Patents

Literature

989 results about "Environmental simulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Audio Spatialization and Environment Simulation

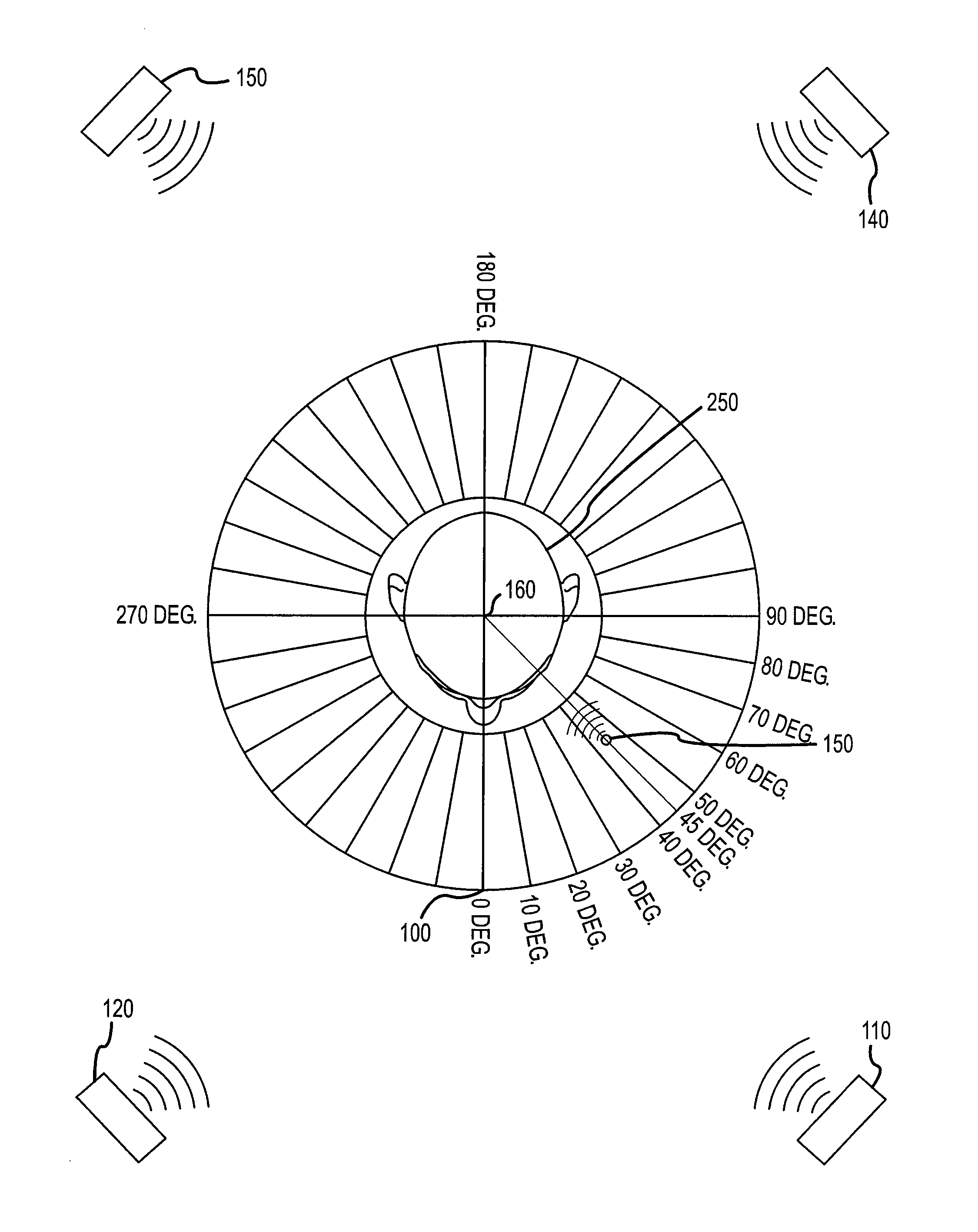

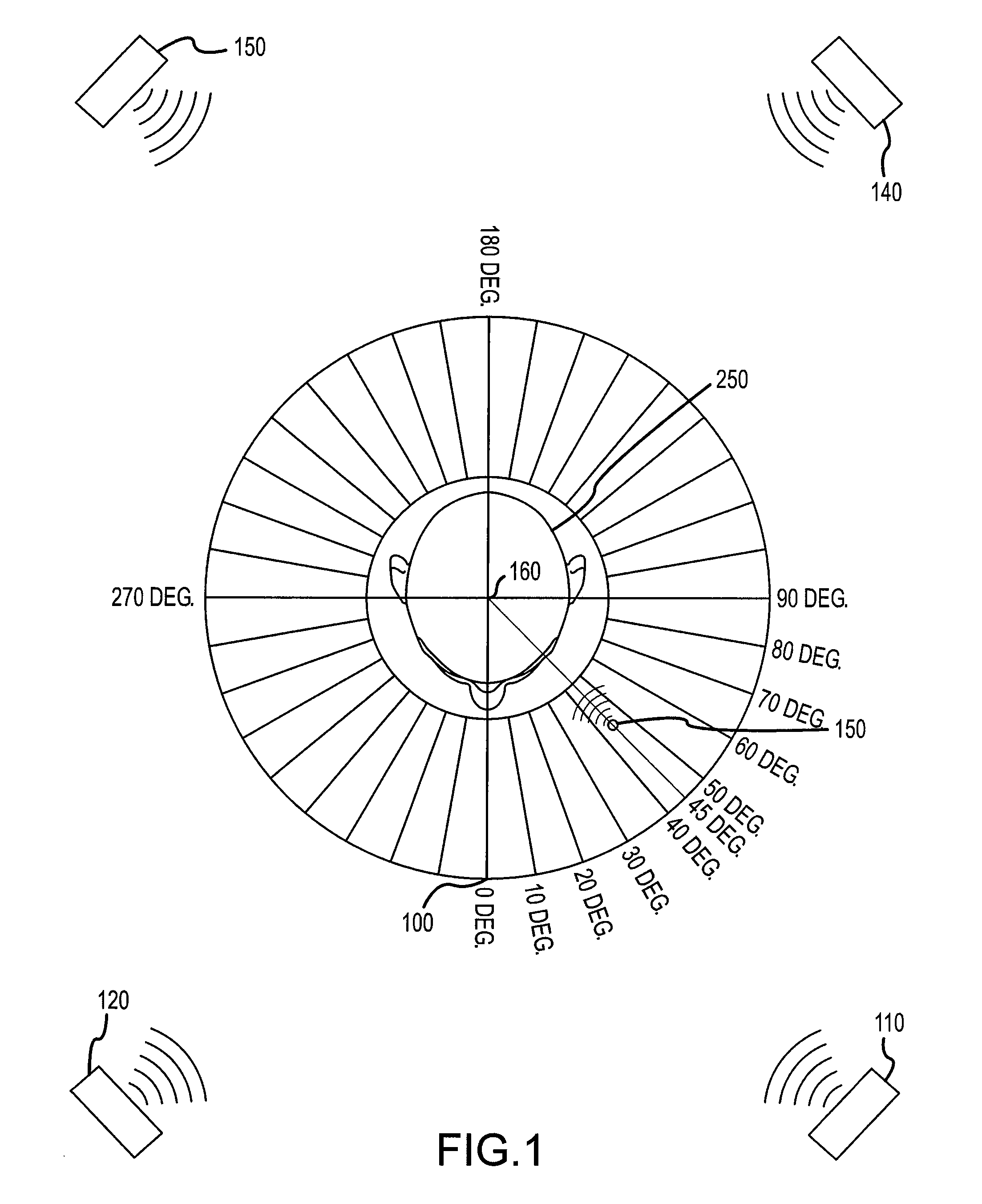

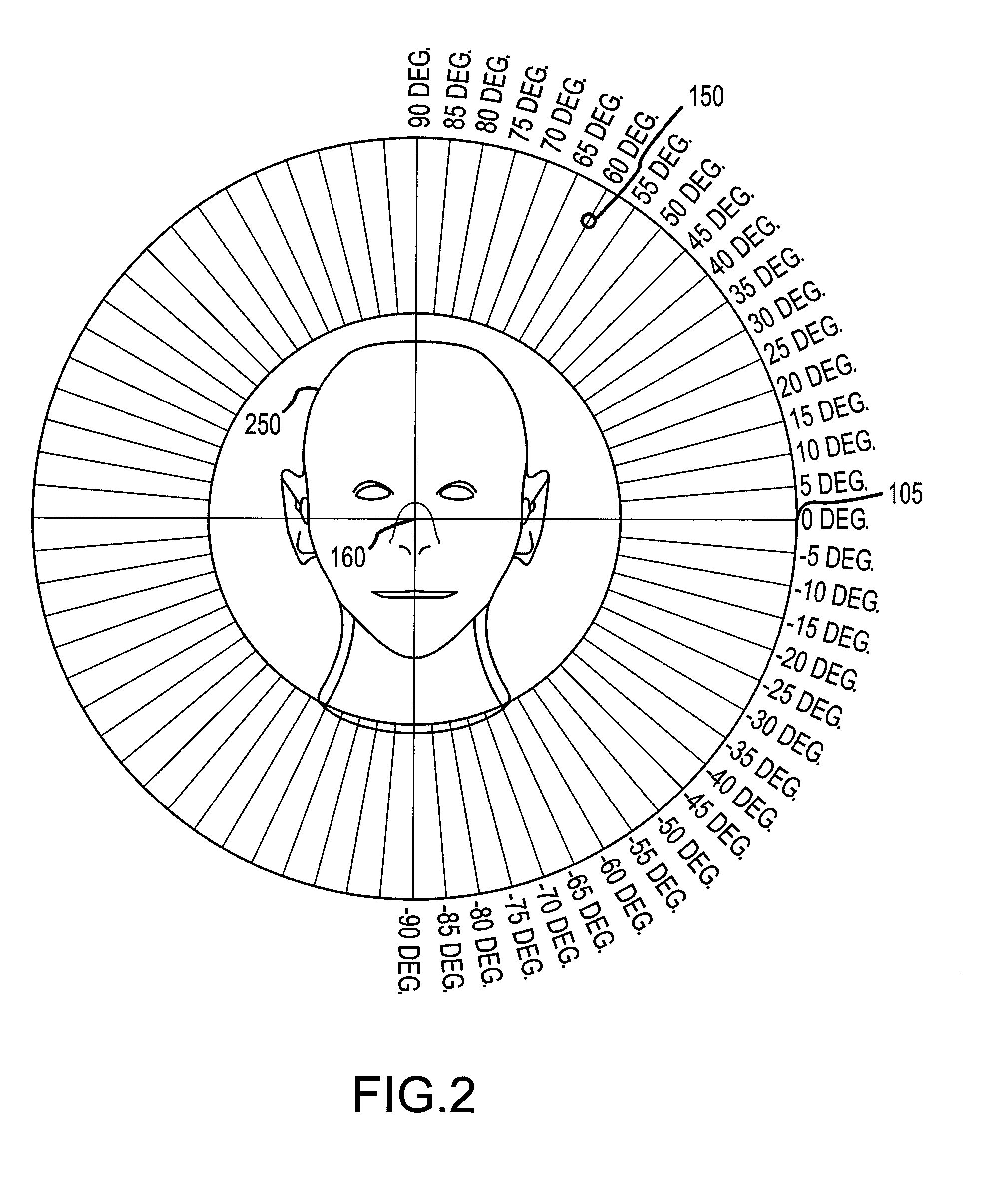

InactiveUS20120213375A1Accurate audio spatializationAccurate transfer functionPseudo-stereo systemsTwo-channel systemsSound localizationEnvironmental simulation

Methods and apparatus are disclosed for processing an audio sound source to create four-dimensional spatialized sound. A virtual sound source may be moved along a path in three-dimensional space over a specified time period to achieve four-dimensional sound localization. The various embodiments described herein provide methods and systems for converting existing mono, 2-channel and / or multi-channel audio signals into spatialized audio signals have two or more audio channels. The incoming audio signals may be down-mixed, up-mixed or otherwise translated into fewer, greater or the same number of audio channels. The various embodiments also describe methods, systems and apparatus for generating low frequency effect and center channel signals from incoming audio signals having one or more channels.

Owner:GENAUDIO

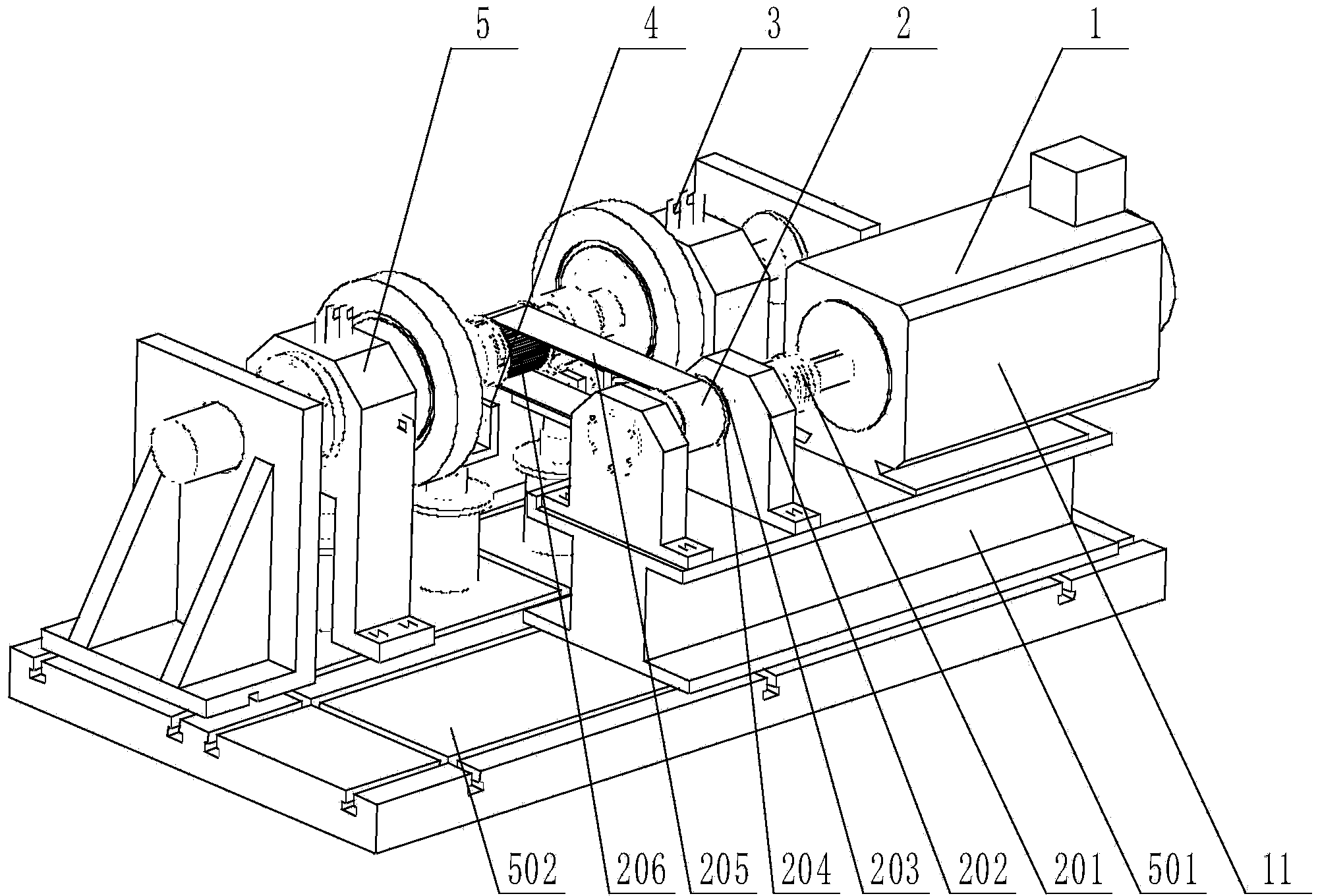

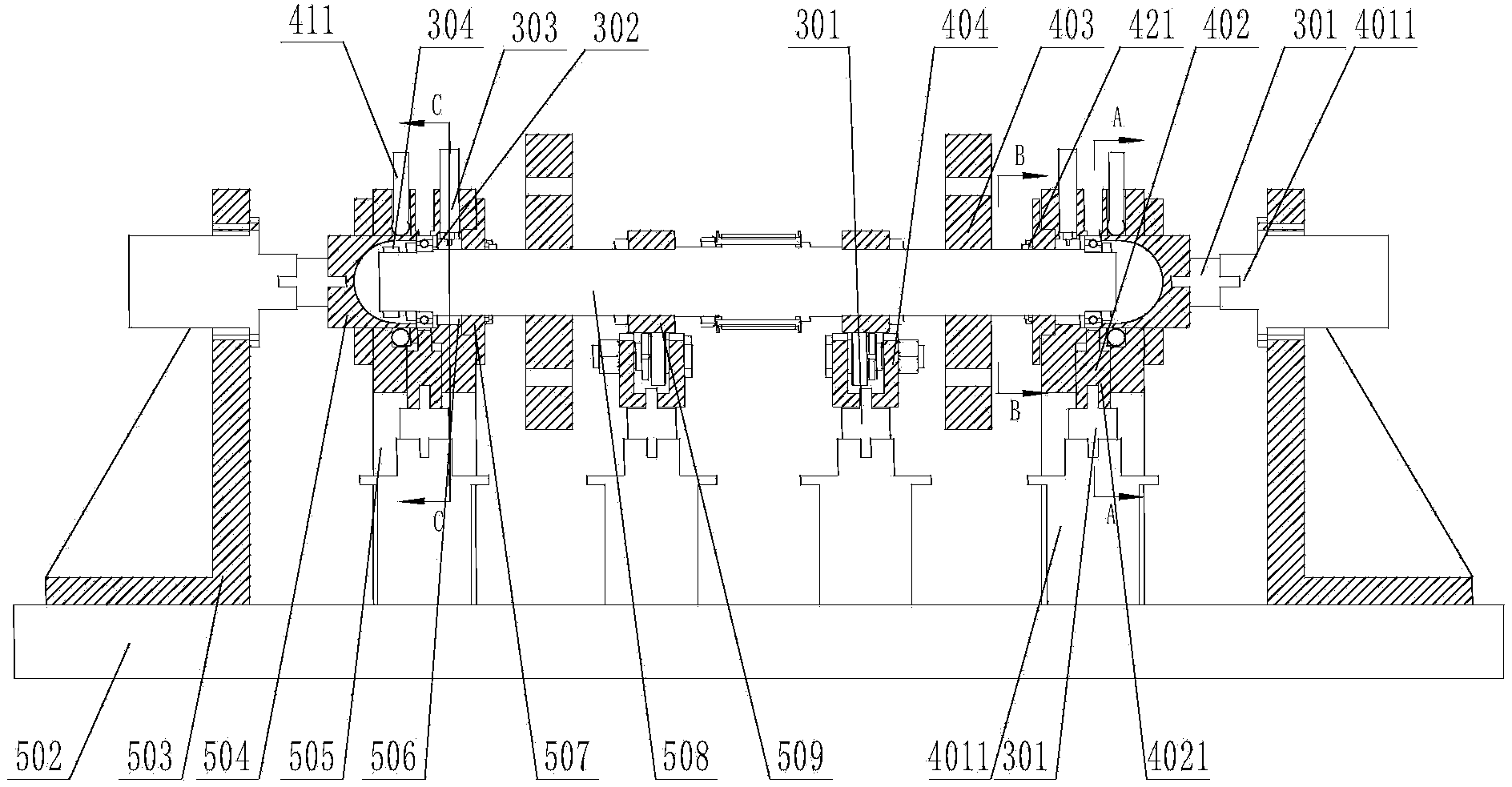

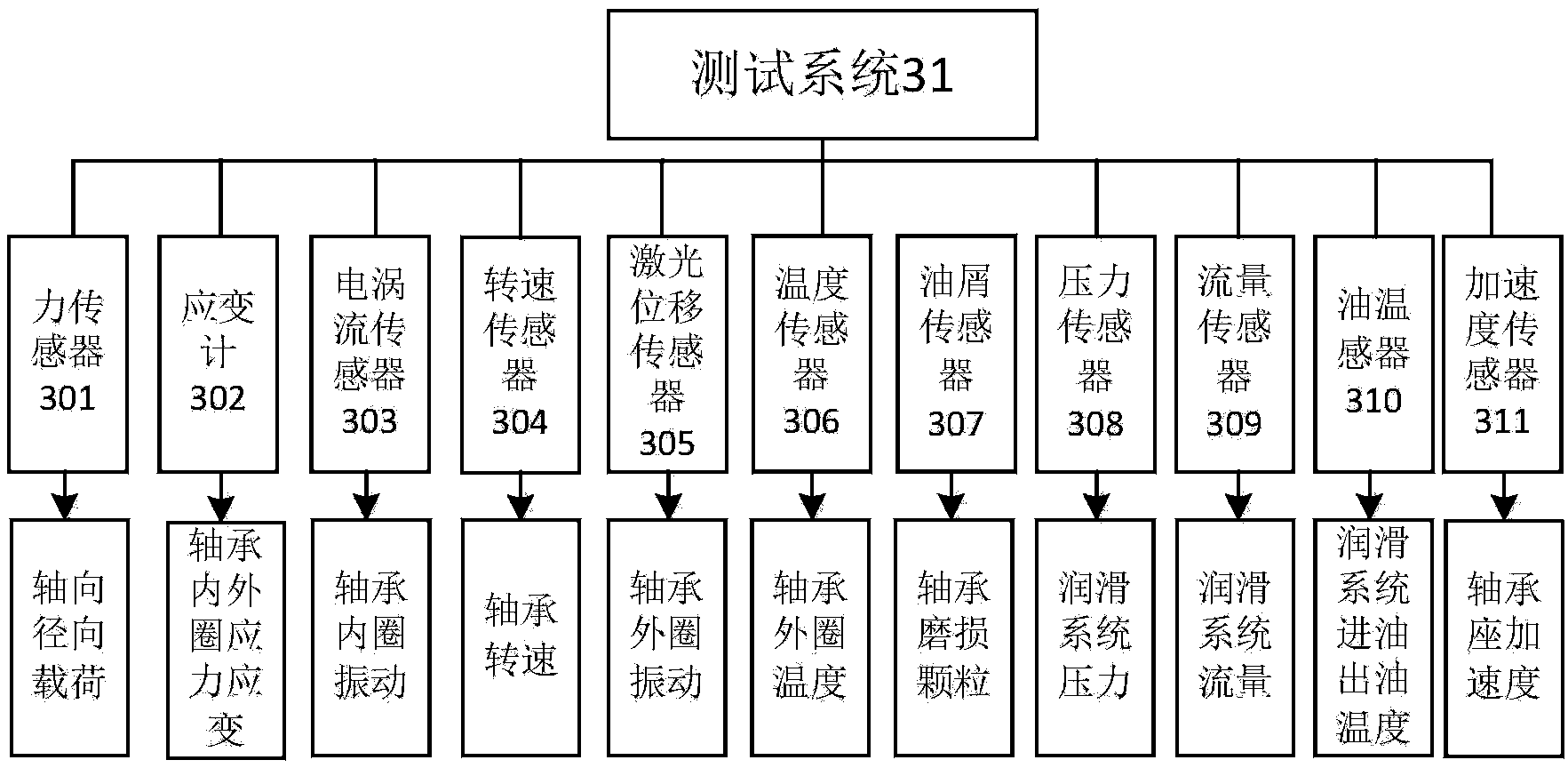

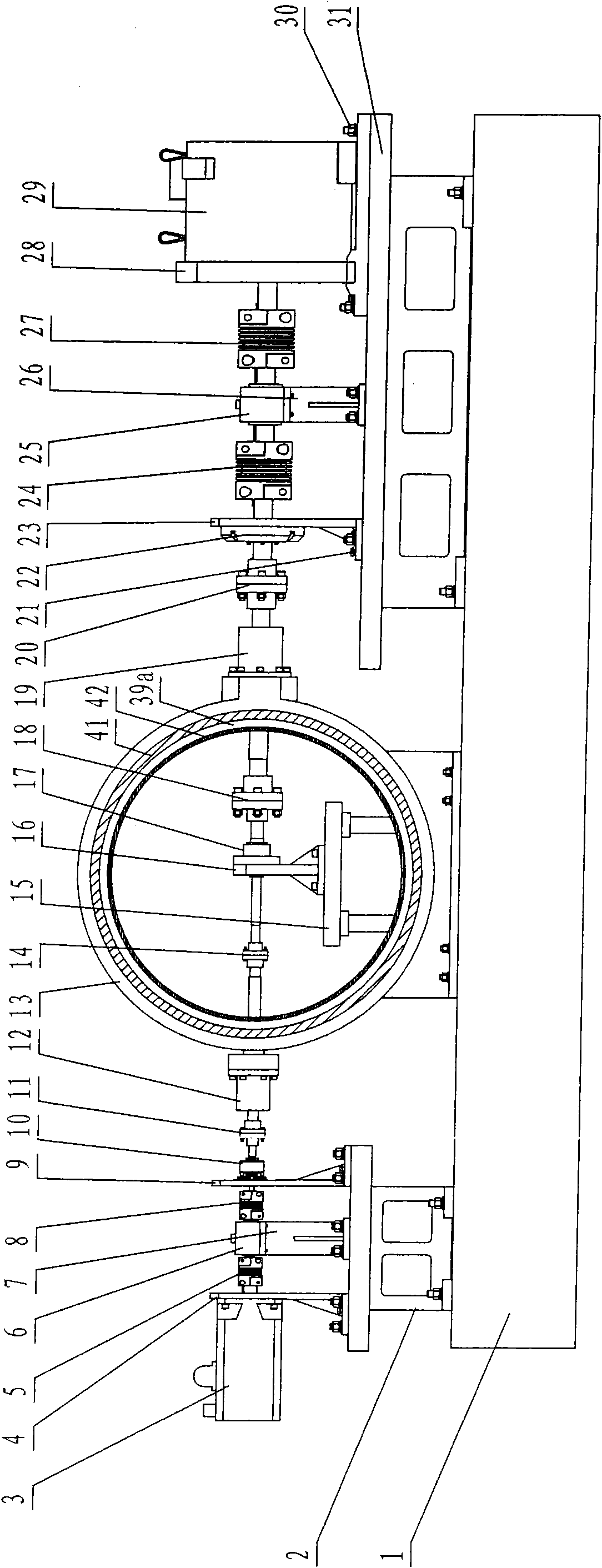

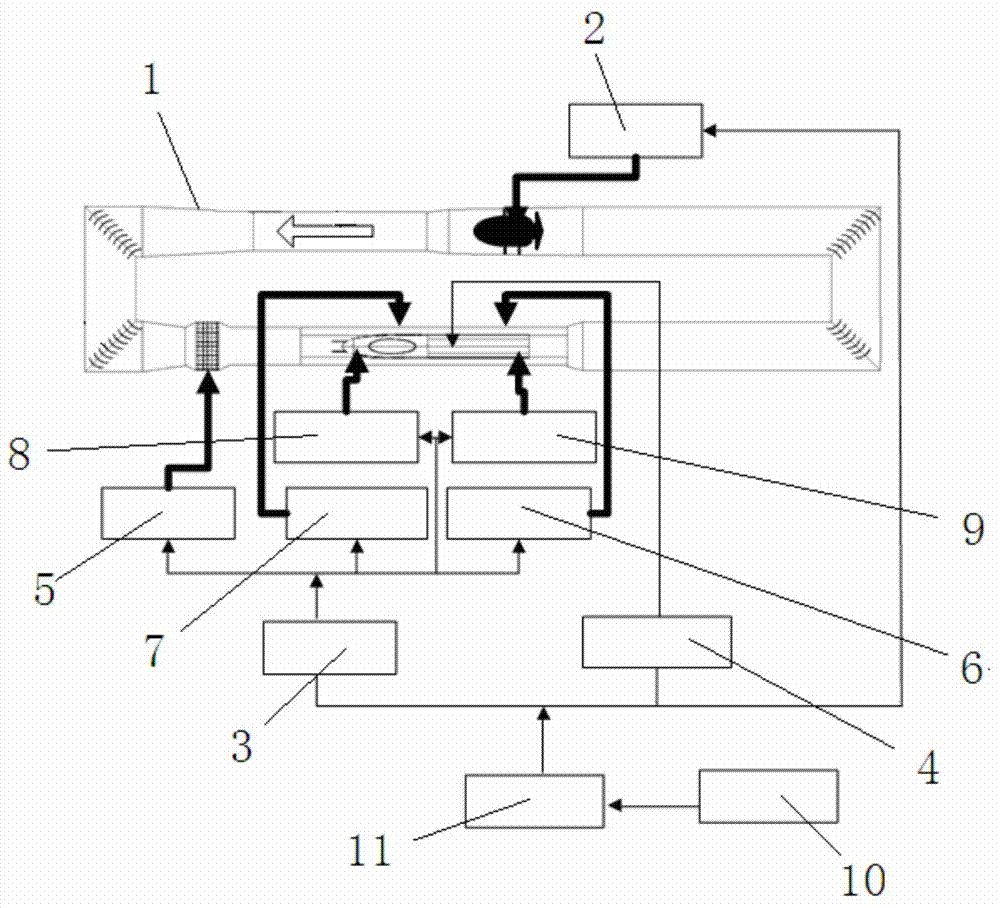

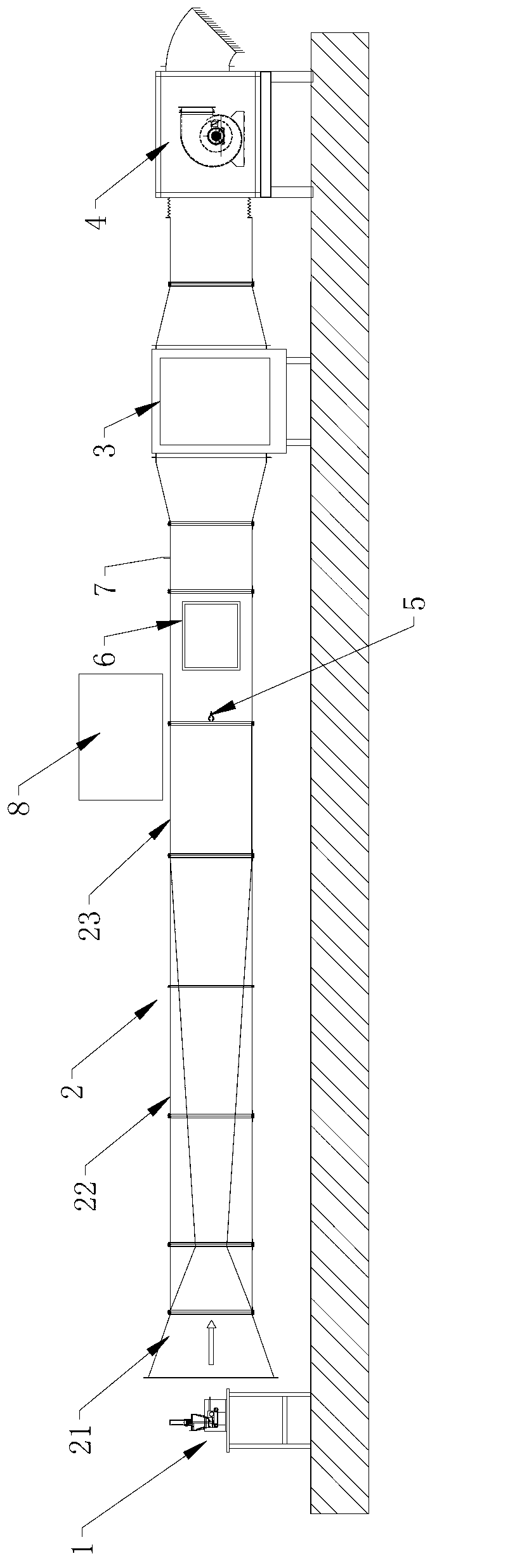

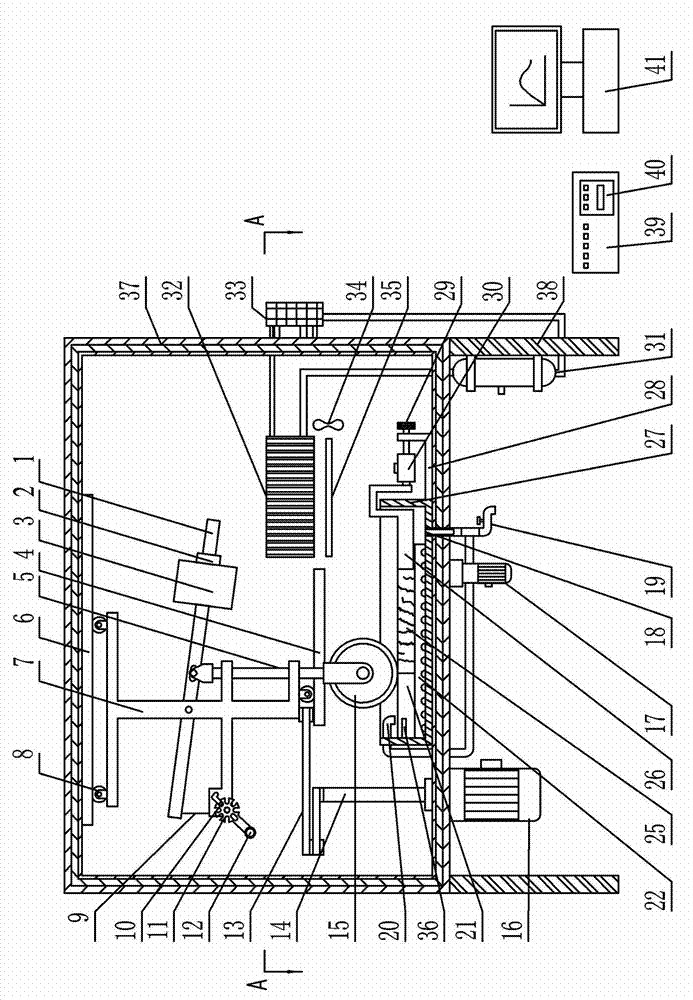

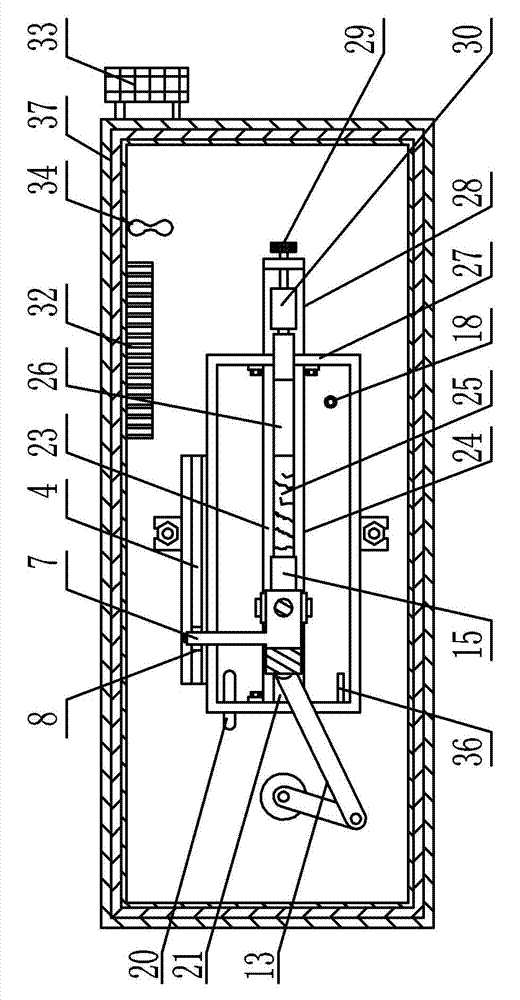

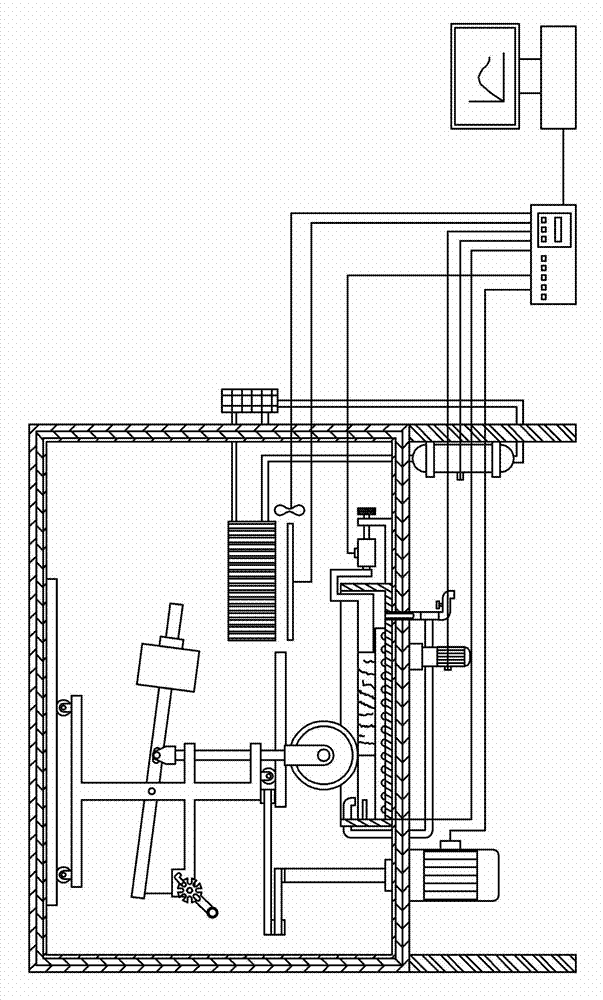

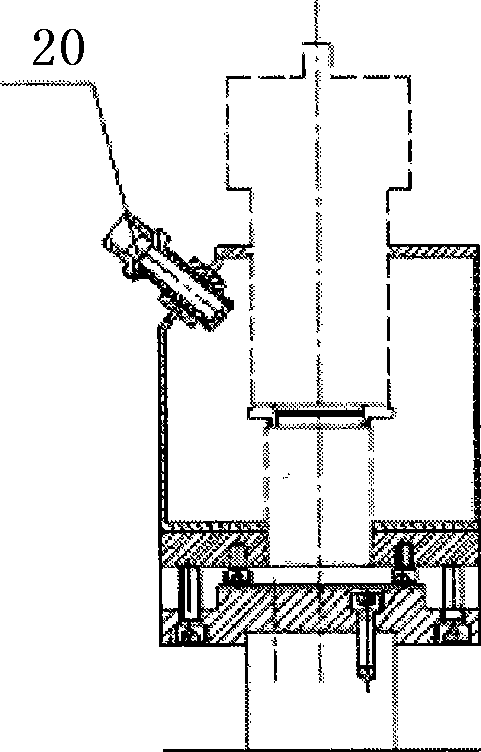

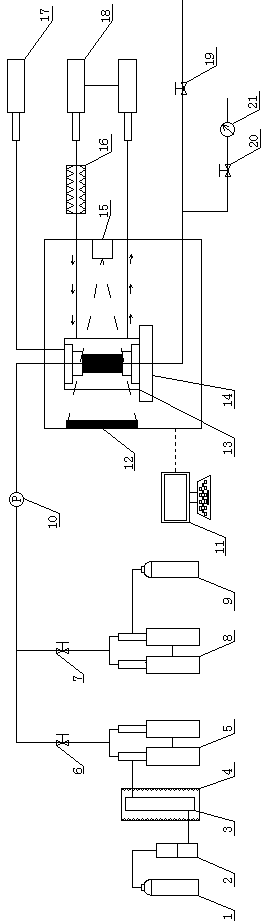

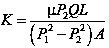

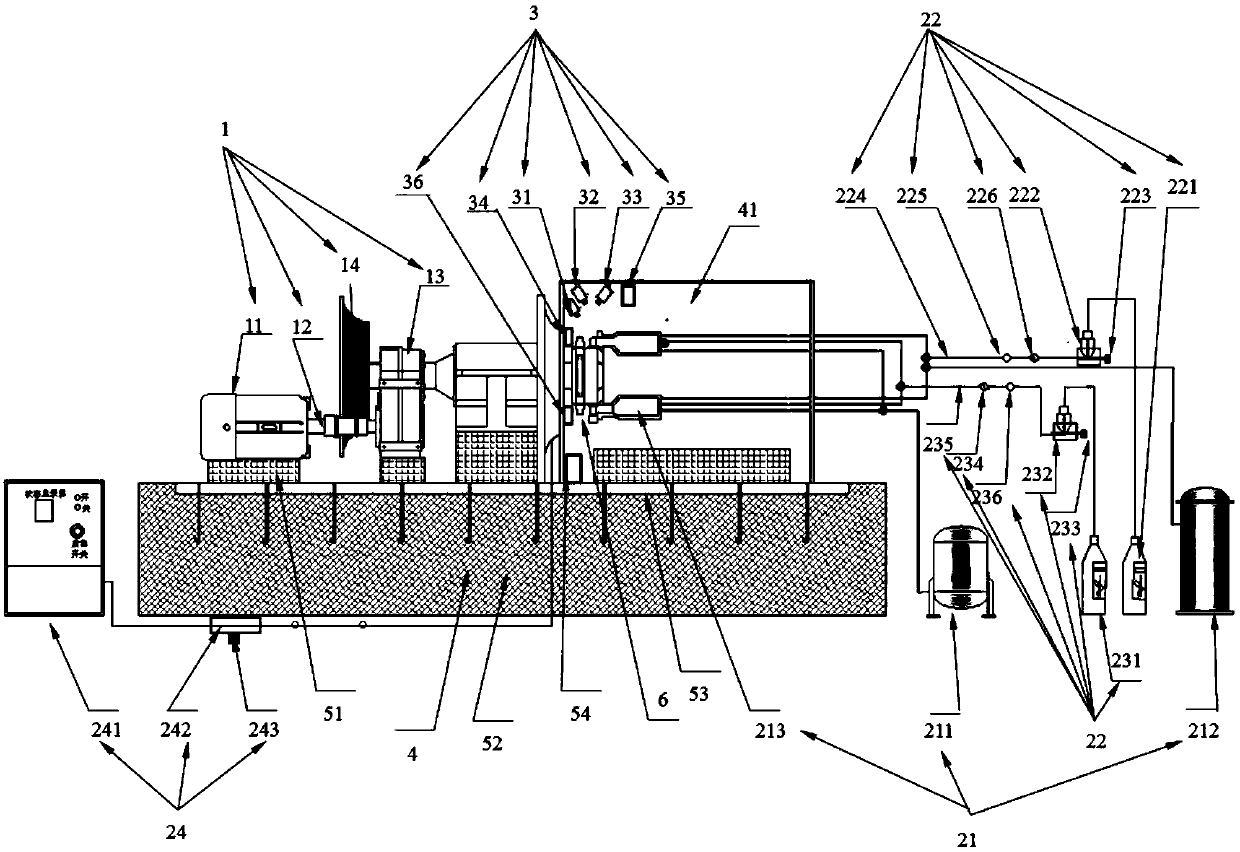

Bearing integrated dynamic performance test device and method

The invention relates to the technical field of bearing testing, in particular to a bearing integrated dynamic performance test device and method. The bearing integrated dynamic performance test device comprises a drive system, a transmission system, a measurement and control system, an environmental simulation system and a mechanical body structure. A motor is adopted by the drive system for driving. The measurement and control system controls the rotation speed of the motor. The transmission system is in a belt transmission mode or a coupler transmission mode. The measurement and control system is provided with a force sensor, a strainmeter, an eddy current transducer, a rotation speed sensor, a laser displacement sensor, a temperature sensor, a magnetic oil residue sensor, a pressure sensor, a flow sensor, an oil temperature sensor, an acceleration sensor and other related sensors used for bearing testing. The control system is driven in a servo mode, and is composed of a frequency converter, a hydraulic solenoid valve, a heating controller, a flow control device and a pressure control device. The environmental simulation system is adopted for simulating a real bearing testing working condition, and the performance and service life testing of the real bearing testing working condition is achieved.

Owner:DALIAN UNIV OF TECH

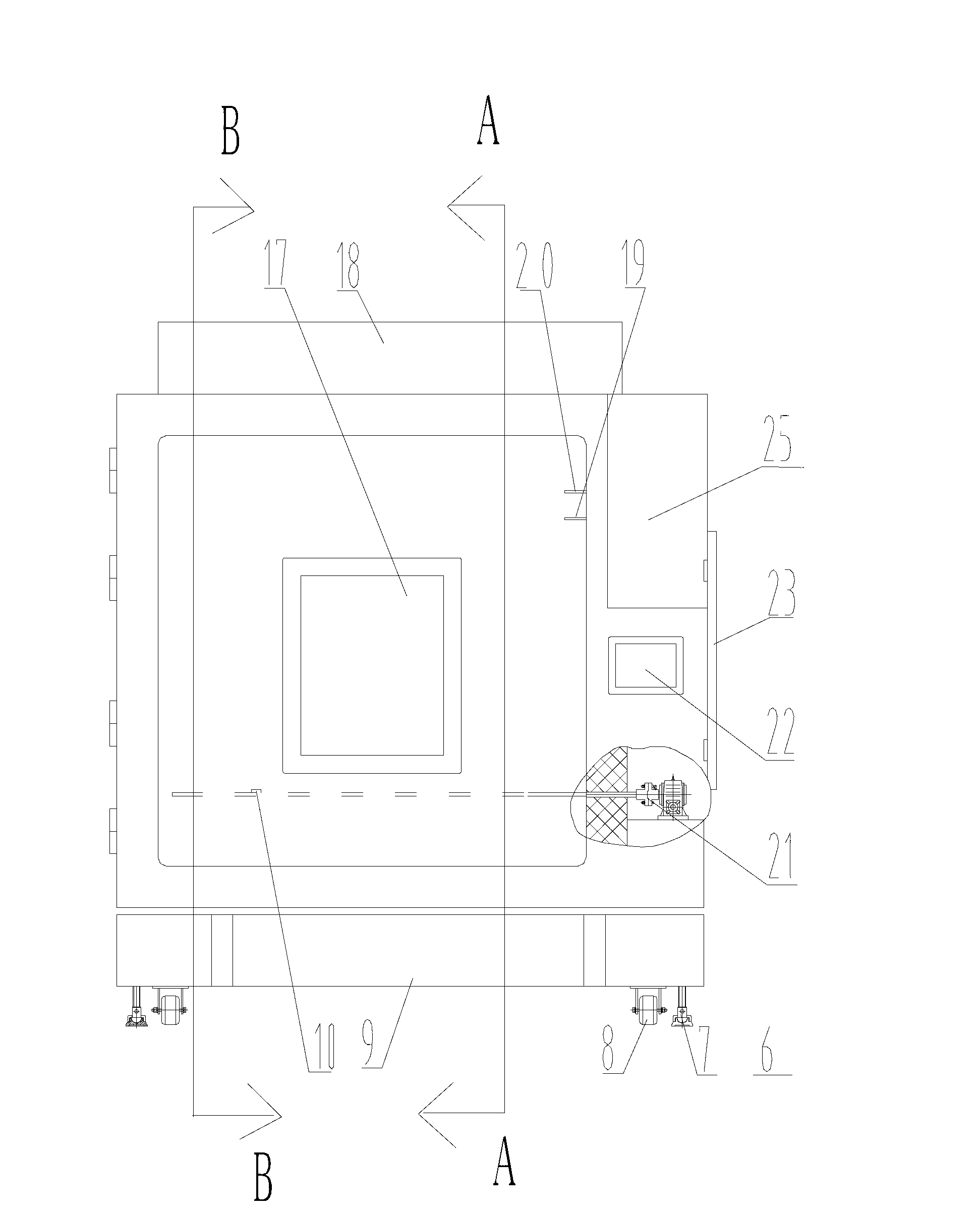

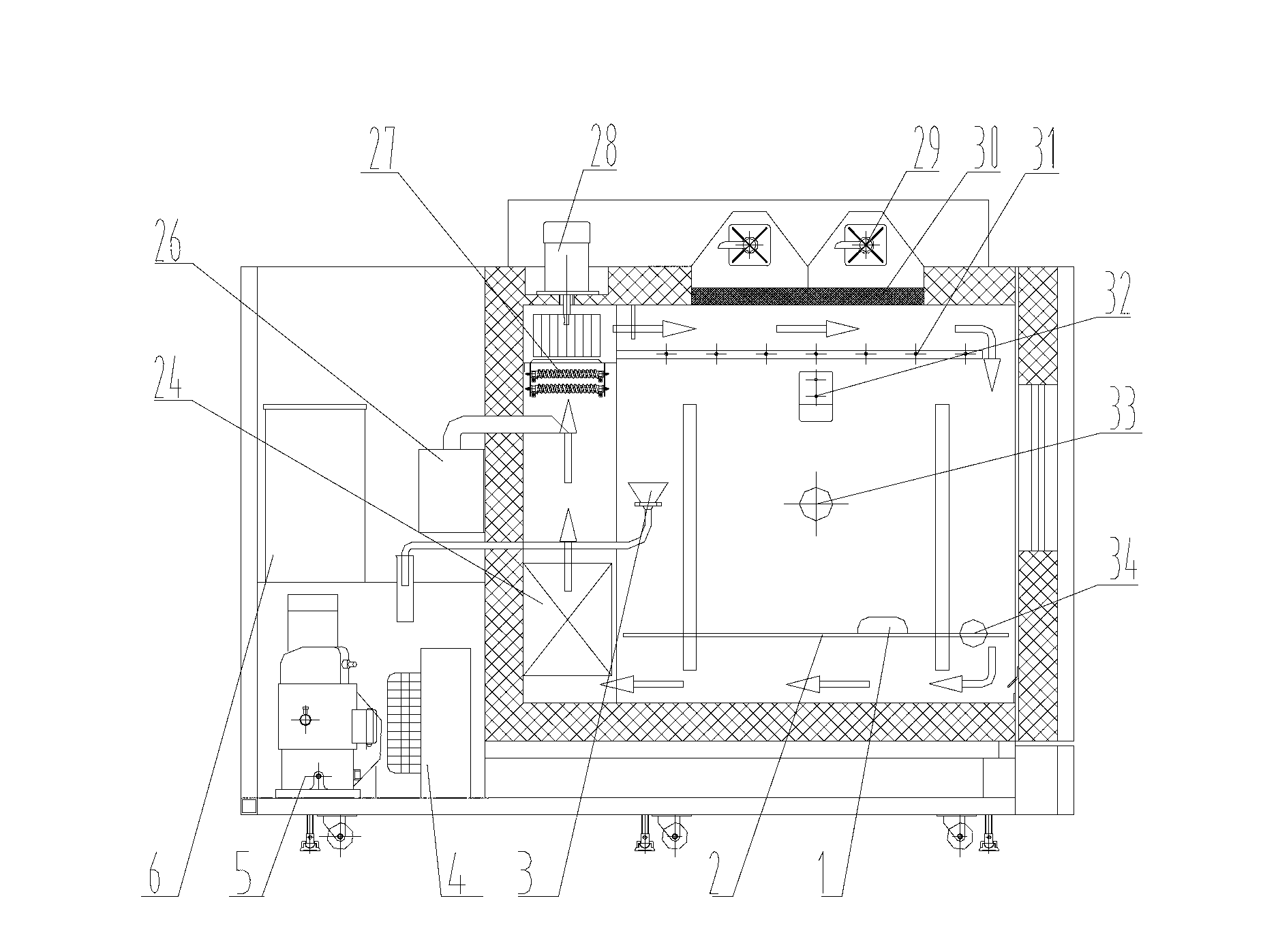

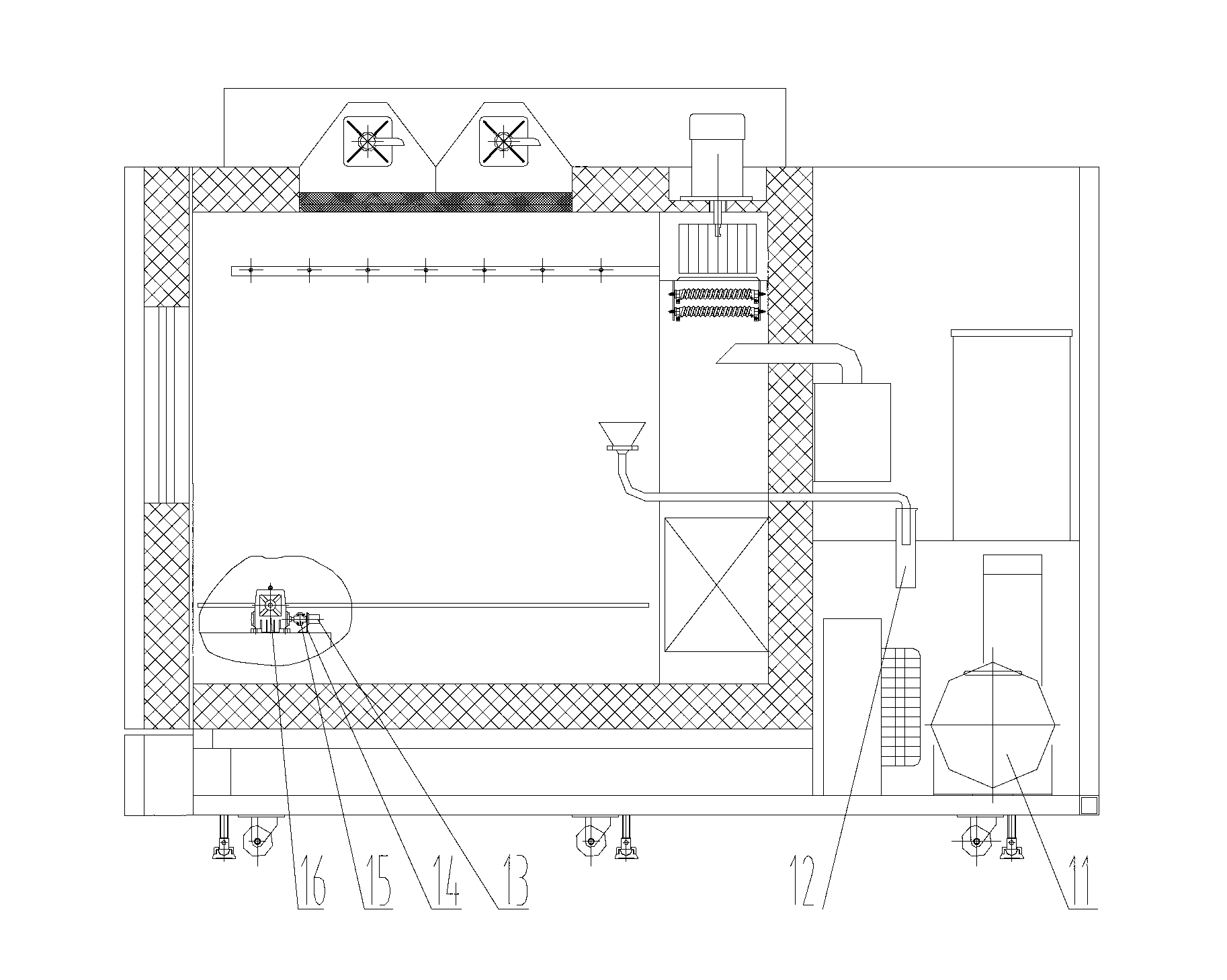

Large multifunctional environmental simulator for electrical test

ActiveCN101799515AUniform temperatureUniform air flowTesting dielectric strengthUltra high voltageHigh pressure

The invention relates to a large multifunctional environmental simulator for electrical tests, which comprises an environmental stimulation chamber and is characterized in that an air heat-exchange circulation system and an ice-melting system are arranged in the environmental stimulation chamber; and the environmental stimulation chamber further comprises an ice-coating, rain-exposing and ultrasonic-atomizing system, a water treatment system, a heat-fogging system, a cooling water circulation system, a refrigeration system, a vacuuming and defogging system, a measurement and control system and an ultra-high voltage power supply system for providing a high-voltage charging state for test-pieces. By achieving the skillful coordination among the systems and the uniform operation control by the measurement and control system, the large multifunctional environmental simulator integrates various testing functions of environmental simulations, such as high-altitude, ice-coating, contamination, rain-exposing and other simulations into a whole. Therefore, the invention is widely suitable for the testing process for large multi-parameter environmental simulations.

Owner:BEIHANG UNIV +1

Multi-factor comprehensive simulation accelerated testing device for climatic environment

InactiveCN102841051AControl the wet and dry cycleHigh magnificationWeather/light/corrosion resistanceMicrocontrollerAir velocity

The invention discloses a multi-factor comprehensive simulation accelerated testing device for a climatic environment. The multi-factor comprehensive simulation accelerated testing device comprises a testing box in which a sample frame is arranged, a light source system, an intelligent spraying system, a temperature and humidity regulating system, a circulation air system and a control system. With the adoption of the device, an environmental effect with five environmental factors, such as illumination, corrosive medium, temperature, humidity and air speed can be simultaneously simulated or strengthened; actions, such as radiation power variation, atomizing (or spraying), heating (or cooling), air speed and the like of the light source can be controlled by using an PLC (programmable logic controller) or a singe-chip so as to simulate and strengthen a plurality of typical climate environments; drying and watering circulation on the surface of a sample in the test box can be controlled well through adopting intelligent atomizing (or spraying) control; and accelerated ratio and relevance are improved. The testing device can be used for developing two kinds of different light aging test and damp heat test so as to achieve the effect that one box has multi purposes.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

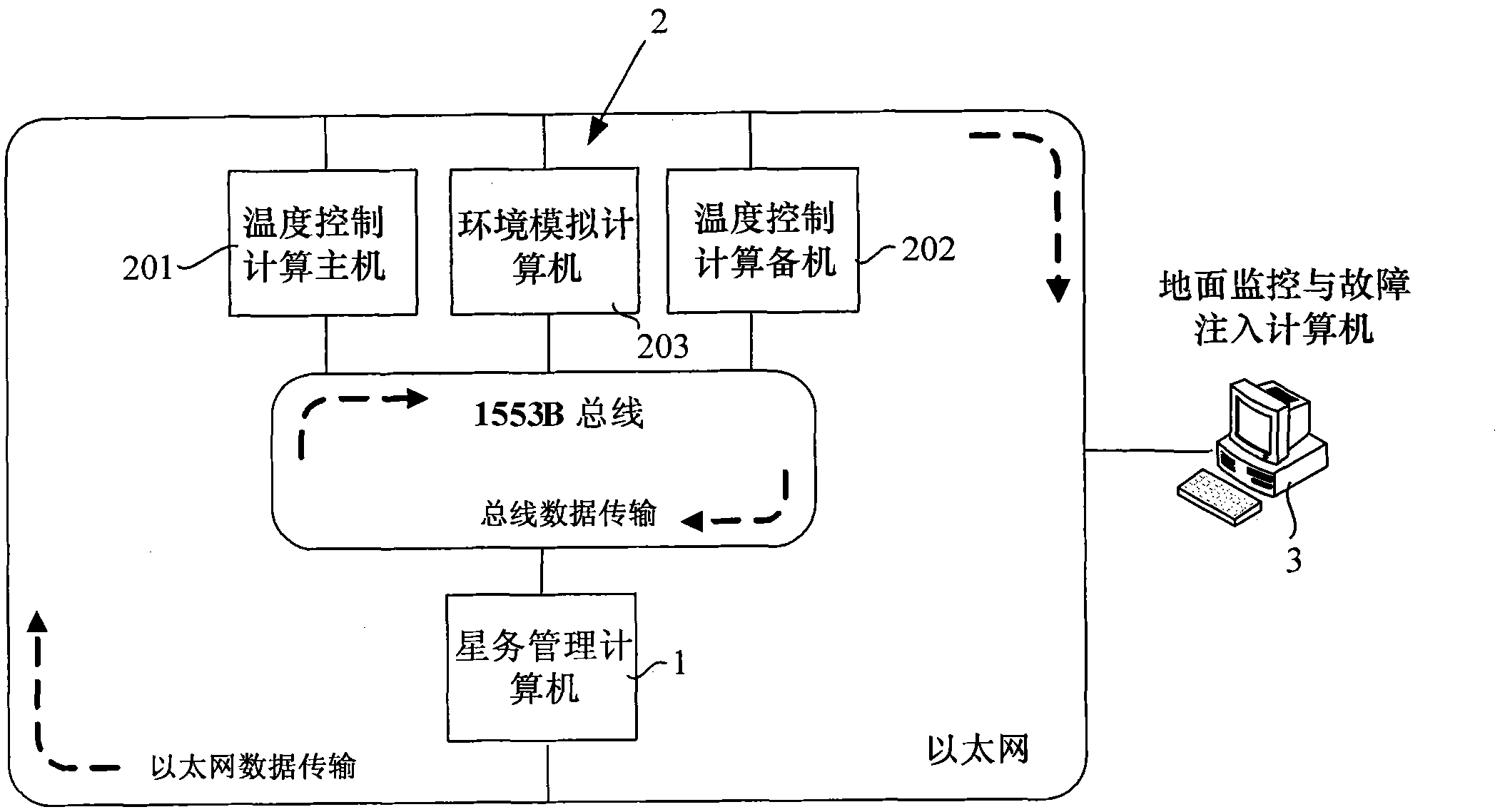

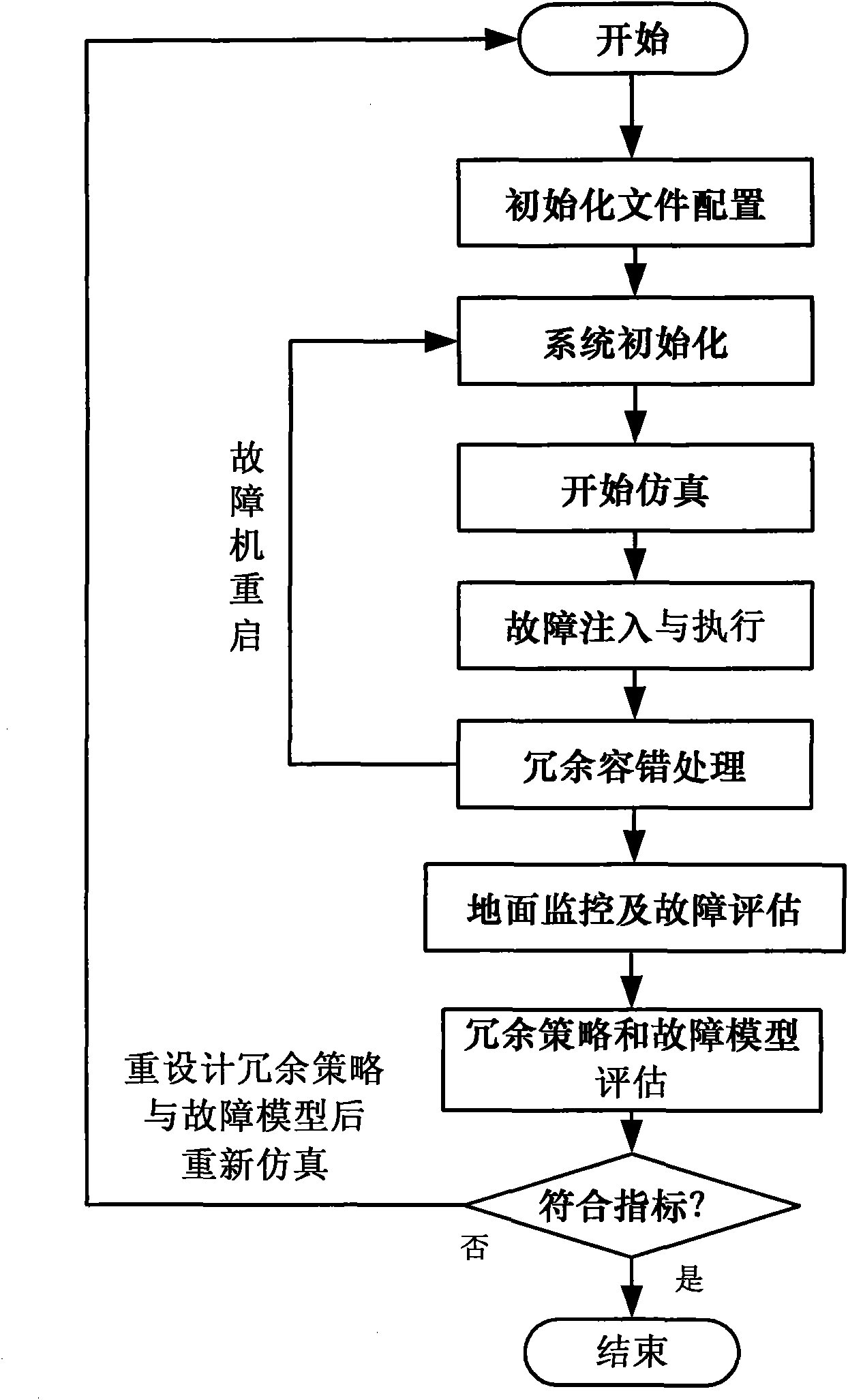

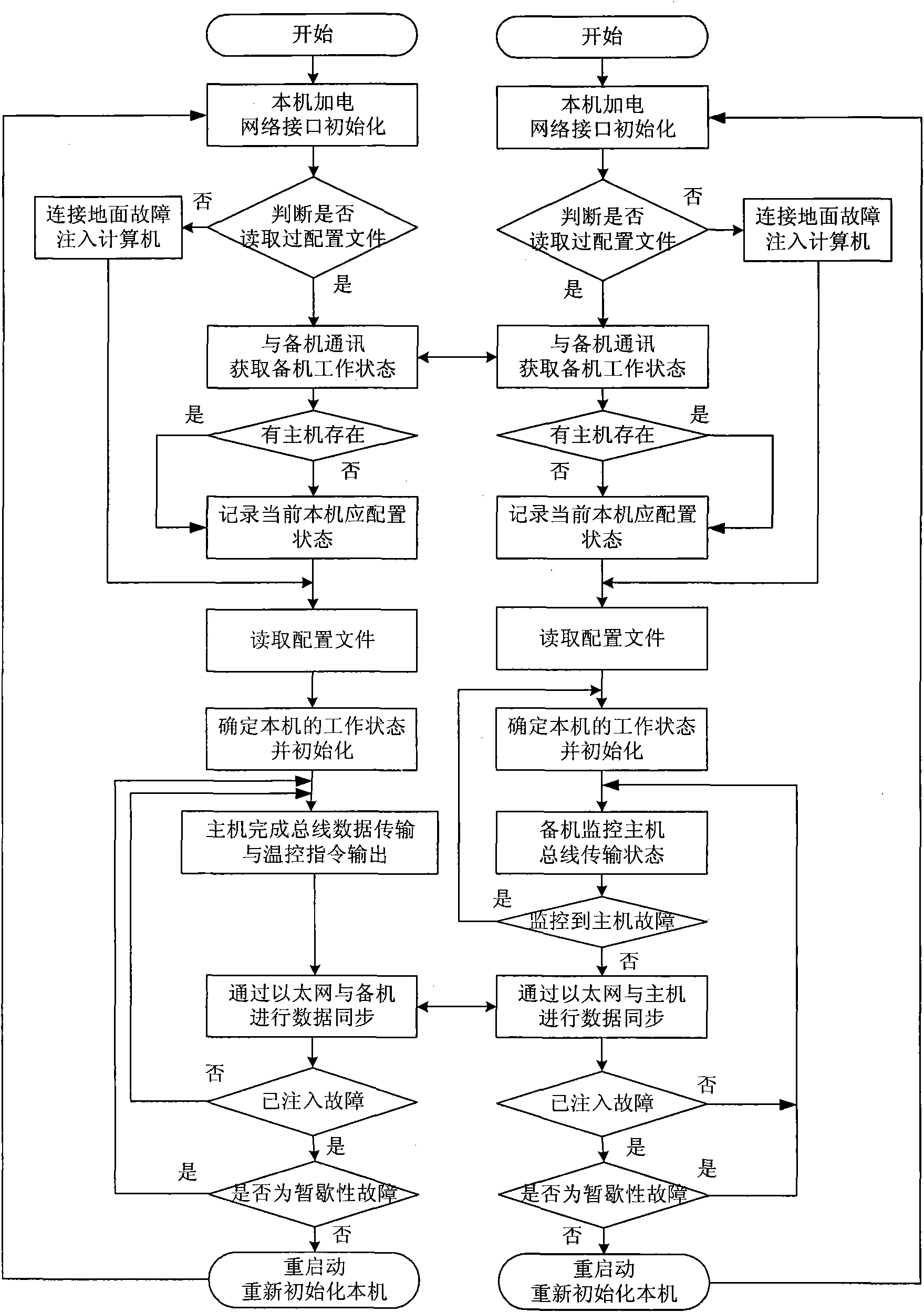

Embedded satellite-borne fault-tolerant temperature control system and verification method thereof

InactiveCN101819445AIn line with the development trendWith real development prospectsTemperatue controlError detection/correctionFault toleranceTemperature control

The invention discloses an embedded satellite-borne fault-tolerant temperature control system and a verification method thereof. The system comprises a satellite management computer, an on-satellite temperature control system and a ground monitoring and fault injection computer; the on-satellite temperature control system comprises a temperature control calculation host machine, a temperature control calculation standby machine and an environmental simulation computer; and the temperature control calculation host machine and the temperature control calculation standby machine are temperature control computers. The verification method comprises the following steps of: 1, initializing a file allocation; 2, initializing the system; 3, beginning simulation; 4, injecting and executing a fault; 5, processing redundant fault tolerance; 6, monitoring the ground and evaluating the fault; and 7, evaluating a fault model and a redundancy strategy of the temperature control system. The fault injection and the verification process of the whole running stage of the real satellite-borne temperature control system are completely realized; and the method is simple, convenient and reliable, and greatly reduces the test time and expense for the practical system.

Owner:BEIHANG UNIV

Vacuum high/low temperature environmental simulation electromechanical transmission mechanism comprehensive performance experimental system

InactiveCN101886978AReduce volumeLow costMachine gearing/transmission testingStands/trestlesTorque motorOptical table

The invention discloses a vacuum high / low temperature environmental simulation electromechanical transmission mechanism comprehensive performance experimental system, which comprises an experimental platform, a driving assembly, a vacuum high / low temperature experimental assembly, a normal temperature and normal pressure experimental assembly and a loading assembly. The driving assembly comprises a servo motor, an input end torque and speed sensor and an input end angle encoder; the vacuum high / low temperature experimental assembly comprises vacuum high / low temperature environmental simulation equipment, an optical platform, and input and output end magnetic fluid sealing shafts; and the loading assembly comprises an output end angle encoder, an output end torque and speed sensor and a torque motor. The vacuum high / low temperature environmental simulation equipment has low cost, the installation of the driving assembly and the loading assembly is performed outside a vacuum tank, and the installation and debugging are convenient. Due to the adoption of a modular design, the experimental system can test the comprehensive performance of a speed reducer and other rotating mechanisms under the conditions of space environment and normal temperature and normal pressure environment on the same experimental system, and has the advantages of strong adaptability of the equipment and high detection accuracy.

Owner:SICHUAN UNIV +1

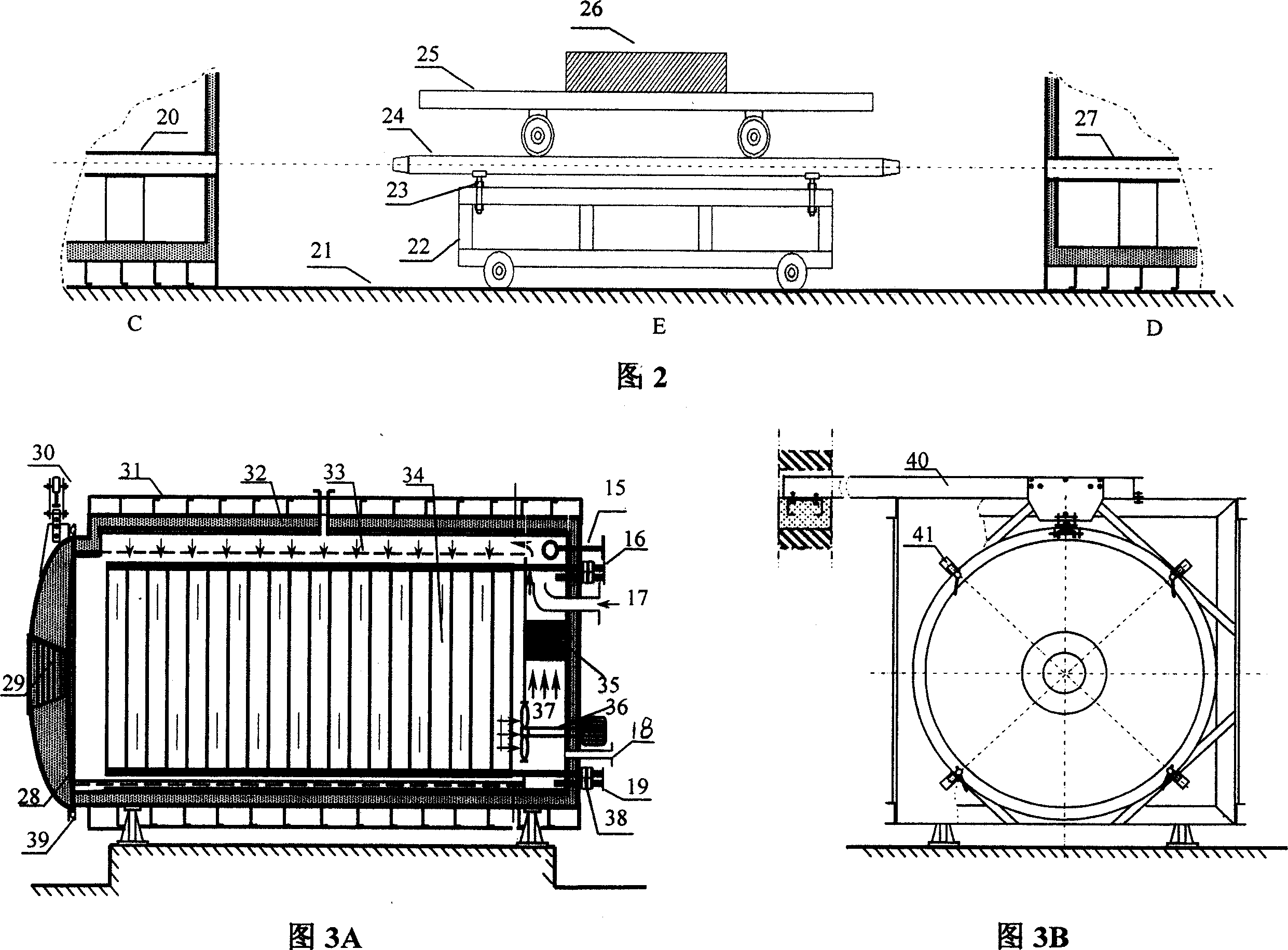

Test apparatus of large-scaled environment simulation

This invention relates to one large integral environment analogue experiment device, which comprises high temperature cabinet, air cooling system, vacuum system, rapid conversion track set and remote test and control system, wherein, the cabinet and temperature cabinet adopts gate to gate parallel distribution; the two cabinet sets rapid conversion track in charge for test parts rapid conversion; the air cooling system and vacuum system is in charge for temperature cabinet cool volume and to lower inside pressure; the temperature cabinet is in constant box structure composed of cooling board recycling system for analogue.

Owner:BEIHANG UNIV

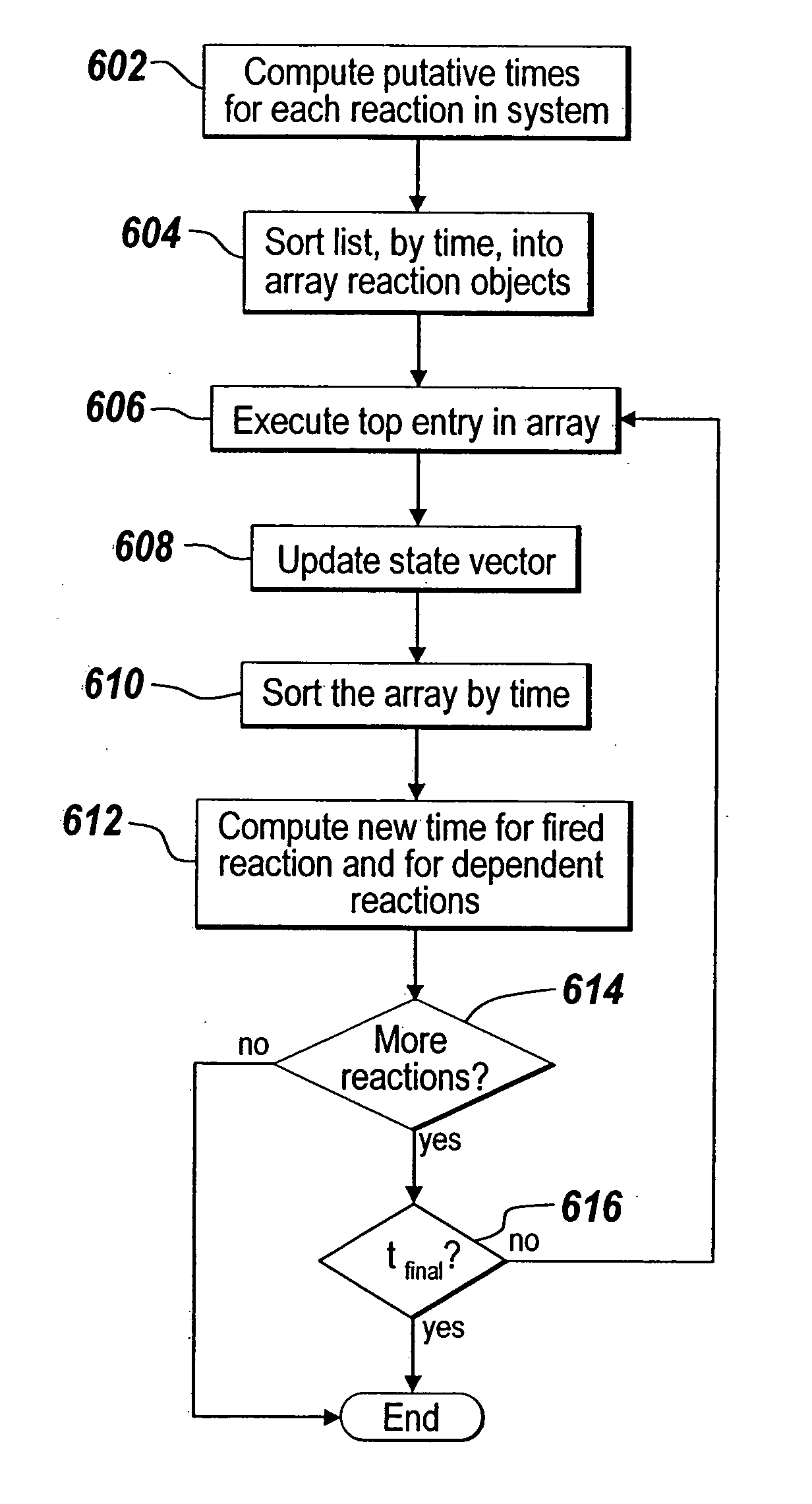

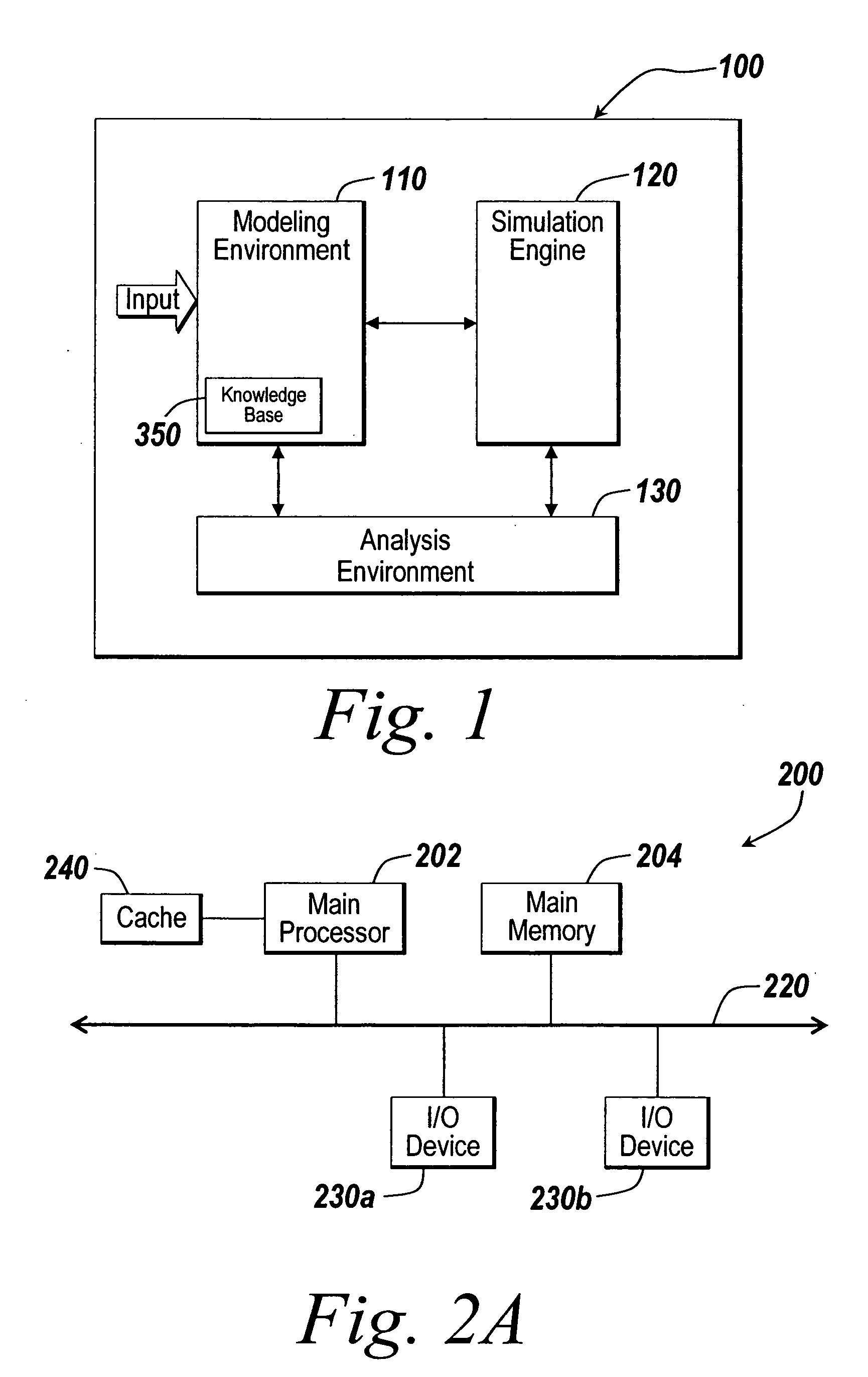

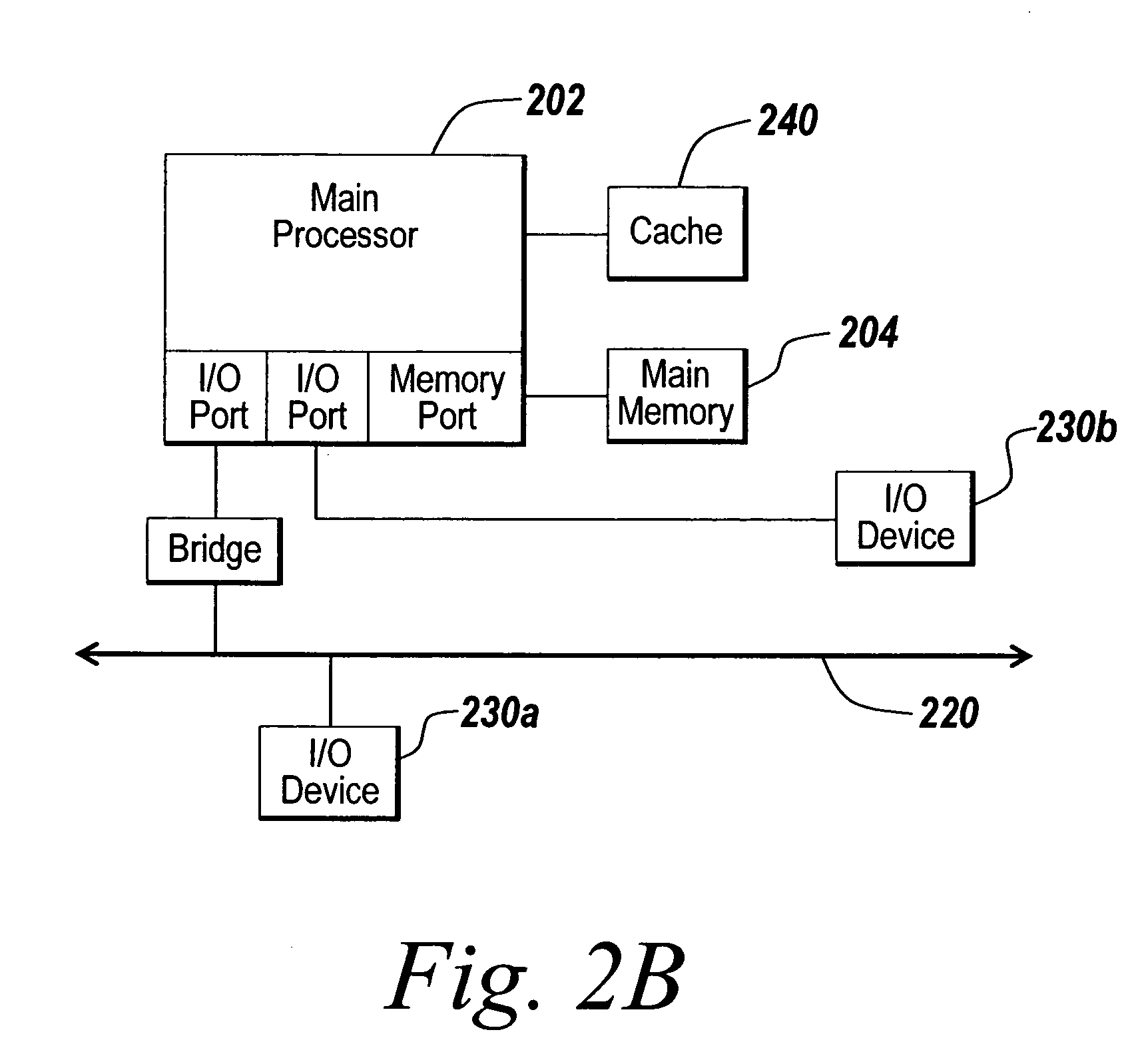

Method and apparatus facilitating communication with a simulation environment

ActiveUS20050187745A1Easy constructionAnalogue computers for chemical processesChemical processes analysis/designChemical reactionBiochemical Process

A system for modifying a model of a chemical reaction or biochemical process responsive to experimental results generated by an in situ experiment conducted on an experimental platform includes a simulation engine and an analysis environment. The simulation engine generates an expected result from a model of the chemical reaction or biochemical process. The analysis environment communicates with the simulation engine, gathers data from an experimental platform, and compares the expected result to data gathered from the platform.

Owner:THE MATHWORKS INC

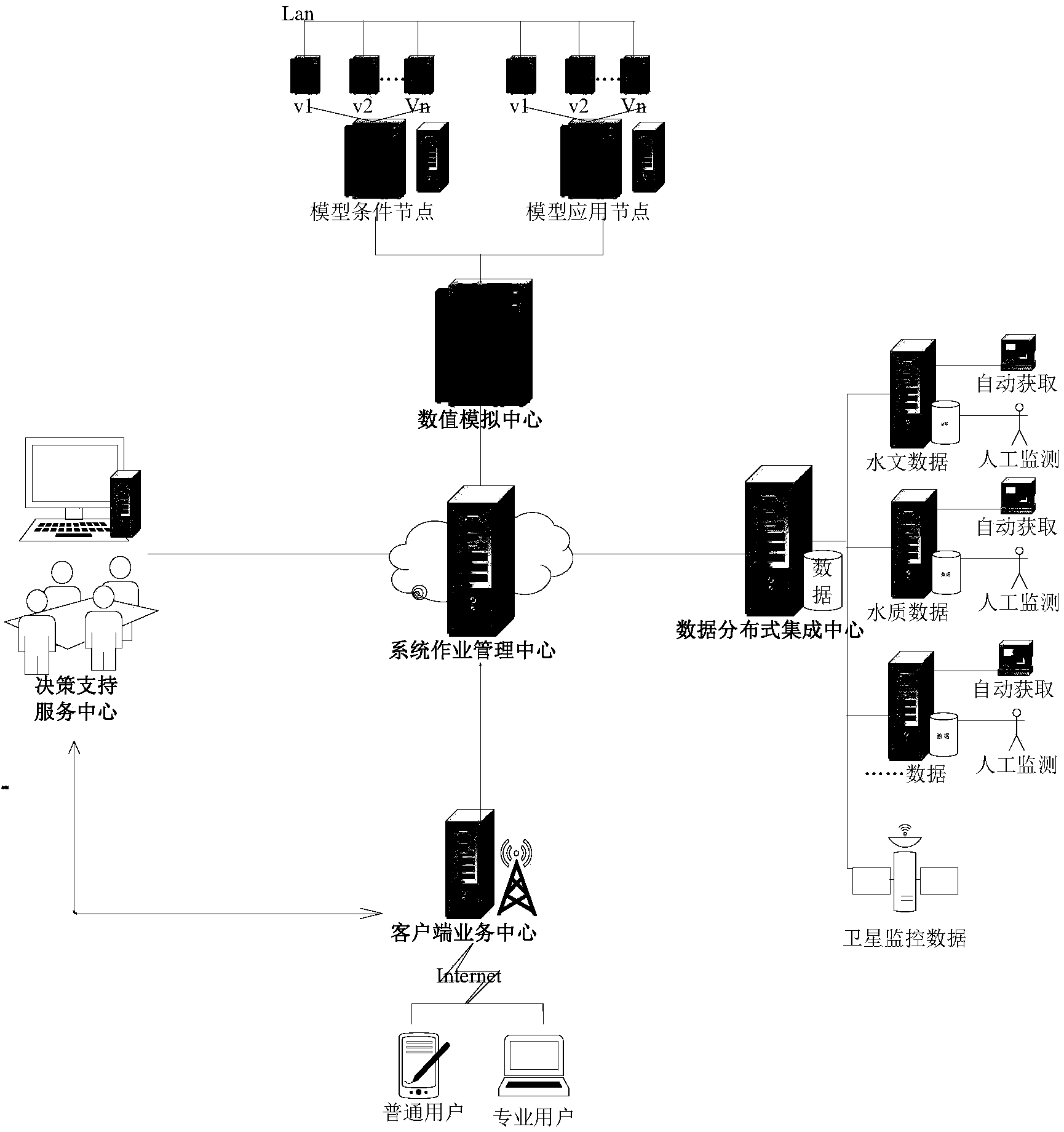

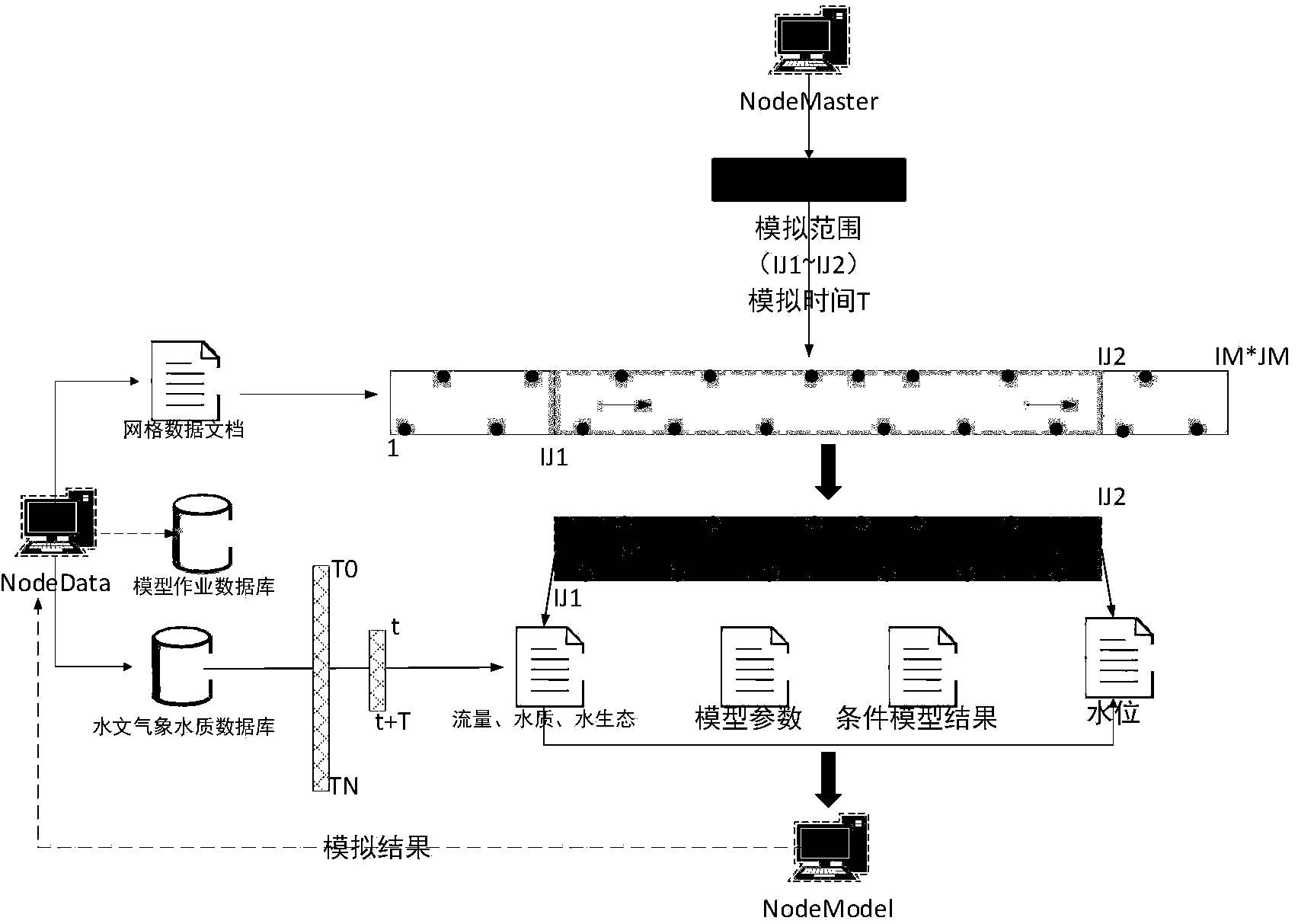

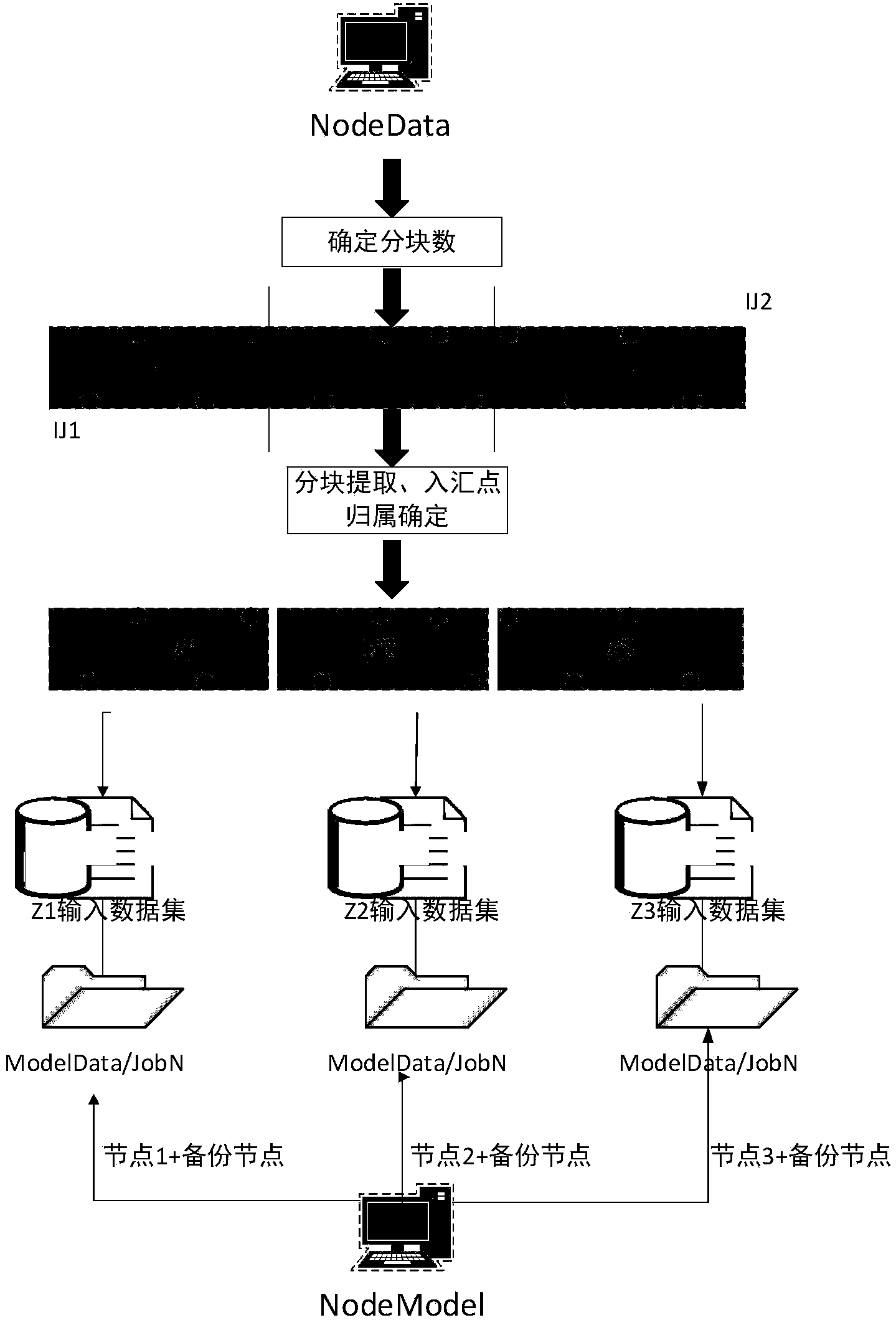

Multi-center watershed water environment distributed cluster management system and method

ActiveCN104268695AEfficient managementEnsure safetyResourcesSpecial data processing applicationsResource poolComputer resources

The invention discloses a multi-center watershed water environment distributed cluster management system and method. The system creates a system operation management center, a numerical simulation center, a data center, a decision command center and a client-side service center, all of which are of different management levels and function levels. By means of division and cooperation of the different centers, computer resources of centers of units of the watershed water environment can be integrated, a resource pool is formed, services are provided according to demands of functions of the centers of the units of the watershed, the problems, such as waiting time losses, the low watershed scale simulation computing speed, low efficiency and resource waste for repeated construction, of a traditional watershed model system due to serial computation can be solved, the watershed water environment simulation efficiency is greatly improved, hardware resources and data resources of the whole watershed are integrated, water environment management, current situation evaluation, future trend prediction and sudden event emergence simulation and decision support of the whole watershed are achieved, and safety of the watershed water environment is guaranteed.

Owner:珞珈浩景数字科技(湖北)有限公司

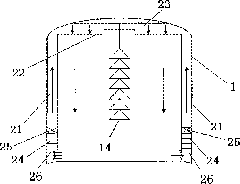

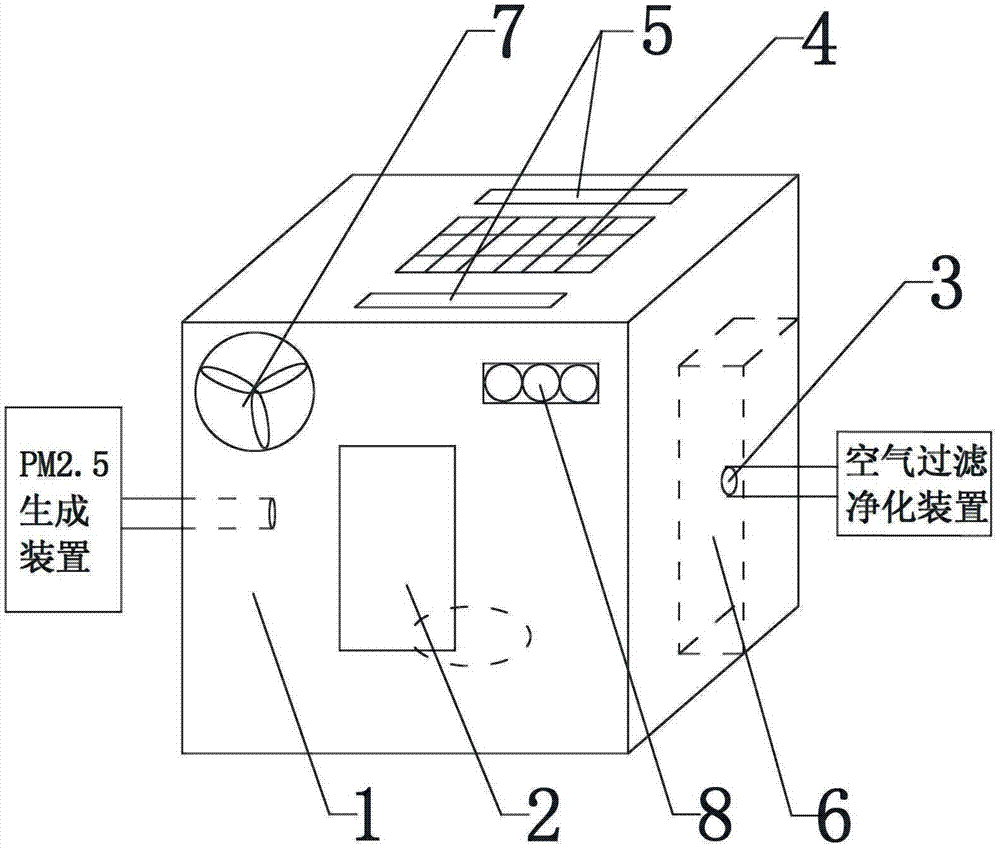

Environmental simulation test box for quantitatively analyzing PM2.5 (fine particulate matter) absorbing capability of plants

ActiveCN103207268AInsulate the influenceAccurate measurementIndividual particle analysisFine particulateEngineering

The invention relates to the field of air quality monitoring, in particular to an environmental simulation test box for quantitatively analyzing PM2.5 (fine particulate matter) absorbing capability of plants. The environmental simulation test box comprises a closable box body, a PM2.5 generator, a PM2.5 measuring device, a constant-temperature constant-humidity device, a lighting simulating device, a raining simulating device and a wind simulating device, wherein the PM2.5 generator and the PM2.5 measuring device are communicated with the box body, and the constant-temperature constant-humidity device, the lighting simulating device, the raining simulating device and the wind simulating device are disposed in the box body. By the structure, influences of natural environments can be isolated, environmental parameters can be simulated quantitatively, and accordingly PM2.5 absorbing capability of plants can be measured accurately, and scientific and effective basis is provided for quantifying PM2.5 absorbing capability of various plants and forest planting selection.

Owner:BEIJING FORESTRY UNIVERSITY

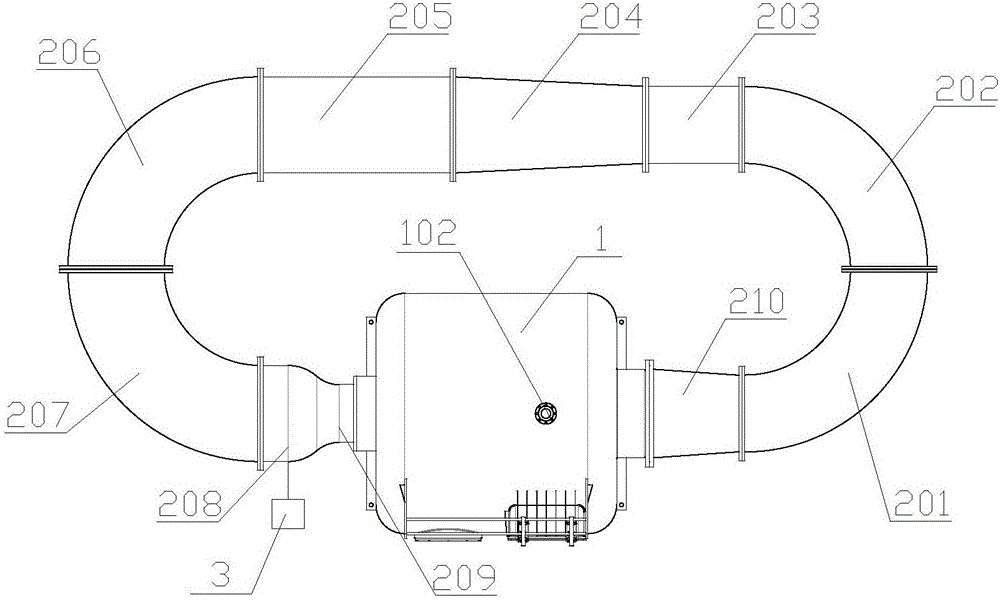

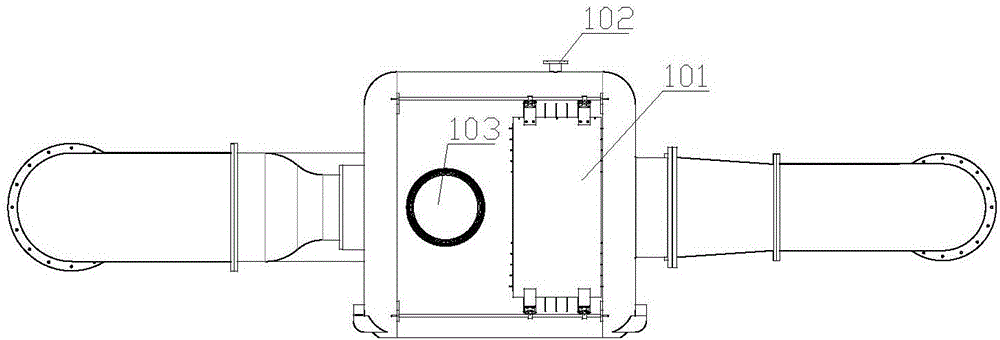

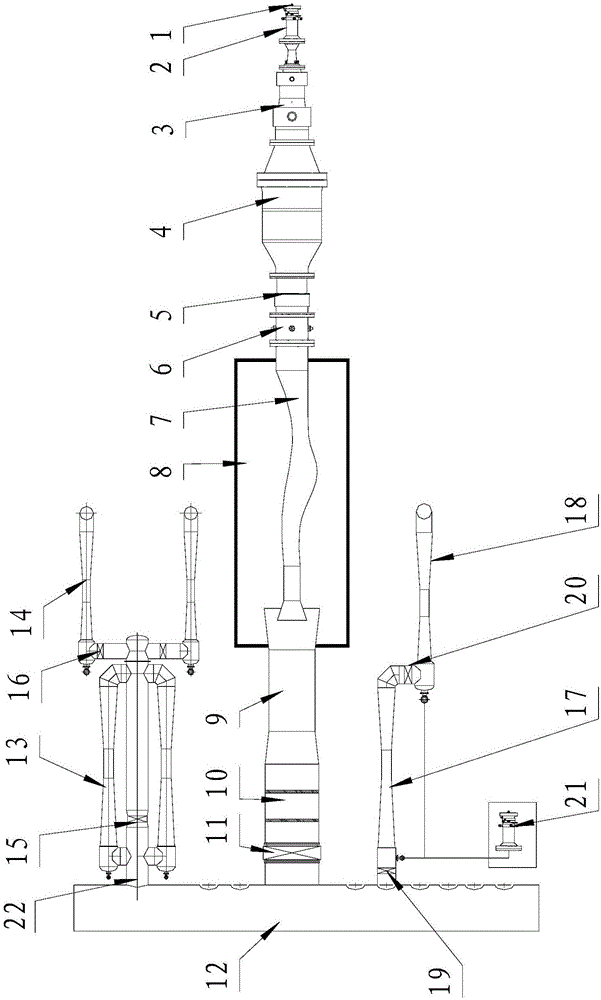

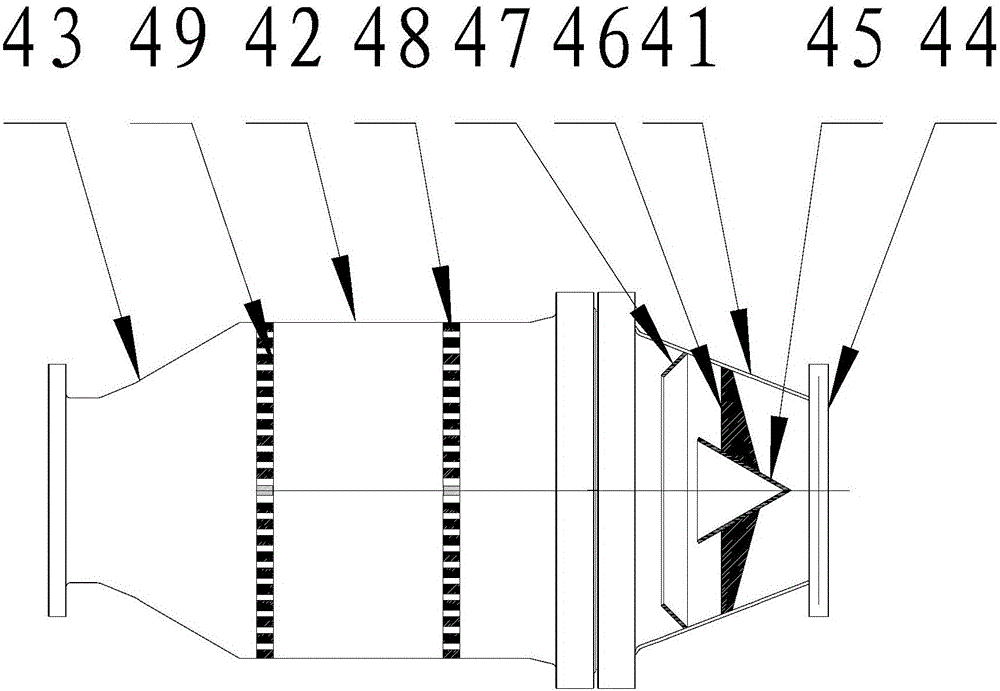

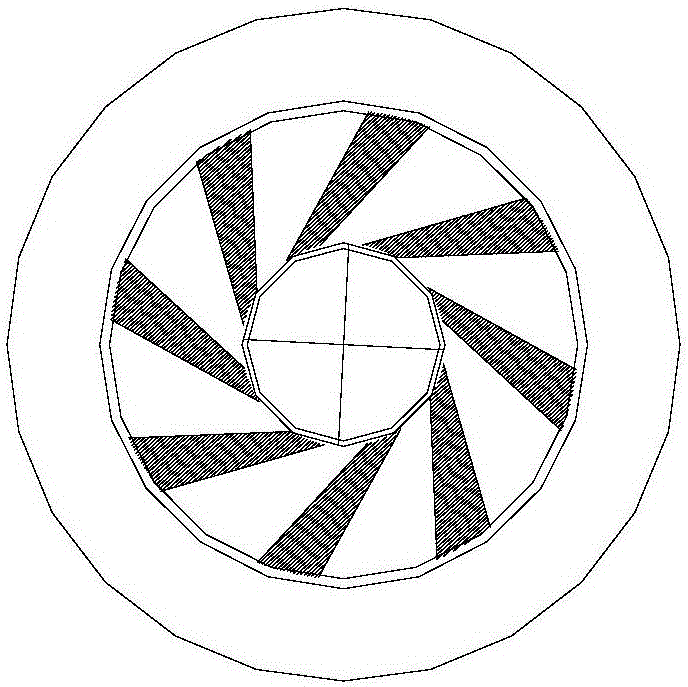

Wind tunnel

ActiveCN104280204AHighly comprehensiveHigh aerodynamic flow field qualityAerodynamic testingScale modelAviation

The invention relates to hydromechanical device, in particular to a wind tunnel used for comprehensive climatic environment tests and aerodynamic tests of railway vehicles. The wind tunnel comprises a tunnel body. The tunnel body is an annular flow channel. A ventilation system used for generating air flow is arranged in the tunnel body. The tunnel body is further provided with an environmental simulation system and an aerodynamic simulation system. The environmental simulation system is used for controlling the weather conditions in the tunnel body. The aerodynamic simulation system is used for enabling the air flow to form a pneumatic flow field. By the adoption of the wind tunnel, the climatic environment tests of the whole real railway vehicle can be carried out, and the aerodynamic tests of a scale model of the railway vehicle can also be carried out. On the basis that the demands for the railway vehicle tests can be met, the wind tunnel can also be used for the related environment tests and the related aerodynamic tests in the fields such as the aerospace field, the automobile field and the construction field.

Owner:CRRC QINGDAO SIFANG CO LTD

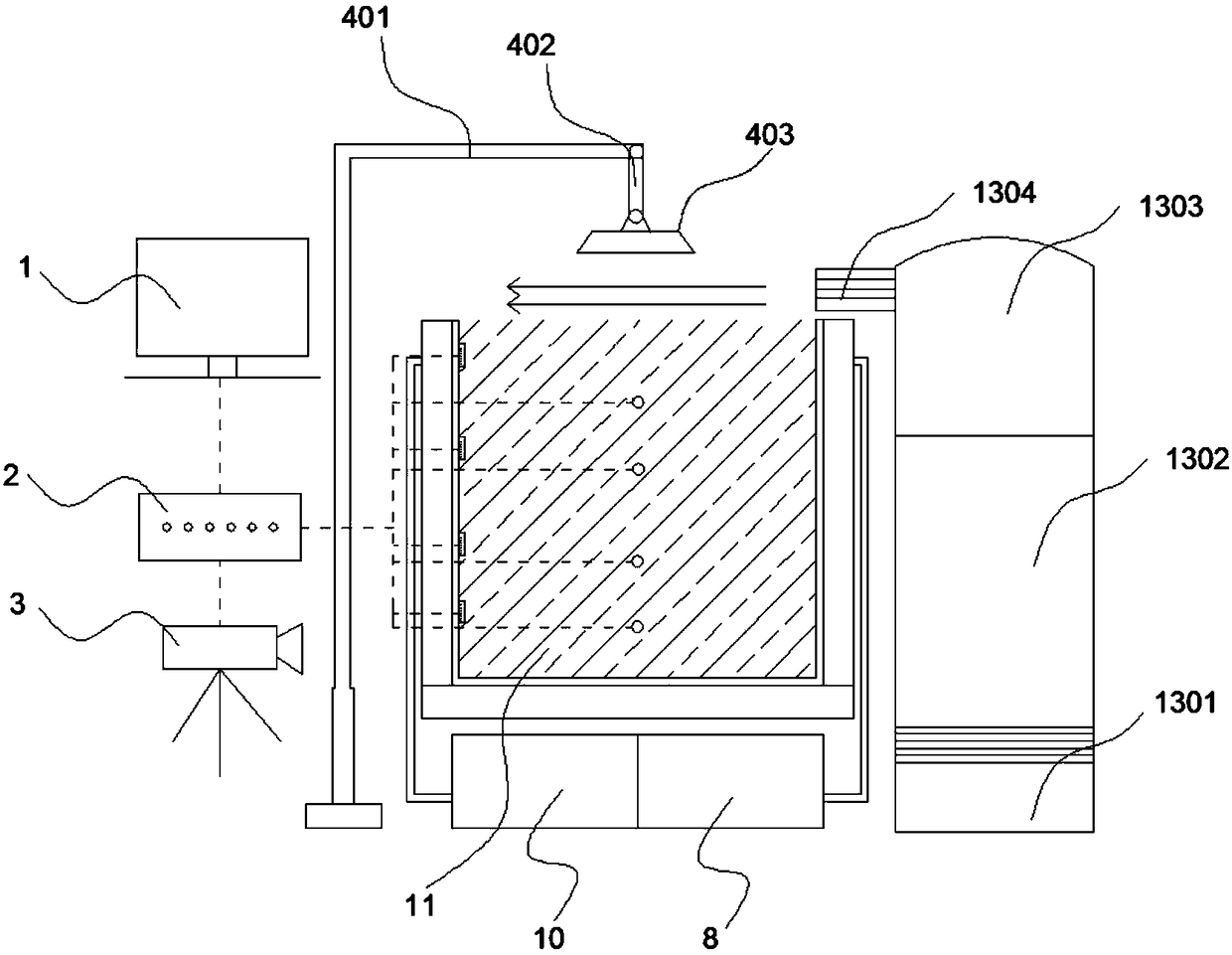

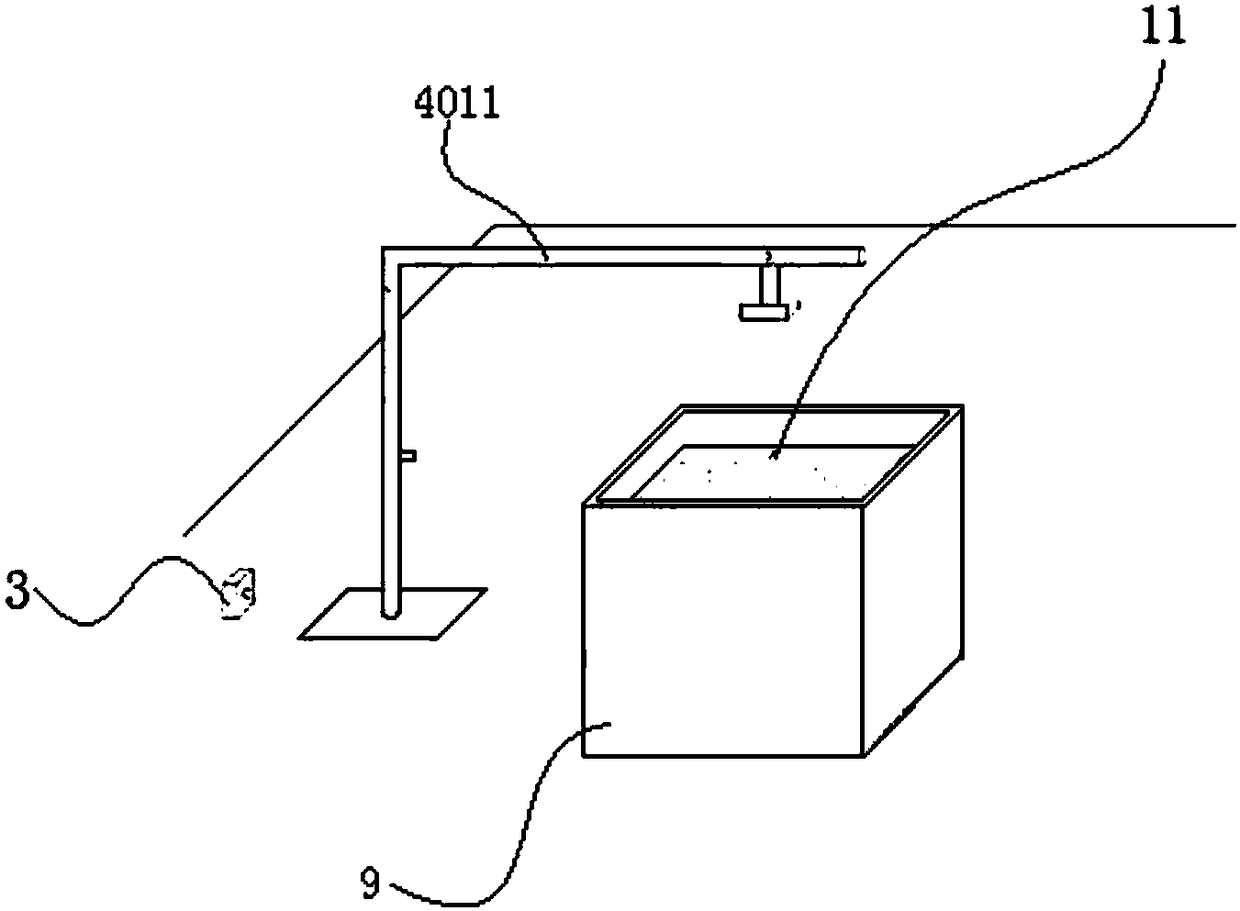

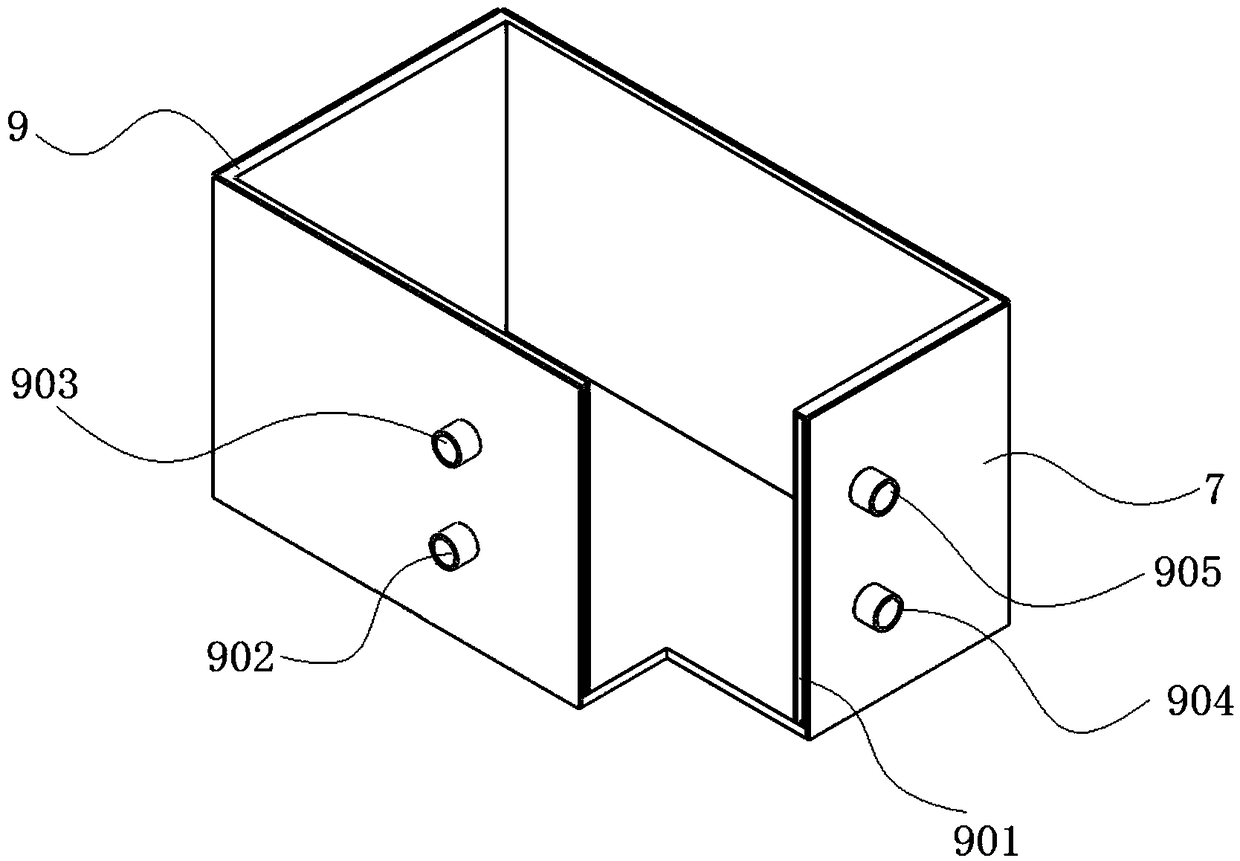

Simulation device for karst collapses

ActiveCN103645297ASolve the inability to different types of collapseSolve the problem of simulating karst collapse under different working conditionsEarth material testingWater dischargeMonitoring system

The invention discloses a simulation device for karst collapses. The device comprises a karst collapse environmental simulation device, a hydrodynamic condition simulating device and a monitoring system, wherein the karst collapse environmental simulation device comprises a box body and a karst simulation device; an opening is formed in the top of the box body; the karst simulation device is arranged at the bottom of the box body; the hydrodynamic condition simulating device comprises a water supplying device and a water discharging device; the monitoring system is distributed in the karst simulation device and is used for monitoring a critical state of the karst collapses. The simulation device for the karst collapses can be used for simulating the karst collapses under different collapse types and different working conditions.

Owner:CHINA SHENHUA ENERGY CO LTD +1

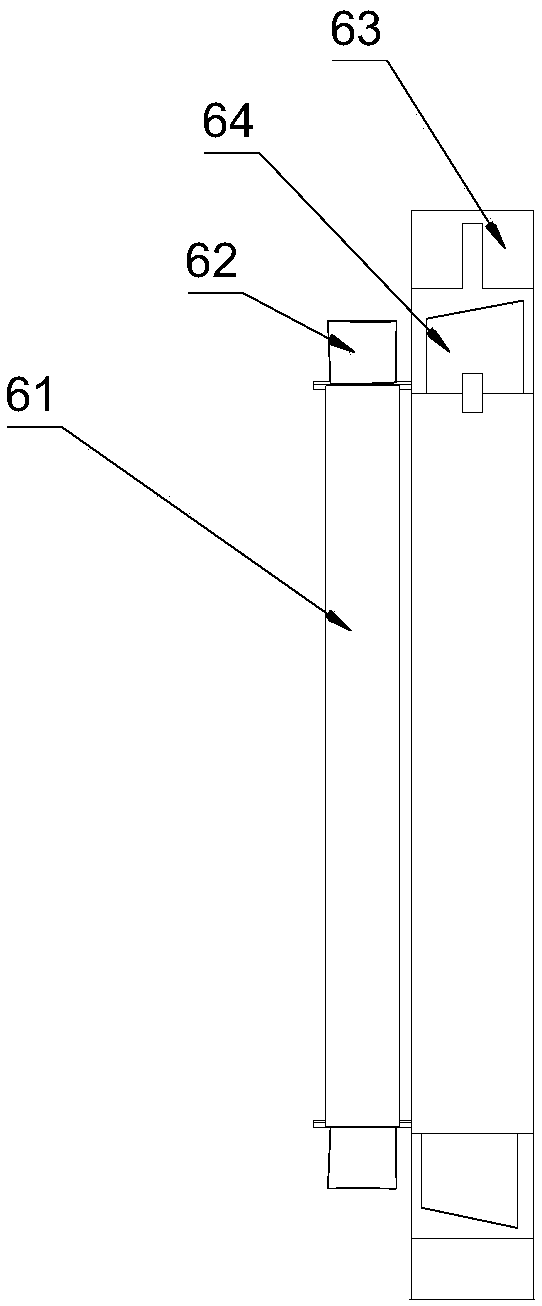

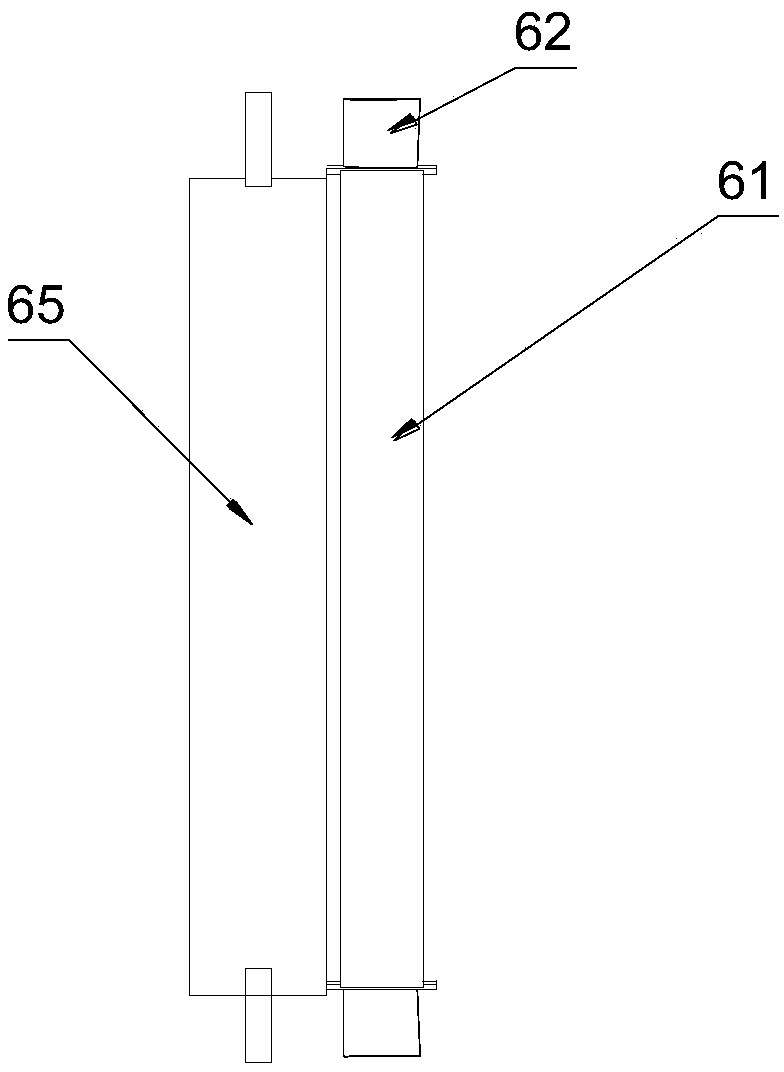

Dust environment simulation equipment

ActiveCN103234573AAccurate structureImprove accuracyParticle suspension analysisElectricityEngineering

The invention discloses dust environment simulation equipment, which comprises a dust generation device, a wind tunnel, a dust collector and a fan. The wind tunnel comprises a wind inlet section, a turbulence section and a testing section. The inner passage of the wind inlet section is horn-shaped. The dust outlet of the dust generation device is formed at the large-aperture end of the wind inlet section. The small-aperture end of the wind inlet section is communicated with the turbulence section. A turbulence structure is arranged on the turbulence section. One end of the testing section is communicated with the turbulence section and the other end of the testing section is communicated with the dust collector. The fan is communicated with the dust collector. An observation window which can be opened and closed is arranged on the testing section. A dust concentration sensor which is used for detecting internal dust concentration is arranged in the testing section and is communicated with an electric control device. The electric control device is electrically connected with the dust generation device. The simulation equipment can simulate a uniform-concentration dust environment, the concentration is adjustable and testing results obtained through product testing by using the simulation equipment are more accurate.

Owner:张家港朗亿机电设备有限公司

Driving simulation control system based on BIM simulation environment

ActiveCN105096688ALong time spanAccurate location information integrationCosmonautic condition simulationsSimulatorsExtreme weatherMultiple sensor

The invention relates to a driving simulation control system based on BIM simulation environment. Traffic safety analysis mainly starts with road alignment design and traffic accident data, and psychological and physiological status change features of a driver and running status data of a vehicle under different road environments cannot be obtained. The system comprises a driving operation module, a driving simulation platform control module, an annular screen fusion display module, a vehicle performance acquisition module and a road characteristic acquisition module, which are all connected to a central processor. The central processor is connected with a BIM simulation environment module. Through the BIM simulation system, different road environments are established accurately, and operating information of the driver is obtained; through control algorithm for a multi-freedom platform carried out by the driving simulation operation module, and an environmental simulation algorithm for simulating various extreme weathers, road feel and vehicle feel can be simulated completely, and real-time acquisition and operation can be carried out on the driver and the vehicle condition; and data of multiple sensors can be collected, transported, processed, displayed and stored through modular design.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

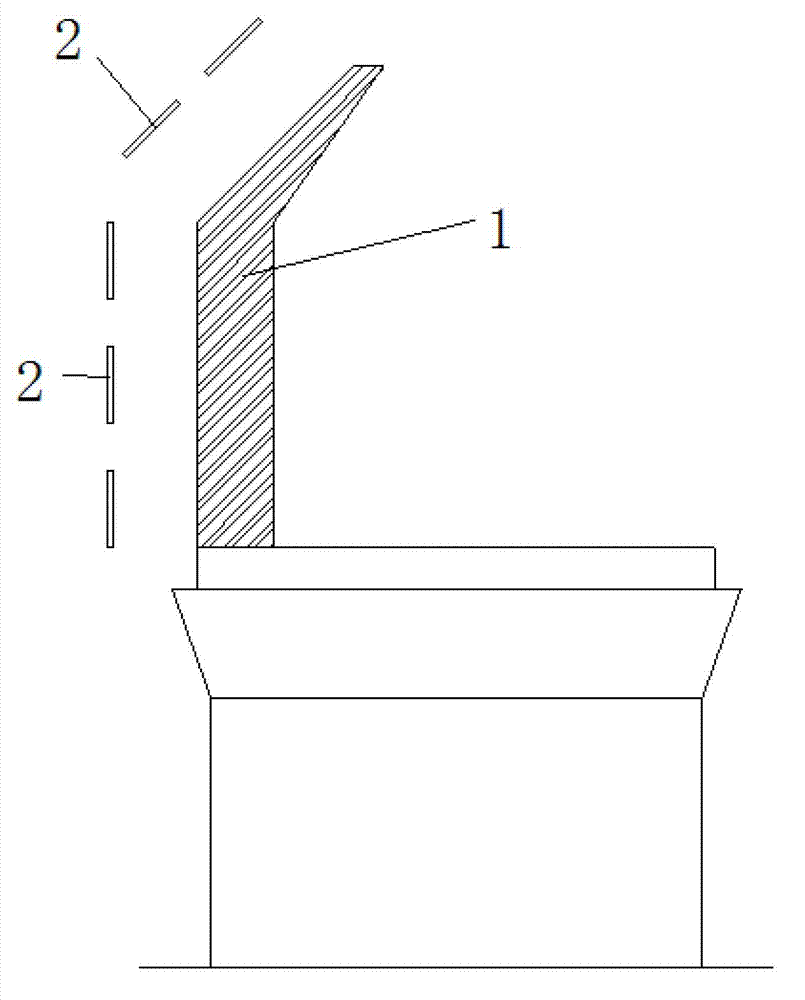

Freeze-thawing and weathering environment simulation system for compacted soil and test method of freeze-thawing and weathering environment simulation system

InactiveCN108614089AFully automatedControllable action timeEarth material testingFreeze thawingData acquisition

The invention provides a freeze-thawing and weathering environment simulation system for compacted soil and a test method of the freeze-thawing and weathering environment simulation system. The devicecomprises an LED fluorescent lamp, liquid nitrogen refrigerating circulating equipment, a freeze-thawing model box, nitrogen heating circulating equipment and wind making equipment which are placed on an experimental platform, wherein a soil test sample is arranged in an inner cavity of the freeze-thawing model box. During working, a computer controls the refrigerating circulating equipment, thenitrogen heating circulating equipment and the wind making equipment. A dynamic camera monitors a freezing character of the soil test sample. A test method of the device comprises test steps of arranging sensors, compacting the soil test sample, installing monitoring equipment, debugging a data acquisition processor and a freeze-thawing circulating controller and the like. The device can control the acting time of freeze thawing cycle to realize automation of winter frozen soil simulation, can observe and measure a displacement change of soil and can observe mesoscopic characteristics in a test process of the test sample.

Owner:CHONGQING JIAOTONG UNIVERSITY

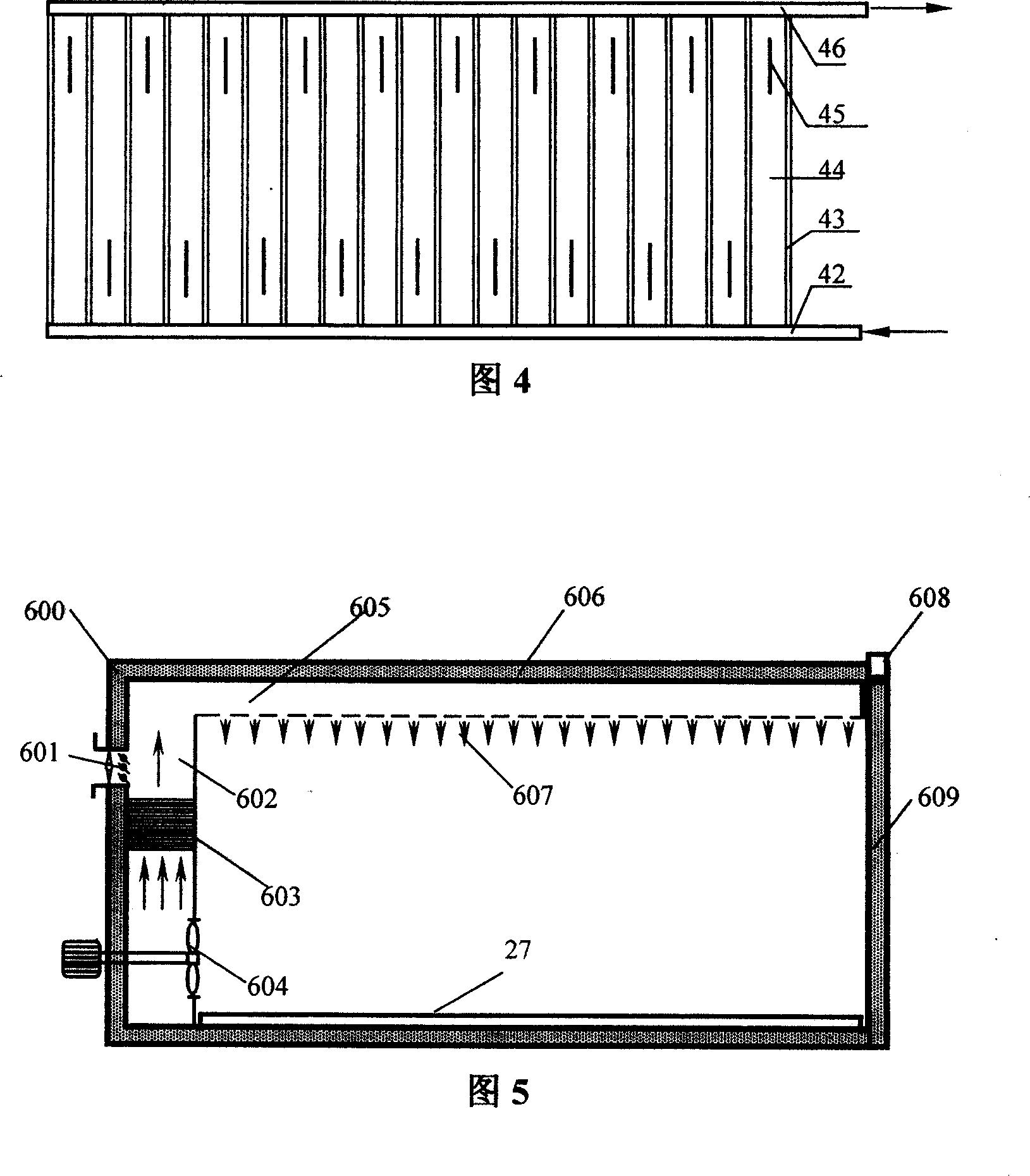

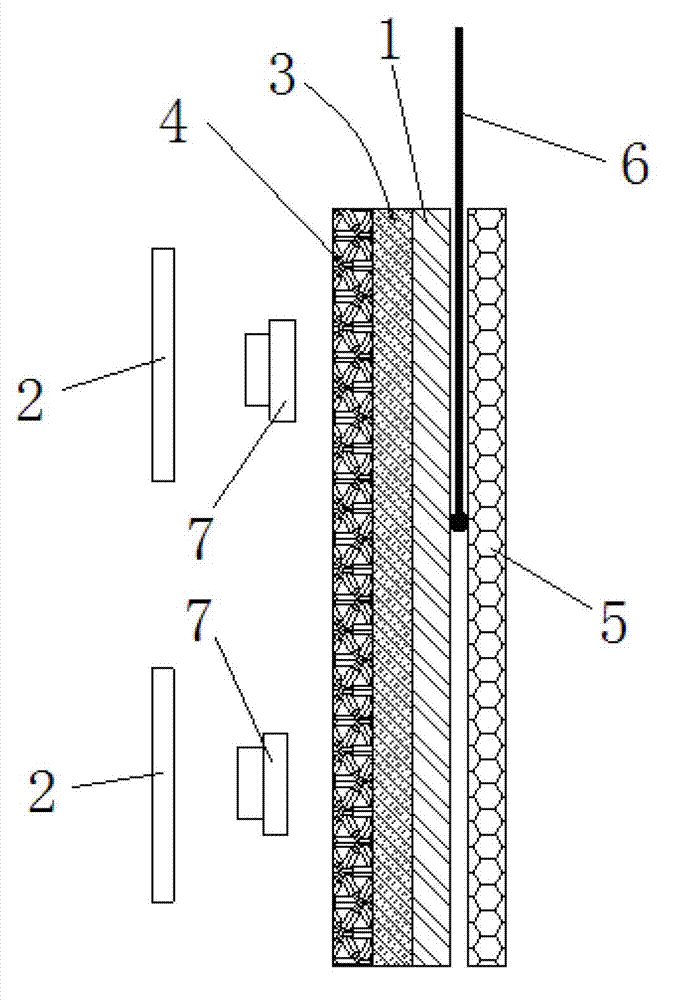

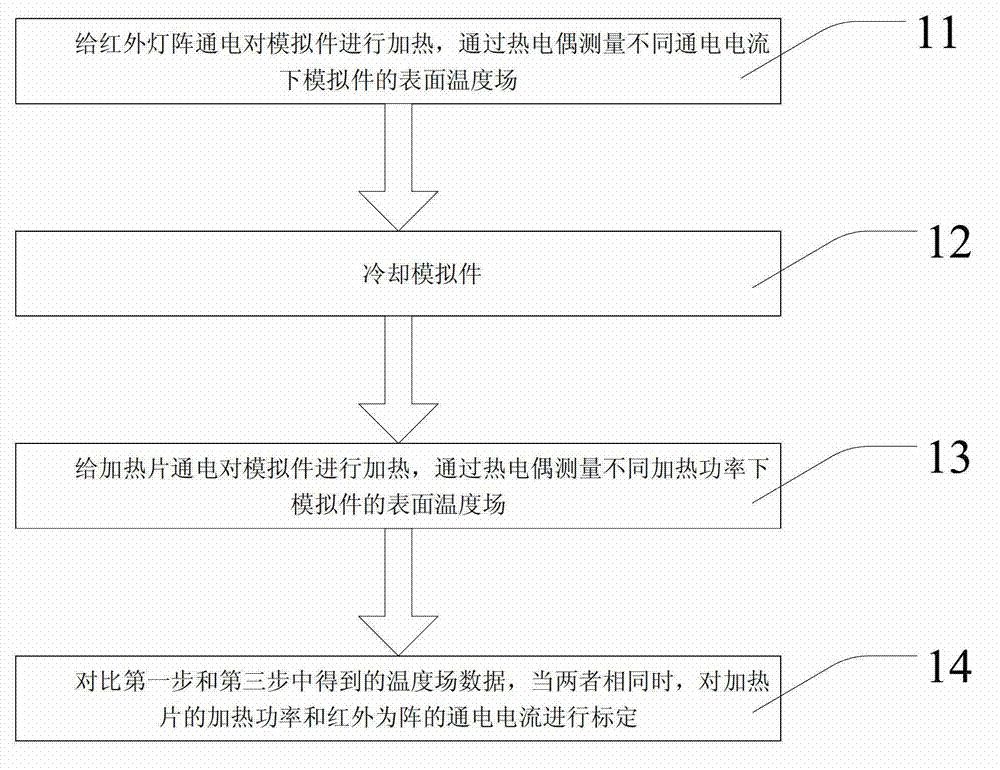

Infrared lamp array heat-flow density calibration device and calibration method

ActiveCN102967623ASolve the problem that the accuracy cannot be assessedImprove reliabilityMaterial heat developmentStructural/machines measurementInfrared lampTwo temperature

The invention relates to the technical field of spacecraft environmental simulation, and discloses an infrared lamp array heat-flow density calibration device. The infrared lamp array heat-flow density calibration device is characterized in that the material and shape of a set simulation piece is in accordance with a product to be calibrated, the outer side of the simulation piece is provided with a heating piece, a thermal control coating is sprayed on the outer side of the heating piece, and a thermal-protective coating is arranged on the inner side of the simulation piece; and a thermocouple is arranged between the simulation piece and the thermal-protective coating, and an infrared lamp array is arranged near the outer side of the simulation piece. The invention also discloses an infrared lamp array heat-flow density calibration method, wherein the simulation piece is respectively heated by energizing the infrared lamp array and by utilizing the heating piece, and the temperature fields in the two heating methods are compared; when the two temperature fields are the same, the heating power of the heating piece and the energizing current of the infrared lamp array are calibrated. The infrared lamp array heat-flow density calibration device provided by the invention solves the problem that the precision cannot be tested when the external heat flow is simulated by the infrared lamp array in a complicated surface spacecraft vacuum thermal test, thereby improving the stability of the test results; and through the calibration of the lamp array, the consumption of the heat flow sensor is lowered, and the test cost is lowered.

Owner:SHANGHAI INST OF SATELLITE EQUIP

Simulation tester for self healing of asphalt concrete cracks

A simulation tester for self healing of asphalt concrete cracks comprises a main frame, a test control and data collection system, an environment simulation box, a rigidity water tank, a test piece, a test piece limit clamp, a wheel load simulation device, a test piece healing force application device, a loading frame horizontal reciprocating moving mechanism, a temperature environment control device and a water circulation system simulating humidity environment. The main frame is provided with the environment simulation box which is at least composed of an inner rigidity layer, an outer rigidity layer and a middle heat insulation layer. The rigidity water tank is installed on the bottom wall in the middle in the environment simulation box, the test piece and the test piece limit clamp are installed in the rigidity water tank, the wheel load simulation device is arranged vertically above one side of the test piece and contains test wheels in rolling fit with the corresponding test piece, a test piece healing force application and test device is arranged horizontally on the other side of the test piece, the wheel load simulation device contains a loading frame which is provided with the loading frame horizontal reciprocating moving mechanism, and the water circulation system simulating humidity environment is arranged under the rigidity water tank. The simulation tester is high in automation degree, accurate in control, capable of simulating and researching self healing actions of the asphalt concrete cracks under various work conditions, convenient to operate, safe and reliable.

Owner:ZHENGZHOU UNIV +1

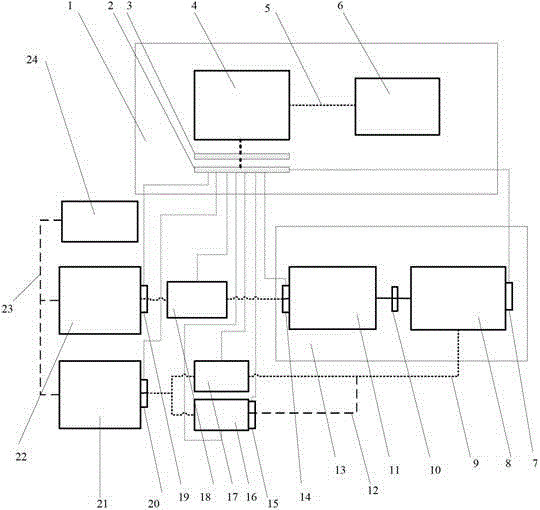

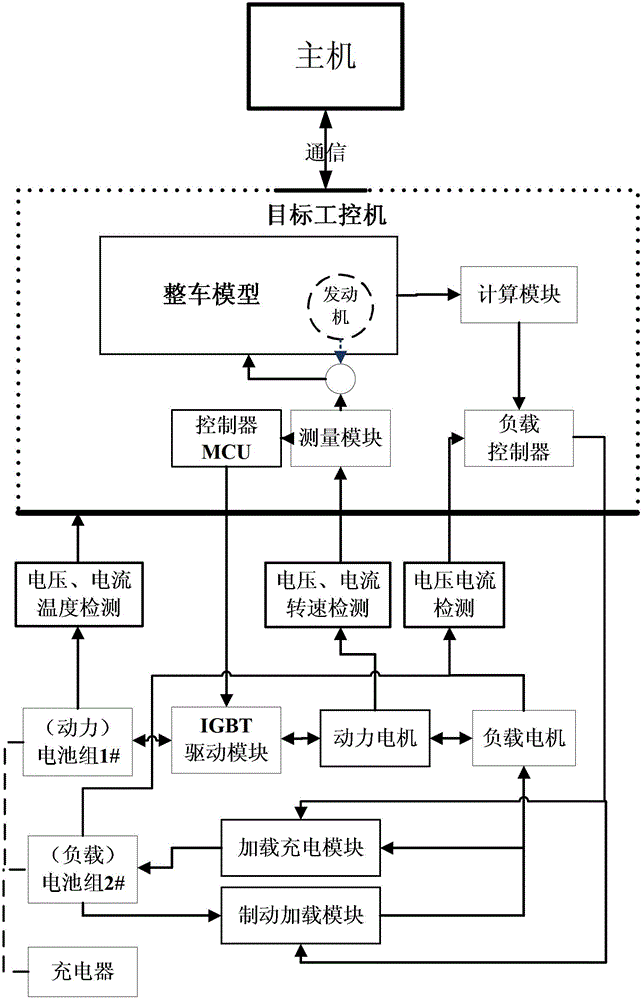

Hybrid power/electric vehicle drive motor system hardware-in-loop algorithm verification test bed

InactiveCN102749583ALow costReduce investmentElectric testing/monitoringDynamo-electric machine testingElectrical batteryEnergy recovery

The invention relates to a hybrid power / electric vehicle power motor / battery hardware-in-loop test bed, in particular to a motor control and braking energy recovery strategy test system under energy-saving hybrid power / electric vehicle-mounted power motor / battery hardware-in-loop vehicle running whole-environmental simulation. A simulation test bed is constructed by using physical objects such as a power motor, a battery pack, power drivers such as IGBT (Insulated Gate Bipolar Transistor) and the like. Power motor control strategies, braking energy recovery strategies and overall vehicle control effects of various vehicle models under whole environment can be quickly verified by cooperating high-quality simulation environment through parameter setting in the established semi-physical simulation system, and the verifications of vehicle motor control strategies and braking energy recovery strategies are dynamically integrated. When energy is saved, the capital investment to real vehicle tests can be reduced, the development cost is saved, the development period is shortened, and the times and the dangerousness of real vehicle tests are reduced.

Owner:JILIN UNIV

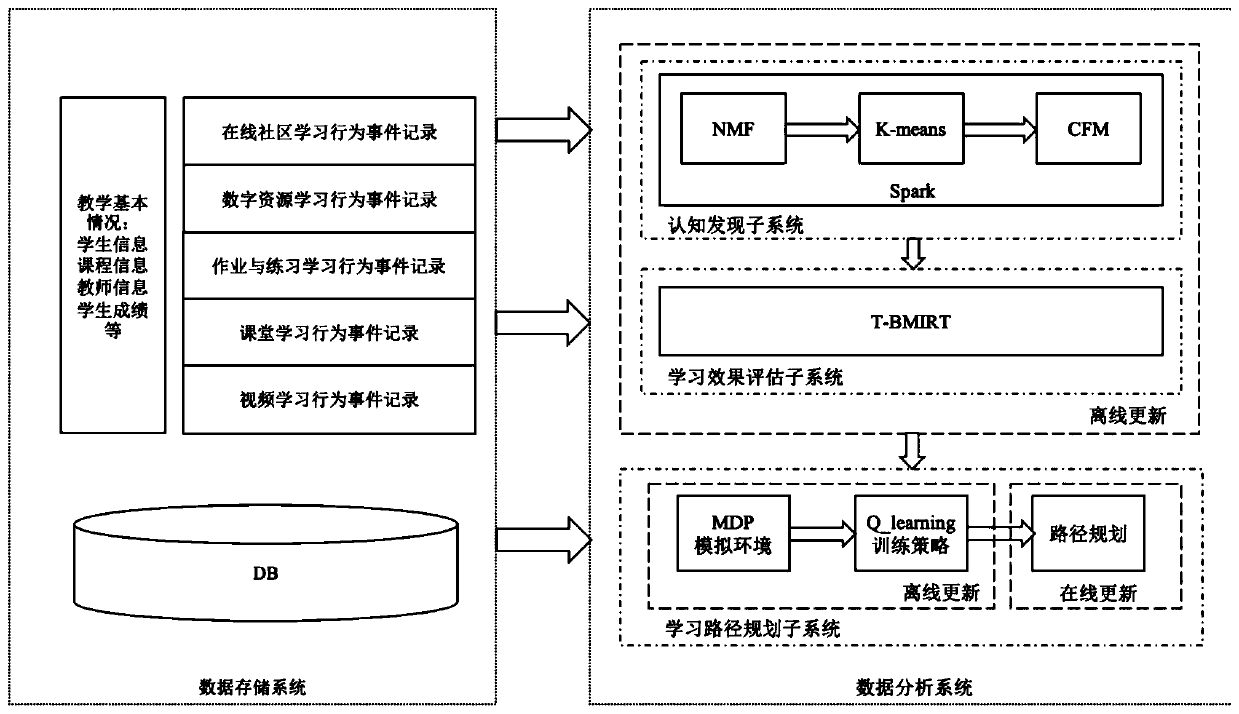

A self-adaptive learning path planning system based on reinforcement learning

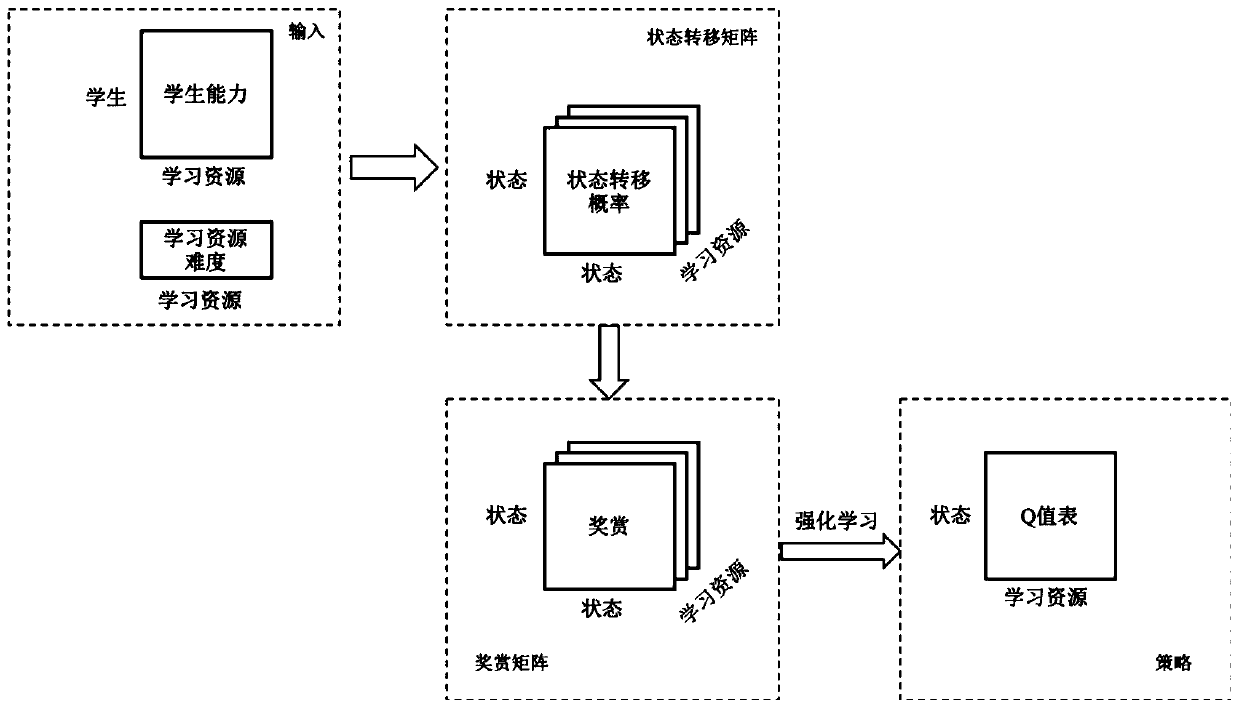

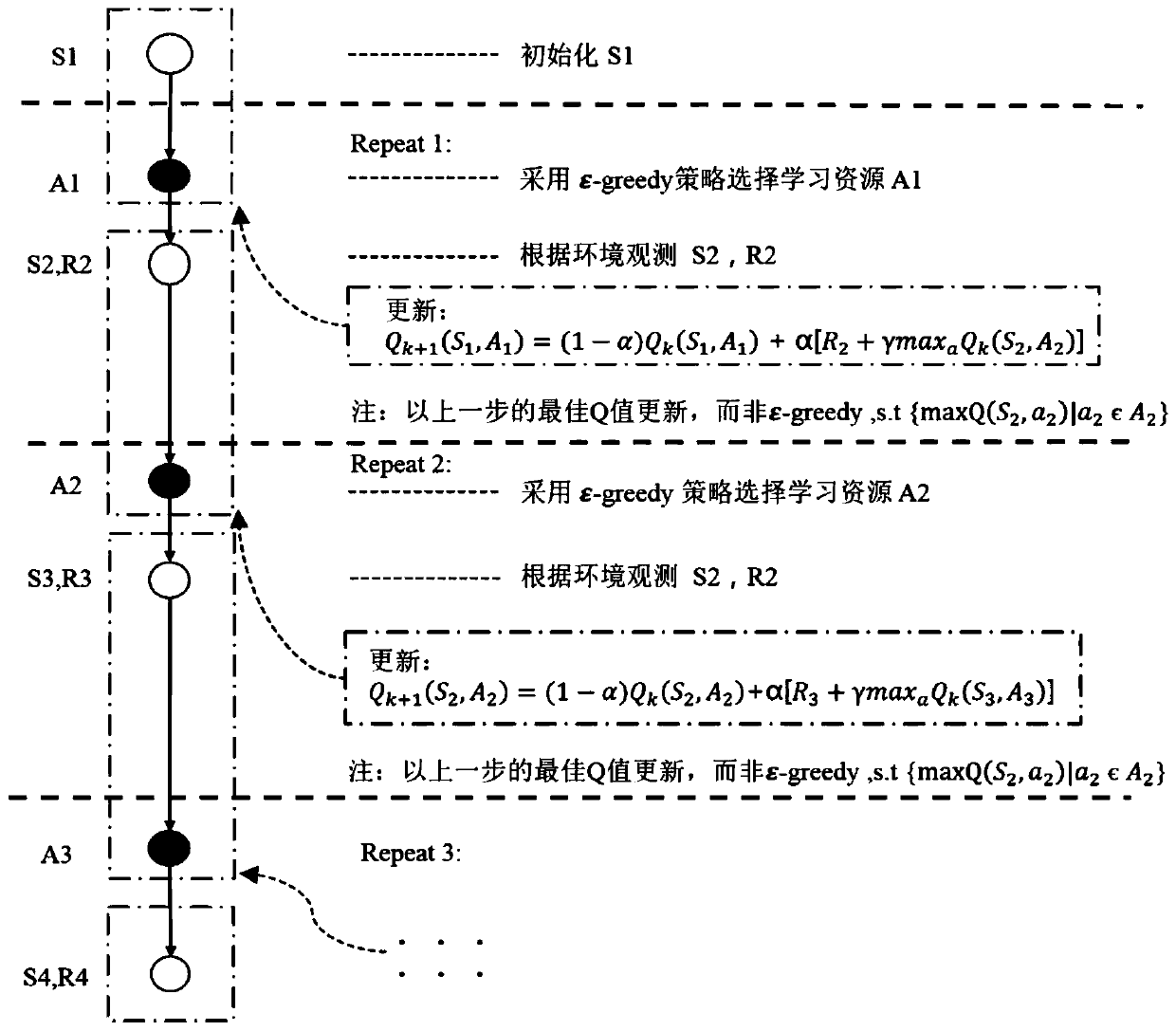

InactiveCN109948054AImprove abilitiesStrong scalabilityDigital data information retrievalForecastingStrategy trainingAdaptive learning

The invention relates to an adaptive learning path planning system based on reinforcement learning. The system comprises an environmental simulation module, a strategy training module and a path planning module. In the whole process, the ability value of the student at each moment is obtained according to the improved project reflection principle; based on a Markov decision process, a complex learning environment is simulated, a reinforcement learning algorithm is reasonably applied to be combined with a student historical learning track offline training path planning strategy, and finally, alearning path is adaptively planned for the student online according to the trained strategy. Finally, based on the idea of reinforcement learning, the complex scene learned on the online education platform is constructed in the framework of the Markov decision process, the purpose of improving the efficient obtaining capability is achieved, continuous recommendation of learning resources is provided for students, the optimal learning path is planned, and therefore the learning effect and learning efficiency of the learner are improved.

Owner:BEIHANG UNIV

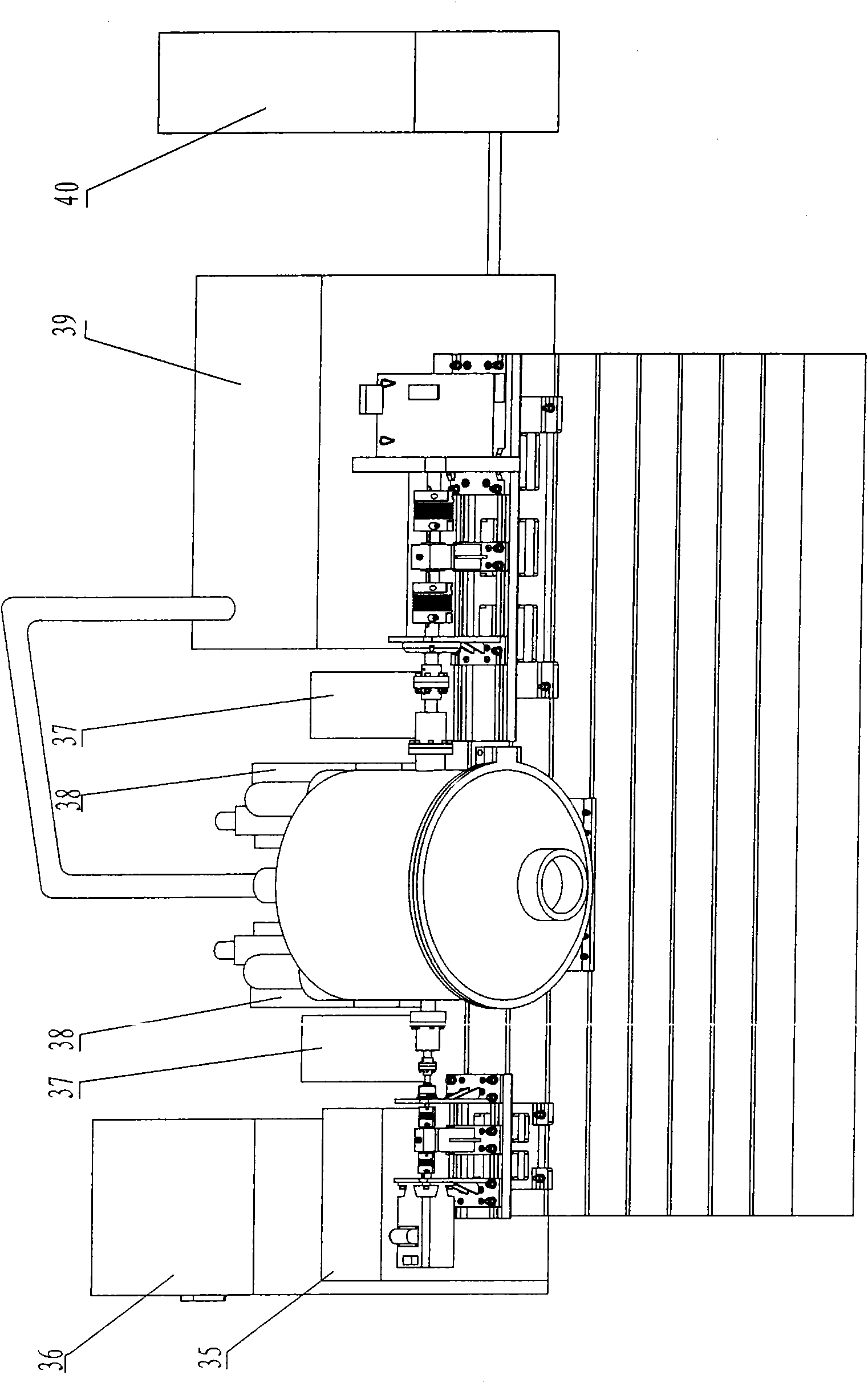

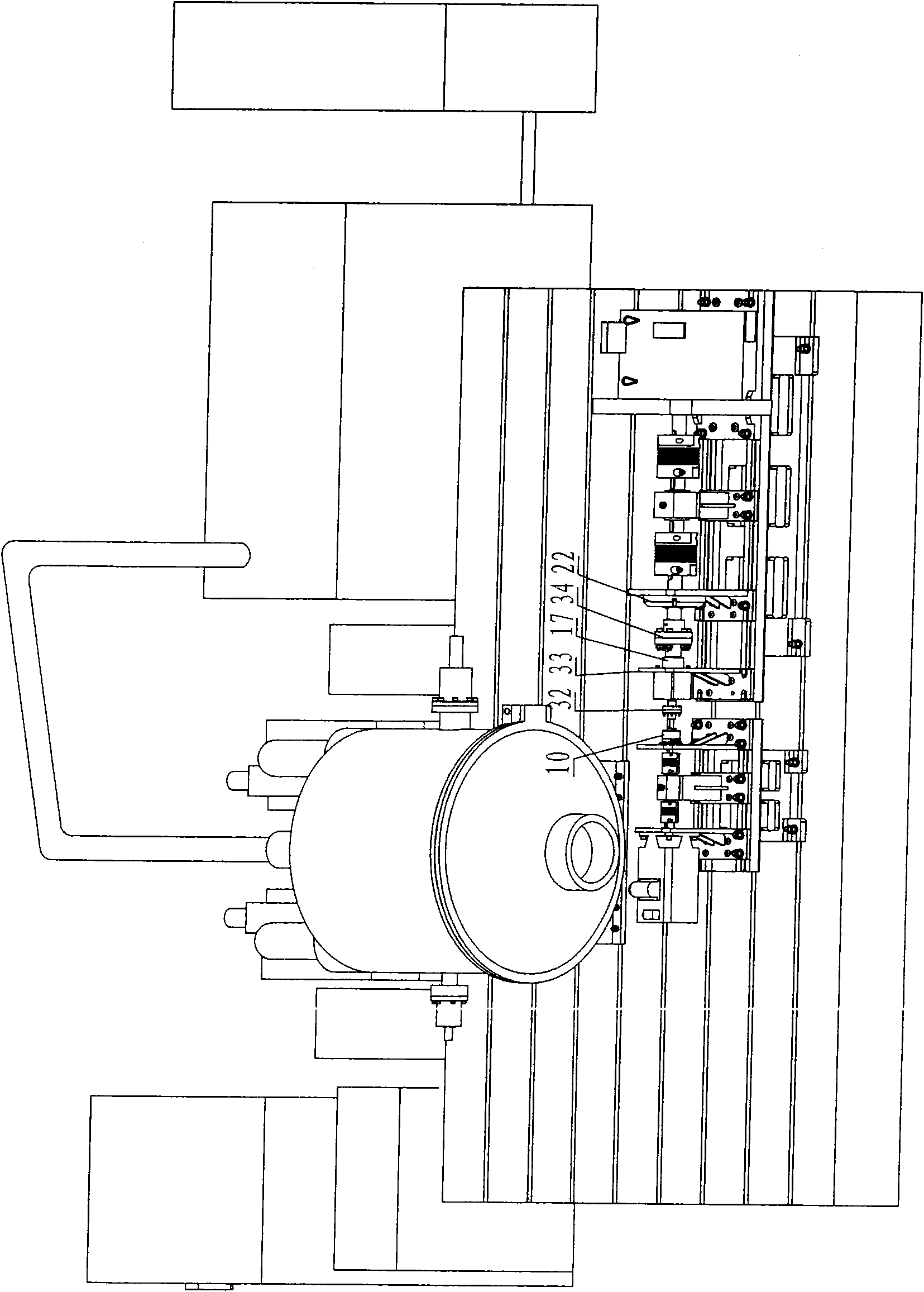

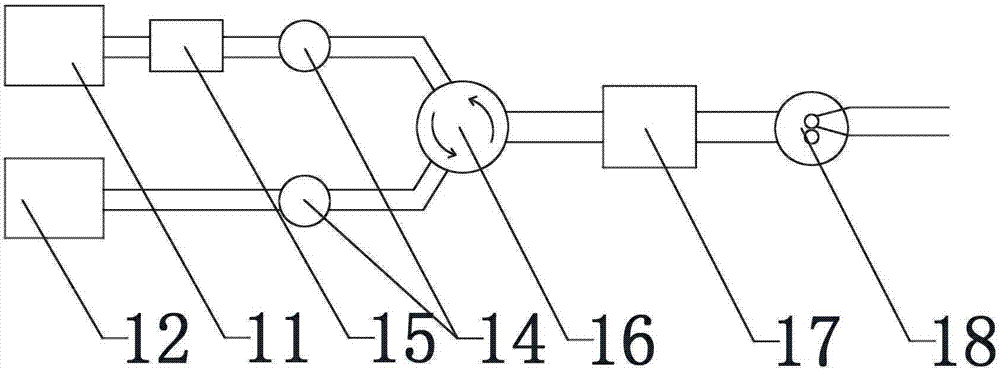

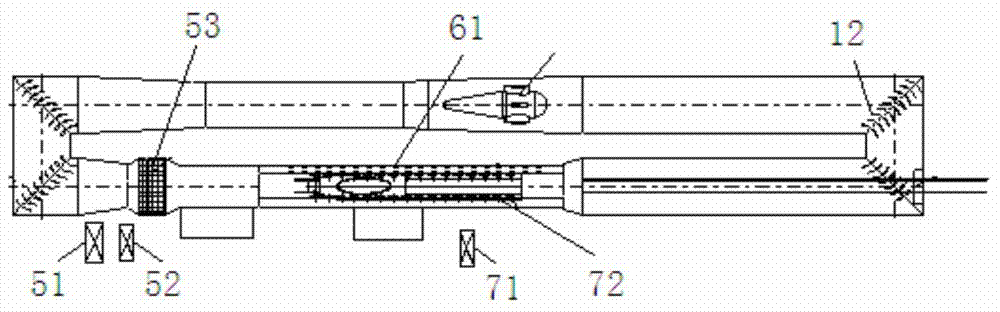

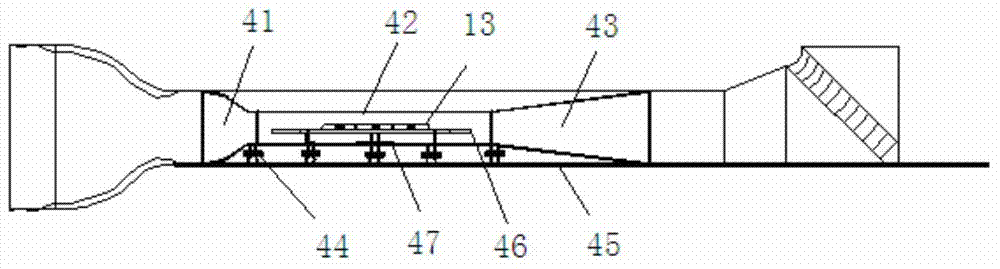

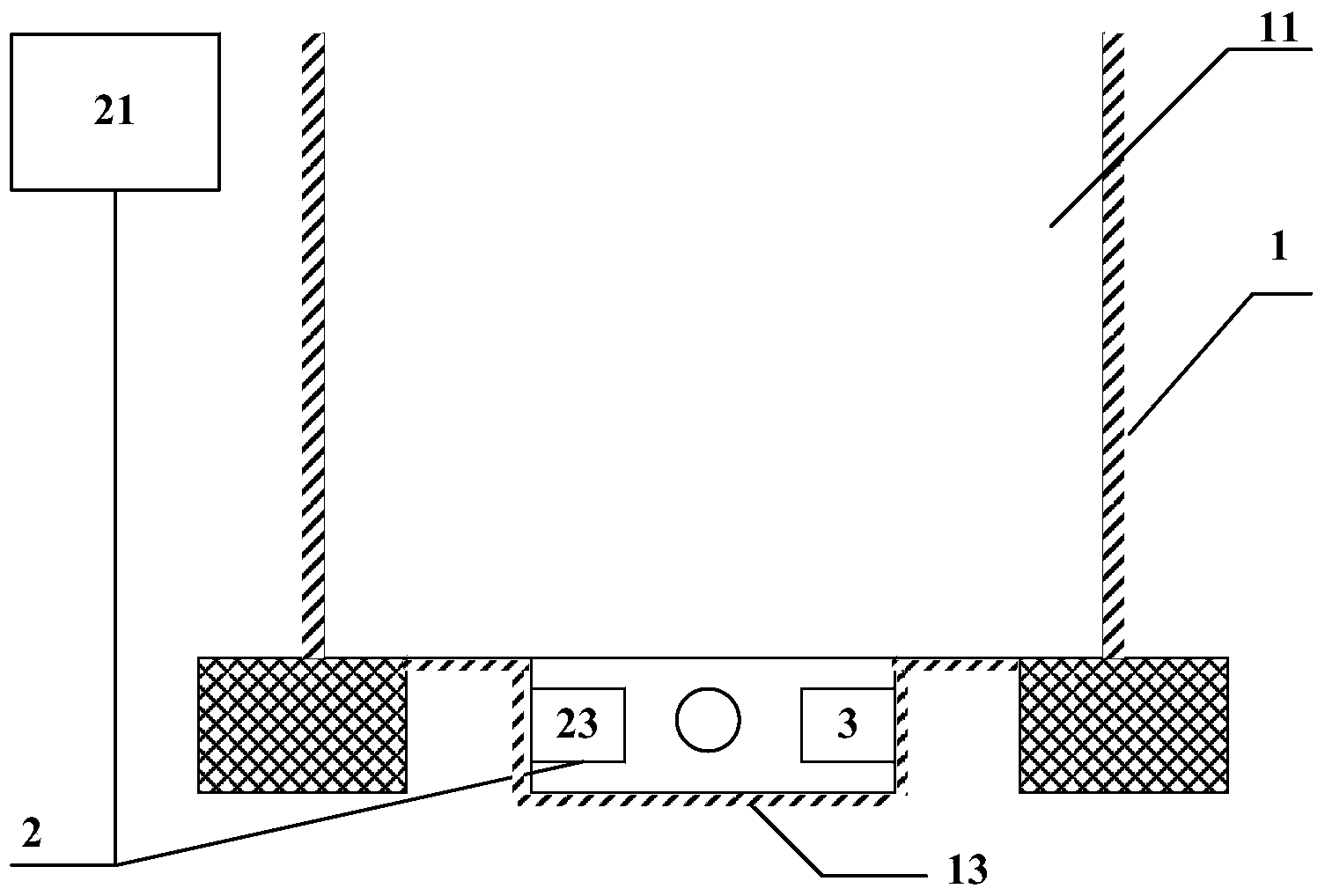

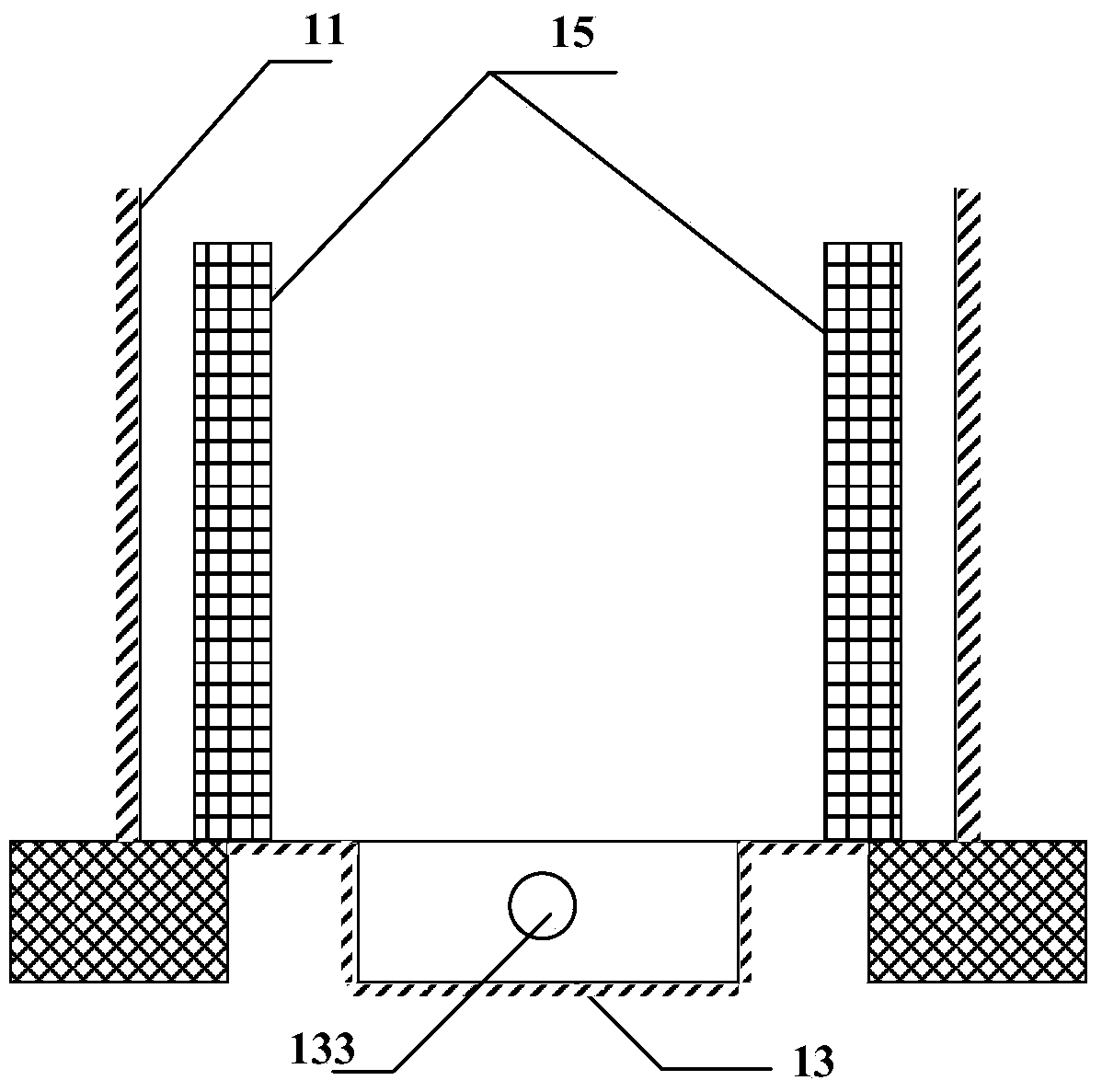

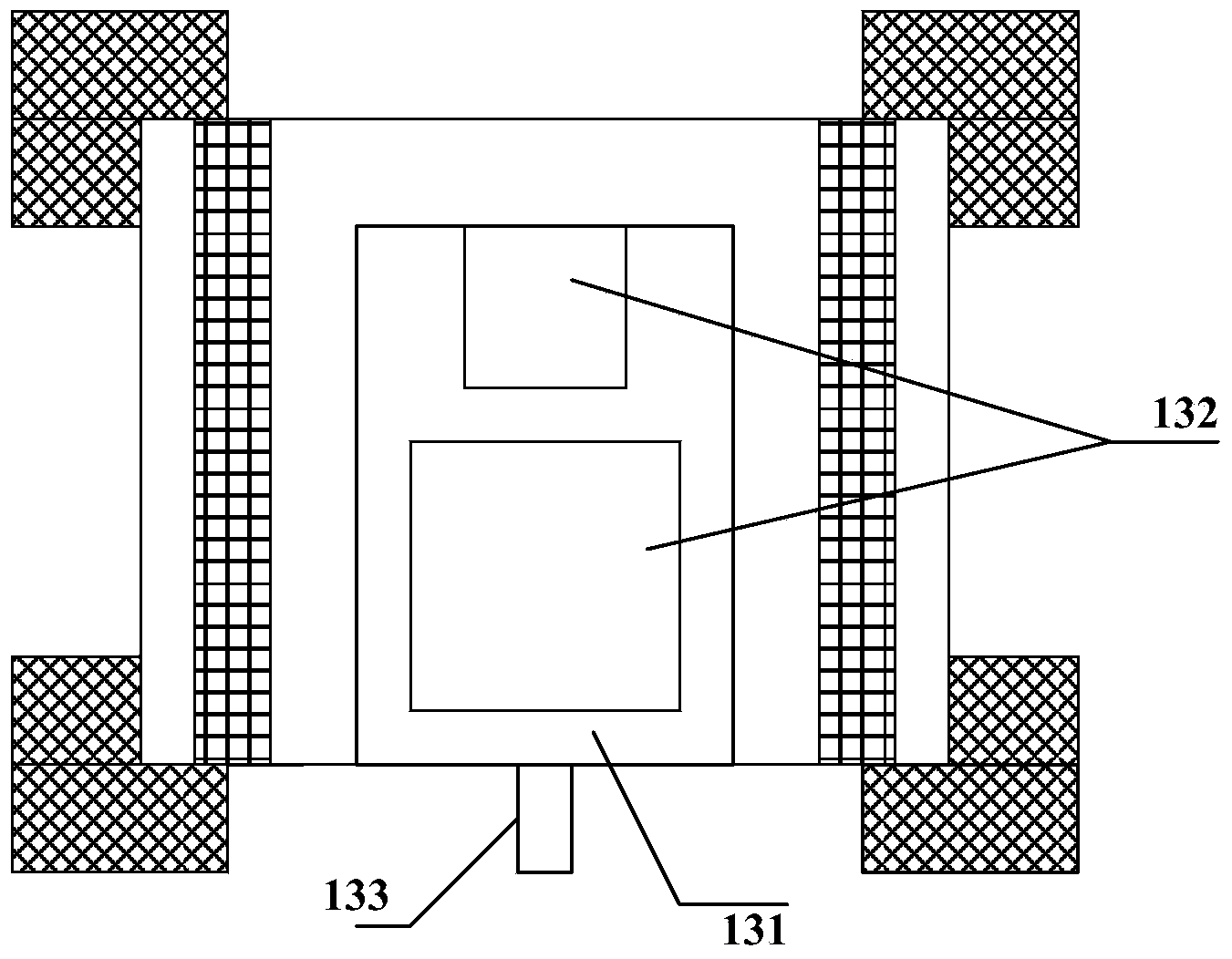

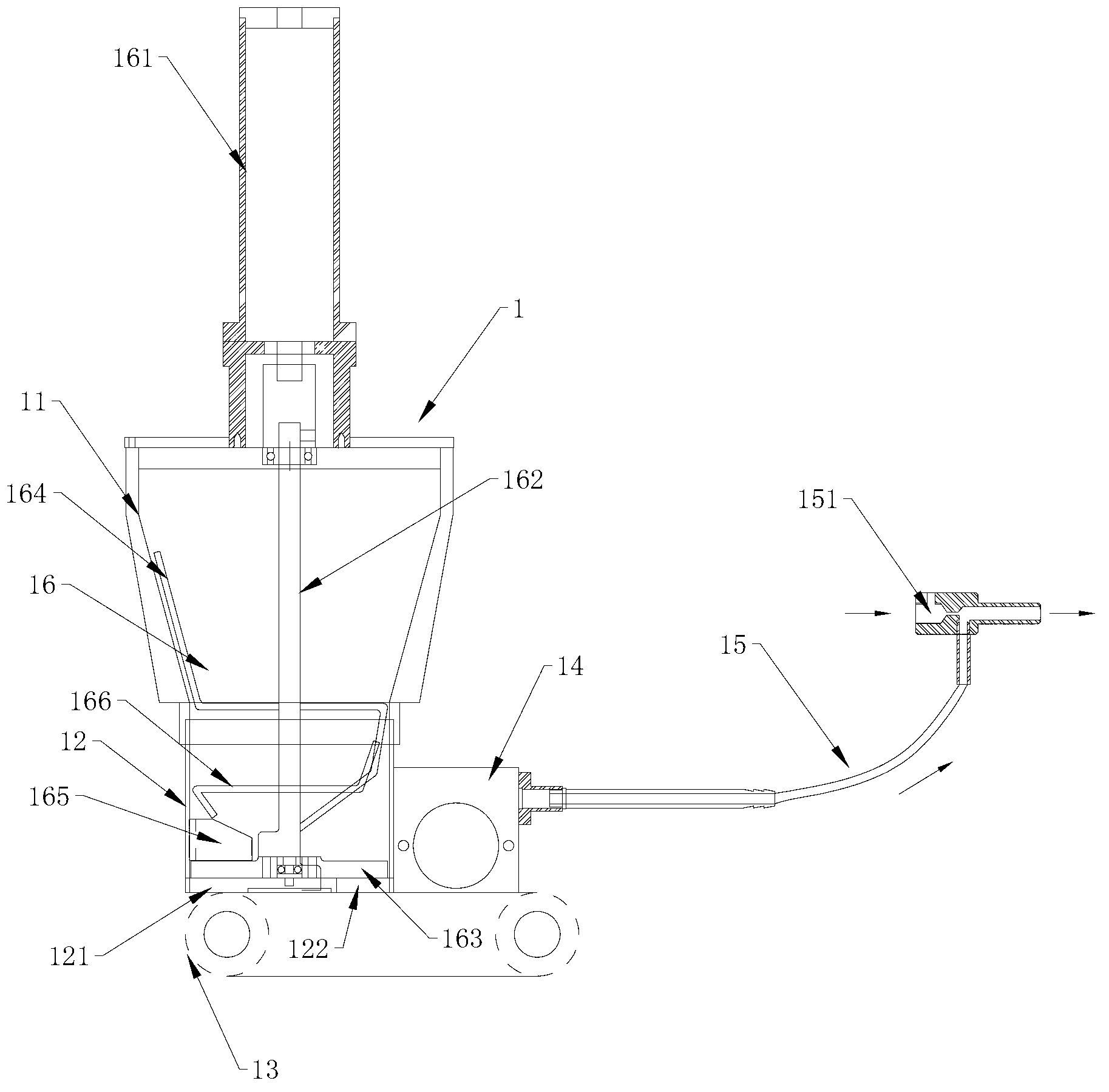

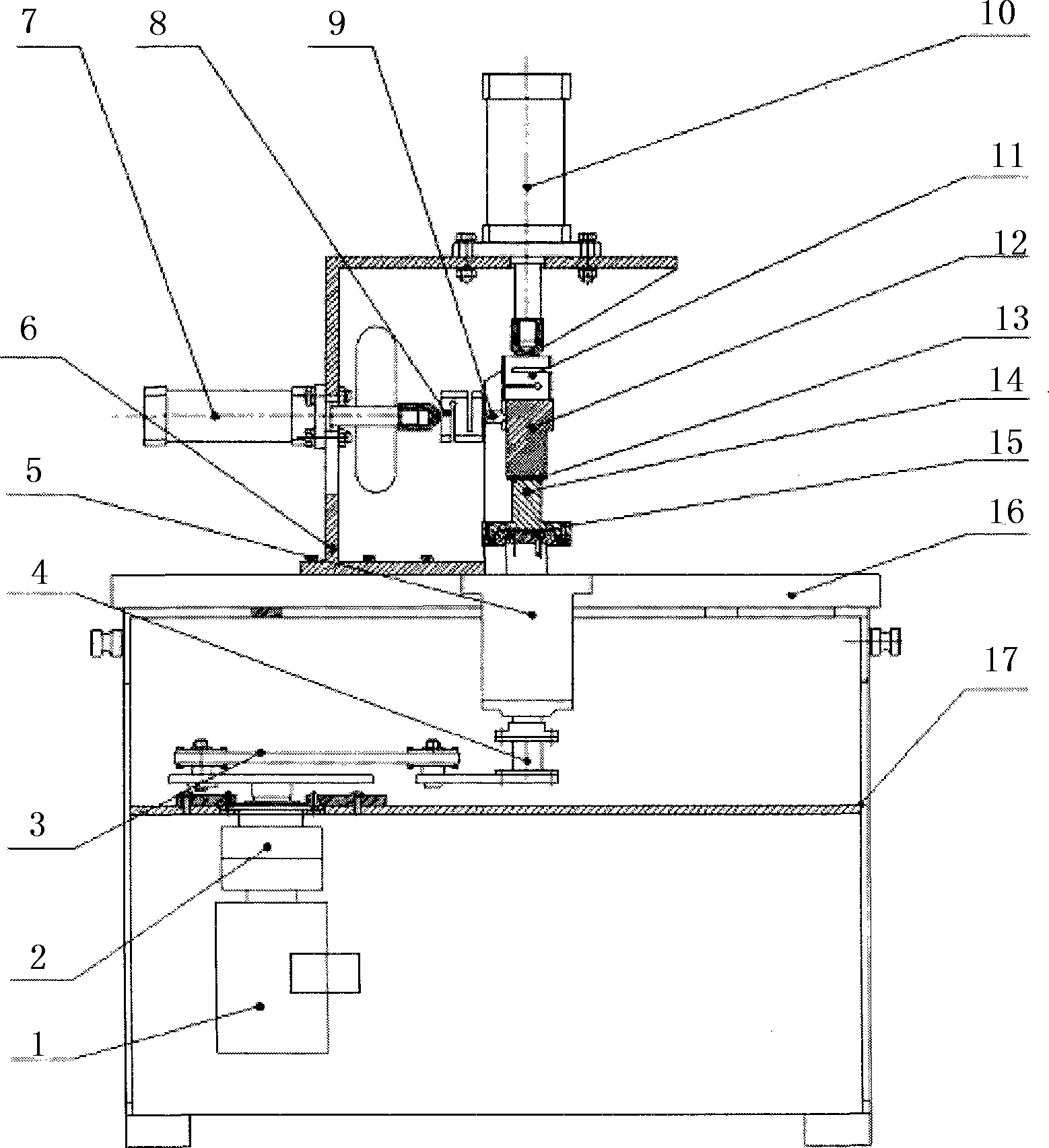

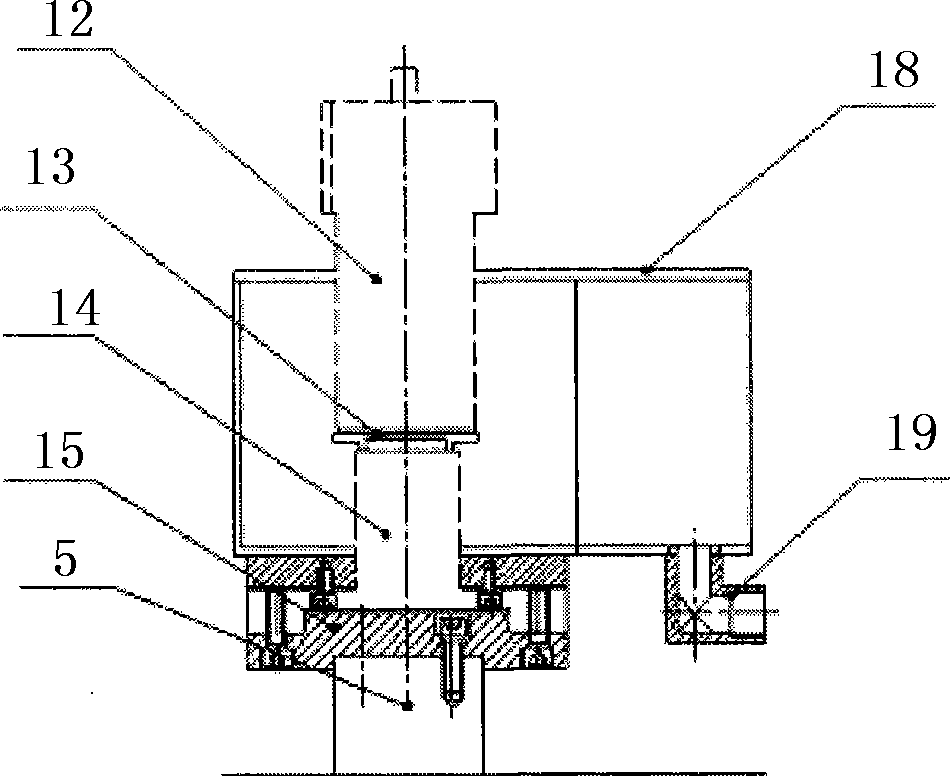

Dynamic simulation test method and testing machine for plastic support bearing used for suspension

InactiveCN101430245AThe test result is accurateIncrease flexibilityMachine bearings testingComputer monitorCoupling

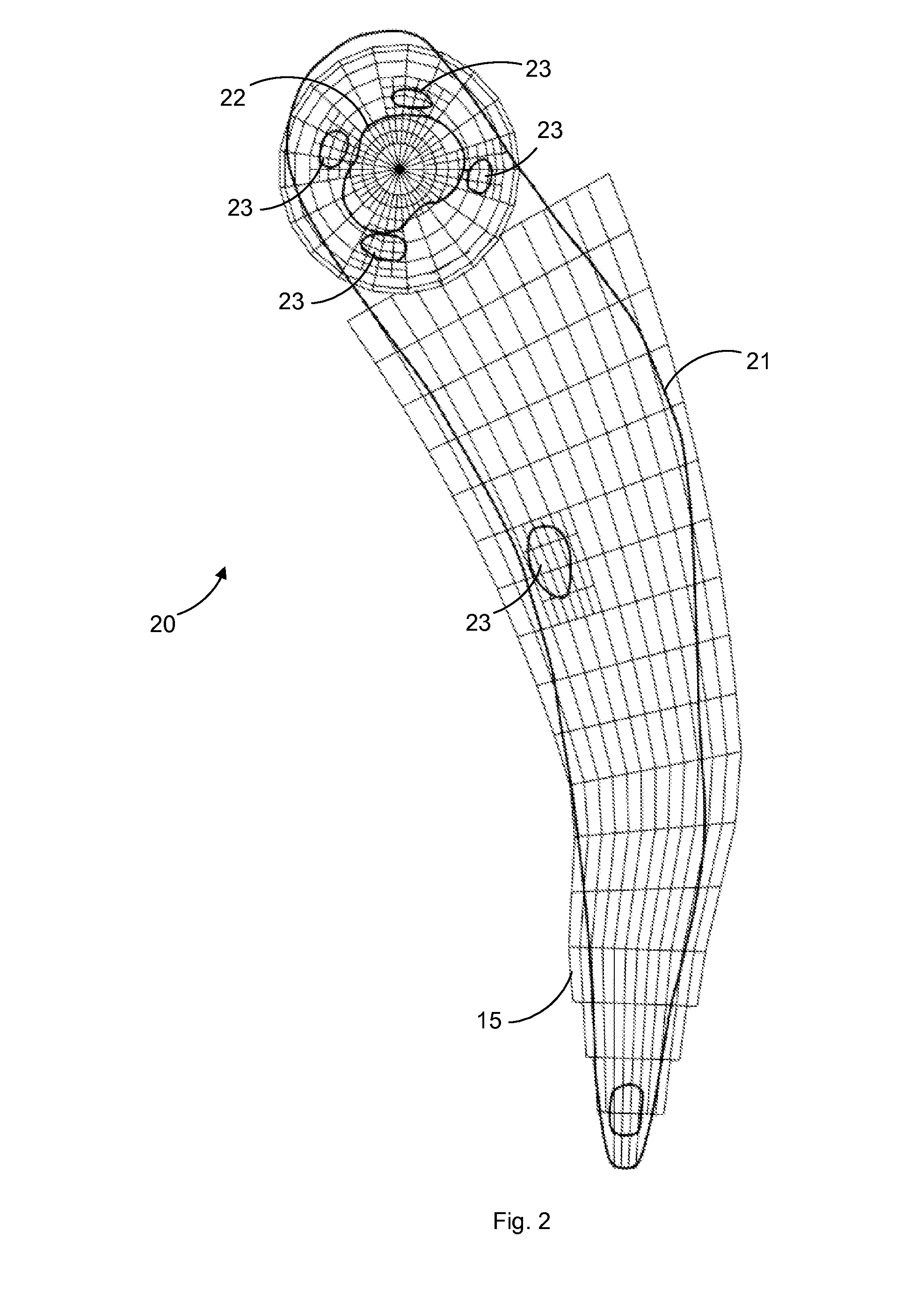

The invention discloses a dynamic simulation test method of a plastic supporting bearing used in automobile suspension and a testing machine. The testing machine is composed of a drive unit, a loading unit, a bed and an optional environmental simulation test auxiliary unit; a transmission shafting 5 in the drive unite is fixed in a work table 16 of the bed 17, the lower end of the transmission shafting 5 is linked with a torque sensor 4, the upper end of the transmission shafting is linked with a coupling 15 and a test shaft 14 is fixed in a groove of the transmission shafting, a bearing to be tested 13 is arranged on the transmission shafting; a frame 6 is fixed on the work table, a radial loading oil cylinder 7 is horizontally fixed on the frame, a sensor 8 is arranged on the head part of the radial loading oil cylinder 7 and abuts on a loading head 9 on the side of a loading block 12, an axial loading oil cylinder 10 is vertically fixed on the frame, a sensor 11 is arranged on the head part of the axial loading oil cylinder 10 and abuts on the loading block, the loading block is arranged on the bearing to be tested; a heating test or a turbid water test can be chosen for the work table or the coupling. During test, a variable frequency motor 1 is directly connected with a reduction gear 2 to drive a multi-link mechanism 3 and converts into swing of the test shaft and drives the tested bearing, and a computer monitors the whole test process and records data.

Owner:LUOYANG BEARING RES INST CO LTD

Supercritical carbon dioxide coal rock fracturing CT imaging and evaluation device under simulated in situ condition and use method thereof

InactiveCN109507077AComprehensive evaluation of fracturing effectsPermeability/surface area analysisLaboratory researchMeasurement device

The invention discloses a supercritical carbon dioxide coal rock fracturing CT imaging and evaluation device under a simulated in situ condition and a use method thereof, belonging to the field of intensified mining of coalbed methane. The device provides a supercritical carbon dioxide fracturing device under a geological environment condition in which the size of a test piece is Phi 50*100 mm, anaxial pressure and a peripheral pressure of the test piece reach 50 MPa separately, environment temperature of the test piece reaches 100 DEG C, burial depth of a simulated coal bed reaches 2000 m. The device consists of an in situ environment simulation device, a CT scanning device, a supercritical carbon dioxide fracturing device, a penetration rate measurement device and a data collection device. By adopting the device provided by the invention, the defect that in existing laboratory study, crack patterns after supercritical carbon dioxide fracturing cannot be observed intuitively under the simulated in situ condition is overcome, the crack patterns in the coal after supercritical carbon dioxide fracturing can be observed in real time, and supercritical carbon dioxide fracturing effectcan be evaluated comprehensively by combining coal penetration changes before and after supercritical carbon dioxide fracturing.

Owner:TAIYUAN UNIV OF TECH

Digital Rendering Method for Environmental Simulation

InactiveUS20130016099A1Less processing powerVideo games3D-image renderingDisplay deviceEnvironmental simulation

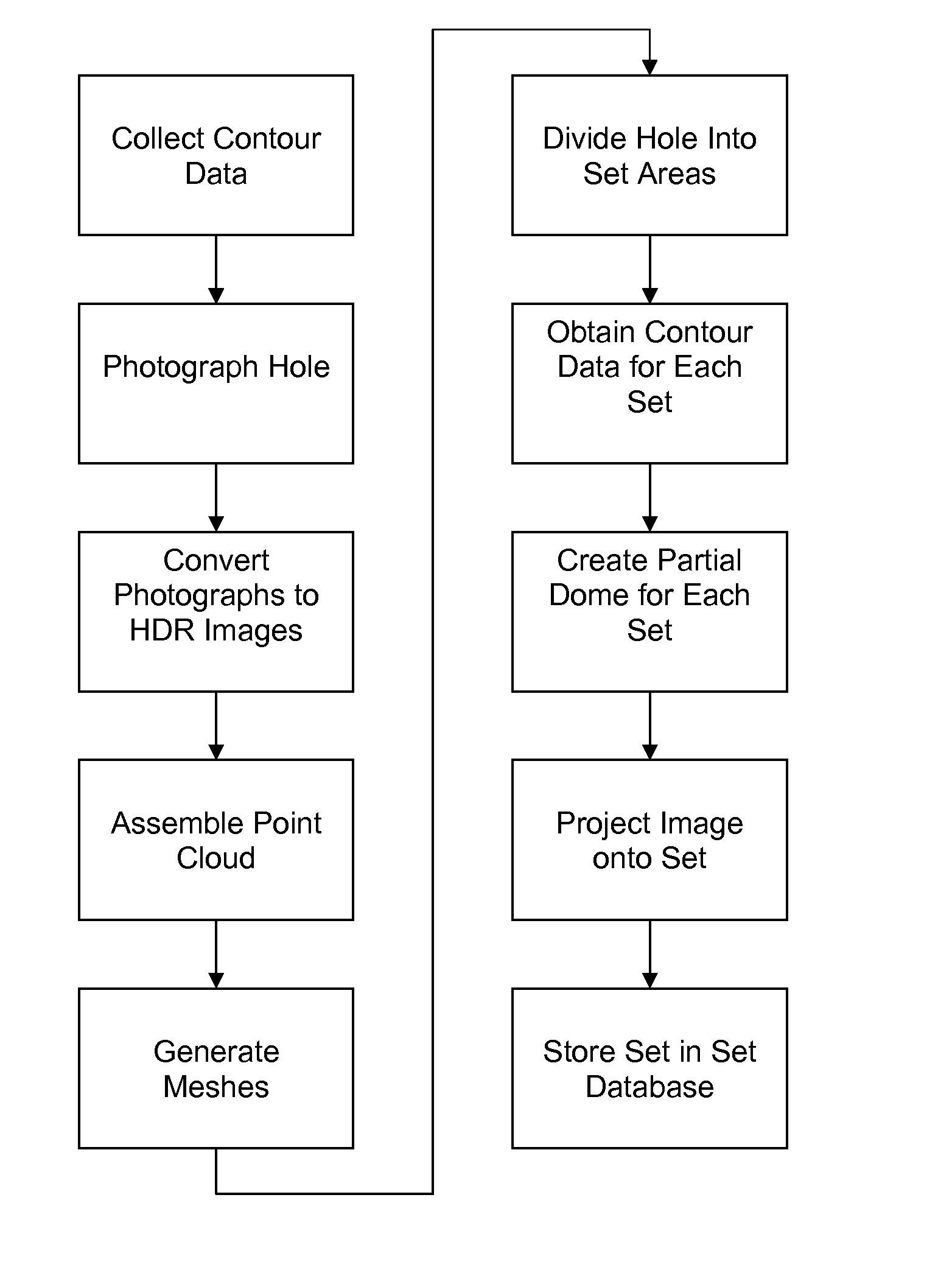

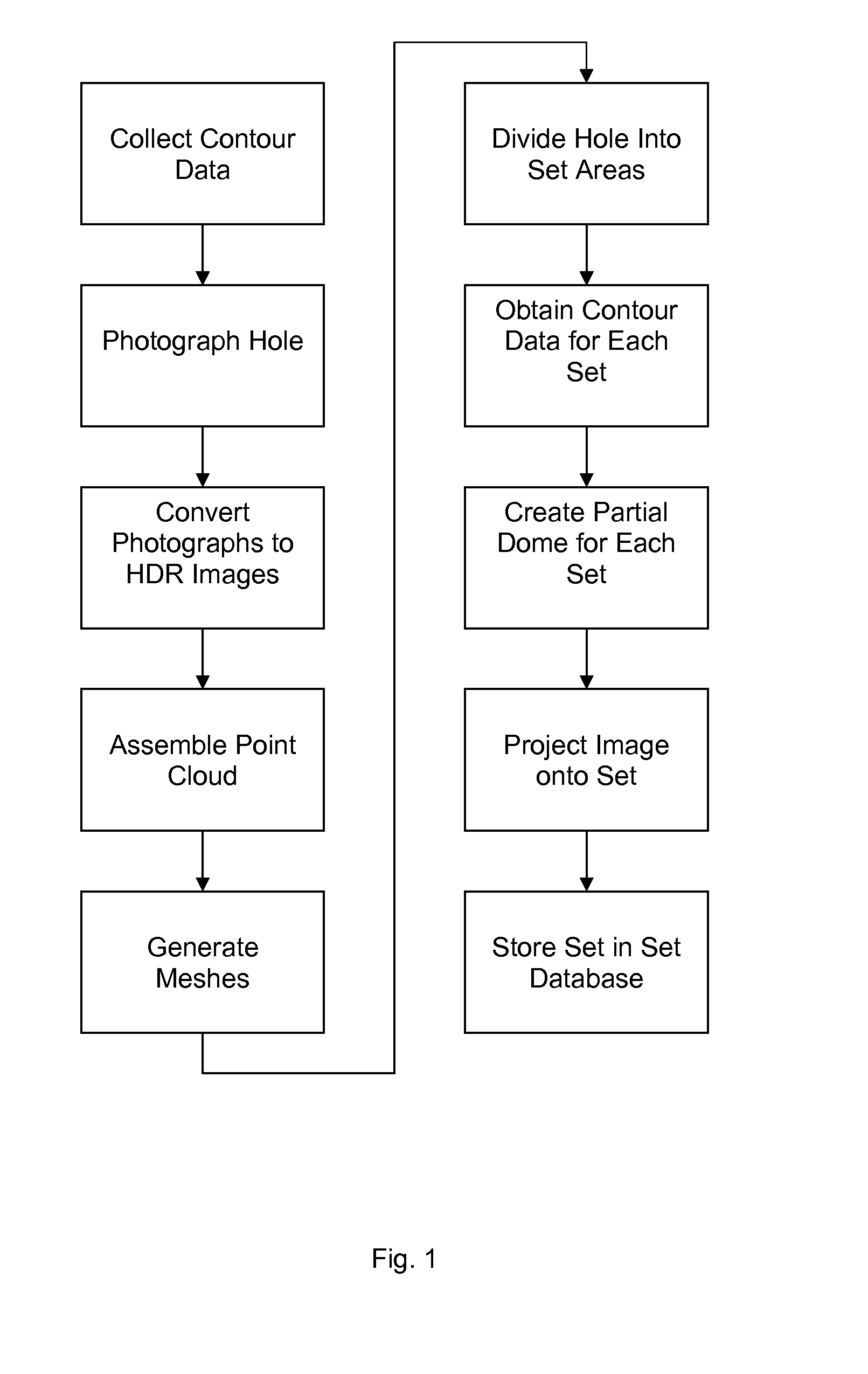

A method for producing video simulations uses two-dimensional HDR images and LIDAR optical sensor data to deliver a photo-realistic simulated sporting event experience to a display. The playing environment is mapped using a data collection process that includes contour mapping the environment, photographing the environment, and associating the images with the contour mapping data. Preferably, the HDR camera is used in conjunction with a differential global positioning system that records the position and heading of the camera when the photo is taken. A polygon mesh is obtained from the contour data, and each image is projected onto a backdrop from the perspective of a simulated camera to create a set, which is then stored in a set database. The simulated environment is created by selecting the set needed for the simulation and incorporating simulation elements into the set before rendering the simulated camera's view to the display.

Owner:2XL GAMES

Dynamic aviation thermal power testing system and rapid temperature and pressure control method

ActiveCN104460790AAvoid coupling effectsLower requirementSimultaneous control of multiple variablesAviationEngineering

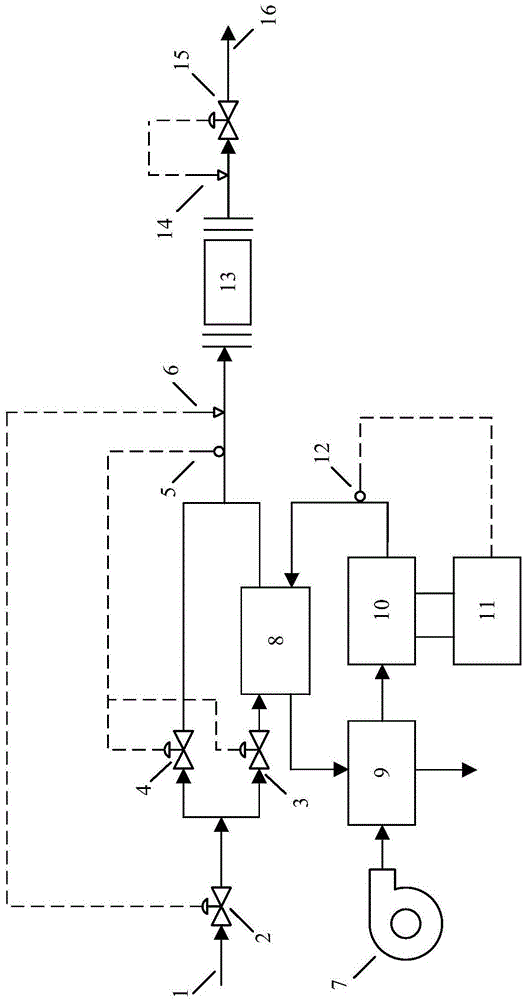

The invention belongs to the field of environment simulation and control, and relates to a dynamic aviation thermal power testing system and a rapid temperature and pressure control method which are mainly used for the airplane environment control system ground simulation test and are capable of achieving rapid temperature, pressure and flow adjustment and carrying out rapid temperature increasing and reducing and pressure increasing and reducing of an environment control system and the full-flight envelope dynamic simulation test. According to the dynamic aviation thermal power testing system, the project achieving difficulty of a heater is lowered through an indirect heating mode, and the possible problem of dried burning due to direct heating can be avoided. The temperature and pressure are independently controlled, and the temperature and pressure coupling effect is eliminated. A rapid adjusting mechanism is arranged in front of a heat exchanger, the project achieving difficulty of the adjusting mechanism is lowered, accordingly, the reliability of the system is improved, and the manufacturing cost of the system is reduced. The system is further provided with a heat regenerator, part of waste heat can be recycled, the system efficiency is improved, and the consumed energy of the system is reduced.

Owner:BEIHANG UNIV

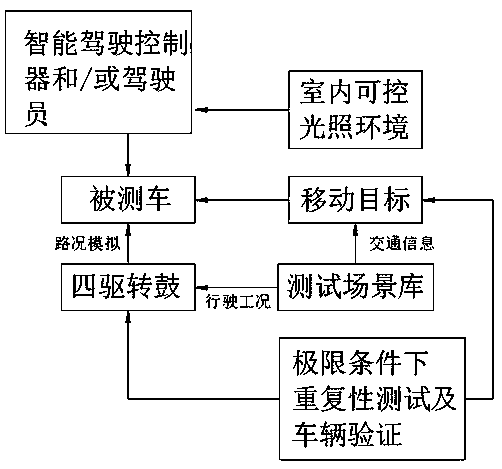

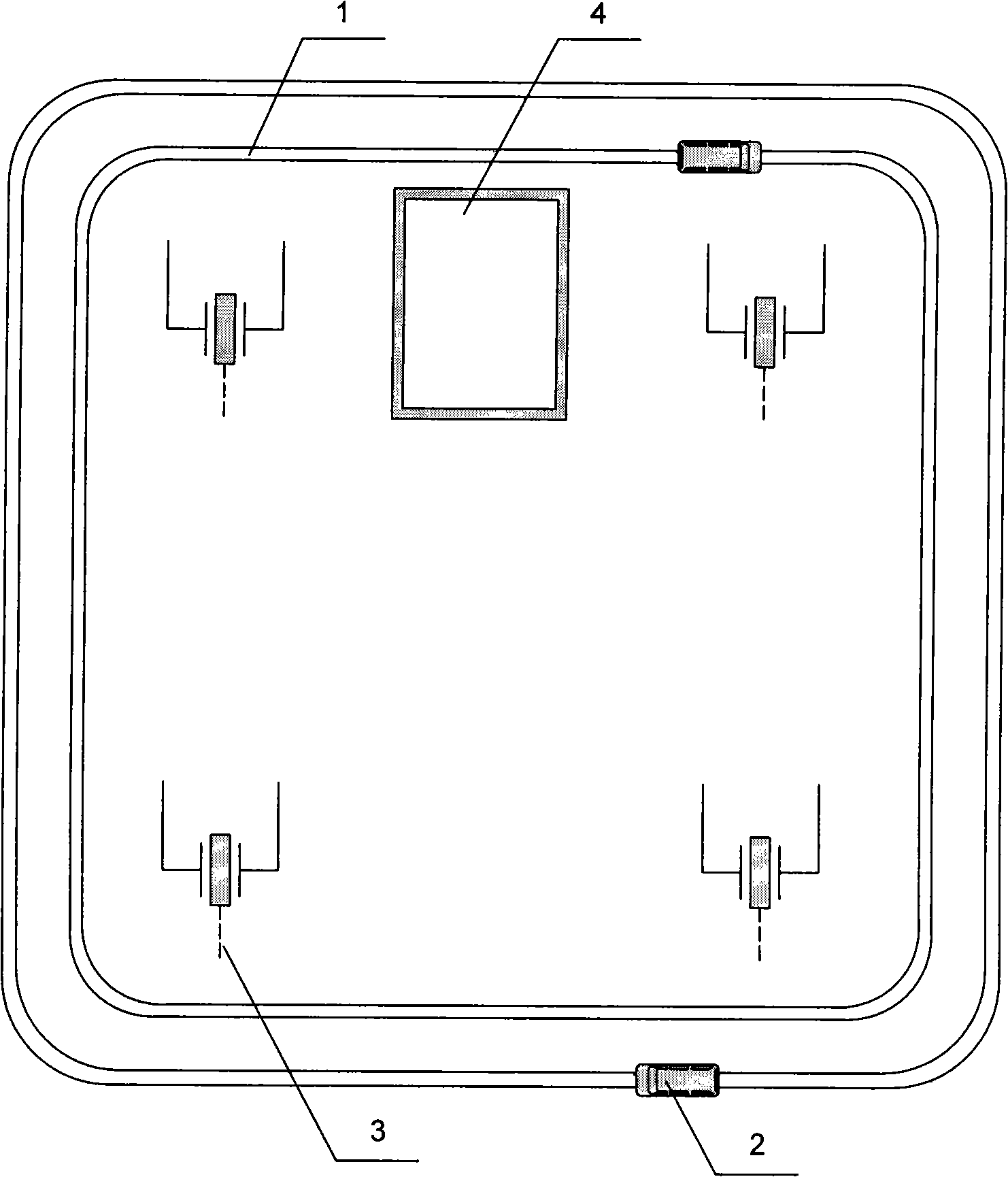

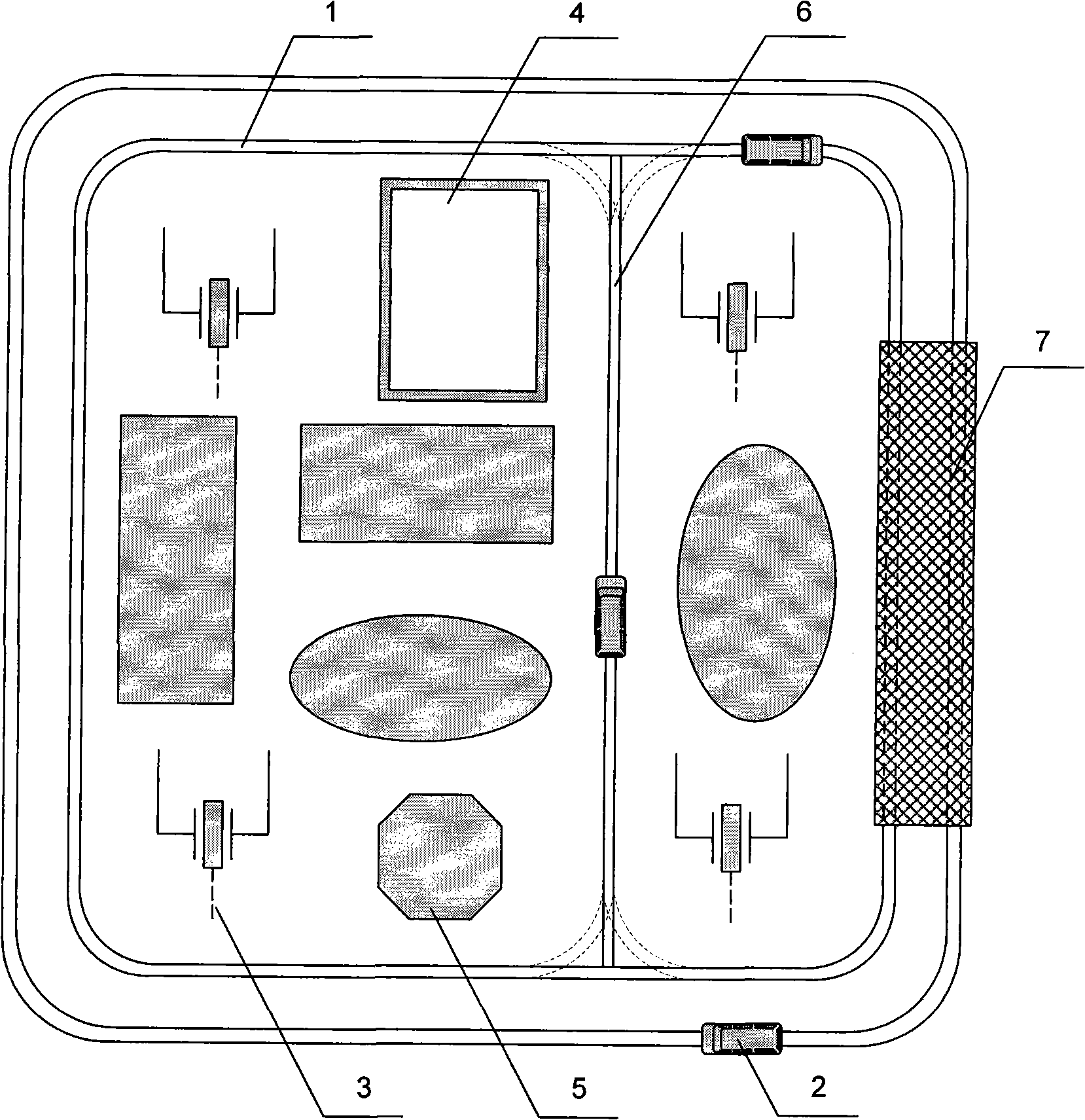

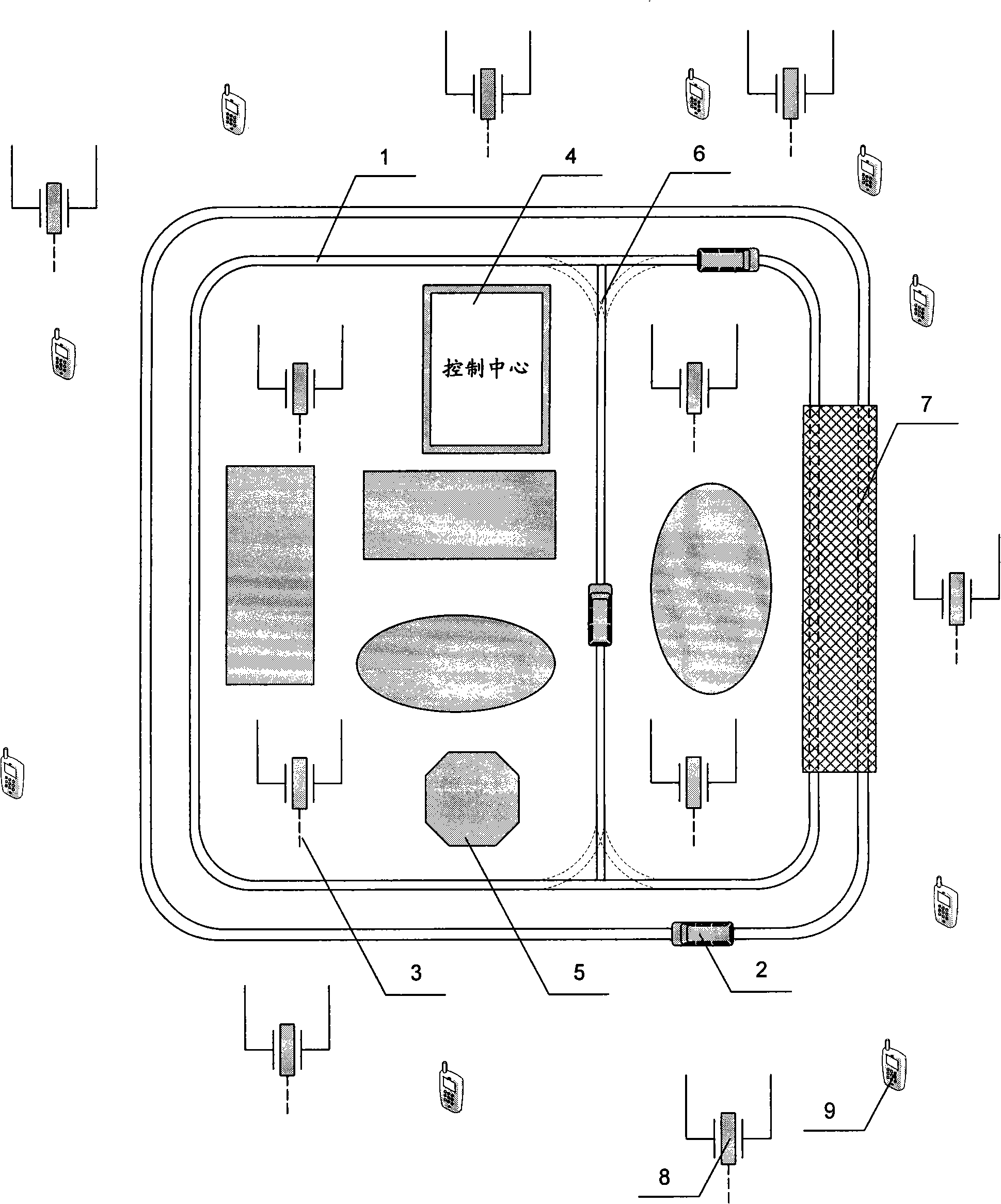

Intelligent connected vehicle environment simulation system based on complete vehicle hardware-in-loop

ActiveCN110647056AImprove test accuracyIncrease credibilityVehicle testingSimulator controlVehicle dynamicsAutomotive product

The invention relates to the technical field of automatic driving of intelligent vehicles, and discloses an intelligent connected vehicle environment simulation system based on complete vehicle hardware-in-loop. The system comprises a hub dynamometer, a control system of the hub dynamometer, a steering and transverse movement platform, a moving target, an environment simulation system, a positioning simulation system, a V2X simulation system, a central control system, a vehicle dynamics model, a vehicle steering and transverse movement platform control unit and a data acquisition module. According to the intelligent connected vehicle environment simulation system based on complete vehicle hardware-in-loop, the whole vehicle comprising a sensor can be taken as a tested object; a test systemintegrates physical weather and traffic simulation devices, so that the test precision and credibility of the system are greatly improved, meanwhile, the test efficiency can be improved; and the system is an effective test tool for accelerating realization of intelligent connected vehicle products.

Owner:苏州智行众维智能科技有限公司

Universal external field wireless test system

ActiveCN101351011AFlexible layoutRealize simulationRadio/inductive link selection arrangementsEngineeringEnvironmental simulation

The invention relates to a general external field wireless test system, including a track, a test carriage for carrying a test terminal and running on the track, an antenna for providing at least one wireless network environment of wireless system and forming at least one track coverage cell on the track, and a control center for controlling the running mode of the test carriage and the work mode of the antenna. The invention can realize various external field wireless environmental simulations, high speed wireless test environmental simulation, various switch tests, test environmental simulation in which various wireless systems coexist, wireless advanced research, wireless arithmetic research, wireless equipment test, terminal test environmental simulation, network performance test of free bearing mobile terminal in order to analyze special wireless network performance, locate special wireless network exception and provide convenient wireless test environment for new technology experiment and frontier study of wireless network.

Owner:CHINA MOBILE COMM GRP CO LTD

Environment simulation calibration wind tunnel

The invention discloses an environment simulation calibration wind tunnel. The environment simulation calibration wind tunnel comprises a simulation control cabin and a wind tunnel unit, wherein the simulation control cabin is communicated with the wind tunnel unit to form an annular loop; the wind tunnel unit is internally provided with a humidity generator, an aerosol generator, a power mechanism, a heater and an evaporator; the wind tunnel unit is connected with a dust generation system; the simulation control cabin is provided with an automatic control cabin door and an automatic air inlet valve; the simulation control cabin is internally provided with a three-dimensional worktable capable of being connected with a testing instrument; and the three-dimensional worktable can be used for adjusting a size in a three-dimensional space. According to the environment simulation calibration wind tunnel disclosed by the invention, the simulation control cabin is connected with the wind tunnel unit and can be used for simulating sampling environments under different wind speeds; the aerosol generator can generate aerosol for simulating a particle environment; high-humidity environments and various pressure environments can also be simulated; different environment conditions and extreme environment conditions can be repeatedly simulated; and an extreme working environment condition of an instrument is determined, and changes of operation parameters and data of the instrument in different environments are determined.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

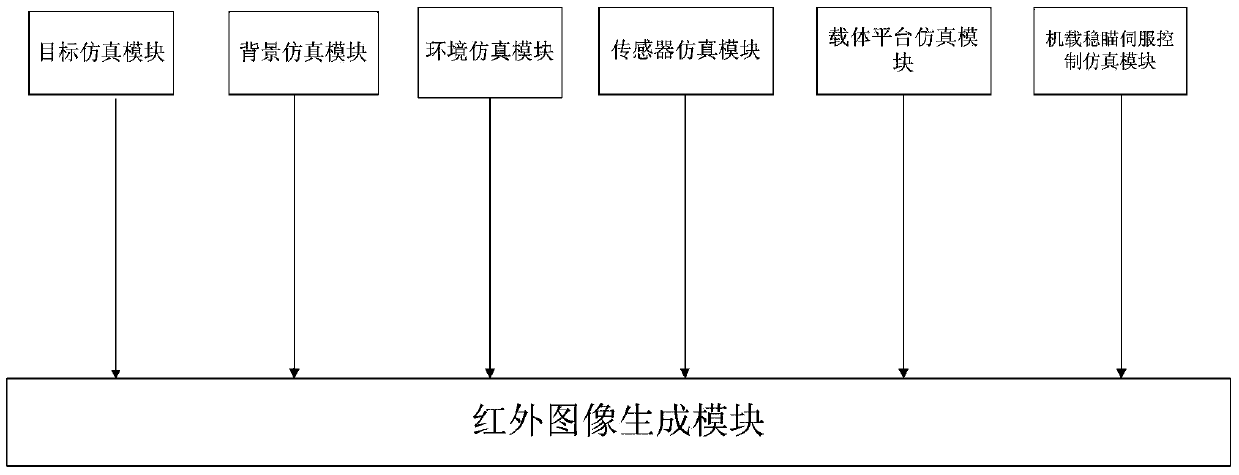

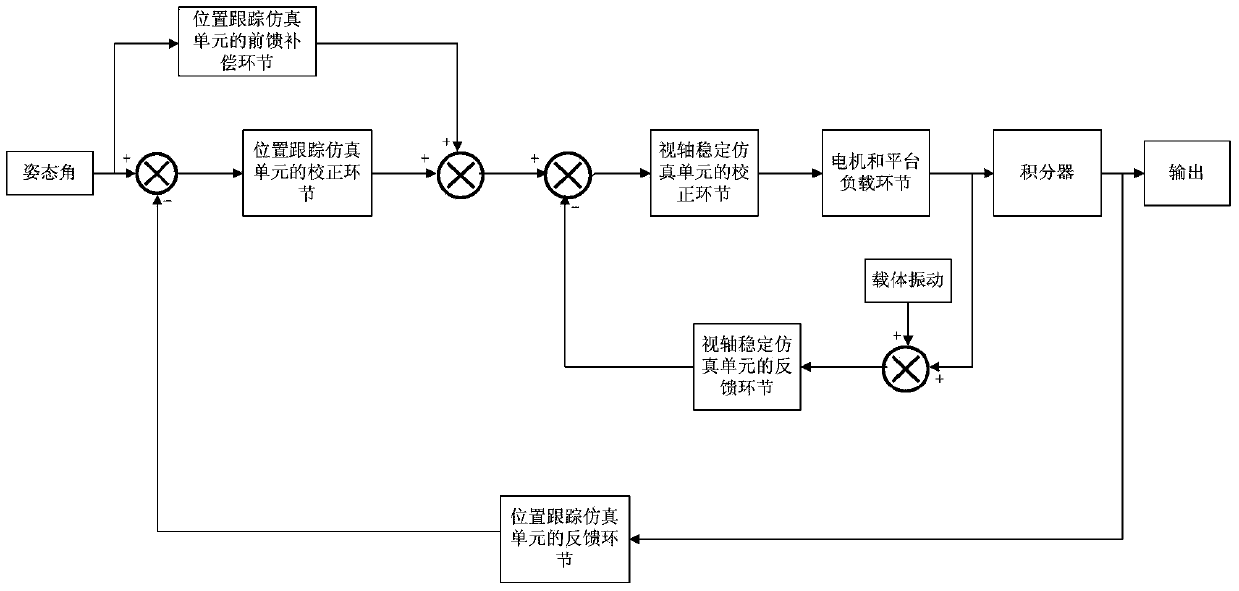

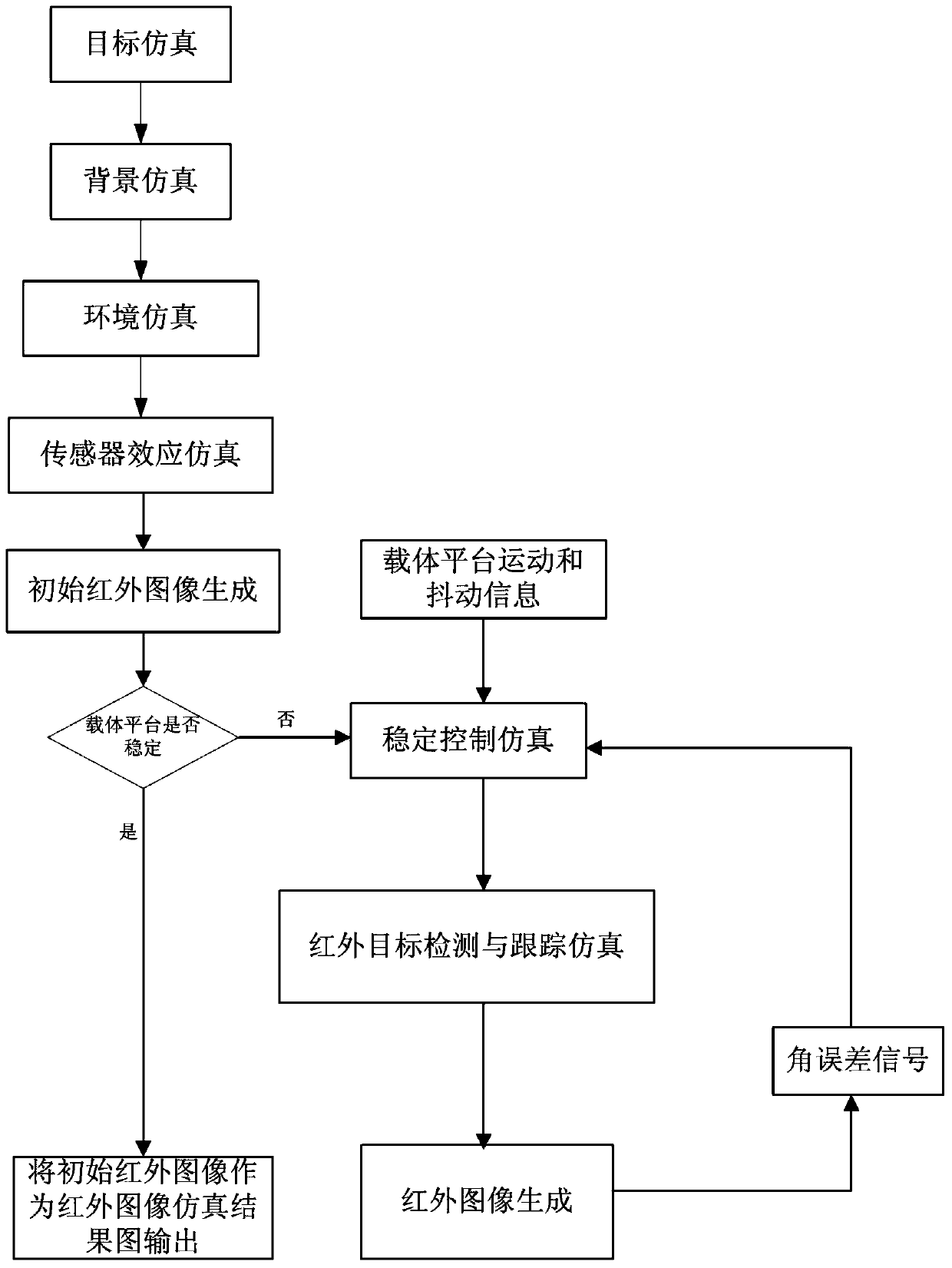

Full-link full-process simulation system and method for airborne infrared stabilized sighting system

ActiveCN104182575ARealize dynamic simulationImplement signal flow deliverySpecial data processing applicationsEnvironmental simulationDynamic simulation

The invention discloses a full-link full-process simulation system and method for an airborne infrared stabilized sighting system and aims to achieve full-link full-process simulation of the airborne infrared stabilized sighting system in laboratory conditions. The system comprises a target simulation module, a background simulation module, an environmental simulation module, a sensor simulation module, a carrier platform simulation module, an airborne stabilized sighting servo control simulation module and an infrared image generation module. The method includes the steps of 1, target simulation; 2, background simulation; 3, atmospheric effect simulation; 4, sensor effect simulation; 5, initial generation of infrared images; 6, judgment of whether a carrier platform is stabilized or not; 7, stabilized control simulation; 8, infrared target detection and tracking simulation; and 9, infrared image generation. The system has the advantages that considered links are complete, and dynamic simulation and signal stream transmission are achieved. The method has the advantage that infrared target tracking can be achieved.

Owner:XIDIAN UNIV

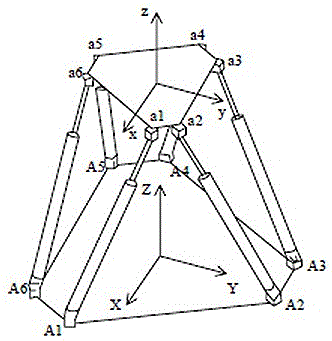

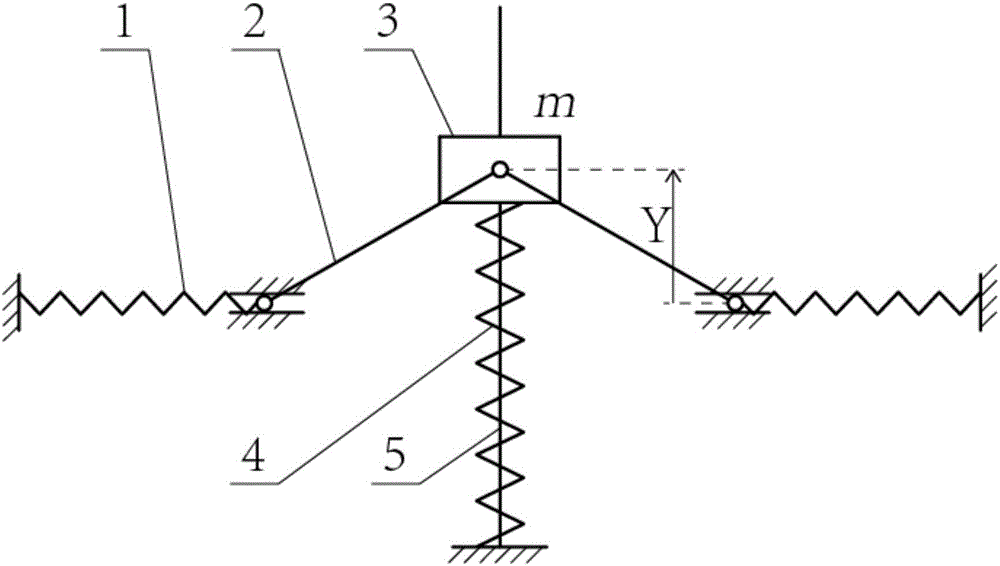

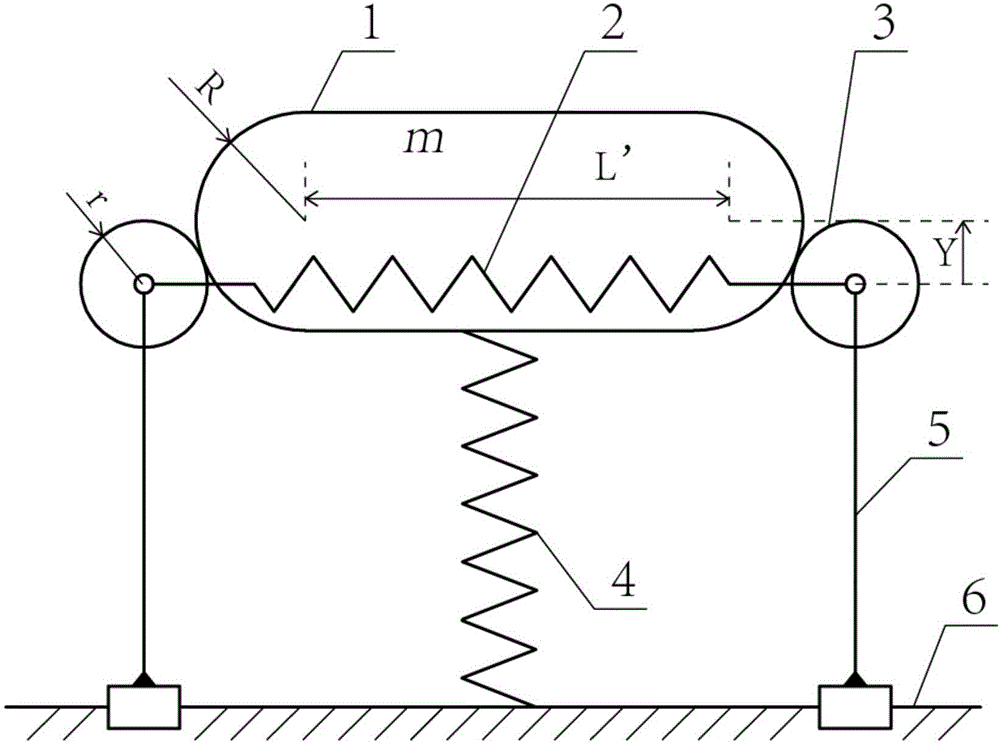

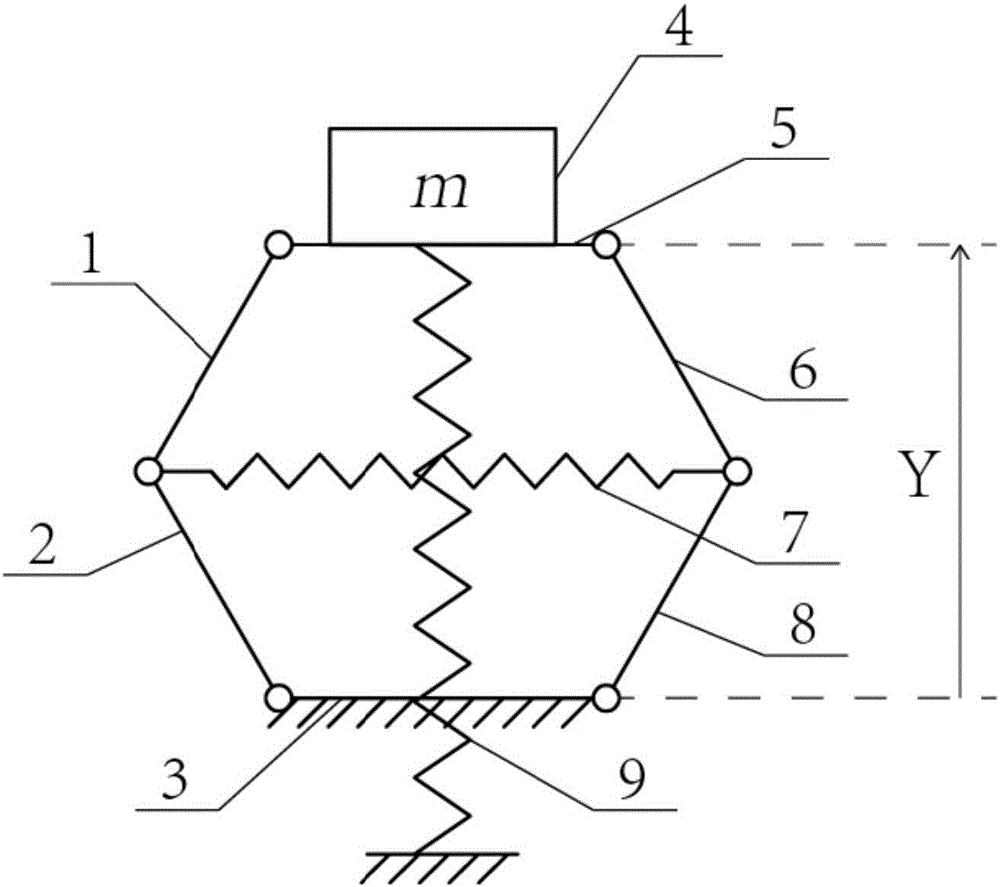

Zero (micro) gravity suspension method and device with zero-frequency vibration isolation characteristic

ActiveCN106742091ASolve vibration isolation problemsOvercome the difficult problem of avoiding system resonanceCosmonautic condition simulationsStructural dynamicsNet force

The invention discloses a zero (micro) gravity suspension method and device with a zero-frequency vibration isolation characteristic and relates to the technical field of zero gravity or micro gravity environmental simulation in the outer space. The problems of space ground simulation, low-frequency and ultralow frequency vibration isolation and the like are solved. The series of suspension devices can be each substantially seen as being formed by connecting a vertical spring and a vertical spring which support gravity support through a connecting rod and a suspended object. According to the basic principle, support force which is equal to the magnitude of the gravity and opposite to the direction of the gravity is provided through geometric nonlinearity arrangement of a spring connecting rod mechanism, so that the resultant force acted on the suspended object within the device design range is zero, and thus the suspended object is in the suspension state. The zero (micro) gravity suspension device can be used for space zero and micro gravity environments including ground simulation experiments such as spacecraft docking, large space flexible structure dynamics performance tests and astronaut training. Through the suspension characteristics of the zero (micro) gravity suspension method device, the problems of low-frequency and ultralow frequency vibration isolation can be solved effectively, and the defect that through a traditional vibration isolation theory, system resonance is difficult to be avoided is overcome.

Owner:HARBIN INST OF TECH

Turbine blade thermal barrier coating working condition simulation experiment test system

ActiveCN109682702ALoad close toThe measured value is accurateGas-turbine engine testingEngine fuctionsProcess optimizationTurbine blade

The invention discloses a turbine blade thermal barrier coating working condition simulation experiment test system. The system comprises working state simulation equipment, service environment simulation equipment and detection equipment; the working state simulation equipment is arranged at one side of a to-be-tested turbine blade thermal barrier coating, connected with the to-be-tested turbineblade thermal barrier coating and used for simulating the high-speed rotation working state of the to-be-tested turbine blade thermal barrier coating; the service environment simulation equipment is arranged at the other side of the to-be-tested turbine blade thermal barrier coating and used for simulating the service environment of the to-be-tested turbine blade thermal barrier coating in the high-speed rotation working state; the detection equipment is used for detecting damage generated when the to-be-tested turbine blade thermal barrier coating rotates at high speed in the service environment. By means of the experiment test system, the working state and the service environment of the to-be-tested turbine blade thermal barrier coating are simulated, so that key damage parameters of theturbine blade thermal barrier coating in the failure process are conveniently detected in real time, and technical support is provided for process optimization and automatic design of the thermal carrier coating.

Owner:XIANGTAN UNIV

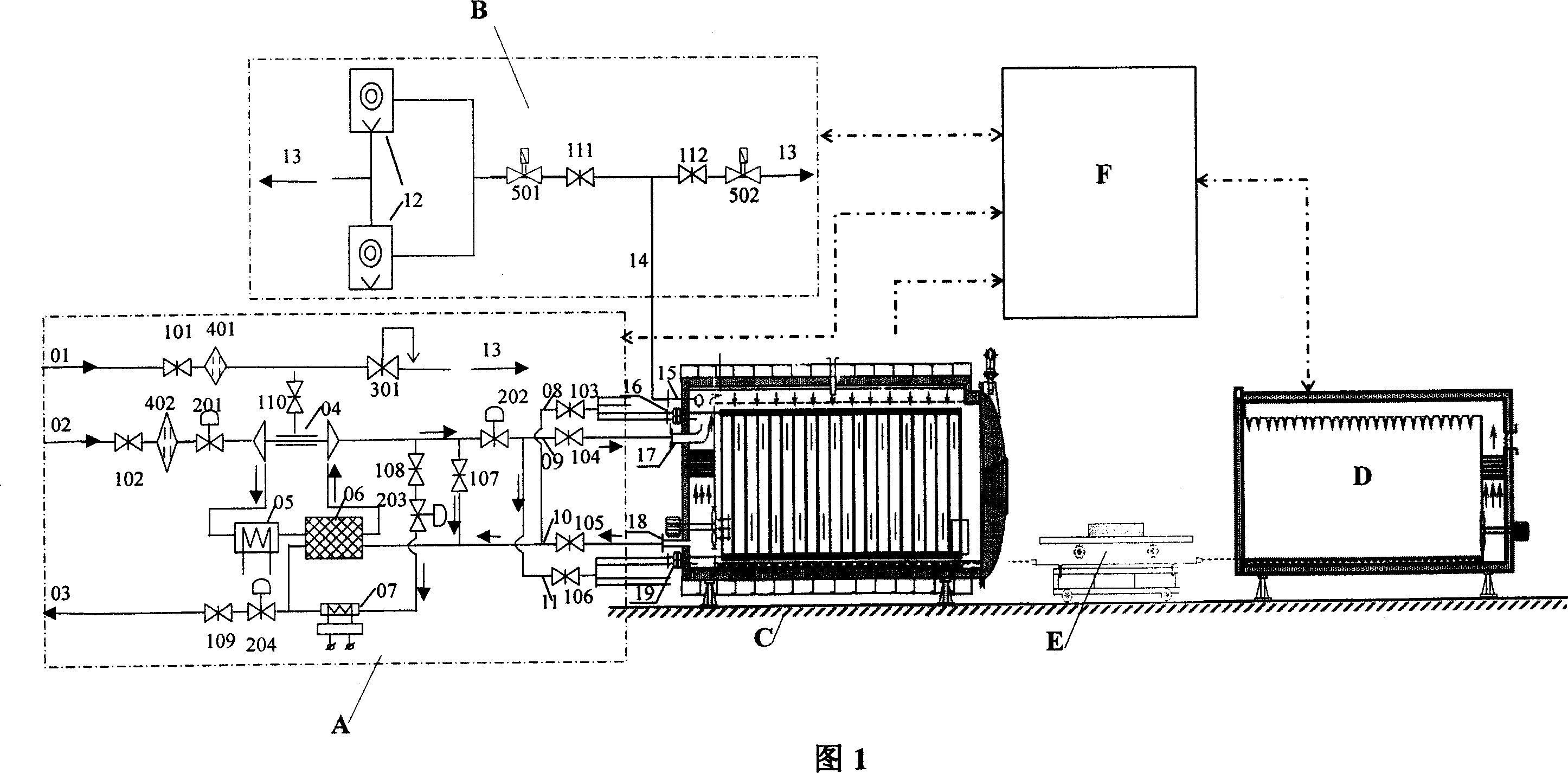

Injecting equipment for direct connection test of novel stamping engine and environment simulation system

The invention discloses injecting equipment and an environment simulation system based on the injecting equipment, wherein the injecting equipment and the environment simulation system are used for the direct connection test of a novel stamping engine. According to the technical scheme of the invention, the equipment and the system solve the problems in the prior art that an existing test environment simulation system cannot simulate the air inflow condition and meet the requirement on the injecting capacity, and is low in injecting efficiency and large in investment scale. The injecting equipment comprises a plurality of steam injecting units arranged on the gas collecting pipe of the simulation system. Each steam injecting unit comprises a high-flow steam generator and a set of two-stage steam injection pumps, wherein the set of two-stage steam injection pumps is formed through the serial connection of a first steam injection pump and a second steam injection pump. The output end of the high-flow steam generator is respectively connected with the first steam injection pump and the second steam injection pump. The first steam injection pump is connected with the gas collecting pipe through a steam injection pipe. A first steam injection and isolation valve is arranged between the first steam injection pump and the gas collecting pipe. A second steam injection and isolation valve is arranged between the first steam injection pump and the second steam injection pump.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com