Patents

Literature

385results about How to "Friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heavy metal stabilizing agent and method for treating heavy metal contaminated soil by using same

ActiveCN102965116ACaptureHarmlessContaminated soil reclamationOrganic fertilisersSodium BentoniteApatite

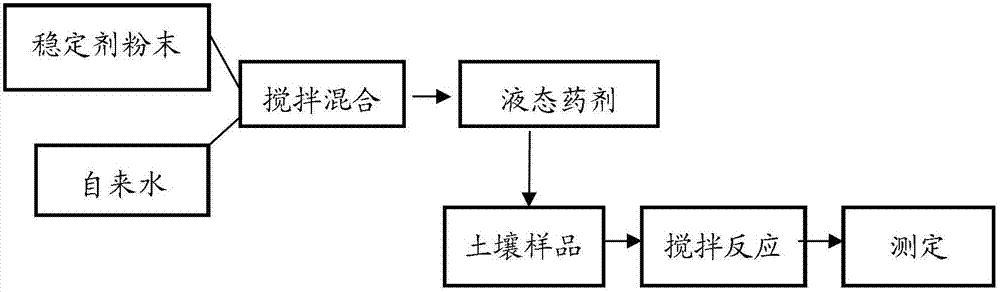

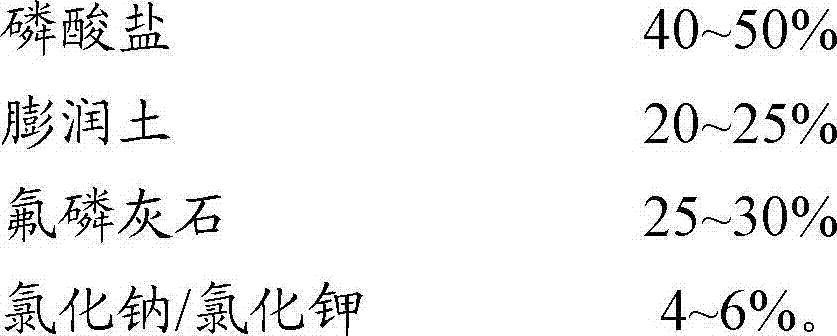

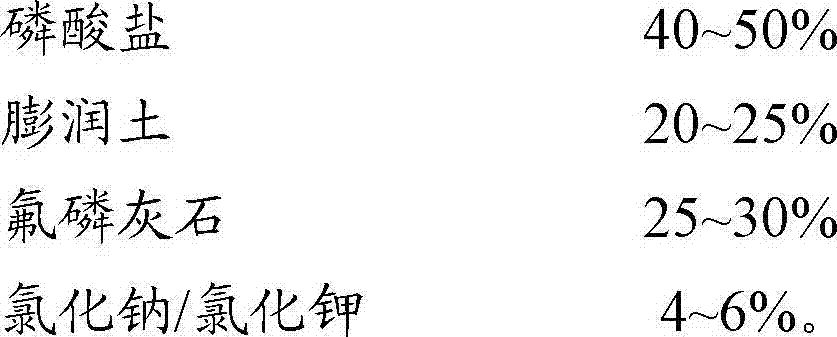

The invention discloses a heavy metal stabilizing agent and a method for treating heavy metal contaminated soil by using the heavy metal stabilizing agent. The heavy metal stabilizing agent is prepared from the following raw materials in percentage by weight: 40 to 50 percent of phosphate, 20 to 25 percent of bentonite, 25 to 30 percent of fluor apatite and 4 to 6 percent of sodium chloride / potassium chloride. When the heavy metal stabilizing agent is used for treating the contaminated soil, the heavy metal stabilizing agent and water are mixed together to form a suspension, then the suspension is added into the heavy metal contaminated soil, and the suspension and the heavy metal contaminated soil are fully mixed. The heavy metal stabilizing agent has high stability for treating soil, and the technical problem that the conventional curing agent and curing method cause reverse dissolution easily is solved.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

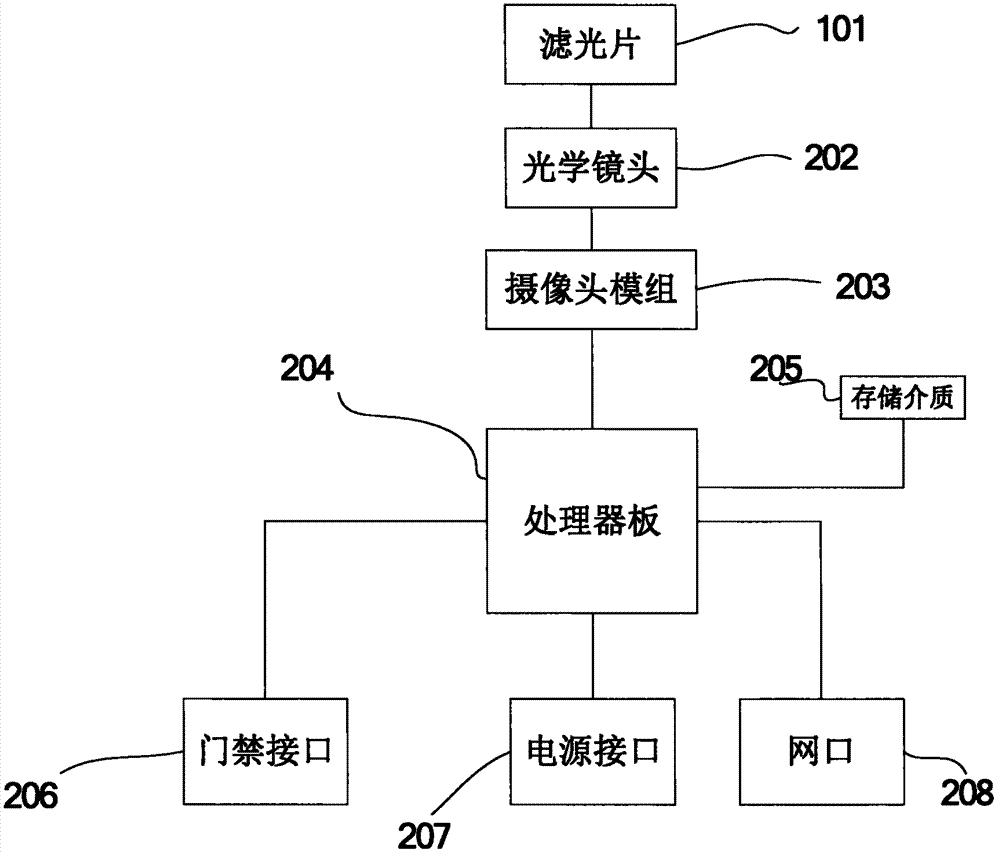

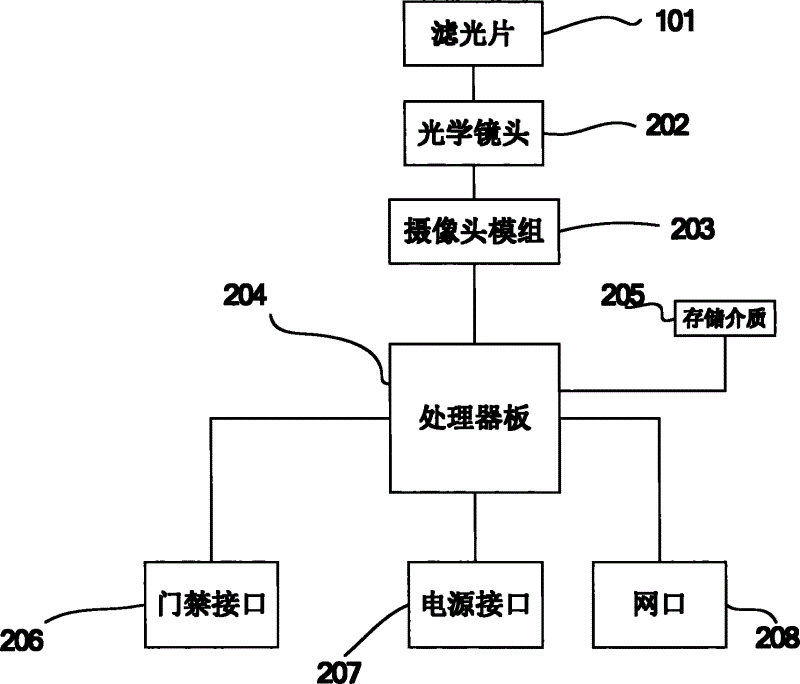

Single-image sensor based double-eye iris recognition equipment

InactiveCN102708357AImprove visual experienceRealize intelligenceCharacter and pattern recognitionIndividual entry/exit registersSingle imageCamera module

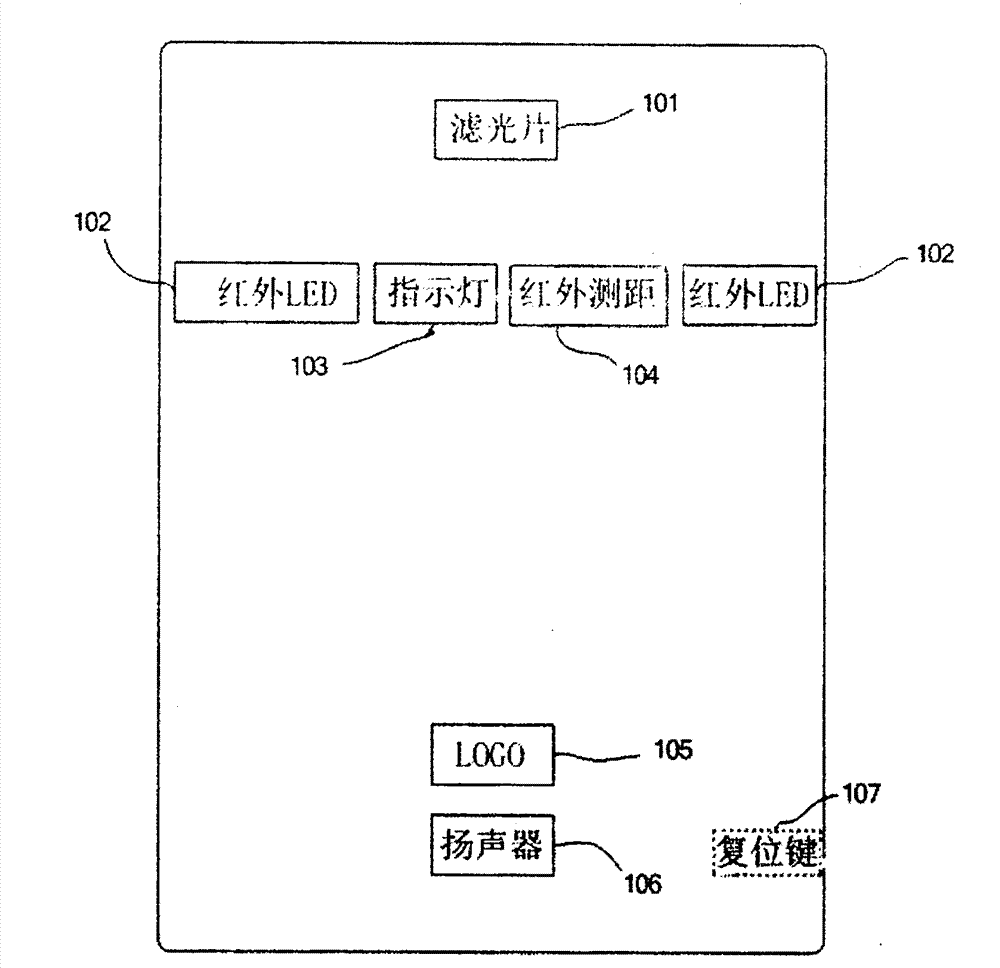

The invention relates to medium-long distance single-image sensor based double-eye iris recognition equipment which comprises a panel, an optical lens, a camera module, a processor plate, a storage media, a power interface and a network interface. The process plate is connected with the camera module, the storage media, the power interface and the network interface, and the optical lens, the camera module, the processor plate and the storage media are embedded in the space limited by the front part and the rear part of the panel. The medium-long distance single-image sensor double-eye iris recognition equipment is characterized in that: the front part of the panel is provided with an automatic positioning optical filter, the optical lens is arranged on one side of the optical filter, which is far from the user, the shooting distance of the optical lens is more than 30cm, and the optical lens is provided with a pitch adjusting mechanism so as to adapt to the user in different height and carry out the non-contact double-eye iris recognition. The embedded double-eye iris recognition equipment has a farther recognition range and a wider activity range, can adopt the human-machine interaction modes of the tri-color light and the voice at the same time and is intelligent and friendly.

Owner:EYESMART TECH

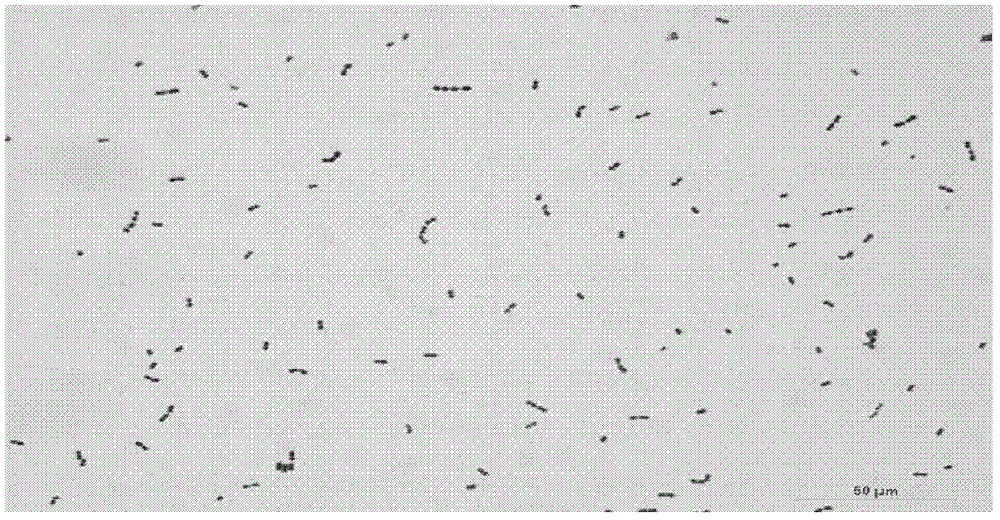

Screening and application of probiotic Enterococcus faecium

ActiveCN102747003AGood antibacterial effectImprove securityAntibacterial agentsBacteriaDiseaseSynechococcus

The invention belongs to the technical field of veterinary microbial additive preparation, and specifically relates to a strain of separated and screened Enterococcus faecium providing significant bacterial inhibition effects for common enteropathogenic bacteria such as staphylococcus aureus, escherichia coli and salmonella in breeding animals, and an application thereof. The probiotic Enterococcus faecium of the present invention is characterized in that: the strain is Enterococcus faecium HDRsEf1, and is preserved in the China General Microbiological Culture Collection Center (CGMCC), and the preservation number is CCTCC NO:M2011031. The probiotic Enterococcus faecium of the present invention has characteristics of fast growth, high acid production capacity, strong stress resistance, safety, disease resistance and growth promotion, and can be used as the microbial feed additive for livestock and poultry feeds.

Owner:武汉华大瑞尔科技有限公司 +1

Single-component self-crosslink emulsion adhesive for dry type composite film and preparation method thereof

InactiveCN101168650AHigh solid contentLow viscosityLaminationLamination apparatusCross-linkSodium bicarbonate

The invention discloses single component self-cross linking emulsion tackiness agent used for dry type compound and the preparation method thereof. The invention has the preparation method as follows: firstly, part of aqueous medium, part of emulsifying agent, and part of initiating agent and baking soda are measured and added in a reactor, and are warmed up 70 to 85 DEG C; secondly, then hard monomer, soft monomer, (methyl) acrylic acid and cross linking monomer are mixed, and form pre-emulsion together with part of the emulsifying agent and water; thirdly, 1 / 10 pre-emulsion is added firstly to form assistant emulsion by reacting, and then the pre-emulsion and initiating agent aqueous solution are added synchronistically to perform reaction, the time lasts for 3 to 5 hours. The water emulsion tackiness agent obtained has good stability, and is free from poison and dissolving agent, and is favor of good health of a worker and environmental protection. A compound produced product obtained by utilizing the emulsion tackiness agent of the invention has the advantages that the ageing resistance is excellent, the viscous force is high, and the foaming is not existent during the impressing and sagging process, and the invention has wide application market.

Owner:吴达文

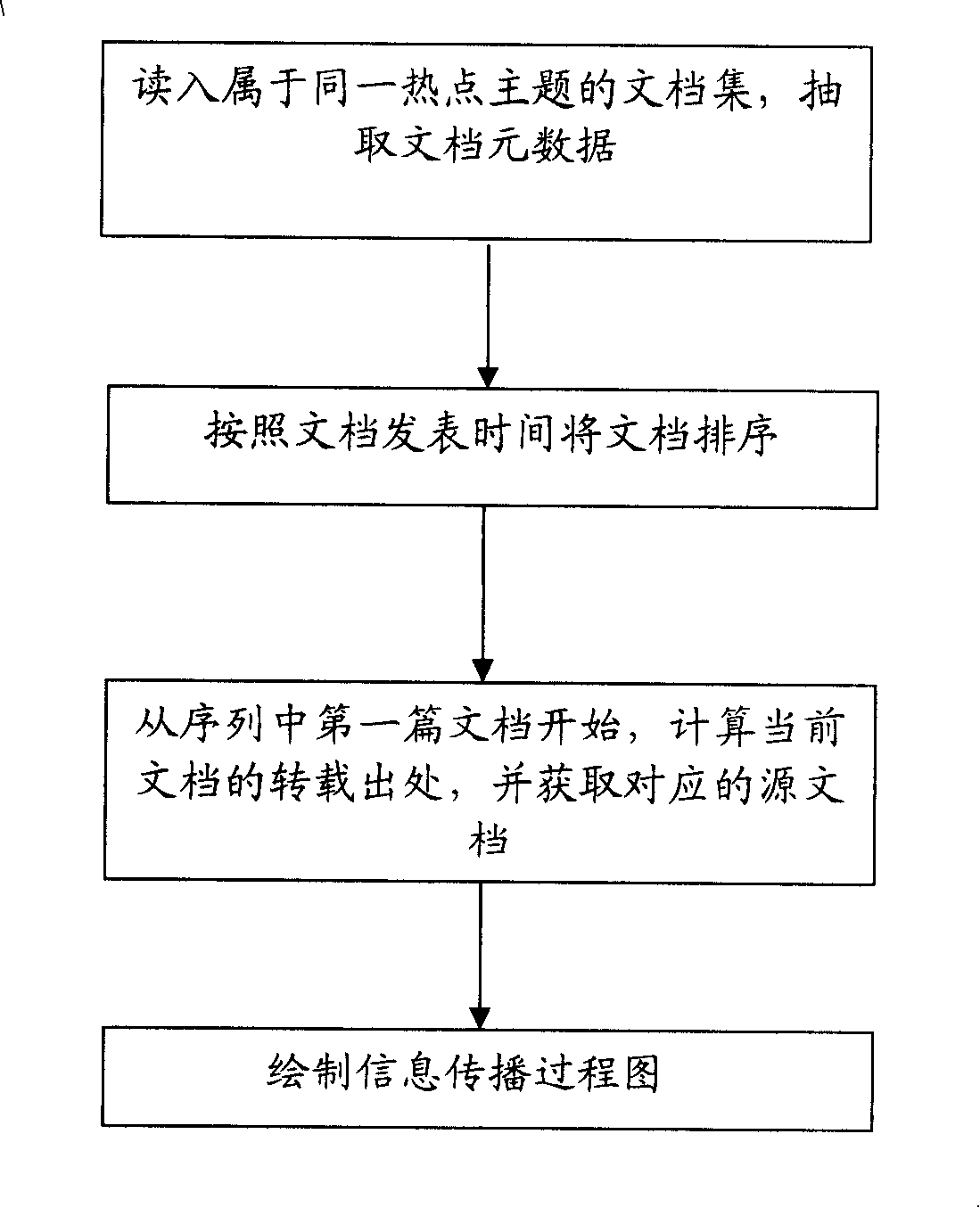

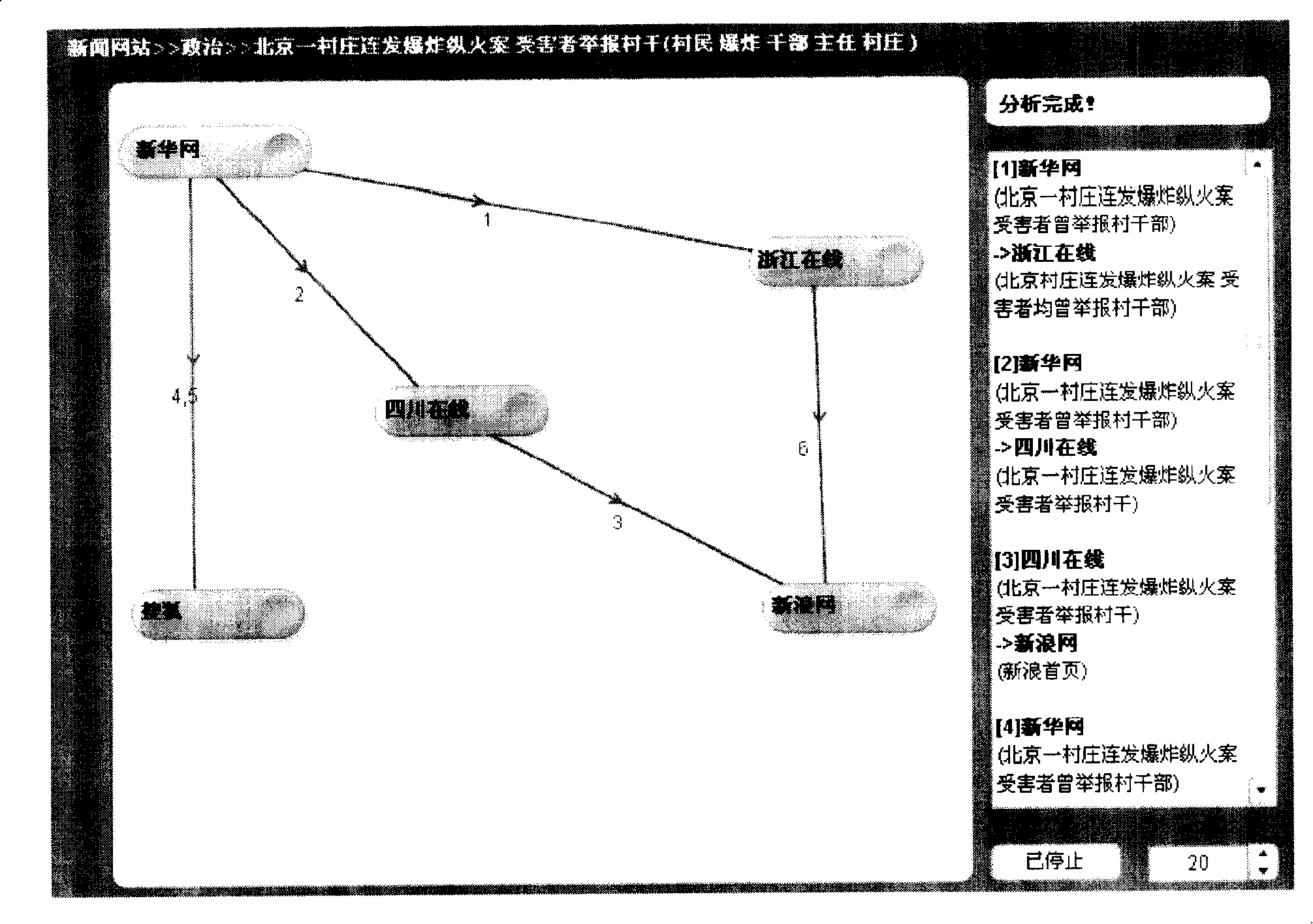

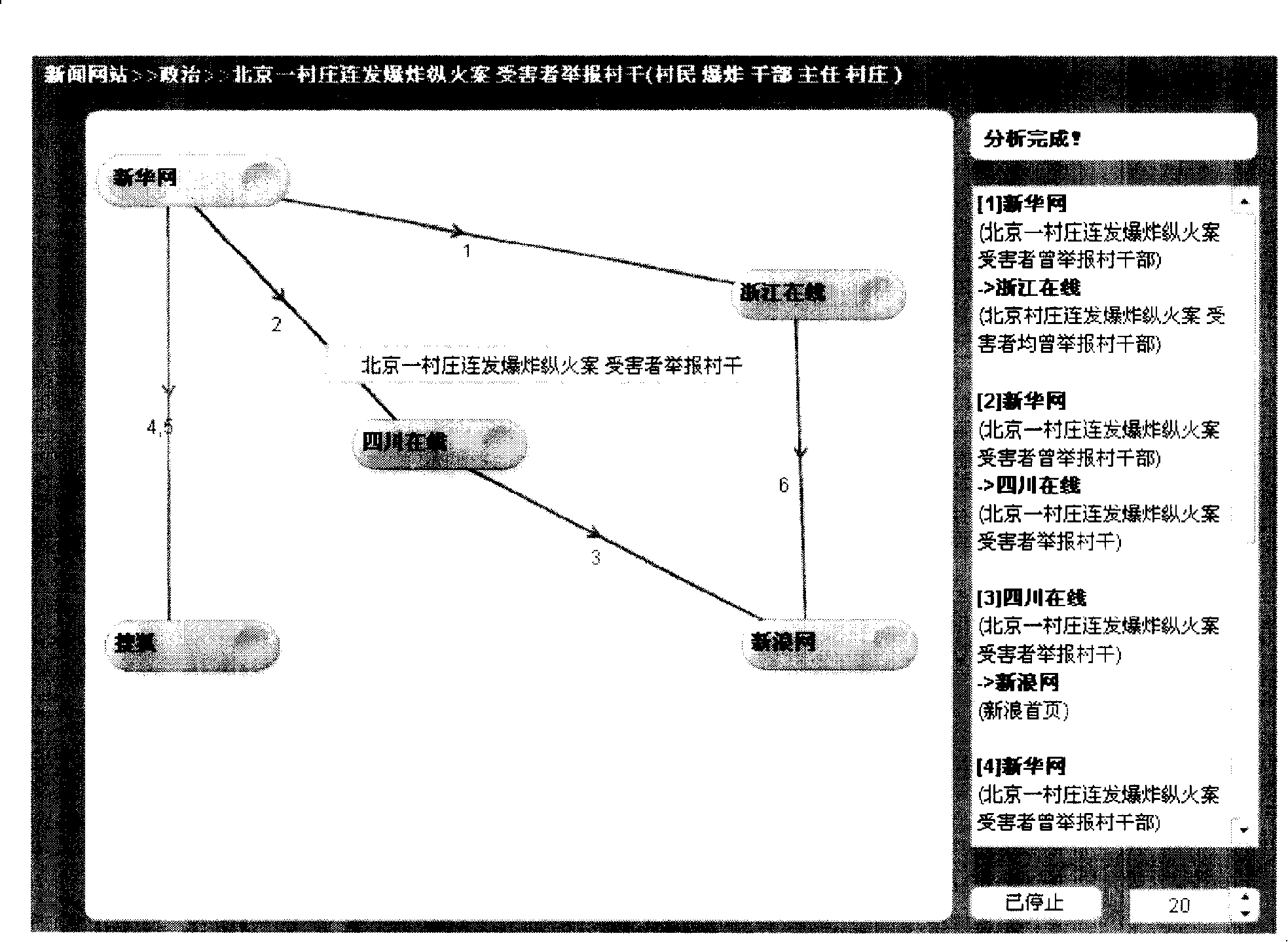

Method and system for automatic analysis of hotspot subject propagation process in the internet

ActiveCN101231641AEfficientRobustSpecial data processing applicationsInformation processingText mining

The invention relates to a method which can automatically analyze the propagation process of an internet hot subject, as well as a system thereof, and belongs to the intelligent information processing technology. As the textual information on the internet gradually increases, an important subject in the text mining and information retrieval field is to automatically detect and analyze the hot or sensitive subject from large text database, the subject has great use value. The invention utilizes the natural language processing approach to automatically analyze the propagation process of the text document in the given hot or sensitive subject; after the text documents in the subject are arranged in a time order, the reference origin of the current text document is searched by utilizing the pattern matching method from the first text document, if the reference origin isn't found, the reference origin is further judged by utilizing the text document similarity comparative method, at the same time, the corresponding source text document is obtained. At last, the reference relation is intuitively presented to the user in a graphic mode. The method is widely applicable to internet intelligent information processing, public opinion analyzing and monitoring, etc.

Owner:PEKING UNIV

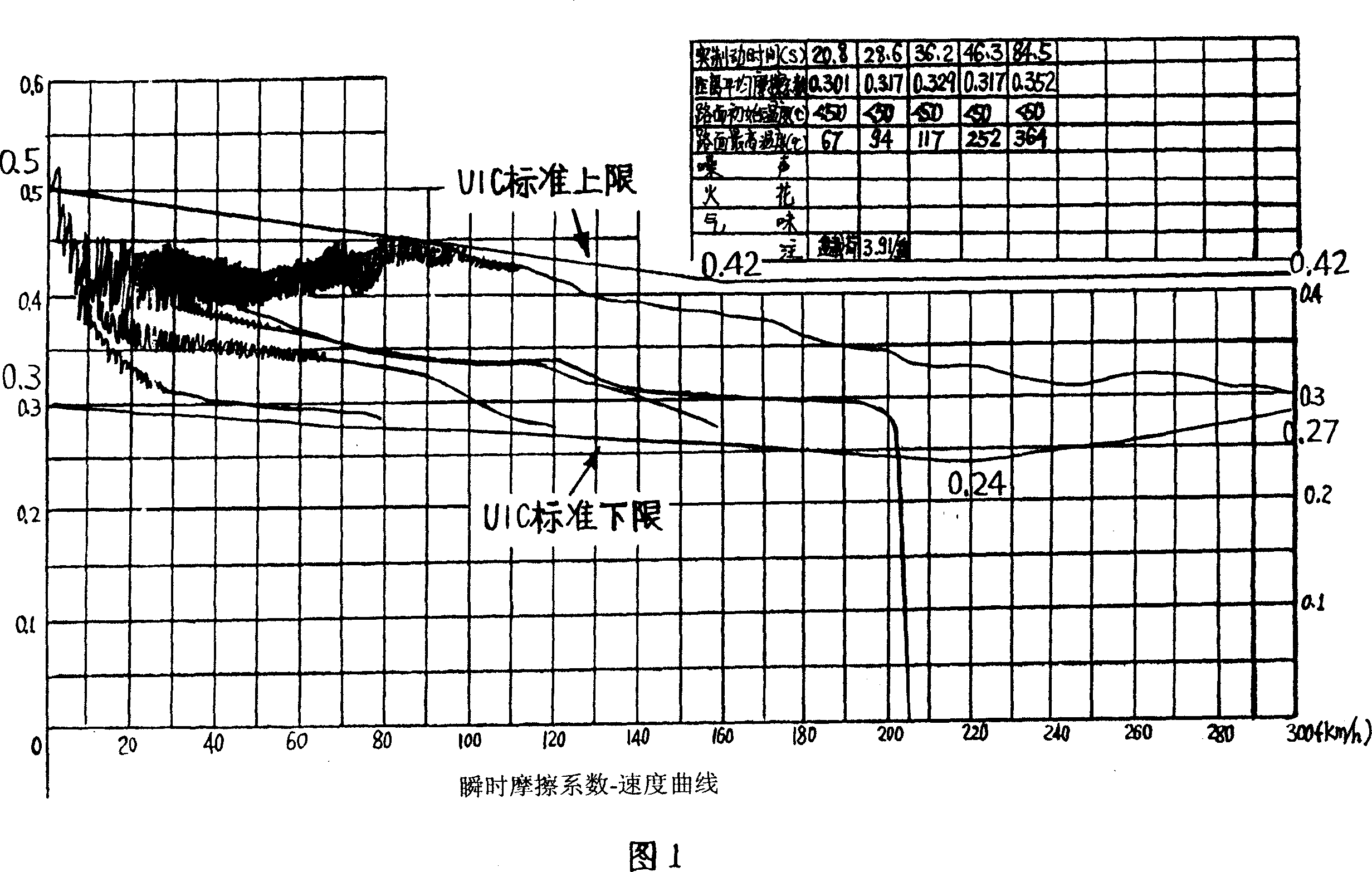

Copper base particle reinforced friction material

InactiveCN1995436AHigh degree of alloyingHigh strengthFriction liningManufacturing cost reductionGraphite

The invention discloses a reinforced friction material of copper-based particle in the friction material making domain, which comprises the following parts: 30-70% Cu, 4-11% Sn, 1-15% Al, 5-18% Fe, 2-15% Al2O3, 2-15% SiO2, 0-15% ferrochrome and 5-20% graphite.

Owner:大连远通制动制品有限公司

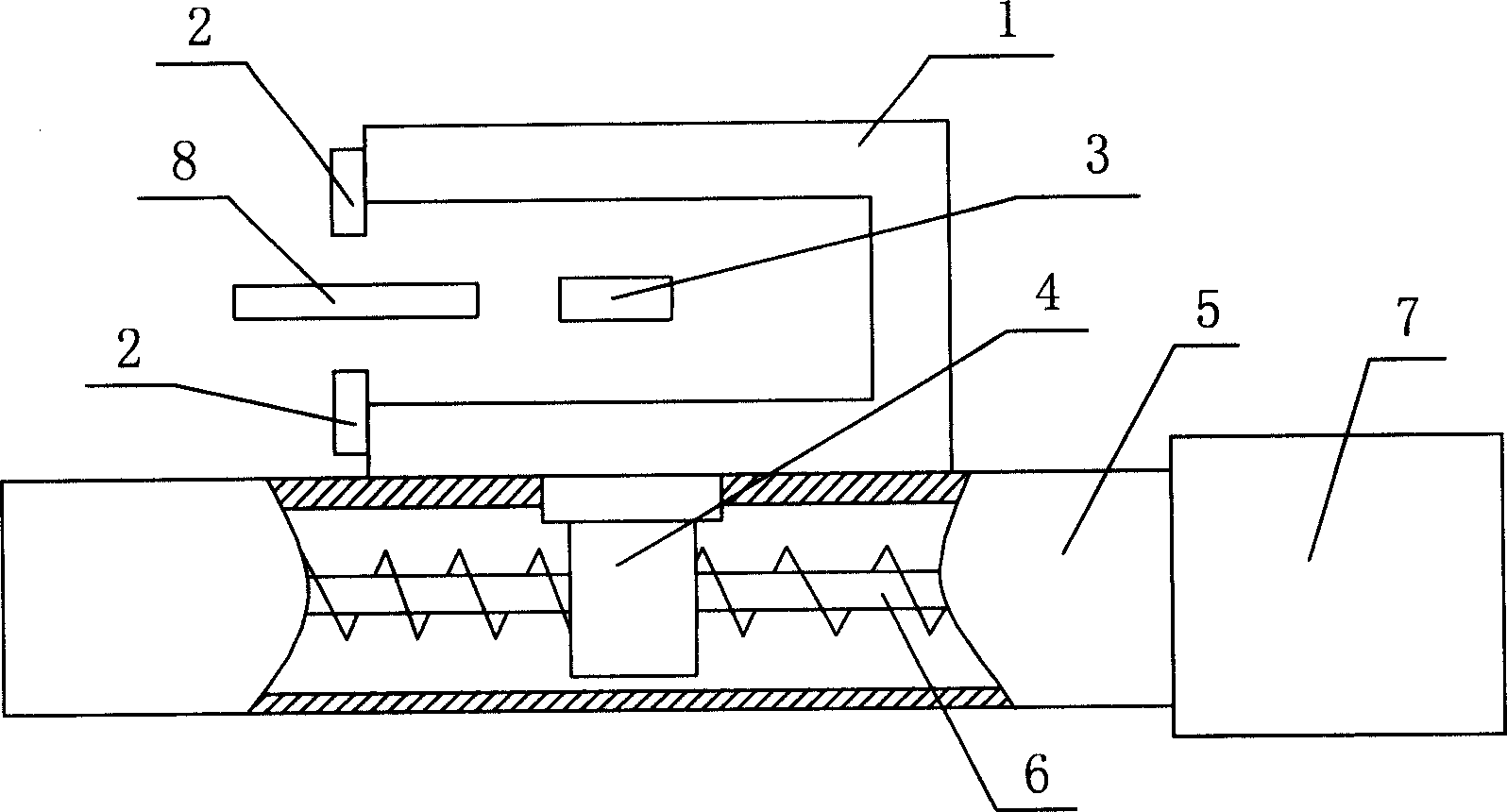

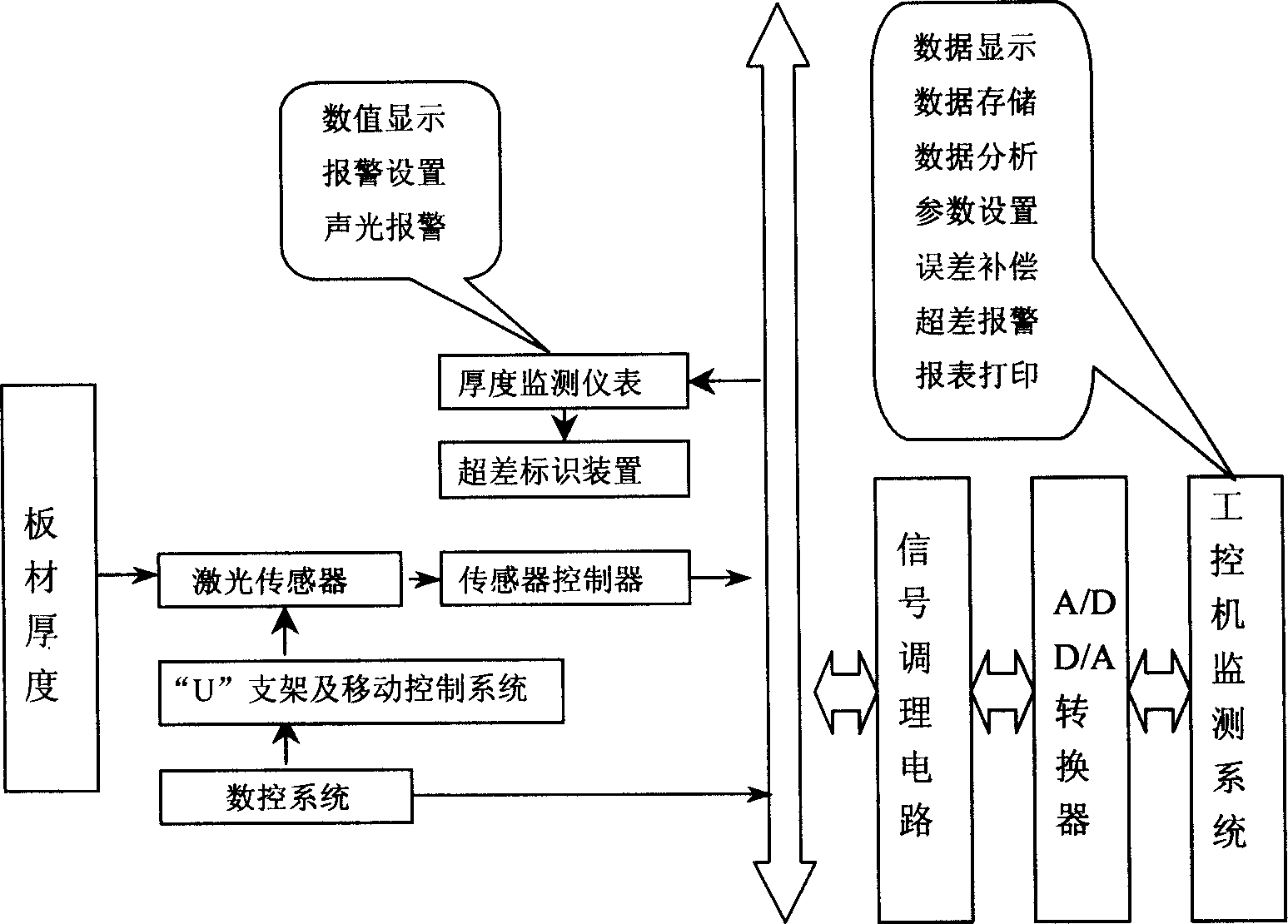

Online monitoring system for measuring thickness of clean-surface panel

InactiveCN1670472ADoes not affect measurement accuracyRealize measurementUsing optical meansSignal conditioning circuitsMonitoring system

This invention relates to smooth surface board materials thickness on-line measurement and especially to the ones influenced by temperature, which comprises the following steps: eliminating the impact on the structure deformation from temperature through extra set mark block in each journey. The measured board thickness signals from laser sensor, temperature compensation thickness signals and rack journey position signals are sent to the working control machine to accomplish the signal process to realize the monitoring.

Owner:JIAXING UNIV

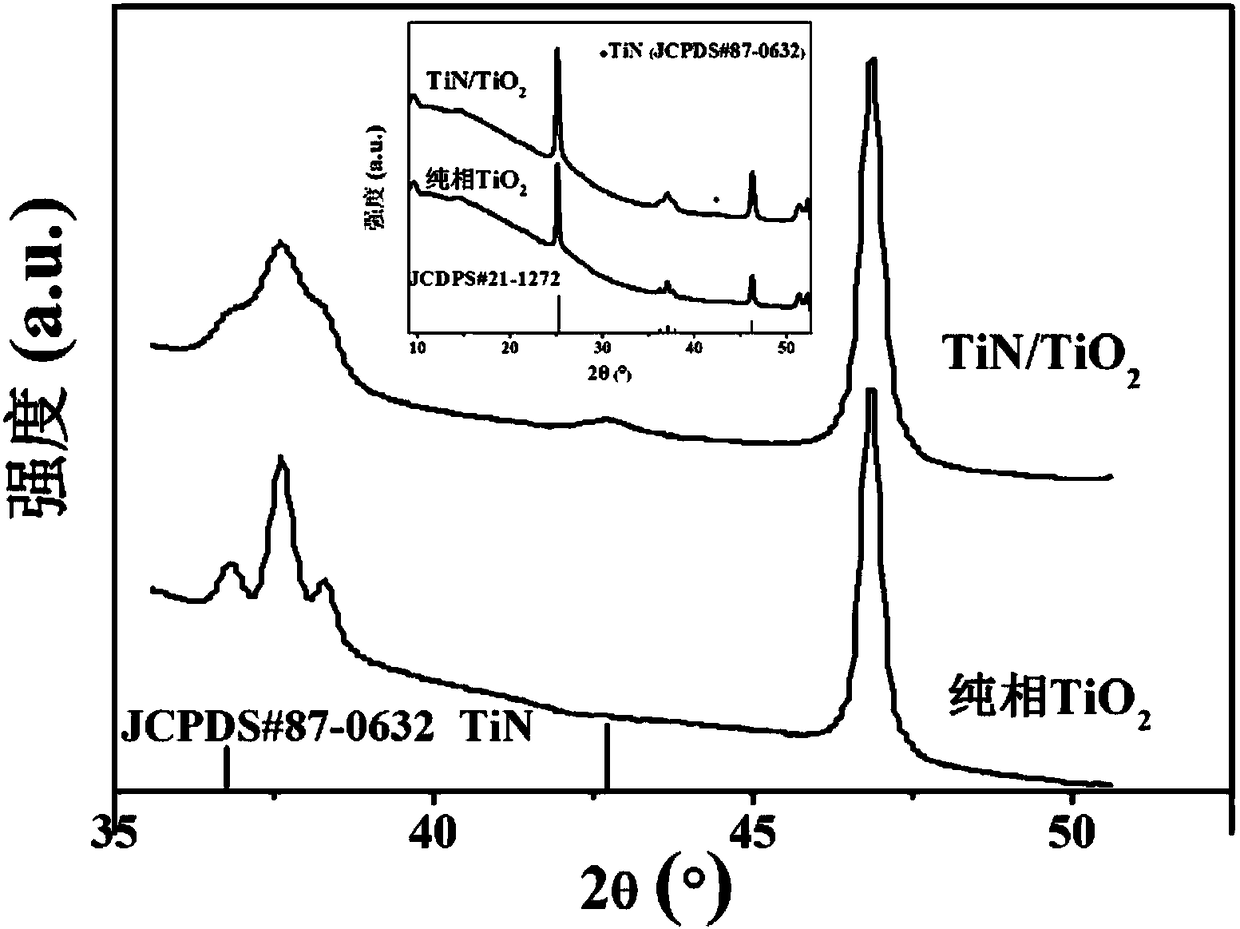

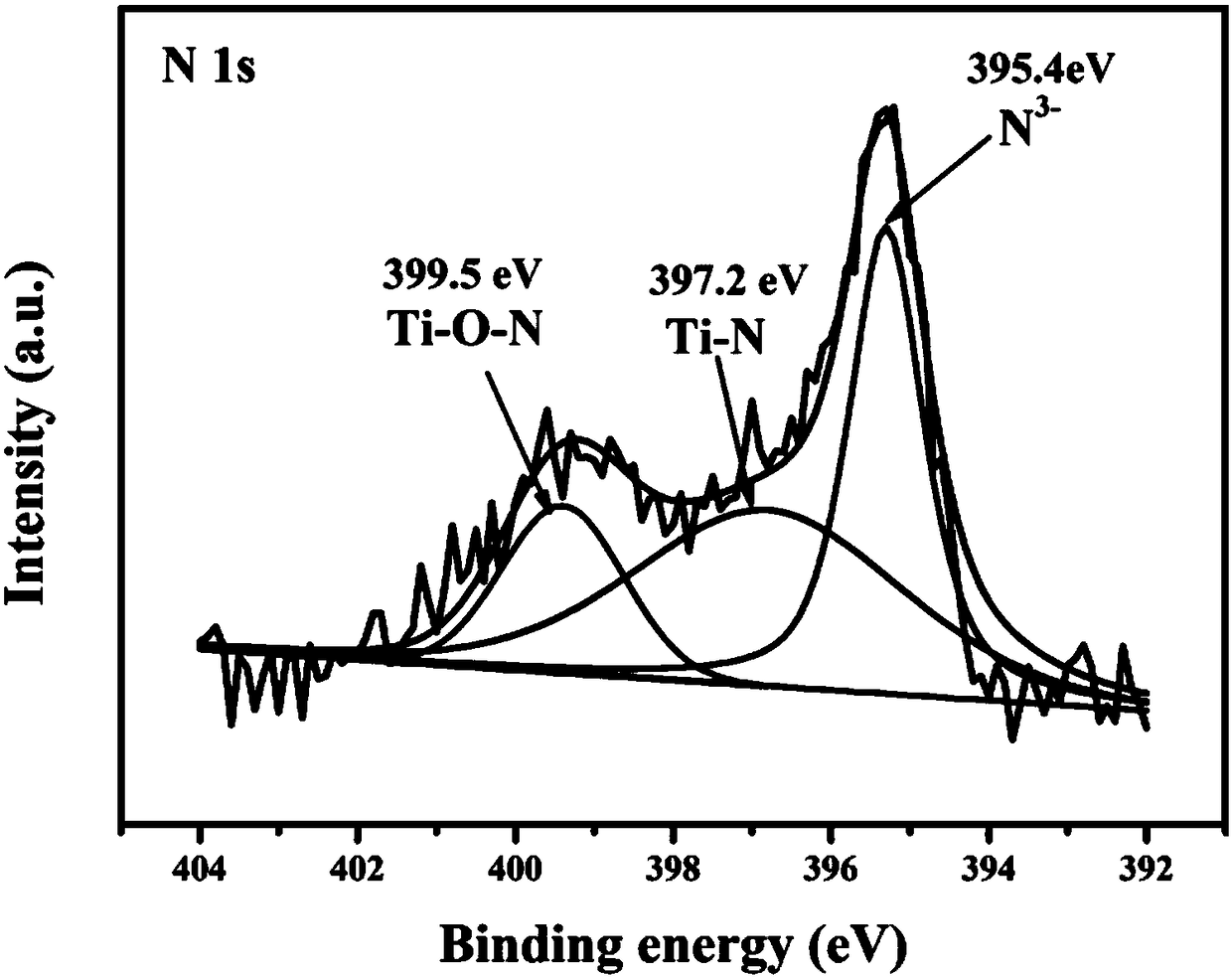

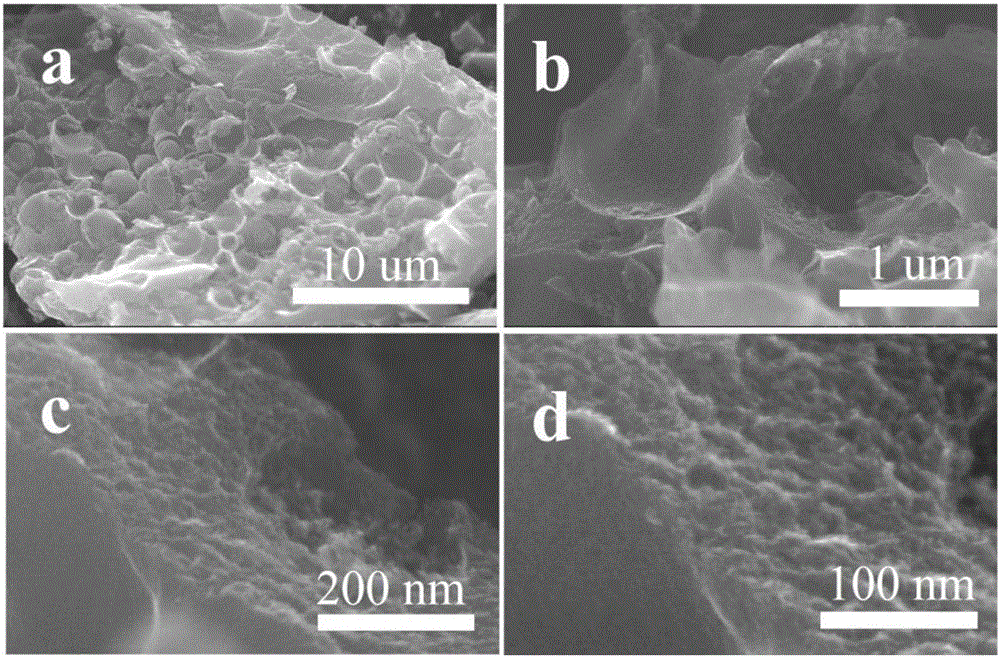

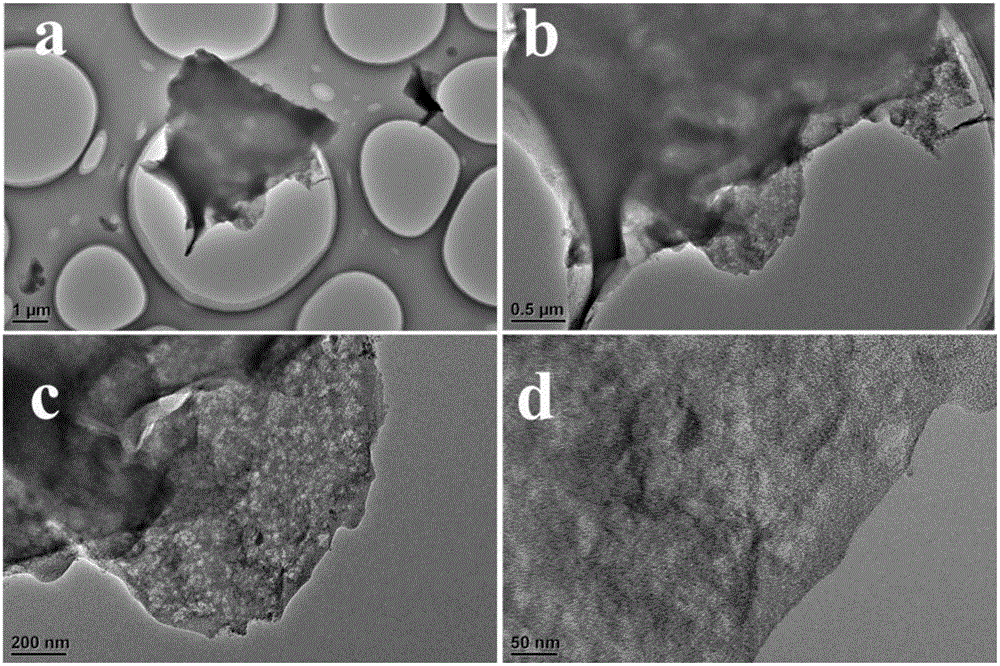

Method for modifying sodium ion battery negative electrode material titanium dioxide

ActiveCN108470903AImprove electronic conductivityImprove sodium storage capacity and rate performanceCell electrodesSolventIon

The invention provides a method for modifying a sodium ion battery negative electrode material titanium dioxide, wherein the method comprises the steps : mixing a titanium source and a structure-directing agent to form a titanium-containing solution, and carrying out a hydrothermal reaction to prepare a nano titanium dioxide precursor, wherein the molar ratio of the titanium source to the structure-directing agent is 1:(0.1-1), and the ratio relationship between the titanium source and a solvent is (0. 01-0.5) mol:1 L; and mixing the obtained nano titanium dioxide precursor with a solid nitrogen source with the mass ratio of the titanium source to the nitrogen source of 1:(0.1-10), stirring and grinding, and calcining the mixture in protective gas to obtain the sodium ion battery negativeelectrode material titanium dioxide. In the method, cladding of a titanium nitride thin film can significantly enhance the electronic conductivity, so the sodium storage capacity and the rate performance of the titanium dioxide material are improved; at the same time, with doping of the nitrogen element, the conductivity of titanium dioxide can be further effectively improved, so excellent electrochemical performance is showed.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

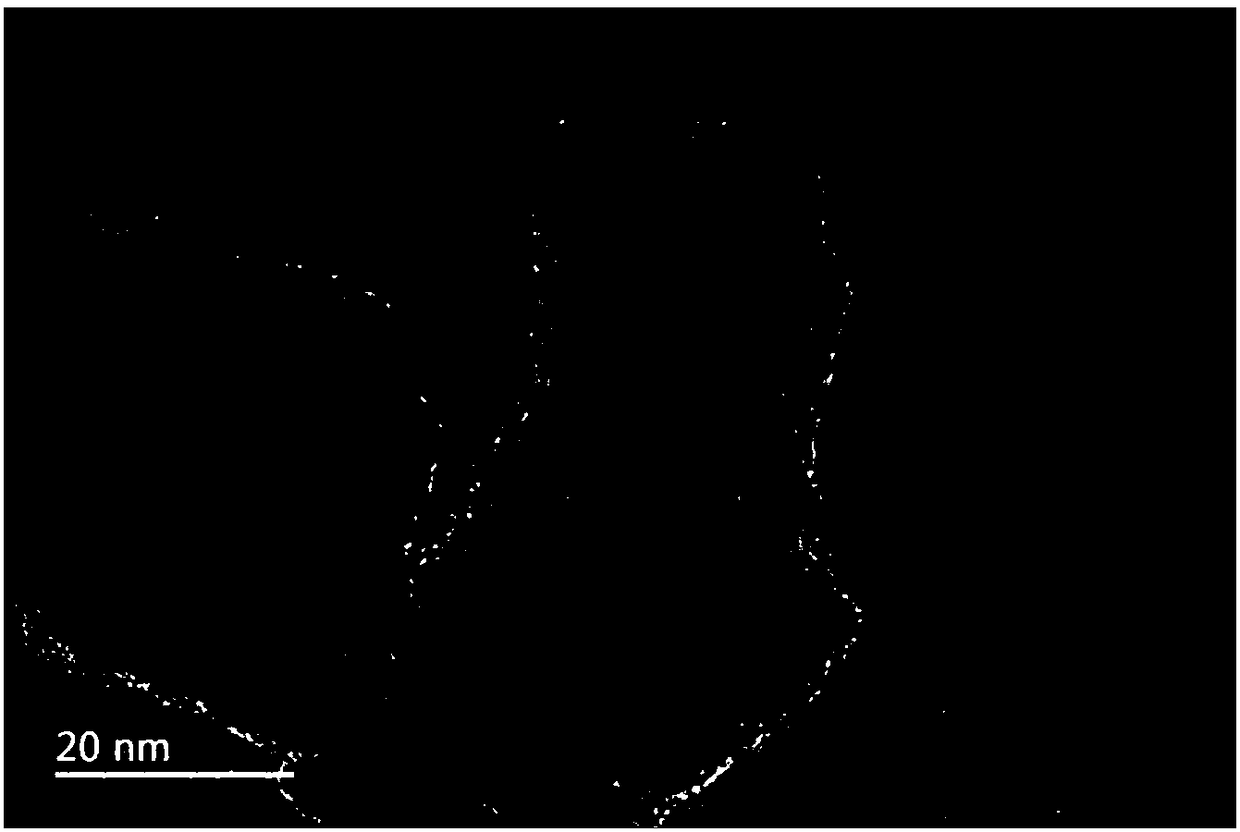

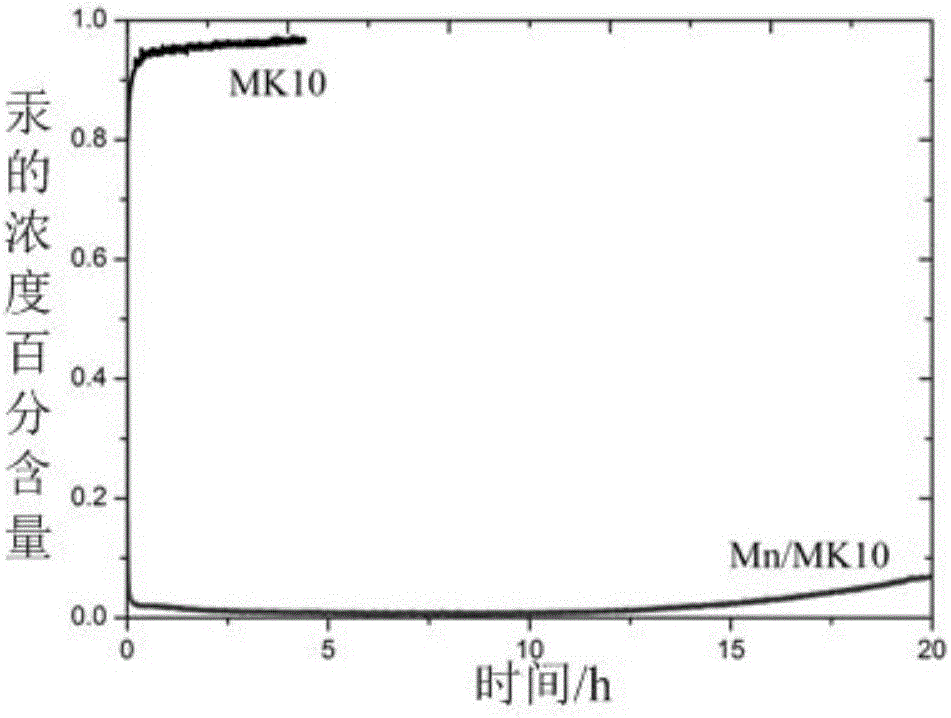

Demercuration adsorbent based on pillared montmorillonite, preparation method and application thereof

InactiveCN105664838AImproving the Ability of Adsorption and Removal of Mercury in Coal-fired Flue GasImprove thermal stabilityGas treatmentOther chemical processesMass ratioSorbent

The present invention provides a mercury removal adsorbent based on pillared montmorillonite, its preparation method and application. The adsorbent includes a carrier and an active component loaded on the carrier. The carrier is pillared montmorillonite. The active component is a metal oxide, and the ratio of the mass of the metal element to the mass of the pillared montmorillonite in the metal oxide is ≤10.0wt.%. The adsorbent makes full use of the structural characteristics of montmorillonite and the activity of the active components to adsorb elemental mercury, so that the two can play a synergistic effect; the mercury removal adsorbent not only has high thermal stability: mercury removal within 100-450 °C The efficiency reaches 99%, and it also has a high mercury removal efficiency: the inlet mercury concentration is 120ug / m 3 The mercury removal efficiency is as high as 99% within 10 hours, and over 94% even within 20 hours. It can be used to remove mercury in flue gas produced by power plants, industrial boilers or industrial kilns.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

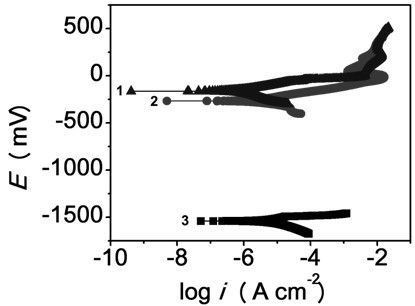

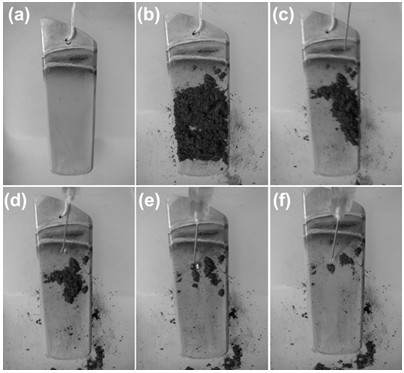

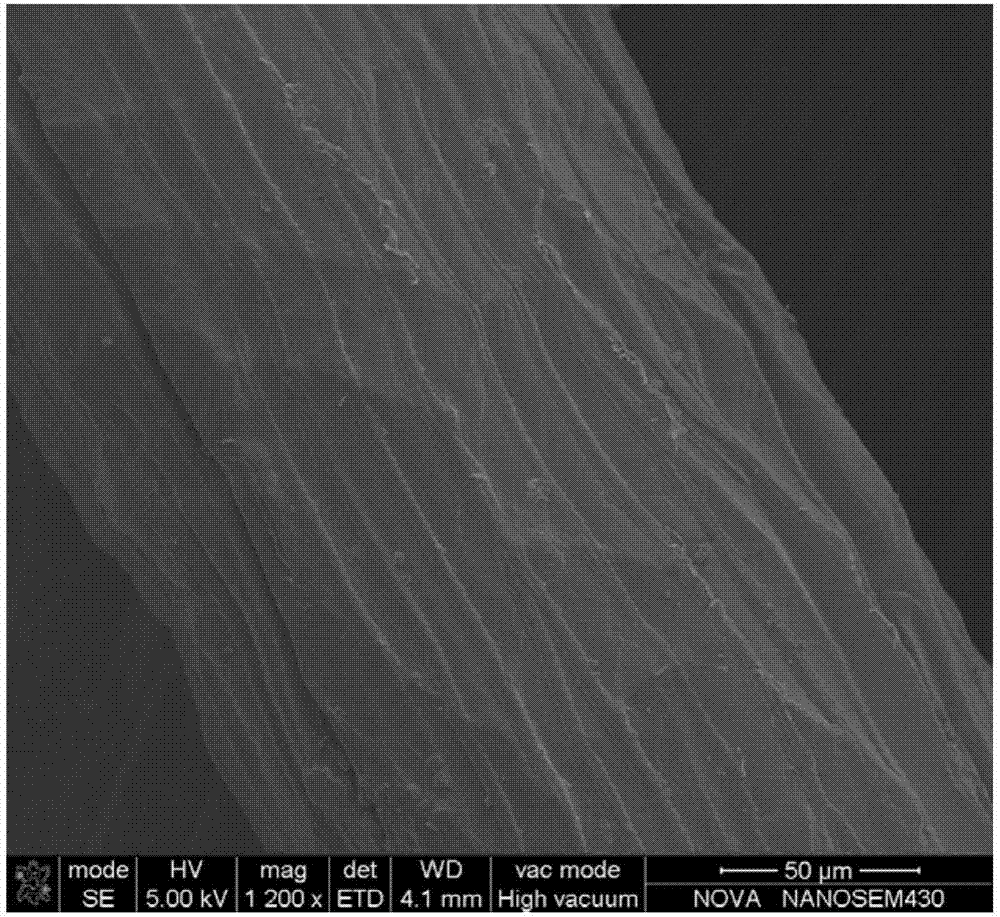

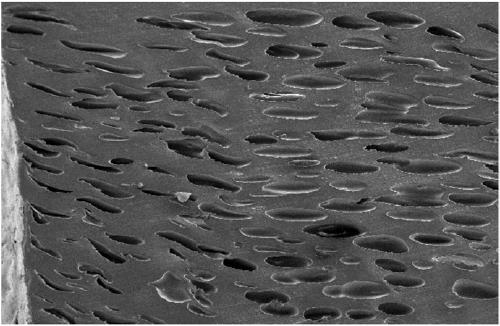

Preparation method of magnesium alloy with super-hydrophobic coating on surface

InactiveCN102618897ASimple processLow costLiquid/solution decomposition chemical coatingCorrosionMagnesium alloy

The invention relates to a preparation method of magnesium alloy with a super-hydrophobic coating on the surface. According to the preparation method, the magnesium alloy is provided with the super-hydrophobic coating through an innovative process to improve the corrosion resistance capacity, and meanwhile, new anti-pollution and self-cleaning functions are given to the magnesium alloy. The method has the characteristics of simplicity, quickness, capability of greatly shortening reaction time, suitability for industrial production and environmental friendliness.

Owner:SOUTHWEST UNIVERSITY

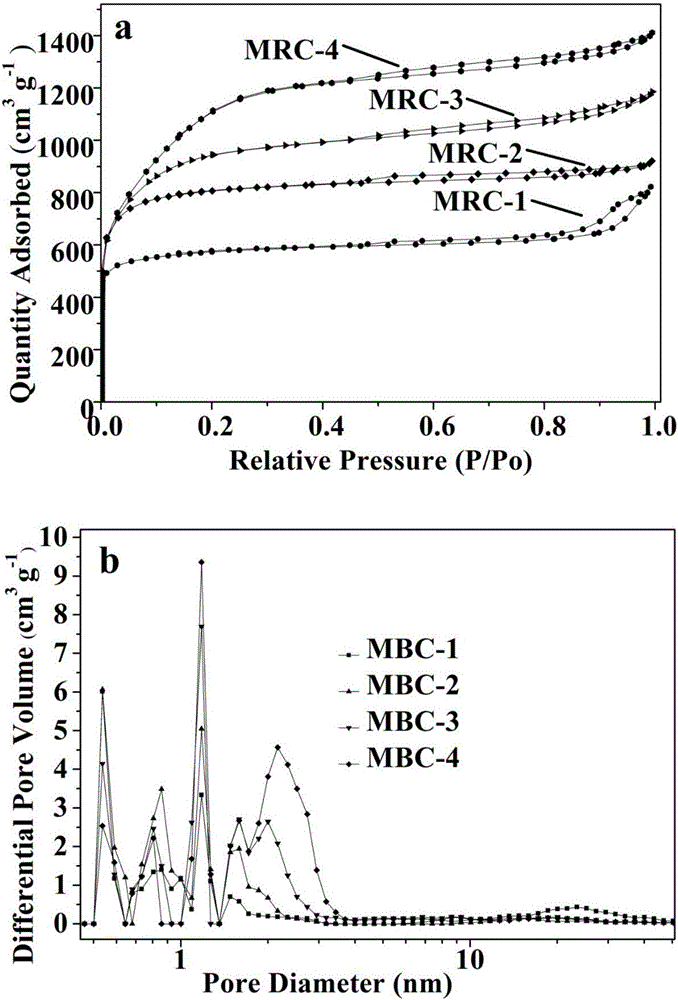

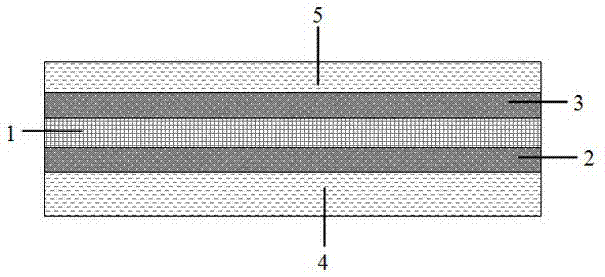

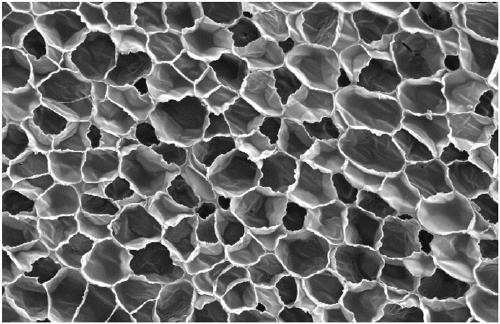

Super capacitor device containing millet-husk-based porous active carbon material

InactiveCN106276888ALow ashLow wettability of the surfaceHybrid capacitor electrodesMicrowave methodFiltration

The invention discloses a super capacitor device containing a millet-husk-based porous active carbon material. The millet-husk-based porous active carbon material is prepared by uniformly mixing dried millet husks and an activator, performing carbonization and activation with a microwave device in the protection of an inert gas, adding distilled water to obtained black powder for suction filtration washing till the pH value is 6.4-7, and performing drying to obtain black powder. The black powder is the prepared millet-husk-based porous active carbon material. The millet-husk-based porous active carbon material (an active substance) prepared through the microwave method is mixed with a binder according to a certain mass ratio, distilled water is added for mixing to prepare a thick liquid, and the thick liquid is repeatedly rolled to obtain a sheet electrode material. The electrode material is put on a current collector with the corresponding size, cold pressing is carried out at 1-40 Mpa for 10-200 s, and drying is performed at 120 DEG C to obtain an electrode plate of the super capacitor device. The electrode material in the electrode plate is more than 14 mg per square centimeter. An electrode plate, a membrane, and an electrode plate are assembled into a sandwich structure, then different electrolytes are dropwise added, so that the super capacitor device is assembled.

Owner:YANGZHOU UNIV

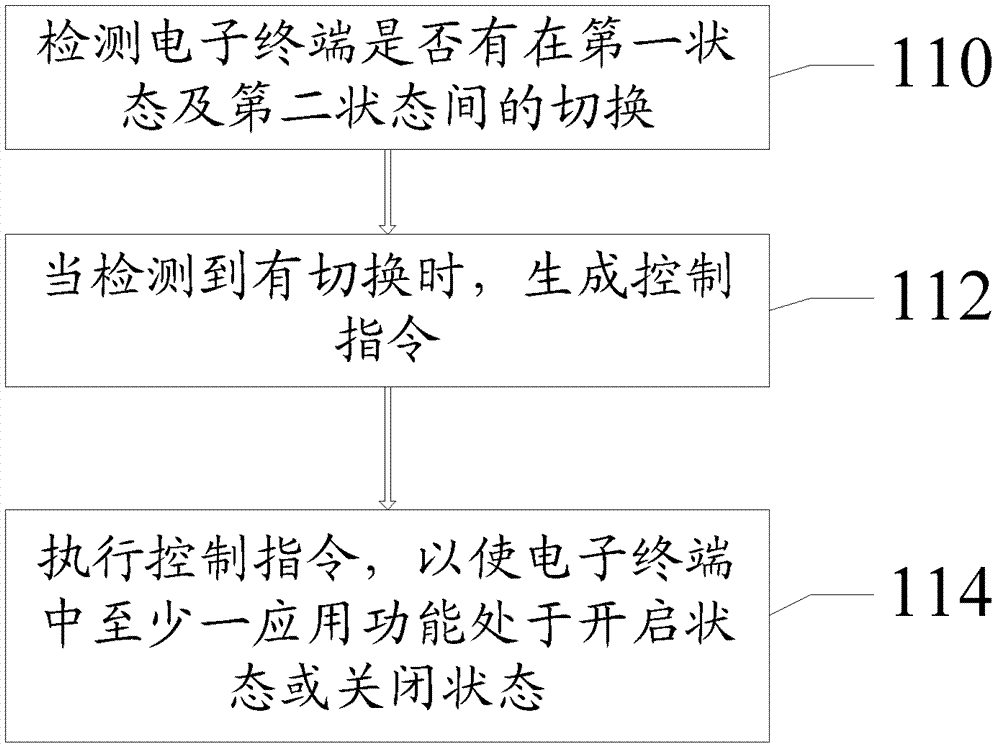

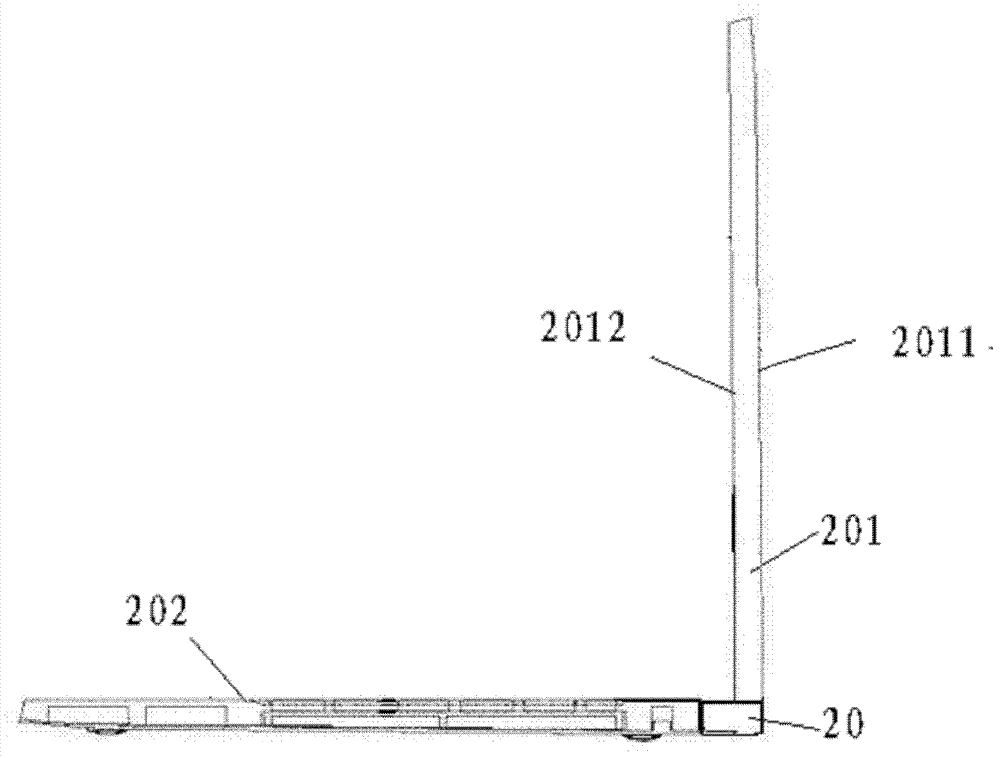

Application function control method and electronic terminal

Owner:LENOVO (BEIJING) LTD

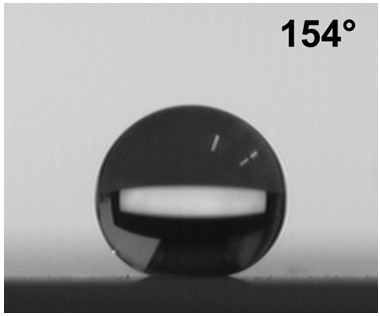

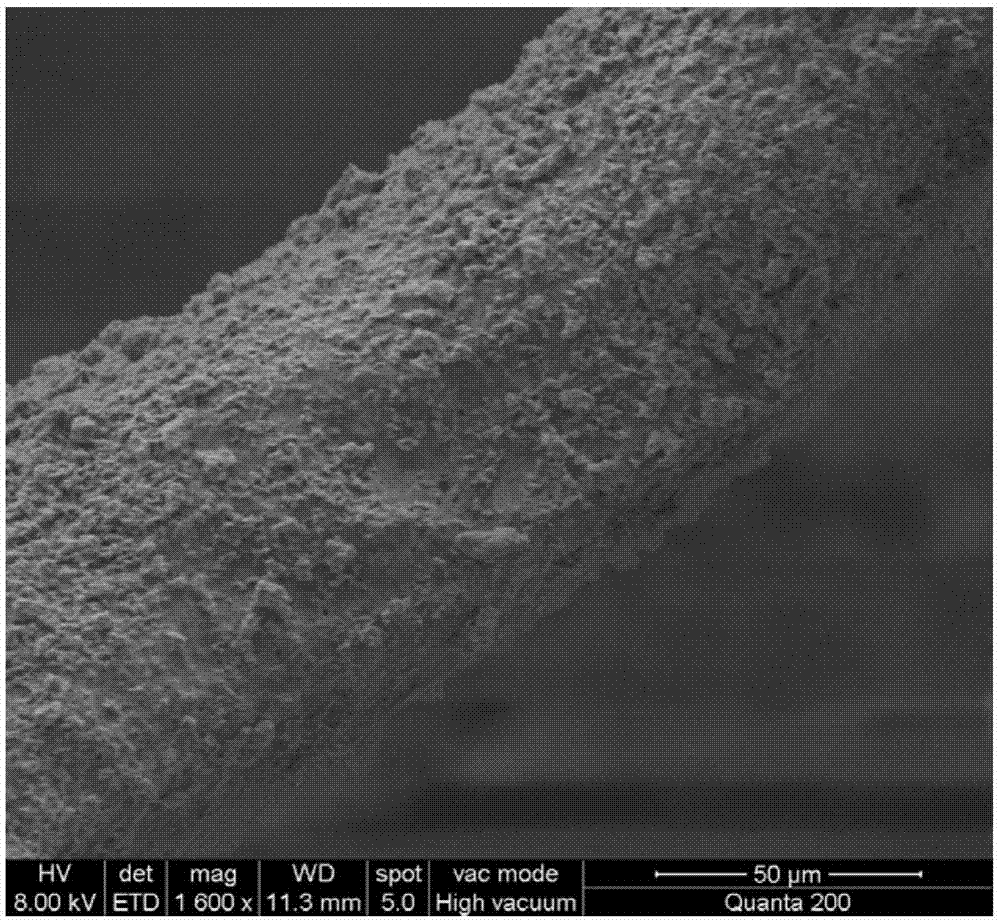

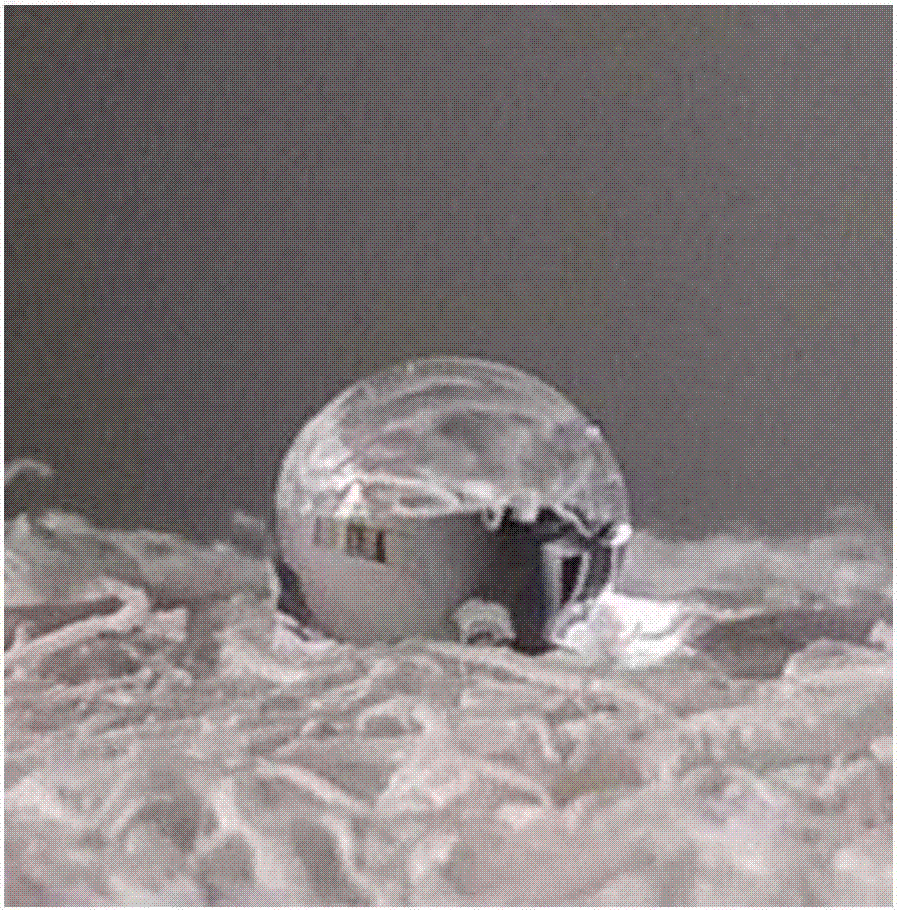

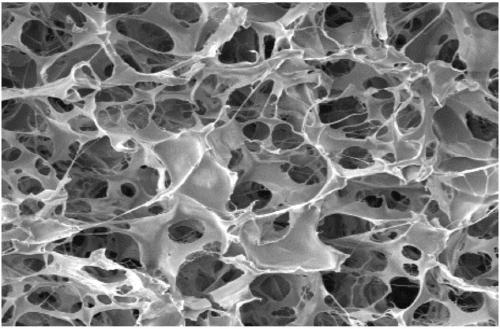

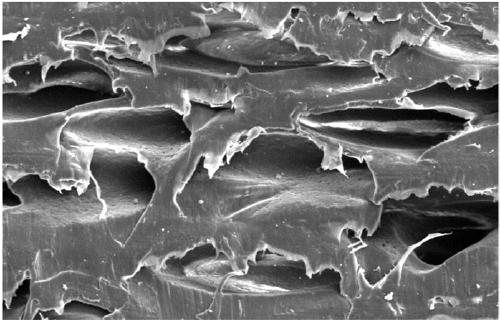

Super-hydrophobic loofah sponge for separating oil and water and preparation method thereof

ActiveCN106883588AUnique three-dimensional porous physical structureGood mechanical strengthNon-miscible liquid separationSolventChemistry

The invention discloses a super-hydrophobic loofah sponge for separating oil and water and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing ammonia water and a first solvent, adding an obtained mixture into a mixed solution of ethyl orthosilicate and the first solvent dropwise, reacting to obtain silicon dioxide nanoparticles, and adding a fluorine-containing silane coupling agent for performing surface hydrophobic modification to obtain hydrophobic silicon dioxide nanoparticles; then, fixing the silicon dioxide nanoparticles being subjected to hydrophobic modification to the surface of a loofah sponge with polyisocyanate to obtain the super-hydrophobic loofah sponge. The super-hydrophobic loofah sponge for separating oil and water has the advantages that a synthetic process is simple and feasible, the raw materials are readily-available, a contact angle with water is 156 degrees, high oil-water separating performance is realized, and the oil-water separating efficiency is 98 percent or above.

Owner:SOUTH CHINA UNIV OF TECH

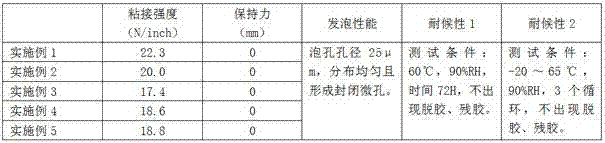

Novel thermally-bonded double-sided tape and making and use methods thereof

InactiveCN104263264AHigh bonding strengthIncreased durabilityNon-macromolecular adhesive additivesFilm/foil adhesivesFoaming agentSolvent

The invention discloses a novel thermally-bonded double-sided tape and a making method thereof. The novel thermally-bonded double-sided tape comprises a heating foamed adhesive layer and a pressure-sensitive adhesive layer coating the upper surface and the lower surface of a substrate layer respectively, wherein glue used in the heating foamed adhesive layer is obtained by mixing and baking the following components in parts by mass: 100 parts of a pressure-sensitive adhesive, 0.5-5 parts of a foaming agent, 0.5-5 parts of a foaming aid, 1-3 parts of a crosslinking agent and 10-30 parts of a solvent. The thermally-bonded double-sided tape made by adopting the making method has high bonding durability. Through transient heating and sticking of the thermally-bonded double-sided tape at the temperature of 90 DEG C and under the pressure of 200KPa for ten seconds, extremely high bonding strength can be achieved on surfaces such as concavo-convex surfaces, porous surfaces and oblique surfaces.

Owner:LONGCHANG YUXI NEW MATERIAL TECH

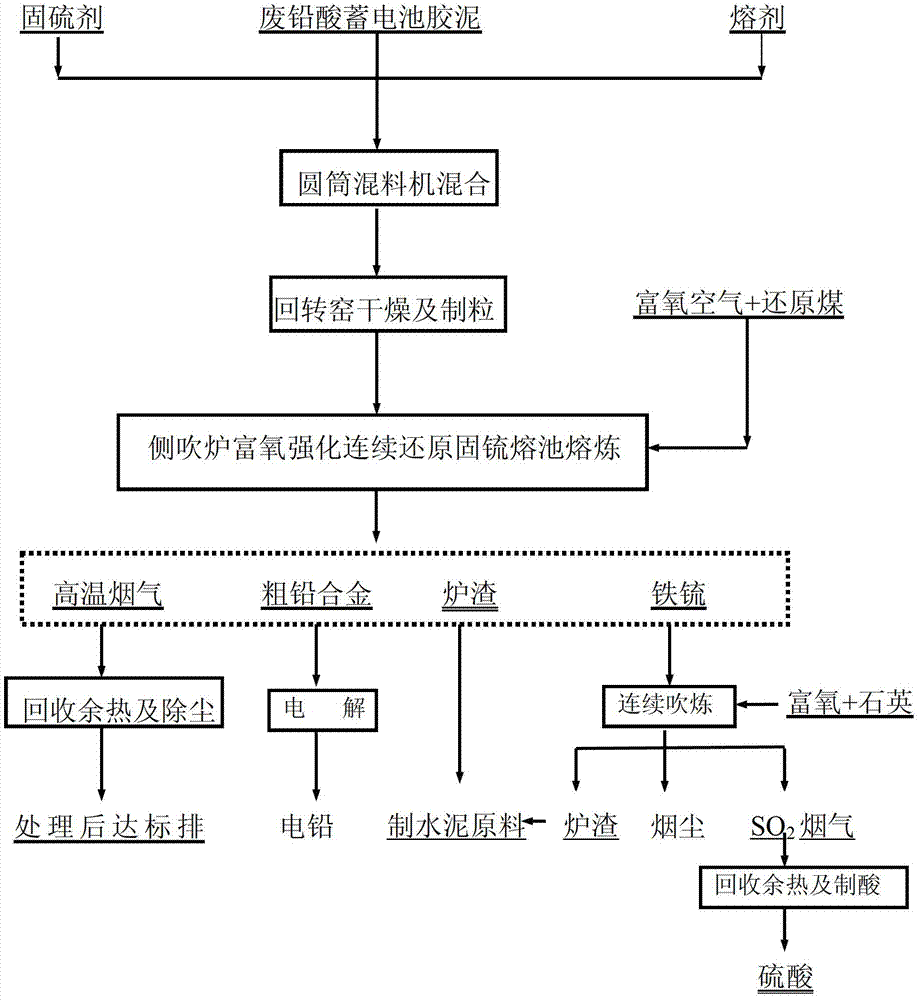

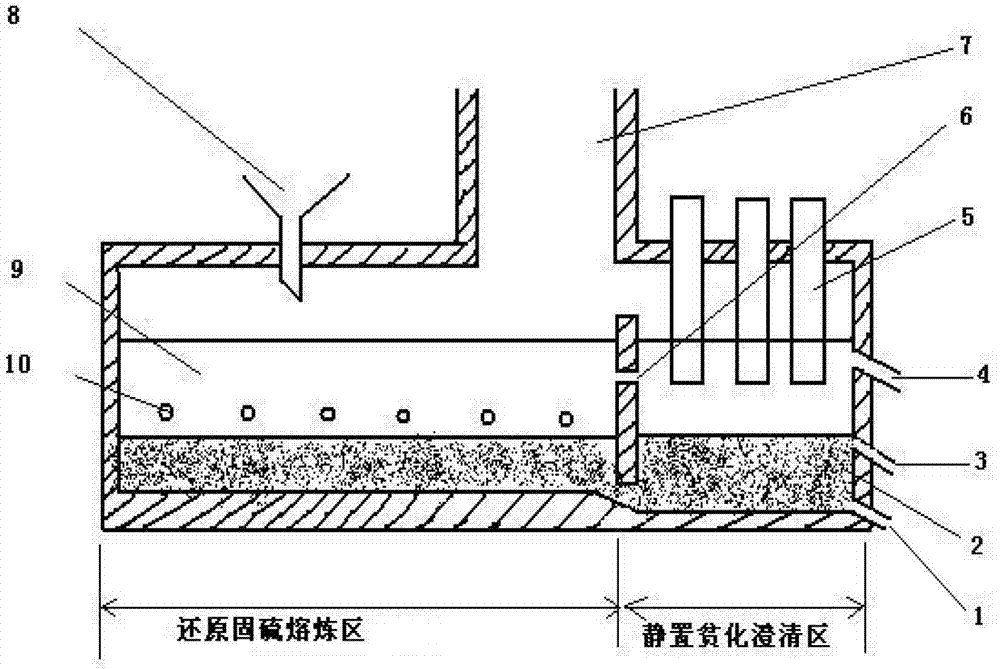

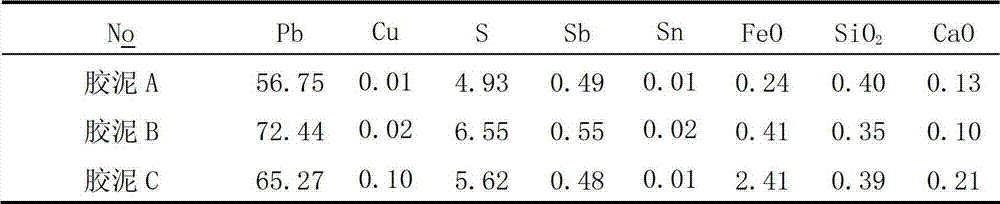

Method and device for treating daub and iron-rich heavy metal solid waste of waste lead-acid storage battery

InactiveCN102965509AEliminate gas pollutionClean and efficient recyclingProcess efficiency improvementSolventHeavy metals

The invention discloses a reduction sulphur-fixing method and device for treating daub and iron-rich heavy metal solid waste of a waste lead-acid storage battery. The method comprises the steps of: with iron-rich heavy metal solid waste as a sulphur-fixing agent and smokeless conny as a reducing agent, firstly, fully uniformly mixing raw materials such as daub of the waste lead-acid storage battery with the sulphur-fixing agent and a solvent, drying and pelleting, then continuously adding the mixture and the reducing agent (fuel) into an oxygen side-blowing bath smelting furnace for reduction sulphur-fixing smelting, further producing lead bullion, iron sulphur and sulphur-containing slag in one step under the condition that no sulfur dioxide is generated. According to the method, sulphur in the raw materials is fixed in the sulphur-containing slag and iron sulphur, so that low-concentration sulfur dioxide pollution is thoroughly eliminated, valuable elements such as iron, gold, silver, tin, antimony and bismuth in the sulphur-fixing agent are recycled with high efficiency at low cost, and continuous cleaning smelting of the daub of the waste lead-acid storage battery and continuous harmless treatment of the iron-rich heavy metal solid waste are realized. The reduction sulphur-fixing method has the advantages of changing harmful substances into beneficial substances, recycling waste materials, and being simple in process, environmentally friendly, and low in cost, and has important significance for continuous clean smelting of the daub of the waste lead-acid storage battery and the treatment and recycling of the heavy metal solid waste.

Owner:CENT SOUTH UNIV +1

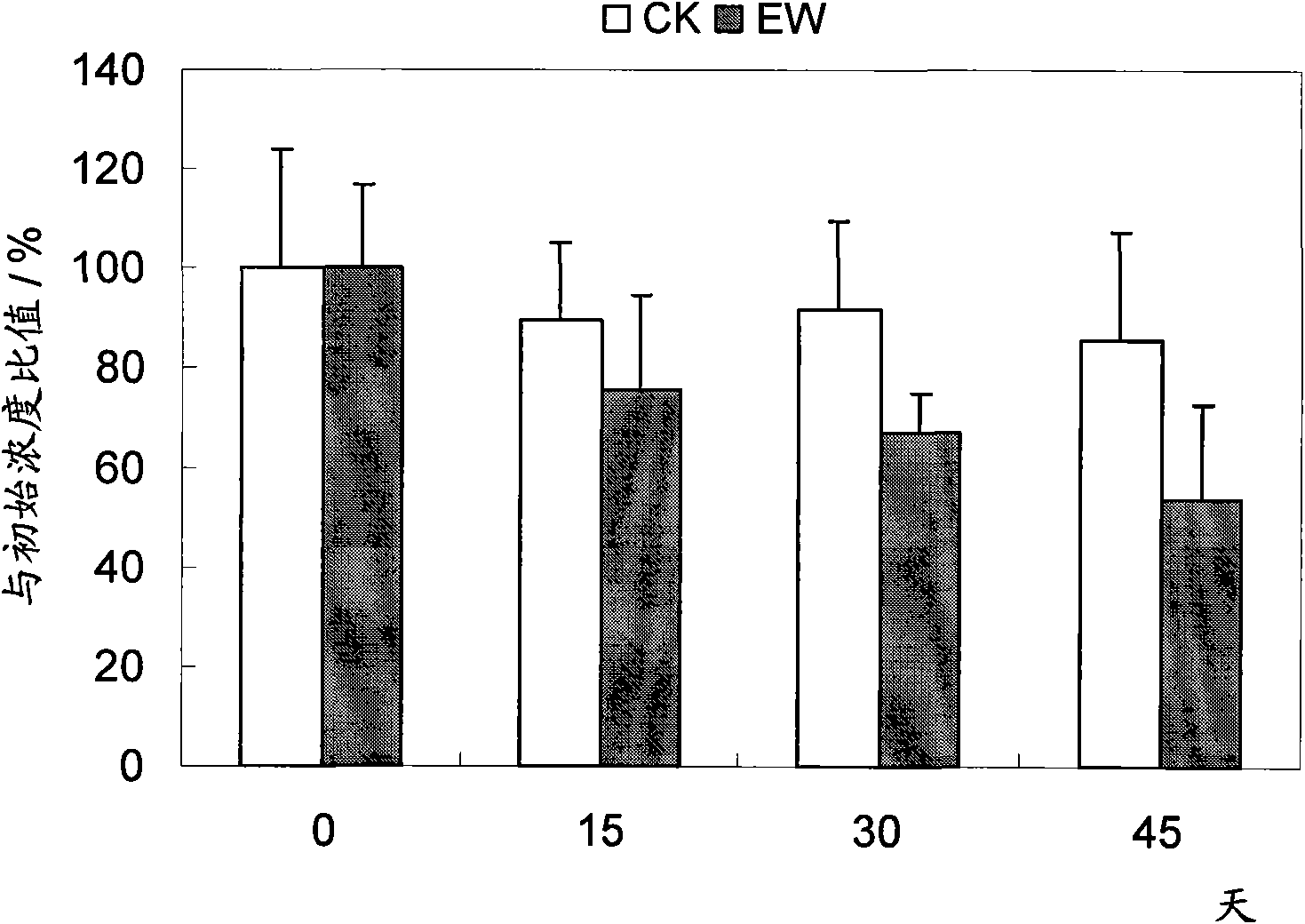

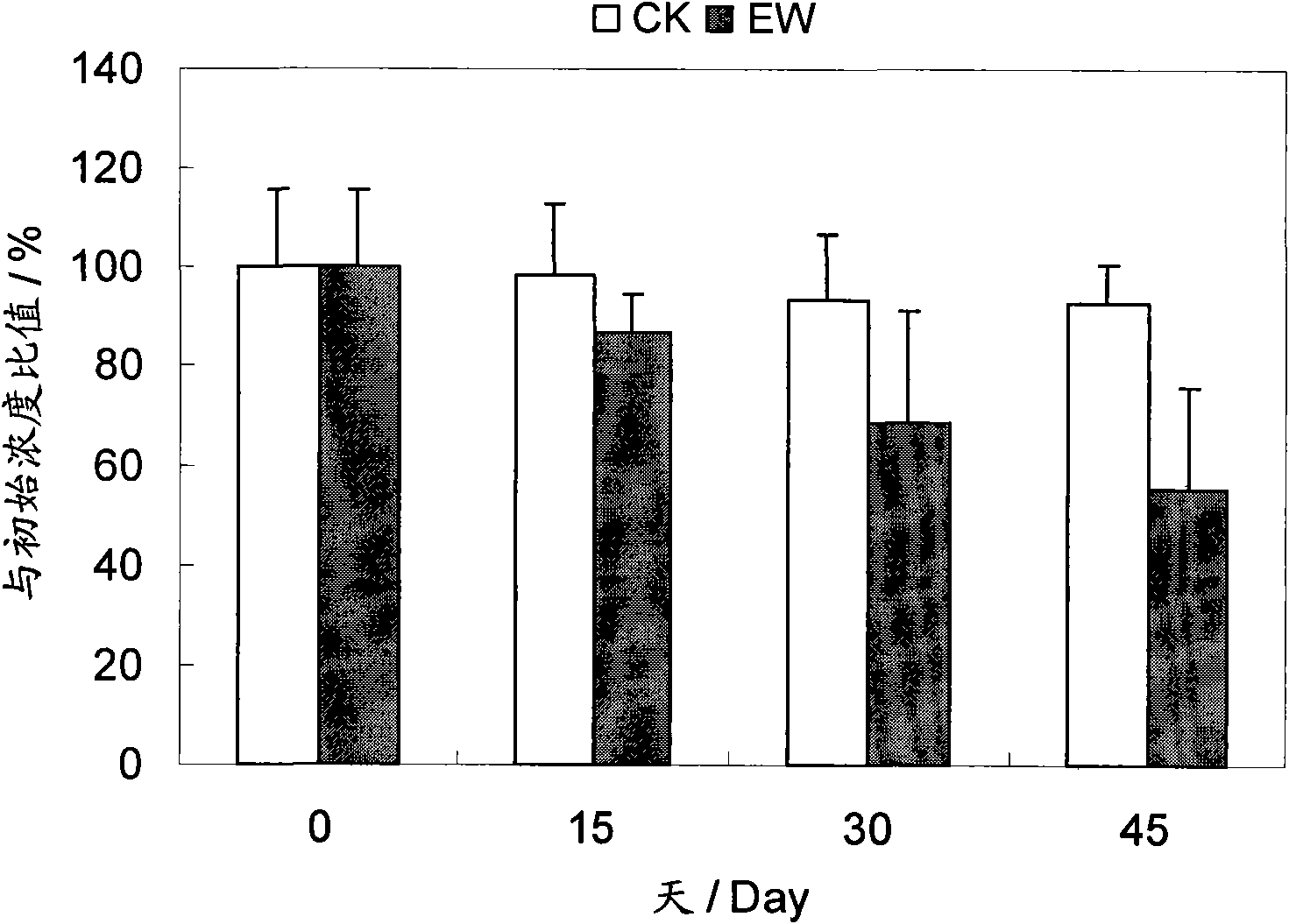

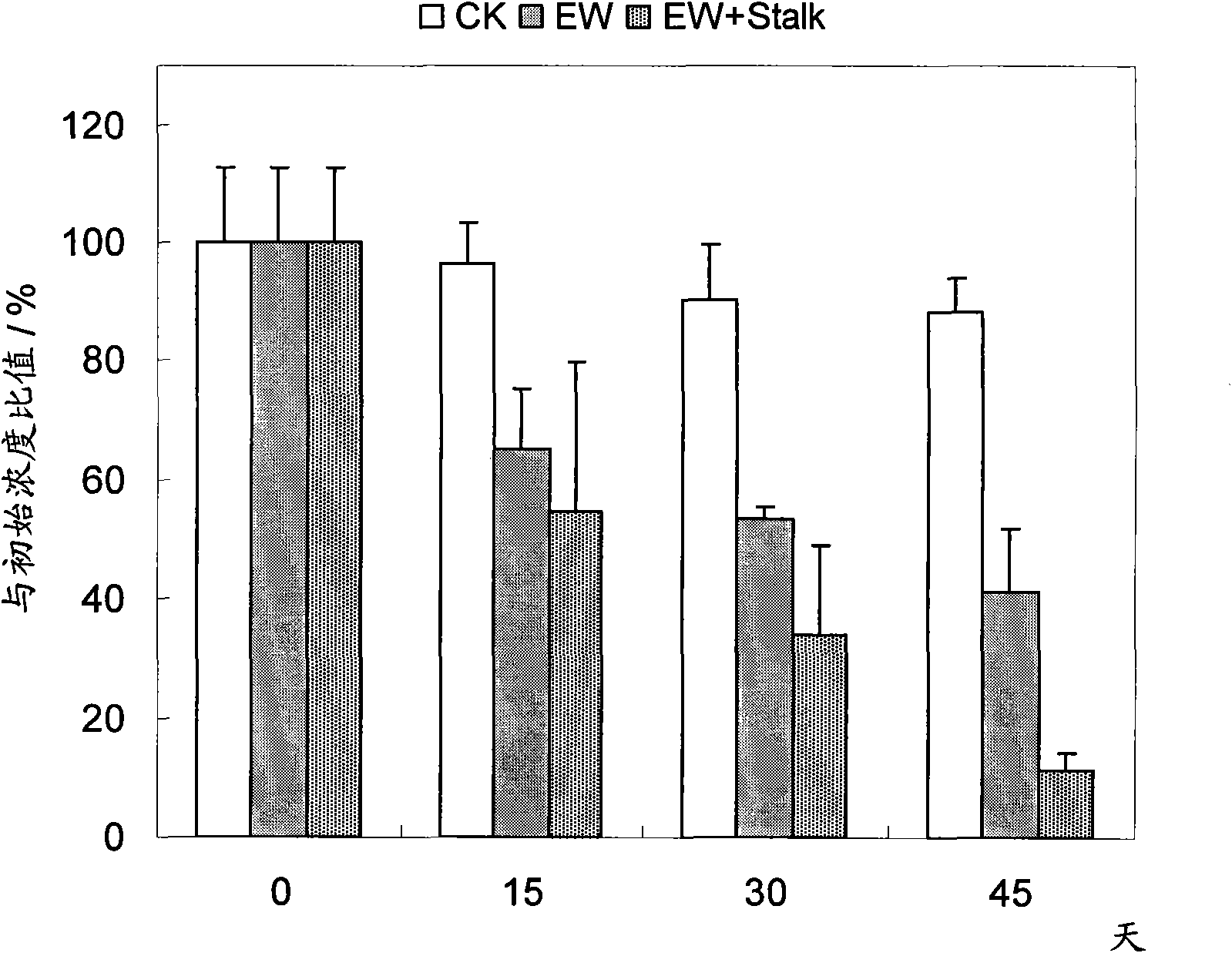

Earthworm strengthening repair method of soil polluted by phenanthrene, pyrene or pentachlorophenol

InactiveCN101648206AFriendlyQuality improvementContaminated soil reclamationHorticulturePentachlorophenolAgricultural reuse

The invention relates to an earthworm strengthening repair method of soil polluted by phenanthrene, pyrene or pentachlorophenol, belonging to the treatment field of soil environment pollution and comprising the following steps: (A) measuring the content of the phenanthrene, pyrene or pentachlorophenol in soil at regular intervals; (B) adding earthworm or the earthworm and straw or the earthworm and a golden weeping willow. The earthworm is M.guillelmi geophagy earthworm, and is singly thrown mutually or thrown together with the golden weeping willow or thrown together with the straws. In the step B, 4-6 golden weeping willows are planted when the content of the phenanthrene, the pyrene and the pentachlorophenol is 5, 50 and 1mg / kg per square meter oil. The earthworm adopted by the invention can greatly improve the quality of cultivated soil and increase the agricultural reuse value of the soil while rapidly removing soil pollutants; the invention is harmonious with the natural ecologyprocess, and combines the earthworm repair with woody plants repair further so that organics are absorbed and utilized by the woody plant while the organics are metabolized.

Owner:NANJING UNIV

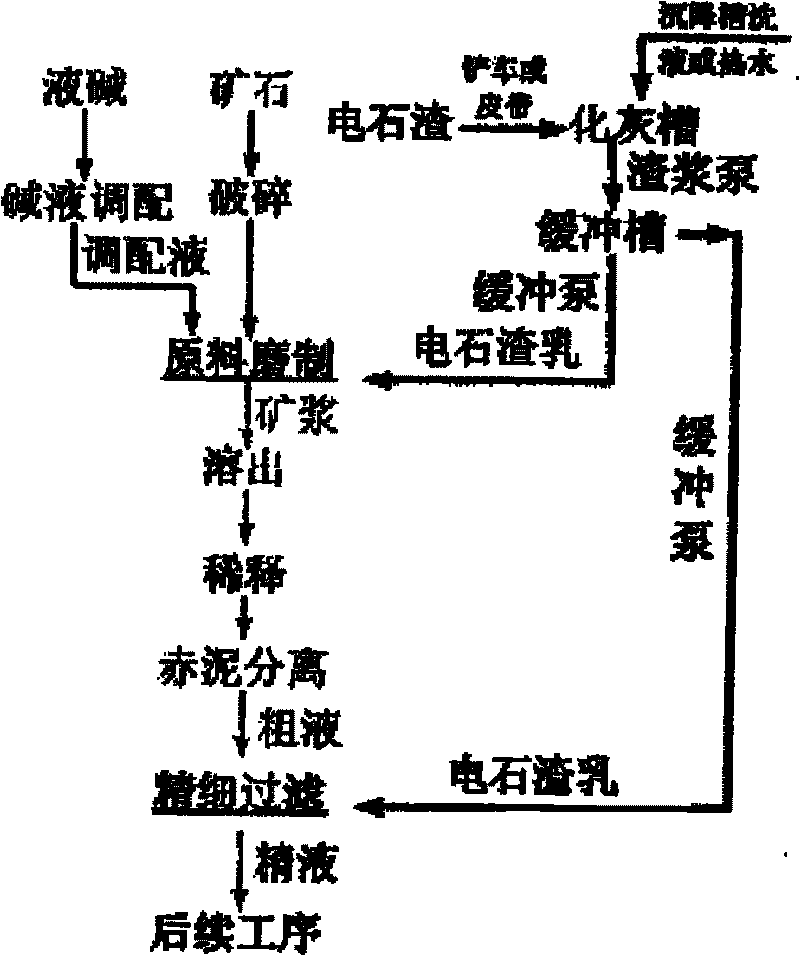

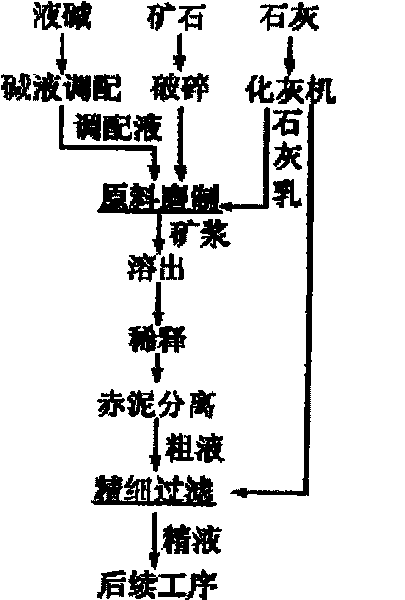

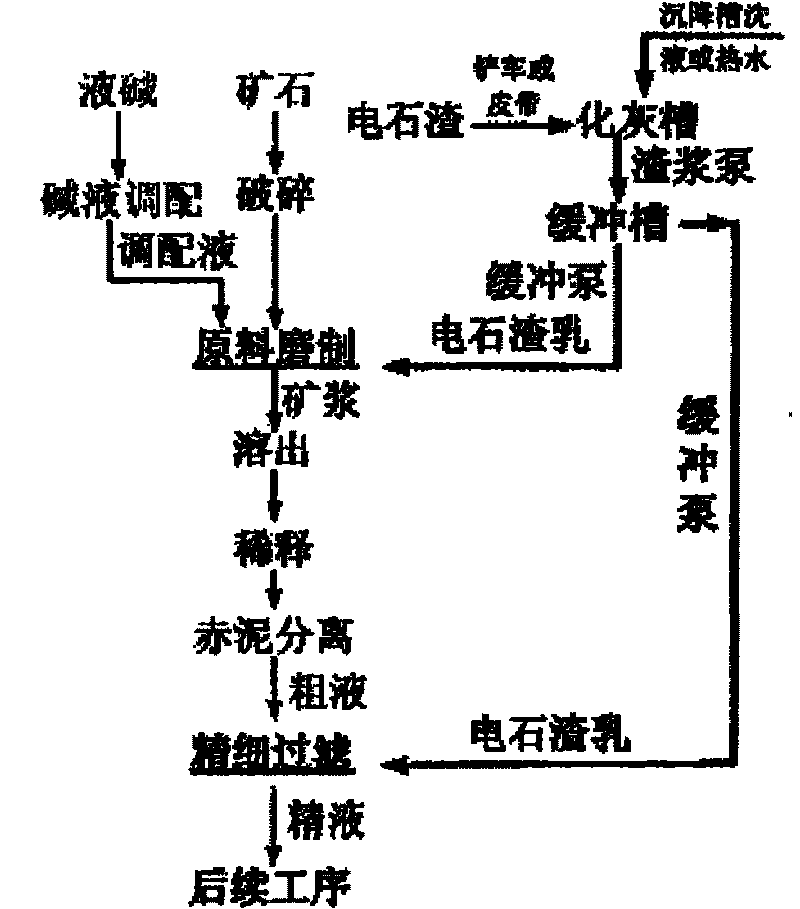

Process for Bayer process aluminum oxide production by replacing carbide slag with lime

ActiveCN101708859ASolve the problem of difficult storageDoes not affect normal productionSolid waste disposalAluminium oxides/hydroxidesSlagFiltration

The invention discloses a process for Bayer process aluminum oxide production by replacing carbide slag with lime, belonging to the technical field of solid waste treatment. Waste-carbide slag of a chemical plant is prepared into carbide slag emulsion with a certain effective calcium content through mixing and stirring with settled washing liquor or hot water, the prepared carbide slag emulsion is pumped to enter grinding, fine filtration and relative processes of raw materials in the Bayer process aluminum oxide production for fully playing a role of effective calcium. The carbide slag is replaced with the lime without influencing the aluminum oxide normal production or damaging the properties of sodium aluminate, the carbide slag can be used as a substitute of the lime to eliminate the influence of titanium dioxide in the ore on the dissolving-out; the addition of the carbide slag applied to the fine filtration procedure is basically equal to the addition of the lime, the indexes accord with the production requirement without influencing the filtering capacity of a leaf filter, thereby greatly reducing the raw material consumption during the Bayer process aluminum oxide production, and solving the problem of difficult carbide slag storage. The process accords with the circular economy standard advocated by our country, embodies the development of circular economy, and realizes the waste reclamation and the environment protection.

Owner:CHIPING XINFA HUAYU ALUMINA

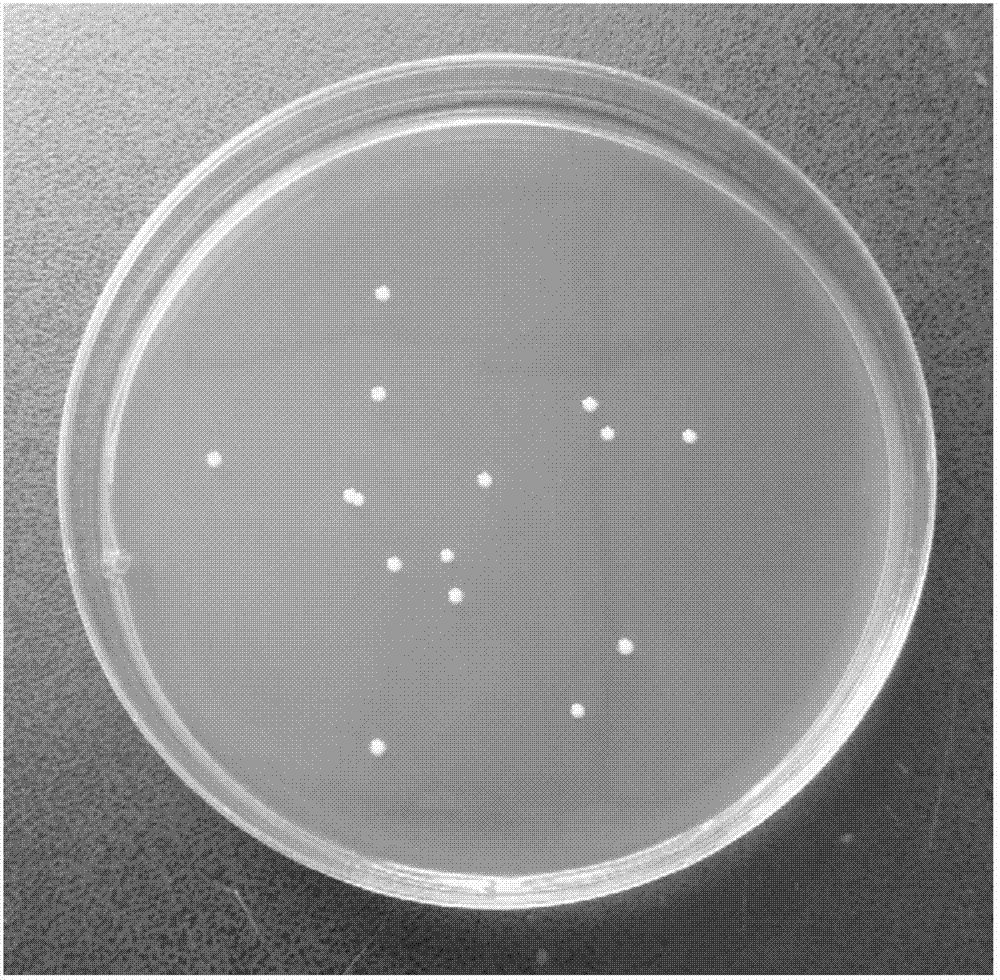

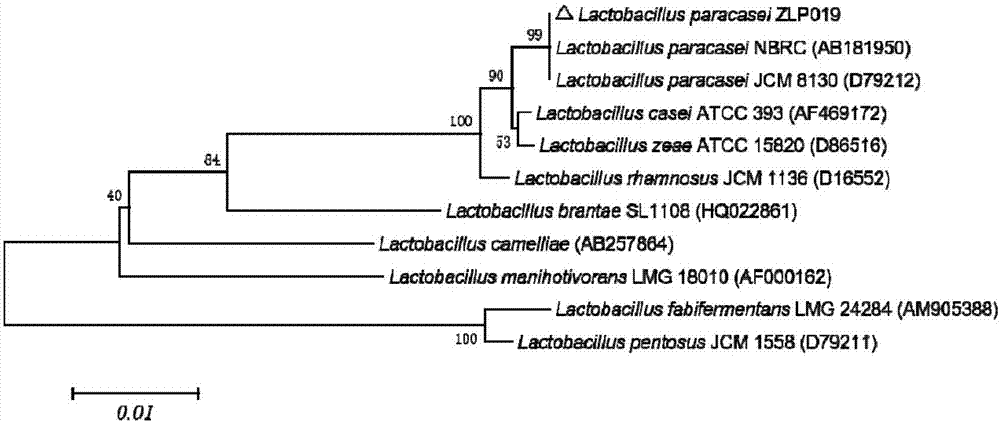

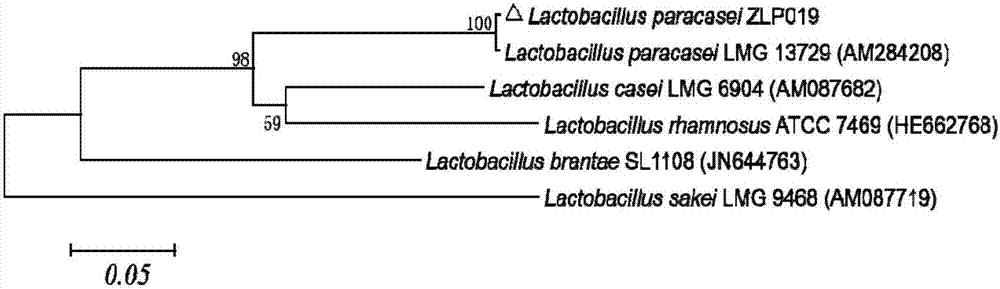

Lactobacillus paracasei, Lactobacillus paracasei preparation, and applications of Lactobacillus paracasei preparation in pig feed

ActiveCN107164269AReduce constipation rateGain weight fastBacteriaMicroorganism based processesBacteroidesFreeze-drying

The present invention discloses Lactobacillus paracasei ZLP019, which has a preservation number of CGMCC No.11532, and has characteristics of good acid resistance, good cholate resistance and good bacterial inhibition. According to the present invention, with the application of the Lactobacillus paracasei ZLP019 to prepare the freeze-drying preparation, the live bacteria survival rate is high, and the preparation is conveniently used in feed enterprises and farms; and after the preparation is directly added to sow feed according to the ratio requirement, the reproductive performance of sows can be improved, the daily weight gain and the survival rate of suckling piglets can be improved, the intestinal health of sows can be improved, the harmful bacteria emission in feces can be reduced, and the environmentally friendly breeding environment can be easily achieved.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Manufacturing method of hot-line work technical training distributing line part 3D (three-dimensional) teaching video

ActiveCN103544723AMeet needsGuaranteed uptimeAnimation3D-image renderingElectric power systemSoftware engineering

The invention relates to a manufacturing method of a hot-line work technical training distributing line part 3D (three-dimensional) teaching video. The method includes: building scene, equipment, character, tool, management document material models, and building a management system which comprises model material library management software, dynamic control engine software, video recording software, video teaching editing software, a 3D animation management subsystem, a window interface GUI (graphical user interface) and a GUI interface generating tool; using the 3D animation technology to manufacture simulation animation courseware, using the 3D animation manufacturing technical and physical engine technology to manufacture an electric power animation material video, and using audio and video editing manners of the editing system to make standard operations, safety technical training and the like of an electric system into the 3D animation teaching video. The method has the advantages that the manufactured teaching video is visualized and vivid, long-term and sustainable, good in teaching effect and low in training cost.

Owner:STATE GRID CORP OF CHINA +1

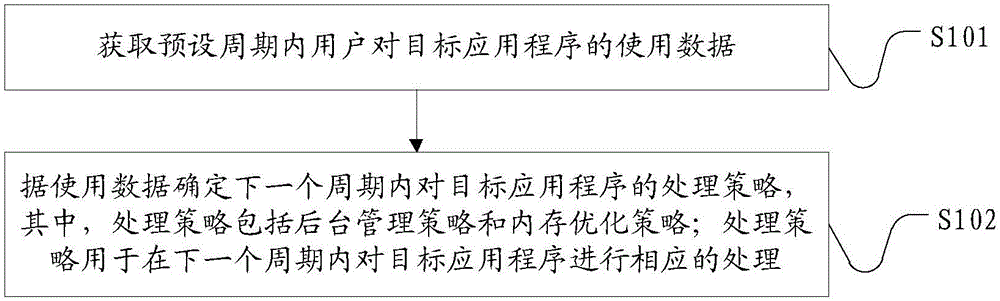

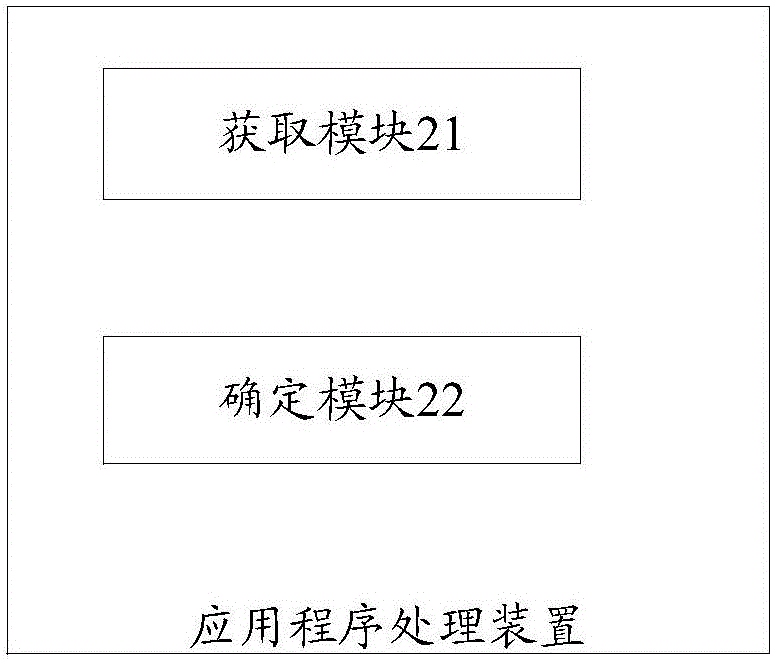

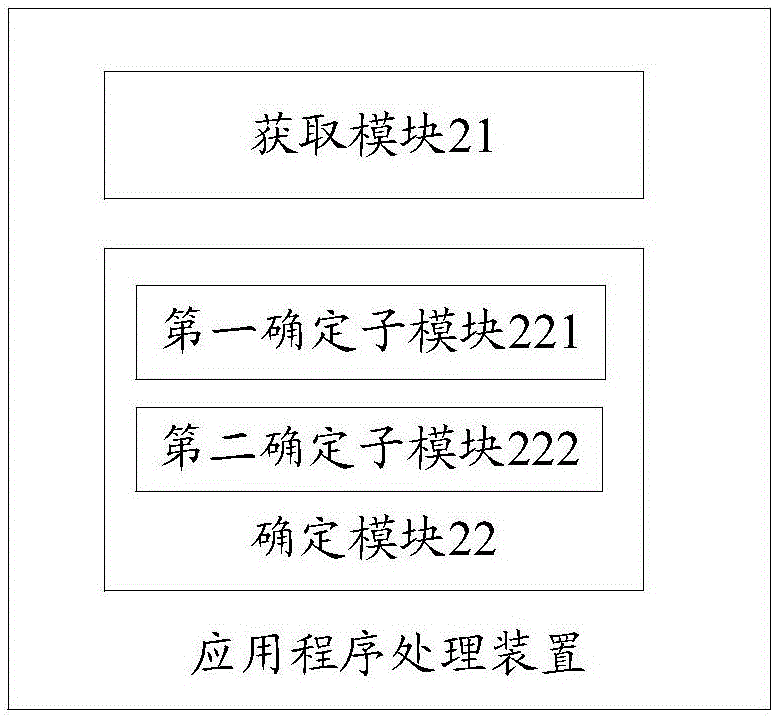

Method, device, terminal and server for application program processing

InactiveCN106502768AUsage data is a real-time reflection of its usage habits of the application in line withMeet usage habitsProgram saving/restoringTransaction processingComputer terminalHabit

The invention discloses a method, device, terminal and server for application program processing, wherein a user's use data aiming at a target application program during a preset cycle can be acquired; and according to the acquired use data, a processing strategy of the target application program in a next cycle is determined, wherein the processing strategy is used to make corresponding processing to the target application program in the next cycle and comprises a backstage management strategy and a memory optimization strategy. For each user, the use data is the data which reflects the user's use habits aiming at the corresponding application program in real time, so the processing strategy disclosed by the invention is the strategy customized for each user. In comparison with the prior art, the processing strategy can better satisfy different use habits of the different users; a problem of terminal pause can be solved in a more friendly and targeted manner; and better use experience is brought to the users.

Owner:NANJING COOLPAD SOFTWARE TECH

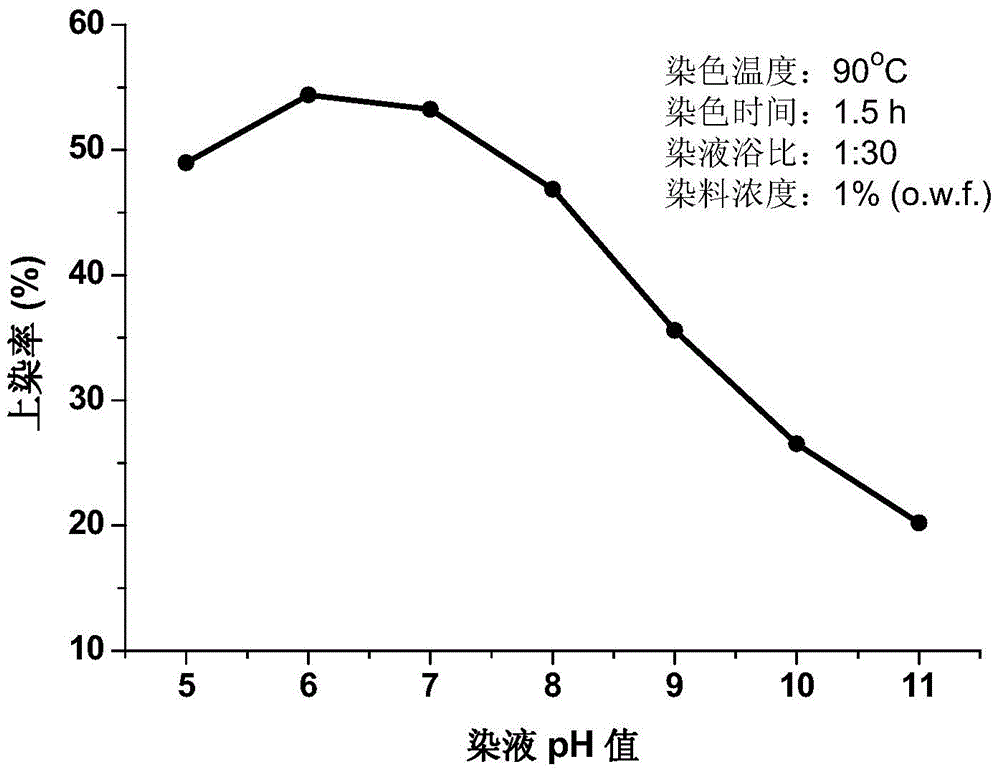

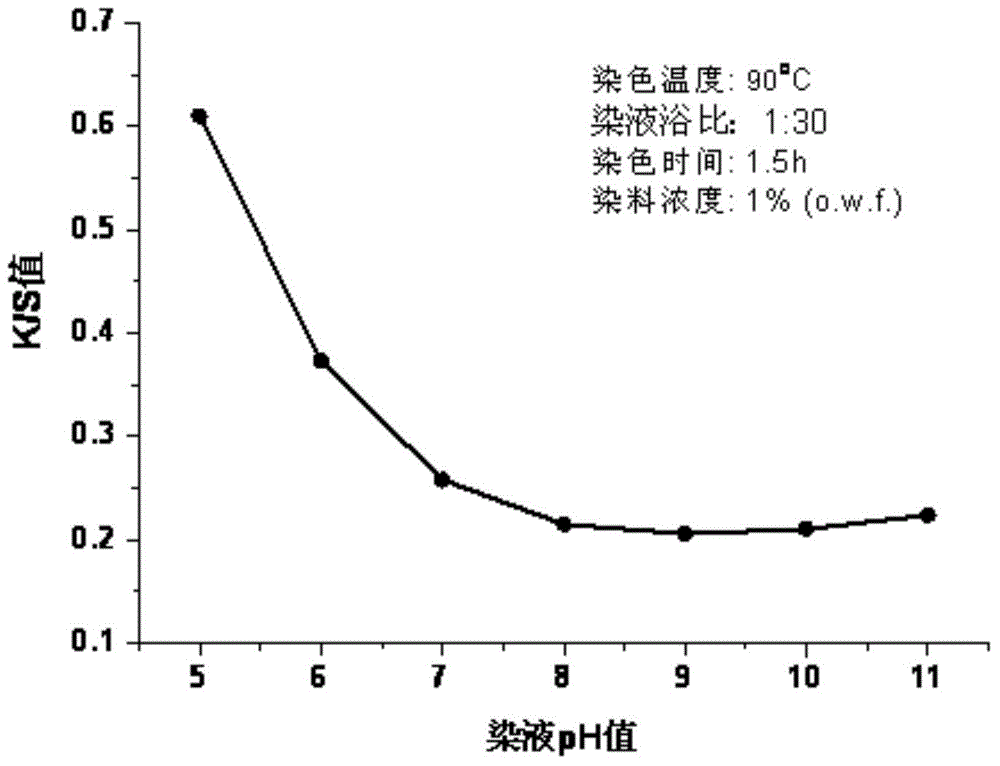

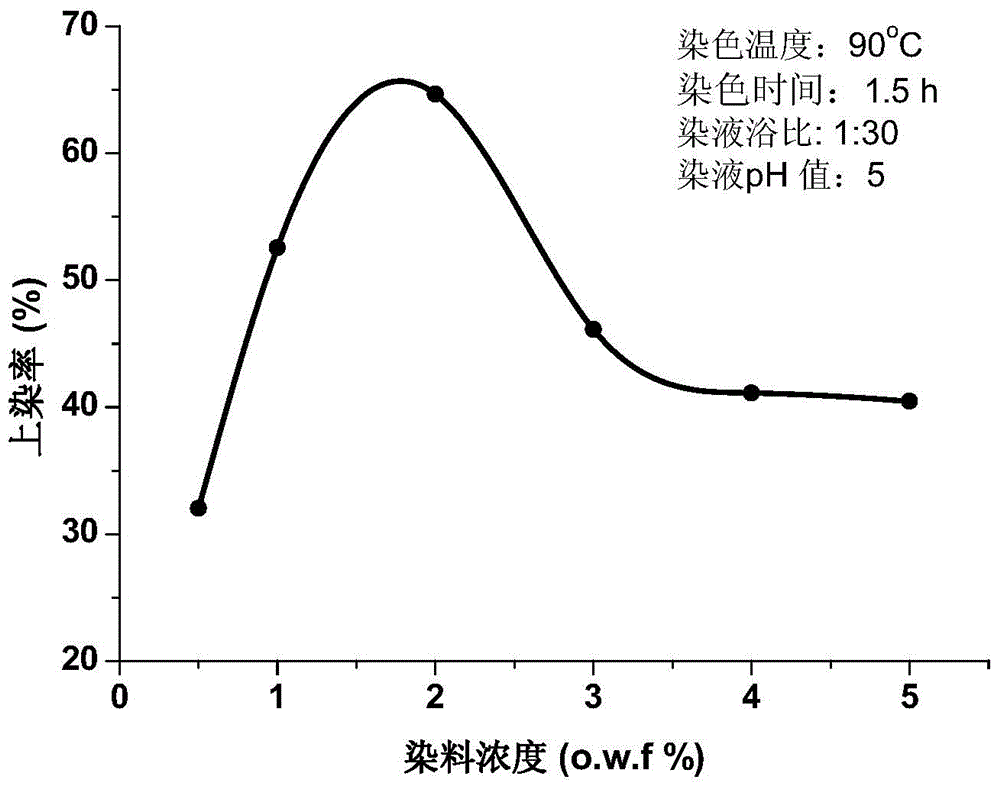

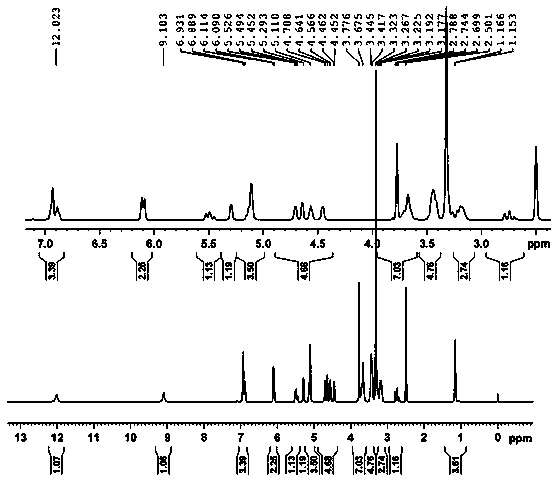

Chemical structure modification-based water-soluble curcumin dye, and preparation method and application thereof

The invention discloses a chemical structure modification-based water-soluble curcumin dye. The invention also discloses a preparation method of the chemical structure modification-based water-soluble curcumin dye. The preparation method comprises the following steps: reacting curcumin with 1,2-dibromoethane, and reacting the above obtained product with triethylamine to obtain the chemical structure modification-based water-soluble curcumin dye. The invention also discloses an application method of the chemical structure modification-based water-soluble curcumin dye. The dye can be directly used for dyeing unmodified cotton fabrics without a dyeing accelerant, a dye leveler or a dye mordant, so the environmental protection property of a dyeing process and the safety of the fabric are improved. All dyeing indexes, especially the indexes comprising the washing color fastness and the like of the water-soluble dye are obviously better than that of natural curcumin for direct dyeing, wherein the washing color fastness reaches 3 level, the staining fastness reaches 5 level, and each of the dry crock fastness and the wet crock fastness reaches 5 level.

Owner:嘉兴君宏光学有限公司

Method for preparing sodium carboxymethylcellulose by abandoned cotton fabrics

The invention discloses a method for preparing sodium carboxymethylcellulose by abandoned cotton fabrics, which includes cleaning, drying and cutting up the abandoned cotton fabrics, placing the abandoned cotton fabrics into a pretreating agent solution for heating and stirring, and filtering out after the abandoned cotton fabrics faded; placing and heating the abandoned cotton fabrics in a sodium hydroxide solution for 45-90 minutes at the temperature from 75 DEG C to 100DEG C until colors of the abandoned cotton fabrics are completely faded, and obtaining celluloses; submerging the celluloses into the sodium hydroxide solution, heating the celluloses for 1.5-2 hours at the temperature from 30 DEG C to 50 DEG C, and then removing the sodium hydroxide solution to obtain alkali celluloses; shredding the alkali celluloses and adding absolute ethyl alcohol and the sodium hydroxide solution; dropwise adding a chloroacetic acid ethanol solution at the temperature from 50 DEG C to 60 DEG C; heating for 80-100 minutes at the temperature from 70 DEG C to 80 DEG C; performing a suction filtration and washing; and adding a phenolphthalein indicator, dropwise adding hydrochloric acid for a neutralization until the solution is colorless, washing 1-2 times, and drying after a suction filtration to obtain a finished product.

Owner:CHANGAN UNIV

Neohesperidin synthesis technology

InactiveCN103408620AHigh activityQuick responseSugar derivativesSugar derivatives preparationPhloroacetophenoneChemical synthesis

The invention relates to the field of organic synthesis and discloses a neohesperidin synthesis technology. The neohesperidin synthesis technology comprises the following steps of adding phloroacetophenone-4'-beta-neohesperidin and isovanillin (CAS: 621-59-0) as initial raw materials and a low-carbon alcohol solvent having the content of more than 98wt% into a three-necked flask, carrying out stirring for dissolution, feeding N2 into the three-necked flask to expel air in the three-necked flask, carrying out heating, orderly adding a main catalyst and a cocatalyst into the three-necked flask, carrying out timing at backflow starting time, stopping heating after the reaction lasts for 2-8h, carrying out cooling to a room temperature, carrying out filtration, washing the filter cake by a small amount of hot low-carbon alcohol, and carrying out vacuum drying at a temperature of 50 DEG C to obtain white solid neohesperidin powder. Compared with the existing neohesperidin synthesis technology, the neohesperidin synthesis technology provided by the invention has the advantages of low cost, high yield, high purity and small environmental pollution and is suitable for neohesperidin industrial production.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

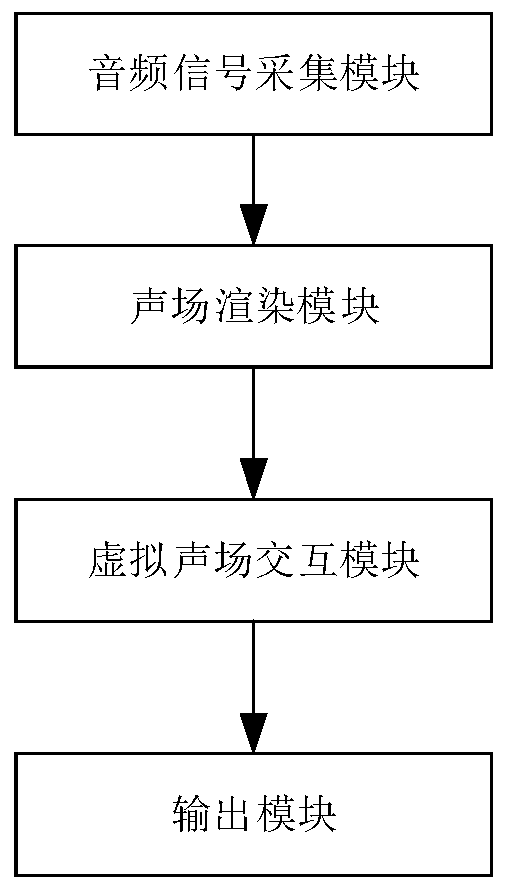

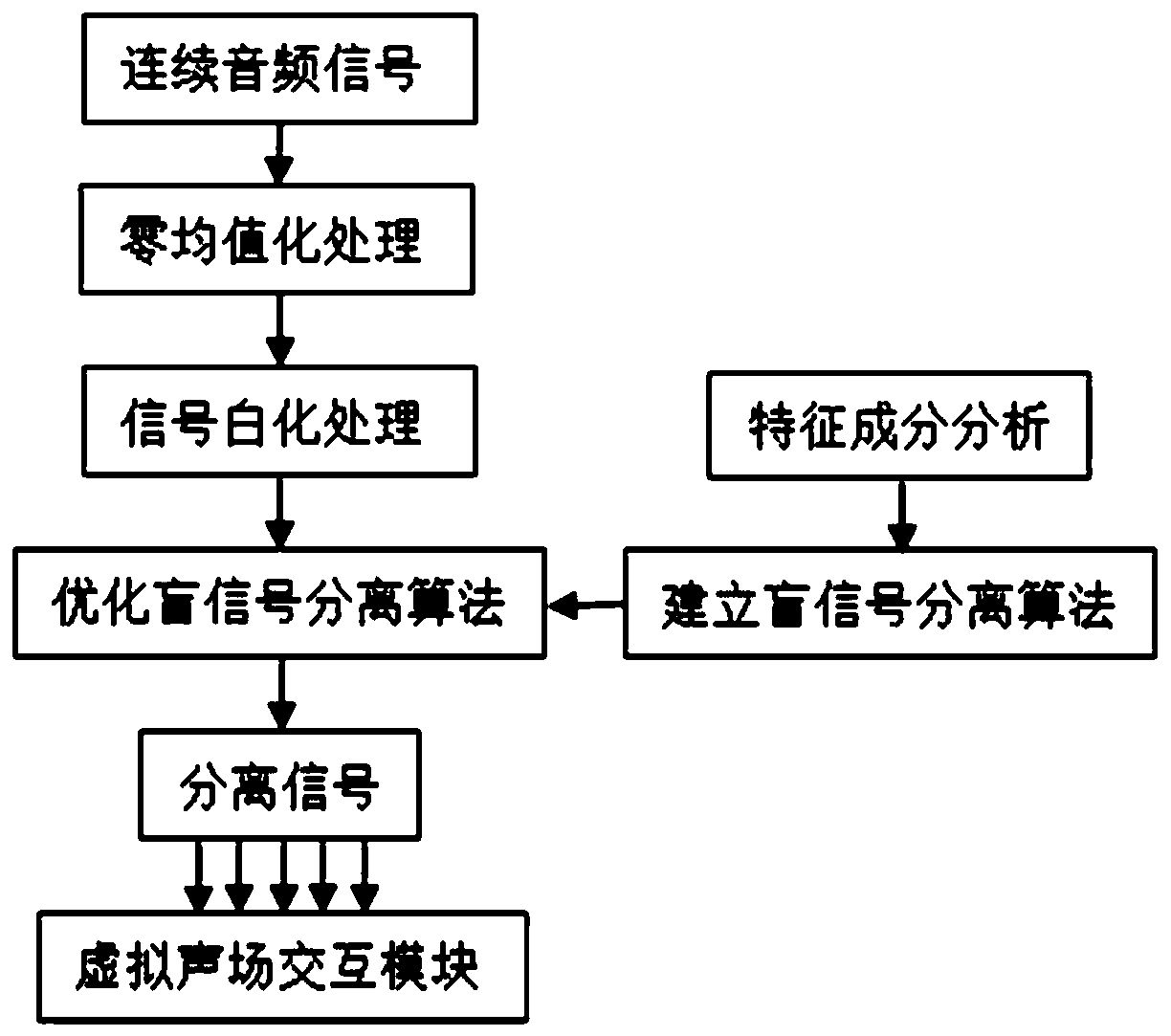

Virtual sound field real-time interaction system based on binaural effect

ActiveCN110267166AConducive to real-time interactionReduce noise interferenceSignal processingLoudspeaker signals distributionInteraction systemsComputer science

The invention relates to a virtual sound field real-time interaction system based on a binaural effect, and the system comprises an audio signal collection module which is used for collecting multiple paths of audio signals; a sound field rendering module which is used for performing sound field rendering on the audio signals and acquiring multiple paths of audio signals with reconstructed sound field information based on a binaural effect; a virtual sound field interaction module which is used for splicing multiple paths of audio signals with reconstructed sound field information in real time according to the head parameters and the user orientation information, and constructing a real-time sound effect in the whole sound field; and the output module is used for outputting a real-time sound effect according to the individual adjustment parameters. Compared with the prior art, audio is processed from the sound and the space sense of the sound field, the original sound field is highly restored and reproduced, and the method has the advantages of flexibility, interactivity, user friendliness and the like.

Owner:SHANGHAI ARTSBANG CULTURE COMM CO LTD

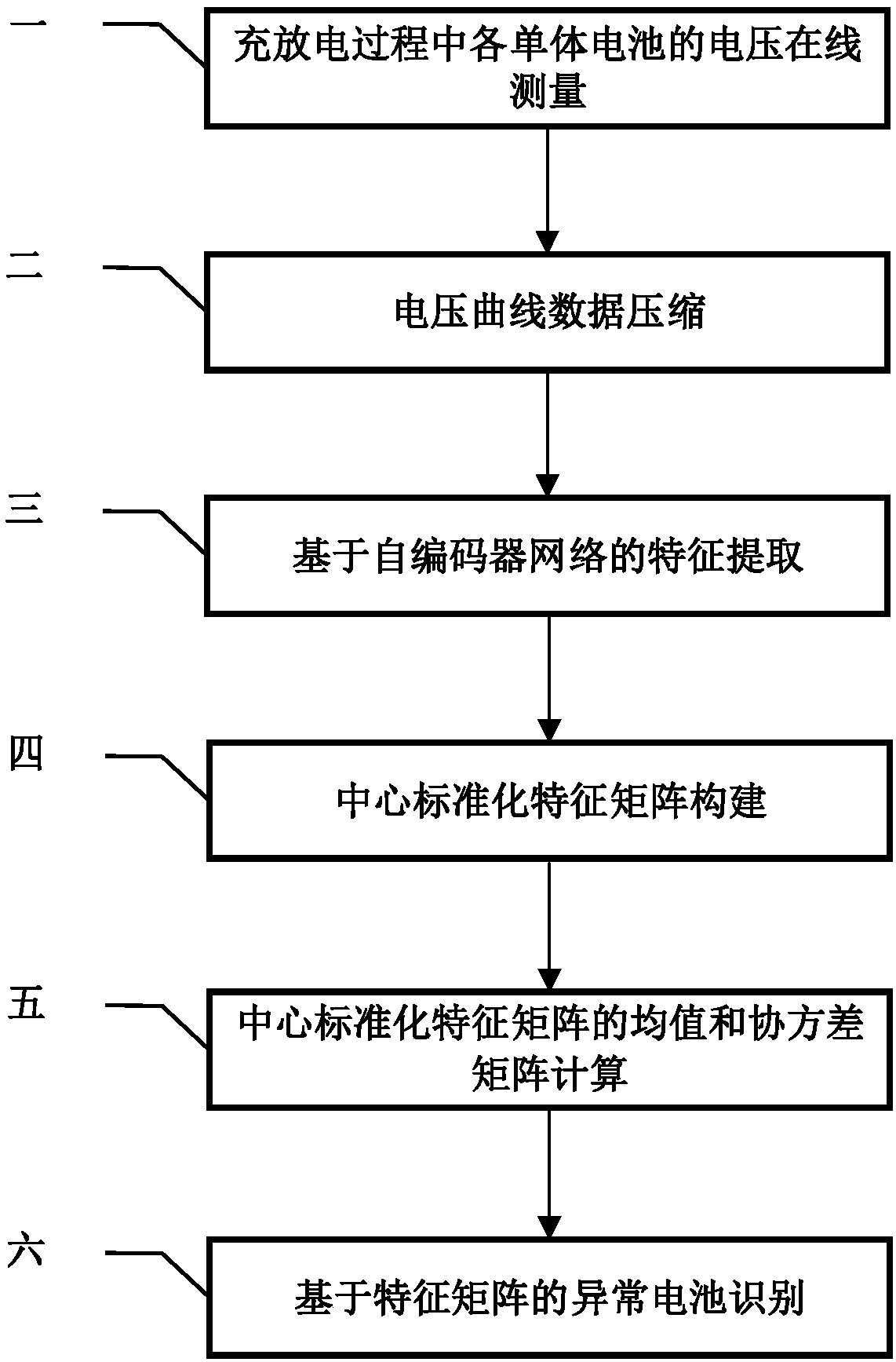

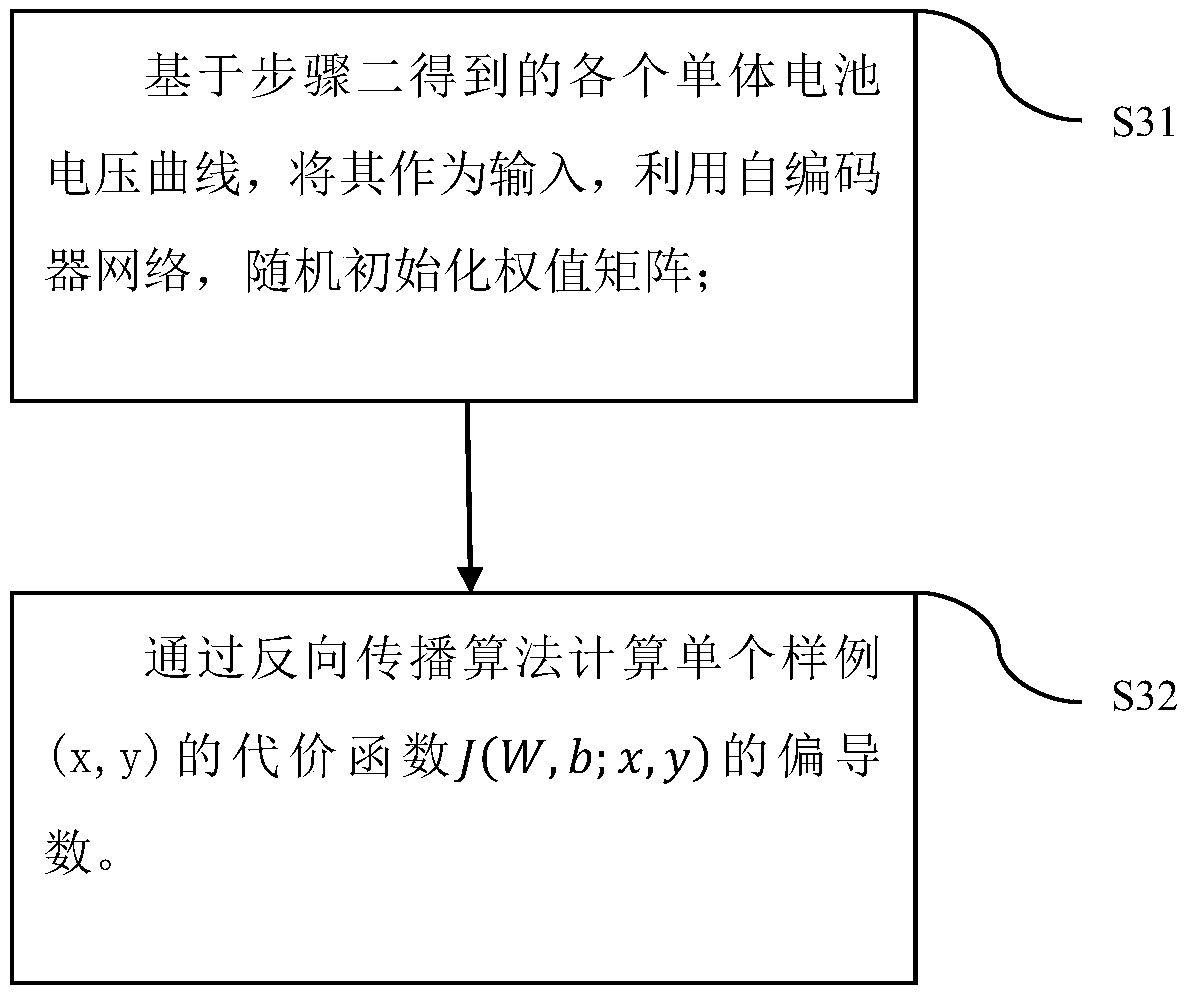

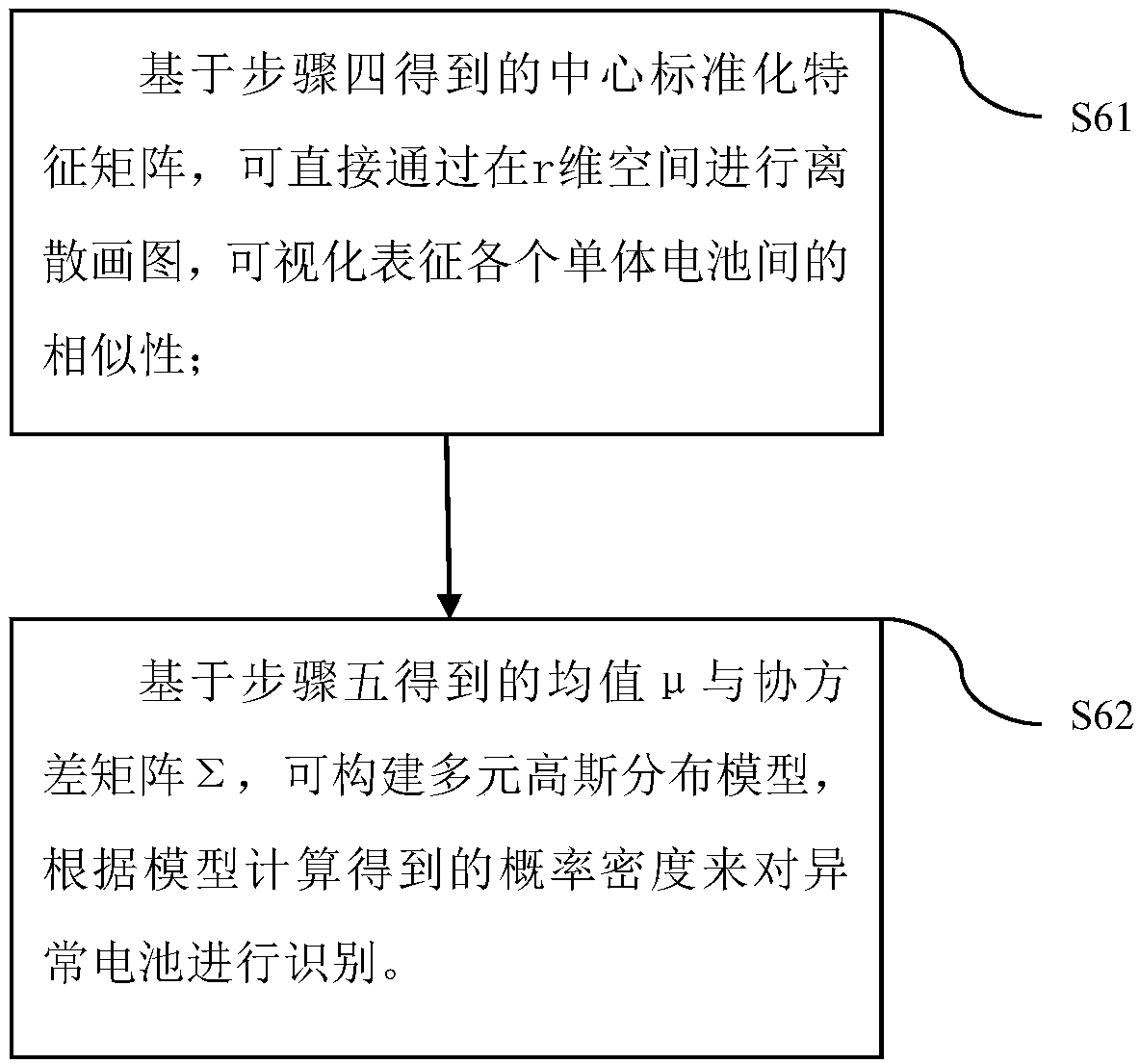

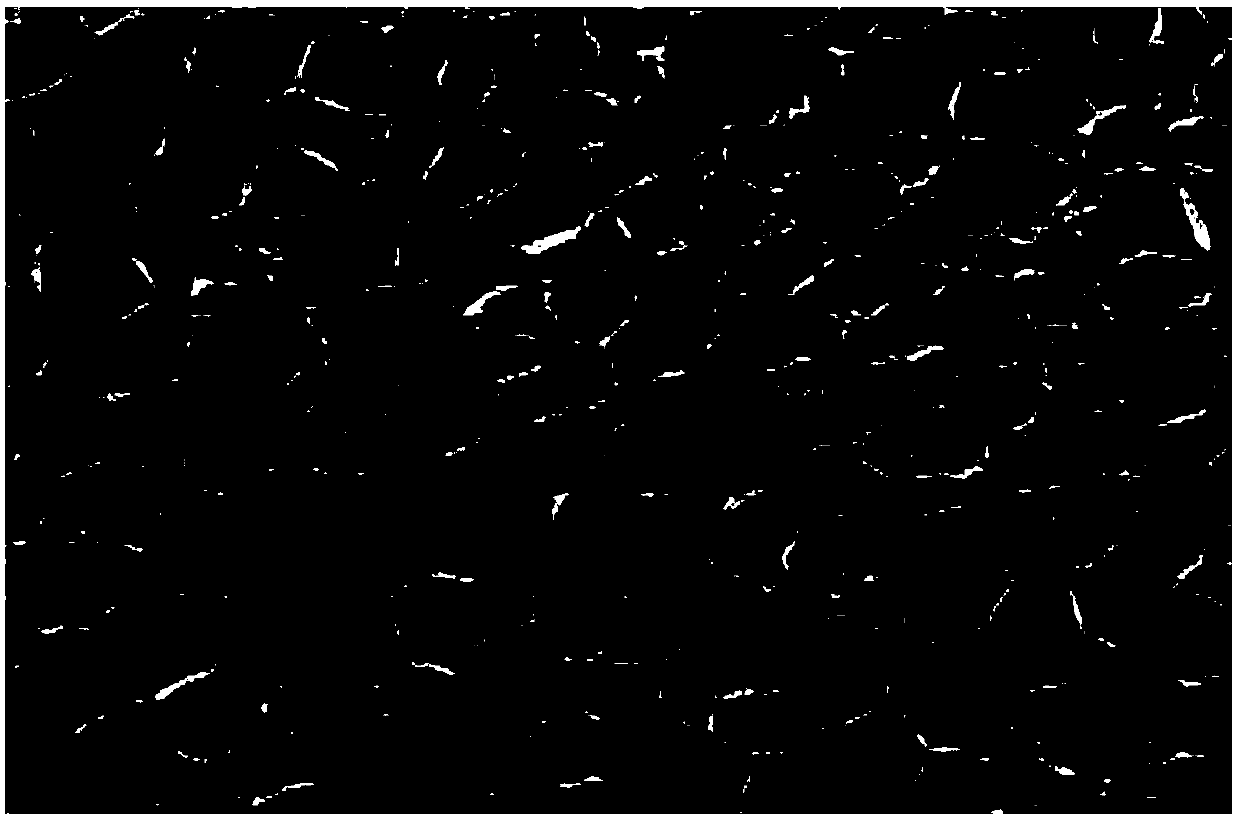

Abnormal cell identification method of cell system based on auto-encoder

ActiveCN109375116AImplement nonlinear dimensionality reductionFriendlyElectrical testingData compressionFeature extraction

The invention relates to the abnormal cell identification method of a cell system based on an auto-encoder. The method comprises the following steps of step1, measuring the voltage of each single cellduring charging and discharging processes in an online mode; step2, carrying out data compression on a voltage curve; step3, carrying out characteristic extraction based on an auto-encoder network; step4, constructing a center standardized characteristic matrix; step5, calculating the mean value and the covariance matrix of the center standardized characteristic matrix; and step6, based on the characteristic matrix, identifying an abnormal cell. Compared with the prior art, by using method of the invention, there are the following advantages that cell characteristics are well visualized; andthe internal characteristic change mechanism of the abnormal cell can be deeply excavated and so on.

Owner:SHANGHAI INT AUTOMOBILE CITY GRP CO LTD +1

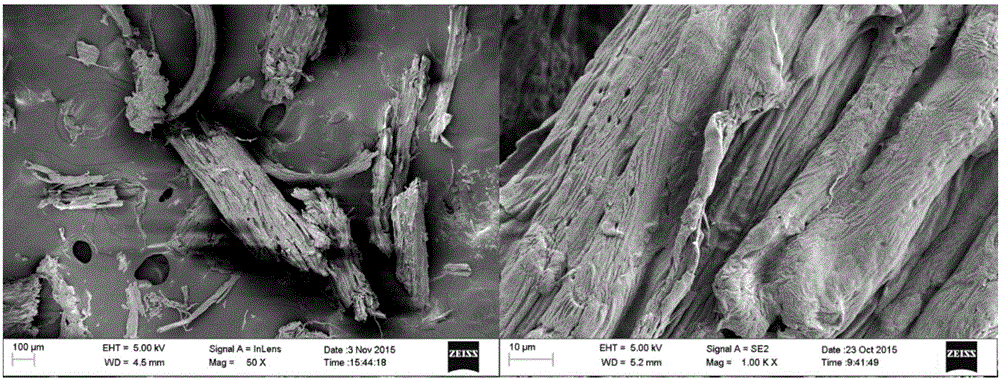

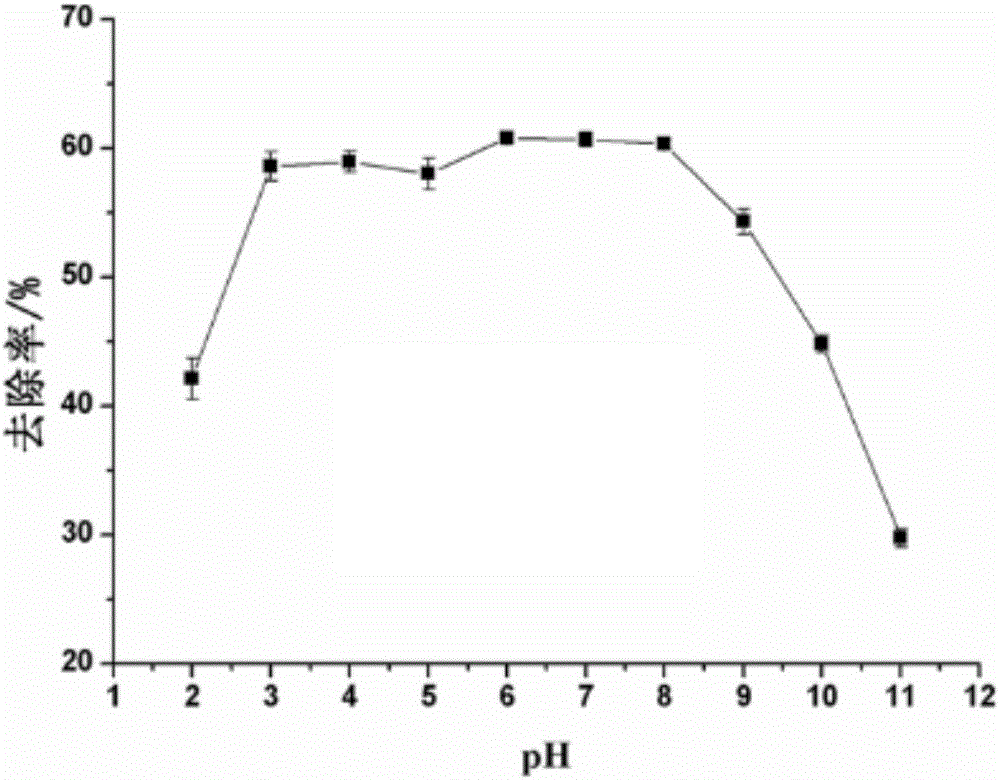

Modified biomass adsorber as well as preparation method and application thereof

InactiveCN106219657ALow priceHigh reactivityWater treatment parameter controlOther chemical processesSorbentEpichlorohydrin

The invention belongs to the technical field of adsorption materials, and discloses a modified biomass adsorber as well as a preparation method and application thereof. The preparation method comprises the following steps: cleaning a straw raw material, soaking and then drying the straw raw material, and performing pulverization; then performing alkalization pretreatment to remove water, and performing crosslinking treatment by using epoxy chloropropane; removing excessive epoxy chloropropane from the crosslinked straw, and performing quaternarization with a trimethylamine aqueous solution; filtering out the trimethylamine aqueous solution, and cleaning and drying an obtained modified straw product so as to obtain the modified biomass adsorber. The preparation method disclosed by the invention is low in preparation cost and environment-friendly, can be used for removing NO3<-> and PO4<3-> from nutrition-enriched water, is high in adsorption efficiency, and is relatively good in adsorption effect at the pH of 3 to 9.

Owner:SOUTH CHINA UNIV OF TECH

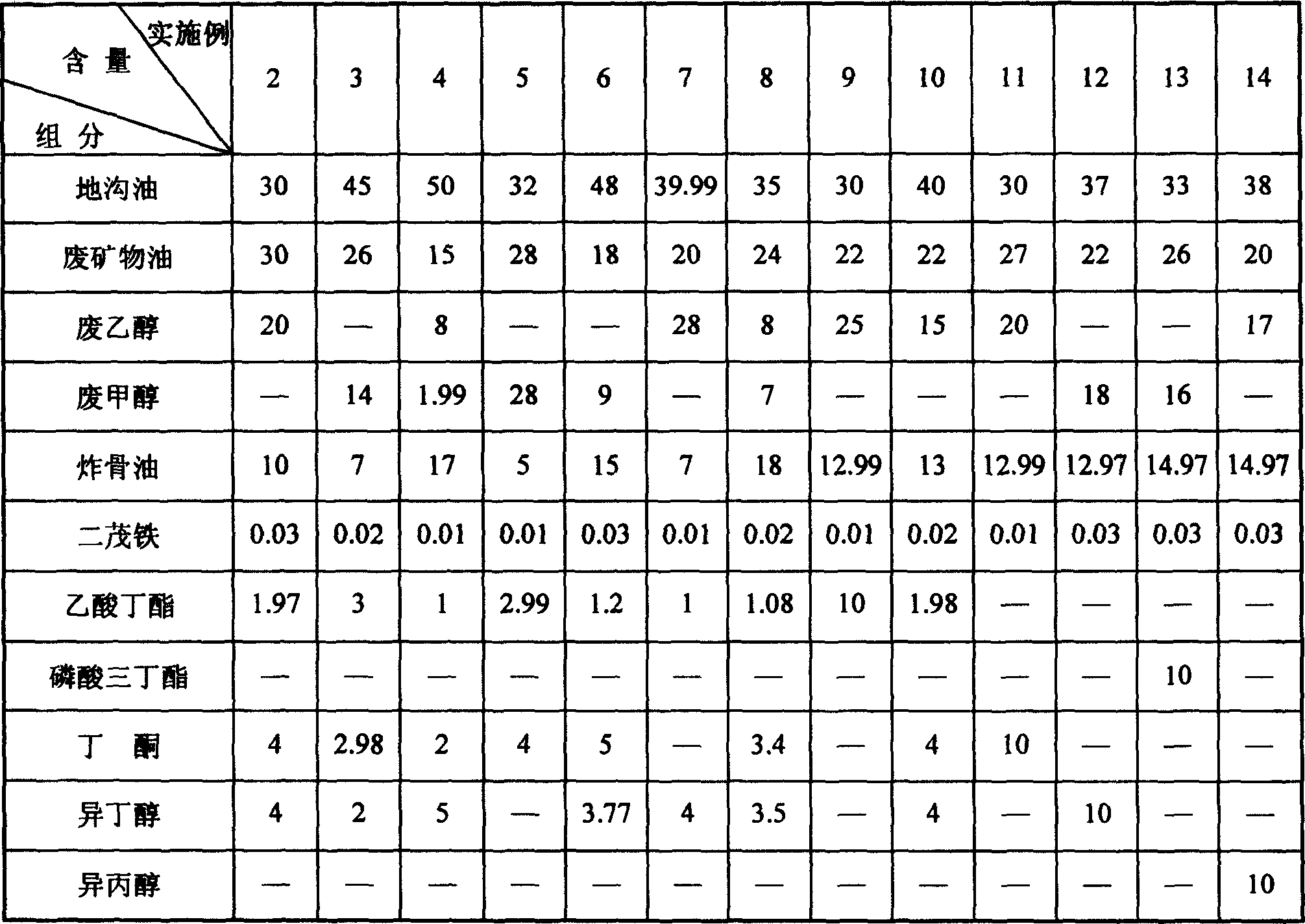

Fuel composition for stove

The invention relates to a furnace use fuel composition, which comprises (by weight percent), trench oil 30-50%, waste mineral oil 15-33%, waste ethanol and / or waste methanol 10-28%, ferrocene 0.01-0.03%, addition agent 5-10%, wherein the addition agent is selected from butanone, lower alcohol or their composition. The invention can provide an industrial or domestic furnace fuel with uniform mixing, ideal thickness, high calorific value, and lower contamination.

Owner:王福成

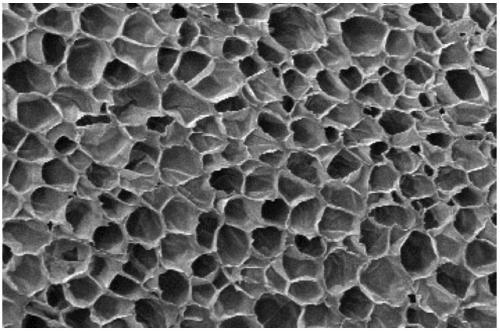

Flame-retardant thermoplastic polyurethane composition and foaming beads thereof

ActiveCN109705563AAdd lessHigh flame retardant efficiencyElectroconductive/antistatic filament manufactureAntistatic agentAntioxidant

The invention provides a flame-retardant thermoplastic polyurethane composition which comprises thermoplastic polyurethane base resin, a flame retardant and an optional antioxidant, wherein the flameretardant comprises a complex formed by phosphine oxide and a transition metal salt. Foaming beads prepared from the thermoplastic polyurethane base resin are dense and uniform in foam pores, and thecompression strength of a prepared foamed bead molded body is very high; meanwhile, when the thermoplastic polyurethane composition provided by the invention is used in cooperation with a specific flame retardant and a specific antistatic agent, the flame retardant and the antistatic agent can generate a synergistic effect, and meanwhile, the flame retardancy and the antistatic property are improved. The foaming beads prepared from the flame-retardant thermoplastic polyurethane composition disclosed by the invention have good low-temperature impact resistance, static resistance, flame resistance, simple and convenient process, high closed pore rate and controllable density.

Owner:CHINA PETROLEUM & CHEM CORP +1

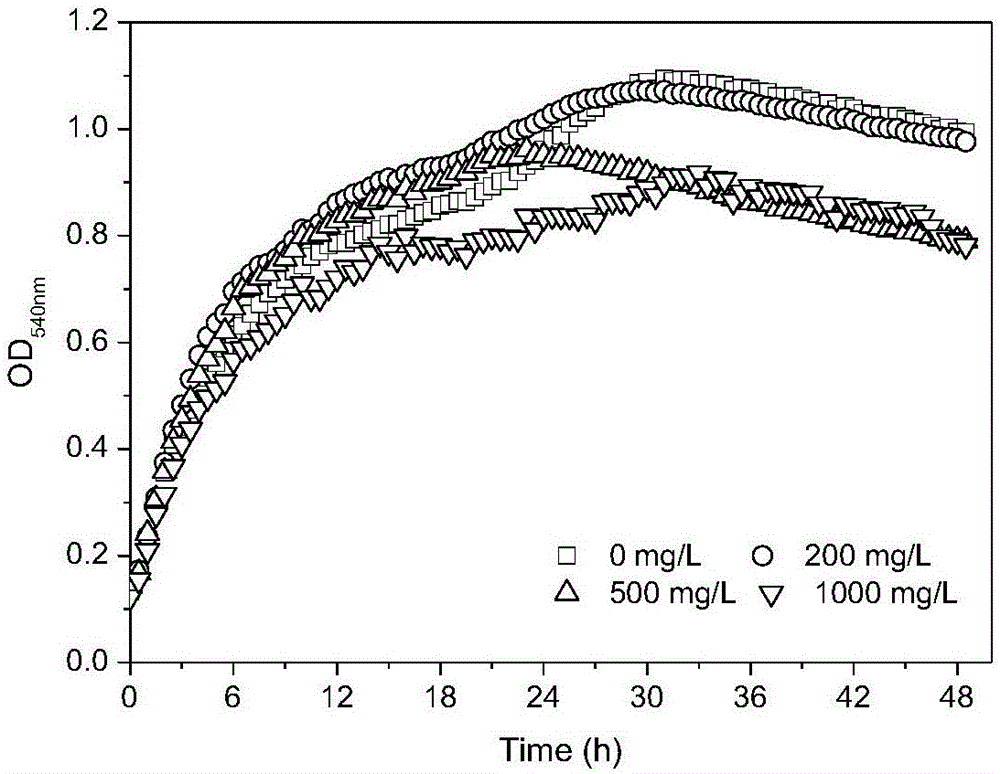

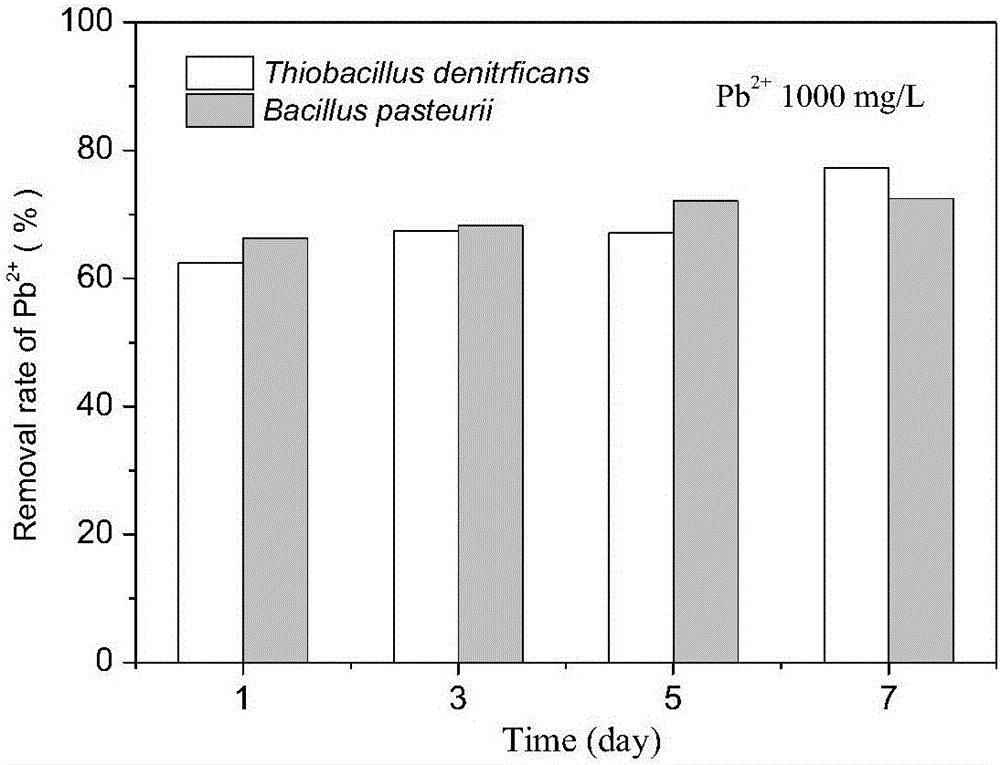

Method for joint treatment of lead ion pollution by using carbonate-mineralization microbe-thiobacillus denitrificans

ActiveCN106269850ATo achieve the purpose of removing heavy metalsImprove removal efficiencyWater contaminantsContaminated soil reclamationThiobacillusAmmonia

The invention discloses a method for joint treatment of lead ion pollution by using carbonate-mineralization microbe-thiobacillus denitrificans. The method includes the steps that nutritional ingredients like fertilizer containing urea and ammonia thiosulfate are applied to soil or a water body; the prepared carbonate-mineralization microbe (0.5*10<8>-5.0*10<8> cfu / mL) is added into the soil or the water body polluted by heavy metal according to the proportion of the soil (0.5-5.0L / m<2>) to the water body being 1:10-1:100; after the carbonate-mineralization microbe is cultivated for 1-5d, the prepared thiobacillus denitrificans with the bacterium concentration being 0.5*10<8>-5.0*10<8> cfu / mL is added according to the volume ratio of the soil (0.5-5.0L / m<2>) to the water body being 1:10-1:100 to be evenly stirred and mixed, and cultivation lasts for 3-15d; and the removal rate of heavy metal Pb2 reaches 83%-99%. The method is low in cost, high in efficiency, easy to implement and broad in application prospect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Flame-retardant polyester composition and foaming beads and plate thereof

ActiveCN109705542AAdd lessHigh flame retardant efficiencyFibre chemical featuresPolyesterAntistatic agent

The invention provides a flame-retardant polyester composition which comprises polyester base resin, a flame retardant and an optional antioxidant, wherein the flame retardant comprises a complex formed by phosphine oxide and a transition metal salt. Foaming beads prepared from the polyester base resin are dense and uniform in foam pores, and the compression strength of a prepared foamed bead molded body is very high; meanwhile, when the polyester composition provided by the invention is used in cooperation with a specific flame retardant and a specific antistatic agent, the flame retardant and the antistatic agent can generate a synergistic effect, and meanwhile, the flame retardancy and the antistatic property are improved. The foaming beads and a plate prepared from the flame-retardantpolyester composition disclosed by the invention have good high-temperature impact resistance, static resistance, flame resistance, simple and convenient process, high closed pore rate and controllable density.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com