Patents

Literature

2834 results about "Chemical production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical production is a broad category that includes manufacturing chemicals for agricultural, pharmaceutical, construction and manufacturing applications, to name a few. Chemical companies, which may range from small producers of specialty chemicals to large global corporations, produce chemicals to meet industry demands in a variety of fields.

Chemical-free production of graphene-reinforced inorganic matrix composites

ActiveUS20170225233A1Low costAdditive manufacturing apparatusTransportation and packagingInorganic particleGraphene flake

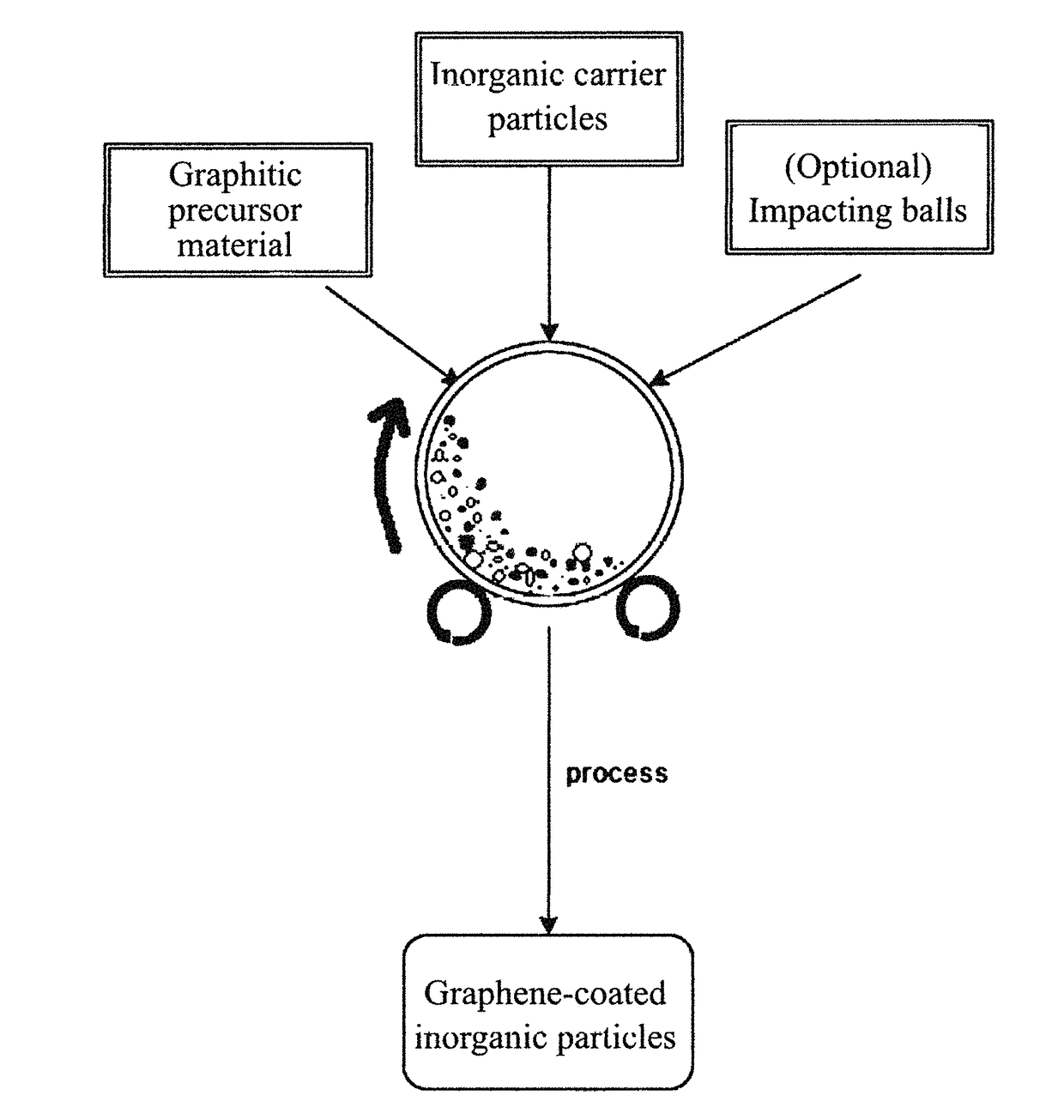

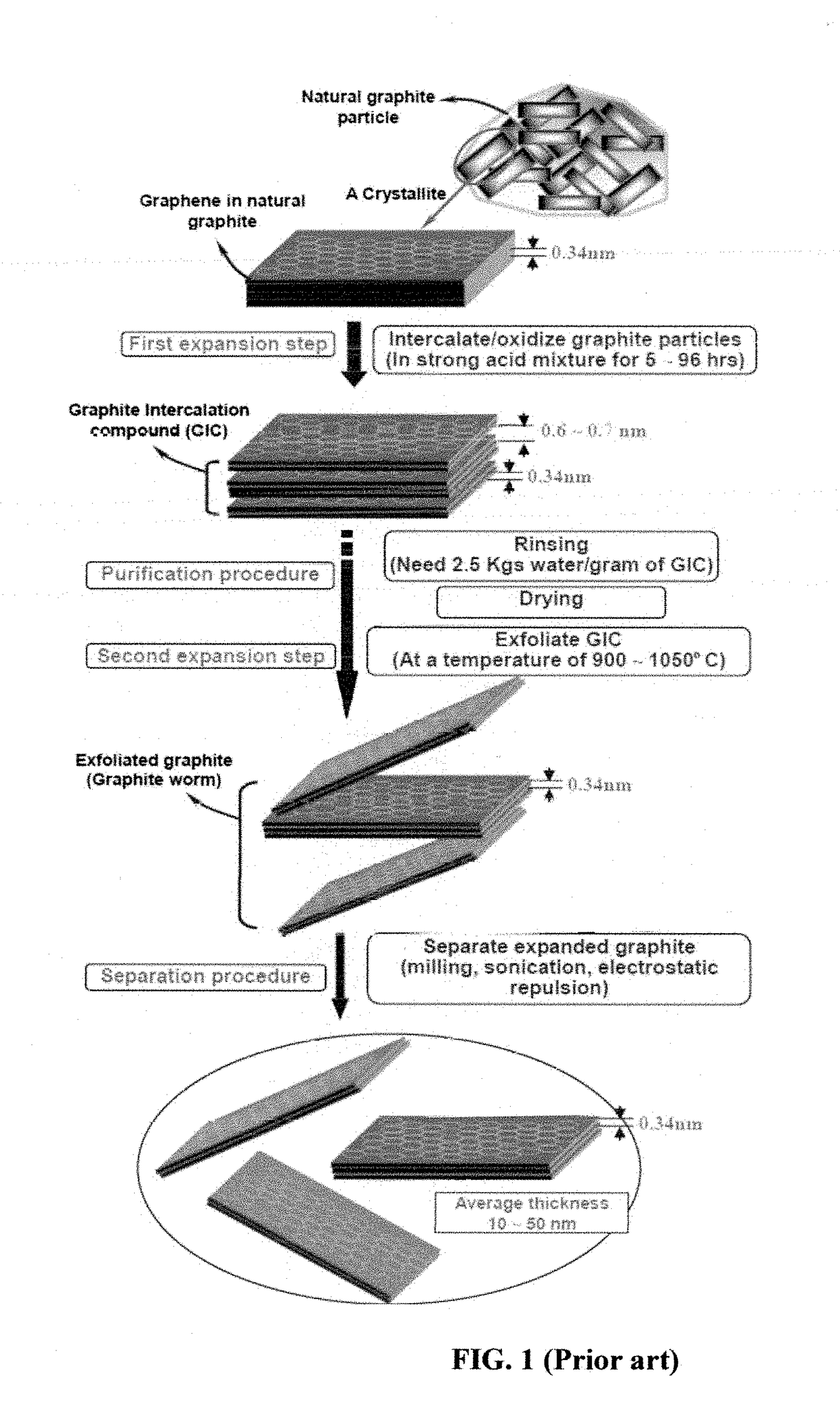

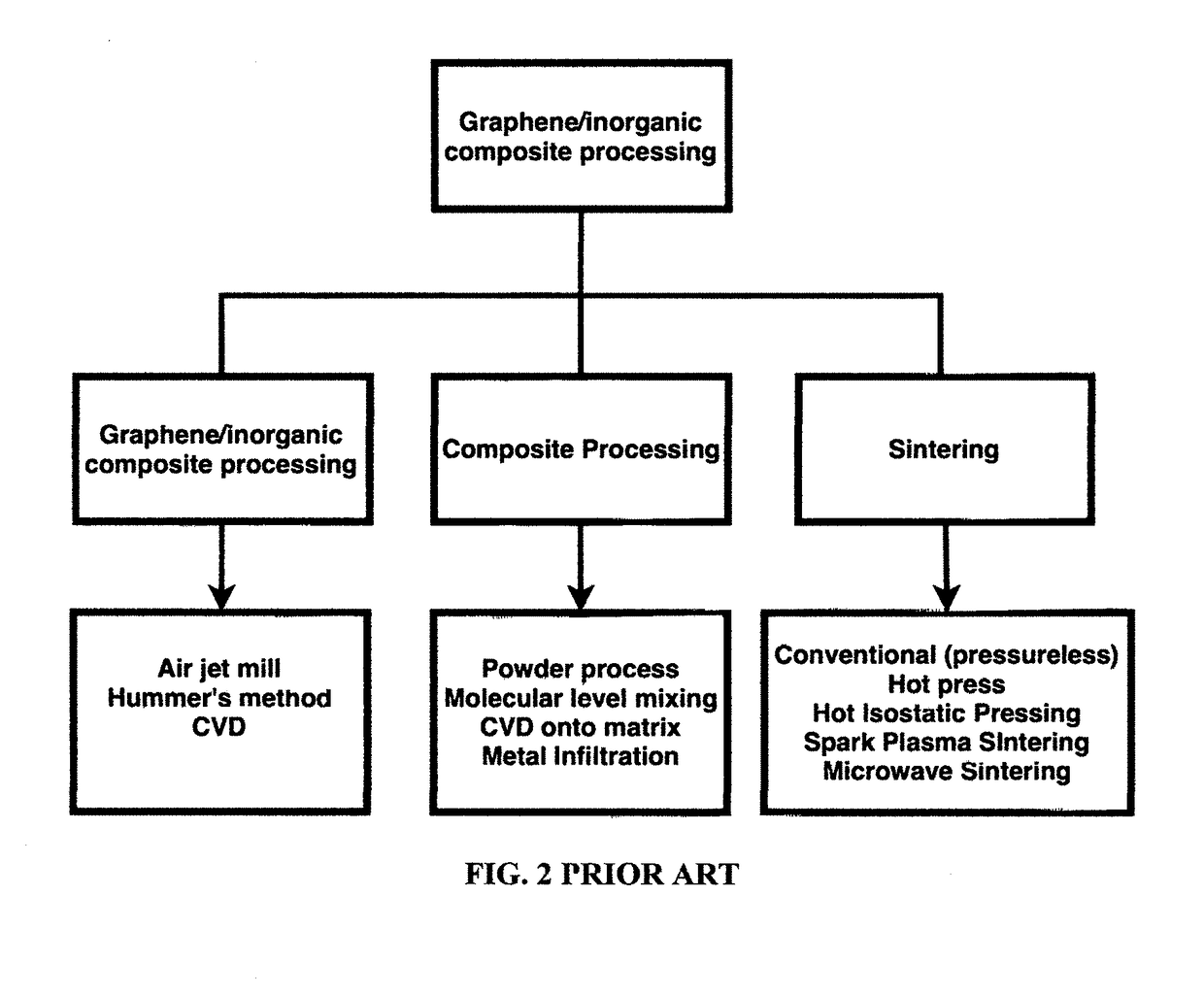

Provided is a simple, fast, scalable, and environmentally benign method of producing a graphene-reinforced inorganic matrix composite directly from a graphitic material, the method comprising: (a) mixing multiple particles of a graphitic material and multiple particles of an inorganic solid carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; (b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for peeling off graphene sheets from the graphitic material and transferring the graphene sheets to surfaces of solid inorganic carrier material particles to produce graphene coated or graphene-embedded inorganic particles inside the impacting chamber; and (c) forming graphene-coated or graphene-embedded inorganic particles into the graphene-reinforced inorganic matrix composite. Also provided is a mass of the graphene-coated or graphene-embedded inorganic particles produced by this method.

Owner:GLOBAL GRAPHENE GRP INC

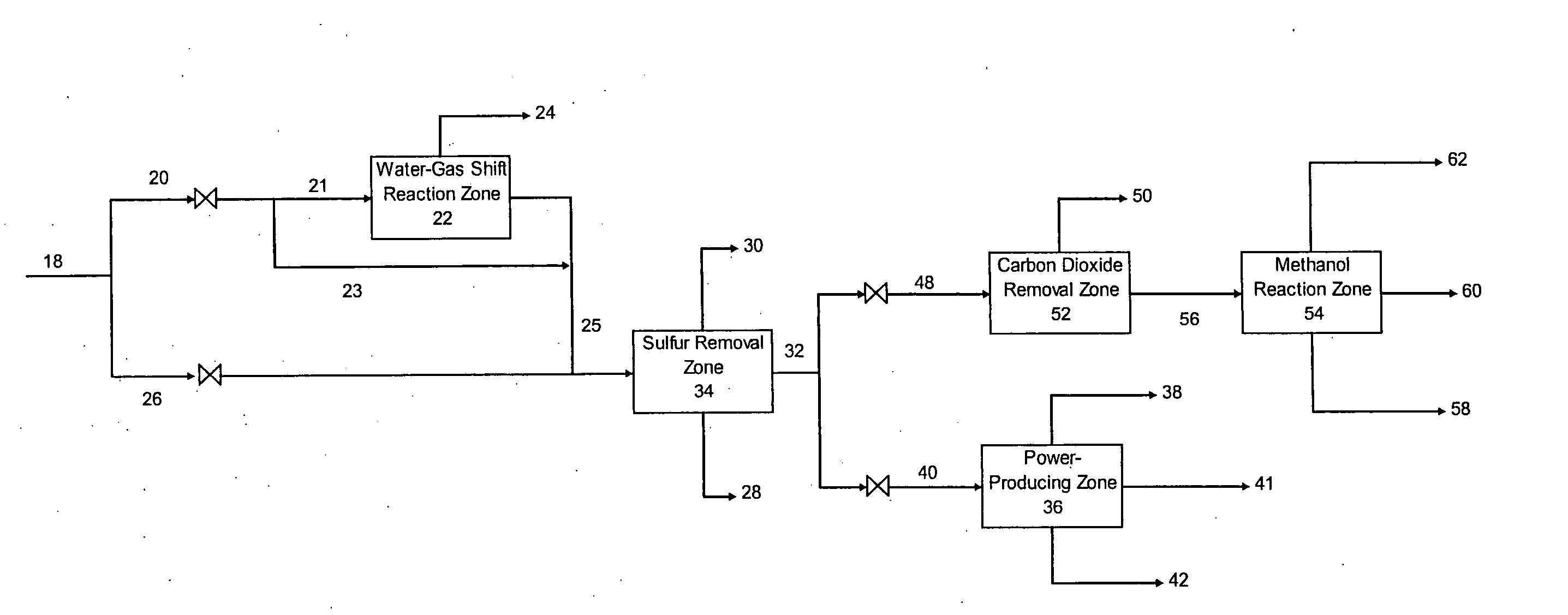

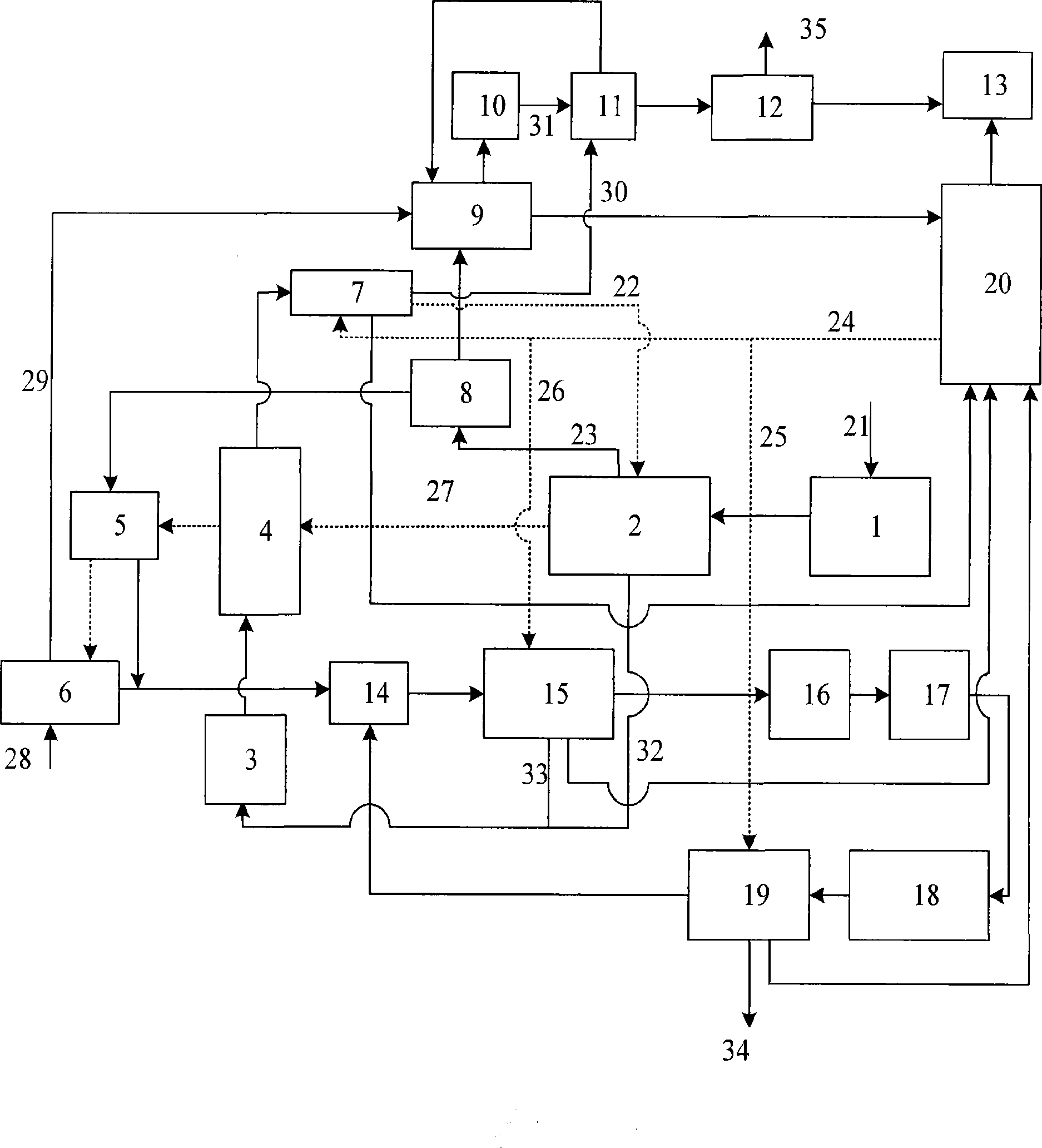

Method for satisfying variable power demand

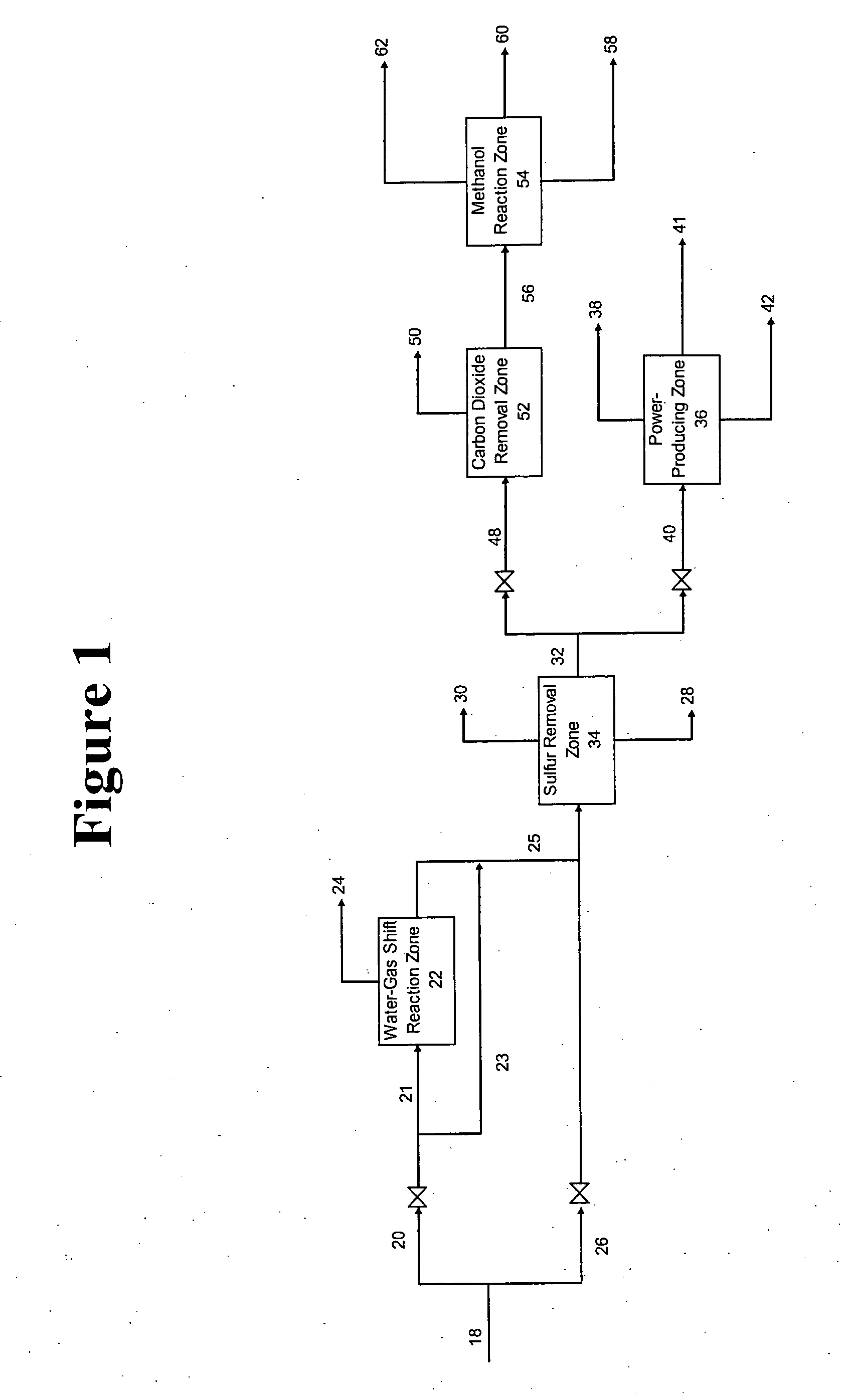

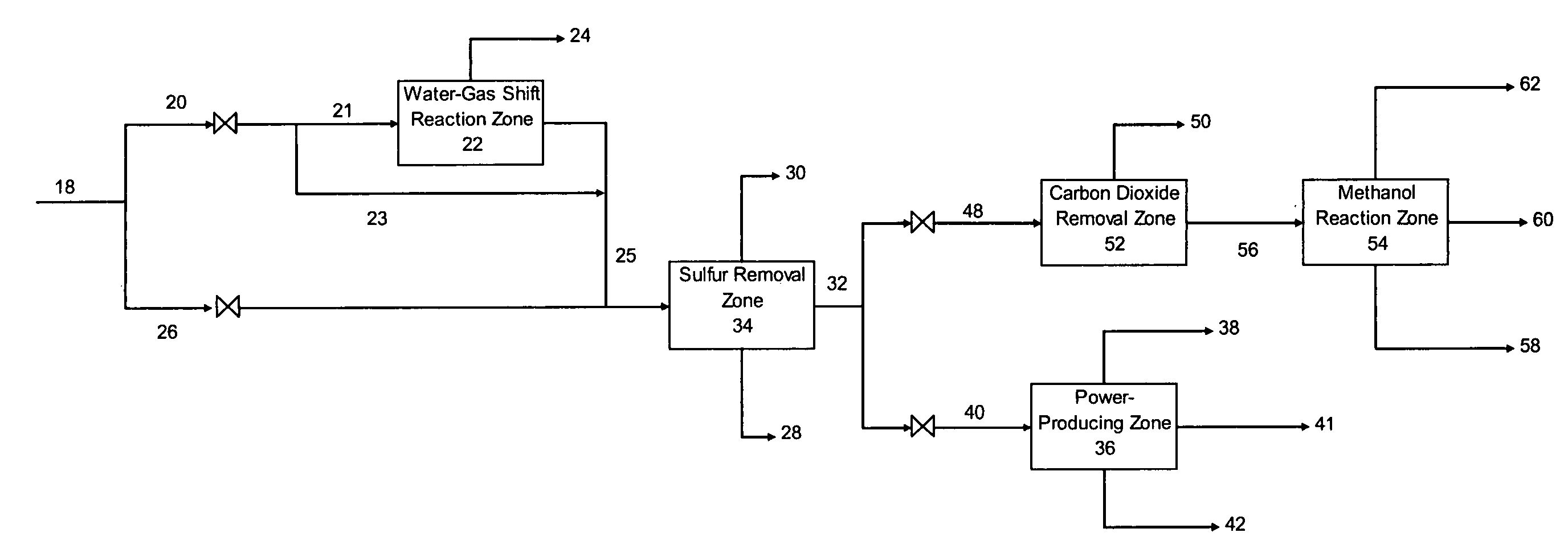

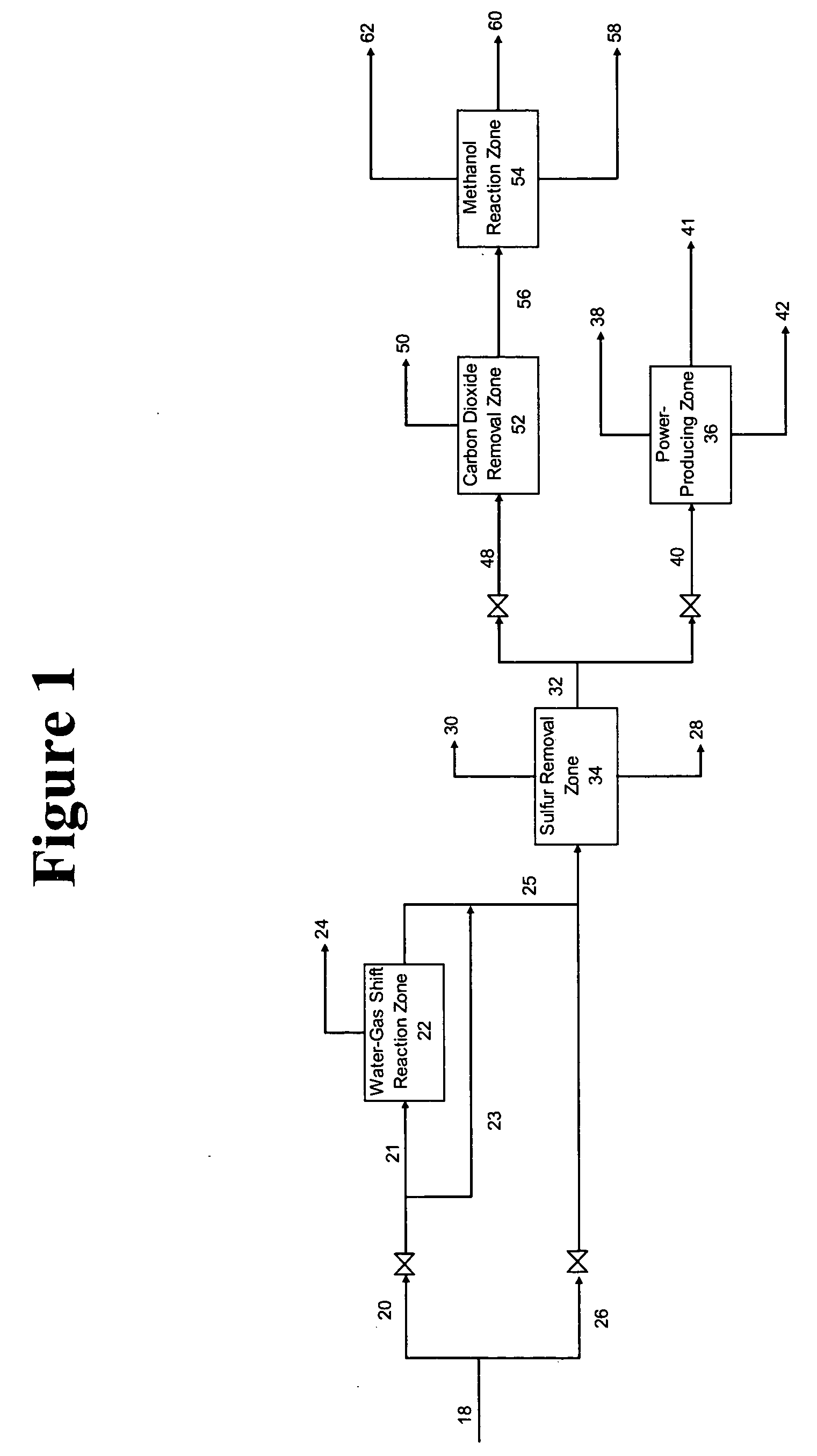

A process for satisfying variable power demand and a method for maximizing the monetary value of a synthesis gas stream are disclosed. One or more synthesis gas streams are produced by gasification of carbonaceous materials and passed to a power producing zone to produce electrical power during a period of peak power demand or to a chemical producing zone to produce chemicals such as, for example, methanol, during a period of off-peak power demand. The power-producing zone and the chemical-production zone which are operated cyclically and substantially out of phase in which one or more of the combustion turbines are shut down during a period of off-peak power demand and the syngas fuel diverted to the chemical producing zone. This out of phase cyclical operational mode allows for the power producing zone to maximize electricity output with the high thermodynamic efficiency and for the chemical producing zone to maximize chemical production with the high stoichiometric efficiency. The economic potential of the combined power and chemical producing zones is enhanced.

Owner:EASTMAN CHEM CO

Method for satisfying variable power demand

InactiveUS20060096298A1Combustible gas catalytic treatmentCombustion enginesChemical measurementElectric power

A process for satisfying variable power demand and a method for maximizing the monetary value of a synthesis gas stream are disclosed. One or more synthesis gas streams are produced by gasification of carbonaceous materials and passed to a power producing zone to produce electrical power during a period of peak power demand or to a chemical producing zone to produce chemicals such as, for example, methanol, during a period of off-peak power demand. The power-producing zone and the chemical-production zone which are operated cyclically and substantially out of phase in which one or more of the combustion turbines are shut down during a period of off-peak power demand and the syngas fuel diverted to the chemical producing zone. This out of phase cyclical operational mode allows for the power producing zone to maximize electricity output with the high thermodynamic efficiency and for the chemical producing zone to maximize chemical production with the high stoichiometric efficiency. The economic potential of the combined power and chemical producing zones is enhanced.

Owner:EASTMAN CHEM CO

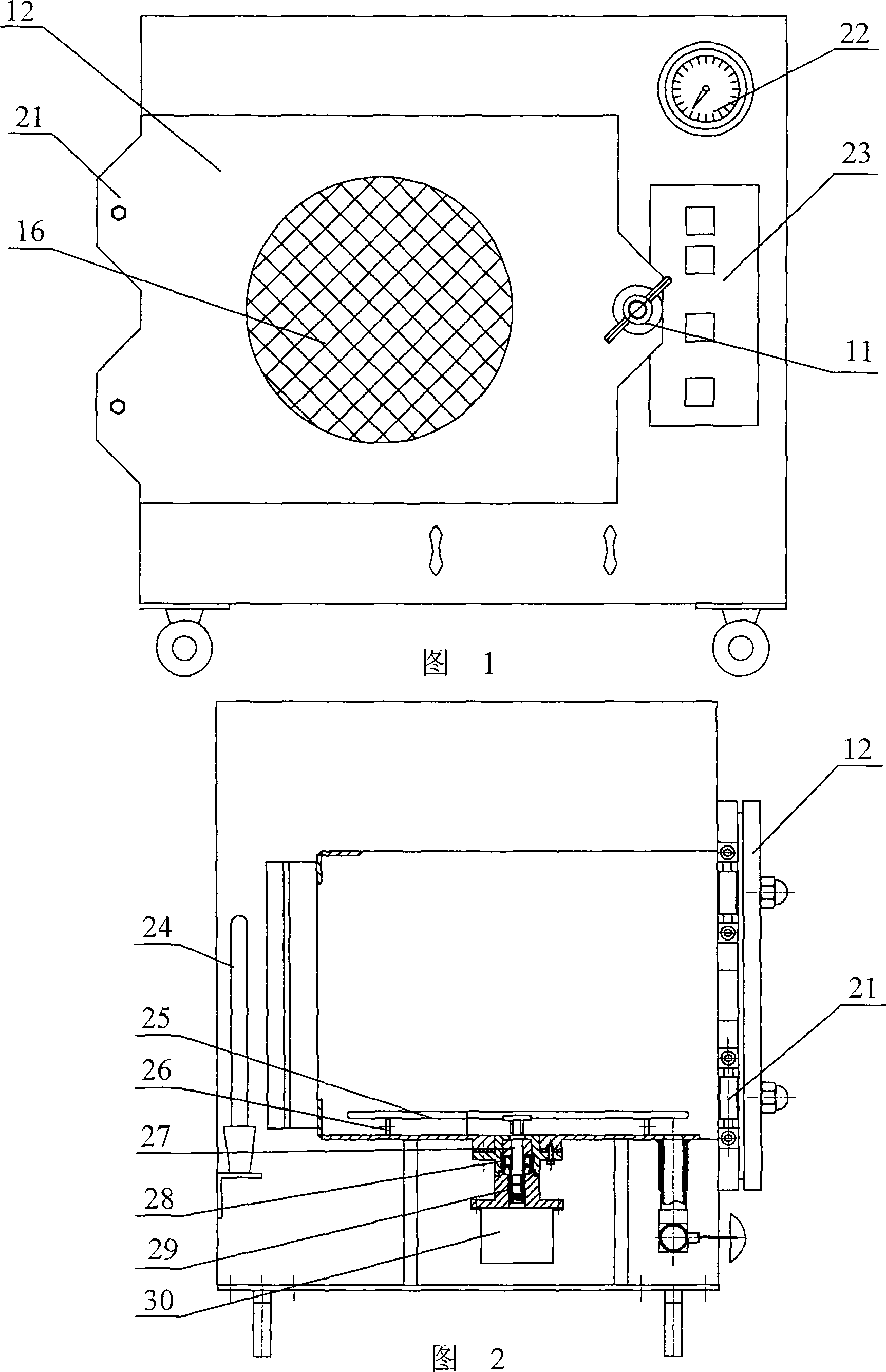

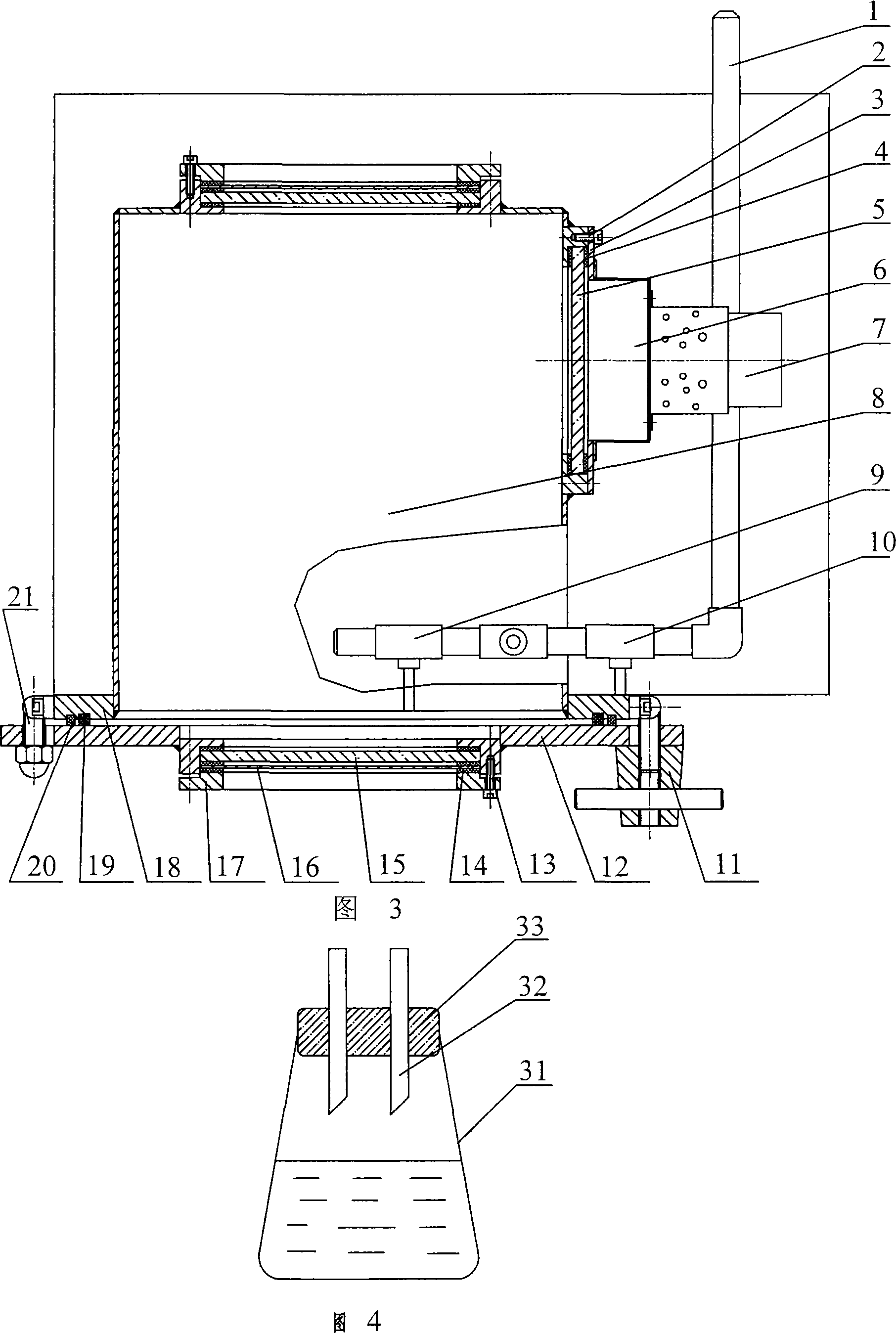

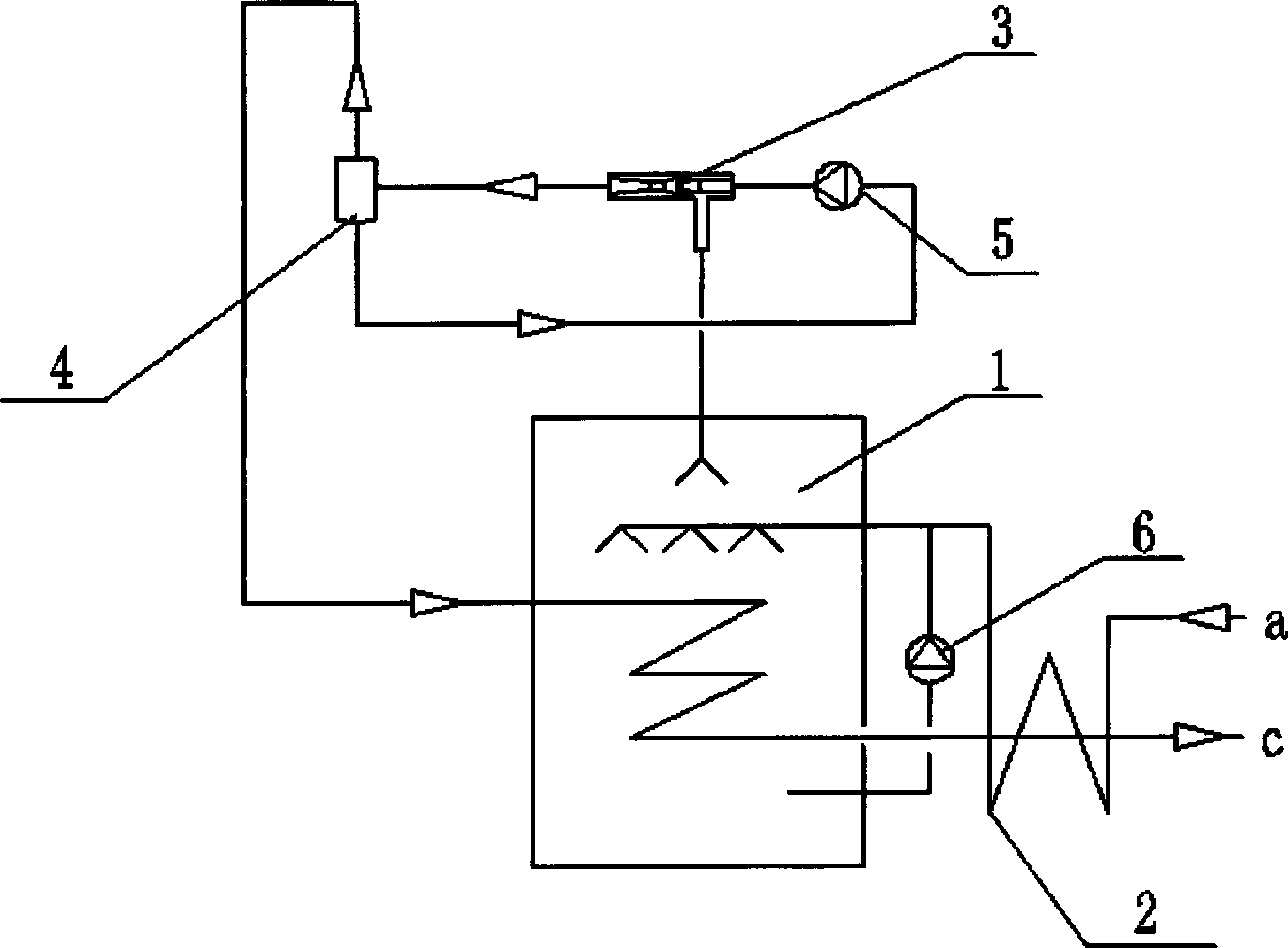

Micro-wave vacuum equipment

InactiveCN101082464AFast dryingFast concentrationDrying solid materials with heatDrying chambers/containersVacuum pumpingMicrowave

This invention relates to a sort of integral dry and dewatering set of the microwave and vacuum system, it consists of a hothouse of hermetic estate which is used to pose the materiel, the on-off door body which is propitious to gain and put materiel is fitted on the wall of the hothouse, the microwave produced by the microwave generator can cross the wall of the hothouse and it use the microwave to heat the materiel of the hothouse, there has the vacuum connector tub which is extended to the hothouse on the wall of the hothouse, the vacuum connector tub connects with the vacuum-pumping set. Because thin invention makes the microwave heating system connects with the vacuum system in the organic way, the speed of its dryness and condensation is fast, the temperature is low (25 to 45 deg. C), It very fit to the use of the lab, and fit to desiccate and condense the multifarious hydrous, and specially fit to food materiel of the heat sensitivity, and so on, and it is widely used to desiccate and condense the multifarious hydrous in the way of small-scale in the lab, such as the food, the medication, the chemical production.

Owner:JIANGNAN UNIV

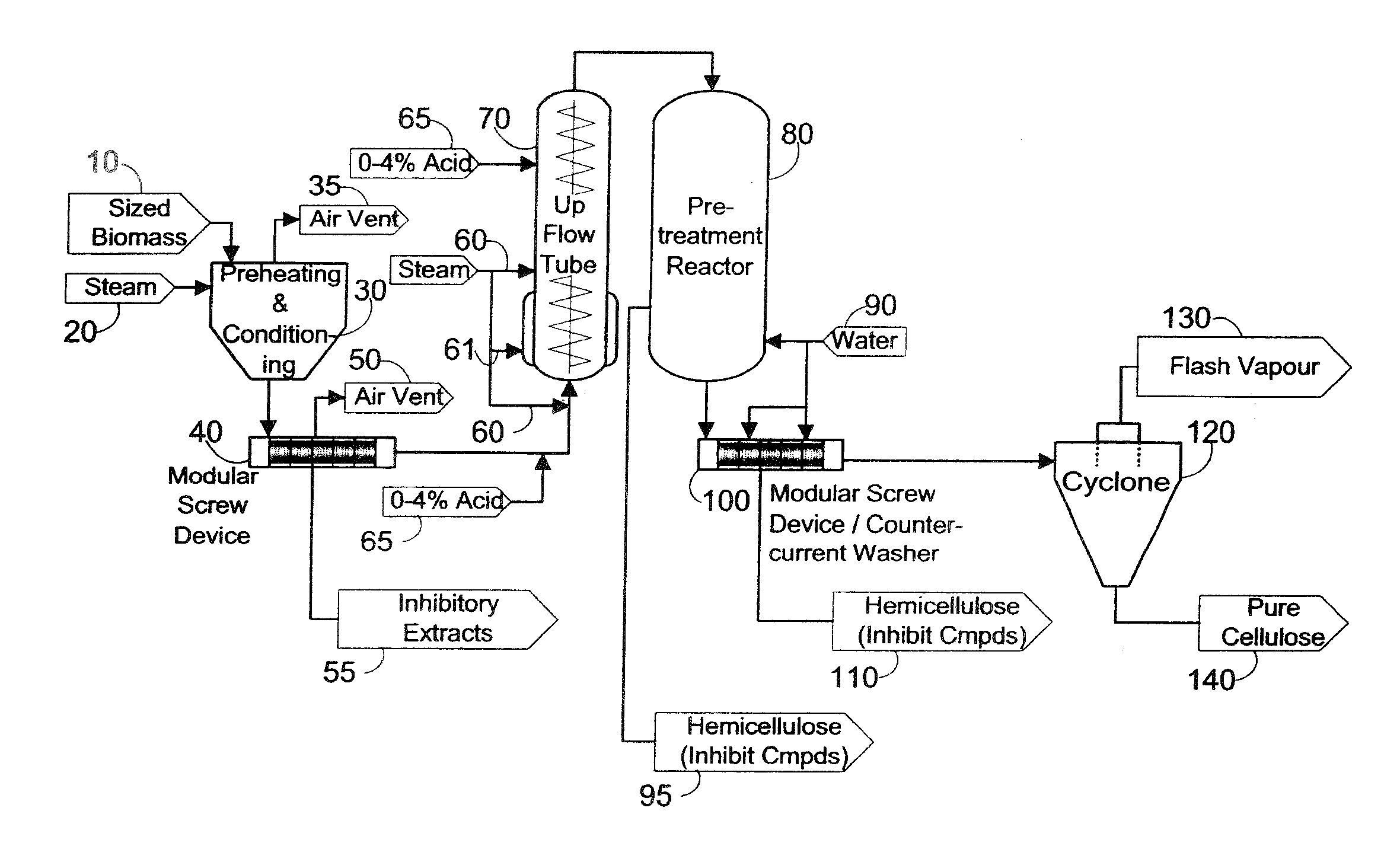

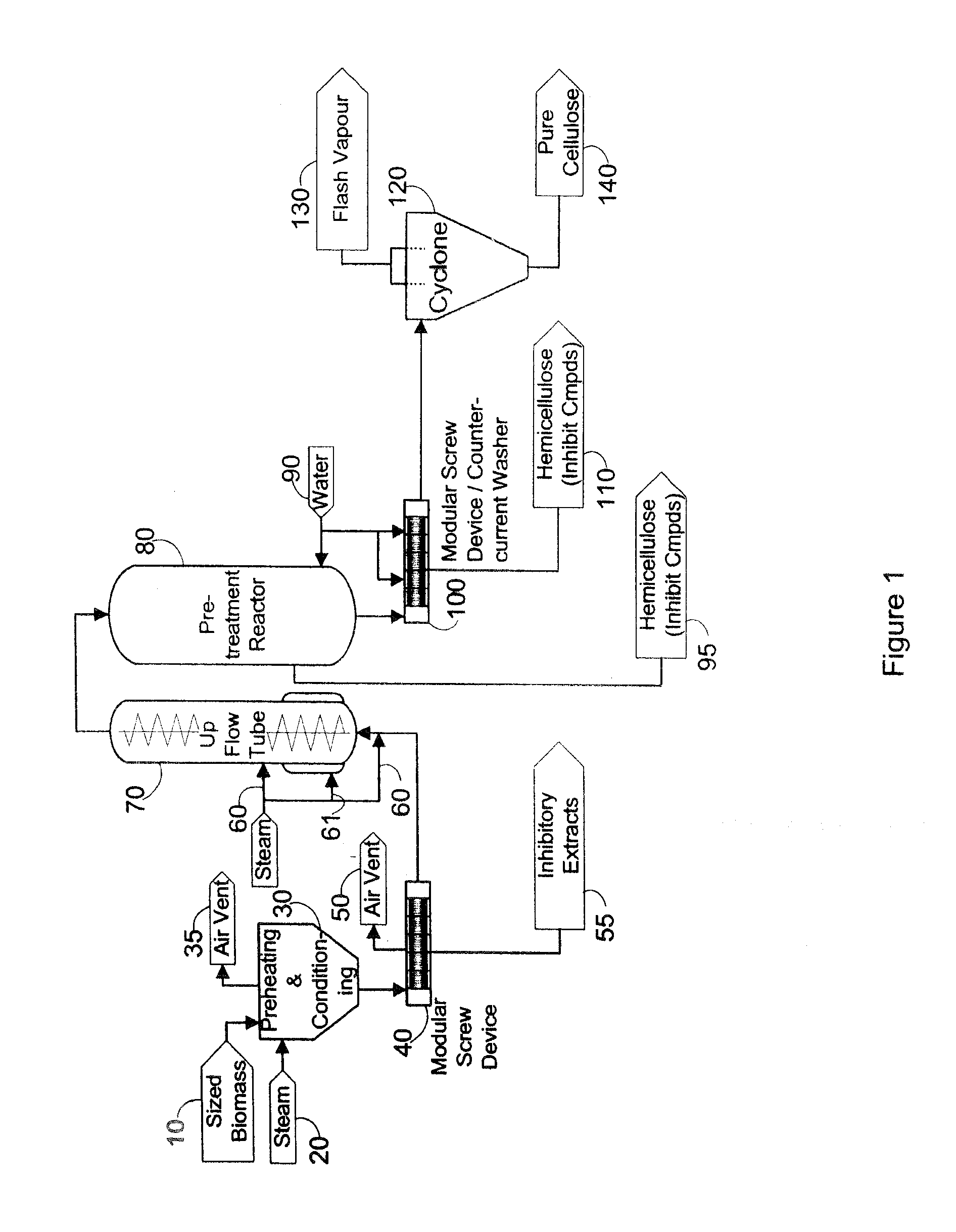

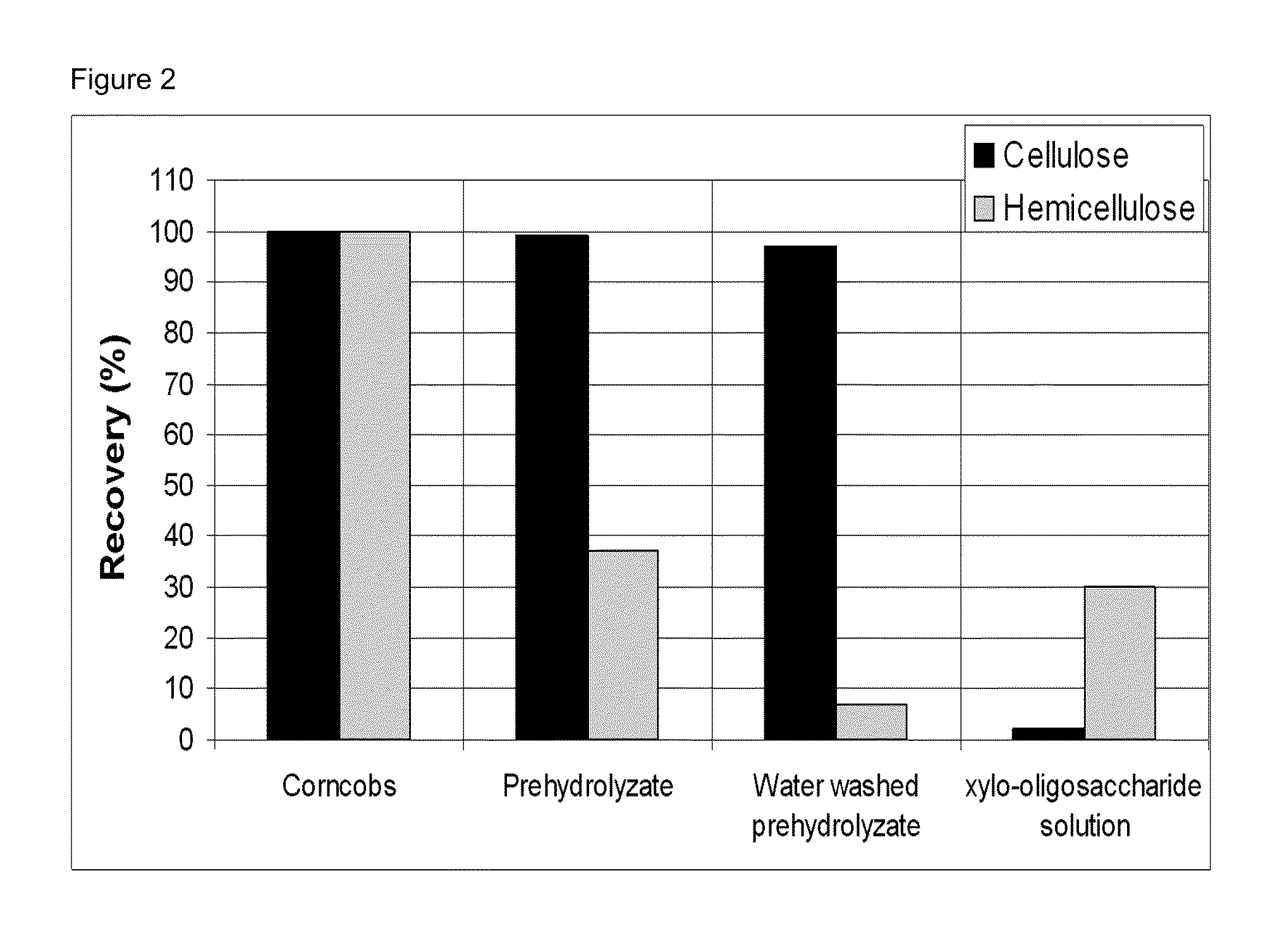

Fractionation of biomass for cellulosic ethanol and chemical production

InactiveUS20100313882A1Reduce inhibitionMore cost-effectivelyBiofuelsGlucose productionFractionationFermentation

A process is defined for the continuous steam pretreatment and fractionation of corn cobs and low lignin lignocellulosic biomass to produce a concentrated cellulose solid stream that is sensitive to enzymatic hydrolysis. Valuable chemicals are recovered by fractionating the liquid and vapor stream composed of hydrolysis and degradation products of the hemicellulose. Cellulosic derived glucose is produced for fermentation to biofuels. A hemicellulose concentrate is recovered that can be converted to value added products including ethanol.

Owner:GREENFIELD SPECIALTY ALCOHOLS

Apparatus for electrolysis of molten oxides

The invention provides improved electrodes for electrolytic cells operating with molten salt electrolytes. Nonconsumable iridium-based anodes of the invention facilitate the release of gaseous oxygen from oxide-containing melts, for example in the electro-chemical production of liquid or gaseous reactive metals from oxides. Cathode substrates of the invention are constructed of a tungsten-based alloy and enable deposition of an overlying liquid-metal cathode. Incorporation of the anode and cathode substrate of the invention into molten-oxide cells establishes a novel method for electrolytic extraction of titanium and other reactive metals.

Owner:MASSACHUSETTS INST OF TECH

Method for producing propylene oxide

ActiveCN101735177AReduce investmentAchieve recyclingOrganic chemistryDispersed particle separationProcess designSodium hydroxide

The invention discloses a chemical production method, in particular a novel green production process for propylene oxide. In the method, the process design is carried out by using bipolar membrane, electrodialysis, antiosmosis, air flotation, heat exchange, oxidation, and other technology. In the production process, sodium hydroxide replaces the conventional calcium hydroxide and generates sodium chloride through reaction; the sodium chloride generates hydrochloric acid and sodium hydroxide by the bipolar membrane technology; and the hydrochloric acid is recovered, and the sodium hydroxide and water can be recycled. Therefore, no new sodium hydroxide is needed and no wastewater is discharged in the production of the propylene oxide. The sodium hydroxide is added at the preliminary stage of the production of the propylene oxide, and the input amount of the sodium hydroxide is controlled between 5 and 15 percent. The novel green production process for the propylene oxide has the advantages that: the recycling of the water, sodium chloride and sodium hydroxide is realized, the effects of zero discharge and input reduction of production materials are substantially achieved, and finally better social and economic benefits are achieved. The novel green production process for the propylene oxide can be widely applied to the chlorohydrin production in China.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

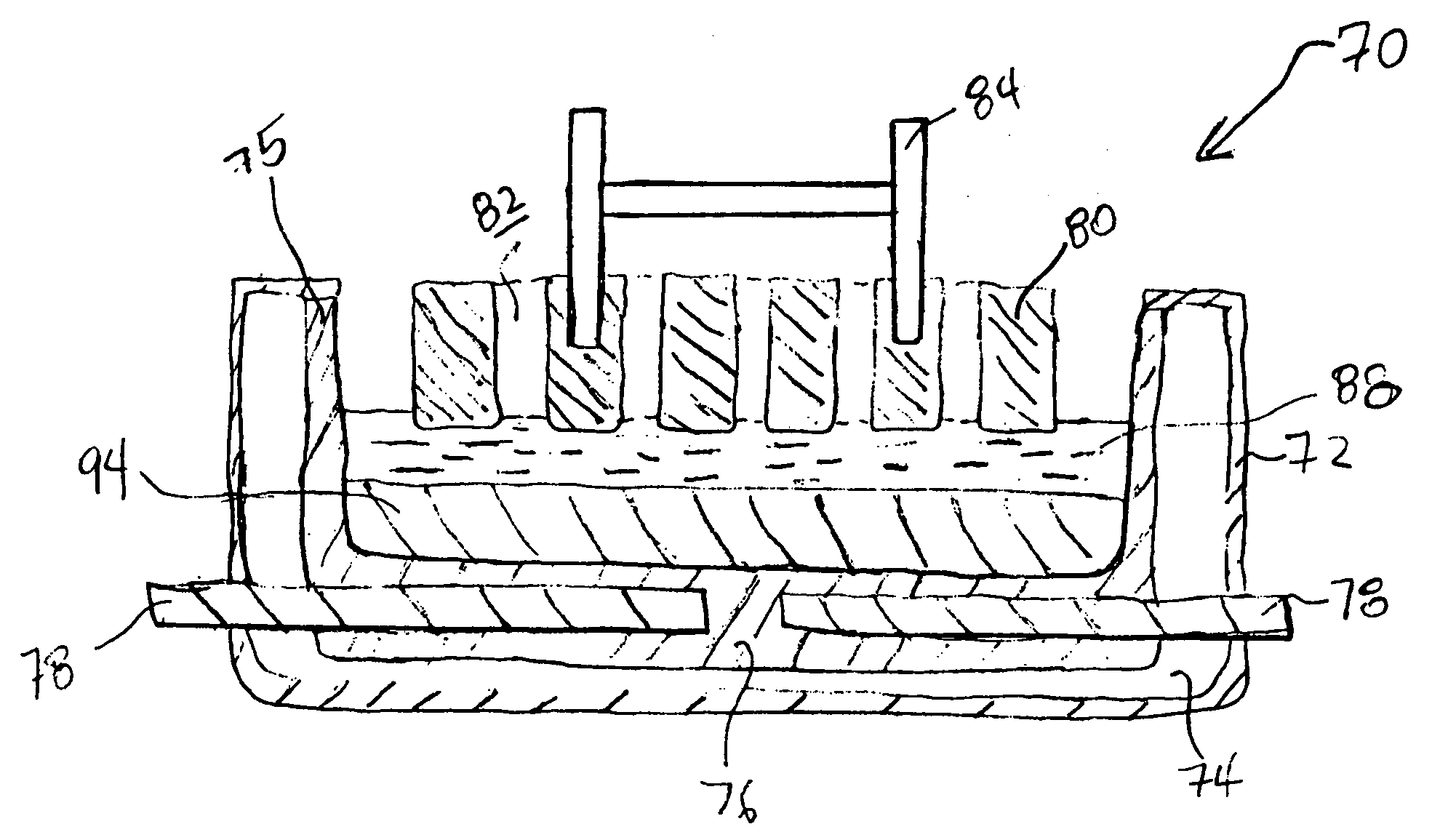

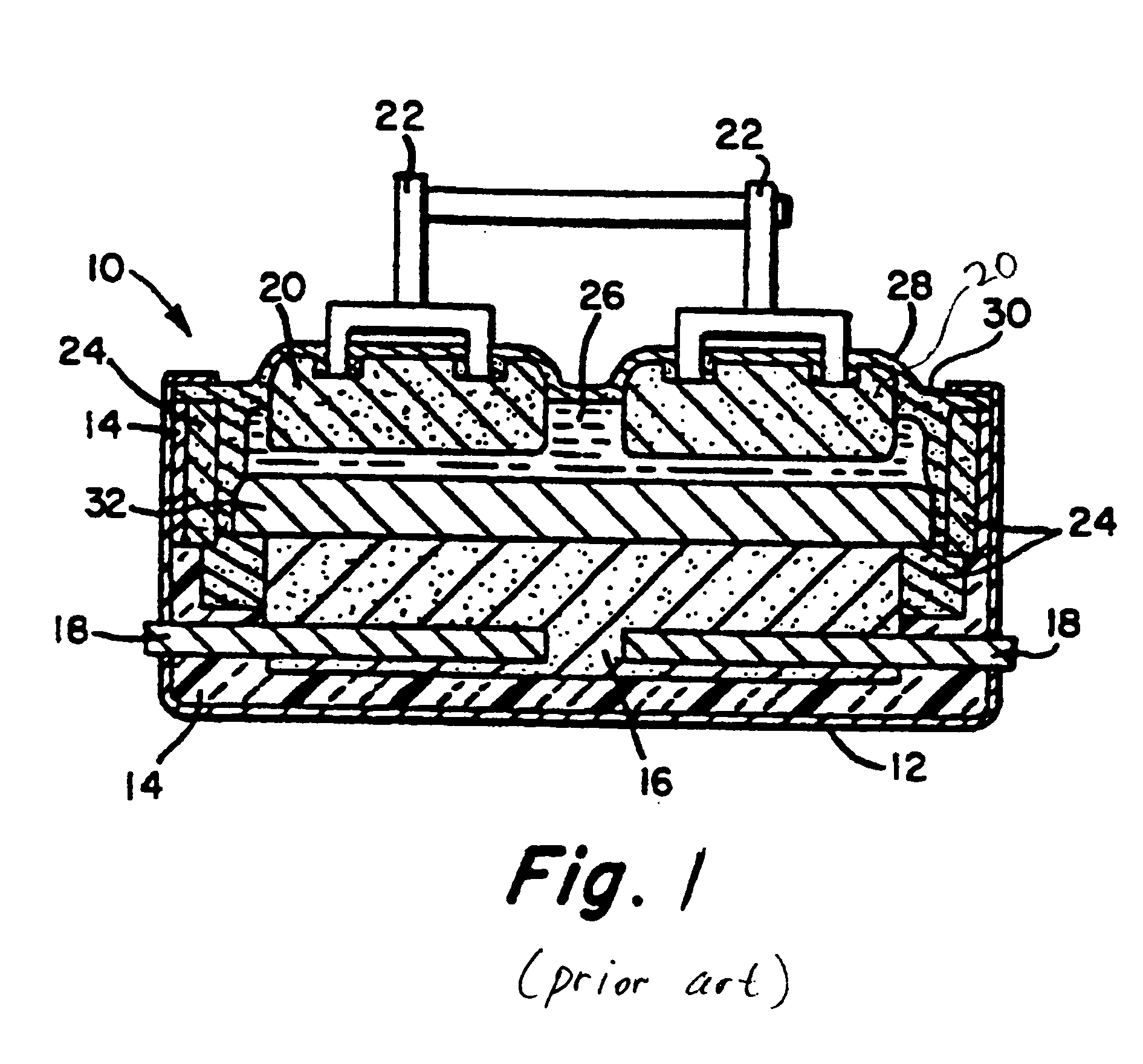

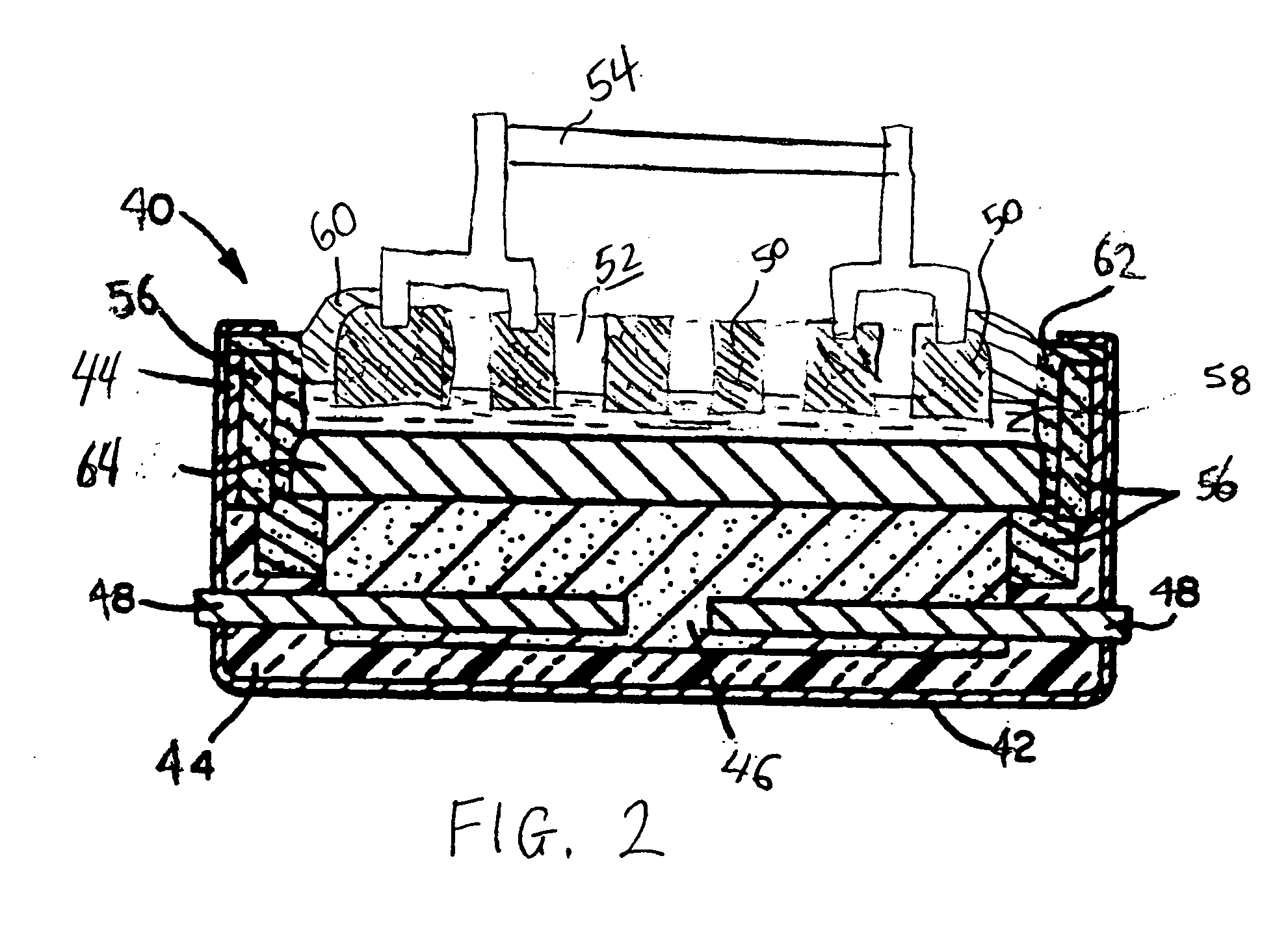

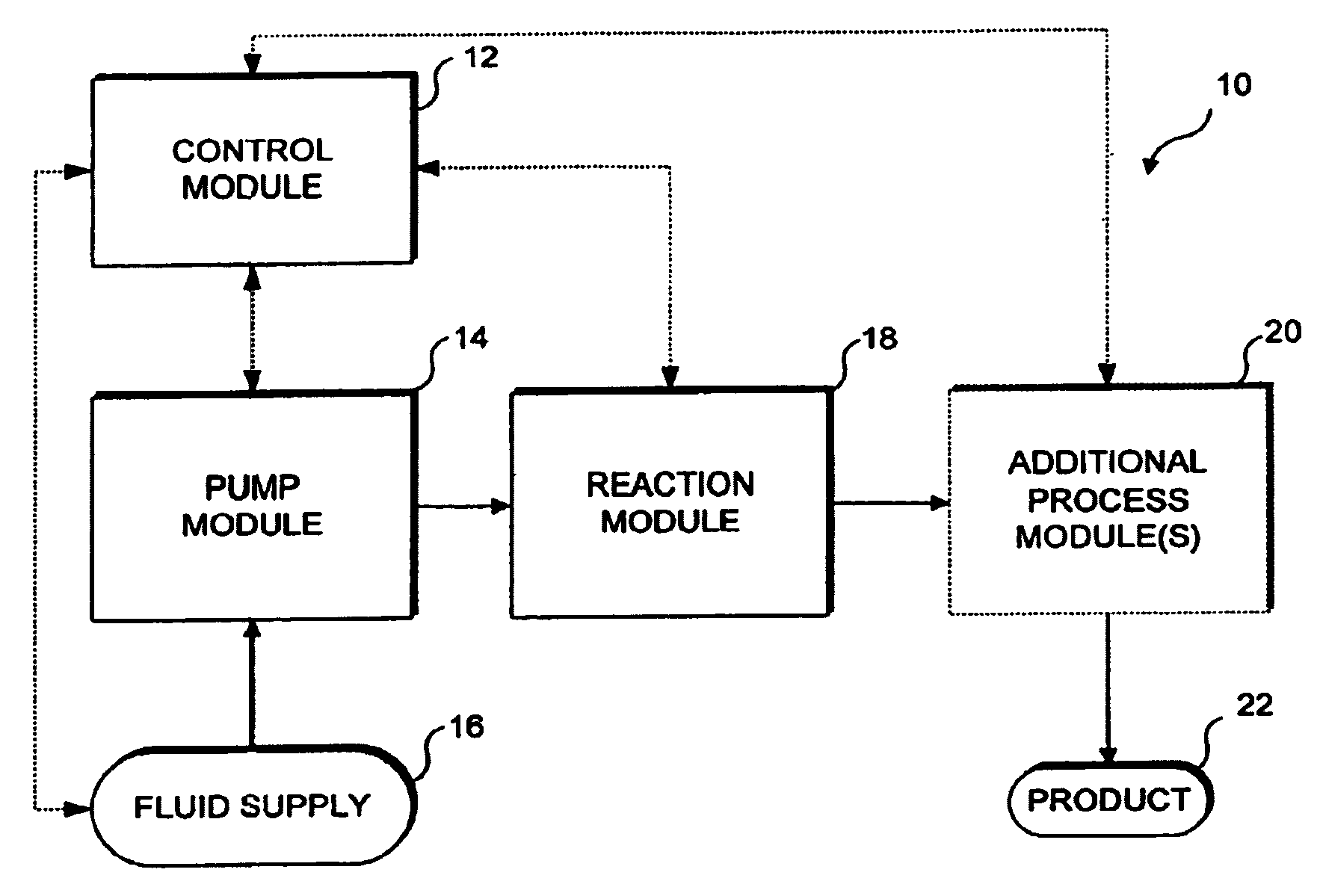

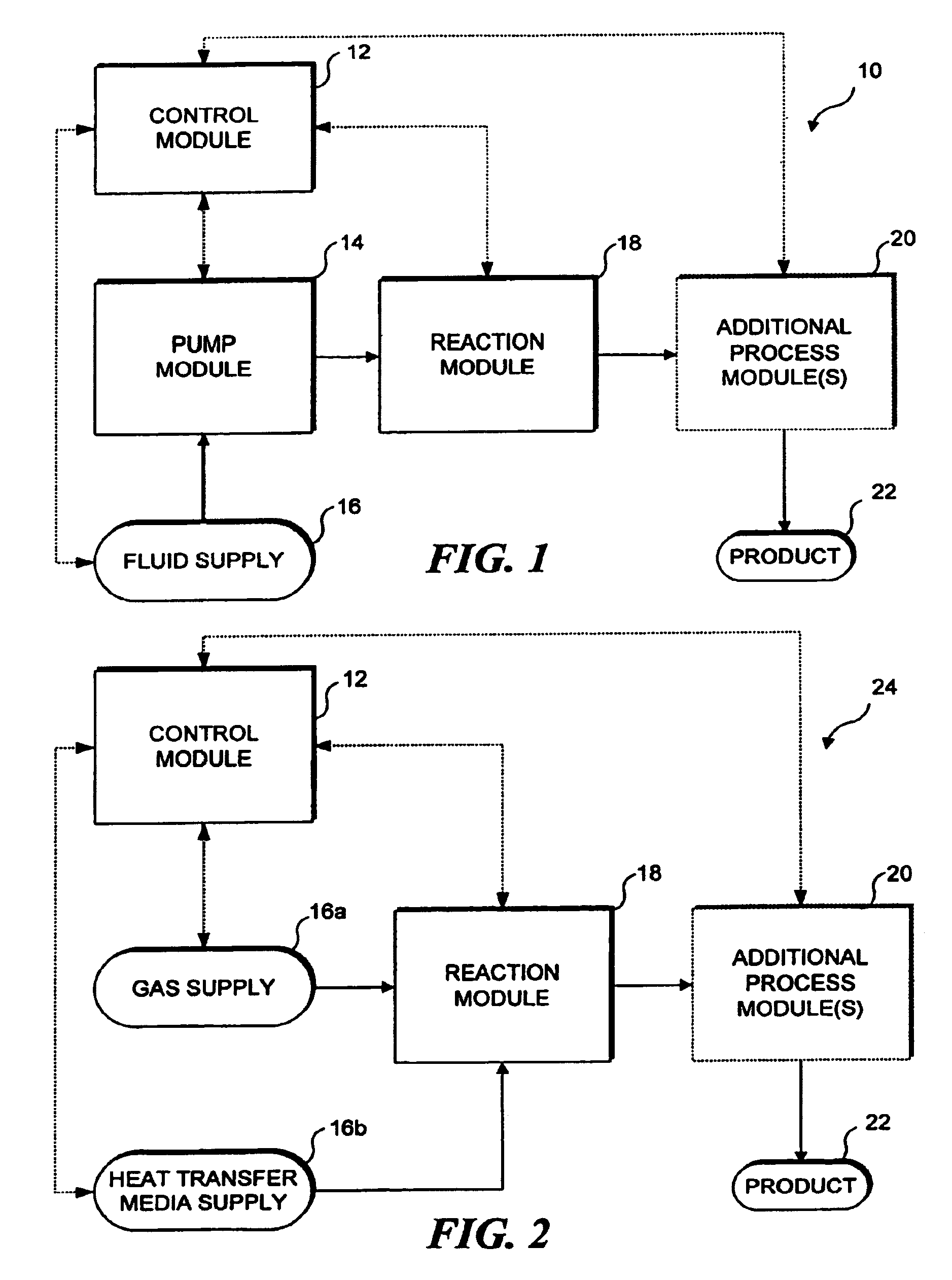

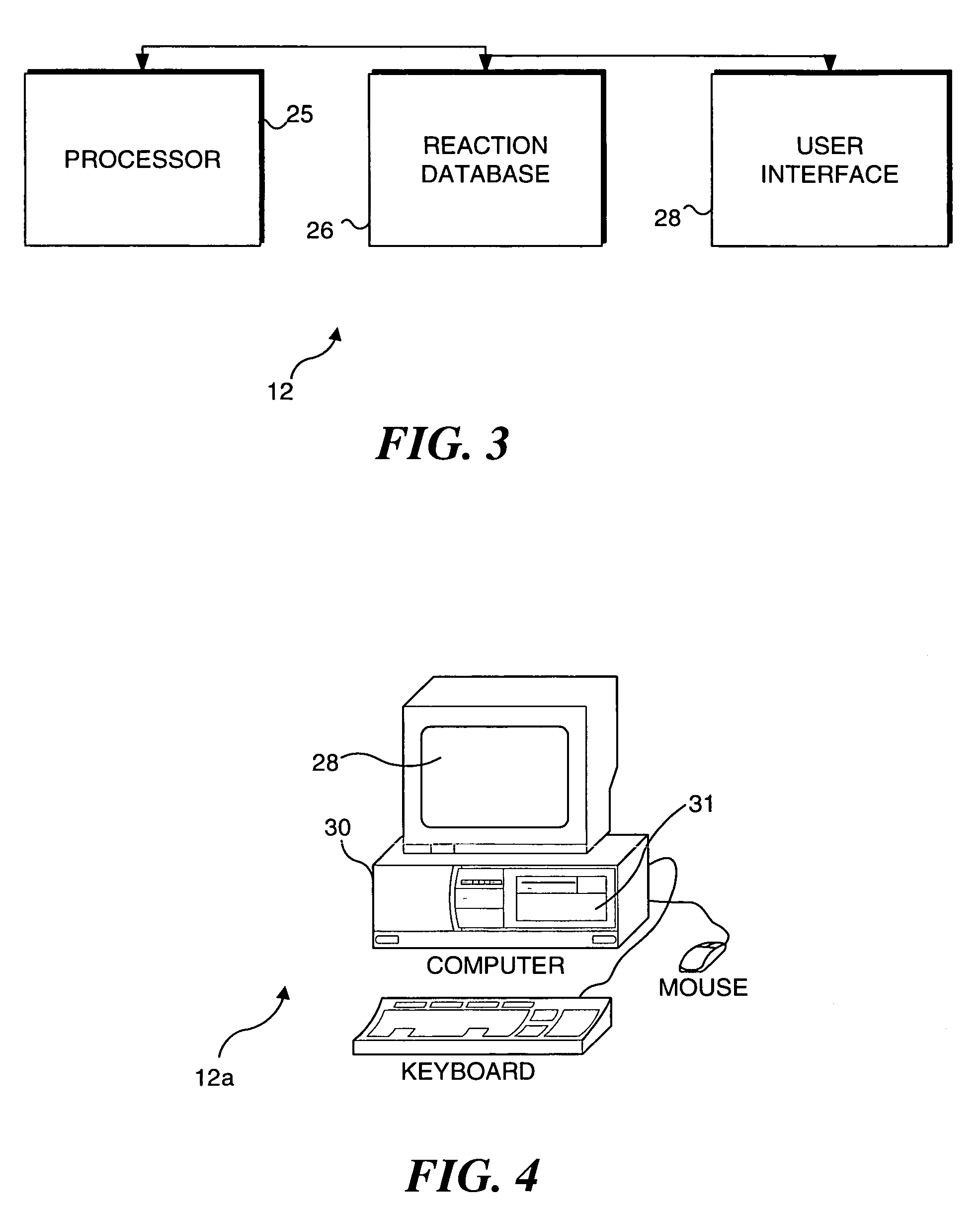

Modular chemical production system incorporating a microreactor

InactiveUS7056477B1Facilitate single stepEasy to completeExhaust apparatusTemperatue controlMicroreactorOperational system

A modular chemical production system that preferably includes a microreactor for producing a product by reacting two or more reactants. Modularization enables components such as controllers, pumps, valves, microreactors, and processing modules to be added or removed from the system as required to produce a desired product. A minimum system includes a control module and a reaction module, which has a mixing volume and a reaction volume. Various pumping modules and residence time modules may also be included in the system. Modules can be changed if malfunctioning, or for producing a different product, or to change a quantity of the chemical produced. The control module preferably accesses a database in which data define parameters for a plurality of different reactions that are optimized for the production of different chemical products. The user selects the product desired and the amount of the product, provides the reactants, solvents, and heat transfer media supplies, and the control module operates the system to automatically produce the product until the desired amount is obtained. The reaction module preferably includes a microreactor, which can be replaced with a microreactor of a different configuration to produce a different product. Connections between modules are designed to enable quick connection and disconnection of modules, and fluid lines are self sealing to prevent leakage of fluids when changing modules.

Owner:YMC

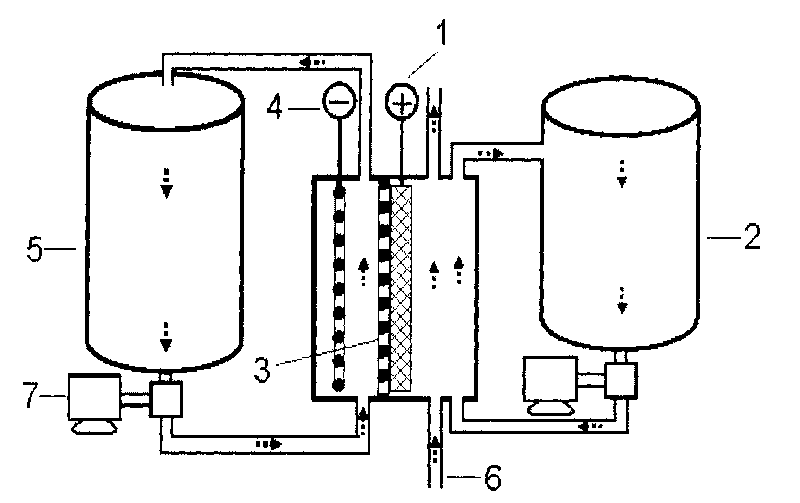

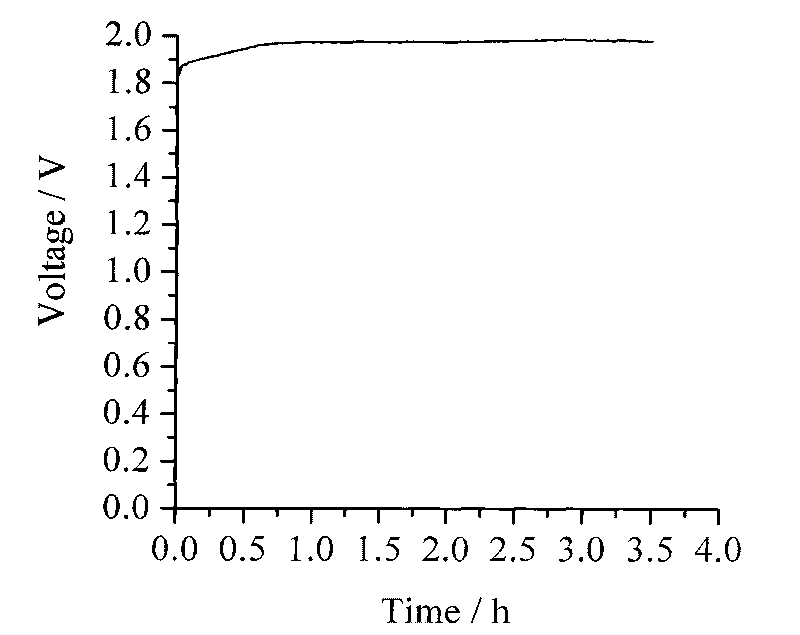

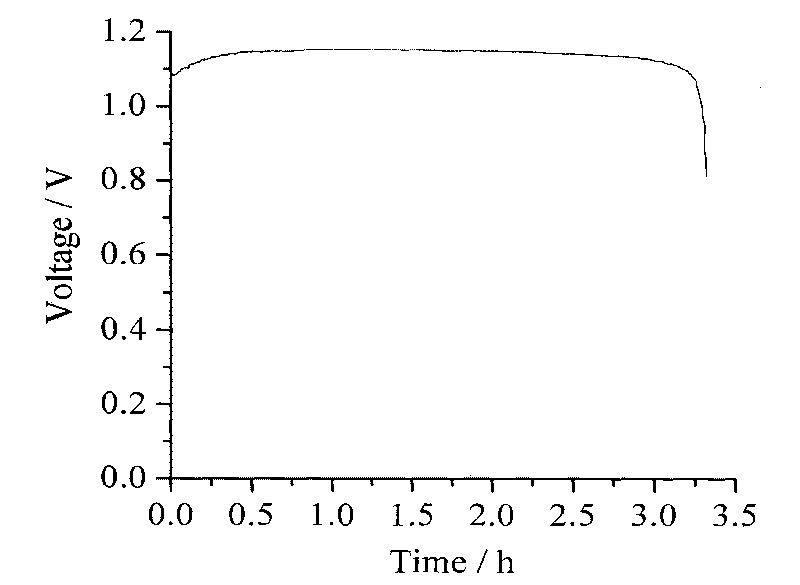

Rechargeable metal-air redox flow battery combining electrochemical preparation

InactiveCN101714680AImprove power utilization efficiencyIncrease energy densityFuel and primary cellsOxygenZinc–air battery

The invention relates to a rechargeable metal-air redox flow battery compatible with electrochemical preparation. When the battery is charged, electric energy input makes metal ions in the electrolyte flowing through a negative electrode reduced and deposited into metal to prepare for discharge, and the electric energy also makes reductive raw materials in the electrolyte flowing through a positive electrode oxidized into a product required to be synthesized. When the battery is discharged, the positive electrode is introduced with air or oxygen, the air or the oxygen is reduced on the electrode, and the positive electrode and a deposition redox flow metal negative electrode form the metal-air redox flow battery to output electric energy. In each charge and discharge cycle, the accumulation and discharge of the metal-air redox flow battery are carried out, and simultaneously electrooxidation chemical production is carried out so as to achieve the effect that one portion of electric energy is consumed and two functions are realized. The redox flow battery combines two functions of rechargeable metal-air accumulation and electrochemical preparation, realizes the combination of electrosynthesis, a deposition redox flow battery and a rechargeable metal-air battery, achieves the effects of energy conservation and high efficiency, improves the utilization rate of the electric energy and has good application prospect.

Owner:NO 63971 TROOPS PLA

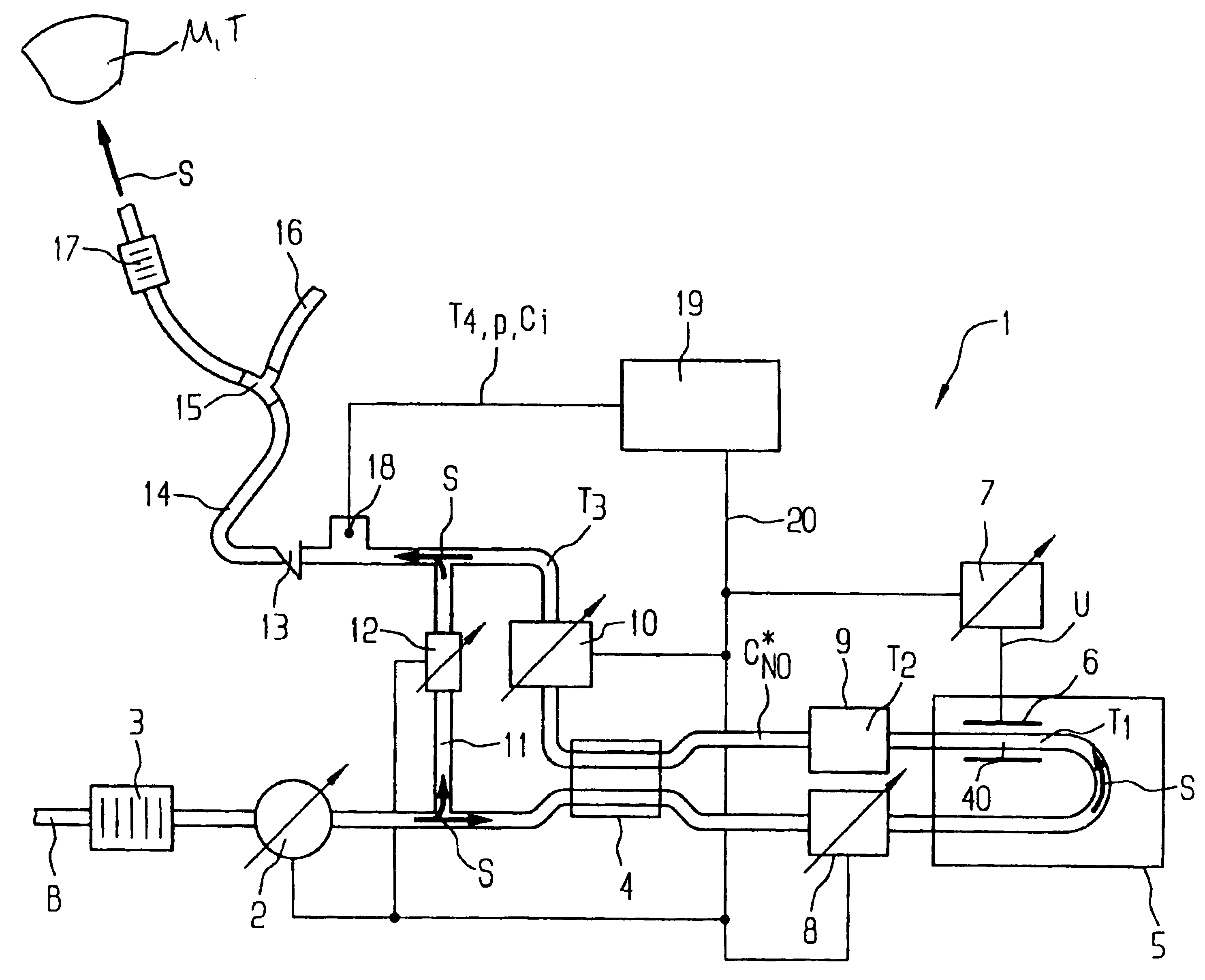

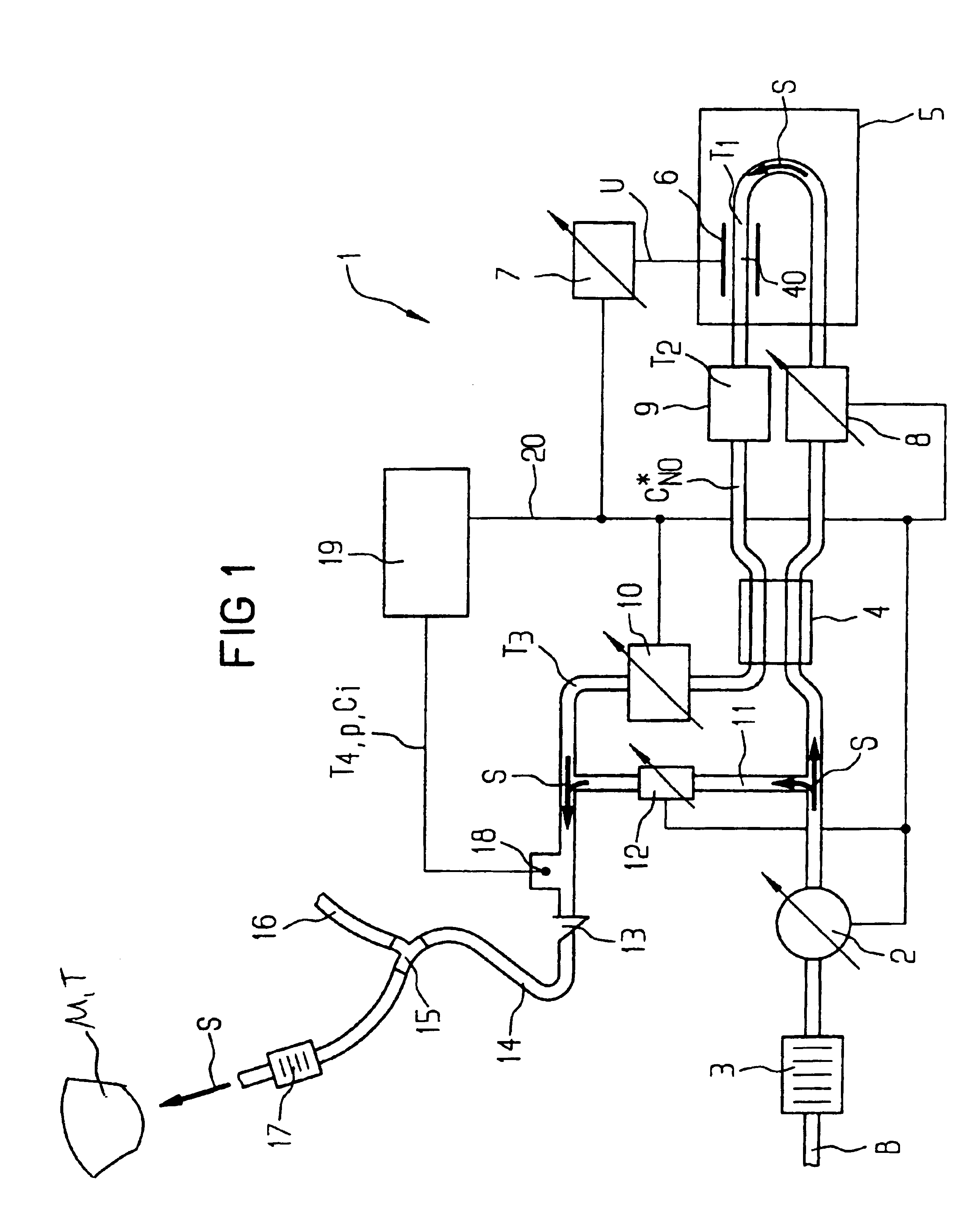

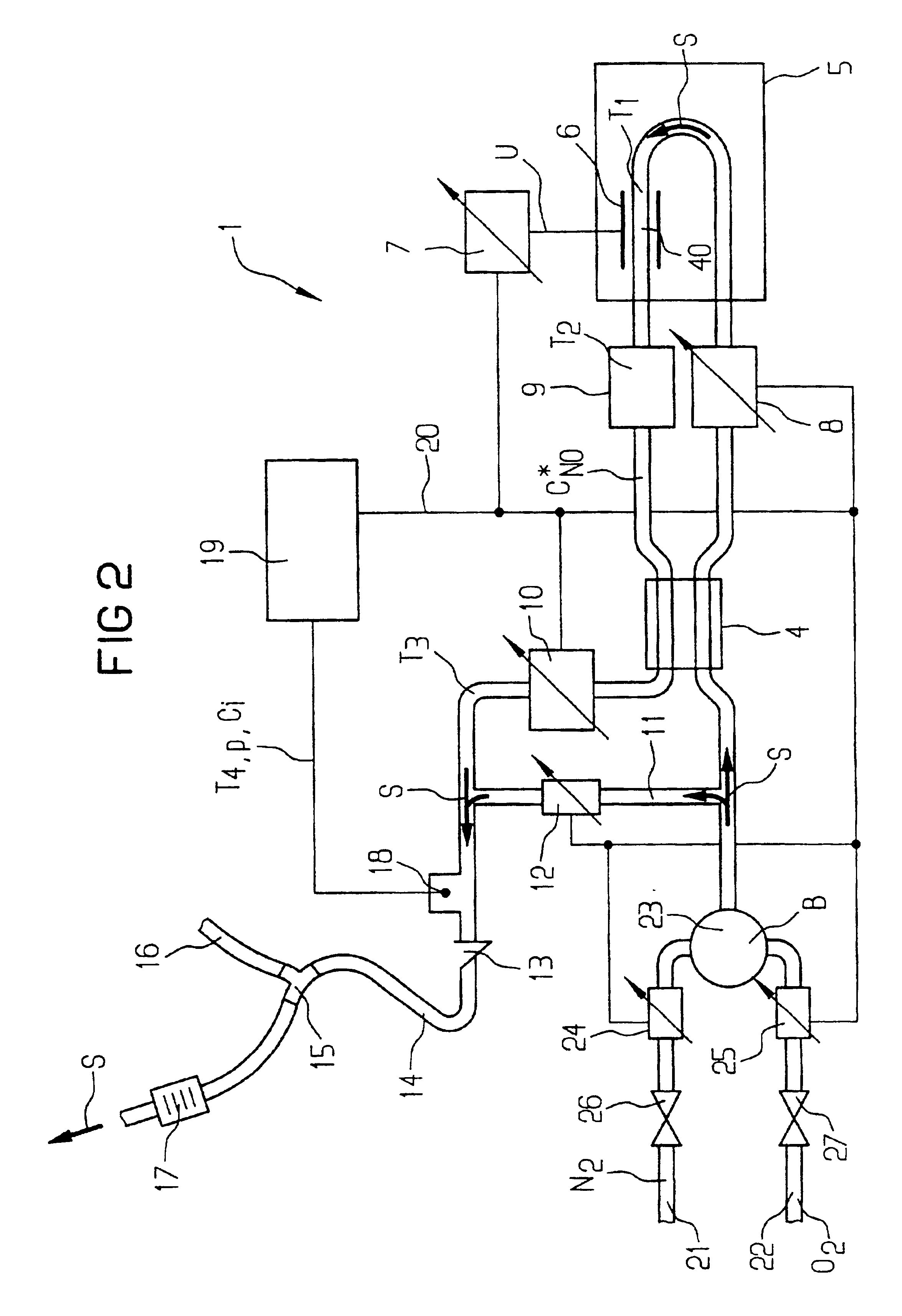

Apparatus for plasma-chemical production of nitrogen monoxide

InactiveUS6955790B2Overcome disadvantagesGas-gas reaction as plasma stateMedical devicesNitrogen monooxideNitrogen

A method and an apparatus for plasma-chemical production of nitrogen monoxide is used to produce inhalation gas enriched with nitrogen monoxide for medical purposes. The nitrogen-monoxide production is achieved through the use of a dielectric barrier discharge created in a process gas containing nitrogen and oxygen.

Owner:MAQUET CRITICAL CARE

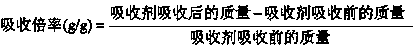

Organic solvent absorbing agent and preparation method thereof

InactiveCN103752289AWide absorption rangeHigh absorption rateOther chemical processesAlkali metal oxides/hydroxidesCross-linkMethacrylate

The invention discloses an organic solvent absorbing agent and a preparation method thereof. The organic solvent absorbing agent is prepared by carrying out suspension polymerization reaction on acrylics, methacrylates, styrene, a cross-linking agent and an initiating agent in the environment that water and a dispersing agent exist. The organic solvent absorbing agent disclosed by the invention has the advantages of wide absorbing range, high absorption rate, high absorption speed and the like; an absorbed surface has small viscosity and a certain jelly strength, the organic solvent absorbing agent is convenient to recover and recycle and good in industrial applicability. The organic solvent absorbing agent disclosed by the invention can be reused more than ten times, the problem of poor reusability of a conventional absorbing material is solved, the secondary pollution caused by emission of a used absorbing agent as a waste is effectively reduced, and meanwhile the effects that the resource utilization rate is improved and the cost is reduced are achieved. The organic solvent absorbing agent can be used for treatment of industrial solvent-containing wastewater, and leakage and emergent absorption of an organic solvent in chemical production and is high in practicability and has a broad development prospect.

Owner:FUZHOU UNIV

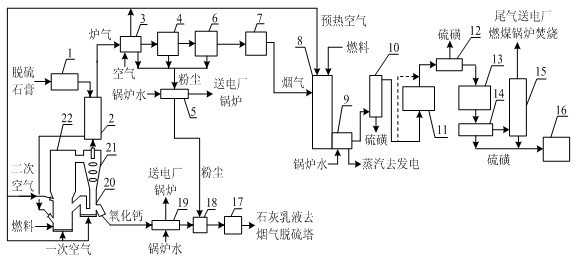

Method for preparing calcium oxide and sulfur by double-atmosphere fluidized roasting of desulfurated gypsum

InactiveCN102303883ASolve the use problemAbundant raw materialsEnergy inputSulfur preparation/purificationDust controlSulfur dioxide

The invention provides a method for preparing calcium oxide and sulfur by double-atmosphere fluidized roasting of desulfurated gypsum, belonging to the technical fields of solid pollutant treatment and in environmental protection chemical production. The method comprises the following steps: drying and dehydrating aged desulfurated gypsum, and then entering a multi-stage suspension heat exchangerfor pre-heating; entering hot-state gypsum into a circulating fluidized bed decomposition furnace, and introducing primary and secondary air for decomposition; cooling discharged hot-state calcium oxide, wherein cooled hot-state calcium oxide is used as a desulfurizer for later use; entering discharged smoke containing sulfur dioxide into the multi-stage suspension heat exchanger; removing calcium oxide dust in cooled hot smoke through multi-stage dust removing equipment; and feeding the smoke without the dust into a high-temperature-resistant high-efficiency filter for further removing the dust, and feeding clean smoke into a sulfur recovery system; and preparing the sulfur product by the processes of hot reduction, catalytic reduction, Clause reaction and the like, and feeding Clause tail gas into a coal burning boiler in a power plant for combustion. The method has the advantages of good environmental protection benefits and strong economic benefits.

Owner:CHINA PETROCHEMICAL CORP +1

Process for preparing 5-hydroxymethyl-furfural

The invention relates to a preparation method for 5-hydroxymethyl furfural, which belongs to production technology of chemicals, in particular to a method for synthesizing 5-hydroxymethyl furfural (HMF) from carbohydrates by adopting a catalytic way. The method for preparing the 5-hydroxymethyl furfural uses heteropolyacid or heteropolyacid salt as a catalyst, and the 5-hydroxymethyl furfural with high purity can be obtained at a high yield by modulating the catalyst activity, choosing proper solvents, adding additives, optimizing the reaction temperature and time and improving the post treatment technologies, and the corrosion to devices and the environmental pollution can be avoided when using liquid super acids. In the system of saturated sodium chloride solution-positive butanol, the yield of the HMF can reach 70 percent under the catalysis reaction of phosphotungstic acid for 4 minutes at 175 DEG C.

Owner:DALIAN UNIV OF TECH

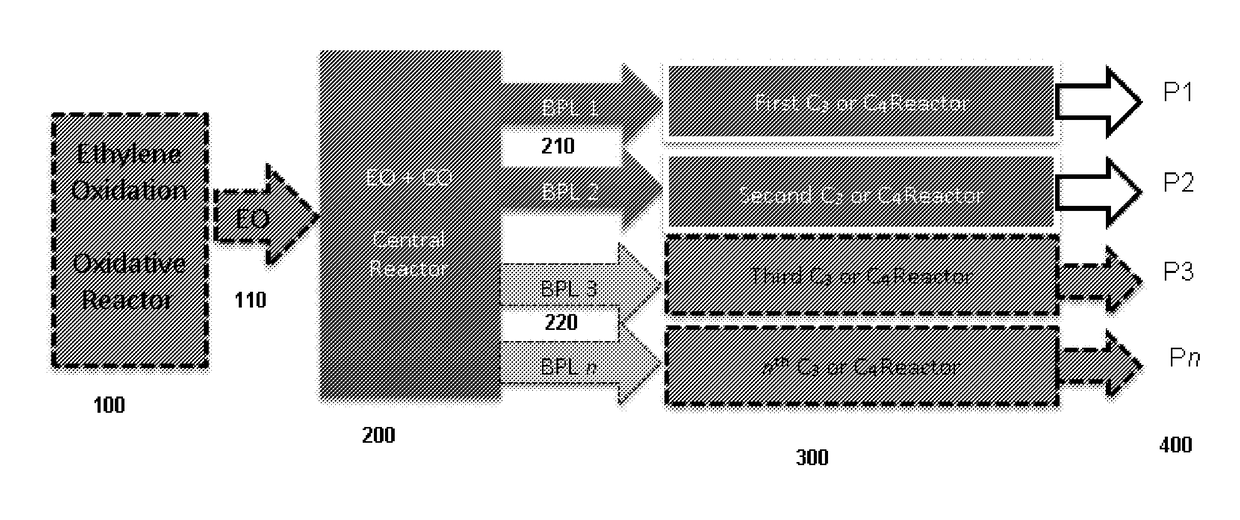

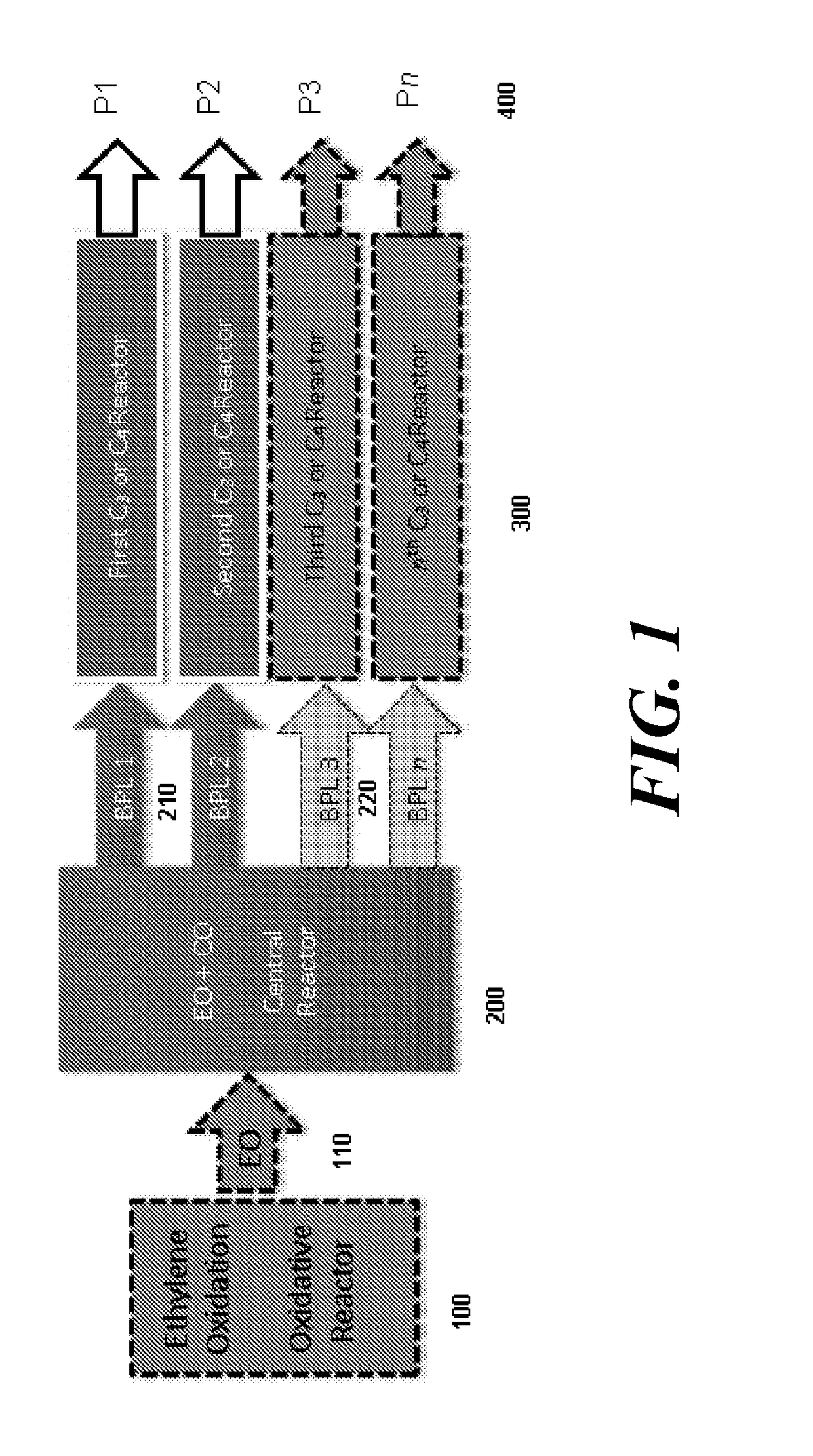

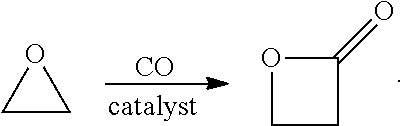

Flexible chemical production platform

InactiveUS20180029005A1Reduce their present relianceProcess control/regulationOrganic compound preparationBiochemical engineeringProcess engineering

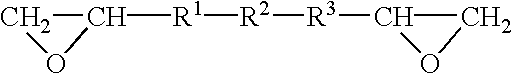

Disclosed are integrated systems and methods for the conversion of epoxides to beta lactones and to multiple C3 products and / or C4 products.

Owner:NOVOMER INC

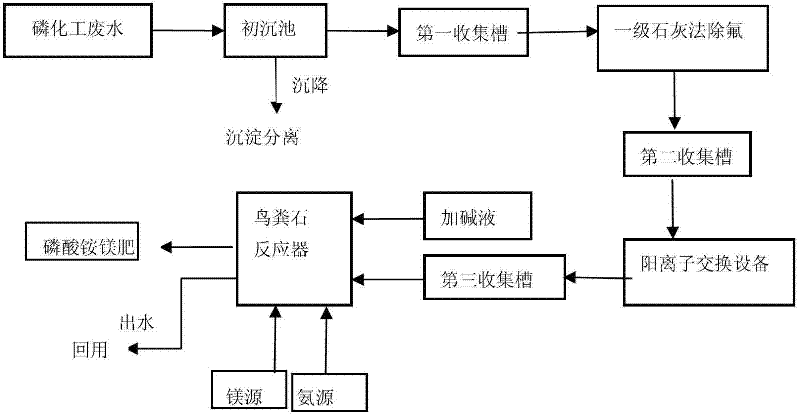

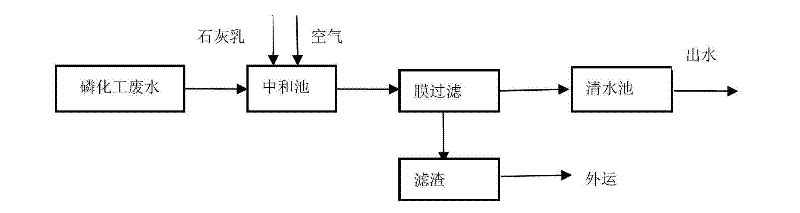

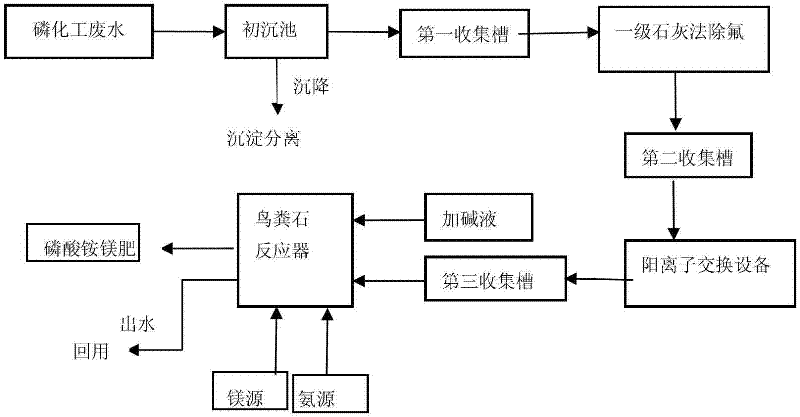

Method for recovering phosphorus in phosphorus chemical wastewater by using struvite production technology

InactiveCN102690000ALess sludgeReduce distractionsMultistage water/sewage treatmentIon exchangeMagnesium ammonium phosphate

The invention relates to a method for recovering phosphorus in phosphorus chemical wastewater by using a struvite production technology. The method is carried out according to the following steps of: firstly carrying out preliminary sedimentation on the phosphorus chemical wastewater, removing impurity precipitation in the wastewater, and collecting the processed wastewater in a first collecting tank; removing inorganic fluoride ion in wastewater in the first collecting tank by adopting a first-level quick lime method, and collecting the processed wastewater into a second collecting tank; removing inorganic cations in the wastewater in the second collecting tank via a cation exchange device, and collecting the processed ion exchange wastewater into a third collecting tank; finally adjusting pH value of the ion exchange wastewater to 7-9 in a struvite reactor by alkali liquor and adding magnesium source and nitrogen source, wherein the molar ratio of magnesium / phosphorus is 1.0-1.5; and the molar ratio of nitrogen / phosphorus is 1.0-1.5; and generating a magnesium ammonium phosphate granulated fertilizer in a crystalline state in the reactor. The water from the struvite reactor achieves the secondary standard of the national wastewater discharge standard and can be directly reused in a phosphorus chemical production system or discharged up to the standard.

Owner:HUBEI FORBON TECH

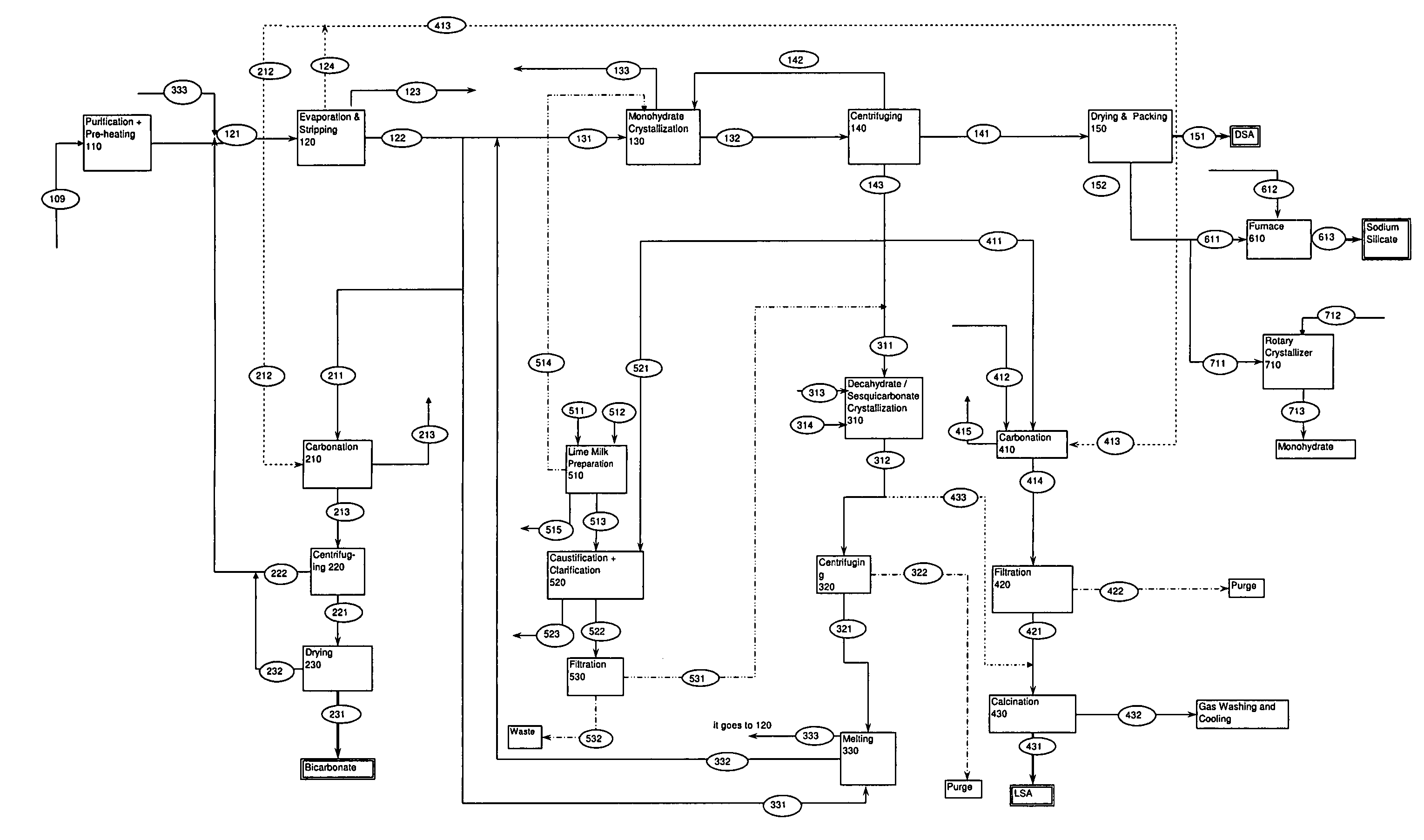

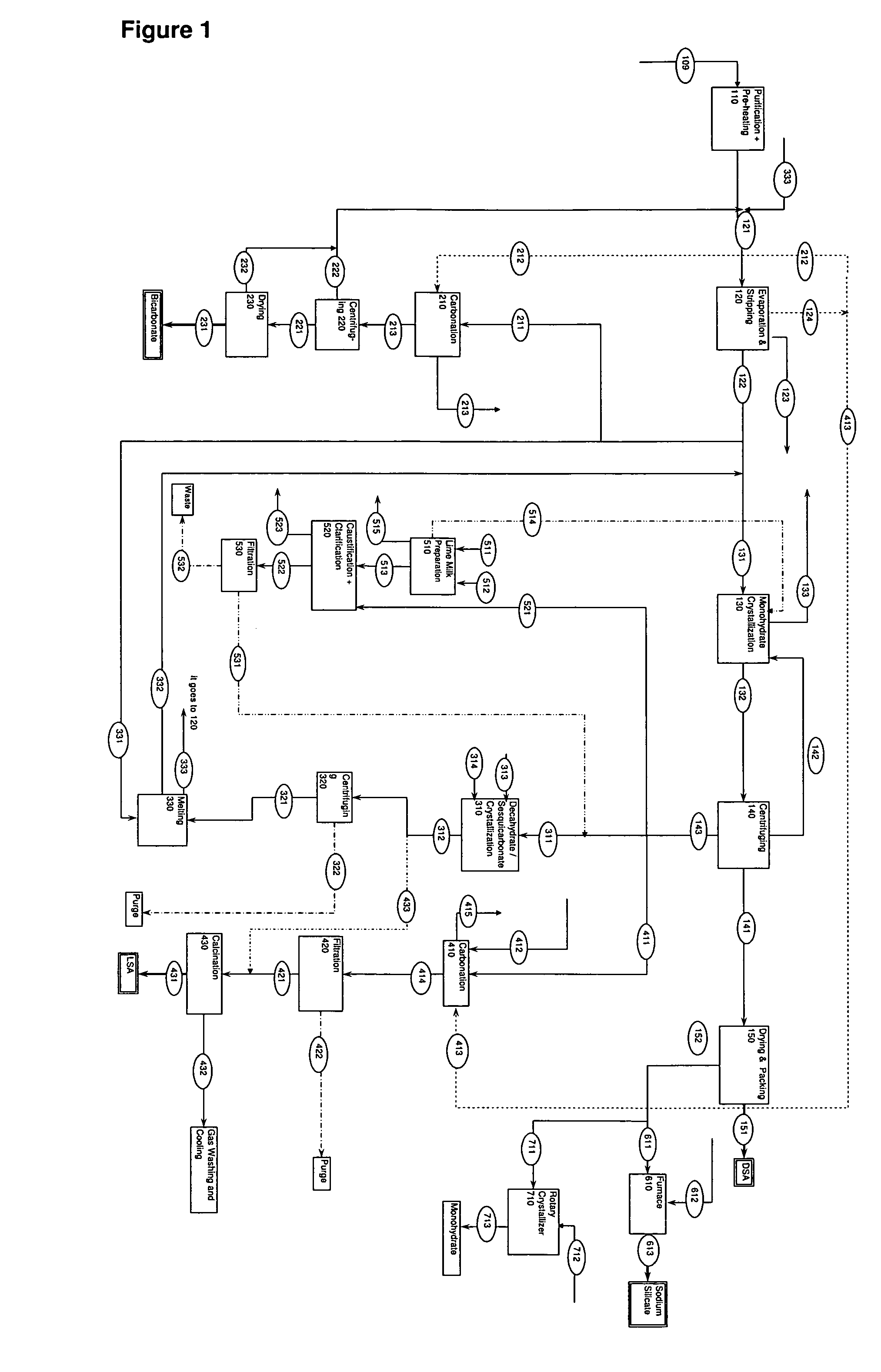

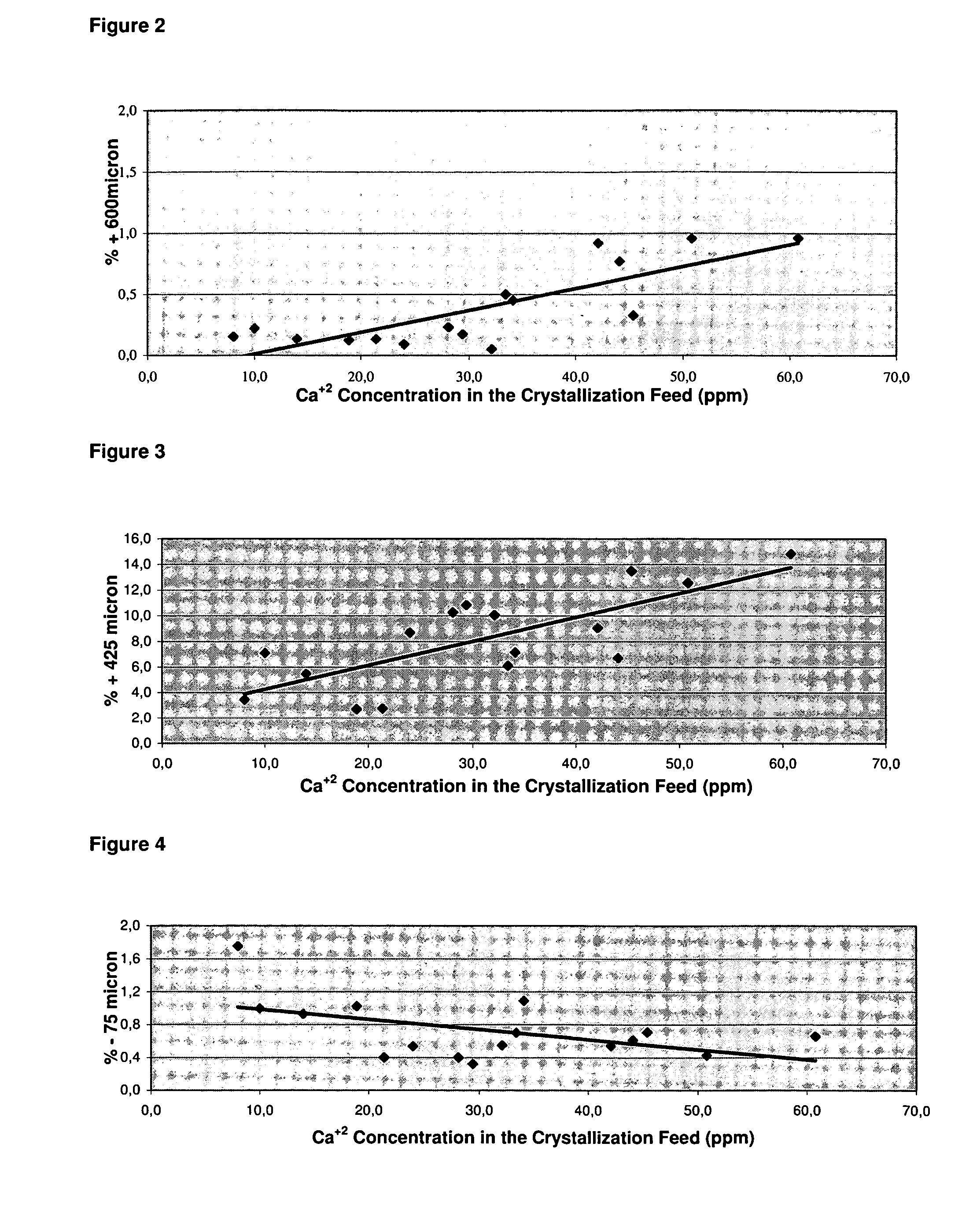

Process for production of dense soda, light soda, sodium bicarbonate and sodium silicate from solutions containing bicarbonate

ActiveUS7507388B2Processing requirementLow production costCrystallization separationAlkali metal silicatesSodium bicarbonateEvaporation

A process related to sodium chemicals production, including the processing of bicarbonate containing solutions obtained by solution mining of trona, nahcolite or wegscheiderite reserves and the lake waters containing bicarbonates, includes the steps of purification, evaporation-decarbonation, crystallization, centrifuging, and drying.

Owner:ETI SODA URETIM PAZARLAMA NAKLIYAT & ELEKTRIK URETIM SANAYI & TICARET A S

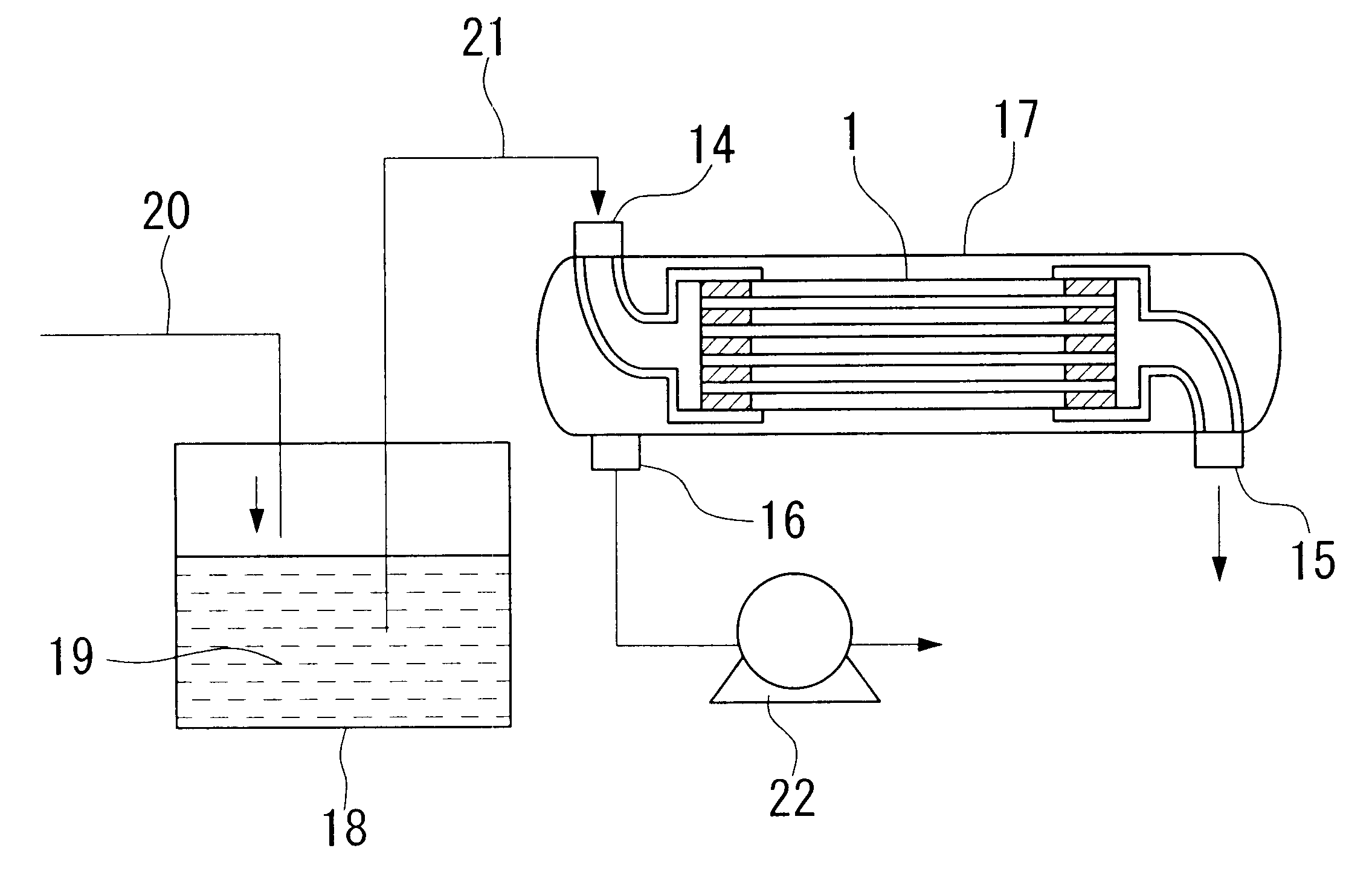

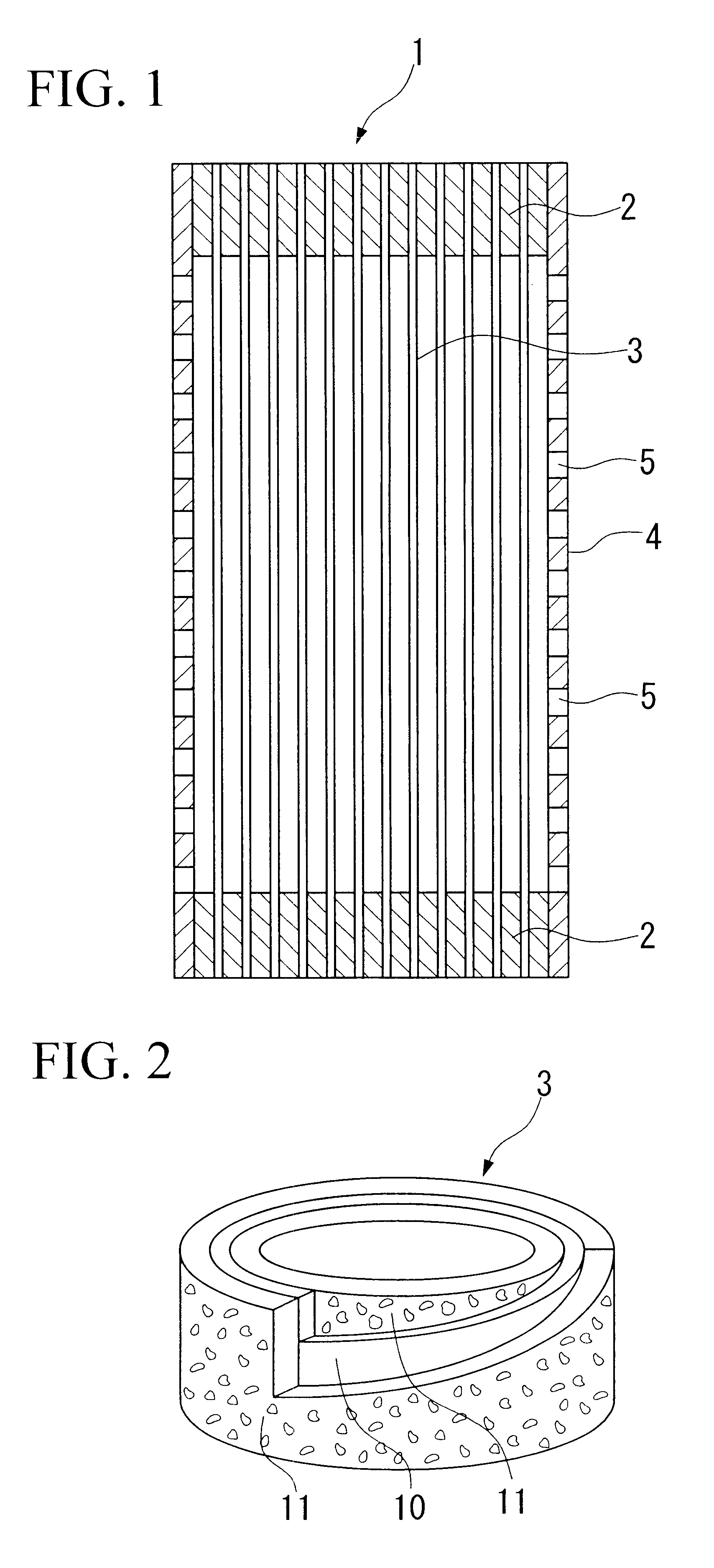

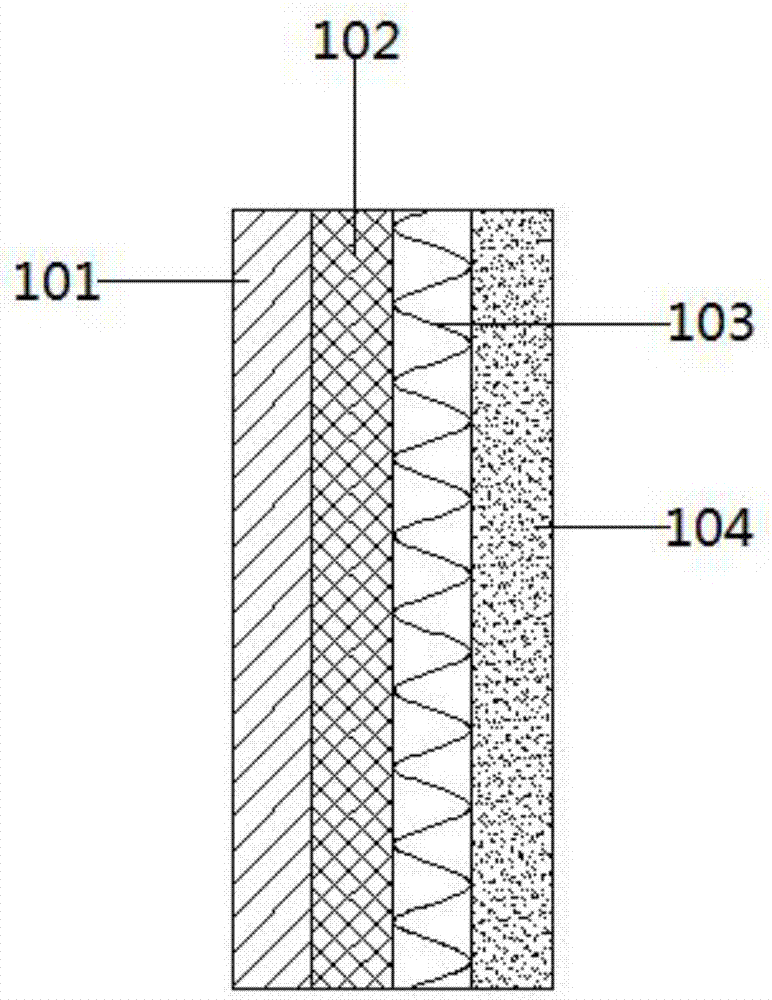

Hollow yarn membrane module, potting agent therefor and method for deaeration of liquid chemicals

InactiveUS6648945B1Good chemical resistanceSolve the blockageMembranesSemi-permeable membranesChemical treatmentEpoxy

A hollow fiber membrane module and potting material can be used for chemical deaeration in a semiconductor production process, in printers, in a liquid crystal sealing process or in a chemical production process. A hollow fiber membrane module 1 includes, as potting material 2, an epoxy resin cured product in which the weight change per unit surface area of a potting material test piece after immersing the test piece in a chemical for 6 months at room temperature is within the range of -20 to +20 mg / cm<2>, and as housing 4, a polyolefin in which the weight change per unit surface area of a test piece after immersing the test piece in a chemical for 6 months at room temperature is within the range of -20 to +20 mg / cm<2>, and the total metal content is 300 ppm or less. The module has a long service life when used for chemical treatment without leakage.

Owner:MITSUBISHI CHEM CORP

Method for preparing sodium sulfhydrate from hydrogen sulfide tail gas

InactiveCN101186280AImprove protectionReduce pollutionSulfur compoundsSodium hydrosulfideAbsorption rate

A purpose of the invention is to provide a sodium hydrosulfide preparation method utilizing hydrogen sulfide exhaust. The invention not only can resolve the treatment problems of the three wastes of barium carbonate and strontium carbonate enterprises, but also can reuse calcium sulfate, the byproduct from the preparation of sodium hydrosulfide, as raw materials for other chemical production, which realizes the recycling of raw materials and products. The production ability of the traditional alkali solution absorbing method, the absorbing adaptability of mixed hydrogen sulfide exhaust and the sodium hydrosulfide preparation rate are enhanced; while the production cost is reduced and the exhaust can be discharged according to standards after being absorbed by alkali solution. The invention resolves the problems of low absorption rate of hydrogen sulfide gas, low production efficiency of preparation of sodium hydrosulfide, large investment of technical devices and difficulty of solid phase recycling existing in a method of 'one step for preparation of sodium hydrosulfide' using hydrogen sulfide gas, calcium hydroxide and sodium sulfide as raw materials.

Owner:QINGDAO AOHAIKE TRADE

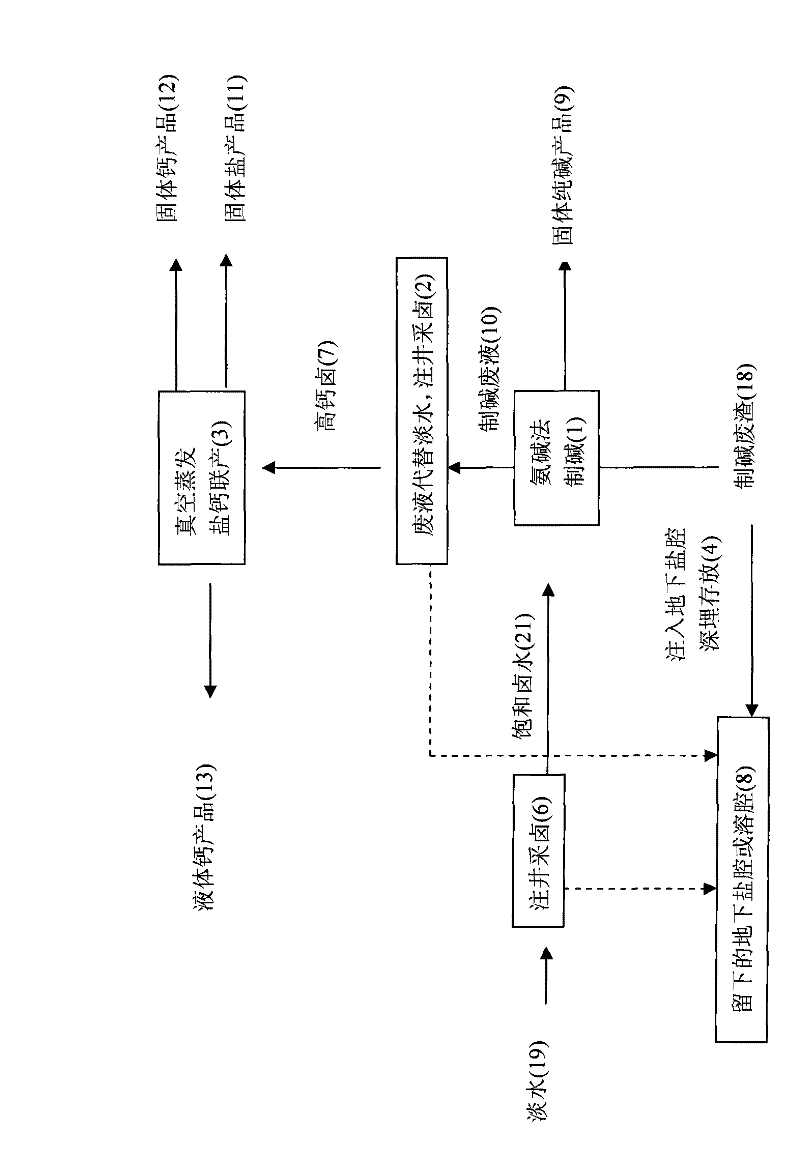

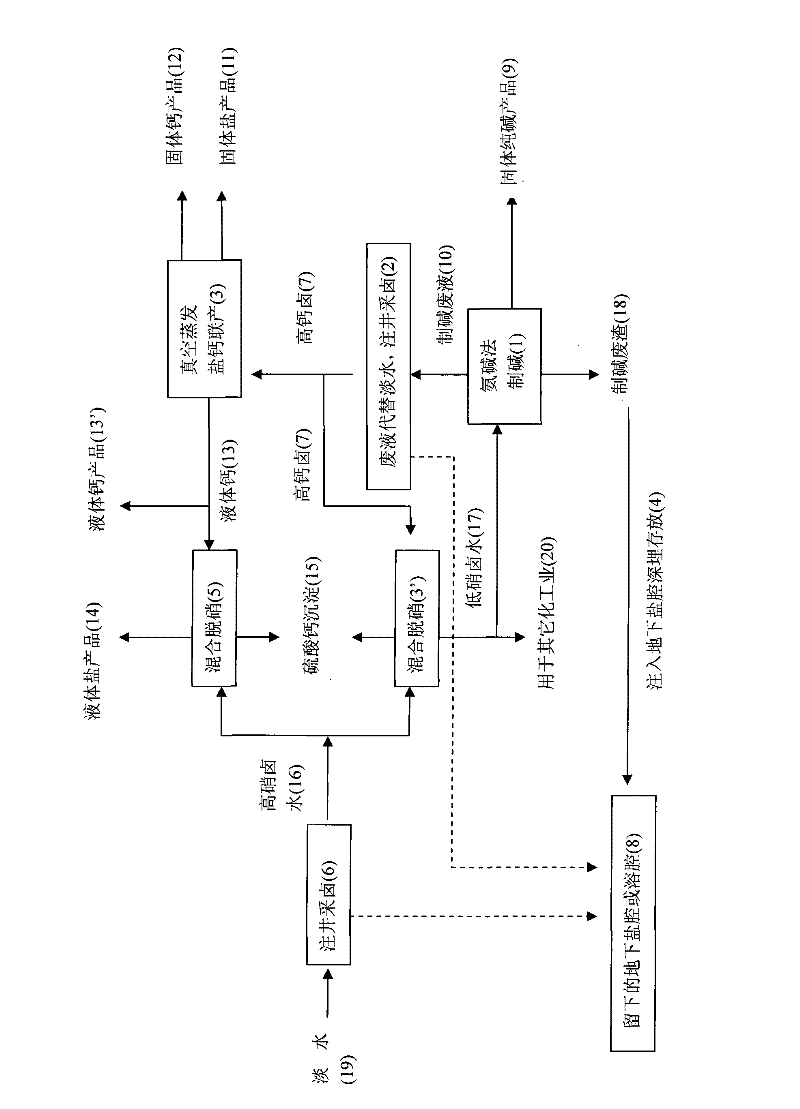

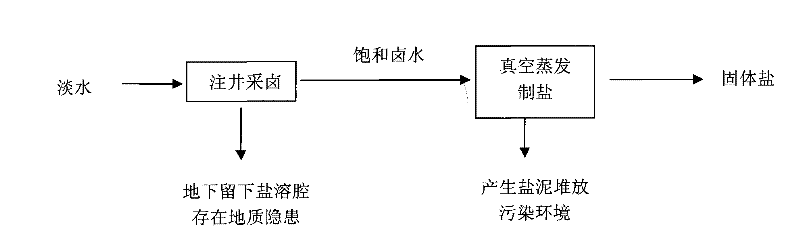

Salt, alkali and calcium combined cycle production technology by the use of well mineral salt

ActiveCN102205979ASolve processing problemsRealize energy saving and consumption reductionCalcium/strontium/barium chloridesAlkali metal chloridesDissolutionCalcium EDTA

The invention relates to a salt, alkali and calcium combined cycle production technology by the use of well mineral salt. Based on the exploitation of brine from well mineral salt, the salt, alkali and calcium combined cycle production technology by the use of well mineral salt is a cycle production technology, which focuses on the technology for making alkali from brine by the ammonia-soda process and takes account of the vacuum salt-making (including the brine refinement) and calcium-making technologies. Alkali-making wastewater replaces most fresh water to be injected into a salt mine well to collect brine, and the obtained high-calcium brine is taken as the raw material of the salt and calcium (including liquid calcium) co-production as well as the raw material for preparing alkali and other chemical production raw materials, wherein the liquid calcium can be used to produce liquid salt; alkali-making waste residues are injected into an underground dissolution cavern, namely a salt cavern which is formed by the exploitation of brine from well mineral salt, thus accomplishing the combined cycle production technology in which alkali-making and salt-making technologies are closely related with materials. The produced wastes are used as resources or undergo a harmless treatment, thus protecting the environment. In addition, the utilization rate of sodium chloride in rock salt reaches 100%, achieving maximum efficiency.

Owner:江苏苏盐井神股份有限公司 +1

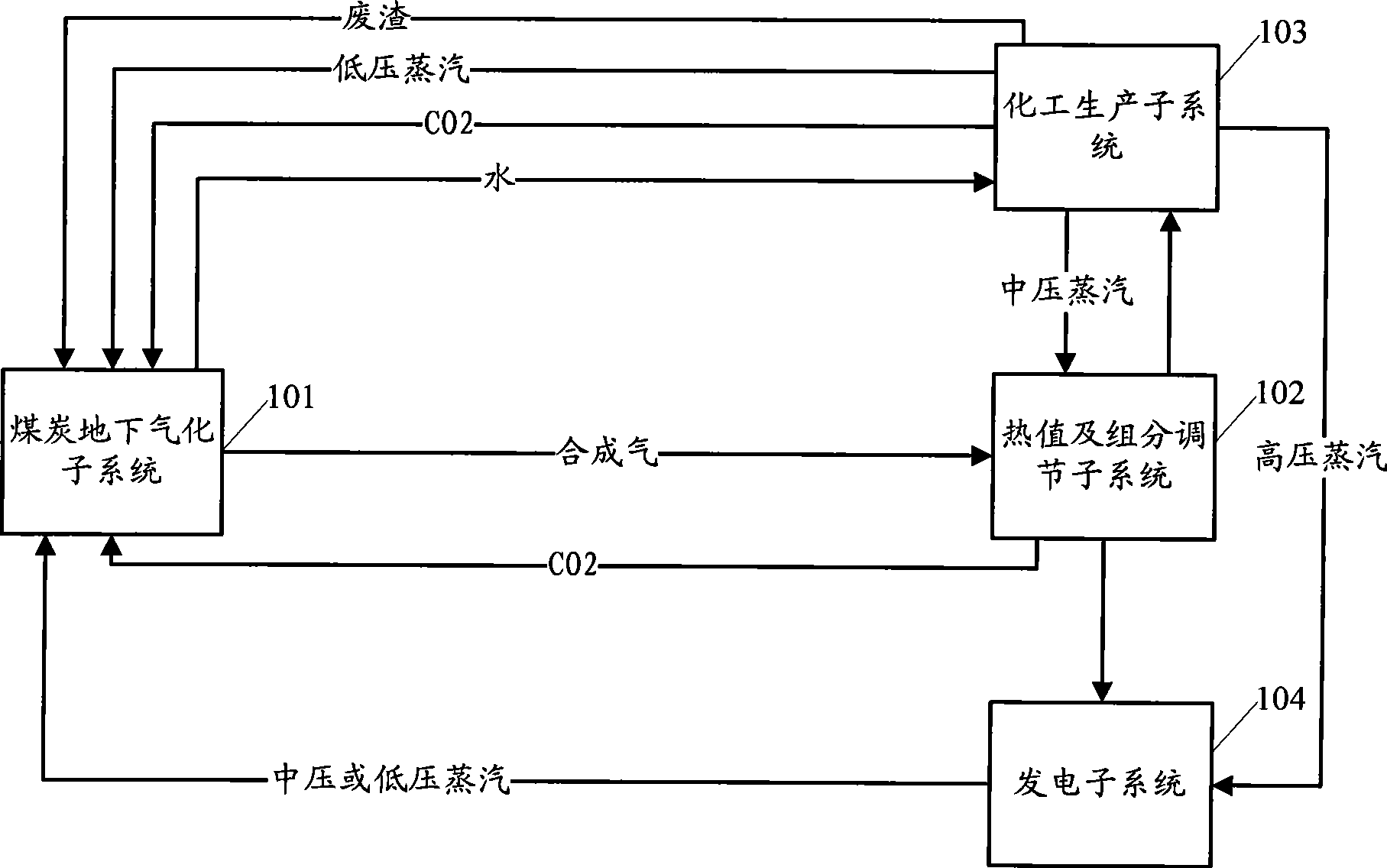

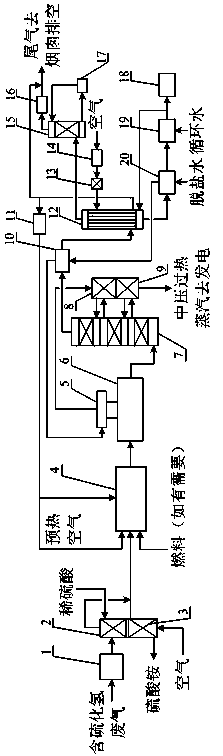

Underground coal gasification multi-combining production system and method

ActiveCN101509368AReasonable useReduce pollutionConstructionsCoal gasificationGeneration processSyngas

The invention discloses a poly-generation system of underground coal gasification (UCG) and a method thereof. .The system comprises a UCG subsystem, a thermal value and component regulation subsystem and a chemical production system; the UCG subsystem is used for injecting gasification agent into a gasification tunnel after gasification fire so that the gasification agent conducts gasification reaction with a coal bed in the gasification tunnel to generate synthesis gas; crude synthesis gas is led into the thermal value and component regulation subsystem; the thermal value and component regulation subsystem is used for reintegrating the component and thermal value of the synthesis gas and sending the reintegrated synthesis gas into the chemical production system as feed gas; the chemical production system is used for producing chemical products by utilizing the synthesis gas sent by the thermal value and component regulation subsystem. By adopting the method and system provided by the invention, coal gasification poly-generation process can be completed under the condition of energy saving and environmental protection.

Owner:ENN SCI & TECH DEV

Persimmon powder and production process thereof

InactiveCN101328194ARetain bioactive ingredientsExcellent enzymatic hydrolysis processGlycosidesGlycosideChemical reactionFiltration

The invention discloses persimmon powder and a production technique thereof. The technique comprises the following steps that: after extraction of juice from persimmon, the juice undergoes zymohydrolysis, filtration, enzyme killing and concentration; after vacuum freeze drying of a concentrated solution, powdery materials with a tannin weight content between 1 and 99 percent are prepared; and the dissolution rate of the powdery materials in water is more than or equal to 50 percent. Compared with the prior art, the technique applies the technologies of zymohydrolysis and vacuum freeze drying in processing and production of persimmons, and selects the superior zymohydrolysis technology to perform cellular level processing on the persimmons on the premise that the compositions of the persimmons are researched; auxiliary materials used by the processing are ecological and environment-friendly and has no chemical pollution, and finished products are superior natural nontoxic chemical raw materials; and the materials are dried by adoption of the vacuum freeze drying technology, thereby the biological active ingredients of the materials are reserved to the maximum degree and the materials are easier to dissolve in water, consequently the materials are convenient to perform various chemical reactions so as to be widely applied in the chemical production. Moreover, the technique greatly releases the pressure of farmers for selling fresh fruit, and raw materials can be purchased from the farmers during the fruit thinning period; and the products obtained can be used for manufacturing cosmetics, recovering heavy metals in sewage, preventing the materials from being corroded, etc, and have a wide market prospect.

Owner:GONGCHENG HUIKUN

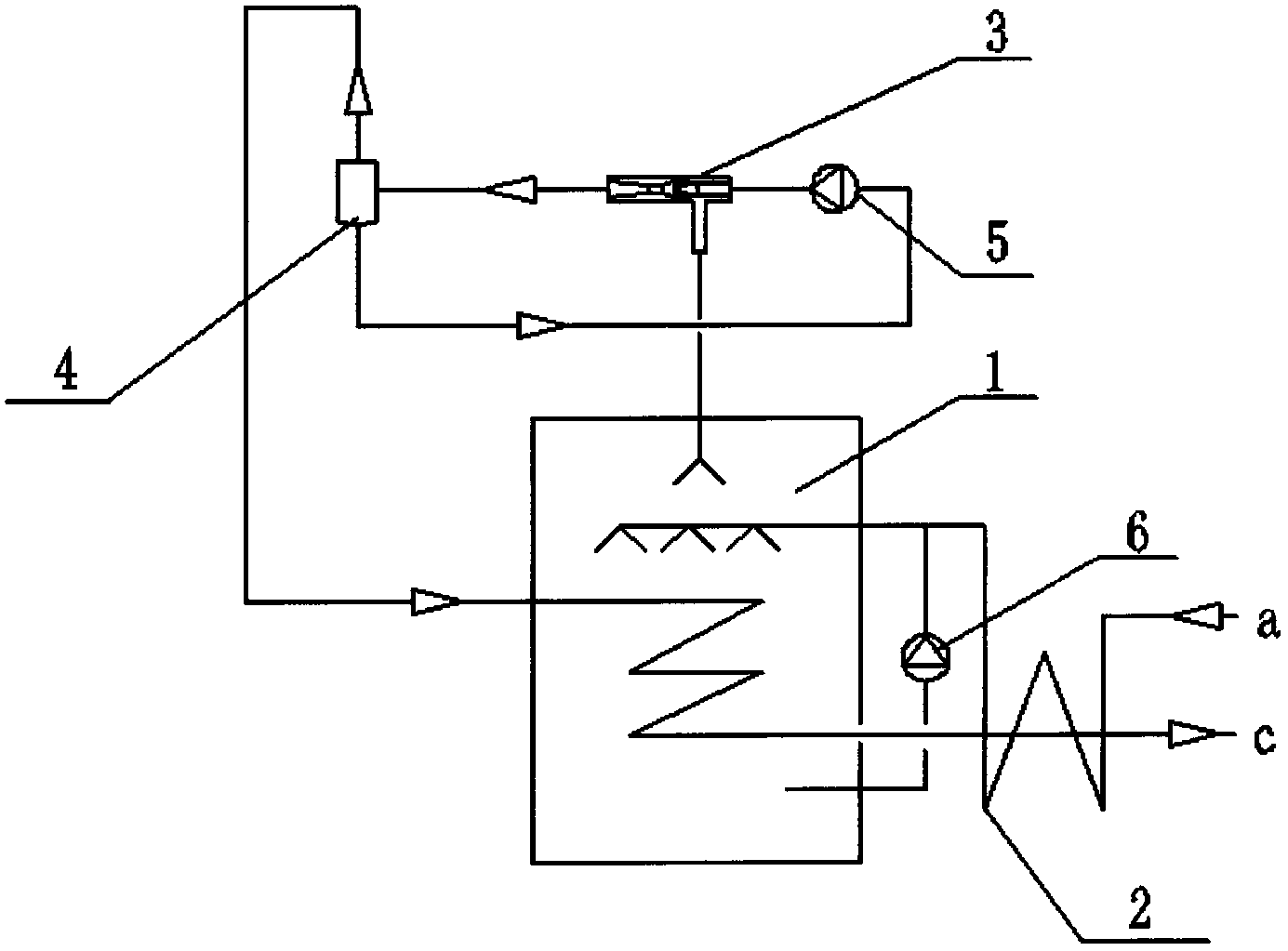

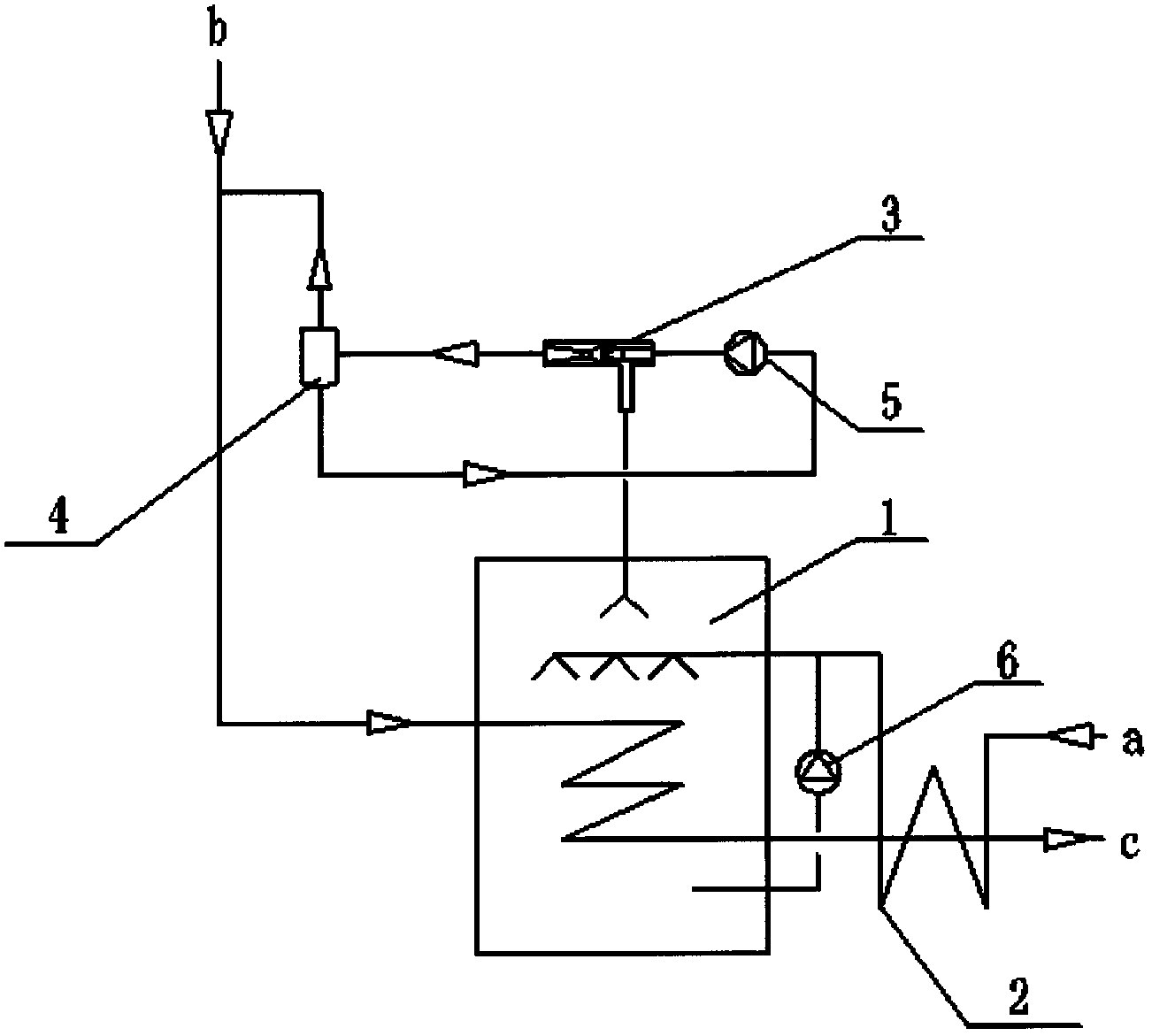

Energy-saving evaporation process and system thereof

InactiveCN102659196ALess investmentEasy operation and maintenanceGeneral water supply conservationSeawater treatmentThermal energyEvaporation

The invention provides an energy-saving evaporation process and an energy-saving evaporation system, belonging to secondary steam waste heat recovery in the field of high-efficiency recycling. The energy-saving evaporation process and the energy-saving evaporation system can be widely applied to sewage and wastewater treatment, desalination of sea water, solution concentration in chemical production and other industrial departments. The main process comprises the following steps: enabling raw material solution to absorb heat in an evaporator and to boil and vaporize to generate secondary steam, pressurizing and heating the secondary steam through a high-temperature high-pressure water jet circulating system, taking the secondary steam as heating steam to be returned to the evaporator, releasing the heat in the evaporator, and heating the raw material solution so as to boil and vaporize the raw material solution to generate the secondary steam; and heating the steam and condensing the steam into condensate so as to recycle the heat, discharging the condensate into a heat exchanger from the evaporator to perform heat exchange with the raw material solution, so that temperature of the raw material solution is raised, heat of the condensate is released, and the condensate is discharged. By adopting the process, waste heat in the secondary steam can be effectively utilized, the operating cost is reduced, and lots of energy is saved.

Owner:天津壹帆水务有限公司 +3

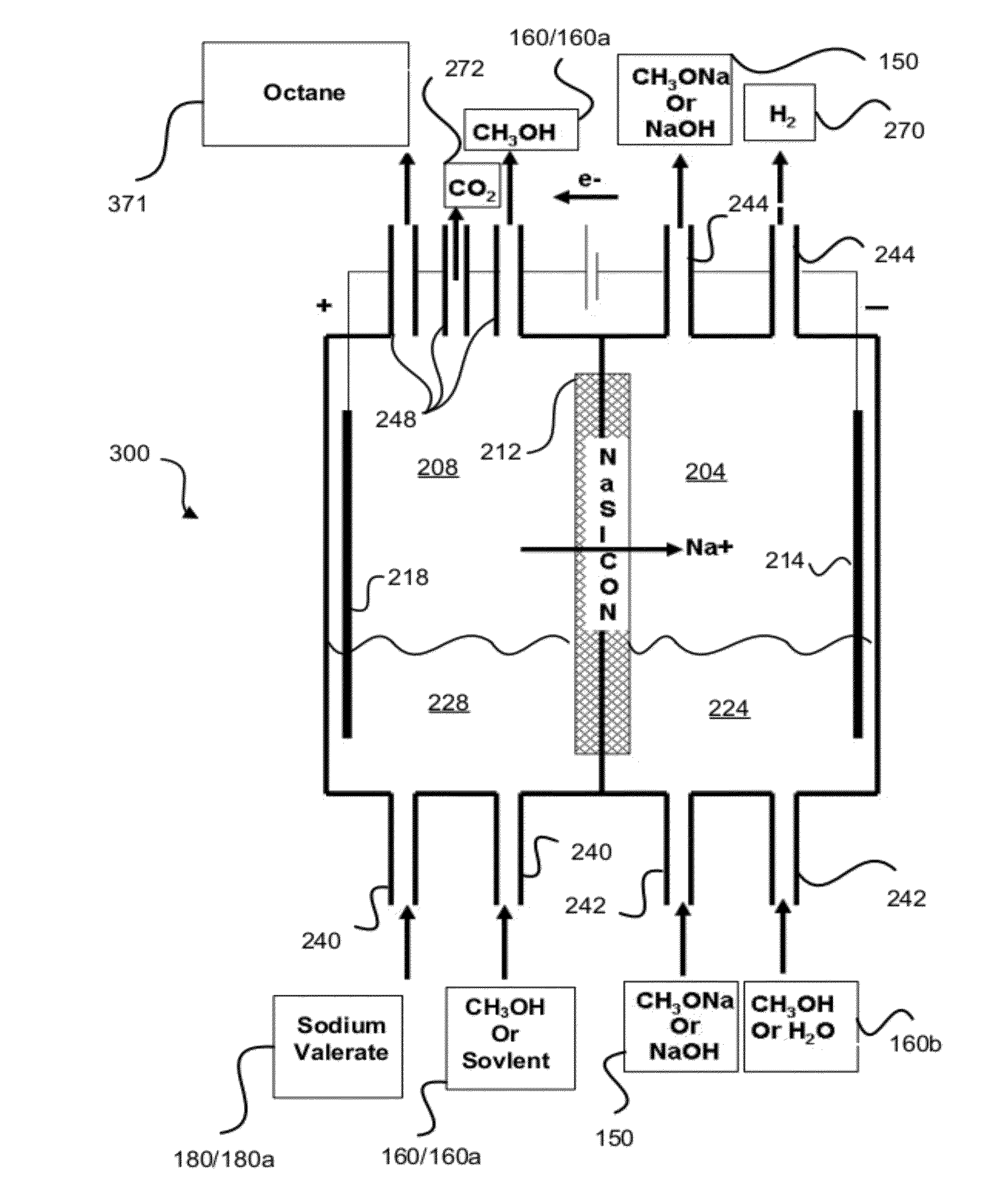

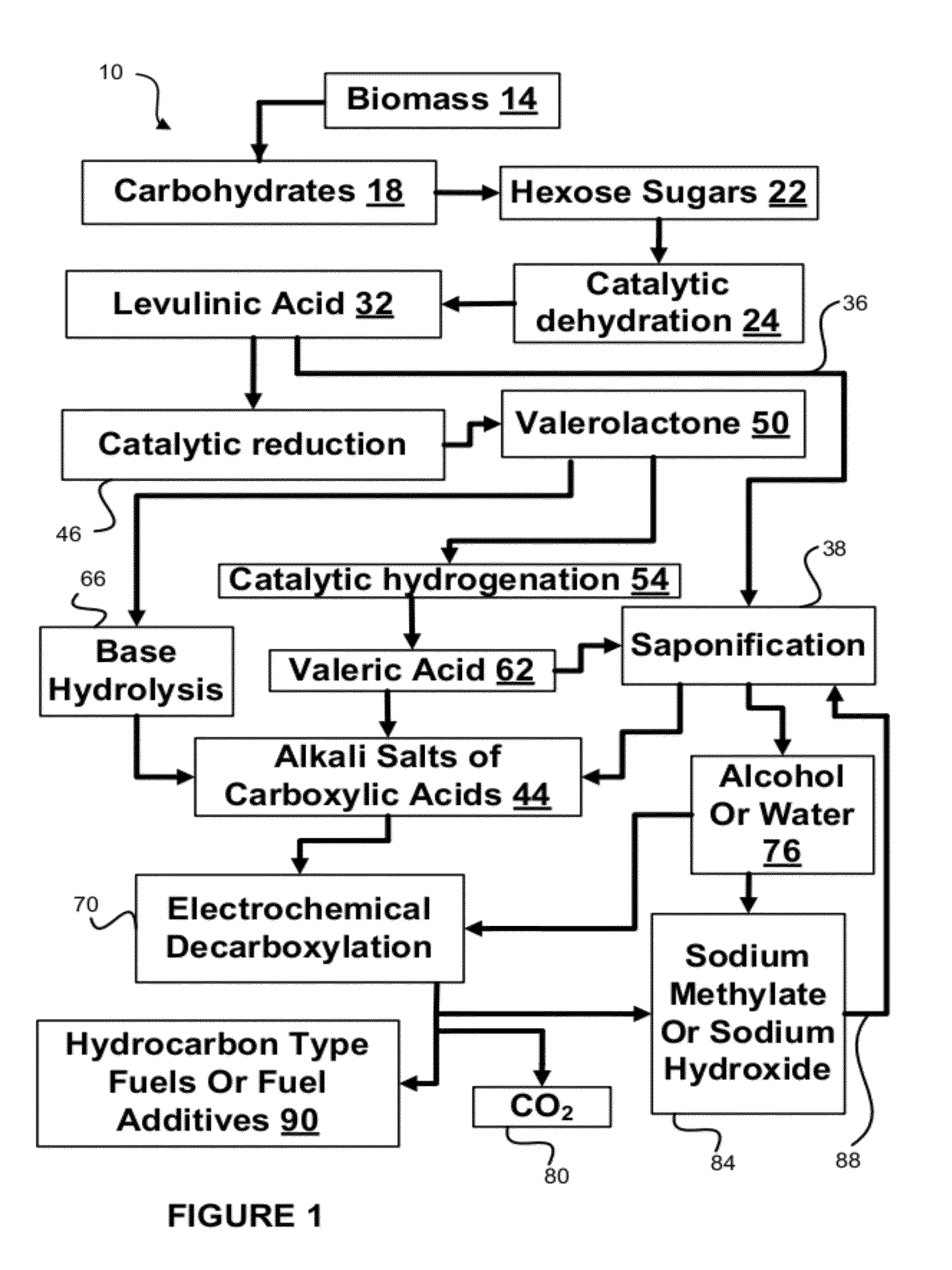

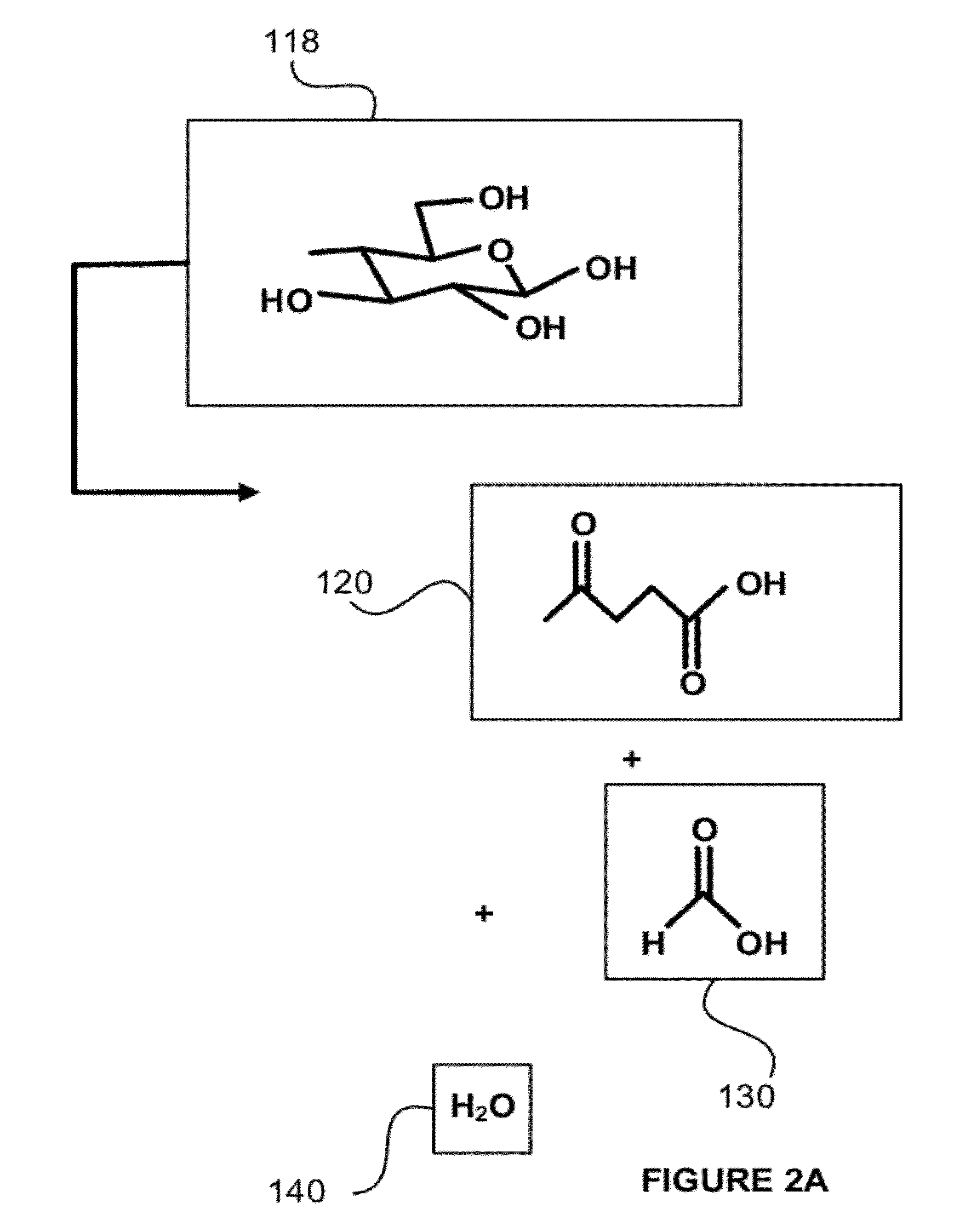

Production of fuel from chemicals derived from biomass

Hydrocarbons may be formed from six carbon sugars. This process involves obtaining a quantity of a hexose sugar. The hexose sugar may be derived from biomass. The hexose sugar is reacted to form an alkali metal levulinate, an alkali metal valerate, an alkali metal 5-hydroxy pentanoate, or an alkali metal 5-alkoxy pentanoate. An anolyte is then prepared for use in a electrolytic cell. The anolyte contains the alkali metal levulinate, the alkali metal valerate, the alkali metal 5-hydroxy pentanoate, or the alkali metal 5-alkoxy pentanoate. The anolyte is then decarboxylated. This decarboxylating operates to decarboxylate the alkali metal levulinate, the alkali metal valerate, the alkali metal 5-hydroxy pentanoate, or the alkali metal 5-alkoxy pentanoate to form radicals, wherein the radicals react to form a hydrocarbon fuel compound.

Owner:ENLIGHTEN INNOVATIONS INC

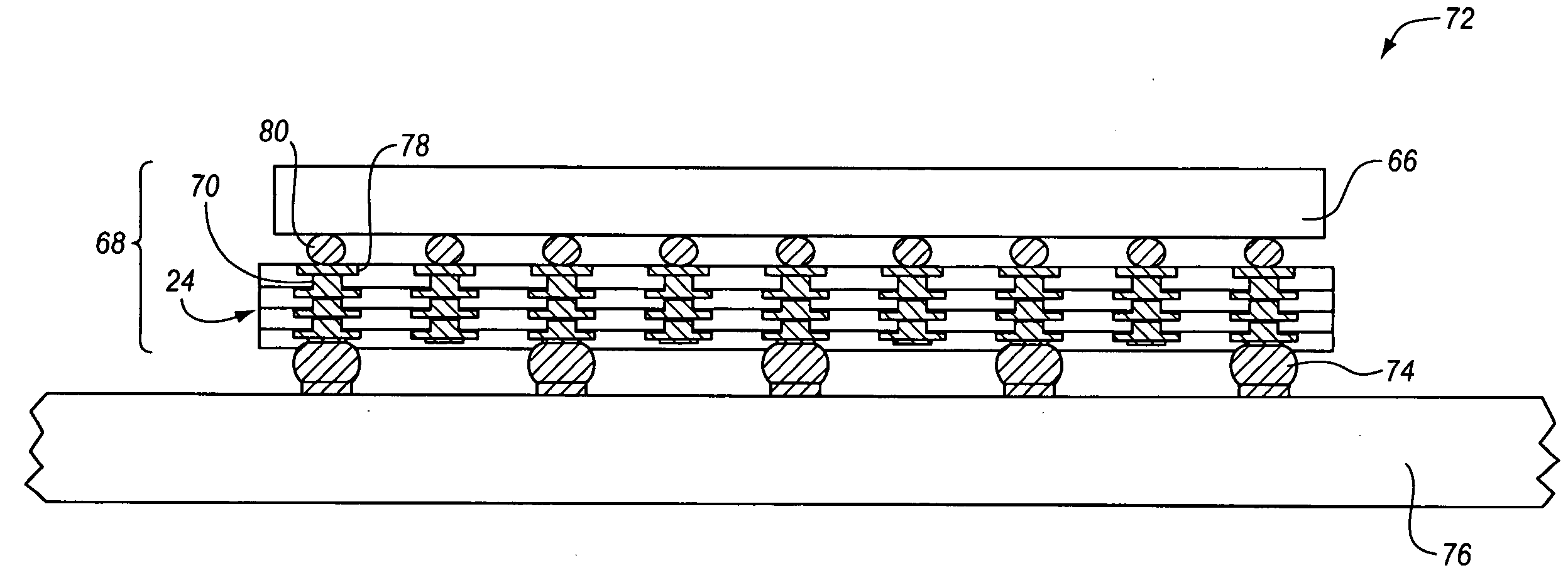

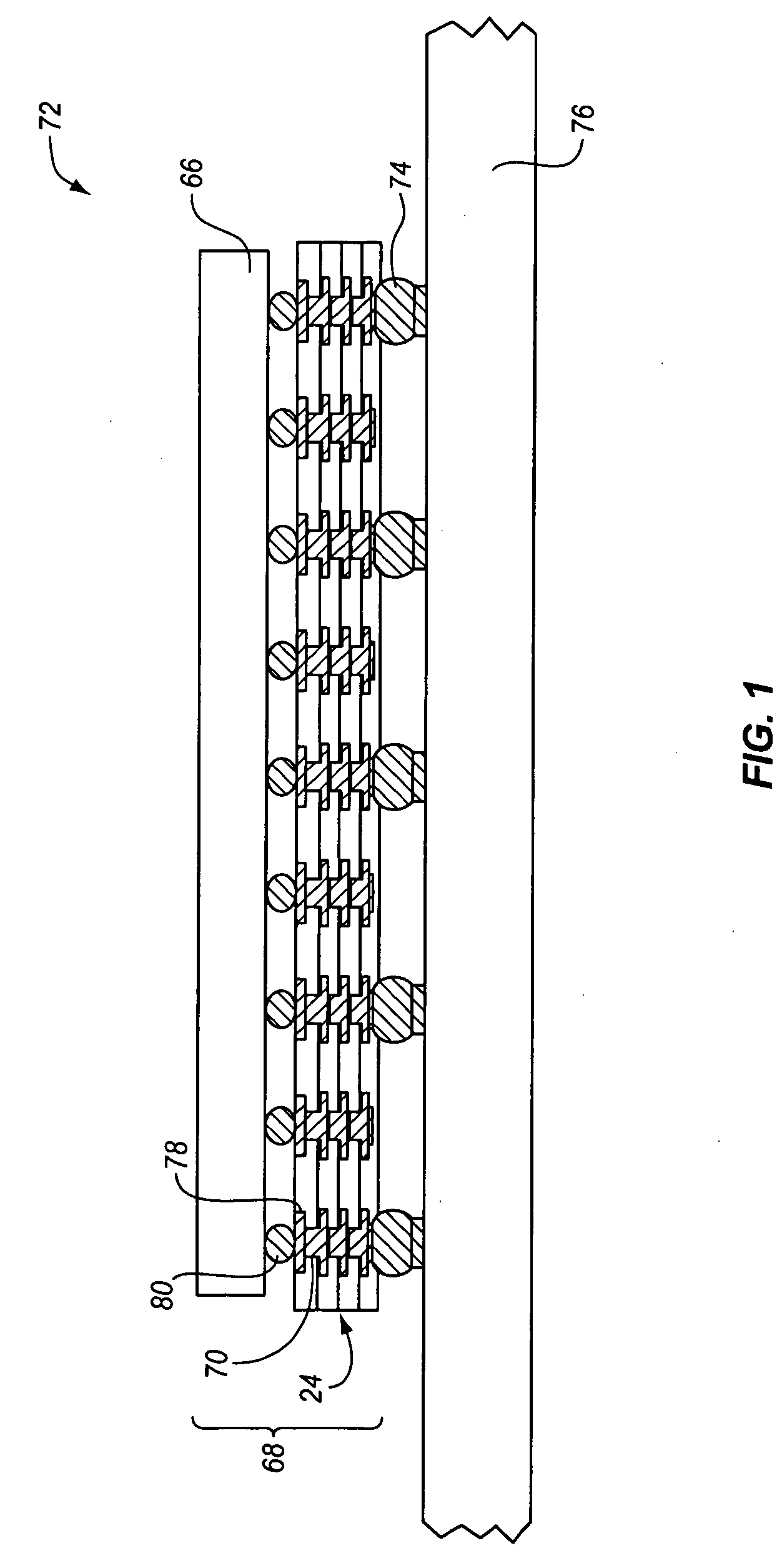

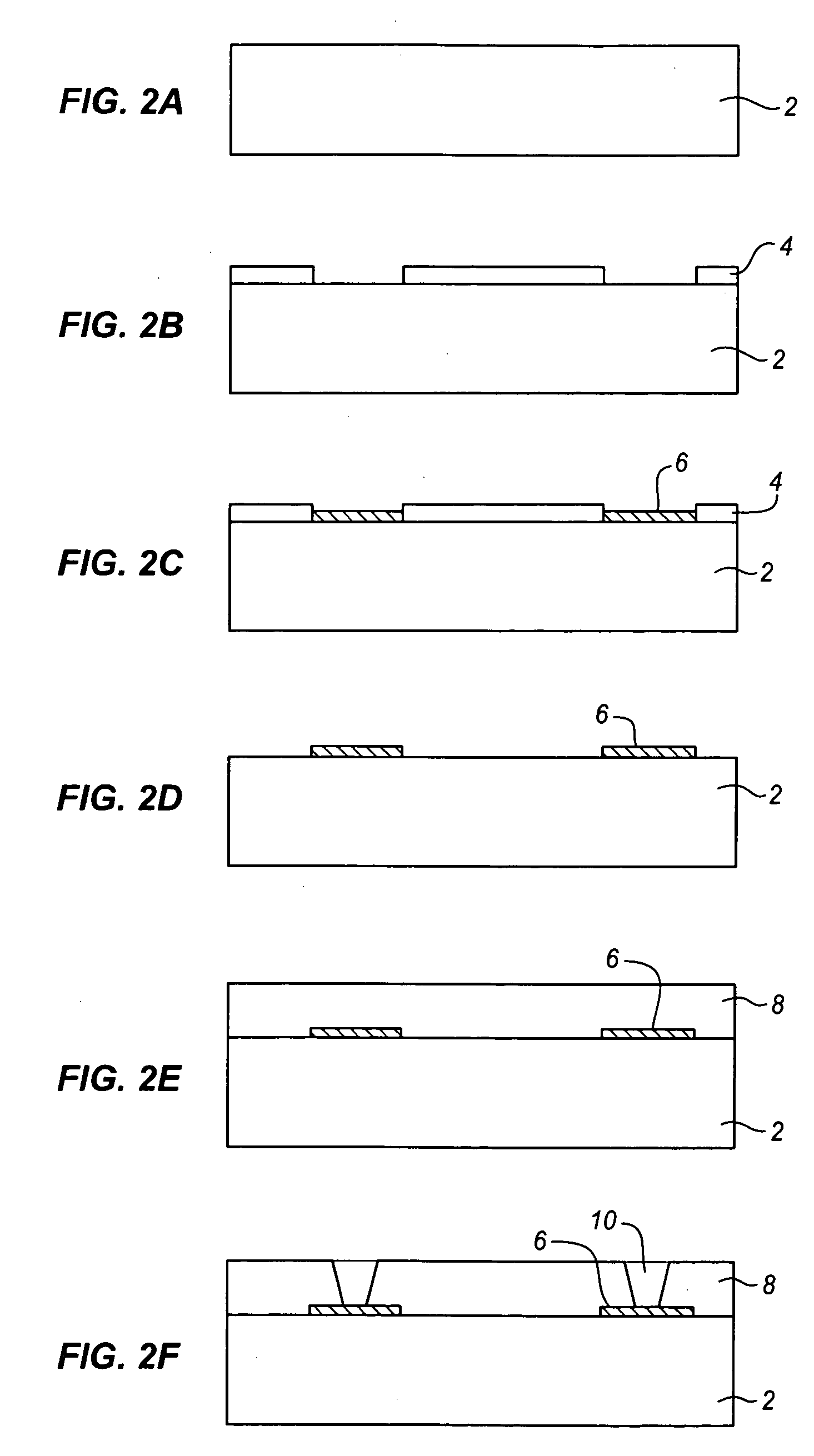

Coreless substrate package with symmetric external dielectric layers

InactiveUS20090321932A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

A thin die Package Substrate is described that may be produced using existing chemistry. In one example, a package substrate is built over a support material. A dry film photoresist layer is formed over the package substrate. The support material is removed from the package substrate. The dry film photoresist layer is removed from the substrate and the substrate is finished for use with a package.

Owner:INTEL CORP

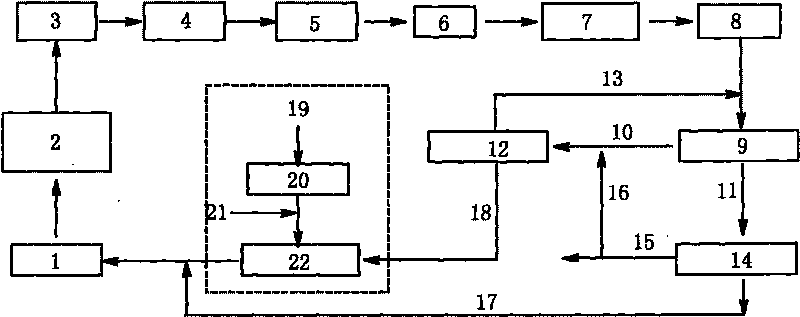

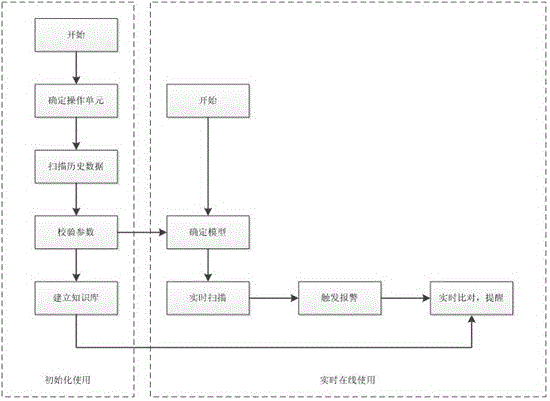

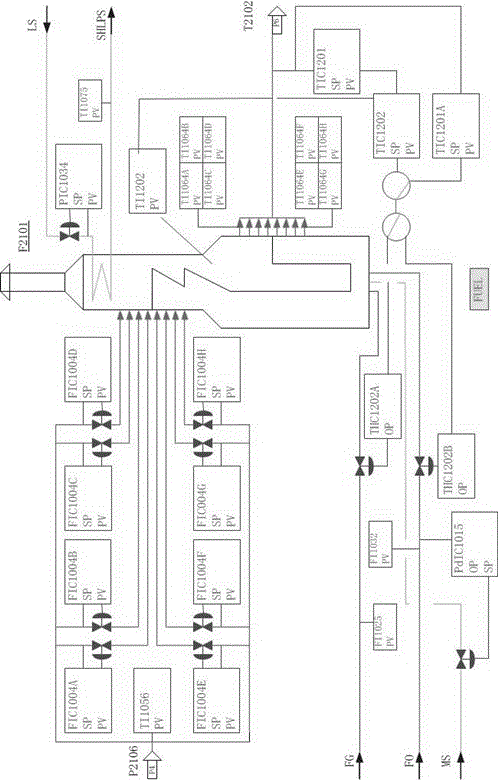

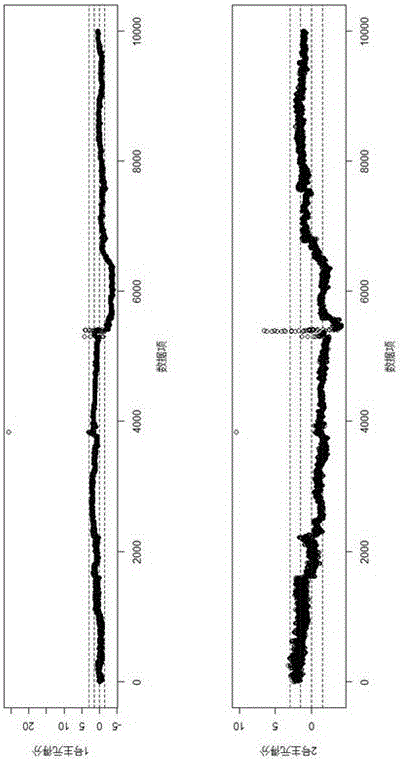

Chemical production on-line fault detection and diagnosis technique based on physical-large data hybrid model

ActiveCN105893700ASafety Production ControlHigh-quality and efficient production controlCharacter and pattern recognitionDesign optimisation/simulationReal-time dataPhysical model

The invention discloses a chemical production on-line fault detection and diagnosis technique based on a physical-large data hybrid model. The chemical production on-line fault detection and diagnosis technique is characterized by comprising the following steps: after selecting a target operation unit, scanning all historical data of the unit, and after parameters are verified, establishing an accident knowledge base and a parameter model; in later on-line detection process, directly loading on-line data into the parameter model, scanning so as to obtain fault data in the on-line data, making an alarm, and comparing the fault data with data in the accident knowledge base, thereby obtaining fault reasons. The method disclosed by the invention is applied to confirmed single chemical unit operation, a reliable physical model can be established, a chemometrical method is used in the whole production process, a big-data processing technique is introduced to process real-time data of years, operators focus on faults of performance indexes within a controllable variable range, and the influence of uncontrollable production process variable to fault detection is eliminated.

Owner:陆新建

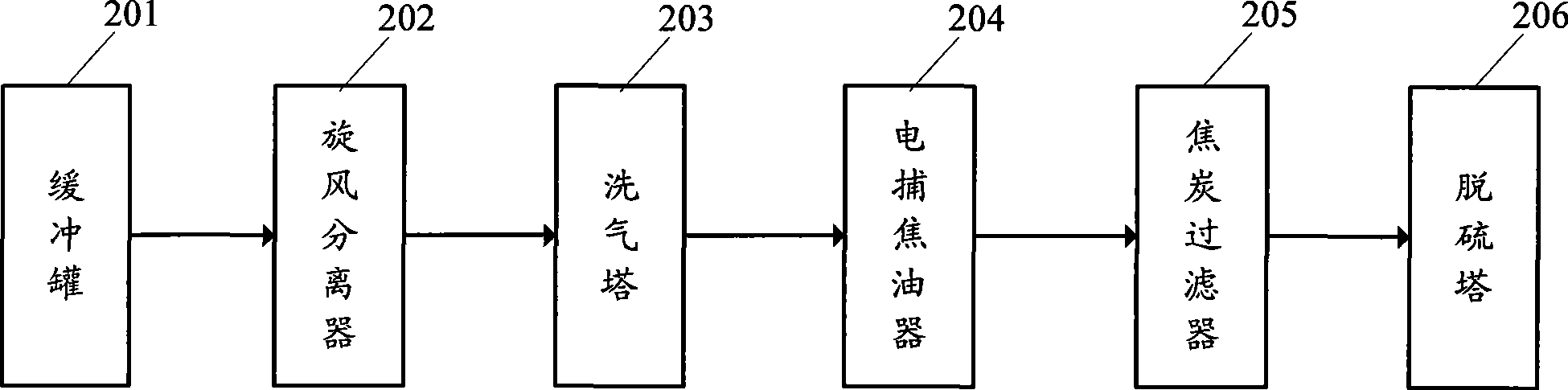

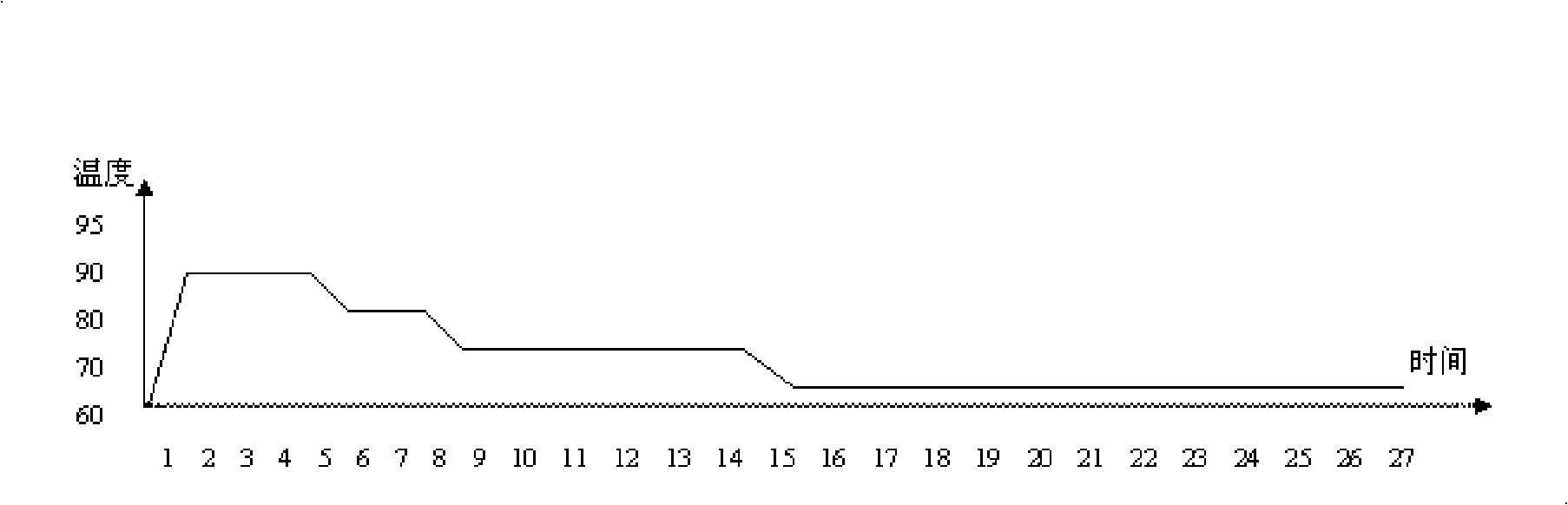

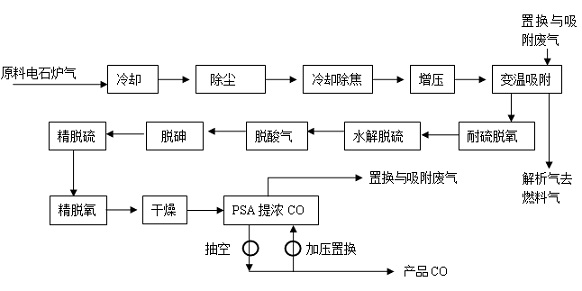

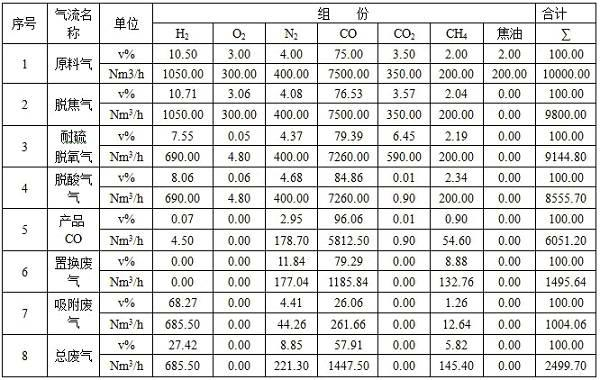

Method for purifying and concentrating CO from calcium carbide furnace gas

ActiveCN102627280AIncrease profitHigh CO yieldCalcium carbideCarbon monoxideDeoxygenationIndustrial scale

The invention discloses a method for purifying and concentrating CO from calcium carbide furnace gas and belongs to a tail gas purification method. The method provided by the invention respectively comprises the following steps of: raw material calcium carbide furnace gas dedusting, cooling and decoking, temperature swing adsorption and precleaning, supercharging, sulphur tolerant catalytic deoxygenation, hydrolysis desulfidation, acid gas removal, arsenic removal, fine desulphurization, fine deoxidation, drying, pressure swing adsorption and concentration of CO. The invention relates to a packaged technology for purifying and concentrating CO from calcium carbide furnace gas. The technology is suitable for industrial scale application and can be adopted to make calcium carbide furnace gas containing various impurities into high-purity CO gas which is suitable for CO raw material for carbonyl synthesis or other chemical production.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Wet method used for preparing sulfuric acid from exhaust gas containing hydrogen sulfide

InactiveCN103626136AAvoid Dew Point CorrosionAvoid corrosionSulfur compoundsEnergy inputWater vaporWaste treatment

The invention discloses a wet method used for preparing sulfuric acid from exhaust gas containing hydrogen sulfide, and belongs to the technical field of waste gas treatment in environmental protection industry and chemical production. The wet method comprises following steps: removal of nitrogen compounds of the exhaust gas containing hydrogen sulfide is realized using dilute sulphuric acid with a mass fraction of 30 to 50%; the treated exhaust gas containing hydrogen sulfide is delivered into an incinerator, preheated air is added so as to maintain a combustion temperature of 700 to 1000 DEG C and a reducing / oxidizing atmosphere, so that sufficient burning of hydrogen sulfide and other combustible components is realized, and generation amount of nitrogen oxide is reduced; high temperature gas at an incinerator outlet is delivered into a medium pressure waste heat boiler so as to recycle heat energy and byproduct saturated vapour; flue gas containing sulfur dioxide at a waste heat boiler outlet is delivered directly into a converter, and flue gas containing sulfur trioxide and vapour is obtained via primary conversion; reaction heat in the converter is removed in time using heat-exchange equipment; flue gas at a converter outlet is delivered into at least primary-stage condenser tube pass, and an appropriate amount of air is delivered into condenser shell pass to be used as a cooling medium; heat energy of high temperature concentrated sulfuric acid flows out from the bottom of the condenser is recycled via a desalting water preheater and an acid cooler; and exhaust gas at a condenser outlet is delivered into a desulfurization tower so as to remove sulfur dioxide and nitrogen oxides.

Owner:CHINA PETROLEUM & CHEM CORP +1

Integrated process of furfural production as well as wastewater, waste slag and waste gas treatment

InactiveCN101481189ACurb emissionsPollution suppressionOrganic chemistryEnergy inputWater vaporDistillation

The invention belongs to the technical field of the chemical production, and relates to a technology for optimizing energy saving and integrating treatment of waste water, waste slag and waste gas in a furfural production process, which is suitable for the energy saving and the three-waste treatment and reformation of furfural production enterprises. The technology is characterized in that limestone and dolomite are used for neutralizing furfural waste water to convert acetic acid into calcium magnesium acetate, and then the water exchanges heat with high-temperature aldehyde gas generated by a hydrolysis kettle to enter an evaporator; high-temperature vapor generated by the vaporization of the waste water enters the hydrolysis kettle to be used as a reaction medium, the residual concentrated liquid is decolorized for extracting calcium magnesium acetate salt, and the residual liquid is used for smoke desulfurization and denitration. After the low-pressure automatic heating and vaporization of high-temperature aldehyde slag for furfural recovery, the high-temperature aldehyde slag is dried at a low temperature to reduce the water content of the aldehyde slag to be lower than 20 percent. The invention has the advantages that the utilization rates of materials and energy are greatly increased, the zero discharge of three wastes is realized without additional energy consumption, and the calcium magnesium acetate salt of high value is also prepared. After the automatic heating distillation and low-temperature drying of the aldehyde slag, the aldehyde slag is used for active carbon and is effectively and cleanly burnt.

Owner:DALIAN UNIV OF TECH

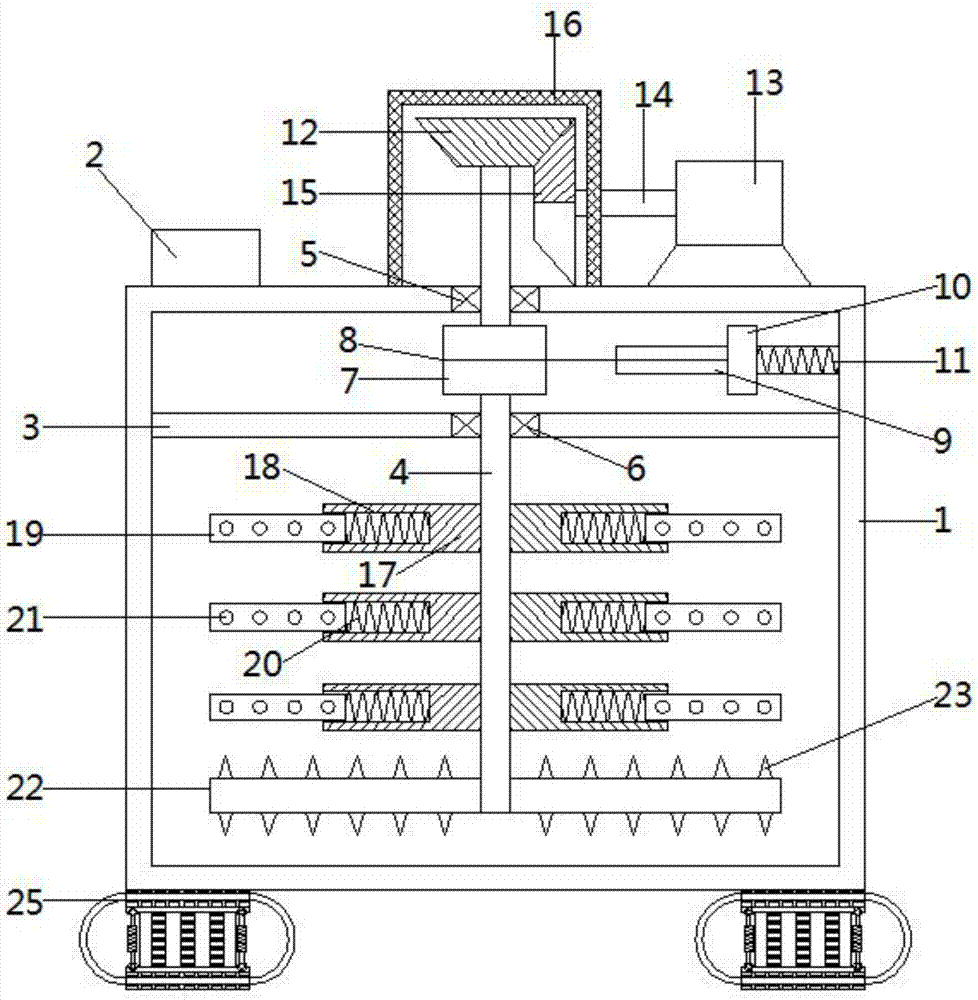

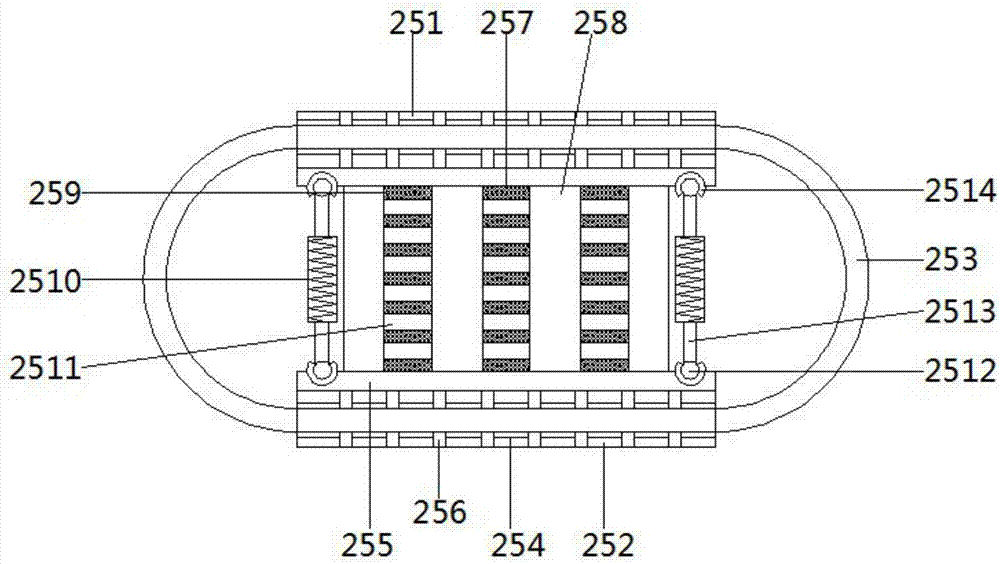

Material mixing device for chemical production

InactiveCN107321224AExtended service lifeStir wellRotary stirring mixersTransportation and packagingElectrical resistance and conductanceEnergy absorption

The invention discloses a material mixing device for chemical production. The material mixing device comprises a device body; the device body comprises a main body, the inner side of the main body is provided with a heat preservation layer, the inner side of the heat preservation layer is provided with a resistance wire heating layer, and the inner side of the resistance wire heating layer is provided with a ceramic layer; a feeding opening is formed in the left end of the upper side of the device body; a clapboard is horizontally arranged on the upper side of the interior of the device body and fixed on the inner wall of the device body; a bearing base is connected to the center of the top of the device body. The material mixing device for the chemical production is reasonable in structural design and long in service life; a stirring rotating shaft rotates clockwise and counterclockwise alternately, so that the material mixing effect and the working efficiency are effectively improved; the length of a stirring rod can be increased or decreased according to the rotation speed, and therefore the mixing radius is changed; through the arrangement of a stirring disc, materials at the bottom can be mixed, and the material mixing effect is further improved; in addition, under the cooperation function of a damping and energy-absorption part, a connecting rod, an annular spring part and an auxiliary damping part, the vibration caused when the device runs can be greatly reduced, and the stability is improved.

Owner:林红英

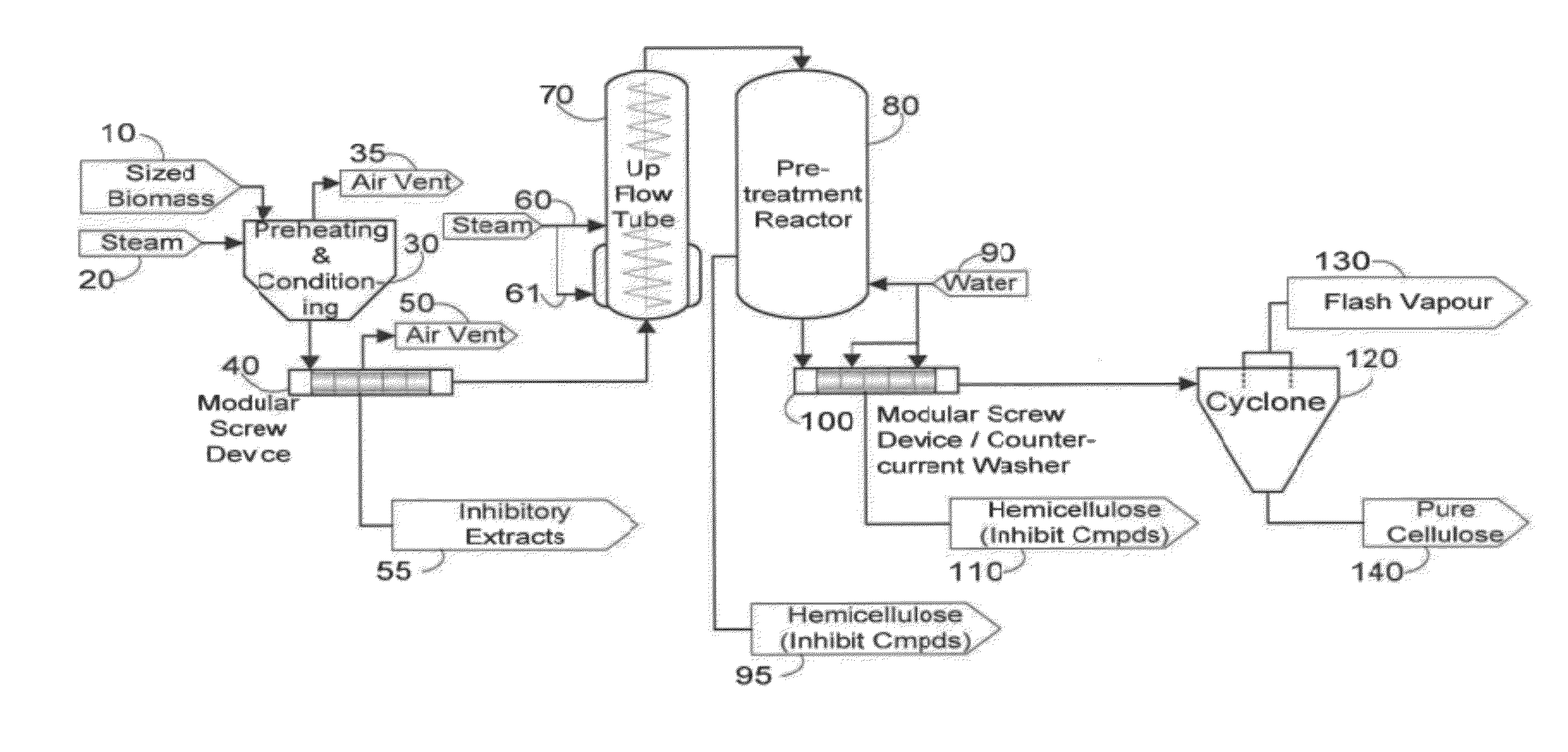

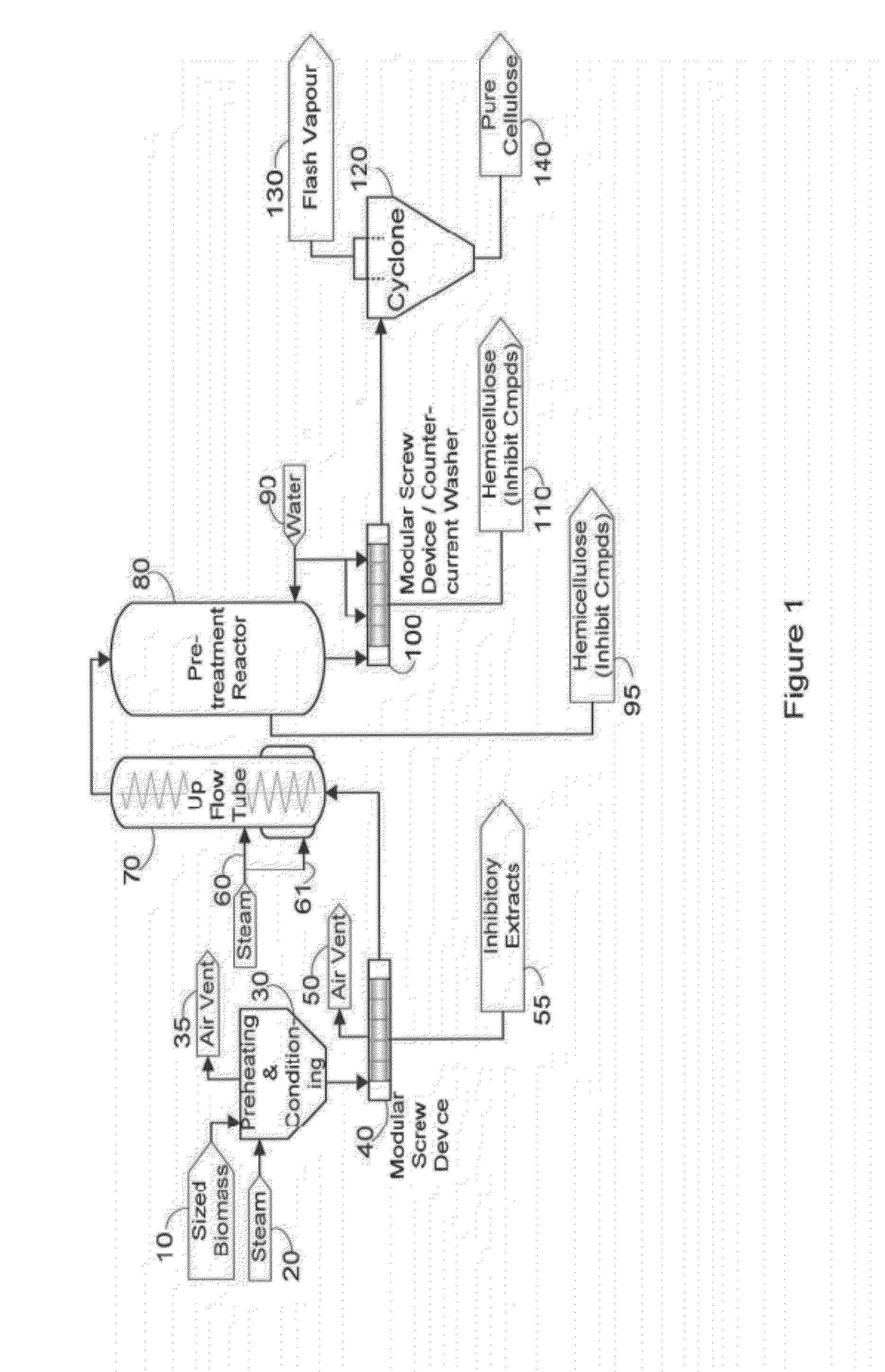

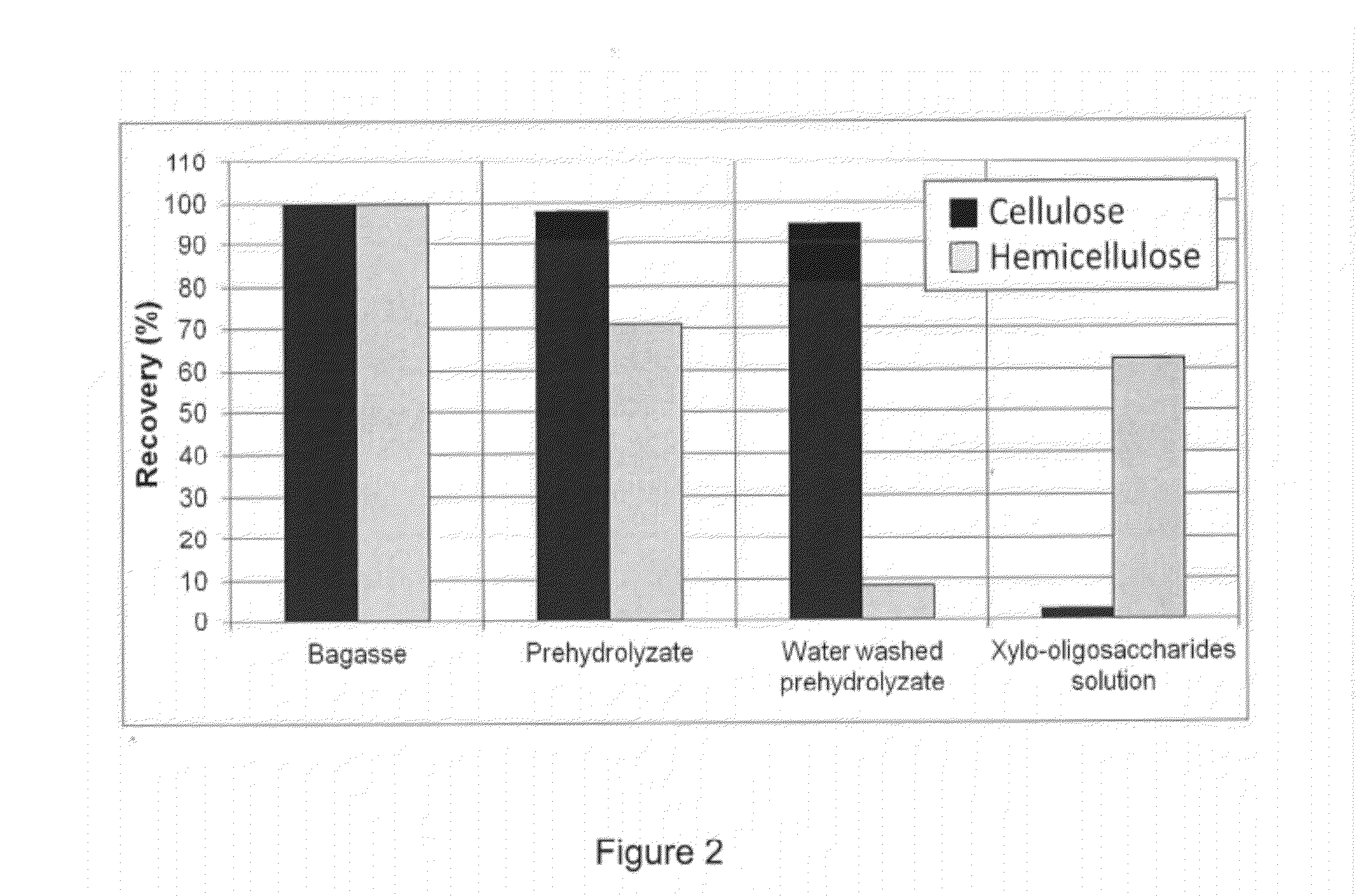

Bagasse fractionation for cellulosic ethanol and chemical production

InactiveUS20120111514A1Reduce contentHigh lignin contentPretreatment with water/steamPretreatment with alkaline reacting compoundsEnzymatic hydrolysisFractionation

A process is defined for the continuous steam pretreatment and fractionation of bagasse to produce a concentrated cellulose solid stream that is sensitive to enzymatic hydrolysis. Valuable chemicals are recovered by fractionating the liquid and vapor stream composed of hydrolysis and degradation products of the hemicellulose. Cellulosic derived glucose is produced for fermentation to biofuels. A hemicellulose concentrate is recovered that can be converted to value added products including ethanol.

Owner:GREENFIELD SPECIALTY ALCOHOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com