Patents

Literature

2499 results about "Pneumatic valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

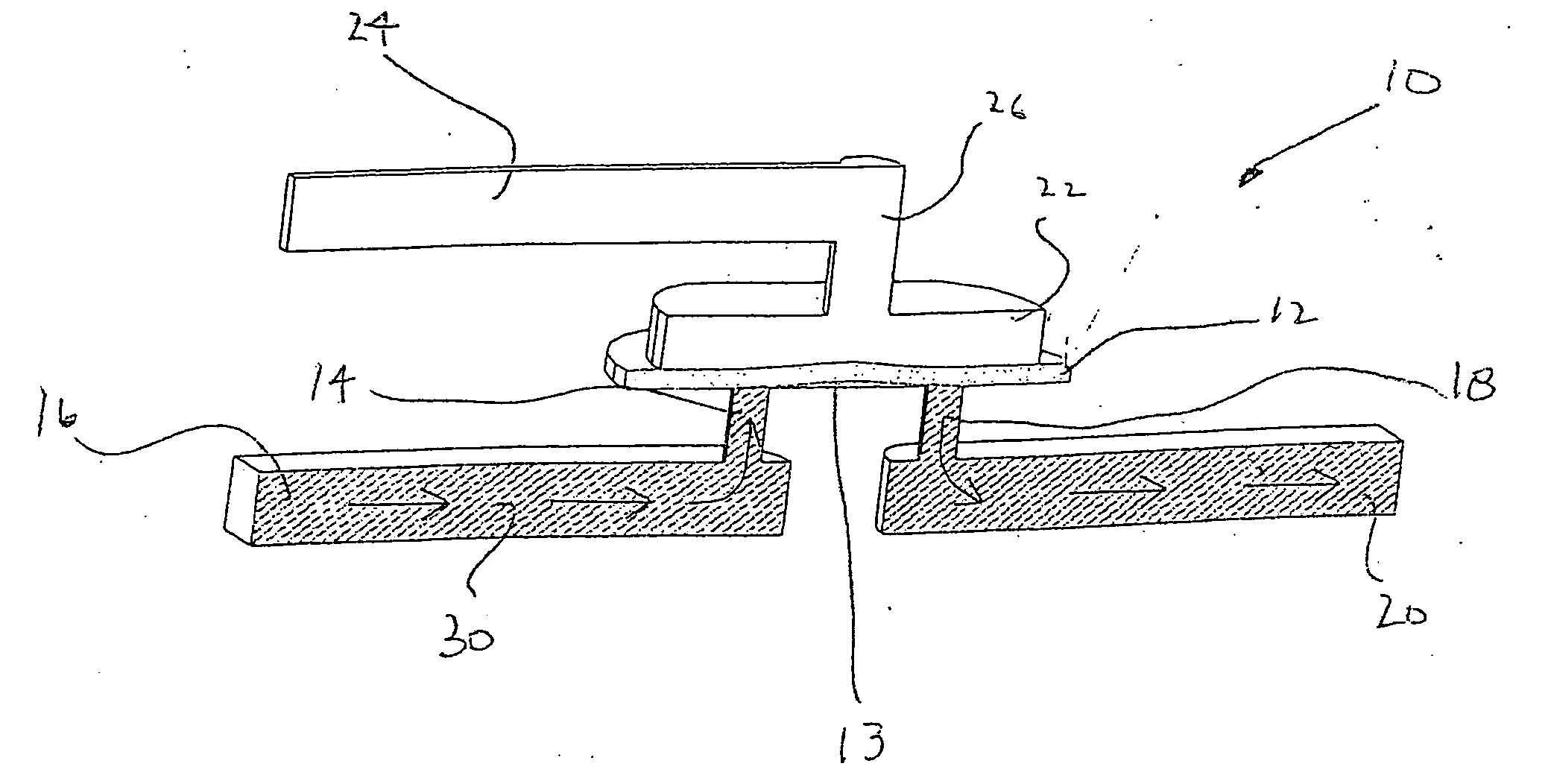

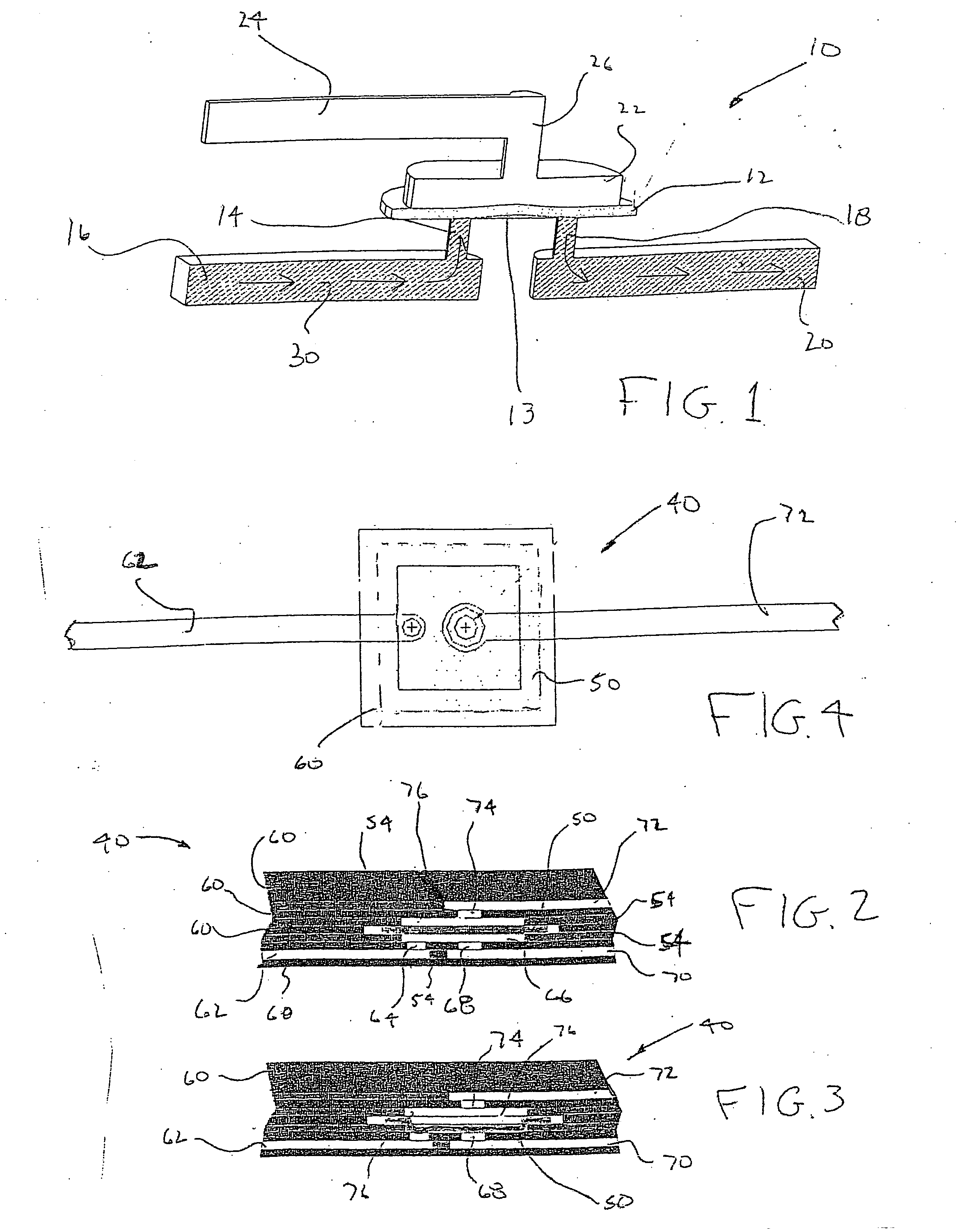

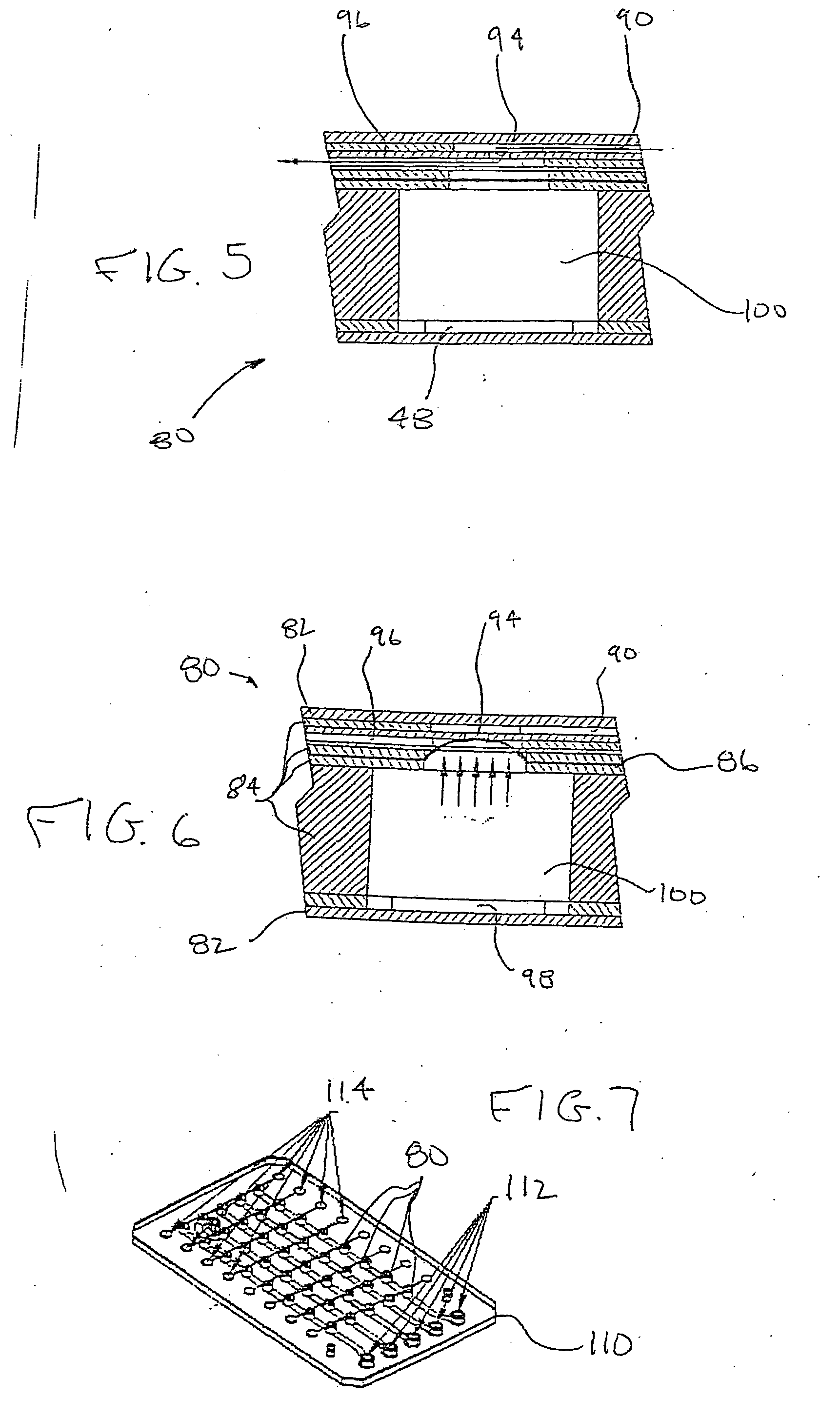

Pneumatic valve interface for use in microfluidic structures

A pneumatic valve for use in laminated plastic microfluidic structures. This zero or low dead volume valve allows flow through microfluidic channels for use in mixing, dilution, particulate suspension and other techniques necessary for flow control in analytical devices.

Owner:PERKINELMER HEALTH SCIENCES INC

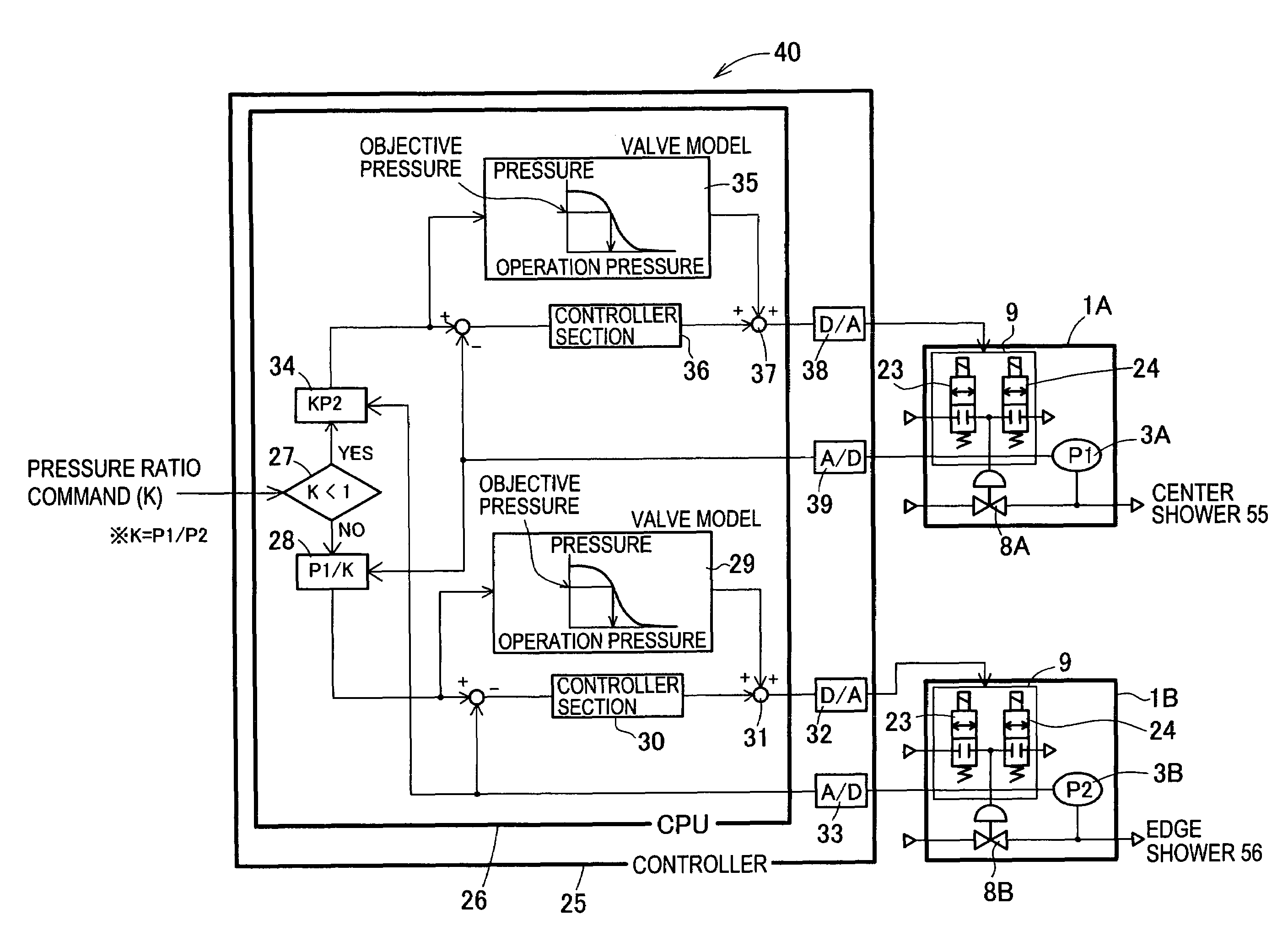

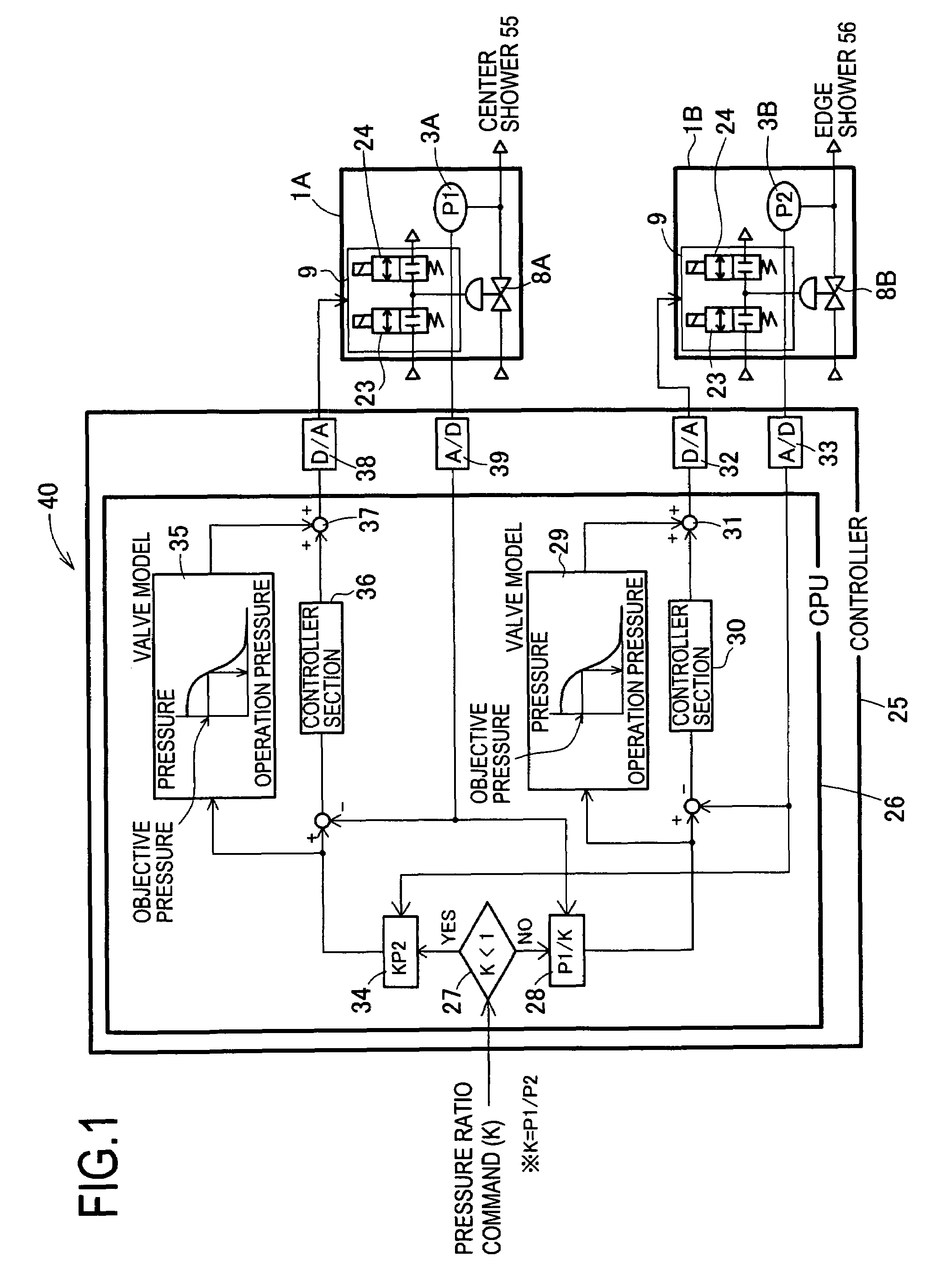

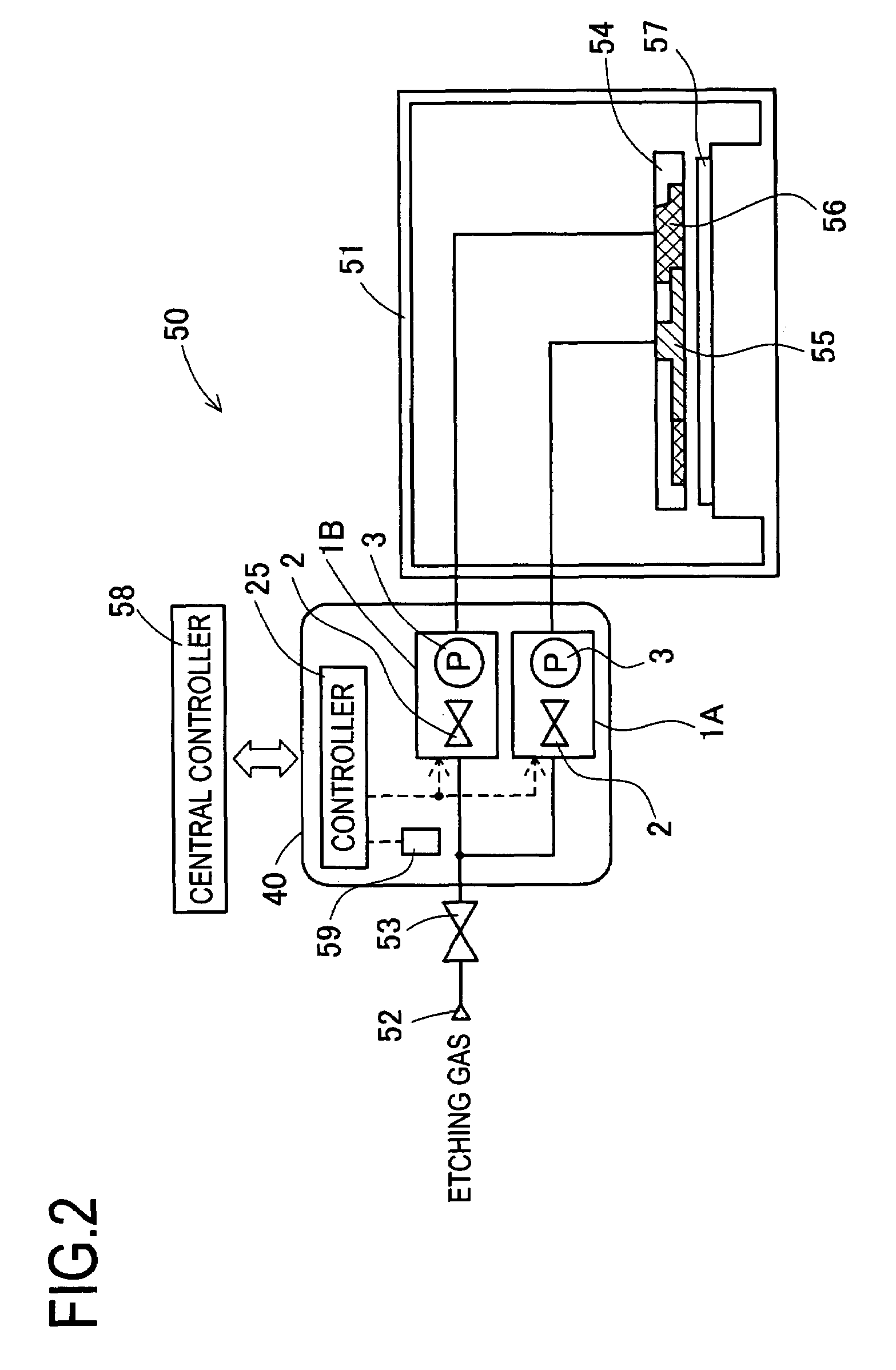

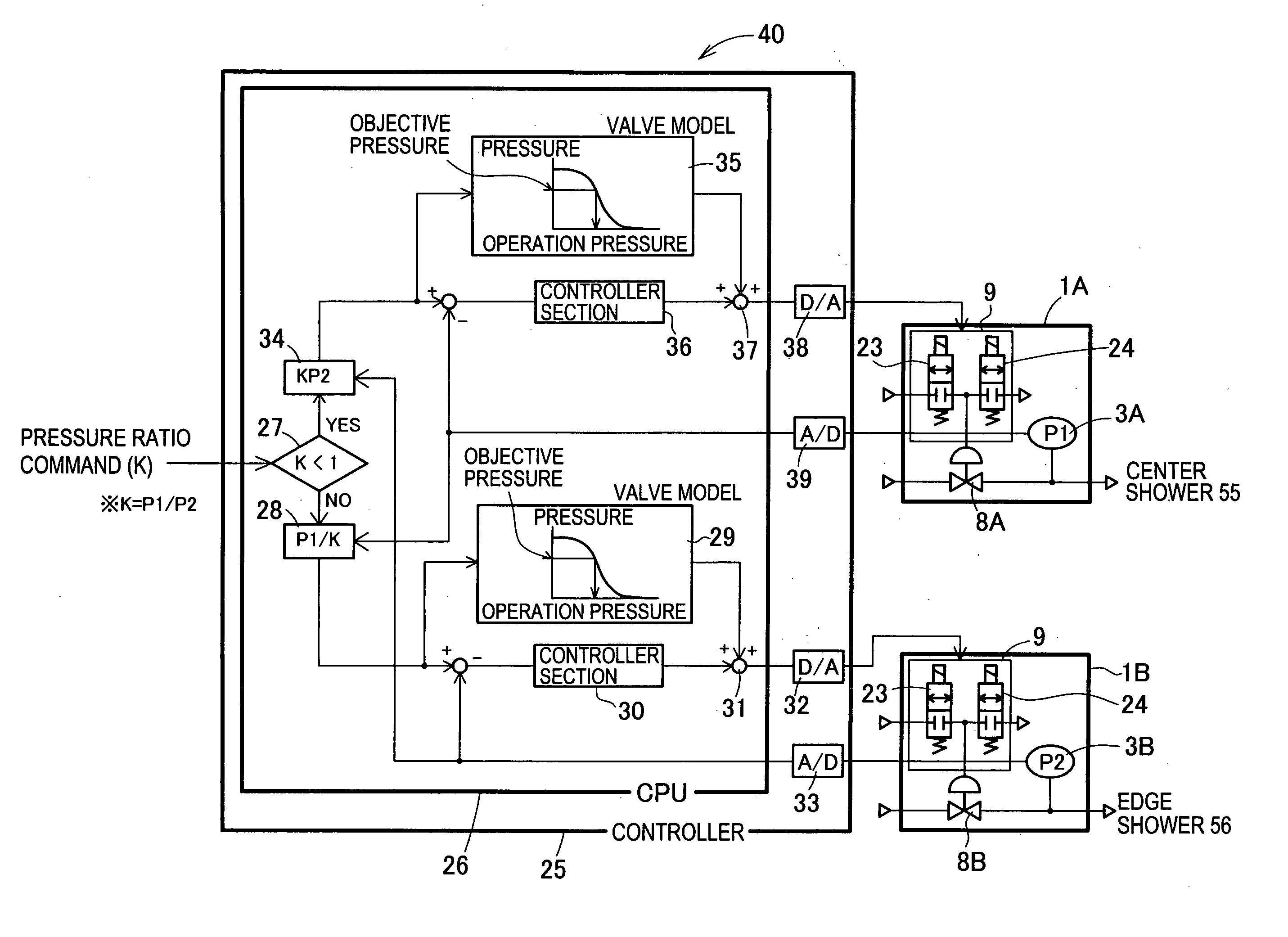

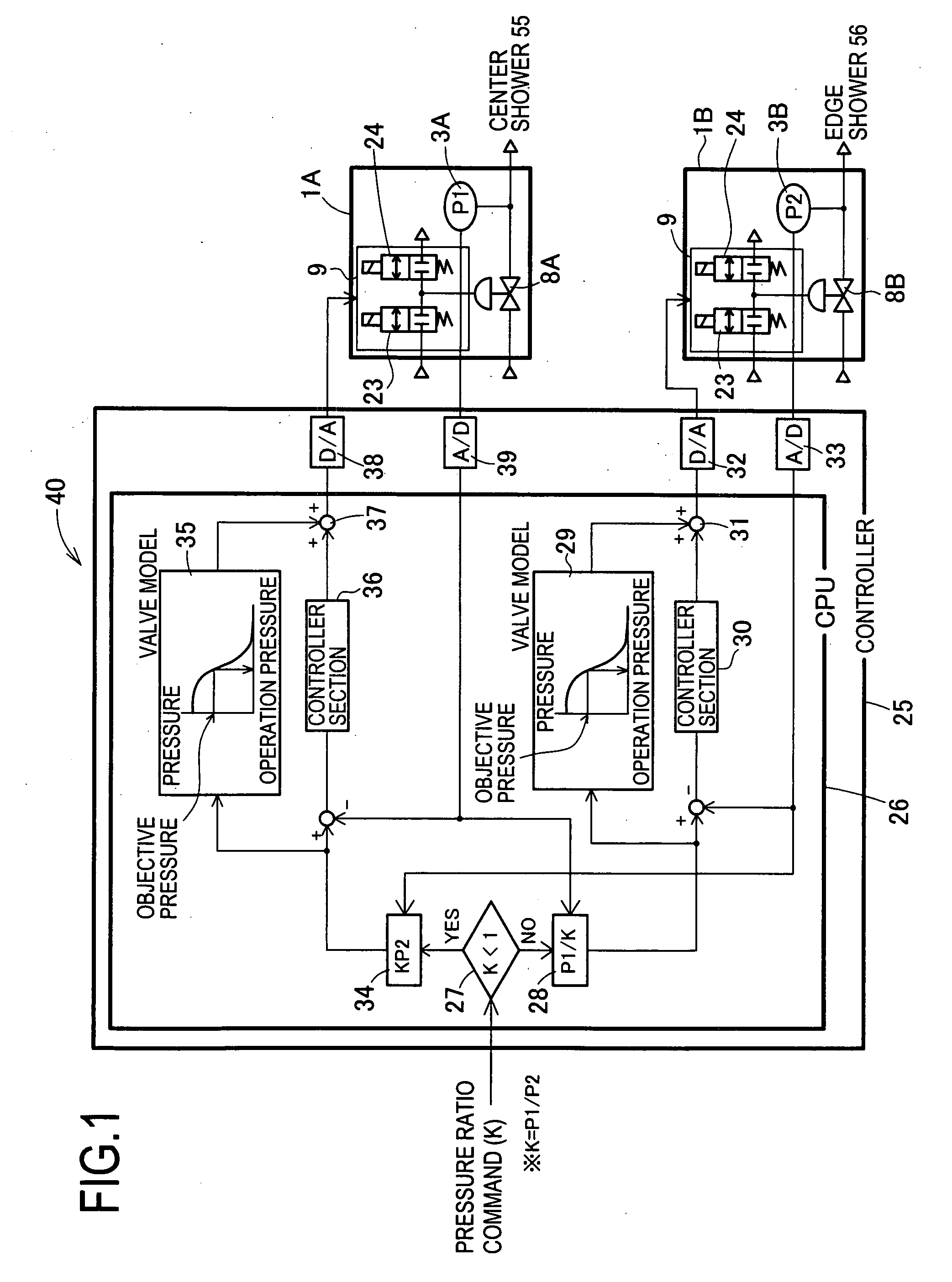

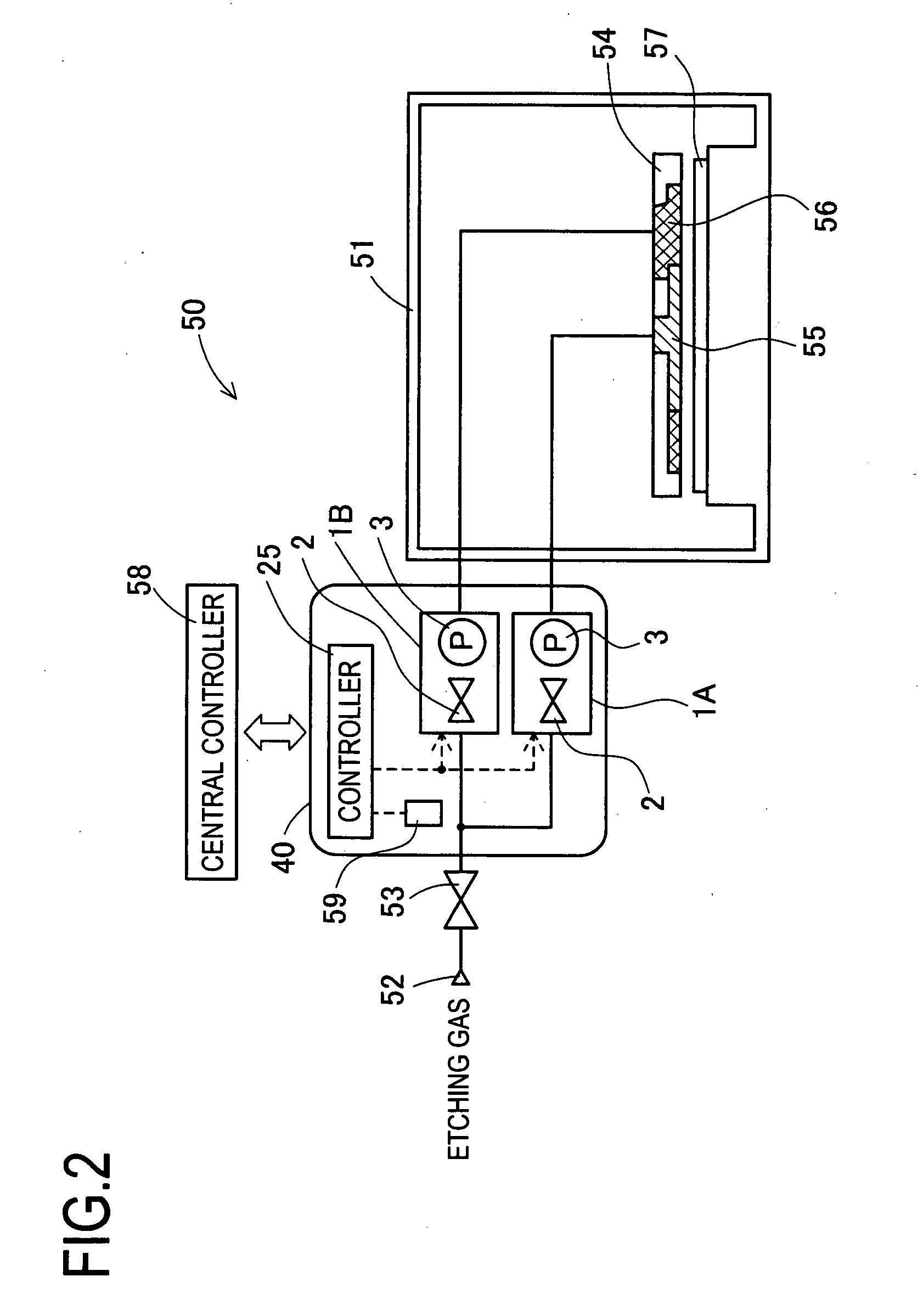

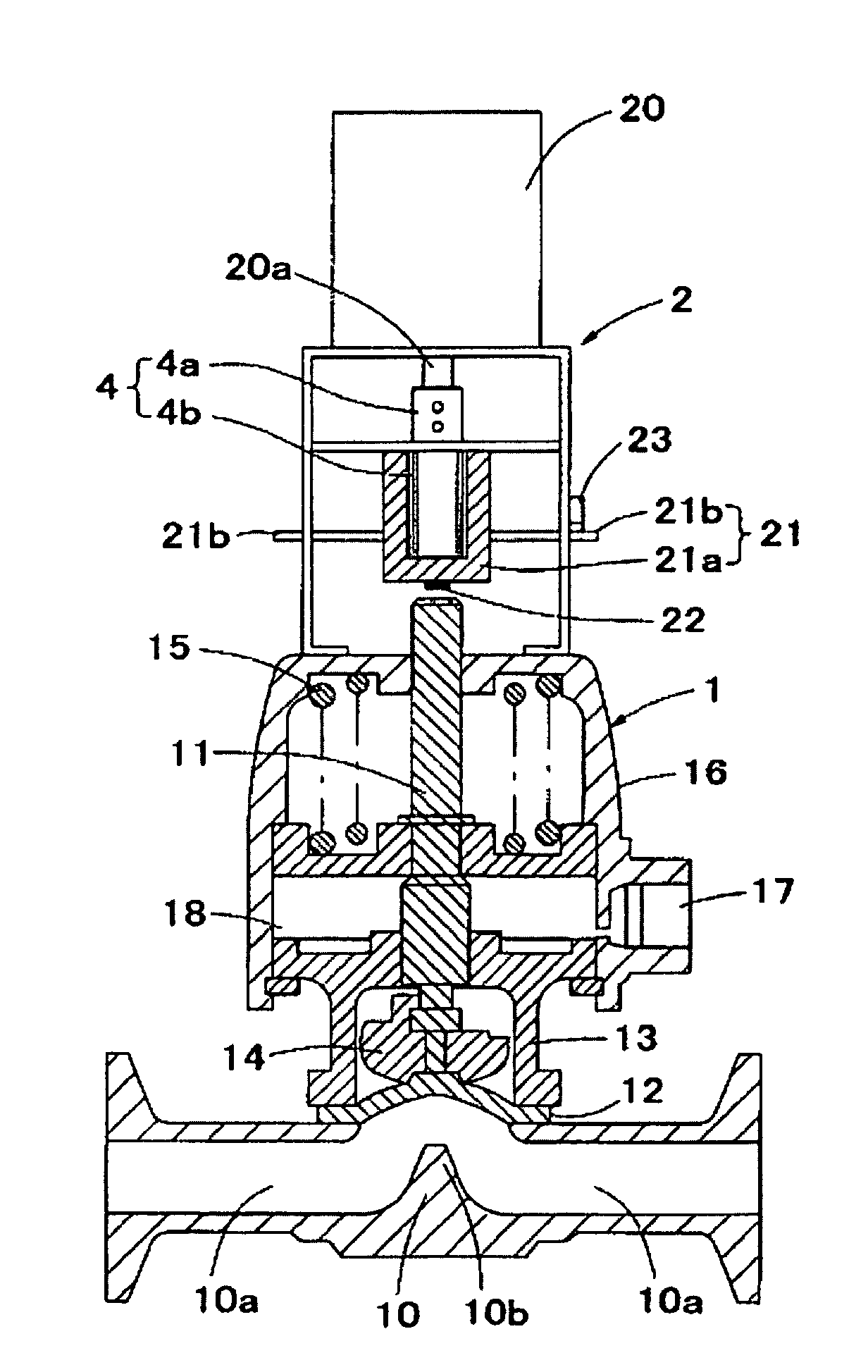

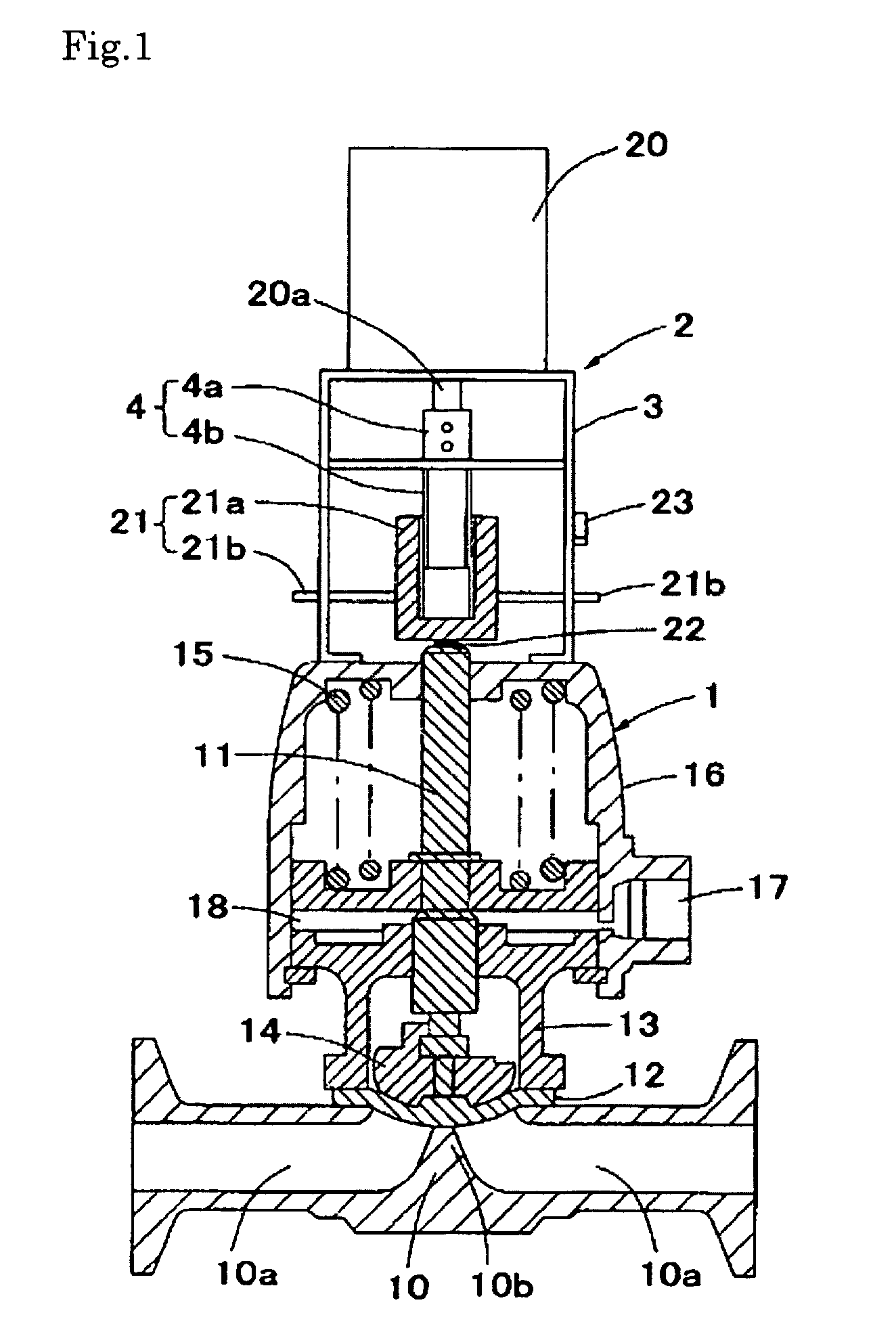

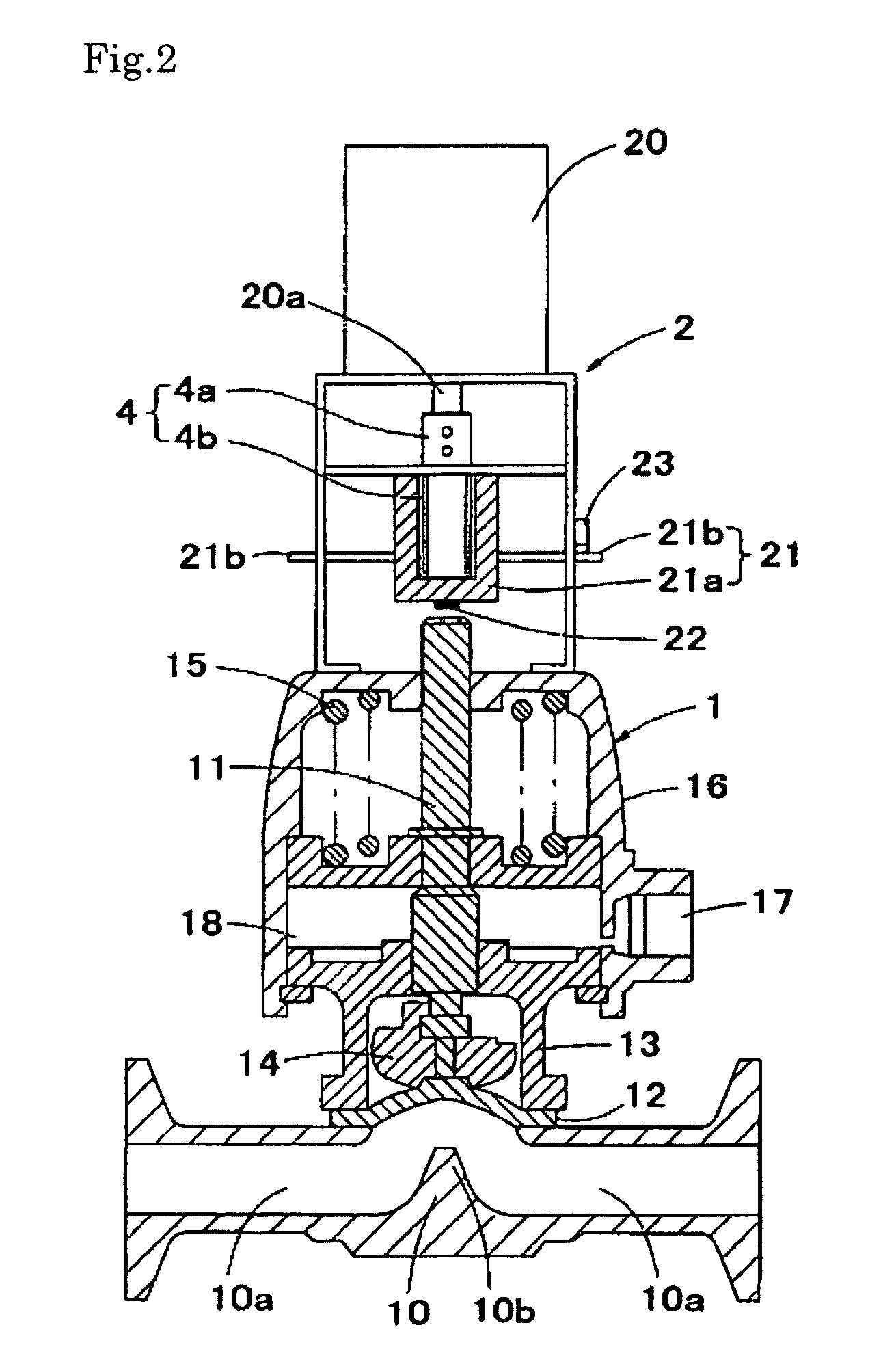

Relative pressure control system and relative flow control system

ActiveUS7353841B2Accurate supervisionReduce the amount of controlOperating means/releasing devices for valvesControlling ratio of multiple fluid flowsRelative pressureSolenoid valve

Provided is a relative pressure control system has a simple configuration, but enables accurate regulation of a division ratio of an operation gas, and concurrently makes it possible to securely drain the operation gas from an operation gas pipeline in case of emergency. The system includes a plurality of air operated valves of a normally open type that are connected to an operation gas pipeline supplied with an operation gas; pressure sensors that are series connected to the respective air operated valves and that detect output pressures of the respective air operated valves; a controller that controls operation pressures of the respective air operated valves in accordance with the pressures detected by the pressure sensors; and a hard interlock solenoid valve that correlates the plurality of air operated valves to one another so that at least one of the plurality of air operated valves is normally opened. In the configuration, an opening of a specified one of the plurality of air operated valves is regulated, the operation gas is output at a predetermined division ratio.

Owner:CKD +1

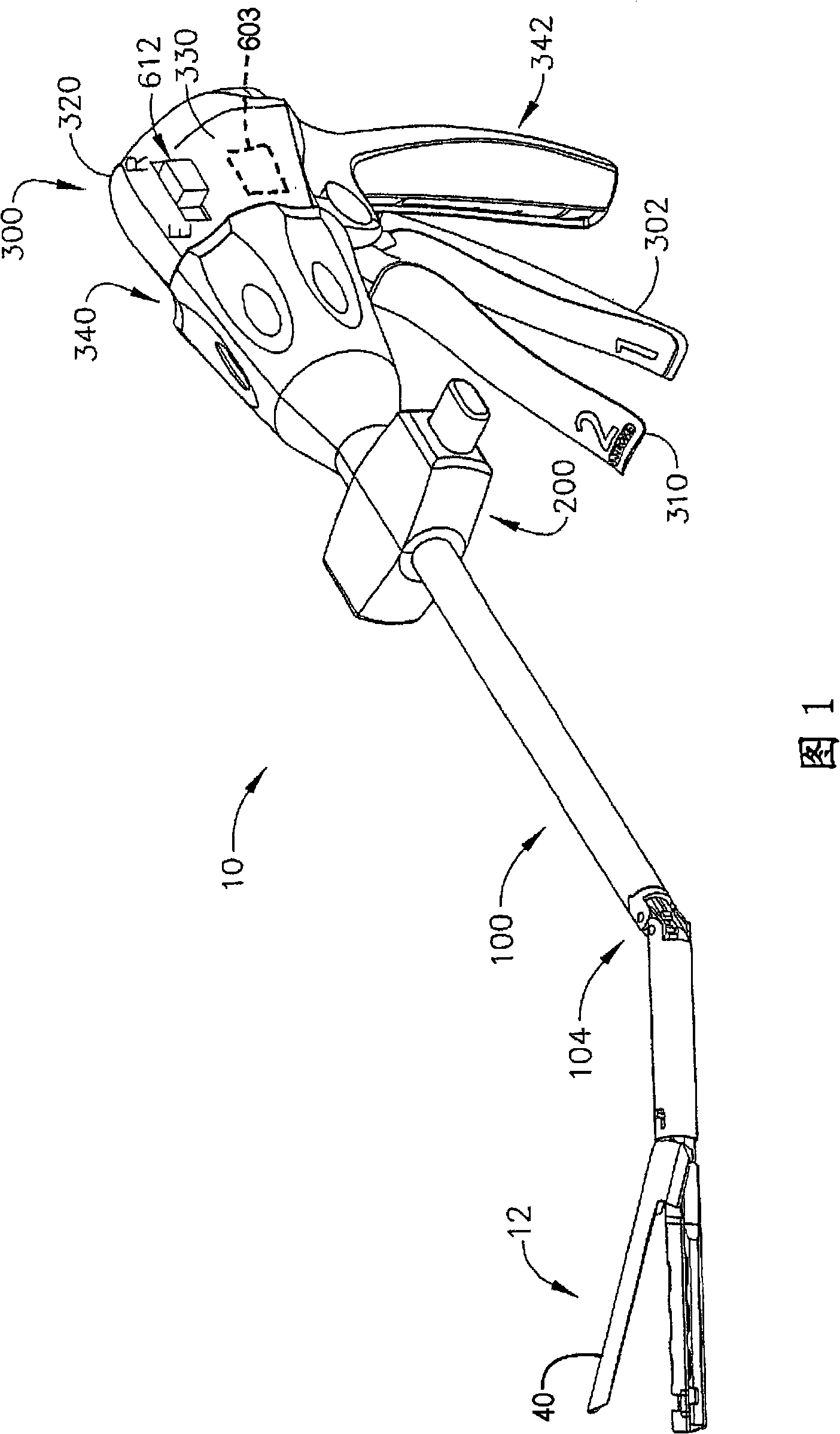

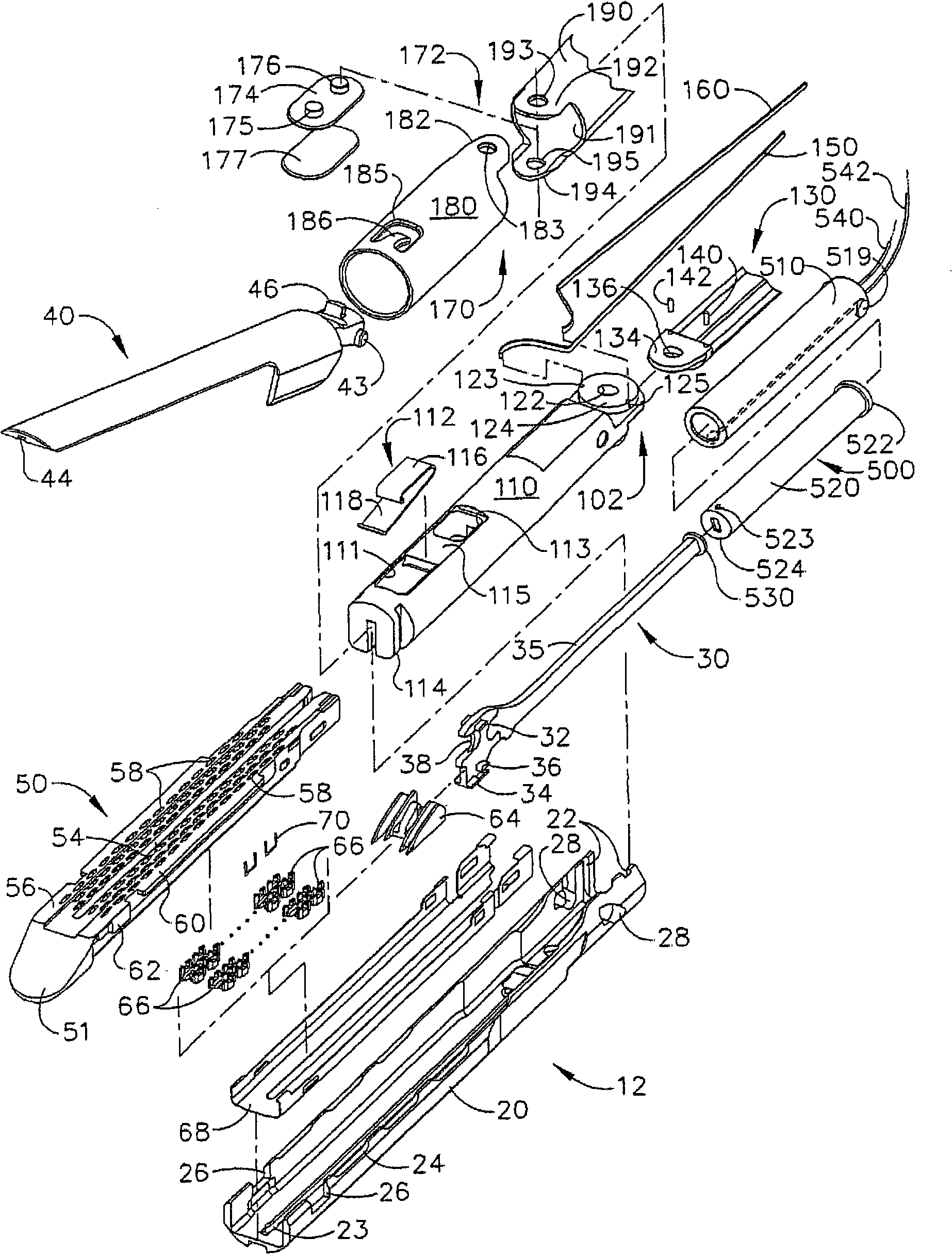

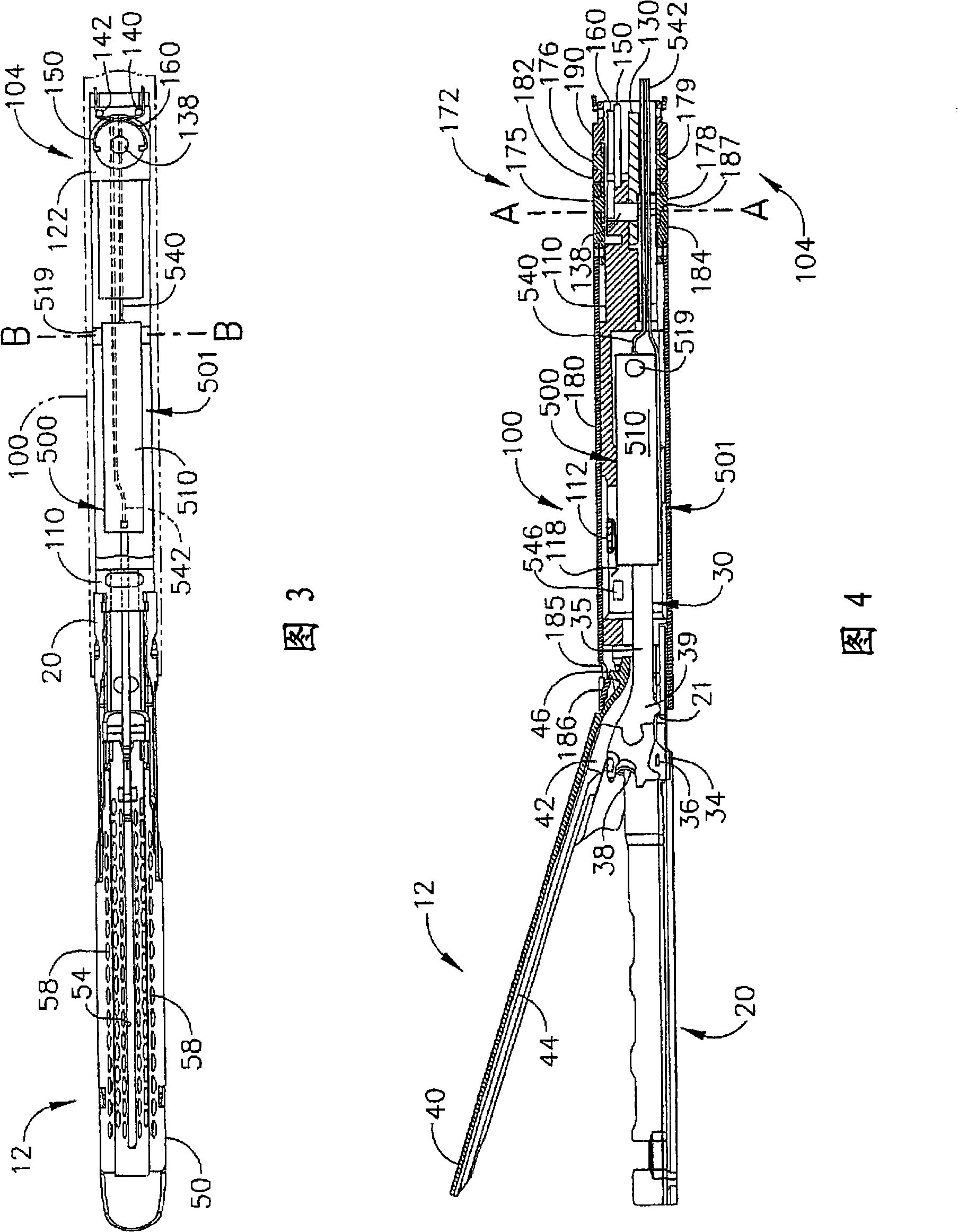

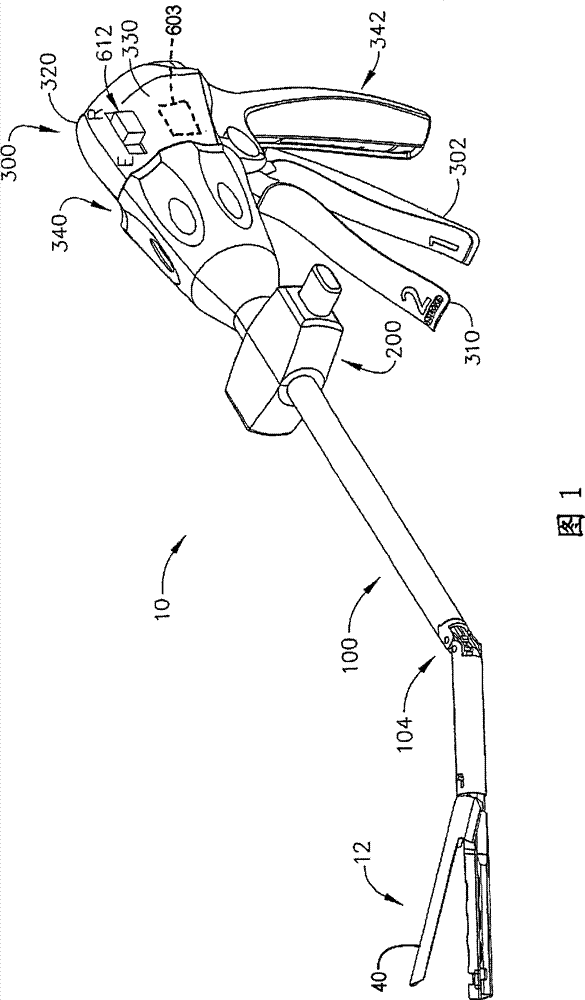

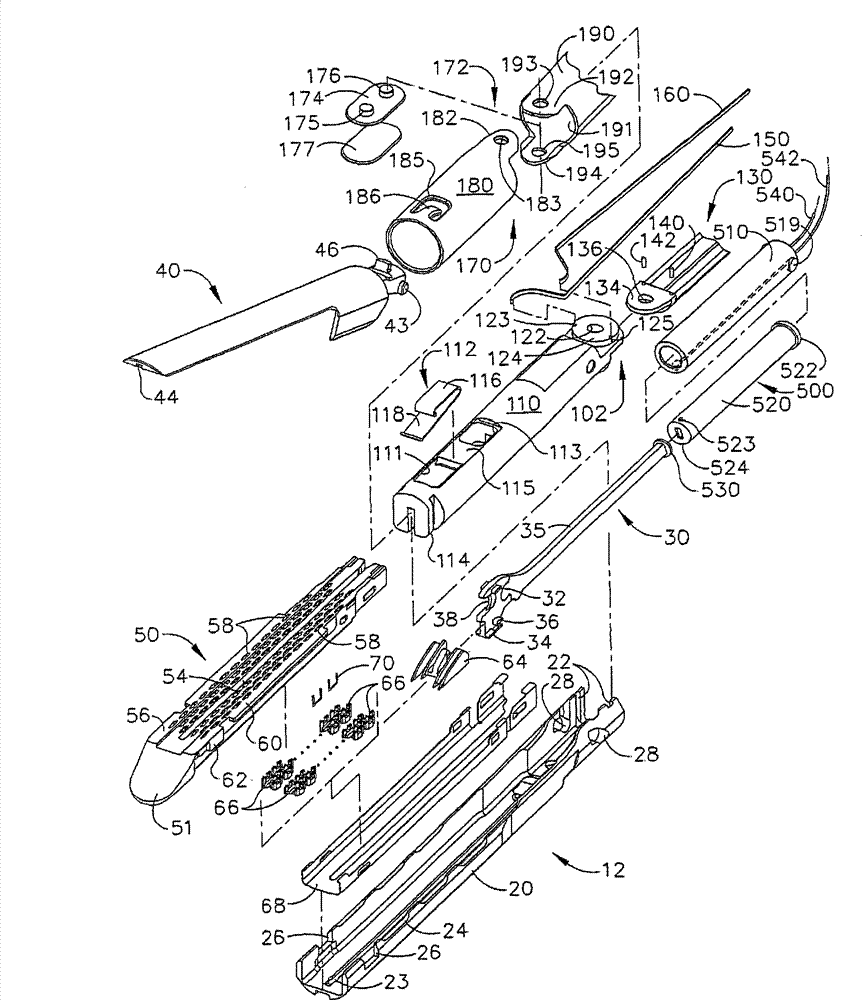

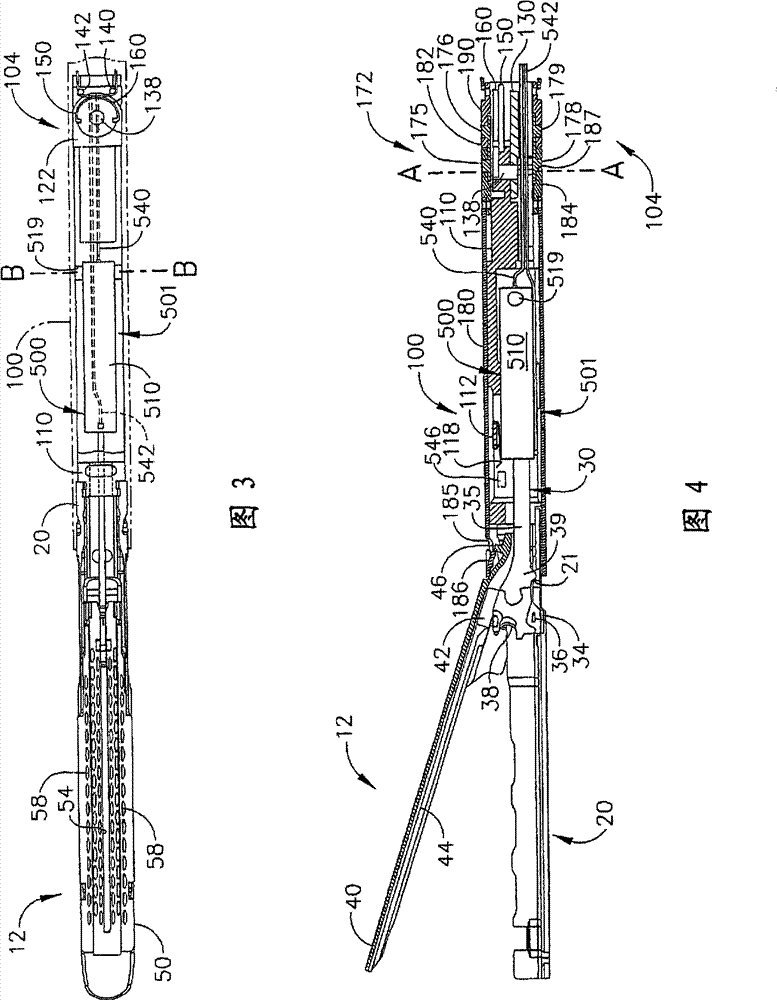

Pneumatically powered surgical cutting and fastening instrument with electrical control and recording mechanisms

The present invention discloses a pneumatically powered surgical cutting and fastening instrument with electrical control and recording mechanisms. A surgical instrument includes an end effector. A moveable cutting instrument for cutting an object positioned in the end effector is disposed within the end effector. A pneumatically-actuated drive member is coupled to the end effector. An electrically controlled variable flow rate pneumatic valve is coupled to the pneumatically-actuated drive member. An electronic control module is coupled to an electrically controlled variable flow rate pneumatic valve to control the flow rate therethrough.

Owner:ETHICON ENDO SURGERY INC

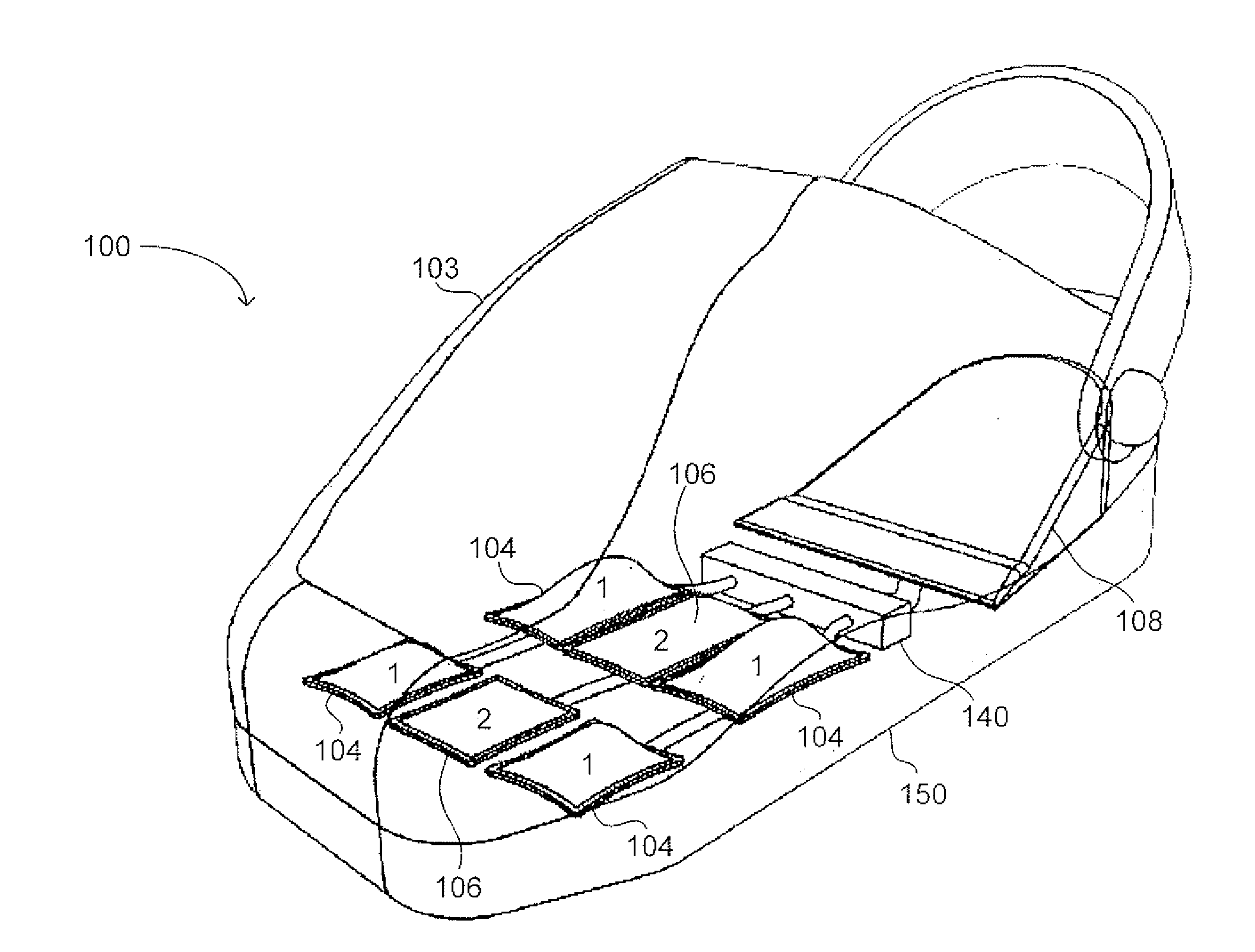

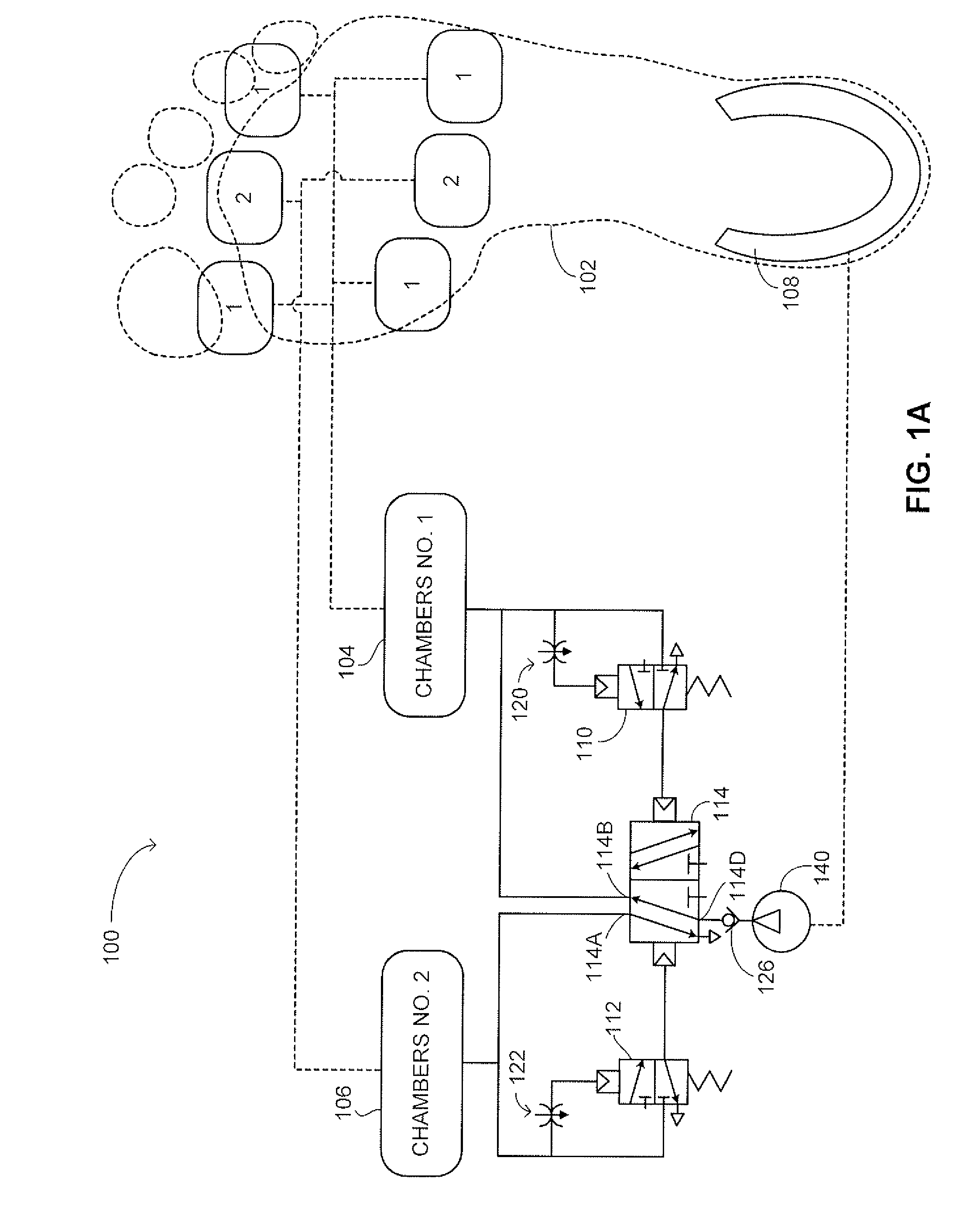

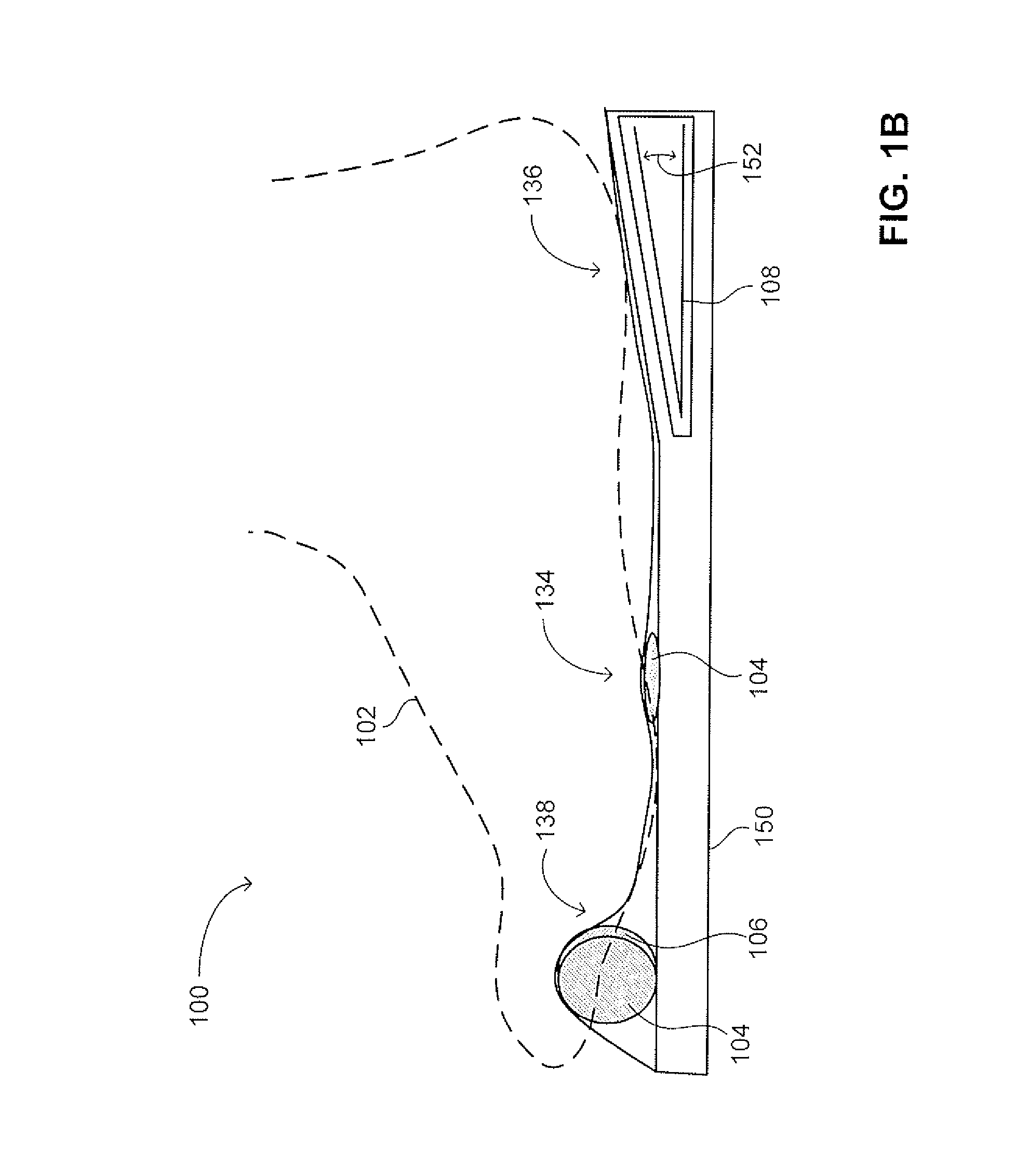

Pneumatic Alternating Pressure Relief of a Foot

A system for alternately applying and relieving pressure of predetermined portions of a foot of a user. The system includes a plurality of inflatable chambers, located at predetermined locations, corresponding to the predetermined portions of the foot and a pump. The system also includes a center pneumatic valve, coupled with the pump and with the inflatable chambers, for receiving air from the pump and inflating at least one of the inflatable chambers. The system further includes a pneumatic valve assembly, coupled with the center pneumatic valve. The pneumatic valve assembly is coupled with at least a respective one of the inflatable chambers. The pneumatic valve assembly is moveable between two positions, and changes position when a predetermined pressure value is achieved in the corresponding inflatable chamber. When the pneumatic valve assembly changes position, the center pneumatic valve changes position, thereby inflating another inflatable chamber.

Owner:C BOOT

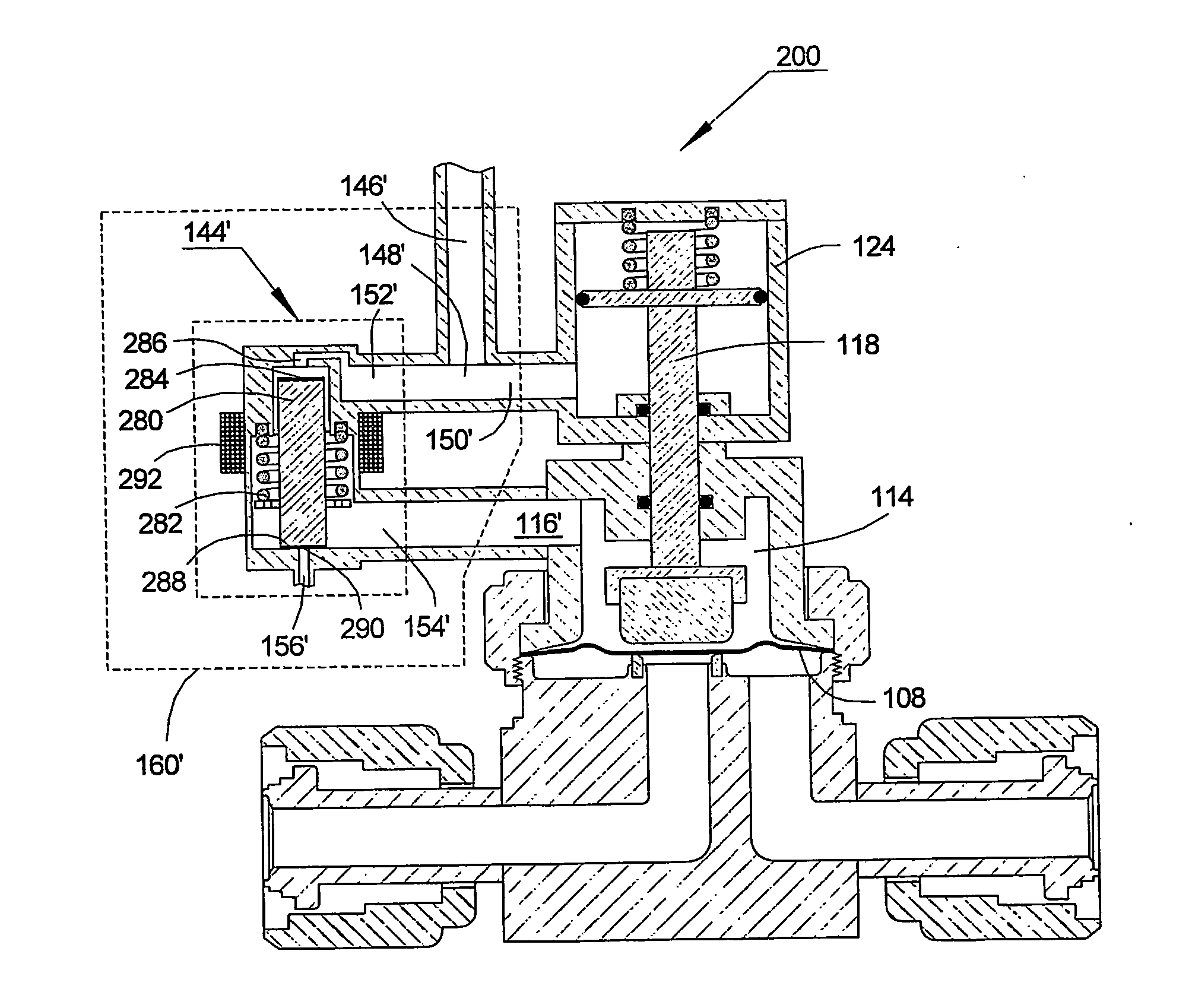

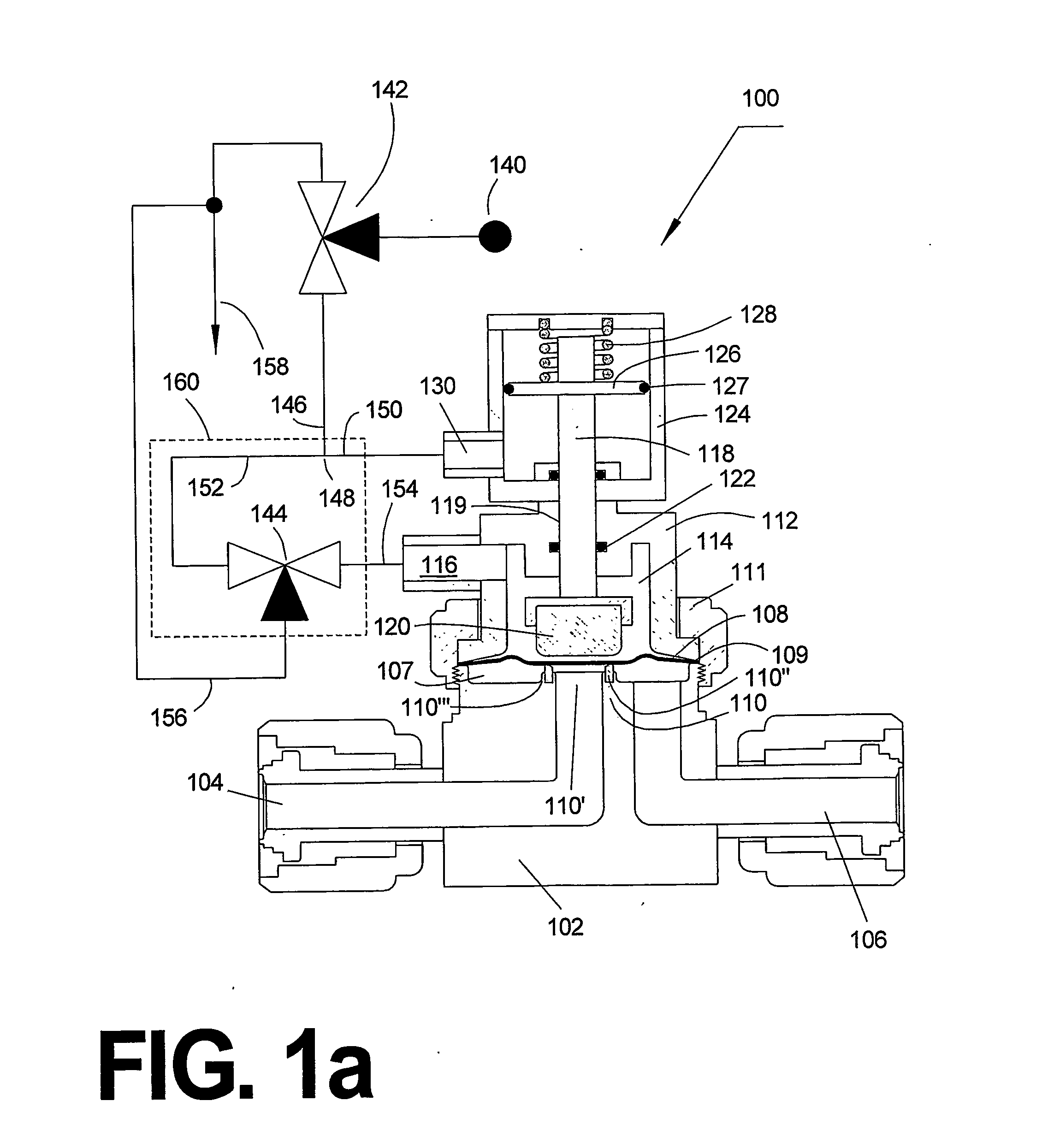

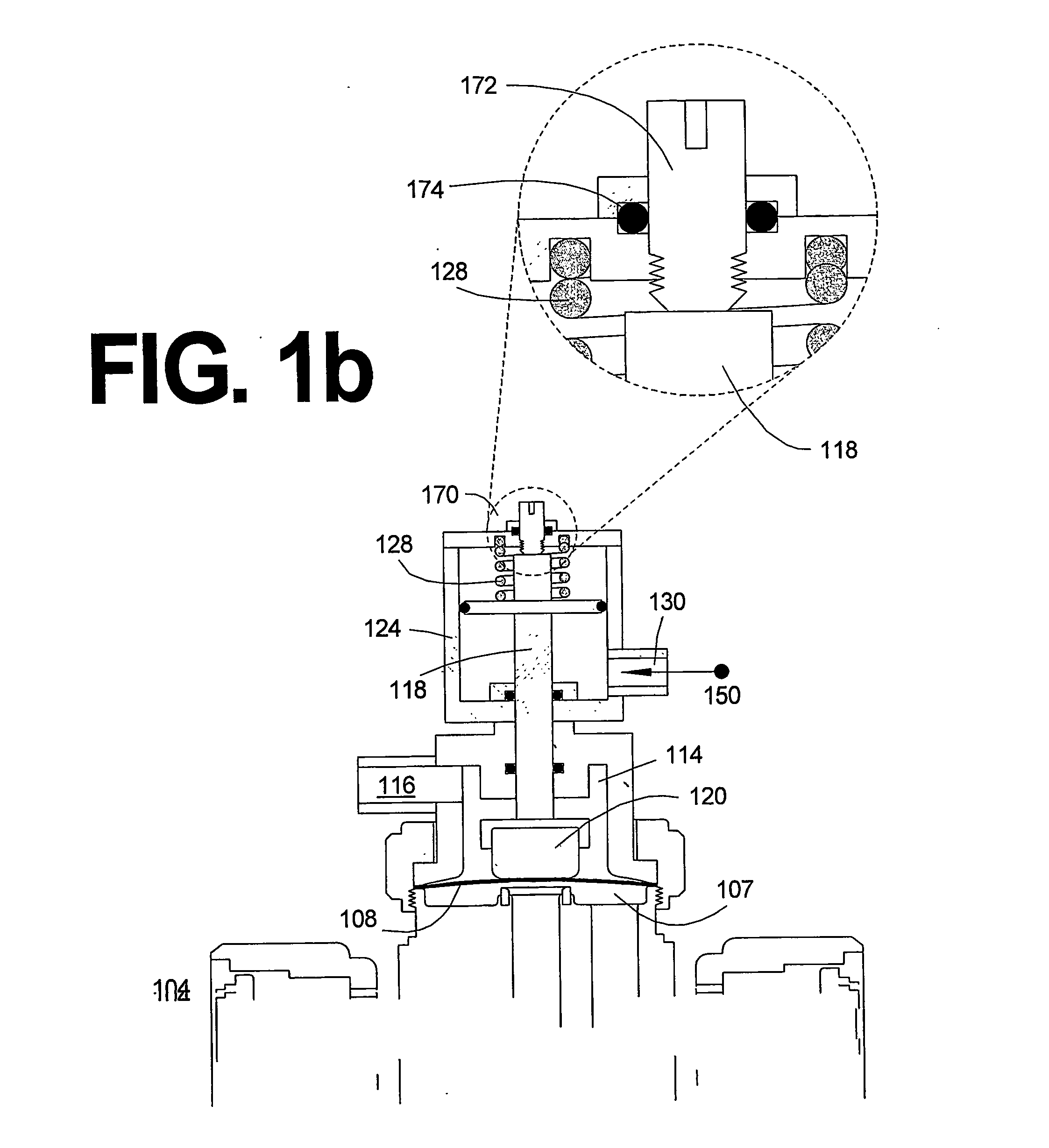

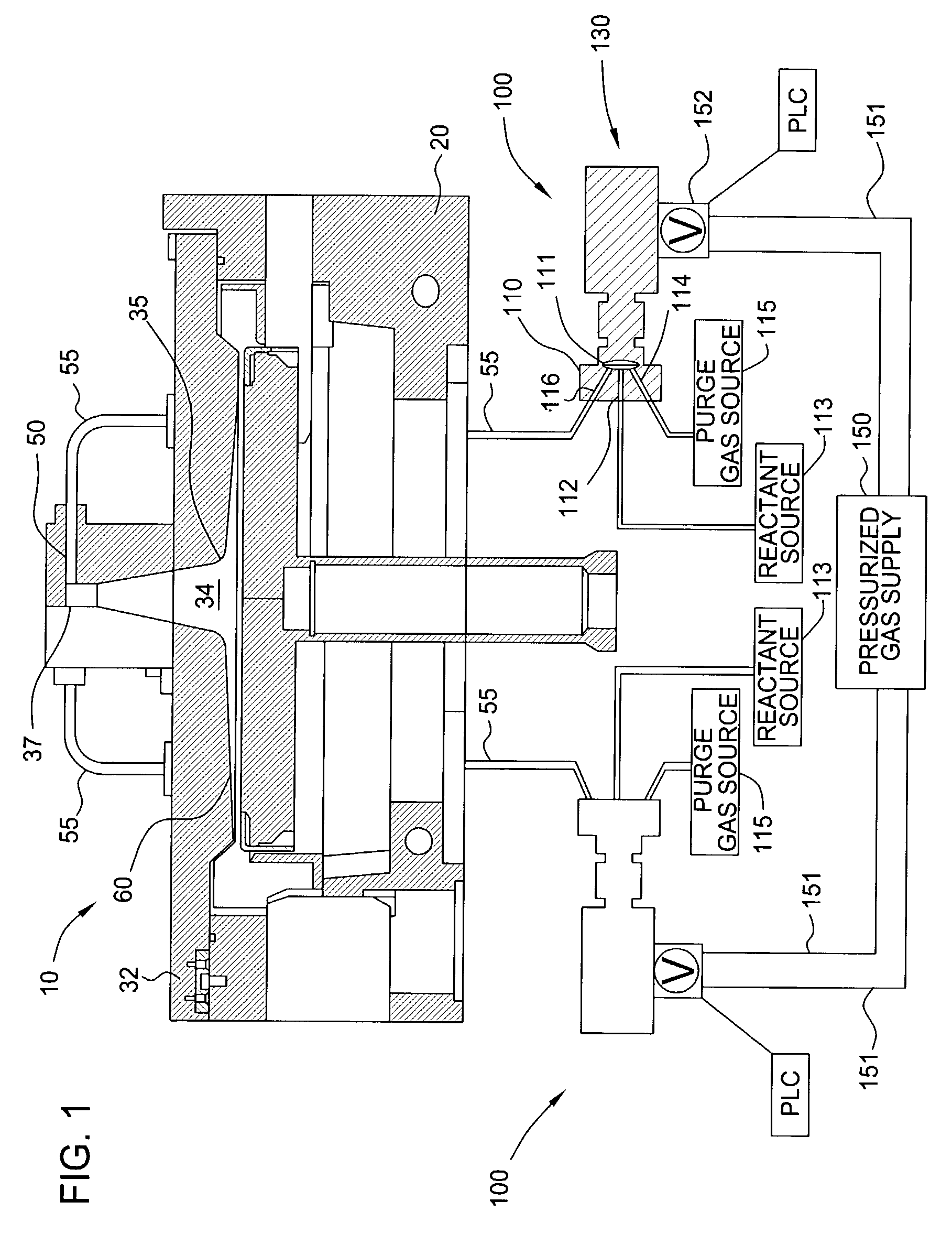

Fail-safe pneumatically actuated valve with fast time response and adjustable conductance

ActiveUS20070187634A1Improve cycle lifeImprove securityDiaphragm valvesOperating means/releasing devices for valvesEngineeringAtomic layer deposition

Apparatus and method for fail-safe high-speed-pneumatic valve is disclosed. Fail-safe dependability is provided by a spring-loaded normally-closed pneumatic actuator. When the spring-loaded actuator is pressurized, the normally closed mechanism is actuated to the valve active position. Concurrently, the pressure is directly applied to deflect a diaphragm or a bellow-assembly back to sealing position. Ultra high purity embodiments with standard dome shaped diaphragms are disclosed. Additional high conductance diaphragms and bellows embodiments are employed for higher conductance valves. Novel flow path layouts are disclosed. The valves are applicable for fast gas and fluid switching and are particularly suitable for high productivity Atomic Layer Deposition (ALD) applications. Additional embodiments cover improved diaphragm and seal reliability, externally adjustable valve conductance, improved valve safety and high temperature valve seals.

Owner:SUNDEW TECH

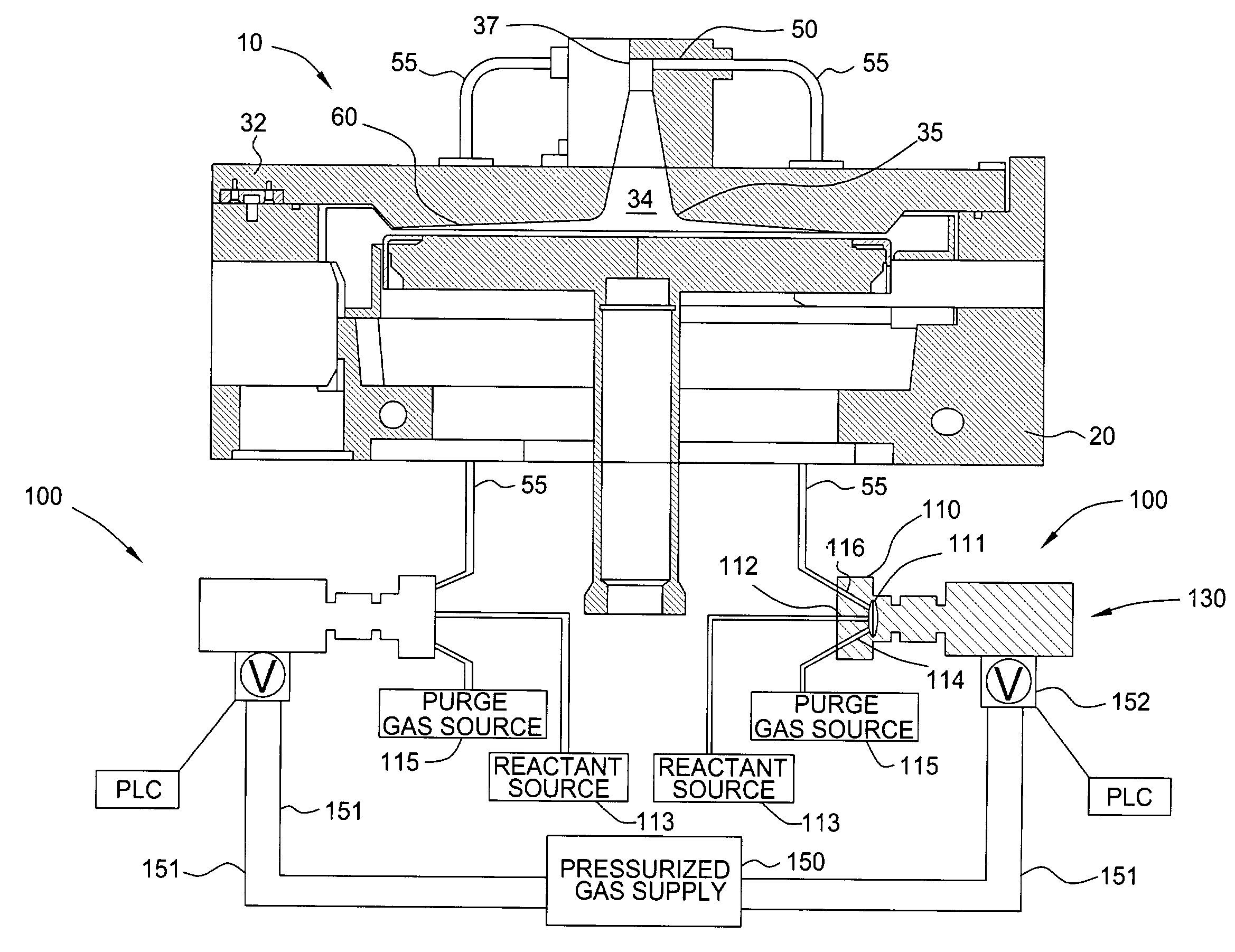

Valve design and configuration for fast delivery system

Embodiments of the present invention relate to a method and apparatus for rapid delivery of pulses of one or more reactants to a substrate processing chamber. One embodiment of a valve body includes a first inlet, a second inlet, and an outlet. A valve chamber is in fluid communication with the first inlet, the second inlet, and the outlet. A valve seat is formed at least around the first inlet. The valve chamber further includes an annular groove formed around the valve seat coupling the second inlet and the outlet. One embodiment of a pneumatic valve assembly includes a valve body having at least two ports. A valve seat surrounds one of the ports. The pneumatic valve assembly further includes a diaphragm assembly having a diaphragm movable to open and close the one port. A piston housed in a cylinder is coupled to the diaphragm to actuate the diaphragm. An actuation chamber is formed between the cylinder and the piston. In certain embodiments, the internal volume of the actuation chamber is about 3.0 cm3 or less.

Owner:APPLIED MATERIALS INC

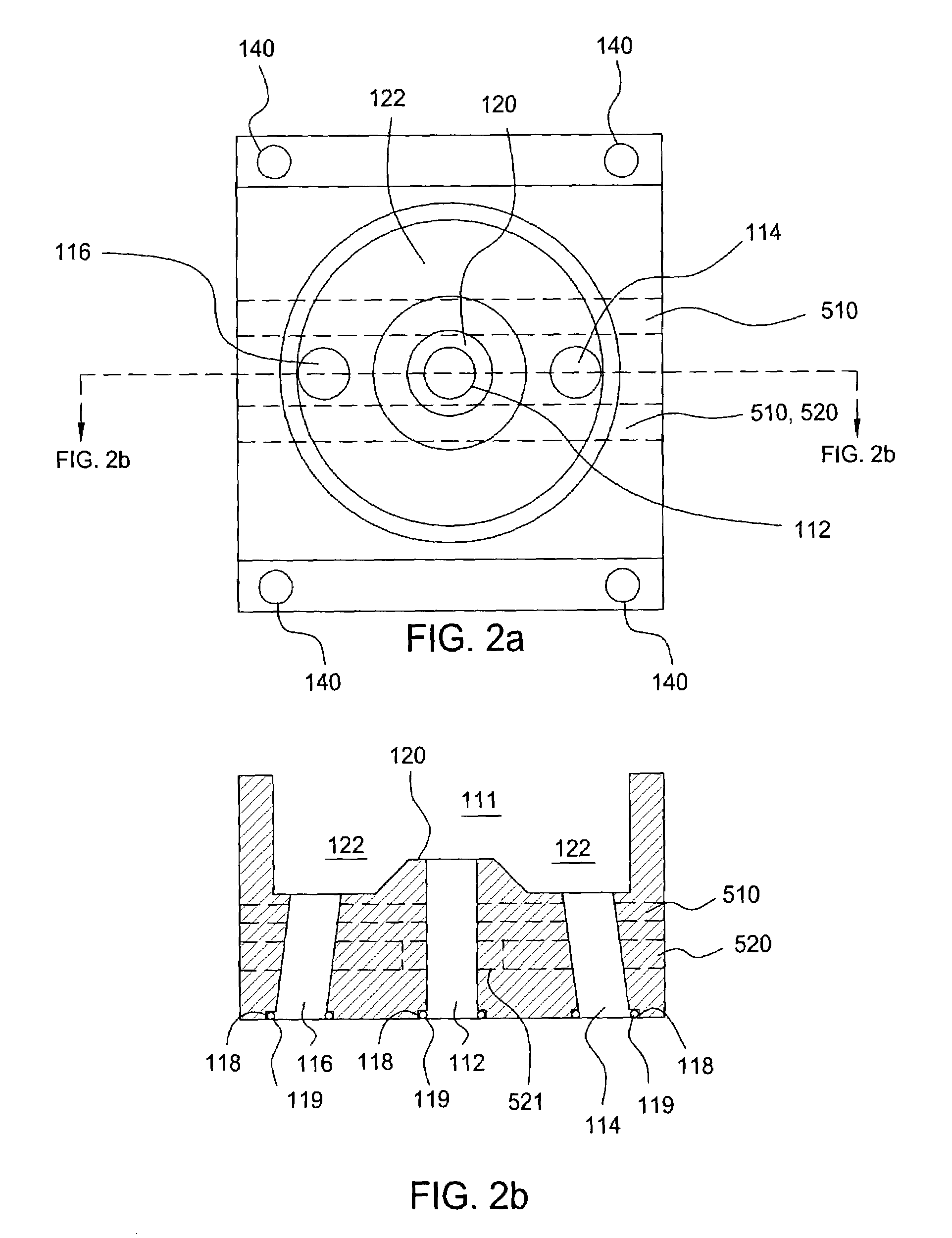

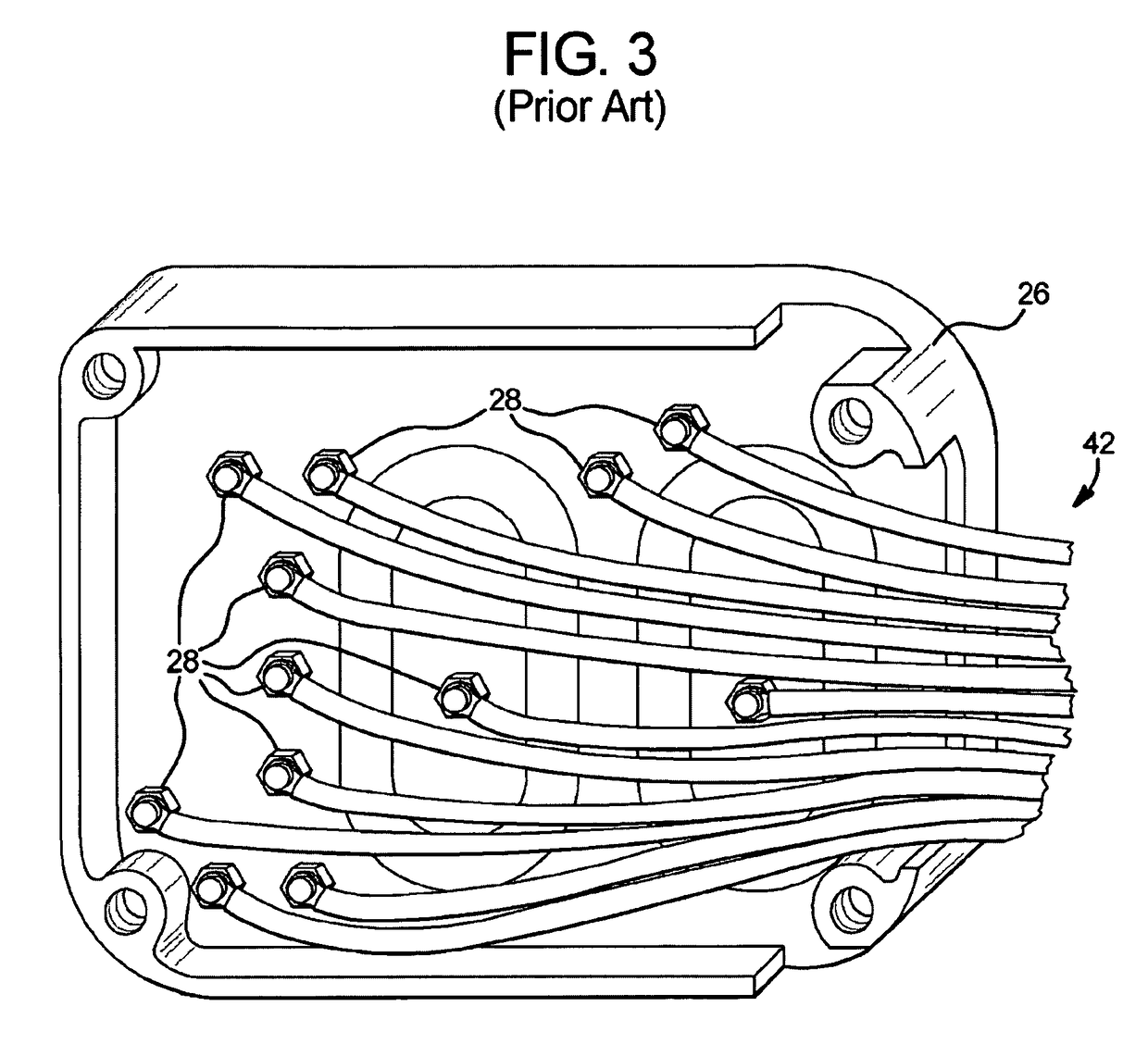

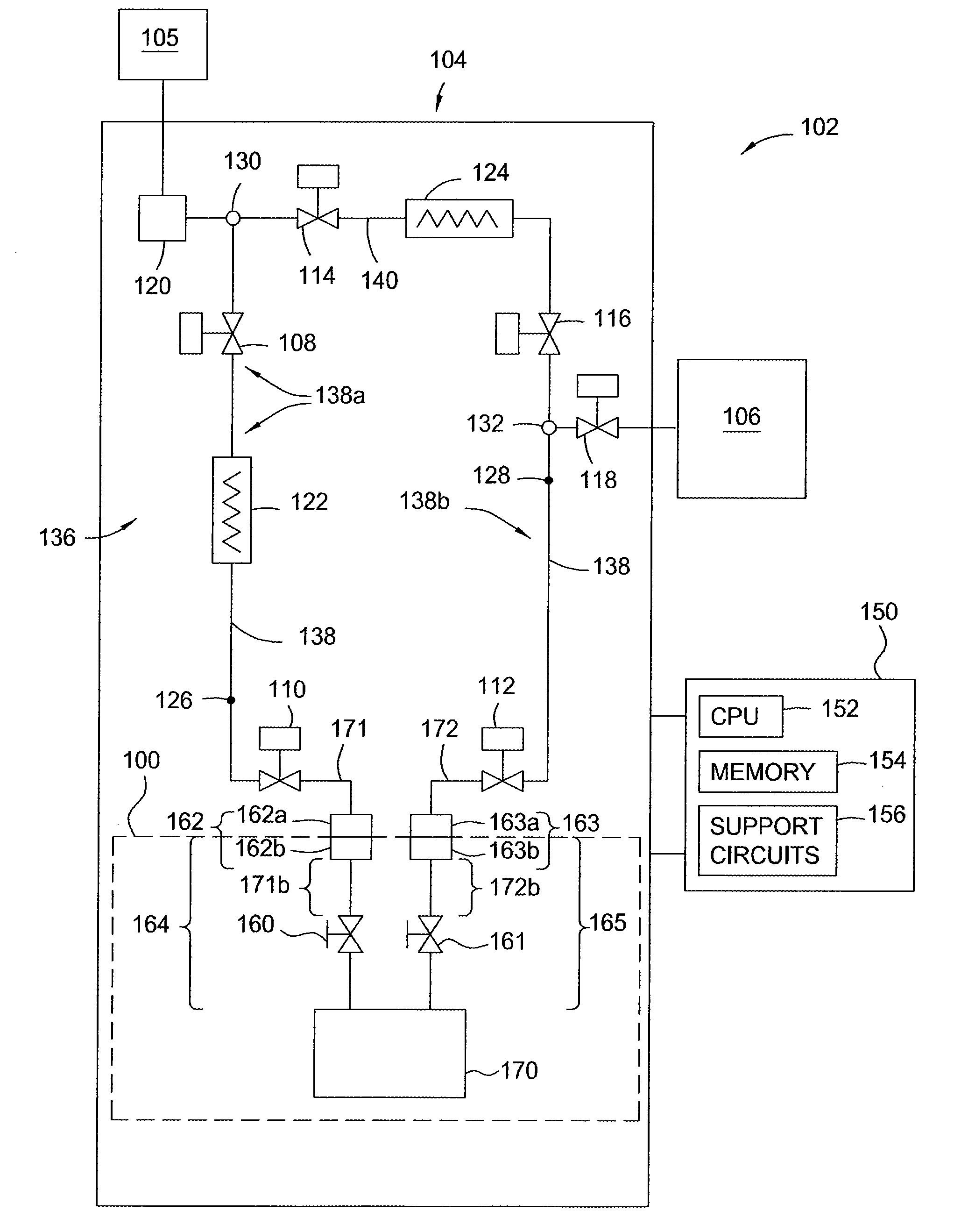

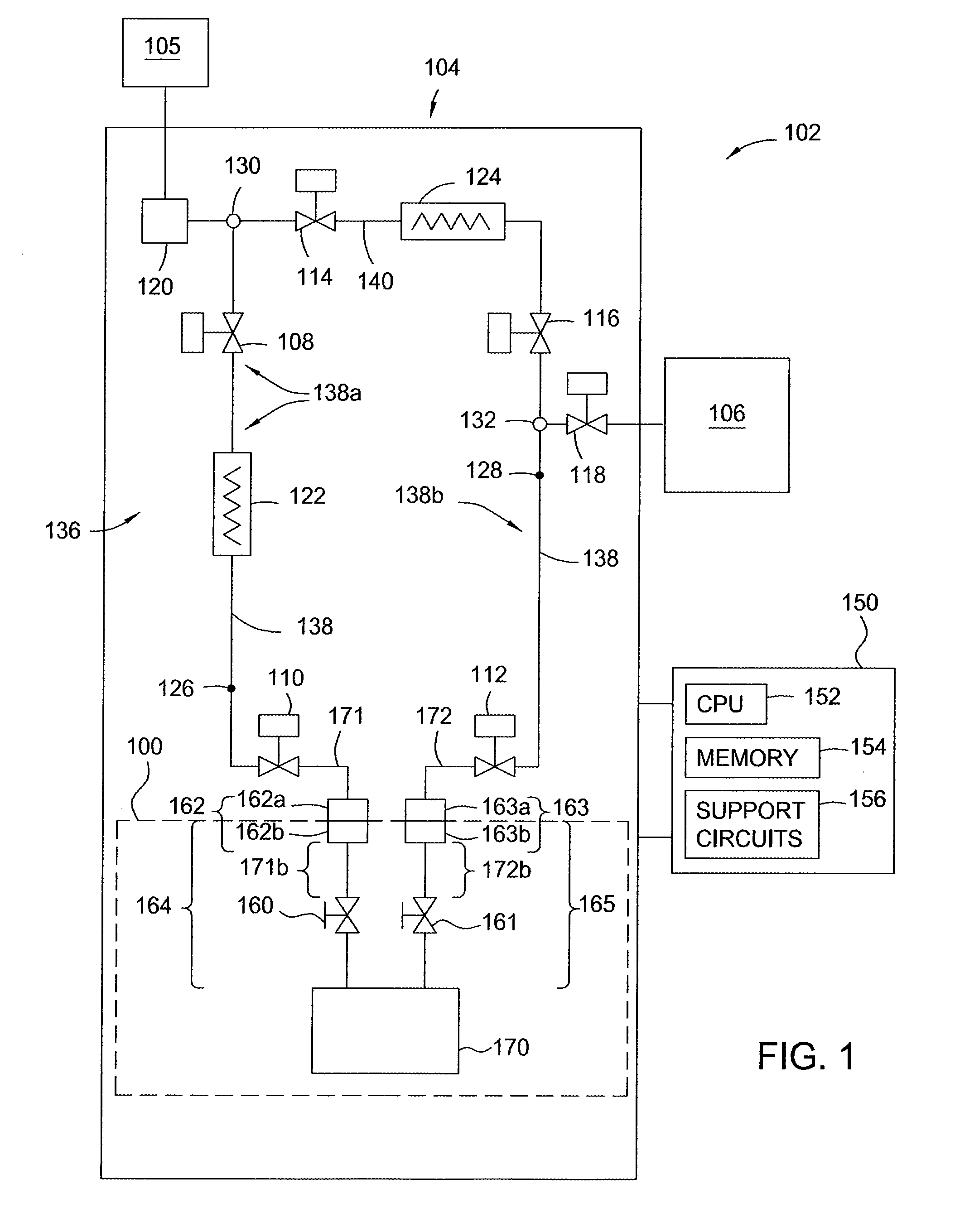

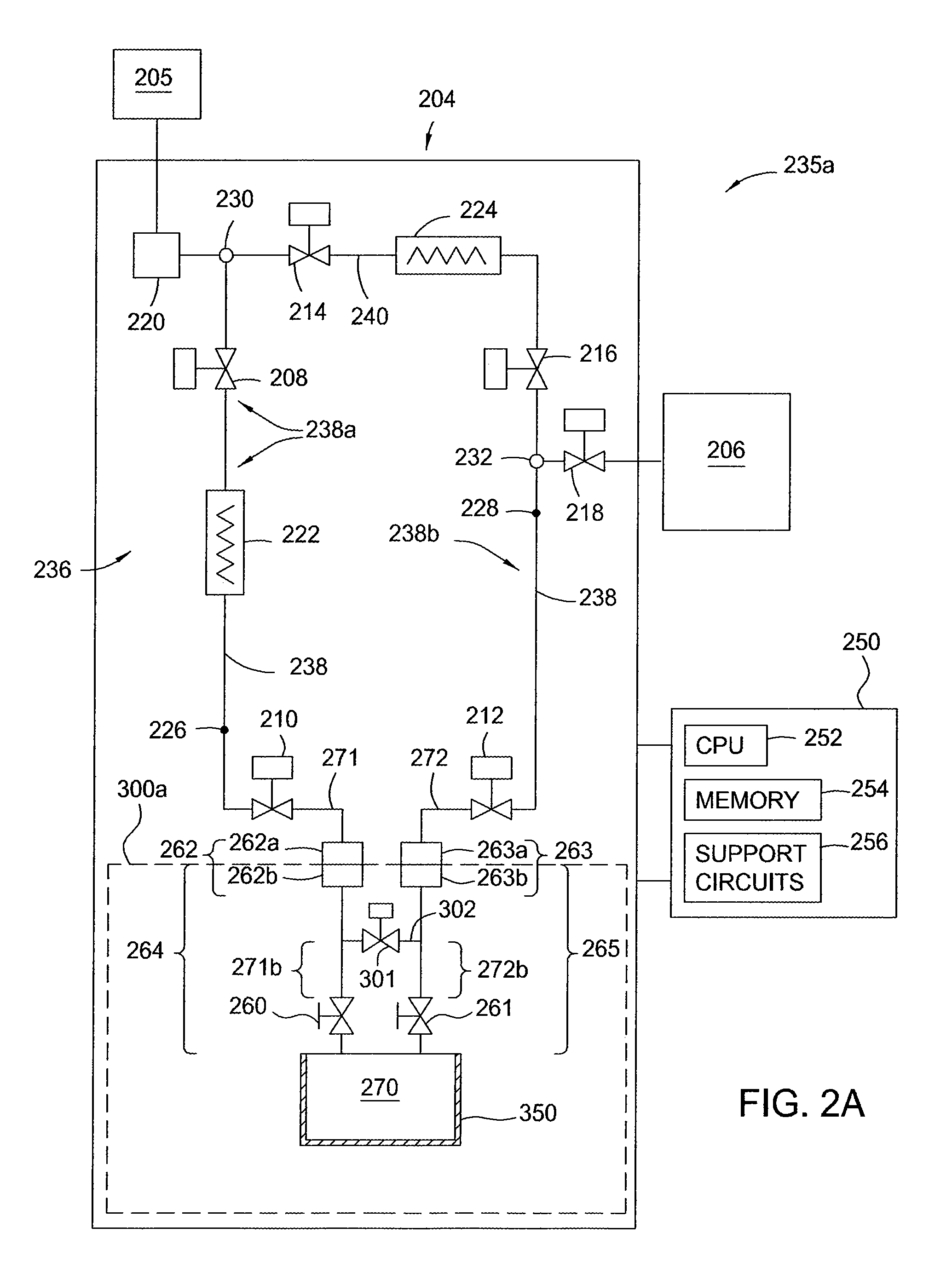

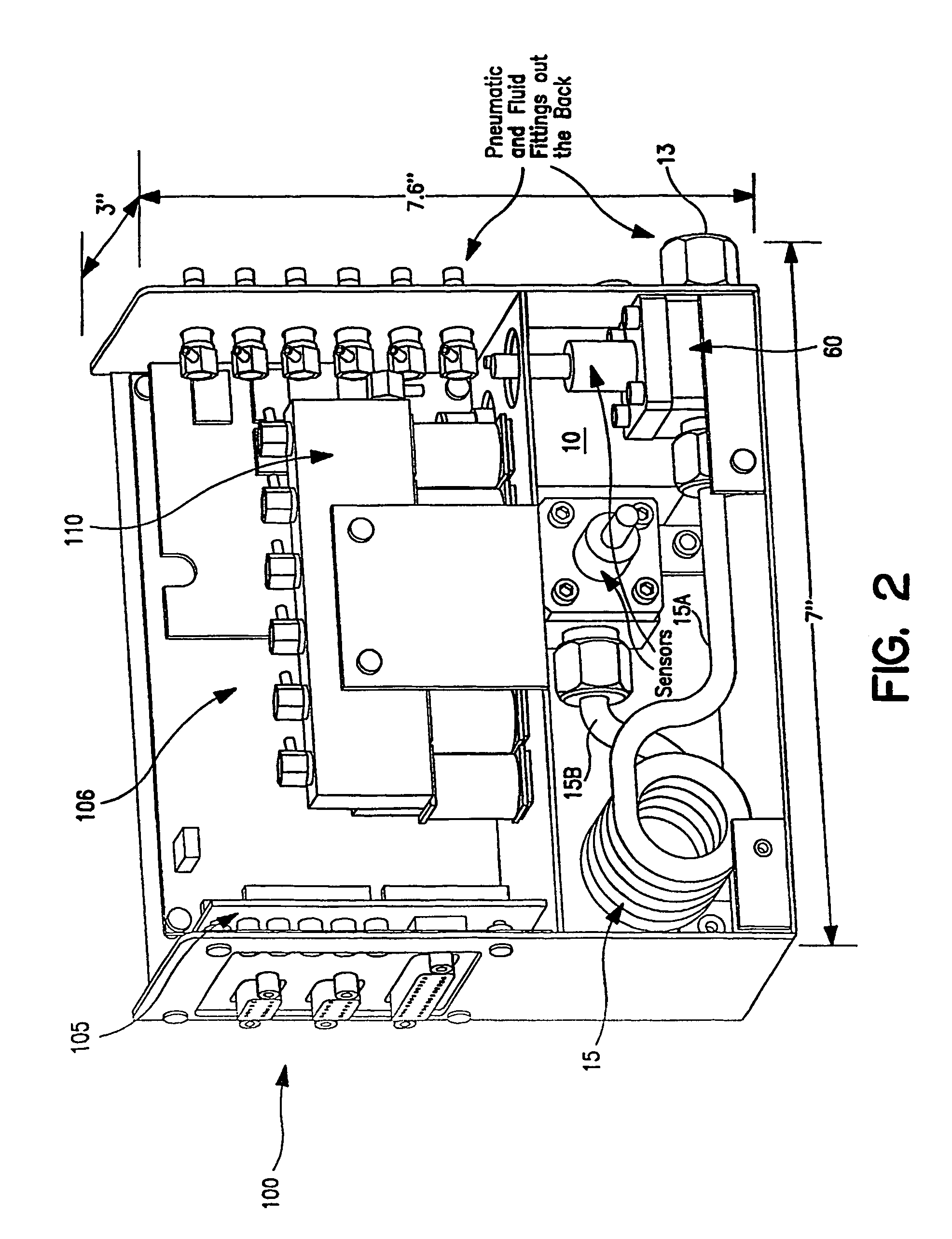

Dialysis system having integrated pneumatic manifold

A dialysis machine valve manifold assembly includes a plurality of pneumatic valves; a plate including a first side and a second side, the plurality of pneumatic valves mounted to the first side of the plate, the second side of the plate defining a plurality of pneumatic flow paths; and a port header mounted removably to the plate, the port header including a plurality of ports configured to connect sealingly to pneumatic tubing, the ports in fluid communication with the pneumatic valves via the pneumatic flow paths defined in the plate.

Owner:BAXTER HEALTHCARE SA +1

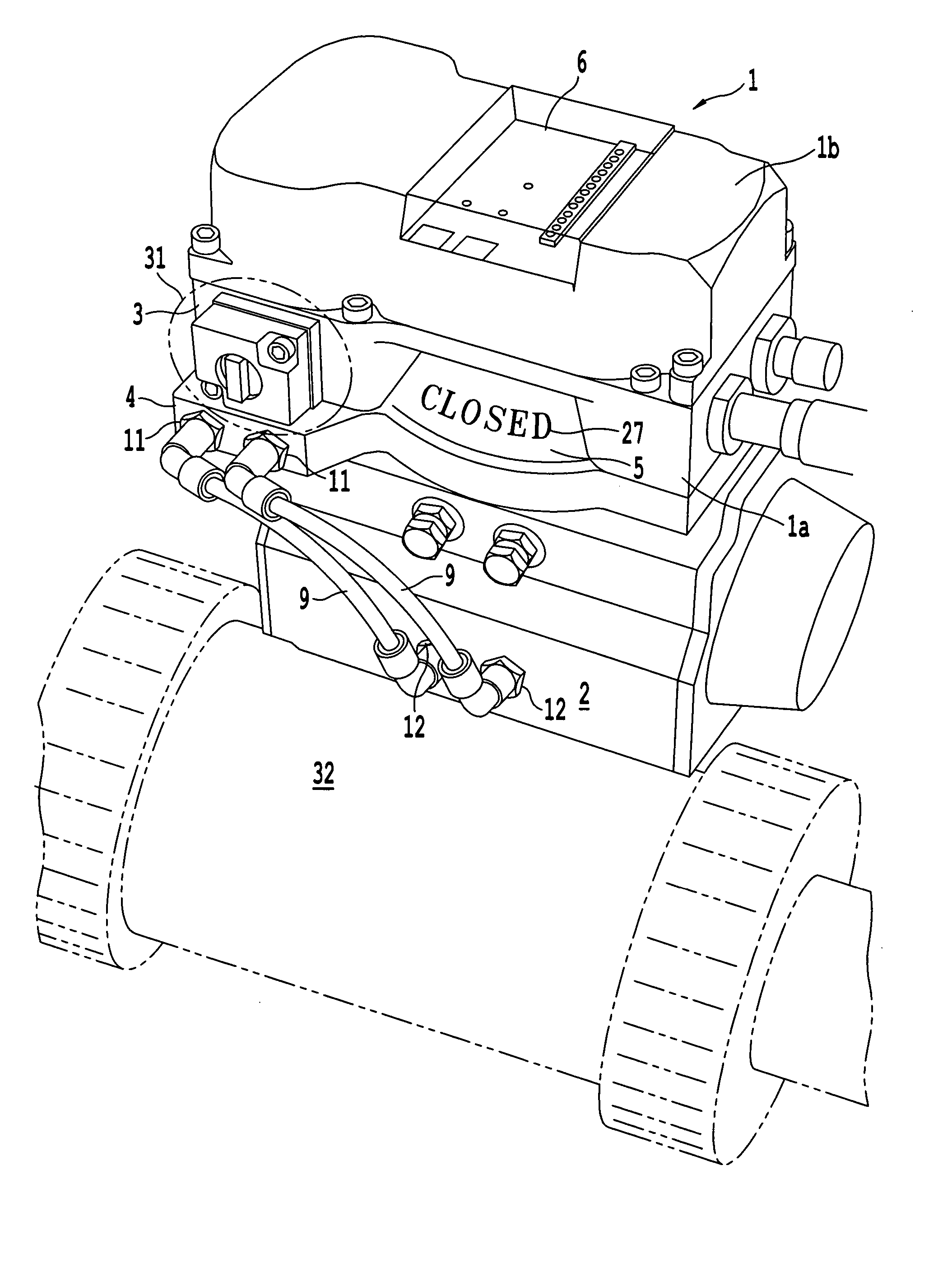

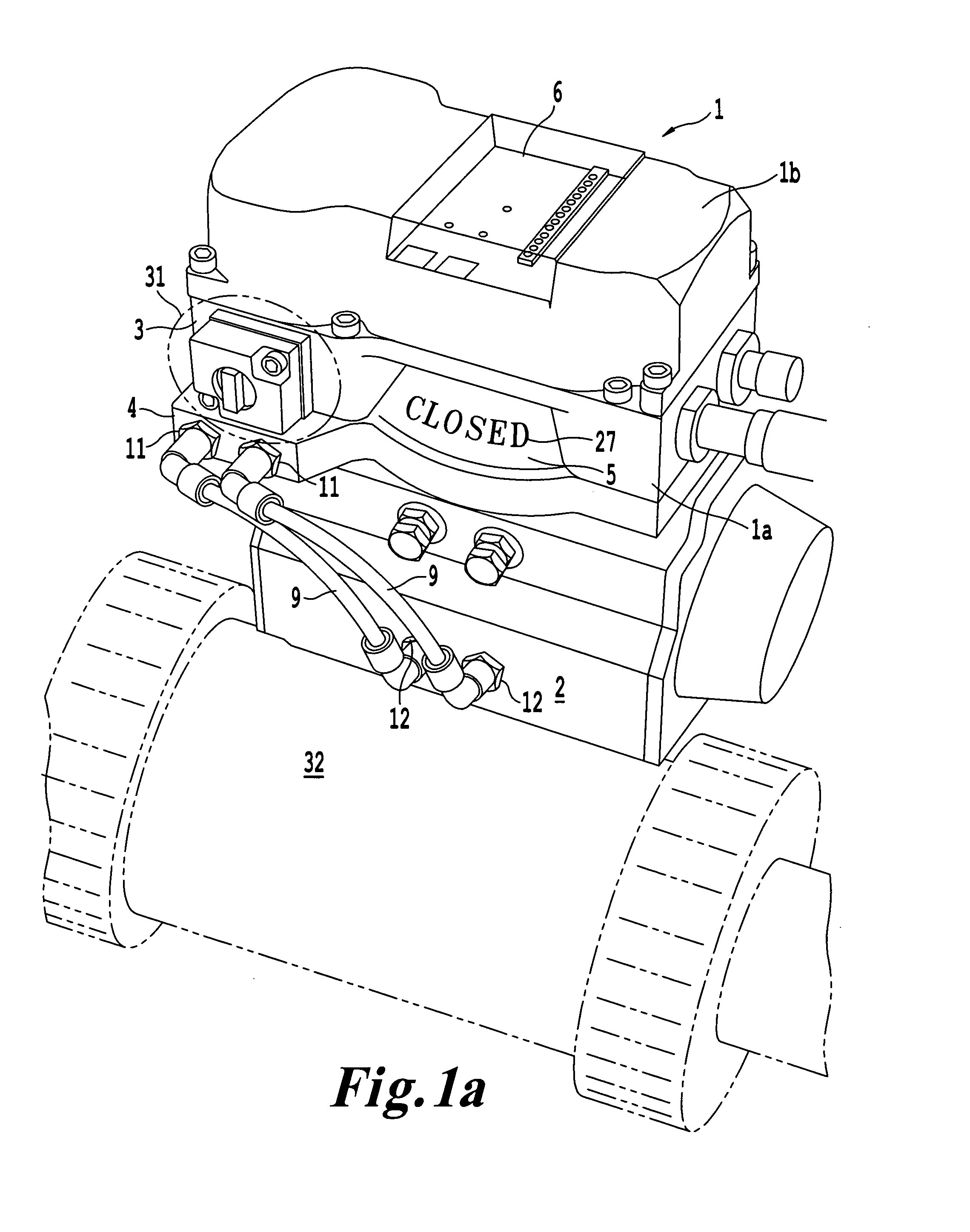

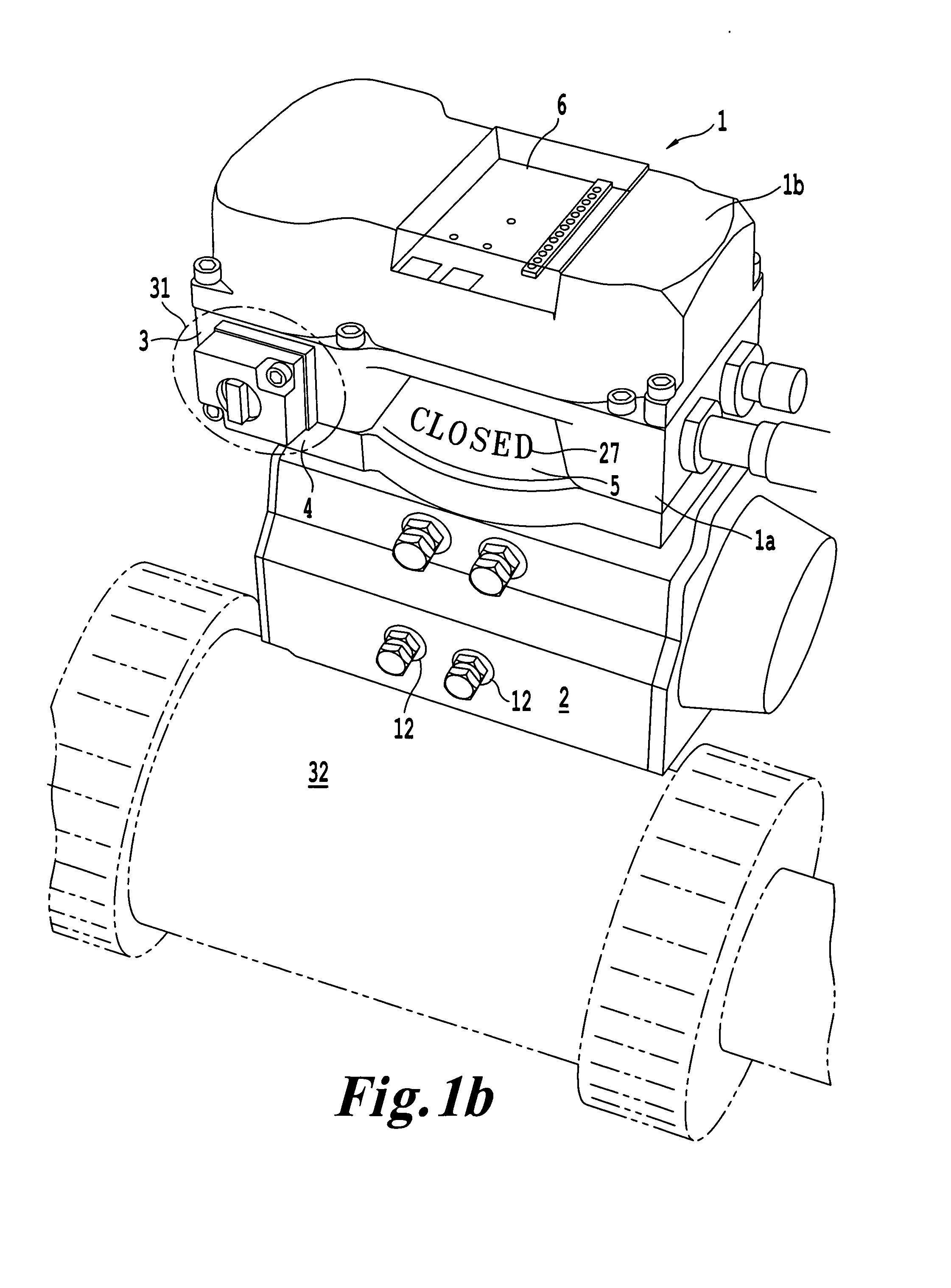

Apparatus for valve communication and control

InactiveUS20070034264A1Operating means/releasing devices for valvesPipeline systemsPneumatic valveRotary actuator

A device for controlling a valve rotary actuator and communicating information regarding the valve rotary actuator, including a non-contact sensor which monitors, through a continuous range of rotation, the rotational position of a rotating unit connected to the valve rotary actuator, a main housing including a pneumatic valve body integrally formed with the main housing, the pneumatic valve body accommodating a valve spool, a sensor housing which supports the non-contact sensor and is connected to the main housing, and a manifold including a pathway in fluid communication with the pneumatic valve body.

Owner:STONEL

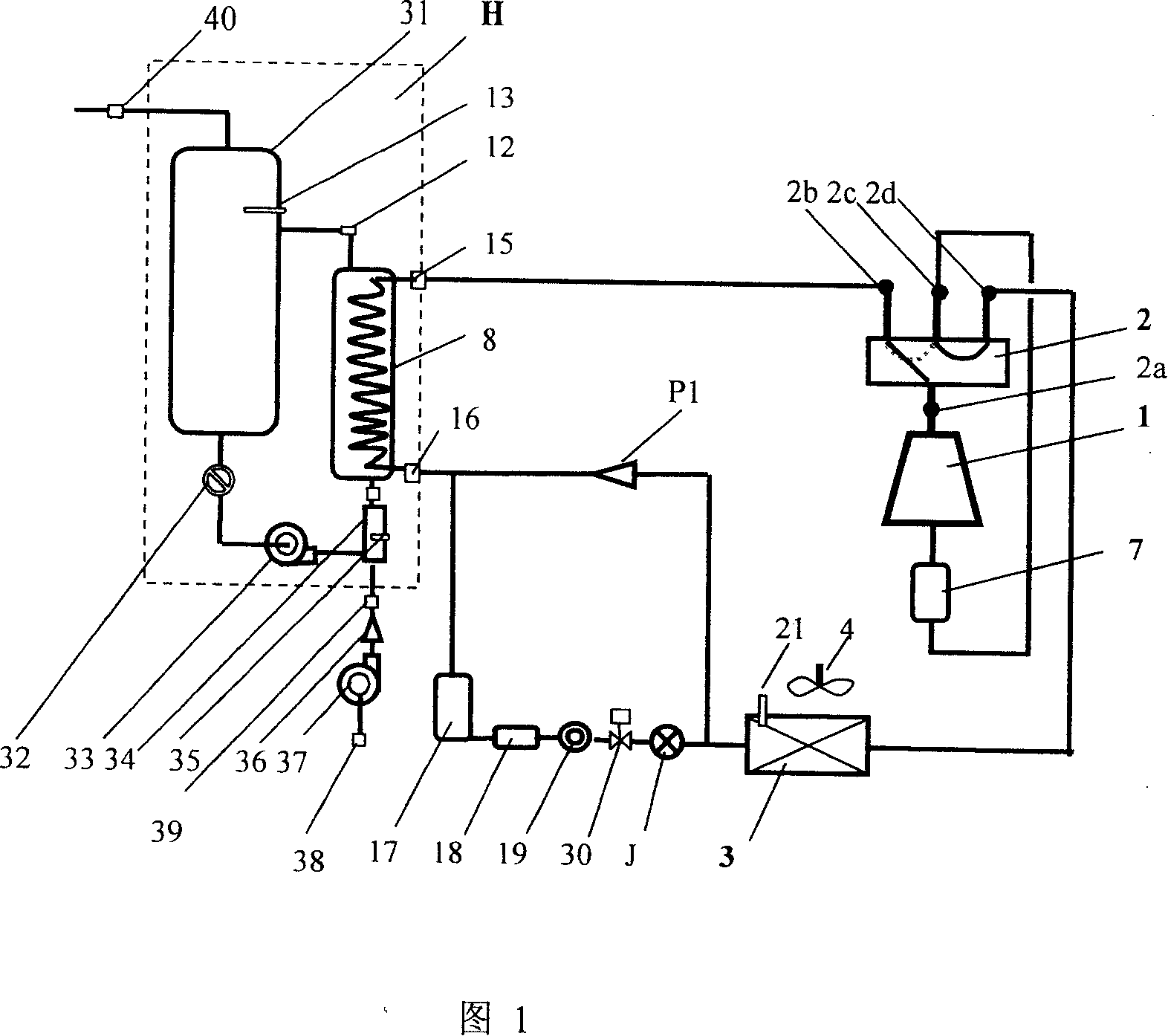

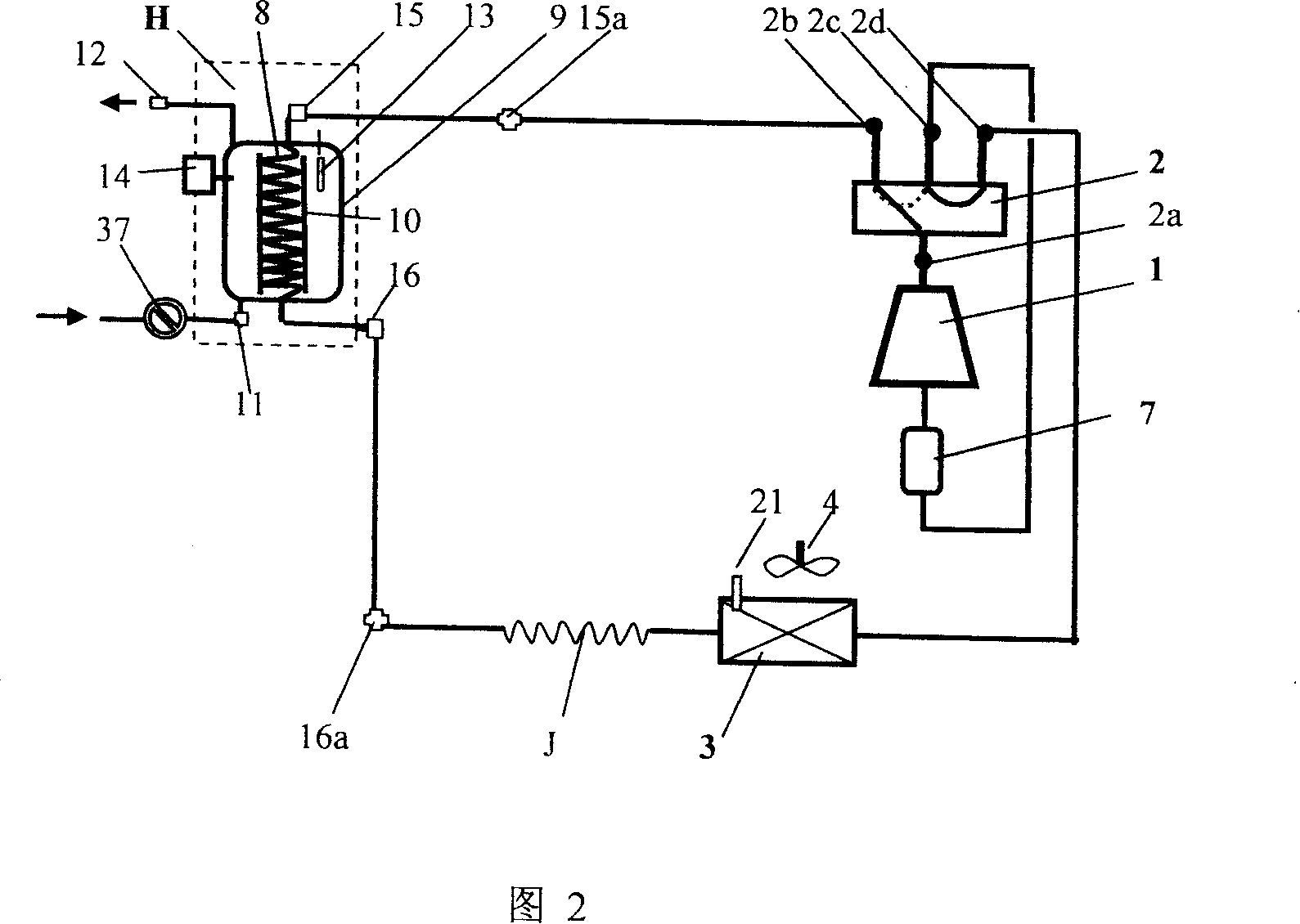

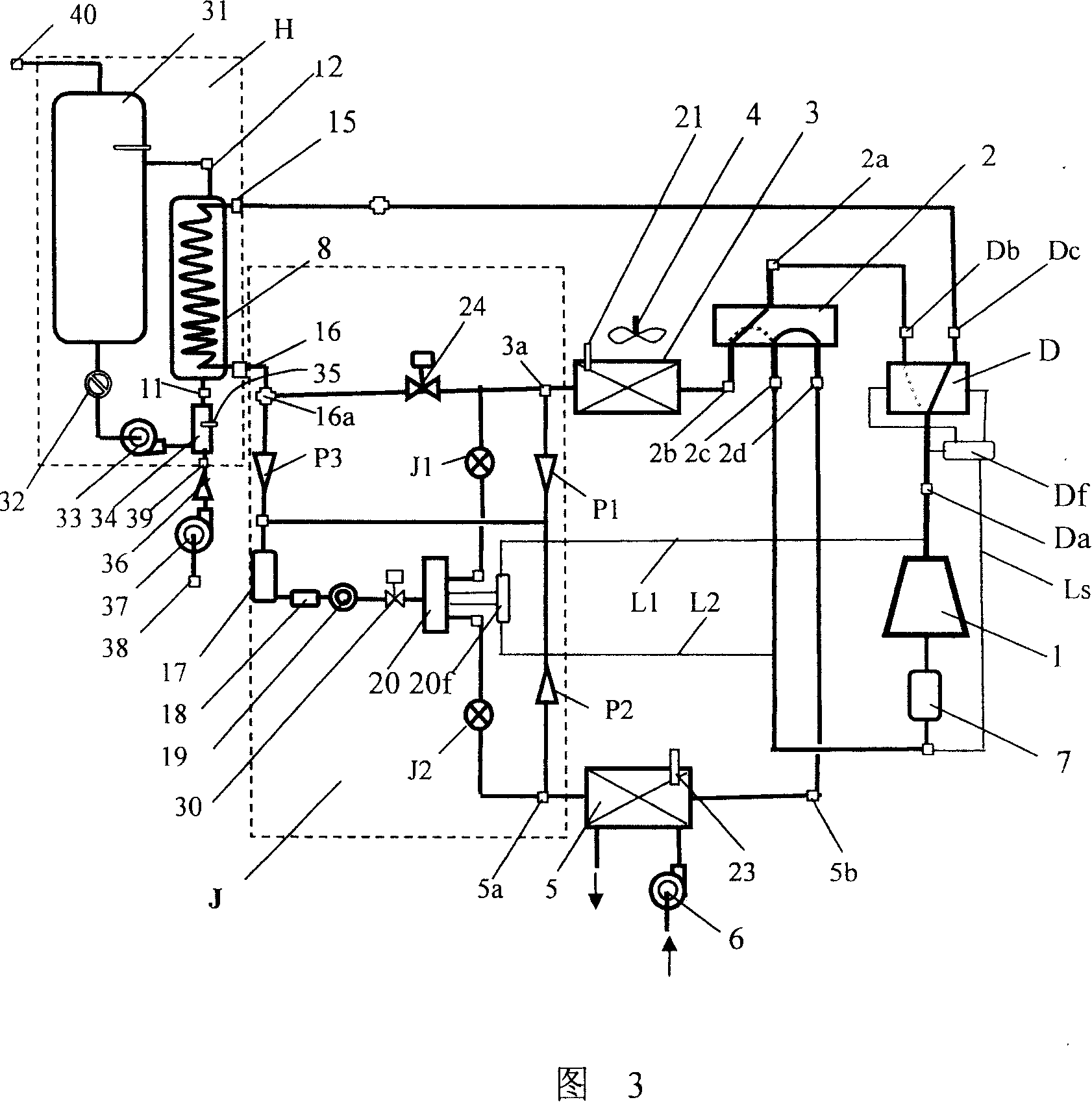

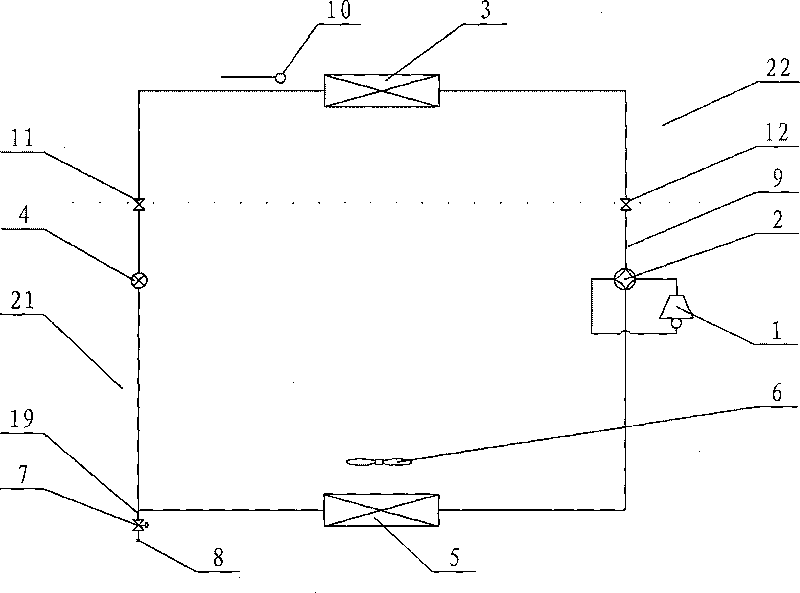

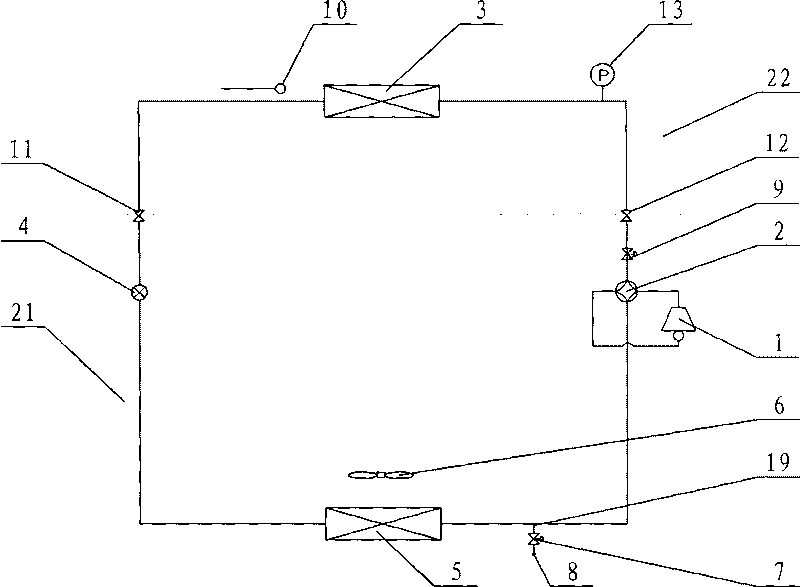

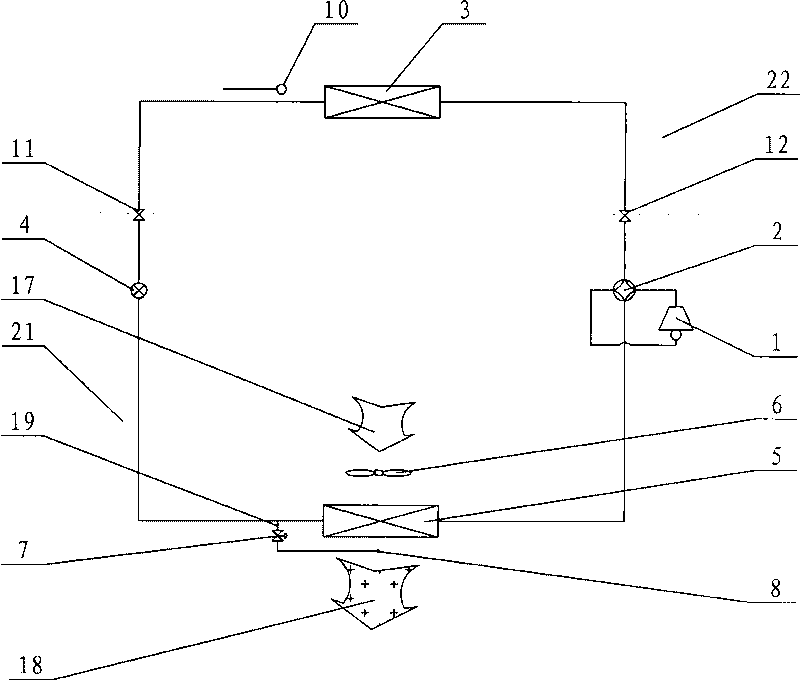

Heat pump hot water machine set of water-containing internal circulation heat-exchanging loop

ActiveCN101078580ASolve defrosting problemsHeat pumpsHeating and refrigeration combinationsFour-way valveWater cycling

The invention relates to a heat pump hot water unit with in-water cycling heat exchanging loop, comprising refrigerant loop system, water-refrigerant heat exchanging system, signal collection and circuit control system. It is characterized in that the water-refrigerant heat exchanging system adopts forced internal-cycling loop constituted by water-refrigerant heat exchanger, reflux tube and internal-cycling pump or natural internal-cycling loop which uses diversion sleeve to separate spiral heat exchanger in heat storing water tank and water pre-heating device can be collocated; the refrigerant loop system has single cycling of single air heat source, independent cycling of double heat source with four functions and adopts the structure of three-way electromagnetic valve with pneumatic valve, four-way valve and multiple-path restrictor so as to make switch of all cycles convenient; wind-cold heat exchanger also has water fin tube. The unit efficiency of invention is high and defrosting in winter is complete. Pressure can not be overloaded in summer. Hot water in 55deg.C can be supplied quickly and continuously. Waste heat can be reclaimed or solar hot water can be made use of. It can save energy by 70-85% compared with electric water heater in annual average. The independent cycling unit with double heat source has refrigeration, heating, heating water and heating water with refrigeration functions.

Owner:江苏恒信诺金科技股份有限公司

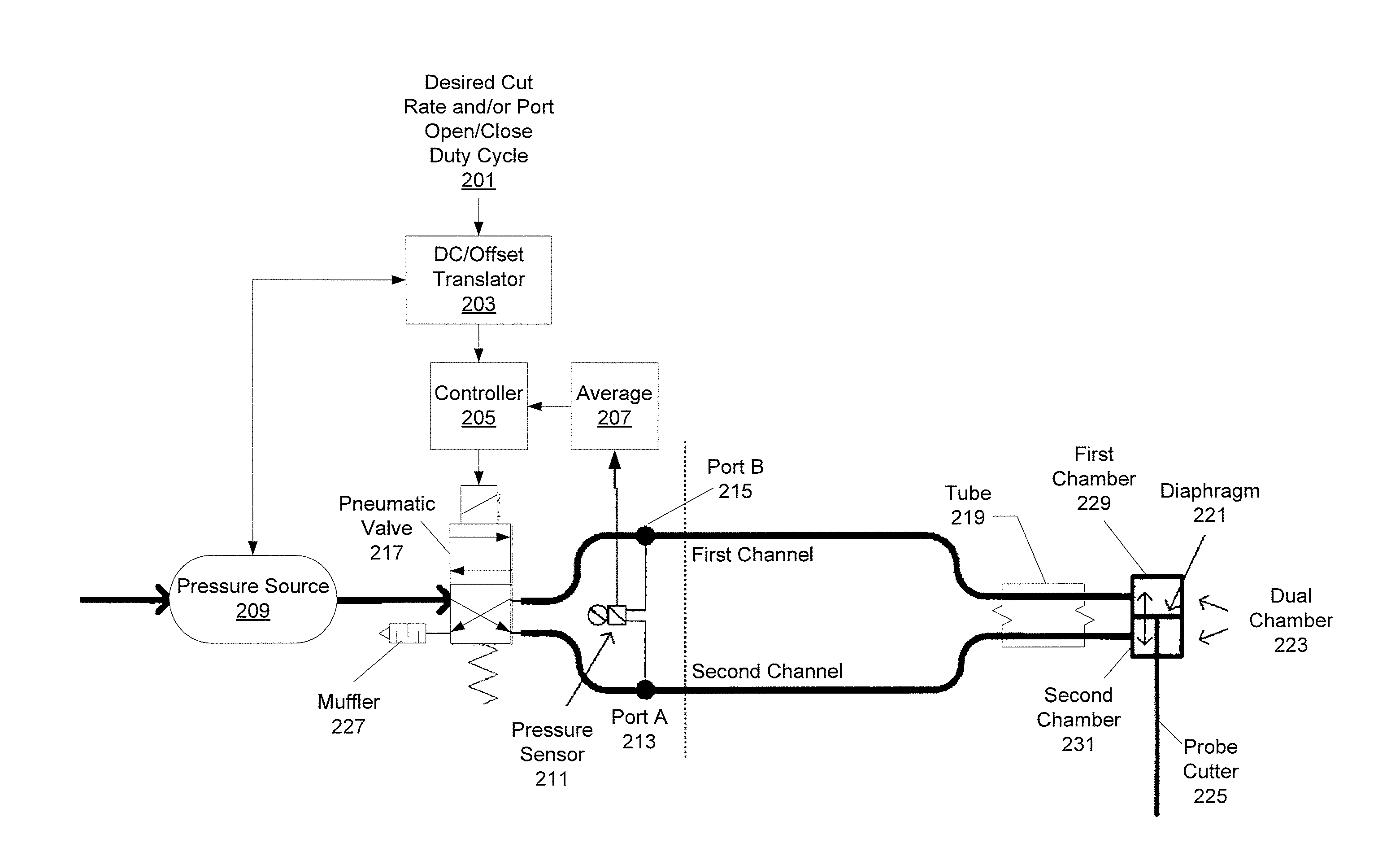

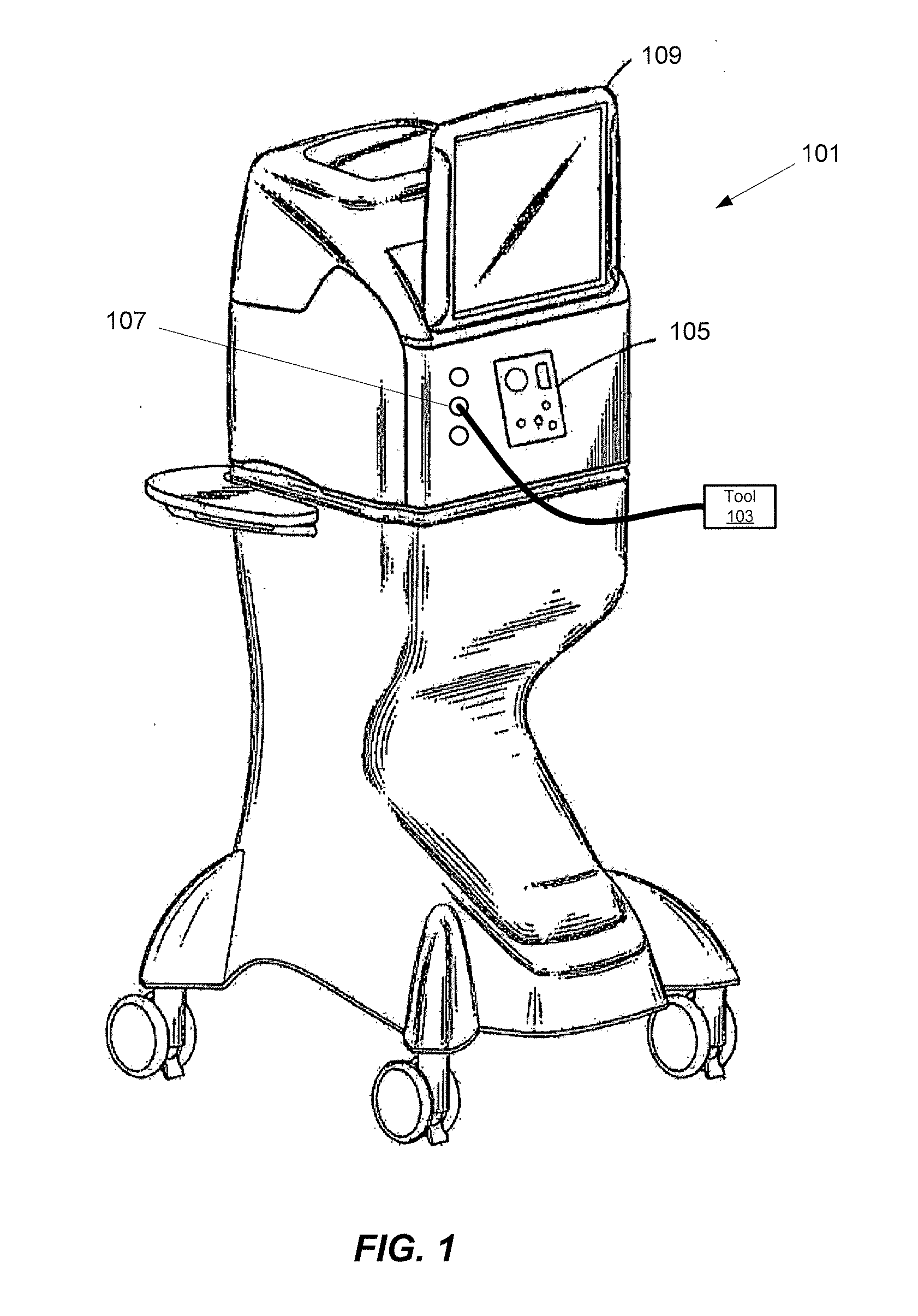

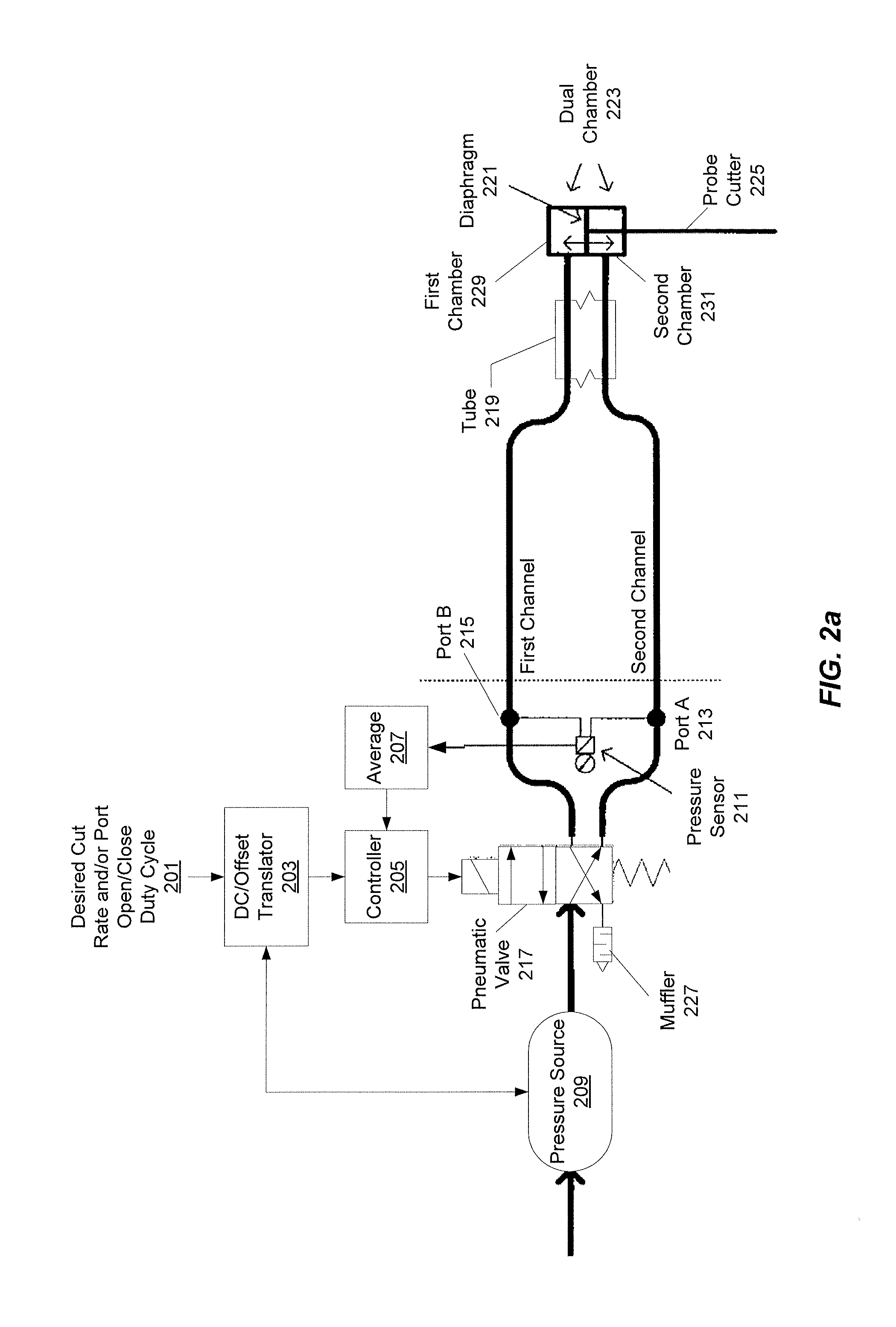

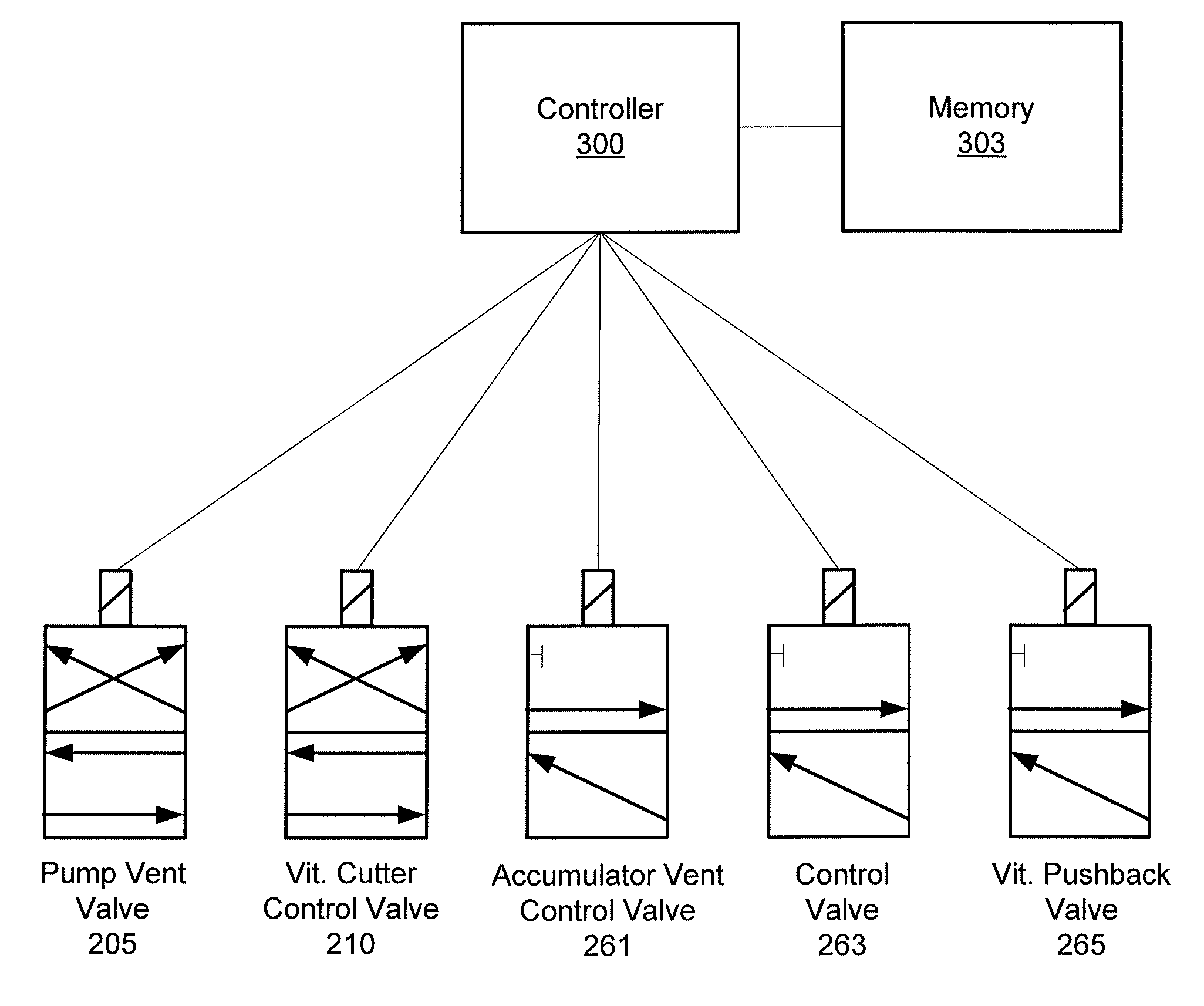

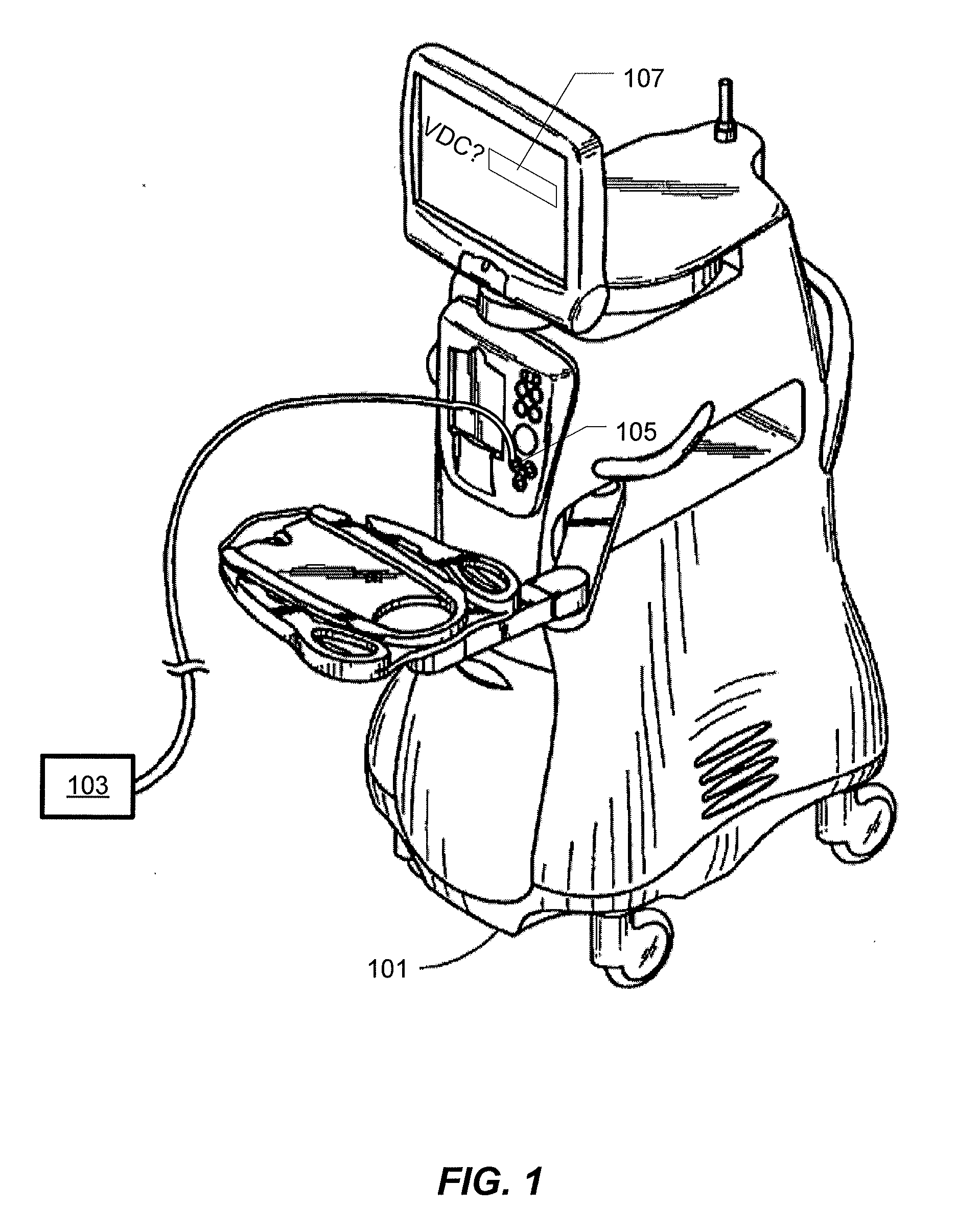

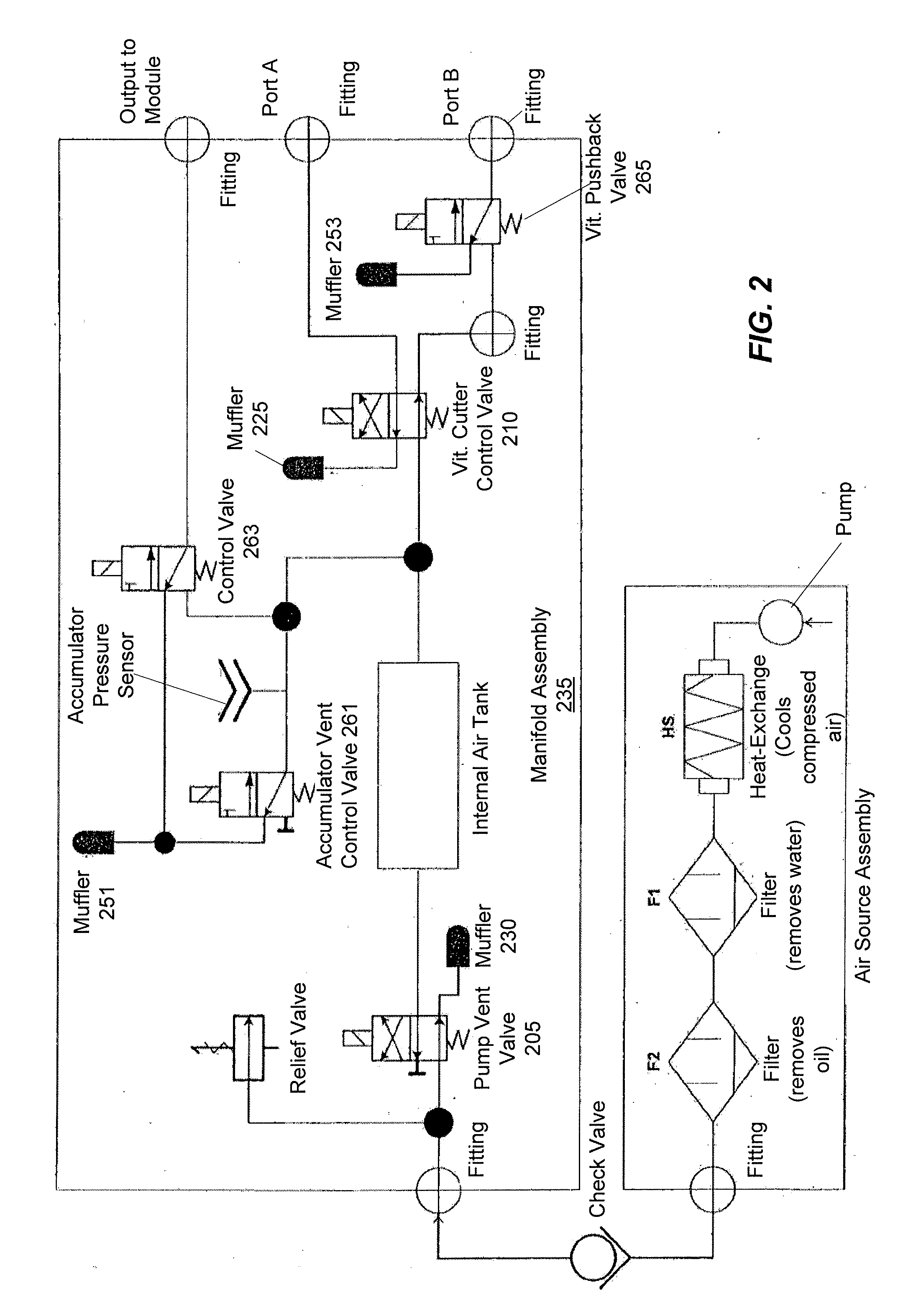

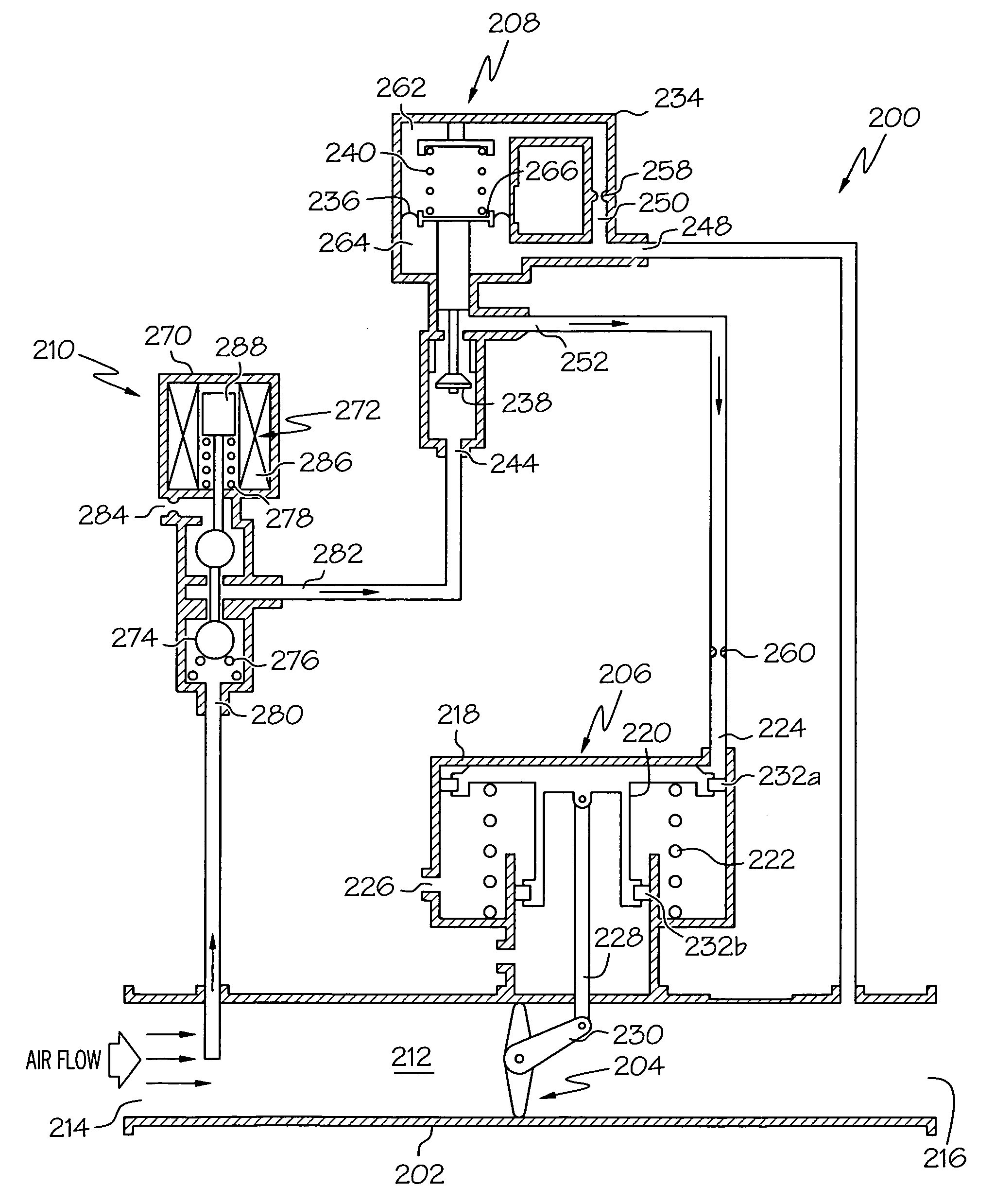

Systems and Methods for Dynamic Pneumatic Valve Driver

In various embodiments, a pneumatic system valve for a surgical console may be controlled by a controller configured to adjust a valve duty cycle (VDC) of the valve to reduce a difference between the valve's differential pressure and a desired differential pressure. In some embodiments, average differential pressures may be detected and relayed from a pressure sensor, coupled to one or more ports of the valve, to the controller. The controller may compare the measured average differential pressure against the desired average differential pressure (e.g., received from the user). The controller may then determine a modified VDC to reduce a difference between the desired average differential pressure and the measured average differential pressure. In some embodiments, the desired average differential pressure may be determined based on input received from a user of the surgical console.

Owner:ALCON INC

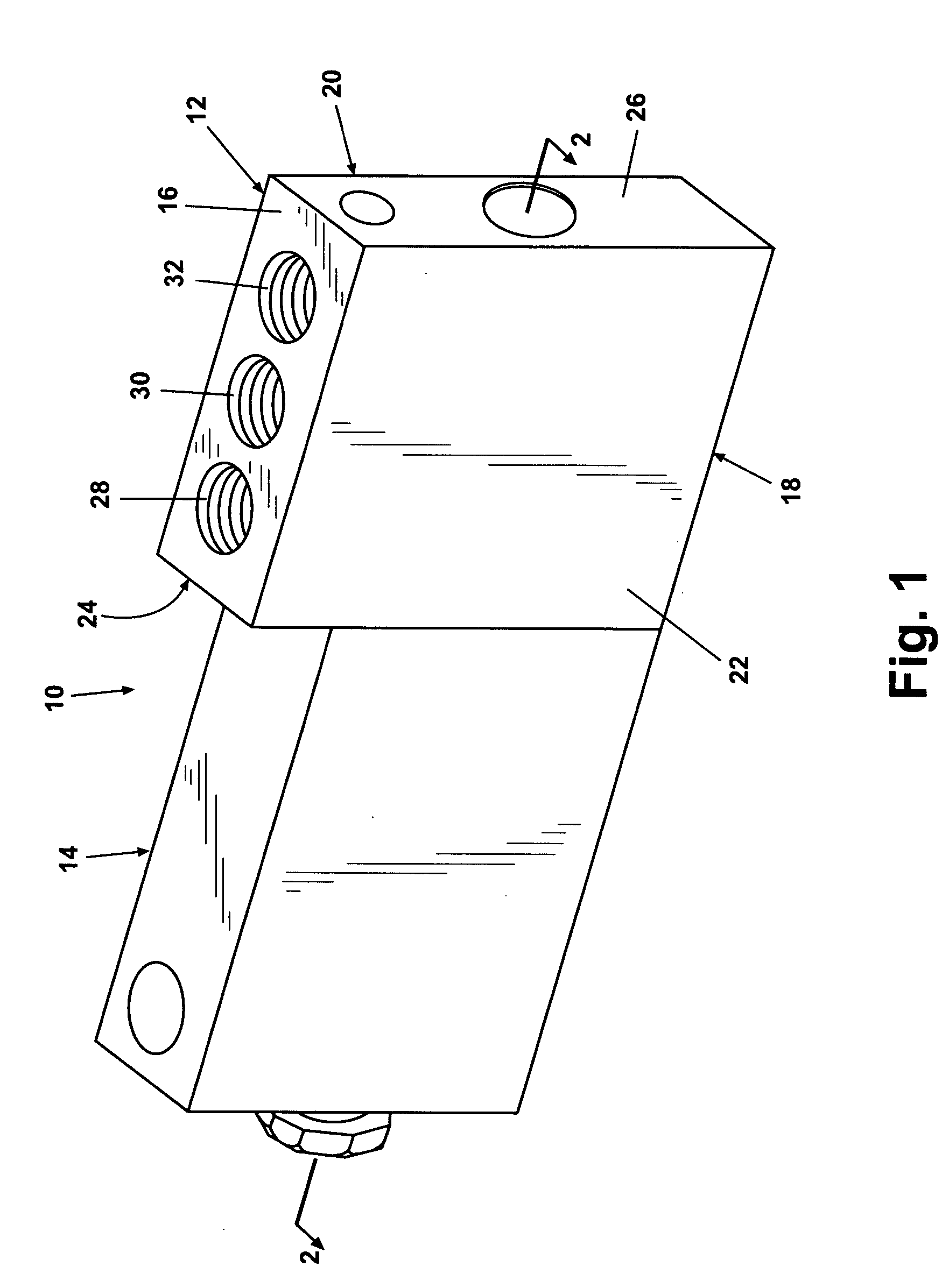

Heated valve manifold for ampoule

InactiveUS20090232986A1Chemical vapor deposition coatingSemiconductor/solid-state device manufacturingInlet channelPneumatic valve

Embodiments of the invention provide an apparatus and a method for generating a gaseous chemical precursor that may be used in a vapor deposition processing system. In one embodiment, the apparatus contains a valve manifold assembly, which includes a valve assembly body having at least one embedded electric heater, an inlet channel passing through the valve assembly body, a first pneumatic valve and a first manual valve coupled to the valve assembly body and positioned to control fluid flow within the inlet channel, an outlet channel passing through the valve assembly body, and a second pneumatic valve and a second manual valve coupled to the valve assembly body and positioned to control fluid flow within the outlet channel. The valve manifold assembly further contains a bypass channel connected to and between the inlet and outlet channels, and containing a bypass valve positioned to control fluid flow within the bypass channel.

Owner:APPLIED MATERIALS INC

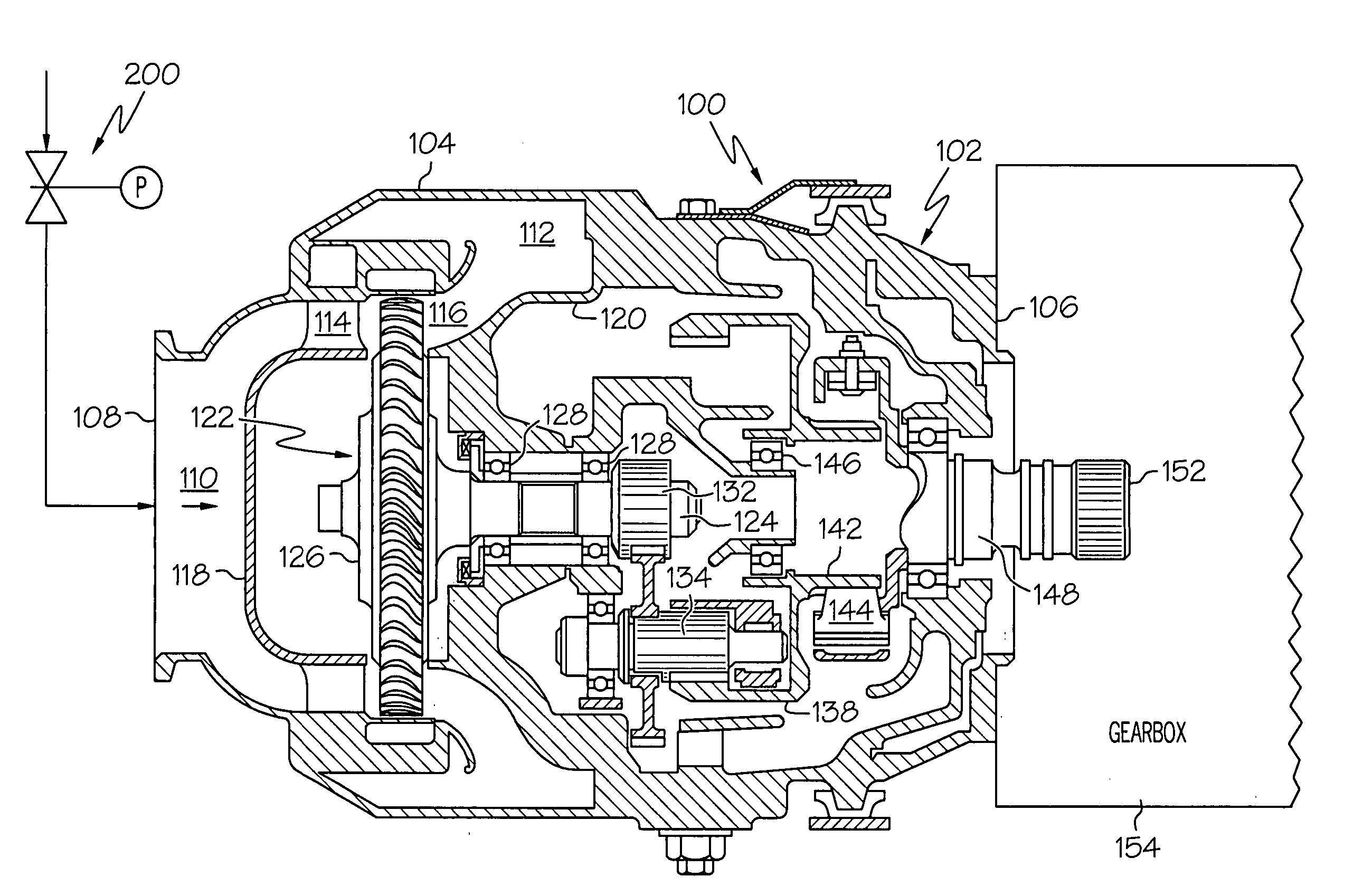

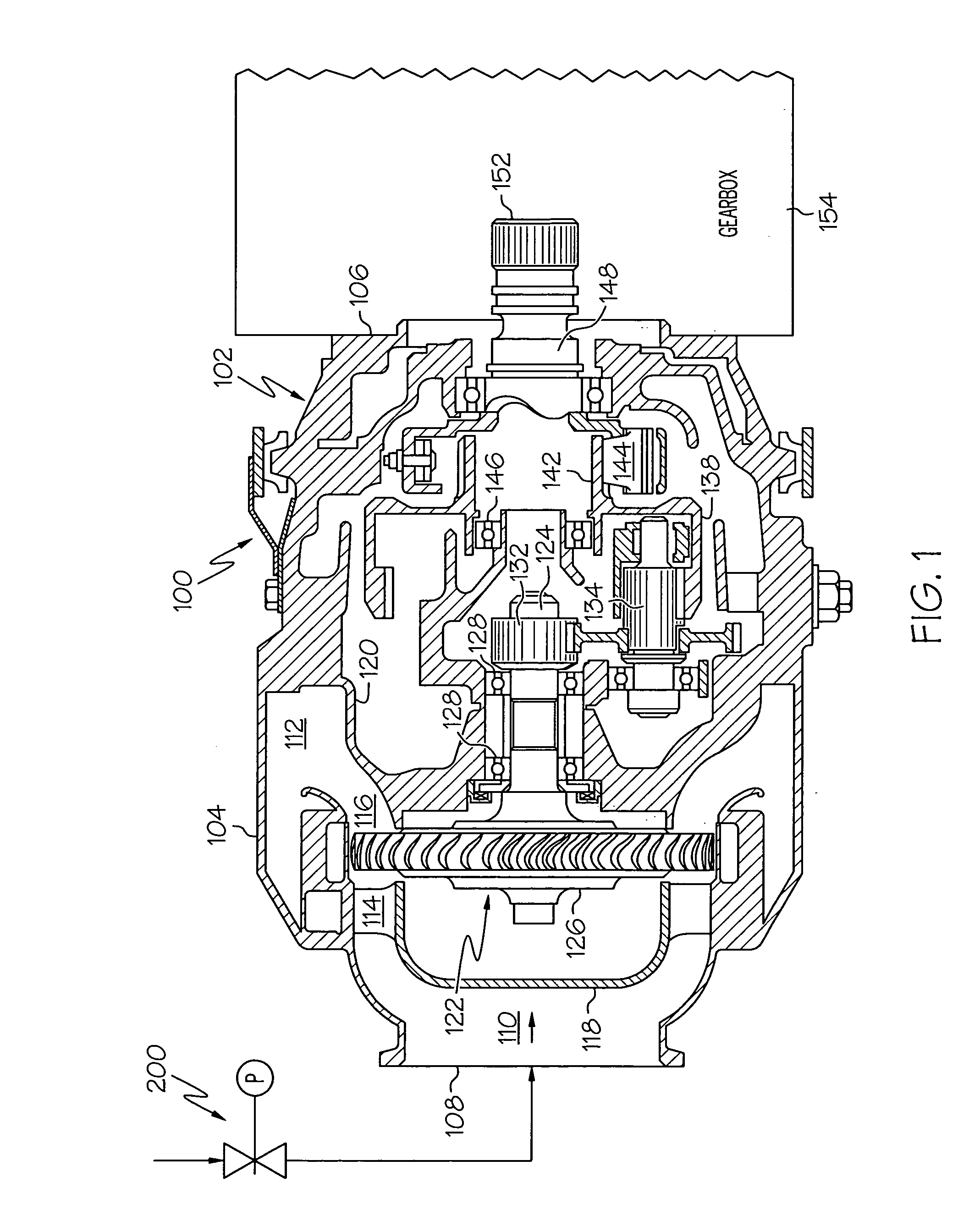

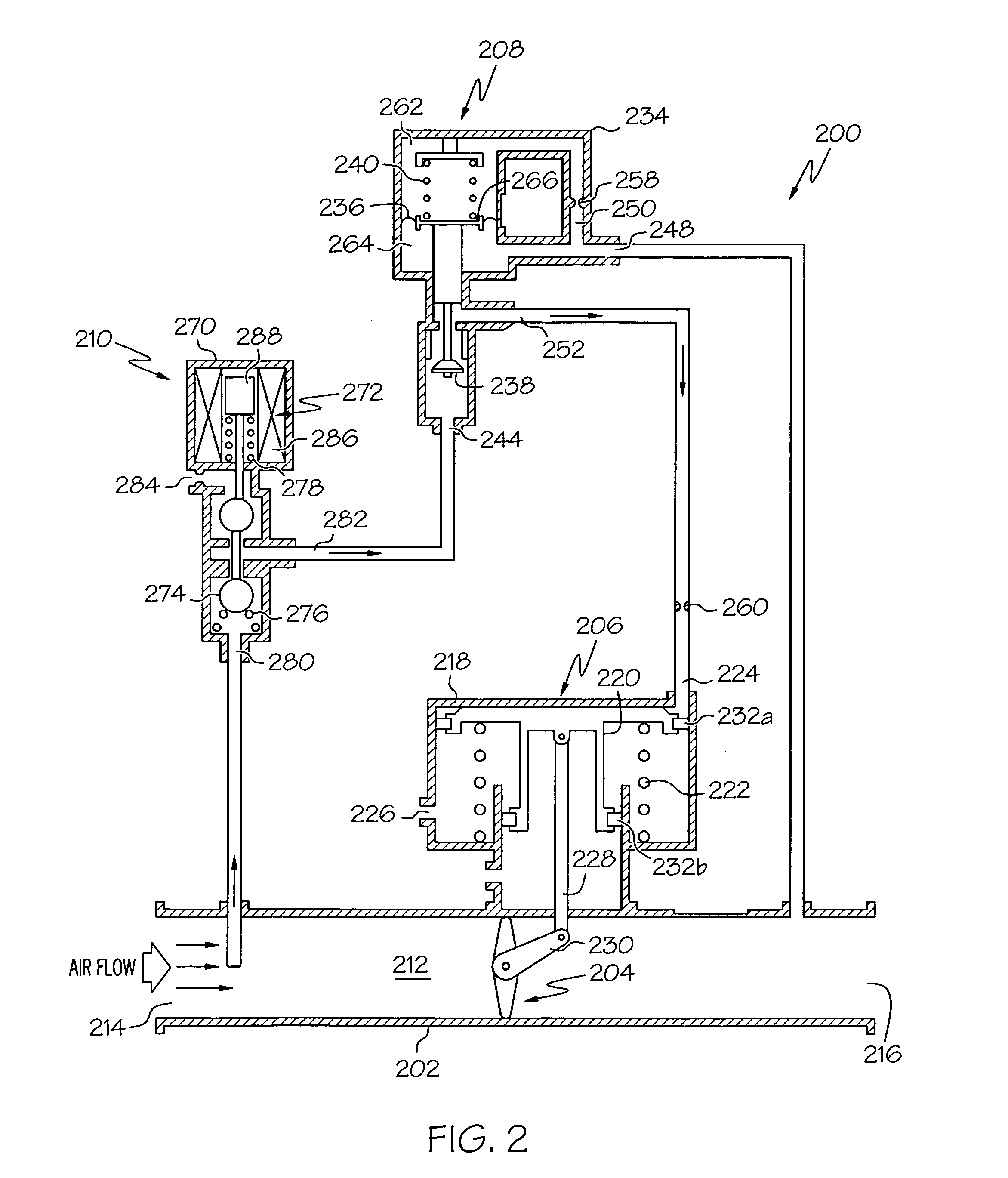

Pneumatic valve control having improved opening characteristics and an air turbine starter incorporating the same

A starter air valve assembly includes a valve body, a flow control valve, a rate control servo mechanism, and a valve actuator. The valve body defines a flow passage having at least an inlet port and an outlet port. The valve is disposed at least partially within the flow passage and is moveable between an open position and a closed position. The rate control servo mechanism is adapted to receive pressurized fluid and is configured, upon receipt thereof, to supply a controlled flow of the pressurized fluid. The valve actuator is coupled to the valve and is in fluid communication with the rate control servo to thereby receive the controlled flow of the pressurized fluid. The valve actuator is configured, upon receipt of the controlled flow of the pressurized fluid, to move the valve between the closed position and the open position at a substantially controlled rate.

Owner:HONEYWELL INT INC

Air conditioner using combustible refrigerant and control method thereof

ActiveCN101737878AReduce leakageAvoid personal injurySpace heating and ventilation safety systemsLighting and heating apparatusAutomatic balancing valvesMachine parts

The invention relates to an air conditioner using a combustible refrigerant and a control method thereof. The air conditioner comprises a refrigeration / heat pump air conditioner system which consists of a compressor, a four-way valve, an indoor heat exchanger, a throttle mechanism, and an outdoor heat exchanger, wherein two ends of the indoor heat exchanger are provided with an air conditioner connecting pipe pneumatic valve and an air conditioner connecting pipe hydraulic valve respectively; a refrigerant working medium concentration sensor is arranged indoors; a drain pipe branch and an automatic drain valve of the drain pipe branch are arranged on the connecting pipes of the outdoor heat exchanger; the refrigerant working medium concentration sensor is arranged beside the indoor heat exchanger; and the drain pipe branch and the automatic drain valve of the drain pipe branch are arranged on the pipes between the throttle mechanism and the outdoor heat exchanger. The air conditioner using the combustible refrigerant is provided with the refrigerant working medium concentration sensor, the drain pipe branch, and the automatic drain valve of the drain pipe branch, and when the combustible refrigerant working medium is detected to be leaked, an outdoor machine part exhausts the refrigerant to the large outdoor space to reduce the indoor leakage quantity, so personal injury and property loss generated when the indoor combustible working medium concentration reaches the combustion limit are avoided.

Owner:MIDEA GRP CO LTD

Pneumatic valve return spring

InactiveUS6745738B1Simple installation and constructionImprove economyMachines/enginesLift valveEngineeringPneumatic valve

A valve spring device using pressurized gas for use in biasing a reciprocating valve which moves between a seated position and open position. The device features a static housing having a static chamber what is translateably engaged with dynamic housing. Chambers inside both housings are sealably engaged such that the dynamic housing translates away from the static housing when pressurized gas is communicated to the engaged sealed chambers thereby biasing the dynamic housing away from the static housing and moving the attached valve. Timing of oscillation of the translation and resulting valve timing is controlled by a controller activating a control valve between a pressurizing state and a venting state. The timing may be adjusted to accommodate the engine timing through varying the controller's activation of the control valve and optionally varying the pressure of the gas using a regulator.

Owner:BOSSCHER RICHARD J

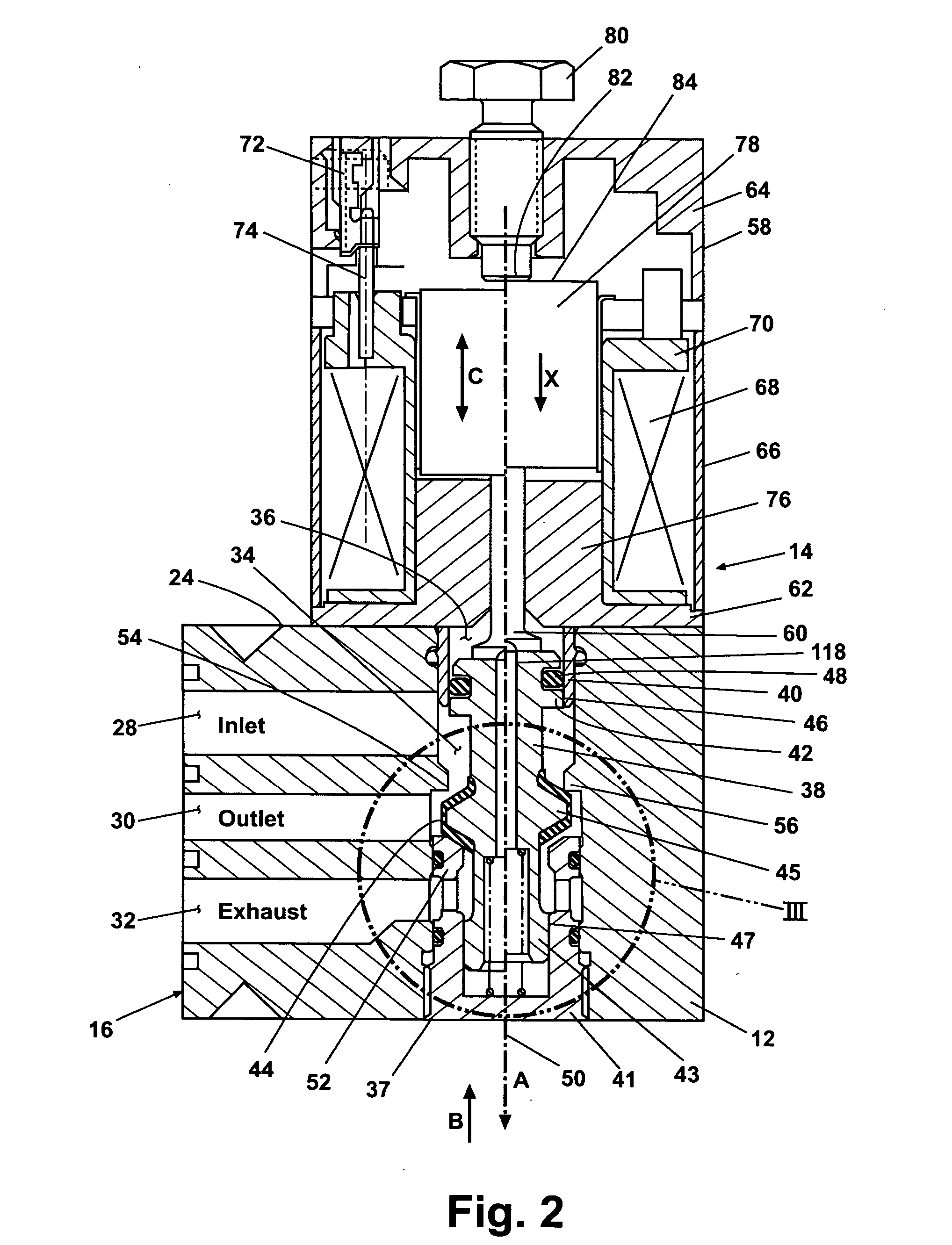

Directly operated pneumatic valve having a differential assist return

ActiveUS20060065315A1Eliminates bypass flowMove quickly and efficientlyOperating means/releasing devices for valvesServomotor componentsFluid controlNet return

A fluid control valve includes a valve body having both fluid inlet and discharge ports. A flow passage axially extending within the valve body communicates with the inlet and discharge ports. A valve member within the flow passage is movable by an actuator force in a first direction to direct a pressurized fluid from the inlet to the discharge port. The valve member includes first and second valve heads having different diameters and a valve seating member. The valve seating member engages first and second sealing diameters of the flow passage, the second sealing diameter being smaller than the first. Fluid pressure acting on the different diameters of the first valve head and valve seating member in contact with the second sealing diameter creates a net return force directing the valve member in a second direction opposite to the first direction upon removal of the actuator force.

Owner:MAC VALVES INC

Relative pressure control system and relative flow control system

ActiveUS20060097644A1Accurate supervisionReduce the amount of controlOperating means/releasing devices for valvesElectric discharge tubesRelative pressureSolenoid valve

Provided is a relative pressure control system has a simple configuration, but enables accurate regulation of a division ratio of an operation gas, and concurrently makes it possible to securely drain the operation gas from an operation gas pipeline in case of emergency. The system includes a plurality of air operated valves of a normally open type that are connected to an operation gas pipeline supplied with an operation gas; pressure sensors that are series connected to the respective air operated valves and that detect output pressures of the respective air operated valves; a controller that controls operation pressures of the respective air operated valves in accordance with the pressures detected by the pressure sensors; and a hard-interlock solenoid valve that correlates the plurality of air operated valves to one another so that at least one of the plurality of air operated valves is normally opened. In the configuration, an opening of a specified one of the plurality of air operated valves is regulated, the operation gas is output at a predetermined division ratio.

Owner:CKD +1

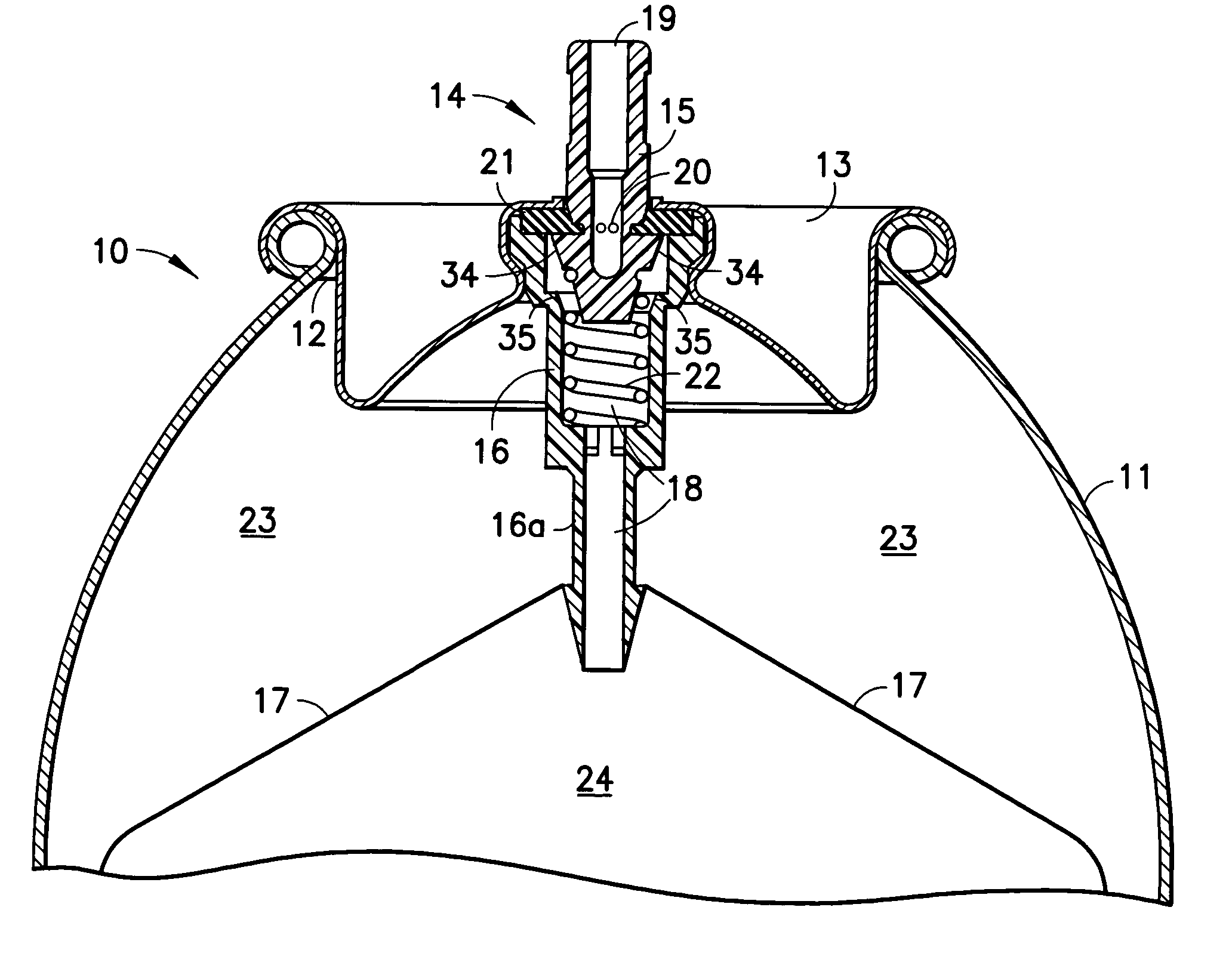

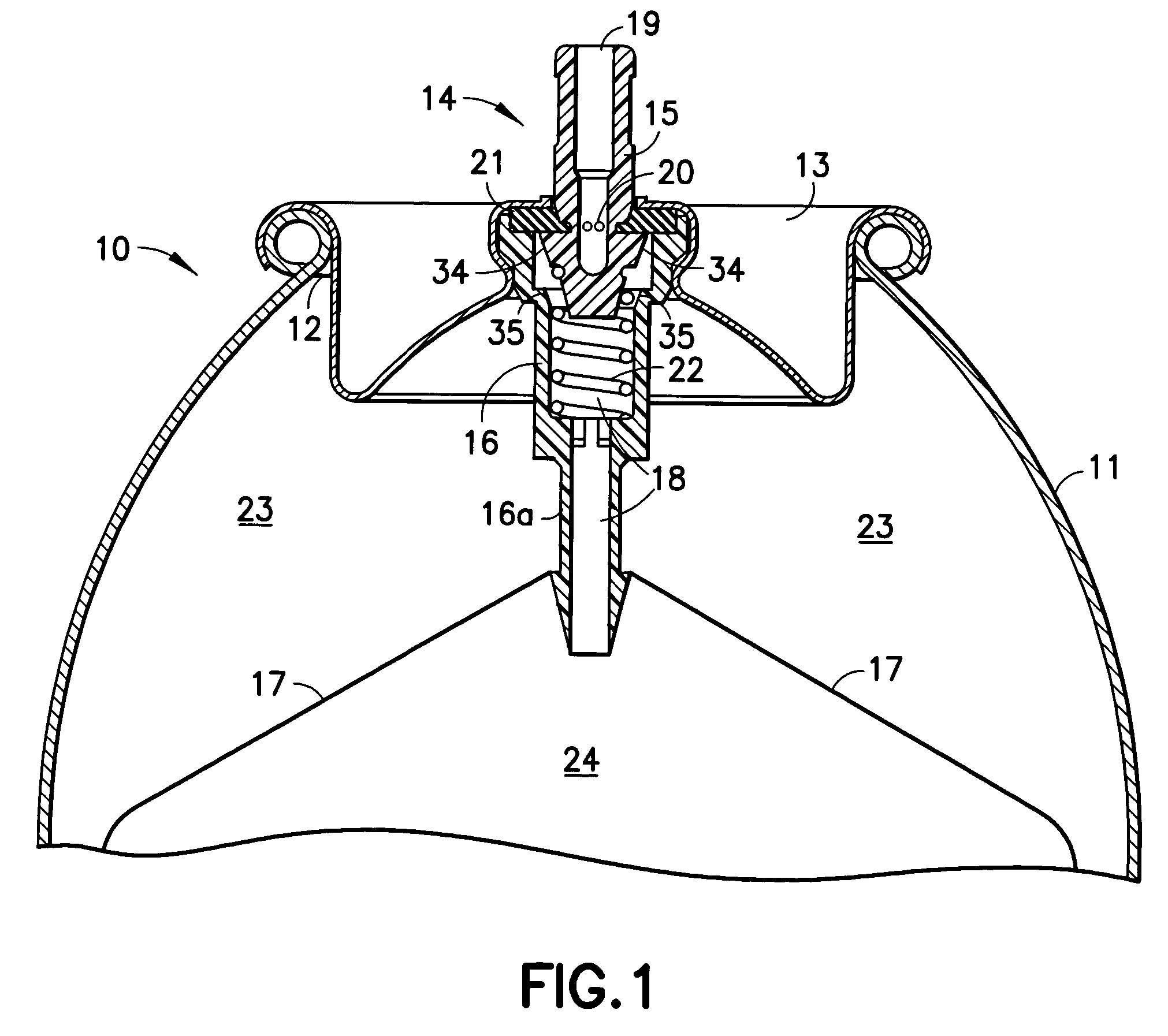

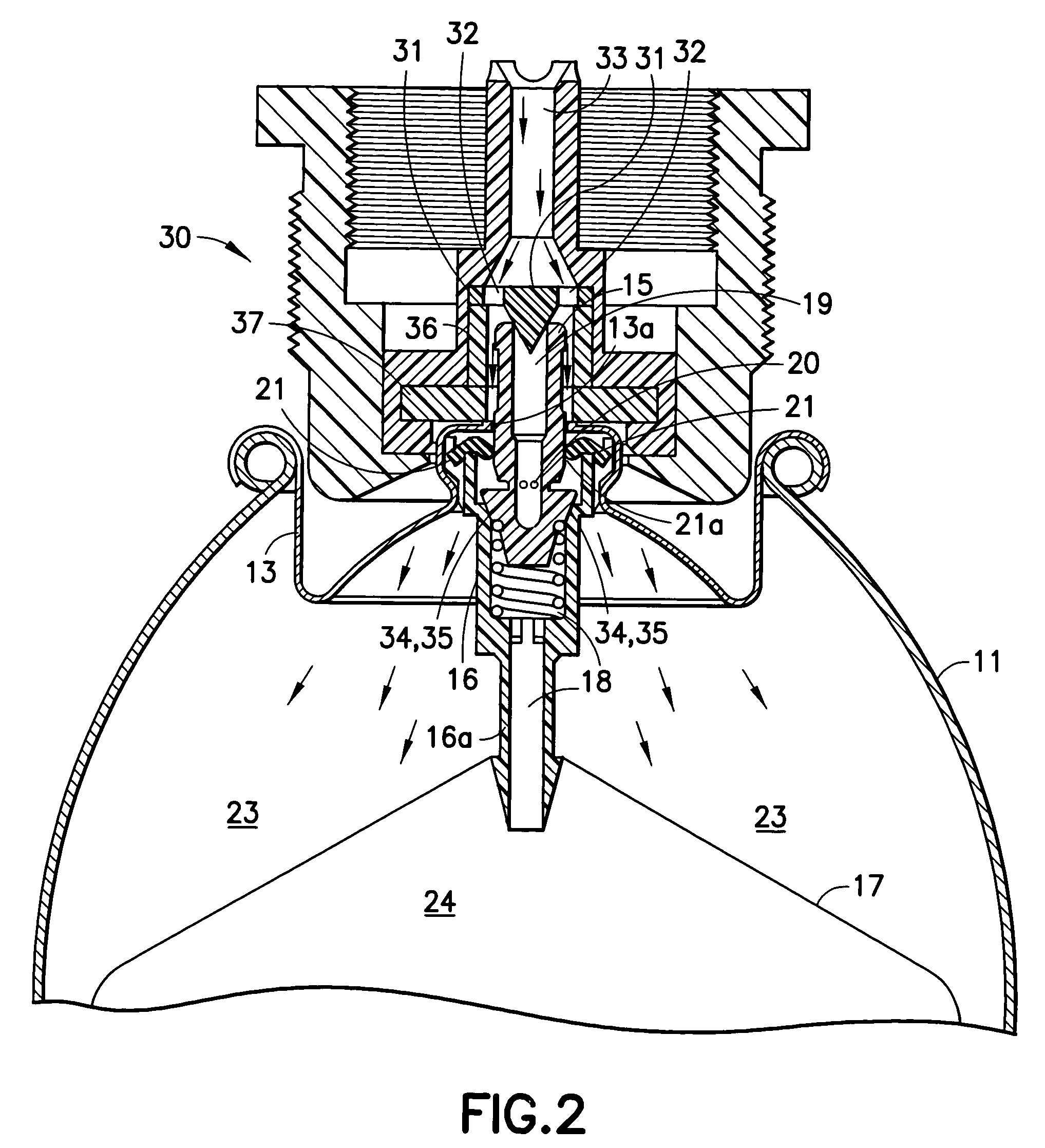

Means and method for filling bag-on-valve aerosol barrier packs

InactiveUS7124788B2Prevent exitMaintain positionSolid materialPackaging under special atmospheric conditionsPneumatic valveValve stem

A bag-on-valve aerosol valve system in a container. Propellant is pressure filled around the valve stem, outwardly over the stem gasket and down into the container space outside the bag. Product is filled through the valve stem into the bag. The valve stem has an exterior intermediate frusto-conical annular surface and the valve housing has an interior frusto-conical annular surface, with both surfaces engaging in annular sealing contact to block propellant access to the bag when the valve stem is deeply depressed to a first predetermined position for propellant pressure filling. A stem exterior surface indent interacts with radially-biased spring-loaded slides to lock the stem in a second less depressed predetermined position for product filling through the stem down into the bag. The propellant and product may be pressure filled in either order using essentially conventional pressure filing equipment, after the valve is mounted on the container and the bag is mounted on the valve.

Owner:PRECISION VALVE CORP

Pneumatically powered surgical cutting and fastening instrument with electrical control and recording mechanisms

A surgical instrument includes an end effector. A moveable cutting instrument for cutting an object positioned in the end effector is disposed within the end effector. A pneumatically-actuated drive member is coupled to the end effector. An electrically controlled variable flow rate pneumatic valve is coupled to the pneumatically-actuated drive member. An electronic control module is coupled to an electrically controlled variable flow rate pneumatic valve to control the flow rate therethrough.

Owner:ETHICON ENDO SURGERY INC

Water hammerless valve

InactiveUS8210493B2Operating means/releasing devices for valvesValve members for absorbing fluid energyPneumatic valveEngineering

A water hammerless valve includes a pneumatically-operated valve having a valve disc for opening and closing a fluid channel by moving upward and downward through a pneumatic actuator operation, and a limiting mechanism for interfering with upward movement of the valve disc when the water hammer occurs. The limiting mechanism includes a stepping motor including a rotation shaft fixed on the upper actuator; a vertical movement component connected to the rotation shaft for moving upward and downward via rotation of the rotation shaft; a lower detecting component for detecting the fact that the vertical movement component contacts the upper end of a stem when the lower detecting component moves downward; and a control device for rotating the stepping motor, for controlling the air supply, and for transmitting a stop signal to the stepping motor when the lower end of the lower detecting component detects the fact.

Owner:FUJIKIN INC

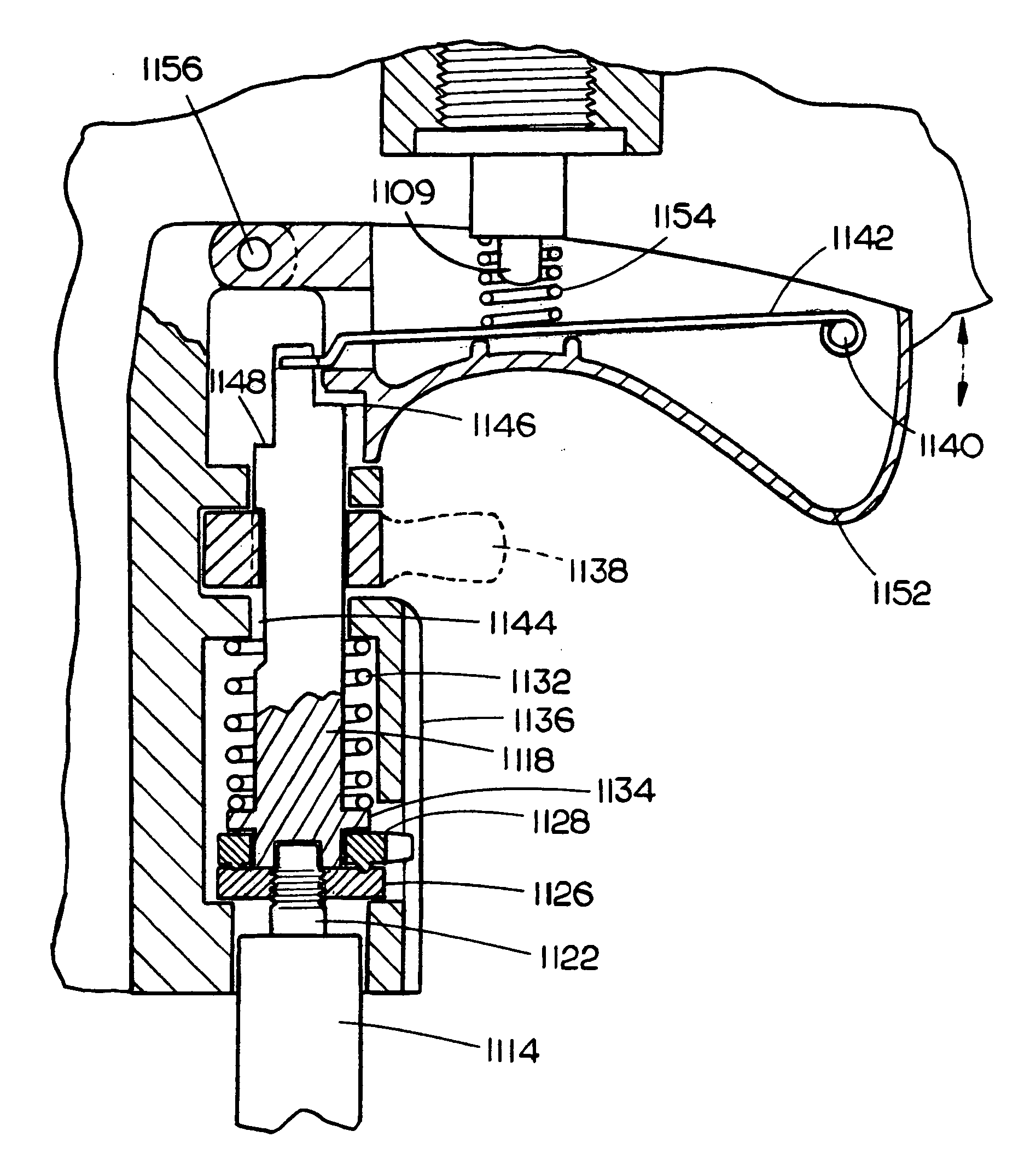

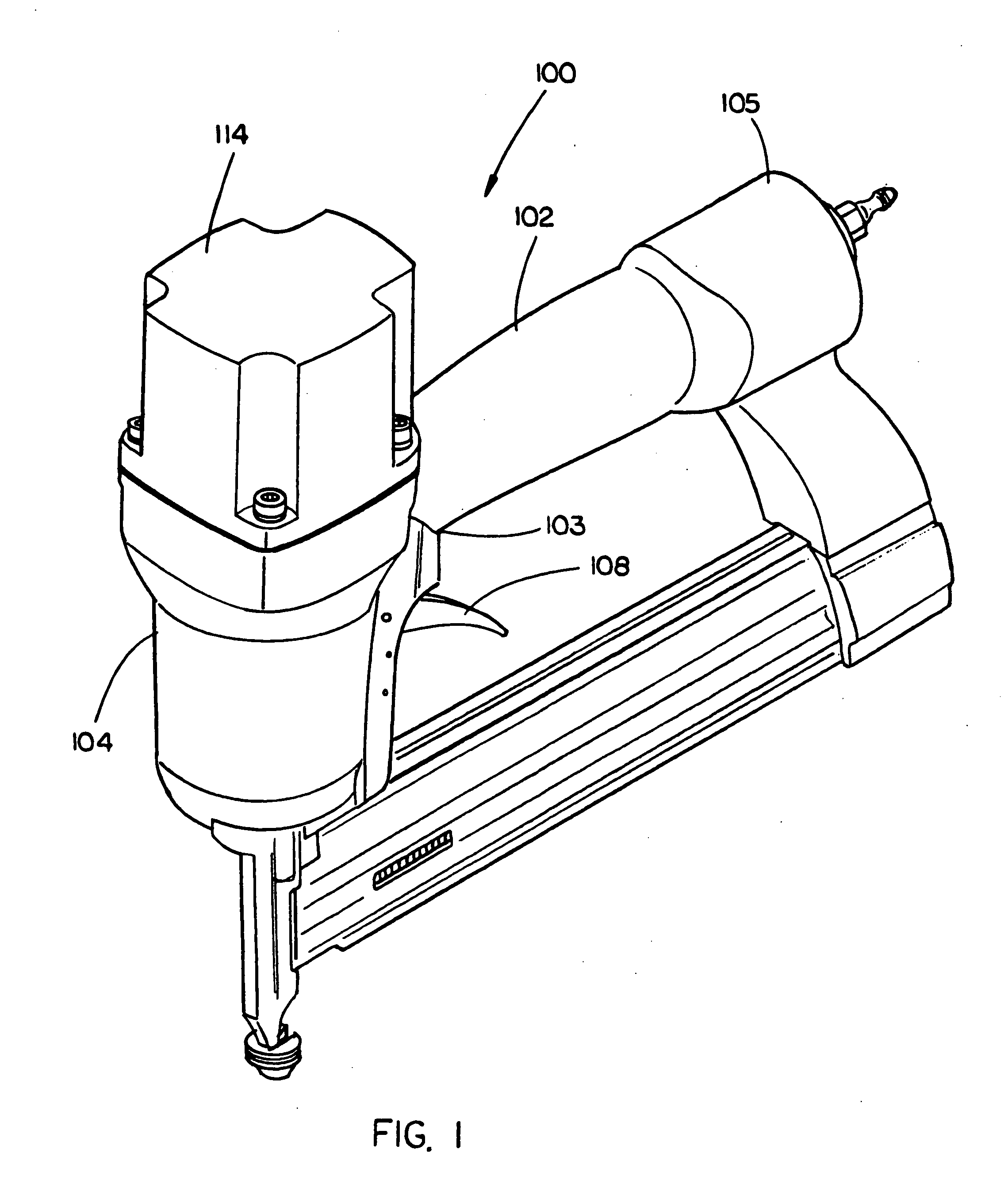

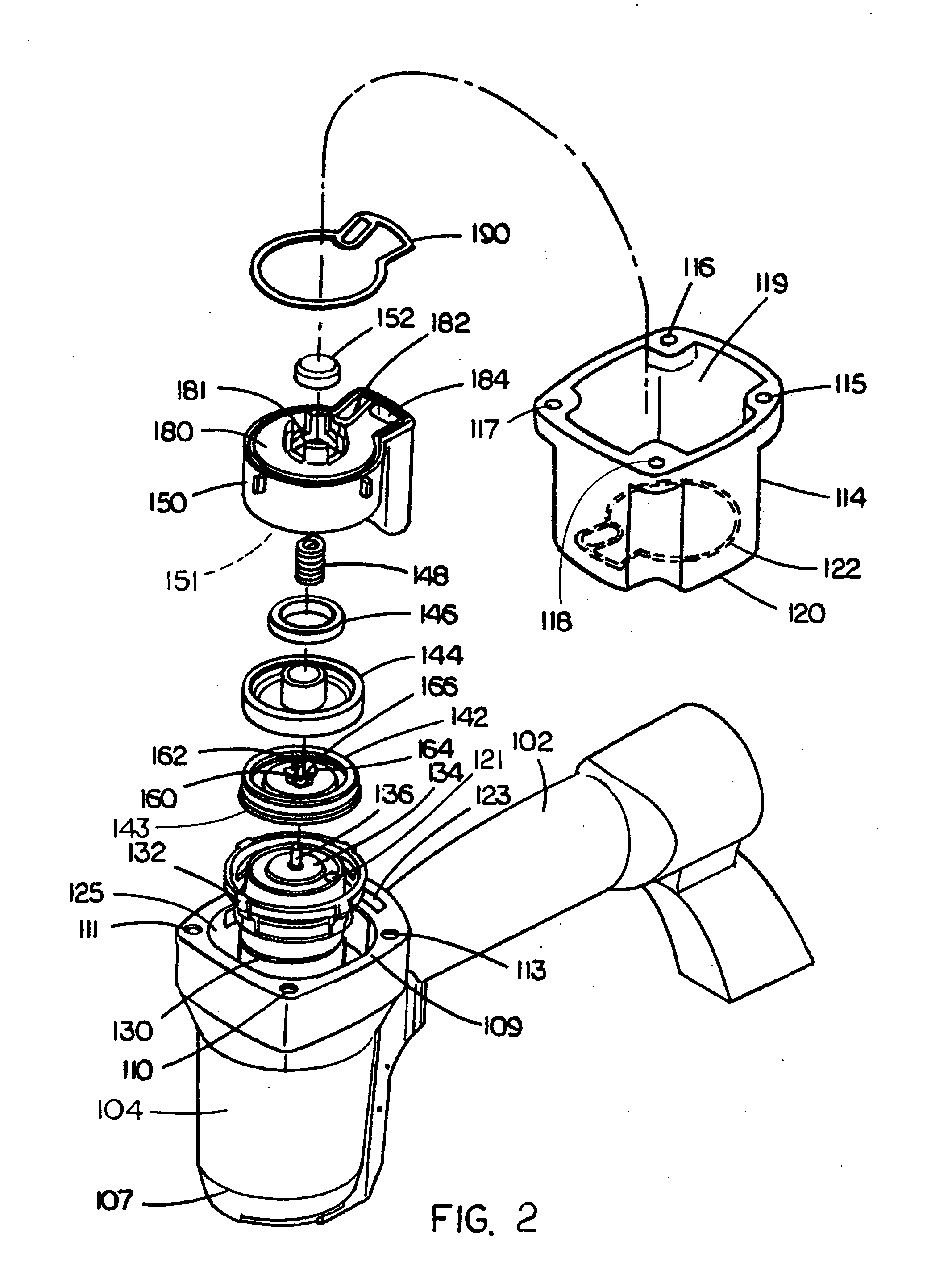

Dual mode pneumatic fastener actuation mechanism

InactiveUS20050184120A1Increase and decrease overall lengthStapling toolsNailing toolsDual modeEngineering

A contact safety and trigger mechanism for use with a pneumatic fastener in order to permit efficient pneumatic fastener actuation mode selection. A rotating rod is included in a contact safety assembly which is constructed to slide toward / away from a driver housing, defining a piston for securing a fastener disposed within the piston's path of travel. The rotating rod includes a first shoulder or ledge and a second shoulder which is off-set from the first shoulder. The rod may be rotated in order to orientate the selected shoulder, to function as a stop for a pivoting trigger assembly, which is constructed to contact a pneumatic valve, to initiate a fastening event in-which a fastener is driven into a workpiece. The configuration of the rotating rod permits for selection between a contact actuation mode wherein movement of the contact safety initiates securing of a fastener and a sequential actuation mode in which the trigger assembly is manipulated by a user to trigger securing of a fastener after the contact safety has be depressed towards the driver housing.

Owner:BLACK & DECKER INC

Pneumatic Pressure Output Control by Drive Valve Duty Cycle Calibration

In various embodiments, a surgical console may include a pneumatic valve to drive a pneumatic tool coupled to the surgical console. The console may further include a controller operable to control and adjust the valve open / close cycle times according to a valve duty cycle. The valve may switch between ports (valve open time for a first port and valve close time for a second port) such that a total valve time may approximately equal the valve open time plus the valve close time. The valve duty cycle may indicate a percentage of the total valve time for the controller to signal the valve to open and may include an adjustment that corresponds to a signal timing of the open and / or closed valve positions that will result in open and closed operating pressures above a predetermined threshold.

Owner:ALCON INC

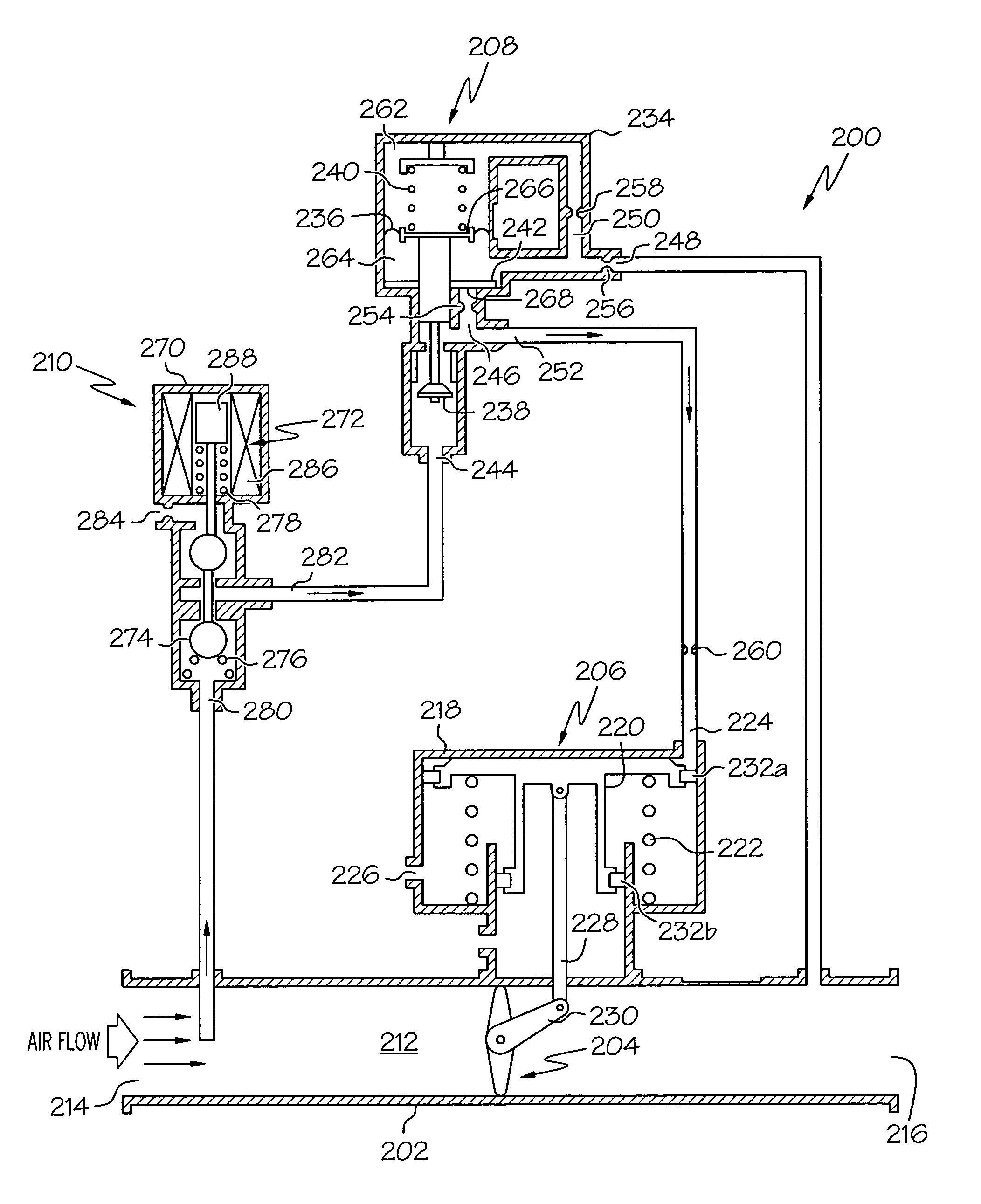

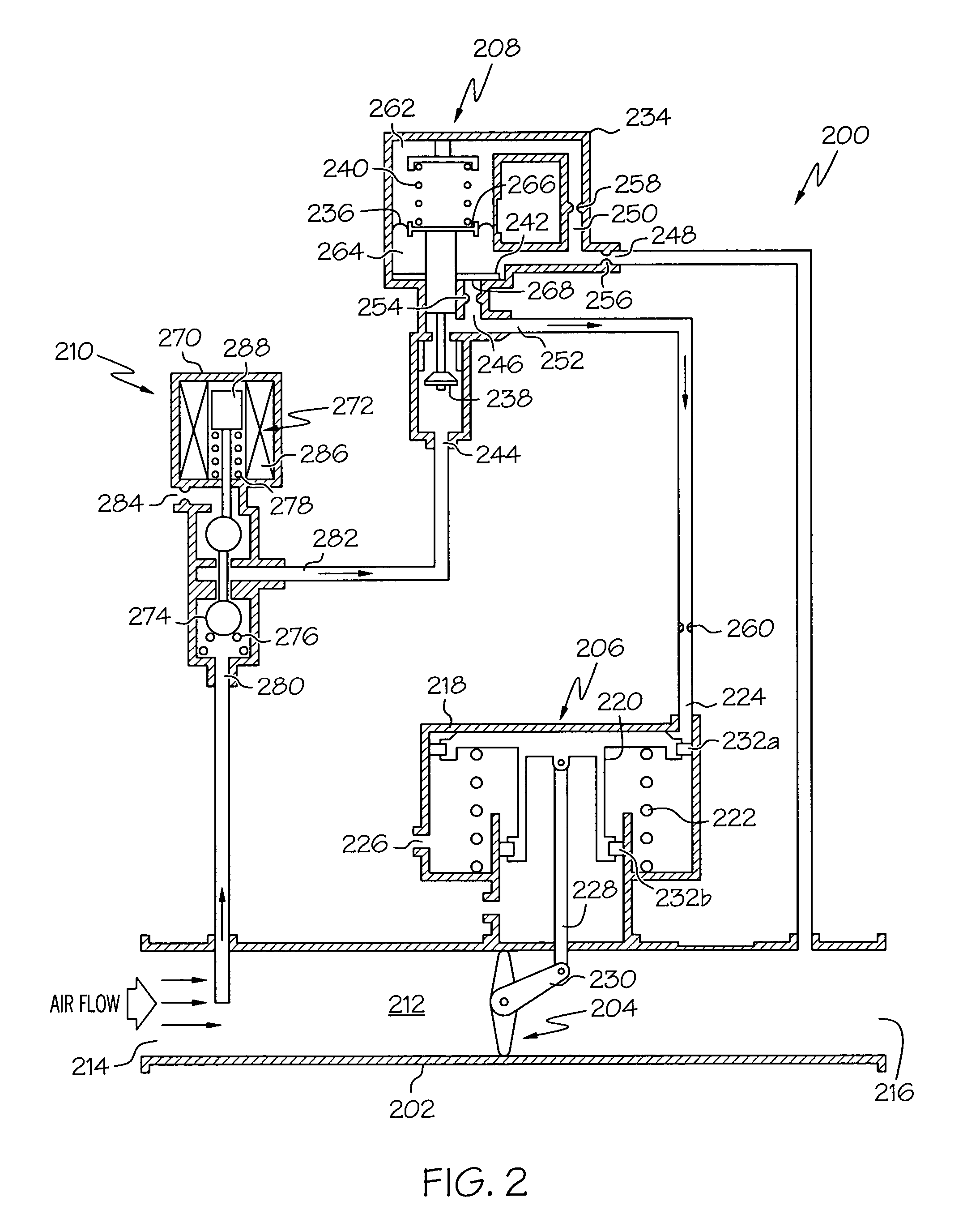

Pneumatic valve control using downstream pressure feedback and an air turbine starter incorporating the same

A starter air valve assembly includes a valve body, a flow control valve, a rate control servo mechanism, and a valve actuator. The valve body defines a flow passage having at least an inlet port and an outlet port. The valve is disposed at least partially within the flow passage and is moveable between an open position and a closed position. The rate control servo mechanism is adapted to receive pressurized fluid and is configured, upon receipt of the pressurized fluid, to supply a controlled flow of the pressurized fluid. The valve actuator is coupled to the valve and is in fluid communication with the rate control servo to thereby receive the controlled flow of the pressurized fluid. The valve actuator is configured, upon receipt of the controlled flow of the pressurized fluid, to move the valve between the closed position and the open position at a substantially controlled rate.

Owner:HONEYWELL INT INC

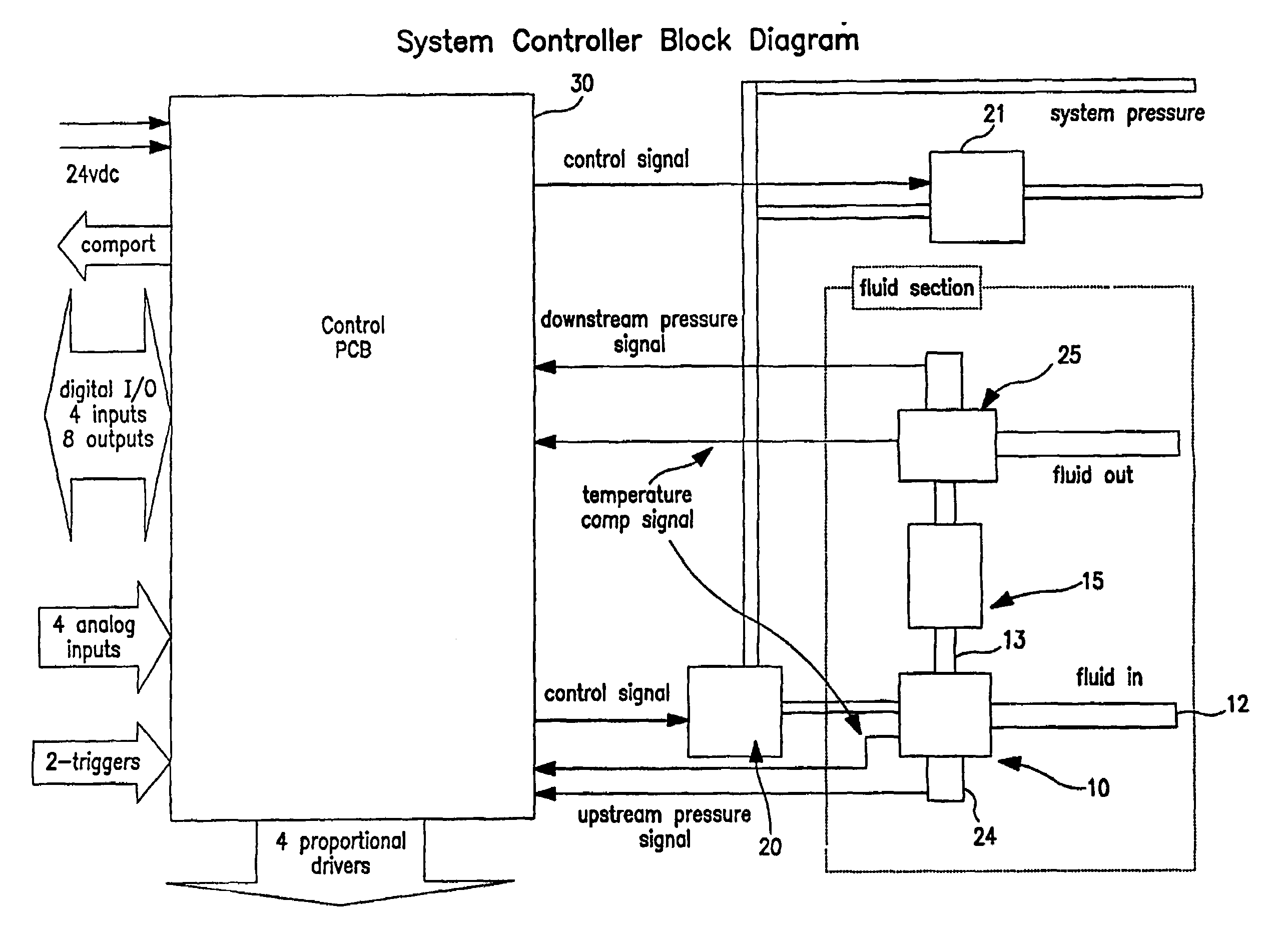

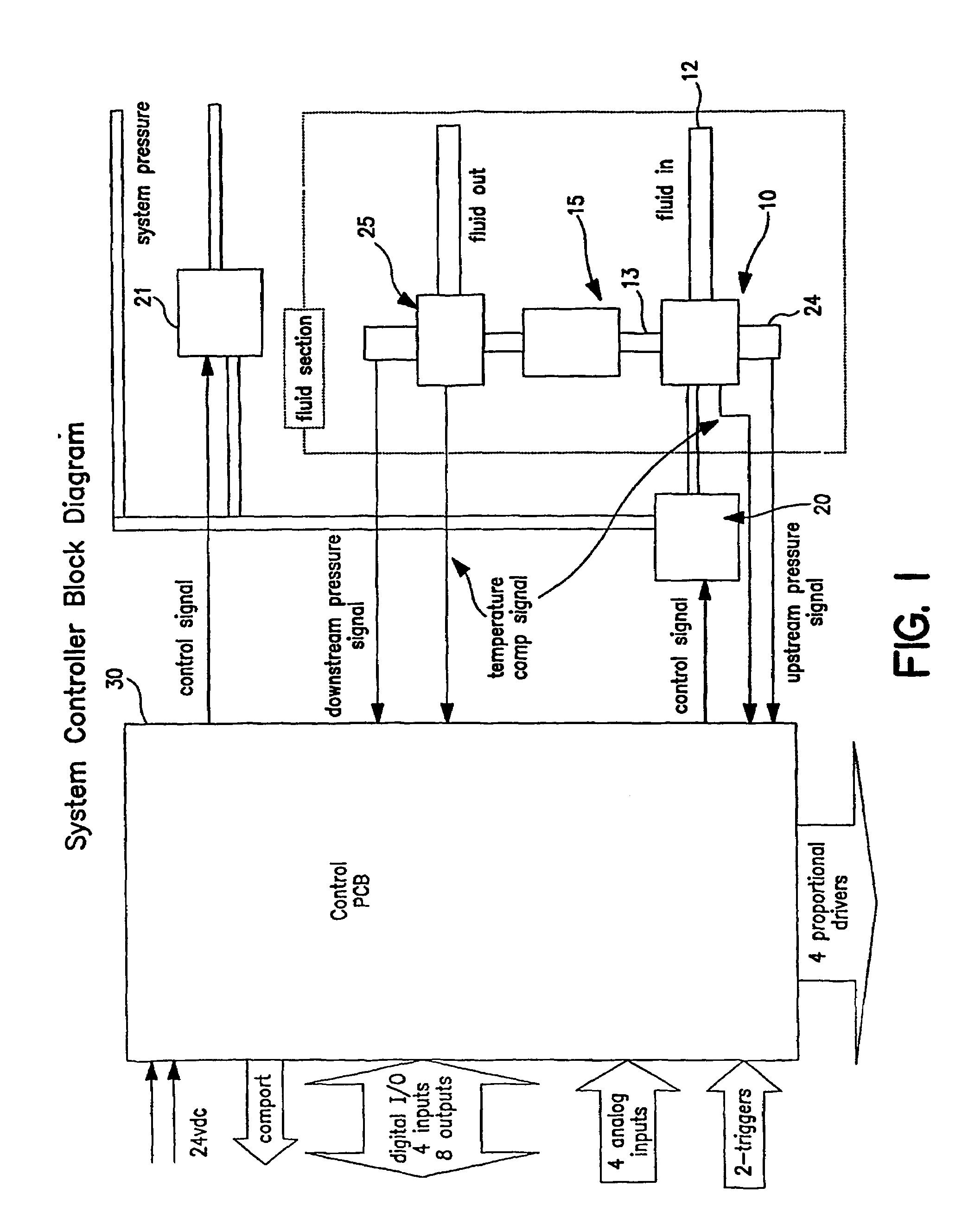

Liquid flow controller and precision dispense apparatus and system

InactiveUS7543596B2Easy to controlCost-effectiveOperating means/releasing devices for valvesFlow control using electric meansMeasurement deviceFluid control

Apparatus and a control system for monitoring (preferably digitally) and / or controlling pressure to a pneumatic load such as a proportional fluid control valve and using a measurement input from a fluid measurement device that responds to a flow rate, the liquid measurement input being used to control the pressure to the pneumatic load so that pneumatic load may be increased or decreased (to proportionally open or close the pneumatic valve) to change the flow rate of the fluid to a desired rate. The pneumatic load can also be adjusted (to proportionally open or close the pneumatic valve) to accommodate changes in temperature and viscosity of a fluid.

Owner:ENTEGRIS INC

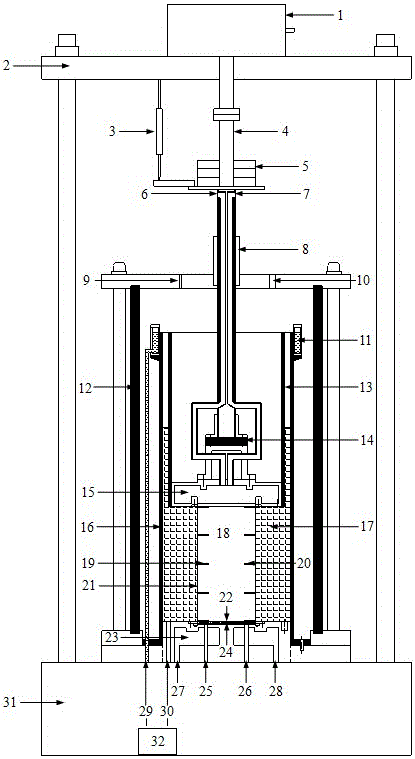

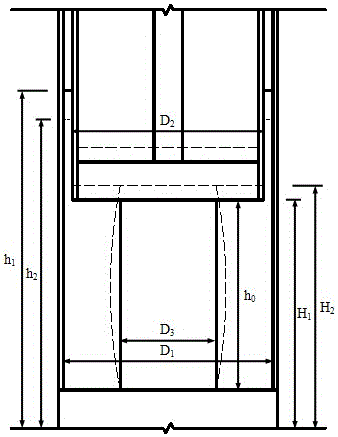

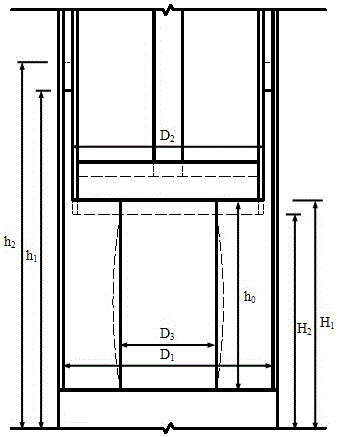

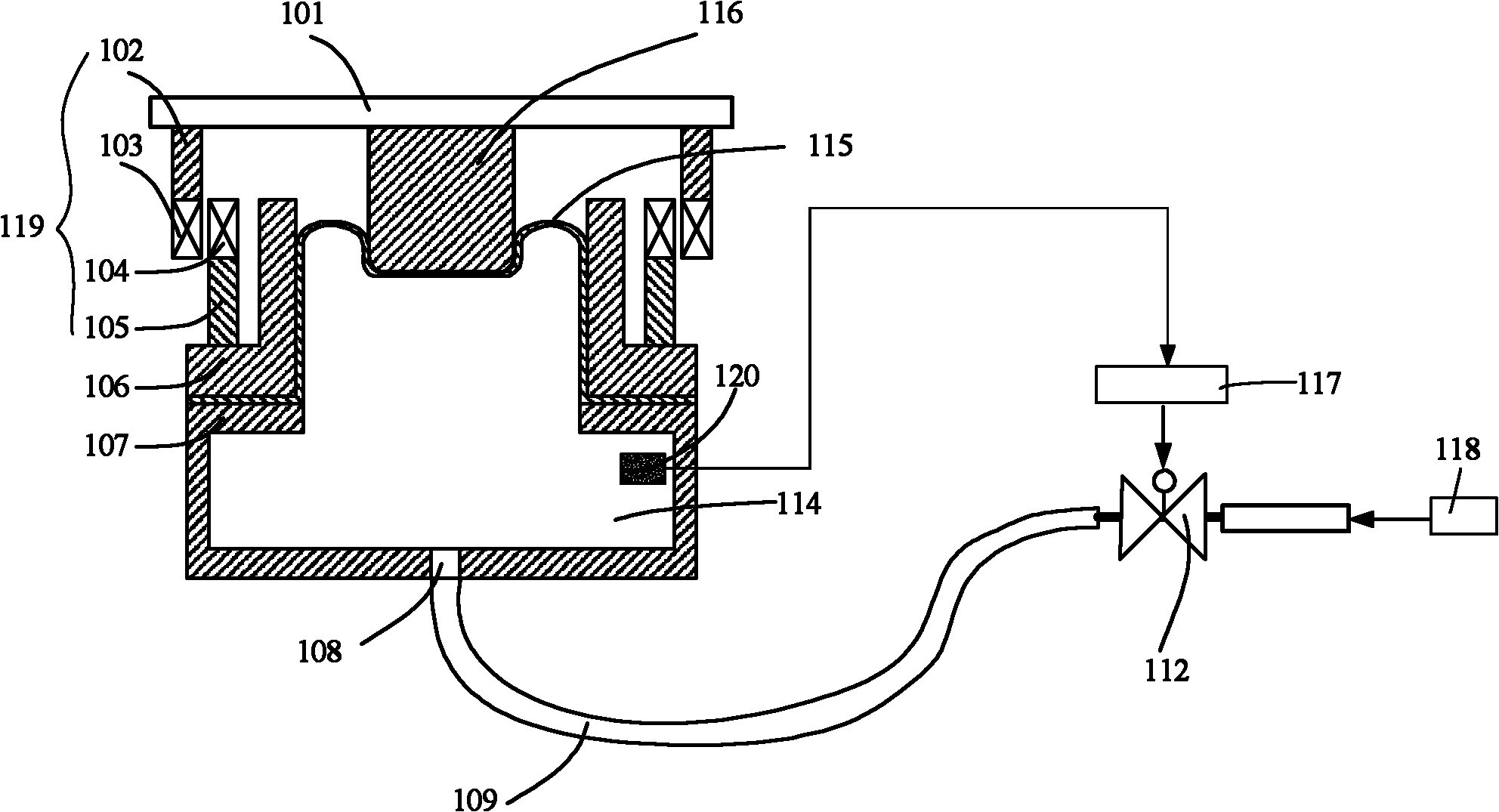

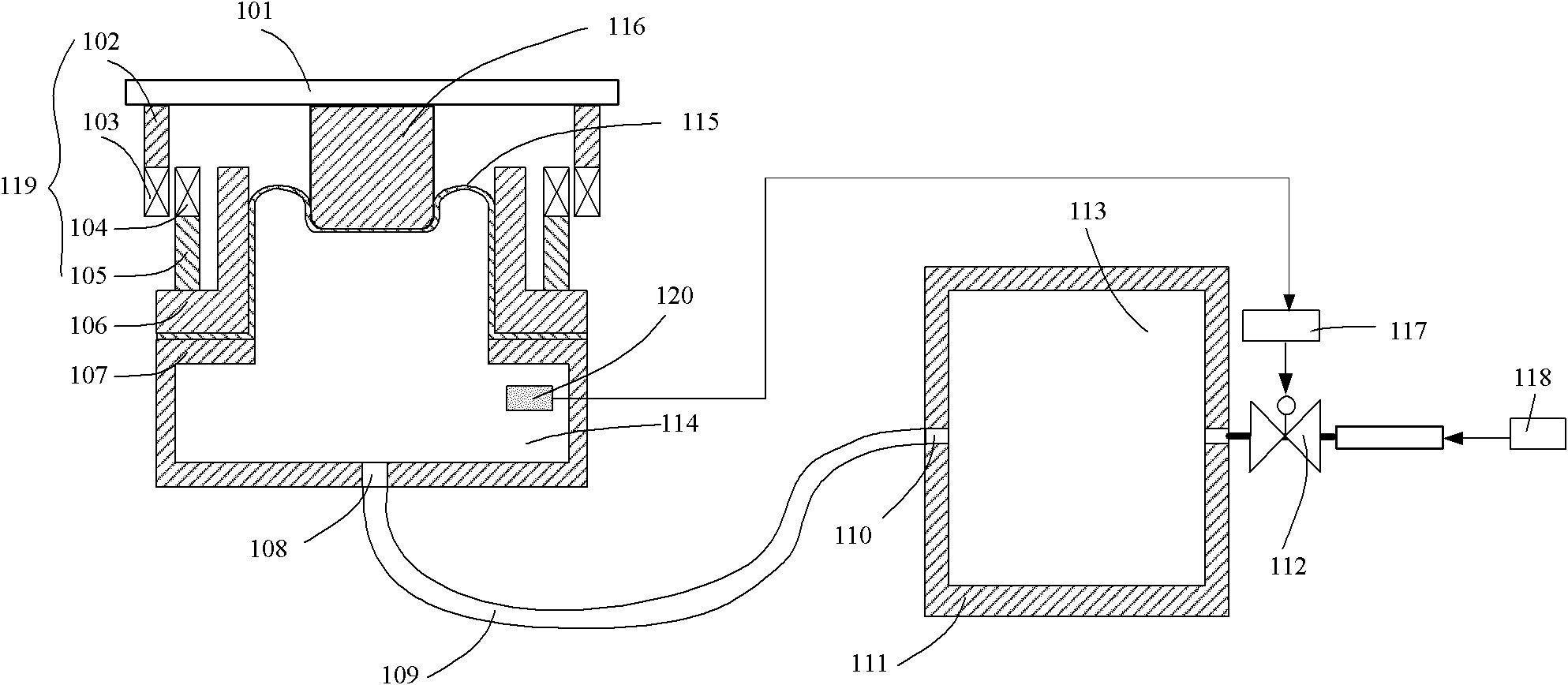

Dynamic and static triaxial tester for frozen and thawed soil in open system

ActiveCN106644750AAdvanced conceptPrinciples of ScienceMaterial strength using tensile/compressive forcesMaterial thermal analysisDifferential pressureData acquisition

The invention discloses a dynamic and static triaxial tester for frozen and thawed soil in an open system. The tester comprises a temperature control system, a water-replenishing system, a loading system, a confining pressure system, and a data acquisition system, wherein the temperature control system comprises a cold end socket, a warn end socket, a high and low-temperature constant-temperature liquid bath circulator, a porous pressure-transmitting medium, and a rubber film; the water-replenishing system comprises a water-replenishing tank, a water-replenishing bottle, and a high-intake value ceramic plate; the loading system comprises an exciter, a reaction frame, a test pedestal, a central force transmission rod, and a counterweight; the confining pressure system comprises a linear bearing, a pneumatic valve, an external pressure chamber, and an internal pressure chamber; and the data acquisition system comprises a displacement sensor, an annular liquid level calibration chamber, a dilatation measurement chamber, a differential pressure sensor, a piezoelectric force sensor, a temperature sensor, and a humidity sensor. The dynamic and static triaxial tester for the frozen and thawed soil in the open system disclosed by the invention can carry out a conventional frozen soil test involved in Code for Soil Test of Railway Engineering (TB10102-2010), an unidirectional freezing or thawing test for a specimen under the action of a dynamic load and different stress states, etc.

Owner:HARBIN INST OF TECH

Pneumatic valve control using downstream pressure feedback and an air turbine starter incorporating the same

ActiveUS20050276685A1Improved valve opening characteristicImprove featuresWind motor controlPump componentsControl flowValve actuator

A starter air valve assembly includes a valve body, a flow control valve, a rate control servo mechanism, and a valve actuator. The valve body defines a flow passage having at least an inlet port and an outlet port. The valve is disposed at least partially within the flow passage and is moveable between an open position and a closed position. The rate control servo mechanism is adapted to receive pressurized fluid and is configured, upon receipt of the pressurized fluid, to supply a controlled flow of the pressurized fluid. The valve actuator is coupled to the valve and is in fluid communication with the rate control servo to thereby receive the controlled flow of the pressurized fluid. The valve actuator is configured, upon receipt of the controlled flow of the pressurized fluid, to move the valve between the closed position and the open position at a substantially controlled rate.

Owner:HONEYWELL INT INC

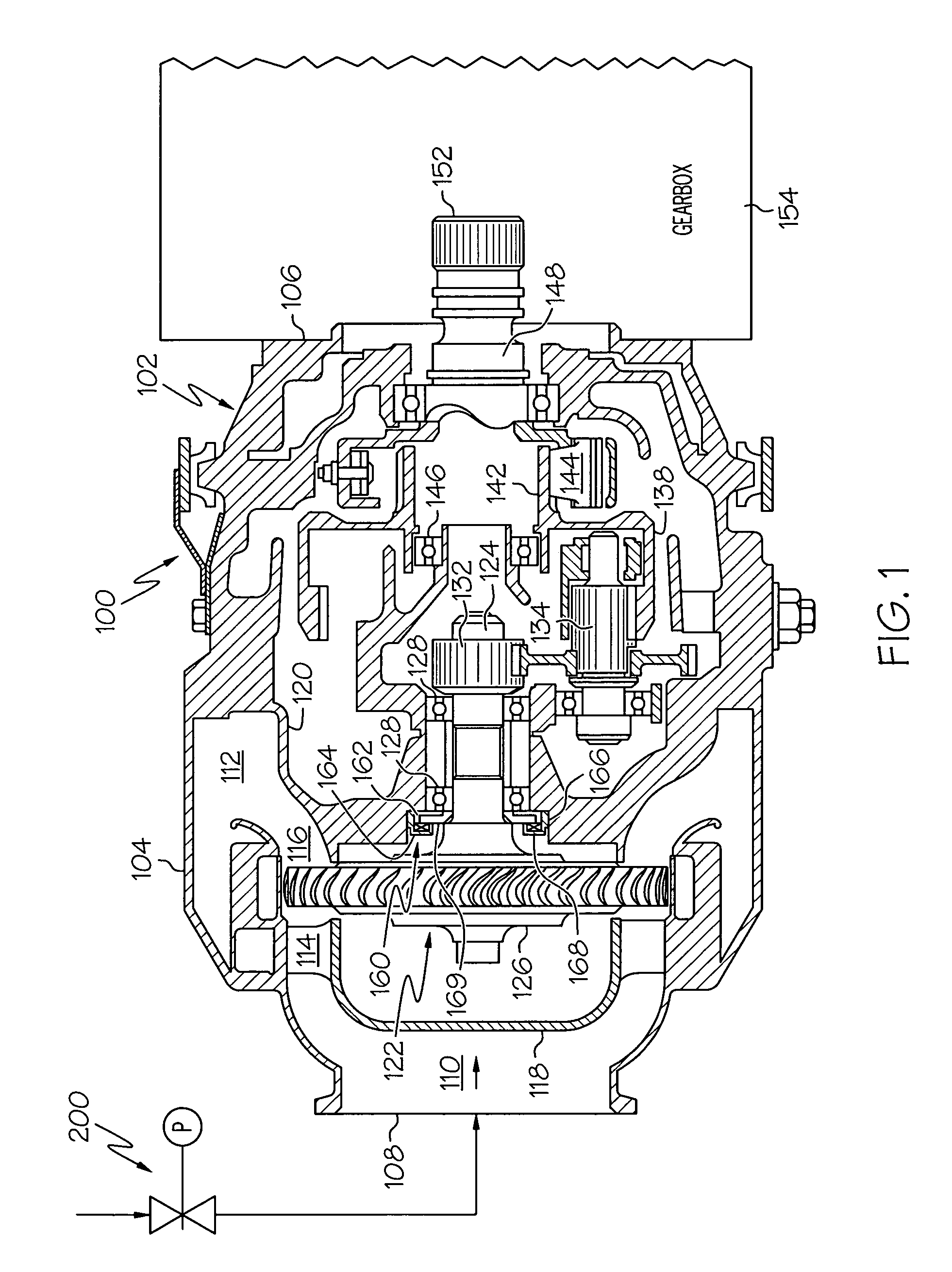

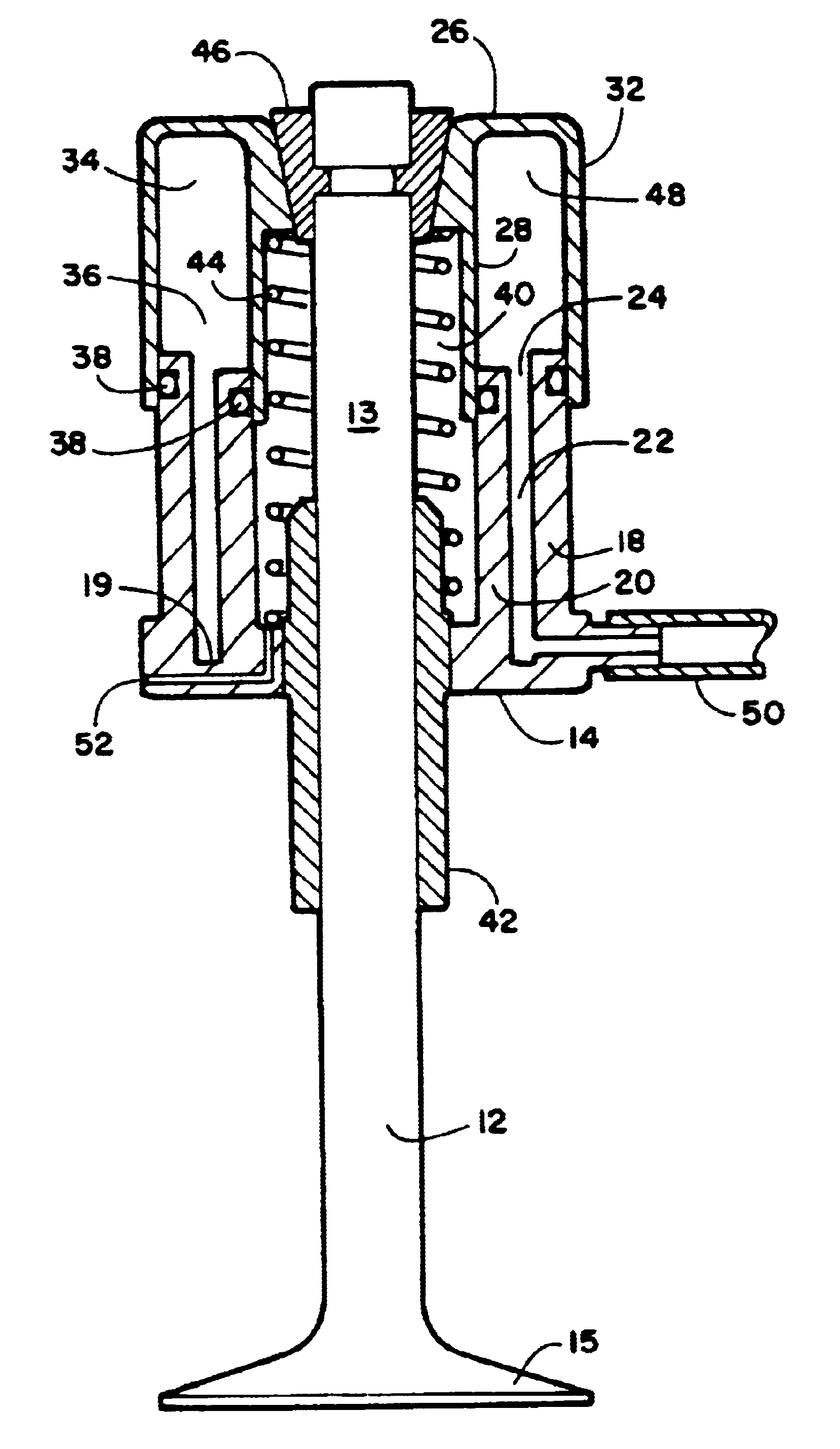

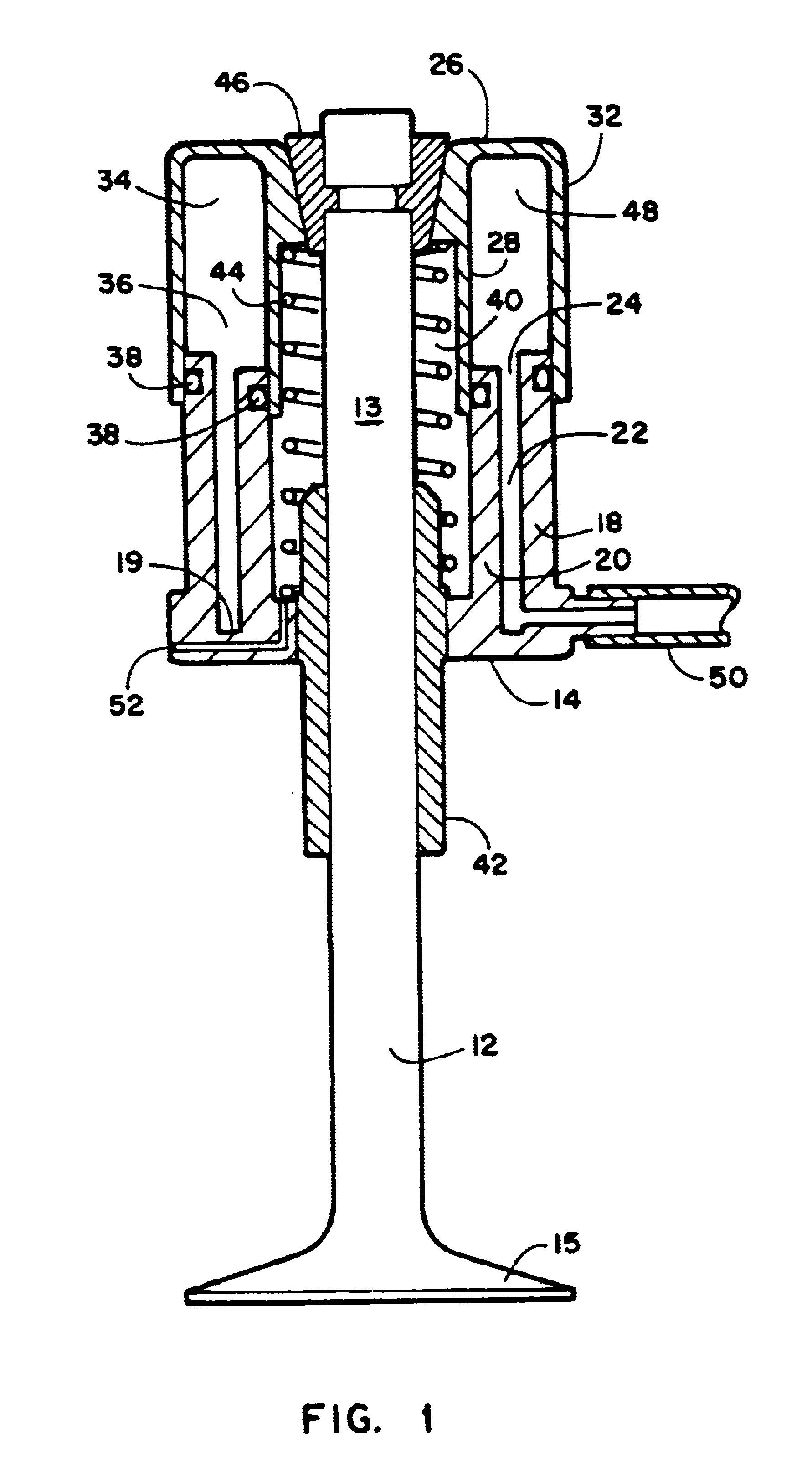

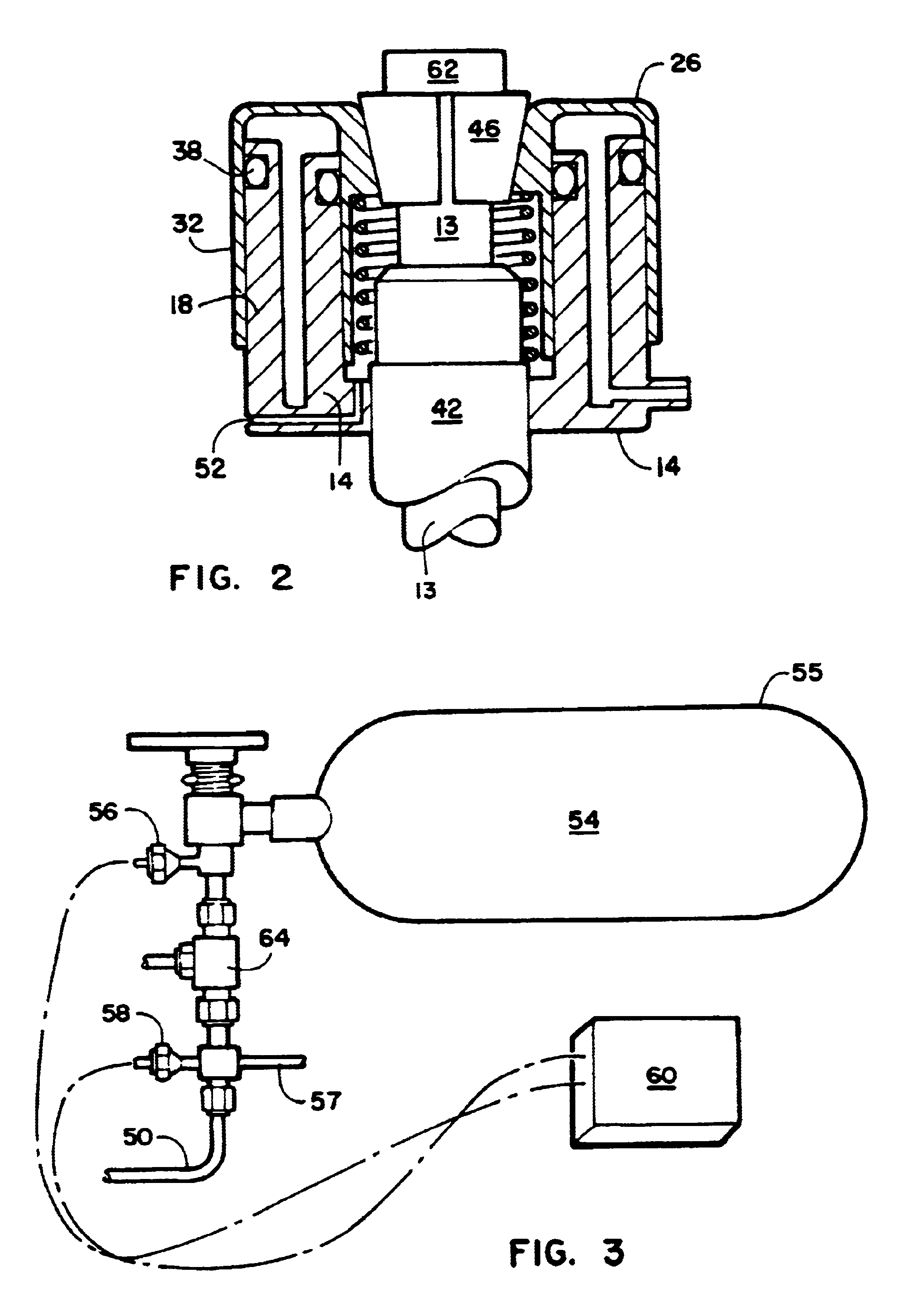

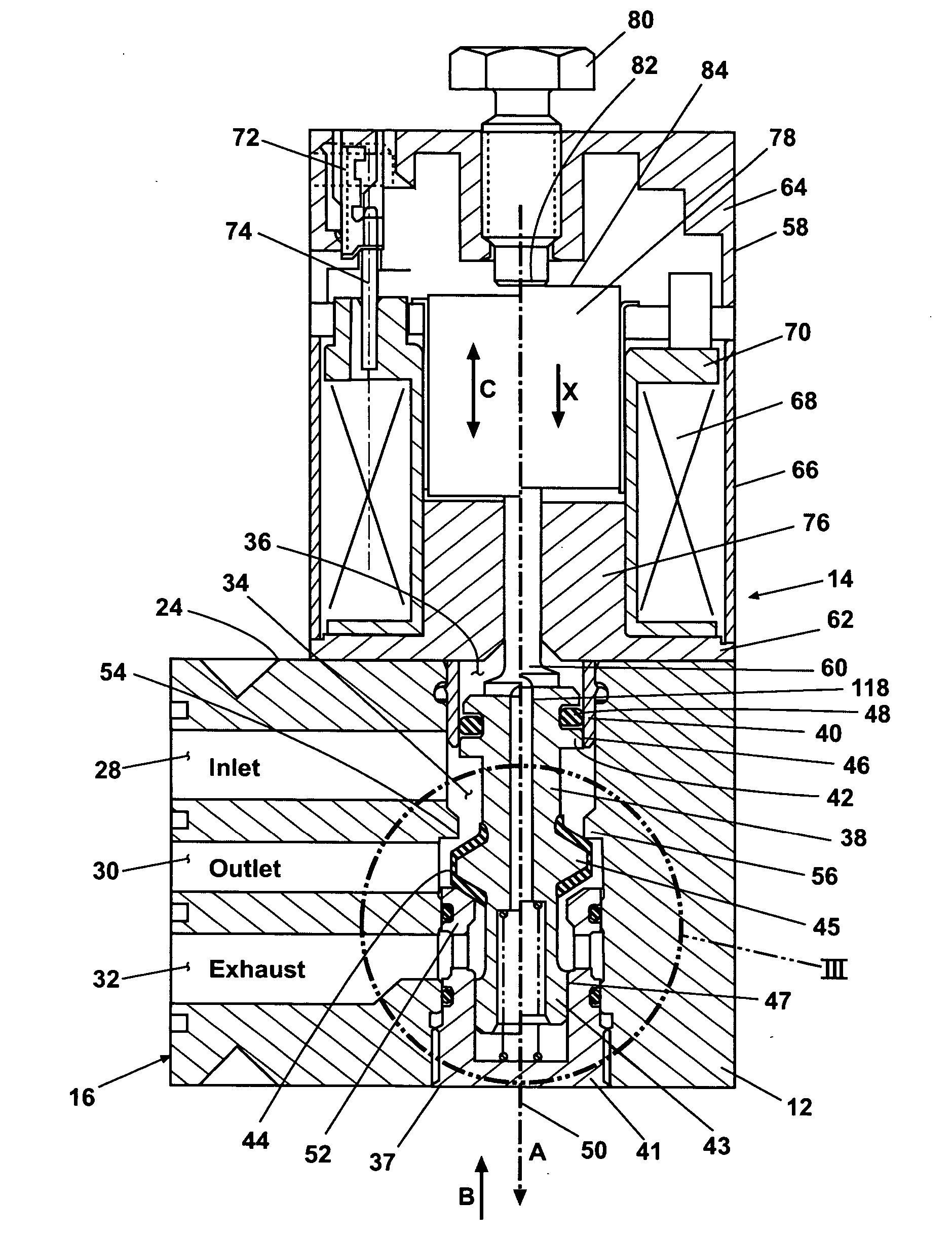

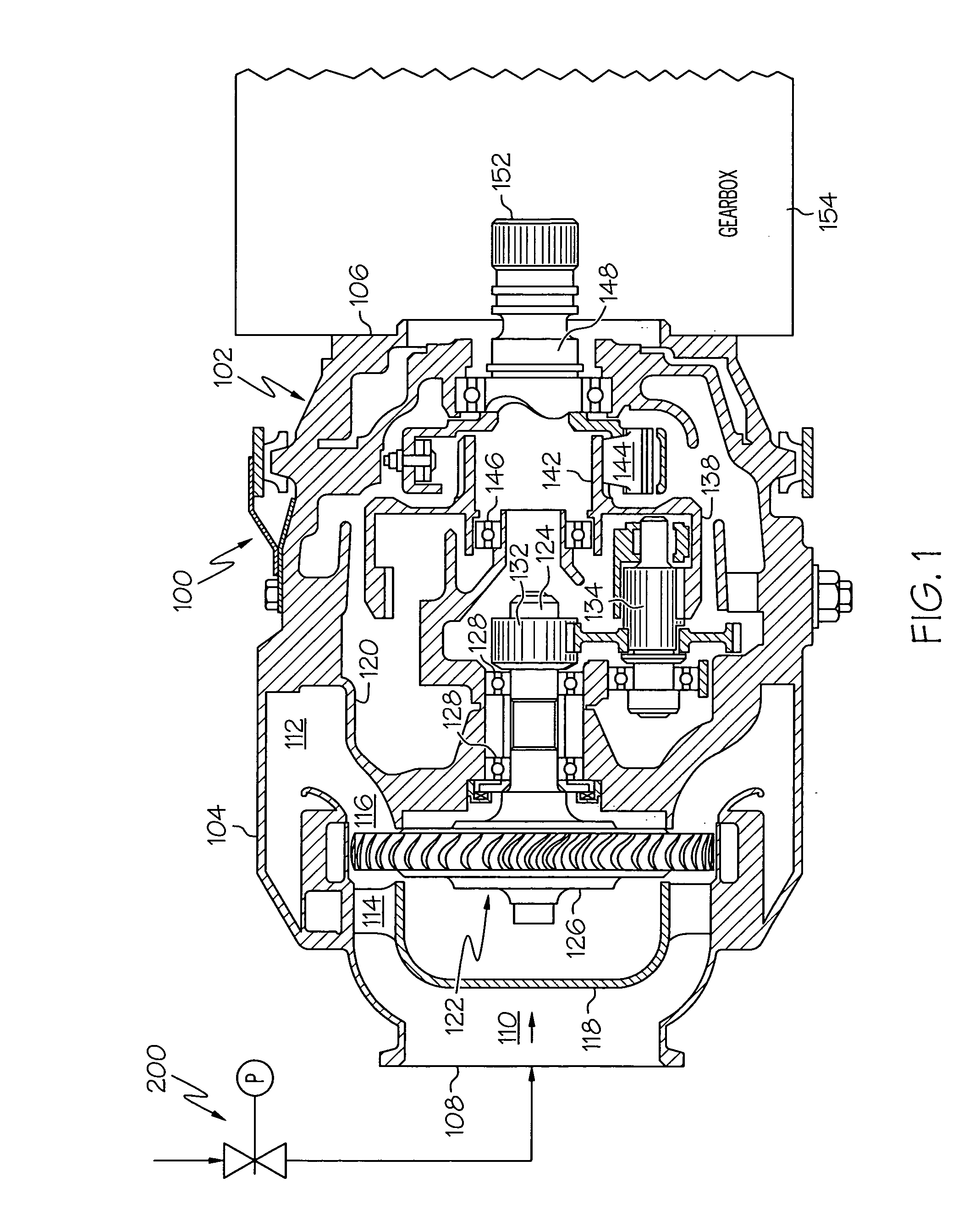

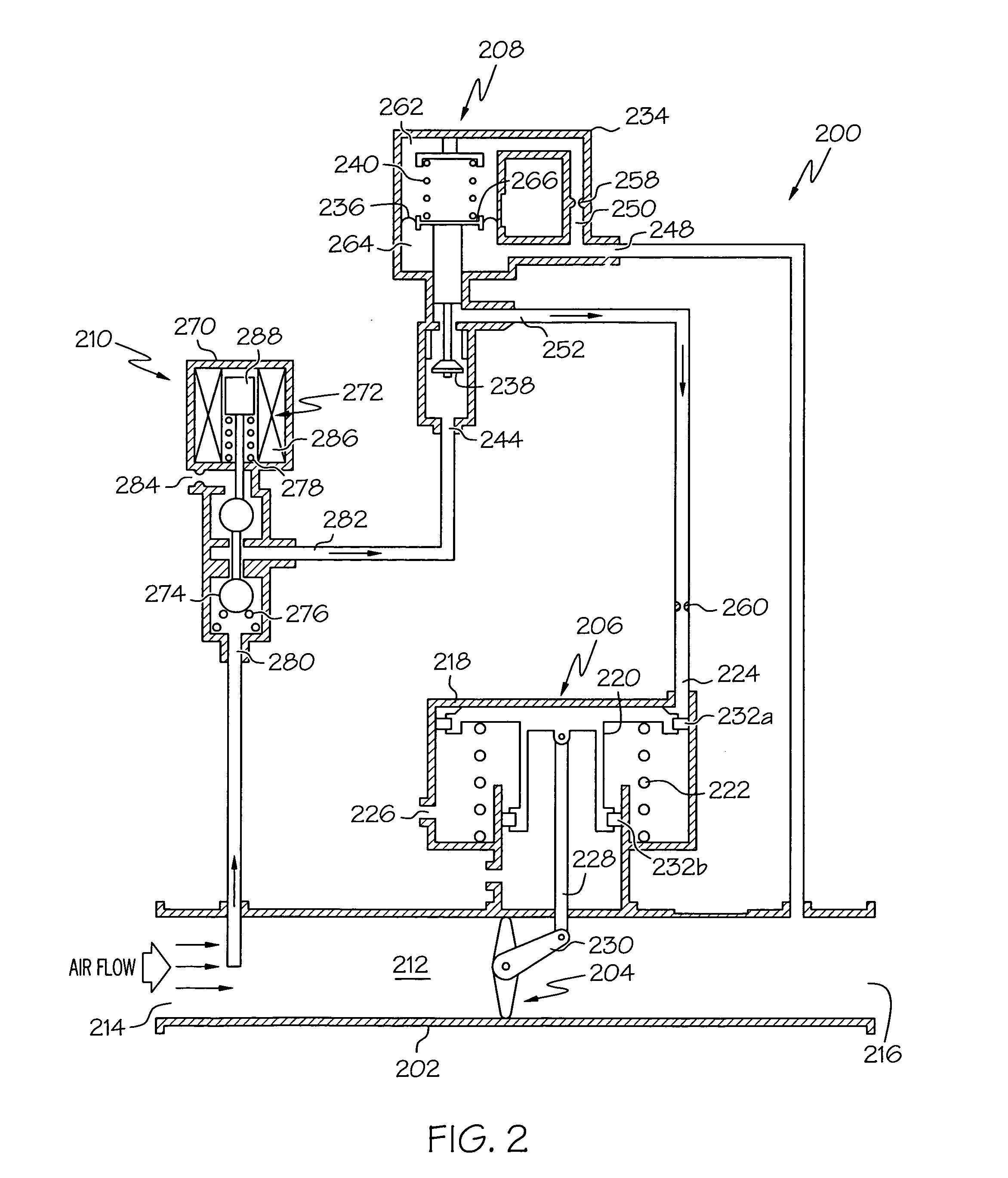

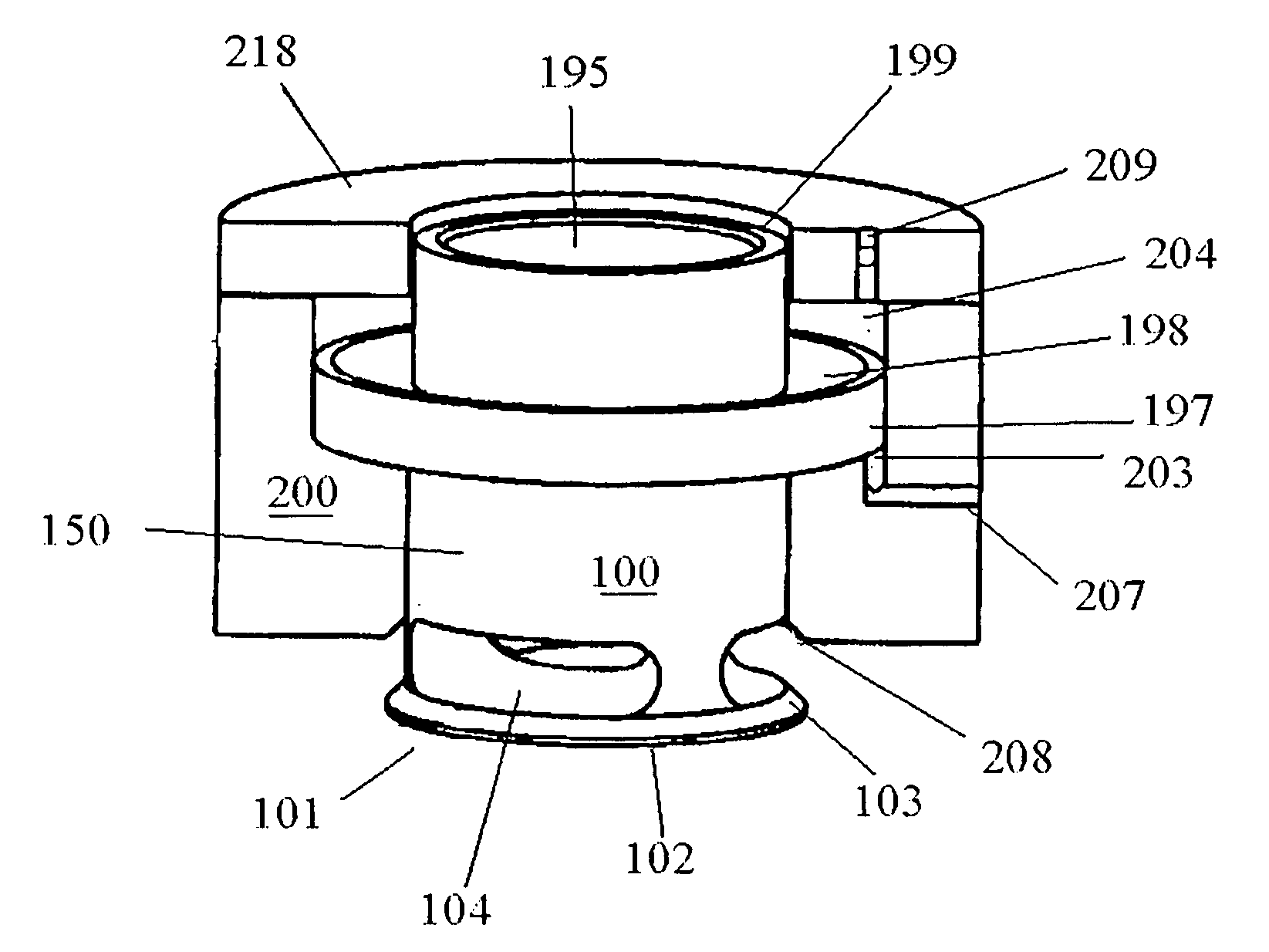

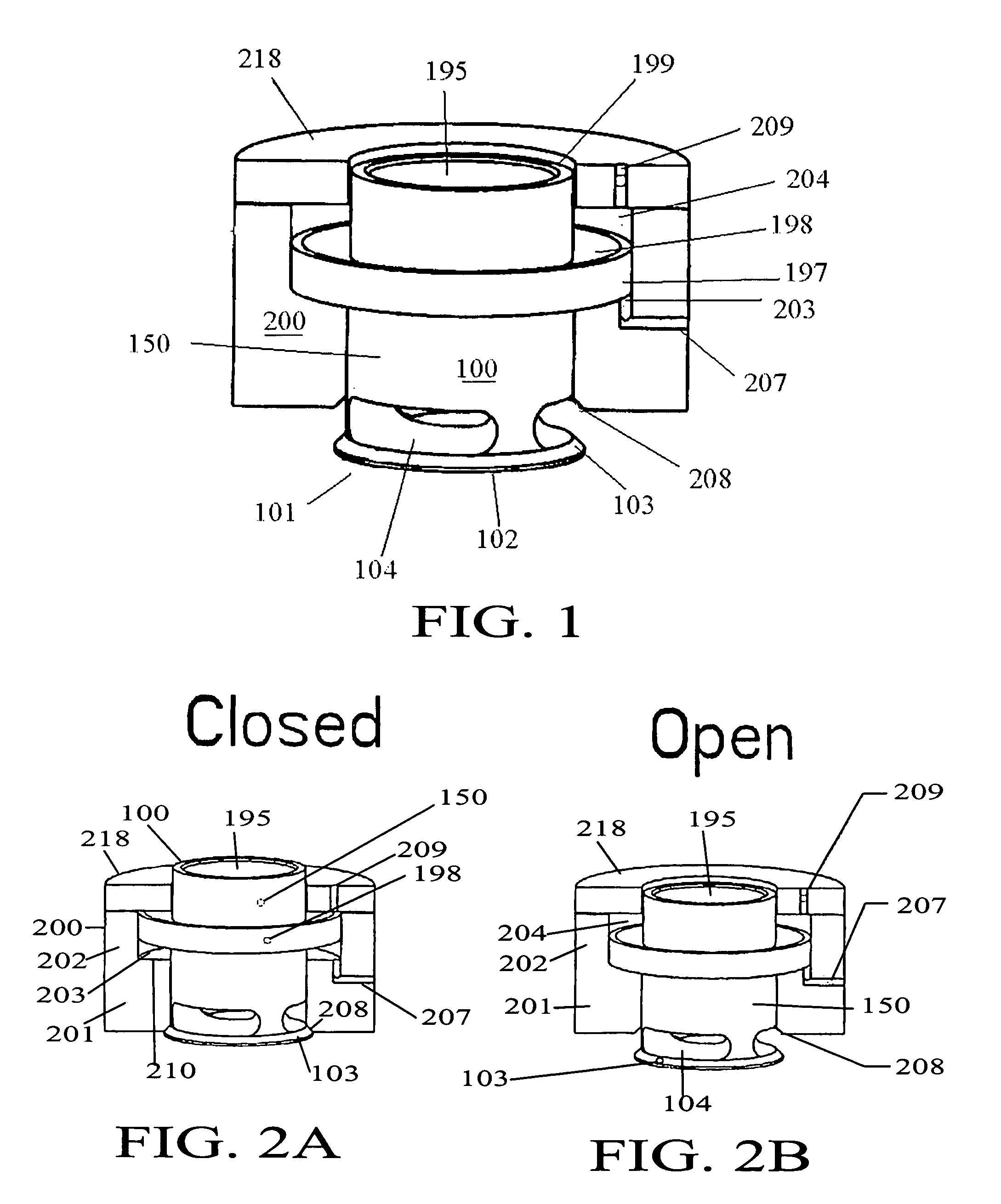

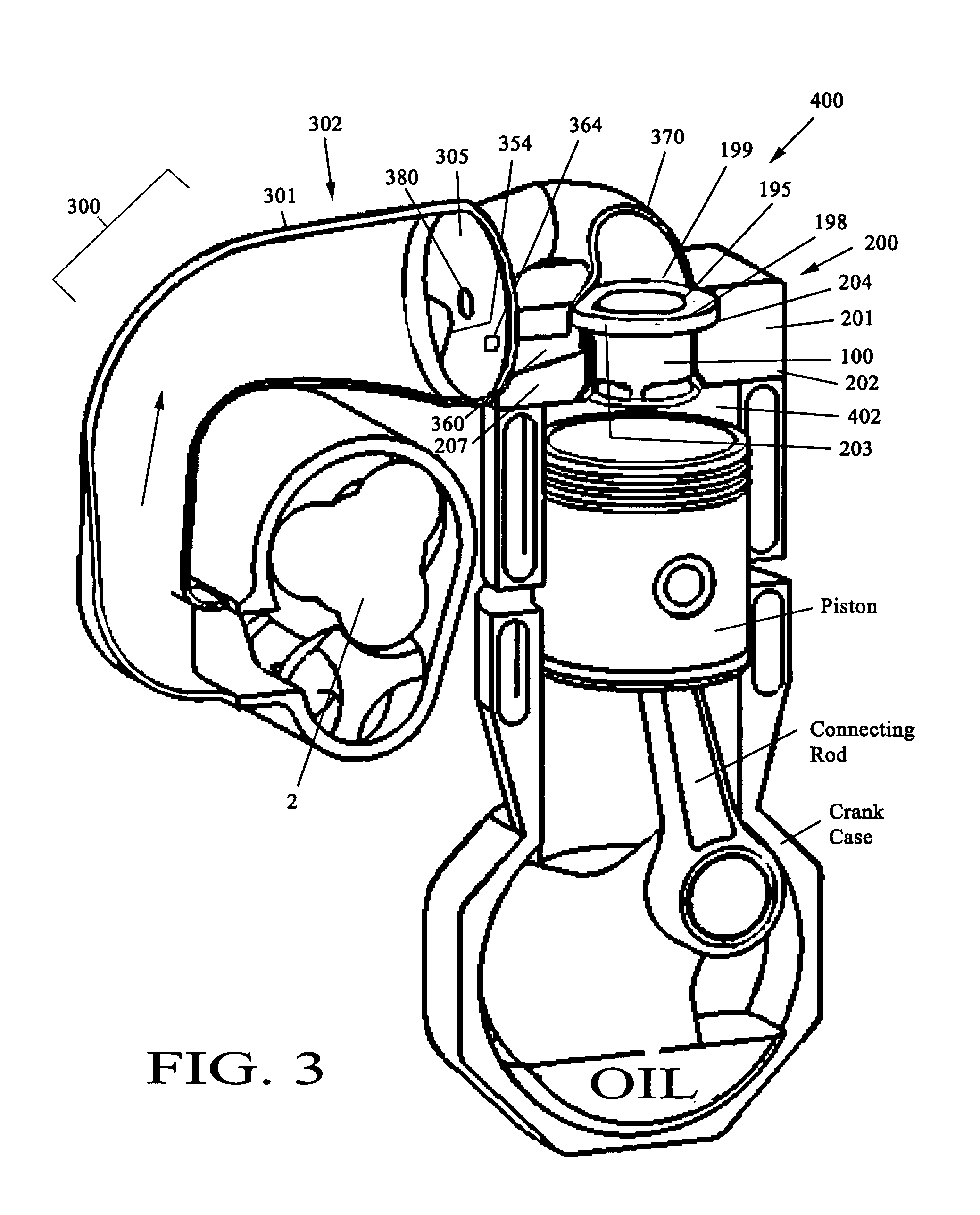

Pneumatically actuated valve for internal combustion engines

A pneumatically actuated valve assembly for use as intake and / or exhaust valves on two- or four-stroke internal combustion engines. The assembly includes a valve (100), valve housing (200), and compressed gas distribution and timing mechanisms (FIGS. 5–8). The valve (100) is comprised of a short light weight hollow cylindrical body with a capped lower end and an opened upper end. The valve is further defined by a plurality of ports (104) adjacent to the lower end and a collar (198) encircling the body adjacent the upper end. The valve housing (200) is hollow and tubular having a larger diameter upper section and a smaller diameter lower section in which the valve (100) slides up to close and down to open. The housing (200) further includes hollow channels which direct compressed gas, managed by the distribution and timing mechanism, alternately towards the areas above and below the valve collar at regular intervals to open and close the valve, respectively.

Owner:KLEIN JEFFREY F +1

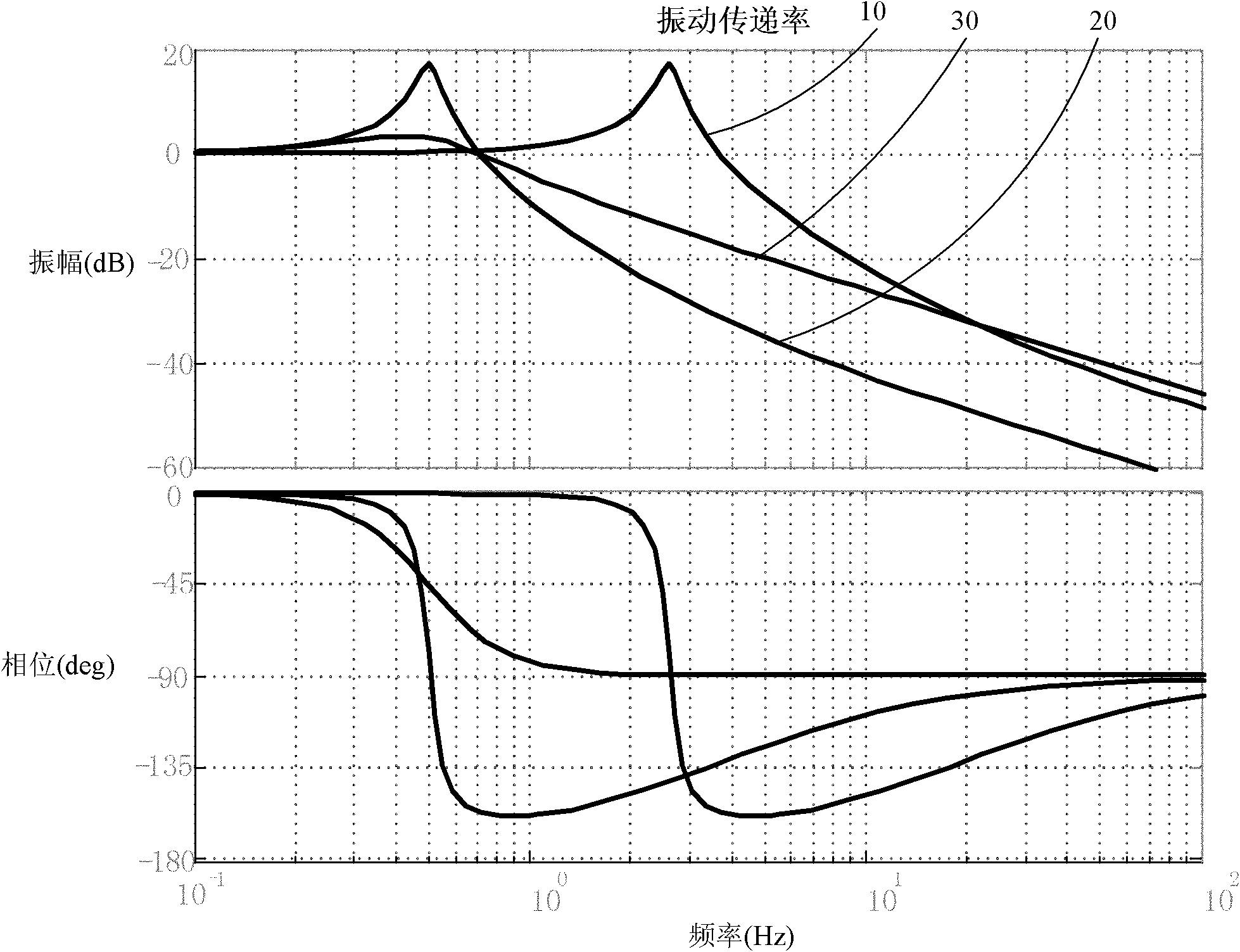

Gravity compensation device

ActiveCN102486215AEliminate errorsReduce structural stiffnessPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringReticle

The invention discloses a gravity compensation device which is used for supporting a micropositioner of a worktable and a reticle stage in a photoetching machine and is communicated with a gas circuit of a gas supplying gas source. The gravity compensation device comprises a first gas chamber, a piston, a supporting plate and a pneumatic valve, wherein the piston is supported by the first gas chamber; the supporting plate is used for supporting the micropositioner, is positioned above the piston and is fixedly connected with the piston; and the valve is communicated with the first gas chamber and is used for adjusting the air pressure of the first air chamber. The gravity compensation device has the advantages that: firstly, the gravity compensation device has a simple structure; secondly, the gravity compensation device has lower rigidity so as to isolate low-frequency vibration; thirdly, the gravity compensation device has certain damping so as to reduce resonance; thirdly, the gravity compensation device has no action of exhausting gas to the environment and can be applied to a vacuum environment; and fourthly, when a load changes, the error of a static position of the reticle stage can be eliminated by adjusting the air pressure of the first gas chamber.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

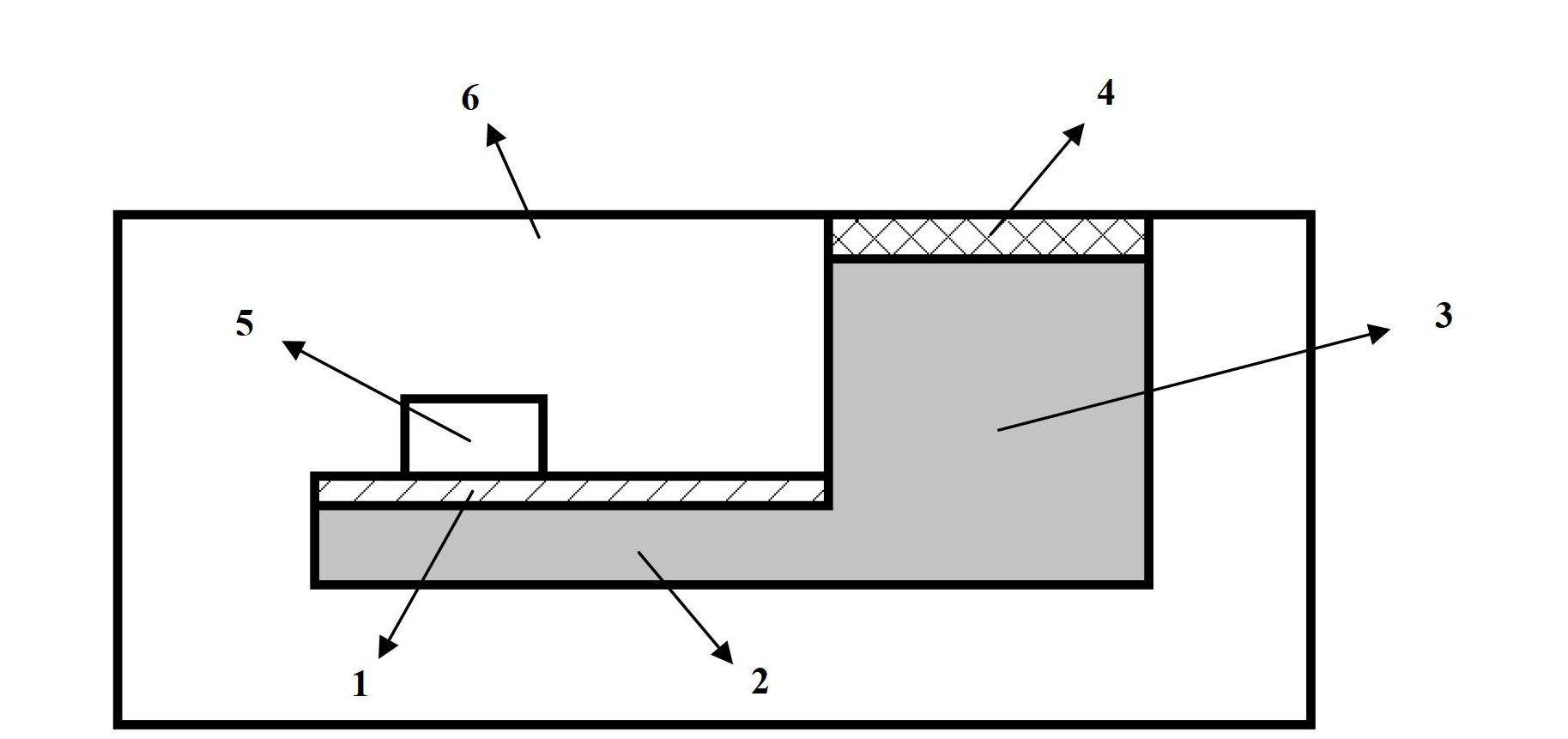

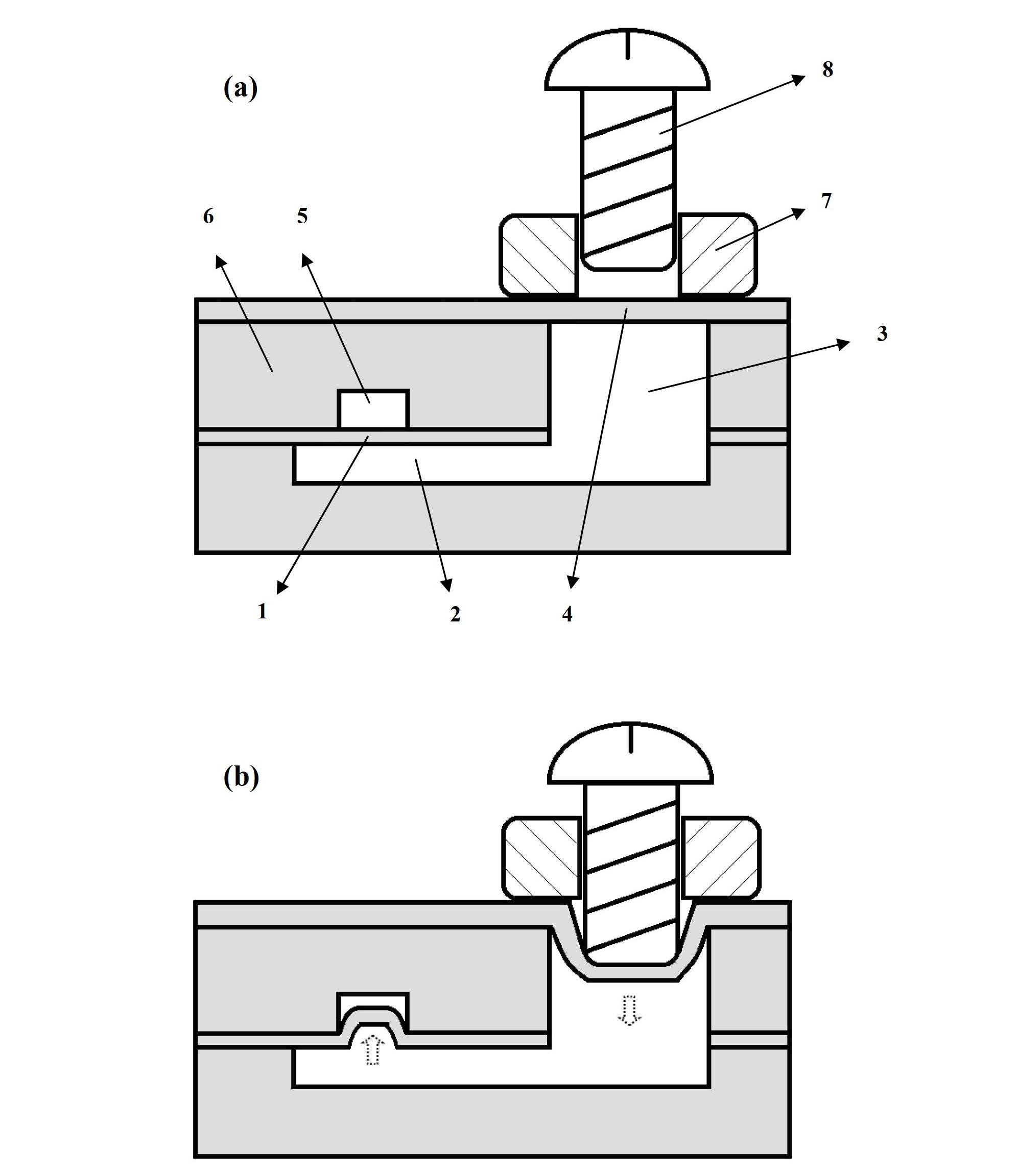

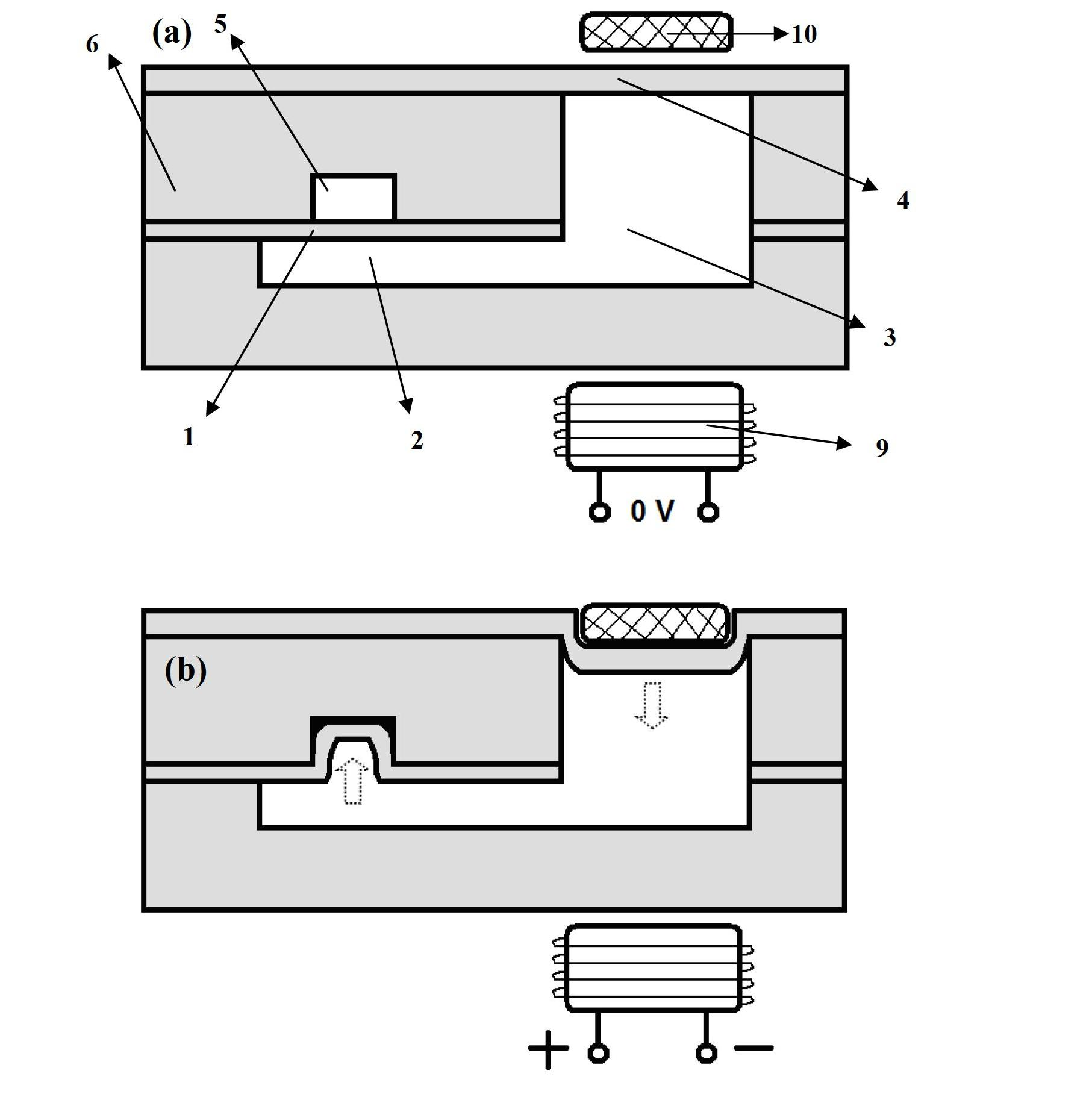

Pneumatic micro-valve integrated in micro-flow control chip

The invention discloses a pneumatic micro-valve integrated in a micro-flow control chip. The pneumatic micro-valve comprises at least one closed cavity which is composed of a control channel and a compressible air bag, wherein an elastic film is used as a side wall of the control channel; the side wall is a common wall intersected by a fluid channel of the micro-flow control chip and the control channel; the control channel is communicated with the compressible air bag; the other end of the compressible air bag is communicated with the outside; and the end part of the compressible air bag is closed by the elastic film. The pneumatic micro-valve integrated in the micro-flow control chip provided by the invention is free from using an external high-pressure air cylinder and a pressure regulating device required by a conventional micro-flow control pneumatic valve; the pressure required by the operation of the pneumatic micro-valve is supplied through a simple action of extruding the air bag; and the pneumatic micro-valve integrated in the micro-flow control chip has the advantages of low cost, convenience in operation, small size, portability, and the like, and is suitable for a portable micro-flow control analysis system.

Owner:CAPITALBIO CORP +1

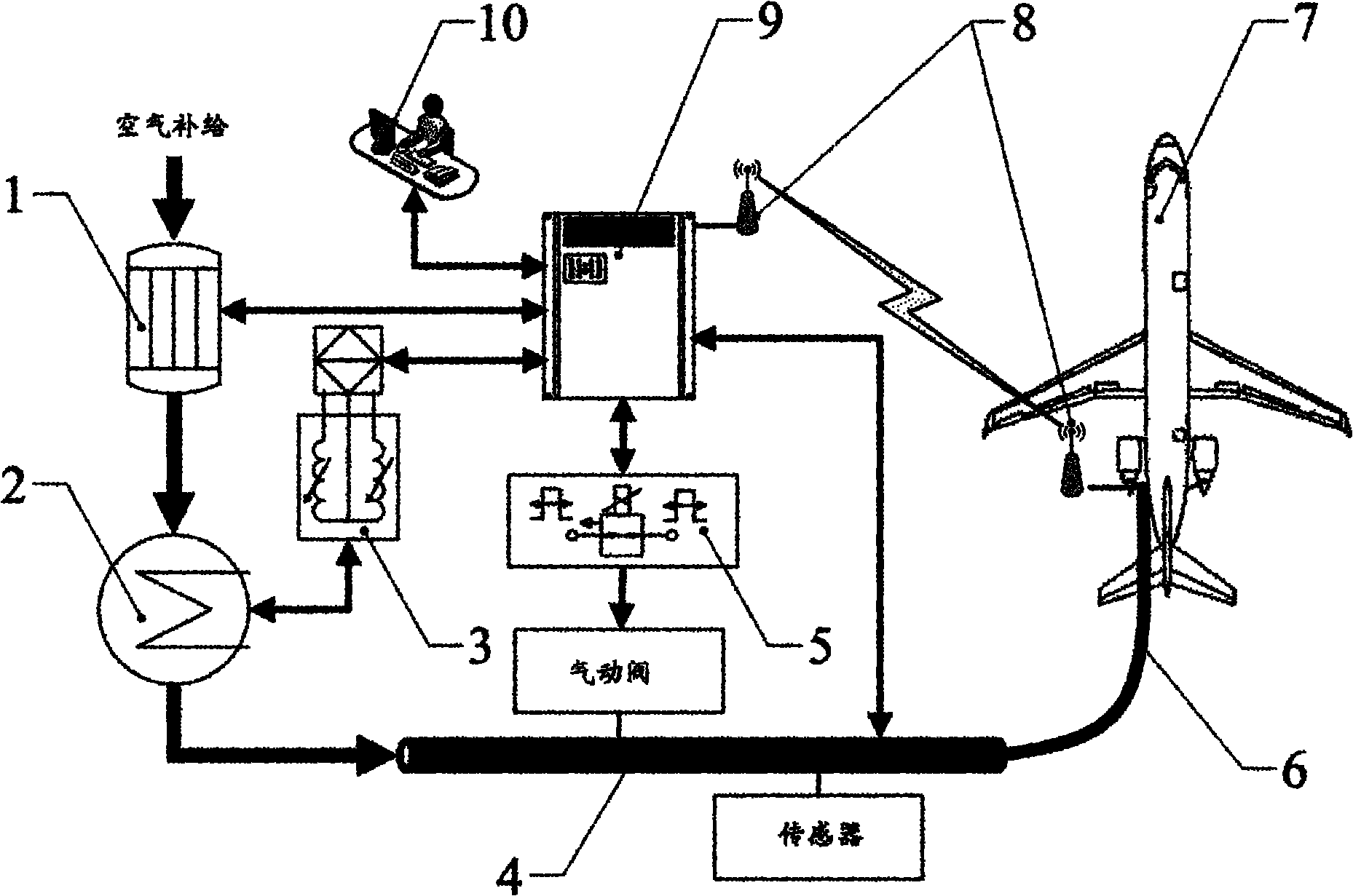

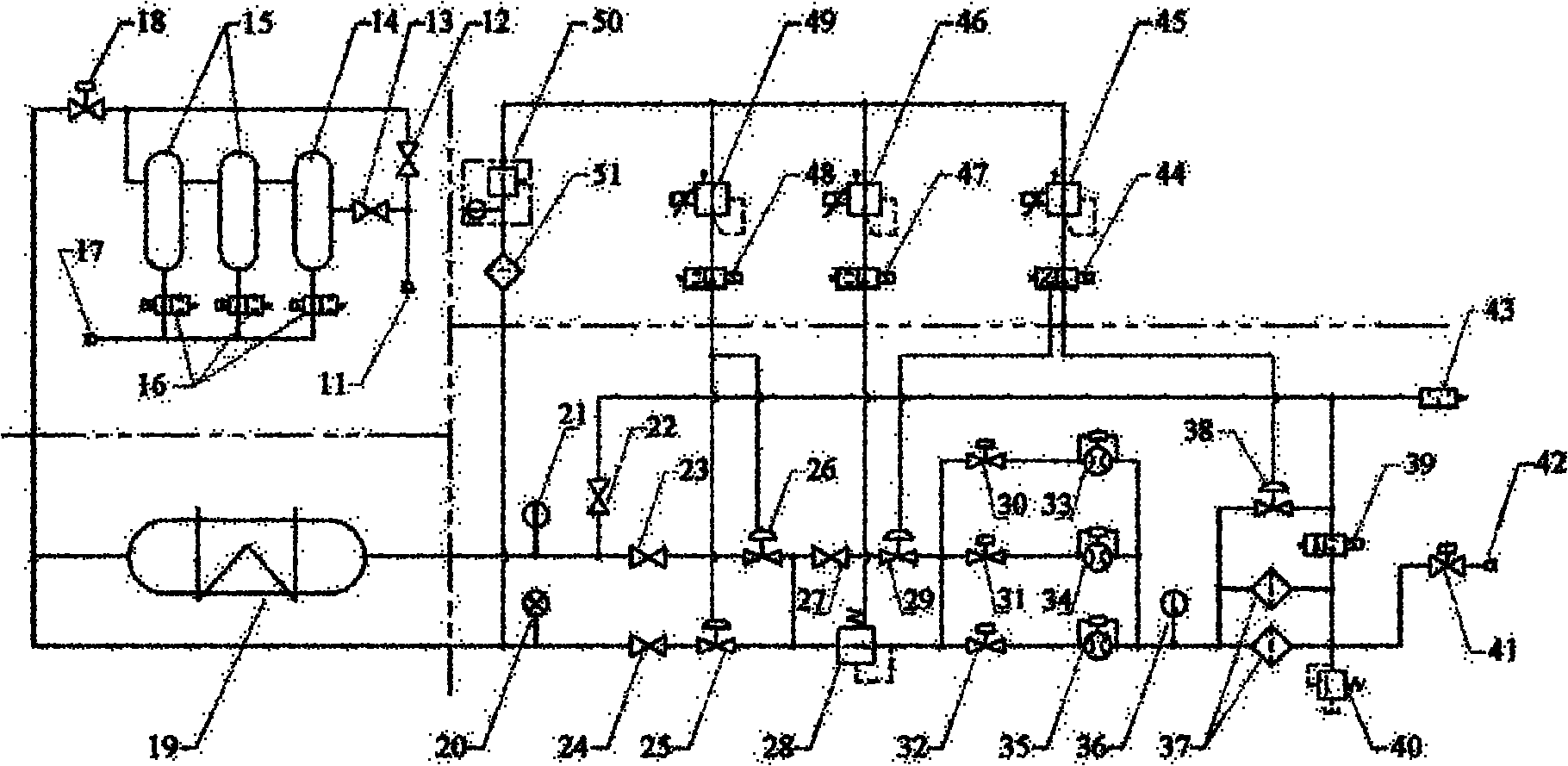

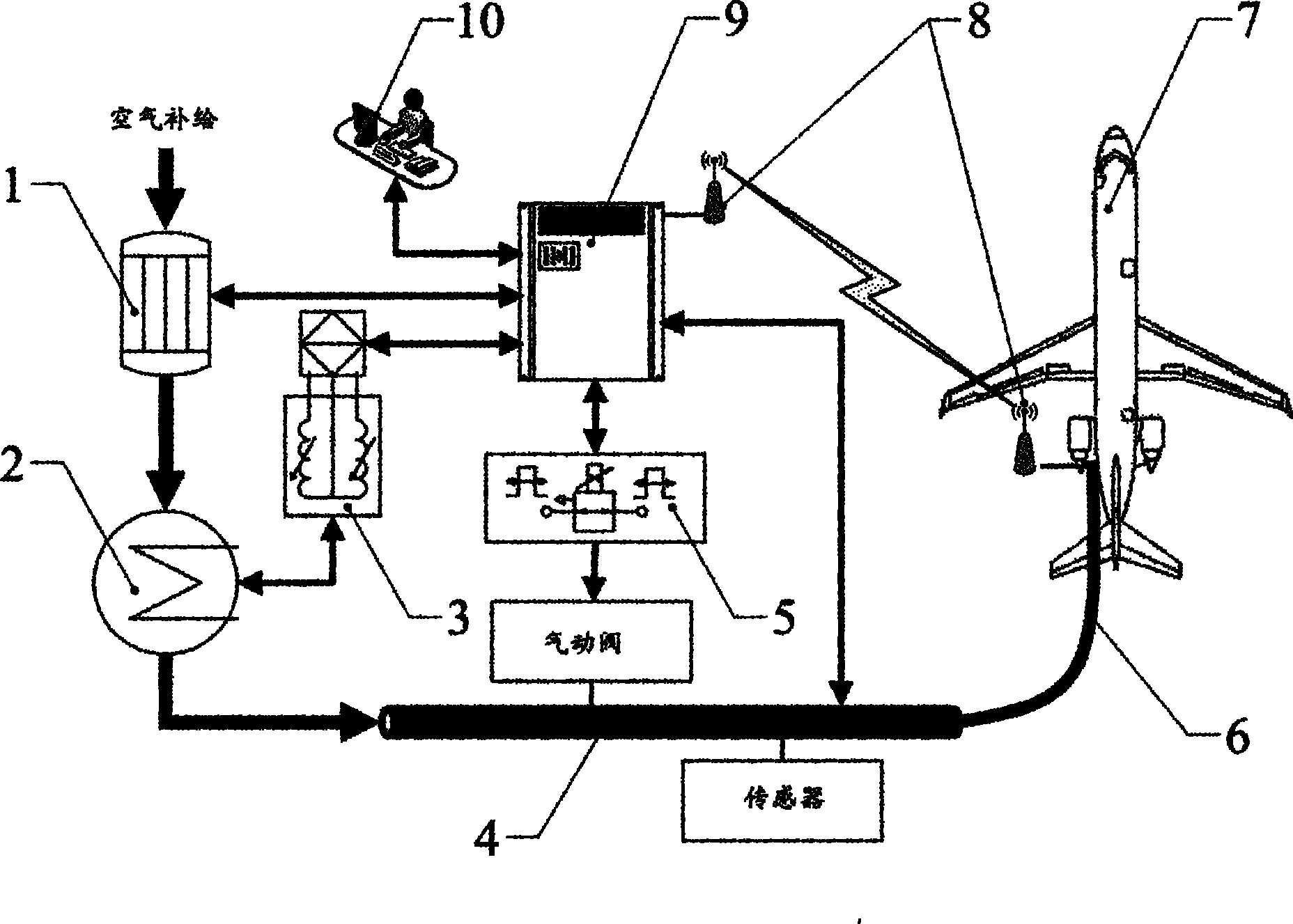

Automation device for use in civil aircraft environment control system function test

InactiveCN101916108AImprove test efficiencyRealize automatic collectionElectric testing/monitoringControl systemProgrammable logic controller

The invention relates to an automation device for use in a civil aircraft environment control system function test, which belongs to the technical field of aircraft manufacturing. The automation device comprises an air source processing component, an electric air heating furnace, an air heating furnace controller, a main pipeline system, a pneumatic valve control component, a metal hose component, a wireless sensing communication module, a programmable logic controller (PLC) control module and an upper machine monitoring computer. In the invention, an aircraft pressure cabin and air conditioner pipeline leakage amount test, a cabin pressure regulating system test, a cabin air temperature regulating system function test and an anti-ice system function test are carried out by using an on-spot air source of an aircraft assembly plant in place of an engine or an auxiliary power unit (APU) unit, so that a plurality of test items in the aircraft environment control function test can be completed, and the requirements of aircraft mass production on the quality and efficiency improvement on the environment control function test in a final assembly process are met.

Owner:SHANGHAI JIAO TONG UNIV +1

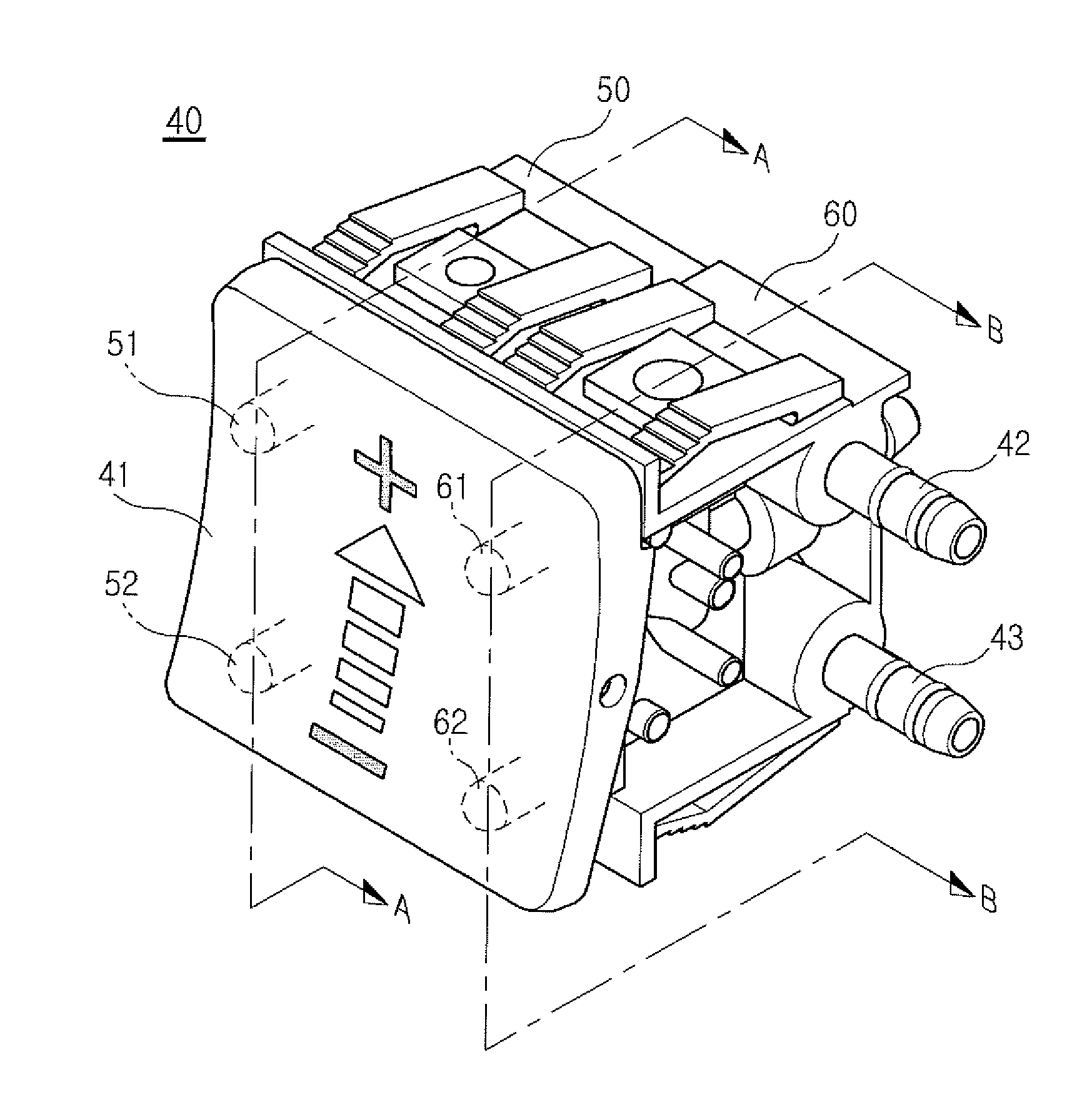

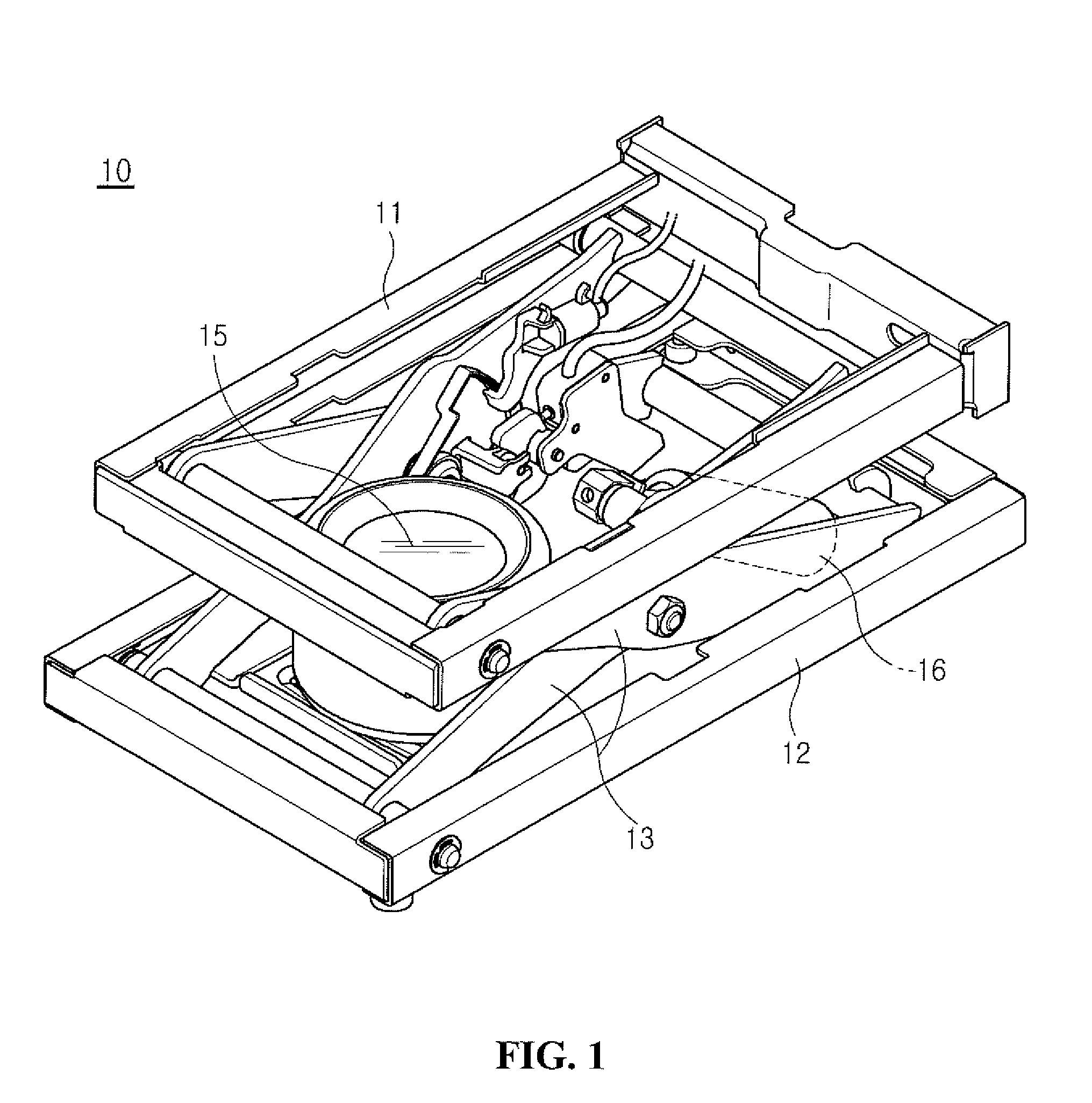

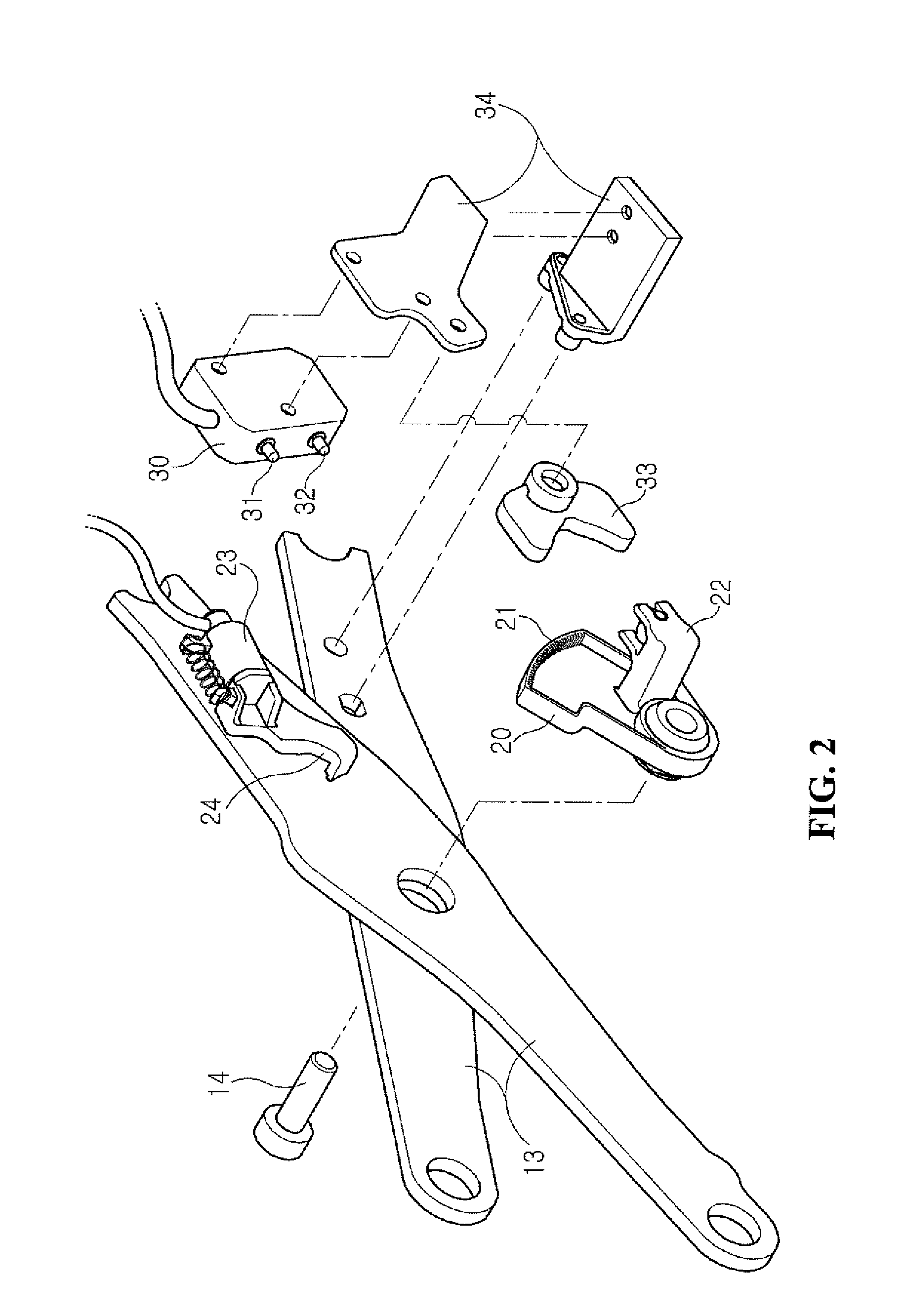

Valve-Intensive Button for Adjusting Height of Cushion Seat for Vehicle

InactiveUS20090050220A1Small failure factorImprove productivityOperating means/releasing devices for valvesSpringsDriver/operatorEngineering

The present invention relates to a manipulation button 40 for adjusting the height of a cushion seat for a vehicle that is capable of absorbing the shocks applied to a driver sitting on the cushion seat while the vehicle is being driven on a relatively rough road, and more particularly, to a button for adjusting the height of a cushion seat for a vehicle that is capable of adjusting the height of the cushion seat according to a driver's physical conditions and his desired driving posture, wherein a plurality of pneumatic valves having flow channels formed therein are intensively configured with one another in such a manner as to be operated by means of the seesaw type button 41, thereby effectively performing the ascending and descending motions of the cushion seat in a simple manner.

Owner:EWON COMFORTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com