Method for producing propylene oxide

A technology of propylene oxide and its production method, which is applied in the field of new green production technology of propylene oxide, can solve the problems such as difficult to handle saponified wastewater and large quicklime, and achieve the reduction of input of production raw materials, reduction of investment, good society and economy benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

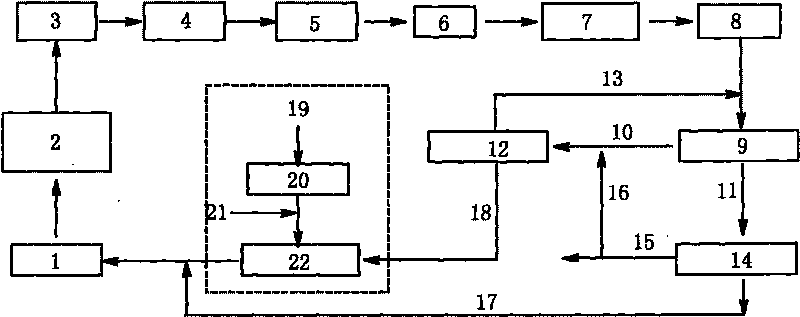

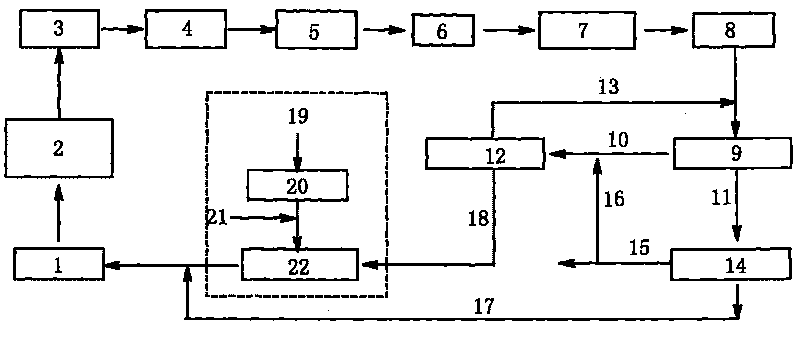

Method used

Image

Examples

Embodiment 1

[0033] With a processing capacity of 50L per hour, the design, installation and commissioning of each processing device in the whole process are carried out, and the test is carried out:

[0034] 1. In the early stage of propylene oxide production, a certain amount of sodium hydroxide is pre-invested to provide the alkali required for saponification reaction, and the concentration is 8% to directly react with chloropropanol. The reaction temperature is 100°C, and the reaction pressure is 1.0 bar. The sodium hydroxide undergoes cyclic saponification to generate equivalent sodium chloride, thereby generating sodium chloride saponification wastewater. The sodium chloride concentration in the generated wastewater is 3.5%, the sodium hydroxide concentration is 0.2%, and the COD CrIt is 1200mg / L, and the water temperature is 83°C.

[0035] 2. The saponification wastewater is oxidized with ozone after one-stage air flotation, and then undergoes two-stage air flotation. The vacuum u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com