Patents

Literature

3172 results about "Butane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Butane (/ˈbjuːteɪn/) is an organic compound with the formula C₄H₁₀ that is an alkane with four carbon atoms. Butane is a gas at room temperature and atmospheric pressure. The term may refer to either of two structural isomers, n-butane or isobutane (also called "methylpropane"), or to a mixture of these isomers. In the IUPAC nomenclature, however, "butane" refers only to the n-butane isomer (which is the isomer with the unbranched structure). Butanes are highly flammable, colorless, easily liquefied gases that quickly vaporize at room temperature. The name butane comes from the roots but- (from butyric acid, named after the Greek word for butter) and -ane. It was discovered by the chemist Edward Frankland in 1849. It was found dissolved in crude petroleum in 1864 by Edmund Ronalds, who was the first to describe its properties.

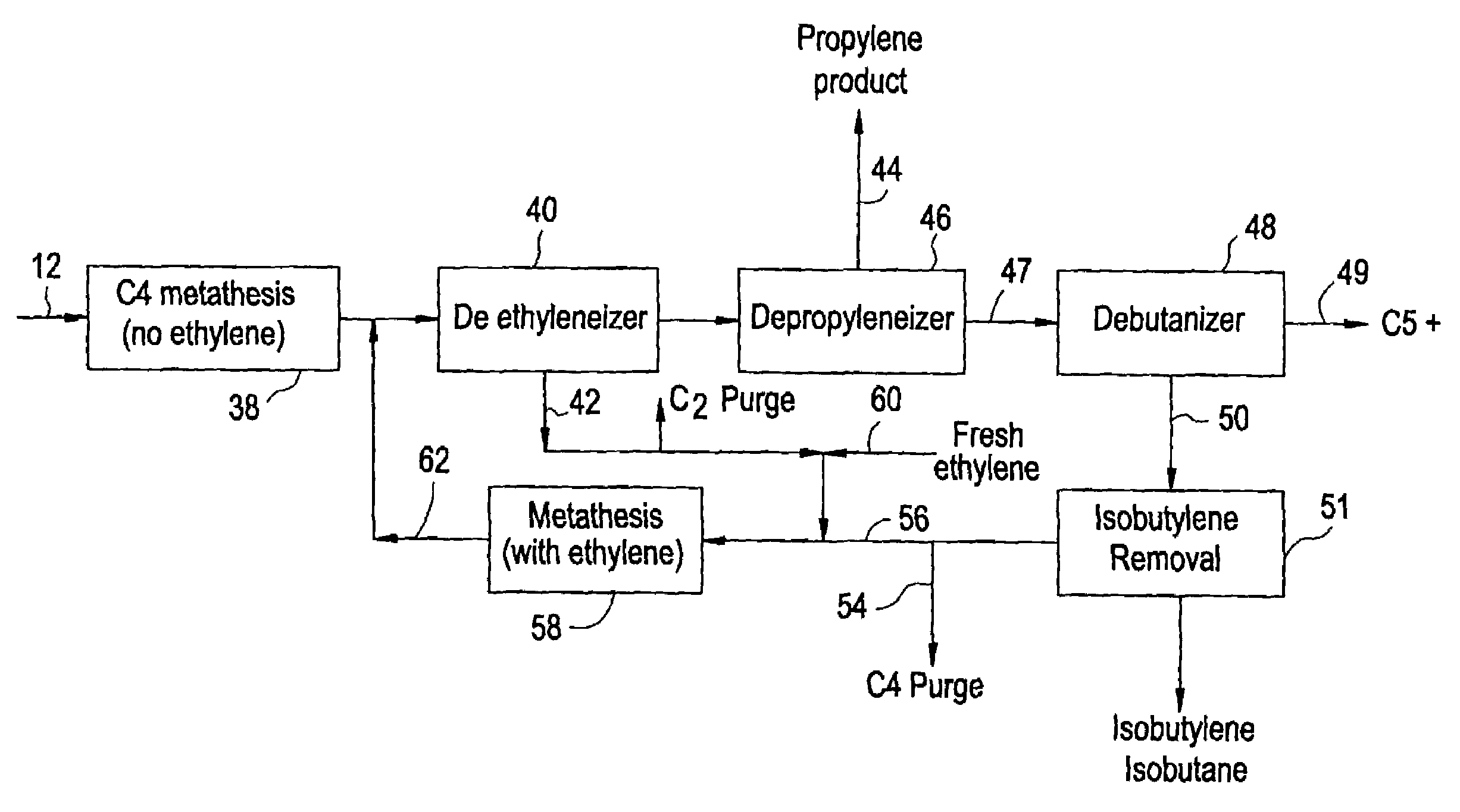

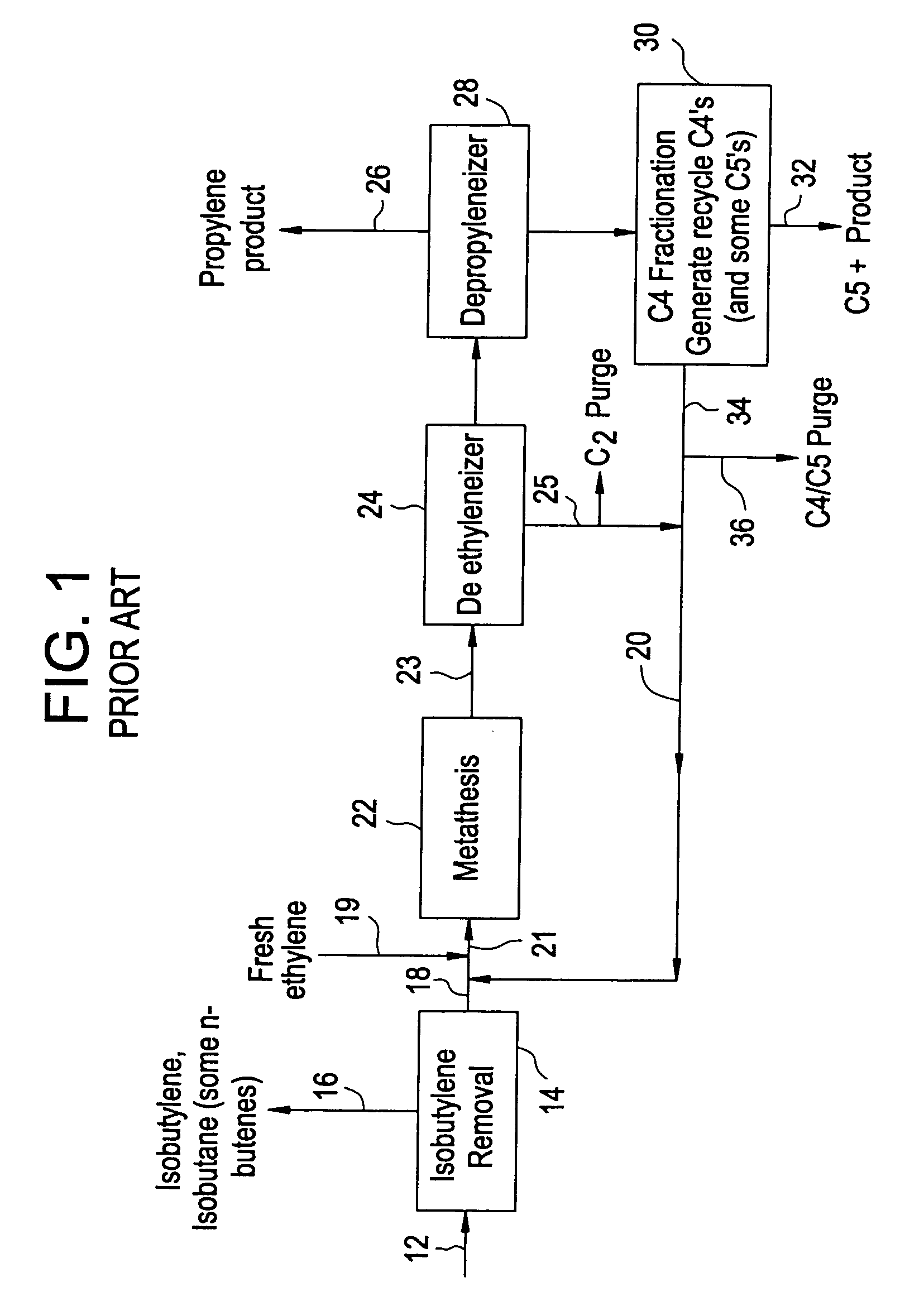

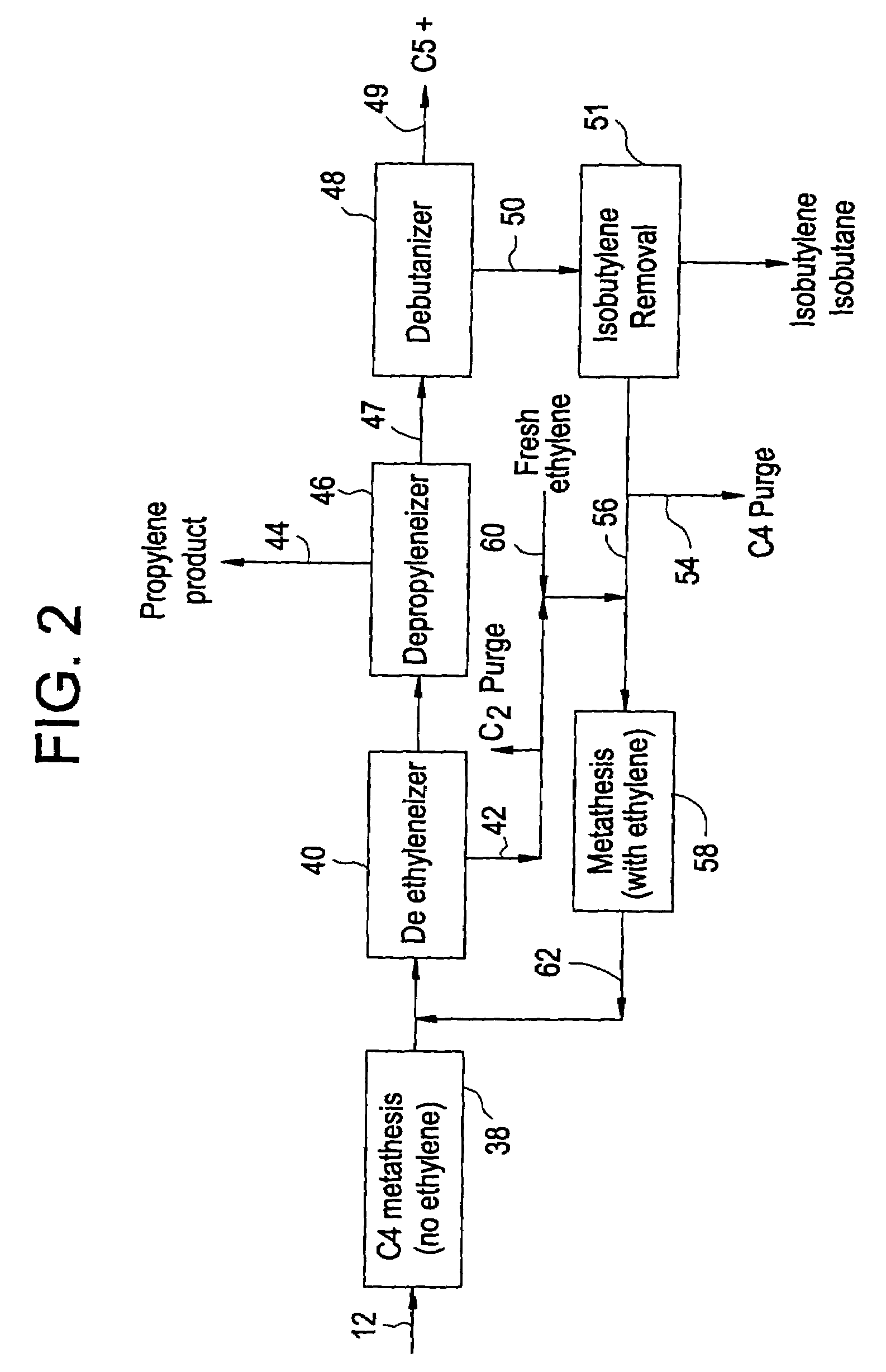

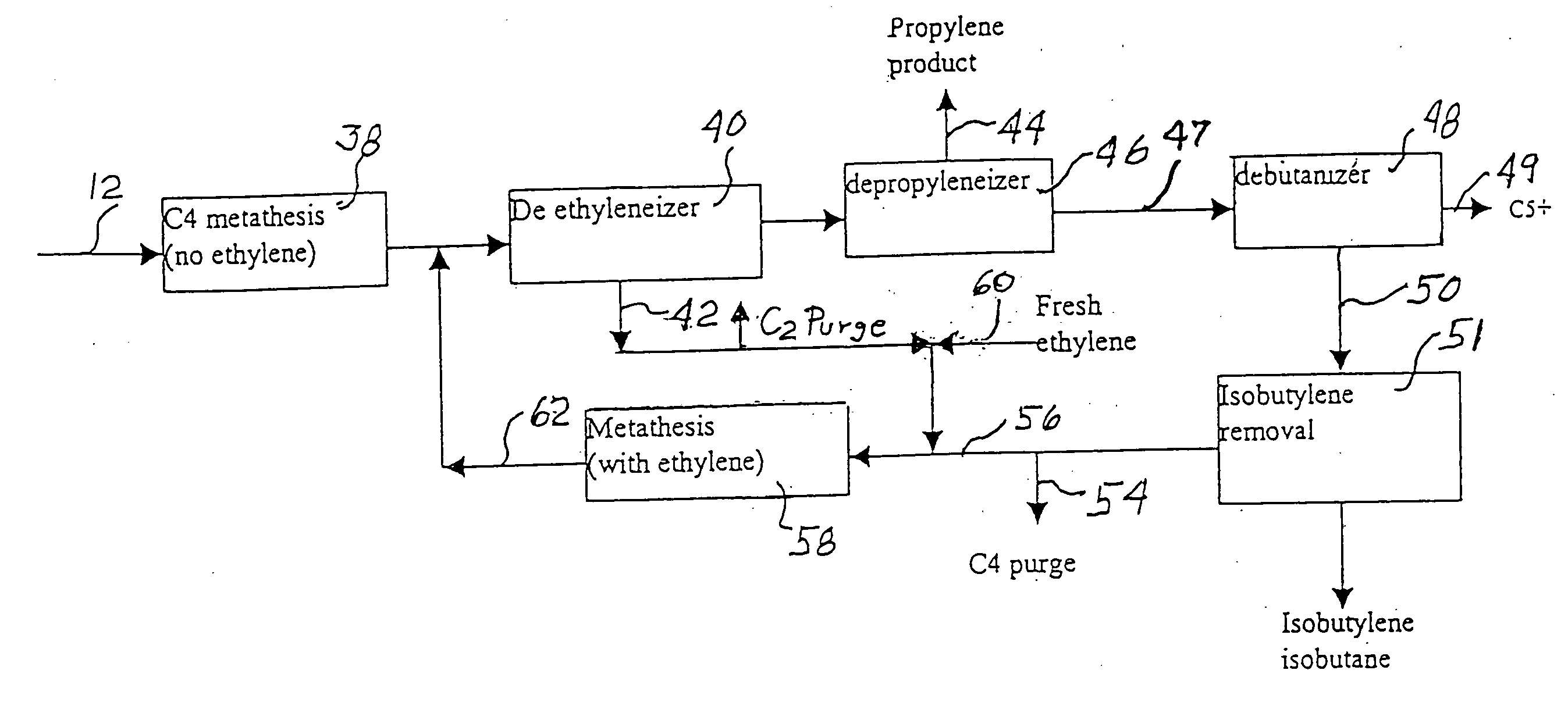

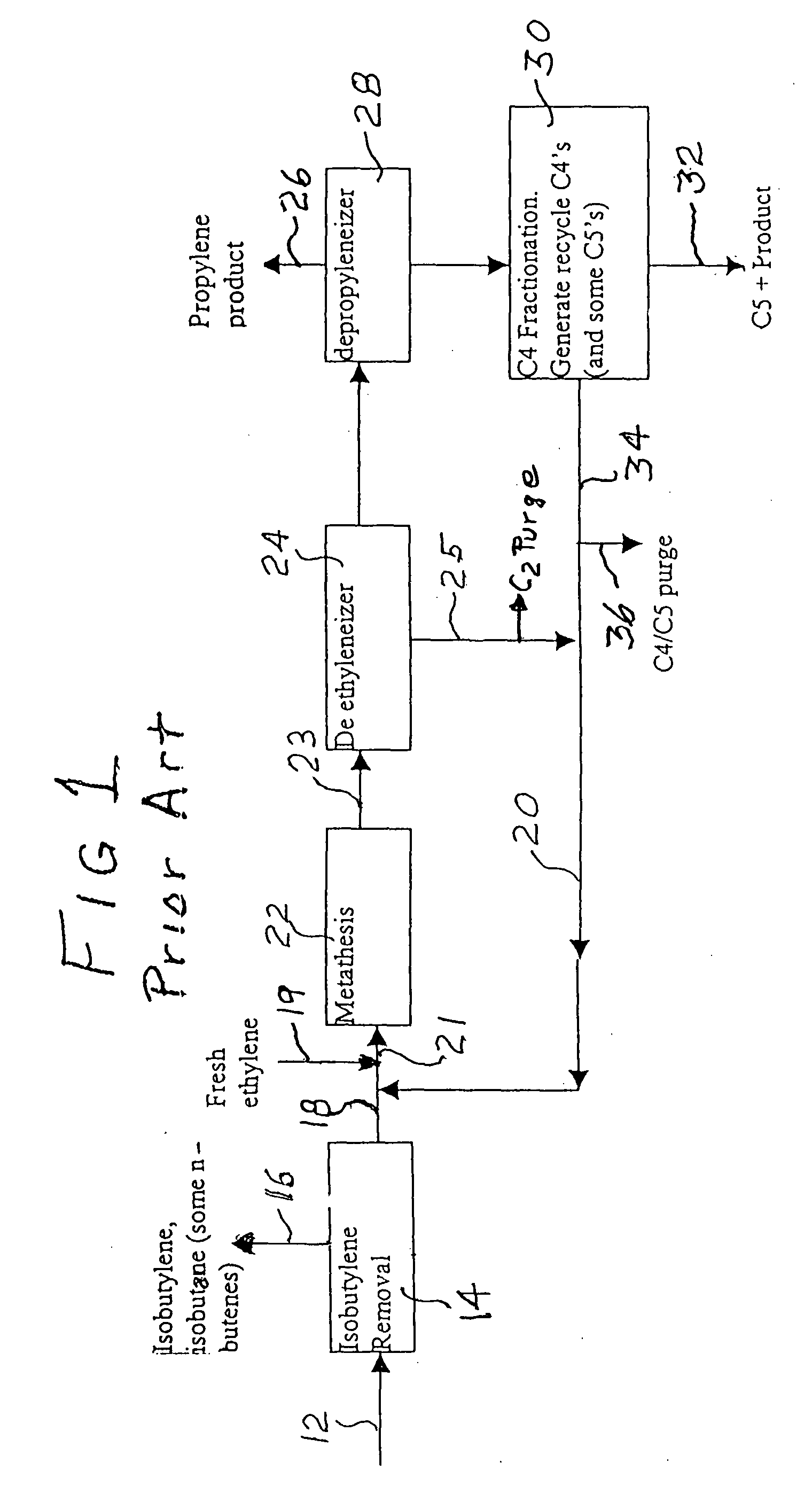

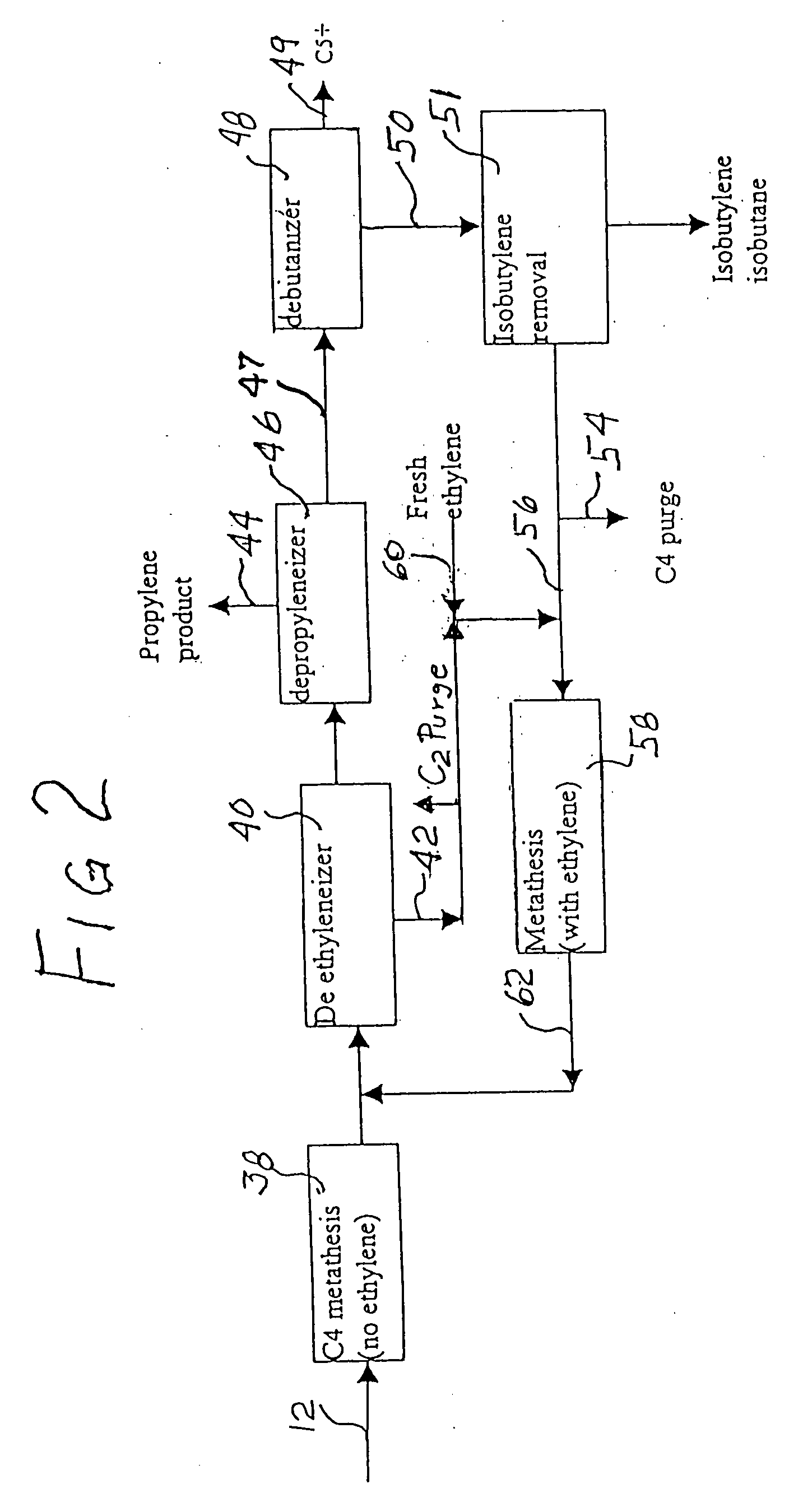

Processing C4 olefin streams for the maximum production of propylene

ActiveUS7214841B2Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

Chemical microreactor and method thereof

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

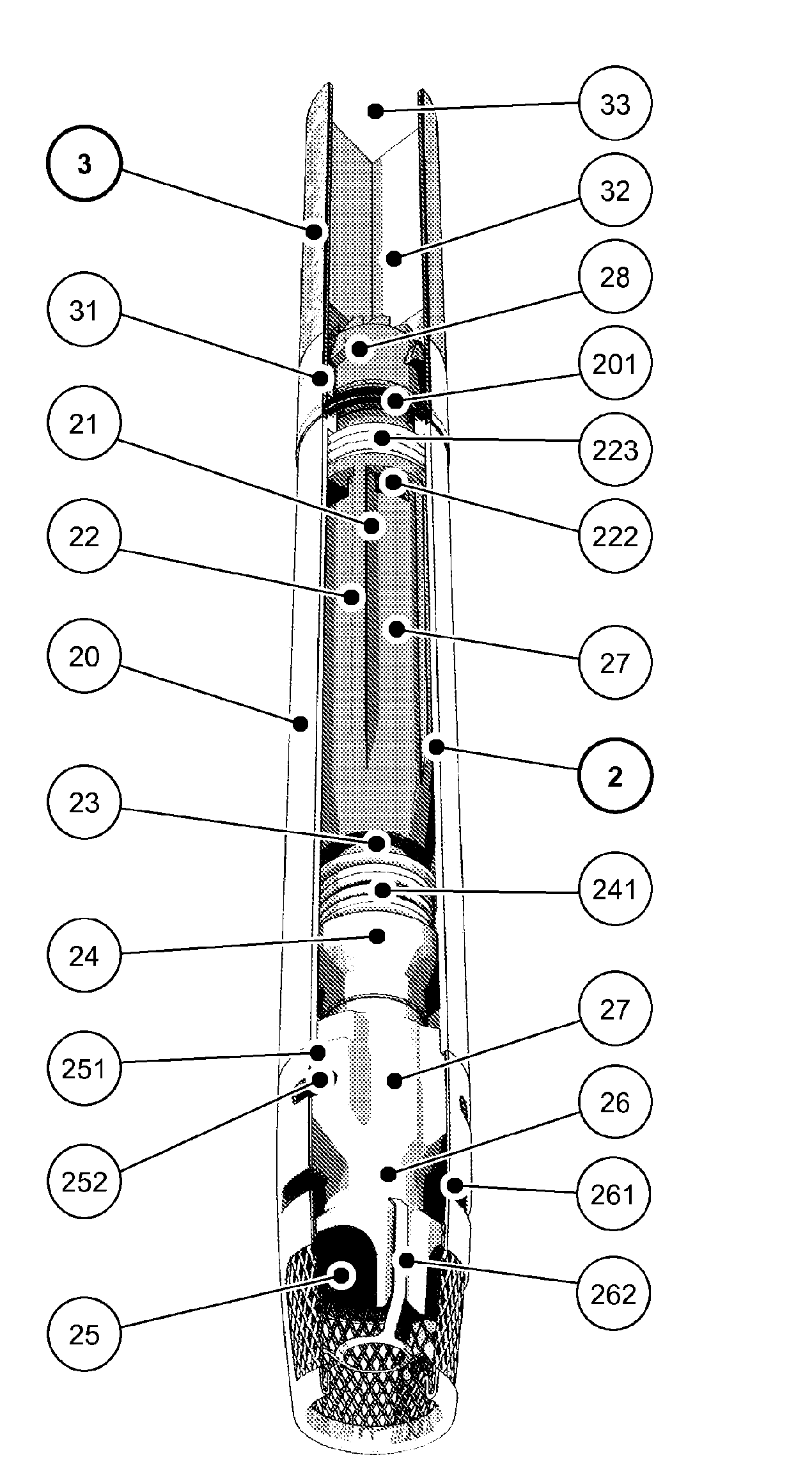

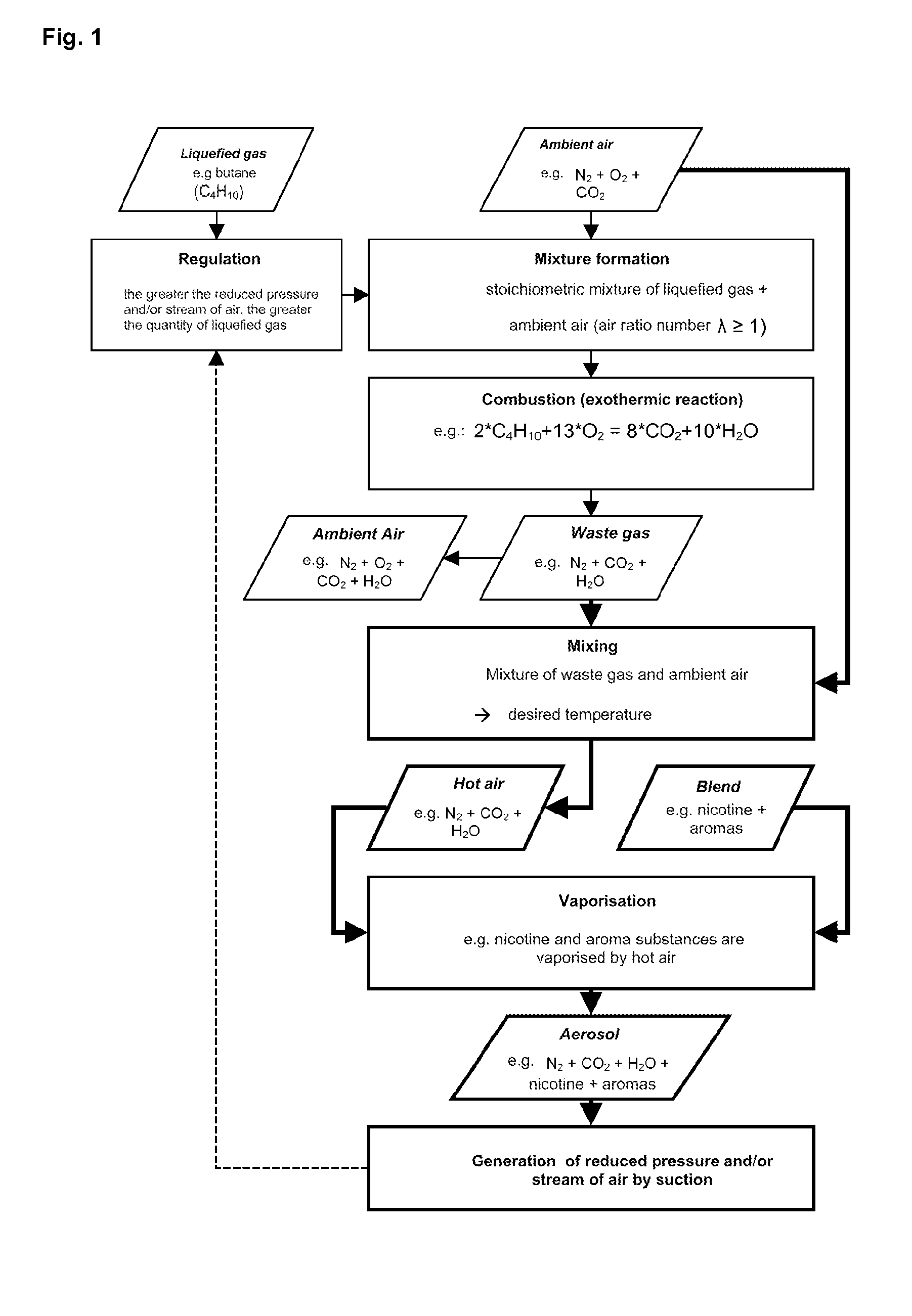

Smoke-free substitute cigarette product

ActiveUS20100126505A1Straightforwardly be carriedReduce weightTobacco treatmentTobacco devicesFlammable gasCigarillo

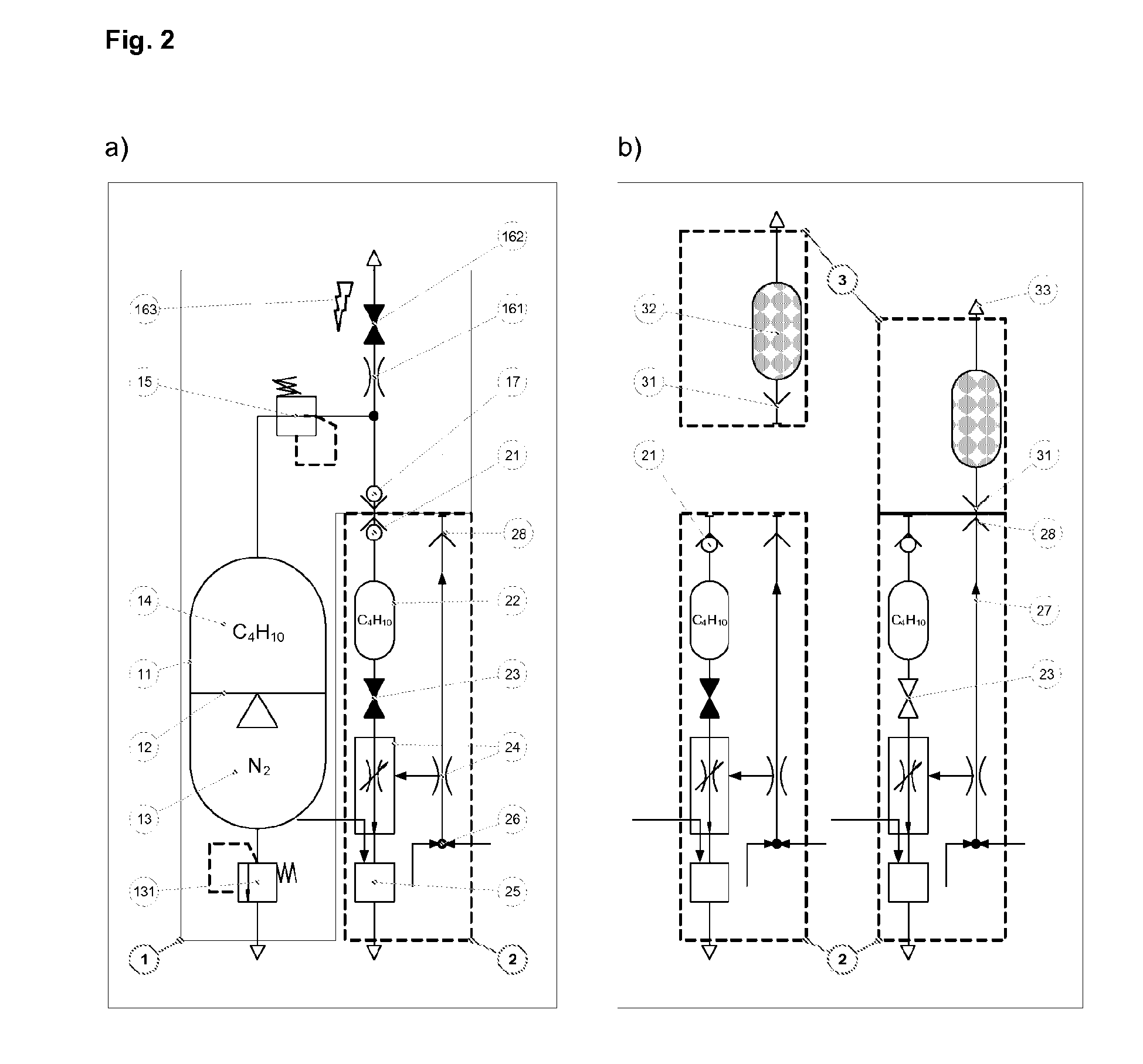

A method for volatilising active and / or aroma substances for the purpose of releasing an inhalable aerosol, wherein combustion gases of a flammable gas, which is preferably combusted with an excess of air, are passed partially or entirely, optionally mixed with ambient air, through an active and / or aroma substance depot and wherein a desired temperature is selectable by the proportion of combustion gases and optionally by the mixing ratio of said combustion gases with ambient air and the device implementing the method in the shape and dimensions of a cigarette or cigar for releasing an inhalable aerosol, comprising a mouthpiece (3) containing an active and / or aroma substance depot (32), a heating member (2) with a housing sleeve with one or more air inlets and one or more hot air outlets at the mouthpiece end, a filling valve (21) for filling a gas tank (22) with a flammable gas, preferably propane or butane gas, a regulating valve (24) for the controlled release of the gas from the gas tank (22) to a burner (25) and a mass transfer exchanger (26) for heating the air by the hot combustion gases produced by means of the burner (24), wherein the mouthpiece (3) is detachably connected to the heating member (2) and control of the regulating valve (24) is effected by means of the reduced pressure and / or stream of air generated by a user's suction on the mouthpiece (3). Fuelling station for such a device.

Owner:PHILIP MORRIS PROD SA

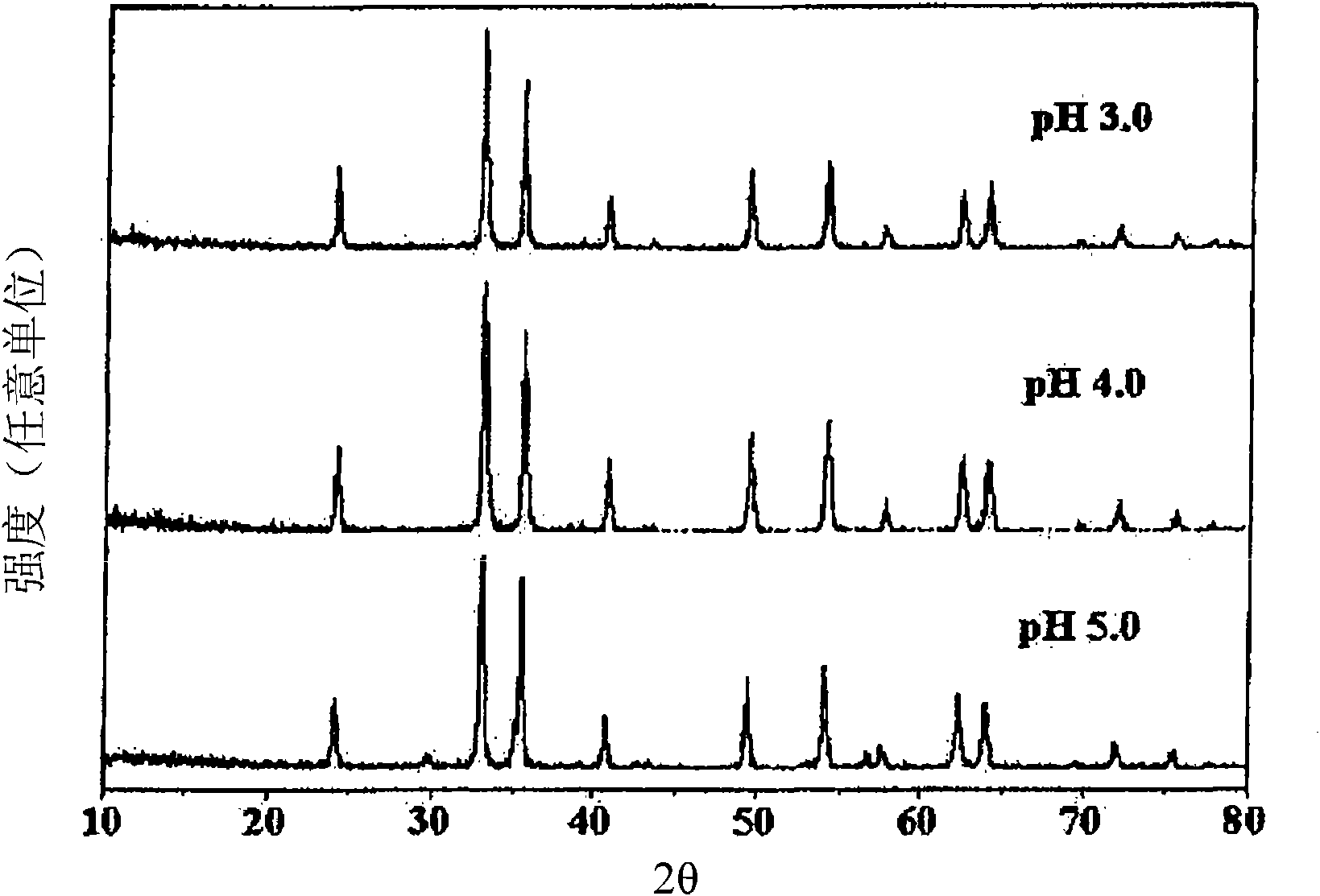

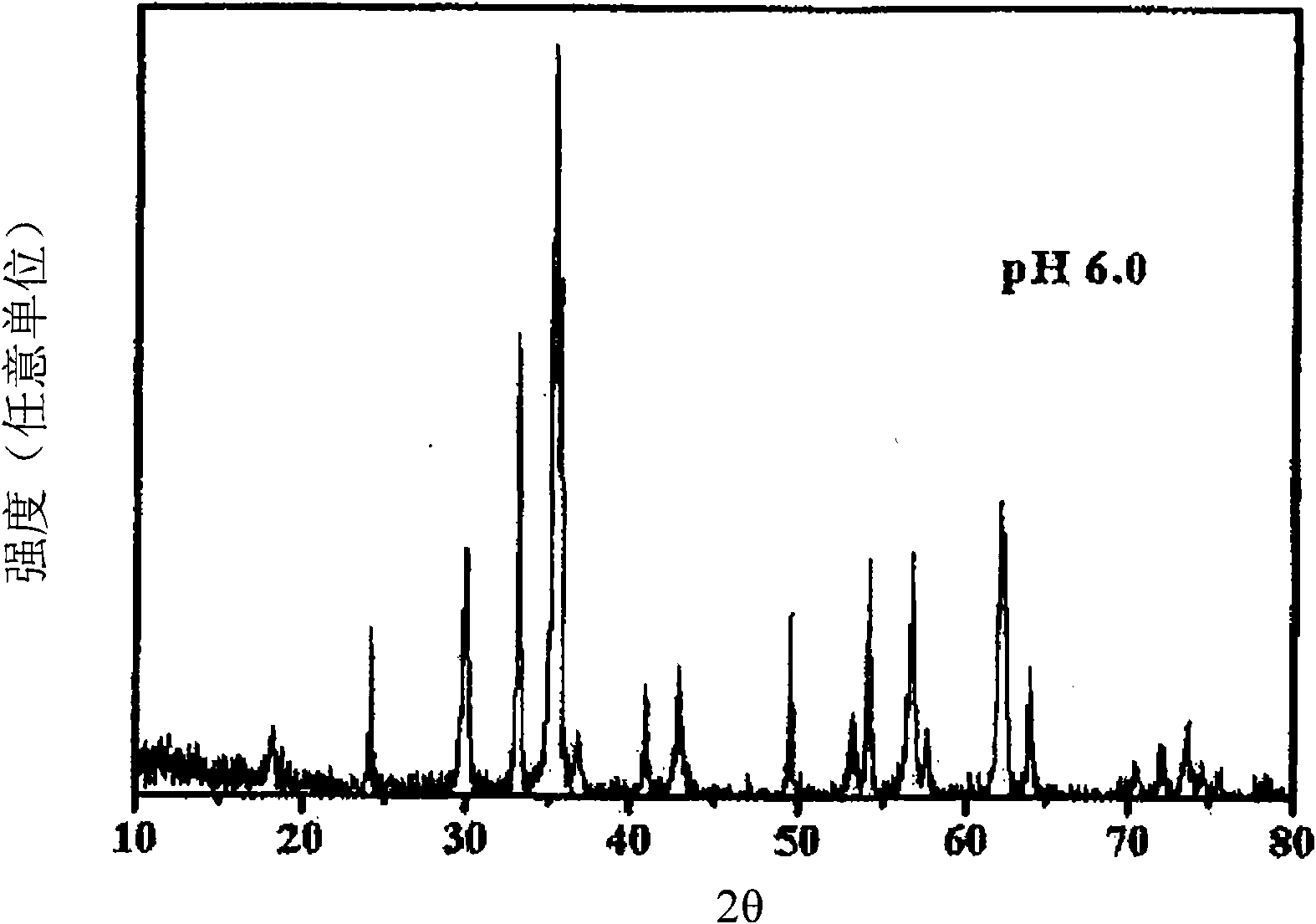

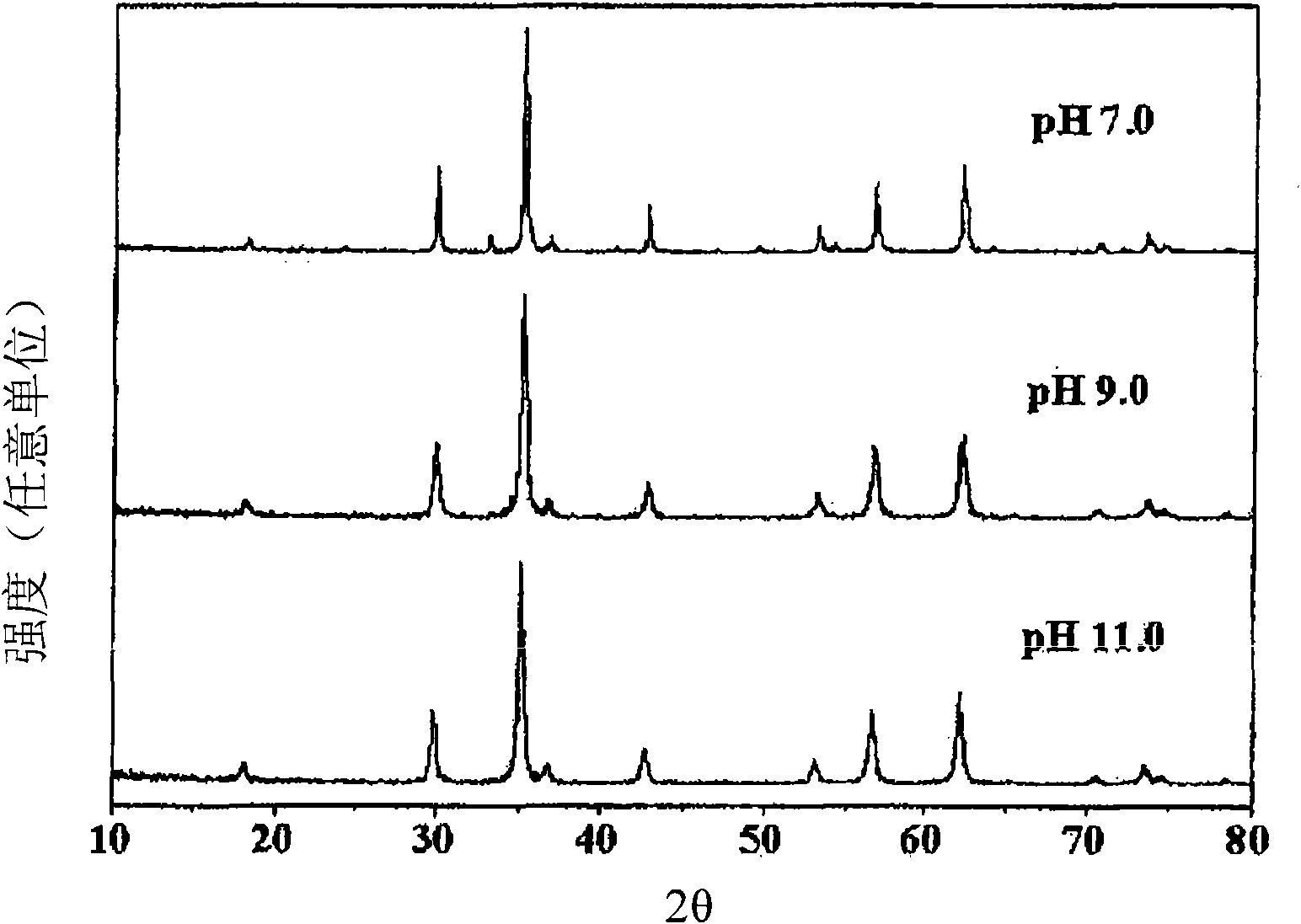

Zinc ferrite catalysts, method of preparing thereof and method of preparing 1,3-butadiene using thereof

ActiveCN101674883ASimple structureEasy to synthesizeHeterogenous catalyst chemical elementsCatalystsButeneDehydrogenation

Owner:SK INNOVATION CO LTD +1

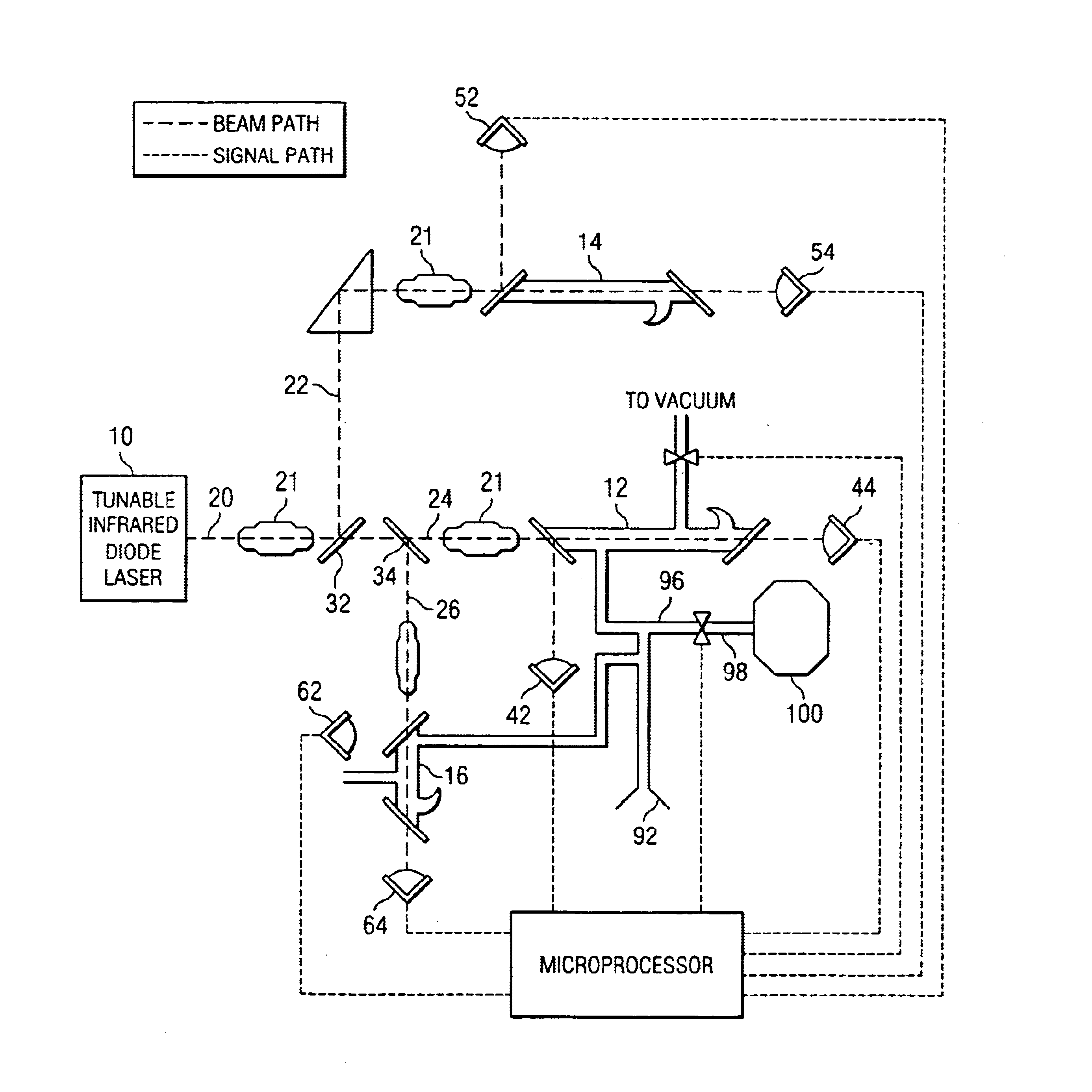

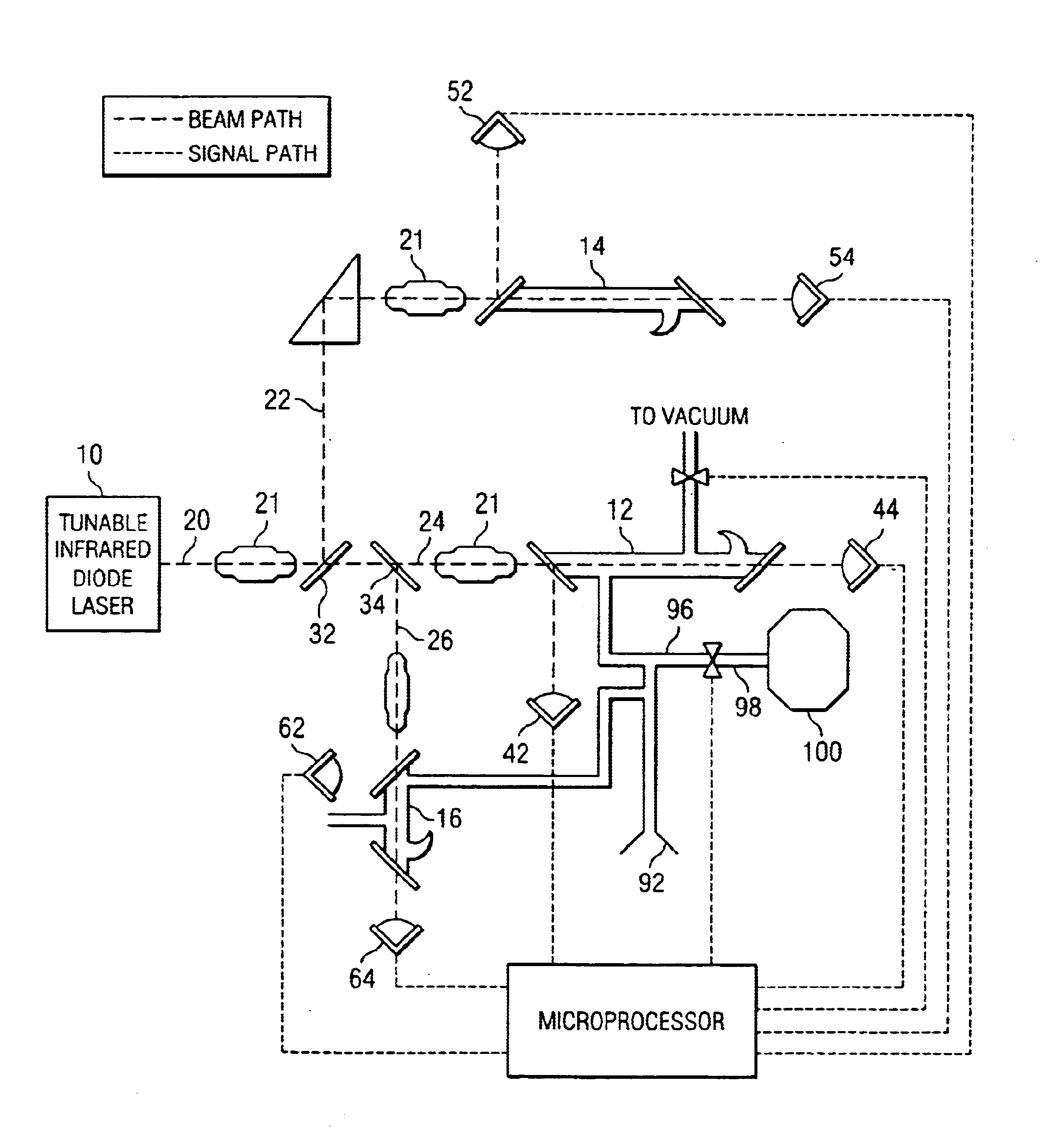

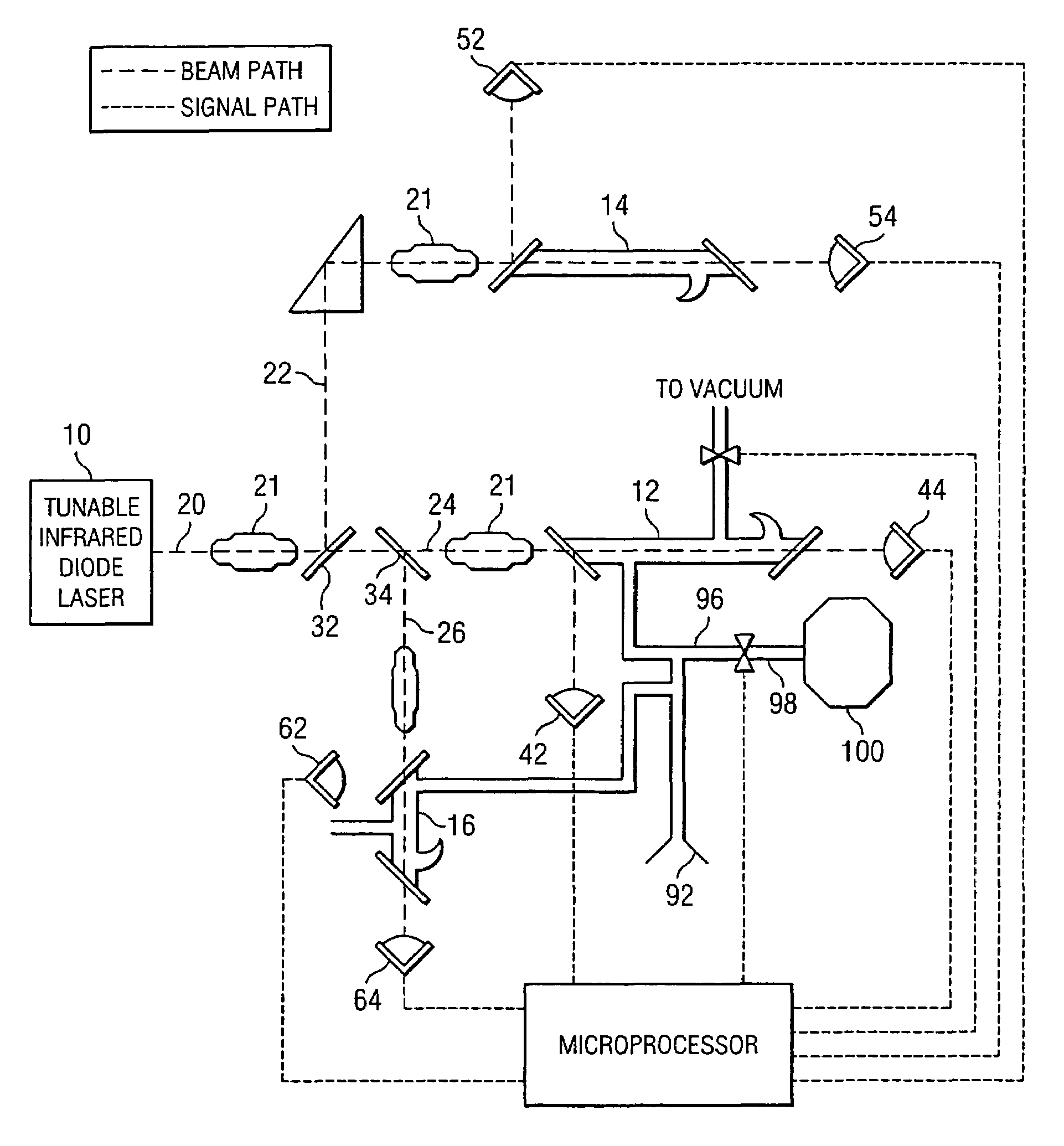

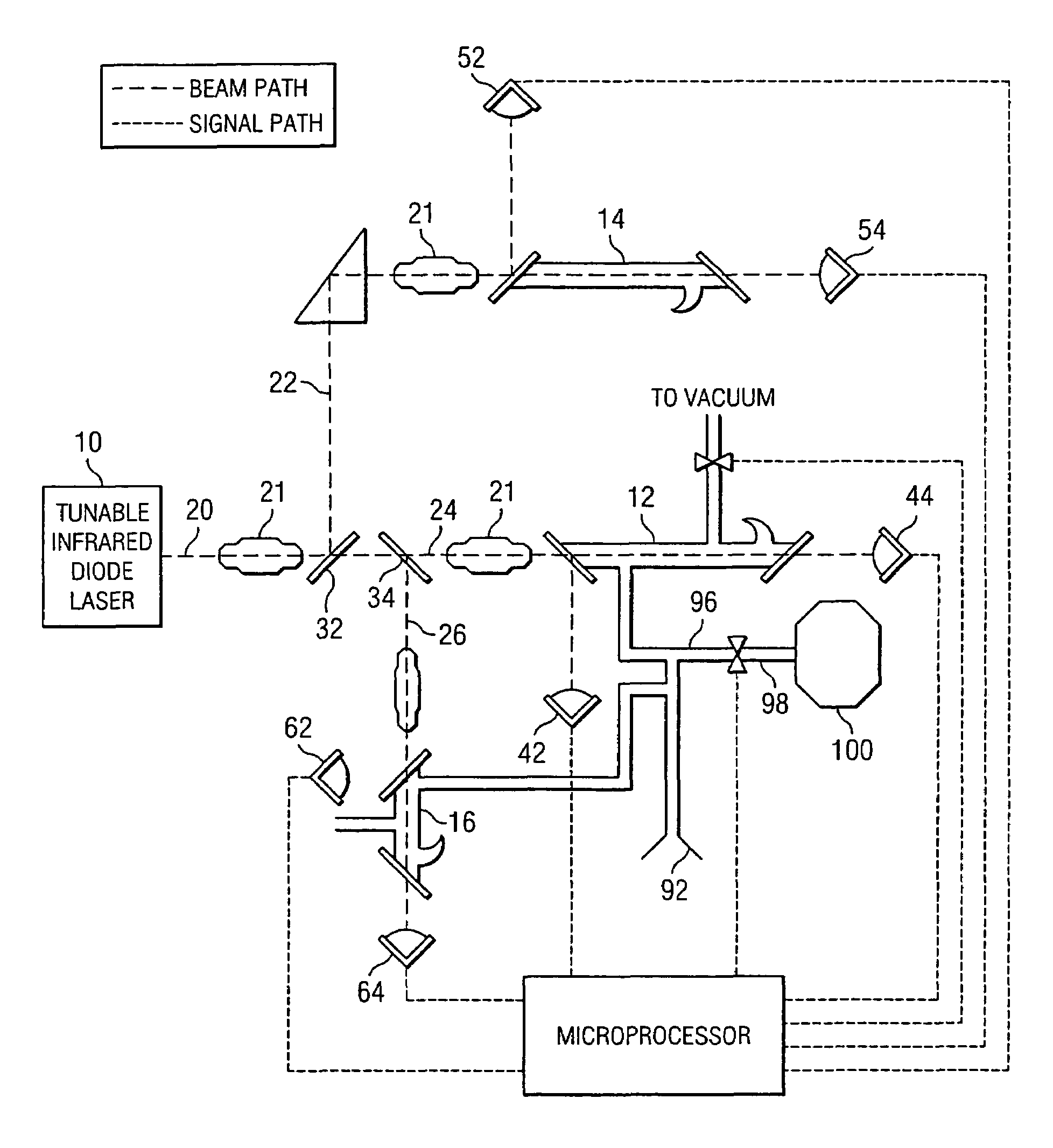

Method and apparatus for performing rapid isotopic analysis via laser spectroscopy

InactiveUS6888127B2Accurate and preciseAccurate and Precise MeasurementsRadiation pyrometryColor/spectral properties measurementsIsotopeLaser beams

Method and apparatus for providing real-time data indicative of the isotopic composition of formation fluids during drilling. The method includes the steps of: (a) providing a reference fluid having a known isotopic composition in a reference cell; (b) capturing a sample of formation; (c) providing at least one laser beam; (e) passing a beam through the reference fluid, measuring the reference-measurement beam before and after it passes through the reference fluid; (f) and passing a beam through the sample, measuring the beam before and after it passes through the sample, and calculating a first isotope concentration from those measurements. The measurements can provide information relating to the carbon isotopic composition of individual compounds in hydrocarbon gas mixtures, with the individual compounds including methane, ethane, propane, iso- or normal butane, or iso- or normal pentane.

Owner:CALEB BRETT USA

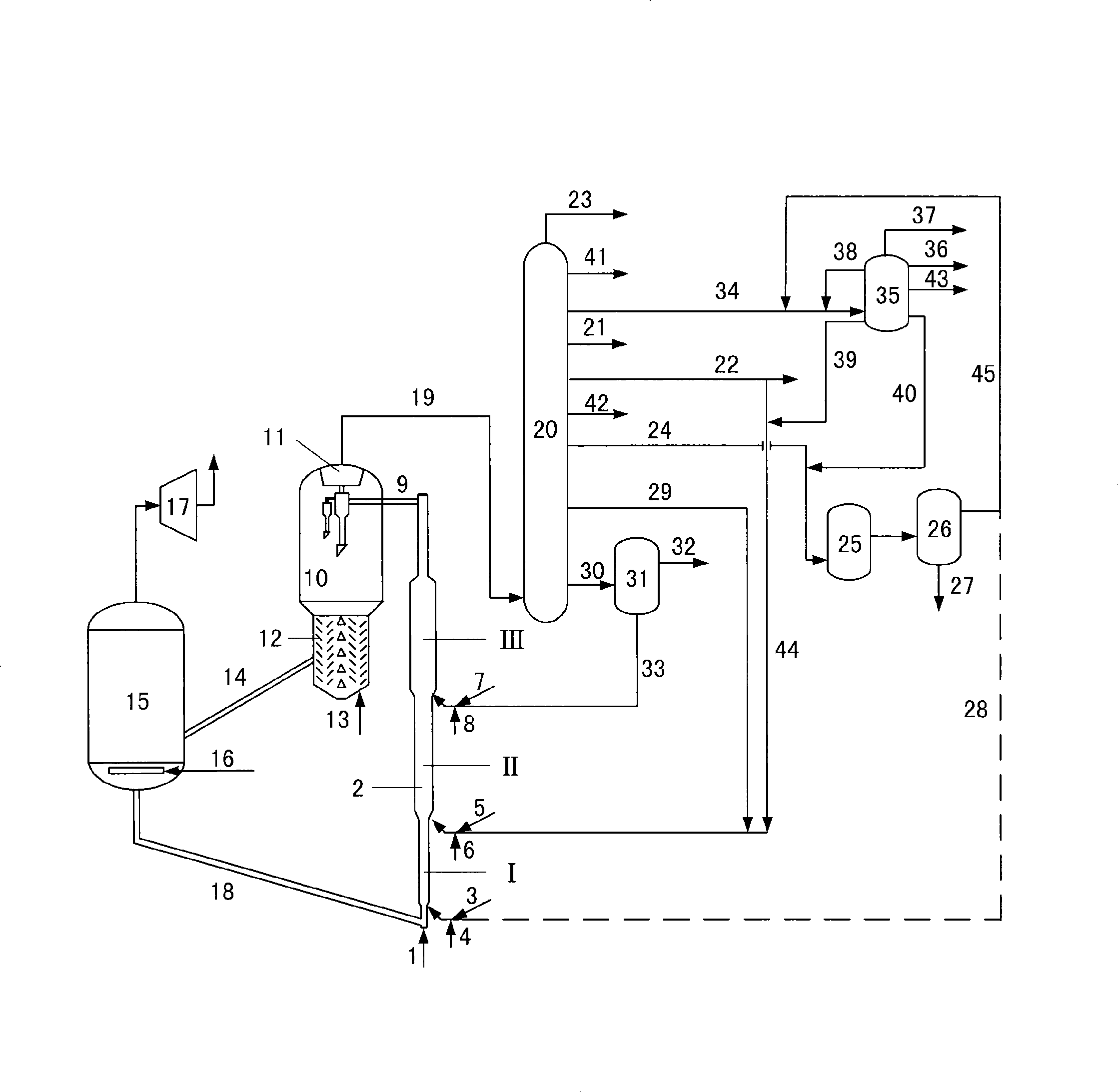

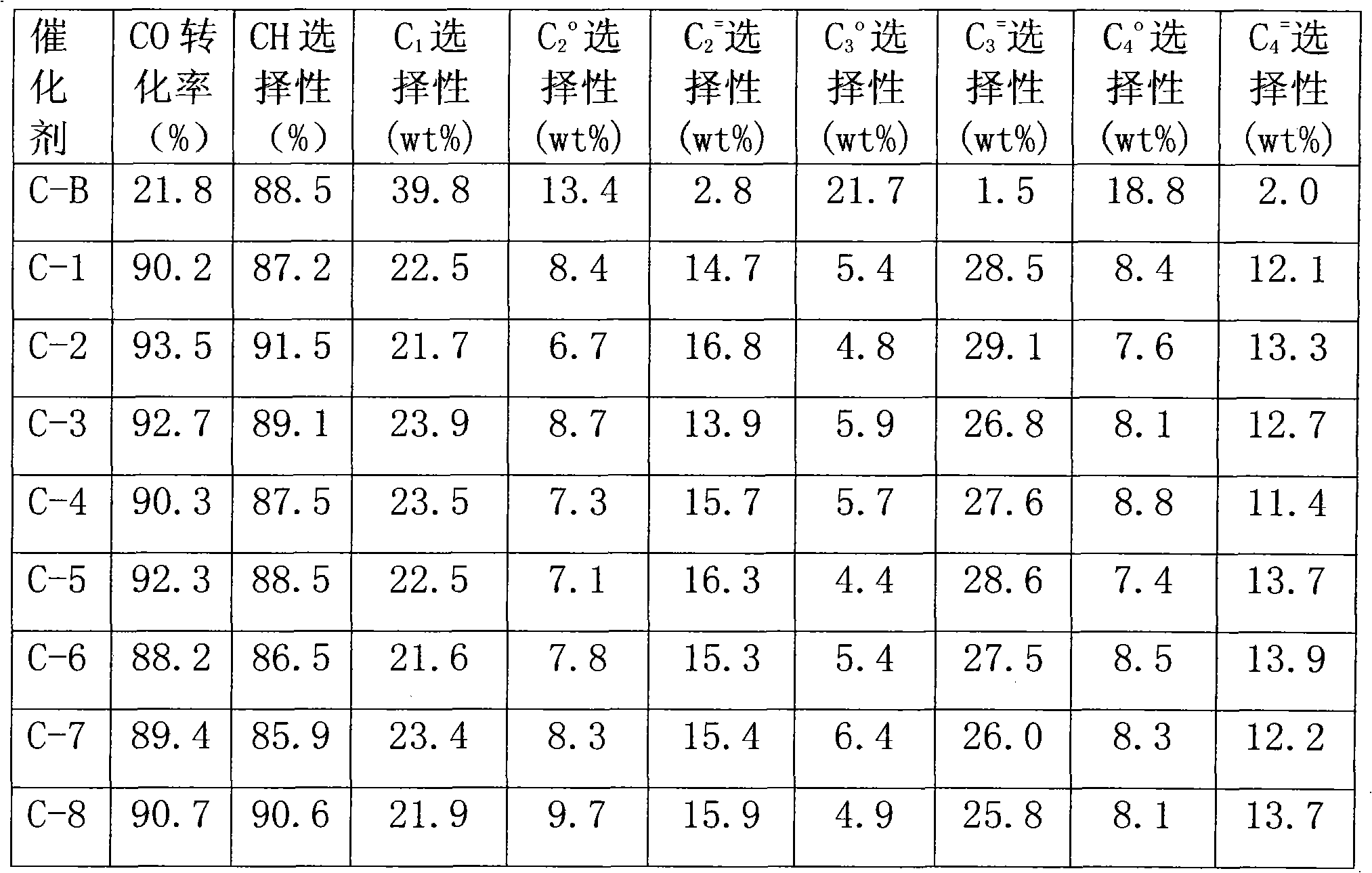

Catalytic conversion method of ethylene, propylene and aromatic hydrocarbon preparation

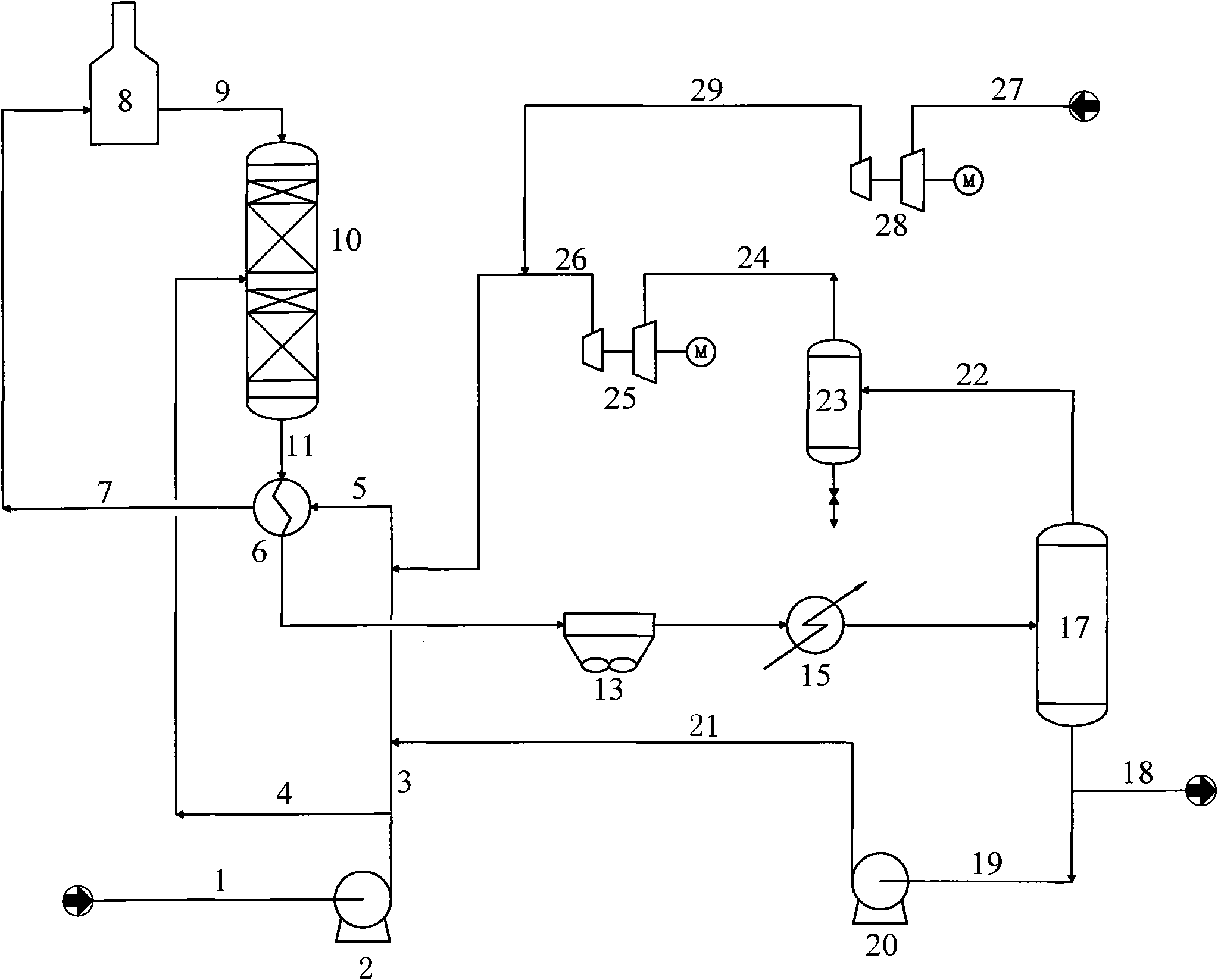

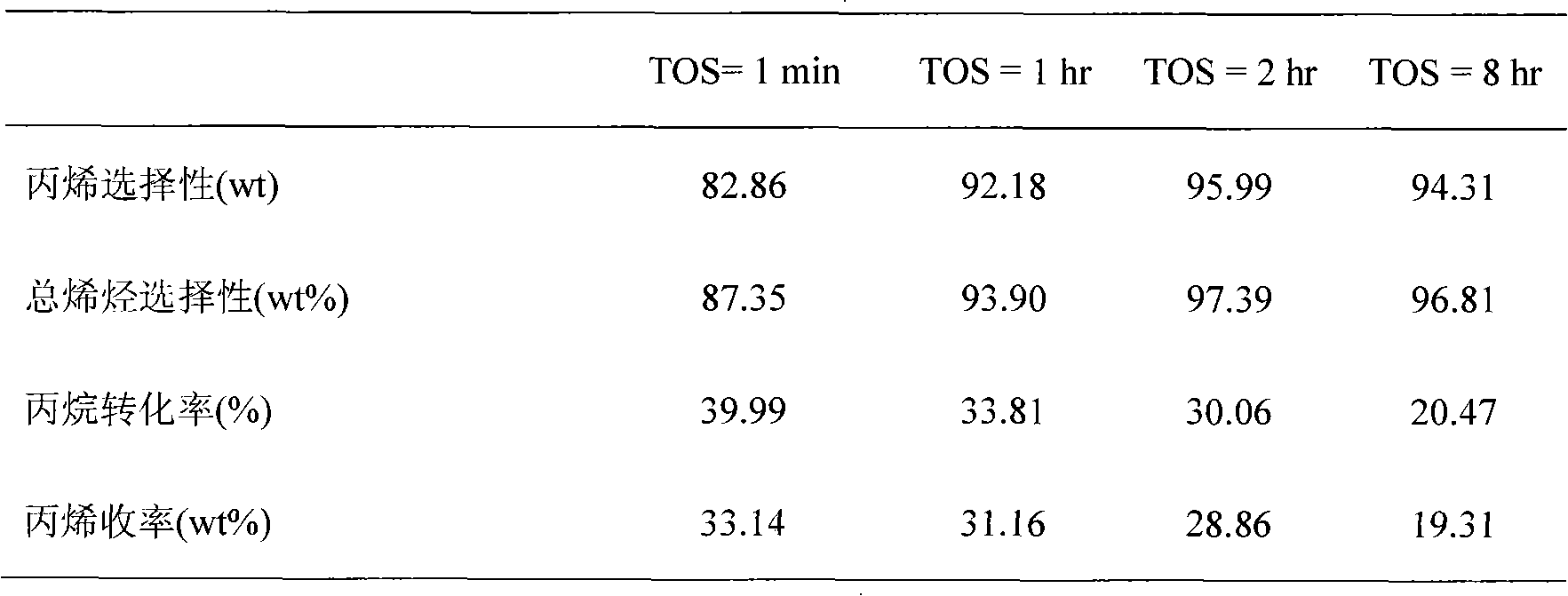

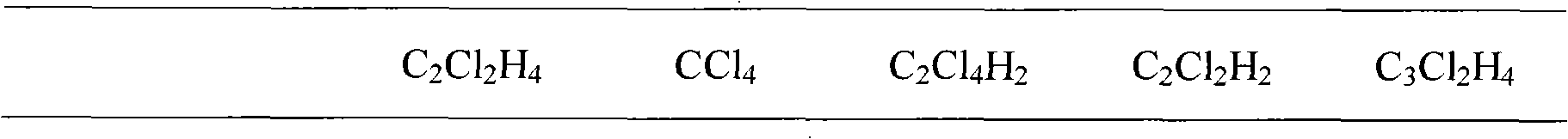

The invention discloses a catalytic conversion method for preparing ethylene, propylene and aromatic hydrocarbon. Hydrocarbon raw material with different cracking performances is contacted with a catalytic cracking catalyst, and cracking reaction is carried out in a fluidized bed reactor under the conditions that the temperature is 550 DEG C to 800 DEG C, the weight hourly space velocity is 0.1-800h<-1>, the reaction pressure is 0.10MPa to 1.0MPa, the weight ratio of the catalytic cracking catalyst and the raw material is 10-150, and the weight ratio of steam and the raw material is 0.15-1.0.Then a spent catalyst and reaction oil gas are separated, the spent catalyst returns to the reactor after regeneration, and the target products comprising low carbon olefin and the aromatic hydrocarbon are obtained by separating the reaction oil gas, wherein, fraction with the temperature to be 160 DEG C to 260 DEG C returns for catalytic cracking as circulating material, and the ethylene and the propylene are further obtained by cracking of ethane, propane, butane, and the steam entered. Low carbon olefin such as ethylene, propylene, and the like, is produced from heavy feedstock to the utmost extent in the method, and the yield of the ethylene and the propylene is over 20% by weight, in addition, the aromatic hydrocarbon such as toluene, xylene, and the like, are produced in an integrated way.

Owner:CHINA PETROLEUM & CHEM CORP +1

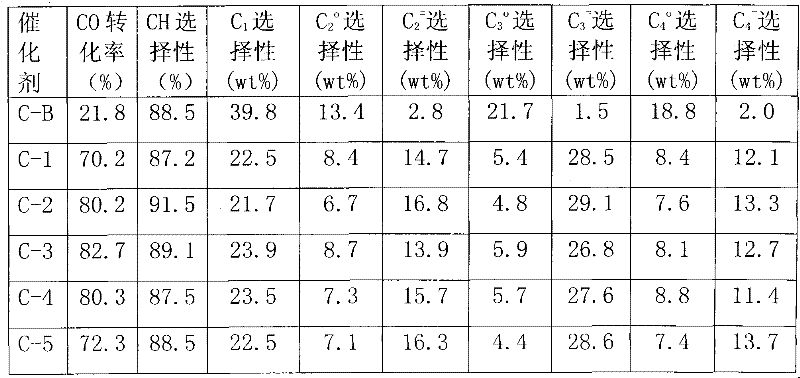

Method for preparing low-carbon olefine catalyst by loading iron-based synthetic gas

ActiveCN102441383AOvercoming strong interactionsHigh activityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSilica gelSurface modification

The invention discloses a method for preparing a low-carbon olefine catalyst by a loading iron-based synthetic gas, which comprises the following steps of: firstly carrying out surface modification on a silica gel carrier by using silica gel as a carrier, and then loading a metal auxiliary agent and an active component Fe by using an immersion method, wherein the surface modification method of the silica gel carrier comprises the following step of carrying out immersion treatment by using the acidic solution of sugar. After the silica gel carrier adopted is modified, the strong interaction between the carrier and the active component is overcome, and the activity and the selectivity of the catalyst are improved. The catalyst prepared by using the method is suitable for a reaction process of producing low-carbon olefines of ethylene, propylene, butane and the like by the synthetic gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

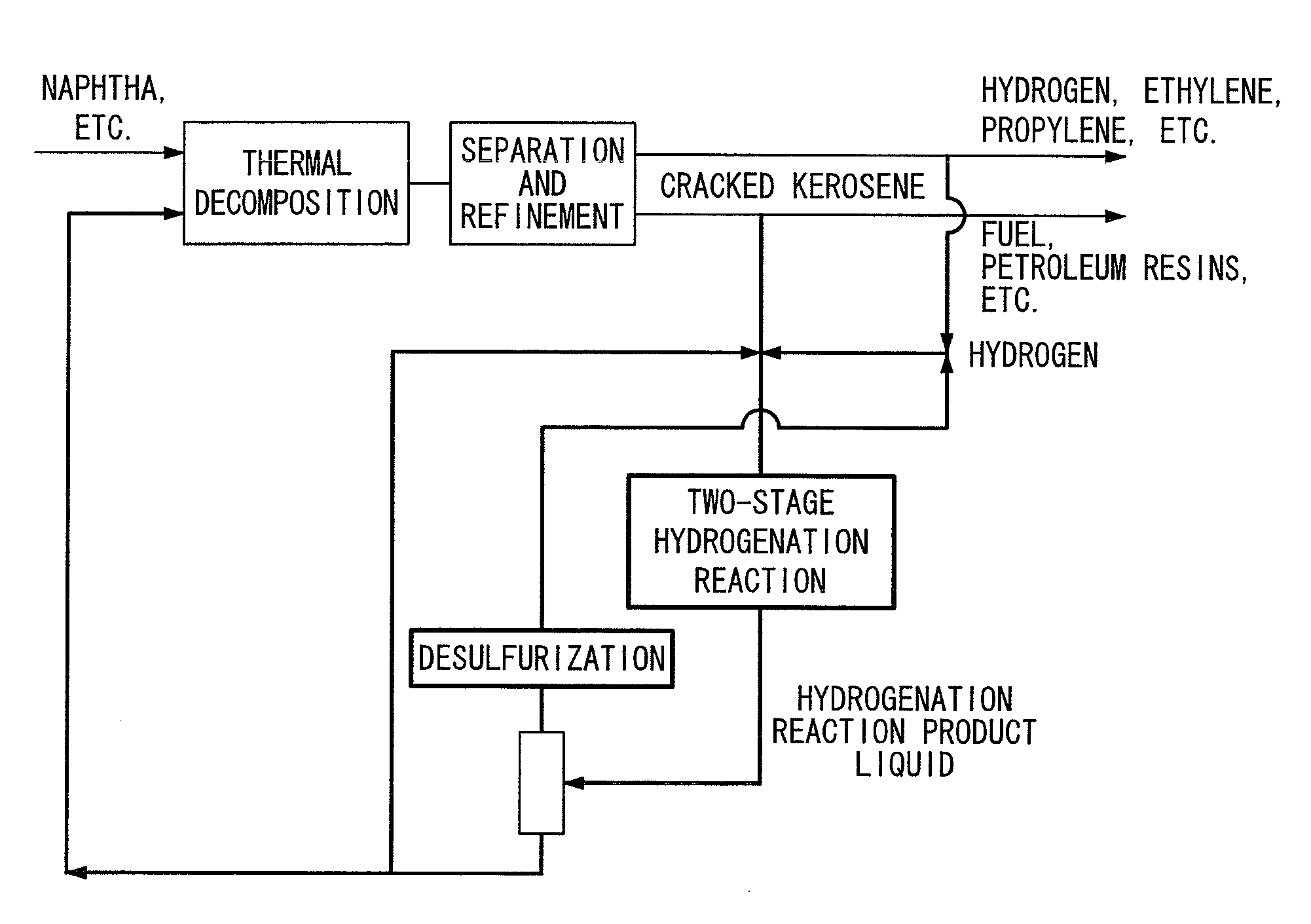

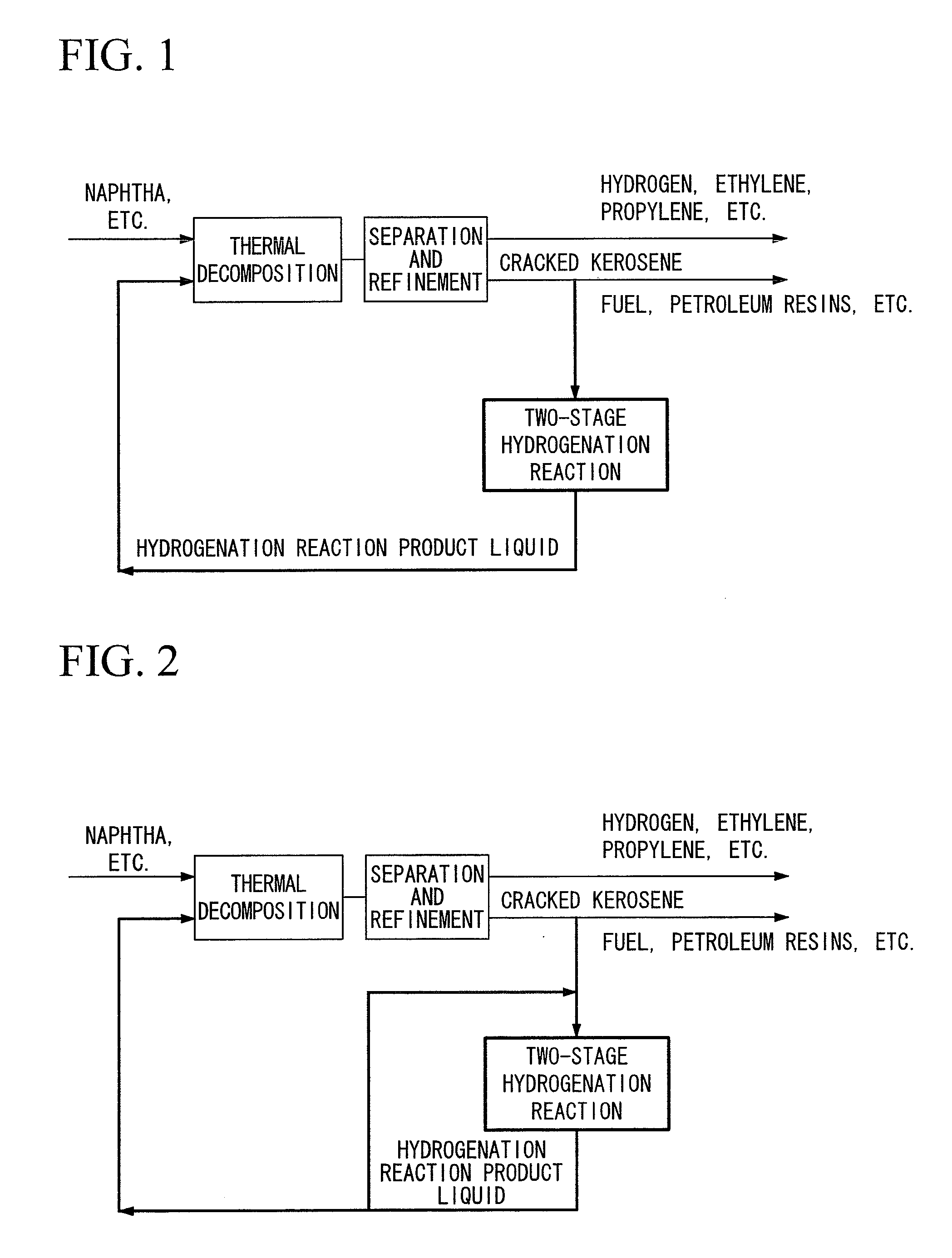

Hydrogenation method and petrochemical process

InactiveUS20100087692A1Long catalyst lifeHigh yieldThermal non-catalytic crackingHydrocarbon by dehydrogenationBenzeneNaphtha

The present invention provides a hydrogenation method capable of converting cracked kerosene into the raw materials for petrochemical cracking having a high thermal decomposition yield by a hydrogenation reaction. The present invention is a petrochemical process for producing at least any of ethylene, propylene, butane, benzene or toluene by carrying out a thermal decomposition reaction at least using naphtha for the main raw material, wherein cracked kerosene produced from a thermal cracking furnace is hydrogenated using a Pd or Pt catalyst in a two-stage method consisting of a first stage (I), in which a hydrogenation reaction is carried out within the range of 50 to 180° C., and a second stage (II), in which a hydrogenation reaction is carried out within the range of 230 to 350° C., followed by re-supplying all or a portion of these hydrogenated hydrocarbons to a thermal cracking furnace.

Owner:SHOWA DENKO KK

Foam of thermoplastic urethane elastomer composition and process for producing the foam

The method of the present invention for producing a urethane-based thermoplastic elastomer composition foam comprises the steps of:adding and mixing 0.1 to 30 parts by weight of carbon dioxide (B) to 100 parts by weight of a urethane-based thermoplastic elastomer composition (A) in a molten state, wherein said urethane-based thermoplastic elastomer composition (A) comprises a urethane-based thermoplastic elastomer (A-1) and other thermoplastic elastomer (A-2) in an (A-1) / (A-2) ratio of 20 / 80 to 99 / 1 by weight, to form a molten urethane-based thermoplastic elastomer composition (C) which is in a state of a mixture of the urethane-based thermoplastic elastomer composition (A) and the carbon dioxide (B) (gas dissolving step); andlowering a temperature of said molten urethane-based thermoplastic elastomer composition (C) (cooling step).The present invention can produce the urethane-based thermoplastic elastomer foam of stable quality over a range from low foamed product to highly foamed product by adding a given quantity of carbon dioxide in the molten urethane-based thermoplastic elastomer quantitatively and stably. It can also produce the foam excellent in flexibility, thermal insulation and surface appearances. It is also excellent in safety, because of use of carbon dioxide in place of the common foaming agent of fluorochlorohydrocarbon or butane, thus causing no air pollution or destruction of the ozone layer.

Owner:MITSUI CHEM INC

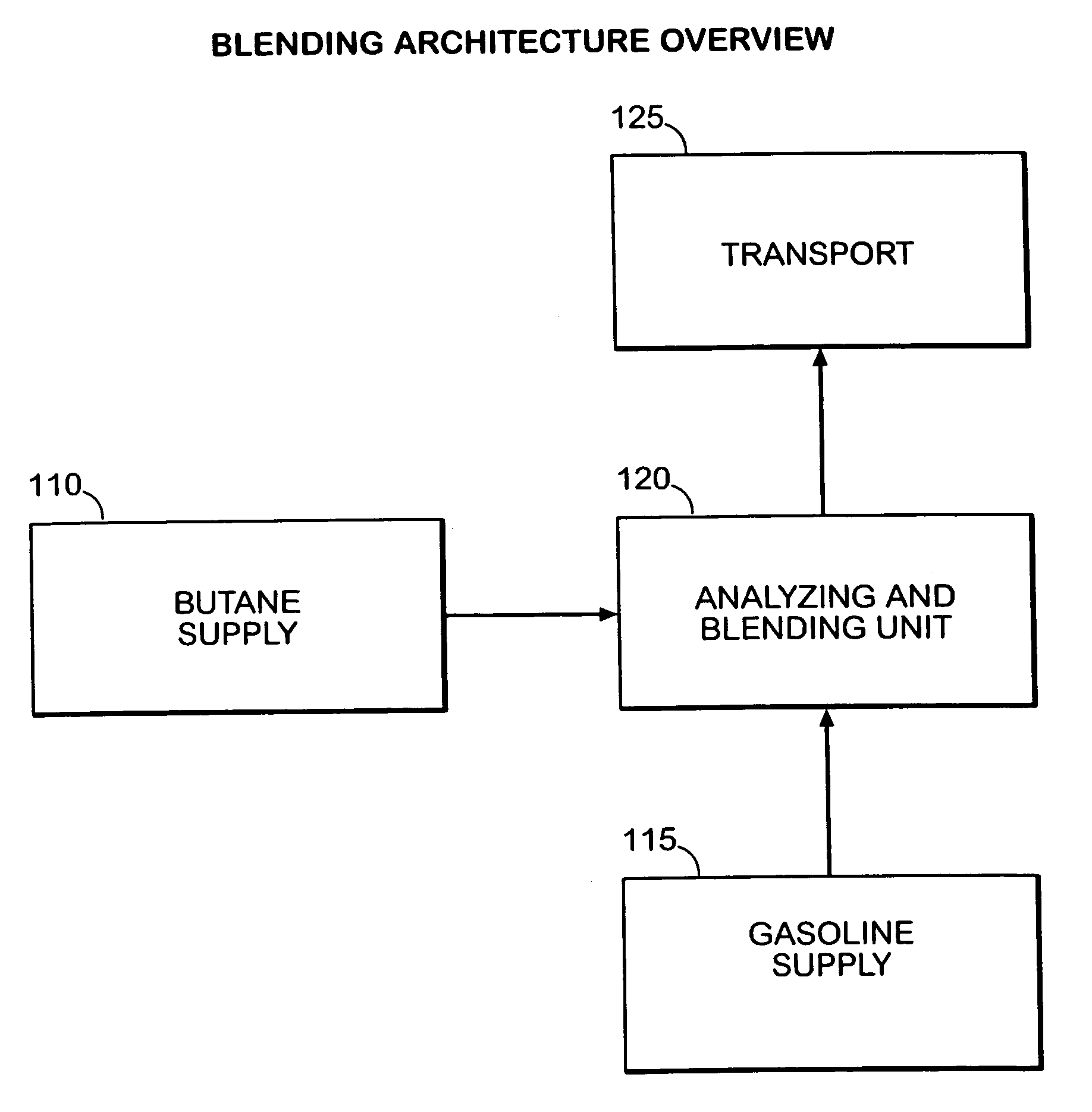

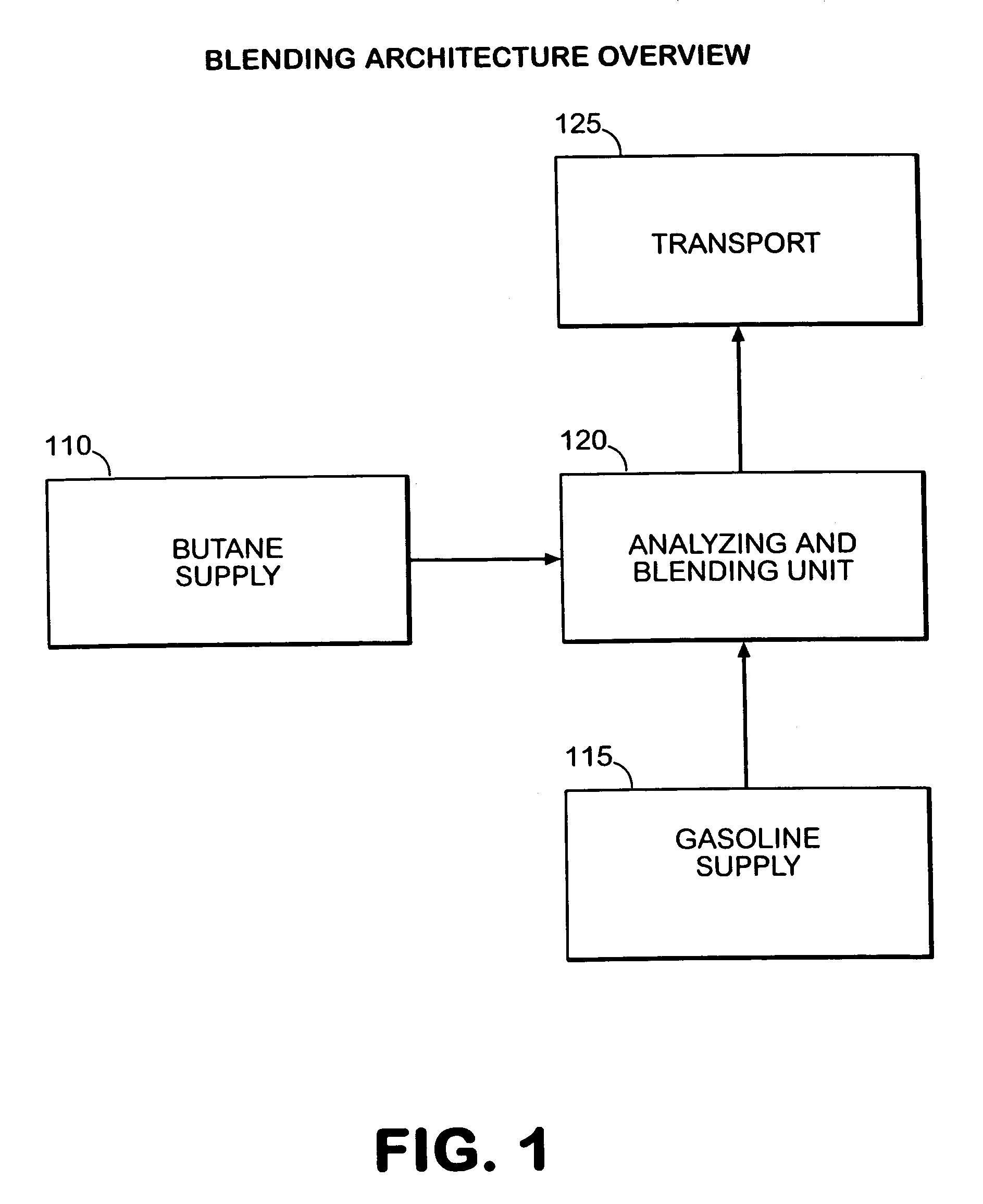

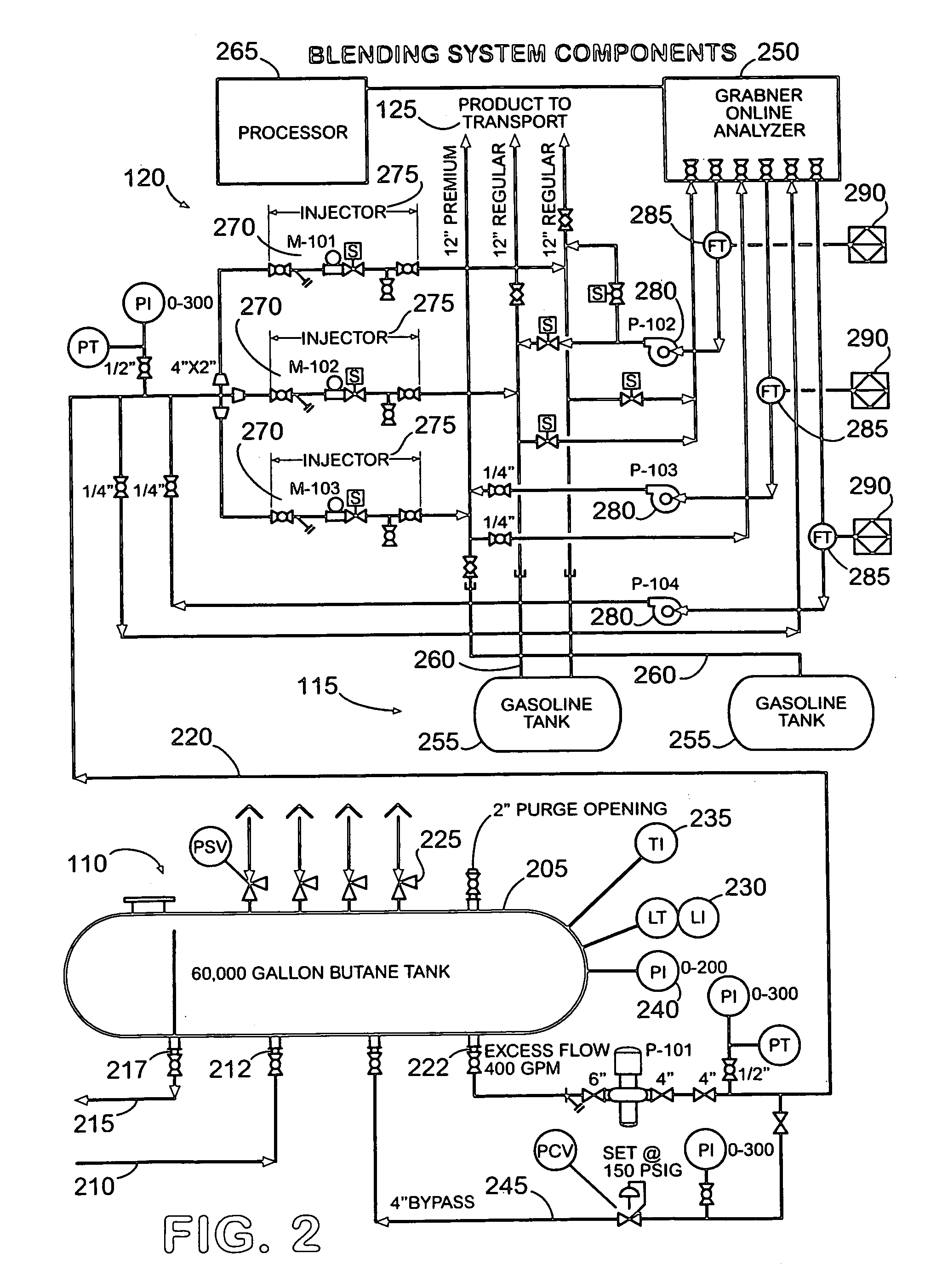

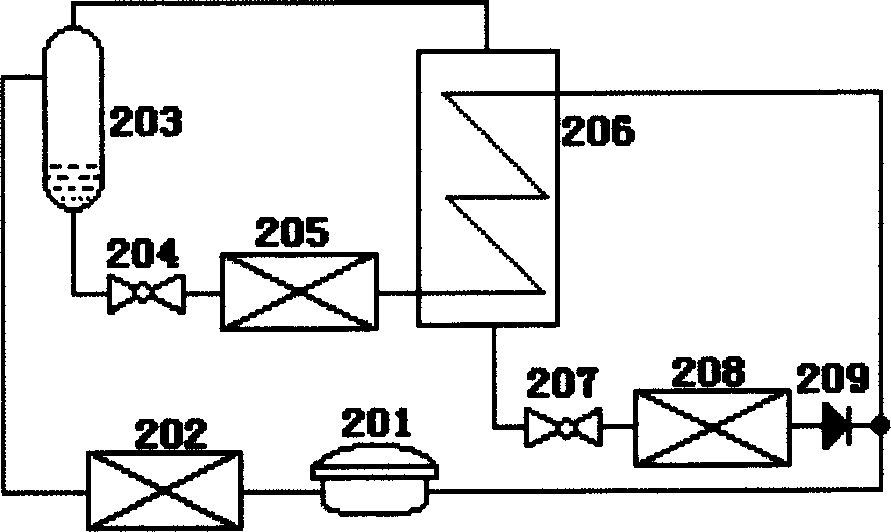

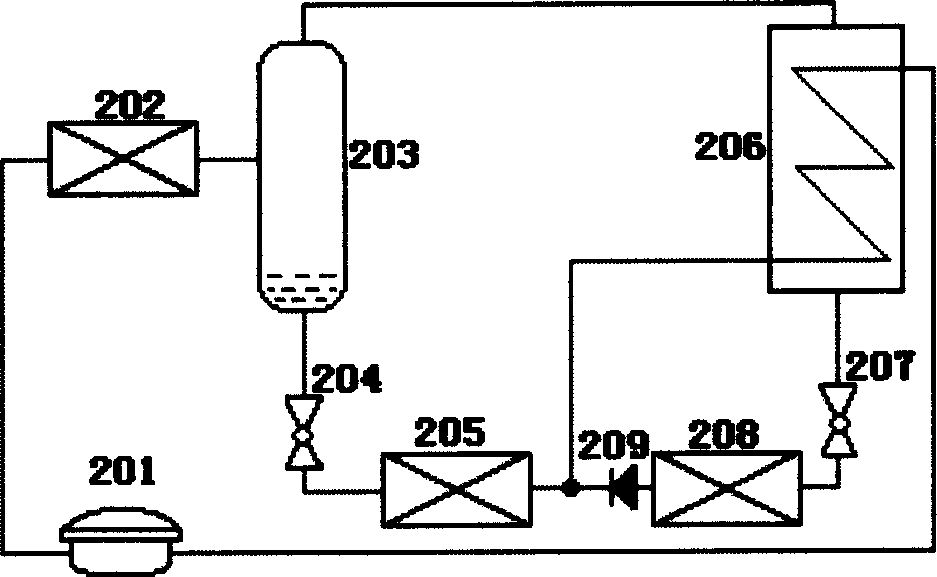

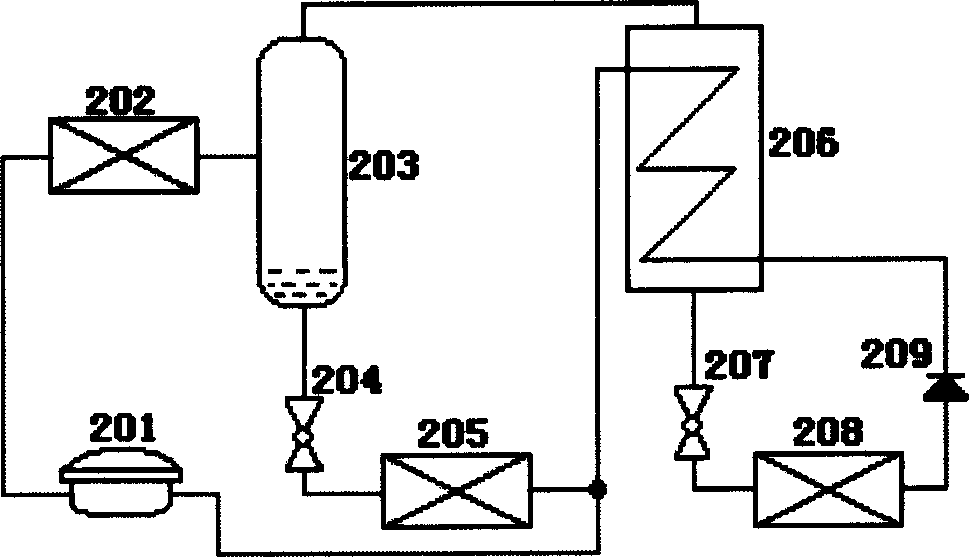

Method and system for blending gasoline and butane at the point of distribution

InactiveUS7032629B1Quantity maximizationMinimize their cost basisLiquid fillingOperating means/releasing devices for valvesEnvironmental regulationGasoline

A system and method is provided for blending butane with gasoline at petroleum tank farms, immediately before distribution to tanker trucks. The invention provides a method for blending gasoline and butane at a tank farm comprising: (a) drawing a gasoline stream from a tank of gasoline; (b) drawing a butane stream from a tank of butane; (c) blending the butane and gasoline streams to form a blend; and (d) dispensing the blend. The blending process can be controlled to ensure that the vapor pressure of the blended gasoline meets vapor pressure requirements of environmental regulations. Information generated by the blending process can be used to efficiently forecast butane purchasing requirements, and to generate regulatory reports.

Owner:SUNOCO PARTNERS MARKETING & TERMINALS LP

Method for desulfurizing a fuel for use in a fuel cell power plant

A fuel processing system is operable to remove substantially all of the sulfur present in an undiluted hydrocarbon fuel stock supply used to power a fuel cell power plant in a mobile environment, such as an automobile, bus, truck, boat, or the like, or in a stationary environment. The power plant hydrogen fuel source can be gasoline, diesel fuel, naphtha, light hydrocarbon fuels such as butane, propane, natural gas, or other like fuels which contain relatively high levels of organic sulfur compounds such as mercaptans, sulfides, disulfides, and the like. The undiluted hydrocarbon fuel supply is passed through a nickel desulfurizer bed wherein essentially all of the sulfur in the organic sulfur compounds react with the nickel reactant, and are converted to nickel sulfide while the desulfurized organic remnants continue through the remainder of the fuel processing system. The system does not require the addition of steam or a hydrogen source to the fuel stream prior to the desulfurizing step. The system operates at relatively low temperatures and can be used to desulfurize either a liquid or a gaseous fuel stream.

Owner:UNITED TECH CORP

A kind of polybutene alloy material and preparation method thereof

The invention discloses a polybutene alloy material and a preparation method thereof, and belongs to the field of polyolefin material, specifically relates to a polybutene alloy material and a preparation method thereof. The polybutene alloy material provided by the present invention comprises, by mass, 50-99% of poly-1-butene, 1-40% of polypropylene and 0-10% of a butane-propylene copolymer. Thepreparation method is characterized by: adopting a TiCl4 / MgCl2 supported titanium catalyst for synthesis of the polybutene alloy material through a two-phase polymerization method. The polybutene alloy material provided by the present invention has a core-shell structure, and has advantages of the combination of the excellent impact resistance of the poly-1-butene, the heat resistance and creep property of the poly-1-butene, the low shrinkage rate of the poly-1-butene, the high modulus of the polypropylene, the high surface hardness of the polypropylene, the rapid shaping of the polypropylene, and the like, such that the polybutene alloy material can replace the partial use of the poly-1-butene and the polypropylene. In addition, the polybutene alloy material can be applicable for preparation of the pipe and the pipe fitting, toughening modification of the polypropylene, or the polybutene alloy material can be used as the general polyolefin material.

Owner:QINGDAO UNIV OF SCI & TECH +1

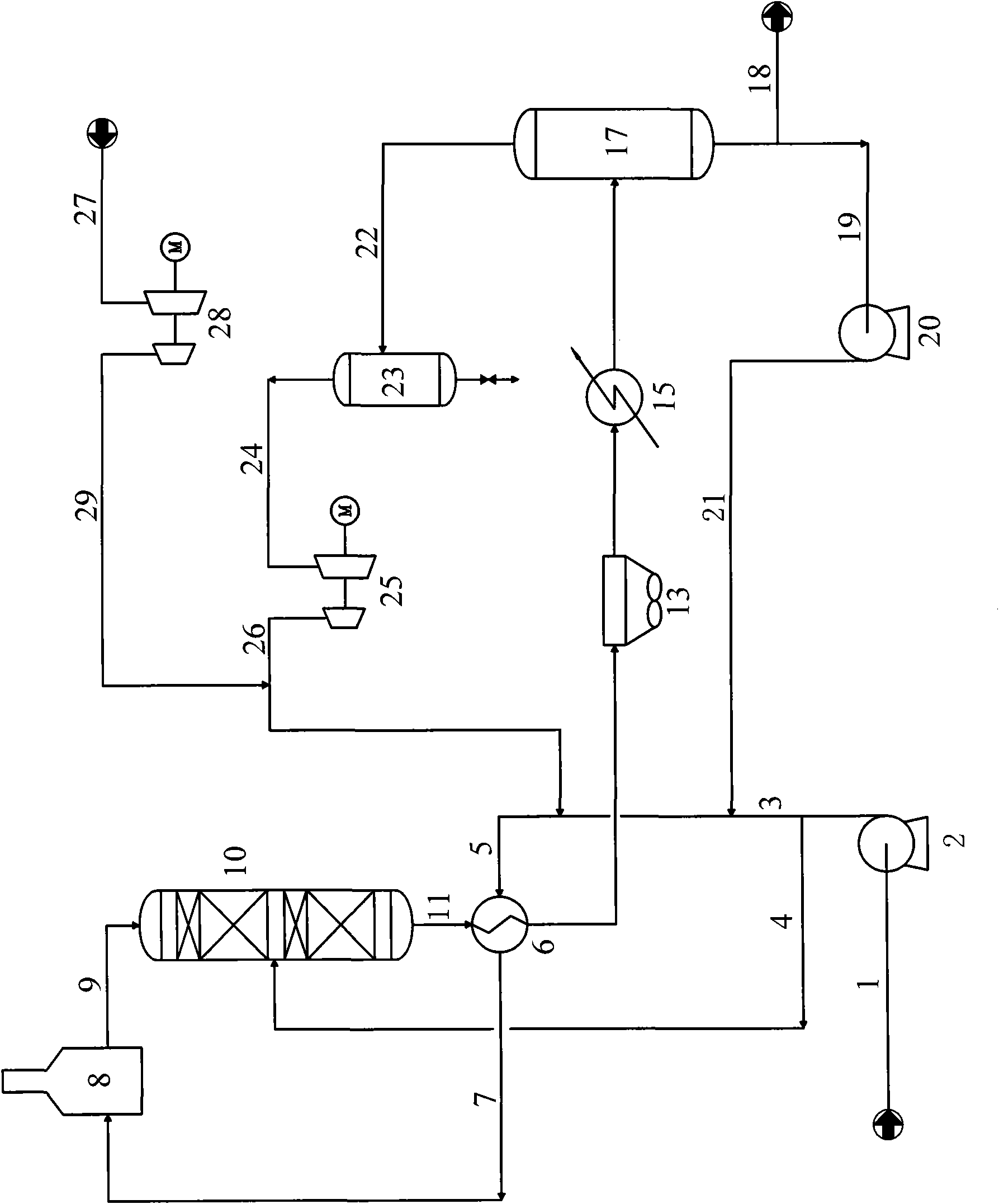

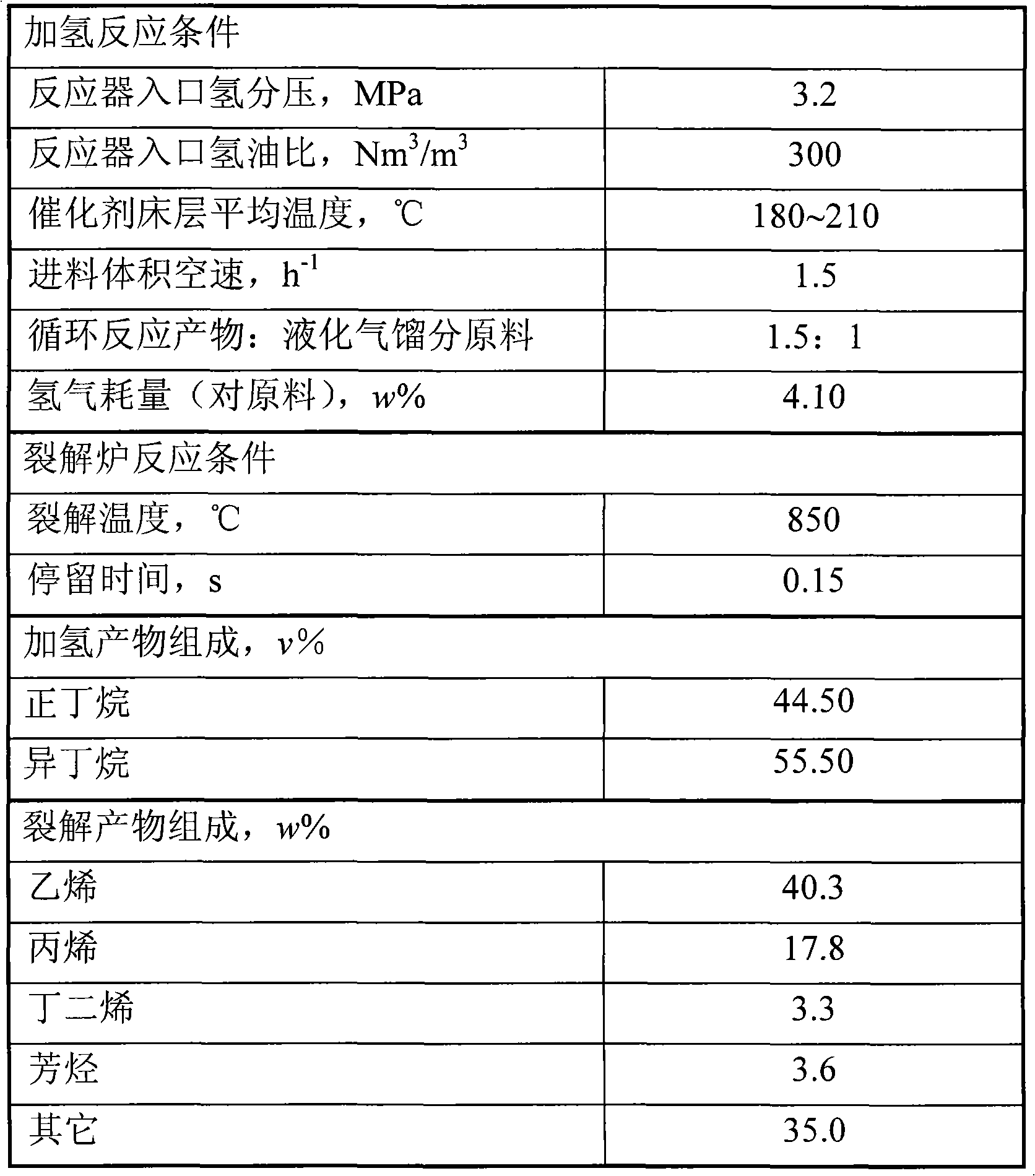

Hydrogenation method for liquefied gas fraction

InactiveCN101880549AExpand application channelsExpand sourceHydrocarbon by hydrogenationTreatment with hydrotreatment processesAlkaneGas phase

The invention discloses a hydrogenation method for liquefied gas fraction, which is characterized by comprising the following steps of: filling at least one section of catalyst bed layer into a reactor, introducing a liquefied gas fraction raw material and hydrogen into the reactor from one or more sections of catalyst bed layers to contact a catalyst and perform hydrogenation saturation reaction, and reacting olefin in the liquefied gas fraction and the hydrogen to generate alkane and release a large amount of heat; after heat exchange, feeding the reaction product into a gas-liquid separator and separating the reaction product into a gas phase and a liquid phase, and introducing the separated gas phase flow into the reactor to perform repeated use; and introducing a part of separated liquid phase flow serving as a cyclic reaction product back to the reactor, and introducing the other part of the separated liquid phase flow serving as a liquefied gas fraction hydrogenation product out of the reactor to perform reuse. The hydrogenation product obtained by the method is saturated light hydrocarbon fraction which can be directly used as a raw material for an ethylene cracking device and also can be fractionated and cut into propane, n-butane and iso-butane and the like serving as high value-added chemical base raw materials so as to increase the economic benefit of an oil refining enterprise.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and apparatus for performing rapid isotopic analysis via laser spectroscopy

Method and apparatus for providing real-time data indicative of the isotopic composition of formation fluids during drilling. The method includes the steps of: (a) providing a reference fluid having a known isotopic composition in a reference cell; (b) capturing a sample of formation; (c) providing at least one laser beam; (e) passing a beam through the reference fluid, measuring the reference-measurement beam before and after it passes through the reference fluid; (f) and passing a beam through the sample, measuring the beam before and after it passes through the sample, and calculating a first isotope concentration from those measurements. The measurements can provide information relating to the carbon isotopic composition of individual compounds in hydrocarbon gas mixtures, with the individual compounds including methane, ethane, propane, iso- or normal butane, or iso- or normal pentane.

Owner:CALEB BRETT USA

Processing C4 olefin streams for the maximum production of propylene

ActiveUS20050014981A1Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

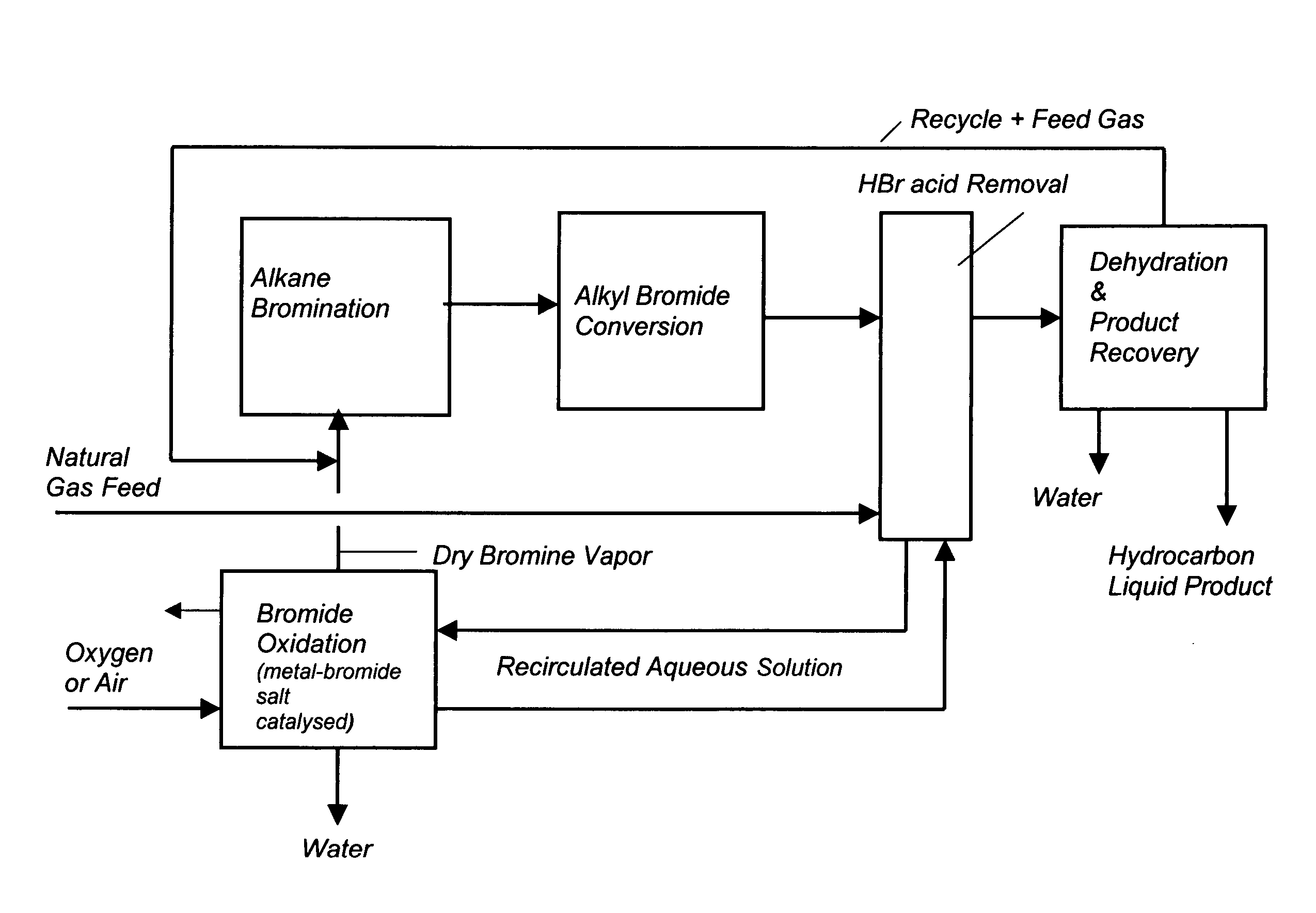

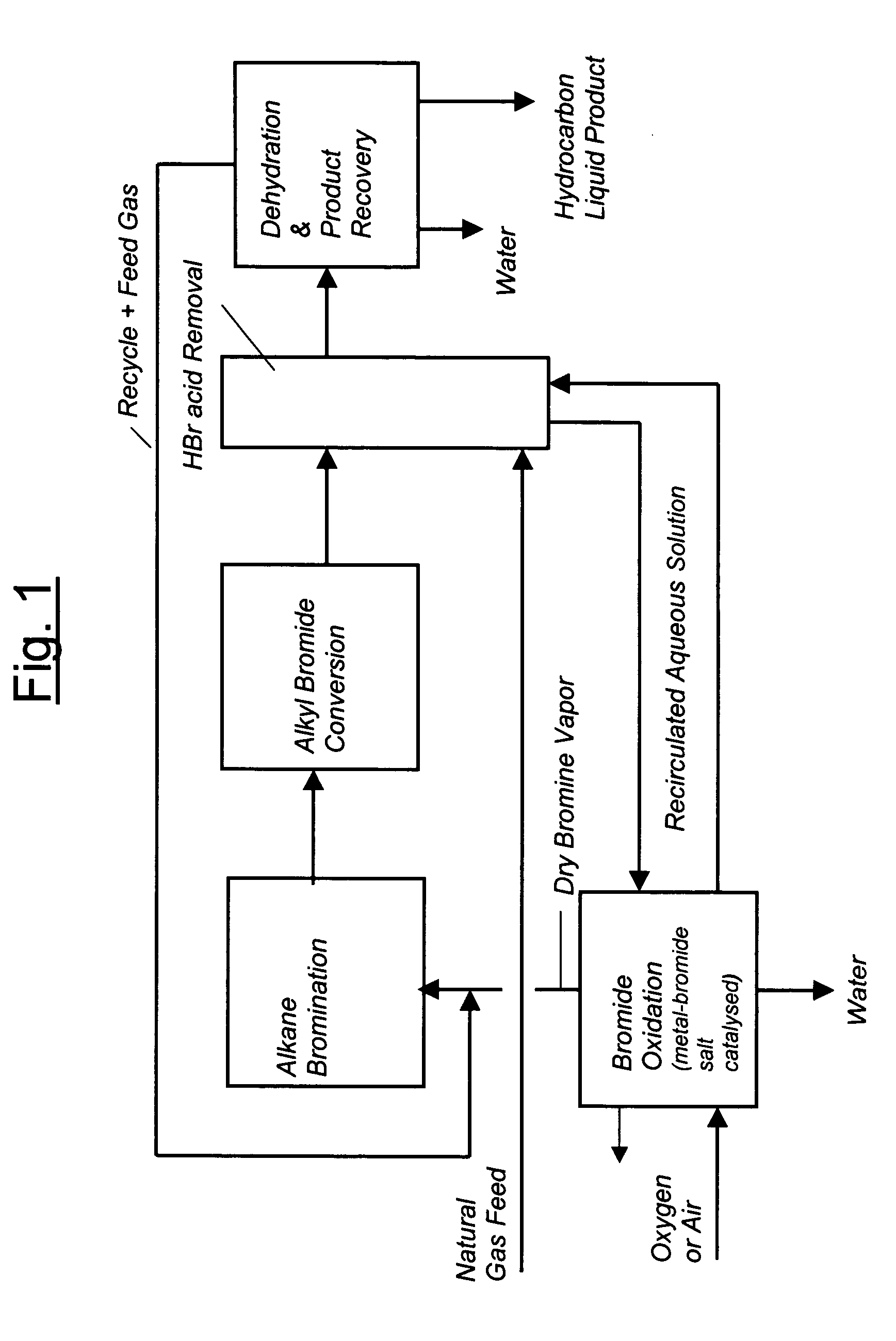

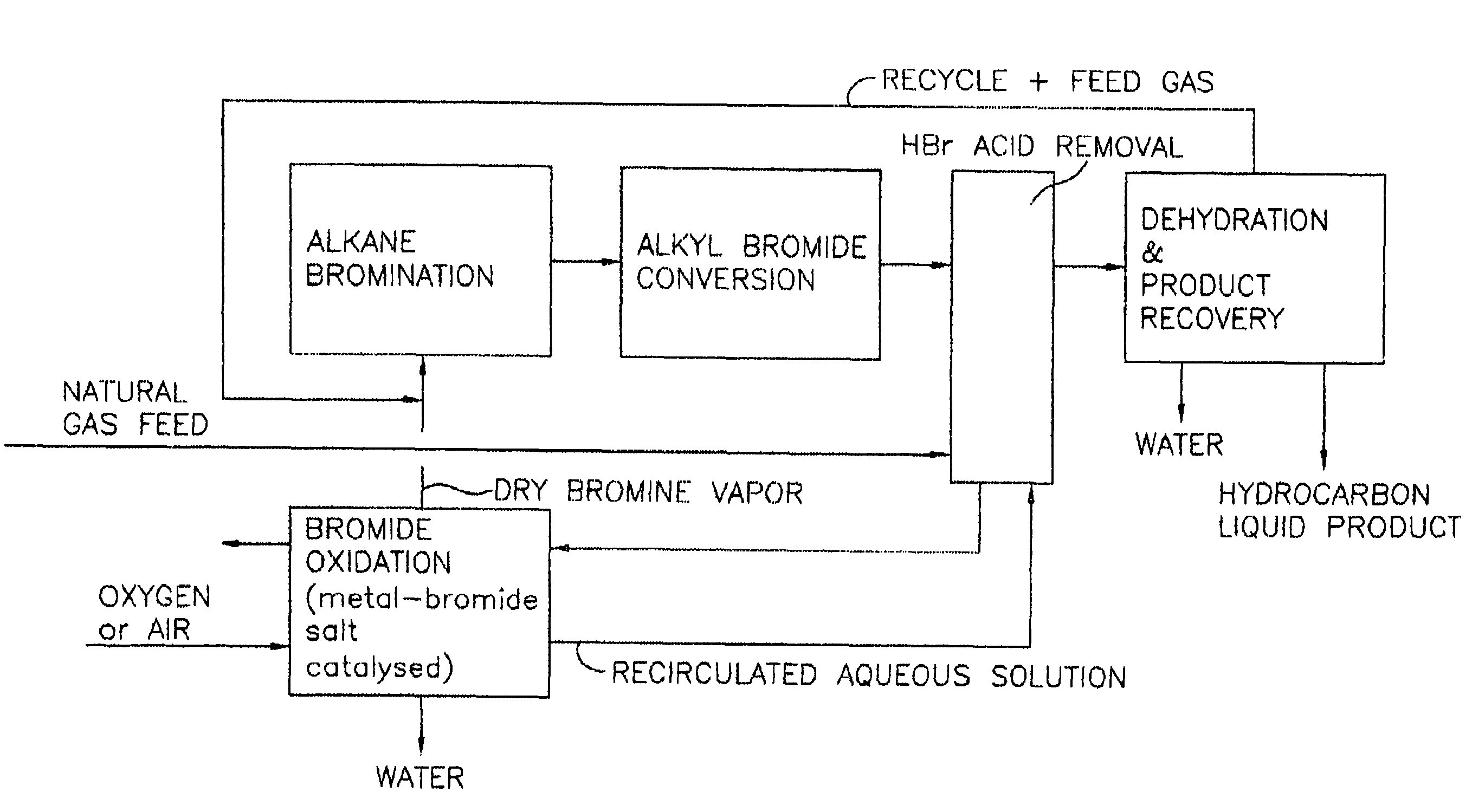

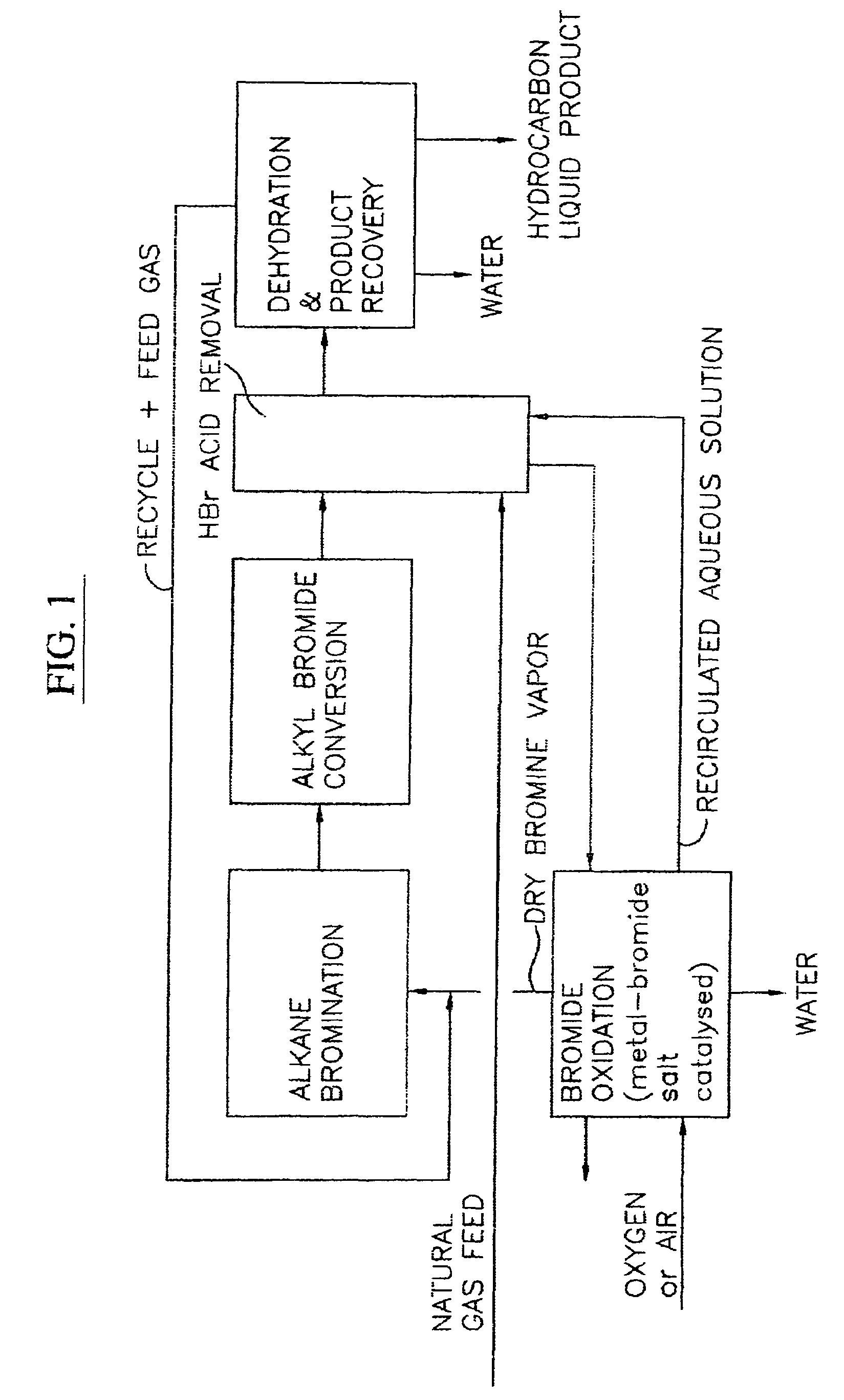

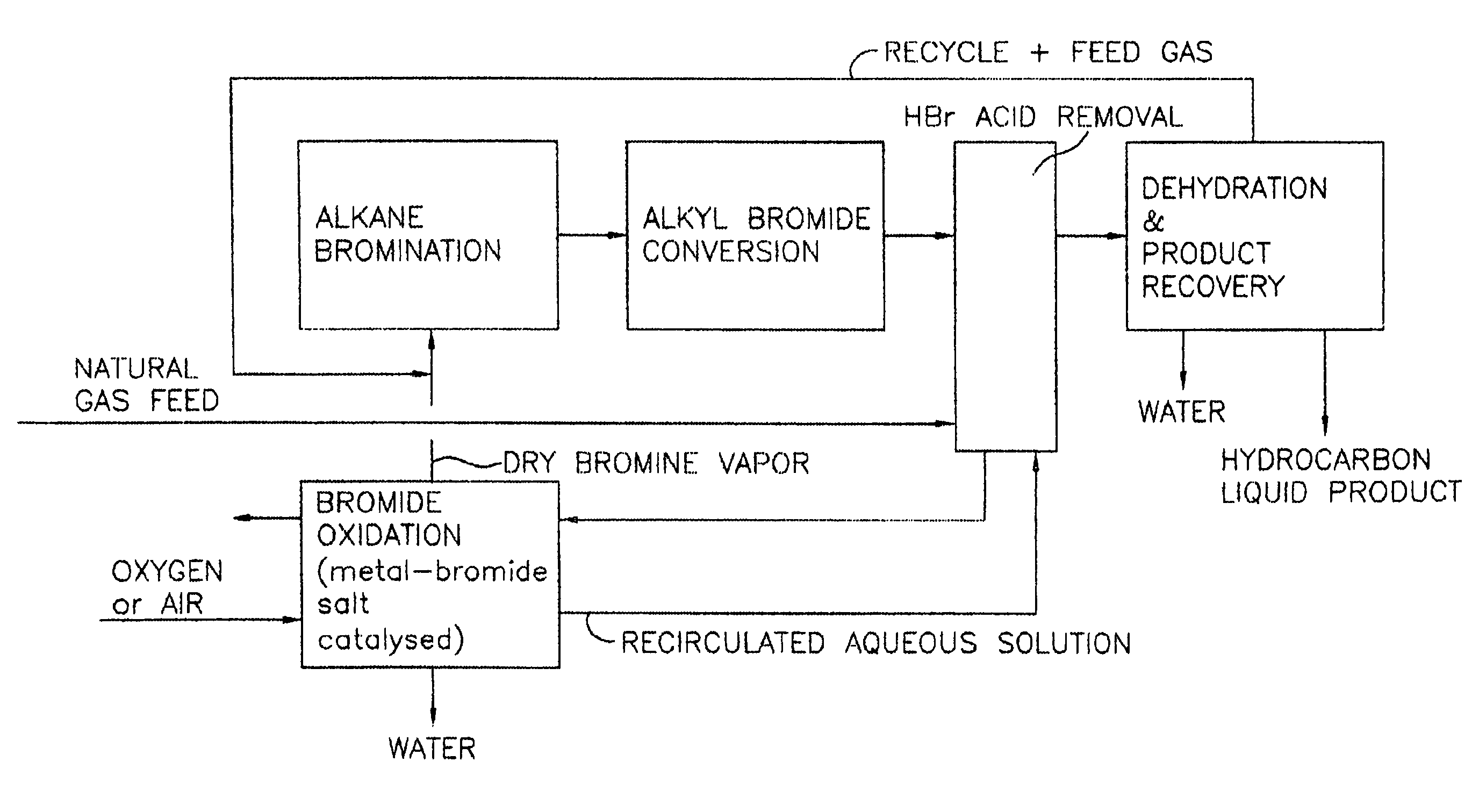

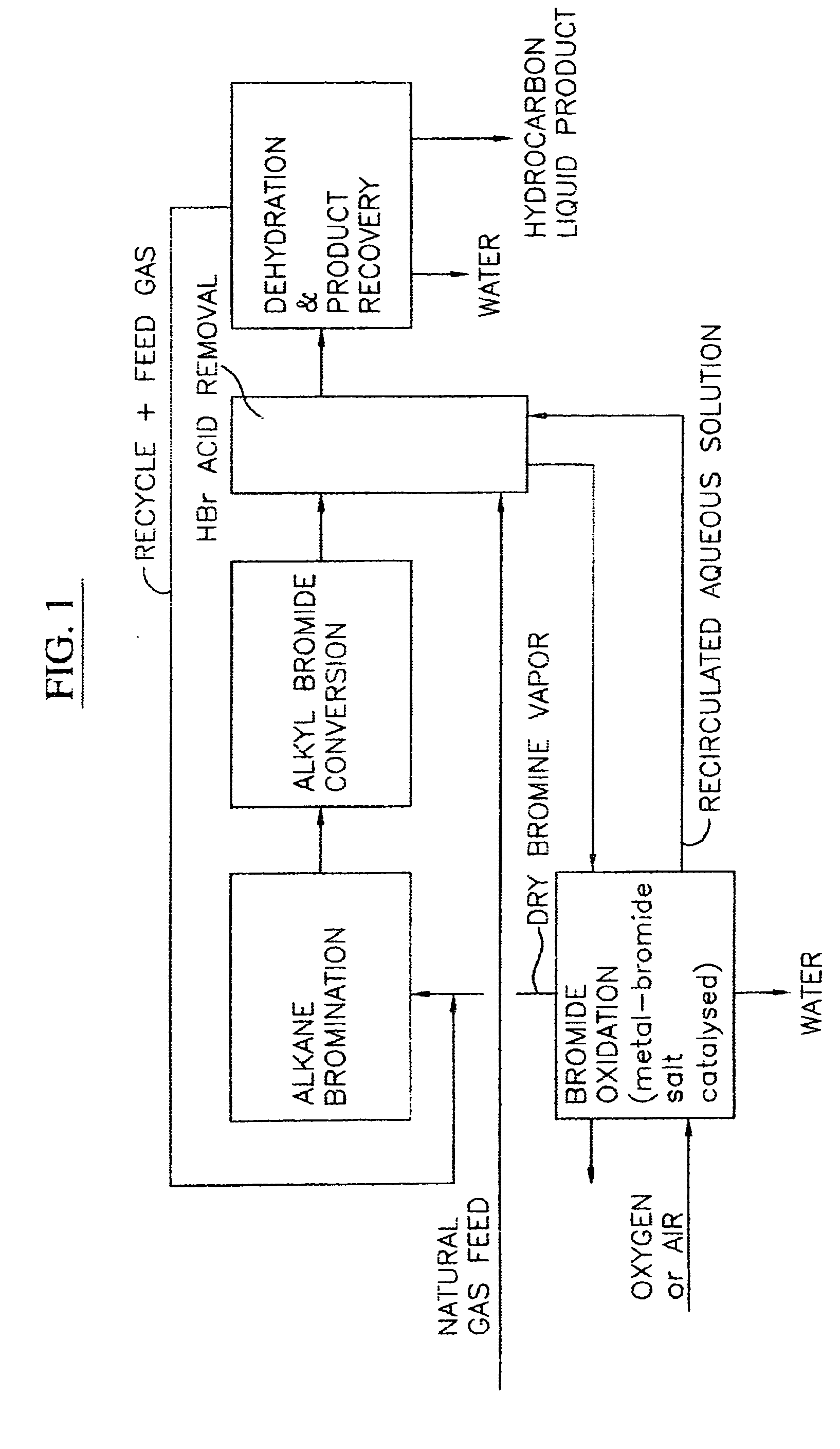

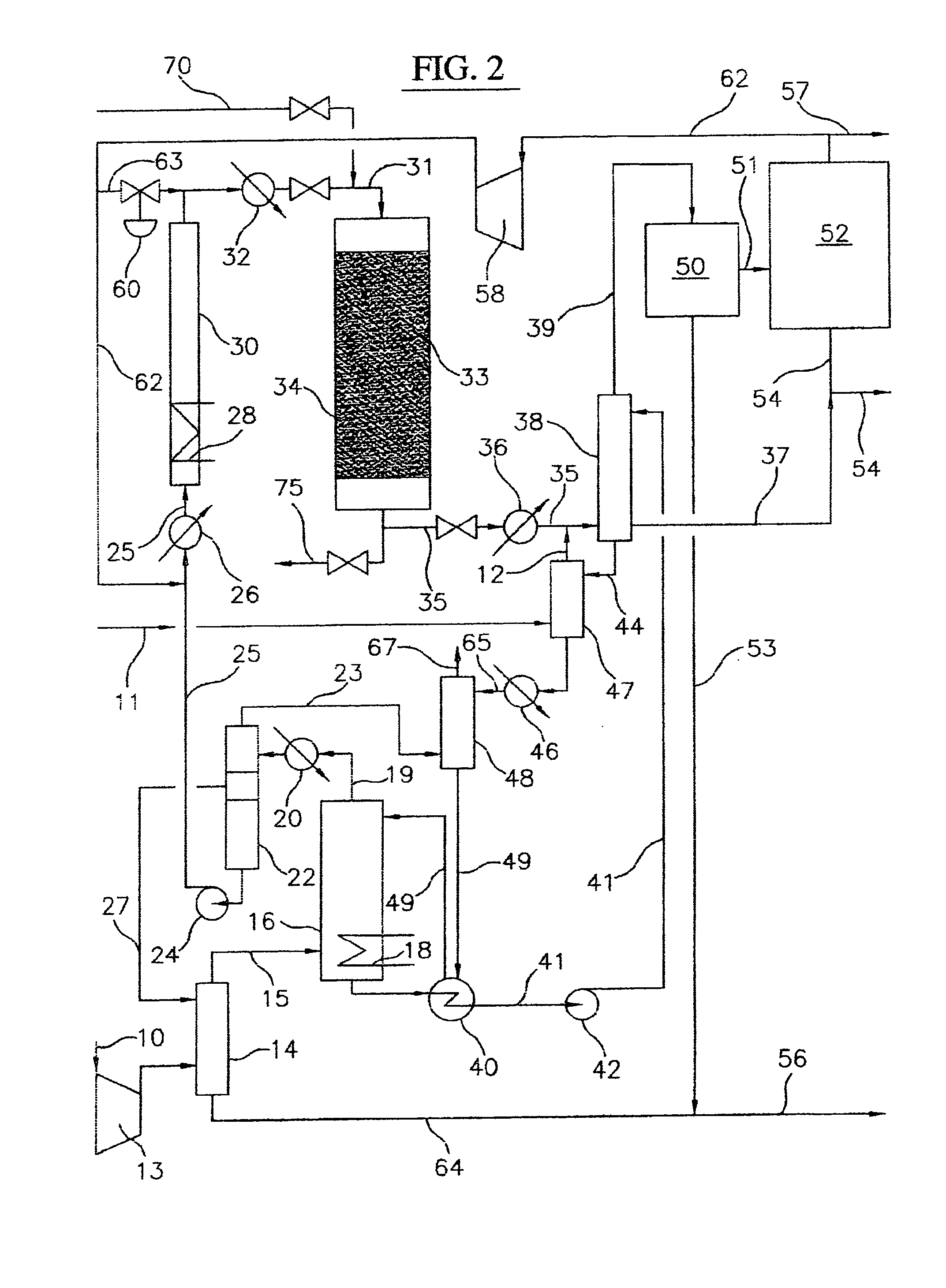

Process for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to liquid hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as a ZSM-5 zeolite, at a temperature of from about 150° C. to about 400° C. so as to form higher molecular weight hydrocarbons and hydrobromic acid vapor. Hydrobromic acid vapor is removed from the higher molecular weight hydrocarbons. A portion of the propane and butane is removed from the higher molecular weight hydrocarbons and reacted with the mixture of alkyl bromides and hydrobromic acid over the synthetic crystalline alumino-silicate catalyst to form C5+ hydrocarbons.

Owner:SULZER MANAGEMENT AG

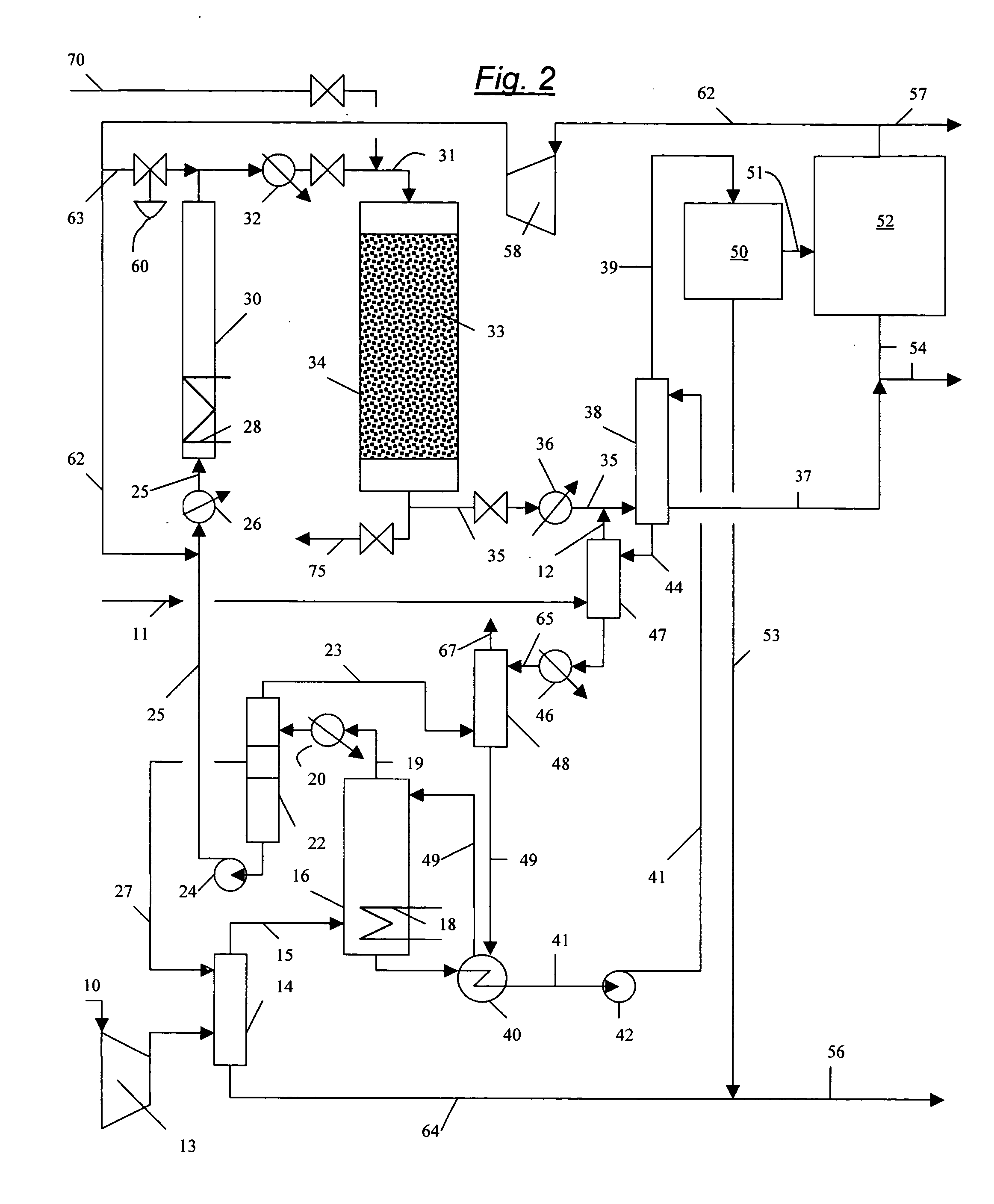

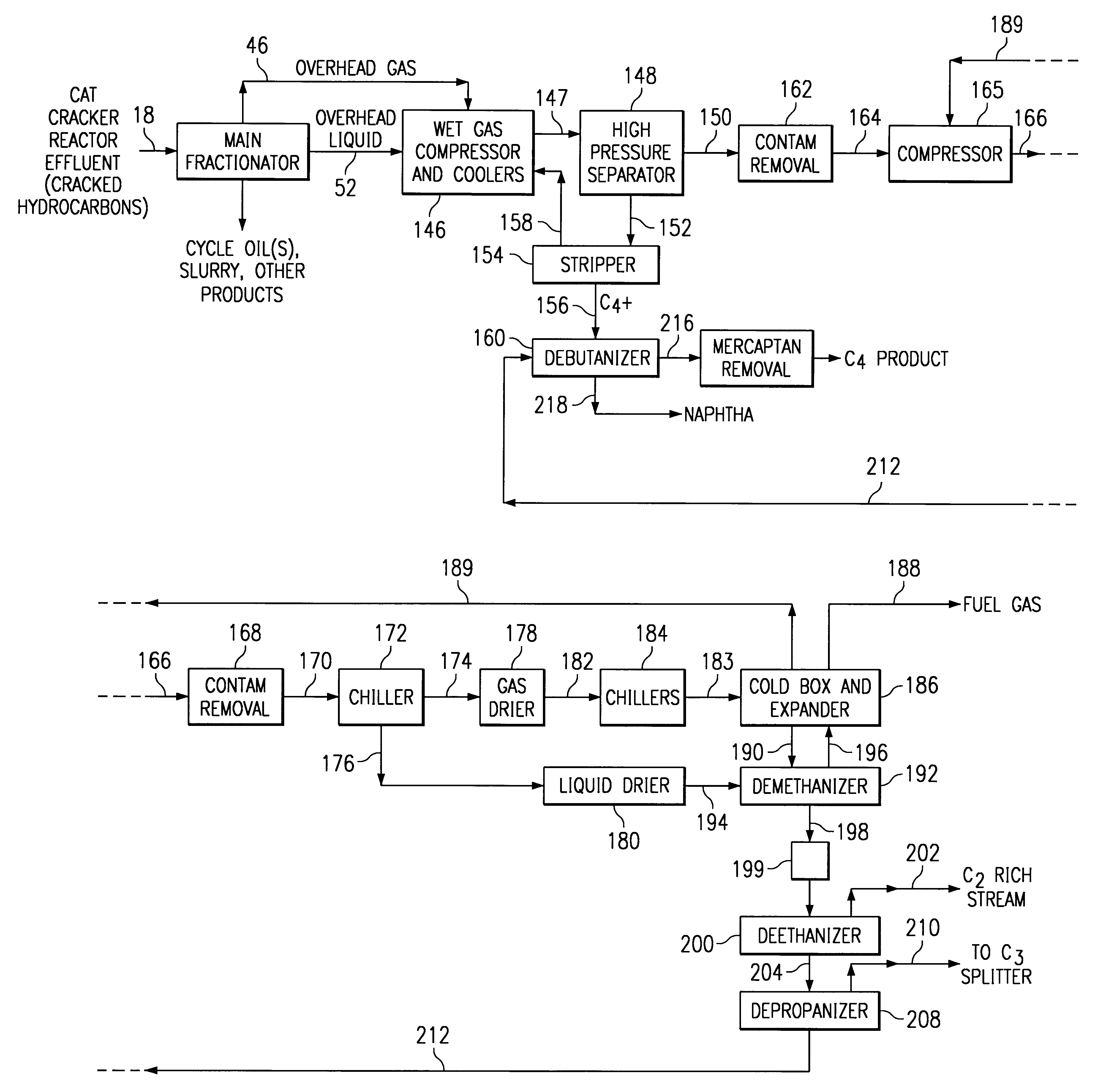

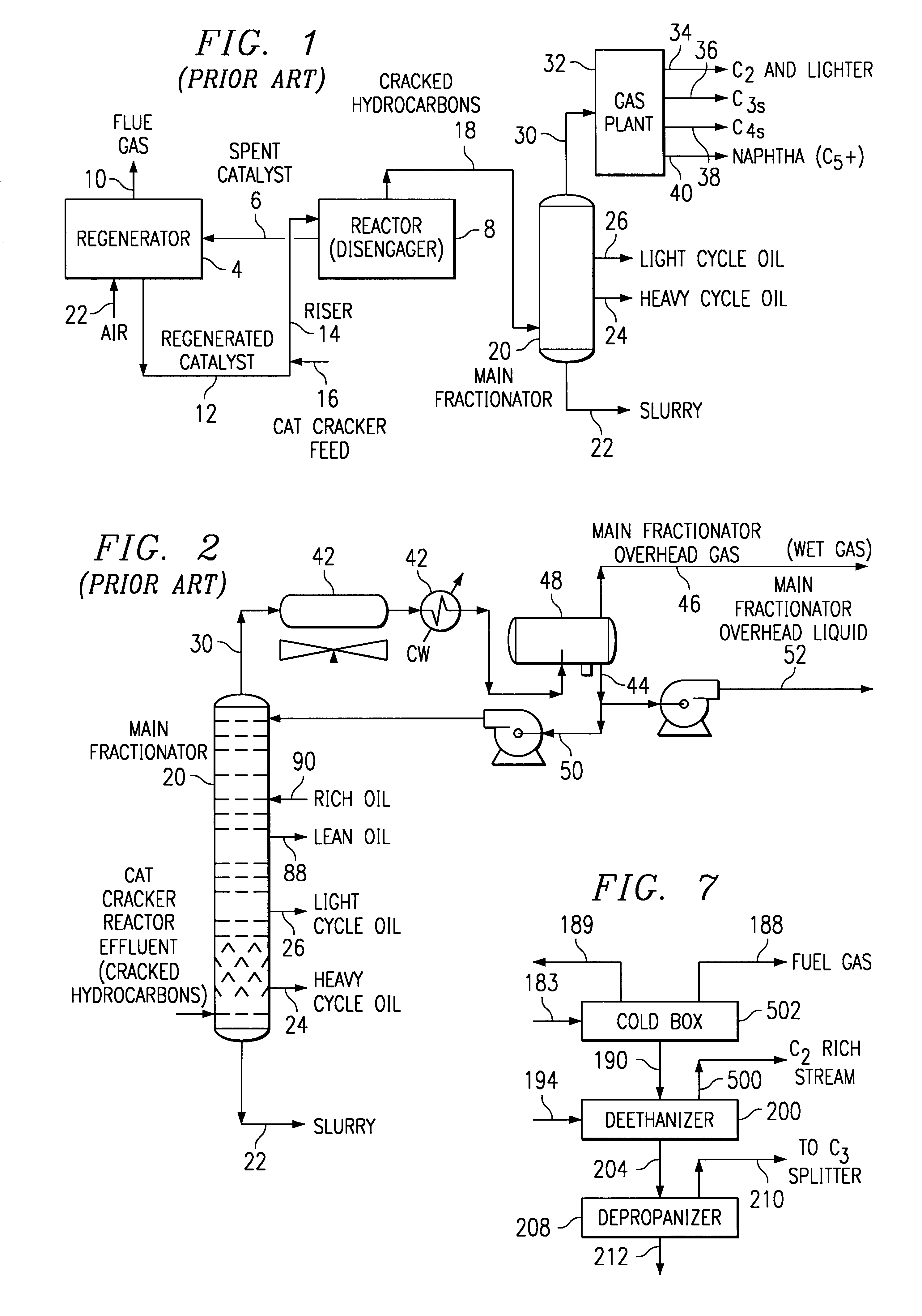

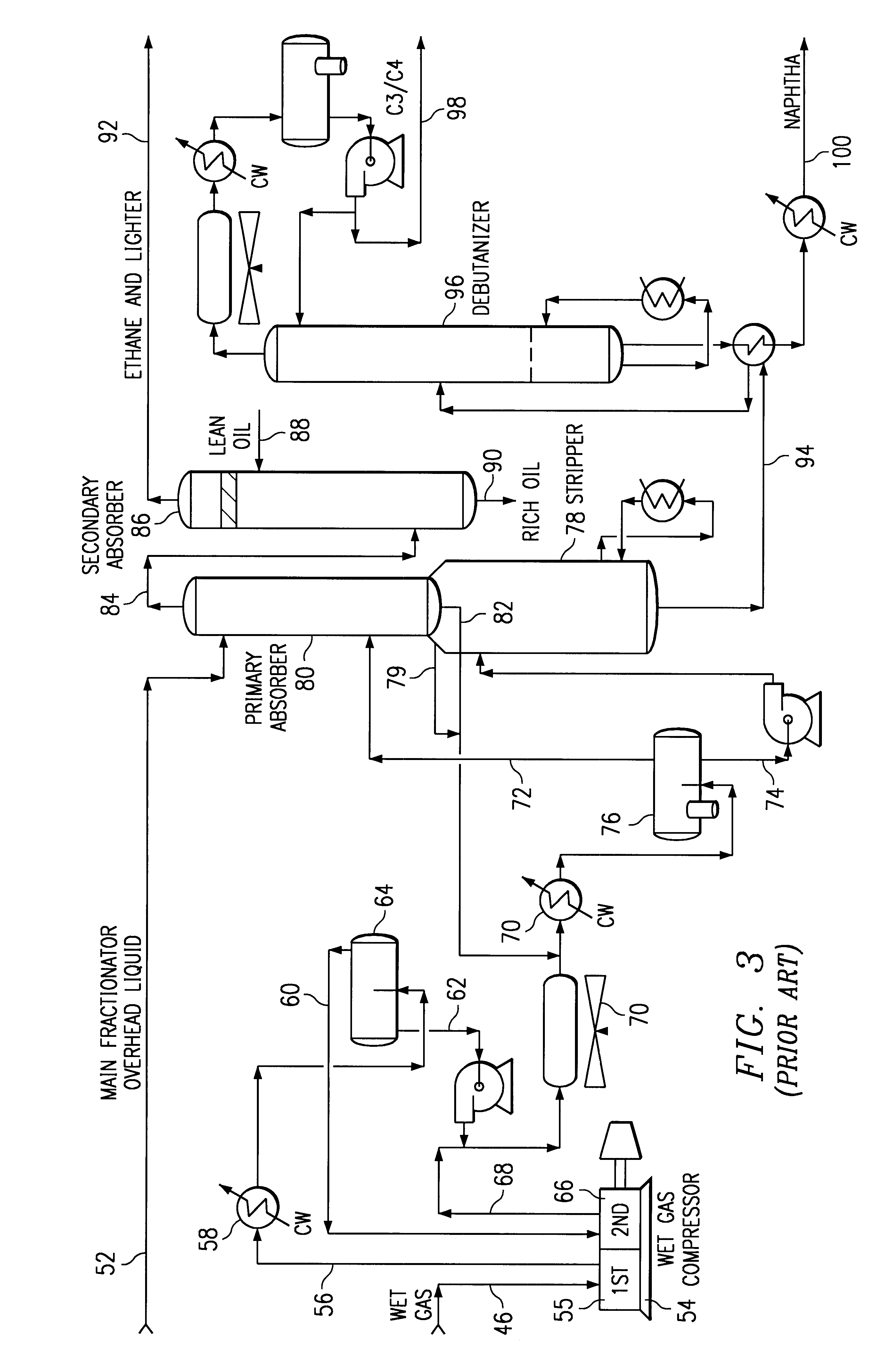

Cat cracker gas plant process for increased olefins recovery

The invention relates to a new process for more efficient separation and recovery of light olefins such as ethylene and propylene from a fluid catalytic cracking unit. The new process invention for recovering olefins from a mixture of cracked hydrocarbons from a fluid catalytic cracker comprises the steps of: (a) providing a mixture of cracked hydrocarbons including methane, ethylene, ethane, propylene, propane, butylene, butane and heavier hydrocarbons such as naphtha produced in a fluid catalytic cracker; (b) separating said mixture into (i) a first stream comprising substantially all of said ethane, ethylene, and methane and a major portion of said propane and propylene and (ii) a second stream comprising a portion of said butylene and butane, and a major portion of said heavier hydrocarbons; and (c) processing said first stream to recover the ethylene and propylene therefrom, and the details of such process described herein.

Owner:STONE & WEBSTER PROCESS TECH

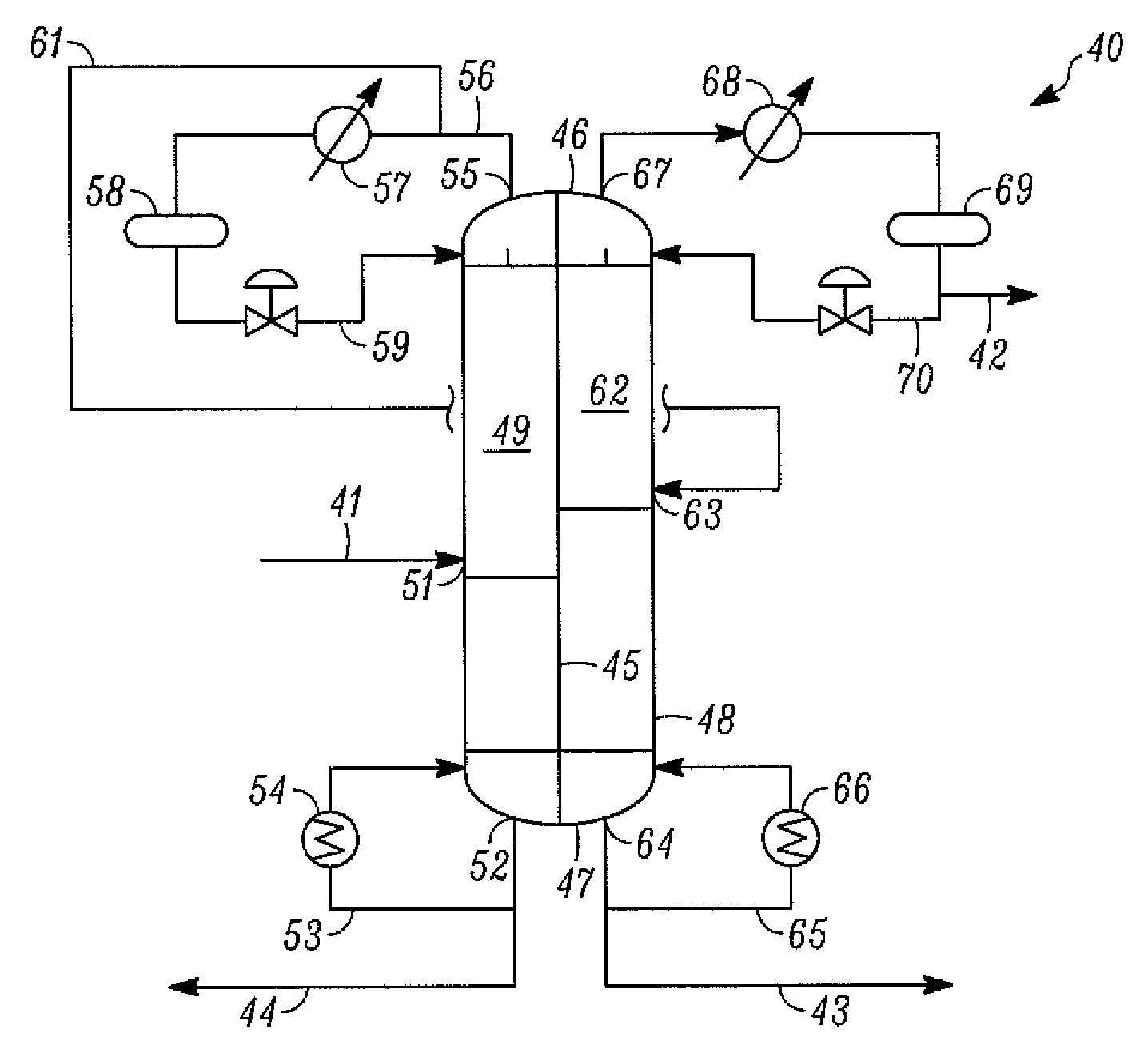

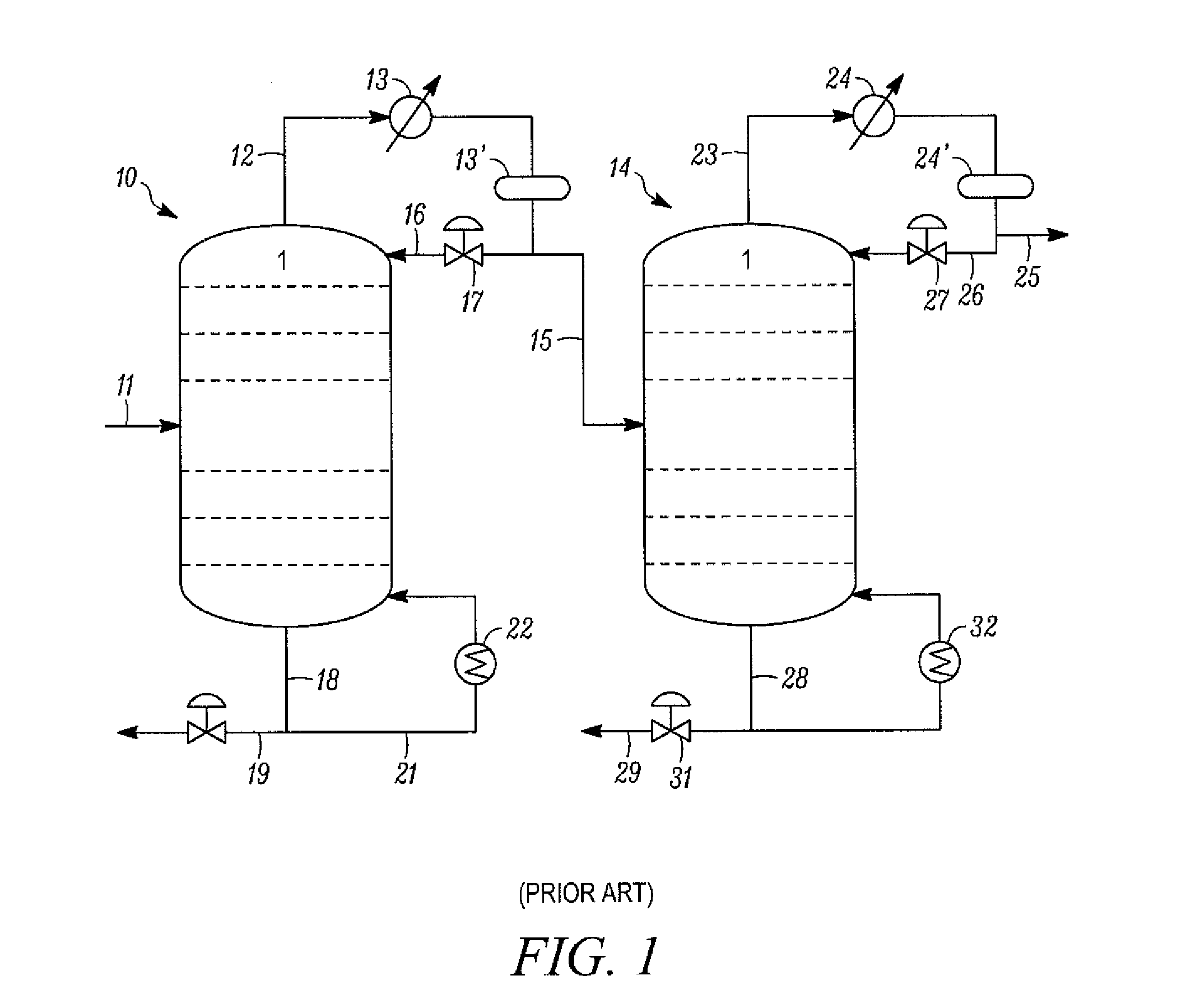

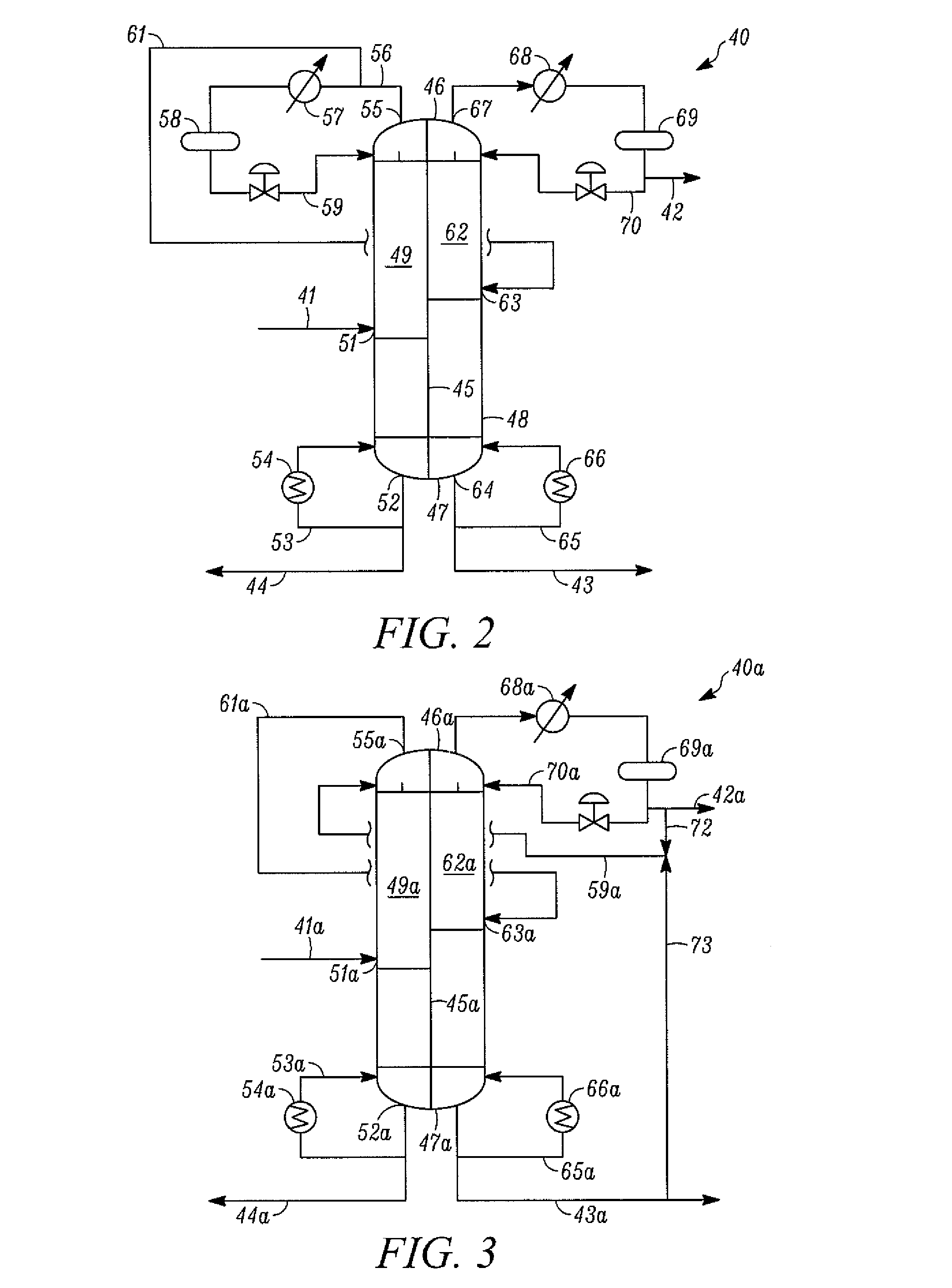

Apparatus and Methods for Separating Butene-1 from a Mixed C4 Feed

ActiveUS20080161618A1Reduce constructionLow costSolvent extractionDistillation in boilers/stillsButeneFractionating column

A process is disclosed for recovering 1-butene from a feed steam comprising n-butane, isobutane and butene isomers using a single, divided wall distillation column. The disclosed process includes introducing the feed steam into an inlet of a first side of a distillation column, wherein the distillation column comprises a top, a bottom and a center dividing wall extending between the bottom and the top of the column and dividing the column into the first side and a second side. The process includes taking off an isobutane stream from the top of the second side of column, taking off a 1-butene stream as a bottoms stream from the second side of the column, and taking off a combination 2-butene and n-butane stream as a bottom stream from the first side of column.

Owner:UOP LLC

Process for converting gaseous alkanes to liquid hydrocarbons

Owner:SULZER MANAGEMENT AG

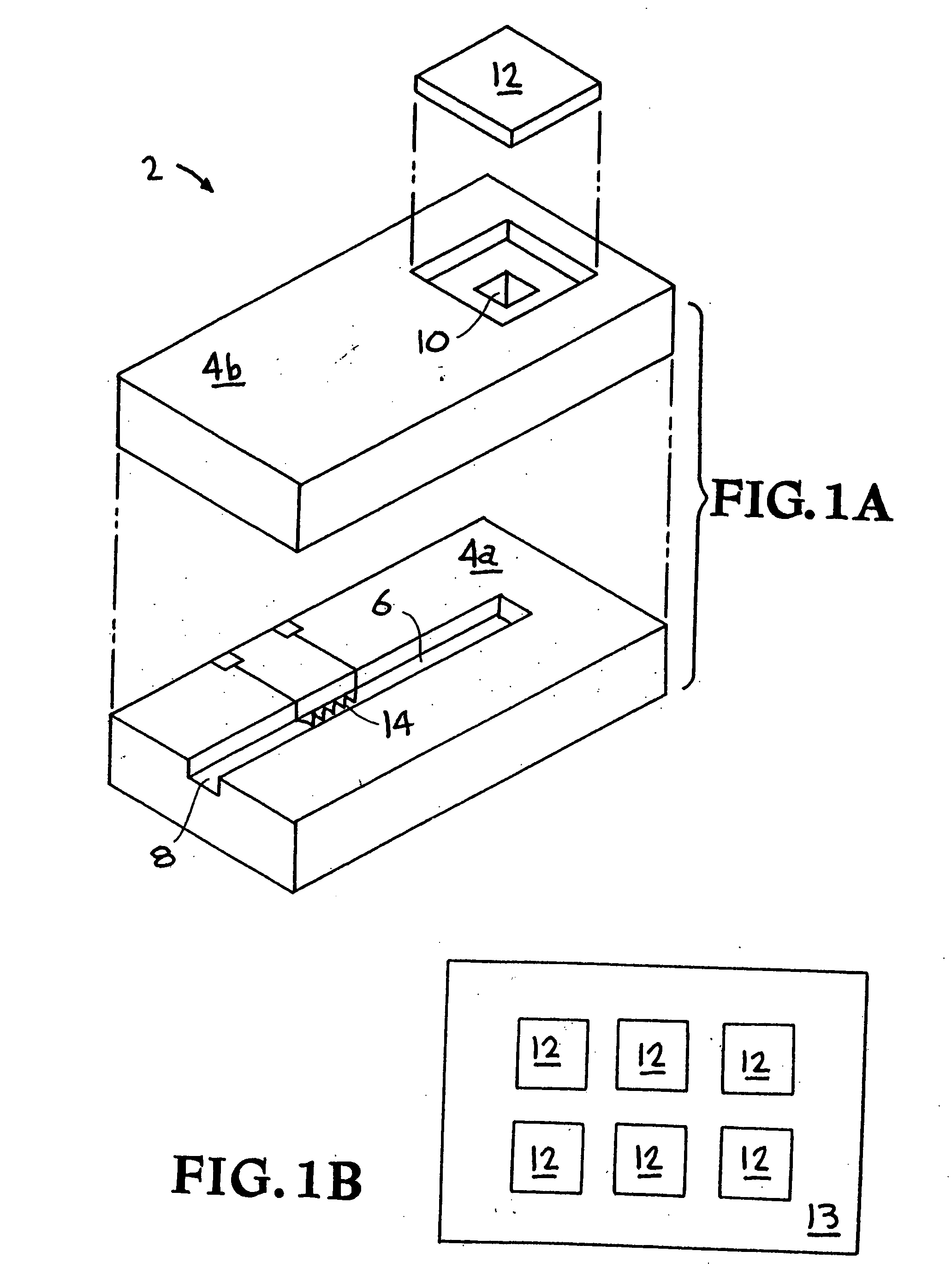

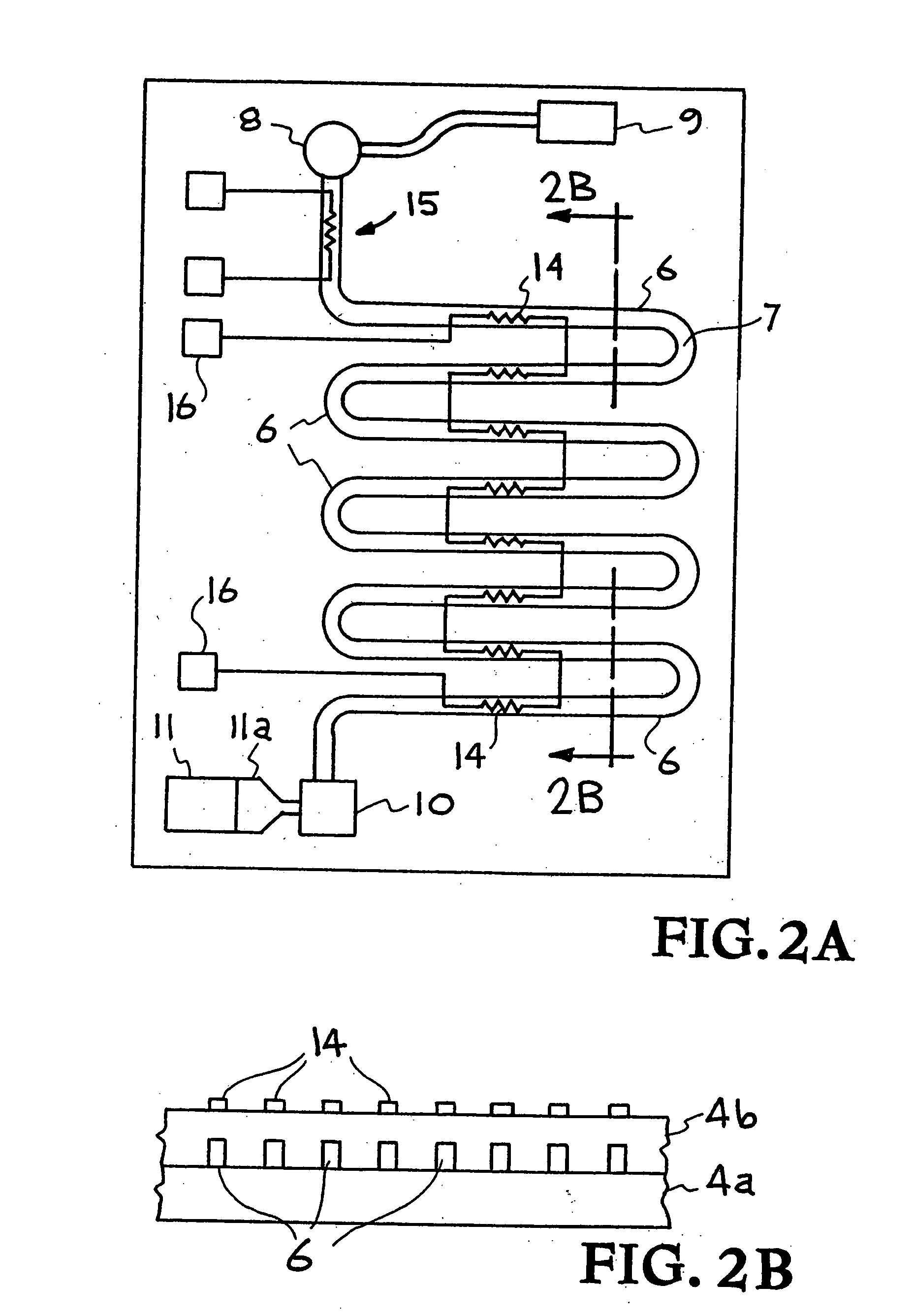

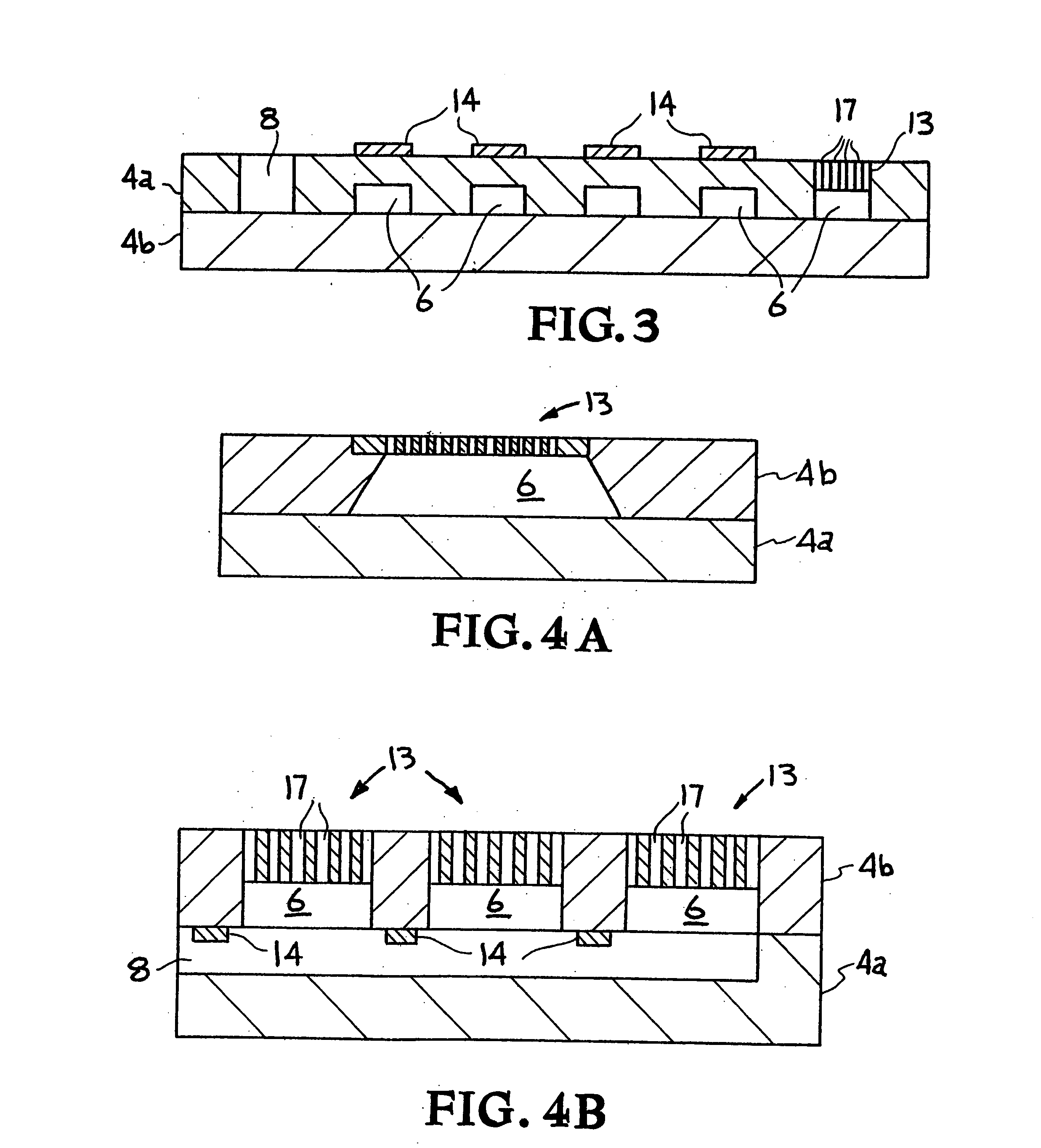

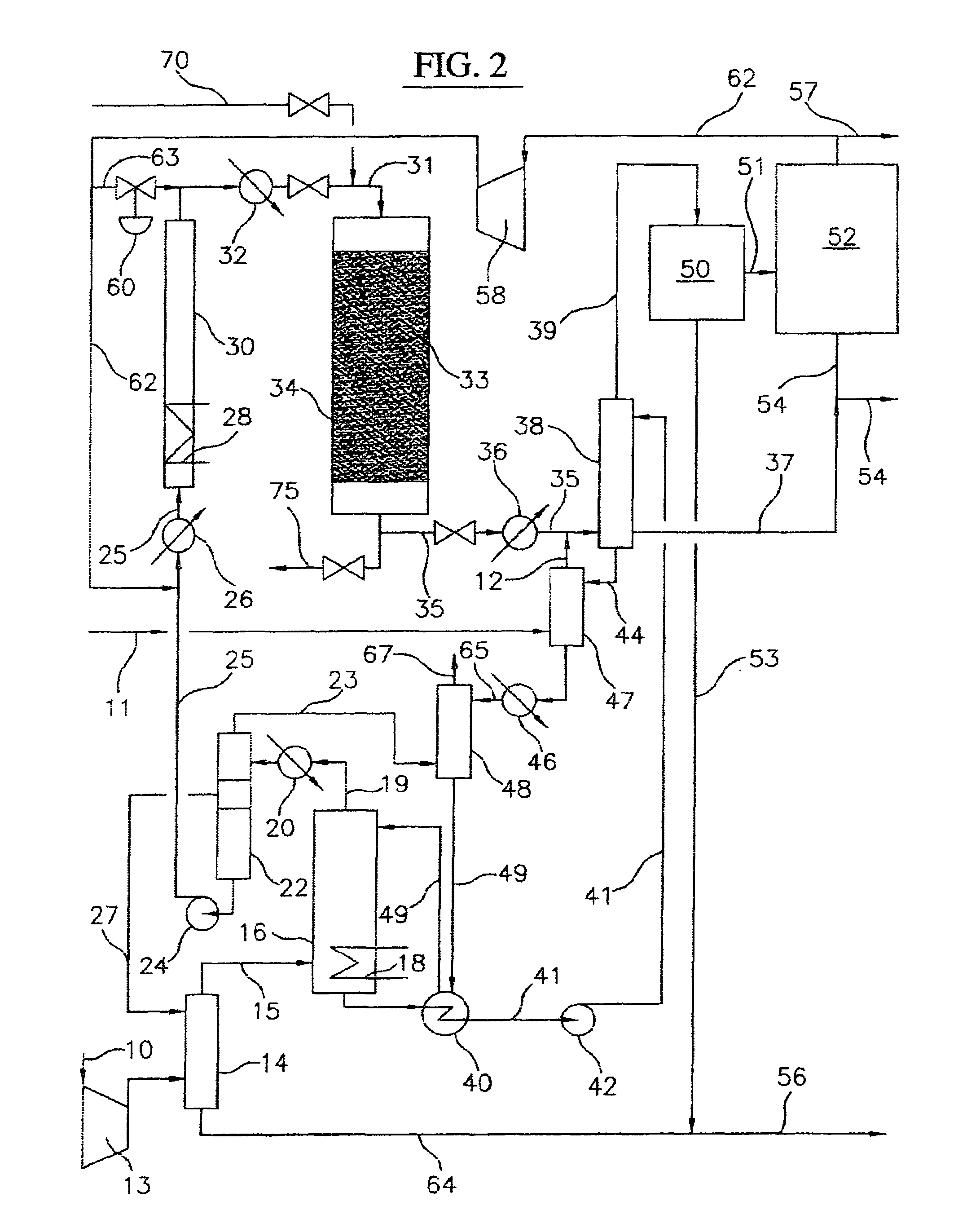

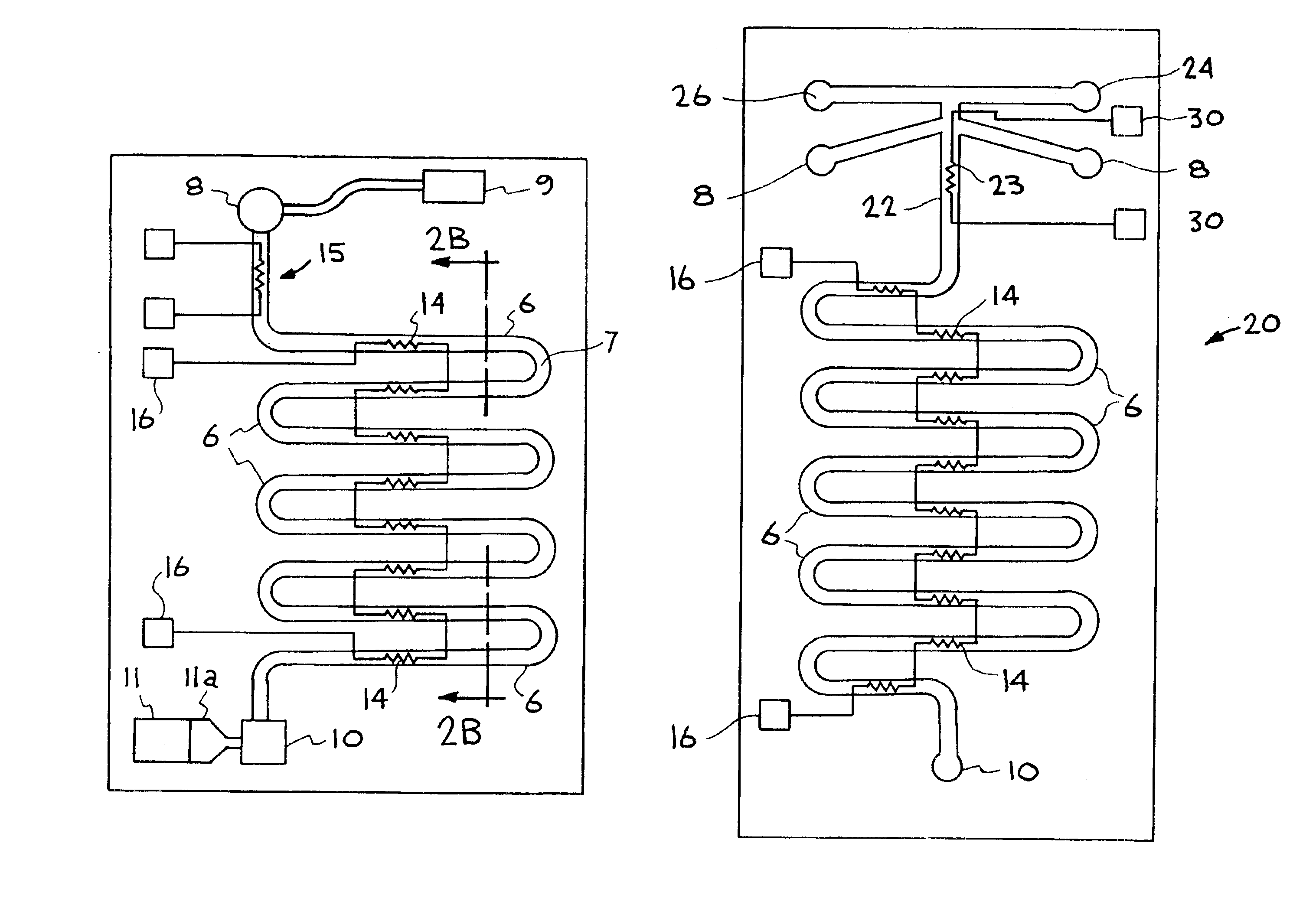

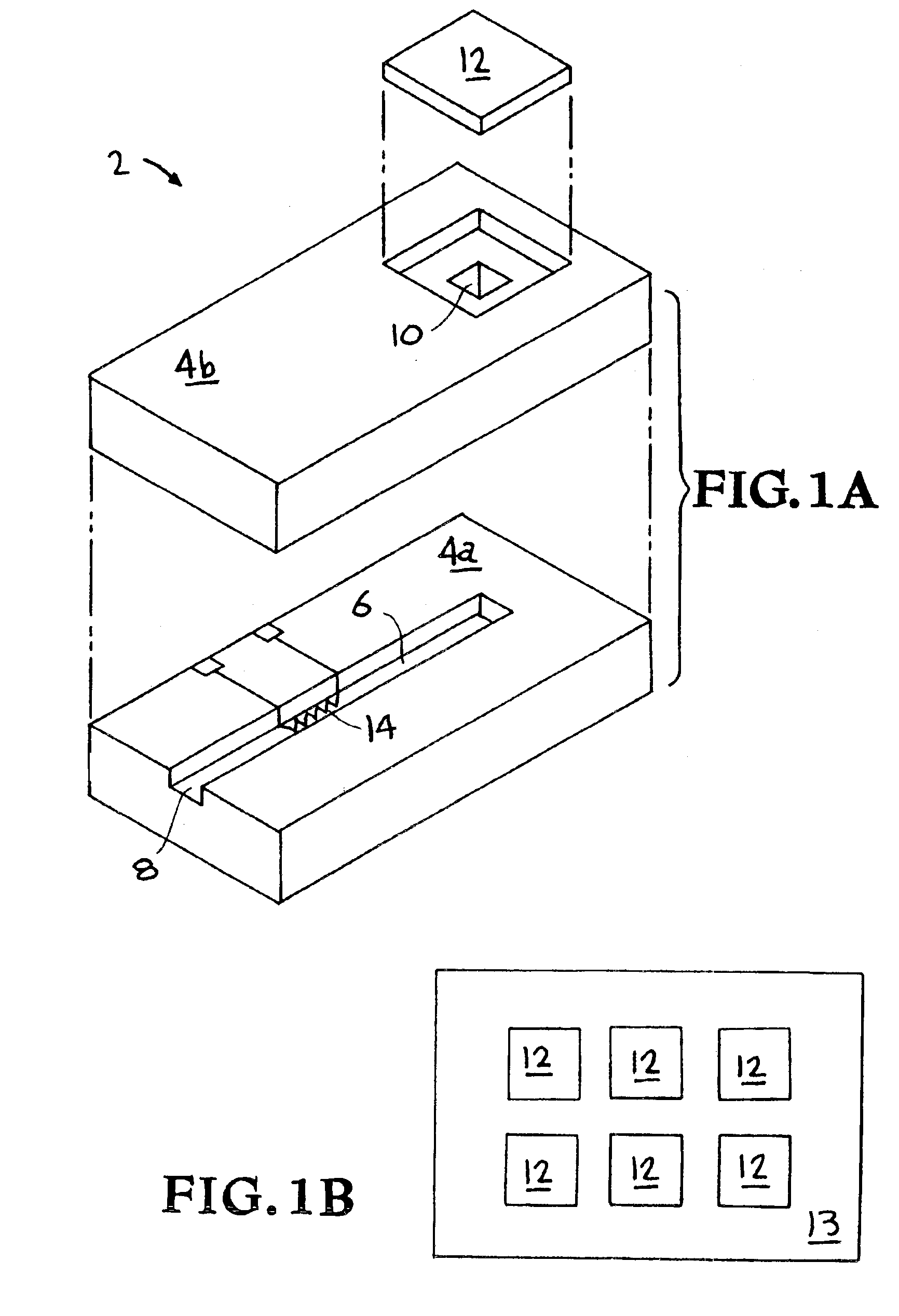

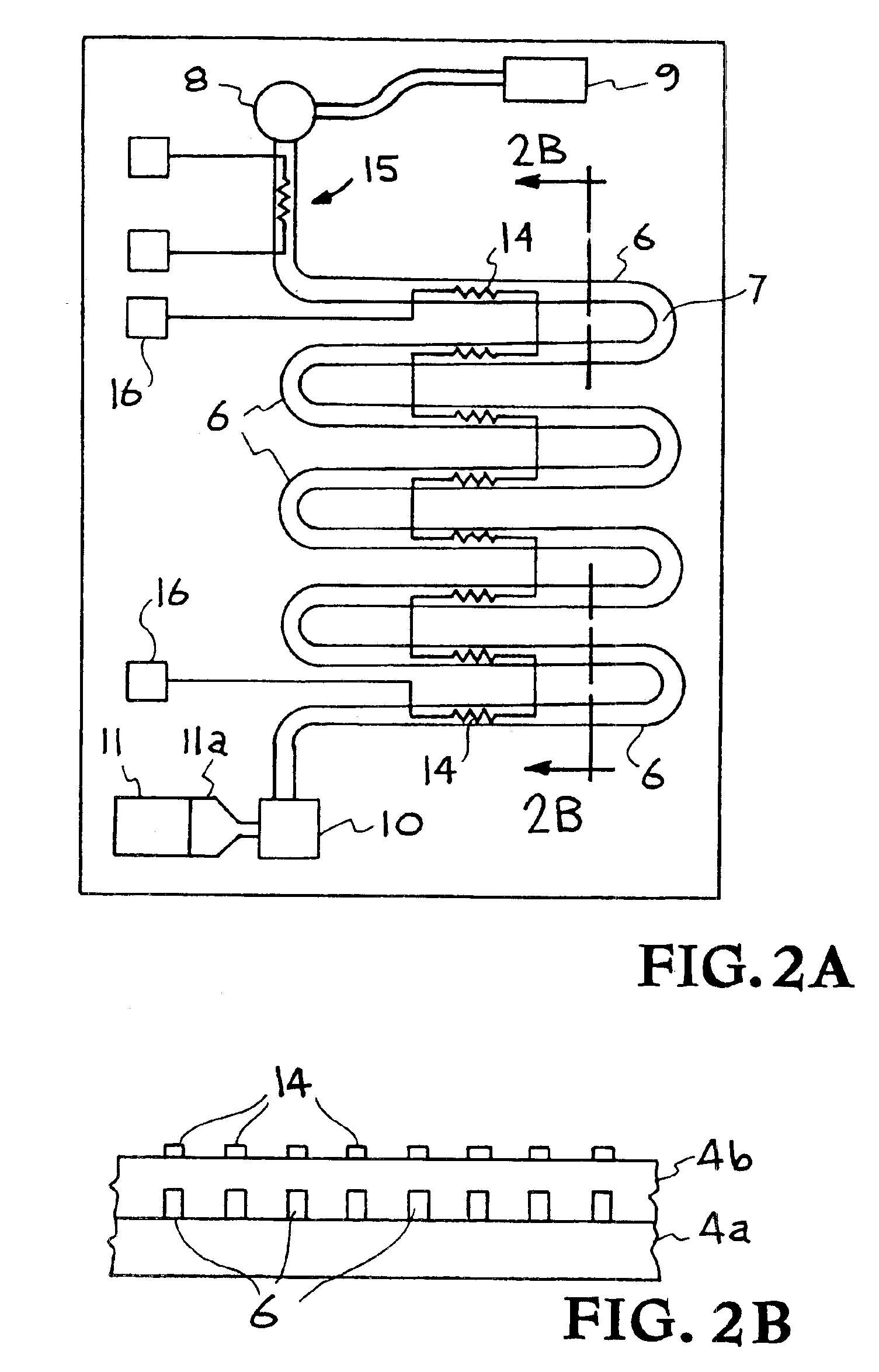

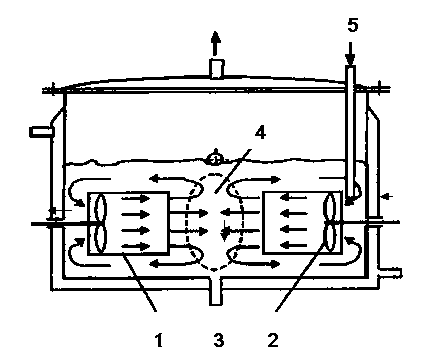

Chemical microreactor and method thereof

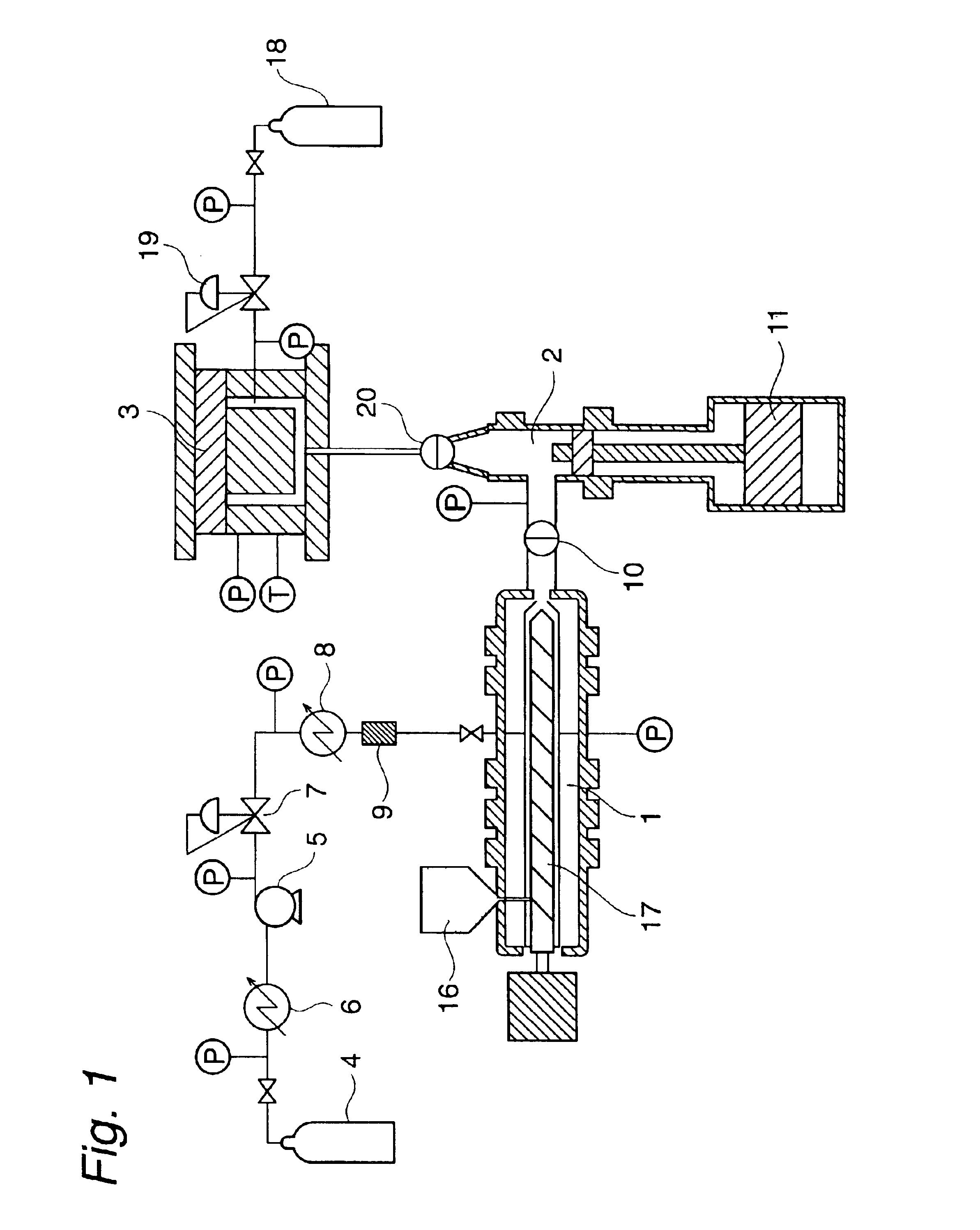

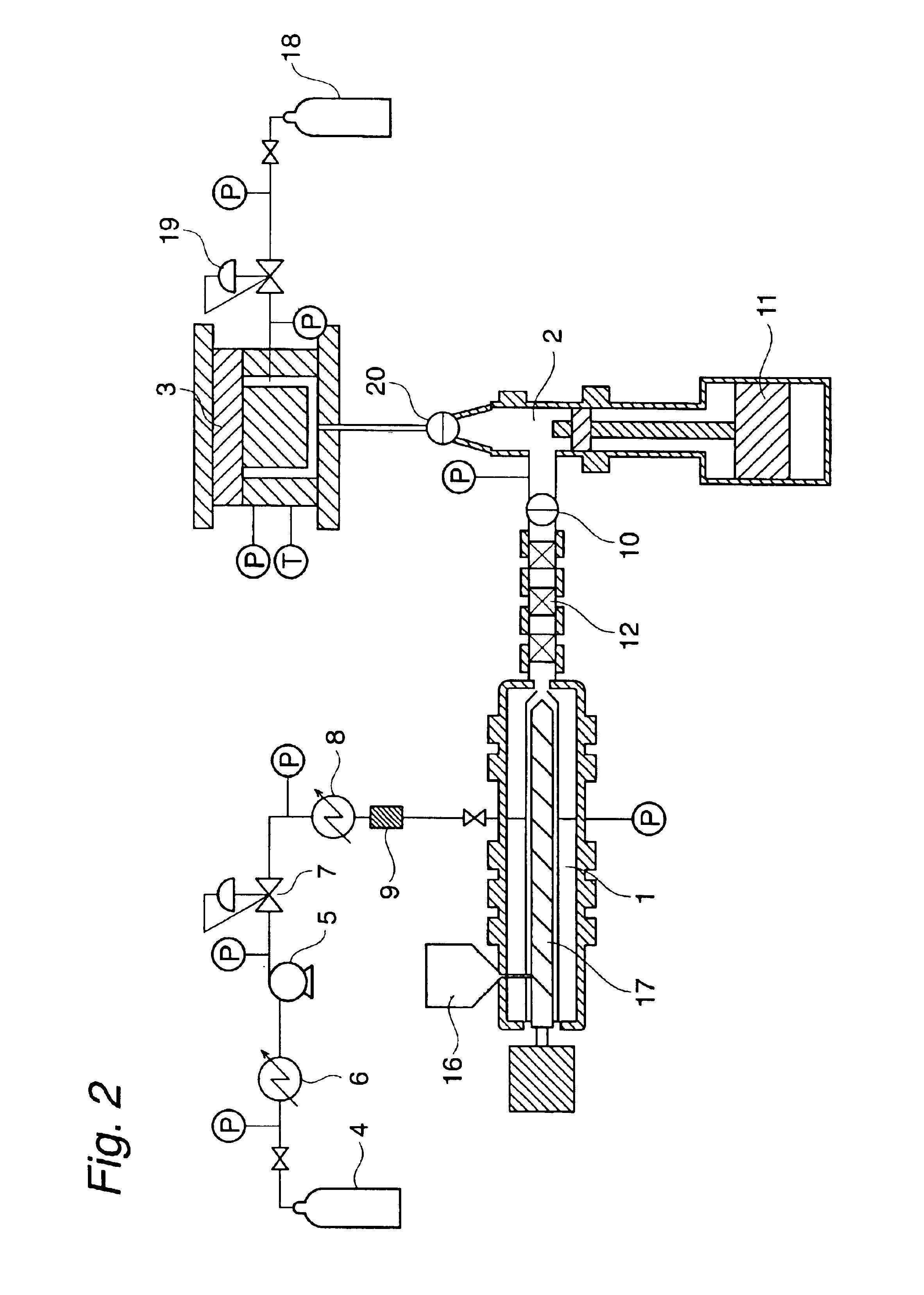

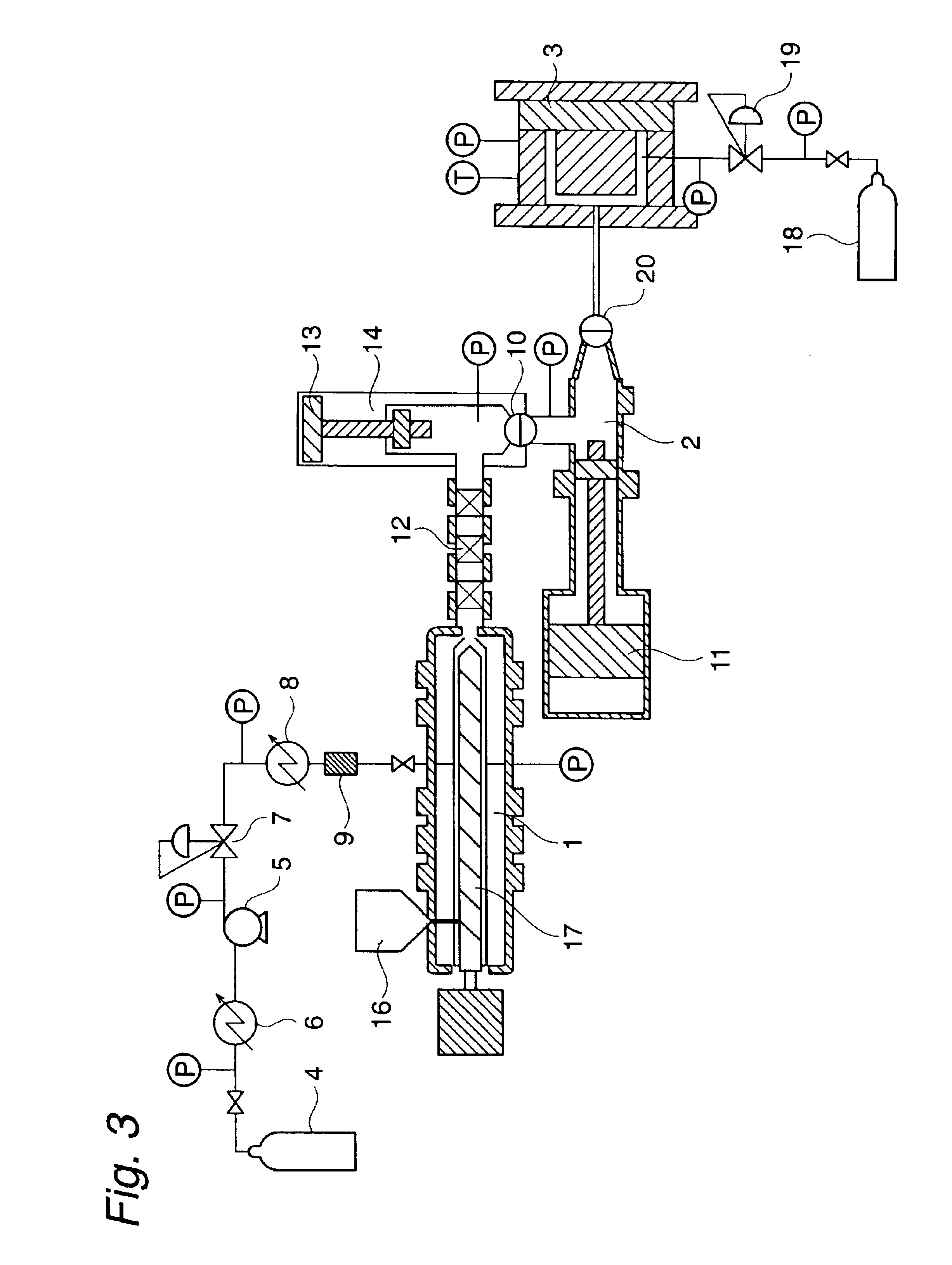

InactiveUS6960235B2Physical/chemical process catalystsHydrogen separationMicroreactorSteam reforming

A chemical microreactor suitable for generation of hydrogen fuel from liquid sources such as ammonia, methanol, and butane through steam reforming processes when mixed with an appropriate amount of water contains capillary microchannels with integrated resistive heaters to facilitate the occurrence of catalytic steam reforming reactions. One such microreactor employs a packed catalyst capillary microchannel and at least one porous membrane. Another employs a porous membrane with a large surface area or a porous membrane support structure containing a plurality of porous membranes having a large surface area in the aggregate, i.e., greater than about 1 m2 / cm3. The packed catalyst capillary microchannels, porous membranes and porous membrane support structures may be formed by a variety of methods.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

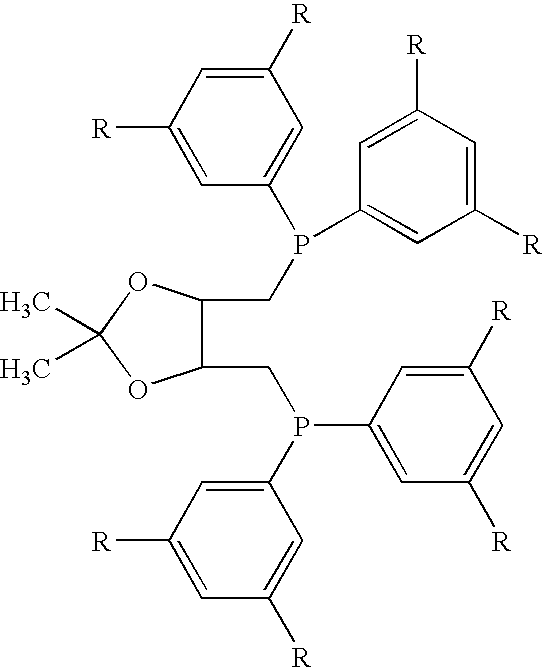

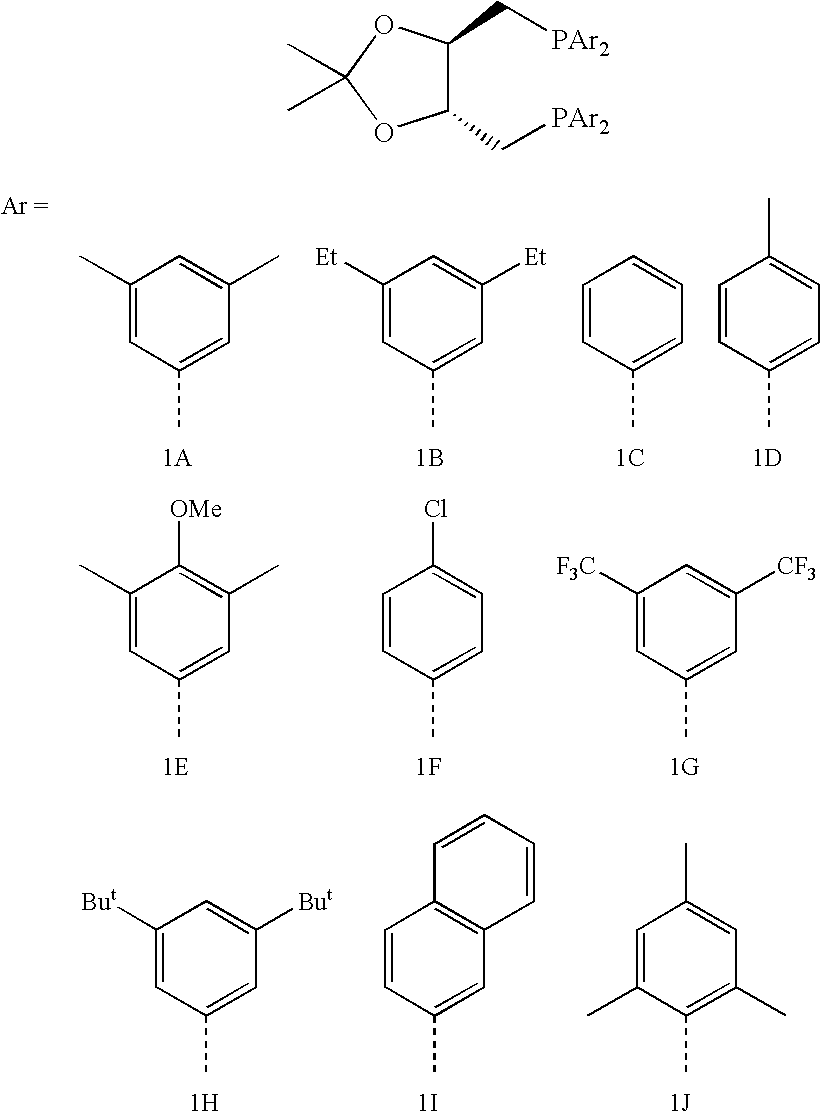

Hydroformylation process

ActiveUS7271295B1Raise the ratioOrganic compound preparationGroup 8/9/10/18 element organic compoundsHydrogenSolvent

A process for the production of 4-hydroxybutyraldehyde is described. The process comprises reacting allyl alcohol with a mixture of carbon monoxide and hydrogen in the presence of a solvent and a catalyst system comprising a rhodium complex and a 2,3-O-isopropylidene-2,3-dihydroxy-1,4-bis[bis(3,5-di-n-alkylphenyl)phosphino]butane. The process gives high yield of 4-hydroxybutyraldehyde compared to 3-hydroxy-2-methylpropionaldehyde.

Owner:LYONDELL CHEM TECH LP

Multi-element mixed working substance adapted to double temperature preparation of single-unit vapor compression type refrigerator

The invention relates the multicomponent mixed working substance used for preparing dual-temperature by single-machine vapor compression refrigerator. The low temperature is between -60- -40Deg.C and the high temperature is between -25- 10Deg.C. The multicomponent mixed working substance comprises lower boiling working substance and high boiling working substance. The lower boiling working substance comprises tetrafluoromethane, ethylene, ethane, fluoroethylene, trifluoromethane, fluoromethane, hydrofluoeic ether, carbon dioxide, difluoromethane and penfluoroethane; the high boiling working substance comprises trifluoro-thane, hydrofluoeic ether, propylene, propane, perfluoropropylamine, propadiene, cyclopropane, difluo-monochloromethane, penta-monochloroethane, perfluoroethane, difluoroethane, isobutene, butane, butylenes, isobutylene, sevofluoropropane, hexafluoropropane, penfluoropropane and tetrachloromonofluoroethane.

Owner:XI AN JIAOTONG UNIV

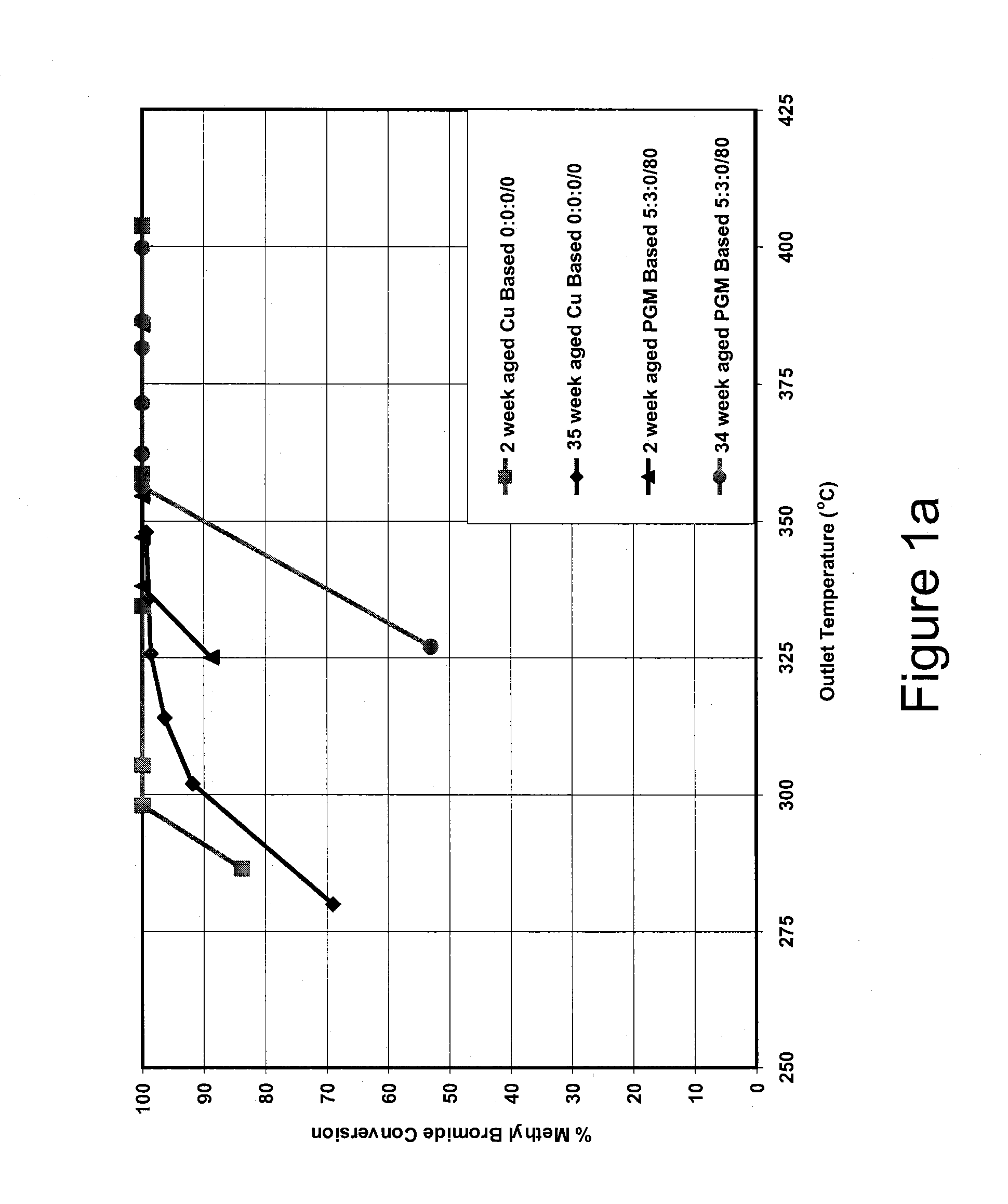

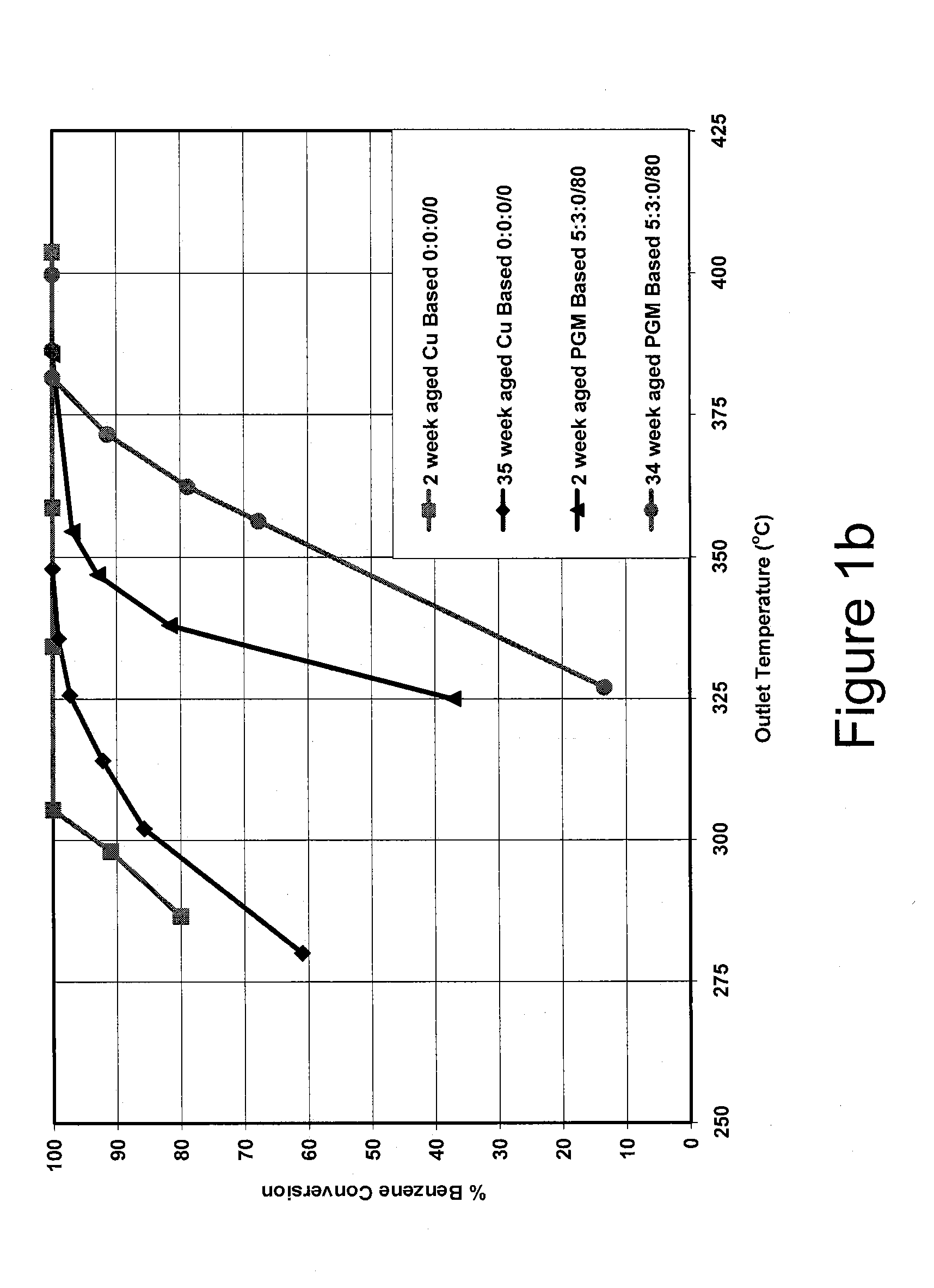

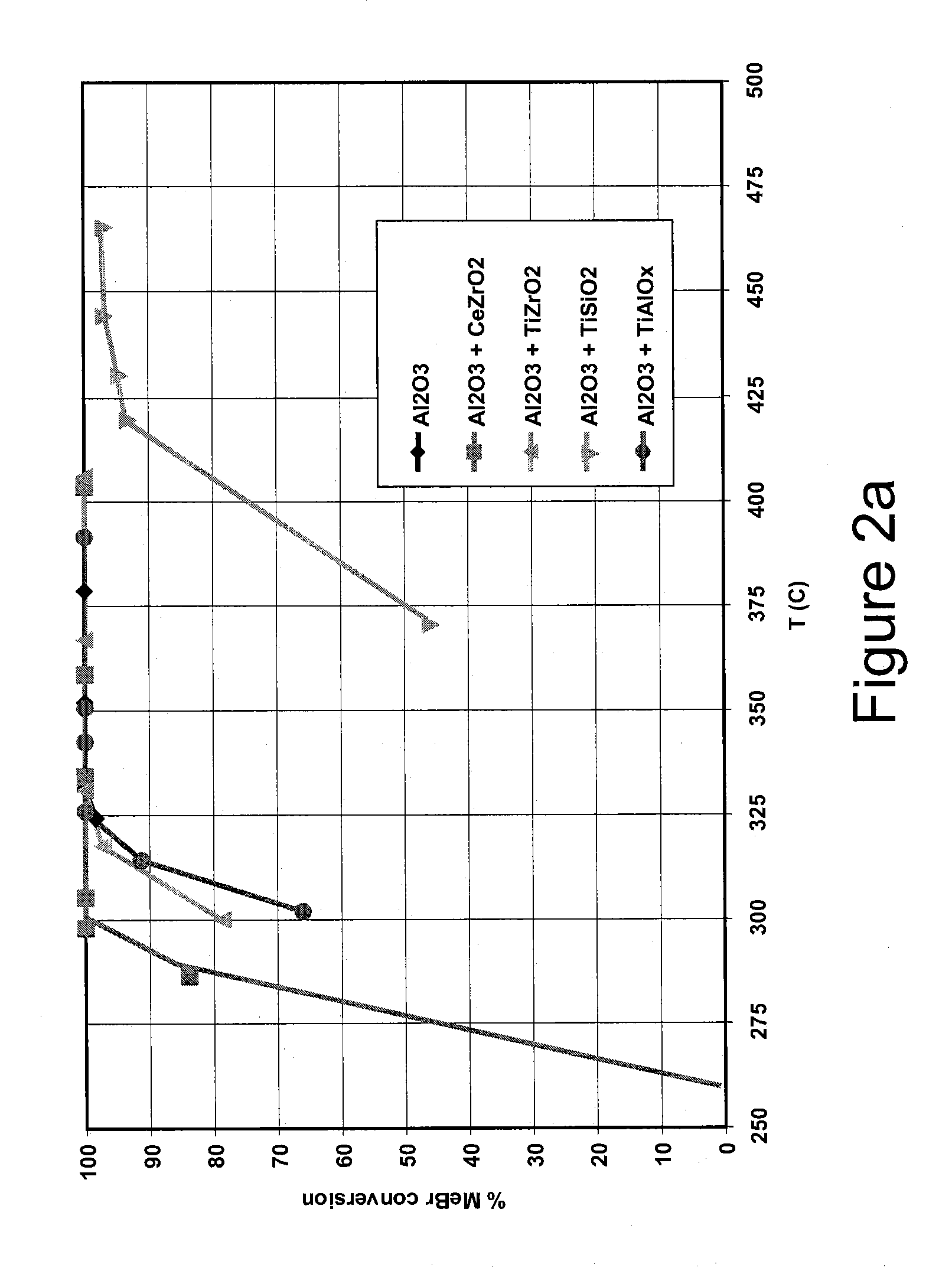

Base metal catalysts for the oxidation of carbon monoxide and volatile organic compounds

A method for oxidizing carbon monoxide (CO) and volatile organic compounds (VOCS) comprises contacting a gas containing water vapor and said CO and VOCs with a catalyst composition comprising at least one base metal promoter and at least one base metal catalyst supported on an oxide support material comprising one or more of alumina, silica, zirconia, ceria, and titania, wherein the VOCs comprise one or more of methyl acetate, methane, methyl bromide, benzene, methanol, methyl ethyl ketone, butane, and butene.

Owner:JOHNSON MATTHEY PLC

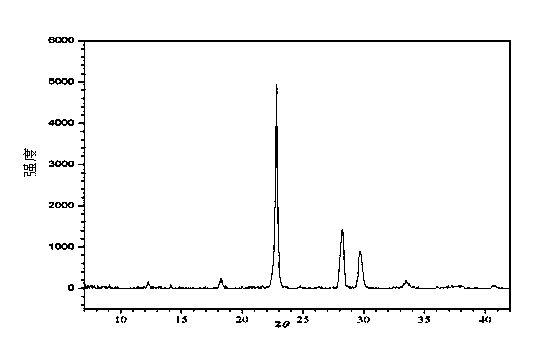

Vanadium-phosphorus-oxygen catalyst, and preparation method thereof

ActiveCN103769181AHigh reactivityEvenly distributedOrganic chemistryPhysical/chemical process catalystsPtru catalystPhysical chemistry

The invention discloses a vanadium-phosphorus-oxygen catalyst, and a preparation method thereof. According to the preparation method, a nano vanadium phosphorus oxide is taken as a precursor, is subjected to activating and then moulding, or is subjected to moulding and then activating so as to obtain the vanadium-phosphorus-oxygen catalyst; grain size of the nano vanadium phosphorus oxide is less than 100nm, and by volume, particles with a grain size of 30 to 50nm accounts for 7 to 14%, particles with a grain size of 50 to 70nm accounts for 54 to 79%, and particles with a grain size more than 70nm accounts for 7 to 39%. According to the vanadium-phosphorus-oxygen catalyst prepared by taking the nano vanadium phosphorus oxide as a precursor, octahedral structure of (VO)2P2O7 is neater, catalyst structure is stable, and catalytic activity and catalyst stability are higher. When the vanadium-phosphorus-oxygen catalyst is used for catalytic preparation of maleic anhydride via oxidation of n-butane, n-butane conversion rate reaches 87 to 95mol%, and maleic anhydride selectivity reaches 72 to 84mol%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing low-carbon olefine catalyst by loading iron-based synthetic gas

ActiveCN101940958AOvercoming strong interactionsHigh activityHydrocarbon from carbon oxidesCatalyst activation/preparationActive componentSilica gel

The invention discloses a method for preparing a low-carbon olefine catalyst by a loading iron-based synthetic gas, which comprises the following steps of: firstly carrying out surface modification on a silica gel carrier by using silica gel as a carrier, and then loading a metal auxiliary agent and an active component Fe by using an immersion method, wherein the surface modification method of the silica gel carrier comprises the following step of carrying out immersion treatment by using the acidic solution of sugar. After the silica gel carrier adopted is modified, the strong interaction between the carrier and the active component is overcome, and the activity and the selectivity of the catalyst are improved. The catalyst prepared by using the method is suitable for a reaction process of producing low-carbon olefines of ethylene, propylene, butane and the like by the synthetic gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for manufacturing olefin by low-carbon alkane dehydrogenation and application thereof

ActiveCN101773850AHigh selectivityHigh activityMolecular sieve catalystsHydrocarbonsAlkaneRare-earth element

The invention discloses a catalyst for manufacturing olefin by low-carbon alkane dehydrogenation and application thereof, belonging to the technical field of preparation of basic organic chemical materials. The catalyst takes silicoaluminophosphate molecular sieve and alumina mixture as carriers, VIII group or IVA group elements as active components and alkaline-earth metal or rare-earth elements as auxiliary agents for the process of olefin preparation by ethane, propane, butane or pentane dehydrogenation. In the process of olefin preparation by low-carbon alkane dehydrogenation, catalyst is firstly reduced by hydrogen and then reacts, and finally the catalyst is in charcoaling regeneration and chlorination update; and reaction regeneration process flow has big choice, the reactor can adopt a fixed bed, a moving bed, a fluidized bed or a double-particle fluidized bed, and catalyst regeneration can be carried out in a device or out of the device. Compared with the existing catalyst for manufacturing olefin by low-carbon alkane dehydrogenation, the catalyst provided by the invention ensures that low-carbon alkane selectivity is above 95% in the olefin preparing process by low-carbon alkane dehydrogenation under high conversion rate.

Owner:TSINGHUA UNIV

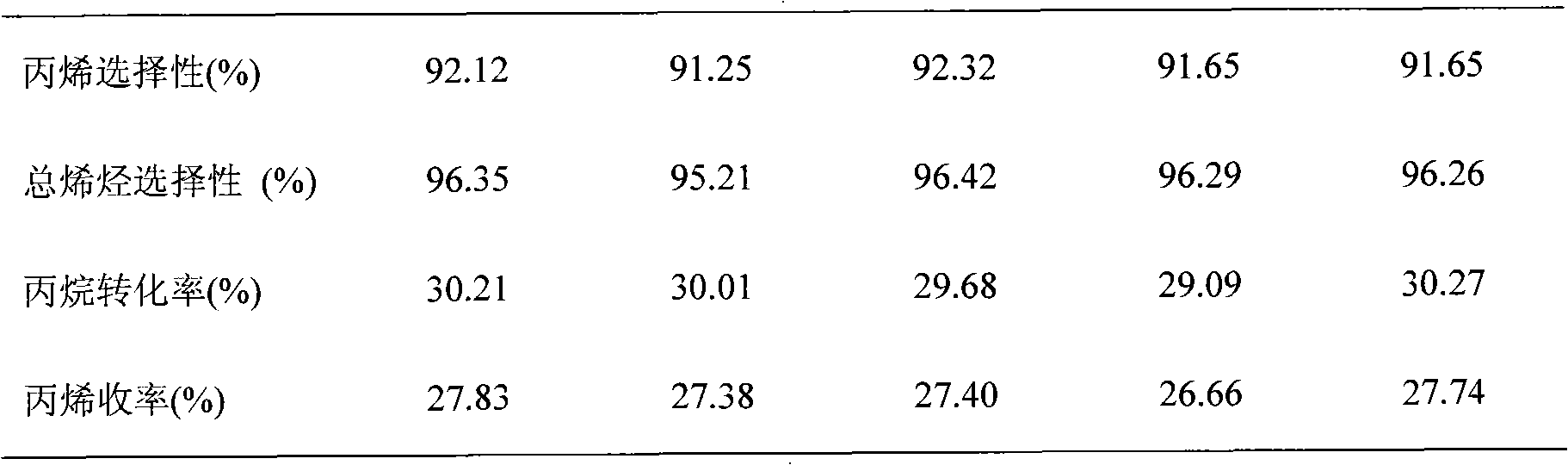

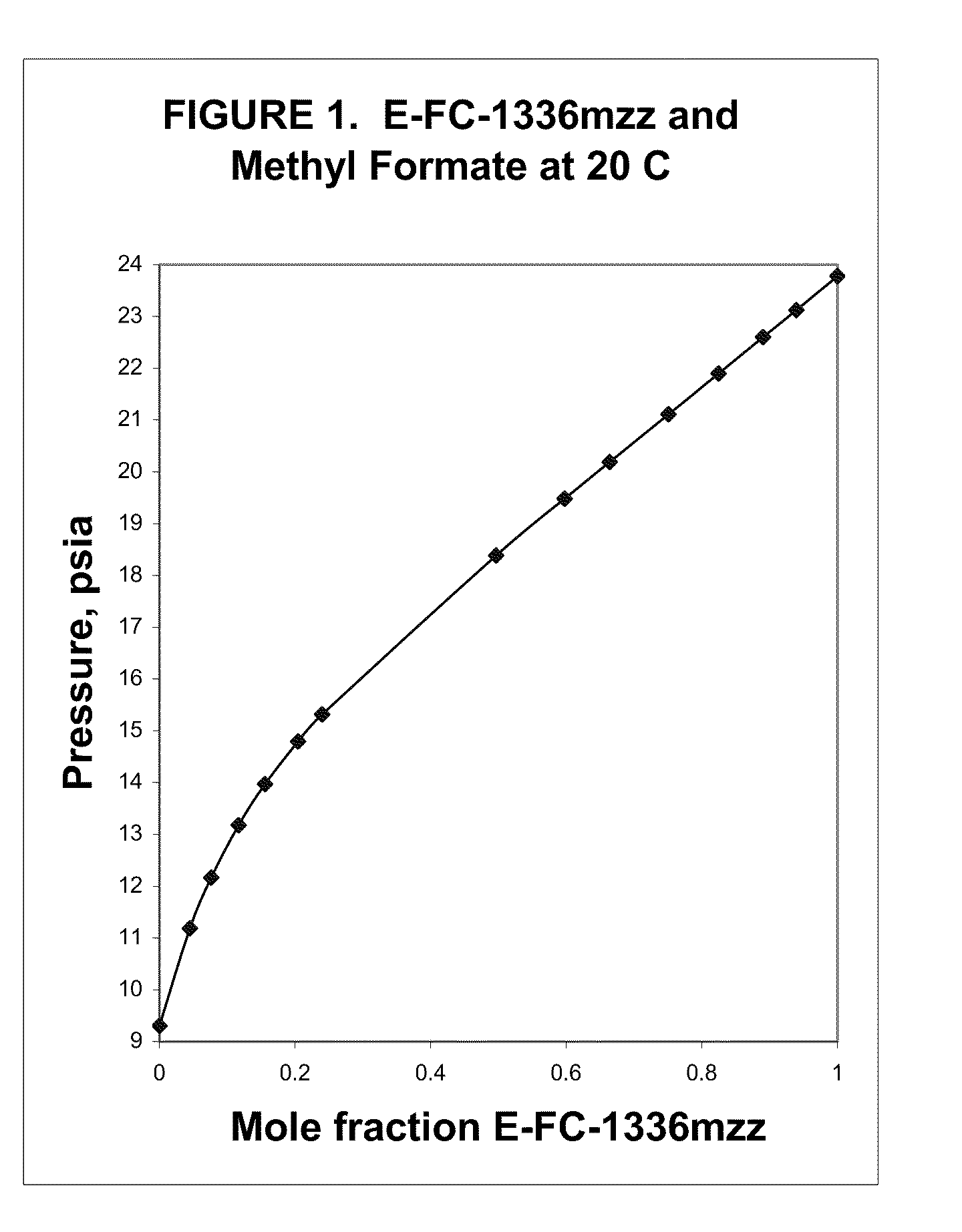

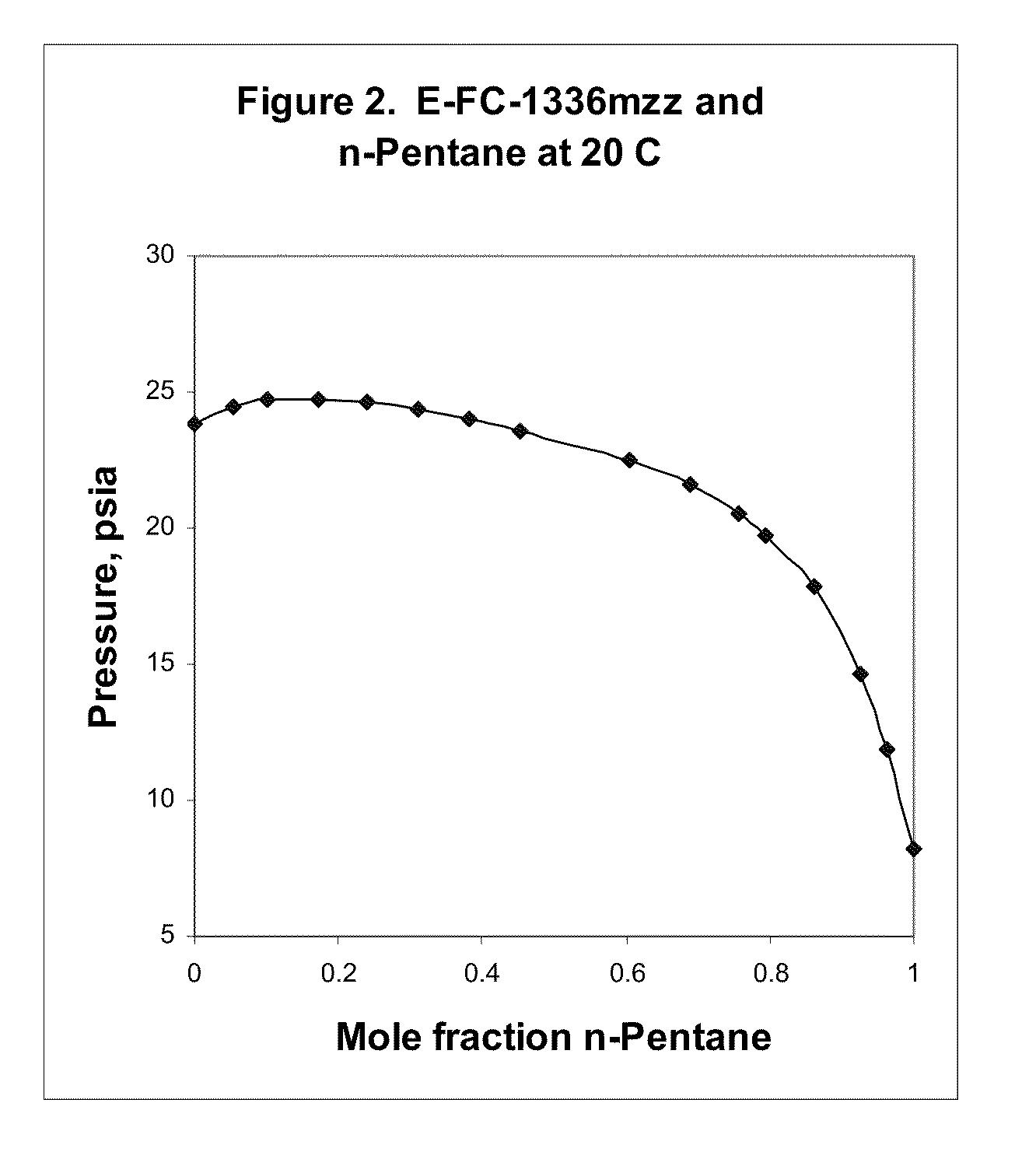

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, n-pentane, 2-methylbutane trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, n-butane or isobutane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

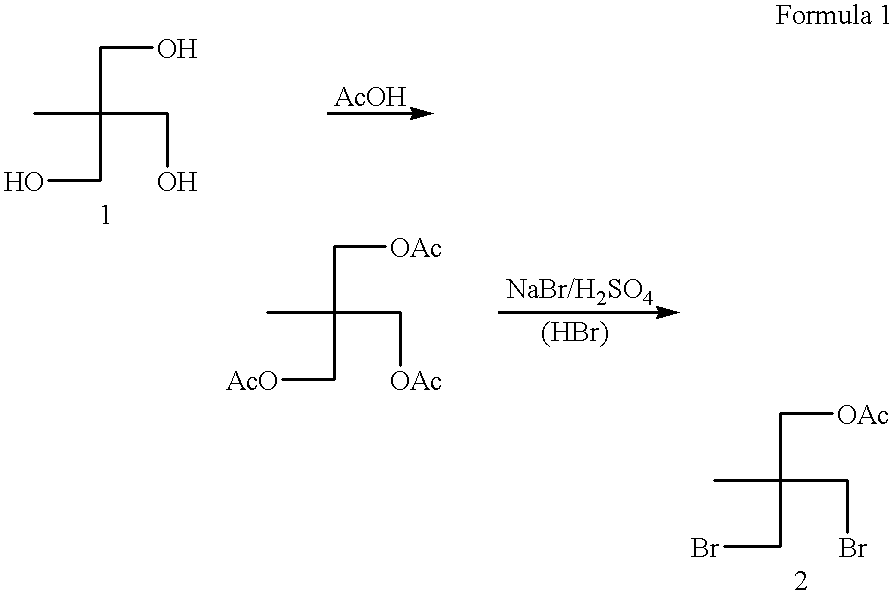

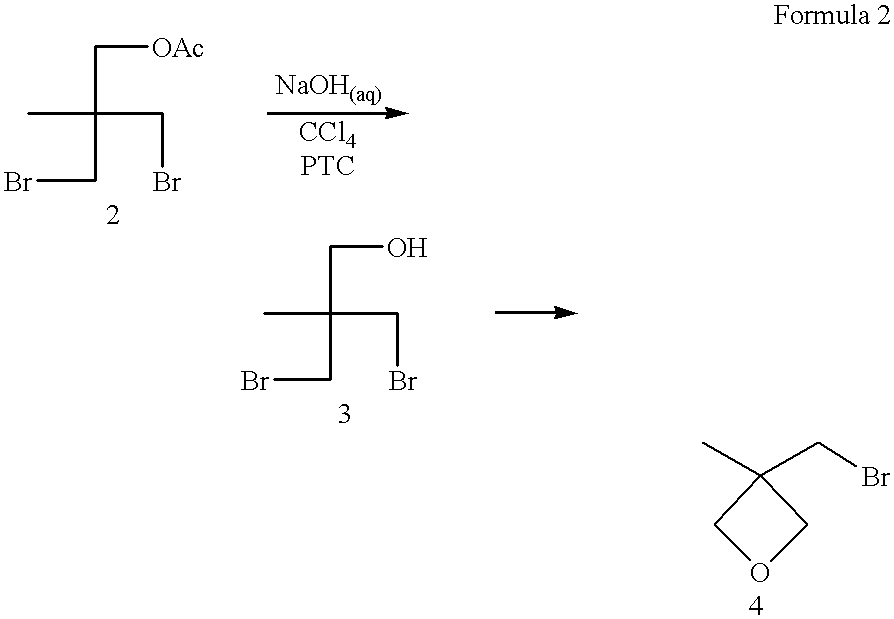

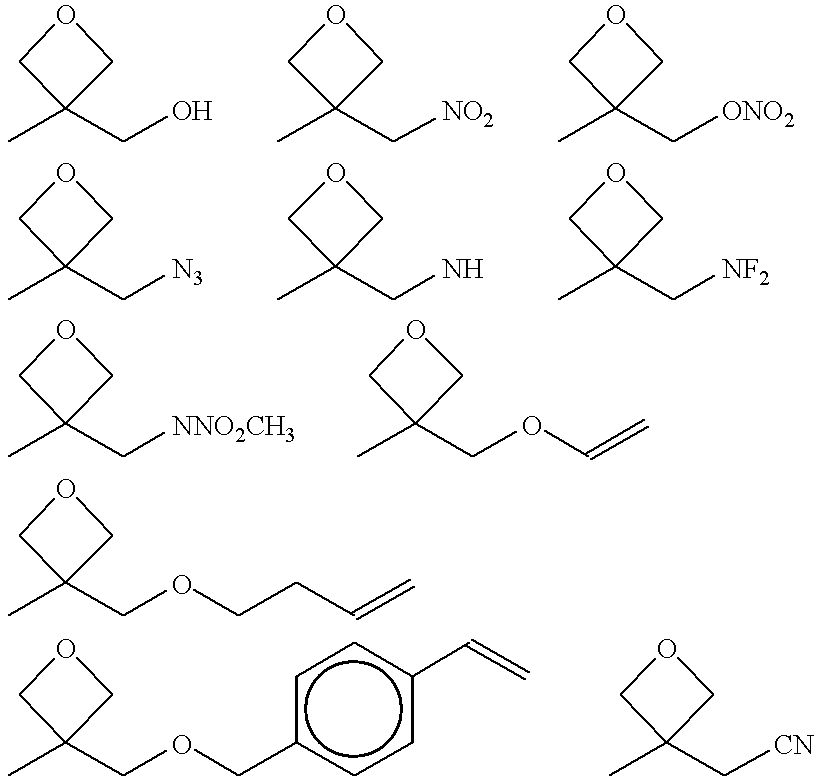

Copolymers and coprepolymers formed from mono-substituted fluorinated oxetane monomers and tetrahydrofuran

InactiveUS6380351B1Improve hydrophobicityLower surface energyOrganic chemistry methodsPolyurea/polyurethane coatingsSide chainButane

Owner:AEROJET GENERAL CORP +1

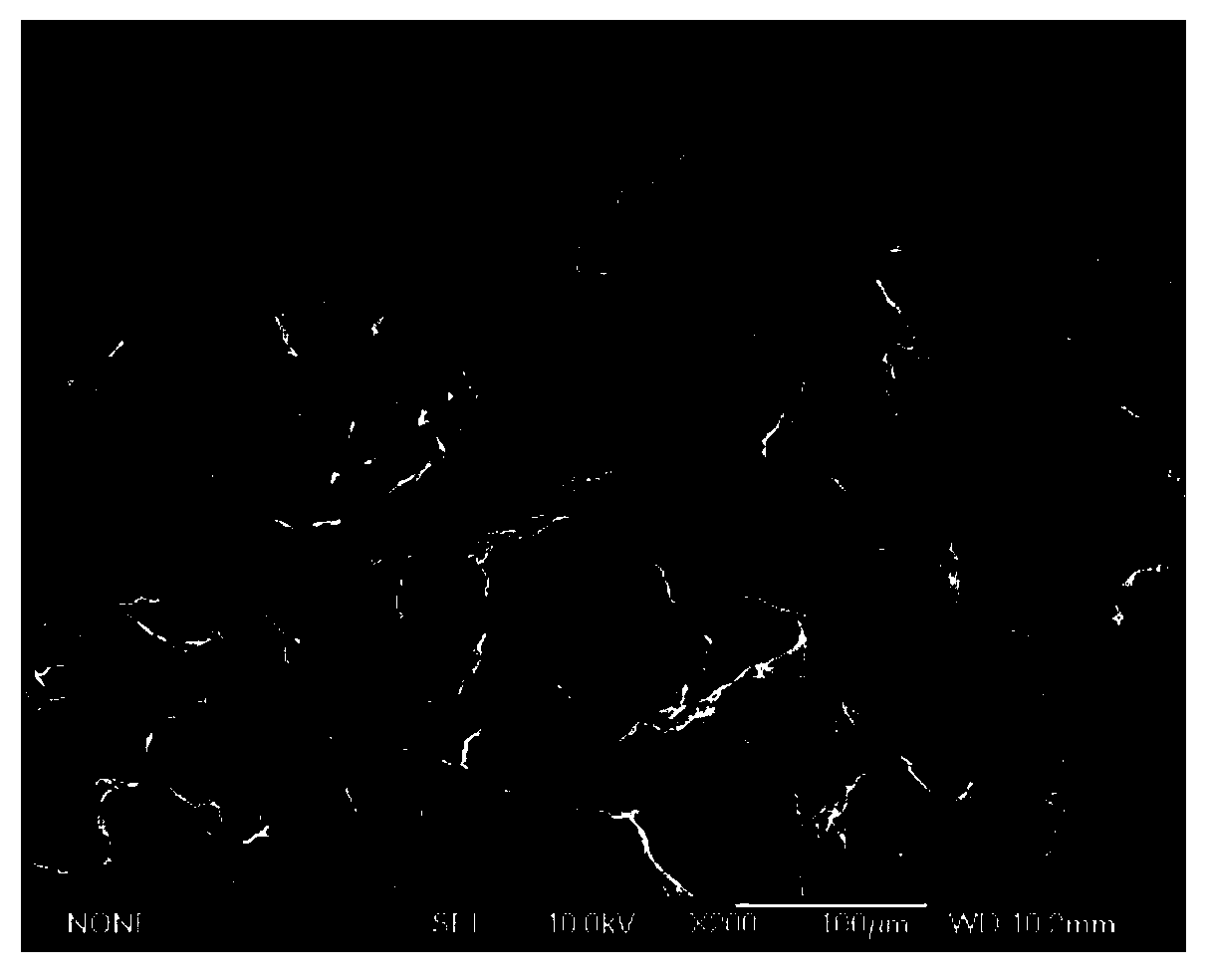

Graphene aerogel as well as preparation method and application thereof

The invention discloses graphene aerogel and a preparation method thereof. The method comprises the following steps: (1) uniformly mixing graphene oxide dispersion liquid with an amine water-soluble compound to obtain graphene oxide mixed liquid, wherein the amine water-soluble compound is selected from one or more of diethylamine, ethidene diamine, propane diamine, butane diamine, diethylene triamine, triethylene tetramine, tetraethylene pentamine, allylamine polymer and N,N'-bis(2-aminoethyl)-1,3-propane diamine; (2) irradiating the graphene oxide mixed liquid by high-energy rays under the anaerobic condition to obtain amino-modified graphene aerogel; (3) performing freeze-drying or supercritical CO2 drying to obtain the graphene aerogel. The graphene aerogel adopts a porous and macroporous structure, is relatively uniform in structure, and can be used for adsorbing an organic solvent; moreover, the preparation method is simple and environment-friendly.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Process for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to liquid hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as a ZSM-5 zeolite, at a temperature of from about 150° C. to about 450° C. so as to form higher molecular weight hydrocarbons and hydrobromic acid vapor. Propane and butane which comprise a portion of the products may be recovered or recycled back through the process to form additional C5+ hydrocarbons. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons and to generate bromine from the hydrobromic acid for use in the process.

Owner:SULZER MANAGEMENT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com