Novel aqueous urethane acrylate copolymer system and preparation method thereof

A technology of polyurethane acrylate and water-based polyurethane, which is applied in the field of preparation of environment-friendly water-based materials, can solve problems such as complex process and toxicity, and achieve the effects of convenient use, easy maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

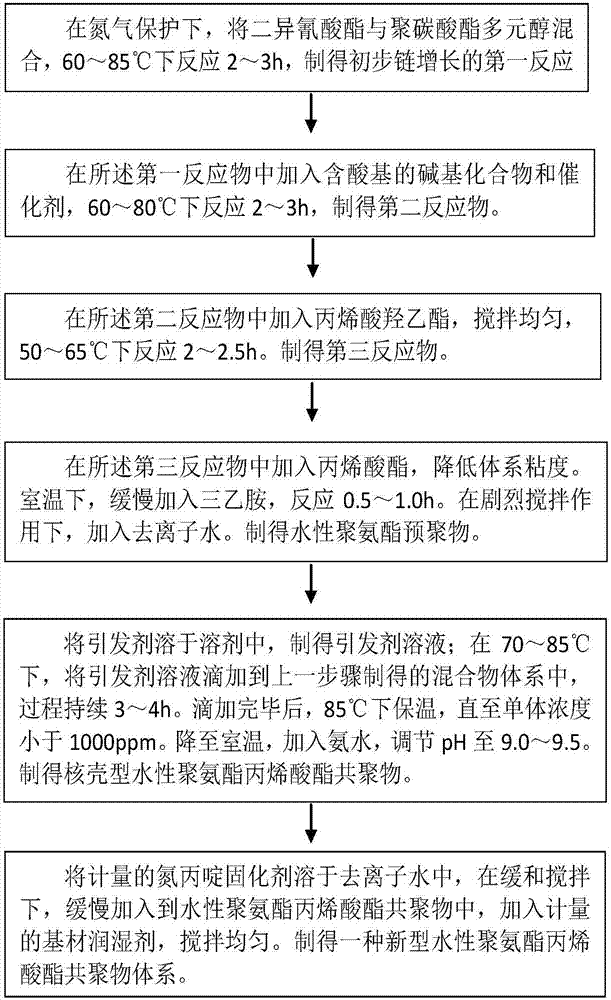

Method used

Image

Examples

preparation example Construction

[0051] A. Preparation of waterborne polyurethane prepolymer:

[0052] Under nitrogen protection, mix diisocyanate and polyol, the mixing ratio is 1.6-4.0, and react at 60-85°C for 2-3 hours to achieve initial chain growth and obtain the first reactant ;

[0053] In an environment of 0-50°C, add an acidic group-containing basic compound and a catalyst to the first reactant, wherein the amount of the acidic group-containing basic compound is diisocyanate, polyol, acidic group-containing 3% to 5% of the total mass of the three basic compounds are reacted at 60 to 80°C for 2 to 3 hours to obtain the second reactant;

[0054] Under the environment of 0-50°C, add hydroxyethyl acrylate to the second reactant, wherein the amount of hydroxyethyl acrylate added is the total mass of diisocyanate, polyol, and acid group-containing base compound 1%~30%, stir evenly, react at 50~65℃ for 2~2.5h, and obtain the third reactant;

[0055] Lower the third reactant system to room temperature, a...

Embodiment 1

[0078] 1. Preparation of Waterborne Polyurethane Prepolymer

[0079] Under the condition of continuing to feed nitrogen, in the device equipped with stirrer, thermometer and heating facility, add 46.46g polycarbonate diol (molecular weight is 1000g / mol), 29.15g isophorone diisocyanate is fully stirred, Raise the temperature to 82°C and react for 2.5 hours; stop the reaction and lower the temperature.

[0080] When the system drops below 50°C, add 0.02g of dibutyltin dilaurate and 4.0g of dimethylolpropionic acid, stir well, then slowly raise the temperature to 80°C, and react for 2.5h; stop the reaction and lower the temperature.

[0081] When the system drops below 50°C, slowly add 12.7g of hydroxyethyl acrylate, and react at 65°C for 2.5h. Stop the reaction and cool down.

[0082] When the system dropped to room temperature, 20 g of methyl methacrylate and 20 g of butyl acrylate were added respectively, and the mixture was fully stirred evenly. Slowly add 3.0g of triethyl...

Embodiment 2

[0092] 1. Preparation of Waterborne Polyurethane Prepolymer

[0093] Under the condition of continuously feeding nitrogen, add 46.46g polycarbonate diol (molecular weight is 1000g / mol), 29.15g isophorone diisocyanate successively to the device equipped with stirrer, thermometer and heating facilities and stir well , raised the temperature to 82°C, and reacted for 2.5 hours; stopped the reaction, and lowered the temperature.

[0094] When the system drops below 50°C, add 0.02g of dibutyltin dilaurate and 4.0g of dimethylolpropionic acid, stir well, then slowly raise the temperature to 80°C, and react for 2.5h; stop the reaction and lower the temperature.

[0095] When the system drops below 50°C, slowly add 12.7g of hydroxyethyl acrylate, and react at 65°C for 2.5h. Stop the reaction and cool down.

[0096] When the system was down to room temperature, 25g of methyl methacrylate and 25g of butyl acrylate were added respectively, and the mixture was fully stirred evenly. Slow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com