Patents

Literature

1592results about How to "The method is simple and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

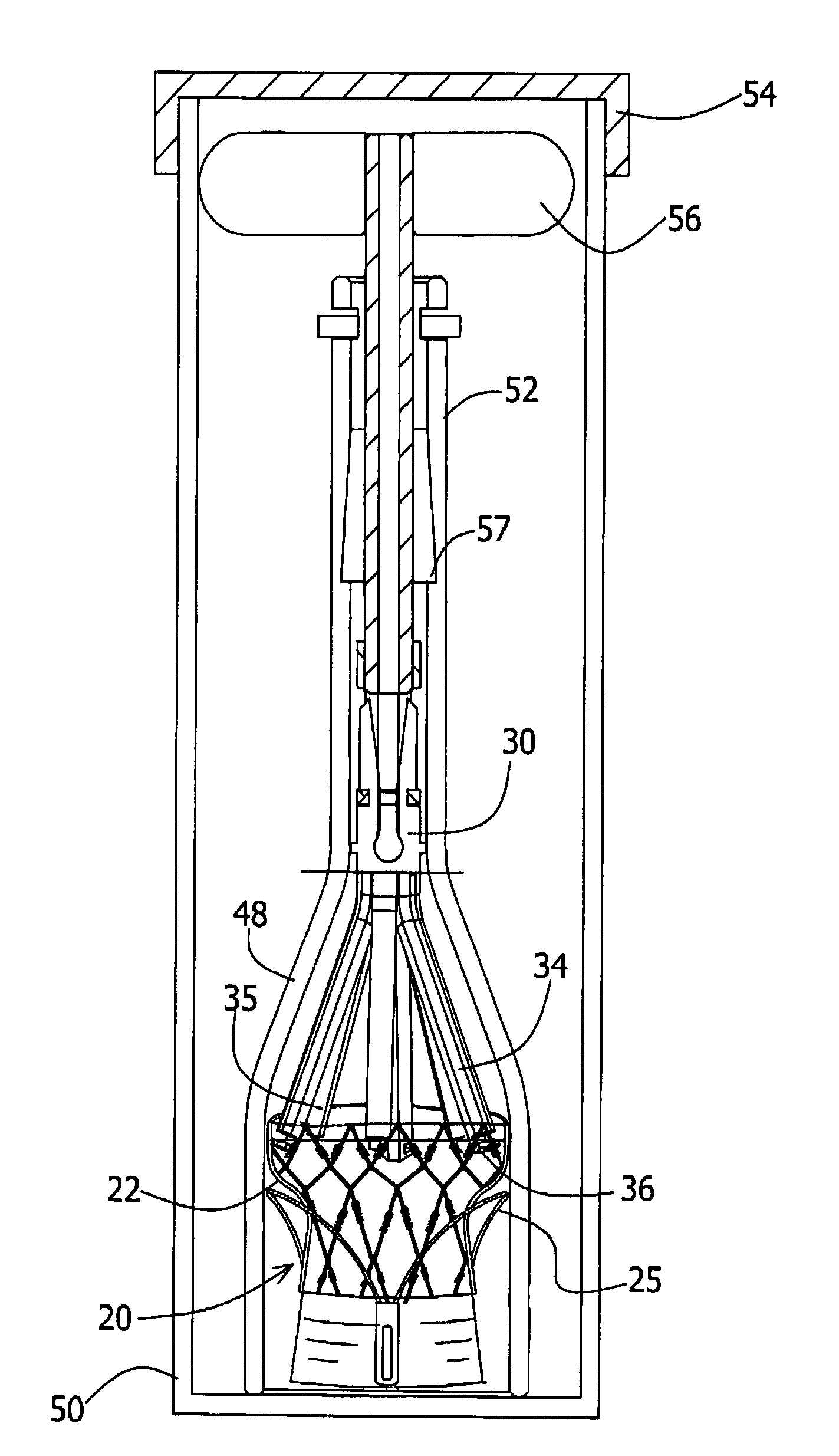

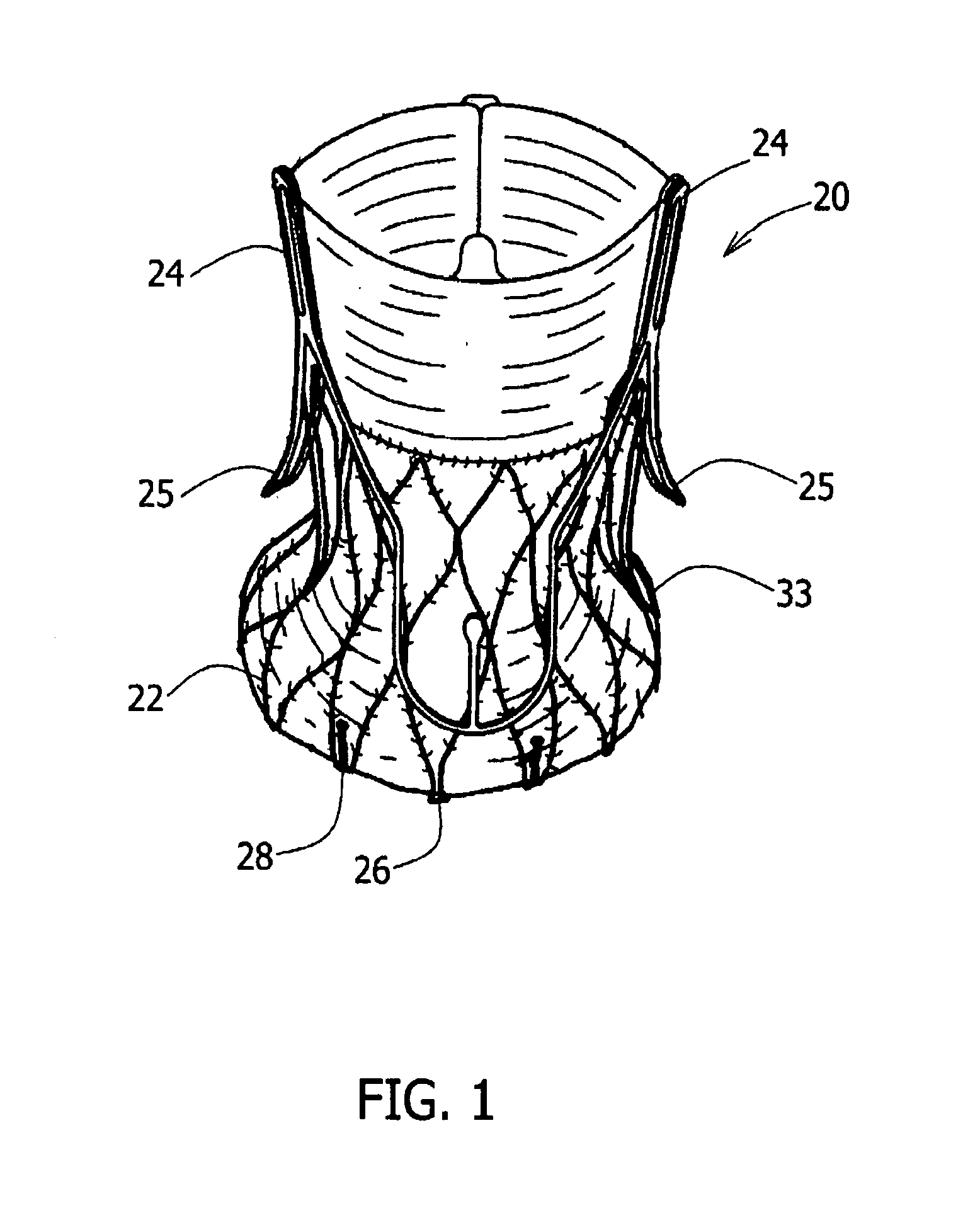

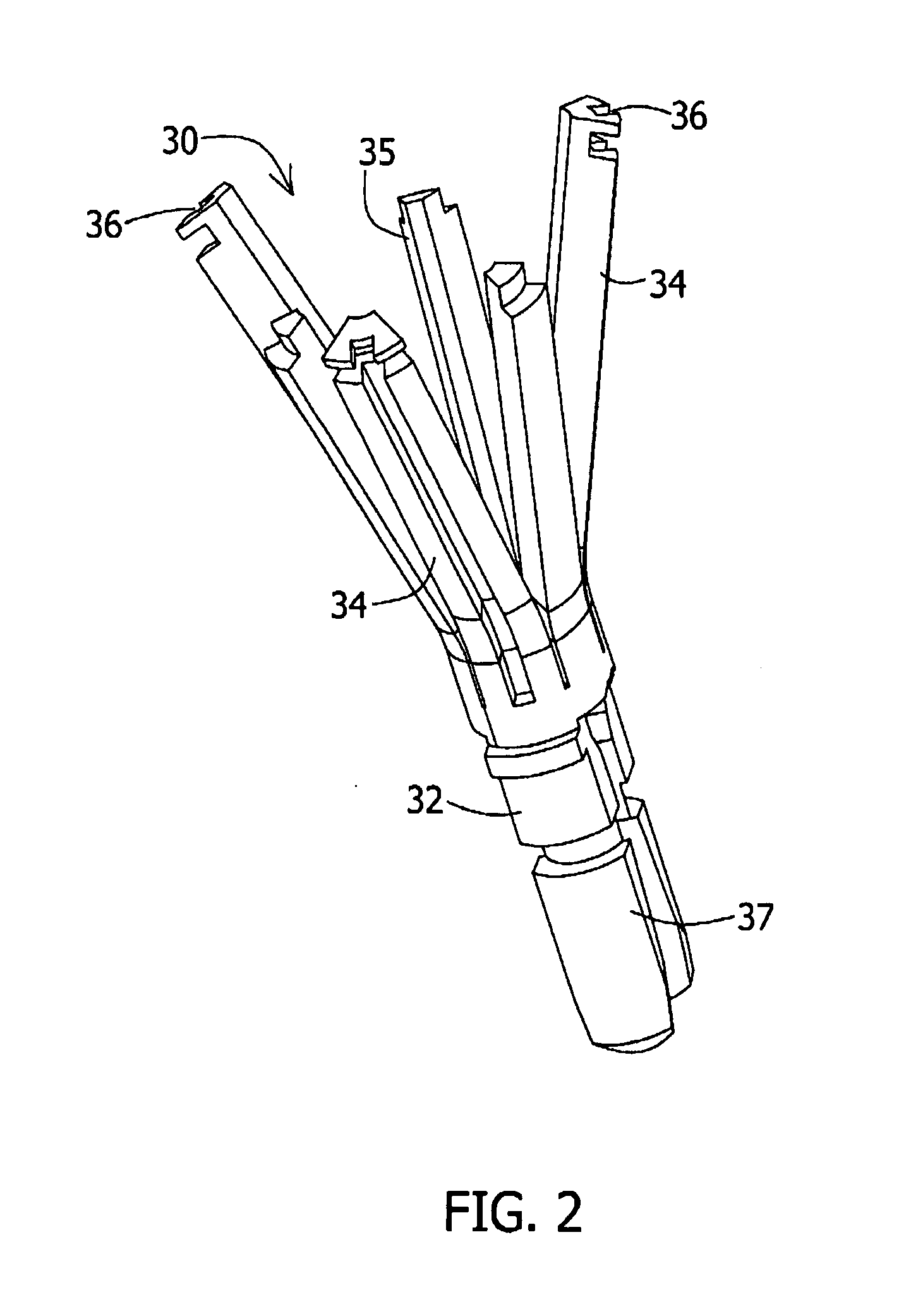

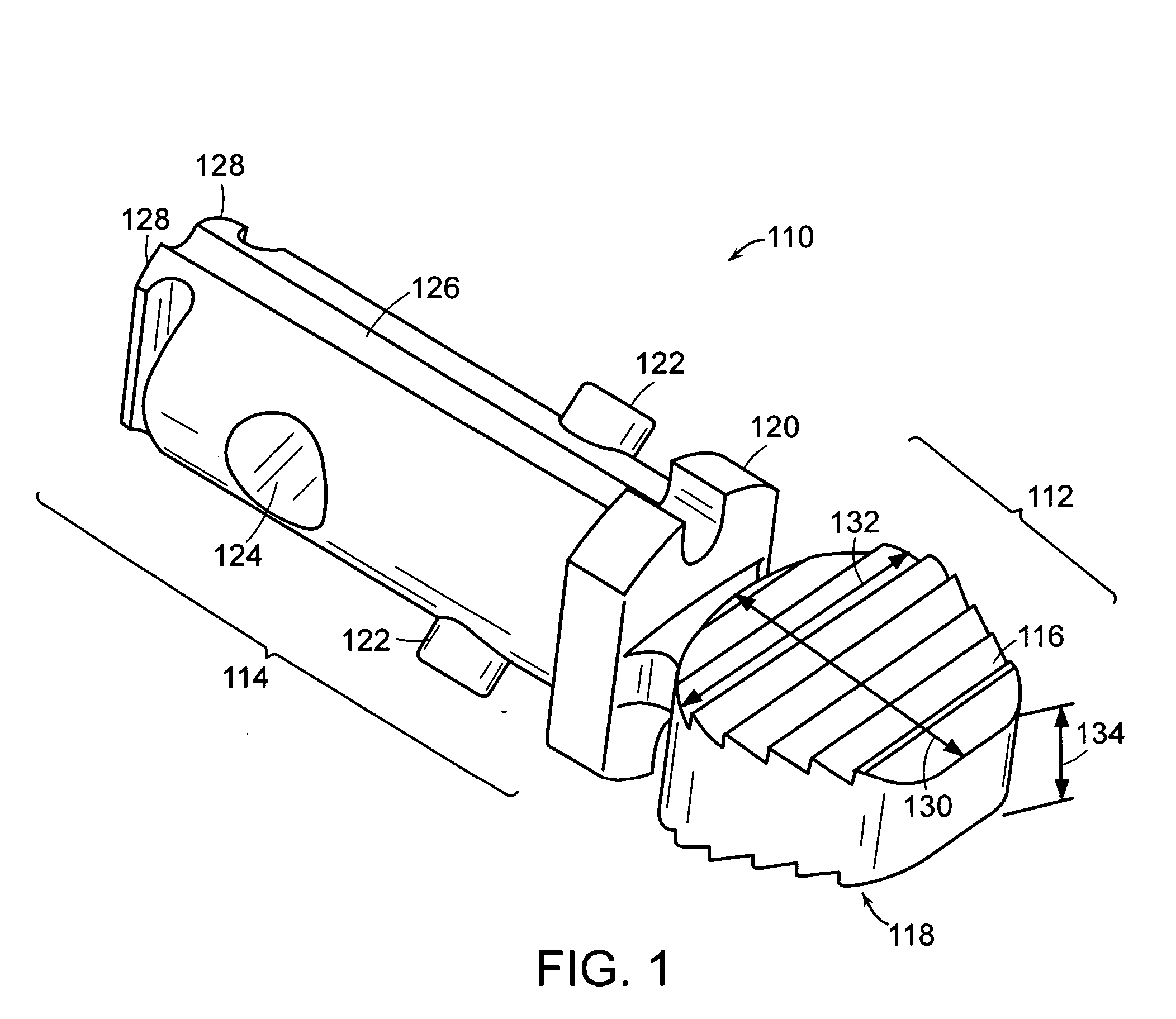

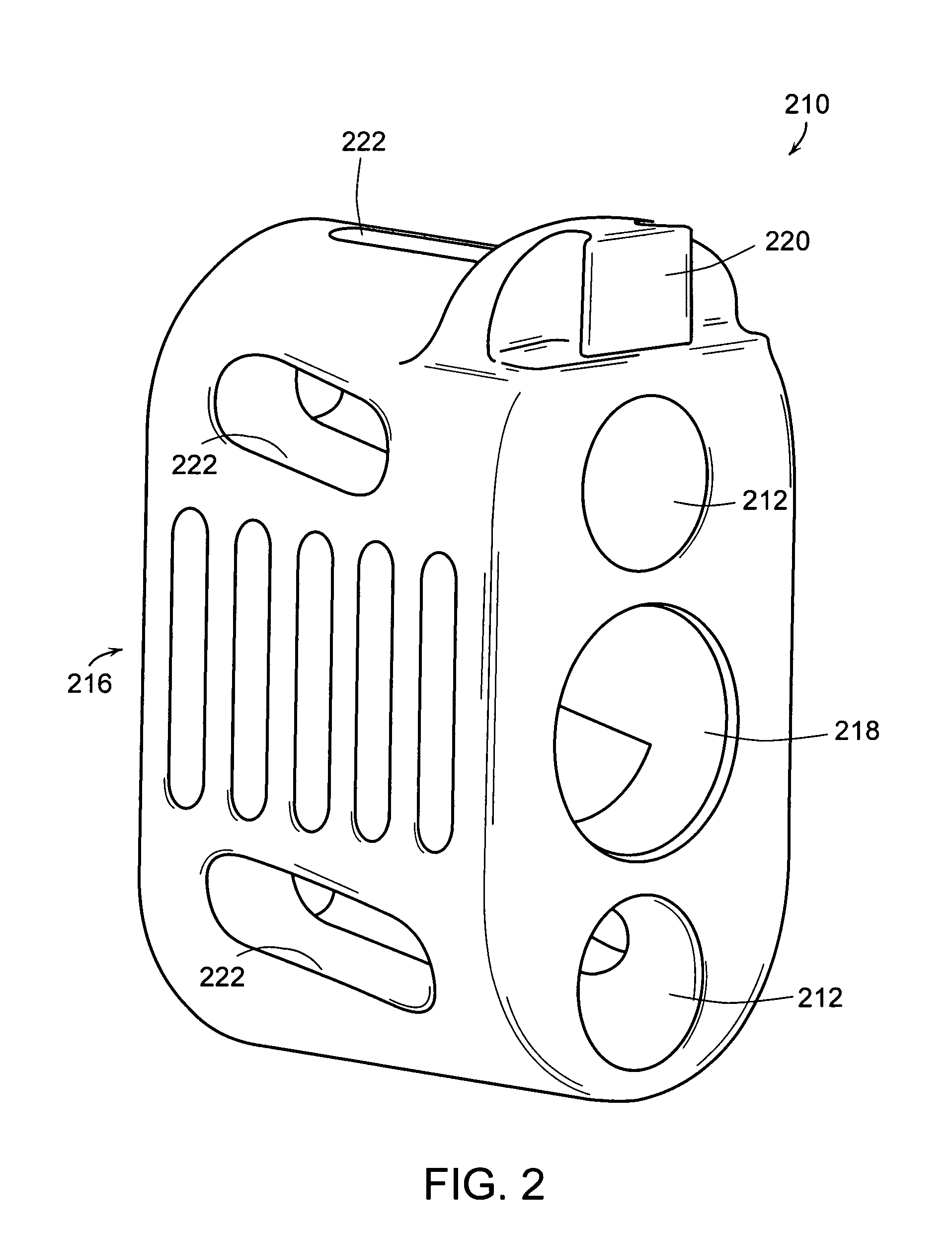

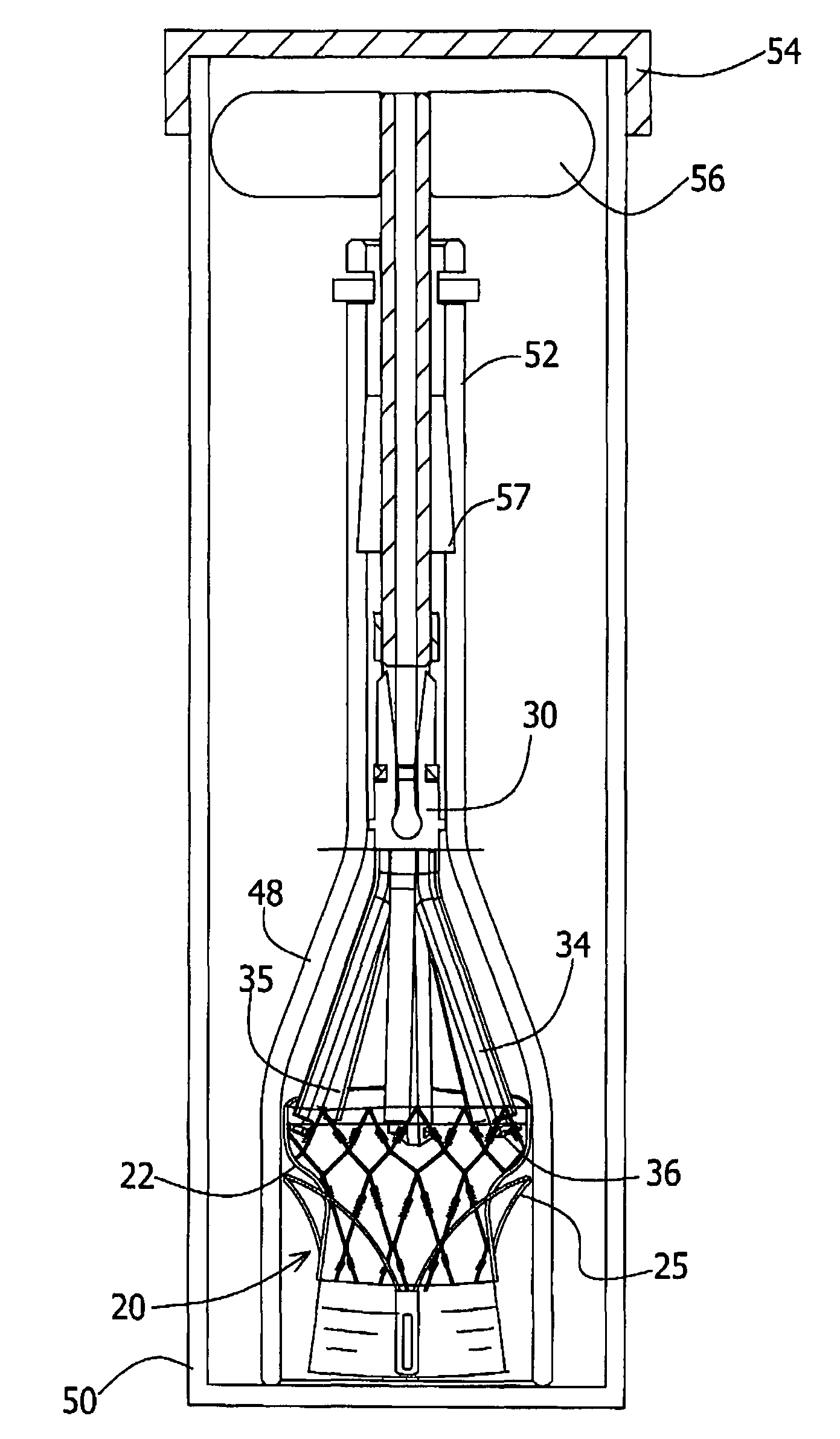

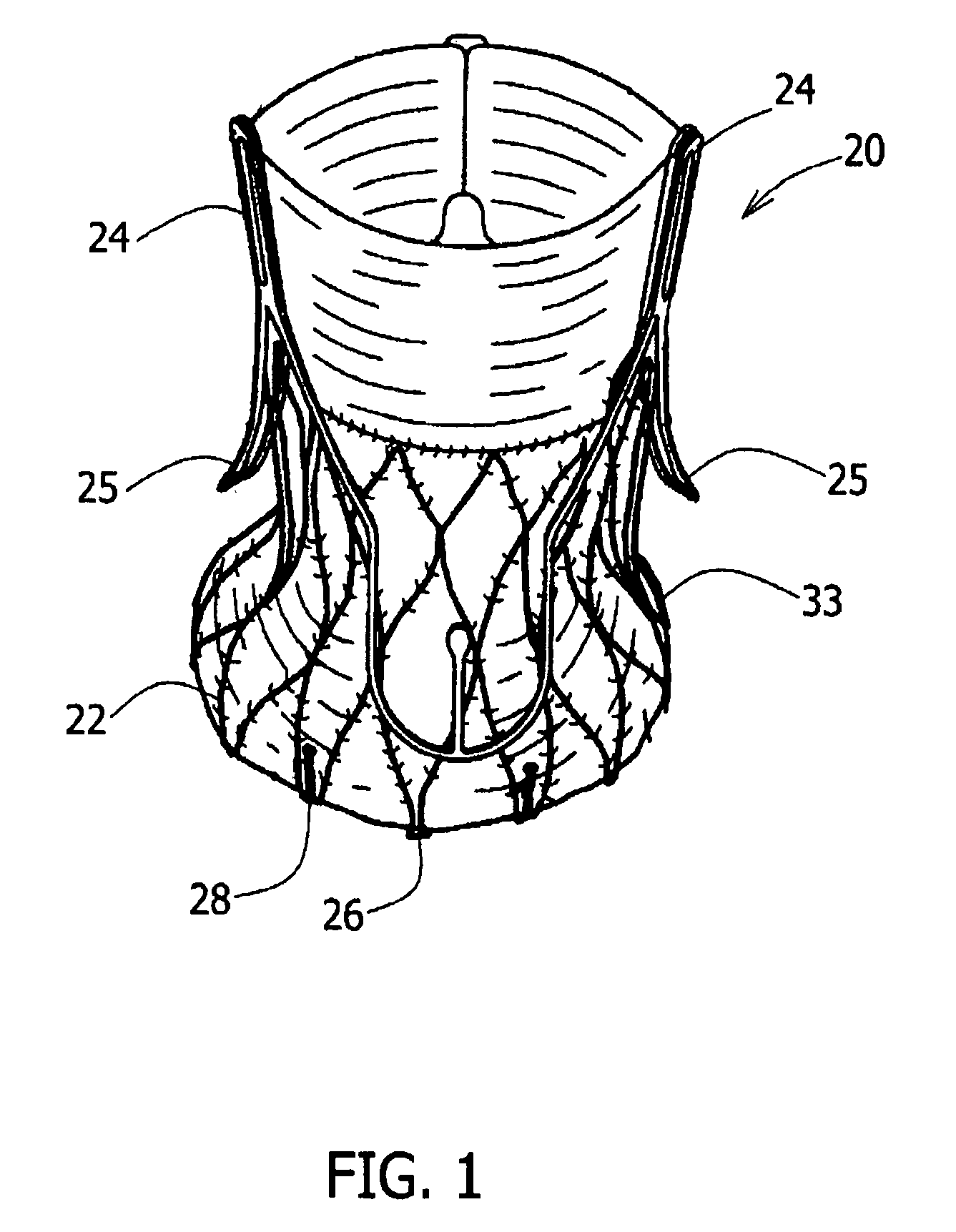

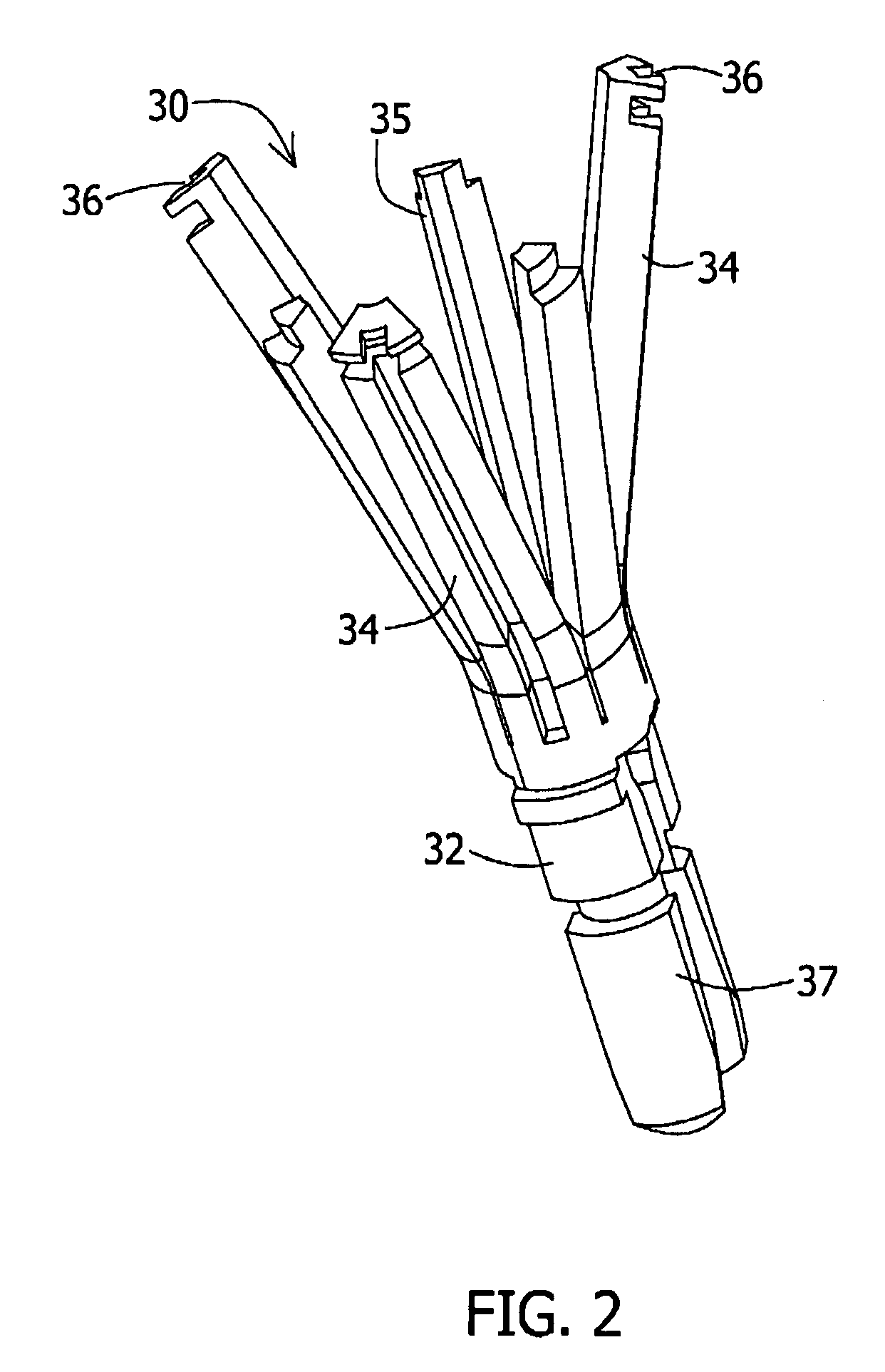

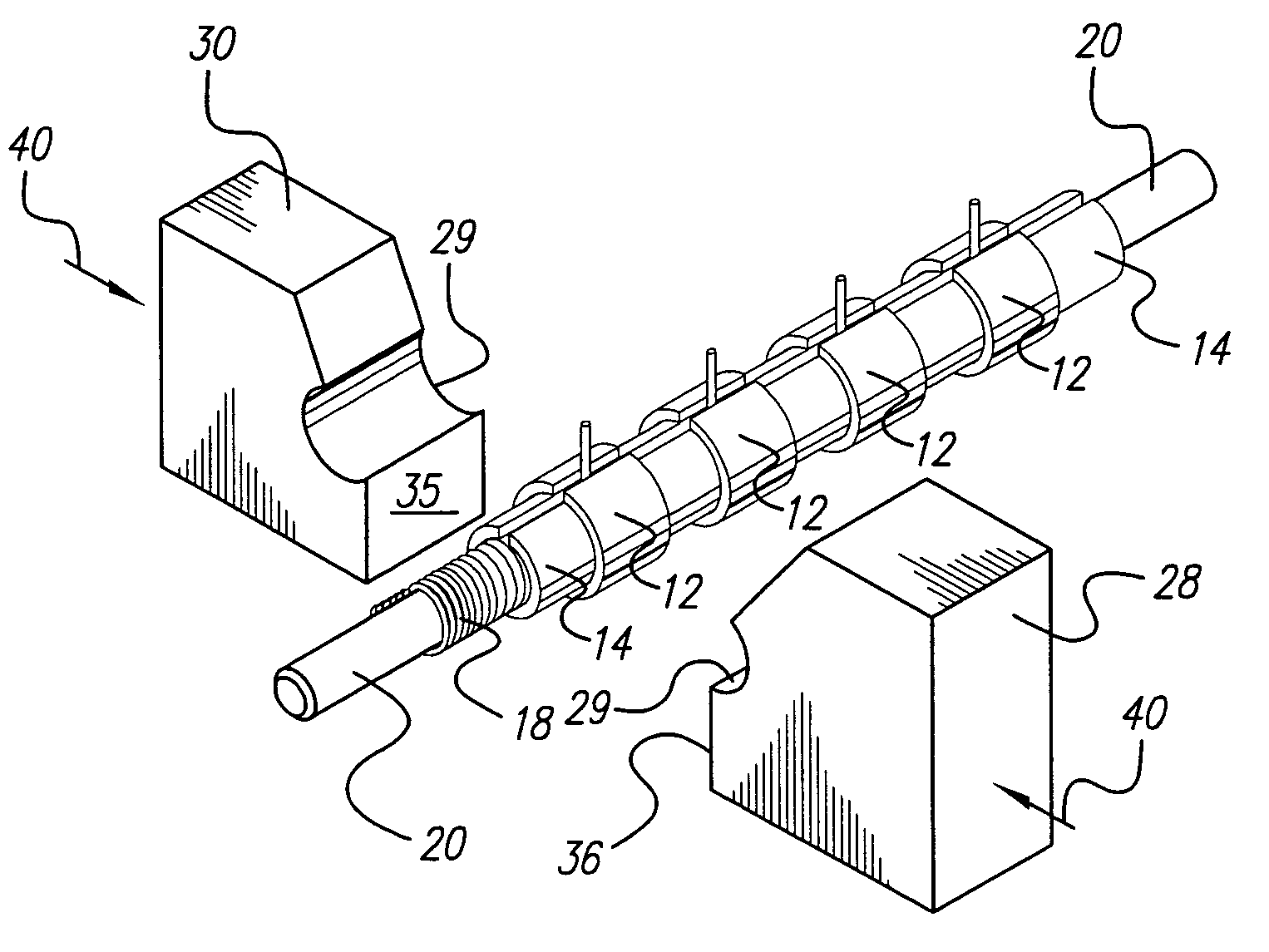

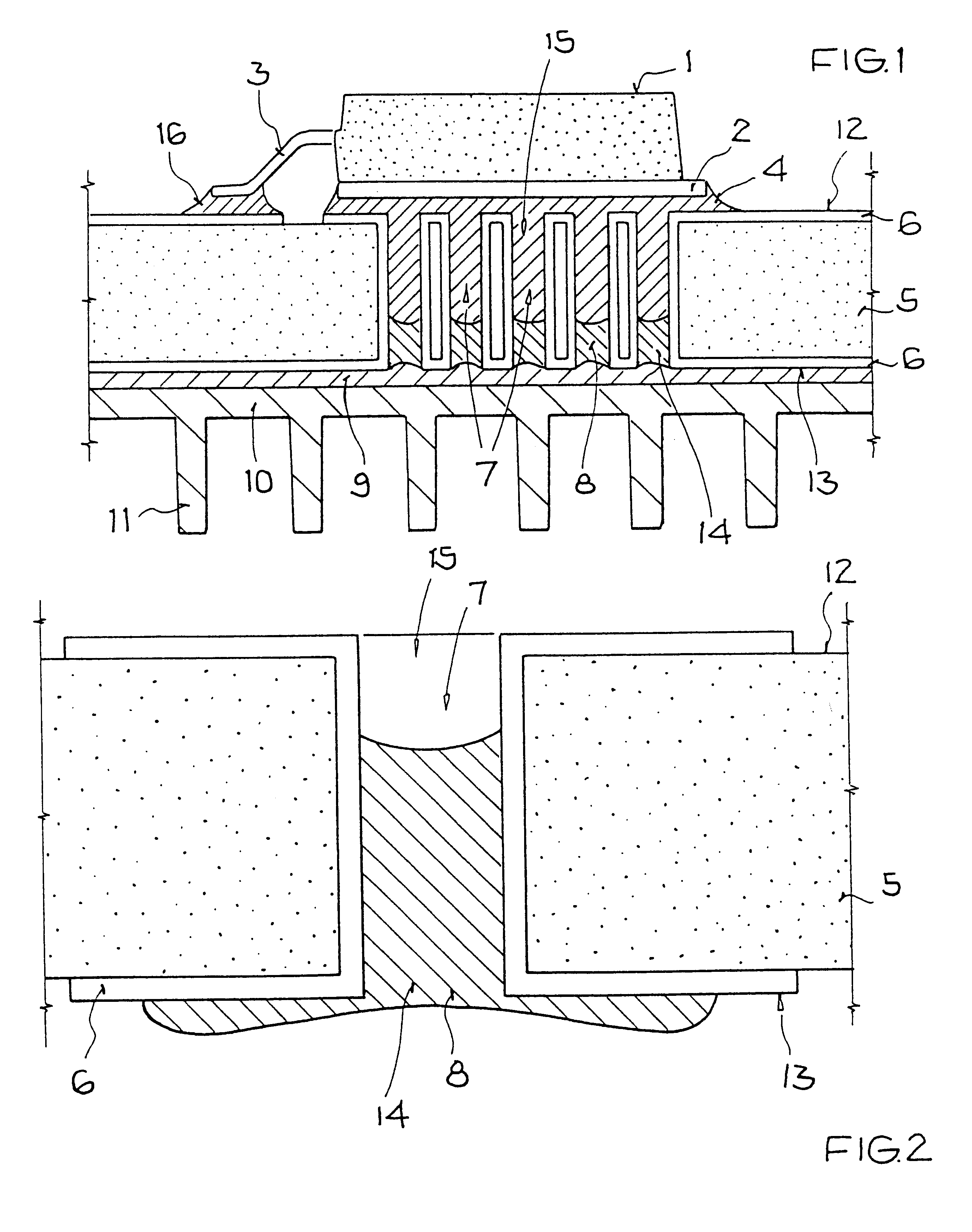

Stent loading tool and method for use thereof

ActiveUS20090054976A1The method is simple and reliableEasy to pushStentsHeart valvesVALVE PORTCatheter device

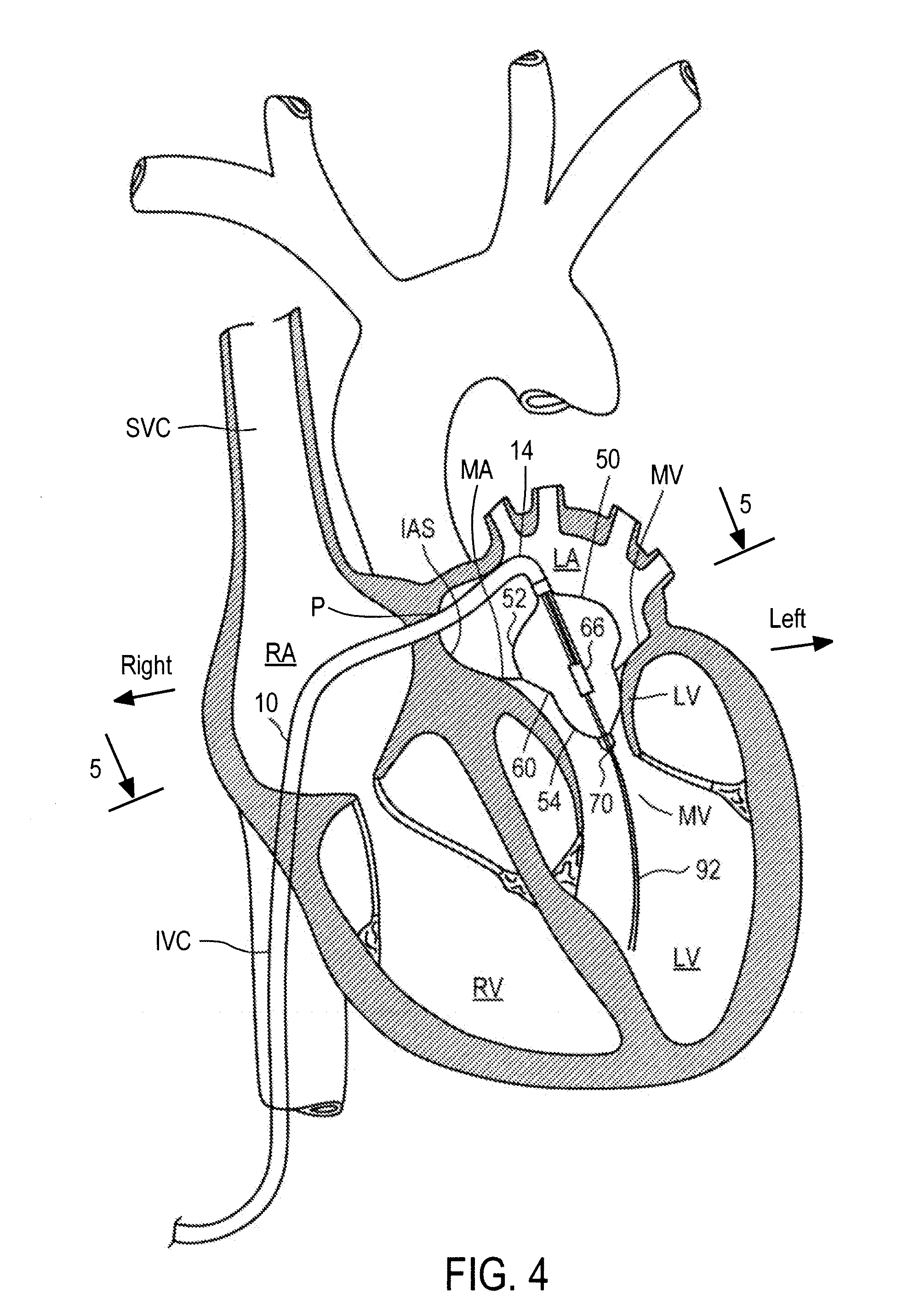

A loading tool for withdrawing, crimping, and loading a stent-mounted valve into a delivery catheter, and for pushing the stent-mounted valve from the delivery catheter into a native heart valve orifice. The loading tool comprises at least one connector adapted for being removably connected to the stent of the stent-mounted valve. A crimping tool having a generally converging shape is adapted for use with the loading tool. Following connection of the loading tool to the stent-mounted valve, the loading tool operates to allow the stent-mounted valve to be drawn through the crimping tool, and loaded, in a crimped state, into a delivery catheter. Also disclosed is a kit of the of the various components for effecting the delivery of the stent-mounted valve and a method for withdrawing, crimping, and loading a stent-mounted valve from a storage container into a delivery catheter for the performance of a transcatheter valve implantation procedure.

Owner:MEDTRONIC VENTOR TECH

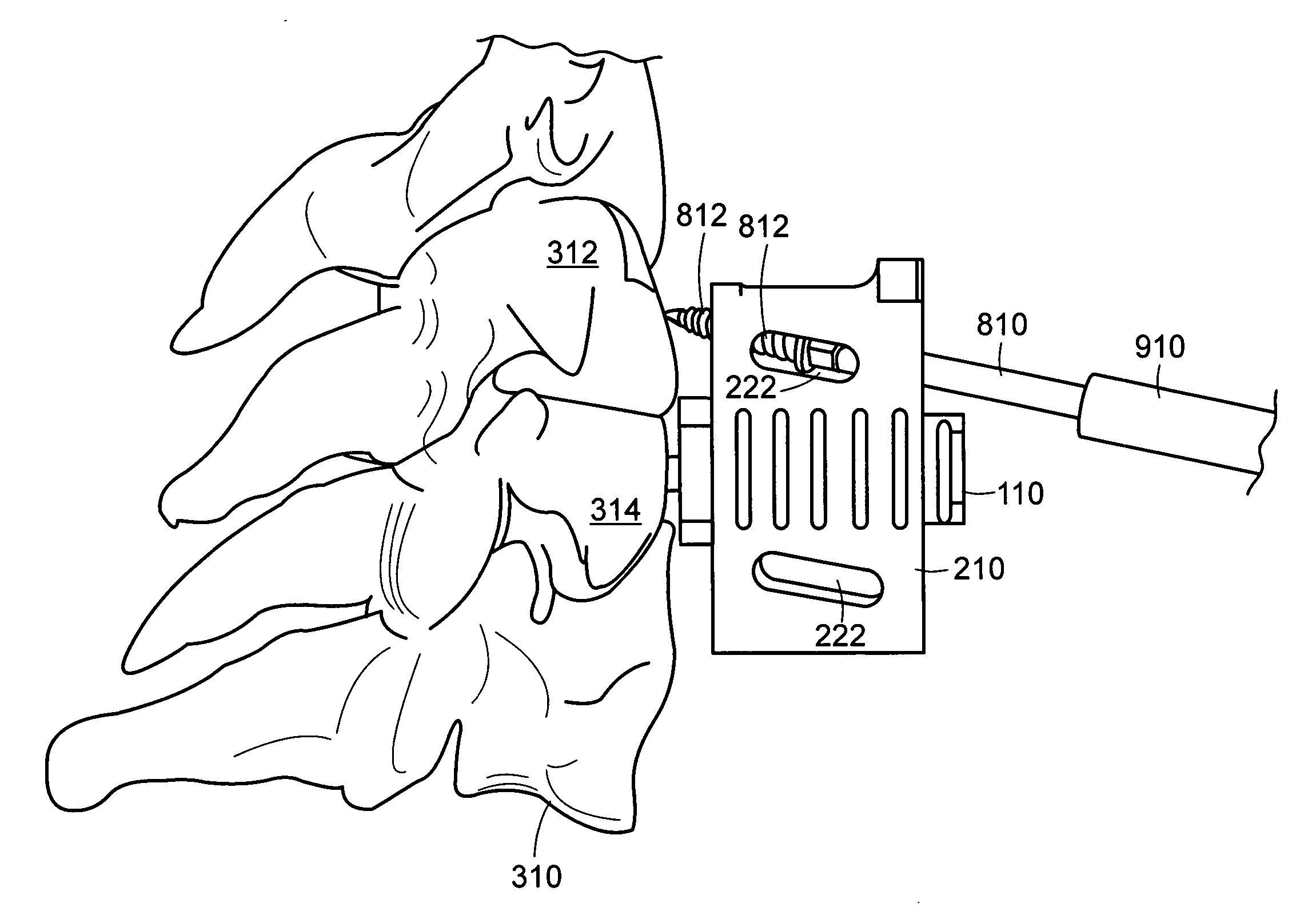

Instrument and method for the insertion and alignment of an intervertebral implant

ActiveUS20060084986A1The method is simple and reliablePrecise alignmentInternal osteosythesisJoint implantsDistractionCoronal plane

The present invention includes pin guides and methods for placing pins in adjacent vertebrae. The present invention also includes methods for placing pins in adjacent vertebrae using the pin guides described herein. The present invention also includes an intervertebral implant insertion and alignment instrument, a distraction instrument, an intervertebral implant insertion guide, and methods for inserting an implant into an intervertebral space. Despite existing tools and techniques, present positioning of implants in intervertebral spaces and pins in adjacent vertebrae often depend on a surgeon's skill, experience and technique. Practice of the present invention can aide in the placement of an implant into an intervertebral space and placement of pins in adjacent vertebrae, e.g., midline to the coronal plane spine and / or parallel to vertebral endplates that abut the intervertebral space.

Owner:DEPUY SPINE INC (US)

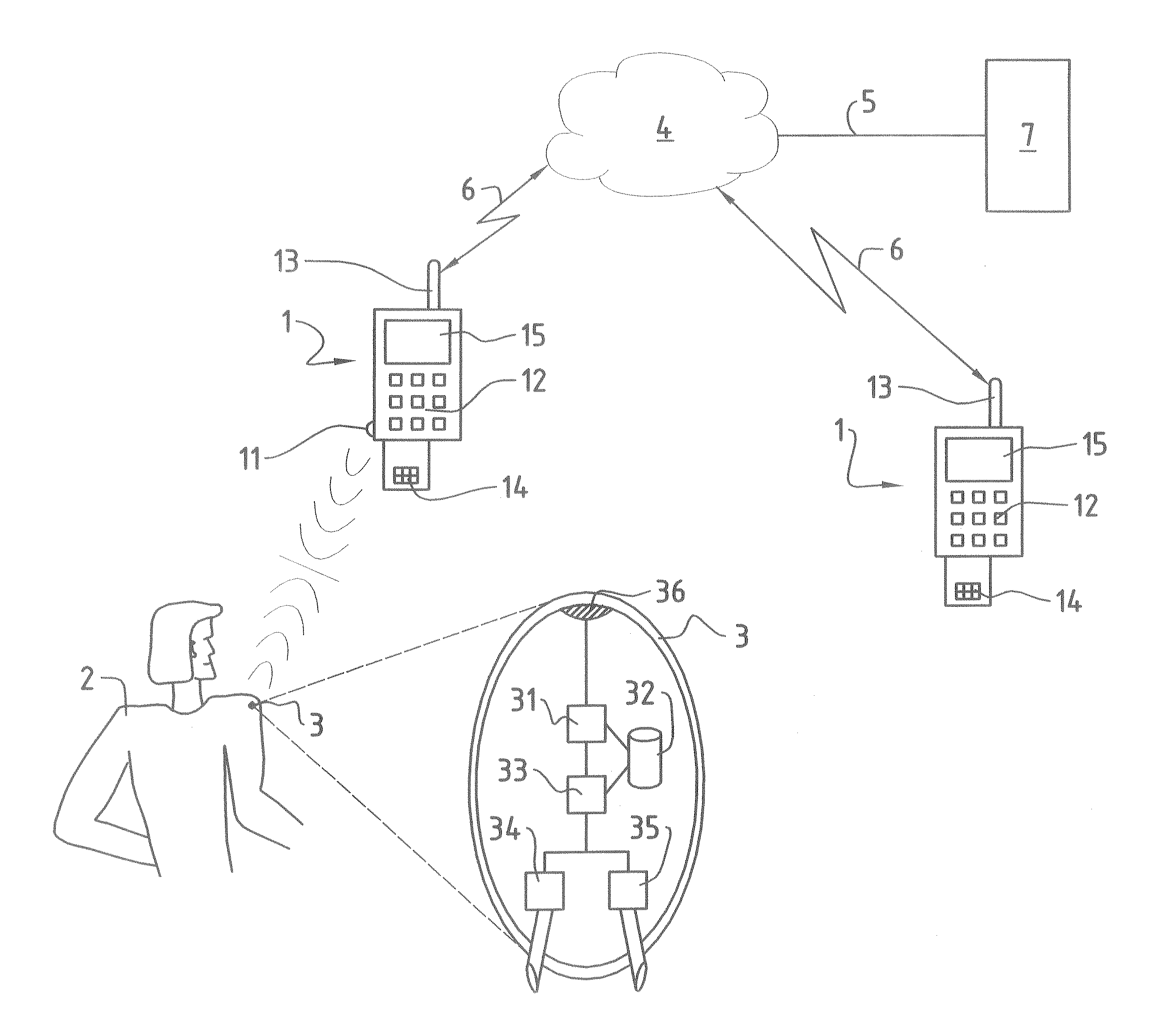

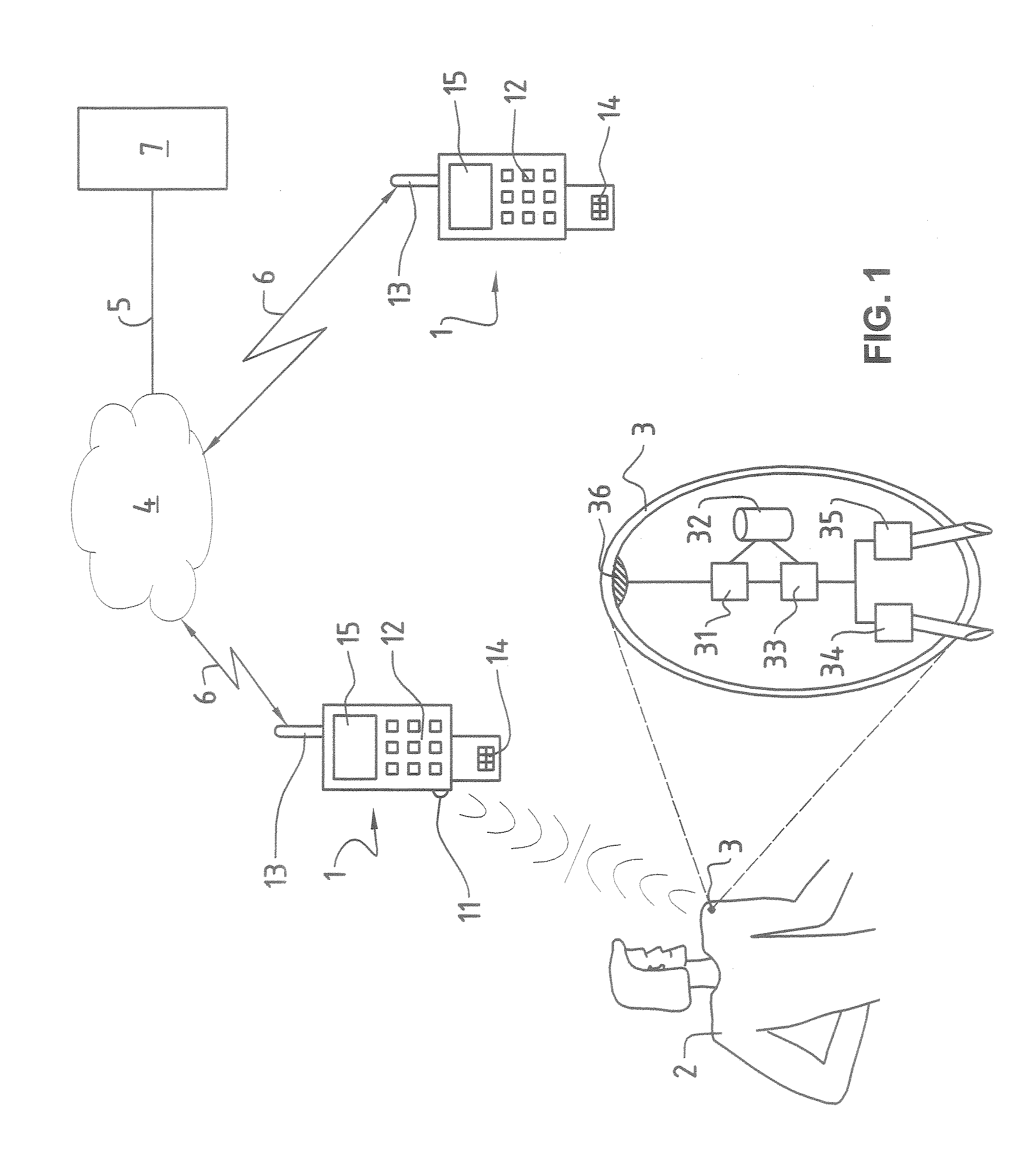

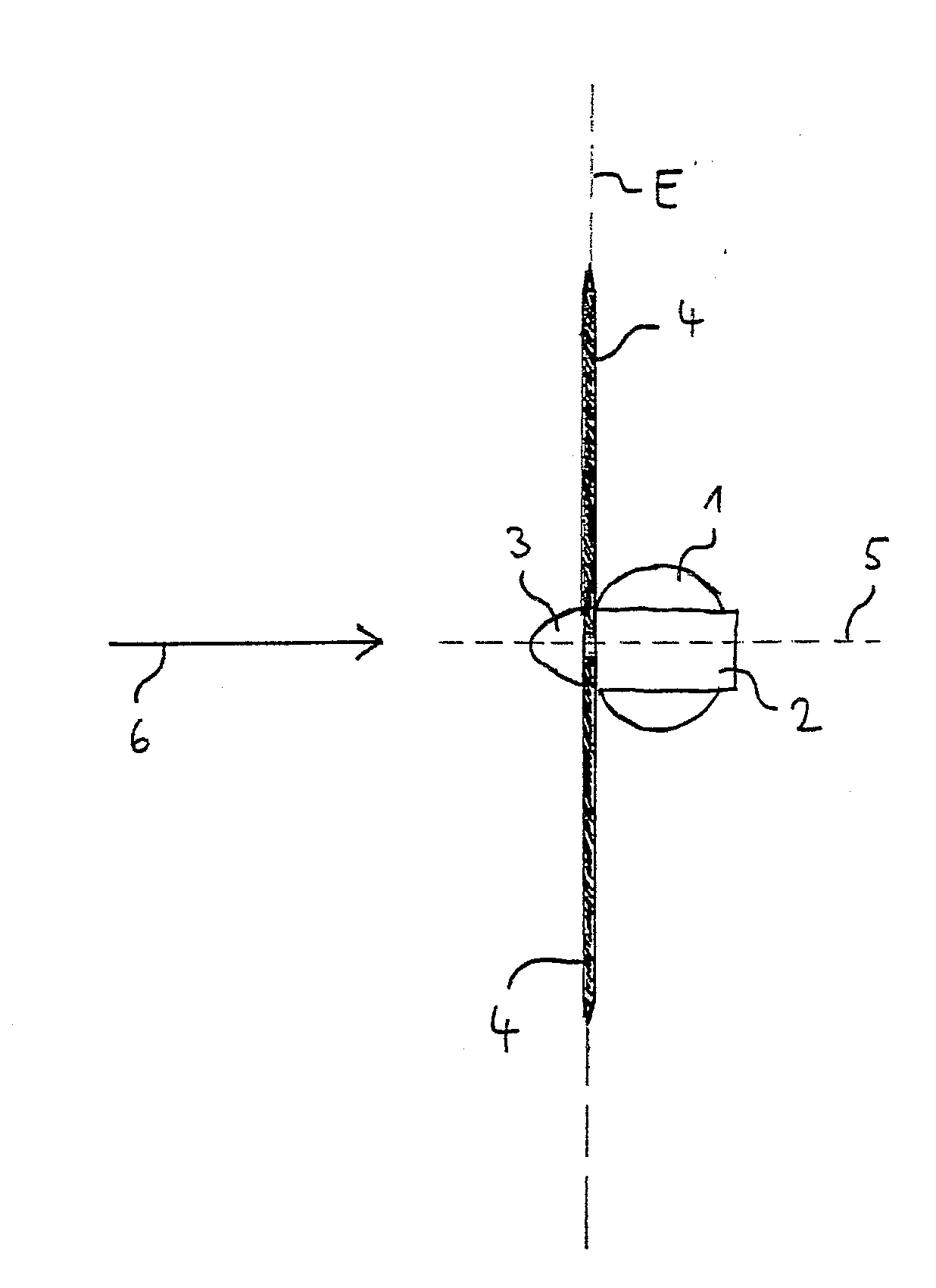

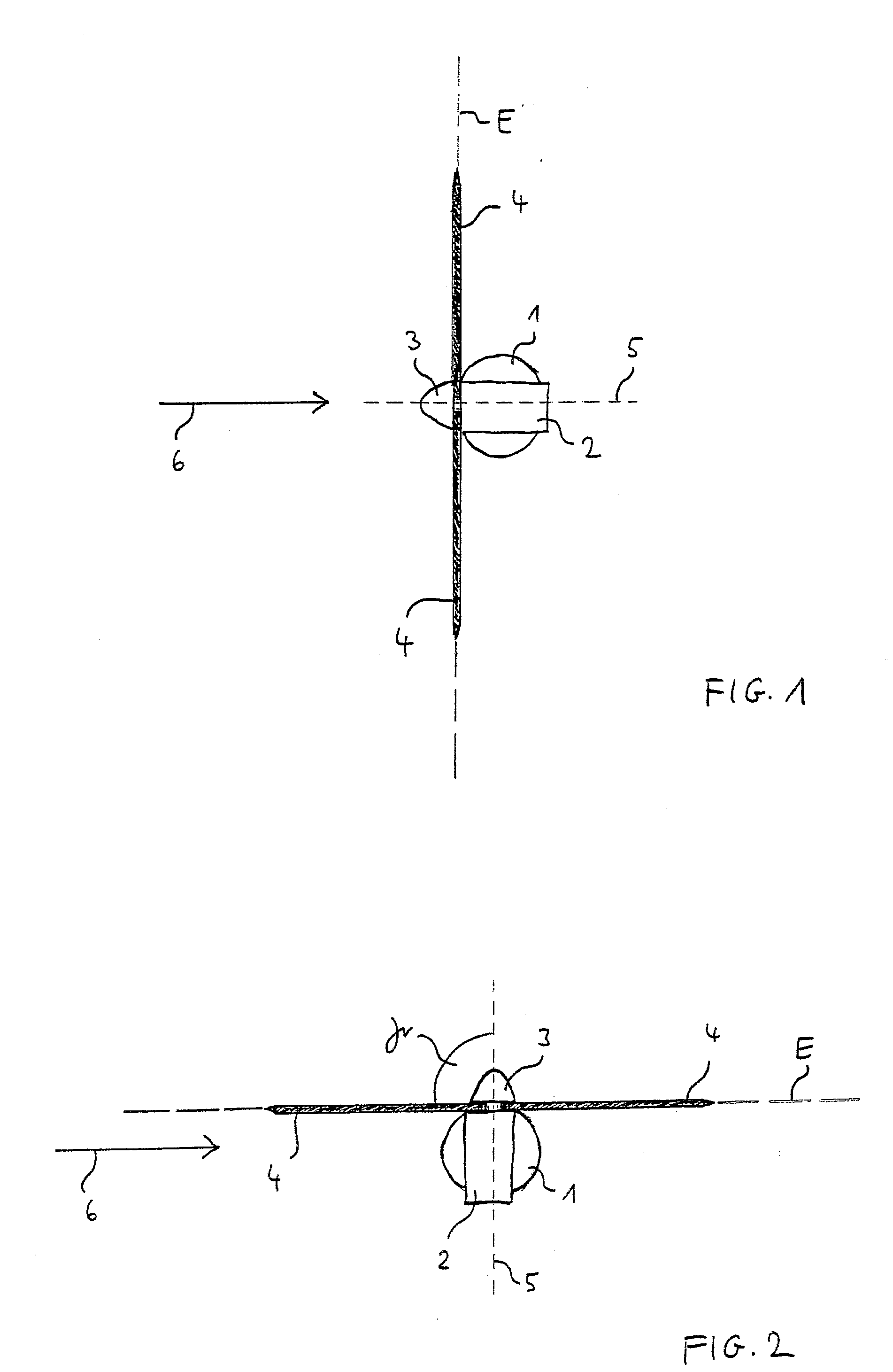

Identification Method and System and Device Suitable for Said Method and System

ActiveUS20080129457A1The method is simple and reliableElectric signal transmission systemsDigital data processing detailsData storingMemory module

The invention relates to a method, a system and a device for identification by means of an identification tag (3), in which a request to a control module (31) of the identification tag (3) is transmitted from an interrogation device via a contactless interface (36) of the identification tag (3), so that identification data stored in a memory module (32) assigned to the identification tag (3) is accessed by means of the control module (31), and that the identification data are transmitted via the contactless interface (36), body-specific identification data of the wearer (2) are captured and transmitted to a verification module (33) by means of a measuring device assigned to the identification tag (3) or a sensor (34) and / or by means of an analysis device (35), the transmitted body-specific identification data of the wearer (2) being compared with the identification data stored in the memory module (32) by means of the verification module (33), and the identity of the wearer (2) being confirmed by means of the verification module (33), and identification tag (3) being injected and / or implanted under the skin of the wearer (2). The identification tag (3) can be in particular an RFID tag and / or an NFC tag.

Owner:INTERDIGITAL CE PATENT HLDG

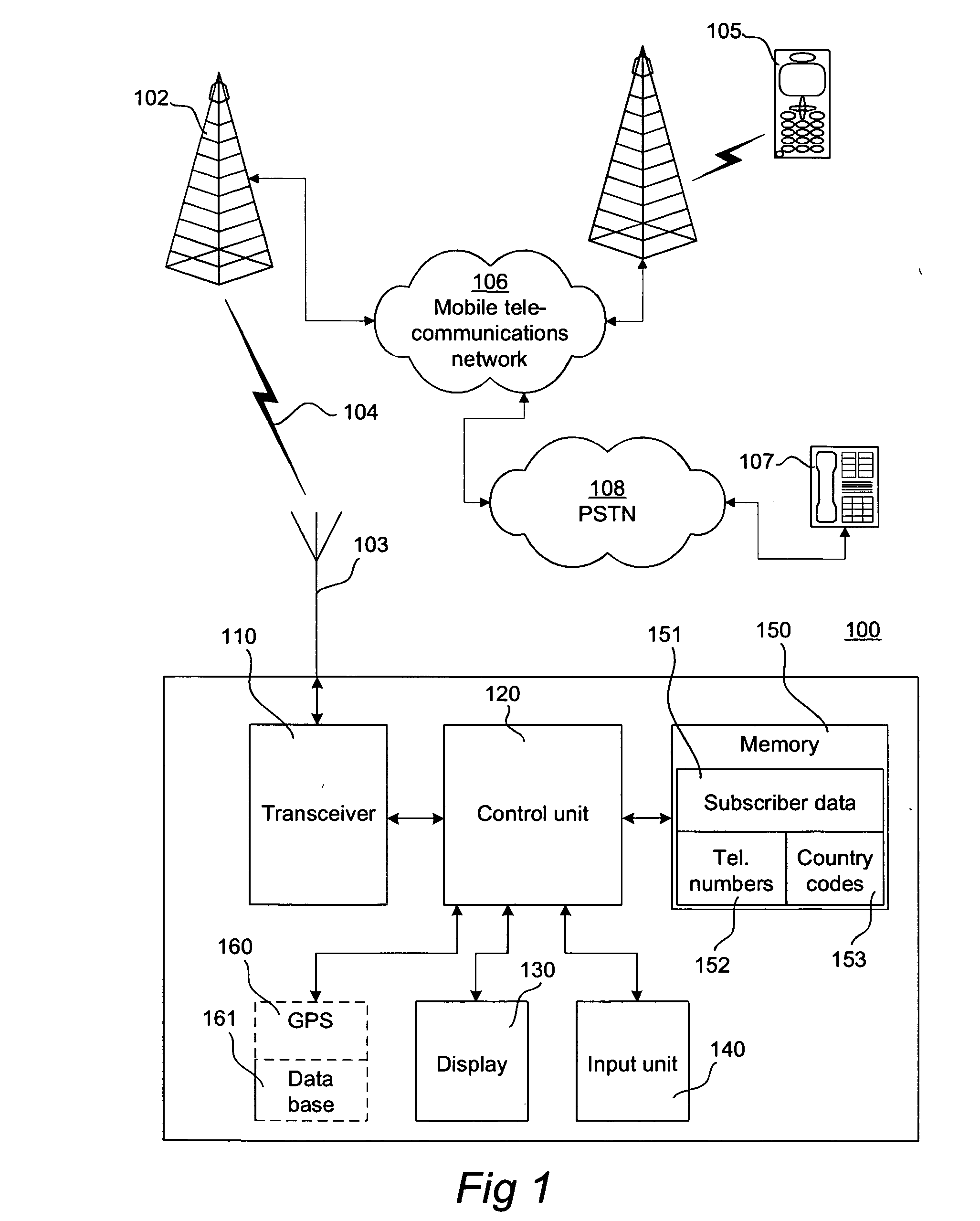

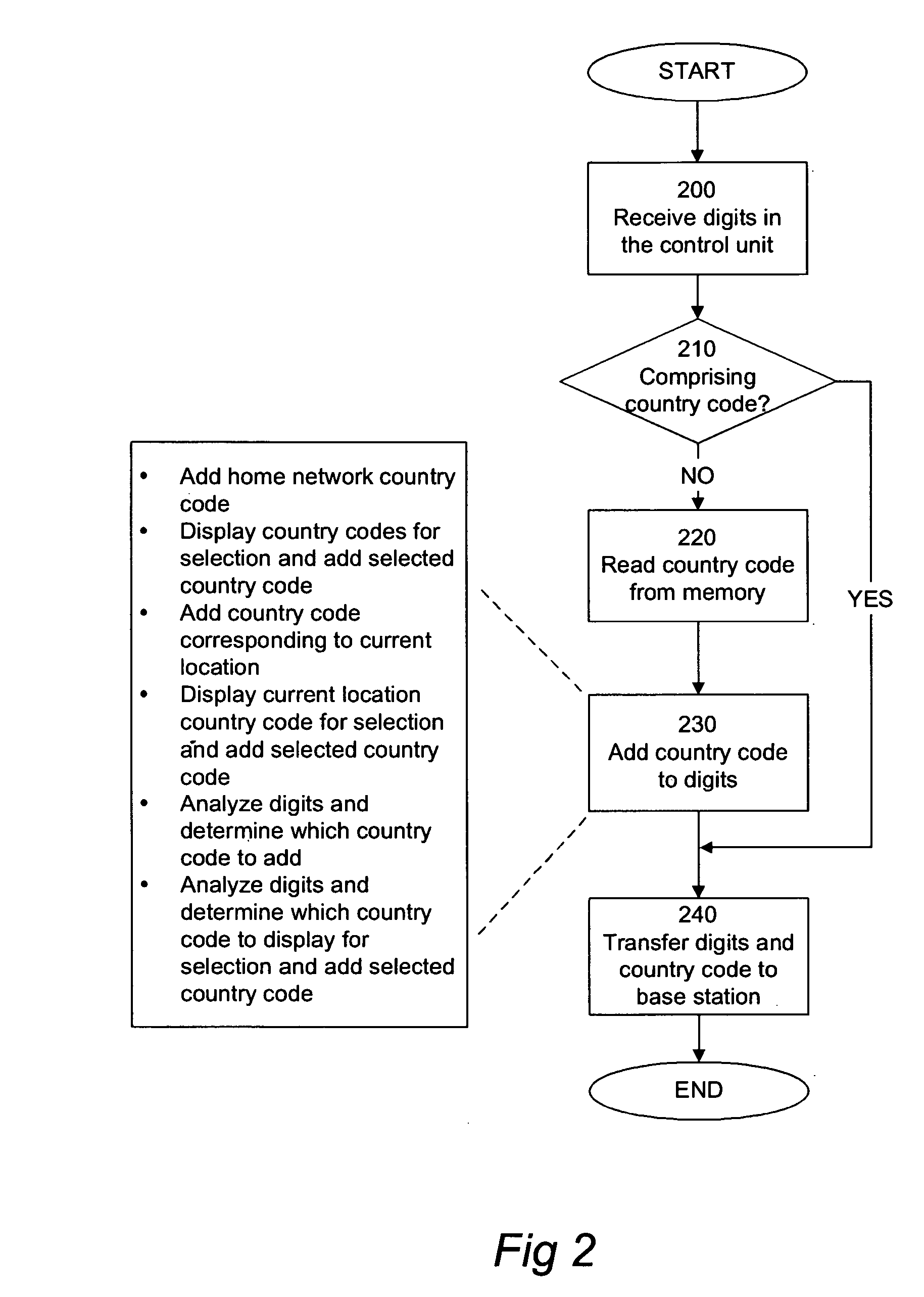

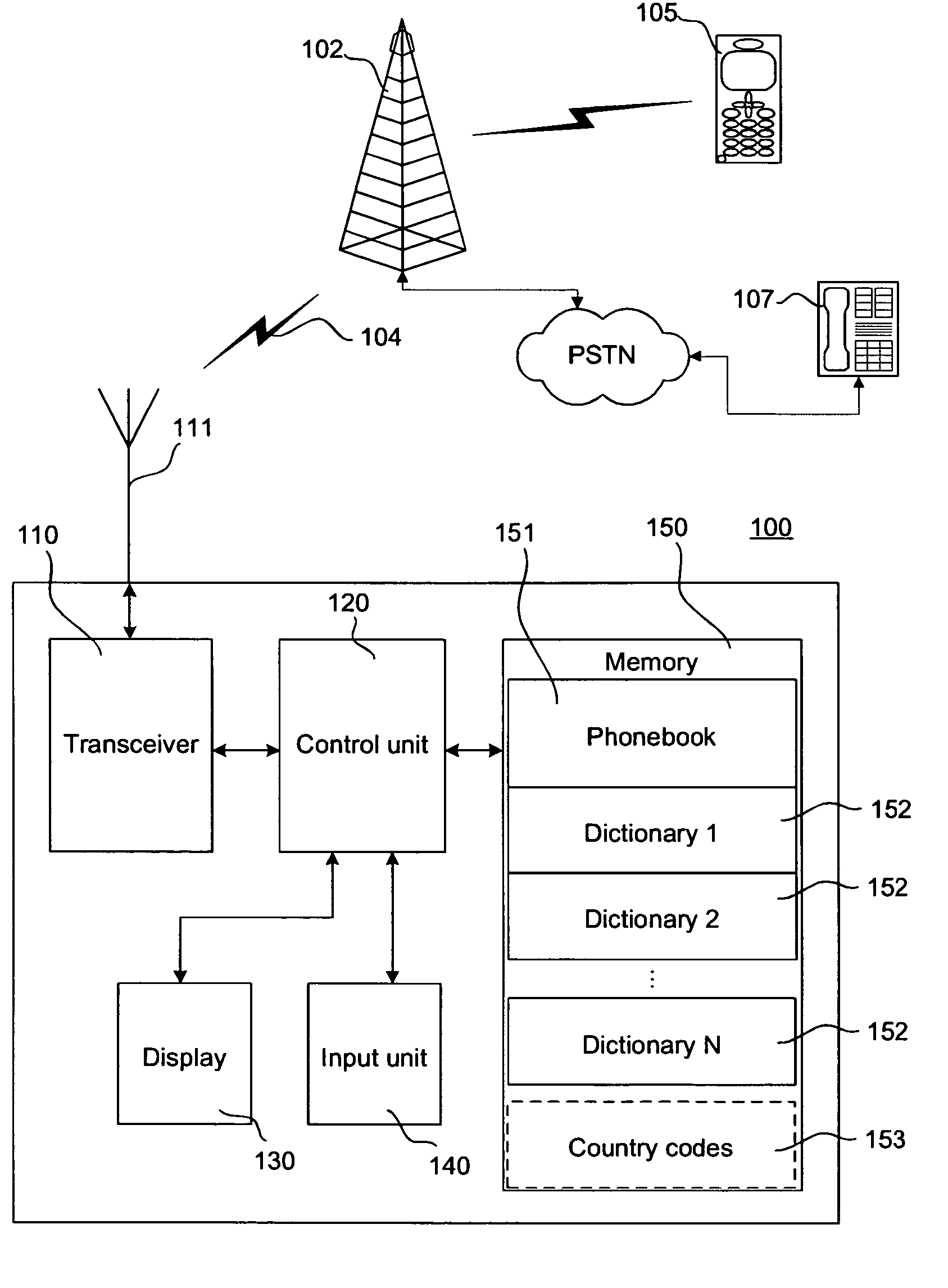

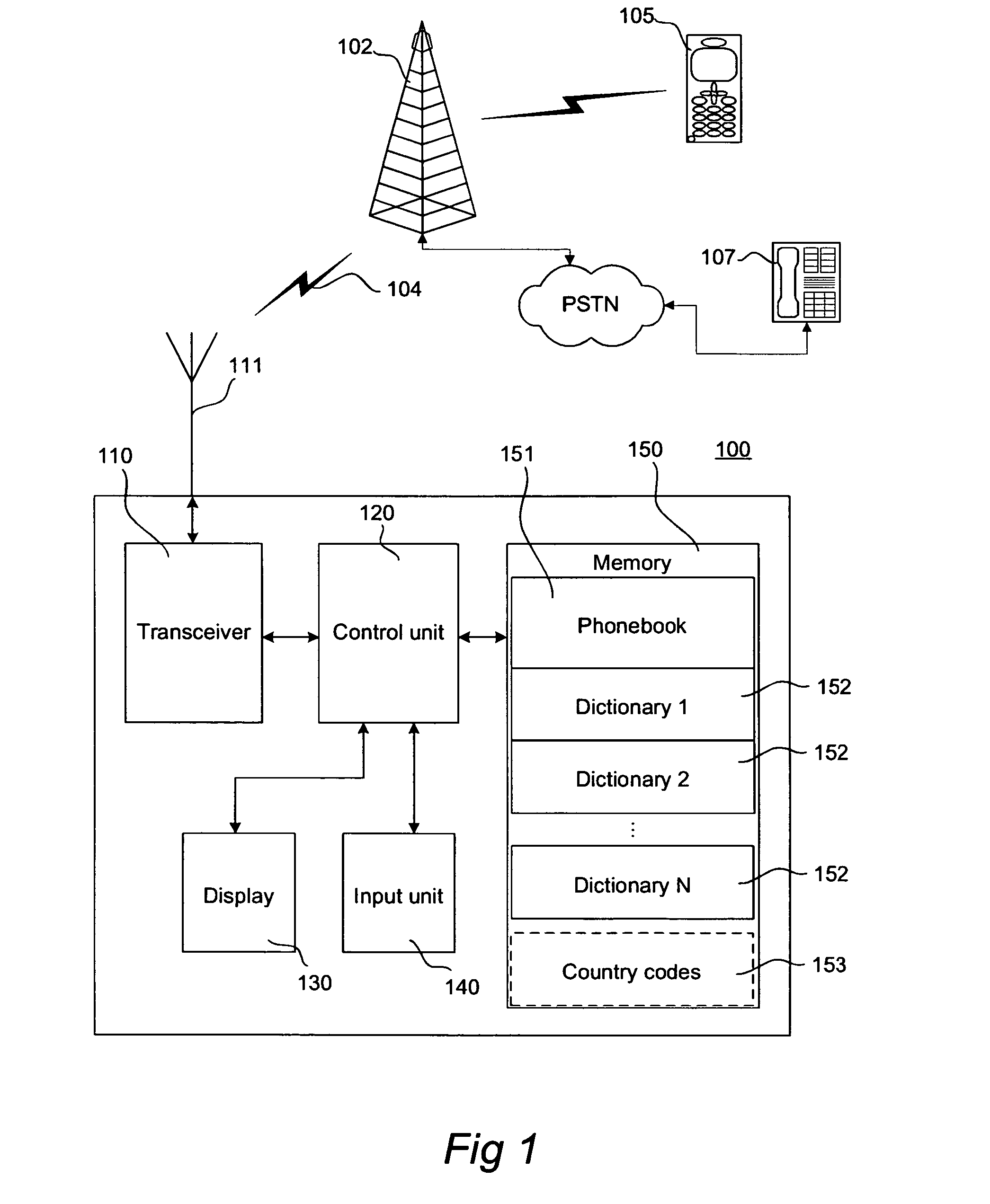

Mobile communication terminal and method therefore

InactiveUS20060094353A1Simple and reliable processThe method is simple and reliableSubstation equipmentRadio relay systemsTelecommunications networkControl unit

A method for providing an international telecommunication number comprising a plurality of digits corresponding to at least a country code, from a mobile telecommunication terminal to a base station, is disclosed. The method comprises receiving a plurality of digits in a control unit in the mobile telecommunication terminal, said digits identifying a subscriber terminal in a telecommunication network, and determining if one or more of the plurality of digits correspond to a country code. If the one or more of the plurality of digits do not correspond to a country code, an international telecommunication number is created by adding a country code to the plurality of digits, whereupon the international telecommunication number is transferred to the base station.

Owner:NOKIA CORP

Stent loading tool and method for use thereof

ActiveUS8747458B2The method is simple and reliableEasy to pushStentsHeart valvesInsertion stentEngineering

Owner:MEDTRONIC VENTOR TECH

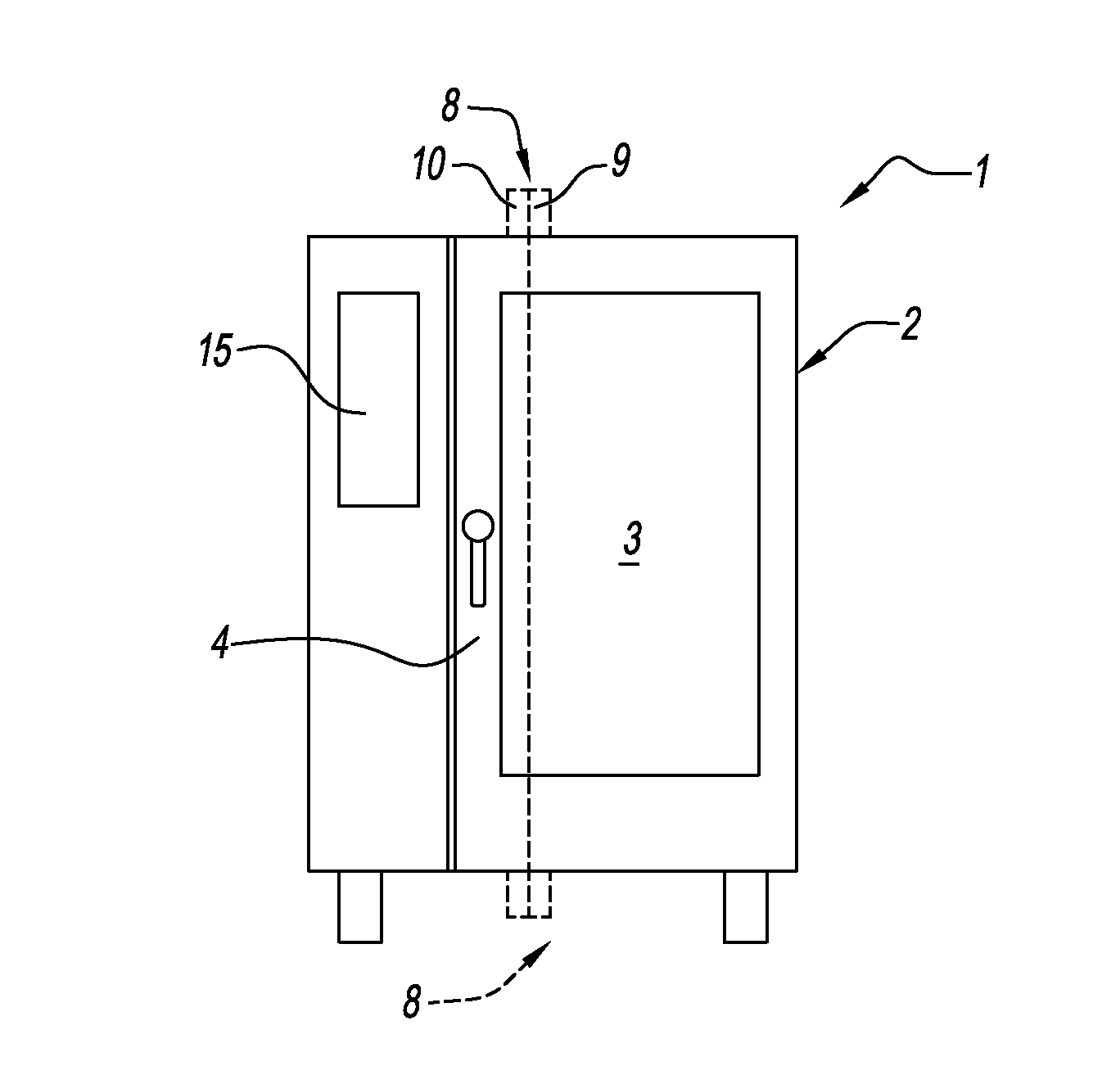

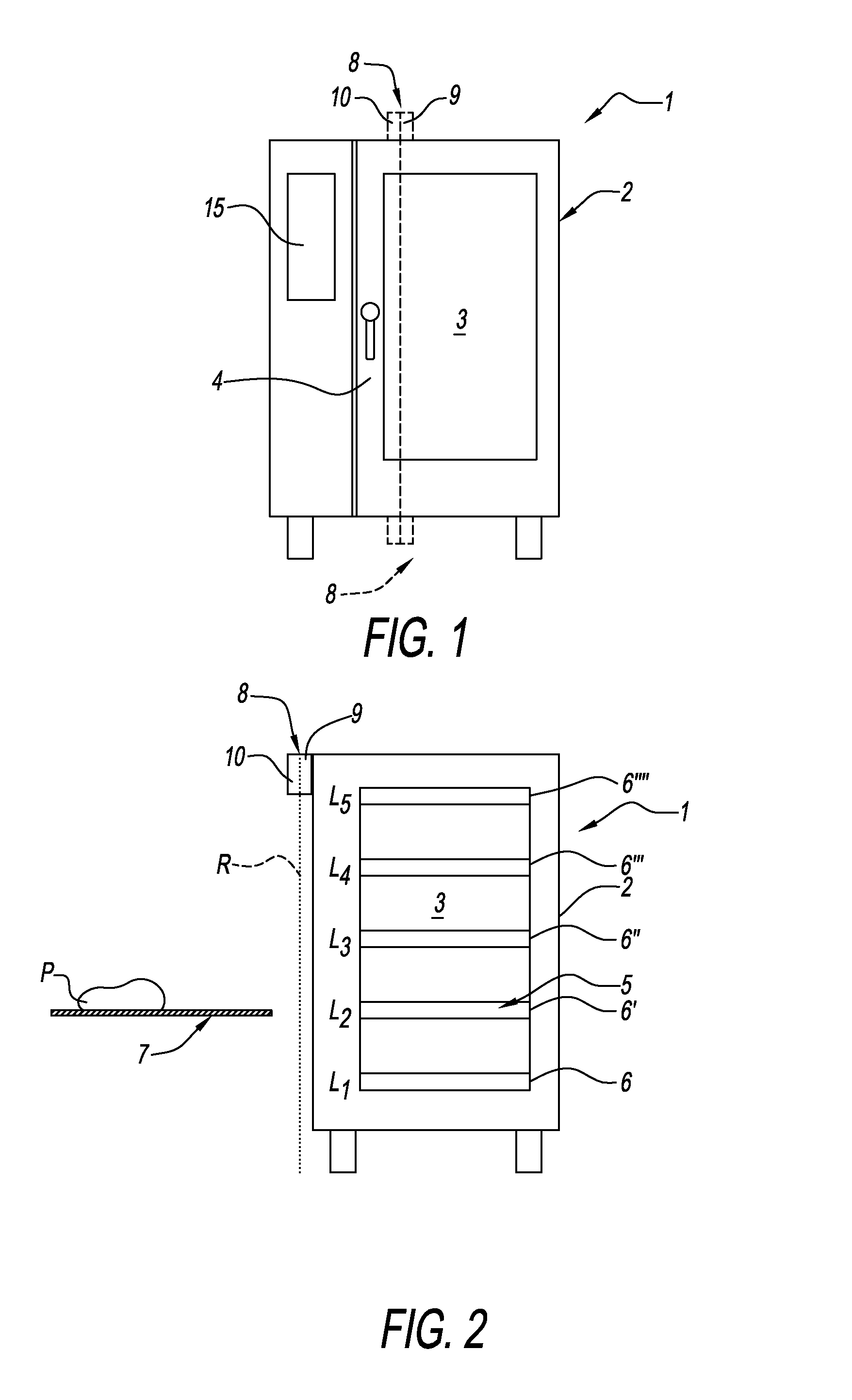

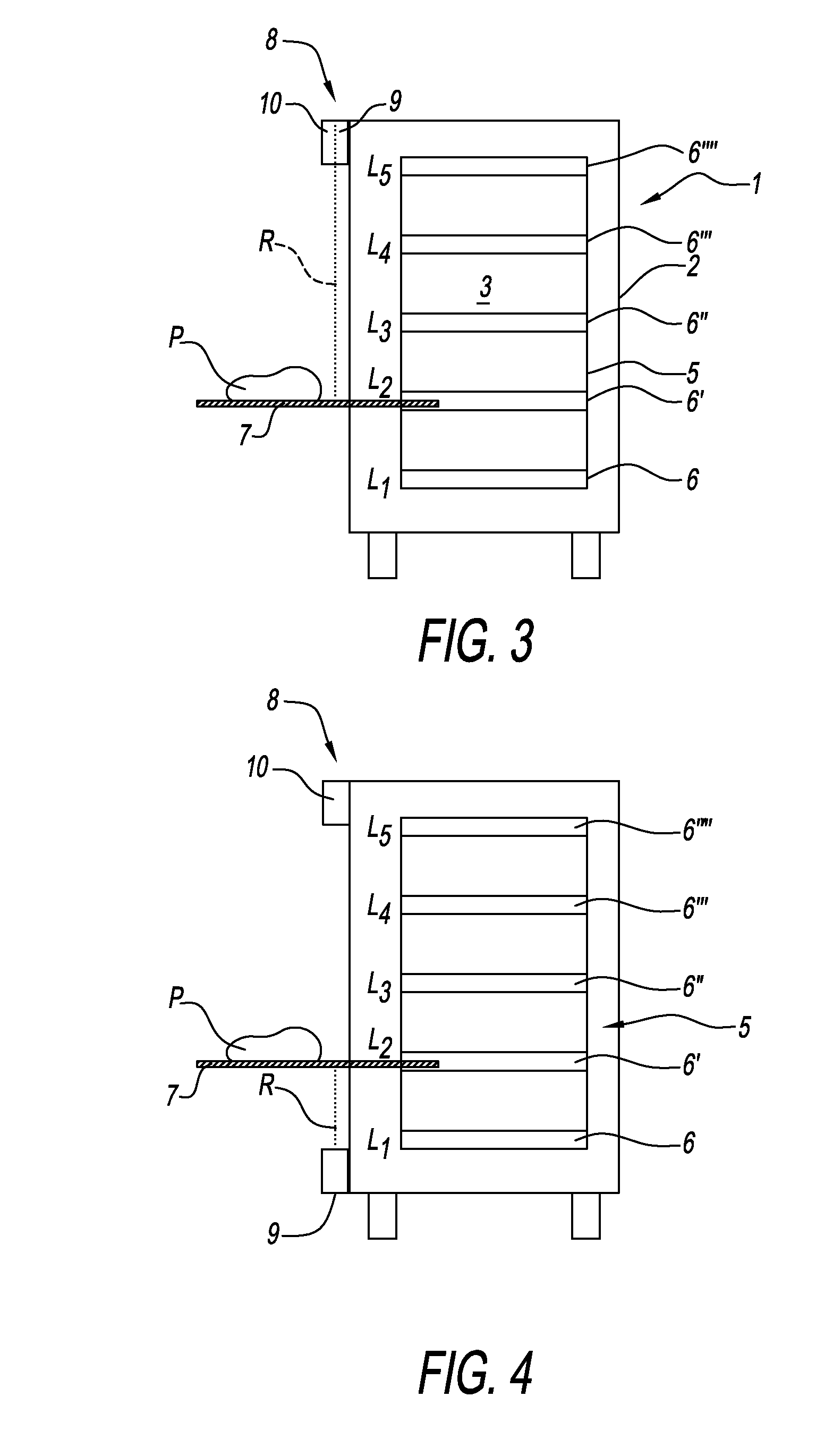

Optical quality control system

ActiveUS20130302483A1The method is simple and reliableMonitor qualityImage enhancementImage analysisControl systemEngineering

Disclosed are cooking devices having inspection systems including: a distance sensor and a digital optical recognition device. The distance sensor detects the position of the food product placed in the cooking device and the digital optical recognition device captures a series of images for the purpose of food product recognition. Once the food product is recognized, the operator is provided with the correct cooking cycle / program for the position and type of food product placed in the cooking device. The inspection systems also ensure that the food product has been properly cooked at the end of the cooking cycle / program. The inspection systems ensure: (1) the food product is correctly recognized; (2) the cooking cycle / program is correctly selected; (3) the correct cooking cycle / program is followed to completion and (4) the quality of the cooked food product meets expected standards.

Owner:WELBILT DEUT GMBH

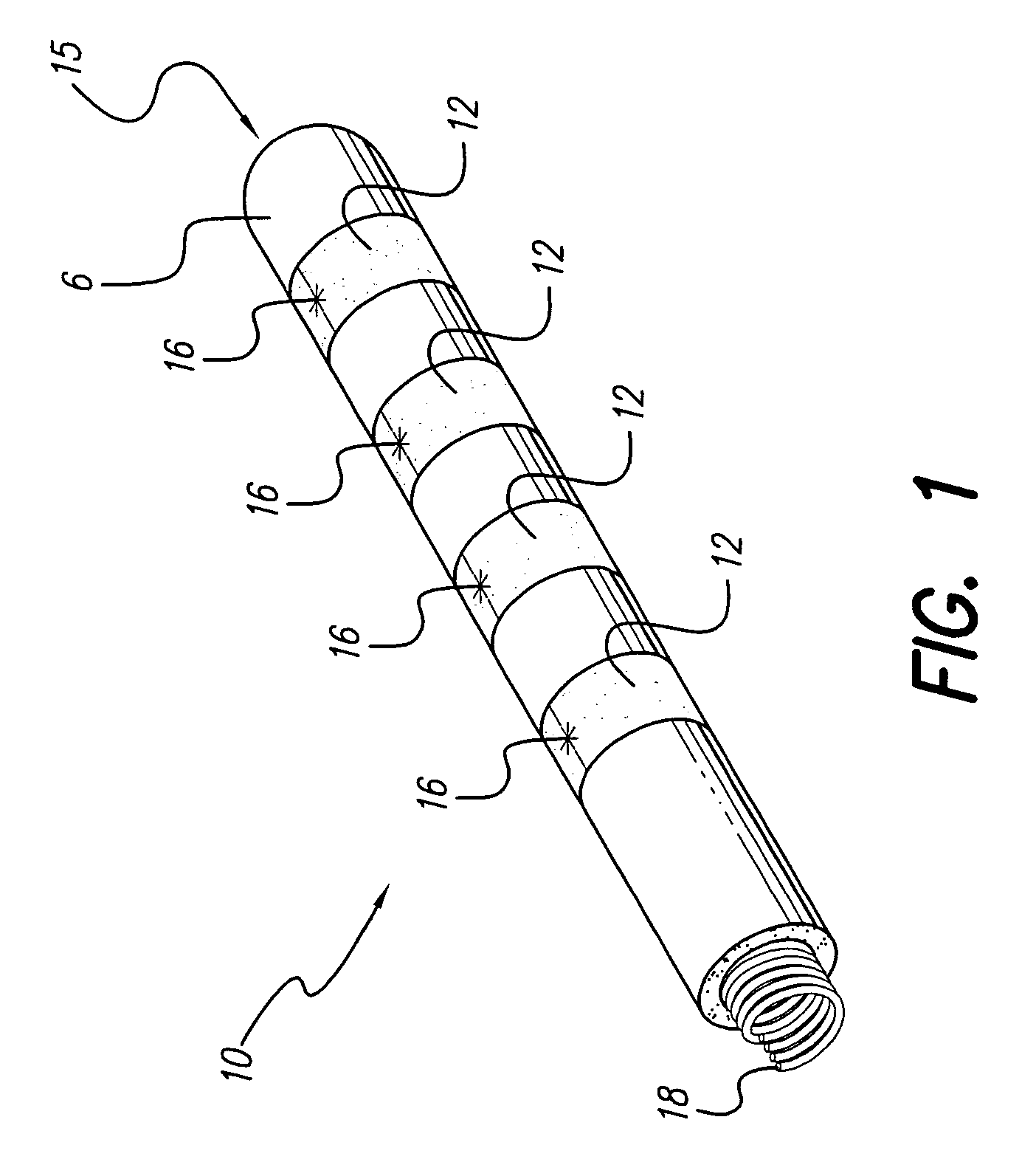

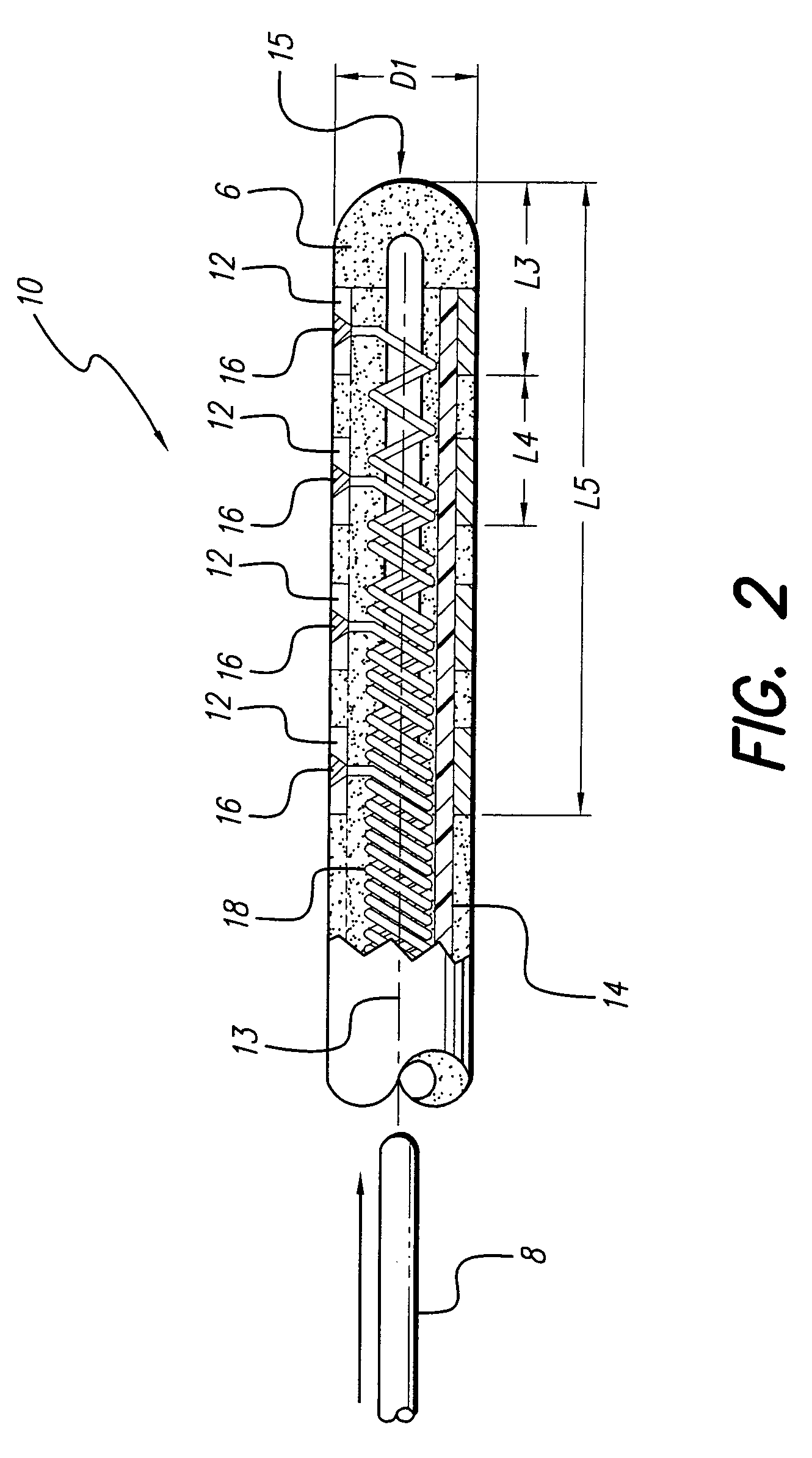

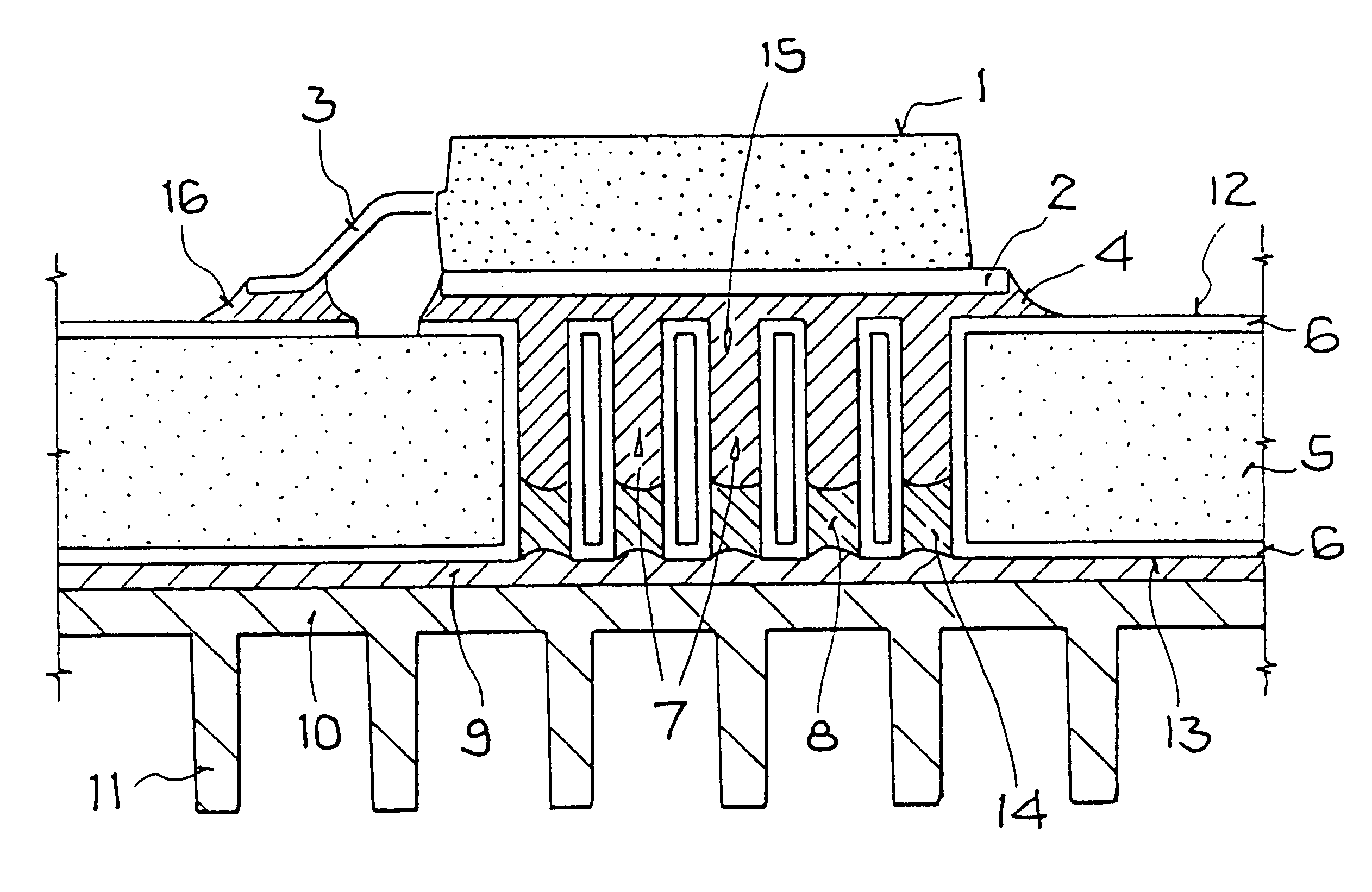

Band type multicontact electrode and method of making the same

InactiveUS7047081B2High yield rateReduce manufacturing costSpinal electrodesHead electrodesWire rodElectrode Contact

A multicontact electrode array suitable for implantation in living tissue includes a distal end having multiple spaced-apart ring or band electrode contacts carried on a flexible tube carrier. Each ring electrode contact is laser welded to a respective wire tip that has a multi-helix orientation on the inside of a separation tube. The center of the multi-helix wire defines a lumen wherein a positioning stylet, or other suitable positioning tool, may be removably inserted when the electrode array is implanted. The method of making the multicontact electrode array includes, as an initial step, winding lead wires around a suitable mandrel so as to form a multi-helix configuration. (Alternatively, the wire may be purchased in a multiwire pre-wound configuration that defines a lumen, in which case the mandrel is slipped inside the lumen.) Then, at a distal end of the electrode, each wire within the multi-helix winding is unwound so as to protrude out from the winding. Next, a non-conductive separation silicone tube which has a longitudinal slit along its length, is placed around the wound wires. Ring contacts are then placed over the silicone tube at a distal end of the electrode array and spaced apart as desired. These ring contacts also have a slit therein through which the protruding wire ends may exit. The silicone tube is used as a spacer to centrally locate the multi-helix wound wires with the ring contacts. A compressive die may be used to hold the pre-assembled ring contact, multi-helix wire, separation tube in their desired positions, and may be used to close the opening or slit of each ring contact through which the wire tips protrude. The wire tips are then individually trimmed to a suitable distance. A laser welding process may then be used to bond each lead wire to a corresponding ring contact. Finally, the preassembled electrode array is placed in a molding die, and a polymer filler is injected into the internal gaps of the electrode array components.

Owner:BOSTON SCI NEUROMODULATION CORP

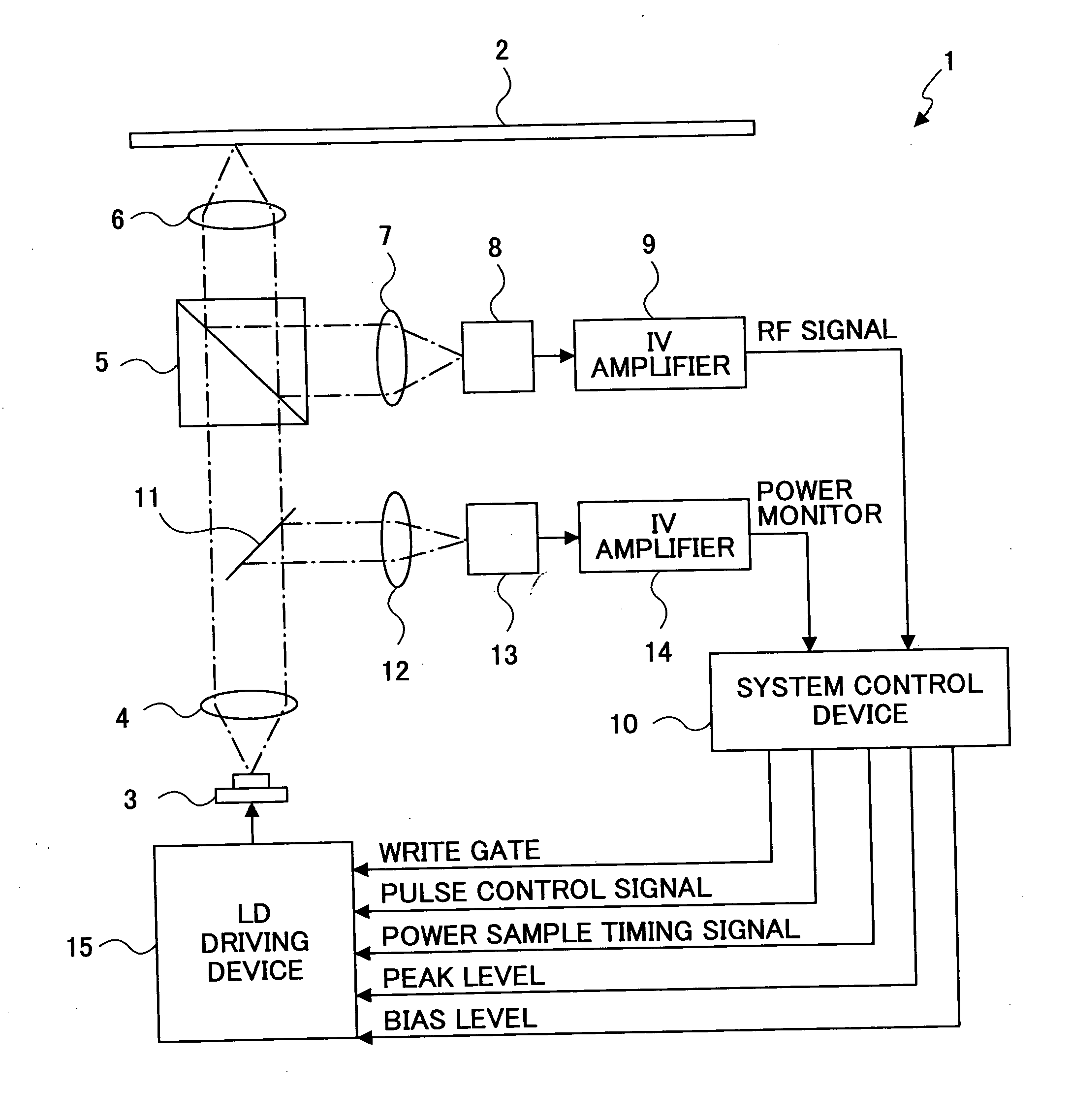

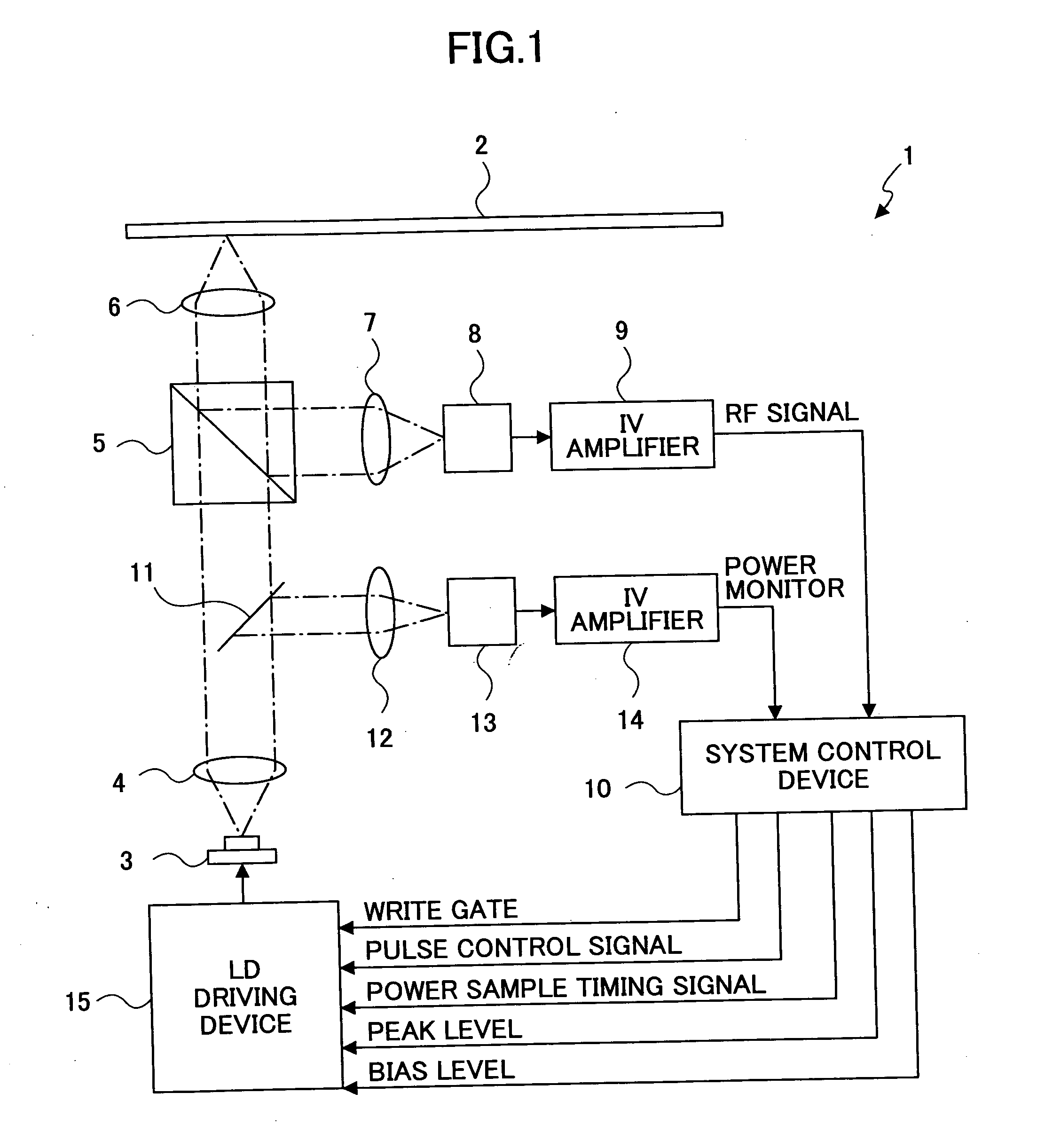

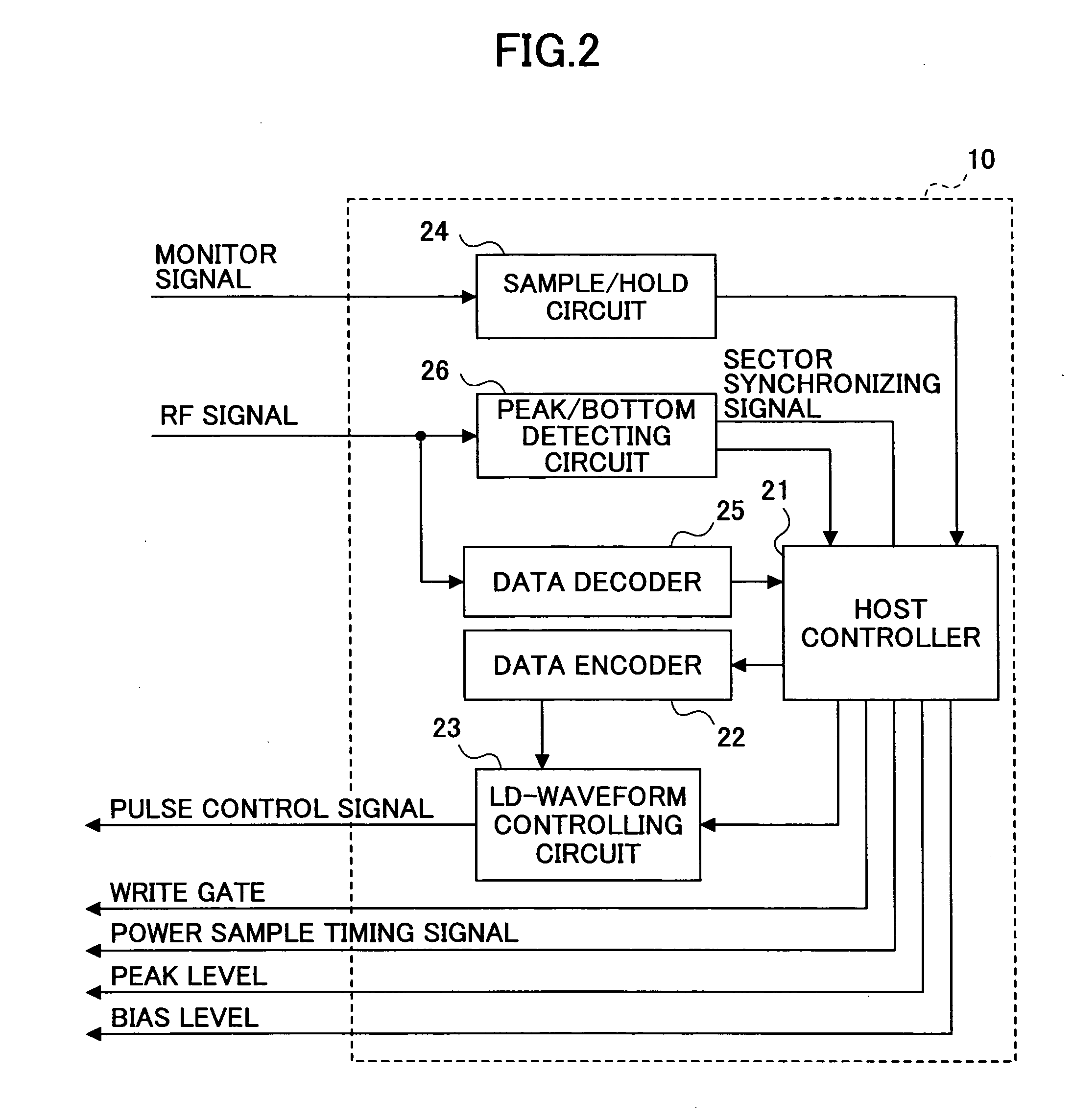

Stable write trial process with respect to optical record medium

InactiveUS20050025013A1The method is simple and reliableStable write trial processTelevision system detailsFilamentary/web record carriersEngineeringRecording layer

Provision is made to perform a write trial process in a stable manner at all times in a write trial area for the purpose of determining optimum recording power. Sub-areas of the write trial area are used successively from an inner circumference side of the medium to an outer circumference side of the medium with respect to the spiral direction that extends from the outer circumference side of the medium to the inner circumference side of the medium, and the sub-areas of the write trial area are used successively from the outer circumference side of the medium to the inner circumference side of the medium with respect to the spiral direction that extends from the inner circumference side of the medium to the outer circumference side of the medium With this provision, the write trial process is performed by accessing a sub-area portion of interest without accessing the sub-area portion having undergone the write trial, no matter which record layer is used. Servo control and address read can thus be stabilized. As a result, a seek operation toward the sub-area of interest is also stabilized, thereby achieving a stable write trial process.

Owner:RICOH KK

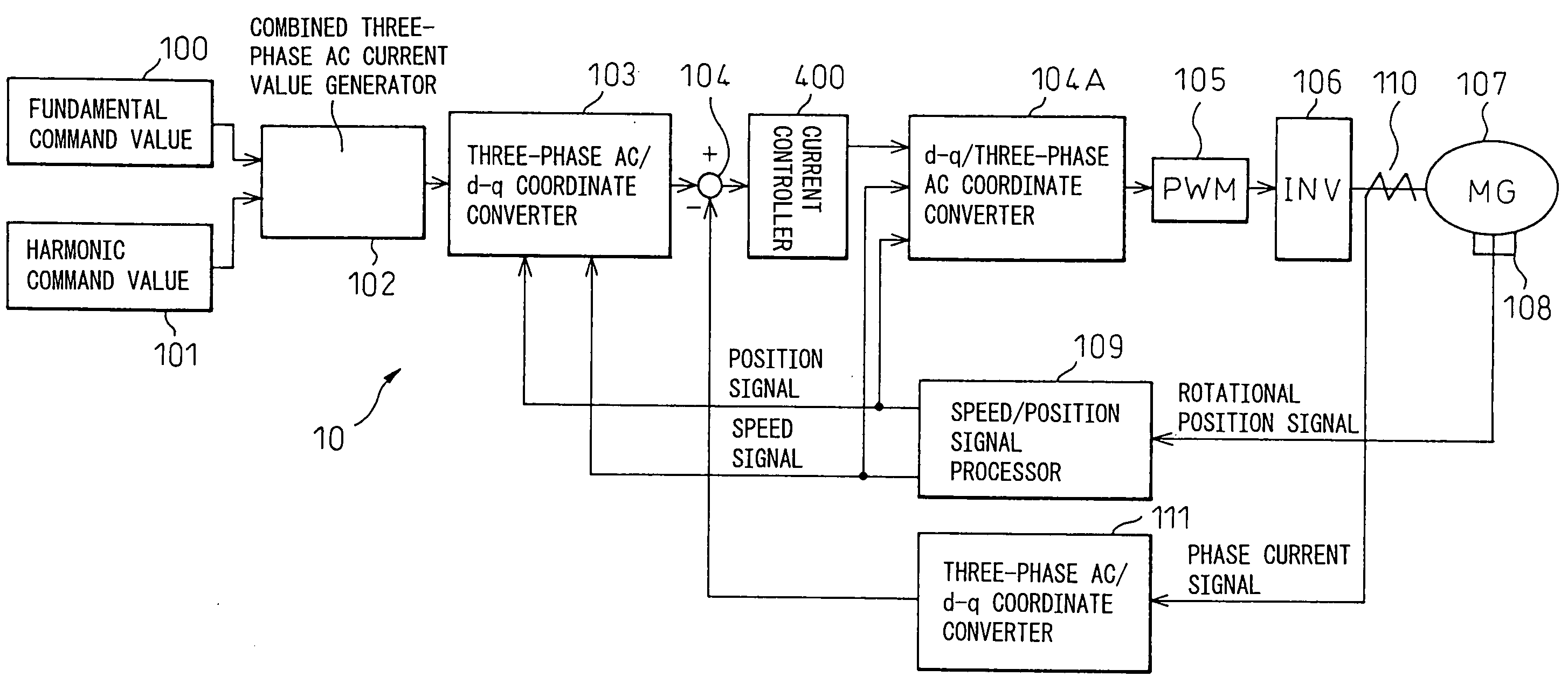

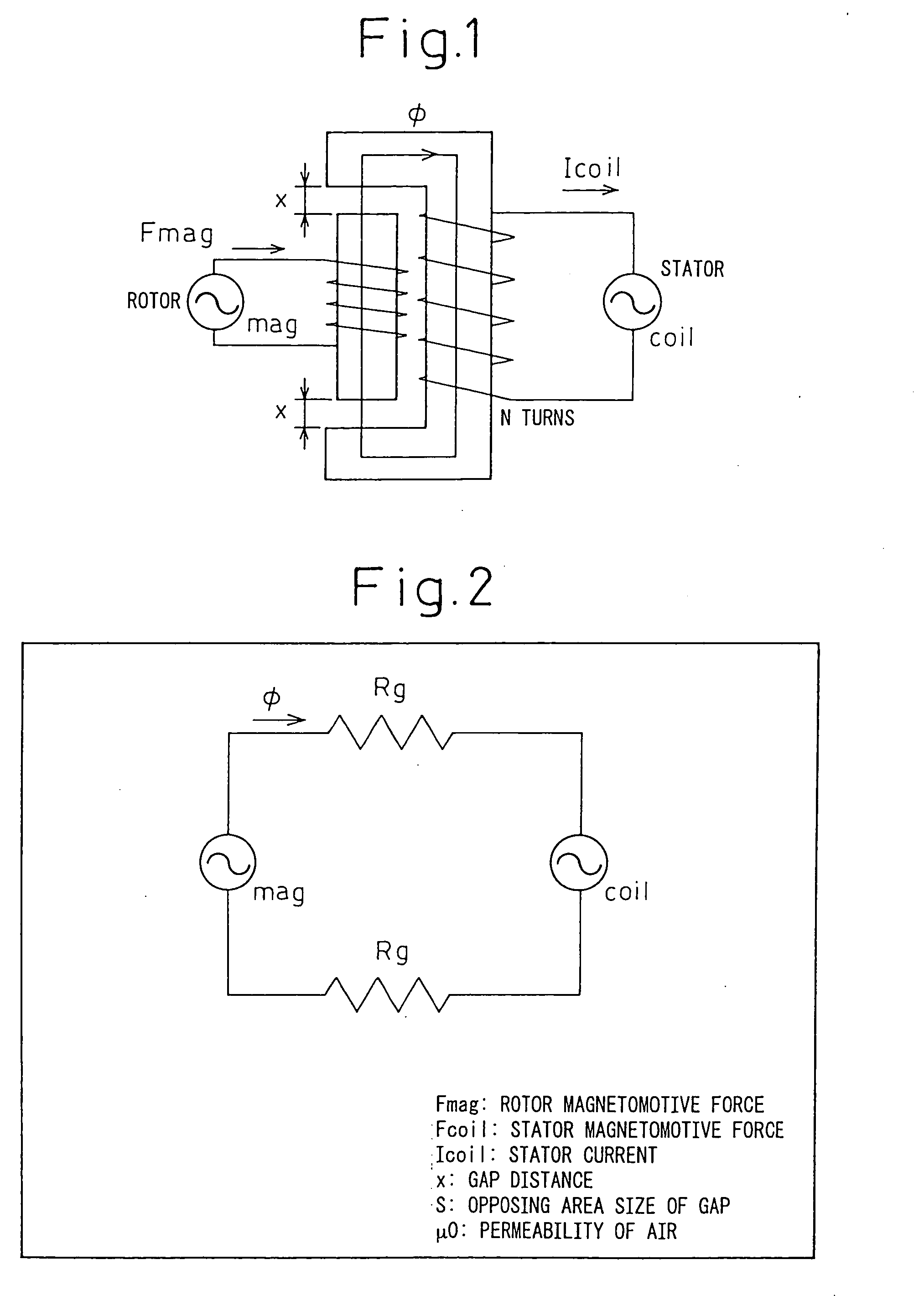

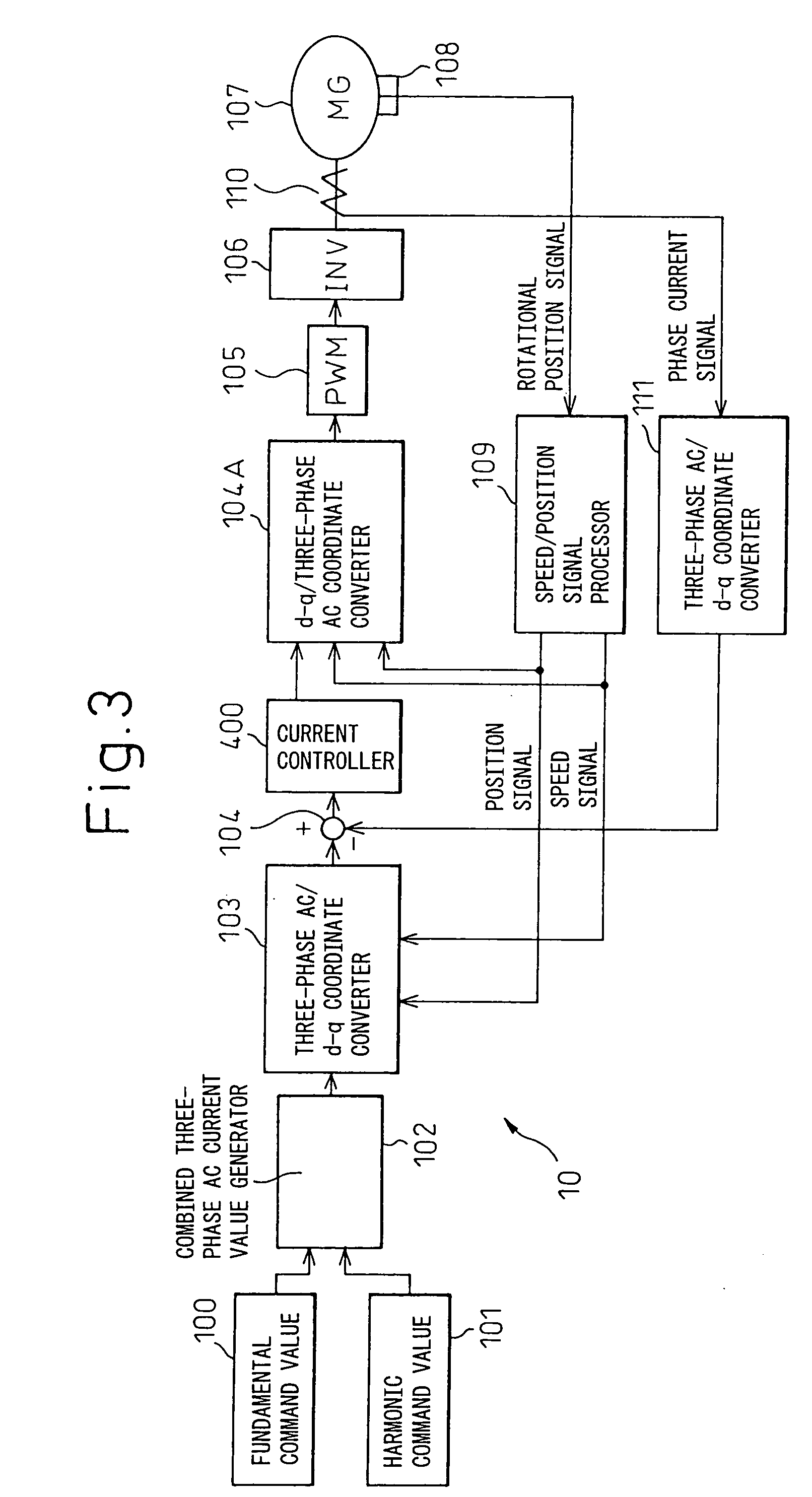

Magnetic noise reduction method for AC rotary electric machine, and motor control apparatus and AC rotary electric machine apparatus using the same

ActiveUS20050073280A1Quieter operationImprove comfortSingle-phase induction motor startersAC motor controlMagnetic noiseFundamental frequency

The invention provides techniques for reducing or altering the magnetic noise of an AC rotary electric machine. A magnetic noise reducing harmonic current of order n, whose frequency is n times the frequency of the fundamental frequency component of a polyphase AC current fed to an armature of a polyphase AC rotary electric machine, is superimposed on the polyphase AC current, thereby reducing or altering a harmonic component having a frequency (n−1) times the frequency of the fundamental frequency component and occurring due to a radial magnetic excitation force acting radially on an iron core of the AC rotary electric machine. Magnetic noise is caused by a vibration whose energy is the sum of the circumferential and radial vibrations of the iron core occurring due to the magnetomotive force of the rotor, and altering the radial vibration is particularly effective in altering the magnetic noise; as the harmonic component of the radially acting magnetic excitation force, occurring due to harmonic components having frequencies 3, 5, 7, and 13 times the fundamental frequency, has a frequency 6 or 12 times the fundamental frequency, the magnetomotive force of the rotor can be effectively reduced or altered when a current having a frequency 7 or 13 times the fundamental frequency is superimposed on the stator current.

Owner:DENSO CORP

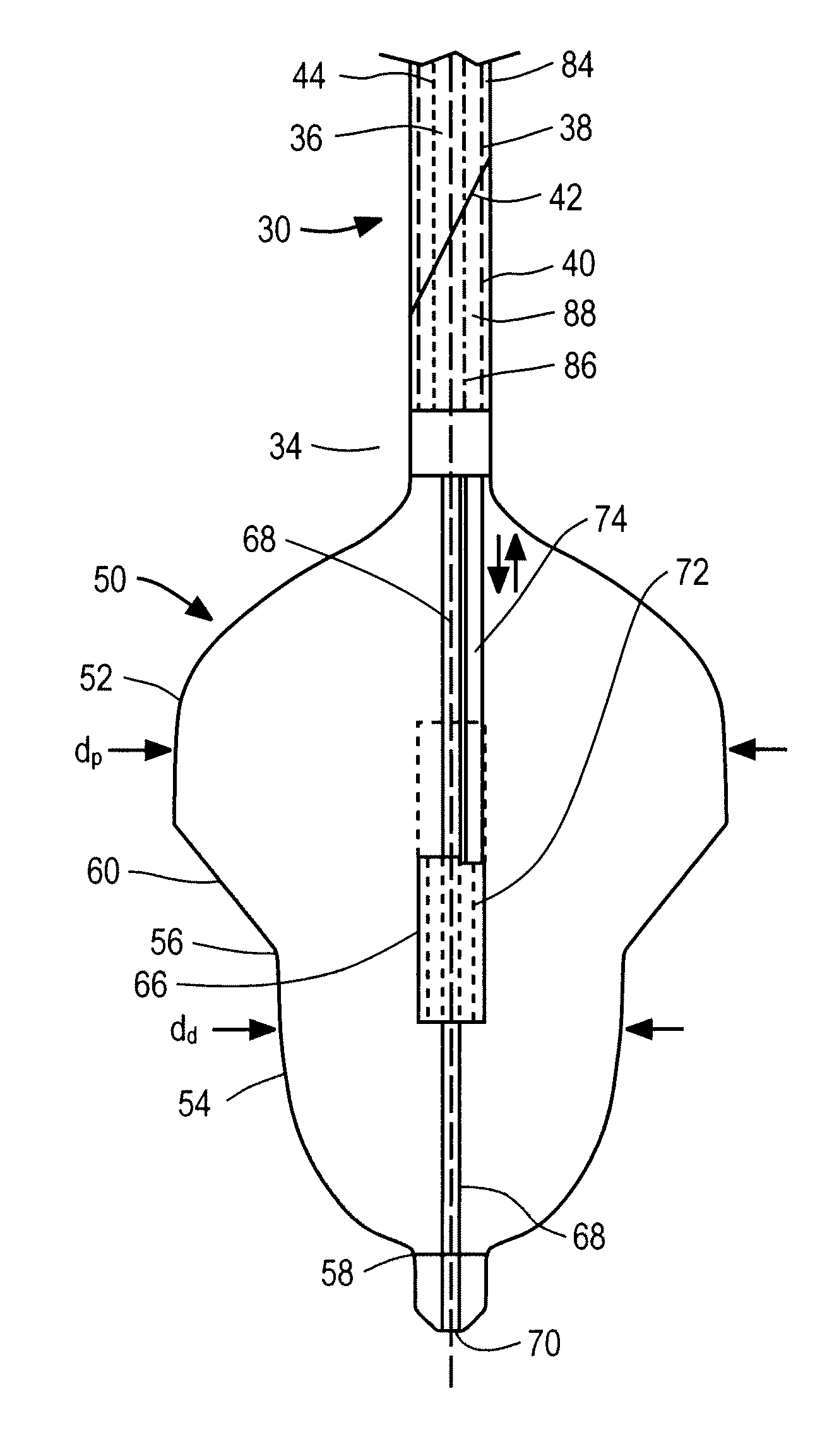

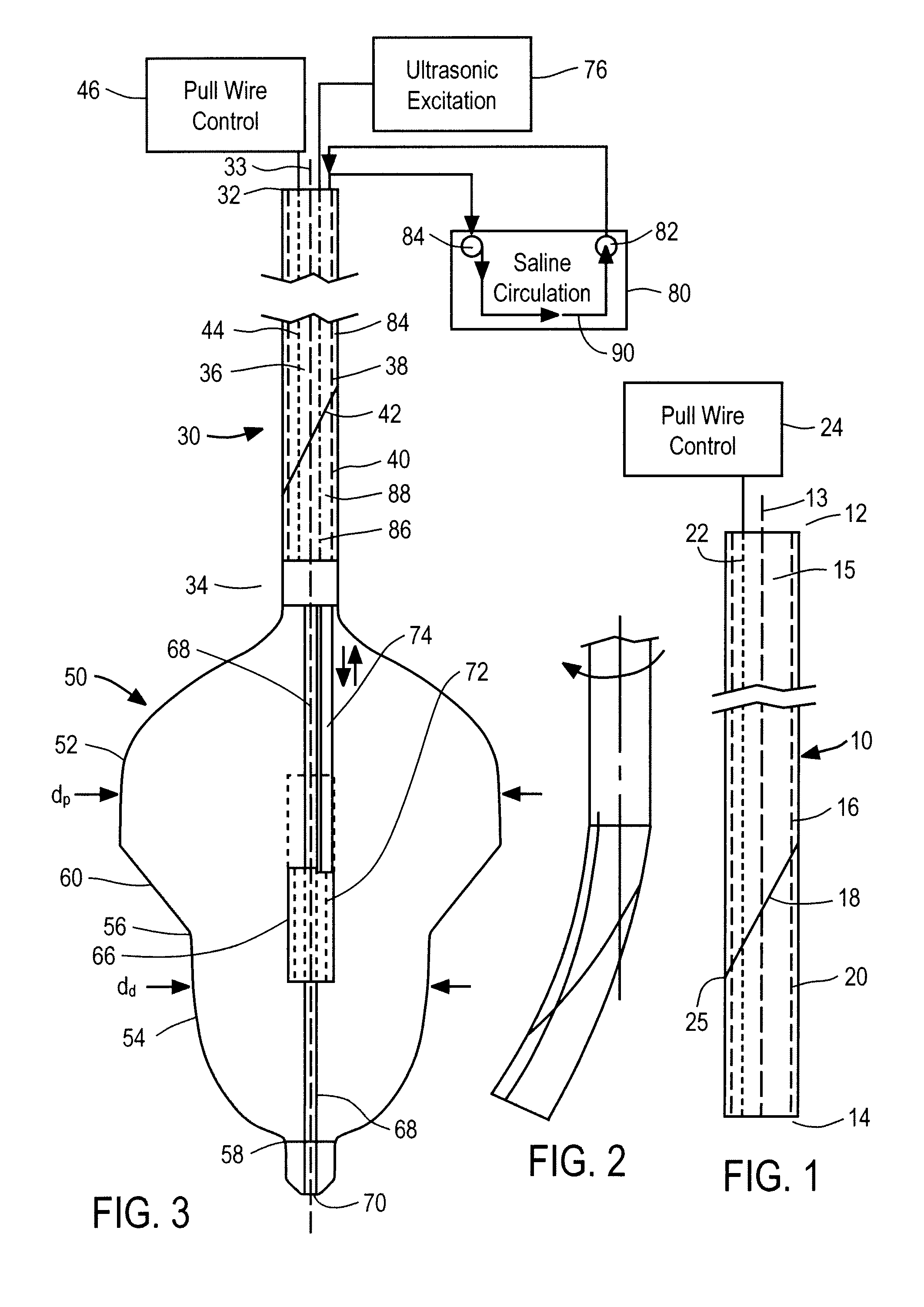

Methods and apparatus for treatment of mitral valve insufficiency

ActiveUS20100179424A1The method is simple and reliableProne to feverUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyMitral valve incompetenceUltrasonic sensor

Mitral valve insufficiency is treated by introducing an expansible device such as a balloon bearing a an ultrasonic transducer into the heart so that the transducer is positioned adjacent the mitral annulus but spaced from the mitral annulus, and actuating the transducer to heat the mitral annulus, denature collagen in the annulus and thereby shrink the annulus.

Owner:RECOR MEDICAL INC

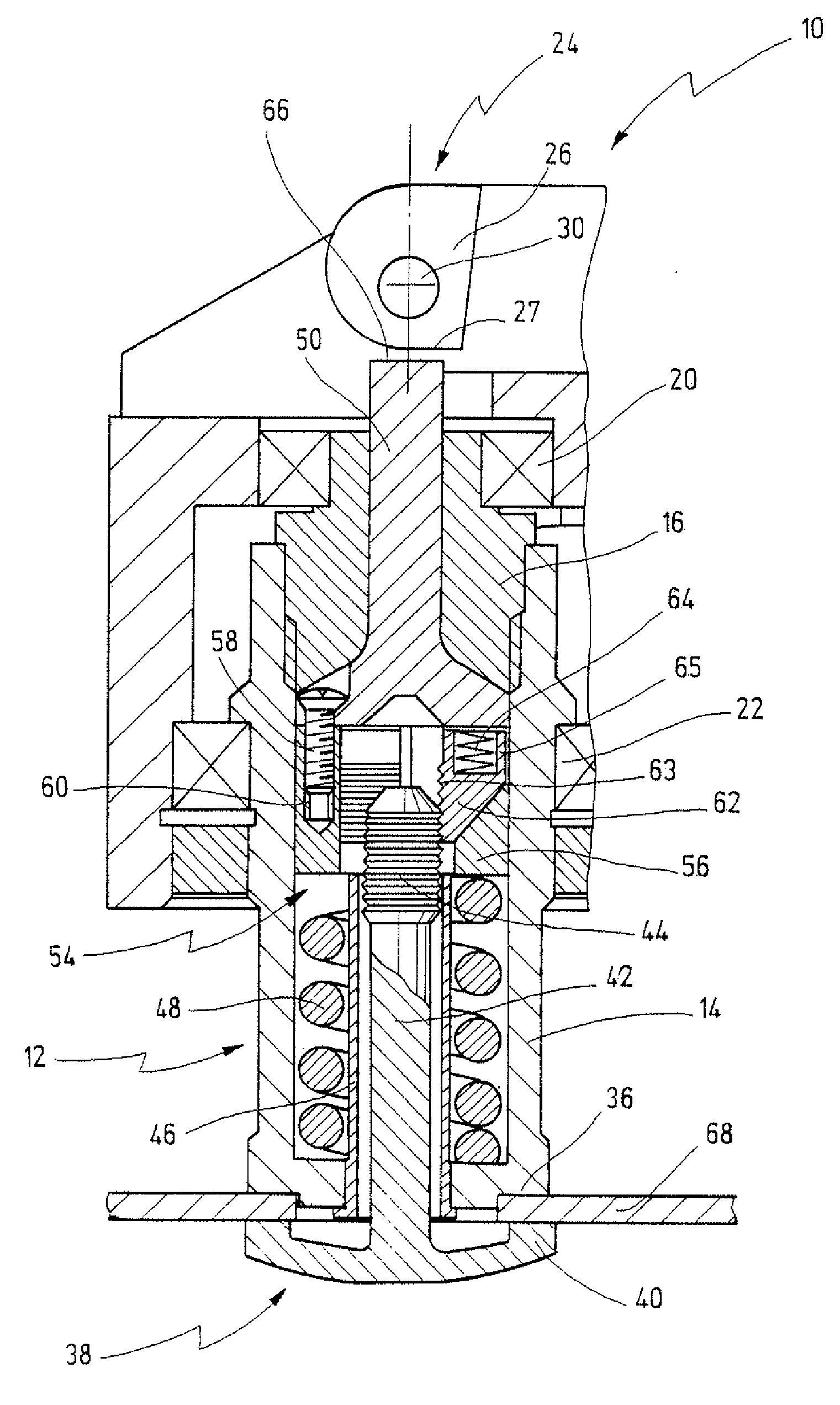

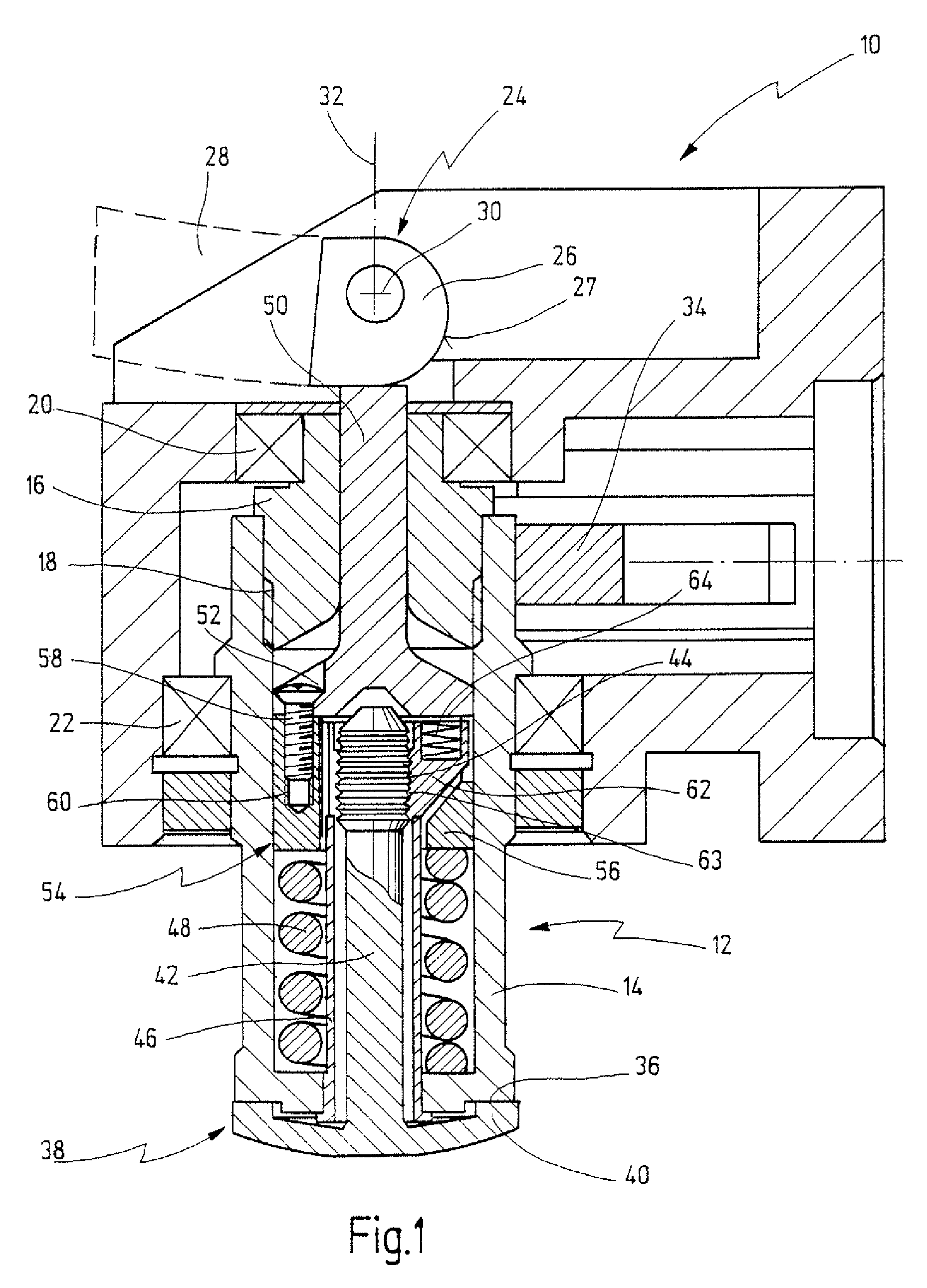

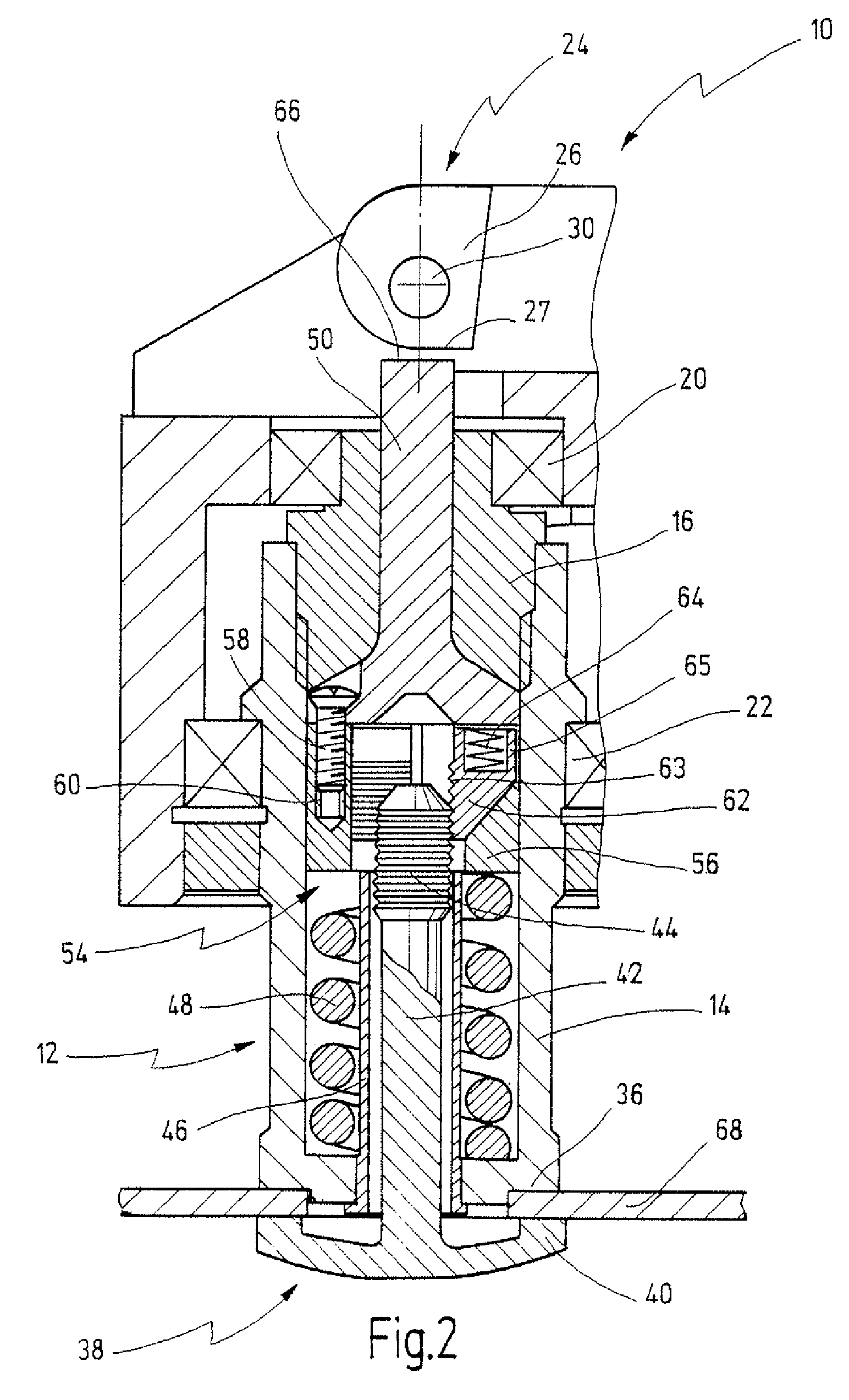

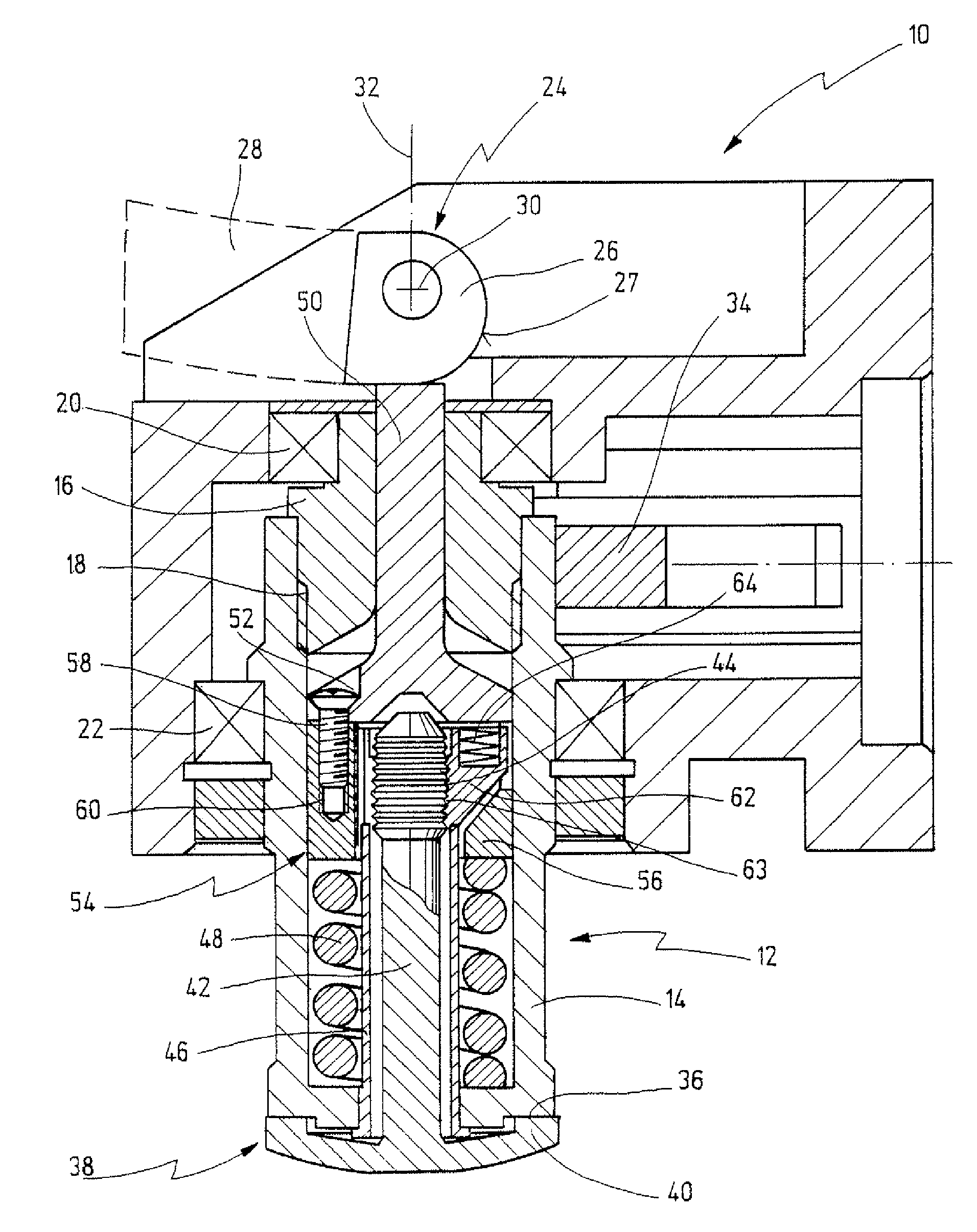

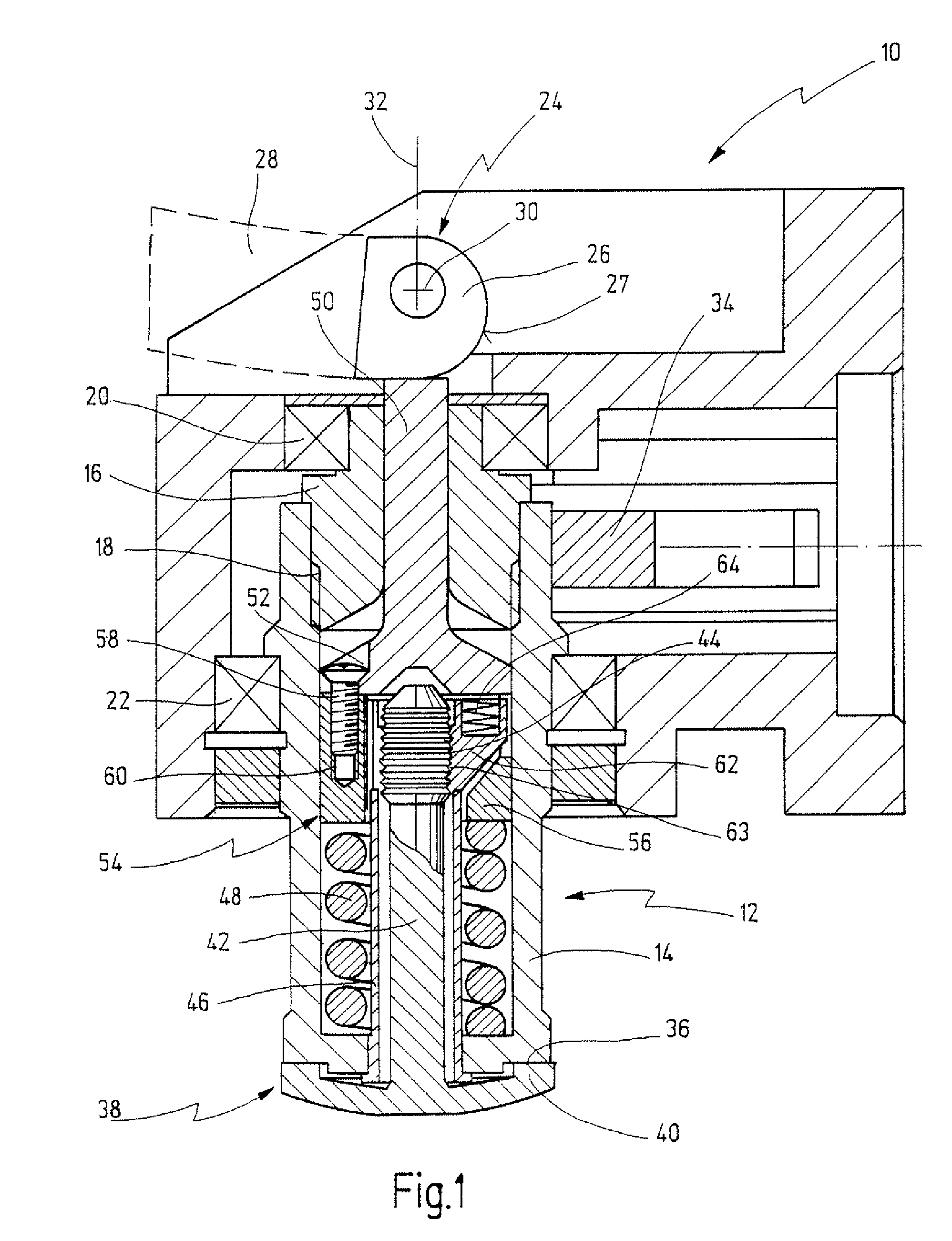

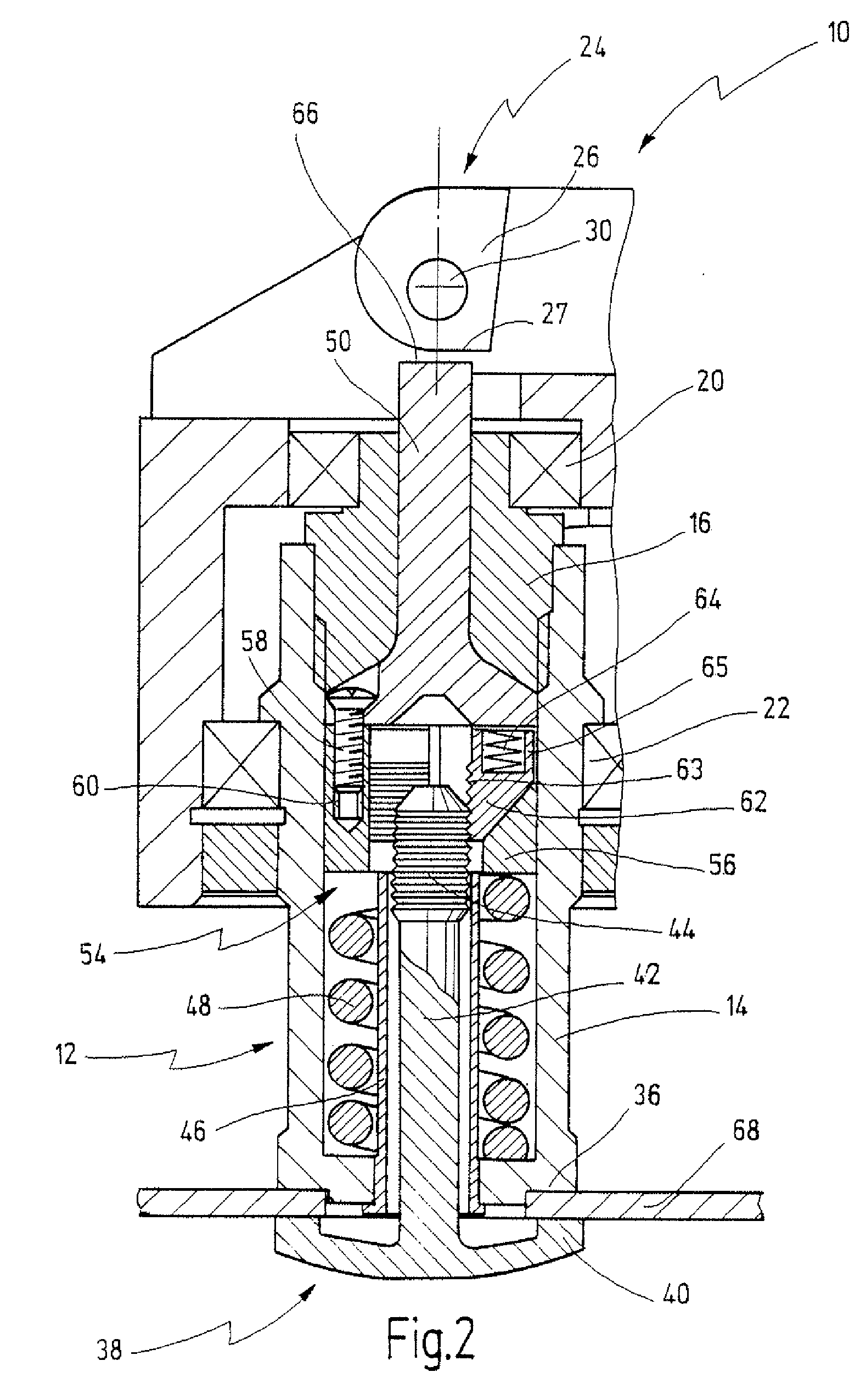

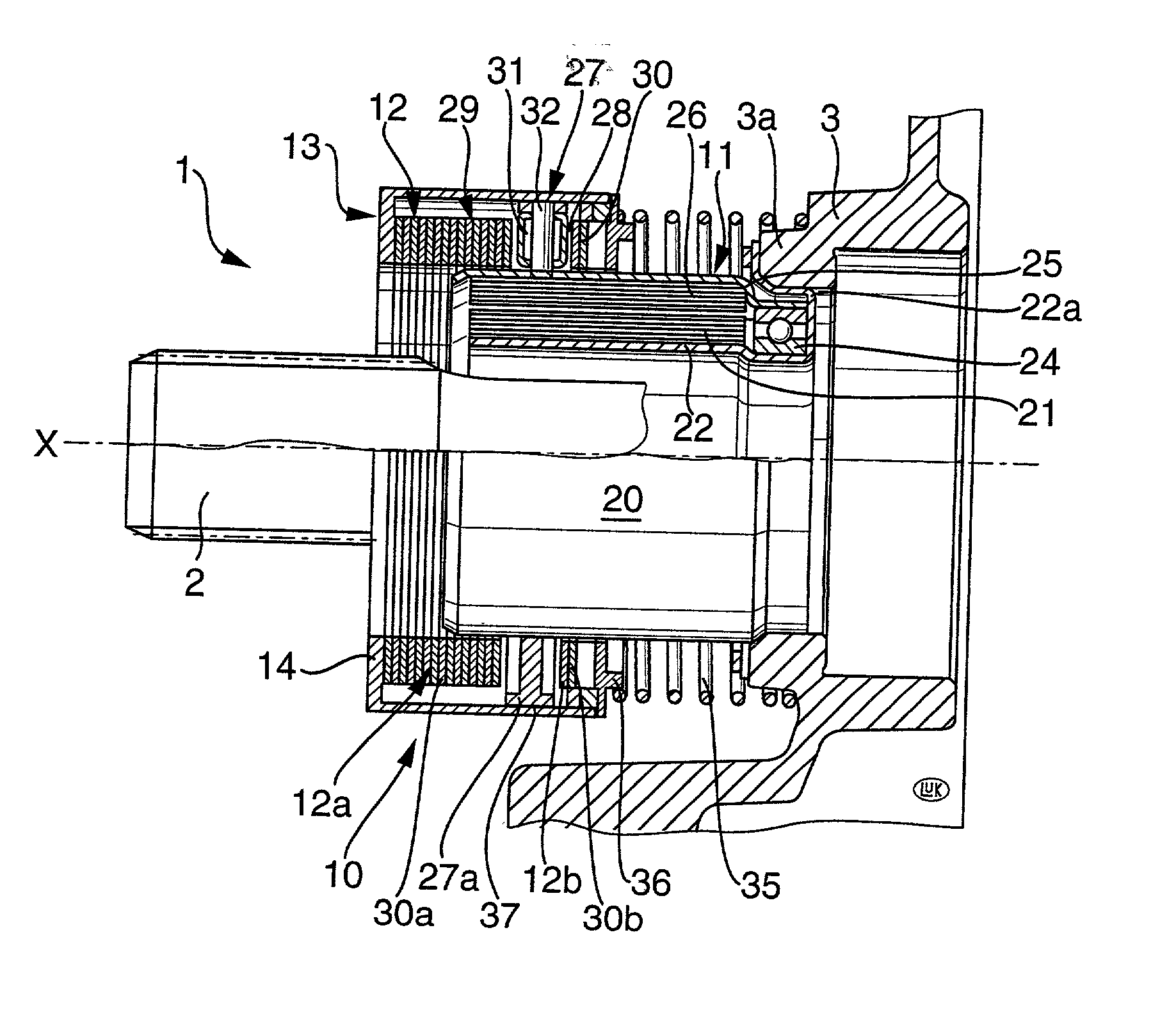

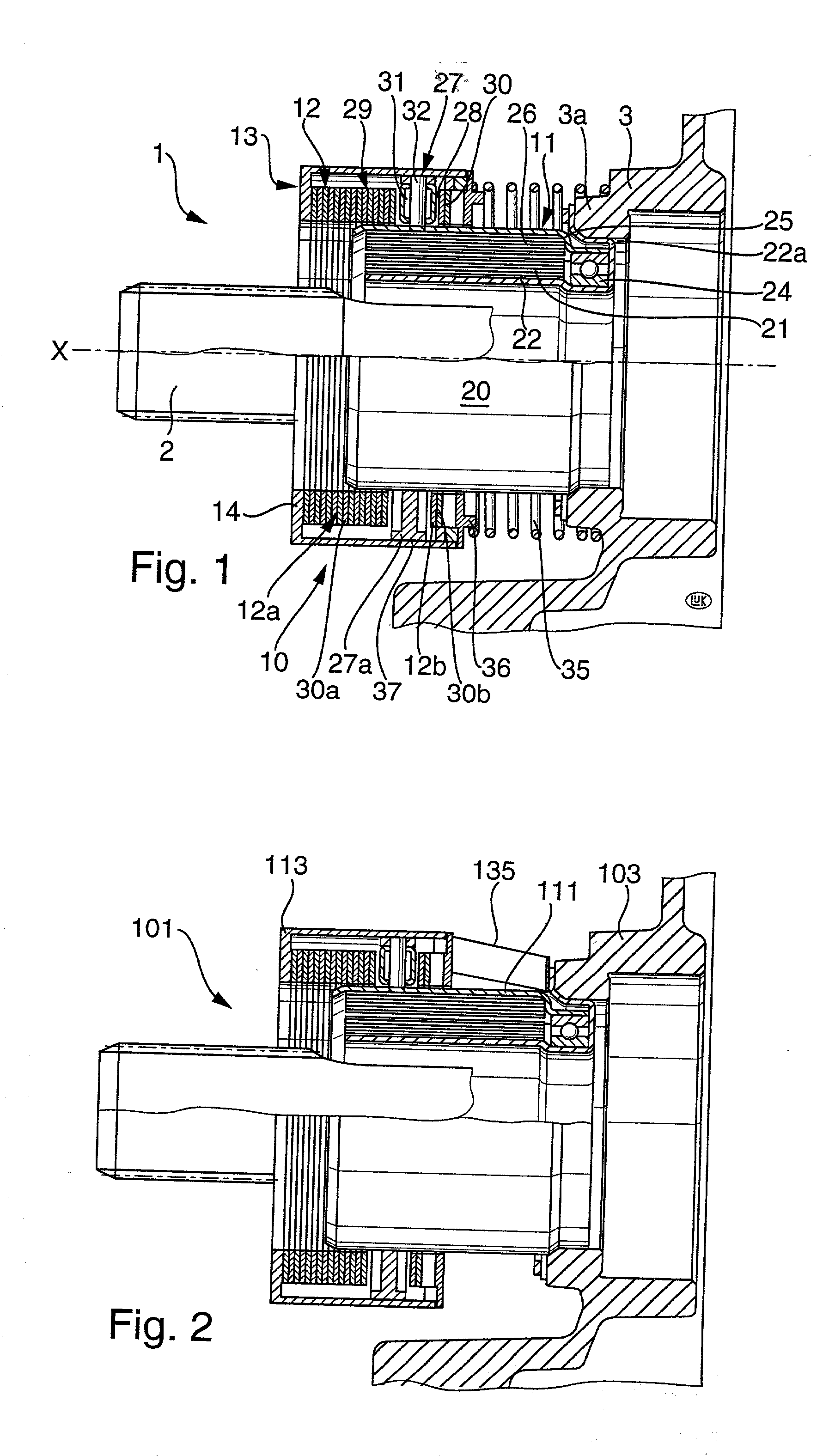

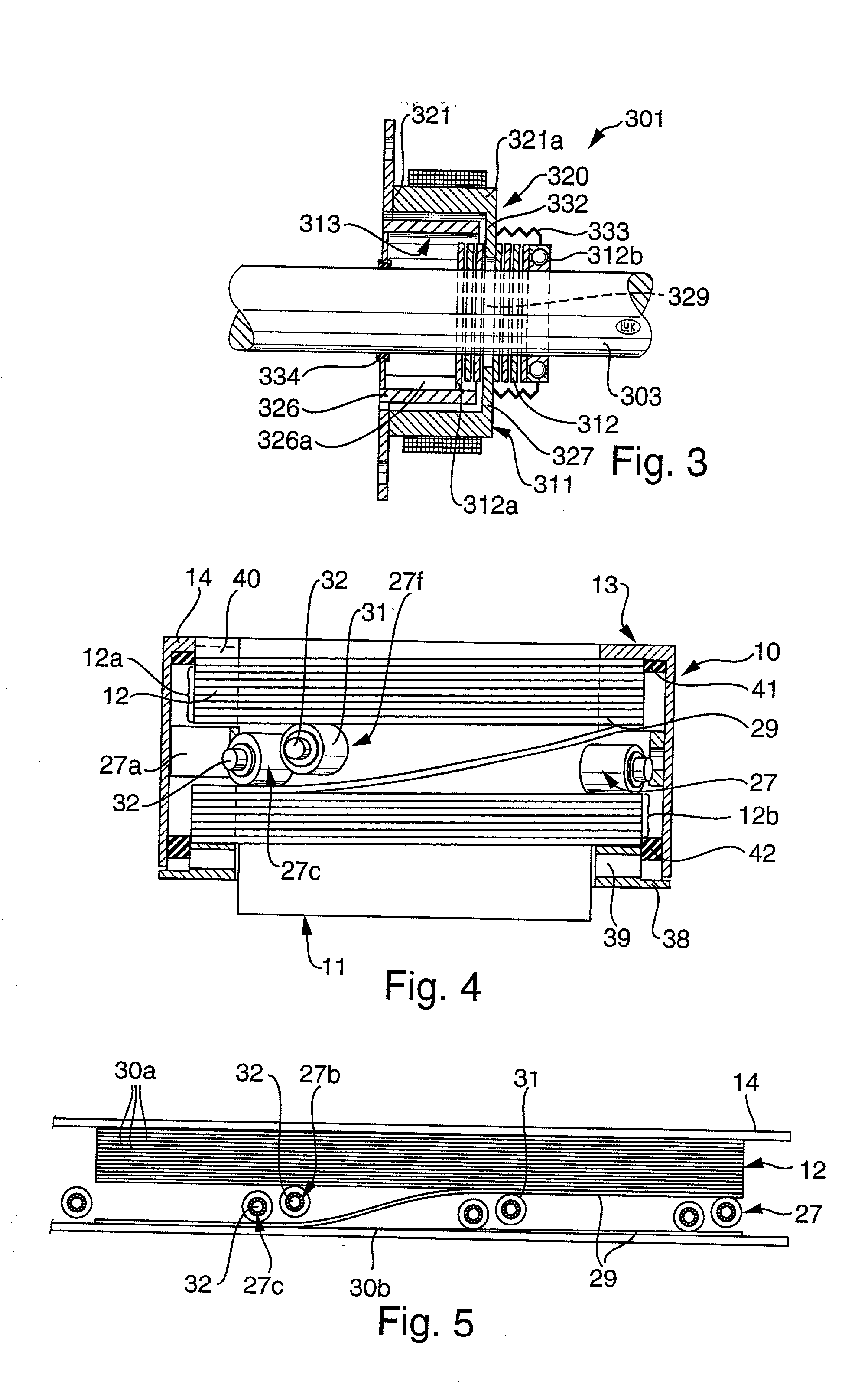

Hand-held power tool with clamping device for a tool

ActiveUS7344435B2The method is simple and reliableStrong clamping forceGrinding wheel securing apparatusPortable grinding machinesHand heldEngineering

A hand-held power tool (10) is specified, comprising a work spindle (12) for driving a tool (68), said tool (68) being fastenable between a fastening element (38) and a holding portion (36) on a tool end of the work spindle (12), and a displacement device (24) for sliding the fastening element (38) between a released position in which the fastening element (38) can be detached from the work spindle (12) and a clamped position in which the fastening element (38) is clamped against the holding portion (36) by a spring element (48). The fastening element (38) includes a clamping shaft (42) that is insertable into the work spindle (12) and held in the clamped position by a lock assembly (54) inside the work spindle (12), and which can be removed when in the released position (FIG. 2).

Owner:C & E FEIN GMBH & CO KG

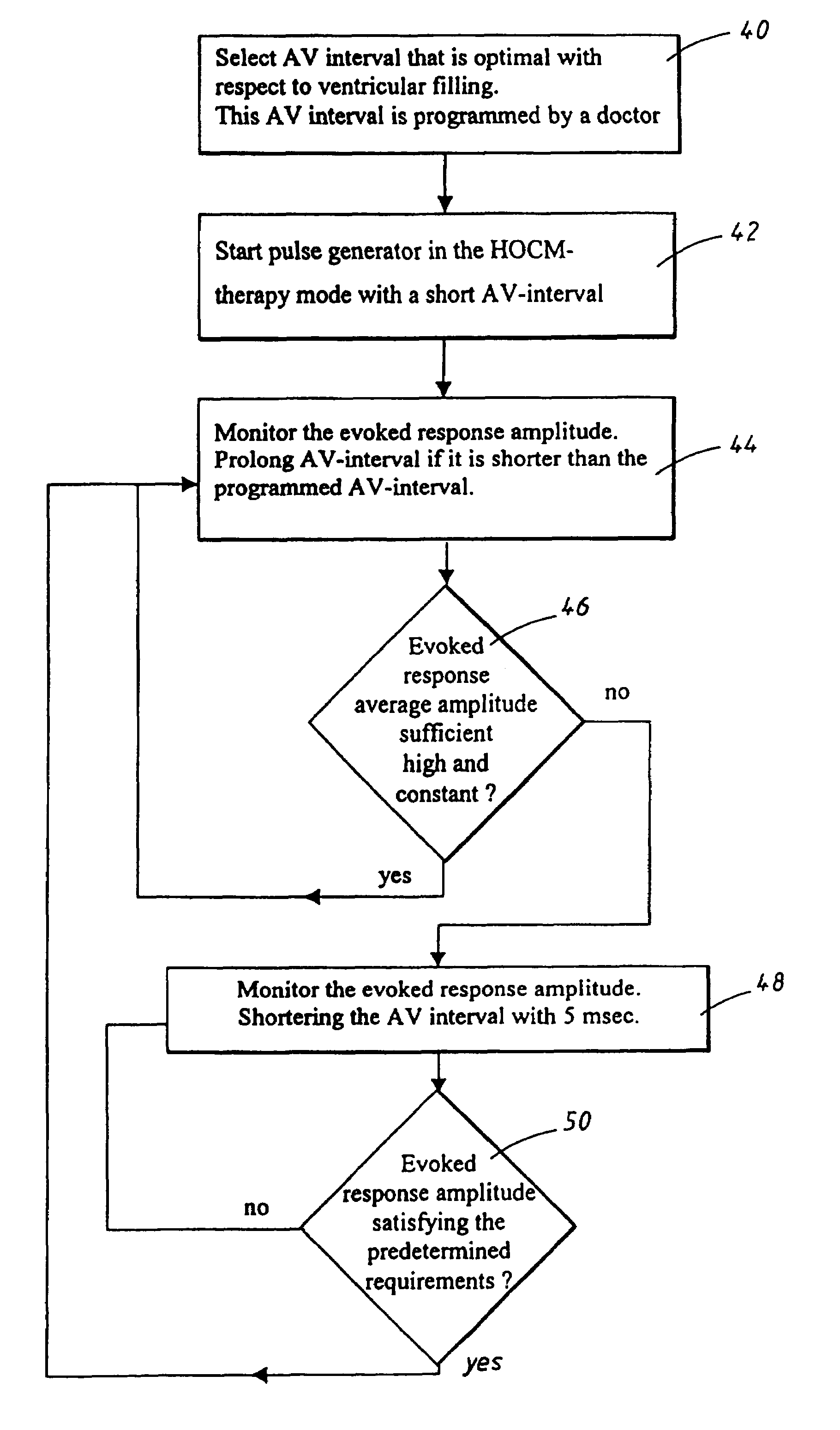

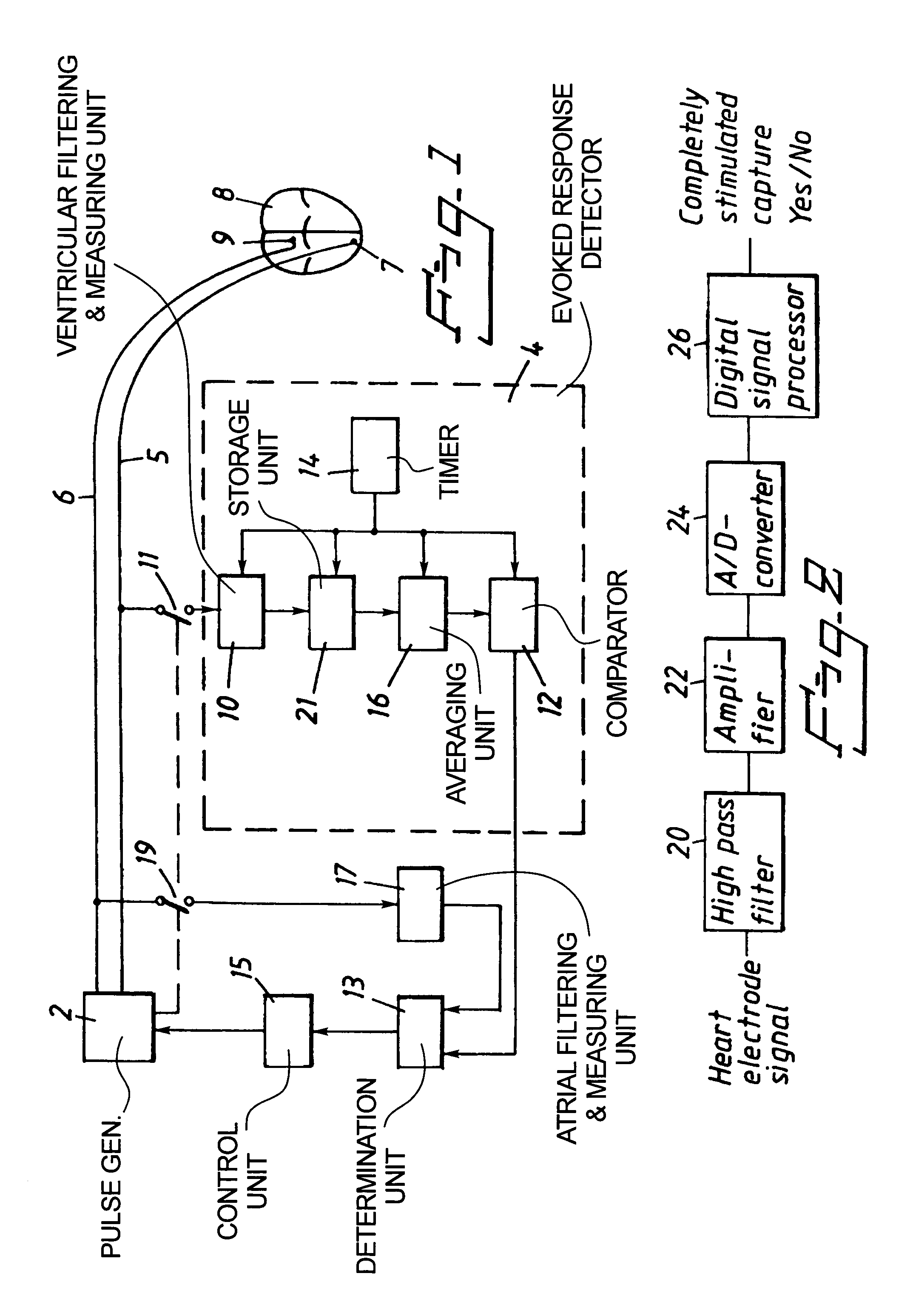

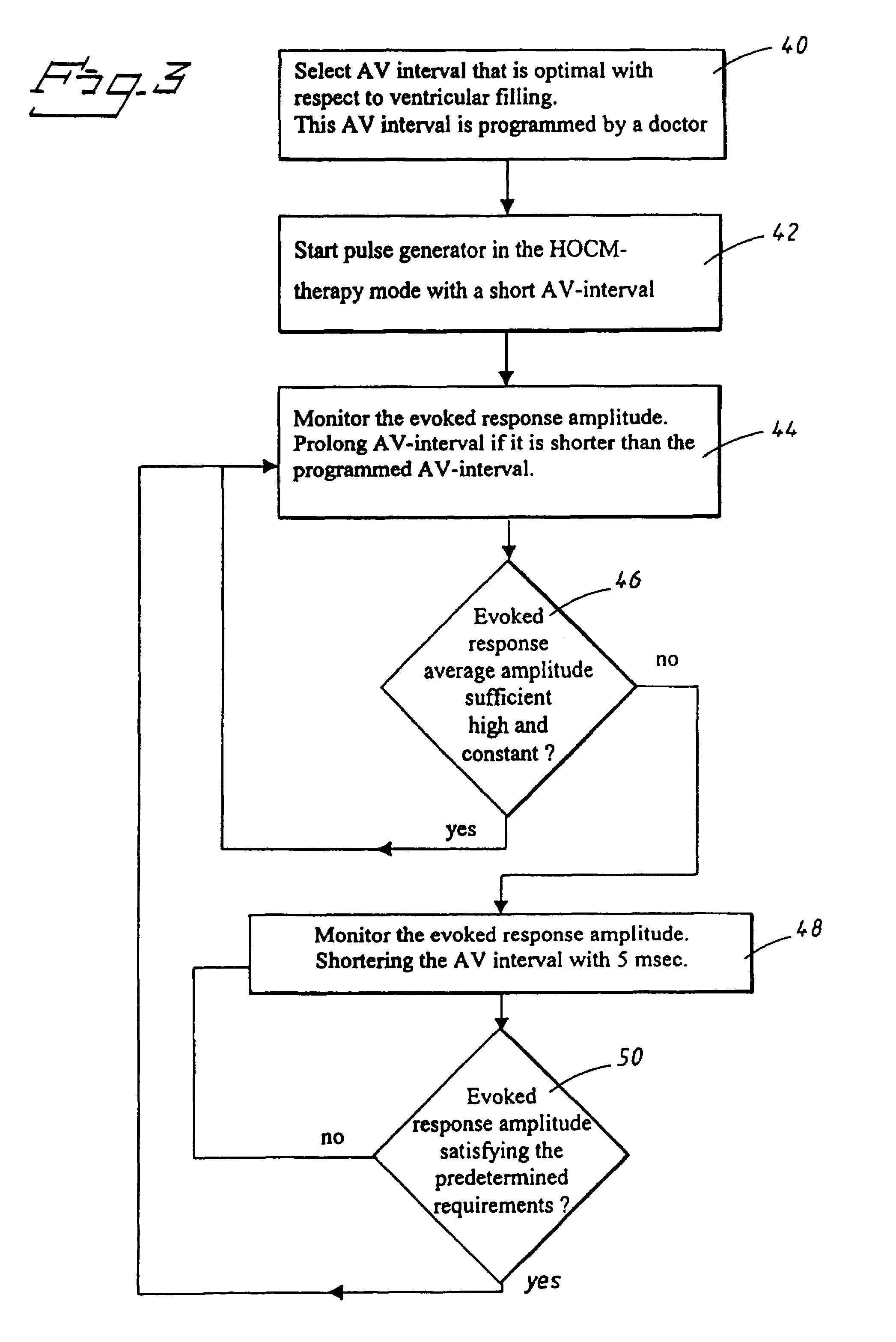

Dual chamber heart stimulator with evoked response detector

InactiveUS7020522B1The method is simple and reliableSimple and reliable processHeart stimulatorsFusion beatCardiac cycle

A heart stimulator has an atrial and ventricular pulse generator for producing atrial and ventricular stimulation pulses, an atrial sensor for sensing atrial signals and an evoked response detector for detecting the occurrence of incipient fusion beats from measured ventricular signals. A determination unit determines an incipient fusion AV-interval from the sensed atrial signals and the detected fusion beats, and a controller controls the pulse generator to deliver stimulation pulses at a controlled AV-interval which is shorter than the incipient fusion AV-interval. The evoked response detector includes an averaging unit which forms an average amplitude value of the measured ventricular signals during a predetermined time window of each cardiac cycle, and a comparator which compares the average value for each cardiac cycle with a predetermined limit criterion, and supplies the result of the comparison to the determination unit for determining a measured ventricular signal resulted from an incipient fusion beat or a completely stimulated capture.

Owner:ST JUDE MEDICAL

Method of fabricating a circuit arrangement with thermal vias

InactiveUS6190941B1Prevent penetrationThe method is simple and reliablePrinted circuit assemblingFinal product manufactureScreen printingEngineering

An electronic component is mounted on a substrate such as a circuit board by means of a soldering process such as reflow soldering. The circuit board has a thermal via hole therethrough to provide a heat dissipation path from the top surface to the bottom surface of the circuit board, for dissipating heat from the electronic component. To prevent molten solder from penetrating through the via hole during the soldering process, the via hole is sealed prior to the soldering process. The via hole is sealed from the bottom surface of the substrate by carrying out a screen printing process including at least two printing passes to print a sealing material into the open hole of the thermal via.

Owner:DAIMLER AG

Hand-Held Power Tool With Clamping Device For A Tool

ActiveUS20070060030A1The method is simple and reliableStrong clamping forceGrinding wheel securing apparatusPortable grinding machinesHand heldEngineering

A hand-held power tool (10) is specified, comprising a work spindle (12) for driving a tool (68), said tool (68) being fastenable between a fastening element (38) and a holding portion (36) on a tool end of the work spindle (12), and a displacement device (24) for sliding the fastening element (38) between a released position in which the fastening element (38) can be detached from the work spindle (12) and a clamped position in which the fastening element (38) is clamped against the holding portion (36) by a spring element (48). The fastening element (38) includes a clamping shaft (42) that is insertable into the work spindle (12) and held in the clamped position by a lock assembly (54) inside the work spindle (12), and which can be removed when in the released position (FIG. 2).

Owner:C & E FEIN GMBH & CO KG

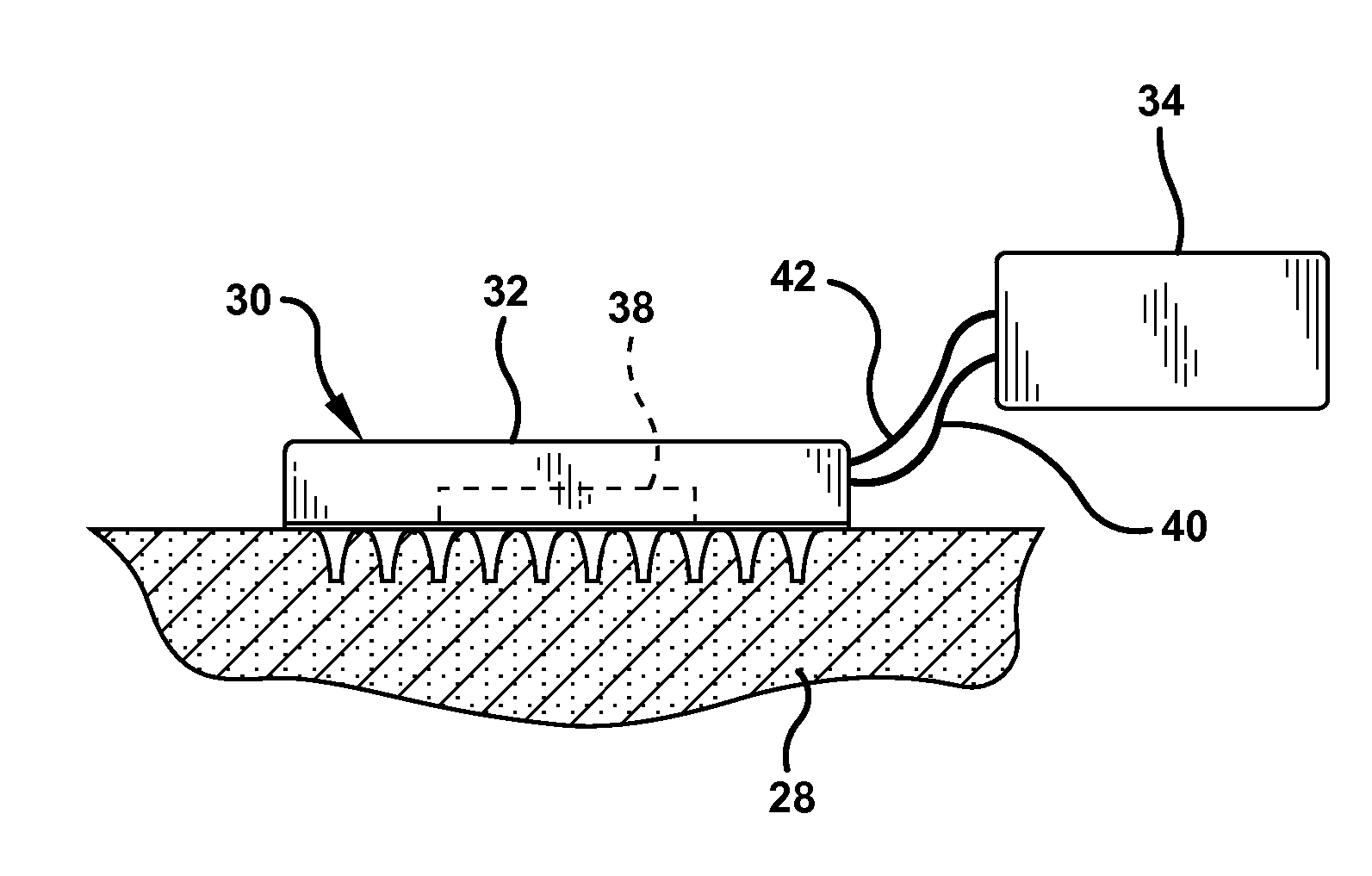

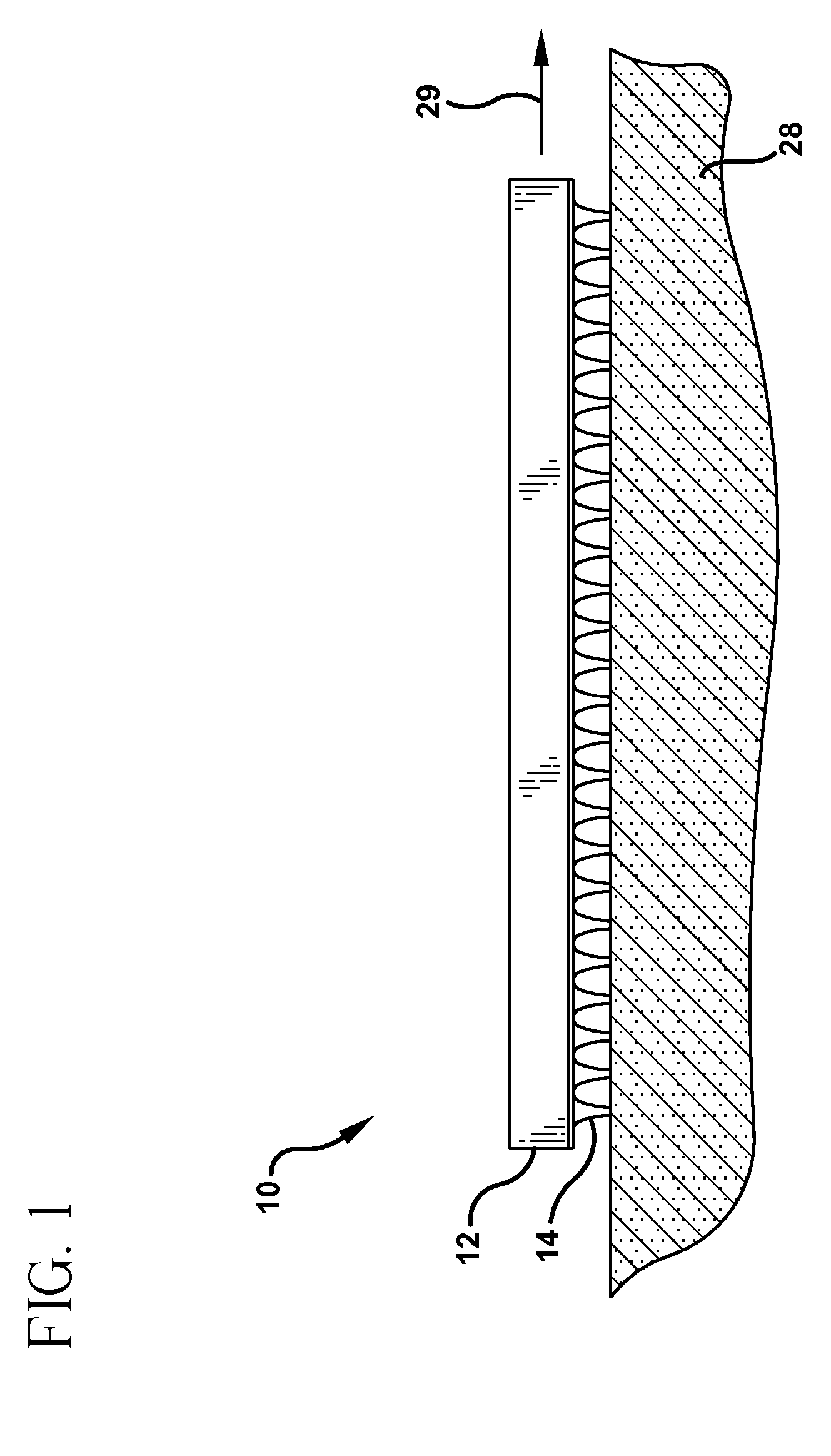

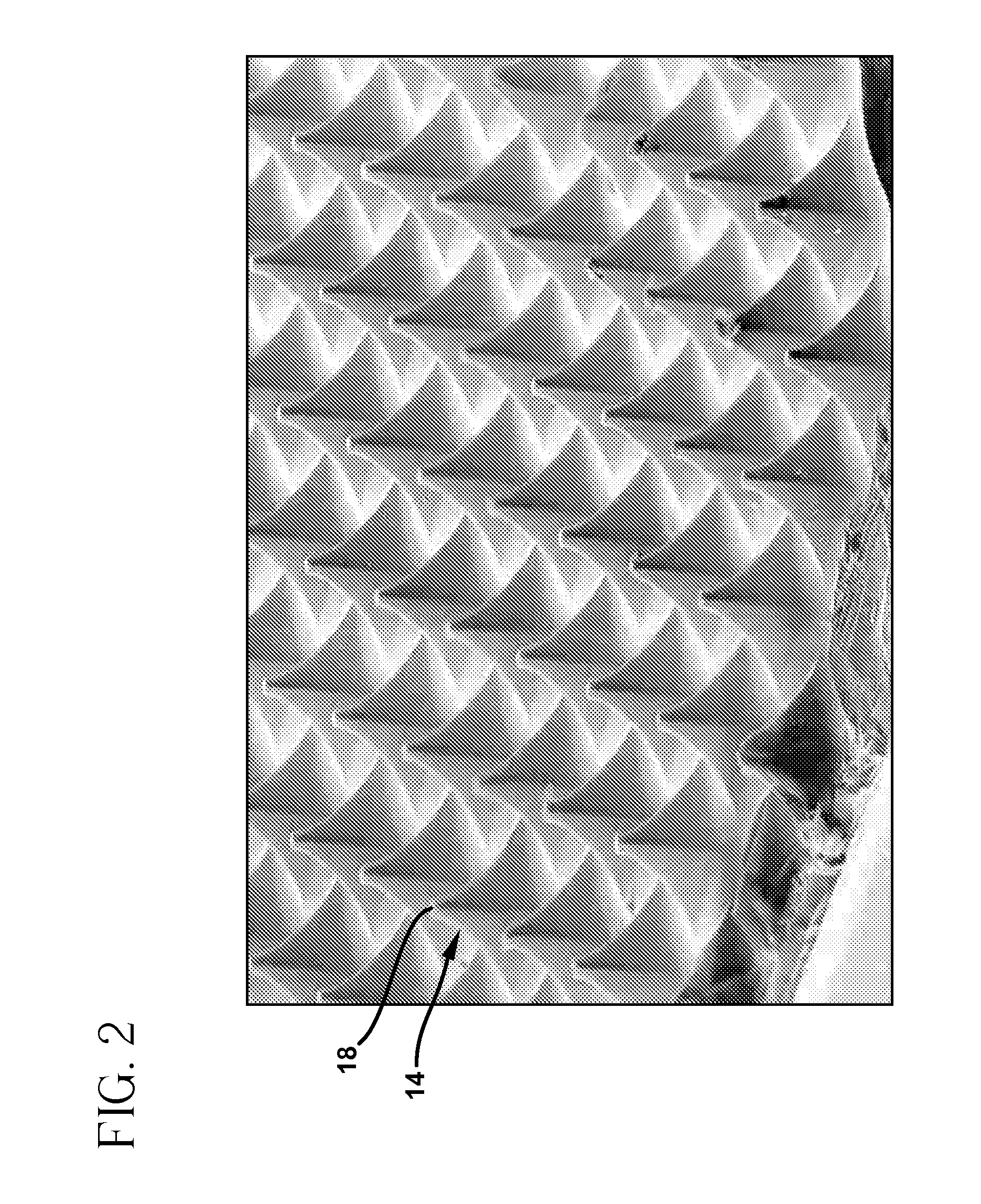

Method and device for abrading skin

InactiveUS20060264893A1Effective penetrationMinimal irritationElectrotherapyMicroneedlesIrritationStratum corneum

A device includes a plurality of microneedles for abrading the stratum corneum of the skin to form a plurality of grooves in the tissue having a controlled depth and width. The microneedles have a length of about 5-250 microns and generally about 5-200 microns. The device is rubbed over the skin to prepare an abraded site after which a transdermal delivery or sampling device is applied to the abraded delivery site. The abrasion increases the permeability of the skin and the rate of delivery and extraction of a substance without pain or irritation to the patient.

Owner:BECTON DICKINSON & CO

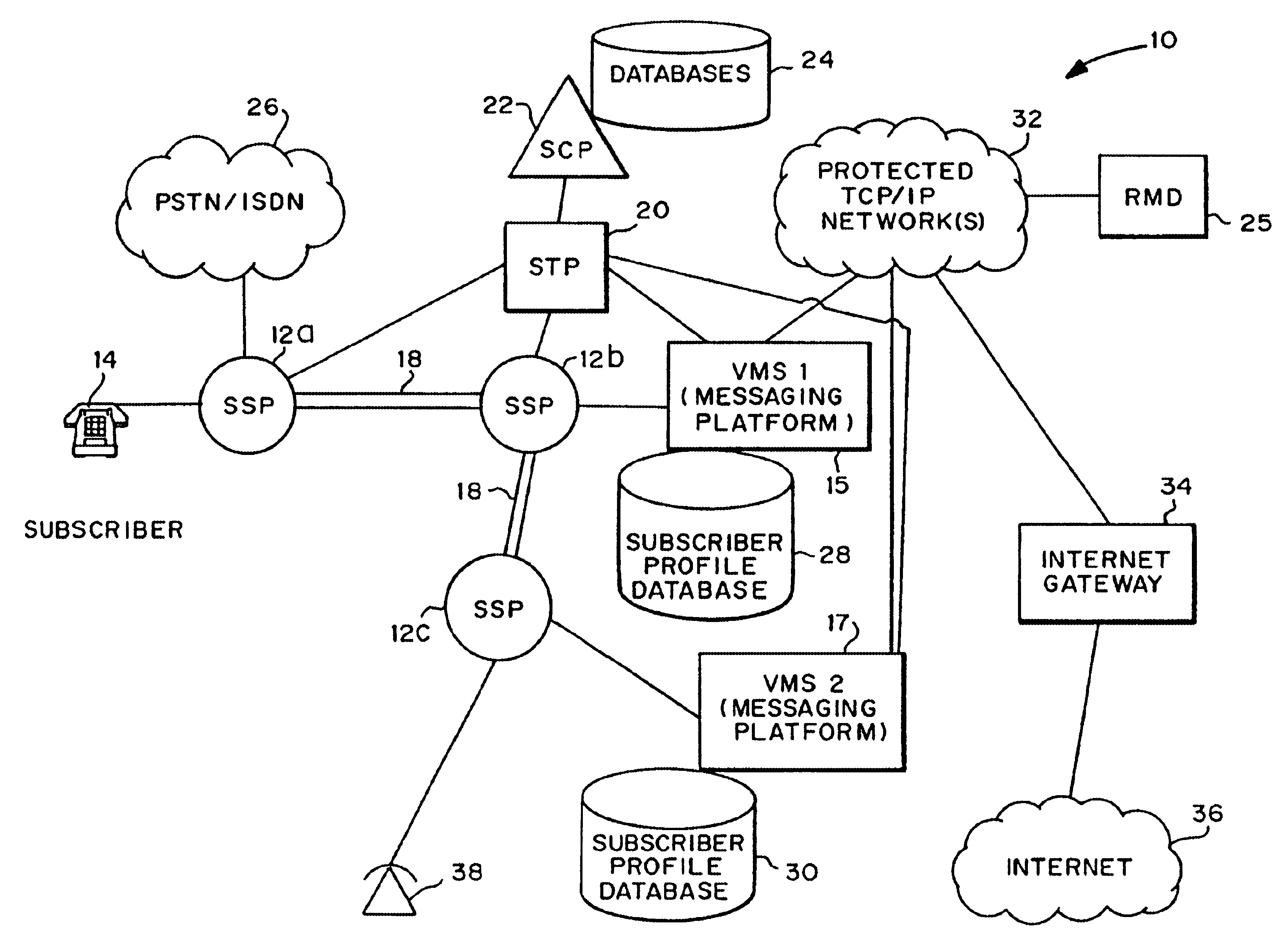

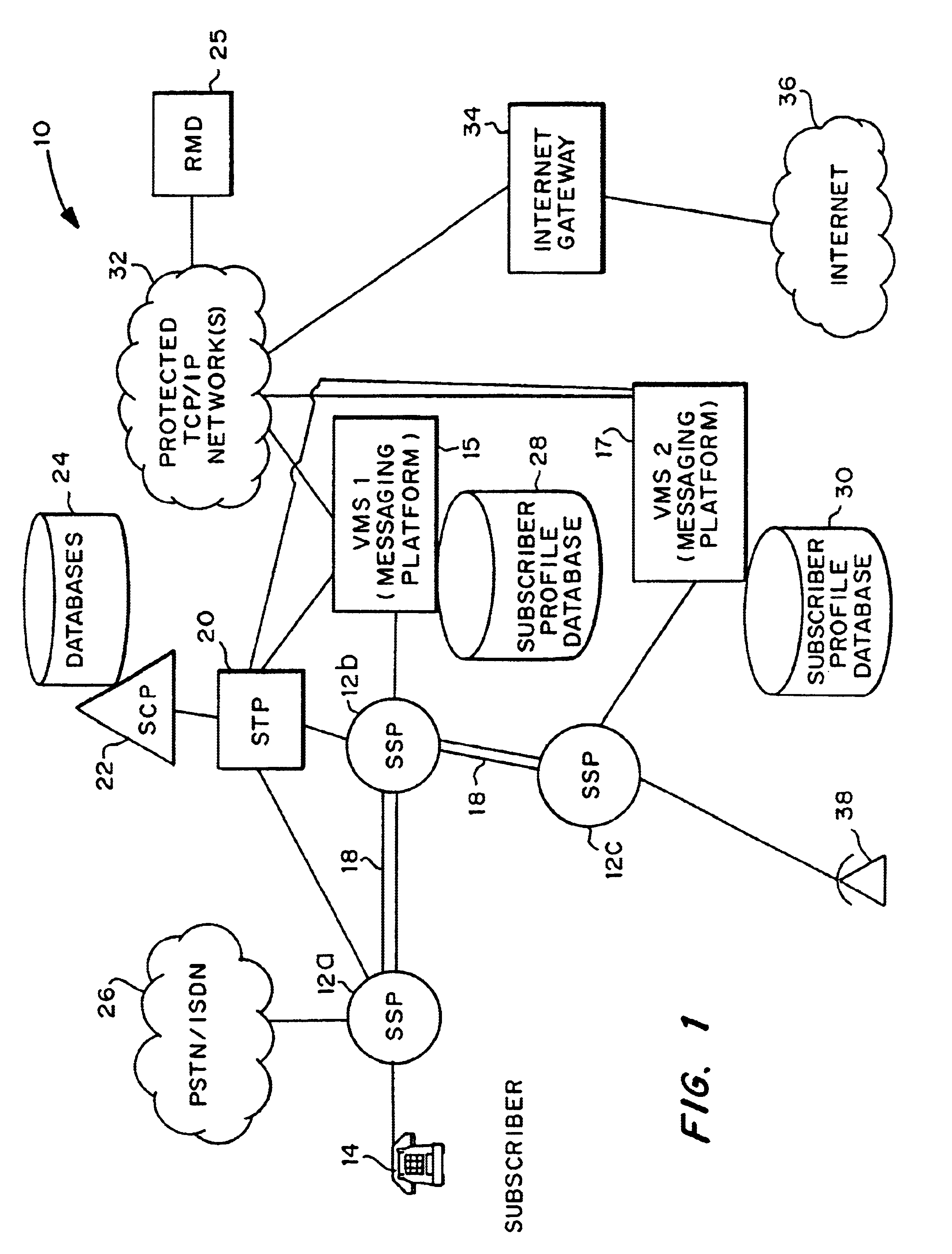

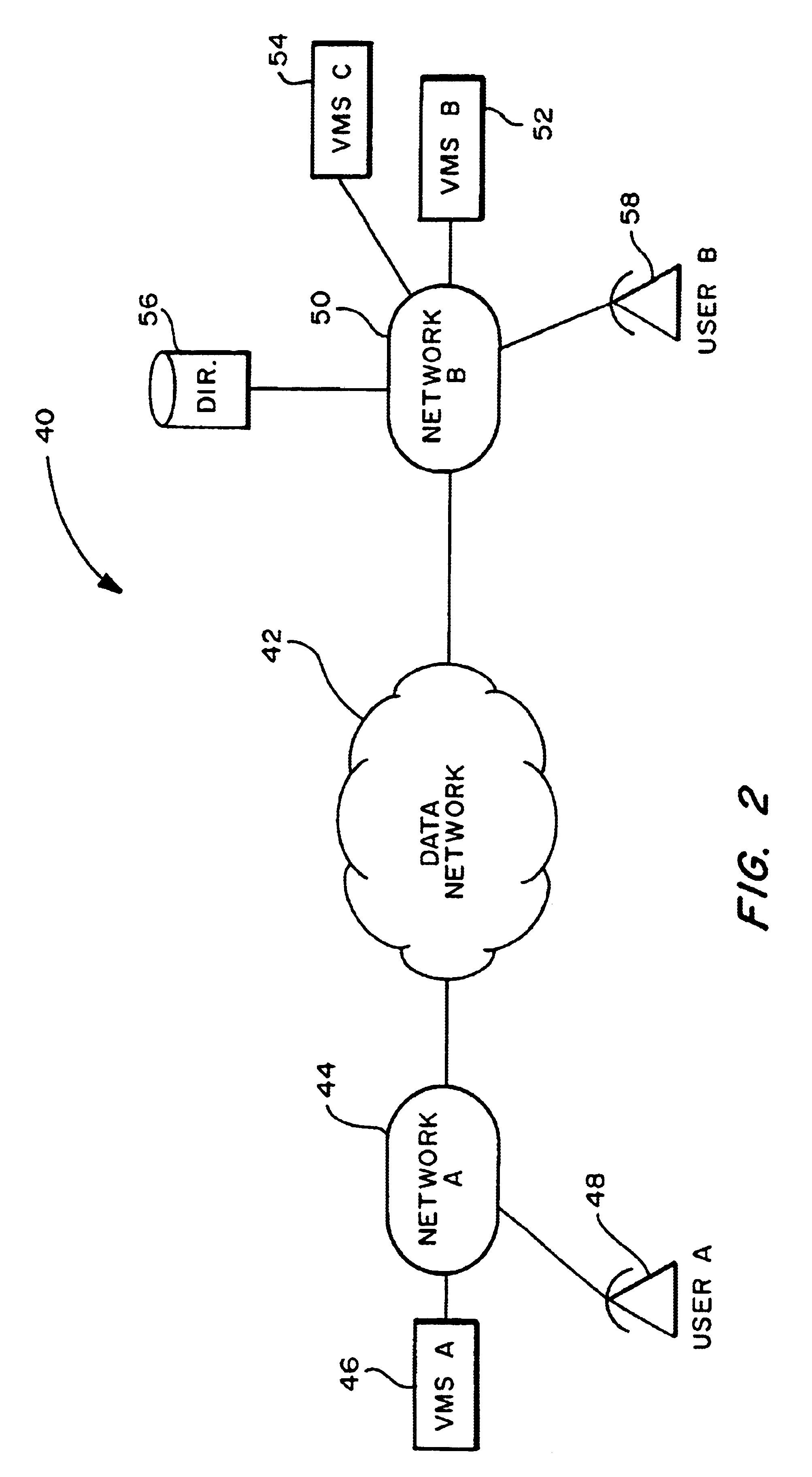

Region-wide messaging system and methods including validation of transactions

InactiveUS6882708B1The method is simple and reliableMultiplex system selection arrangementsInterconnection arrangementsComputer networkEngineering

Methods and systems are disclosed that allow for the exchange of voice mail messages between different VMSs of different service providers and / or in different networks by the transmission of such messages through a data network using a standard protocol of the data network. Methods and systems also are disclosed that validate message transactions among subscribers receiving regional messaging services over the PSTN. The subscribers are located in different geographic areas and may be provided their voice, facsimile or data messaging services by different companies. The present invention validates passing messages (data) among customers of potentially different companies located in different areas by assessing the validity of the transaction in light of a number of conditions, including applicable regulatory or business conditions.

Owner:BELLSOUTH INTPROP COR

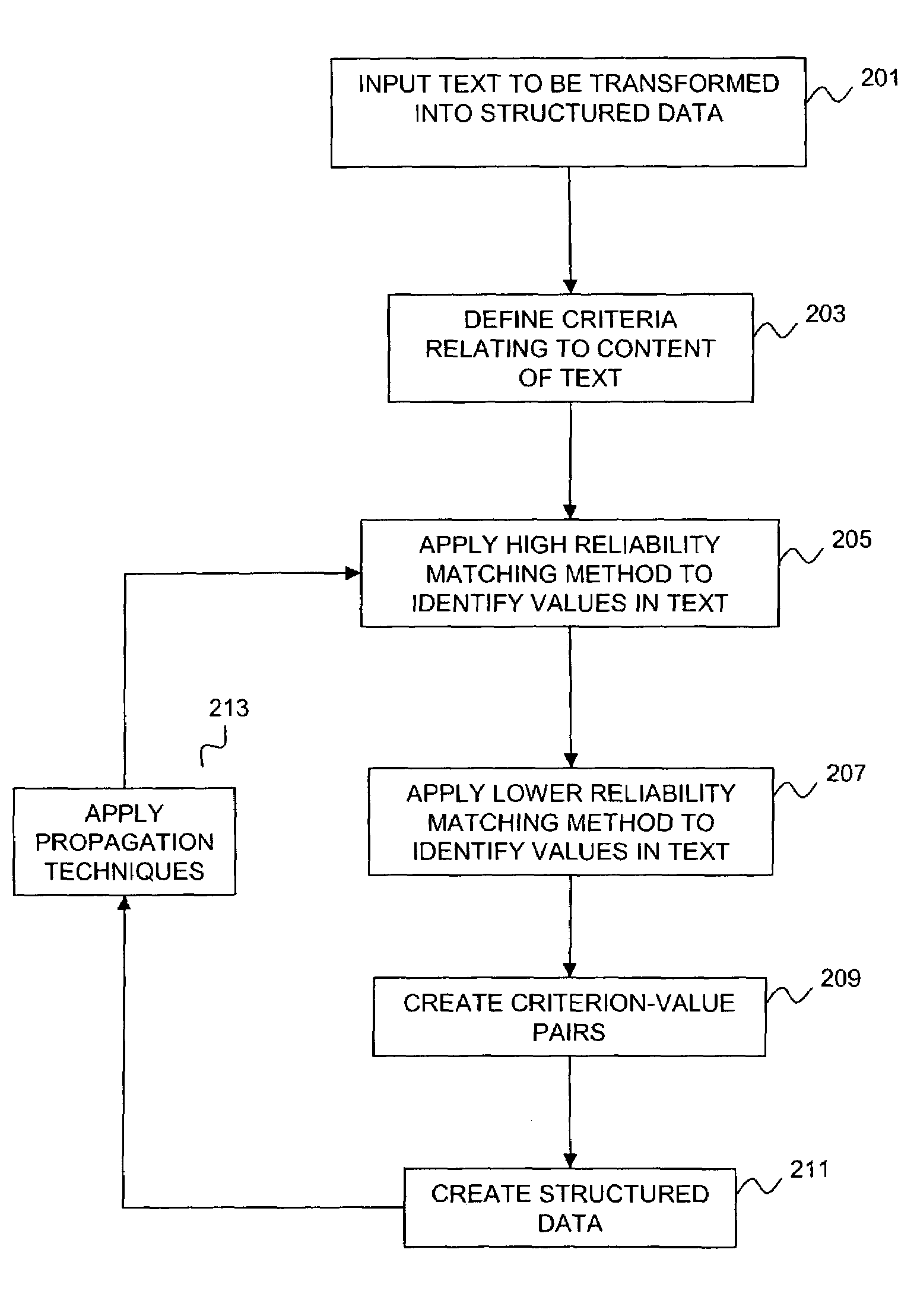

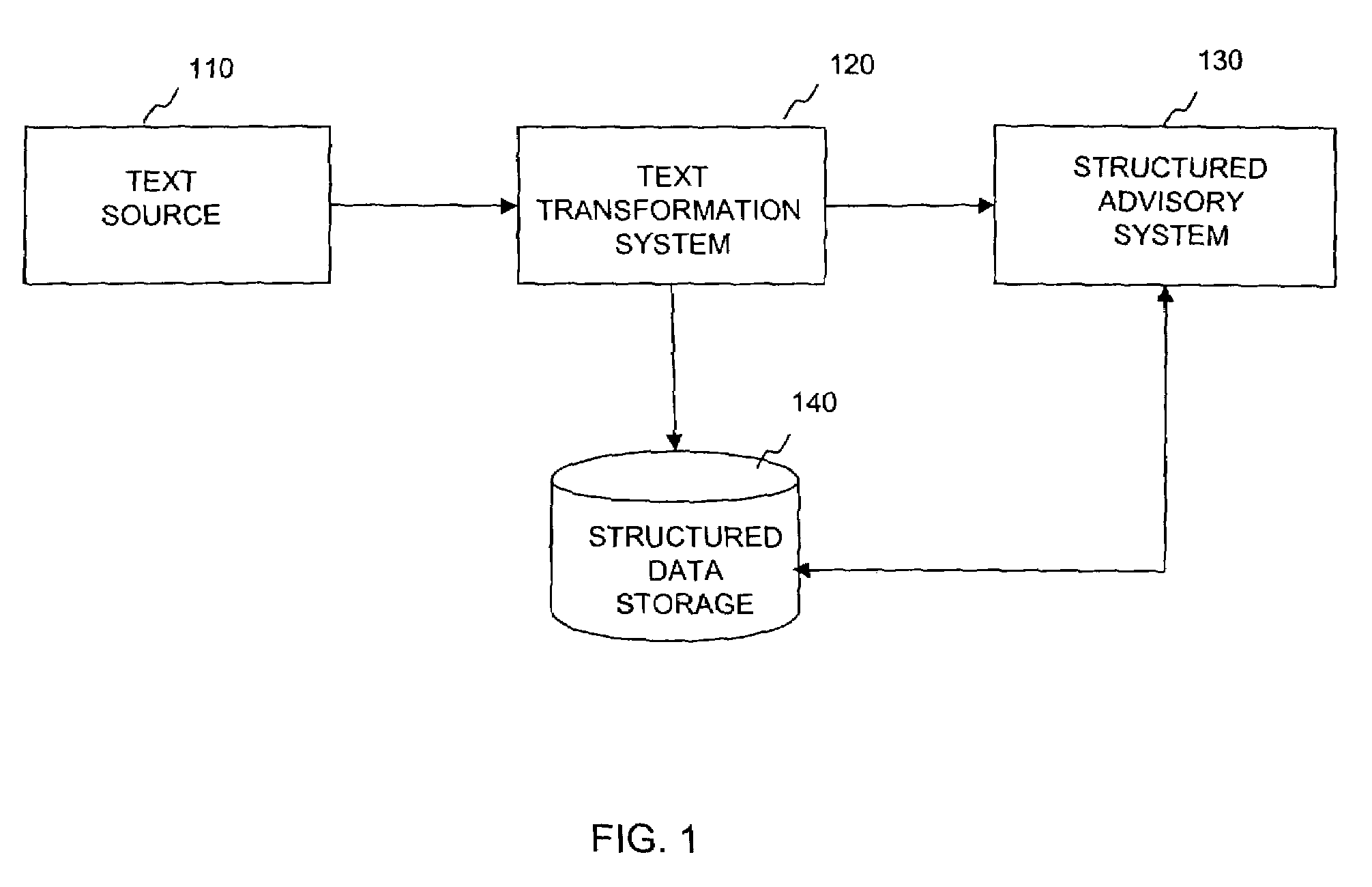

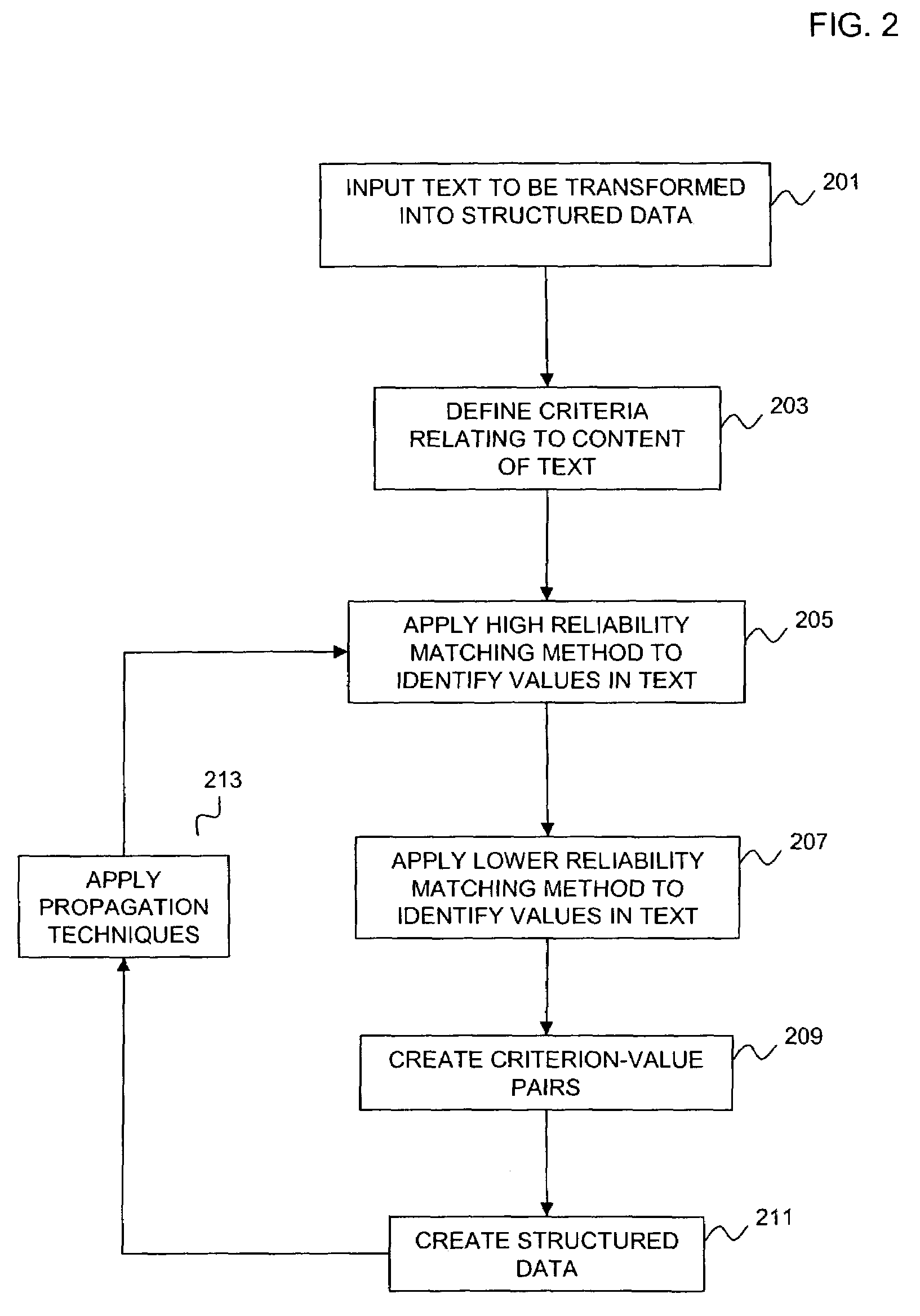

System method and computer program product for obtaining structured data from text

ActiveUS7174507B2Simple and reliable processImprove reliabilityDigital data information retrievalDigital computer detailsTheoretical computer scienceInto-structure

A method, system, and computer program product for obtaining structured data from text includes inputting text to be transformed into structured data, defining at least one criterion relating to content of the text, applying a first matching method to the text to identify a value in the text for each of the criterion, and applying a second matching method to the text to identify a value in the text for each of the criterion that the first matching method fails to identify a value for. Each of the criterion is then associated with a value obtained by the first or second matching method to create at least one criterion-value pair, and structured data is created based on the at least one criterion-value pair. The first matching method has a higher reliability than the second matching method.

Owner:KAIDARA

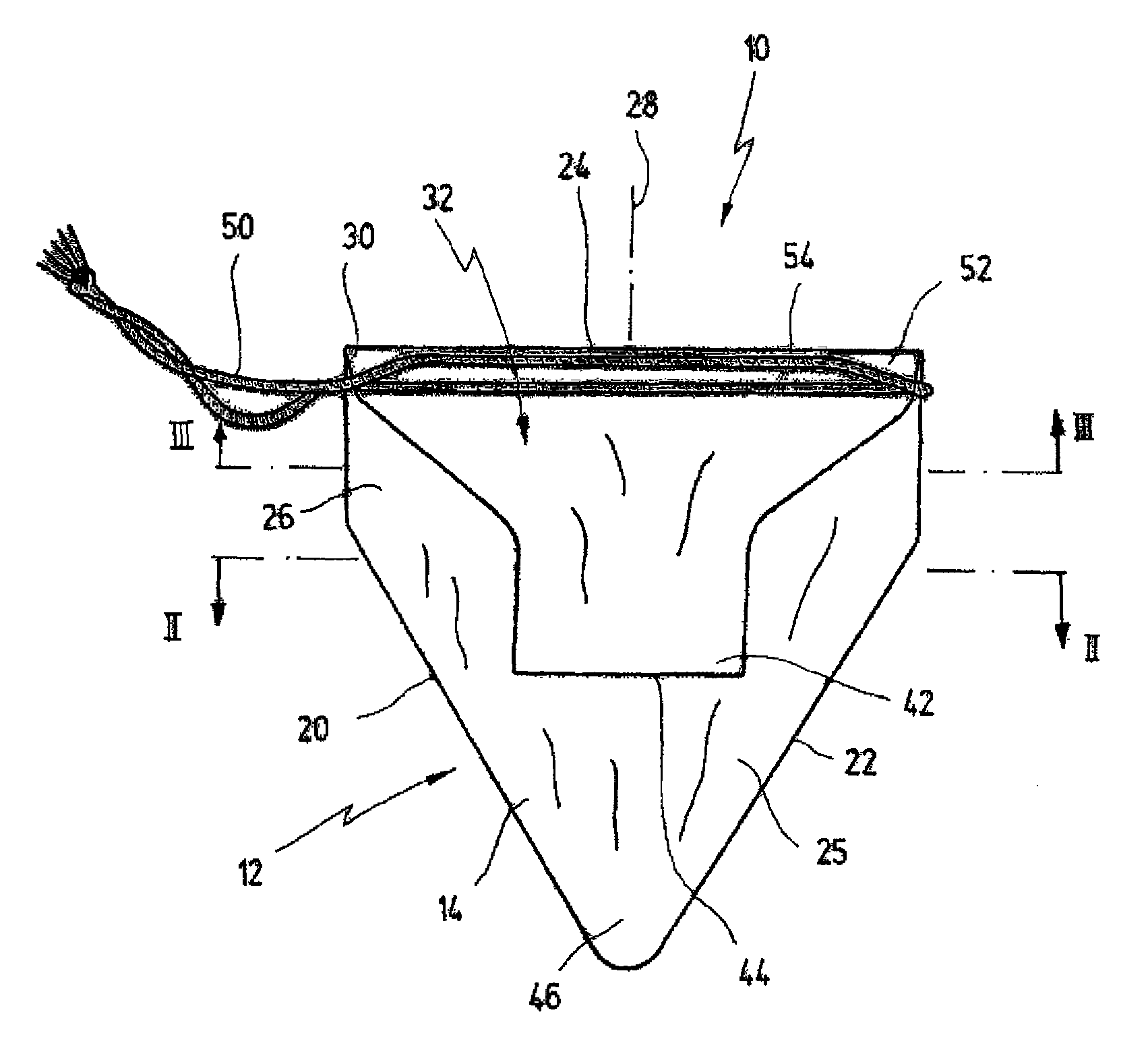

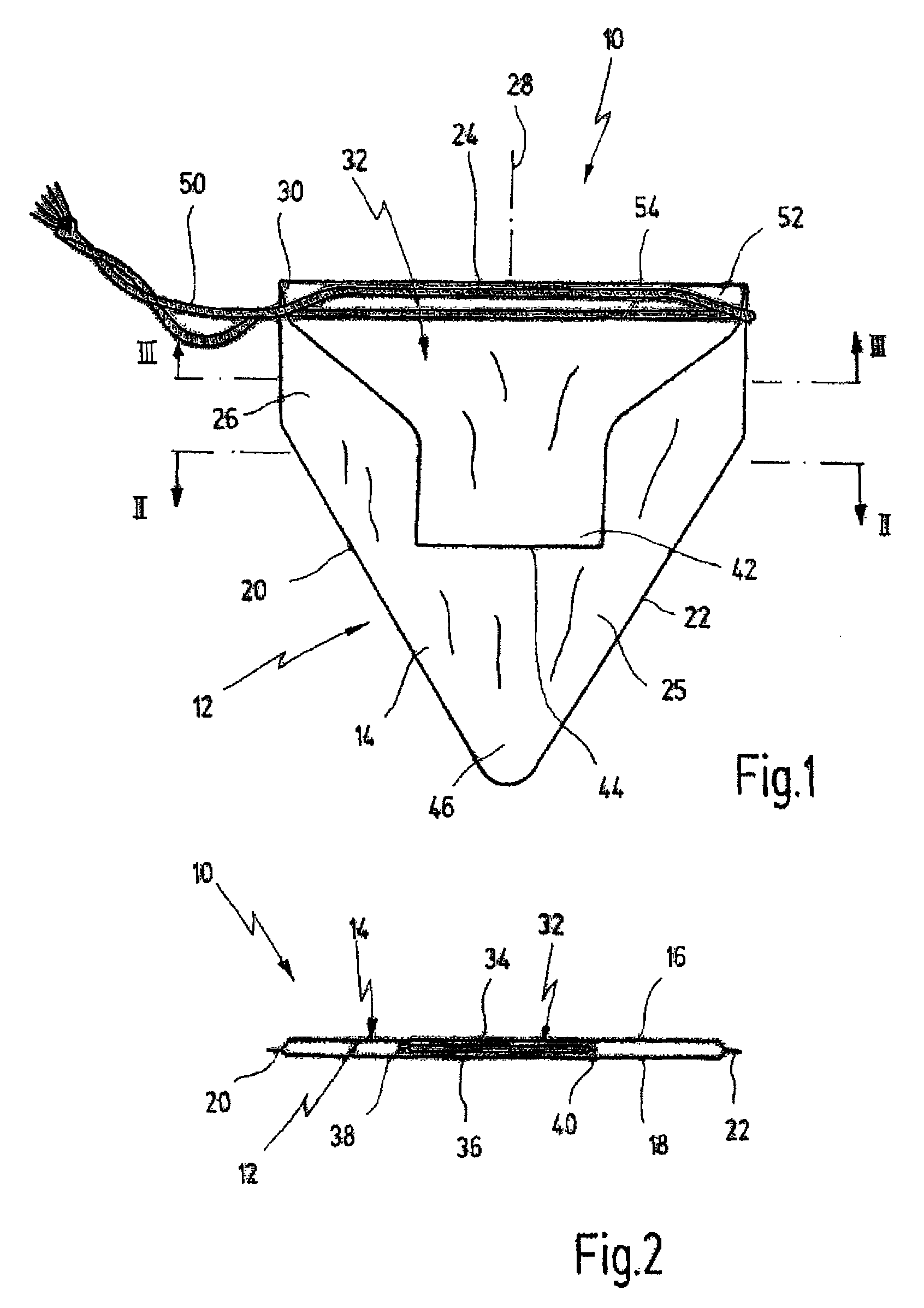

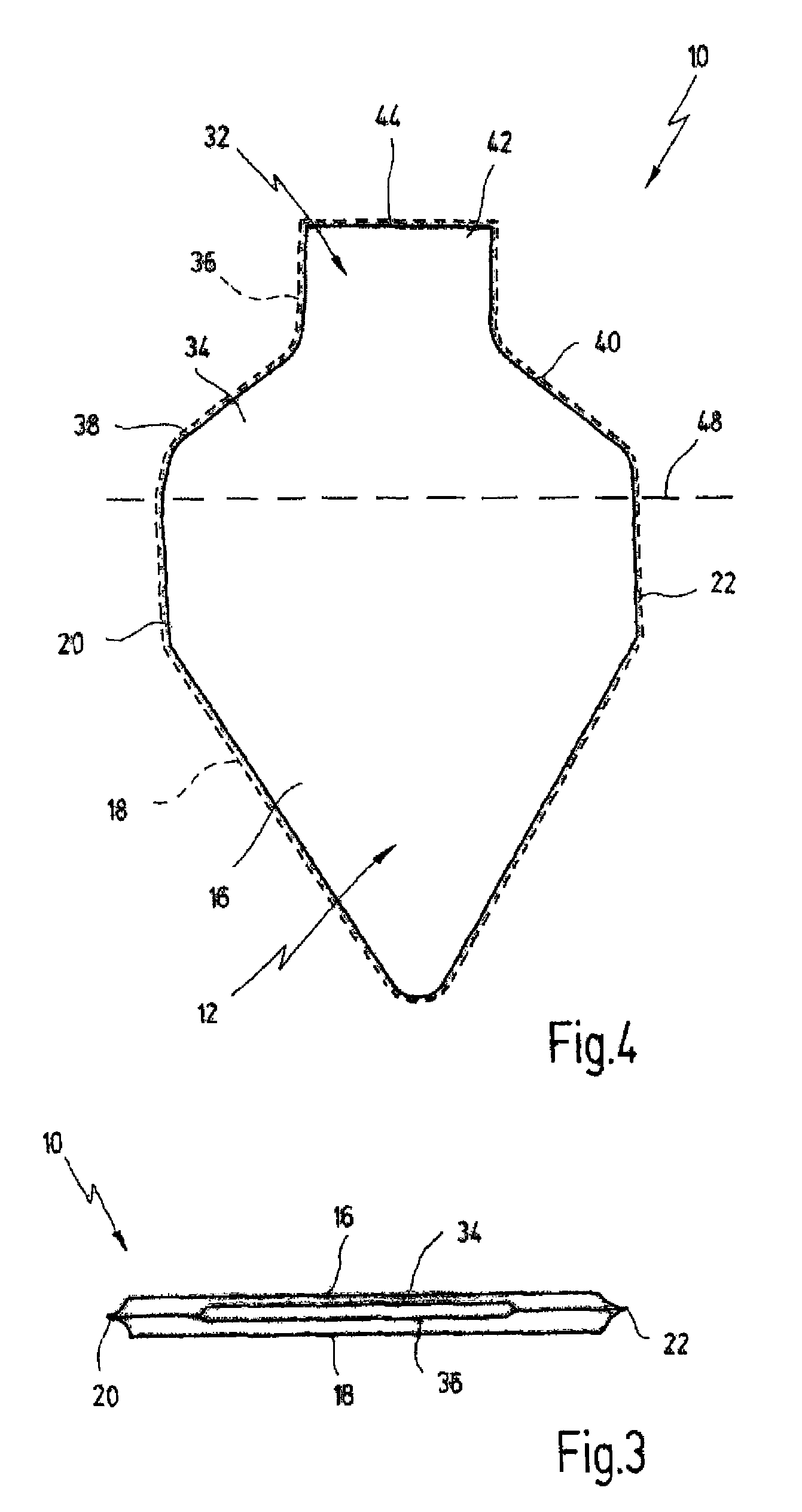

Endosurgical extraction bag for collecting body tissue or body fluid

InactiveUS7955292B2Safe removalThe method is simple and reliableWrappersSurgical needlesFirst admissionBody fluid

The invention relates to an endosurgical extraction bag for collecting body tissue or body fluid, with a bag main part formed from a flexible envelope, and with a first admission opening for introducing tissue or fluid into the bag main part of the bag. Arranged in the bag main part, there is an inner envelope which is connected to the main part (bag) and opens toward the first admission opening, but adjoins the bag main part sealingly in respect of the first admission opening, and which has a second admission opening at its second end remote from the first admission opening and spaced apart from an end of the bag main part remote from the first admission opening, through which second admission opening the tissue or fluid can be introduced into the bag main part.

Owner:MTP MEDICAL TECHN PROMOTION

Method for separating and extracting stem cells from placenta, umbilical cord or adipose tissue

ActiveCN101693884AEasy accessSpecification acquisitionSkeletal/connective tissue cellsArtificially induced pluripotent cellsFicollDisease

The invention relates to a method for separating and extracting stem cells from a placenta, umbilical cord or adipose tissue, which comprises the following process steps: firstly mixing the placenta, umbilical cord or adipose tissue and a cell maintenance fluid according to the proportion by weight of 2.5-4:1, putting the mixture into a tissue crushing barrel, adding collagenase after crushing, uniformly mixing, hatching at the temperature of 37 DEG C, filtering, adding a precipitator, sucking a supernatant fluid after settling, centrifuging, removing the supernatant fluid, adding concentrated cells into a liquid of diatrizoate sodium-ficoll 400#, then centrifuging, collecting 10-15 ml of intermediate cell layer, washing with the cell maintenance fluid, counting the collected cells, and providing the cells for clinical use when the cell survival ratio is more than or equal to 95 percent. The invention not only realizes the separation and the extraction of all stem cells from the placenta, umbilical cord or adipose tissue, but also realizes industrialized production, and enables doctors to conveniently, safely and canonically obtain the adult stem cells in clinic and use the adult stem cells for treating the diseases of patients as using medicaments, thereby solving the bottleneck problem of difficult obtainment of adult stem cells in clinic and popularizing a cell treatment technology.

Owner:NINGXIA ZHONGLIANDA BIOPHYSICS

Motion transmitting apparatus

InactiveUS20020065171A1More versatileLess expensiveFluid actuated clutchesMagnetically actuated clutchesMobile vehicleCoil spring

A motion transmitting apparatus wherein an electric motor, an engine or another prime mover rotates an axially fixed first part relative to a coaxial axially movable non-rotatable second part. The structure which serves to move the second part axially in response to clockwise or counterclockwise rotation of the first part includes a follower borne by the first part and a helical spring having end convolutions affixed to the first part. The follower extends between two intermediate convolutions of the helical spring. If the apparatus is utilized in the power train of a motor vehicle, the axially movable part can serve to engage or disengage or change the extent of engagement of the friction clutch between the output element of the engine and the input element of the change-speed transmission.

Owner:SCHAEFFLER TECH AG & CO KG

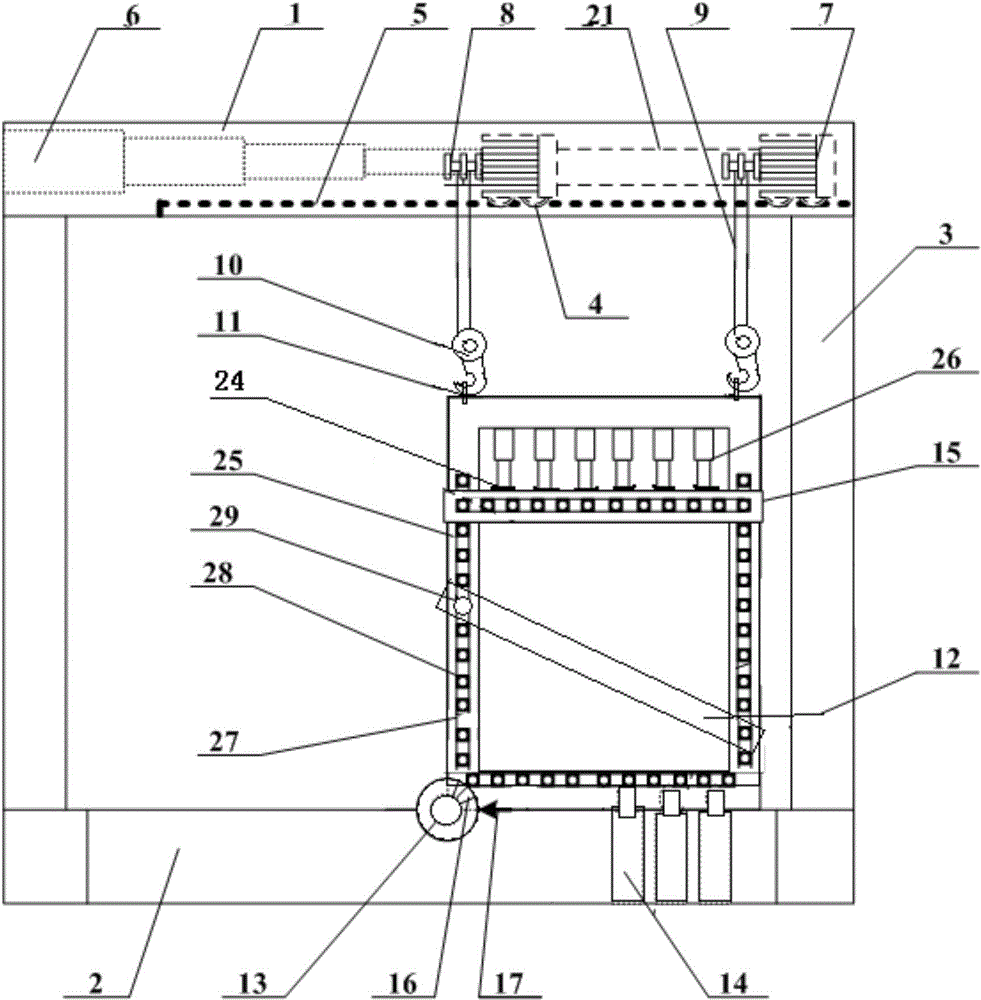

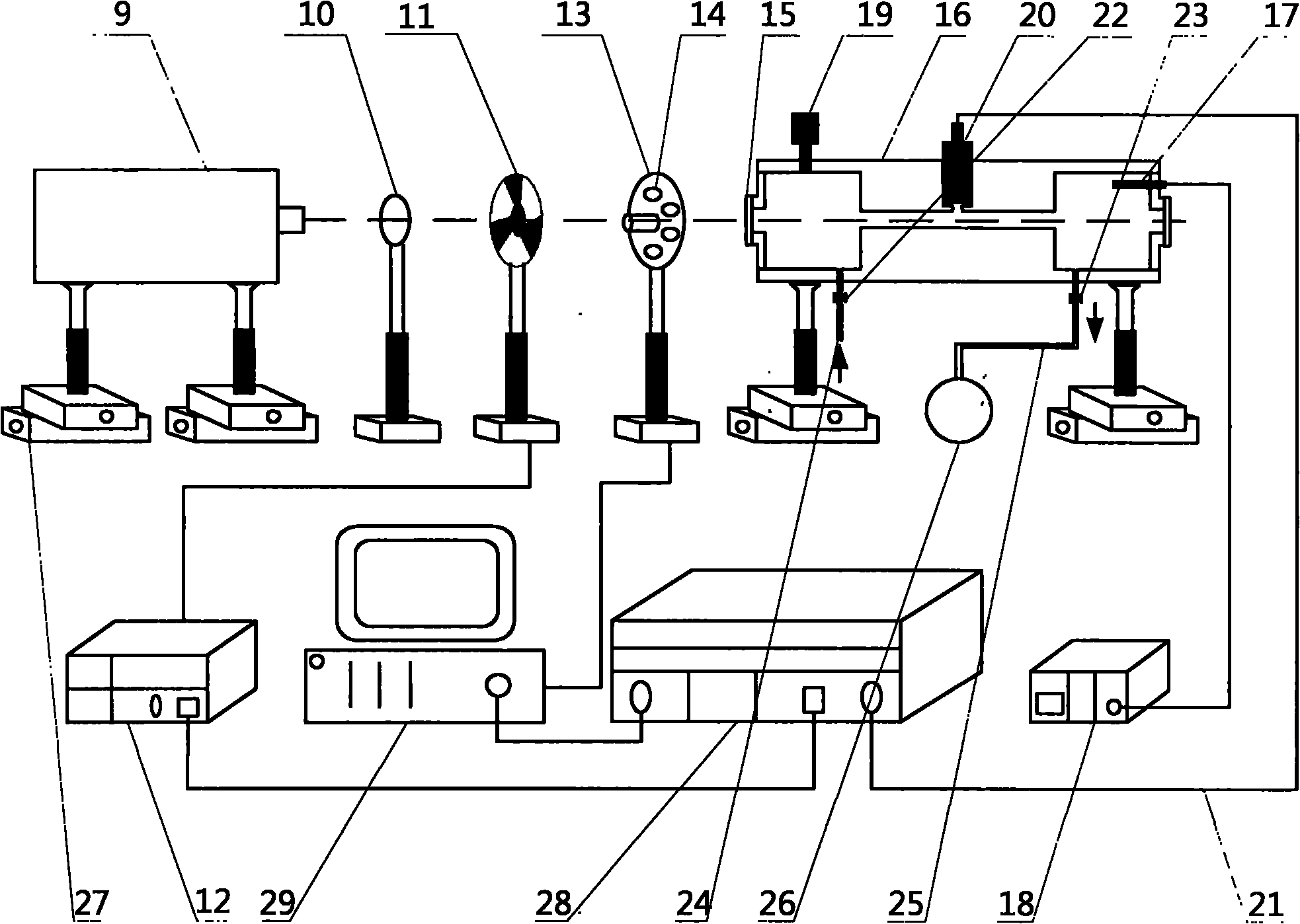

Physical similar simulation test device and physical similar simulation test method for tilted stratums

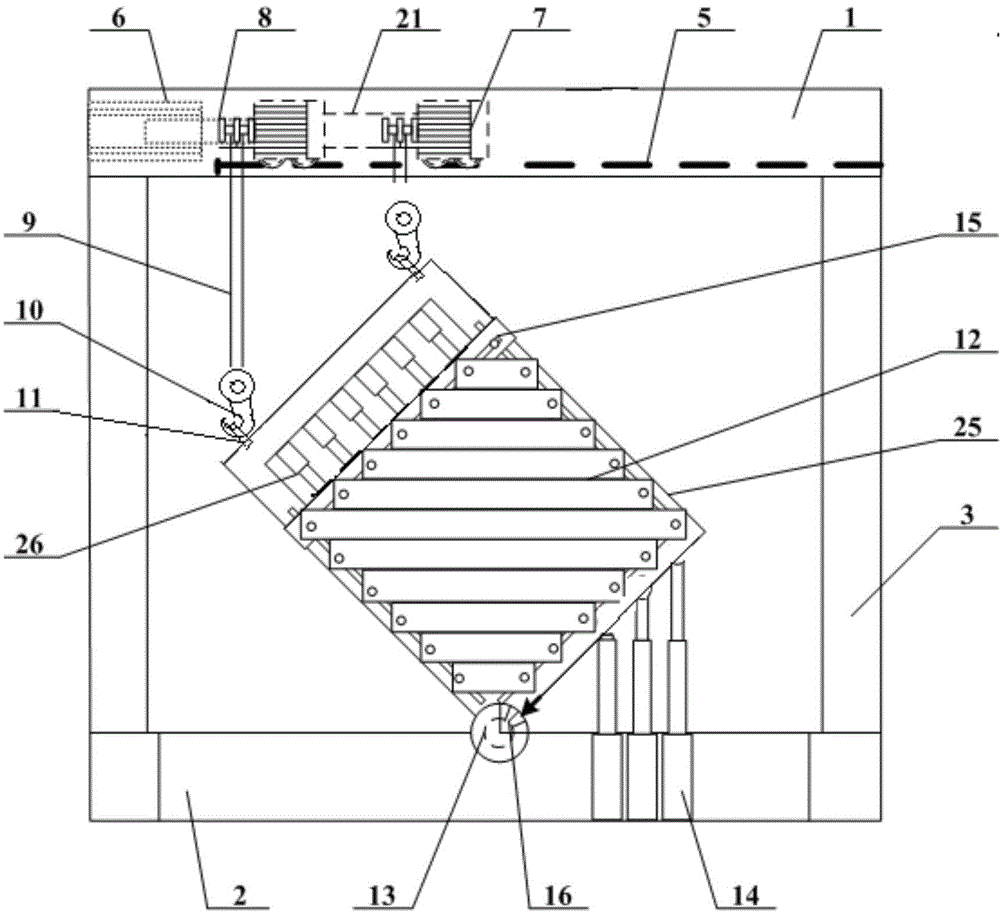

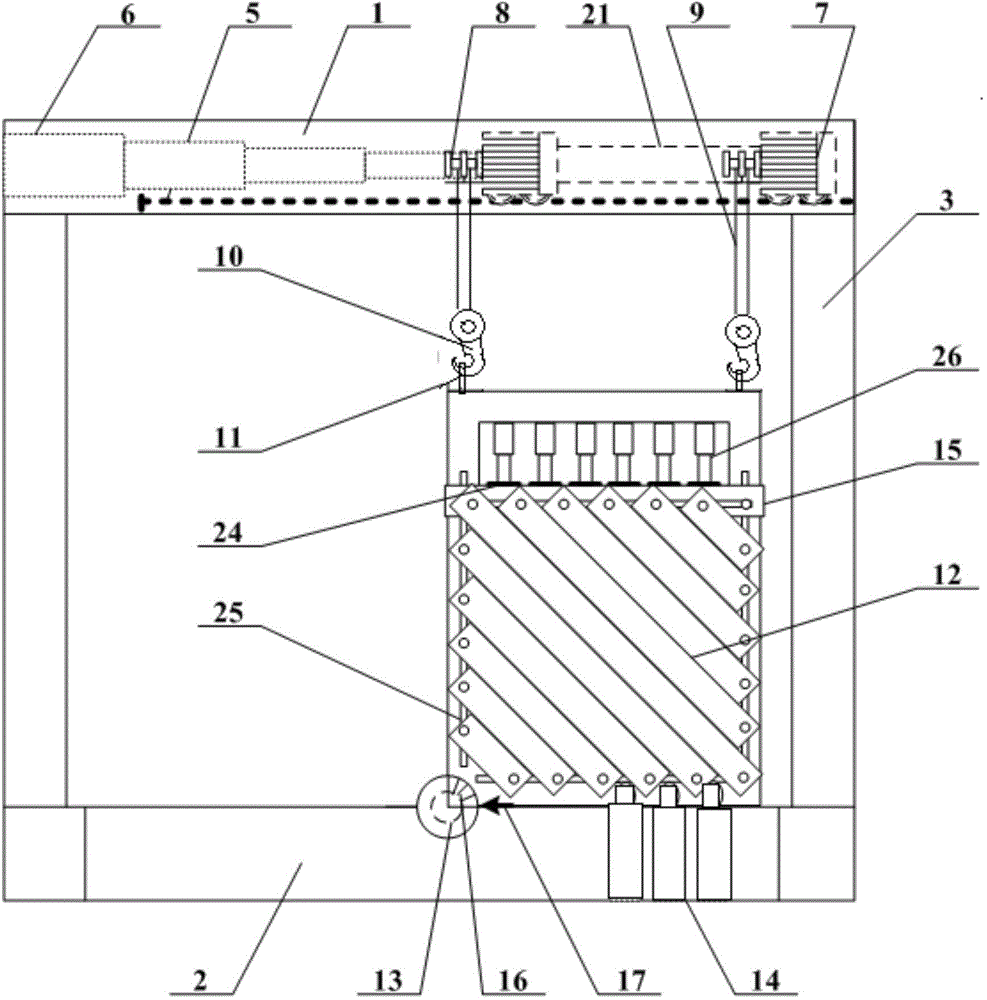

ActiveCN104596855AGuaranteed balance and stabilityEliminate potential safety hazardsMaterial strength using tensile/compressive forcesUsing optical meansStress distributionComputer science

The invention discloses a physical similar simulation test device and a physical similar simulation test method for tilted stratums. The physical similar simulation test device comprises an external framework, a tiltable rack, a front baffle, a rear baffle, a hydraulic supporting device and a hanging hoisting device, a similar simulation test is performed on stratums with different tilt angles by adopting the device and the method, physical mechanical performances of stress distribution, displacement change and the like inside the stratums under the action of external disturbance, ground stress, external force application and the like can be measured to obtain related technical indexes and parameters so as to research the rule of the true stratums in the process, and the effective struts can be facilitated during the construction of the stratums, thus providing a guarantee for the safety construction of the stratums.

Owner:SHANDONG UNIV OF SCI & TECH

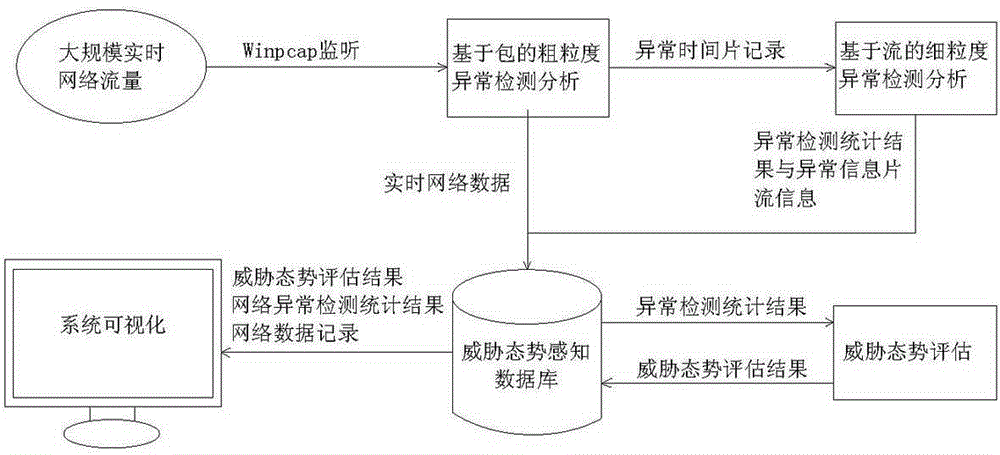

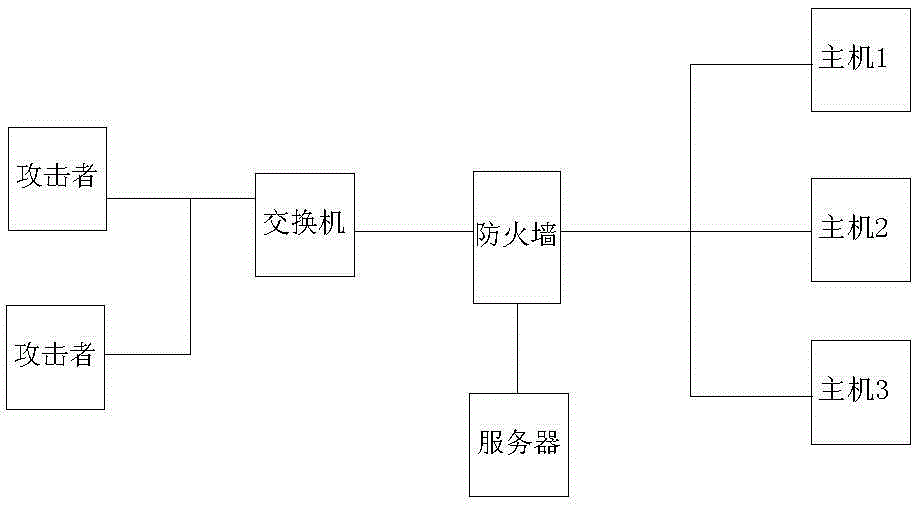

Network threat evaluation method based on multi-granularity anomaly detection

ActiveCN105407103AEasy to operateThe method is simple and reliableTransmissionTraffic volumeEmergency response

The invention relates to a network threat evaluation method based on multi-granularity anomaly detection, and can effectively solve the problem that the existing threat situation evaluation technology based on a network data packet or a network flow cannot be well suitable for rapidly and accurately identifying an attack event and perceiving a threat situation in a high-speed network environment. The network threat evaluation method comprises the following steps: analyzing a time slice including an abnormal network flow by utilizing a packet-based coarse granularity anomaly detection; performing flow reassembly of the network flow of the abnormal time slice and extracting a flow characteristic attribute through flow-based fine granularity anomaly detection, and judging the attack type by utilizing a flow characteristic anomaly detection algorithm; and finally, quantifying and evaluating the serious degree of the threat event in a current network according to the detected threat event. The method disclosed by the invention is easy to operate and can detect the serious degree of the threat event subjected by the network precisely in real time; network workers can easily know the security threat subjected by the current network in time; and effectively emergency response measures can be taken in time.

Owner:THE PLA INFORMATION ENG UNIV

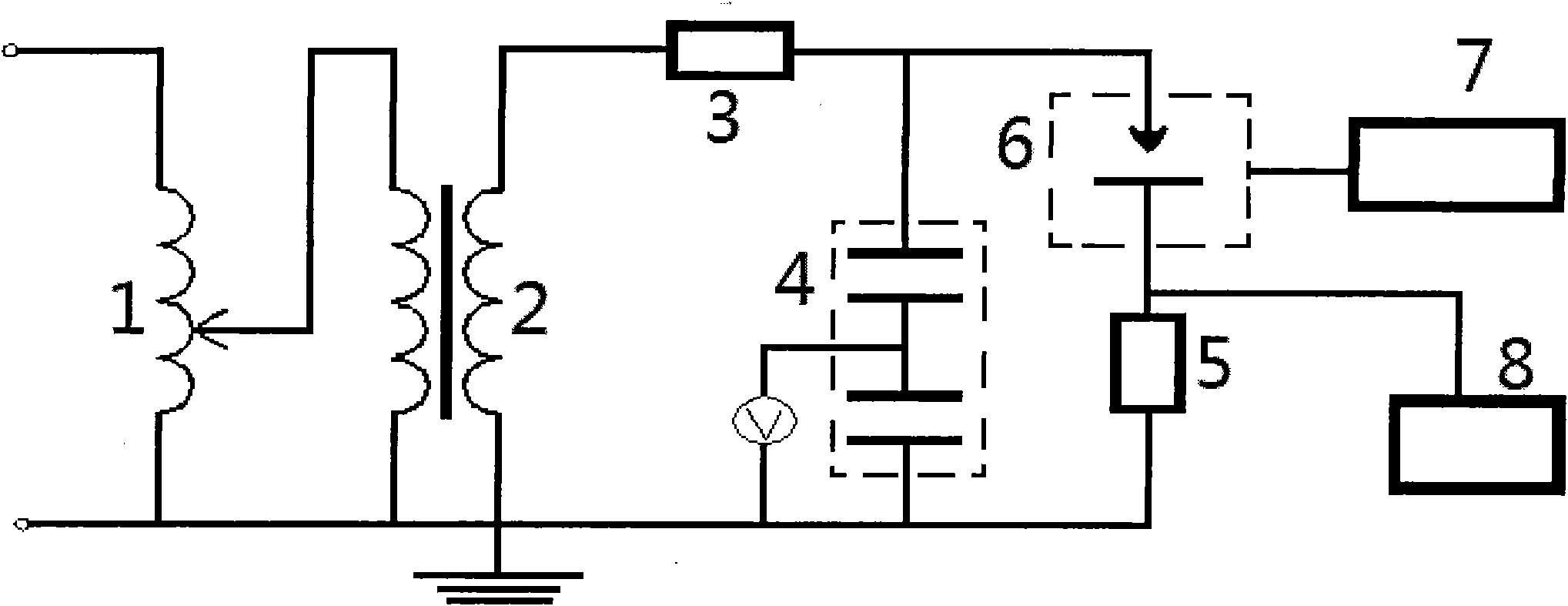

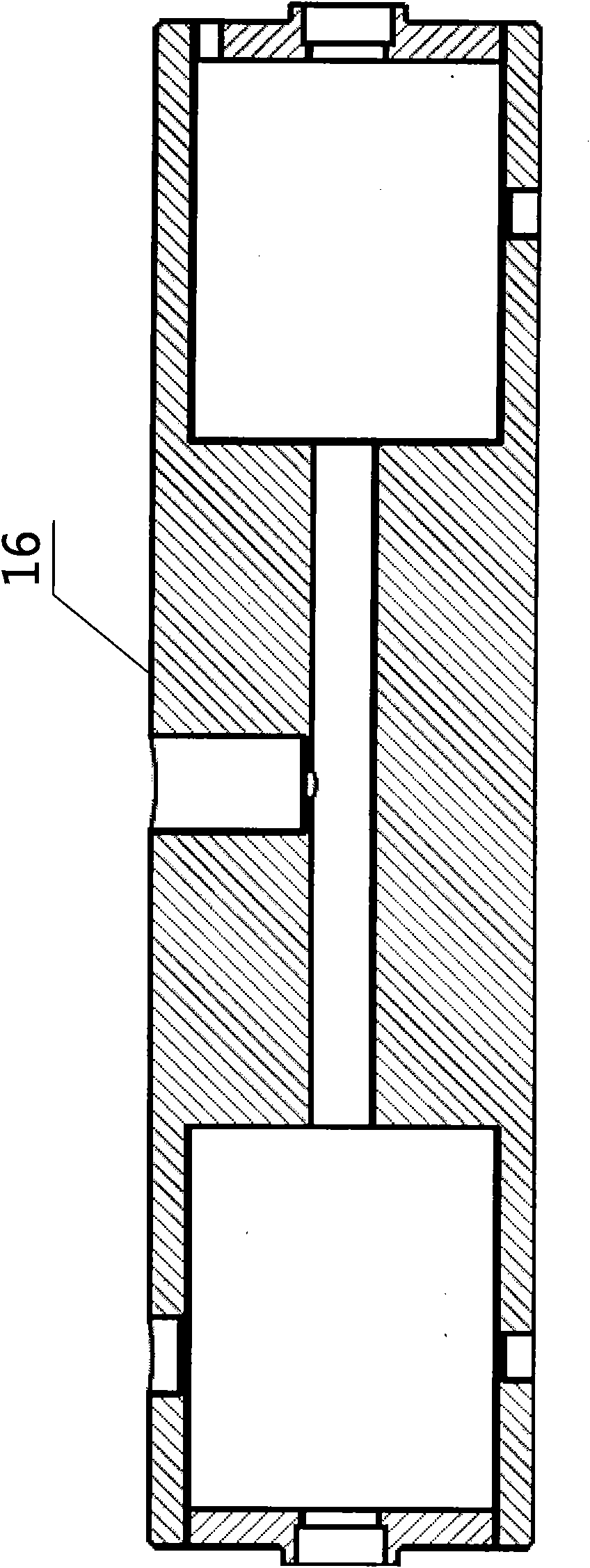

Infrared photoacoustic spectroscopy detection device and method for decomposed components of sulfur hexafluoride under partial discharge

InactiveCN101982759AQualitatively accurateAccurate quantitative analysisColor/spectral properties measurementsAnti jammingSulfur hexafluoride

The invention relates to an infrared photoacoustic spectroscopy detection device and method for decomposed components of sulfur hexafluoride under partial discharge, belonging to the technical field of partial discharge on-line monitoring of SF6 gas insulating electrical equipment. The device of the invention mainly comprises an induction voltage regulator, a corona free experimental transformer, a partial discharge free protective resistor, a standard capacitive voltage divider, a non-inductive resistor, a GIS analog element, a wide-frequency high-speed ultrahigh-capacity digital storage oscillograph and an infrared photoacoustic spectroscopy system. In the method of the invention, infrared photoacoustic spectroscopy detection is carried out on the decomposed gas of SF6 under partial discharge in the GIS analog element by the device of the invention. The invention has high sensitivity, little gas consumption, multiple detection components and strong anti-jamming capability, can effectively detect SF6, CF4, SO2F2, SOF2, SO2, HF and the like as low as 0.01 muL / L, and is suitable for on-line detection. The invention can be widely used for detection of partial discharge decomposed gas of SF6 in the SF6 gas insulating electrical equipment, especially the GIS equipment.

Owner:CHONGQING UNIV

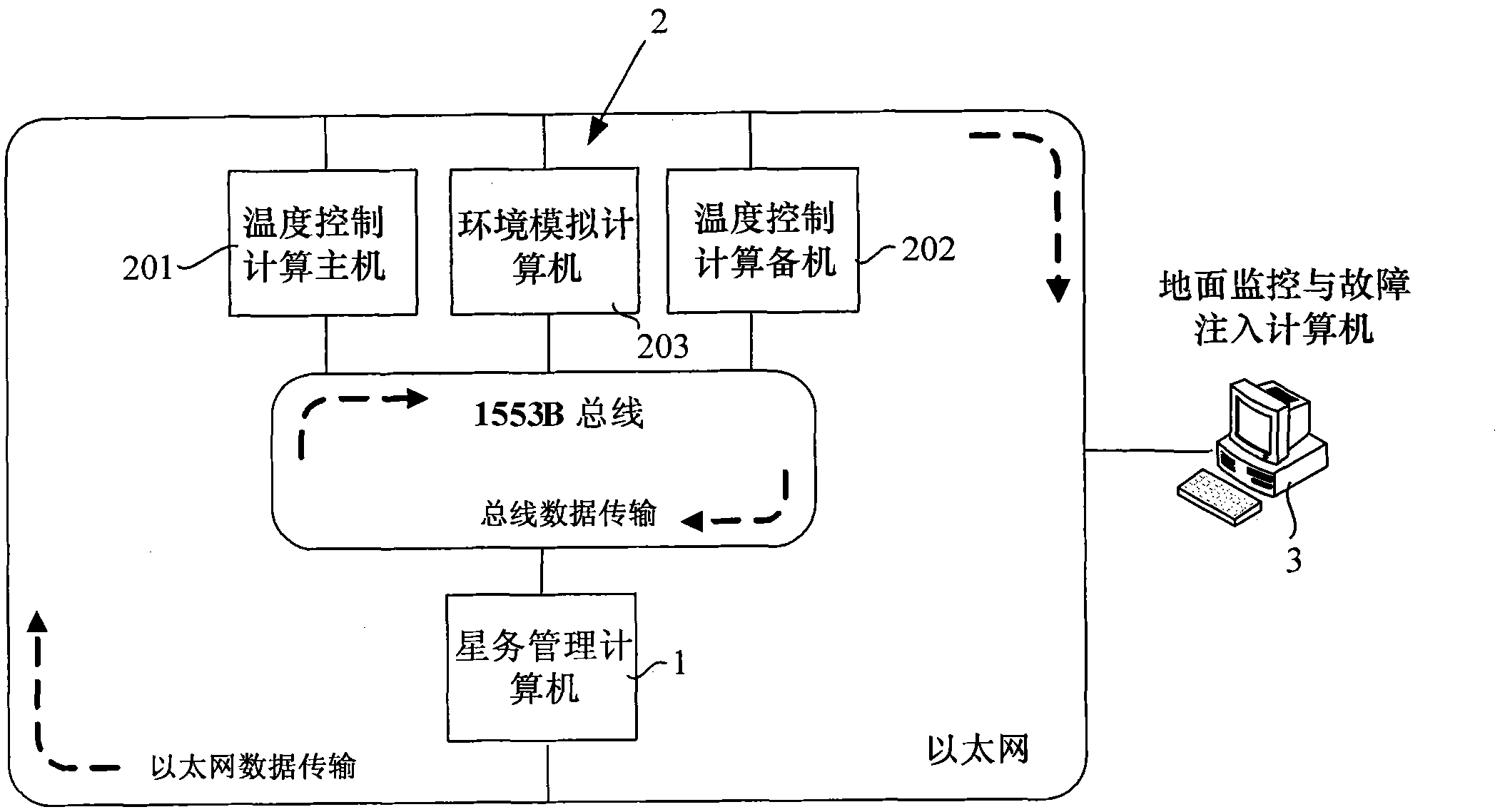

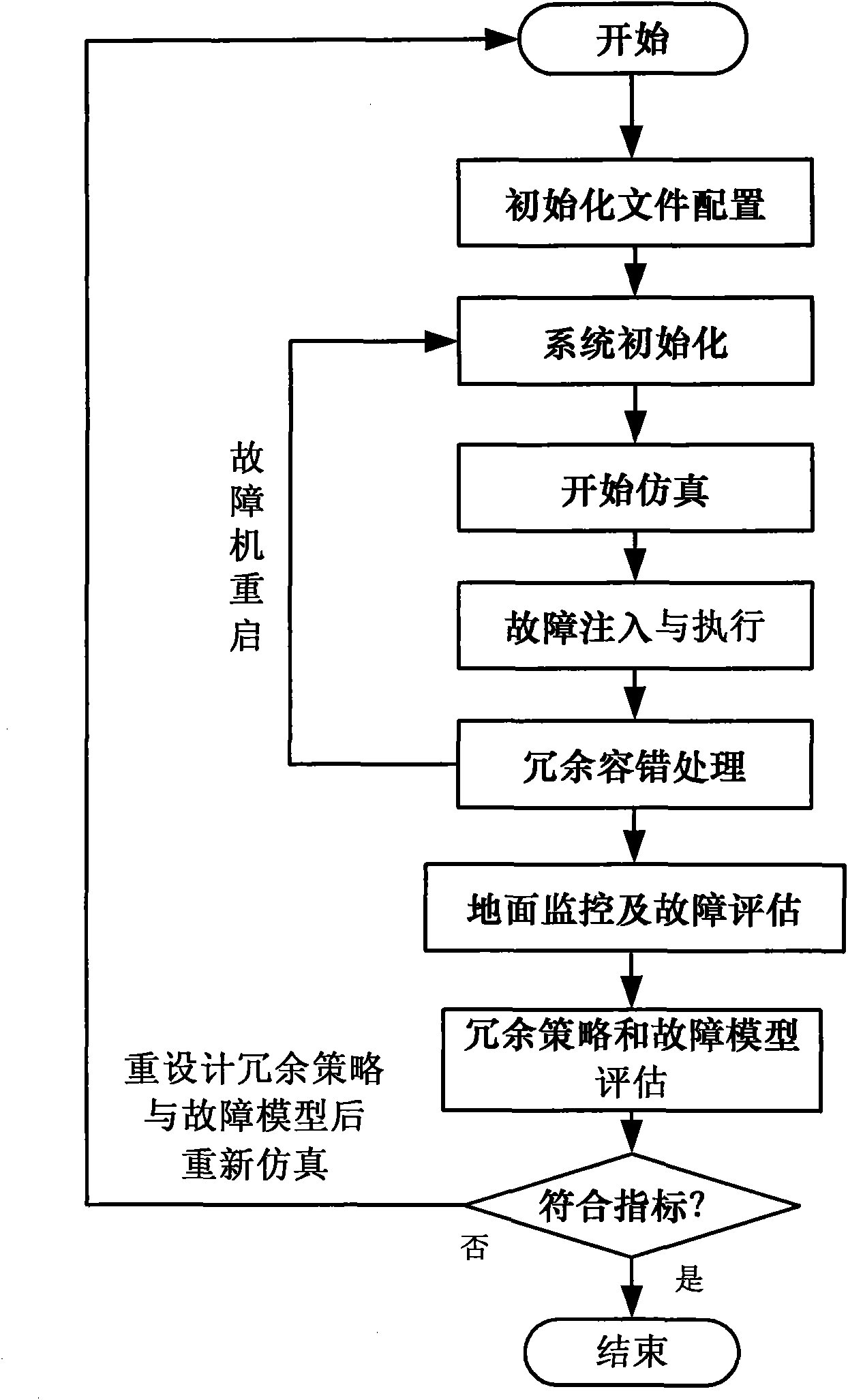

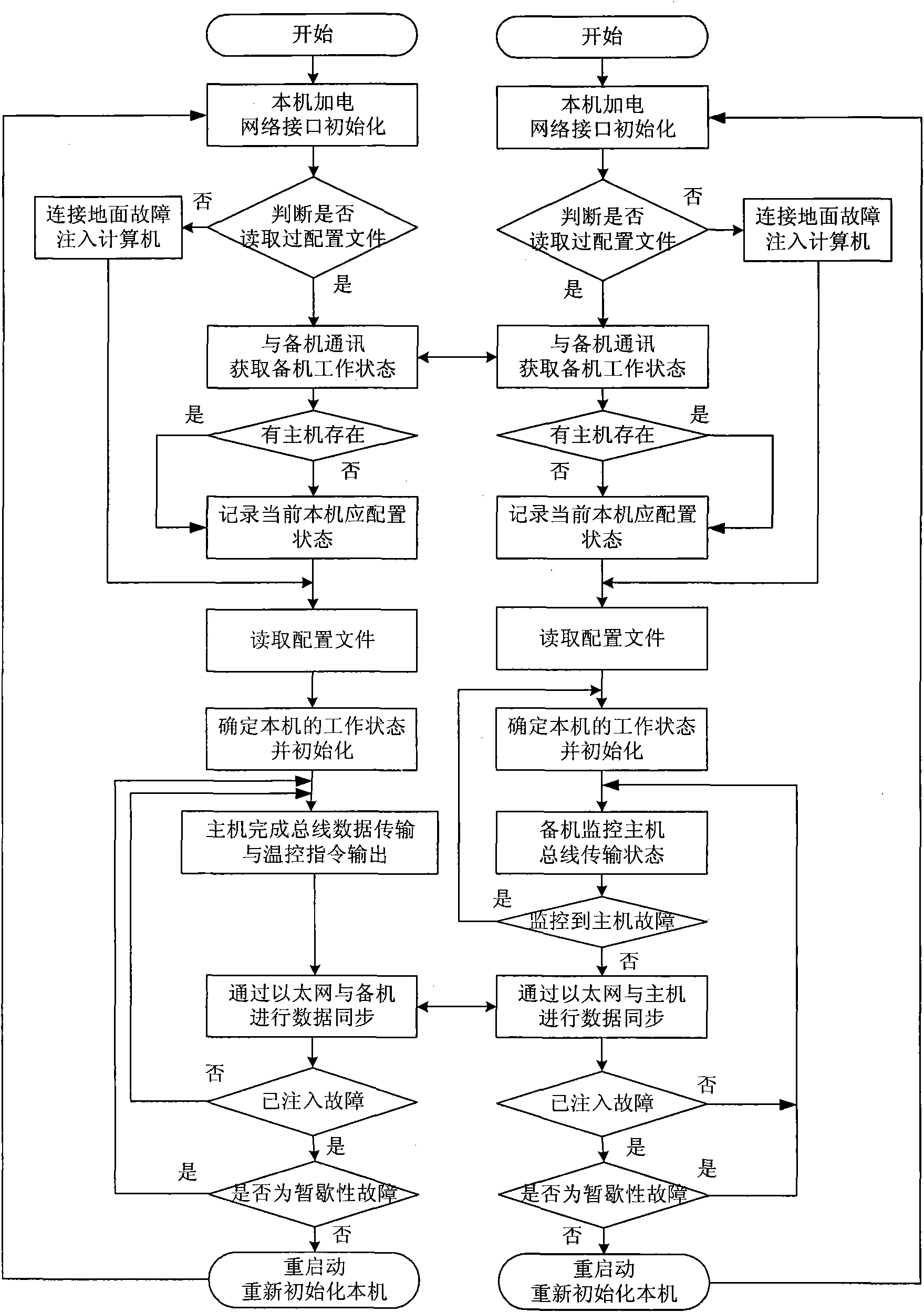

Embedded satellite-borne fault-tolerant temperature control system and verification method thereof

InactiveCN101819445AIn line with the development trendWith real development prospectsTemperatue controlError detection/correctionFault toleranceTemperature control

The invention discloses an embedded satellite-borne fault-tolerant temperature control system and a verification method thereof. The system comprises a satellite management computer, an on-satellite temperature control system and a ground monitoring and fault injection computer; the on-satellite temperature control system comprises a temperature control calculation host machine, a temperature control calculation standby machine and an environmental simulation computer; and the temperature control calculation host machine and the temperature control calculation standby machine are temperature control computers. The verification method comprises the following steps of: 1, initializing a file allocation; 2, initializing the system; 3, beginning simulation; 4, injecting and executing a fault; 5, processing redundant fault tolerance; 6, monitoring the ground and evaluating the fault; and 7, evaluating a fault model and a redundancy strategy of the temperature control system. The fault injection and the verification process of the whole running stage of the real satellite-borne temperature control system are completely realized; and the method is simple, convenient and reliable, and greatly reduces the test time and expense for the practical system.

Owner:BEIHANG UNIV

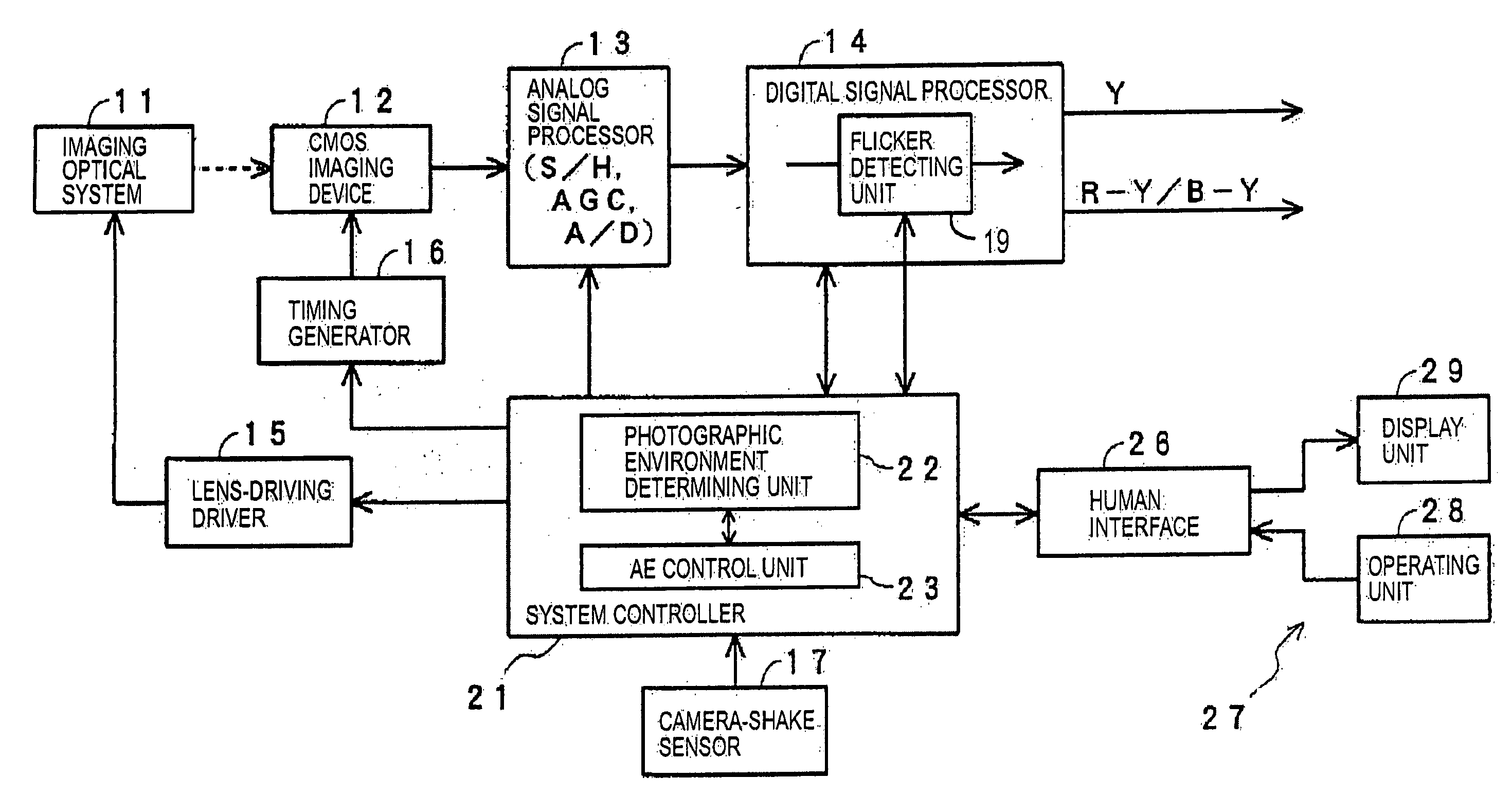

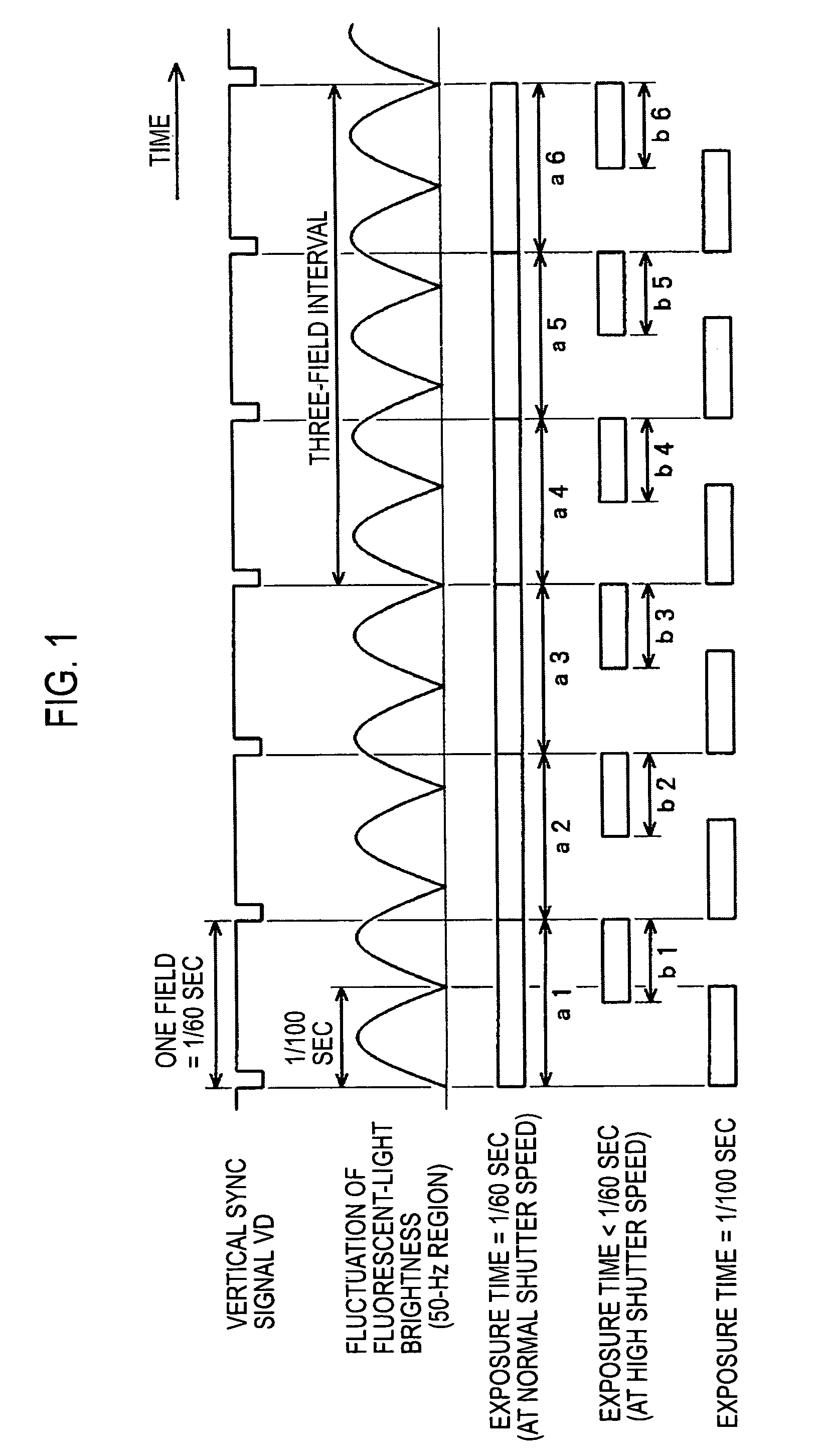

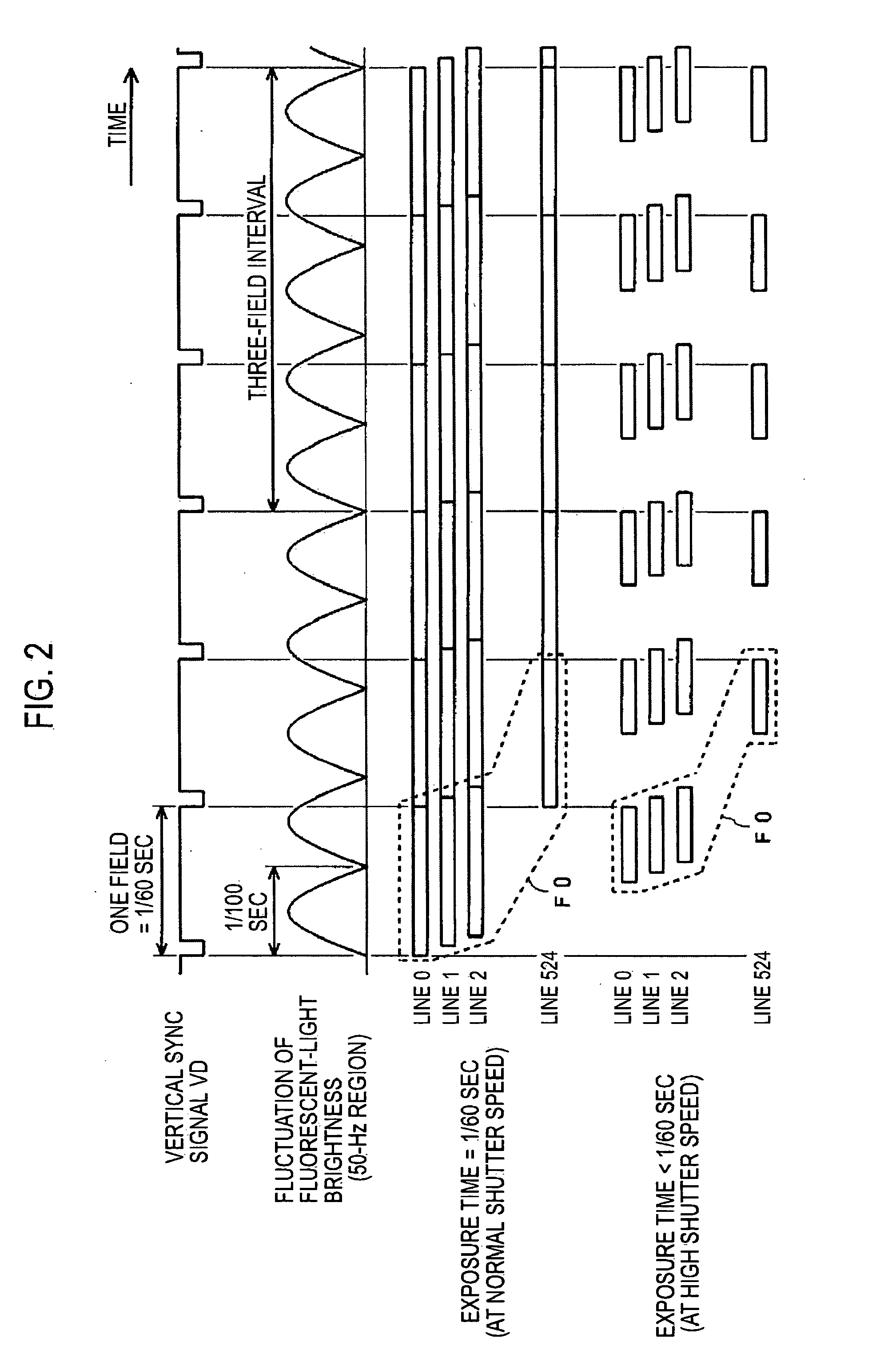

Method for determining photographic environment and imaging apparatus

InactiveUS20050093996A1Sure easyThe method is simple and reliableTelevision system detailsColor signal processing circuitsEngineeringImaging equipment

In an NTSC imaging apparatus, the shutter speed is set to a first value other than N / 120 second, and a flicker detecting process is performed on a video signal obtained at the first shutter speed to extract a particular frequency component. If the level of this frequency component is higher than a threshold value, it is determined that photographing is conducted under fluorescent light with a power supply frequency of 50 Hz. If it is not higher than the threshold value, the shutter speed is set to a second value other than N / 100 second, and a flicker detecting process is performed on a video signal obtained at the second shutter speed to extract a particular frequency component. If the level of this frequency component is higher than a threshold value, it is determined that photographing is conducted under fluorescent light with a power supply frequency of 60 Hz.

Owner:SONY CORP

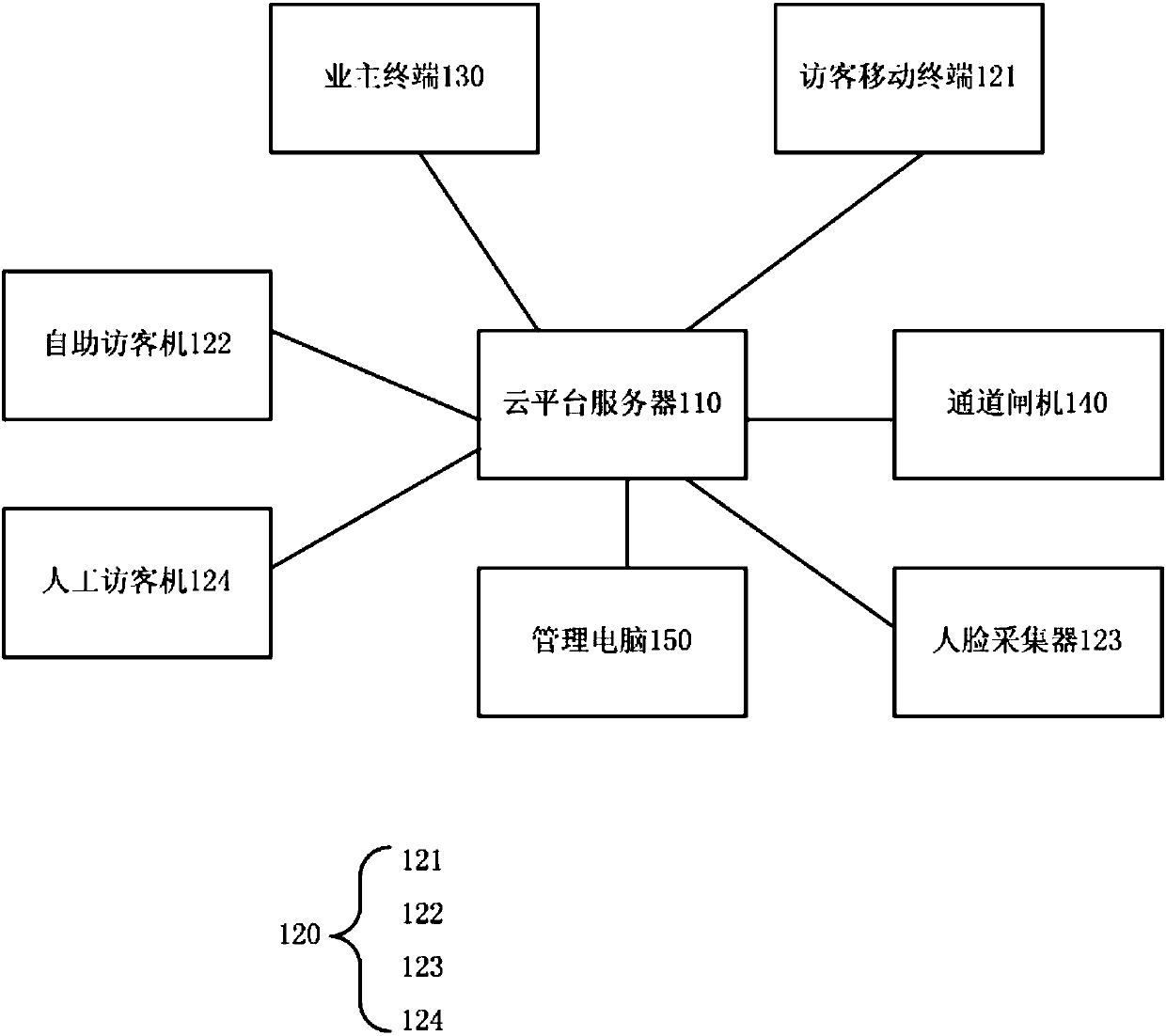

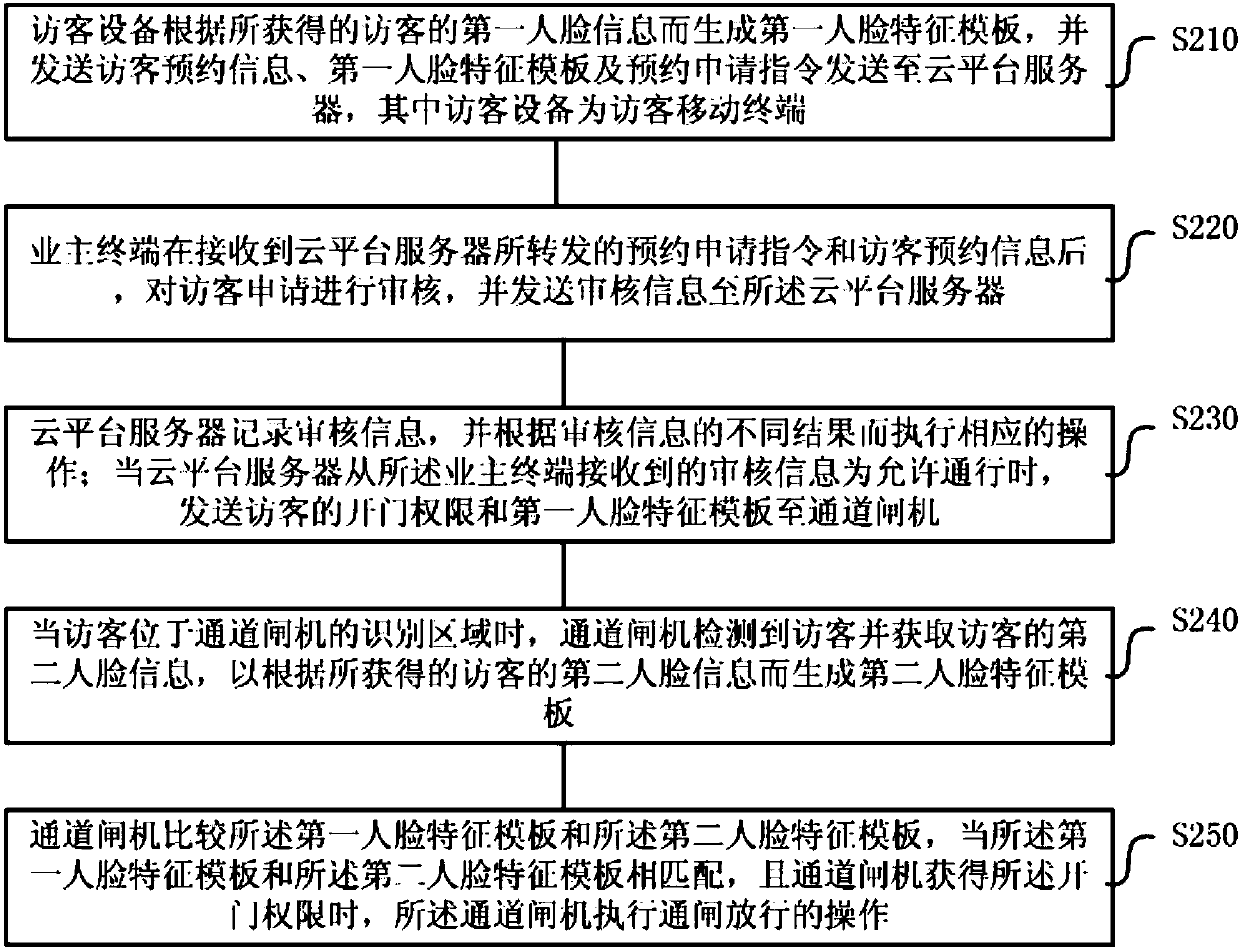

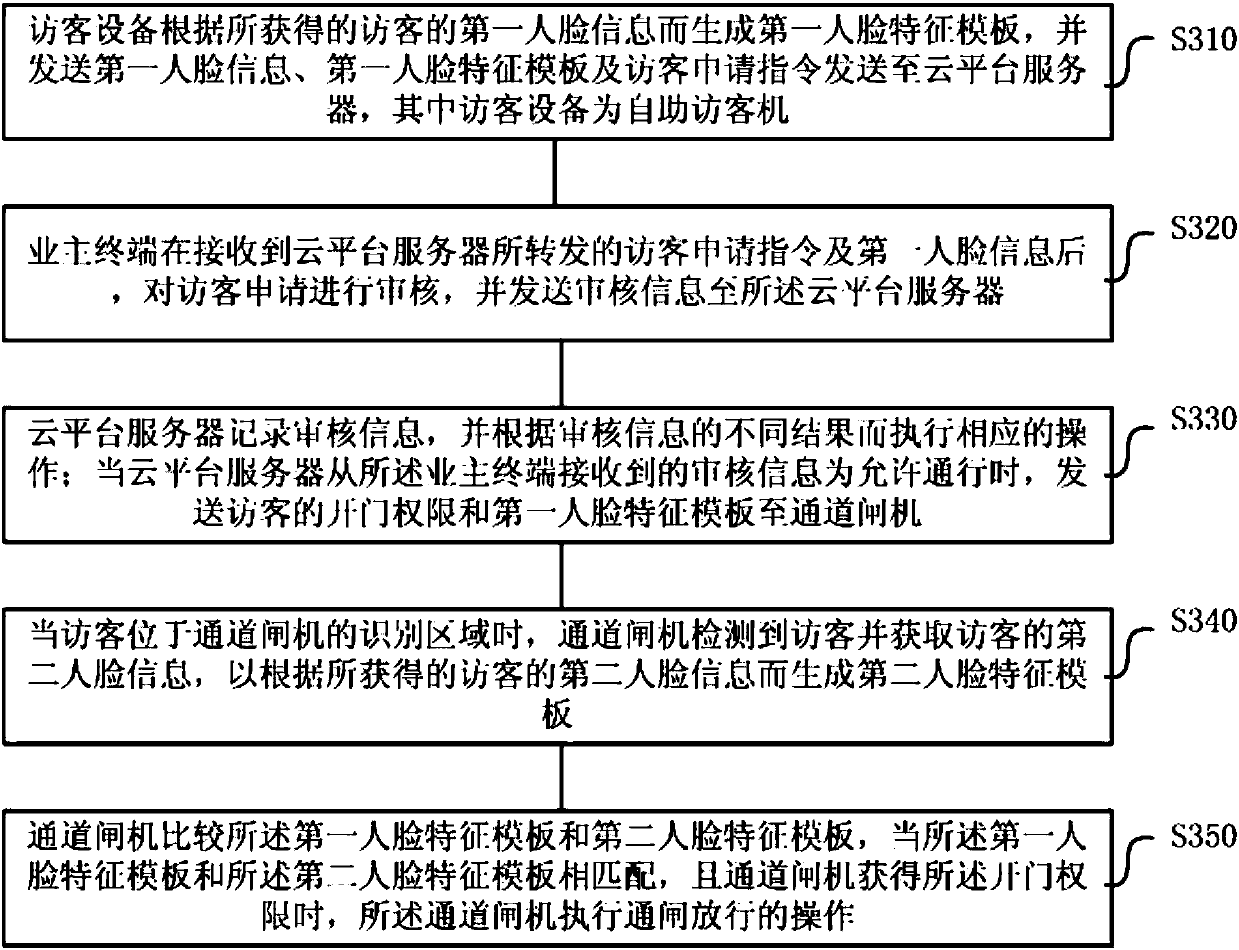

Reservable type human face identification door access visitor system and method

PendingCN107862773ASpeed up entry and exitImprove recognition accuracyIndividual entry/exit registersWorld Wide WebComputer security

The invention discloses a reservable type human face identification door access visitor system and a method. The reservable type human face identification door access visitor system comprises a visitor equipment, an owner terminal, a passage gate and a cloud platform server, wherein the visitor equipment is connected with the cloud platform server to obtain a first human face information of a visitor and generate a first human face feature template; the owner terminal is connected with the cloud platform server to check the application of the visitor and send the check information to the cloudplatform server; the cloud platform server is connected with the passage gate to send the door opening authority of the visitor and the first human face feature template to the passage gate when thereviewing information is passing allowance; the passage gate is used for detecting whether the visitor stays in the identifying area or not; when the visitor stays in the identifying area, a second human face information of the visitor is obtained so as to further generate a second human face feature template; the first human face feature template and the second human face feature template are compared; when the first human face feature template is matched with the second human face feature template, and the passage gate obtains the door opening authority, the gate passing and releasing are executed.

Owner:上海亦源智能科技有限公司

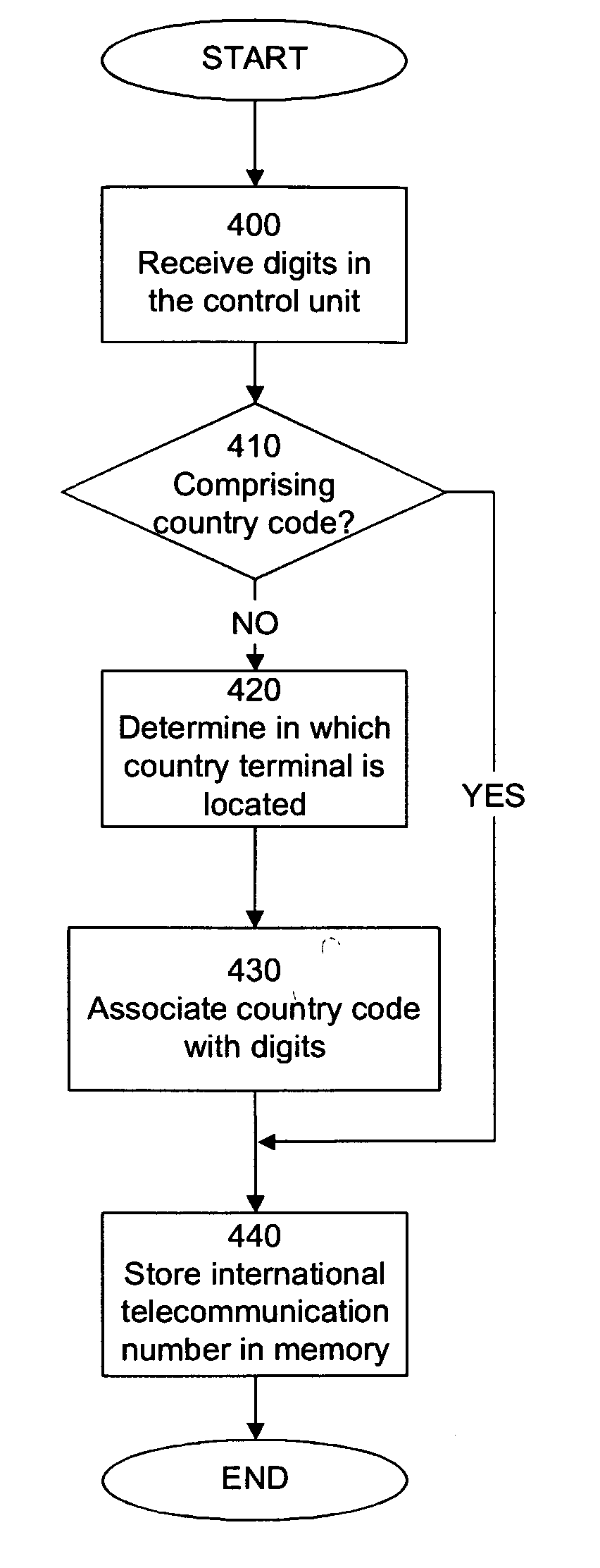

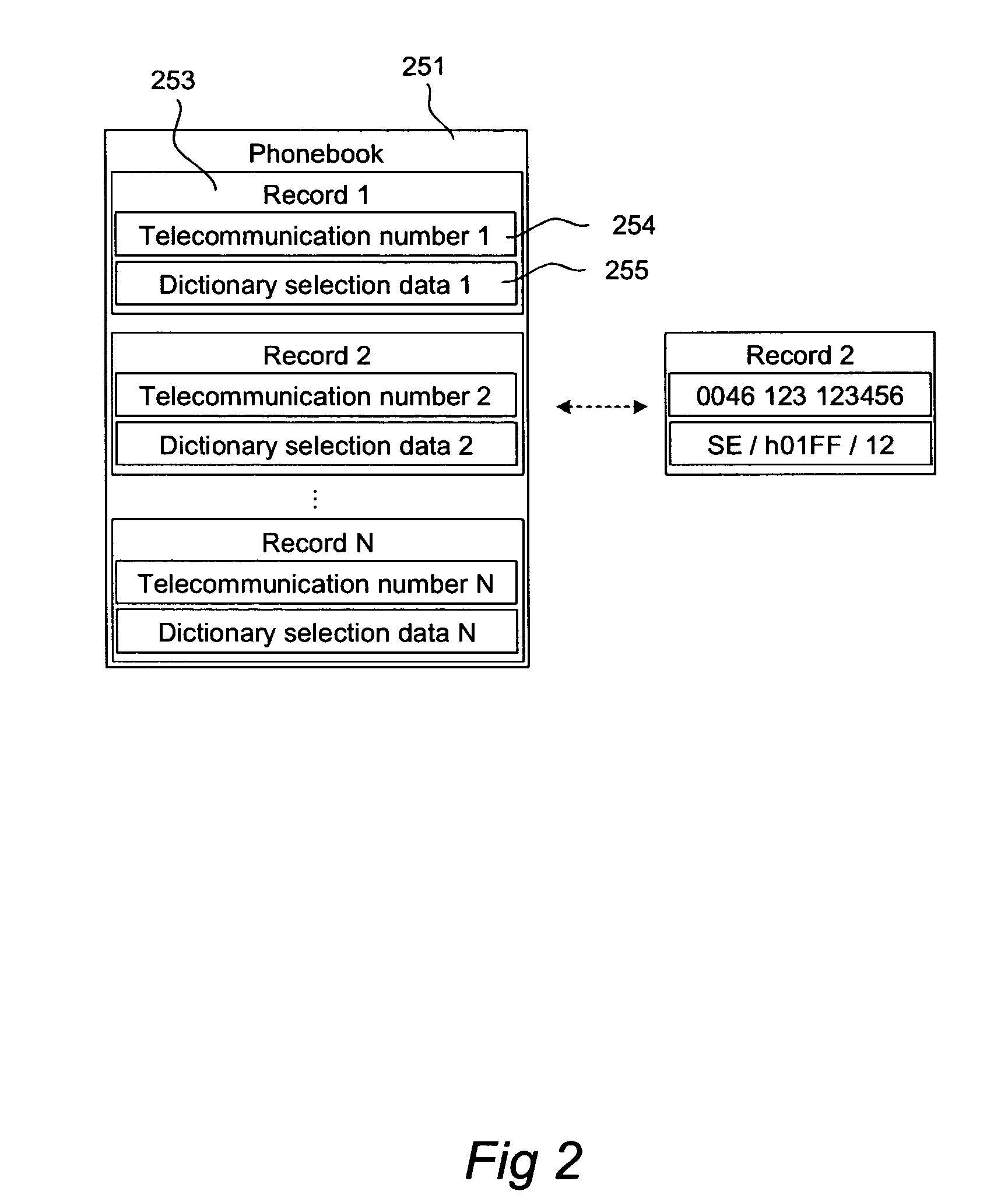

Mobile communication terminal and method therefore

ActiveUS7623860B2The method is simple and reliableAlphabetical characters enteringNatural language data processingTelecommunications networkComputer science

A method for organizing data records in a memory in a mobile telecommunication terminal is disclosed. The method comprises receiving a plurality of digits, which identify a subscriber terminal in a telecommunication network, in a control unit in the mobile telecommunication terminal. The method moreover comprises storing the plurality of digits in a memory in the mobile telecommunication terminal, and associating the plurality of digits with dictionary selection data designating at least one dictionary stored in the memory.

Owner:RPX CORP

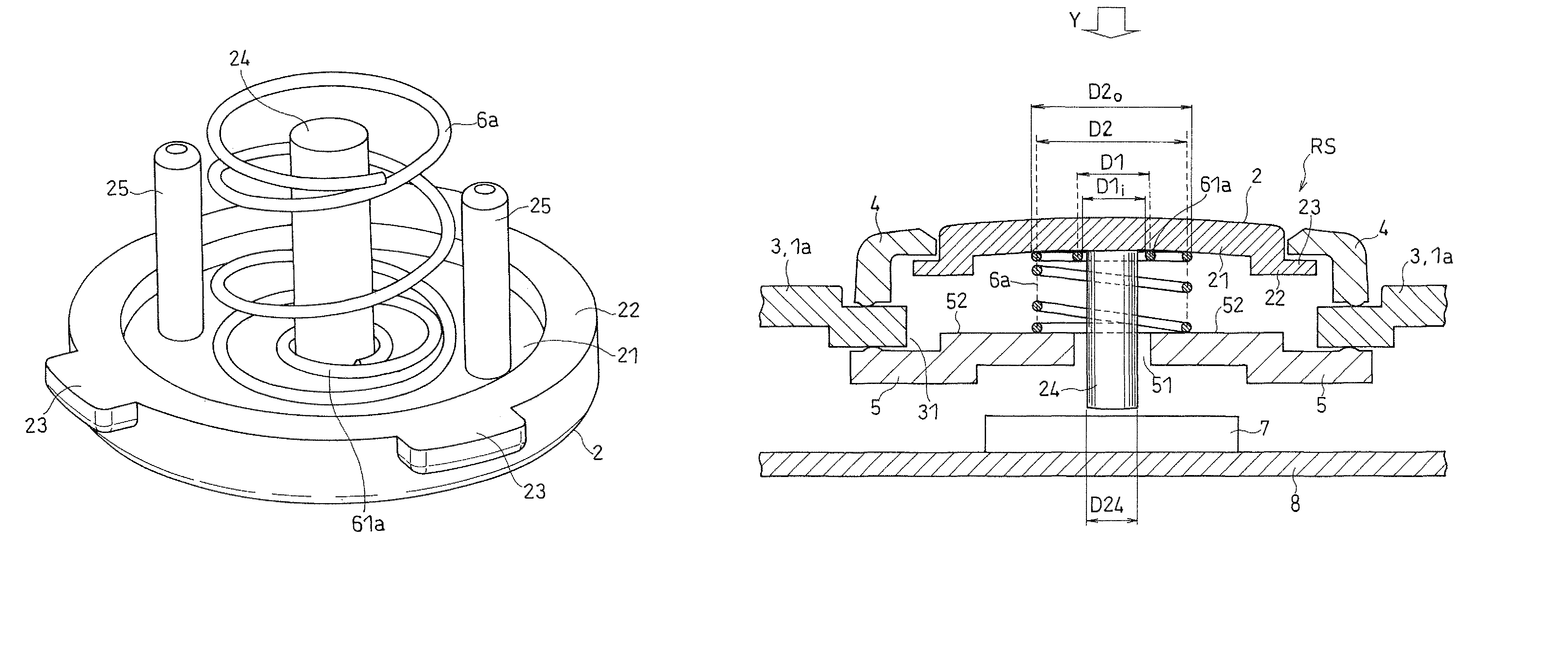

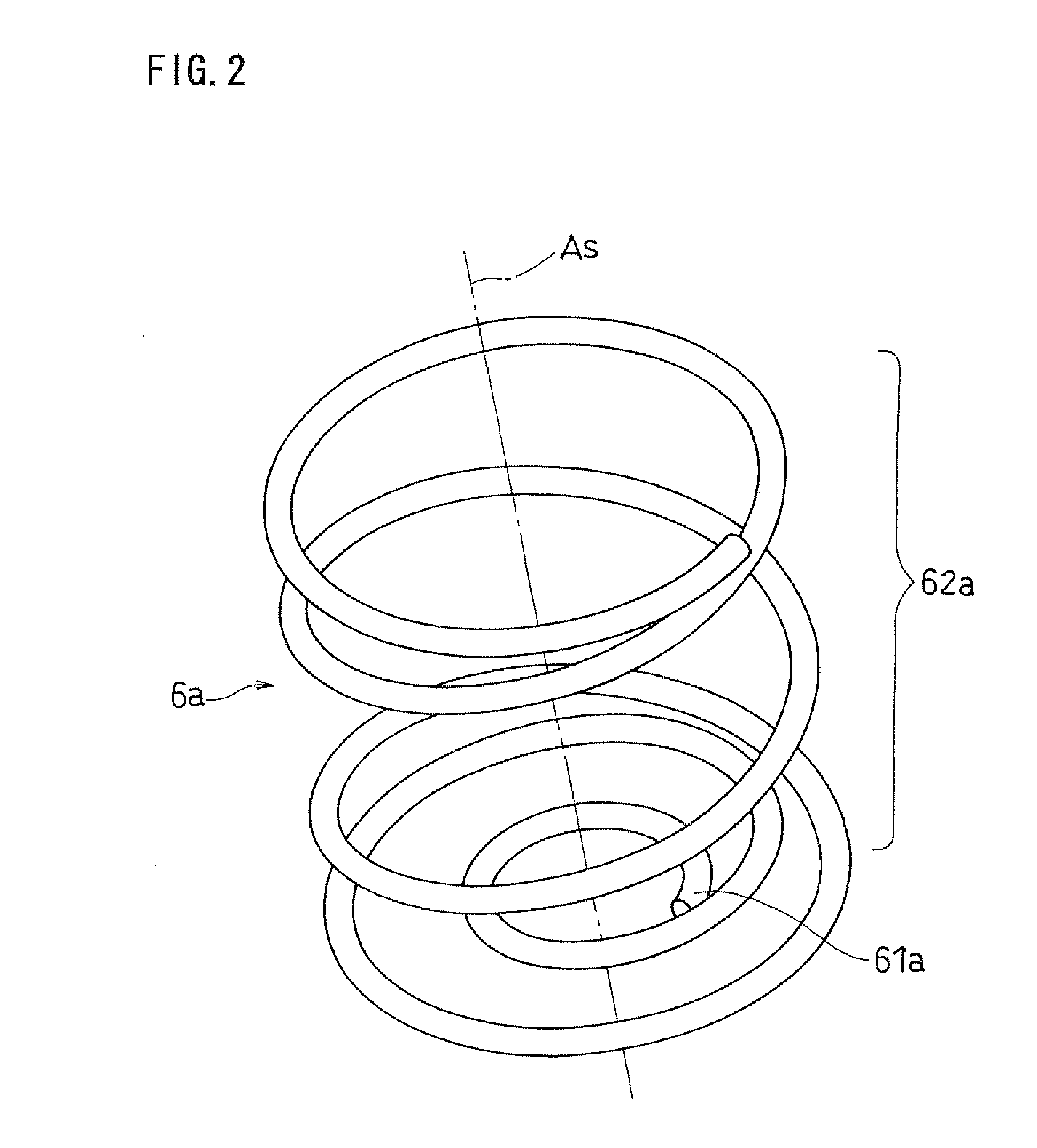

Coil spring structure of shutter button camera device and button structure of electronic device

InactiveUS7929859B2Press evenlyThe method is simple and reliableMultiple spring combinationsCamera body detailsCoil springElectronic equipment

In a camera device 1a with a shutter button 2 for transmitting an externally-applied pressing force to a switch 7, a boss 24 has a first end attached to the shutter button 2, and a second end opposed to the switch 7, a coil spring 6a has a first winding portion 61a and a second winding portion 62a, which are respectively wound into first and second shapes about a common central axis As, the second shape includes the first winding portion 61a, and the second end of the boss 24 is inserted into the first winding portion 61a.

Owner:PANASONIC CORP

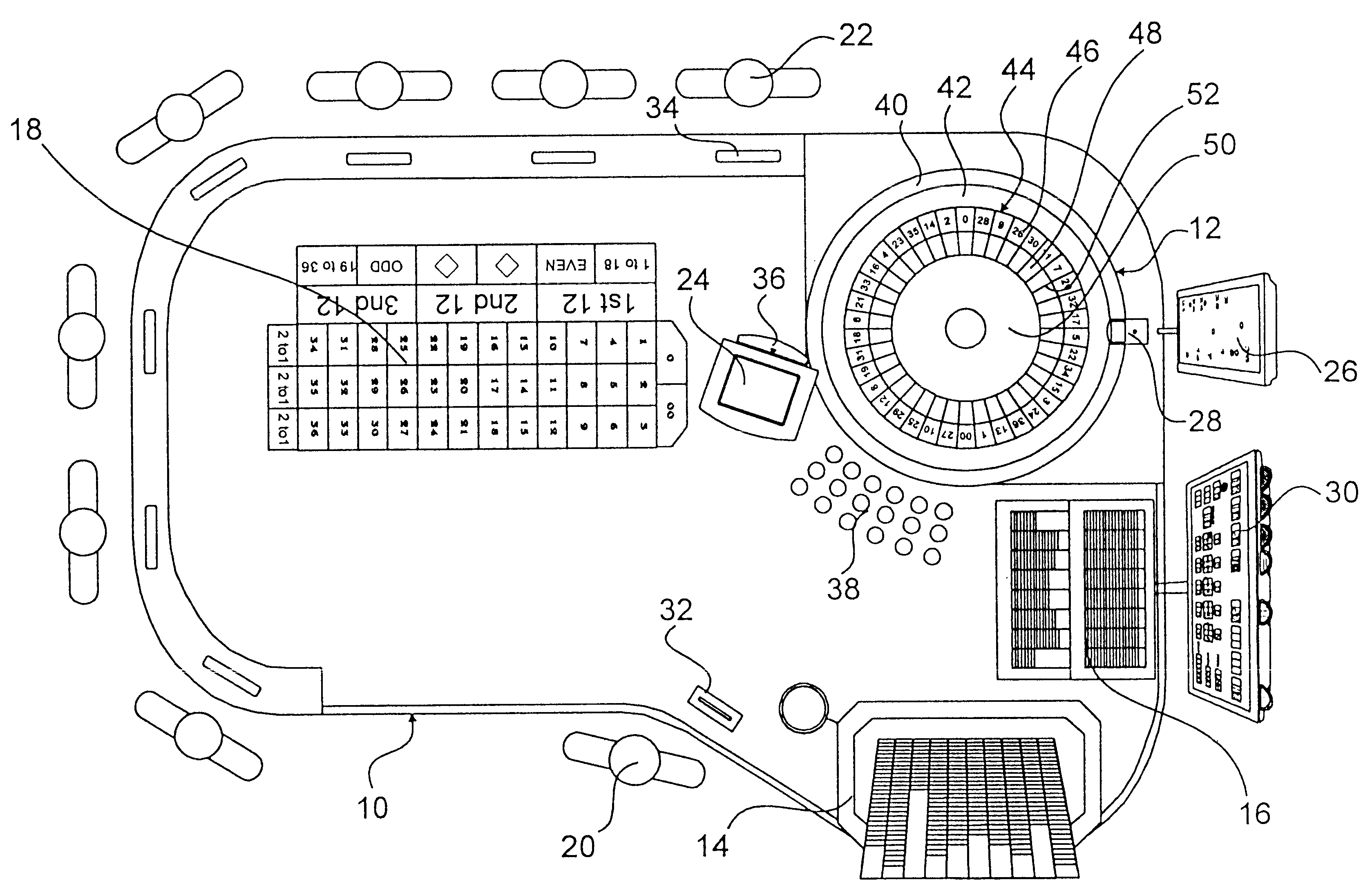

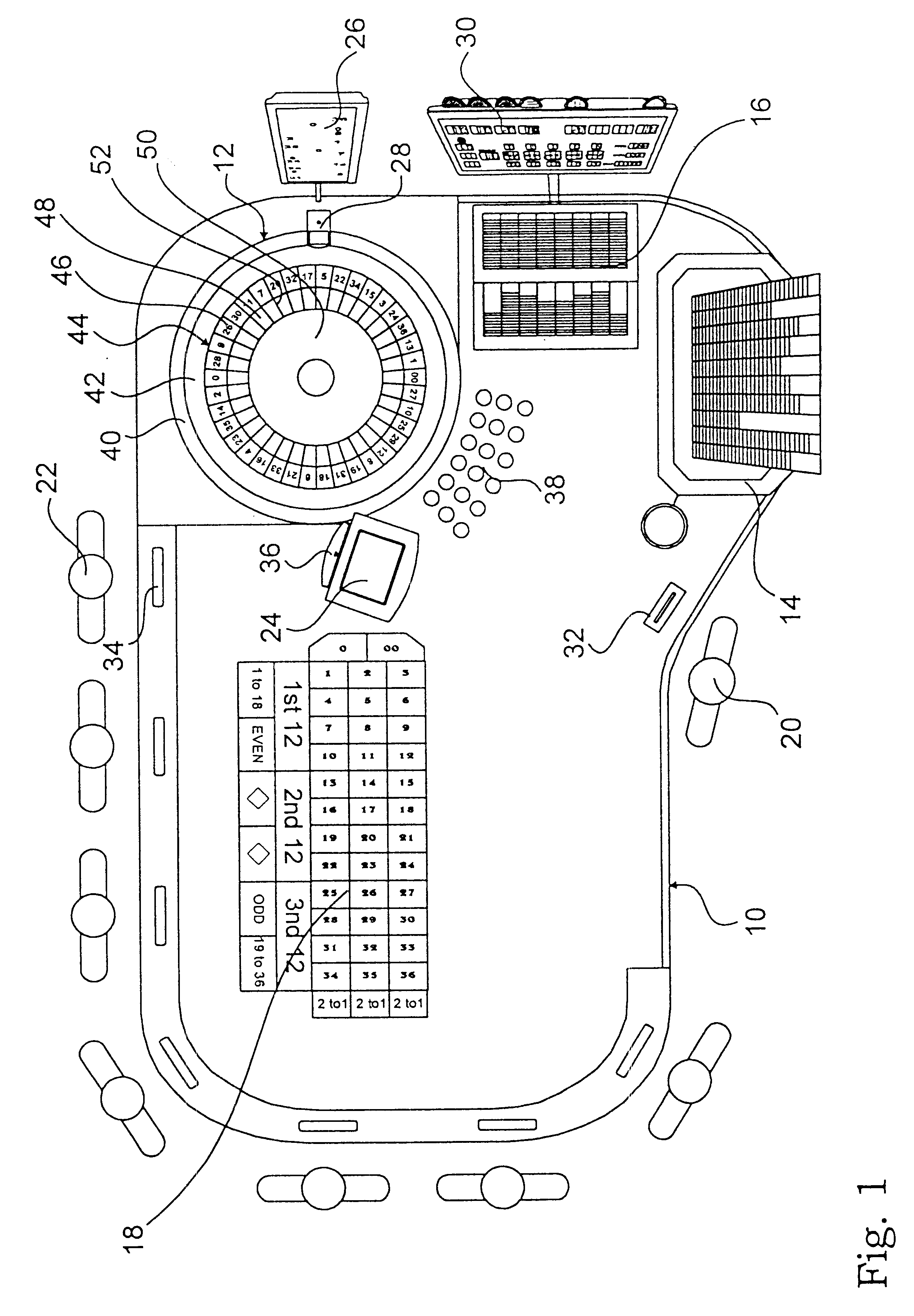

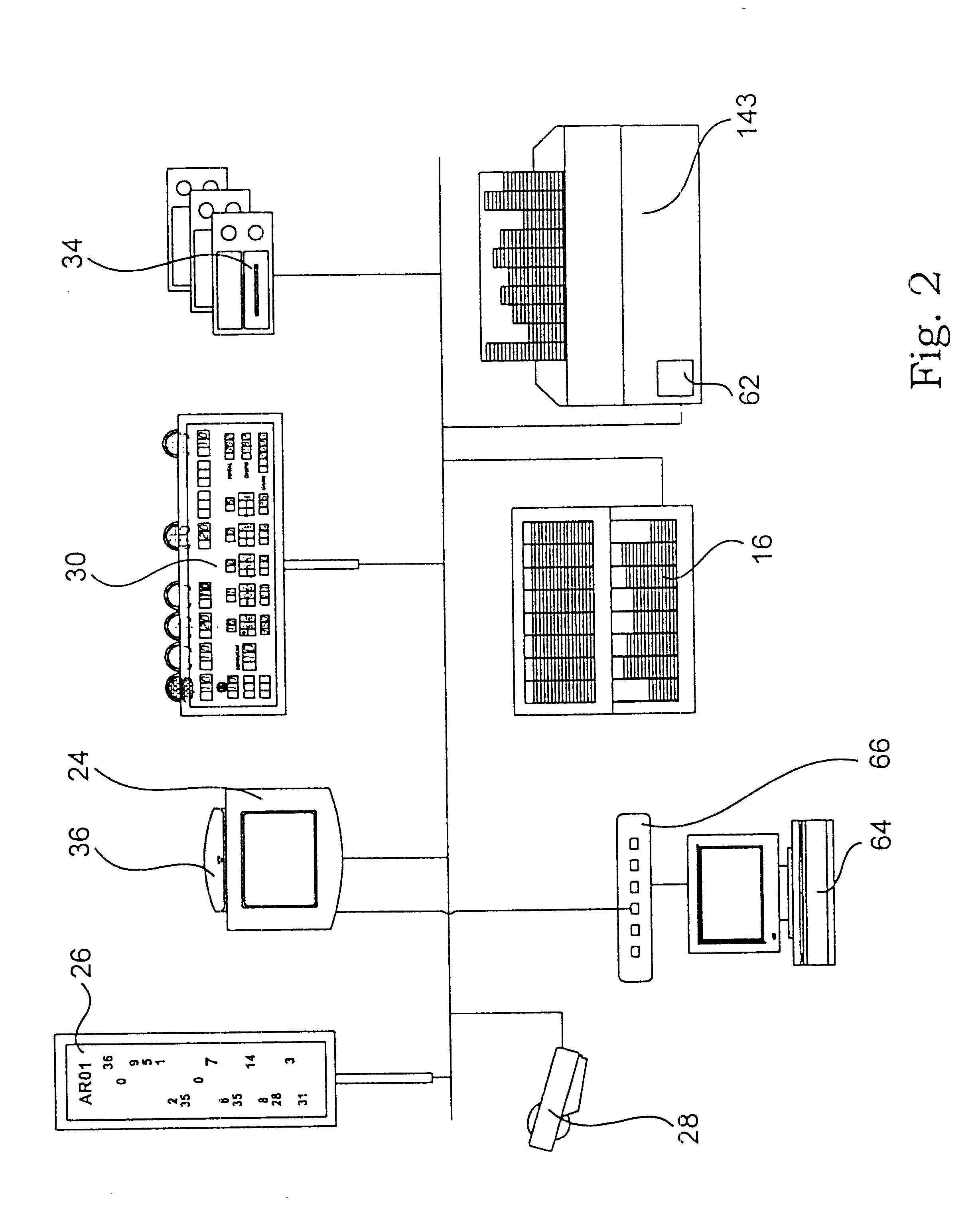

Method of estimating the performance of a croupier at a roulette table

InactiveUS6506115B1Avoid disadvantagesThe method is simple and reliableBoard gamesRoulette gamesAlgorithmComputer terminal

A method for estimating the performance of a croupier at a roulette table. For each period of time the croupier is working at a roulette table the total amount bet by individual players participating in multiple spins of a roulette game is determined. The game that has a chipper machine and an intelligent table terminal. The method involves interfacing the chipper sorting machine with the table terminal, allocating a chip to a patron at the terminal, counting the number of color chips sorted by the chipper machine per color, and associating the number of color chips sorted by the machine per color with the patron. The total amount bet by that patron is then determined by mathematically linking the chip value of the color chip of the patron with the number of chips of the individual color sorted by the chipper machine in the time period in which the color chip is associated with that patron.

Owner:GTECH AUSTRIA

Method for controlling a wind energy plant

ActiveUS20090081041A1The method is simple and reliableReduce loadRotational speed controlPropellersNacelleRest position

The present invention is related to a method for controlling a wind energy plant, with a nacelle disposed on a tower and with a rotor with at least one rotor blade, the blade adjustment angle of which can be adjusted by means of a blade adjustment equipment. The objective to provide a reduction of the loads acting on the plant when there is a malfunction of the blade adjustment equipment is resolved according to the present invention in that the function of the blade adjustment equipment is monitored, and when an error of the blade adjustment equipment occurs, the nacelle is rotated from an operating position into a rest position, in which there is a flow of the wind against the surface extended by the at least one rotor blade (4) in a rotation of the rotor which is reduced with respect to the operating position.

Owner:NORDEX ENERGY SE & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com