Patents

Literature

2616 results about "Calcium carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium carbide, also known as calcium acetylide, is a chemical compound with the chemical formula of CaC₂. Its main use industrially is in the production of acetylene and calcium cyanamide. The pure material is colorless, however pieces of technical-grade calcium carbide are grey or brown and consist of about 80–85% of CaC₂ (the rest is CaO (calcium oxide), Ca₃P₂ (calcium phosphide), CaS (calcium sulfide), Ca₃N₂ (calcium nitride), SiC (silicon carbide), etc.). In the presence of trace moisture, technical-grade calcium carbide emits an unpleasant odor reminiscent of garlic.

Calcium carbide production method

The invention relates to a carbide preparation method belonging to the field of carbide preparation. The conventional carbide preparation technology adopts block materials and electric arc as a heat-supply, while the preparation method according to the invention adopts powdery carbon-containing materials and powdery calcium-containing materials, and the combustion of partial carbon-containing materials and oxygen-containing gas as a heat-supply at 1700-2300 DEG C to prepare carbide, wherein the carbon-containing materials is coal or coke, calcium-containing materials is calcium carbonate, calcium oxide, calcium hydroxide or carbide slag, the granularity of the carbon-containing materials and calcium-containing materials is less than 1mm, and the quality ratio is 0.5-3:1. The oxygen-containing gas for combustion is oxygen, oxygen-enriched air or air. The method solves the problems of high energy consumption and high pollution of the carbide preparation and has advantages of wide choice scope of materials, high energy utilization rate, continuous operation and large production capacity. The technology also couples with the process of carbon-containing materials coking and calcium-containing materials calcining, preheats the materials to 500-1500 DEG C utilizing the combustion of by-products CO of the carbide preparation and the assistant fuel, thereby further reducing the oxygen and energy consumption of the carbide preparation.

Owner:BEIJING UNIV OF CHEM TECH

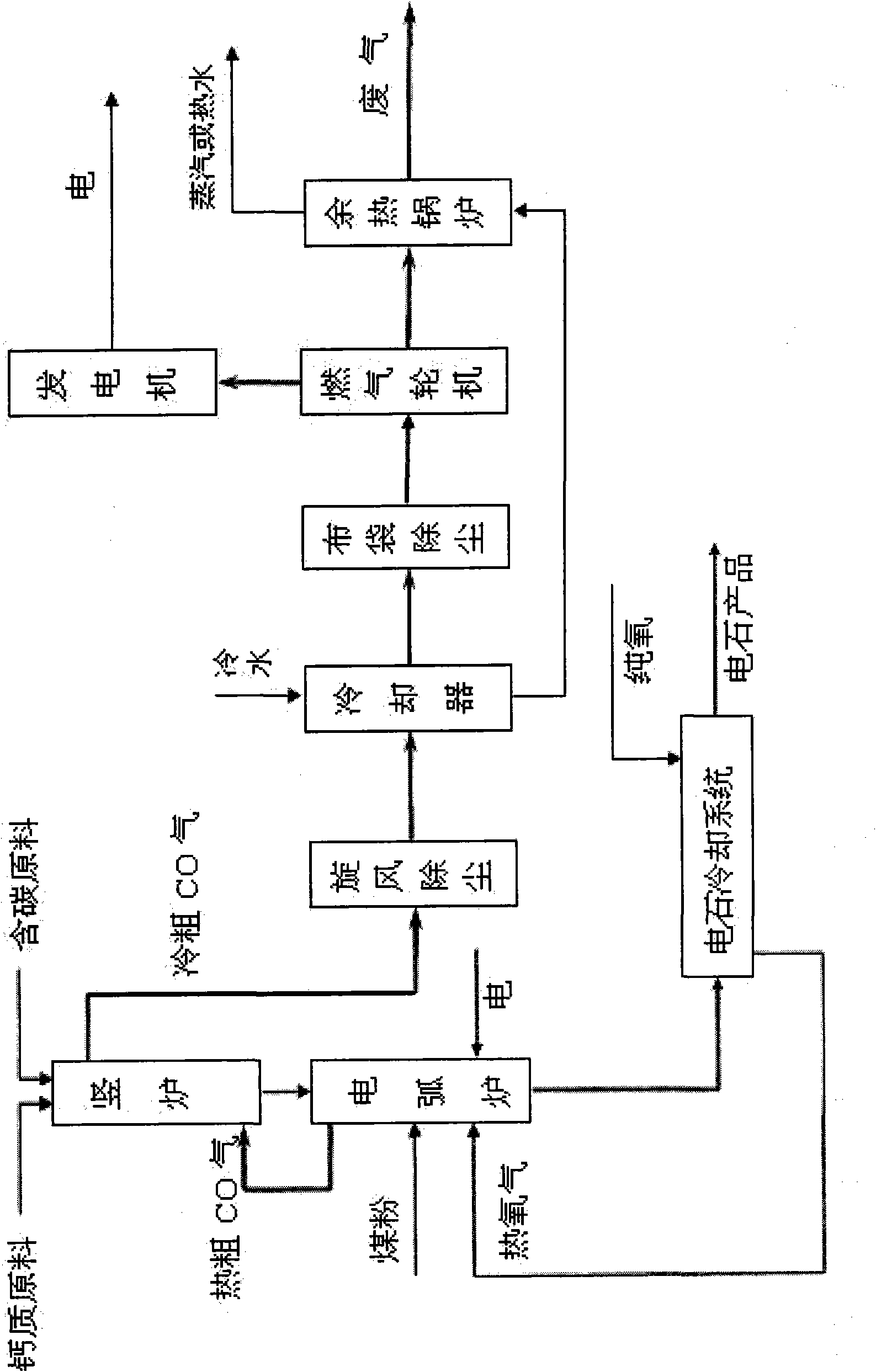

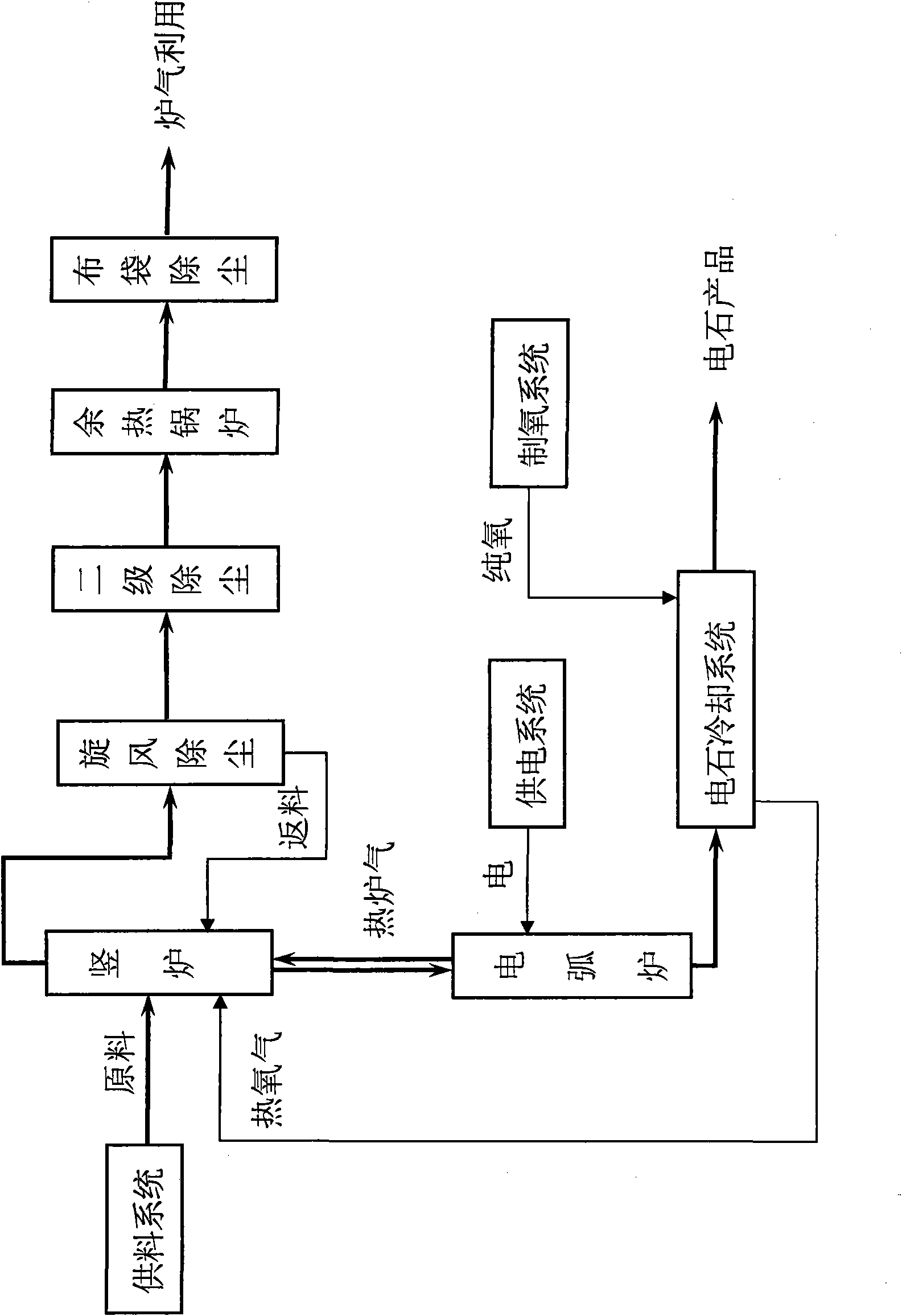

Technique for producing calcium carbide and cogeneration by two-stage method and device thereof

InactiveCN101830464AQuality assuranceReduce consumptionEnergy inputCalcium carbideElectric arc furnaceCogeneration

The invention relates to a technique for producing calcium carbide and cogeneration by a two-stage method and a device thereof. The technique comprises the following steps: after being preheated at a shaft furnace at the upper section, massive carbonous raw material and massive calcic raw material enter an arc furnace at the lower section; while blowing oxygen and coal powder and supplying heat by the electrode in the arc furnace, the raw materials react to produce calcium carbide; and the produced calcium carbide furnace gas is dedusted and combusted by a gas turbine so as to drive the generator to generate power, and sensible heat of exhaust gas is recycled by an exhaust-heat boiler, thereby centrally supplying heat to cities and towns. The invention has the advantages of capability of continuous production, high yield, low investment, low energy consumption, high calcium carbide grade, energy saving, high efficiency and investment saving, and realizes coordinated development of economy, environment and energy sources.

Owner:山西亿众公用事业有限公司

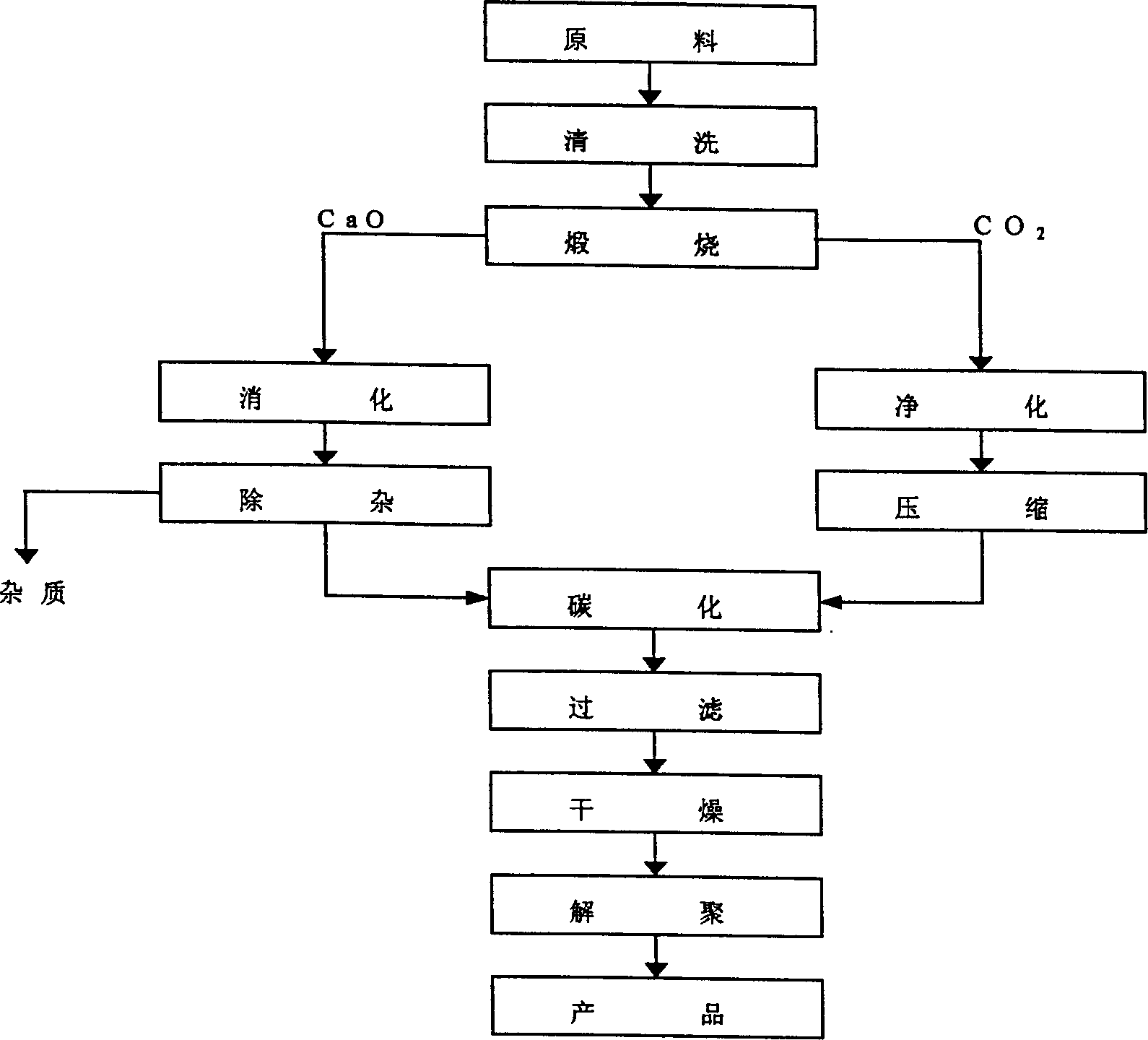

Method for preparing high-white ness nano calcium carbide

InactiveCN1438279AIncrease productivityImprove product qualityInorganic pigment treatmentDepolymerizationFiltration

The invention is a method of preparing high-whiteness degree nano CaCO3. It uses limestone, CaCO3 content>98%, whiteness degree>92% as raw material, washes to calcine into CaO, then adds in the cleaned hot water to get Ca(OH)2, prepares milk of lime by purifying, the concentration 2-10%, uses the cleaned flue gas of CaCO3, calcinations as CO2 source, makes the solution of milk of lime react with CO2 in special synthesis reactor, and adds in crystal-shaped controlling agent to control the time, temperature and stirring speed of the reaction, and after the reaction is finished, makes filtration, drying and depolymerization on the solution. The whole course adopts the technique of controlling whiteness degree.

Owner:NORTHEASTERN UNIV +1

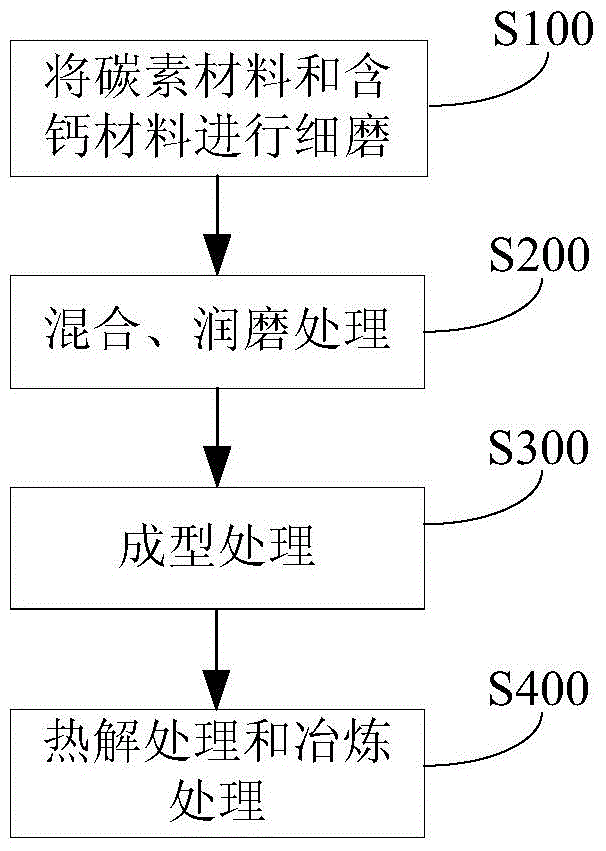

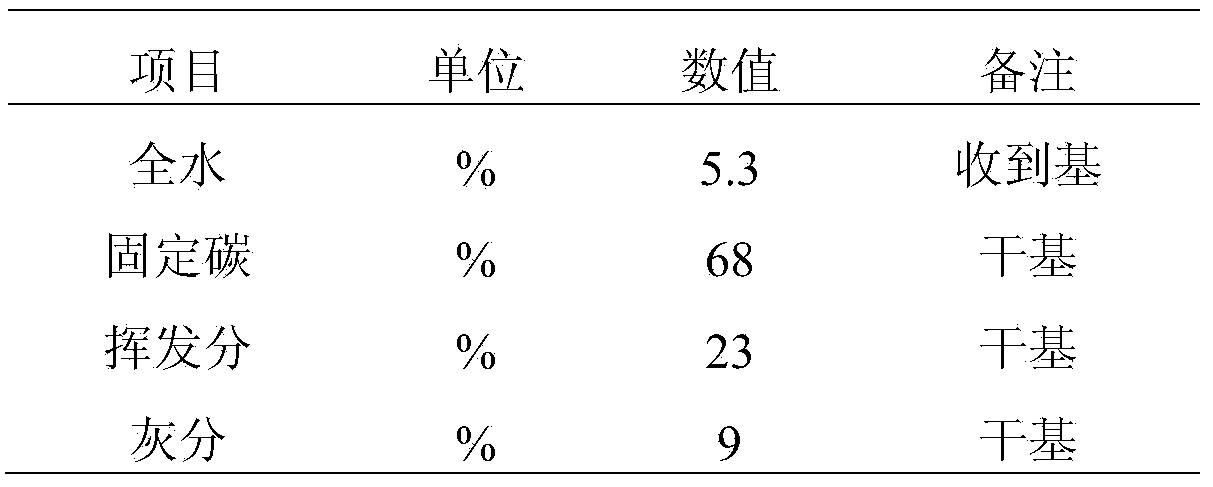

Method for preparing solid calcium carbide

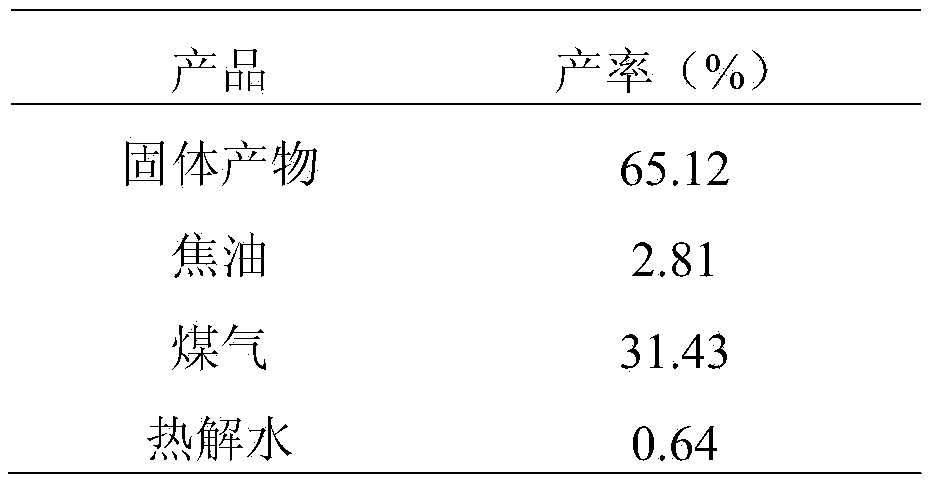

ActiveCN104556036AIncrease productivityReduce manufacturing costCalcium carbideMixed materialsWet grinding

The invention discloses a method for preparing solid calcium carbide. The method comprises the following steps: (1), finely grinding a carbon material and a calcareous material so as to respectively obtain a carbon material powder and a calcareous material powder; (2), mixing and then wet-grinding a mixture containing the carbon material powder and the calcareous material powder, and a bonding agent so as to obtain a mixed material; (3), performing molding on the mixed material so as to obtain material balls; (4), successively distributing the material balls in a rotary hearth furnace, successively pyrolyzing the material balls in a pyrolysis furnace chamber of a radiant tube with the rotation of the bottom of the rotary hearth furnace, and smelting the pyrolyzed material balls in the chamber of a smelting furnace under a temperature of 1200-1380 DEG C, so as to finally obtain solid calcium carbide, coal gas and coal tar. The method disclosed by the invention can be used for preparing solid calcium carbide, the coal gas and the coal tar at the same time, and the production cost of the calcium carbide is obviously lowered.

Owner:SHENWU TECH GRP CO LTD

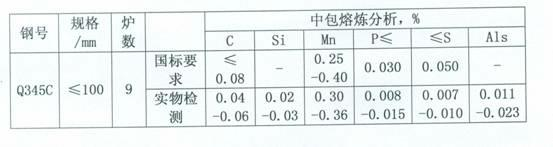

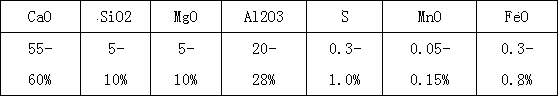

Low-carbon low-silicon high-quality carbon structural steel and production method thereof

The invention discloses a low-carbon low-silicon high-quality carbon structural steel and a production method thereof. The structural steel comprises the following chemical components in percentage by weight: less than or equal to 0.06% of C, less than or equal to 0.03% of Si, 0.35-0.50% of Mn, less than or equal to 0.018% of P, less than or equal to 0.012% of S, 0.005-0.025% of Als, and the balance of Fe and residual elements. The production method disclosed by the invention comprises the following steps: KR (knotted reactor) hot metal pretreatment of high-quality hot metal, processing with a top-bottom combined blowing converter, pre-deoxidization of molten steel, alloying of molten steel, final deoxidization process of molten steel, argon blowing process, continuous casting and casting blank stack cooling. In order to ensure the high quality of molten steel smelted with converter, the good quality of raw and auxiliary materials used in the converter smelting process must be guaranteed, wherein the raw and auxiliary materials include hot metal, waste steel, lime, light-burnt magnesium ball, ore, alloy, deoxidizer, aluminum wire, refining slag, calcium carbide, fluorite and covering agent. The invention has the advantages of simple process, strong adaptability and relatively low cost.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

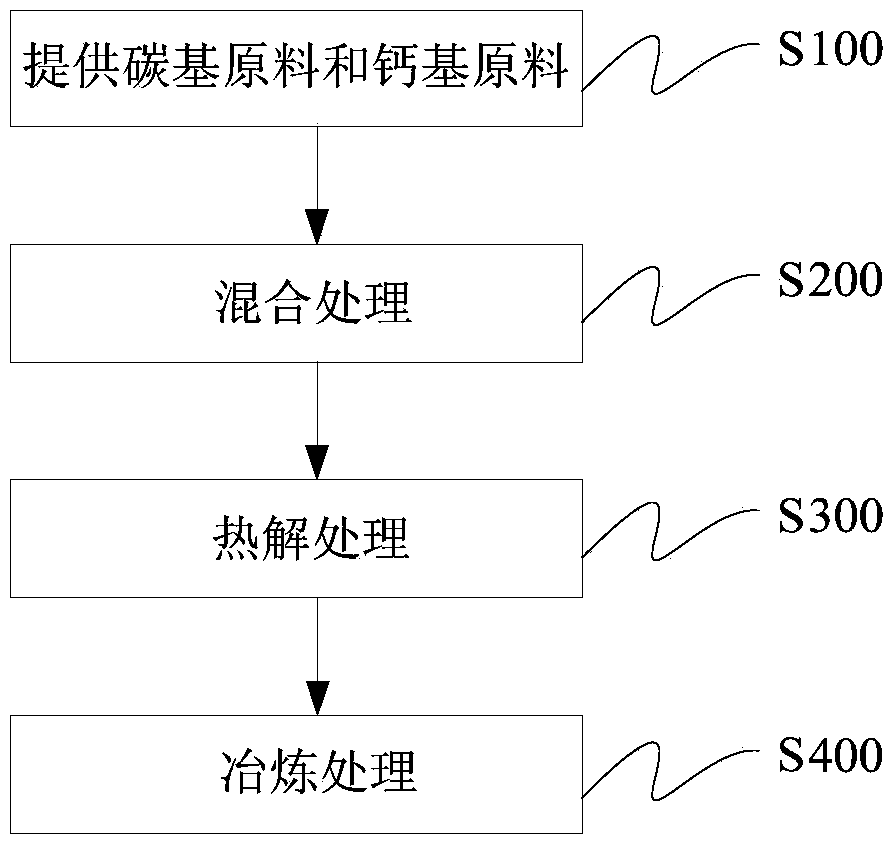

Method for preparing calcium carbide

The invention discloses a method for preparing calcium carbide, which comprises the following steps: providing carbon-base particles and calcium-base particles, wherein the average particle size of the carbon-base particles and calcium-base particles is not greater than 5 millimeters, and the water content is lower than 5%; mixing the carbon-base particles and calcium-base particles to obtain a mixture; pyrolyzing the mixture to obtain high-quality tar, high heating value gas and a pyrolytic solid product, wherein the pyrolytic solid product contains quicklime and one of coke, semicoke and carbon black; and feeding the pyrolytic solid product into a gas smelting furnace at the temperature of not lower than 450 DEG C to perform smelting in the gas smelting furnace, thereby obtaining the calcium carbide. Thus, the method can further enhance the heat utilization ratio and production efficiency, lower the production cost and reduce the energy consumption and pollution.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

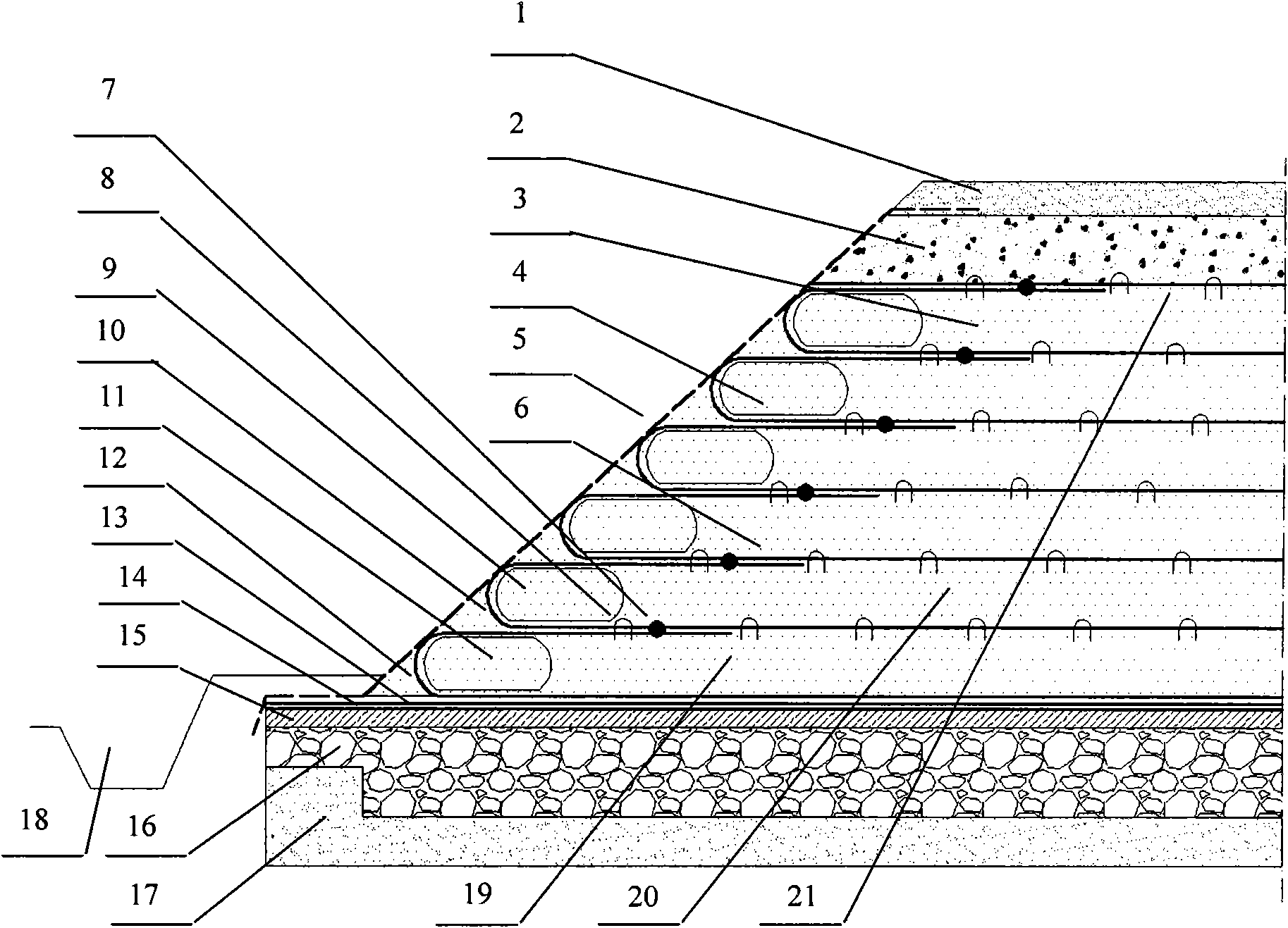

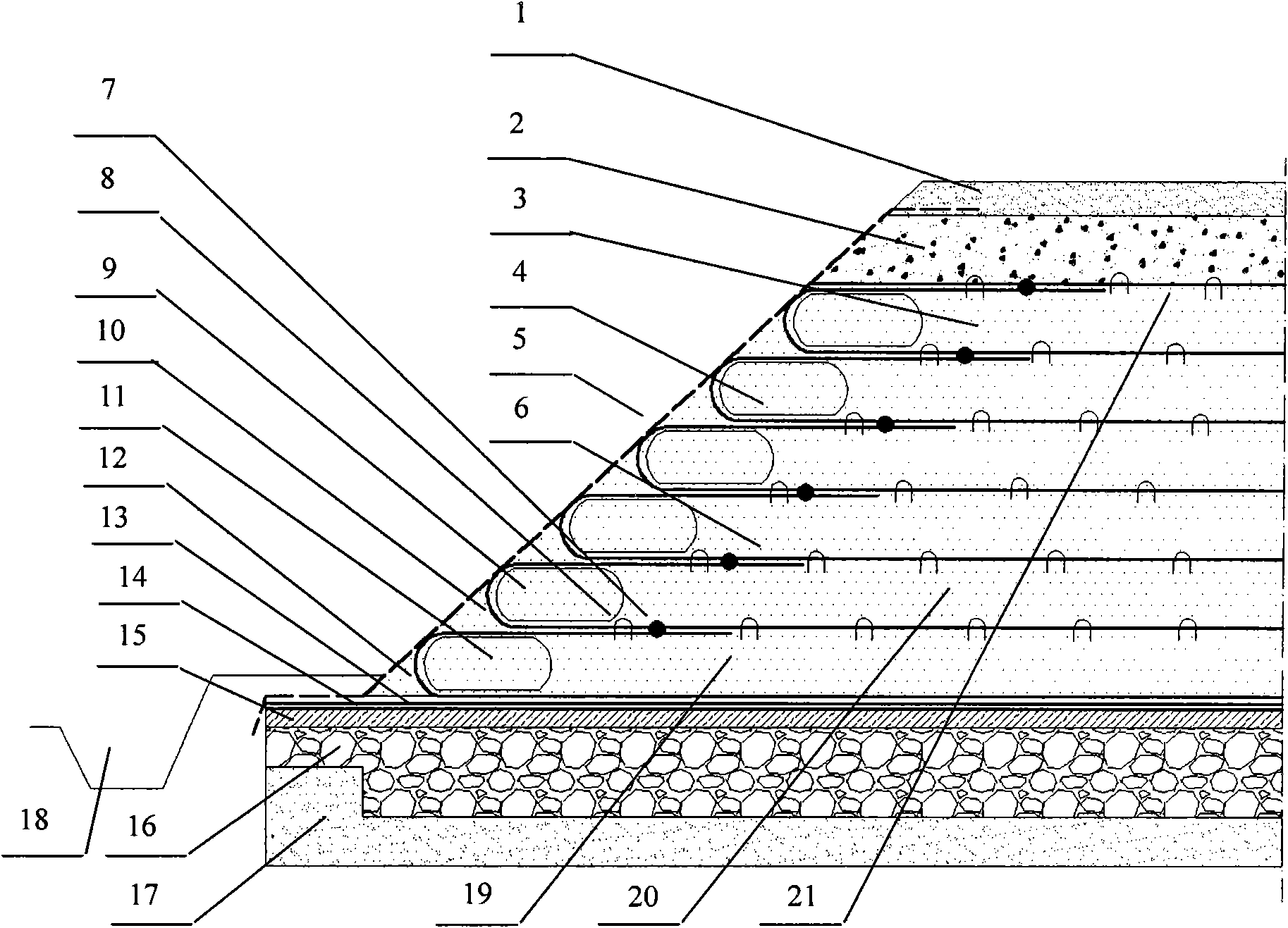

Protection method for improving salt expansion or dissolution sink of salty soil

InactiveCN101851894ARealize comprehensive utilizationFix stability issuesExcavationsRoads maintainenceCrushed stoneProtection system

The invention relates to a protection method for improving the salt expansion or the dissolution sink of salty soil, which is characterized in that calcium carbide ash, fly ash, zeolite and salty soil are adopted, are mixed and stirred according to the volume ratio of 1:1:1:9 and are used for the filler improvement of a road embankment, broken stone and gravel are adopted as a buffer layer, bitumen, geomembranes and geotextiles are adopted as a partition layer, a geogrid reinforcement improved filler is adopted, a sack filled with greening grass seeds, shrub seeds and improved soil is adopted to press the toe of a slope, and a side slope adopts the protection of the companion planting of grass and shrub and the combination of a hanging net. The invention has the following advantages of: (1) adjusting measures to local conditions, making full use of the salty soil, saving resources, utilizing wastes, such as the fly ash and the like, and realizing the utilization of the wastes; (2) adopting a structural protection system formed by the improved salty soil and a geogrid together and solving the problems of stability and uniform settlement of a fill slope; and (3) combining the grass and the shrub, reaching the ecological requirement on one hand, solidifying a sloping surface on the other hand and preventing the water and soil loss and the salt expansion or the dissolution sink. The invention is suitable for the problem of engineering improvement of the salty soil in civil engineering and can be used for the engineering of the filling of a highway embankment, the protection of the side slope, the construction of a foundation, the improvement treatment of a foundation pit and the like.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

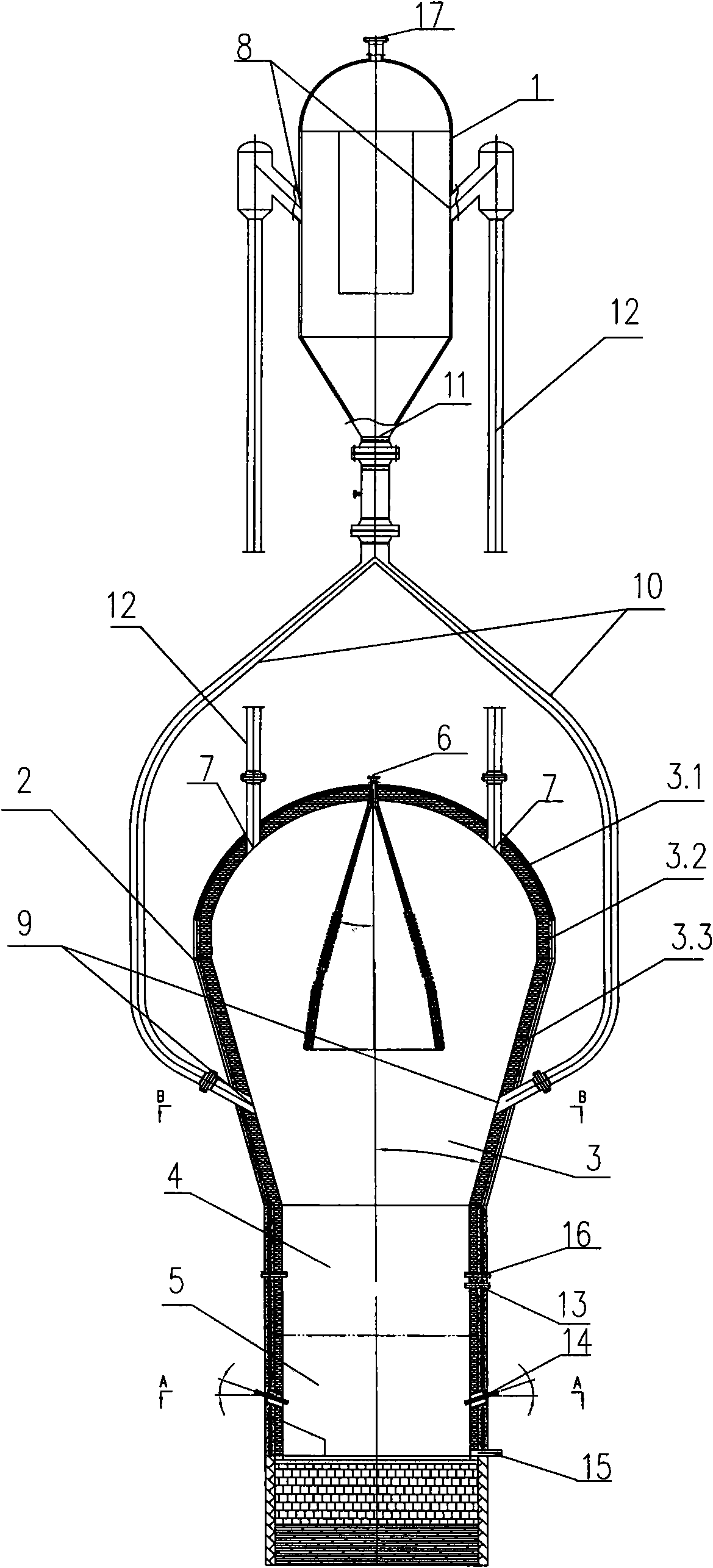

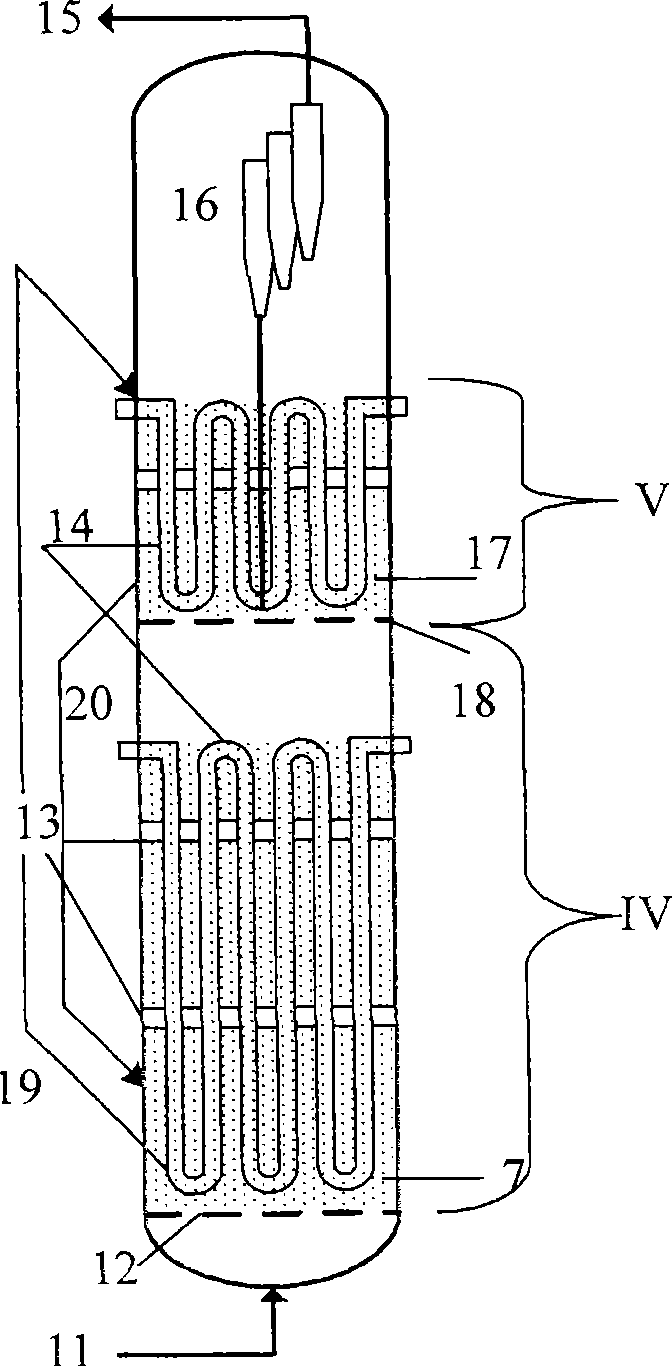

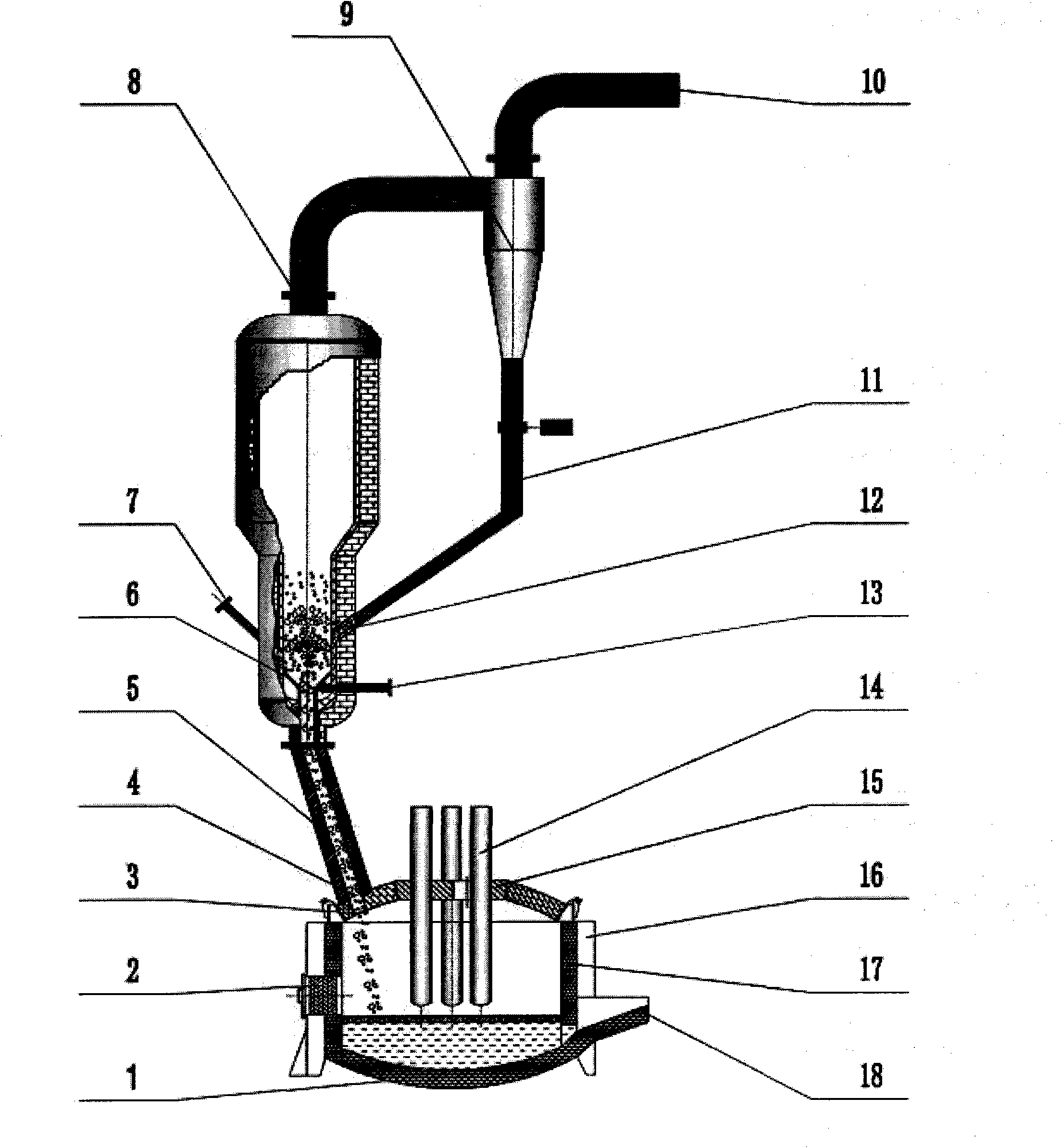

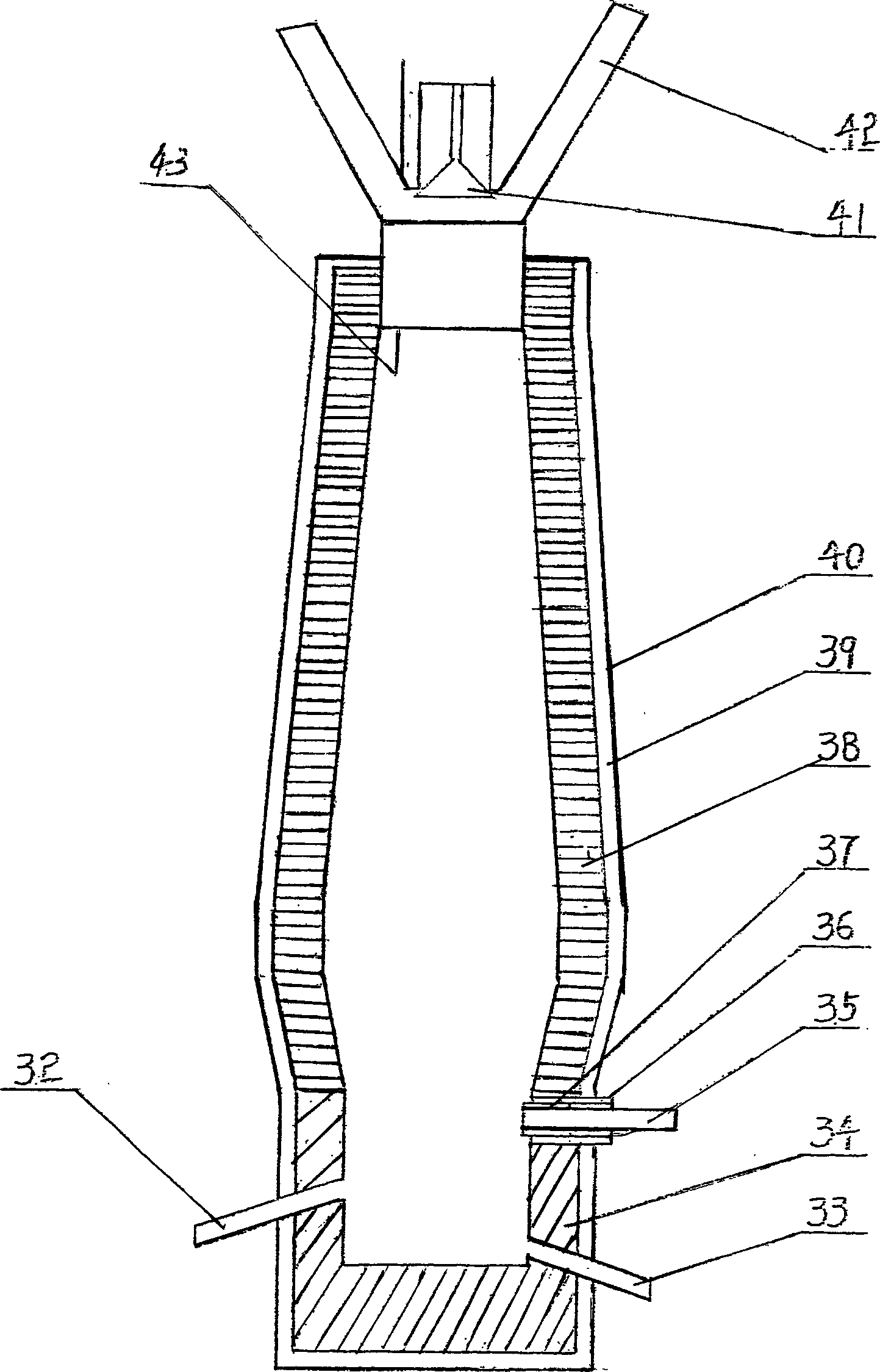

Method for preparing calcium carbide and synthesis gas through thermal oxidation reaction and calcium carbide reactor

ActiveCN102153085ACompact structureLess investmentCalcium carbideGranular/pulverulent flues gasificationGas solidCalcium carbide

The invention discloses a method for preparing calcium carbide and a synthesis gas through a thermal oxidation reaction and a calcium carbide reactor, which solve the problems of great raw material consumption, more equipment, large investment, complex process, less CO byproduct quantity and difficult industrial application of the traditional calcium carbide preparation method. The calcium carbide reactor comprises a gas-solid separator, a closed reacting furnace is arranged below the gas-solid separator, and the closed reacting furnace comprises an upper preheating chamber, a middle vaporizing chamber and a lower reaction chamber. In the method provided by the invention, a special calcium carbide reactor is adopted; when calcium carbide is synthesized, a large amount of produced CO can be industrially applied; and thus, the method has low production and operation costs, low energy consumption, great by-product gas quantity and a broad market prospect.

Owner:WUHUAN ENG +1

A method for producing desulfurizer from calcium carbide slag

ActiveCN102266715AReduce in quantityReduce energy consumptionSolid waste disposalDispersed particle separationForeign matterSlag

The invention provides a method for producing a desulfurizing agent from carbide slag, which is classified as a dry process and a wet process according to the source of carbide slag; the carbide slag produced by dry acetylene production serves as raw material of the dry process; carbide slag slurry produced by wet acetylene production serves as raw material of the wet process; the dry process comprises the following steps of: 1) cyclone separation: removing heavy foreign matters from the carbide slag and carbide slag particles with fineness larger than 4mm; 2) raised dust filtration and separation at negative pressure: intercepting carbide slag particles with fineness larger than 0.04mm in a solid state at one time, and reducing the water content to less than 5%; 3) drying: controlling the water content to be between 1% and 3% to obtain dry powder of the desulfurizing agent; and (4) pulping: adding water accounting for 15%-30% of the final solid content and stirring evenly to obtain a liquid desulfurizer. The wet process comprises the following steps of: 1) sedimentation of washing sand: primarily removing large foreign matters and silicon iron particles from the carbide slag slurry; 2) selective filtration: removing solid particles with fineness larger than 0.04mm through controlling the thickness of a filter cake; 3) filtration and concentration: controlling solid content to be between 15% and 30% to obtain liquid desulfurizing agent; and 4) dewatering and drying: finally controlling the water content to be between 1% and 3% to obtain the desulfurizing agent.

Owner:肖郁春

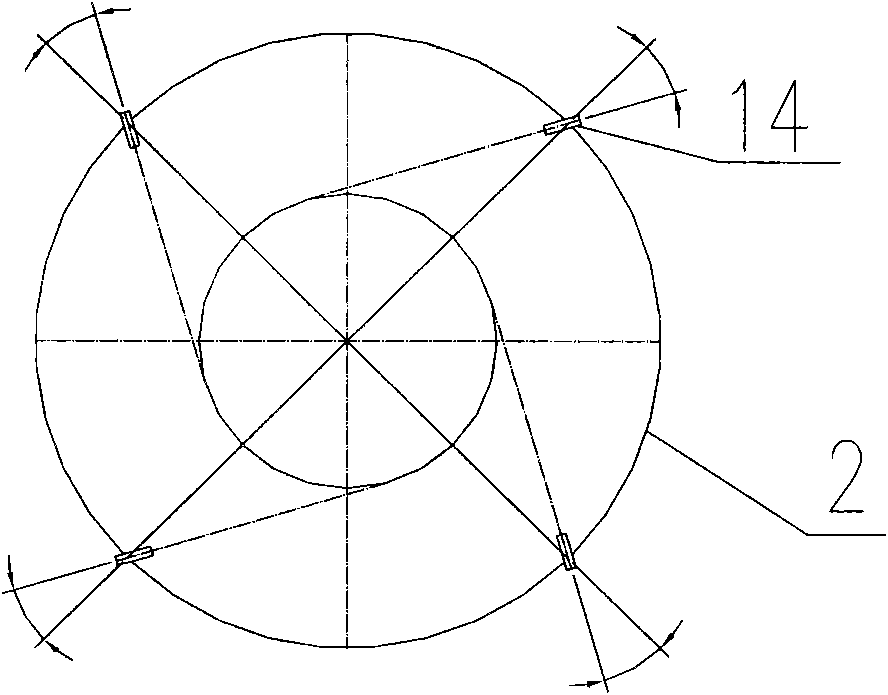

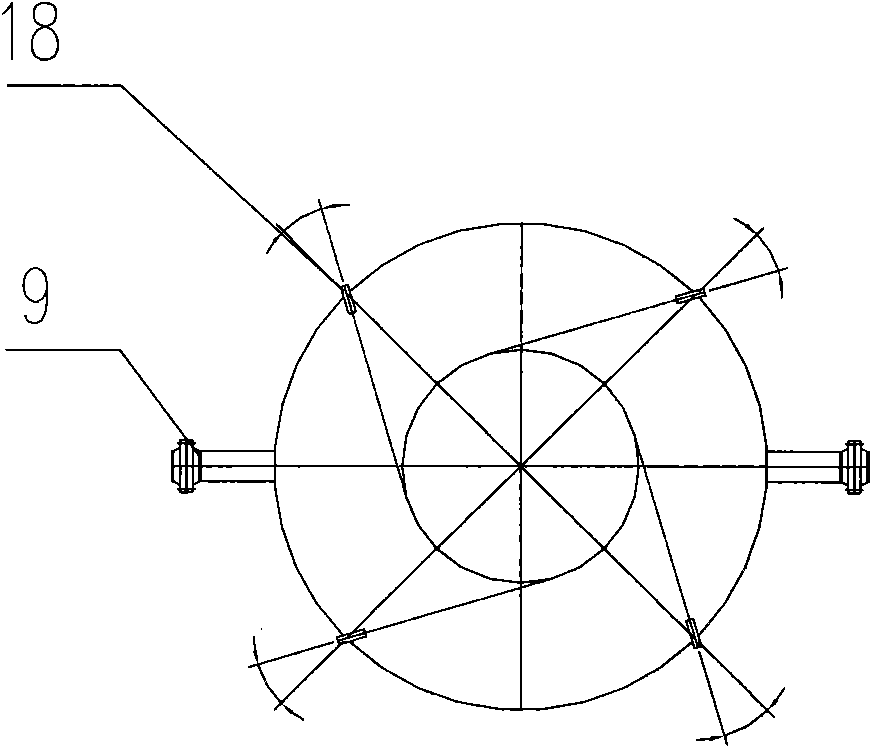

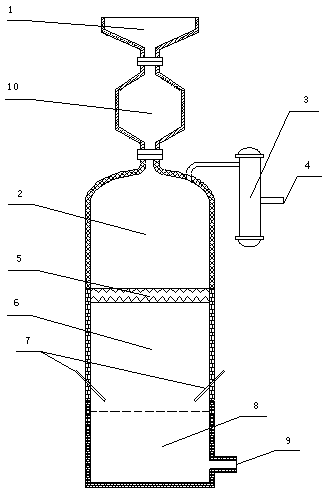

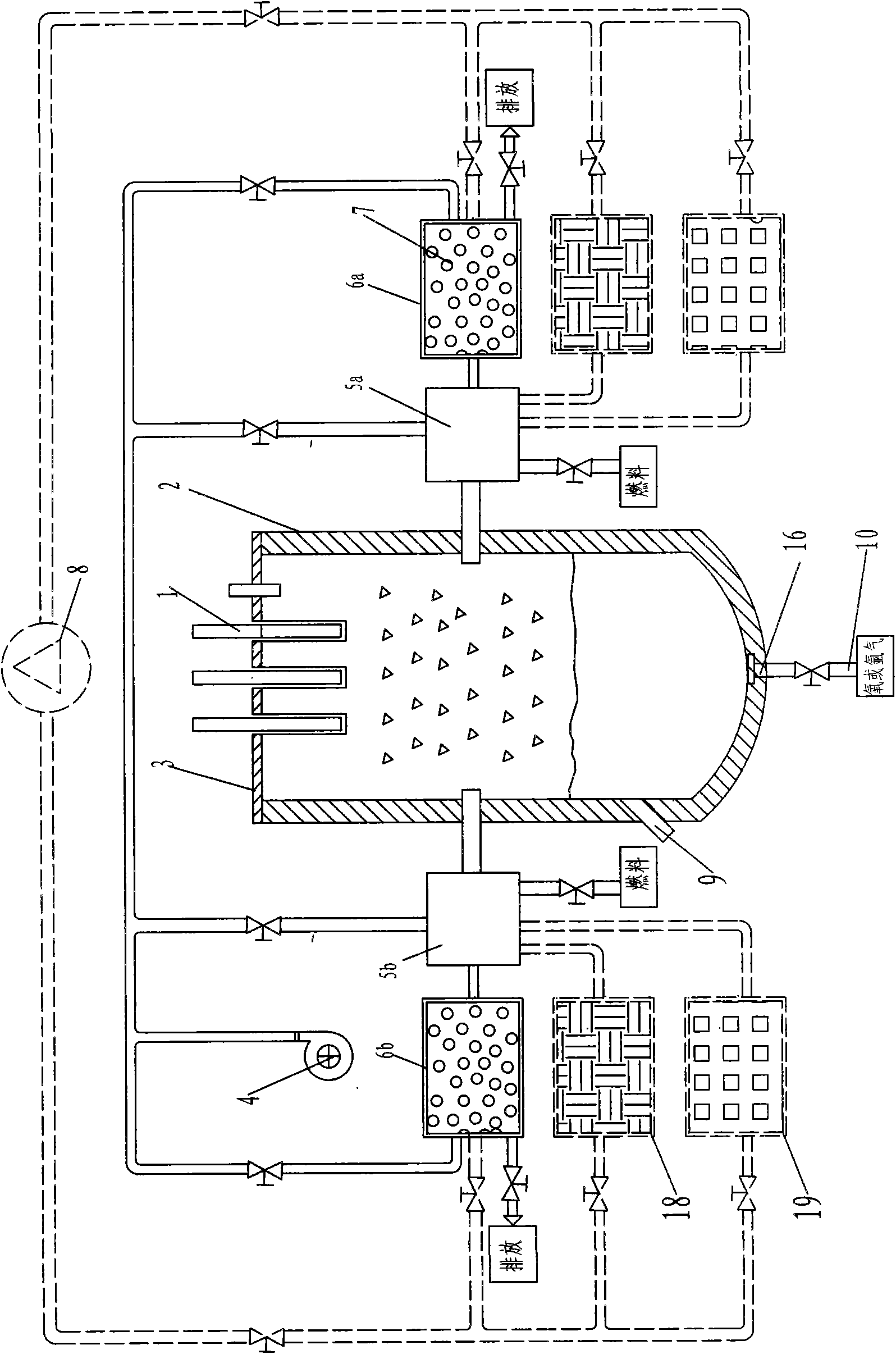

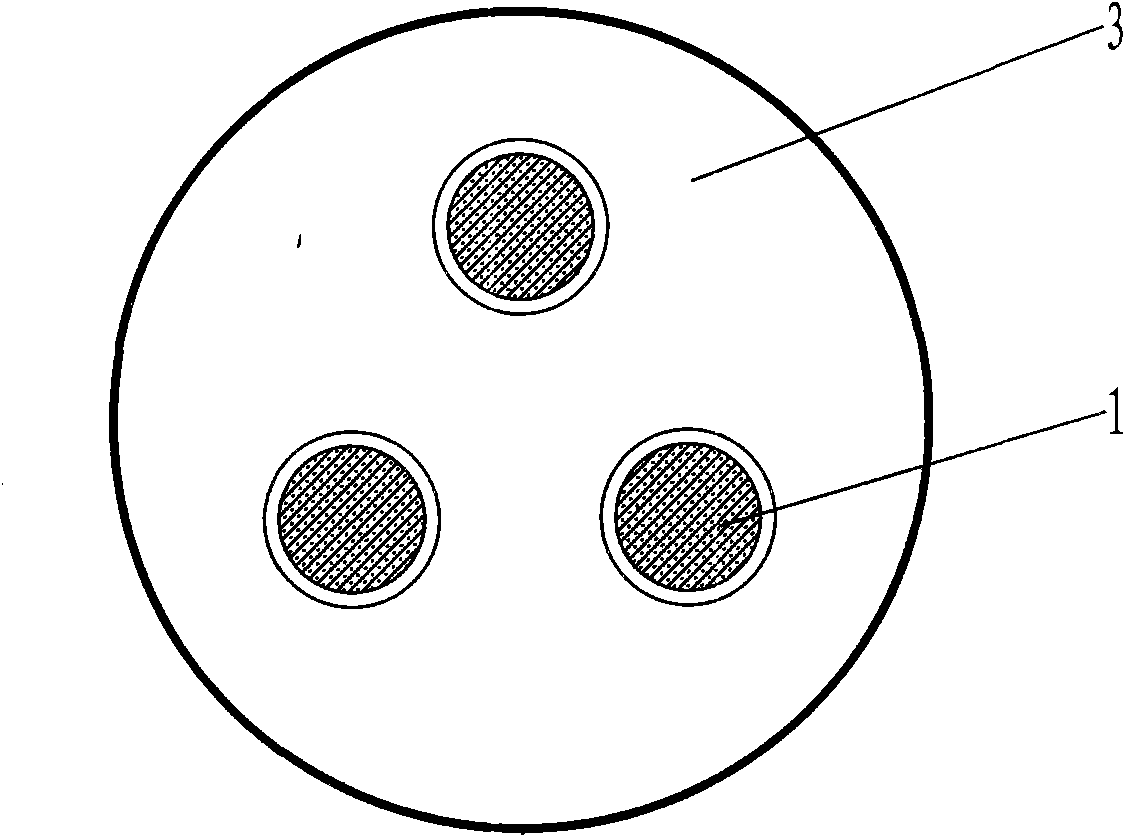

Composite bed reactor and method for combined production of calcium carbide, gas and tar

ActiveCN103272536ATake advantage ofReduce heat lossCalcium carbideSpecial form destructive distillationReaction rateMolten bath

The invention relates to a composite bed reactor and a method for combined production of calcium carbide, gas and tar, and belongs to the field of calcium carbide production. The reactor comprises a hopper, a brake bunker, a moving bed preheating chamber, a tar collector, a gas outlet, a distributing device, an oxygen heat reaction chamber, oxygen spraying burners, a product molten pool and a product outlet, and the hopper is connected with the moving bed preheating chamber by the brake bunker, and the top side surface of the moving bed preheating chamber is provided with the tar collector, and the tar collector is provided with a gas outlet, and the moving bed preheating chamber bottom is provided with a distributing device, and the moving bed preheating chamber is communicated with an oxygen heat reaction chamber by a distributing device, and the oxygen heat reaction chamber bottom is connected with a product molten pool, and the upper portion of the connection between the oxygen heat reaction chamber and the product molten pool is provided with the oxygen spraying burner, and the middle bottom of the product molten pool is provided with a product outlet. The reactor of the invention has the advantages of simple structure and high efficiency, and large scale production is easy to realize, and the raw material is pelleted by powder form carbonaceous raw material and powder form calcium containing raw material, and the contact surface between raw materials is large, the reaction rate is fast, and reactor is convenient for reusing calcium carbide slags.

Owner:BEIJING UNIV OF CHEM TECH

Non-noble metal mercury-free catalyst for hydrochlorination of acetylene and preparation method thereof

InactiveCN103007972AHarm reductionAvoid inactivationPhysical/chemical process catalystsPreparation by halogen halide additionAlkaline earth metalVinyl chloride

The invention discloses a non-noble metal mercury-free catalyst for hydrochlorination of acetylene and a preparation method thereof. The catalyst mainly contains copper, chlorine, a carrier and the balance of catalysis-promoting metallic elements, wherein the copper exists in the form of copper chloride, the chlorine exists in the form of an inorganic salt of chlorine, the carrier is activated carbon or nitrided activated carbon which is subjected to acid cleaning, and the catalysis-promoting metallic elements are one of or a mixture of any of alkali metals, alkaline-earth metals and non-noble metals of which the chloride is non-volatile in transition metallic elements. The preparation method comprises the process steps of preparing impregnation motor liquor, adding a catalyst carrier to perform equivalent-volume impregnation, drying the mixture and the like. The non-noble metal mercury-free catalyst prepared by adopting the method is better in activity, high in selectivity, long in service life, low in cost and environment-friendly, and can be used for hydrochlorination of acetylene during the production of vinyl chloride by using a calcium carbide method.

Owner:TIANJIN UNIV

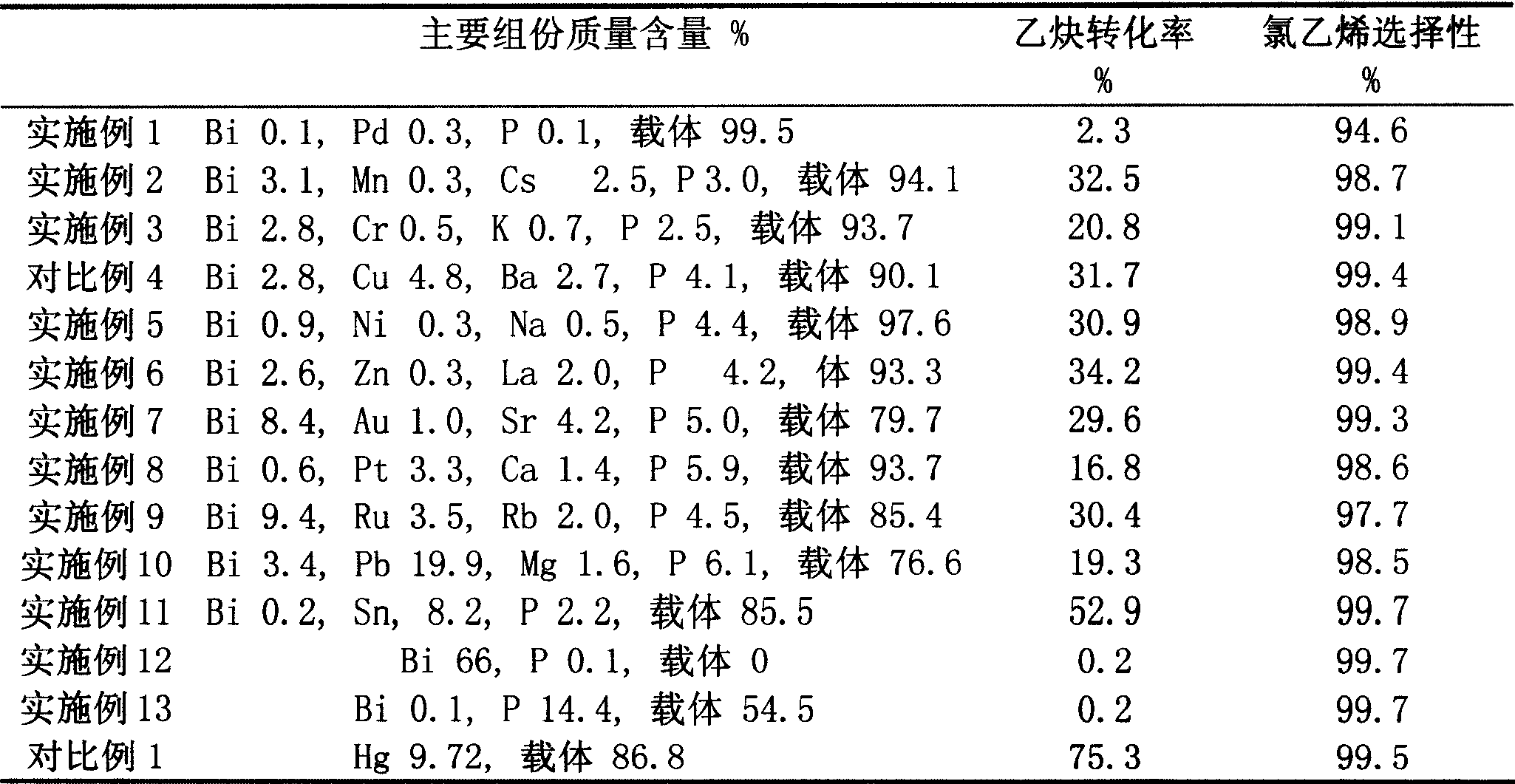

Catalyst without mercury for hydrochlorination of acetylene as well as preparation method and use thereof

InactiveCN101497046ALow costEliminate the disadvantages of high toxicity and high pollutionPhysical/chemical process catalystsPreparation by halogen halide additionCooking & bakingPolyvinyl chloride

The invention provides a mercury-free catalyst for an acetylene hydrochlorination reaction, a preparation method and application thereof, and relates to a catalyst for preparing chloroethylene by the acetylene hydrochlorination reaction, preparation and regeneration methods, and application thereof. The catalyst contains a bismuth element and a phosphor element, and the balance being an accelerative catalytic metal element and a carrier, wherein the bismuth element exists as oxide of bismuth, inorganic salt of bismuth or organic salt of bismuth; and the phosphor element exists as one or mixture of substances of inorganic acid containing phosphor, inorganic salt of phosphor and oxide containing the phosphor. The preparation method comprises preparation of an impregnating mother solution, addition of a catalyst carrier by incipient impregnation, drying and baking and other process steps. The catalyst prepared by the method has the advantages of good activity, high selectivity, high strength and regeneration capability, and can be used for the acetylene hydrocchlorination reaction for producing polyvinyl chloride by a calcium carbide process. The invention also provides the method for preparing chloroethylene by the catalyst and a regenerating method of the mercury-free catalyst.

Owner:TSINGHUA UNIV

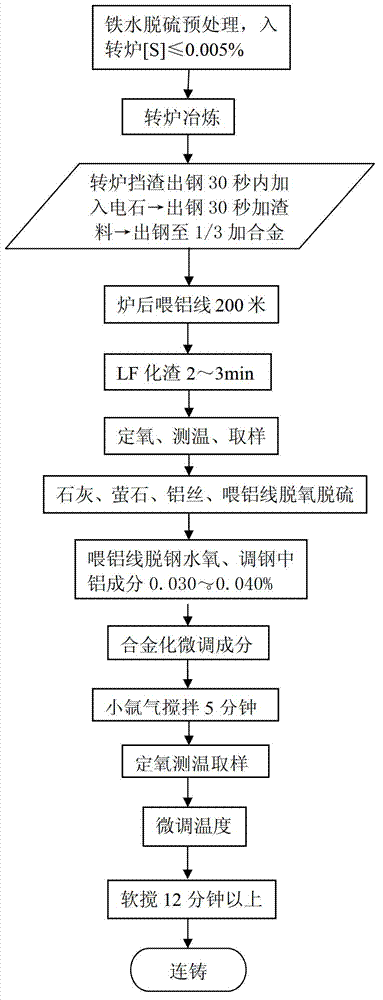

Aluminum-containing cold forging steel smelting process

ActiveCN103469050AEfficient control back to SiGuaranteed liquidityManufacturing convertersAluminateSmelting process

The invention discloses an aluminum-containing cold forging steel smelting process, comprising the steps of blast furnace molten iron making, processing by a converter, refining and continuous casting, wherein requirements of molten iron are as follows: P is not more than 0.10%, Si is not more than 0.50% and not less than 0.30%, S is not more than 0.030%; requirements in converter refining are as follows: CaO is not less than 85%, activity degree is not less than 280 and SiO2 in fluorite is not more than 6%; low-Si pre-melted slag or refining agent replaces partial CaO and fluorite in a converter steel discharging process for rapid slag making, a refining furnace deoxidizing agent is applicable to slag deoxidization after stirring calcium carbide and aluminum particles, and Si-containing material is prohibited; during continuous casting, pure Ca lines are applicable between a medium packet impact zone and various flows, so that calcium aluminate which is low in melting point and is from reaction of Al2O3 generated from medium packet through secondary oxidation and Ca floats and is removed. The process can reduce the content of Si in steel, improve Al content and guarantee continuous pouring of molten steel.

Owner:ZENITH STEEL GROUP CORP

Anion modified mercury-free catalyst for ethyne hydrochlorination reaction, and preparation method thereof

InactiveCN103272619AHarm reductionAvoid inactivationPhysical/chemical process catalystsPreparation by halogen halide additionPhosphatePyrophosphate

The invention discloses an anion modified mercury-free catalyst for an ethyne hydrochlorination reaction, and a preparation method thereof. The catalyst comprises a catalyst carrier and an active component, wherein the catalyst carrier is active carbon, the active component is a sulfate, a chloride, a phosphate or a pyrophosphate of copper or tin, and the carrier is acid-washed active carbon or phosphorus doped active carbon. The preparation method comprises preparing an active component impregnating solution, adding a catalyst carrier to carry out equivalent volume impregnation, drying, baking and other process steps. According to the present invention, acetylene and hydrogen chloride are mixed and then are subjected to a reaction in the catalyst system, wherein the catalysis system of the present invention has characteristics of environmental protection and safety compared with the current mercury catalyst in the industry; and the catalyst prepared by the preparation method has characteristics of high activity, high selectivity, good stability, and longer service life, and is more suitable for ethyne hydrochlorination reactions for producing vinyl chloride through a calcium carbide method compared with the general mercury-free catalyst.

Owner:TIANJIN UNIV

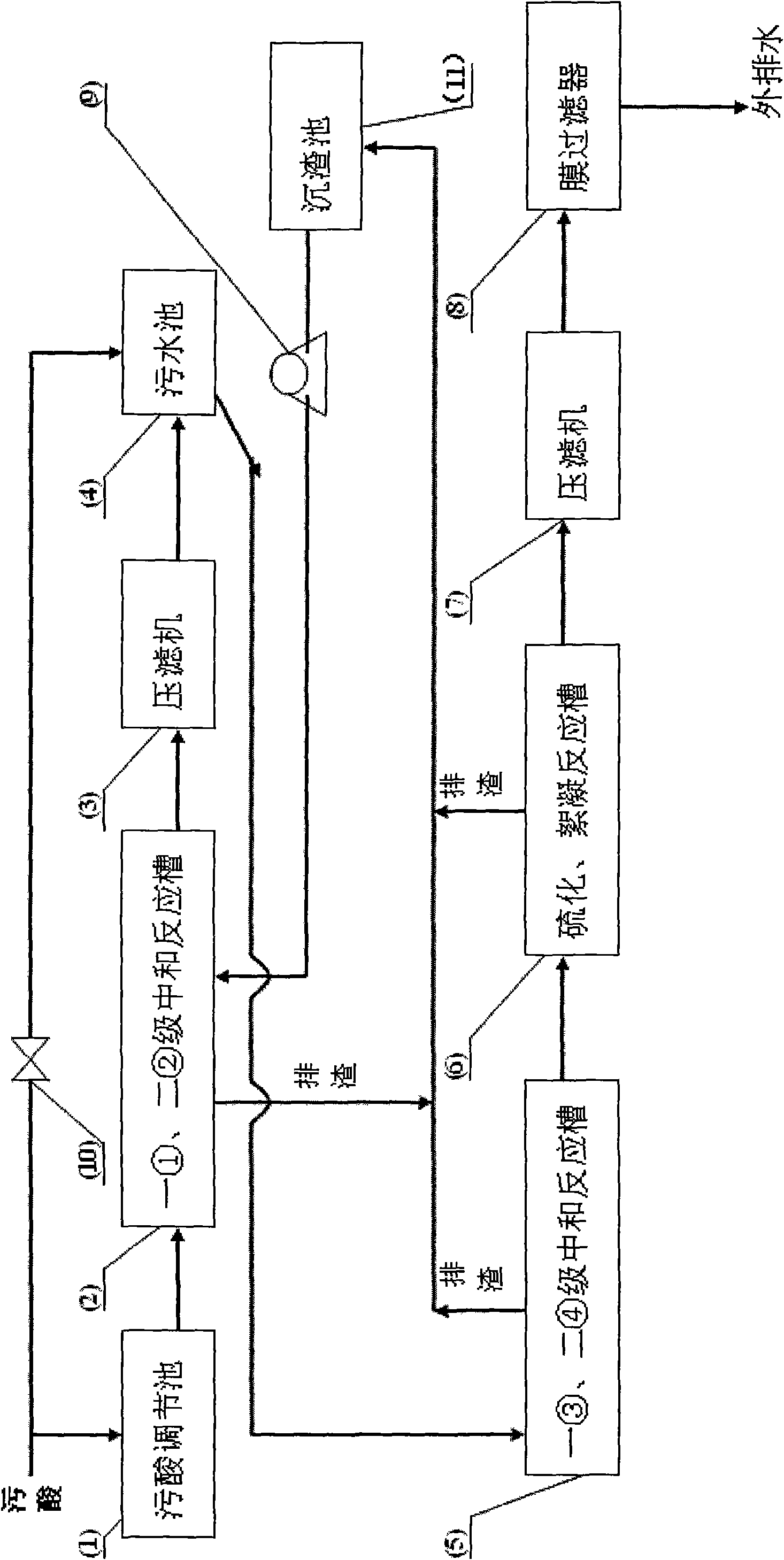

Processing equipment and technique for waste acid and water

InactiveCN101628763AAchieve separationEasy to achieve precise adjustmentWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFlocculationVulcanization

The invention relates to waste acid and water processing equipment and a technique for processing acidic sewage generated in the process of purification of an acid making system. The technique comprises the following steps: pumping the waste acid into a first-level neutralizing reaction tank in the first stage; adding calcium carbide slag to adjust the pH value between 1 and 6; adding calcium carbide slag to adjust the pH value between 5 and 6, when the liquid overflows into a second-level neutralizing reaction tank in the first stage; carrying out solid-liquid separation; entering a sewage pool; pumping the liquid in the sewage pool into a first-level neutralizing reaction tank in the second stage; adding lime milk to adjust the pH value between 6 and 7; adding lime milk to adjust the pH value between 7 and 8, when the liquid gravitationally flows into a second-level neutralizing reaction tank in the second stage; adding 7% of sodium sulphide and 15% of ferrous sulfate according to weight percentage into a vulcanization and flocculation reaction tank, when the liquid gravitationally flows into the vulcanization and flocculation reaction tank; carrying out solid-liquid separation of fine particles on the liquid by a filter press and a film filter; discharging the liquid, thus the continuous up-to-standard discharging of effluent water is easily realized.

Owner:HENAN YUGUANG ZINC IND

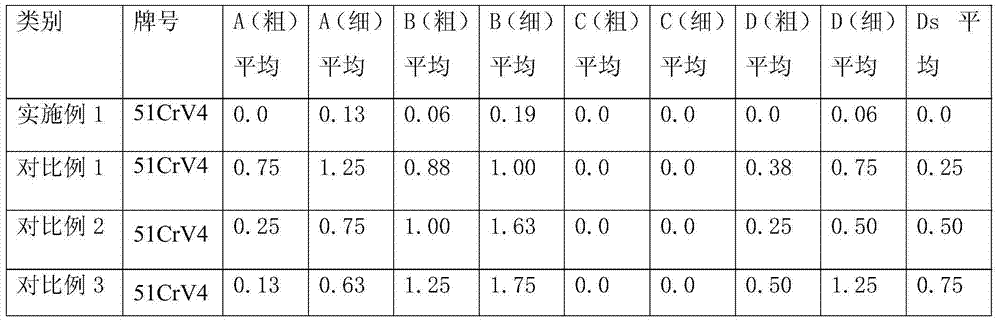

Smelting process of Cr-Mn series spring steel

ActiveCN104745765AImprove liquiditySolve the problem of high alkalinity slag and difficult adsorption and inclusionElectric furnaceProcess efficiency improvementNon-metallic inclusionsSmelting process

The invention belongs to the field of metallurgy and discloses a smelting process of Cr-Mn series spring steel. The smelting process of Cr-Mn series spring steel comprises the following steps: (1) by taking a low-sulfur molten iron and a high-quality steel scrap as the electric furnace smelting iron and steel materials, controlling the electric furnace end point carbon content to greater than 0.15%; (2) adding active lime and composite refining slag in the electric furnace tapping process, and adding calcium carbide to perform pre-deoxidation in the tapping process; (3) feeding an Al line in an argon station before LF refining; (4) producing high basicity white slag in the refining earlier stage and controlling the basicity of slag in the refining middle and later stages to 1.5-2.5; (5) controlling the ultimate vacuum front argon flow to 15-25 L / min and controlling the ultimate vacuum late argon flow to 30-45 L / min; (6) adding a granular alkaline covering agent and a carbonized rice hull to perform double protection by VD emptying; and (7) stabilizing the speed of continuous casting to 0.8-0.9 m / min, and controlling the degree of superheat to 20-30 DEG C. By adopting the process, the non-metallic inclusion content in the molten steel is reduced.

Owner:ZENITH STEEL GROUP CORP +1

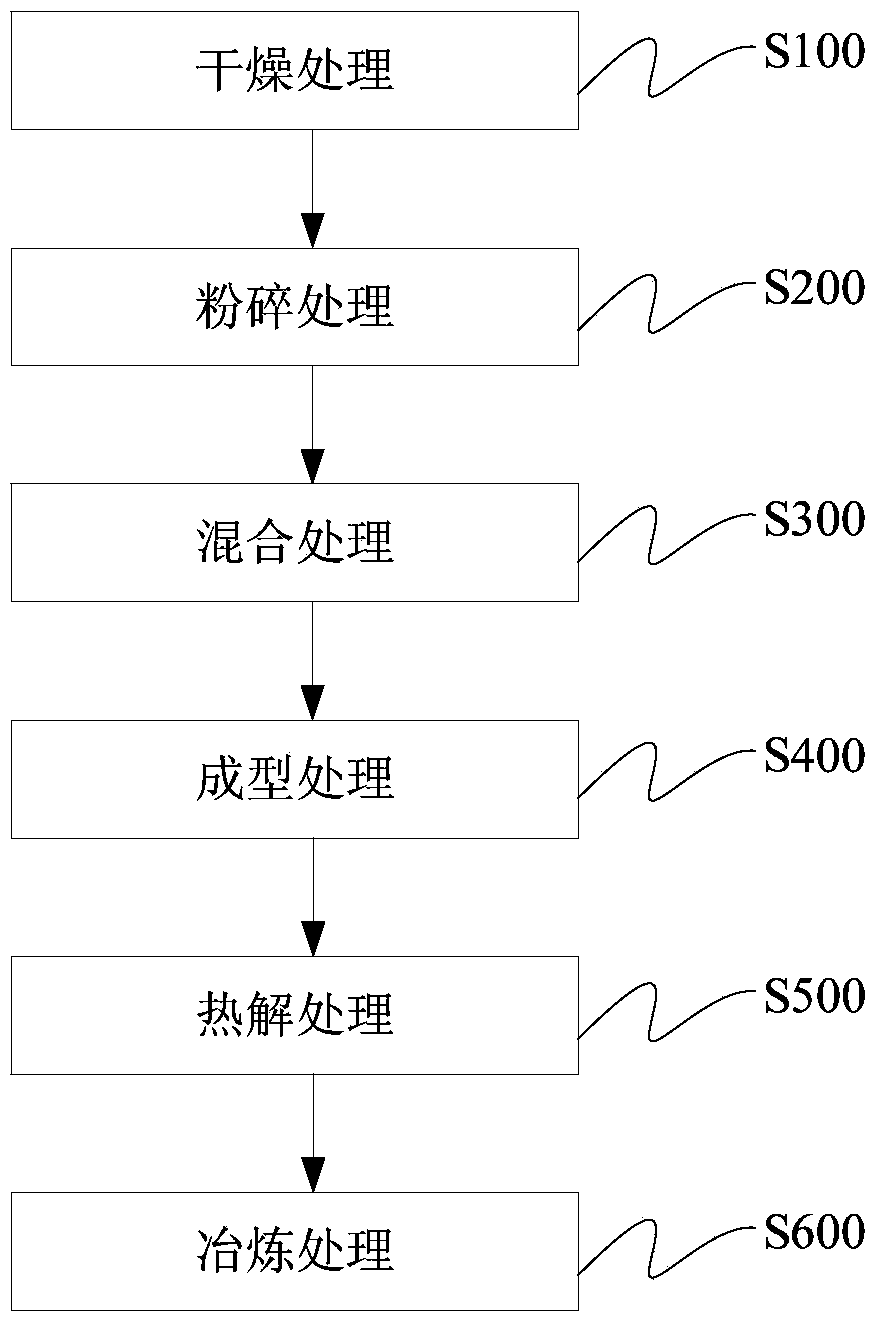

Method for preparing calcium carbide

InactiveCN103708456AIncrease profitIncrease productivityCalcium carbideElectric arc furnaceForming gas

The invention discloses a method for preparing calcium carbide, which comprises the following steps: drying a carbon-base raw material to obtain a dried carbon-base raw material; respectively crushing the dried carbon-base raw material and a calcium-base raw material to obtain a carbon-base powder and a calcium-base powder; mixing the carbon-base powder and calcium-base powder to obtain a mixture; forming the mixture to obtain a lump material; pyrolyzing the lump material to obtain high heating value synthetic gas, tar and a pyrolytic solid product, wherein the pyrolytic solid product contains coke, semicoke, carbon black and quicklime; and feeding the pyrolytic solid product into an arc furnace at the temperature of not lower than 450 DEG C to perform smelting in the arc furnace, thereby obtaining the calcium carbide. The method can obviously lower the smelting energy consumption and production cost, and further enhances the preparation efficiency and quality of the calcium carbide.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

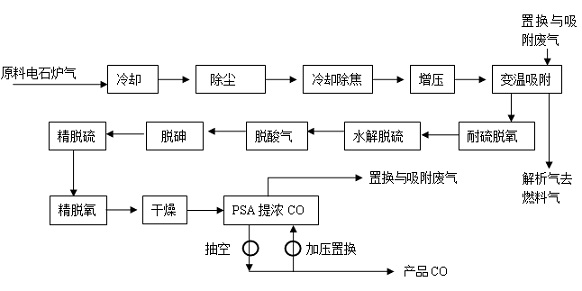

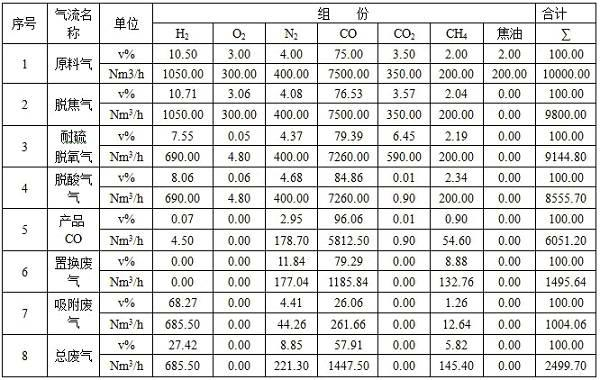

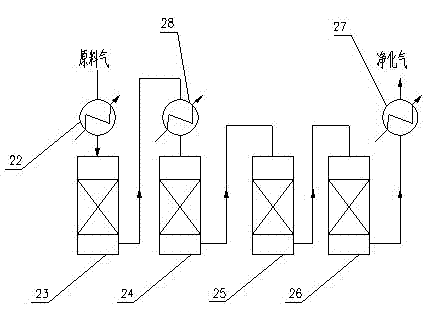

Method for purifying and concentrating CO from calcium carbide furnace gas

ActiveCN102627280AIncrease profitHigh CO yieldCalcium carbideCarbon monoxideDeoxygenationIndustrial scale

The invention discloses a method for purifying and concentrating CO from calcium carbide furnace gas and belongs to a tail gas purification method. The method provided by the invention respectively comprises the following steps of: raw material calcium carbide furnace gas dedusting, cooling and decoking, temperature swing adsorption and precleaning, supercharging, sulphur tolerant catalytic deoxygenation, hydrolysis desulfidation, acid gas removal, arsenic removal, fine desulphurization, fine deoxidation, drying, pressure swing adsorption and concentration of CO. The invention relates to a packaged technology for purifying and concentrating CO from calcium carbide furnace gas. The technology is suitable for industrial scale application and can be adopted to make calcium carbide furnace gas containing various impurities into high-purity CO gas which is suitable for CO raw material for carbonyl synthesis or other chemical production.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

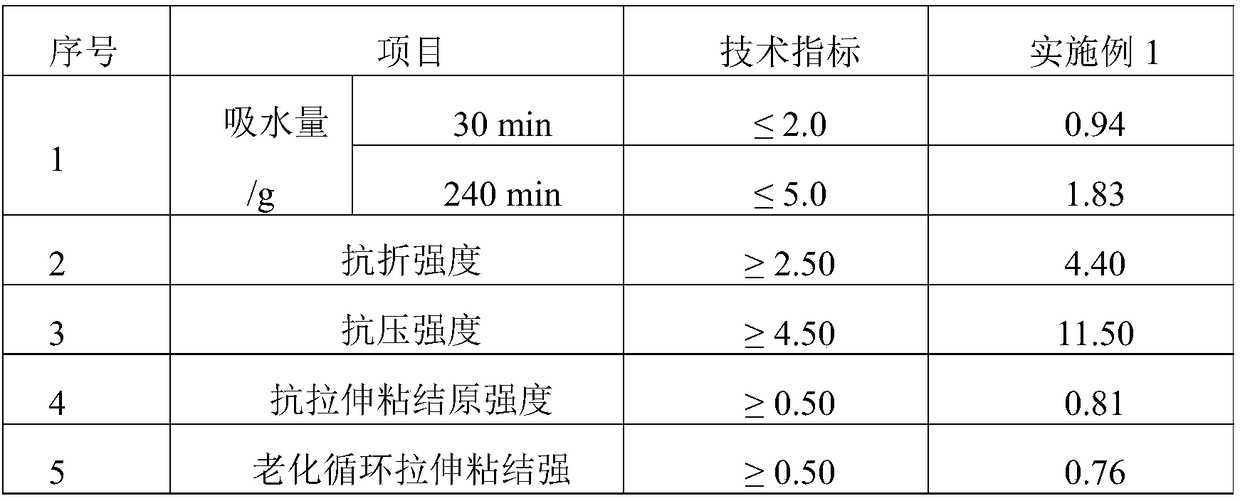

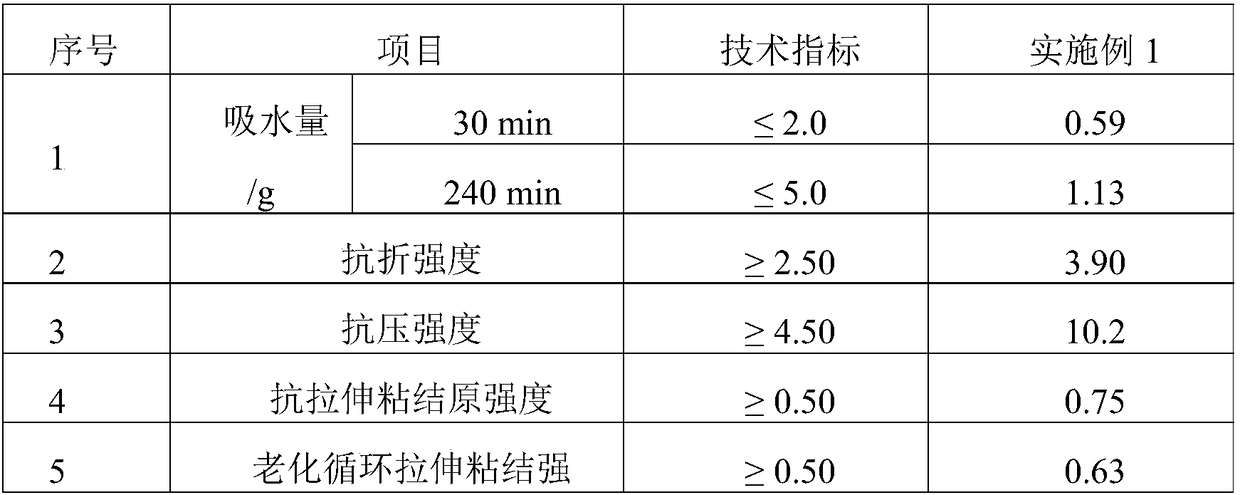

White wall veneer mortar prepared by calcium carbide slag

The invention provides a white wall veneer mortar prepared by calcium carbide slag. The mortar is prepared from the calcium carbide slag, white cement, coarse whiting, quartz sand, redispersible powder and other admixtures. The veneer mortar adopts the calcium carbide slag as a gel material, which is of great significance for reducing the environmental pollution of industrial waste residues and reducing the production cost. In addition, high-belite-sulphoaluminate cement is hydrated to generate expanded ettringite, which is beneficial to improve the crack resistance of the veneer mortar. The veneer mortar has excellent flexibility, flexural strength, compressive strength, gas permeability and the like, and is suitable for the decoration of a building wall.

Owner:BEIJING UNIV OF TECH

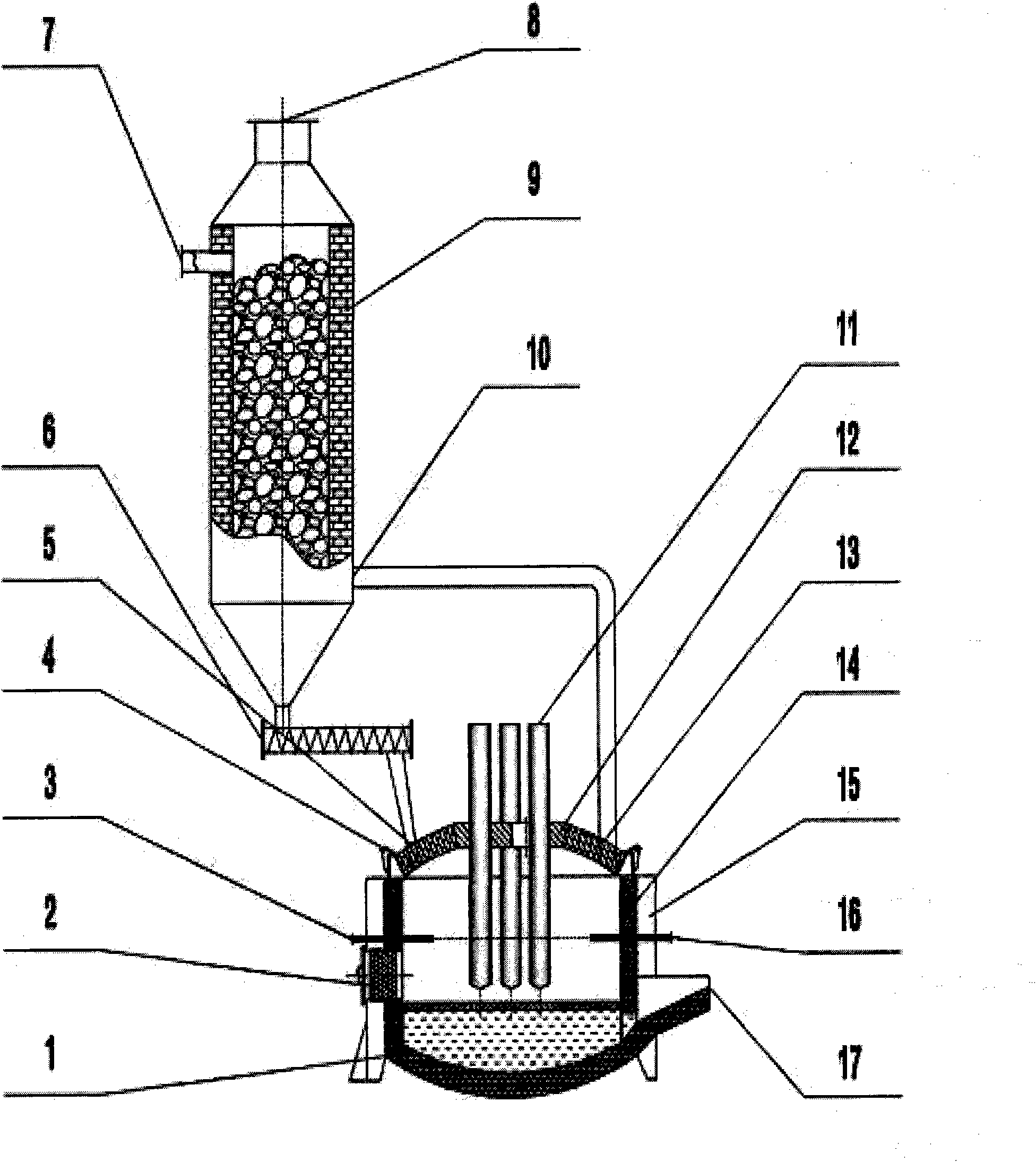

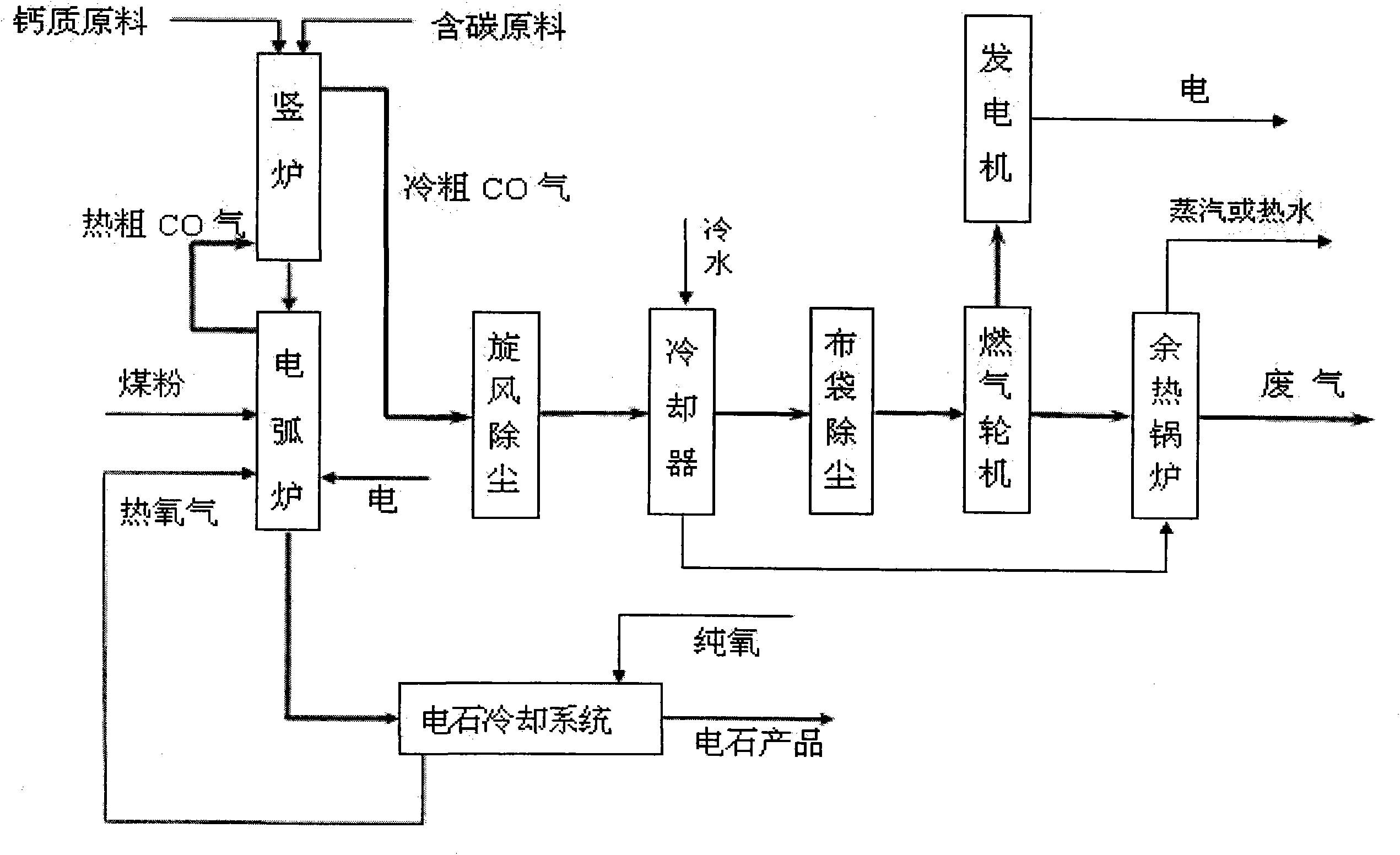

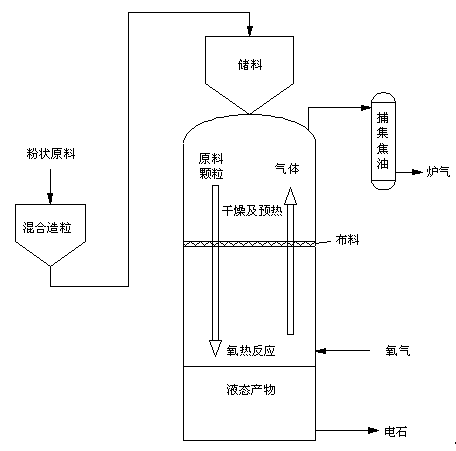

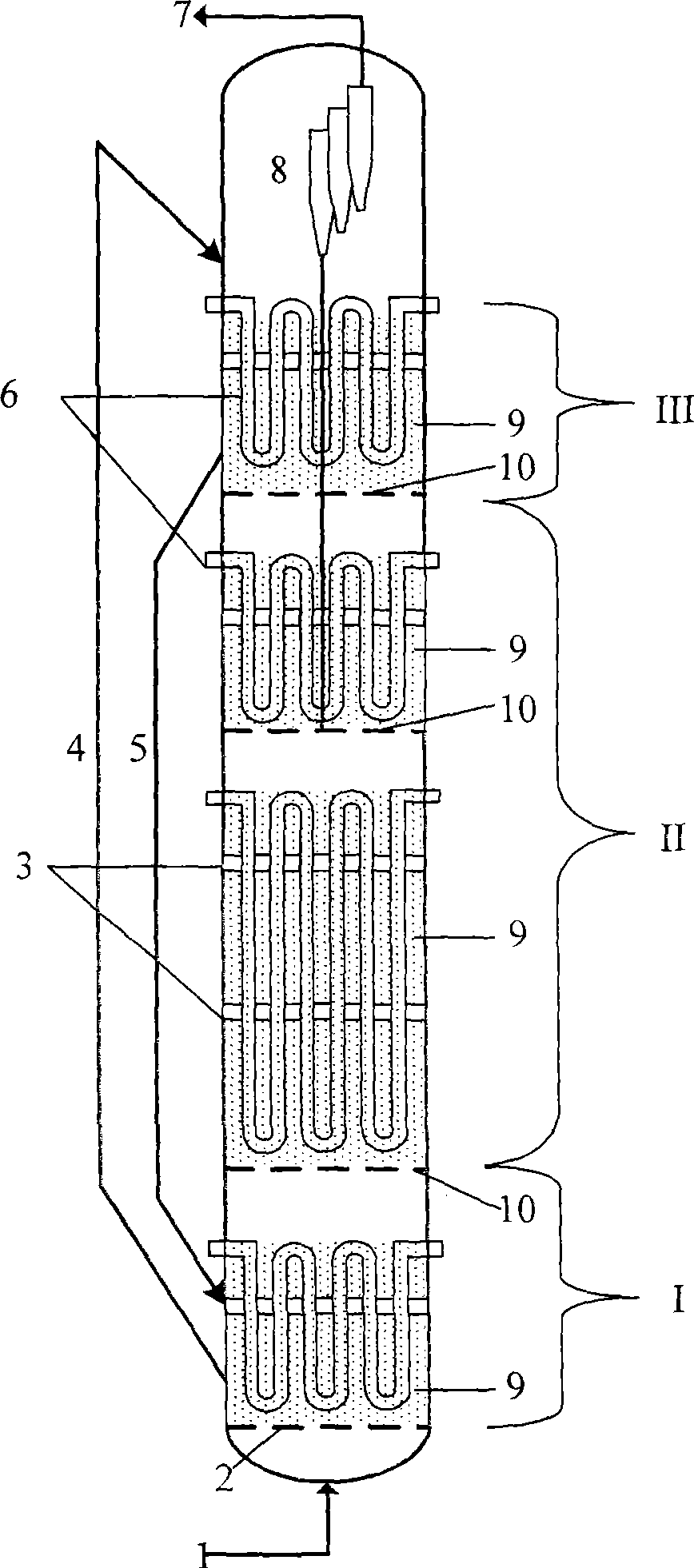

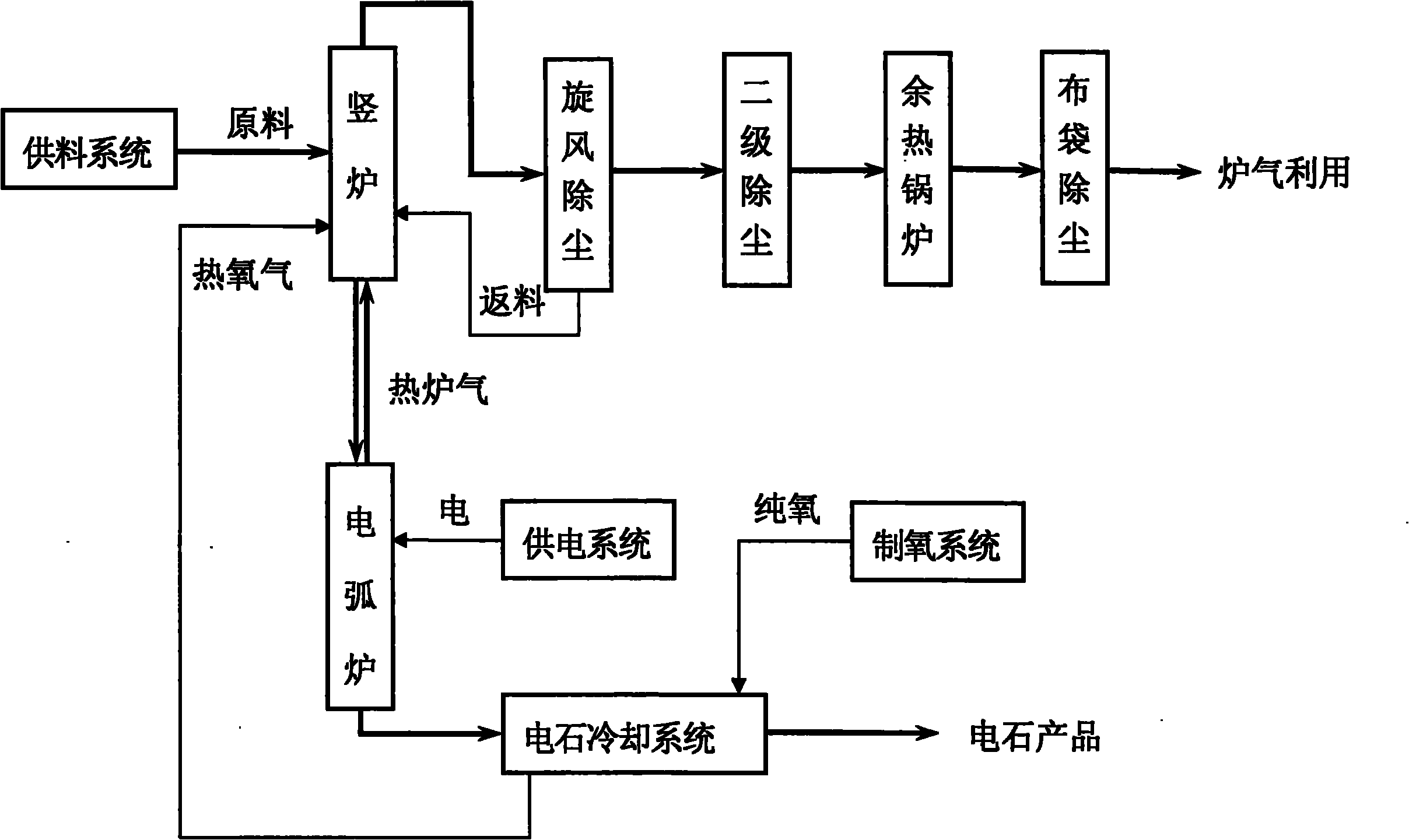

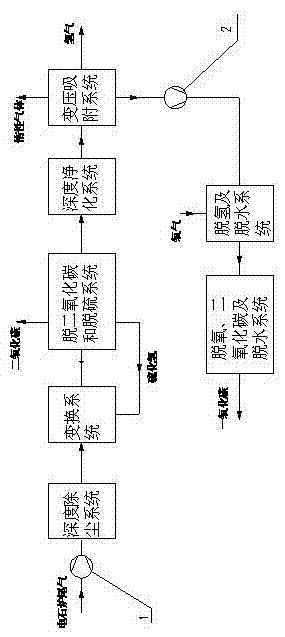

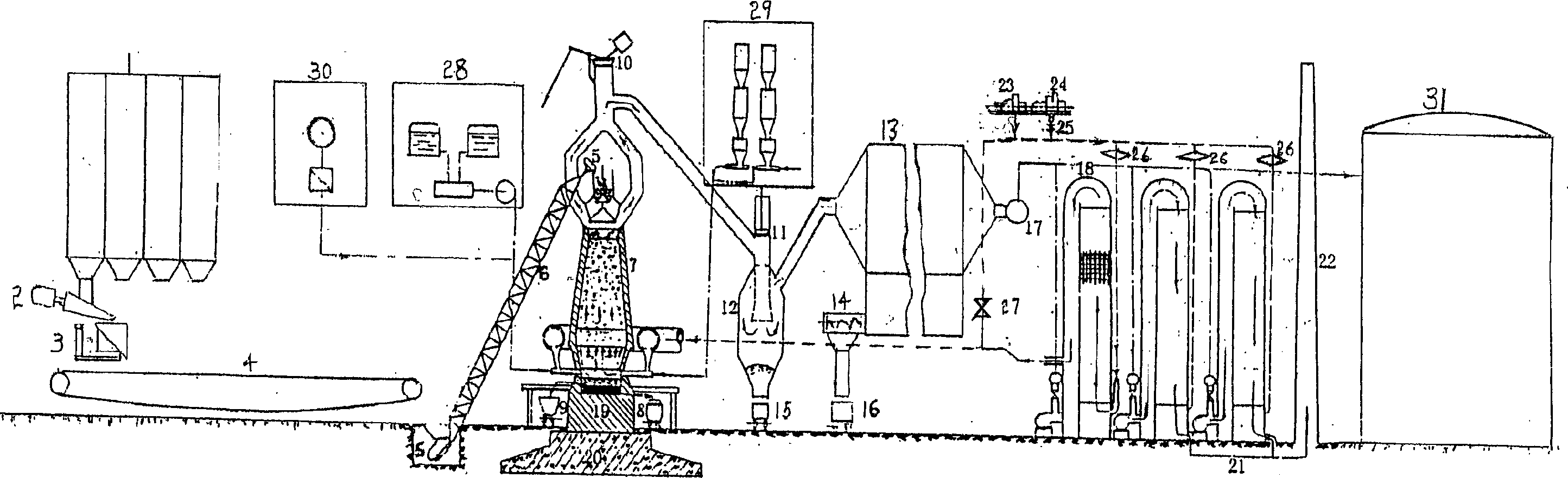

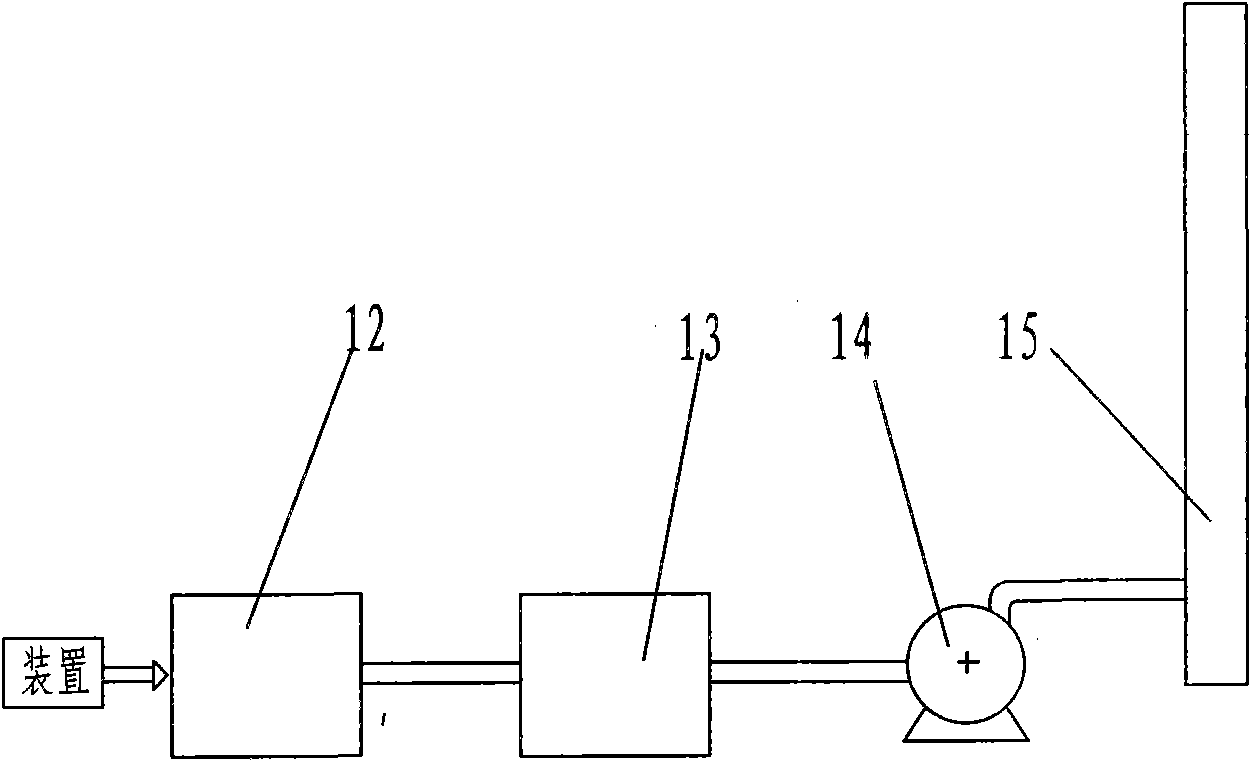

Process and device for producing calcium carbide by using powder raw materials through two-stage method

InactiveCN101817525AWide variety of sourcesIncrease profitEnergy inputCalcium carbideElectric arc furnaceOxygen

The invention relates to a process for producing calcium carbide by using powder raw materials through the two-stage method, which comprises the following steps: leading power carbon-containing material, powder calcium-containing material and oxygen to burn, increasing the temperature of furnace materials in a vertical furnace to above 1300 DEG C, leading the hot furnace materials discharged from the bottom of the vertical furnace to enter into an electric arc furnace, increasing the temperature of the hot furnace materials to 1700-2200 DEG C under the thermal effect of electric arc of an electrode, and carrying out reaction for generating the calcium carbide. Gas containing solids in the vertical furnace is discharged by a furnace gas outlet pipe at the top of the vertical furnace and separated by a cyclone dust collector from, secondary dust collection, residual heat recovery and cloth bag dust collection are carried out on the separated gas to reduce the dust content to below 1-5mg / Nm3, the temperature is reduced to 30-45 DEG C, and then the gas can be recycled as fuel gas or chemical raw material gas. The process has the advantages of powder raw materials, low energy consumption, low cost, continuous production and high grade of the calcium carbide.

Owner:山西亿众公用事业有限公司

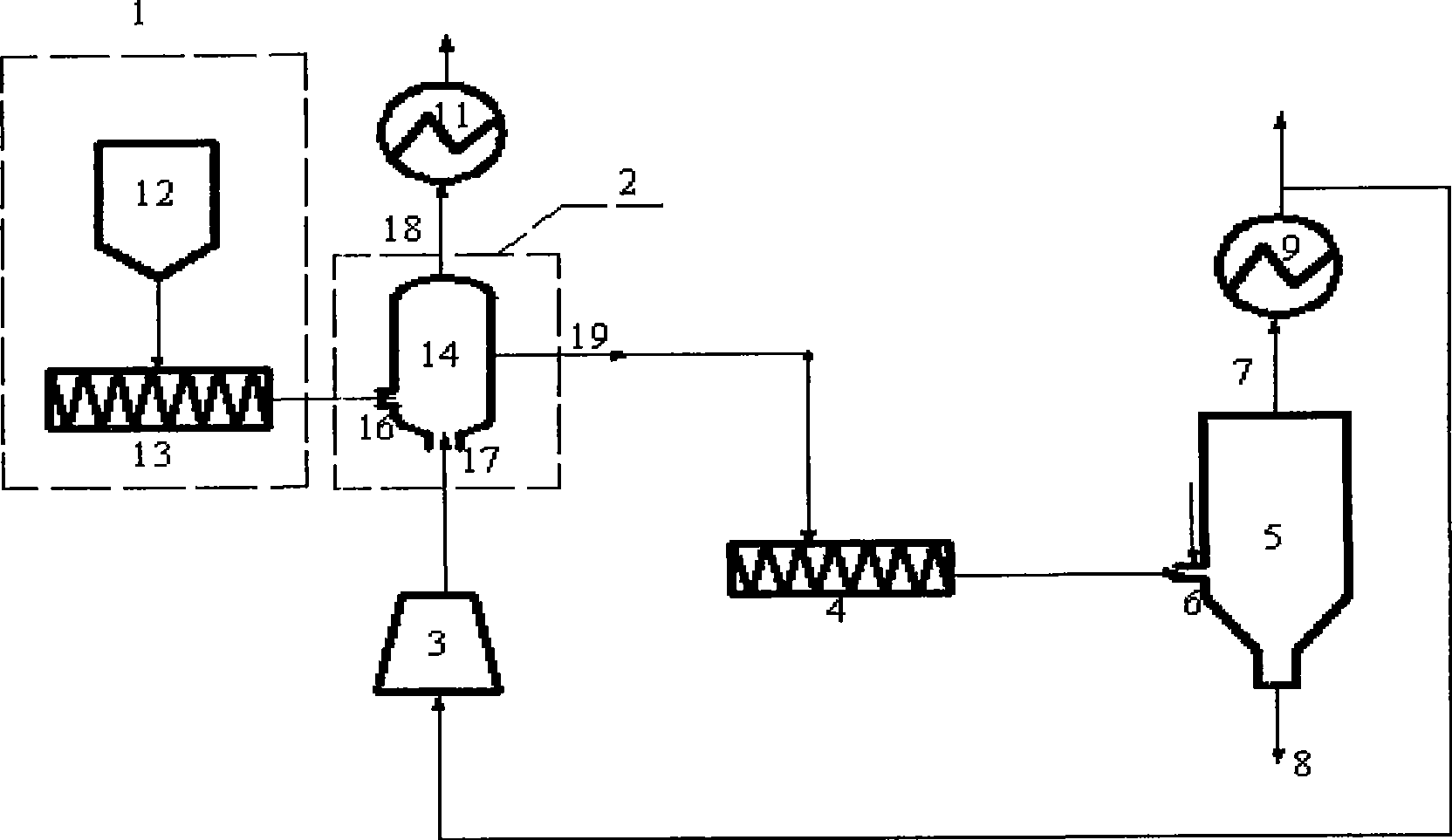

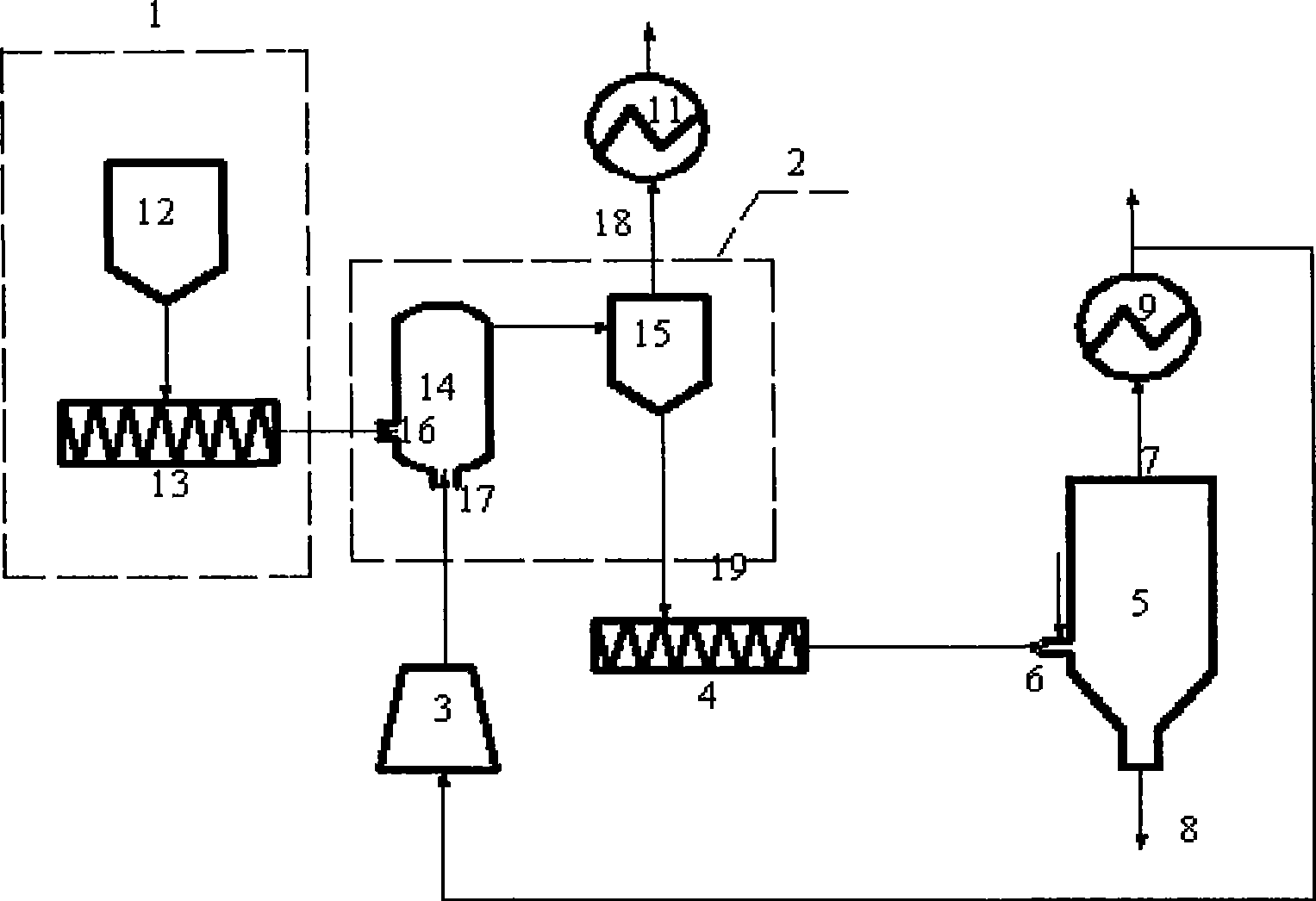

System for producing calcium carbide

InactiveCN101428799AIncrease production capacityEnergy inputCalcium carbideCouplingCompression device

A calcium carbide production system belongs to the field of calcium carbide production. The calcium carbide production system includes a raw material preheating unit and a reaction unit; the raw material preheating unit includes a raw material mixing and feeding device, a preheating device, a gas compression device and a heat exchanger; the raw material mixing and feeding device includes a solid raw material mixer and a feeder; a raw material inlet, a gas inlet, a gas outlet and a solid material outlet are formed on the preheating device; the raw material mixing and feeding device is communicated with the preheating device; the reaction unit includes a feeding device, a reactor and a heat exchanger; a raw material nozzle, a gas outlet and a product outlet are arranged on the reactor; the solid material inlet of the feeding device is communicated with the preheating device; the solid material outlet of the feeding device is communicated with the raw material nozzle on the reactor; the reactor is communicated with the heat exchanger; and the heat exchanger is connected with the gas compression device of the preheating unit. The system realizes the coupling of the process of coal coking and lime calcining and the production of calcium carbide; the capacity usage ratio is high; the powdery material is adopted; the selection range of the raw material is wide; the production capacity is large; and the furnace type is simple.

Owner:BEIJING UNIV OF CHEM TECH

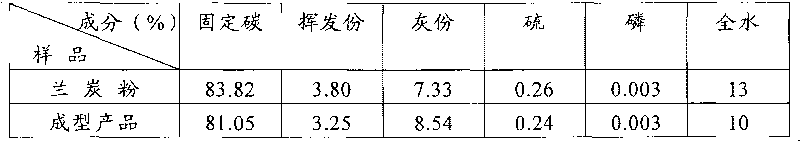

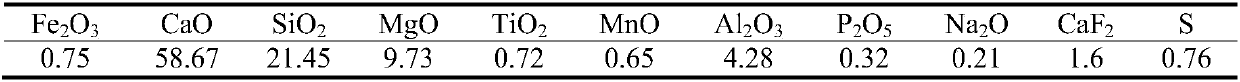

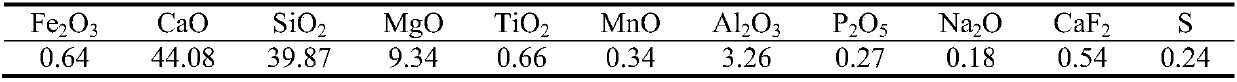

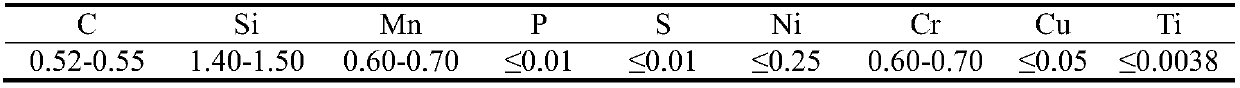

Binder for coke powder molding and application method thereof

InactiveCN101760276AReasonable formulaEasy to applySolid fuelsCarbonizationUltimate tensile strength

The invention discloses a binder for coke powder molding and an application method thereof which belong to the field of coal. The binder of the invention comprises an A component and a B component, wherein the A component comprises adhesive, adhesion promoter and filling agent; and the B component is surface modifier. The binder of the invention is applicable in the cold bonding forming of coke powder (comprising blue carbon powder, petroleum coke), and finished products can serve as submerged arc furnace raw material, chemical gas raw material, calcium carbide production raw material and thelike, replace some coke and are applied. The application method of the binder of the invention has the advantages of simplicity, no need of raw material for heating and stirring, no need of product carbonization, no pollution in the whole production process, above 95 percent forming rate, more than 3 times of falling from 1m up of wet ball strength, more than 800N / ball finished product strength, 1,000DEG C high temperature resistance, and no dispersion and no powder.

Owner:北京中科圣宝荷新材料科技有限公司

Method for producing silicon deoxygenation low-sulfur high-carbon steel through LF refining double slag method

The invention relates to a method for producing silicon deoxygenation low-sulfur high-carbon steel through an LF refining double slag method. An electric furnace-LF-VD continuous casting technology isadopted. The method includes the steps that in the electric furnace tapping process, carbon powder is mixed firstly, then a silicon alloy and a manganese alloy are added for conducting deoxygenationalloying treatment, and lime, calcium carbide and aluminum-free refining slag are added for conducting modification treatment; secondly, after an LF enters a station, lime, calcium carbide, silicon iron and aluminum-free refining slag are added into the furnace for making high-alkalinity reducing refining slag; thirdly, low-alkalinity reducing slag is made, and the content of components in moltensteel is adjusted; and fourthly, the LF withdraws from the station after refining, VD and continuous casting processes are conducted in sequence, and the silicon deoxygenation low-sulfur high-carbon steel is obtained. The method is simple, reliable, high in operability and easy to achieve, the production cost of the whole process is reduced, the sulfur removing efficiency is high, the cleanlinesslevel of molten steel is high, the problem that when a non-molten-steel pretreatment sulfur removing process is adopted for producing high-quality silicon deoxygenation low-sulfur high-carbon steel, sulfur removing is difficult is solved well, and therefore the product quality is improved, and the economic benefits of a steel enterprise are increased.

Owner:CENT IRON & STEEL RES INST

Method for increasing molten steel finishing point manganese content by adding manganese ore outside furnace

The invention provides a method for increasing the molten steel finishing point manganese content by adding manganese ore outside a furnace, which comprises the steps of: setting the tapping temperature of the revolving furnace to be medium or upper limit according to the type of the made steel, adding the manganese ore and a little reducing agent, and controlling the finishing point carbon content and the slag thickness; adopting strong argon for stirring in a ladle furnace (LF), and replenishing aluminum particles and calcium carbide for making reducing slag according to the top slag condition; and reducing manganese oxide in the slag into metal manganese to realize manganese alloying. Compared with the prior art, the method has the advantages of being simple in technology, convenient to operate and control, short in smelting time, low in energy consumption and high in yield of manganese alloy, reducing pollution, prolonging the service life of a furnace liner and the like; and the yield of manganese in the manganese ore reaches more than 96.5%, so that the consumption of the manganese alloy is greatly reduced, and the steel-making cost is remarkably reduced. Meanwhile, the original equipment does not need to be reformed, and other production processes are not influenced, so that the investment is low, and the effect is rapid.

Owner:ANGANG STEEL CO LTD

Soil firming agent

InactiveCN1442465AAdaptableStrong soil effectOrganic fertilisersSoil conditioning compositionsFirming agentMaterials science

A soil solidifying agent is prepared from calcium carbide dregs (25-90 portions), granualr slags (10-75 portions) of blast furnace and chemical trigger (0.1-5 portions) through grinding, and proportional mixing. Its advantages are broad spectrum, and high effect and durability.

Owner:TIANZHUJIE SPECIAL BUILDING MATERIAL TECH DEV BEIJING

Method for producing calcium carbide

InactiveCN101172605AEasy to crushIncrease surface areaCalcium carbideElectric arc furnaceGranularity

The invention relates to a production method of calcium carbide, which takes coal powder and calcium oxide as raw materials. According to the method, the coal powder is crashed to 120 meshes, and then mixed with the calcium oxide at the weight rate of 1:0.8 to 1. A certain amount of water is added into the mixture which then can be stirred to be even and compressed into cubic honeycomb blocks; and then the cubic honeycomb blocks are sent into an electric-arc furnace for smelting the calcium carbide after airing water. The invention crashes the coal powder into a nanometer particle size, thereby ensuring the cubic honeycomb blocks to have a comparatively large surface area, improving the reaction activation energy and being good for the rapid generation of the calcium carbide. The production method of the calcium carbide of the invention not only reduces reaction temperature and shortens reaction time, but also extends the service life of the electric arc furnace.

Owner:李书堂

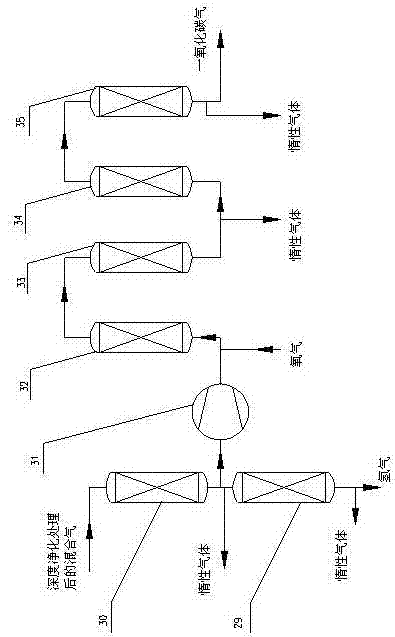

Gas transformation deep purifying technique for separating and purifying CO and H2 of calcium carbide furnace

ActiveCN103204470AIncrease profitEasy to controlHydrogenChemical industryHigh concentrationDehydrogenation

The invention relates to a gas transformation deep purifying technique for separating and purifying CO and H2 of a calcium carbide furnace. The gas transformation deep purifying technique comprises a pressurizing and deep dedusting system, a transforming system, a decarbonization and desulfurizing system, a deep purifying system, a pressure swing adsorption system, a dehydrogenation and dehydration system, and a deoxidizing, decarbonization and dehydration system. The assorted gas transformation deep purifying technique which is capable of realizing industrial scale and high purity is firstly provided for separating and purifying CO and H2, the problems about dust extraction of tail gas of the calcium carbide furnace, high-concentration CO transformation, various complicated-component impurities in the tail gas of the calcium carbide furnace, removal of low-concentration sulfur and the like are solved, the gas transformation deep purifying technique has the advantages of high CO and H2 yield, stability of operating of devices, high heat utilization rate, and industrial exhaust gas can be effectively recycled, energy is saved, and emission is reduced. The gas transformation deep purifying technique is applicable to the technical field of gas separation.

Owner:XINJIANG TIANYE GRP +1

Method and apparatus for preparing calcium carbide by oxygen-fuel blowing of high furnace

InactiveCN1843907AReduce manufacturing costRealize the comprehensive utilization of resourcesChemical industryCalcium carbideFerrosiliconHearth

The invention relates to field of preparing calcium carbide with oxygen jetting in tower furnace. The calcium carbonate is heat decomposed into calcium oxide and reduced to calcium carbide by carbon material by jetting with preheating oxygen or oxygen-enriched air. The device comprises: tower furnace and systems of feeding, charging, oxygen producing, heating air, blasting air, oxygen enriching, jetting, cooling, cleaning and recoverying coal gas and recovering calcium carbide and ferrosilicon. The ration between said furnace height and furnace hearth diameter is less than or equal to 3.5, and diameter ratio between furnace hearth and furnace hearth is 0.8-1.1. The invention is to produce calcium carbide of 80%, the proportioning of raw material is lime carbonate: coke: fluorite =(1.2-2.0): (1.5-4.0): (0.039-0.046); jetting material is coal powder, light oil or natural gas; relative oxygen-enriched air amount, the xygen-enriched rate is 9-39%, and prepares side products of calcium carbide of more than 65%, ferrosilicon more than or equal to 54% and carbon monoxide of more than or equal to 54% at high temperature. The invention is characterized by energy saving, high quality and environmental protection.

Owner:岳书才

Process for smelting aluminum containing steel through calcium carbide deoxidation

ActiveCN102952923ASolve outstanding problems with high consumptionDoes not affect billet qualityManufacturing convertersSteelmakingSmelting process

The invention belongs to a steelmaking process in the metallurgy field and relates to a process for smelting aluminum containing steel through calcium carbide deoxidation without the aluminum deoxidation in the whole process. The process belongs to a production process that the converter steel tapping deoxidation system and the slagging system are optimized, aluminum wires are fed behind a converter, the aluminum in molten steel is regulated, the LF (ladle furnace) calcium carbide and aluminum wire deoxidation slagging is carried out, and in addition, the LF aluminum wire feeding is matched for finely regulating the aluminum in molten steel. The characteristics of calcium carbide and aluminum wires are utilized, and the diffusive deoxidation and the bulk deoxidation in the smelting process are fully and reasonably combined. The process has the advantages that the converter steel tapping deoxidation is stable, the LF slagging desulfurization effect is obvious, the casting blank quality is good, the flaw detection qualified rate of steel plates is high, the aluminum consumption of each ton of steel in the aluminum containing steel production is reduced by about 0.80kg, and the economic benefit of the aluminum containing steel production is greatly improved.

Owner:NANJING IRON & STEEL CO LTD

Method and device for making iron by smelting reduction

ActiveCN101649366ALess investmentReduce pre-restore timeCalcium carbideManufacturing convertersElectric arc furnaceSlag

The invention relates to a method and a device for making iron by smelting reduction. The method for making iron by smelting reduction comprises the following steps: putting raw material forming matters into a smelting ironmaking device; heating and reducing the raw material forming matters into metallic iron; after the reduced metalation rate of various oxides of iron reaches 40-95 percent in rawmaterials, heating and melting products of a reducing furnace; and producing direct reduction molten steel or molten iron produced by the similar blast furnace. The raw materials comprise a breath shell or a half-breath shell or an opening shell or the combination of the raw materials, a coating shells of the breath shell, the half-breath shell and the opening shell is prepared by adding an adhesive in calcium oxide or calcium carbonate or calcium carbide or the combination of the materials. The device for making iron by smelting reduction comprises an arc furnace, a buried arc furnace, a converter, an induction furnace, and the like. After reduction products are heated and melted, and oxygen or inert gas is blown into the arc furnace in order to remove slag. Due to the adoption of a shell coating technology, the method and the device effectively prevent from oxidizing reduced matters in the process, avoid bonding formed matters for contact and are combined with blowing gas and are good for making slag. Slag iron has good separation effect, and the produced iron and steel products have good quality.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com