System for producing calcium carbide

A production system, calcium carbide technology, applied in the direction of carbide, energy input, calcium carbide, etc., can solve the problems of high energy consumption, high investment, high pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

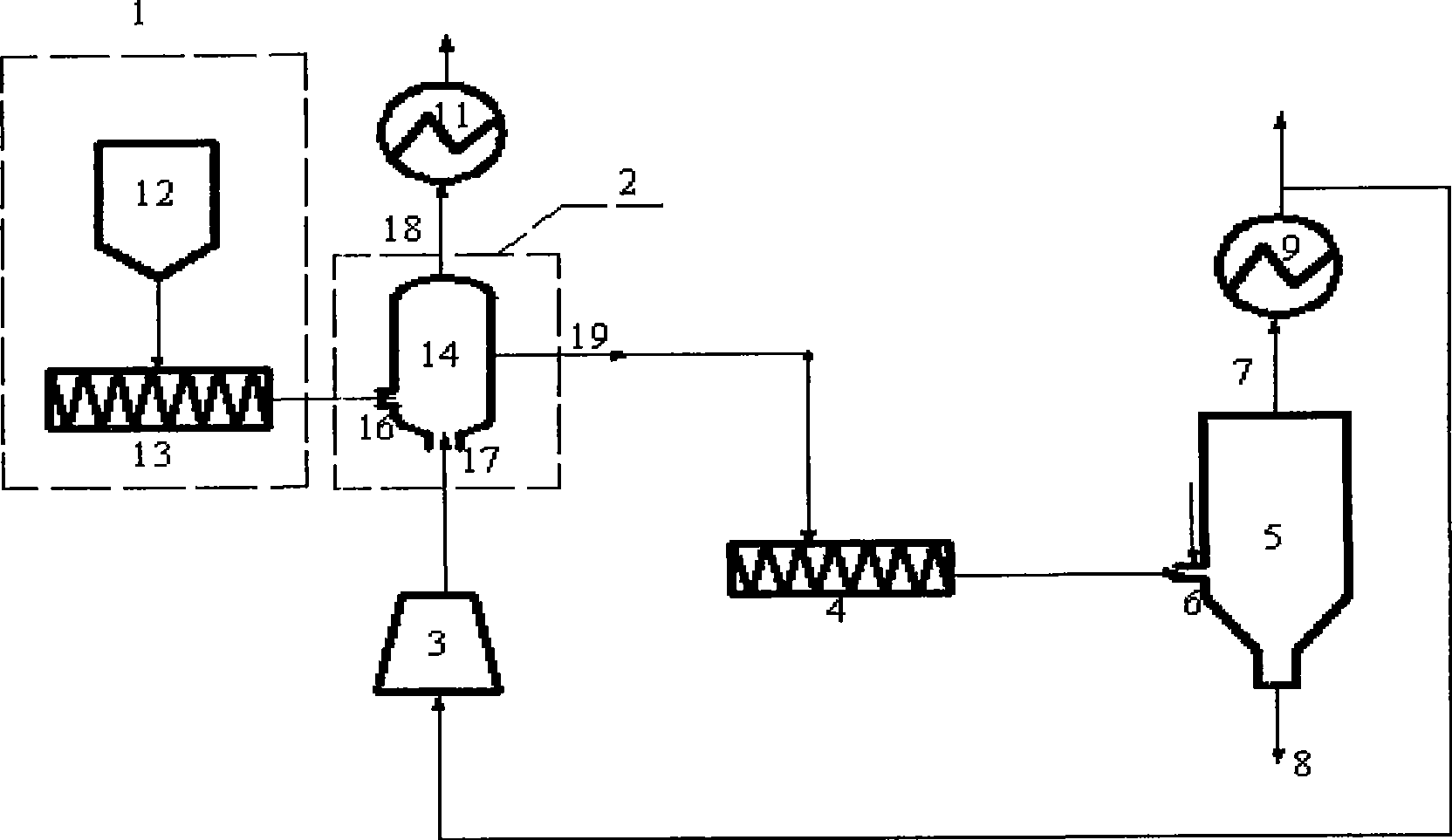

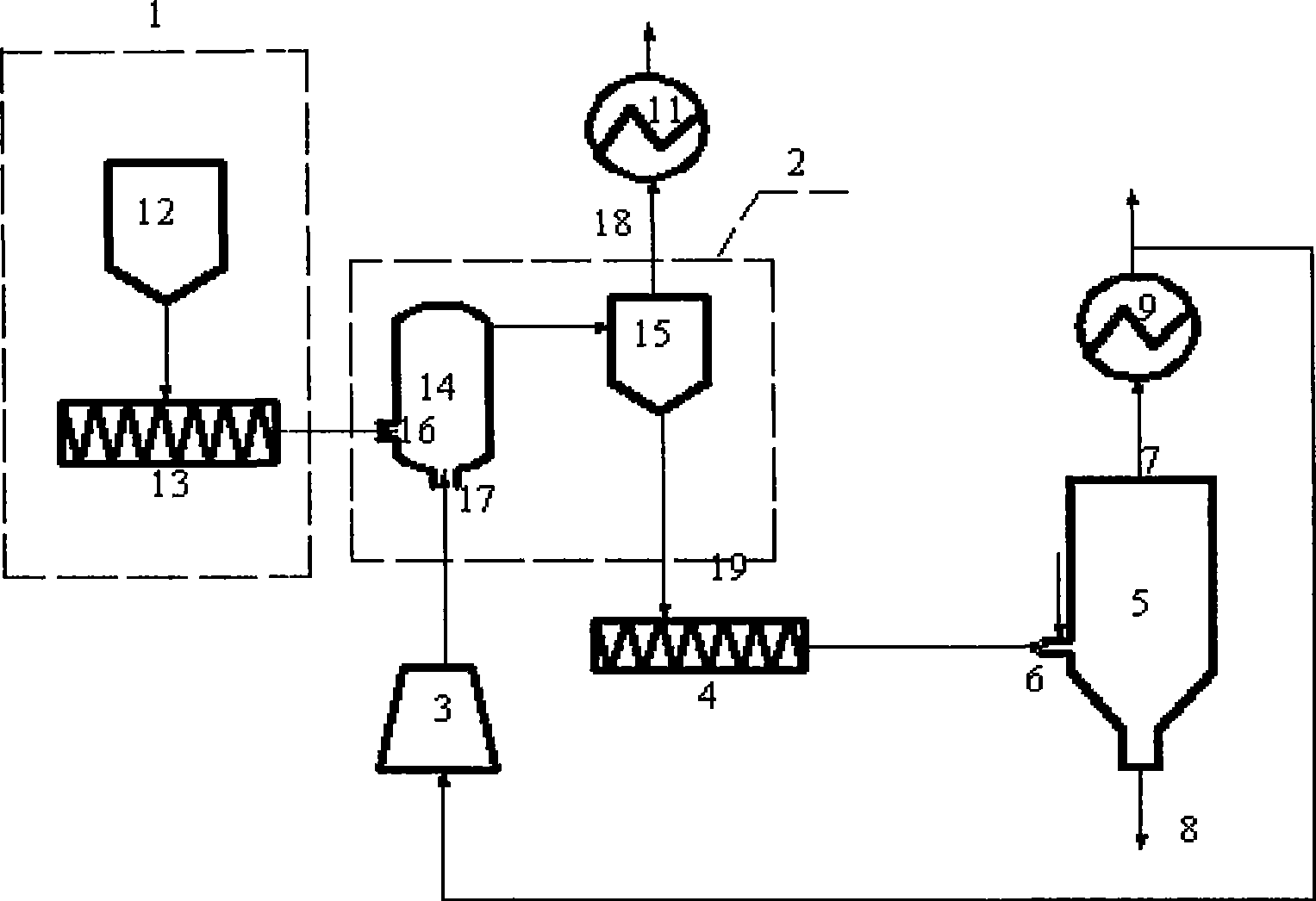

[0022] Method 1: If figure 1 As shown, the powdery carbon-containing raw material and powdery calcium-containing raw material are mixed in the solid raw material mixer, and then sent to the fluidized bed preheater through the screw feeder; The compression device is sent to the gas inlet at the bottom of the preheater; part of the carbon-containing raw material and the gas after heat exchange in the waste heat boiler are burned in the preheater under the action of oxygen-containing gas, and the raw material is heated to 700-1000°C to make the carbon-containing The raw material is pyrolyzed into coke powder, and the calcium-containing raw material is pyrolyzed into calcium oxide powder. The generated high-temperature gas is discharged through the tube-bundle heat exchanger after heat exchange, and the formed high-temperature solid mixture is sent to the raw material nozzle of the reactor through the U-shaped pneumatic valve feeder, and is sprayed into the reactor through the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com