Patents

Literature

107results about How to "Low incorporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

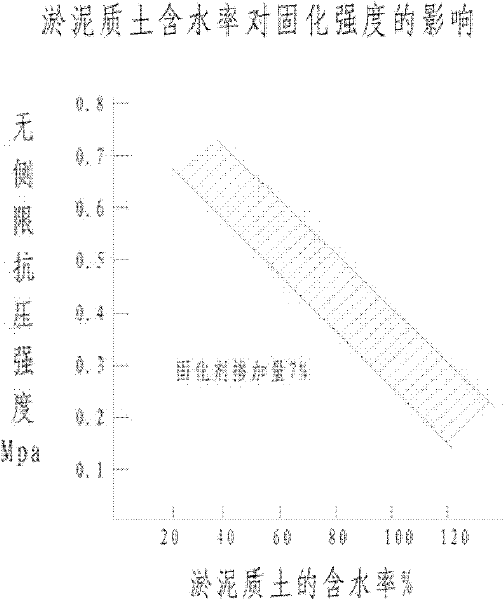

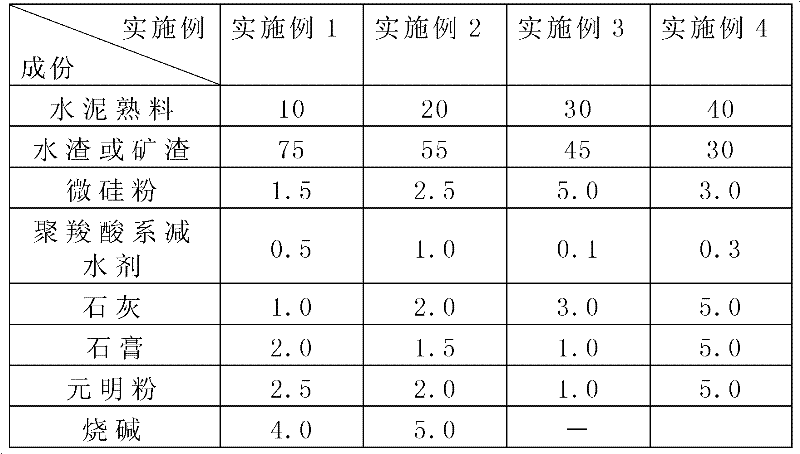

Curing agent for curing marine poor subsoil

ActiveCN102344813ASimple ingredientsCompatibility is reasonableBuilding constructionsOrganic fertilisersSlagSodium silicate

The invention relates to a curing agent for curing marine poor subsoil, which belongs to the technical field of poor subsoil curing. The curing agent for curing the marine poor subsoil is composed by the components of cement clinker, granulating slag or slag, silica fume, polycarboxylic acid type water-reducer, lime, plaster, anhydrous sodium sulphate, caustic soda, sodium silicate and sodium fluosilicate. The adulteration amount of the poor subsoil curing agent is 5%-12% in application, good curing functions can be realized, and the curing agent for curing the marine poor subsoil can be applied in the poor soil curing of building sites, road embankments, roadbeds and ground base layers. The invention has the advantages that: the components of the curing agent are simple, the compatibility is reasonable, the doping amount is less, and the curing effect is good; and during the application process, the construction period is short, the construction cost is low, the induration bearing capacity is high, the induration compression modulus is strong, and the induration permeable resistance is strong.

Owner:徐辰楚 +1

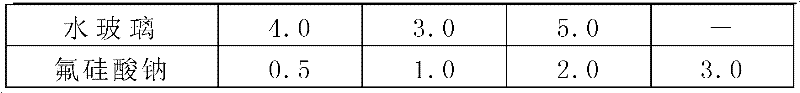

Silicate cement grinding aid and preparation method thereof

The invention discloses a silicate cement grinding aid and a preparation method thereof. The silicate cement grinding aid is prepared from the following main raw materials by weight: 3-6 parts of sodium hexametaphosphate, 2-5 parts of aluminum sulfate, 5-8 parts of tetra sodium salt of amino trimethylene phosphonic acid (ATMP.Na4), 4-6 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 38-45 parts of polymeric alkylol amine, 34-42 parts of triisopropanolamine, 8-12 parts of waste engine oil, 2-5 parts of sodium alpha-olefin sulfonate, 10-16 parts of sorbitol, 15-20 parts of diethylene glycol, 8-13 parts of polypropylene wax, 6-10 parts of oxidized polyethlene wax, 4-8 parts of lignite wax, 20-30 parts of odium thiosulfate, 12-18 parts of sodium thiosulfate and 15-20 parts of quicklime powder. The prepared silicate cement grinding aid has the advantages that the quality is stable, the effect is remarkable, the adding amount is small, the use is simple, and the adding is more convenient and reliable to control.

Owner:王金奎

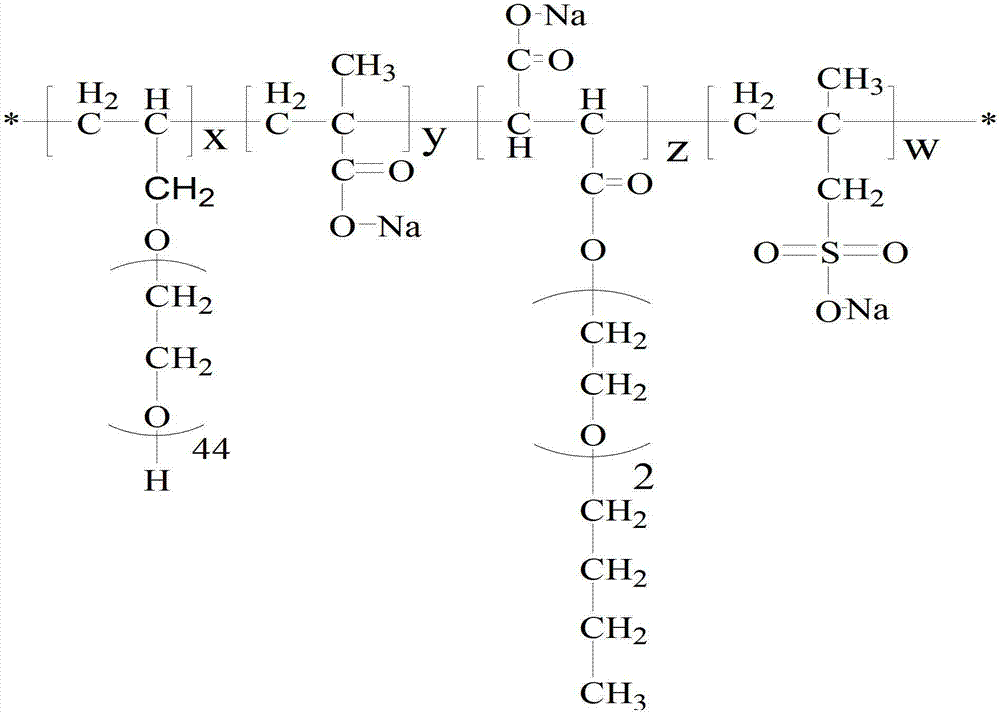

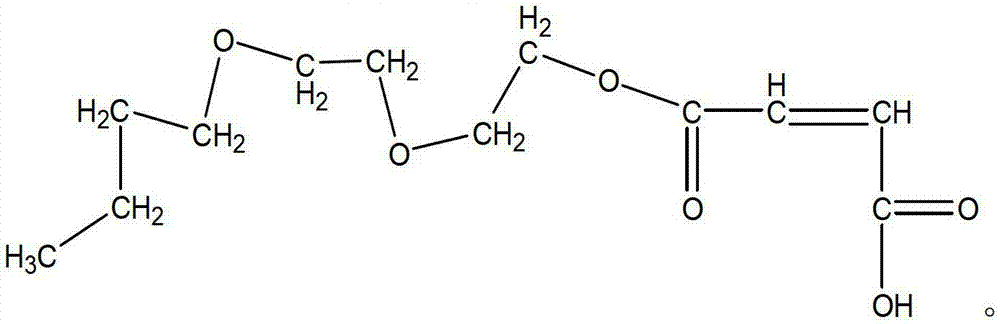

Shrinkage-reducing poly carboxylic acid water reducing agent and preparation method

InactiveCN103193410ALarge physical space hindrance effectGood water reduction effectPolyethylene glycolCarboxylic acid

The invention discloses a method for preparing a poly carboxylic acid water reducing agent. According to the method, sodium methallyl sulfonate, allyl polyethylene glycols, methacrylic acid, diethylene glycol dimethyl monobutyl ether maleic monoester and water are mixed according to an appropriate proportion and are subjected to thermostatic reaction for 3-7 hours under the temperature of 50-100 DEG C under the initiation of the initiator ammonium persulfate, the reaction products are cooled and then the pH value is adjusted to 6-8 by using a NaOH solution to obtain the water solution of macromolecule copolymer, i.e. the shrinkage-reducing poly carboxylic acid water reducing agent. The invention further discloses a novel shrinkage-reducing poly carboxylic acid water reducing agent. The raw materials of the shrinkage-reducing poly carboxylic acid water reducing agent of the invention are abundant in source, and the synthesis process is simple and easily operated; the shrinkage-reducing poly carboxylic acid water reducing agent has good water reducing and shrinkage reducing functions when the mixing amount is lower, can appropriately entrain air, and has better market prospect and economic benefit.

Owner:SOUTH CHINA UNIV OF TECH

Bitumen modifier

InactiveCN101041744AHigh softening pointImprove anti-aging propertiesBuilding insulationsEpoxyStearic acid

The invention discloses a modifier of pitch for road and water-proofing material, which comprises the following steps: allocating with mass percent as 20-30% polypropylene, 3-10% epoxide resin, 8-10% polyethylene, 8-10% geoceric acid and 40-60% ethylene distearamide; mixing; stirring for 10-15 min; getting the product. This product possesses good stability and predominant water resistance, which can be fit for all of asphalt.

Owner:上海诚鸿道路新材料有限公司

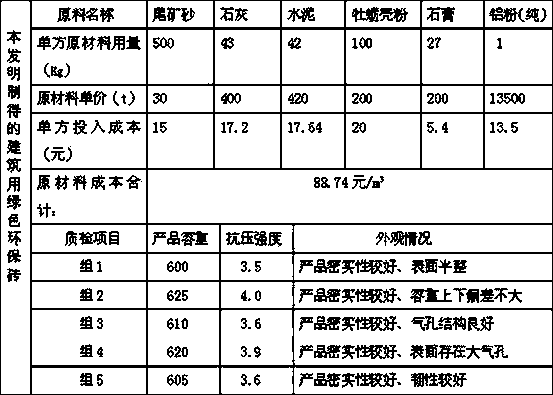

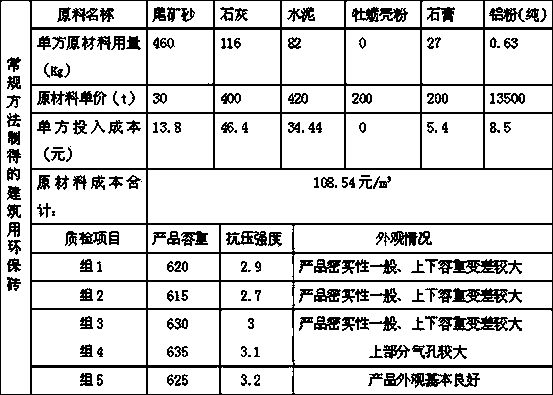

Green and environment-friendly brick for building and making technology thereof

The invention discloses a green and environment-friendly brick for building and a new technology production mode for preparation of the green and environment-friendly brick for building, and the green and environment-friendly brick for building uses calcined oyster shell powder to replace part of expensive building raw materials such as lime, cement and the like. Compressive strength and dry density and other technical parameter requirements of a product are ensured, meanwhile mixing amounts of the cement and the lime are reduced, the production cost is reduced, the oyster shell powder is mixed for mixed grinding with tailing sand to prepare good-performance mortar, so that a tailing sand early-stage processing technology requires that the fineness needs to increase from 0.08 mm-sieve screen residue weight of 30% to 60%, the tailing sand processing time and processing power consumption are reduced, the energy is saved, oyster shell produced by coastal oyster breeding is effectively used and duly processed, and the environment is improved.

Owner:东山县金石混凝土有限公司

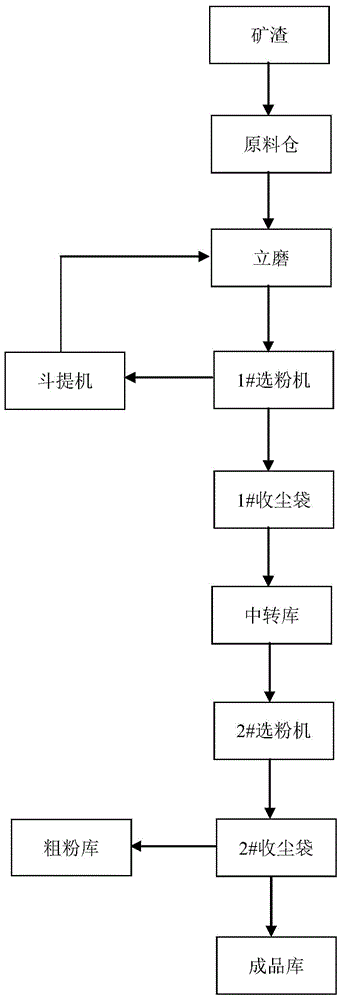

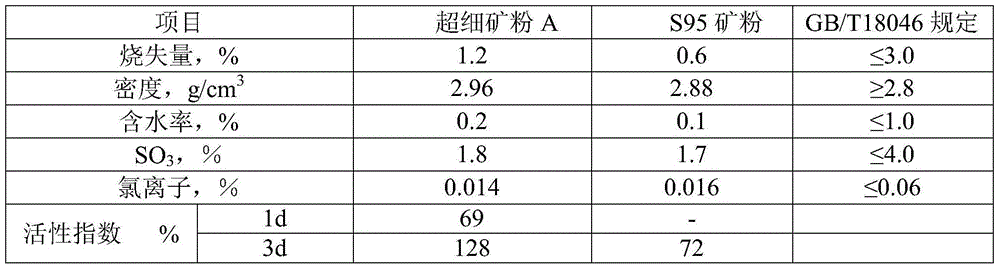

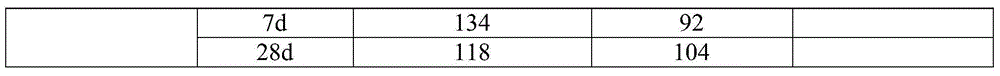

Ultrafine slag powder, and preparation method and application thereof

InactiveCN104478269AImprove finenessHigh activitySolid waste managementSlagUltimate tensile strength

The invention belongs to the field of comprehensive utilization of solid waste resource, and especially relates to an ultrafine slag powder, and a preparation method and application thereof. Vertical-milling grinding and two stages of sorting technologies are combined, a slag pre-grinded material subjected to vertical milling is subjected to a first stage of grading processing, so that a mineral powder with the specific surface area according with a requirement is sorted out, and unqualified slag crude powder falls into a vertical mill for grinding. The slag powder according with the requirement is subjected to a second stage of grading processing, so that a slag powder with the particle size of 20 mu m or less is sorted out, overly grinding phenomenon is avoided, and energy consumption and cost are reduced. The prepared slag powder has relatively high activity, can be applied to concrete as a mineral doping material, is capable of reducing the cost of concrete and concrete products, increasing the strength of concrete and improving the endurance of concrete, and also is applicable to production of pipe sheets and pipe piles. After the concrete is doped with the ultrafine slag powder, the doping amount of a cementing material can be properly reduced, and thus the purpose of saving energy and reducing cost and improving effect are realized.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

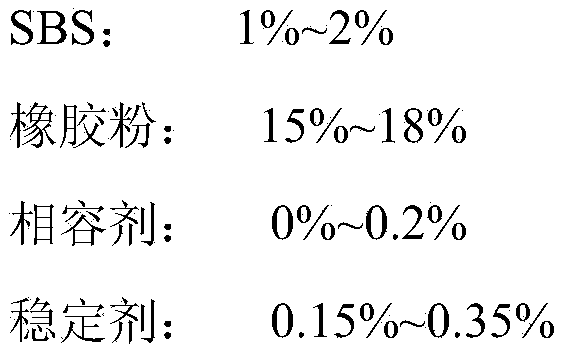

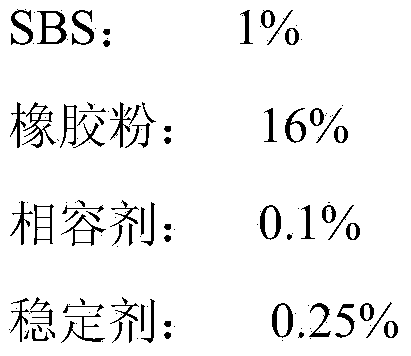

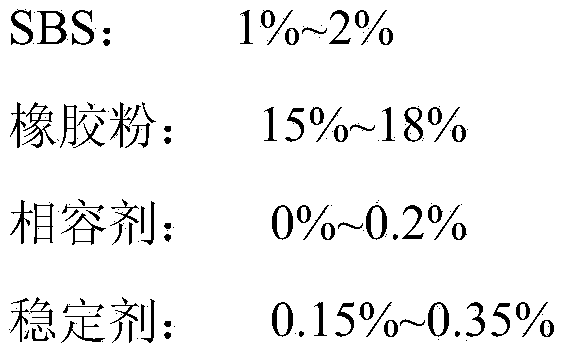

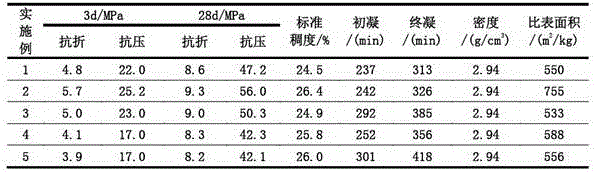

Preparation method of stable rubber modified asphalt

InactiveCN103980723AImprove performanceLarge specific surface areaBuilding insulationsPolymer scienceButadiene-styrene rubber

The invention discloses a preparation method of stable rubber modified asphalt and belongs to the technical field of modified asphalt. The preparation method comprises the following steps: adding SBS (Styrene Butadiene Styrene), rubber powder and a compatilizer into heated matrix asphalt, stirring, subsequently adding a stabilizer, shearing, and putting a sheared product into an oven for swelling, thereby obtaining the stable rubber modified asphalt. By adopting the preparation method of the stable rubber modified asphalt provided by the invention, the mixing amount of SBS is reduced, so that the cost of the modified asphalt is greatly lowered, the preparation process is simple and practicable, a prepared product is stable in property, can be stored for a long time in factories, and is applicable to large-scale application.

Owner:福建省燕宁顺通科技发展有限责任公司

Retarded portland cement and preparation method thereof

InactiveCN105948544AProlong clotting timeIncrease late strengthCement productionSlagMaterials science

The invention relates to a retarded Portland cement and a preparation method thereof. The retarded Portland cement is prepared from the following components in percentage by weight: 52 to 58 percent of Portland cement clinkers, 22.2 to 25.5 percent of mixed slags, 14.8 to 17.5 percent of silica fume, and 5 percent of gypsum. The preparation method comprises the following steps of premixing a phosphorus slag, a vanadium-titanium bearing slag and a zinc slag according to the proportion to obtain a mixed slag a; mixing and grinding the mixed slag a, the Portland cement clinkers, the silica fume and the gypsum to prepare the retarded Portland cement. According to the retarded Portland cement provided by the invention, the usage amount of the Portland cement clinkers is reduced, so that the ingredient cost of producing the cement is effectively reduced, and the discharge of carbon dioxide is reduced; meanwhile, with the adding of the phosphorus slag and the silica fume, the problem that the long-term strength is reduced since the Portland cement clinkers are reduced is solved. The defects that the setting time is prolonged and the strength is reduced, or the strength is increased and the setting time is shorter due to the utilization of other materials in the prior art are overcome, and the obtained retarded Portland cement is remarkably prolonged in initial setting time and remarkably improved in long-term strength.

Owner:四川省宁南县白鹤滩水泥有限责任公司

Cement grinding aid

The invention relates to the technical field of cement additives, in particular to a cement grinding aid. The cement grinding aid comprises the following raw materials in parts by weight: 100 parts of triethanolamine and 60-90 parts of maleic anhydride or maleic acid. In the cement grinding aid, the maleic anhydride or maleic acid is preferably 75-85 parts by weight. The cement grinding aid is prepared by adopting the following steps of: adding the triethanolamine into a reactor, and adjusting the pH value to be neutral by using acetic acid or propionic acid; adding the maleic anhydride or maleic acid, stirring and heating to 60-105 DEG C, reacting for 2-5h, cooling to room temperature, and regulating the pH value to be neutral by using a sodium hydroxide solution. The cement grinding aid has the advantages of uniformity and stability, no layering after long-term standing, low alkali content, no chloride ions, low doping amount only accounting for 0.01-0.03 percent of the cement amount, simple formula design, simplified production steps, good grinding aid effect and excellent reinforcement effect, can promote the energy-saving and emission-reduction effects of the cement industry and can completely meet market requirements.

Owner:安徽海螺材料科技股份有限公司

Waterproof concrete compacting agent and preparation method thereof

The invention discloses a waterproof concrete compacting agent and a preparation method thereof. The compacting agent consists of the following raw material components in percentage by weight: 10 to 13 percent of potassium hydroxide, 0.5 to 1 percent of volcanic ash, 0.5 to 1 percent of potassium oleate, 10 to 12 percent of sulfur, 0.5 to 1 percent of glycerol, 3 to 5 percent of triethanolamine, 0.5 to 1 percent of citric acid, 0.5 to 1.5 percent of ferric oxide, 0.5 to 1 percent of sodium fluosilicate, and the balance of water. Chemical crystal or colloid generated by chemical reaction of components in the compacting agent and silicon, calcium, sodium, magnesium and the like in cement can effectively prevent permeation of water molecules and effectively control cracking. The compacting agent contains extremely low harmful substances, particularly has extremely low chlorine ion content and ammonia content, reduces damage to steel bars and concrete, and is beneficial to environmental protection.

Owner:北京龙阳伟业科技股份有限公司

Liquid high-efficiency cement grinding aid reinforcing agent and producing method thereof

InactiveCN101209908AReduce coagulationEliminate hazardsSolid waste managementCement productionAluminium sulfatePolyol

The invention relates to a liquid cement grinding-assisting reinforcing agent and a production method thereof, particularly to a high-efficient liquid compound non-chlorinated and low alkali cement grinding-assisting reinforcing agent of a defoaming mechanism and cement stability performance and a production method thereof. Pulp waste liquid is used as main material which is in complexation with triethanolamine and polyol and added with small amount of stabilizers of phosphogypsum and aluminum sulfate, etc., to eliminate the harm of free state CaO, and ethal etc. is added to play a role of defoaming, thereby the stability and density of the cement is enhanced and the intensity of the cement is further enhanced. The production method is to separate grinding-assisting reinforcing ingredient and additive ingredient respectively and averagely which are then stirred and mixed. In addition to simple technique and low price, the product is easy for storage and transportation, which occupies little cement mixed weight, obviously enhances the early and later period intensity of the cement and is extremely applicable to wide application in cement industry.

Owner:DALIAN UNIV OF TECH

Chlorine-free highly effective composite enhanced solid cement grinding aids and production method

The invention provides a chlorine-free high-efficiency composite reinforcing type solid cement grinding aid and production method, the grinding aid is composed of inorganic substrate material, organic material and water, strong antifreeze and antirust; the inorganic substrate material is composed of powder coal ash, sodium carbonate and sodium silicate, the mixing solution of any three or four among triethanolamine, glycol, propanediol, glycerolor paper pulp waste liquid is selected as the organic material, the inorganic strong antifreeze is composed of aluminum sulfate, calces or sodium hydrogen, sodium acetate or carbamide, and the antirust is sodium dihydrogen phosphate. The production method is the following: first the inorganic strong antifreeze is utilized to perform the complexation and modification of the organic material solution, and then the obtained mixing solution and the inorganic substrate material are furthermore compounded, reacted, blended and crushed. The invention has simple process, low cost, wide application range, good anti-freezing anti-rusting functions, and can improve later strength of cement obviously without disadvantage influence, and also obviously reduce the using amount of cement clinker by 20 percent, thereby having outstanding economical benefit.

Owner:DALIAN UNIV OF TECH

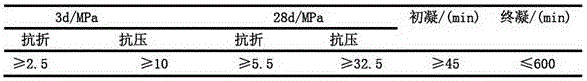

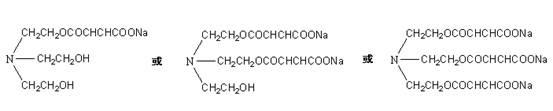

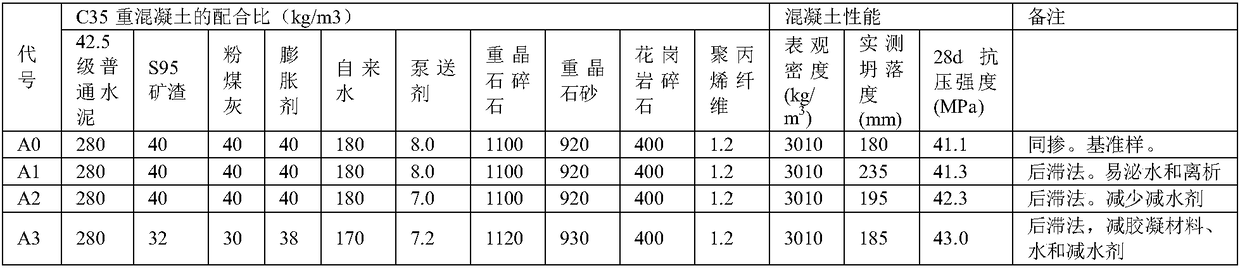

Production method of ready-mix pumped heavy concrete

InactiveCN108081466AWorkability is goodEnhanced pumpabilityCement mixing apparatusEconomic benefitsContinuous mixing

The invention discloses a production method of ready-mix pumped heavy concrete. The method comprises the following steps: preparing raw materials for heavy concrete: a binding material, coarse and fine aggregate, an additive and water; adding the binding material, coarse and fine aggregate and water into a mixer in a condition of continuous mixing of the mixer of a mixing plant, perform primary mixing for 3 to 60s, then adding the additive, performing secondary mixing, and ensuring that the time of secondary mixing is not smaller than 30s, so as to obtain the ready-mix pumped heavy concrete. According to the method, the ready-mix pumped heavy concrete is produced in a mixing plant through a mixing plant water reducer delay infiltration method, a polycarboxylic type high performance water reducer and barite aggregate, and through the adoption of the method, the dosage of the water reducer can be reduced by 8 to 25 percent, and the obvious economic benefit is produced.

Owner:ZHEJIANG UNIV OF TECH

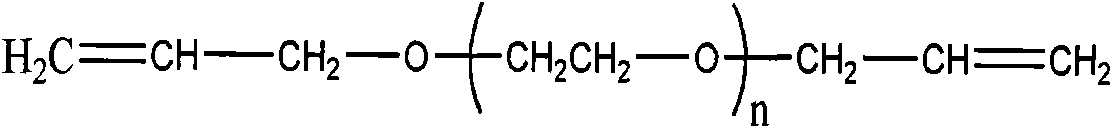

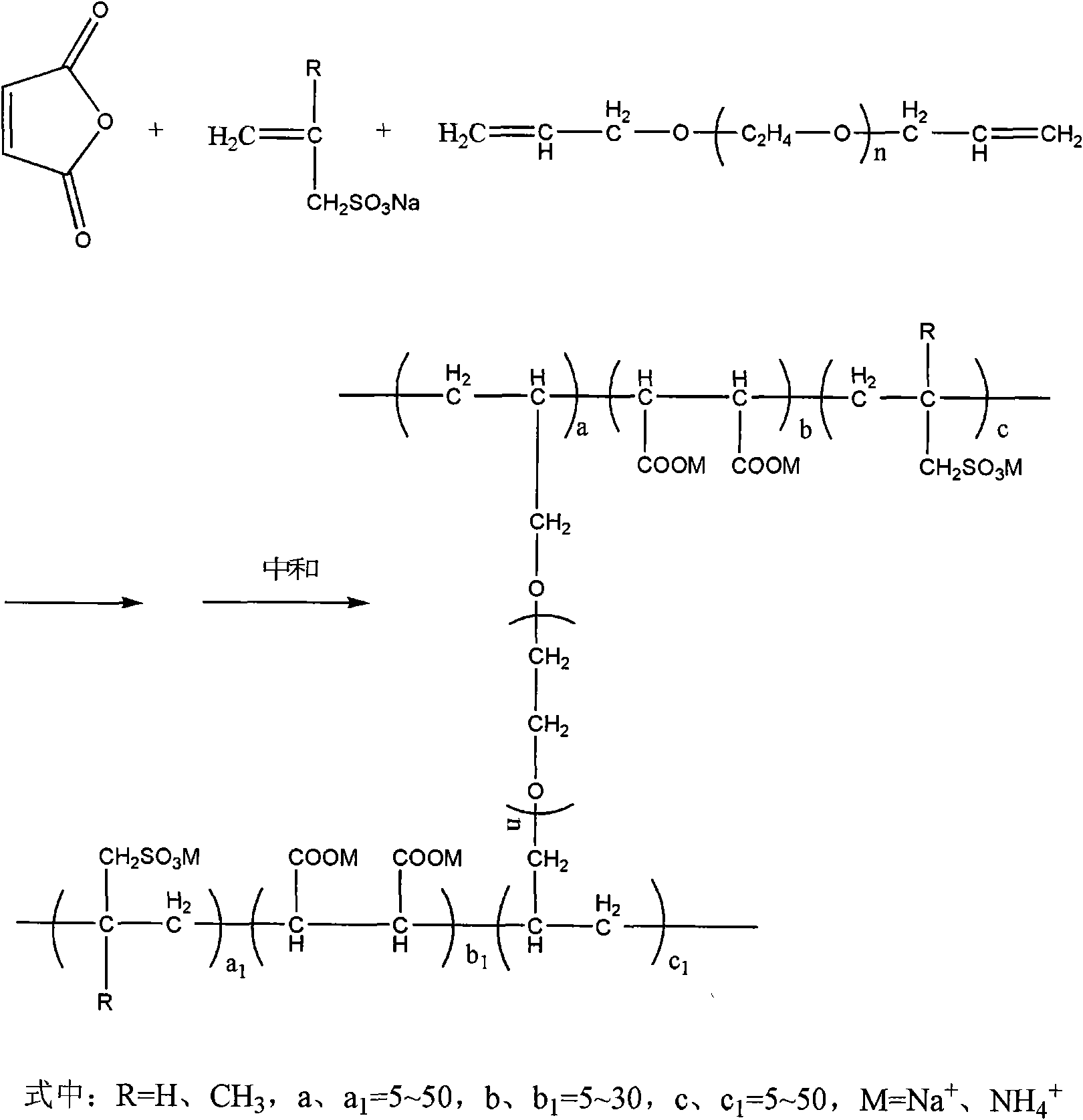

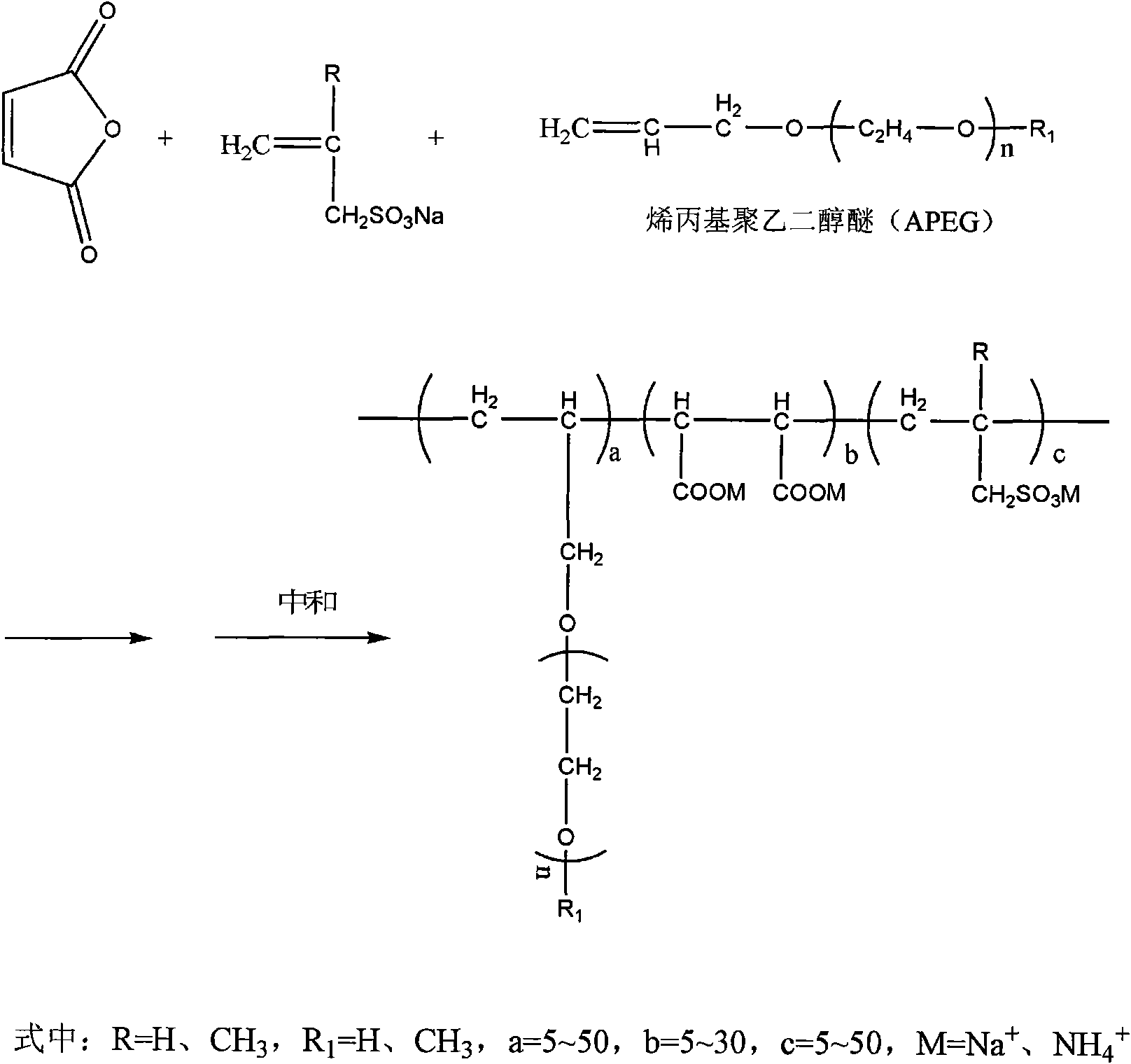

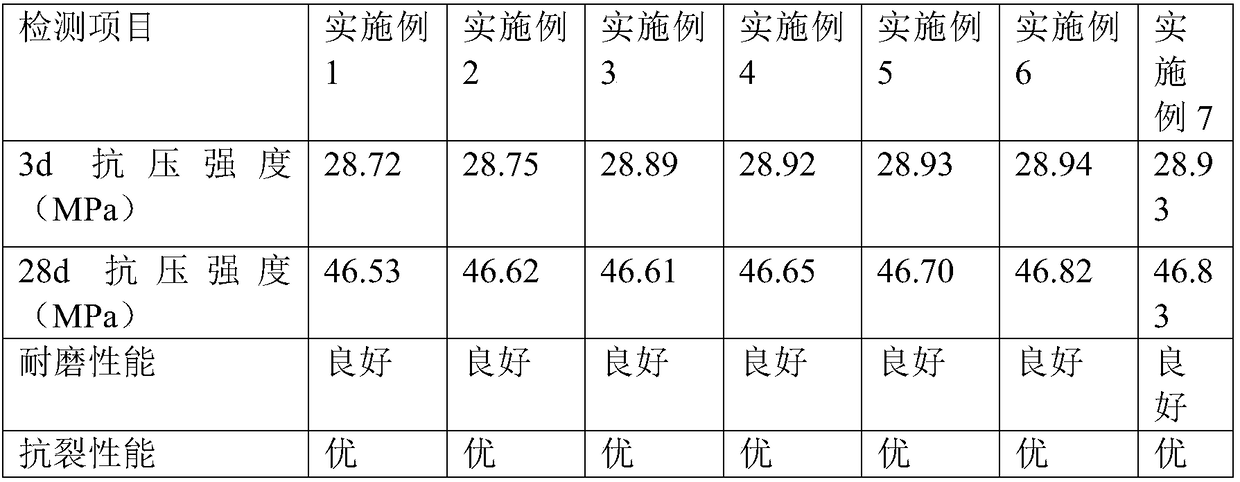

Polycarboxylic acid water reducing agent using diallyl polyethylene glycol (DAPEG) as raw material and preparation method thereof

The invention belongs to the technical field of concrete additives and in particular relates to preparation of macromonomer-diallyl polyethylene glycol (DAPEG) and a novel polycarboxylic acid water reducing agent prepared by using DAPEG as a raw material. The water reducing agent is prepared by carrying out heating reaction on the DAPEG, maleic anhydride (MA), sodium allyl sulfonate (SAS) or methyl sodium allyl sulfonate (MSAS), ammonium persulfate (APS), sodium hydroxide and water according to proper mass proportion by using nitrogen as shielding gas. In the invention, the polycarboxylic acid serial water reducing agent is prepared from the DAPEG for the first time, thus the variety of the polycarboxylic acid serial water reducing agent is enriched; and meanwhile, the prepared polycarboxylic acid serial water reducing agent has favorable performance, such as low doping amount, high water reducing rate, no delayed coagulation, low slump loss, and the like, thereby having more favorable market prospect and economic benefits.

Owner:安徽海螺材料科技股份有限公司

Concrete composite water reducer

The invention relates to a concrete composite water reducer, comprising a water reducer and a hydrophilic colloid. The concrete composite water reducer can improve the workability after using the water reducer, simultaneously an air entraining agent is added, a low-strength grade concrete with reasonable cost performance can be prepared by using a polycarboxylic acid water reducer, thus the problem of difficult popularization of the application of the polycarboxylic acid water reducer in the low-strength grade concrete.

Owner:SHANGHAI TAIJIE CHEM

Frost-resistant habitat base material for alpine region and preparation method thereof

ActiveCN104478320AUniform distribution of poresStrong filling effectCeramicwarePore distributionVegetable fibers

The invention relates to a frost-resistant habitat base material for alpine region and a preparation method thereof, which are applied to the fields of slope ecological protective engineering, landscape greening engineering and the like. The method comprises the following steps: firstly, evenly mixing nanometer Al2O3, nanometer SiO2, jute fiber, palm leaf sheath fibers and a powdery air entraining agent, to obtain a mineral and vegetable fiber mixture; then evenly mixing the mineral and vegetable fiber mixture with concrete greening additive, organic matters and cement to obtain an admixture; and finally, mixing the admixture with dry soil, evenly stirring to obtain the frost-resistant habitat base material for the alpine region, and spraying the frost-resistant habitat base material to slopes by utilizing an air compressor. In the habitat base material, pore distribution is finer and more uniform, the fiber reinforcement network develops better, the capability of ecological protective engineering on resisting the frost damage can be effectively enhanced, and the frost-resistant habitat base material for alpine region has significant meaning to the popularization and application of the ecological protection technology in the alpine regions.

Owner:CHINA THREE GORGES UNIV +2

Curing agent for solidification/stabilization of dewatered sludge of sewage plant and application of curing agent

ActiveCN102603153AHigh strengthLow incorporationSludge treatment by de-watering/drying/thickeningFirming agentSewage

Disclosed are curing agent for solidification / stabilization of dewatered sludge of a sewage plant and application of the curing agent. Chemical components of the curing agent includes, by mass, from 3 to 8 parts of SiO2, from 25 to 35 parts of Al2O3, from 32 to 43 parts of CaO, from 15 to 23 parts of SO3, from 1 to 3 parts of Fe2O3 and from 0.1 to 0.3 part of Li2O. After the curing agent is addedinto the dewatered sludge, solidification materials quickly react with moisture in the dewatered sludge to form a needle-shaped framework, and accordingly the strength of solidified sludge is improved. Besides, the yield of products is increased along with reaction, the specific surface area of the products is large, the products have a high adsorption effect, and effects of stabilization and pollutant sealing are achieved along with increase of compactness of solidified bodies.

Owner:HOHAI UNIV

Infrared isolation glass composition for preventing ultraviolet radiation

The invention relates to an infrared isolation glass composition for preventing ultraviolet radiation. A colorant is added to ordinary sodium-calcium-silicon glass; the proportion of the colorant is as below: total iron content (Fe2O3) is between 0.3 and 0.9wt%, the content of ferrous iron (Fe<2+>) in total iron is 24-36%, the content of CuO is between 0.1-0.5wt%, the content of CeO2 is between 0.1-0.5wt%, the content of TiO2 is between 0.2-1.5wt%, and the content of MnO is 0-0.02wt%. The glass excellent heat absorbing performance, more than 75% visible light transmittance no more than 24% of the total infrared transmittance, no more than 15% of ultraviolet transmittance, and no more than 42% of the total solar energy transmittance when the glass thickness is at 4mm. The glass not only does not interfere with people's vision, but also has good effects of sun shading, heat insulation and ultraviolet radiation.

Owner:江苏通天光学科技有限公司

Nickel iron slag gelling material and production technology thereof

The invention relates to a nickel iron slag gelling material and a production technology, relate to the nickel iron slag gelling material, and especially relates to cement produced by the nickel ironslag and a production method thereof. The nickel iron slag gelling material comprises the following components in parts by weight: 40-70 parts of Portland cement clinker, 30-60 parts of nickel iron slag low-temperature clinker, and 1-2 parts of gypsum, wherein the nickel iron slag low-temperature clinker comprises the following components in parts by weight: 20-30 parts of nickel iron slag, 9-15 parts of quicklime, 0.5-1 part of gypsum, 5-10 parts of water, and 0.2-0.6 parts of an alkaline electrolyte. The method can effectively solve the environment problem of stacking of nickel iron slag, realizes high-efficiency resource utilization of the nickel iron slag, and reduces CO2 discharge capacity during a cement preparation process, the nickel iron slag low-temperature clinker can substitutethe Portland cement clinker to produce the gelling material, and the produced nickel iron slag low-temperature gelling material has the characteristics of low hydration heat and good anti-sulfate erosion performance.

Owner:HOHAI UNIV

Mass concrete and preparation process thereof

The invention discloses mass concrete and a preparation process thereof. The mass concrete comprises 230-235 parts by weight of cement, 110-120 parts by weight of fly ash, 160-165 parts by weight of water, 75-80 parts by weight of mineral powder, 850-860 parts by weight of medium sand, 735-740 parts by weight of broken stones with a respective particle size of 5-25 mm, 220-225 parts by weight of broken stones with a respective particle size of 5-10 mm, 1-1.5 parts by weight of a modifying agent, 0.001-0.005 part by weight of a retarder and 7-7.8 parts by weight of a water reducing agent. The mass concrete and the preparation process thereof disclosed by the invention have the beneficial effects that through the addition of the fly ash and the mineral powder, the adding amount of the cementis reduced, and the heat release of the cement in the hydration process is reduced; meanwhile, the added modifying agent selects copolymer methacrylic acid and copolymerized isoprene polyoxyethyleneether capable of being complexed with the cement or the water reducing agent, so that the degree of hydration of the cement can be changed, the cement hydration peak is delayed, and the staggered peakhydration can be performed during use in the mass concrete. Through integrally selecting the above components, not only is the heat release in the hydration process of the cement reduced, but also the cement hydration peak is delayed, so that the temperature contraction affected by a sharp temperature change is avoided, and further the cracking phenomenon of the mass concrete is avoided.

Owner:成都精准混凝土有限公司

Construction waste sintering-free brick and preparation method thereof

InactiveCN107311539AHigh compressive strengthLow thermal conductivityCeramic shaping apparatusCement mixing apparatusBrickThermal insulation

The invention belongs to the technical field of energy-saving construction materials and provides a construction waste sintering-free brick and a preparation method thereof. The construction waste sintering-free brick comprises the following raw materials in parts by weight: 20-25 parts of basalt powder, 16-29 parts of glass powder, 25-46 parts of arsenic rock, 15-28 parts of construction wastes, 1-3 parts of activated clay waste residues, 5-11 parts of vermiculite, 9-14 parts of high-bauxite fine powder, 11-15 parts of cement, 1-6 parts of calcium oxide, 2-5 parts of a stabilizing agent and 1-2 parts of a gelatinizing agent. The invention aims to provide the construction waste sintering-free brick and the preparation method thereof; the construction waste sintering-free brick overcomes the defect that the strength, the thermal insulation, the energy conservation and other performances of an existing sintering-free brick cannot meet the demands on modern industrial development.

Owner:合肥一片美环保科技有限公司

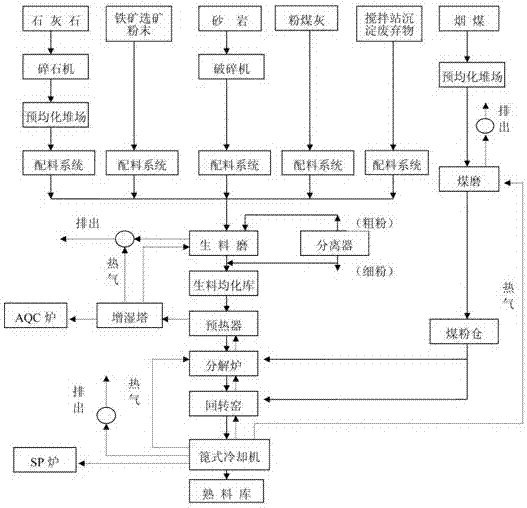

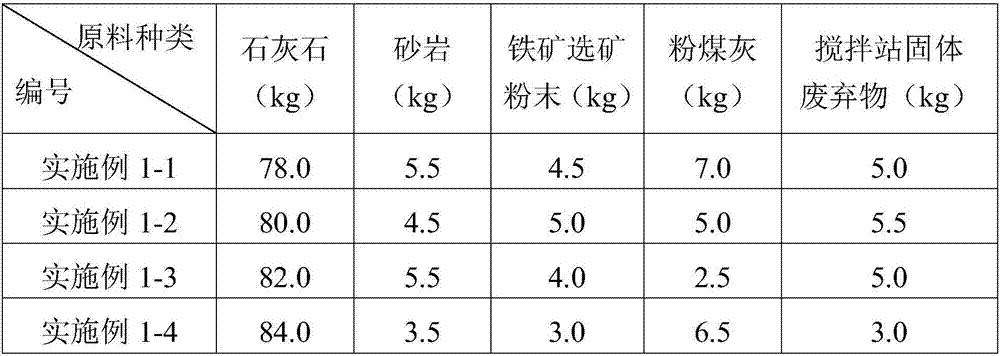

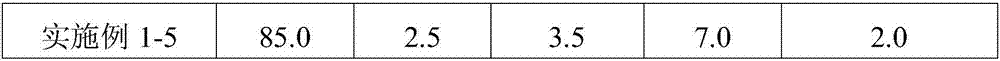

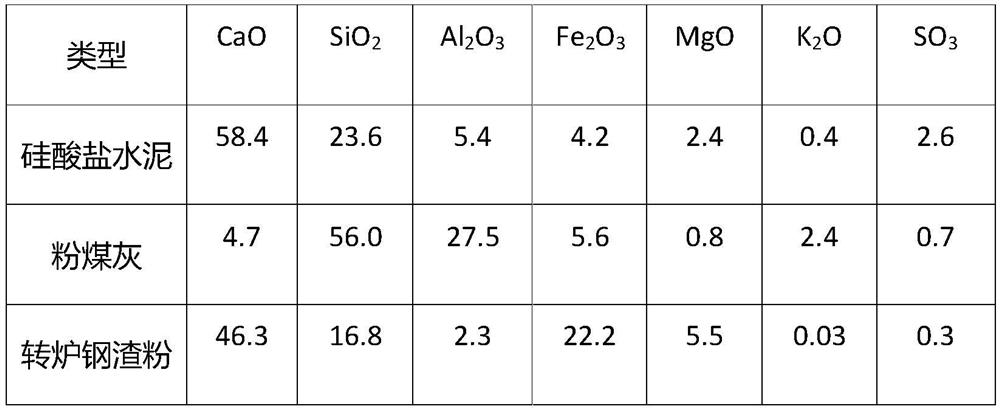

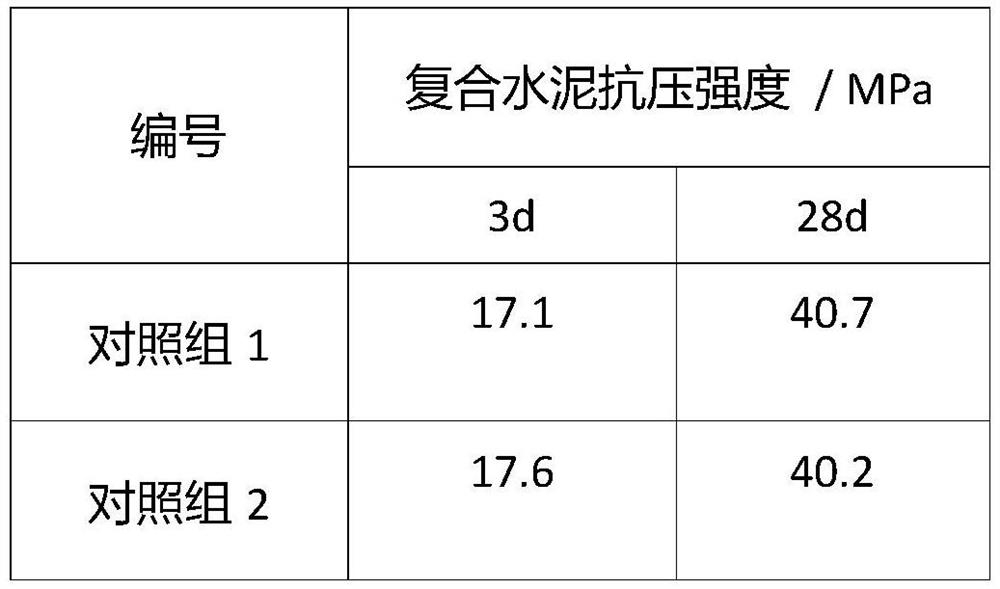

Formula for preparing cement clinker by solid waste of mixing plant and preparation method thereof

The invention discloses a formula for preparing cement clinker by solid waste of a mixing plant and a preparation method thereof, and belongs to the production field of cement clinker. The technical problem to be solved is that massive solid wastes in the mixing plant are accumulated to occupy the land, and not good for high-efficient land use and environment protection, and the cement production raw materials are in shortage. The technical scheme is that the formula of the cement clinker is prepared by the solid waste of the mixing plant, and the formula is formed by mixing raw materials by weight, 78.0-85.0 parts of limestone, 2.5-6.0 parts of sandstone, 3.0-5.0 parts of iron mine beneficiation powder, 2.5-7.0 parts of fly ash, and 2.0-5.5 parts of solid waste of mixing plant. The invention further discloses a preparation method of the cement clinker.

Owner:SHANDONG LUZHU GRP

Electric furnace steel slag-based cement admixture or concrete admixture as well as preparation method and application thereof

ActiveCN111689701ASolve the accumulationMitigate insufficient resourcesCement productionSlagPhosphogypsum

The invention discloses an electric furnace steel slag-based cement admixture or concrete admixture comprising the following components in parts by mass: 80-93 parts of ladle furnace refined steel slag, 2-8 parts of phosphogypsum, 5-12 parts of lithium slag and 0-0.2 part of an additive. The invention further provides a preparation method of the electric furnace steel slag-based cement admixture or concrete admixture and an application of the electric furnace steel slag-based cement admixture or concrete admixture in production and preparation of cement and concrete. The electric furnace reduction steel slag is utilized to the maximum extent, byproducts such as phosphogypsum and lithium slag are combined to serve as auxiliary components, the characteristics of self-hydration hardening andhigh adaptability are achieved, the superposition effect and synergistic efficient utilization of multiple kinds of waste are achieved, waste utilization is achieved, environmental protection is achieved, the cost is low, the cost performance is high, and the application prospect is wide.

Owner:SUN YAT SEN UNIV

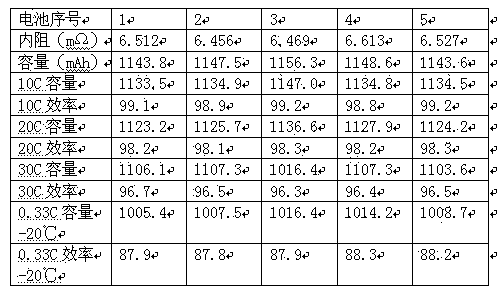

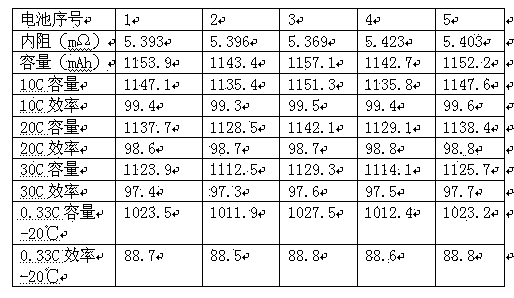

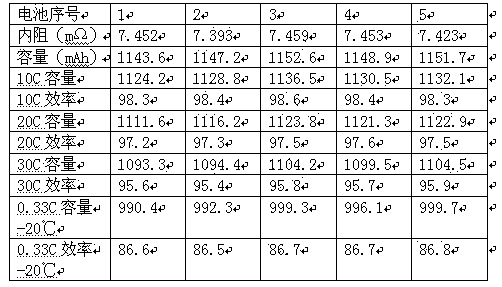

Preparation method of lithium iron phosphate positive plate with high rate and superior low-temperature performance

The invention discloses a preparation method of a lithium iron phosphate positive plate with high rate and superior low-temperature performance. The preparation method comprises the following steps: pretreating a current collector aluminum foil with a lithium chloride solution; adding a water-soluble binder to pre-prepared graphene suspension liquid; coating the pretreated current collector aluminum foil with the graphene suspension liquid and drying in vacuum; mixing dried lithium iron phosphate with a conductive agent, a binder and a solvent in a ratio to prepare slurry, coating the dried current collector aluminum foil with the slurry, and drying in vacuum; and rolling and slicing to obtain the lithium iron phosphate positive plate with high rate. The lithium iron phosphate positive plate prepared by the method has very high rate performance and superior low-temperature performance, is low in cost due to small use amount of graphene, and is suitable for industrial production.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

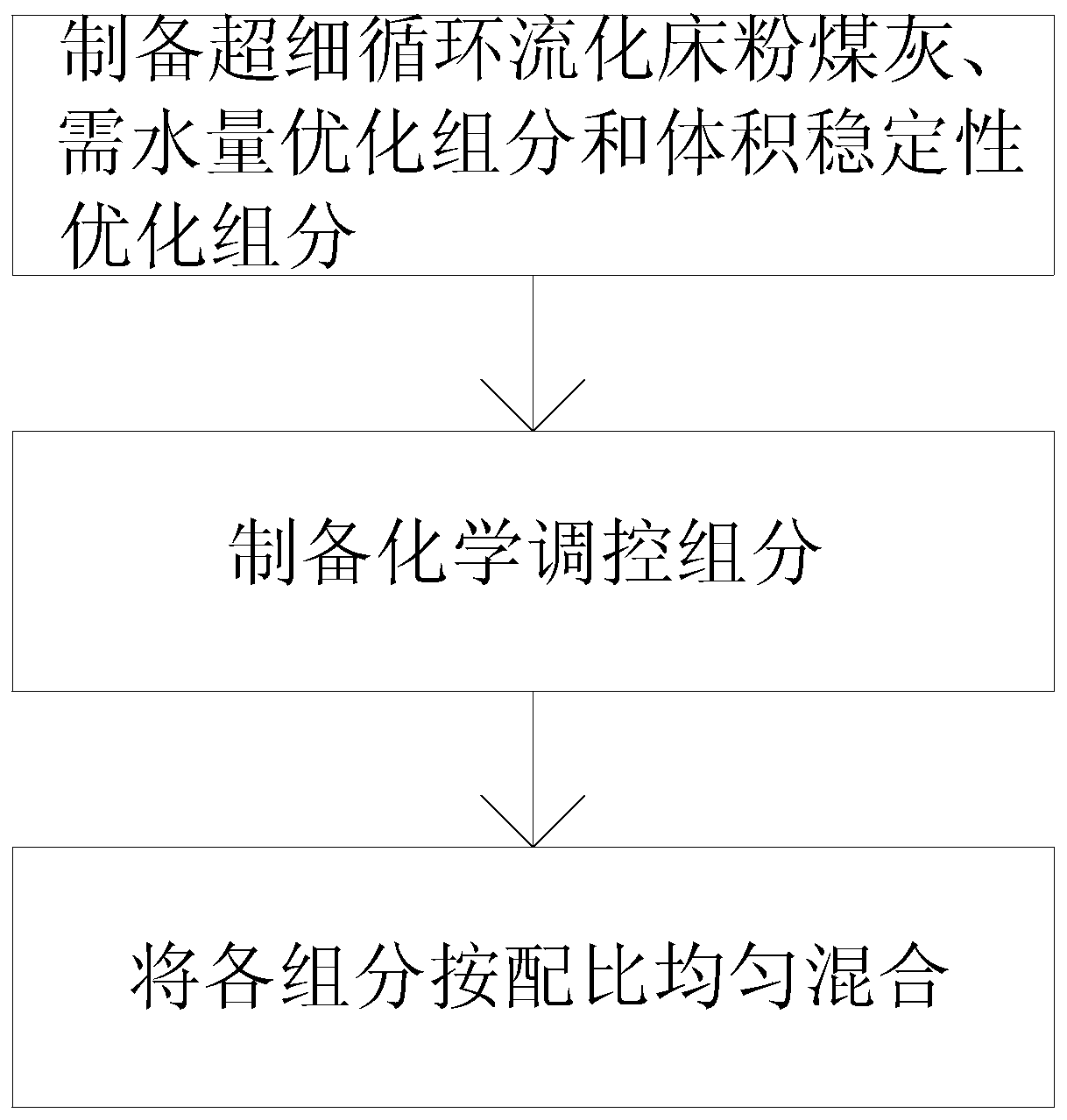

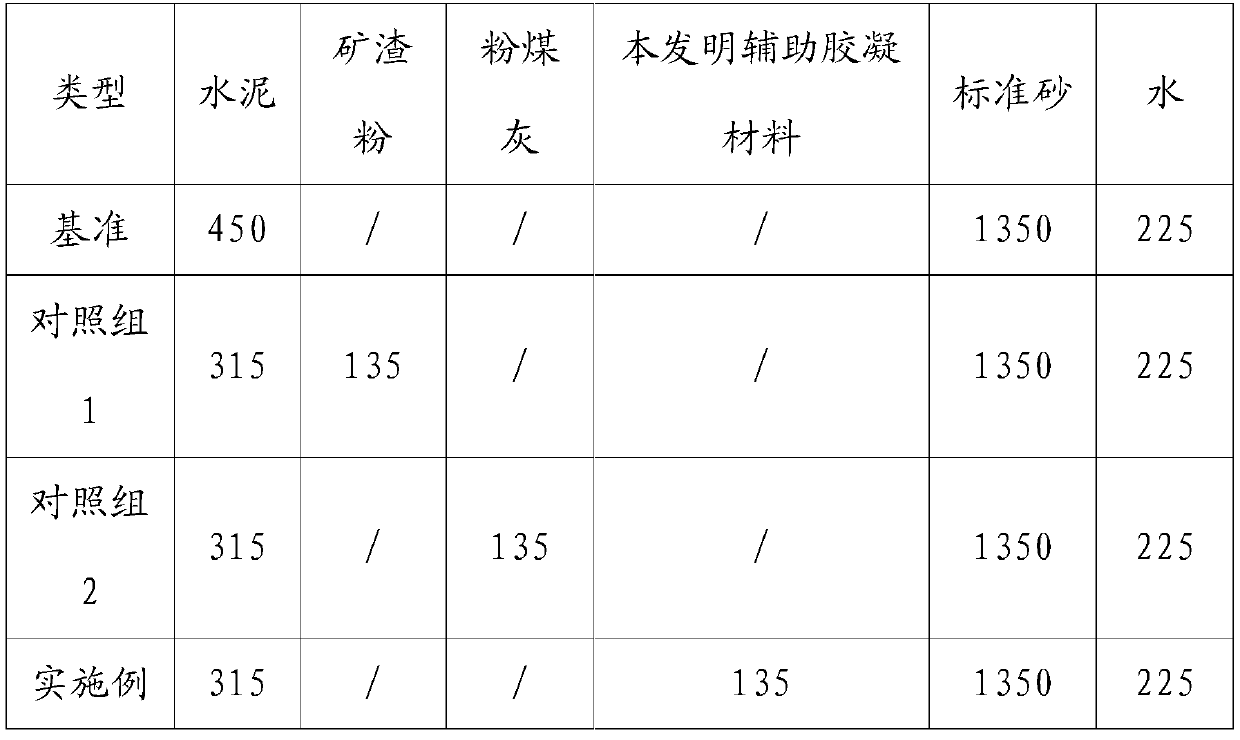

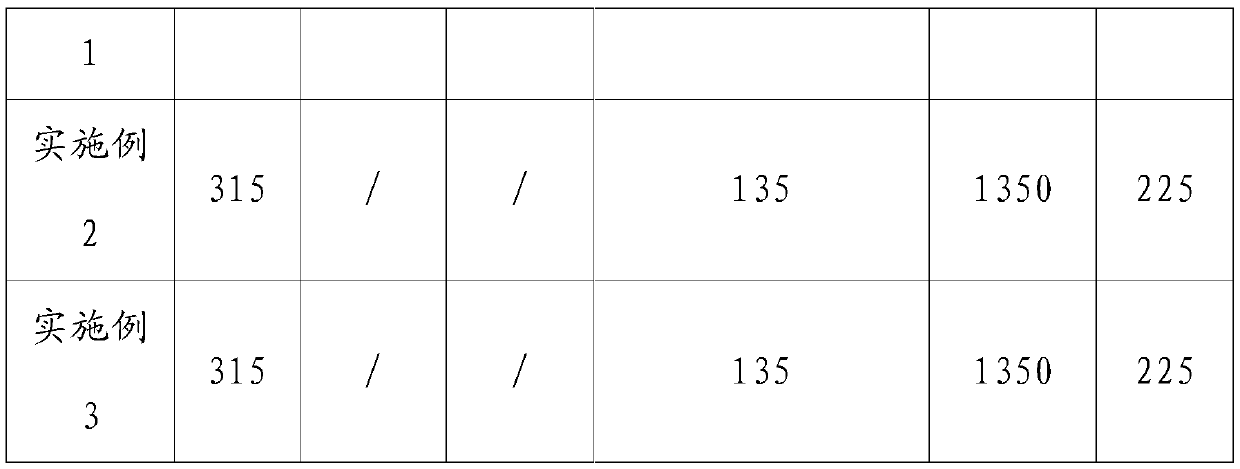

Auxiliary cementing material utilizing circulating fluidized bed fly ash and preparation method thereof

The present invention discloses an auxiliary cementing material using circulating fluidized bed fly ash and a preparation method thereof, the auxiliary cementing material comprises: 60-80% of ultrafine circulating fluidized bed fly ash, of which the particle size is less than 17 [mu]m, and the median particle size D50 is equal to 5 + / - 1 [mu]m; 5-20% of water demand optimization component, of which the particle size of the water demand optimization component is less than 10 [mu]m, and the median particle size D50 is equal to 4 + / - 1 [mu]m; 10-25% of a volume stability optimization component, wherein the median particle size D50 of the volume stability optimization component is 15-20 [mu] m; and 0-0.5% of a chemical regulation and control component, wherein the chemical regulation and control component is a liquid additive with the solid content of 30-50%. Specifically, the building material resource utilization rate of the circulating fluidized bed fly ash can be promoted, the application effect of the circulating fluidized bed fly ash as an auxiliary cementing material in cement concrete is improved, and the problem that the circulating fluidized bed fly ash is difficult to effectively utilize in the prior art is practically solved.

Owner:SUN YAT SEN UNIV +1

Plate glass highly doped with broken glass and preparation method of plate glass

ActiveCN107010831AHigh mechanical strengthIncrease the amount of participationGlass productionFlat glassDolomite

The invention discloses a plate glass highly doped with broken glass. The plate glass contains broken glass and auxiliaries in a mass fraction ratio of (70 to 30)-(90 to 10), wherein the auxiliaries include silica sand, fluorite, dolomite, limestone, calcined soda, mirabilite, a crystallization agent and coal powder. By substantially increasing the adding amount of the broken glass, the efficient utilization of waste is realized, and meanwhile, the problem of clarifying of the glass in a secondary re-melting process can be solved. Meanwhile, the invention further discloses a preparation method of the plate glass highly doped with the broken glass. The preparation method comprises the following steps: preprocessing, examination, mixing, smelting, forming and the like. The preparation method is applied to cooperative preparation of the plate glass highly doped with the broken glass, the highest melting temperature of the plate glass is decreased, the service life of a kiln is prolonged, and the melting efficiency is improved.

Owner:HUNAN JUQIANG RENEWABLE RESOURCES SCI & TECH DEV CO LTD

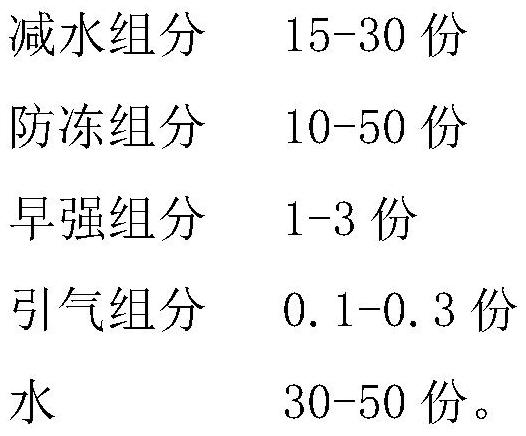

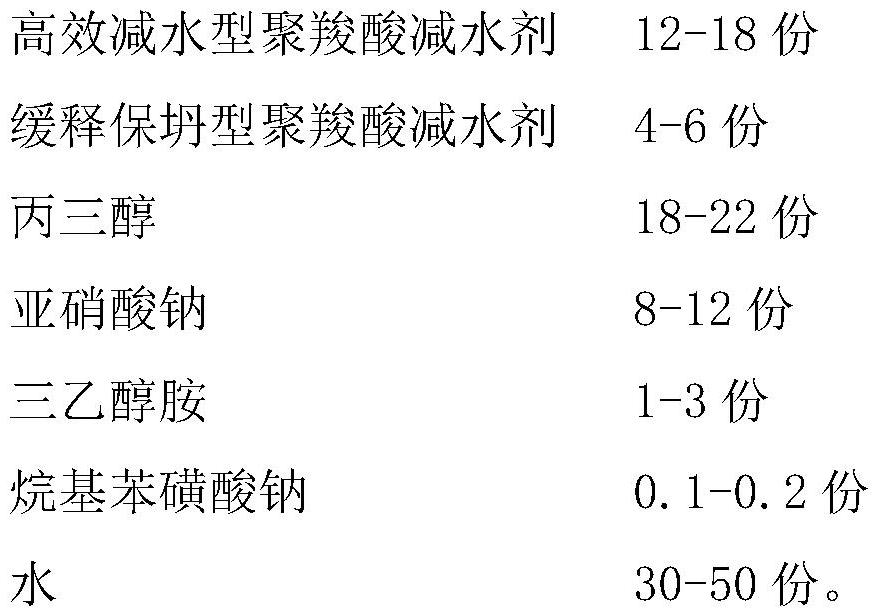

Concrete composite anti-freezing agent and preparation method thereof

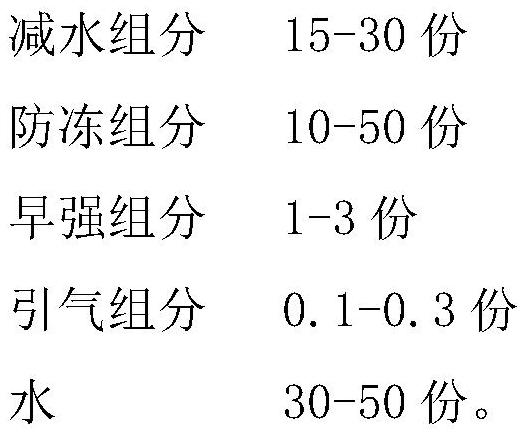

The invention discloses a concrete composite anti-freezing agent and a preparation method thereof. The concrete composite anti-freezing agent comprises the following raw materials by mass: 15-30 parts of a water reducing component, 10-50 parts of an anti-freezing component, 1-3 parts of an early strength component, 0.1-0.3 part of an air entraining component, and 30-50 parts of water. The obtained composite anti-freezing agent is free of pungent smell; the doping amount in a cementing material is small; the composite anti-freezing agent is free ofchlorine and low in alkali, and has no corrosion effect on reinforced concrete; no flocculent substance overflows after the anti-freezing agent solution is stored at the temperature of -20 DEG C for 7 days; and the compressive strength ratio of the concrete composite anti-freezing agent at the temperature of -20 DEG C is obviously higher than the set requirement of -15 DEG C specified in JC457-2004.

Owner:SHANXI SUNWAY INTION TRADE CO LTD

Cement grinding aid for cement grinding and preparation method thereof

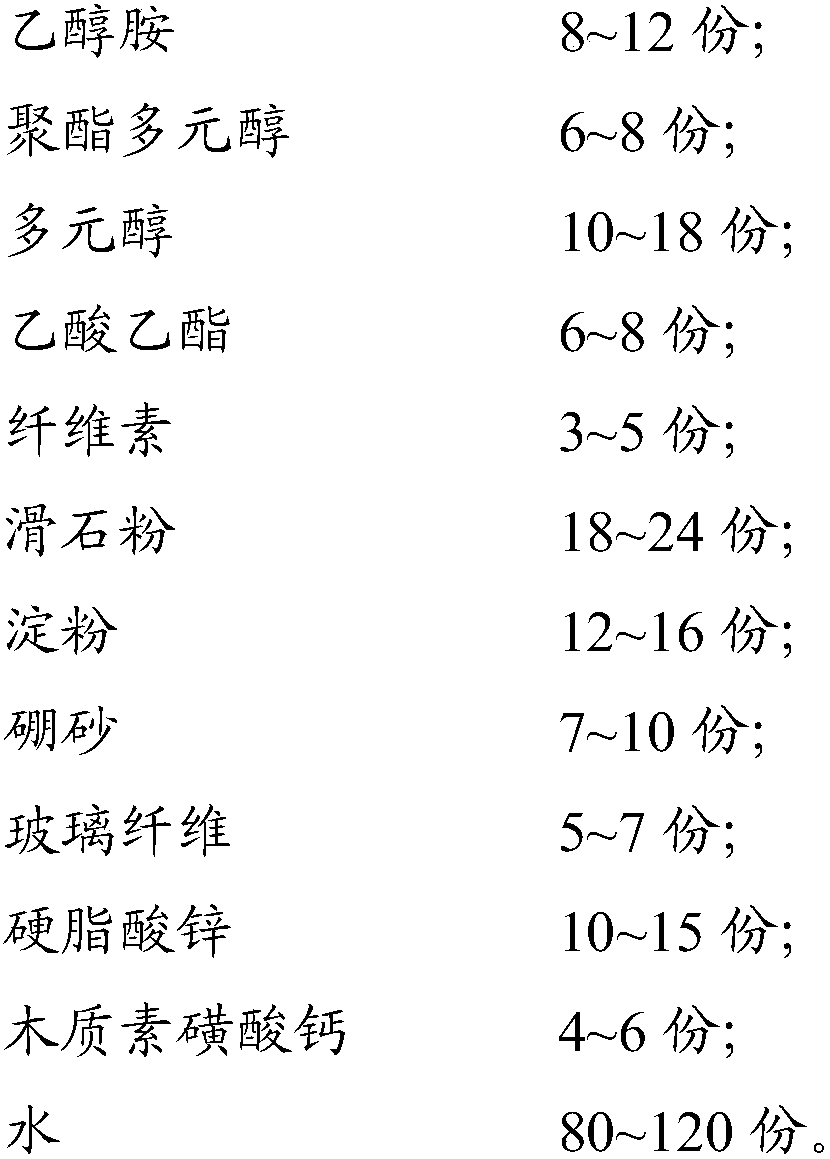

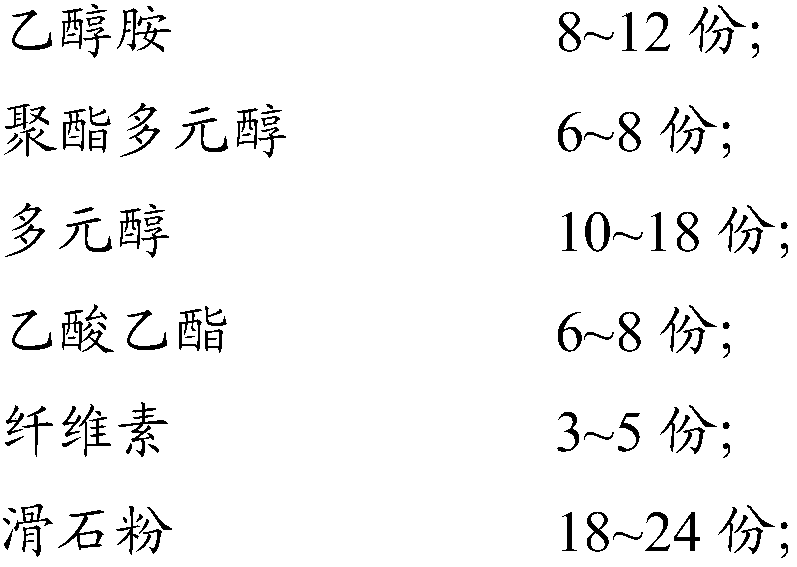

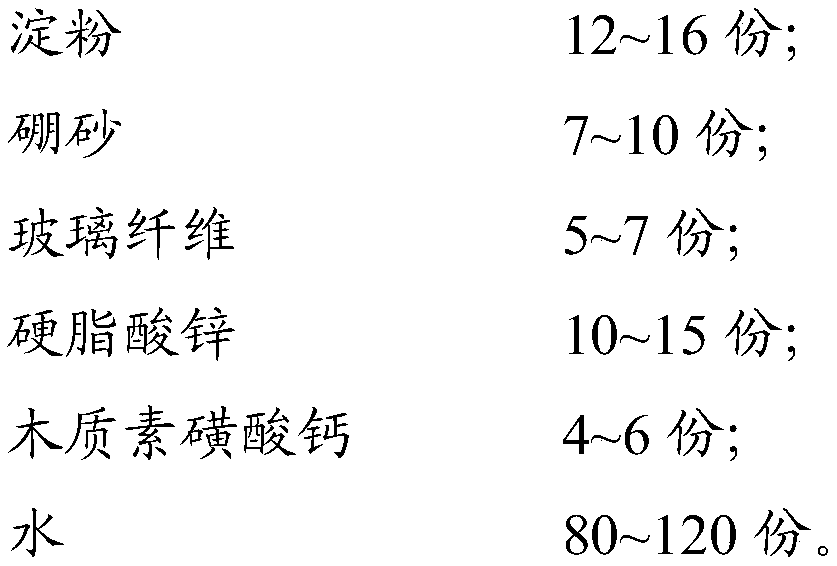

The invention discloses a cement grinding aid for cement grinding and a preparation method thereof. The cement grinding aid comprises, by weight, 8-12 parts of ethanol amine, 6-8 parts of polyester polyol, 10-18 parts of polyol, 6-8 parts of ethyl acetate, 3-5 parts of cellulose, 18-24 parts of talcum powder, 12-16 parts of starch, 7-10 parts of borax, 5-7 parts of glass fiber, 10-15 parts of zincstearate, 4-6 parts of calcium lignosulfonate and 80-120 parts of water. When the cement grinding aid prepared by adopting the above raw materials is used in the process of cement grinding, power consumption can be saved, and cement yield, mass and performance can be improved. Experiments show that by using the cement grinding agent, machine-hour yield is increased obviously, doping amount of thecement grinding aid is lowered greatly, and cement strength can be excited.

Owner:山东天汇科技有限公司

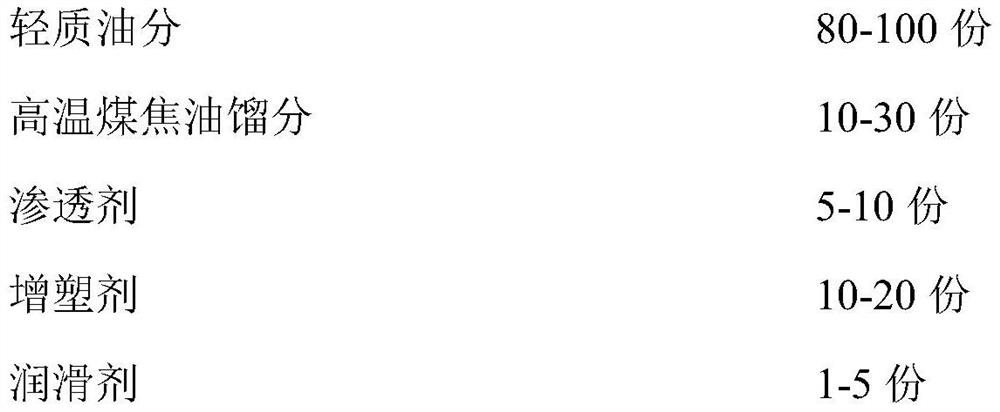

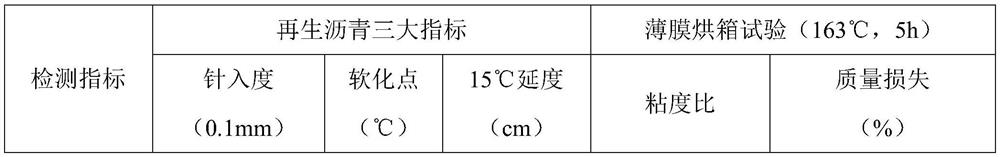

Low-dosage asphalt regenerant and preparation method and application method thereof

PendingCN112029300AExcellent solubility and dilution abilityLow incorporationBuilding insulationsPlasticizerProcess engineering

The invention discloses a low-dosage asphalt regenerant and a preparation and application methods thereof. The regenerant comprises light oil, high-temperature coal tar fraction, a penetrating agent,a plasticizer, a lubricating agent and an anti-aging agent. The dissolving regeneration effect of the regenerant on the aged asphalt is improved by utilizing the high-temperature coal tar fraction andthe penetrant, and meanwhile, the performance of the regenerant is improved by doping multiple modifiers. The regenerant prepared by the invention can recover the component balance of the aged asphalt under the condition of low doping amount (5%-7%), so that the recycling of RAP is realized, and the waste is turned into wealth.

Owner:HUNAN YUNZHONG REGENERATION TECH CO LTD

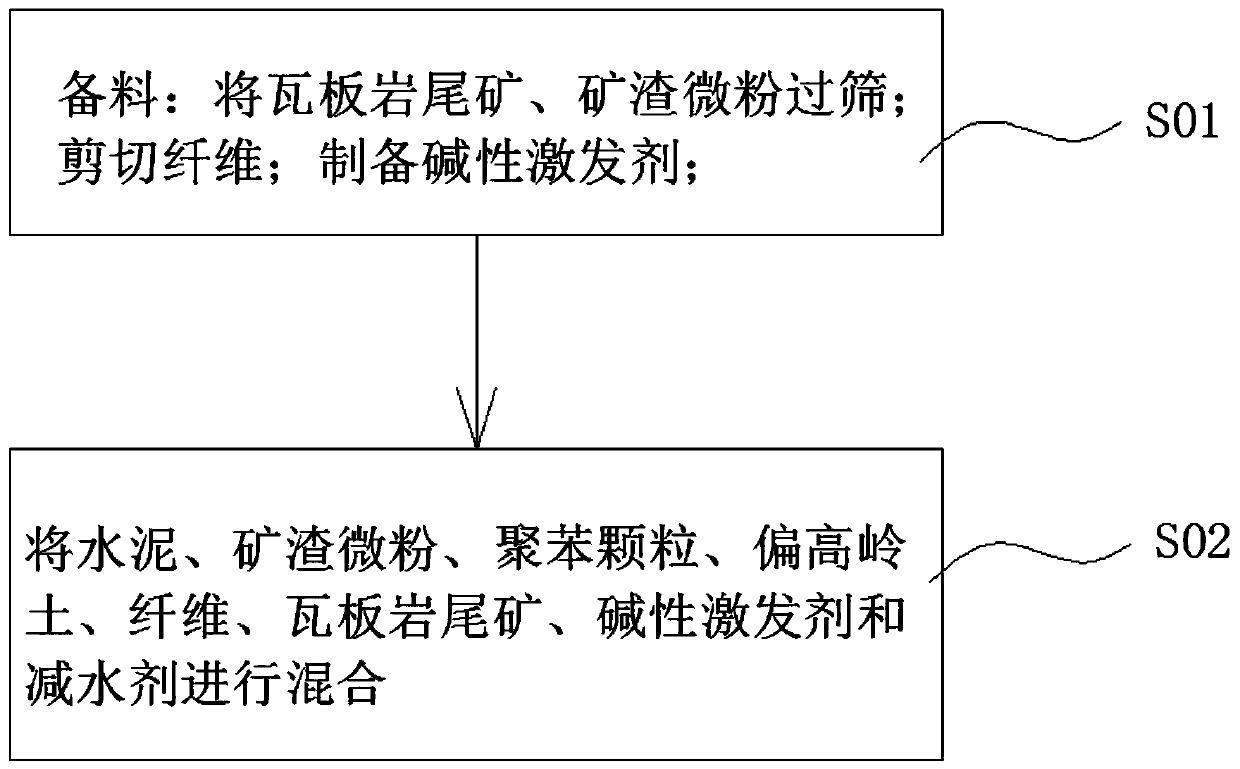

Light thermal insulation material and preparation method of light thermal insulation material

ActiveCN111423201AImprove impact resistanceCompressive strength is not affectedFiberThermal insulation

The invention relates to building materials, the invention particularly discloses a light thermal insulation material. The light thermal insulation material is prepared from the following components in parts by mass: 25 to 40 parts of cement, 5 to 15 parts of superfine slag powder, 1 to 5 parts of polyphenyl granules, 10 to 25 parts of metakaolin, 1 to 10 parts of fiber, 5 to 15 parts of tile slate tailings and 5 to 10 parts of an alkaline excitant. The preparation method of the light thermal insulation material comprises the following steps: 1, preparing materials, namely sieving tile slate tailings and the superfine slag powder to enable the tile slate tailings and the superfine slag powder to meet the particle size requirement; adopting hemp ropes, and preparing hemp rope fine fibers from the hemp ropes through shearing; 2, carrying out dry mixing on cement, superfine slag powder, polyphenyl granules, metakaolin, fibers, tile slate tailings and the alkaline excitant to obtain a mixture. The light thermal insulation material is light in weight, high in strength and suitable for popularization.

Owner:河南建筑材料研究设计院有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com