Patents

Literature

145 results about "Trifluoroethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trifluoroethane may refer to either of two isomeric fluorocarbons which differ by the location of attachment of the fluorine atoms: 1,1,1-Trifluoroethane 1,1,2-Trifluoroethane Both are used as refrigerant and propellant gasses.

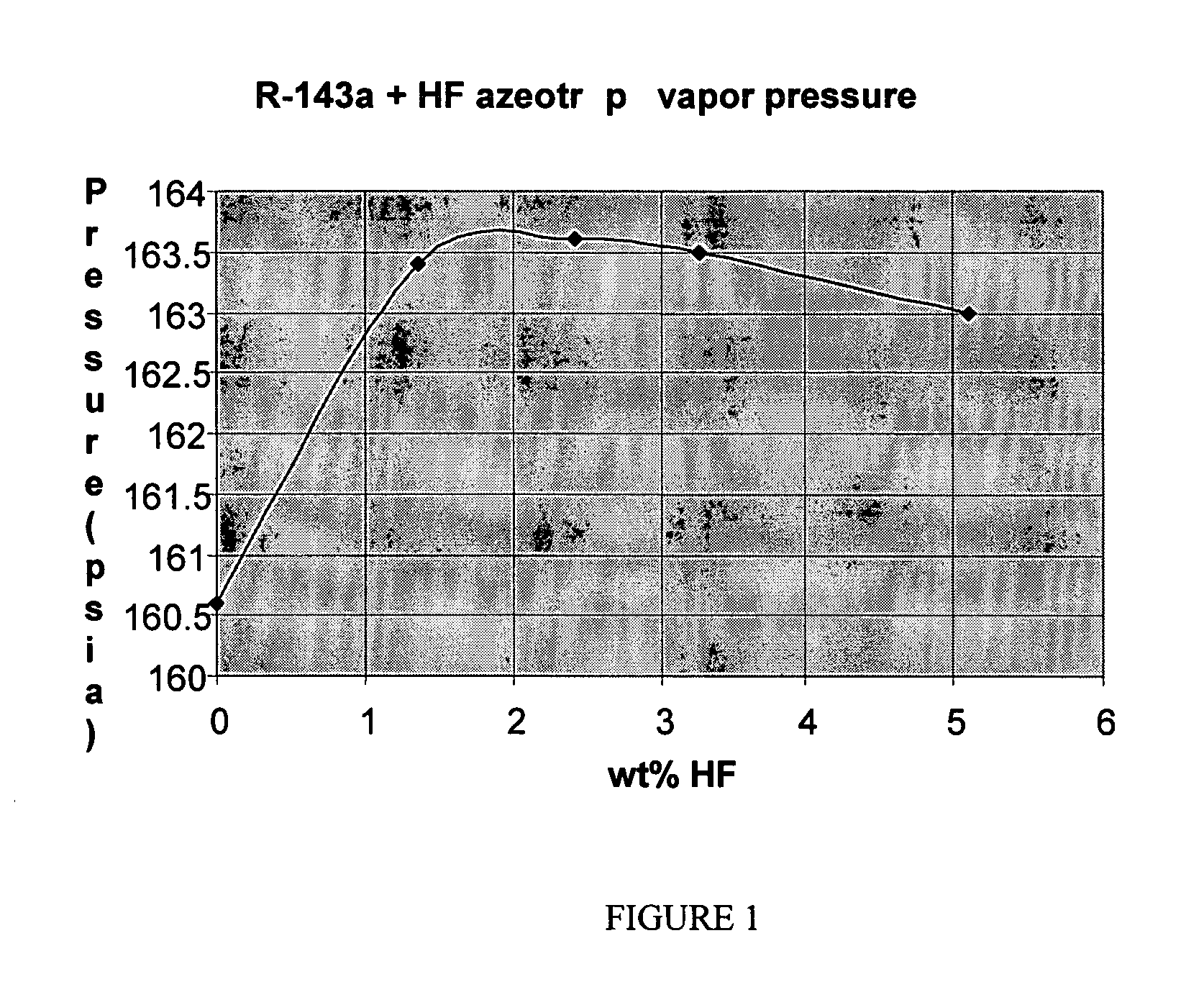

Azeotrope-like compositions of trifluoroethane and hydrogen fluoride

The invention relates to azeotropic and azeotrope-like mixtures of 1,1,1-trifluoroethane (HFC-143a) and hydrogen fluoride and a process for separating the azeotrope-like mixtures. The compositions of the invention are useful as an intermediate in the production of HFC-143a. The latter is useful as a nontoxic, zero ozone depleting fluorocarbon useful as a solvent, blowing agent, refrigerant, cleaning agent and aerosol propellant.

Owner:HONEYWELL INT INC

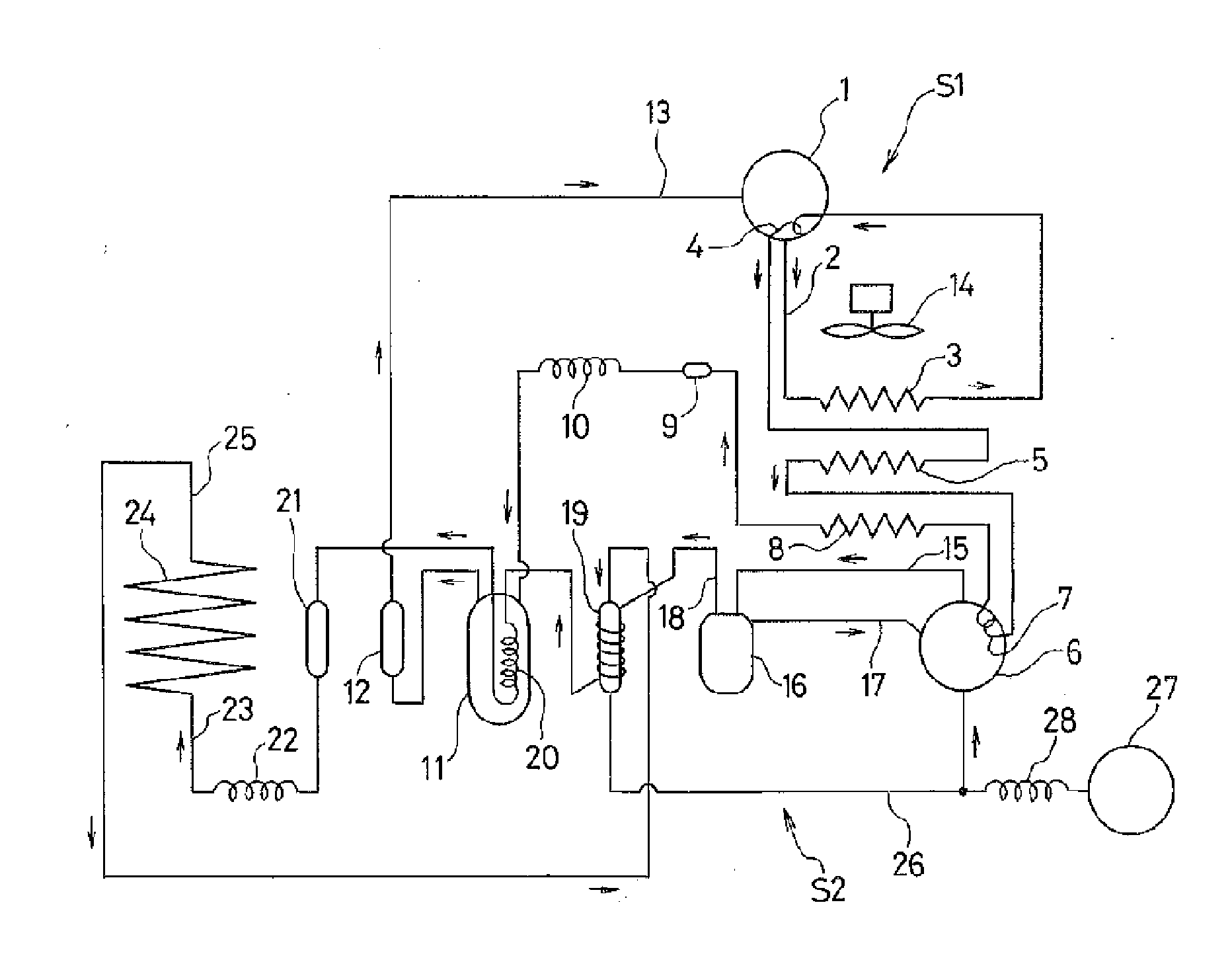

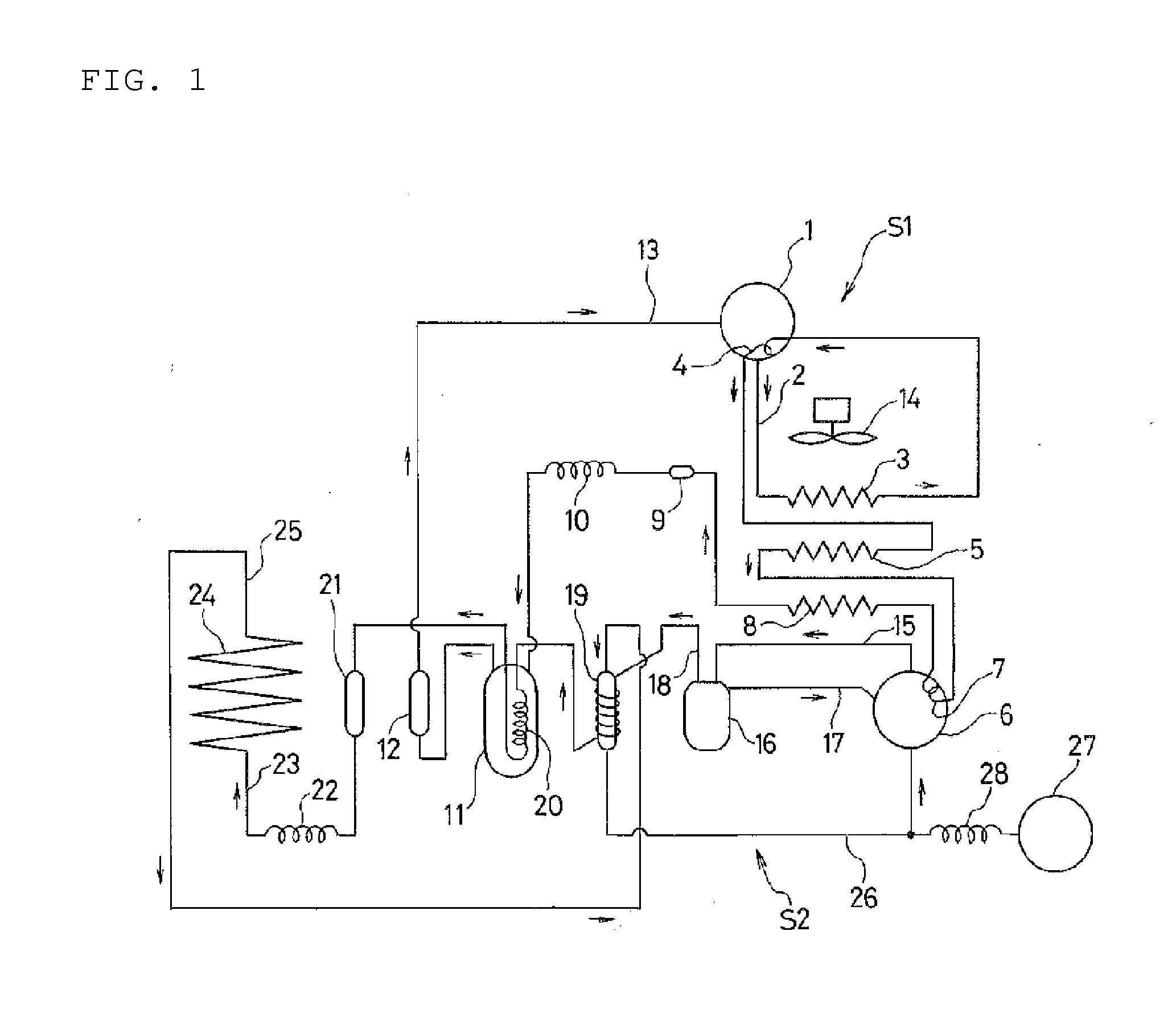

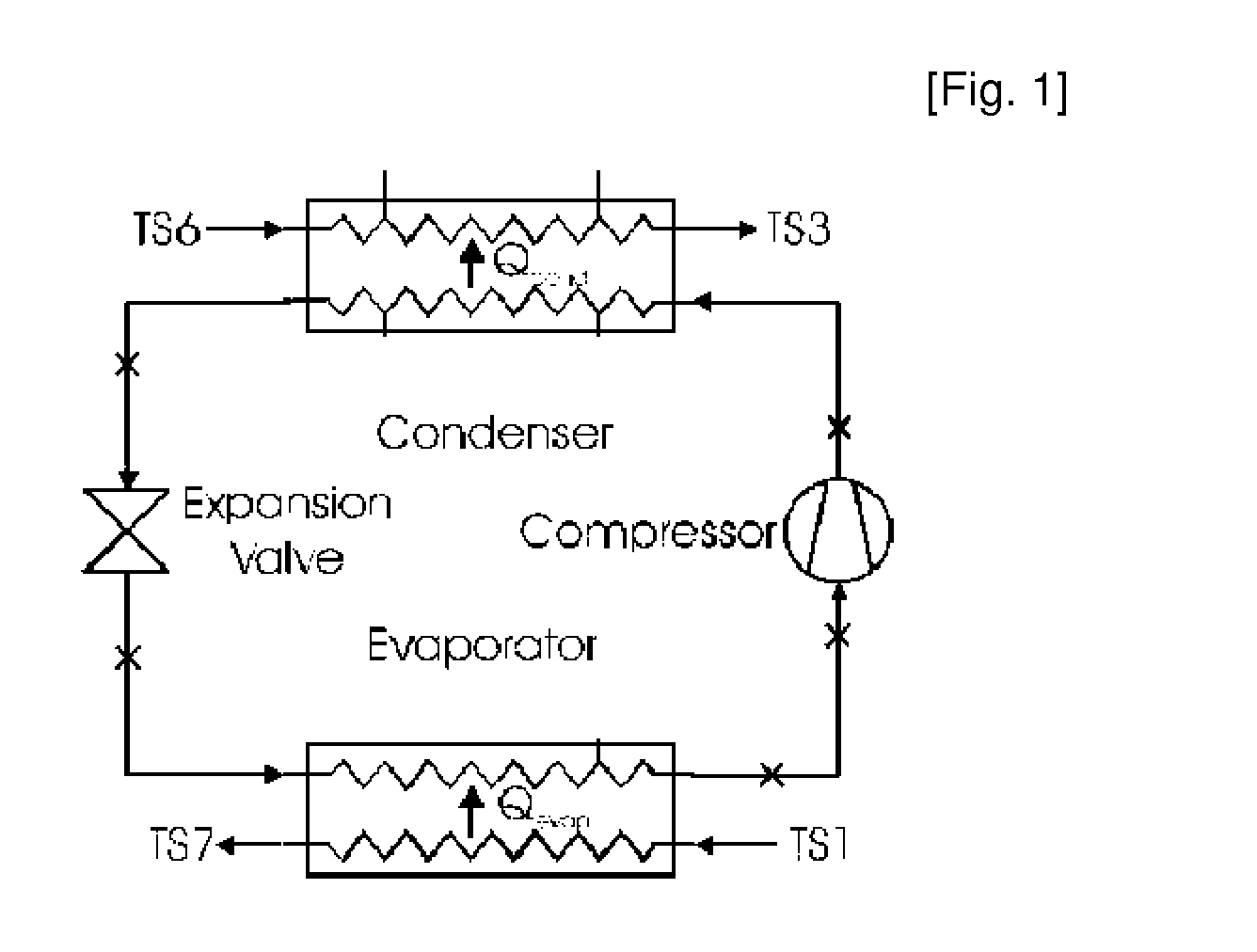

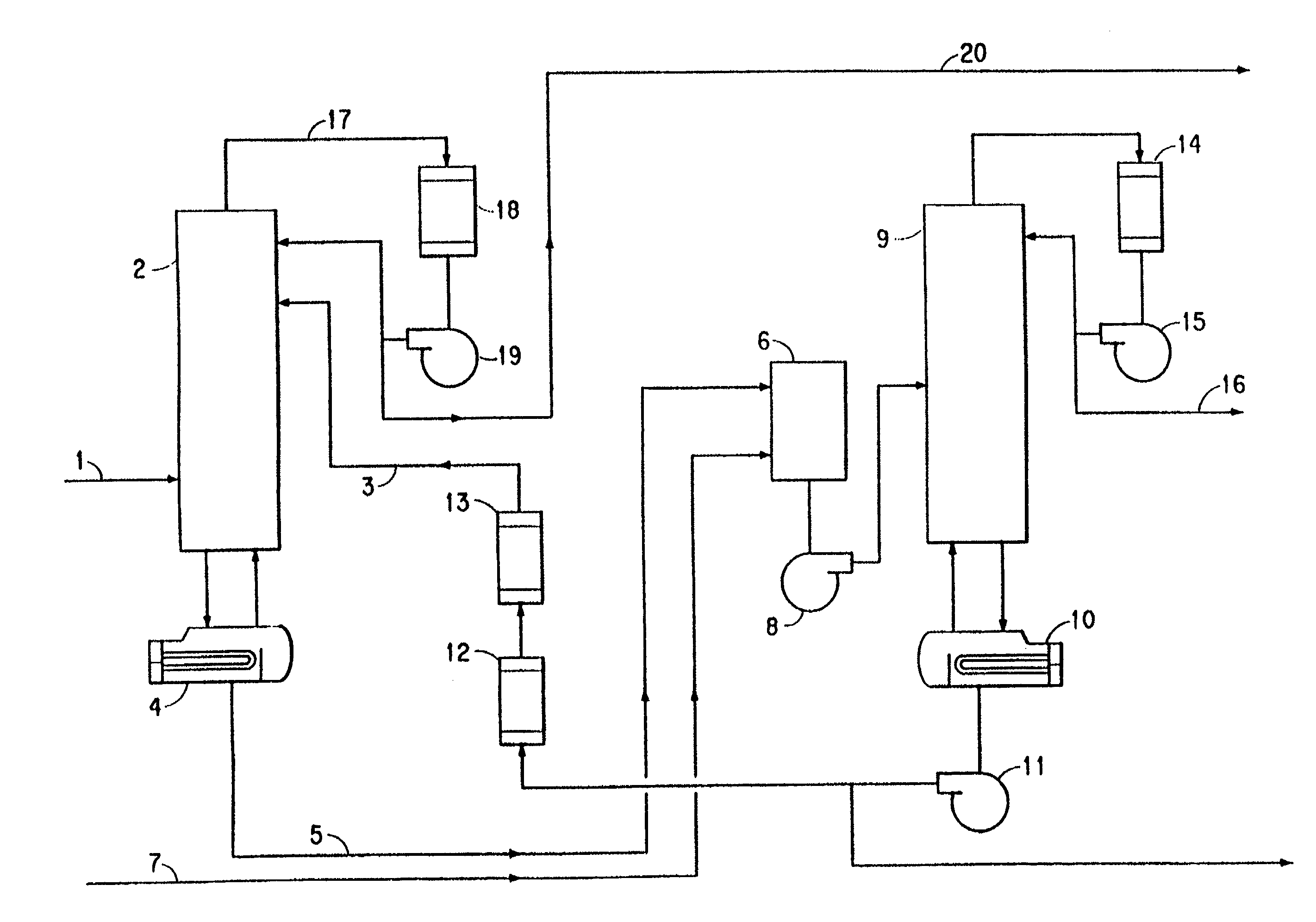

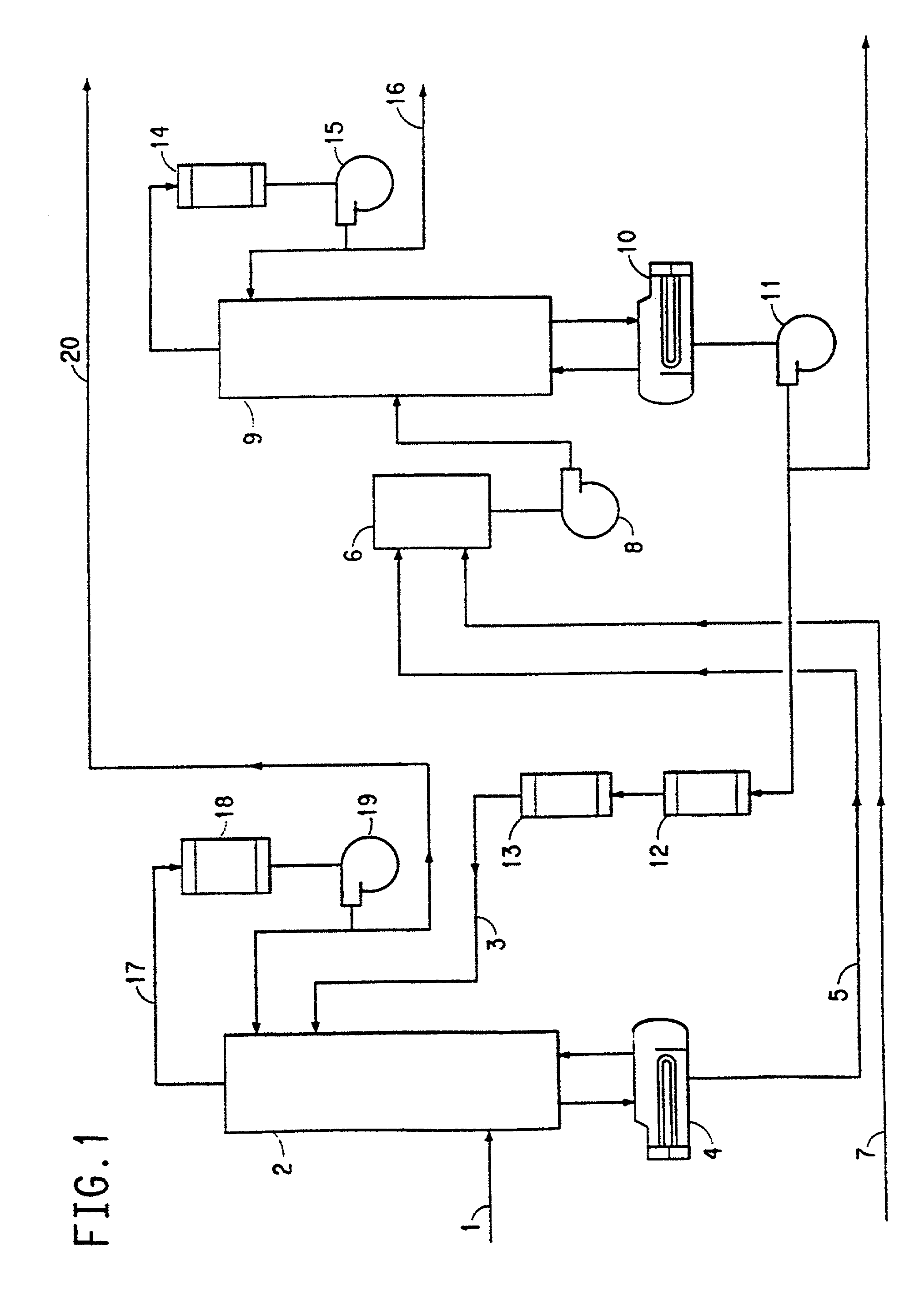

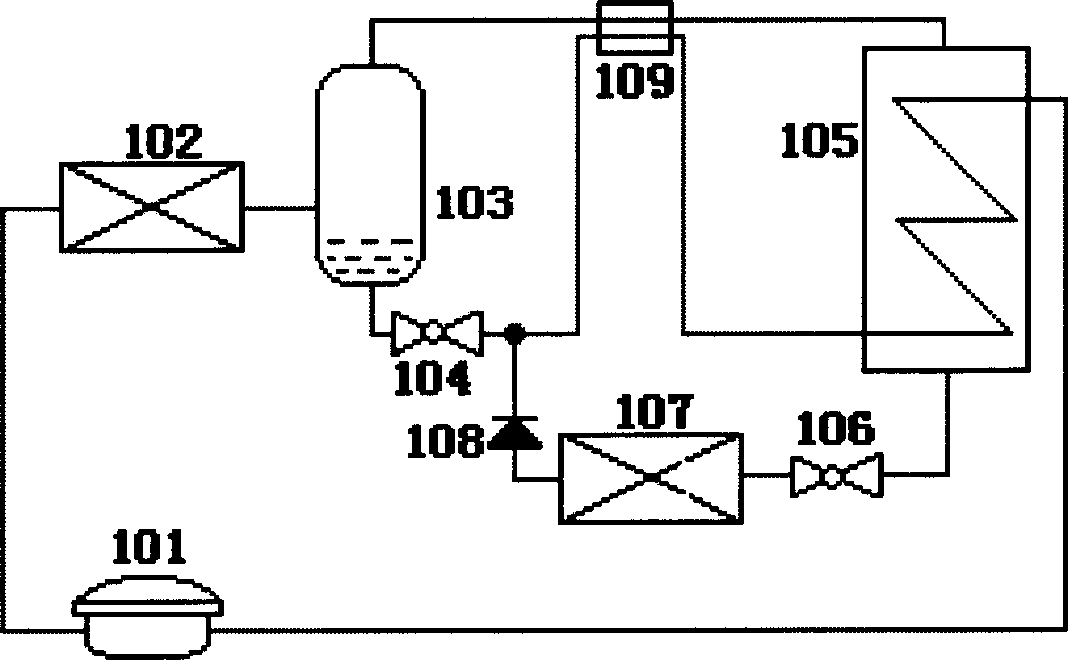

Binary refrigerating apparatus

InactiveUS20160018135A1Low GWP valueIncrease volumeCompression machines with cascade operationHeat-exchange elementsZeotropic mixtureEngineering

A binary refrigerating apparatus employs a refrigerant composition that has a small global-warming potential (GWP) to be earth friendly, can be used as a refrigerant capable of achieving a low temperature of −80° C., and is excellent in refrigerating capacity and other performance. A refrigerant composition used as a low-temperature-side refrigerant is a refrigerant mixture including a non-azeotropic mixture in which 20% by mass or less of carbon dioxide (R744) is mixed to difluoroethylene (R1132a). A refrigerant composition used as a high-temperature-side refrigerant is a combination of: a non-azeotropic mixture comprising the refrigerant group of difluoromethane (R32), pentafluoroethane (R125), 1,1,1,2-tetrafluoroethane (R134a) and 1,1,3-trifluoro ethane (R143a); and 1,1,1,2,3-pentafluoropentene (HFO-1234ze), having a global-warming potential (GWP) of 1500 or less.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

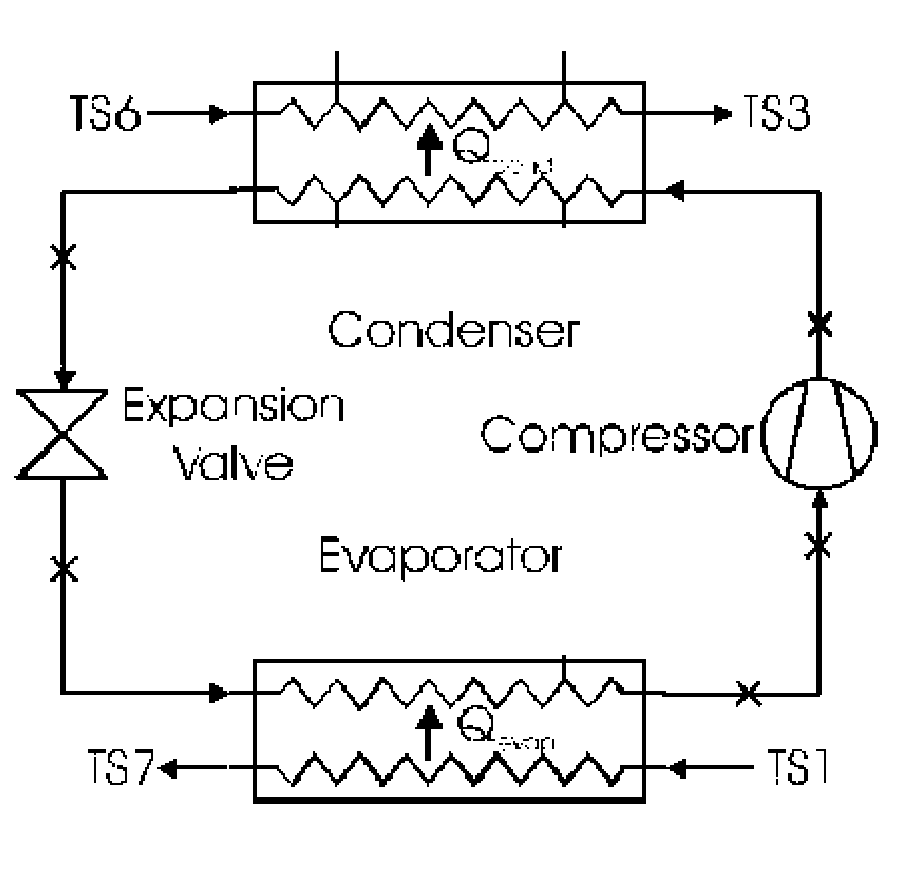

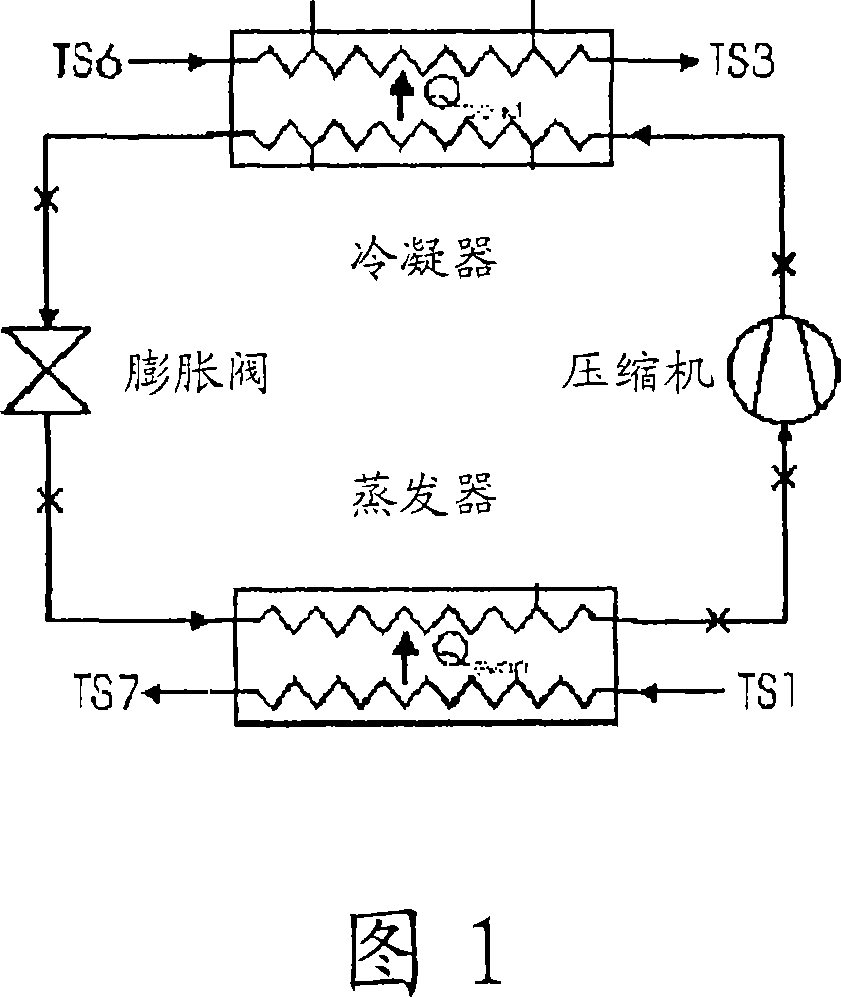

R502, R12 or R22 Substitute Mixed Refrigerant and Refrigeration System Using Thereof

InactiveUS20090261289A1Avoid destructionShorten the timeHeat-exchange elements1,1-DifluoroethaneEngineering

The present invention relates to a refrigerant mixture for substituting R502, R22 or R12 used in a vapor compression refrigerator or air conditioner and a refrigeration system using the same. More specifically, the present invention relates to a refrigerant mixture comprising a combination of two or three components, which is capable of being used without causing ozone layer destruction and global warming and at the same time, without replacement of the existing refrigeration system, wherein the components are selected from the group consisting of propylene, propane, 1,1,1,2-tetrafluoroethane, pentafluoroe thane, 1,1,1-trifluoroethane, 1,1-difluoroethane, dimethylether and isobutane; and a refrigeration system using the same.

Owner:HAM YOON SIK +1

Method of dry etching, dry etching gas and process for producing perfluoro-2-pentyne

InactiveUS20050247670A1Improve etch selectivityImprove stabilityPreparation by hydrogen halide split-offDecorative surface effectsResist2-Pentyne

A dry etching method wherein a resist film is irradiated with radiation having a wavelength of not more than 195 nm to form a resist pattern having a minimum line width of not more than 200 nm, and the substrate having the resist pattern formed thereon is subjected to dry etching using a fluorine-containing compound having 4 to 6 carbon atoms and at least one unsaturated bond as an etching gas. As the fluorine-containing compound, perfuloro-2-pentyne, perfuloro-2-butyne, nonafluoro-2-pentene and perfluoro-2-pentene are preferably used. Perfuloro-2-pentyne is produced by a process wherein a 1,1,1-trihalo-2,2,2-trifluoroethane is allowed to react with pentafluoropropionaldehyde to give a 2-halo-1,1,1,4,4,5,5,5-octafluoro-2-pentene, and the thus-produced halo-octafluoro-2-pentene is dehydrohalogenated.

Owner:ZEON CORP

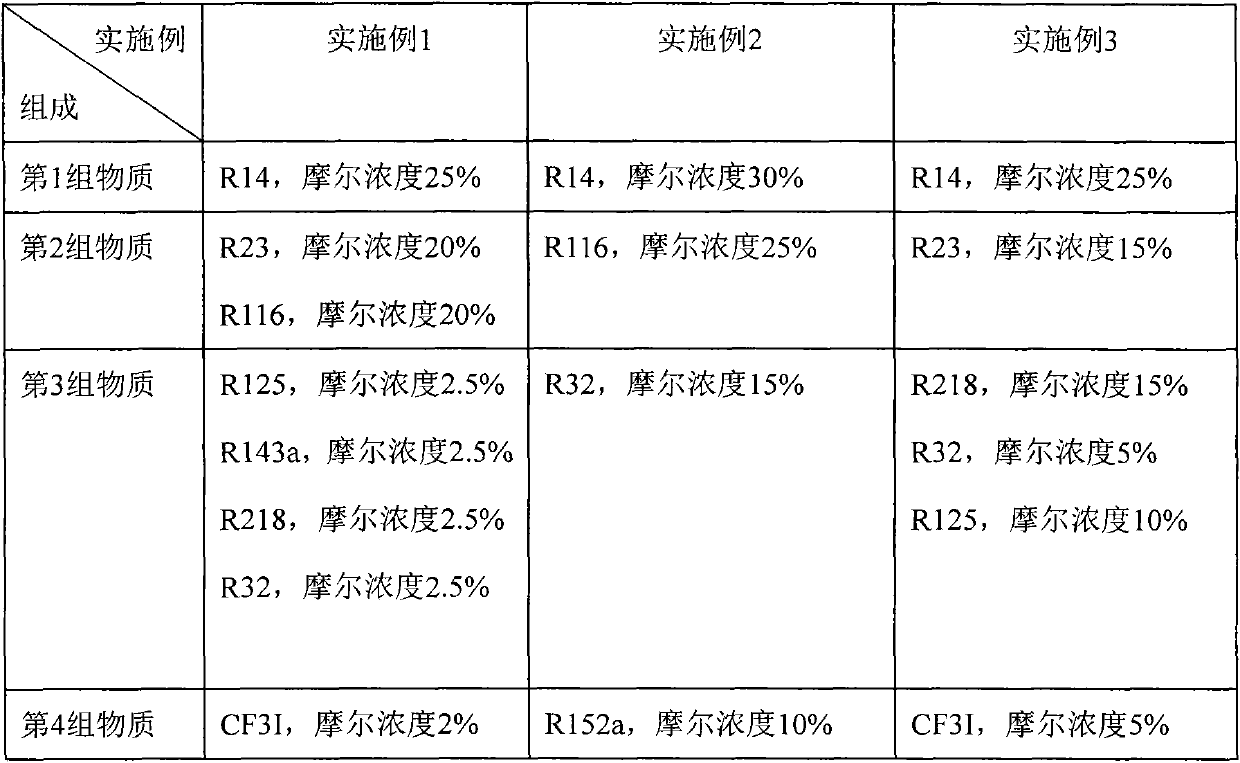

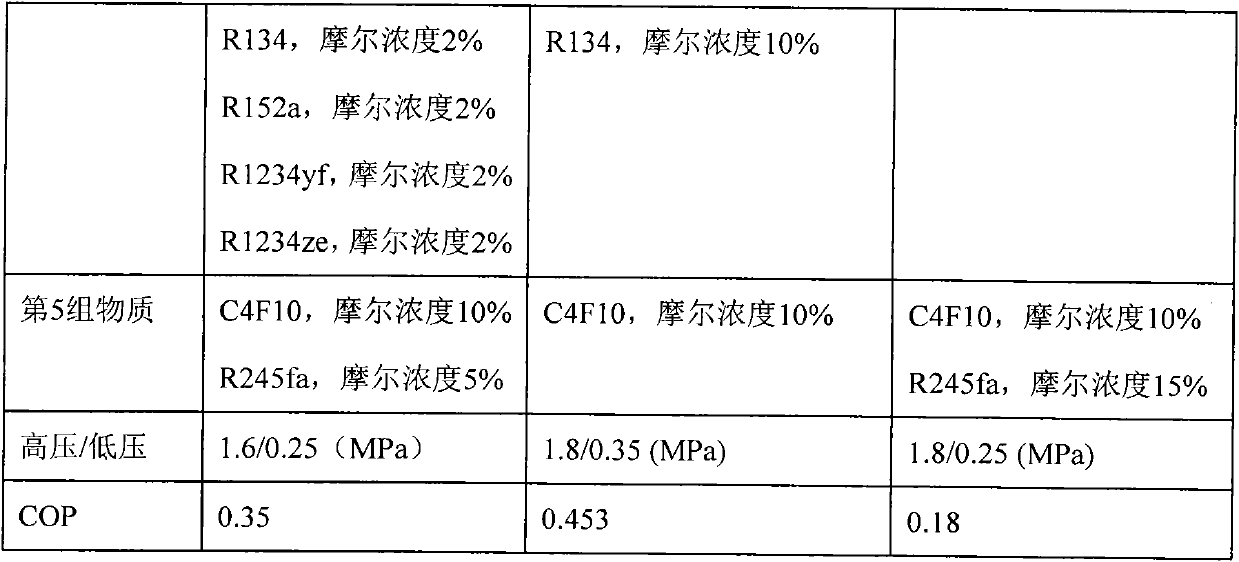

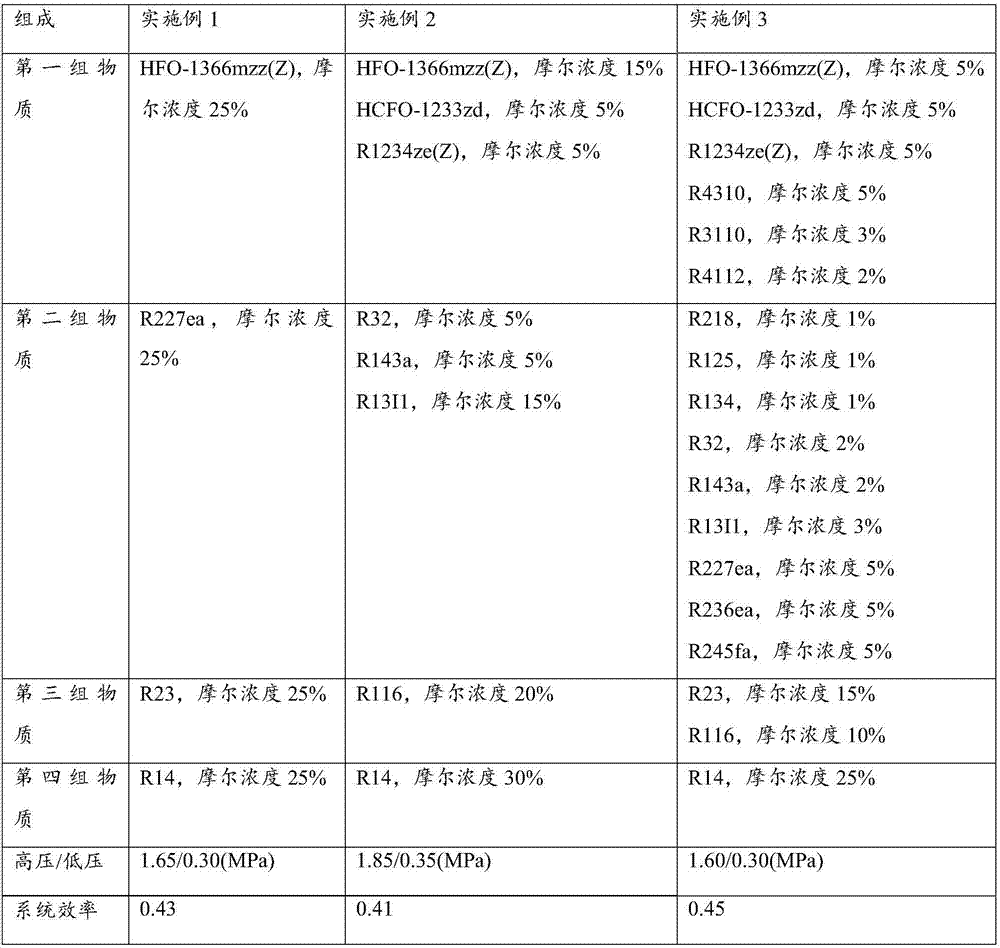

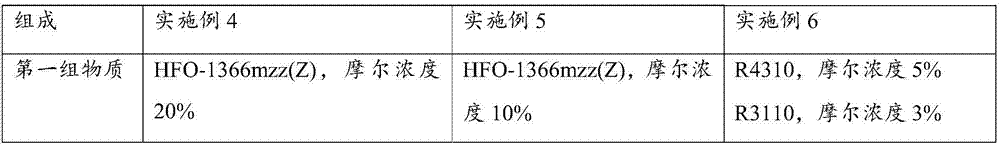

Non-combustible mixing refrigerant suitable for deep refrigeration temperature of minus 80 DEG C to minus 100 DEG C

ActiveCN102559146ANo destructive effectNon-flammableHeat-exchange elementsHexafluoroethanePolymer science

The invention relates to a non-combustible mixing refrigerant suitable for deep refrigeration temperature of minus 80 DEG C to minus 100 DEG C. The non-combustible mixing refrigerant comprises five groups of materials, where the first group of material is tetrafluoromethane; the second group of material is trifluoromethane, hexafluoroethane or a mixture of the trifluoromethane and the hexafluoroethane; the third group of material is pentafluoroethane, trifluoroethane, perfluoropropane, difluoromethane or a mixture of two, three or multiple of the pentafluoroethane, the trifluoroethane, the perfluoropropane and the difluoromethane; the fourth group of material is iodotrifluoromethane, 1, 1, 2, 2-tetrafluoroethane, 1,1-difluoroethane, 2, 3, 3, 3-tetrafluoropropene, 1, 3, 3, 3-tetrafluoropropene or a mixture of two, three or multiple of the iodotrifluoromethane, the 1, 1, 2, 2-tetrafluoroethane, the 1,1-difluoroethane, the 2, 3, 3, 3-tetrafluoropropene and the 1, 3, 3, 3-tetrafluoropropene; the fifth group of material is perfluoro-n-butane, 1, 1, 1, 3, 3-perfluoropropane or a mixture of the perfluoro-n-butane and the 1, 1, 1, 3, 3-perfluoropropane; the molar concentrations of the five groups of materials are respectively 25-50%, 15-40%, 10-30%, 5-20% and 10-25%; and the non-combustible mixing refrigerant is safe in a back-heating type throttling refrigeration system, can realize the refrigeration in the temperature range of minus 80 DEG C to minus 100 DEG C and has low whole green house effect without ozone depletion effect.

Owner:中科赛凌(北京)科技有限公司

R502, r12 or r22 substitute mixed refrigerant and refrigeration system using thereof

InactiveCN101006154AAvoid destructionLow application costOrganic chemistryCompression machines with non-reversible cycleEngineeringRefrigeration

The present invention relates to a refrigerant mixture for substituting R502, R22 or R12 used in a vapor compression refrigerator or air conditioner and a refrigeration system using the same. More specifically, the present invention relates to a refrigerant mixture comprising a combination of two or three components, which is capable of being used without causing ozone layer destruction and global warming and at the same time, without replacement of the existing refrigeration system, wherein the components are selected from the group consisting of propylene, propane, 1,1,1,2-tetrafluoroethane, pentafluoroe thane, 1,1,1-trifluoroethane, 1,1-difluoroethane, dimethylether and isobutane; and a refrigeration system using the same.

Owner:咸允植 +1

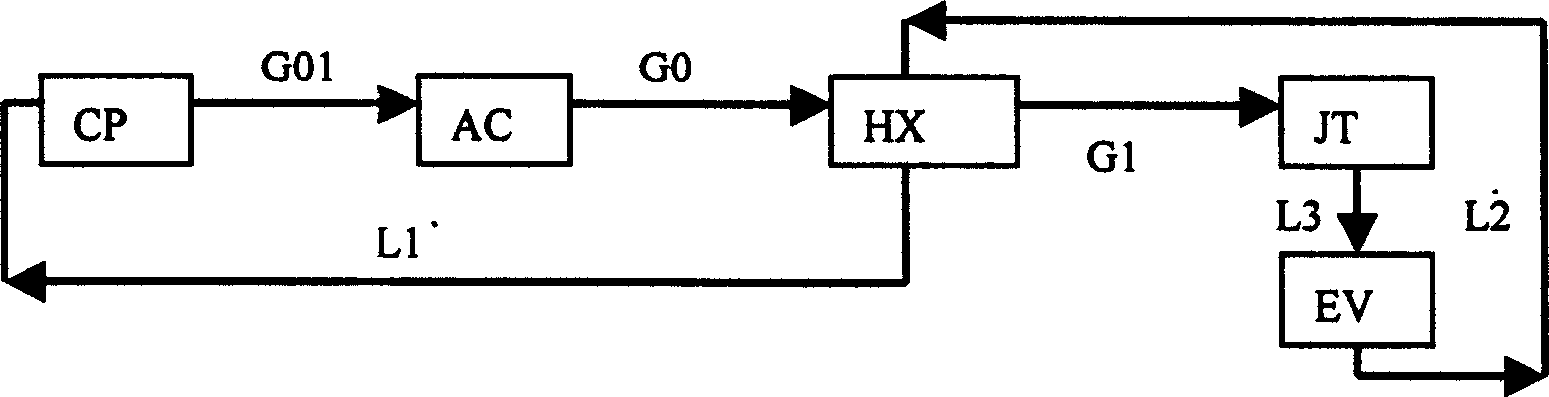

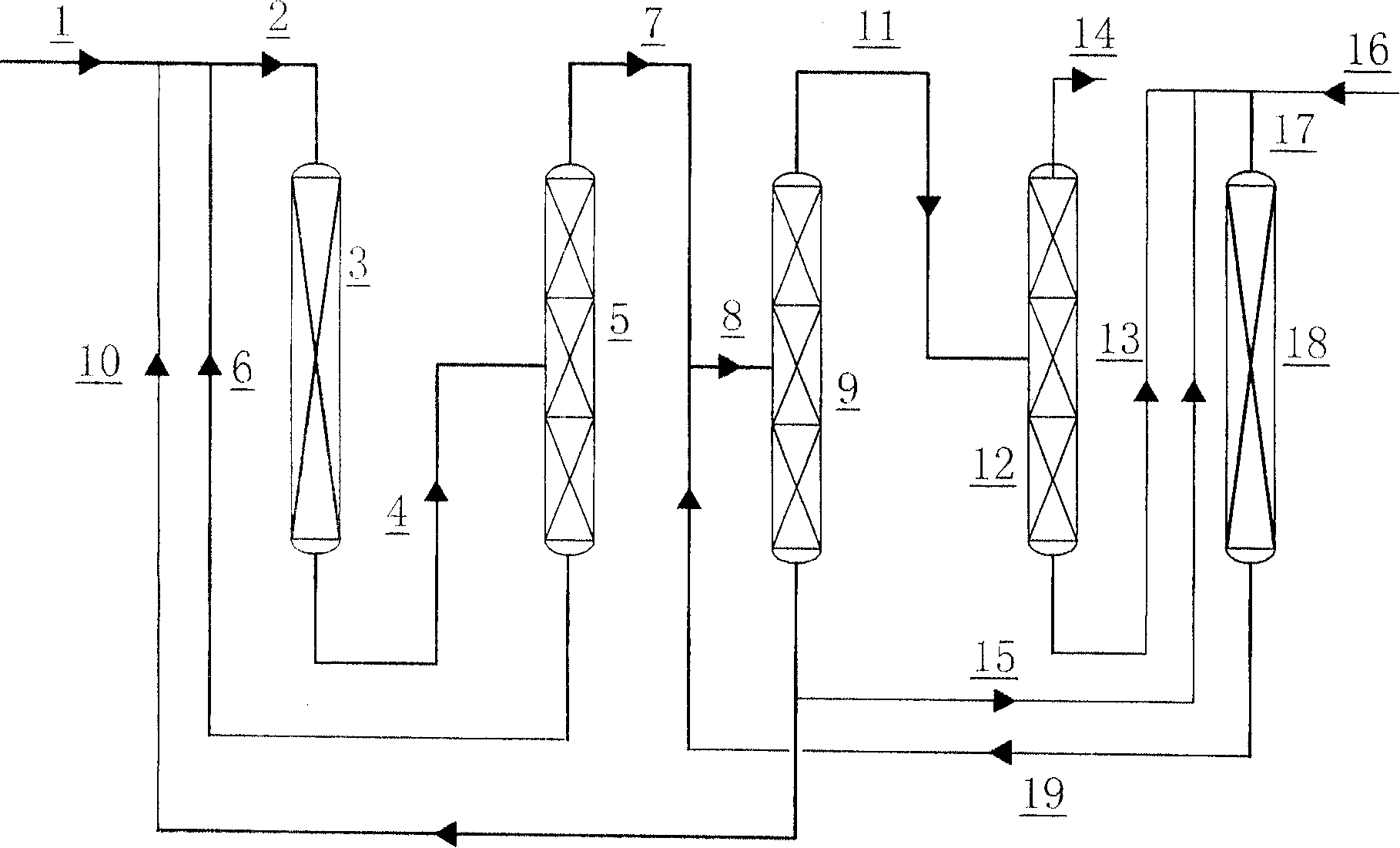

Multicomponent mixed work medium throttling refrigerant applicable to 200-204K refrigerating temperature zone

The multicomponent mixed work medium throttling refrigerating agent applicable to 200-240 k temp. zone includes four groups of substances, respectively are: first group includes tetrafluoromethane, nitrogen trifluoride or mixture; second group includes ethylene, ethane, fluoroform, xenon, fluromethane, perfluoroethylene, fluoroethylene, perfluoroethane or their any two, three and several kinds or mixture of all them; fourth group includes 1-butylene, isobutane, 2-methyl butane, 1-pentene, 3-methyl-1-butylene, 2-methylpentane, 2-butylene, cyclobutane, isobutylene, n-butane, pefluorobutane, n-pentane, perfluoropentane or their two, three, several kinds ormixture of all the them; and third group includees propylene, propane, perfluoropropane, 1,1,1-trifluoroethane, 1,1,-bifluoroethane.

Owner:中科赛凌(北京)科技有限公司

Process for making 1,1,1,4,4,4-Hexafluoro-2-butene

Owner:THE CHEMOURS CO FC LLC

Process for producing 1,1,1,2,2-pentafluoroethane

InactiveUS6392106B1Reduce productionReduce the amount requiredPreparation by halogen halide additionPreparation by halogen replacementHydrogen fluoride1,1,1,2-Tetrafluoroethane

Owner:DAIKIN IND LTD

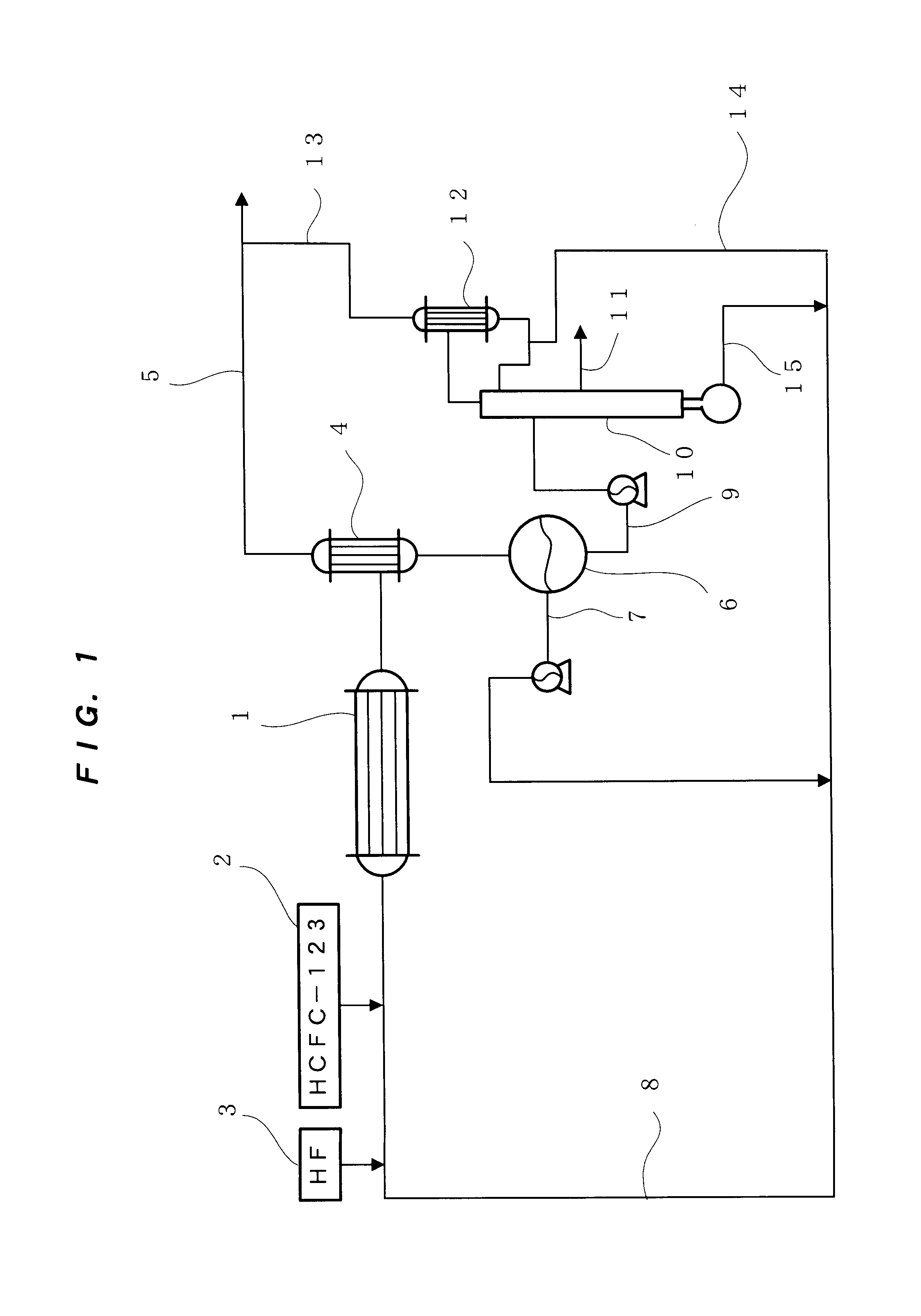

Method for preparing pentafluoroethane

ActiveCN101157595AReduce contentReduce coking ratePreparation by halogen replacementHydrogen fluorideDistillation

The invention discloses a method of preparing the pentafluoroethane (HFC-125), which adopts the hydrogen fluoride (HF) and the perchlorethylene (PCE) as the material, and takes two reactors and two steps of gas phase catalysis fluorination reaction. A first reactor fluorinates the PCE and synthesizes 2,2-dichlor-1,1,1-trifluoroethane(HCFC-123) and 2-chlorin-1,1,1,2-tetrafluorothane(HCFC-124), and the second reactor fluorinates HCFC-123 and HCFC-124 and synthesizes HFC-125. The unreacted PCE in the resultant flow of the first reactor is separated by a first distillation tower and then circulates to the first reactor; the HF, HCFC-126, HCFC-124, HFC-125 and HCL in the resultant flow of the first reactor and the second reactor are separated by a second distillation tower and a third distillation tower, and then the separated HF circulates to the first reactor and the second reactor, while the HCFC-123, the HCFC-124 and the HFC-134a circulate to the second reactor. The invention can prolong the service life of the catalyst and improve the one-way conversion of PCE as well as remarkably reduce the content of chloropentafluoroethane(CFC-115) in the desired product HFC-125.

Owner:XIAN MODERN CHEM RES INST +1

Purification of difluoromethane by extractive distillation

InactiveUS7371309B2Halogenated hydrocarbon separation/purificationExtractive distillationExtractive distillationOxygen

The present invention provides extractive distillation processes for removing difluoromethane (HFC-32) from a mixture comprising HFC-32 and at least one of chlorodifluoromethane (CFC-12), 1,1,1-trifluoroethane (HFC-143a), chloropentafluoroethane (CFC-115), and pentafluoroethane (HFC-125) using hydrocarbon, chlorocarbon, and oxygen-containing extractive agents.

Owner:EI DU PONT DE NEMOURS & CO

Non-flammable mixed refrigerant applicable to temperature zone from -60 to -100 DEG C

The invention provides a non-flammable mixed refrigerant applicable to a temperature zone from -60 to -100 DEG C. The non-flammable mixed refrigerant comprises at least one selected from a group consisting of cis-1,1,1,4,4,4-hexafluorobutene, trans-1,1,1,4,4,4-hexafluorobutene, 1-chloro-3,3,3-trifluoropropene, cis-1,3,3,3-tetrafluoropropene, 1,1,1,2,2,3,4,5,5,5-decafluoropentane, perfluorobutane and perfluoropentane, at least one selected from a group consisting of perfluoropropane, pentafluoroethane, 1,1,2,2-tetrafluoroethane, 1,1,1,2-tetrafluoroethane, difluoromethane, 1,1,1-trifluoroethane, trifluoroiodomethane, 1,1,1,2,3,3,3-heptafluoropropane, 1,1,1,2,3,3-hexafluoropropane and 1,1,1,3,3-pentafluoropropane, at least one selected from a group consisting of trifluoromethane and perfluoroethane, and perfluoromethane. The non-flammable mixed refrigerant provided by the invention can safely and efficiently realize cooling in a temperature range of -60 to -100 DEG C, does not have flammability at all, and is low in overall greenhouse effect and free of ozone depletion effect.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

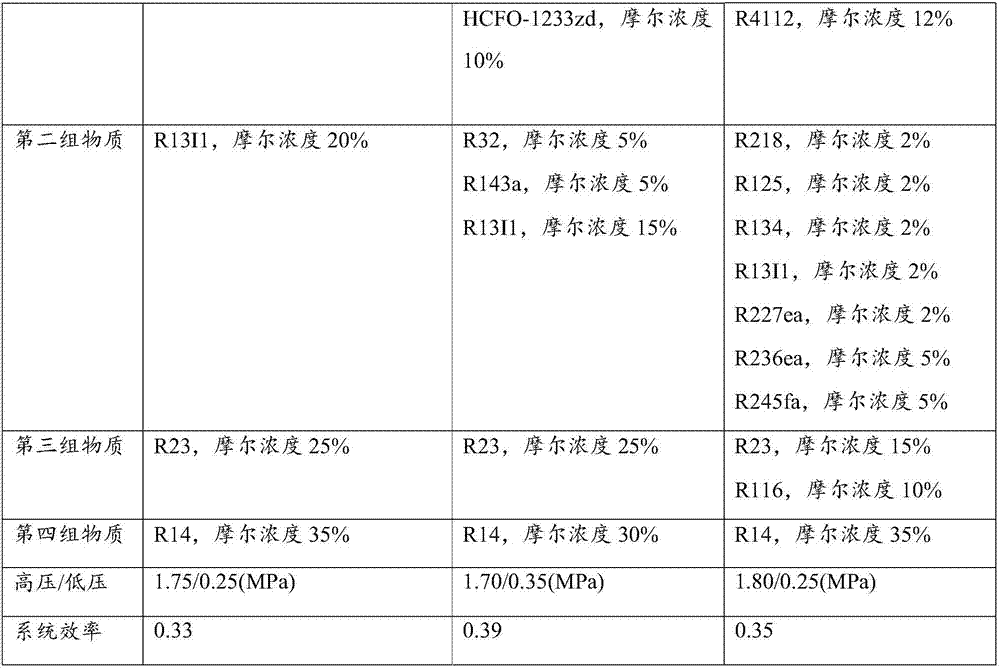

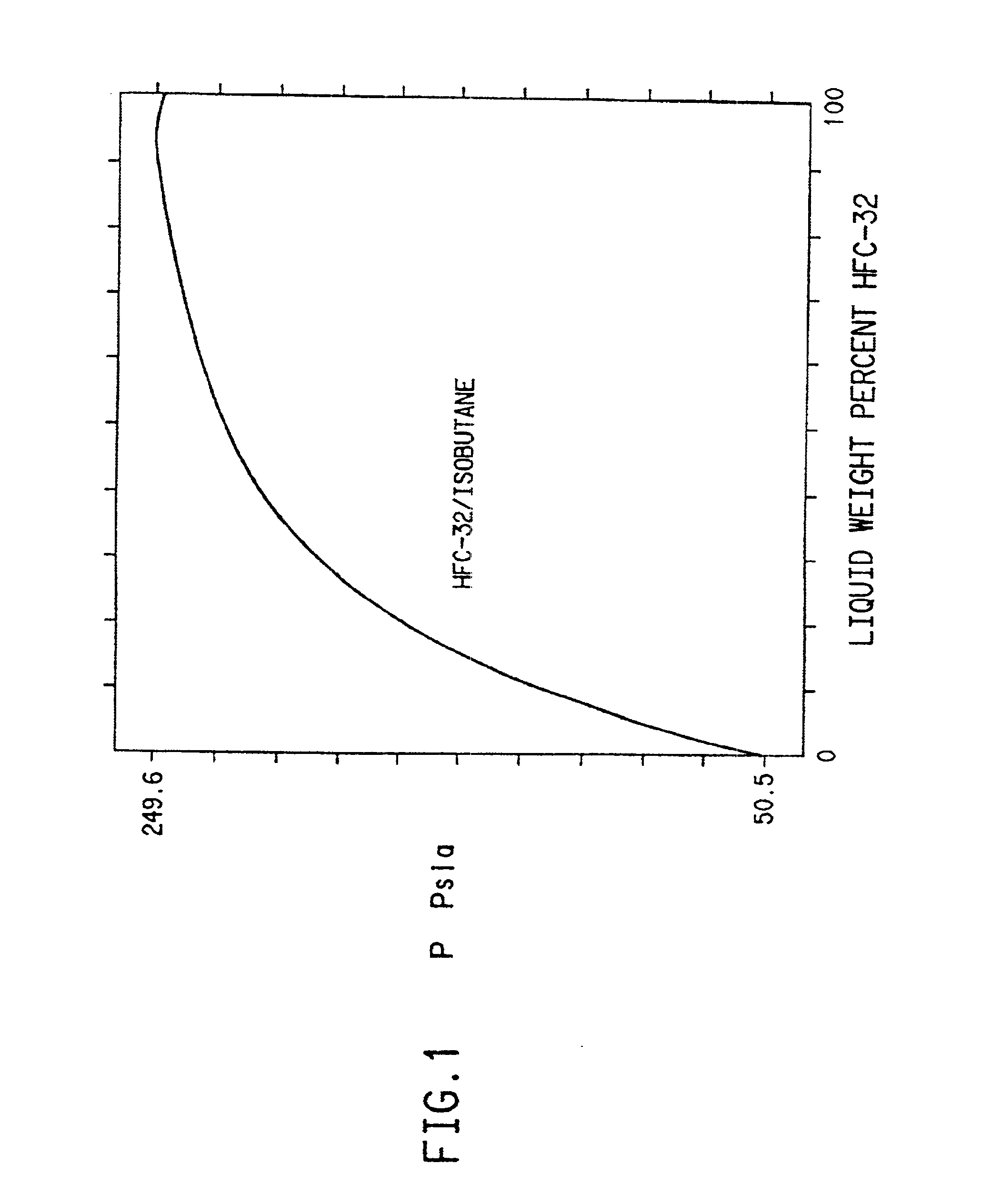

Hydrofluorocarbon compositions

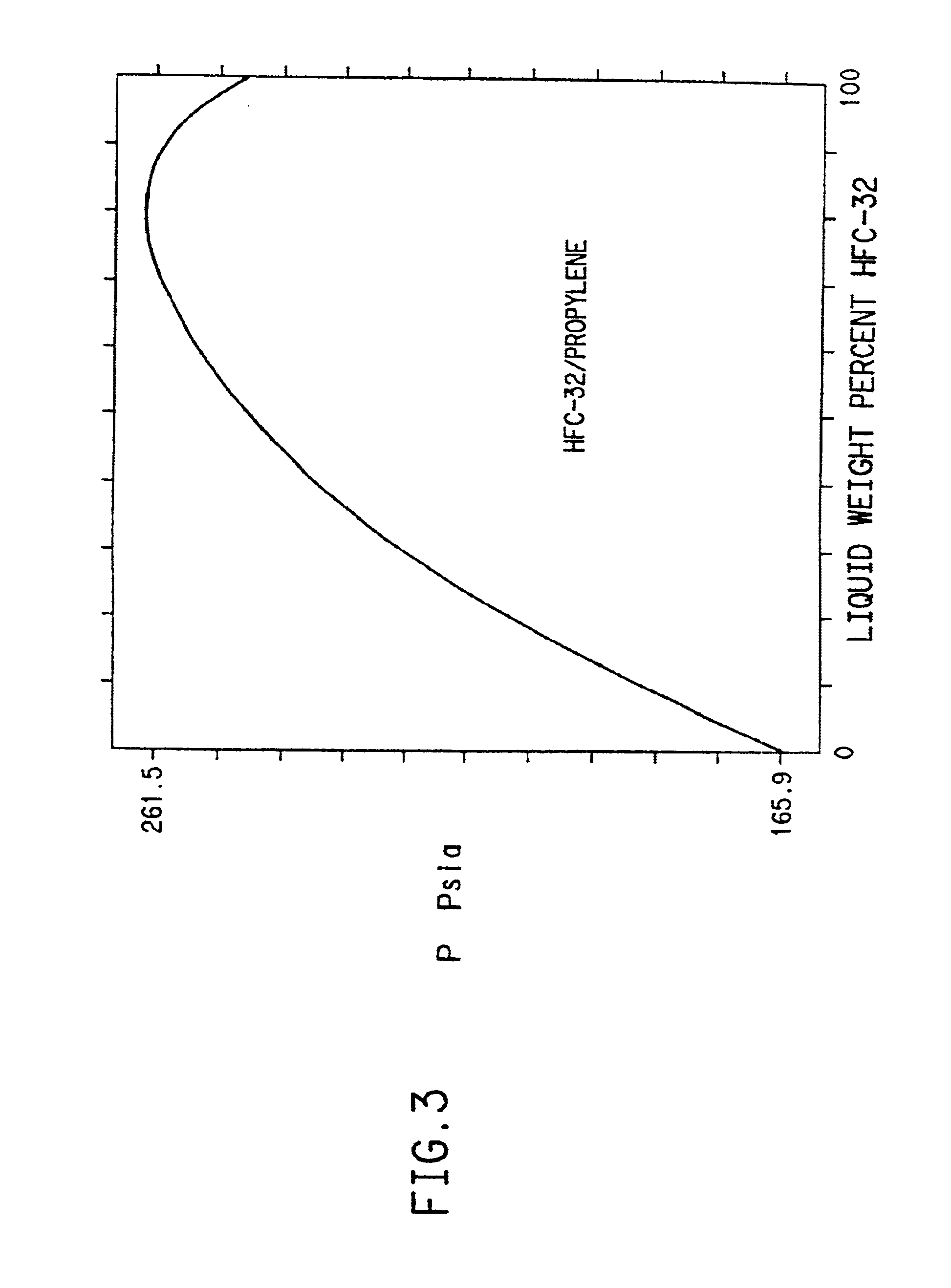

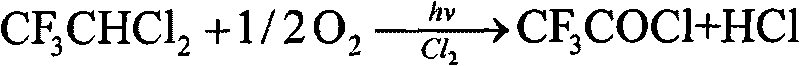

Refrigerant compositions include mixtures of difluoromethane and isobutane, butane, propylene or cyclopropane; pentafluoroethane and propylene or cyclopropane; 1,1,2,2-tetrafluoroethane and propane; 1,1,1,2-tetrafluoroethane and cyclopropane; 1,1,1-trifluoroethane and DME or propylene; 1,1-difluoroethane and propane, isobutane, butane or cyclopropane; fluoroethane and propane or cyclopropane; 1,1,1,2,2,3,3-heptafluoropropane and butane, cyclopropane, DME, isobutane or propane; or 1,1,1,2,3,3,3-heptafluoropropane and butane, cyclopropane, isobutane or propane.

Owner:EI DU PONT DE NEMOURS & CO

Refrigerant mixture comprising difluromethane, pentafluroethane and 1,1,1-trifluoroethane

A novel refrigerant composition useful as a substitute for HCFC-22, comprising a first constituent of difluoromethane (CH2F2, HFC-32); a second constituent of pentafluoroethane (CHF2CF3, HFC-125); a third constituent of 1,1,1-trifluoroethane (CH3CF3, HFC-143a); a fourth constituent selected from the group consisting of cyclopropane (C3H6, RC-270), 1,1,1,2,3,3,3-heptafluoropropane (CF3CHFCF3, HFC-227ea), 1,1,1,2,2-pentafluoropropane (CH3CF2CF3, HFC-245cb), isobutane (CH(CH3)2CH3, R-600a), octafluorocyclobutane (C4F8, RC-318), 1,1,1,2,3,3-hexafluoropropane (CHF2CHFCF3, HFC-236ea), butane (C4H10, R-600), bis(difluoromethyl)ether (CHF2OCHF2, HFE-134) and pentafluoroethylmethylether (CF3CF2OCH3, HFE-245).

Owner:KOREA INST OF SCI & TECH

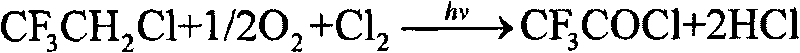

Method for preparation of trifluoro acetyl chloride with trifluoroethane chlorinated mixture

ActiveCN101747176AReduce consumptionThe synthetic route is simpleCarboxylic acid halides preparationAcetyl chlorideGas phase

The invention discloses a method for preparation of trifluoro acetyl chloride with trifluoroethane chlorinated mixture, which comprises the following steps: 1) adding trifluoroethane chlorinated mixture into a reactor, continuously introducing oxygen and chlorine under stirring, irradiating with a mercury lamp for photochemical oxidation, continuously discharging reactants in the form of gas phase from the upper part of the reactor, and continuously supplementing the trifluoroethane chlorinated mixture to maintain the level in the reactor constant; and 2) condensing the gasified trifluoroethane chlorinated mixture in the reactor through a condensation and separation tower and making the condensed trifluoroethane chlorinated mixture return to the reactor to continuously react, discharging the product trifluoro acetyl chloride from the top of the condensation and separation tower and collecting the trifluoro acetyl chloride after compression and condensation. Compared with the existing preparation method, the invention has the advantages that: the trifluoroethane chlorinated mixture can be directly used for preparation of the trifluoro acetyl chloride without separation, the processis advanced and reasonable, the synthesis route is simplified, the time is reduced, the production efficiency is greatly enhanced, and the equipment investment and energy consumption are reduced.

Owner:福建舜跃科技股份有限公司

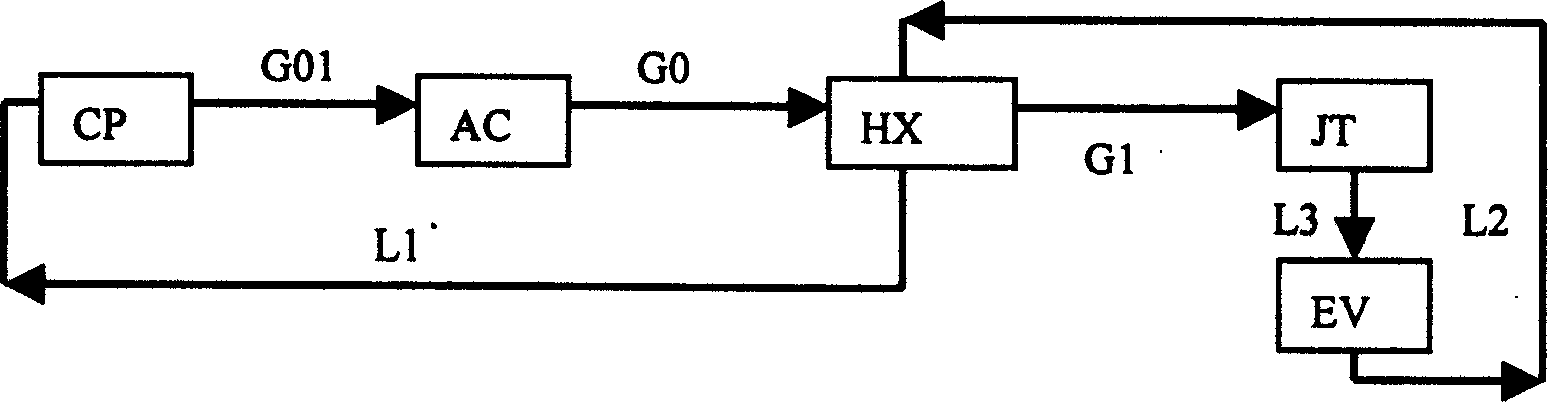

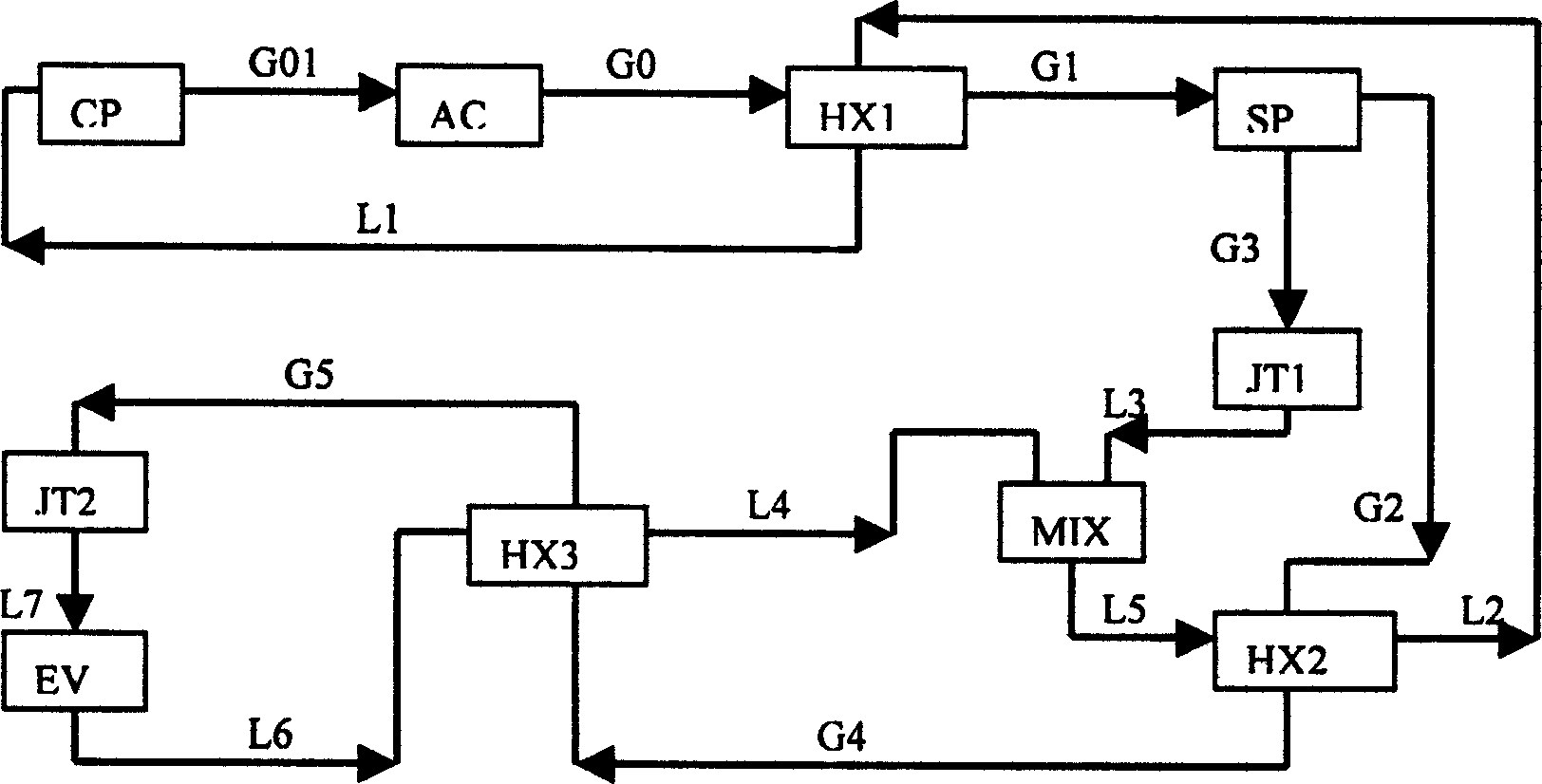

Use of alternate refrigerants in optimized cascade process

Methods and systems for liquefying natural gas using nonflammable refrigerants are provided. Methods of liquefaction include cooling a natural gas stream via indirect heat exchange with a first nonflammable refrigerant selected from the group consisting of: difluoromethane, pentafluoromethane, trifluoromethane, hexafluoroethane, tetrafluoroethane, pentafluorethane, trifluoroethane, pentafluoroethane, any derivative thereof, and any combination thereof during a first refrigeration cycle; and cooling the natural gas stream via indirect heat exchange with a second refrigerant during a second refrigeration cycle.

Owner:CONOCOPHILLIPS CO

Process for making 1,1,1,4,4,4-hexafluoro-2-butene

A process is disclosed for making 1,1,1,4,4,4-hexafluoro-2-butene. The process involves reacting 2,2-dichloro-1,1,1-trifluoroethane with copper in the presence of an amide solvent and 2,2′-bipyridine. A process is also disclosed for making 1,1,1,4,4,4-hexafluoro-2-butene. The process involves reacting 2,2-dichloro-1,1,1-trifluoroethane with copper in the presence of an amide solvent and a Cu(I) salt. A process is further disclosed for making 1,1,1,4,4,4-hexafluoro-2-butene. The process involves reacting 2,2-dichloro-1,1,1-trifluoroethane with copper in the presence of an amide solvent, 2,2′-bipyridine and a Cu(I) salt.

Owner:THE CHEMOURS CO FC LLC

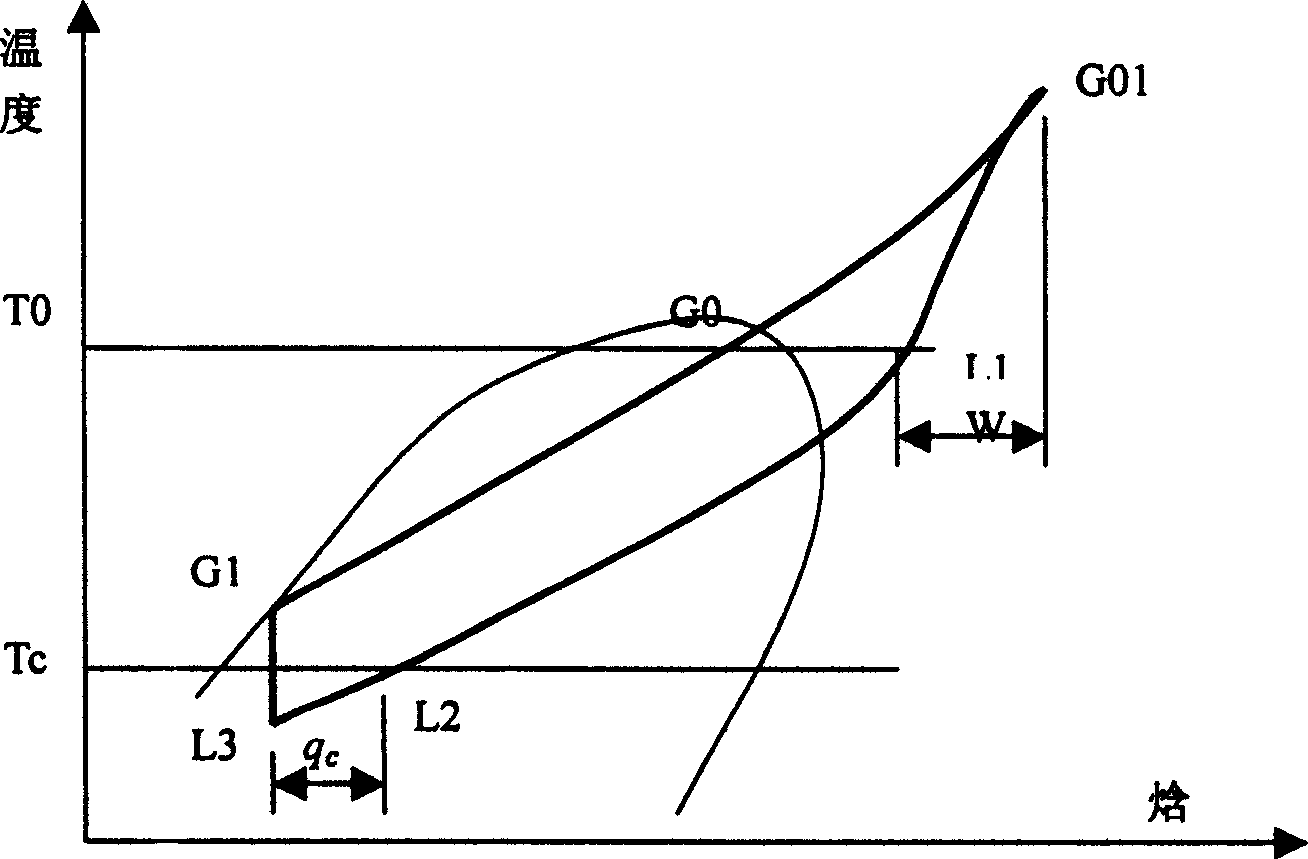

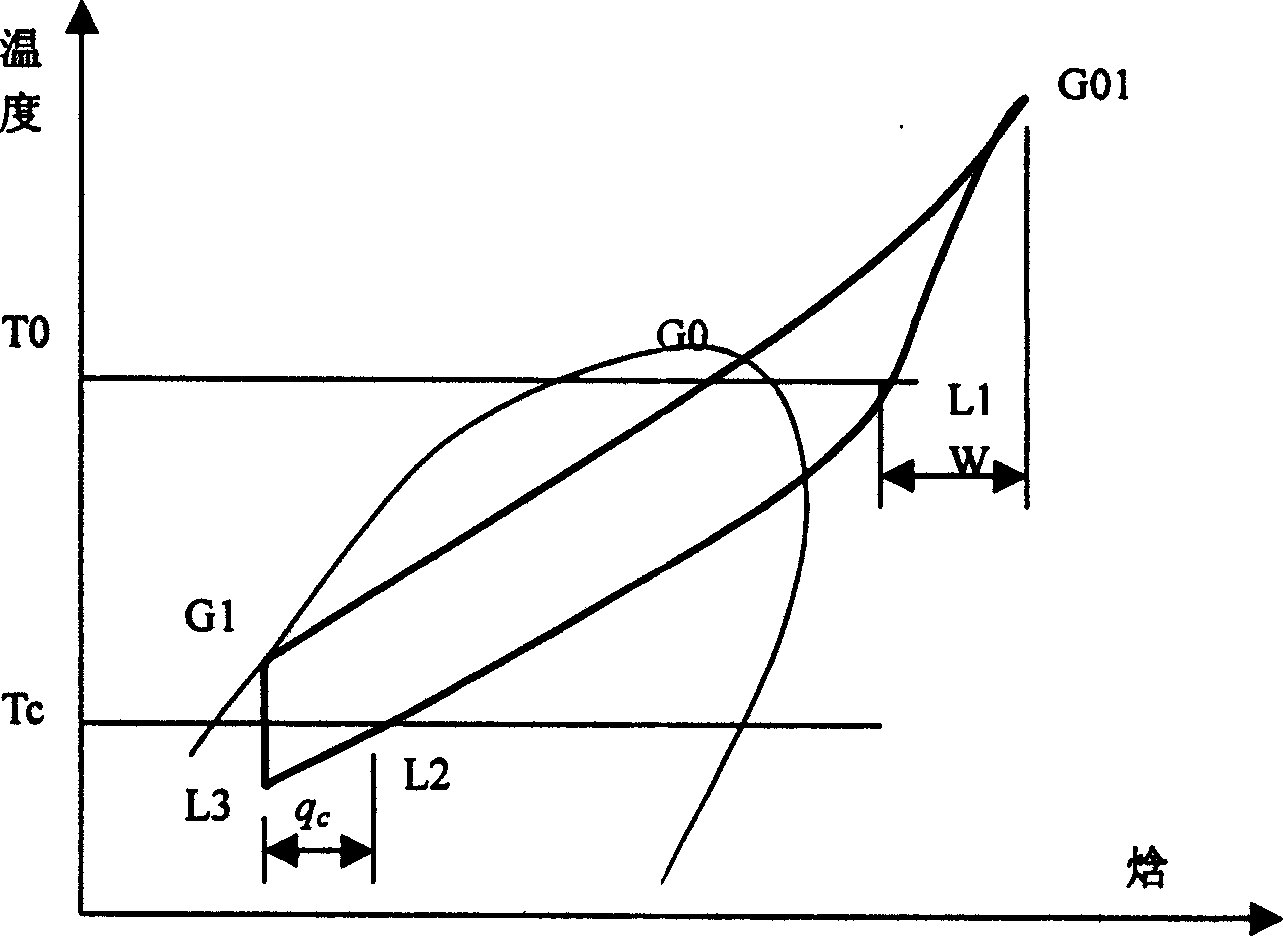

Multicomponent mixture work medium suitable for fractional condensation type heat pump circulation system

InactiveCN1810914AFully consider the operating pressure ratio rangeConsider operating pressure ratio rangeFluid heatersHeat-exchange elementsDichlorodifluoromethaneOctafluorocyclobutane

The present invention discloses one kind of multicomponent mixture work medium suitable for fractional condensation type heat pump circulation system. The mixture work medium or mixed refrigeratant consists of two components, including one low boiling point component and one high boiling point component. The low boiling point component is one or several selected from difluro methane, trifluoro ethane, fluoro ethane, propylene, propane, pentafluoro ethane, etc. The high boiling point component is one or several selected from isobutane, n-butane, butene, isobutene, octafluoro isobutene, octafluoro cyclobutane, etc.

Owner:XI AN JIAOTONG UNIV

Liquid-phase reaction preparation method of fluorides

ActiveCN103709009APreparation by halogen replacementPreparation by hydrolysisChemical reactionPotassium fluoride

The invention relates to a liquid-phase reaction preparation method of fluorides. The liquid-phase reaction preparation method comprises the following steps: raw material mixing: mixing a potassium fluoride water solution and CHF2CH2Cl according to the weight ratio of (1-10): 1, wherein the concentration of the potassium fluoride water solution is 1%-6%; reaction: performing chemical reaction on the mixed raw materials, wherein the reaction temperature is 80-360 DEG C, the reaction pressure is 0.1-25MPa, and the reaction retention time is 10-90min; cooling, and receiving the materials so as to obtain trifluoroethane and difluoroethanol. According to the liquid-phase reaction preparation method of the fluorides, provided by the invention, the one-time yield of difluoroethanol can achieve 30-60%, and the one-time yield of trifluoroethane can achieve 5-25%.

Owner:JIANGSU BLUESTAR GREEN TECH

Method for producing 1,1,1-trifluoro-ethane

InactiveCN101028990AEasy to industrializePhysical/chemical process catalystsPreparation by halogen replacementAluminum fluorideHydrogen fluoride

A process for preparing 1,1,1-trifluoroethane (HFC-143a) features the gas-phase reaction between HF and 1,1,1-trichloroethane (HCC-140a) under the existence of fluorinating Cr-base catalyst at 150-280 deg.C. It has high output rate and selectivity.

Owner:江西百炼氟材料有限公司

Multicomponent mixed work medium throttling refrigerant applicable to medium-low temperature zone

The multicomponent mixed work medium throttling refrigerating agent applicable to medium-low temp. zone includes five groups of substances, the sum of their mole concentration is 100%, in which first group includes methane, krypton or mixture, total mole concentration is 5%-45%, second group includes tetrafluoromethane, nitrogen trifluoride or mixture, total mole concentration is 15%-55%; fourth group includes propylene, propane, perfluoropane, 1,1,1-trifluoroethane, 1,1-bifluoroethane, fluoroethane, propadiene, cyclopropane, or mixture, total mole concentration is 5%-25%; fifth group includes 1-butylene, isobutane, 2-methylbutane, 1-pentene, 3-methyl-1-butylene, 2-methylpentane, 2-butylene, isobutylene, n-butane, perfluorobutane, n-pentane or mixture, total mole concentration is 5%-25%.

Owner:中科赛凌(北京)科技有限公司

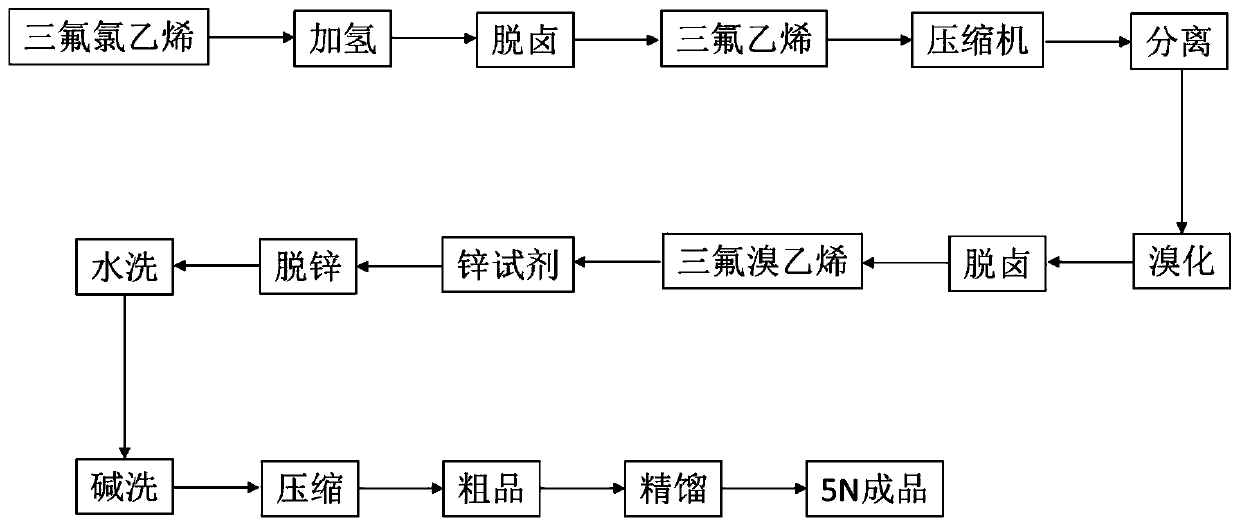

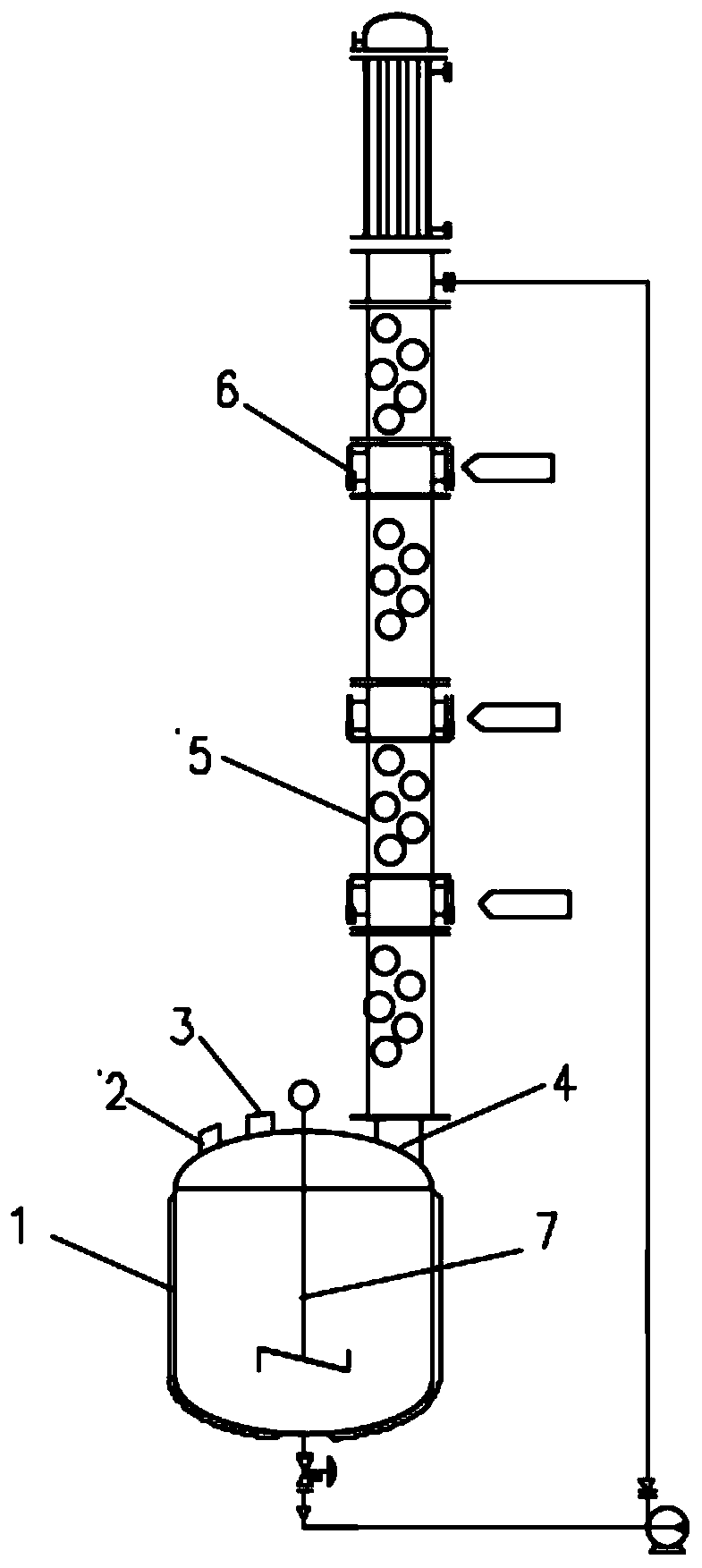

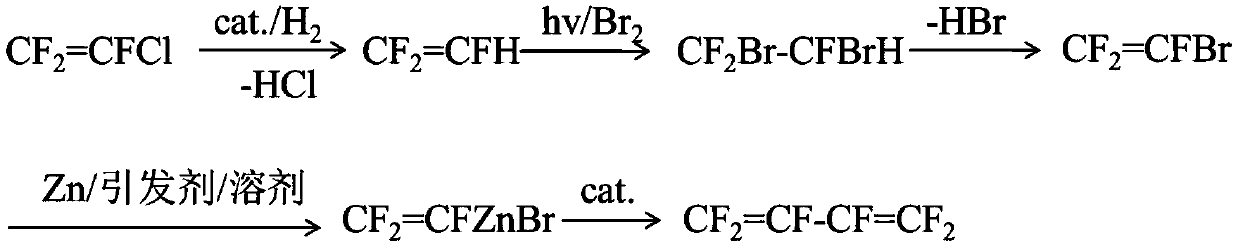

Method for preparing hexafluorobutadiene

ActiveCN105399599AHigh purityIncrease added valuePreparation by hydrogen halide split-offPtru catalystButadiene Dioxide

The invention discloses a method for preparing hexafluorobutadiene. The method comprises the following steps: carrying out a hydrogenation dechlorination dimerization reaction on 1,1-dichloro-1,2,2-trifluoroethane or 1,2-dichloro-1,1,2-trifluoroethane on a supported metal catalyst in H2 atmosphere, separating out a target product hexafluorobutadiene, carrying out gas phase thermal cracking on an intermediate hydroflurochlorobutane to remove HCl in order to prepare hexafluorobutadiene, filtering the product generated after above reactions, washing the filtered product with an alkali, washing the washed product with water, drying the product, compressing, and carrying out rectifying purification to obtain the highly pure hexafluorobutadiene. The method for preparing hexafluorobutadiene overcomes the disadvantages of long operating period, low unit volume output and large device investment of present technologies, and has the advantages of high yield, few steps, easy industrialization, realization of production of the highly pure hexafluorobutadiene through selection of reactants and control of reaction conditions, simple process, cheap and easily available raw material, low cost, facilitation of industrial production, continuous production, and great improvement of the unit device productivity.

Owner:ZHEJIANG UNIV OF TECH

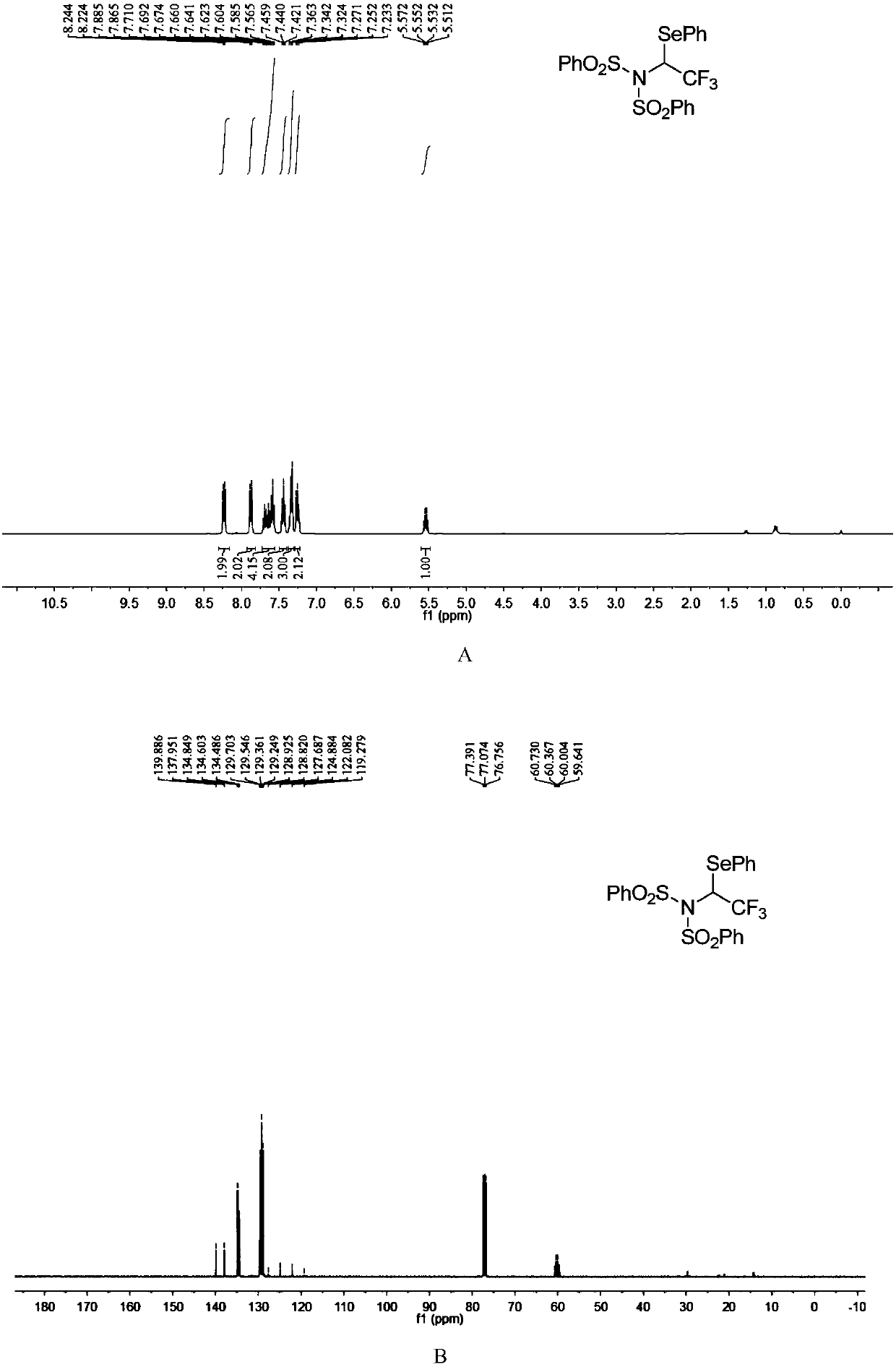

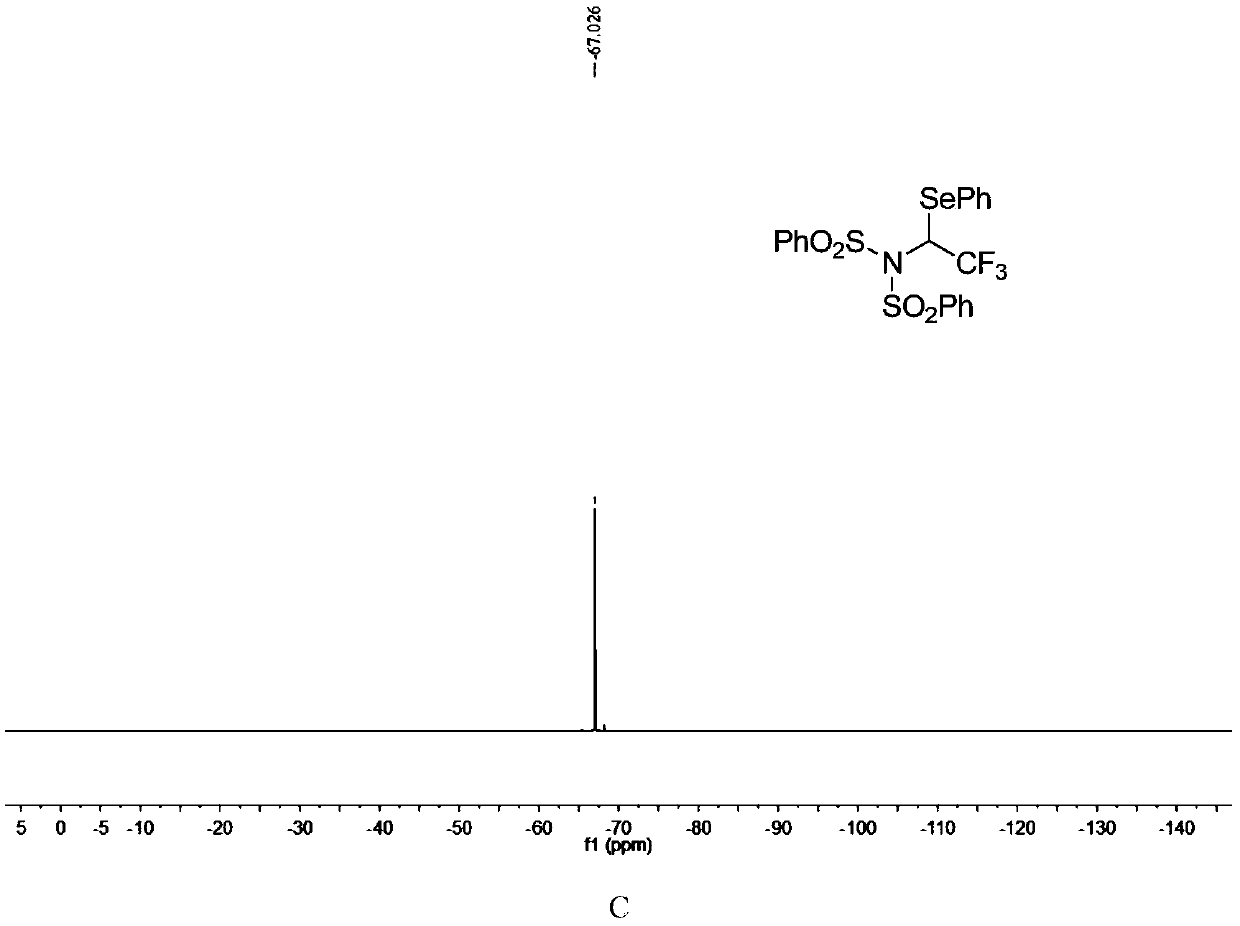

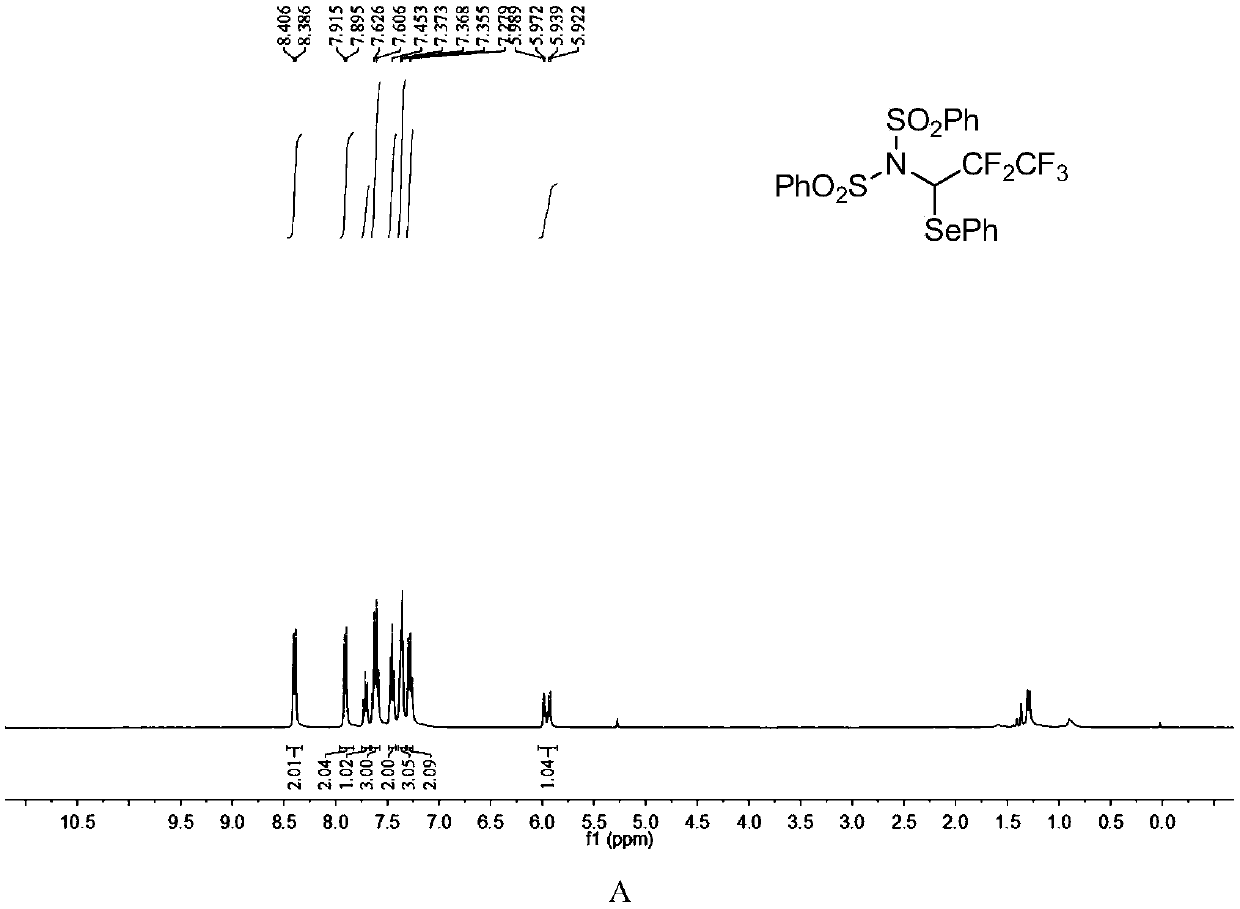

N-bisbenzenesulfonyl-1-phenylseleno trifluoroethane derivative, synthesis method and applications thereof

ActiveCN110857281AEfficient atom economyRaw materials are easy to obtainGroup 5/15 element organic compoundsPtru catalystOrganic synthesis

The invention discloses an N-bisbenzenesulfonyl-1-phenylseleno trifluoroethane derivative synthesis method, which comprises: carrying out a one-step reaction by using a diazo compound, a diether compound and N-fluorobisbenzenesulfonyl imide as raw materials and using an organic solvent as a solvent in the absence of a catalyst to obtain the N-bisbenzenesulfonyl-1-phenylseleno trifluoroethane derivative. According to the invention, the synthesis method has efficient atom economy, does not need any organic catalysts or metal catalysts, and is simple and safe to operate, and the synthesized N-bisbenzenesulfonyl-1-phenylseleno trifluoroethane derivative is an important organic synthesis and medical intermediate.

Owner:EAST CHINA NORMAL UNIVERSITY

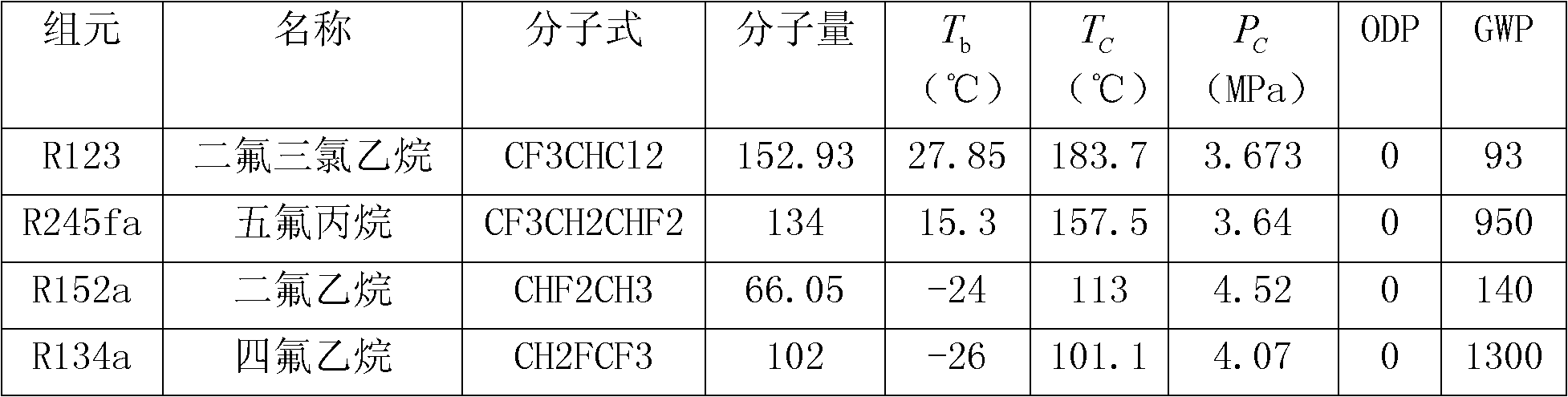

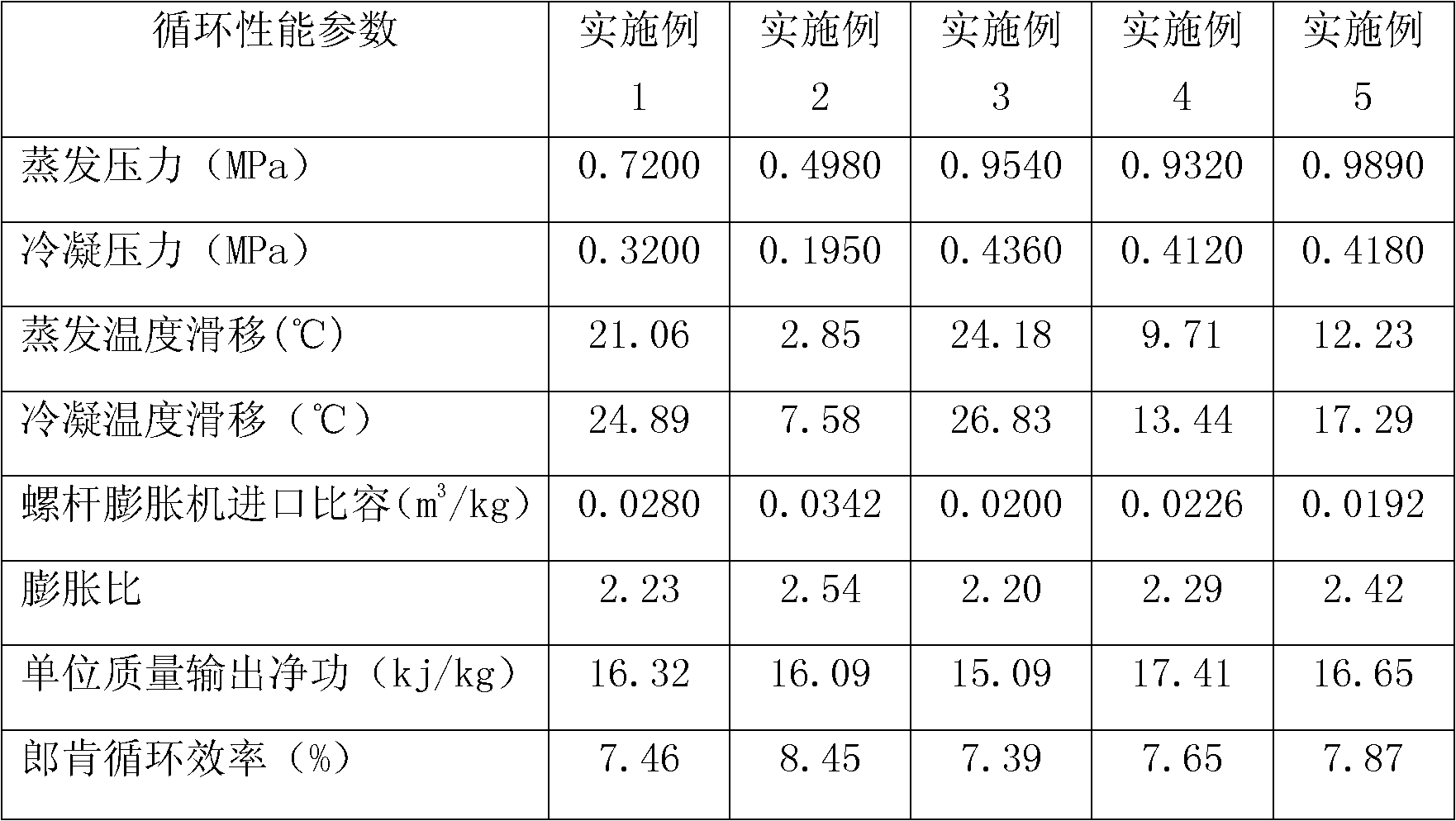

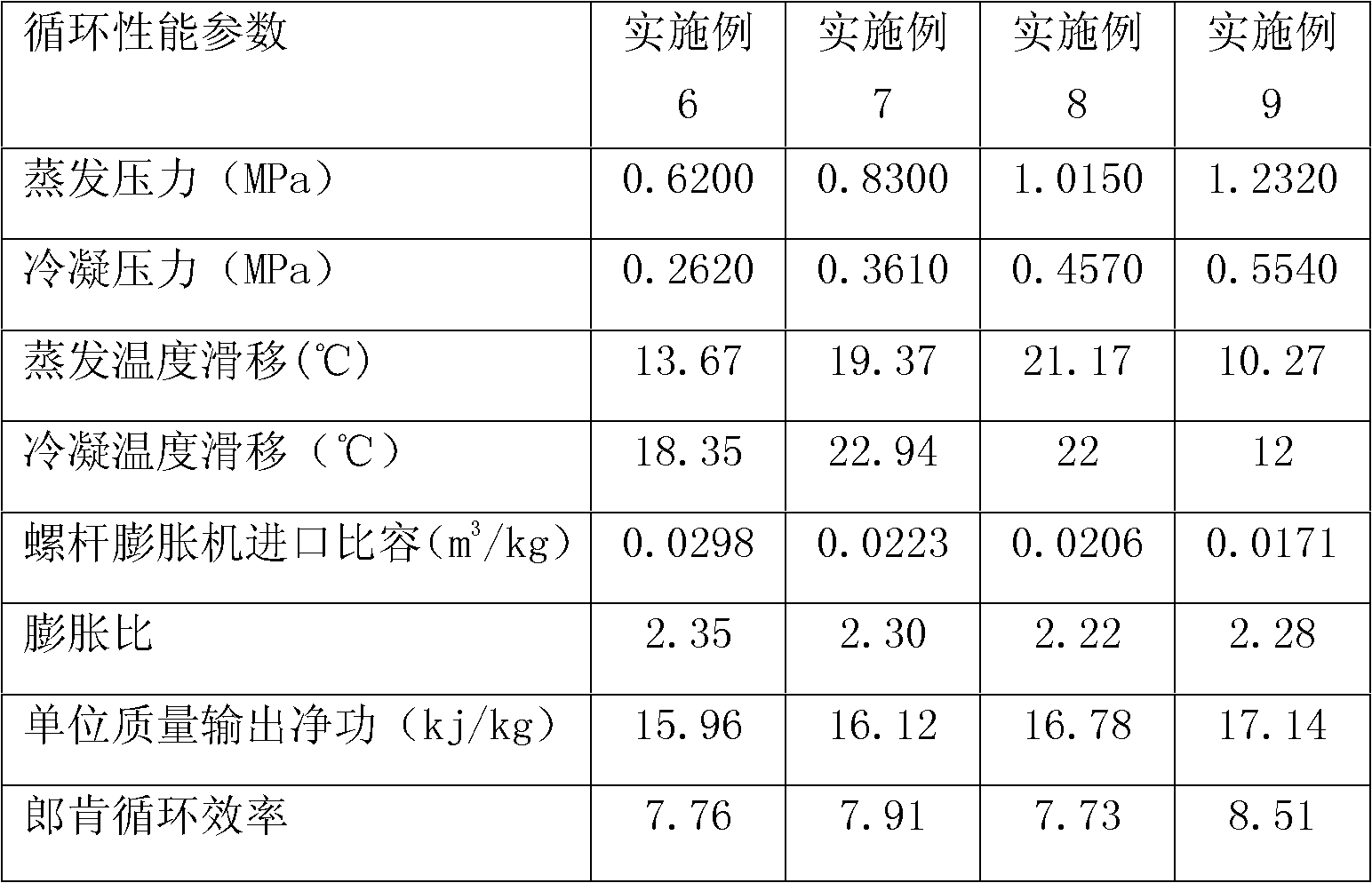

Mixed working medium for organic working medium rankine cycle system of screw expander

InactiveCN102127397APromote circulationIncreased net work output per unit mass cycleHeat-exchange elementsMass ratioOzone depletion potential

The invention discloses a mixed working medium for an organic working medium rankine cycle system of a screw expander. The mixed working medium consists of two or three of four organic working media, namely HCFC(hydrochlorofluorocarbon)-123 (2,2-dichloro-1,1,1-trifluoroethane), HFC(hydro-fluoro-carbon)-245fa (1,1,1,3,3-pentafluoropropane), HFC-152a (1,1-difluoroethane) and HFC-134a (1,1,1,2-tetrafluoroethane). The sum of mass percentage of components of each mixed working medium is 100 percent. The preparation method for the mixed working medium comprises the following step of: physically mixing the components in the set mass ratio at normal temperature. The mixed working medium meets environmental protection requirement, namely has the ozone depletion potential (ODP) of zero, low global warming potential (GWP), suitable thermal parameters, good cycle performance and high cycle heat utilization rate.

Owner:TIANJIN UNIV

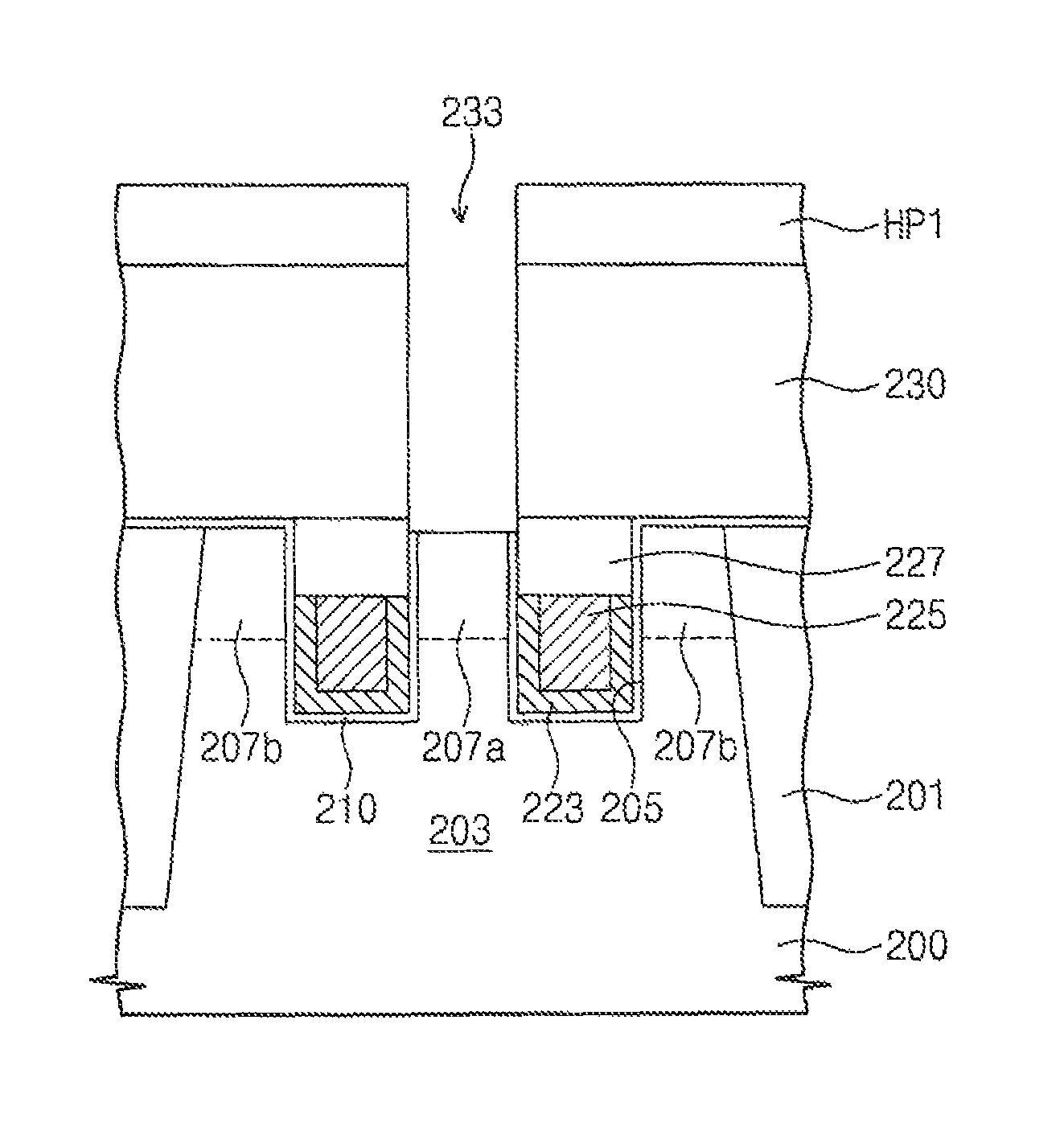

Method for fabricating semiconductor devices

ActiveUS9460935B2Semiconductor/solid-state device manufacturingSurface treatment compositionsThiolSemiconductor

The invention relates to a method for fabricating a semiconductor device. The method comprises forming a first etching layer and a second etching layer stacked on a substrate, and forming a recess region by etching the first and second etching layers under plasma generated from an etching gas including a compound. The compound comprises at least one of 1,1,1,2,3,3-hexafluoropropane, 2,2,2-trifluoroethane-1-thiol, 1,1,1,3,3-pentafluoropropane, 1,1,2,2,3-pentafluoropropane and 1,1,2,2-tetrafluoro-1-iodoethane, 2,3,3,3-tetrafluoropropene and 1,1-difluoroethene.

Owner:SAMSUNG ELECTRONICS CO LTD

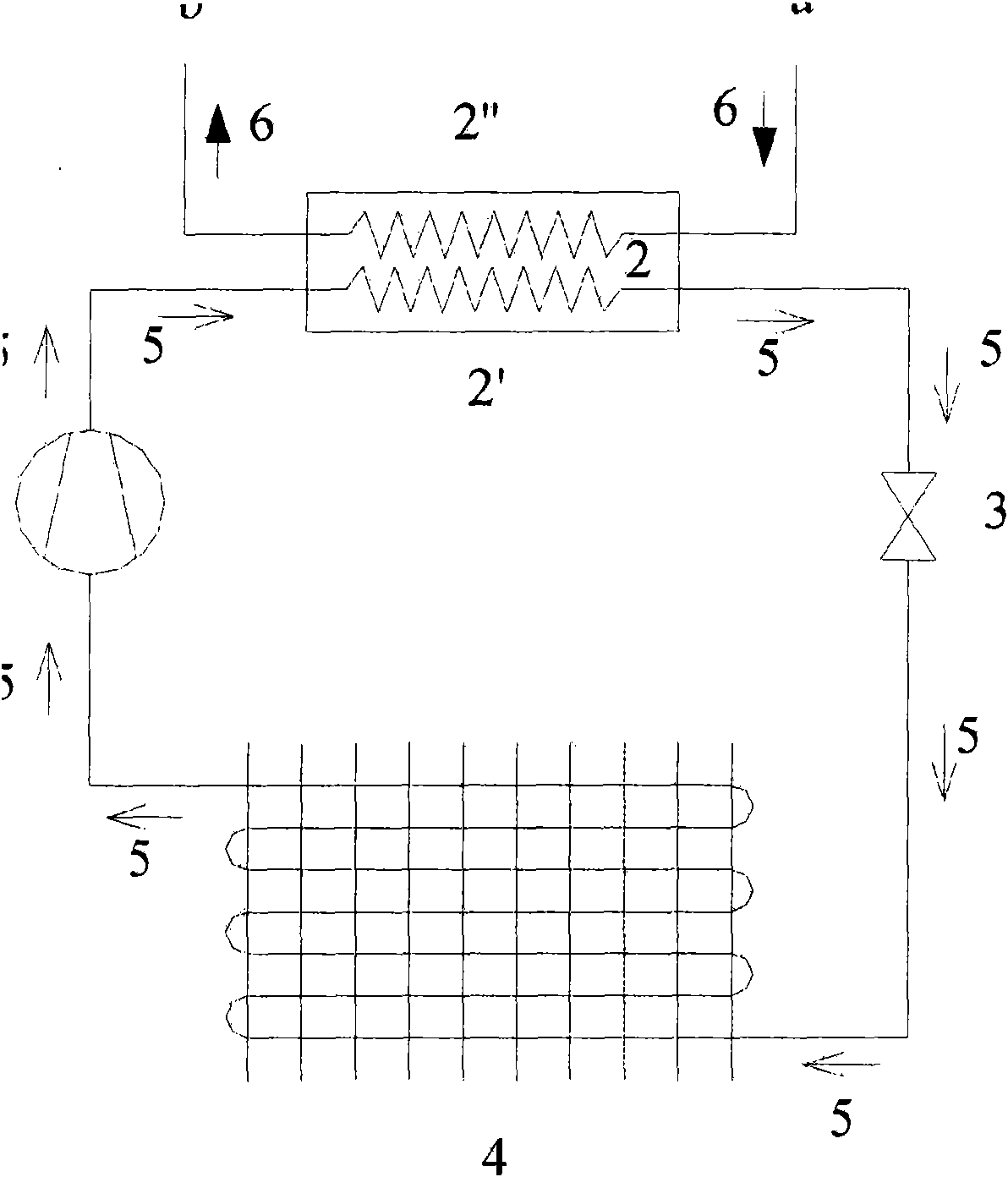

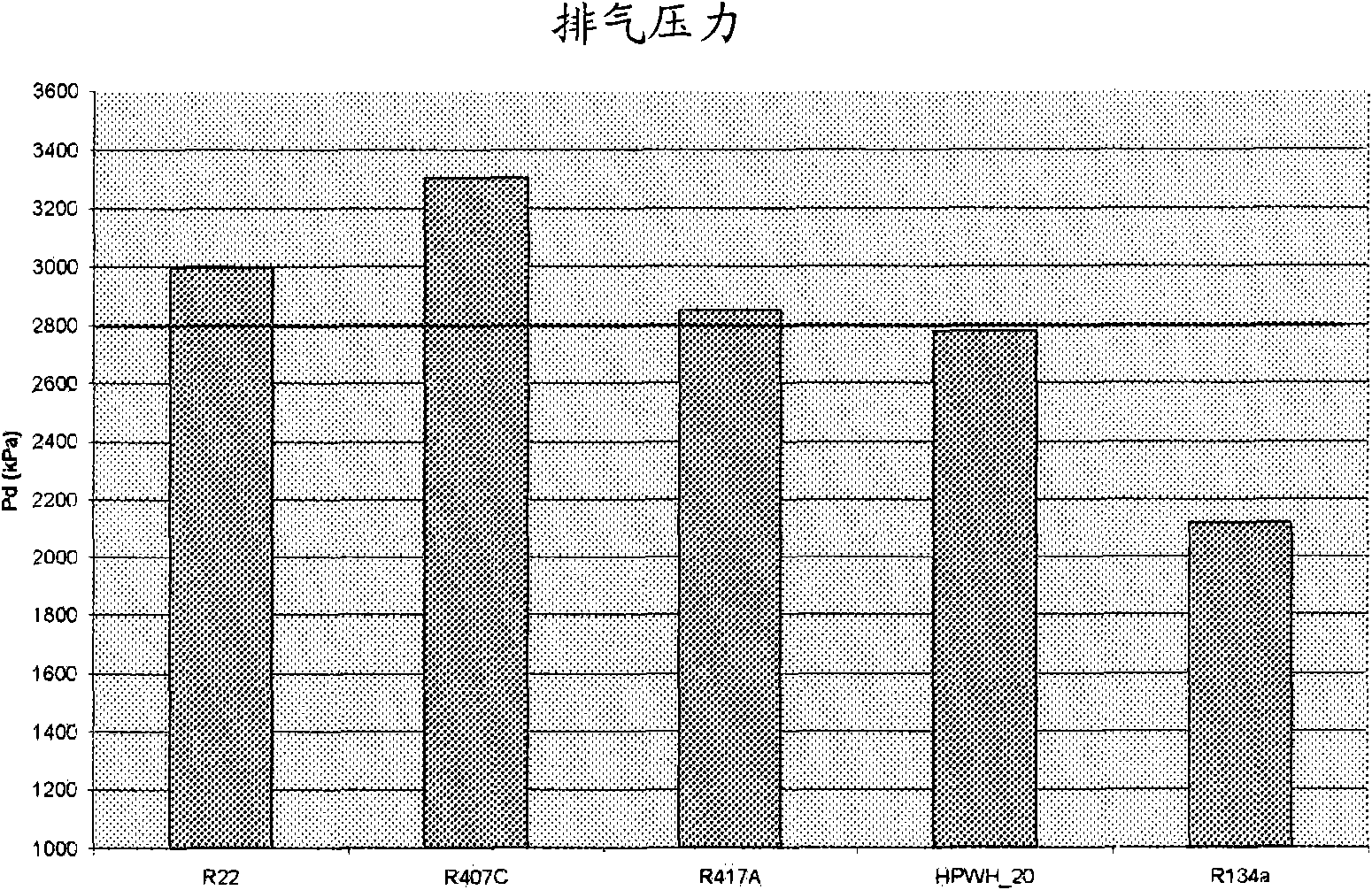

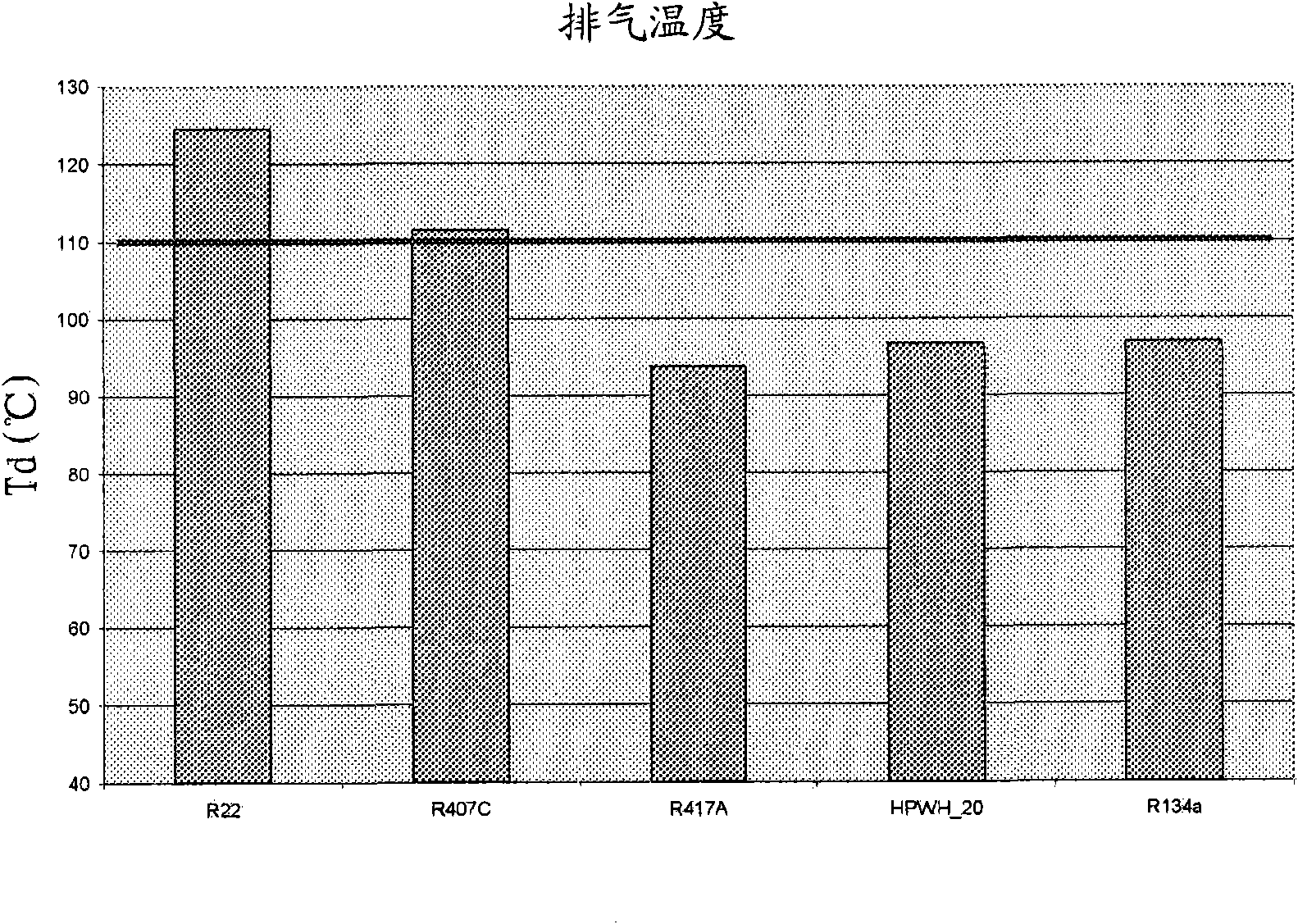

Hydrofluorocarbon refrigerant composition for heat pump water heater

A hydrofluorocarbon refrigerant composition ensures the existing compressor technique to be applied to the field of the heat pump water heater reliably (low exhaust temperature and pressure) and high efficiently (high productability and efficiency). On one hand, the refrigerant includes an admixture of HFC-125, HFC-134a and HFC-143a. On the other hand, the refrigerant includes an admixture of HFC-125, HFC-32, HFC-134a and HFC-143a.

Owner:HONEYWELL INT INC

Preparation method of hexafluorobutadiene

PendingCN110590495ALower reaction costQuick responsePreparation by hydrogen halide split-offPreparation by halogen additionZinc bromideHydrogenation reaction

The invention discloses a preparation method of hexafluorobutadiene. The preparation method includes the following steps that (1) a hydrogenation reaction is carried out with trifluorochlor oethyleneas raw materials under the action of a first catalyst to obtain trifluoroethylene; (2) the trifluoroethylene is introduced into a bromination reactor for conducting a bromination reaction with brominein the reactor, 1,2-dibromo-1,1,2-trifluoroethane is obtained, and then trifluorobromoethylene is obtained by dehydrobromination; (3) the trifluorobromoethylene reacts in a reactor containing a solvent, an initiator and zinc powder to generate zinc reagent trifluorovinyl zinc bromide; and (4) the zinc reagent trifluorovinyl zinc bromide is coupled under the action of a second catalyst to obtain the hexafluorobutadiene. The preparation method has the advantages of low energy consumption, high yield, high reaction efficiency and the like.

Owner:FUJIAN DEER TECH CORP

Method for preparing trichloroethylene

InactiveCN102372593AHigh selectivityEasy to separatePreparation by dehalogenationOrganic solventSolvent

The invention discloses a method for preparing trichloroethylene, which is characterized in that: with the existence of organic solvent, 1,1,2-tribromo trifluoroethane is adopted to be reacted with metal dehalogenating agent to generate metallorganics of trichloroethylene-base bromide, then water is dropped into the metallorganics to obtain trichloroethylene gas, the metal dehalogenating agent is metal zinc powder or metal magnesium powder, and the organic solvent is nonprotonic polarity polar solvent. The product produced through the method has high selectivity and is easy to separate and purify.

Owner:CHANGSHU 3F ZHONGHAO NEW CHEM MATERIALS +1

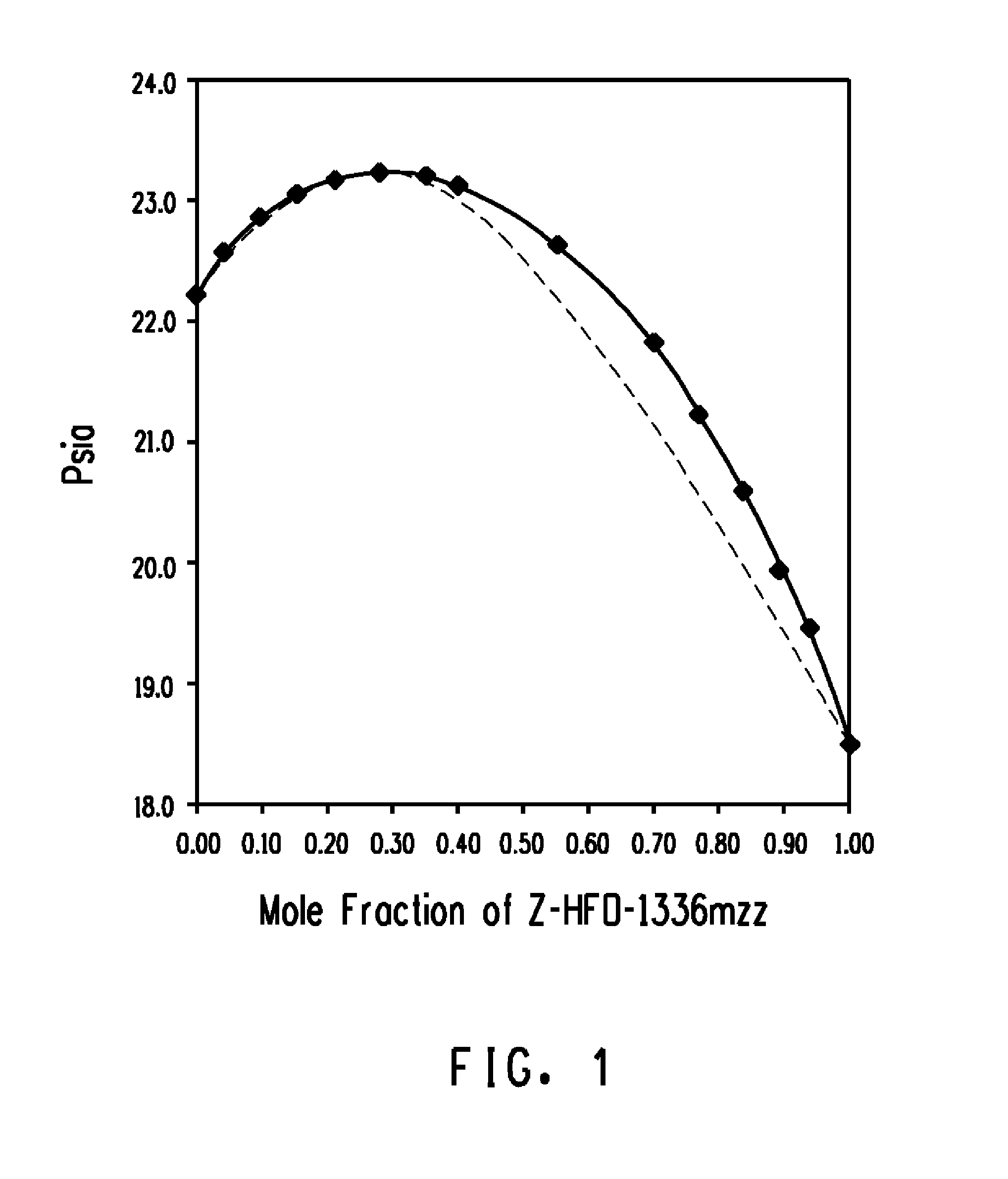

Compositions comprising z-1,1,1,4,4,4-hexafluoro-2-butene and 2,2-dichloro-1,1,1-trifluoroethane and methods of use thereof

In accordance with the present invention a composition is provided. The composition comprises Z-1,1,1,4,4,4-hexafluoro-2-butene (Z-HFO-1336mzz) and 2,2-dichloro-1,1,1-trifluoroethane (HCFC-123). Also in accordance with the present invention a method is provided for topping-off or replenishing a refrigerant charge. The method comprises adding a second refrigerant to a refrigeration, air conditioning, heat pump or power cycle system containing HCFC-123 as a first refrigerant, wherein said second refrigerant comprises Z-HFO-1336mzz and optionally HCFC-123, thus producing a refrigerant composition comprising the first refrigerant and the second refrigerant. Also in accordance with the present invention another method is provided. The method comprises replacing HCFC-123 in a refrigeration, air conditioning, heat pump or power cycle system with a refrigerant composition comprising Z-HFO-1336mzz and optionally HCFC-123.

Owner:THE CHEMOURS CO FC LLC

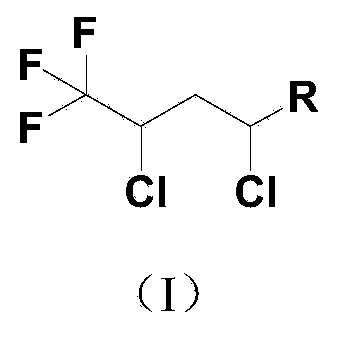

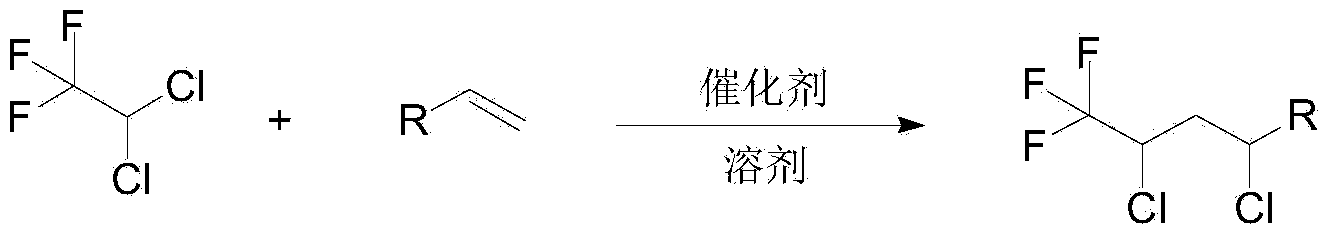

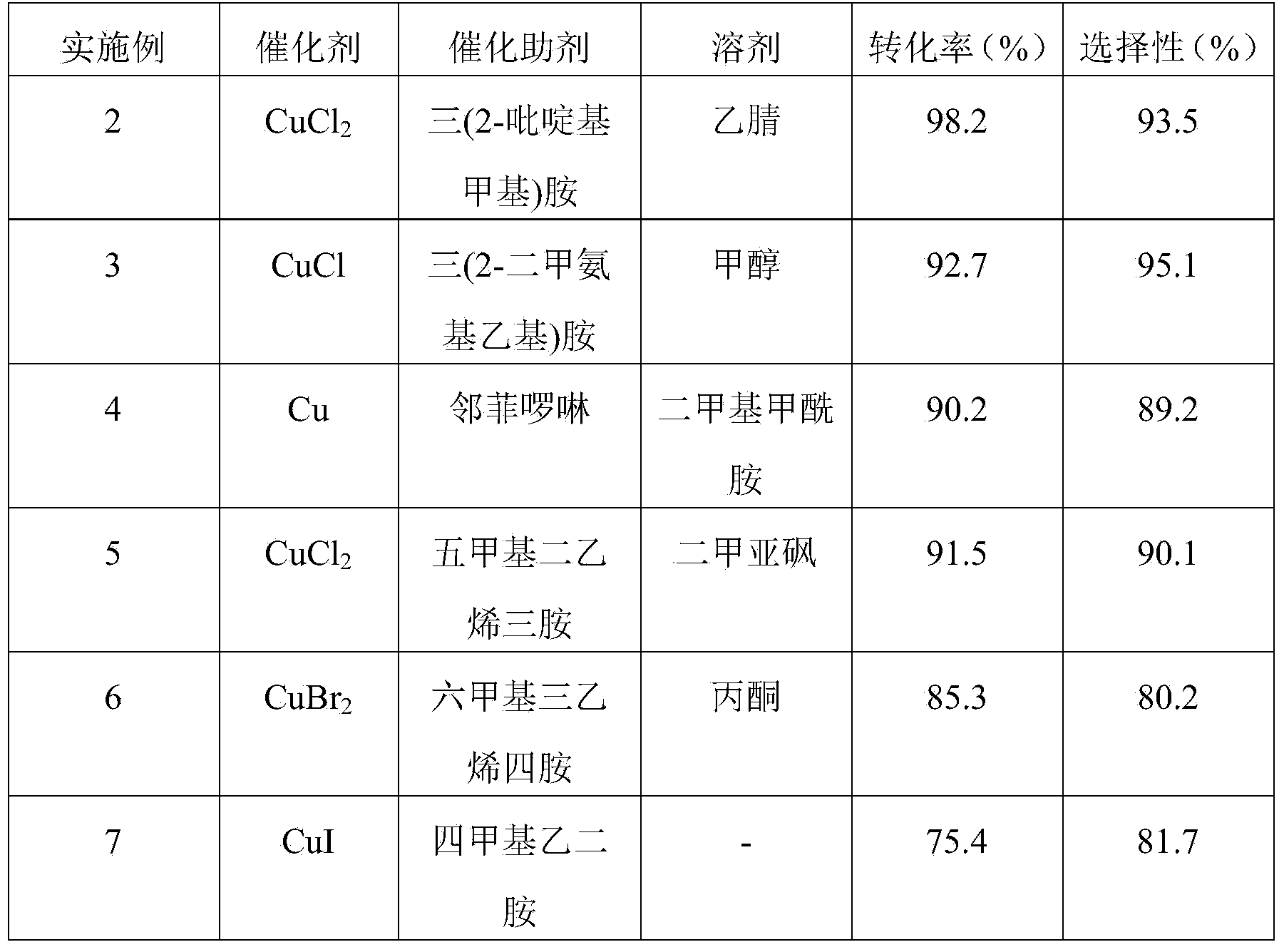

Preparation method of 2,4-dichloro-1,1,1-trifluorobutane derivative

ActiveCN104326862AIndustrial production technology is matureHigh catalytic efficiencyOrganic compound preparationHydroxy compound preparationDiethylenetriamineSolvent

The invention discloses a preparation method of a 2,4-dichloro-1,1,1-trifluorobutane derivative. The 2,4-dichloro-1,1,1-trifluorobutane derivative is prepared by taking 2,2-dichloro-1,1,1-trifluoroethane and CH2=CHR as raw materials in the presence of a polymerization regulating catalyst, a catalytic promoter and a solvent, wherein the polymerization regulating catalyst is copper chloride or cuprous chloride, the catalytic promoter is 2,2-dipyridyl, pentamethyl diethylenetriamine, tri(2-pyridyl methyl) amine or tri(2-dimethylamino ethyl) amine, the solvent is acetonitrile, methyl alcohol or dimethyl sulfoxide. The invention provides a novel synthesis route which produces less three wastes and is high in catalytic efficiency, and is mainly used for preparing the 2,4-dichloro-1,1,1-trifluorobutane derivative.

Owner:XIAN MODERN CHEM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com