Shale gas-content comprehensive analysis device and method thereof

A comprehensive analysis and shale technology, applied in the field of oil and gas exploration and development, which can solve problems such as inconvenient analysis, unfavorable decision-making, gas loss and component changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

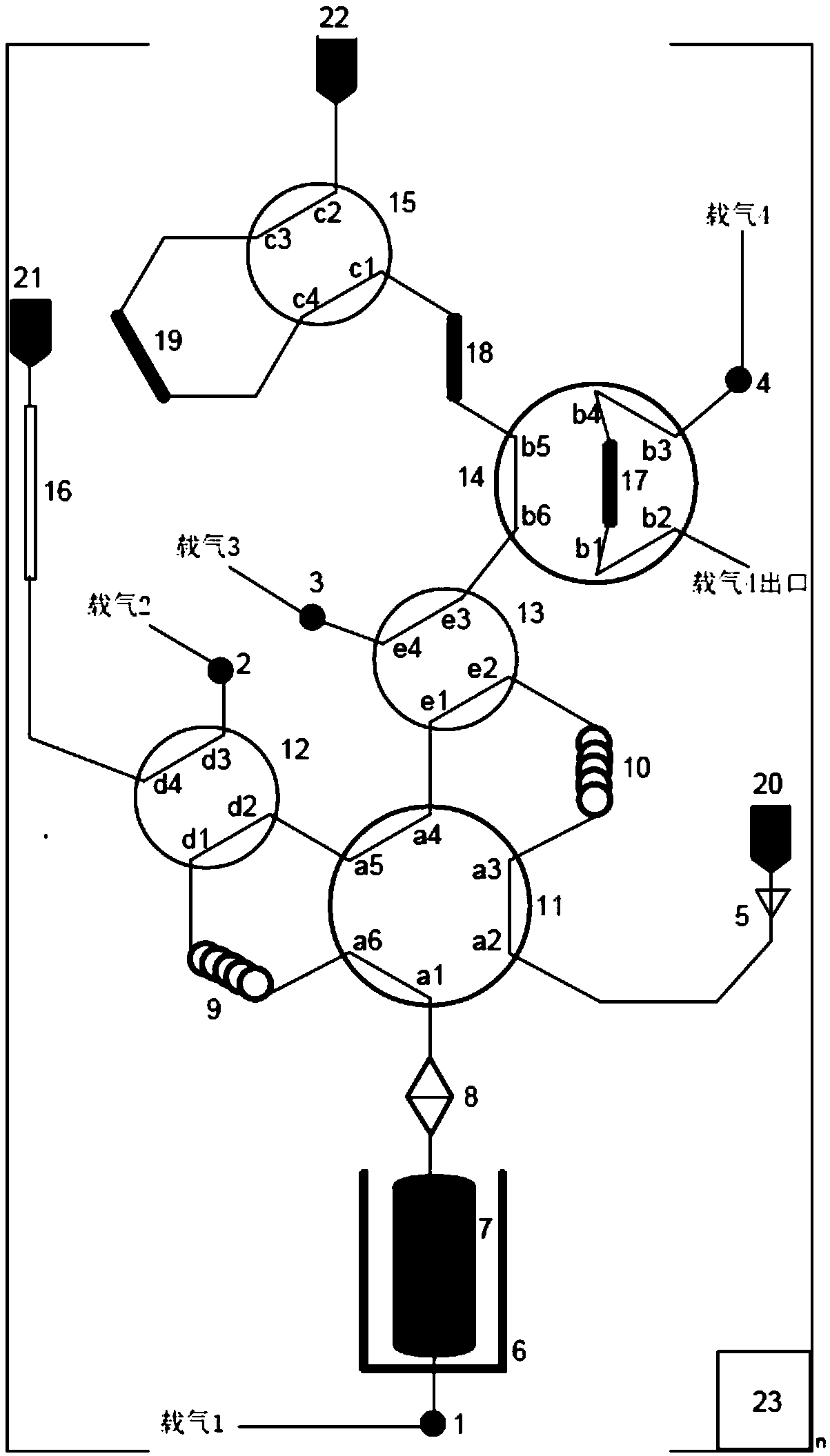

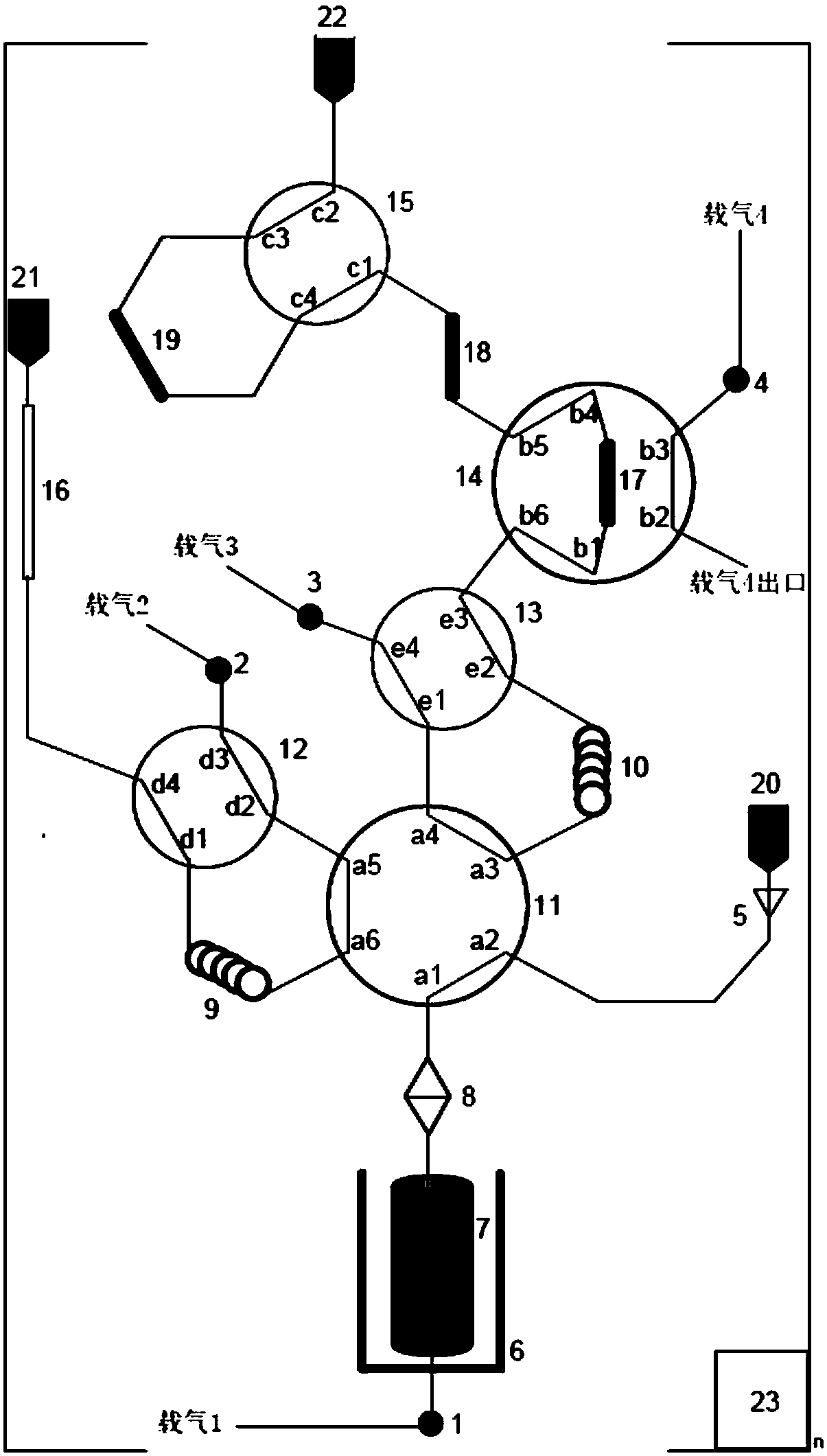

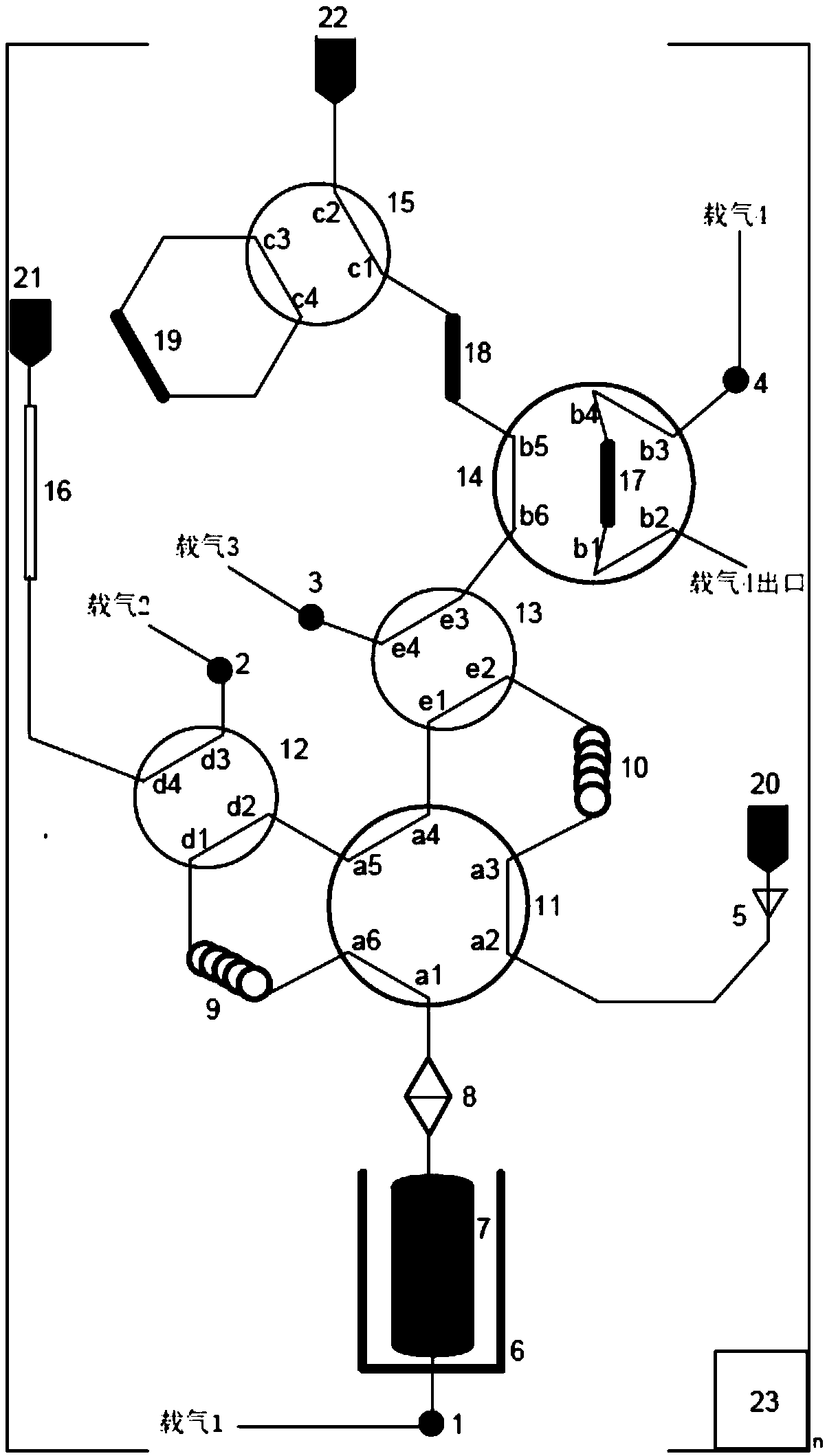

[0071] Analysis operation process

[0072] Based on the shale gas content measurement and gas component analysis of the shale gas-bearing comprehensive analysis device of the present invention, except that the loading, unloading, crushing and weighing of core samples are done manually, the rest of the instrument control work is performed by the described operation. The control unit is implemented under the control of the computer in accordance with the set procedures and parameters. Specifically, the following steps and contents are included:

[0073] 1. Instrument Preparation

[0074] (1) Connect the power supply of the instrument, start the computer of the operation control unit 23, and run the operation control software. Adjust the gas path of the instrument so that it is in "gas path mode A" (see figure 1 ). Open the pressure reducing valves for carrier gas 1, carrier gas 2, carrier gas 3, and carrier gas 4.

[0075] (2) Set the temperature of the thermostatic analysi...

Embodiment 2

[0105] Calculation and processing of analysis results

[0106] 1. Detector Calibration

[0107] 1.1 Detector calibration test

[0108]Close the carrier gas 1 on-off switch on the gas filter 8. From the standard gas inlet port that is installed on the gas filter 8, it is connected with all gas containing methane, ethane, propane, isobutane, n-butane, isopentane, n-pentane, nitrogen, oxygen, carbon monoxide, carbon dioxide, etc. A standard gas for the gas component to be detected. Let the standard gas flow into the gas filter 8 at a constant speed, and test the standard gas according to the normal sample testing instrument conditions and operating procedures, so as to determine the relationship between the detection signal intensity of the first detector 20 at the flow rate and the total volume of hydrocarbon gas For calibration, the relationship between the relative peak areas of the chromatographic peaks of the components of the second detector 21 and the third detector 22 ...

Embodiment 3

[0200] Standard gas analysis

[0201] (1) Gas composition: methane 85.88%, ethane 3.04%, propane 0.77%, isobutane 0.29%, n-butane 0.22%, isopentane 0.10%, n-pentane 0.10%, nitrogen 3.01%, oxygen 0.57% , carbon monoxide 4.98%, carbon dioxide 0.96%, other 0.08%.

[0202] (2) Test conditions

[0203] Carrier gas and its flow rate: carrier gas 1, hydrogen, flow 20mL / min; carrier gas 2, hydrogen, flow 63mL / min; carrier gas 3, hydrogen, flow 22mL / min; carrier gas 4, hydrogen, flow 30mL / min.

[0204] Limiting value of gas flow limiting valve 5: 200mL / min at 0.2MPa.

[0205] Sample loading loop volume: the volume of the first sample loading loop 9 is 0.5mL; the volume of the second sample loading loop 10 is 2.5mL.

[0206] Analytical constant temperature analytical chamber 6 temperature: 100°C,

[0207] Separation column temperature: The temperature of the separation column oven is 50°C.

[0208] Multi-way valve temperature: the temperature of the first multi-way valve 11 is 60°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com