Patents

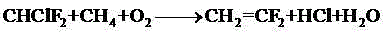

Literature

201 results about "Fluoroform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluoroform is the chemical compound with the formula CHF₃. It is one of the "haloforms", a class of compounds with the formula CHX₃ (X = halogen) with C₃ᵥ symmetry. Fluoroform is used in diverse applications in organic synthesis. It is not an ozone depleter but is a greenhouse gas.

Method for resource utilization of fluoroform

ActiveCN104628513AReduce processing costsReduce equipment investmentPreparation by halogen replacementChemical recyclingHalohydrocarbonResource utilization

The invention discloses a method for resource utilization of fluoroform. The method is characterized by mixing fluoroform with one or a plurality of halohydrocarbon, converting the mixture into a product containing monochlorodifluoromethane in the presence of a catalyst, and reacting unreacted fluoroform with other reaction products in a reactor. According to the method, chlorofluorocarbon containing chlorine or bromine or chlorofluorocarbon which contains chlorine or bromine and needs to be processed during a production process is utilized as reaction material to perform chlorine / fluorine exchange reaction with fluoroform to prepare monochlorodifluoromethane, better economic benefits and social benefits are provided; and in products, monochlorodifluoromethane can be recycled though separation, remained waste gas does not need to be processed, and can still enter the reactor as gas reacted with fluoroform, the conversion rate of reactants is improved, and zero-discharge is realized.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

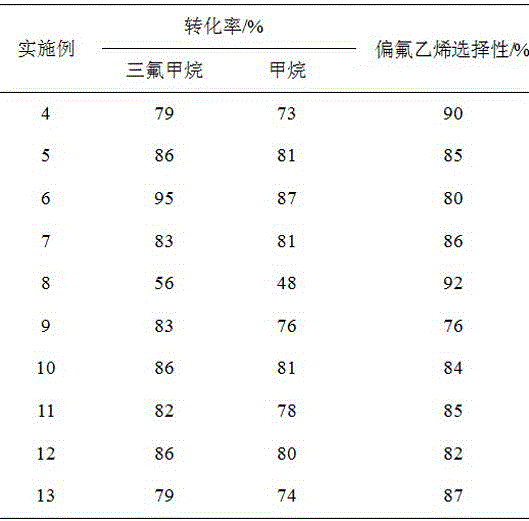

Preparation method of vinylidene fluoride and preparation method of catalyst used by same

ActiveCN104628514AIncrease added valueImprove conversion rateHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsSocial benefitsOxygen

The invention discloses a preparation method of vinylidene fluoride and a preparation method of a catalyst used by the same. The preparation method of vinylidene fluoride comprises the following steps: mixing methane, oxygen and fluoroform or monochlorodifluoromethane or the mixed gas of fluoroform and monochlorodifluoromethane at any ratio or the mixed gas of multiple gases including fluoroform and monochlorodifluoromethane; adding O2 at a certain proportion, and reacting at a temperature of 550-1,050 DEG C under a total pressure of 1-10bar and at an air speed of 50-10,000h<-1>; and reacting in the presence of a catalyst to generate vinylidene fluoride. According to the method disclosed by the invention, the vinylidene fluoride with relatively high added value is generated under a catalytic action from several waste fluoroform raw materials which are cheap or need forced treatment, has relatively high added value, and brings good economic and social benefits.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

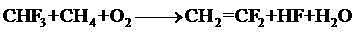

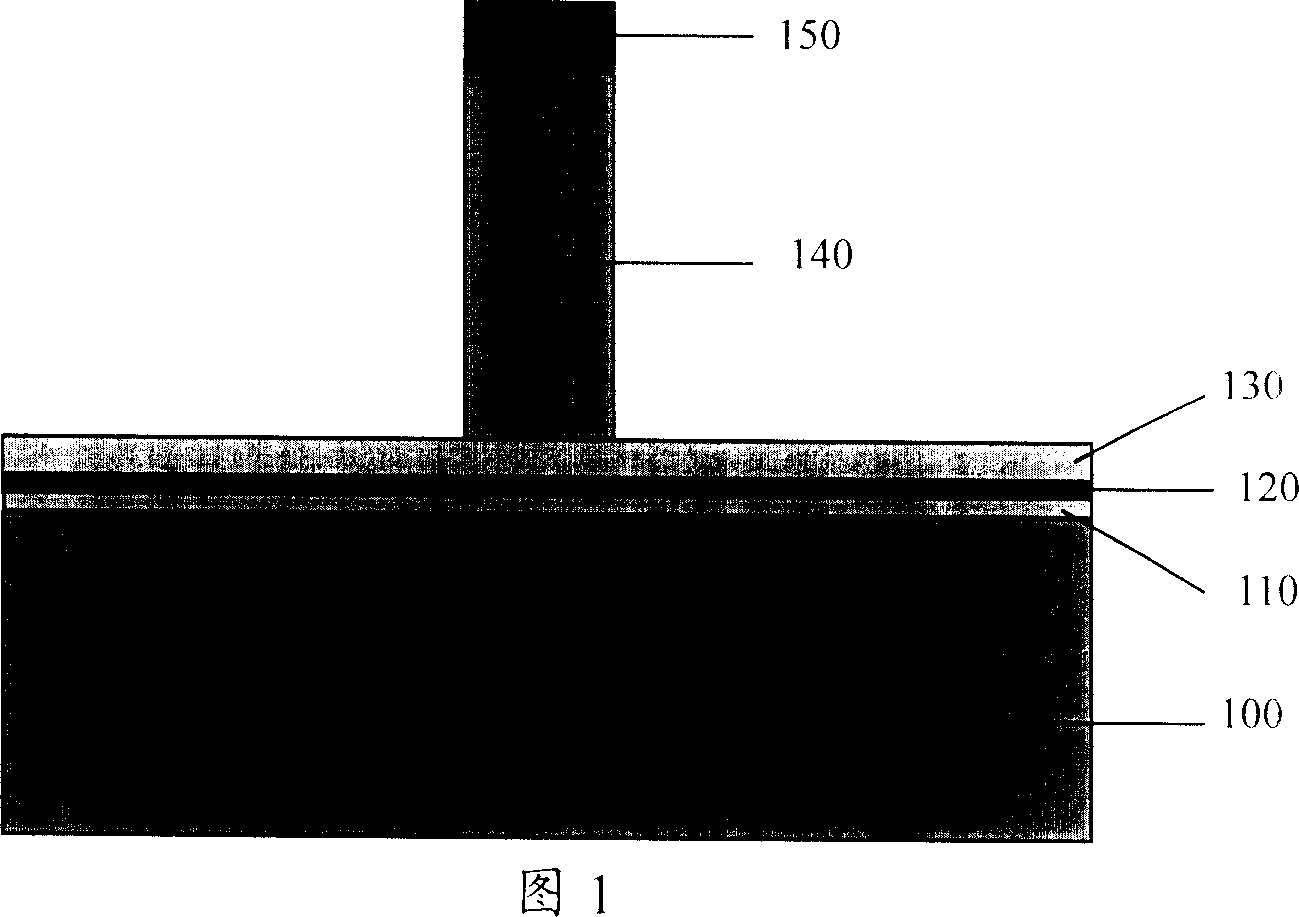

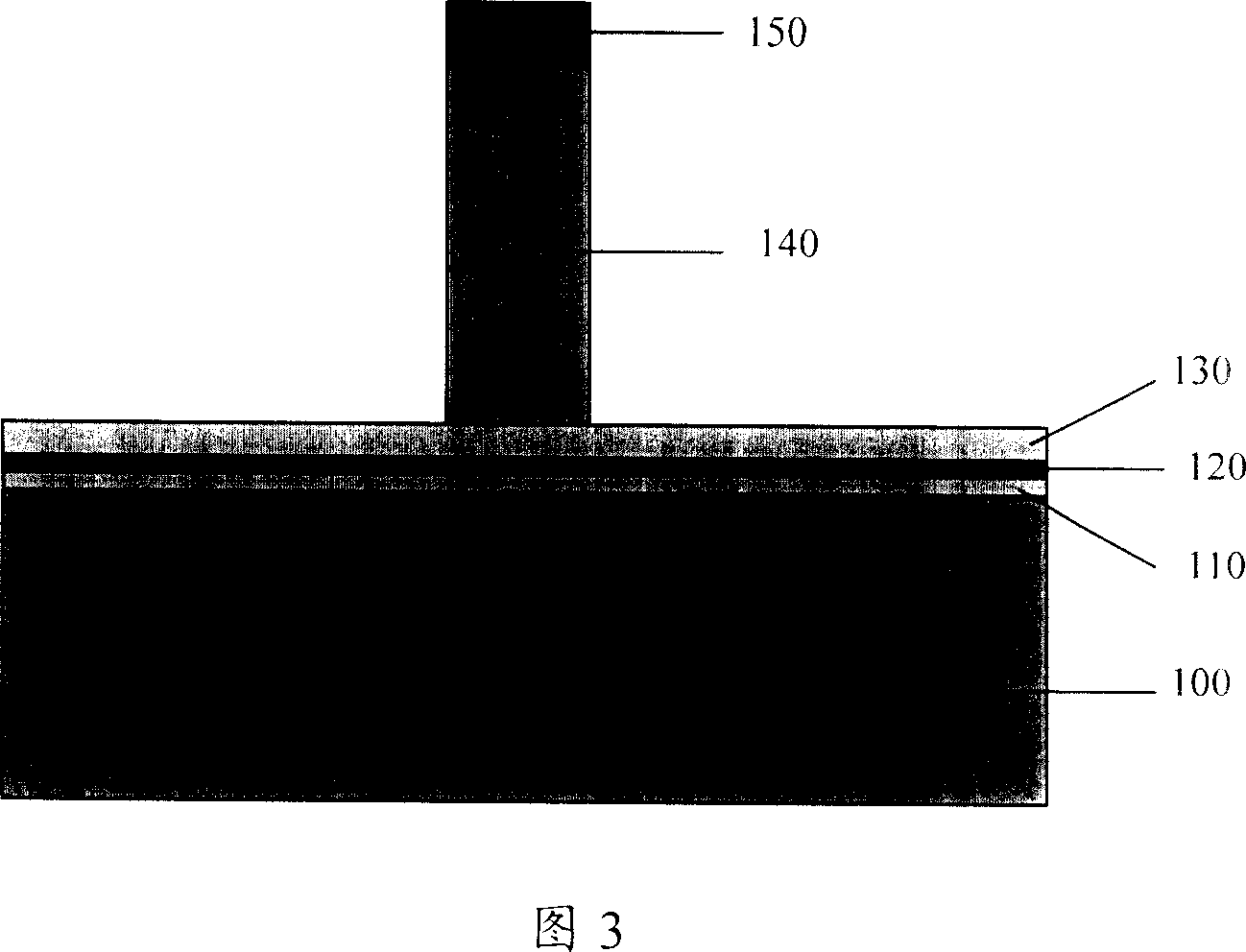

Method for producing semiconductor device

InactiveCN101051610AEliminate dentsSimplify the etch processSemiconductor/solid-state device manufacturingSemiconductor devicesPolysilicon gateSemiconductor

When etching ONO laminated construction of SONOS parts, the method uses mixed gas of carbon tetrafluoride (CF4) and fluoroform (CHF3) as main etching gas instead of mixed gas of HBr and C2F6, and uses CHF3 as over etching gas instead of mixed gas of CH2F2 / SF6. Using mixed gas of CF4 and CHF3 accomplishes main etching and over etching step for one time so as to simplify etching technique. Based on good etching selectivity and suitable etching speed, the method controls and buffers effect for etching ONO laminated construction by plasma of etching gas. In procedure for etching wafer thin oxidizing layer of grid electrode, the method is capable of controlling etching depth accurately, stopping etching at oxidation surface at low layer of ONO. Moreover, the method eliminates concave phenomena at sidewall and root part of polysilicon gate caused by transversal etching.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

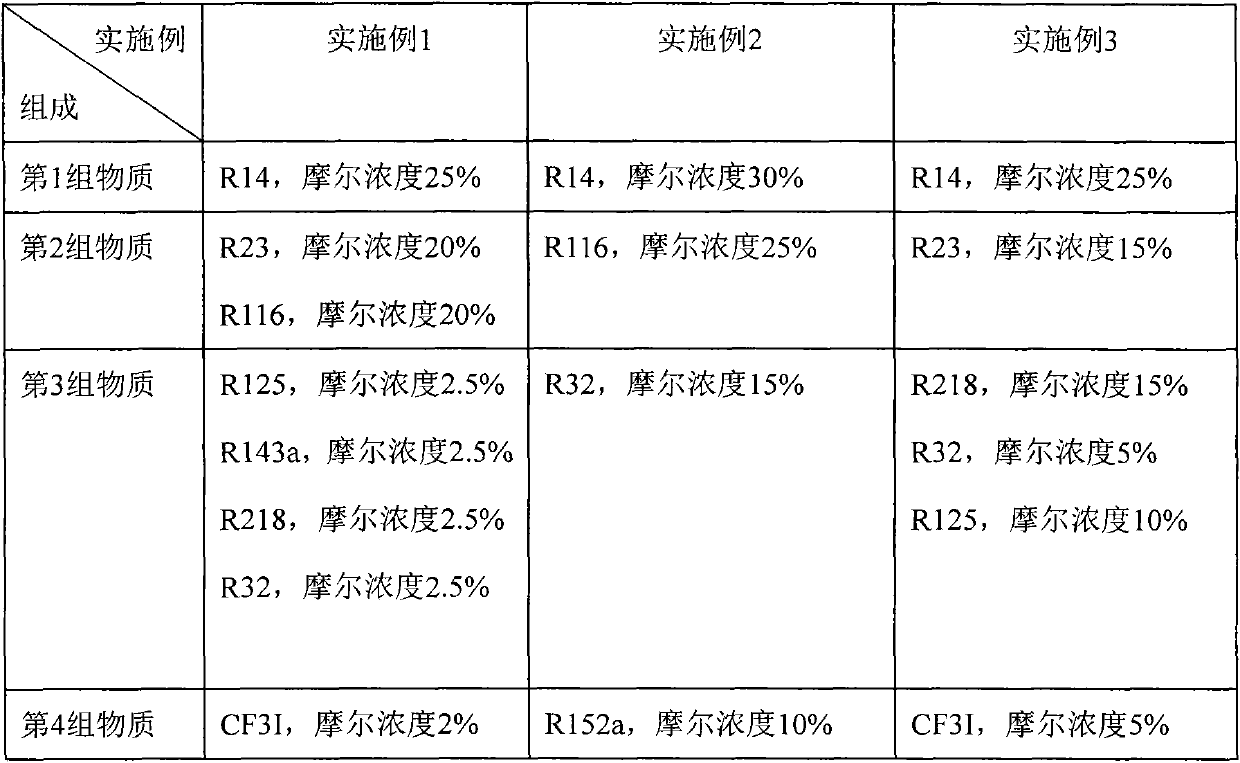

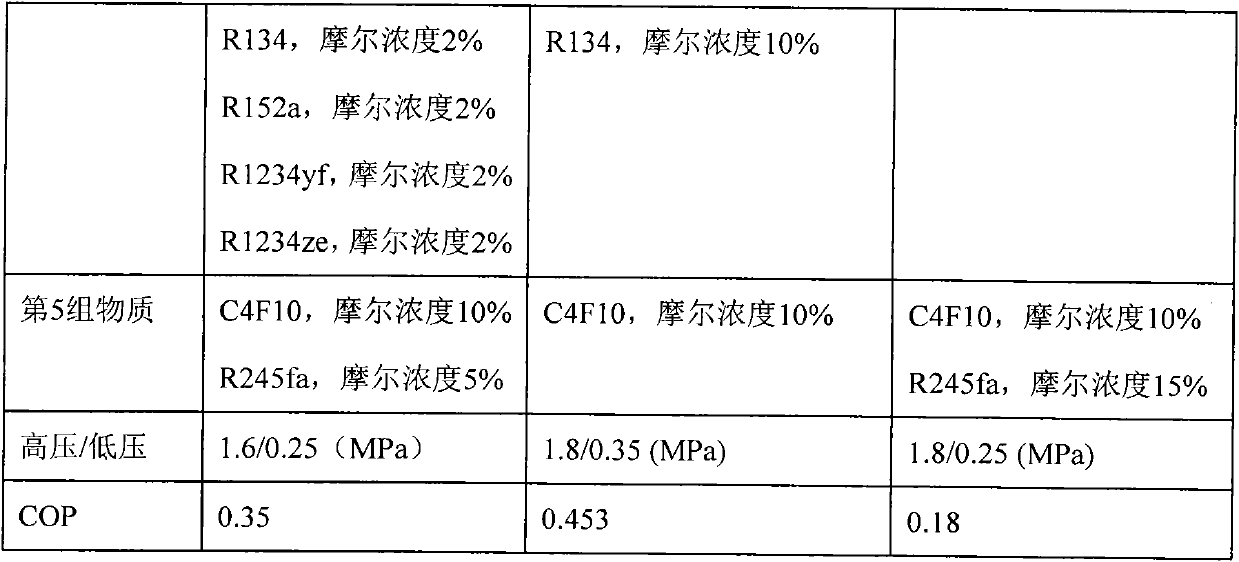

Non-combustible mixing refrigerant suitable for deep refrigeration temperature of minus 80 DEG C to minus 100 DEG C

ActiveCN102559146ANo destructive effectNon-flammableHeat-exchange elementsHexafluoroethanePolymer science

The invention relates to a non-combustible mixing refrigerant suitable for deep refrigeration temperature of minus 80 DEG C to minus 100 DEG C. The non-combustible mixing refrigerant comprises five groups of materials, where the first group of material is tetrafluoromethane; the second group of material is trifluoromethane, hexafluoroethane or a mixture of the trifluoromethane and the hexafluoroethane; the third group of material is pentafluoroethane, trifluoroethane, perfluoropropane, difluoromethane or a mixture of two, three or multiple of the pentafluoroethane, the trifluoroethane, the perfluoropropane and the difluoromethane; the fourth group of material is iodotrifluoromethane, 1, 1, 2, 2-tetrafluoroethane, 1,1-difluoroethane, 2, 3, 3, 3-tetrafluoropropene, 1, 3, 3, 3-tetrafluoropropene or a mixture of two, three or multiple of the iodotrifluoromethane, the 1, 1, 2, 2-tetrafluoroethane, the 1,1-difluoroethane, the 2, 3, 3, 3-tetrafluoropropene and the 1, 3, 3, 3-tetrafluoropropene; the fifth group of material is perfluoro-n-butane, 1, 1, 1, 3, 3-perfluoropropane or a mixture of the perfluoro-n-butane and the 1, 1, 1, 3, 3-perfluoropropane; the molar concentrations of the five groups of materials are respectively 25-50%, 15-40%, 10-30%, 5-20% and 10-25%; and the non-combustible mixing refrigerant is safe in a back-heating type throttling refrigeration system, can realize the refrigeration in the temperature range of minus 80 DEG C to minus 100 DEG C and has low whole green house effect without ozone depletion effect.

Owner:中科赛凌(北京)科技有限公司

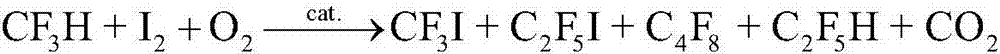

Method for synthesizing trifluoroiodomethane and pentafluoroethyliodide meanwhile

ActiveCN101219925AConvenient sourceImprove stabilityHalogenated hydrocarbon preparationChemical synthesisAlkaline earth metal

The invention relates to a method of synthesizing CF_3I and C2F5I simultaneously, which belongs to the filed of organic chemical synthesis. The method of synthesizing CF_3I and C2F5I simultaneously is characterized in that a alkali metal salt, a alkali earth metal salts or / and a copper salt are taken as a catalyst to be attached to a porous carrier; an oxygen or mixed gas of oxygen and an inert gas is pumped; a CHF3 and / or a HFC_125 are taken as a raw material; an iodine is taken as an iodinating agent; then iodination occurs in a reactor under high temperature to generate the C2F5I and the CF_3I. The porous carrier is a fluoride or an oxyfluoride. The raw material of the invention is nontoxic and is convenient to get; the catalyst does not react with a reaction medium and has good stability. The synthesis process is safe and suitable for technical production.

Owner:泉州宇极新材料科技有限公司

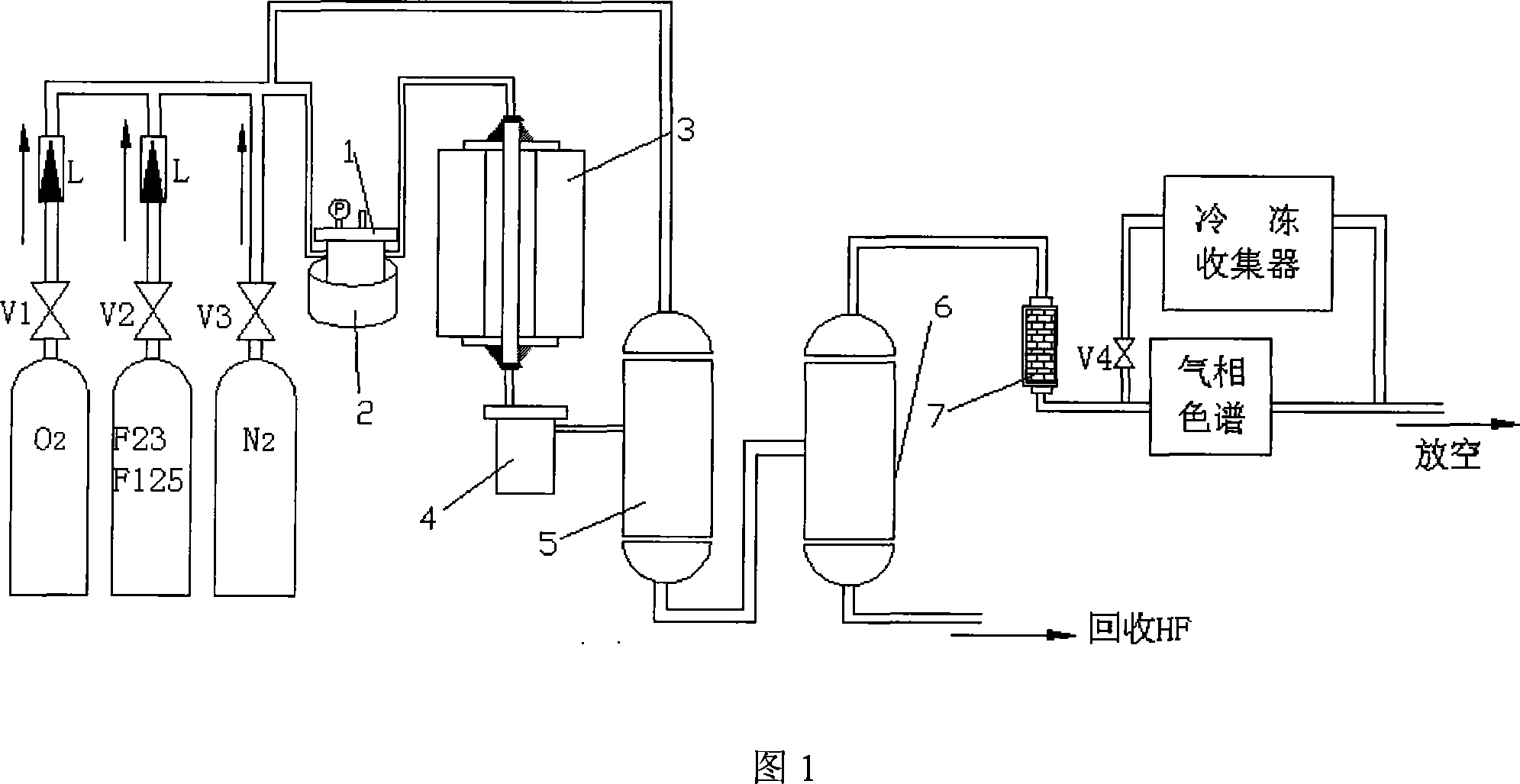

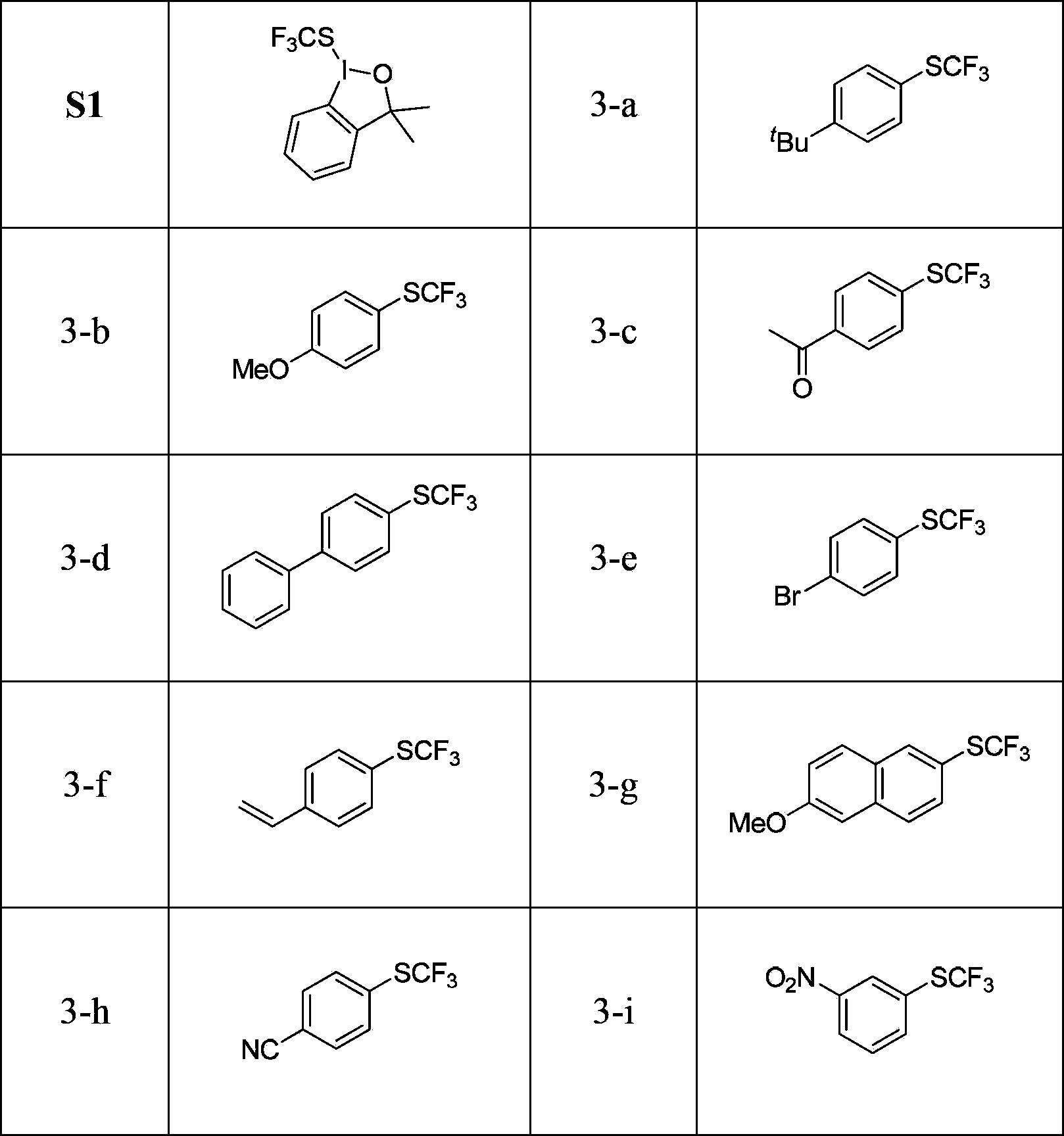

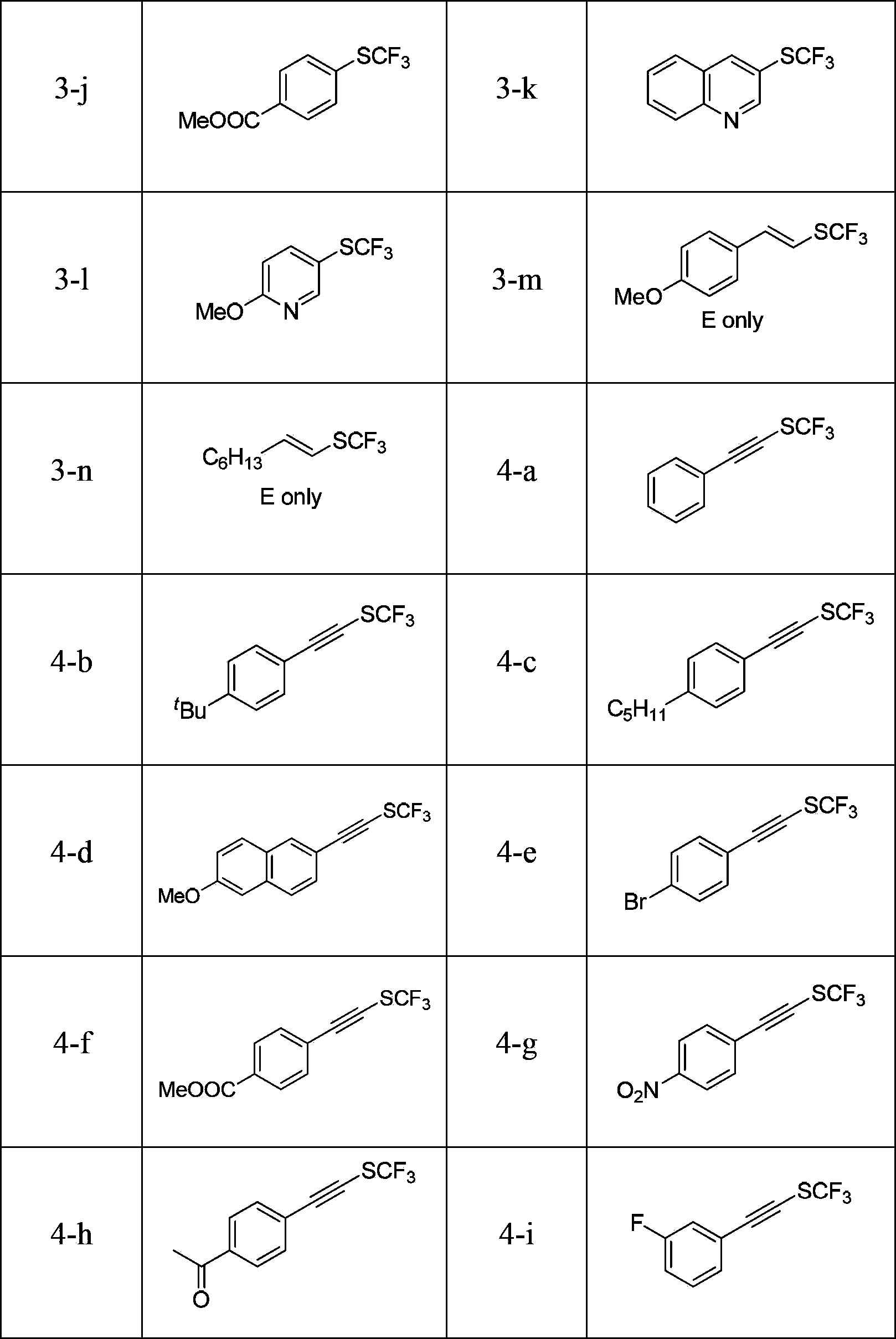

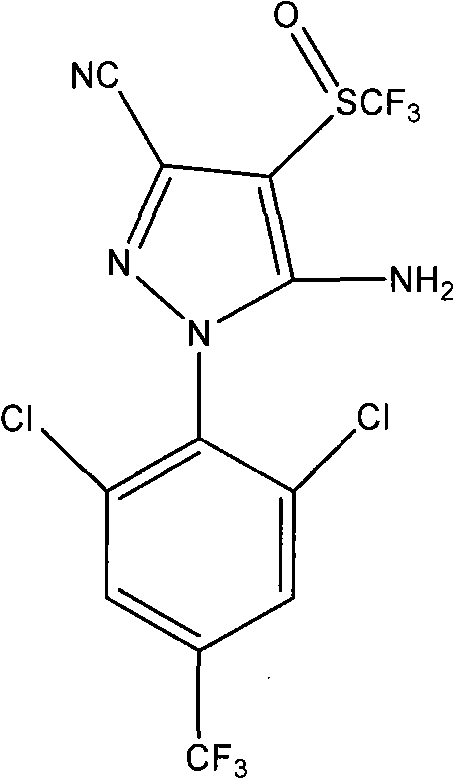

Electrophilic fluoroform sulfenyl reagent and synthetic method and application thereof

ActiveCN103804348ASimple methodSimple and efficient synthesisSulfide preparationStructural formulaPhotochemistry

The invention relates to an electrophilic fluoroform sulfenyl reagent and a synthetic method and application thereof. The structural formula of the electrophilic fluoroform sulfenyl reagent is shown in the specification. The synthetic method disclosed by the invention is simple and convenient and can be used for preparing a fluoroform sulfenyl product by reacting the electrophilic fluoroform sulfenyl reagent with a nucleophilic reagent.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

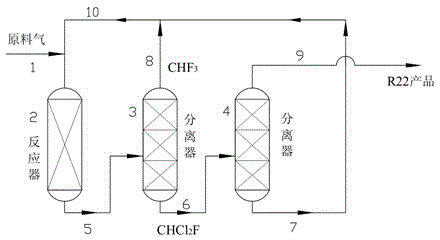

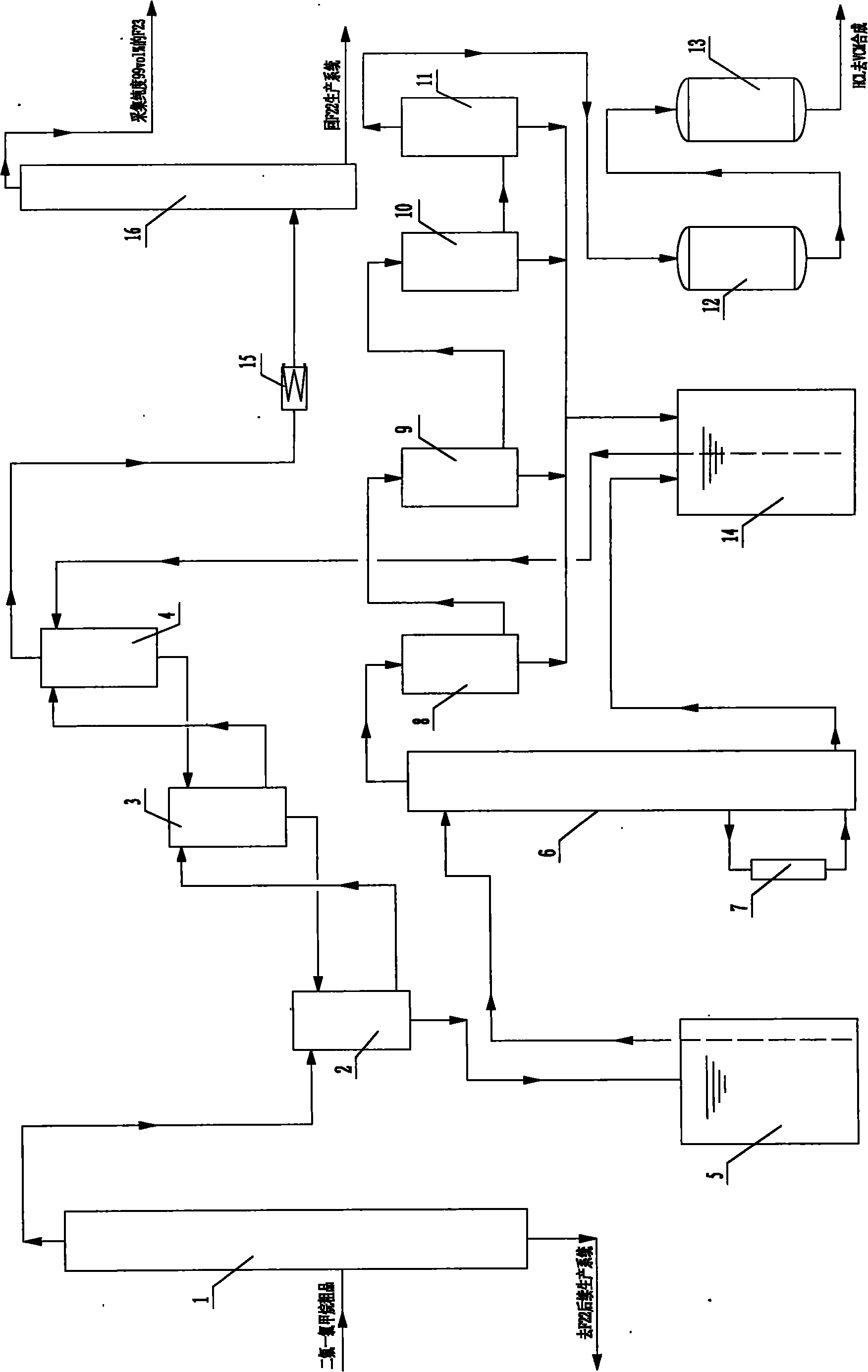

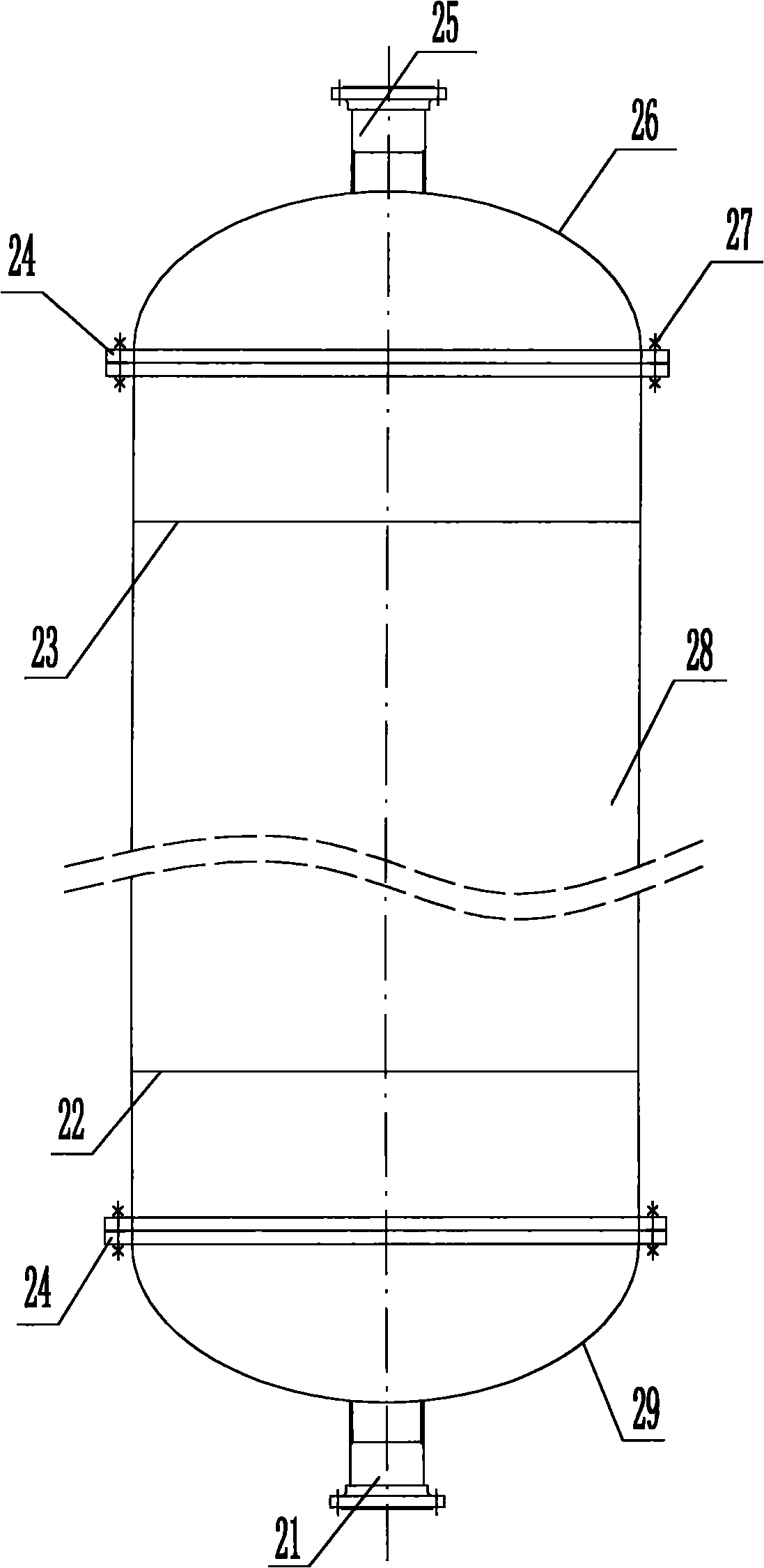

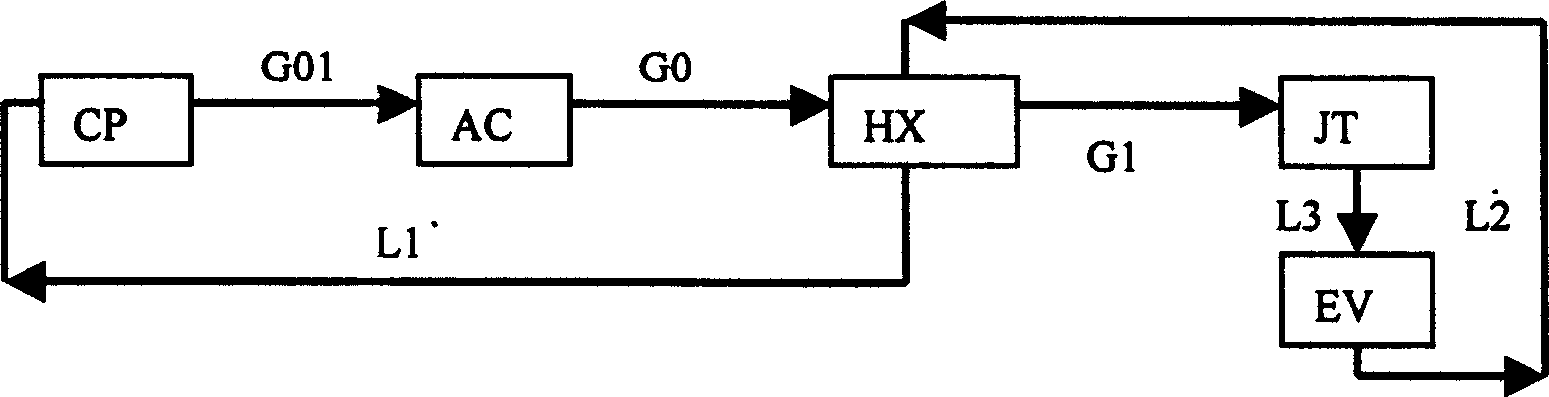

Method and device for refining chlorine hydride byproduct and recovering trifluoromethane in production of monochlorodifluoromethane

ActiveCN102101651AAchieve cycle productionAvoid pollutionChlorine/hydrogen-chloride purificationHalogenated hydrocarbon separation/purificationPolyvinyl chlorideWater resources

The invention relates to a method for refining a chlorine hydride byproduct and recovering trifluoromethane in production of monochlorodifluoromethane. Refined high-purity chlorine hydride can directly serve as a raw material for synthesizing vinyl chloride monomers; and the trifluoromethane byproduct separated in the refining process can be effectively recovered, wherein the refining of the HCl comprises the following steps of: crude separation, absorption, analysis, condensation, capture of acid mist, and adsorption; and after a F23 byproduct in the production of the monochlorodifluoromethane is separated in the absorption process in the refining of the HCl, the F23 byproduct is subjected to lossless compression and rectification to form the trifluoromethane with the purity of over 99 vol percent. By combining the recovery and comprehensive utilization of the HCl and the recovery of the trifluoromethane, the high consumption of water resources and liquid caustic soda is avoided, and the production cost of the monochlorodifluoromethane is reduced; and the effective recovery of the trifluoromethane prevents environmental pollution, and the chloroalkali, the monochlorodifluoromethane and polyvinyl chloride (PVC) can be circularly produced.

Owner:SHANDONG DONGYUE CHEM

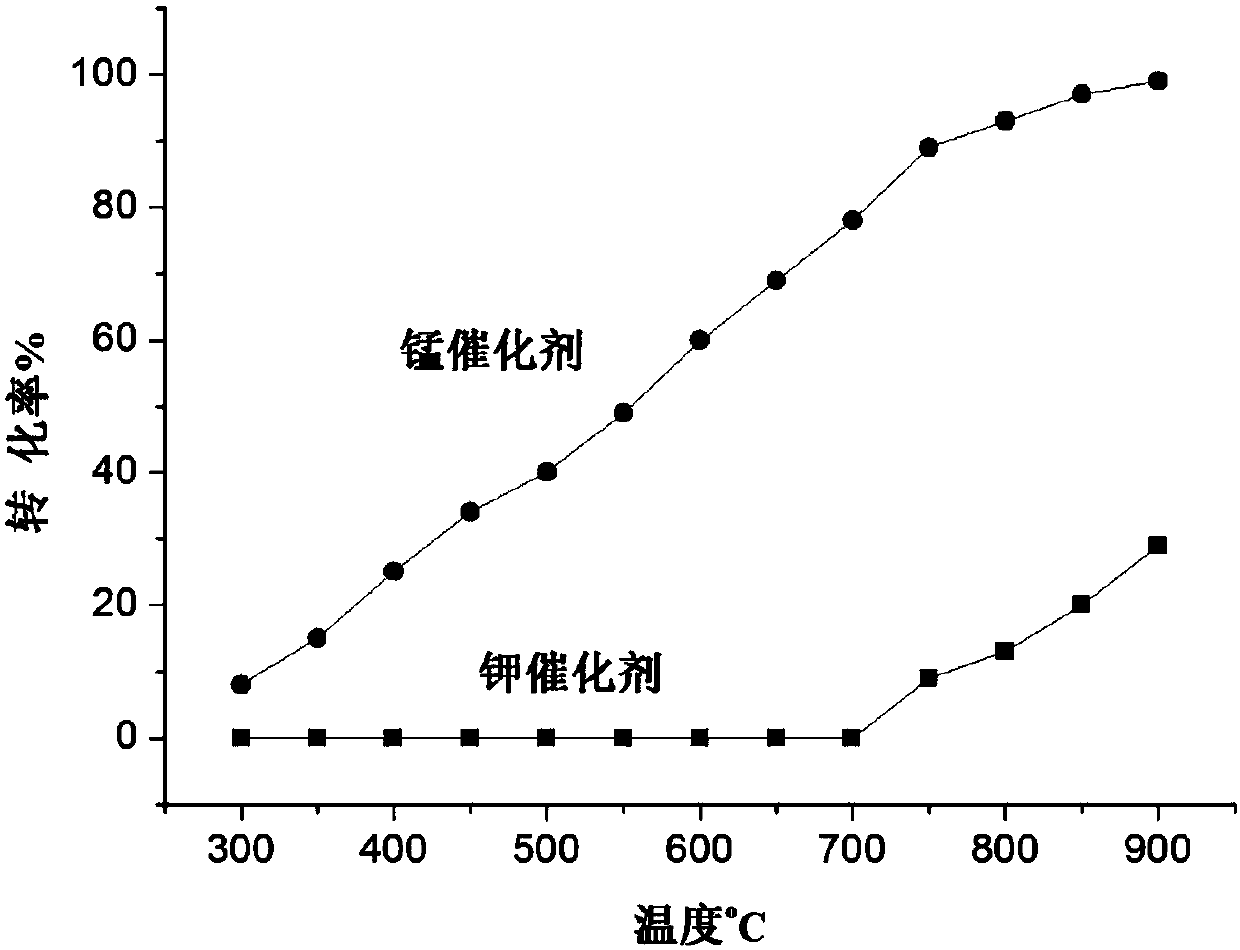

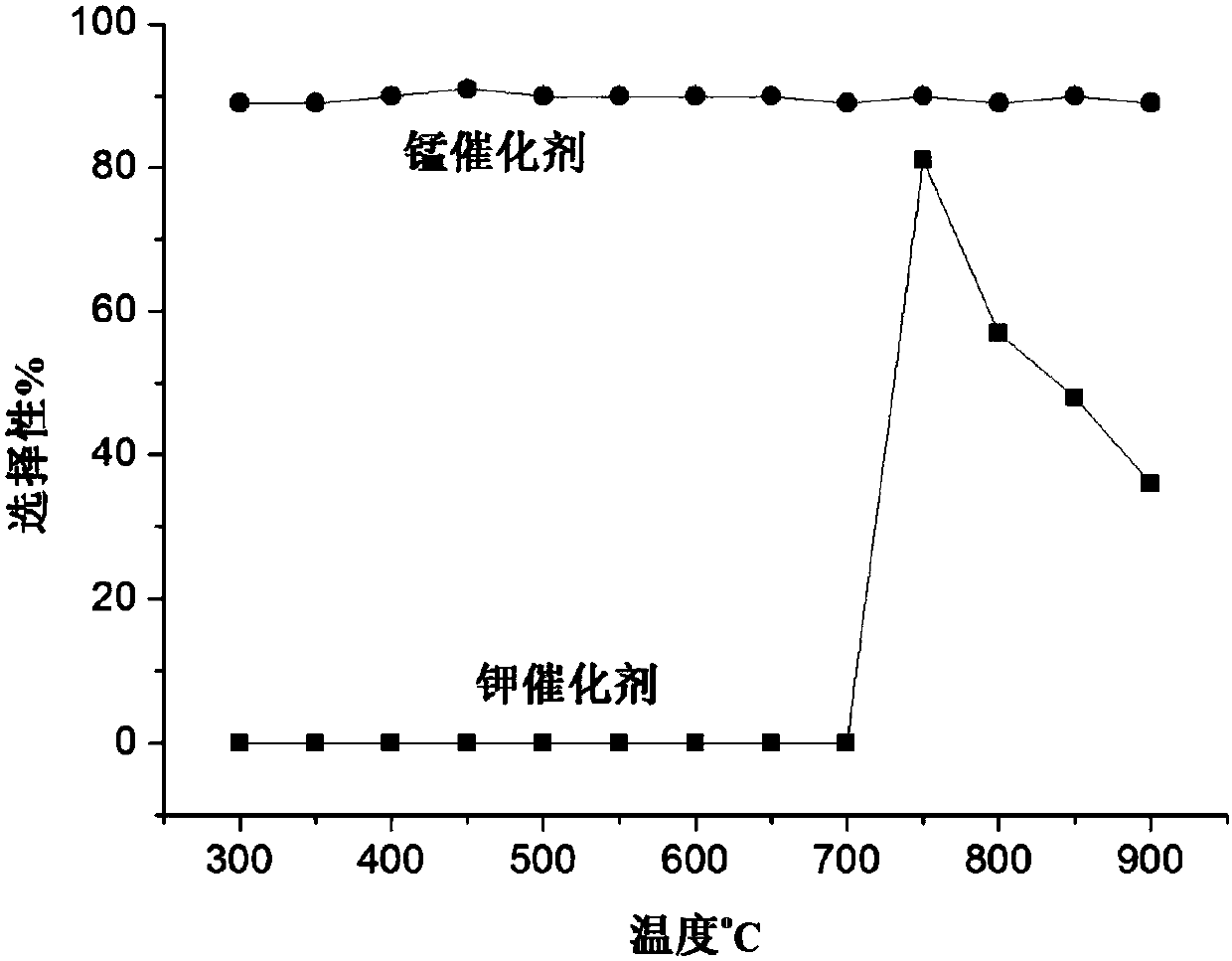

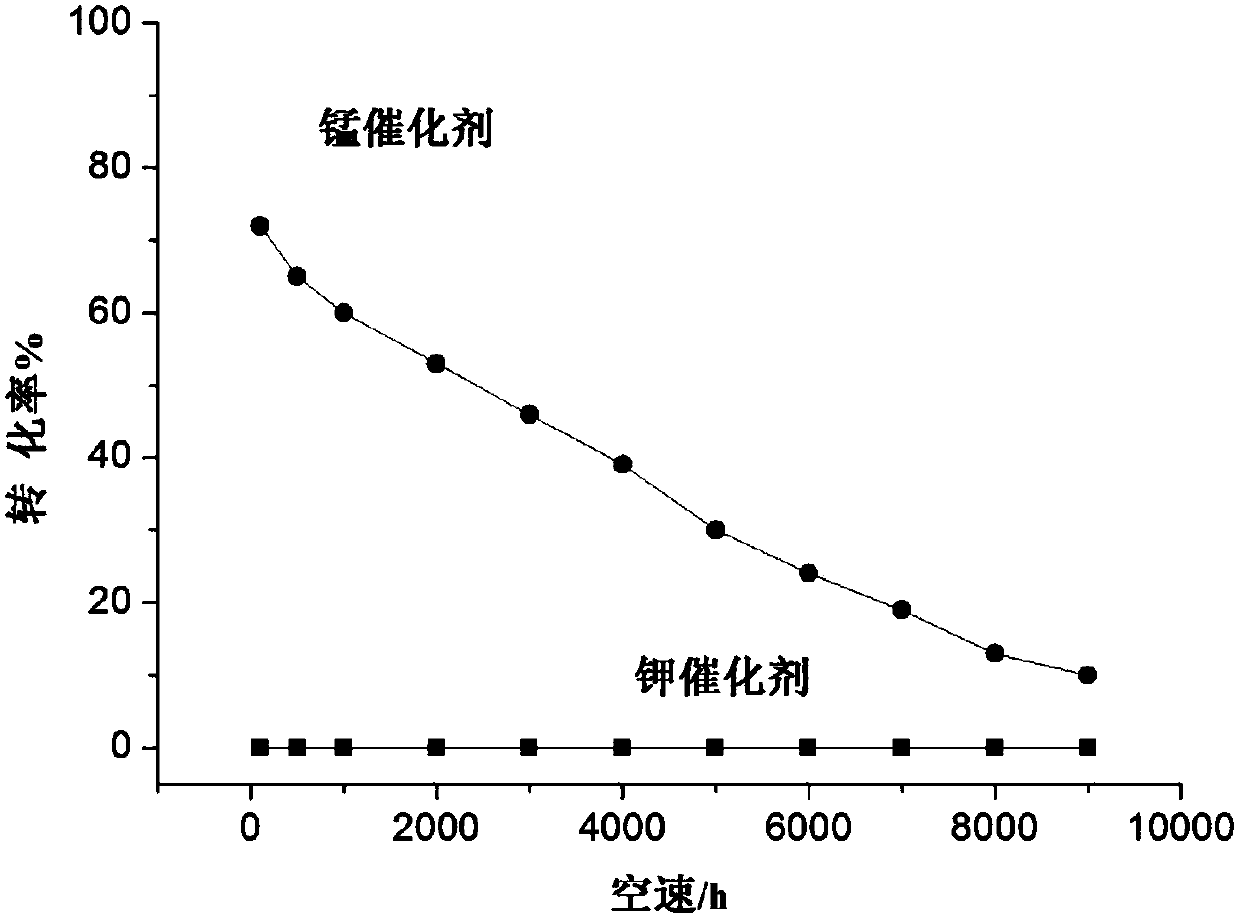

Application of supported catalyst in cracking of trifluoromethane

ActiveCN107626291AReduce dosageImprove conversion rateHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsStrong acidsTemperature resistance

The invention relates to a catalyst used in cracking of trifluoromethane and preparation thereof. The catalyst is characterized by adopting zirconium oxide, magnesium oxide, activated carbon, acid treated activated carbon, alumina and the like as carriers, auxiliaries contain alkali metals K, Na and Cs, carrying capability of active components is 1-50% (mass percent), and molar content of metal auxiliaries is not higher than 50% of the total molar content of the active components and the metal auxiliaries. The catalyst provided by the invention has the characteristics that trifluoromethane catalytic cracking reaction temperature is low and is lower than 600 DEG C, catalyst dosage is low, conversion rate and yield are high, selectivity is high, high temperature resistance and strong acid resistance are good and high value-added products can be obtained; the catalyst is not only effectively improved in thermal stability resistant to high temperature agglomeration but also effectively improved in corrosion resistance through fluorination treatment, so that use stability of the catalyst is improved; and raw materials are available, technology is simple, and industrialization application can be realized.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

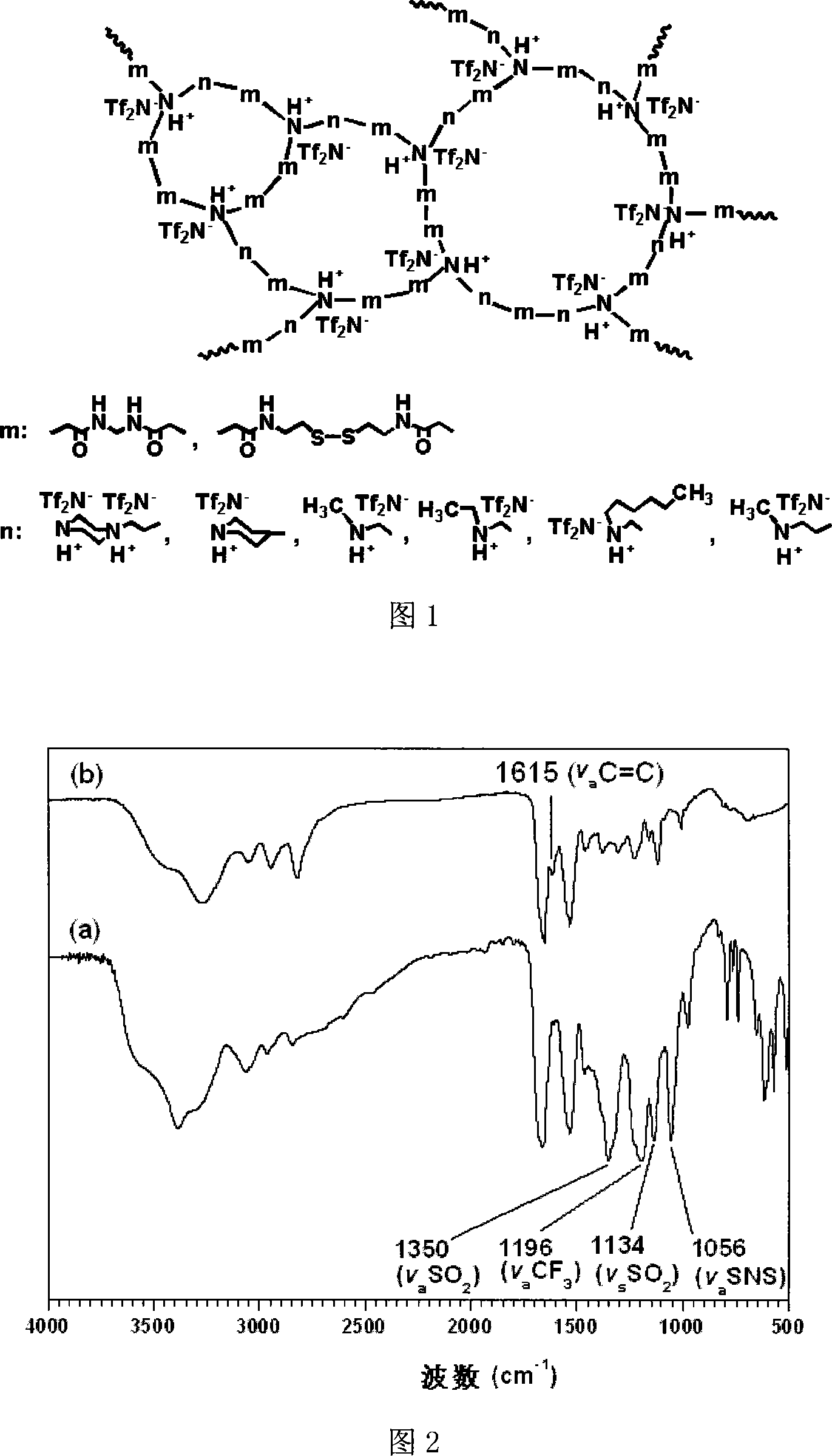

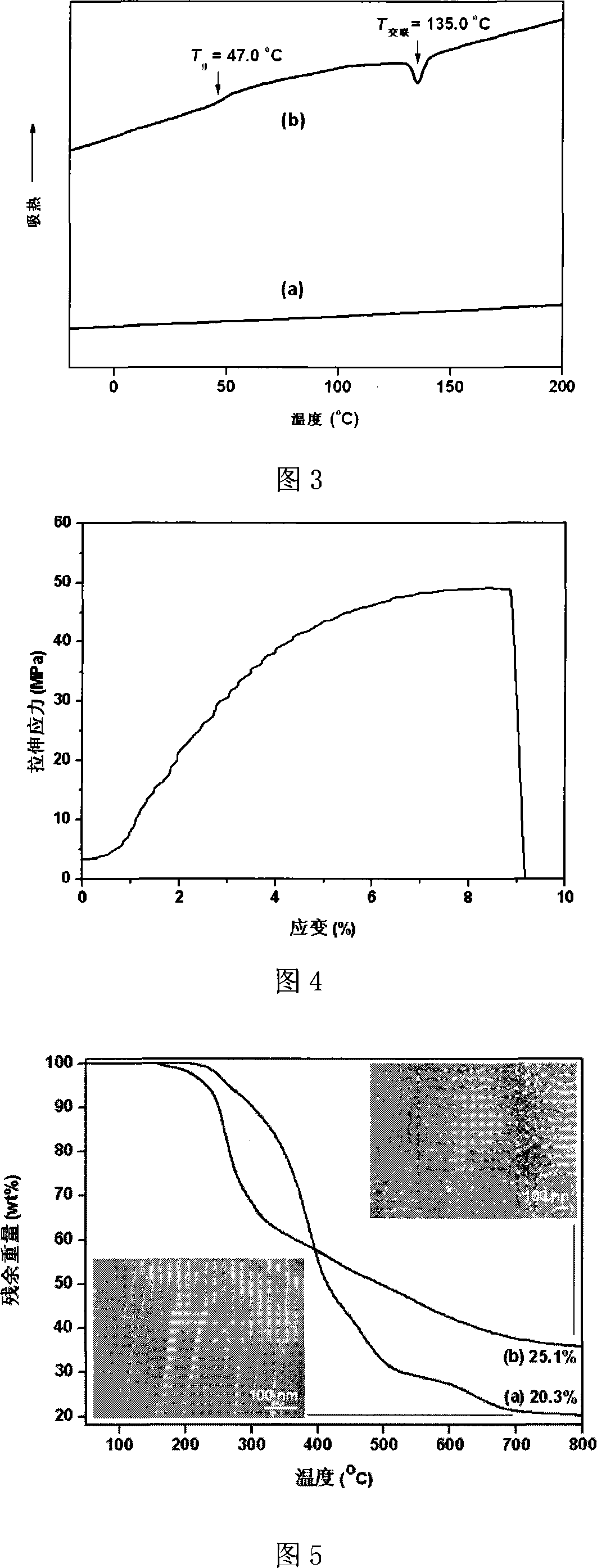

Crosslinked polyalcohol membrana body material, method for producing the same and process of using

InactiveCN101220154AEfficient enrichmentFriendlyWater contaminantsWater/sewage treatment by reductionProtonationPolyamide

The invention relates to a main material of a crosslinking polymer film in the technical field of high molecular material and a preparation method and a using method thereof. Through Michael addition polymerization, the invention obtains hyper branched polyamide containing an end double bond. By the protonation of a tertiary amine unit, the introducing of anion ligand and thermal initiation and self crosslinking of the end double bond, the main material of the crosslinking polymer film can be prepared. The components of the material the contents of the weight percentage are as follows: 12 to 19wt percent of amide group, 17 to 29wt percent of methylene, 2 to 3wt percent of protonated tertiary amine and 52 to 66wt percent of fluoroform sulfonate radical. The material of the invention can not only efficiently enrich object dye molecules from an aqueous solution, but also can efficiently enrich precious metal ions from the aqueous solution and restore the metal ions to be internally embedded metal nanoparticles in position. The invention has simple operation and is environment friendly; therefore, the invention can be applied to the treatment of waste water containing dye, the recycling of precious metal or metal-catalyzing and other fields.

Owner:SHANGHAI JIAO TONG UNIV

Multicomponent mixed work medium throttling refrigerant applicable to 200-204K refrigerating temperature zone

The multicomponent mixed work medium throttling refrigerating agent applicable to 200-240 k temp. zone includes four groups of substances, respectively are: first group includes tetrafluoromethane, nitrogen trifluoride or mixture; second group includes ethylene, ethane, fluoroform, xenon, fluromethane, perfluoroethylene, fluoroethylene, perfluoroethane or their any two, three and several kinds or mixture of all them; fourth group includes 1-butylene, isobutane, 2-methyl butane, 1-pentene, 3-methyl-1-butylene, 2-methylpentane, 2-butylene, cyclobutane, isobutylene, n-butane, pefluorobutane, n-pentane, perfluoropentane or their two, three, several kinds ormixture of all the them; and third group includees propylene, propane, perfluoropropane, 1,1,1-trifluoroethane, 1,1,-bifluoroethane.

Owner:中科赛凌(北京)科技有限公司

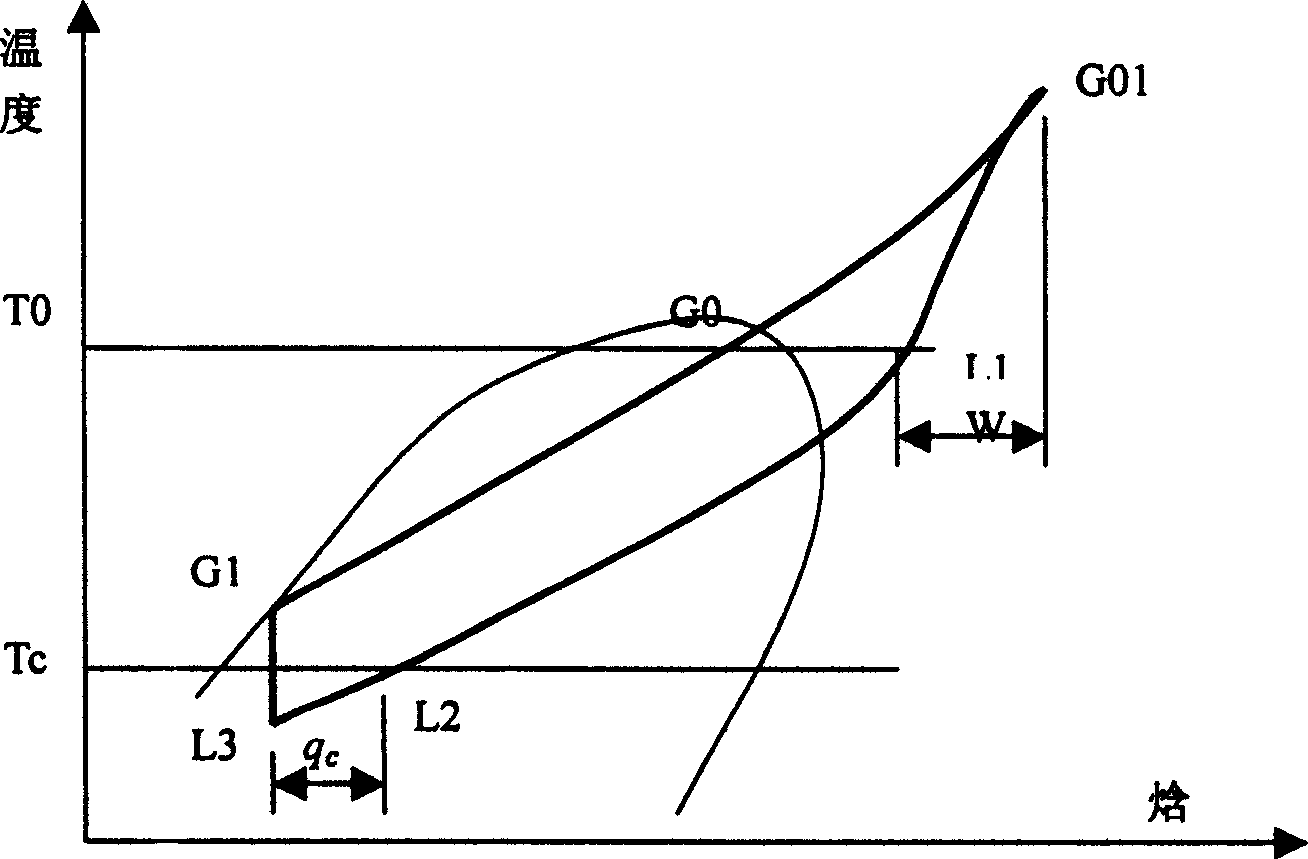

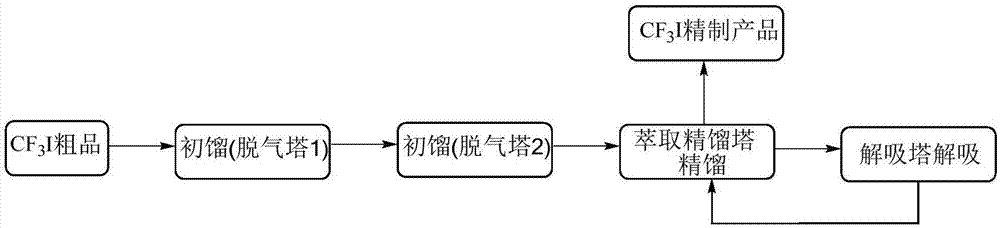

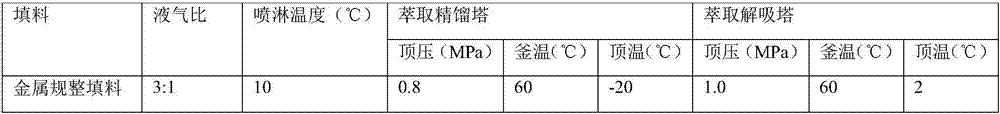

Technology for separating and purifying trifluoroiodomethane

ActiveCN107176902AResidue reductionHalogenated hydrocarbon separation/purificationTrifluoroiodomethaneMixed gas

The invention discloses a technology for separating and purifying trifluoroiodomethane. The technology is a method for obtaining a trifluoroiodomethane monomer by separating and purifying a mixed gas product from the gaseous phase preparation of the trifluoroiodomethane by utilizing trifluoromethane. The trifluoroiodomethane is separated and purified in the manner of separating the components in the mixed gas in steps. The system has the characteristics of high recovery rate, excellent separating effect, low cost, and the like. The technology has the characteristics of high recovery rate, high product purity, complete separation and the like in the process of separating and purifying the trifluoroiodomethane; the technological process is simple, the safety factor is high, the operation is easy, and the separating and purifying cost is low; and the technology has the value of industrial production.

Owner:泉州宇极新材料科技有限公司

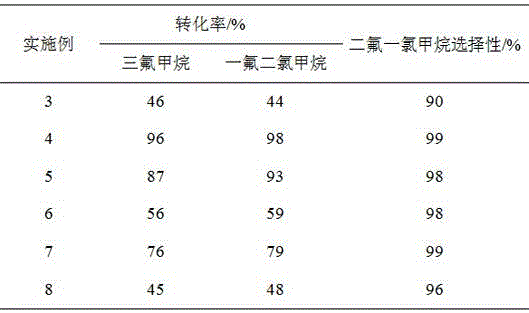

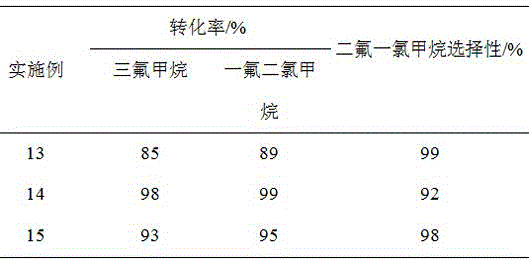

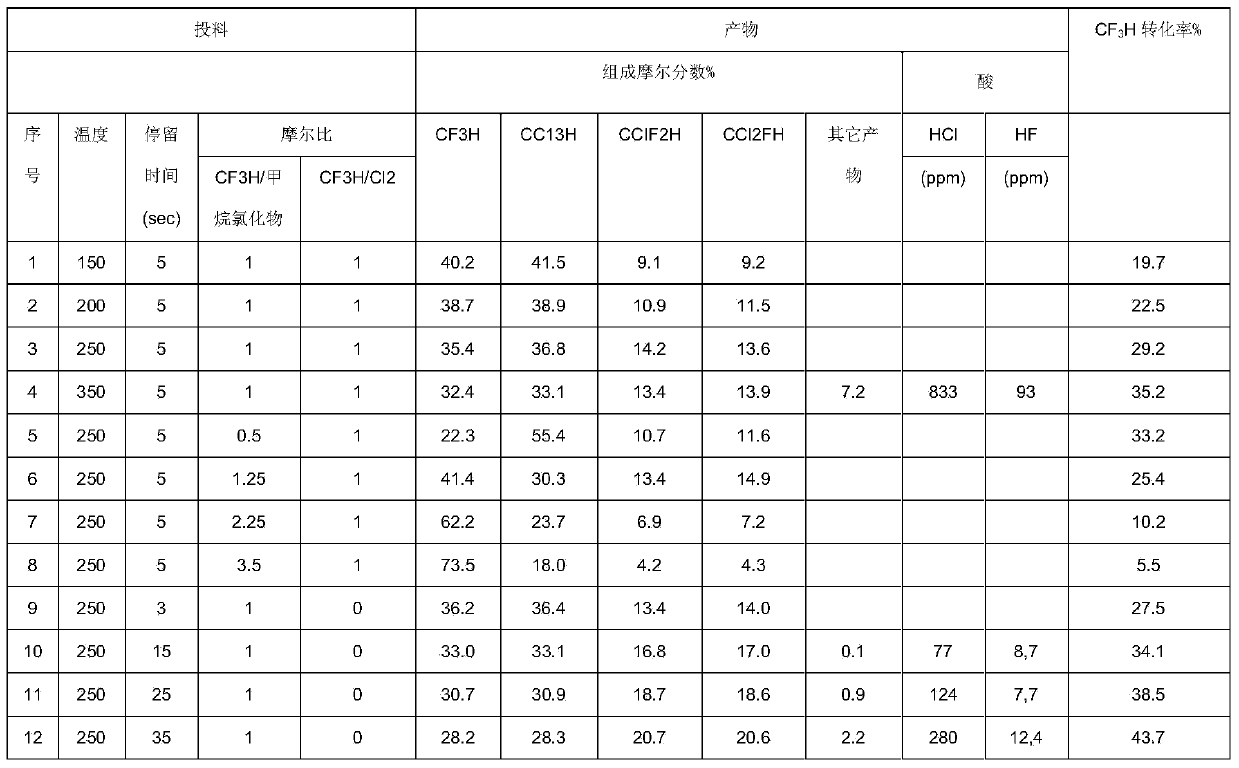

Technique for preparing monochlorodifluoromethane by decomposing trifluoromethane

ActiveCN103467239AReduce outputAvoid harmPreparation by halogen replacementChlorodifluoromethane productionHydrogen fluorideDecomposition

The invention provides a technique for preparing monochlorodifluoromethane by decomposing trifluoromethane. The technique comprises the steps of: feeding the raw materials trifluoromethane and methane chloride into a reactor filled with a catalyst in the mol ratio of 0.1-10, and carrying out a decomposition reaction at a temperature ranging from 150 to 350 DEG C for 3-30 seconds to obtain a mixture of trifluoromethane, methane chloride, dichloromonofluoromethane and monochlorodifluoromethane; obtaining monochlorodifluoromethane directly through separation, reacting dichloromonofluoromethane separated out with hydrogen fluoride to produce monochlorodifluoromethane, and separating out and recovering trifluoromethane and methane chloride in the mixture as the reaction mixture continuously. The method has the advantage that the harm on the environment caused by trifluoromethane emission is greatly avoided.

Owner:CHANGSHU 3F ZHONGHAO NEW CHEM MATERIALS

Recycling method of byproduct-trifluoromethane in HCFC-22 production

ActiveCN109748775ARealize resource utilizationIncrease valuePreparation by halogen replacementEconomic benefitsChlorodifluoromethane

The invention discloses a method of recycling trifluoromethane. The method includes: under action of at least one catalyst of MgF2, Al2O3, partially fluorinated alumina and AlF3, allowing trifluoromethane and dichloromethane to react to obtain a reaction product containing difluoromethane and monochlorodifluoromethane, and rectifying to obtain difluoromethane. The method can realize recycling of trifluoromethane, can convert the same into difluoromethane with high value and has great economic benefit.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +1

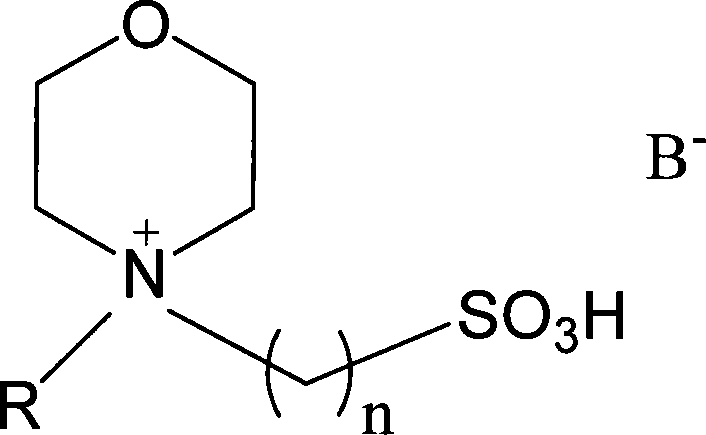

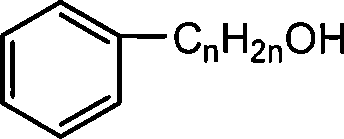

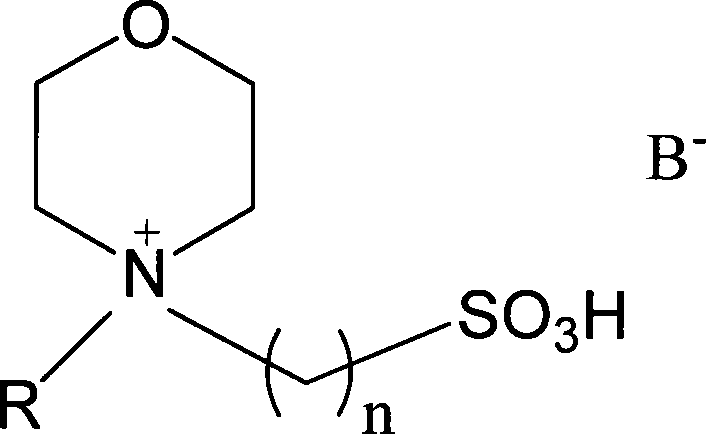

Catalytic esterification method for sulfonic group functionalization morpholine hyamine ion liquid

InactiveCN101172949AStrong acidThe synthesis process is simpleOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen SulfateSulfate radicals

The invention discloses a method for catalyzing and esterifying sulfoacid basal functional ion liquid in the formula (1), wherein, n equals to 2, 3 and 4; R is H or C1 to C4 saturated or unsaturated alkyl of straight chain or branched chain; negative ion B- is chlorine, bromine, iodine, sulfate radical, hydrogen sulfate radical, nitric acid radical, dihydrogen phosphate radical, tetrafluoride boric acid radical, hexaflurate phosphoric acid radical, acetic acid radical, methyl sulfoacid radical, paratoluenesulfonic acid radical, fluoroform sulfoacid radical and trifluoroacetic acid radical. The adding dosage of the ion liquid is 0.5 to 100 percent of the total mol of the alcohol and acid, reacting for 0.5 to 12 hours under the normal pressure and the temperature of 20 to 140 DEG C, the esterifying reaction is catalyzed to produce the ester. Compared with the traditional acidic catalyst, the ion liquid simplifies the separation of the product of the esterifying reaction and provides higher selectivity. The invention is distinctly characterized in that the phase separation between the produced ester and the catalyst is automatically finished, and the ion liquid is reusable after simple or non treatment.

Owner:GUANGDONG UNIV OF TECH

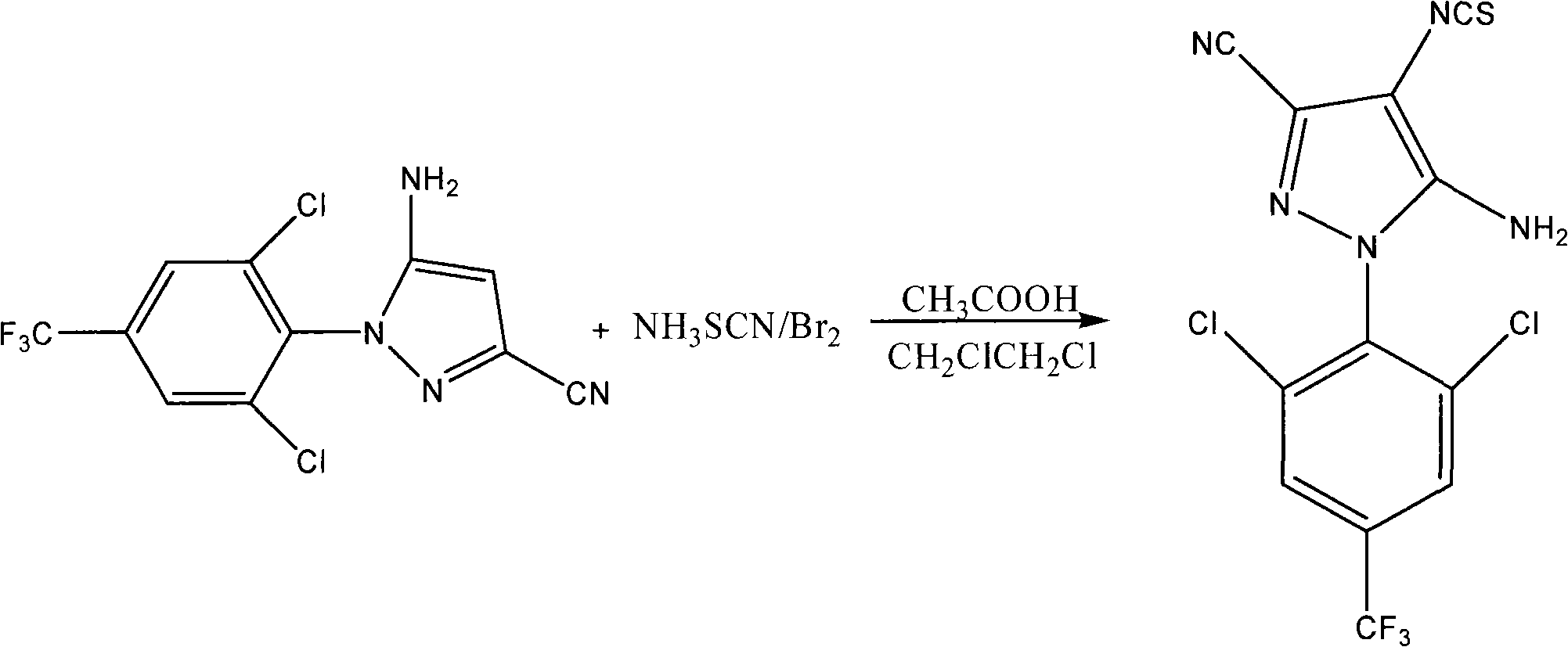

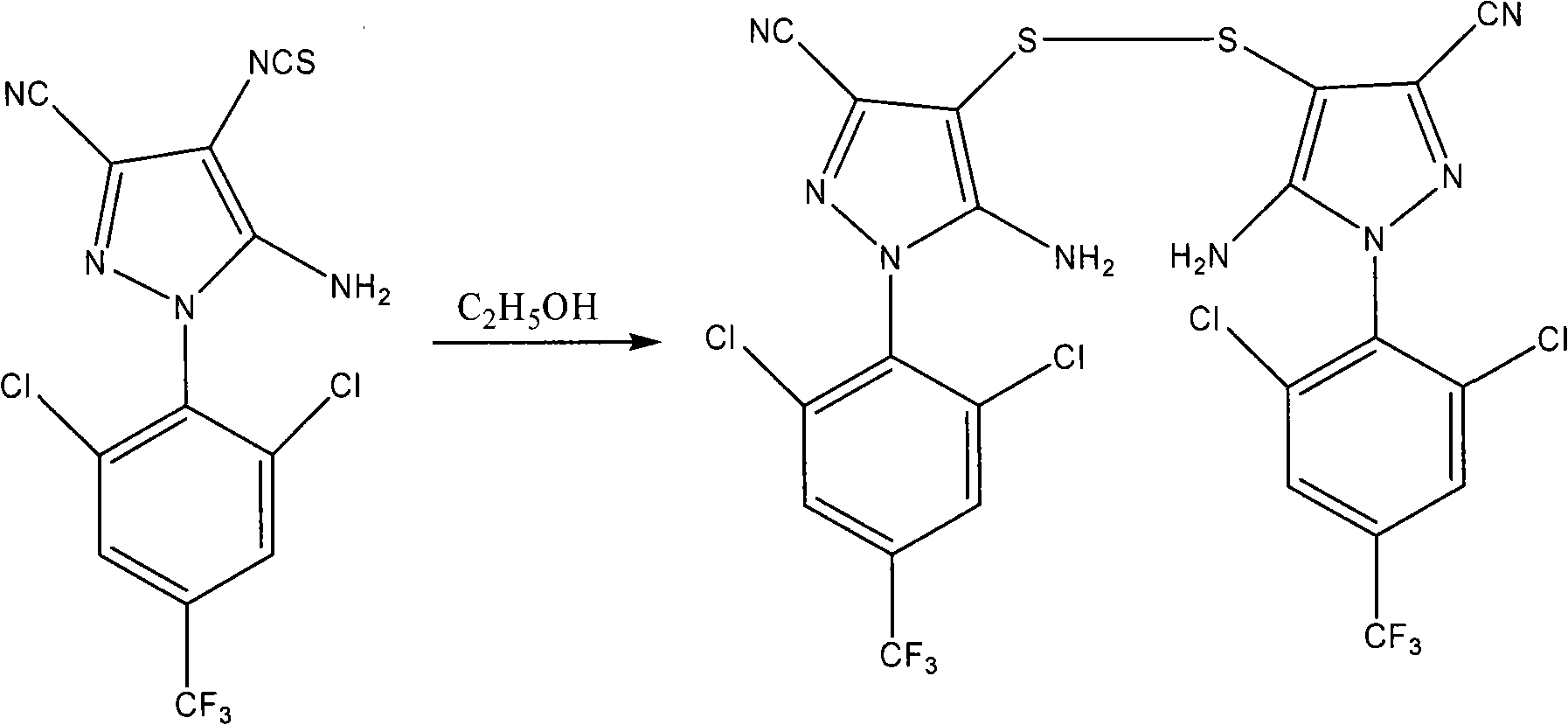

Method for synthesizing fipronil

The invention relates to a method for synthesizing pesticide, in particular to a method for synthesizing fipronil and provides a method for synthesizing fipronil having the characteristics of simplicity in operation, mild condition, high yield and environmental friendliness. In the technical scheme, fipronil is synthesized by a catalytic oxidation method. The method comprises the following steps of: synthesizing 5-amino-3-cyan-1-(2,6-dichloro-4-trifluoro methyl-phenyl)-4-sulfur cyan-pyrazol; synthesizing a disulfide; synthesizing 5-amino-3-cyan-1-(2,6-dichloro-4-trifluoro methyl-phenyl)-4-fluoroform-sulfenyl-pyrazol; and synthesizing the fipronil.

Owner:李家波

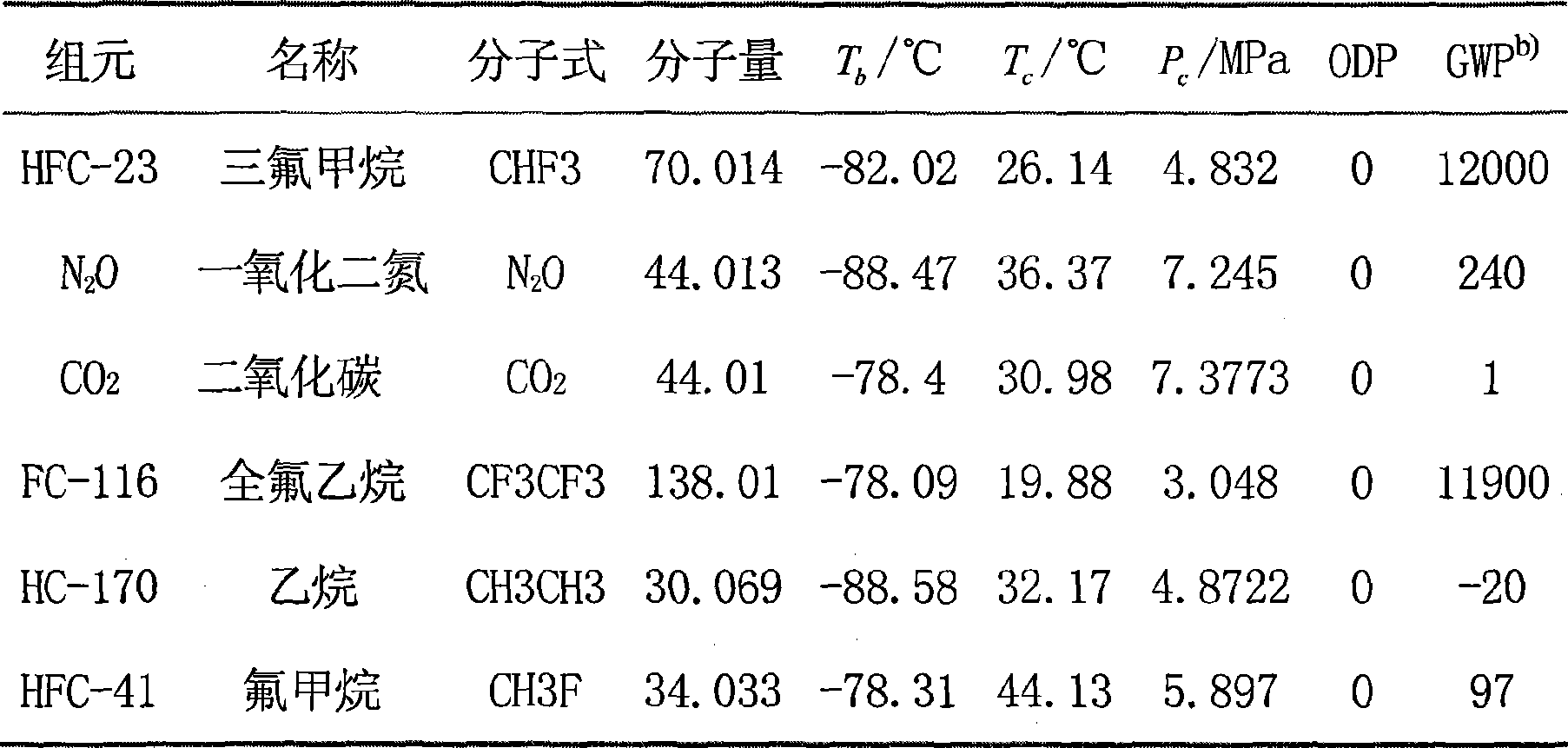

N2O-containing low temperature mixing working substance for cascade refrigeration system

InactiveCN101434831ADestruction will notSmall slip temperatureHeat-exchange elementsHexafluoroethaneBoiling point

The invention relates to a cascade refrigeration system low-temperature mixed refrigerant which is applicable to the temperature area of 180-220K and contains N2O, and a preparation method thereof; the low-temperature mixed refrigerant comprises one or two components of low-boiling point refrigerant N2O(R744A), ethane (R170), fluoromethane (R23), hexafluoroethane (R116), fluoromethane (R41), and CO2 (R744) and is formed by physical mixing at normal temperature. The low-temperature mixed refrigerant damages no ozonosphere, has low greenhouse effect potential, meets the requirement of environmental protection, has suitable thermal parameters and excellent circulation performance, and can optimize and design the new refrigerant system by the existing cascade low-temperature compressor. The mixed refrigerant can be used for replacing the refrigerant in the existing cascade refrigeration low-temperature system.

Owner:XI AN JIAOTONG UNIV

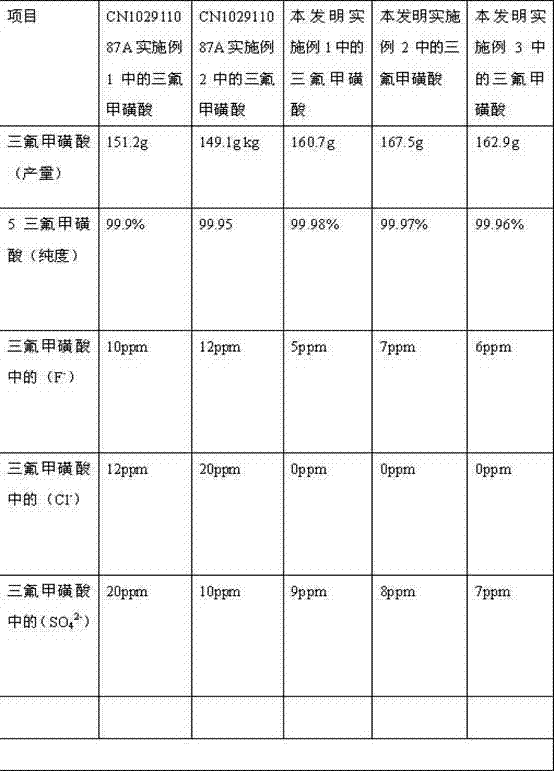

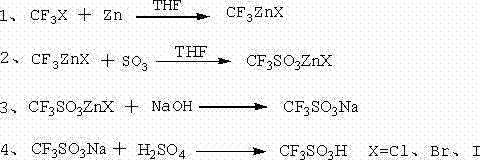

Trifluoromethanesulfonic acid preparation method

ActiveCN104725283AHigh yieldAvoid it happening againSulfonic acid preparationDistillationTriflic acid

Owner:JIANGXI GUOHUA IND CO LTD

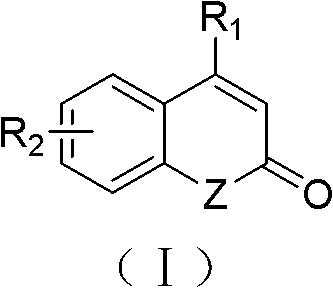

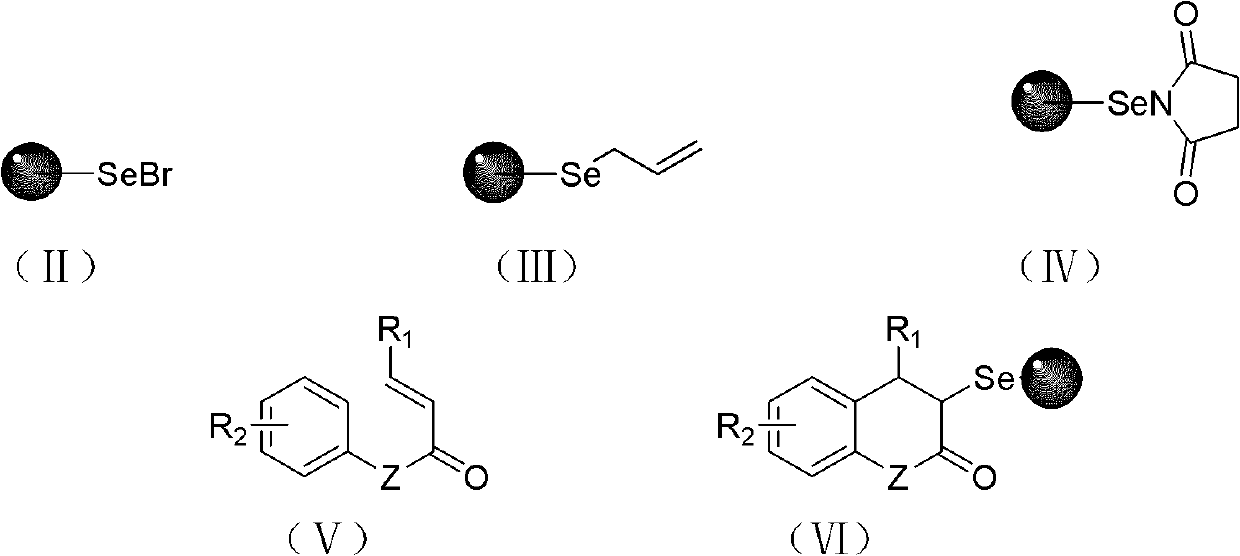

Solid-phase synthesis method of coumarin and analogue thereof

InactiveCN102532015AHigh yieldOvercome the disadvantage of low yield of cyclization reactionOrganic chemistryPolystyreneKetone

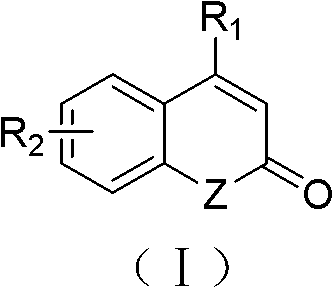

The invention relates to a solid-phase synthesis method of coumarin and an analogue (I) thereof and belongs to the field of organic chemistry. The method comprises the following steps: 1) taking 1% of cross-linked polystyrene resin as a carrier to prepare a polystyrene-supported seleno-succimide reagent (III); 2) using the III to induce phenyl acrylate (V) to perform intramolecular cyclization under the catalysis of trimethylsilyl trifluoromethanesulfonate so as to form 3-polystyrene-supported seleno-3,4-dihydro-benzopyran-2-ketone (VI); and 3) performing oxidation elimination on the VI via an oxidant so as to directly get the coumarin (I) without further separation. When the phenyl acrylate (V) is replaced by N-phenyl acrylamide, the analogue of the coumarin, namely a 2-quinolone compound, can be prepared through the same steps. The solid-phase synthesis method disclosed by the invention has the advantages of easily available raw materials, good product yield, high purity, simplicityand convenience in operation, simple post-treatment and great industrial application prospects.

Owner:YUNNAN UNIV

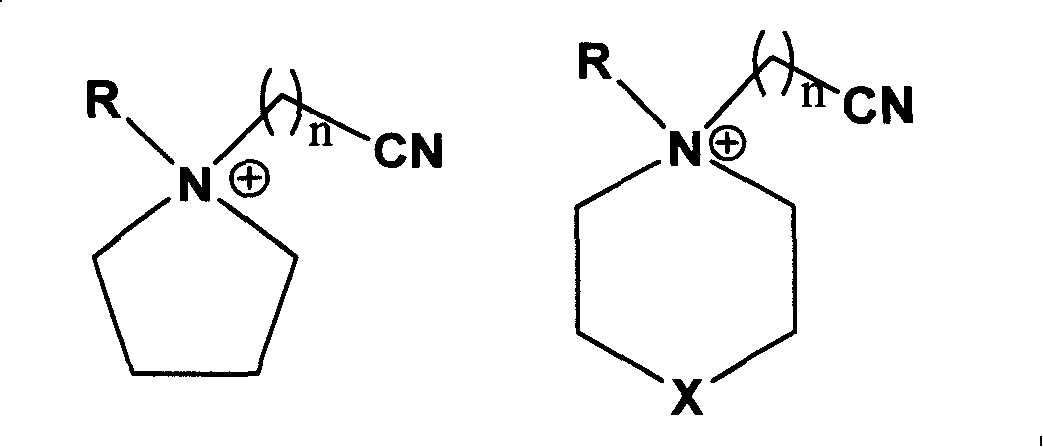

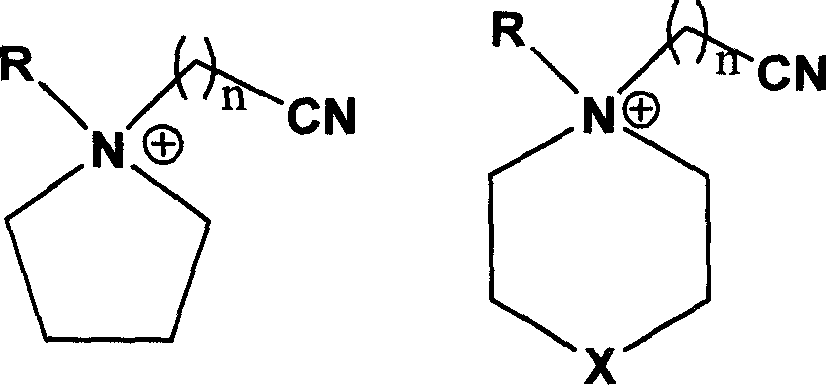

Ionic liquid with high electrochemical stability and preparing method thereof

InactiveCN101210000ALower melting temperatureImprove electrochemical stabilityOrganic chemistrySulfate radicalsOrganic synthesis

The invention discloses a functional ionic liquid that has high electrochemical stability and a preparation method thereof. Positive ion of the ionic liquid is selected from nitrile-functionalized quaternary ammonium positive ion and negative ion thereof from one of chlorine, bromine, iodine, fluoborate, fluorophosphates, sulfate radical, nitrate radical, trifluoroacetic radical, trifluorochloromethane sulfonic acid group, bi (perfluoroalkyl group sulfonyl) imino negative ion, dinitrile amic radical and saccharin acid radical. Nitrile functional ionic liquid, the negative ion of which is halogen negative ion, is firstly prepared through reaction of pentagons or hexatomic tertiary amine with the alkyl halide that has nitrile functional groups, then ionic liquid that contains different negative ions is prepared by exchange of the negative ions. The ionic liquid has very low melting temperature, can bear the high temperature of 150 DEG C and be stable to water, hardly has vapor pressure but has good electrochemical stability, thereby the invention can be taken as solvent, catalyst ligand, electrochemical electrolyte, etc. that are applied in the fields of organic synthesis, catalytic reaction and lithium-ion battery, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

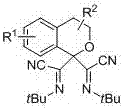

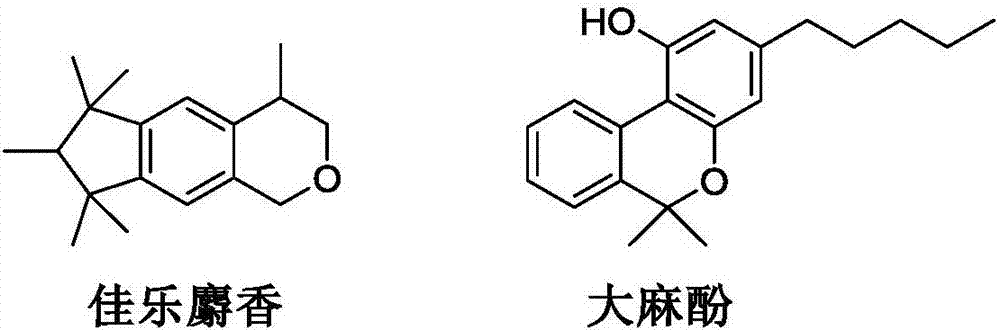

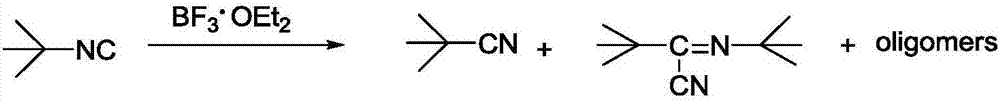

Bis alpha-cyanoimino substituted isochroman compound and synthetic method thereof

InactiveCN107082771AEasy to operateRaw materials are easy to obtainOrganic chemistryStructural formulaMedicinal chemistry

The invention relates to a bis alpha-cyanoimino substituted isochroman compound. The structural formula of the compound is as shown in the specification. Raw materials used in the method are simple and easily available. Under the action of DDQ, tert-butyl isocyanide is used as a cyano source of the reaction and shows high reaction activity under the catalysis of silver trifluoromethanesulfonate. During the reaction process, the operation is simple, conditions are mild, the method is environment-friendly, and yield is generally medium. The generated product has a special bis alpha-cyanoimino substituted skeleton. A series of chemical conversion can be carried out to generate various substituted isochroman derivatives. Therefore, the compound of the invention has a good development prospect in industrial production.

Owner:SHANGHAI UNIV

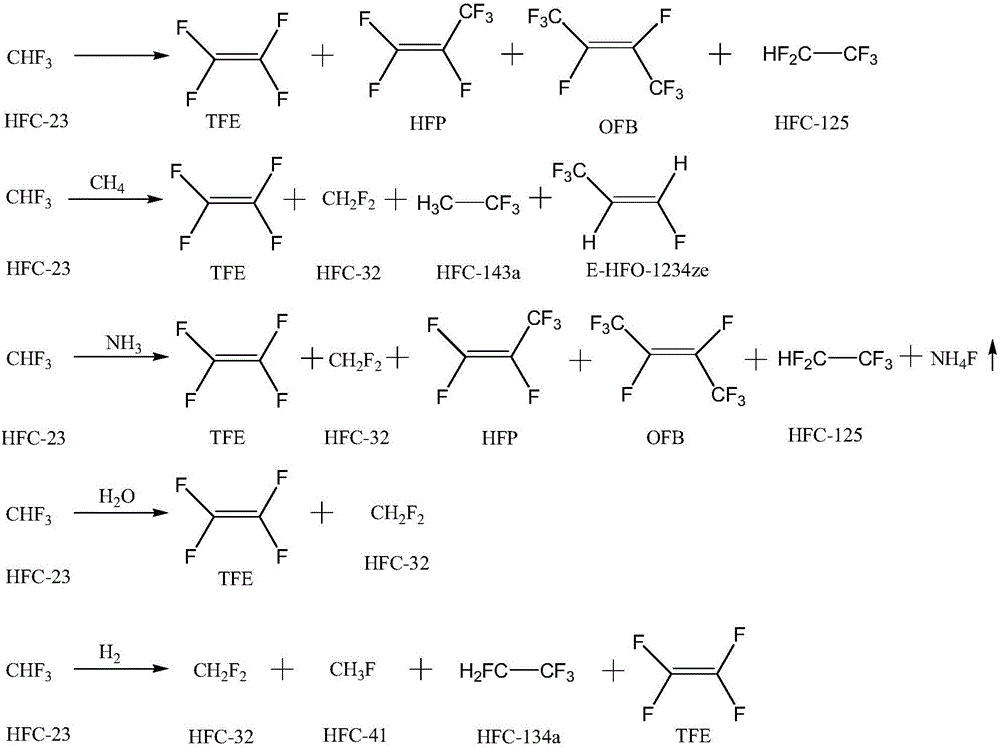

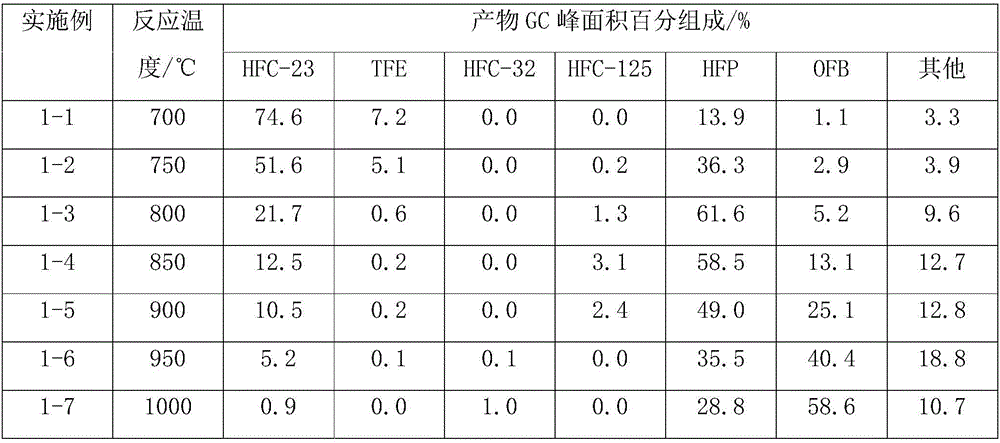

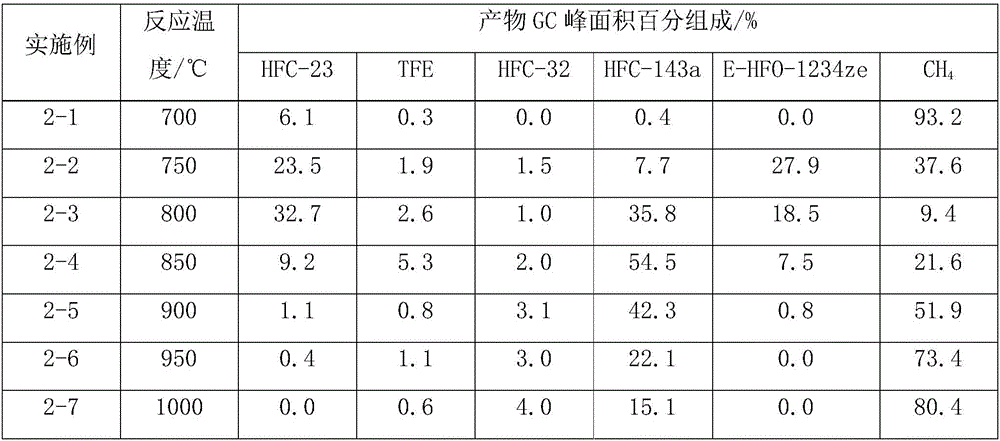

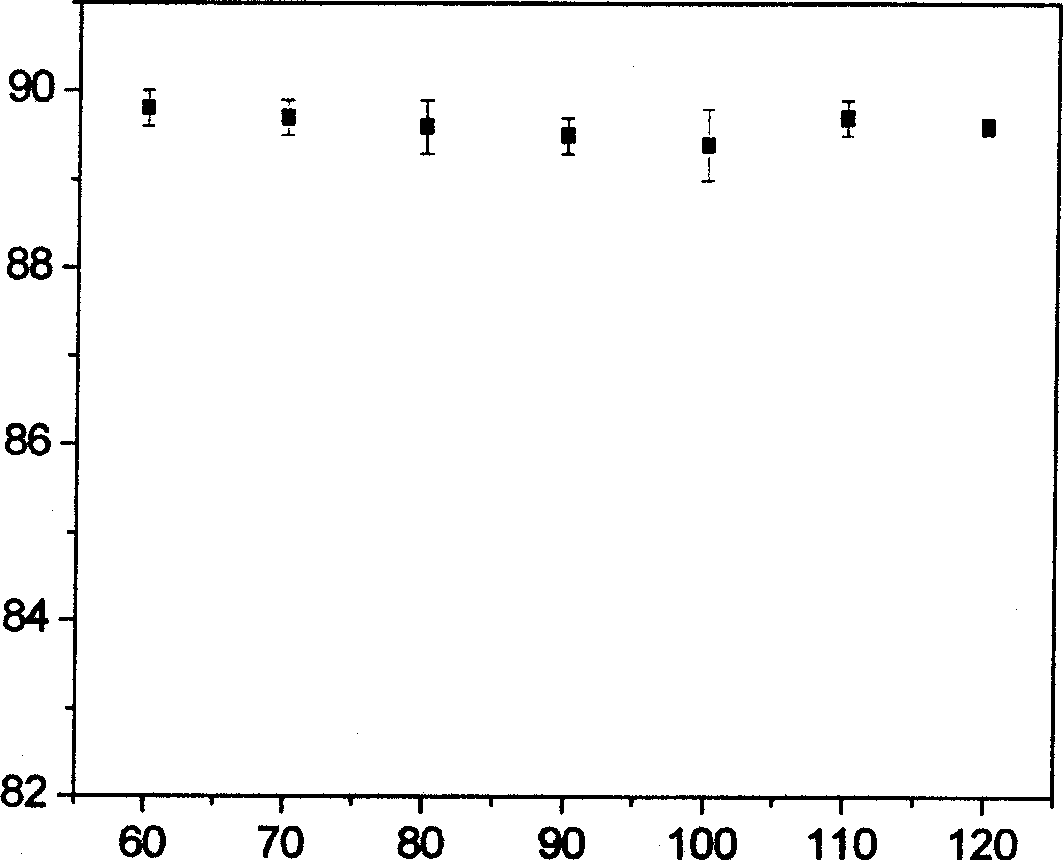

Method for preparing fluorinated compound CFR1=CFR2 (R1, R2=F or -CF3) through trifluoromethane thermolysis

ActiveCN106565410ANo deactivationGood repeatabilityHydrocarbon by hydrogenationHalogenated hydrocarbon preparationHydrogenReaction temperature

The invention discloses a method for preparing a fluorinated compound CFR1=CFR2 (R1, R2=F or -CF3) through trifluoromethane thermolysis. The method comprises the following steps that under the condition of no catalyst, trifluoromethane takes a gas phrase reaction with CH4, NH3, H2O or hydrogen gas to obtain the fluorinated compound under the reaction conditions that the reaction pressure is 0.1 to 1.5 MPa; the reaction temperature is 700 to 1000 DEG C; the mol ratio of the trifluoromethane to any one or several kinds of materials of CH4, NH3, H2O or hydrogen gas is (1:0) to (1:40); and the dwell time is 0.1 to 50s. The method provided by the invention has the advantages that the raw materials can be easily obtained; a catalyst does not need to be used; the operation and the control are easy; in addition, the experiment repeatability is high; and meanwhile, the conversion and reutilization of HFC-23 are well realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

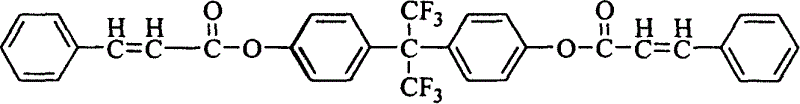

Method for preparing liquid crystal vertical orented membrane

InactiveCN1641449AAvoid high temperature heat treatmentSimple processNon-linear opticsCinnamic acidFluoroform

This invention is a method of producing the liquid crystal vertical tropism membrane. This invention chooses the monomer with cinnamonic acid structure at both ends of the molecule, and the hexafluorodiphene A dicinnamonic acid ester containing fluoroform radicle. At the normal temperature, dissolve the hexafluorodiphene A dicinnamonic acid ester in the solvent of quadplex hydroxy furan to confect into solution. Smear the solution on the basal board reelingly to form membrane. Shine the monomer membrane material of the hexafluorodiphene A dicinnamonic acid ester with the ultraviolet radiation, and make the both ends of the monomer molecule take place [2+2] cycloaddition reaction, then produce a tropism membrane that can induce the liquid crystal vertical tropism array. This invention avoids heat treatment at high temperature in the confecting process, which consumedly simplified the traditional technics of confecting the liquid crystal vertical tropism membrane. Compared with the traditional method of confecting the liquid crystal vertical tropism membrane, this invention has a simpler technics, and is a new method of confecting the liquid crystal vertical tropism membrane.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

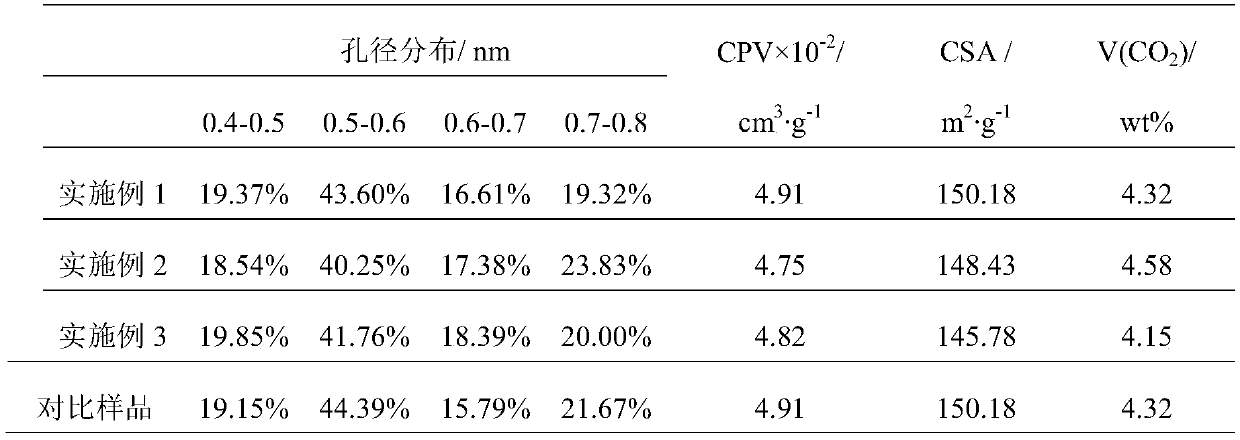

Porous silica gel supported ionic liquid polymer for adsorbing CO2 and preparation method thereof

ActiveCN105504121AImprove adsorption capacityStrengthen cross-penetrationProductsGas treatmentSorbentSilica gel

The invention discloses a porous silica gel supported ionic liquid polymer for adsorbing CO2 and a preparation method thereof. Raw materials of the porous silica gel supported ionic liquid polymer comprise porous silicon dioxide, 1-ethyl-3-ethylamino imidazole bi-fluoroform sulfonyl imide ion solution and azodiisobutyronitrile. According to the method, the porous silicon dioxide and the 1-ethyl-3-ethylamino imidazole bi-fluoroform sulfonyl imide ion solution are added into absolute ethyl alcohol; after the materials are mixed and uniformly stirred, the temperature is raised to 60 to 70 DEG C; then, the azodiisobutyronitrile is added; the constant temperature is maintained for reaction for 8 to 10h to obtain reaction liquid; then, the reaction liquid is put in an environment under the condition of 90 to 100 DEG C to be subjected to Soxhlet extraction for 12 to 24h; the porous silica gel supported ionic liquid polymer for adsorbing CO2 is obtained. The ionic liquid polymer for adsorbing CO2 can be singly used as an adsorbent for adsorbing CO2, and can also be used in a way of being compounded with other adsorption or absorption materials, and the adsorption performance is better.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

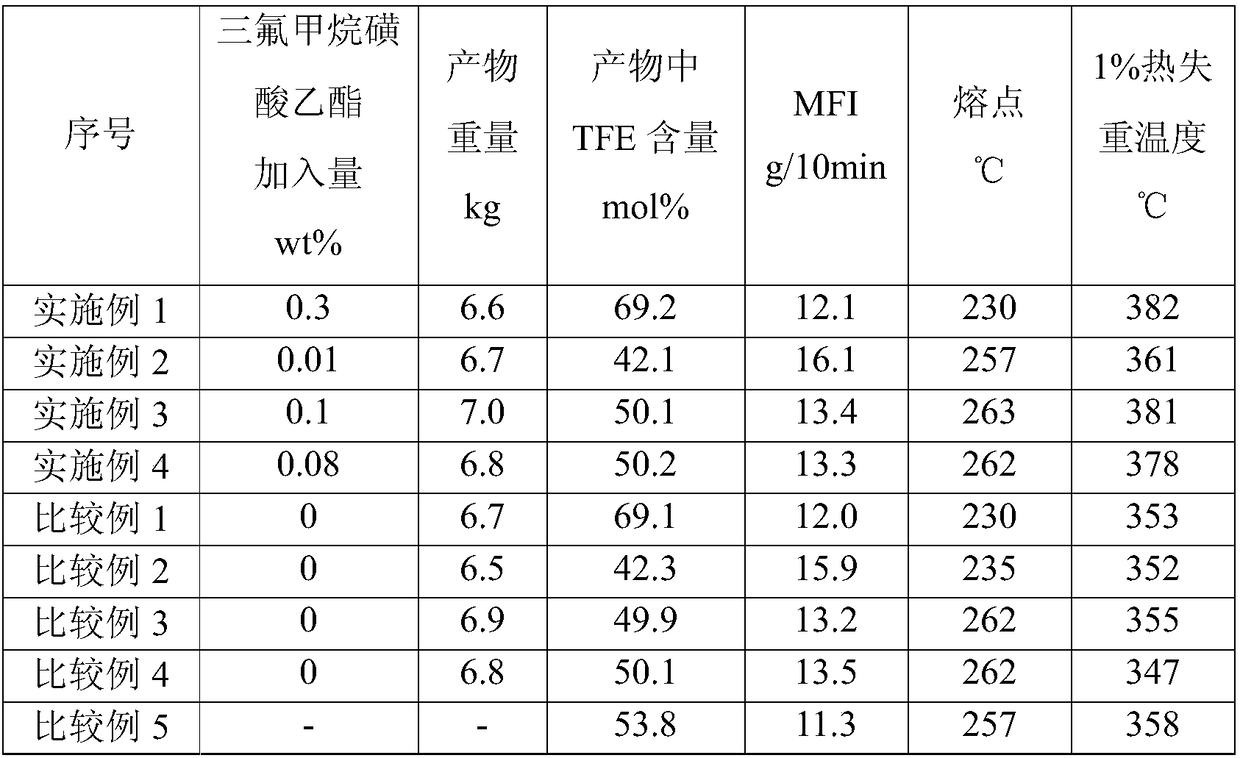

Preparation method of ethylene-tetrafluoroethylene copolymer with high thermal stability

The invention discloses a preparation method of an ethylene-tetrafluoroethylene (ETFE) copolymer with high thermal stability. The preparation method comprises the following steps: based on weight parts, adding 500 to 1000 parts of solvent, 4 to 8 parts of liquid-phase monomer, 0.5 to 1.5 parts of chain transferring agent and 0.05 to 5 parts of ethyl trifluoromethanesulfonate into a reaction kettle; introducing a first mixed monomer of tetrafluoroethylene and ethylene to raise the pressure of the reaction kettle to 10 to 20bar; then adding 0.1 to 1 part of initiator and carrying out polymerization reaction at 40 to 80 DEG C; after the polymerization reaction is started, additionally adding a second mixed monomer of the tetrafluoroethylene and the ethylene and keeping the pressure of the reaction kettle at 10 to 20bar; when additionally adding the second mixed monomer to 20 to 100 parts, finishing the polymerization reaction; drying obtained slurry containing the ETFE to obtain an ethylene-tetrafluoroethylene product with the high thermal stability. The preparation method disclosed by the invention has the advantages of simple technology, great operation elasticity, good product performance and wide application field.

Owner:JUHUA GROUP TECH CENT

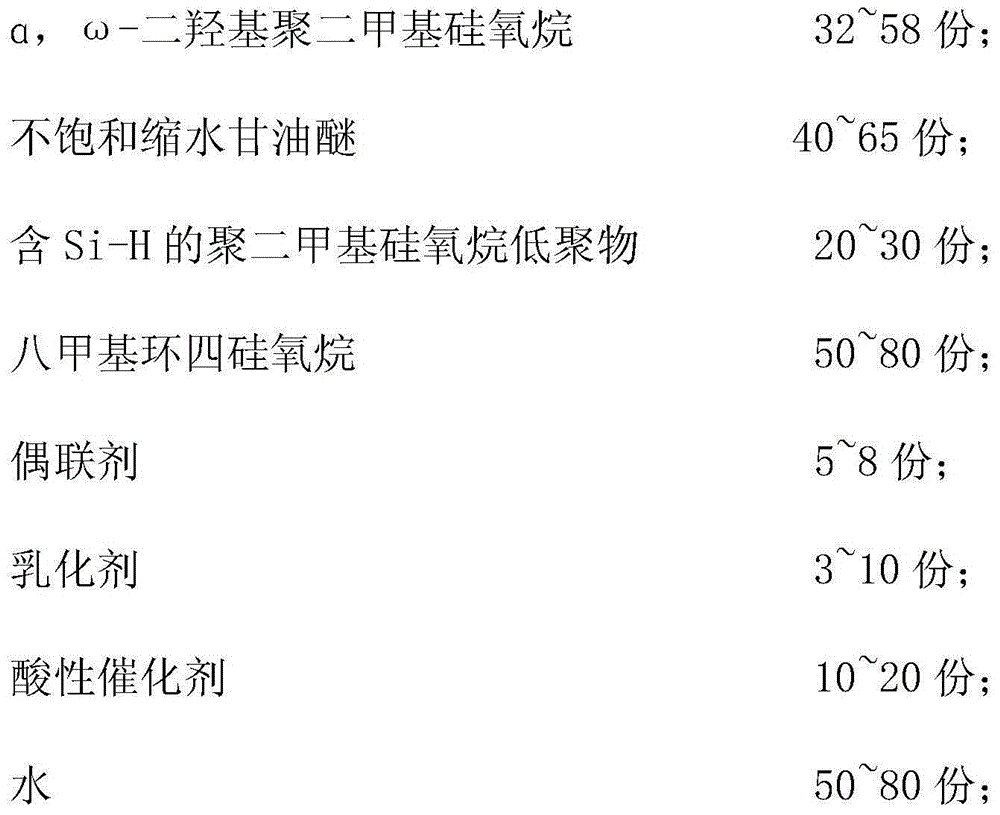

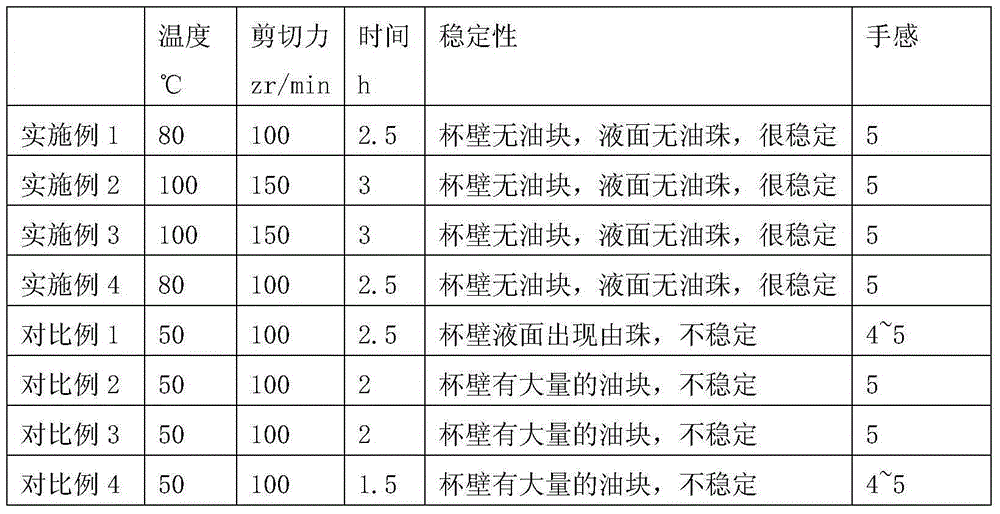

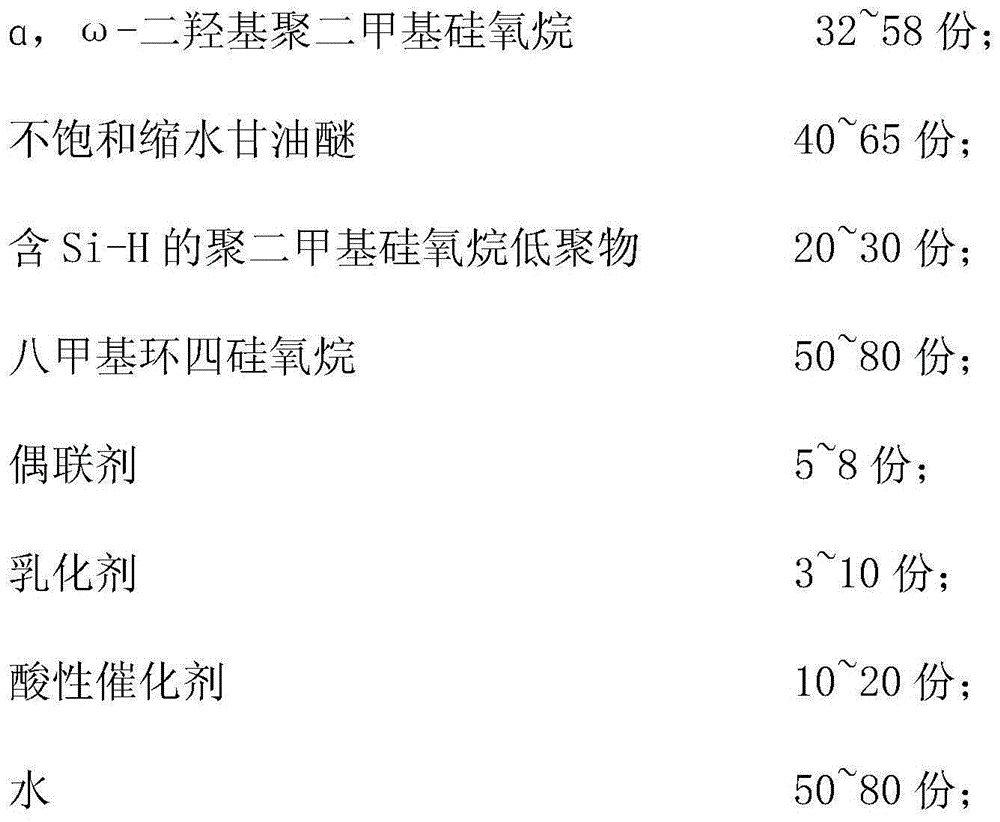

Fabric softening agent

The invention discloses a fabric softening agent. The fabric softening agent comprises the following raw materials: alpha, omega-dihydroxy polydimethyl siloxane, unsaturated glycidyl ether, Si-H-containing polydimethyl siloxane oligomer, octamethyl cyclotetrasiloxane, coupling agents, emulsifiers, an acid catalyst and water, wherein a preparation method for Si-H-containing polydimethyl siloxane oligomer comprises the following steps: mixing 20-40 parts in weight of trimethoxy silane and 1-2 parts in weight of trifluoromethanesulfonic acid, dropwise adding 10-20 parts in weight of deionized water within 20-30 min while stirring at room temperature, heating reflux for 1-2 h, cooling to room temperature, adding toluene and water for cleaning, and performing reduced pressure distillation at 60-80 DEG C to obtain the Si-H-containing polydimethyl siloxane oligomer. The fabric softening agent provided by the invention is excellent in hand feeling, resistant to washing, low in yellowing, high in hydrophilic effect, resistant to high temperature and high in shearing, and can be applied to a cheese high-shearing process and the like.

Owner:WUJIANG CITY QIDU TOWN MIAOGANG YADI KNITTING GARMENT FACTORY

Method for synthesizing crylic acid by catalyzing acetylene carbonyl through palladium

InactiveCN101768070AReduce energy consumptionLow investment costOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic preparation from carbon monoxide reactionReaction temperatureP-Toluenesulfonic acid

The invention provides a method for synthesizing crylic acid by catalyzing acetylene carbonyl through palladium. Acetylene, carbon monoxide and water are used as raw materials and are catalyzed to synthesize the crylic acid under the conditions that the reaction temperature is between 15 and 70 DEG C and the pressure is between 1.5 and 6MPa. The adopted catalyst uses palladium diacetate as a main catalyst; the dosage of the main catalyst is less than that of a traditional nickel-copper catalyst and is only 1 / 50; sulfoacid, such as methane sulfonate, trifluoromethane sulfonic acid, p-toluenesulfonic acid or the like, serves as an aid; an addition amount of the additive is that the ratio of n(-SO3H) to n(Pd2<+>) is equal to 1:1-10:1; and organic phosphine such as 2-pyridyl diphenylphosphine (2-PyPPh2) as a ligand. Compared with the nickel-copper catalyst, the catalyst has remarkable advantages that: under the mild conditions, such as the temperature of 40 DEG C and the pressure of 5 MPa, the catalyst can catalyze the acetylene carbonyl to synthesize the crylic acid at high efficiency, can effectively avoid the acetylene and the crylic acid undergoing polymerization and other side reactions, saves energy, and has safe operation and low operating expense.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

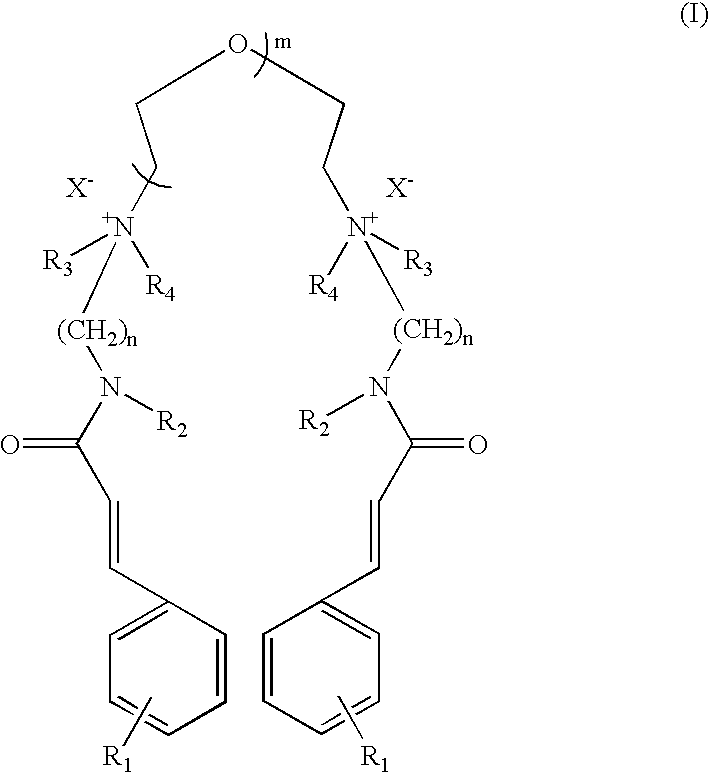

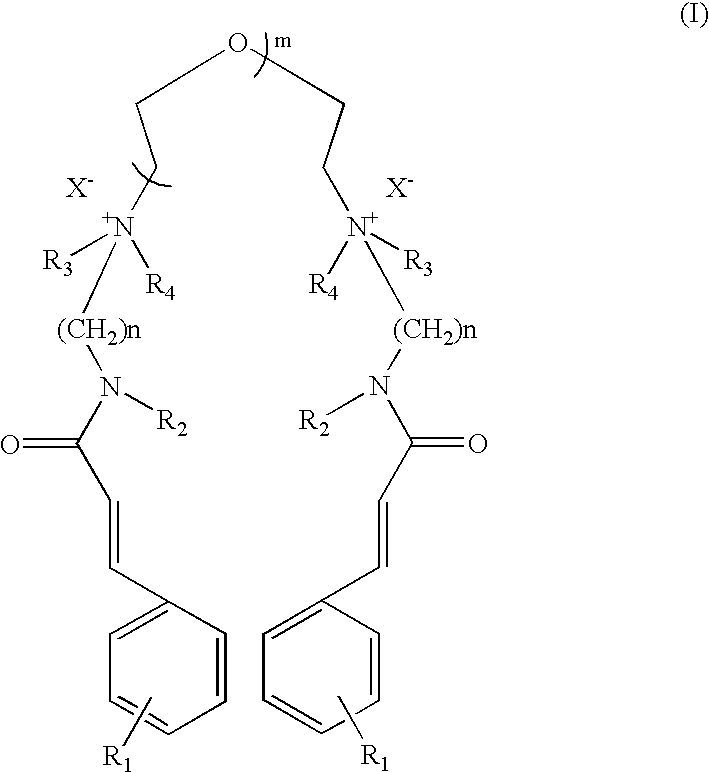

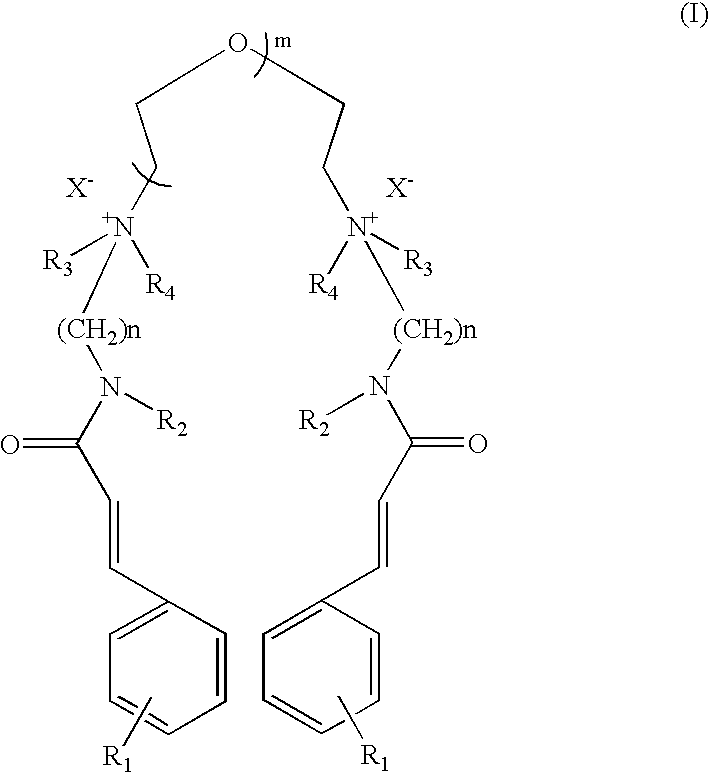

Substantive water-soluble bis-quaternary salts of cinnamidoalkylamines

Substantive UV-absorbing water-soluble quaternary salts of cinnamidoalkylamine of formula I. Hair, skin and fabric care compositions containing the compounds of formula I;wherein R1 represents up to four substituents, same or different, selected from H, halo, -OH, -NH2, -NO2, -OCH3, -N(CH3)2, alkyl groups containing up to 6 carbon atoms, alkoxy groups containing up to 6 carbon atoms, alkylamino or N,N-dialkylamino groups containing up to 6 carbon atoms; R2 is selected from hydrogen, alkyl group containing up to 6 carbon atoms; R3 and R4 are independently selected from benzyl, alkyl group containing up to 6 carbon atoms; n is an integer from 1 to 6; m is an integer from 1 to 10; X- is a counter anion of quaternary centres selected from halides including chloride, bromide, iodide and methane sulphonate and its derivatives such as trifluoro methane sulphonate, benzene sulphonates including its p-bromo, nitro and methyl derivative.

Owner:GALAXY SURFACTANTS LTD

Separation analyzing method for lipophilicity extraction in agricultural waste

InactiveCN1560626AReduce usageSimple and fast operationComponent separationTrimethylsilyl chlorideOrganic solvent

The invention discloses a separating and analyzing method for lipophilic extracted substances from the agricultural waste, introduces a method using double-trimethyl silicane group fluoroform acetamide and trimethyl chlorosilane to carry on methyl silicane process after the lipophilic extracted substances is extracted through organic solvent, then using high temperature Rtx-1 capillary to carry on gas phase chromatogram analysis, determining the content and composition of the lipophiltic extracted substances.

Owner:SOUTH CHINA UNIV OF TECH

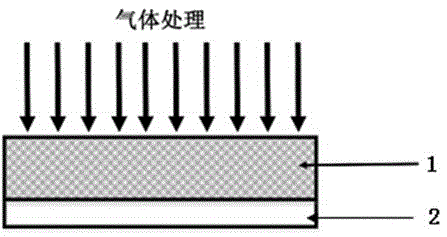

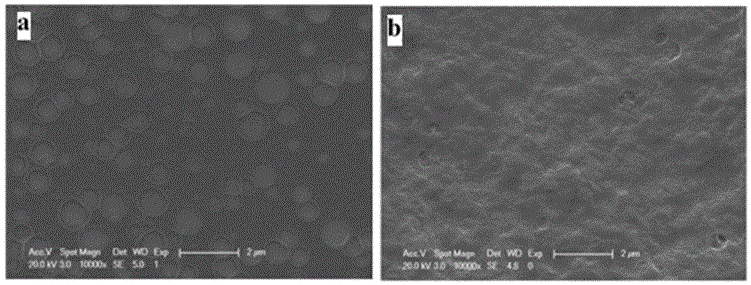

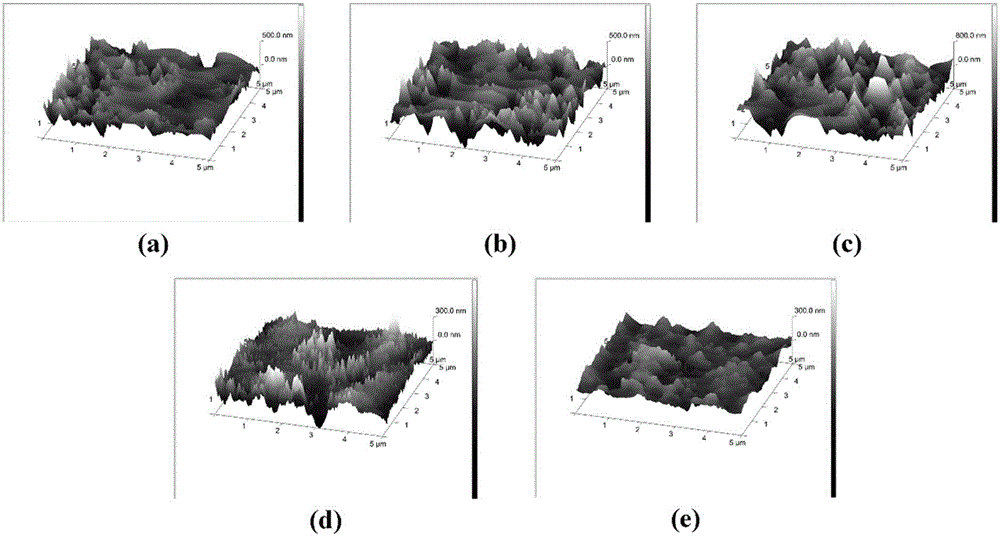

Preparation method of superhydrophobic dielectric material and dielectric material prepared by method

InactiveCN105622975AImprove the defect of porous structure on the surfaceReduce process complexityLaboratory glasswaresDielectricElectricity

The invention discloses a preparation method of a superhydrophobic dielectric material and a dielectric material prepared by the method. The method comprises the following steps: 1. treating a dielectric material by using a carbon tetrafluoride reaction gas source, wherein the power is 100-50W, and the gas flow rate is 30-10sccm; and 2. treating the dielectric material treated in the step 1 by using a fluoroform reaction gas source, wherein the power is 50-75w, and the gas flow rate is 10-30sccm. The superhydrophobic dielectric material implements surface modification of the biological compatible material, and thus, has superhydrophobicity. The method is simple, is compatible with the current integrated circuit technique, and has important meanings for the application of the dielectric electrowetting digital microfluidic chip prepared from the material.

Owner:FUDAN UNIV

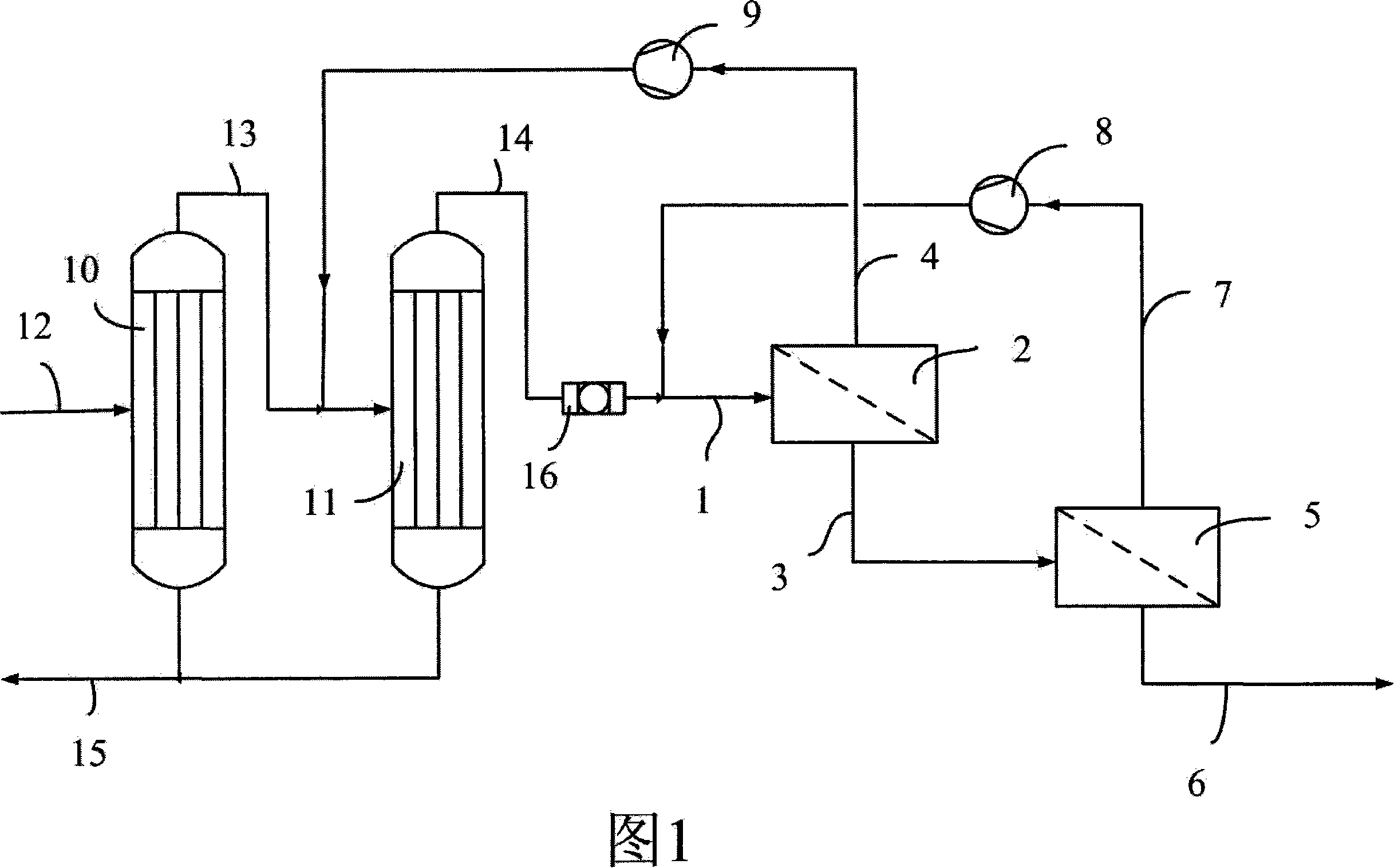

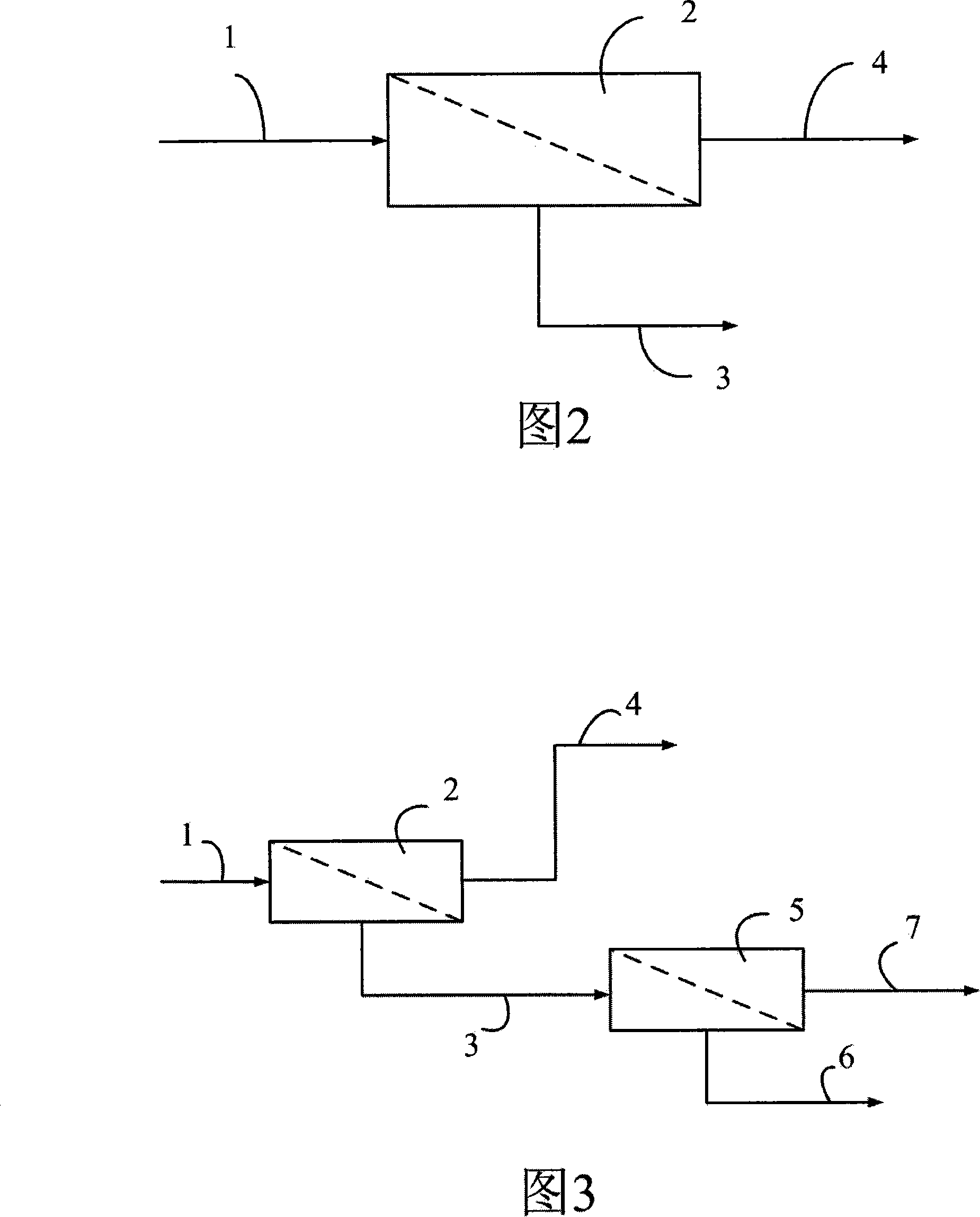

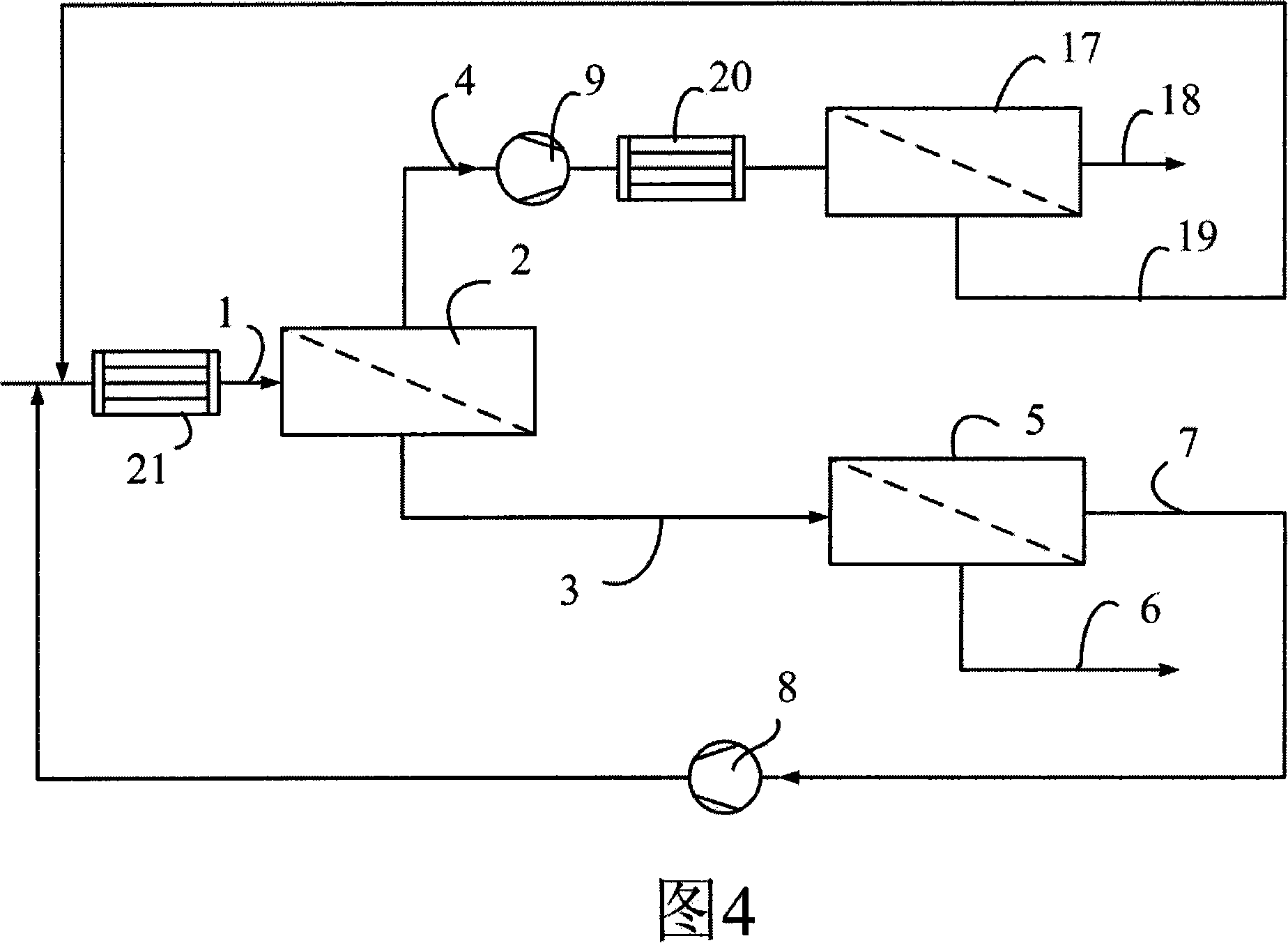

Film separation method for difluo-monochloromethane and trifluoromethane mixture

InactiveCN101239884AHigh puritySimple processHalogenated hydrocarbon separation/purificationChlorodifluoromethane productionHigh concentrationTorch

The invention discloses a method for membrane separating gas mixture of difluo-monochloromethane and trifluoromethane, belonging to the fluorin-containing organic steam separation field. The gas mixture of difluo-monochloromethane and trifluoromethane, which is unseparated after condensation during producing refrigerants R22, passes through a gas membrane separation equipment under ambient temperature and pressure, difluo-monochloromethane first penetrates through a gas separation membrane to the other side, the gas mixture is divided into two section by the gas separation membrane, the collected difluo-monochloromethane penetration gas is compressed and reflowed into a refvigeratory-tower, difluo-monochloromethane is cooled, Liquefied and recoveried as the product, high-concentration trifluoromethane penetration gas can be directly sent to a torch to burn after standard-reach detection. The method has advantages of simple process, small device, convenient operation, high purity of obtained trifluoromethane, no secondary pollution, small investment, low operation cost and safe usage.

Owner:DALIAN UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com