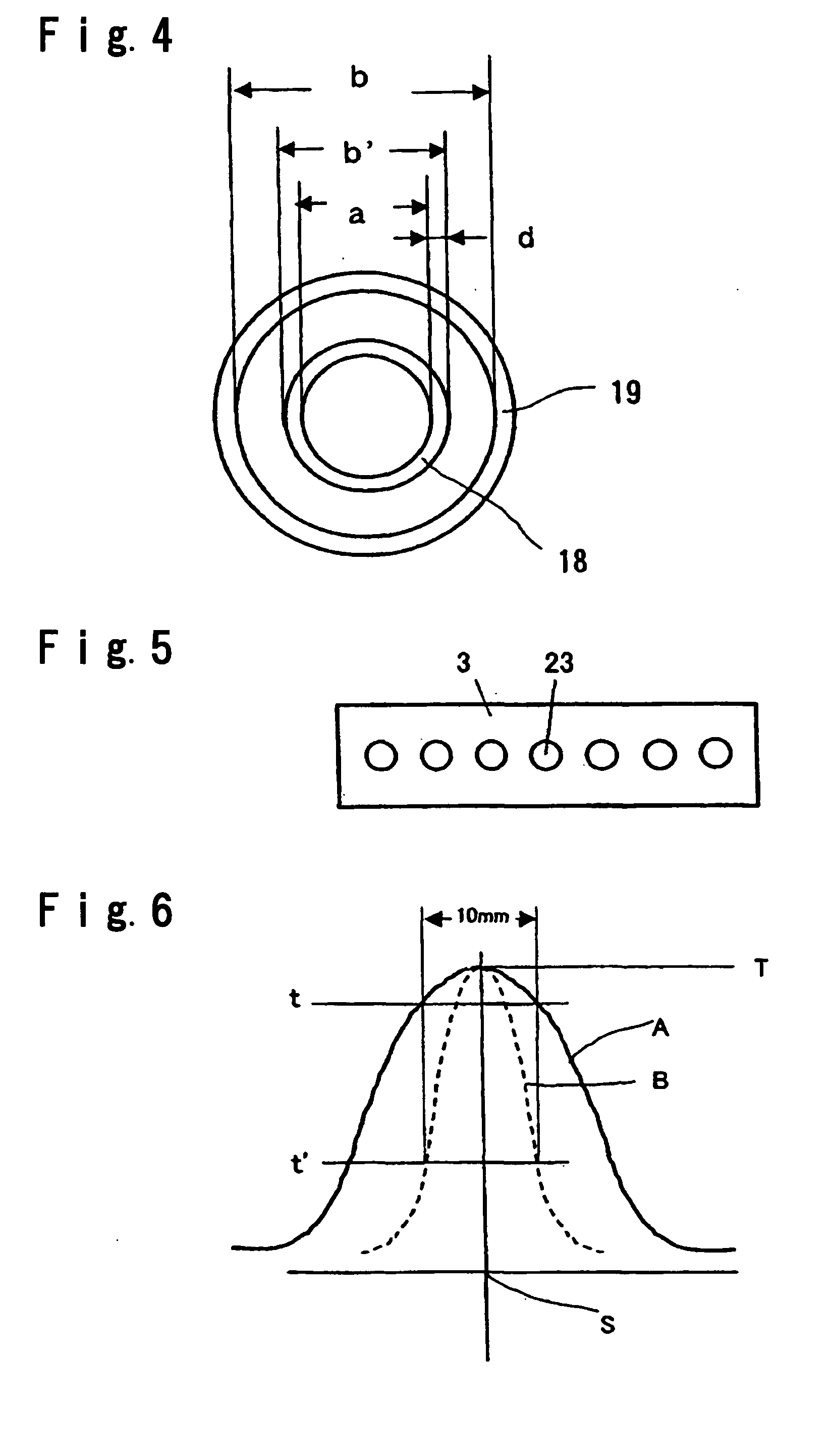

Method and apparatus for separating sheet glass

InactiveUS20060191970A1Heating evenlyQuality improvementWood compressionGlass severing apparatusFlat glassInitiation point

In separation of sheet glass by making use of thermal strain, separated surfaces can be obtained to avoid the occurrence of glass chips and to have excellent linearity even in relatively thick sheet glass. After a score, which serves as a crack initiation point is engraved at a separation initiation point in sheet glass, the sheet glass is heated along an imaginary line of by a heating burner; the heated portion of the sheet glass with the imaginary line of separation set therein is locally cooled by a mist, which is produced by a cooling nozzle comprising a liquid-ejecting port disposed at a central portion thereof and a gas-ejecting port disposed around an outer periphery of the liquid-ejecting port, the liquid-ejecting port projecting farther than the gas-ejecting port; and a minute crack of the score is caused to propagate along the imaginary line of separation to form a crack required for separation of the sheet glass.

Owner:ASAHI GLASS CO LTD

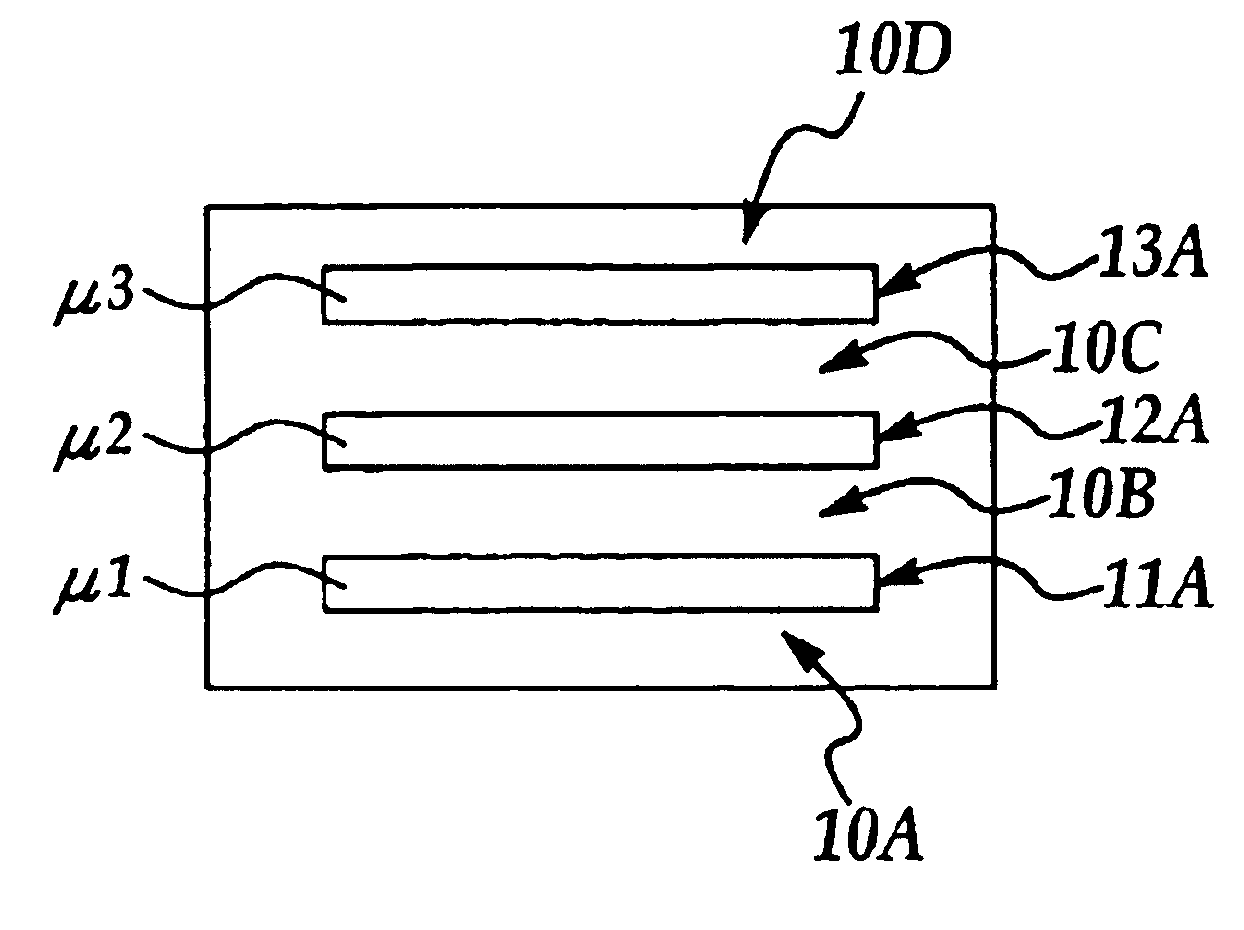

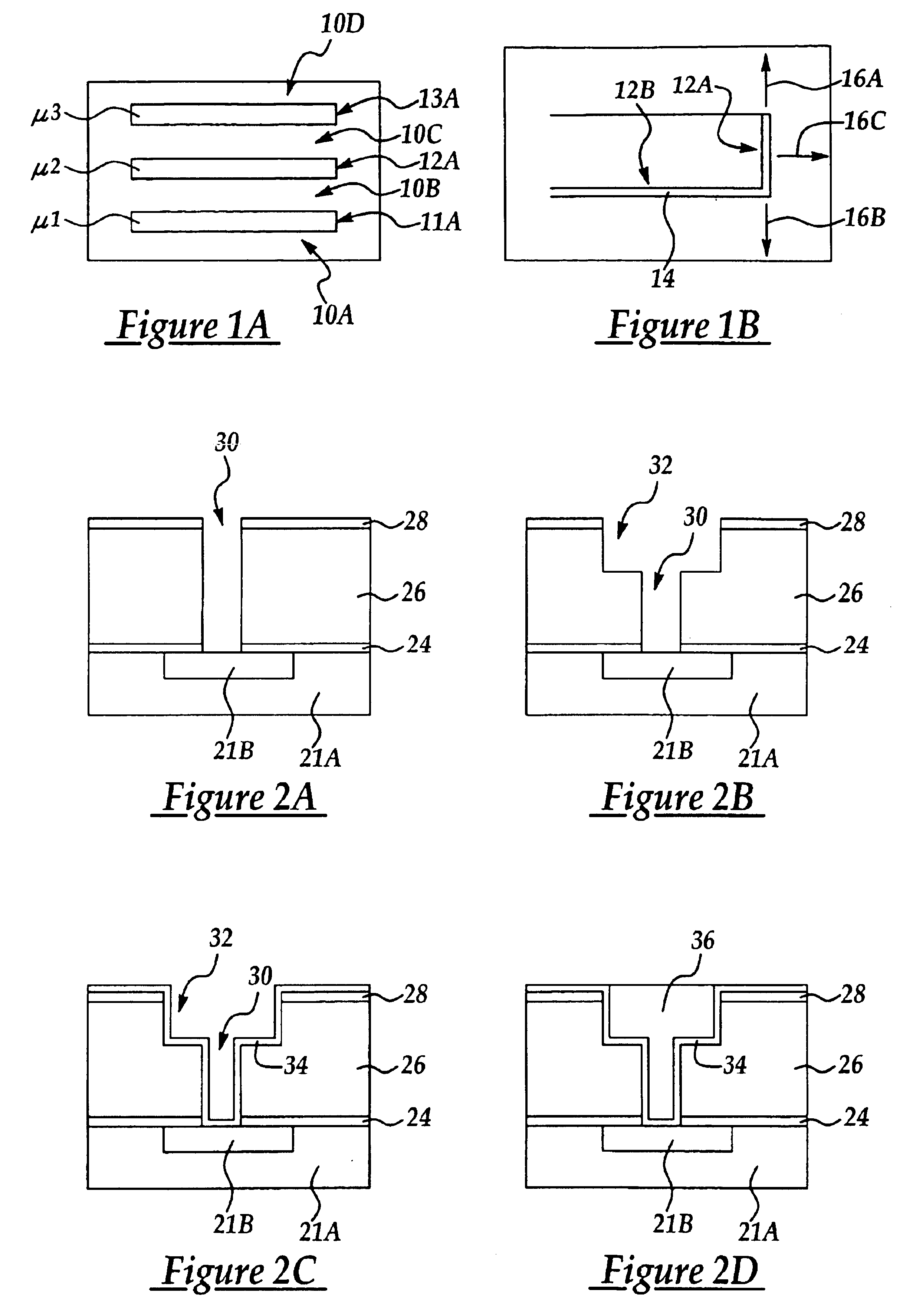

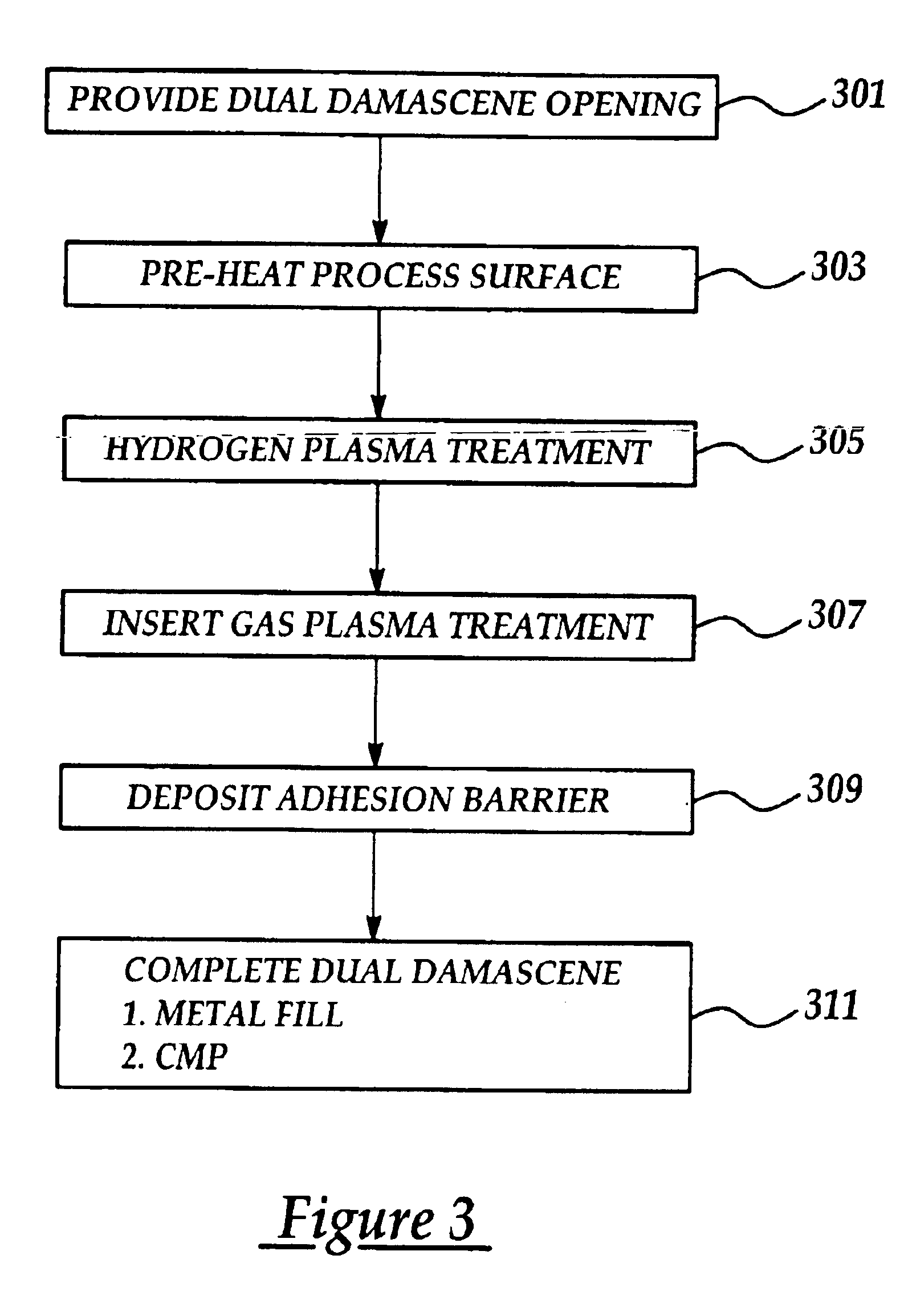

Method for preventing low-k dielectric layer cracking in multi-layered dual damascene metallization layers

InactiveUS6846756B2Increase initiativeImprove propagationSemiconductor/solid-state device manufacturingCrazingAnisotropic etching

A method for plasma treatment of anisotropically etched openings to improve a crack initiation and propagation resistance including providing a semiconductor wafer having a process surface including anisotropically etched openings extending at least partially through a dielectric insulating layer; plasma treating in at least one plasma treatment the process surface including the anisotropically etched openings to improve an adhesion of a subsequently deposited refractory metal adhesion / barrier layer thereover; and, blanket depositing at least one refractory metal adhesion / barrier layer to line the anisotropically etched openings.

Owner:TAIWAN SEMICON MFG CO LTD

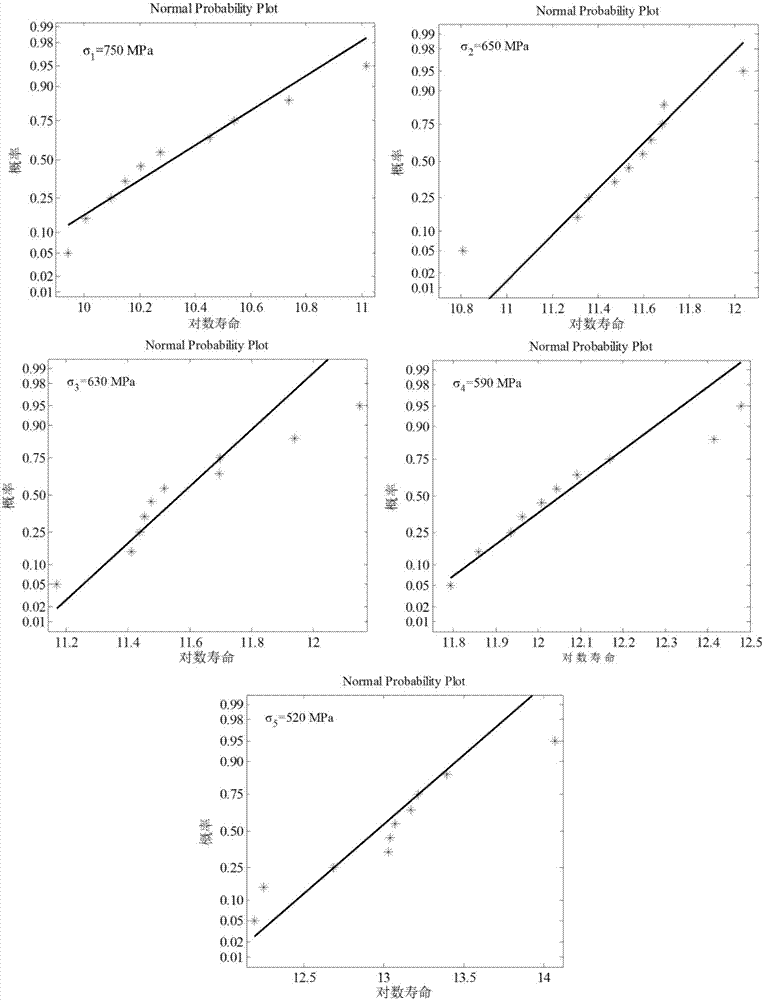

Time-dependent fatigue reliability analysis method based on bilinear cumulative damage

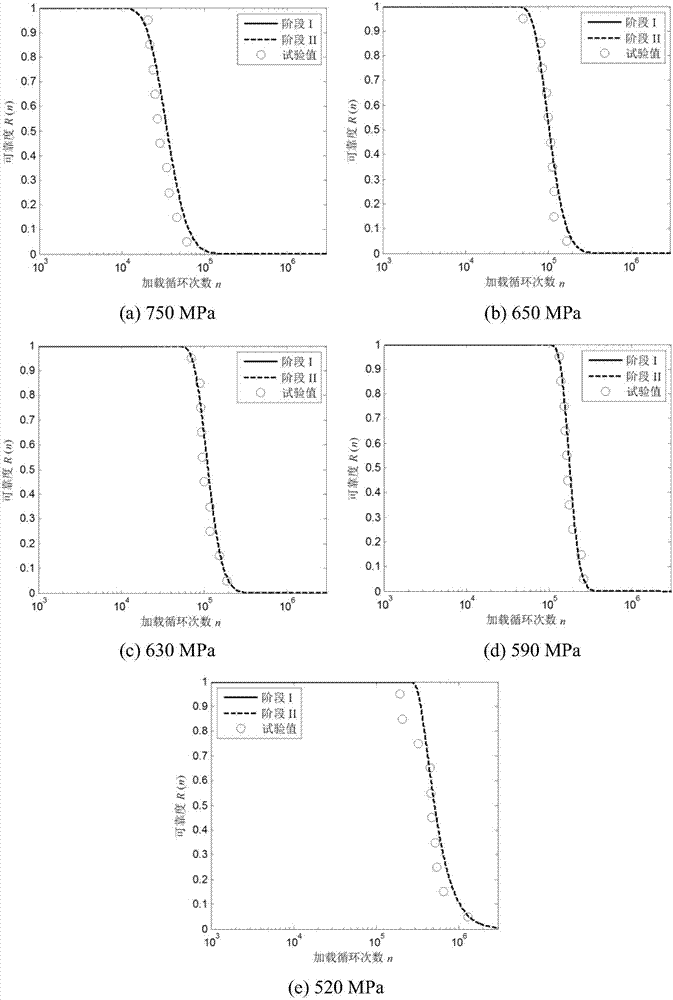

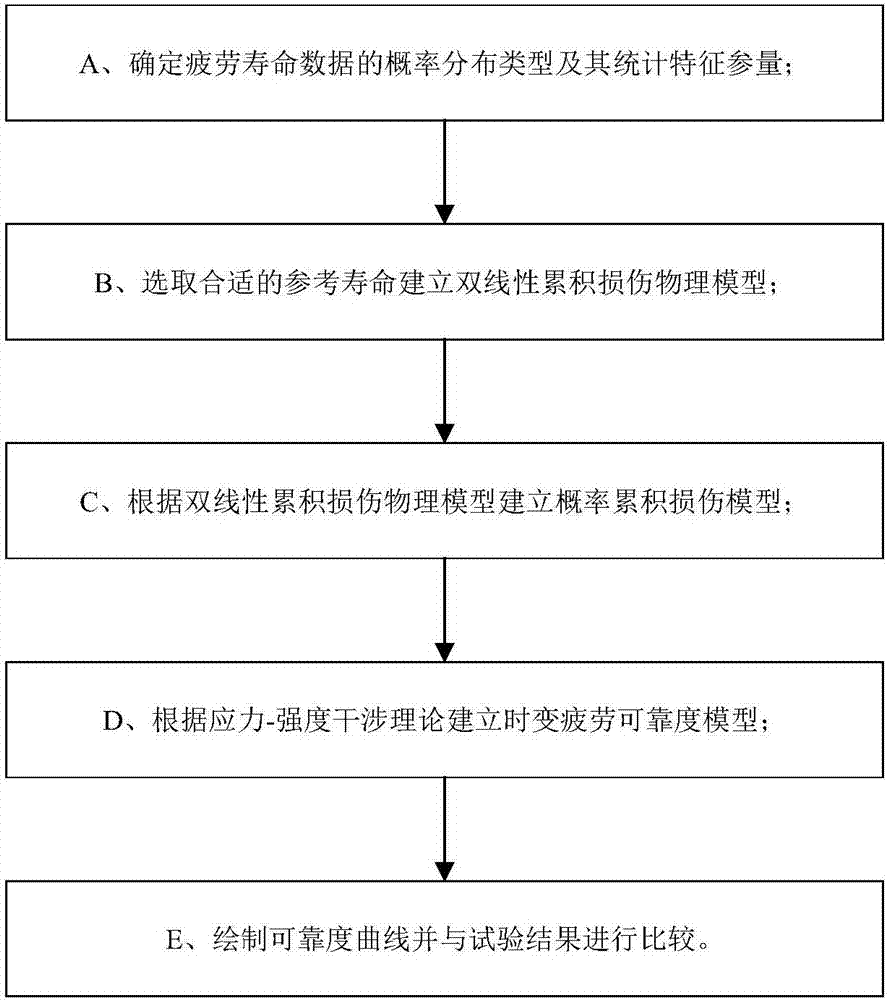

InactiveCN107103140AReflect time-varying characteristicsAchieving Reliability PredictionGeometric CADDesign optimisation/simulationFatigue loadingPhysical model

The invention discloses a time-dependent fatigue reliability analysis method based on bilinear cumulative damage. The method includes the steps that 1, the probability distribution type and statistical characteristic parameter of fatigue life data are determined; 2, the appropriate reference life is selected, and a bilinear cumulative damage physical model is built; 3, according to the bilinear cumulative damage physical model, a probability cumulative damage model is built; 4, according to the stress-strength interference theory, a time-dependent fatigue reliability model is built; 5, a reliability curve is drawn and compared with an experimental result; the characteristics of a crack initiation stage and a crack propagation stage in the fatigue failure process and the randomness in the damage accumulation process are comprehensively considered, the bilinear damage theory serves as a modeling base, the probability cumulative damage model is built, through the combination with the stress-strength interference theory, the time-dependent fatigue reliability model based on cumulative damage and critical damage is built, the time-varying characteristics of fatigue loading and the dynamic behavior of the damage accumulation process are reflected, and the reliability prediction in the whole fatigue life cycle is achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

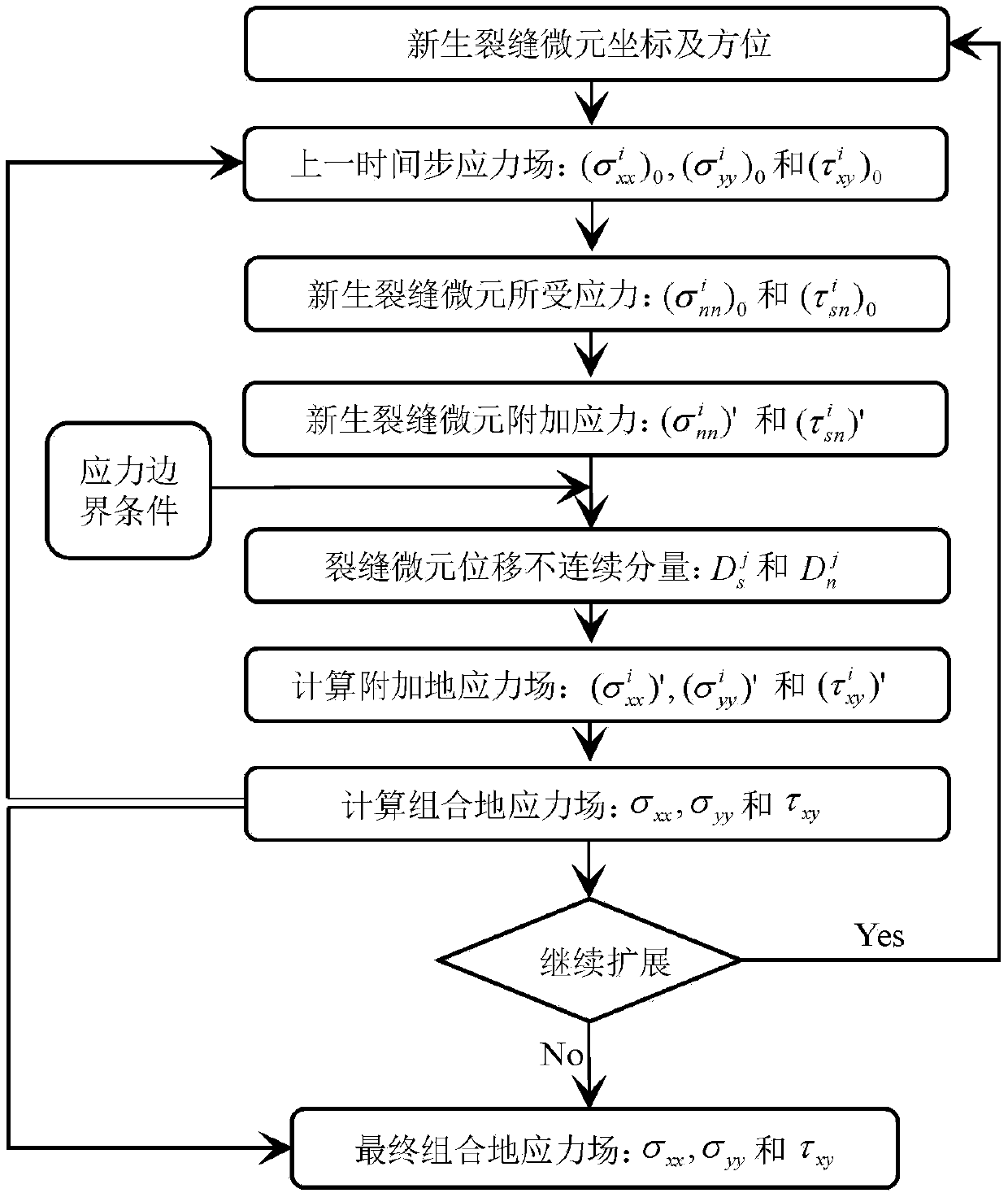

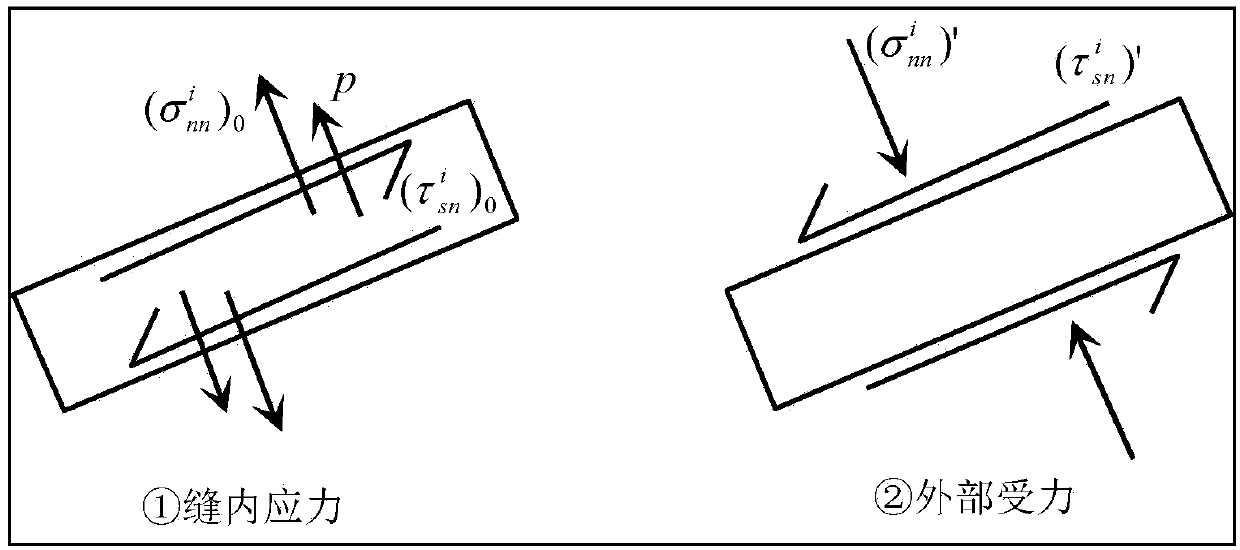

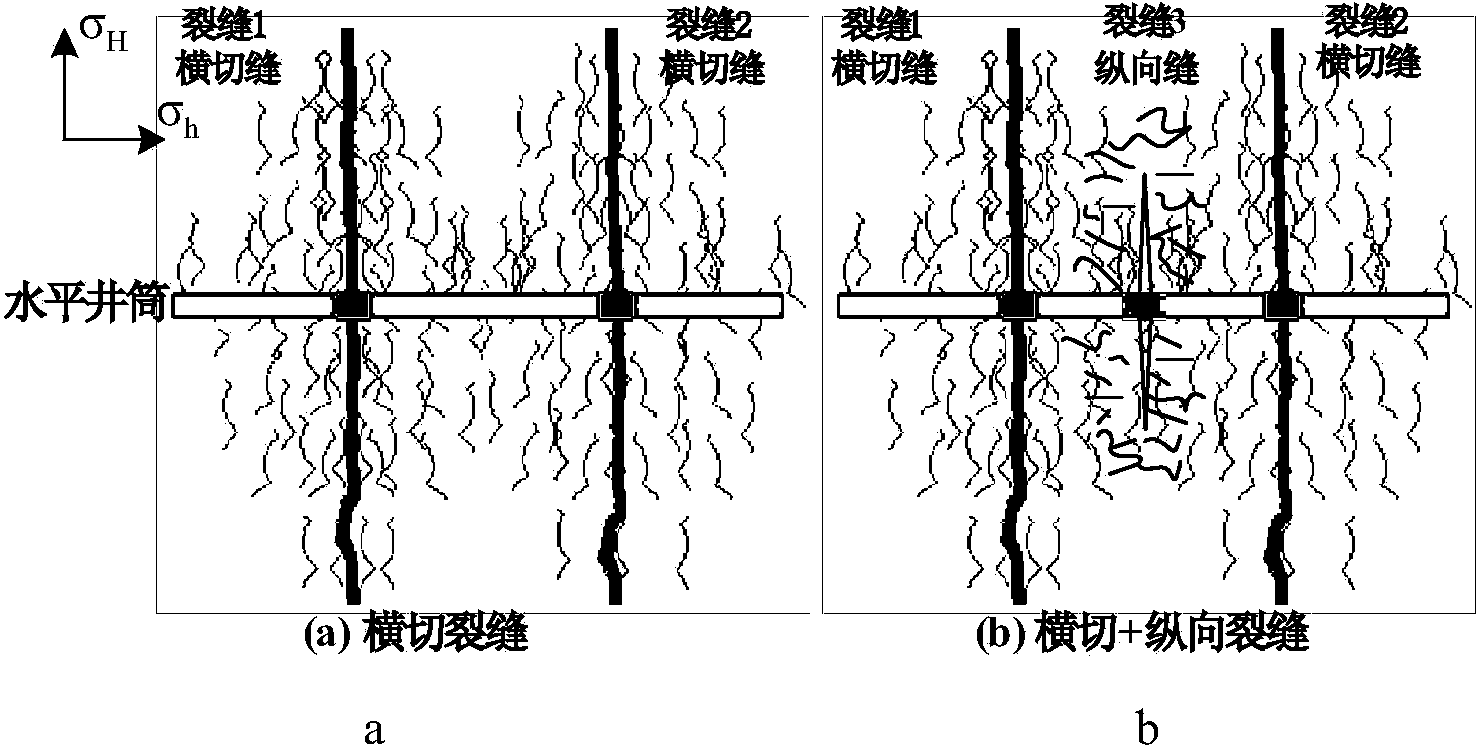

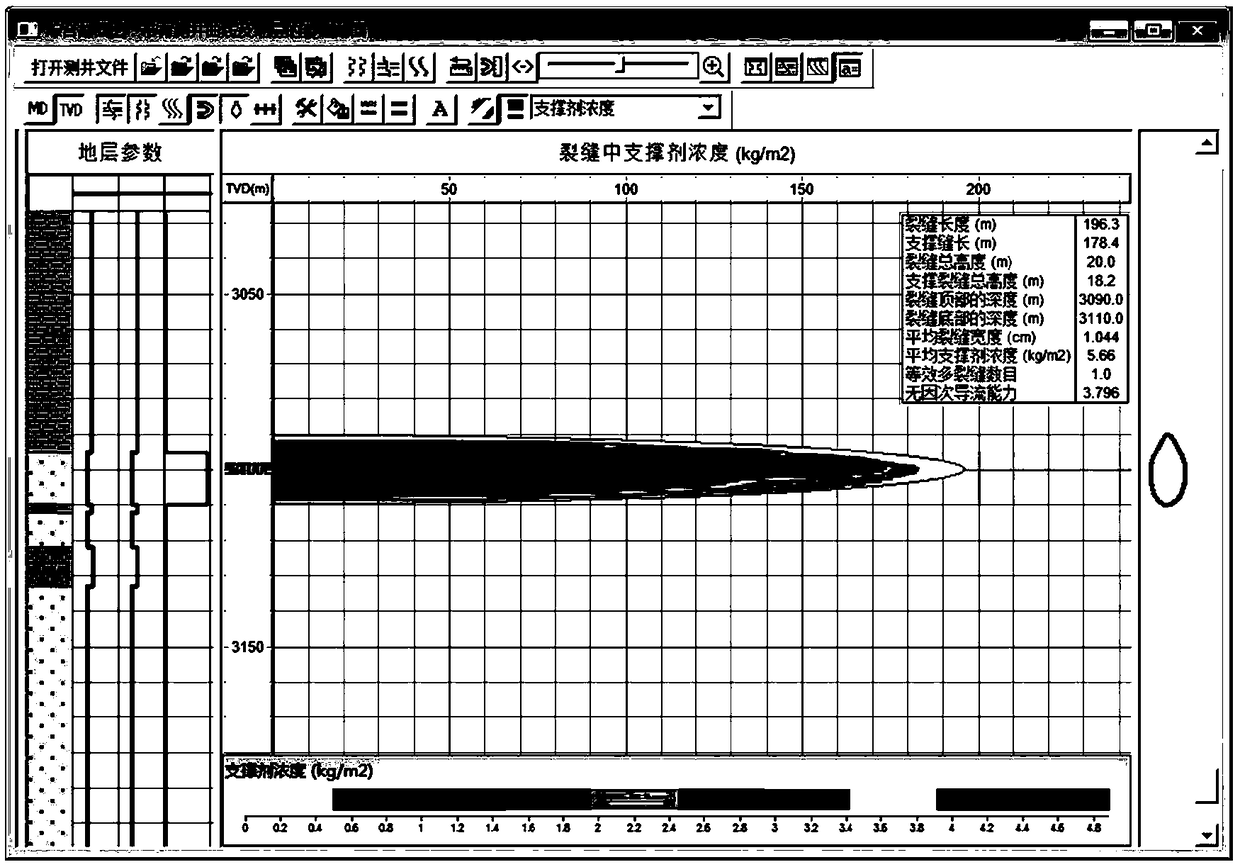

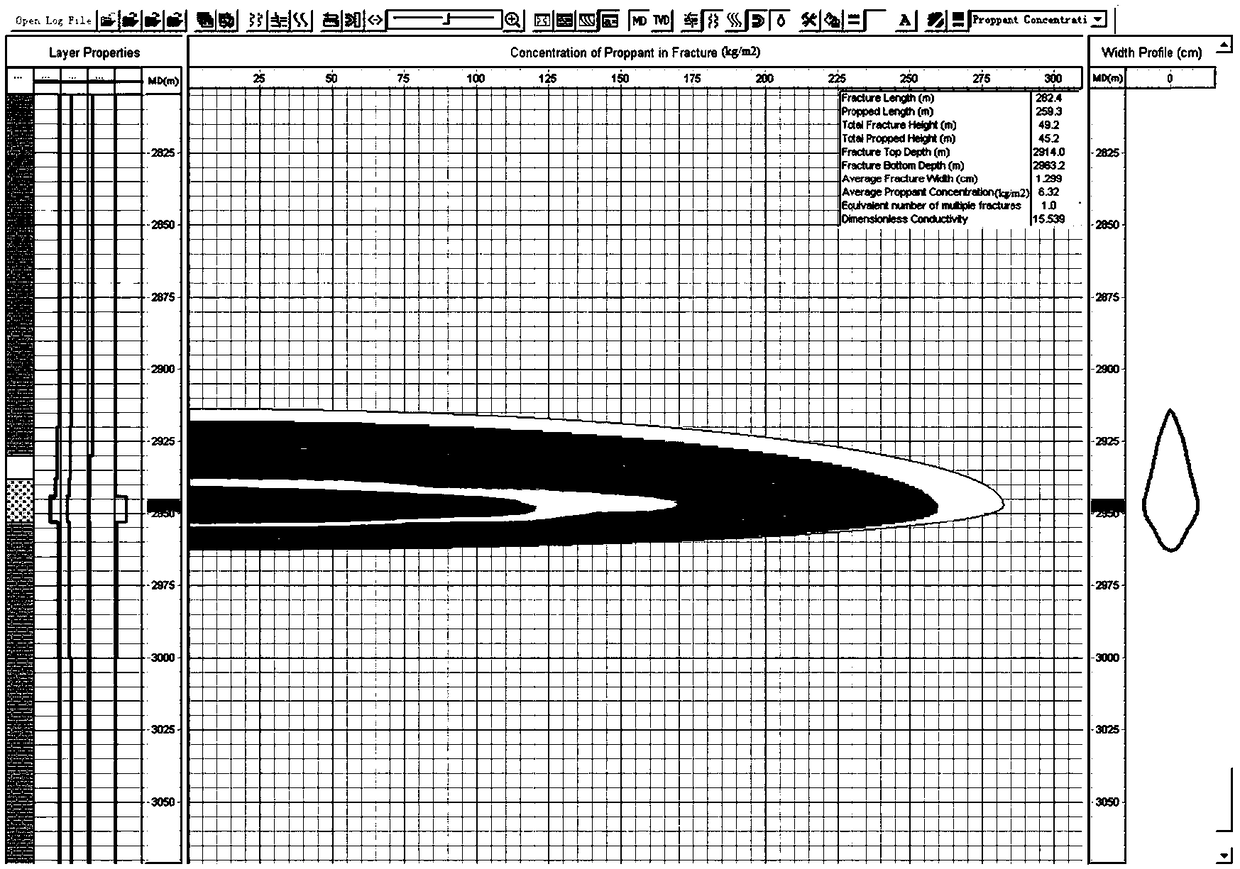

Tight reservoir volume pressure crack network extension simulation and representation method

ActiveCN108319756AMake up for the shortcomings of incomplete considerationDesign optimisation/simulationSpecial data processing applicationsNetwork structureFracturing fluid

The invention discloses a tight reservoir volume pressure crack network extension simulation and representation method. The method comprises the following steps of: firstly establishing a multi-crackstress interference-considered tight reservoir combined ground stress field calculation model by utilizing a displacement discontinuity method, mechanical mechanism analysis and crack initiation and extension criterions; aiming at a stress interference problem in volume pressure crack multi-crack extension process, establishing flow pressure drop distribution models, in primary and secondary cracks, of a fracturing fluid, so as to form a tight reservoir volume pressure crack horizontal well crack network extension theoretical model; and finally comprehensively analyzing influences, on volume pressure crack network structural morphology, of different factors, and defining a plurality of feature parameters to represent crack network structure morphology and attribute features. At last, the tight reservoir volume pressure crack network extension simulation and representation method is established. The tight reservoir volume pressure crack network extension simulation and representation method has the advantages of being comprehensive in model factor consideration, high in simulation effect and visual in result, and has a certain guiding significance for optimum design and efficient development of tight reservoir cracks.

Owner:XI'AN PETROLEUM UNIVERSITY

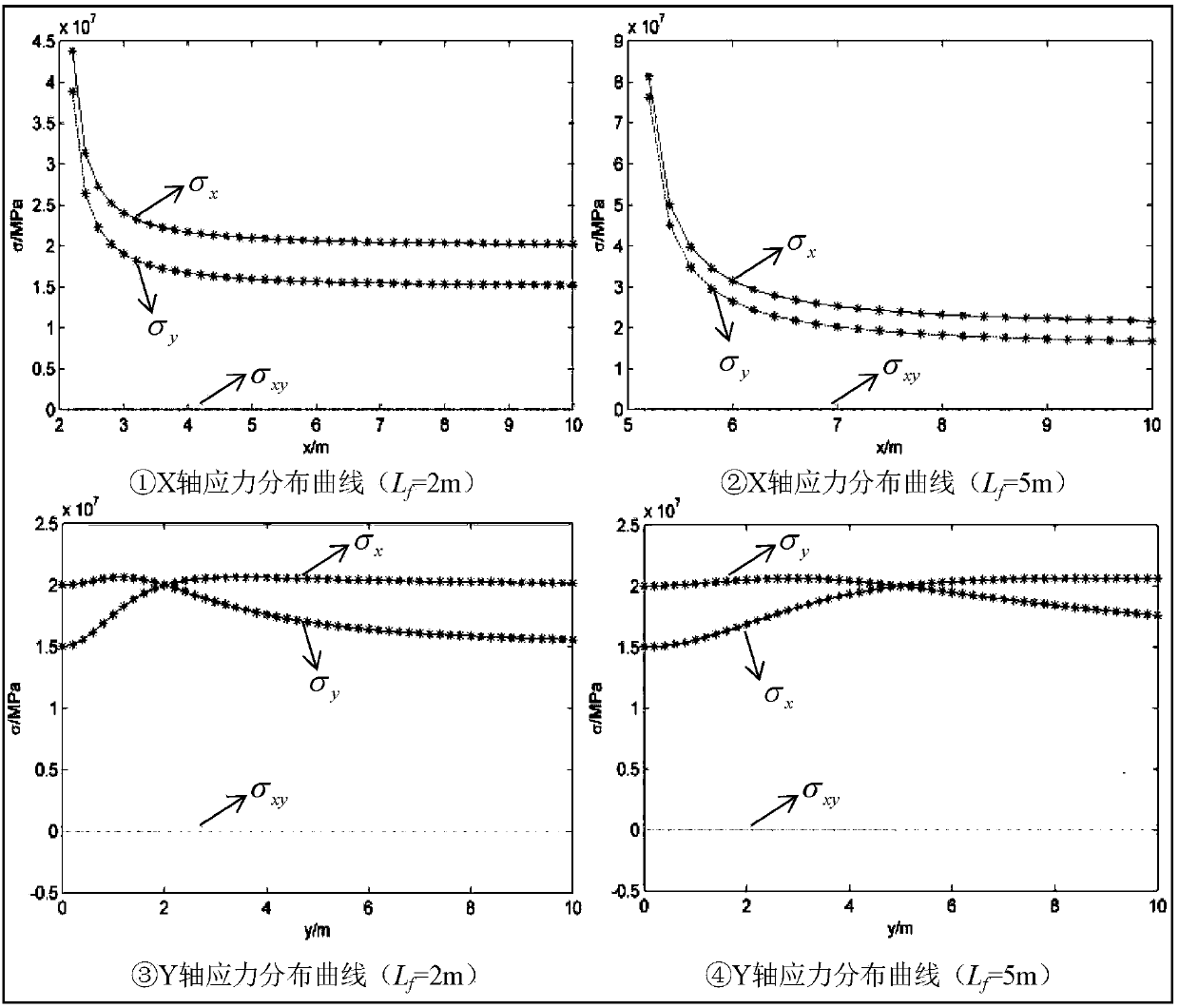

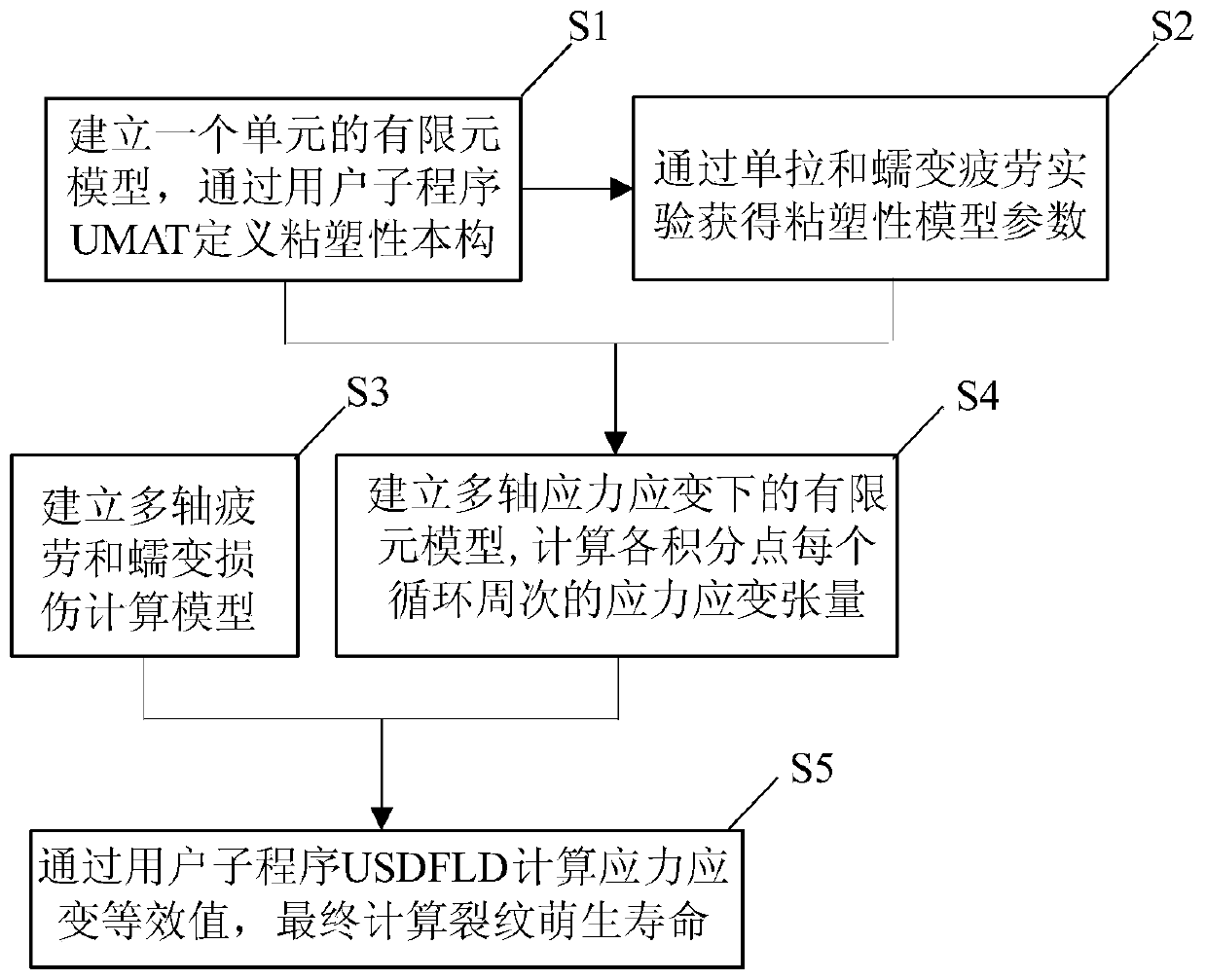

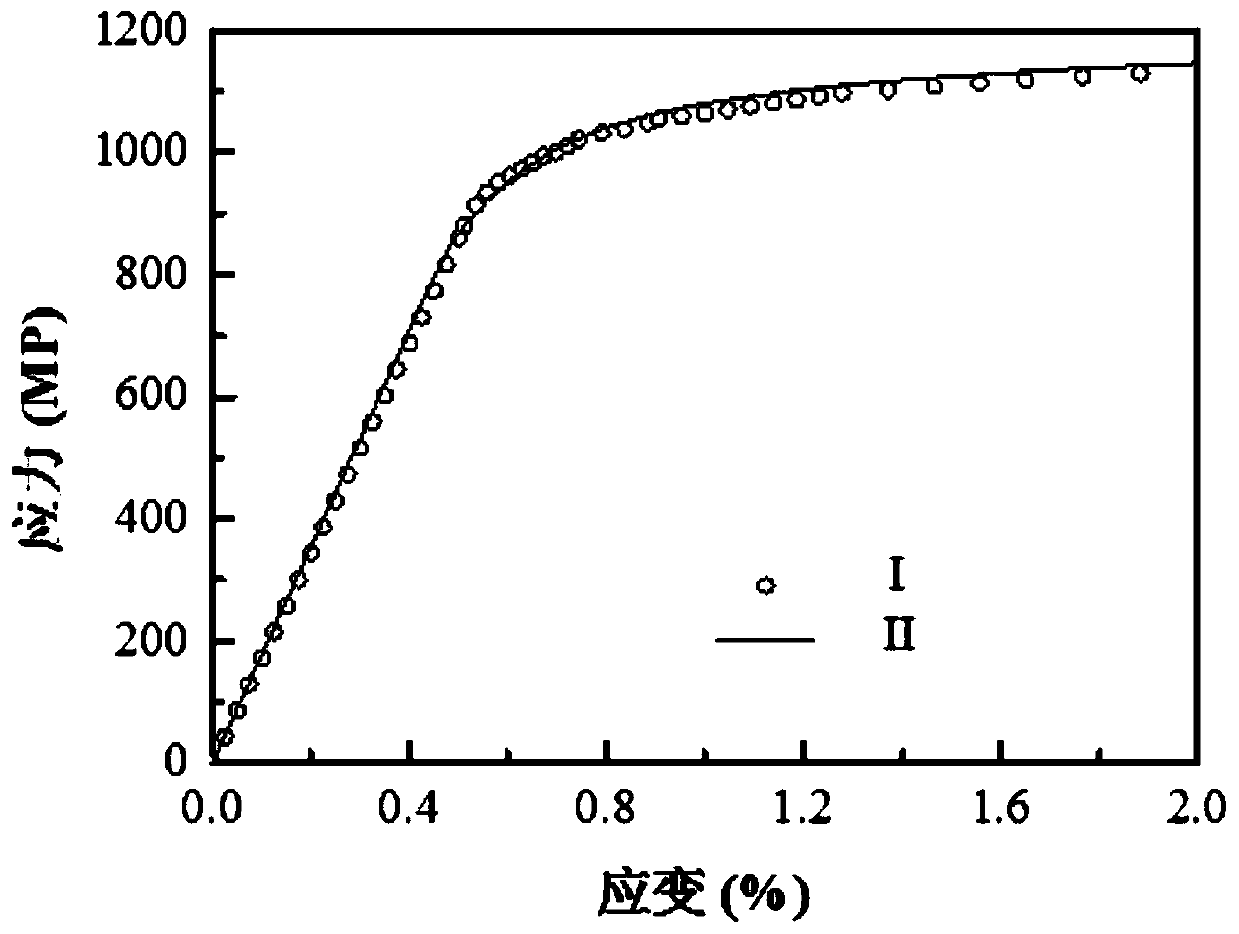

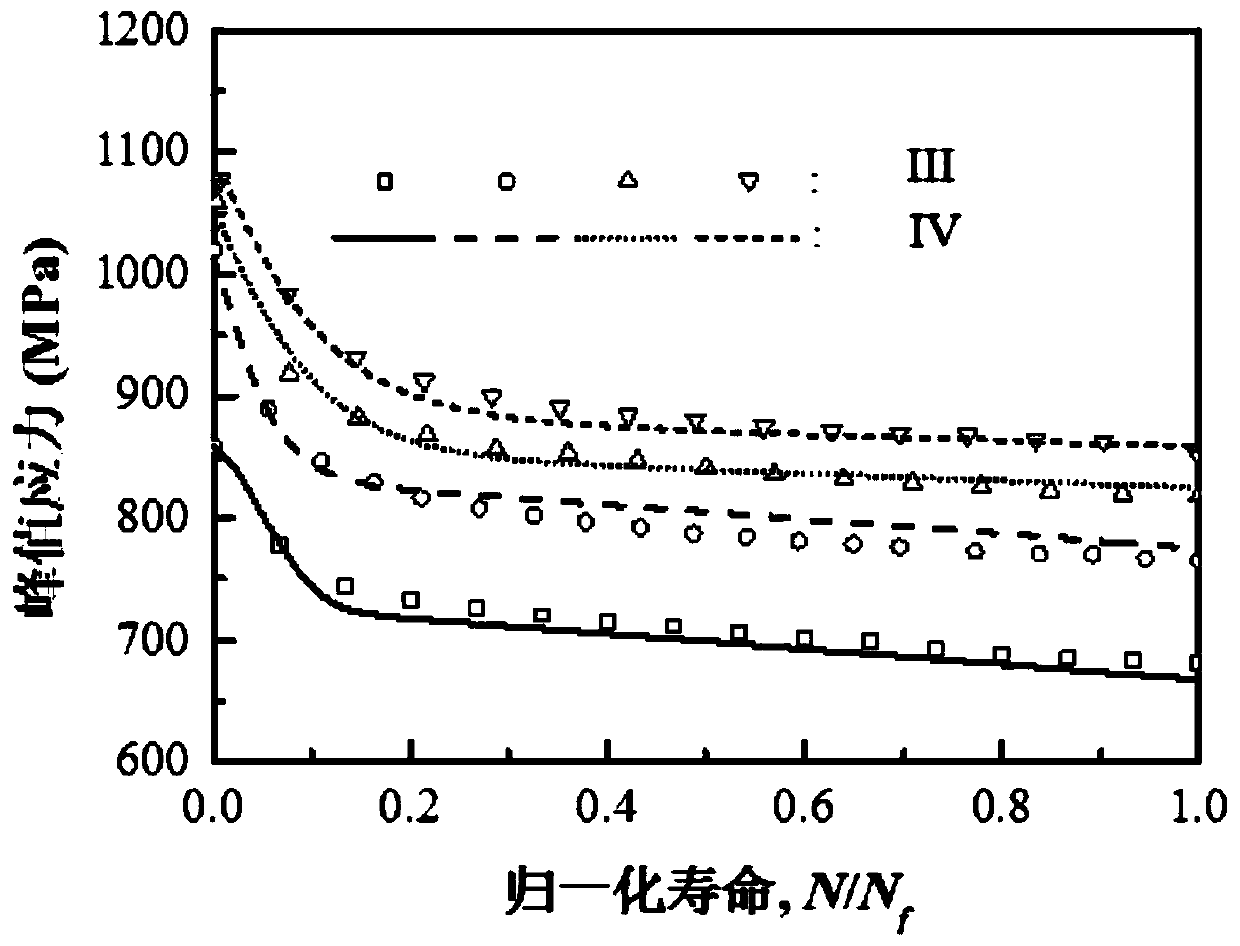

A multi-axis creep fatigue prediction method based on ABAQUS

ActiveCN109885874AGain creep damageIntuitiveMaterial strength using tensile/compressive forcesDesign optimisation/simulationFatigue damageElement model

The invention discloses a multi-axis creep fatigue prediction method based on ABAQUS, and the method comprises the steps of S1, building an ABAQUS finite element model, and defining a viscoplastic constitutive equation of a to-be-tested material through a user subprogram UMAT; S2, determining model parameters required by the viscoplastic constitutive equation; S3, establishing a fatigue damage calculation model and a creep damage calculation model of the multi-axis stress-strain state of the to-be-tested material; S4, establishing an ABAQUS finite element model in a multi-axis stress-strain state, and calculating to obtain a stress-strain tensor of each cycle on the basis of the defined viscoplastic constitutive equation and model parameters; and S5, calculating equivalent stress and equivalent plastic strain through a user subprogram USDFLD, and superposing fatigue damage and creep damage of each cycle through a linear cumulative damage criterion on the basis of the fatigue damage calculation model and the creep damage calculation model in combination with the stress strain tensor to obtain the crack initiation life.

Owner:EAST CHINA UNIV OF SCI & TECH

Crack initiation and propagation and supporting crack stress sensitivity evaluation device and method

ActiveCN110617045ARealize fracking hydraulic fracturingAchieve fracturingMaterial strength using tensile/compressive forcesEarth material testingRock coreFracturing fluid

The invention relates to a crack initiation and propagation and supporting crack stress sensitivity evaluation device and method. The device comprises a core part, a confining pressure loading part, afracturing fluid pumping part, a stress sensitivity test part and a crack monitoring part. The method comprises: step 1, setting X, Z, and Z triaxial pressures, and applying triaxial load to a core;step 2, calculating the uniaxial permeability or the triaxial overall permeability of the core flowing from a shaft to a reservoir or from the reservoir to the shaft; step 3, adding fracturing fluid into an intermediate container I as prepad fluid, and adding the fracturing fluid and a proppant into an intermediate container II as sand carrying fluid; step 4, injecting the prepad fluid into the core and injecting the sand-carrying fluid into the core after the core is pressed open; and step 5, injecting water or gas into the shaft or a triaxial seepage plate, and calculating the uniaxial permeability or triaxial overall permeability of the core flowing from the shaft to the reservoir or from the reservoir to the shaft after fracturing. The crack initiation and propagation and supporting crack stress sensitivity evaluation device and method can guide the optimization of hydraulic fracturing construction parameters and effectively improve the productivity of oil and gas wells.

Owner:SOUTHWEST PETROLEUM UNIV

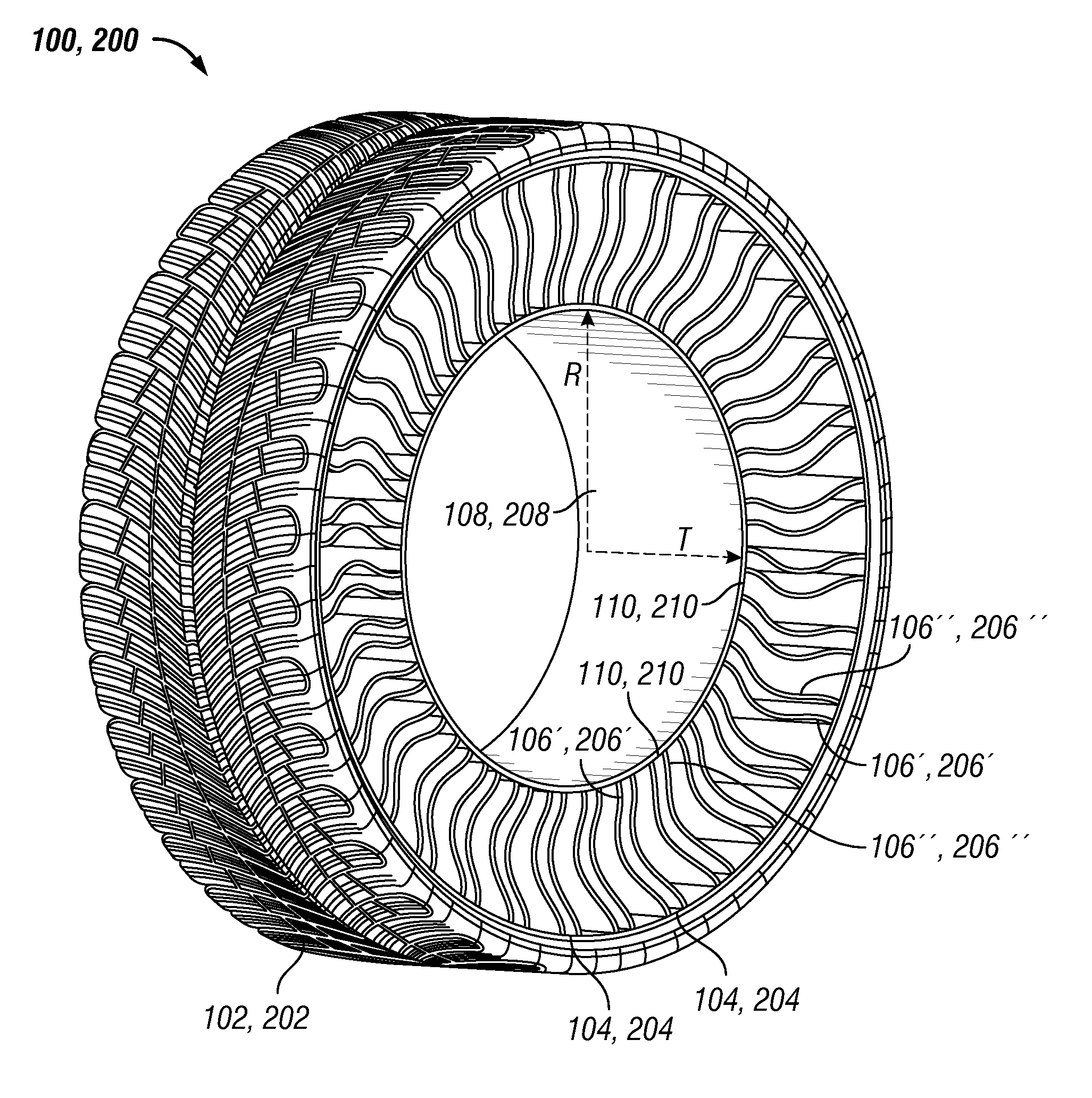

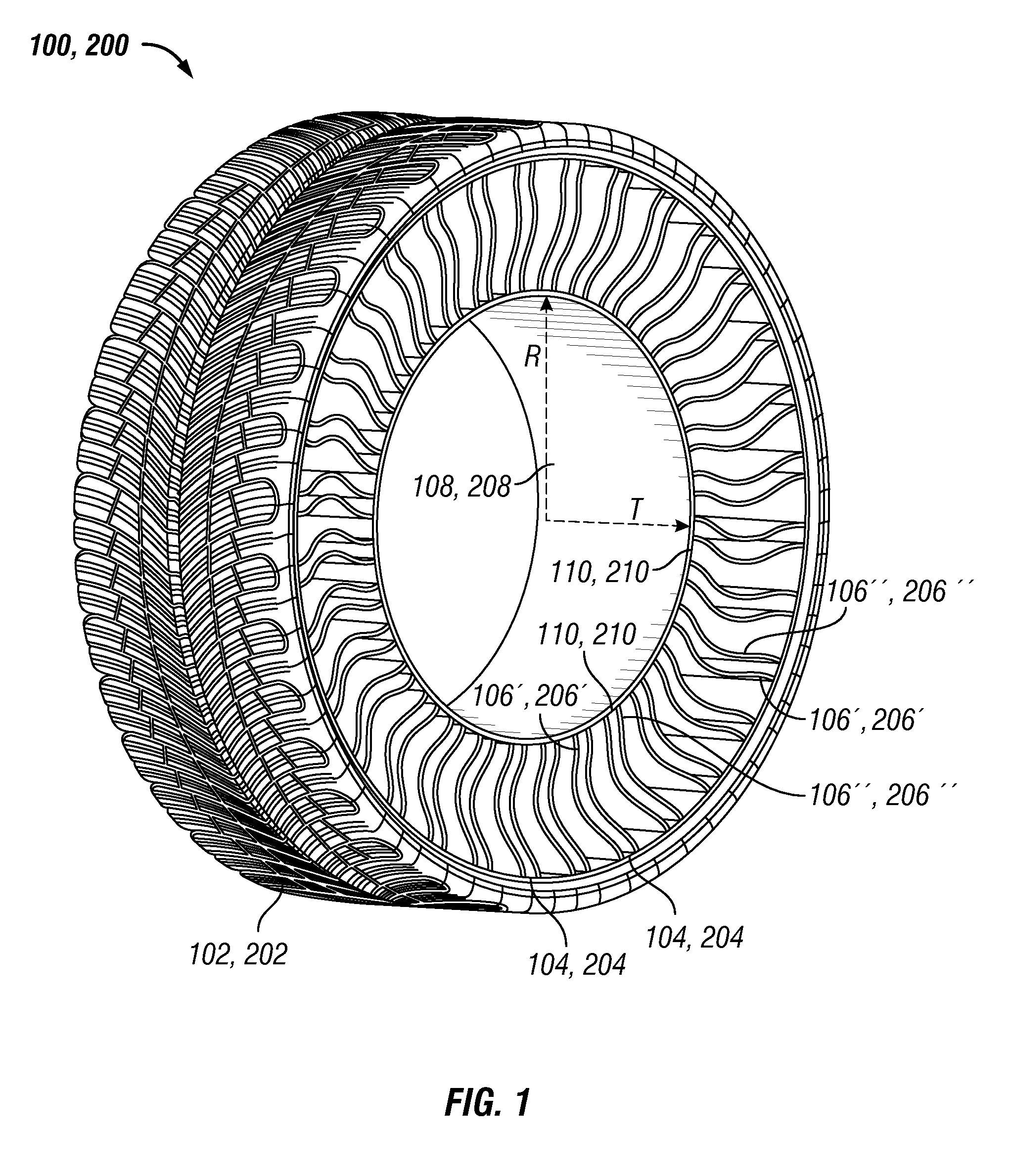

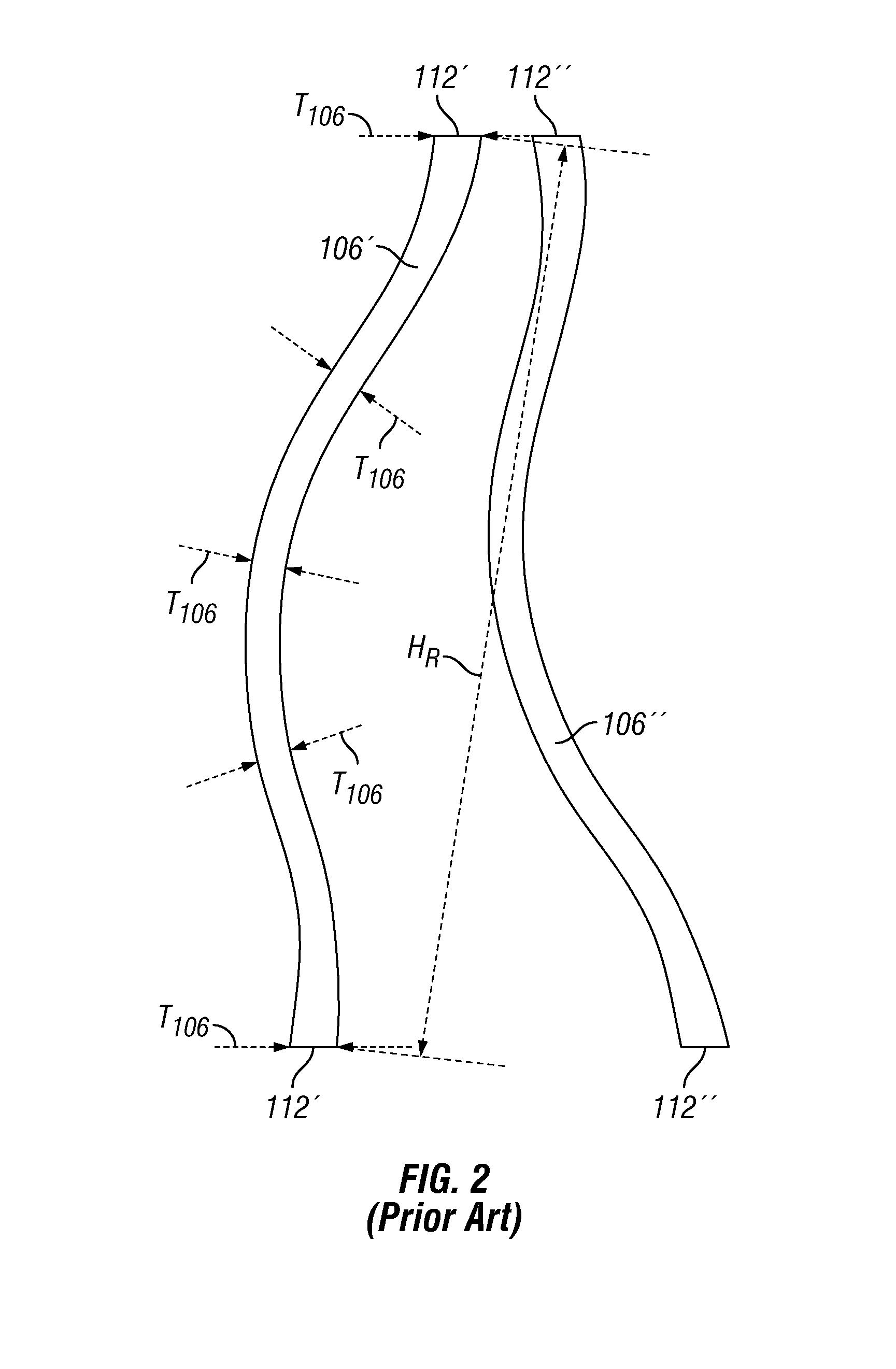

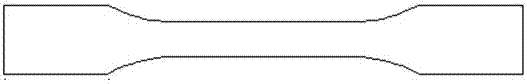

Spoke for a tire with optimized thickness for improved durability

ActiveUS20150174953A1Non-inflatable tyresNon-metallic wheel bodyStrain energyVolumetric Mass Density

The present invention provides spoke geometry for a non-pneumatic tire that is less prone to fatigue when used. In particular, the spoke geometry is provided with an optimized thickness profile over the length of the spoke. This optimization results in a reduction in the peak strain energy density levels in the spoke, thereby reducing the likelihood of crack initiation and propagation which in turn enhances the durability of the spoke and tire.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

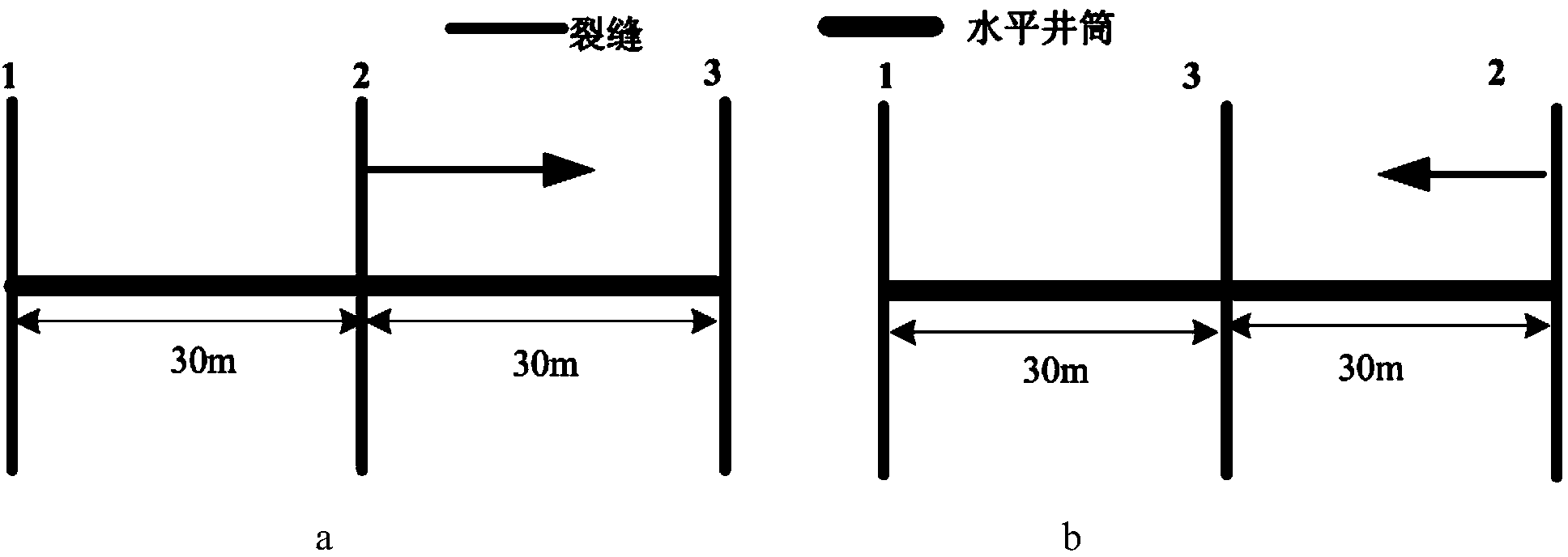

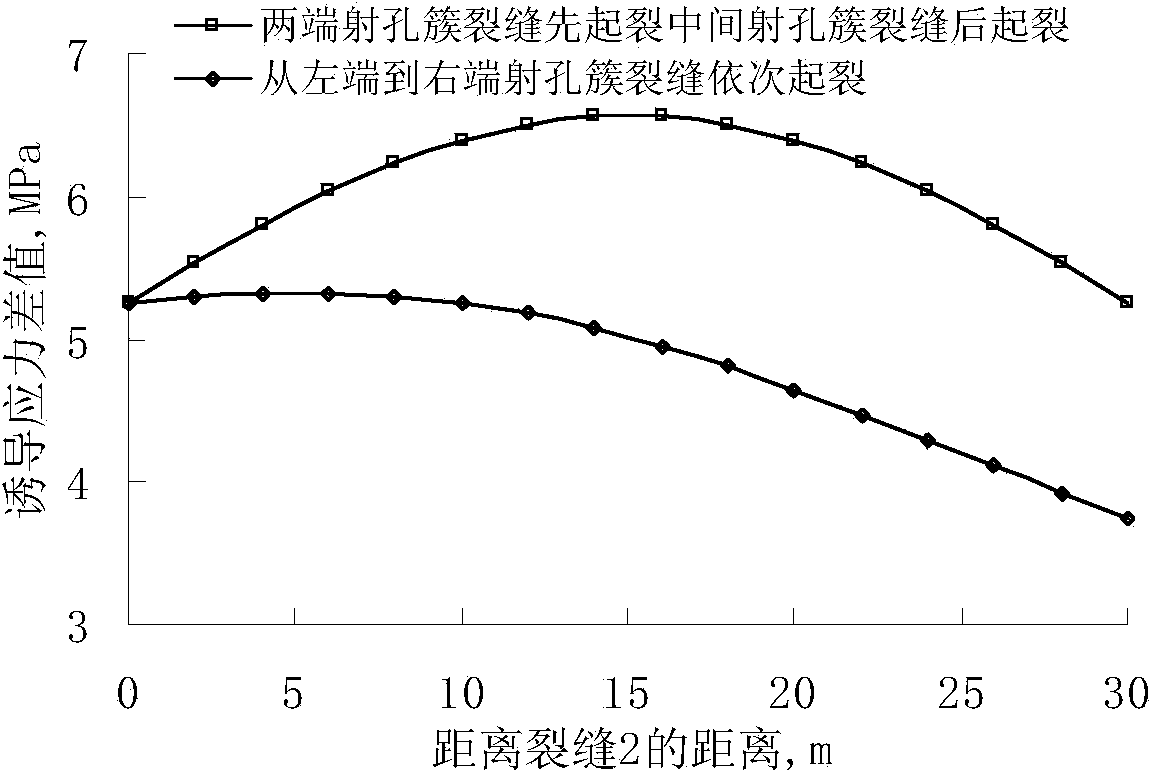

Tight reservoir horizontal well volume fracturing process

InactiveCN103527163AIncrease success rateSolve the problem of inadequate transformationFluid removalBottom hole pressureWell logging

The invention relates to a tight reservoir horizontal well volume fracturing process. Data including in-situ stress magnitude and direction, horizontal well azimuth and length, reservoir Young moduli, a Poisson ratio, a well logging interpretation result and the like are collected and used as basic parameters for calculating induced stress needed for generation of complex cracks in tight reservoir horizontal well volume fracturing; according to reservoir physical characteristics, induced stress difference value variation conditions of three or more perforation clusters in the same fracturing segment according to different crack initiation sequences are contrasted, and preference is given to the perforation cluster crack initiation sequences with the maximal induced stress difference value as the target; preference is given to perforation cluster gaps so that the complex cracks can be formed through fracturing in the same fracturing segment of a horizontal well; in cooperation with perforation parameter optimization and with bottom hole pressure control as the target, the effect that the cracks of the perforation clusters at the two ends are initiated and extended for a certain distance through discharge capacity adjustment and then the discharge capacity is improved to utilize perforation friction for pressing open the cracks of the perforation clusters in the middle is achieved; then, prepad fluid and sand-carrying fluid containing a propping agent are poured into the cracks in sequence to realize transformation of the shape of the complex cracks of the fractured horizontal well.

Owner:SOUTHWEST PETROLEUM UNIV

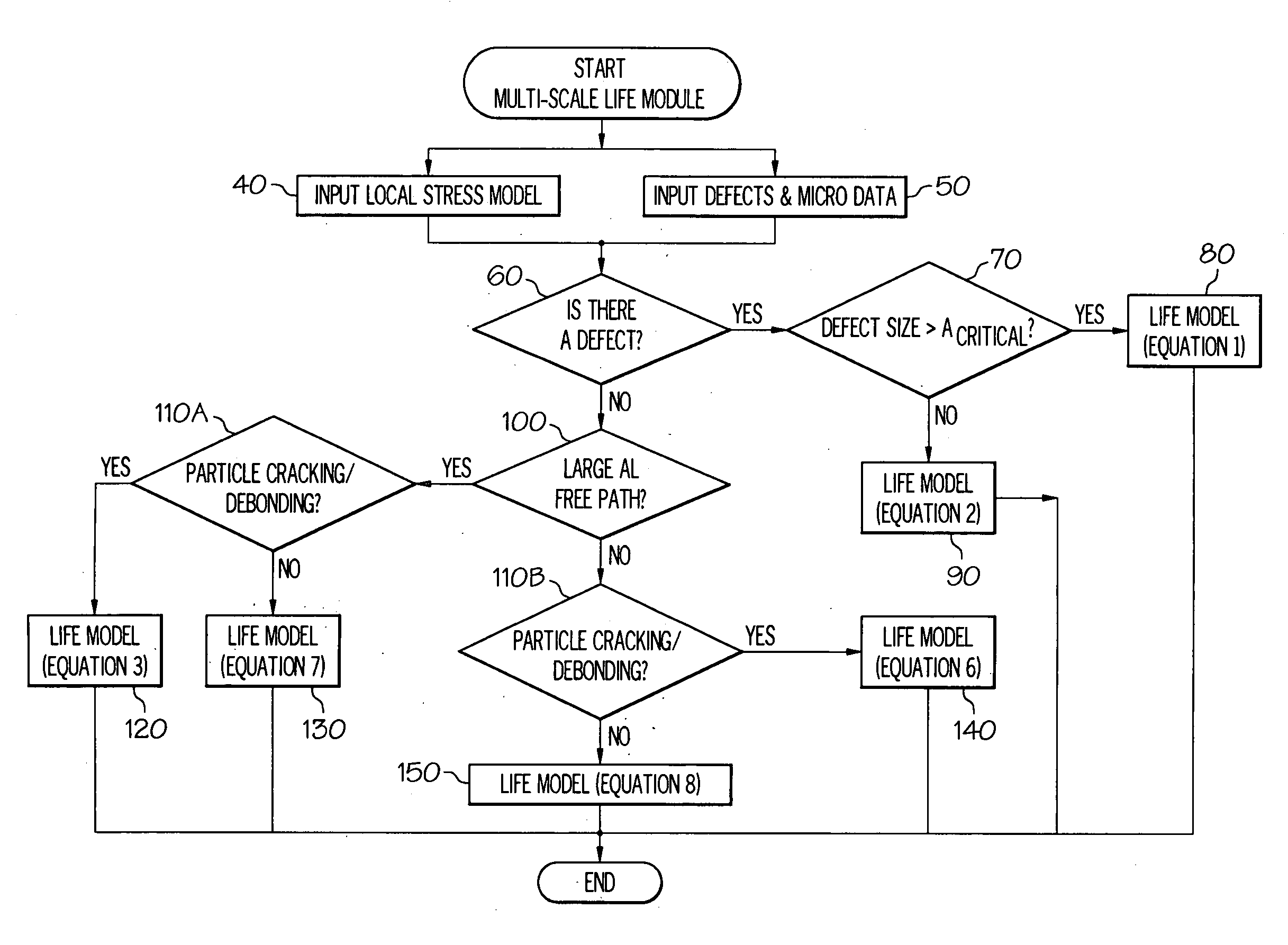

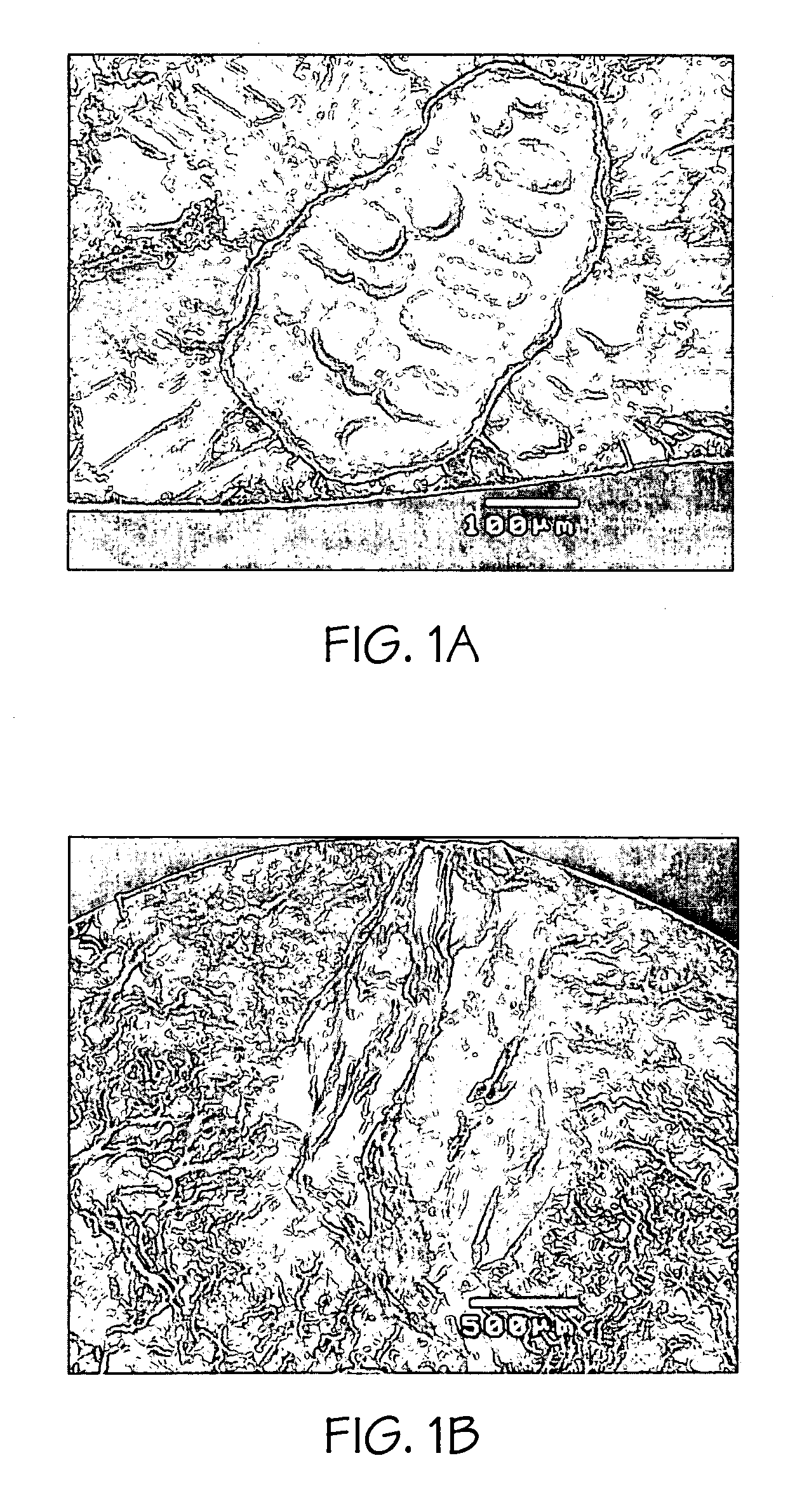

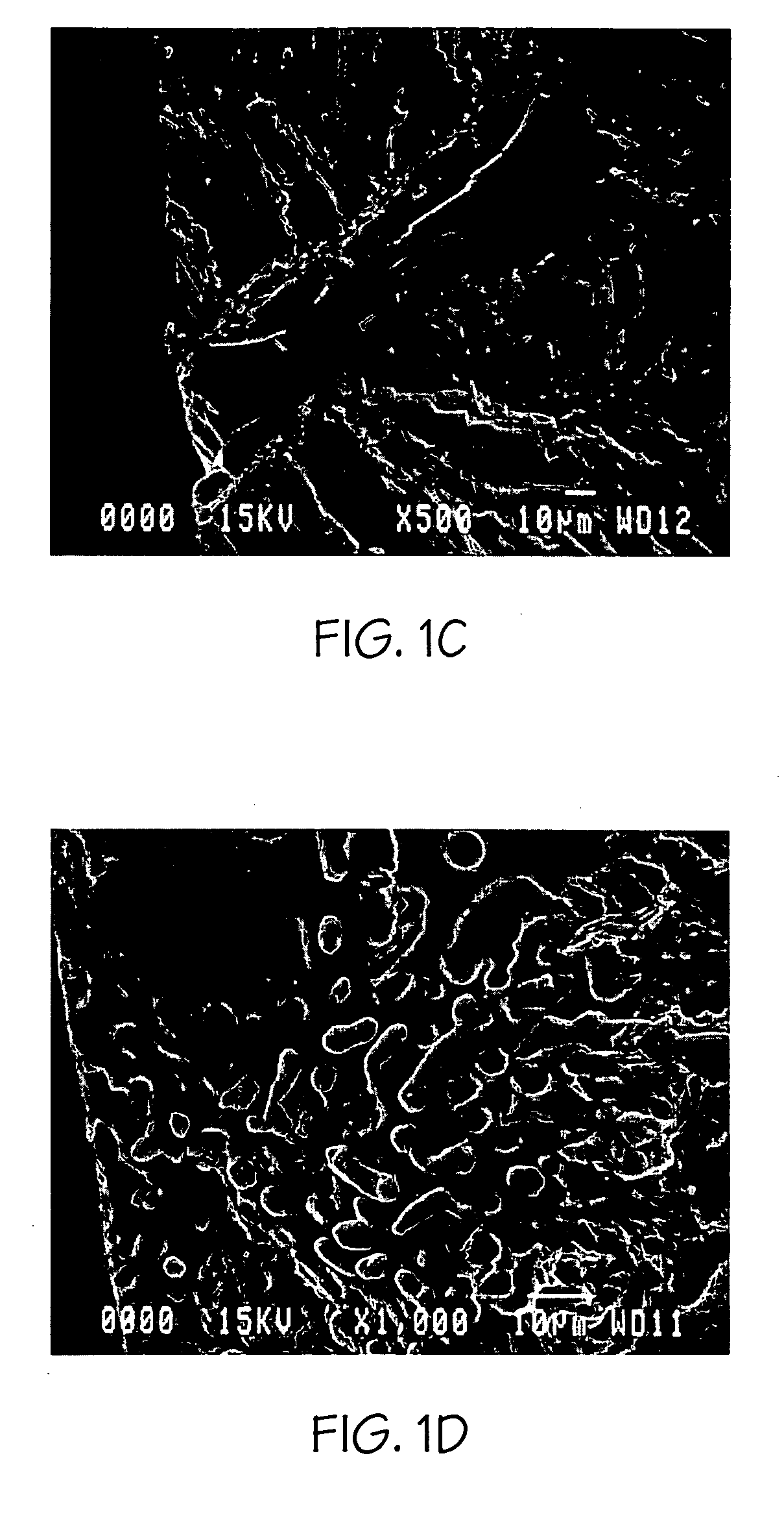

Methods and systems to predict fatigue life in aluminum castings

InactiveUS20090276166A1Accurately fatigue propertyAccurate of fatigue propertyPlug gaugesDigital computer detailsCrazingCasting defect

Methods and systems of predicting fatigue life in aluminum castings that combines extreme values of both casting flaws and microstructures with multiscale life models. The multiscale life models account for differing fatigue crack initiation based on the size scale of the defect and microstructure features, including provisions for generally millimeter scale casting flaws, generally micrometer scale second phase particles by cracking or debonding, or submicrometer scale dislocation interactions with precipitates which form persistent slip bands. In the presence of casting flaws, the fatigue initiation life is negligible and the total fatigue life is spent in propagation of a fatigue crack from such flaws. In the absence of casting flaws, however, the total fatigue life is spent in both crack initiation and propagation, except for the case where fatigue cracks initiate from large second phase particles in a coarse microstructure. The extreme values of casting flaws, second phase particles, mean free path through an aluminum matrix or grain sizes are obtained from extreme value statistics when two or three dimensional sizes of casting flaws and microstructure features are provided by either direct measurement or analytical prediction. The upper bound flaw or microstructure feature size is calculated by extreme value statistics.

Owner:GM GLOBAL TECH OPERATIONS LLC

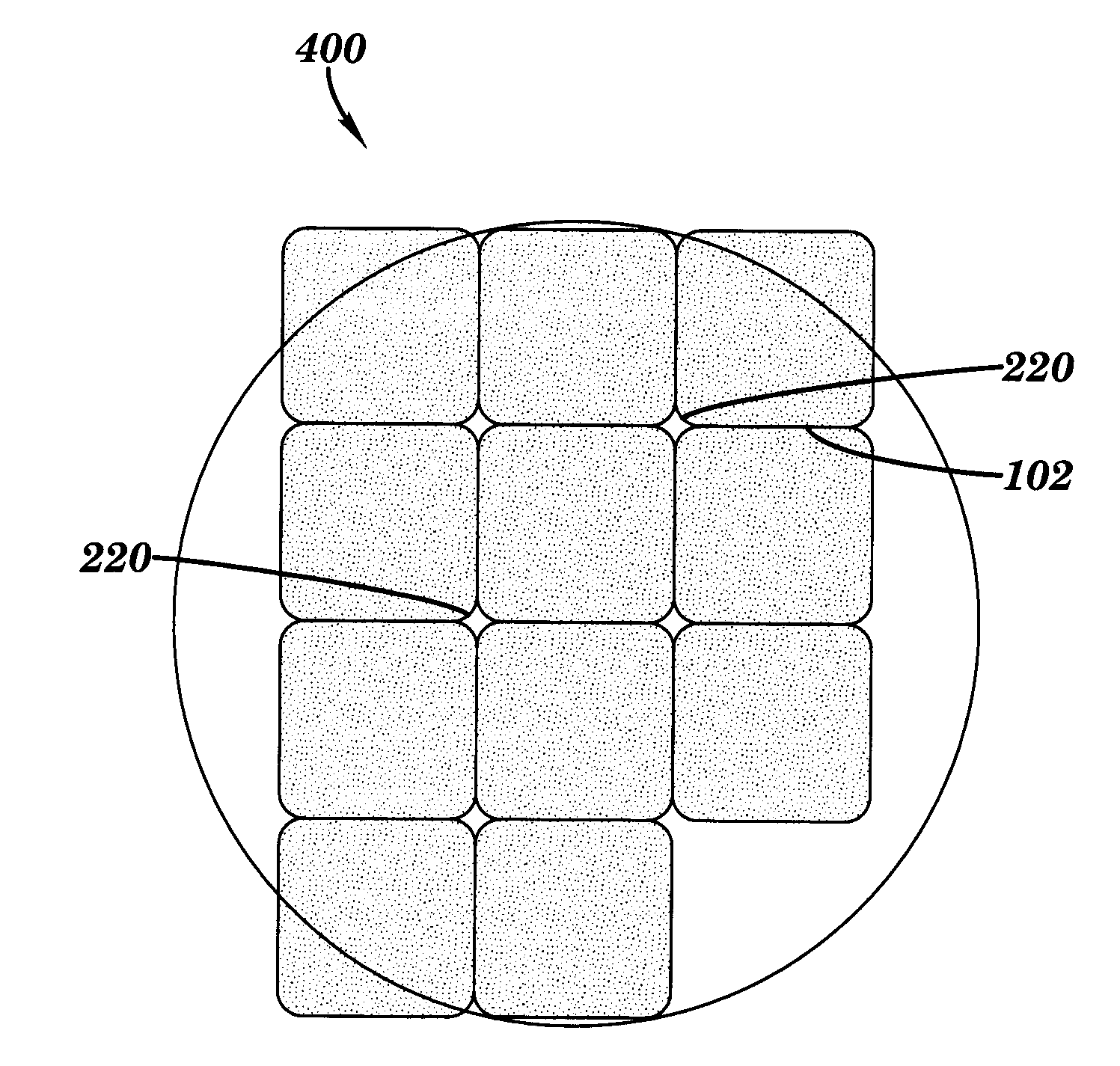

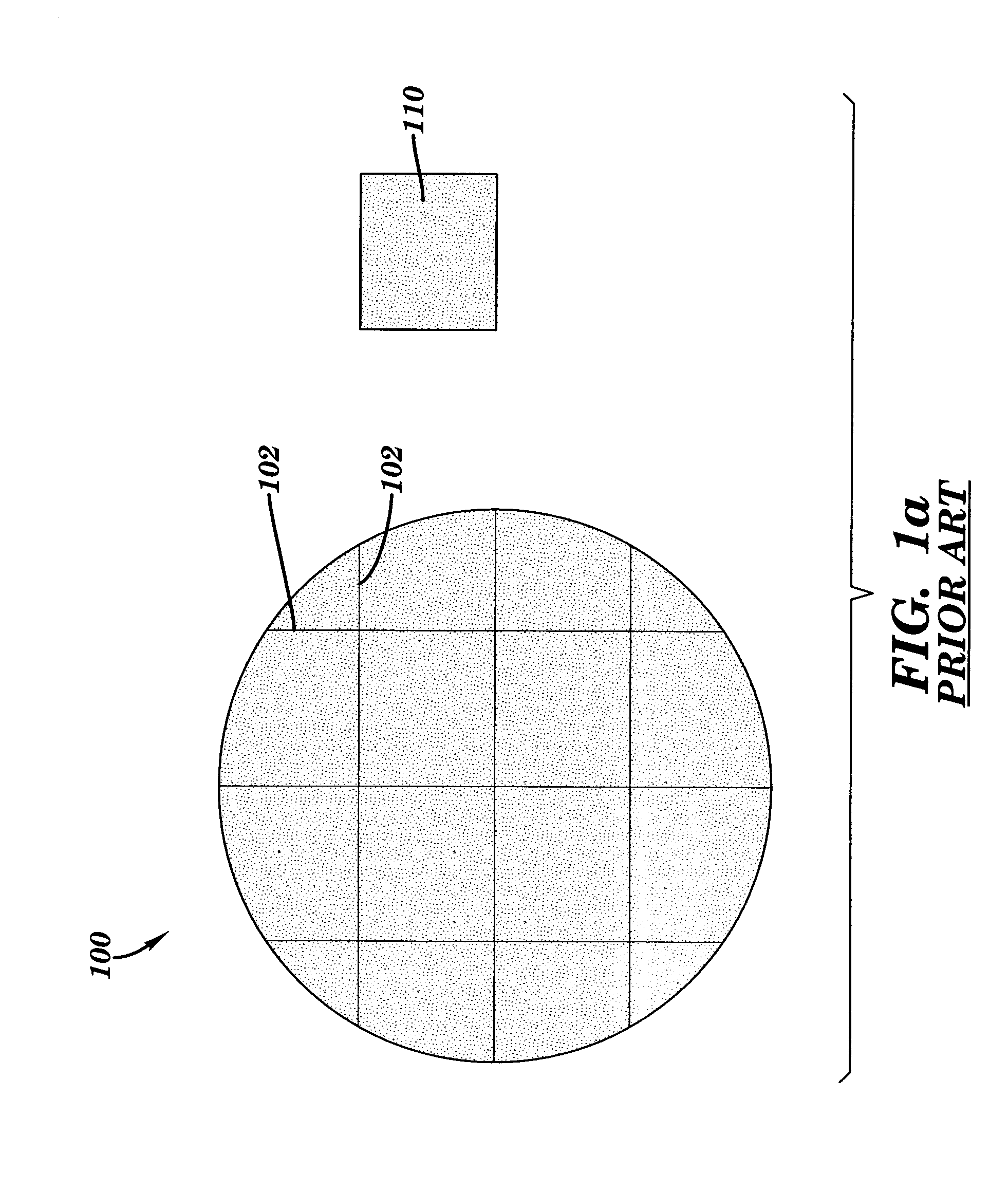

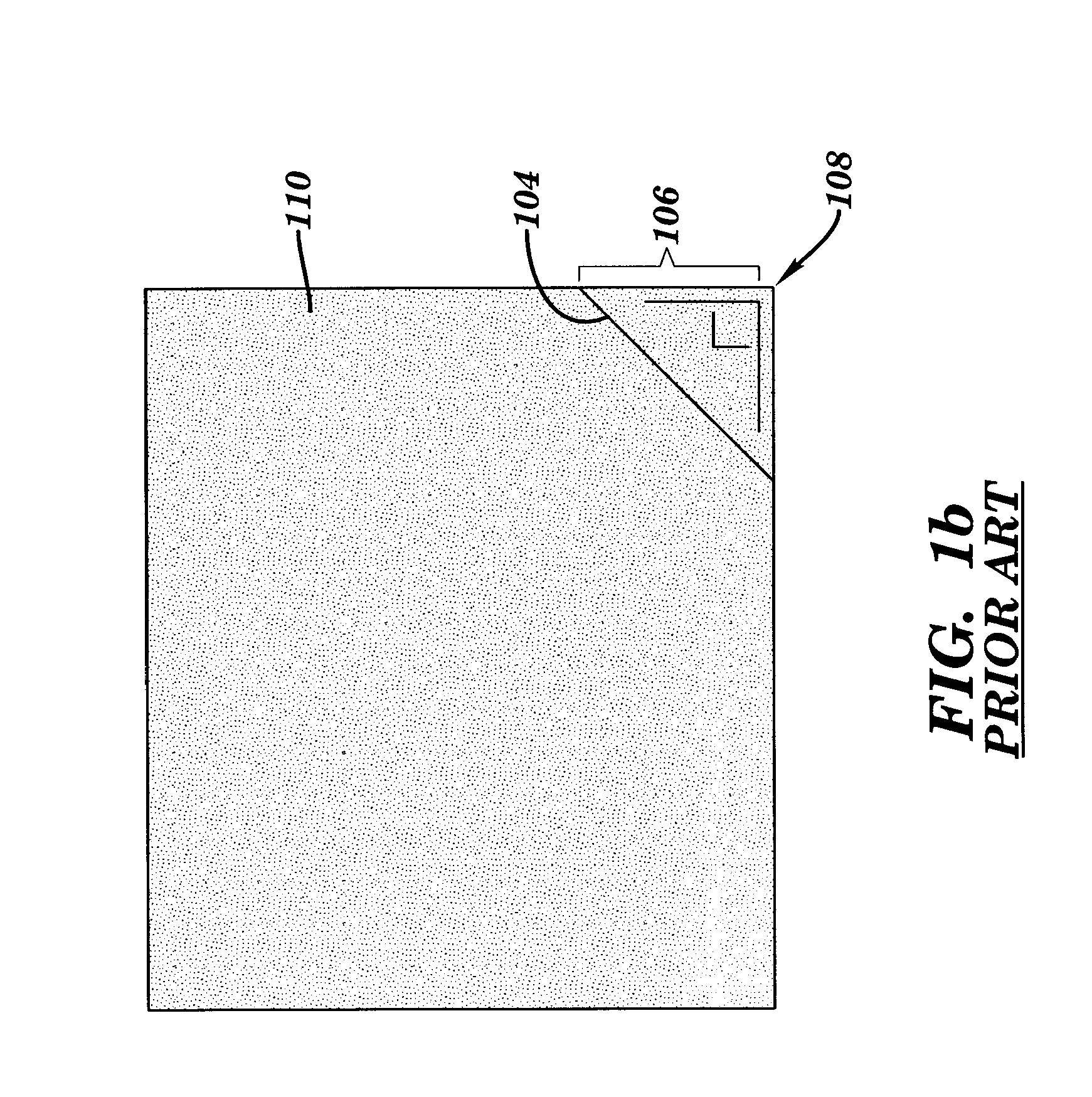

Semiconductor chip shape alteration

InactiveUS20080150087A1Reduce physical stressReduce layeringSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The invention is directed to an improved semiconductor chip that reduces crack initiation and propagation into the active area of a semiconductor chip. A semiconductor wafer includes dicing channels that separate semiconductor chips and holes through a portion of a semiconductor chip, which are located at the intersection of the dicing channels. Once diced from the semiconductor wafer, semiconductor chips are created without ninety degree angle corners.

Owner:GLOBALFOUNDRIES INC

Expandable crack inhibitors and methods of using the same

ActiveUS20120304577A1Extended service lifeImprove fatigue performanceBuilding repairsFoundation repairInterference fitEngineering

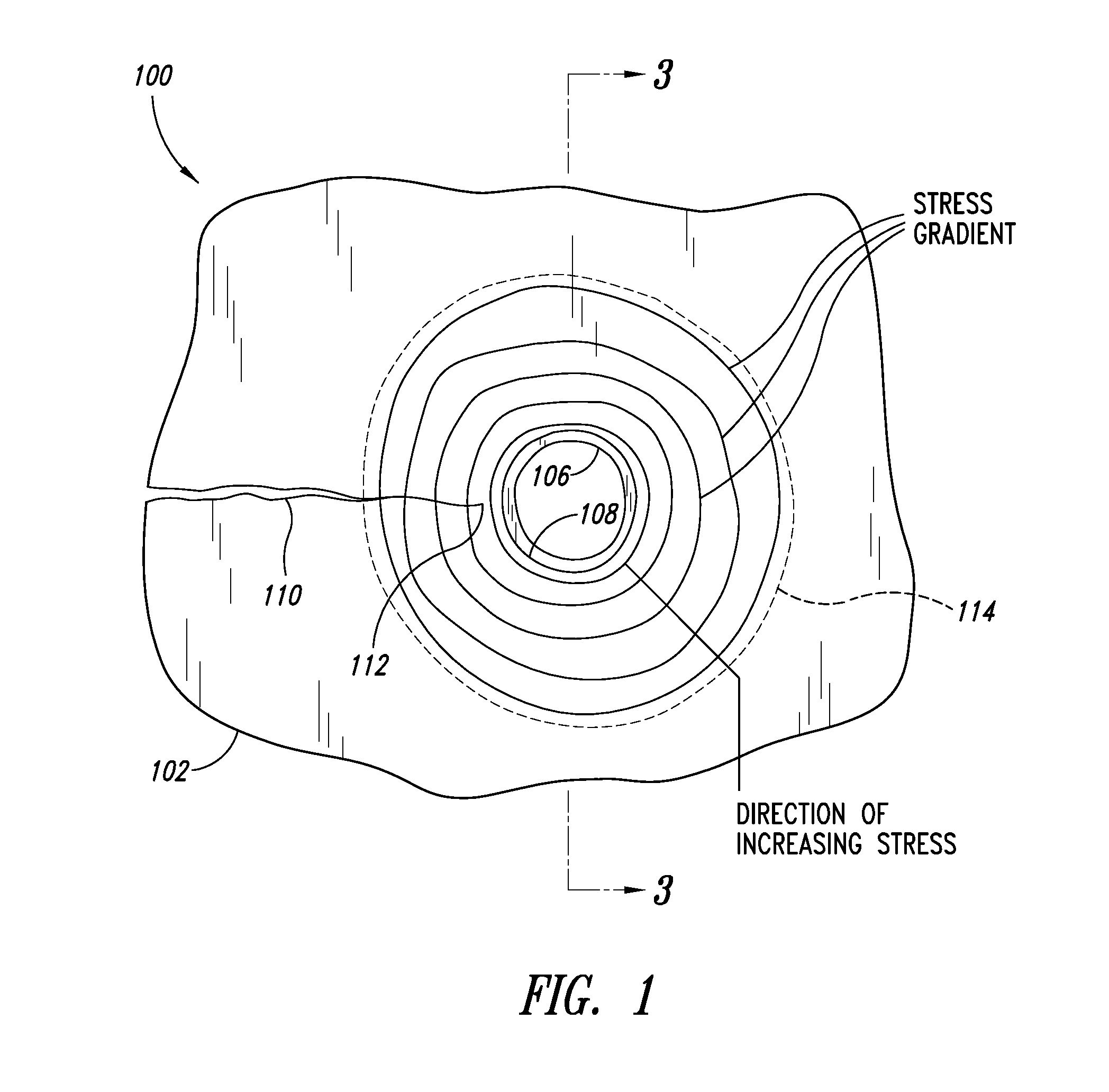

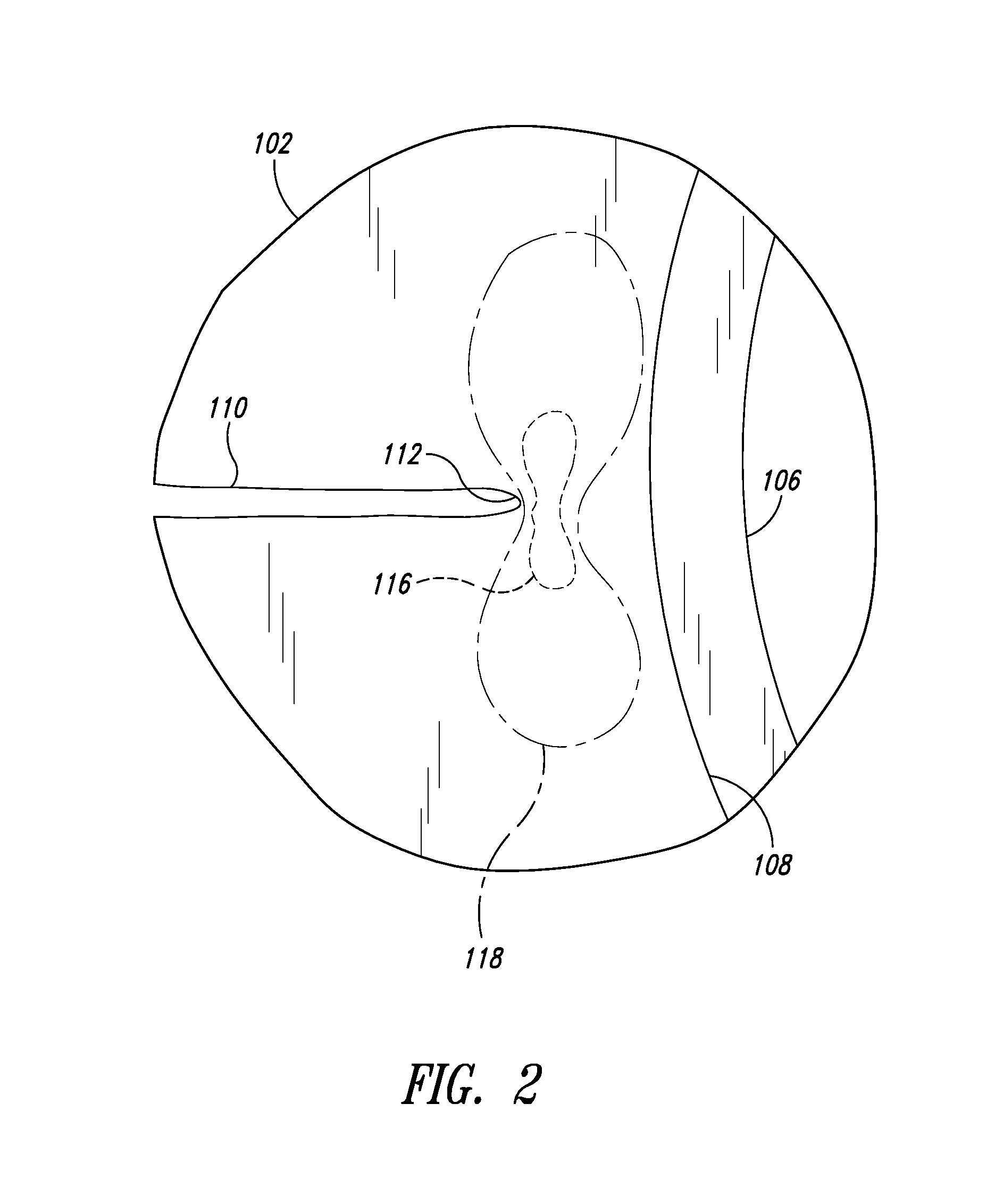

One or more crack inhibitors can be installed to improve fatigue performance by producing stress states that prevent or inhibit crack initiation. Crack inhibitors can also prevent or retard crack growth. A mandrel can be used to radially expand the crack inhibitors to both induce compressive residual stresses and to form an interference fit between the crack inhibitor and a workpiece. The mandrel can be removed from the installed crack inhibitor, which is left in the workpiece to ensure proper stress states are maintained.

Owner:FATIGUE TECH

Continuous casting method of large-length hollow ductile cast iron sections and method for arcing hollow ductile cast iron sections after local continuous heating

InactiveCN101638748ASolve technical problems that are difficult to produceCorrosion resistancePhysical fieldVolumetric Mass Density

The invention relates to a continuous casting method of large-length hollow ductile cast iron sections and a method for arcing the hollow ductile cast iron sections after local continuous heating. Thesection comprises the following components by weight percent: 3.4-3.6% of C, 2.8-3.2% of Si, 0.40-0.60% of Mn, S less than or equal to 0.1%, P less than or equal to 0.1% and the balance Fe. Molten iron is subjected to shaping and continuous casting under multiple physical fields to become the hollow sections. The molten iron in heat preserving furnaces is separated from dross, sand and gas in twoways, thus completely solving the defects of dross inclusion, sand inclusion and pores; liquid column cores in a crystallizer carry out continual feeding on condensing tube shells, thus eliminating the possibility of shrinkage porosity inside the tube walls, obtaining highly dense cast structure of (ferritic matrix+spherical graphite) and eliminating crack initiation origins in thermoplastic deformation to be carried out later. The intense cooling speed in the crystallizer enables the volumes of eutectic cells to be only 1 / 15-1 / 25 of the volumes of traditional sand mould casts. The density ofthe graphite balls reaches around 500 / mm<2>. In plastic deformation, the micro slip orientation is increased and the ductility is enhanced, therefore, the hollow cast iron sections can be arced by medium frequency induction heating and bending.

Owner:SHAN XI TONGXIN LIANZHU PIPE IND

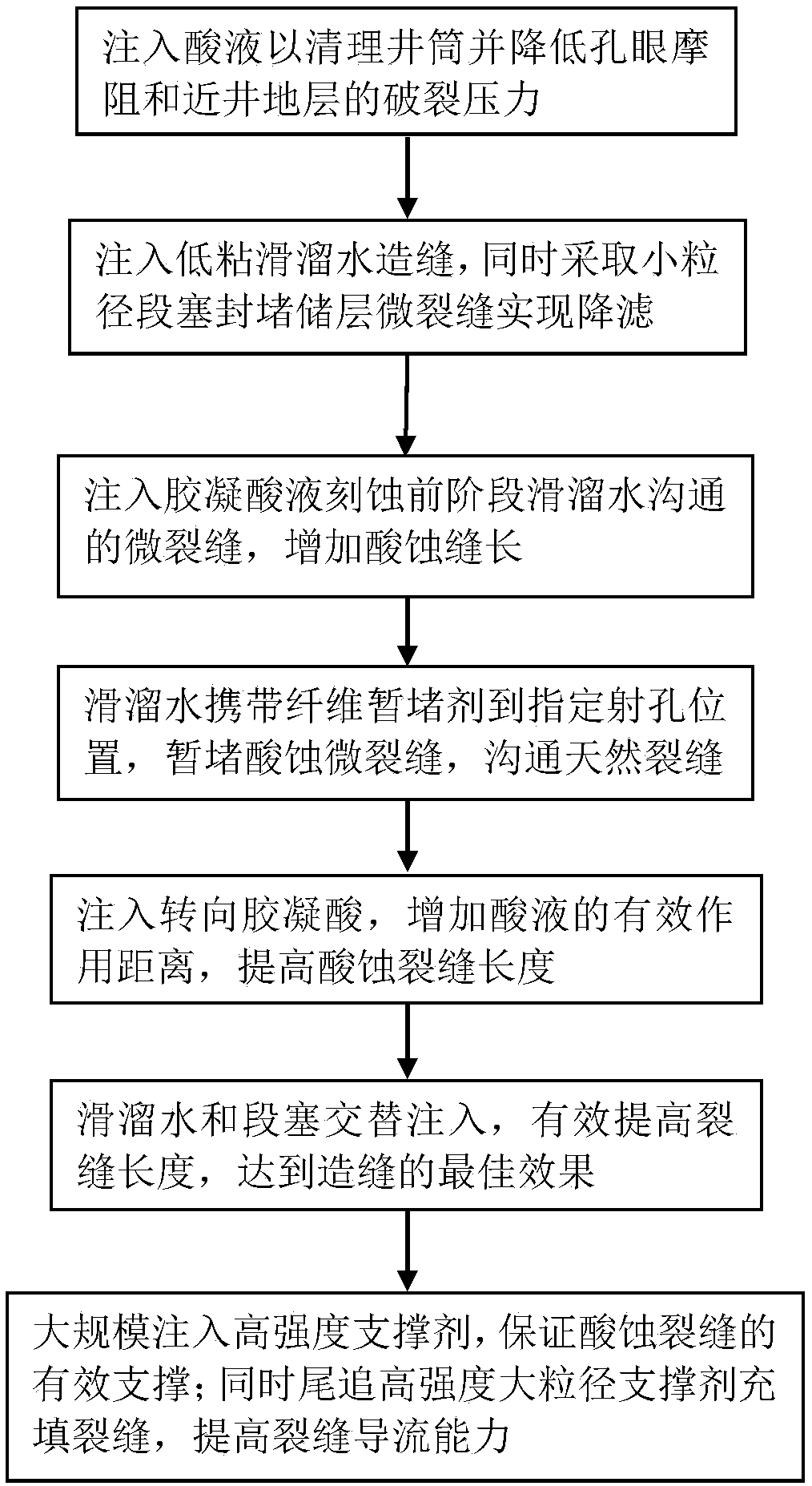

Volume fracturing method for crack net of carbonate reservoir

ActiveCN109296350AImprove diversion capacityReduce shut-in timeFluid removalAcid fracturingAcid etching

The invention relates to a volume fracturing method for a crack net of a carbonate reservoir. The volume fracturing method comprises the following steps that (1) initial crack initiation is conducted,specifically, slickwater is injected into a pretreated formation for crack making, then gel acid is injected for conducting acid etching transformation on cracks, and the crack length is increased; (2) temporary blocking in the cracks is conducted, specifically, microcracks formed by acid etching formation are temporarily blocked through temporary blocking agents carried by the slickwater; (3) turning for acid fracturing is conducted, specifically, gel acid is injected into the temporarily-blocked formation, and after the temporary blocking agents are displaced in place by the gel acid, the gel acid turns to other parts for acid etching transformation; (4) crack making through slickwater is conducted, specifically, slickwater is injected into the formation subjected to acid etching transformation in the step (3) for crack making; and (5) crack-expansion supporting is conducted, specifically, sand-carrying fluid is injected into the formation subjected to crack making in the step (4) for supporting. According to the volume fracturing method for the crack net of the carbonate reservoir, liquid leak-off can be effectively reduced, the effect of 'near-control and far-expansion' is achieved, the abundant secondary cracks can be formed, connectivity with main cracks and natural cracks is improved, and thus the transformation effect of volume fracturing is improved.

Owner:中石化石油工程技术服务有限公司 +1

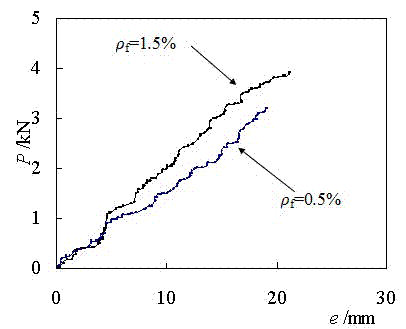

Testing method of steel fiber reinforced concrete fracture test crack initiation load

ActiveCN103760036AReduce test costsLower requirementMaterial strength using steady bending forcesStress intensity factorClassical mechanics

The invention relates to a testing method of steel fiber reinforced concrete fracture test crack initiation load, and belongs to the technical field of concrete cracking parameter testing. The testing method provided by the invention is characterized in that when a steel fiber reinforced concrete coped beam specimen cracks, a stress intensity factor of a prefabrication crack front edge achieves concrete fracture toughness, and the steel fibre blocking action is not exerted; the stress intensity factor generated by external load and concrete cracking toughness(i)K( / i) IC are equal, the external load value which is corresponding to a numerical value (i)K( / i)IC of the stress intensity factor generated by the external load can be used for determining the crack initiation load according to the curve relation graph of the external load and the stress intensity factor (i)K generated by the external load (img file='2014100081259100004dest_path_image002.TIF'wi='8'he='21' / )( / i)-(i)P( / i) curve relational graph. The testing method provided by the invenytion has the advantages that the required equipment, analyzing and processing method are simple, the cost is low, and the precision is high.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

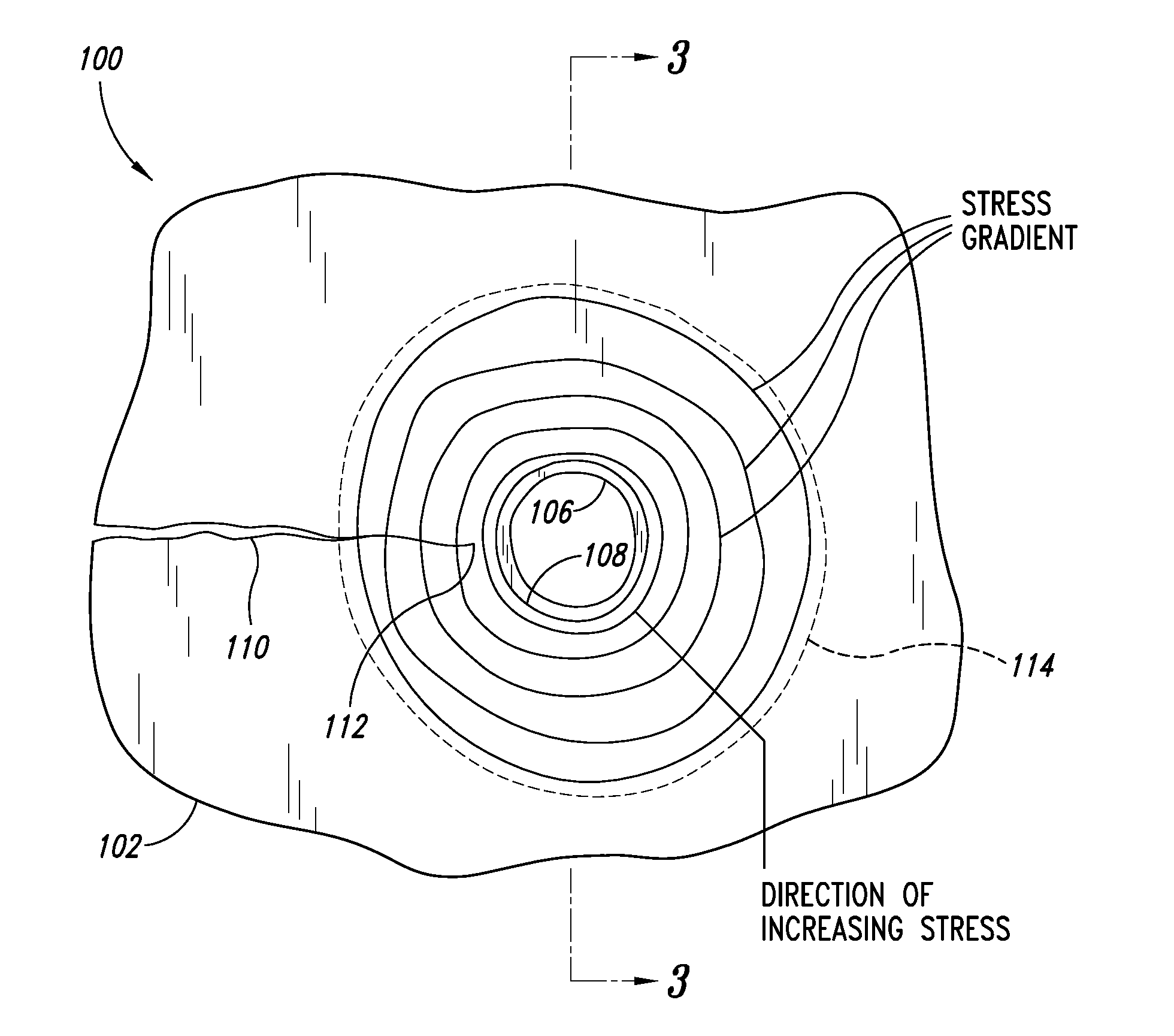

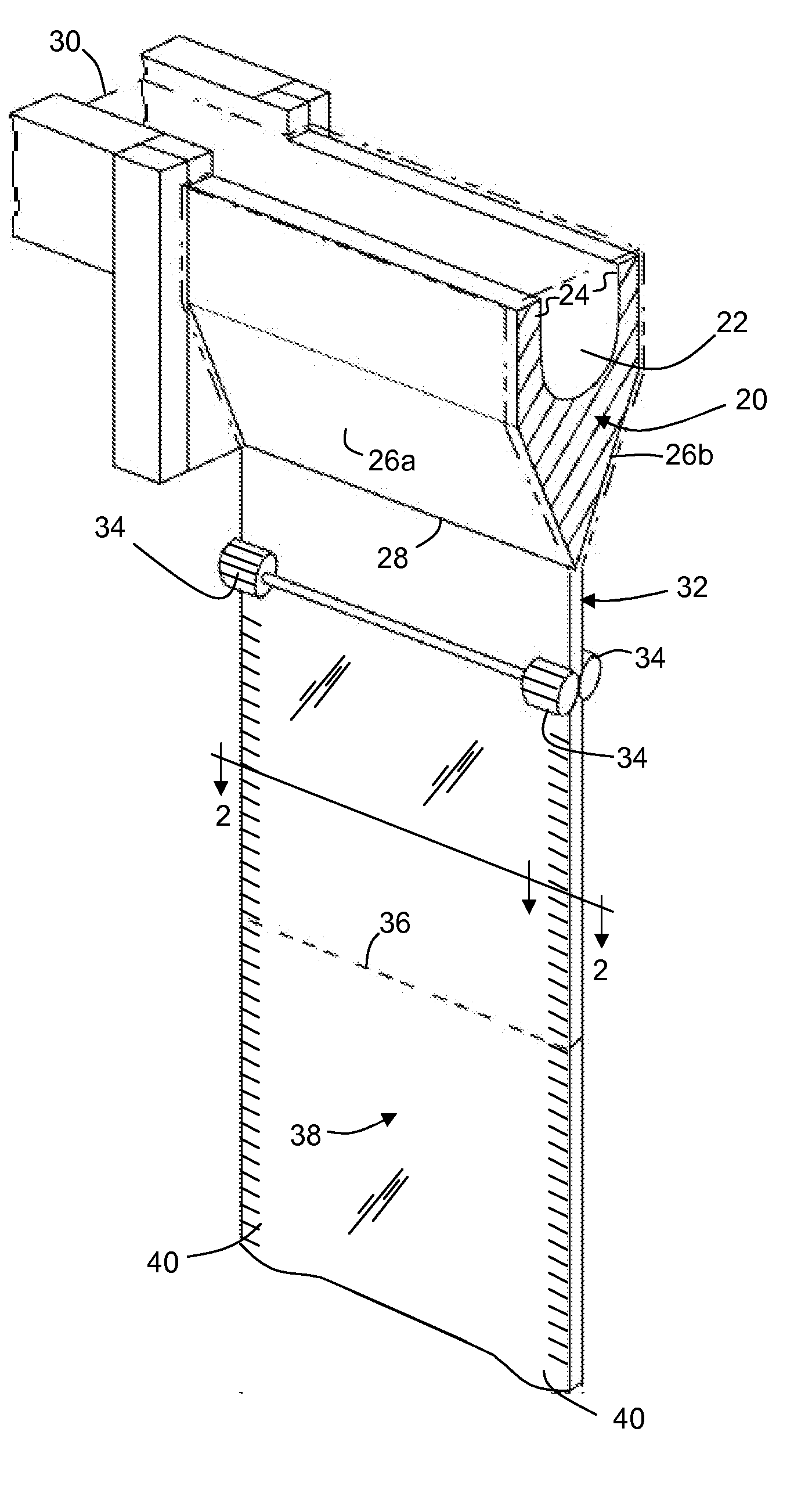

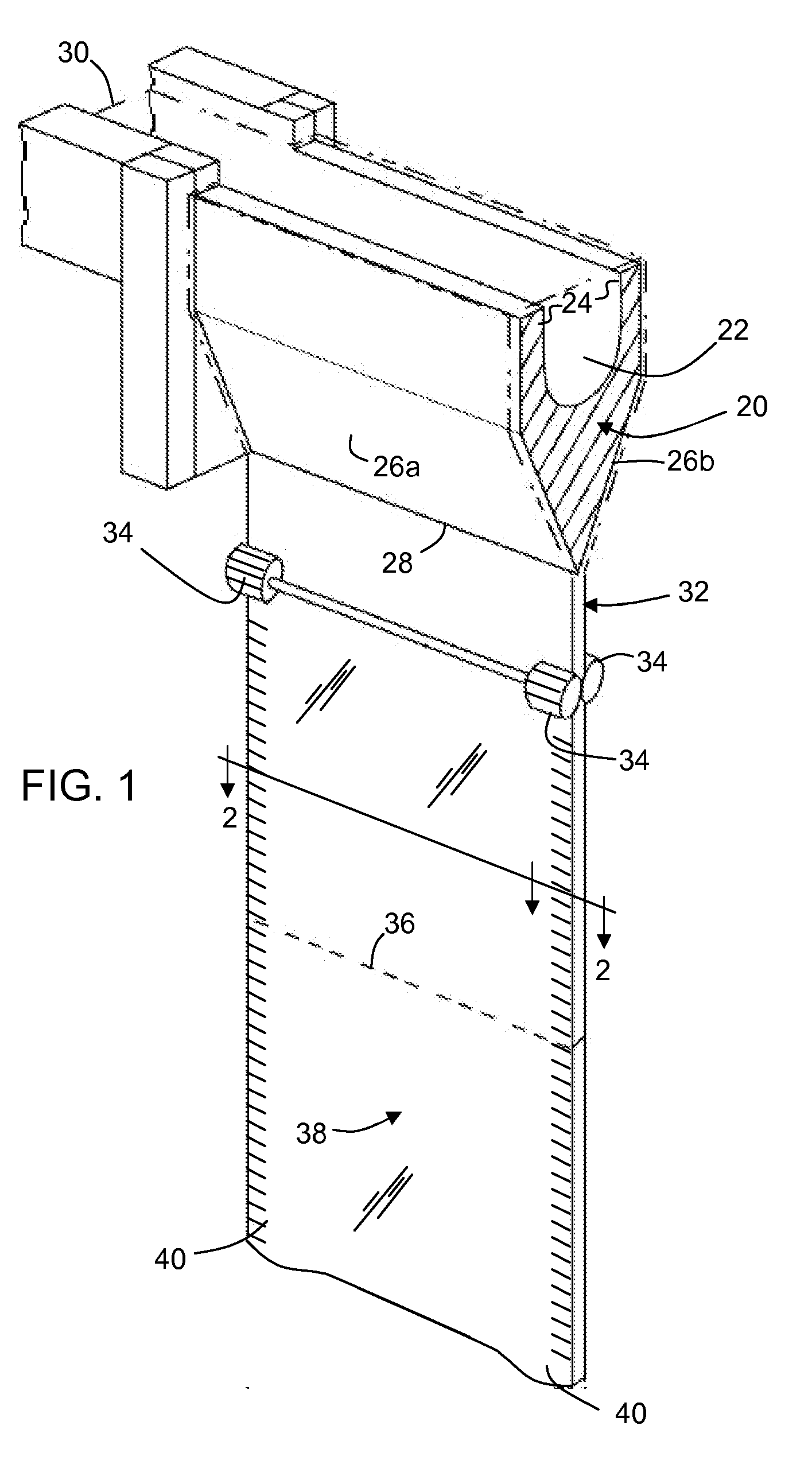

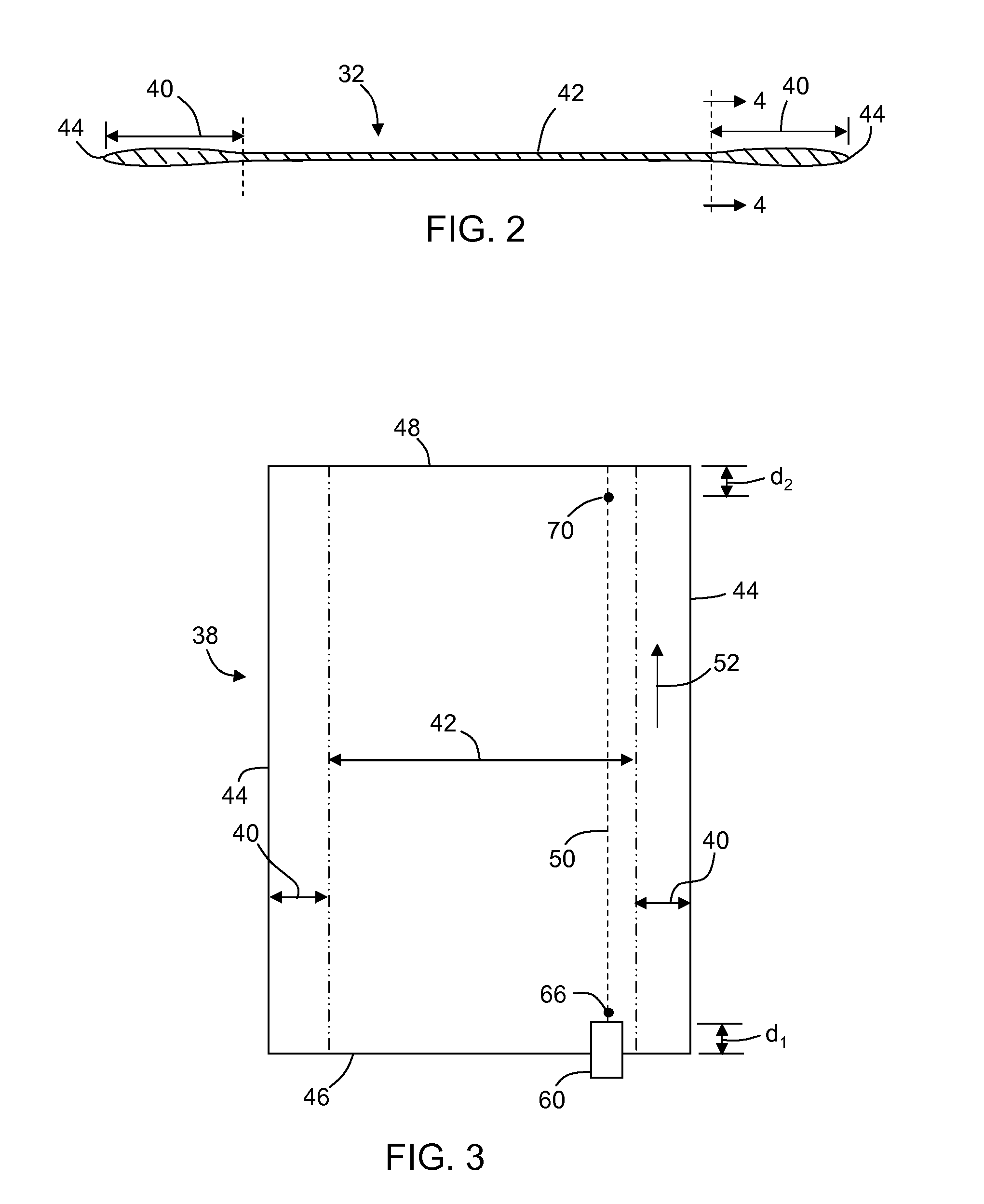

Method for scoring a sheet of brittle material

InactiveUS20100212361A1Increase pressureImprove scoreGlass reforming apparatusGlass severing apparatusCutting glassLight beam

A method of cutting glass that prevents uncontrolled crack propagation when high background stress is present, either in the form of thermal residual stress, external mechanical stress or a combination thereof. The method includes masking an edge of the glass by blocking the beam using highly reflective or absorptive material located near the glass surface, or deposited on the surface in a form of a thin film (or highly reflective paint) to prevent uncontrolled crack initiation and propagation starting from the glass edge. The initiation of the laser scoring is located at a predetermined distance from the glass edge. Yet another aspect of the invention embodies stopping propagation of the vent at the exiting end of the score line.

Owner:CORNING INC

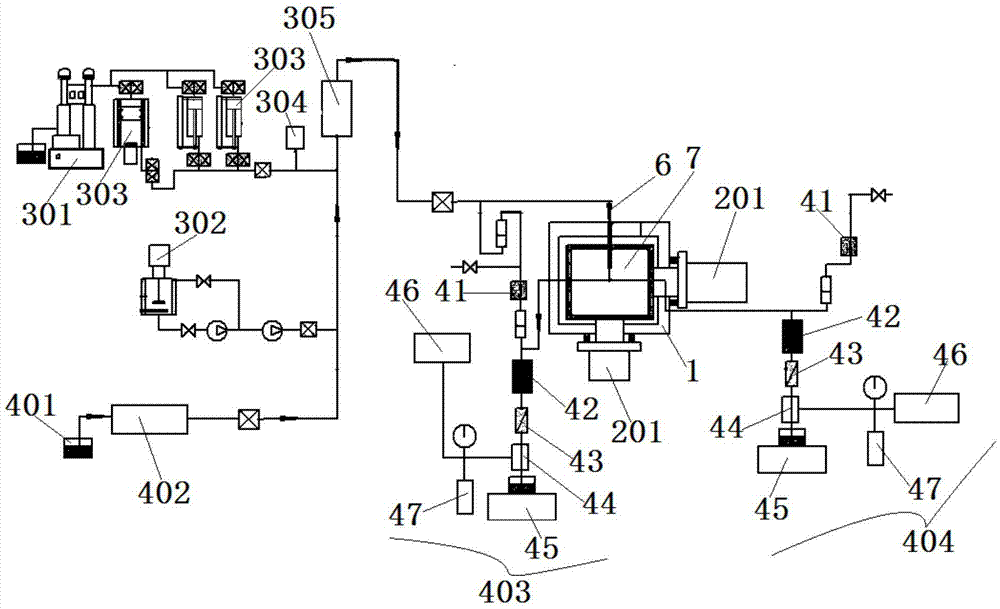

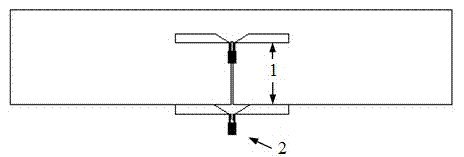

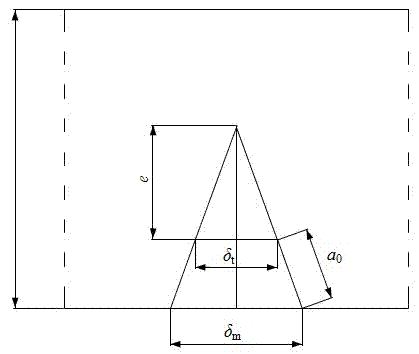

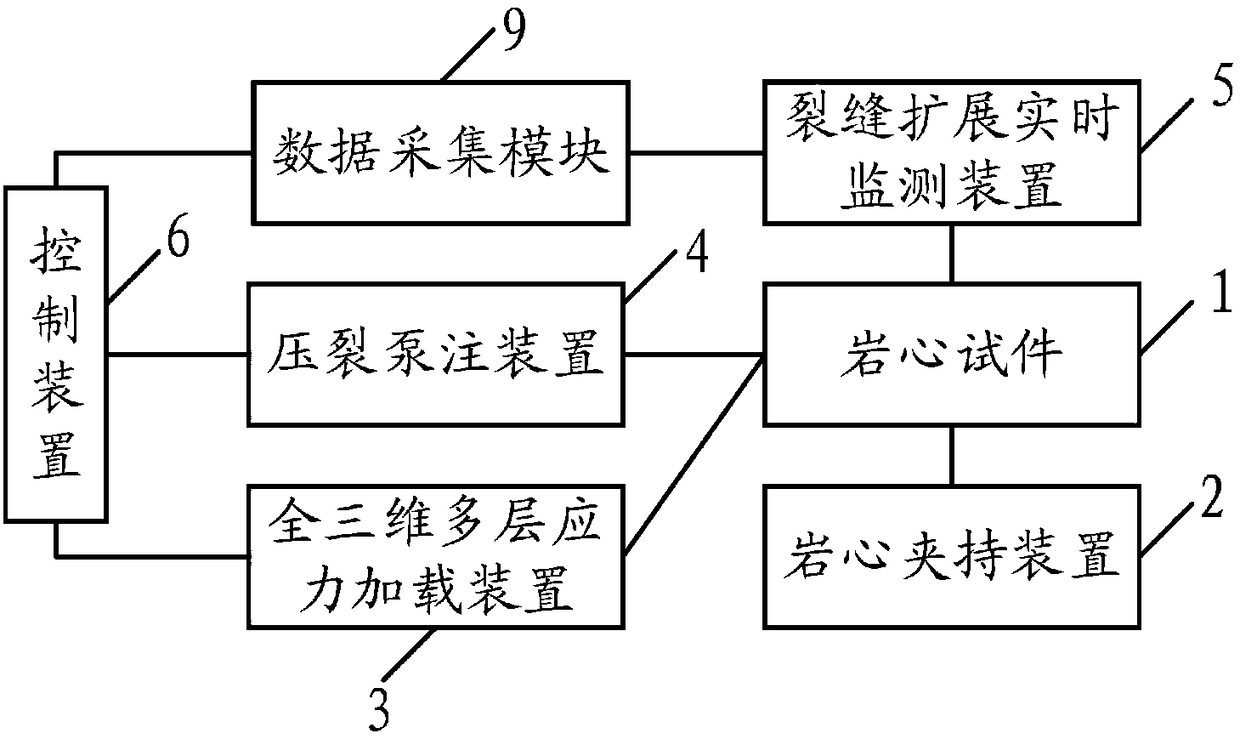

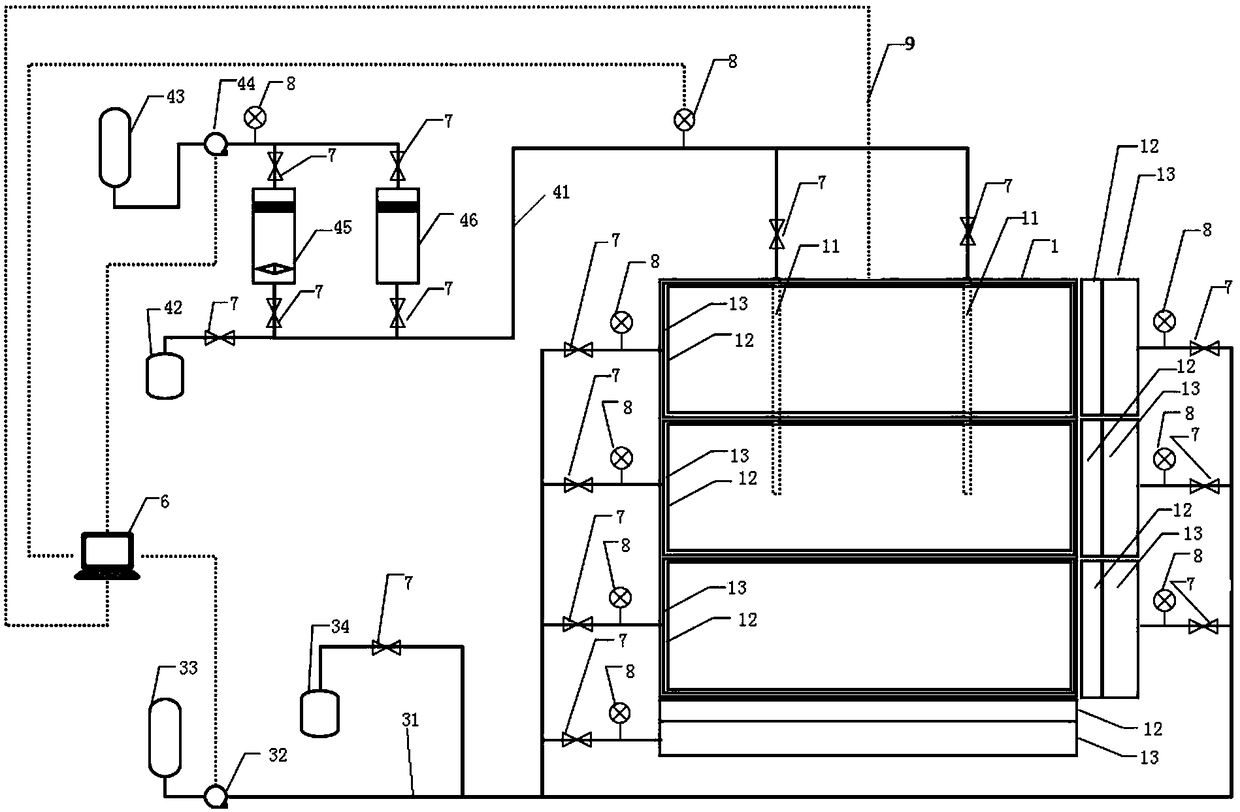

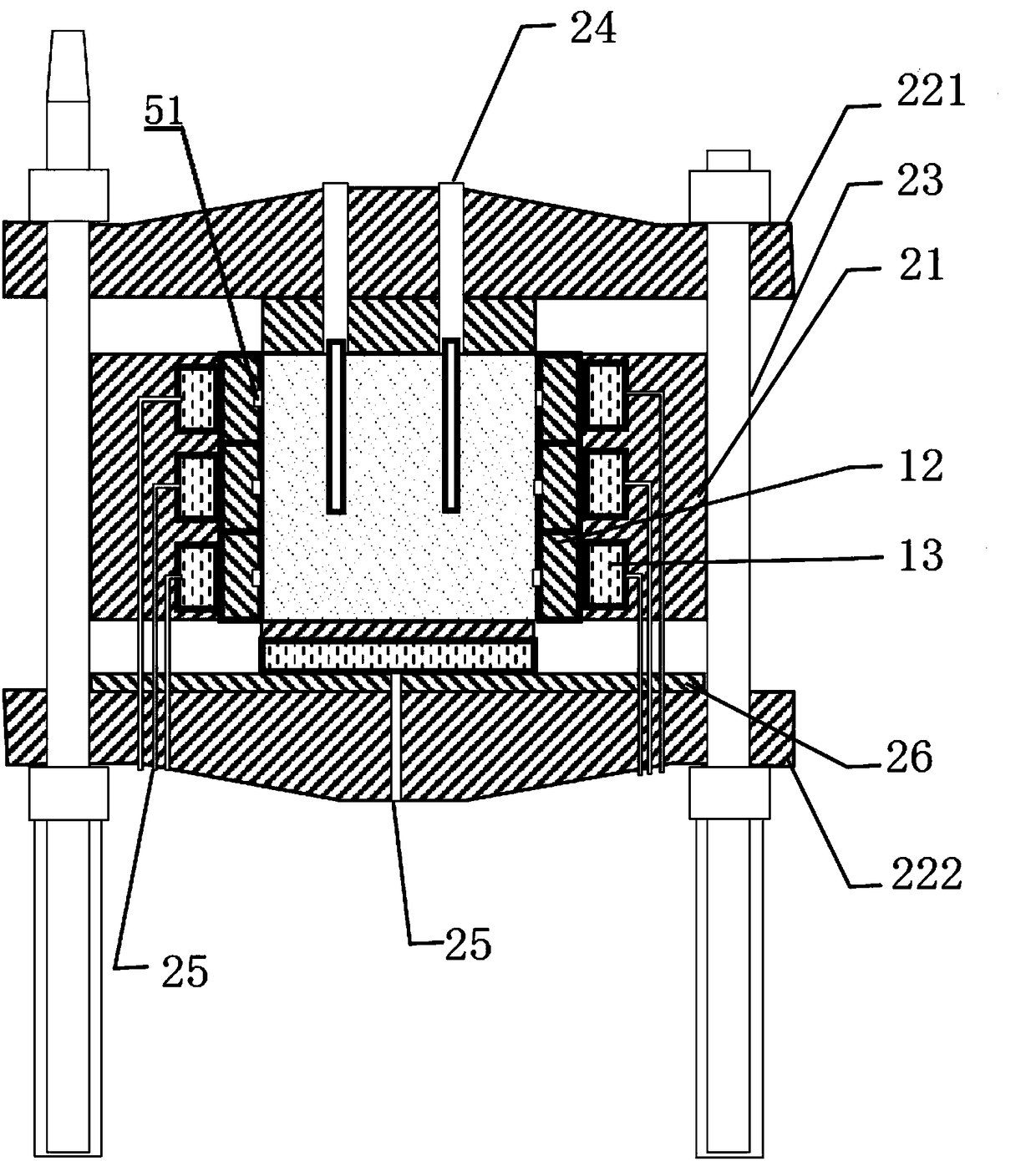

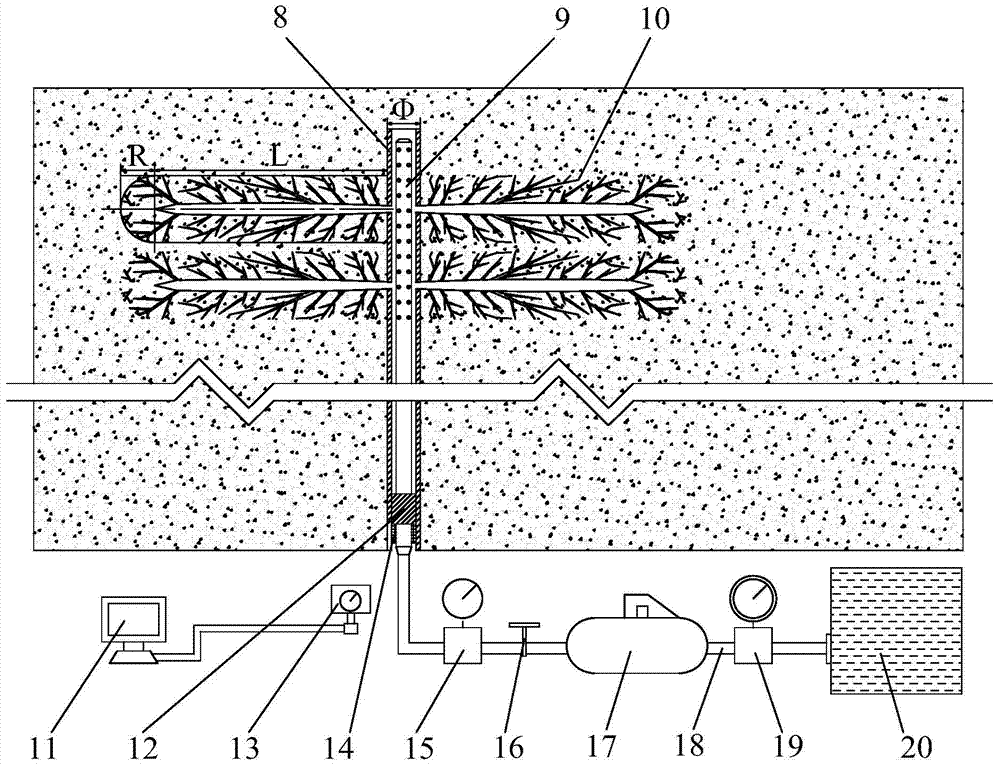

Three-dimensional multilayered multi-well fracturing prop crack real-time monitoring experimental system and method

The invention discloses a three-dimensional multilayered multi-well fracturing prop crack real-time monitoring experimental system and method. The experimental system comprises a core test specimen, acore clamping device, a fully-three-dimensional multilayered stress loading device, a fracturing pumping-in device, a crack expansion real-time monitoring device and a control device. The invention provides the three-dimensional multilayered multi-well fracturing prop crack real-time monitoring experimental system and method, under the conditions that three-directional stress is applied, and twohorizontal directions are layered stresses, the core specimen which includes a plurality of shafts simulates hydraulic fracturing and sand supporting, by crack initiation on fracturing cracks and real-time and quantitative monitoring and later interpretation on crack induction stress of an expansion process, crack initiation of three-dimensional multilayered multi-well fracturing prop cracks and quantified description of the expansion process are realized, and the laying state of a propping agent in the cracks can be obtained.

Owner:唐山合众启航科技有限公司

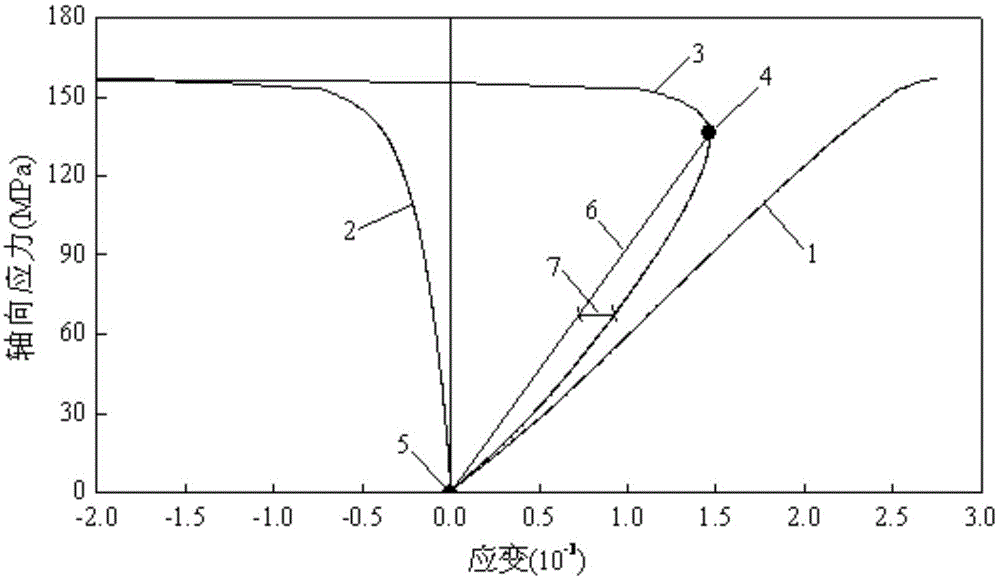

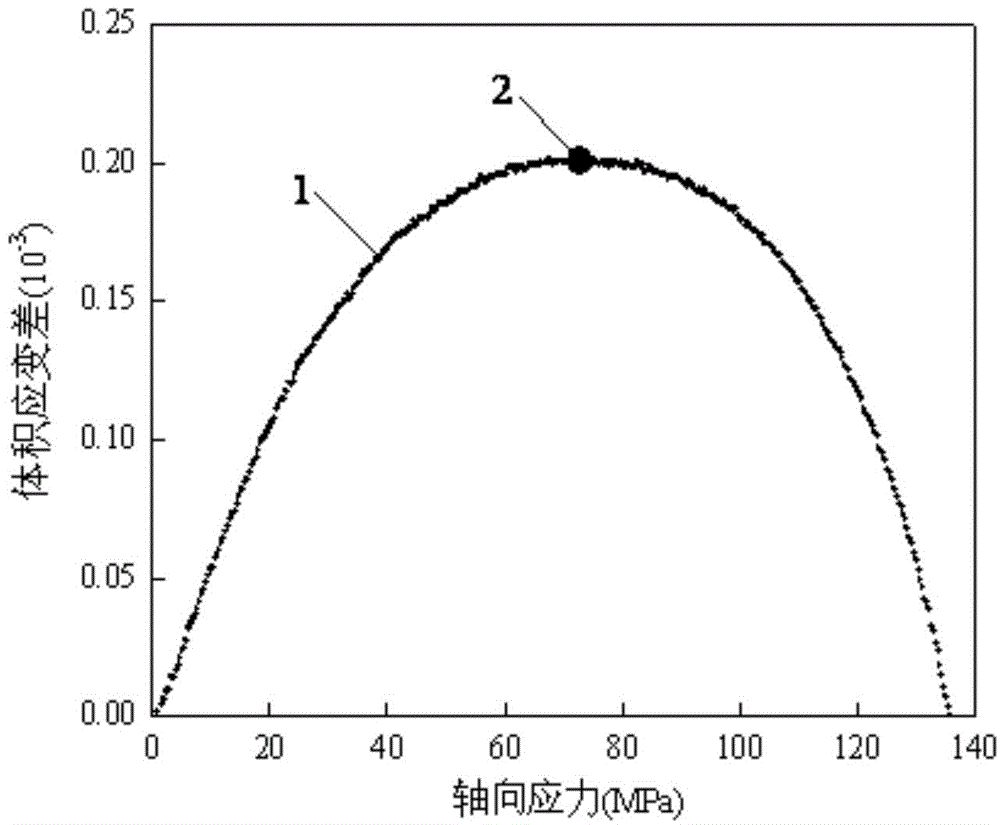

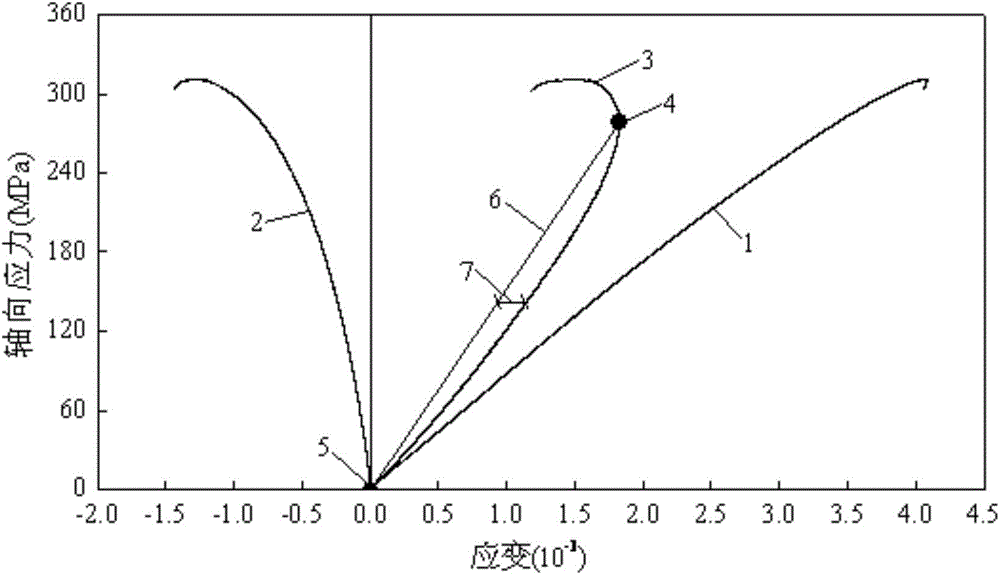

Method for determining crack initiation strength of rock under compressive conditions

InactiveCN104458413AUniqueness guaranteedThe method is simple and reliableMaterial strength using tensile/compressive forcesStress levelRock sample

The invention relates to a method for determining the crack initiation strength of a rock under compressive conditions. The method includes the following steps: 1, processing a rock sample; 2, arranging the rock sample on the sample bench of a press; 3, axially loading the sample in a load control mode until the sample is destroyed; 4, calculating the volumetric strain of the sample; 5, determining the crack damage strength in a volumetric strain-axial stress curve; 6, connecting a zero point with the crack damage strength point in the volumetric strain-axial stress curve to form a reference line; 7, calculating a difference between the strain value in the volumetric strain-axial stress curve and a strain valve corresponding to the reference line under a same stress level from the zero point to the end of the crack damage strength; and 8, making a volumetric strain and axial stress relation point diagram, and determining the stress corresponding to the peak of the volumetric strain difference as the crack initiation strength of the rock. The method is suitable for mechanical test of the rock, serving for underground engineering.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Perforation fracturing permeability-improvement method for high-stress low-porosity coal seam

InactiveCN103939077AEffective anti-reflection for fracturingHigh densityFluid removalGas removalPorosityHigh pressure water

The invention discloses a perforation fracturing permeability-improvement method for a high-stress low-porosity coal seam, and belongs to the field of disaster prevention and control of mining working faces of coal mines. The method comprises the steps that firstly, coal body mechanical properties are measured, and related technical parameters such as the perforation depth, coal body crack initiation pressure, the fracturing permeability-improvement radius, the separation distance between drilled holes and the separation distance between perforations are determined; then, a coal seam perforation system is installed, and perforation operation is conducted on the coal seam perforation system; after perforation operation is accomplished, a hydraulic fracturing system is installed, fracturing is started, water is injected, and changes of a pressure value are observed until fracturing operation is accomplished. According to the method, a fracturing structure is additionally arranged in a coal body, elastic potential energy of the coal body can be released effectively, and a preparation is made for rock burst prevention and control work of the working faces; meanwhile, high-pressure water can play a good role in moistening the coal seam, the quantity of dust produced during mining of the coal seam is reduced, creation of a good working environment is facilitated, and physical health of underground workers is protected.

Owner:SHANDONG UNIV OF SCI & TECH

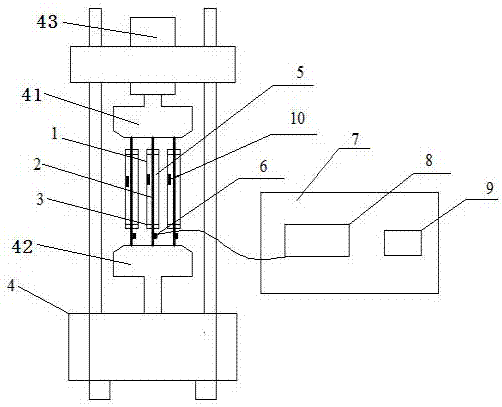

Test method and device for monitoring steel wire fretting fatigue state

InactiveCN102353590AReal-time dynamic recording of tangential force changesReal-time dynamic recording of acoustic emission signalsMaterial strength using tensile/compressive forcesInvestigating abrasion/wear resistanceFrettingAcoustic emission

The invention discloses a test method and a device for monitoring a steel wire fretting fatigue state. The device comprises a base, a support column, a top beam, a hydraulic lifting platform and a horizontal loading device. The test method comprises the following steps that two ends of a tested steel wire passing through the horizontal loading device are fixed respectively; the tested steel wire is stretched until the tested steel wire bears a preset initial load; the horizontal loading device is moved so that loading steel wires in the horizontal loading device compress tightly the tested steel wire; the hydraulic lifting platform is controlled to move up and down to apply alternate loads to the tested steel wire; the tested steel wire generates fretting fatigue; a tangential force is transmitted to a spoke-type pull-press sensor through an internal thread connecting rod arranged on a loading block, wherein an acoustic emission sensor is arranged on an upper grip block of the top beam; and the test is stopped when the tested steel wire is broken because of fretting fatigue. The device can dynamically record a tangential force between contact steel wires and tested steel wire acoustic emission signals in an experimental process, and provides an effective basis for research on a steel wire fretting zone, crack generation and fracture mechanisms of a fretting zone, and influences of the crack generation and the fracture mechanisms on a fretting fatigue life. The device has a simple structure, is convenient for operation and has good effects.

Owner:CHINA UNIV OF MINING & TECH

Test method for acoustic emission detection cable coating corrosion fatigue crack initiation and growth

ActiveCN107219119AOptimal critical thicknessMaterial analysis using acoustic emission techniquesMaterial strength using tensile/compressive forcesCrazingAcoustic emission

The invention relates to a test method for acoustic emission detection cable coating corrosion fatigue crack initiation and growth. The test method comprises the following steps of manufacturing a coating cable sample, searching for critical rupturing tensile force, configuring a corrosion medium, filling with the corrosion medium, clamping the coating cable sample, carrying out a fatigue test, recording a crack initiation moment, carrying out a crack growth test, evaluating a crack growth rate, drawing an S-N curve and searching for the optimal coating thickness. According to the test method provided by the invention, the crack initiation moment and the crack growth rate of the coating cable sample can be effectively monitored, the optimal coating thickness under different stress amplitudes can be found, the service life of the cable coating is prolonged, and the economic loss is reduced.

Owner:HOHAI UNIV

Coal series fault formation simulation test device and forward and reverse fault simulation test method

InactiveCN110006757AAchieve regulationGuaranteed to move up and downMaterial strength using tensile/compressive forcesLifting devicesNormal faultCoal

The invention discloses a coal series fault formation simulation test device and a forward and reverse fault simulation test method. The invention relates to the technical field of similar material simulation tests. The device comprises a hydraulic lifting device, a lower angle adjusting device, a push rod device, an upper loading device, an upper angle adjusting device, a lateral loading device and a transparent side plate, the hydraulic lifting device and the angle adjusting mechanism are arranged below the experiment body, the upper loading device and the upper angle adjusting device are arranged above the experiment body, the transparent side plate is arranged on the rear side face of the experiment body, and the lateral loading device is arranged on the end face of the experiment body. When the device is used for simulating the normal fault, the inclination angle of the inclined plate of the lower angle adjusting device is the same as that of the inclined push plate of the upper angle adjusting device, and the upper loading system loads downwards to form the normal fault; when the reverse fault is simulated, a fault inducing device is arranged at the bottom of the experimentalbody, and the reverse fault is formed through loading of a lateral loading device. The technical problem that the fault inclination angle and the crack initiation position of the simulated fault areinconvenient to control is solved.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com