Green and environment-friendly brick for building and making technology thereof

It is a technology of green environmental protection and manufacturing technology, which is applied in the field of building materials. It can solve the problems of not being effectively used and properly handled, polluting the rural environment, and affecting the construction of new rural areas in urban and rural living environments. It can improve particle suspension, improve the environment, Effect of reducing machining power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail through the following examples, but the present invention is not limited thereto.

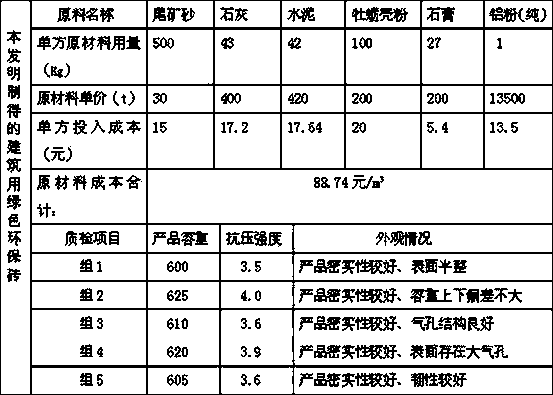

[0020] A green environmental protection brick for construction and its manufacturing process, the green environmental protection brick for construction includes material and water, the ratio of the material to water is 1:0.463, the material is made of the following by weight Raw materials configured in proportions are prepared by the production process:

[0021] Tailing sand 500Kg Oyster shell powder 100 Kg Lime 43 Kg Cement 42 Kg Gypsum 27 Kg Pure aluminum powder 1 Kg;

[0022] The manufacturing process is as follows:

[0023] (1) Put the tailings sand and oyster shell powder into the corresponding feeding equipment by the forklift according to the proportion of the process requirements. After feeding and mixing, the tailings sand and oyster shell powder enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com