Patents

Literature

415results about How to "Improve chemical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

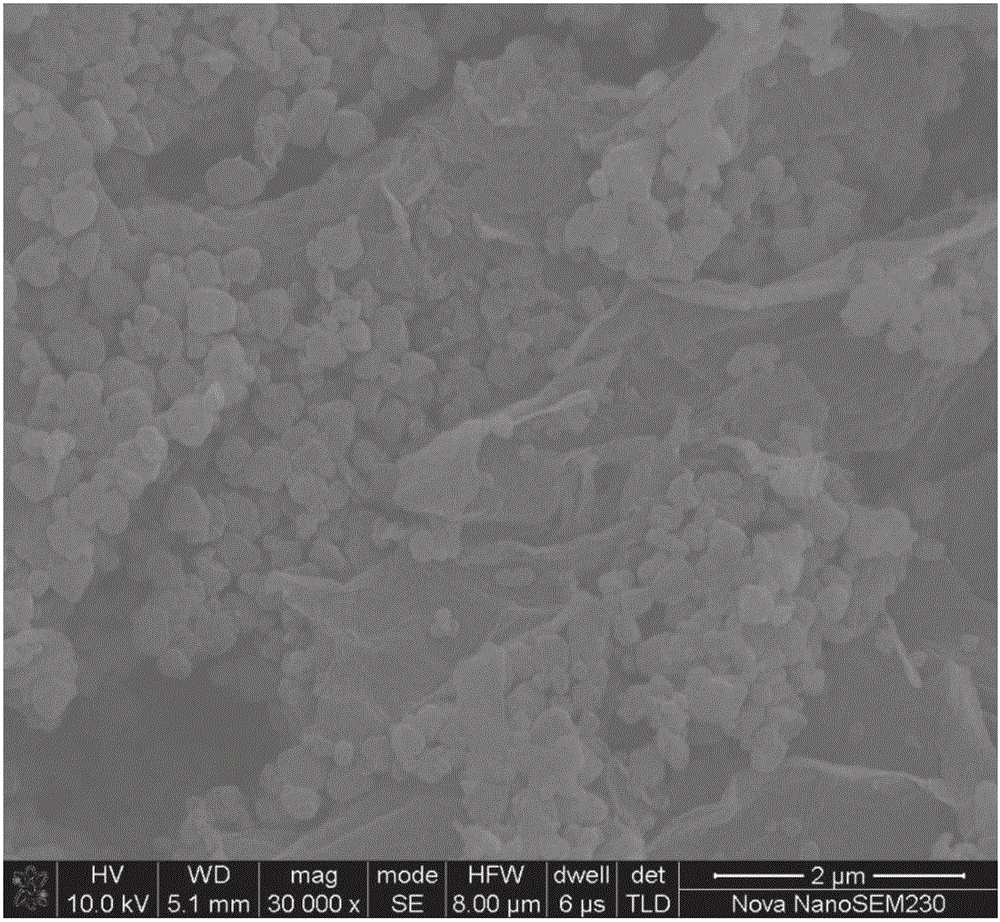

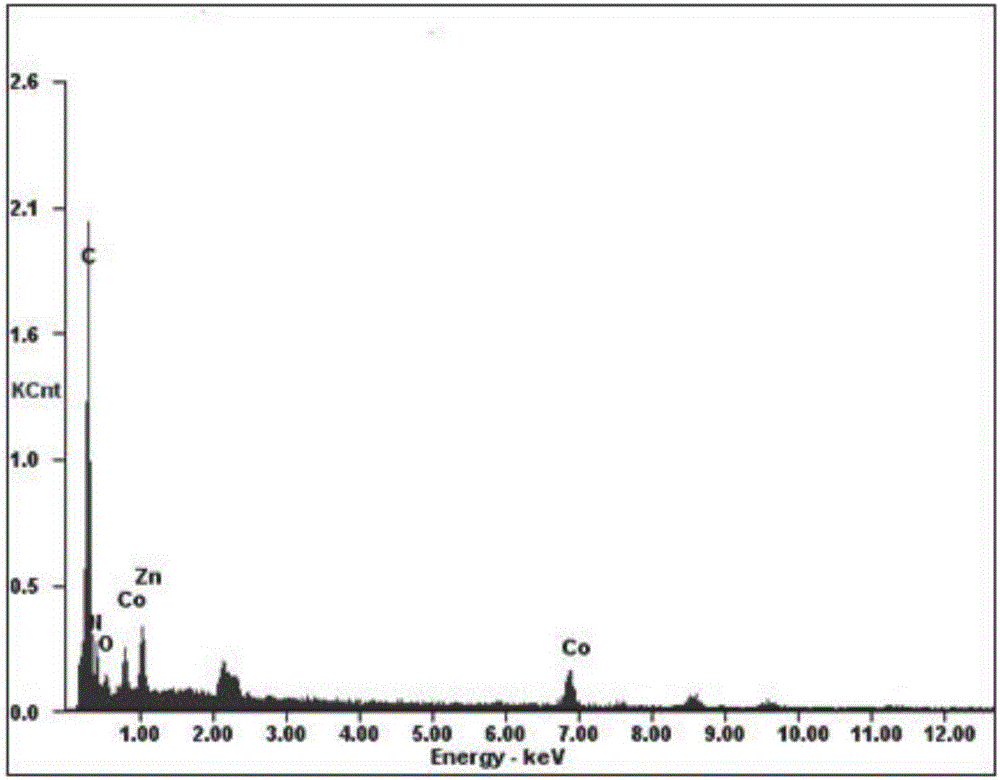

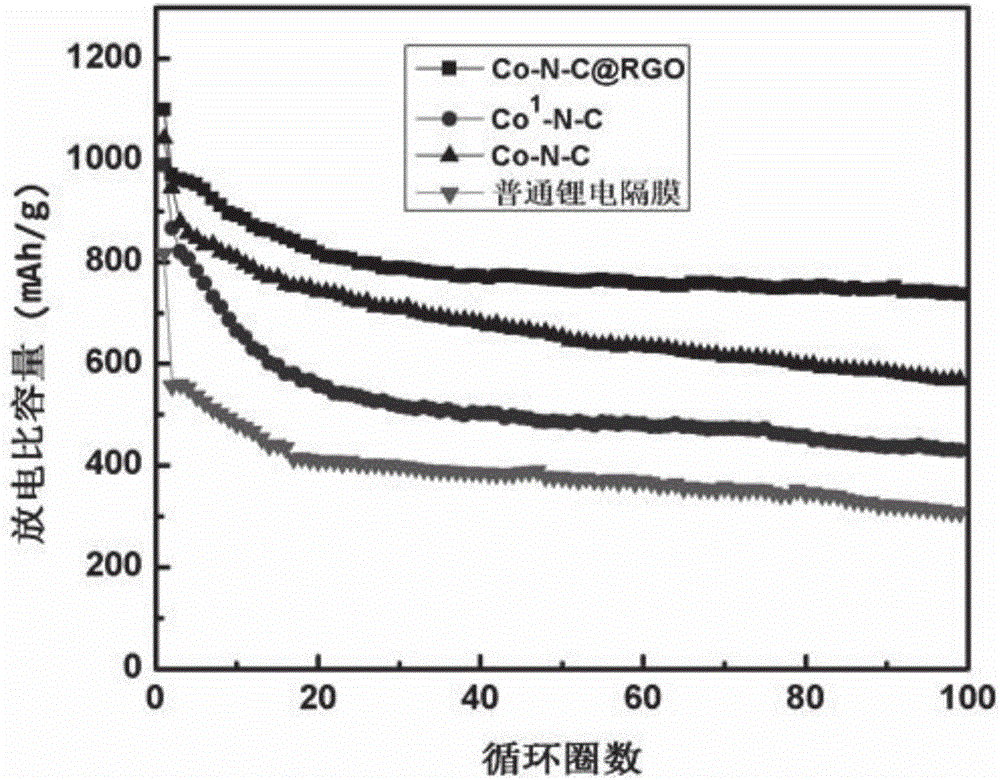

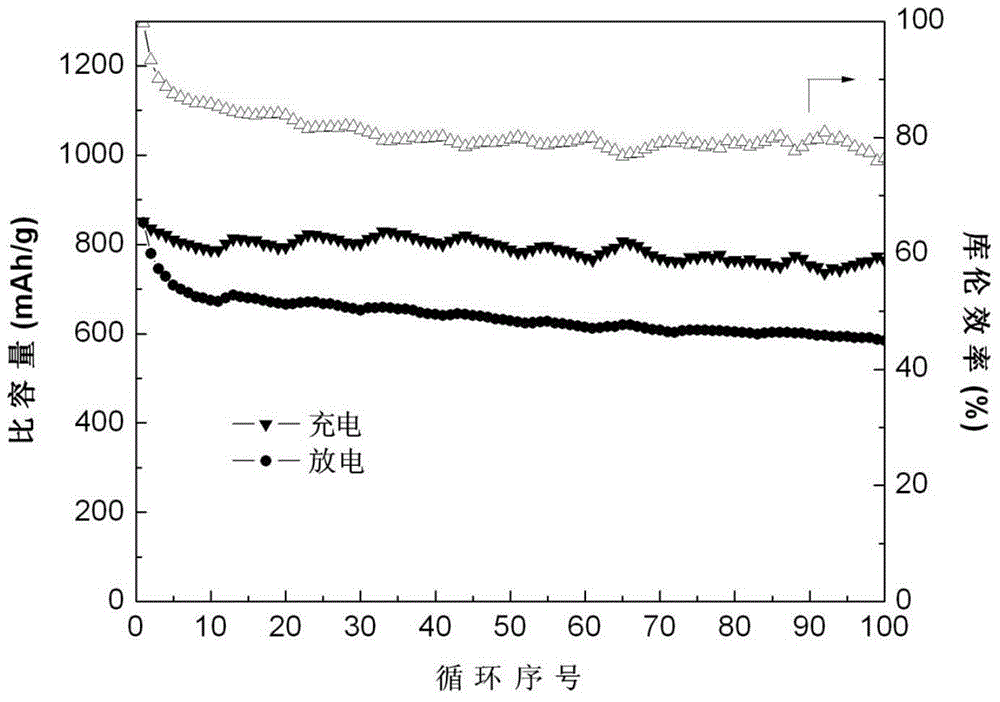

Co-N-C@RGO composite material, preparation method and application to modification of lithium-sulfur battery diaphragms

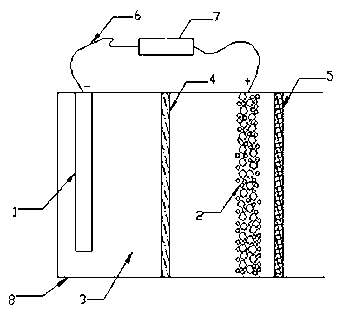

ActiveCN106784525AIncrease the areaHigh porosityLi-accumulatorsCell component detailsPorous carbonElectrical battery

The invention discloses a method for preparing porous carbon@graphene composite material by taking a bimetal organic framework material as a precursor and application to modification of lithium-sulfur battery diaphragms thereof. The preparation method comprises the following steps: taking zinc salt and cobalt salt in a certain ratio as the raw materials, synthesizing a zinc / cobalt-bimetal organic framework@graphene composite material through a room-temperature liquid phase method, taking the zinc / cobalt-bimetal organic framework@graphene composite material as the precursor, carrying out high-temperature reaction under inert atmosphere, pickling and drying to obtain a cobalt / nitrogen double-doped porous carbon@graphene (Co-N-C@RGO) composite material. Co-N-C@RGO has high conductivity; the specific surface area of Co-N-C@RGO reaches up to 750-1000m<2> / g; the content of Co is 2-4At%; the content of N is 10-20At%. When the material is applied to the modification of the lithium-sulfur battery diaphragms, the material has the function of obviously inhibiting polysulfide shuttle effect and is capable of greatly improving actual specific capacity and cyclic performance of the lithium-sulfur batteries; meanwhile, the raw materials needed for synthesizing the material are simple; the operation is convenient; the large-scale production can be achieved; the material has certain promoting effect on commercialization of lithium-sulfur battery systems.

Owner:CENT SOUTH UNIV

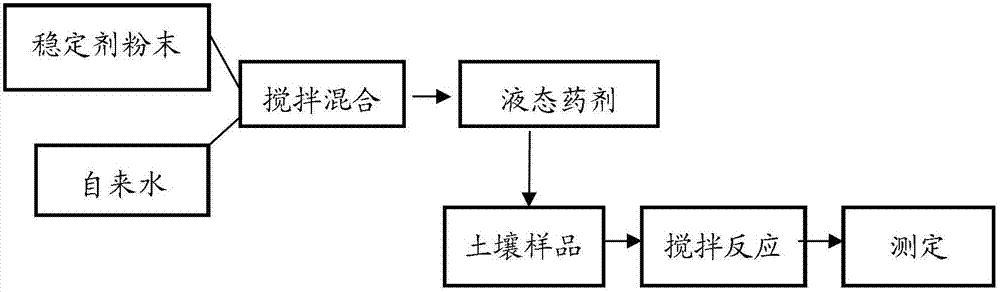

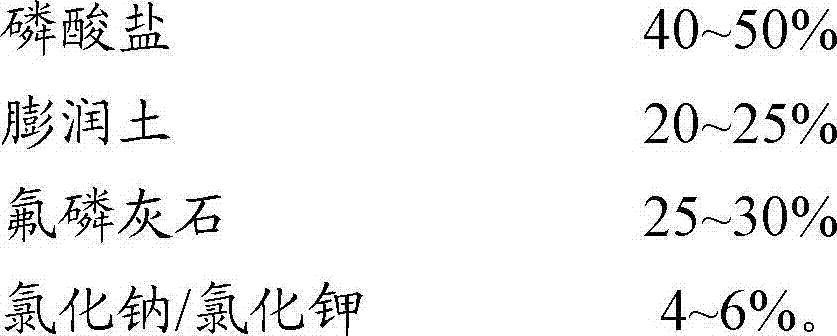

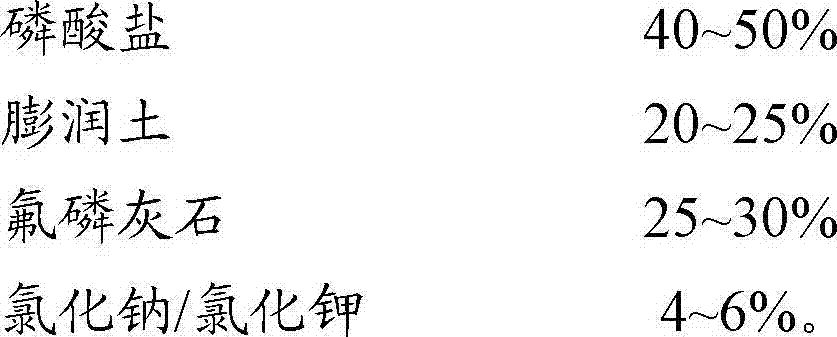

Heavy metal stabilizing agent and method for treating heavy metal contaminated soil by using same

ActiveCN102965116ACaptureHarmlessContaminated soil reclamationOrganic fertilisersSodium BentoniteApatite

The invention discloses a heavy metal stabilizing agent and a method for treating heavy metal contaminated soil by using the heavy metal stabilizing agent. The heavy metal stabilizing agent is prepared from the following raw materials in percentage by weight: 40 to 50 percent of phosphate, 20 to 25 percent of bentonite, 25 to 30 percent of fluor apatite and 4 to 6 percent of sodium chloride / potassium chloride. When the heavy metal stabilizing agent is used for treating the contaminated soil, the heavy metal stabilizing agent and water are mixed together to form a suspension, then the suspension is added into the heavy metal contaminated soil, and the suspension and the heavy metal contaminated soil are fully mixed. The heavy metal stabilizing agent has high stability for treating soil, and the technical problem that the conventional curing agent and curing method cause reverse dissolution easily is solved.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

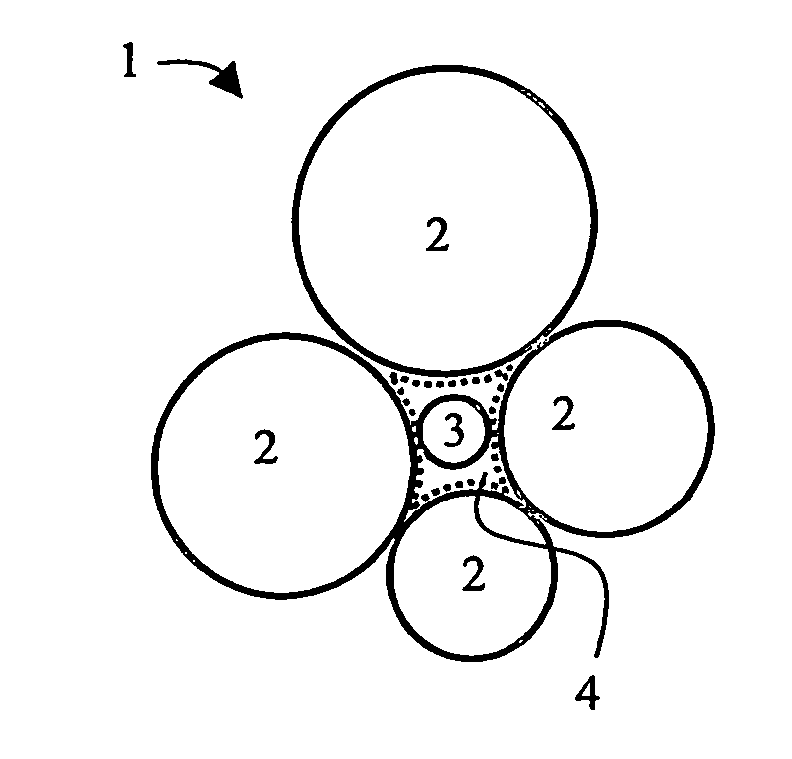

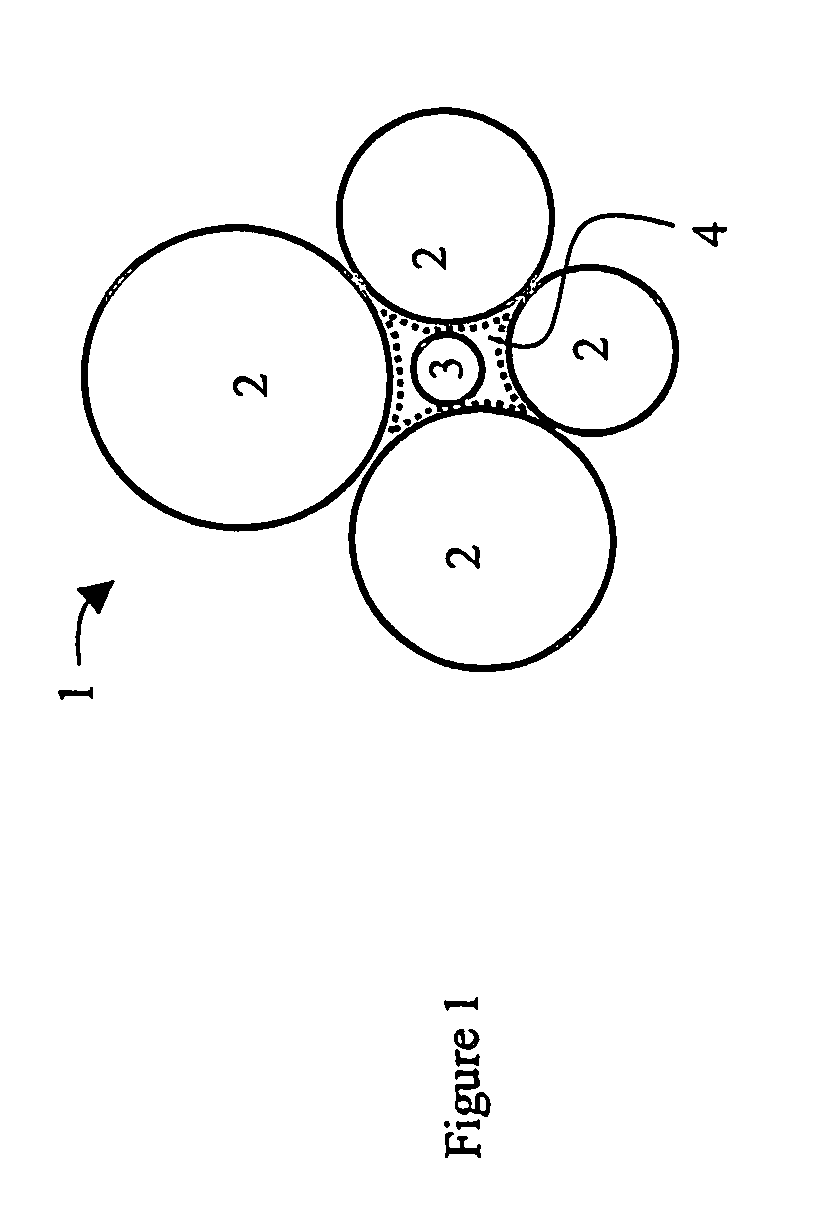

Hydrophobic composites and particulates and applications thereof

InactiveUS20060257643A1Physical improvementImprove chemical performanceSynthetic resin layered productsCellulosic plastic layered productsParticulatesHydrophobe

Novel hydrophobic composites, particularly hydrophobic particulates and free-flowing hydrophobic aggregates and methods utilizing same are disclosed.

Owner:SEALSAND

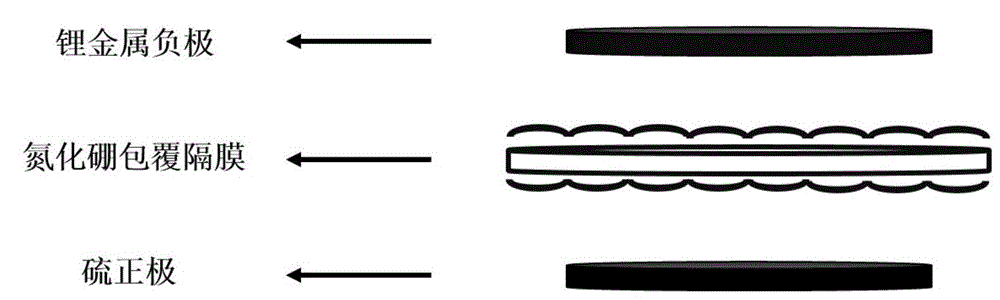

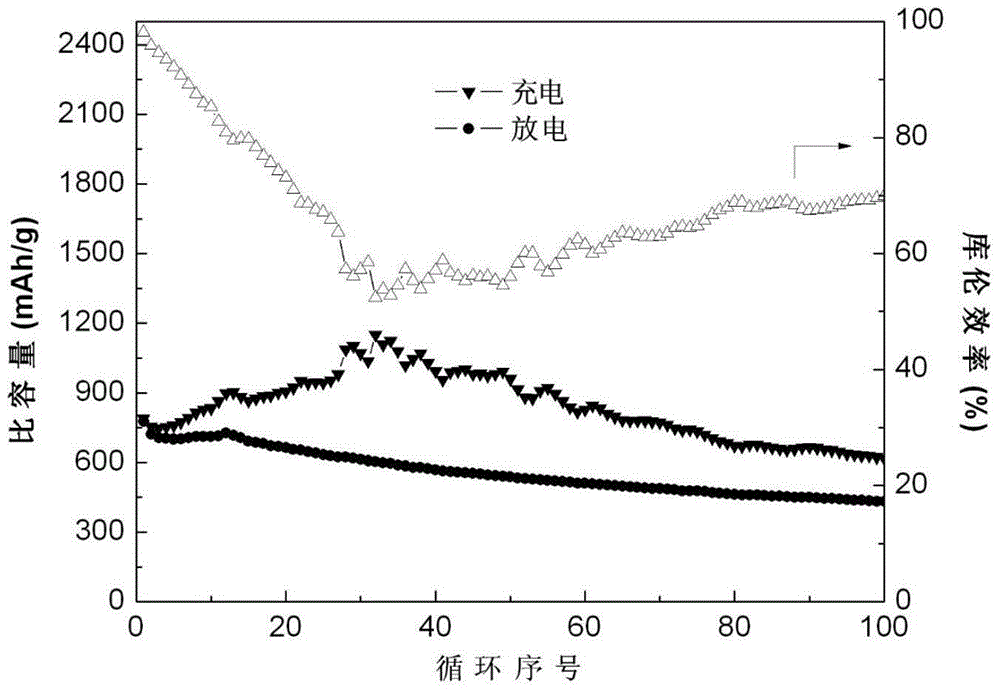

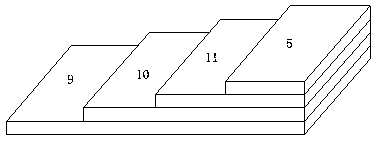

Production method of boron nitride coated diaphragm of lithium-sulfur battery

ActiveCN104993083AIncrease capacityImprove Coulombic efficiencyLi-accumulatorsCell component detailsHexagonal boron nitrideBoron nitride

The invention relates to a production method of a boron nitride coated diaphragm of a lithium-sulfur battery. The diaphragm is produced from a commercial polypropylene diaphragm, two sides of the diaphragm are uniformly covered with hexagonal boron nitride, and the characteristics of hexagonal boron nitride 'white graphite' are used, so lithium ions are allowed to pass, shuttle of polysulfide anions is obstructed, a reaction of a lithium negative electrode with the polysulfide anions is inhibited, formation of lithium dendrites, lithium sulfide precipitate and fixed lithium is prevented, the capacity, the coulombic efficiency and the cycle stability of the lithium-sulfur battery are improved, the growth of the negative electrode metal dendrite in the cycle process is effectively inhibited, and the safety of the battery is improved. The method has the advantages of simple process route and clear purpose, and the produced diaphragm has multiple functions, and can greatly overcome disadvantages of present technologies.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

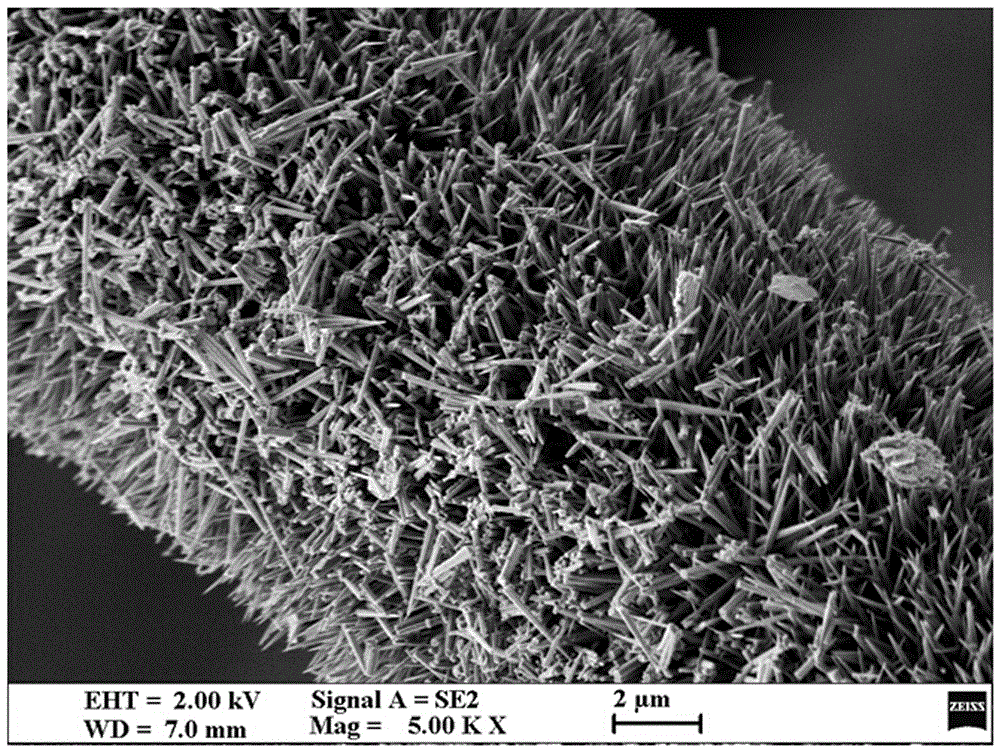

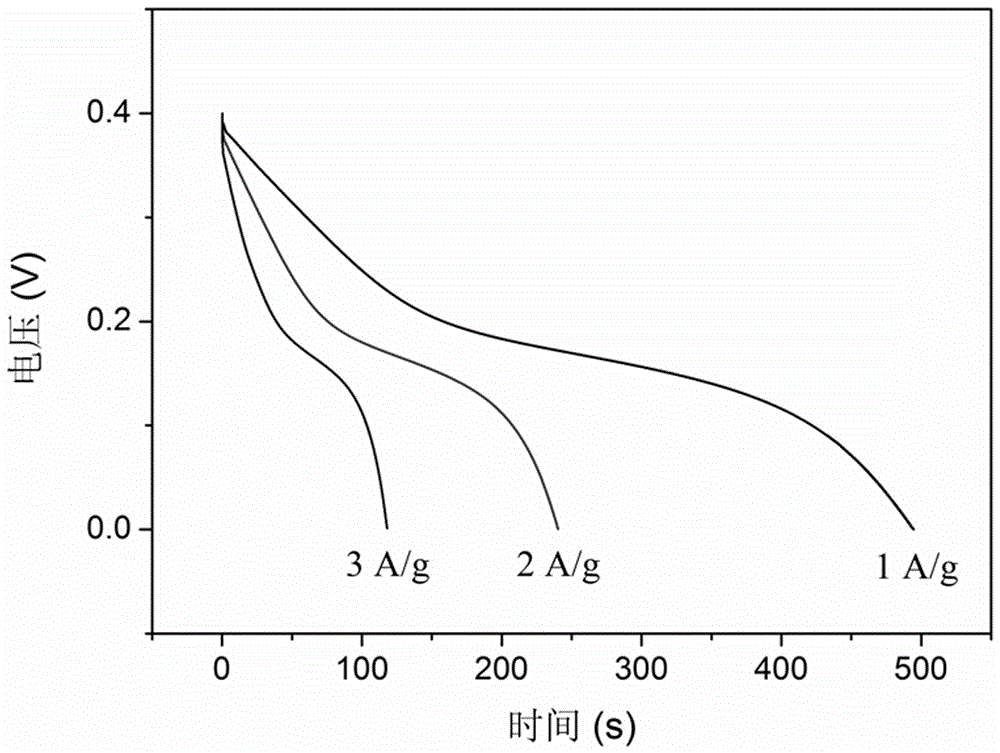

Preparation method and application of NiCo2S4/graphite felt composition electrode material

ActiveCN106206059AStable structureCoated evenlyHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceSolvent

The invention discloses a preparation method and application of a NiCo2S4 / graphite felt composition electrode material. Water and ethyl alcohol serve as solvents, baking soda serves as an alkali source, ammonium fluoride serves as surfactant, cobalt chloride and nickel chloride serve as a cobalt source and a nickel source respectively, and a nickel-cobalt precursor is constructed on pre-oxidized graphite felt through hydrothermal reaction; then thioacetamide serves as a sulfur source, and the needle-shaped NiCo2S4 / graphite felt composition electrode material is prepared through the secondary hydrothermal method. The nickel-cobalt precursor can increase the sulfur loading amount and stabilize appearance of NiCo2S4, ammonium fluoride greatly increases the nucleation rate of NiCo2S4, and accordingly the specific capacitance of the composite material is increased and is as high as 1260-1265 F / g. The prepared NiCo2S4 / graphite felt composition electrode material is good in conductivity and high in specific capacitance, has the mechanical property of softness, and can be used as a supercapacitor electrode material.

Owner:FUZHOU UNIV

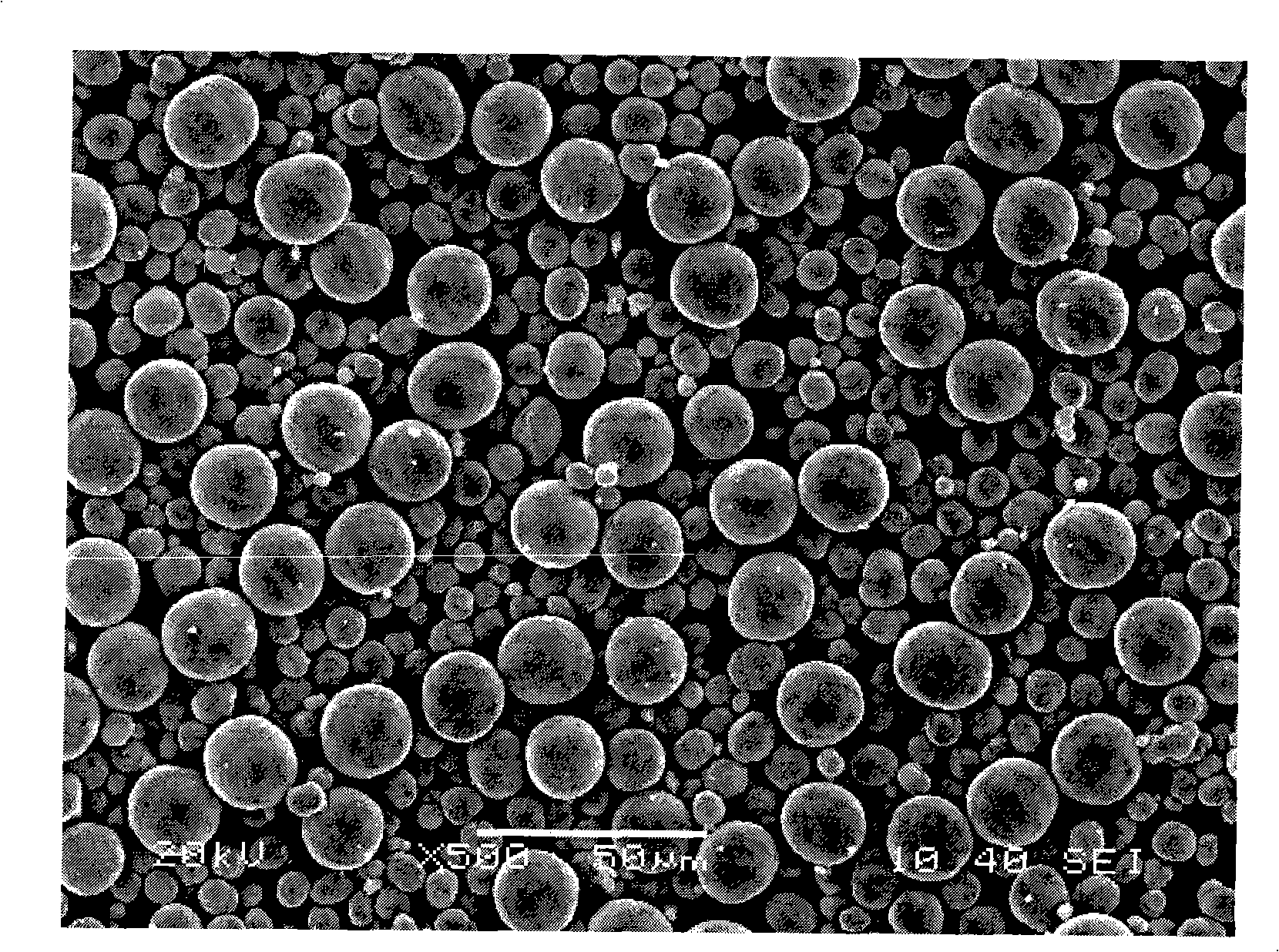

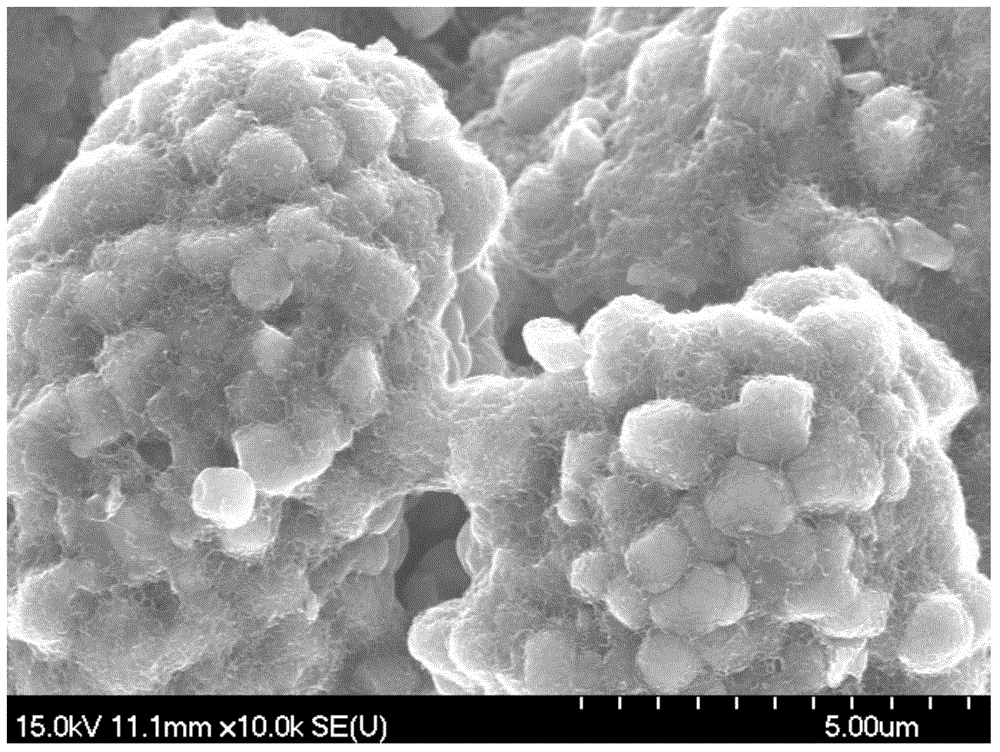

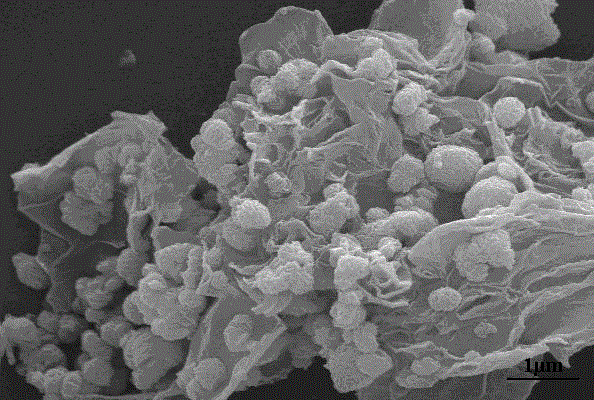

High-density spherical cobaltic-cobaltous oxide and method for preparing the same

InactiveCN101269848AImprove liquidityImprove performanceCobalt oxides/hydroxidesHigh densityCobalt(II,III) oxide

The invention provides a high density spherical shape Co3O4 and a preparation method thereof, and relates to a Co3O4, in particular to the preparation of the high density spherical shape Co3O4, which is mainly used for preparing lithium cobaltoxide of anode material of a lithium ion battery, and also is used as Co3O4 of electronic grade, and belongs to the products of chemical industry. The invention provides a preparation method of the high density spherical shape Co3O4 with good fluidity, the prepared Co3O4 is enabled to be a spherical shape particle which has best stacking density and can effectively improve the tap density of the particle, thereby improving the electrochemistry property of the lithium ion battery and the quality of the lithium ion battery. The Co3O4 prepared by the method is a spherical shape crystal, the mean grain size is 5-25 micrometers, the loose packed density is more than or equal to 1.0g / cm<3>, the tap density is more than or equal to 2.0g / cm<3>, and the cobalt content is more than or equal to 73 percent. The process of the method is simple, and the lithium cobaltoxide synthesized by the Co3O4 presents better property, compared with the past Co3O4, the electrochemistry property of the lithium ion battery can be improved.

Owner:GUANGZHOU RONGJIE MATERIAL TECH

Chemical mechanical polishing solution for large-sized silicon wafers and preparation method thereof

ActiveCN101870852AImprove consistencyReduce hardnessPolishing compositions with abrasivesCompound (substance)Cleansing Agents

The invention relates to a chemical mechanical polishing solution for large-sized silicon wafers and a preparation method thereof, and the chemical mechanical polishing solution is mainly applied to the ultraprecision machining of large-sized semiconductor silicon substrate slices, and can obtain a nanometer-level ultrasmooth surface. The polishing solution consists of the following components inpercentage by weight: 5 to 50 percent of silicon dioxide abrasive, 1 to 10 percent of pH value regulator, 0.01 to 5 percent of surfactant, 0.01 to 0.05 percent of cleaning auxiliary, 0.01 to 2 percent of chelator and the balance of deionized water; and the silicon dioxide is added in the state of silicasol. Under proper polishing technological conditions, the polishing solution prepared with the components according to the contents can obtain a high-quality polished surface and meet the requirement of the semiconductor industry on the surface quality and removal rate of silicon substrate slices, and moreover, the invention has the advantages of low cost, easy cleaning, low corrosiveness and the like, and has a good application prospect.

Owner:BEIJING GRISH HITECH

Porous nano composite abrasive particle containing polishing active elements, polishing solution composition and preparation method thereof

ActiveCN102408871AImprove chemical performanceFast polishingOther chemical processesPolishing compositions with abrasivesCeriumSilicon oxide

The invention relates to a porous nano composite abrasive particle containing polishing active elements, a polishing solution composition and a preparation method thereof. The composite abrasive particle is: a. composite silicon oxide abrasive particle formed by silicon oxide and oxide containing polishing active elements; or b. composite aluminum oxide abrasive particle formed by aluminum oxide and oxide containing polishing active elements. The composite abrasive particle is in a nano pore structure, and can lower the abrasive hardness and reduce the excess collision of the inorganic compact abrasive particle onto the substrate, thereby reducing the polishing damage; the abrasive particle contains iron or copper, cerium, nickel, titanium, silver or any other polishing active element in the aspect of chemical composition, and can enhance the chemical action of the abrasive particle; and the porous structure of the abrasive particle can adsorb and store the polishing solution component to enhance the chemical activity of the abrasive particle. The enhancement of the chemical action can increase the polishing speed of the abrasive particle, and the abrasive particle designed in such a way can simultaneously achieve the goals of high speed and high precision in polishing. When being used for polishing an electronic device, such as a hard disk substrate, the polishing solution provided by the invention can effectively lower the surface roughness of the memory hard disk substrate, and has high polishing speed.

Owner:昆山捷纳电子材料有限公司

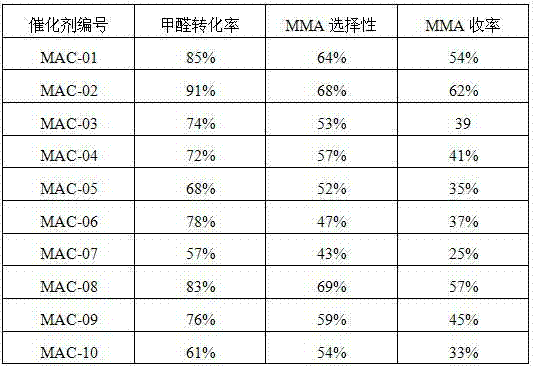

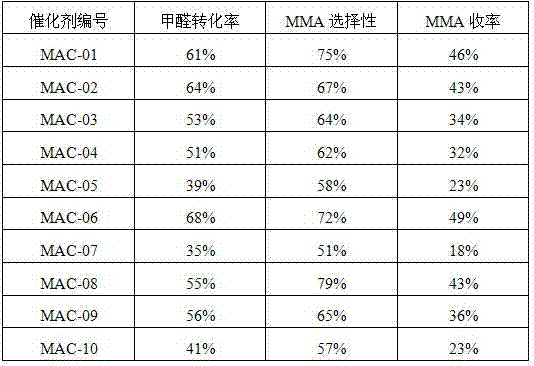

Catalyst for synthesis of methyl methacrylate by formaldehyde and methyl propionate and preparation method of catalyst

ActiveCN102962062ALarge specific surface areaImprove physicsOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses a catalyst for synthesis of methyl methacrylate by formaldehyde and methyl propionate and a preparation method of the catalyst. The catalyst mainly comprises a main active component, an activated auxiliary and a carrier, wherein the main active component is Cs, the activated auxiliary is selected from one or more of Sb, Nb and Ag, and the carrier is a nanometer SiO2 / Al2O3-ZrO2 composite carrier; and metered by oxides and according to mass percentage, the main active component Cs accounts for 5%-20%, the activated auxiliary accounts for 1%-5%, and the balance is the carrier. Simultaneously, the invention discloses a preparation method of the catalyst. The catalyst provided by the invention is good in activity, selectivity and stability, simple in manufacture technology, suitable for large-scale industrialized application and environment-friendly.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Polishing liquid for grinding and polishing lithium niobate optical wafer

InactiveCN1858131AEasy to break awayIncrease viscosityOptical surface grinding machinesAqueous dispersionsLithiumLiquid viscosity

The present invention discloses polishing liquid for grinding and polishing optical lithium niobate wafer. The polishing liquid consists of silica sol 30-90 vol%, organic amine alkali 1-10 vol%, inorganic alkali 1-5 vol%, activator 0.5-5 vol%, chelating agent FA / O 0.5-5 vol%, and deionized water for the rest. Under CMP and high pH condition, lithium is formed into stable complex and water soluble niobate to raise polishing efficiency and surface quality. The present invention has organic alkali and lithium niobate surface matter to form soluble amine salt easy to separate from the reaction surface, and this avoids the increase in the abrasive granularity and polishing liquid viscosity to ensure no scoring, high flatness and no adsorbate.

Owner:HEBEI UNIV OF TECH

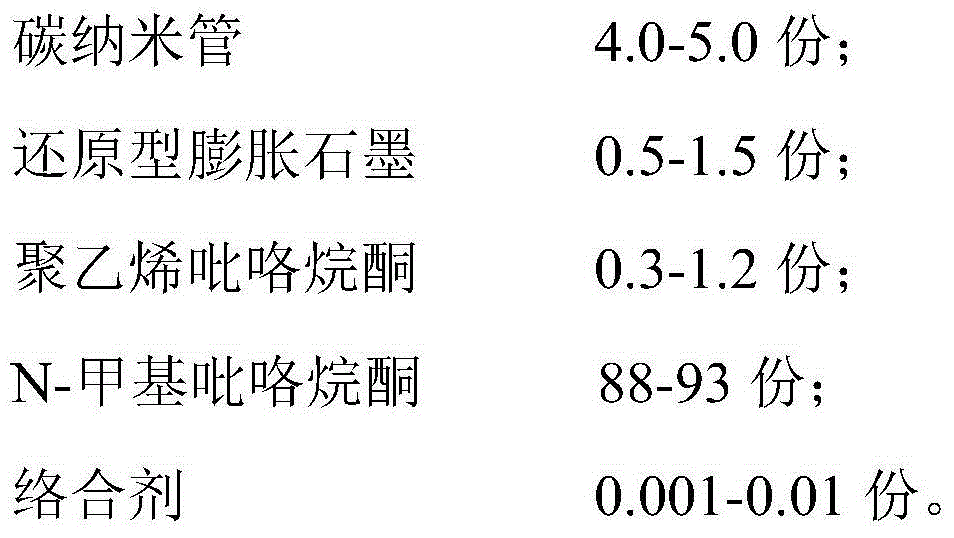

Composite conductive paste for anodes and cathodes of lithium ion batteries as well as preparation method for composite conductive paste

ActiveCN104795570AImprove chemical performanceLarge capacityElectrode manufacturing processesSecondary cellsHigh energySodium-ion battery

The invention belongs to the technical field of lithium ion batteries, and provides composite conductive paste for anodes and cathodes of the lithium ion batteries as well as a preparation method for the composite conductive paste. The composite conductive paste comprises the following ingredients in parts by weight: 4.0-5.0 parts of carbon nanotubes, 0.5-1.5 parts of reduced expanded graphite, 0.3-1.2 parts of polyvinylpyrrolidone, 88-93 parts of N-methyl pyrrolidone and 0.001-0.01 part of a complexing agent. The composite conductive paste can be combined with active substances to form a favorable conductive network, so that the lithium ion batteries have such electrochemical properties as long cycle life and high energy density.

Owner:卡博特高性能材料(珠海)有限公司

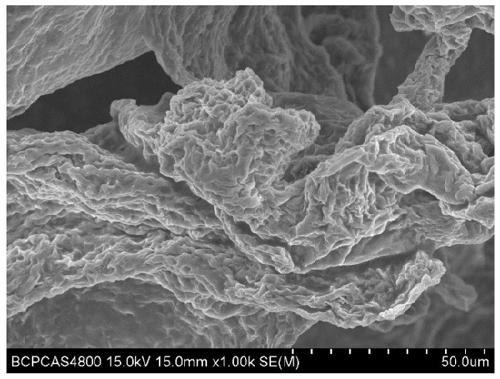

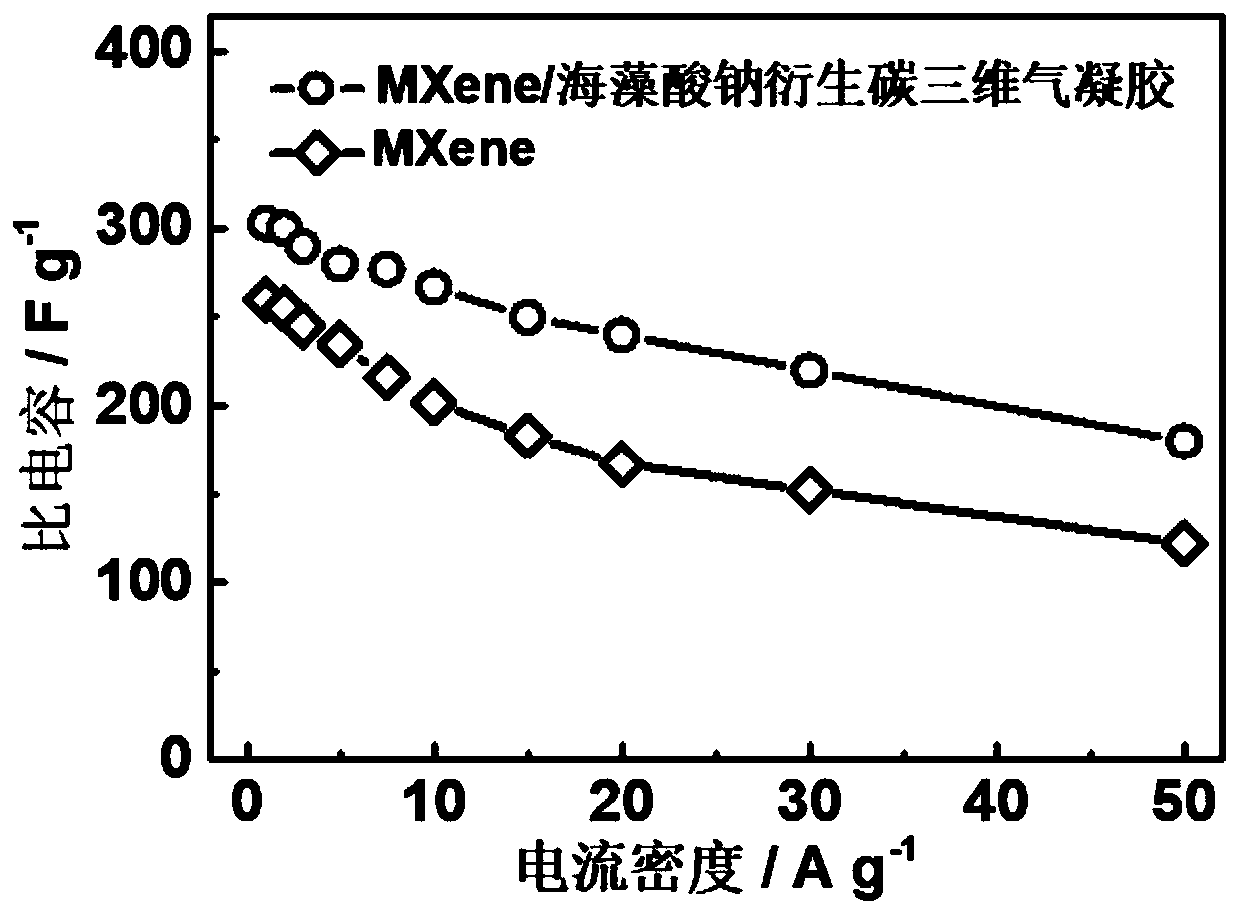

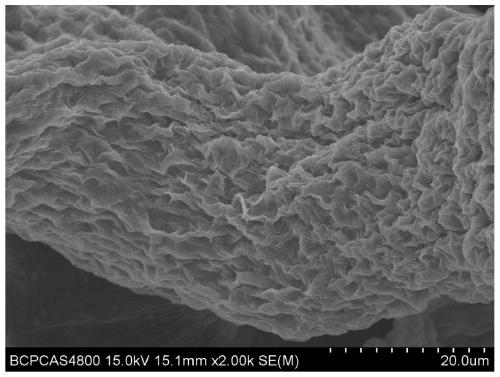

MXene/sodium alginate derived carbon three-dimensional aerogel as well as preparation method and application thereof

ActiveCN111422873AAvoid stackingImprove electrochemical performanceMaterial nanotechnologyHybrid capacitor electrodesFluid phaseSupercapacitor

The invention provides MXene / sodium alginate derived carbon three-dimensional aerogel as well as a preparation method and application thereof. The preparation method of the MXene / sodium alginate derived carbon three-dimensional aerogel, provided by the invention, comprises the following steps: carrying out liquid-phase mixing on an MXene dispersion liquid and a sodium alginate aqueous solution toobtain an MXene / sodium alginate mixed solution; adding a calcium chloride solution into the MXene / sodium alginate mixed solution, and gelatinizing sodium alginate to obtain MXene / sodium alginate hydrogel; carbonizing sodium alginate through high-temperature treatment, and then washing with 1-3mol / L hydrochloric acid and deionized water to obtain the MXene / sodium alginate derived carbon three-dimensional aerogel material. The MXene / sodium alginate derived carbon three-dimensional aerogel material provided by the invention has good electrochemical performance when used in the field of supercapacitors.

Owner:BEIJING UNIV OF CHEM TECH

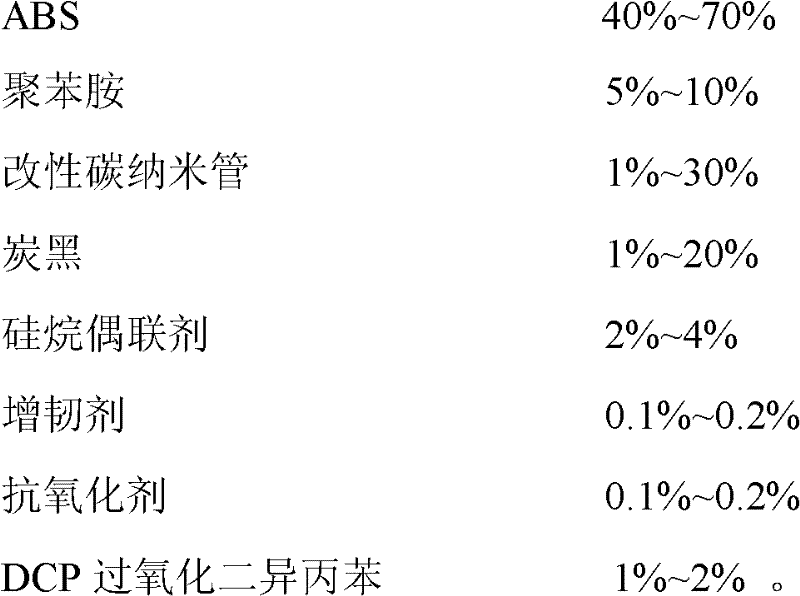

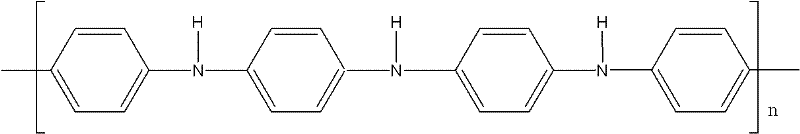

A new type of antistatic ABS resin material and preparation method thereof

ActiveCN102268171AImprove mechanical propertiesImprove chemical performanceOther chemical processesModified carbonOmega

The invention discloses a novel antistatic ABS (Acrylonitrile Butadiene Styrene) resin material and a preparation method thereof. The antistatic ABS resin material comprises the following components in percentage by weight: 40-70 percent of ABS, 5-10 percent of polyaniline, 1-30 percent of modified carbon nanotube, 1-20 percent of carbon black, 2-4 percent of silane coupling agent, 0.1-0.2 percent of toughener, 0.1-0.2 percent of anti-oxidant and 1-2 percent of DCP (Dicumyl Peroxide). The antistatic ABS resin material has the advantages of permanent antistatic property, good effect, high mechanical property, high processability, good application prospect and good comprehensive performance; the surface resistance of the ABS resin can be lowered to 105 omega.centimeter or lower; a permanentantistatic material can be obtained; the used raw materials do not have toxic or side effects; and the method is safe to operate, and has a simple and practical process.

Owner:5ELEM HI TECH CORP

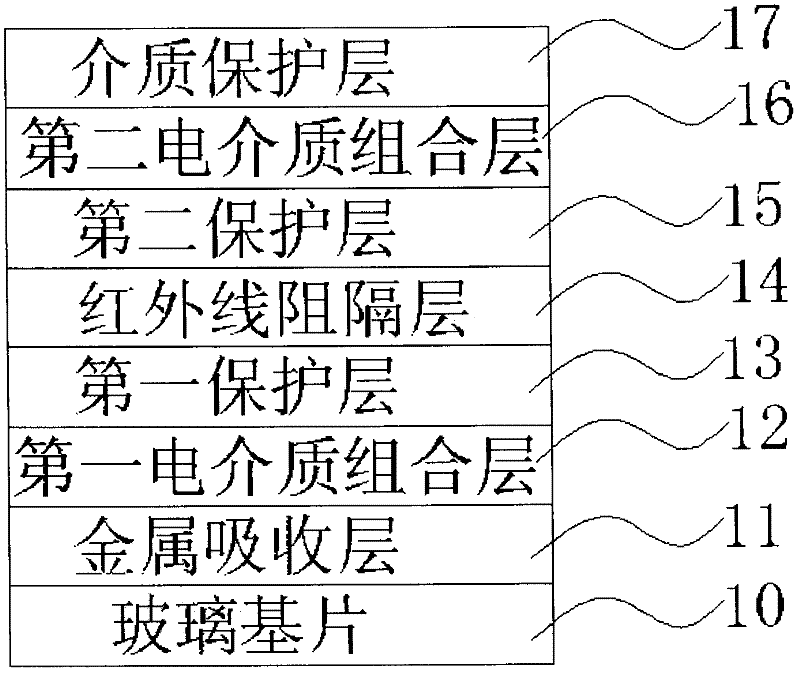

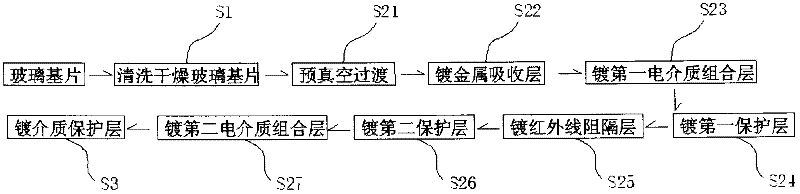

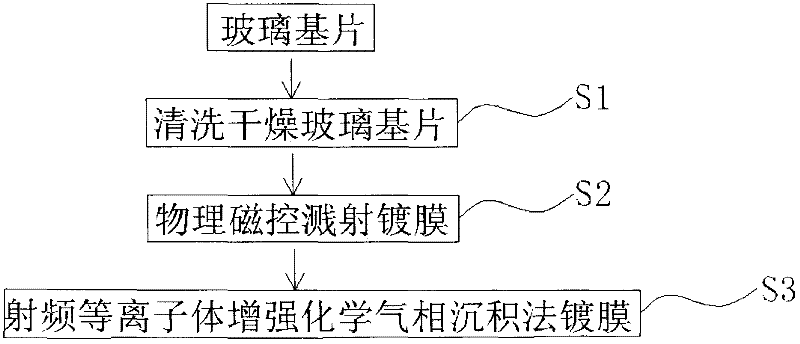

Enhanced protection type toughened low-radiation coated glass and manufacturing process thereof

InactiveCN102529209APromote absorptionReduce reflectionVacuum evaporation coatingSputtering coatingLight pollutionOptical transmittance

A medium protecting layer is added to the outermost layer of ordinary low-radiation coated glass to serve as an enhanced protecting layer so that the ordinary low-radiation coated glass has high chemical stability, abrasion resistance and oxidation resistance and low friction coefficient and particularly improves scratch resistance, toughened low-radiation coated glass is convenient and simple to transport and process, and the finished product rate of production is greatly improved. In particular, the lowered processing requirements enable more small glass deep-processing enterprises to produce the low-radiation coated glass, and a foundation is established for popularization of environment-friendly energy-saving products. In addition, a metal absorbing layer is first coated on the glass, reflectivity of coated products can be greatly reduced, the problem of light pollution of the toughened low-radiation coated glass with low light transmittance is solved, and the toughened low-radiation coated glass products can meet the requirements of the market at present.

Owner:林嘉宏

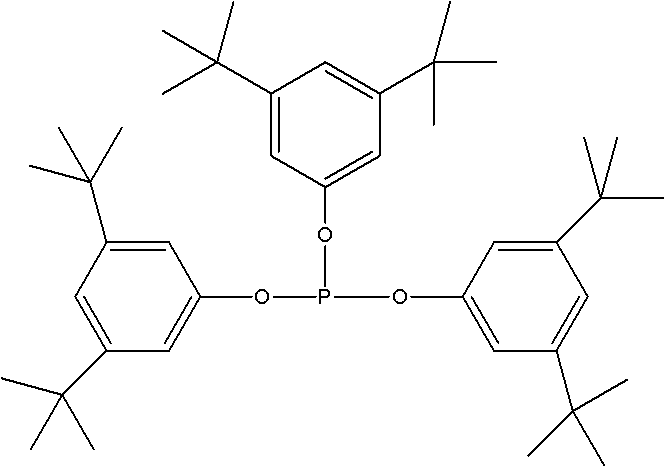

PET(PETG) (poly(ethylene terephthalate)(polyethylene terephthalate glycol)) tackifying and toughening agent

InactiveCN104086956ASimple manufacturing processEasy to implementPolyethylene terephthalate glycolAntioxidant

The invention discloses a PET(PETG) (poly(ethylene terephthalate)(polyethylene terephthalate glycol)) tackifying and toughening agent. The PET(PETG) tackifying and toughening agent comprises the following components in parts by weight: 10-40 part of PET particles, 1-10 parts of SEBS (hydrogenated styrene-butylenes-styrene), 10-40 parts of liquid toughening agent, 10-30 parts of liquid brightening agent, 0.2-0.8 part of antioxidant, 0.1-1.0 part of heat stabilizer, 0.1-1.0 part of chain extender and 2-4 parts of talcum powder. The PET(PETG) tackifying and toughening agent provided by the invention has the advantages that a preparation technology is simple and can be easily realized, production efficiency is high, the PET(PETG) tackifying and toughening agent can be applied to a raw material and also can be applied to a return material, the problem that a chain extender can be applied to the PET return material only is solved, and effect is much better compared with the chain extender; the PET(PETG) tackifying and toughening agent is directly crosslinked with molecules, so that viscosity and physical and chemical properties are improved.

Owner:SHENZHEN XIN HENGLI SCI & TECH LIMITED

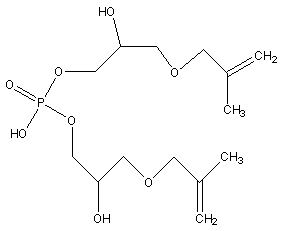

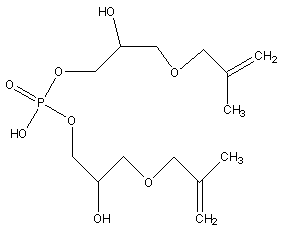

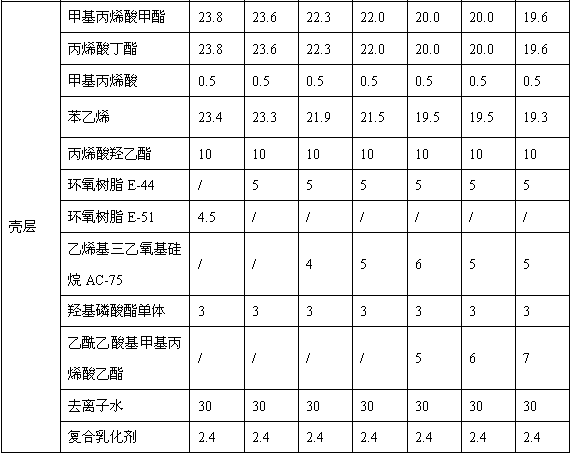

Room temperature crosslinkage and curable styrene-acrylate emulsion, and its preparation method

ActiveCN103130948AImprove corrosion resistanceImprove mechanical propertiesAnti-corrosive paintsEpoxy resin coatingsSolventChemistry

The invention discloses a room temperature crosslinkable and curable styrene-acrylate emulsion, and its preparation method. The styrene-acrylate emulsion adopts a non-APEO emulsifier to emulsify, proper amounts of phosphate groups, hydroxy groups, siloxane groups, epoxide groups and acetylacetoxy groups are introduced to a system to make the adhesion of a film of a styrene-acrylate emulsion anti-corrosion coating reach first order, and the coating cures at 25DEG C for 6 days to form the film, so the salt mist resistance is not less than 240h, the impact resistance is 50Kg / cm, and excellent anti-corrosion performance and mechanical performances are possessed; and the substitution of traditional organic solvents by a water solvent reduces the VOC discharge, accords with a 8E' principle, and reaches environmental protection and energy saving purposes.

Owner:广东优贝精细化工有限公司

High-energy-density Li-air battery air electrode, and battery and making method thereof

ActiveCN103280586AEffective protectionImprove catalytic reaction efficiencyCell electrodesMetallic lithiumHigh energy

The invention belongs to the chemical power supply field, and concretely relates to a high-energy-density Li-air battery air electrode, and a battery and a making method thereof. The air battery is a non-aqueous chargeable Li-air (or Li / O2) battery concretely, and comprises a lithium metal negative electrode, a non-aqueous electrolyte, a diaphragm and the air electrode, the air electrode comprises a catalyst, a carrier and a binder, and the carrier is a composite double pore system material composed of nano-graphene having a two-dimensional nanostructure, a high heat conduction coefficient (-5000W / m.k), a high specific surface area (-2630m<2> / g) and a high electrical conductivity (10<3>-10<4>Sm<-1> and an SiO2 aerogel, provides a circulation channel and a storage space for O2 and discharge reaction products respectively, and adopts a double-surface electrode structure; and the non-aqueous electrolyte adopts a lithium salt and organic solvent mixed electrolyte, and has the advantages of high electrical conduction, low volatility, good chemical stability and the like. The oxygen-selective diaphragm is added to the air battery to increase the pressure of O2 in a reaction area and prevent water in air from entering the battery, so the metallic lithium is effectively protected, and the safety of the battery is increased.

Owner:深圳市集创云天新材料有限公司

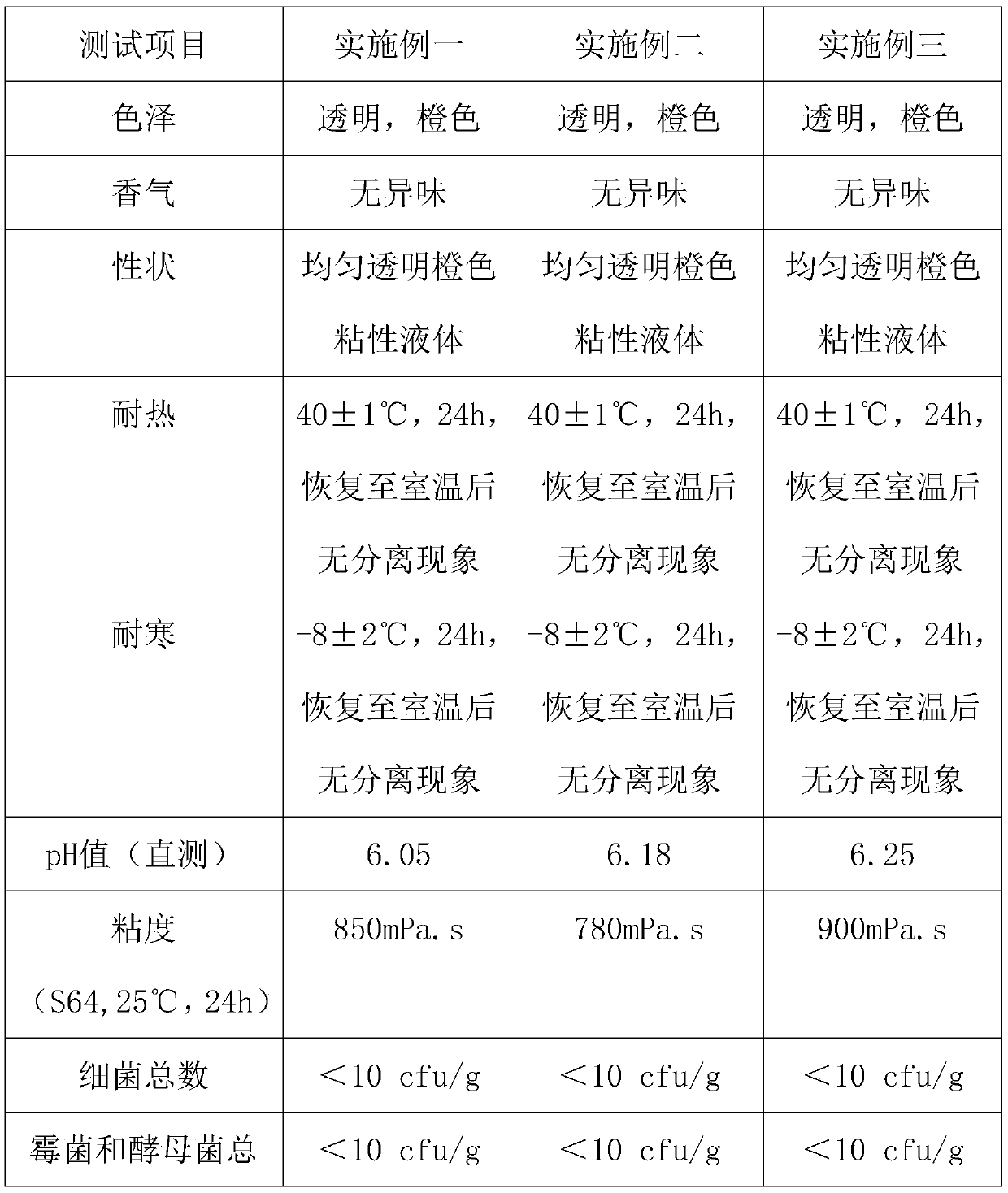

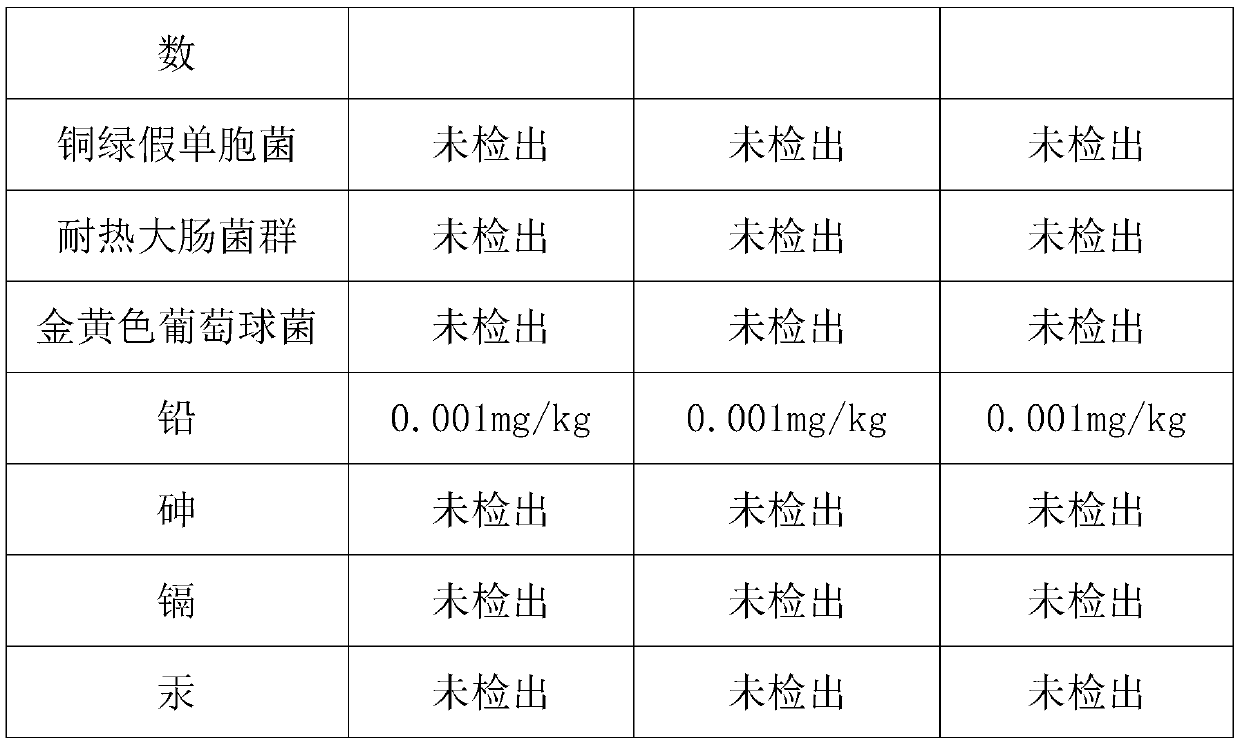

Whitening and spot-removing facial mask containing coenzyme Q10, and preparation method of whitening and spot-removing facial mask

InactiveCN111568792AImprove immunityImprove permeabilityCosmetic preparationsToilet preparationsSilanesGlycerol

The invention discloses a whitening and spot-removing facial mask containing coenzyme Q10, and a preparation method of the whitening and spot-removing facial mask. The whitening and spot-removing facial mask containing coenzyme Q10 comprises the following ingredients: disodium EDTA, allantoin, panthenol, bis-PEG-18 methyl ether dimethyl silane, a thickener, sodium hyaluronate, sodium polyglutamate, a polyol, acetyl chitin, hydroxyethylpiperazine ethane sulfonic acid, alpha-arbutin, beta-dextran, glycerin polyether-26, a PEG / PPG-17 / 6 copolymer, carboxymethyl chitosan, biosaccharide gum-1, hydroxylated lecithin, hydroxyethyl urea, a nano whitening and spot-removing agent, a nano coenzyme Q10 emulsion, an anti-sensitive soothing agent, an antiseptic and antibacterial agent, and purified water. The whitening and spot-removing facial mask containing coenzyme Q10 has excellent stability and skin compatibility, has obvious whitening and spot-removing effects, is mild to the skin, and has broad application prospects.

Owner:帅发(厦门)投资有限公司

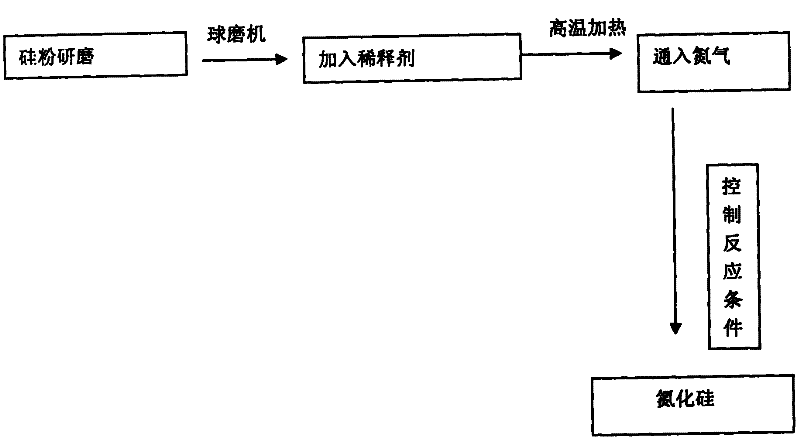

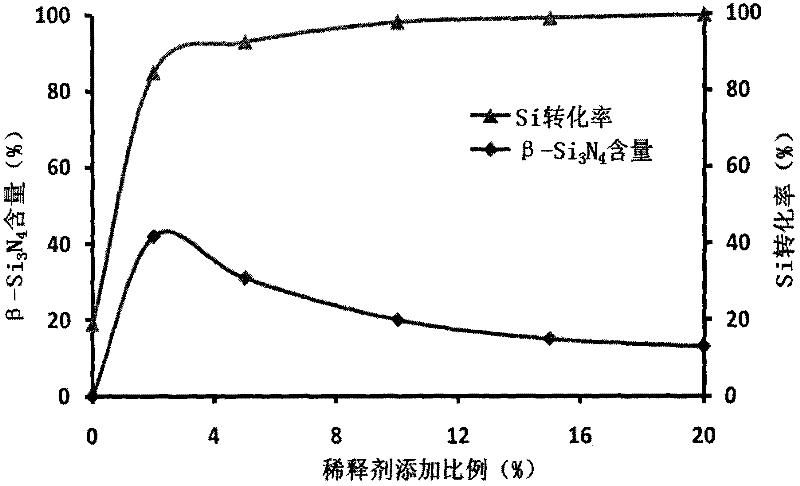

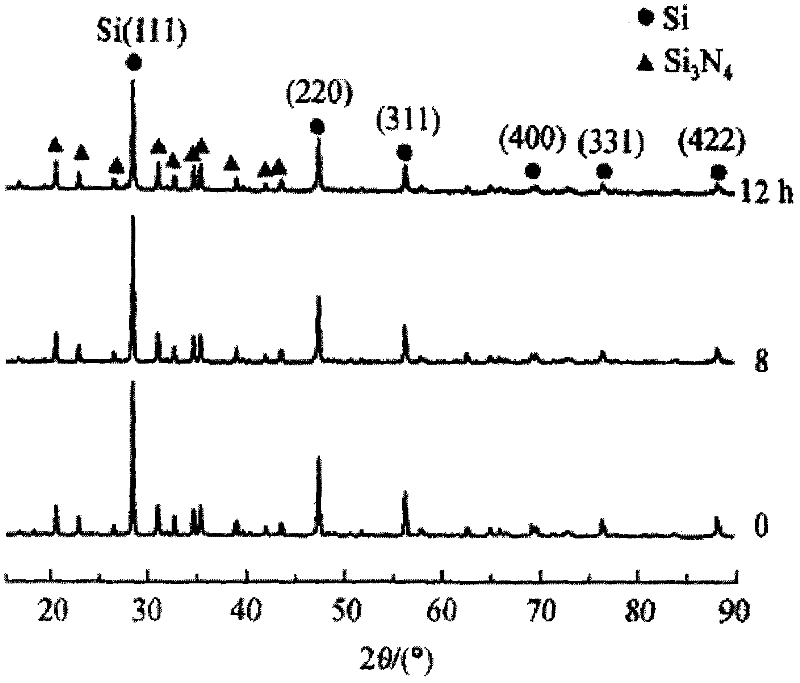

Production method of high-content alpha-crystal form silicon nitride powders

InactiveCN102173396ASmall granularityImprove defectsNitrogen compoundsChemical industryInorganic ChemicalSolid reaction

The invention discloses a production method of silicon nitride powders, in particular relates to a novel production method of silicon nitride powders with high content of alpha-Si3N4, and belongs to the technical field of inorganic chemistry. The method comprises the following steps: firstly pre-treating powdery raw materials by mechanical activation, and feeding a mixed diluting agent of alpha-Si3N4 and non-crystalline Si3N4 during the direct nitridation of silicon powders at a high temperature under normal pressure. By controlling the addition ratio of the diluting agent and the nitridation time and temperature, the silicon nitride powders with high content of alpha-Si3N4 are synthesized. The process improves the activity of solid-phase reactants, promotes the reaction between Si and N2, does not need high-temperature and high-pressure conditions, is easy to operate, adopts easily-available raw materials, increases the purity of products, has a low coat and a high efficiency, and is environment-friendly and energy-saving. The process is economical and highly-efficient and suitable for large-scale production.

Owner:GONGYI CITY HONGTAI SILICON NITRIDE MATERIAL

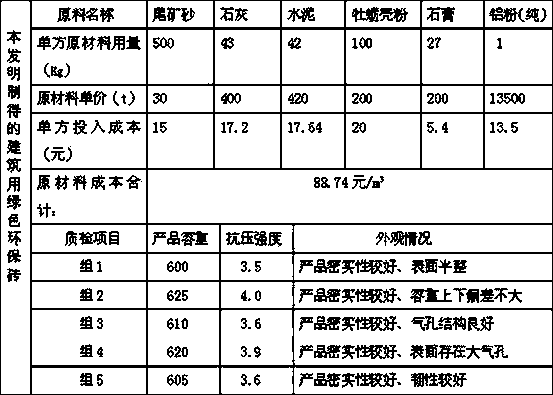

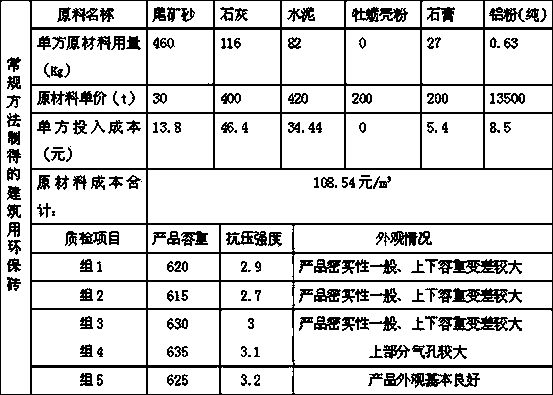

Green and environment-friendly brick for building and making technology thereof

The invention discloses a green and environment-friendly brick for building and a new technology production mode for preparation of the green and environment-friendly brick for building, and the green and environment-friendly brick for building uses calcined oyster shell powder to replace part of expensive building raw materials such as lime, cement and the like. Compressive strength and dry density and other technical parameter requirements of a product are ensured, meanwhile mixing amounts of the cement and the lime are reduced, the production cost is reduced, the oyster shell powder is mixed for mixed grinding with tailing sand to prepare good-performance mortar, so that a tailing sand early-stage processing technology requires that the fineness needs to increase from 0.08 mm-sieve screen residue weight of 30% to 60%, the tailing sand processing time and processing power consumption are reduced, the energy is saved, oyster shell produced by coastal oyster breeding is effectively used and duly processed, and the environment is improved.

Owner:东山县金石混凝土有限公司

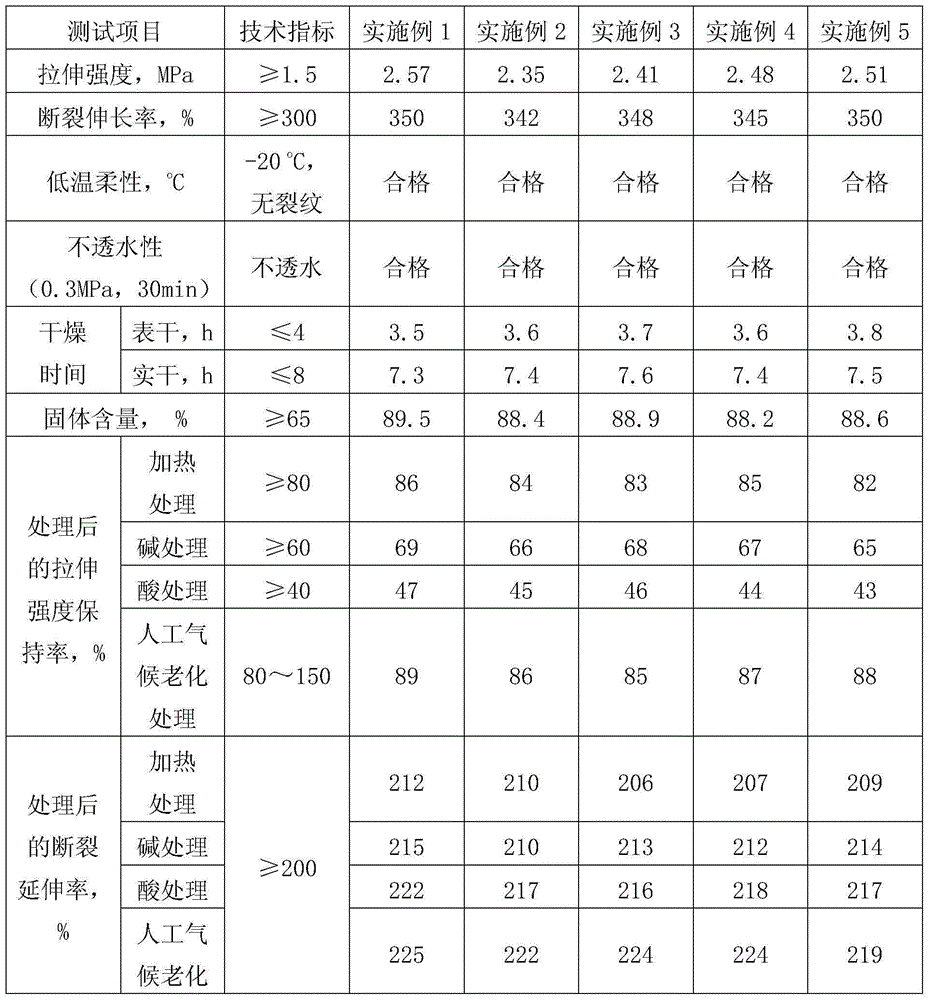

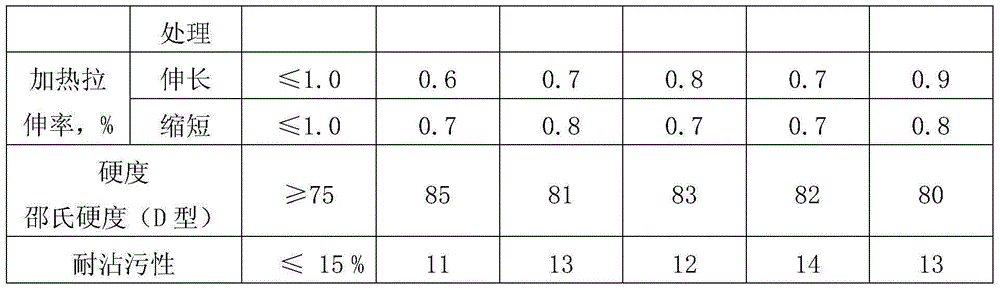

Modified acrylic ester waterproof coating

InactiveCN105199529AOvercome the hardnessOvercome the technical problems of poor stain resistanceAntifouling/underwater paintsPaints with biocidesGlass fiberEmulsion

The invention discloses a modified acrylic ester waterproof coating. The waterproof coating is prepared from components in parts by weight as follows: 35-55 parts of an acrylic ester modified compound emulsion, 2-6 parts of a fluorocarbon surfactant, 2-8 parts of nano-modified materials, 20-30 parts of pigment filler, 0.1-0.3 parts of a humidity controlling agent, 0.3-0.7 parts of a dispersing agent, 0.2-0.4 parts of a defoaming agent, 1-2 parts of a coalescing agent, 0.5-0.7 parts of a thickening agent, 0.2-0.6 parts of an antioxidant, 0.4-0.8 parts of glass fiber, 0.1-0.3 parts of a preservative sterilizing agent, 0.4-0.6 parts of emulsified paraffin and 25-35 parts of water. The waterproof coating adopts a reasonable formula, has good stain resistance, high hardness and excellent overall performance and can be applied to waterproofing work of a roof, a basement, a toilet and the like.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Sandwich structure pre-lithiated negative electrode and lithium ion battery

ActiveCN110828778AImprove lithium ion conductivityReduce etchingCell electrodesSecondary cellsElectrical batteryLithium metal

The invention provides a sandwich structure pre-lithiated negative electrode, which comprises a negative electrode current collector; a negative electrode active layer is arranged above the negative electrode current collector, and a sandwich structure is arranged above the negative electrode active layer; the sandwich structure comprises a first-stage protective layer, a lithium-containing metallayer and a second-stage protective layer; the lithium-containing metal layer is located between the first-stage protective layer and the second-stage protective layer, the second-stage protective layer is located above the first-stage protective layer, and the first-stage protective layer is located on the negative electrode active layer. The sandwich structure pre-lithiation negative electrode can maintain a relatively stable state in the production process and the storage process, the potential safety hazard in the pole piece transfer and battery preparation process is reduced while the electrochemical performance of the battery is improved, the safety performance of the battery is greatly improved, and the negative electrode pre-lithiation effect is greatly improved.

Owner:复阳固态储能科技(溧阳)有限公司

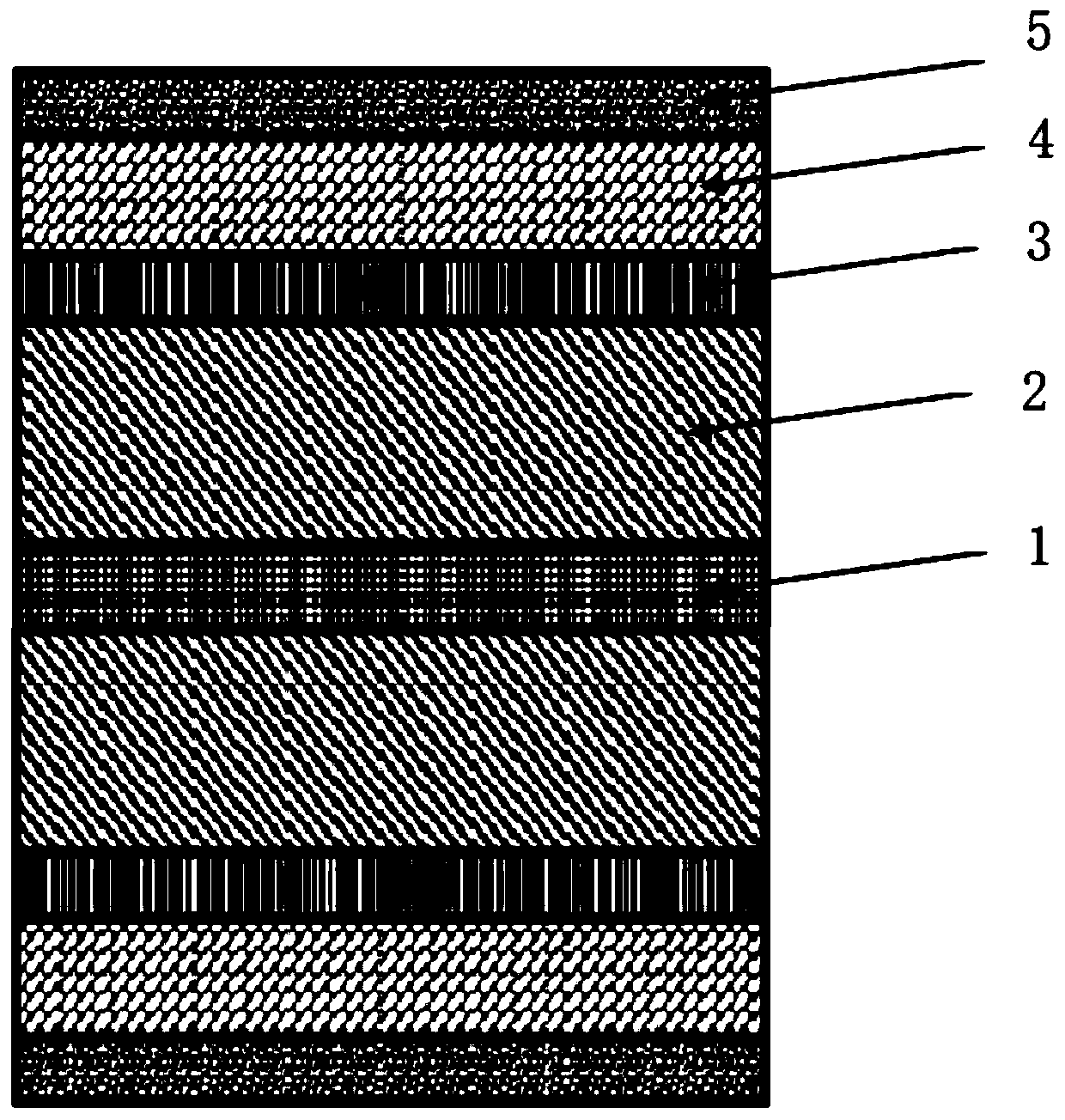

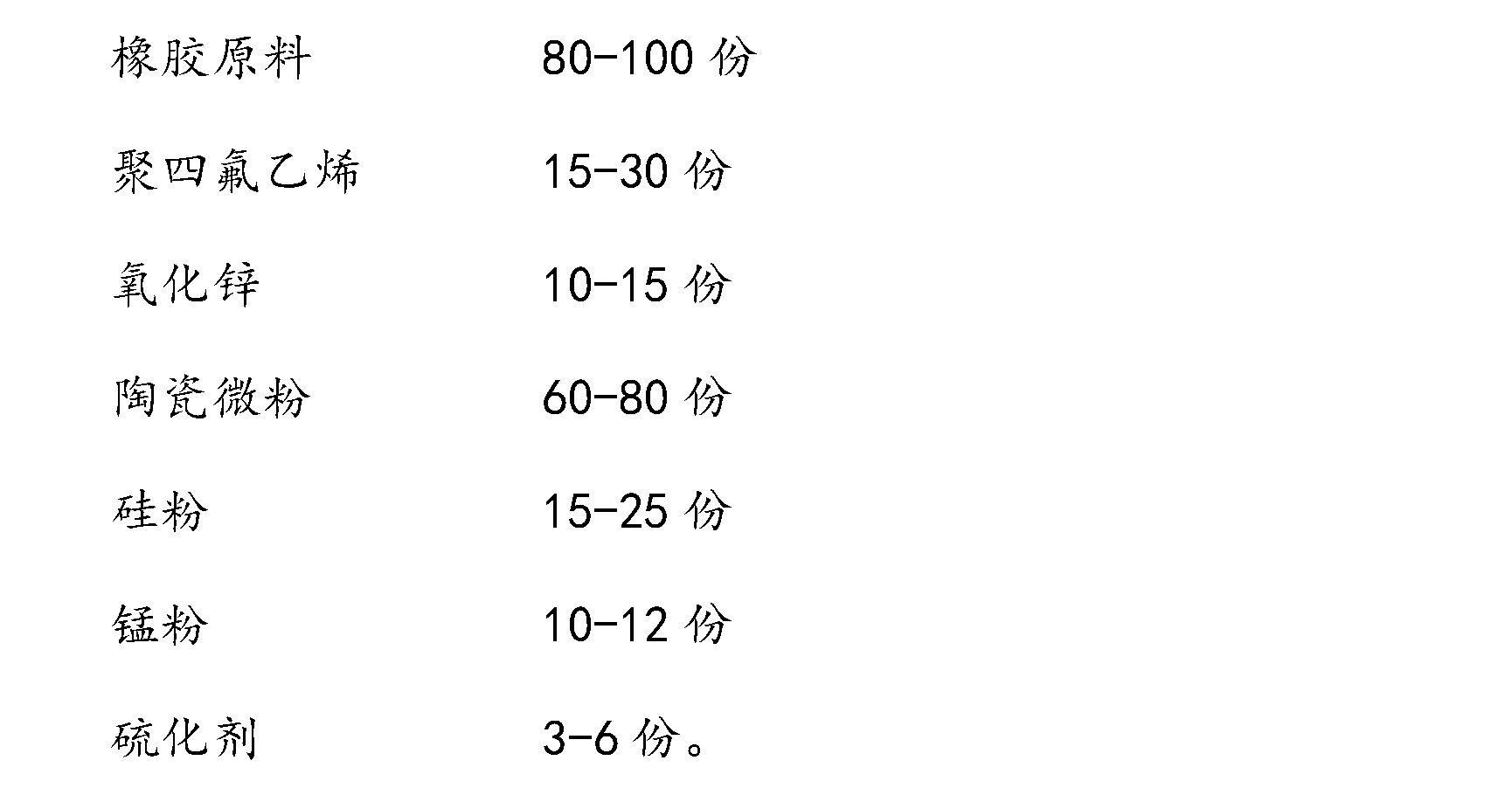

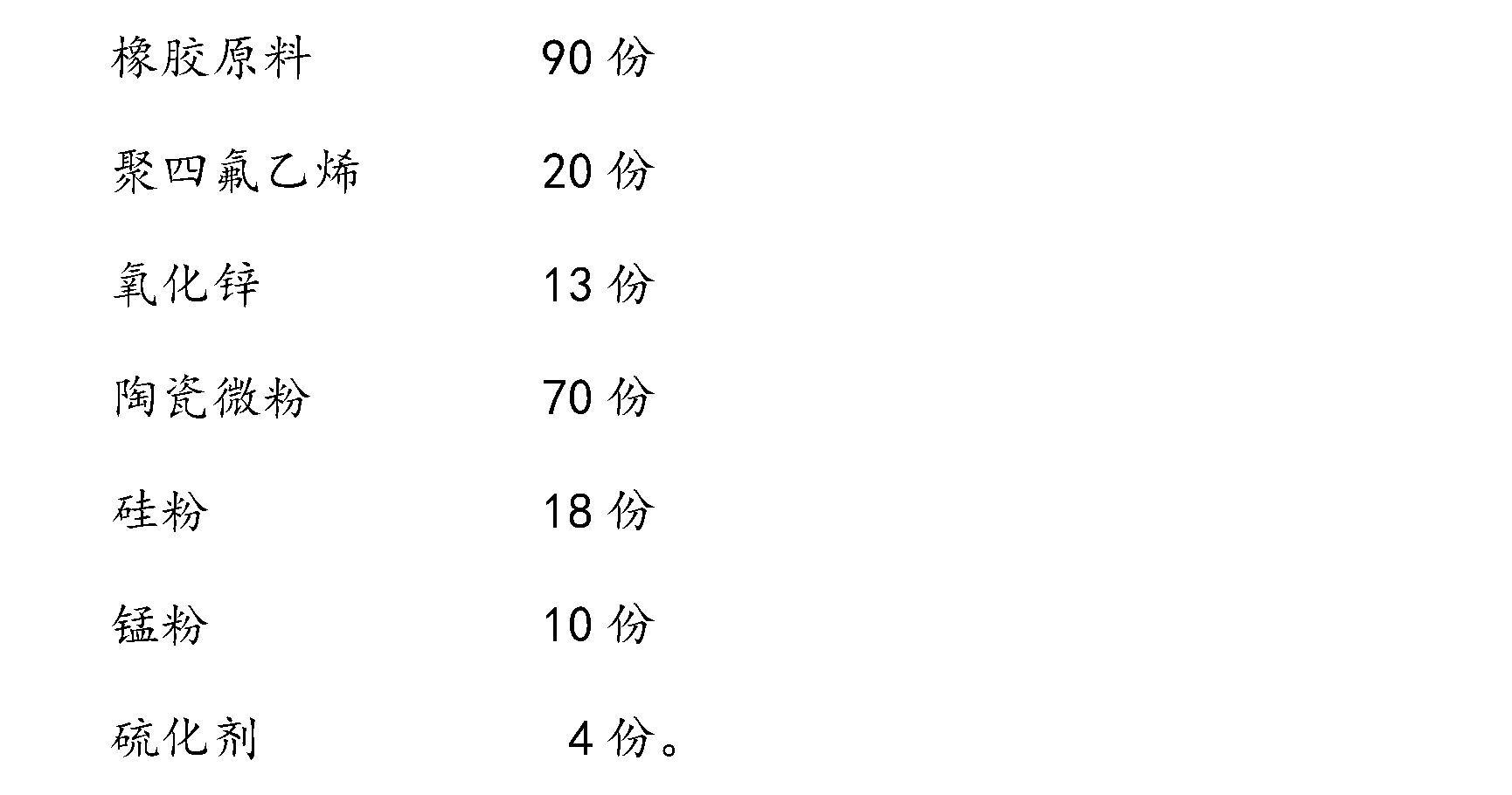

Rubber sealing member

The invention discloses a rubber sealing member, which is composed of a rubber raw material, polytetrafluoroethylene, zinc oxide, ceramic micro-powder, silicon powder, manganese powder and a vulcanizing agent, wherein the rubber raw material is composed of nitrile rubber buna, fluorubber, butadiene styrene rubber and polyimide resin. By synergism among components, volume density of the rubber sealing member is greatly raised, gaps between rubber molecules are reduced, and wear resistance and intensity of the rubber sealing member are raised. Physical properties, chemical properties and usage properties are all substantially raised, and temperature toleration can reach 450 DEG C, thereby greatly prolonging long service life of the rubber sealing member. The ceramic micro-powder, the silicon powder and the manganese powder are used as filling materials, which greatly raises rubber wear resistance; and the improved vulcanizing agent greatly raises rubber fluidity, and increases high temperature resistance and stability.

Owner:镇江春环密封件集团有限公司

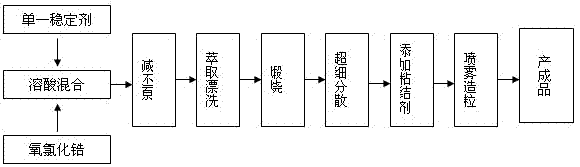

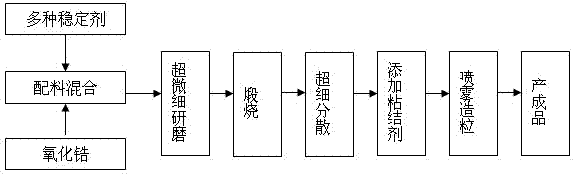

Composite stable microcrystal zirconium oxide ceramic mixed powder and manufacturing process

The invention provides composite stable microcrystal zirconium oxide ceramic mixed powder and a manufacturing process. Industrial-grade zirconium oxide powder is used as a main material and a suitable amount of cerium oxide (CeO), yttrium oxide (Y2O3), aluminum oxide and calcium carbonate (CaCO3) are used as stabilizing agents; all the components are prepared according to the following percentage by weight: 10-12% of the cerium oxide (CeO), 1-2% of the yttrium oxide (Y2O3), 3-8% of the aluminum oxide (Al2O3), 1-2% of the calcium carbonate (CaCO3) and the balance of the industrial-grade zirconium oxide powder; and the powder materials are mixed according to the proportion and the composite stable microcrystal zirconium oxide ceramic mixed powder is prepared by the steps of physically mixing, super-thinning, calcining, dispersing and granulating. With the adoption of a plurality of the stabilizing agents, the stable composition of zirconium oxide is realized, and zirconium oxide ceramic which is stably composited has better physiochemical performances.

Owner:株洲市创锐高强陶瓷有限公司

Method for preparing composite modified starch

The invention discloses a method for preparing composite modified starch. The method comprises the following steps: 1) slurrying a raw material, namely a natural starch, and adjusting pH value of the natural starch by caustic alkali; 2) adding an oxidizing agent into the starch slurry to carry out oxidation modification treatment; 3) filtering, washing and drying the starch slurry into a powdered semi-finished product for standby; 4) spraying a catalyst and composite phosphate into the semi-finished product to carry out dry modification treatment; and 5) cooling the semi-finished product to a temperature of between 25 and 35 DEG C, adjusting the pH value of the semi-finished product to 6-8 to carry out secondary drying, and crushing the product to obtain a finished product. The product obtained by the method greatly improves dispersibility of the starch slurry, can be easily stewed with stable slurry, cannot be frozen, can completely replace the chemical synthetic slurry to size pure coarse cotton and medium yarns, and can replace the synthetic slurry in large scale to size high grade cotton yarns and union yarns, thereby greatly reducing yarn sizing cost, facilitating desizing, and contributing to environment-friendly waste water treatment.

Owner:GUANGDONG HUIMEI STARCH SCI & TECH

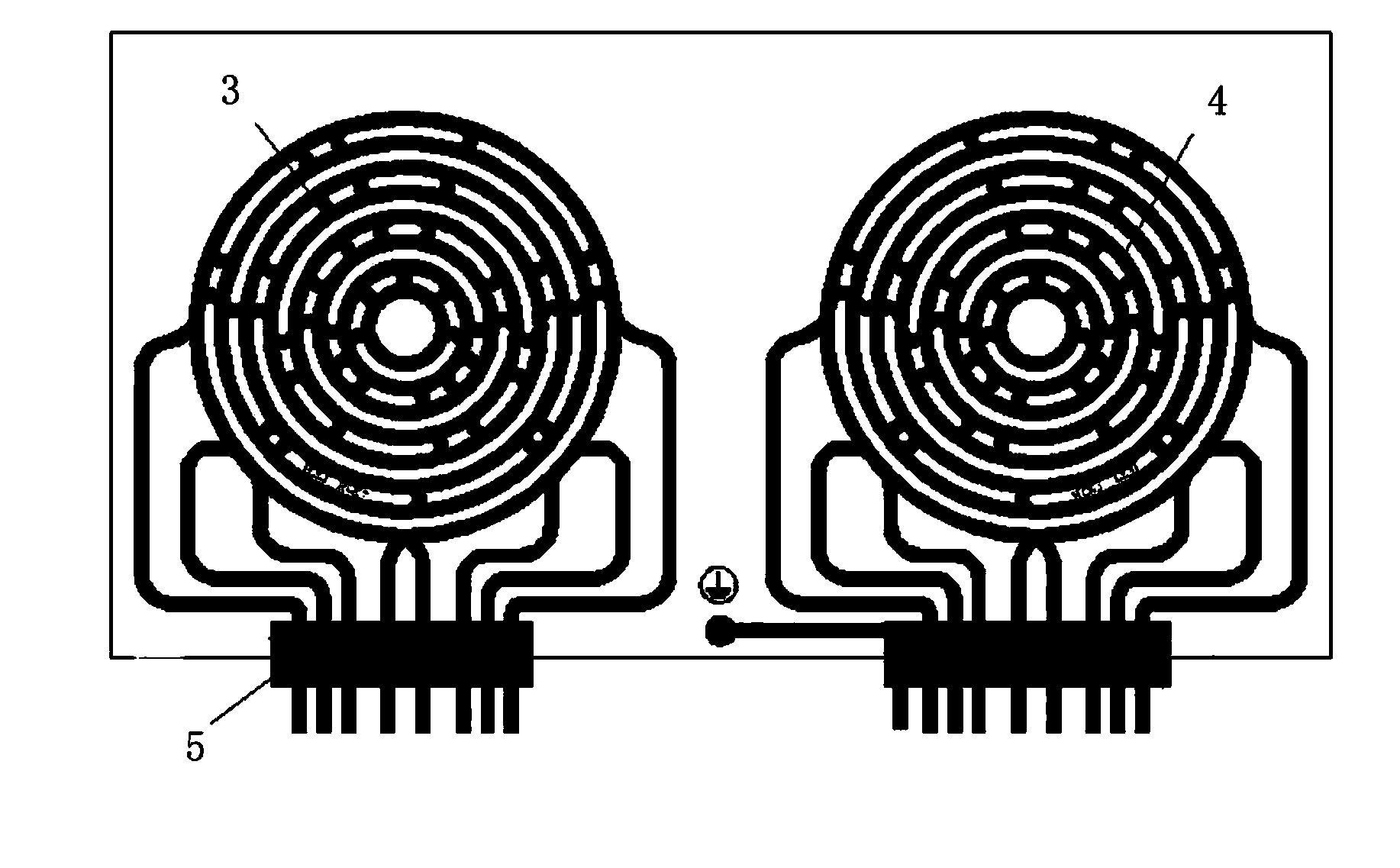

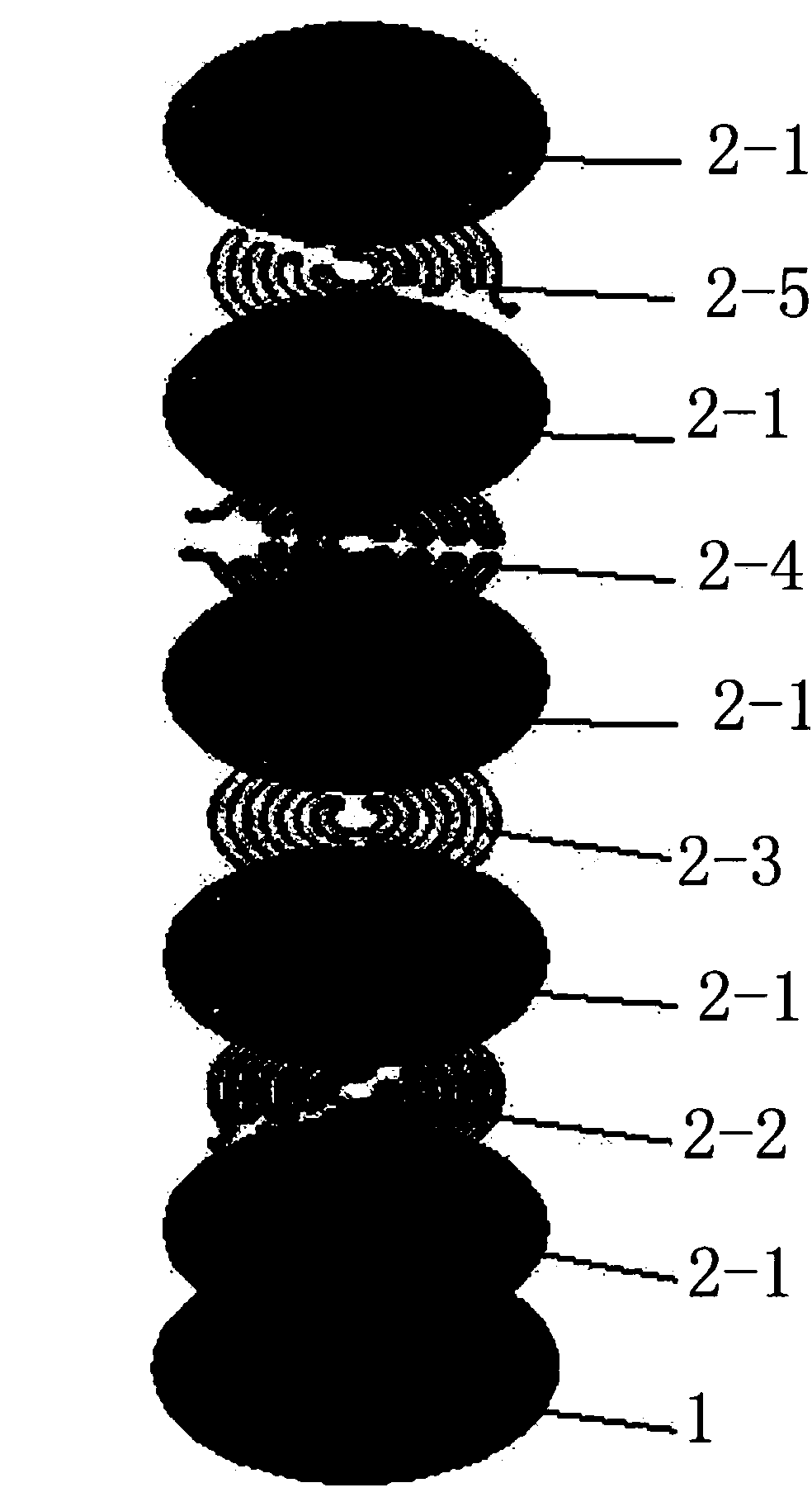

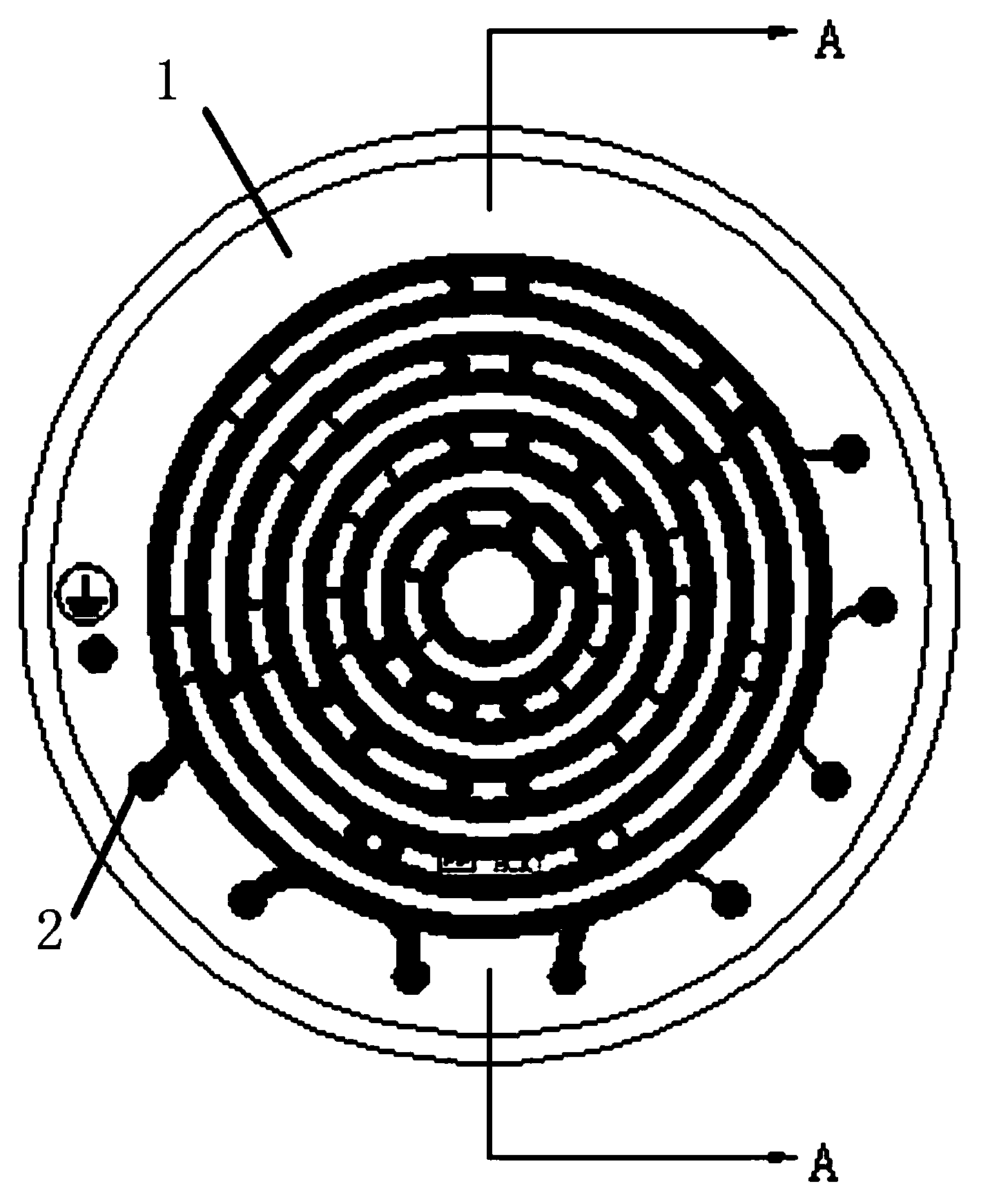

Rare earth thick film circuit electric heating chip and manufacturing technology thereof

ActiveCN103716924AGood compatibilityImprove wettabilityHeating element materialsManufacturing technologyRare earth

The invention discloses a rare earth thick film circuit electric heating chip and a manufacturing technology of the chip. The rare earth thick film circuit electric heating chip is characterized in that the chip comprises a bacteriostatic copper and aluminum composite metal substrate and a rare earth thick film circuit manufactured on the composite metal substrate, the rare earth thick film circuit comprises a rare earth thick film dielectric layer, a rare earth thick film resistor circuit, a rare earth thick film control circuit, a rare earth thick film electrode connection circuit and a rare earth thick film function circuit, the rare earth thick film resistor circuit, the rare earth thick film control circuit, the rare earth thick film electrode connection circuit and the rare earth thick film function circuit are curved, wound and superposed in multiple layers, and the rare earth thick film function circuit integrates and is connected with the output port of a split electronic component and the output port of a temperature control component in a combined mode. The rare earth thick film circuit electric heating chip has the advantages of being high in film compactness, good in uniformity, excellent in performance, short in production period, few in work procedures, low in energy consumption, little in material loss and the like.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

Composite alkali polishing solution for sapphire substrate material and recycling method thereof

InactiveCN104449403ALow costHigh Efficiency Efficiency Surface ProcessingSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesGramNano sio2

The invention relates to a composite alkali polishing solution for a sapphire substrate material. The composite alkali polishing solution comprises the following main components in percentage by weight: 10%-50% of 2wt%-50wt%nanometer SiO2 hydrosol with the particle diameter of 15-150 nanometers, 0.05%-1% of active agents, 0.1%-1% of chelating agents and 0.1%-2% of pH regulating agents, wherein the pH regulating agents are composite alkali formed by a mixture of inorganic alkali and organic alkali. The recycling steps are as follows: the flow rate of polishing solution is 100-300 grams / minute, the polishing pressure is 0-0.2 MPa, the polishing rotation speed is 40-60 rpm, and the polishing temperature is 30-40 DEG C. The composite alkali polishing solution disclosed by the invention has the has the beneficial effects that a composite alkali mode is adopted, the inorganic alkali can effectively increase the polishing removal velocity through strong alkalinity, ensure the stability of the pH of the polishing solution by continuously releasing hydroxy and ensure the chemical effect of the polishing solution in a circular polishing process and the technical problems of low polishing velocity and low efficiency are solved.

Owner:HEBEI UNIV OF TECH

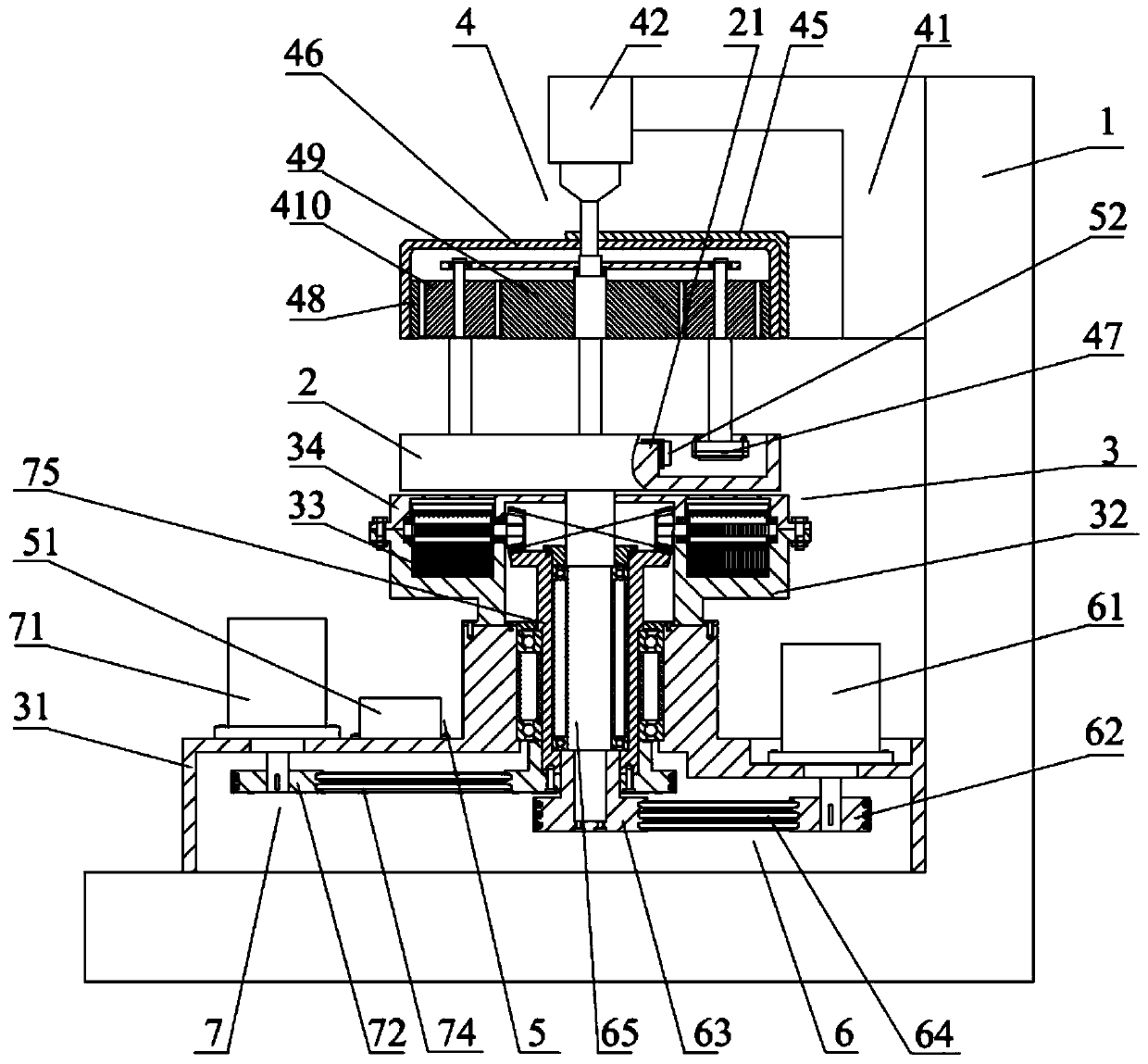

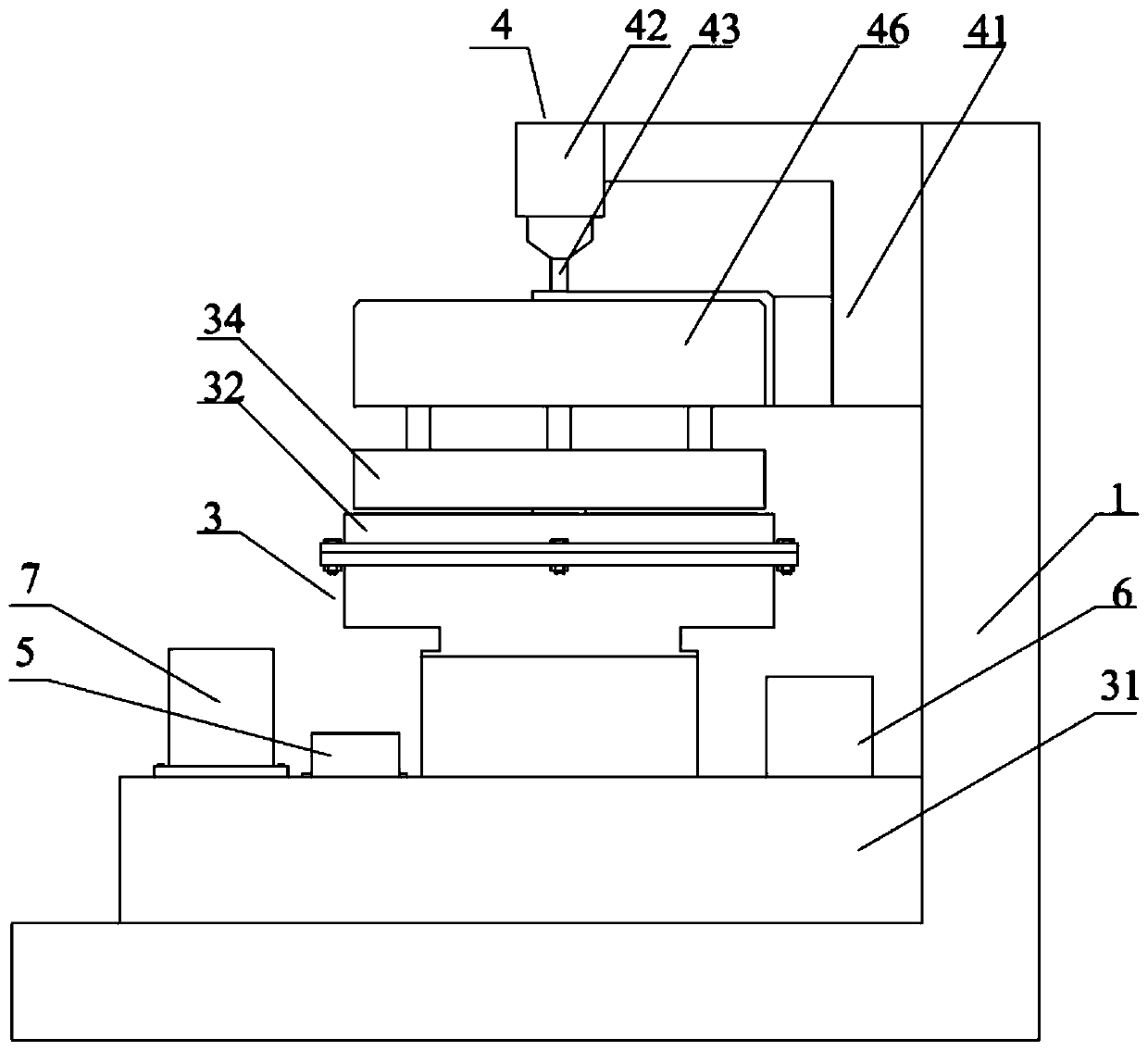

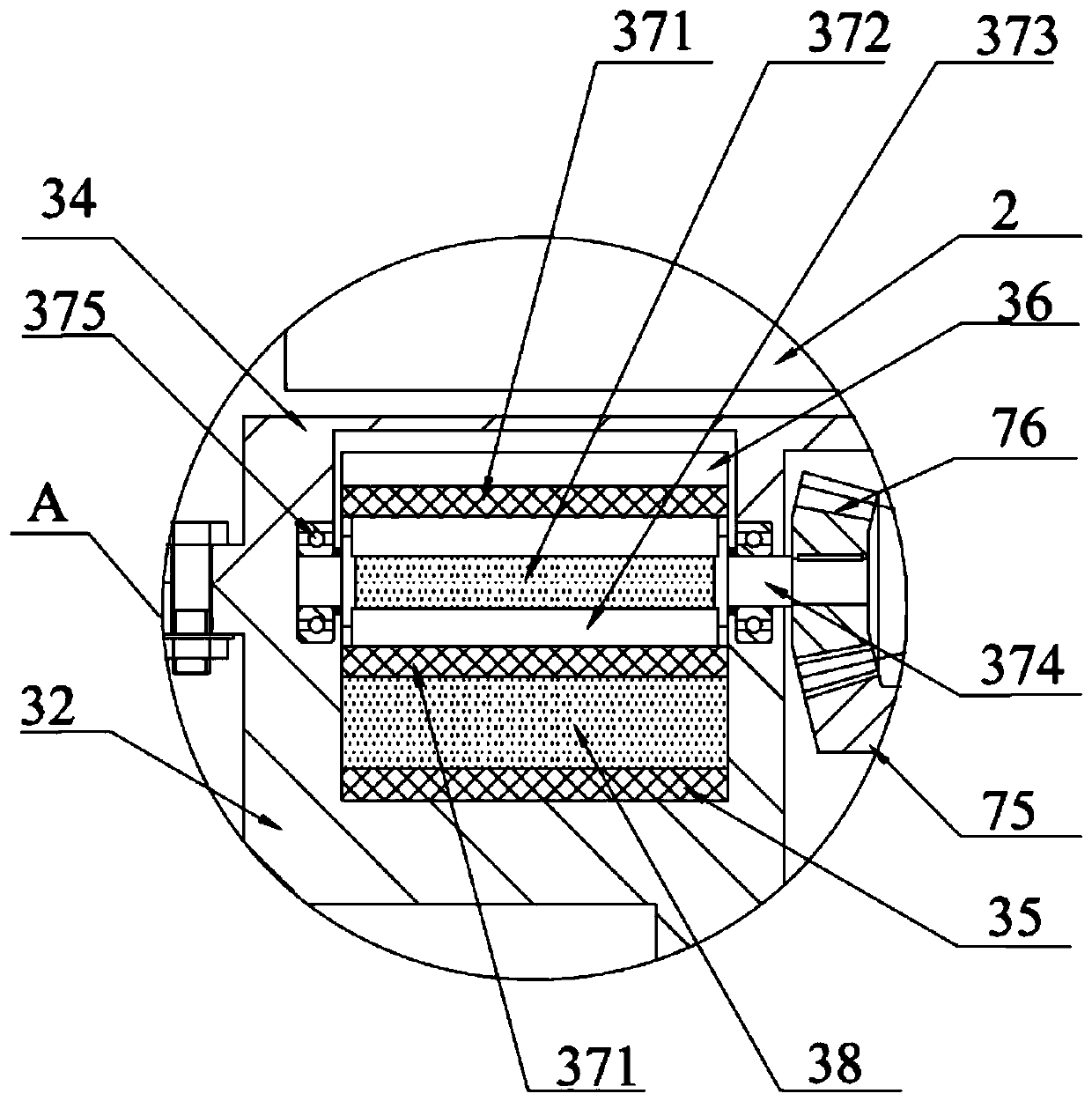

Magneto-rheological polishing device and polishing method for dynamic magnetic field

PendingCN111069984AImprove polishing effectEnhanced chemistryPolishing machinesGrinding drivesPhysicsGrinding

The invention relates to the technical field of ultraprecision machining, in particular to a magneto-rheological polishing device and polishing method for a dynamic magnetic field. The magneto-rheological polishing device for the dynamic magnetic field comprises a base, a polishing disk, a dynamic magnetic field generation assembly, a workpiece clamping assembly, an ultrasonic assembly, a first driving assembly and a second driving assembly, wherein the workpiece clamping assembly is mounted on the base and is arranged above the polishing disc, the polishing disc is connected to the first driving assembly, the dynamic magnetic field generation assembly is connected to the second driving assembly and is arranged below the polishing disc, the first driving assembly and the second driving assembly are mounted on the base, the ultrasonic assembly is mounted on the lateral part of the polishing disc, and a magneto-rheological polishing solution is contained in the polishing disc. A magneticchain string is rearranged by means of the dynamic magnetic field, so that a grinding material is updated and self-sharpened. A chemical reaction is fuller by means of an ultrasonic assistant chemical reaction. As a clamping disc revolves and rotates, a workpiece is in full contact with the magneto-rheological polishing solution, so that the polishing efficiency is improved.

Owner:GUANGDONG UNIV OF TECH

Composite carbon electrode for all-vanadium flow battery and preparation method thereof

InactiveCN103682384AImprove chemical performanceHigh mechanical strengthCell electrodesElectrical batteryGas phase

The invention relates to a composite carbon electrode material for an all-vanadium flow battery and a preparation method of the composite carbon electrode material. The electrode material for the all-vanadium flow battery is made into a composite carbon electrode by directly growing a carbon nano-tube array on a carbon element substrate. The preparation process comprises the following steps of (1) precipitating a catalyst for growing the carbon nano-tube on the carbon element substrate by adopting a magnetron sputtering method; and (2) placing the carbon element substrate with the catalyst into a high-temperature reaction furnace, and preparing the carbon nano-tube array layer through a chemical vapor deposition method. The specific surface area, the electrochemical activity and the mechanical strength of the composite carbon electrode material for the vanadium flow battery prepared by adopting the preparation method are obviously improved, so that the battery property of the all-vanadium flow battery is improved, and the service life is prolonged.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI +1

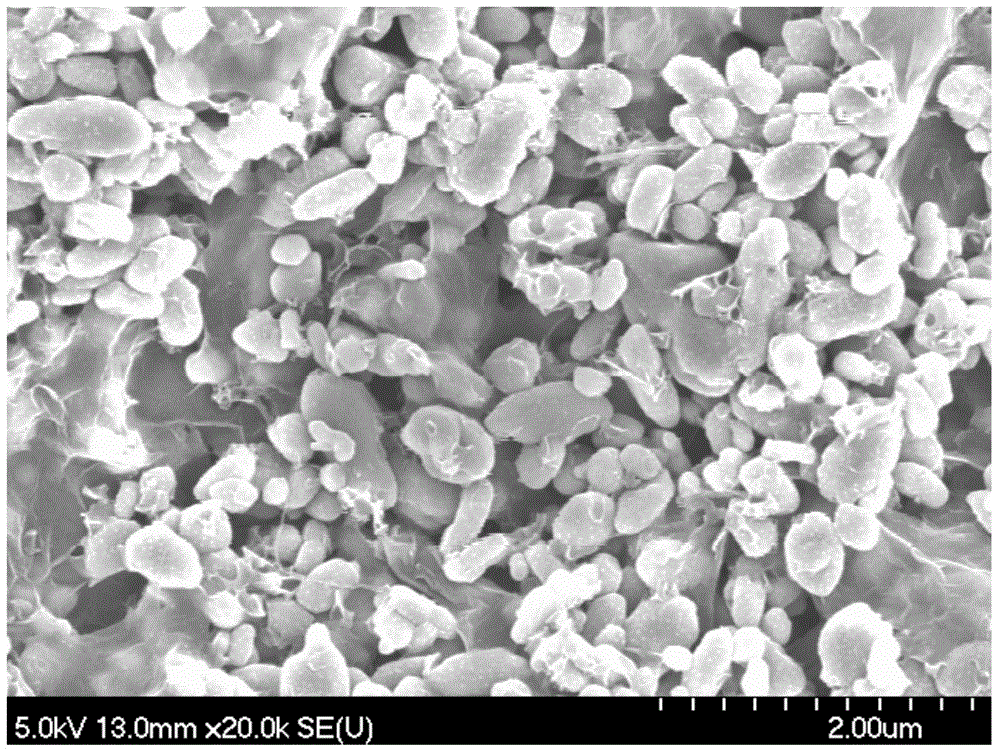

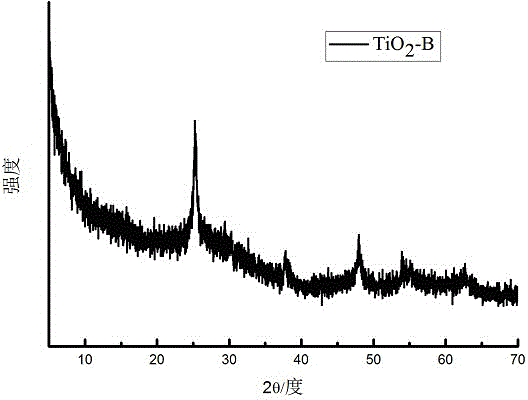

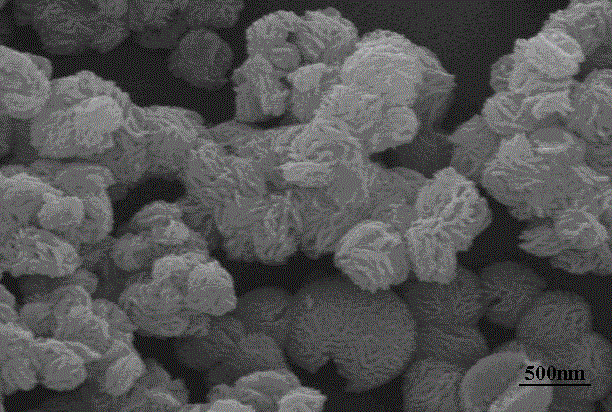

Preparation method of graphite-TiO2-B composite material

The invention relates to a preparation method of a graphite-TiO2-B composite material. The method comprises the following steps: (1) preparing graphite oxide by utilizing a Hummers method, and then preparing graphene by utilizing a hot swelling method; (2) preparing bud-shaped TiO2-B from titanium source and additives by utilizing a hydrothermal method; and (3) physically stirring the graphene and the TiO2-B at the room temperature, and mixing the graphene and the TiO2-B to obtain a graphene-coating bud-shaped TiO2-B composite material. The composite material is the graphene-coating bud-shaped TiO2-B, and the size of the bud is about 400nm to 500nm. The preparation method of the graphene-coating bud-shaped TiO2-B composite material has advantages of being simple and low in cost, the prepared graphene-coating bud-shaped TiO2-B composite material can be widely applied to a lithium battery negative electrode material and is good in rate capacity and circulating stability, and the chemical performance can be remarkably improved.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com