Patents

Literature

83 results about "Synthetic Detergents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A synthetic detergent is any synthetic substance, other than soap, that is an effective cleanser and functions equally well as a surface-active agent in hard or soft water.

Fibrous matrix of synthetic detergents

ActiveUS7226899B2Convenient and cost-effective methodInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsFiberWax

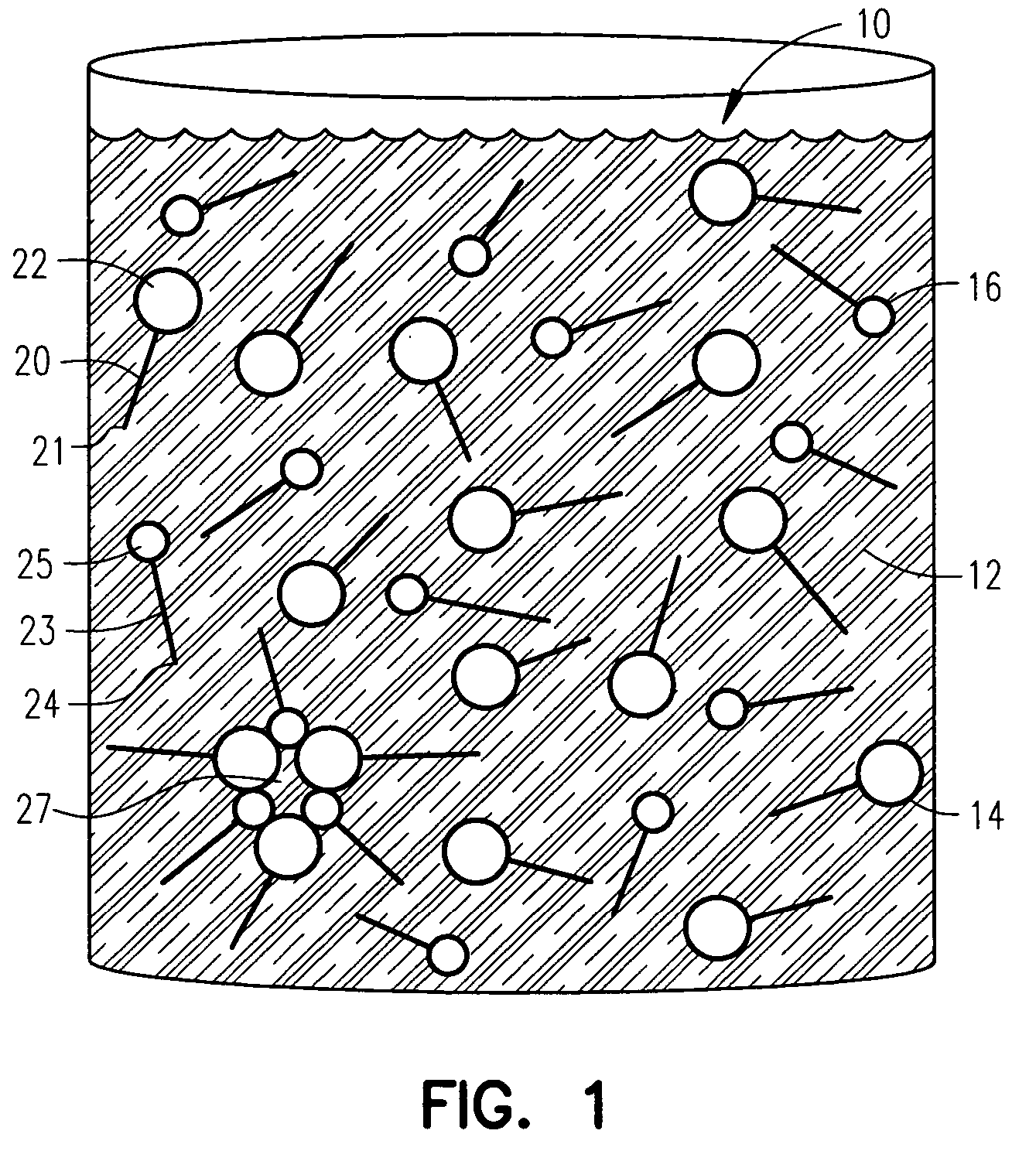

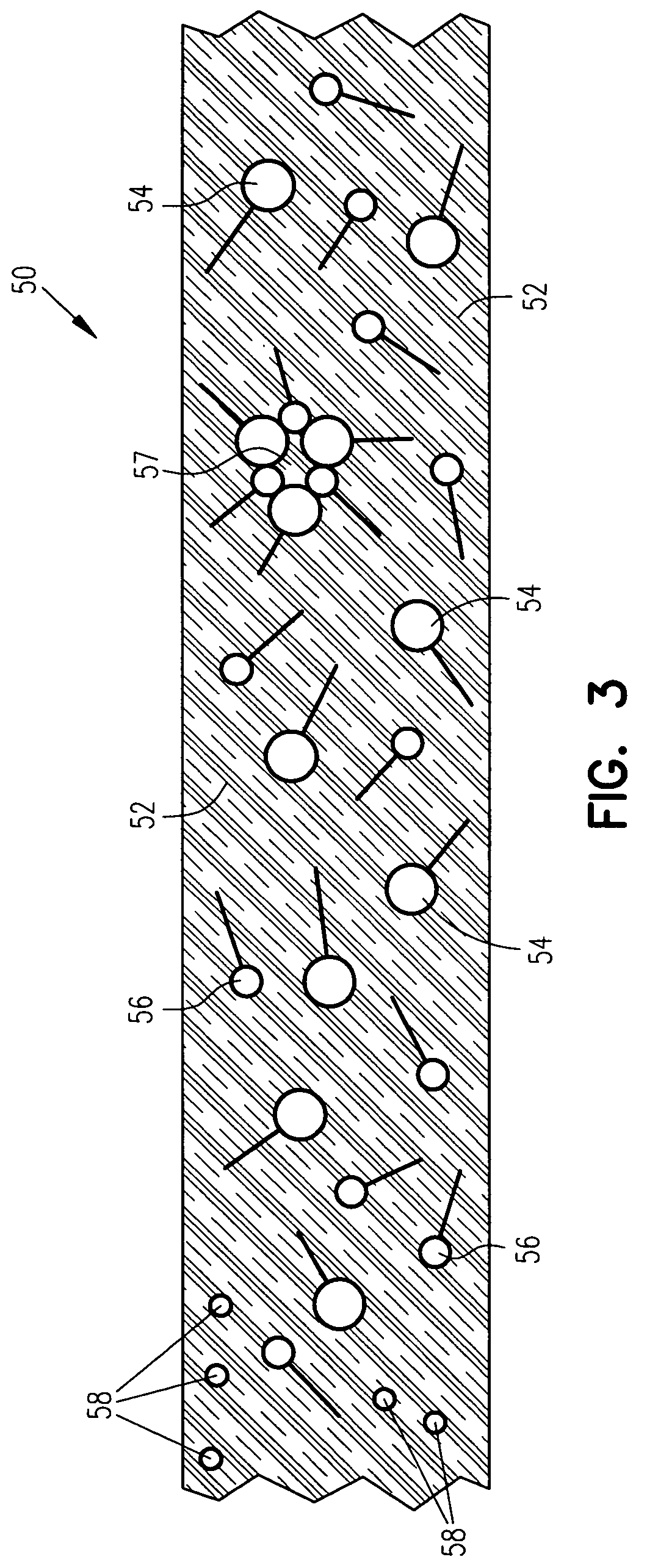

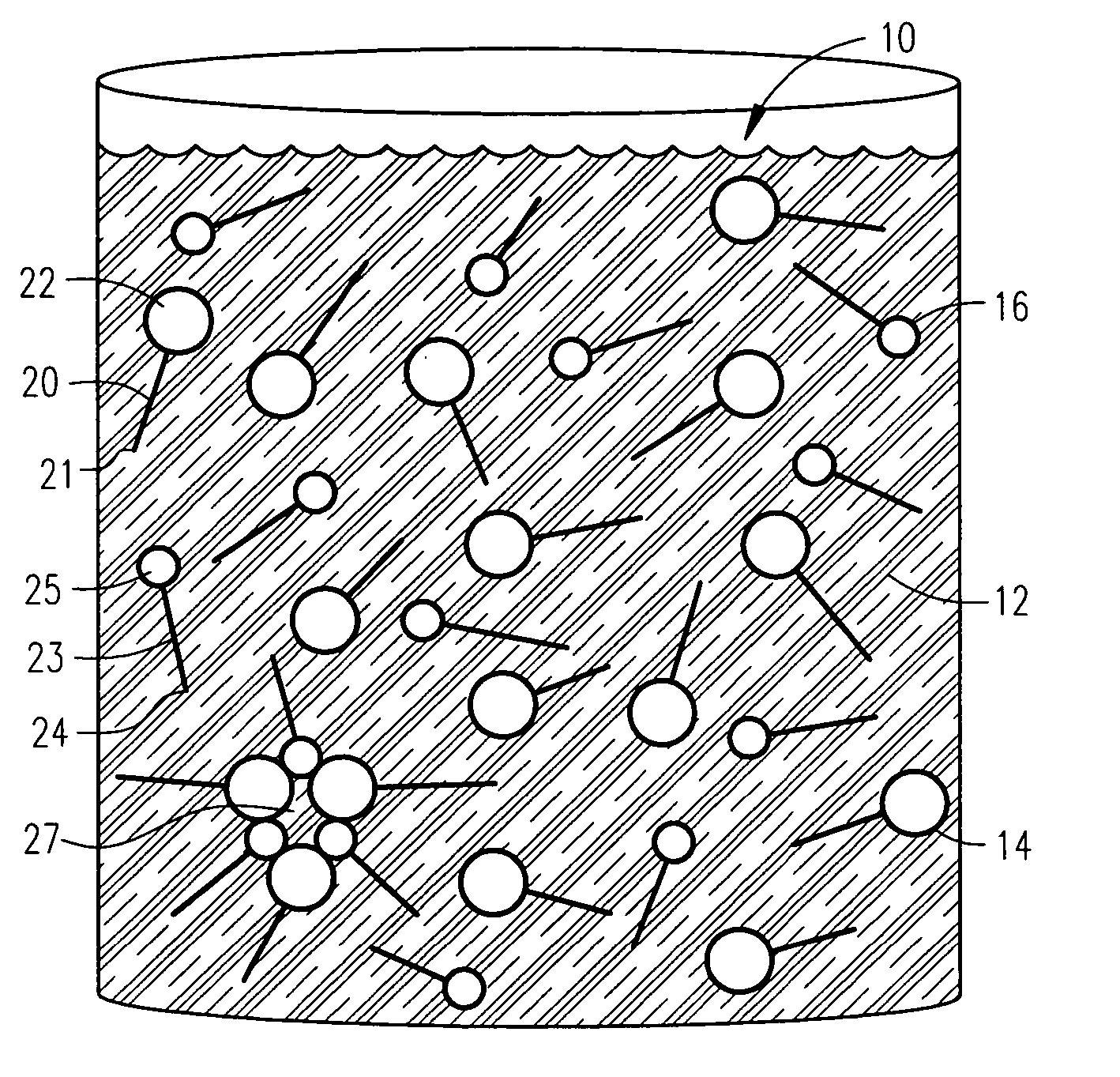

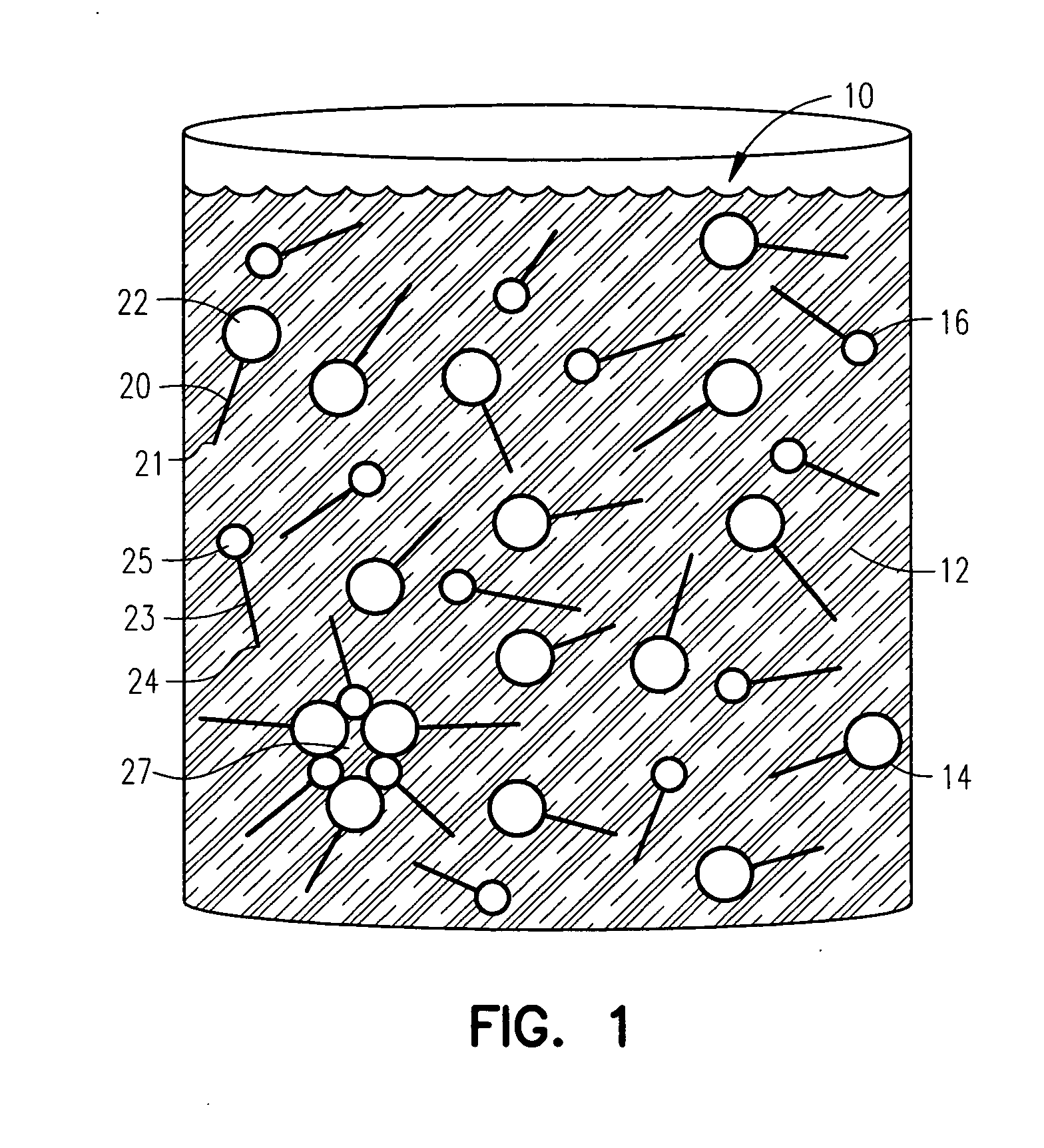

The present invention relates to a fibrous matrix of synthetic detergents. The fibrous matrix includes fibers formed of a synthetic wax and a primary surfactant embedded in the fibers. The fibrous matrix further includes a secondary surfactant embedded in the fibers.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Compositions and methods for forming fibers of synthetic detergents

ActiveUS20050137115A1Convenient and cost-effective methodInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWaxSynthetic Detergents

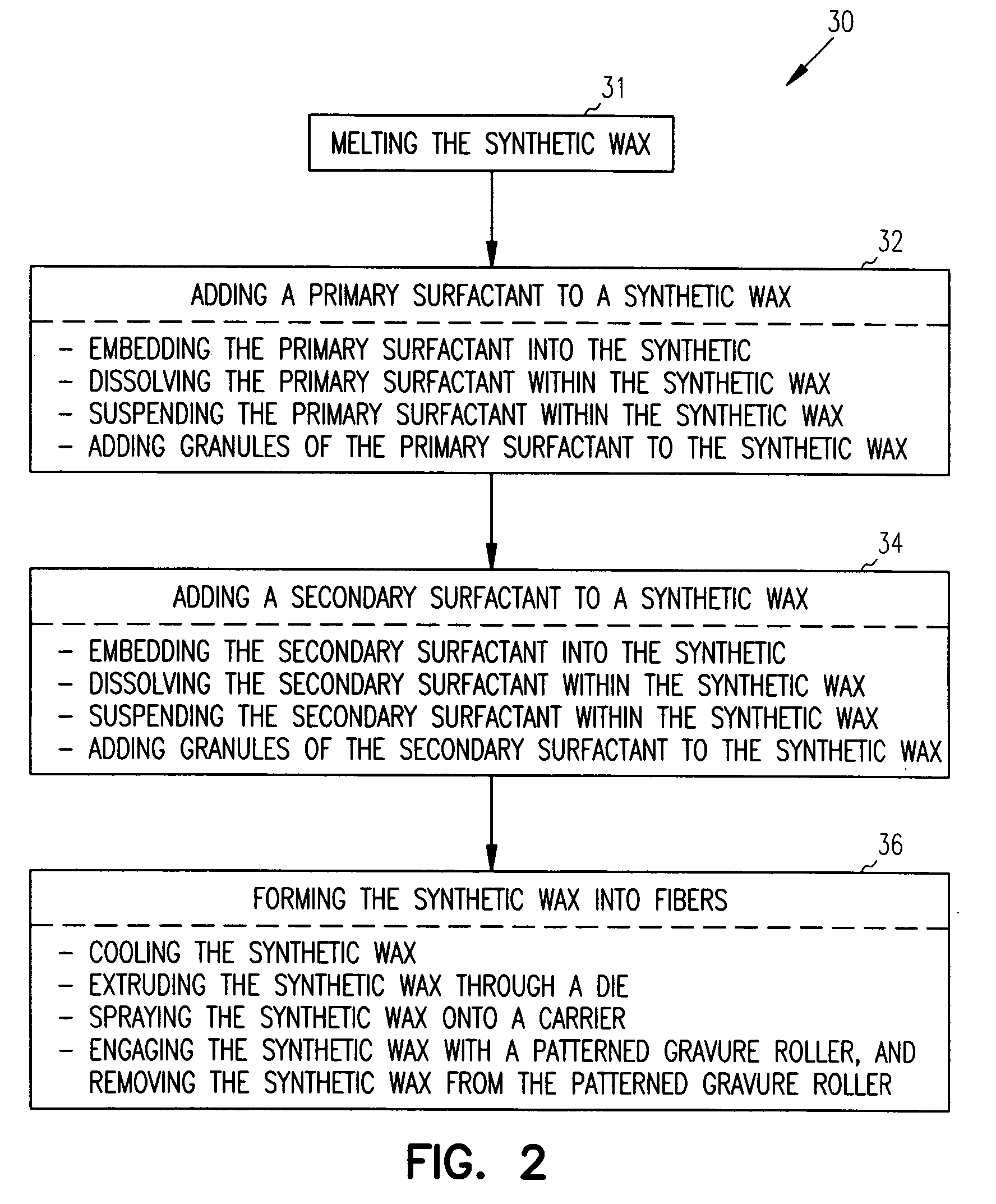

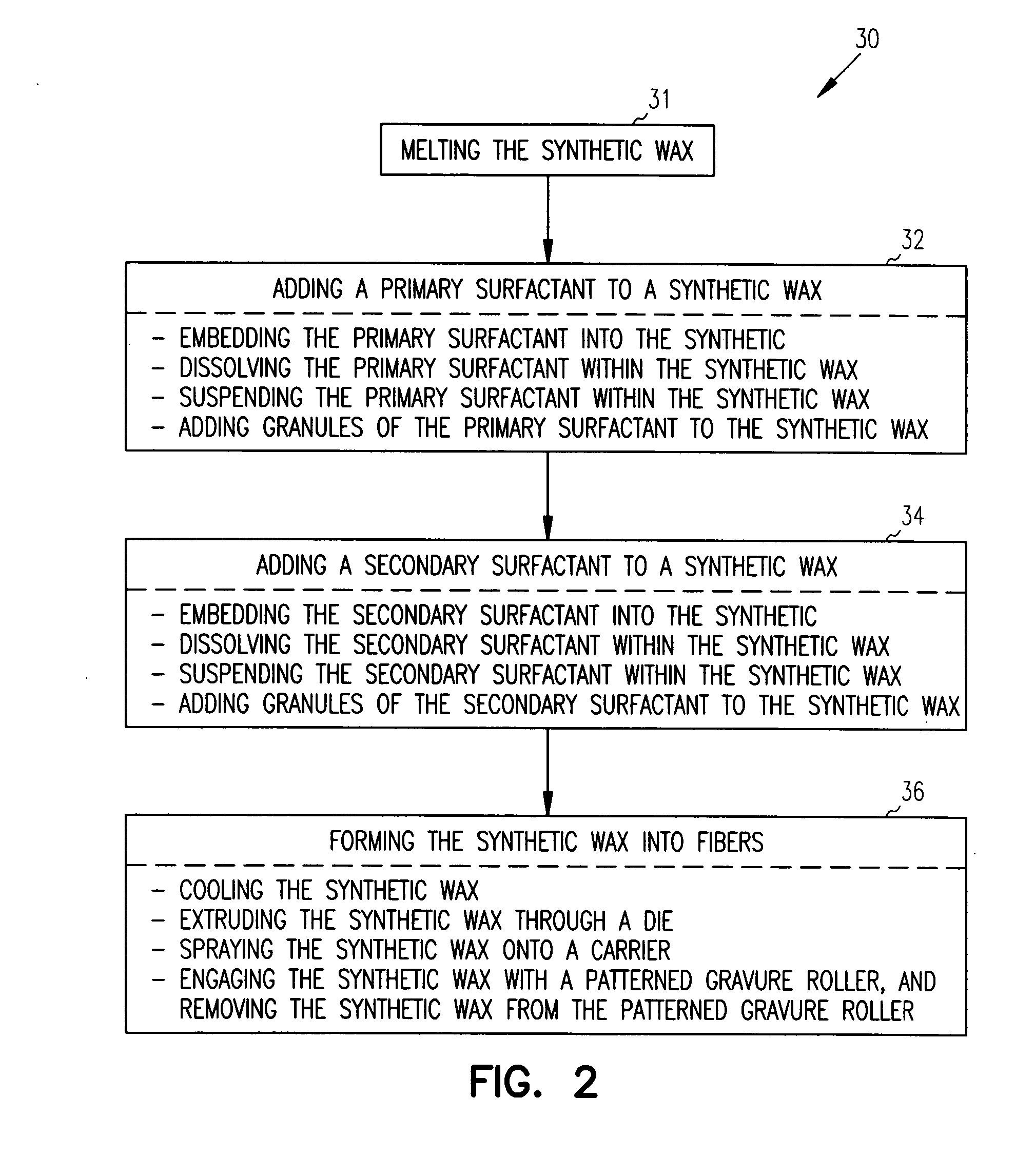

The present invention relates to a composition for forming fibers of synthetic detergents. The composition includes a synthetic wax, a primary surfactant added to the synthetic wax, and a secondary surfactant added to the synthetic wax. The present invention also relates to a method for developing fibers of synthetic detergents. The method includes adding a primary surfactant to a synthetic wax; adding a secondary surfactant to the synthetic wax; and forming the synthetic wax into fibers. In another form, the present invention relates to a fiber that includes a synthetic wax, a primary surfactant embedded in the synthetic wax, and a secondary surfactant embedded in the synthetic wax. The present invention also relates to a fibrous matrix of synthetic detergents. The fibrous matrix includes fibers formed of a synthetic wax and a primary surfactant embedded in the fibers. The fibrous matrix further includes a secondary surfactant embedded in the fibers.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Cyclocarya paliurus seed treatment method

ActiveCN104365220AReduced mechanical propertiesAlleviate permeability barriersSeed and root treatmentGrowth plantCyclocarya

The invention discloses a cyclocarya paliurus seed treatment method and belongs to the field of tree reproduction. The method includes the steps: (1) collecting seeds, removing fruiting wings and grinding thin seed coats with a mechanical method; (2) rubbing and elutriating the seeds in clear water added with alkaline synthetic detergent for six to eight times for removing part of inhibitors in the seed coats; (3) adopting the low-warm-low temperature-variable stratification and plant growth regulator (gibberellin) treatment combined dormancy release technique for accelerating germination. Inhibition of cyclocarya paliurus seed germination is eliminated or alleviated by the above taken measures, germination of the cyclocarya paliurus seeds is accelerated and increased, and high germination rate of 78.1-82.6% is obtained. By the technique, the seeds harvested in the current year can be sowed for seedling raising in the next spring.

Owner:江苏美好超市有限公司

System for treating overproof radioactive laundry waste water

InactiveCN102930912ALow running costImprove processing qualityRadioactive decontaminationActivated carbon filtrationIon exchange

The invention discloses a system for treating overproof radioactive laundry waste water, which comprises a bag filter, an active carbon filter and a zeolite filter; the outlet of the bag filter is connected with the inlet of the active carbon filter; and the outlet of the active carbon filter is connected with the inlet of the zeolite filter. According to the system for treating the overproof radioactive laundry waste water, the bag filter can effectively remove suspended solids and large particle impurities in laundry waste water; the active carbon filter can remove surface active agent and micromolecule organics in the waste water to further retain the suspended solids in the water and can eliminate toxic action of organic macromolecule such as the suspended solids generated during washing clothes, synthetic detergent in the waste water and the like; the zeolite filter has good ion exchange characteristic and can effectively remove radionuclide ions (cesium and strontium) in lower radioactive waste water. The system for treating the overpoorf radioactive laundry waste water is simple in structure, low in energy consumption and operating cost and high in treating quality for the overproof radioactive laundry waste water.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

Mild synthetic detergent toilet bar composition

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Cotton cloth reduced dye dyeing process

The invention discloses a cotton cloth reduced dye dyeing process. The cotton cloth reduced dye dyeing process includes the following steps of a, dye liquor preparation, wherein a wetting agent and reduced dye are added into deionized water in the environment of the 15 DEG C to 20 DEG C temperature, and the mixture circulates evenly; b, suspensoid cold dyeing, wherein cotton cloth is placed in dye liquor prepared in the step a, and cyclic dyeing is carried out; c, alkalifying circulation, wherein caustic soda is added into the dye liquor obtained in the step b, and circulation is carried out; d, adding of sodium hydrosulfite for circulation; e, heating reduction dye up-take, wherein the pH value of a dye bath is adjusted to range from 4 to 4.5 with acetic acid, the temperature is raised to 100 DEG C at the speed of 1.5 DEG C / min, heat preservation dyeing is carried out for 40-60 min, then the temperature is reduced to 60 DEG C from 100 DEG C at the speed of 1 DEG C / min, and heat preservation is carried out for 30 min; f, soaping, wherein a soap or a synthetic detergent is added into Na2CO3, washing is carried out till the material is neutral, and airing is carried out at room temperature. The cotton cloth reduced dye dyeing process has the advantages of being high in dyeing rate and good in migration property.

Owner:安徽融创化工科技股份有限公司

Composition for cleaning and article including the same

InactiveUS20130225471A1Easy to cleanComparable performanceNon-ionic surface-active compoundsAnionic surface-active compoundsAlcoholOrganic solvent

A composition for cleaning a surface and an article including a substrate and the composition for cleaning the surface are provided herein. The composition comprises a biocide, a first alcohol alkoxylate, an alkyl polyglycoside, a supplemental alcohol alkoxylate, and water. The composition is substantially free of organic solvents and has a cleaning performance of from 30% to 70% as determined in accordance with the Federal Test method Std. No. 536A / GEN, “Soap and Soap-Products (Including Synthetic Detergent)”.

Owner:BASF AG

Method for producing toothpaste by utilizing protein with surface activity as cleaning and washing component

InactiveCN103211716AThe composition is clear and effectiveCleans the mouth and teeth with obvious effectCosmetic preparationsToilet preparationsBiotechnologyCarrageenan

The invention relates to a production method of toothpaste and particularly relates to a method for producing toothpaste by utilizing protein with surface activity as a cleaning and washing component. The method adopts the protein with surface activity or a protein-based surfactant as the sole cleaning and washing component for completely replacing a conventional synthetic detergent to produce the toothpaste by matching with components such as sorbitol, carrageenan, essence and a food preservative, wherein the protein with surface activity or the protein-based surfactant is one, two, three or four of soybean protein sodium alginate, silk protein calcium silicate, a natural silk protein emulsifier or sodium caseinate. The method is mainly characterized by achieving the purpose of cleaning an oral cavity and teeth through the dispersing emulsification and foaming effects of the protein with surface activity. The toothpaste prepared by the method has the characteristics of being safe, natural, nutritional and environment-friendly, and has a very obvious effect of cleaning an oral cavity and teeth. After the toothpaste is used, the mouthfeel of a user is very clear, smooth and natural.

Owner:LIUZHOU YANGSHENG TECH

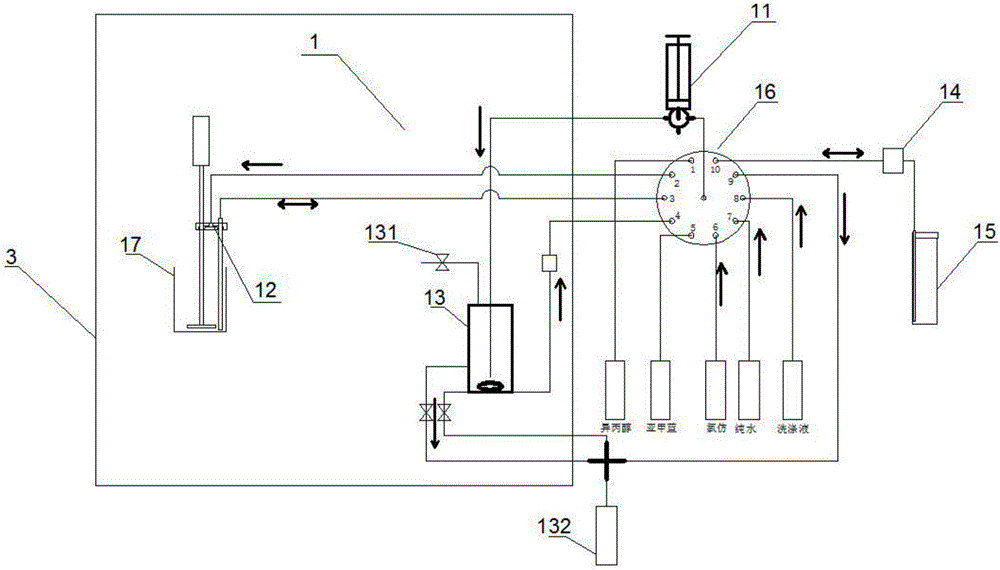

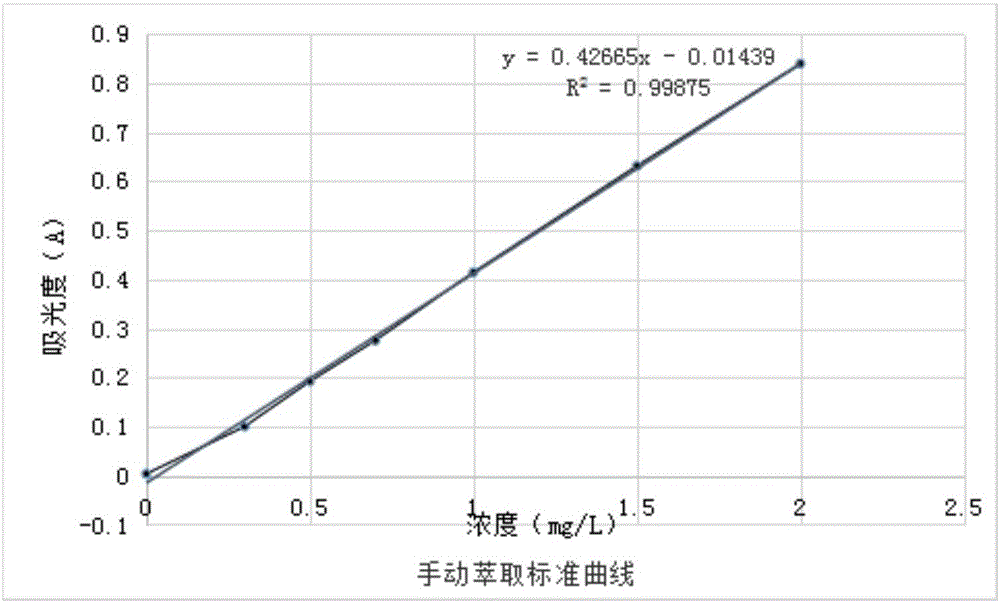

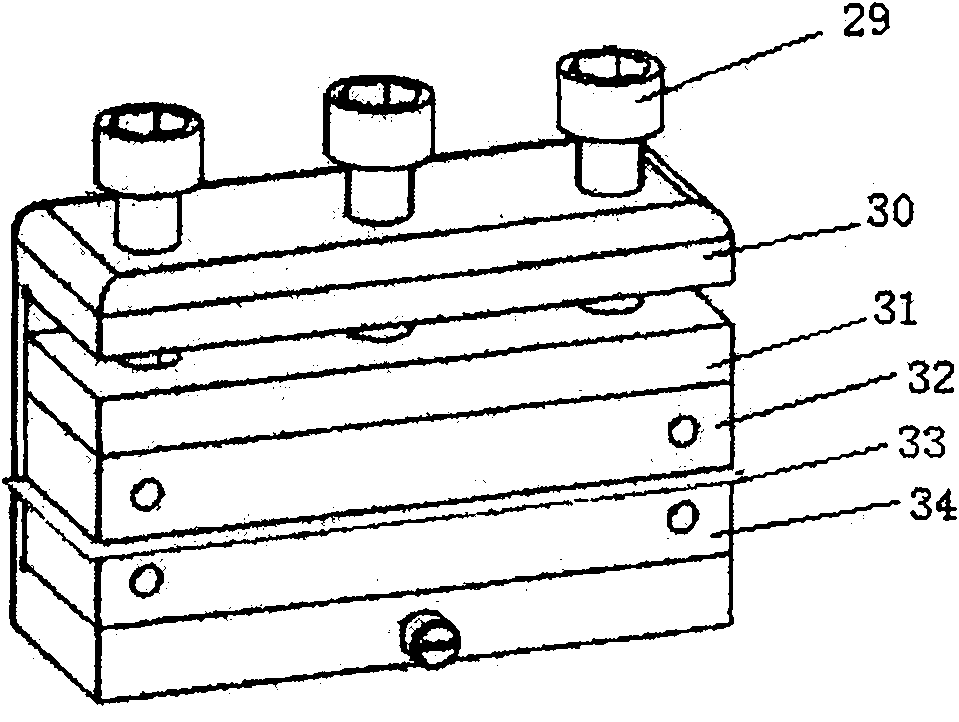

Anion synthetic detergent extracting and analyzing method and device

InactiveCN105865892ASatisfy batch analysisFulfil requirementsPreparing sample for investigationColor/spectral properties measurementsCuvetteWater filter

The invention relates to an extracting method, in particular to an anion synthetic detergent extracting and analyzing method and device. The method includes the steps of firstly, injecting a sample into a sample bottle, then injecting a methylene blue reagent to be stirred and mixed, slowly adding a certain amount of chloroform in the stirring process to continue to be evenly stirred for stirring extraction, and then conducting standing; secondly, extracting chloroform and part of residual solution out of the sample bottle, injecting chloroform and part of residual solution into a back extraction bottle to be evenly stirred, sealing the back extraction bottle, discharging residual solution and chloroform into a waste liquid bucket through pressure, and injecting detergent into the rest certain amount of chloroform for back extraction; thirdly, making back extraction chloroform enter a water filter, and injecting filtered chloroform into a cuvette for test detection. The detection method is simple, the method is high in accuracy and precision and can be controlled, and detection sensitivity is improved. Automatic continuous sampling can be achieved in the extraction process, and the extracted sample can meet the requirement for batched analysis and real-time monitoring of water samples.

Owner:QINGDAO SHUNXIN ELECTRONICS SCI & TECH CO LTD

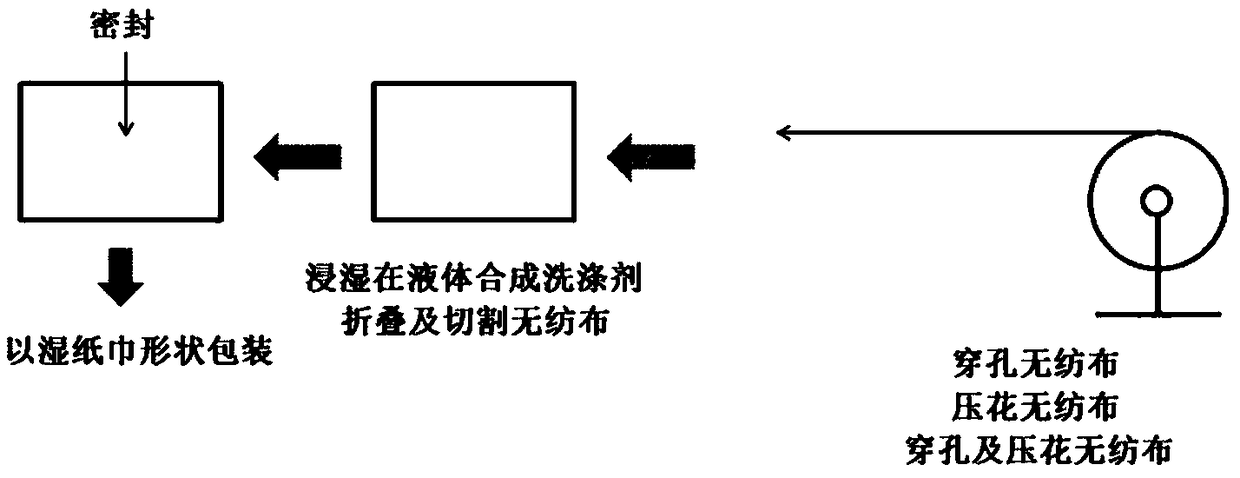

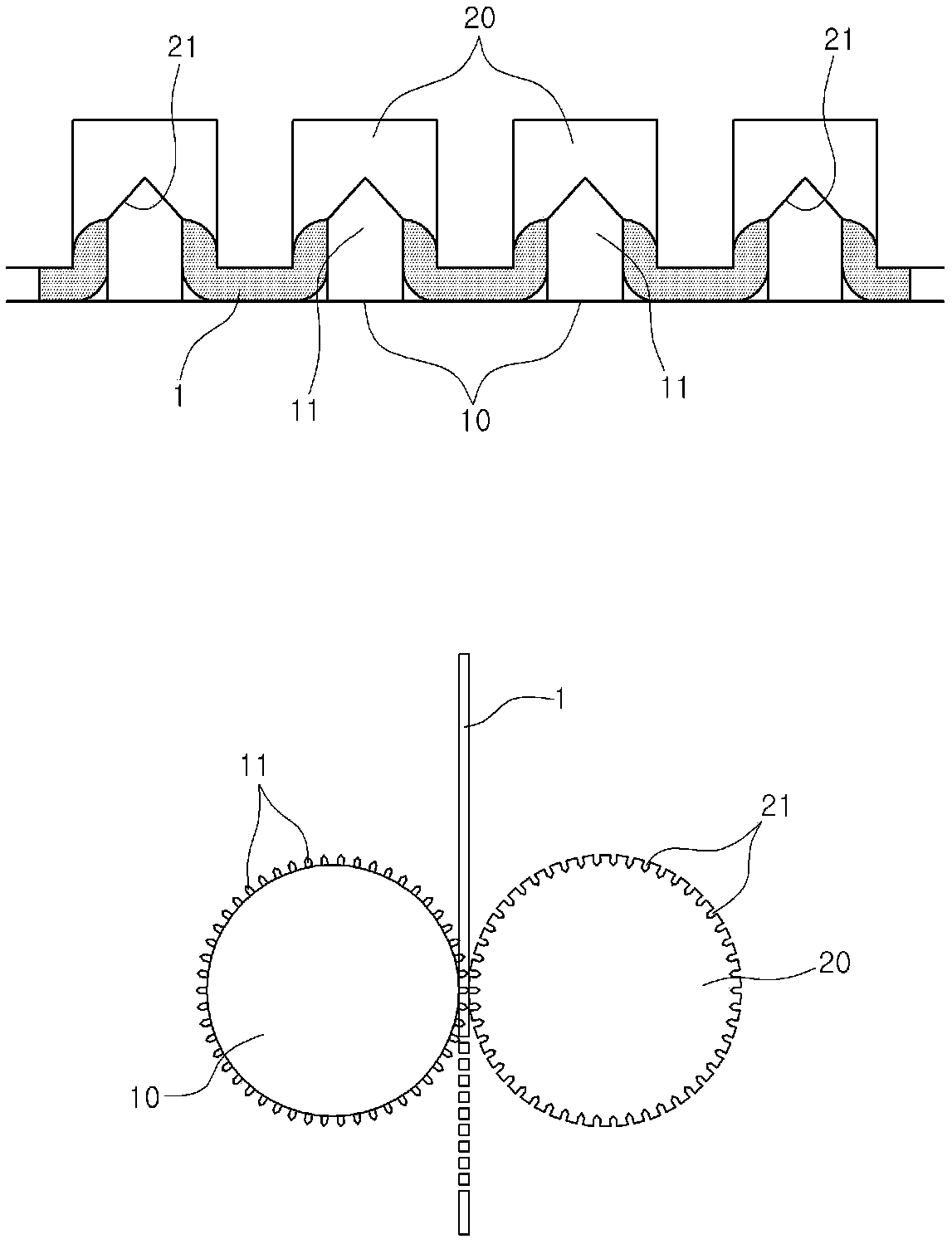

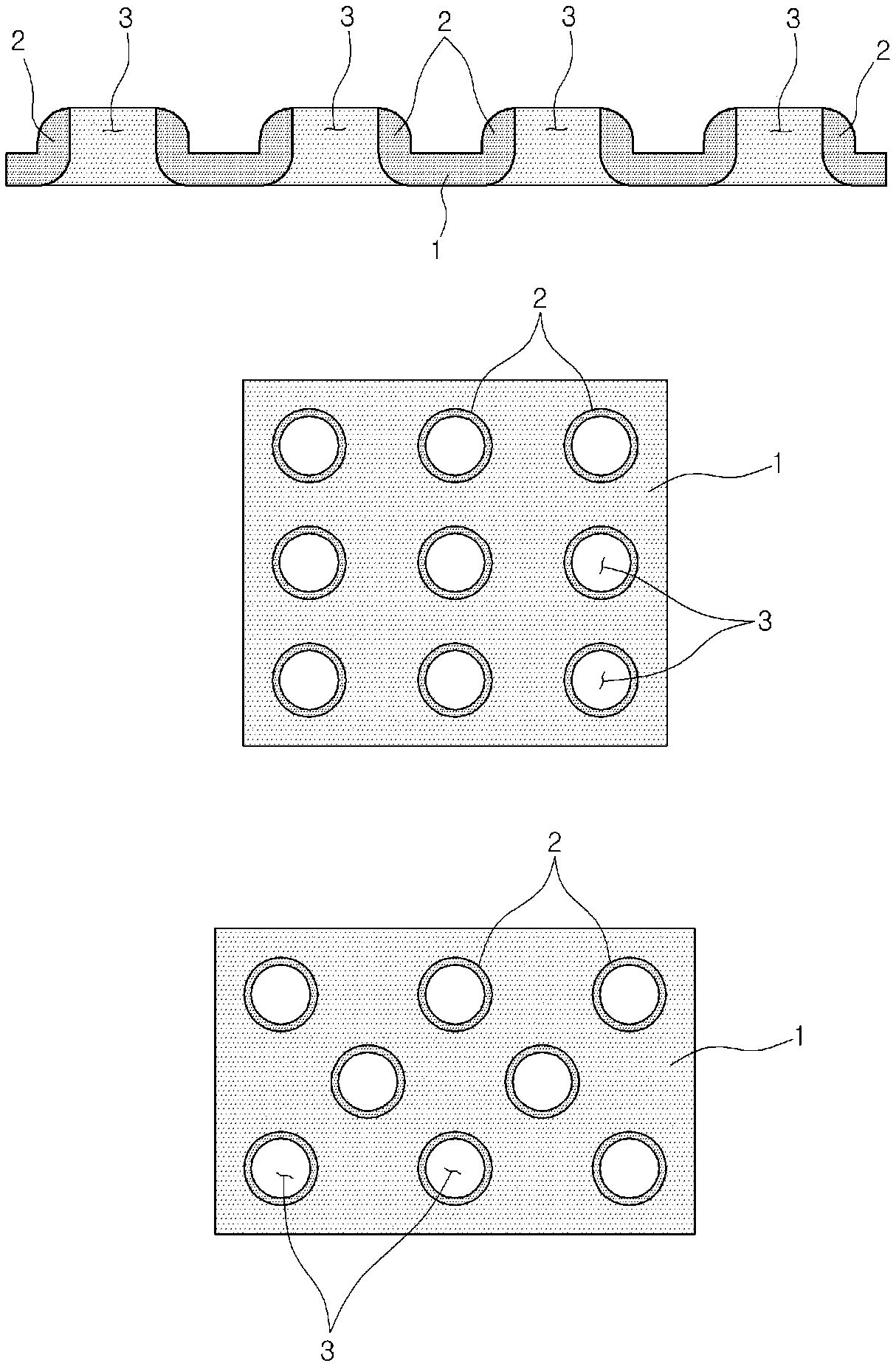

Non-woven fabric tissue containing detergent and method for manufacturing same

InactiveCN109429482AImprove ease of useReduce absorptionPattern makingBathroom accessoriesYarnPolyolefin

The present invention relates to a non-woven fabric tissue containing detergent and a method for manufacturing the same, wherein a non-woven fabric has synthetic detergent for kitchen, body shampoo, hair shampoo, face washing, cleansing, fiber softening, laundering, dish washing, cleaning, or pet shampoo adsorbed therein, and each sheet of non-woven fabric can be taken out or incised in a preset size and then used. To this end, the present invention is configured as follows: an adsorption liquid comprising liquid synthetic detergent is adsorbed in a spun-bonded non-woven fabric made of polypropylene, propylene copolymer, or polyolefin, a melt-blown non-woven fabric, a non-woven fabric comprising multiple layers of spun-bonded and melt-blown non-woven fabrics, or a non-woven fabric comprising at least 50% of polyolefin-based raw yarn; said non-woven fabric is cut into a preset size; multiple pieces of the non-woven fabric obtained through cutting are laminated, or incision lines are formed at a preset interval on the non-woven fabric; and the non-woven fabric is configured in a roll shape. Each of such non-woven fabric tissues or a group thereof can be packaged and used as a sponge,as a shower towel, as a cleaning cloth, or as a detergent bubble-enhancing tissue. Such a non-woven fabric tissue and the adsorbed synthetic detergent liquid can provide synergy that can reduce or remove the amount of use at least one selected from a thickener, a builder, a bubble forming agent, an acid surfactant, and sodium hydroxide in the liquid synthetic detergent.

Owner:沈希永 +1

Mild synthetic detergent toilet bar composition

Mild toilet bar compositions are described that contain synthetic anionic surfactants, and monohydroxy C16-20 normal alkyl carboxylic acids and have a pH range of 3.0-7.0. The inventive bars have excellent processing properties and can be extruded and stamped into finished toilet bars.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Solid base catalyst for synthesizing alkanolamide type compound and preparation method thereof

InactiveCN101507917AImprove surface activityNon-ionic surface-active compoundsOrganic compound preparationAntistatic agentHydrotalcite

The invention relates to a solid base catalyst for synthesizing alkanolamide compounds and a preparation method thereof, and belongs to the technical field of solid base catalyst. Magnalium hydrotalcite is taken as a precursor of the catalyst and used to prepare the solid base catalyst through calcination and rehydration, and the formulation of the magnalium hydrotalcite solid base catalyst is Mg1-xAlx(OH)2(OH-)x.mH2O. The alkanolamide compounds are reaction products, have good surface activity, are one of the most important varieties of non-ionic surface active agents, are important active monomers of a modern synthetic detergent, and are widely applied to detergents, foam stabilizers, thickeners, softening agents, anti-rust agents, antistatic agents, and the like.

Owner:BEIJING UNIV OF CHEM TECH

Syndet Bars Having Ultraviolet Radiation Protection

InactiveUS20080063613A1Cosmetic preparationsSoap detergents with organic compounding agentsSunscreen agentsActive agent

The present invention is drawn to a syndet soap bar that after the washing process leaves a residual deposit on a substrate that provides protection from ultraviolet radiation comprising (a) a non-emulsifying surfactant having an HLB greater than 15; (b) from greater than 10% to about 25% by weight red petrolatum; and (c) at least one surface-treated metal oxide sunscreen. Optionally, compositions of the present invention may also include (d) at least one wetting agent having a log P value of greater than about 4.0 and / or (e) an organic sunscreen having a log P value of greater than about 4.0.

Owner:COCKERELL CLAY +1

Method for stripping cured paint with synthetic surfactants low in volatile organic compounds

InactiveUS20060189496A1Improve permeabilityImprove solubilityNon-surface-active detergent compositionsChemical paints/ink removersDie castingSynthetic Detergents

A method of stripping cured paint from plastic, aluminum, brass, magnesium, galvanized steel, zinc die cast, and non-ferrous metal substrates, said method comprising: a) adding a stripping composition to a strip tank, consisting of a mixture of, not limited to, two synthetic detergent surface active agents, referenced in this invention as surfactants low in volatile organic compounds, specifically containing less than 50-percent by total weight or volume of any volatile organic compounds comprising 51% to 100% of the total weight or volume of the composition, with the remaining 0.5% to 49% balance consisting of additives; b) immersing said cured painted substrate in said strip tank containing said stripping composition; c) heating said stripping composition from 150 F. to 350 F for approximately 1-3 hours, wherein cured paint is removed from said substrate.

Owner:MILES SAMUEL L

Low density detergent composition

InactiveUS20020198120A1Cosmetic preparationsSoap detergents with other compounding agentsEngineeringLow density

Aerated, ultra low-density cast-dehydrated syndet detergent bars for use in personal wash, fabric wash and hard surface cleaning. A process for preparing aerated, ultra low-density cast-dehydrated detergent bars wherein the air is entrained in the bars after rigidification and shaping the product is also provided.

Owner:CONOPCO INC D B A UNILEVER

Marine biological resource based micro-nano healthy and environment-friendly washing product and preparation method thereof

ActiveCN103710182AImprove adsorption capacitySimple componentsNon-surface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsMicro nanoResource based

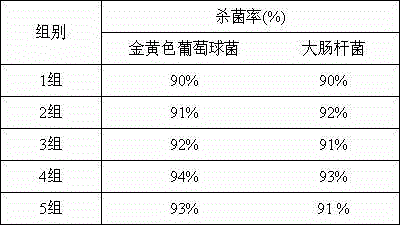

The invention discloses a marine biological resource based micro-nano healthy and environment-friendly washing product and a preparation method thereof, belonging to the technical field of detergent products. According to the invention, through taking a waste shell micro-nano skeleton material as a carrier, and being supplemented by marine algae active substances, biological active catalyst and deionized water, in certain proportion and at appropriate temperature, the marine biological resource based micro-nano healthy and environment-friendly washing product is prepared by using an optimized process. Raw materials adopted in the product are all natural active substances, and no chemical additives are added, therefore, the product is green and environment-friendly, non-toxic and harmless, and avoids residues of artificial chemical synthetic detergents in clothes; the washing product is strong in penetrability, strong in decontamination ability and obvious in sterilization effect, and can degrade pollutants without producing secondary pollution, therefore, the product has a wide industrialization prospect and a far-ranging market value.

Owner:CIXI SHUNDA IND

Poly-epoxy itaconic acid, preparing method and uses thereof

The invention relates to polyepoxy itaconic acid, and a preparation method and an application thereof. The polyepoxy itaconic acid is prepared by (A) reacting itaconic acid and alkali to obtain itaconate; (B) subjecting to catalytic epoxidation to obtain epoxy itaconate; and (C) treating the obtained epoxy itaconate with calcium hydroxide or other basic calcium salts under a basic condition. The step (A) is optional. The prepared polyepoxy itaconic acid can be used for treatment of industrial recirculating water and in synthetic detergent, cleaning agent and scaling agent; and the polyepoxy itaconic acid has excellent scaling performance to CaCO3 and Ca3(PO4)2 and a certain capacity for stabilizing Zn<2+> in water when it is applied for treating circulated cooling water.

Owner:CHINA PETROLEUM & CHEM CORP

Release agent for storage battery cast-weld mold

InactiveCN102935487AGood effect in removing carbon depositsLow costFoundry mouldsFoundry coresUltrasonic vibrationSynthetic Detergents

The invention discloses a release agent for a storage battery cast-weld mold and relates to storage battery manufacture. Methods for cleaning machine cast-weld molds in most of domestic enterprises at present include: cast-weld molds are detached from machine cast-weld stoves, immersed in strong alkaline solutions, and decontaminated by ultrasonic vibration, however, the dismounting and mounting of the cast-weld molds from the machine cast-weld stoves is time and labor consuming, the production efficiency is affected, and the cost is high; and traditional release agents for manual cast-weld are used, however, the deposited carbon removing effect is not good, and the cost is high. The release agent for the storage battery cast-weld mold is characterized in that the proportioning formula of the release agent comprises 50g to 80g of water, 30g to 50g of talcum powder, 70g to 80g of sodium alginate, 30g to 60g of synthetic detergents and 20g to 50g of stabilizing agents, and the compositions are added successively to be stirred and prepared into a solvent. The release agent for the storage battery cast-weld mold has the advantages that the mold is not needed to be dismounted for cleaning; the mold can be used as long as the release agent is sprayed; the deposited carbon removing effect is good, the cost is low, and the usage amount is saved.

Owner:SHANDONG SACRED SUN POWER SOURCES

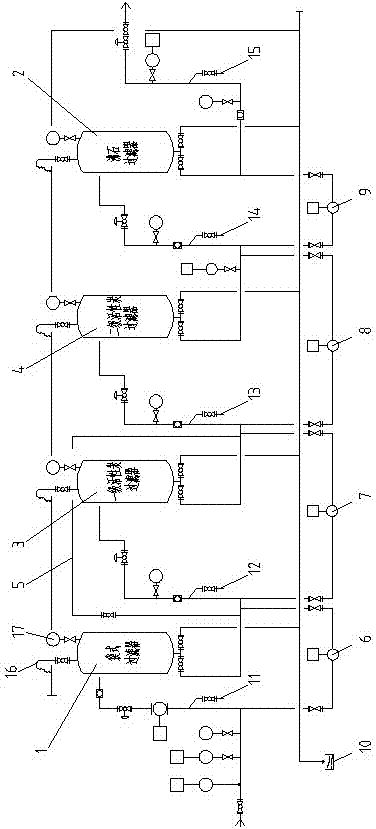

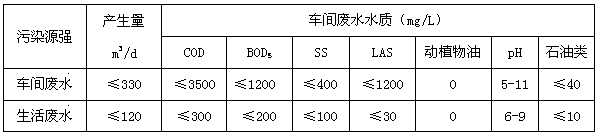

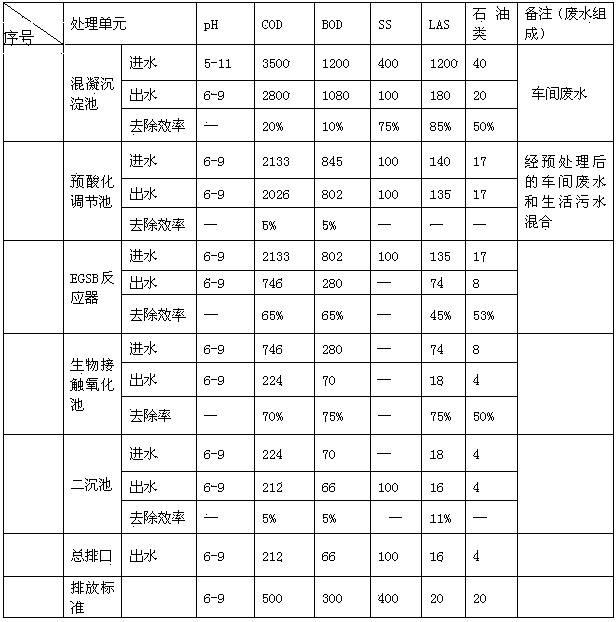

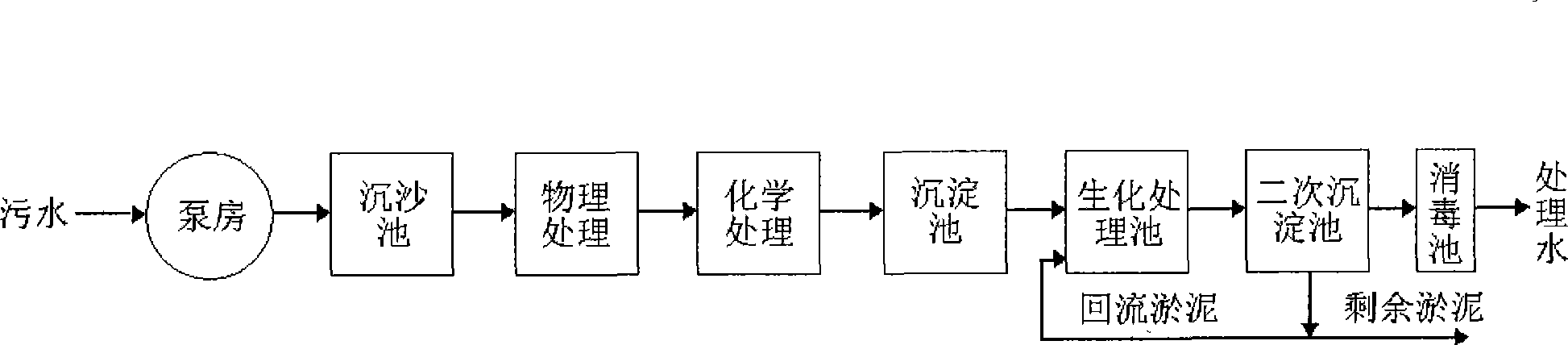

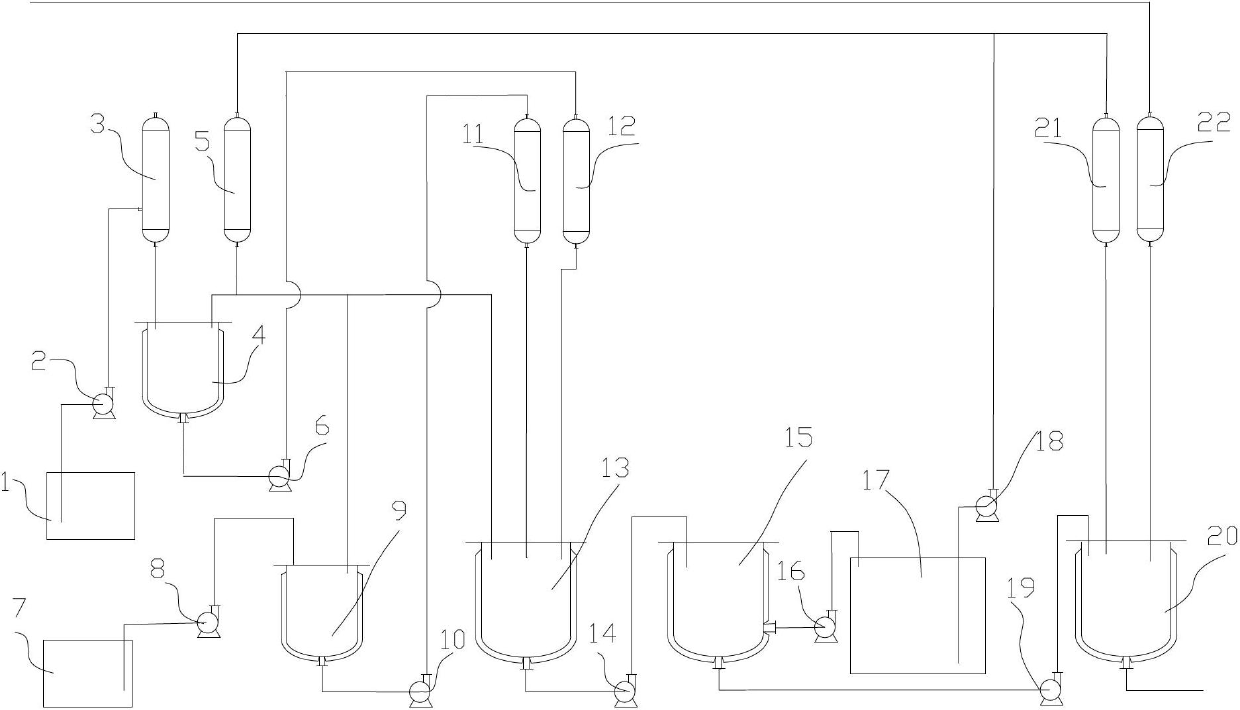

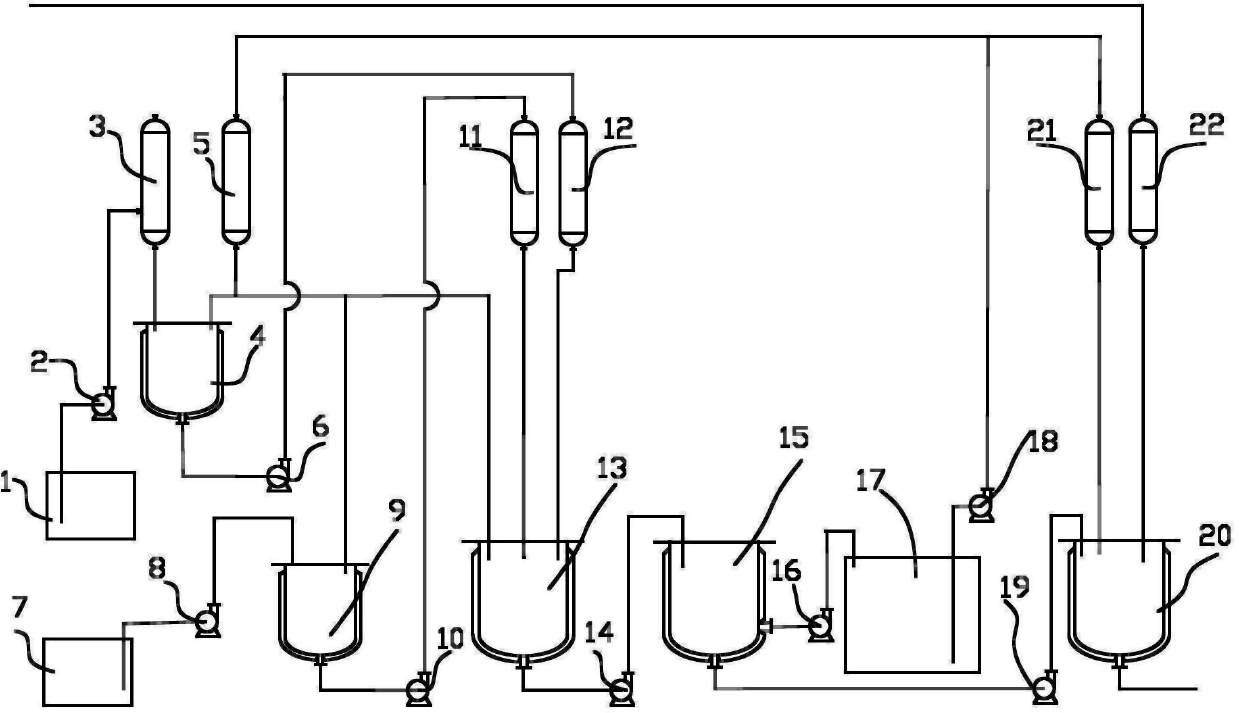

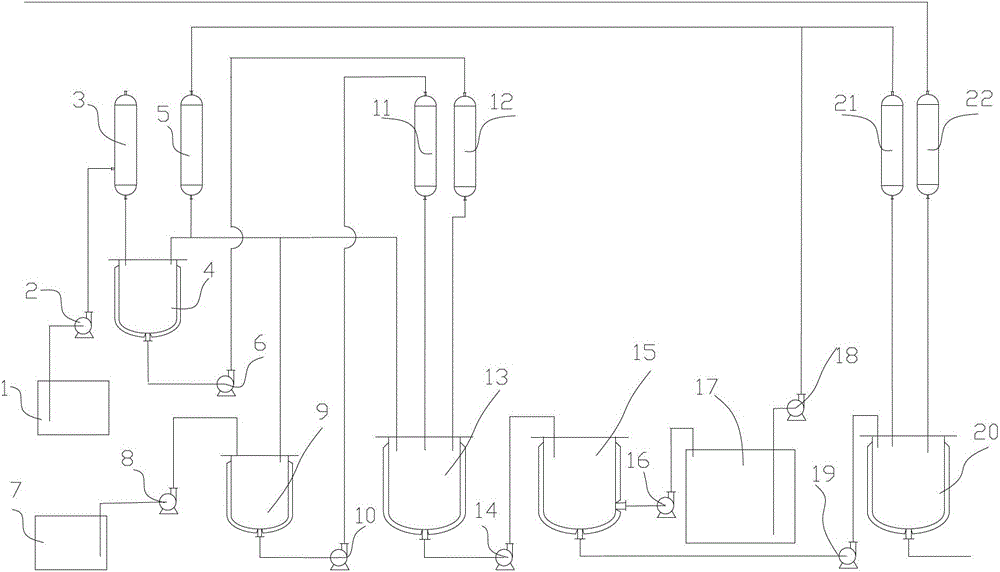

Detergent synthesis wastewater treatment technology

InactiveCN103739144AReduce inhibitionMake the most of alkalinityMultistage water/sewage treatmentAnaerobic bacteriaImpurity

The invention discloses a detergent synthesis wastewater treatment technology. The technology comprises the following steps: workshop cleaning wastewater, ground flushing wastewater and tail gas washing wastewater enters a grid well I to realize the removal of large-granule impurities, the impurity removed wastewater enters a water collection tank and is lifted to a coagulation integrated tank, medicine adding coagulation deposition is adopted to remove surfactants, suspensions and organic matters in the wastewater, water discharged from the coagulation integrated tank enters a pre-acidifying equalizing tank and is uniformly mixed with living wastewater treated through a grid well II, the obtained mixed wastewater is lifted to an EGSB reactor, water discharged from the EGSB reactor automatically flows into a bio-contact oxidation tank, water discharged from the bio-contact oxidation tank enters a secondary deposition tank, water discharged from the secondary deposition tank enters a clear water pool, and the water discharged from the clear water pool is discharged in a standard reaching manner. The technology adopts the coagulation deposition pretreatment and flocculation polymerization effect to remove the surfactants and the most organic matters in the wastewater; and the technology adopts an external reflux process, so the inhibition effect of harmful substances in the wastewater on anaerobic bacteria can be reduced, and the alkalinity of the discharged water can be fully utilized.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

Low density detergent bar composition

InactiveCN1501972ASoap detergents with other compounding agentsAnionic surface-active compoundsSurface cleaningSynthetic Detergents

Aerated, ultra low-density cast-dehydrated syndet detergent bars for use in personal wash, fabric wash and hard surface cleaning. A process for preparing aerated, ultra low-density cast-dehydrated detergent bars wherein the air is entrained in the bars after rigidification and shaping the product is also provided.

Owner:UNILEVER NV

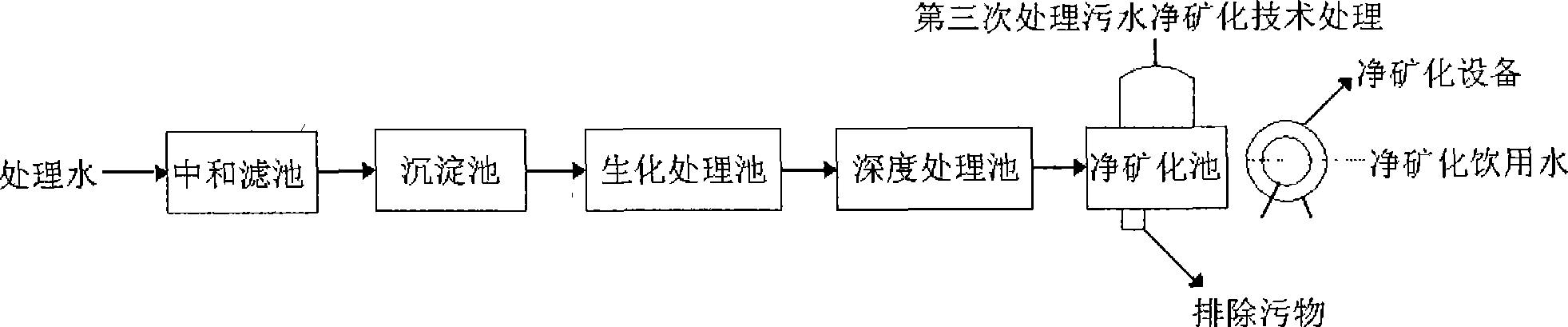

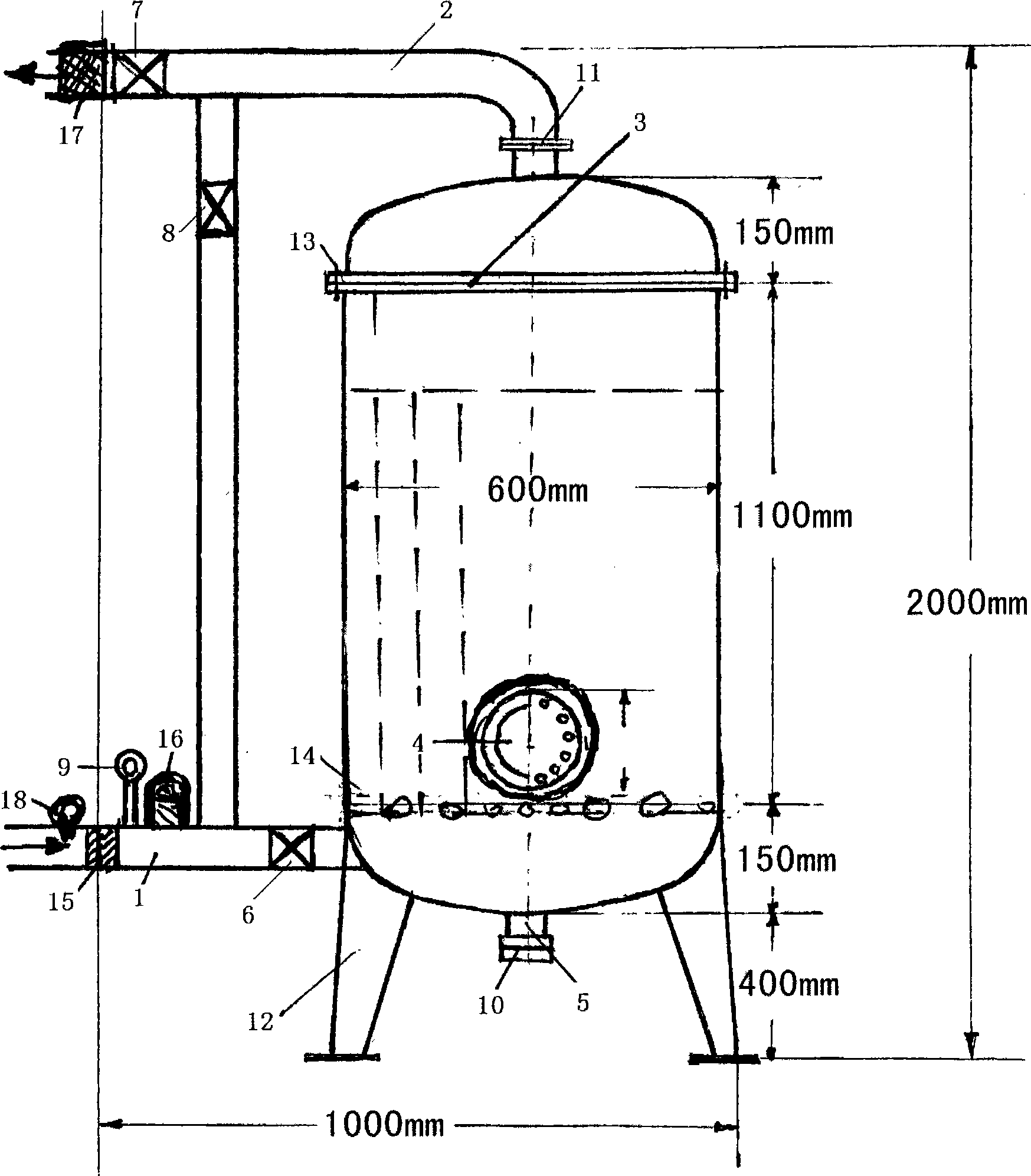

Environment-friendly clean mineralized drinking water and sewage disposal method as well as material and equipment thereof

InactiveCN101497018AWith environmental fitness functionWide range of technology applicationsOther chemical processesEnergy based wastewater treatmentCarcinogenNon toxicity

The invention provides a method, a material and equipment for treating environmental protection purification mineralization drinking water and sewage. The material comprises the following raw materials in portion by mass: 35 to 50 portions of opal which is taken as a main material, and the auxiliary materials: 12.5 to 25 portions of zeolite, 3 to 12.5 portions of medical stone, 1 to 3.5 portions of Qingtian stone, 5 to 6.8 portions of silver-carrying active carbon and 3 to 6 portions of coal gangue. The invention can achieve the aims of purifying and sterilizing water in high efficiency and deeply mineralizing water. Practical tests prove that: by purifying and mineralizing water, various harmful substances, virus, bacteria, cancerogenous substances, anion synthetic detergents, sulfates, chlorides, cyanides, arsenic, mercury, cadmium, hexavalent chrome, silver, nitrates, chloroforms, carbon tetrachloride, iron, manganese, copper, chlorophenothane, benzene hexachloride, phenols and the like in the water can be removed, and the effective removal rate is between 80 and 90 percent. The method, the material and the equipment have the advantages of non-toxicity, odorlessness, no side effect, greenness and environmental protection, and achieve the aims of purifying and sterilizing the water in high efficiency and deeply mineralizing the water.

Owner:许君德

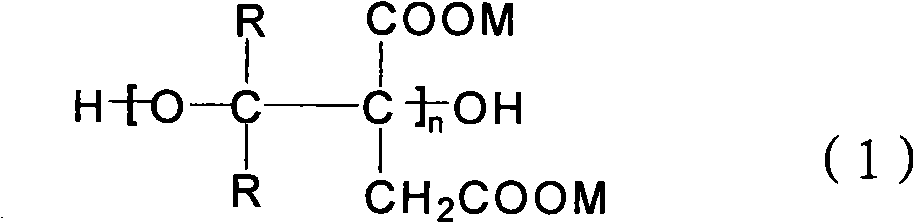

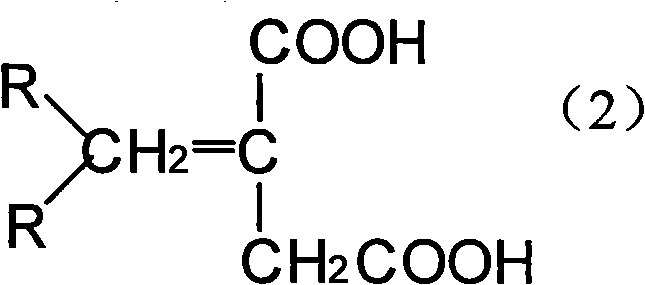

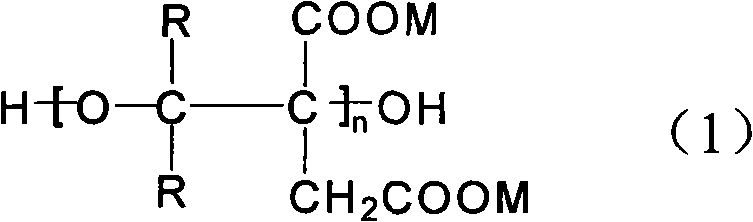

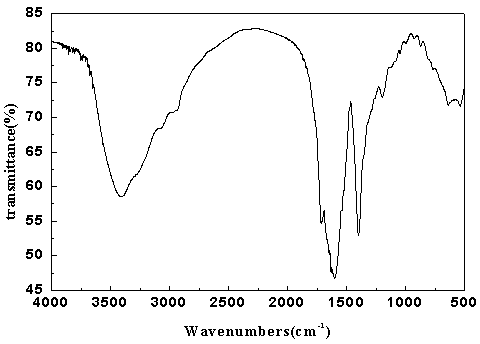

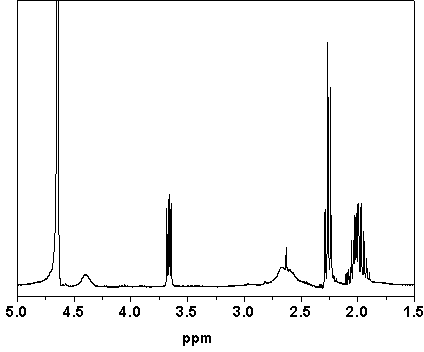

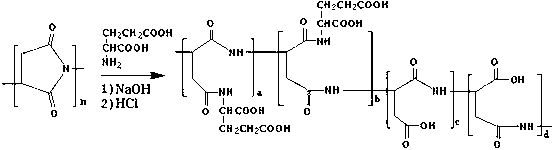

Biodegradable phosphorus-free detergent additive and preparation method thereof

InactiveCN103255006AHigh chelating and dispersing performanceIncreased side chain charge densityOrganic detergent compounding agentsNon-surface-active detergent compositionsSolubilitySide chain

The present invention discloses a biodegradable phosphorus-free detergent additive and a preparation method thereof. Specifically the biodegradable phosphorus-free detergent additive is a polyaspartic acid grafted copolymer with a side chain containing a glutamic acid group, wherein maleic anhydride and urea are adopted as starting raw materials, reactions such as amination and heat condensation polymerization are performed to produce polysuccinimide, the polysuccinimide and sodium glutamate are subjected to an aminolysis reaction, and then neutralization, cold precipitation, filtration, concentration and drying are performed to obtain the polyaspartic acid grafted copolymer with the side chain containing the glutamic acid group. According to the present invention, the molecular structure of the polyaspartic acid grafted copolymer does not contain phosphorus, and the polyaspartic acid grafted copolymer has characteristics of no toxicity, good biodegradability, good water solubility, good calcium chelation performance and good calcium dispersion performance, and is a highly efficient and environmental-protection synthesis detergent additive.

Owner:GUANGDONG UNIV OF TECH

Method for producing phosphorus-free pulpy detergent by comprehensively utilizing 4A zeolite and production liquid waste thereof

InactiveCN102676326AReduce dosageAchieving zero emissionsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSynthetic DetergentsChemistry

The invention relates to a method for producing phosphorus-free pulpy detergent by comprehensively utilizing 4A zeolite and production liquid waste generated during the production of the 4A zeolite. In order to overcome a washing liquid waste discharging defect generated when the 4A zeolite is produced in the prior art, the method disclosed by the invention is characterized in that surplus liquidwaste in the 4A zeolite production in the prior art can be completely and comprehensively utilized, so that the zero discharge of the production liquid waste is realized, the energy consumption is lowered, raw material NaOH and water resource are saved, equipment investment is saved, and the production cost is lowered. With the method disclosed by the invention, three steps of filtering, washing and drying are omitted from the steps of burdening, blending glue, crystalizing, filtering, washing, drying, obtaining a finished product and synthetizing detergent ingredients in the production process of the detergent accessory ingredient 4A zeolite in the prior art, and the production process is simplified into the following steps of burdening, blending glue, crystalizing, obtaining the semi-finished product slurry of 4A zeolite, obtaining a phosphorus-free pulpy detergent ingredient and obtaining a finished product of the phosphorus-free pulpy detergent.

Owner:UNIV OF JINAN

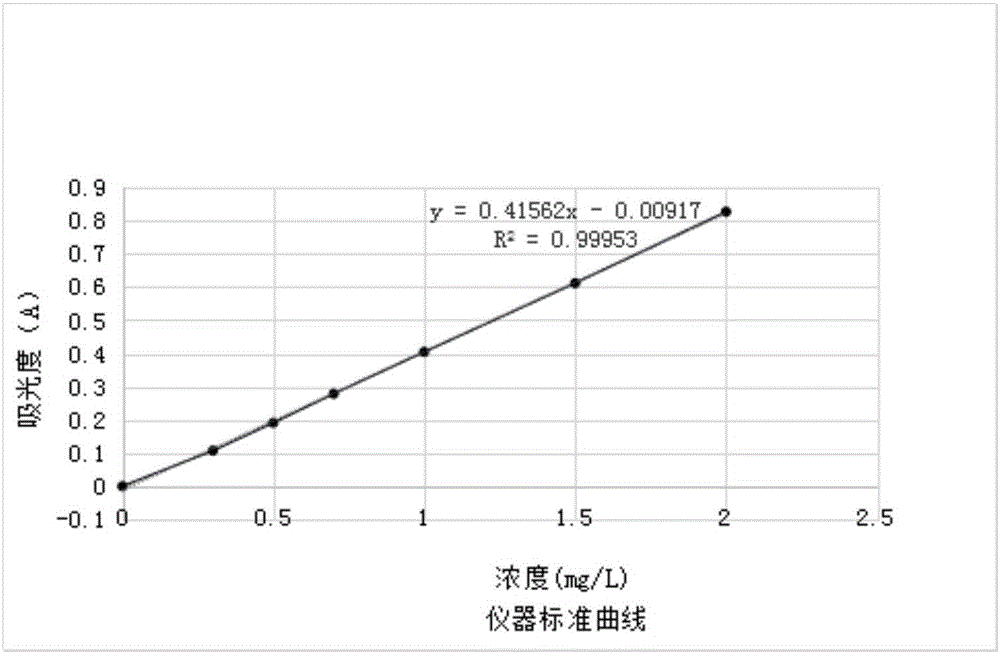

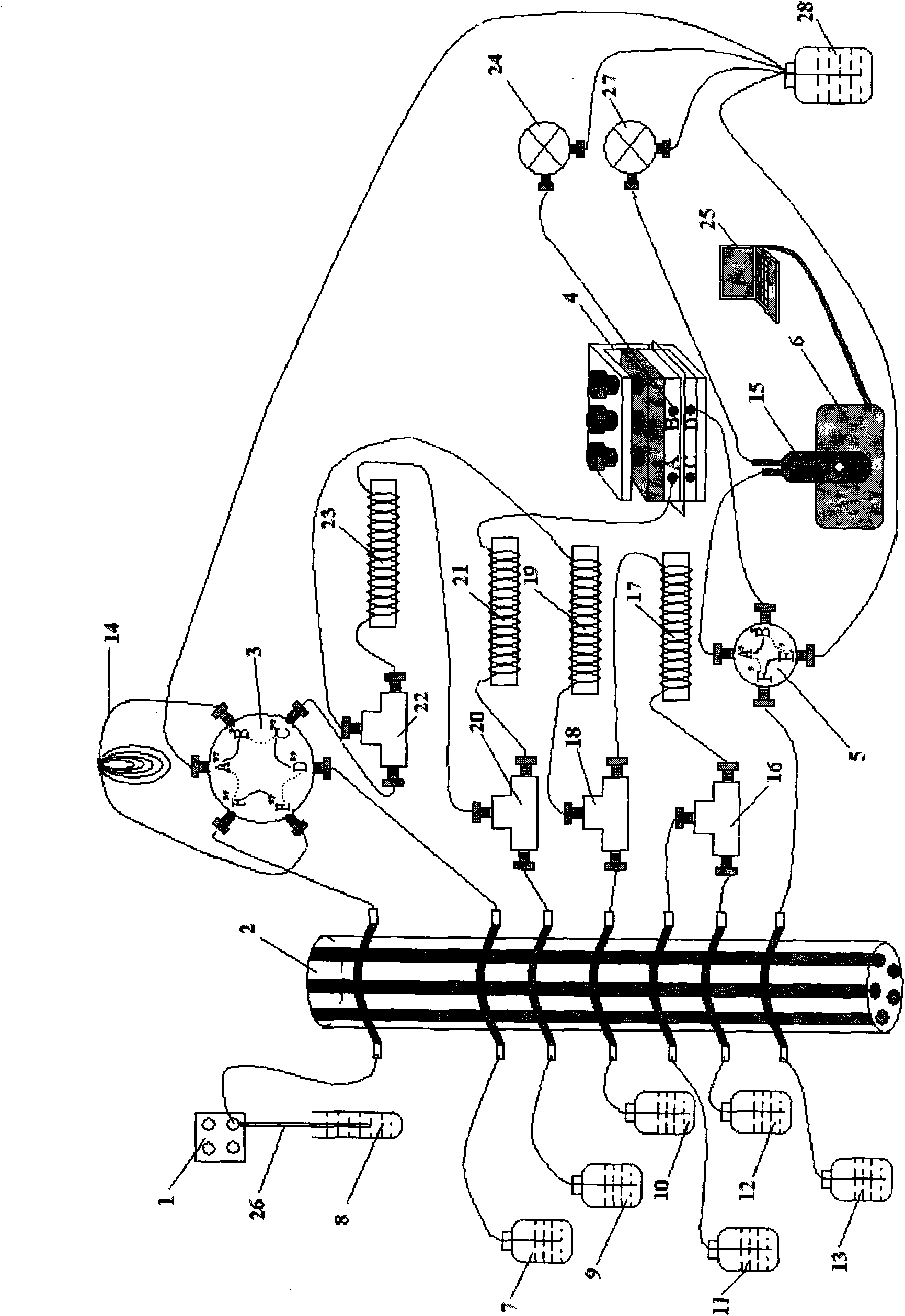

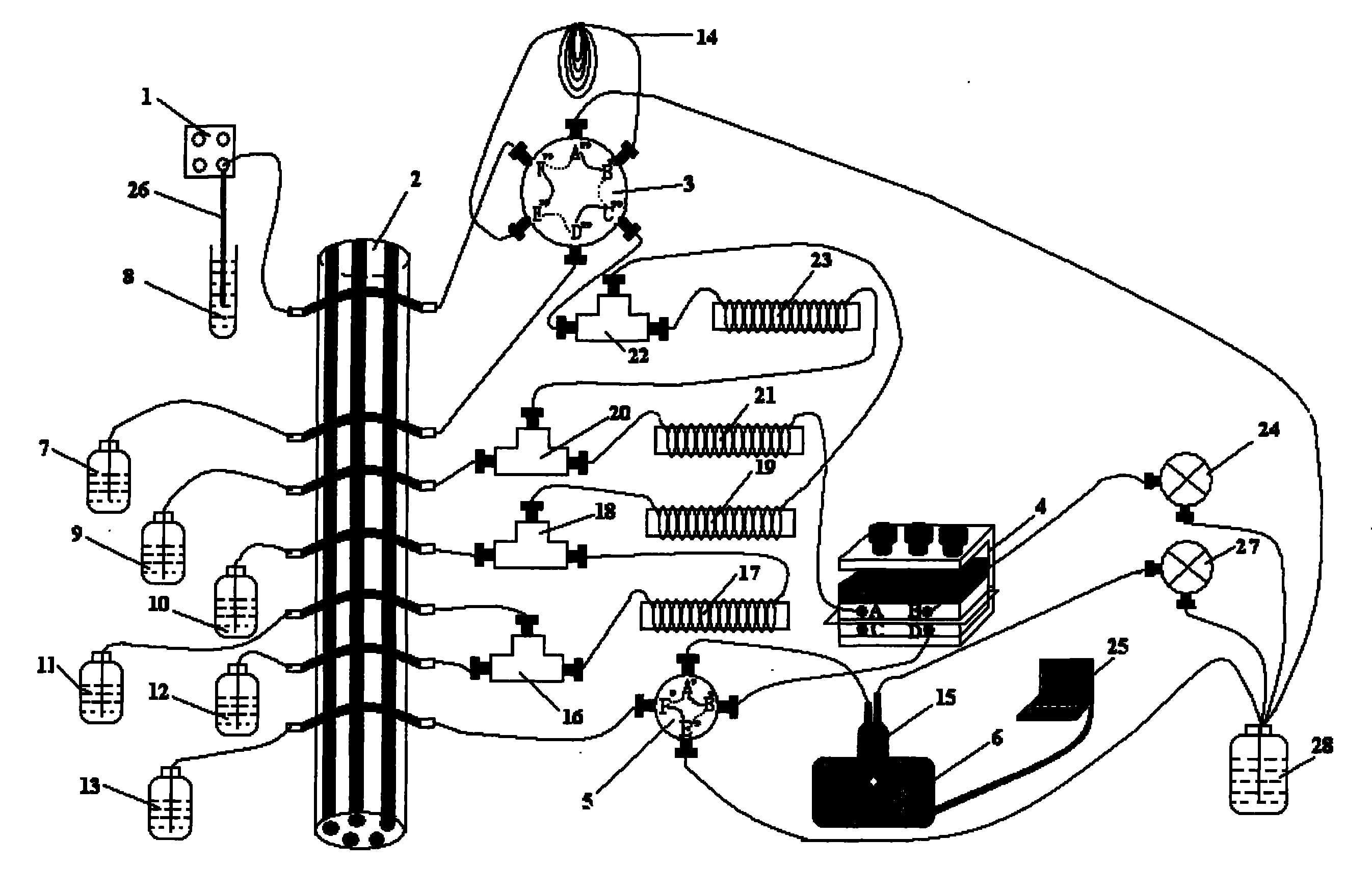

Flowing injection colorimetric measurement method and device for anion synthetic detergent content of water

InactiveCN101776582AConvenient online automatic detectionFast online automatic detectionColor/spectral properties measurementsAmmonium ferrous sulfateFlow through cell

The invention provides a flowing injection colorimetric measurement method for an anion synthetic detergent content of water. The method comprises the following steps of: (1) mixing acid aqueous solution of naphthisodiazine and buffer solution in a first knotted reactor of which the length of capillaries is 0.5 to 10 meters; (2) mixing the obtained mixed solution and aqueous solution of ammonium ferrous sulfate in a second knotted reactor of which the length of capillaries is 0.5 to 10 meters; (3) mixing the mixed solution obtained by the step(2) and solution to be detected in a fourth knotted reactor of which the length of capillaries is 0.9 to 9 meters; (4) mixing the mixed solution obtained by the step(3) and extraction solution of chloroform in a third knotted reactor of which the length of capillaries is 0.5 to 9 meters; (5) separating the obtained mixed solution by an on-line extraction module, making the extraction solution enter a flow through cell and mapping the generated spectrogram; and (6) comparing the drawn sample spectrogram with the standard sample spectrogram, and calculating the anion synthetic detergent content of the sample.

Owner:BEIJING JITIAN INSTR CO LTD

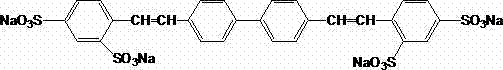

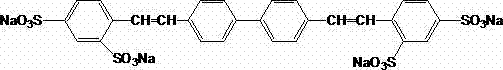

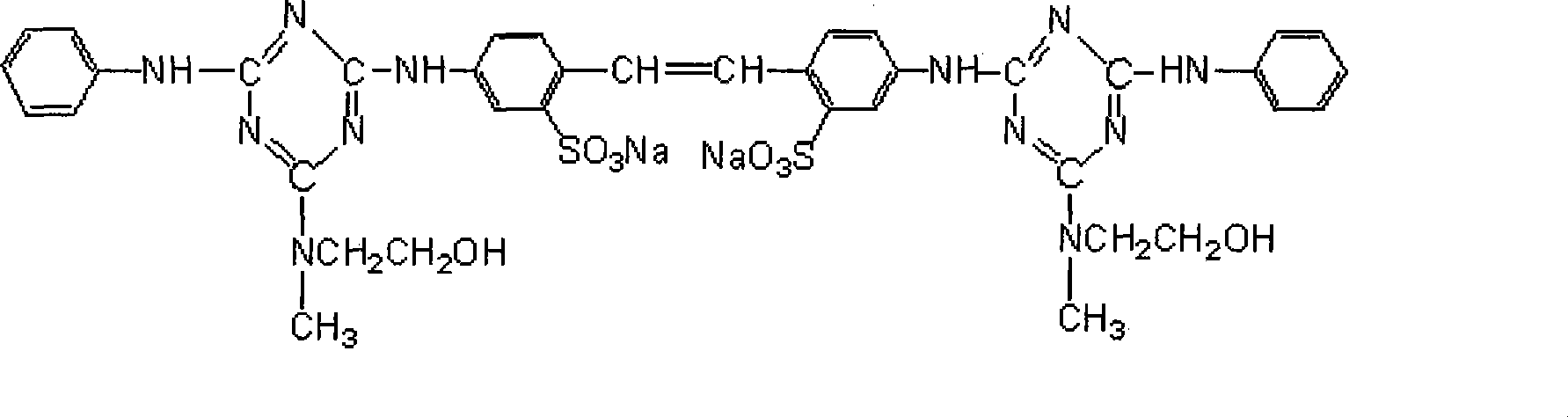

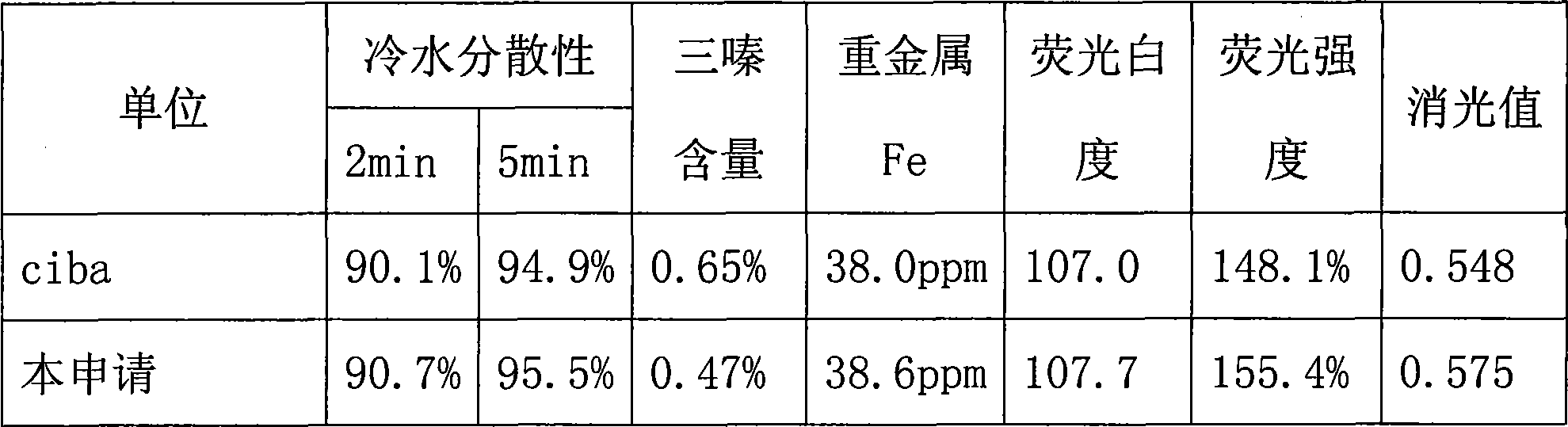

Mixed toluylene biphenyl type fluorescent whitening agent and preparation method thereof

InactiveCN102924971AStable storageImprove solubilityStyryl dyesSynthetic DetergentsDimethyl formamide

The invention discloses a mixed toluylene biphenyl type fluorescent whitening agent and a preparation method thereof, relates to a fluorescent whitening agent used in industries of printing and dyeing, synthetic detergent and the like, and solves the problems that the current product is easy to layer and liquid is easy to precipitate. The method comprises the following steps of dissolving 4, 4'-diethoxy phosphonic methyl diphenyl, o-sulfonic acid sodium benzaldehyde and 2, 4-disulfonic acid sodium benzaldehyde into an organic solvent DMF (Dimethyl Formamide), dropwise adding sodium methoxide at 43-47 DEG C to react, and conducting a thermal reaction for a period of time; warming, reducing pressure, and steaming out the solvent DMF; and after a filter cake is dissolved and filtered with water to remove impurities, the filter cake is concentrated and filtered and dried to obtain a finished product. The product can be stored stably and has high solubility. After the product is put for 100 days at the room temperature, the product is still clear, colorless and deposit-free. During the temperature of 25 DEG C, the solubility in water can achieve 38 g / L.

Owner:山西青山化工有限公司

Marine fish oil washing product and preparation method thereof

InactiveCN104962408AImprove decontamination abilityPromote degradationSoap detergents with organic compounding agentsAlkali/ammonium soap compositionsGreen matterMarine fish

The invention discloses a marine fish oil washing product and a preparation method thereof. The washing product is prepared in the steps of taking marine fish oil as a basic component and taking strong base, washing additive, essential oil, preservative, antibacterial agent, deionized water and the like as auxiliary components and mixing the marine fish oil and the strong base to have saponification in a given ratio under appropriate condition, and the natural environment-friendly and healthy washing product based on the marine fish oil is formed by adopting an optimized process. Raw materials in the marine fish oil washing product are environment-friendly substances, non-toxic, harmless and healthy, and the harm of synthetic washing agent to washed articles and residue of the synthetic washing agent in water can be avoided; in addition, the washing product is high in decontamination capacity, convenient to use, pollution-free, high in degradation capacity, free from producing secondary pollution and favorable for the environment-friendly rapid development.

Owner:ZHEJIANG OCEAN UNIV

Method for scouring and bleaching silk fabric

ActiveCN103882680AQuality improvementFeel goodBiochemical fibre treatmentDry-cleaning apparatus for textilesEthylene diamine tetra aceticAlkaline protease

The invention discloses a method for scouring and bleaching a silk fabric. The method comprises the following steps: performing pretreatment, namely soaking the silk fabric in a first scouring tank, wherein 1-2g / L of sodium carbonate and 0.2-0.5g / L of penetrating agent JFC are contained in the first scouring tank; scouring, namely putting the silk fabric in a second scouring tank, wherein 8-15g / L of silk scouring agent, 1-3g / L of synthetic detergent, 1-3g / L of liquid sodium silicate and 0.2-0.5g / L of liquid sodium hydroxide are contained in the second scouring tank; washing, namely putting the scoured silk fabric into a third scouring tank for washing; performing enzyme scouring, namely putting the washed silk fabric into a fourth scouring tank, wherein 0.4-1g / L of alkaline protease, 0.5-1g / L of ethylene diamine tetraacetic acid and 1-3g / L of sodium carbonate are contained in the fourth scouring tank; bleaching, namely putting the silk fabric subjected to enzyme scouring into a fifth scouring tank, wherein 6-10g / L of peroxysulphate and 2-4g / L of sodium pyrophosphate are contained in the fifth scouring tank; and repeatedly washing, airing or drying, and finishing scouring and bleaching of the silk fabric.

Owner:浙江钱皇网络科技股份有限公司

Method for producing phosphorus-free pulpy detergent by comprehensively utilizing 4A zeolite and production liquid waste thereof

InactiveCN102676326BAchieving zero emissionsSave waterInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsLiquid wasteFiltration

The invention relates to a method for producing phosphorus-free pulpy detergent by comprehensively utilizing 4A zeolite and production liquid waste generated during the production of the 4A zeolite. In order to overcome a washing liquid waste discharging defect generated when the 4A zeolite is produced in the prior art, the method disclosed by the invention is characterized in that surplus liquid waste in the 4A zeolite production in the prior art can be completely and comprehensively utilized, so that the zero discharge of the production liquid waste is realized, the energy consumption is lowered, raw material NaOH and water resource are saved, equipment investment is saved, and the production cost is lowered. With the method disclosed by the invention, three steps of filtering, washing and drying are omitted from the steps of burdening, blending glue, crystalizing, filtering, washing, drying, obtaining a finished product and synthetizing detergent ingredients in the production process of the detergent accessory ingredient 4A zeolite in the prior art, and the production process is simplified into the following steps of burdening, blending glue, crystalizing, obtaining the semi-finished product slurry of 4A zeolite, obtaining a phosphorus-free pulpy detergent ingredient and obtaining a finished product of the phosphorus-free pulpy detergent.

Owner:UNIV OF JINAN

Process for producing fluorescent whitening agent 5BM

InactiveCN101429343AReduce pollutionImproved cold water dispersibilityStyryl dyesLuminescent compositionsIce waterWhitening Agents

The invention relates to a method for preparing a synthetic detergent and a ring whitening agent for printing industry, in particular to a method for preparing a fluorescent whitening agent 5BM. The method solves the problem that the product obtained through the prior method for processing and preparing the fluorescent whitening agent 5BM has low quality. The method comprises the following steps: cyanuric chloride and DSD acid are put into a reaction kettle and are added with ice water; the PH value of the mixture of the ice water, the cyanuric chloride and the DSD acid is regulated to between 1 and 1.5; the hydrochloric acid generated in the reaction is neutralized; the PH value is regulated to between 6 and 6.5; after the amido value of the DSD acid disappears, the hydrochloric acid is added with aniline; after the aniline disappears, N-methylethanolamine is added to the mixture; the PH value is finally regulated to between 10 and 12; the mixture is cooled to the temperature of 5 DEG C through the ice water so that a target product is precipitated out; and the target product is filtered, dried and pulverized to obtain the 5BM product.

Owner:山西青山化工有限公司

Method of laundering clothes and detergent composition therefor

InactiveUS20040082490A1Reduce the burden onReduce usageInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsInorganic saltsSynthetic Detergents

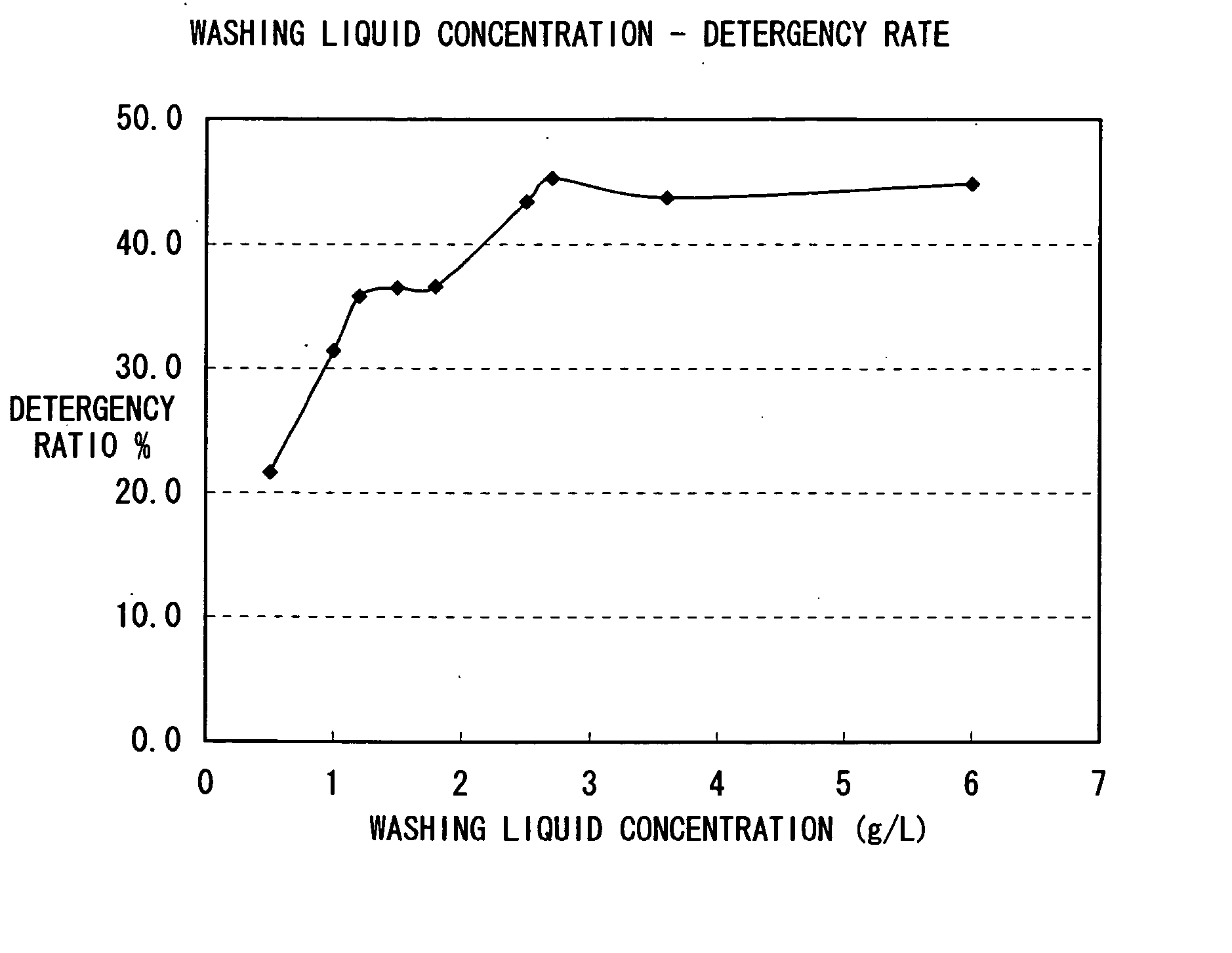

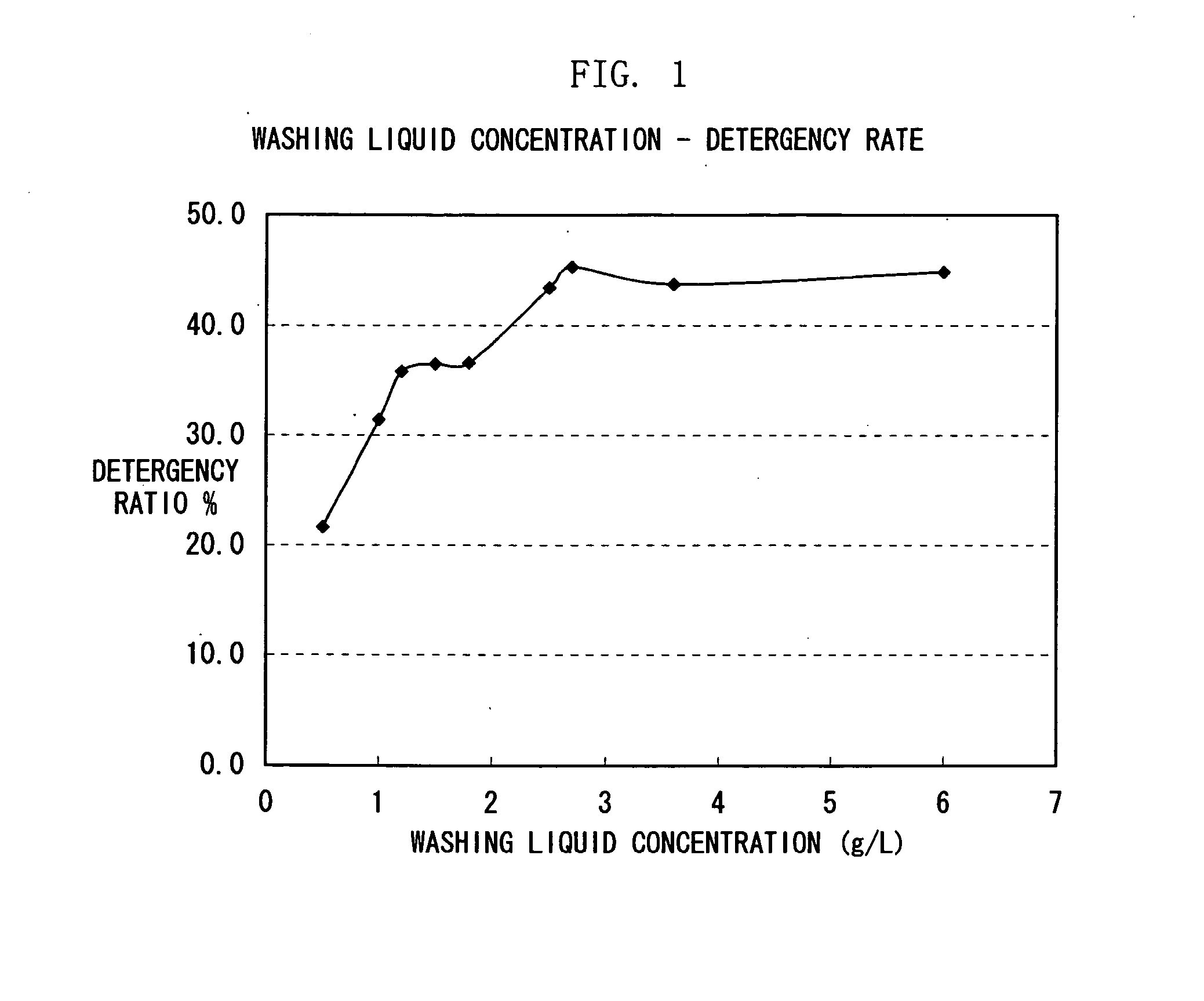

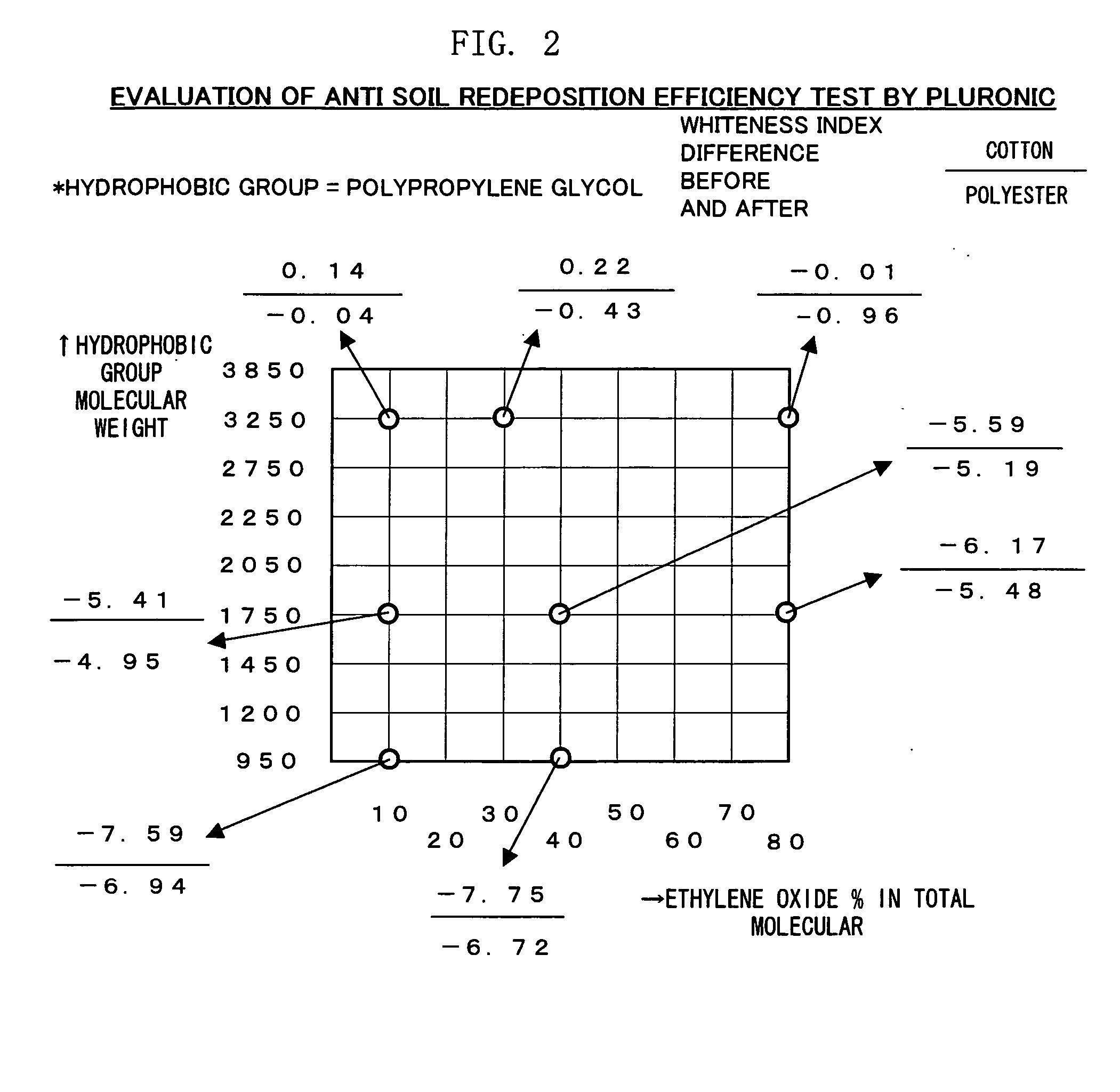

Washing is carried out using a detergent composition having main detergency obtained through an alkaline inorganic salt and further including at least an anti-soil redeposition agent. There is provided a clothes washing method, and a detergent composition for the same, that uses a detergent having detergency equivalent to or greater than that of synthetic detergents containing a surface active agent as the main detergency ingredient and also has excellent anti-soil redeposition efficiency wherein main detergency is obtained by an alkaline inorganic salt.

Owner:MIZ CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com