Patents

Literature

211results about How to "Avoid test error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

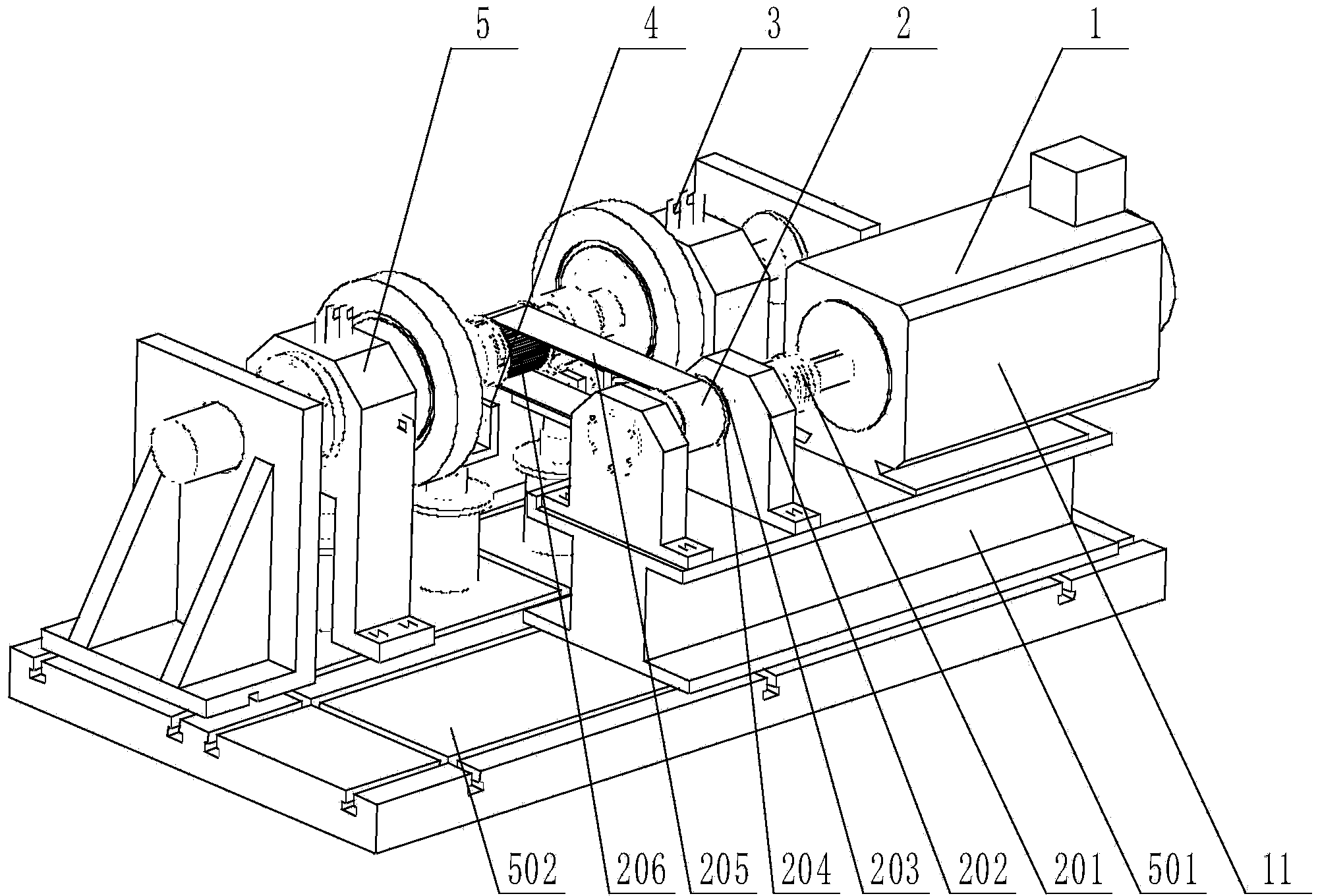

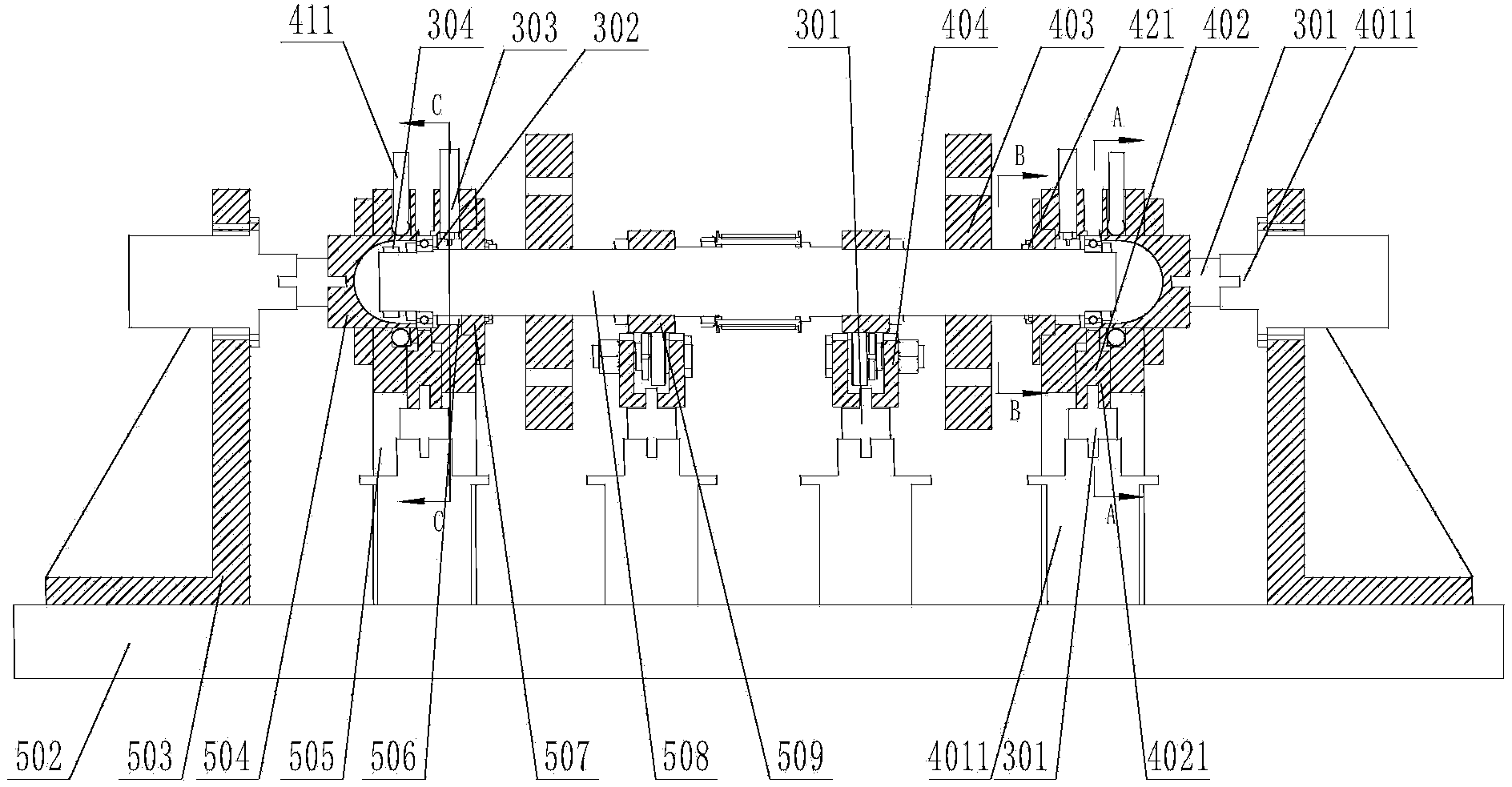

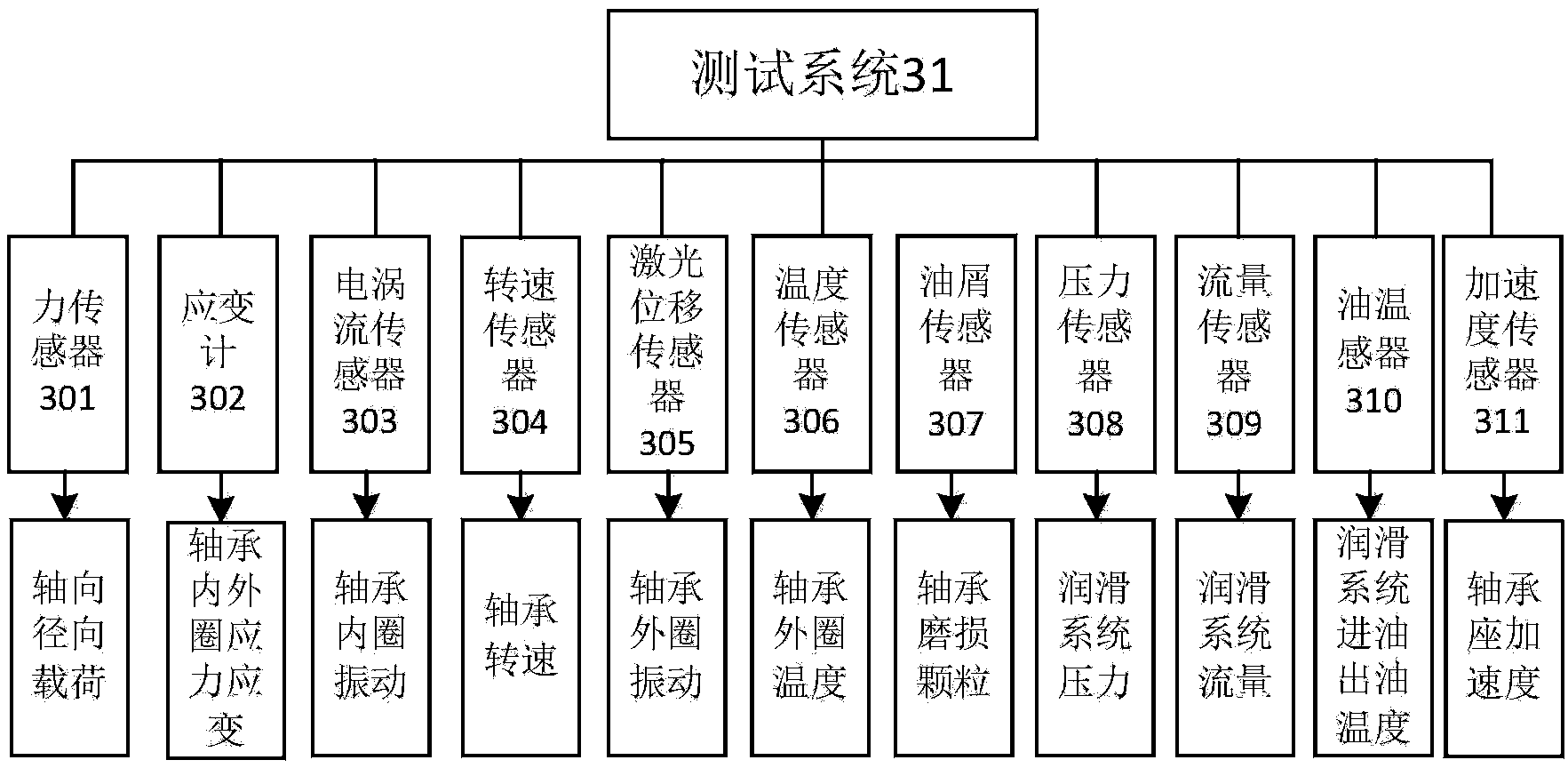

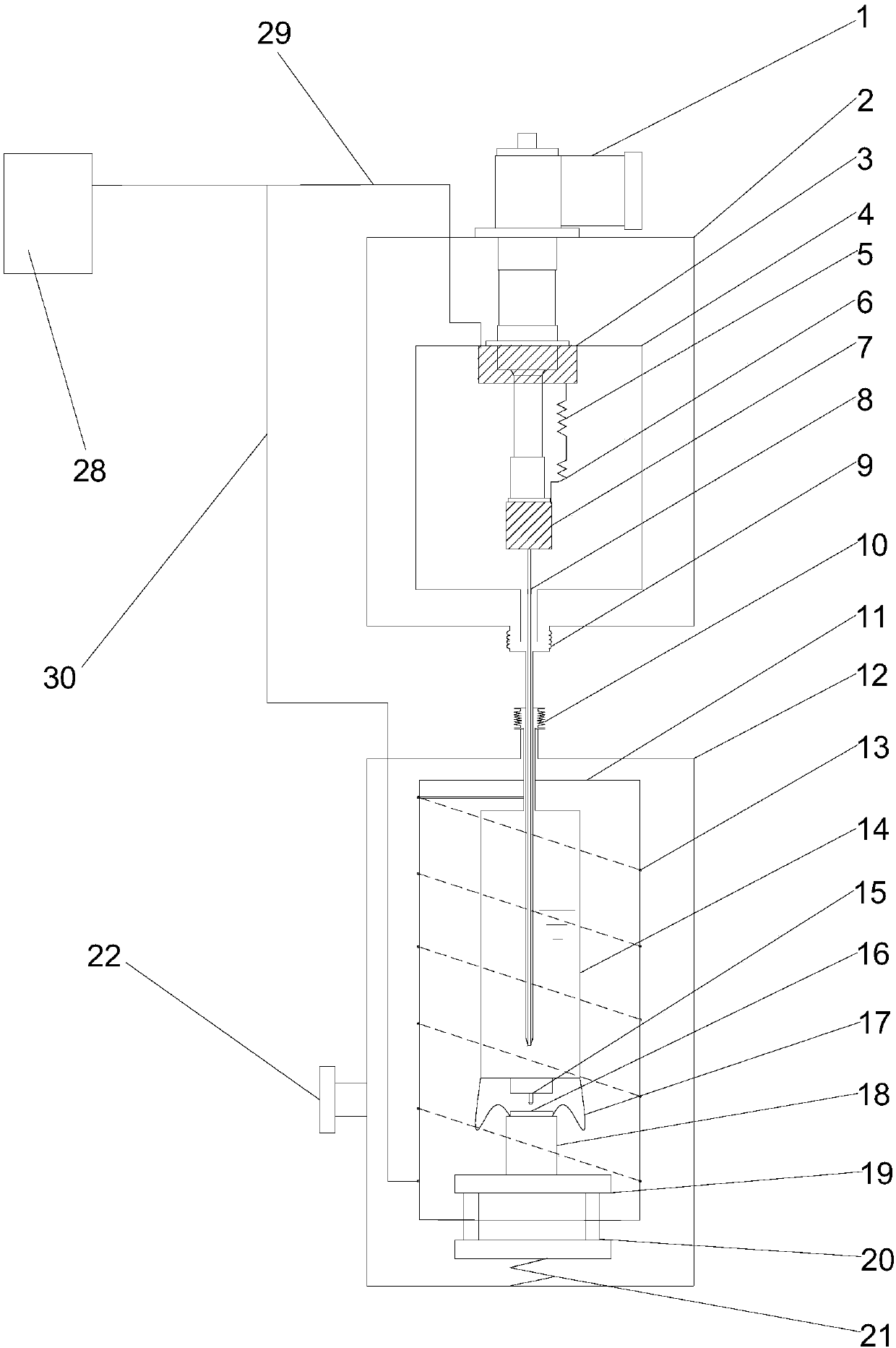

Bearing integrated dynamic performance test device and method

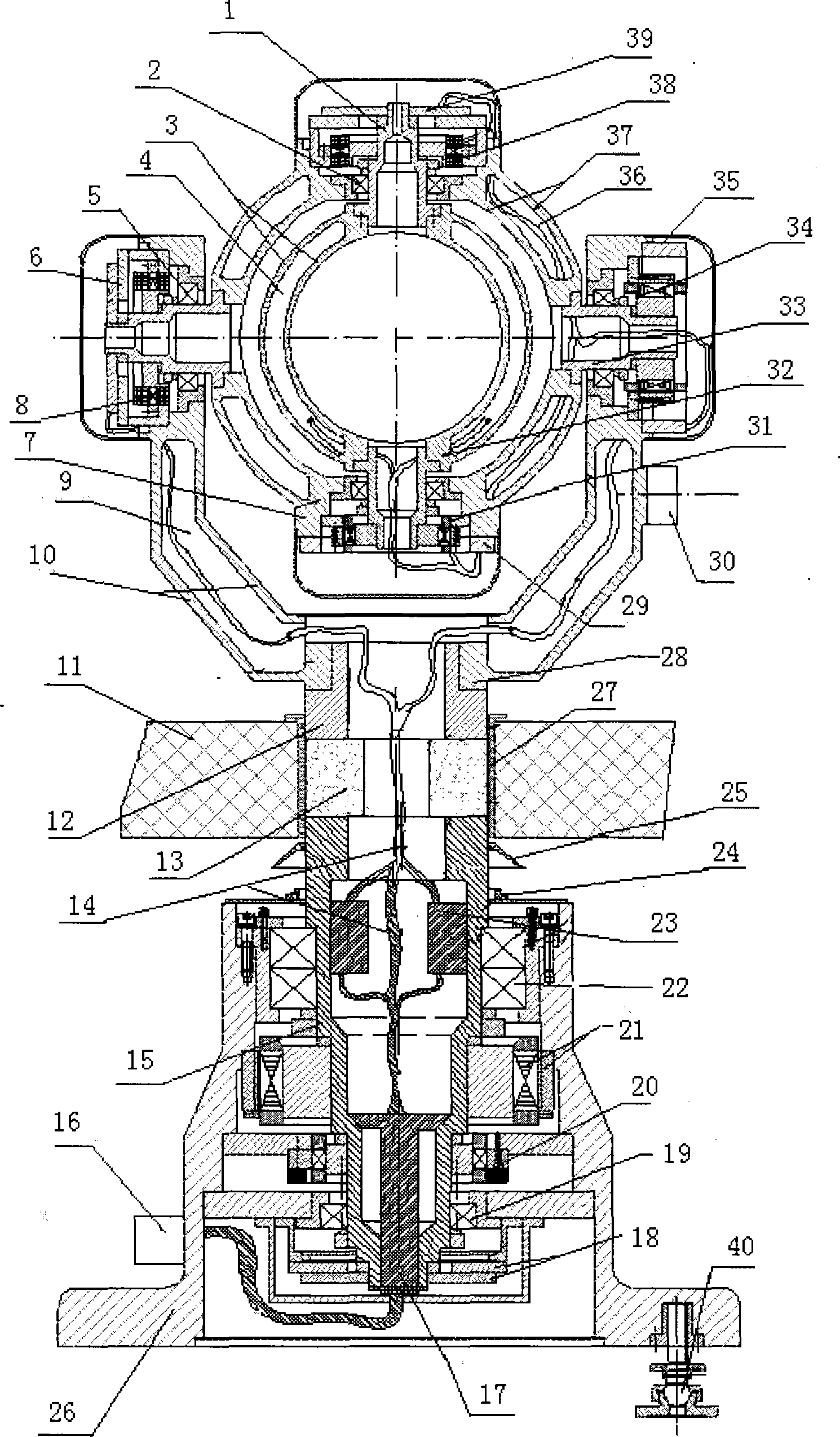

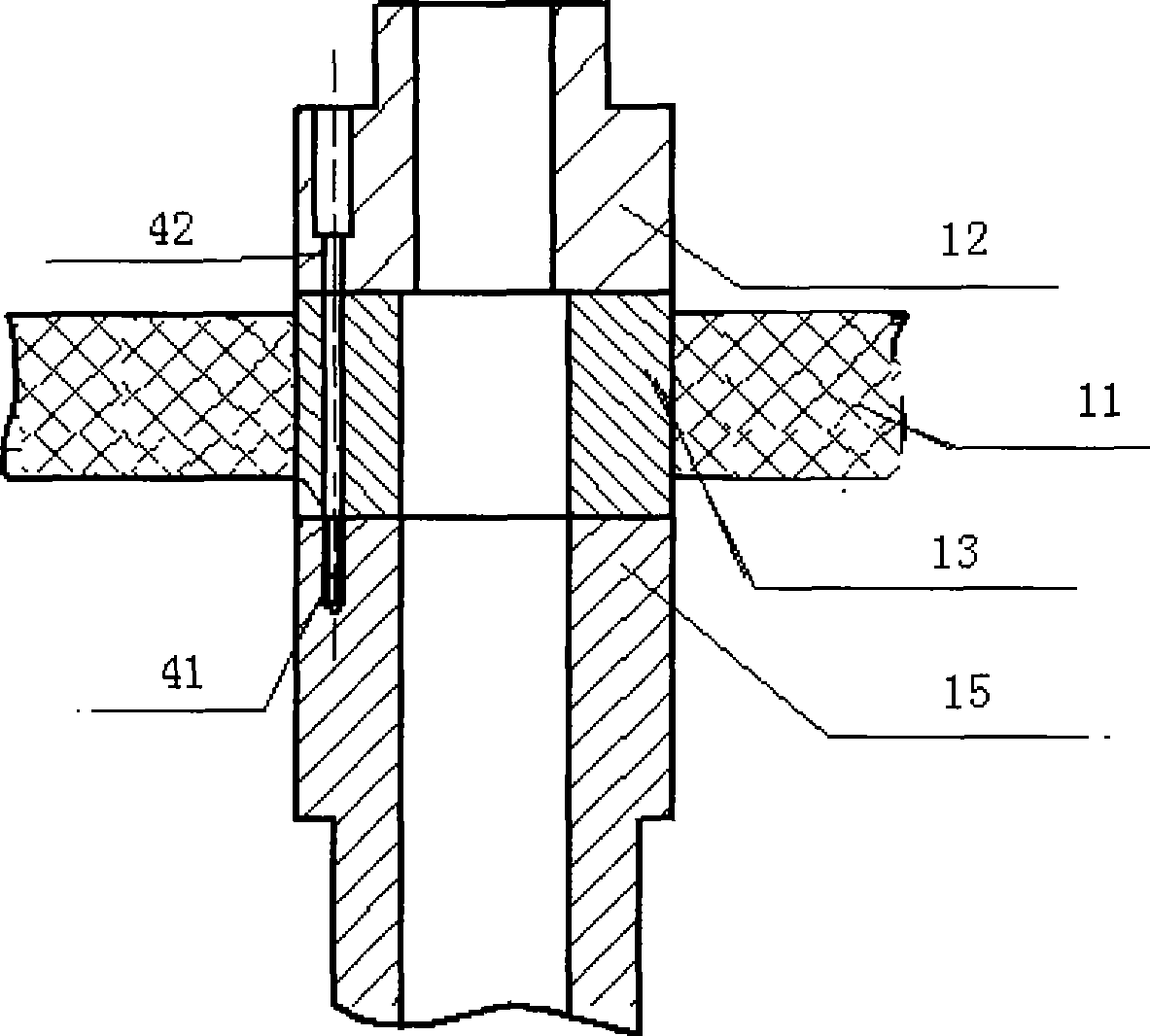

The invention relates to the technical field of bearing testing, in particular to a bearing integrated dynamic performance test device and method. The bearing integrated dynamic performance test device comprises a drive system, a transmission system, a measurement and control system, an environmental simulation system and a mechanical body structure. A motor is adopted by the drive system for driving. The measurement and control system controls the rotation speed of the motor. The transmission system is in a belt transmission mode or a coupler transmission mode. The measurement and control system is provided with a force sensor, a strainmeter, an eddy current transducer, a rotation speed sensor, a laser displacement sensor, a temperature sensor, a magnetic oil residue sensor, a pressure sensor, a flow sensor, an oil temperature sensor, an acceleration sensor and other related sensors used for bearing testing. The control system is driven in a servo mode, and is composed of a frequency converter, a hydraulic solenoid valve, a heating controller, a flow control device and a pressure control device. The environmental simulation system is adopted for simulating a real bearing testing working condition, and the performance and service life testing of the real bearing testing working condition is achieved.

Owner:DALIAN UNIV OF TECH

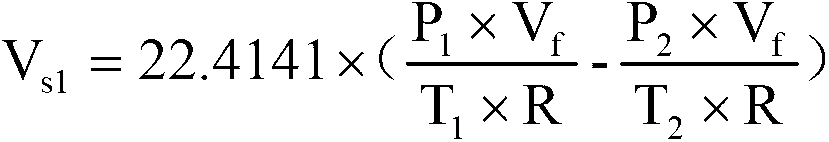

Novel shale gas content tester and shale gas content detecting method

InactiveCN103063545ASolve problems where measurements have a direct impactAvoid test errorMaterial analysisDesorptionTester device

The invention relates to a novel shale gas content tester and a shale gas content detecting method. The novel shale gas content tester comprises a device, a real-time testing system, a system and a computer collecting and processing system, wherein the device is used for desorbing a sample at a constant temperature; the real-time testing system is used for testing pressure and temperature of the sample in the desorbing process; the system is used for detecting the volume of a sample desorbing space; through a pipeline, the device for desorbing the sample at the constant temperature is connected with the real-time testing system for testing the pressure and the temperature of the sample in the desorbing process; through a pipeline, the real-time testing system for testing the pressure and the temperature of the sample in the desorbing process is connected with the system for detecting the volume of the sample desorbing space; and the real-time testing system for testing the pressure and the temperature of the sample in the desorbing process and the system for detecting the volume of the sample desorbing space are connected with the computer collecting and processing system through data wires. According to the invention, the sample is placed in the constant temperature desorbing and detecting system to detect desorption, the problem that the measurement of desorbed gas is affected because the gas of a free space can be changed with temperature and pressure conditions of a testing environment is solved.

Owner:HENGTAISHANGHE ENERGY TECH BEIJING

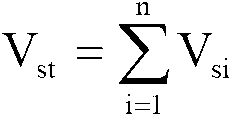

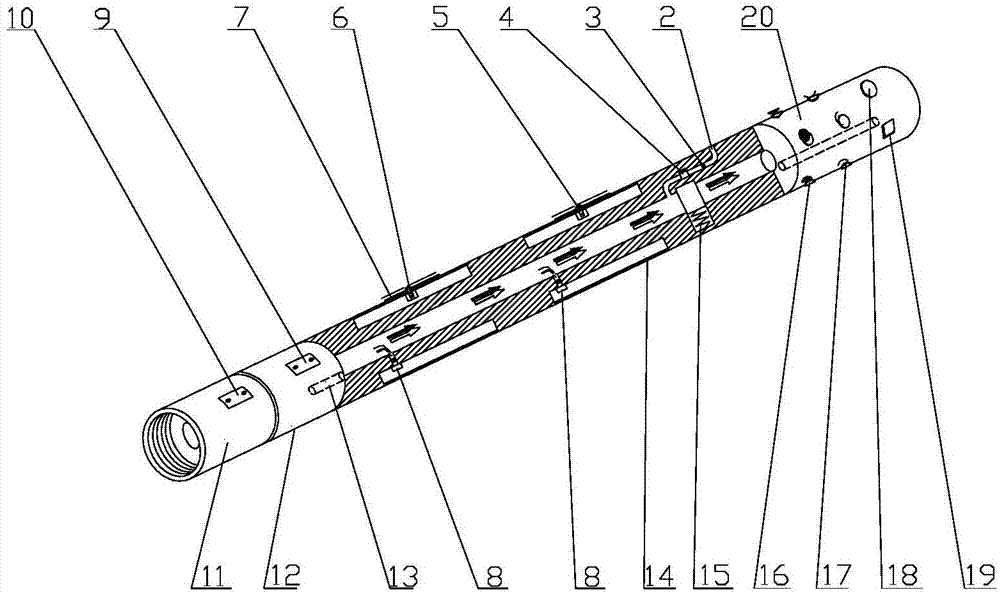

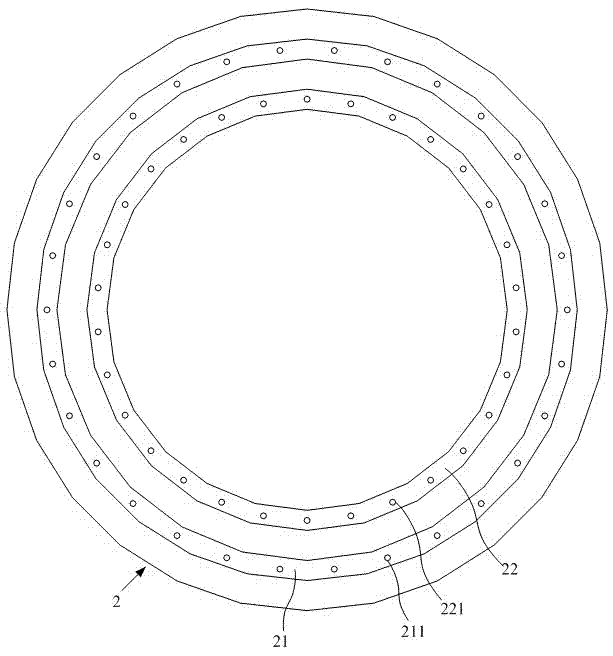

Coal seam outburst danger testing while drilling method and device

The invention provides a coal seam outburst danger testing while drilling method and device. The coal seam outburst danger testing while drilling method and device are applicable to outburst danger predication, methane gas extraction and exploitation effect evaluation and the like. By drilling a coal seam and testing methane gas parameters while drilling, lithology and coal seam information while drilling in real time, a test while drilling and grounding of the coal seam outburst danger is achieved. The device comprises a cabin body, a pressure sensor, a temperature sensor, a flow sensor, an electromagnetism sensor, an ultrasonic wave sensor, a wave velocity testing module, a monitoring control module, a power source module and a communication module and is installed between a drill and an inclinometer while drilling or a first drill rod. In the period when the coal seam is drilled or drilling is stopped for replacing the drill, the gas pressure, the temperature, the flow speed, the coal body wave velocity, the electromagnetic radiation and an ultrasonic wave signal on a testing point can be monitored and recorded in real time, and the methane gas pressure, the methane gas content, the initial desorbed methane gas content, the medium lithology, the wave speed, the coal body stress and the coal seam outburst danger on the testing point are analyzed and calculated. The coal seam outburst danger testing while drilling method and device have the advantages of being free of sampling tests and achieving testing while drilling and grounding, multi-parameter synchronous comprehensive evaluation and the like.

Owner:徐州中国矿业大学资产经营有限公司 +1

Three-shaft high-low temperature speed turntable

The invention belongs to a gyro calibrator and discloses a three-shaft high-low temperature speed turntable adaptable to high and low temperature ranges. The turntable comprises a turntable base, an outer frame, a middle frame, an inner frame, driving shafts of the outer frame, the middle frame and the inner frame, and a driving motor, wherein the outer frame has a U-shaped structure, the driving shaft of the outer frame is arranged in the turntable base; the turntable also comprises a temperature box, the outer frame, the middle frame and the inner frame are arranged in the temperature box, and a base plate of the temperature box is provided with a shaft hole which allows the driving shaft of the outer frame to pass through; the middle frame and the inner frame are standard positive circular ring shaped; and the wall of the temperature box is provided with a glass window. The three-shaft high-low temperature speed turntable has the advantages that tests on a gyro in three directions in a high temperature environment and a low temperature environment can be performed simultaneously, and the turntable has low requirement on the motor moment and has high test efficiency.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH

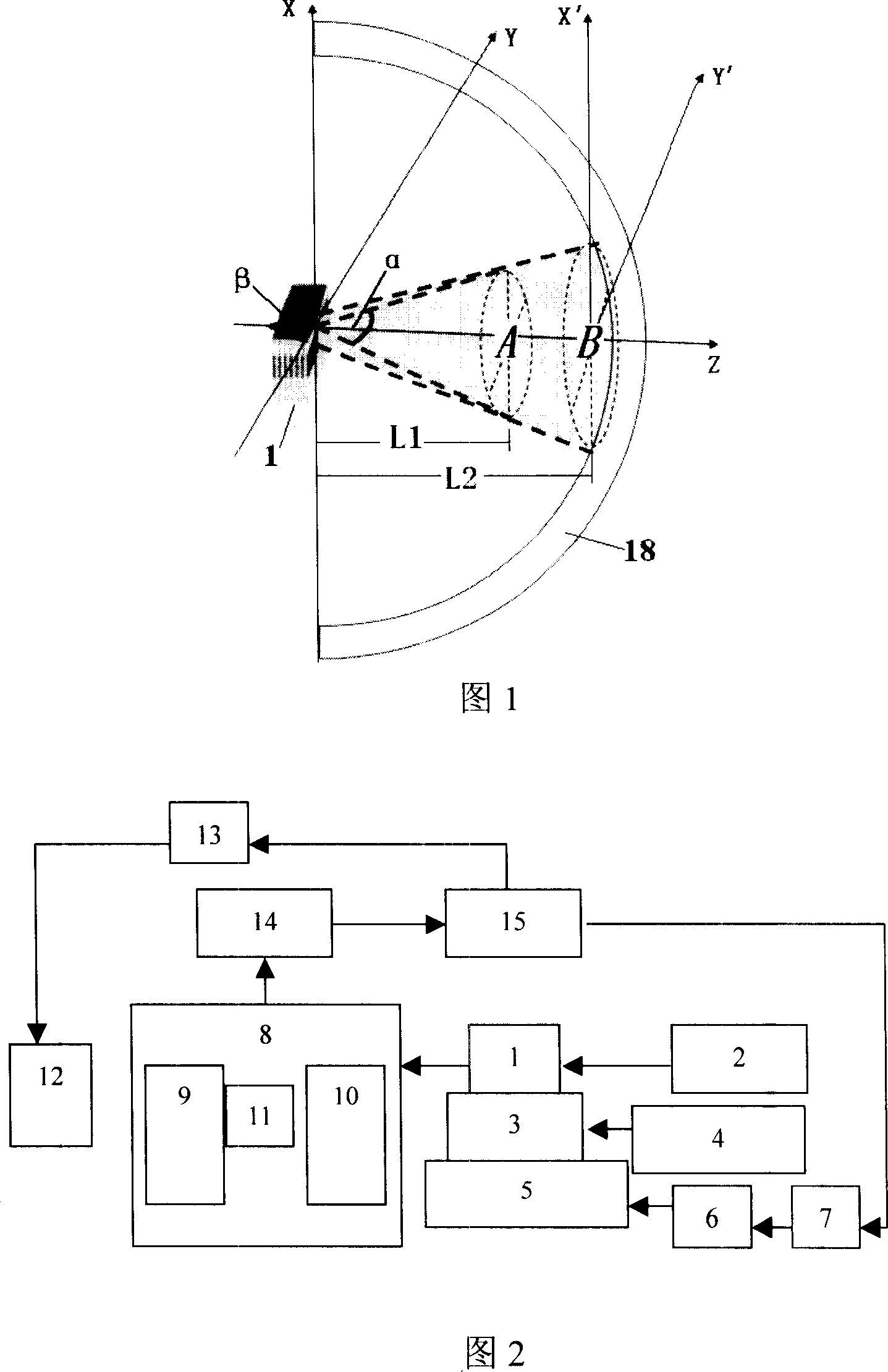

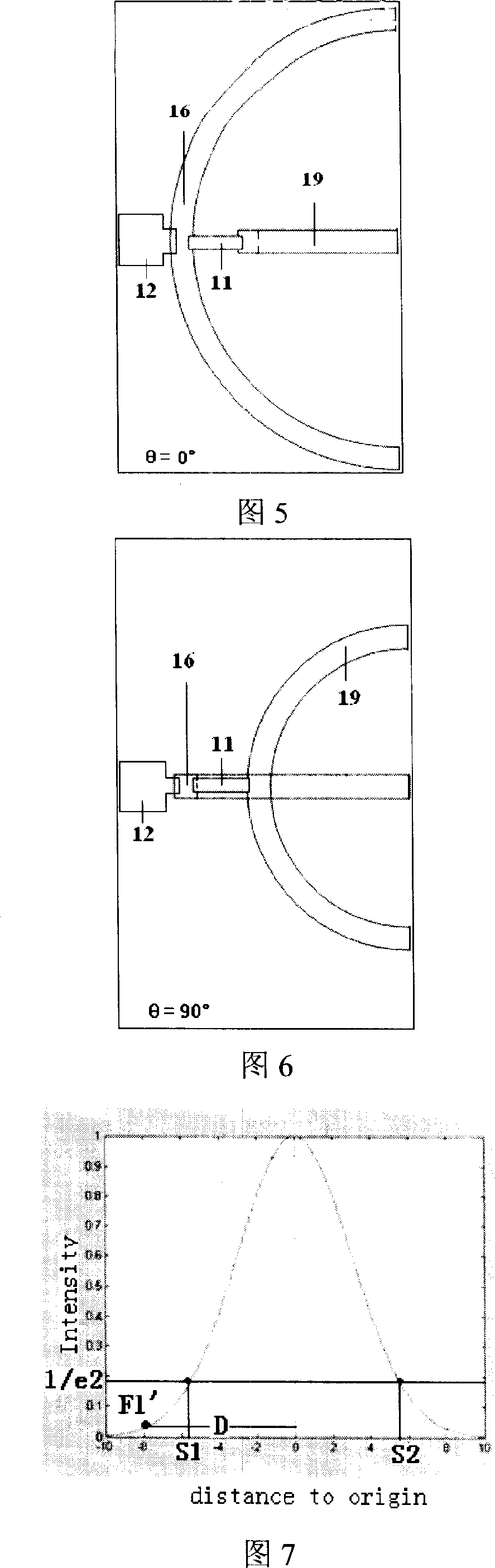

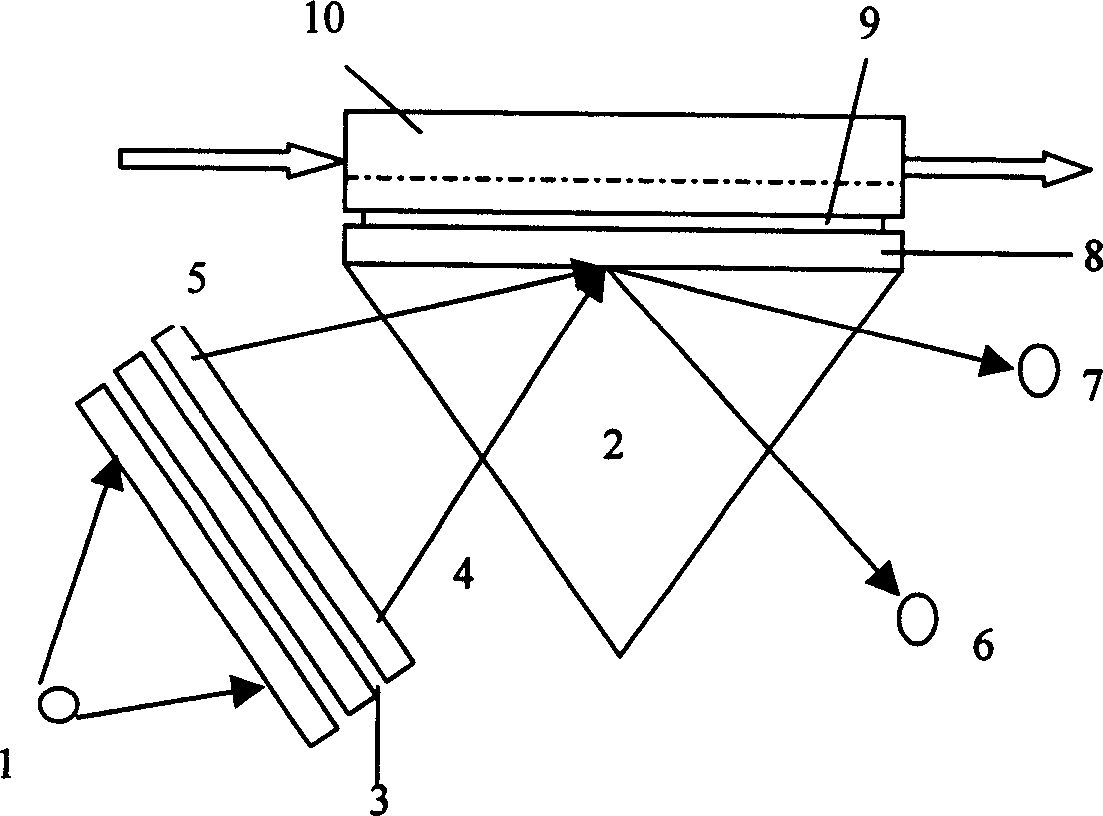

Method and its device for detecting high energy semiconductor laser divergence angle

InactiveCN101005191AAvoid test errorSolve the problem that the divergence angle of high-energy lasers cannot be testedLaser detailsSemiconductor lasersHigh energyLight spot

Using geometric characteristics of outer margin curves of two light spots at different distances along direction of beam transmission, the disclosed method obtains divergence angle of laser. Through rotational scanning detection, concentric placed two light detectors perpendicular to each other obtain outer margin curves. Multiple optical fibers are distributed on the said light detector evenly. The disclosed device is composed of drive power supply, cooling water platform, cooling water circulation system, 4D traveling platform, electrical motor set, drive, data acquisition module, and PC etc. The light-receiving module includes light detectors. The light-receiving module, data acquisition module, and PC are connected electrically. The invention solves issue of test error caused by regarding face radiation of area array laser as spot light source so as to avoid damaging and burning detector caused by too large power of laser. Advantages are: accurate and reliable.

Owner:DALIAN MARITIME UNIVERSITY

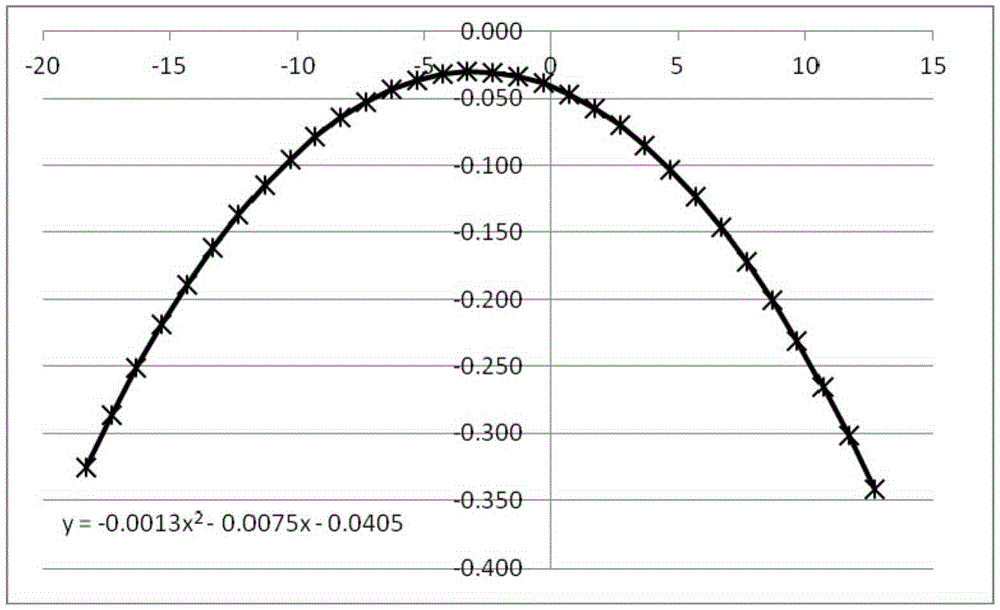

Calibration method and calibration apparatus for positioning error of position sensitive detector

InactiveCN105423917AEasy to adjustImprove test accuracyUsing optical meansSemiconductor packageLight beam

The invention provides a calibration method and calibration apparatus for a positioning error of a position sensitive detector (PSD). The calibration apparatus is composed of an electrically controlled translation bench, a single-shaft precision rotary table, a semiconductor laser for transmitting a light beam to the PSD, and a laser clamping device for clamping the semiconductor laser. The single-shaft precision rotary table is fixed on the electrically controlled translation bench and the PSD is arranged on the electrically controlled translation bench. According to the method, the normal of the photosensitive surface of the PSD can be adjusted to be perpendicular to the moving direction of the electrically controlled translation bench easily, thereby avoiding a testing error caused by coordinate system rotation and improving the testing precision of the PSD positioning error.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

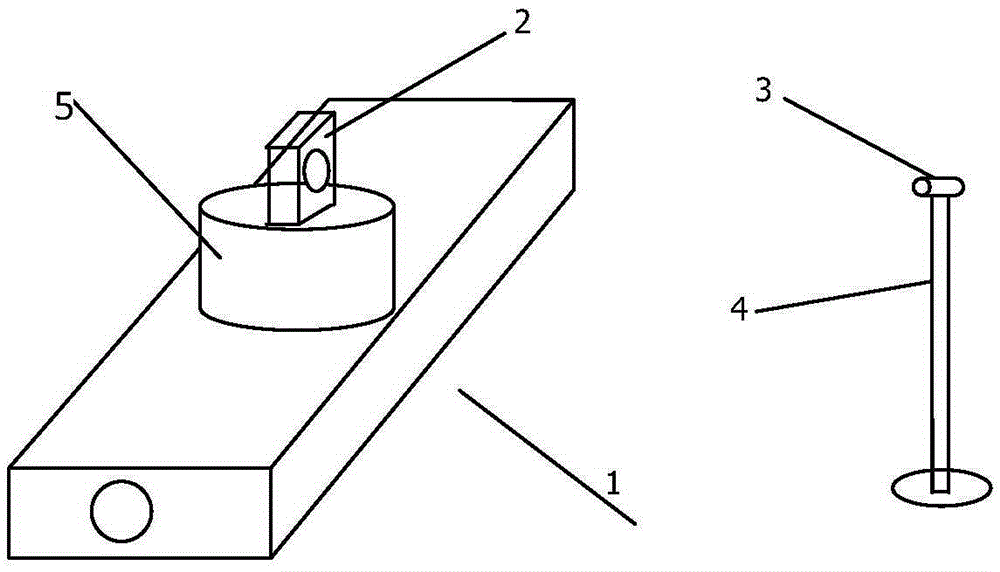

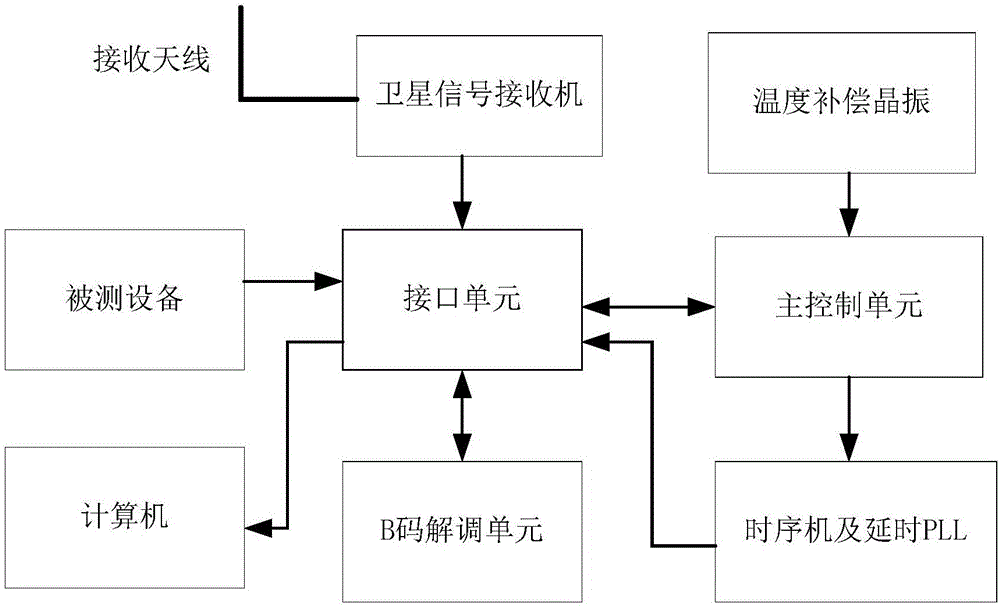

Time-keeping and timing precision test device, time-keeping precision test method and timing precision test method based on satellite timing system

ActiveCN106656451AThe testing process is simpleEasy to implementSynchronisation information channelsRadio-controlled time-piecesSequential machineArrival time

The invention belongs to the field of a photoelectric test and relates to a time-keeping and timing precision test device, time-keeping precision test method and timing precision test method based on the satellite timing system. The device comprises a receiving antenna, a satellite signal receiver, an interface unit, a B code demodulation unit, a master control unit, a sequential machine and delay PLL unit, a computer and a temperature compensation crystal oscillator. The time-keeping precision and timing precision are calculated in a mode of recording arrival time of a to-be-tested signal, and the time-keeping and timing precision test device, the time-keeping precision test method and the timing precision test method based on the GPS / Beidou system are simple in test process and easy in engineering realization.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

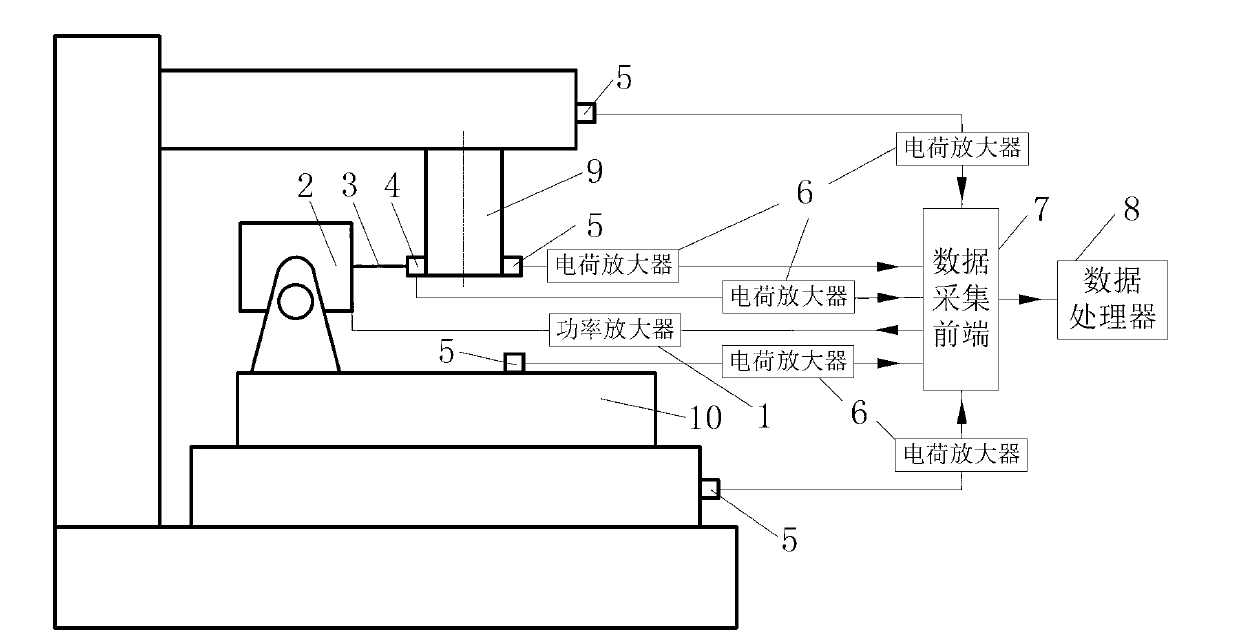

System and method for synchronously acquiring load and response signals of machine tool vibration test

InactiveCN103217266ARealize synchronous acquisitionAvoid test errorVibration testingObservational errorData acquisition

The invention relates to a system and a method for synchronously acquiring load and response signals of a machine tool vibration test. The system comprises four parts, namely an excitation subsystem, a response signal acquisition subsystem, a data acquisition front end and a data processor, wherein the excitation subsystem comprises a power amplifier, a vibration exciter and a vibration exciting rod; the response signal acquisition subsystem comprises a force sensor, multiple acceleration sensors and multiple charge amplifiers; the input end of the data acquisition front end is connected with the response signal acquisition subsystem; one output end of the data acquisition front end is connected with the excitation subsystem, and the other output end of the data acquisition front end is connected with the input end of the data processor; and the data processor prestores a program for performing data processing on the load and response signals. The test system can be used for avoiding measurement errors caused by signal delay, filtering out errors in acceleration signals, and accurately analyzing the dynamic vibration response of each part and the complete machine of a machine tool, and has the advantages that the test is accurate, the operation is simple and the like.

Owner:TSINGHUA UNIV

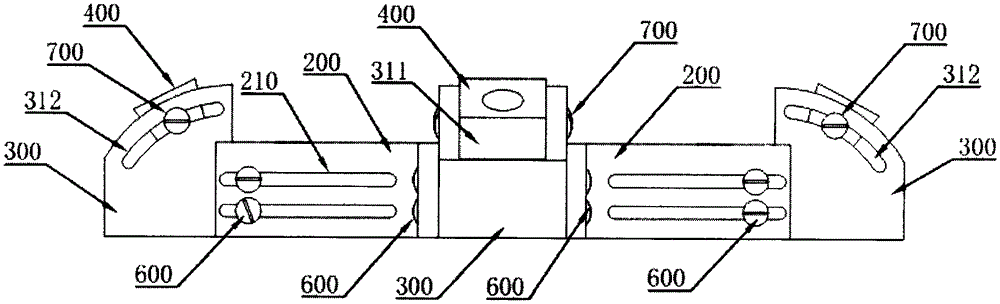

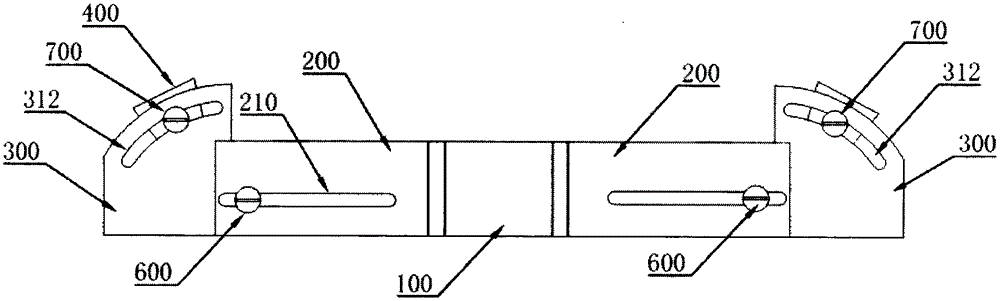

Ultrasonic-wave stress detection device capable of adjusting acoustic beam angle and test area

ActiveCN105300578AAchieving Residual Stress TestingSatisfy customersForce measurementBeam angleHeat-affected zone

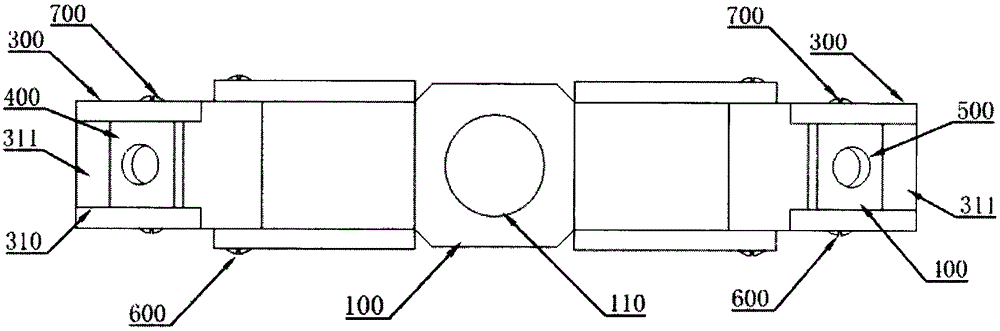

Provided is an ultrasonic-wave stress detection device capable of adjusting an acoustic beam angle and a test area. The detection device comprises a center positioning bench (100). Parallel guide rail racks (200) are fixed on opposite side faces of the center positioning bench (100) and are slidably connected with a glass pedestal (300). A U-type groove rail (310) with a protruding arc guide rail face (311) is arranged on the upper part of the glass pedestal (300). A probe fixing wedge (400) is slidably connected with the side wall of the U-type groove rail (310). The recessed arc face of the probe fixing wedge (400) cooperates with the protruding arc guide rail face (311) of the U-type groove rail (310). A probe fixing cavity (500) used for fixing an ultrasonic-wave probe is arranged on the upper part of the probe fixing cavity (500). According to the invention, adjustment and correction of first critical angles of a welded seam and of a heat affected zone and residual stress tests for different kinds of materials can be achieved; and residual stress tests of to-be-tested workpieces in different areas of regions can be achieved.

Owner:SOUTHWEST JIAOTONG UNIV

Test method and device of working fluid level of oil well

ActiveCN102080536AImprove test accuracyAvoid test errorSurveyConstructionsStandard stateWorking fluid

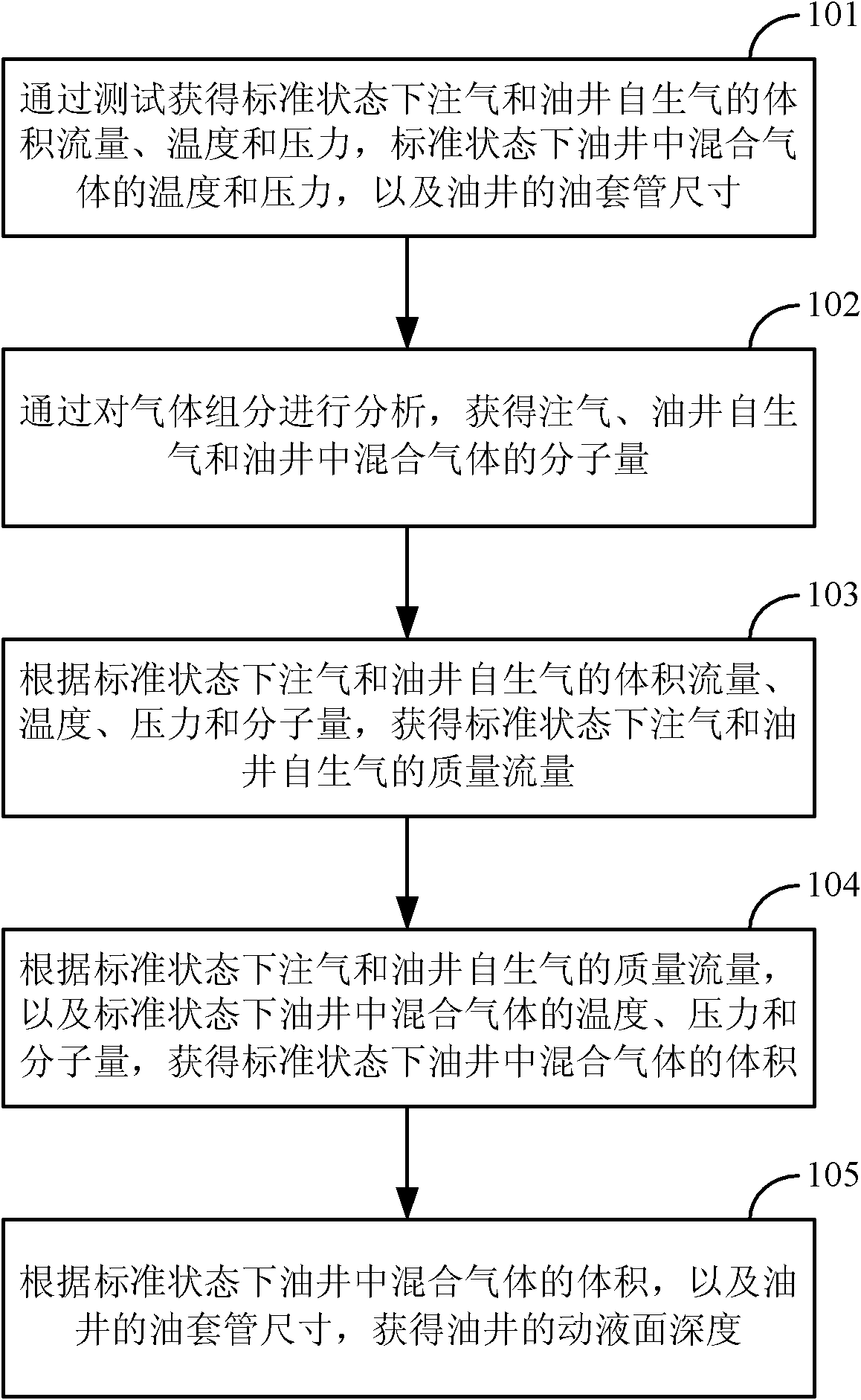

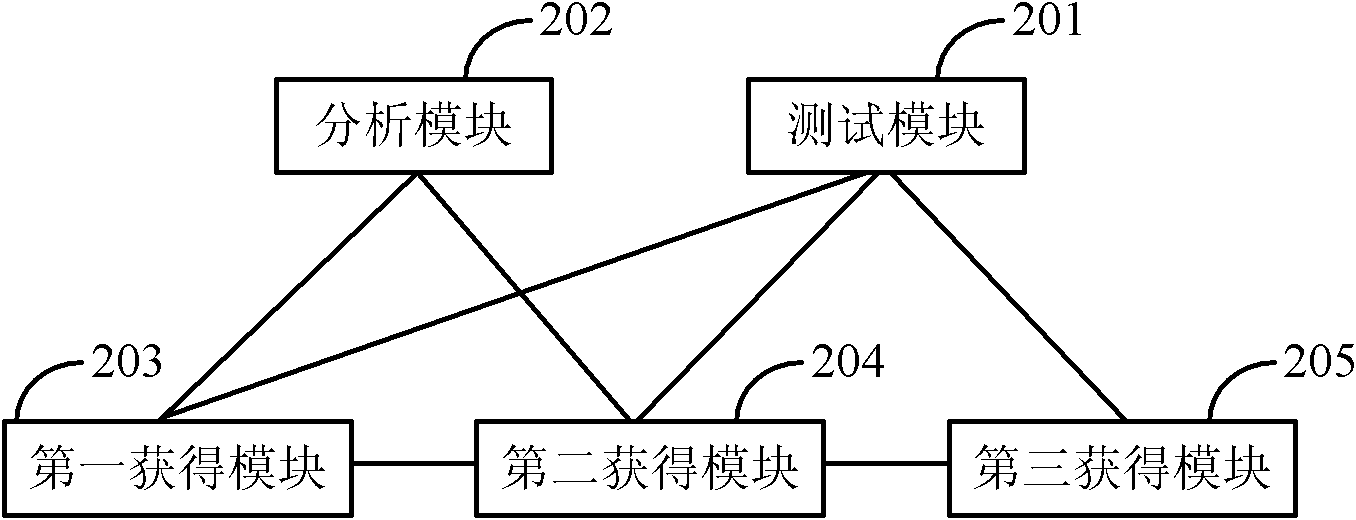

The invention discloses a test method and device of a working fluid level of an oil well. The test method comprises the following steps: obtaining volume flow rate, temperature and pressure of injected gas and self-produced gas of the oil well under a standard state, temperature and pressure of mixed gas in the oil well, and size of an oil sleeve of the oil well through test; analyzing gas components to obtain molecular weight of the injected gas, the self-produced gas of the oil well and the mixed gas in the oil well; obtaining mass flow rate of the injected gas and the self-produced gas of the oil well under the standard state according to the volume flow rate, the temperature, the pressure and the molecular weight of the injected gas and the self-produced gas of the oil well under the standard state; obtaining volume of the mixed gas in the oil well under the standard sate according to the mass flow rate of the injected gas and the self-produced gas of the oil well under the standard state as well as the temperature, the pressure and the molecular weight of the mixed gas in the oil well under the standard state; and obtaining depth of the working fluid level of the oil well according to the volume of the mixed gas in the oil well under the standard state and the size of the oil sleeve of the oil well. By utilizing the method and the device, the test accuracy of the working fluid level of the oil well can be improved, thus being particularly applicable to a production well with higher gas-oil ratio or a heavy oil production well.

Owner:PETROCHINA CO LTD

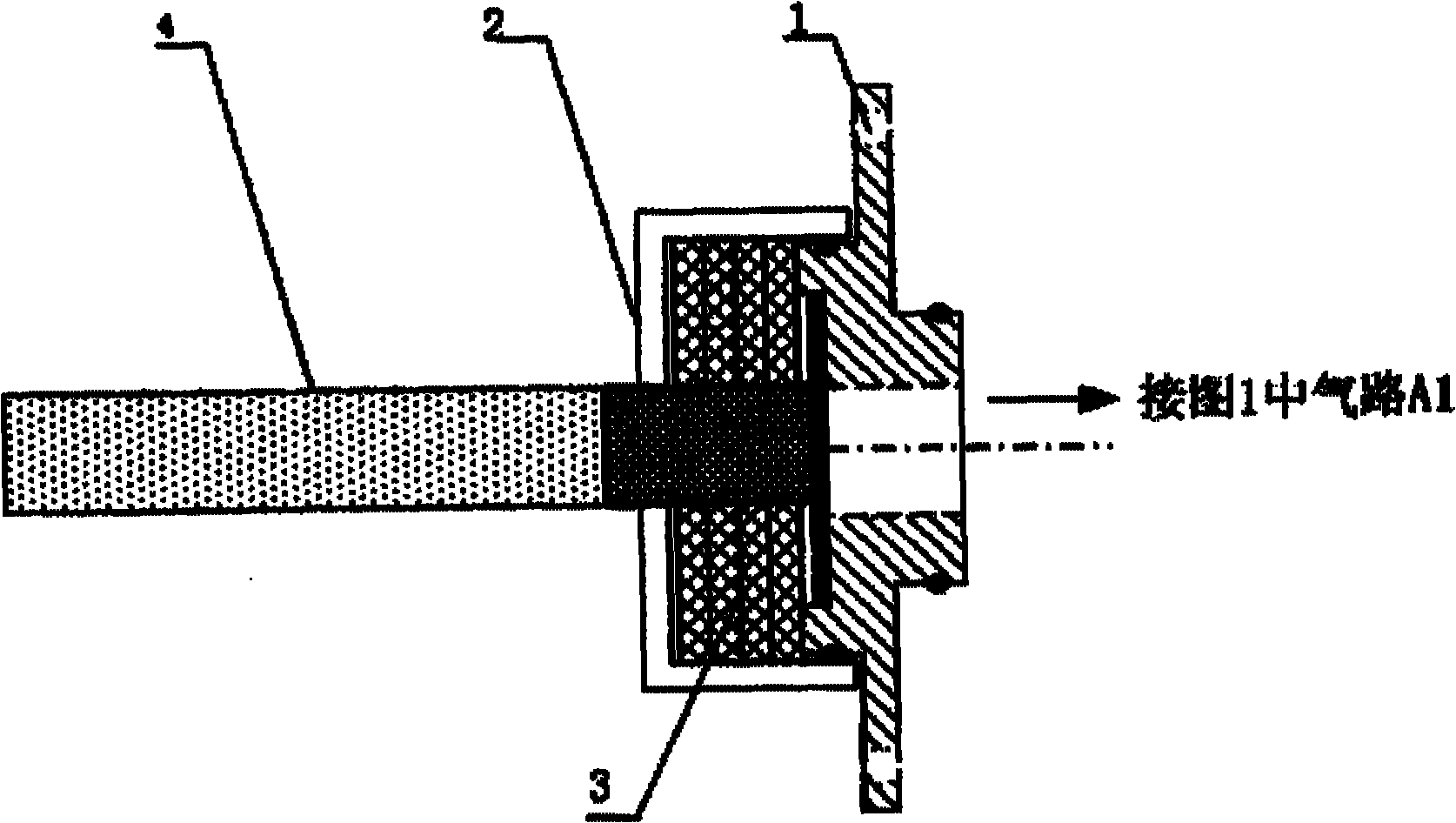

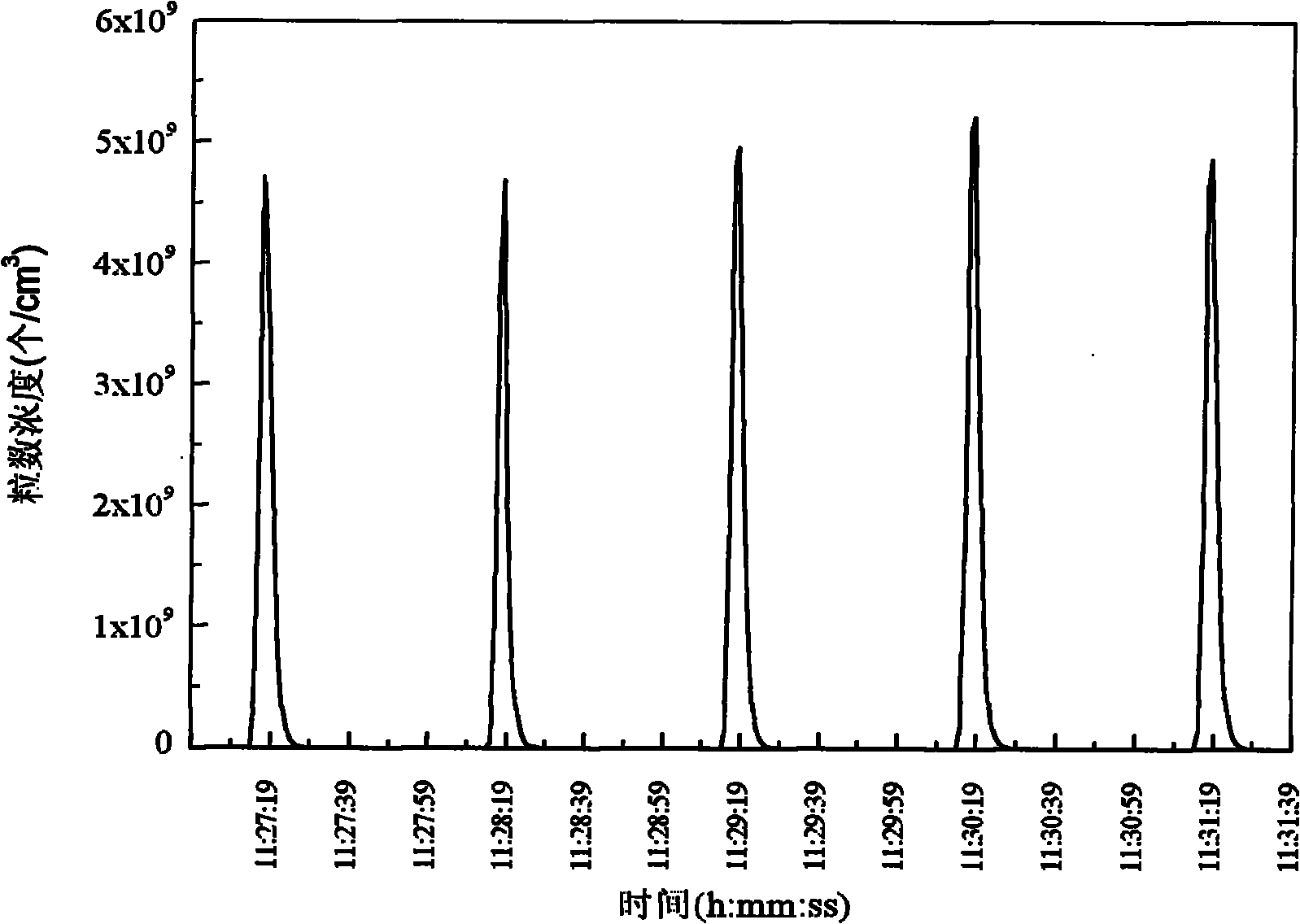

Cigarette smoke aerosol real-time testing system

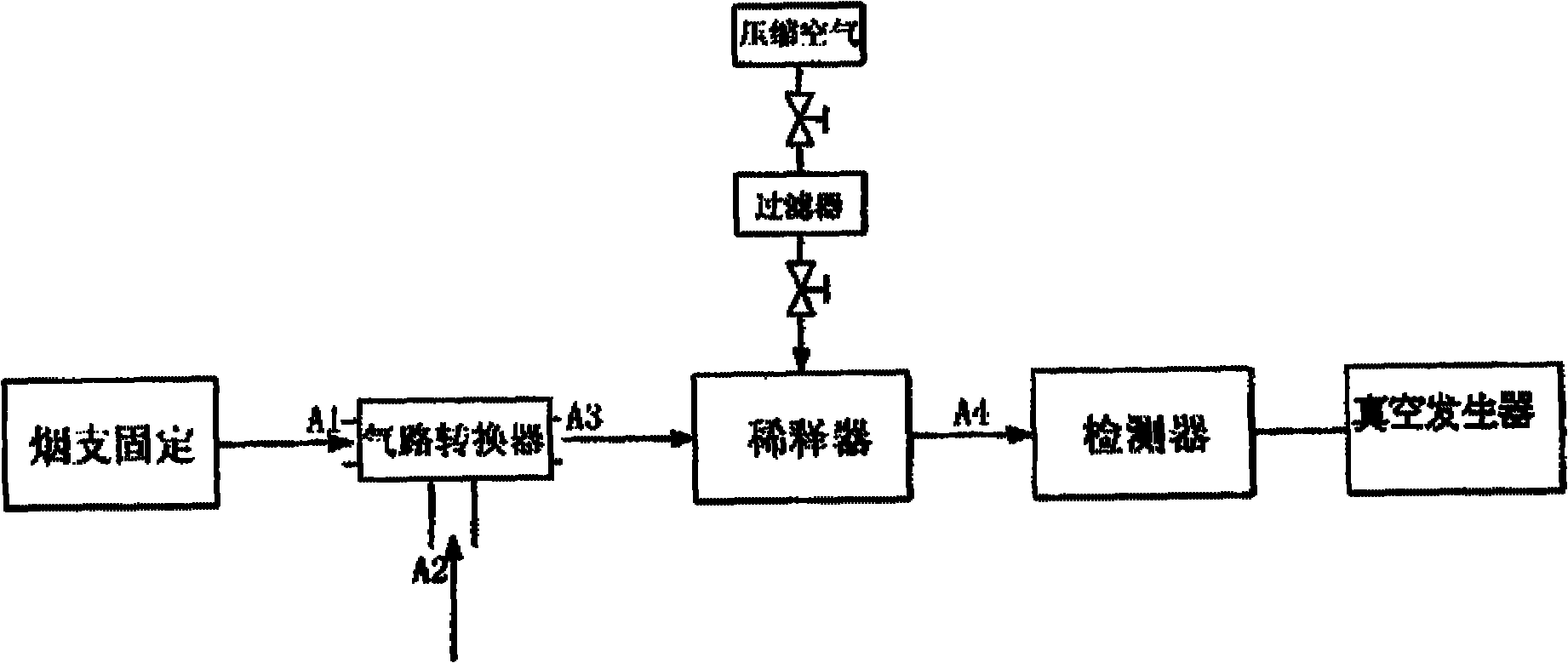

ActiveCN101788447ASample Time AdjustmentFlow adjustableWithdrawing sample devicesPreparing sample for investigationParticulatesEngineering

The invention provides a cigarette smoke aerosol real-time testing system, which is characterized in that the testing system comprises a sample smoke generation device, a smoke dilution device, an aerosol particulate detection device and connecting pipelines. Compared with the prior art, the system has outstanding substantial characteristics and remarkable progress mainly shown in: 1) the real-time measurement of the particles size, particle concentration and distribution states of cigarette smoke aerosol particles can be realized; 2) fresh smoke is produced and then is immediately diluted and detected so as to avoid test errors caused by the intensive interaction of long pipelines, long residence time and high particle concentration when a smoke-sucking machine samples; 3) the connecting pipelines among the sample smoke generation device, the smoke dilution device and an aerosol particulate detection system are short and can adopt pipe material of which lining is anti-adsorption material so as to reduce test errors caused by pipe-wall adsorption; 4) the system is compact in structure, small in volume and convenient to move; and 5) the system can regulate smoke-sampling time, flow and other parameters so as to satisfy the measurement under a standard suction mode and a non-standard suction mode.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Ultralow-temperature and ultralow-vibration friction testing device

InactiveCN107560958AAchieve vibration isolationLow costInvestigating abrasion/wear resistanceCold shieldEngineering

The invention discloses an ultralow-temperature and ultralow-vibration friction testing device, which comprises a helium liquefying mechanism, a friction mechanism and a storage tank, wherein the helium liquefying mechanism comprises a first vacuum hood and a first cold shield arranged in the first vacuum hood; a refrigerator penetrates through the first vacuum hood; a first-level heat exchanger and a second-level heat exchanger connected with a liquid conveying pipe are arranged on the refrigerator; the first-level heat exchanger and the second-level heat exchanger are positioned in the firstcold shield; the friction mechanism comprises a second vacuum hood, a second cold shield and an insulating bracket; the second cold shield and the insulating bracket are arranged in the second vacuumhood; the second vacuum hood is connected below the first vacuum hood; a liquid helium cavity is formed in the second cold shield; an exit of the liquid conveying pipe is formed in the liquid heliumcavity; an upper sample support is arranged on the outer bottom wall of the second cold shield; a movable displacement platform is arranged on the insulating bracket; a lower sample support is arranged on the displacement platform; the upper sample support and the lower sample support face each other up and down; the storage tank is connected with the first-level heat exchanger through a gas supplementing pipe and connected with the liquid helium cavity through a gas return pipe. According to the invention, a friction test of a sample can be realized in an environment with ultrahigh vacuum degree and ultralow temperature.

Owner:TSINGHUA UNIV

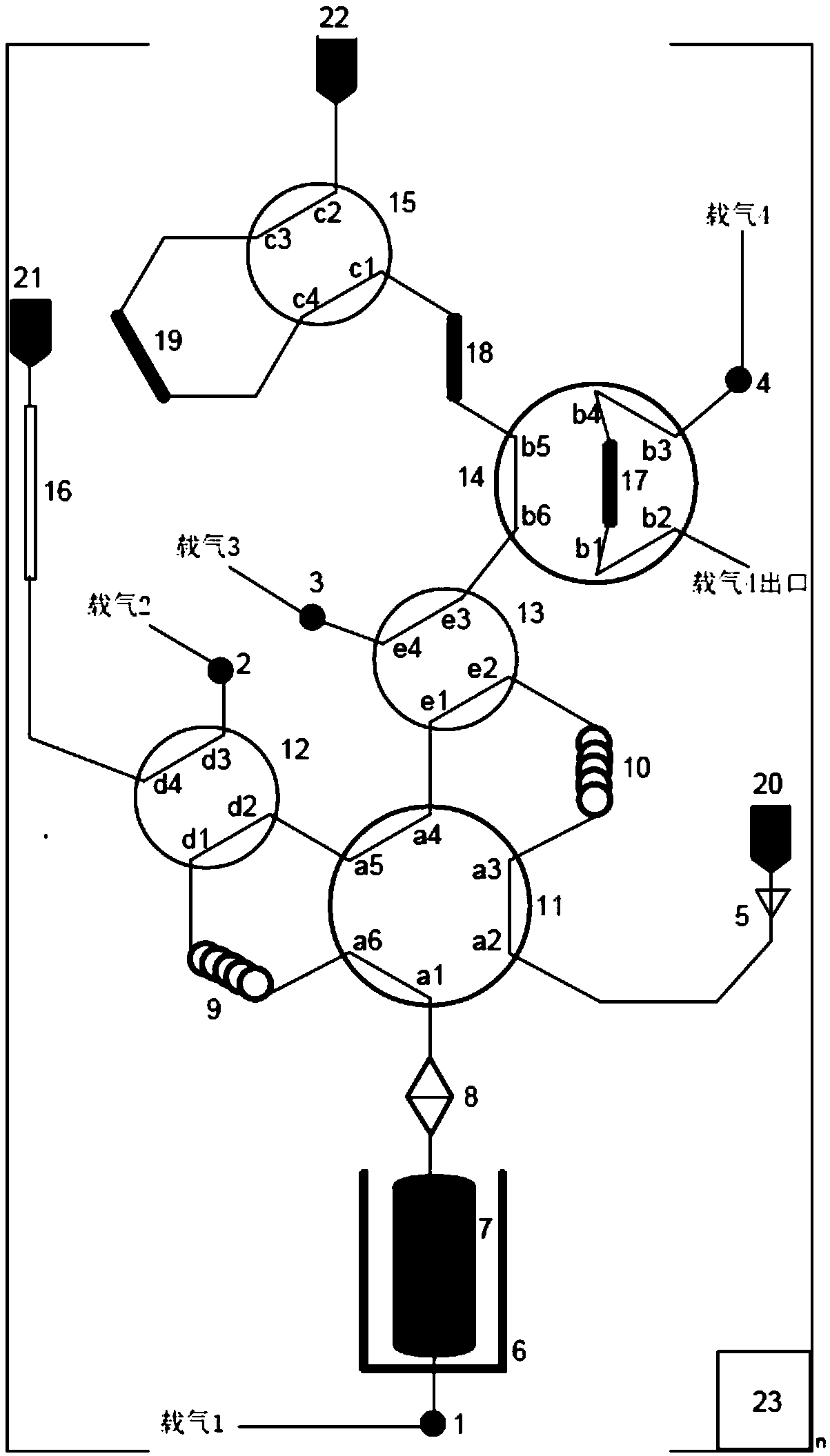

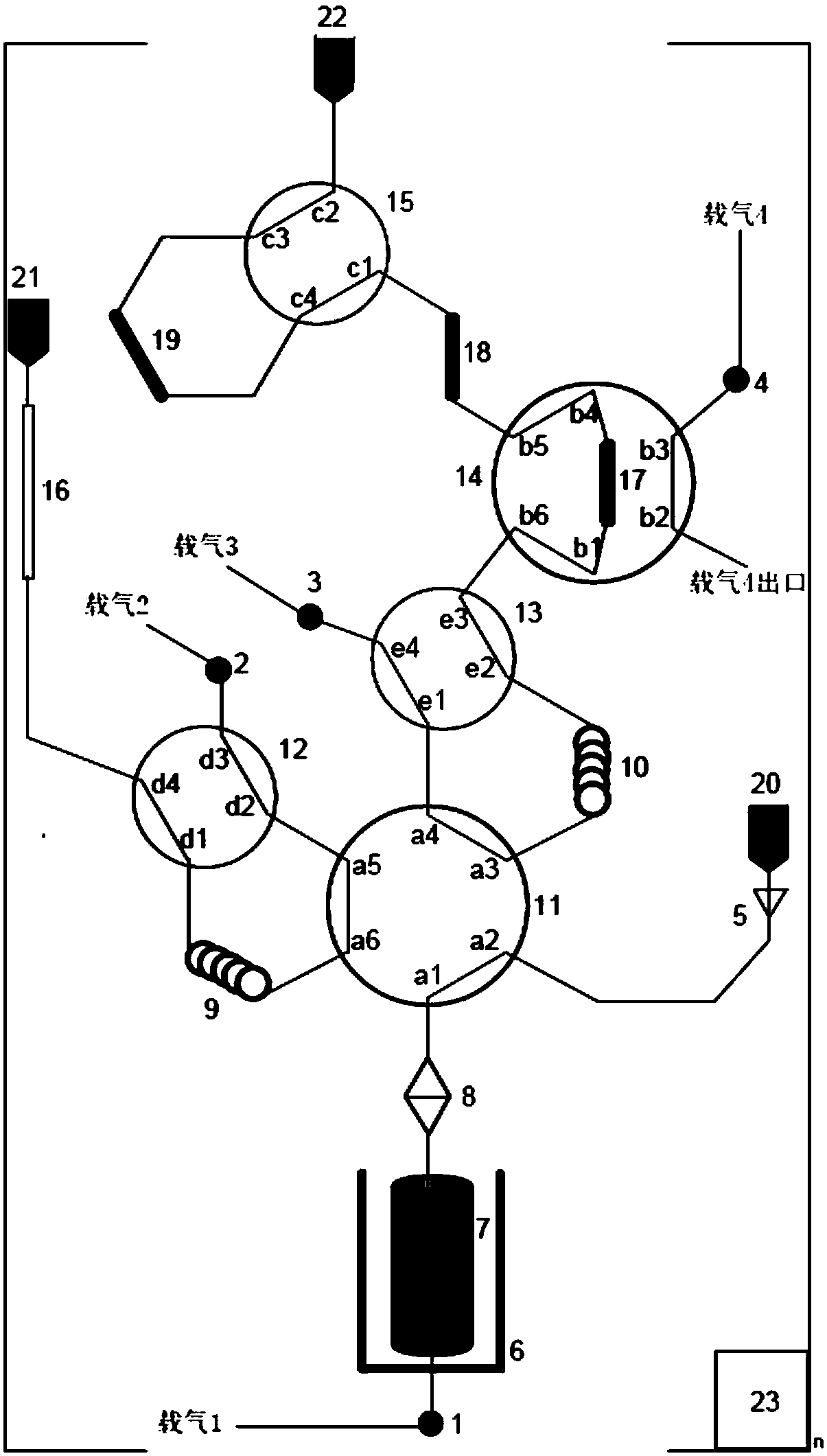

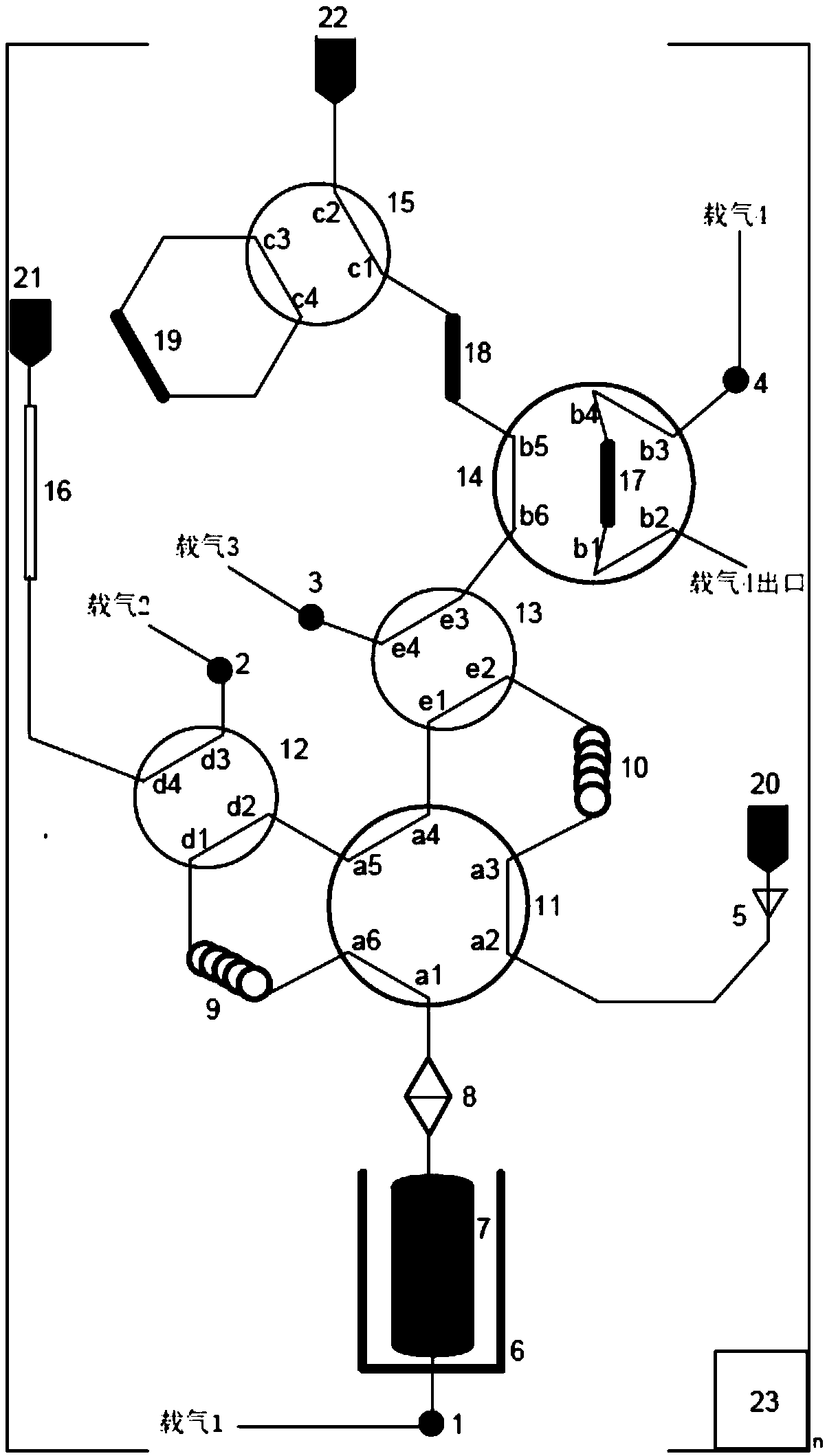

Shale gas-content comprehensive analysis device and method thereof

PendingCN109540735AImprove reliabilityGuaranteed timelinessComponent separationProduct gasAnalysis method

The invention relates to a shale gas content comprehensive analysis device. The device comprises a gas content test unit, a hydrocarbon gas component analysis unit, an inorganic gas component analysisunit, and an operation control unit. The invention further discloses a shale gas content comprehensive analysis method based on the device. The technical scheme for resolving gas component and the change thereof in the online analysis and monitoring resolution process is realized when performing the gas content resolution test on the shale core at a shale gas drilling field by using the technicalscheme disclosed by the invention, the reliability and the instantaneity of the test data can be effectively improved, so that the test data can preferably serve the shale gas exploration and development engineering implementation, and provide more scientific and more reliable gas content data for the shale gas resource exploration and assessment.

Owner:NAT RESERACH CENT OF GEOANALYSIS

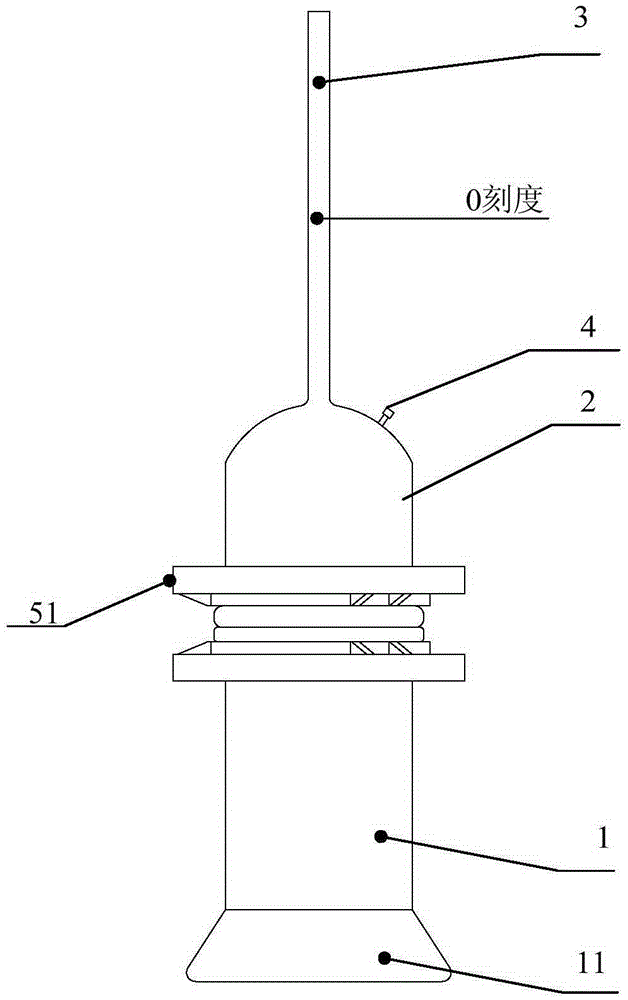

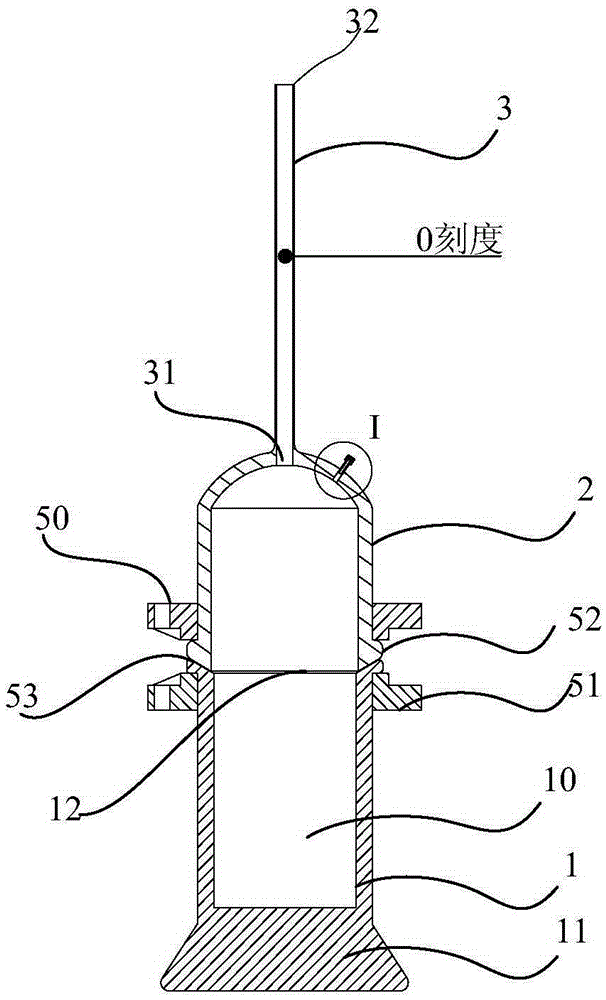

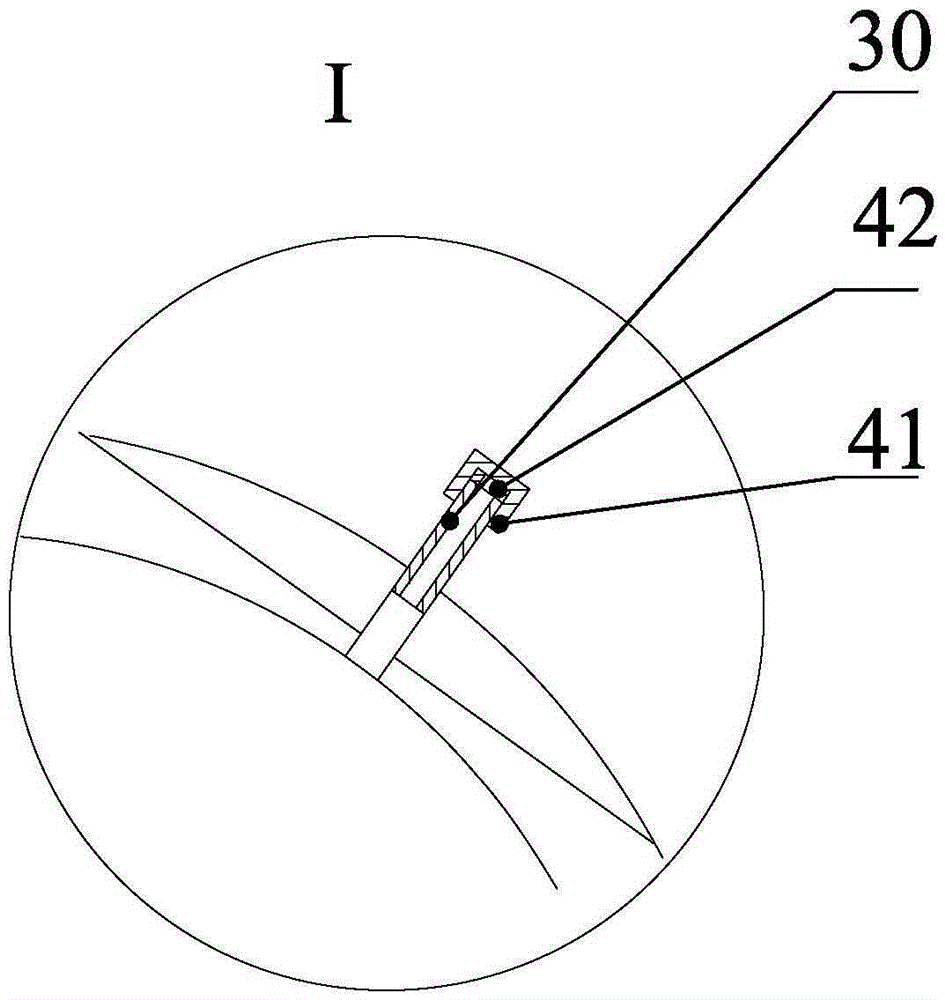

Volume expansion and shrinking percentage testing device and method

InactiveCN105277463AAvoid test errorSimple structureMaterial analysisContraction rateBiomedical engineering

The invention discloses a volume expansion and shrinking percentage testing device and method. The device comprises a body and a cover body, wherein the body is used for containing a cement sample to be tested and provided with an opening end and a closed base back on to the opening end, the cover body is used for sealing the opening end, and a closed containing cavity is formed after the cover body and the body are matched in a sealed mode. The cover body is provided with an injection hole for inputting liquid into the containing cavity and a graduated tube communicated with the containing cavity, wherein the injection hole is provided with a detachable sealing mechanism; the graduated tube is provided with a first end and a second end opposite to the first end, the first end is communicated with the containing cavity, the second end is an opening end, and scale marks are arranged on the surface of the graduated tube. The volume expansion and shrinking percentage testing device and method are capable of accurately measuring the volume expansion and shrinking percentage, and the testing device is simple in structure and convenient to operate.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

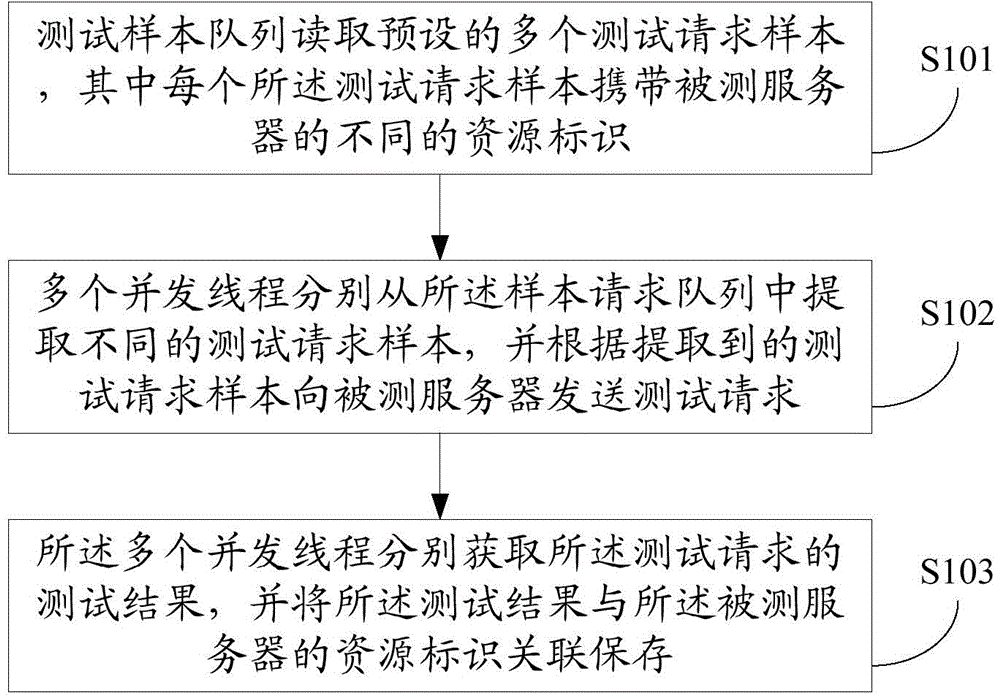

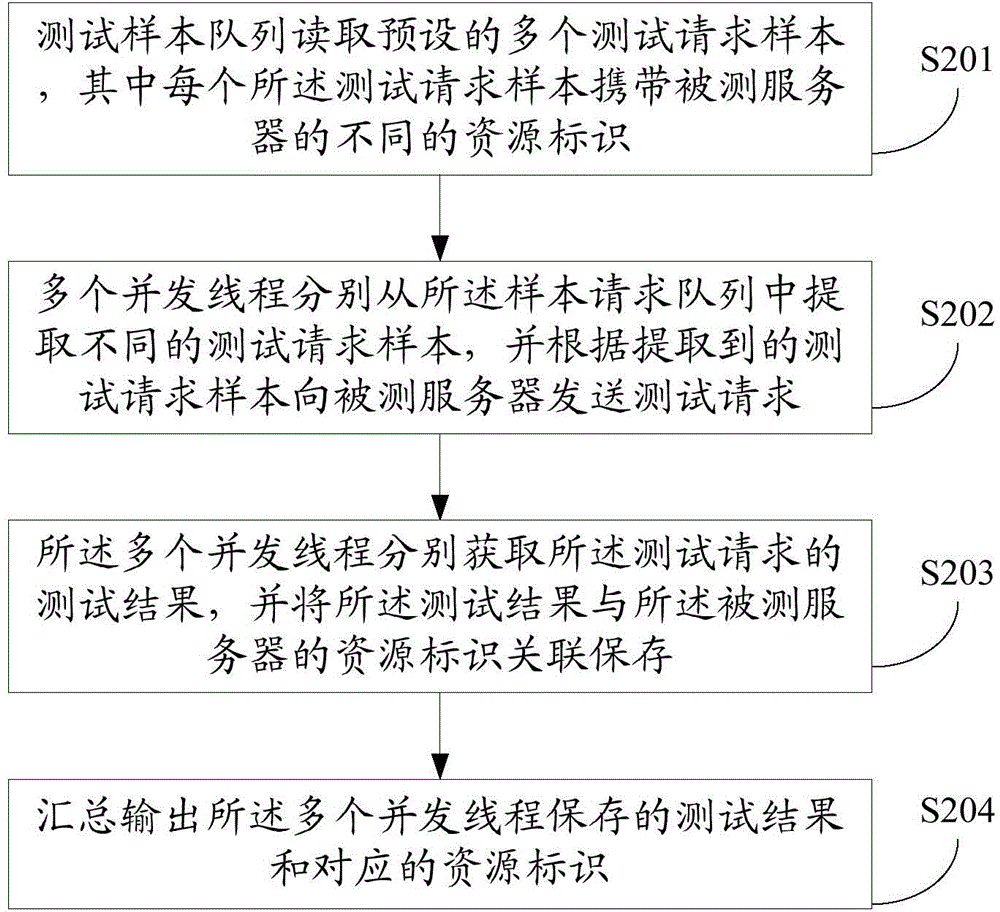

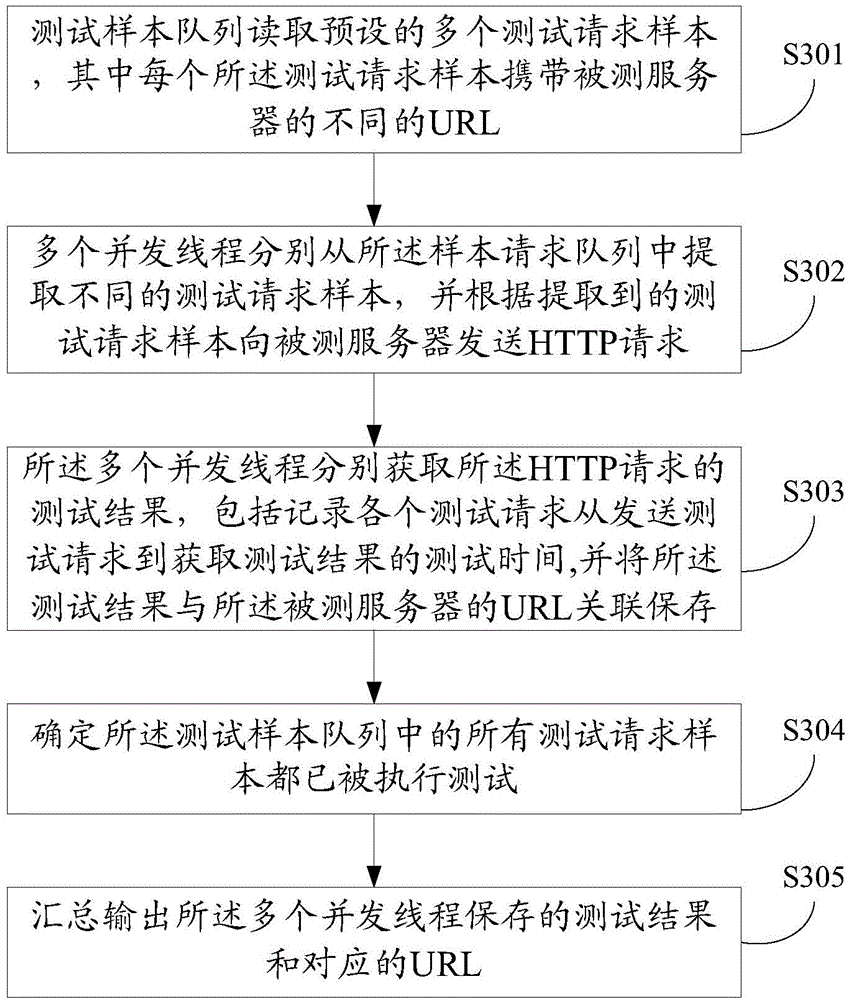

Server stress testing method and device

ActiveCN105207832AEasy to findAvoid test errorHardware monitoringMultiprogramming arrangementsComputer hardwareTest sample

The embodiment of the invention discloses a server stress testing method which comprises the following steps that (1) a test sample queue reads multiple preset test request samples, wherein each of the test request samples carries different resource identifies of a tested server, (2) multiple concurrent threads extract different request samples from the sample request queue and sends testing requests to the tested server according to the extracted test request samples, (3) the multiple concurrent threads obtain the testing results of the testing requests and associate the testing results and the resource identifies of the tested server and stores the testing results. The embodiment of the invention also discloses a server stress testing device. By using the server stress testing method and the server stress testing device, the detailed testing result of the stress test of the server can be obtained.

Owner:TENCENT TECH (SHENZHEN) CO LTD

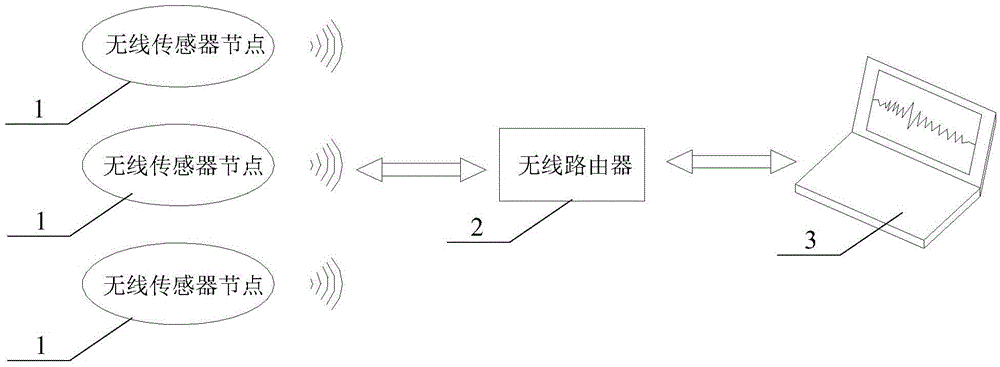

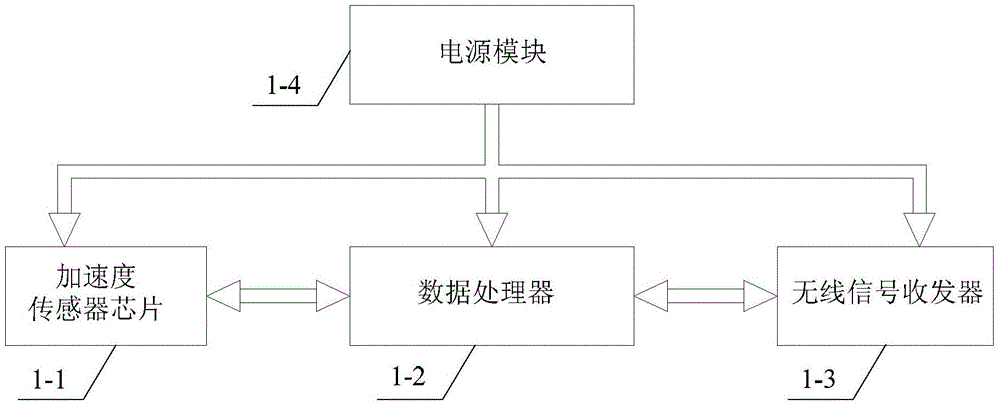

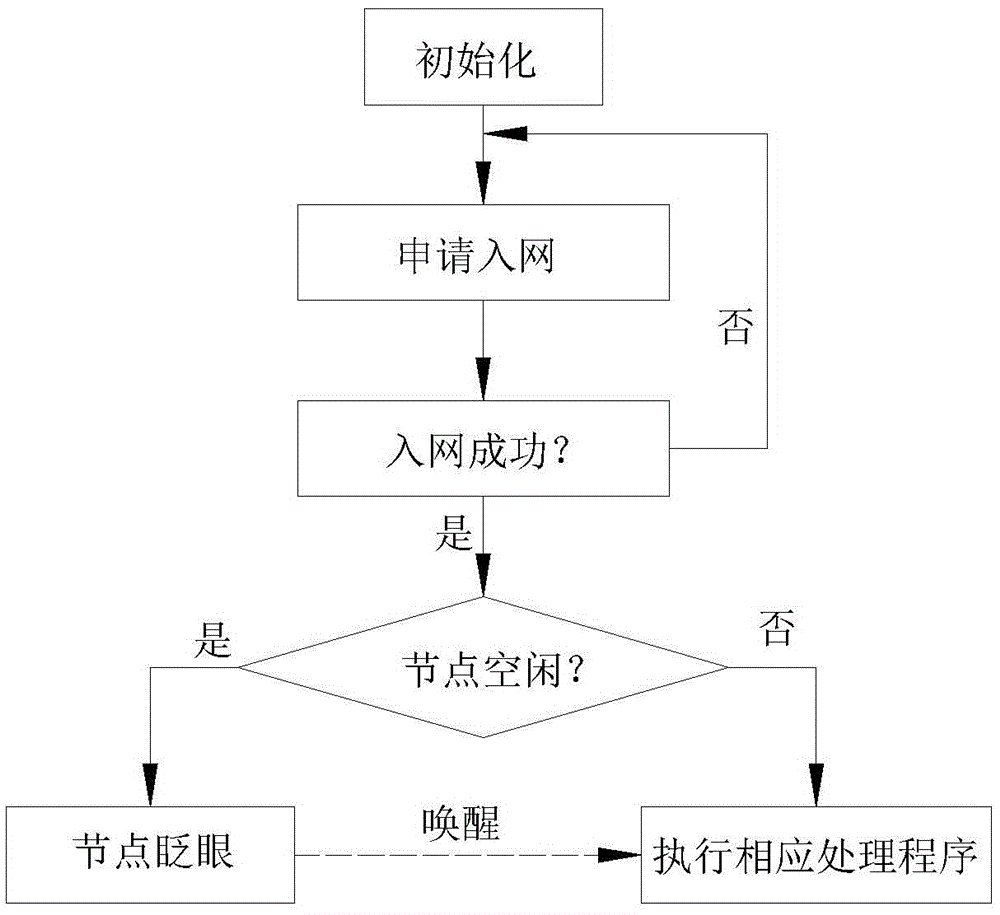

Vibration monitoring system based on wireless sensor network

InactiveCN105424169AImplement storageAchieve outputSubsonic/sonic/ultrasonic wave measurementNetwork topologiesLine sensorTransceiver

The invention relates to a vibration monitoring system based on the wireless sensor network, belongs to the technical field of engineering structure vibration and safety monitoring, and aims at solving the problem that the test error is large and the data transmission speed is limited due to the fact that the wireless sensor network used in the present engineering structure vibration monitoring transmits data signals in the wired manner. An acceleration sensor chip of the system is used to collect acceleration data in three axial directions of a monitoring point, transmits the acceleration data to a data processor; the data processor is used to store the received acceleration data, and transmits the acceleration data to a wireless signal transceiver; the wireless signal transceiver is used to send the acceleration data to a wireless router in a wireless manner; the wireless router is used to realize wireless communication connection between wireless sensor nodes and a computer; and the computer includes a data collection module. The system of the invention is used to monitor vibration.

Owner:HARBIN INST OF TECH

LED (Light Emitting Diode) performance test box, calibrating method and performance test method

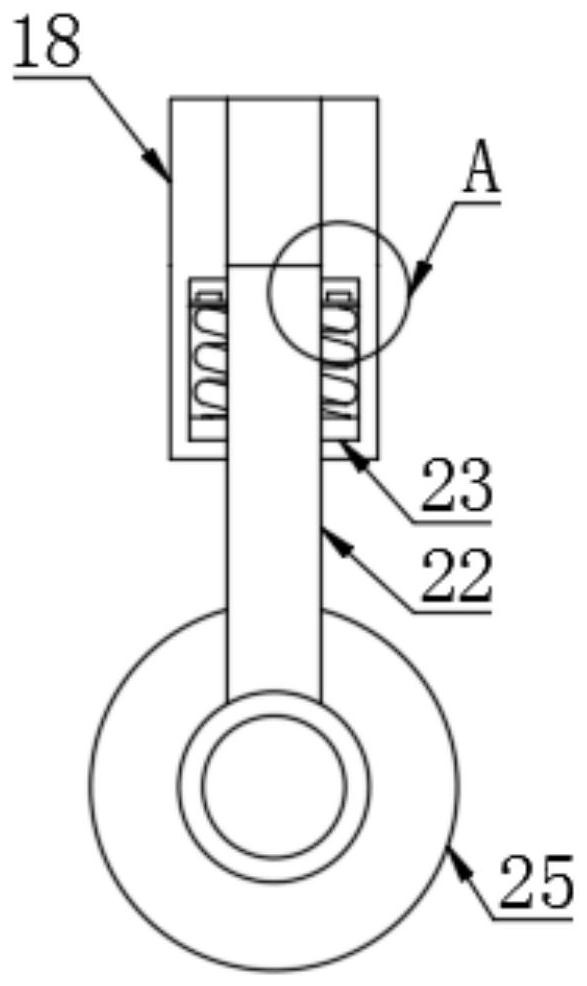

ActiveCN102967446AImprove sealingSimple structureTesting optical propertiesIndividual semiconductor device testingMotor driveElectric machine

The invention discloses an LED (Light Emitting Diode) performance test box, a calibrating method and a performance test method. The test case comprises a box body and a light taking device, and also comprises a first motor, a second motor, a rotating shaft, an optical fiber and a connecting piece, wherein the box body is provided with a through hole, and the rotating shaft and the optical fiber pass through the through hole; the light taking device is arranged inside the box body; the first motor arranged outside the box body drives the rotating shaft to rotate; the fixing piece is fixed at the end of the rotating shaft located inside the box body, and the second motor is fixed on the connecting piece; the second motor drives the light taking device to approach or move away from the rotating shaft; and a first end of the optical fiber is connected with the light taking device, and a second end of the optical fiber is outside the box body. The LED performance test box is simple in structure, and easy and simple to operate, and can detect LED performance parameters on line.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

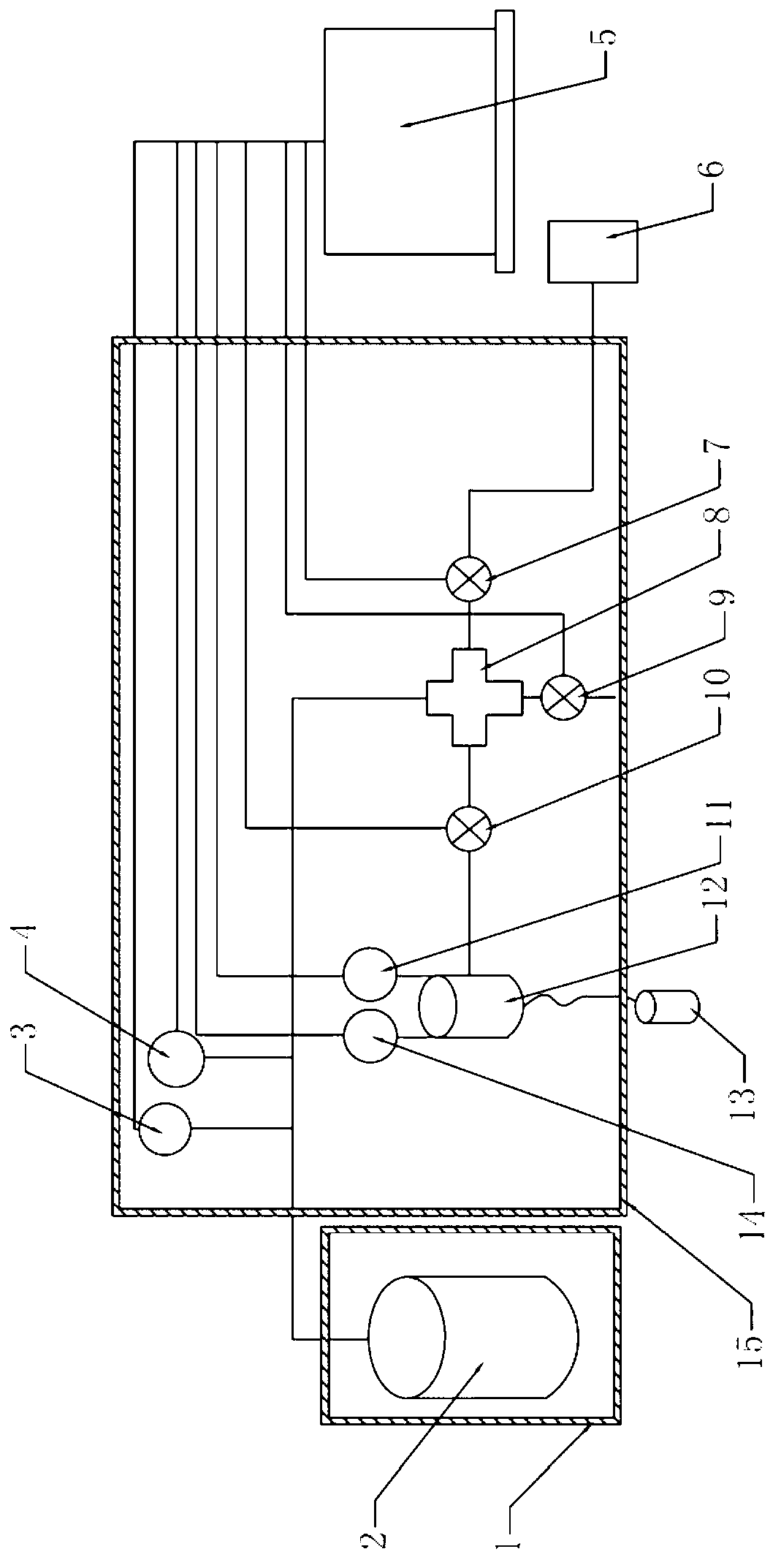

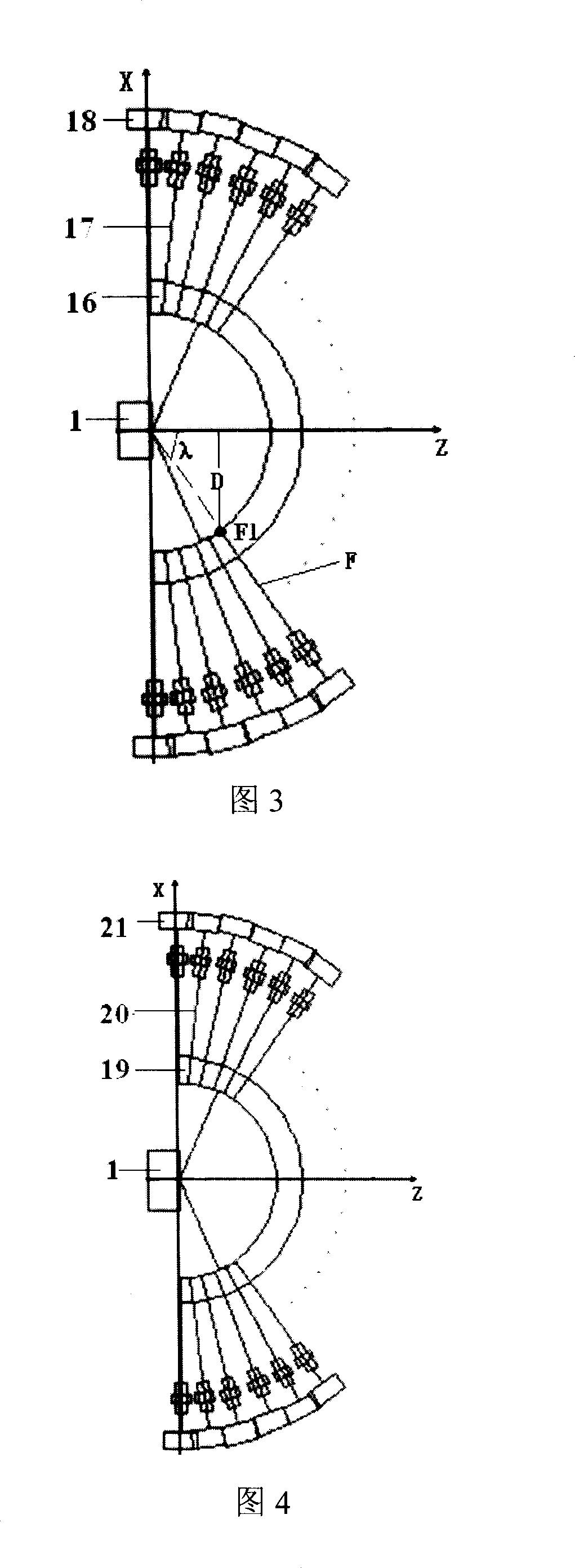

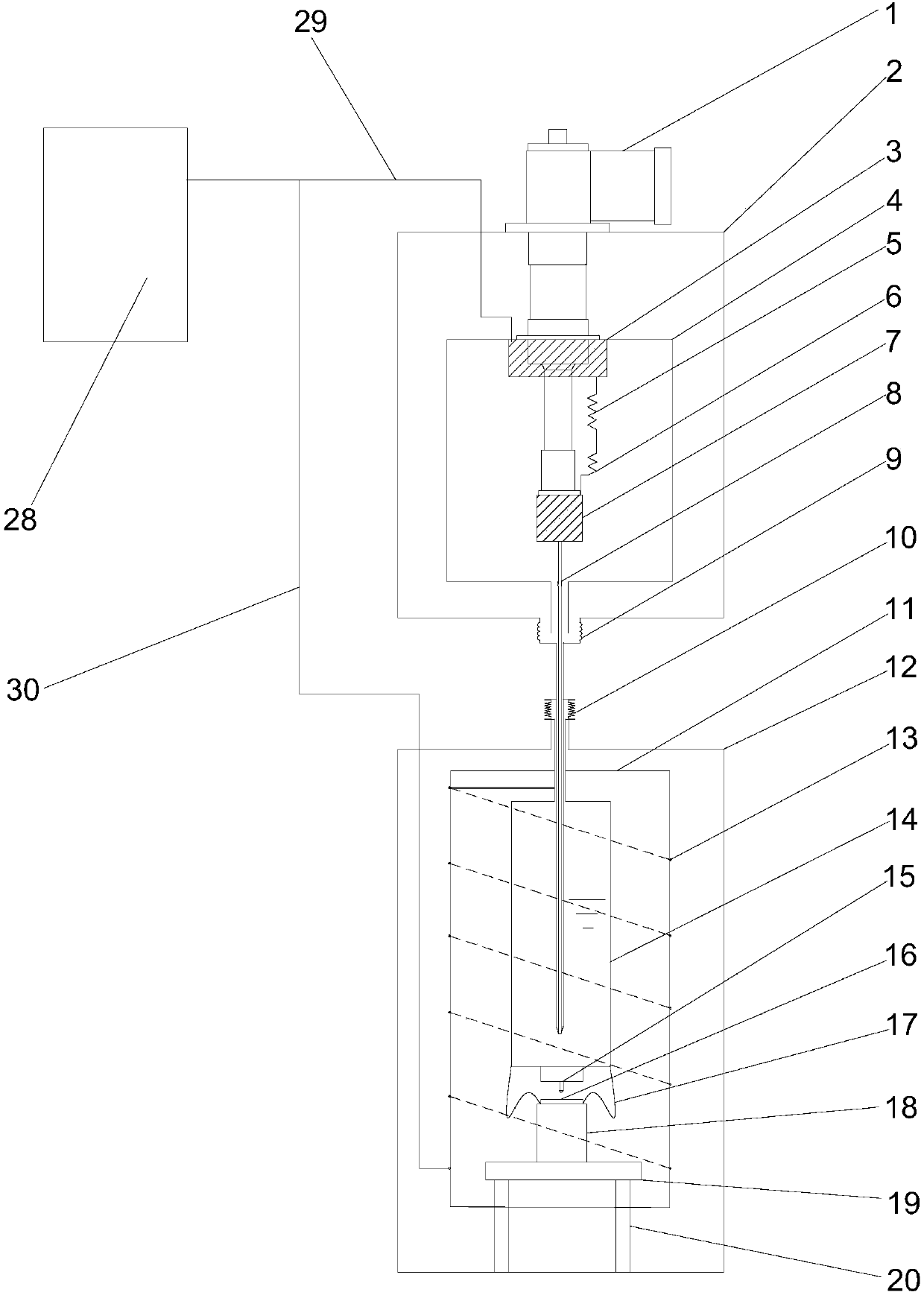

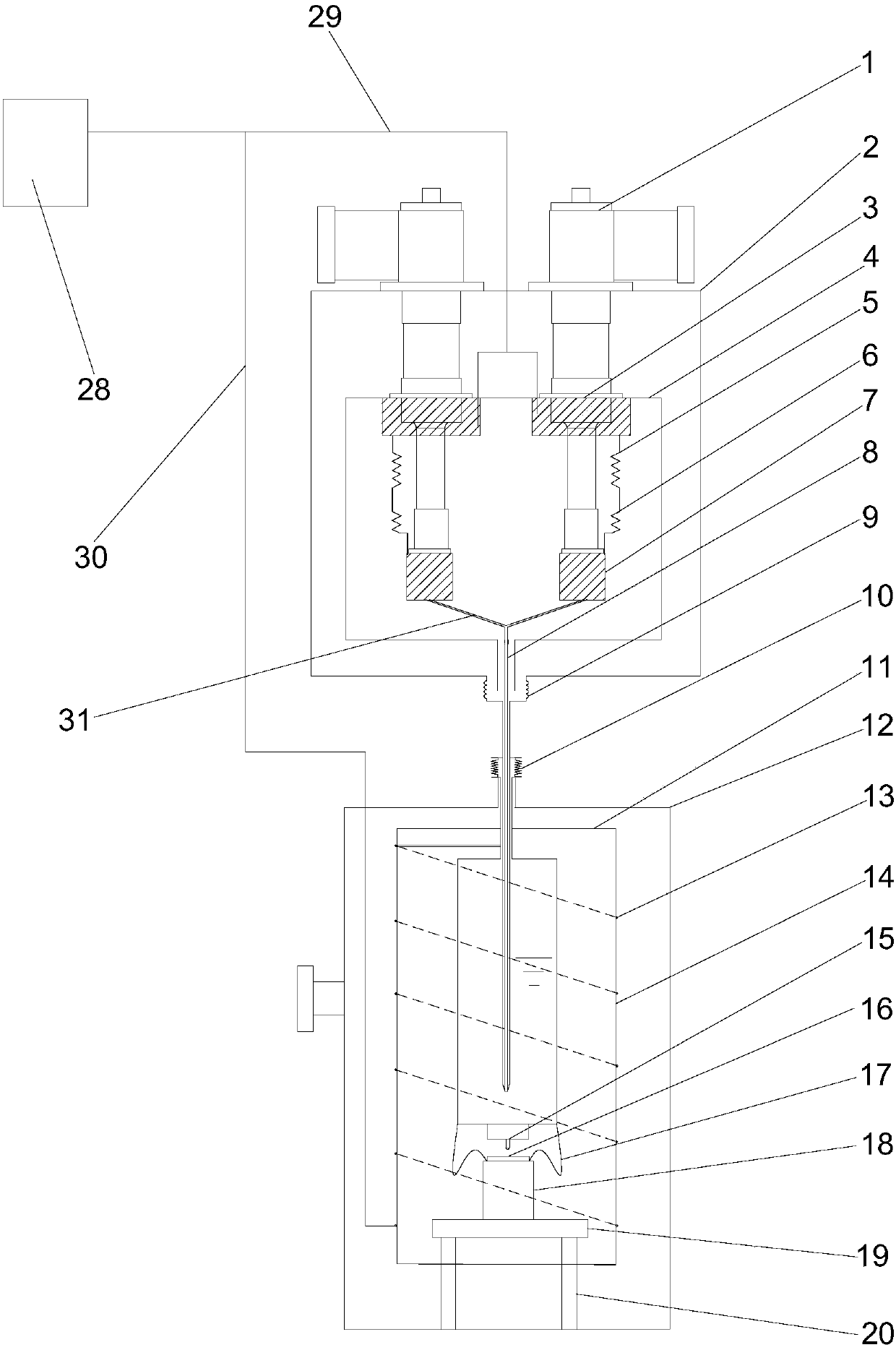

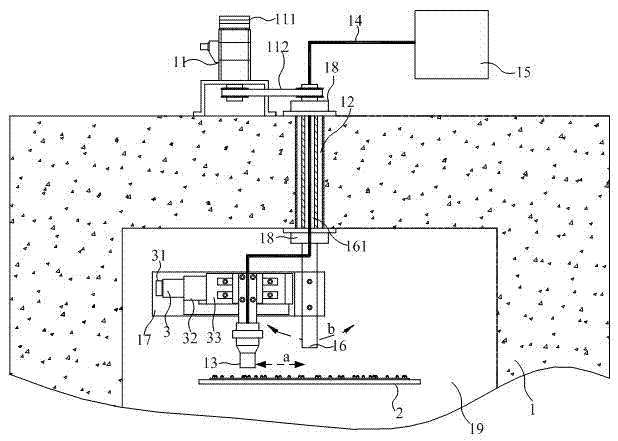

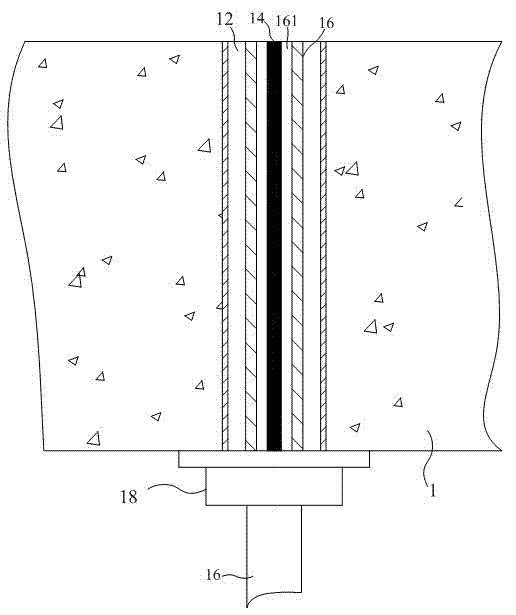

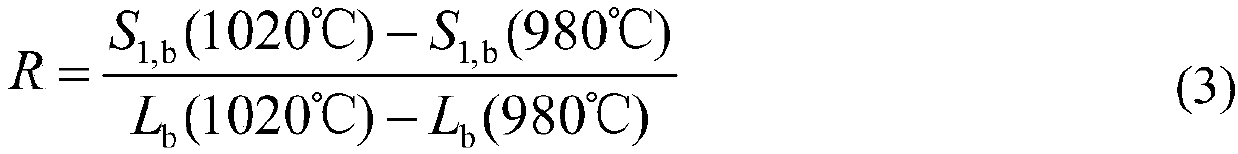

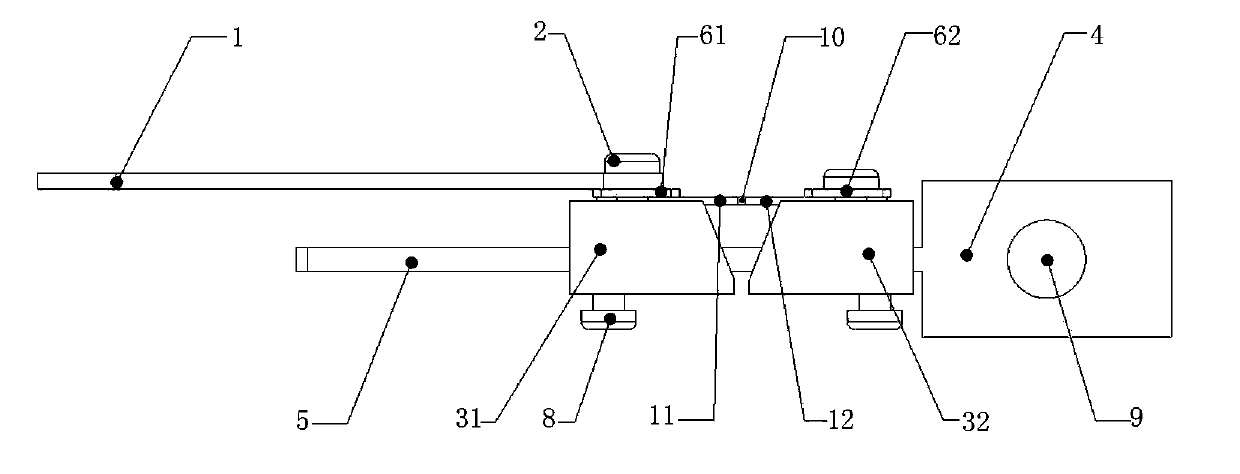

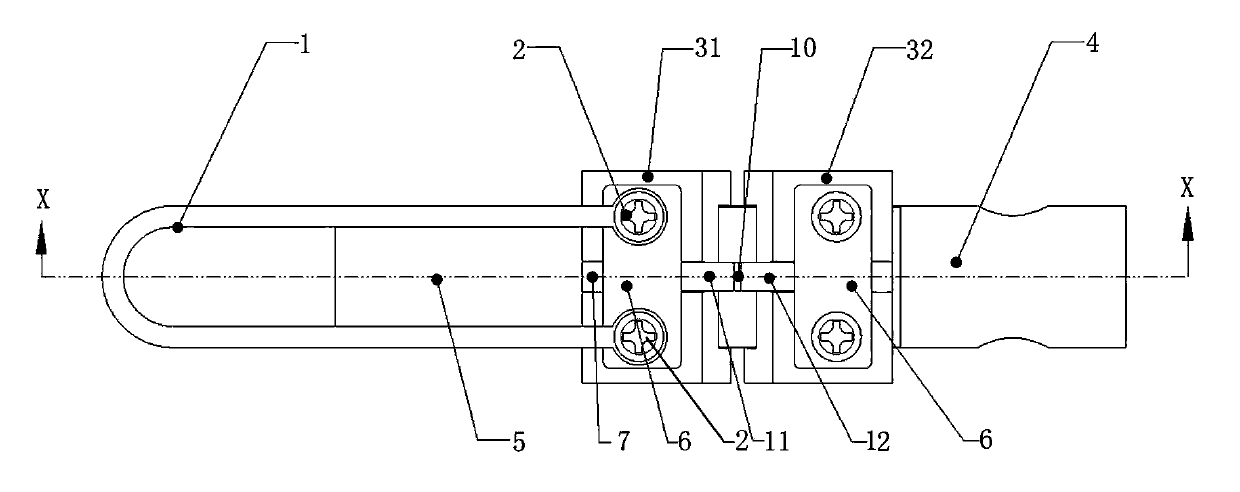

Method and device for testing laser absorptivity of powdery material

The invention discloses a method and a device for testing the laser absorptivity of a powdery material, wherein the testing method mainly comprises the steps of drying powder, cleaning a heat transfer body (a sample table surface), coating a heat conduction silicone grease, laying the to-be-tested powder and testing the laser absorptivity, and the device mainly comprises a laser (1), a spectroscope (2), the heat transfer body (5), an insulating box body (6), a water containing box body (8), a laser power meter (9), temperature sensors (10 and 11), A / D converters (12 and 13), a singlechip (14) and a computer (15). The invention provides the method and the device for testing the laser absorptivity of the powdery material, so that the limitation that the present laser absorptivity is only applicable to a block material or a thin film on the block material is broken through and a foundation for pushing the theoretical research development and engineering practical application of the powder laser cladding technology is laid, and meanwhile, the method and the device have the characteristics of high testing precision, simplicity, feasibility, good generality and the like.

Owner:JIANGSU UNIV

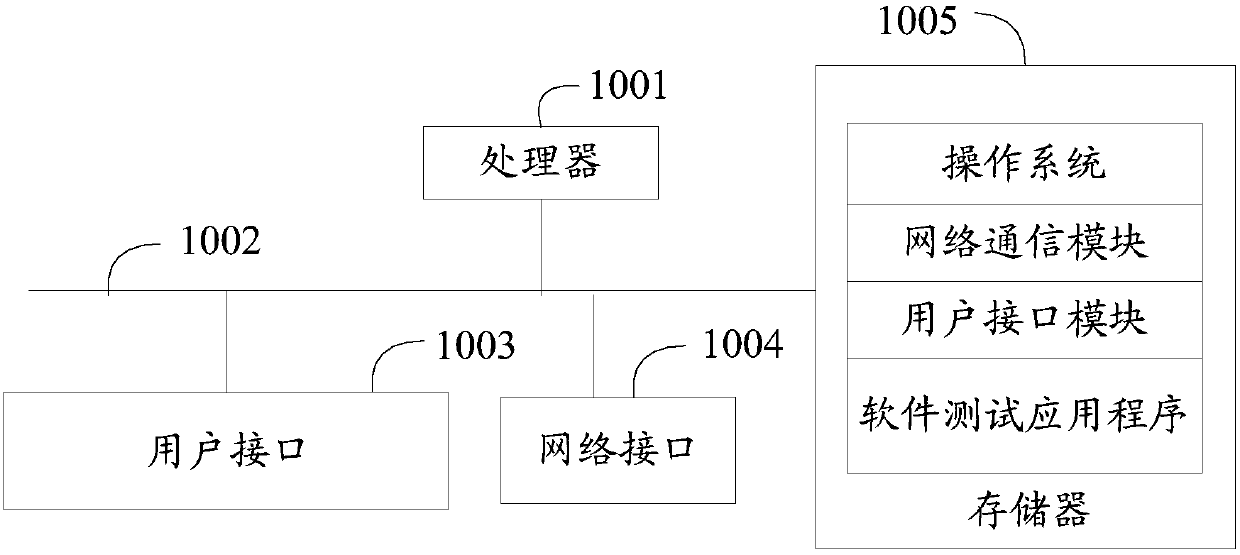

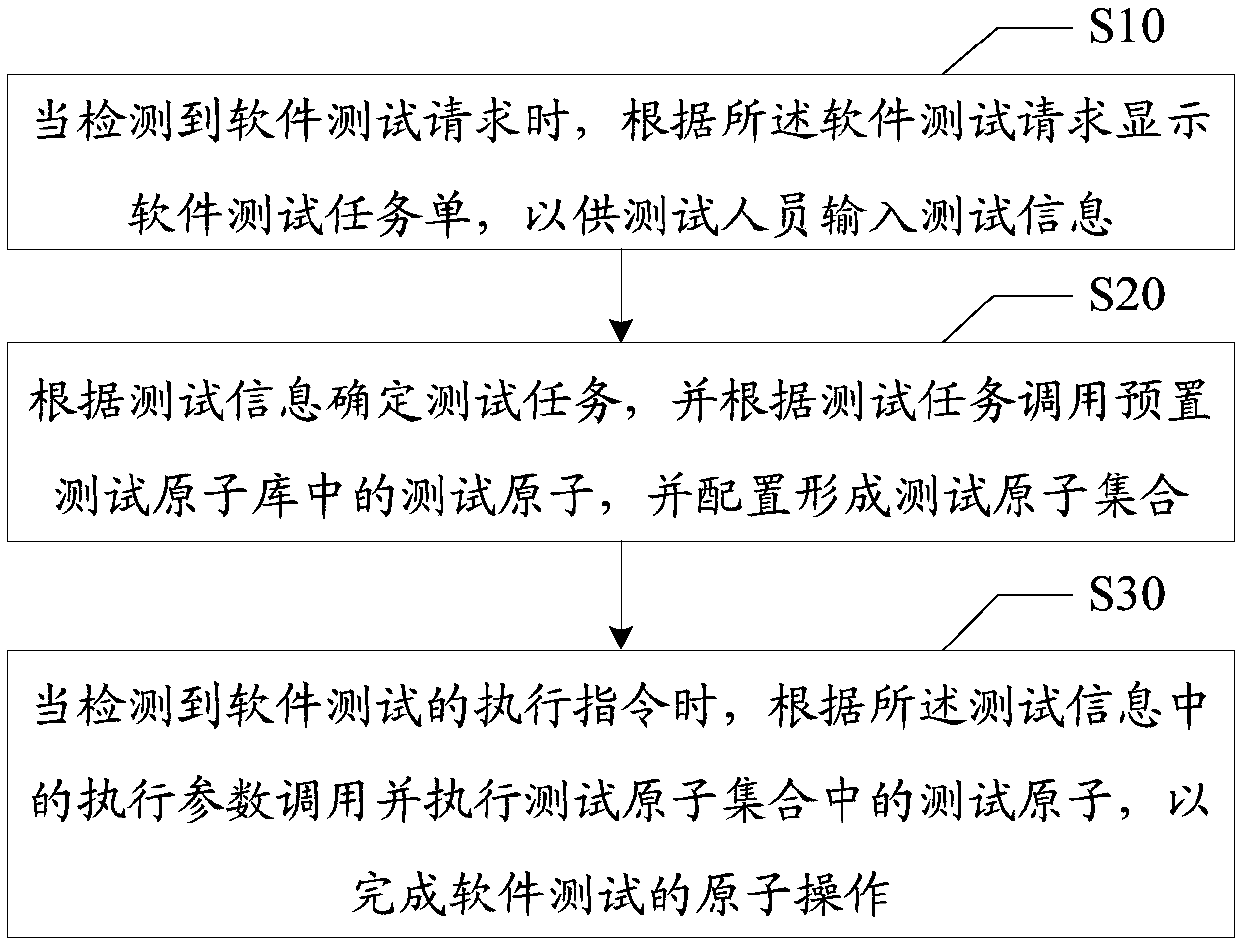

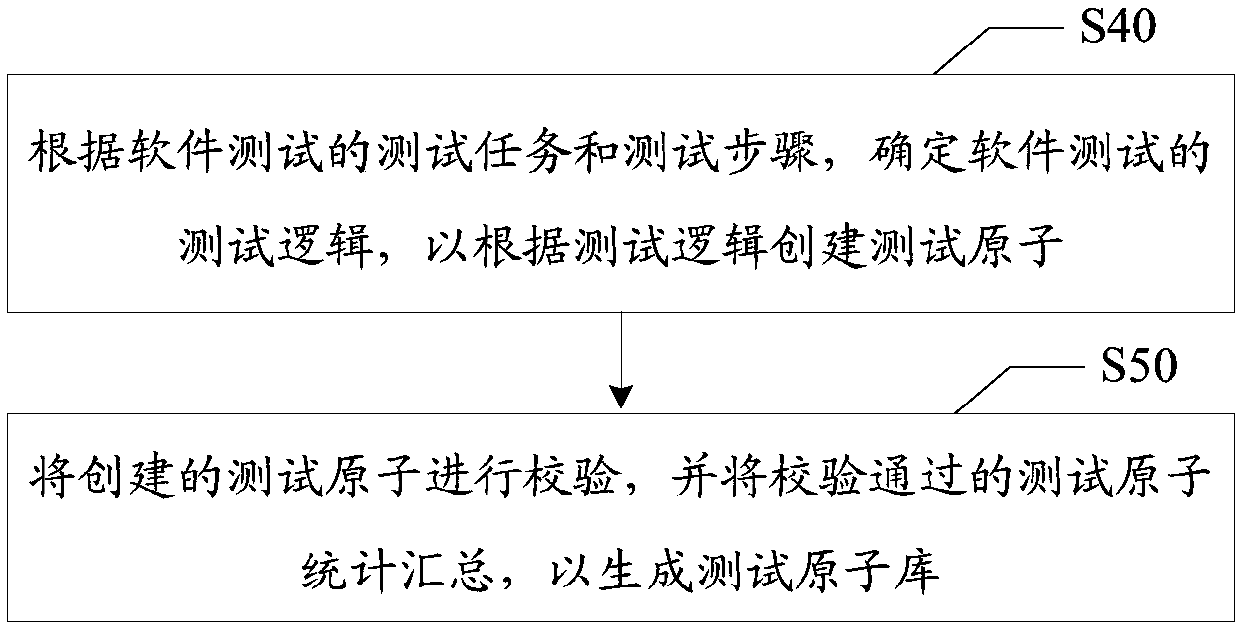

Software test method, apparatus and device, and computer storage medium

ActiveCN107656872AImprove test efficiencyReduce cost inputSoftware testing/debuggingTest efficiencySoftware engineering

The invention discloses a software test method. The software test method comprises the following steps of displaying a software test task list according to a software test request when the software test request is detected, thereby enabling test personnel to input test information; according to the test information, determining a test task, and according to the test task, calling a test atom in apreset test atom library, and performing configuration to form a test atom set; and when an executive instruction of a software test is detected, calling and executing the test atom in the test atom set according to executive parameters in the test information, thereby finishing atom operation of the software test. The invention furthermore discloses a software test apparatus and device, and a computer storage medium. By utilizing atom operation, the software test cost is reduced, the software test efficiency is improved, and the error caused by manual operation is avoided.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

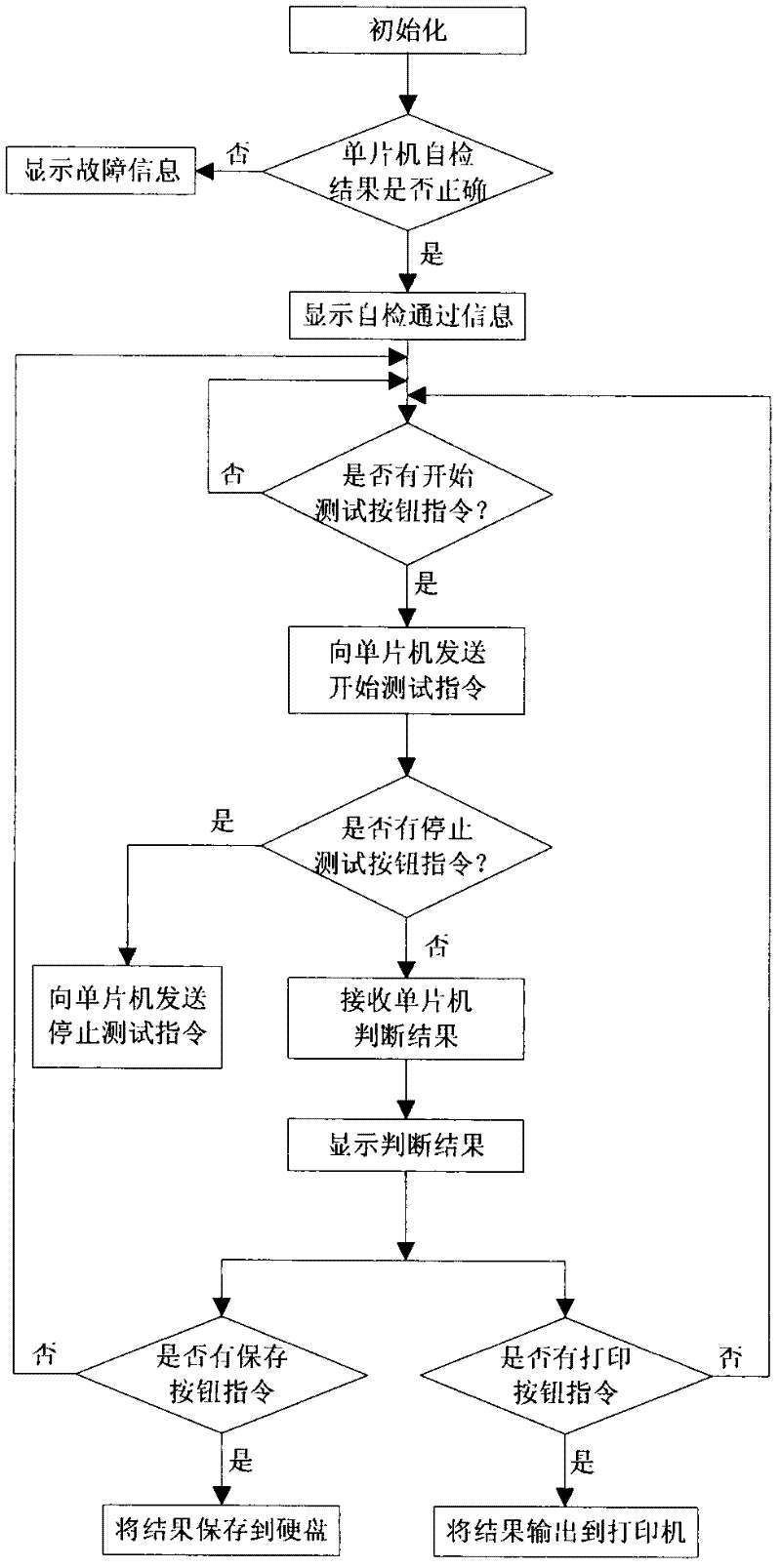

On-off automatic detection device for loops of collector ring

ActiveCN102508090ATroubleshoot auto-detection issuesShort test elapsed timeElectrical testingMicrocontrollerElectricity

The invention discloses an on-off automatic detection device for loops of a collector ring and belongs to the field of electric performance testing of an electromechanical device. The device is respectively connected with a loop lead and an electric brush lead of the detected collector ring through two complex programmable logic devices CPLD to establish a plurality of measuring loops and is used for realizing a man-machine operation interface by operating and controlling a computer; a used singlechip is used for realizing locking and gating of each measuring loop by an address latch and two decoders; and the singlechip is used for sequentially sending high-level data to an output pin at an initial end, i.e. the CPLD 1, of each measuring loop by built-in software and reading the level data transmitted back through the collector ring on all input pins at a tail end, i.e. the CPLD 2, of each measuring loop each time when sending one piece of high-level data so as to judge the state of the loops of the collector ring, i.e. switching-on or switching-off or shirt circuit. The device solves the problem of automatically detecting the on-off states of a plurality of loops of the collector ring. The on-off automatic detection device for the loops of the collector ring has high detection efficiency, is convenient to operate, is visual to display and has higher superiority for the collector ring with a large number of the loops.

Owner:CHINA NORTH IND NO 205 RES INST

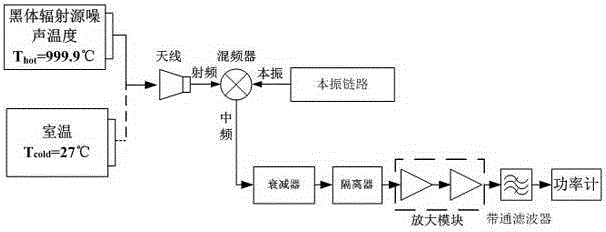

Terahertz receiver noise temperature test system and method

InactiveCN105187136AAvoid the problem of out-of-sync testing frequencyAvoid test errorReceivers monitoringFrequency mixerIntermediate frequency

The invention discloses a terahertz receiver noise temperature test system and method. The system comprises an intermediate frequency link and a power meter. The output end of the intermediate frequency link is connected with the detection port of the power meter. The intermediate frequency link comprises an attenuator, an isolator, an amplifier module and a band-pass filter. The input end of the attenuator is connected with the intermediate frequency signal port of a terahertz receiver to be detected. The output end of the attenuator is connected with the input end of the isolator. The output end of the isolator is connected with the input end of the amplifier module. The output end of the amplifier module is connected with the input end of the band-pass filter through a cable. The output end of the band-pass filter is connected with the power meter. According to a test result, the double-sideband conversion loss and the double-sideband equivalent noise temperature of a mixer are calculated. According to the invention, local frequency is adjusted through a fixed intermediate frequency; the problems of unsynchronized test frequency and test errors can be avoided; and physical characteristic changes caused by the fact that the entire system cannot continuously work under a traditional test method are avoided.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

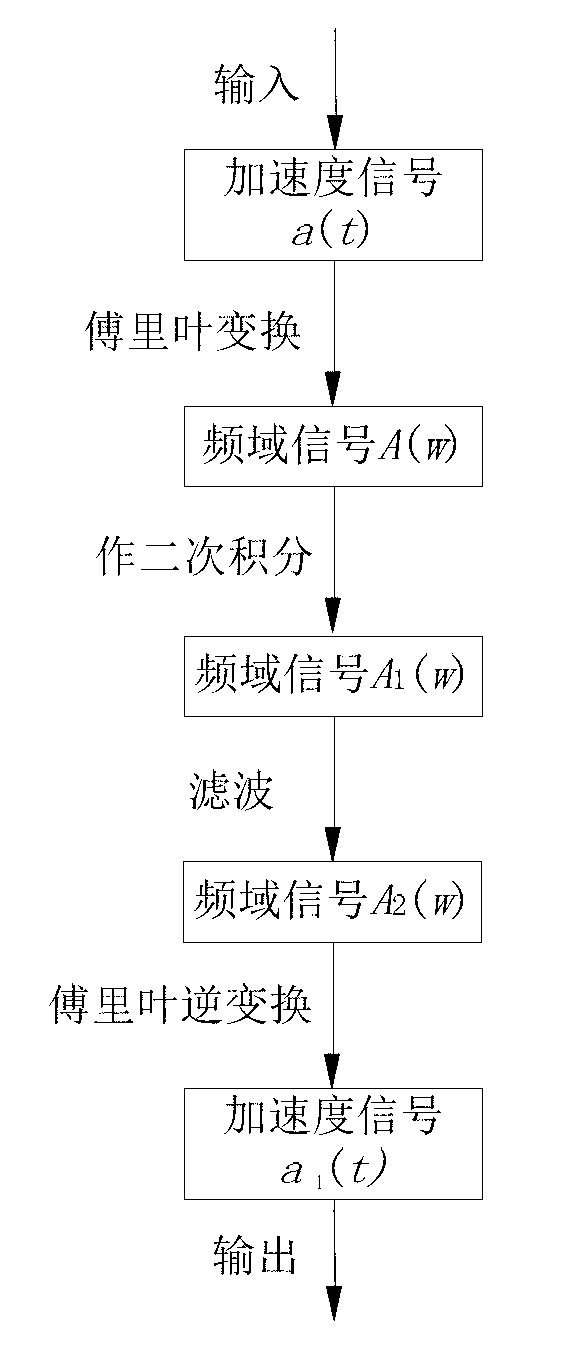

Positioning method of indoor personnel

InactiveCN103591959AAvoid large operationsHigh positioning accuracyNavigation by speed/acceleration measurementsThree-dimensional spaceAtmospheric pressure

The invention relates to a positioning method of indoor personnel. The method specifically comprises the following steps: a, positioning the plane position of the indoor personnel by a stride frequency and stride method; b, positioning the plane position of the indoor personnel by a time-frequency transformation integral method; c, reading the altitude value Zi of the position of the indoor personnel detected by a pressure height sensor by a CPU (Central Processing Unit); d, fusing the personal position results obtained in the steps a and b; and finally, combining the altitude value Zi of the indoor personnel at the ith moment obtained by the step c to obtain a three-dimensional spatial position (Xi, Yi and Zi) of the indoor personnel at the ith moment as a positioning result of the three-dimensional space to position the indoor personnel. The positioning method provided by the invention measures the position information of the personnel in real time by means of the sensor which measures data such as pressure, motion acceleration and azimuth angle in real time, so that the method is not only high in positioning precision, but also high in reliability.

Owner:南京巴乌克智能科技有限公司

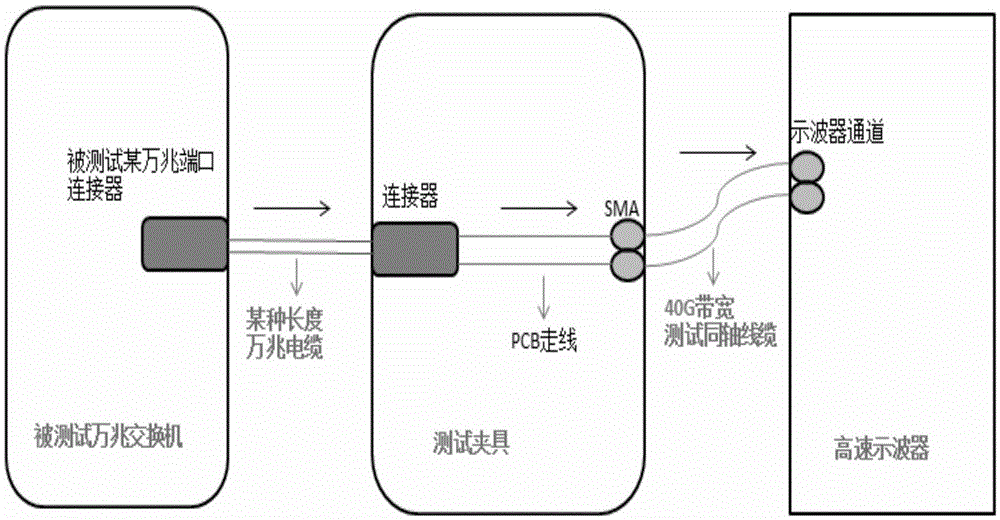

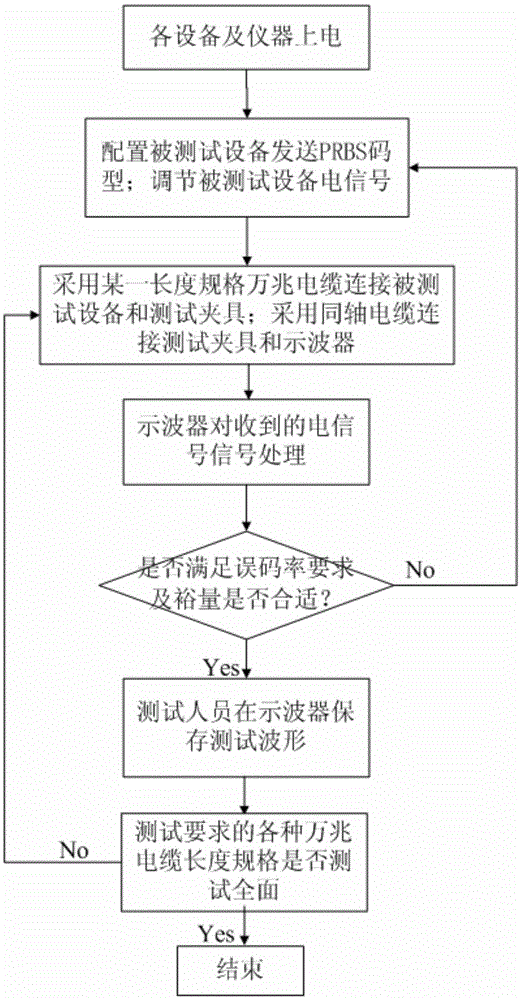

A system and method for testing 10-gigabit electrical signals

ActiveCN105391603AAvoid test errorImprove test accuracyData switching networksElectricityCoaxial cable

The invention relates to the 10-gigabit Ethernet communication test technology, discloses a system and method for testing 10-gigabit electrical signals and solves the problems of not high test precision, incomprehensive test and high cost in the prior art. The test system comprises a testes device, a test clamp and an oscilloscope. The testes device is connected with the test clamp through a 10-gigabit cable; and the test clamp is connected with a channel of the oscilloscope through a test coaxial cable. Besides, the invention also provides the method for testing the 10-gigabit electrical signals, and the method is suitable for testing the 10-gigabit electrical signals obtained through cable connection.

Owner:MAIPU COMM TECH CO LTD

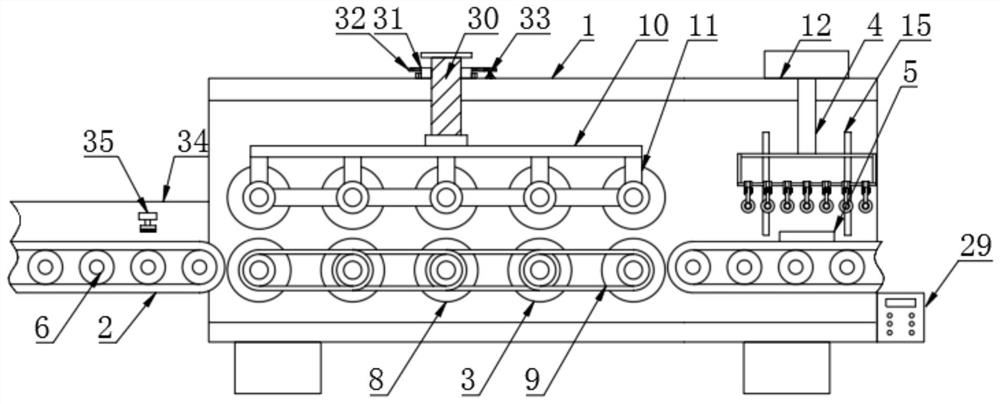

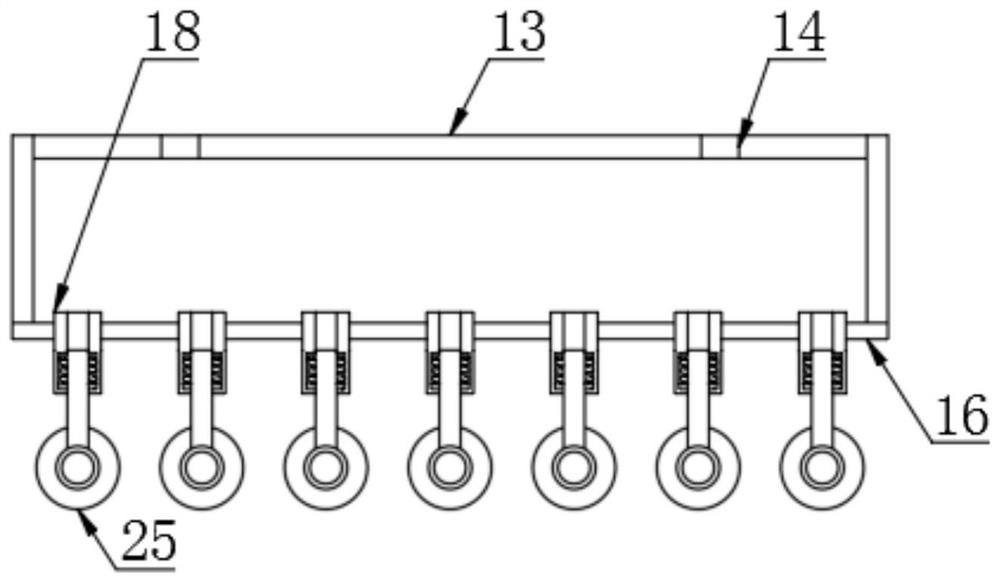

Aluminum alloy template leveling machine

InactiveCN112296132AImprove the leveling effectIncreased flexibility of useShaping toolsCleaning using toolsMachineChain link

The invention discloses an aluminum alloy template leveling machine, and relates to the field of aluminum alloy template leveling. The aluminum alloy template leveling machine comprises a machine body, a conveying mechanism, a leveling mechanism, a testing mechanism and a returning mechanism are installed in the machine body, the conveying mechanism comprises a first conveying belt and a second conveying belt, the leveling mechanism comprises a fixed steel roller set, chains are connected between the steel rollers of the fixed steel roller set in a sleeved mode, a first lifting frame is arranged at the top of the fixed steel roller set, and a movable steel roller set is installed in the first lifting frame. According to the aluminum alloy template leveling machine, rotating wheels make contact with the aluminum alloy template, the rotating wheels drive movable supports to move, the movable supports generate different degrees of displacement through bearing blocks, therefore a spring iscompressed to different degrees, pressure of different magnitudes is exerted on pressure sensors, the unqualified parts are sent back again through a U-shaped conveying belt to be subjected to multiple times of leveling and testing until leveling is achieved, and the leveling effect can be effectively improved on the whole.

Owner:江西邦展建筑模板科技有限公司

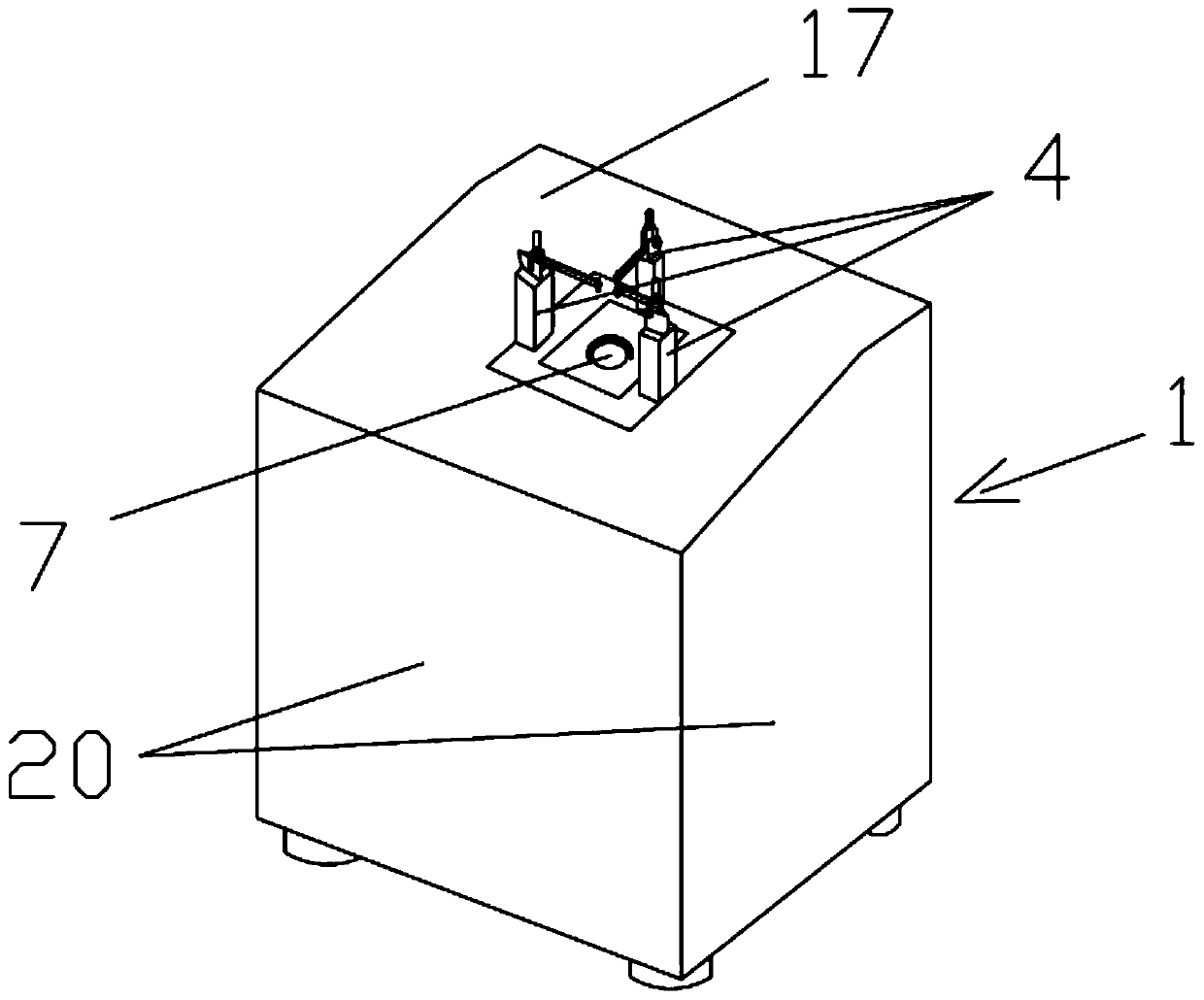

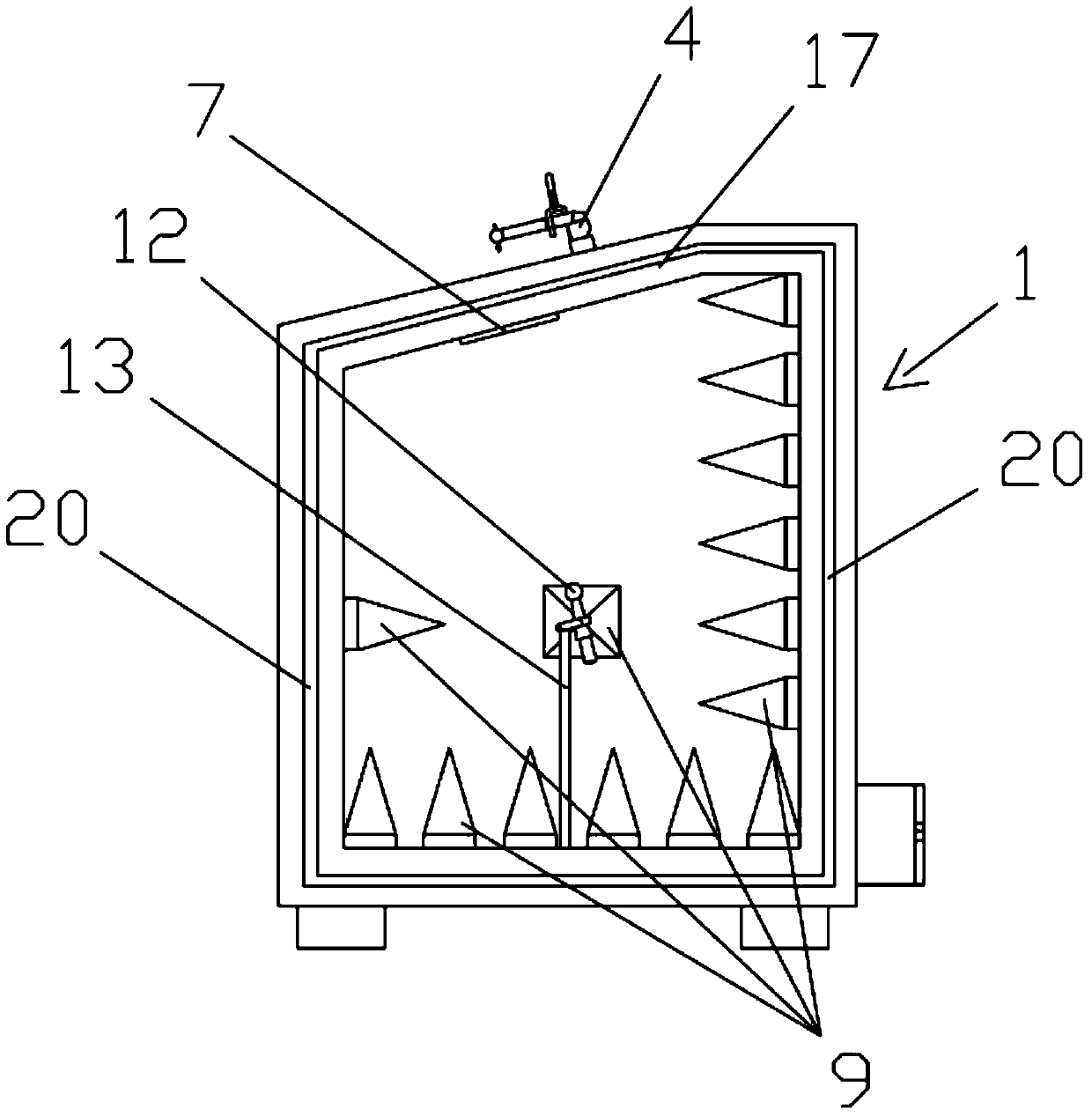

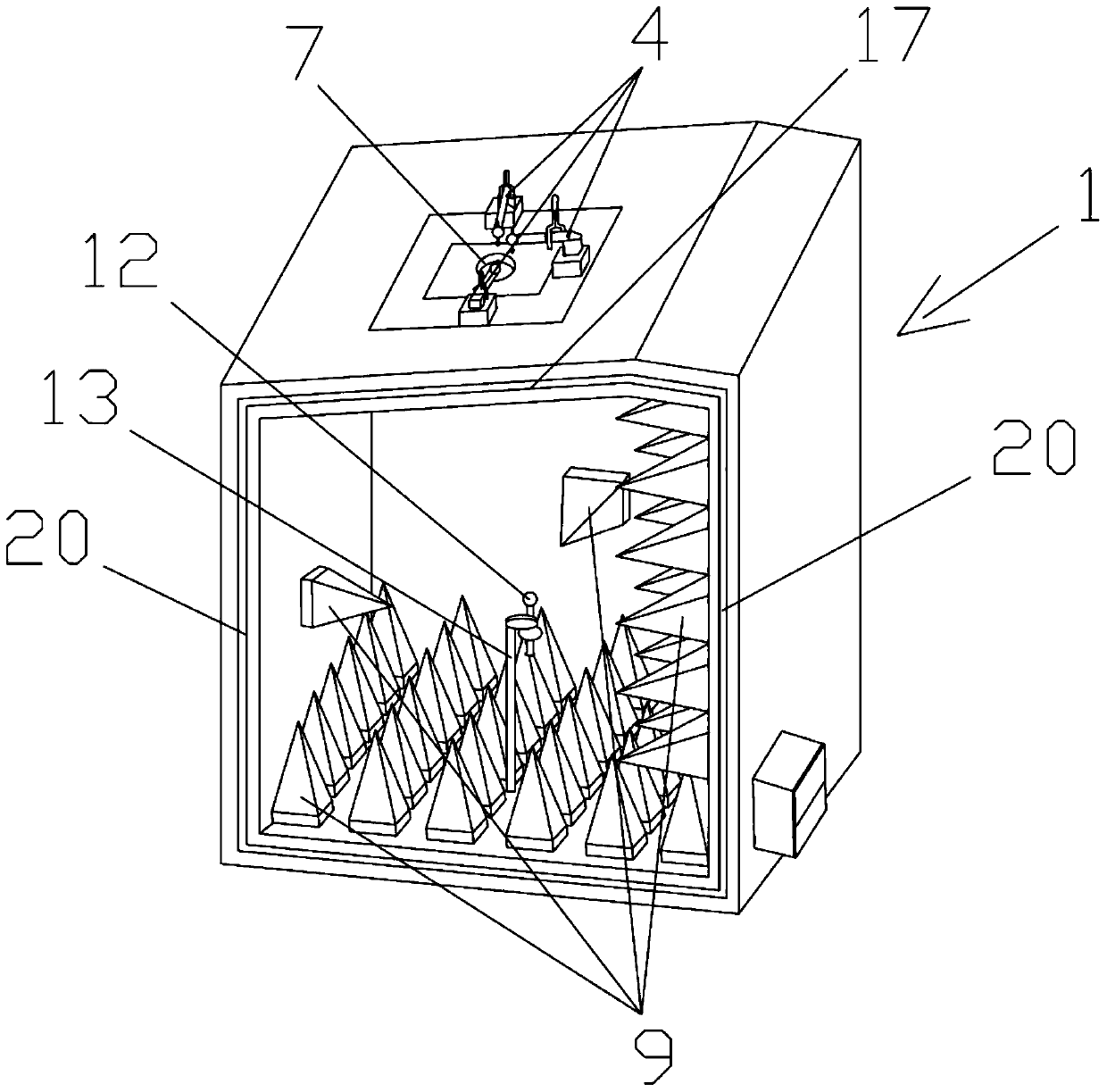

Silencing box for test speaker

InactiveCN103475989AThe test effect is goodReduce manufacturing costElectrical apparatusEngineeringSound pressure

The invention discloses a silencing box for a test speaker. The silencing box comprises a box body, a plurality of sound absorption elements in the box body and a microphone, wherein the box body comprises a smooth wall body with an opening, the test speaker is matched and connected with the opening, a front sound cavity of the test speaker is positioned on the inner side of the smooth wall body, a rear sound cavity of the test speaker is positioned on the outer side of the smooth wall body, and the inner surface of the wall body is set to be a smooth surface. The smooth surface can play the role of a baffle plate and isolate the front and the rear sound cavity of the test speaker to avoid the sound pressure produced by the front and the rear sound cavity of the test speaker, so that the silencing box for the test speaker has the advantages of good test effect, low manufacturing cost, small occupied space and the like.

Owner:SUZHOU ANKEN ELECTRONICS TECH

Double light beam detection modulation device based on surface plasma wave sensing

InactiveCN1715878AAvoid test errorEasy to operatePhase-affecting property measurementsPd detectorLight beam

The double light beam detection and modulation device based on surface plasma wave sensing has laser, optical assembly to split the laser beam into the first polarized light beam and the second polarized light beam, prism with vaporization coated Au film, grown biosensitive film and pond for the measured sample to flow in to total reflect the incident two light beams, and the first PD detector and the second PD detector to receive these two reflected light beams separately. The present invention has the characteristic of surface plasma resonance (SPR) sensing technology maintained, and the double light beam SPR sensors, which need no precise scanning incident angle and thus simplified angle regulating mechanism, less measurement error and increased operation performance. The detection of double light beam light strength signal may be completed with cheap photodiode, and this can simplify the system, lower the manufacture cost and make the instrument portable.

Owner:ZHEJIANG UNIV

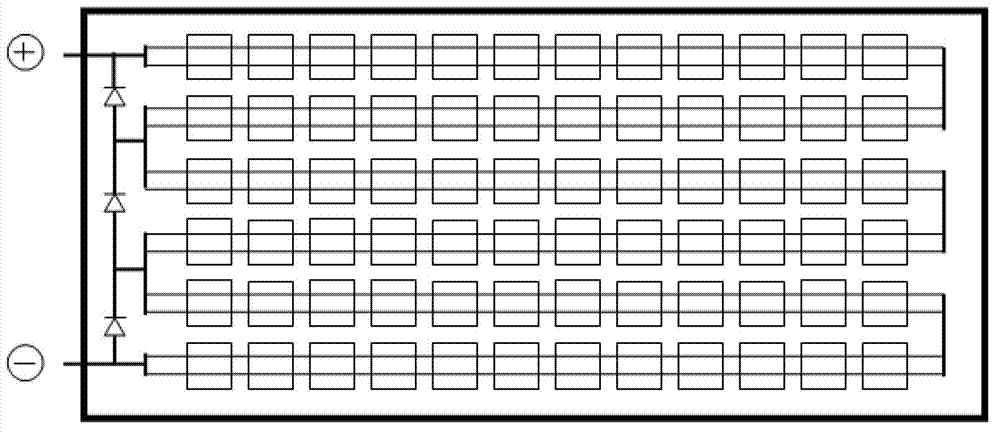

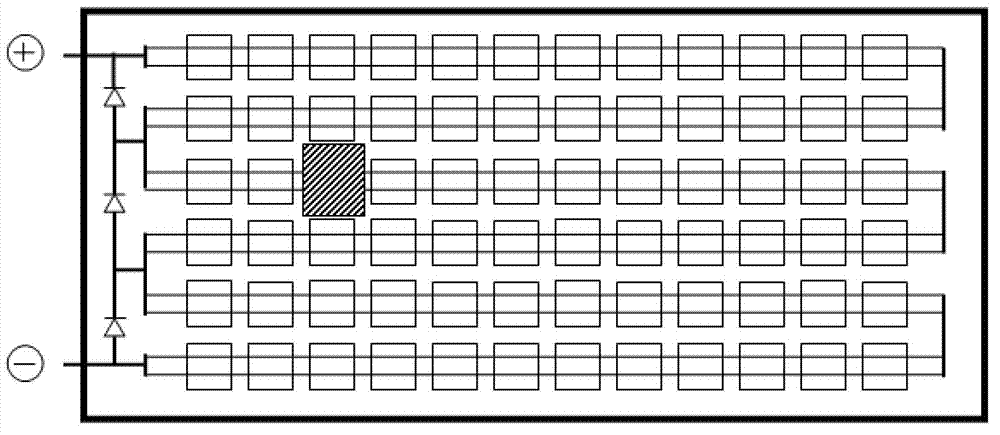

Battery pick-out equipment for hot-spot test of photovoltaic components

ActiveCN102928762ARealize full inspectionImprove tolerancePhotovoltaic monitoringPhotovoltaic energy generationData acquisitionEngineering

The invention relates to battery pick-out equipment for a hot-spot test of photovoltaic components. The battery pick-out equipment comprises a machine frame and is characterized in that baffle guide rails and photovoltaic component guide rails are mounted on a machine frame, a photovoltaic component support frame is mounted on the photovoltaic component guide rails and can move along the photovoltaic component guide rails; steady-state light sources and a plurality of light sources in array distribution are mounted on the machine frame above the photovoltaic component support frame; one or more group of baffle components are mounted between the steady-state light sources and the photovoltaic component support frame; the baffle components comprise baffle supports of which the two ends are arranged on the baffle guide rails, and the baffle supports can move along the baffle guide rails; a plurality of baffles capable of shielding the steady-state light sources are arranged on the baffle supports; a space for placing photovoltaic components is formed between the baffles and the photovoltaic component support frame; and a data acquisition circuit is mounted at one end of the machine frame. The battery pick-out equipment only requires measurement of the reverse dark-state leakage current of batteries, and can achieve multi-way monitoring at the same time, thereby greatly speeding up the test.

Owner:WUXI INSPECTION TESTING & CERTIFICATION INST

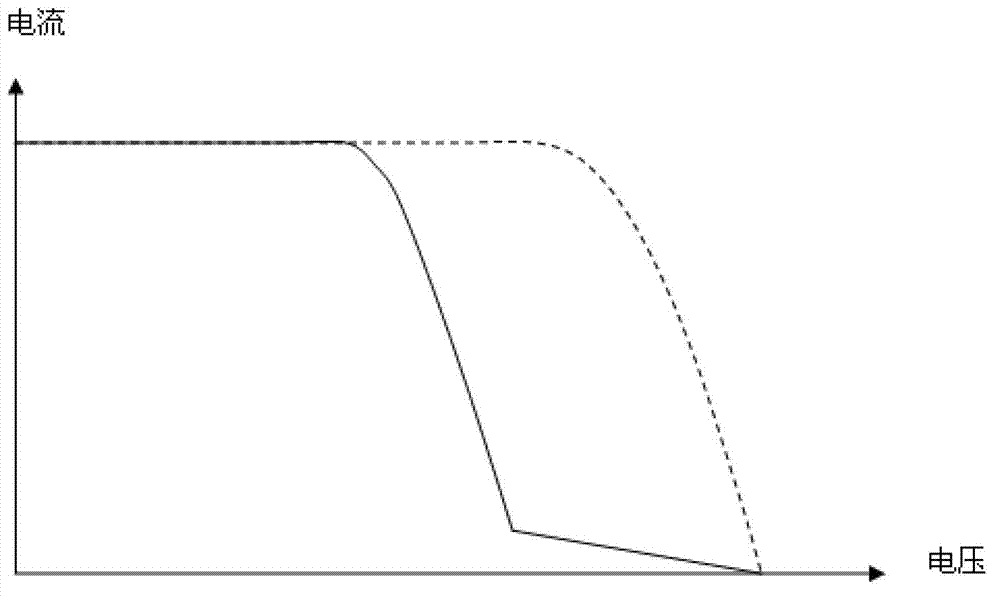

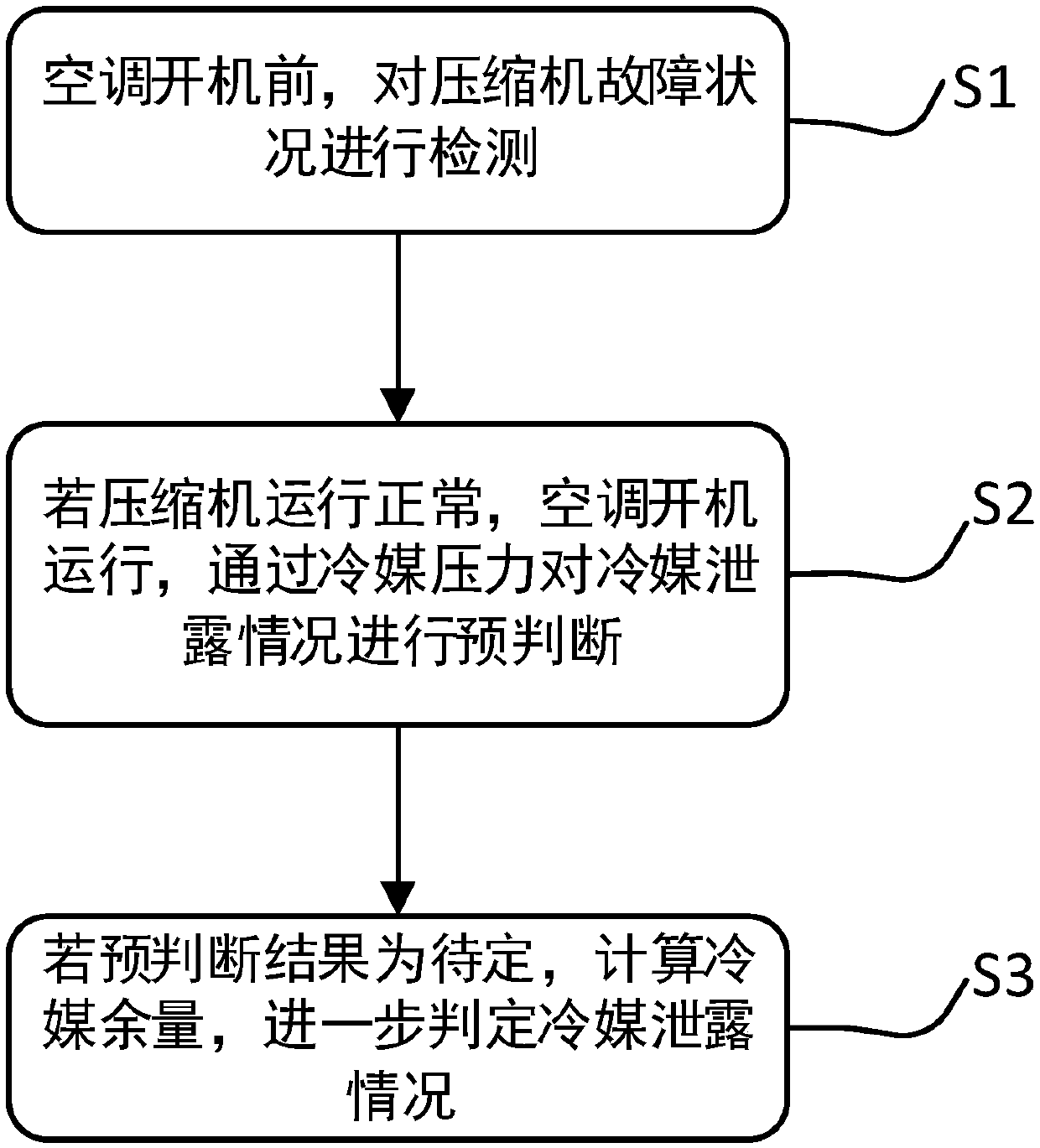

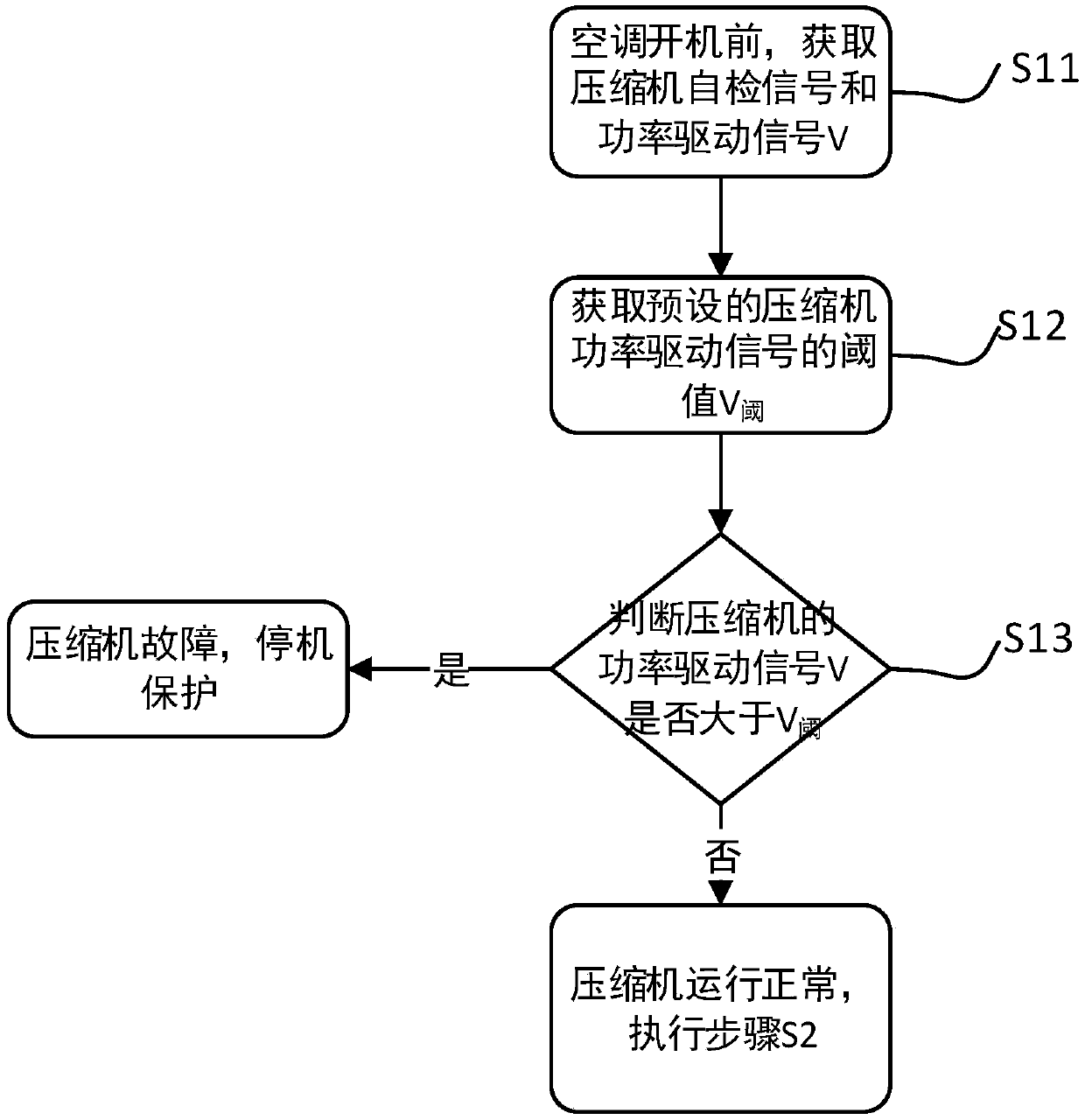

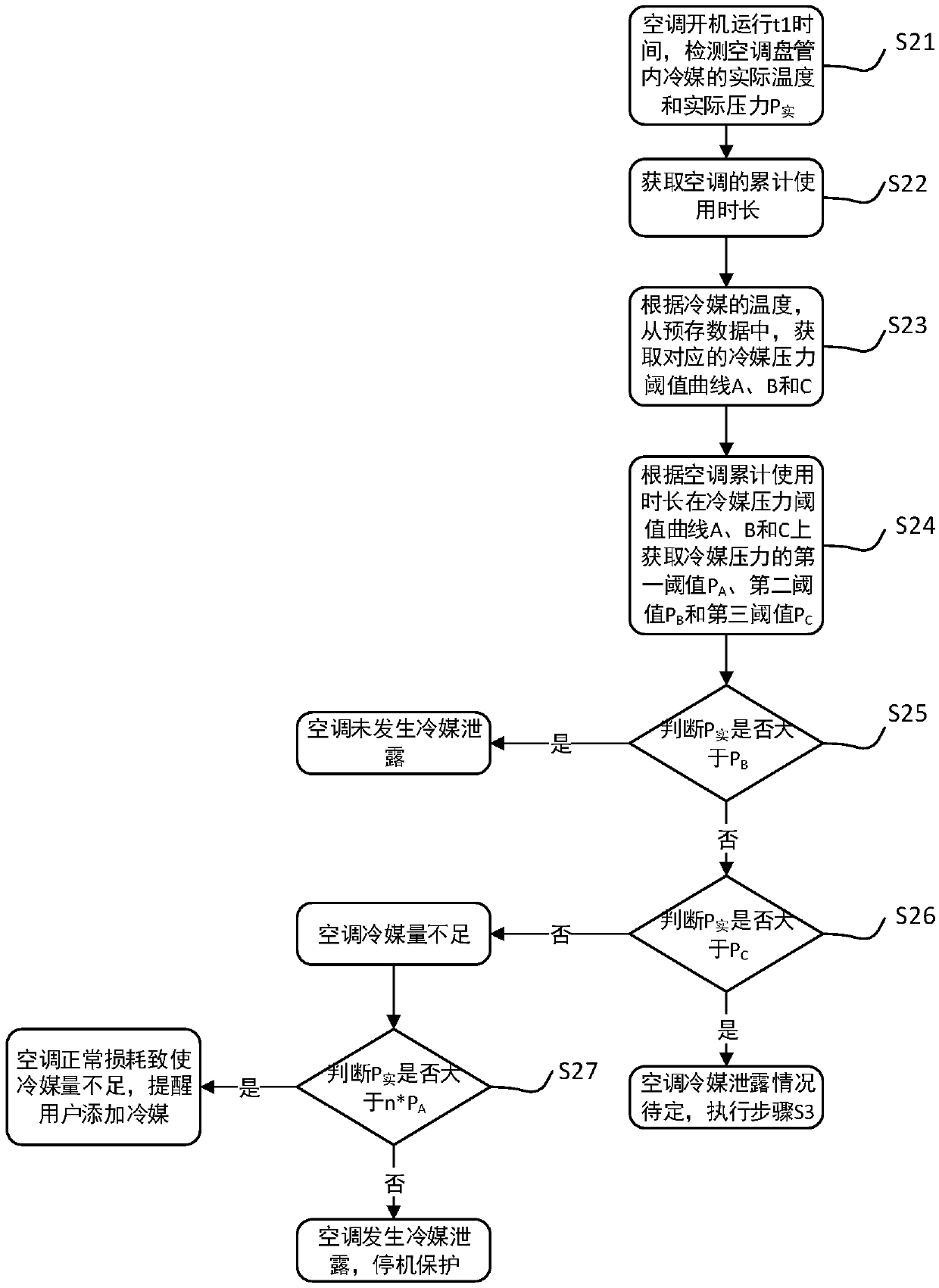

Method for detecting air conditioner refrigerant leakage and air conditioner

ActiveCN110940045AAdvantages of detection methodAvoid the impact of leak detection accuracyMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsMechanical engineering

The invention provides a method for detecting air conditioner refrigerant leakage and an air conditioner. The method comprises the following steps: S1, detecting the fault condition of a compressor before the air conditioner is started; and if the compressor operates normally, executing the step S2; S2, starting the air conditioner to operate, and judging refrigerant leakage conditions in advancethrough refrigerant pressure; and if the pre-judgment result is to be determined, executing the step S3; and S3, calculating the refrigerant remain and further judging the refrigerant leakage conditions. The method for detecting the air conditioner refrigerant leakage and the air conditioner have the advantages of high detection precision and low misjudgment rate.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

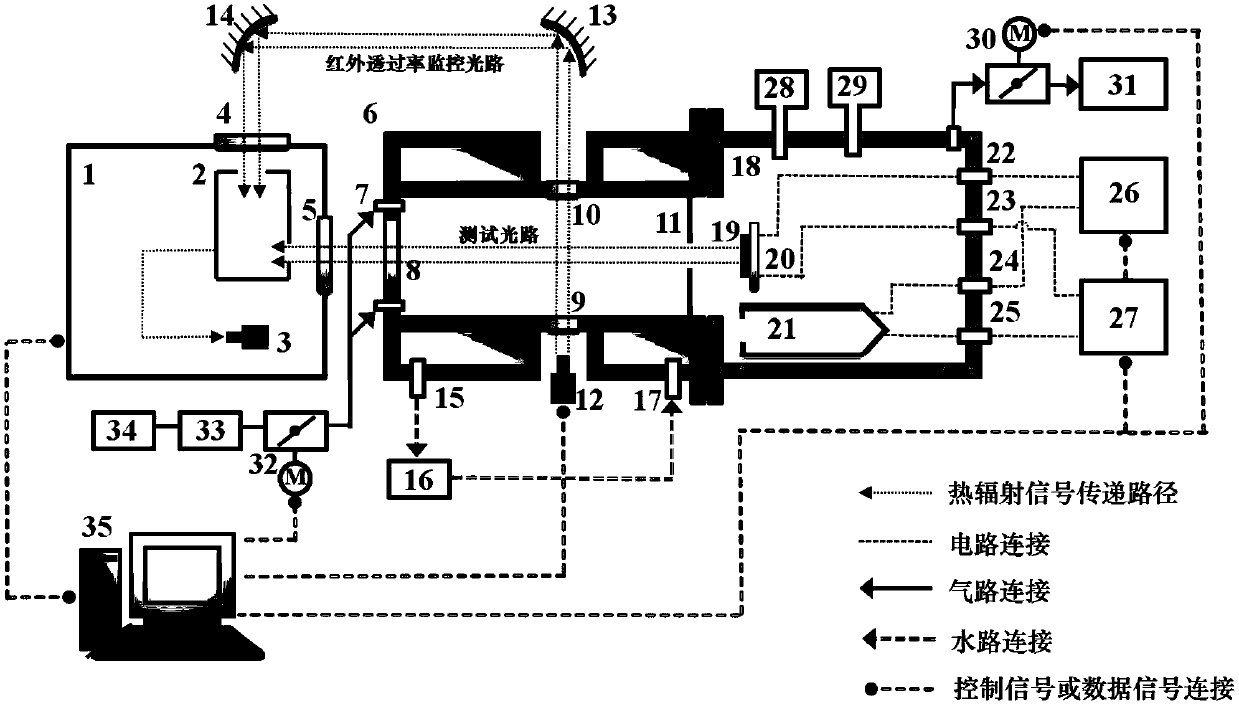

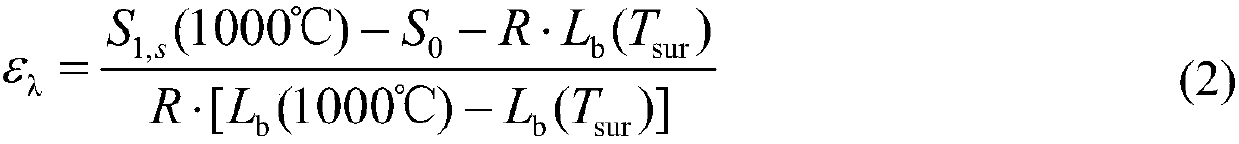

High-temperature thermal radiation coefficient testing device and method for ablative heat-proof material

ActiveCN107870157APrevent oxidationEliminate distractionsMaterial analysis by optical meansSignal onGas release

The invention relates to a high-temperature thermal radiation coefficient testing device and method for an ablative heat-proof material. According to the device and the method, oxygen can be preventedfrom oxidizing the ablative heat-proof material in a test sample heating process, interference of pyrolysis gas for thermal radiation signals on the ablation surface of the material is eliminated, and accurate testing for high-temperature thermal radiation coefficients of the ablative heat-proof material is realized. An inert atmosphere purge system and an oxygen concentration sensor can be controlled online in real time according to air strength, real-time monitoring and control of oxygen concentration in the test sample heating environment are realized, surface state change caused by oxidation reaction of the ablative heat-proof material in a high-temperature environment is avoided, and a high-temperature and oxygen-poor real service environment of the material in a state close to an atmosphere reentry or near-space hypersonic flight can be constructed; real-time online control for the inert atmosphere purge system and a real-time monitoring system for test optical path infrared transmittance can be realized on the basis of the air strength, so that real-time monitoring and control for transmitting optical path transmittance of the thermal radiation signals of the test sample are realized, the absorption of the pyrolysis gas released by the ablative heat-proof material on the thermal radiation signals of the test sample can be effectively inhibited, and accuracy of a testingresult of the thermal radiation coefficients is guaranteed. The effective testing device and method can be provided for disclosing evolvement rules of normal spectral thermal radiation coefficients and normal full-wavelength thermal radiation coefficients of the ablative heat-proof material in the high-temperature service environment.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Micro-tensile bonding strength testing fixture for dental bonding agent

InactiveCN103737516AEasy to fixFunction increaseWork holdersUsing mechanical meansEngineeringUltimate tensile strength

The invention discloses a micro-tensile bonding strength testing fixture for a dental bonding agent. The front portion of a connecting shaft is provided with a guide rod, and the side face of the back portion of the connecting shaft is provided with a bolt hole; an upper slide block and a lower slide block sliding along the guide rod are fixedly connected to the guide rod; a rigid pull rod is fixedly connected to the upper portion of the upper slide block; the central lines of the upper and lower slide blocks are provided with sample limiting grooves. The micro-tensile bonding strength testing fixture has the advantages that the connecting shaft of a universal test is used together with the universal test, thereby greatly reducing the cost of separate use of a micro-tensile tester and expanding the function of the universal tester; a bonded article is compressed through dual nuts and a gasket without bonding the bonded article on a test table by using the bonding agent; during cutting of a bonded sample, the bonding surface is kept flat, and the strain defect during cutting of the bonded sample can be avoided by directly cutting the bonded sample into small pieces as required; the testing fixture is stable in clamping, convenience in use, simple in structure, and very low in cost; by adopting the guide rod, the bonding strength test result is more accurate.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com