Patents

Literature

3164results about "Packaging under special atmospheric conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

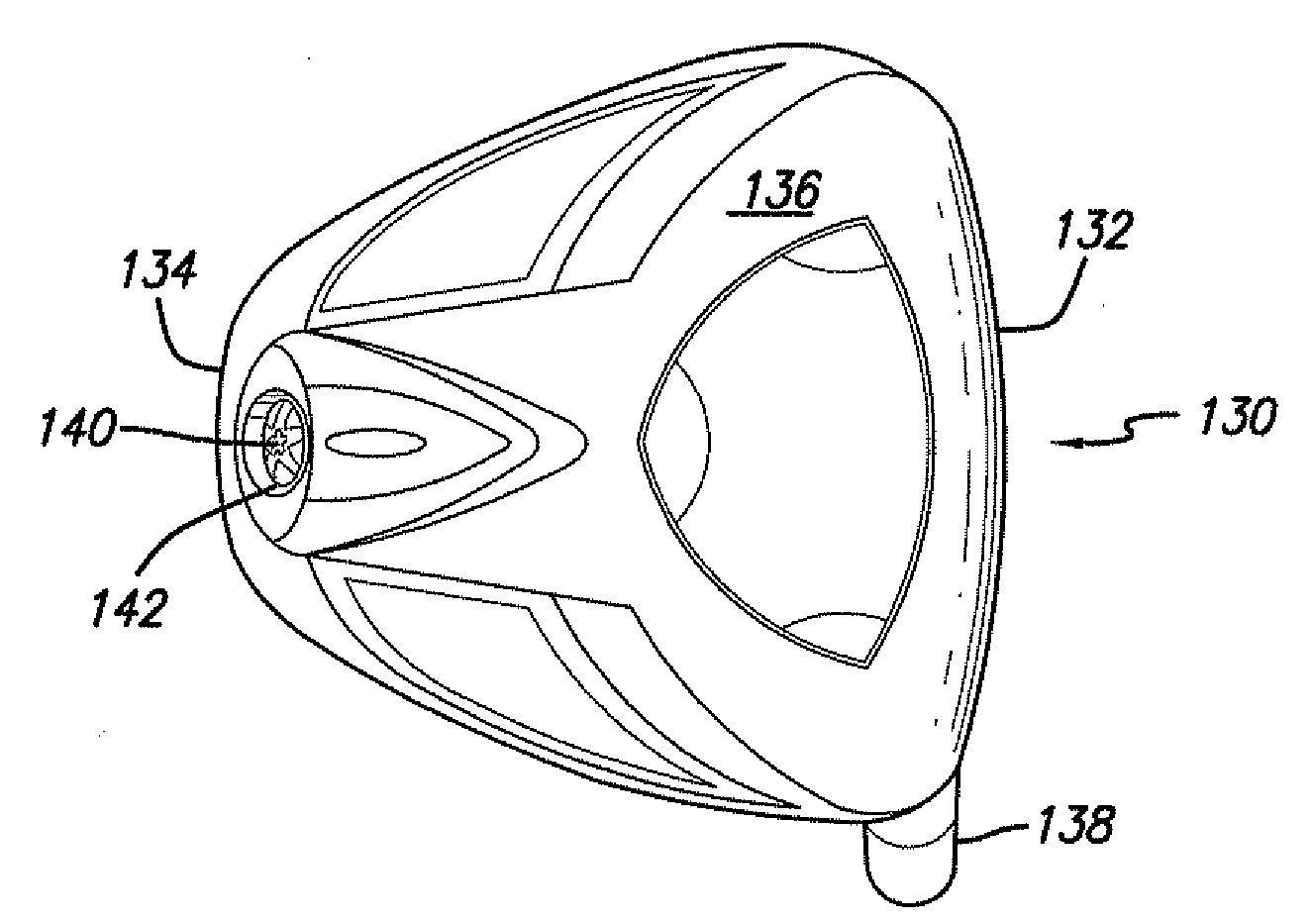

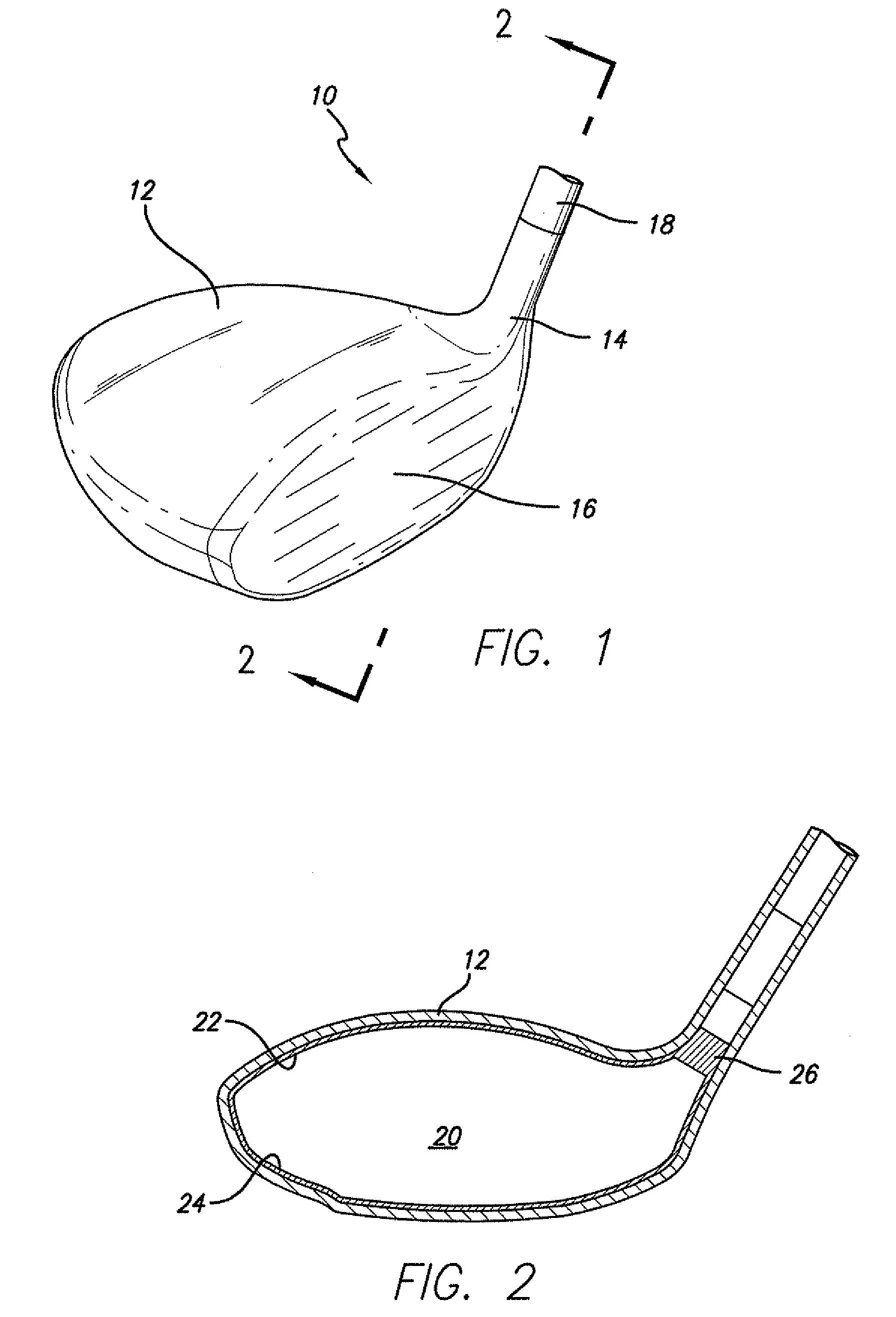

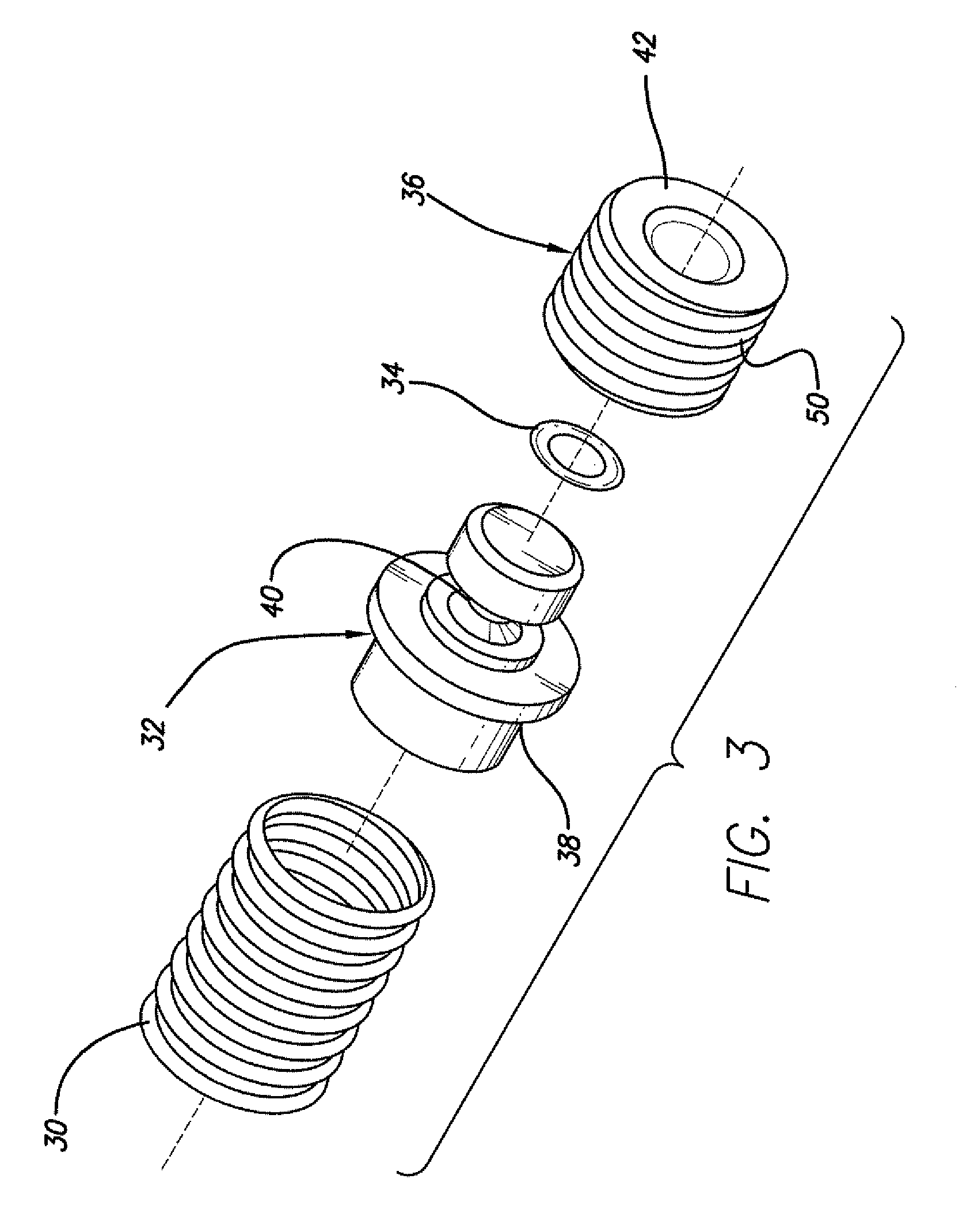

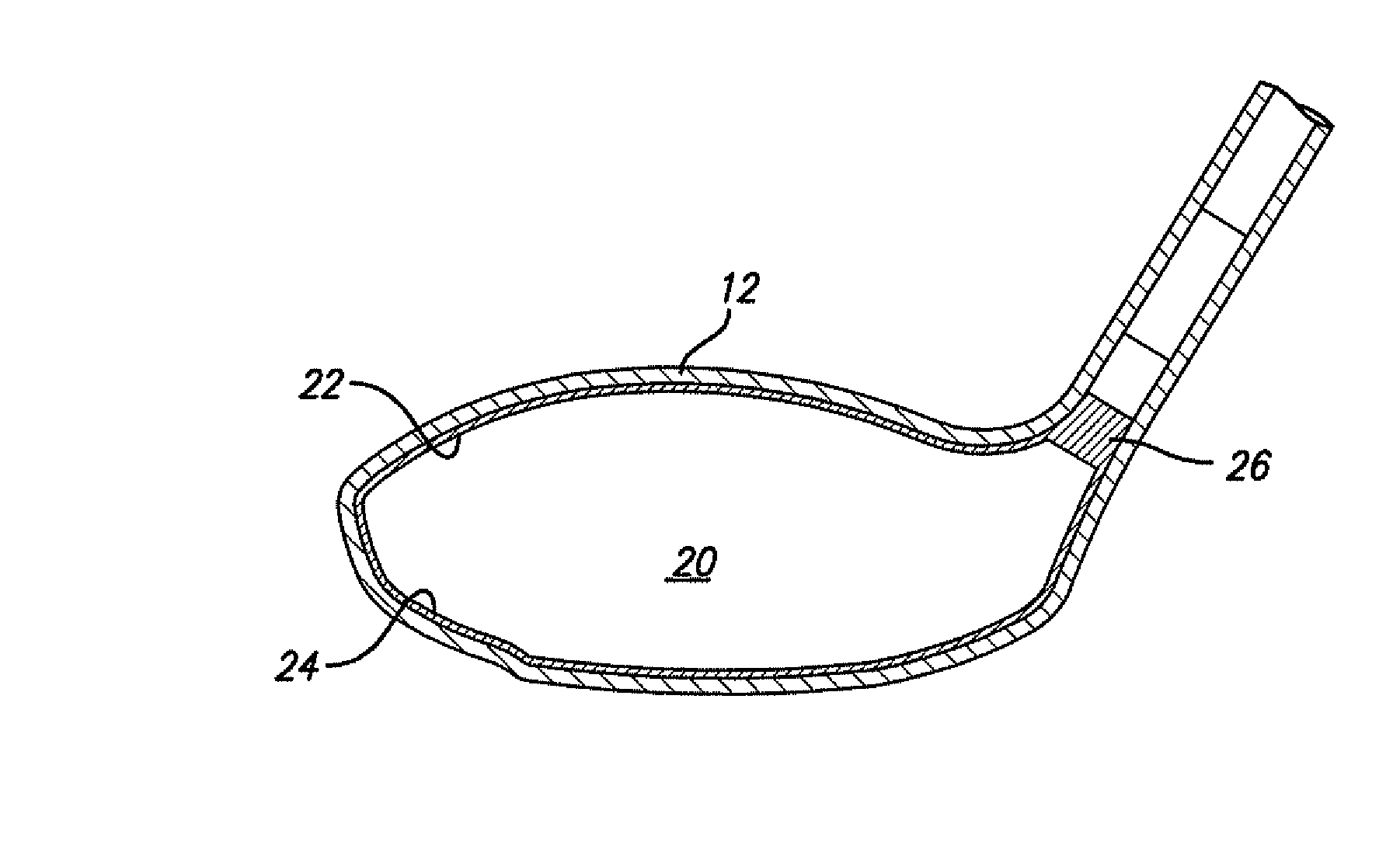

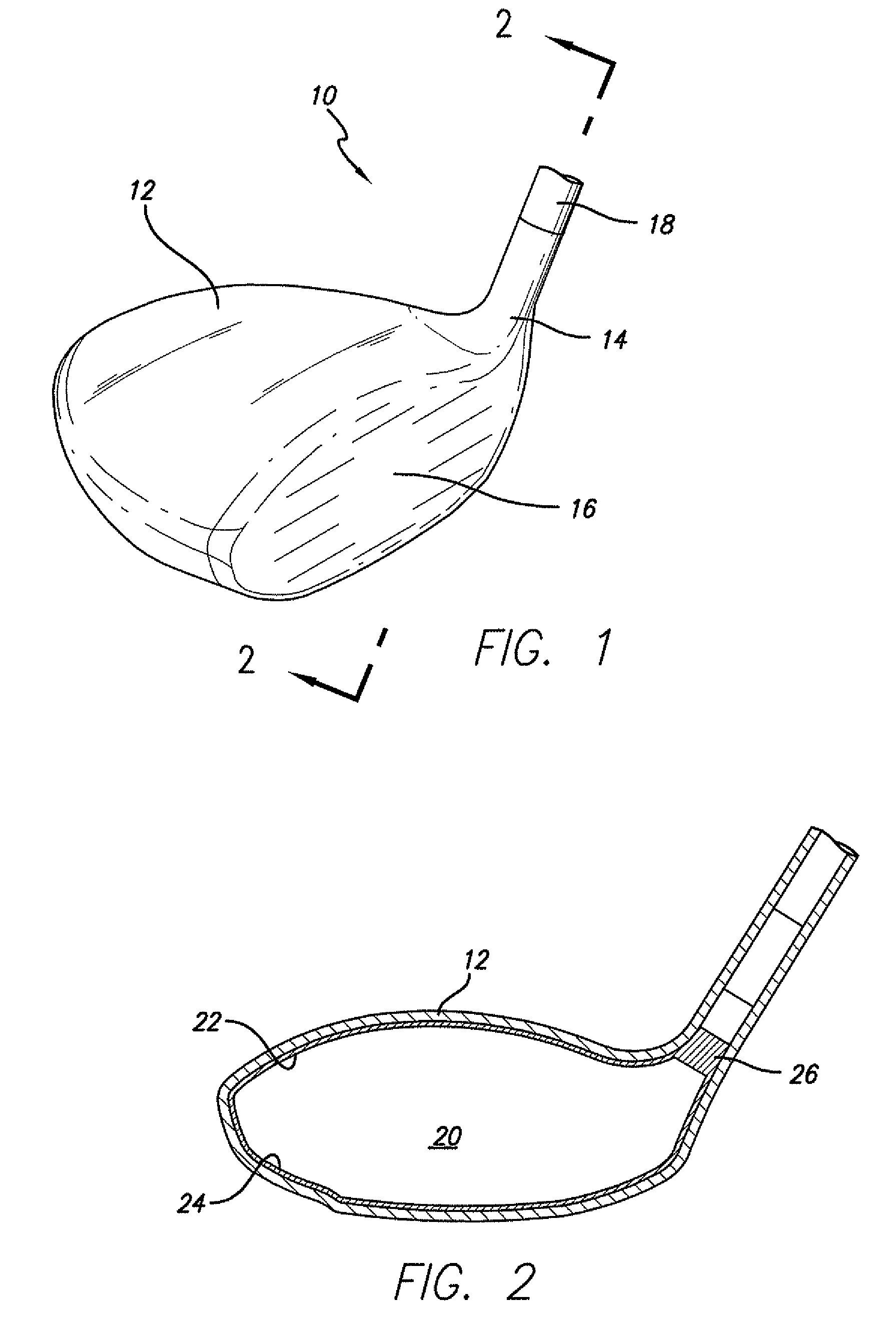

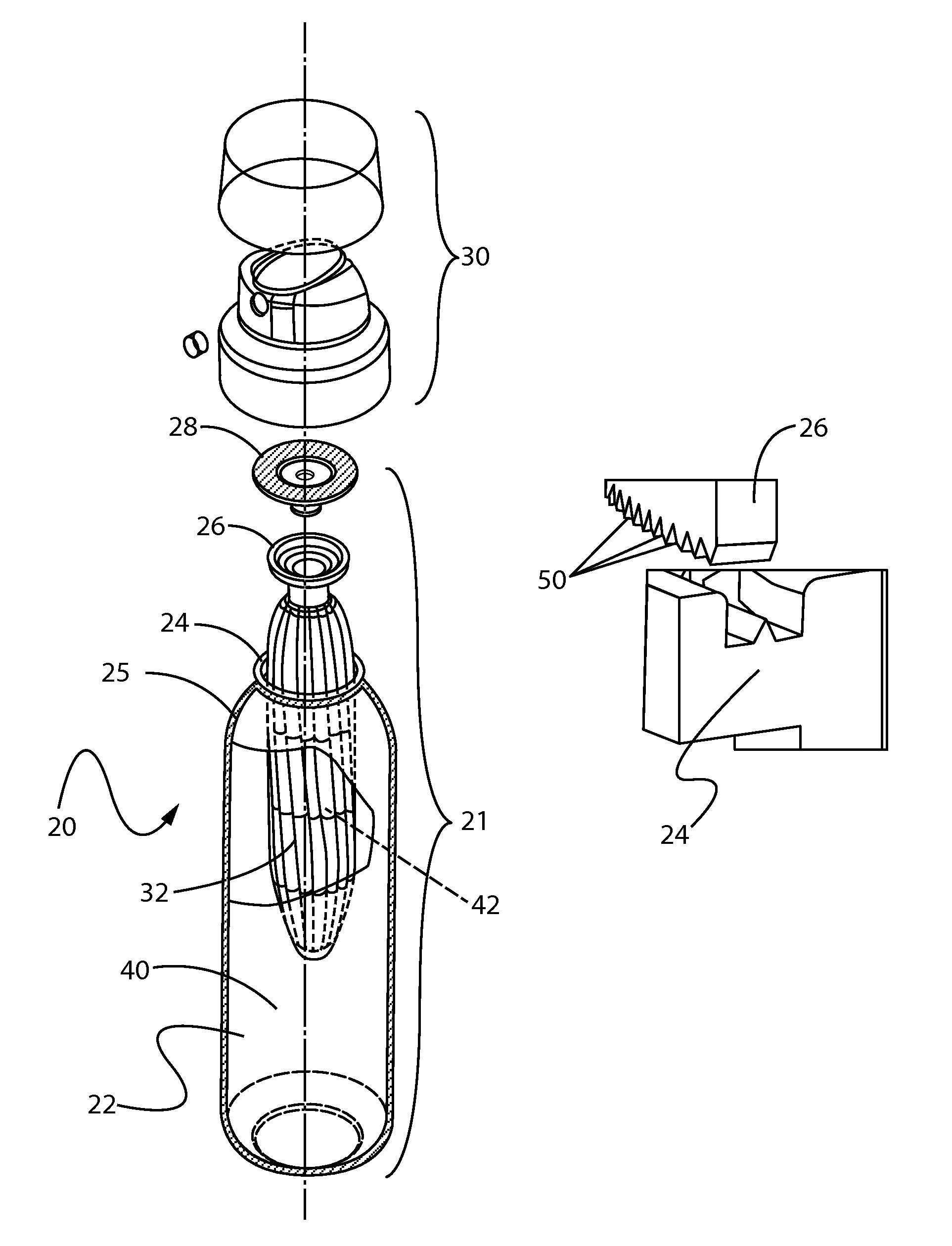

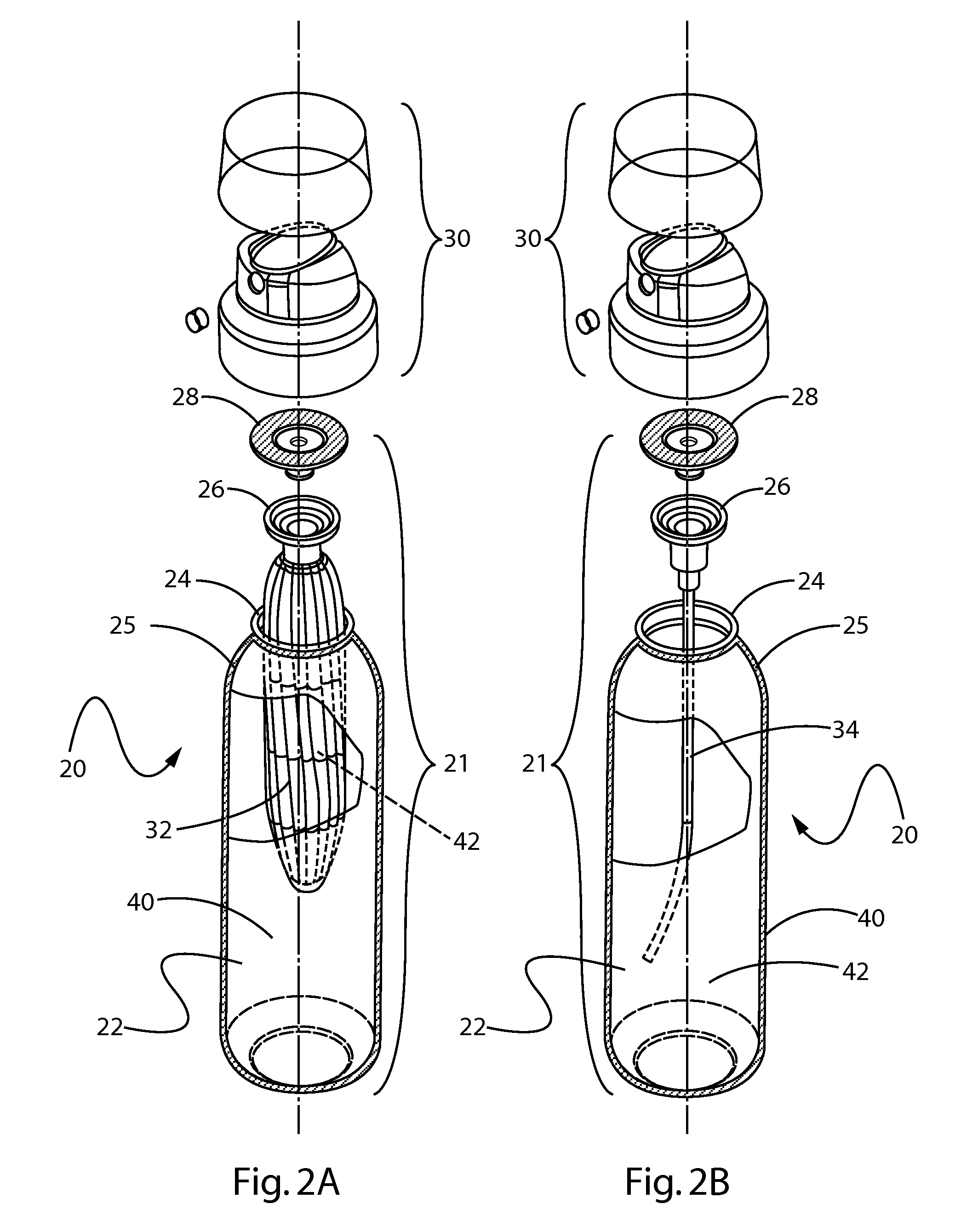

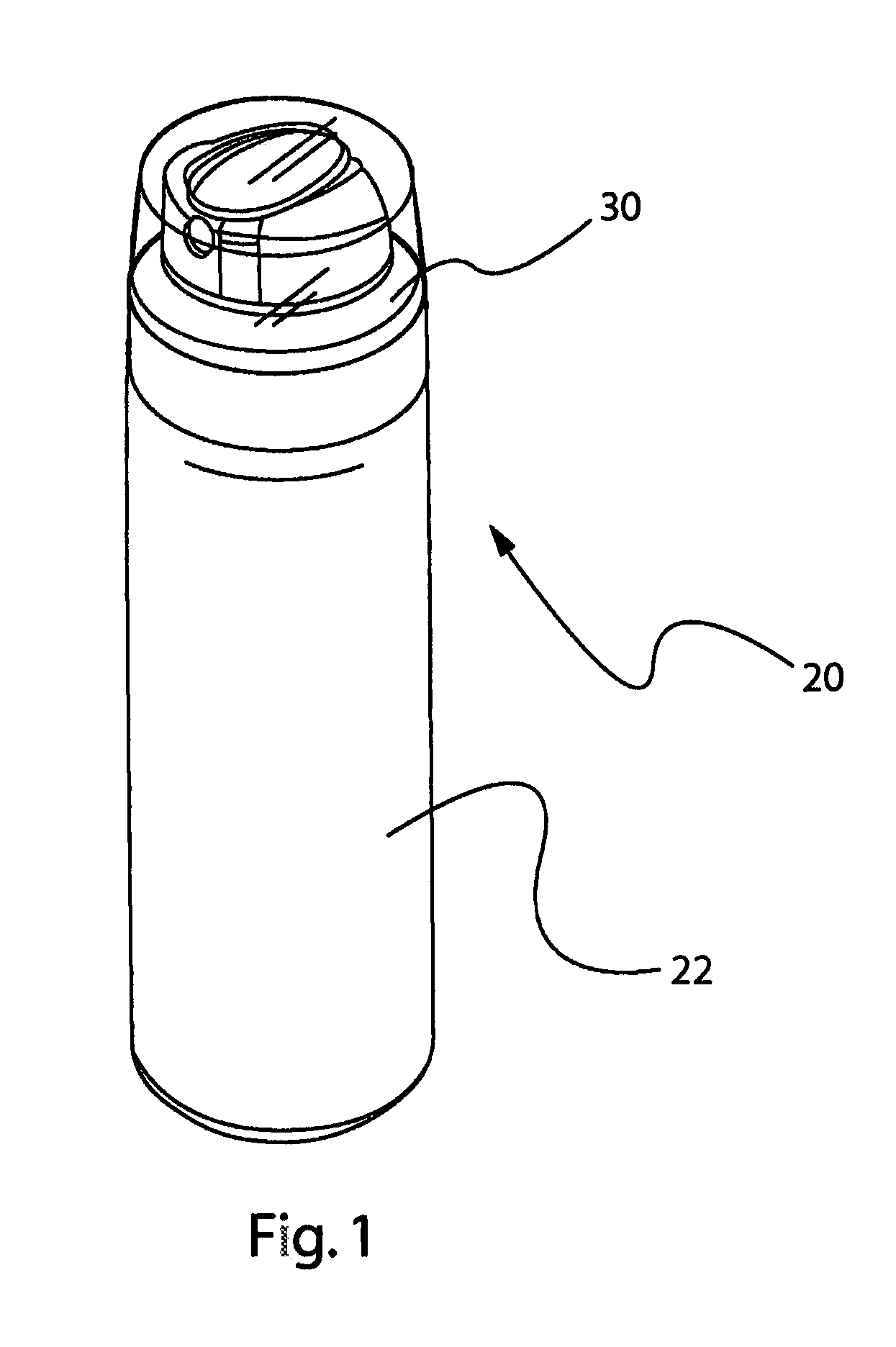

Golf club having a hollow pressurized metal head

ActiveUS20080188322A1Avoid passingPrevent escapeFilling using counterpressureMetal rolling stand detailsShell moldingPlastic materials

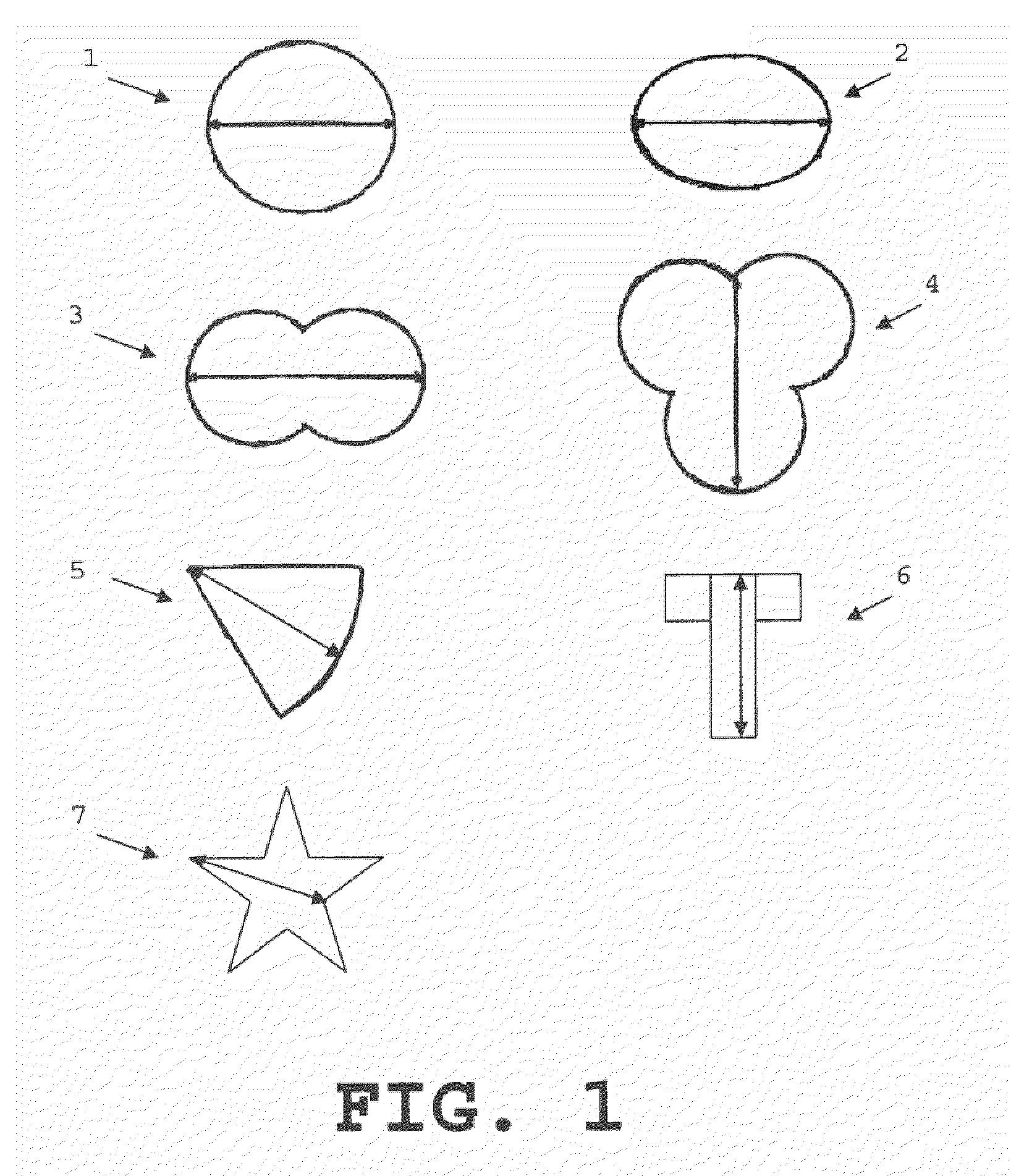

A golf club having a hollow golf club head which is filled with a gas under pressure. The interior surface of the golf club head is coated with a solidified layer of plastic material. The pressurized gas permits the use of thinner face plates by compensating for forces generated when the face plate strikes a golf ball. The plastic layer is preferably applied through the process of rotational molding using a thermoplastic material.

Owner:BLOWERS ALDEN J

Golf club having a hollow pressurized metal head

ActiveUS8663026B2Prevent escapeMetal rolling stand detailsPackaging under special atmospheric conditionsPlastic materialsEngineering

A golf club having a hollow golf club head which is filled with a gas under pressure. The interior surface of the golf club head is coated with a solidified layer of plastic material. The pressurized gas permits the use of thinner face plates by compensating for forces generated when the face plate strikes a golf ball. The plastic layer is preferably applied through the process of rotational molding using a thermoplastic material.

Owner:BLOWERS ALDEN J

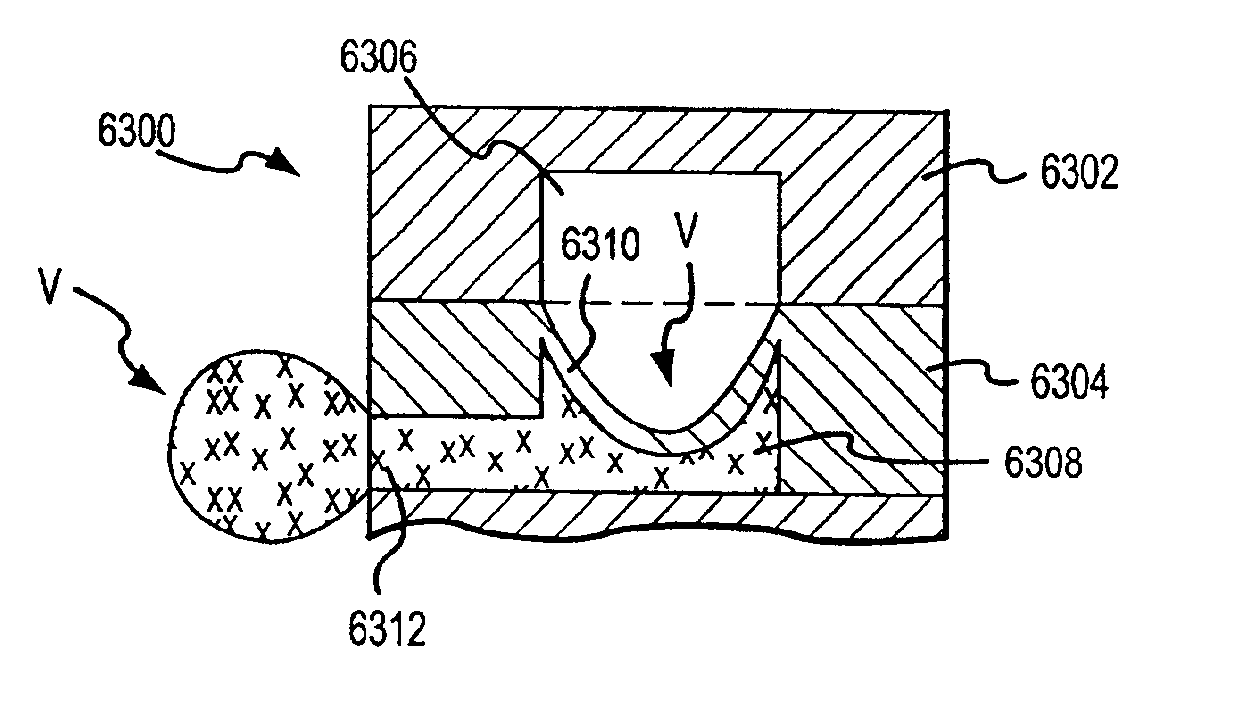

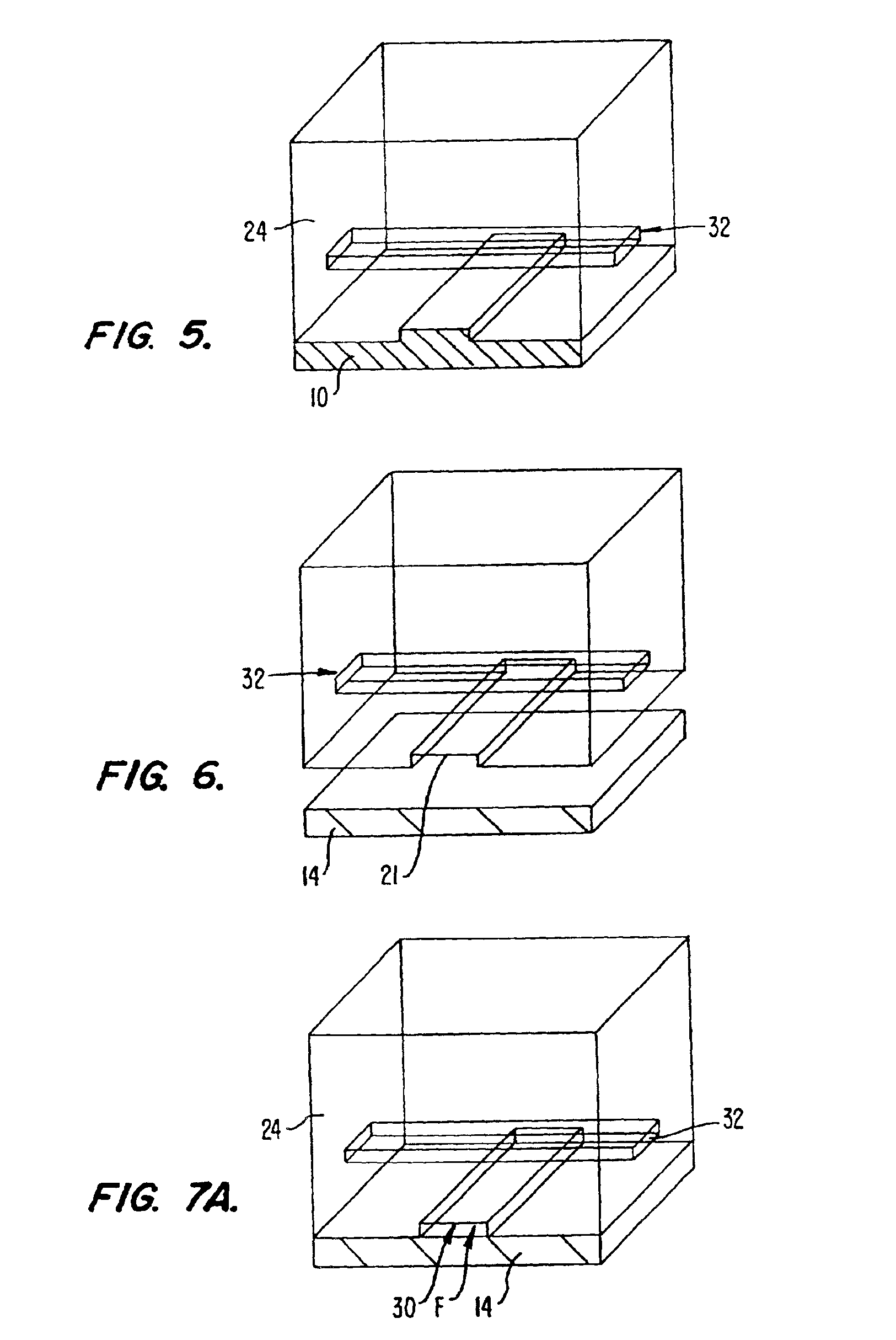

Microfabricated elastomeric valve and pump systems

InactiveUS6899137B2Increase speedSmall sizeFixed microstructural devicesVolume/mass flow measurementElastomerPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

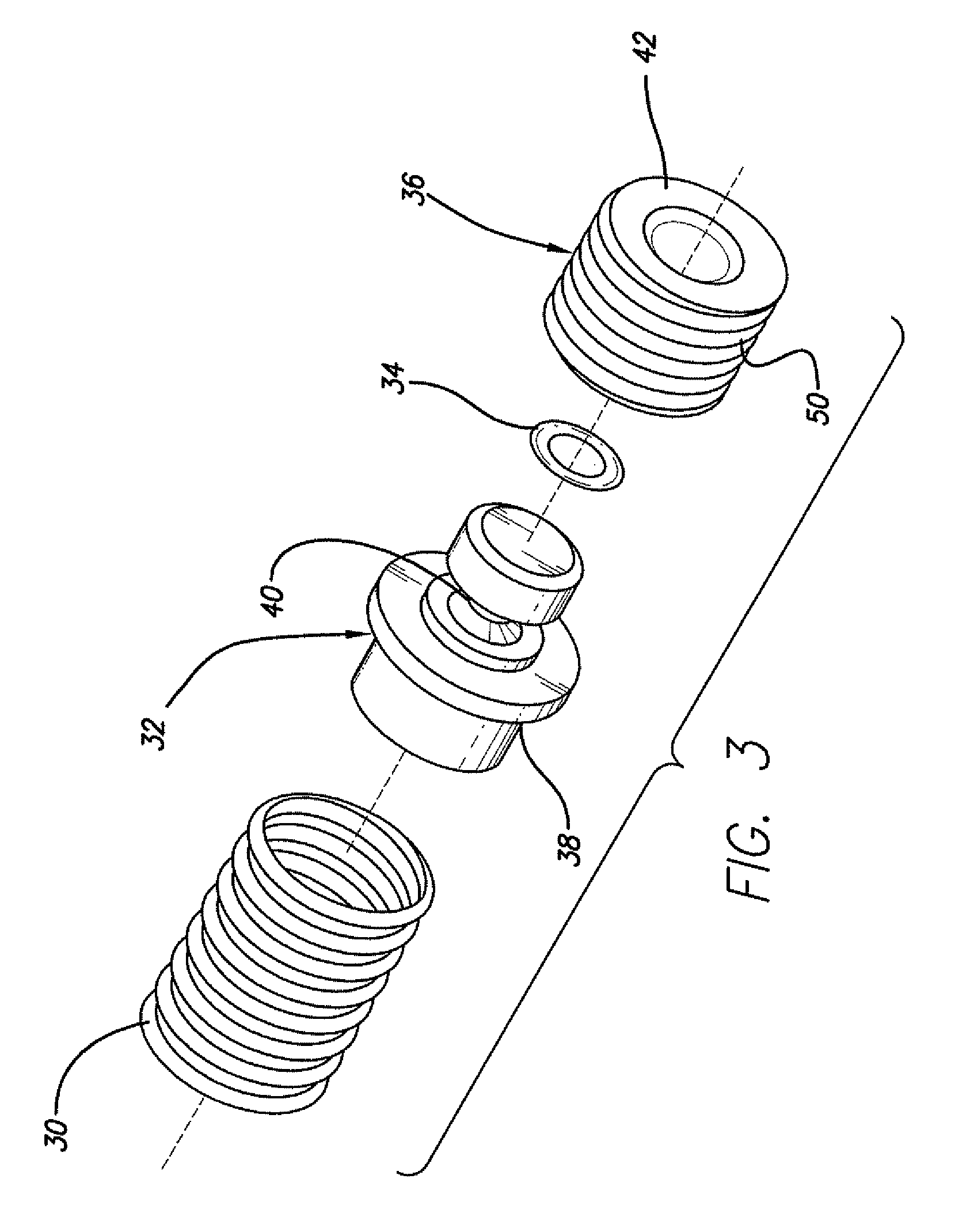

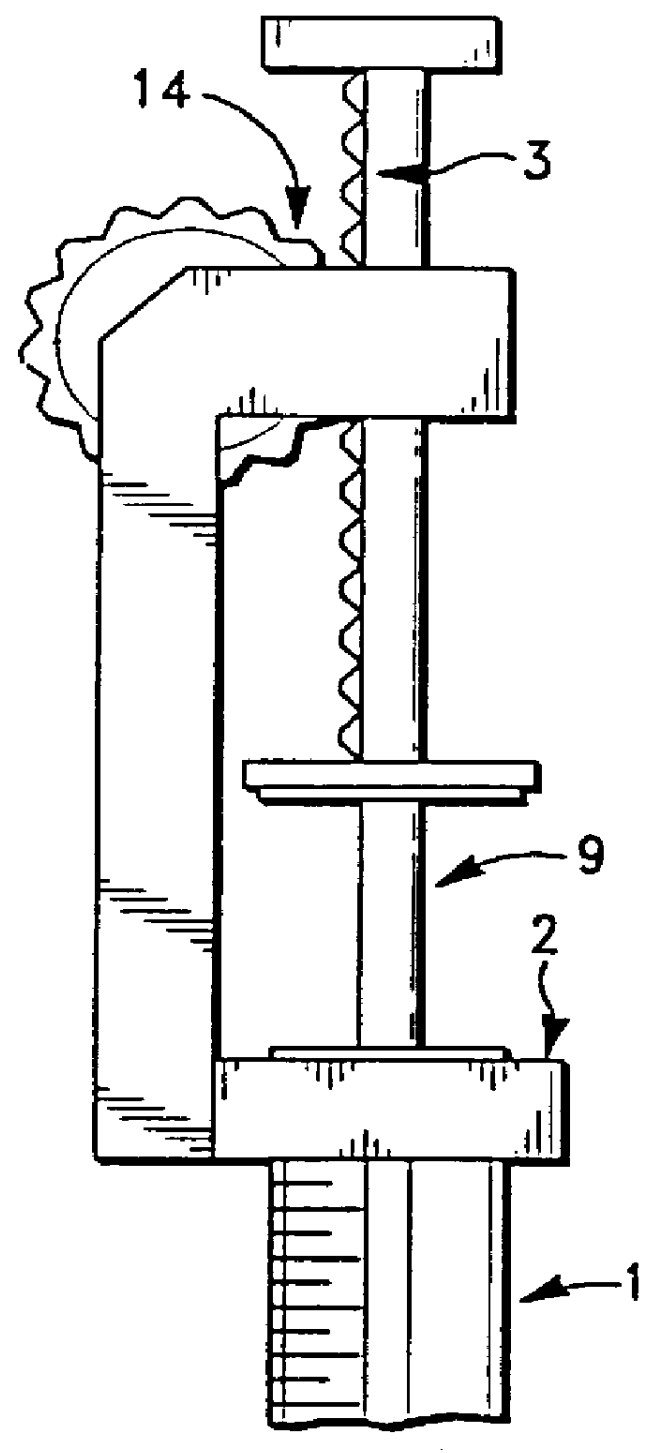

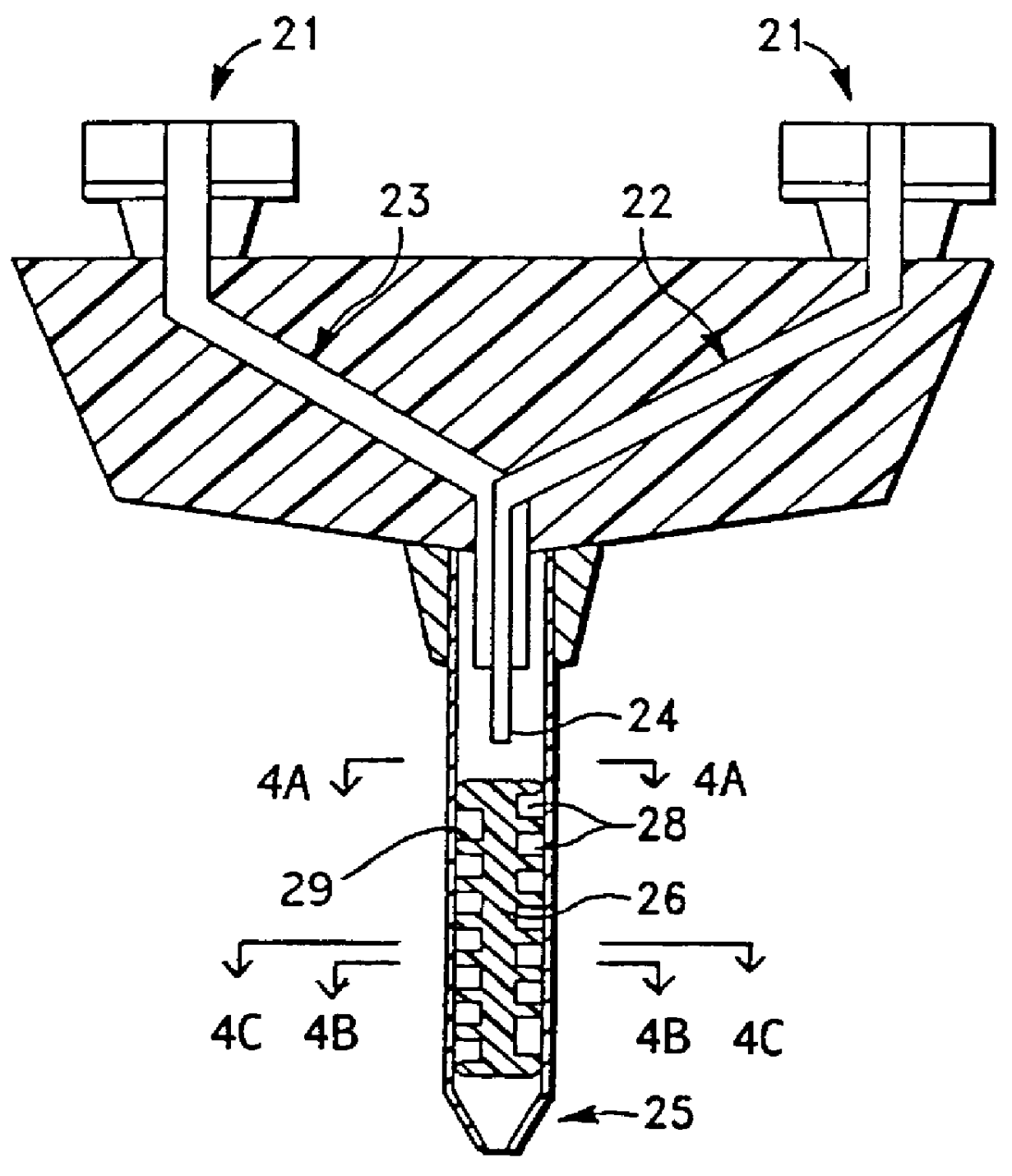

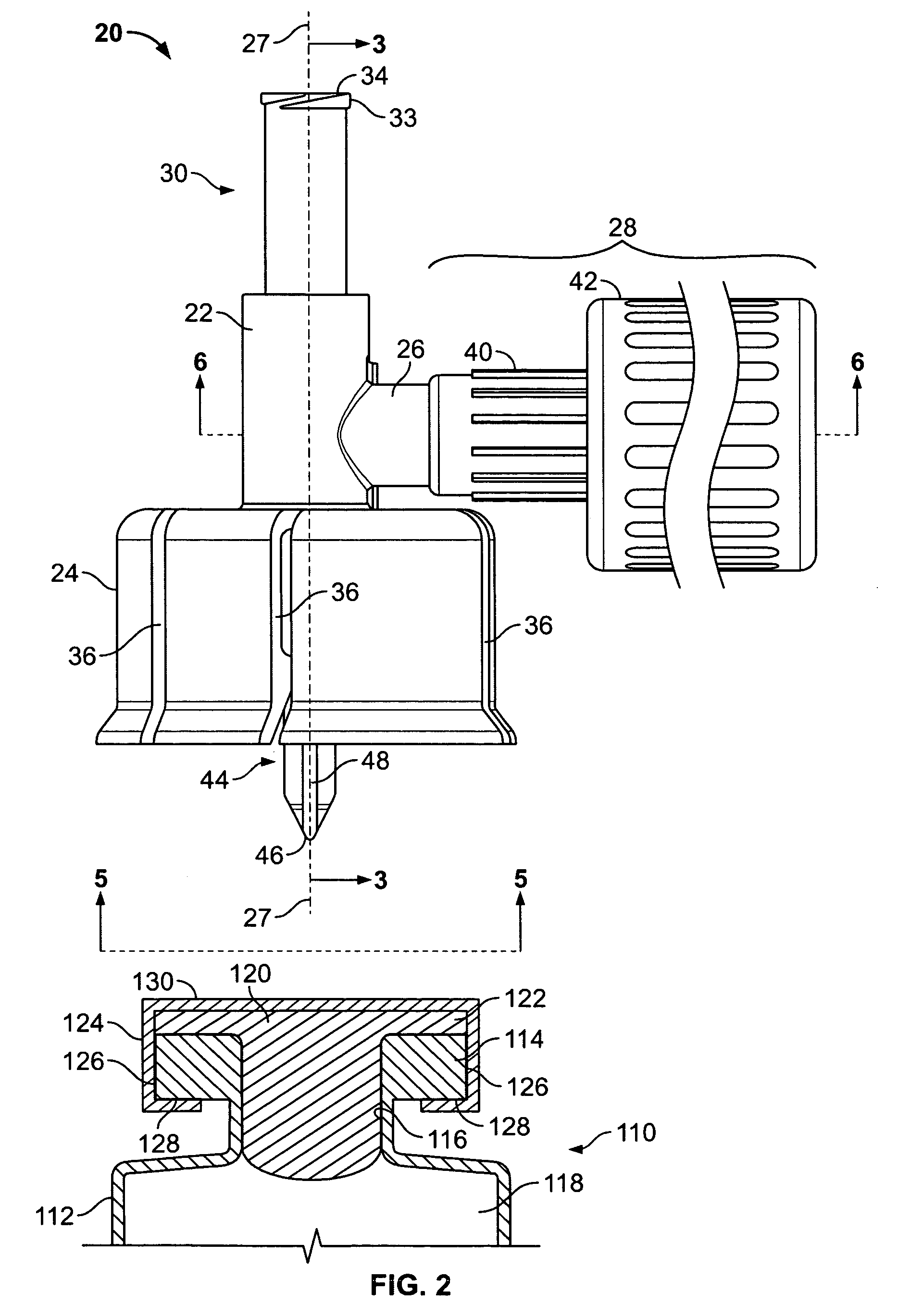

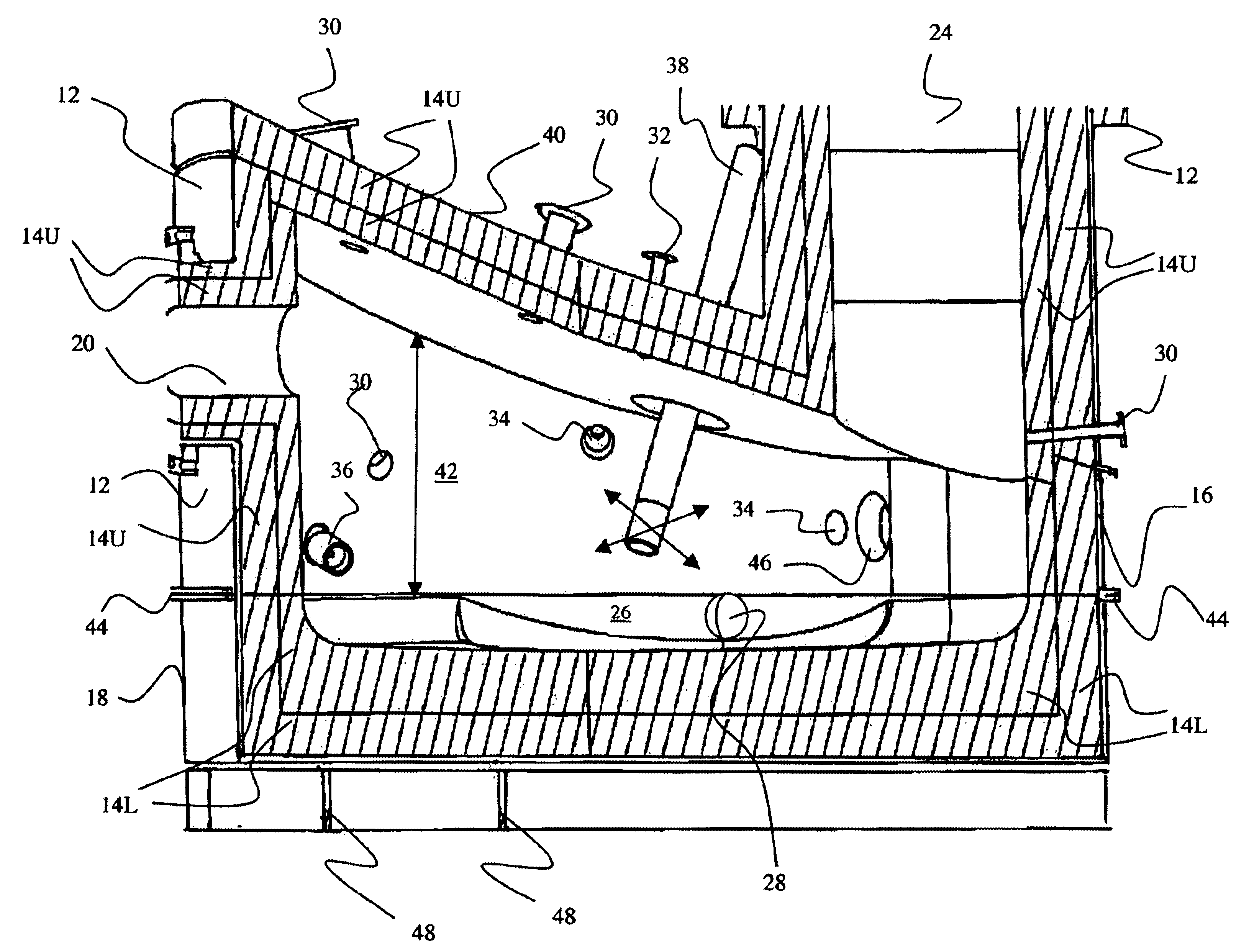

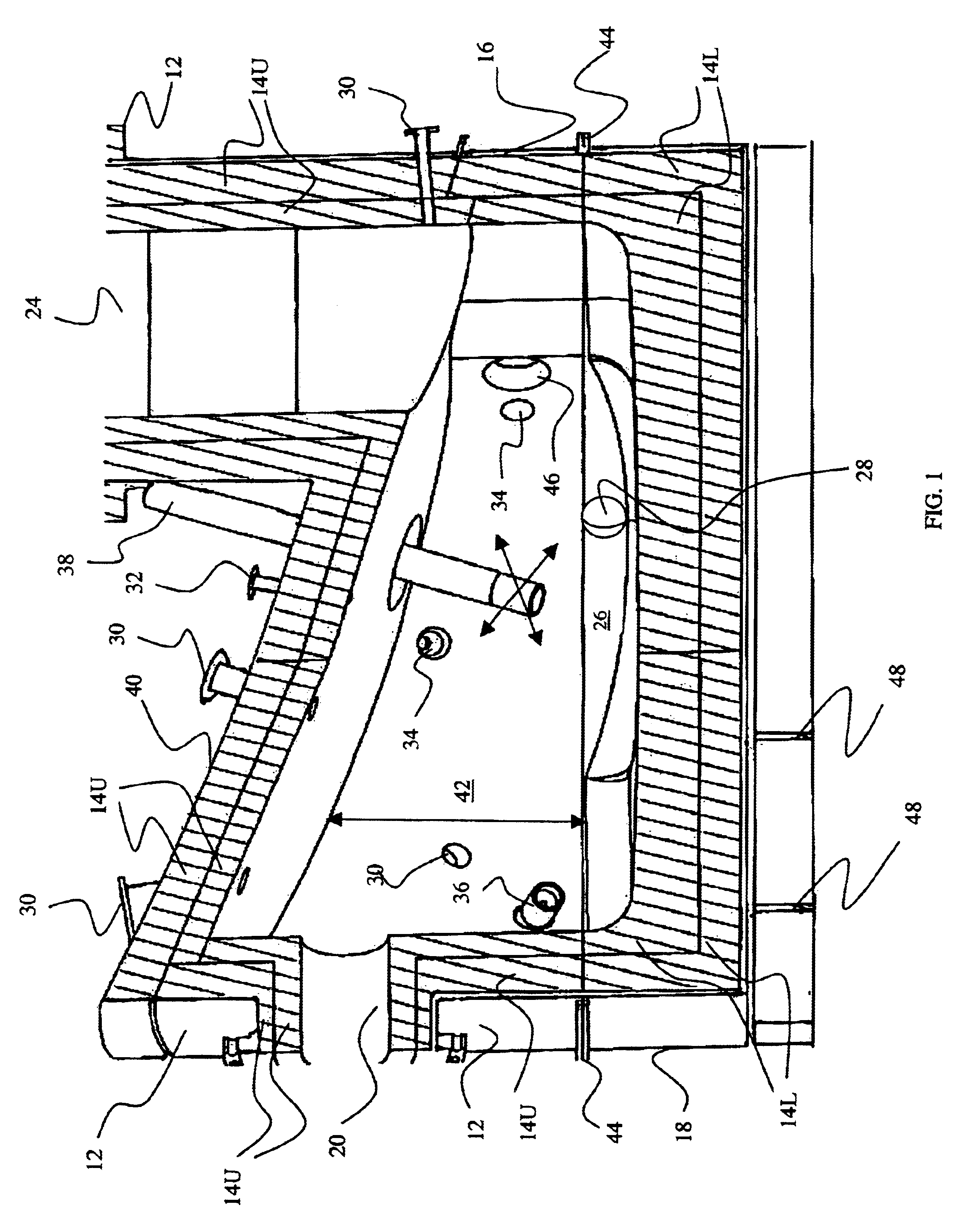

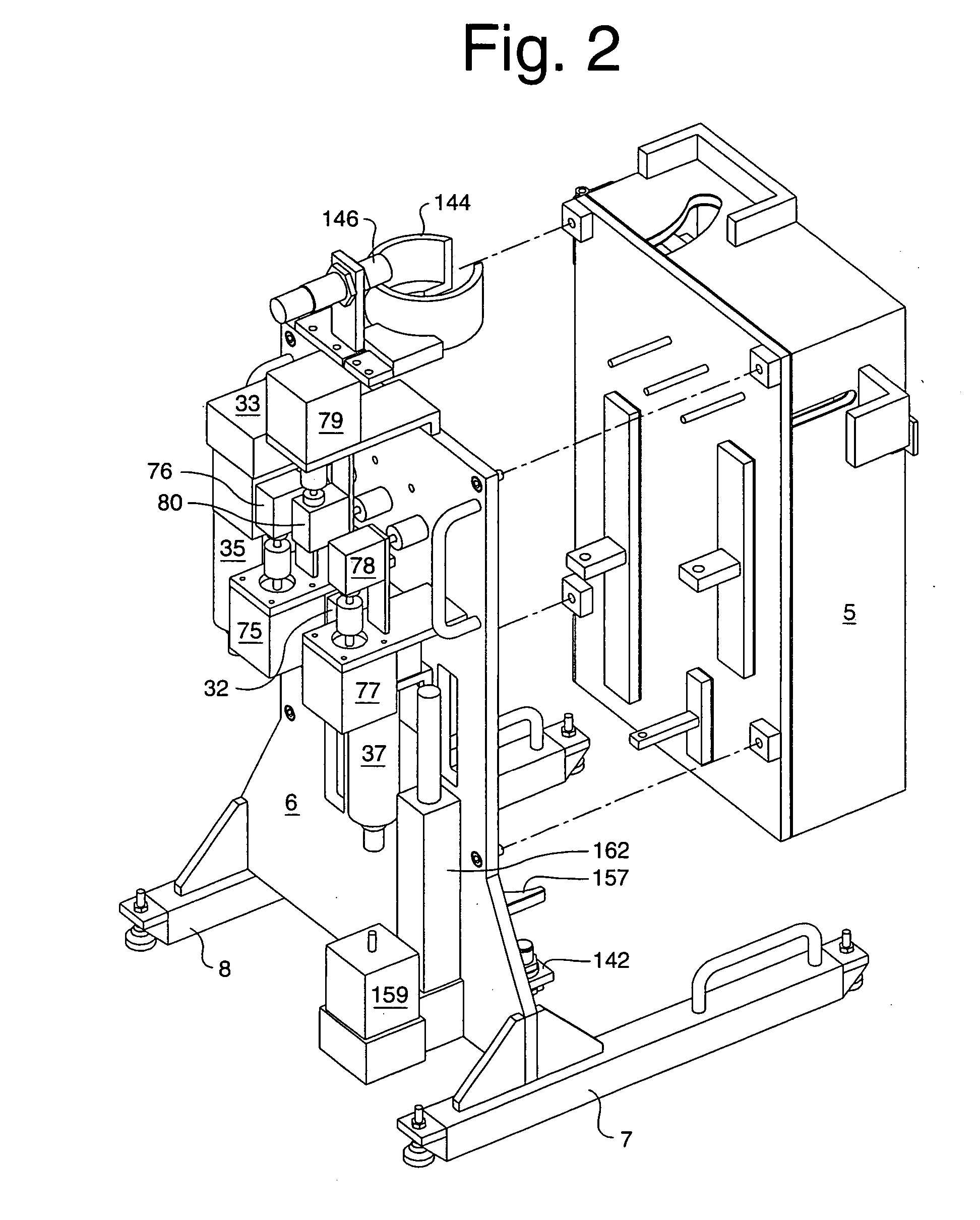

Apparatus for applying tissue sealant

InactiveUS6132396AEasy to fillEasy to assembleLiquid surface applicatorsSurgeryTissue sealantGear wheel

A device and method for applying a fibrinogen-based tissue sealant to seamlessly connect human or animal tissues or organ parts, to seal wounds, stop bleeding and the like by mixing fibrin or fibrinogen with blood clot-promoting coagulation factors are disclosed. The device includes two cylindrical compartments for separately containing the separate fluid components of the sealant preparation, which are simultaneously displaced from the respective compartments by plungers commonly depressable with the same effective strokes. The plungers may be depressed directly or by a common mechanism (e.g., rack and pinion) for accurately controlling the rate of dispensing fluid. The cylindrical compartments are of the same or different cross-sectional area and are arranged either concentrically or side-by-side. The device further includes structure for merging the two fluid components within an outer sleeve housing an inner needle. The sleeve and needle contain conduits for the flow of the two fluid sealant components as they are expressed from the respective compartments. Also disclosed are a convenient device for filling the two compartments, structure for mixing the fluid components, and for atomizing the effluent sealant fluid stream (i.e., spraying).

Owner:PLASMASEAL

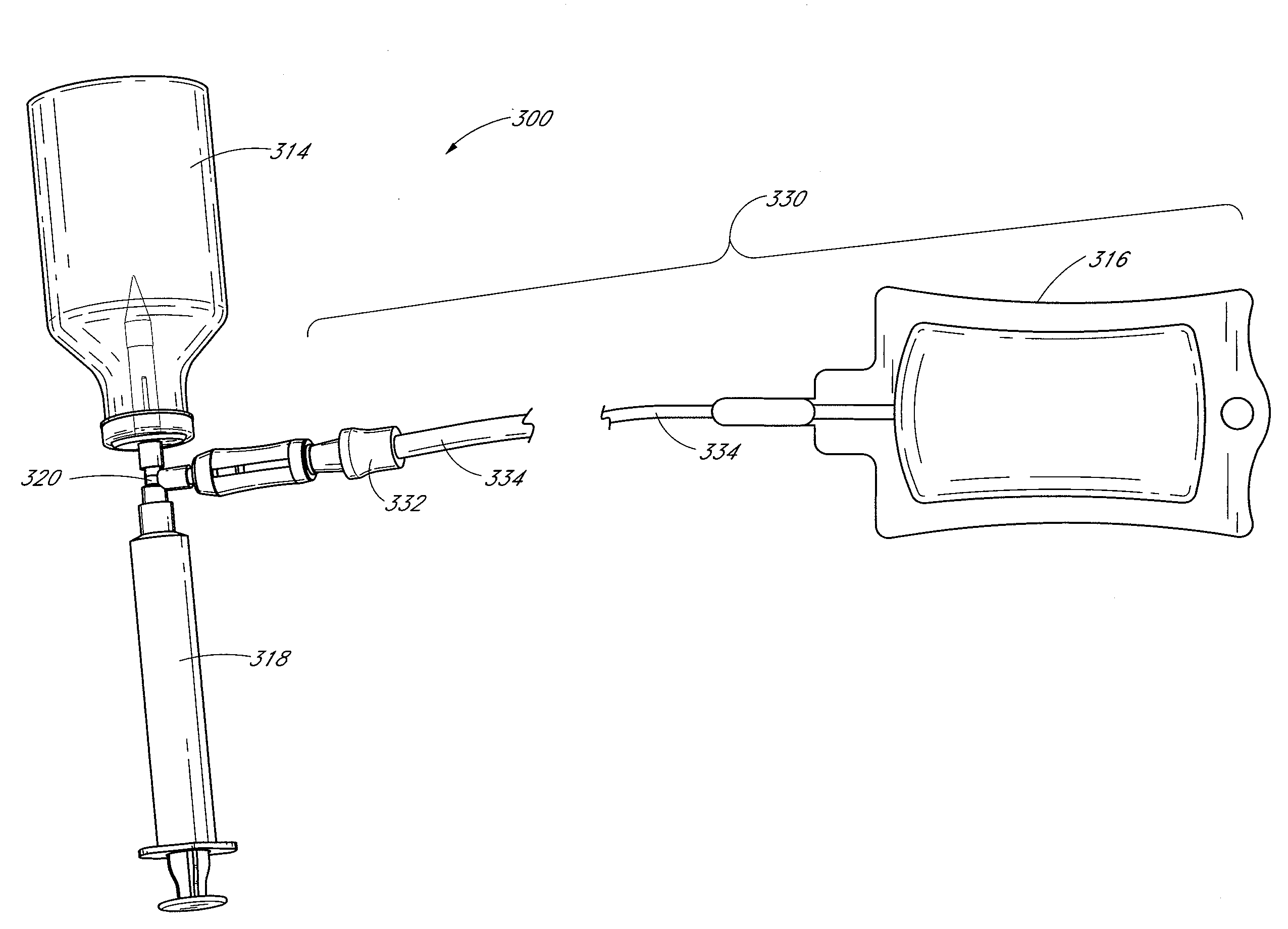

Fluid transfer devices and methods of use

Some embodiments disclosed herein related to a device for transferring precise amounts of fluid from at least one source container to a at least one target container. In some embodiments, the fluid is first transferred from the source container (e.g., a vial) through a connector to an intermediate measuring container (e.g., a syringe). In some embodiments air can pass through an air inlet and enter the vial to compensate for the volume of fluid withdrawn from the vial. An air check valve or a bag or a filter can prevent the fluid from escaping through the air inlet. The precisely measured amount of fluid can then be transferred from the intermediate measuring container to the target container (e.g., an IV bag). In some embodiments the connector can include a source check valve and a target check valve to direct fluid first from the source container to the intermediate measuring container and then from the intermediate measuring container to the target container. Some embodiments of the device can include a motor and a controller for automatically actuating a plunger of the syringe to transfer the desired amount of fluid.

Owner:ICU MEDICAL INC

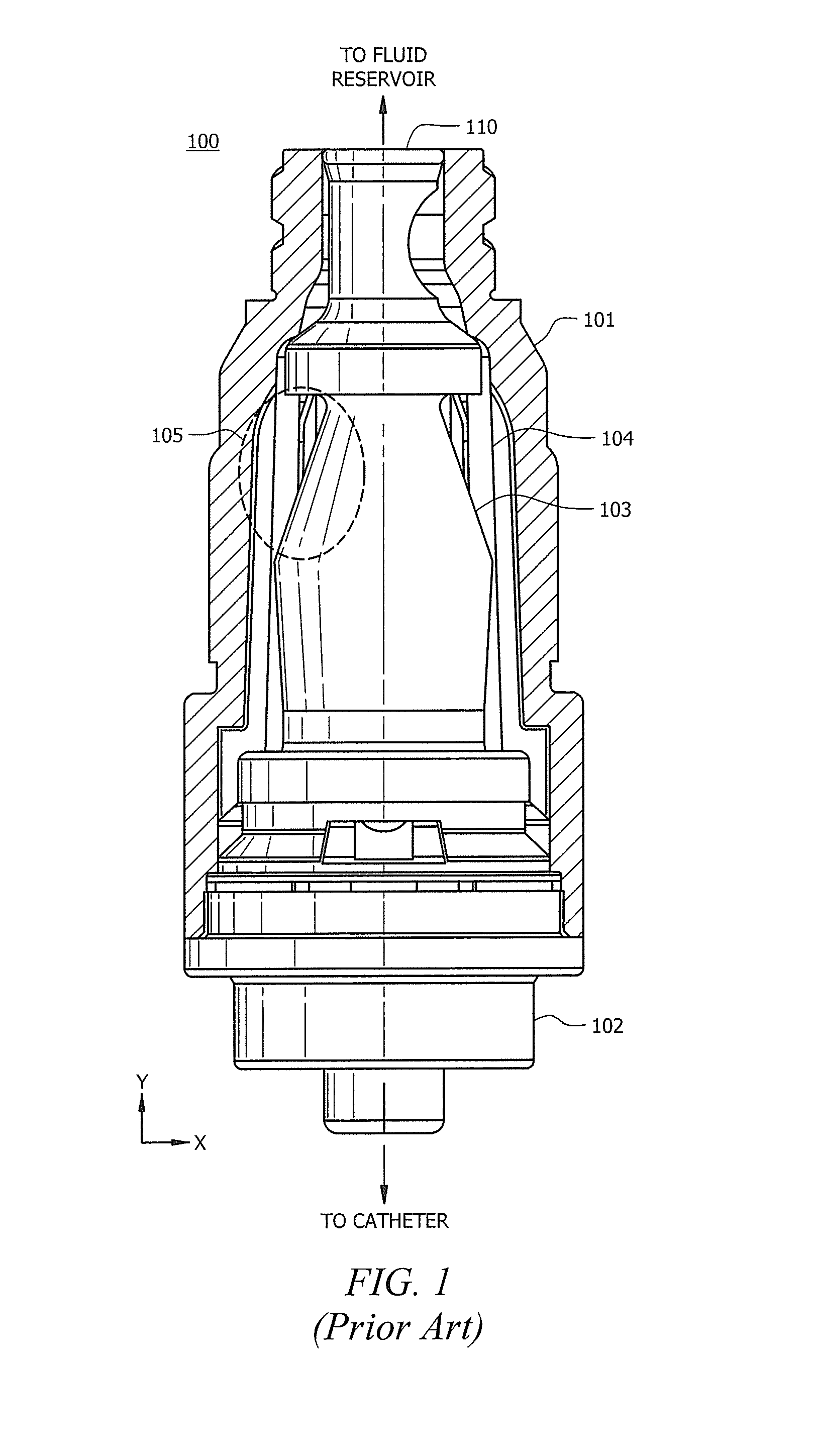

Pressure equalizing device for vial access

ActiveUS7900659B2Prevent buildupPrevent escapeDiagnosticsSurgeryPressure balanceAtmospheric pressure

A pressure-equalizing vial access device and method providing closed and sealed reconstitution of vial contents. A rigid container with a fixed internal volume is connected with a vent lumen extending into the vial. As pressure in the vial increases, the pressure is equalized with atmospheric pressure by varying the volume of a compartment within the rigid container. The compartment is formed with a volume control device that automatically varies the volume of the compartment in the rigid container to accommodate and equalize the pressure in the vial by increasing or decreasing the volume of the compartment. In one case the volume control device comprises a sliding disk and in another, a bladder that compresses with an increase in volume in the container and expands with a decrease.

Owner:CAREFUSION 303 INC

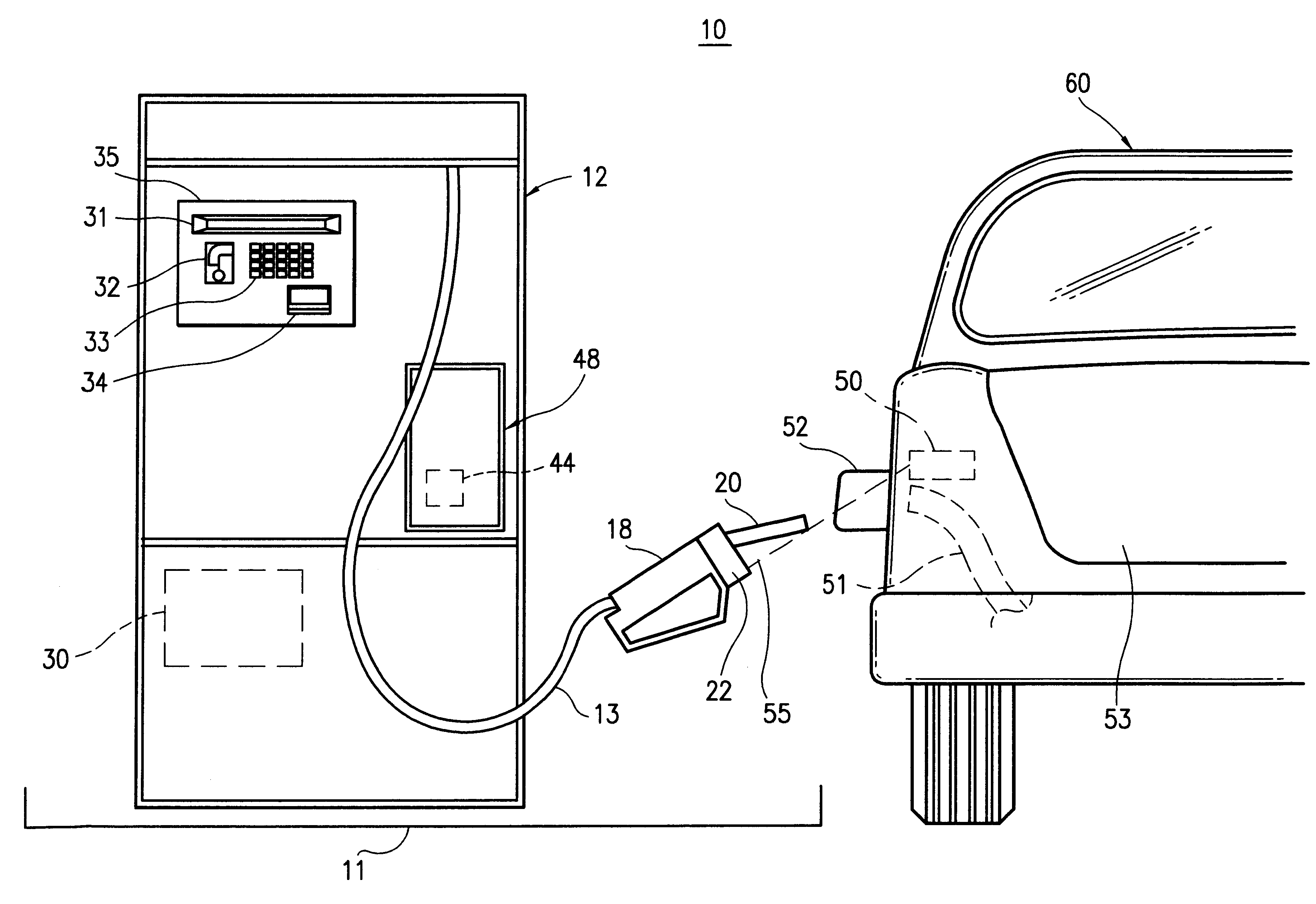

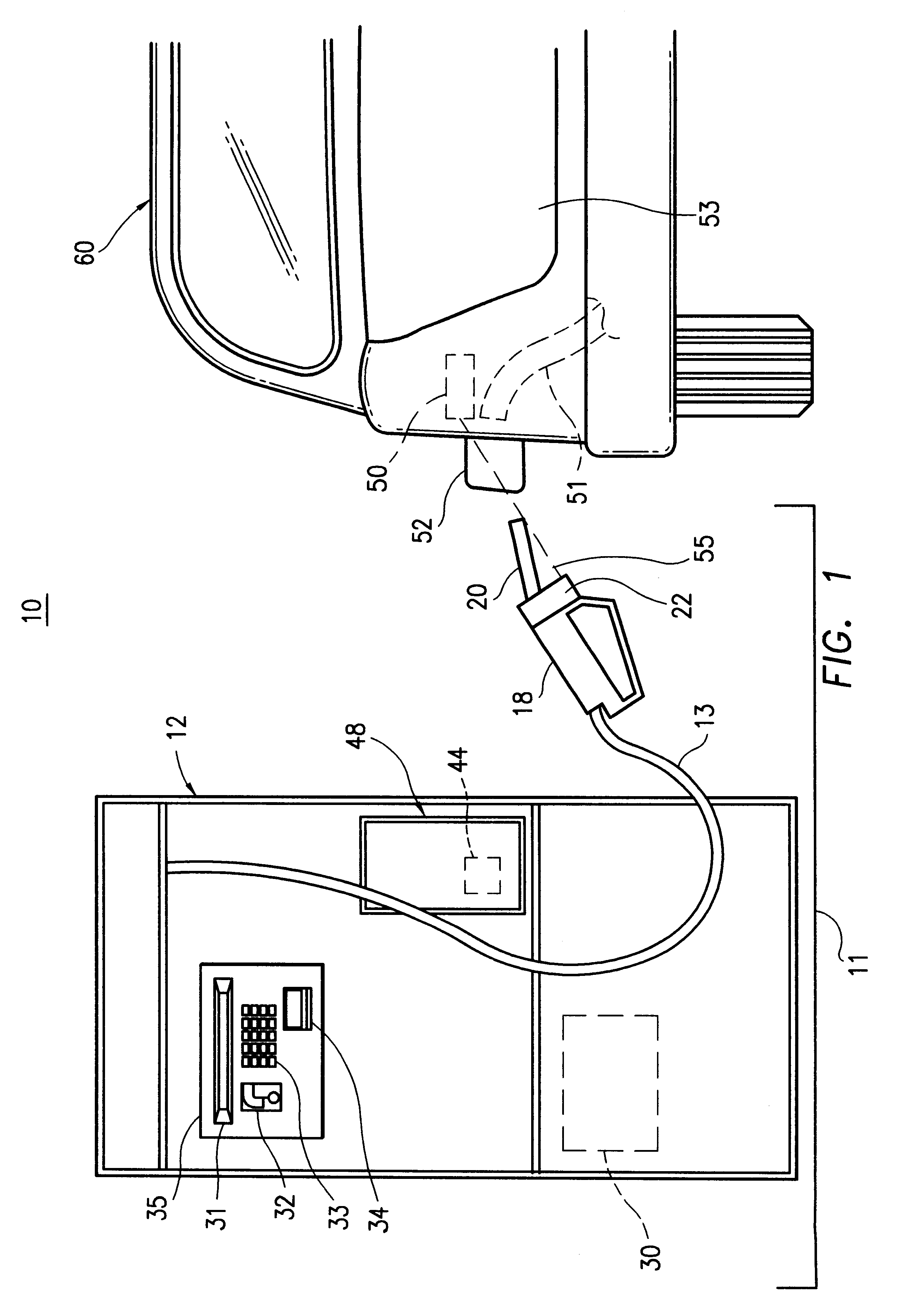

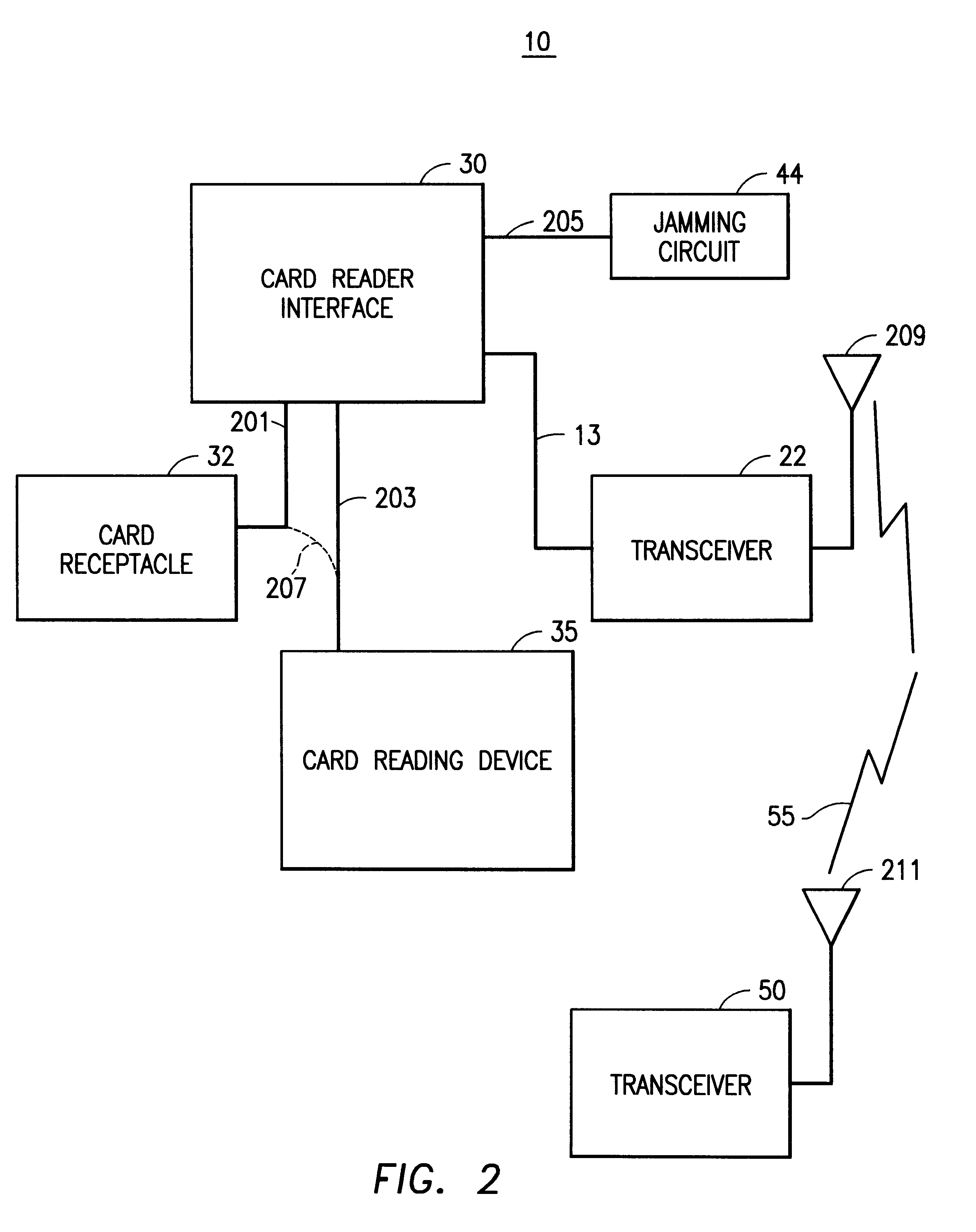

Method and apparatus for transmitting a digital information signal and vending system incorporating same

A cashless business transaction system (e.g., a vending system, a material tracking system, or a highway toll system) incorporates a method and apparatus for transmitting a digital information signal. A signal generator (311) generates a constant frequency signal. A phase modulator (305) varies the instantaneous phase of the constant frequency signal to represent digital information, thereby producing a phase modulated signal (325). A tuned resonant circuit (307) filters and averages the phase modulated signal to produce a simulated FM signal, and transmits the simulated FM signal via its antenna (309). One such business transaction system (e.g., a vending system) incorporates such a transmitter to facilitate transmission of billing information from a device located within a substantially electrically shielded environment. Another such business transaction system preferably incorporates such a transmitter to facilitate half-duplex transmission of digital information regardless of whether or not the digital information is transmitted from a device located within a substantially electrically shielded environment.

Owner:POLE ZERO ACQUISITION

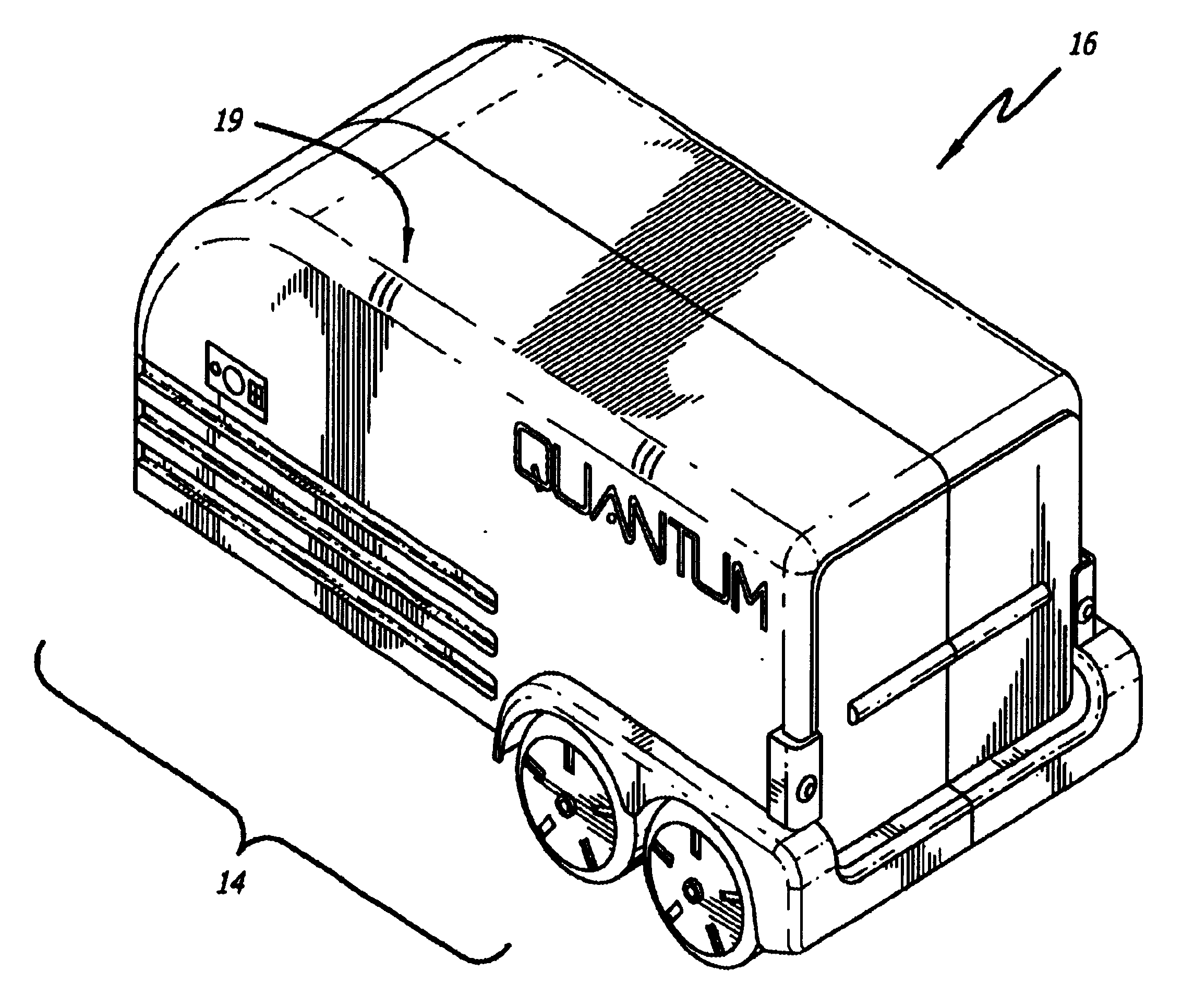

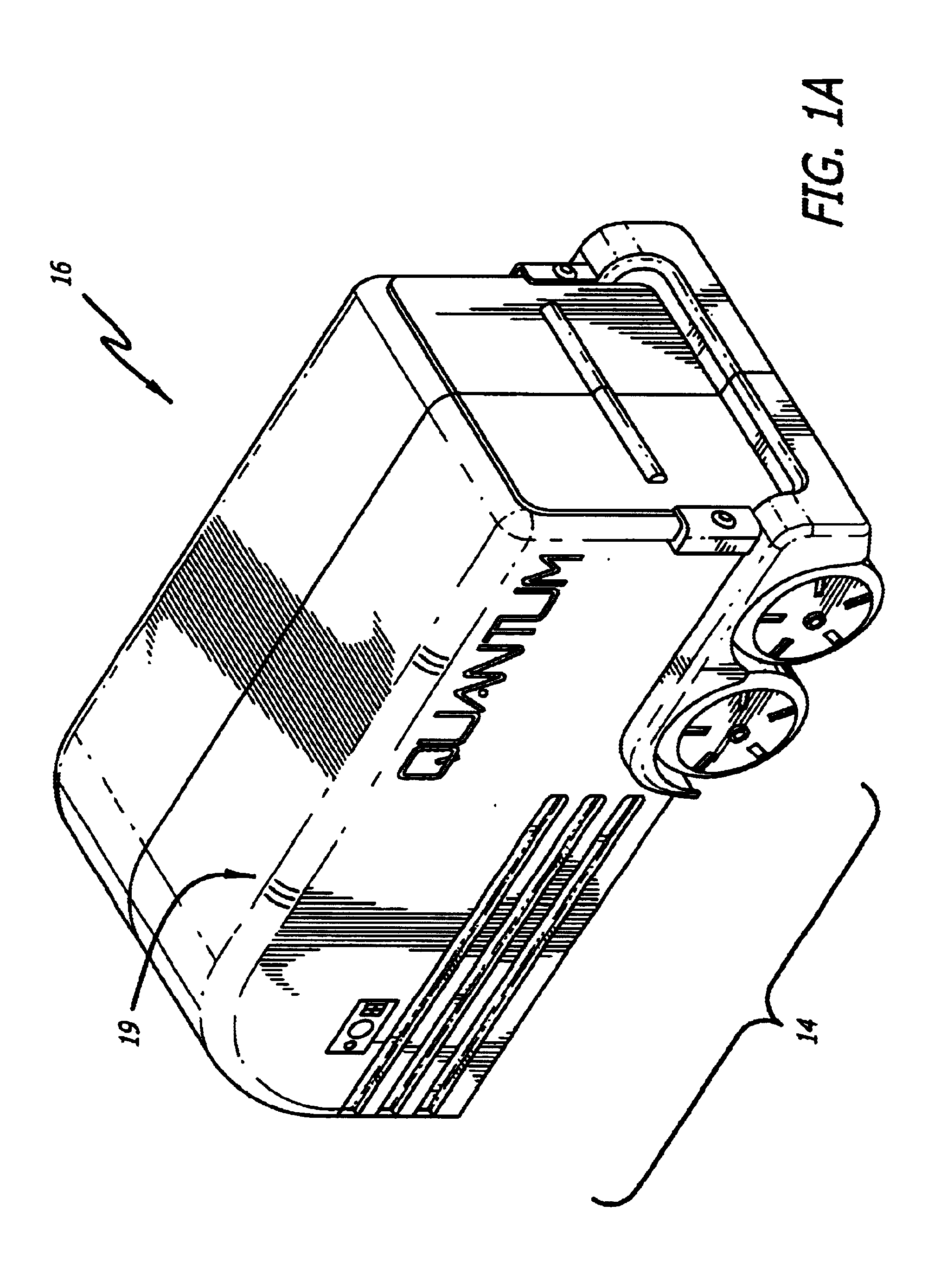

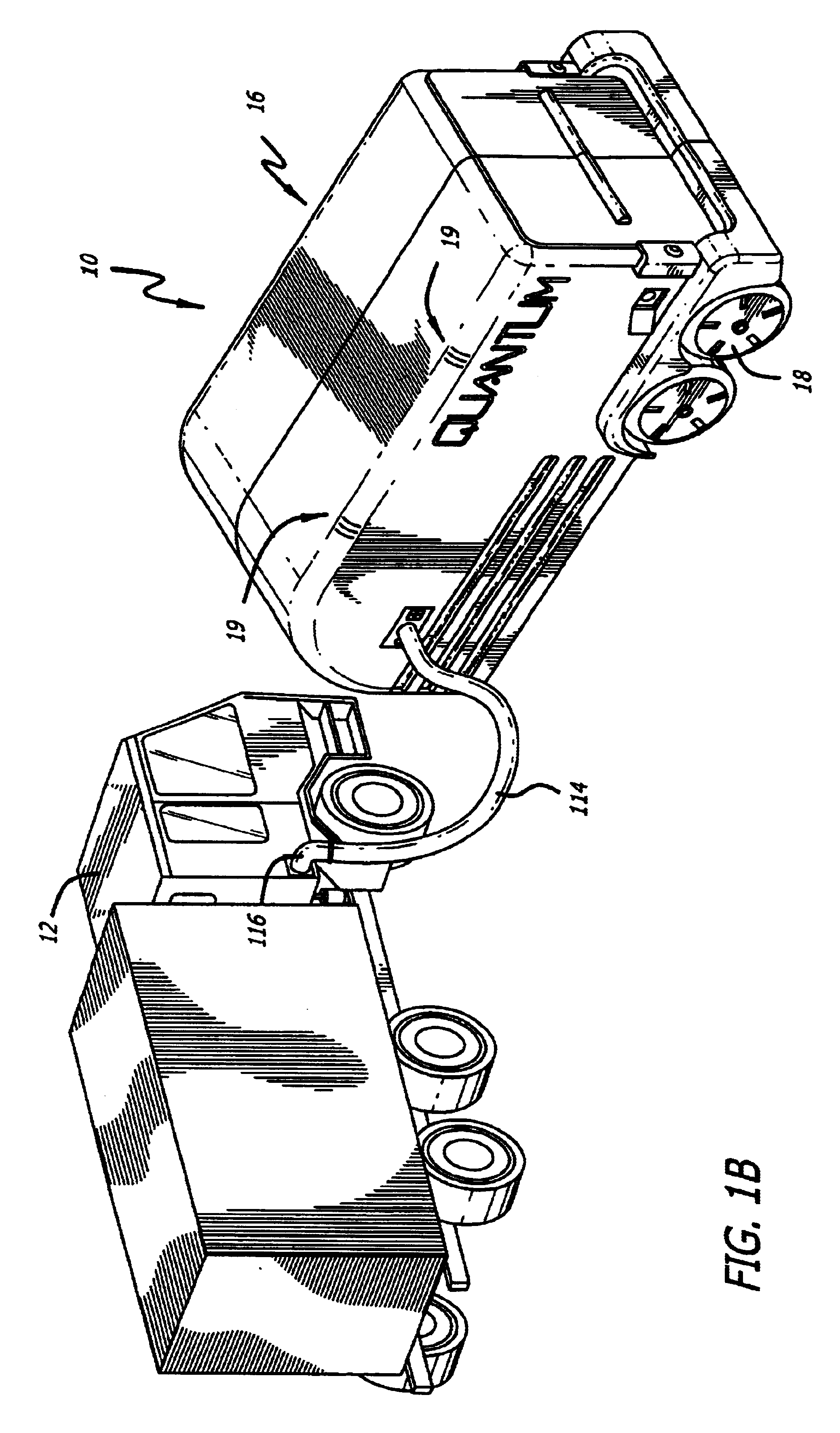

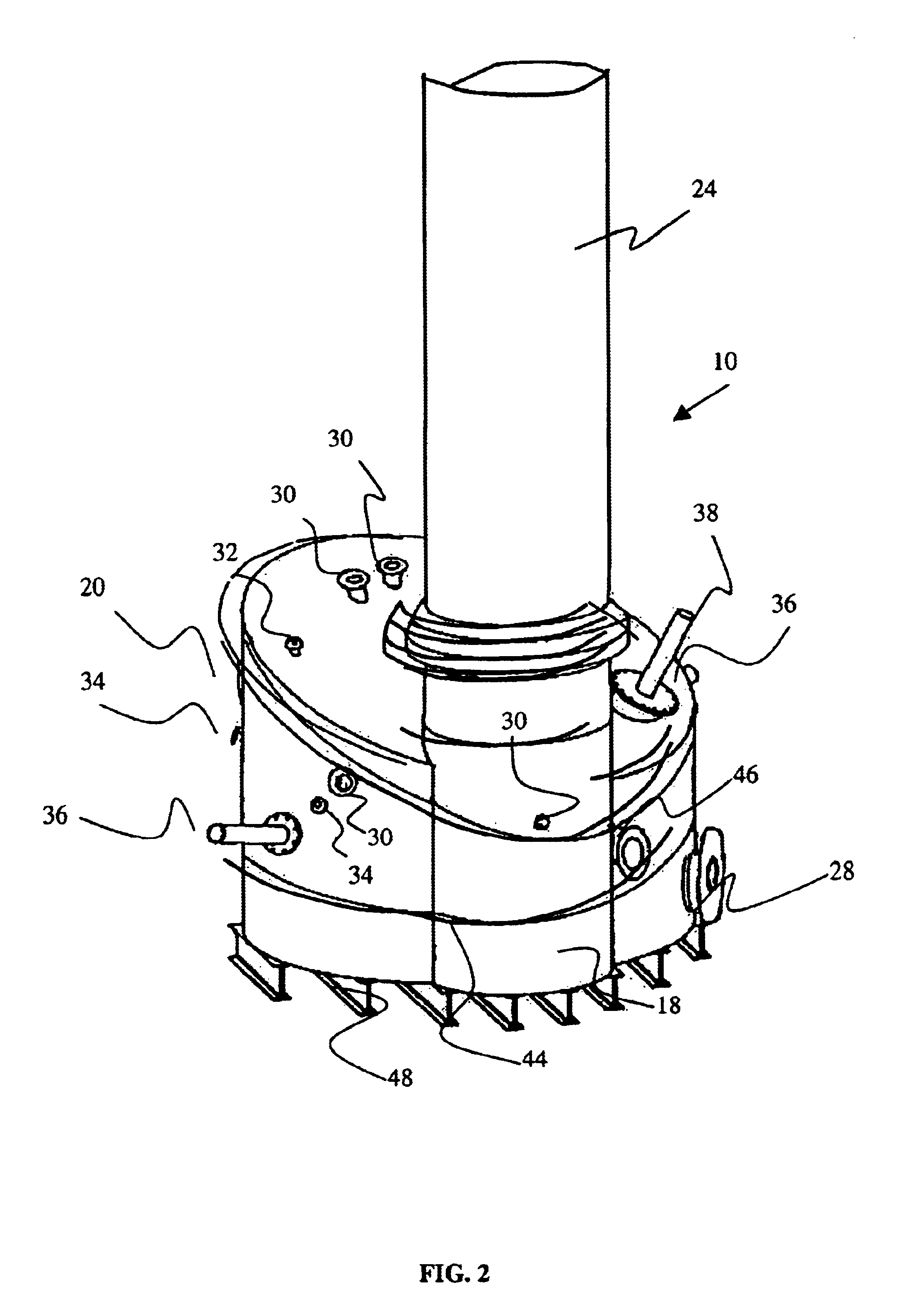

Transportable hydrogen refueling station

InactiveUS6755225B1Easy to monitorReduce riskTank vehiclesGas handling applicationsHigh pressureGaseous hydrogen

A portable hydrogen refueling stations which can dispense gaseous hydrogen from one or more internal high pressure tanks. The refueling station can be refilled with a lower pressure hydrogen gas feed and then compressed for storage within the refueling station.

Owner:QUANTUM FUEL SYST TECH WORLDWIDE INC

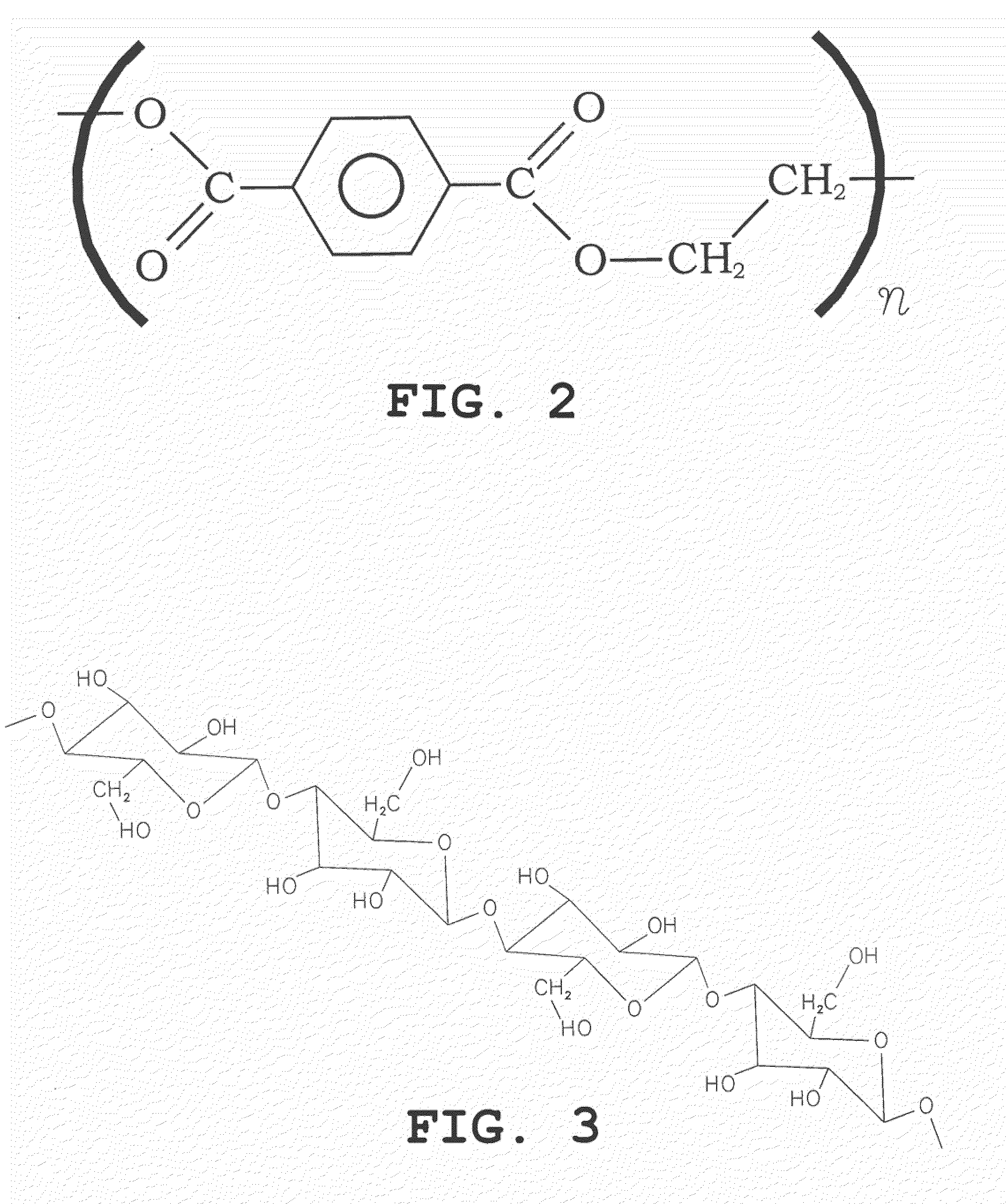

Hydraulically-Formed Nonwoven Sheet with Microfibers

InactiveUS20100272938A1Non-fibrous pulp additionNatural cellulose pulp/paperNonwoven fabricMedical device

In a first embodiment, a hydraulically-formed nonwoven sheet, a package comprising such sheet, a method of packaging a medical device using a package with such sheet and a method of manufacturing such sheet are provided. This nonwoven sheet comprises first and second non-cellulosic polymeric fibers. The first non-cellulosic polymeric fibers have an average diameter less than about 3.5 micron, an average cut length less than about 3 millimeters and an average aspect ratio of about 400 to about 2000; the second non-cellulosic polymeric fibers have an average diameter greater than about 3.5 micron and an average aspect ratio of about 400 to about 1000. In a second embodiment, a hydraulically-formed nonwoven sheet is provided. This nonwoven sheet comprises binding material, non-cellulosic polymeric fibers and cellulosic based materials. The non-cellulosic polymeric fibers have an average diameter less than about 3.5 micron, an average cut length less than about 3 millimeters and an average aspect ratio of about 400 to about 2000. The second nonwoven sheet has a bacterial filtration efficiency of at least about 98%.

Owner:BEMIS COMPANY INC

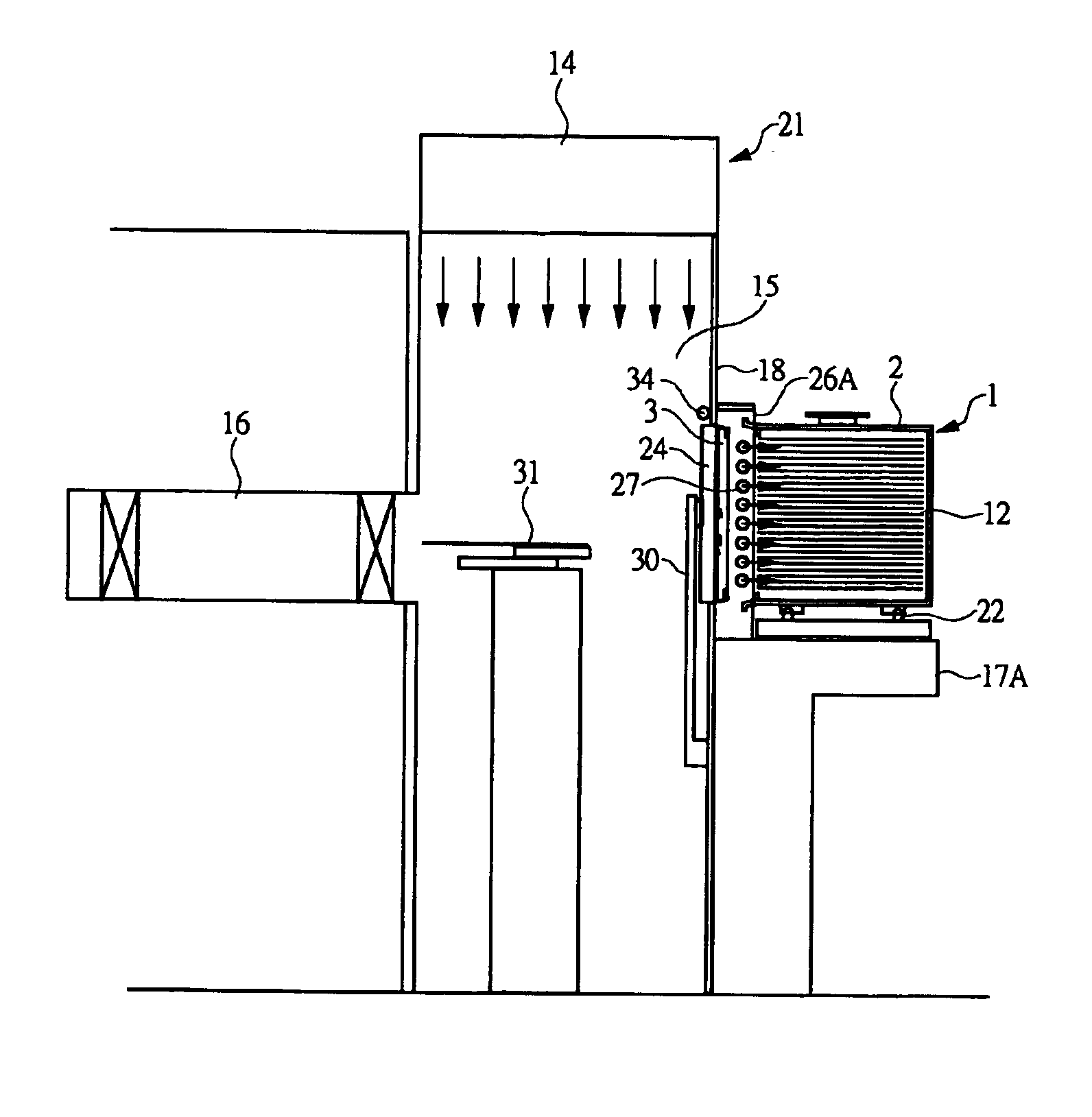

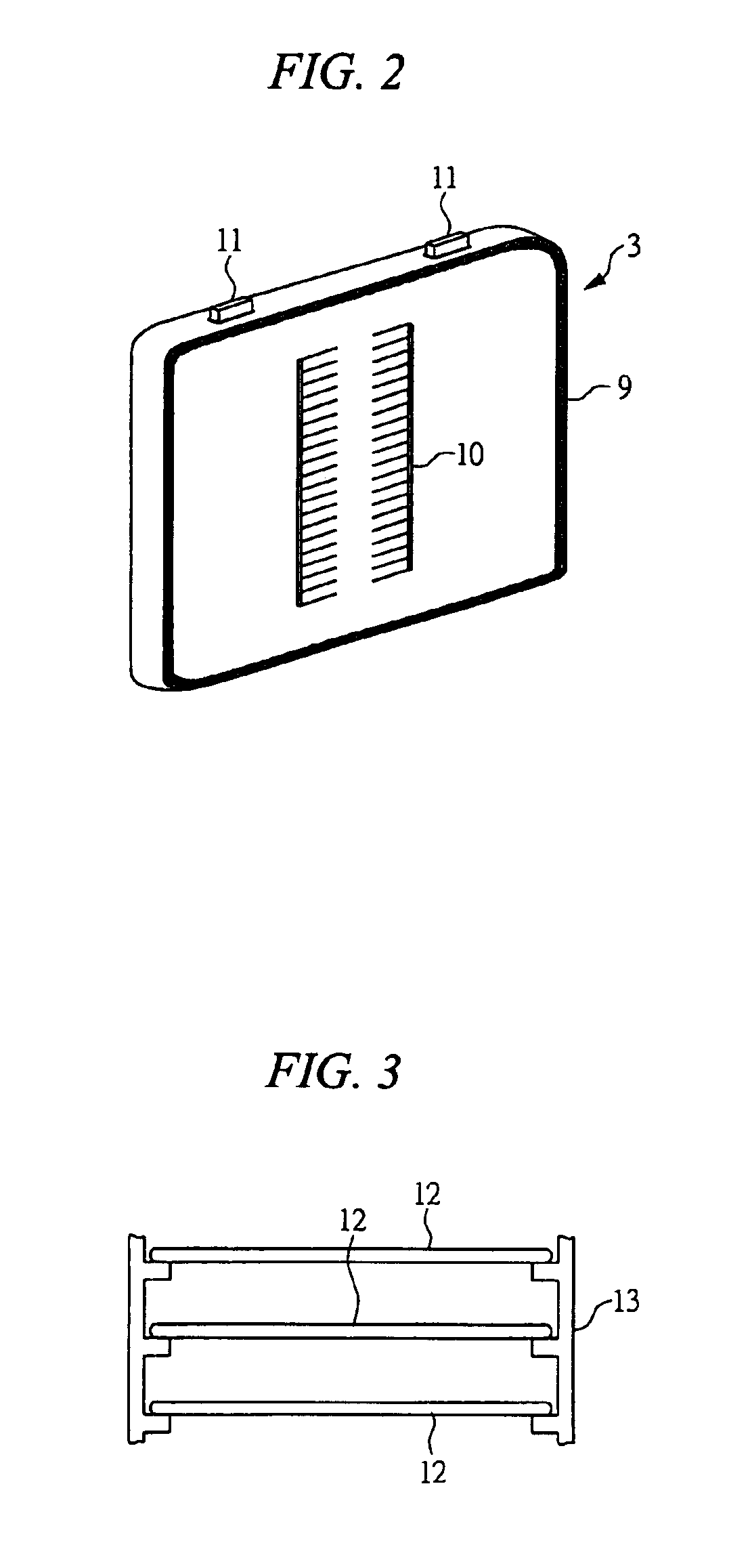

Method of purging wafer receiving jig, wafer transfer device, and method of manufacturing semiconductor device

InactiveUS6867153B2Drying gas arrangementsSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A FOUP having semiconductor wafers received therein is transferred to a loading port and then the door of the FOUP is fixed and removed by a FIMS door and then the semiconductor wafers are taken out of the shell of the FOUP and then a predetermined manufacturing processing is performed to the semiconductor wafers. After performing the manufacturing processing, the semiconductor wafers are returned into the shell and the FIMS door is returned to a closed position and the shell is retracted about 50 mm to 65 mm to form a gap between the FIMS door and the shell. Then, purge gas is introduced from a gas introduction pipe arranged above the loading port on the left and right sides in a slanting forward direction of the FIMS door into the shell to replace the atmosphere in the shell with the purge gas.

Owner:TRECENTI TECHNOLOGIES INC

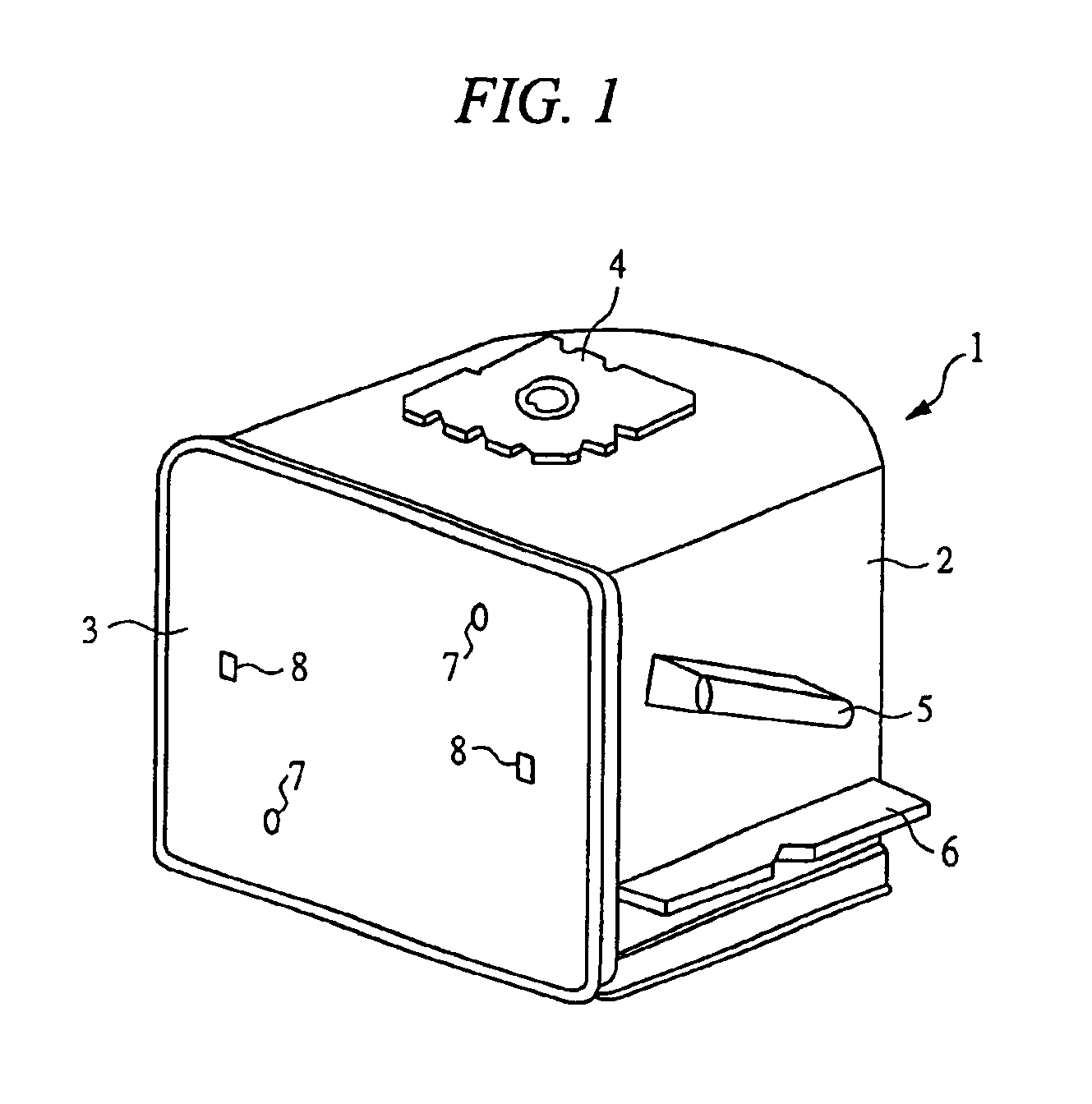

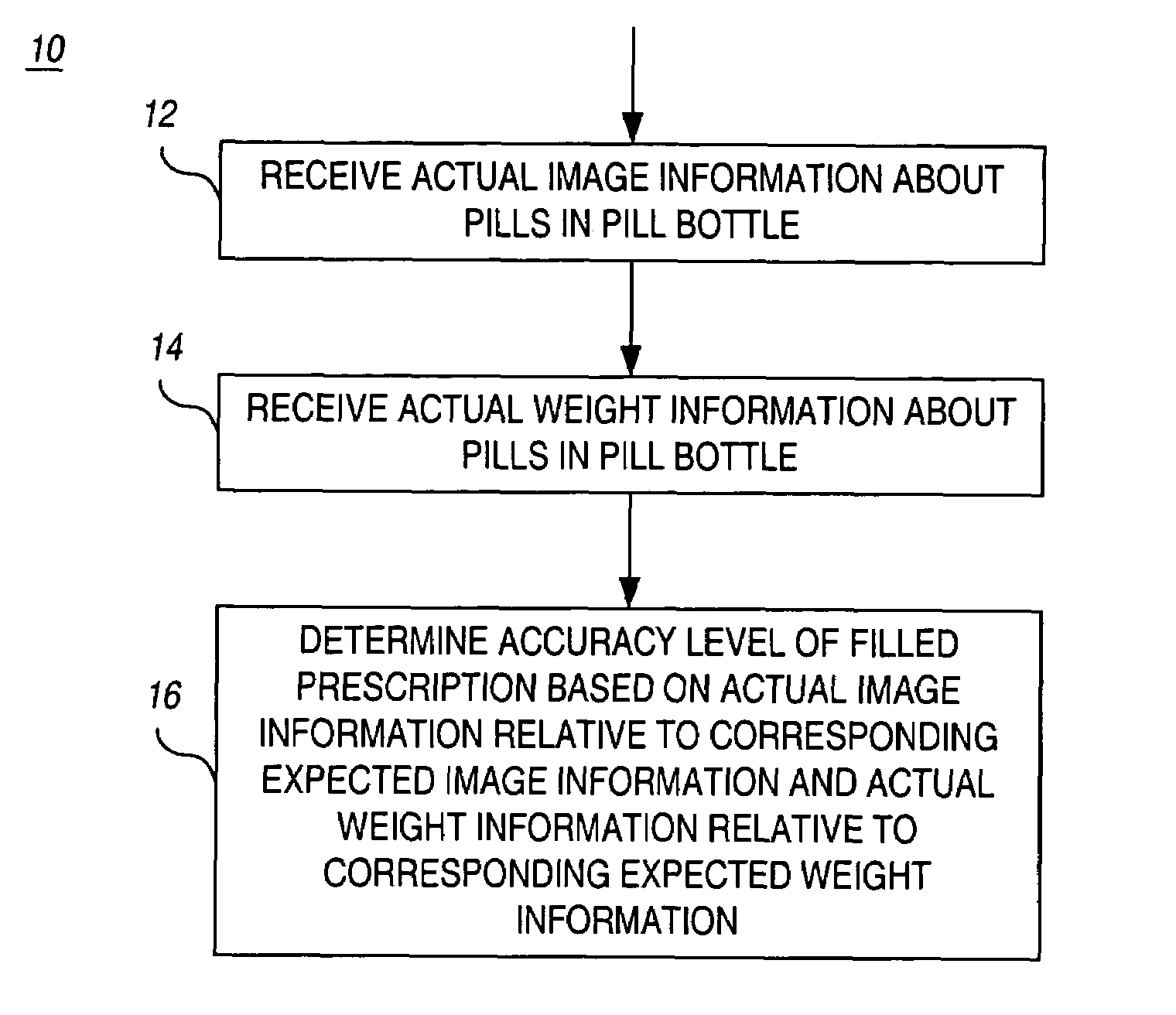

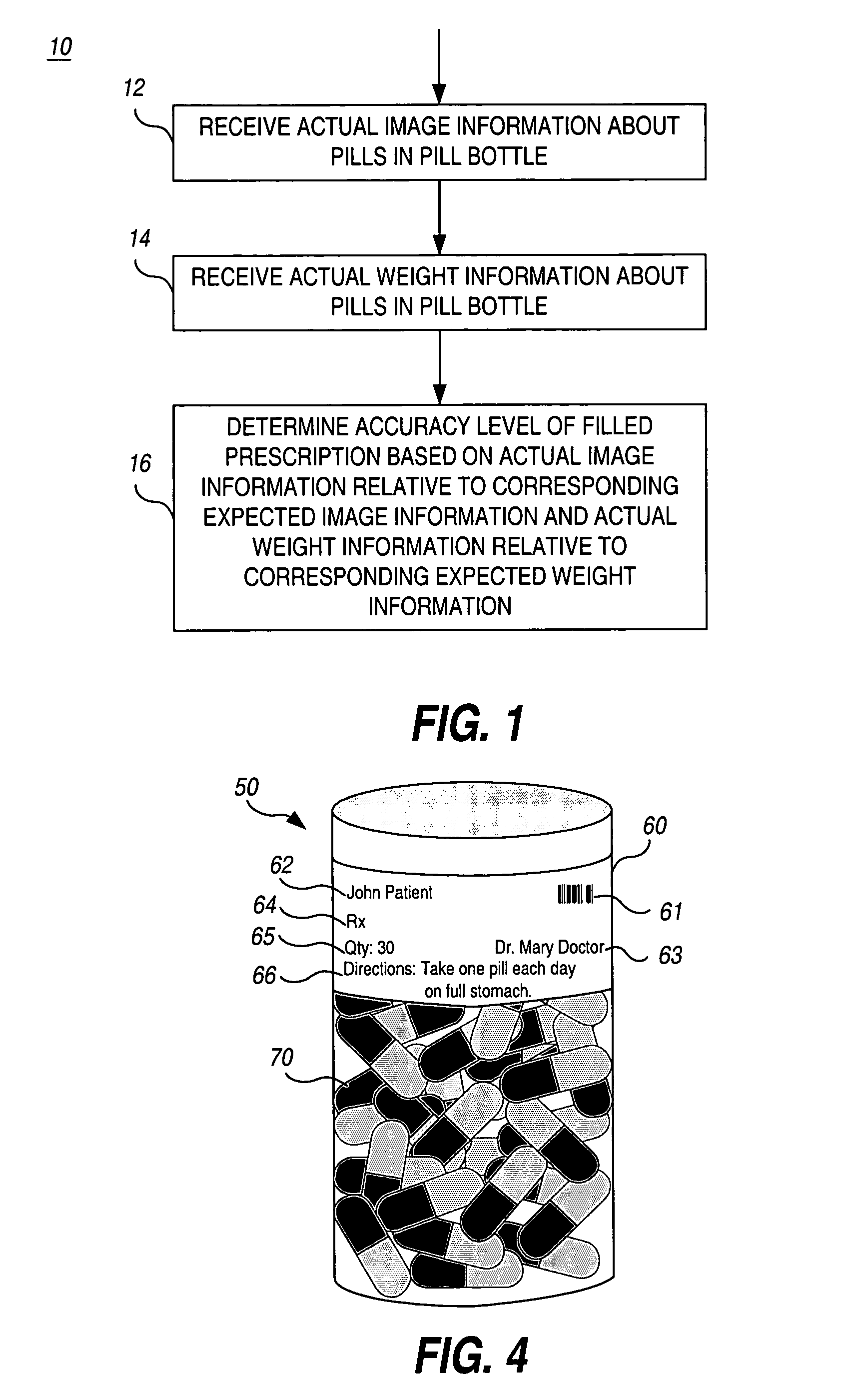

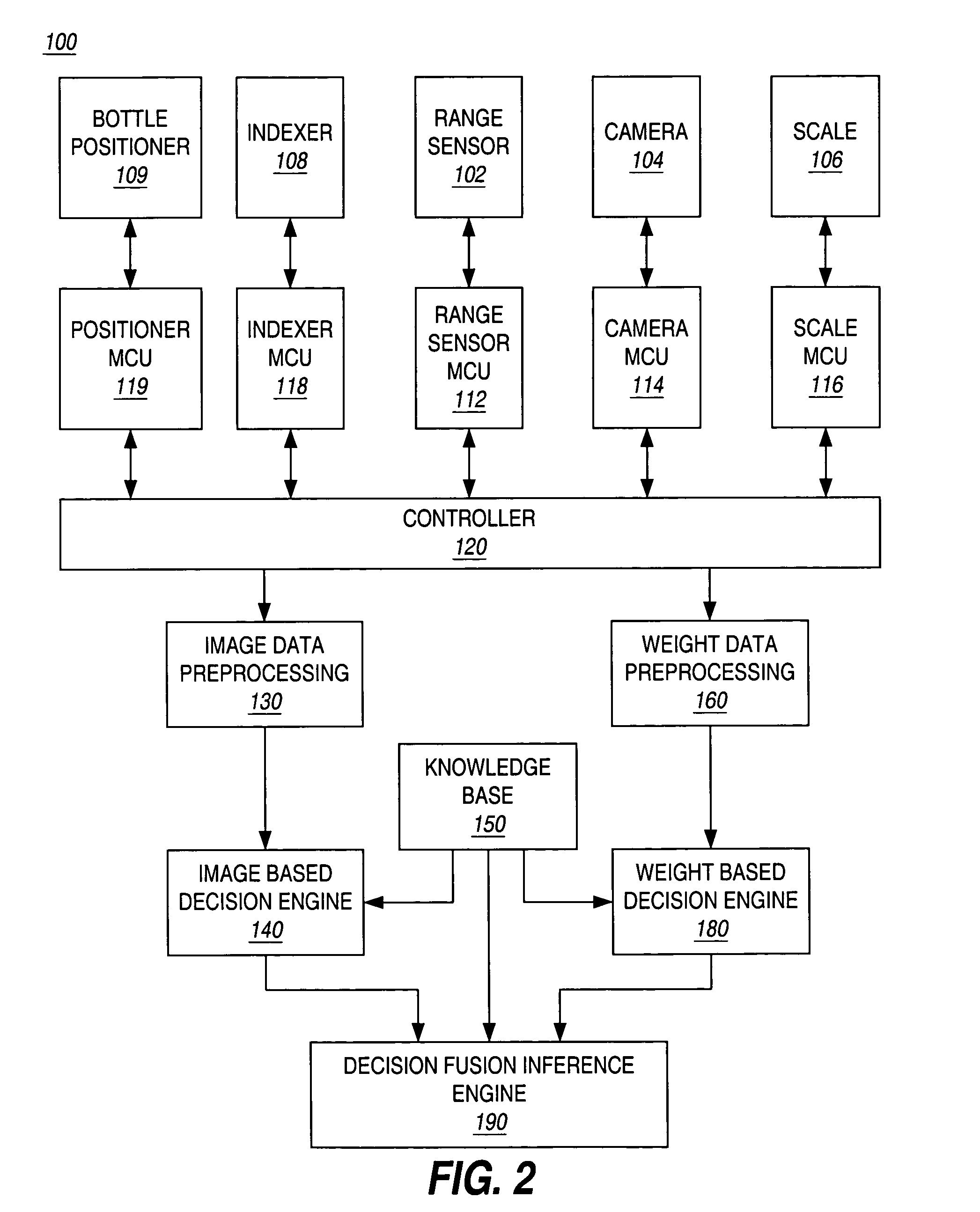

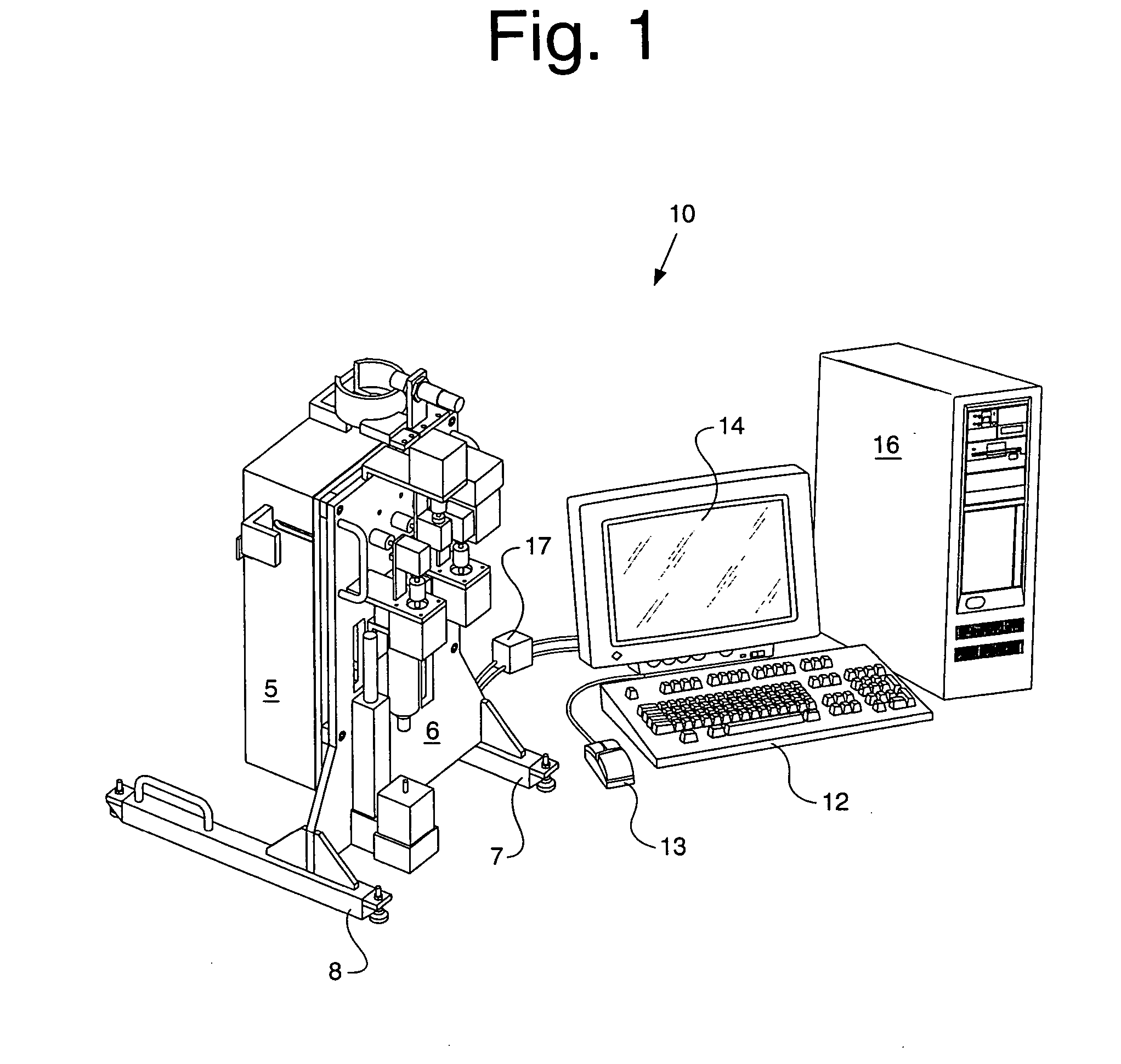

Apparatus and method for automatic prescription verification

InactiveUS7028723B1Eliminate unnecessary idle timeLiquid fillingDrug and medicationsThe InternetOrder form

An apparatus and method are used to perform the verification of a pharmaceutical prescription after it is filled but prior to shipment. Due to the high volume of mail / internet orders, the analysis is to be performed on the whole prescription, not on each individual pill of the prescription. The apparatus automatically gathers information about the pills contained in a pill bottle, including image and weight information, and incorporates a decision-making engine to decide whether the content of the pill bottle matches the prescription order.

Owner:ALOUANI ALI TAHOR +1

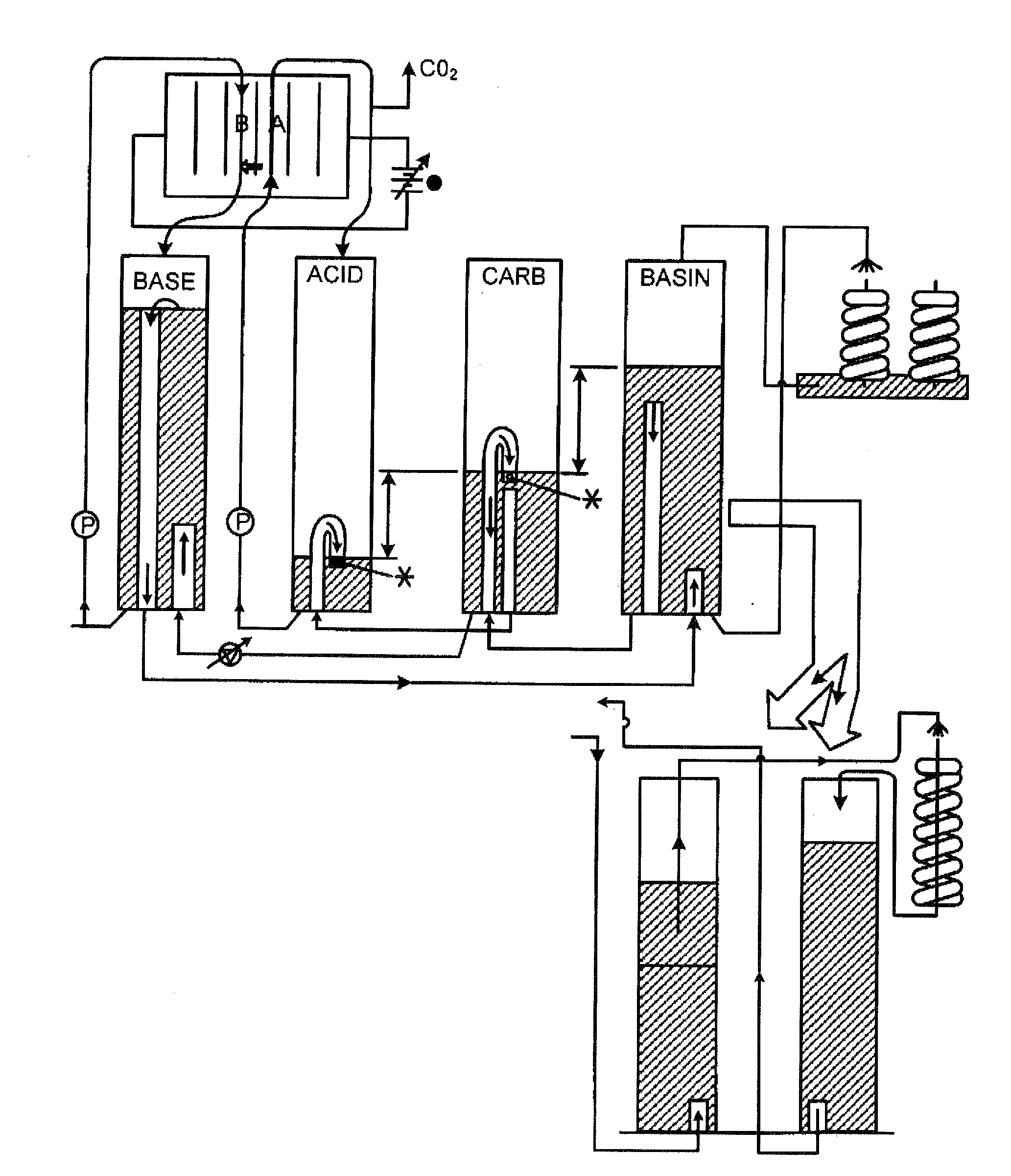

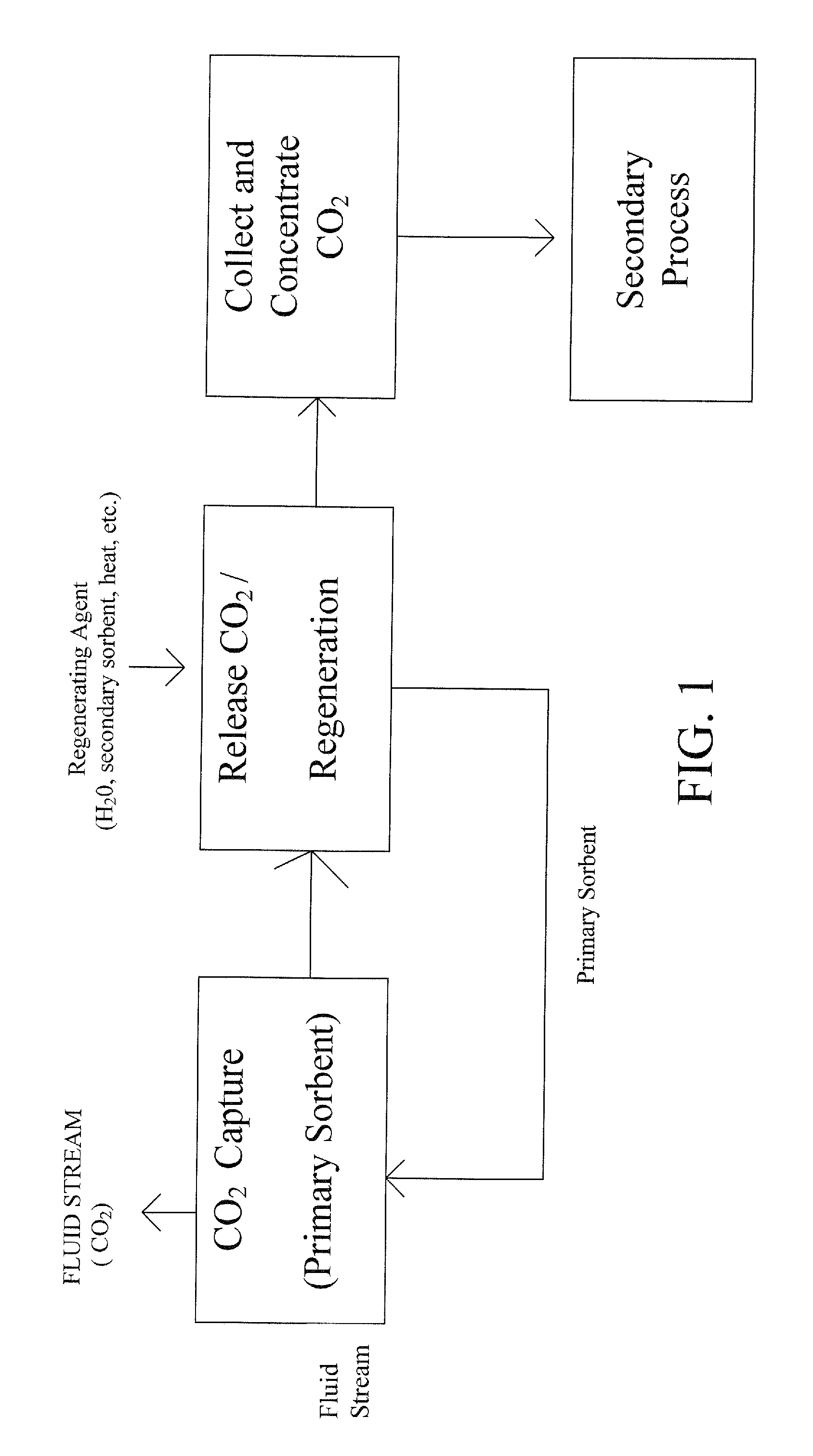

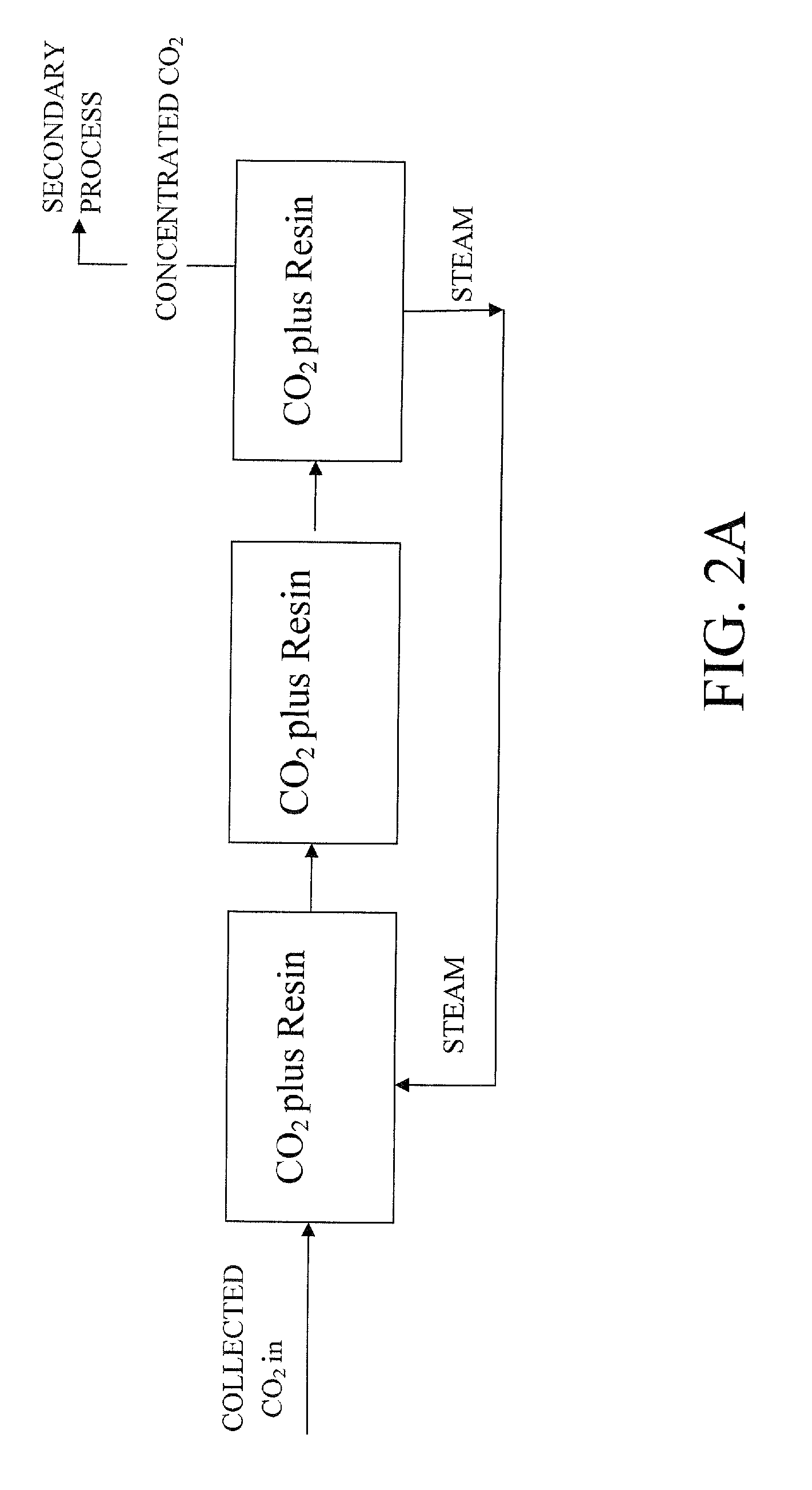

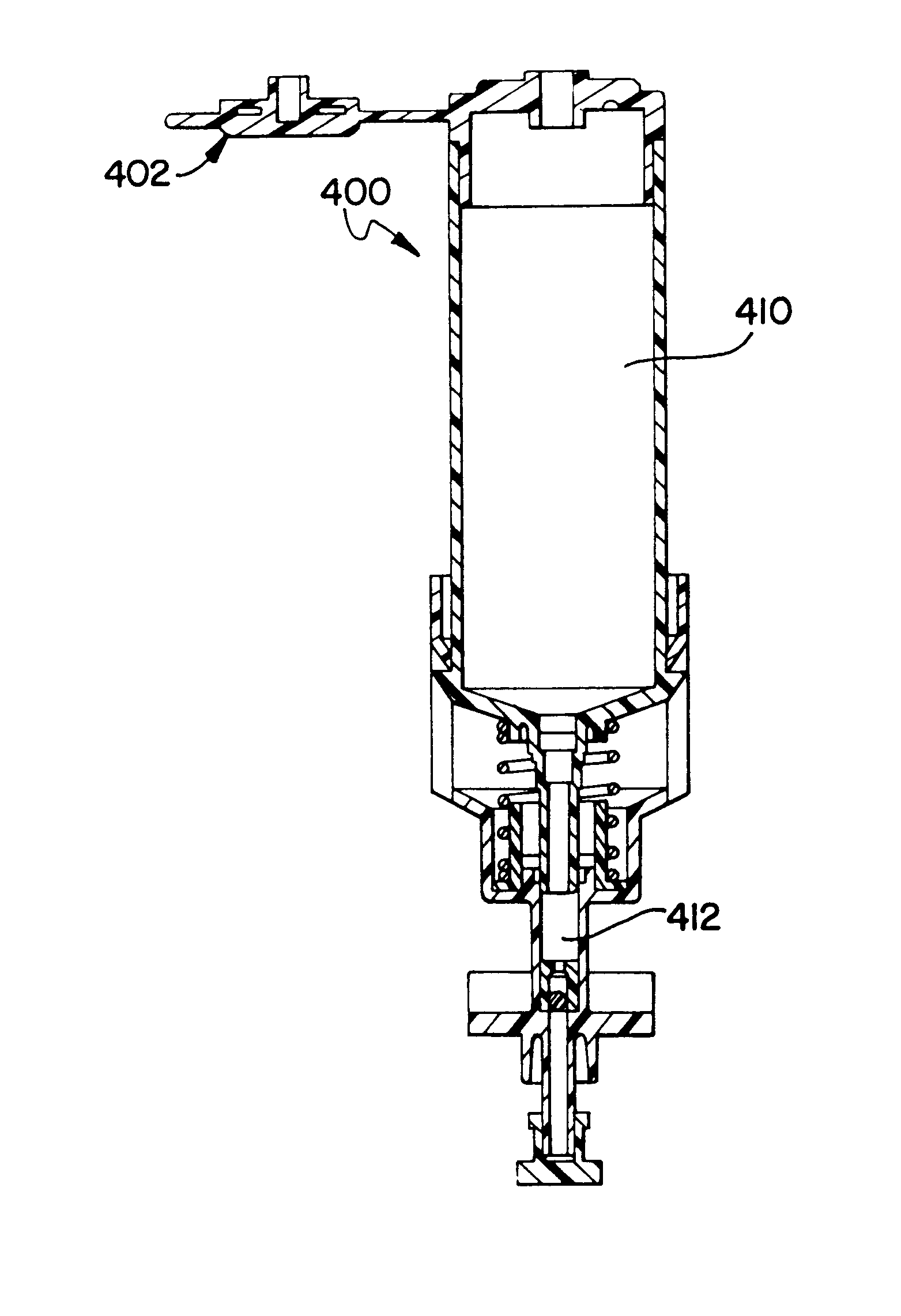

Extraction and sequestration of carbon dioxide

The present disclosure provides a method and apparatus for extracting carbon dioxide (CO2) from a fluid stream and for delivering that extracted CO2 to controlled environments for utilization by a secondary process. Various extraction and delivery methods are disclosed specific to certain secondary uses, included the attraction of CO2-sensitive insects, the ripening and preservation of produce, and the neutralization of brine.

Owner:KILIMANJARO ENERGY

Fluid dispenser

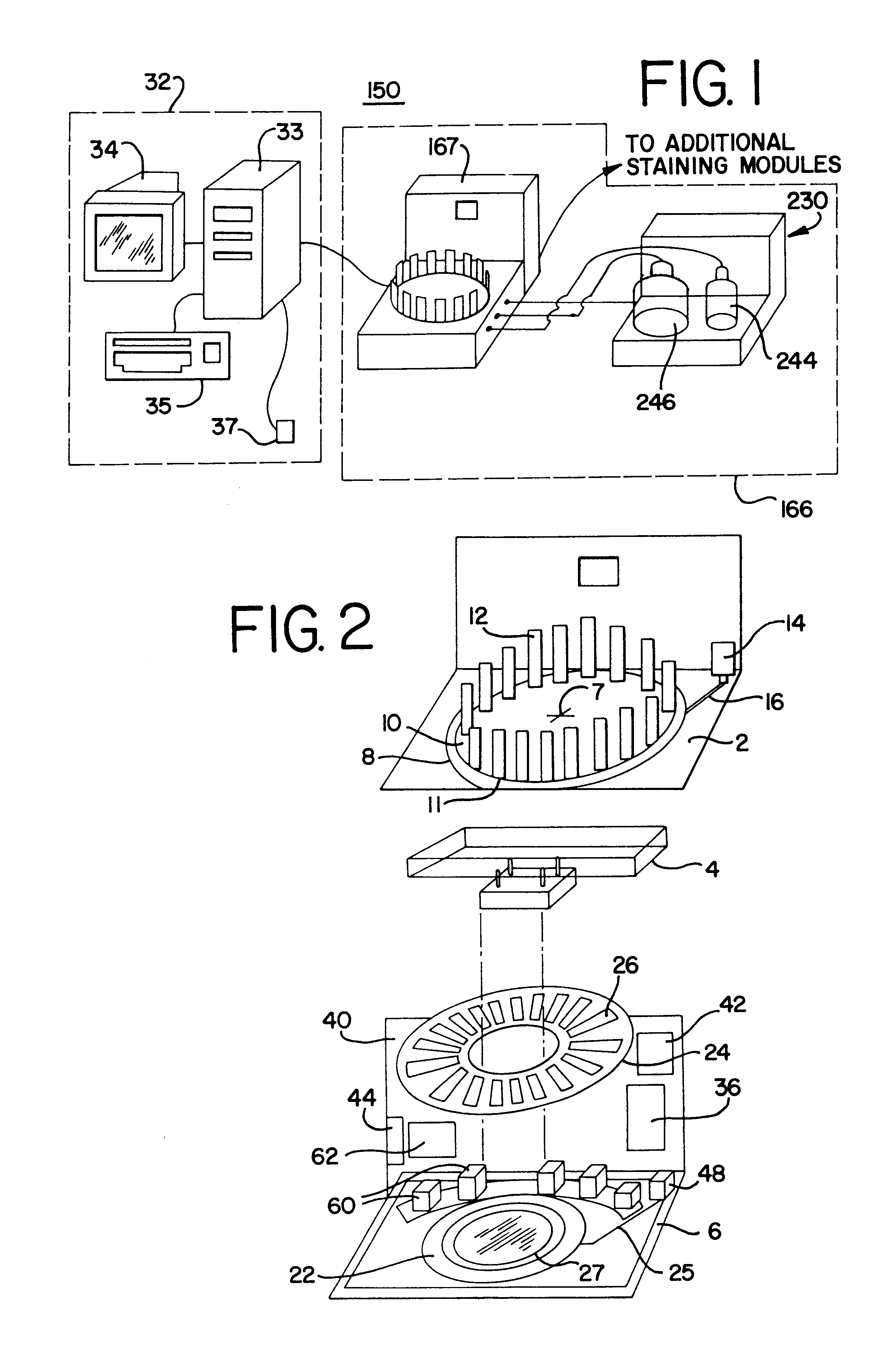

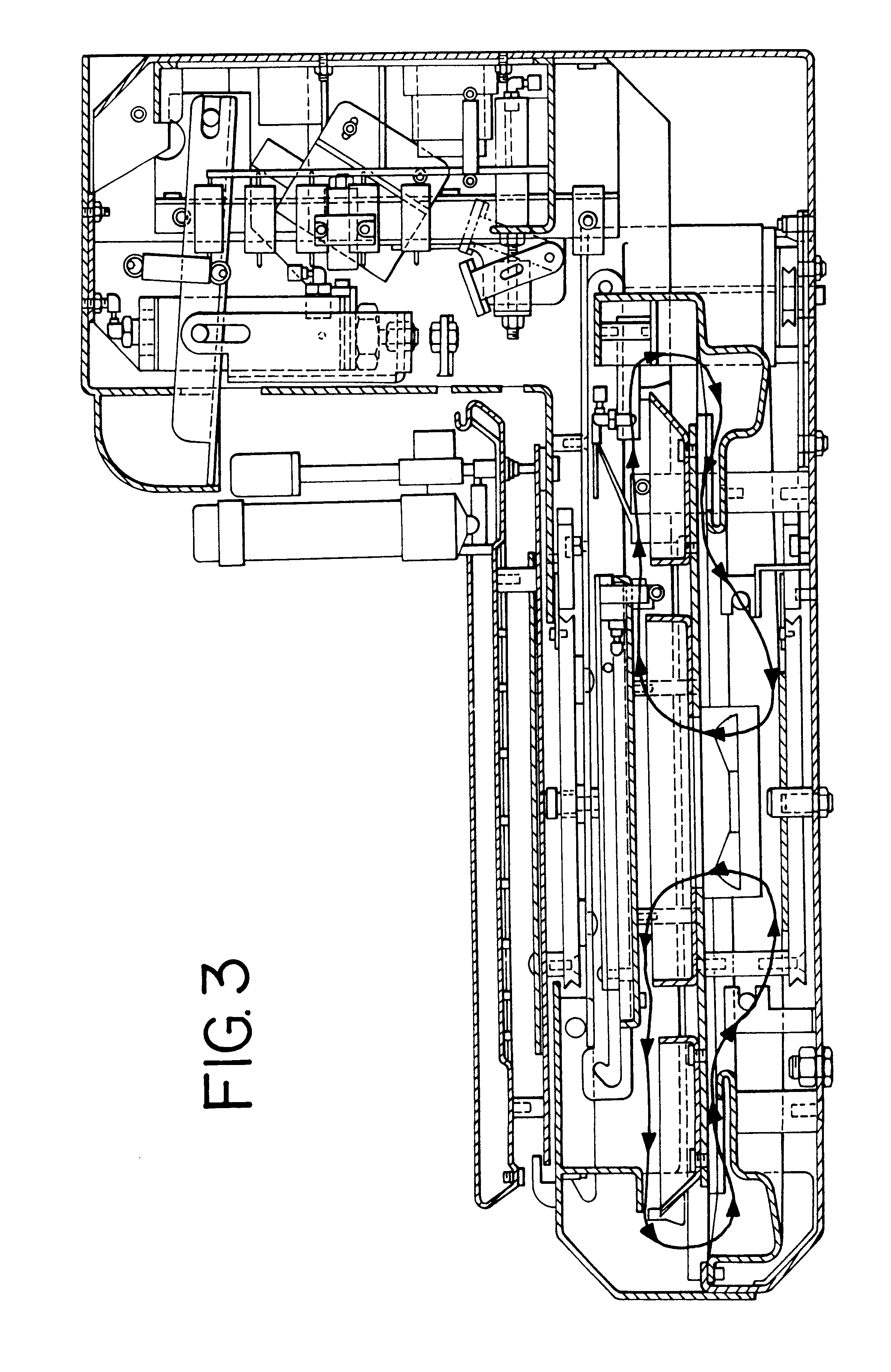

InactiveUS6192945B1Efficient and reliableEasy to manufacturePreparing sample for investigationLiquid flow controllersModularityReactive system

A method and apparatus for an automated biological reaction system is provided. In the processing of a biological reaction system, there is a need for consistently placing an amount of fluid on a slide. In order to accomplish this, several methods are used including a consistency pulse and a volume adjust means. Moreover, in order to reliably operate an automated biological reaction system, the dispenser must be reliable, easy to assemble and accurate. Among other things, in order to accomplish this, the dispense chamber is substantially in line with the reservoir chamber, the reservoir chamber piston is removed, and the flow of fluid through the dispenser is simplified. Further, in order to operate the automated biological reaction system more reliably, the system is designed in modular pieces with higher functions performed by a host device and the execution of the staining operations performed by remote devices. Also, to reliably catalog data which is used by the automated biological reaction system, data is loaded to a memory device, which in turn is used by the operator to update the operator's databases. The generation of the sequence of steps for the automated biological reaction device based on data loaded by the operator, including checks to determine the ability to complete the run, is provided.

Owner:VENTANA MEDICAL SYST INC

Multiple plasma generator hazardous waste processing system

A waste processing system is provided herein which entails the use of at least one fixed-position plasma arc generator for primary processing and at least one moveable plasma arc generator for secondary processing assistance and / or final conditioning of the slag prior to exit from the reactor vessel. This optimum processing environment is provided by control of reactor vessel configuration and real time control of processing characteristics to ensure maximum processing efficiency.

Owner:PLASCO ENERGY GROUP INC

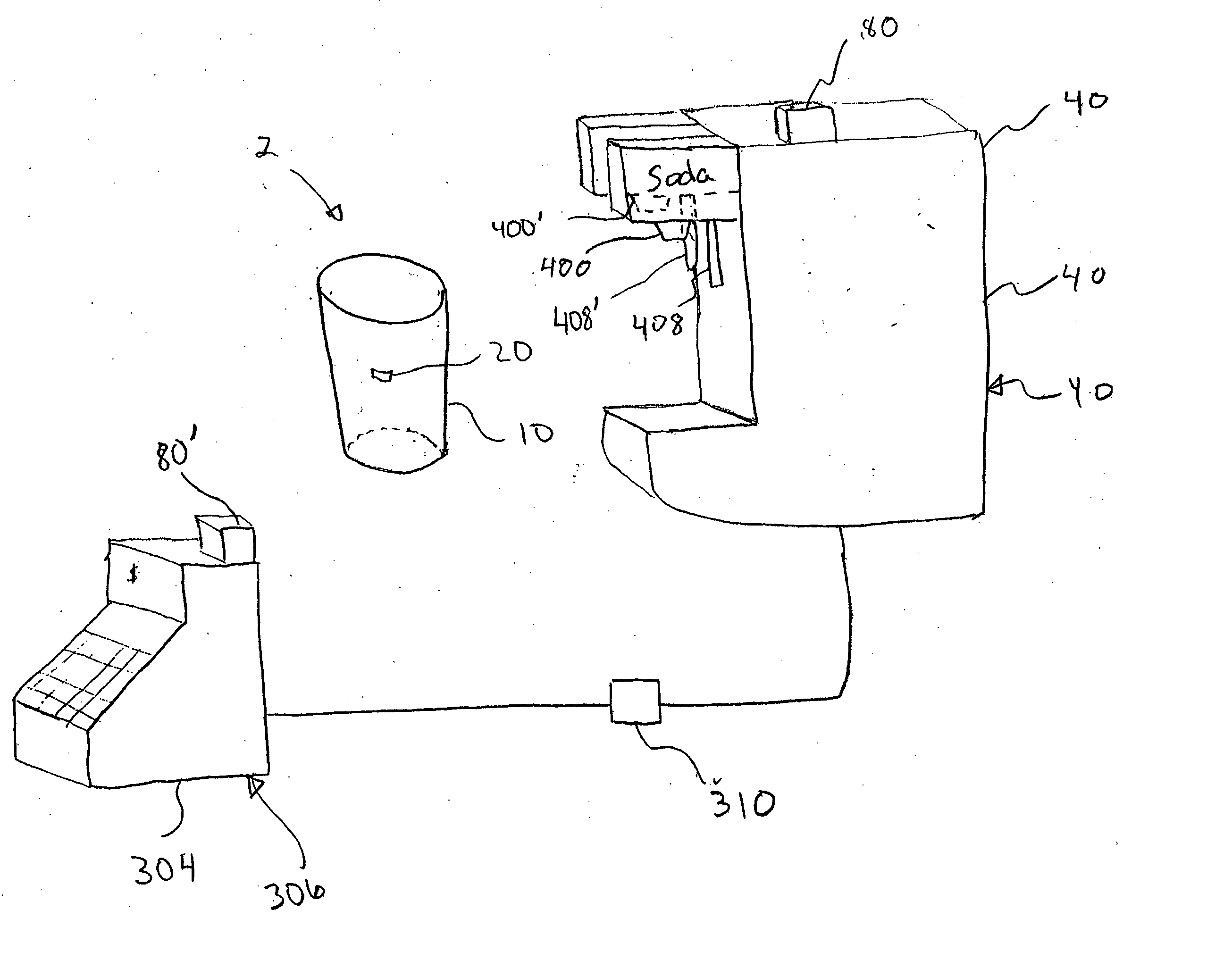

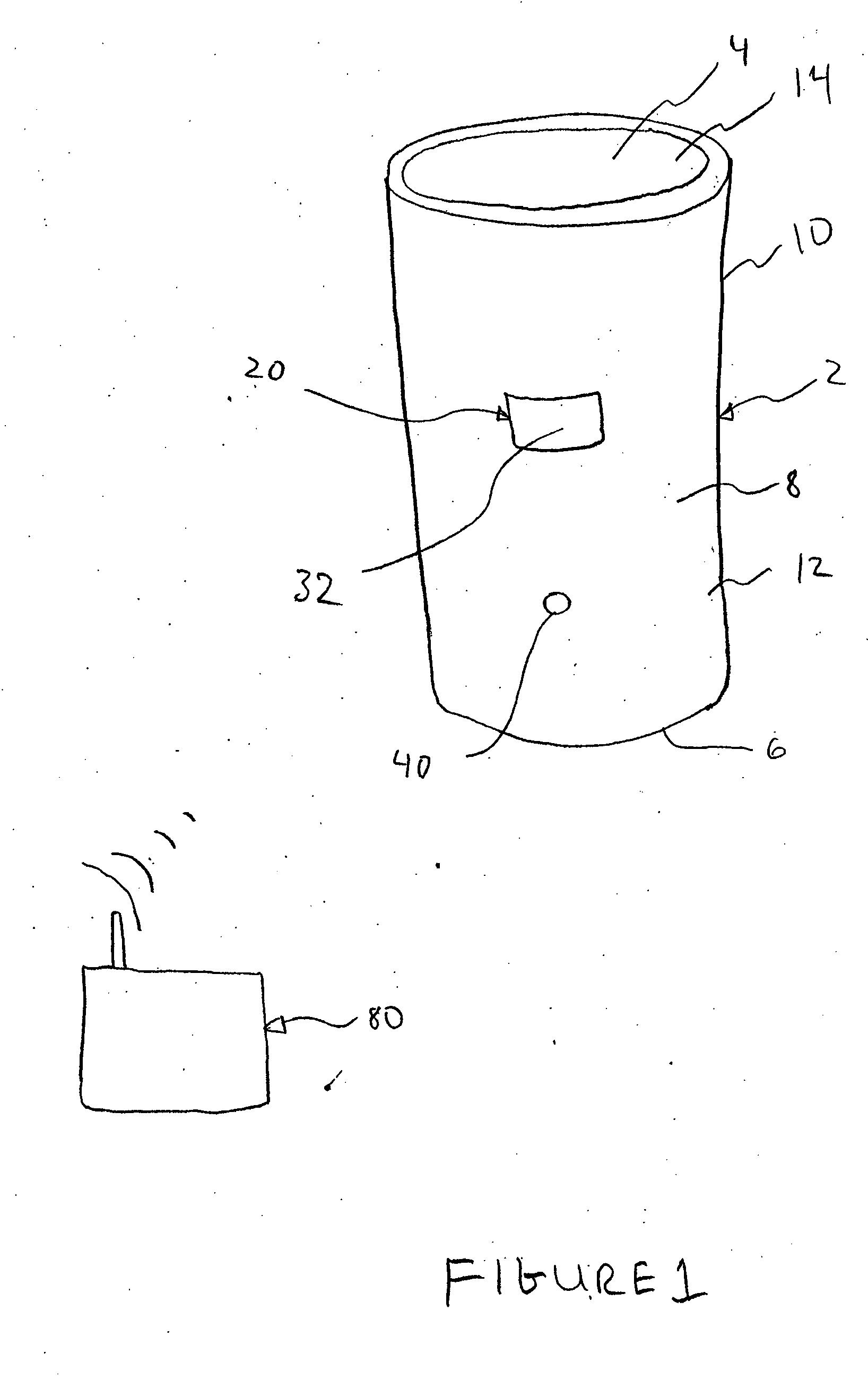

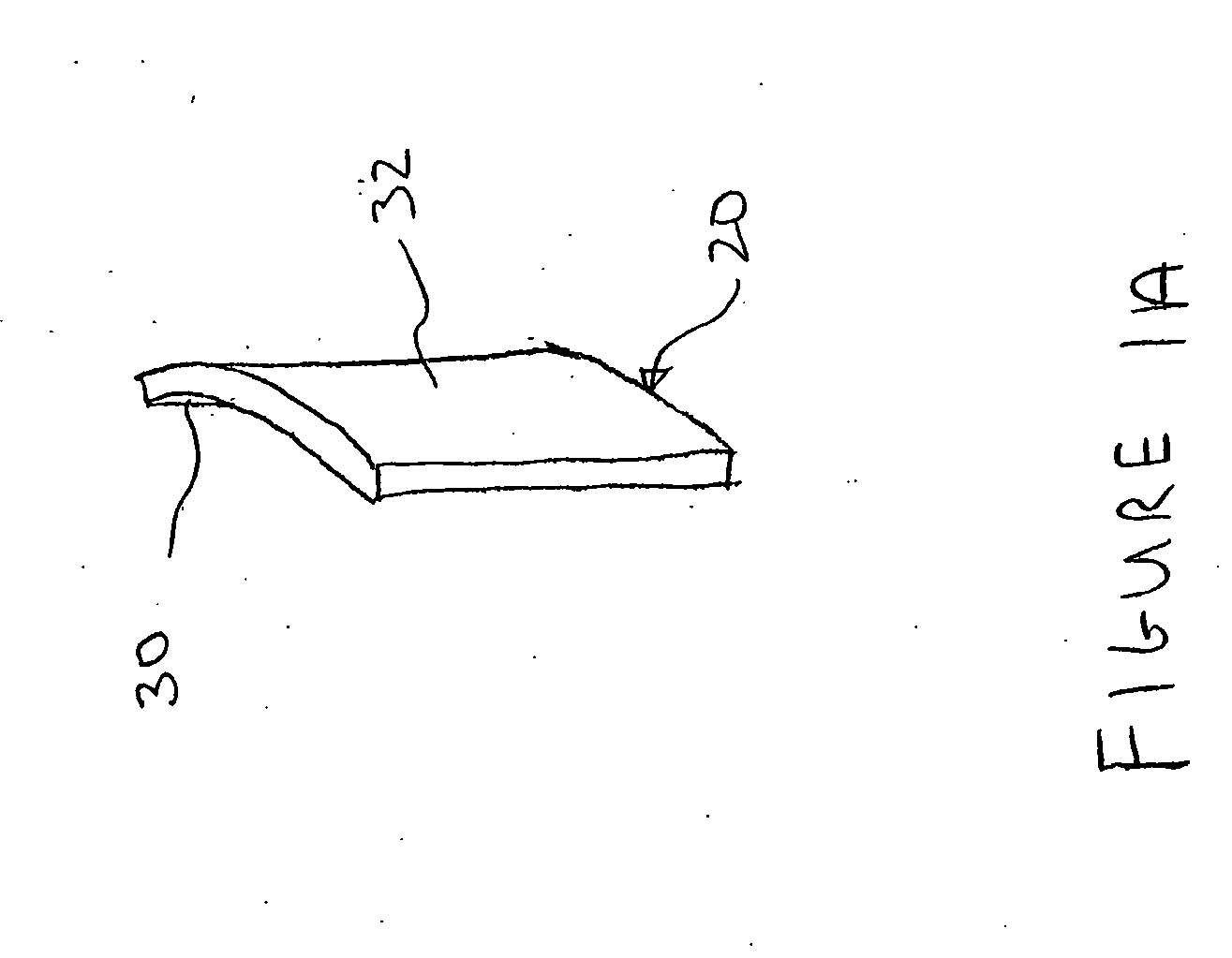

RF device in drinkware to record data/initiate sequence of behavior

InactiveUS20050087255A1Easy and efficient to manufactureDurable and reliable constructionCredit registering devices actuationLiquid fillingEngineeringCommunication device

A drinkware is provided to provide information to a receiver. The drinkware is a RF device coupled to a handheld drinking container. The RF device can receive and send RF signals and communicate with a sensory device. A transmitter can send a signal to the communication device, which then activates sensory device. The RF device can communicate with the transmitter to control a fountain machine.

Owner:WHIRLEY IND

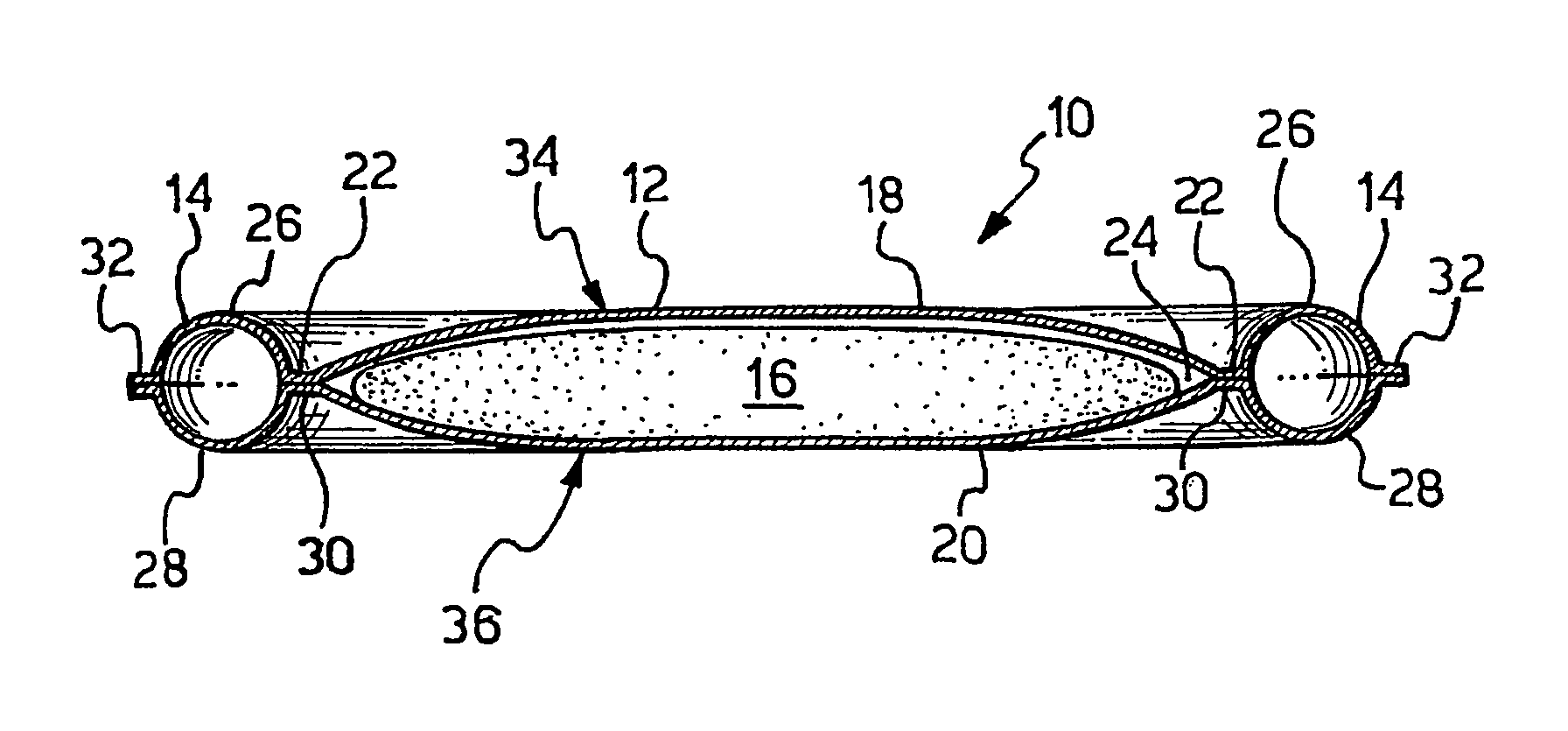

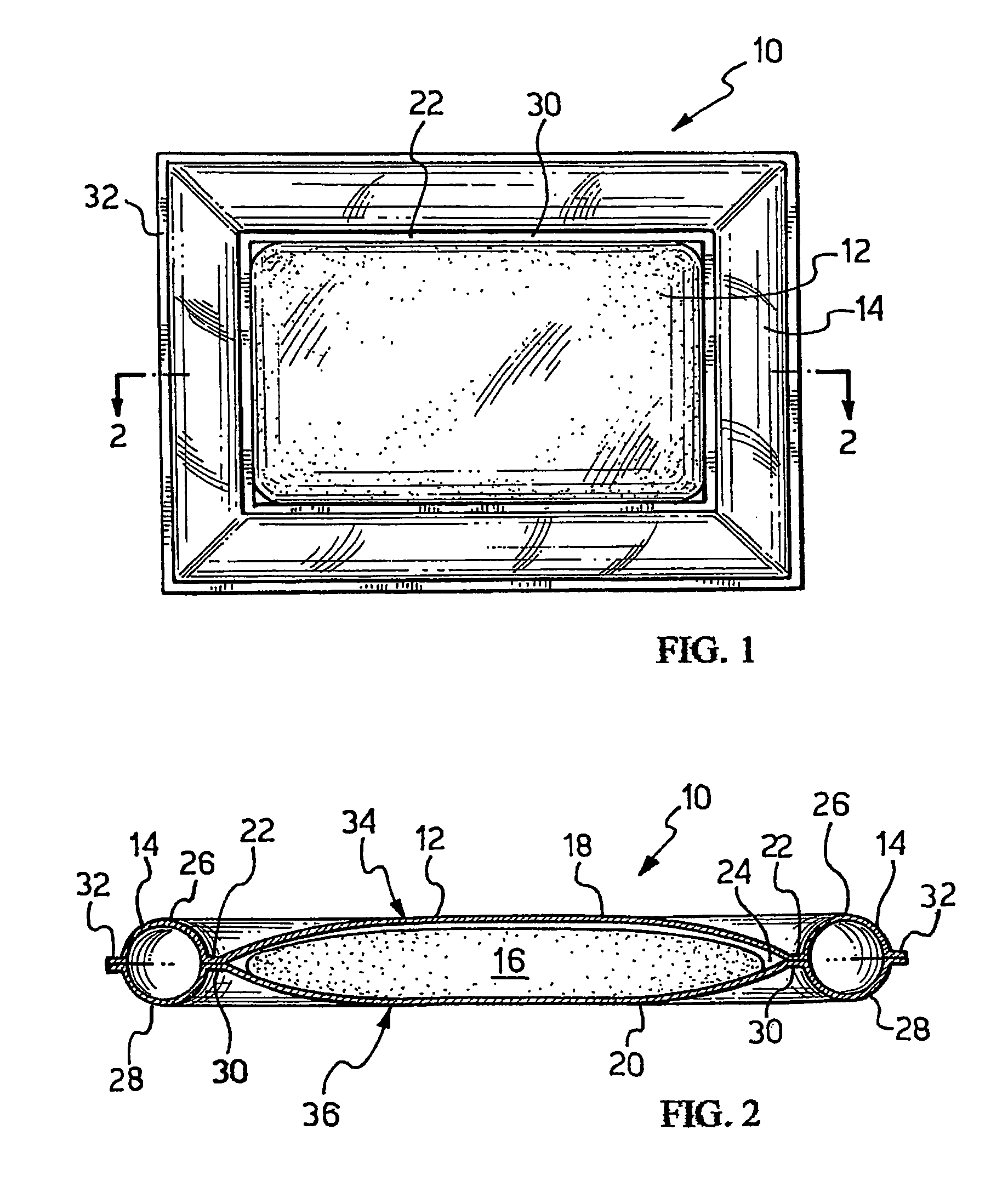

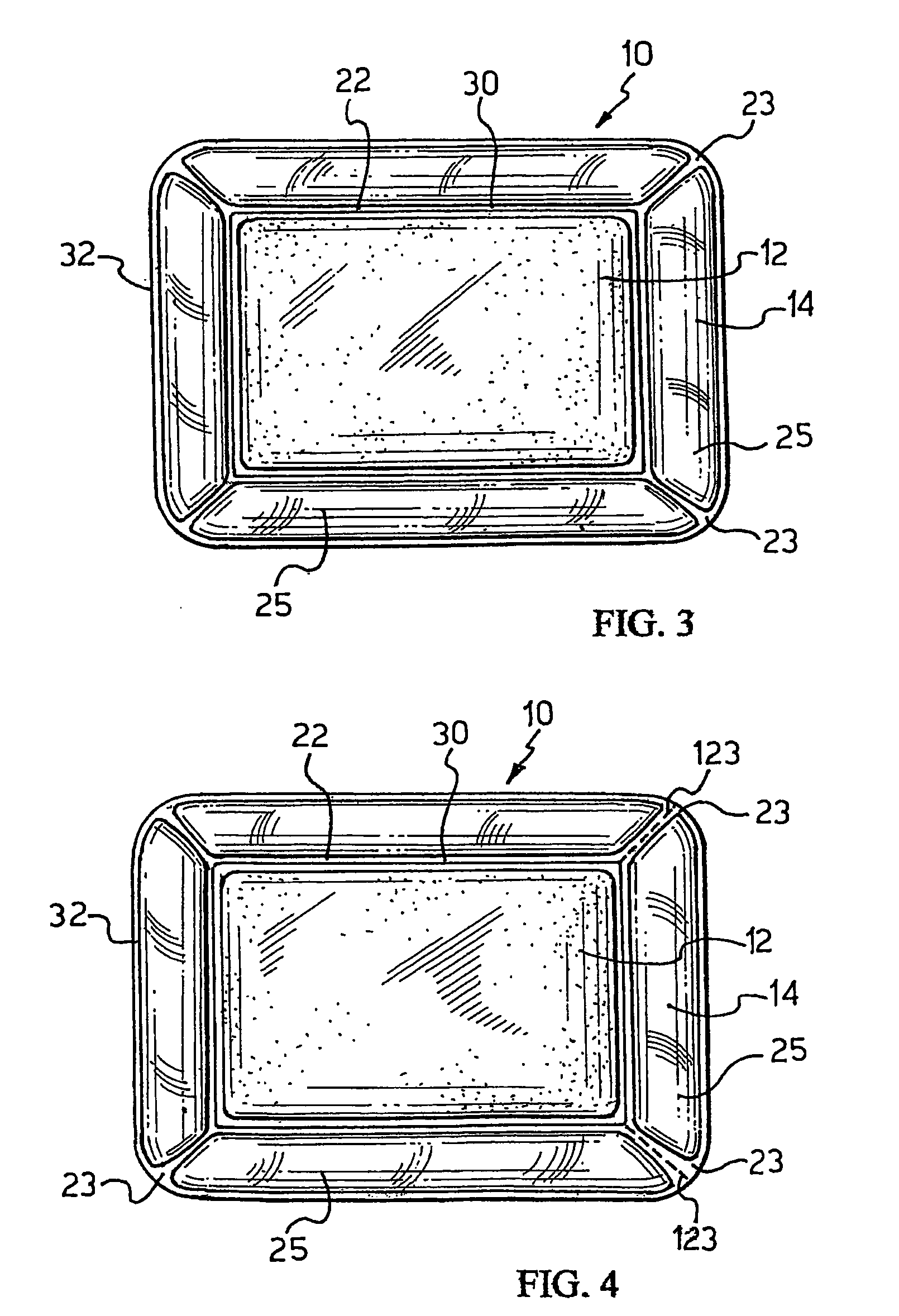

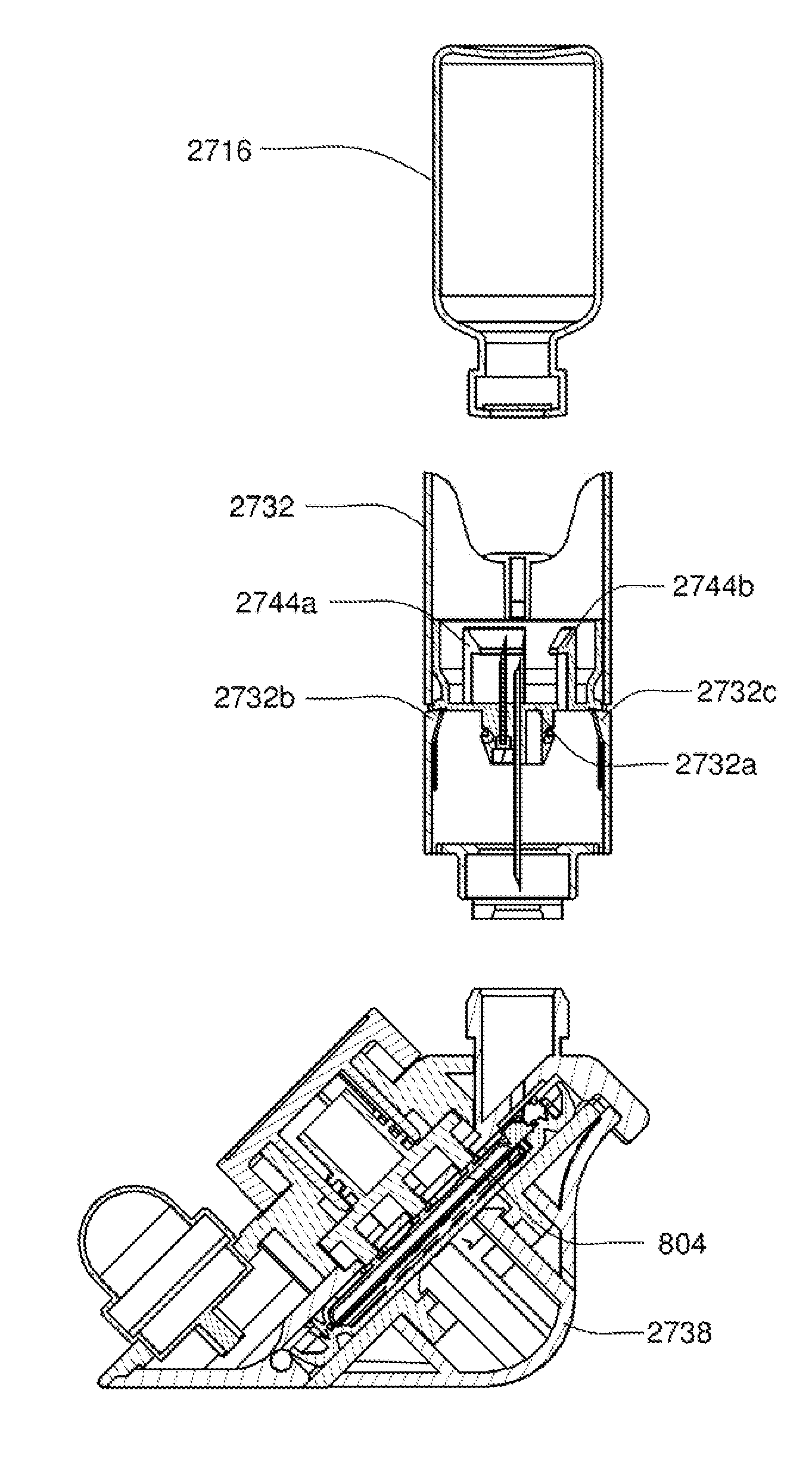

Package having an inflated frame

A package for containing a product such as meat. The package includes top and bottom opposing flexible chamber sheets. These sheets are sealed together in a selected chamber seal zone to define a watertight chamber portion that is capable of containing the product. A hollow frame circumscribes the chamber portion. The frame supports the chamber portion when the frame is inflated. The need for a rigid tray may be eliminated by the inventive package.

Owner:CRYOVAC ILLC

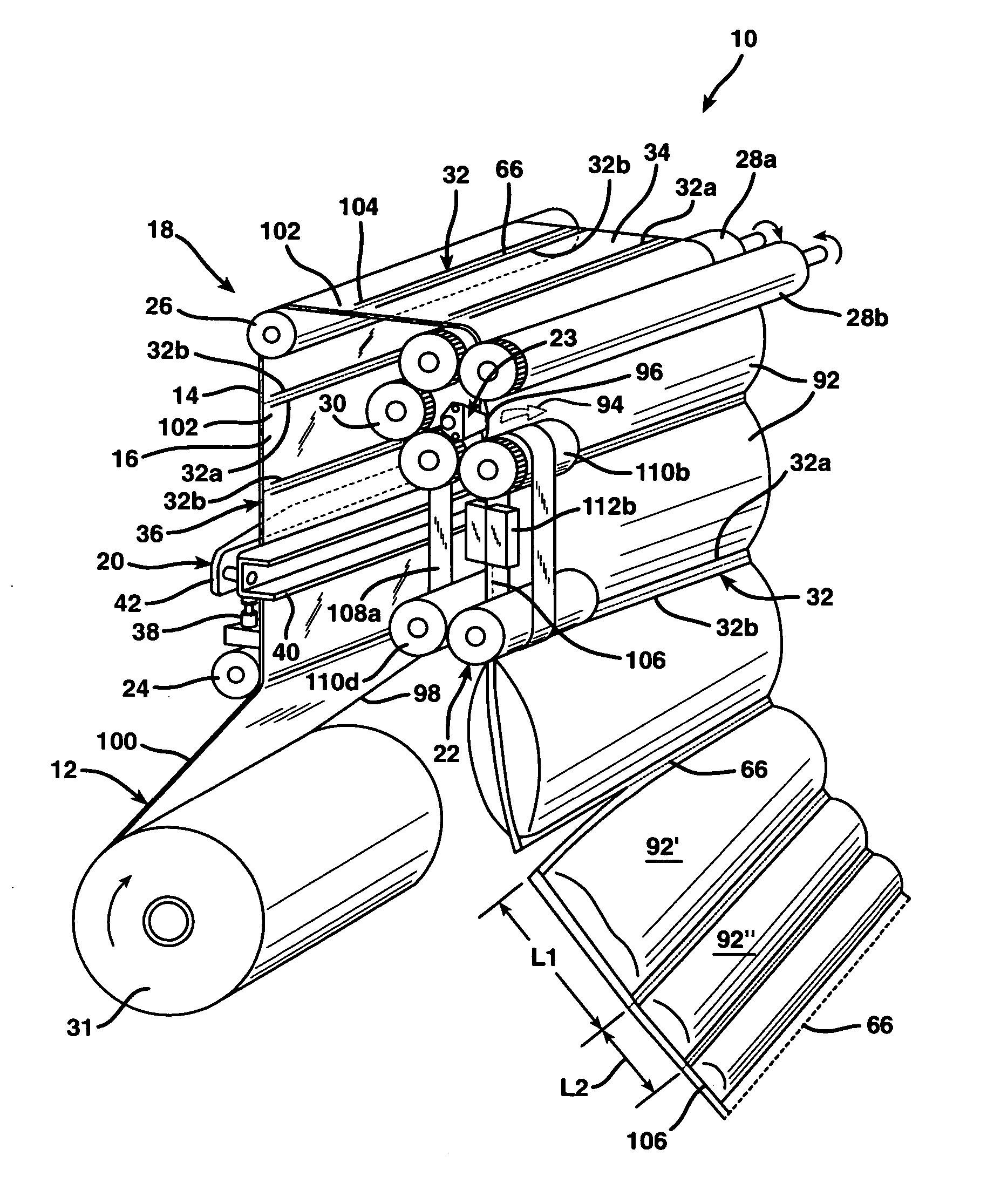

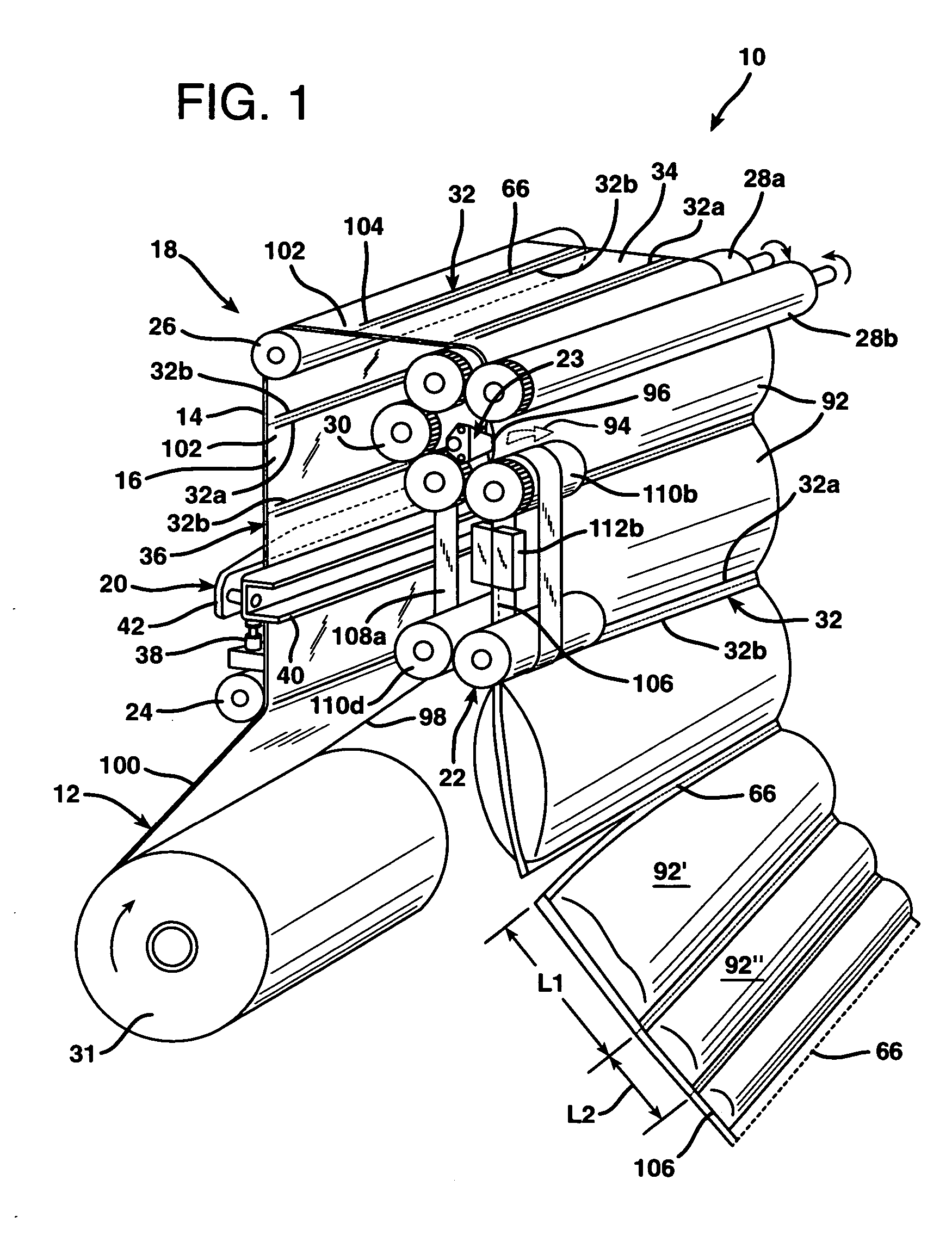

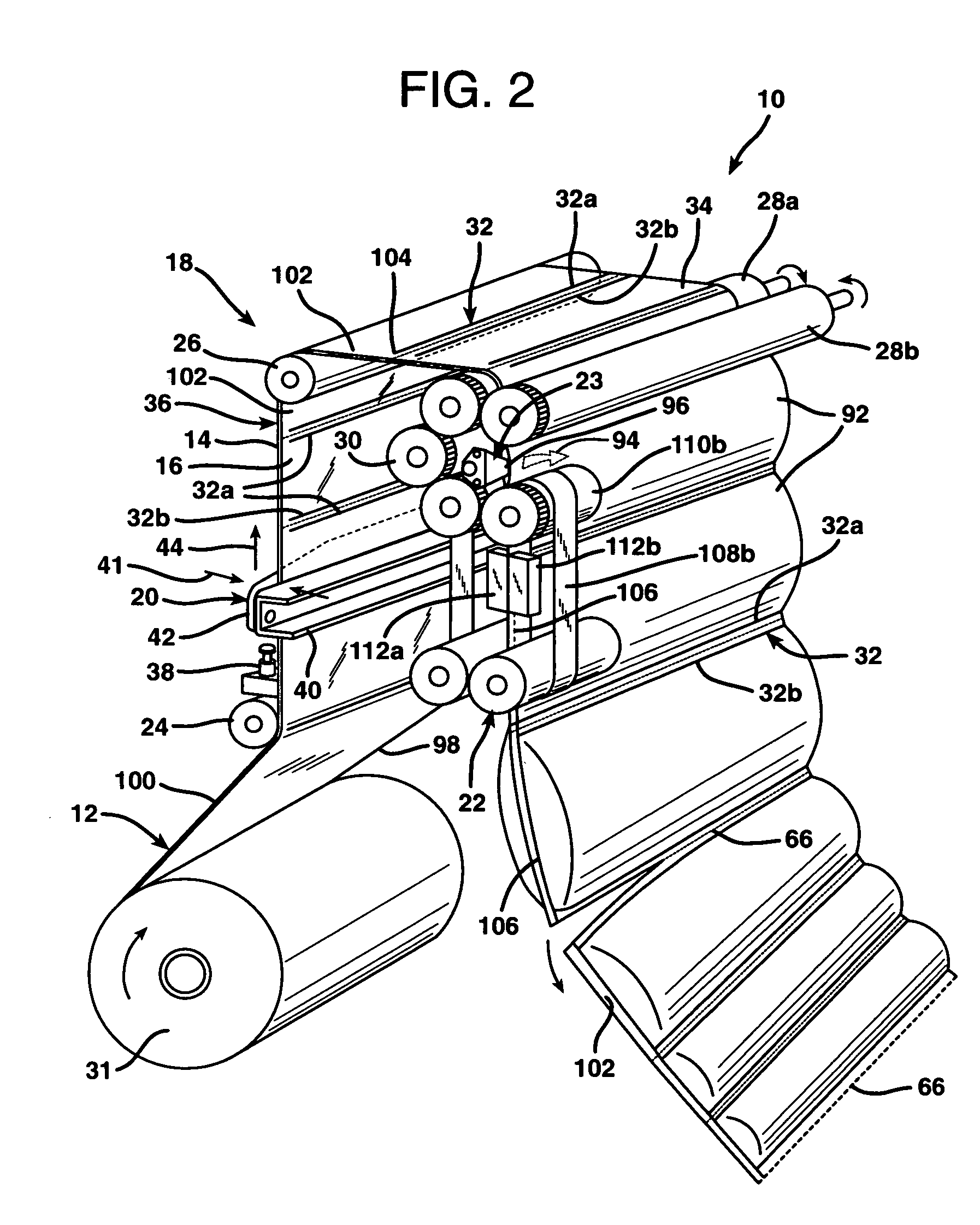

Apparatus and method for forming inflated containers

ActiveUS20060090421A1No sacrifice in production speedImprove sealingCapsPaper/cardboard articlesThin membraneEngineering

An apparatus for forming inflated containers from a film web having two juxtaposed film plies includes: a. a mechanism that conveys the film web along a path of travel; b. a first sealing device for producing one or more seals that bond the film plies together to form a container having at least one opening; c. an inflation assembly for inflating the container by directing a stream of gas into the opening thereof; and d. a second sealing device for sealing closed the opening of the inflated container.

Owner:SEALED AIR U S

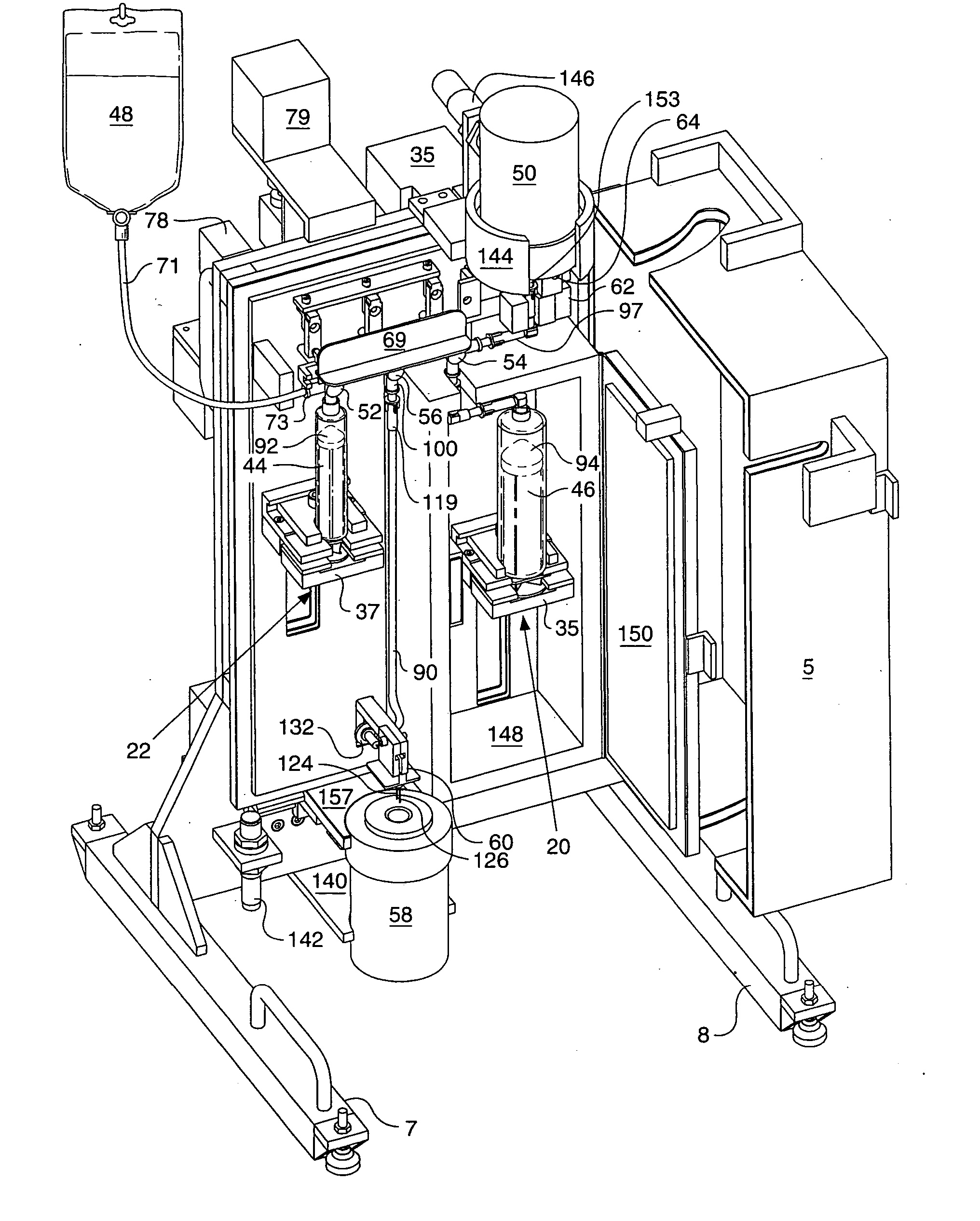

Automated dispensing system and associated method of use

An automated bulk dispensing system and a method of use including selectively receiving a predetermined amount of radioactive liquid from a second container into a third container, selectively receiving a predetermined amount of nonradioactive liquid from a first container into a fourth container or directly into the third container depending on whether kits or multi-dose containers of medicine are desired. Preferably, this is for nuclear pharmaceuticals. Displacement mechanisms that are connected to the third container and fourth container are for mixing and dispensing liquid. There is at least one control valve, preferably three control valves, which are each controlled by drive mechanisms. The mixed liquid from the third container can be transferred to a recipient container. There is also a gas vent and bubble detector to eliminate bubbles with a processor that is also utilized to control the displacement mechanisms and the drive mechanisms.

Owner:MALLINCKRODT INC

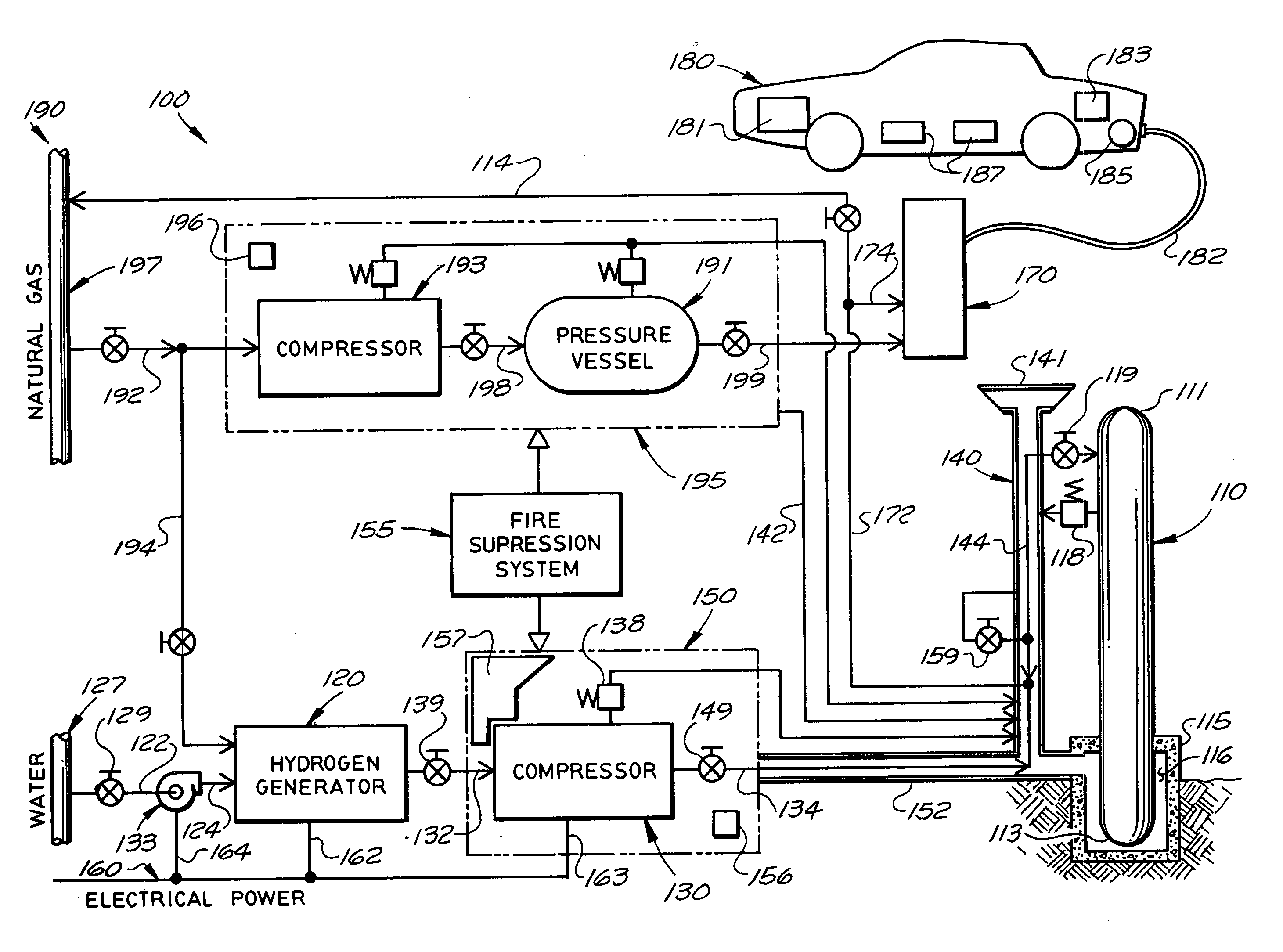

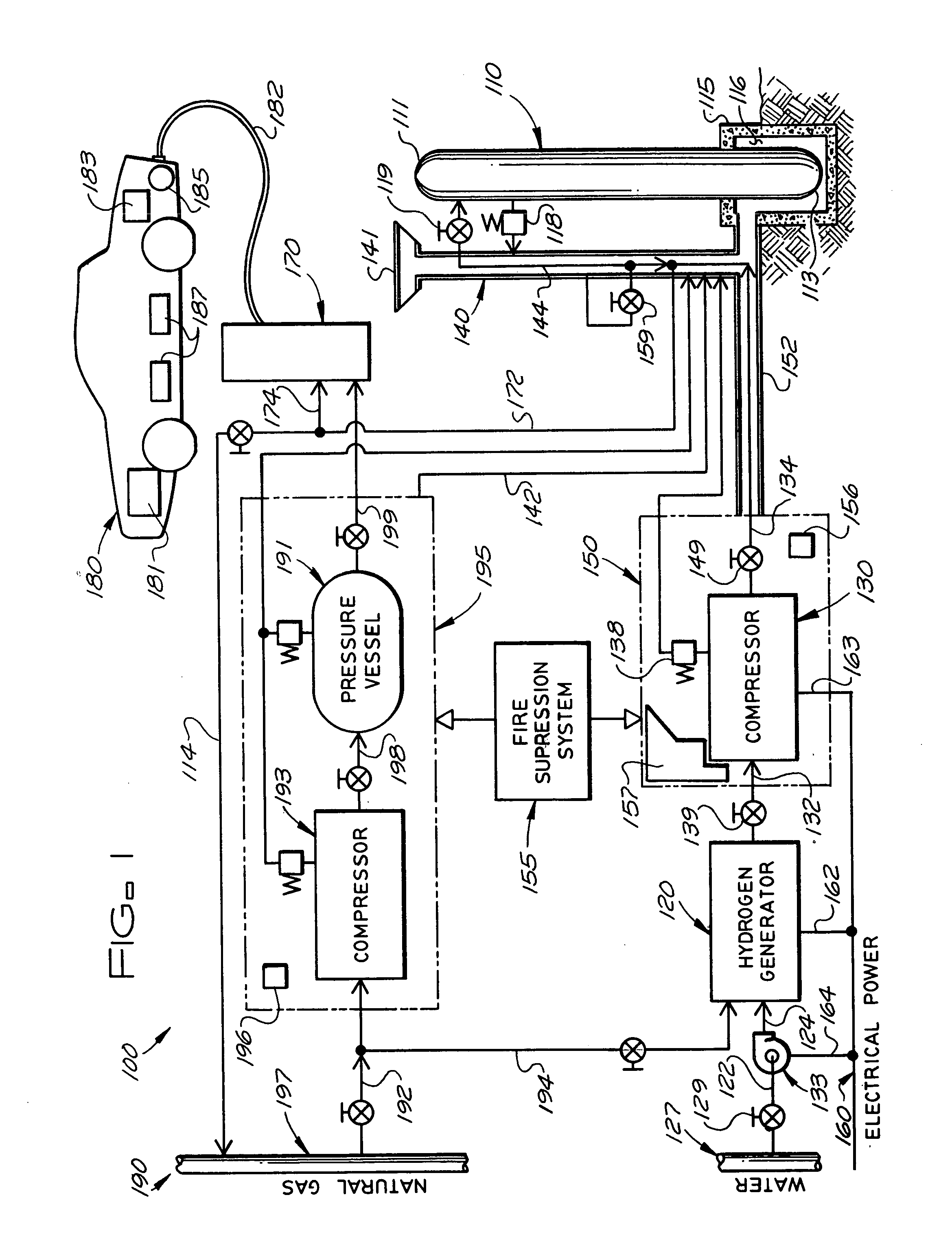

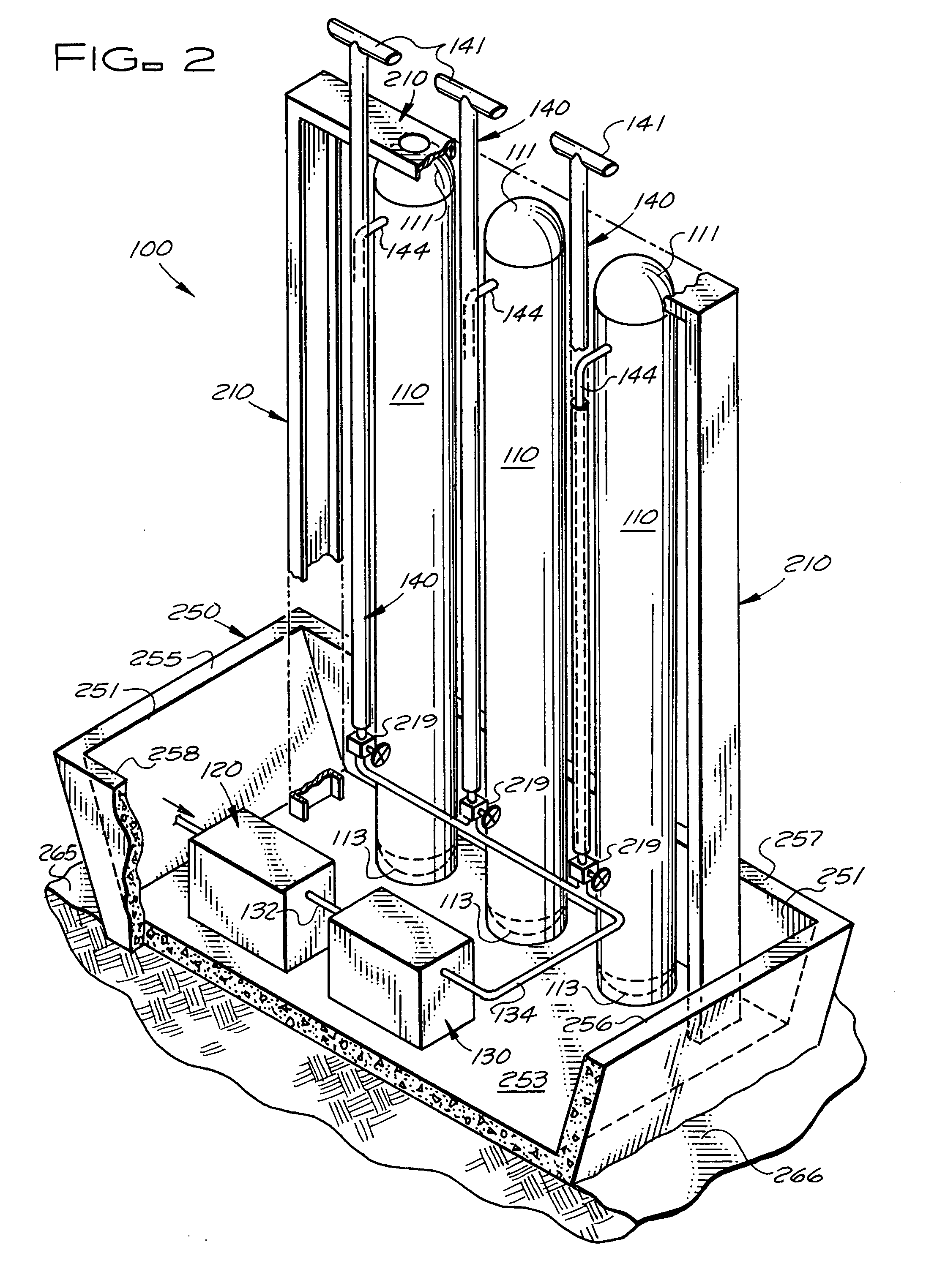

Hydrogen handling or dispensing system

InactiveUS20050000802A1Avoid burnsCheap manufacturingLiquid fillingGas handling applicationsHydrogenHuman life

Systems for handling and / or dispensing hydrogen or a mixture of fuels containing hydrogen gas including refueling stations for hydrogen-powered vehicles. Pure hydrogen or various mixtures ratios of hydrogen and CNG may be dispensed. Hydrogen handling equipment may include a hydrogen generator, a pressurizing apparatus or compressor, pressure vessels, piping, valves, vent pipes, and / or a dispenser. Substantially vertical orientation of pressure vessels may reduce the amount of land required and facilitate installation in urban environments. Pressurization may take place before hydrogen generation to reduce the power required for pressurization. Safety features include enclosures and surrounding walls that lean away from the equipment. Any leaking hydrogen, fires, or explosions may be contained and / or directed upward, protecting human life and property. Systems may be shop assembled and certified.

Owner:ARIZONA PUBLIC SERVICE

Method of filling and sealing an aerosol dispenser

A method of pressurizing a container usable for an aerosol dispenser. The method comprises providing a pressurizeable outer container and complementary valve cup, at least one having a channel into the container. A manifold is brought into sealing relationship with the channel of the container. Propellant is supplied from the manifold, goes through the channel and into the container. While the manifold is still sealed to the container, the channel is sealed shut to maintain the pressure. Sealing may be accomplished by sonic or ultrasonic welding.

Owner:PROCTER & GAMBLE CO

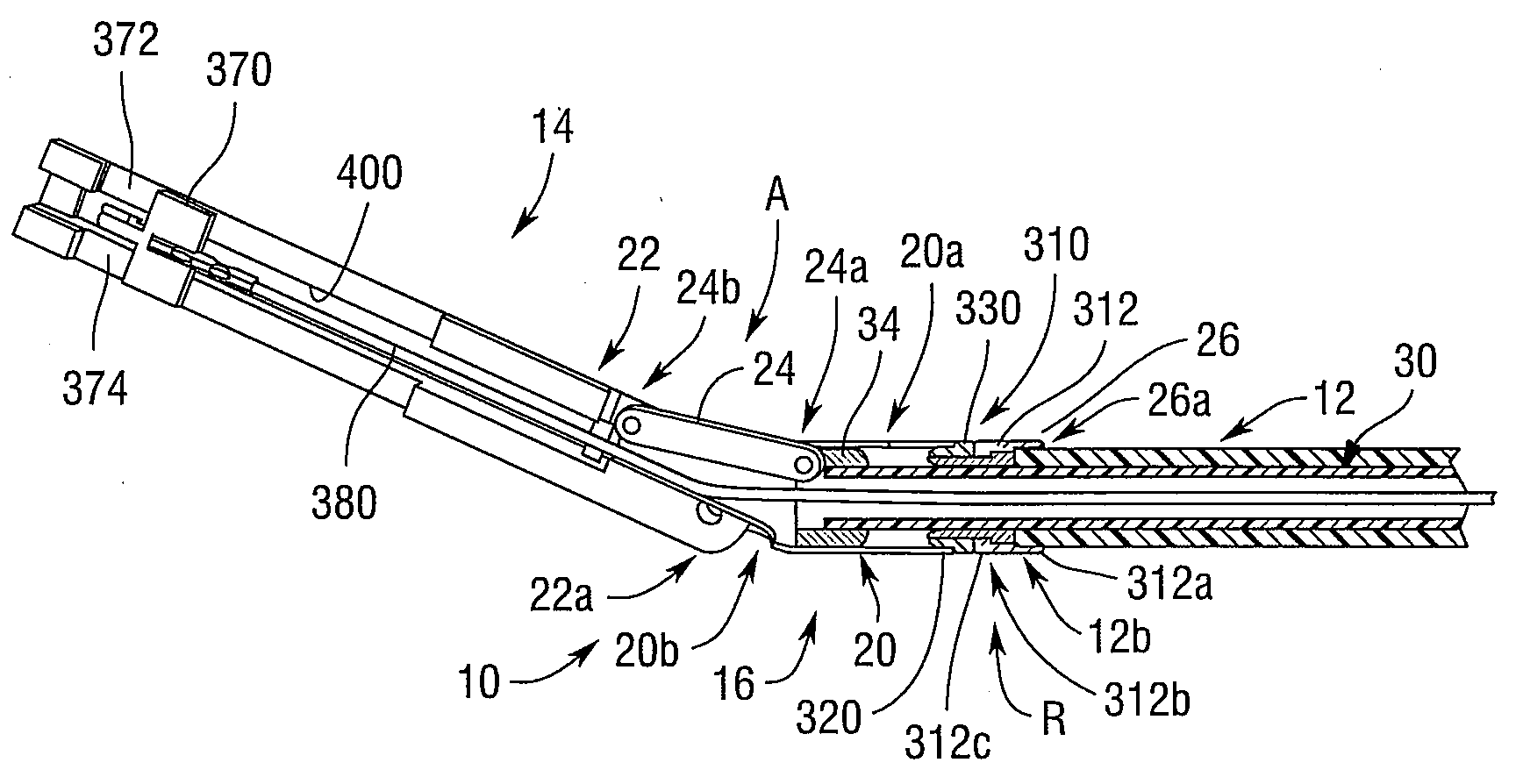

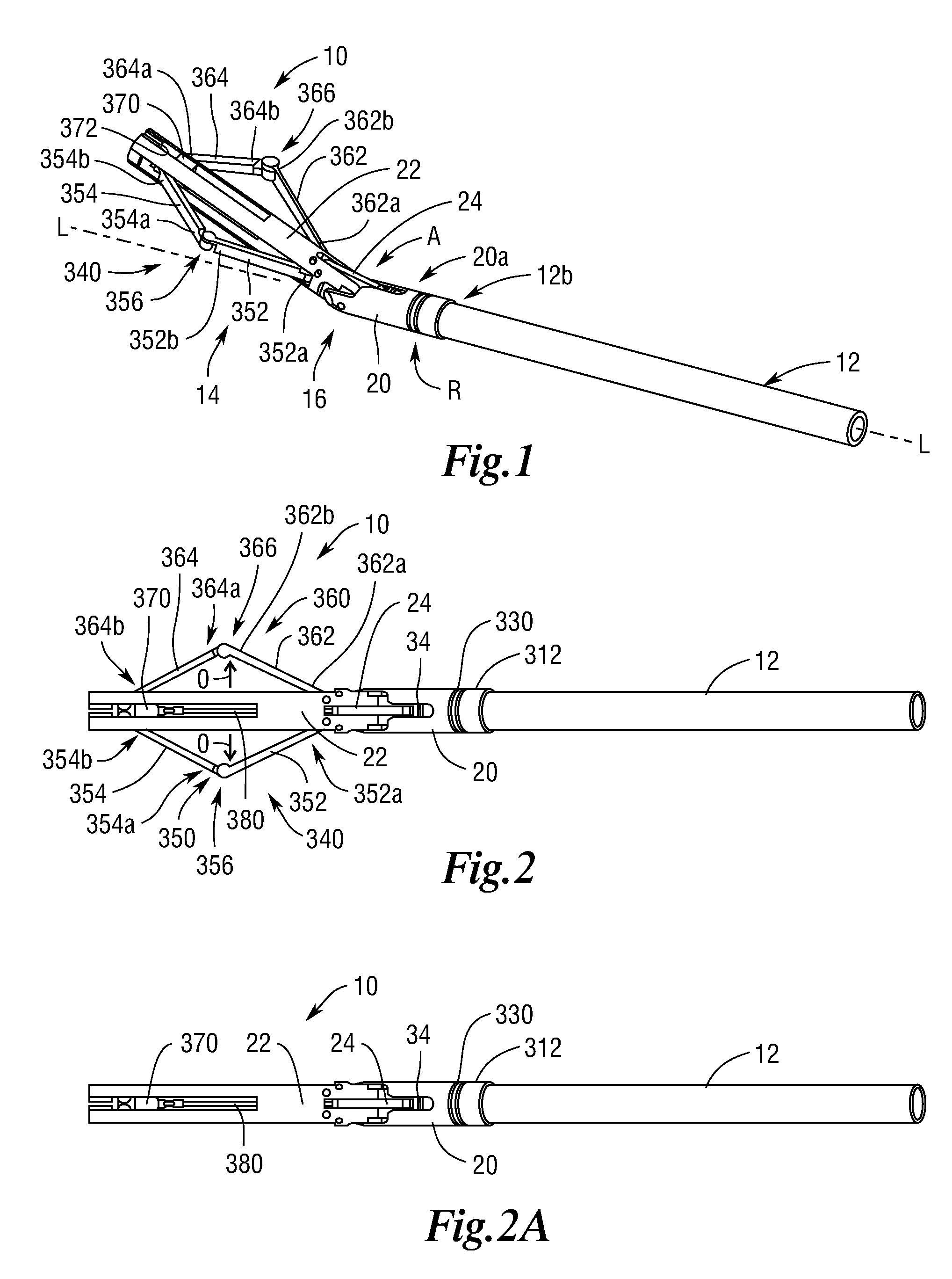

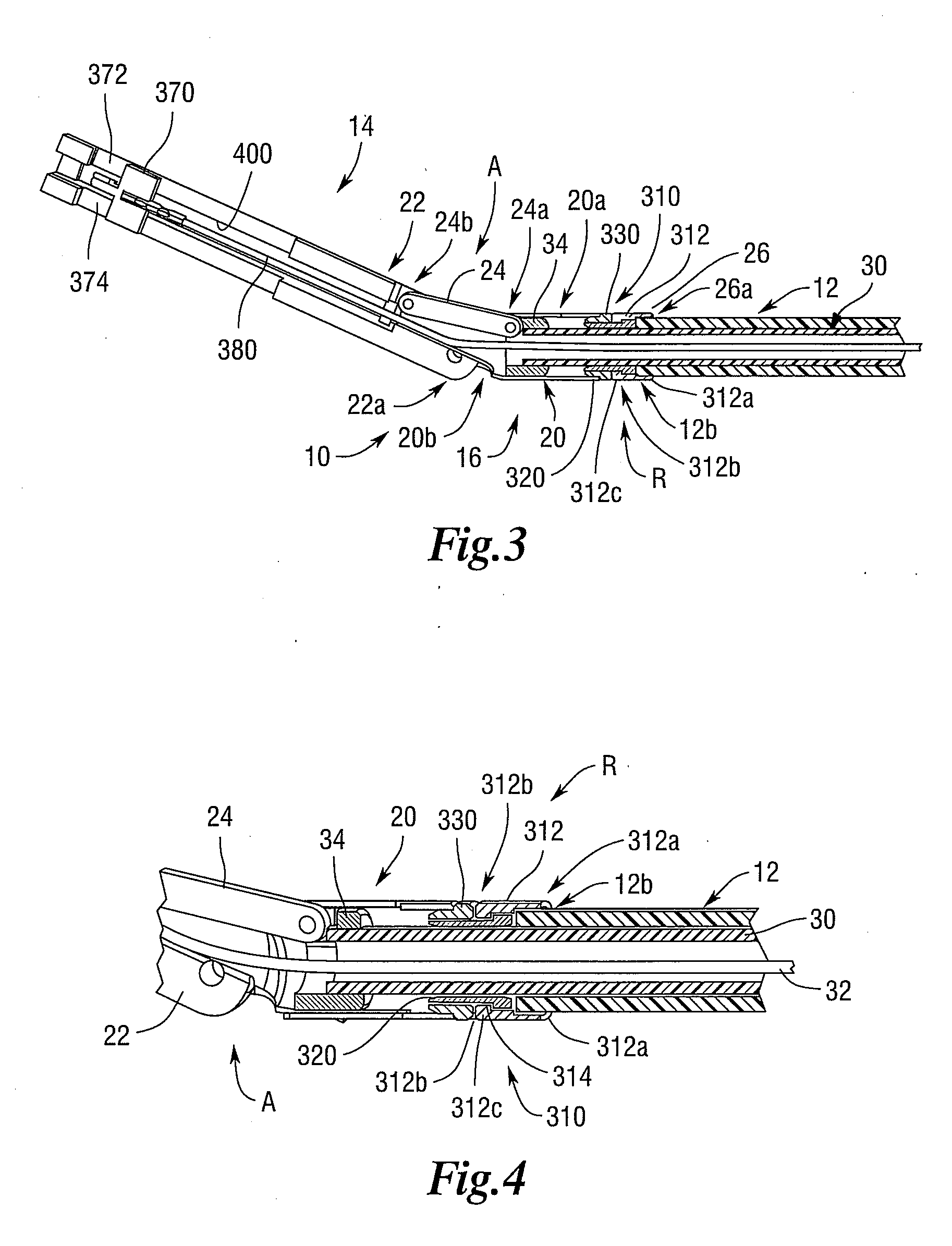

Tissue manipulation devices

Devices are provided for manipulating tissue during a surgical procedure. In certain embodiments, an end effector is operably coupled to the end of an elongate shaft. The end effector has at least one tissue support linkage movably coupled thereto such that upon application of a first actuation force thereto, the tissue support linkage moves laterally outward from within the end effector to enable the surgeon to manipulate / support adjacent tissue therewith. Upon application of another actuation force to the tissue support linkage, the tissue support linkage is caused to move substantially completely within the outer perimeter of the end effector to enable the end effector to be inserted through a lumen / opening or passageway. In various embodiments, the end effector may be selectively articulateable relative to the elongate shaft.

Owner:ETHICON ENDO SURGERY INC

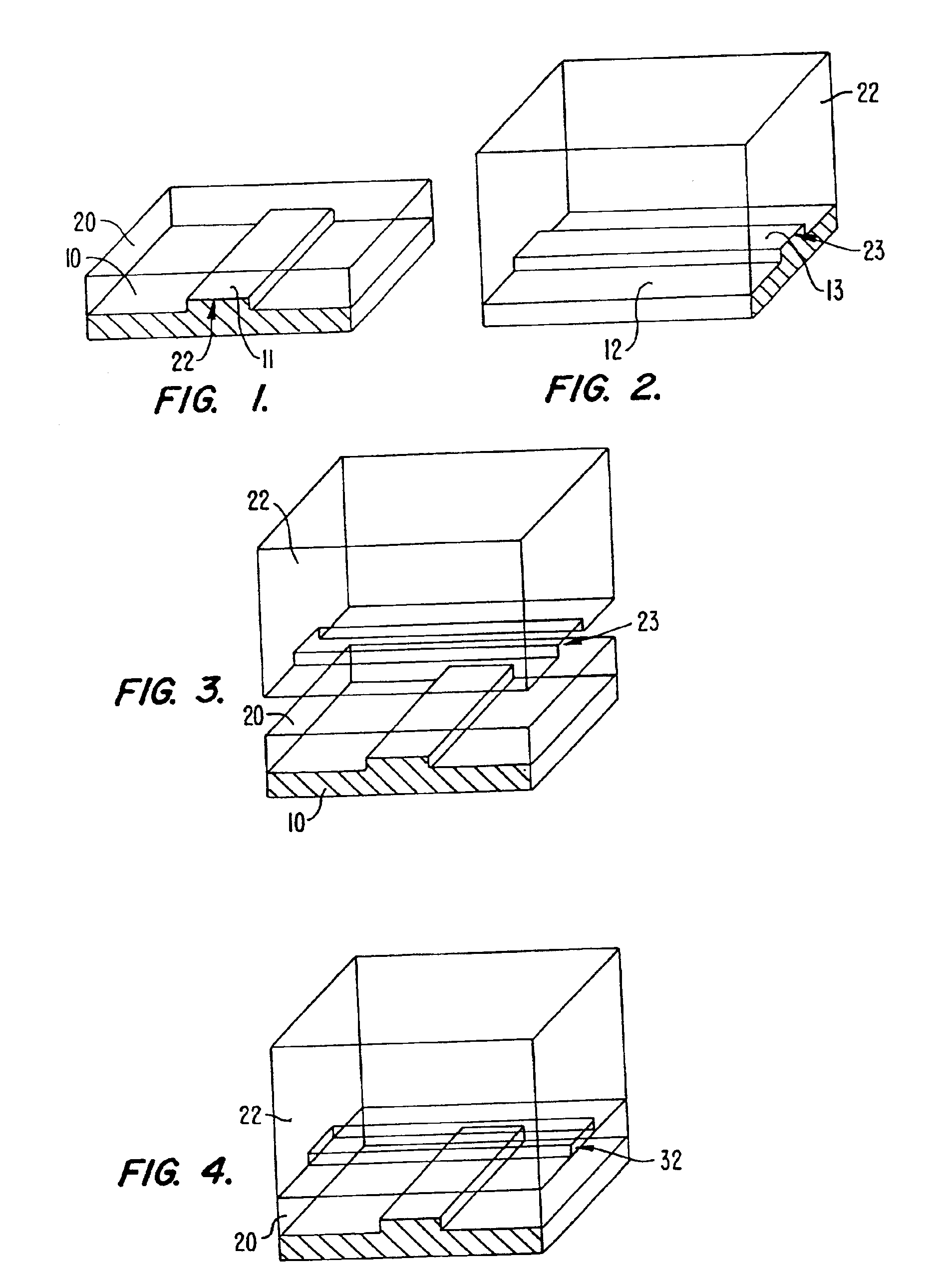

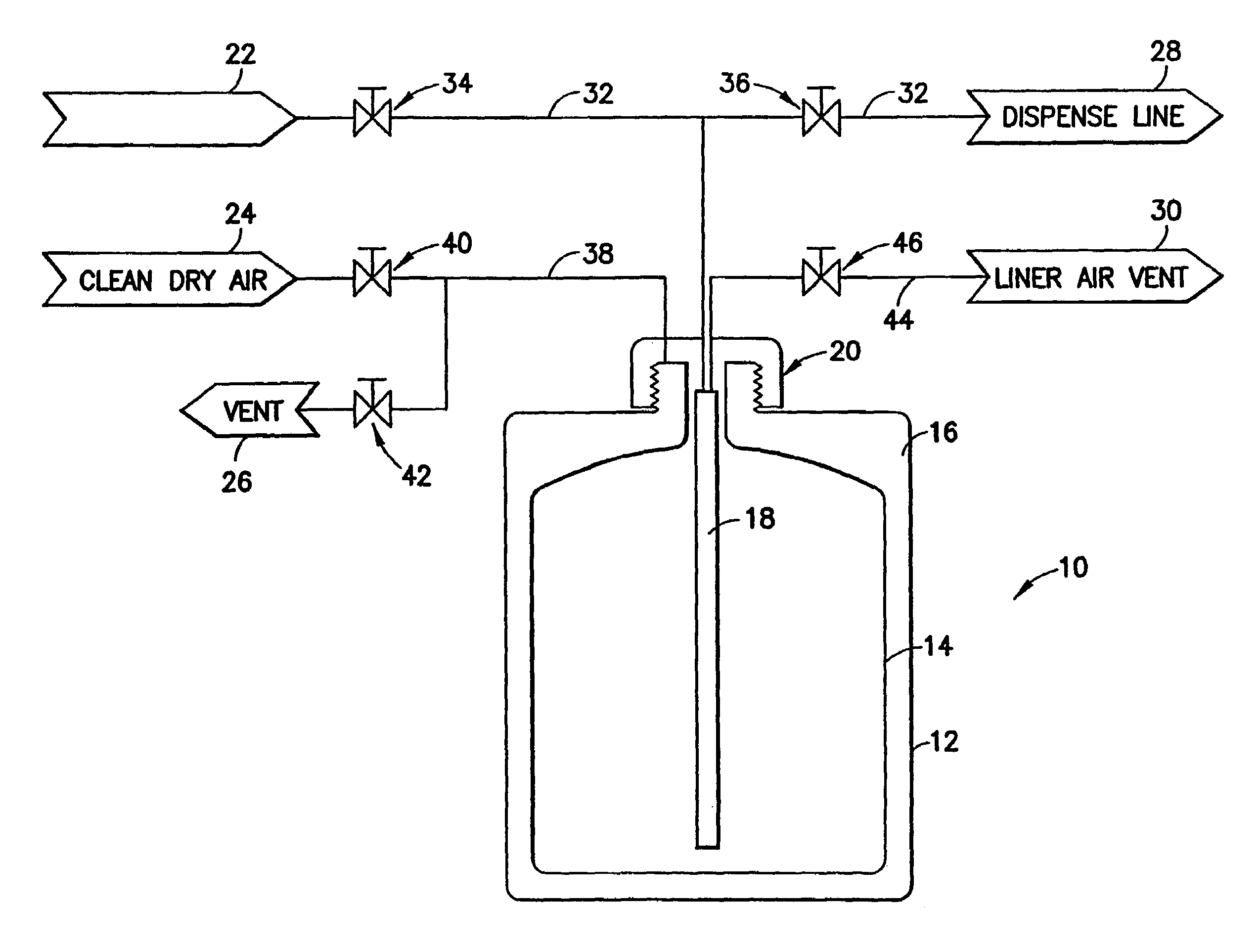

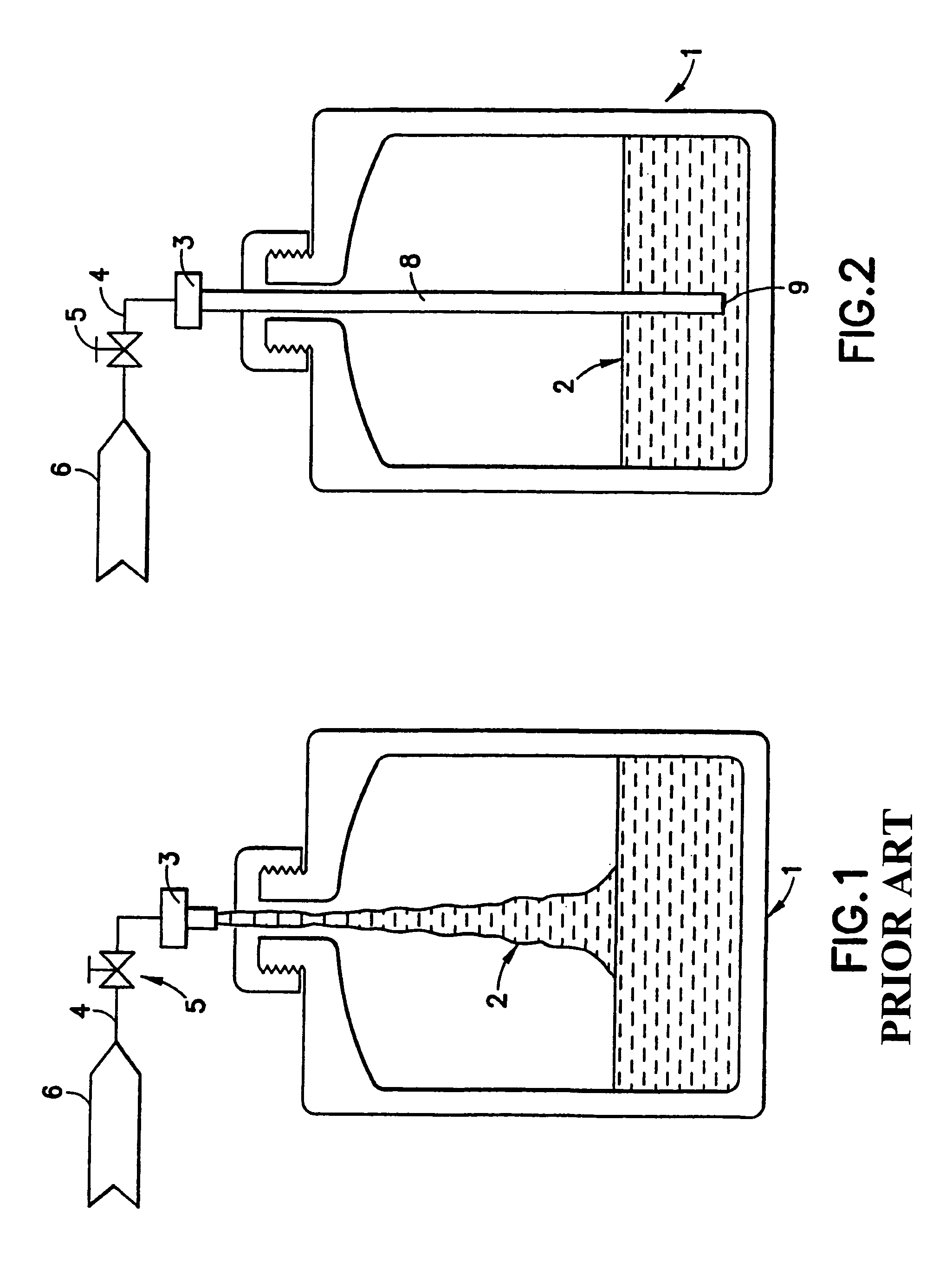

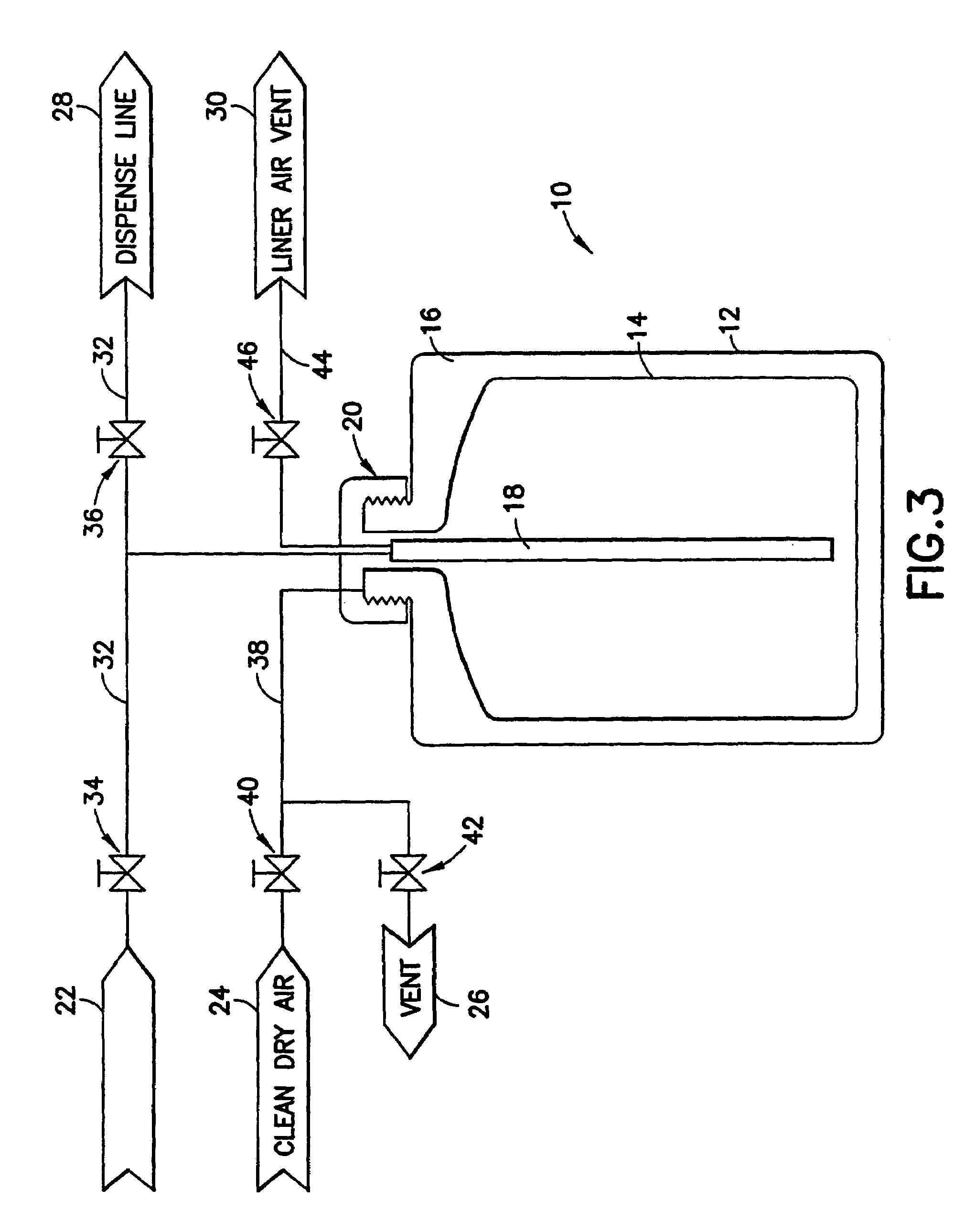

Apparatus and method for minimizing the generation of particles in ultrapure liquids

ActiveUS7188644B2Reduce Particle GenerationLess particle generationSpraying apparatusLiquid transferring devicesAir liquid interfaceEngineering

A system and method of reducing particle generation in packaging containers used to transport ultra pure liquids. Particle generation in the containers is reduced by reducing the air-liquid interface present during filling, transport, and dispensing of the liquid.

Owner:ADVANCED TECH MATERIALS INC

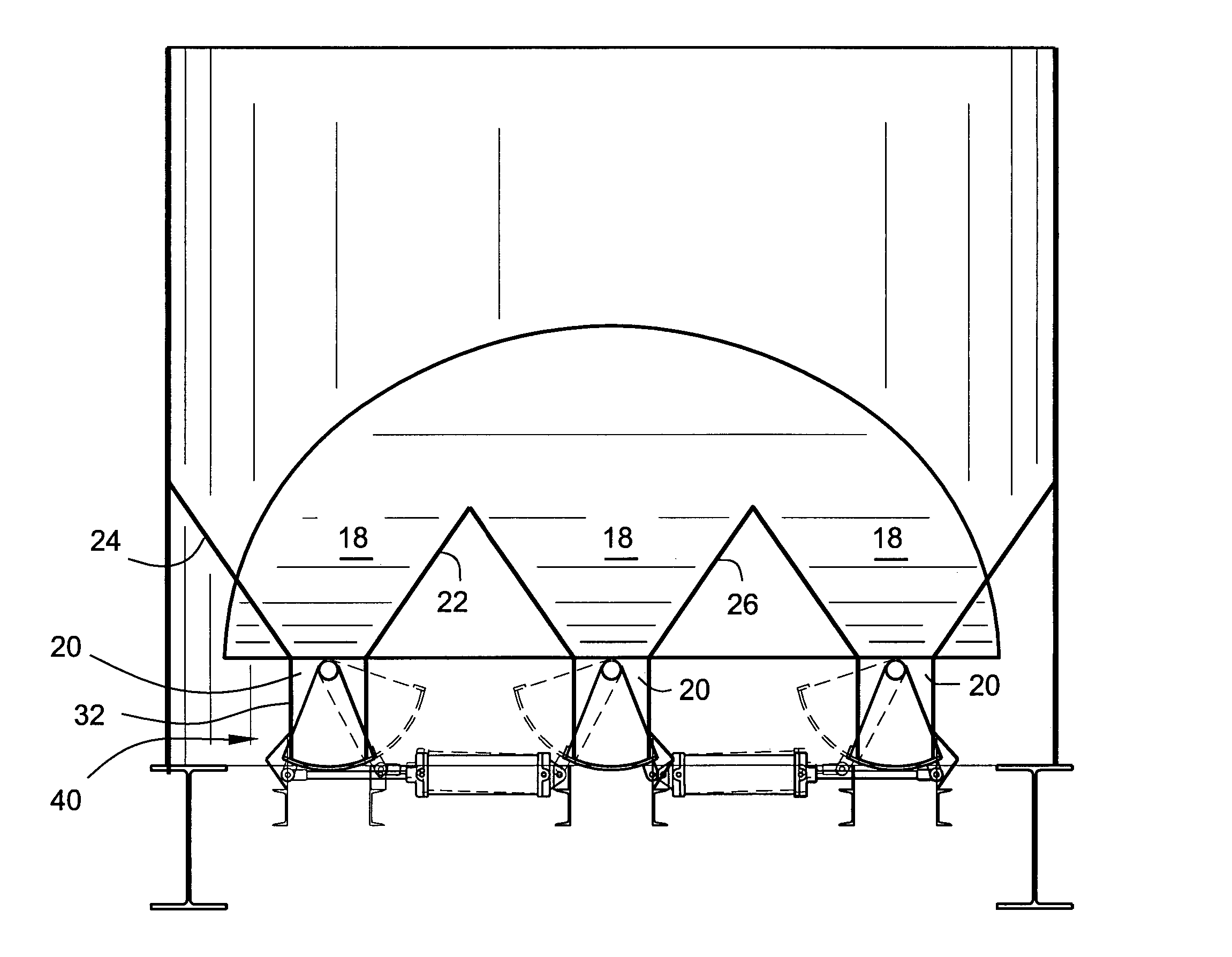

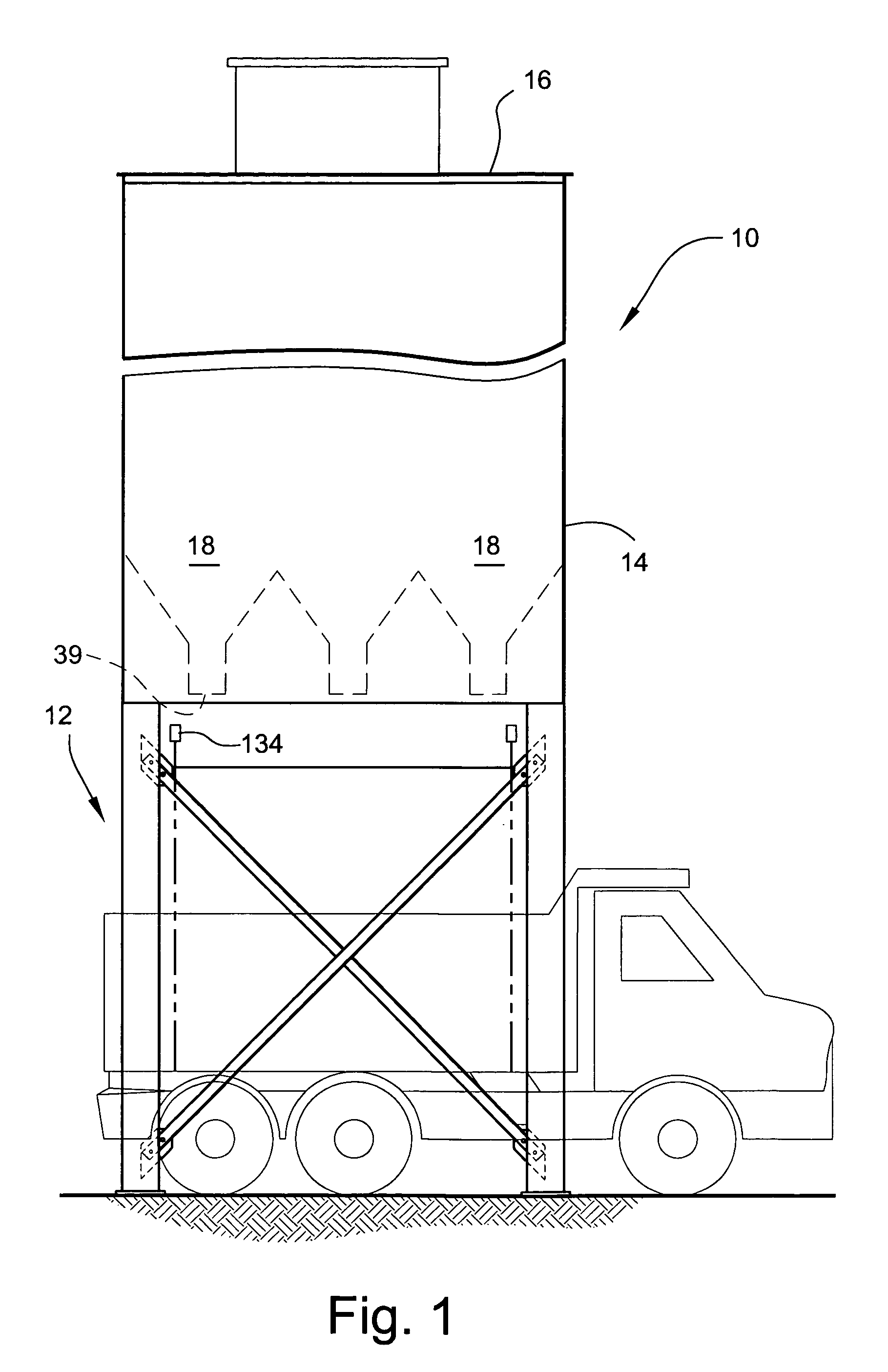

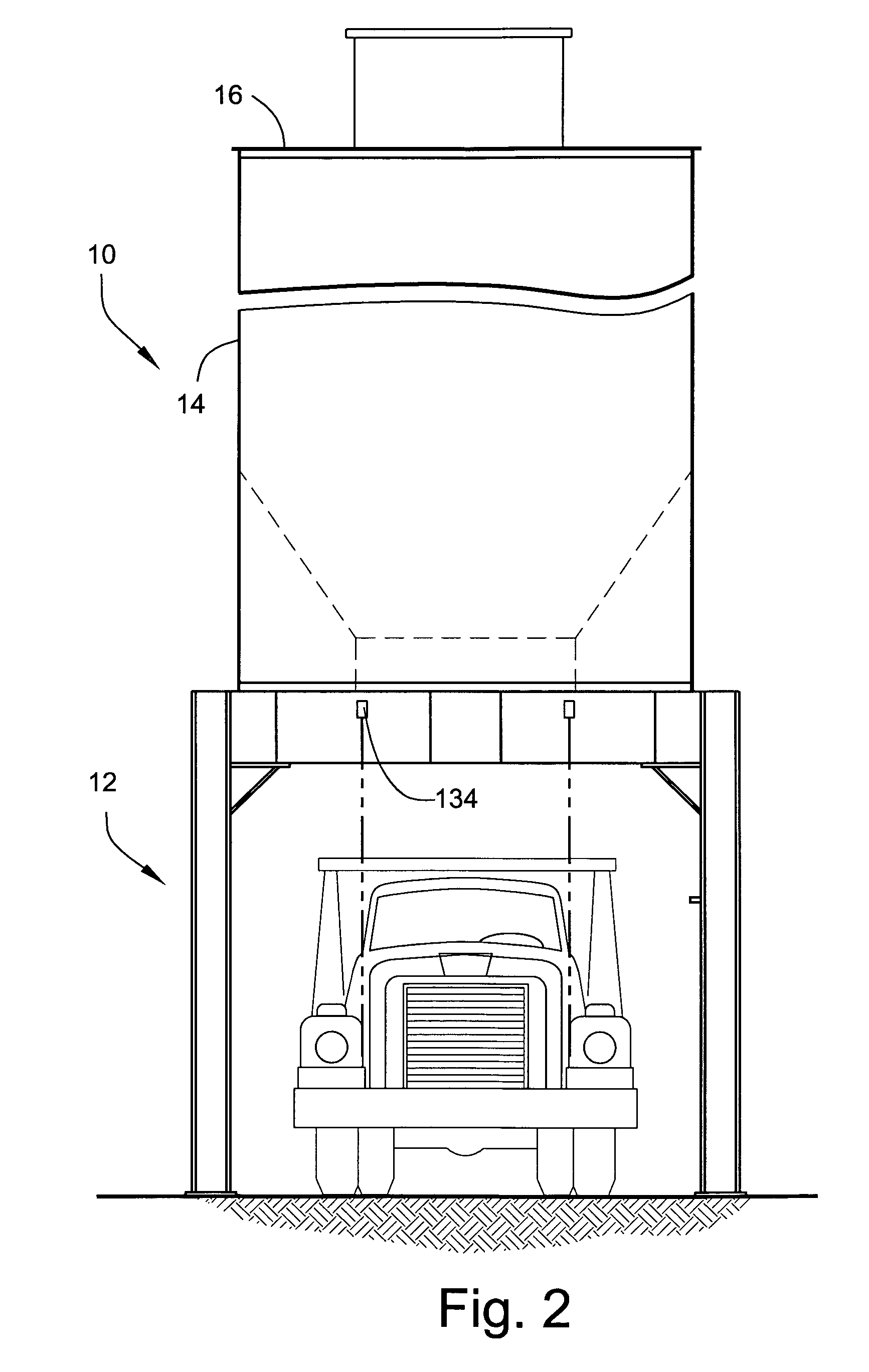

Apparatus and methods for discharging particulate material from storage silos

The silo includes at least three hoppers terminating in rectilinear discharge openings extending lengthwise transversely of a loading area below the discharge openings. Clam gates are movable between open and closed positions to discharge material. The discharge area at the bottom of the silo is increased, facilitating faster loading of trucks with the particulate material.

Owner:GENCOR IND INC

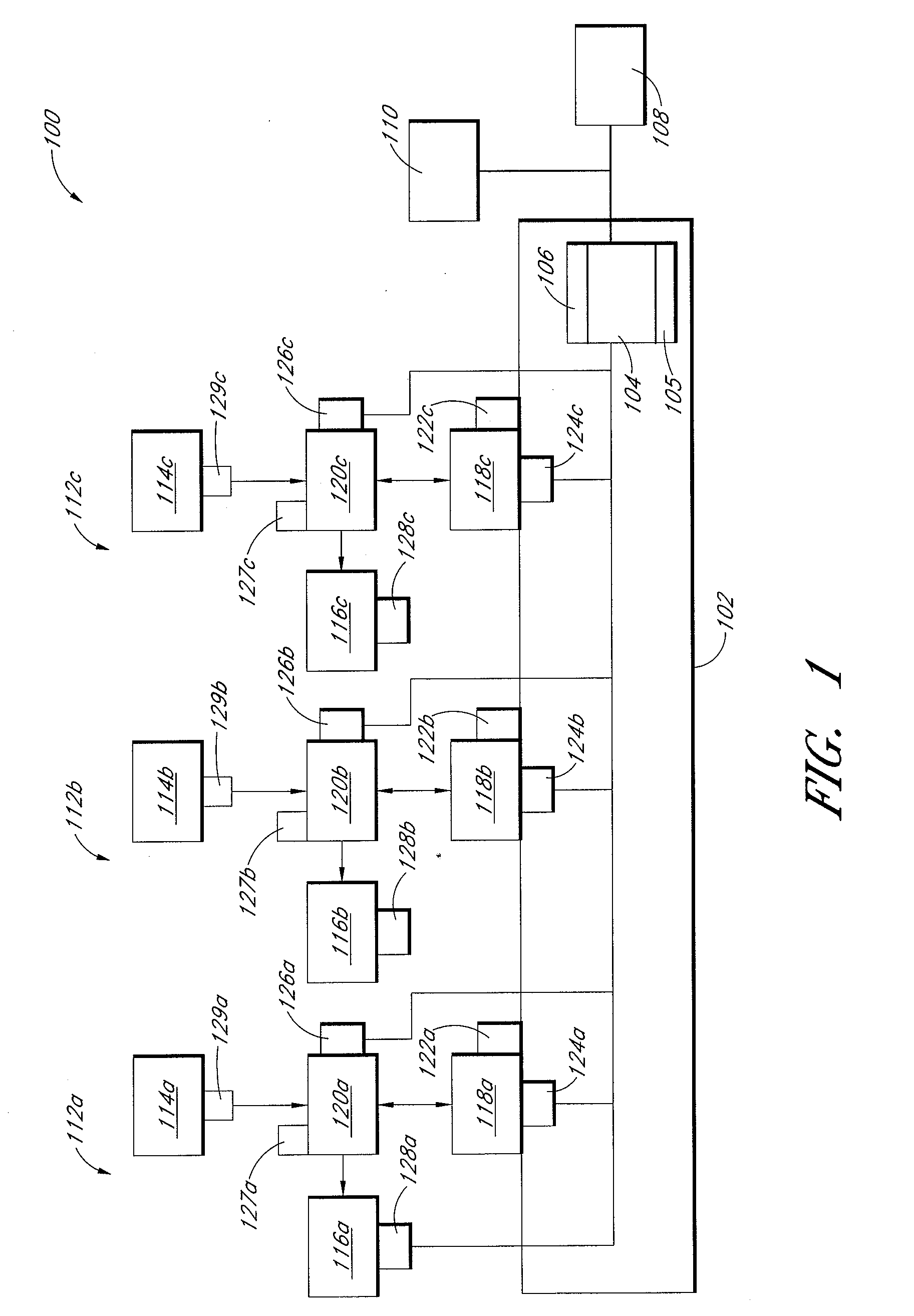

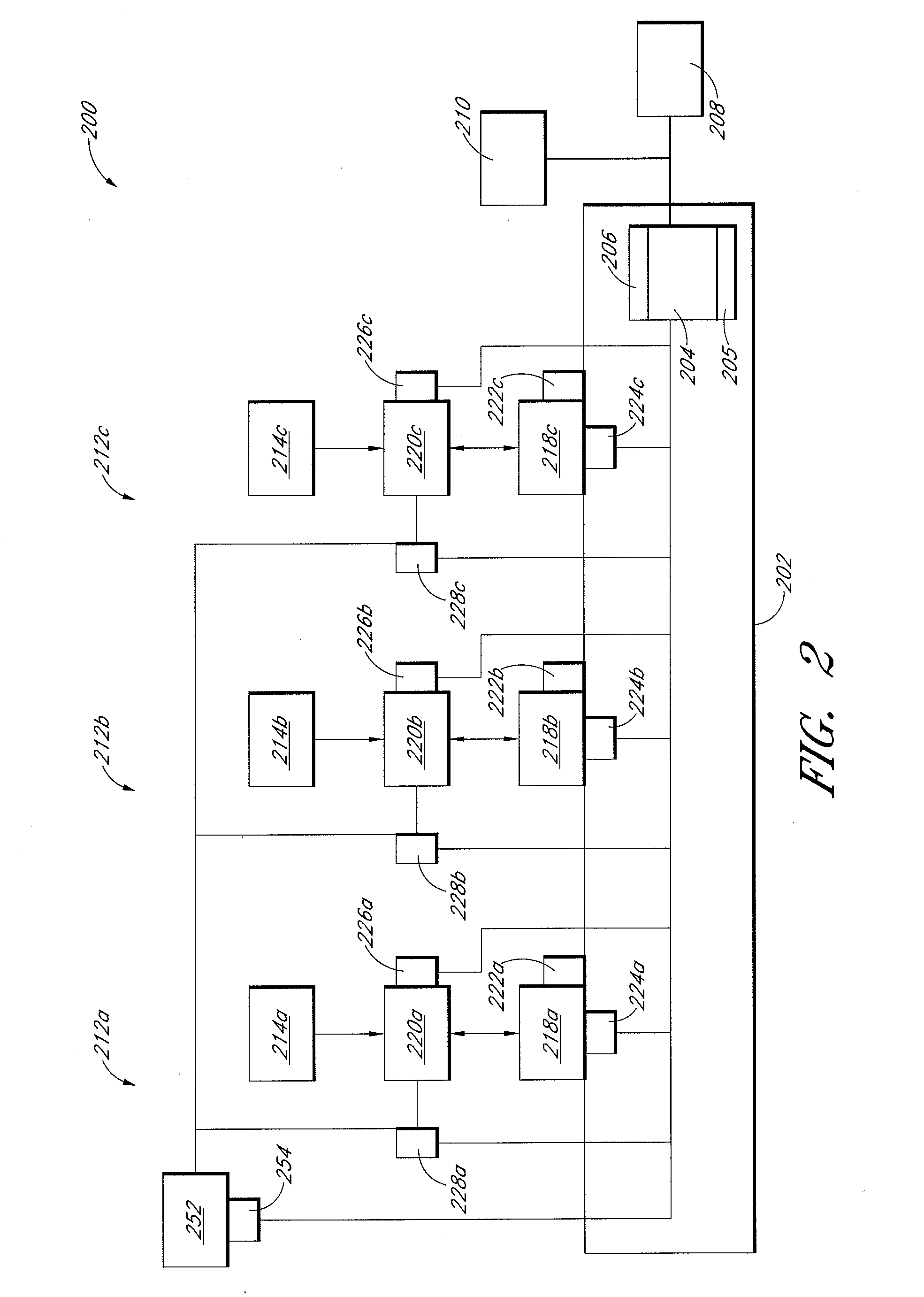

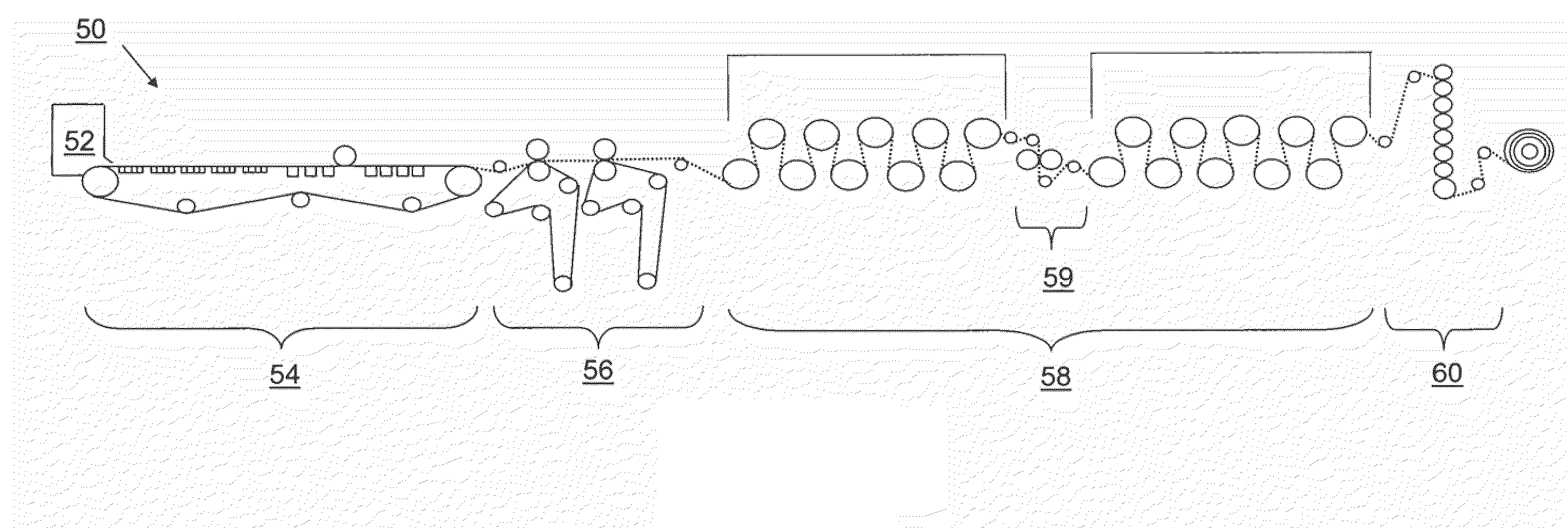

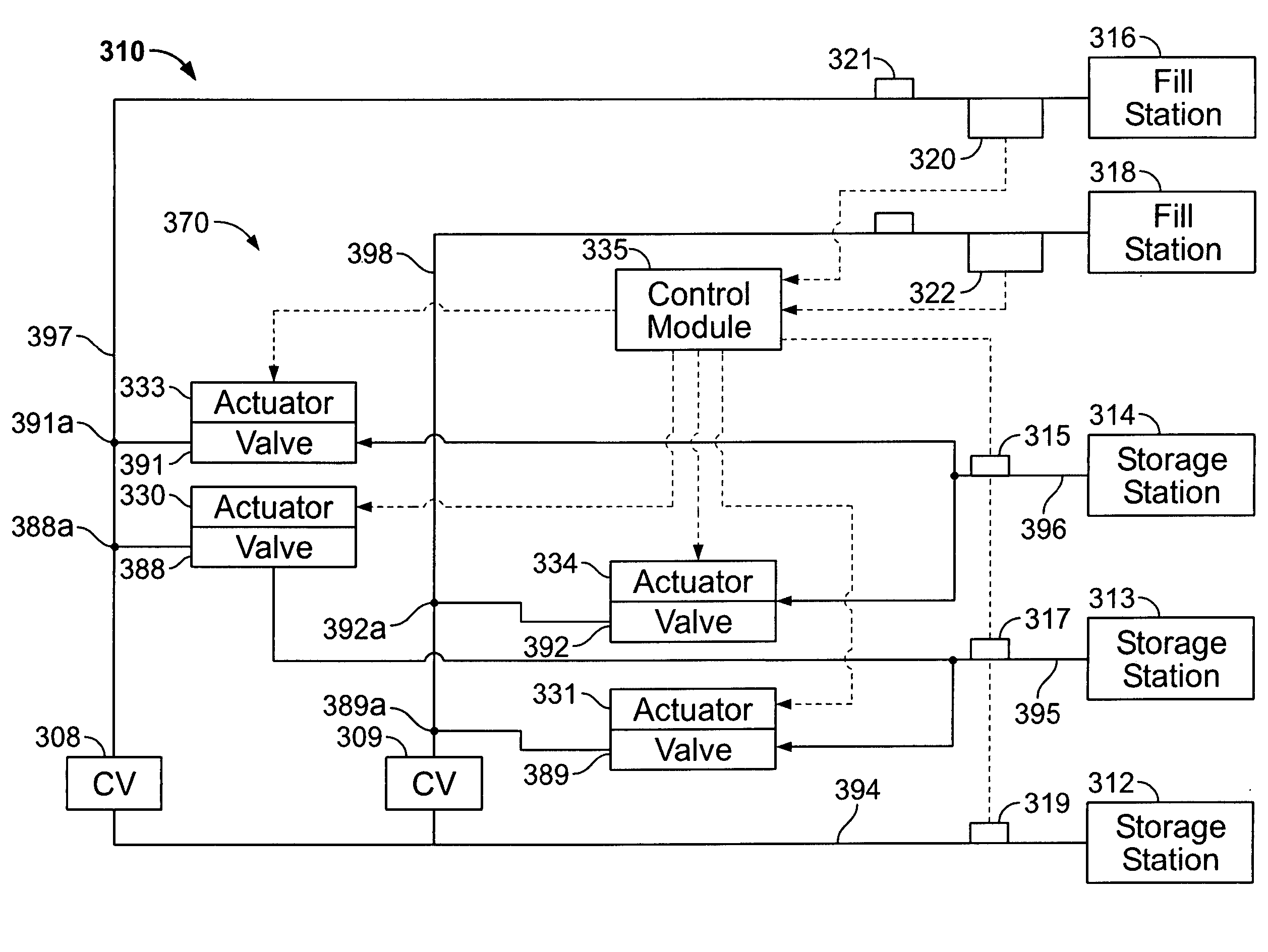

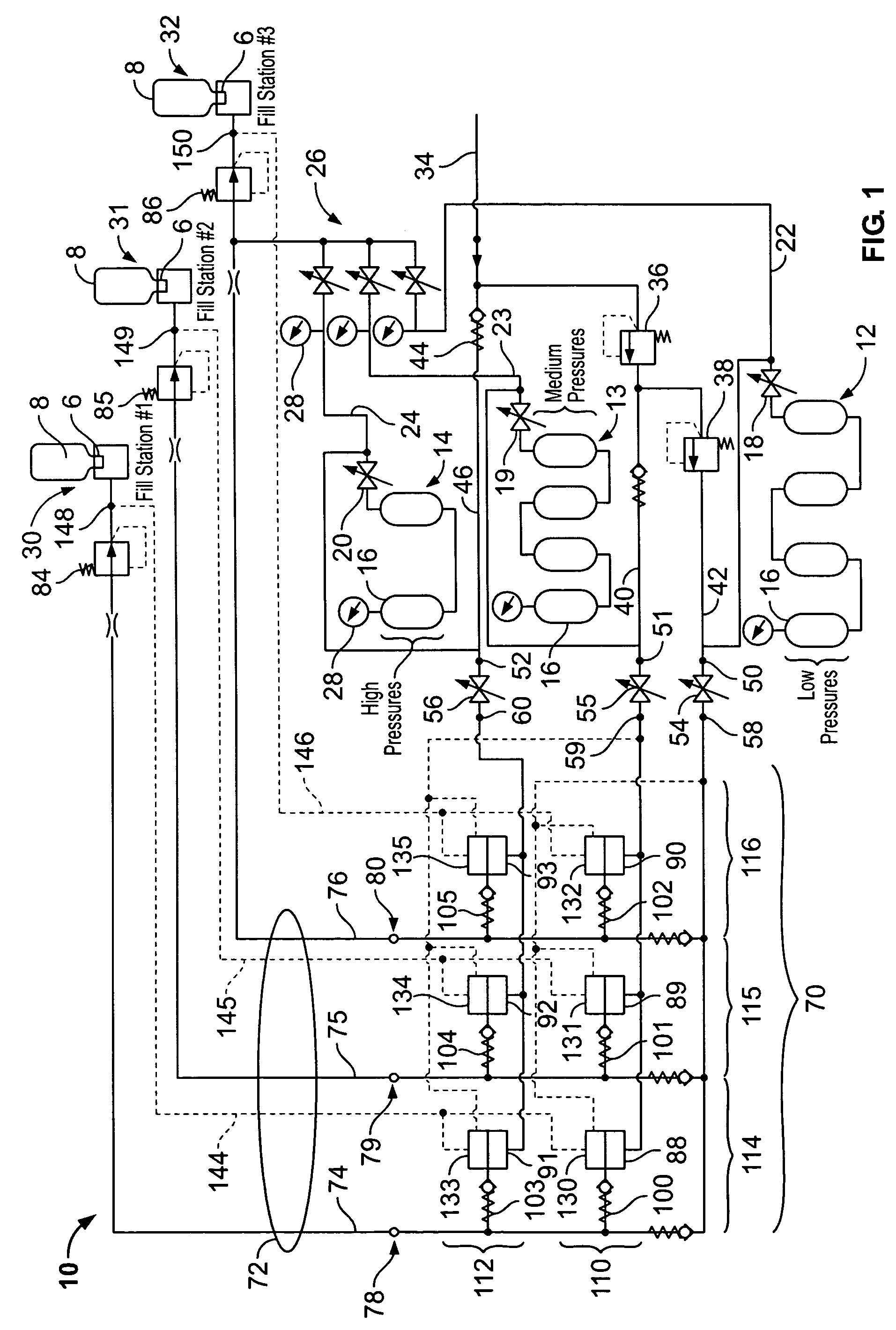

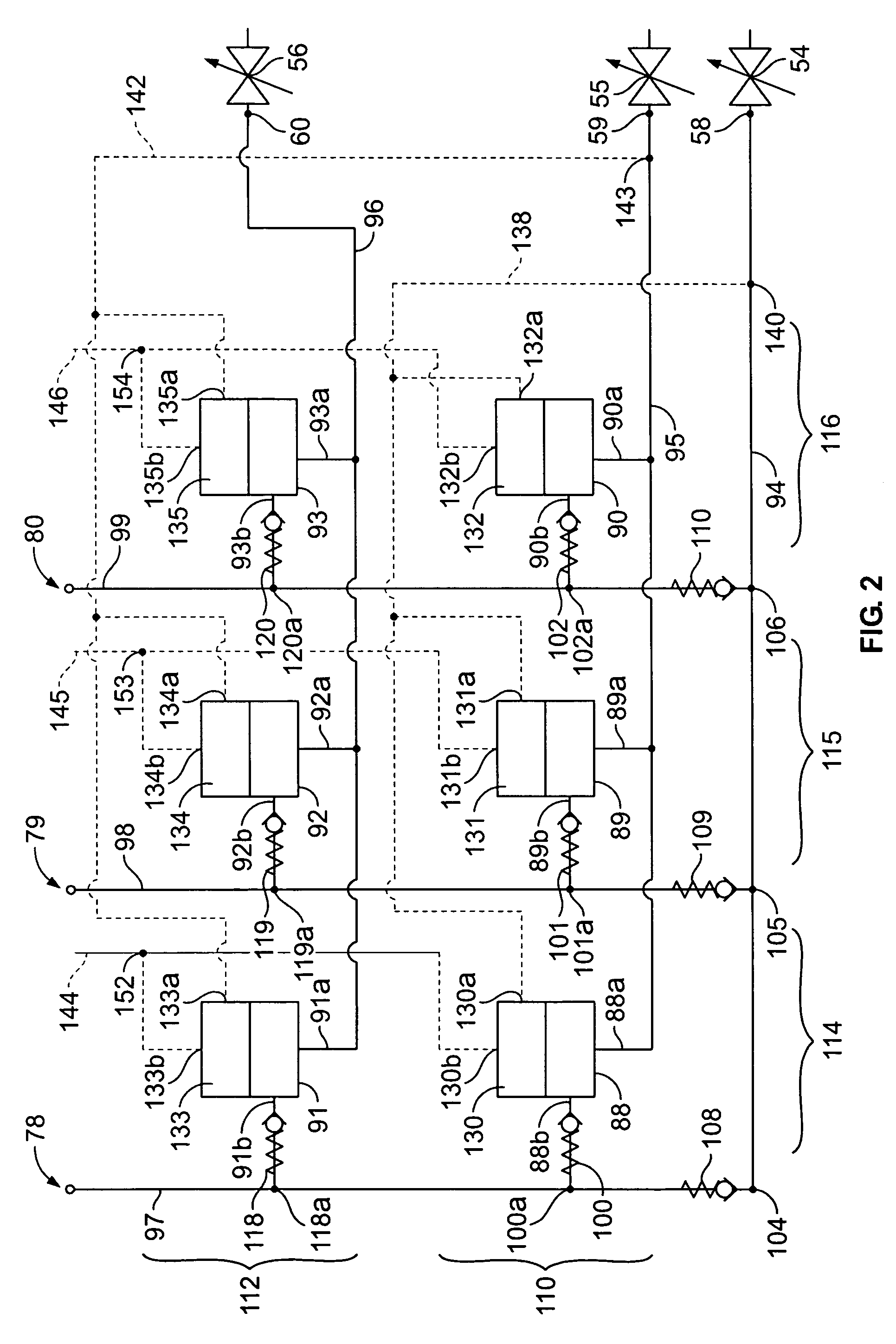

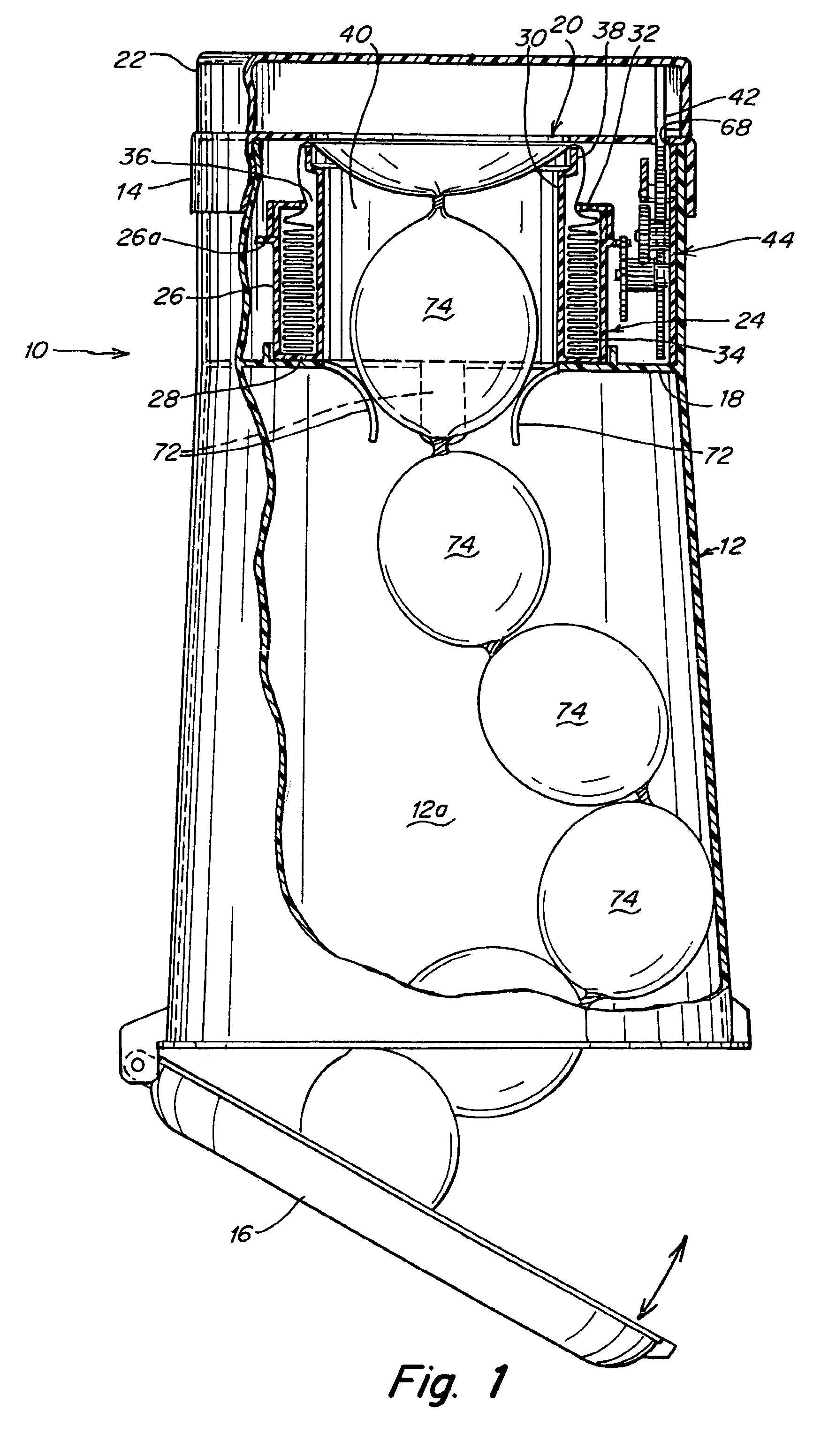

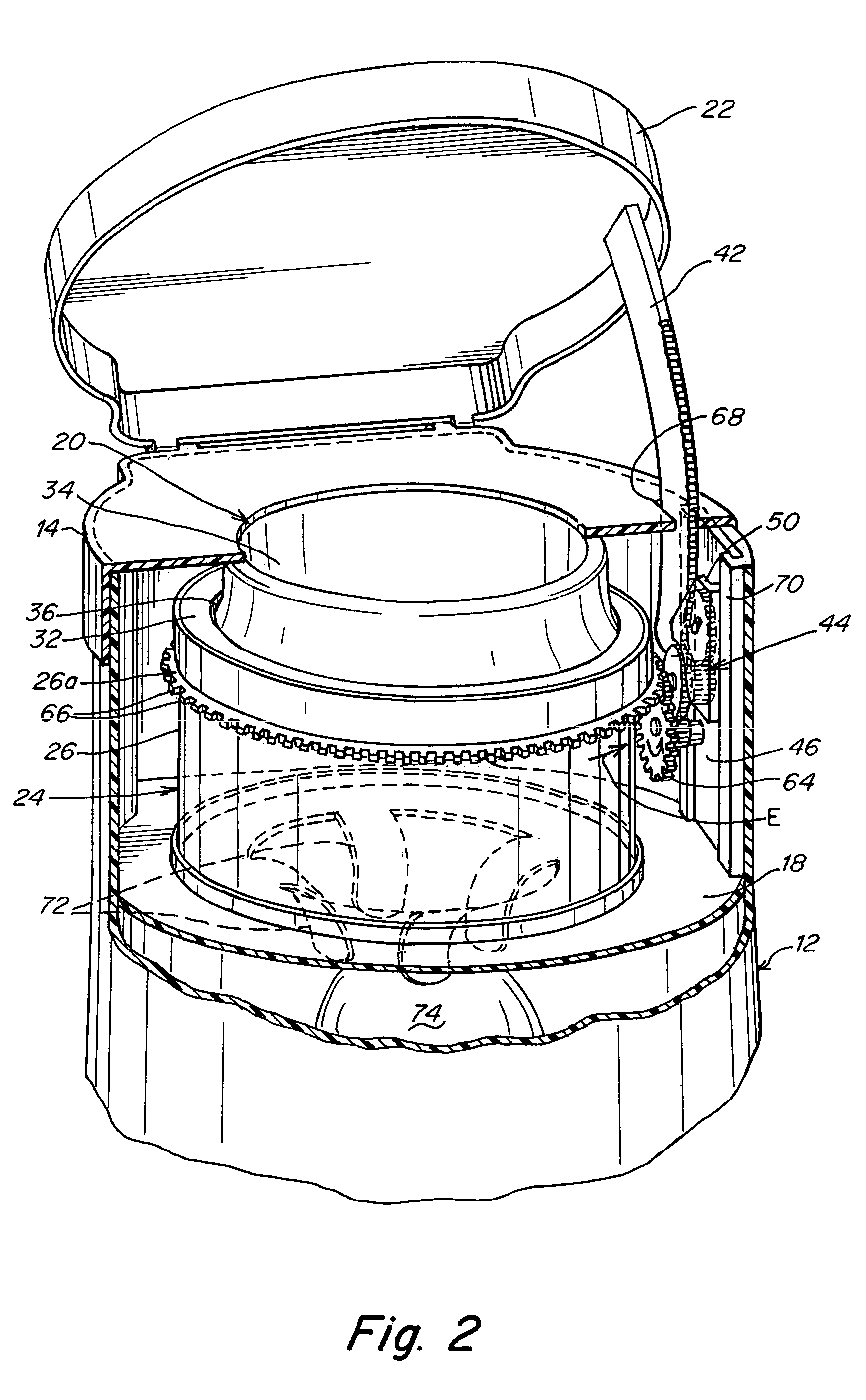

Method and system for independently filling multiple canisters from cascaded storage stations

A canister filling system is provided for independently filling multiple canisters from a common set of storage stations prioritized in a cascaded manner. The system includes first and second fill stations configured to receive and independently fill canisters with pressurized gas. First and second storage stations store gas at corresponding first and second charge pressures, respectively. A supply-chain joins each of the first and second fill stations to both of the first and second storage stations. First and second valve assemblies are provided in the supply-chain to monitor, independent of one another, the canister pressures at the corresponding first and second fill stations. The canister pressures represent the pressure within corresponding canisters. The first and second valve assemblies automatically open and close to permit and prevent discharge of gas from the first and second storage stations, independent of one another, to automatically switch between the first and second storage stations based on the canister pressures. In one embodiment, the valve assembly includes a combination of sequence valves and check valves. Alternatively, the valve assembly may be controlled by electronic sensors and electronic solenoids. The electronic sensors detect the canister pressures and the charge pressures at the storage stations. The electronic solenoids open and close the valves based on the sensed canister pressures.

Owner:SCOTT TECH INC

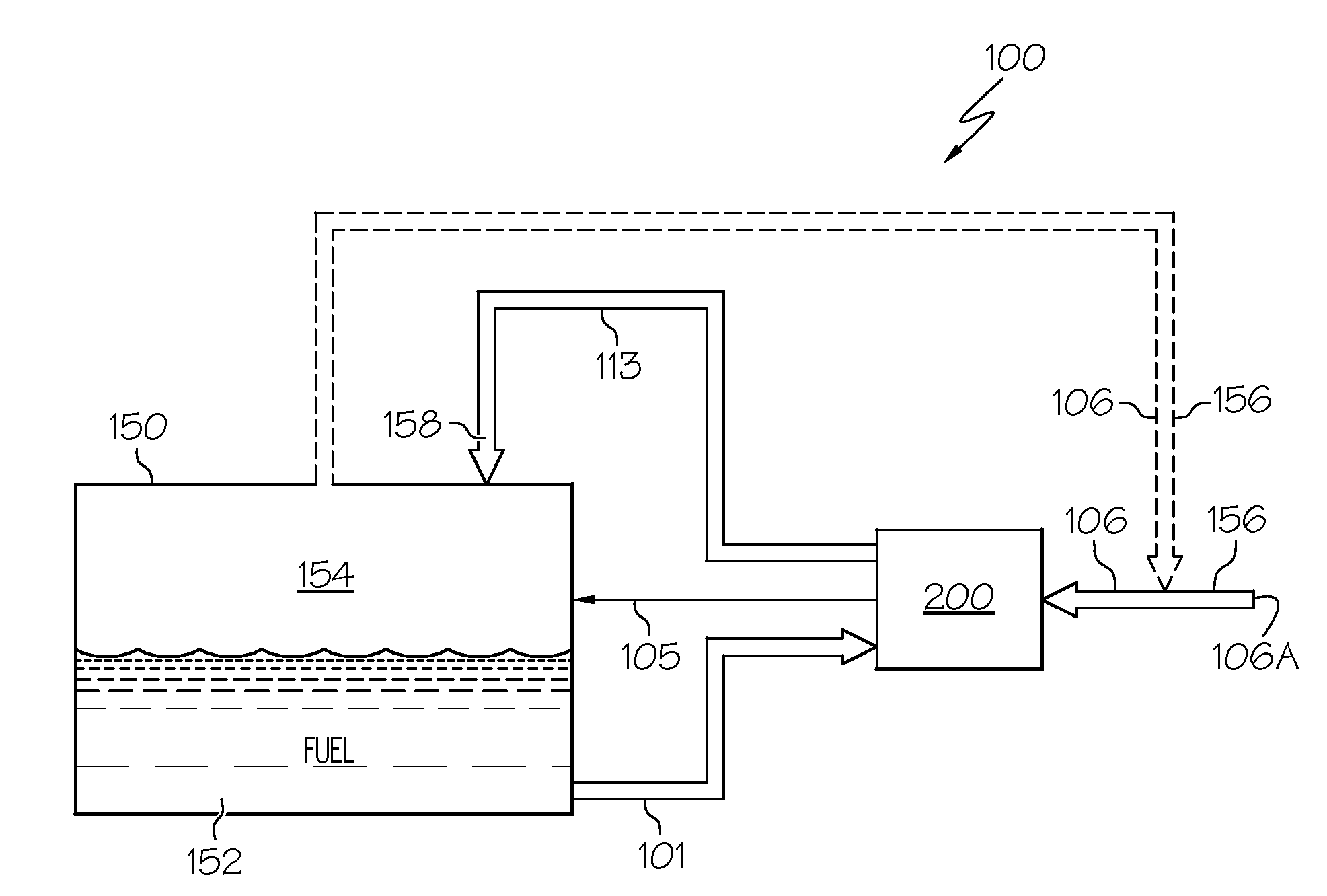

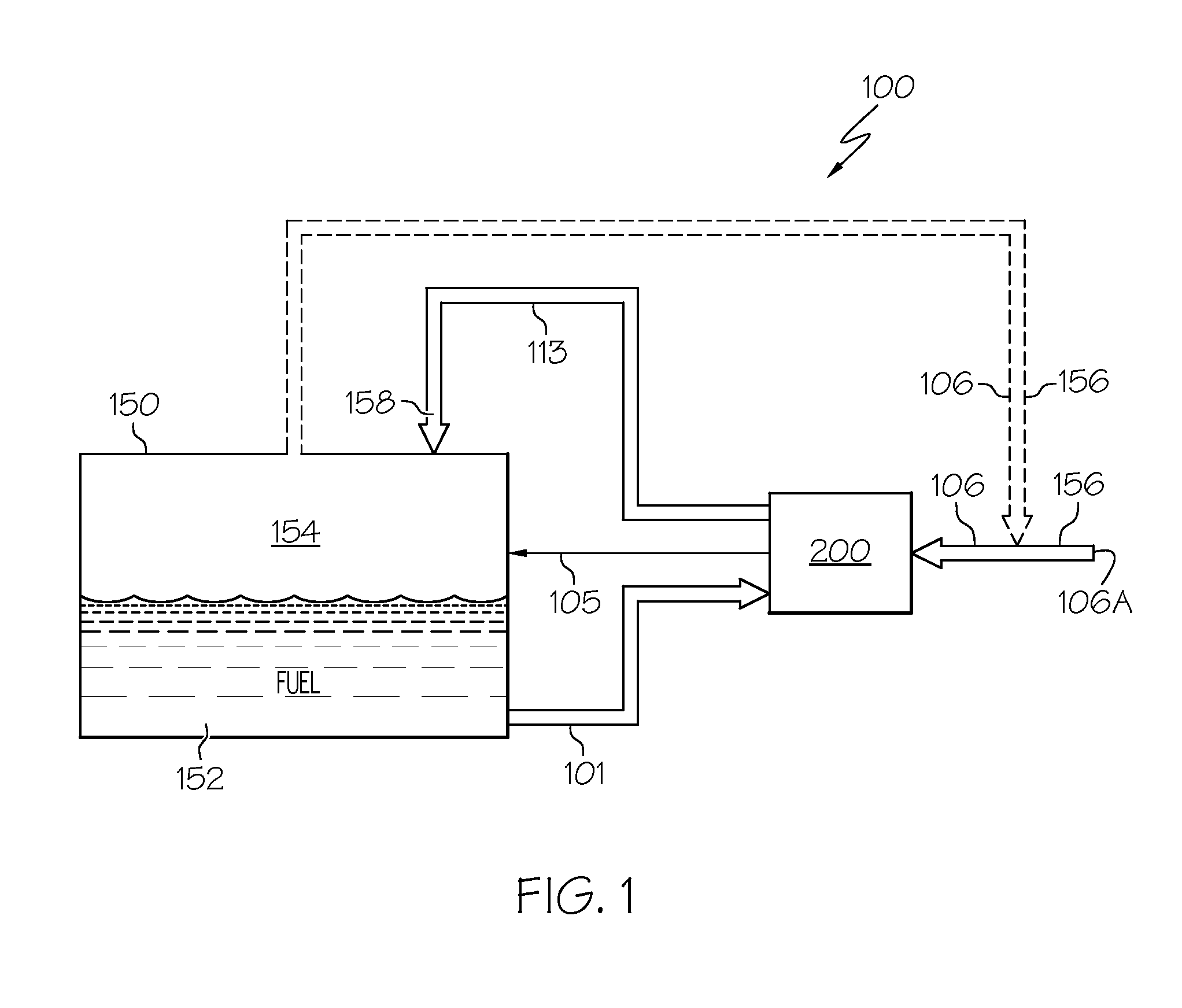

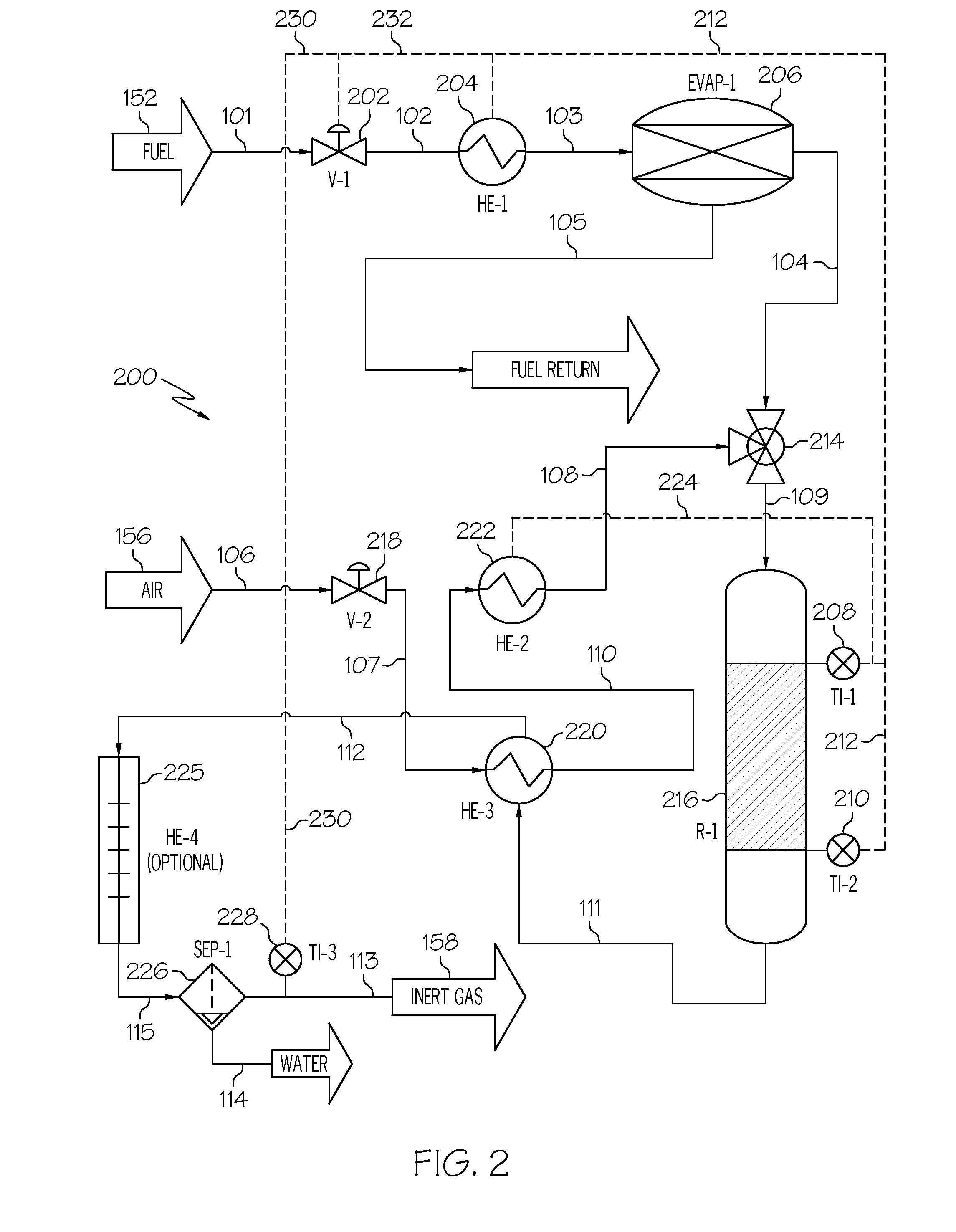

Advanced carbon dioxide fuel tank inerting system

An onboard inert gas generation system includes an evaporator comprising a vessel that receives a hydrocarbon fuel from a fuel tank, separates vapor fuel components from liquid fuel components, establishes a nearly constant fuel vapor composition, and outputs the fuel vapor to be mixed with air prior to combusting the fuel vapor and air mixture in a catalytic reactor. Water is separated from the inert gas produced and the inert gas is introduced into the ullage space of the fuel tank to prevent or reduce possible hazardous conditions in the fuel tank.

Owner:HONEYWELL INT INC

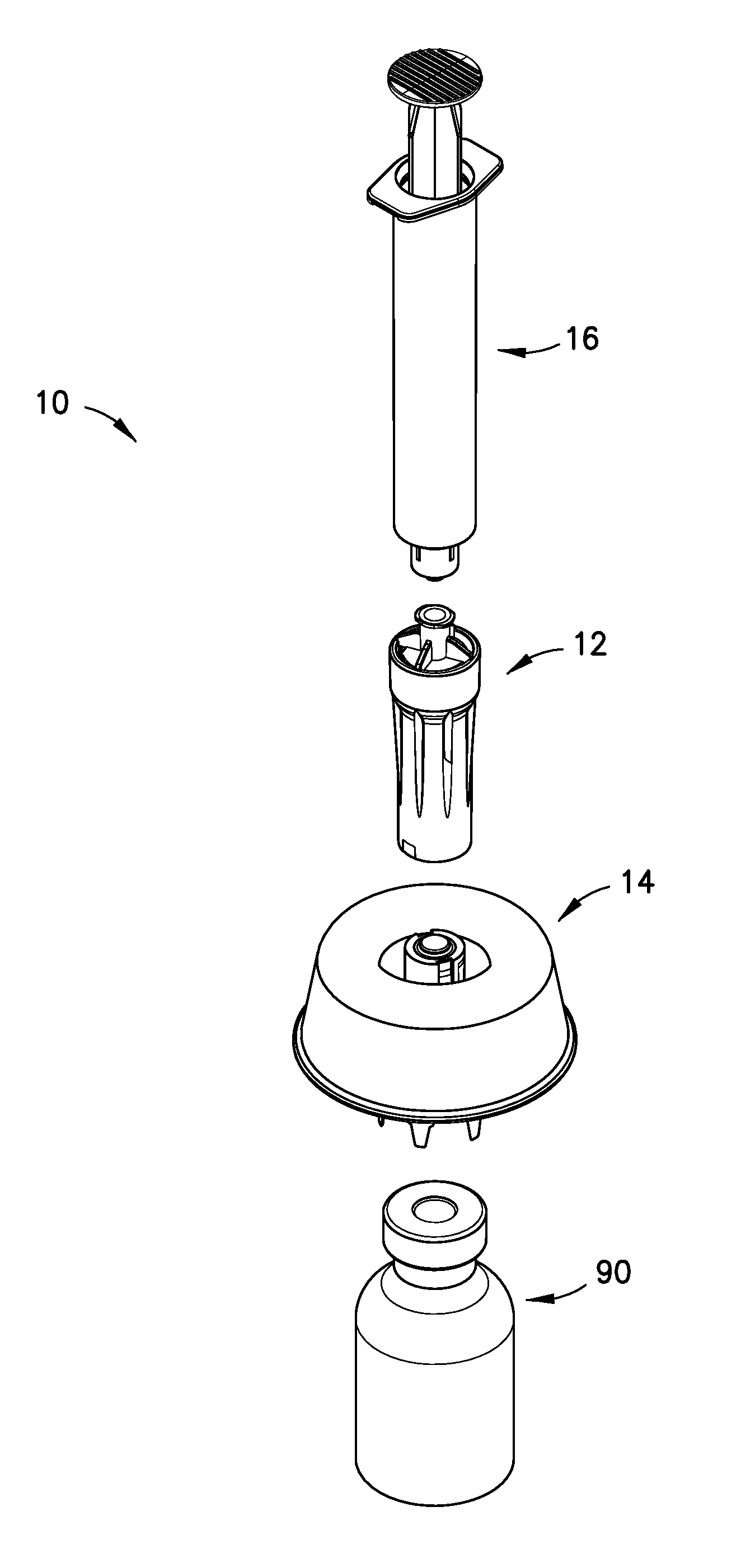

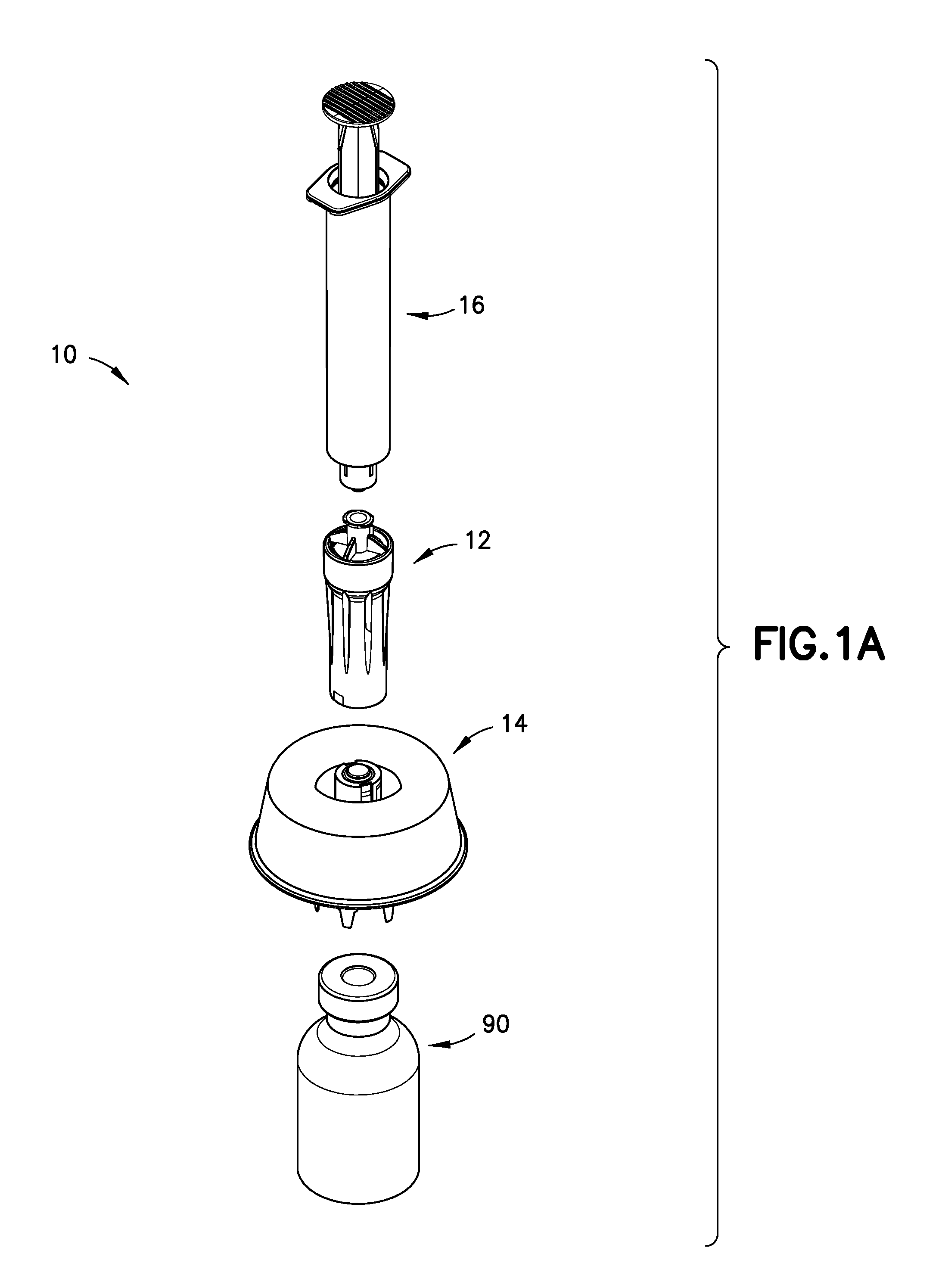

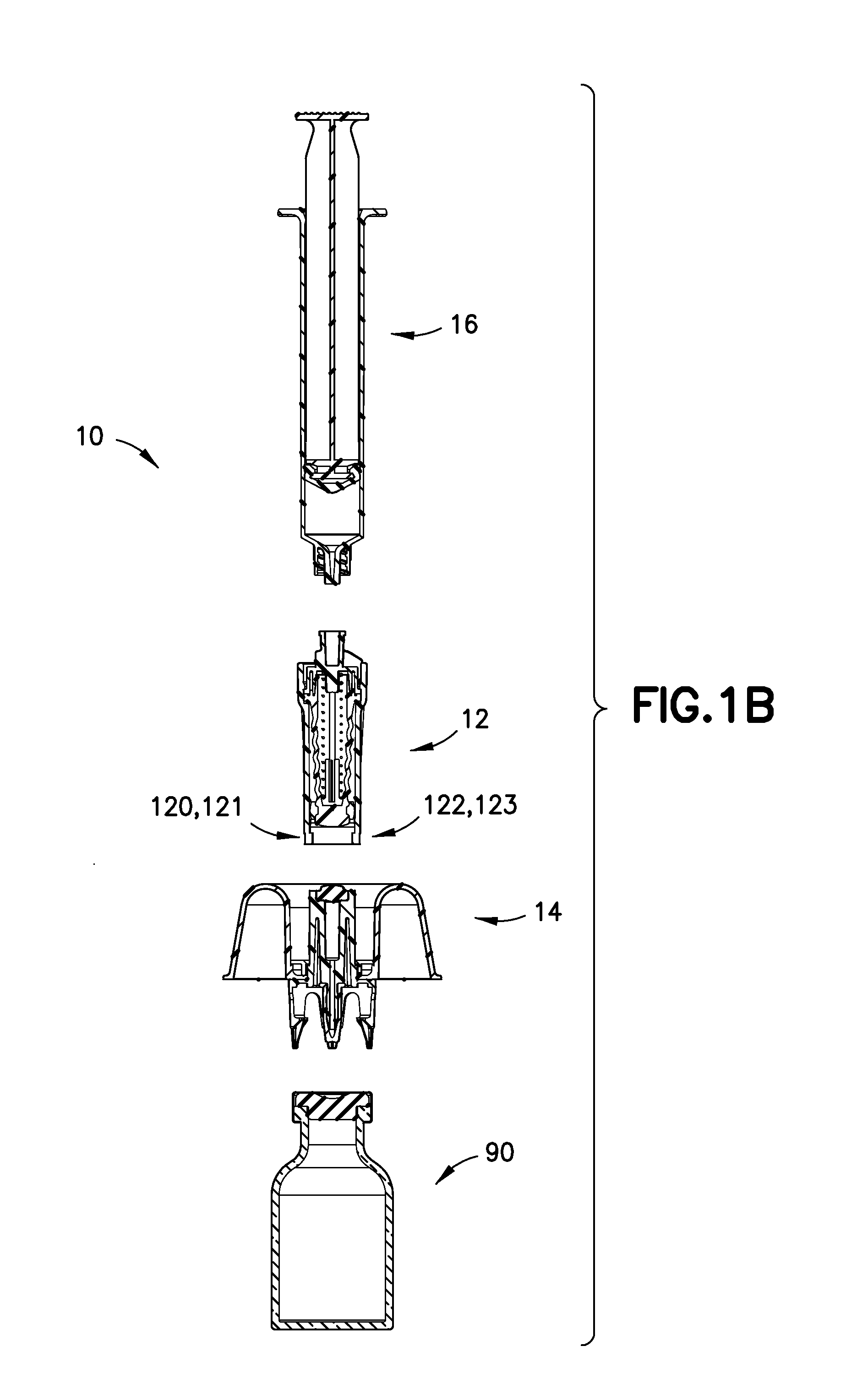

System for Closed Transfer of Fluids

ActiveUS20140261877A1Uniform pressurePrevent leakagePharmaceutical containersMedical packagingTransfer systemEngineering

A system for the closed transfer of fluids that provides substantially leak-proof sealing and pressure equalization during engagement of a cannula with a vial, during transfer of a substance from a vial chamber to a barrel chamber via the cannula, and during disengagement of the cannula from the vial is disclosed. The leak-proof sealing of the system substantially prevents leakage of both air and liquid during use of the system. The system of the present disclosure also permits pressure equalization between a vial and the system when the system is attached to the vial. The system is compatible with a needle and syringe assembly for accessing a medication contained within a vial for administering the medication to a patient.

Owner:BECTON DICKINSON & CO

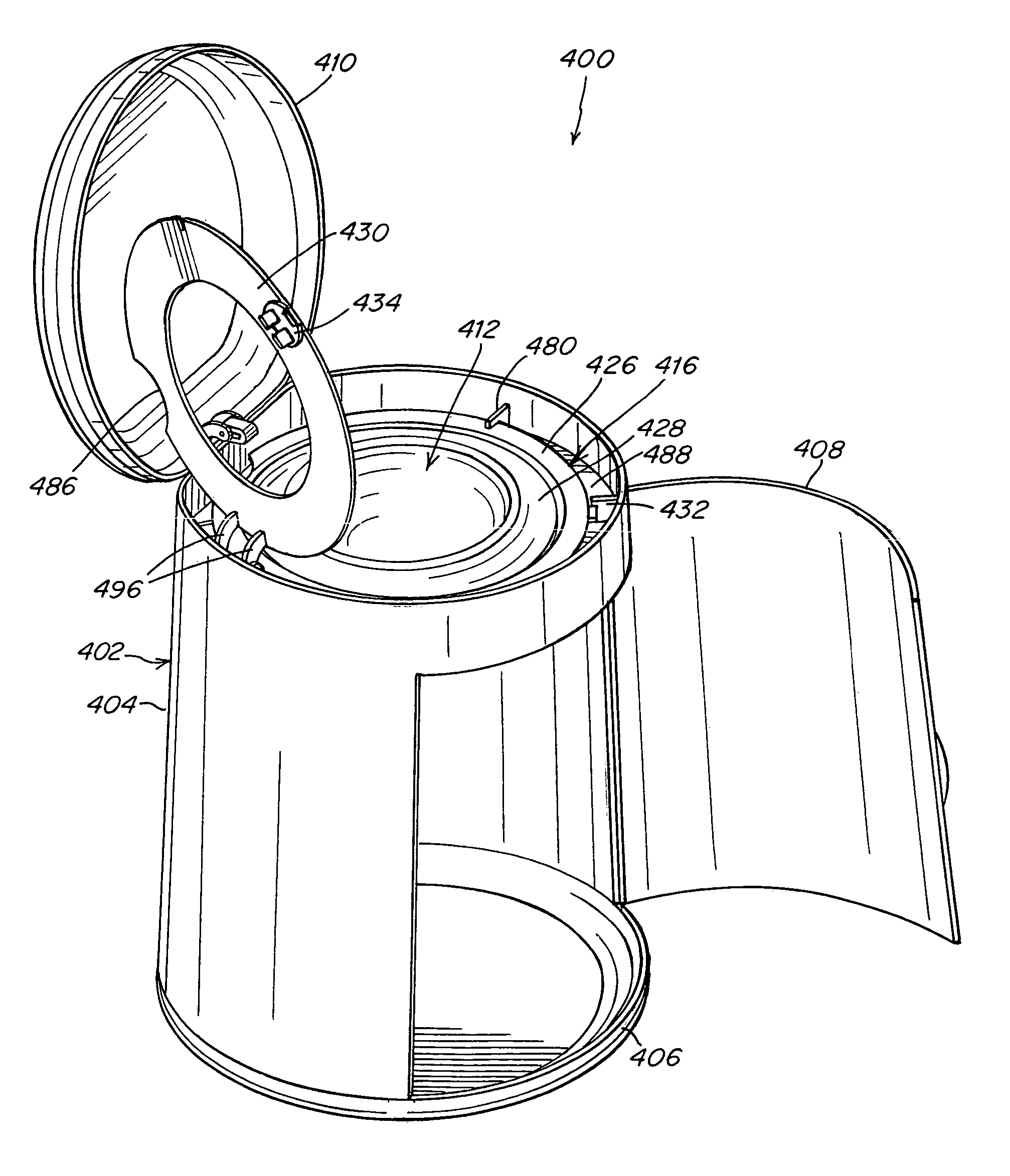

Waste disposal devices

InactiveUS7146785B2Effectively contains and prevents the release of odors from waste packagesReduce decreaseRefuse receptaclesWrappingWaste treatment

Owner:MUNCHKIN INC

Method of manufacturing an aerosol dispenser

A method of manufacturing an aerosol dispenser. The method comprises making part of the dispenser having an outer container at a first location, and sealing that container. The sealed container may be charged with propellant. The sealed container may then be shipped to a second location to add product and complete manufacture.

Owner:THE PROCTER & GAMBLE COMPANY

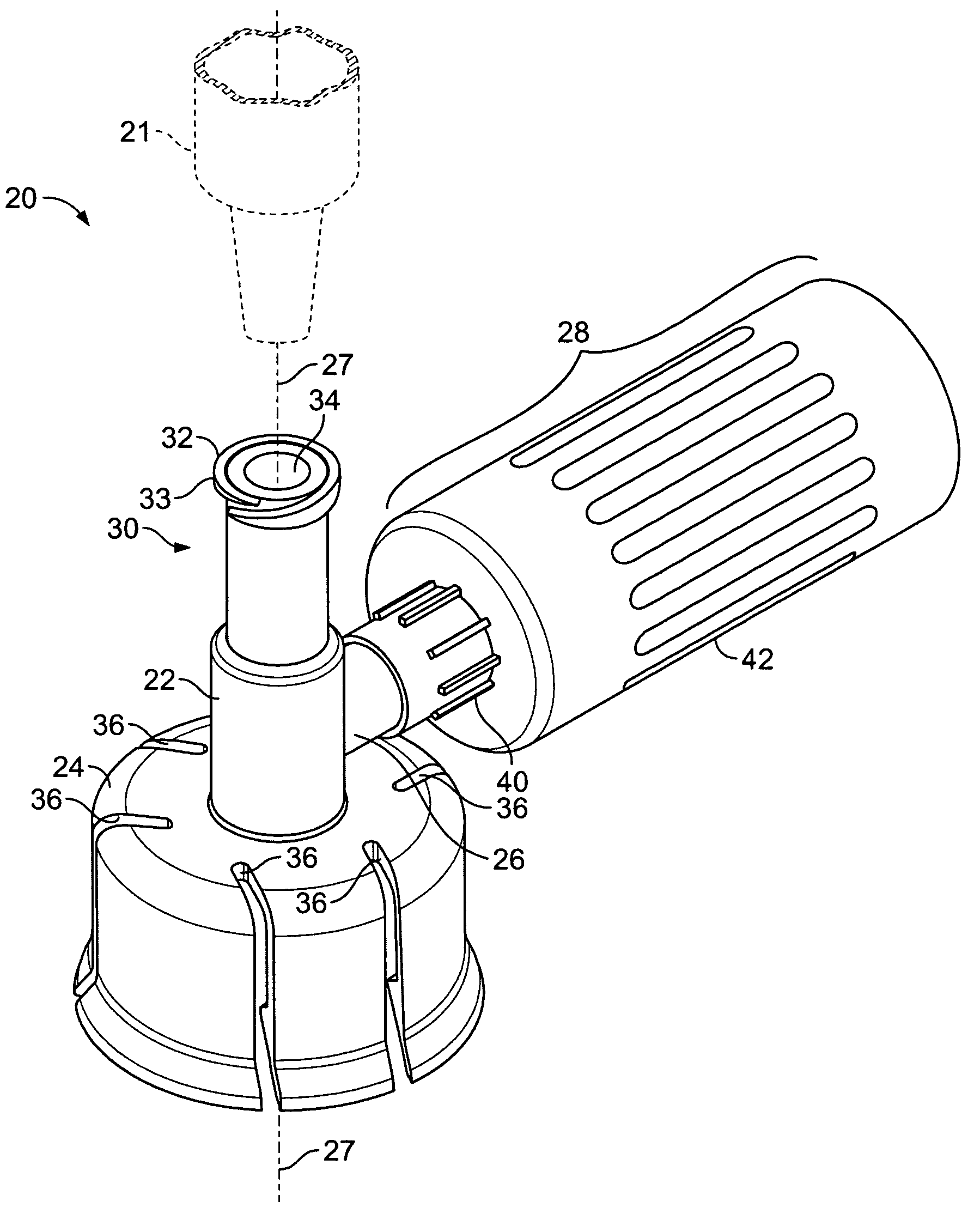

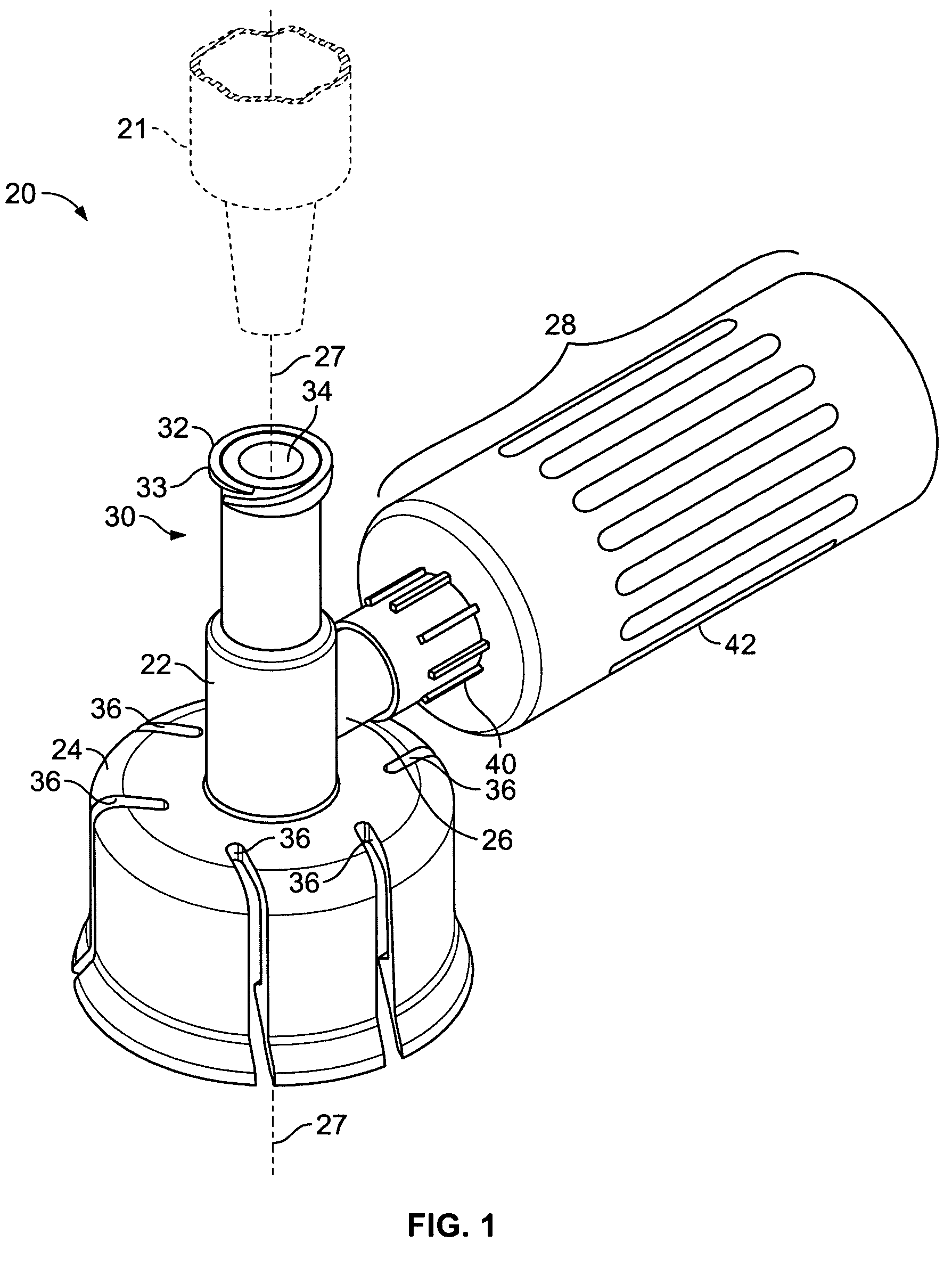

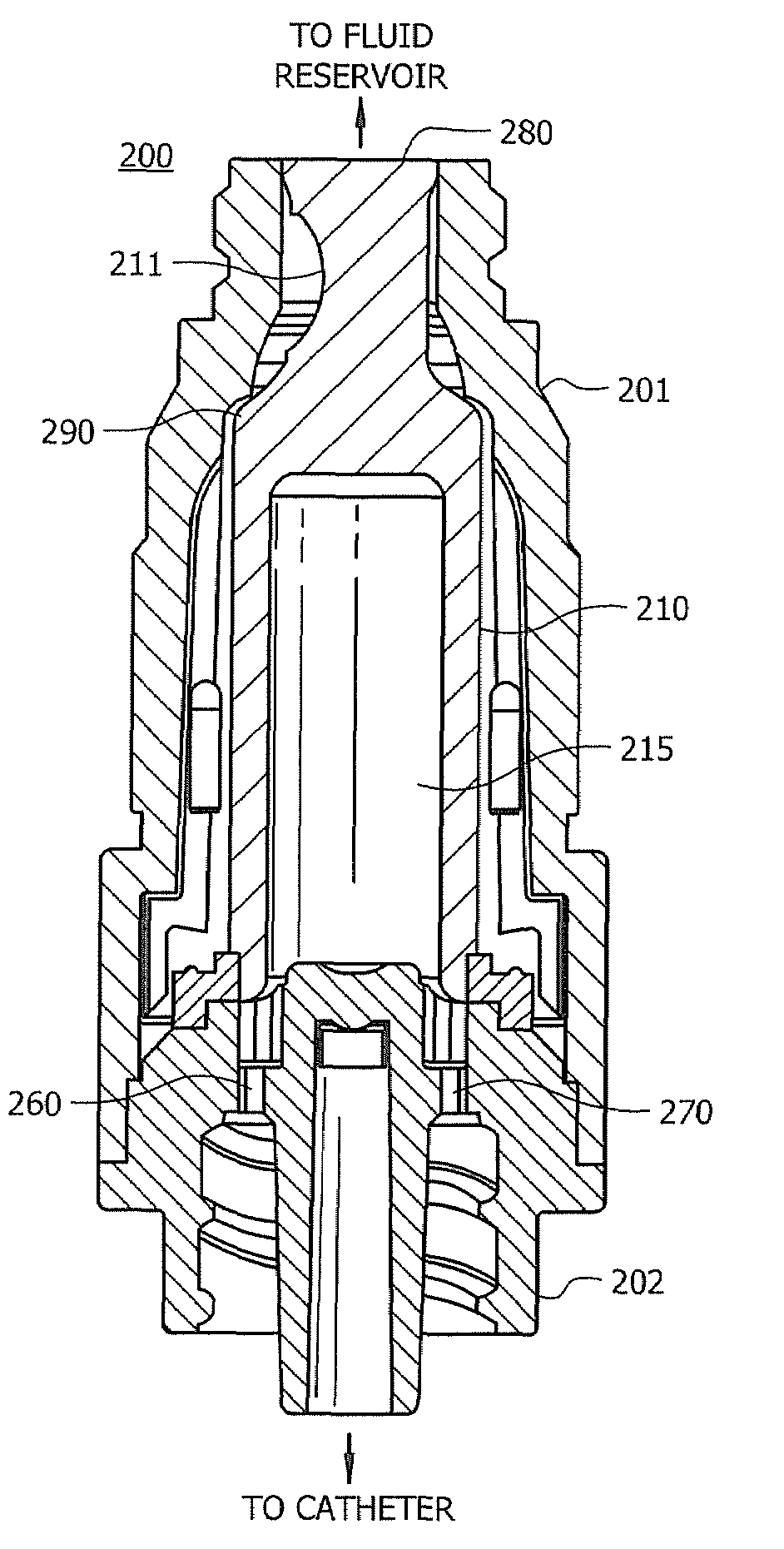

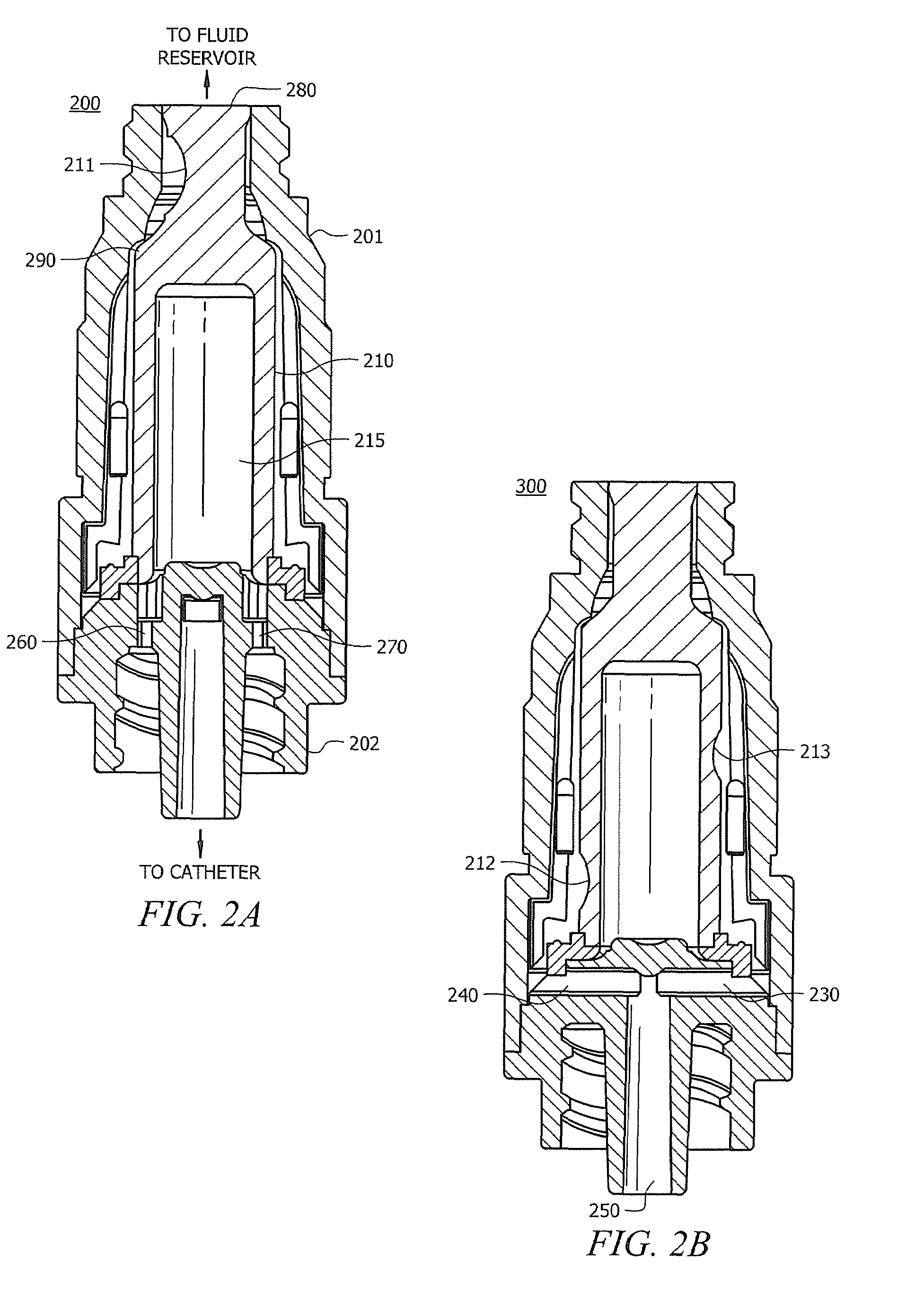

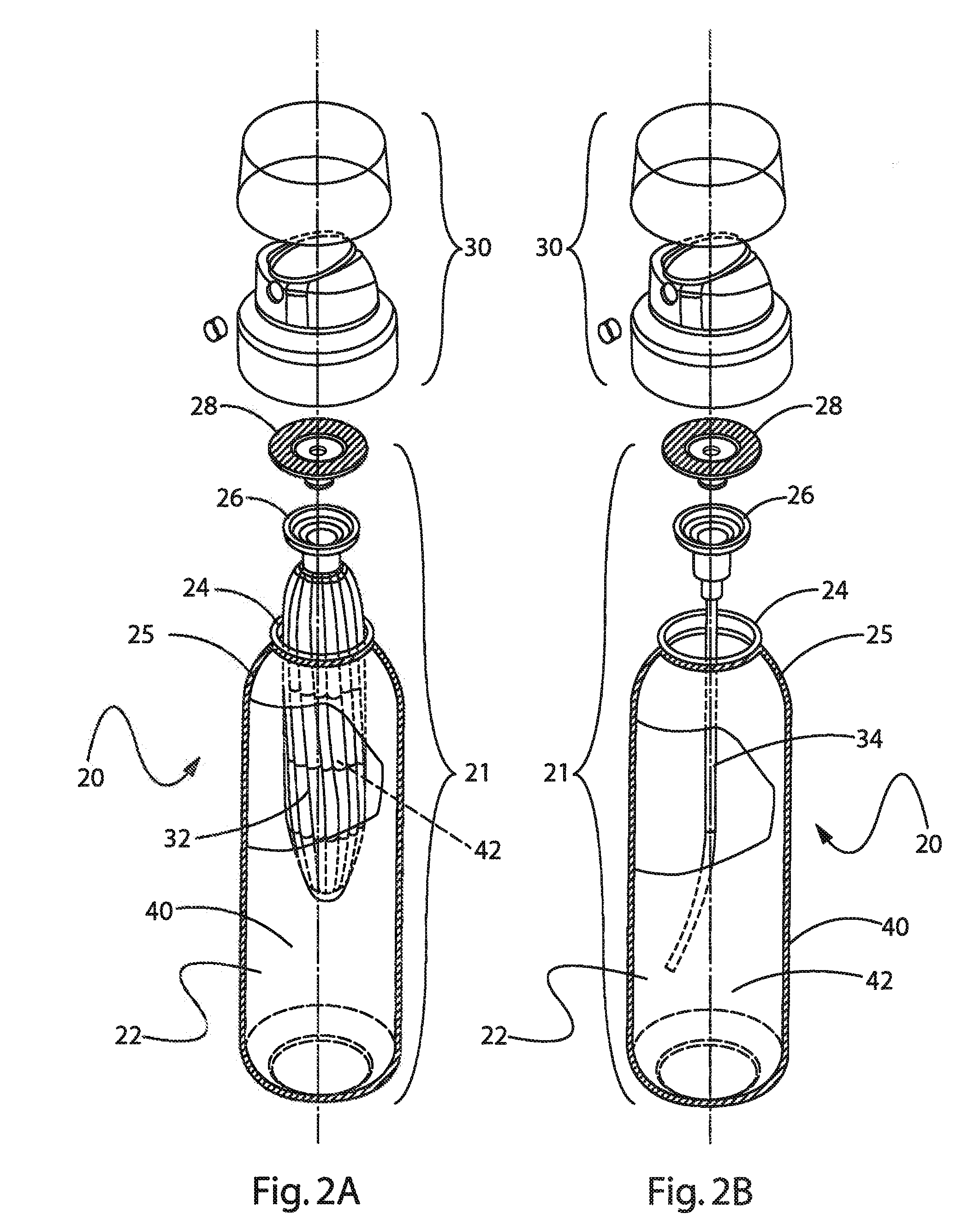

Apparatus, system and method for fluid delivery

A fill adapter system for an infusion pump assembly. The system includes a reusable fill adapter base, the base including a volume control mechanism to adjust an available fill volume of a reservoir of the infusion pump assembly and a pump mechanism configured to pump air into a fluid vial. The system also includes a vial adapter assembly including a first needle configured to penetrate a septum of the fluid vial for fluidly coupling the pump mechanism to the fluid vial and a second needle having a first end configured to penetrate the septum of the fluid vial and a second end configured to penetrate a septum of the reservoir of the infusion pump assembly to allow transfer of fluid from the fluid vial to the reservoir of the infusion pump assembly in response to air being pumped into the fluid vial and a needle carriage adapted to carry the first needle and the second needle, wherein the needle carriage slidably attached to the interior of the vial adapter assembly, wherein the needle carriage adapted to slide from a vial end of the vial adapter to a receptacle end of the vial adapter.

Owner:DEKA PROD LLP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com