Method for preparing building material products through hydration-carbonation coupling technique

A technology of building materials and combined technology, applied in the field of building materials, can solve problems such as limitations, and achieve the effect of excellent product performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Select calcium carbide slag discharged by a company in Shandong and fly ash from a company in Dalian to mix at a ratio of 1:2, add an appropriate amount of water (water-solid ratio 0.25), and make a 240mm×120mm×55mm brick, and resist compression after 2 days of hydration curing The strength reaches 6.8MPa, at a concentration of 25% CO 2 After 12 hours of carbonation and curing in the gas, the weight gain rate reaches 15.2%, and the compressive strength of the hydration-carbonation brick reaches 17.6MPa.

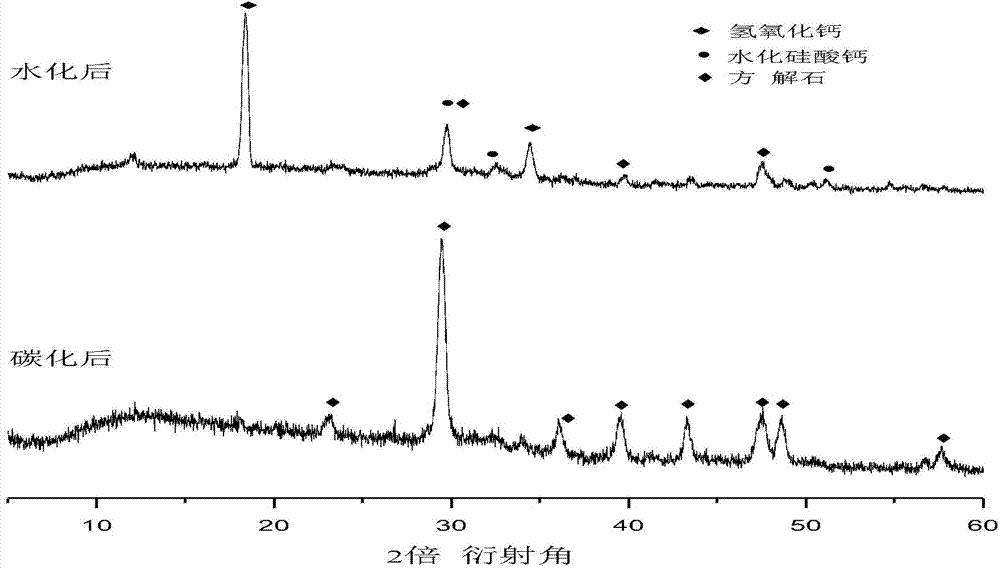

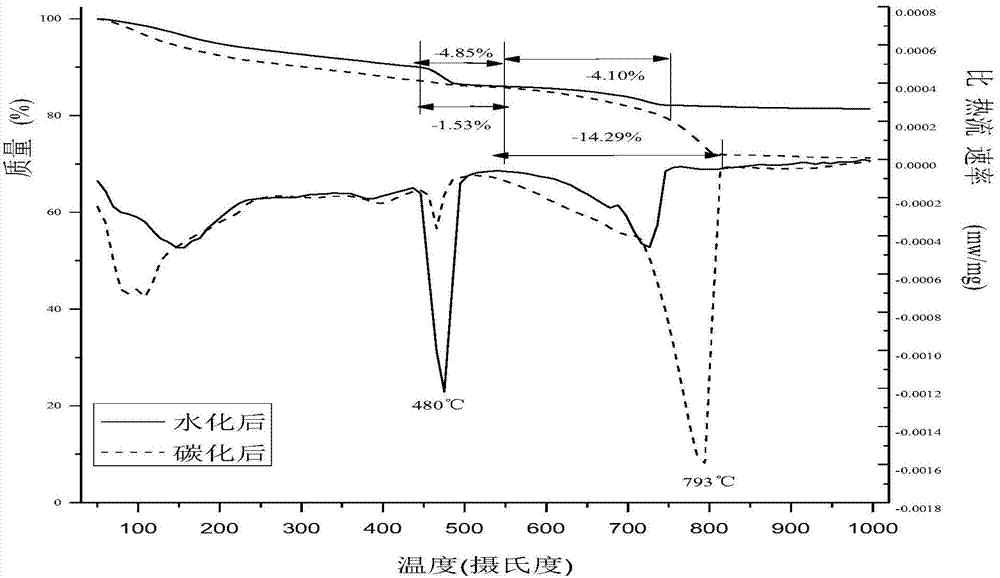

[0032] figure 1 It is calcium carbide slag, the XRD pattern of fly ash after hydration for 3 days and carbonization for 12 hours. It can be seen from the pattern that after hydration for 3 days, in addition to remaining a large amount of calcium hydroxide, C-S-H is also formed. After carbonization for 12 hours, the X-ray diffraction peak of calcium hydroxide disappeared, the X-ray diffraction peak of C-S-H weakened, and the content of calcium carbonate increased obvio...

Embodiment 2

[0035] The calcium carbide slag discharged from a company in Shandong and the slag from a company in Dalian were mixed at a ratio of 1:2, and an appropriate amount of water (water-solid ratio 0.20) was added to make bricks of 240mm×120mm×55mm. After 3 days of hydration curing, the compressive strength reached 6.2MPa, at a concentration of 50% CO 2 After carbonation and curing in gas for 12 hours, the weight gain rate reached 18.2%, and the compressive strength of the hydration-carbonation brick reached 25.6MPa.

Embodiment 3

[0037] Select calcium carbide slag discharged from a company in Shandong and steel slag from a company in Dalian to mix at a ratio of 1:3, add an appropriate amount of water (water-solid ratio 0.20), and make bricks with a size of 240mm×120mm×55mm. After 3 days of hydration curing, the compressive strength reaches 8.6MPa, at a concentration of 25% CO 2 After 12 hours of carbonation and curing in the gas, the weight gain rate reaches 20.3%, and the compressive strength of the hydration-carbonation brick reaches 32.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com