Formula for preparing cement clinker by solid waste of mixing plant and preparation method thereof

A technology of solid waste and cement clinker, applied in the field of cement clinker production, can solve the problems of lack of raw materials for cement production, unfavorable land efficient use and environmental protection, backlog of land occupation, etc., to achieve resource utilization and reduce land occupation The effect of reducing pressure and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Tested on a φ4.4×66m new type dry rotary kiln rotary kiln production line.

[0028] Limestone is mined from limestone mines, CaO: 50.2%, MgO: 2.9%.

[0029] Sandstone is taken from Yiyuan natural sandstone, SiO2: 90.6%.

[0030] Iron ore beneficiation powder is produced in Dongping, Fe2O3: 17.5%.

[0031] The fly ash was taken from a thermal power plant.

[0032] The solid waste of the mixing plant is taken from the waste dump of the mixing plant.

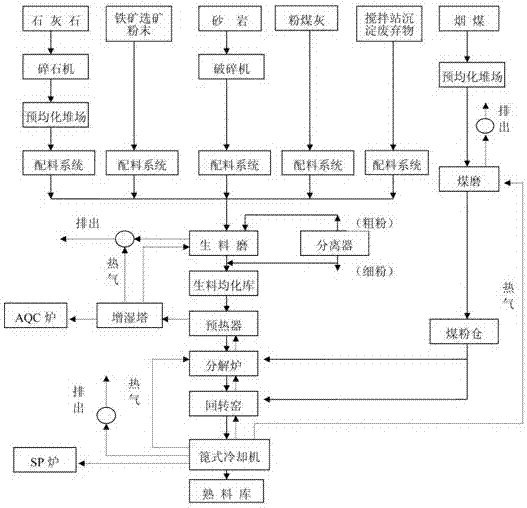

[0033] as attached figure 1 Shown, the present invention adopts the preparation method of the method for making cement clinker with mixing plant solid waste, and this preparation method comprises the steps:

[0034] (1) Batching: transport limestone, sandstone, iron ore beneficiation powder, fly ash, and solid waste from the mixing station to the batching system, and carry out batching through a computer to obtain a mixture for use;

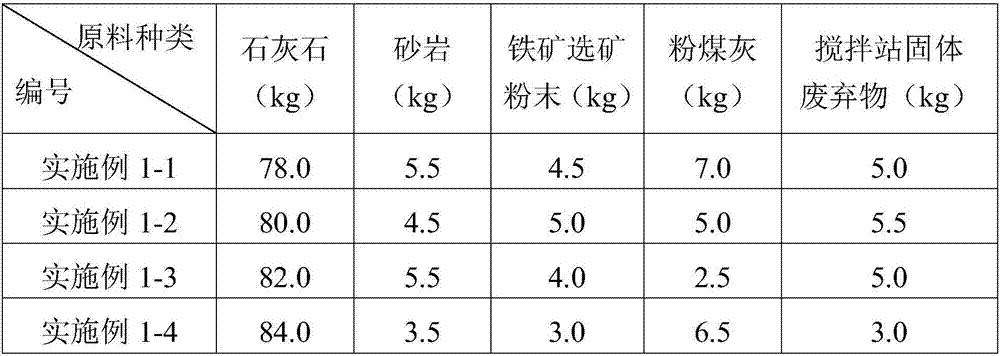

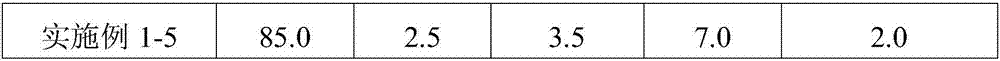

[0035] Wherein, the weight ratio of each raw material is shown in the following table:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com