Patents

Literature

71 results about "Tetrafluoromethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetrafluoromethane, also known as carbon tetrafluoride or R-14, is the simplest fluorocarbon (CF₄). It has a very high bond strength due to the nature of the carbon–fluorine bond. It can also be classified as a haloalkane or halomethane. Tetrafluoromethane is a useful refrigerant but also a potent greenhouse gas.

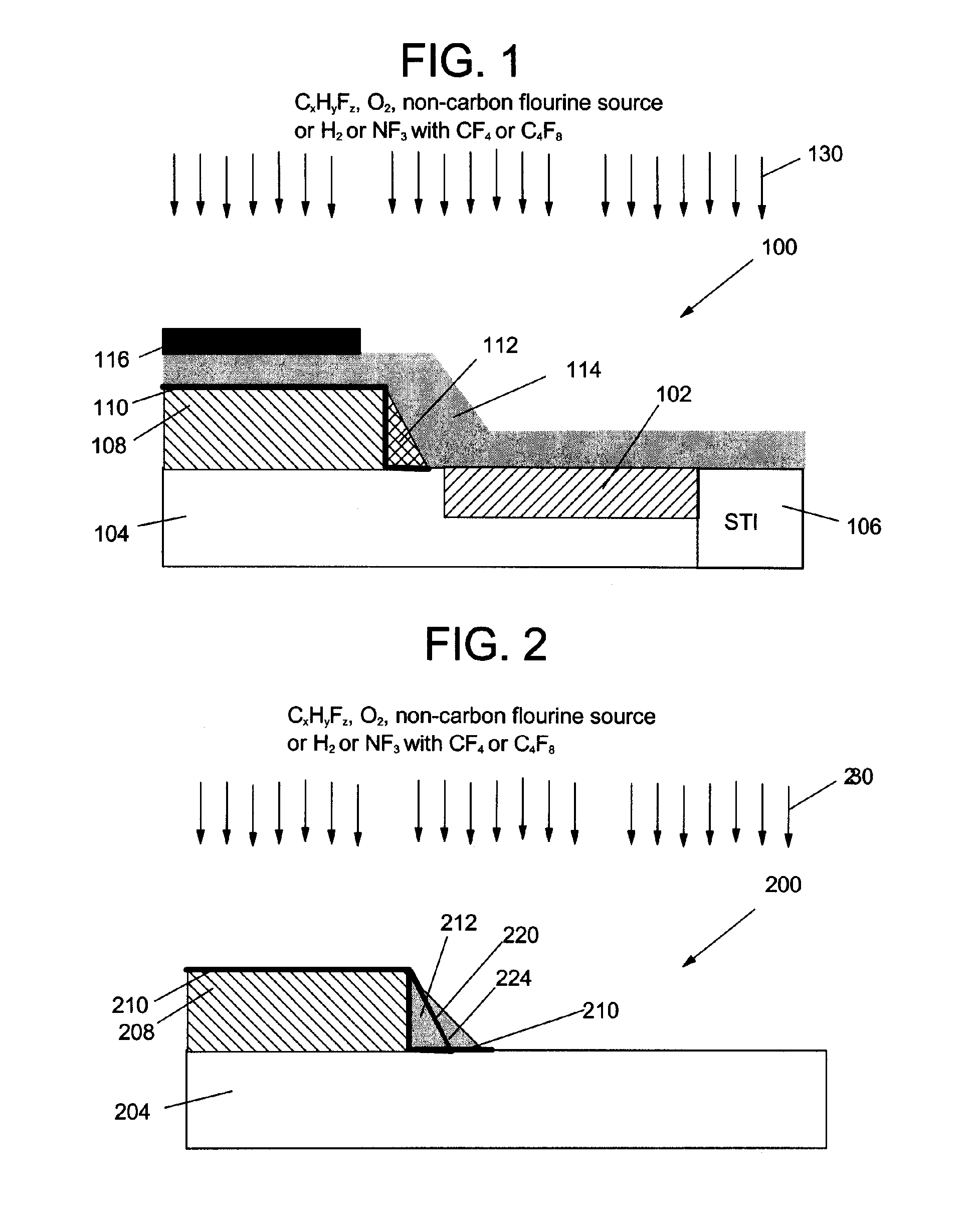

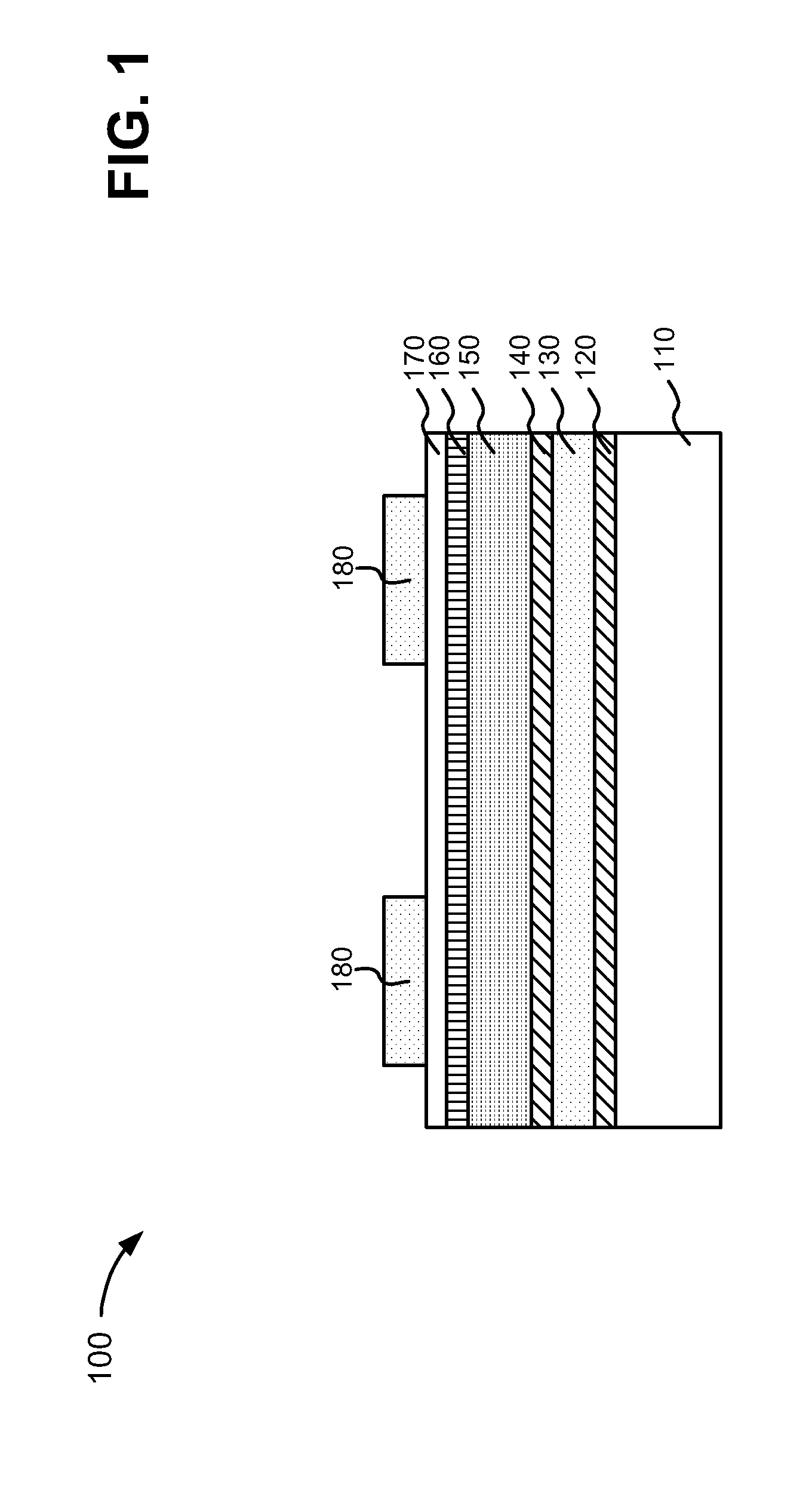

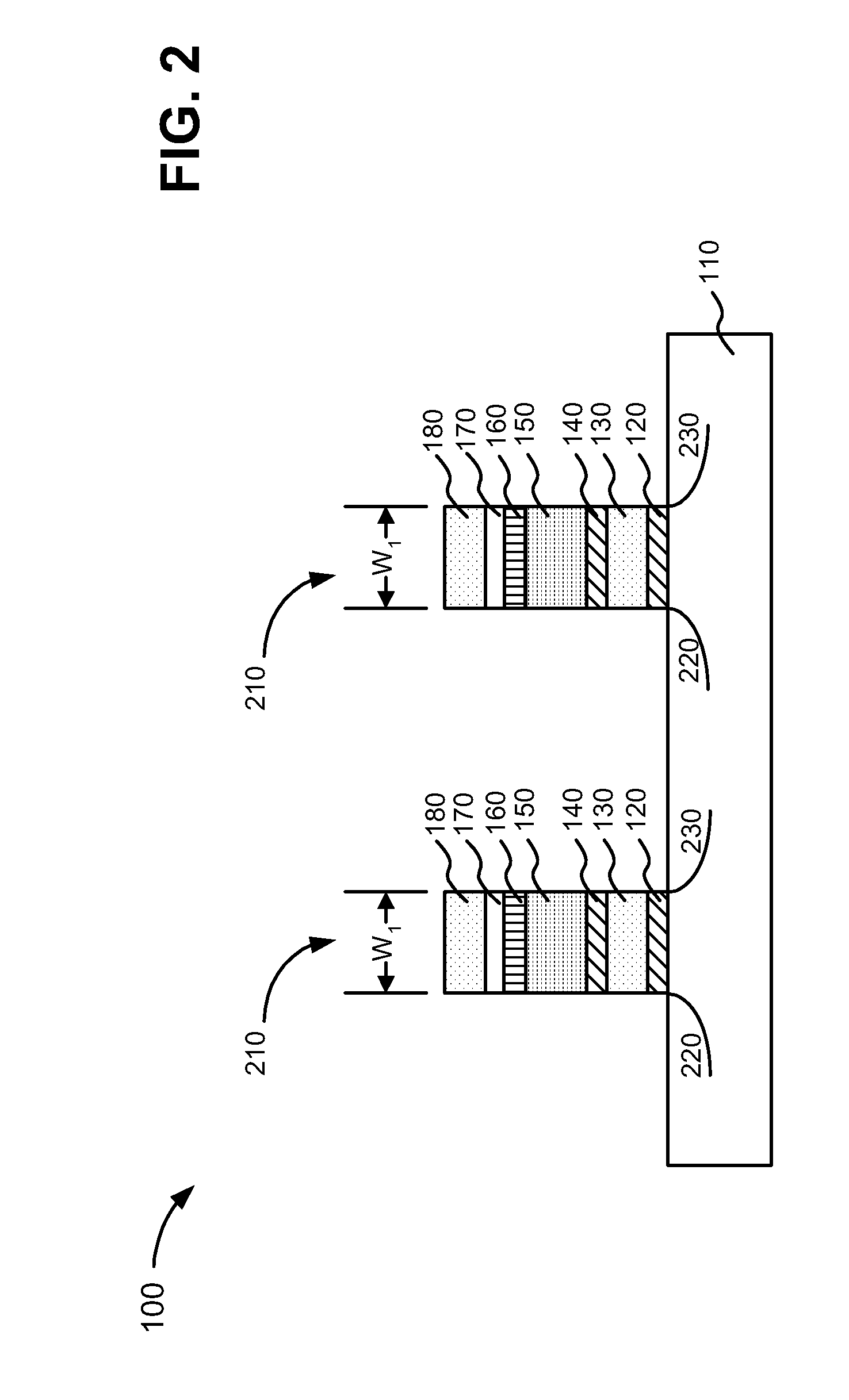

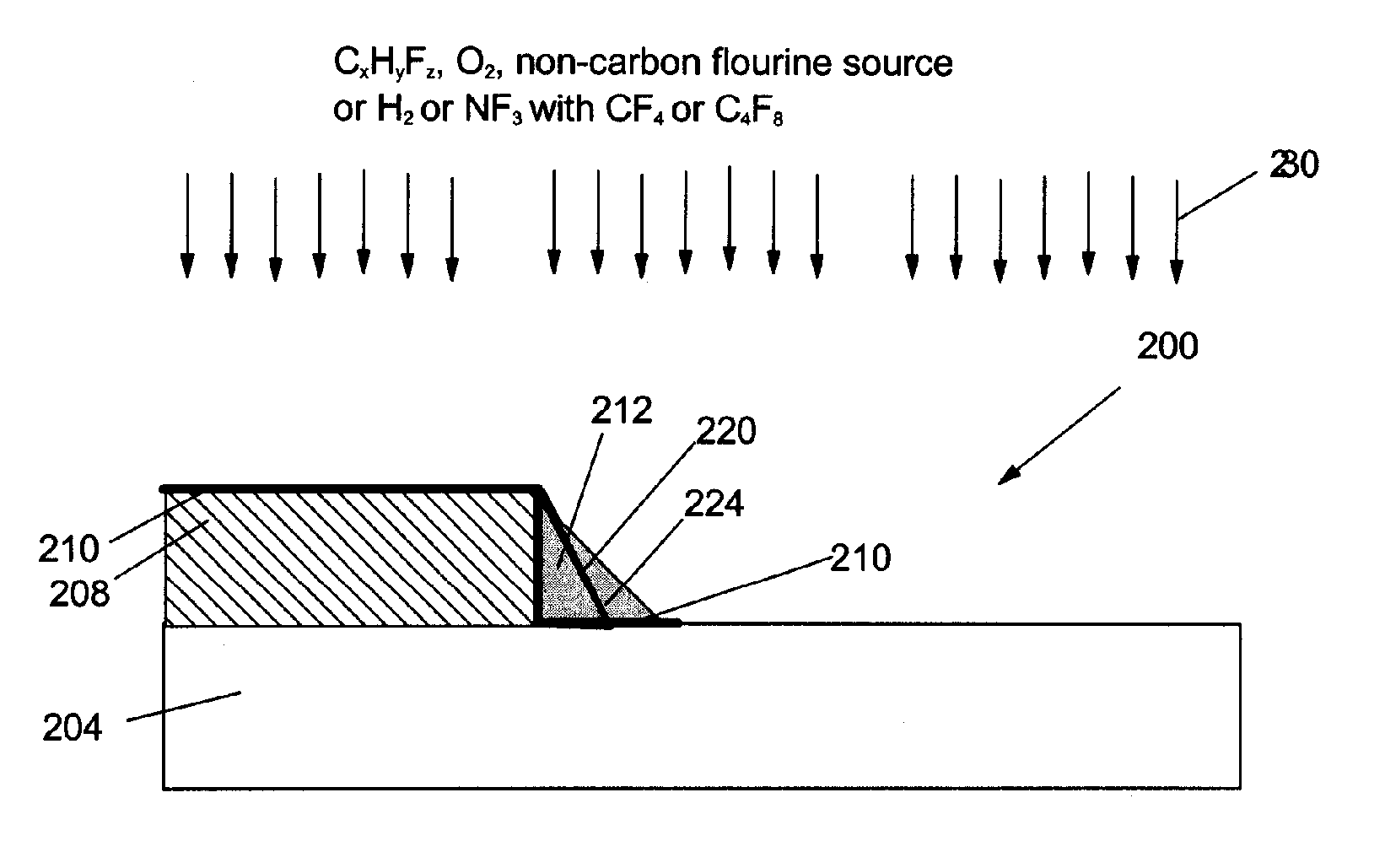

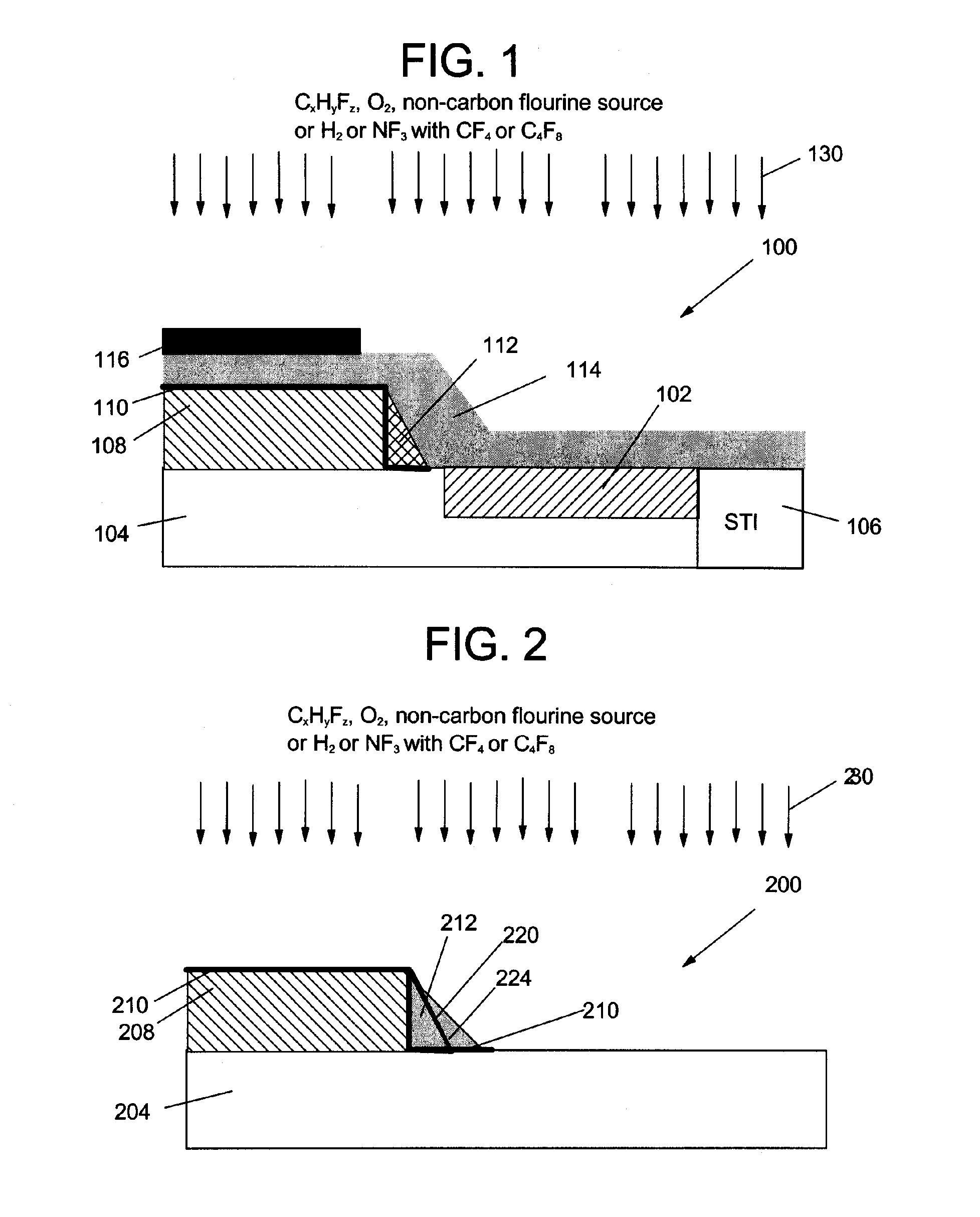

Silicon nitride etching methods

ActiveUS7288482B2Semiconductor/solid-state device manufacturingSulfur hexafluorideOctafluorocyclobutane

Methods of etching silicon nitride material, and more particularly, etching nitride selective to silicon dioxide or silicide, are disclosed. The methods include exposing a substrate having silicon nitride thereon to a plasma including at least one fluorohydrocarbon and a non-carbon containing fluorine source such as sulfur hexafluoride (SF6). The plasma may also include oxygen (O2) and the fluorohydrocarbons may include at least one of: trifluoromethane (CHF3), difluoromethane (CH2F2), and methyl fluoride (CH3F). In an alternative embodiment, the plasma includes one of hydrogen (H2) and nitrogen trifluoride (NF3) and one of tetrafluoromethane (CF4) and octafluorocyclobutane (C4F8). The methods are preferably carried out using a low bias voltage, e.g. <100 V.

Owner:IBM CORP +1

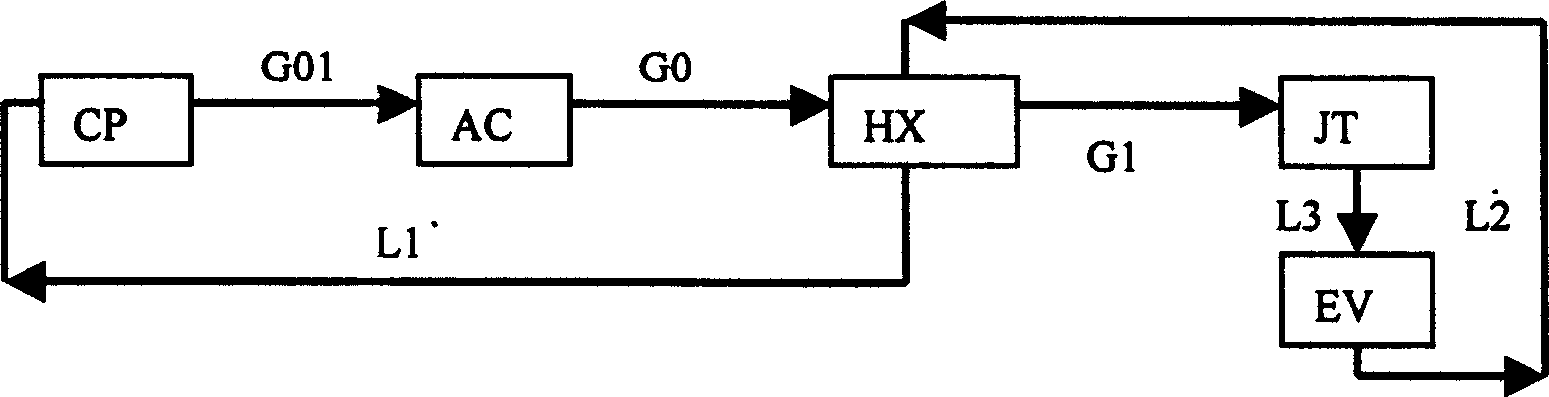

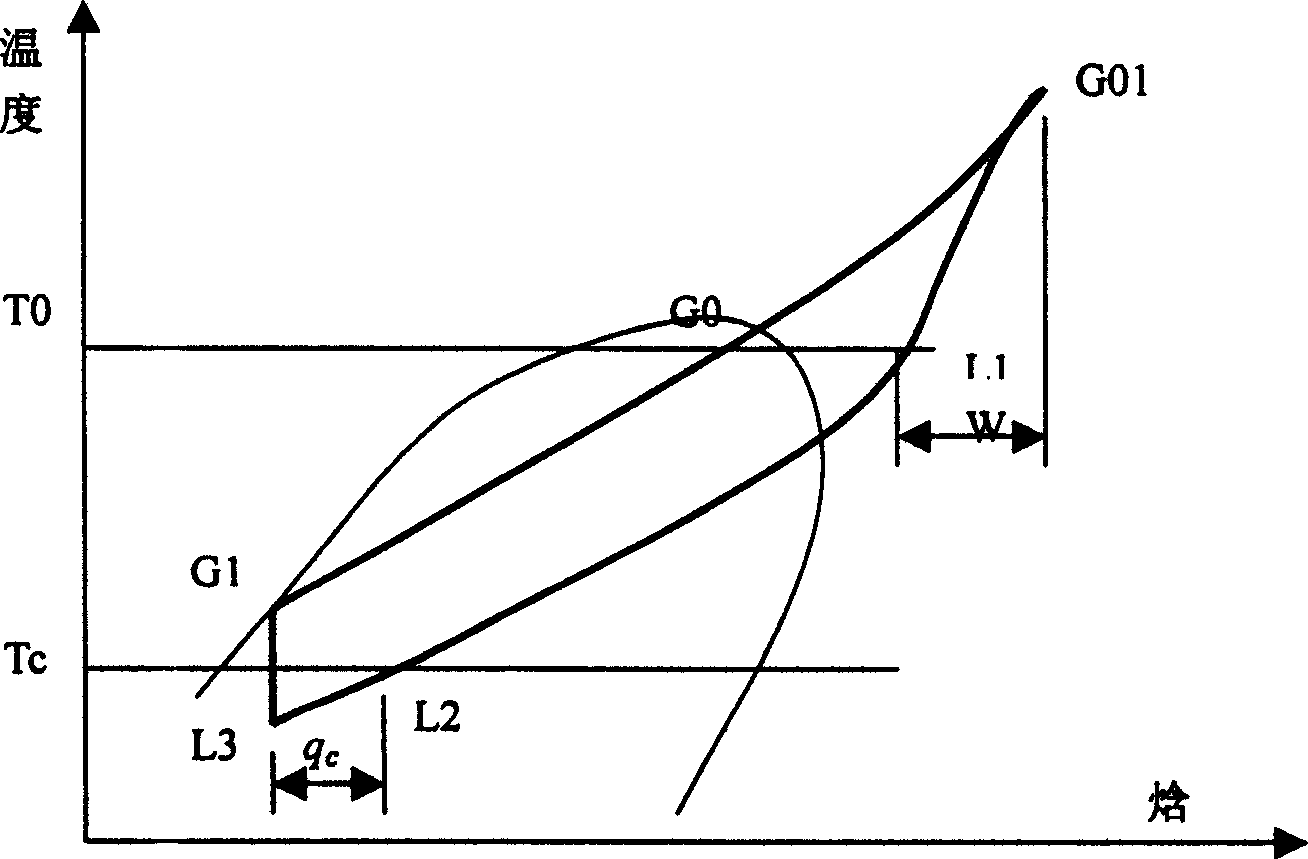

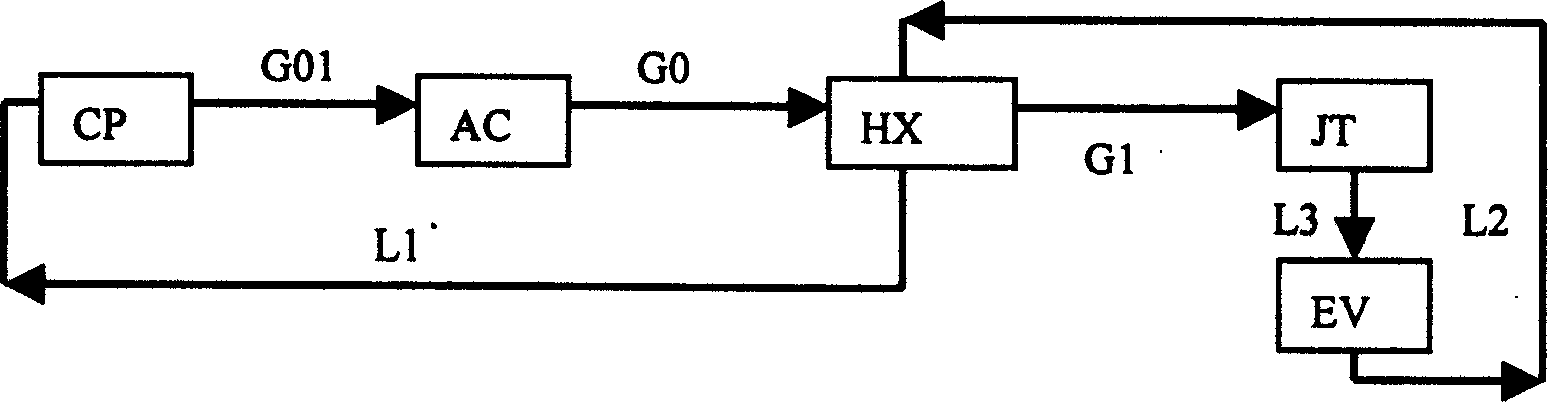

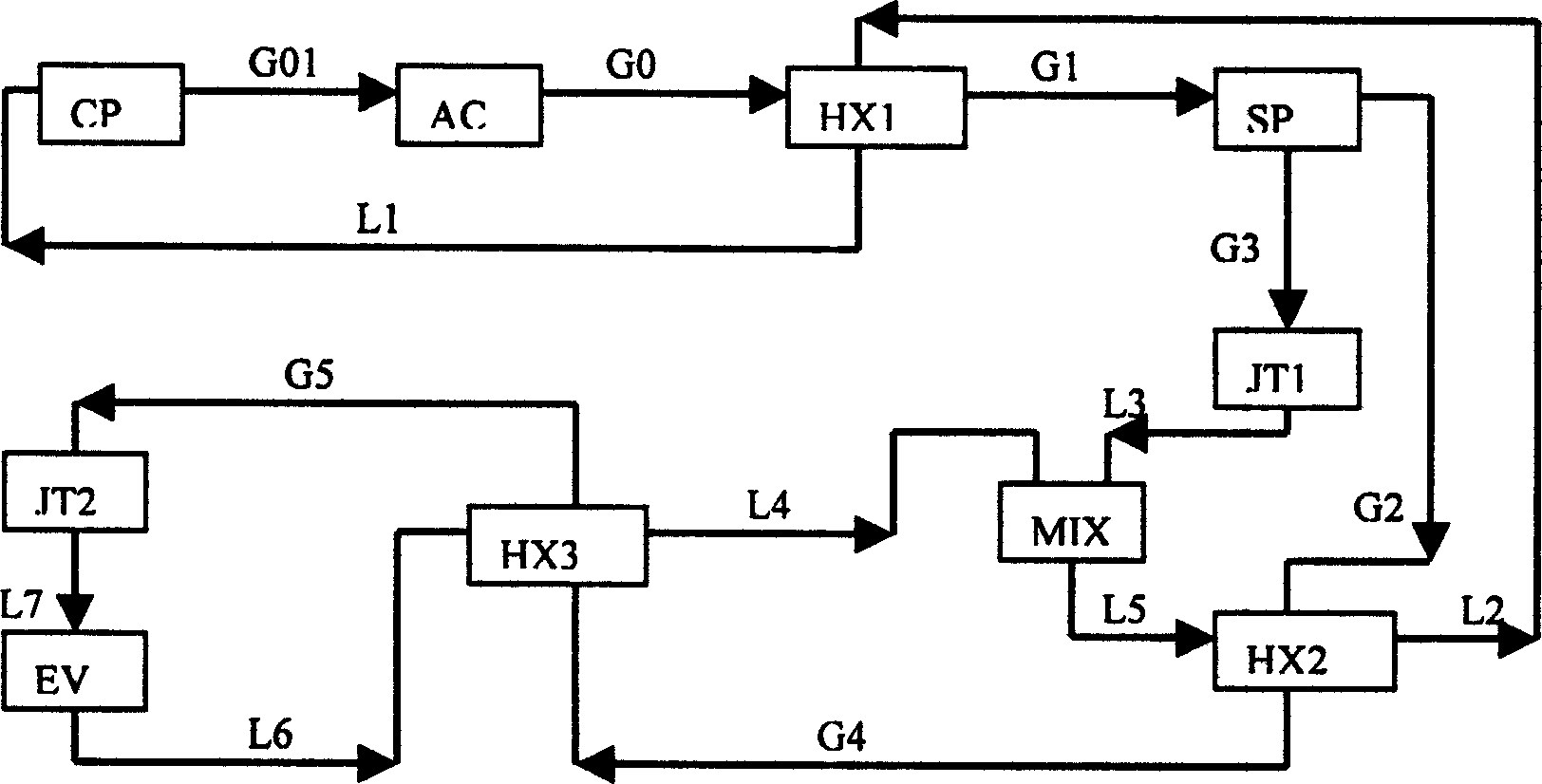

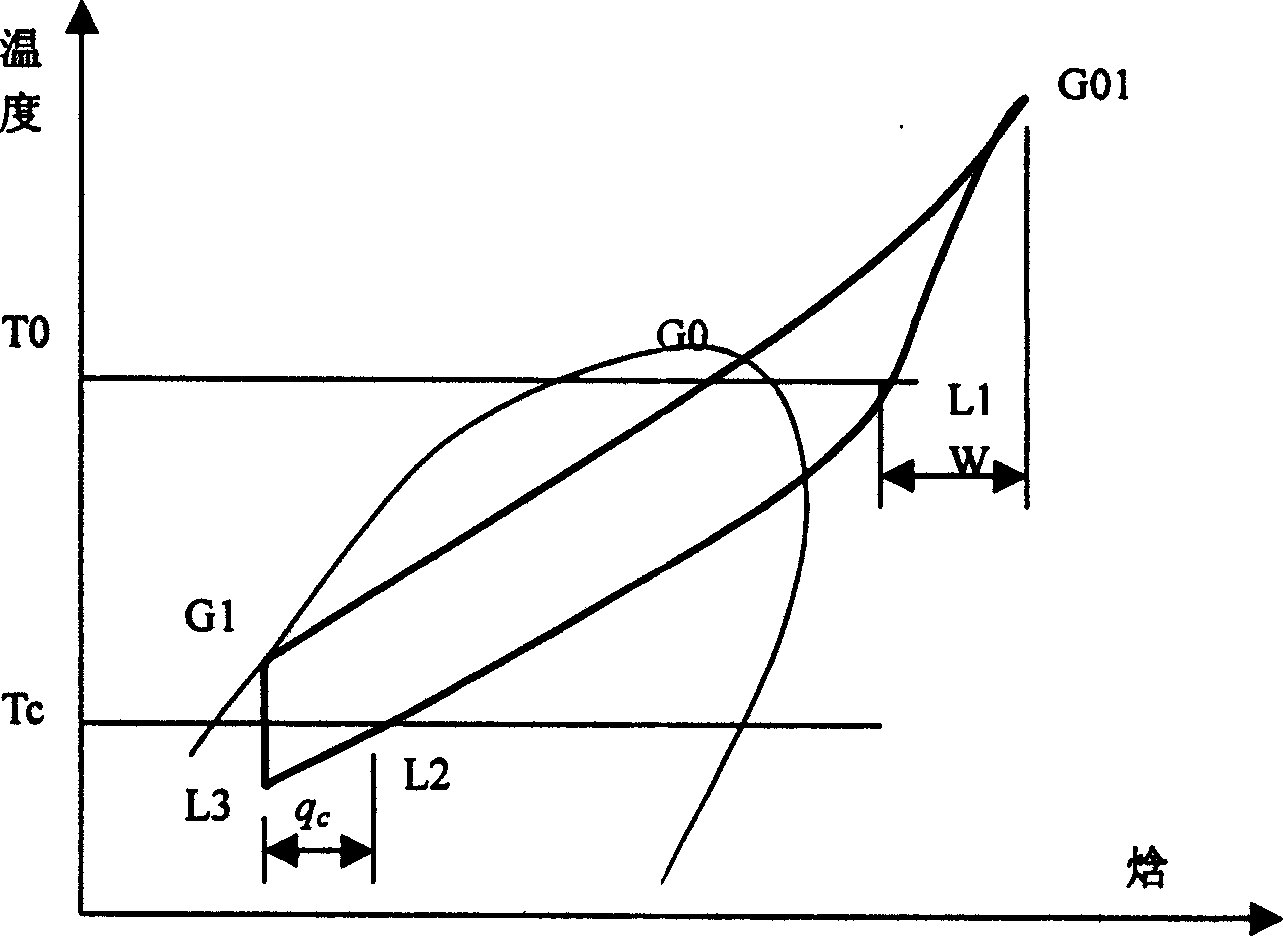

Multi-element mixed working substance adapted to double temperature preparation of single-unit vapor compression type refrigerator

The invention relates the multicomponent mixed working substance used for preparing dual-temperature by single-machine vapor compression refrigerator. The low temperature is between -60- -40Deg.C and the high temperature is between -25- 10Deg.C. The multicomponent mixed working substance comprises lower boiling working substance and high boiling working substance. The lower boiling working substance comprises tetrafluoromethane, ethylene, ethane, fluoroethylene, trifluoromethane, fluoromethane, hydrofluoeic ether, carbon dioxide, difluoromethane and penfluoroethane; the high boiling working substance comprises trifluoro-thane, hydrofluoeic ether, propylene, propane, perfluoropropylamine, propadiene, cyclopropane, difluo-monochloromethane, penta-monochloroethane, perfluoroethane, difluoroethane, isobutene, butane, butylenes, isobutylene, sevofluoropropane, hexafluoropropane, penfluoropropane and tetrachloromonofluoroethane.

Owner:XI AN JIAOTONG UNIV

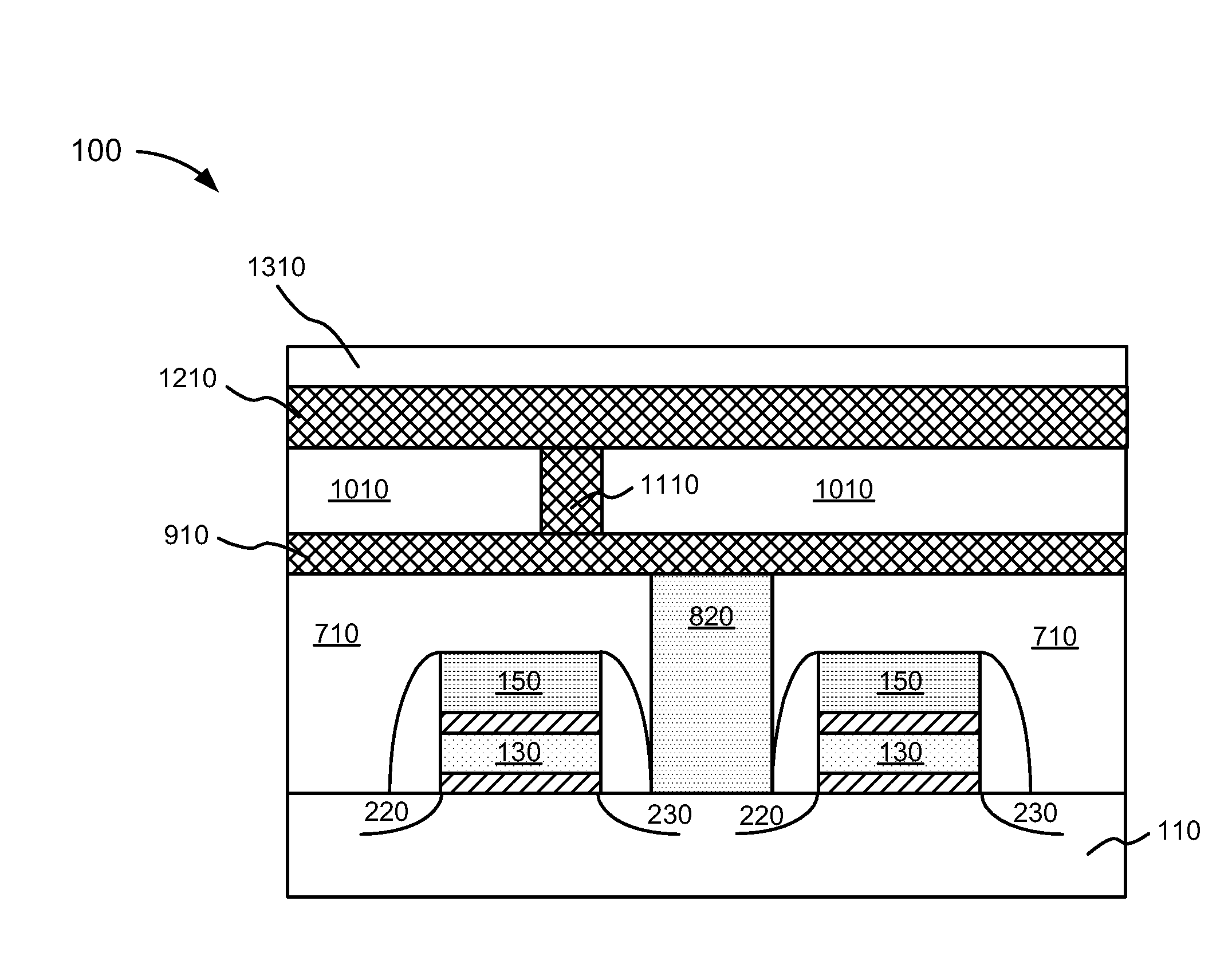

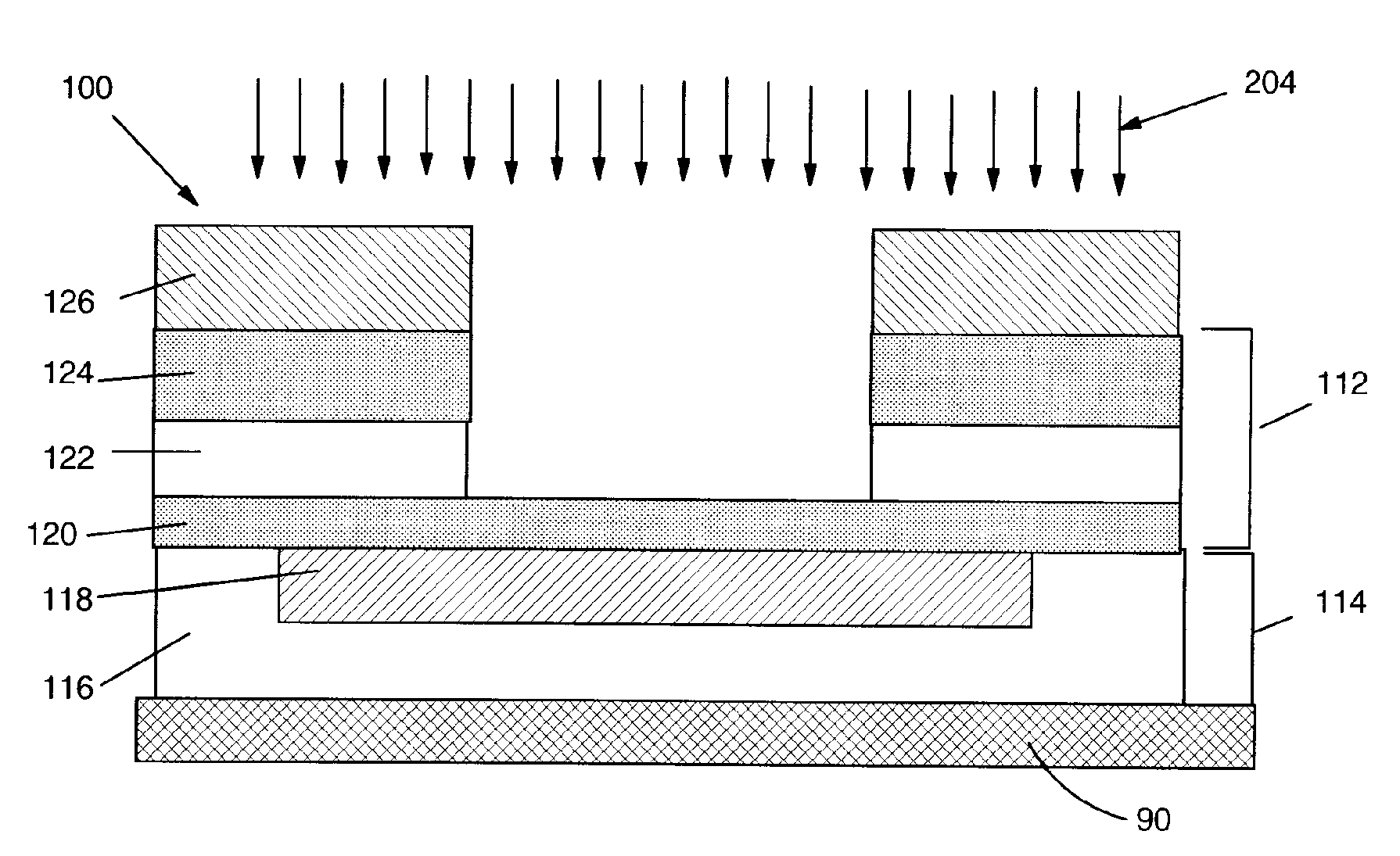

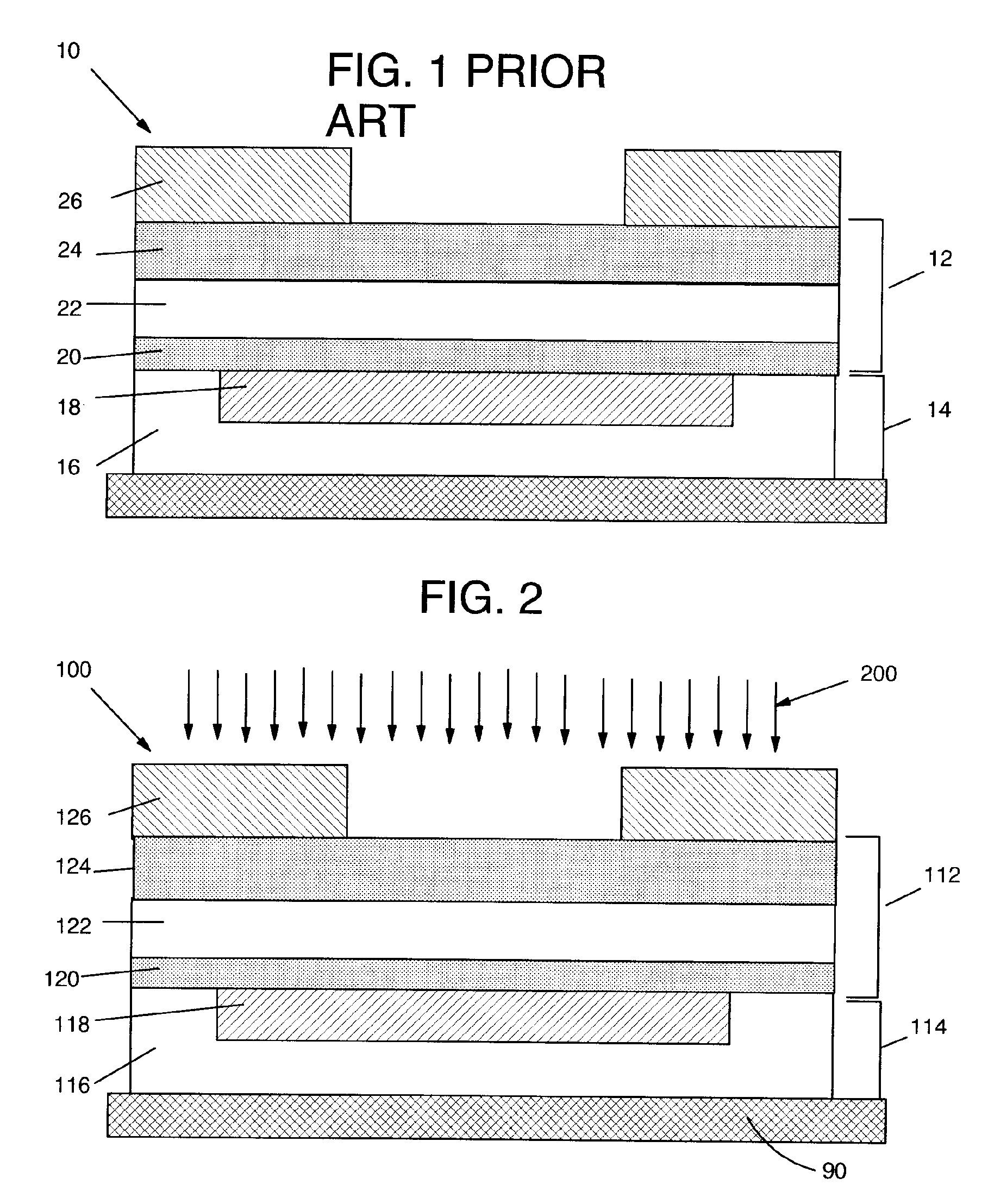

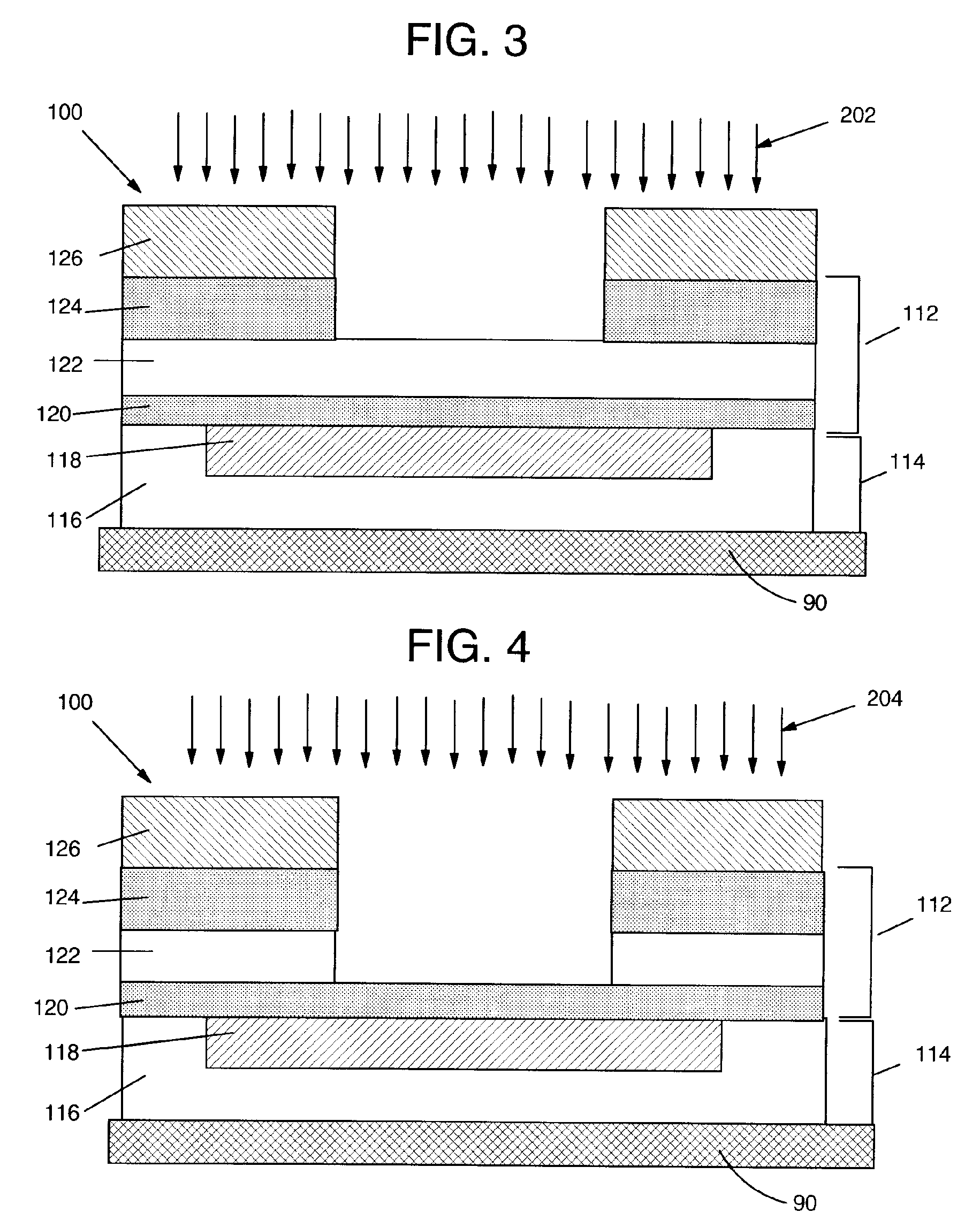

Memory device etch methods

ActiveUS20080153298A1Solid-state devicesSemiconductor/solid-state device manufacturingAnti-reflective coatingDevice form

A method of manufacturing a memory device forms a first dielectric layer over a substrate, forms a charge storage layer over the first dielectric layer, forms a second dielectric layer over the charge storage layer, and forms a control gate layer over the second dielectric layer. The method also forms a hard mask layer over the control gate layer, forms a bottom anti-reflective coating (BARC) layer over the hard mask layer, and provides an etch chemistry that includes tetrafluoromethane (CF4) and trifluoromethane (CHF3) to etch at least the control gate layer.

Owner:SPANSION LLC

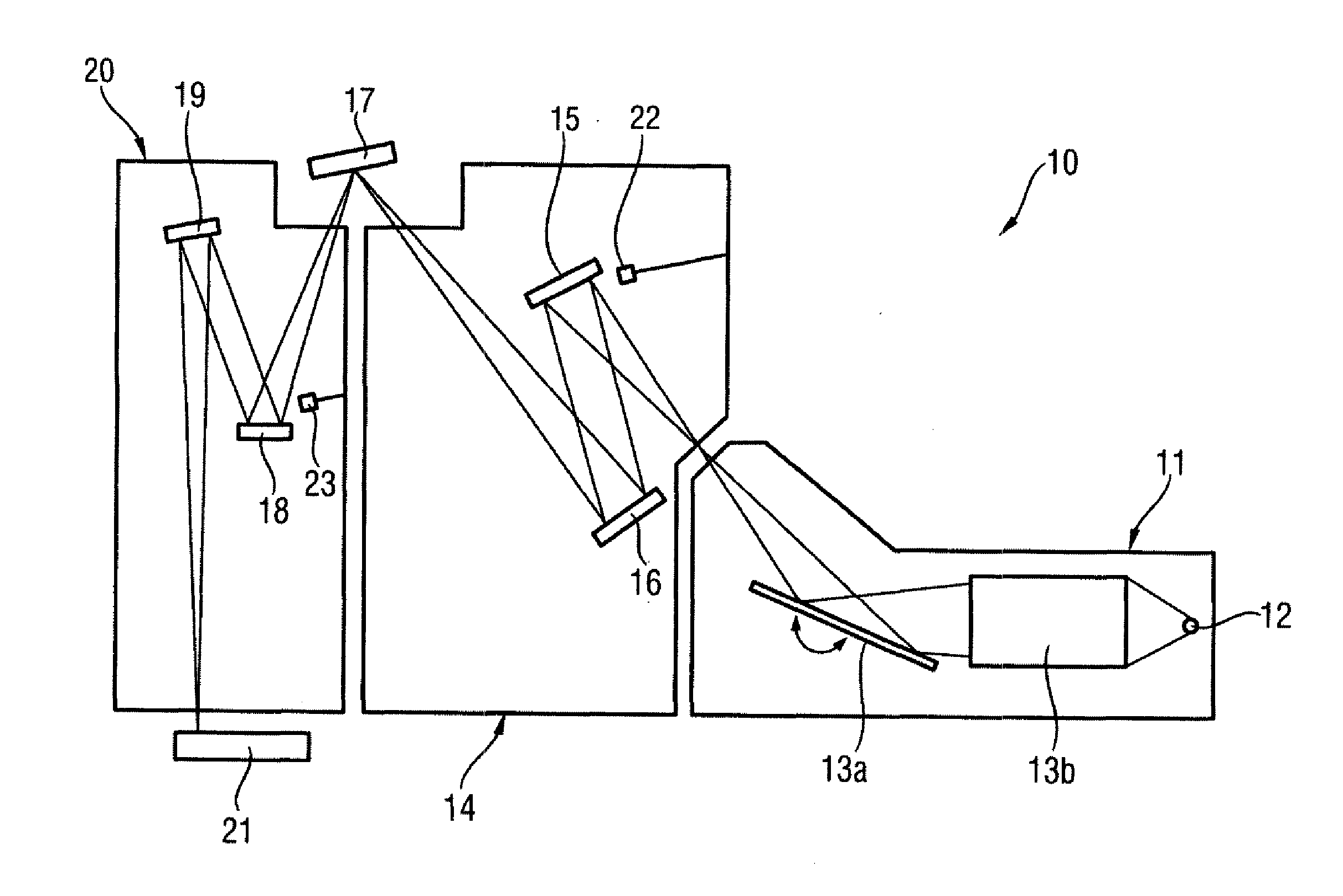

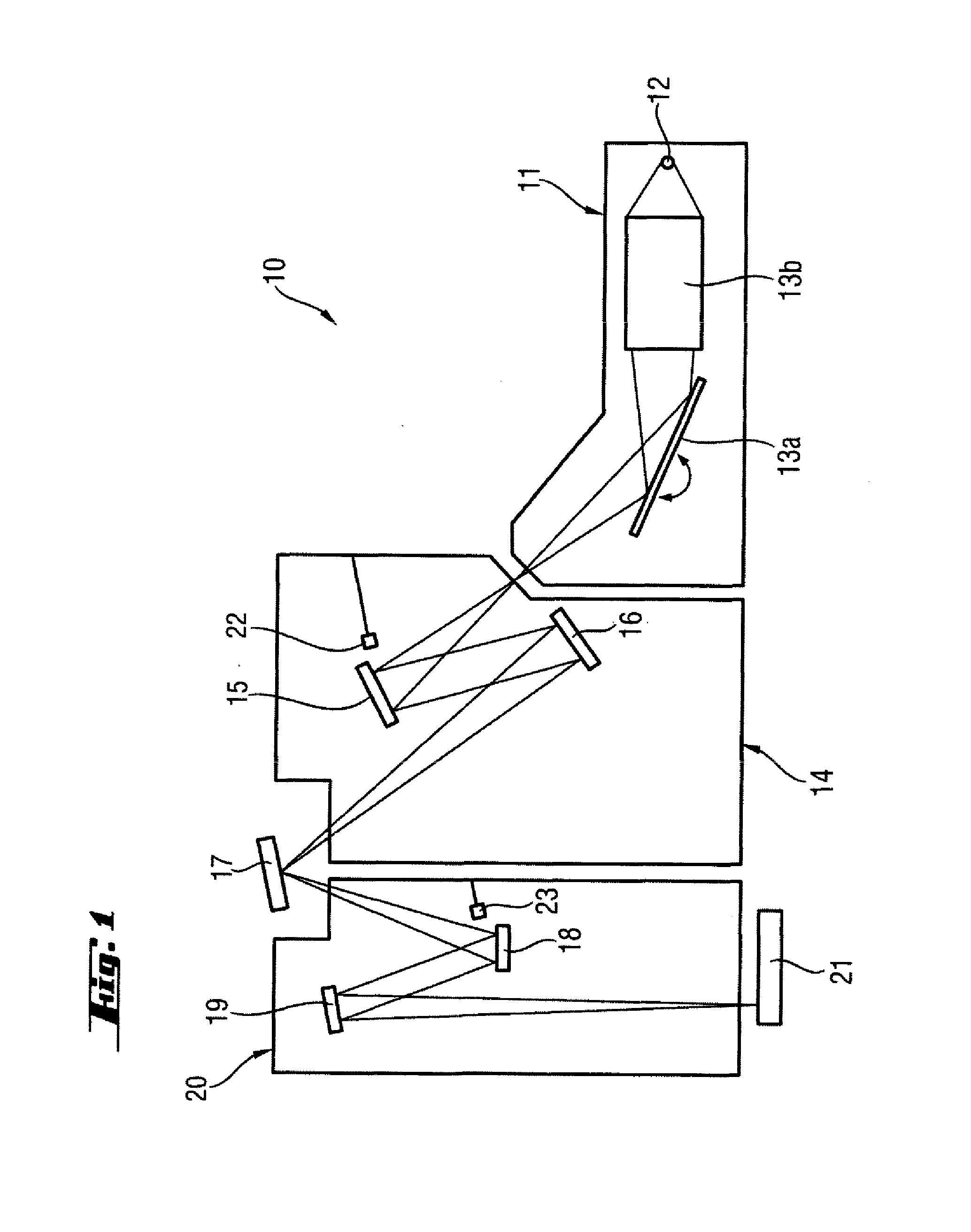

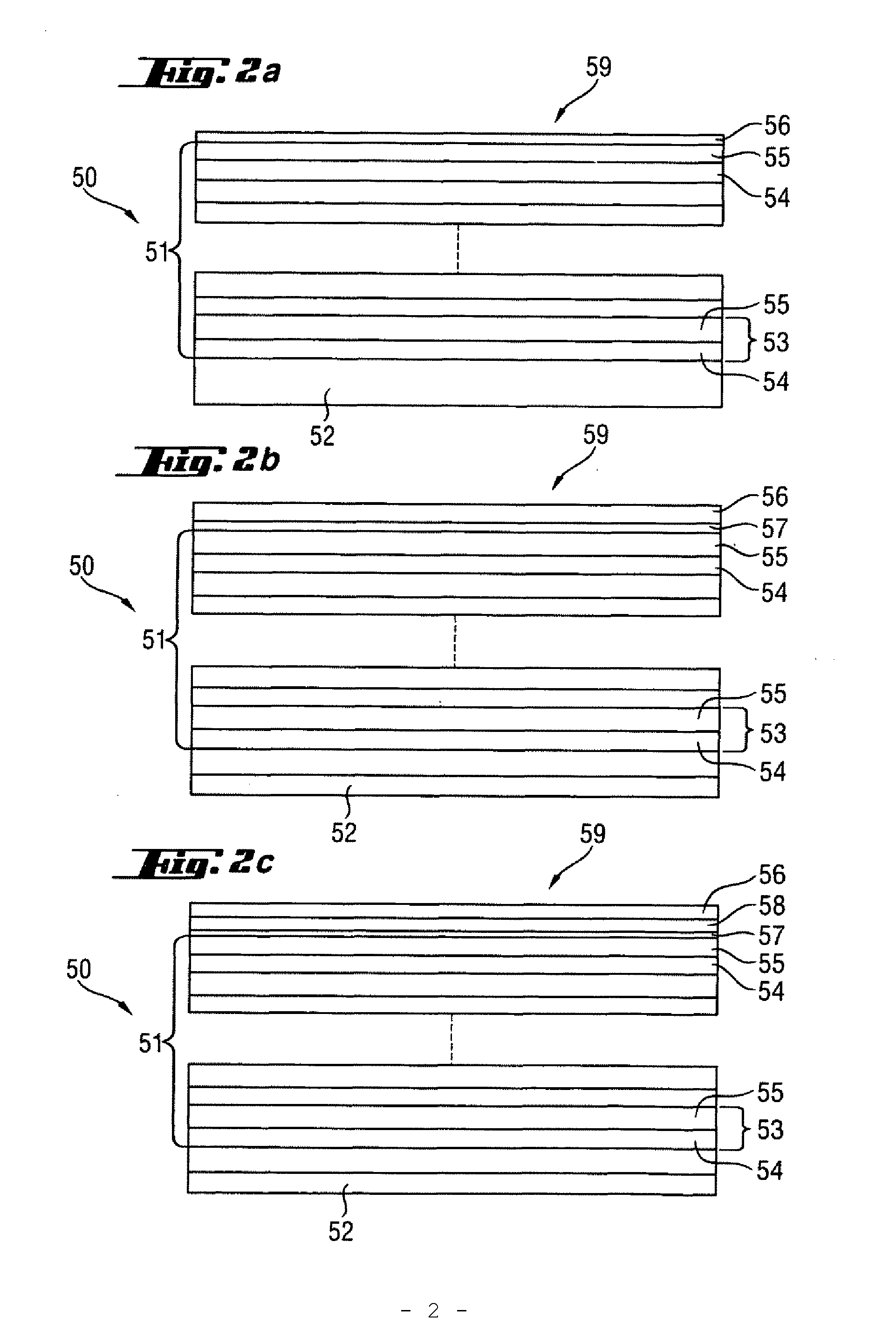

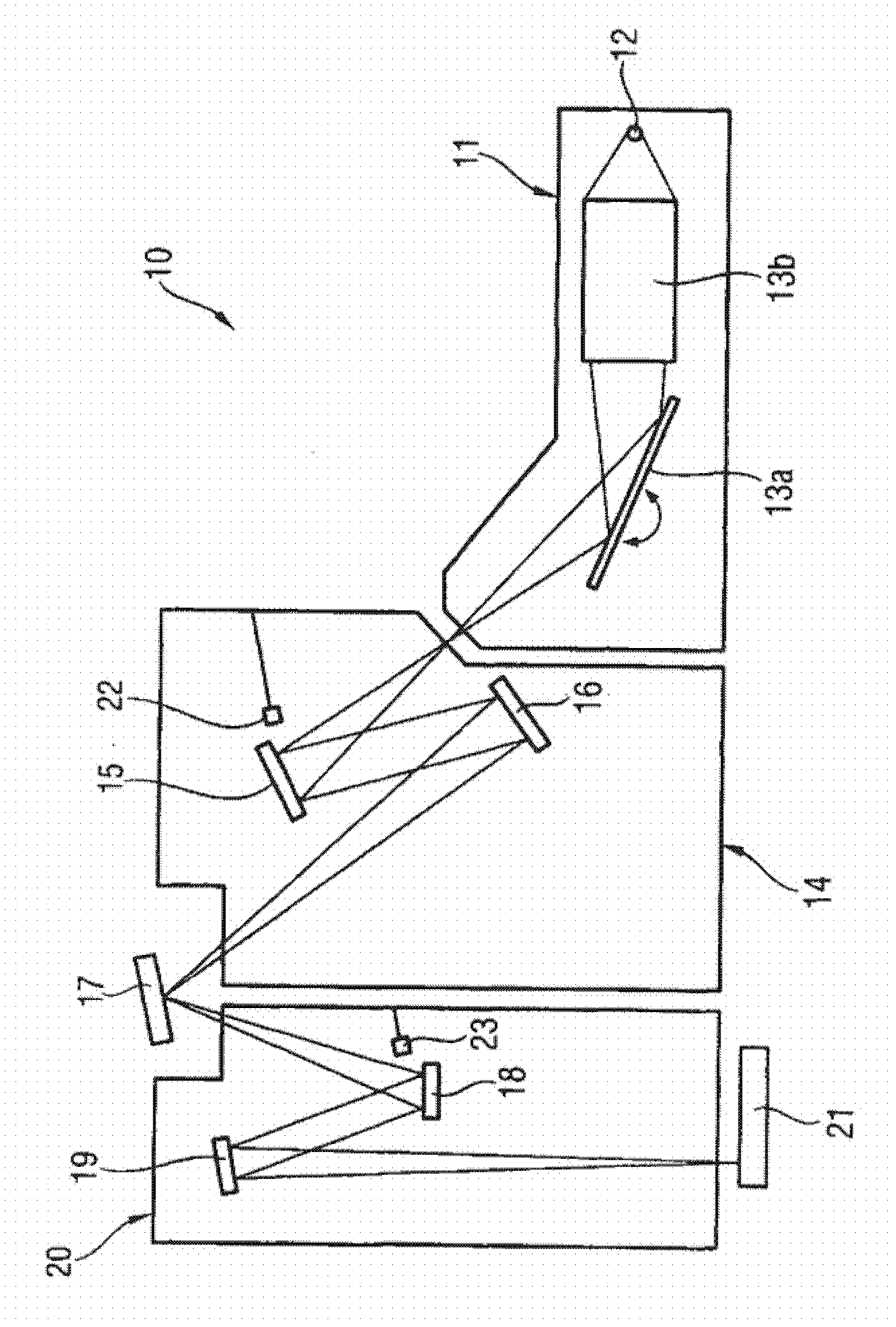

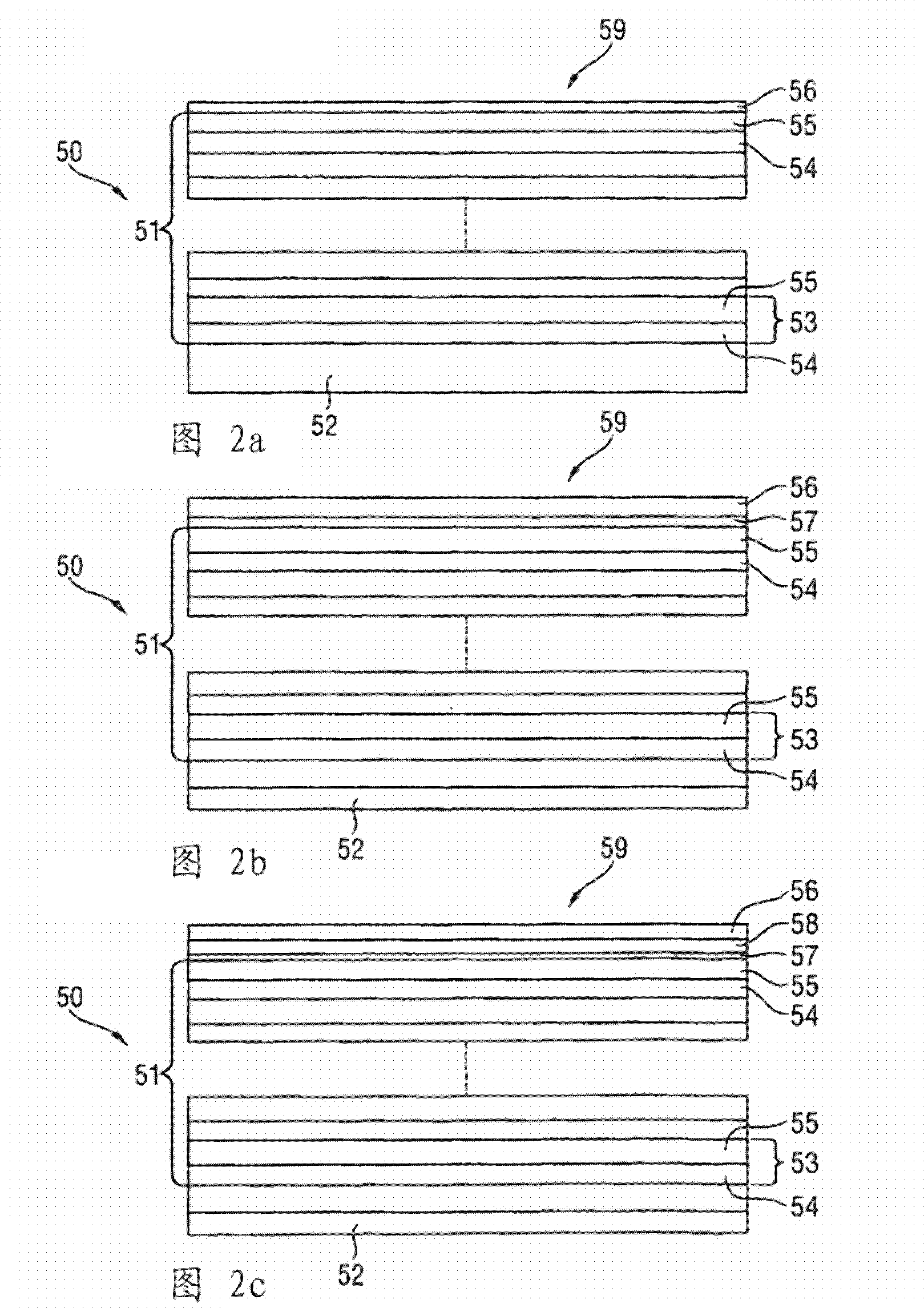

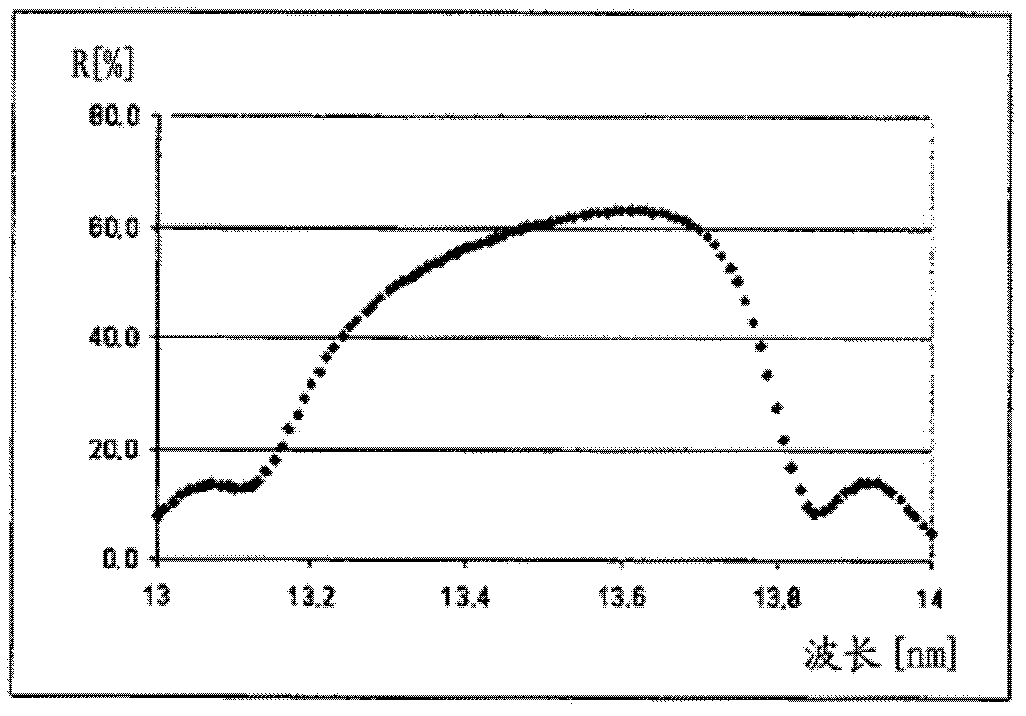

Reflective optical element and method for operating an EUV lithography apparatus

In order to reduce the adverse influence of contamination composed of silicon dioxide, hydrocarbons and / or metals within an EUV lithography apparatus on the reflectivity, a reflective optical element (50) for the extreme ultraviolet wavelength range having a reflective surface (59) is proposed, wherein the multilayer coating of the reflective surface (59) has a topmost layer (56) composed of a fluoride. The contaminations mentioned, which deposit on the reflective optical element (50) during the operation of the EUV lithography apparatus, are converted into volatile compounds by the addition of at least one of the substances mentioned hereinafter: atomic hydrogen, molecular hydrogen, perfluorinated alkanes such as e.g. tetrafluoromethane, oxygen, nitrogen and / or helium.

Owner:CARL ZEISS SMT GMBH

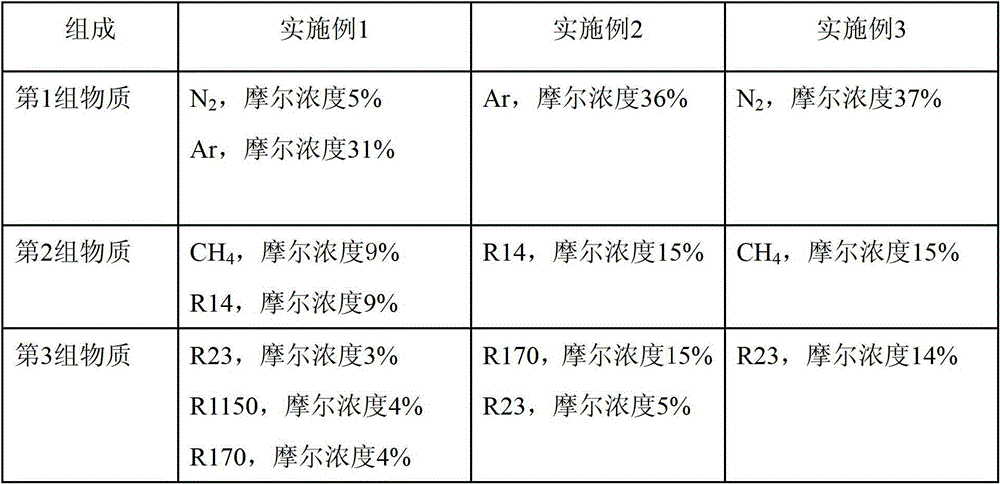

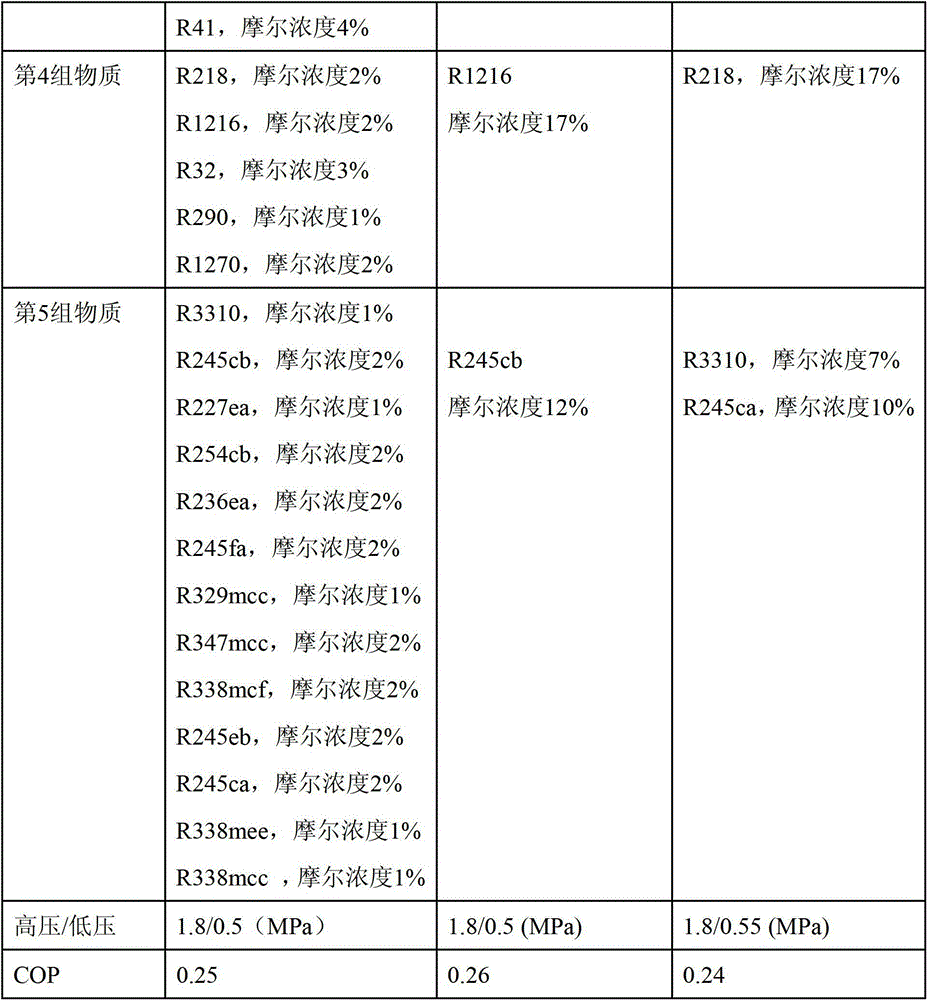

Multi-element mixed refrigerant suitable for cryogenic regions of -130 to -180 DEG C

ActiveCN102719226AIncrease concentrationReduce concentrationHeat-exchange elementsHexafluoropropylenePerfluorobutane

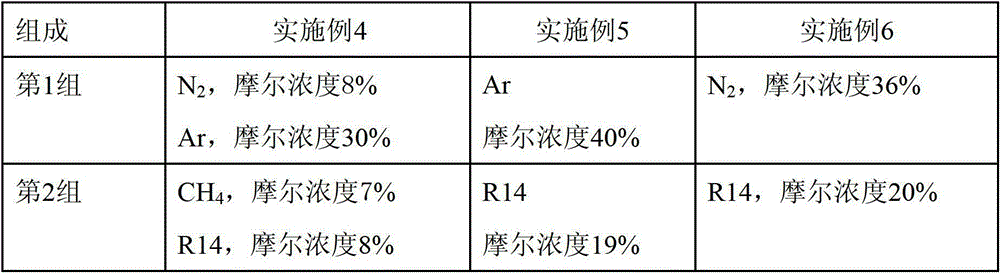

A multi-element mixed refrigerant suitable for cryogenic regions of -130 to -180 DEG C comprises five groups of substances: 1) the combination of at least two of nitrogen, argon, neon or alkyl; 2) tetrafluoromethane and methane or the combination thereof; 3) trifluoromethane, ethane, ethylene and fluoromethane or the combination of at least two thereof; 4) perfluoropropane, difluoromethane, propane, propylene and hexafluoropropylene or or the combination of at least two thereof; 5) 1,1,1,2,2-perfluoropropane, 1,1,1,2,3,3,3-heptafluoropropane, perfluoro-n-butane, 1,1,2,2-tetrafluoropropane, 1,1,1,2,3,3-hexafluoropropane, 1,1,1,3,3-perfluoropropane, 1,1,1,2,2,3,3,4,4-nonafluorobutane, 1,1,1,2,2,3,3-sevofluorobutane, 1,1,1,2,2,4,4,4-perfluorobutane, 1,1,2,3-perfluoropropane, 1,1,2,2,3-perfluoropropane, 1,1,1,2,3,4,4,4-perfluorobutane and 1,1,1,2,2,3,3,4-perfluorobutane or the combination of at least two thereof. The multi-element mixed refrigerant can achieve refrigeration of -130 to -180 DEG C safely and efficiently, the greenhouse effect is low and no ozone layer is destroyed.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Non-combustible mixing refrigerant suitable for deep refrigeration temperature of minus 80 DEG C to minus 100 DEG C

ActiveCN102559146ANo destructive effectNon-flammableHeat-exchange elementsHexafluoroethanePolymer science

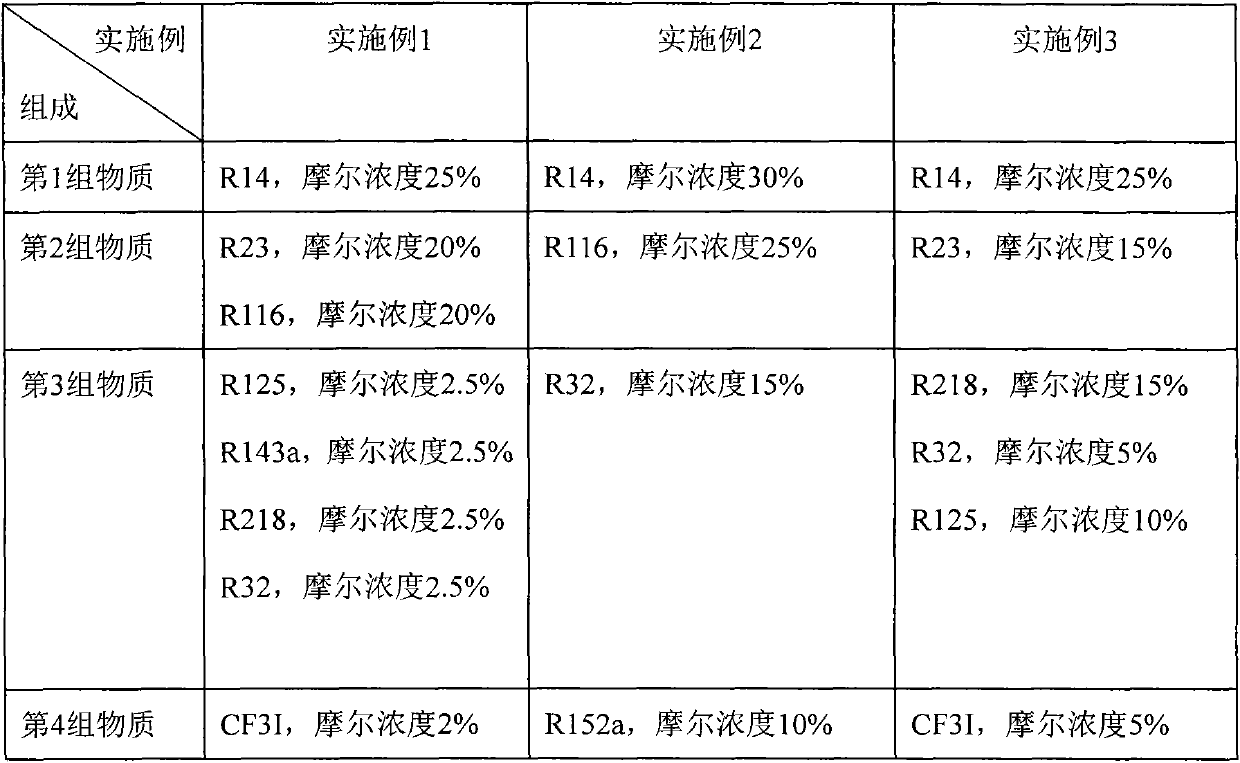

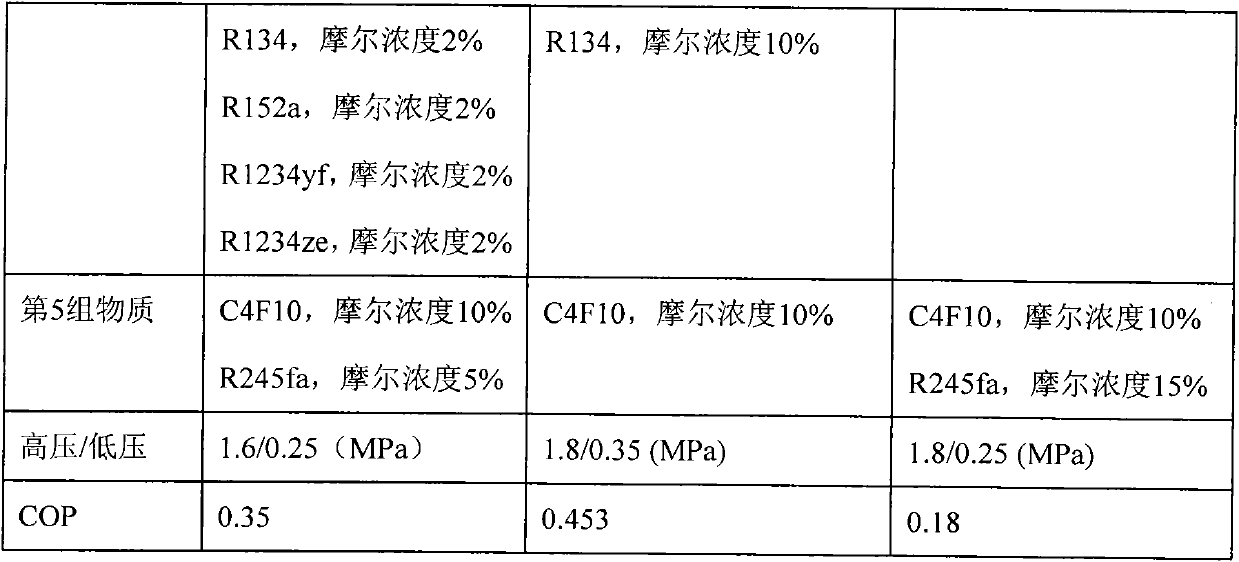

The invention relates to a non-combustible mixing refrigerant suitable for deep refrigeration temperature of minus 80 DEG C to minus 100 DEG C. The non-combustible mixing refrigerant comprises five groups of materials, where the first group of material is tetrafluoromethane; the second group of material is trifluoromethane, hexafluoroethane or a mixture of the trifluoromethane and the hexafluoroethane; the third group of material is pentafluoroethane, trifluoroethane, perfluoropropane, difluoromethane or a mixture of two, three or multiple of the pentafluoroethane, the trifluoroethane, the perfluoropropane and the difluoromethane; the fourth group of material is iodotrifluoromethane, 1, 1, 2, 2-tetrafluoroethane, 1,1-difluoroethane, 2, 3, 3, 3-tetrafluoropropene, 1, 3, 3, 3-tetrafluoropropene or a mixture of two, three or multiple of the iodotrifluoromethane, the 1, 1, 2, 2-tetrafluoroethane, the 1,1-difluoroethane, the 2, 3, 3, 3-tetrafluoropropene and the 1, 3, 3, 3-tetrafluoropropene; the fifth group of material is perfluoro-n-butane, 1, 1, 1, 3, 3-perfluoropropane or a mixture of the perfluoro-n-butane and the 1, 1, 1, 3, 3-perfluoropropane; the molar concentrations of the five groups of materials are respectively 25-50%, 15-40%, 10-30%, 5-20% and 10-25%; and the non-combustible mixing refrigerant is safe in a back-heating type throttling refrigeration system, can realize the refrigeration in the temperature range of minus 80 DEG C to minus 100 DEG C and has low whole green house effect without ozone depletion effect.

Owner:中科赛凌(北京)科技有限公司

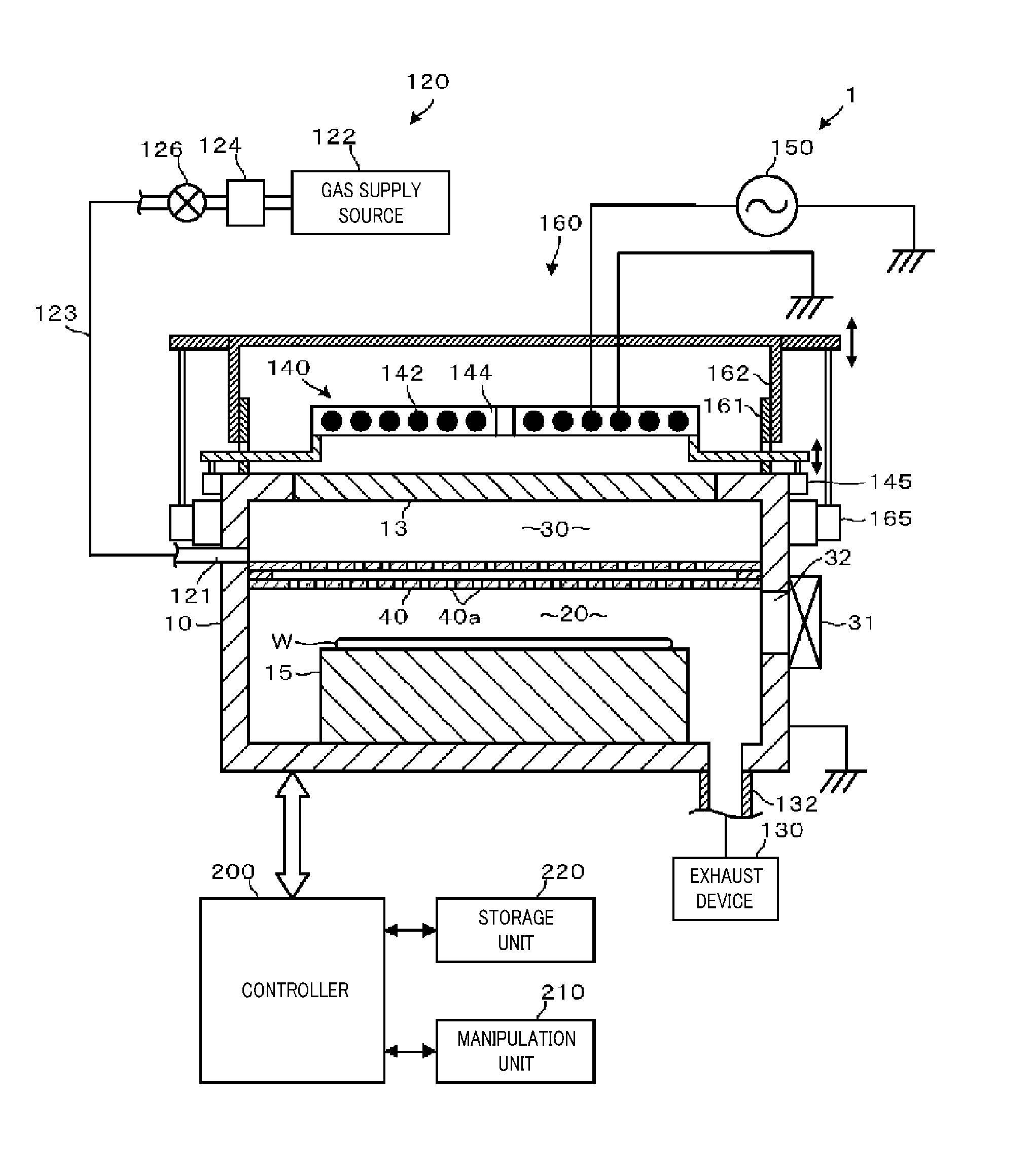

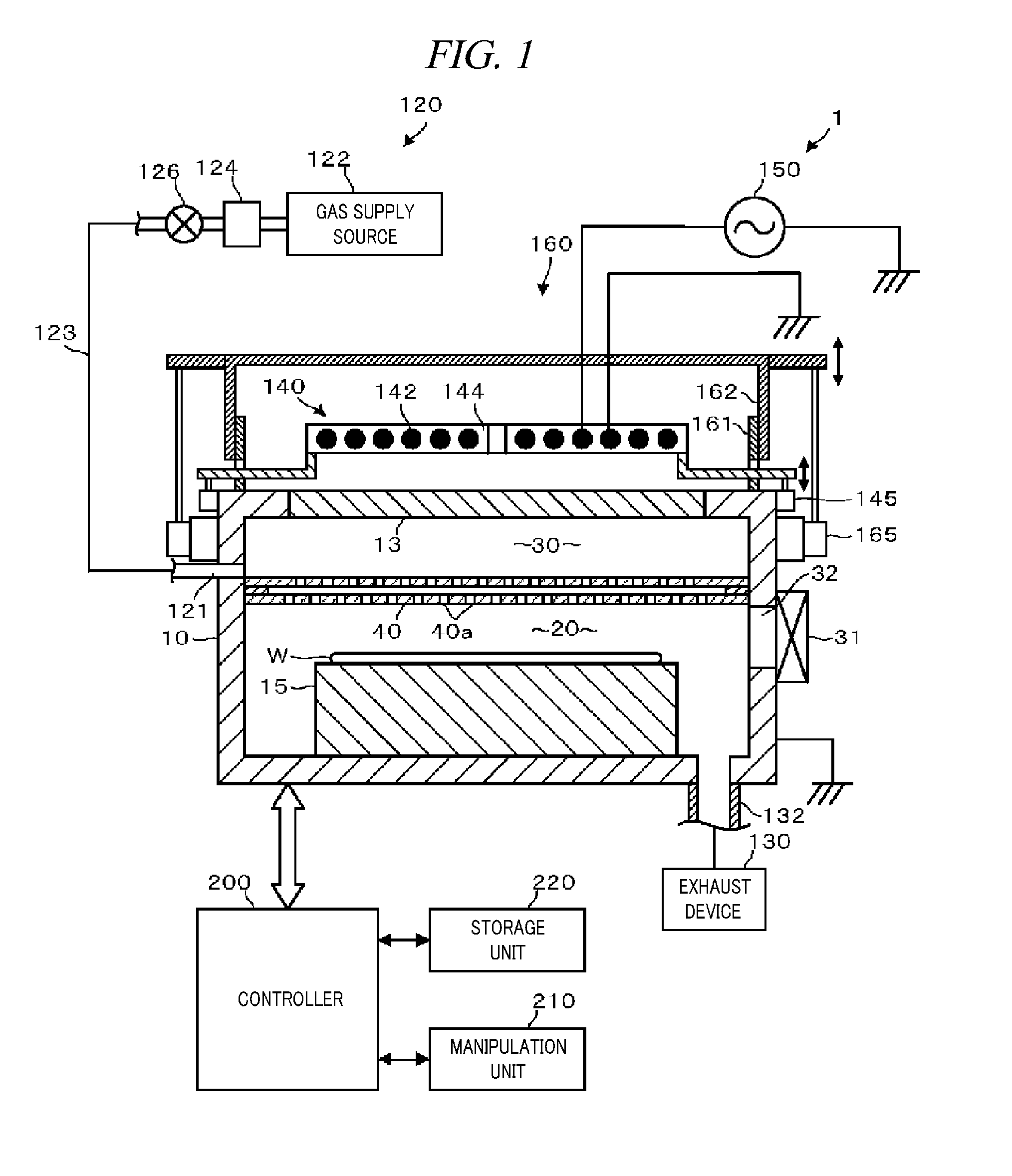

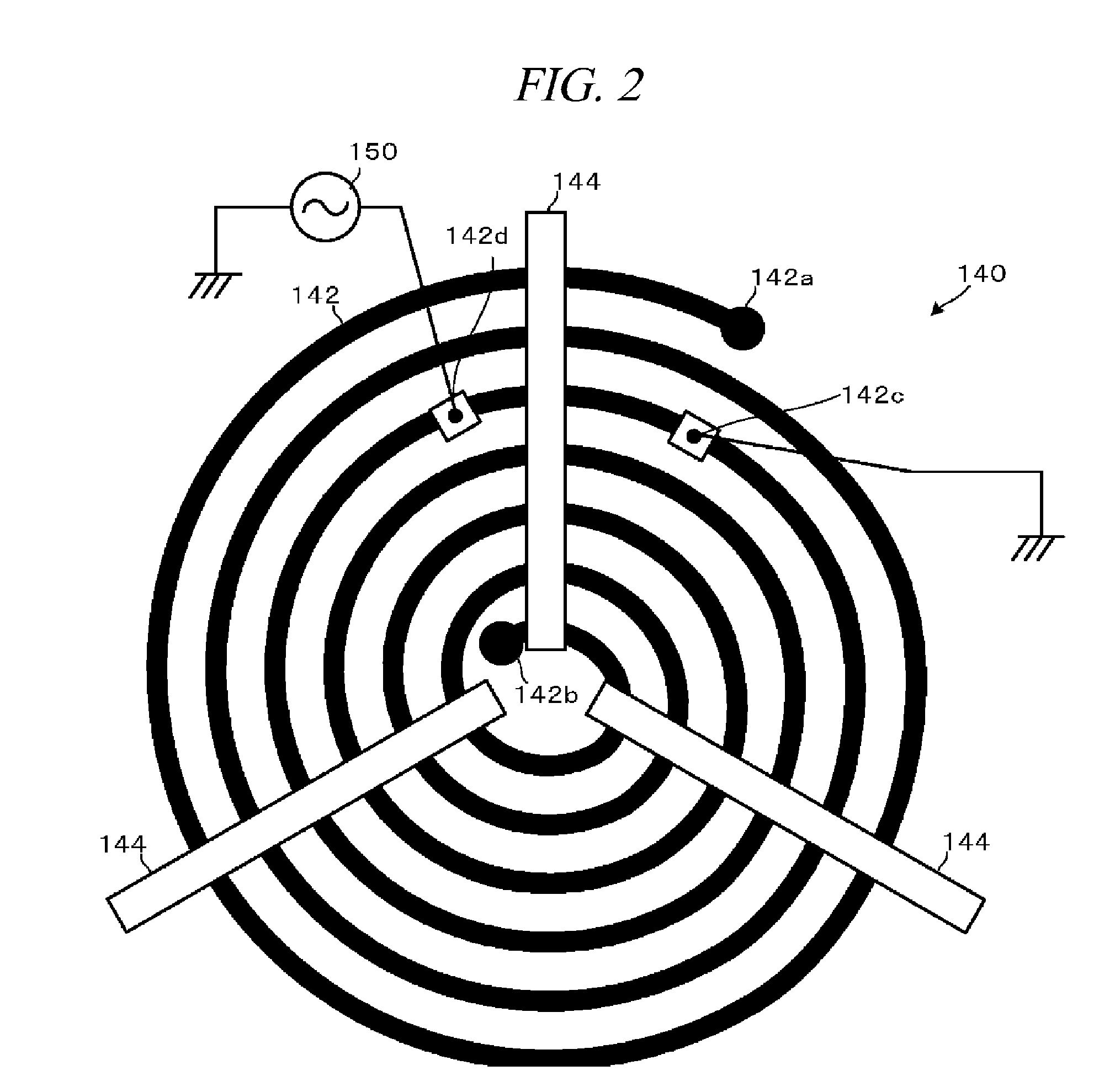

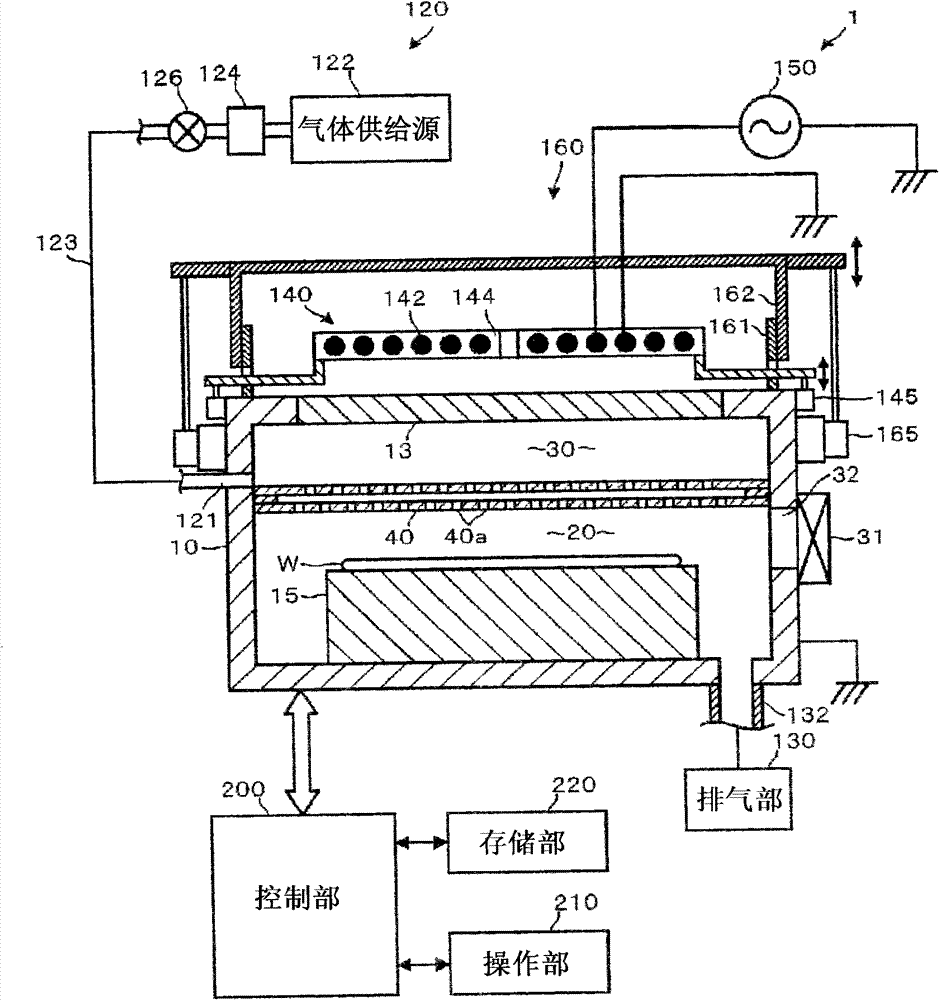

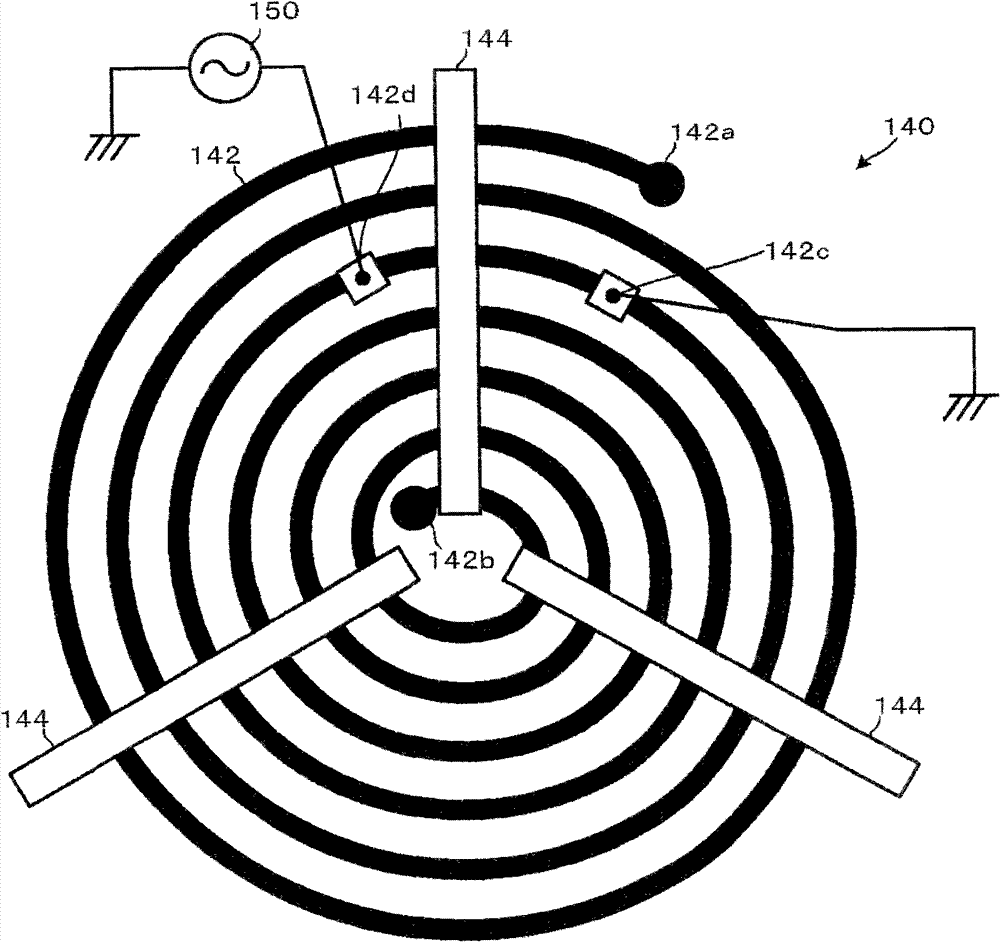

Cleaning method of plasma processing apparatus and plasma processing method

InactiveUS20120270406A1Electric discharge tubesElectrostatic cleaningTetrafluoromethanePlasma processing

A plasma processing apparatus in which a cleaning method is performed includes a plasma generating chamber, having a silicon-containing member, for generating therein plasma by exciting a processing gas; a plasma processing chamber communicating with the plasma generating chamber via a partition member; and a high frequency antenna, having a planar shape, provided at an outside of a dielectric window of the plasma generating chamber. The cleaning method includes exciting a hydrogen-containing processing gas into plasma in the plasma generating chamber, introducing hydrogen radicals in the plasma into the plasma processing chamber through the partition member, performing a plasma process on a processing target substrate by allowing the hydrogen radicals to act on the processing target substrate, unloading the processing target substrate, and removing silicon-based deposits generated in the plasma generating chamber by introducing a tetrafluoride (tetrafluoromethane) gas into the plasma generating chamber.

Owner:TOKYO ELECTRON LTD

Multicomponent mixed work medium throttling refrigerant applicable to 200-204K refrigerating temperature zone

The multicomponent mixed work medium throttling refrigerating agent applicable to 200-240 k temp. zone includes four groups of substances, respectively are: first group includes tetrafluoromethane, nitrogen trifluoride or mixture; second group includes ethylene, ethane, fluoroform, xenon, fluromethane, perfluoroethylene, fluoroethylene, perfluoroethane or their any two, three and several kinds or mixture of all them; fourth group includes 1-butylene, isobutane, 2-methyl butane, 1-pentene, 3-methyl-1-butylene, 2-methylpentane, 2-butylene, cyclobutane, isobutylene, n-butane, pefluorobutane, n-pentane, perfluoropentane or their two, three, several kinds ormixture of all the them; and third group includees propylene, propane, perfluoropropane, 1,1,1-trifluoroethane, 1,1,-bifluoroethane.

Owner:中科赛凌(北京)科技有限公司

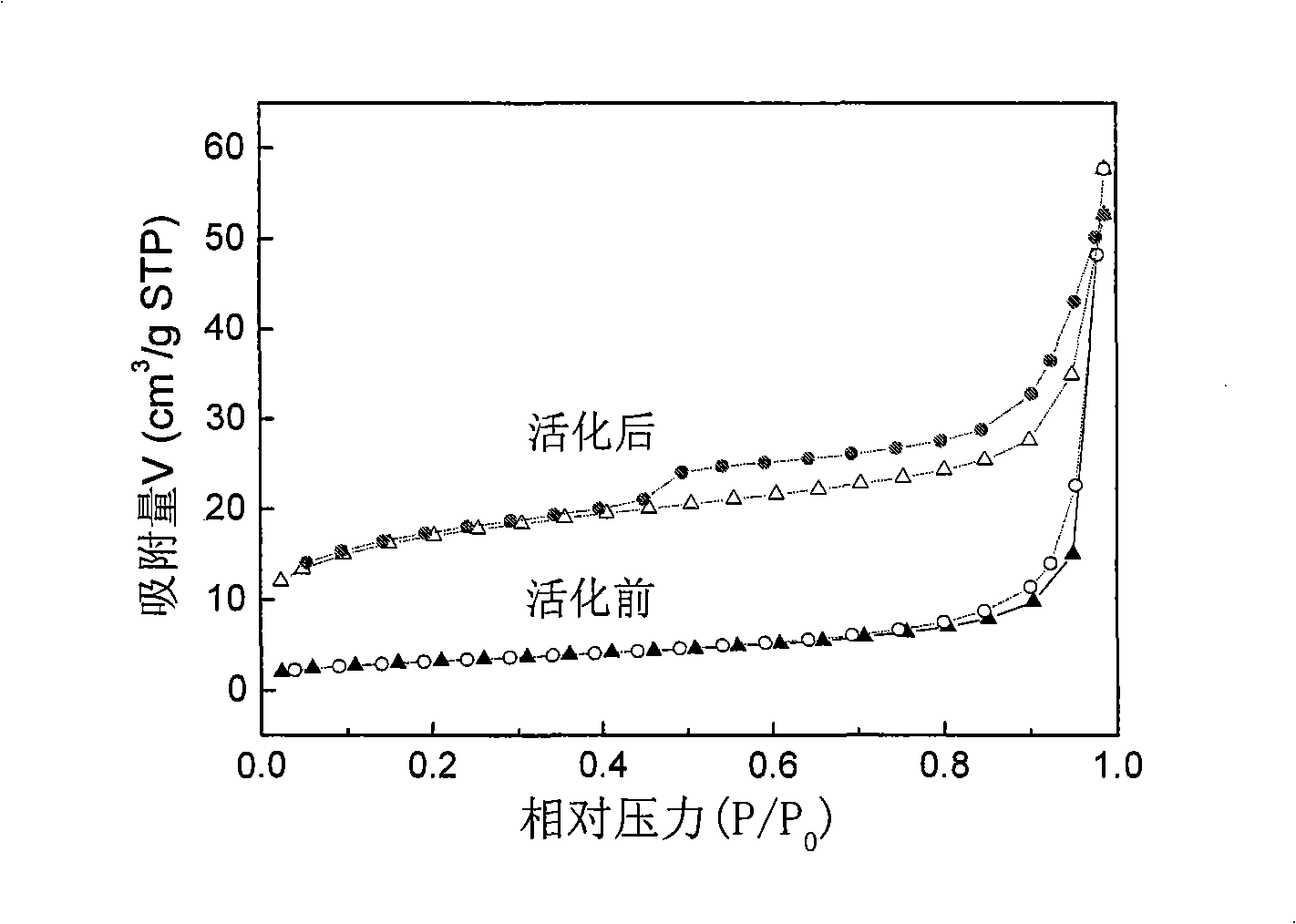

Catalyst for producing tetrafluoromethane with gas-phase fluoridation and production method

InactiveCN101269323AEasy to operateThe method of operation is quickPreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsIndiumGas phase

The invention relates to a catalyst used for making tetrafluoromethane through gas-phase fluorination and a preparation method thereof, and aims at providing a catalyst used for making tetrafluoromethane through gas-phase fluorination characterized by high activity and high stability and a preparation method thereof in consideration of poor activity and low stability existing in the existing gas-phase fluorination catalyst. The preparation method of the catalyst of the invention is as follows: one or more than one compound of Y, compound of Cr, compound of magnesium, aluminum, indium, gallium, zinc, scandium, strontium, iron, cobalt, nickel and cadmium are measured according to a certain proportion; the precipitator adopts one among ammonia, sodium hydroxide, ammonium carbonate, sodium carbonate and potassium hydroxide, and sediments are obtained by a coprecipitation method, and the precursor of the catalyst is obtained by baking and roasting the sediments then the catalyst is obtained after being treated with anhydrous hydrogen fluoride.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

Silicon nitride etching methods

ActiveUS20060252269A1Reduce bias voltageSemiconductor/solid-state device manufacturingSulfur hexafluorideOctafluorocyclobutane

Methods of etching silicon nitride material, and more particularly, etching nitride selective to silicon dioxide or silicide, are disclosed. The methods include exposing a substrate having silicon nitride thereon to a plasma including at least one fluorohydrocarbon and a non-carbon containing fluorine source such as sulfur hexafluoride (SF6). The plasma may also include oxygen (O2) and the fluorohydrocarbons may include at least one of: trifluoromethane (CHF3), difluoromethane (CH2F2), and methyl fluoride (CH3F). In an alternative embodiment, the plasma includes one of hydrogen (H2) and nitrogen trifluoride (NF3) and one of tetrafluoromethane (CF4) and octafluorocyclobutane (C4F8). The methods are preferably carried out using a low bias voltage, e.g. <100 V.

Owner:IBM CORP +1

Cleaning method of plasma processing apparatus and plasma processing method

InactiveCN102737948APrevent adhesionElectric discharge tubesSemiconductor/solid-state device manufacturingCleaning methodsEngineering

The invention provides a plasma processing method and a cleaning method of a plasma processing apparatus, capable of preventing particles generated from a silicon-containing member for forming a plasma generating chamber from adhering to a processing target substrate. The plasma processing apparatus in which a cleaning method is performed includes a plasma generating chamber, having a silicon-containing member, for generating therein plasma by exciting a processing gas; a plasma processing chamber communicating with the plasma generating chamber via a partition member; and a high frequency antenna, having a planar shape, provided at an outside of a dielectric window of the plasma generating chamber. The cleaning method includes exciting a hydrogen-containing processing gas into plasma in the plasma generating chamber, introducing hydrogen radicals in the plasma into the plasma processing chamber through the partition member, performing a plasma process on a processing target substrate by allowing the hydrogen radicals to act on the processing target substrate, unloading the processing target substrate, and removing silicon-based deposits generated in the plasma generating chamber by introducing a tetrafluoride (tetrafluoromethane) gas into the plasma generating chamber.

Owner:TOKYO ELECTRON LTD

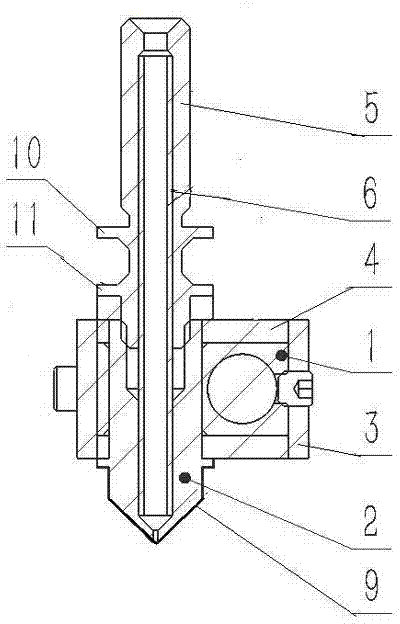

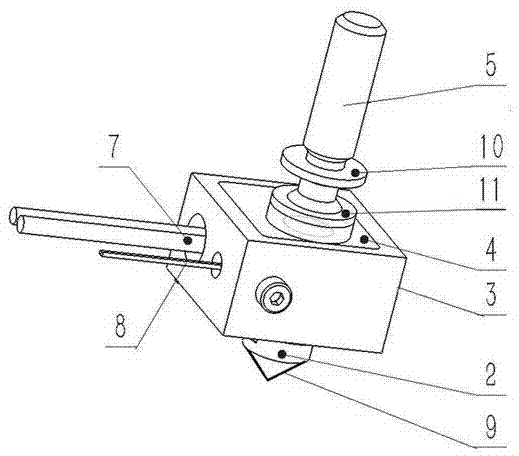

Extruding head of FDM 3D printer

InactiveCN104760289ANot easy to stickNot easy to fall offAdditive manufacturing apparatusTetrafluoromethane3d printer

The invention discloses an extruding head of an FDM 3D printer. The extruding head comprises a heating block, a brass nozzle (2), a stainless steel choke (5), a tetrafluoromethane liner pipe (6), a single-head heating pipe (7) and a temperature sensor (8), and further comprises tetrafluoromethane thermal-insulating housings (3 and 4), wherein the heating block is a brass heating block (1), the tetrafluoromethane thermal-insulating housings are arranged outside the brass heating block, a tetrafluoromethane anti-sticking and anti-oxidizing layer (9) is additionally arranged on the outer surface of the brass nozzle (2), so that the brass nozzle is not oxidized, without sticking an extruded material, a limit flange (10) is arranged in the middle of the stainless steel choke (5), the tetrafluoromethane liner pipe extends into the brass nozzle (2) and penetrates through the inside of the stainless steel choke (5) with the limiting flange and the inside of the brass nozzle (2), so that no gap exists in the tetrafluoromethane liner pipe at the connecting part of the stainless steel choke (5) and the brass nozzle (2) to prevent the extruded material from leaking. The extruding head has the advantages of stable performance, stability and durability, no leakage and sticking, no blockage, good printing effect, and the like.

Owner:梁智明

Multicomponent mixed work medium throttling refrigerant applicable to medium-low temperature zone

The multicomponent mixed work medium throttling refrigerating agent applicable to medium-low temp. zone includes five groups of substances, the sum of their mole concentration is 100%, in which first group includes methane, krypton or mixture, total mole concentration is 5%-45%, second group includes tetrafluoromethane, nitrogen trifluoride or mixture, total mole concentration is 15%-55%; fourth group includes propylene, propane, perfluoropane, 1,1,1-trifluoroethane, 1,1-bifluoroethane, fluoroethane, propadiene, cyclopropane, or mixture, total mole concentration is 5%-25%; fifth group includes 1-butylene, isobutane, 2-methylbutane, 1-pentene, 3-methyl-1-butylene, 2-methylpentane, 2-butylene, isobutylene, n-butane, perfluorobutane, n-pentane or mixture, total mole concentration is 5%-25%.

Owner:中科赛凌(北京)科技有限公司

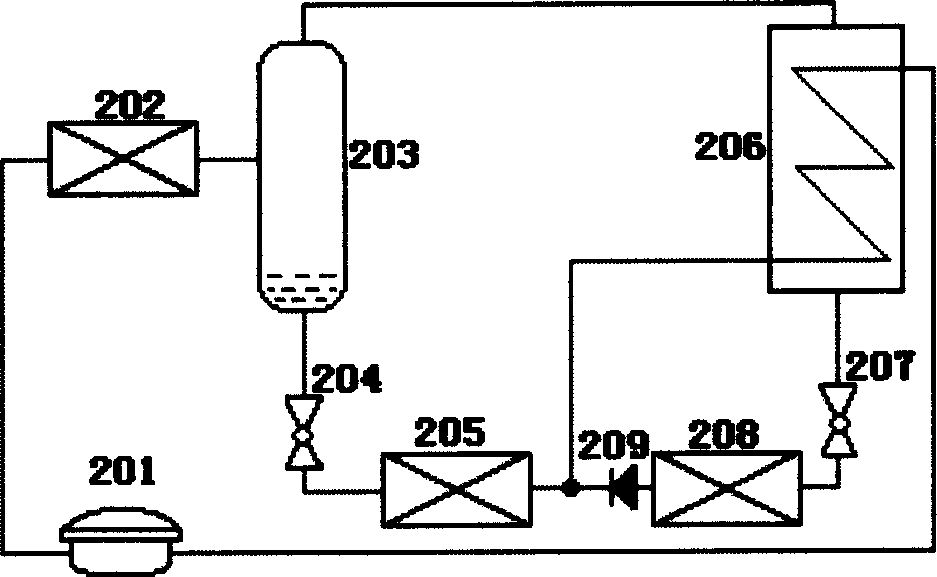

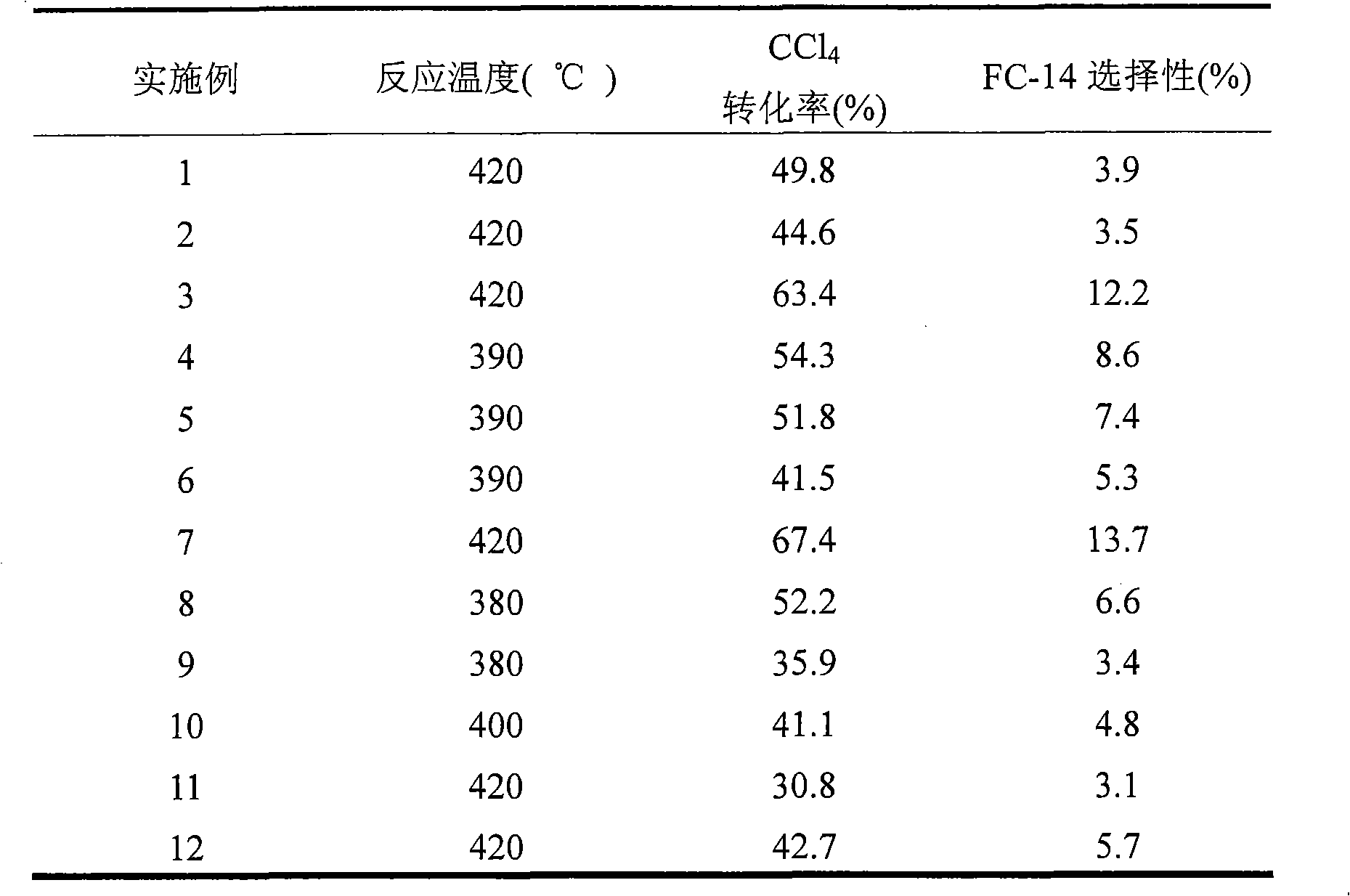

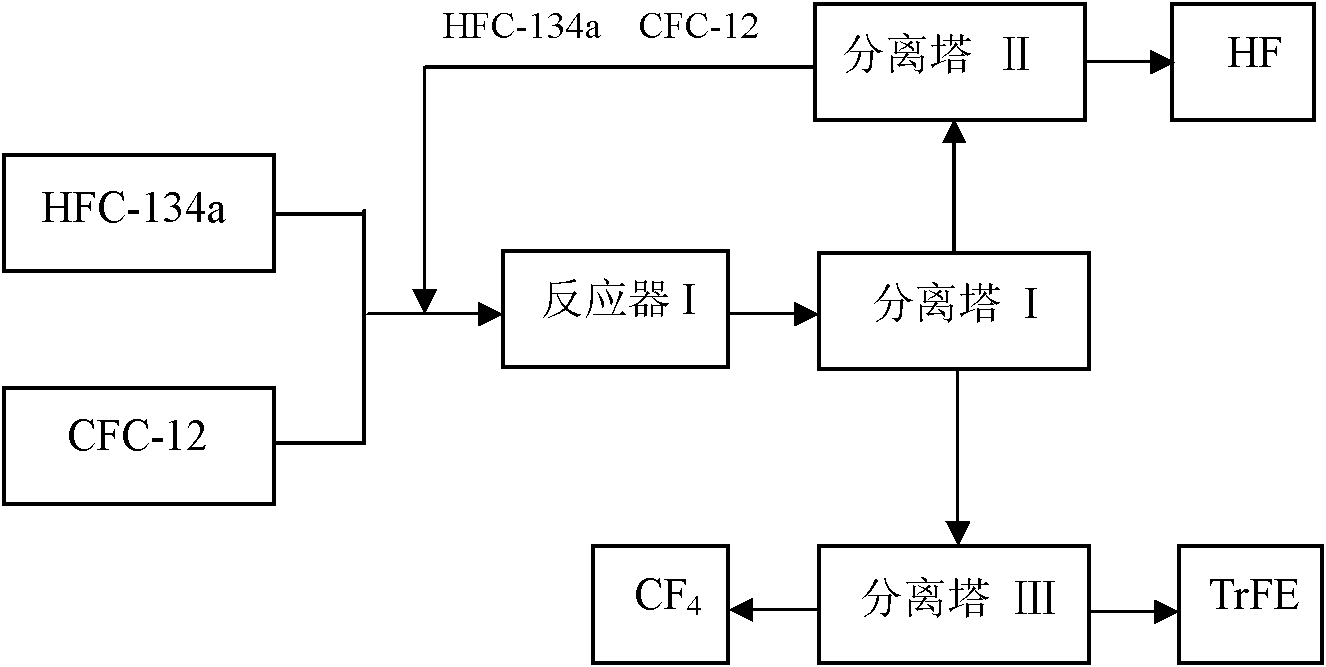

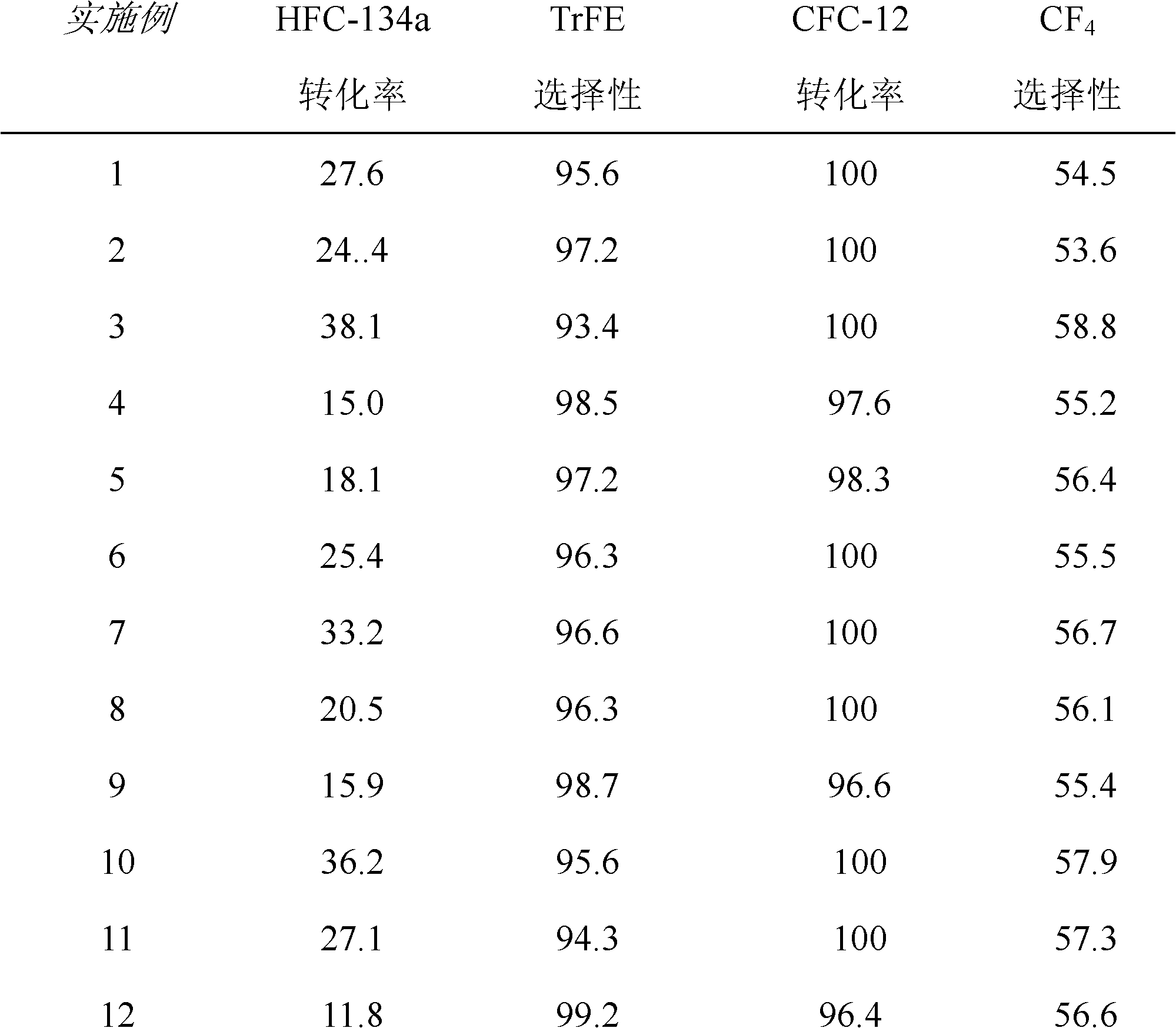

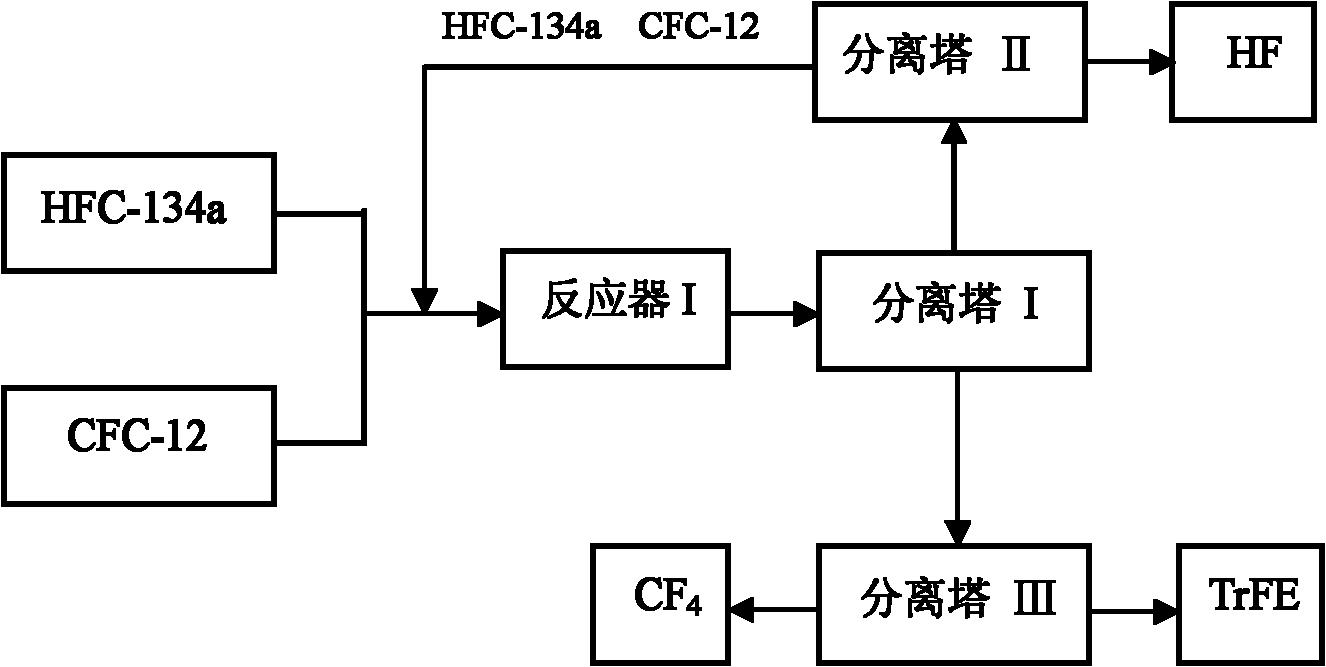

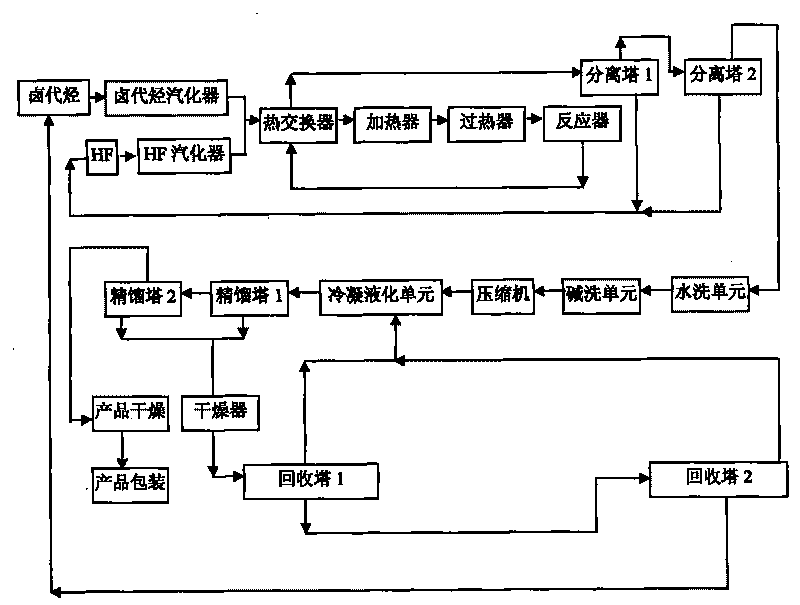

A kind of preparation method of trifluoroethylene and tetrafluoromethane

InactiveCN102267866AImprove conversion rateSolving the industrial problem of damagePreparation by hydrogen halide split-offPreparation by halogen replacementDichlorodifluoromethaneReaction temperature

The invention relates to a preparation method for trifluoroethylene and tetrafluoromethane. The method is characterized in that: dichlorodifluoromethane and 1,1,1,2-tetrafluoroethane are mixed according to a mole ratio of the dichlorodifluoromethane to the 1,1,1,2-tetrafluoroethane of 1:2-9, and are subjected to a reaction at a temperature of 350-500 DEG C and space velocity of 700-1500 hour<-1> under normal pressure through a catalytic action of a fluorination catalyst; the resulting end gas is separated through a partition column I; the separated dichlorodifluoromethane, the separated fluoride hydrogen and the separated 1,1,1,2-tetrafluoroethane are separated through a partition column II, wherein the resulting dichlorodifluoromethane and the resulting 1,1,1,2-tetrafluoroethane are recycled, the resulting fluoride hydrogen is adopted as the by-product to be collected; the separated trifluoroethylene and the separated tetrafluoroethane are subjected to separation through a partition column III, and purification to obtain the pure trifluoroethylene and the pure tetrafluoroethane. The preparation method provided by the present invention has characteristics of low reaction temperature, low energy consumption and less damage to the equipment.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

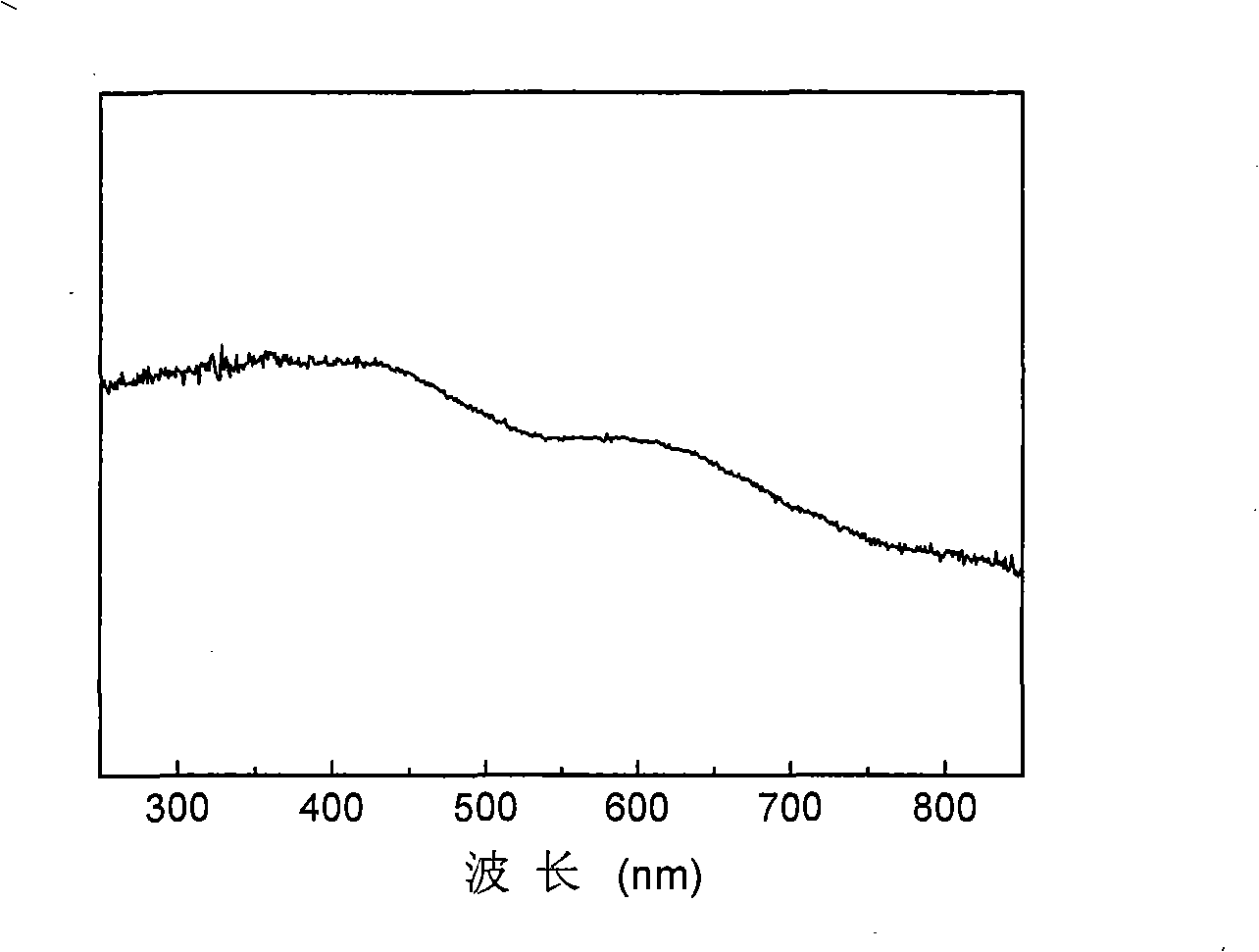

Catalyst for producing tetrafluoromethane by gas-phase fluorination and preparation method thereof

InactiveCN101337187AHigh catalytic activityImprove catalytic selectivityPreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsGas phaseTetrafluoromethane

The invention relates to a catalyst used for fluoridation. Aiming at the deficiencies that the activity is worse and the stability is not high in the prior catalyst used for producing FC-14 through gas phase fluorination, the invention provides a catalyst used for producing tetrafluoromethane through the gas phase fluorination and possessed of high activity, high selectivity, high stability and low application temperature, as well as the preparation method thereof. The catalyst of the invention comprises a carrier and an active ingredient, wherein, the carrier adopts the compound of aluminum; and the active ingredient adopt the compound of chromium. The catalyst of the invention comprises the following preparation process: firstly, the compound of Al and the compound of Cr are weighed out according to a certain proportion, after water is added and the compounds are uniformly mixed, a precipitating agent is added until the compounds are completely precipitated, then separation and washing are carried out until the filtrate is neutral, and the precipitate is dried; secondly, the dried precipitate is calcined after being shaped, so as to obtain a fluorination catalyst precursor; and thirdly, the fluorination catalyst precursor is processed by HF, so as to obtain the catalyst of the invention.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

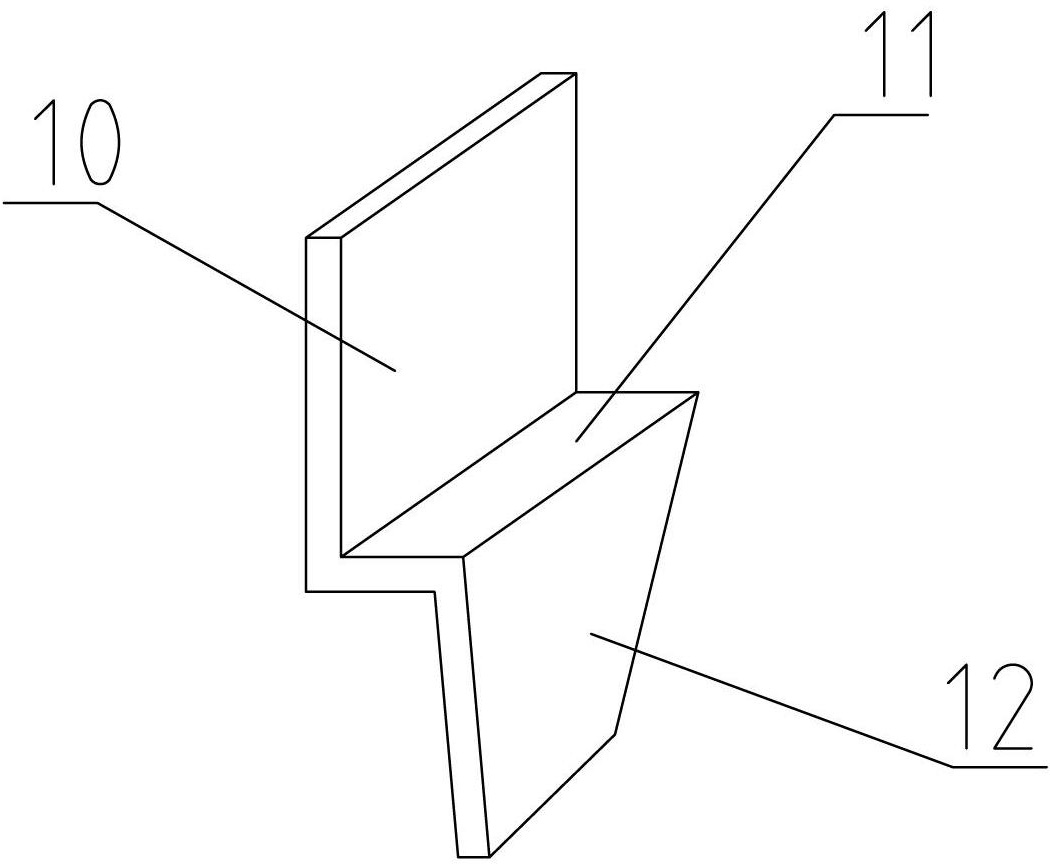

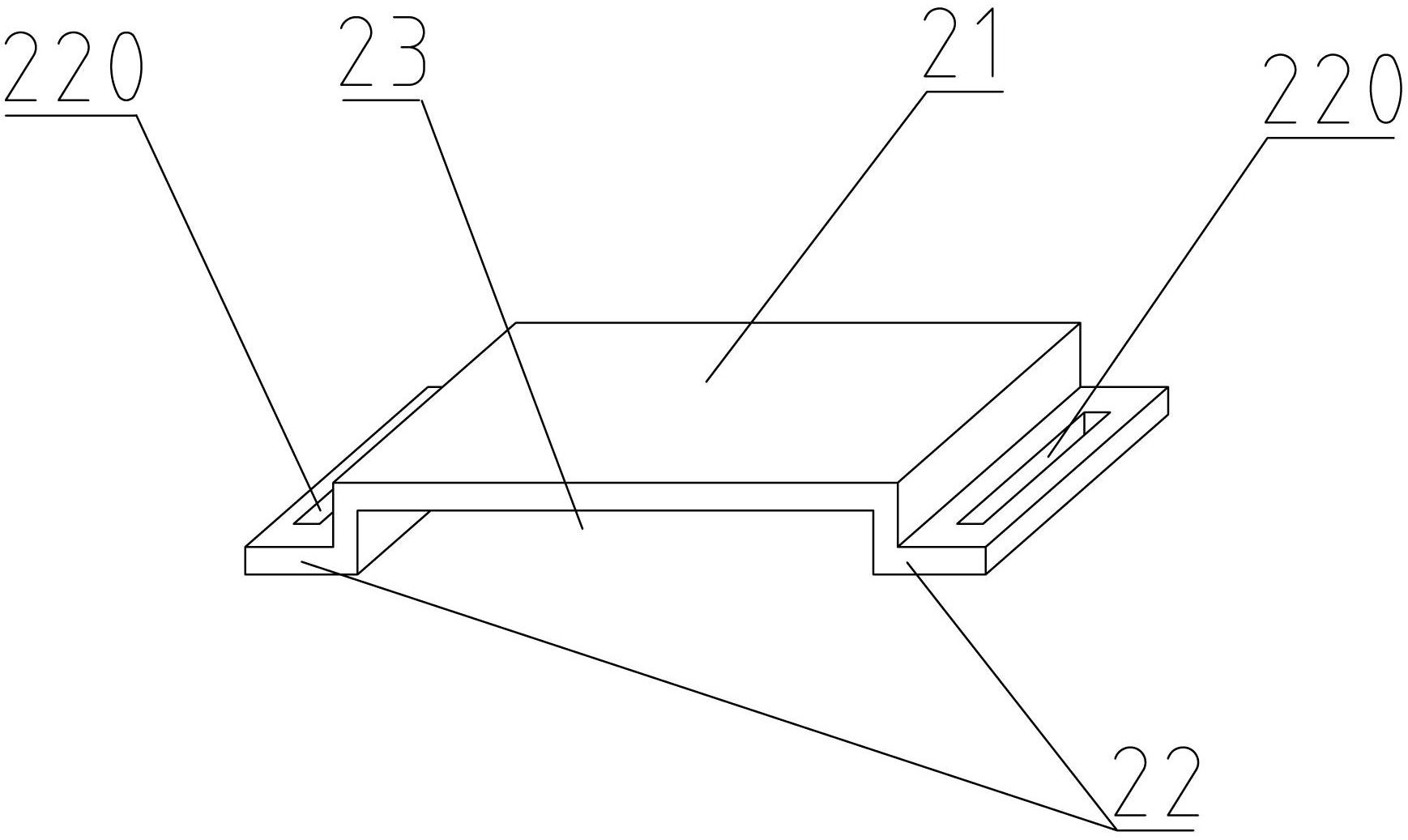

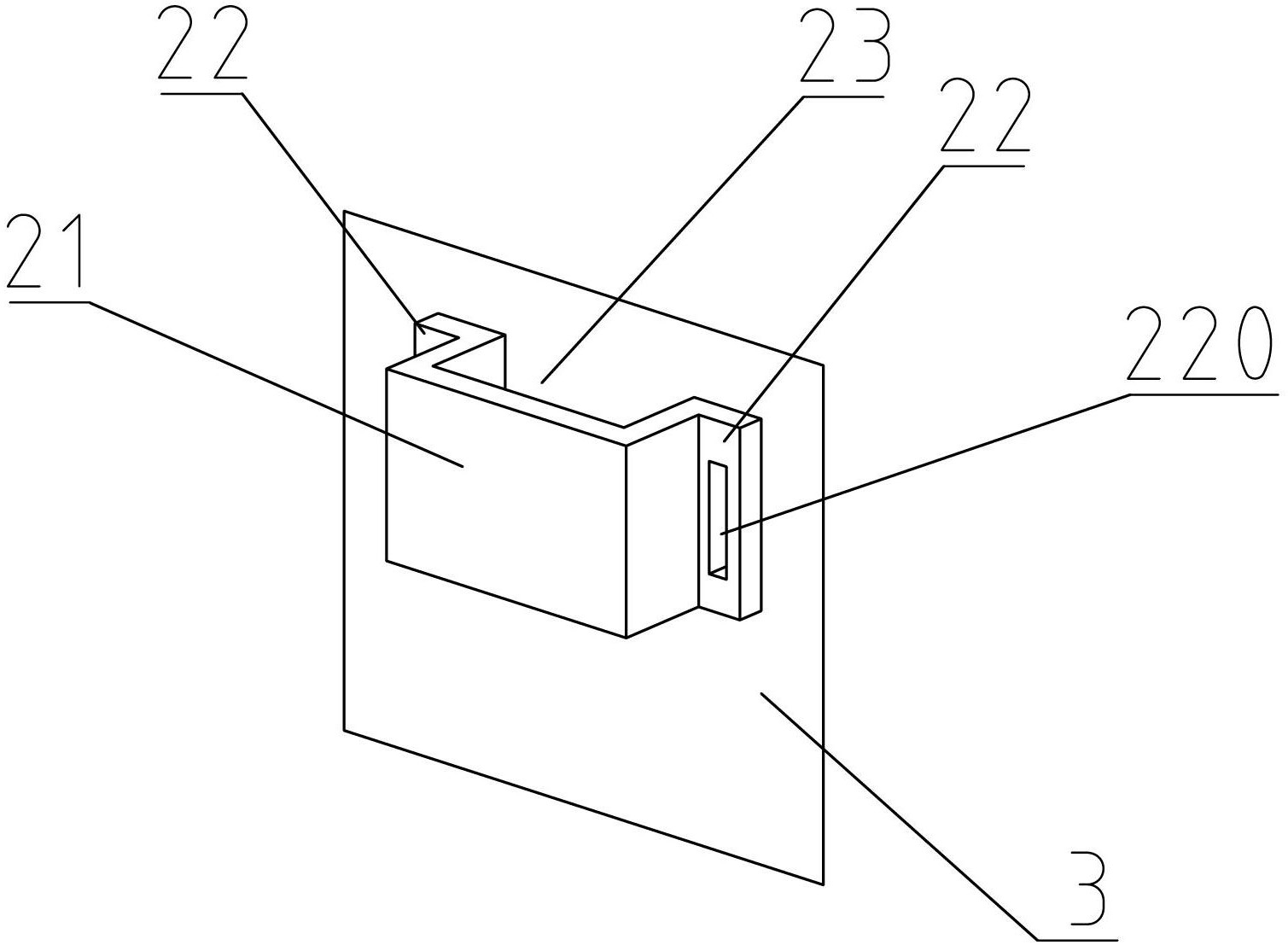

Back hanging piece for installing decorative inorganic tetrafluoromethane veneer and construction method of back hanging piece

The invention provides a back hanging piece for installing a decorative inorganic tetrafluoromethane veneer and a construction method of the back hanging piece. The back hanging piece comprises an insertion piece and a positioning piece which are matched for use, wherein the insertion piece is an integral metal piece and is divided into three sections, i.e. a fixing part adhering to the decorative inorganic tetrafluoromethane veneer, an insertion part matched with the positioning piece, and a connection part between the fixing part and the insertion part. The three sections are connected end to end, the connection part is vertical to the fixing part and the insertion part, the fixing part and the insertion part are parallel, and the positioning piece is an integral metal piece; and the positioning piece comprises a support part of which the two ends are tightly adhered to a wall surface, and a convex part which extrudes out of the planes on which the two support parts are arranged, wherein fixing holes for fixing the positioning piece are formed on the two support parts, and an interval capable of being inserted by the insertion part is formed between the convex part and the wall surface. The back hanging piece can meet the requirements of the high level wind pressure resistance and the deformation resistance, the use safety of the decorative inorganic tetrafluoromethane veneer is greatly improved, and the use range of the back hanging piece is expanded.

Owner:SHENZHEN MINGYUAN BUILD MATERIALS TECH

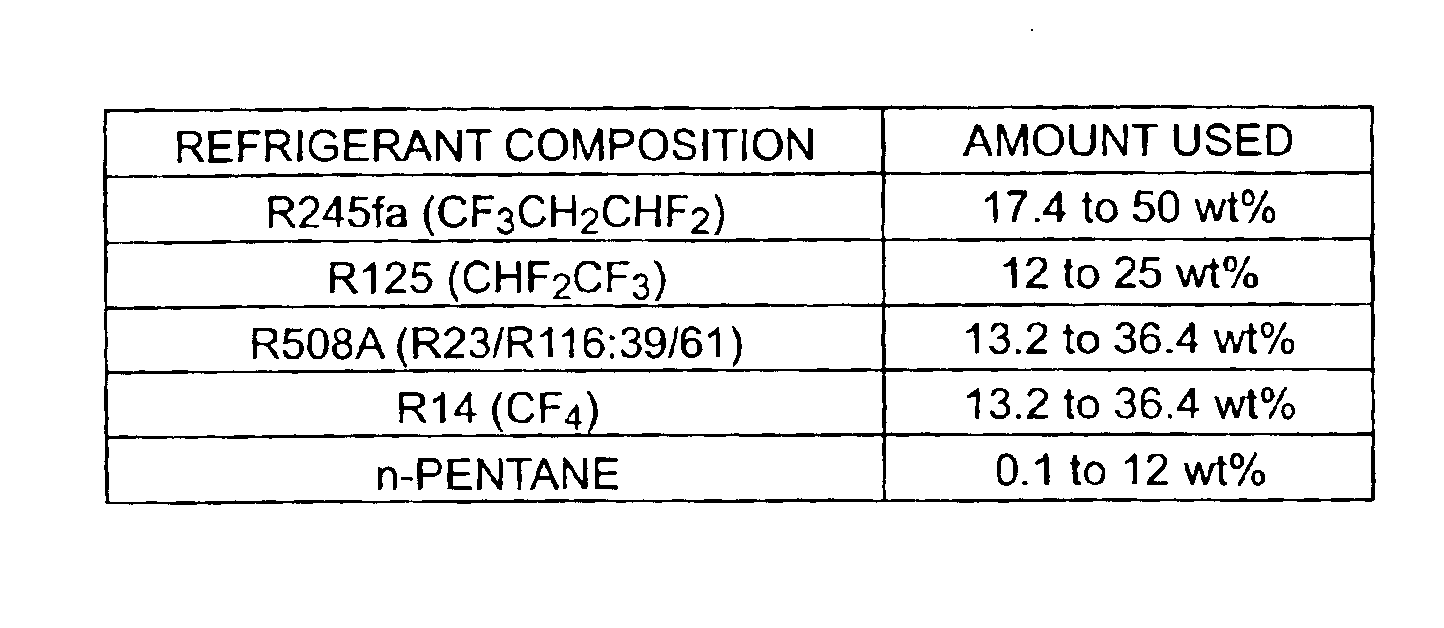

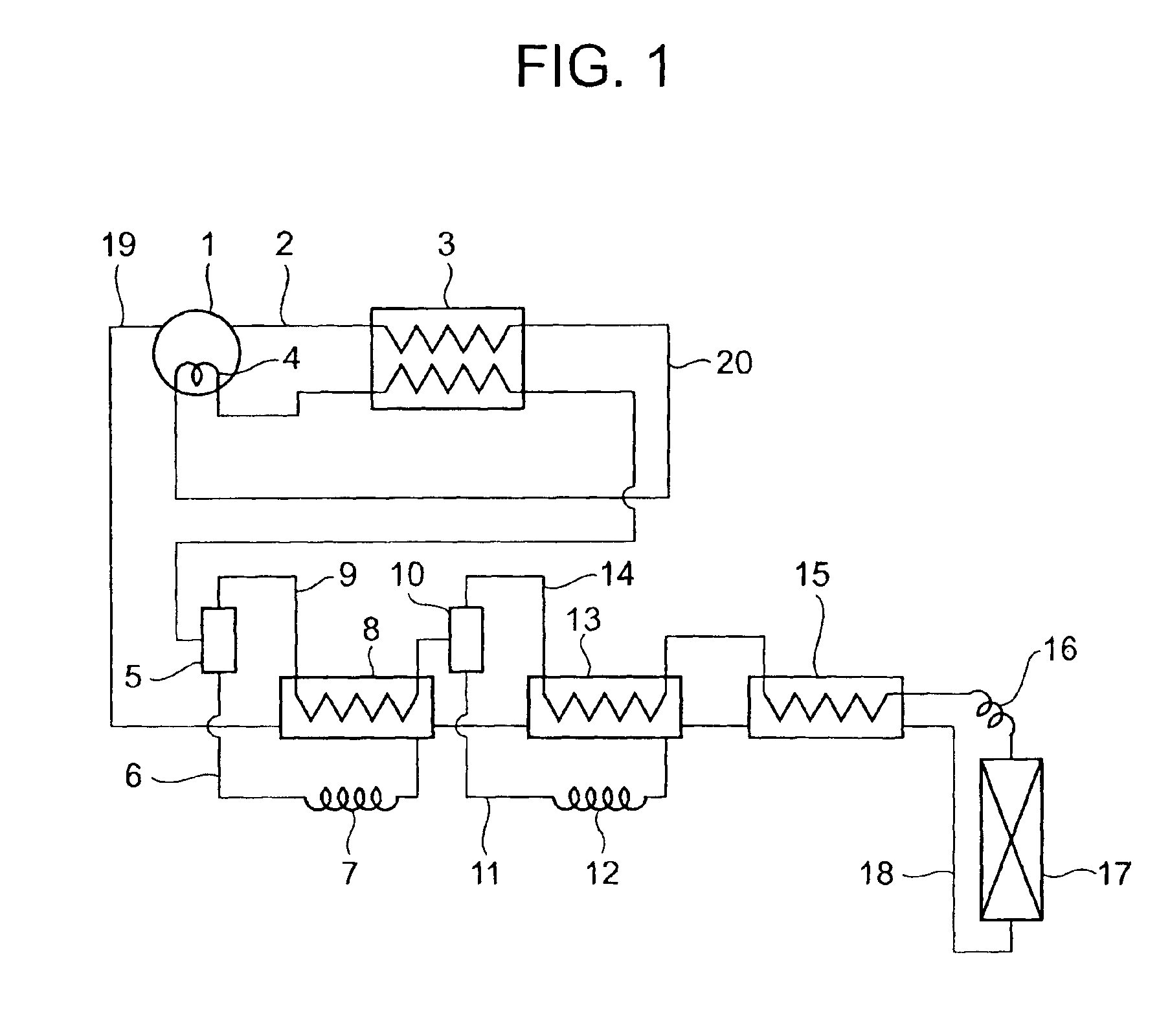

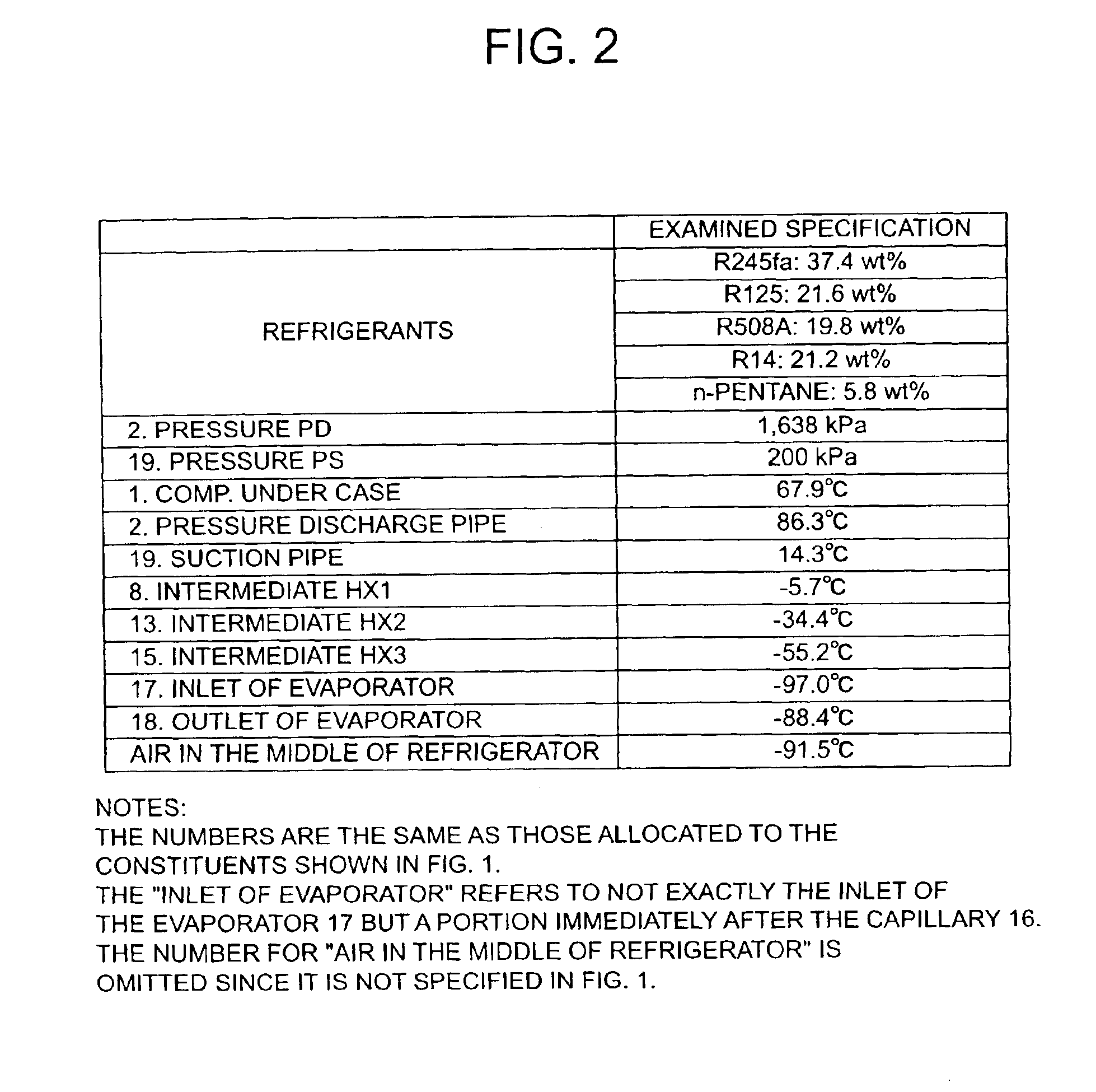

Refrigerant composition and refrigerating circuit using the same

InactiveUS6951115B2Compression machines with non-reversible cycleHeat-exchange elementsCombustionEngineering

The development of an alternate refrigerant composition which is free from a possibility of causing depletion of the ozone layer and capable of maintaining the performance of a conventional refrigerating circuit without modifying the circuit is desired. An object of the present invention is to provide such a refrigerant composition and a refrigerating circuit using the refrigerant composition. A refrigerant composition of the present invention comprises R245fa (CF3CH2CHF2), R125 (CHF2CF3), R508A (R23 / R116:39 / 61) and R14 (tetrafluoromethane: CF4). Thus, the refrigerant composition has no possibility of causing depletion of the ozone layer. Further, since the composition is noncombustible, possible combustion can be prevented even if it leaks.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

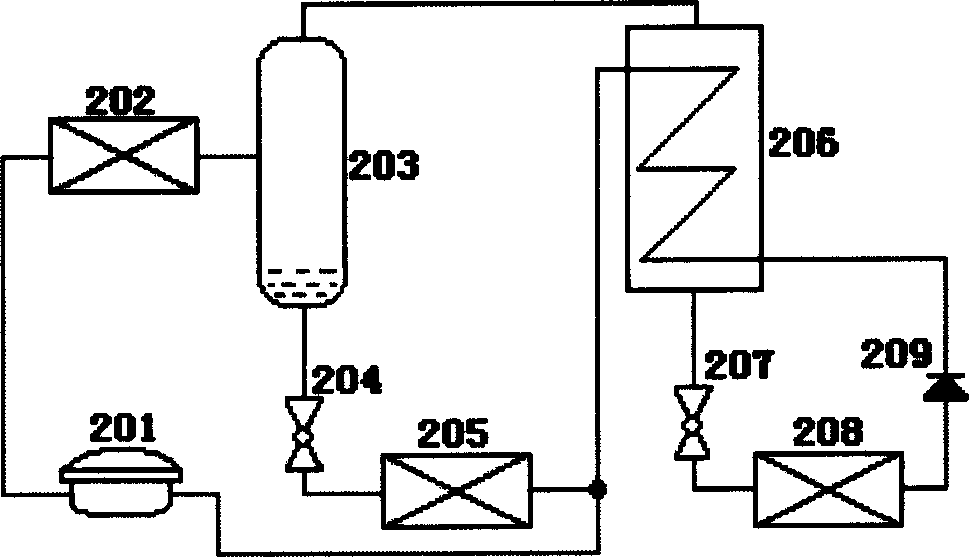

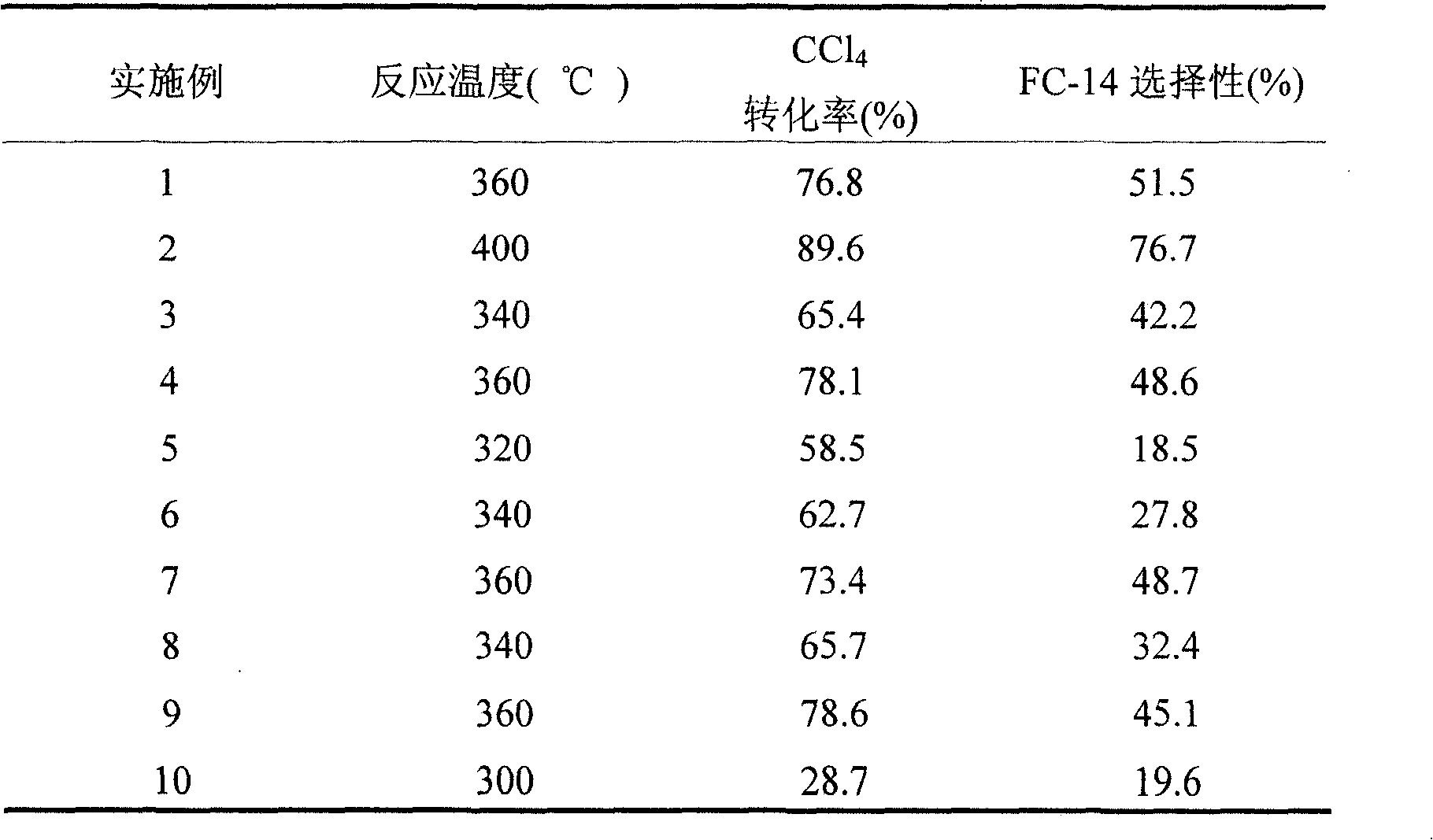

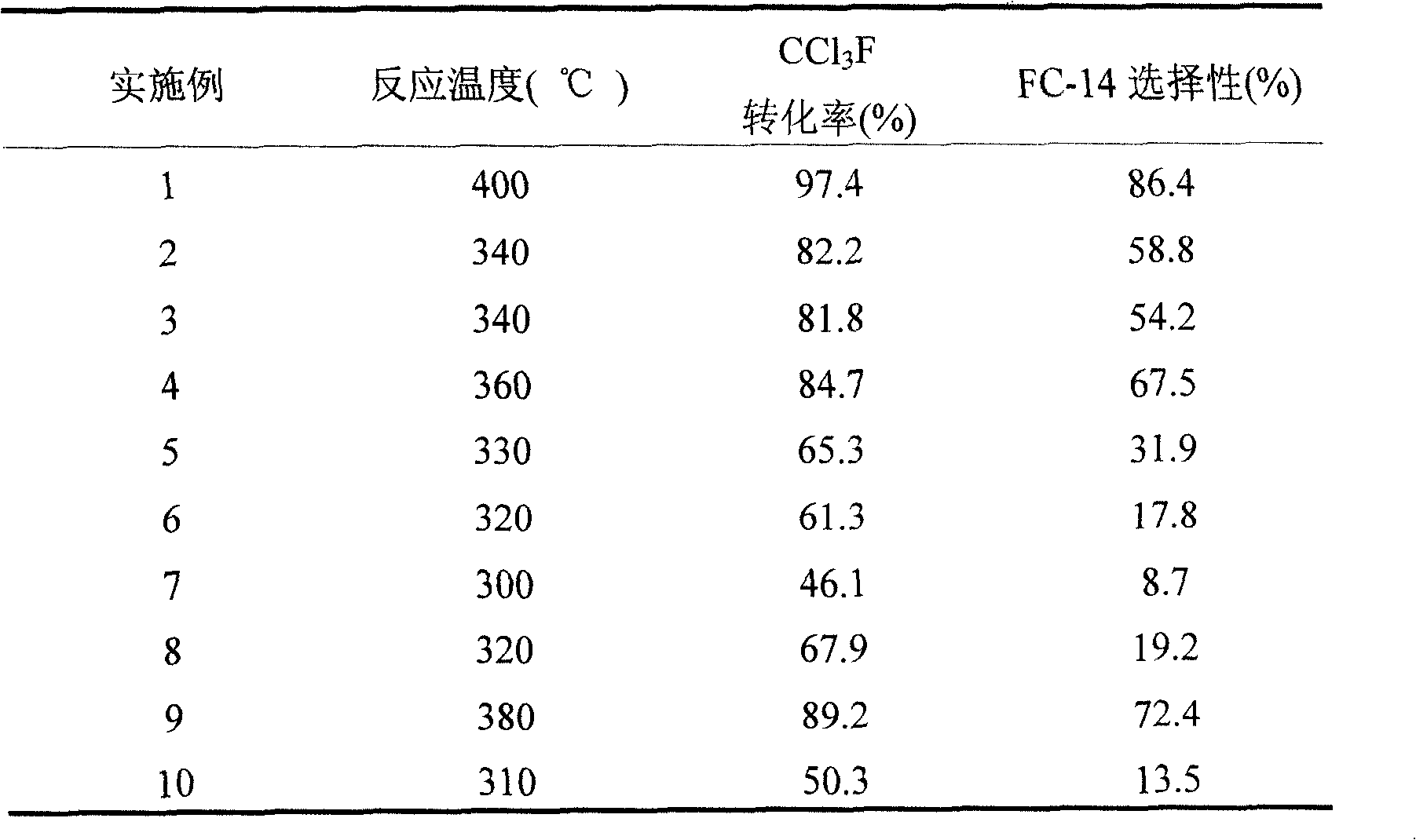

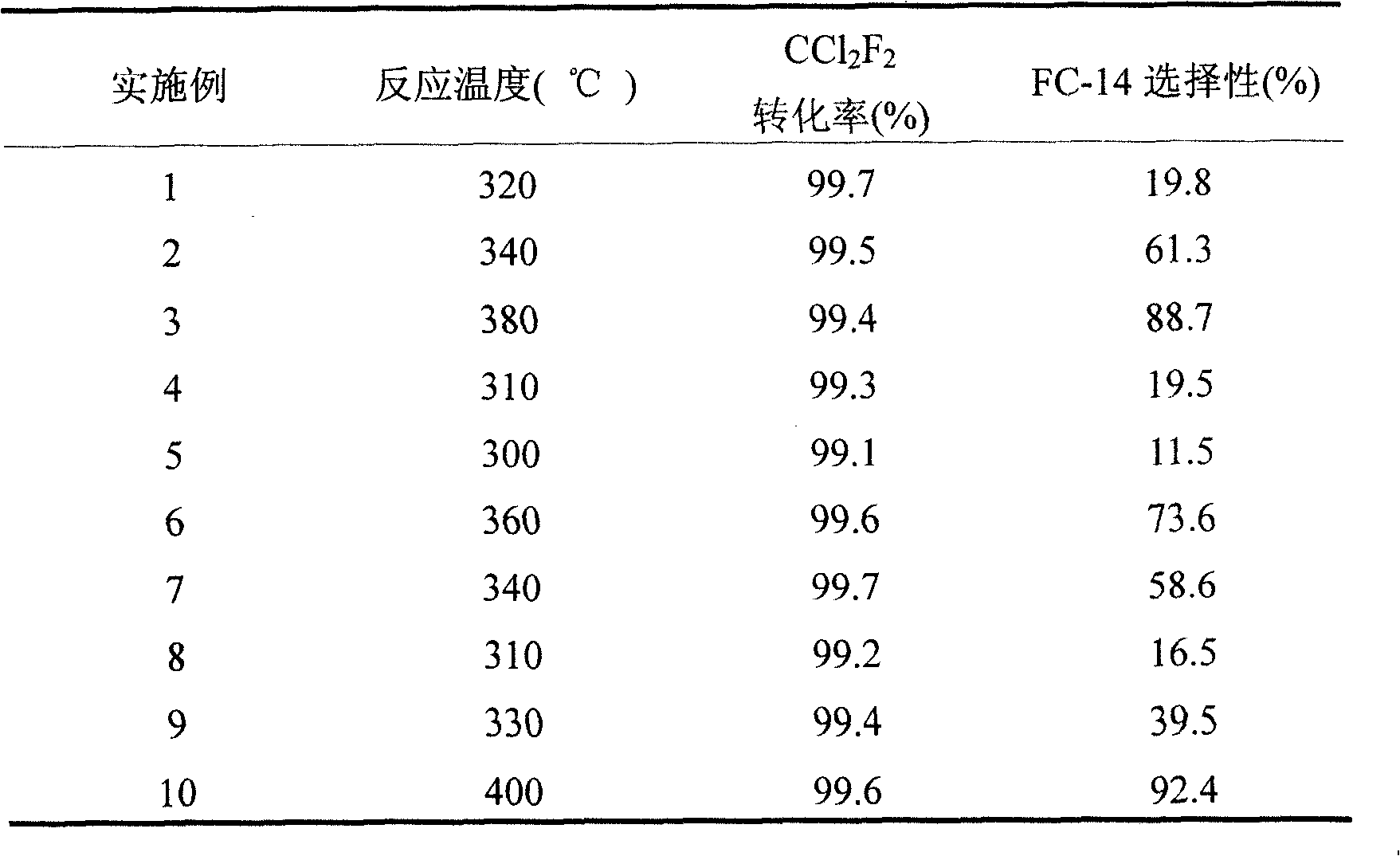

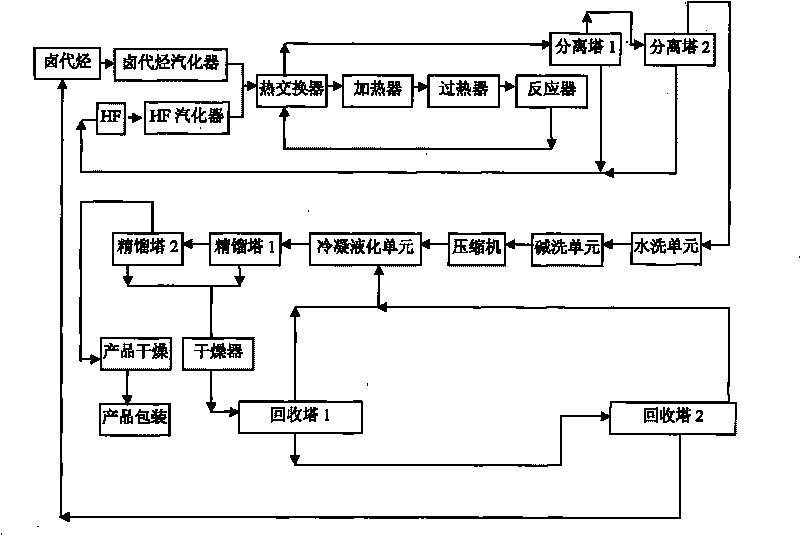

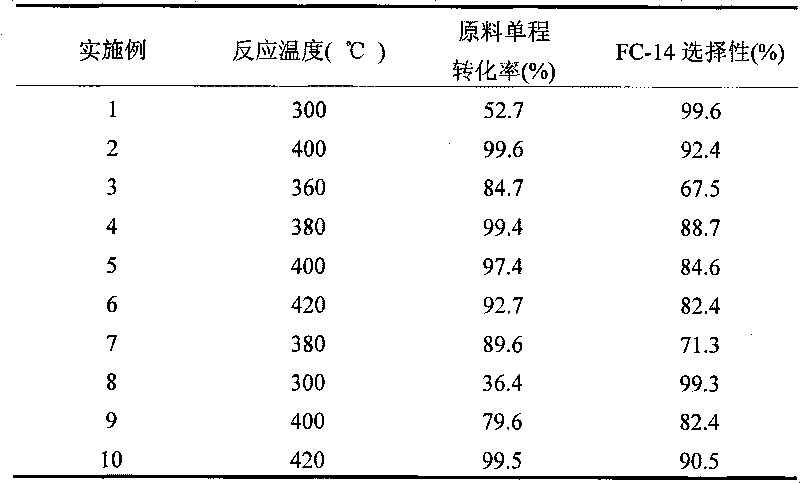

Method for producing tetrafluoromethane by gas phase catalysis

InactiveCN101723797AExtended service lifeImprove conversion ratePreparation by halogen replacementChromium CompoundsHydrogen fluoride

The invention discloses a method for producing a tetrafluoromethane by gas phase catalysis. Aiming at the defects of high needed reaction temperature and low conversion per pass existing in the conventional process for producing FC-14 by gas phase fluorination, the invention provides an economic and high-efficient method for producing the tetrafluoromethane by gas phase catalysis, which has the advantages of low needed reaction temperature and high conversion per pass. The method for producing the tetrafluoromethane comprises the following step: reacting halohydrocarbon with hydrogen fluoride at the presence of a gas phase fluorination catalyst in a gas phase to produce the tetrafluoromethane, wherein the molar ratio of the halohydrocarbon to the hydrogen fluoride is 1:1-10; the halohydrocarbon is one or more of the tetrafluoromethane, trichloromonofluomethane, dichlorodifluoromethane and monochlorotrifluoromethane; the used gas phase fluorination catalyst adopts a chromium compound as an active component and an aluminum compound as a carrier; and the molar ratio of the chromium to the aluminum is 1:1-19. The method for producing the tetrafluoromethane has the characteristics of long service life and high percent conversion of the halohydrocarbon.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

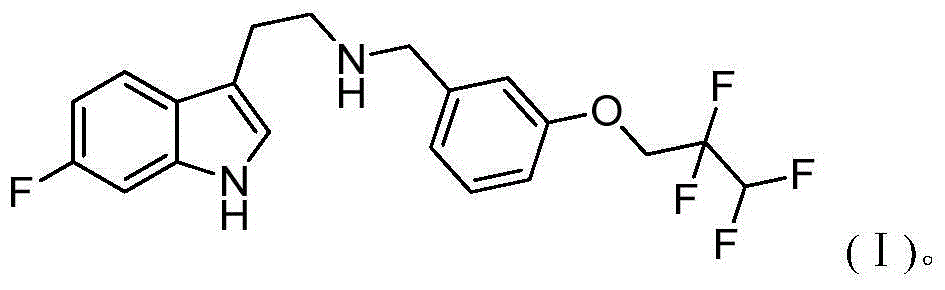

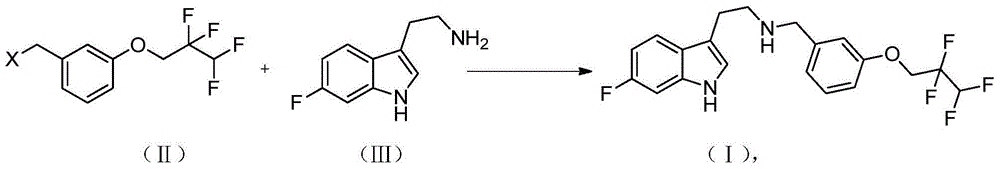

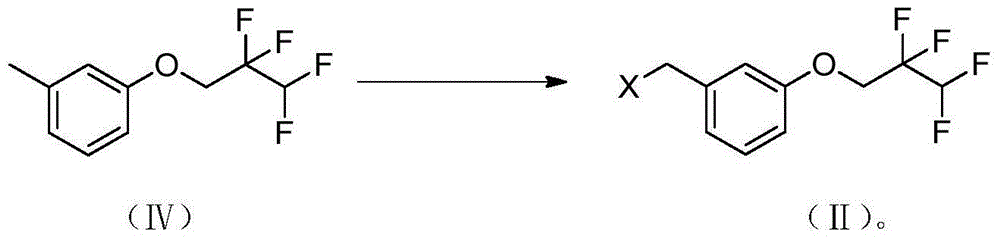

Method for preparing medicine Lu-AE-58054 for resisting alzheimer's disease

ActiveCN104418793AOrganic compound preparationEther preparation by ester reactions3-HydroxybenzaldehydeMethyl group

The invention discloses a novel method for preparing a medicine Lu-AE-58054 for resisting an alzheimer's disease. The novel method comprises the following steps: firstly, reacting 2,2,3,3-tetrafluoromethane-1-propyl alcohol with paratoluensulfonyl chloride, so as to obtain 2,2,3,3-teflon propoxy-4-methyl benzene sulfonate; reacting 2,2,3,3-tetrafluoropropoxy-4-methyl benzene sulfonate with m-cresol, and generating 1-methyl-3-(2,2,3,3-tetrafluoropropoxy) benzene; and obtaining 1-(halogen methyl)-3-(2,2,3,3-tetrafluoropropoxy) benzene by halogenating reaction, and carrying out nucleophilic reaction together with a segment 6-fluorotryptamine, so as to obtain 2-(6-fluorin-1H-indolyl-3-yl)-N-(3-(2,2,3,3-tetrafluoropropoxy) benzyl) ethylamine, namely Lu-AE-58054. According to the preparation method disclosed by the invention, the raw materials are cheap and available, for example, the price of the cresol is only one half of the sodium borohydride; the price of NBS is one half of that of sodium borohydride; and the method is relatively mild in reaction condition, safe, controllable, relatively high in total yield, and especially suitable for industrial production.

Owner:SUNSHINE LAKE PHARM CO LTD

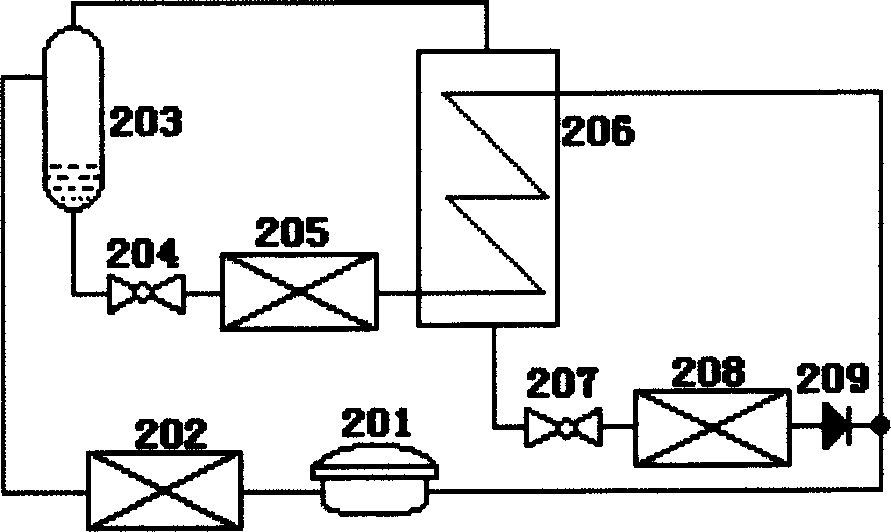

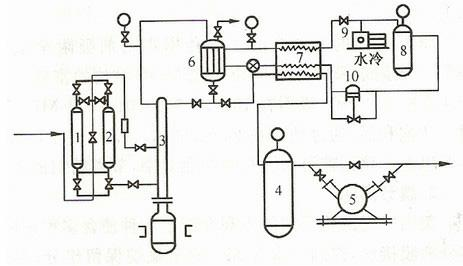

Method for preparing high purity tetrafluoromethane through combination of rectification and adsorption

InactiveCN102399126AContinuous and stable purificationSolve the disadvantages of unstable purificationHalogenated hydrocarbon separation/purificationHydrogen fluoridePhysical chemistry

The invention discloses a method for preparing high purity tetrafluoromethane through combination of rectification and adsorption. The method is mainly characterized in that: equipment for generating tetrafluoromethane continuously supplies the tetrafluoromethane, and fluorochloromethane and potassium bifluoride are subjected to gas-phase reaction to form the tetrafluoromethane. In the method for preparing the high purity tetrafluoromethane, a raw material preparation system, a tetrafluoromethane gas preparation system and a liquefying and gasifying system for the tetrafluoromethane purified through combination of rectification and adsorption. The method has the advantages that: the product has high yield and high purity (99.0-99.9 percent), has a few impurities which are easy to separate; and besides the product, other harmful and toxic byproducts are absent, the operation is convenient, and the method is an ideal technology for preparing the high purity tetrafluoromethane.

Owner:TIANJIN TAIYUAN INDAL GAS

Etching processes using C4F8 for silicon dioxide and CF4 for titanium nitride

InactiveUS7276450B2Reduced ESD defectsDecorative surface effectsSemiconductor/solid-state device manufacturingElectrical conductorOctafluorocyclobutane

Methods of etching a dielectric layer and a cap layer over a conductor to expose the conductor are disclosed. In one embodiment, the methods include the use of a silicon dioxide (SiO2) etching chemistry including octafluorocyclobutane (C4F8) and a titanium nitride (TiN) etching chemistry including tetrafluoro methane (CF4). The methods prevent etch rate degradation and exhibit reduced electro-static discharge (ESD) defects.

Owner:GOOGLE LLC

Reflective optical element and method for operating an EUV lithography apparatus

In order to reduce the adverse influence of contamination composed of silicon dioxide, hydrocarbons and / or metals within an EUV lithography apparatus on the reflectivity, a reflective optical element (50) for the extreme ultraviolet wavelength range having a reflective surface (59) is proposed, wherein the multilayer coating of the reflective surface (59) has a topmost layer (56) composed of a fluoride. The contaminations mentioned, which deposit on the reflective optical element (50) during the operation of the EUV lithography apparatus, are converted into volatile compounds by the addition of at least one of the substances mentioned hereinafter: atomic hydrogen, molecular hydrogen, perfluorinated alkanes such as e.g. tetrafluoromethane, oxygen, nitrogen and / or helium.

Owner:CARL ZEISS SMT GMBH

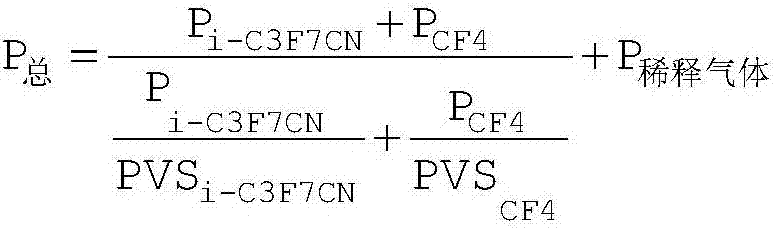

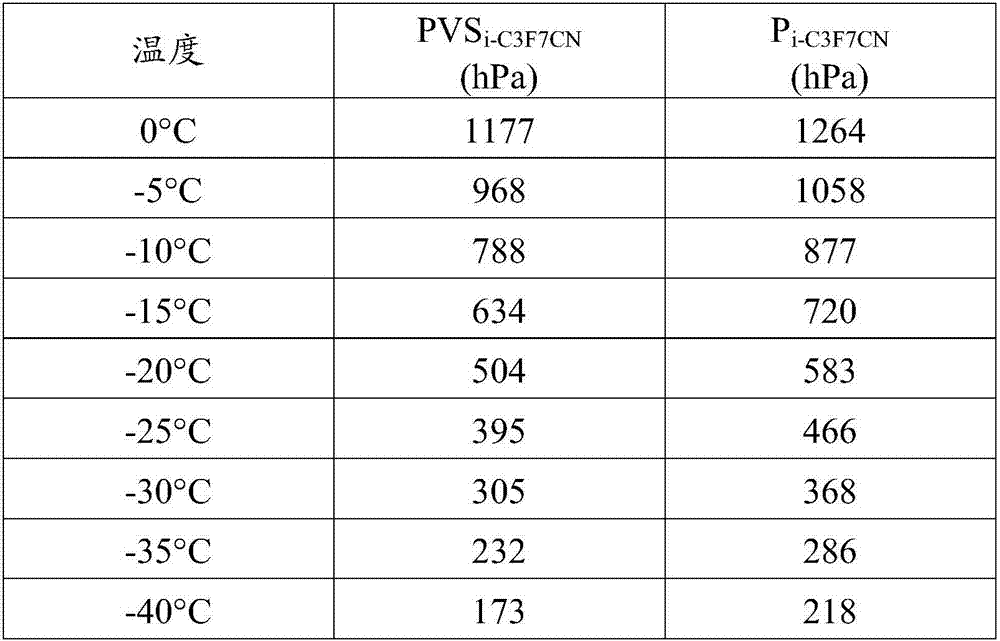

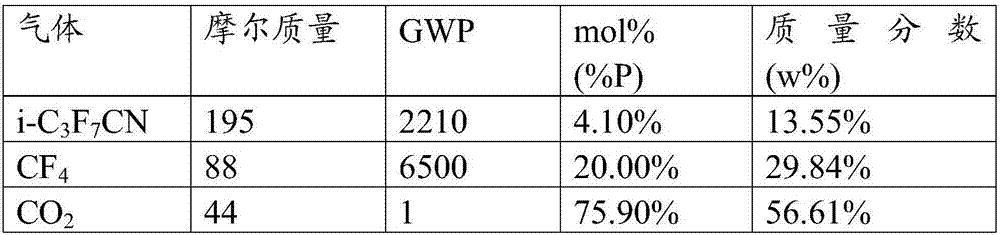

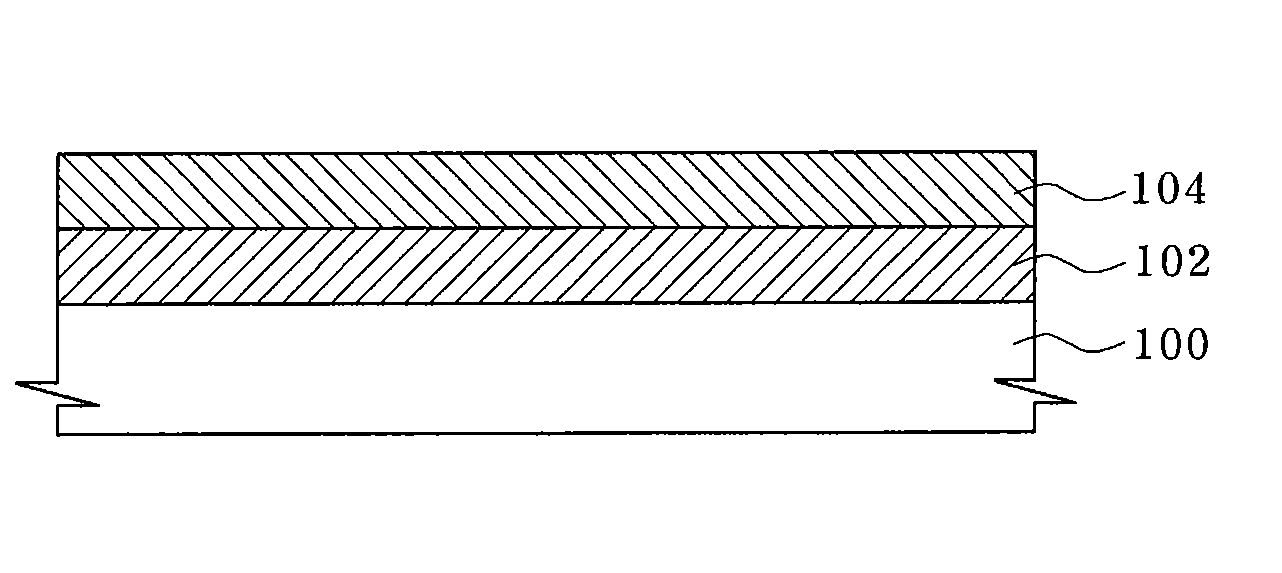

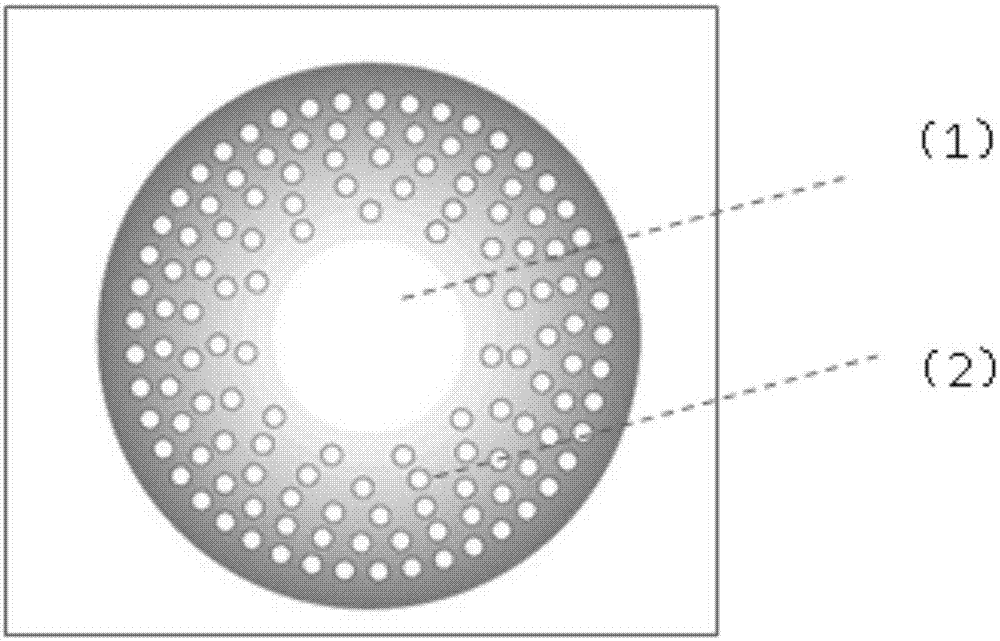

Gas-insulated medium- or high-voltage electrical apparatus including heptafluoroisobutyronitrile and tetrafluoromethane

InactiveCN107430901ASwitchgear arrangementsHigh-tension/heavy-dress switchesVariable thicknessElectricity

Owner:GENERAL ELECTRIC TECH GMBH

Middle-high temperature heat pump mixing working substance containing trifluoroiodomethane (R13I1) and tetrafluoromethane (HFCl34a)

InactiveCN101033388AComply with protectionMeet environmental protection requirementsHeat-exchange elementsTetrafluoroethyleneOzone layer

The invention relates to a kind of middle / high temperature heat pump refrigerant mixture containing trifluoroiodomethane (R13I1) and tetrafluoroethylene (HFC134a), which is suitable for using as the refrigerants for middle / high temperature heat pump system with a temperature of 60~120deg.C. The material is composed of 35-95% of R13I1, 0-55% of HFC134a and 5-65% of HFC245fa by weight share. The preparation method is that it physically mixes the above materials according to the designated ratio. The invention does not destroy the ozone layer, and the greenhouse effect is weak.

Owner:TIANJIN UNIV

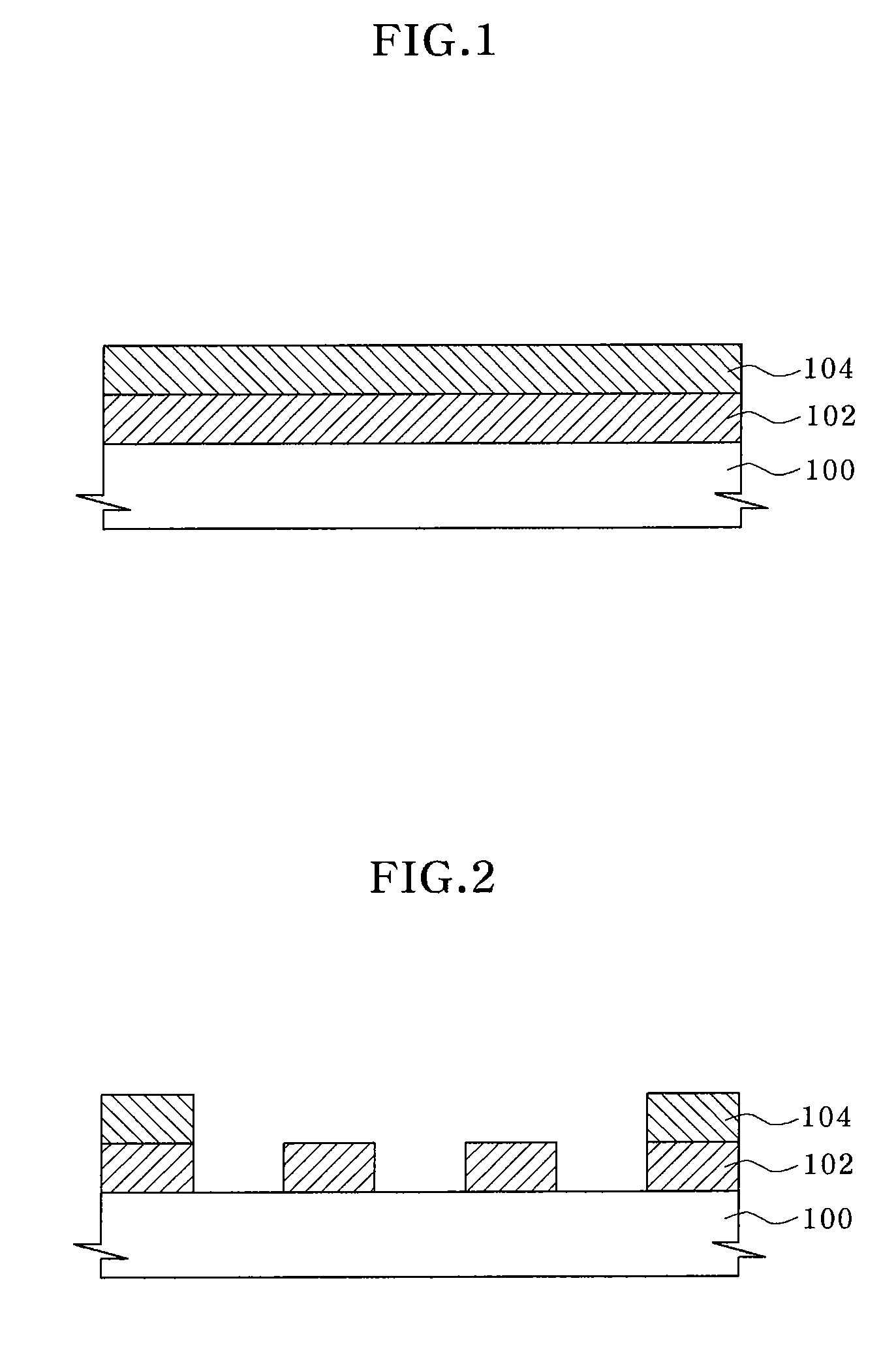

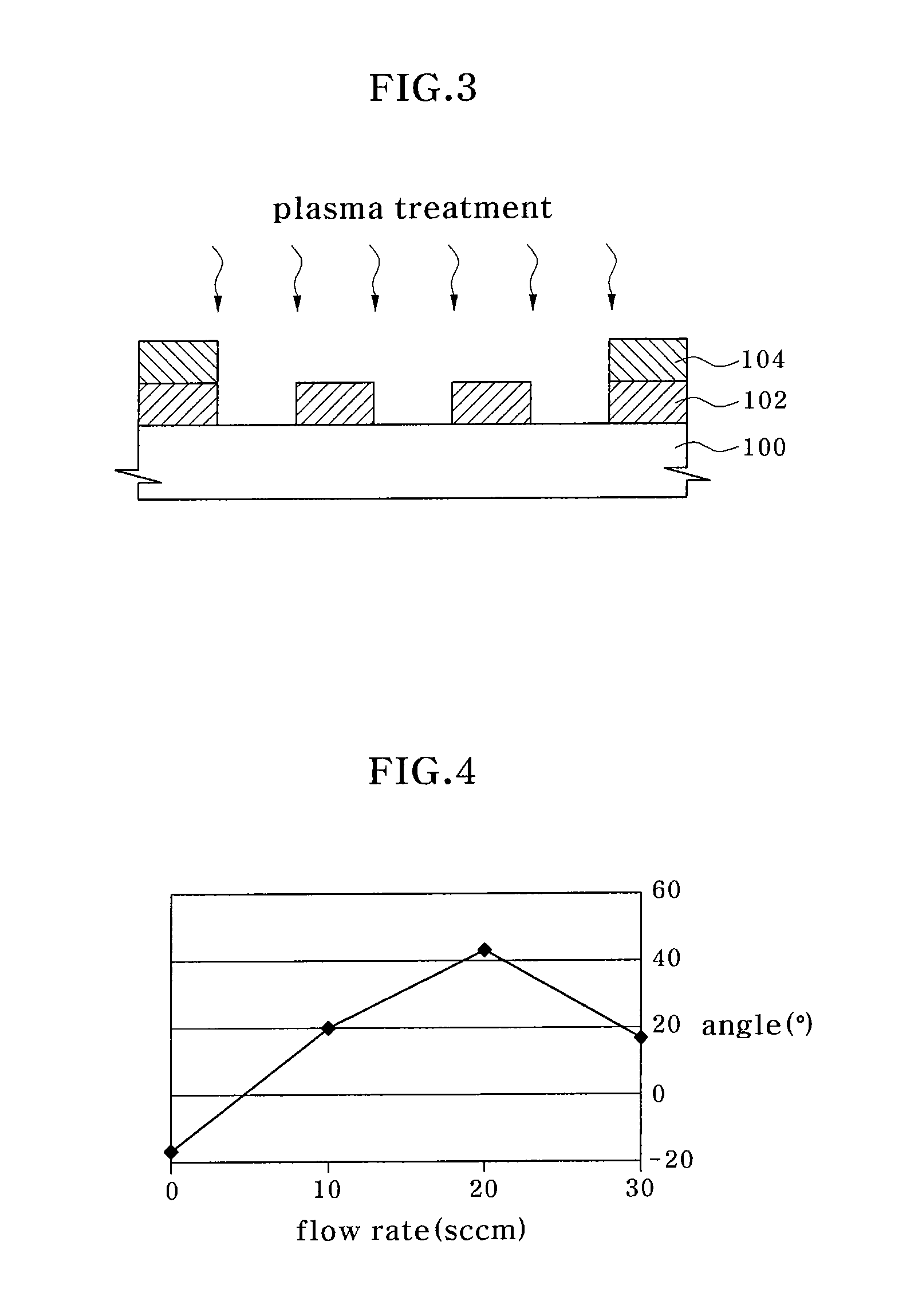

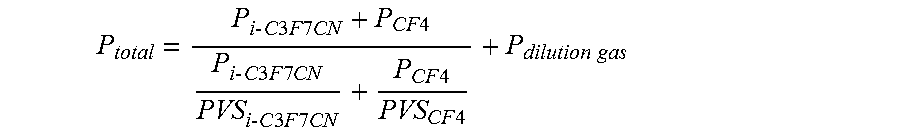

Method for fabricating photomask

InactiveUS20090004574A1Fabrication yield can be improvedHigh yieldSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentHydrogenOptoelectronics

Provided is a method for fabricating a photomask. The method includes following processes. Light blocking patterns are formed on a mask substrate, and surface properties of the mask substrate on which the light blocking patterns are formed are changed into hydrophobicity. When the surface properties of the mask substrate are changed into the hydrophobicity, the mask substrate is treated using plasma gas. The plasma gas may be a gas mixture of trifluoromethane (CHF3), tetrafluoromethane (CF4), and hydrogen (H2).

Owner:SK HYNIX INC

Defluorination agent for carbon tetrafluoride anhydrous scission reaction and method of use thereof

InactiveCN101254333AEasy to operateLow reaction temperatureChemical protectionCerium(IV) oxidePrice ratio

The invention relates to a defluorinating agent for water-free cracking reaction of tetrafluoromethane and an application method thereof. The defluorinating agent is composed of 21 to 39 percent sodium fluoride, 41 to 53 percent metal oxides and the rest of silicon powder. The metal oxides which are provided by the invention are aluminum oxide, lanthanum oxide, cerium dioxide, calcium oxide or magnesium oxide. The invention further provides the application method of the defluorinating agent. The defluorinating agent which is prepared by the invention is prominently characterized by cheap prices of the raw materials and simple preparation process. The defluorinating agent is used for the tetrafluoromethane waste gas which is generated during the cracking industrial process, the performance-price ratio is high and the application is wide.

Owner:徐秀峰

Gas-insulated medium-or high-voltage electrical apparatus including heptafluoroisobutyronitrile and tetrafluoromethane

InactiveUS20180040391A1Reduce environmental impactImprove breaking capacitySwitchgear arrangementsHigh-tension/heavy-dress switchesElectricityEngineering

The present invention relates to medium- or high-voltage equipment comprising a leaktight enclosure in which there are located electrical components and a gas mixture for providing electrical insulation and / or for extinguishing electric arcs that are likely to occur in the enclosure, the gas mixture comprising heptafluoroisobutyronitrile and tetrafluoromethane. Electrical components covered in solid dielectric layers of varying thickness are located inside the leaktight enclosure of the equipment of the invention.

Owner:GENERAL ELECTRIC TECH GMBH

Preparation method of tetrafluoromethane

ActiveCN108863710AShort reaction timeSimple processPreparation by halogen replacementAlkaline earth metalContinuous use

The invention discloses a preparation method of tetrafluoromethane. Waste gas exhausted in the fluoro-hydrocarbon product production process and hydrogen fluoride are proportionally introduced into amicro-channel reactor containing catalysts; reaction is performed for 1 to 30 minutes at the temperature being 150 to 350 DEG C; reaction products are purified to obtain the tetrafluoromethane; the catalyst is prepared from carriers and one kind of materials or a mixture of more than one kind of materials in persulfate, fluoride or bifluoride of alkali metal or alkaline earth metal and oxides or carbonates of titanium, vanadium, chromium, iron, cobalt, nickel, copper and aluminum through roasting; the carriers are one kind of materials or a mixture of more than one kind of materials in activecarbon, molecular sieve, kieselguhr or silicon dioxide. The catalyst can be continuously used; the reaction time is short; the process is simple; safety is realized; the cost is low; the product purity is high and reach 99.99 percent; the technology belongs to a green clean energy-saving environmental-friendly sustainable production technology.

Owner:LINHAI LIMIN CHEM

Active artificial cornea and preparation method thereof

InactiveCN107007879ASolve the strength problemFix compatibility issuesPharmaceutical delivery mechanismTissue regenerationBiocompatibility TestingSynthetic Polymeric Macromolecules

The invention discloses an active artificial cornea and a preparation method thereof. The artificial cornea has a one-piece synthetic high-molecular polymer hydrogel structure containing gradient components, and is prepared from a biological inactive central optical part and a biological active peripheral part. According to the preparation method, a substrate, which is optically transparent in the center and has gradient hydrogel properties at the periphery, of the artificial cornea is prepared; the central parts (inner face and outer face) of the substrate of the artificial cornea are coated with polyvinylidene fluoride, tetrafluoromethane and heptafluoropropane by using a nano-coating technology and are then subjected to plasma treatment, so that inert surfaces are formed; after that, collagen grafting as well as small molecule peptide and growth factor induced activation are carried out on the periphery of the substrate, so that the biological activity and tissue engineering of the substrate are realized; finally, the active artificial cornea which is excellent in center optical properties, good in peripheral biocompatibility, simple in structure and convenient for operation and can stably exist for a long time without prolapsing can be obtained. Perforated hole structures are made at the periphery of the artificial cornea, so that the artificial cornea is facilitated to be closely jointed with the eyes of a patient.

Owner:JINAN UNIVERSITY

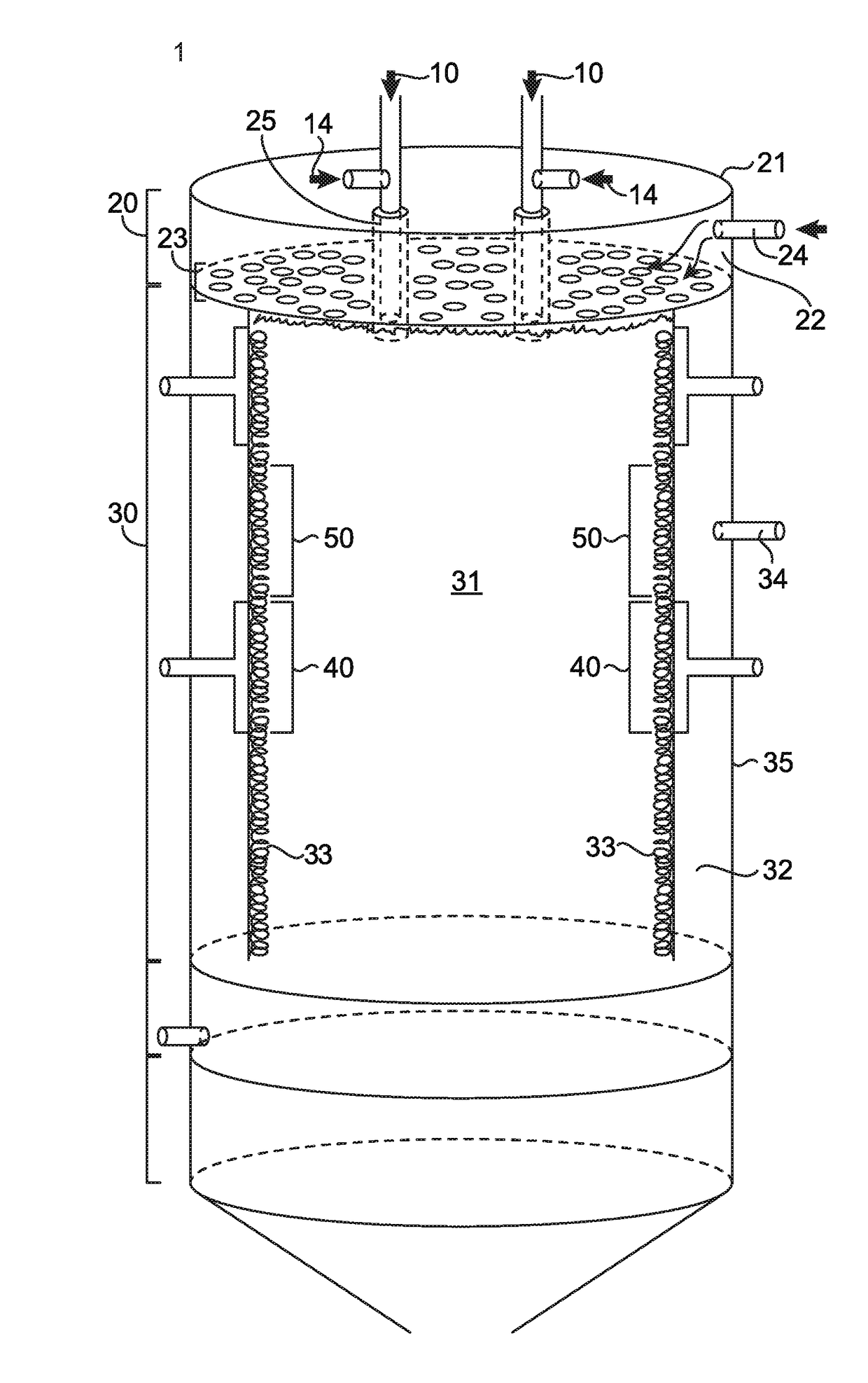

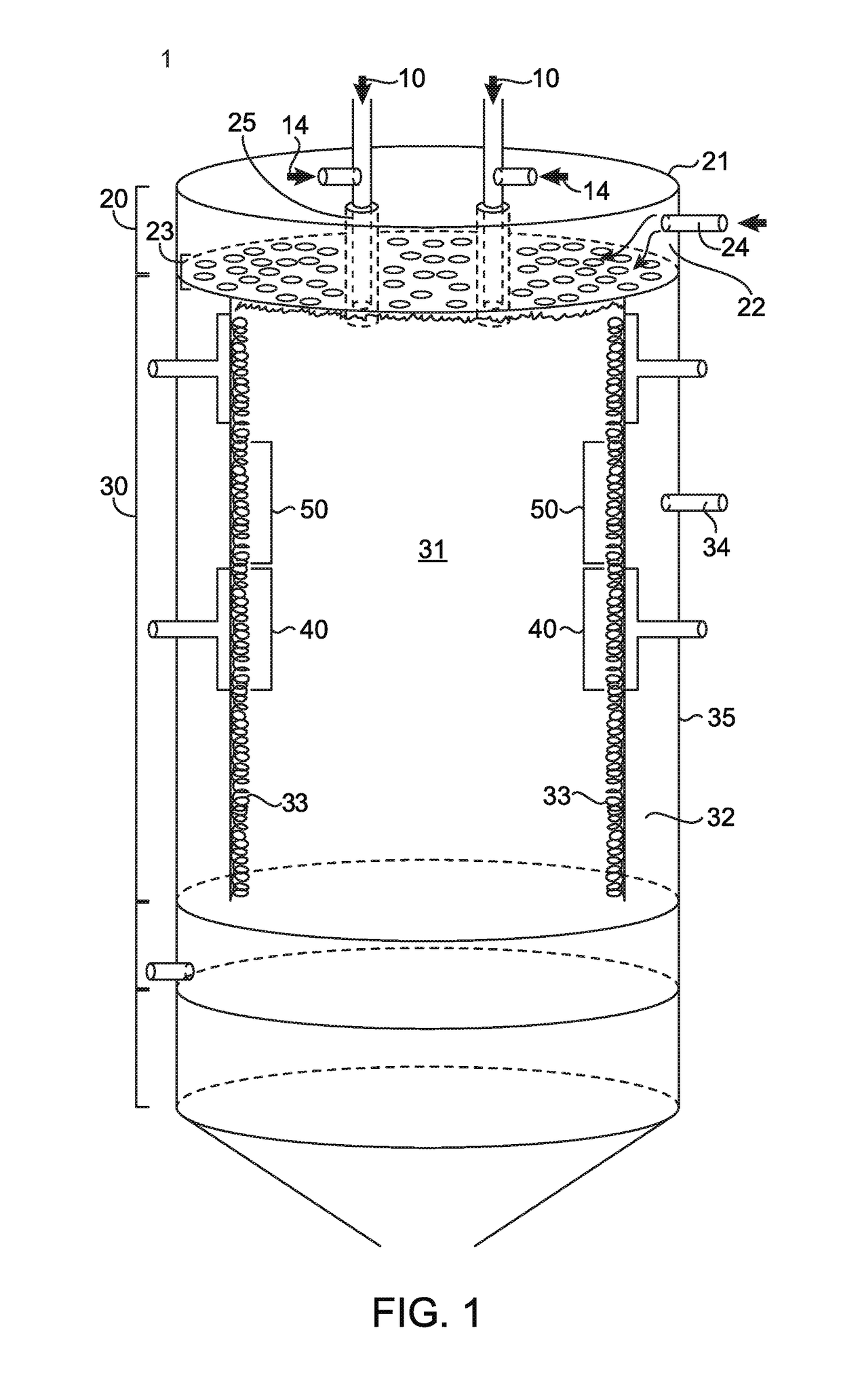

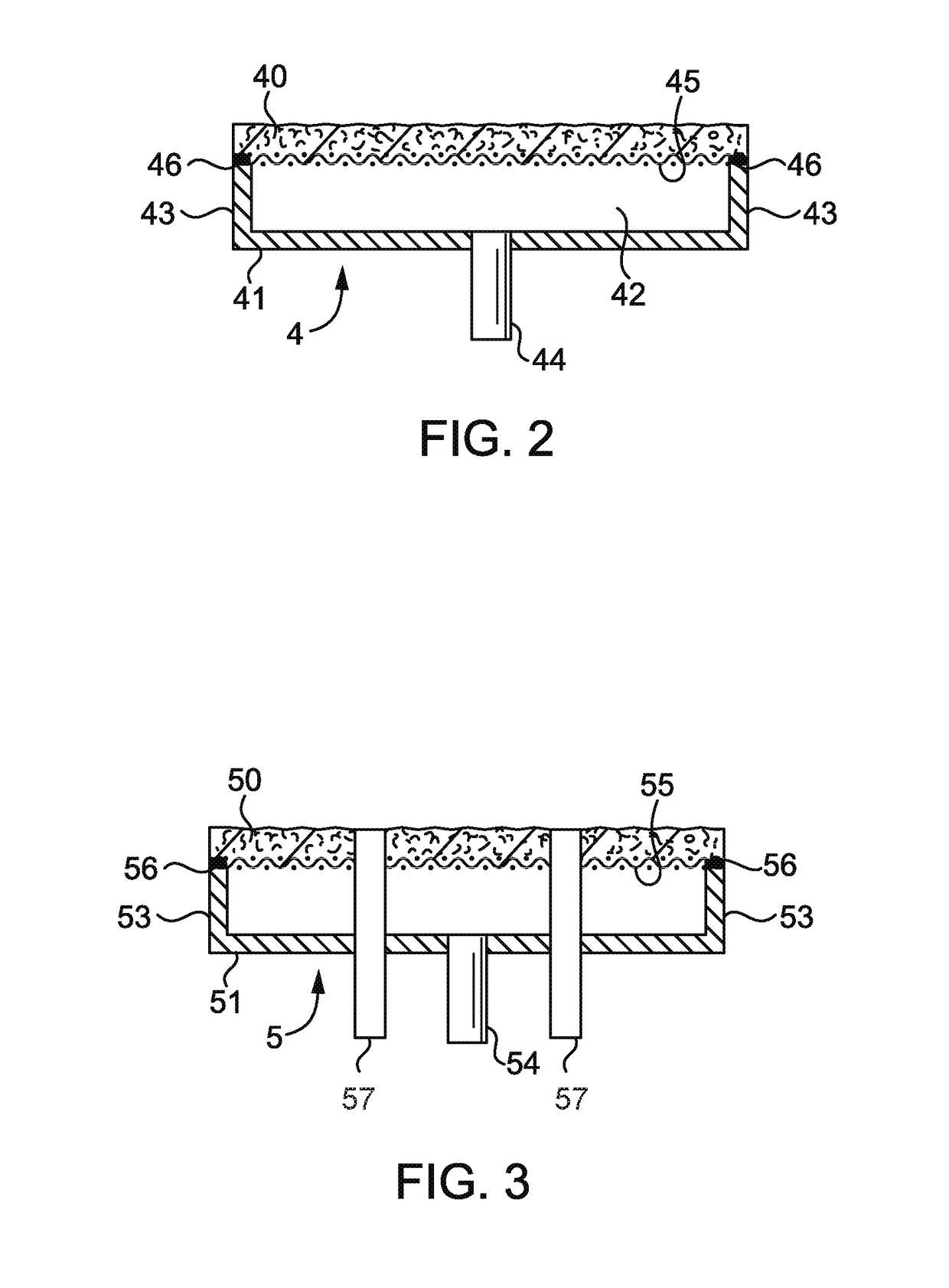

Systems and methods for improved waste gas abatement

ActiveUS20180259182A1Reduce accumulationLong lastingGas treatmentDispersed particle separationParticulatesHexafluoroethane

The present disclosure generally relates to systems and methods for the combustive abatement of waste gas formed during the manufacture of semiconductor wafers. In particular, the systems described herein are capable of combusting air-polluting perfluorocarbons, including those having high greenhouse gas indexes such as hexafluoroethane (C2F6) and tetrafluoromethane (CF4), as well as particulate-forming silicon dioxide precursors, such as silane (SiH4) and tetraethoxysilane (Si(OC2H5)4, abbreviated TEOS), with greater efficiency and lower energy usage than prior abatement systems. More particularly, and in one preferred embodiment, the present disclosure is directed to a waste gas abatement system that utilizes a combination of non-combustible and combustible gases (or gas mixtures) for thermal combustion, which are directed through multiple permeable interior surfaces of a reaction chamber, efficiently combusting waste gas and preventing undesirable accumulation of solid particulate matter on the chamber surfaces.

Owner:ALZETA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com