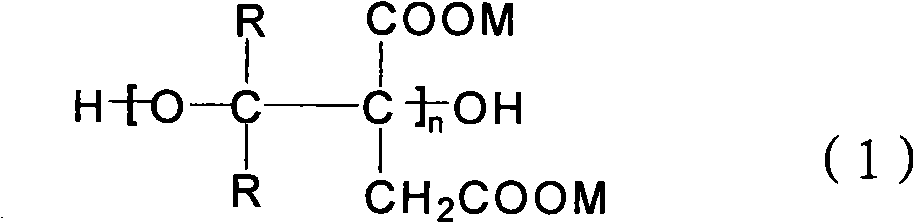

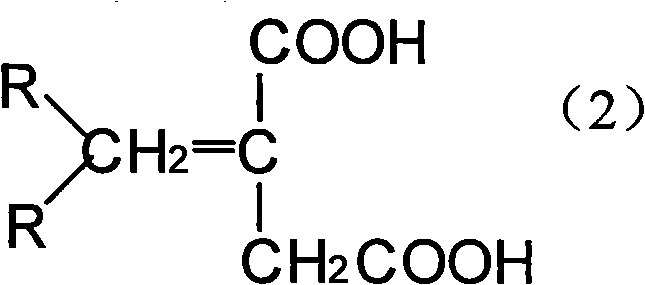

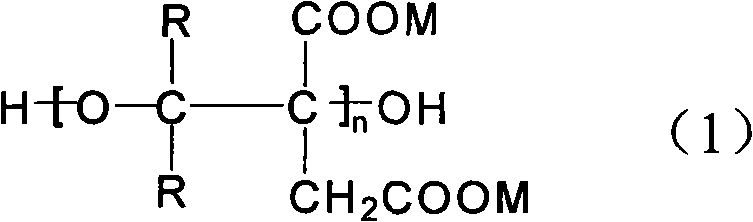

Poly-epoxy itaconic acid, preparing method and uses thereof

A technology of polyepoxy itaconic acid and polyepoxy coating, which is used in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Take a 500mL four-necked flask equipped with a thermometer, a dropping funnel, a magnetic stirrer, a reflux tube, and a pH meter, first add 0.25mol of itaconic acid and 12mol of deionized water, and slowly add 48% sodium hydroxide solution under stirring to adjust pH = 3, then add 0.00125 mol of sodium tungstate dihydrate, slowly raise the temperature to 60°C after adding, drop 0.30 mol of 30% hydrogen peroxide in 1 hour at this temperature, and keep it at 55-65 during the dropping process ℃, keep warm and react for 4hrs after dripping, then add 0.0125mol calcium hydroxide, and adjust pH=11 with sodium hydroxide, react at 80℃ for 8 hours, then cool and filter to obtain polyepoxy sodium itaconate (calcium) The light yellow viscous liquid, yield 90.3%. The product was purified by cation exchange resin 001*7 (produced by Jiangyin Organic Chemical Factory, the same below), and the average molecular weight of the polymer was analyzed and measured to be 1200 (average degree o...

Embodiment 2

[0051] Take a 500mL four-necked flask equipped with a thermometer, a dropping funnel, a magnetic stirrer, a reflux tube, and a pH meter, first add 0.25mol of itaconic acid and 12mol of deionized water, and slowly add 48% sodium hydroxide solution under stirring to adjust pH = 4, then add 0.00125 mol of sodium tungstate dihydrate, slowly raise the temperature to 60°C after adding, drop 0.30 mol of 30% hydrogen peroxide in 1 hour at this temperature, and keep it at 55-65 during the dropping process ℃, keep warm and react for 4hrs after dripping, then add 0.0125mol calcium hydroxide, and adjust pH=12 with sodium hydroxide, react at 80℃ for 8 hours, then cool and filter to obtain polyepoxy sodium itaconate (calcium) The light yellow viscous liquid, yield 92.2%. The product was purified by cationic exchange resin, and the average molecular weight of the polymer was determined to be 1100 (average degree of polymerization n=8.5).

Embodiment 3

[0053] Take a 500mL four-necked flask equipped with a thermometer, a dropping funnel, a magnetic stirrer, a reflux tube, and a pH meter, first add 0.25mol of itaconic acid and 12mol of deionized water, and slowly add 48% sodium hydroxide solution under stirring to adjust pH = 5, then add 0.00125 mol of sodium tungstate dihydrate, slowly raise the temperature to 60°C after adding, drop 0.30 mol of 30% hydrogen peroxide in 1 hour at this temperature, and keep it at 55-65 during the dropping process ℃, keep warm for 4hrs after dripping, then add 0.0125mol calcium carbonate, and adjust pH=13 with sodium hydroxide, react for 8 hours at 80℃, then cool and filter to obtain polyepoxy sodium itaconate (calcium) Pale yellow viscous liquid, yield 94.5%. The product was purified by cation exchange resin, and the average molecular weight of the polymer was determined to be 1300 (average degree of polymerization n=10).

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com