Patents

Literature

30results about How to "In line with the concept of green environmental protection development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer type phosphor-containing fire retardant, preparation method and application thereof

InactiveCN101805620AIn line with the concept of green environmental protection developmentHigh phosphorus contentGroup 5/15 element organic compoundsAluminium chlorideChemical reaction

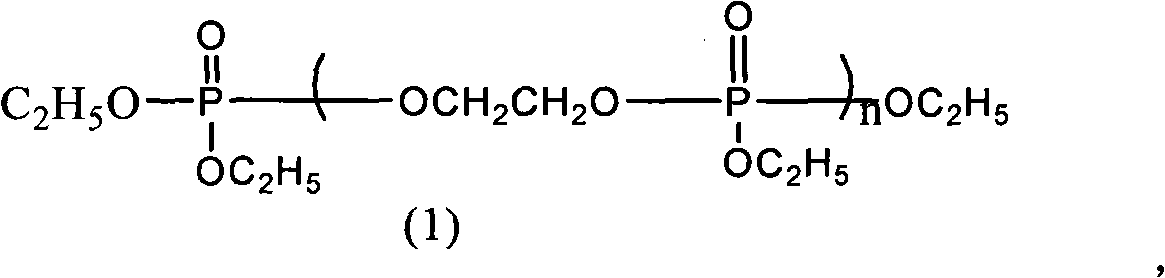

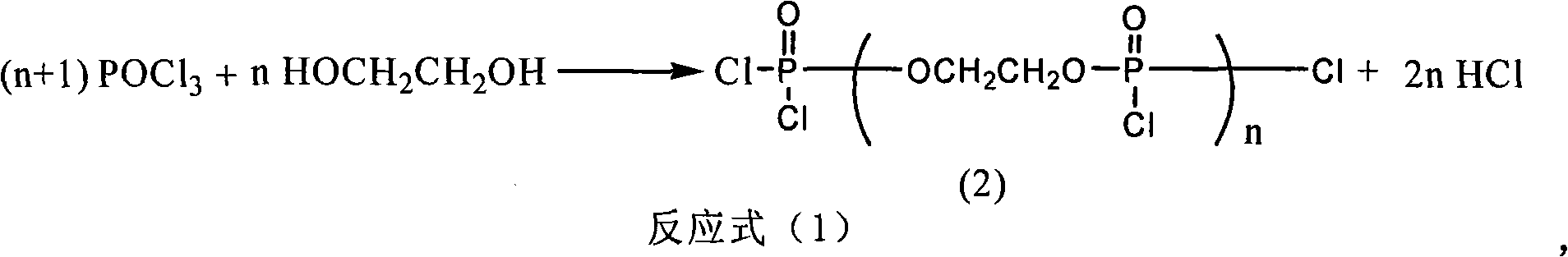

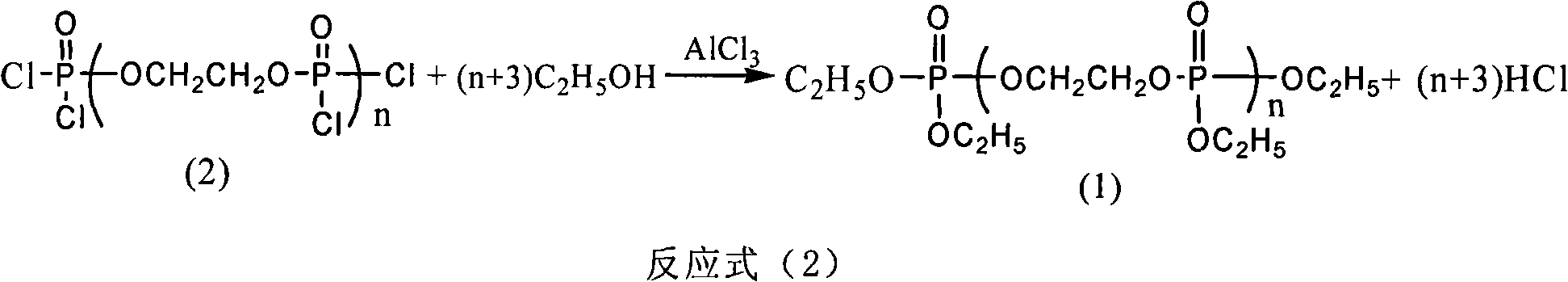

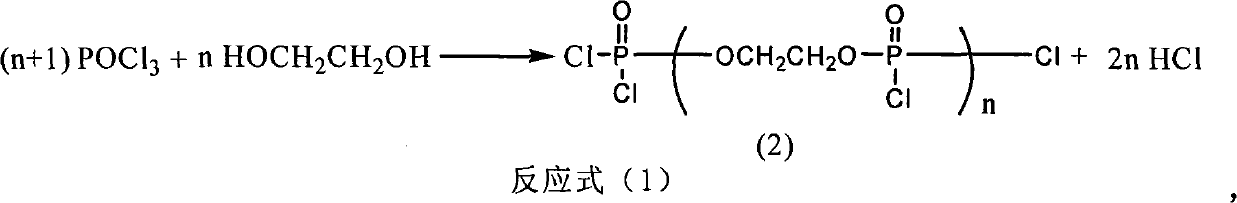

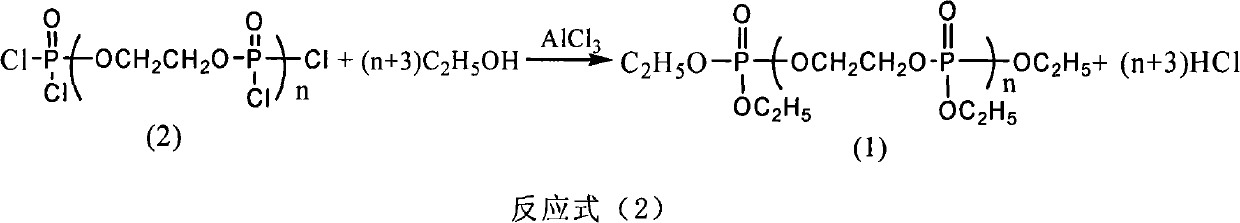

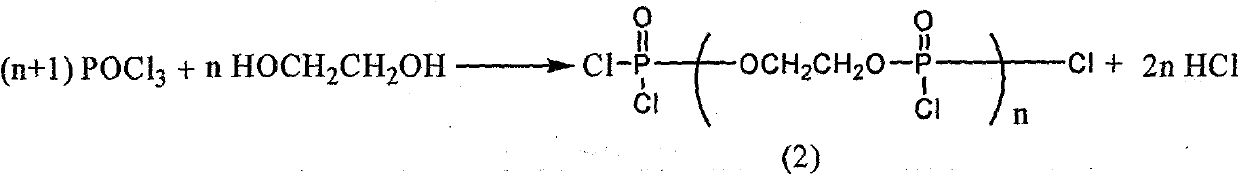

The invention belongs to the field of chemical materials, and discloses a polymer type phosphor-containing fire retardant, a preparation method and application thereof. The invention discloses the polymer type phosphor-containing fire retardant PNX is a compound shown in formula (1): n is an integer of between 5 and 8; and the molecular weight of the fire retardant is between 900 and 1,400. The method for preparing the fire retardant PNX comprises the following steps: reacting phosphorus oxychloride with ethylene glycol in nitrogen environment through a chemical reaction shown in a reaction formula (1) to prepare a compound (2); and preparing the fire retardant PNX by the compound (2) and absolute ethanol through a chemical reaction shown in a reaction formula (2) under the action of a catalyst aluminum chloride. The fire retardant PNX belongs to halogen-free series fire retardant, is in accordance with the concept of national green and environment-friendly development, ensures the phosphor content reaches 18 to 20 percent, and has excellent fire retardant performance.

Owner:JIANGSU DAMING TECH

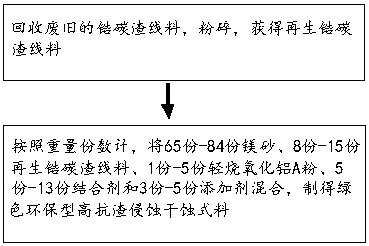

Preparation method of environment-friendly high-slag-corrosion-resistance dry material, and dry material

ActiveCN111732415AGive full play to the high resistance to slag erosionGive full play to the erosion performanceSlagZirconium

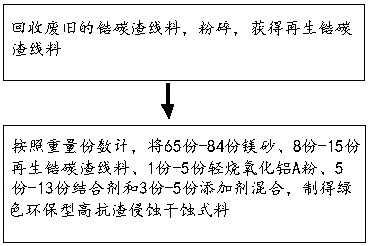

The invention relates to the technical field of refractory materials for continuous casting, and relates to a preparation method of an environment-friendly high-slag-corrosion-resistance dry material,and the high-slag-corrosion-resistance dry material. The method comprises the following steps: waste zirconium-carbon slag line materials are recycled and smashed to obtain a regenerated zirconium-carbon slag line material; and 65-85 parts by weight of magnesia, 8-15 parts by weight of the regenerated zirconium-carbon slag line material, 1-5 parts by weight of light calcined alumina A powder, 5-13 parts by weight of a binding agent and 3-5 parts by weight of an additive are mixed to prepare the environment-friendly high-slag-corrosion-resistance dry material. The invention aims to provide thepreparation method of the environment-friendly dry material with high slag corrosion resistance, and the dry material with high slag corrosion resistance. The expensive zirconium oxide raw material is reasonably recycled, the high slag corrosion resistance of zirconium oxide is brought into full play, the casting service life of the continuous casting tundish is prolonged, the refractory materialconsumption cost per ton of steel is reduced, pollution of refractory materials to molten steel is reduced, and the casting blank quality is improved.

Owner:日照瑞华新材料科技有限公司 +2

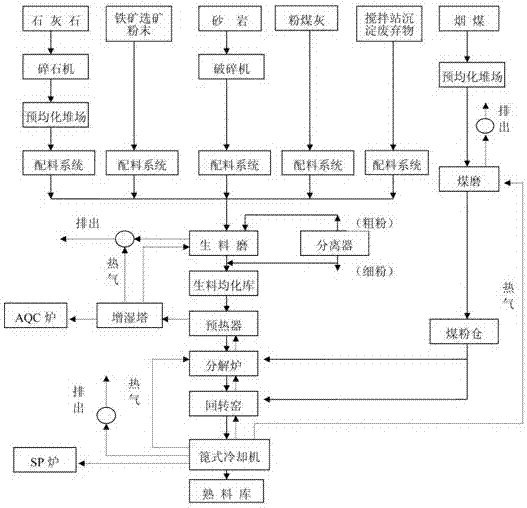

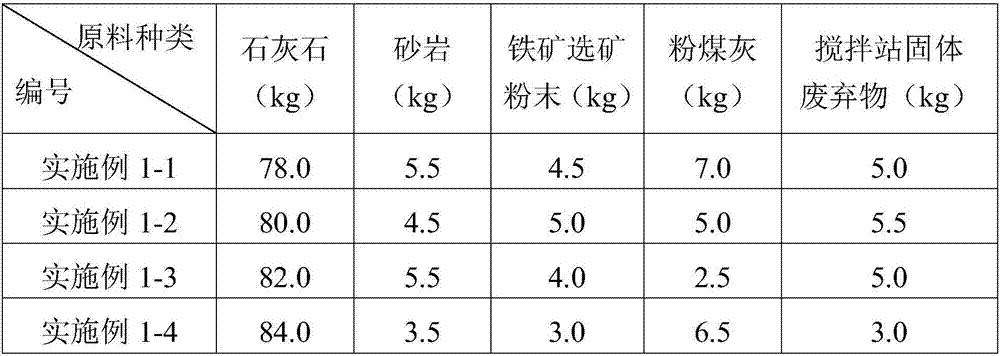

Formula for preparing cement clinker by solid waste of mixing plant and preparation method thereof

The invention discloses a formula for preparing cement clinker by solid waste of a mixing plant and a preparation method thereof, and belongs to the production field of cement clinker. The technical problem to be solved is that massive solid wastes in the mixing plant are accumulated to occupy the land, and not good for high-efficient land use and environment protection, and the cement production raw materials are in shortage. The technical scheme is that the formula of the cement clinker is prepared by the solid waste of the mixing plant, and the formula is formed by mixing raw materials by weight, 78.0-85.0 parts of limestone, 2.5-6.0 parts of sandstone, 3.0-5.0 parts of iron mine beneficiation powder, 2.5-7.0 parts of fly ash, and 2.0-5.5 parts of solid waste of mixing plant. The invention further discloses a preparation method of the cement clinker.

Owner:SHANDONG LUZHU GRP

Preparation method of cellulosic ethanol

PendingCN112608950AEasy to manufactureReduce energy and water consumptionBiofuelsMicroorganism based processesXylanPulp and paper industry

The invention discloses a preparation method of cellulosic ethanol, which comprises the following steps of pulverizing lignocellulosic biomass, carrying out hydrothermal reaction, cooling to obtain a mixed solution, regulating the pH value, adding cellulase and xylanase, carrying out enzymolysis, inoculating yeast, and fermenting to prepare cellulosic ethanol. According to the method, hydrothermal short-time depolymerization pretreatment is utilized to obtain the low-toxicity pretreatment liquid, and the cellulosic ethanol is prepared by a one-pot method, so that the operation steps are simplified, xylan in the pretreatment liquid is retained, pentose and hexose co-fermentation is realized, the yield of the cellulosic ethanol is remarkably increased, and the method is low in cost, low in energy consumption, free of wastewater discharge and effective sugar components in lignocellulose can be comprehensively utilized.

Owner:GUANGDONG UNIV OF TECH

Pure cotton active salt-free dyeing solution, dyed pure cotton shell fabric using same and technology

The invention belongs to the technical field of textile finishing processing, and specifically relates to a pure cotton active salt-free dyeing solution, a dyed pure cotton shell fabric using the purecotton active salt-free dyeing solution and a technology. The pure cotton active salt-free dyeing solution comprises the following components in concentrations: 0.5 to 80 g / L of active dye, an alkaline agent whose using amount is 55% to 65% of that of the active dye and is not lower than 9 g / L, NaOH whose using amount is 2.5% to 3.5% of that of the active dye and is not lower than 0.6 g / L, and the balance is water; the active dye is one or more of active yellow O, active red R and active blue B; the alkaline agent is SFA-01. The dyeing solution has good permeability for the pure cotton shellfabric, and can be used for dyeing under the condition without salt acceleration; the dyed pure cotton shell fabric is stable in quality, excellent in color fastness, colorful and plump in yarn-dyed weaving and excellent in comprehensive performance; according to the technology dyed by using the dyeing solution, surface dyeing can be removed effectively, the color fastness and washing fastness ofthe shell fabric are promoted, the COD value of wastewater discharge is reduced, and the technology is environmentally friendly and good in economic benefit.

Owner:鲁丰织染有限公司

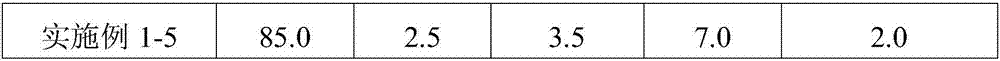

Novel aqueous urethane acrylate copolymer system and preparation method thereof

The invention provides a novel aqueous urethane acrylate copolymer system and a preparation method thereof, which belong to the technical field of environment-friendly type aqueous material preparation. According to the invention, an aqueous polyurethane prepolymer and acrylic acid ester are linked by a chemical bond, a core-shell aqueous urethane acrylate copolymer is obtained, wherein, aqueous polyurethane is taken as a shell, and polyacrylate is taken as a core. The performance advantage superposition of the aqueous polyurethane and acrylic acid ester is realized. A core-shell heterogeneous structure can effectively increase the mechanical properties of a glue membrane under condition of unchanged raw material composition and usage amount, the glue membrane has the advantages of high hardness and high elasticity, can improve the film-forming performance of an emulsion, and can easily form a film under room temperature. By using characteristic of an aziridine curing agent capable of performing a cross-linking polymerization with carboxyl group under normal temperature, a proper amount of the aziridine curing agent is subjected to compounding for the aqueous urethane acrylate copolymer, and the novel aqueous urethane acrylate copolymer system is prepared.

Owner:QILU UNIV OF TECH

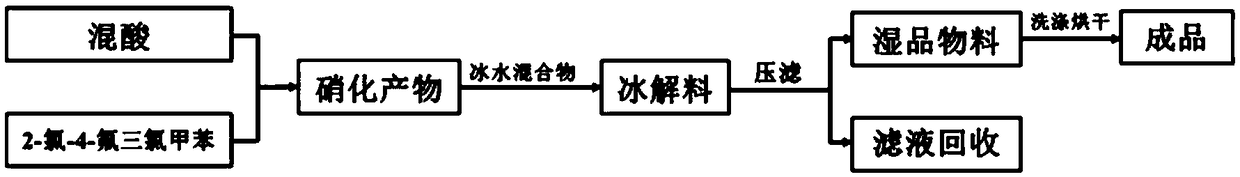

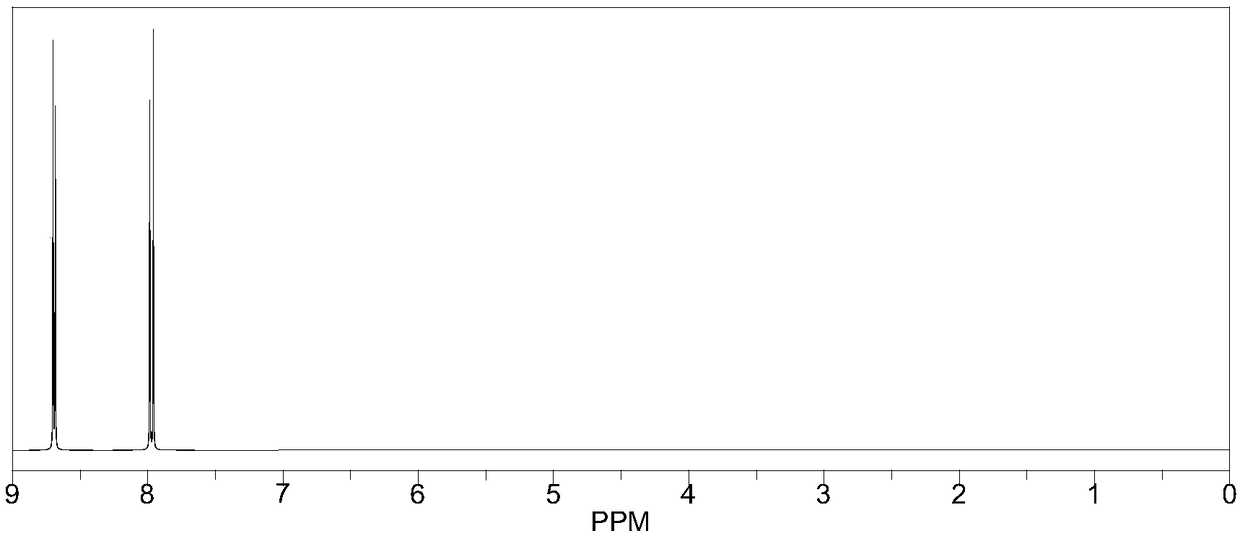

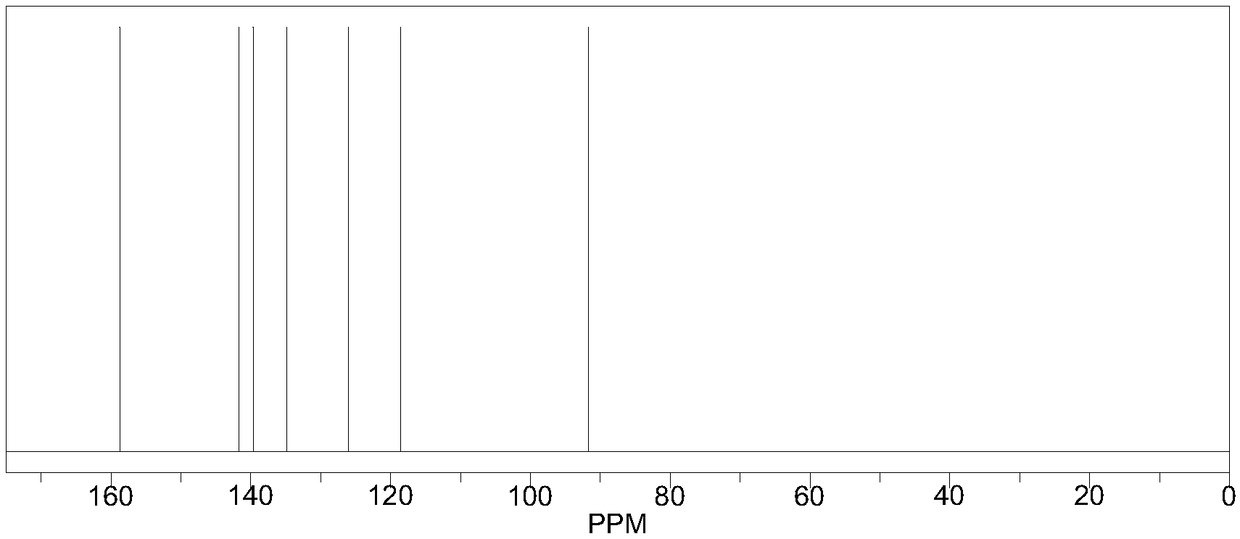

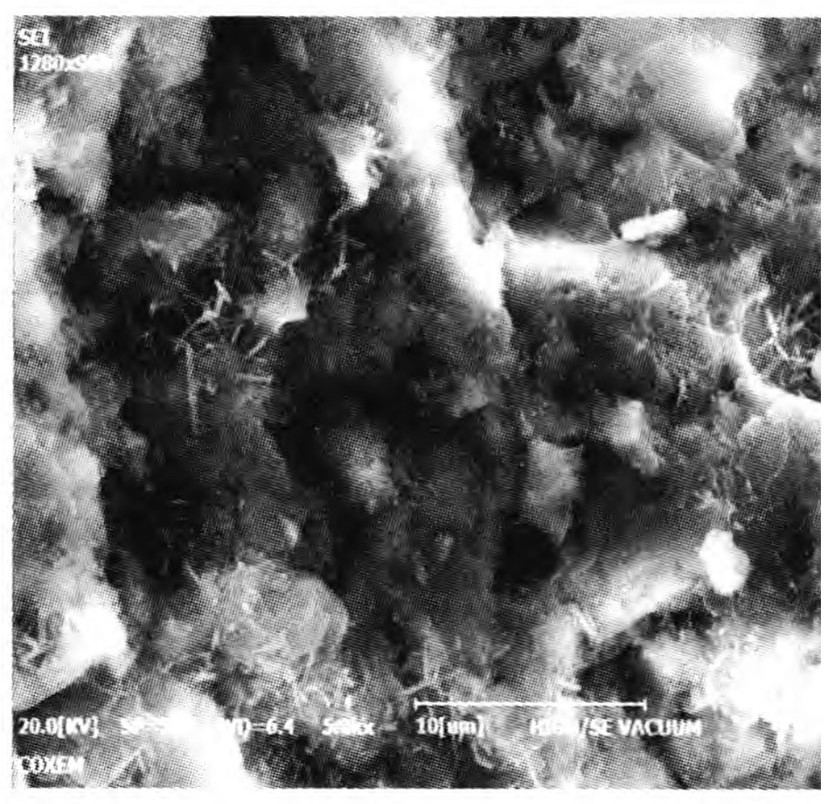

Method for efficient synthesis of 2-chloro-4-fluoro-5-nitrotrichlorotoluene

InactiveCN109265349AImprove nitrification capacityReduce the amount of sulfuric acidNitro compound preparationQuenchingSulfuric acid

The invention discloses a method for efficient synthesis of 2-chloro-4-fluoro-5-nitrotrichlorotoluene. The method comprises the following steps of (1) a nitrification reaction, wherein concentration sulfuric acid with the mass concentration of 98% and concentrated nitric acid with the mass concentration of 98 % are mixed according to the mass ratio of 1:1 to prepare mixed acid, and 2-chloro-4-fluorotrichlorotoluene is added dropwise into the mixed acid under the condition of stirring to carry out the nitration reaction; (2) quenching of the reaction, wherein a nitrified material obtained afterthe nitrification reaction is put into an ice-water mixture for stirring to quench the reaction; (3) preparation of a dry product, wherein after the reaction is quenched, a circulating water vacuum pump is adopted for suction filtration, and then washing and drying are conducted to obtain the dry product of 2-chloro-4-fluoro-5-nitrotrichlorotoluene; (4) recycling, wherein a filtrate obtained after the suction filtration and washing water are recovered for recycling. The method can improve the production efficiency, the color of the finished product is pure, and the yield and purity of the product are also high and are both 90% or above.

Owner:宿州学院

Waterproof concrete synergist and preparation method thereof

The invention discloses a waterproof concrete synergist and a preparation method thereof, and relates to the technical field of concrete admixtures. The waterproof concrete synergist comprises the following components by mass: 12-16% of polyaminated cellulose microspheres, 17-32% of modified waterborne polyurethane, 7-10% of a dispersant, 4-7% of a retarder, 2-5% of polyaluminum ferric sulfate, and the balance of water. According to the synergist, cement can be more sufficiently dispersed in concrete, so that the early strength and the later strength of the concrete are improved; and in addition, the synergist has the waterproof capability, and the practical engineering application range of the agent is expanded due to the improvement of the waterproof capability.

Owner:浙江鑫月新材料科技有限公司

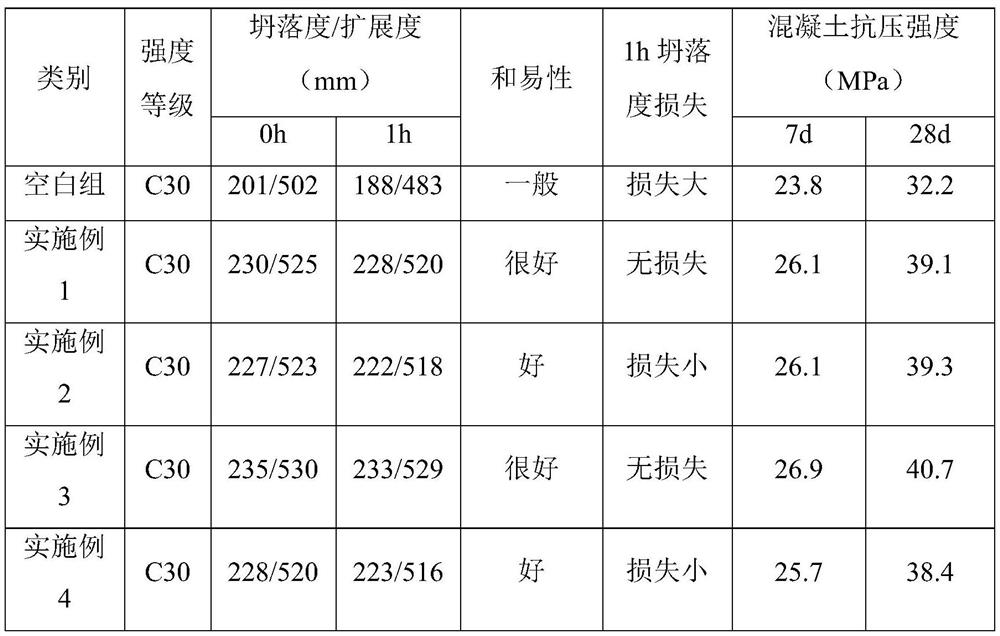

Slump retaining type concrete synergist and preparation method thereof

The invention discloses a slump retaining type concrete synergist and a preparation method thereof. The concrete synergist is prepared from the following substances in parts by weight: 12-20 parts ofa reinforcing agent, 8-15 parts of a regulator, 5-10 parts of an alkanol acrylate copolymer, 3-8 parts of maleic anhydride, 4-8 parts of a retarder, 2-5 parts of a lubricant and the balance of water.According to the invention, the polyol can make the cement fully hydrated; after the active sodium salt is doped into the concrete to promote the generation of low-sulfur calcium sulphoaluminate and hexagonal plate solid solution, the hexagonal plate solid solution fills internal pores and capillary channels of the concrete, so that the compactness of the concrete is improved, and the strength ofthe concrete is promoted to be improved. The alkanol acrylate copolymer can control the slump loss of concrete over time, so that the [xi] potential of the surface layer of cement particles is kept unchanged, and the cement particles are uniformly dispersed. Under the synergistic effect of the components, the synergist can obviously improve the early strength and later strength of concrete.

Owner:浙江鑫月新材料科技有限公司

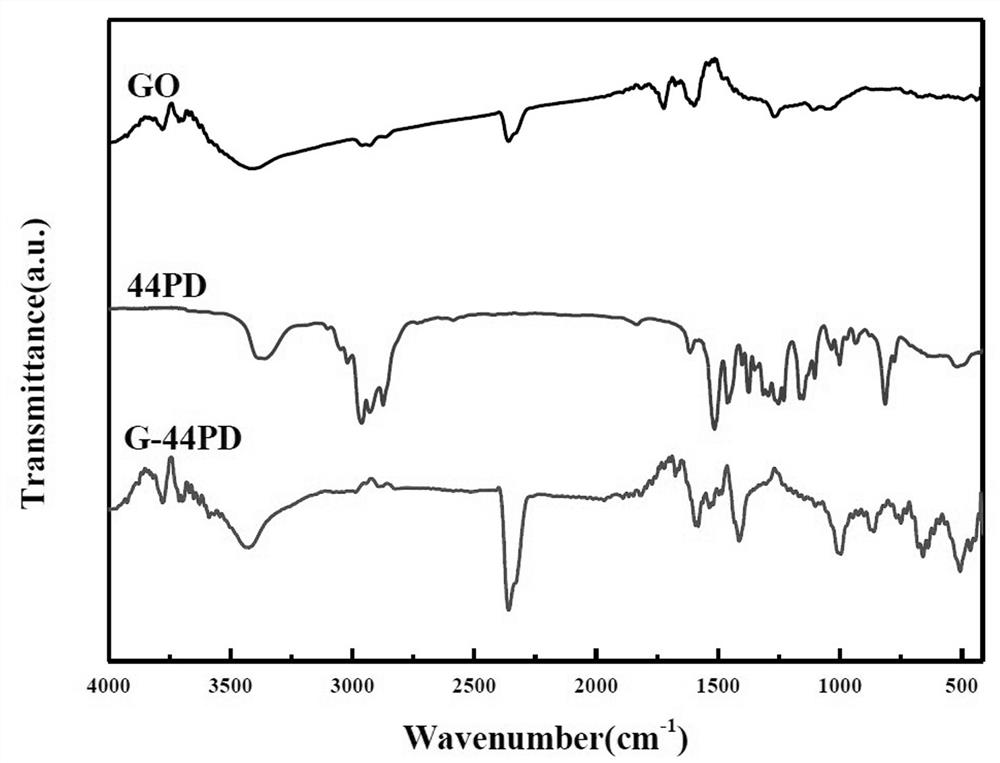

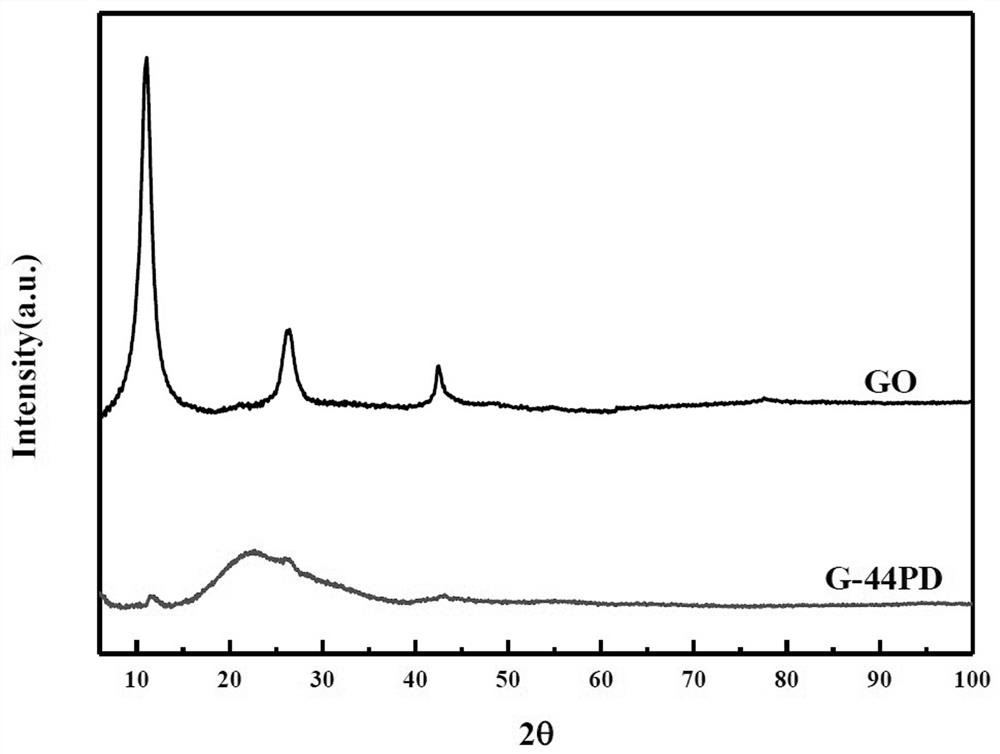

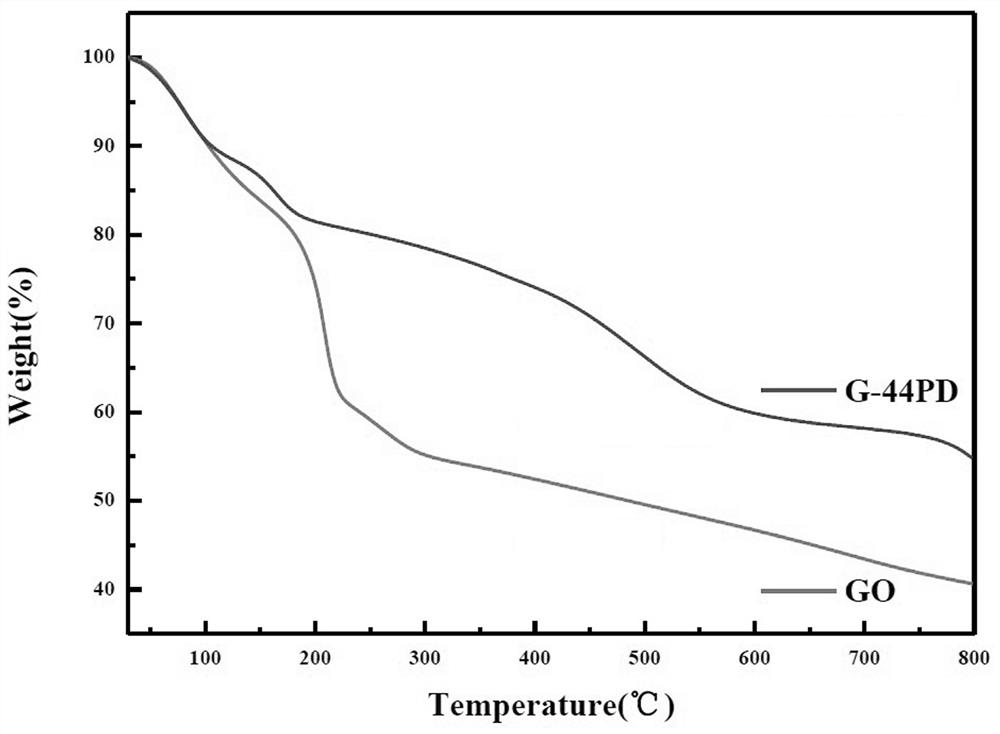

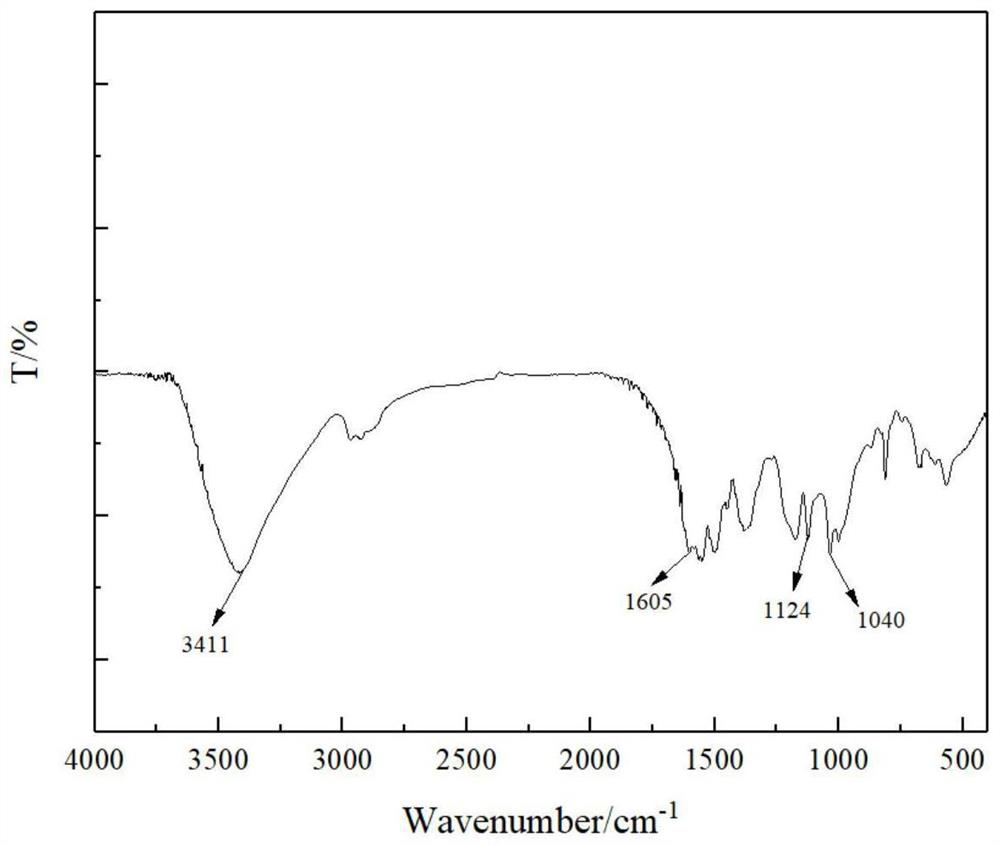

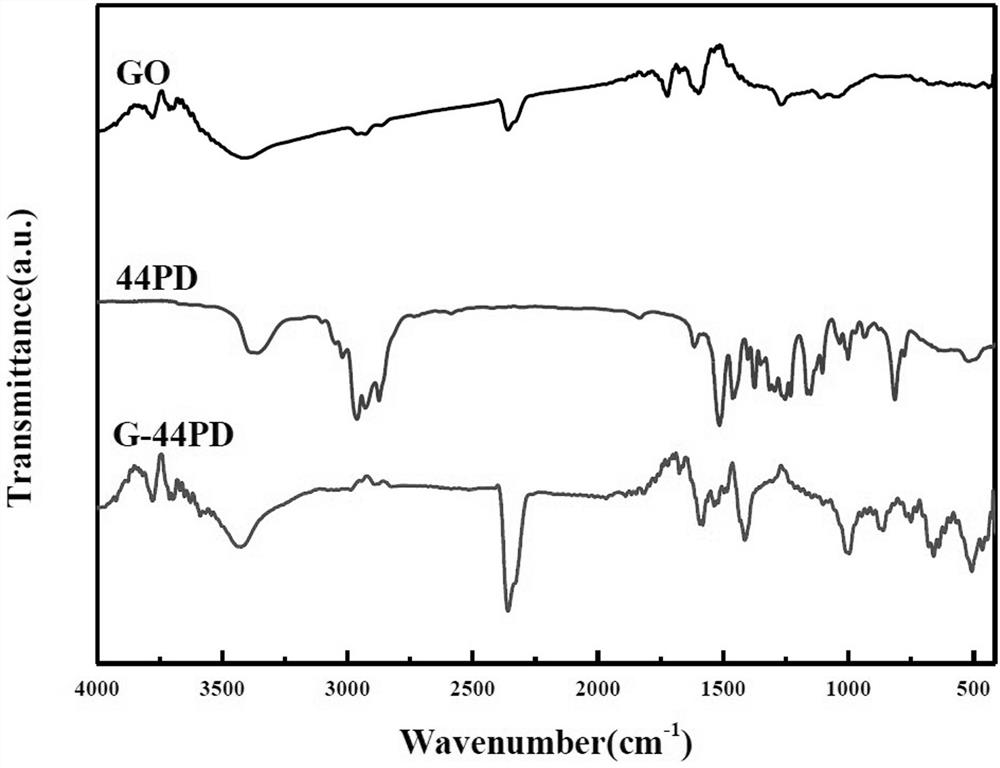

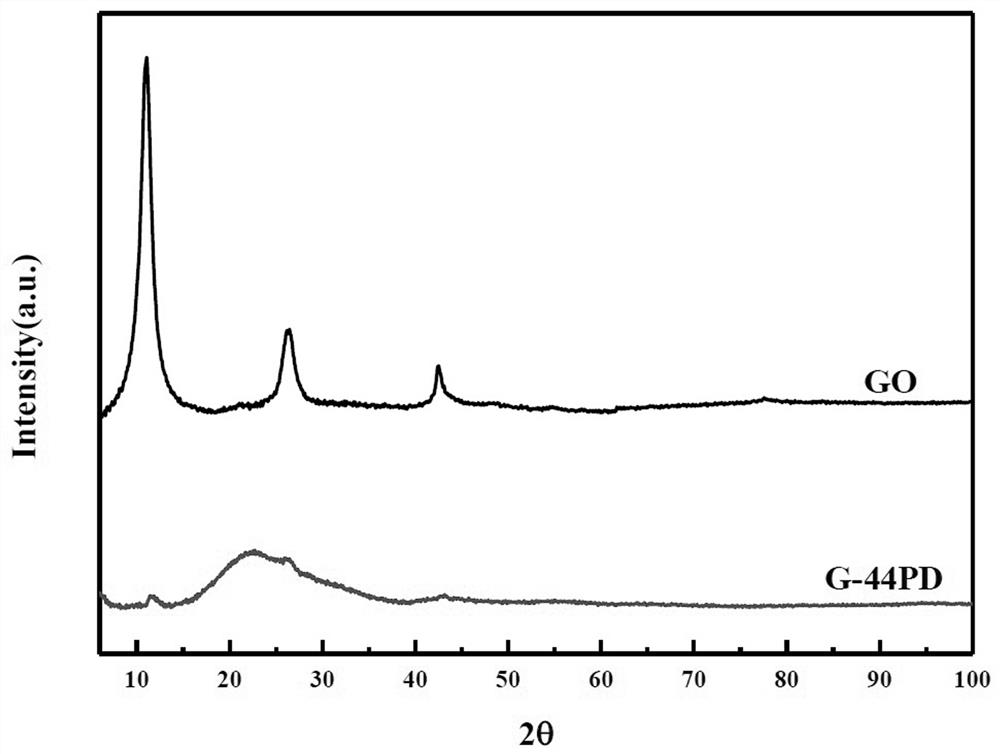

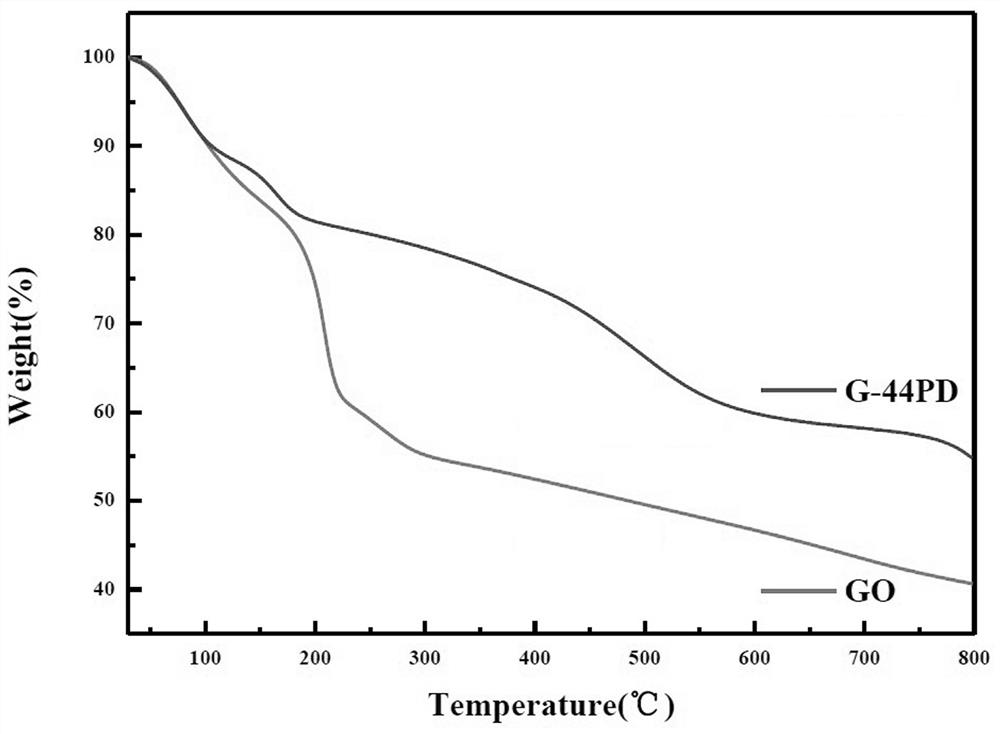

Functionalized graphene, preparation method thereof and application of functionalized graphene in rubber base plate

The invention relates to functionalized graphene. The functionalized graphene is prepared from the following raw materials of: an alkyl p-phenylenediamine antioxidant and graphene oxide; and the alkyl p-phenylenediamine antioxidant is one or more of N, N'-di-sec-butyl p-phenylenediamine, N, N'-bis (1, 3-dimethyl butyl) p-phenylenediamine, N, N'-bis (1, 4-dimethyl amyl) p-phenylenediamine, N, N'-di-iso-octyl p-phenylenediamine and N, N'-bis (1-ethyl-3-methyl amyl) p-phenylenediamine. The functionalized graphene provided by the invention is applied to an existing railway rubber base plate, and a high-performance rubber base plate with excellent mechanical property, good aging property and large resistance value can be prepared.

Owner:HEBEI TIEKE YICHEN NEW MATERIAL TECH CO LTD

Environment-friendly mildew-proof agent

InactiveCN107410357ASolve situations where there is no environmental performanceAvoid pollutionBiocideFungicidesPentachlorophenolPropanoic acid

The invention discloses an environment-friendly mildew-proof agent. The environment-friendly mildew-proof agent comprises the main materials by weight: quaternary ammonium salt derivative, casson, phenol, pentachlorophenol, organic mercuric salt, organic tin salt, inorganic-salt copper sulfate, mercuric chloride and sodium fluoride. The environment-friendly mildew-proof agent also comprises the auxiliary materials by weight: surface active agent, synergist, propionic acid and anhydrous calcium chloride. The invention relates to the field of mildew-proof technologies of objects. The environment-friendly mildew-proof agent disclosed by the invention has the beneficial effects that the condition that the mildew-proof agent sold on the market contains certain chemical components polluting the environment so as to be not environment-friendly is solved, the toxic components polluting air is better reduced, the odor is thoroughly reduced, the larger pollution caused to surrounding air is avoided, and the concept of green and environment-friendly development is conformed; and the environment-friendly mildew-proof agent is more stable for oxidizing and reducing agents, is uniform in dispersion, stable in heat and wide in PH range, can be used in the range of 2.0-12.0, and is low in use amount, difficult in combustion, easy in transportation and convenient in use.

Owner:广州优吸环保科技有限公司

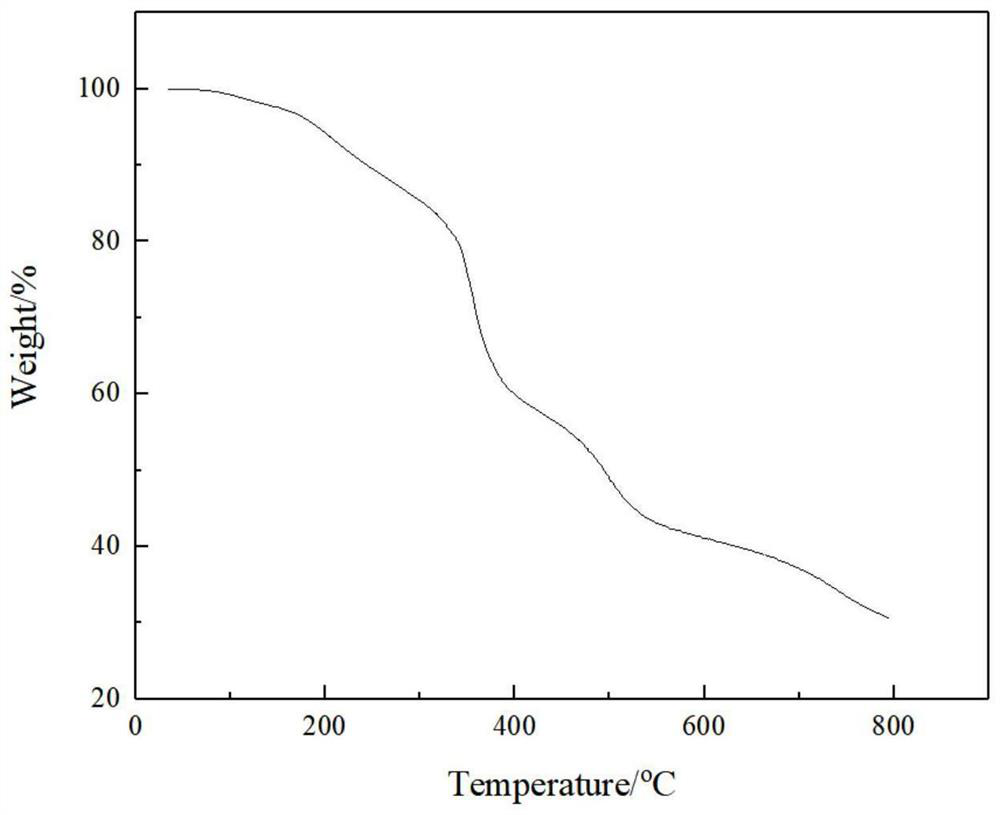

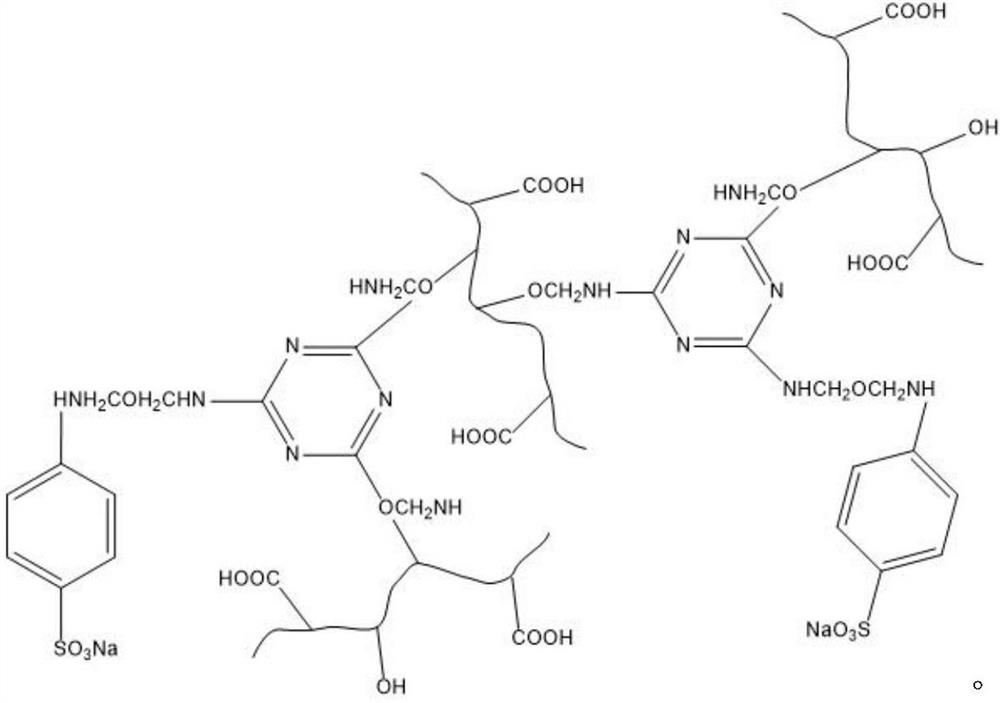

Sulfur-containing intumescent flame retardant and preparation method thereof

The invention discloses a sulfur-containing intumescent flame retardant and a preparation method thereof, and aims to catalyze a sulfur element in an acid source to replace a toxic phosphorus element. Environment-friendly melamine, sodium sulfanilate, carboxymethyl cellulose and other raw materials are selected and subjected to aldol condensation to obtain the high-molecular intumescent flame retardant connected through covalent bonds. Through sulfur-nitrogen synergistic flame retardance, the additive amount is small, a good flame retardant effect is obtained, and the flame retardant is suitable for materials such as polyurethane and epoxy resin. The preparation process is simple and is suitable for large-scale production and application.

Owner:SOUTHEAST UNIV

Polymer type phosphor-containing fire retardant, preparation method and application thereof

InactiveCN101805620BIn line with the concept of green environmental protection developmentHigh phosphorus contentGroup 5/15 element organic compoundsAluminium chlorideChemical reaction

Disclosed are a polymer type phosphor-containing flame retardant, preparation method and application thereof, which belong to the field of chemical materials. The polymer type phosphor-containing flame retardant PNX is a compound shown in formula (1), wherein n is an integer of 5~8 and the molecular weight of the flame retardant is between 900 and 1400. The method for preparing the flame retardant PNX is as follows: reacting phosphorus oxychloride with ethylene glycol in a nitrogen environment through a chemical reaction shown in the reaction formula (1) to obtain a compound (2), then reacting the compound (2) with anhydrous ethanol through a chemical reaction shown in reaction formula (2) under the action of a catalyst aluminum chloride to produce the flame retardant PNX. The flame retardant PNX belongs to a halogen-free, phosphorous type flame retardant. It coincides with the national concept of green-environmentally-friendly development. The content of phosphor is as high as 18%~20%, and the flame retardant properties are excellent.

Owner:JIANGSU DAMING TECH

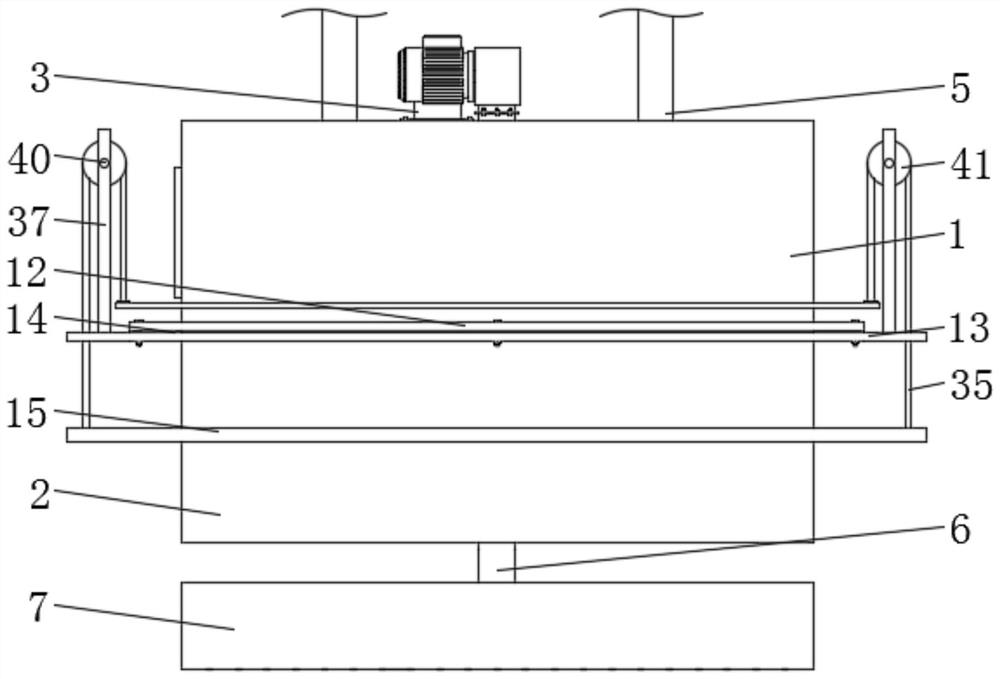

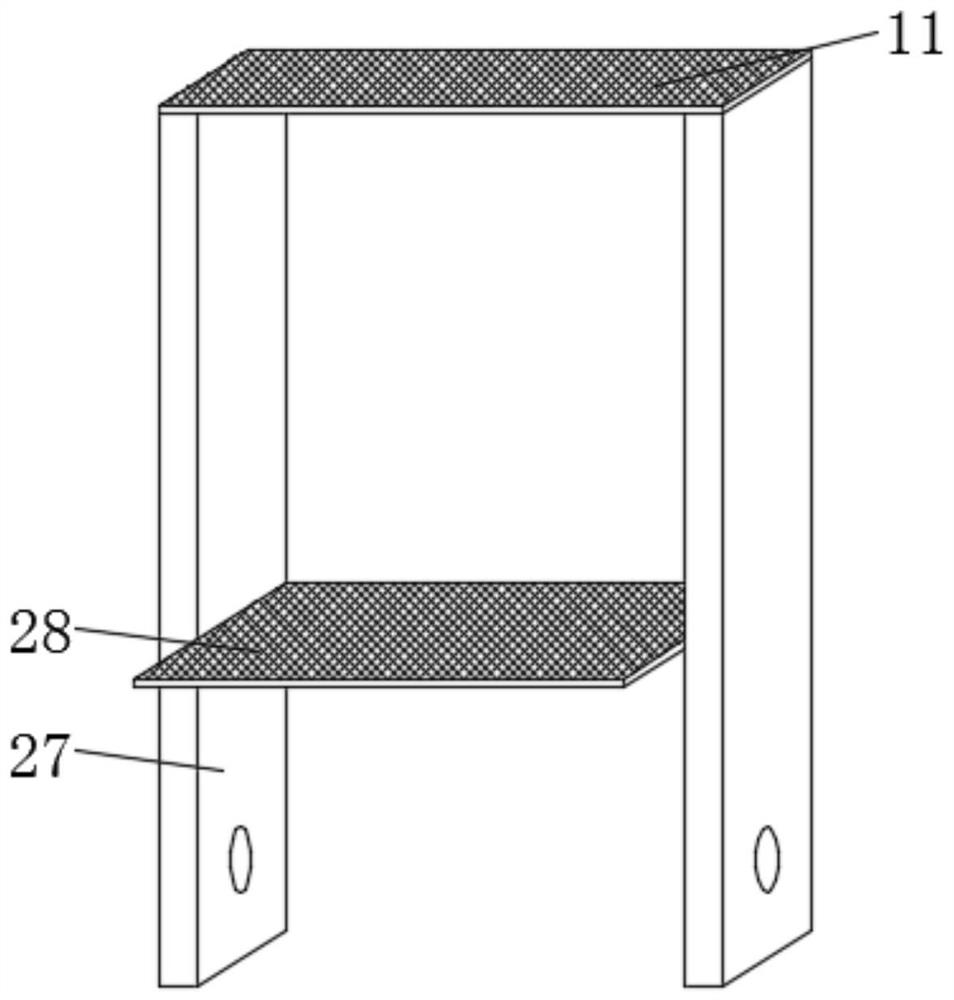

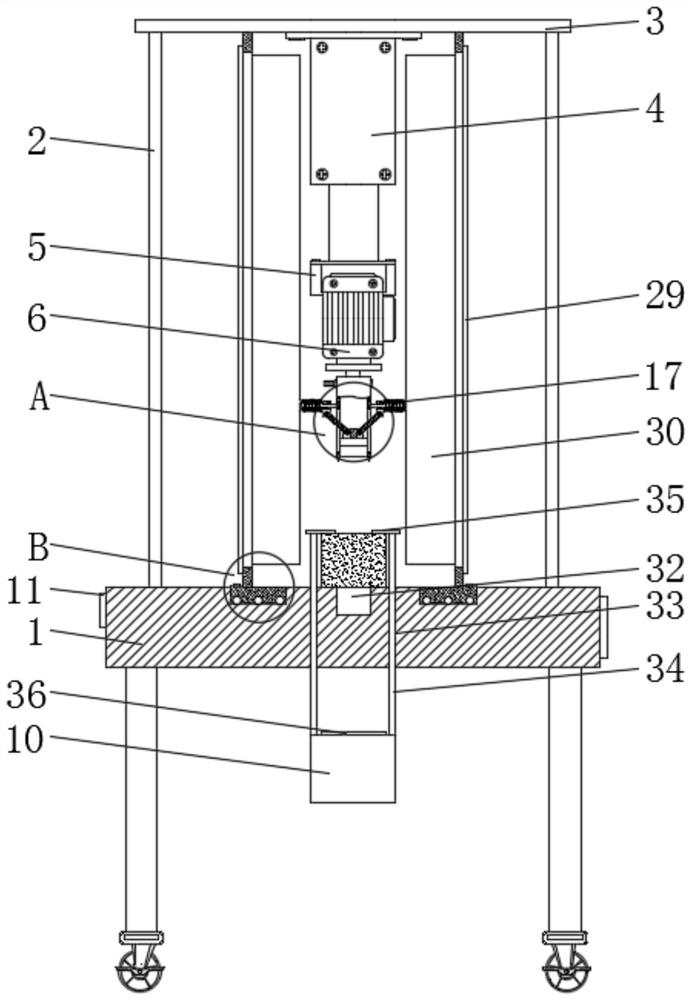

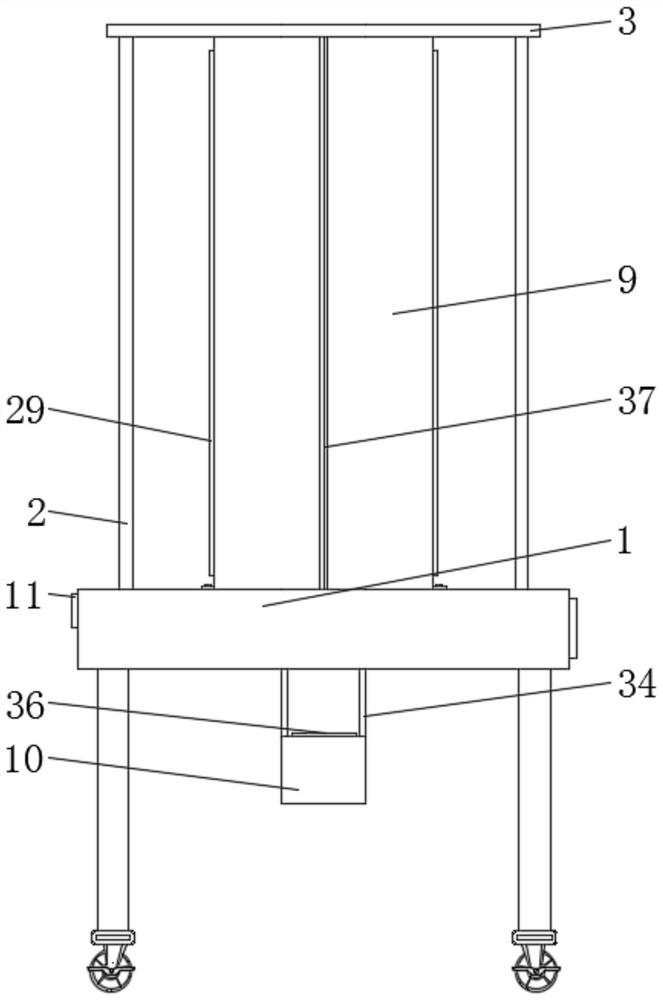

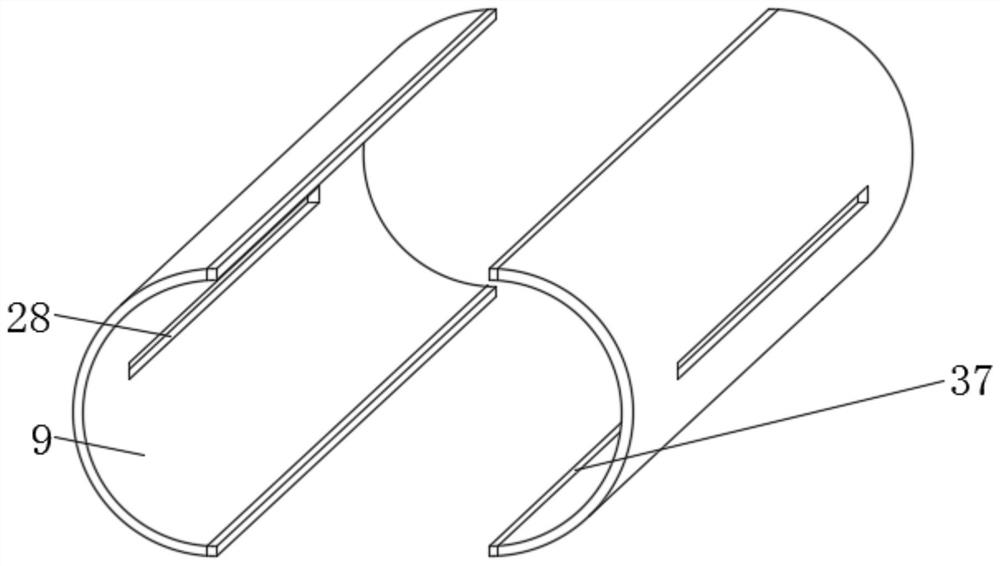

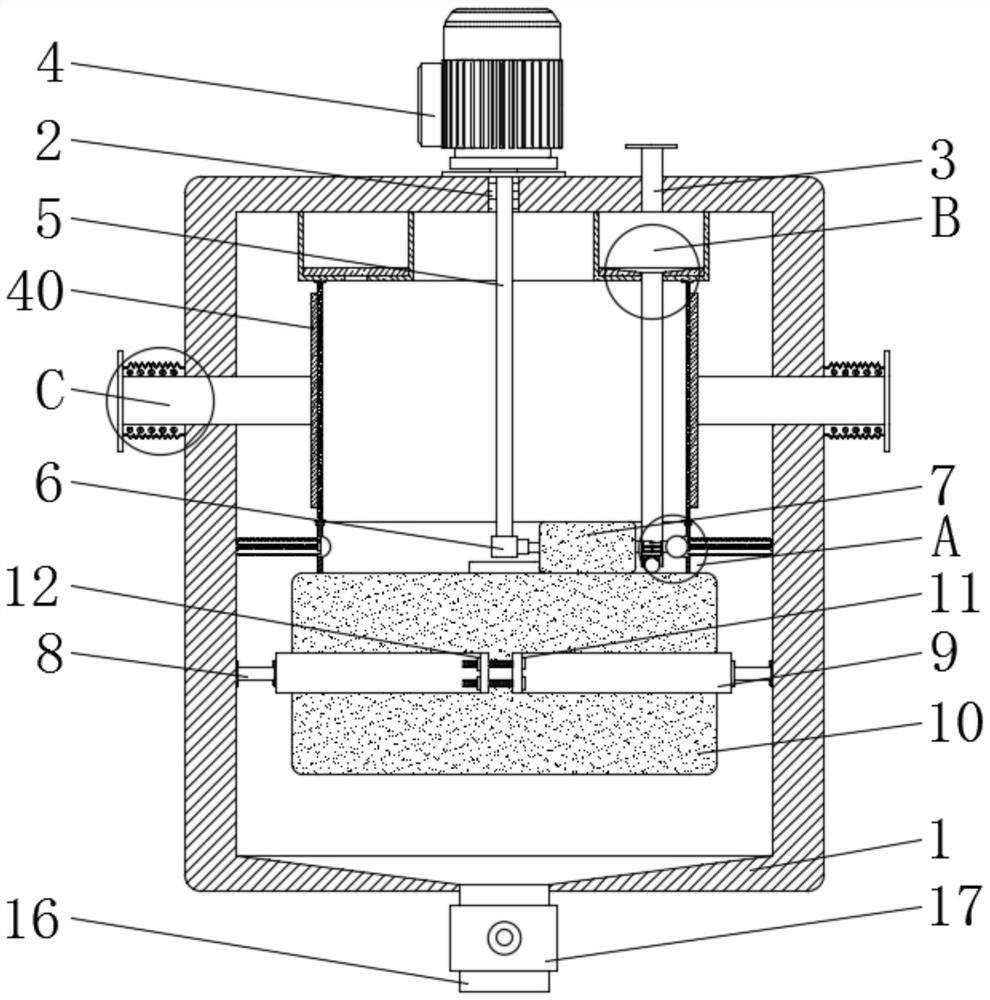

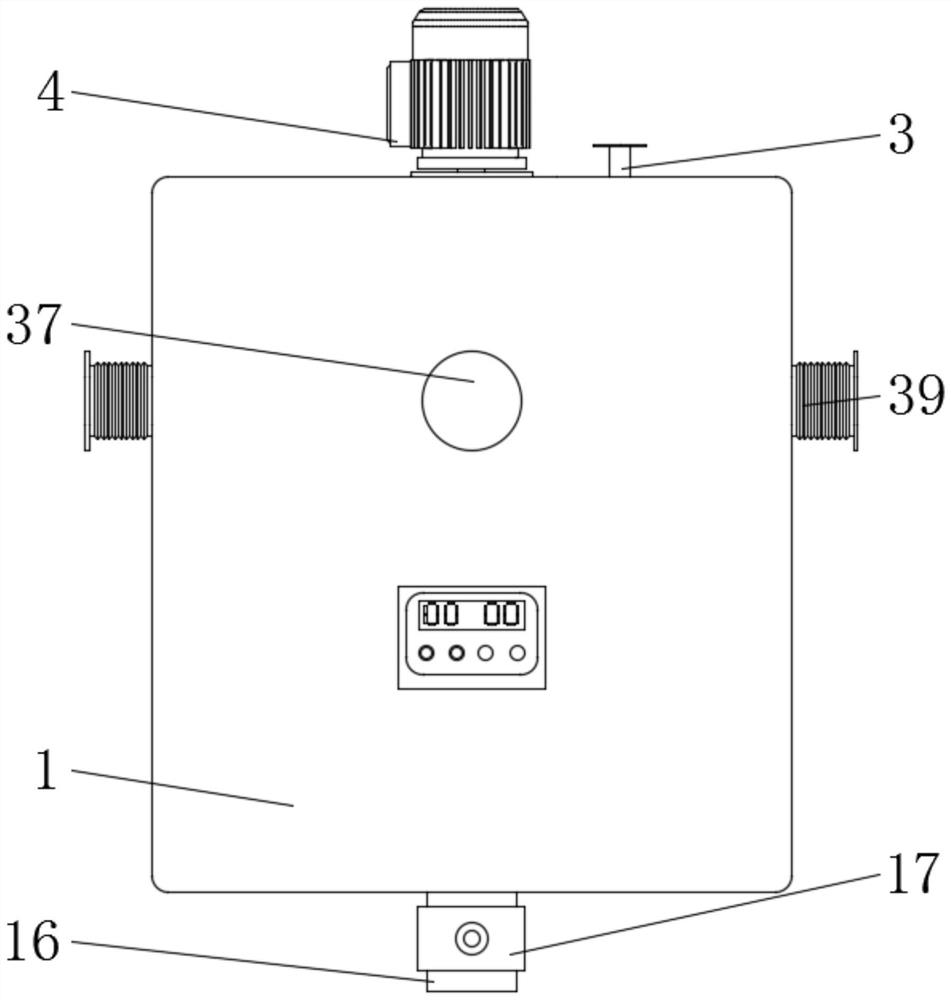

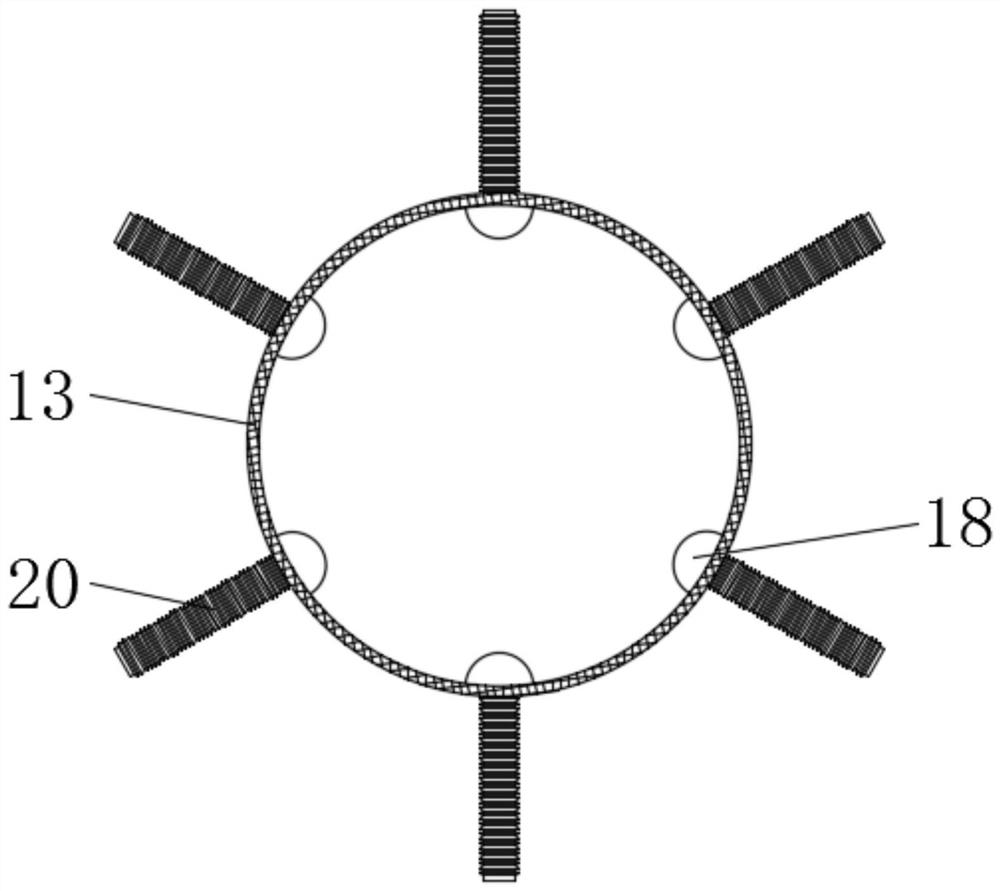

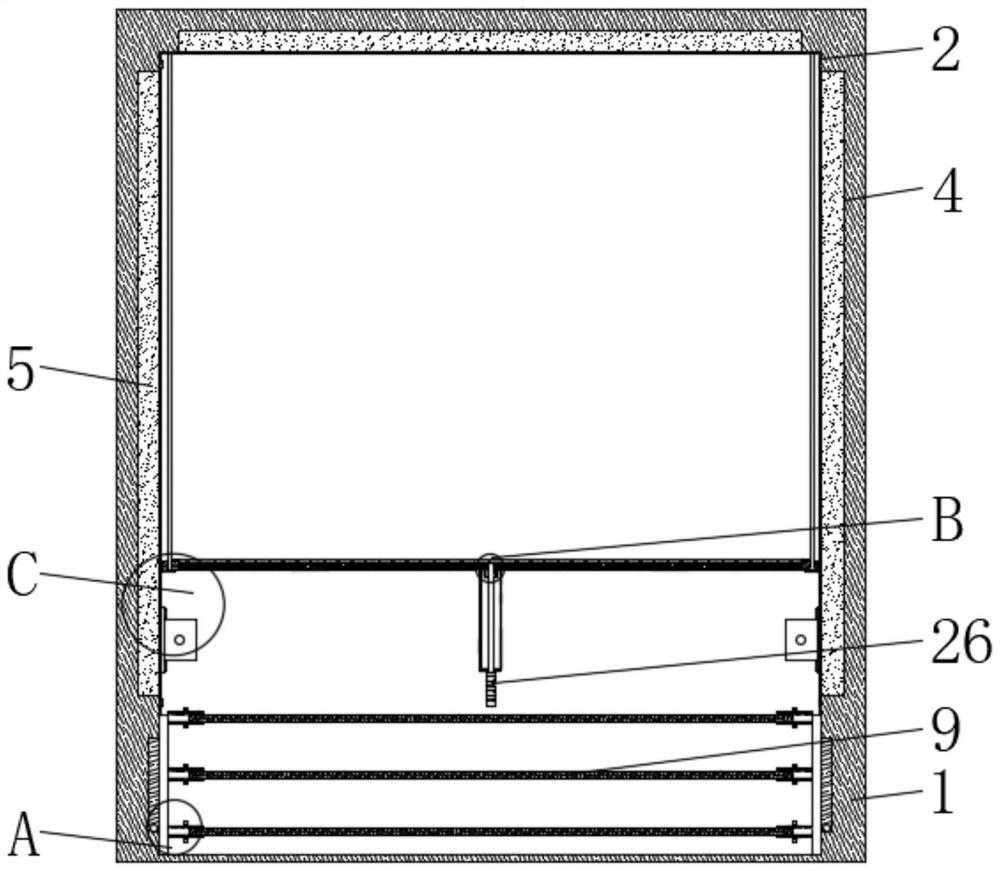

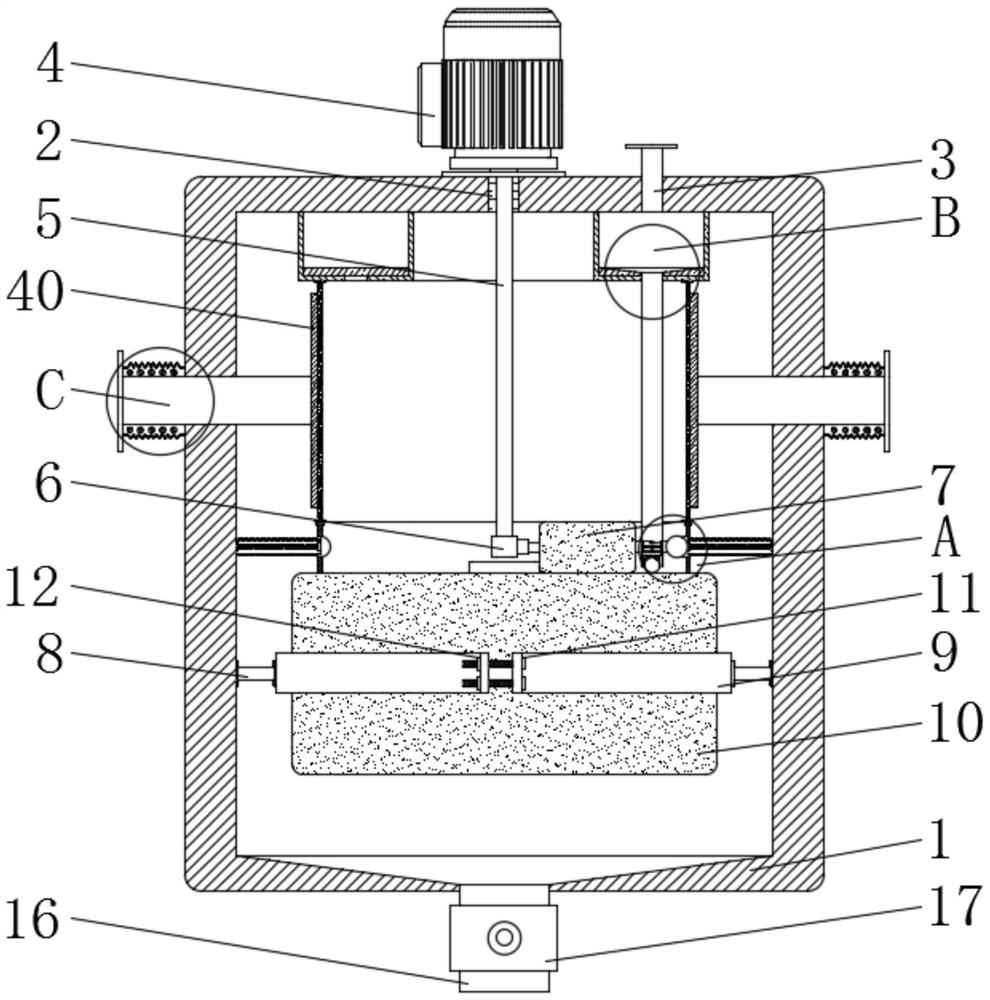

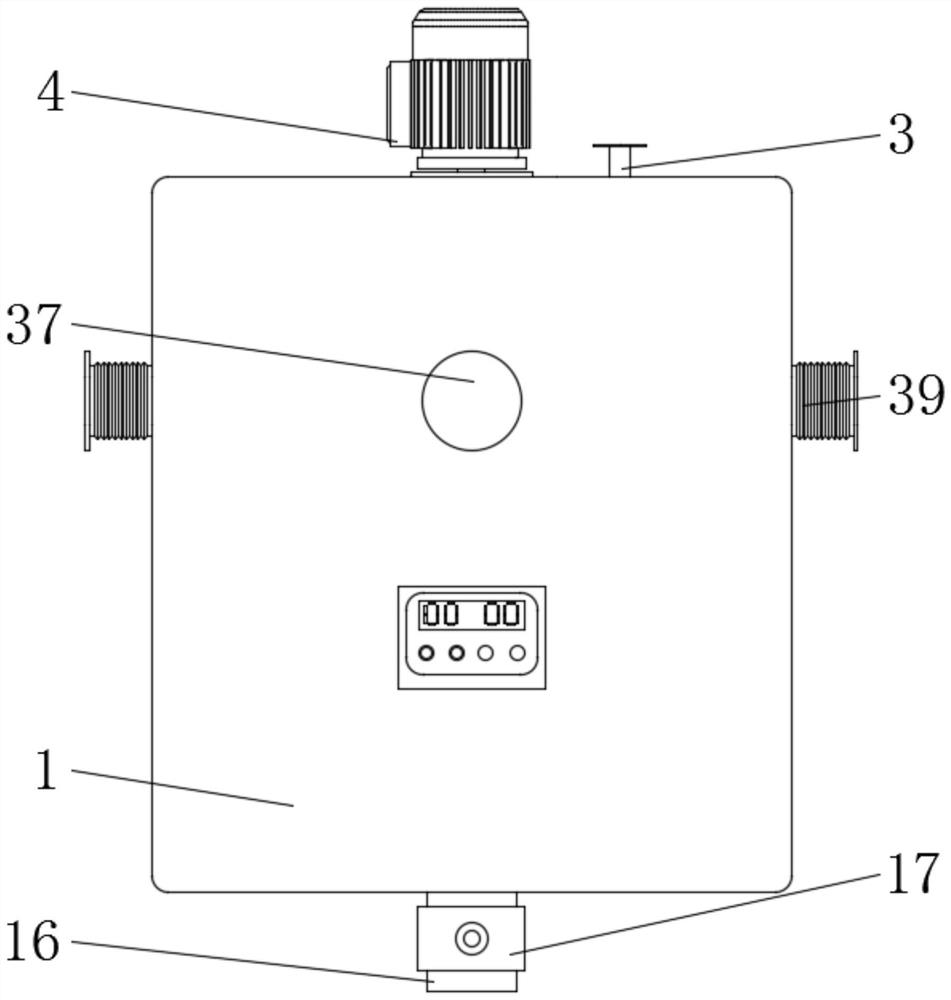

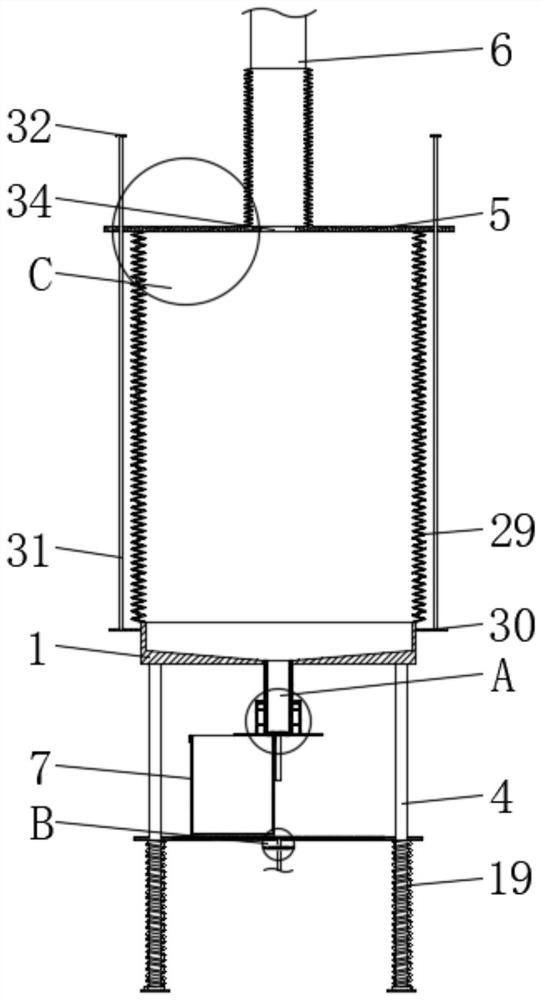

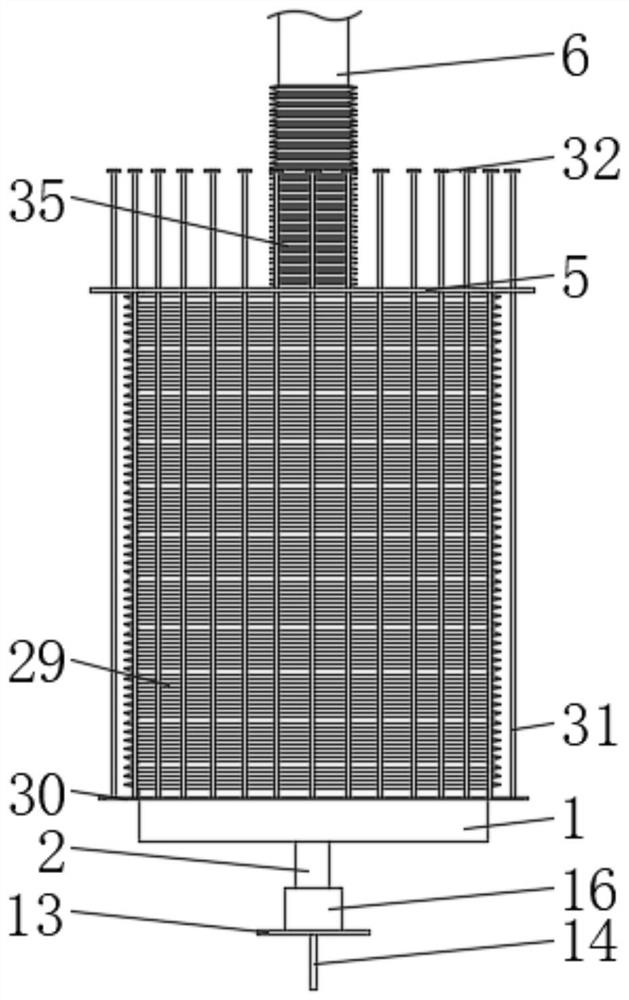

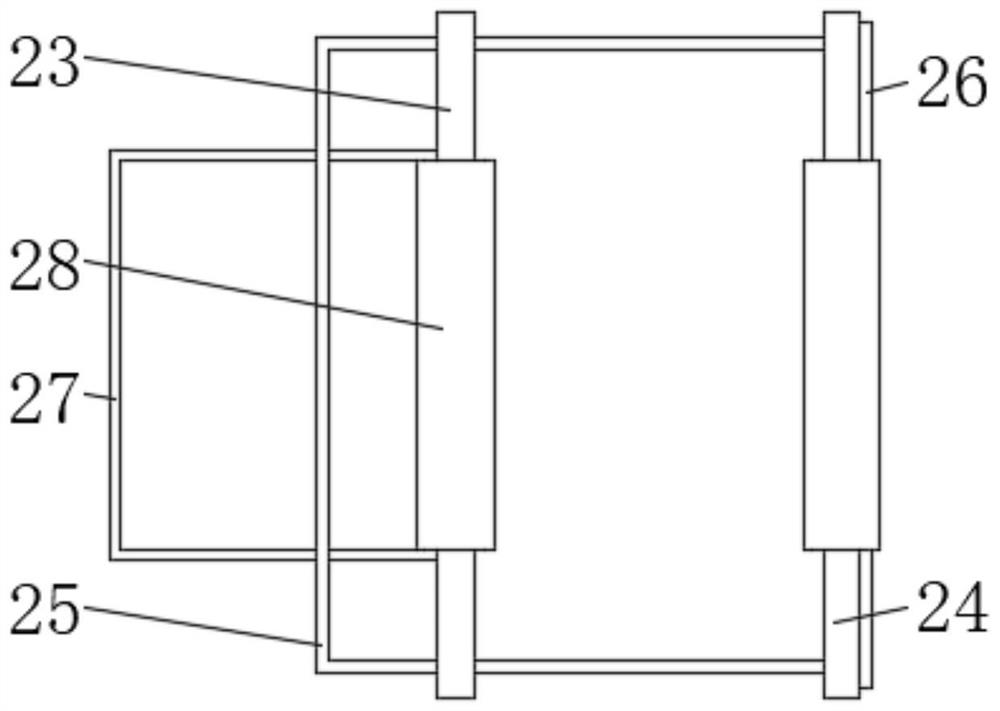

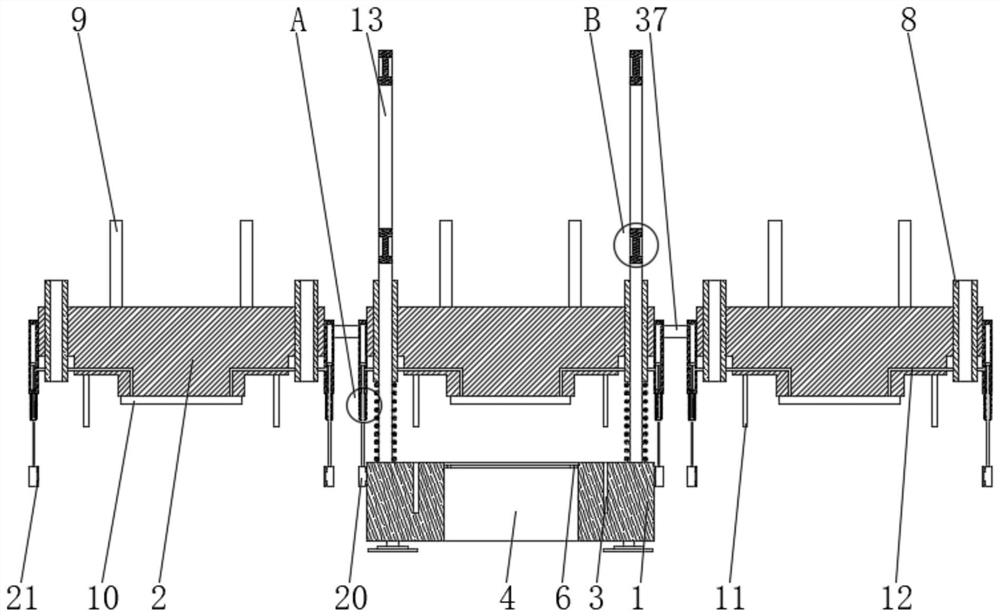

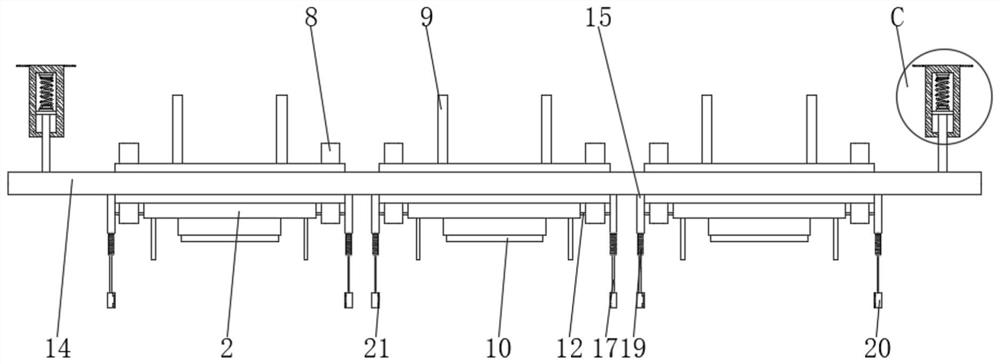

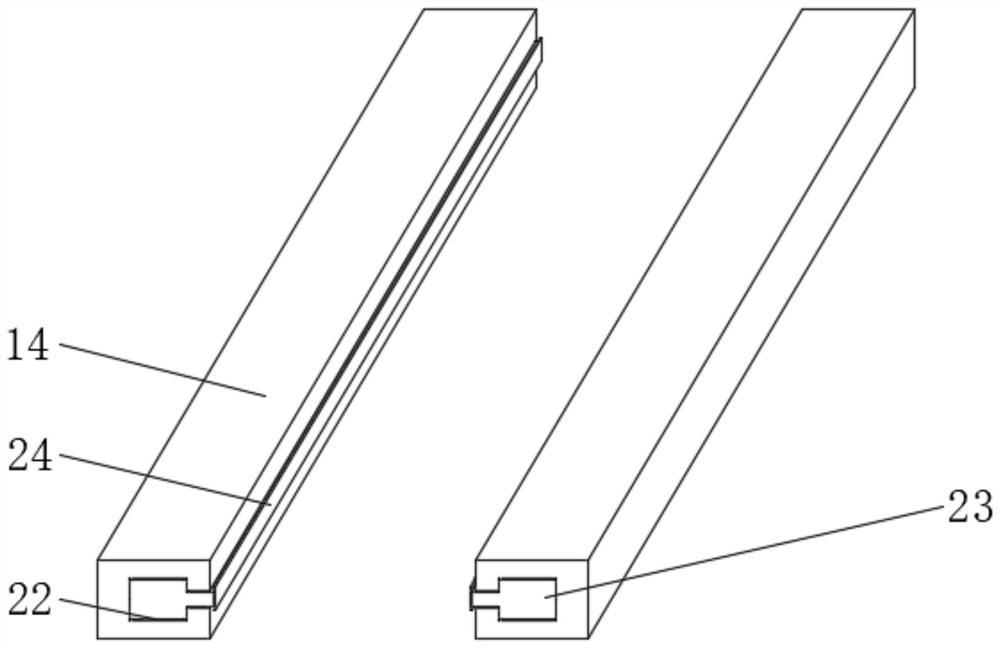

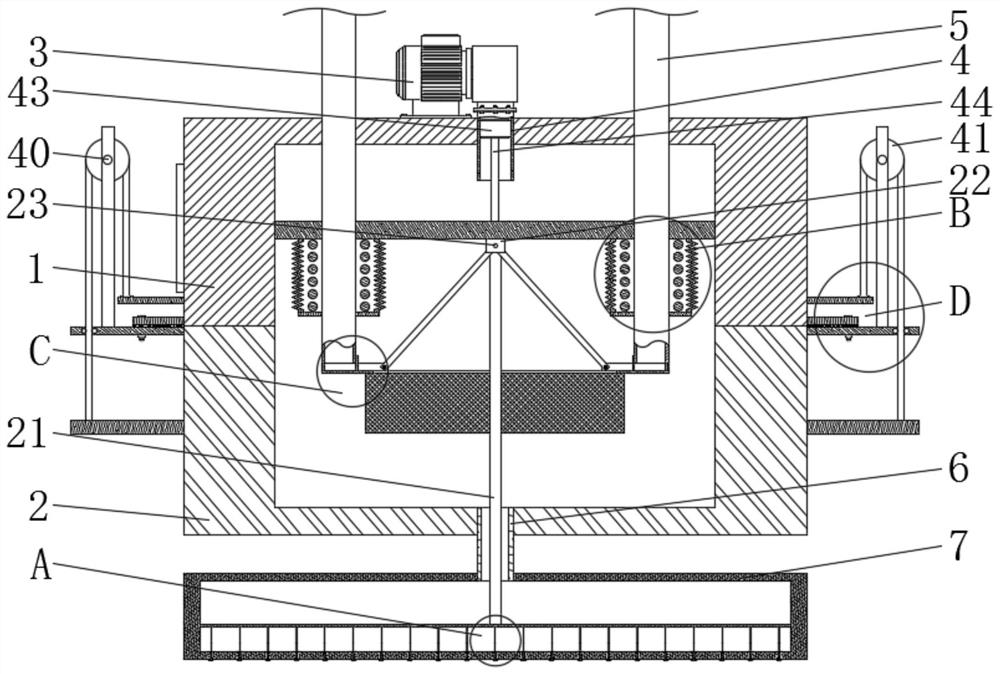

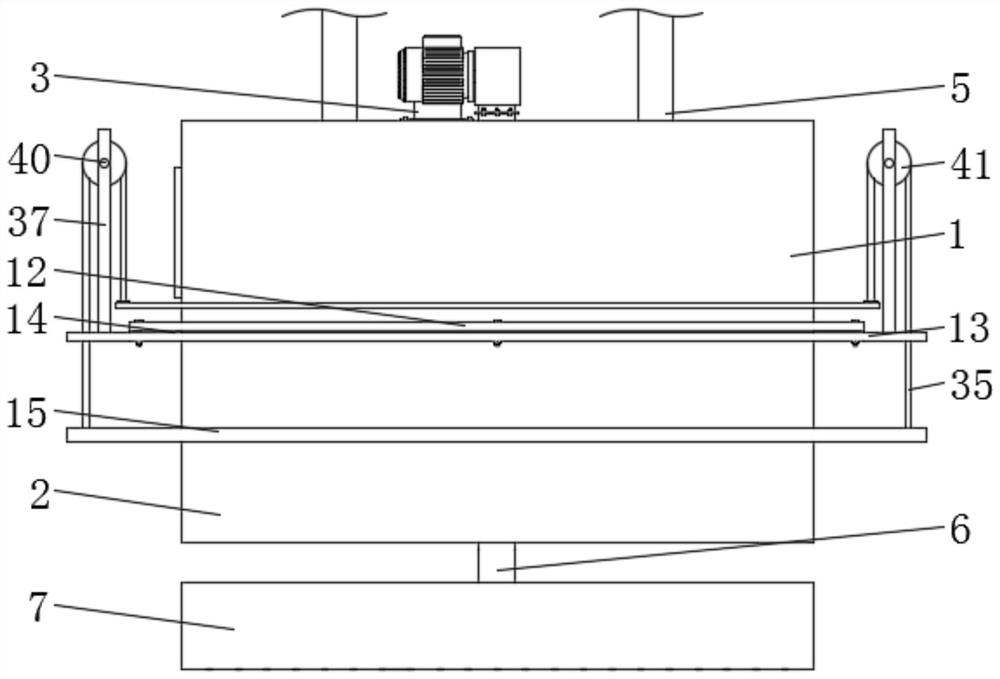

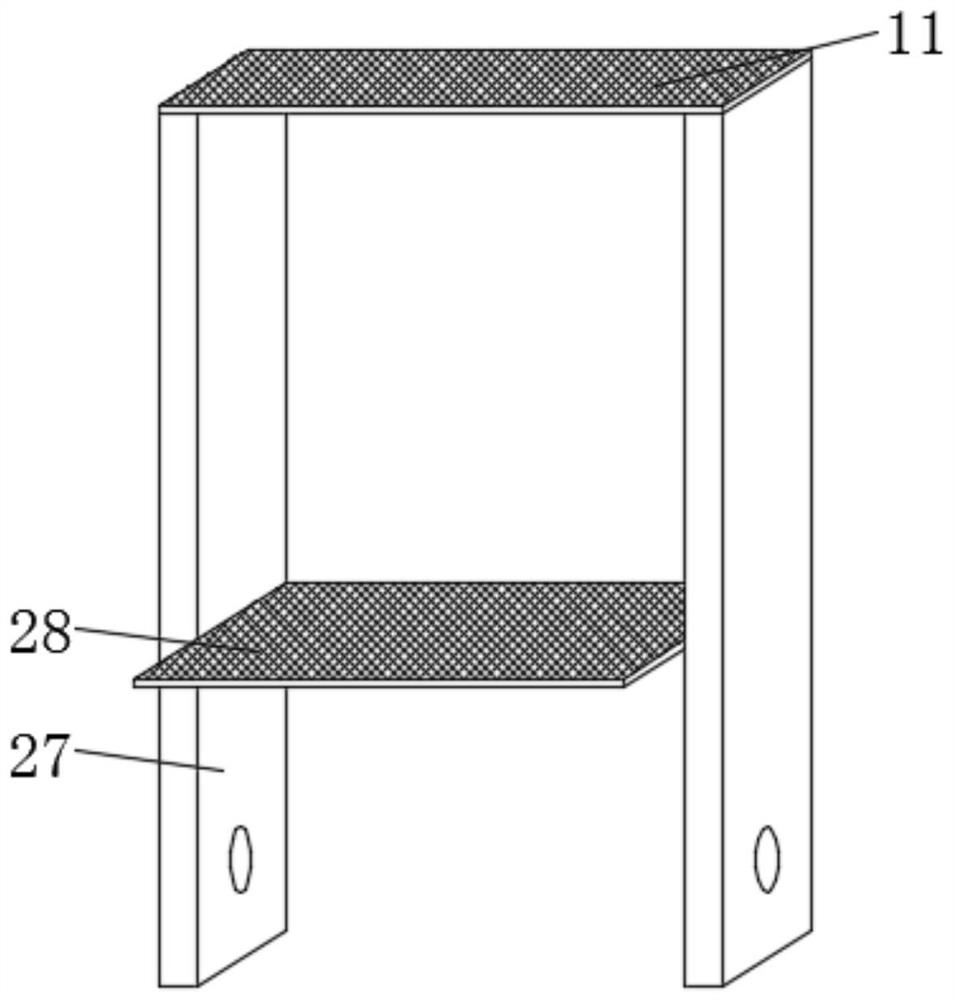

A spraying and immersion equipment for catalyst

ActiveCN113289792BSquirt in timeIn line with the concept of green environmental protection developmentCatalyst activation/preparationLiquid spraying apparatusPtru catalystEnvironmental engineering

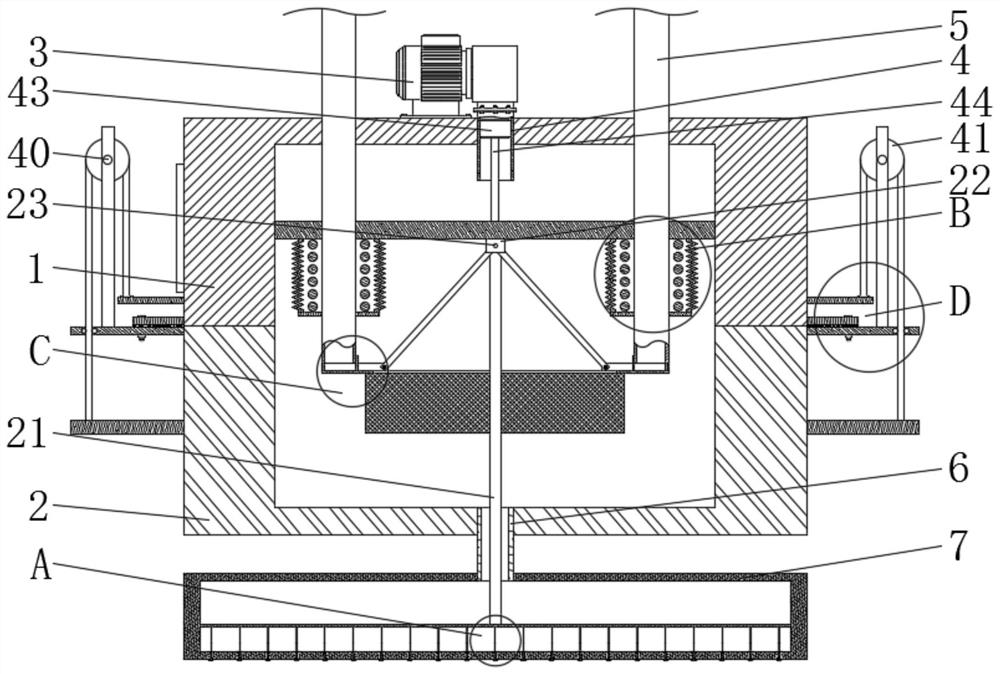

The invention discloses a catalyst spraying and immersion equipment, which comprises an upper casing and a lower casing. The upper part of the upper casing is fixedly installed with conduits and two sets of water inlet square pipes. The upper part of the upper casing is A booster pump is fixedly installed, and one end of the booster pump is fixedly connected to the outer end of the conduit, the inner bottom surface of the lower casing is fixedly installed with a water outlet pipe, and one end of the water outlet pipe is fixedly sleeved with a water spray box , and the lower part of the water spray box is provided with several groups of fixed through holes, and the interior of several groups of said fixed through holes is installed with I-shaped tubes, and the external ends of several groups of said I-shaped tubes are all provided with adjustable sealing plates , the insides of the built-in ends of the water inlet square pipes of the two groups are all slidably installed with scraping filter screens. Beneficial effects: the present invention adjusts the sealing plate, and through the setting of the adjusting sealing plate, there is no need to add multiple sets of electromagnetic valves to control the flow of liquid ejection, and at the same time, it can stop the flow of liquid in time, so that the spraying and immersion equipment used for catalysts conforms to the concept of green and environmental protection development.

Owner:PINGXIANG FXSINO PETROCHEM PACKING CO LTD

Tea packaging can forming and processing equipment

ActiveCN113334521AGuarantee the safety of useReduce frictional resistanceDrilling machinesBark-zones/chip/dust/waste removalHydraulic cylinderProcess equipment

The invention discloses tea packaging can forming and processing equipment. The tea packaging can forming and processing equipment comprises a workbench, wherein two groups of supporting rods and a yielding groove are arranged at the upper part of the workbench; a cover plate is fixedly mounted at one ends of the two groups of supporting rods; a hydraulic cylinder is fixedly mounted at the lower part of the cover plate; two groups of right-angle plates are fixedly mounted at one end of the hydraulic cylinder; a motor is fixedly mounted at one ends of the two groups of right-angle plates; a drilling cylinder is fixedly mounted at the output end of the motor; a discharging circular plate is mounted in the drilling cylinder in a sliding manner; two groups of semicircular transparent pipes are mounted on the side of the drilling cylinder; a treading mounting plate is mounted below the workbench; and a power socket is mounted on the side wall of the workbench. The tea packaging can forming and processing equipment has the beneficial effects that through the discharging circular plate, an operator does not need to manually take out wood in the drilling cylinder, so that the working steps of the tea packaging can forming and processing equipment are reduced, and the working efficiency of the tea packaging can forming and processing equipment is improved.

Owner:萍乡市时代工艺包装有限公司

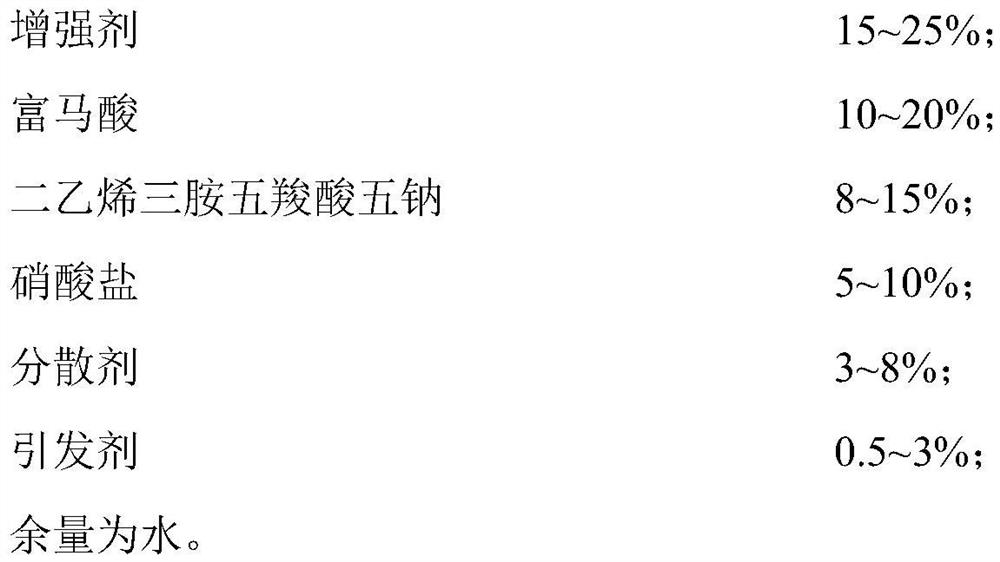

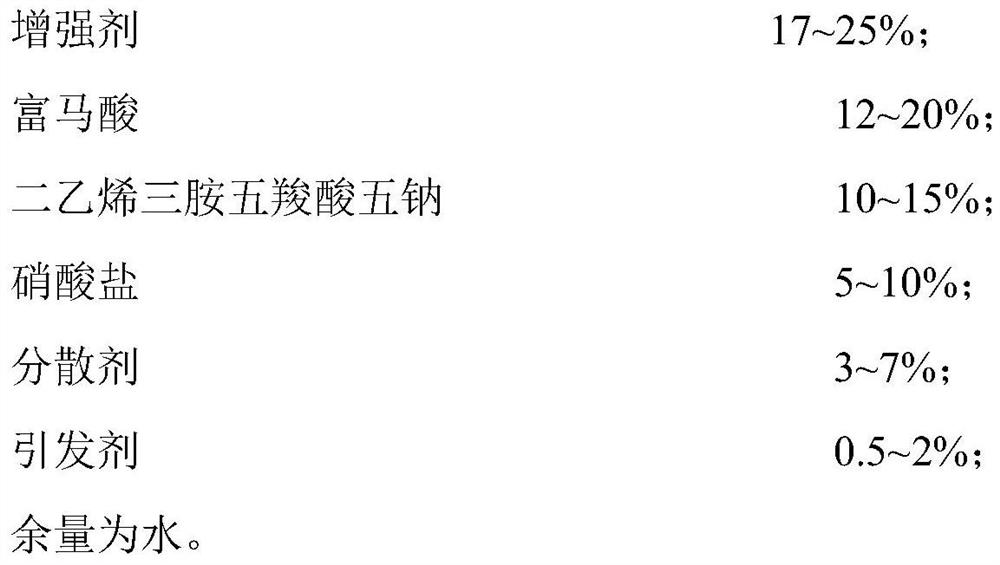

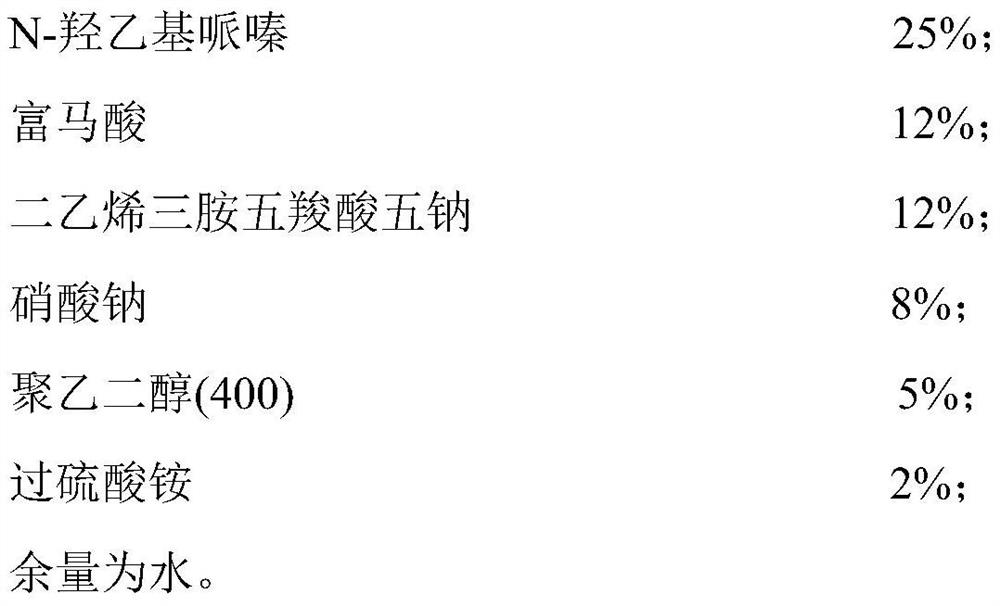

A kind of hydroxypiperazine concrete glue reducer and preparation method thereof

ActiveCN111908823BImprove compatibilityGive full play to the effect of water reductionSolid waste managementPolymer scienceEngineering

The invention discloses a hydroxypiperazine type concrete glue reducer and a preparation method thereof. The concrete glue reducer is composed of the following substances by weight: 15-25% of reinforcing agent, 10-20% of fumaric acid, diethylene 8-15% of pentasodium triaminepentacarboxylate, 5-10% of nitrate, 3-8% of dispersant, 0.5-3% of initiator, and the balance of water. In the present invention, the piperazine polymer can promote the formation of ettringite crystals such as tricalcium aluminate in the concrete slurry, form an early skeleton, and promote the improvement of the strength of the concrete; the dispersant can fully disperse the fine particles of the cement, so that the utilization of the cement in the concrete is improved. Under the synergistic effect of each component, this glue reducer can significantly improve the early strength and late strength of concrete. In addition, the glue reducing agent can improve the frost resistance of concrete, so that the concrete can also exert its proper working performance in a low temperature environment.

Owner:浙江鑫月新材料科技有限公司

An enameled wire painting equipment

ActiveCN113210155BAvoid frictional damageReduce wasteCleaning using toolsLiquid spraying apparatusAir pumpEngineering

The invention discloses an enameled wire painting equipment, which comprises a casing, a paint storage box and an isolation tube are fixedly installed inside the casing, and tapered mounting rings are fixedly installed at both ends of the paint storage box. Both ends of the isolation tube are sleeved with tapered mounting blocks, and the outer side walls of the casing are equipped with two sets of high-pressure air pumps and paint inlet pipes, and one end of the two sets of high-pressure air pumps is snap-fitted with an air guide tube One end of the two groups of air guide pipes and the two groups of paint inlet pipes runs through the outer side wall of the shell and the paint storage box, the interior of the two groups of paint inlet pipes is slidingly installed with anti-backflow plugs, and the isolation pipes A dividing blade is slidingly installed on the side wall, and a cleaning pipe is fixedly installed on the lower part of the shell. Beneficial effects: the invention uses the splitting blade, and through the set splitting blade, the operator can use his own gravity to cut the enameled wire without adding power equipment, which saves the waste of power resources and conforms to the concept of green and environmental protection development.

Owner:华尔达线缆集团有限公司

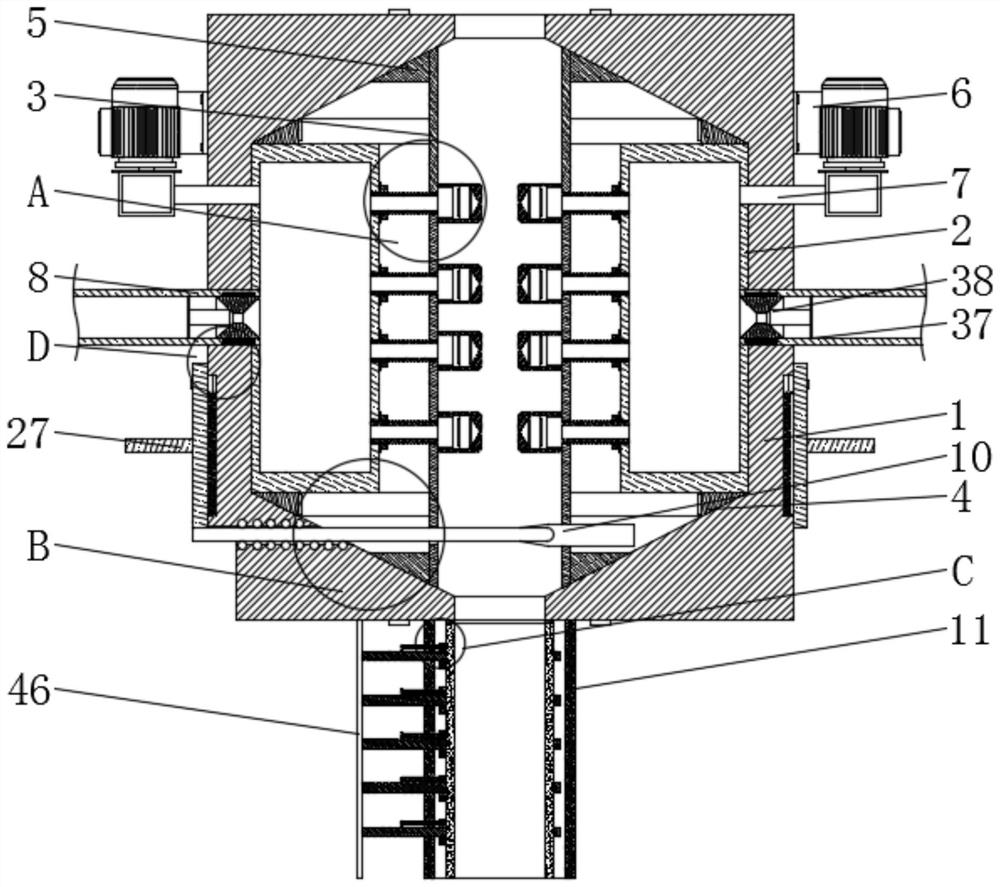

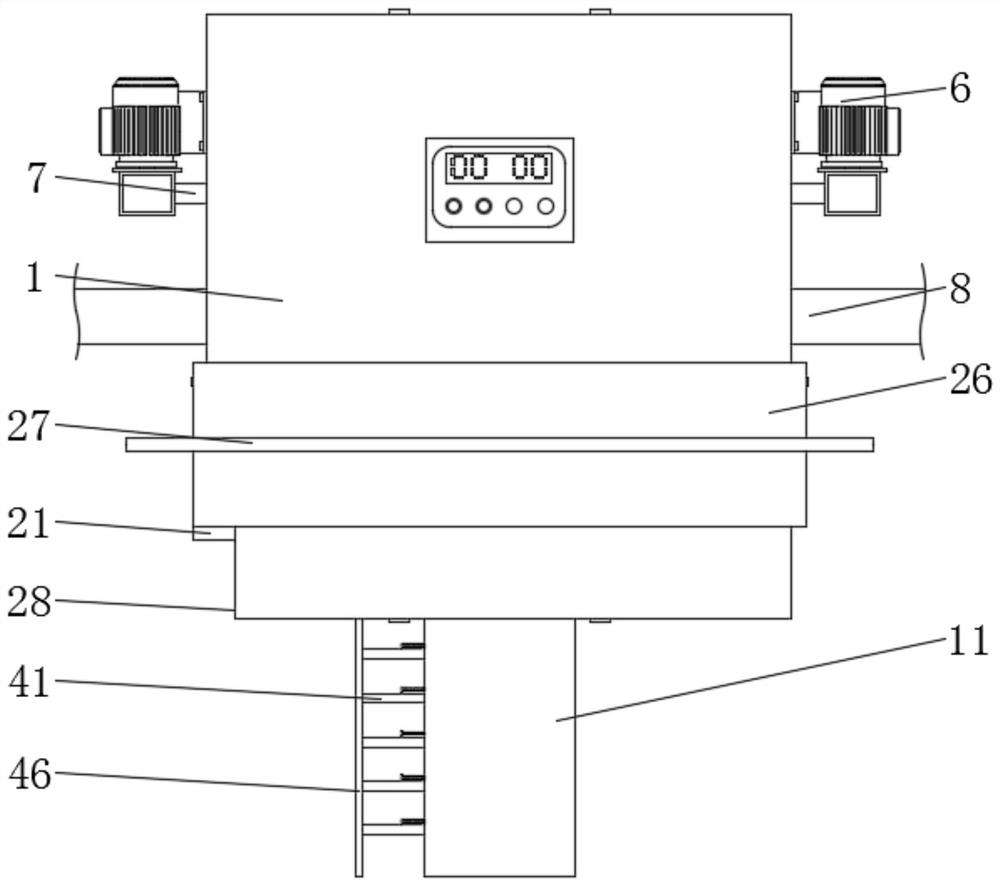

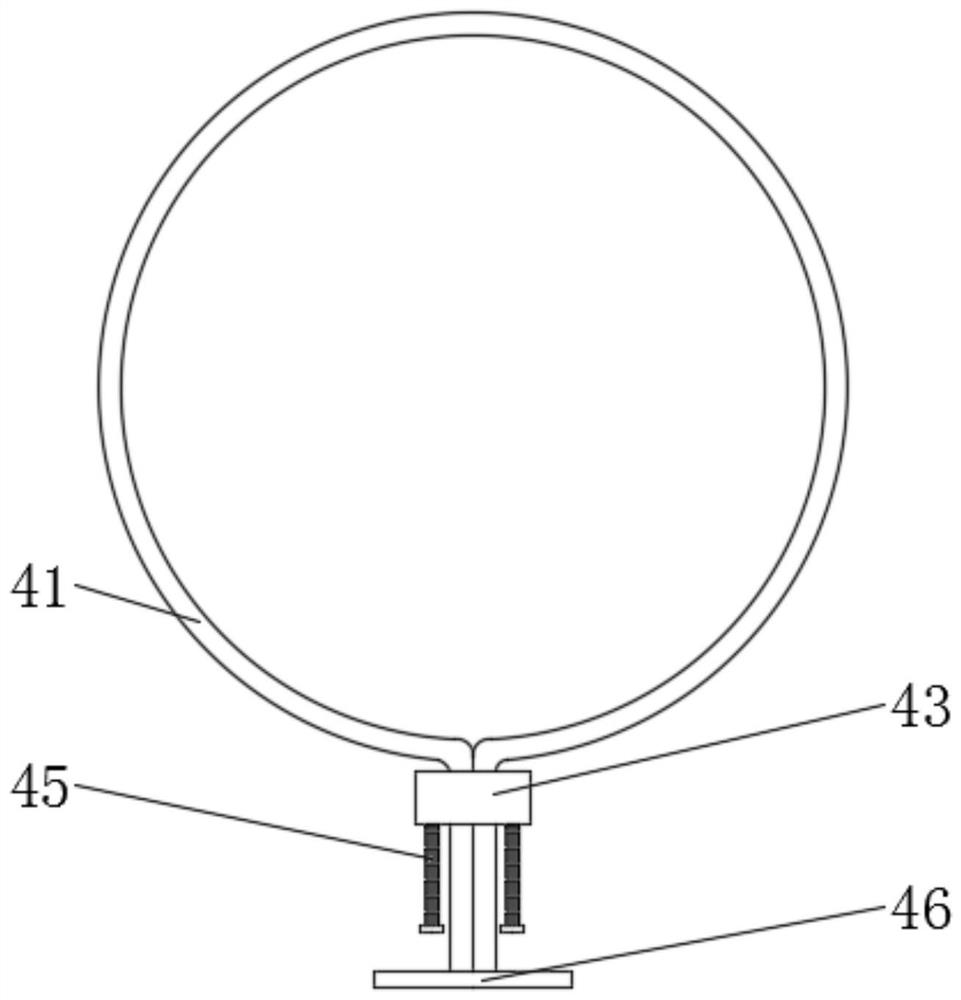

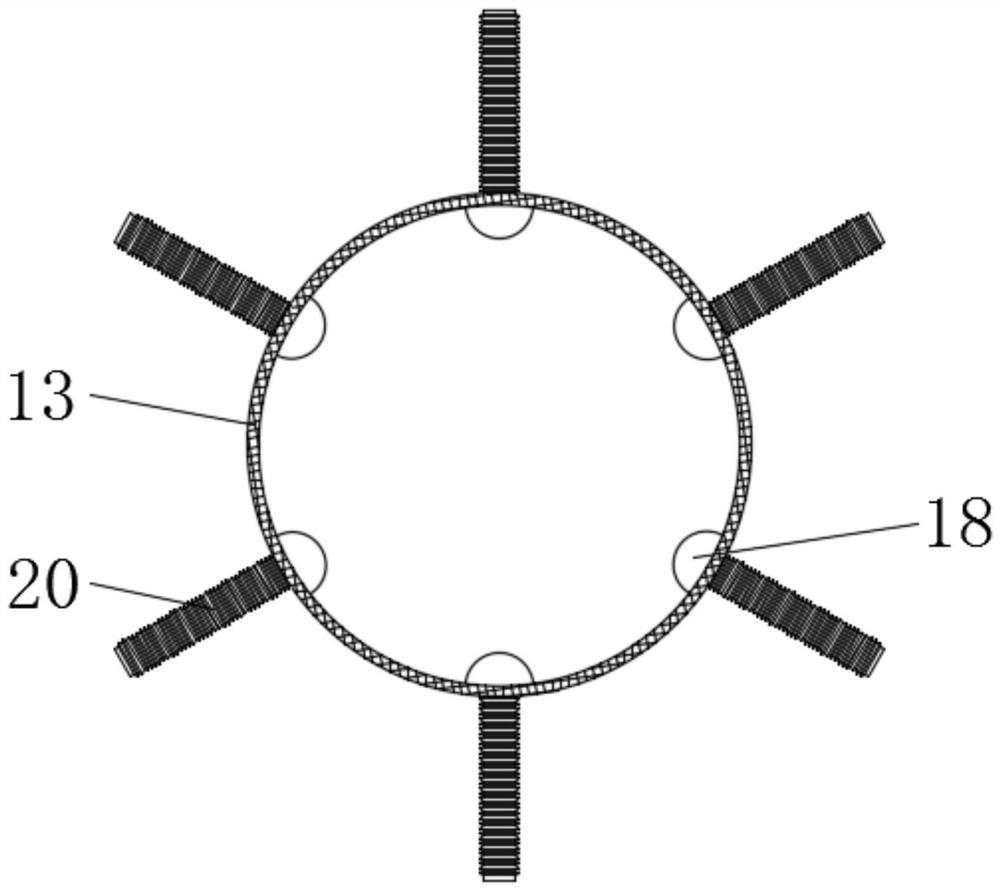

A kind of grinding equipment for alumina production

ActiveCN113333105BIn line with the concept of green environmental protection developmentImprove pass rateDirt cleaningGrain treatmentsDrive shaftElectric machinery

The invention discloses a grinding device for alumina production, comprising a casing, a bearing and a feed pipe are installed through the upper part of the casing, a motor is fixedly installed on the upper part of the casing, and an output end of the motor is clamped and installed with a transmission One end of the transmission shaft penetrates the bearing, a connecting sleeve is fixedly installed on the side of one end of the transmission shaft, and one end of the connecting sleeve is clamped and installed with a grinding roller, and two groups are fixedly installed on the inner side wall of the casing connecting plates, and the opposite ends of the two groups of the connecting plates are fixedly installed with clamps, and two sets of bolts are installed through the opposite faces of the two groups of the clamps. Beneficial effects: The present invention can automatically guide ungrind qualified alumina chips to the grinding range of the grinding roller through the return filter screen pipe and the set return filter screen pipe without adding a power mechanism, so that alumina production can be achieved. The use of grinding equipment is in line with the concept of green development.

Owner:PINGXIANG HUASHUN ENVIRONMENTAL PROTECTION CHEM PACKING CO LTD

Preparation method and dry material of green environment-friendly high slag erosion resistance dry material

ActiveCN111732415BGive full play to the high resistance to slag erosionGive full play to the erosion performanceSlagZirconium

The invention relates to the technical field of refractory materials for continuous casting, and relates to a preparation method of an environment-friendly high-slag-corrosion-resistance dry material,and the high-slag-corrosion-resistance dry material. The method comprises the following steps: waste zirconium-carbon slag line materials are recycled and smashed to obtain a regenerated zirconium-carbon slag line material; and 65-85 parts by weight of magnesia, 8-15 parts by weight of the regenerated zirconium-carbon slag line material, 1-5 parts by weight of light calcined alumina A powder, 5-13 parts by weight of a binding agent and 3-5 parts by weight of an additive are mixed to prepare the environment-friendly high-slag-corrosion-resistance dry material. The invention aims to provide thepreparation method of the environment-friendly dry material with high slag corrosion resistance, and the dry material with high slag corrosion resistance. The expensive zirconium oxide raw material is reasonably recycled, the high slag corrosion resistance of zirconium oxide is brought into full play, the casting service life of the continuous casting tundish is prolonged, the refractory materialconsumption cost per ton of steel is reduced, pollution of refractory materials to molten steel is reduced, and the casting blank quality is improved.

Owner:日照瑞华新材料科技有限公司 +2

Pure cotton active salt-free dyeing solution, pure cotton fabric dyed with it and process

The invention belongs to the technical field of textile finishing processing, and specifically relates to a pure cotton active salt-free dyeing solution, a dyed pure cotton shell fabric using the purecotton active salt-free dyeing solution and a technology. The pure cotton active salt-free dyeing solution comprises the following components in concentrations: 0.5 to 80 g / L of active dye, an alkaline agent whose using amount is 55% to 65% of that of the active dye and is not lower than 9 g / L, NaOH whose using amount is 2.5% to 3.5% of that of the active dye and is not lower than 0.6 g / L, and the balance is water; the active dye is one or more of active yellow O, active red R and active blue B; the alkaline agent is SFA-01. The dyeing solution has good permeability for the pure cotton shellfabric, and can be used for dyeing under the condition without salt acceleration; the dyed pure cotton shell fabric is stable in quality, excellent in color fastness, colorful and plump in yarn-dyed weaving and excellent in comprehensive performance; according to the technology dyed by using the dyeing solution, surface dyeing can be removed effectively, the color fastness and washing fastness ofthe shell fabric are promoted, the COD value of wastewater discharge is reduced, and the technology is environmentally friendly and good in economic benefit.

Owner:鲁丰织染有限公司

Short-flow processing technology for dope-dyed fabric

PendingCN114164671AContinuityRealize continuous productionBiochemical treatment with enzymes/microorganismsGrip property fibresTextile printerColour fastness

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a short-flow processing technology for a dope-dyed fabric. The method comprises the following steps: singeing, desizing and tentering a dope-dyed fabric to obtain a dope-dyed fabric; a feed liquid used in the pretreatment desizing procedure is prepared from 6-8 g / l of desizing enzyme OPT-280, 1-5 g / l of chelating agent and 6-8 g / l of penetrant. And a feed liquid used in the after-finishing tentering process is formed by mixing a modified polysiloxane softening agent TF-4865C and a polyethylene polyamine color fixing agent GD-80. The fabric is soft in hand feeling and excellent in color fastness, the invention further provides a processing technology of the fabric, processing, desizing, scouring and dyeing are not needed in the dyeing and finishing process, the fabric is diversified in color and bright in finishing mode, the technological process is short, discharge of printing and dyeing wastewater is greatly reduced, and the fabric conforms to the green and environment-friendly development concept at the present stage.

Owner:鲁丰织染有限公司

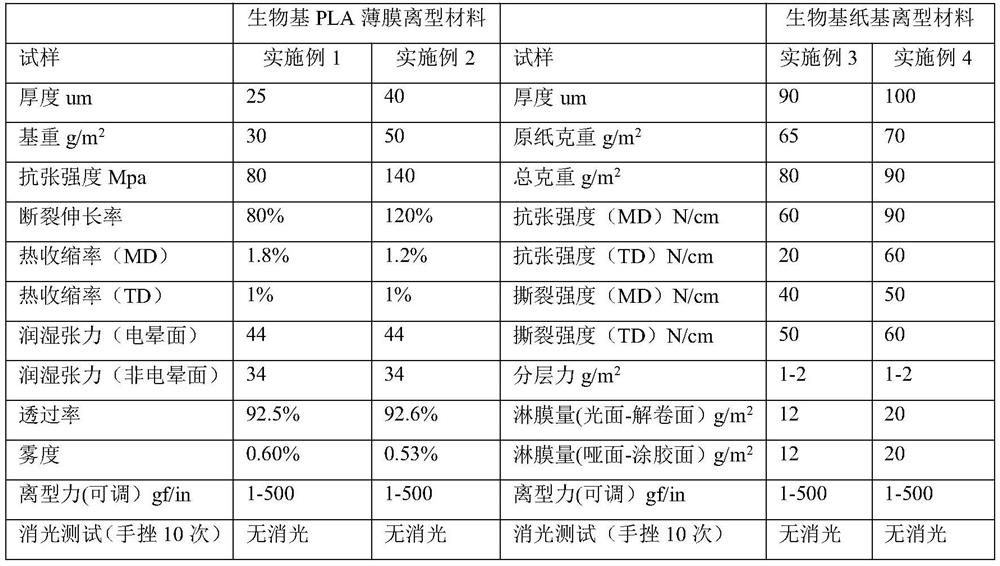

Recyclable and degradable release material and preparation method thereof

PendingCN113603916AGood strength and scratch resistanceAbundant sources of raw materialsNon-fibrous pulp additionCoatings with pigmentsPolymer chemistryPolylactic acid

The invention relates to a recoverable and degradable release material and a preparation method thereof, and belongs to the technical field of release materials. The release material comprises a base material layer and a release agent coating arranged on the base material layer, and further comprises a biological substrate coating arranged between the base material layer and the release agent coating, the base material layer is a film-based material layer or a paper-based material layer; the paper-based material layer comprises bio-based raw paper and a film-based material; and the biological substrate coating is acrylate. The raw material components of the acrylate are SARBIO@5201, SARBIO@5400, SARBIO@6100 and an initiator 184, and the raw material components of the film base material are polylactic acid resin, poly (butylene carbonate), an antioxidant and an inorganic filler; the bio-based body paper comprises the following raw material components: gelatinized starch glue and paper powder. The prepared release material can be recycled, waste is reduced, and the concept of green and environment-friendly development is met.

Owner:CROWN TAICANG ADHESIVE PROD CO LTD

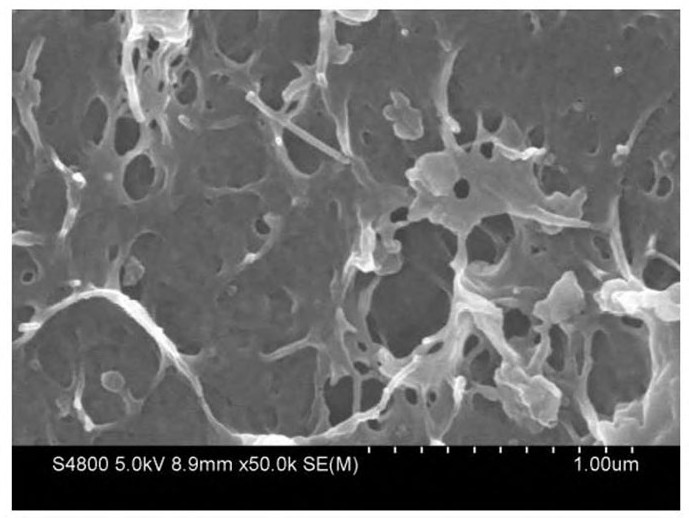

A kind of functionalized graphene and its preparation method and its application in rubber backing plate

The present invention relates to a kind of functionalized graphene, the raw material of described functionalized graphene comprises alkyl-p-phenylenediamine antioxidant and graphene oxide; The alkyl-p-phenylenediamine antioxidant is N,N' ‑Di-sec-butyl-p-phenylenediamine, N,N`‑bis(1,3‑dimethylbutyl)-p-phenylenediamine, N,N`‑bis(1,4‑dimethylpentyl) One or more of phenylenediamine, N,N`-diisooctyl-p-phenylenediamine, N,N`-bis(1-ethyl-3-methylpentyl)-p-phenylenediamine. The functionalized graphene provided by the invention is applied to the existing railway rubber backing plate, and a high-performance rubber backing plate with excellent mechanical properties, good aging performance and large resistance value can be prepared.

Owner:HEBEI TIEKE YICHEN NEW MATERIAL TECH CO LTD

A dedusting and noise reduction device for dismantling and processing scrapped automobiles

ActiveCN113562100BReduce the workload of classificationReduce frictionCombination devicesVehicle dissasembly recoveryDust controlStructural engineering

The invention discloses a dedusting and noise reduction device for dismantling and processing scrapped automobiles. The inner two sides and the top surface of the casing are fixedly installed with a fixed filter screen, the inner two sides and the top surface of the casing are provided with built-in grooves, and the interior of the three groups of the built-in grooves are installed with sound-absorbing rock wool boards, so Two sets of hinges are fixedly installed at the openings at both ends of the casing, and sealed doors are fixedly installed at one end of the two sets of hinges on the same side. Beneficial effects: The present invention can preliminarily classify parts according to size through the layered vertical plates, greatly reducing the workload of parts classification, and bringing convenience to the use of the dedusting and noise reduction device for the dismantling and processing of scrapped automobiles. By installing the electric dust collection structure, the dust removal work can be completed, so that the dust removal and noise reduction device for the dismantling and processing of scrapped automobiles conforms to the concept of green environmental protection development.

Owner:萍乡泽昊新材料有限责任公司

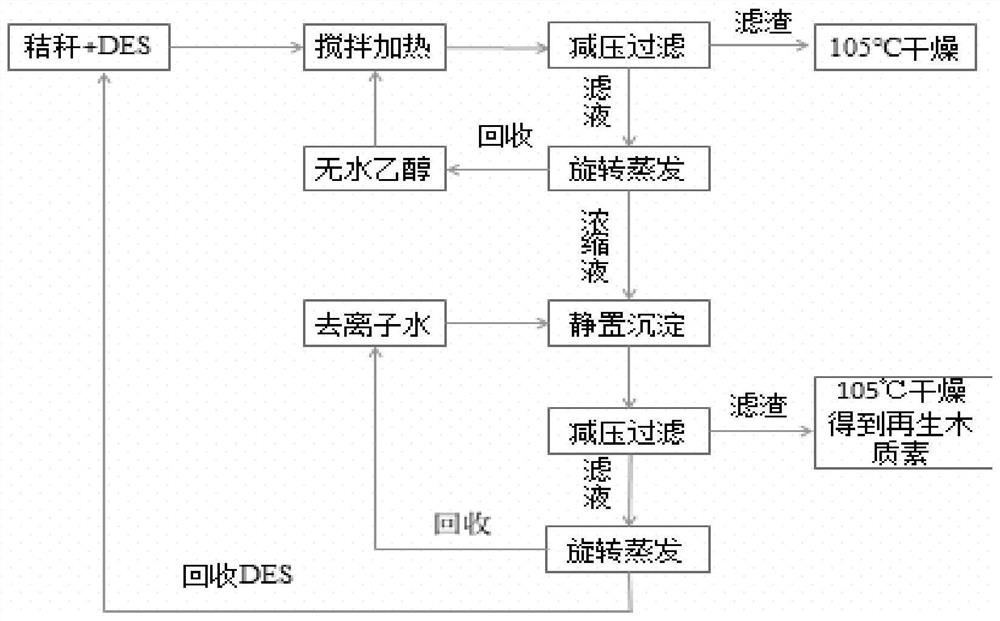

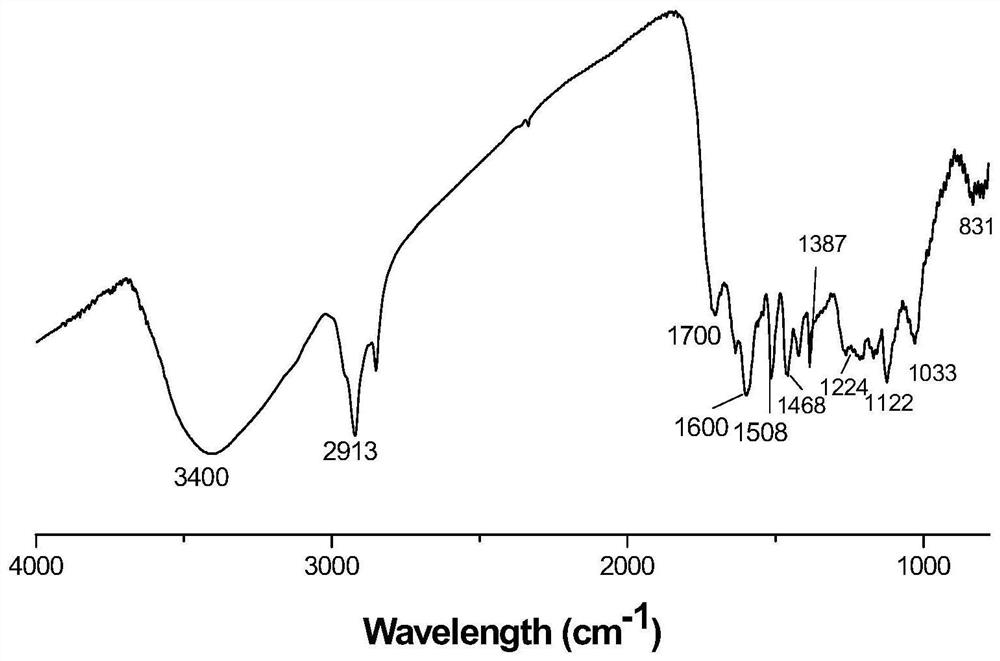

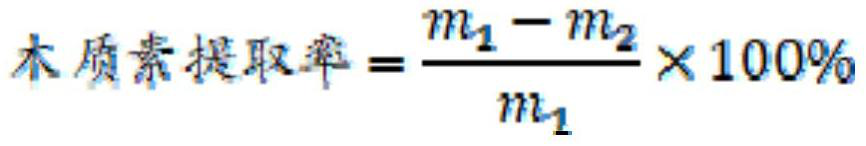

A method for extracting lignin by ternary deep eutectic solvent

ActiveCN110218335BImprove extraction efficiencyHigh puritySolid solvent extractionAlcohol ethylPhysical chemistry

Owner:GUANGDONG UNIV OF TECH

Grinding equipment for aluminum oxide production

ActiveCN113333105AIn line with the concept of green environmental protection developmentImprove pass rateDirt cleaningGrain treatmentsElectric machineryAluminium oxides

The invention discloses grinding equipment for aluminum oxide production. The grinding equipment for aluminum oxide production comprises a shell, a bearing and a feeding pipe are installed at the upper portion of the shell in a penetrating mode, a motor is fixedly installed at the upper portion of the shell, a transmission shaft is installed at the output end of the motor in a clamped mode, and one end of the transmission shaft penetrates through the bearing. A connecting sleeve is fixedly installed at the side portion of one end of the transmission shaft in a sleeving mode, a grinding roller is installed at one end of the connecting sleeve in a clamped mode, two sets of connecting plates are fixedly installed on the side wall of the interior of the shell, hoops are fixedly installed at the end portions of the opposite ends of the two sets of connecting plates, and two sets of bolts are mounted on the opposite surfaces of the two ends of the two sets of hoops in a penetrating manner. The grinding equipment for aluminum oxide production has the beneficial effects that aluminum oxide chips which are not ground to be qualified can be automatically guided to the grinding range of the grinding roller under the condition that a power mechanism is not additionally arranged through an arranged material returning filter screen pipe, so that the grinding equipment for aluminum oxide production conforms to the concept of green and environment-friendly development.

Owner:PINGXIANG HUASHUN ENVIRONMENTAL PROTECTION CHEM PACKING CO LTD

Full-automatic filling machine for outer wall surface water-based paint

ActiveCN113929043AIn line with the concept of green environmental protection developmentPrevent backflowBarrels/casks fillingContainer/bottle contructionElectric power equipmentStructural engineering

The invention discloses a full-automatic filling machine for outer wall surface water-based paint. The full-automatic filling machine for the outer wall surface water-based paint comprises a containing base, and an automatic discharging pipe is fixedly installed on the inner bottom face of the containing base in a penetrating mode. The full-automatic filling machine for the outer wall surface water-based paint has the beneficial effects that through the automatic discharging pipe, when the outer wall surface water-based paint needs to be filled, the side wall of a containing barrel can abut against a transverse moving rod to move, when the interior of a limiting ring and a sealing circular plate are staggered, the outer wall surface water-based paint falls into the containing barrel through a gap between the sealing circular plate and an intercepting hole plate, as the outer wall surface water-based paint is guided into the containing barrel, the containing barrel abuts against a recycling plate and vertically moves downwards, when the downward moving height of the containing barrel exceeds the length of a transverse moving rod, multiple sets of telescopic springs abut against a sleeving pipe, the sealing circular plate and the transverse moving rod are made to return to the original positions, and at the moment, the limiting ring is sealed; and through the arranged automatic discharging pipe, an infrared position sensor, a liquid level sensor and a plurality of sets of power equipment do not need to be installed, and the paint can be automatically guided into the containing barrel.

Owner:九江立帆科技有限公司

Dyeing process for improving color fastness of vegetable dye

The invention belongs to the technical field of textile finishing and processing, and particularly relates to a dyeing process for improving color fastness of vegetable dye. The dyeing process comprises the following steps: (1) padding a to-be-dyed fabric in a vegetable dye dyeing solution, and then drying the to-be-dyed fabric to obtain a dyed fabric; (2) padding the dyed fabric obtained in the step (1) in a color fixing solution, performing steaming reduction, then performing oxidation color fixing through a H2O2 solution with the concentration of 1-2.5 g / L, and then performing soft finishing to obtain a plant dye dyed fabric; the vegetable dye staining solution comprises the following components: 0.5-40g / L of vegetable dye, 10-15g / L of migration inhibitor and the balance of water; and the color fixing liquid comprises the following components: 2-6 g / L of NaOH, 10-15 g / L of Na2S2O4 and the balance of water. The dyed fabric is stable in quality, bright and plump in yarn-dyed weaving, excellent in color fastness and good in washable performance, and the dyeing process is green and environmentally friendly.

Owner:鲁丰织染有限公司

Mold for metal casting molding

ActiveCN113500180AIn line with the concept of green environmental protection developmentEasy to useStampingElectric power

The invention discloses a mold for metal casting molding. The mold comprises a lower mold plate and an upper mold plate, wherein two sets of alignment grooves, a stamping groove and two sets of guide rods are arranged at the upper part of the lower mold plate; a limiting frame is fixedly installed in the stamping groove; damping springs sleeve the side walls of the two sets of guide rods; two guide pipes and two sets of connecting rods are arranged at the upper part of the upper mold plate; a stamping head and two sets of abutting plates are fixedly installed at the lower part of the upper mold plate; a plurality of blowing air pipes are installed in the upper mold plate; alignment steel cables are installed above the two sets of guide rods; and replacement clamping plates are installed at the front part and the rear part of the upper mold plate. The mold has the beneficial effects that cleaning work of the stamping head can be automatically completed through the blowing air pipes without an electric power structure, so that consumption of electric power resources is reduced, meanwhile, the production and installation cost is reduced, and the mold for metal casting molding conforms to the concept of green and environment-friendly development.

Owner:江西维海机械设备有限公司

Spraying and dipping equipment for catalyst

ActiveCN113289792ASquirt in timeIn line with the concept of green environmental protection developmentCatalyst activation/preparationLiquid spraying apparatusEngineeringMechanical engineering

The invention discloses spraying and dipping equipment for a catalyst. The spraying and dipping equipment for the catalyst comprises an upper shell and a lower shell, wherein a guide pipe and two groups of water inlet square pipes are fixedly installed on the upper part of the upper shell in a penetrating mode; a booster pump is fixedly installed on the upper part of the upper shell; one end of the booster pump is fixedly connected with the external end of the guide pipe; a water outlet pipe is fixedly installed on the inner bottom surface of the lower shell in a penetrating manner; a water spraying tank is fixedly installed at one end of the water outlet pipe in a sleeving manner; a plurality of groups of fixed through holes are formed in the lower part of the water spraying tank; I-shaped pipes are installed in the plurality of groups of fixed through holes in a penetrating manner; adjusting sealing plates are arranged at the external ends of the plurality of groups of I-shaped pipes; and scraping filter screens are slidably installed in the built-in ends of the two groups of water inlet square pipes. The spraying and dipping equipment for the catalyst provided by the invention has the beneficial effects that through the adjusting sealing plates, multiple groups of electromagnetic valves do not need to be additionally arranged to control liquid spraying, meanwhile, liquid flowing can be stopped in time, and the spraying and soaking device used for the catalyst conforms to the green and environment-friendly development concept.

Owner:PINGXIANG FXSINO PETROCHEM PACKING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com