Patents

Literature

2444results about "Pipeline expansion-compensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

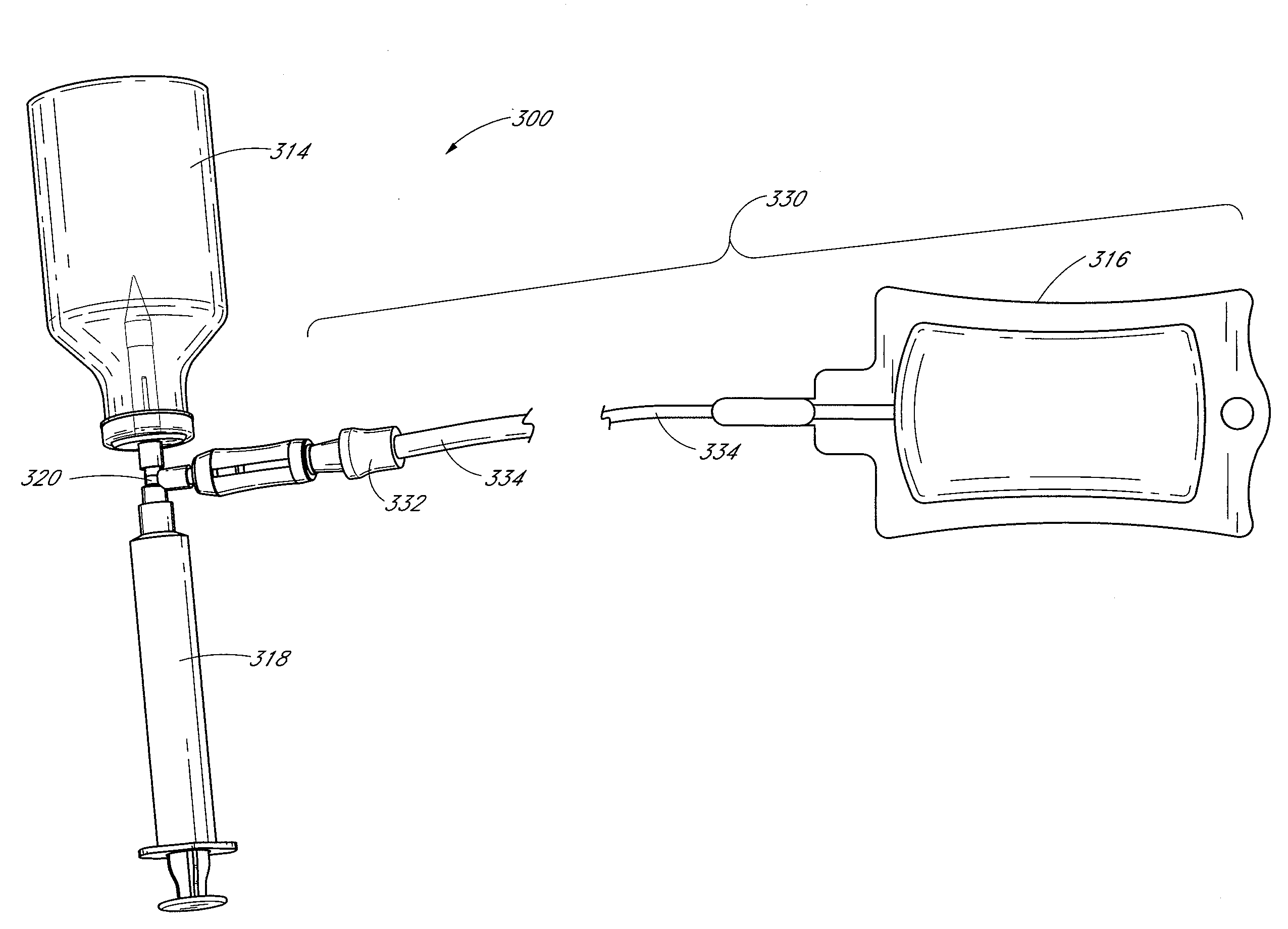

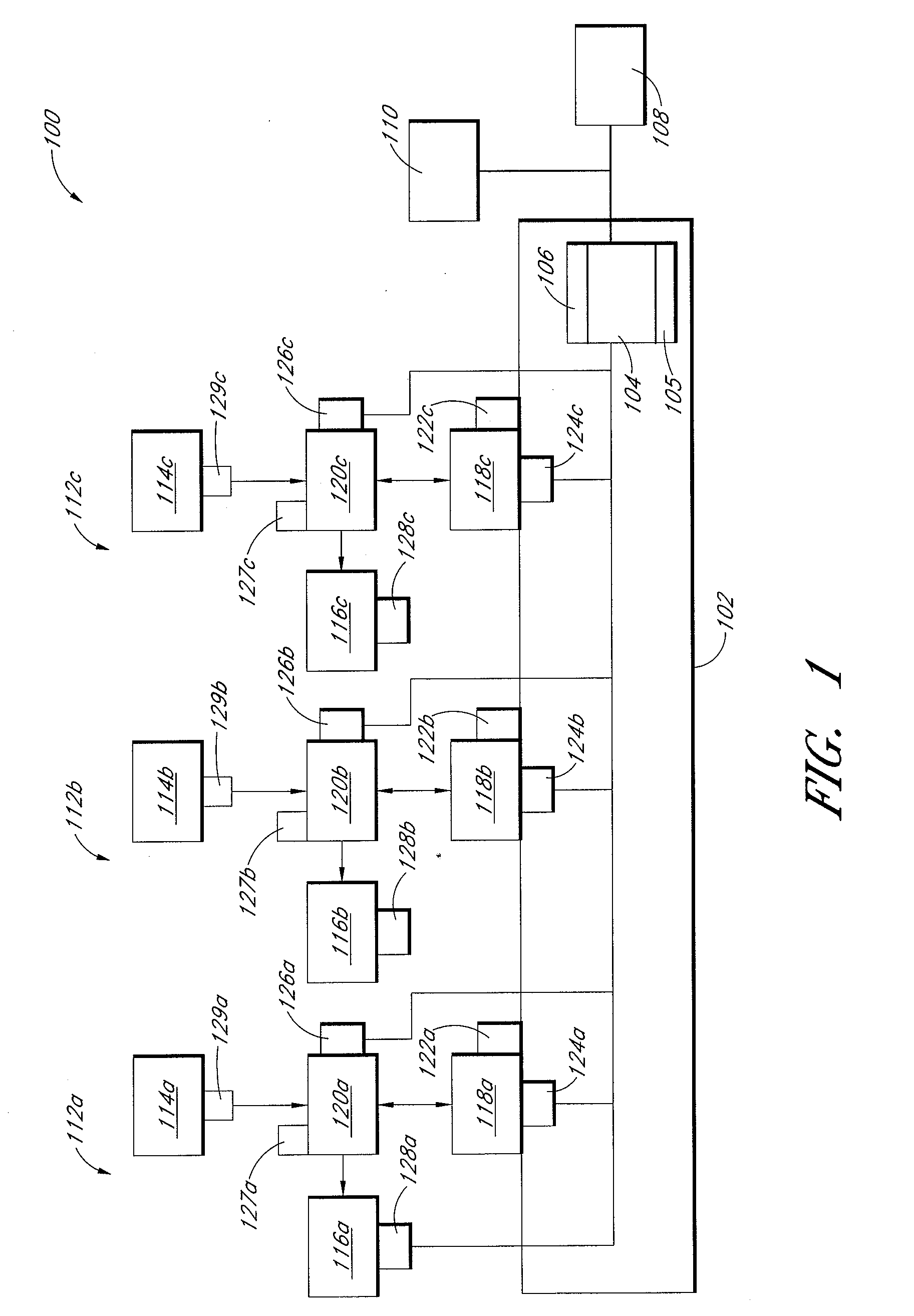

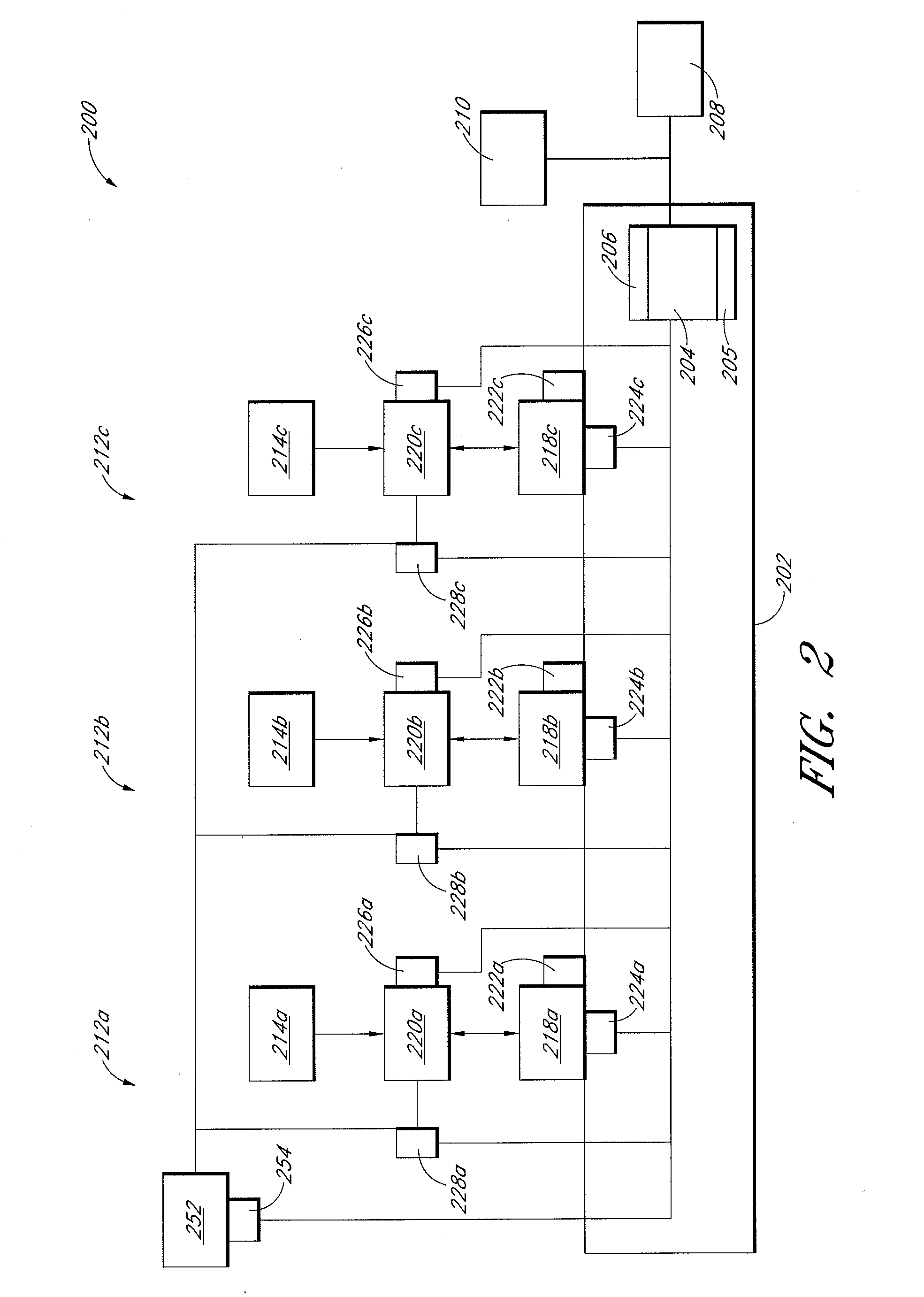

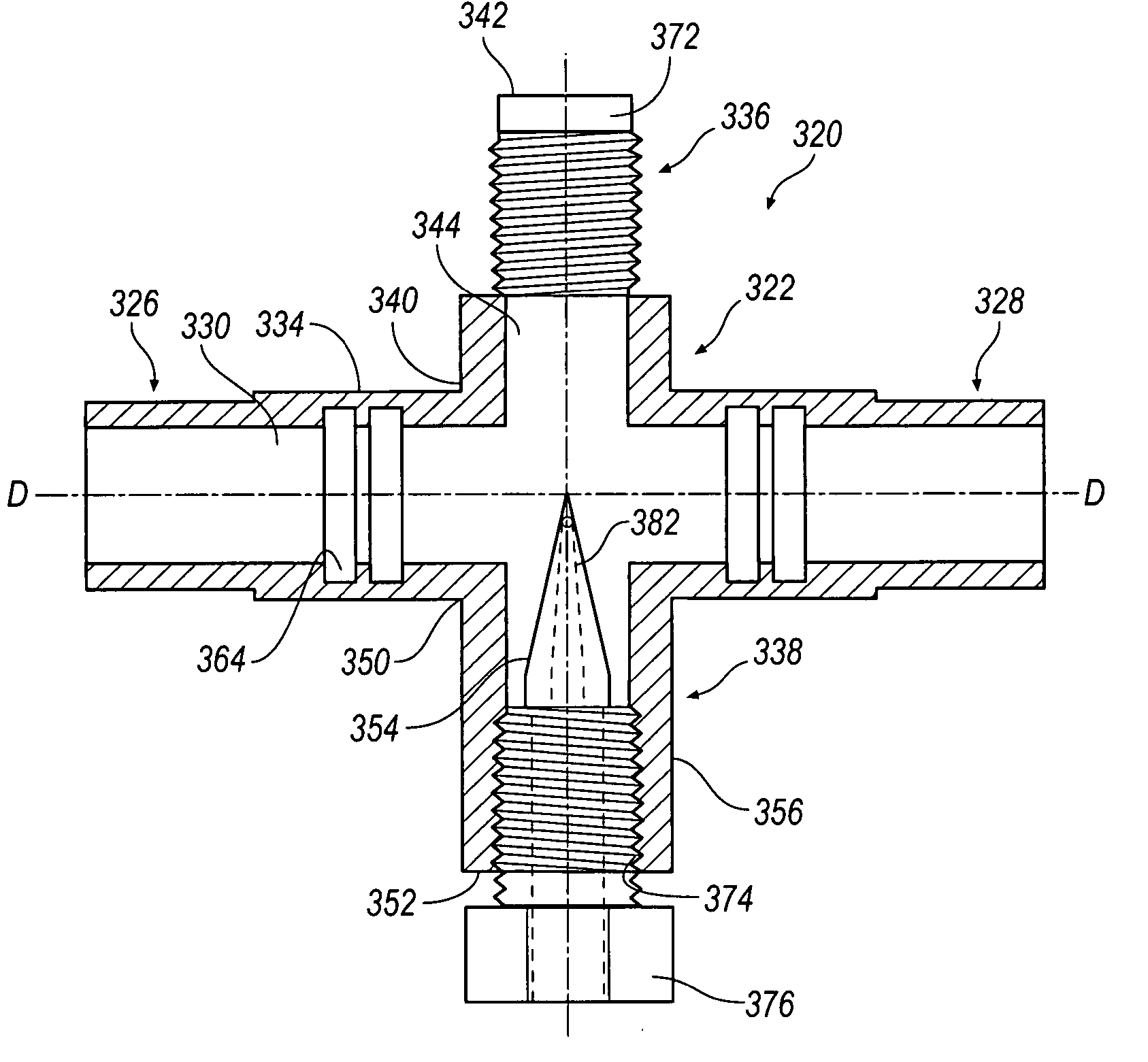

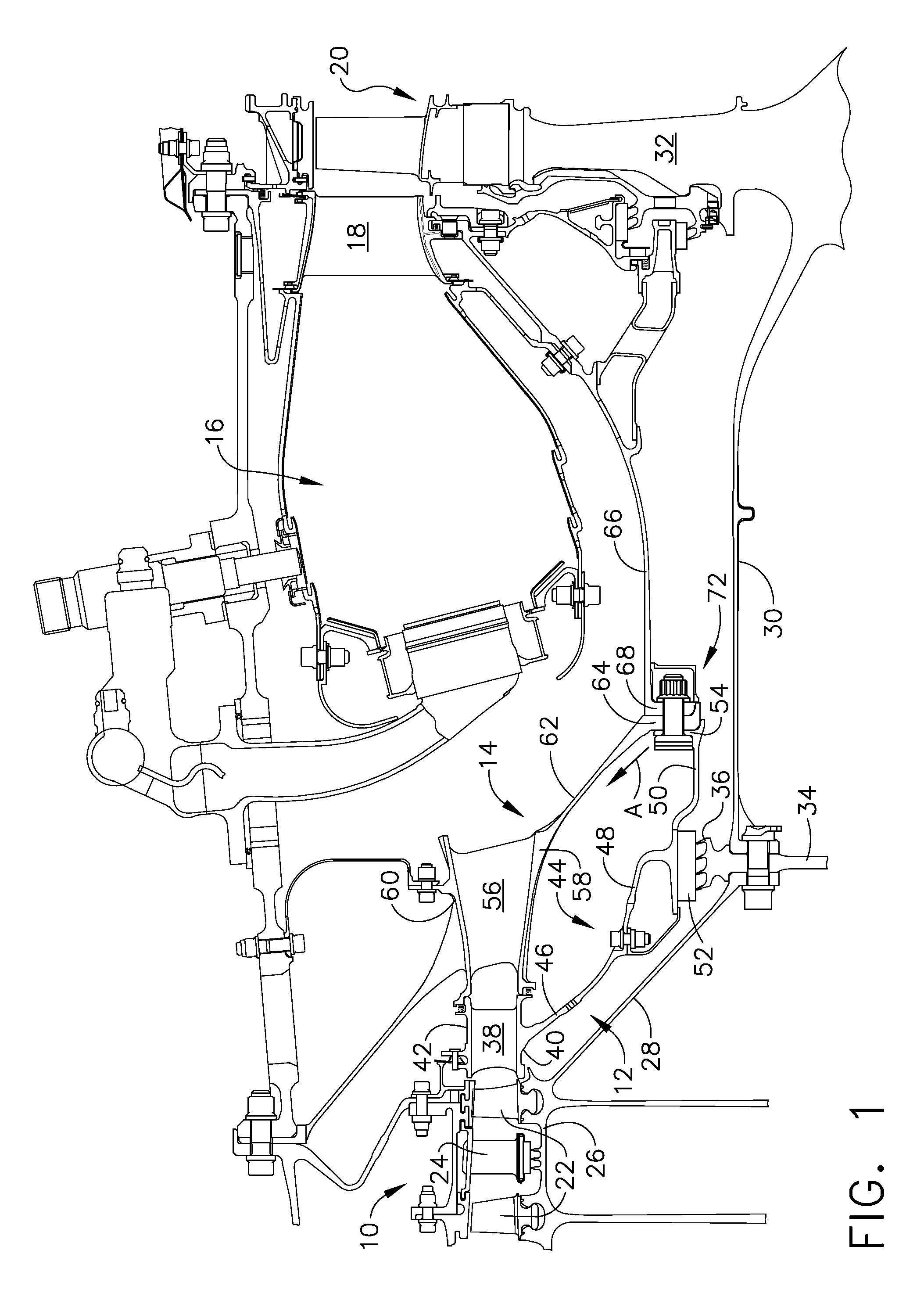

Fluid transfer devices and methods of use

Some embodiments disclosed herein related to a device for transferring precise amounts of fluid from at least one source container to a at least one target container. In some embodiments, the fluid is first transferred from the source container (e.g., a vial) through a connector to an intermediate measuring container (e.g., a syringe). In some embodiments air can pass through an air inlet and enter the vial to compensate for the volume of fluid withdrawn from the vial. An air check valve or a bag or a filter can prevent the fluid from escaping through the air inlet. The precisely measured amount of fluid can then be transferred from the intermediate measuring container to the target container (e.g., an IV bag). In some embodiments the connector can include a source check valve and a target check valve to direct fluid first from the source container to the intermediate measuring container and then from the intermediate measuring container to the target container. Some embodiments of the device can include a motor and a controller for automatically actuating a plunger of the syringe to transfer the desired amount of fluid.

Owner:ICU MEDICAL INC

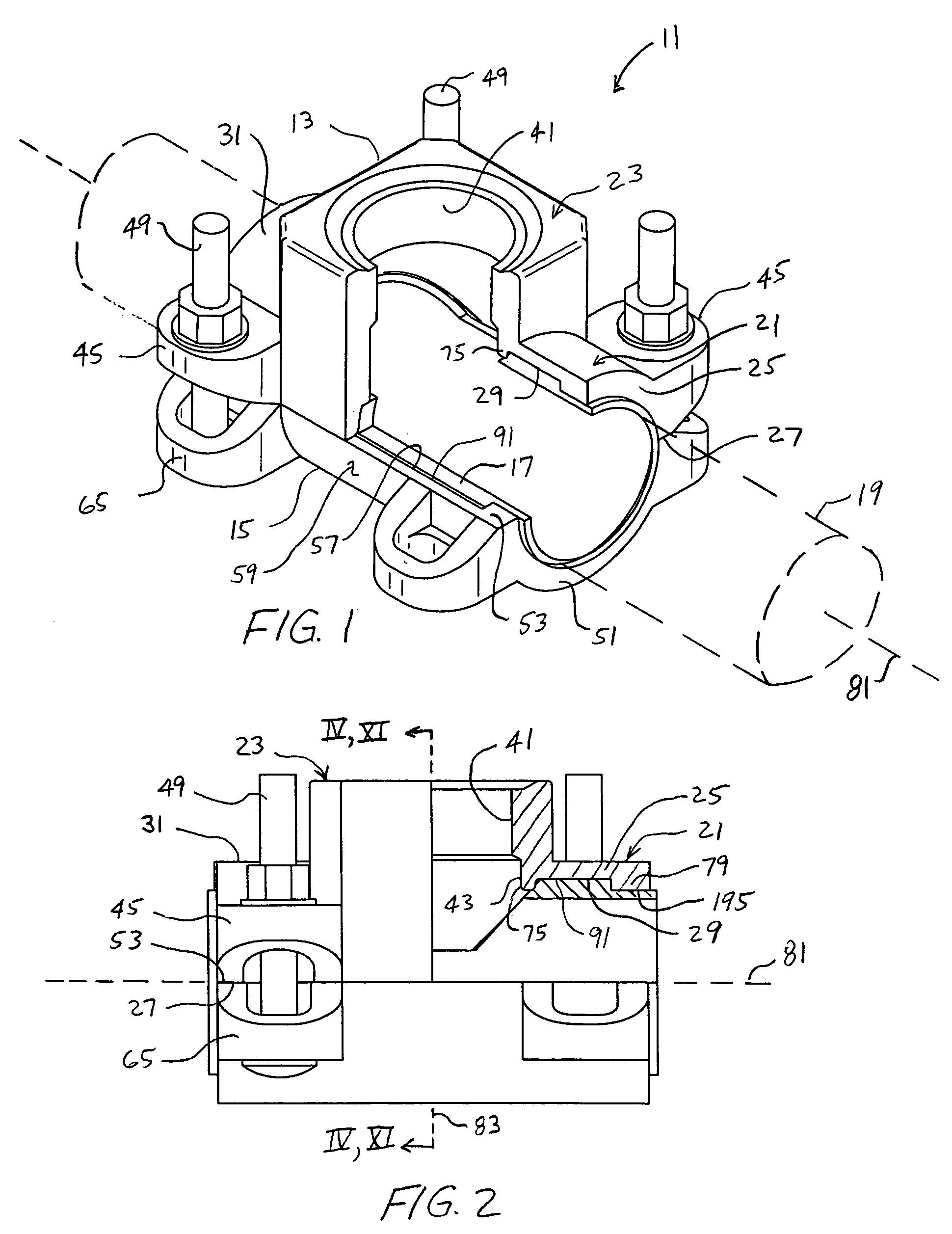

Fitting for fluid conveyance

InactiveUS20050134038A1Takes number of stepLow costPipeline expansion-compensationBranching pipesEngineering

Owner:EATON CORP

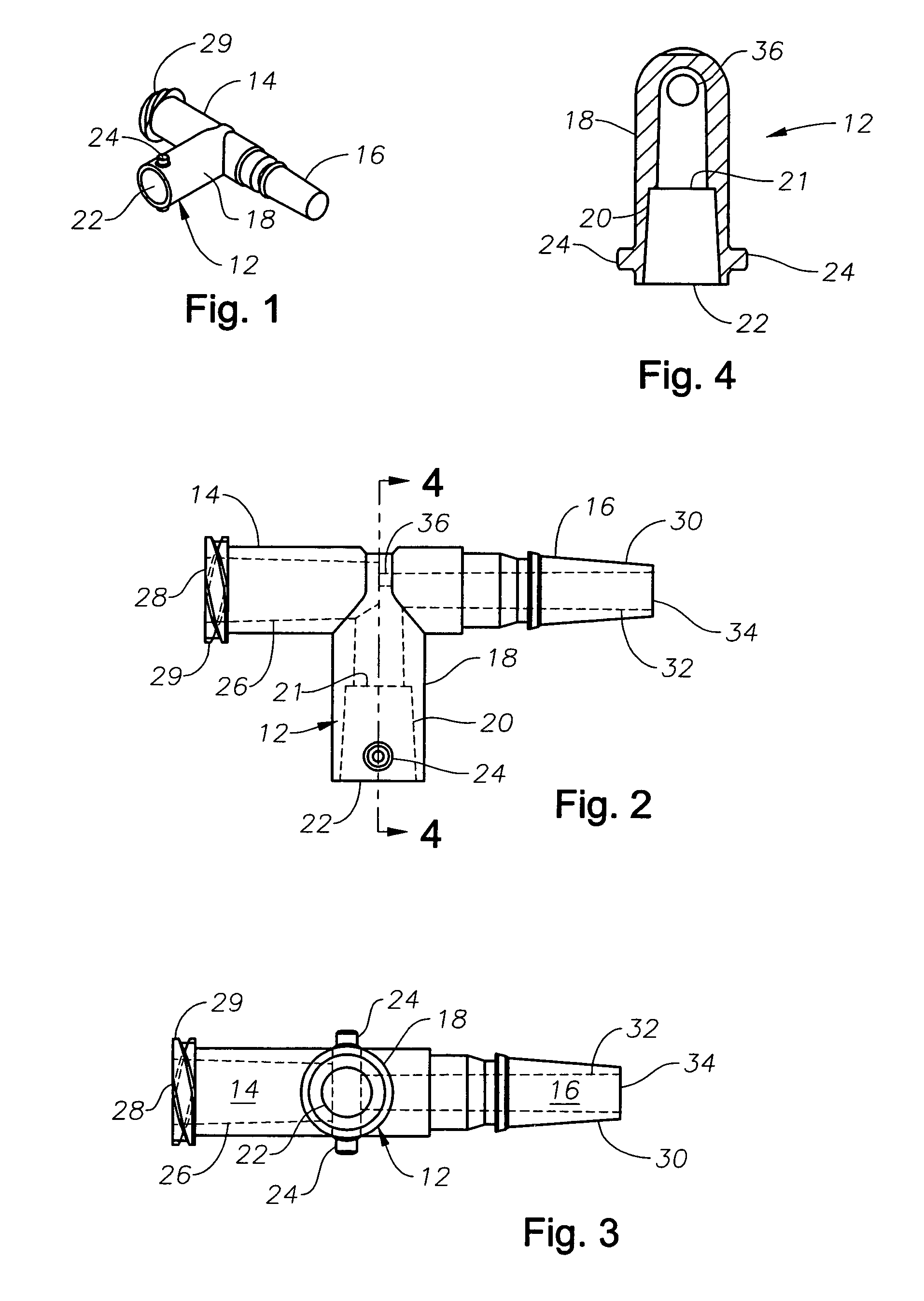

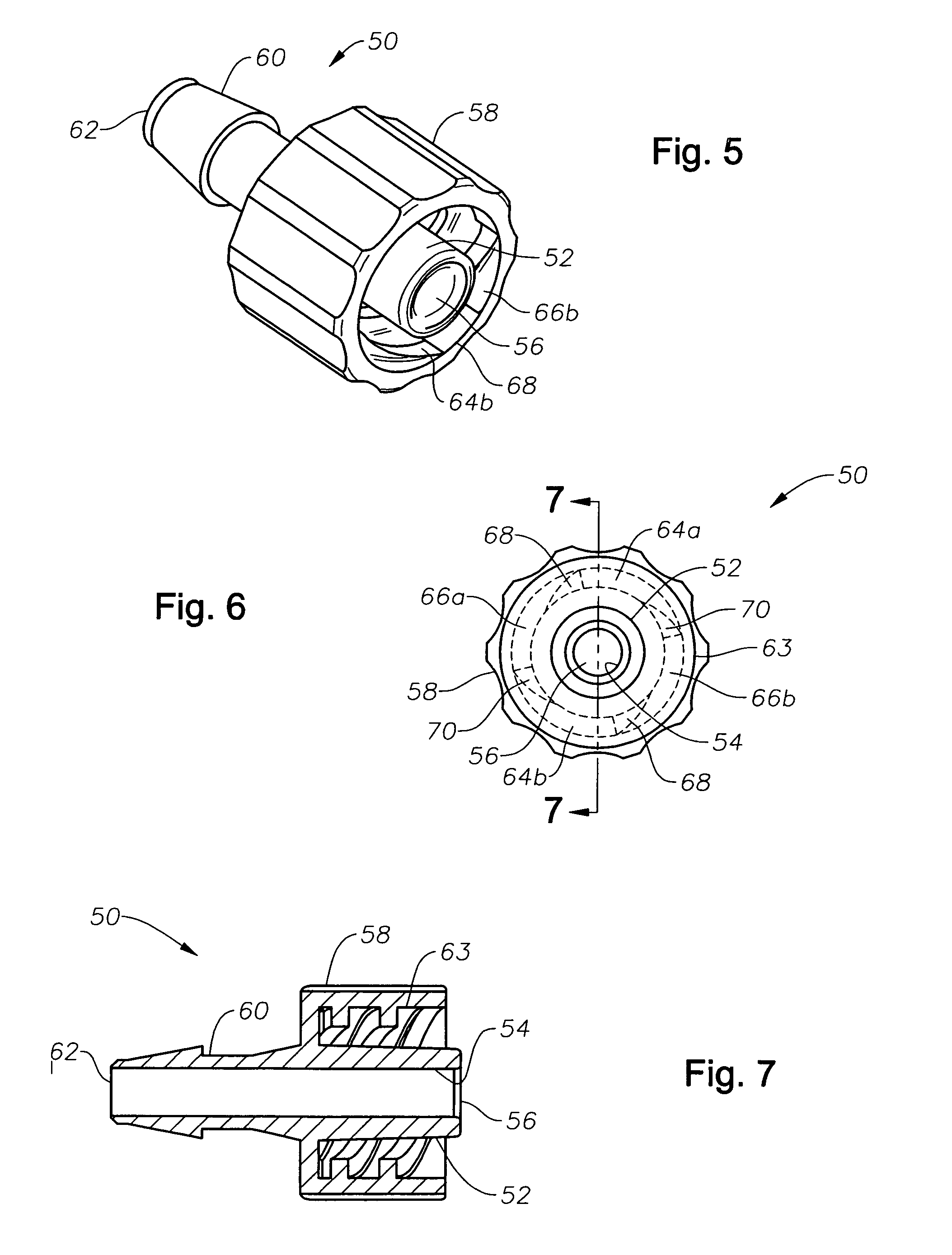

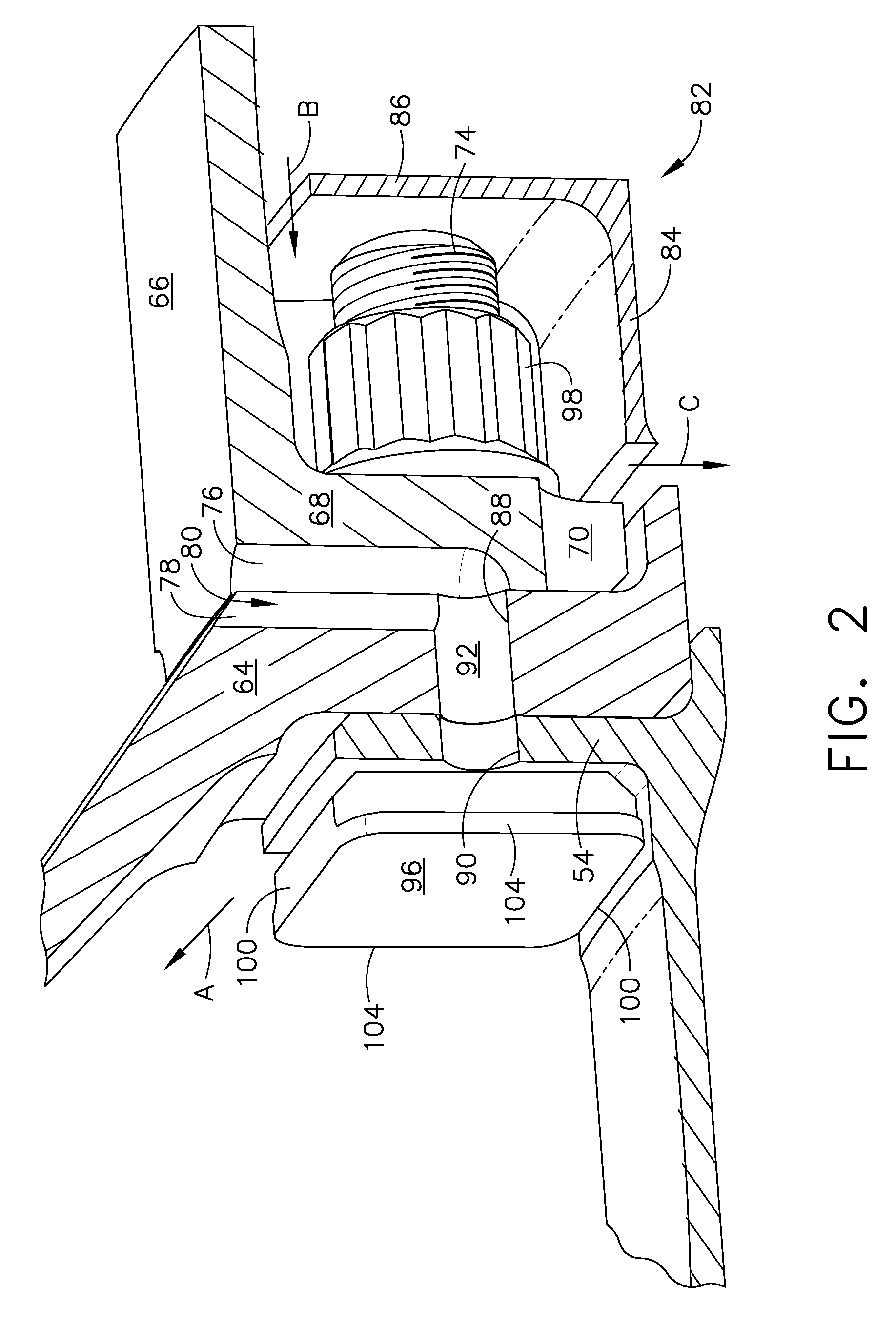

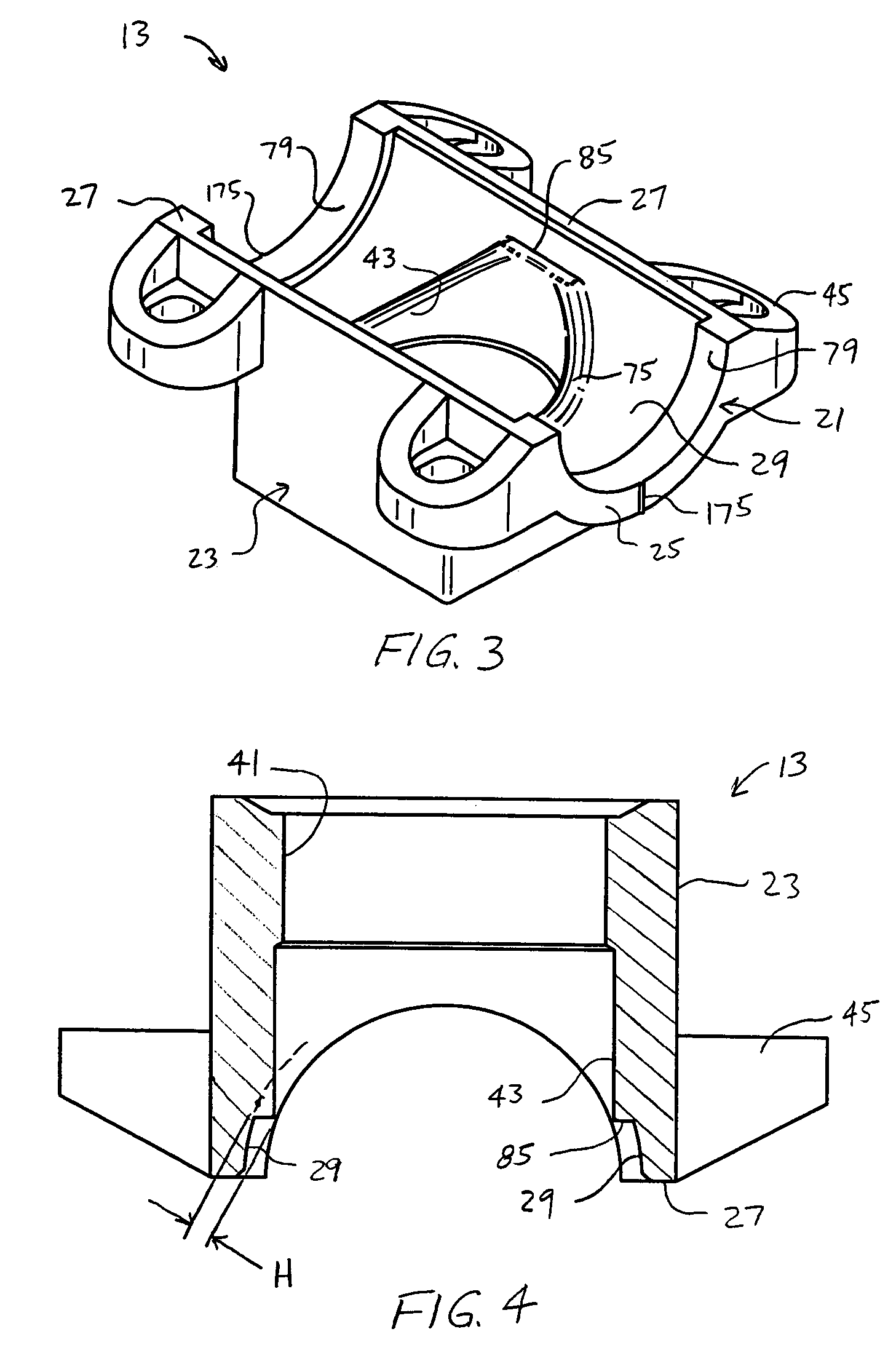

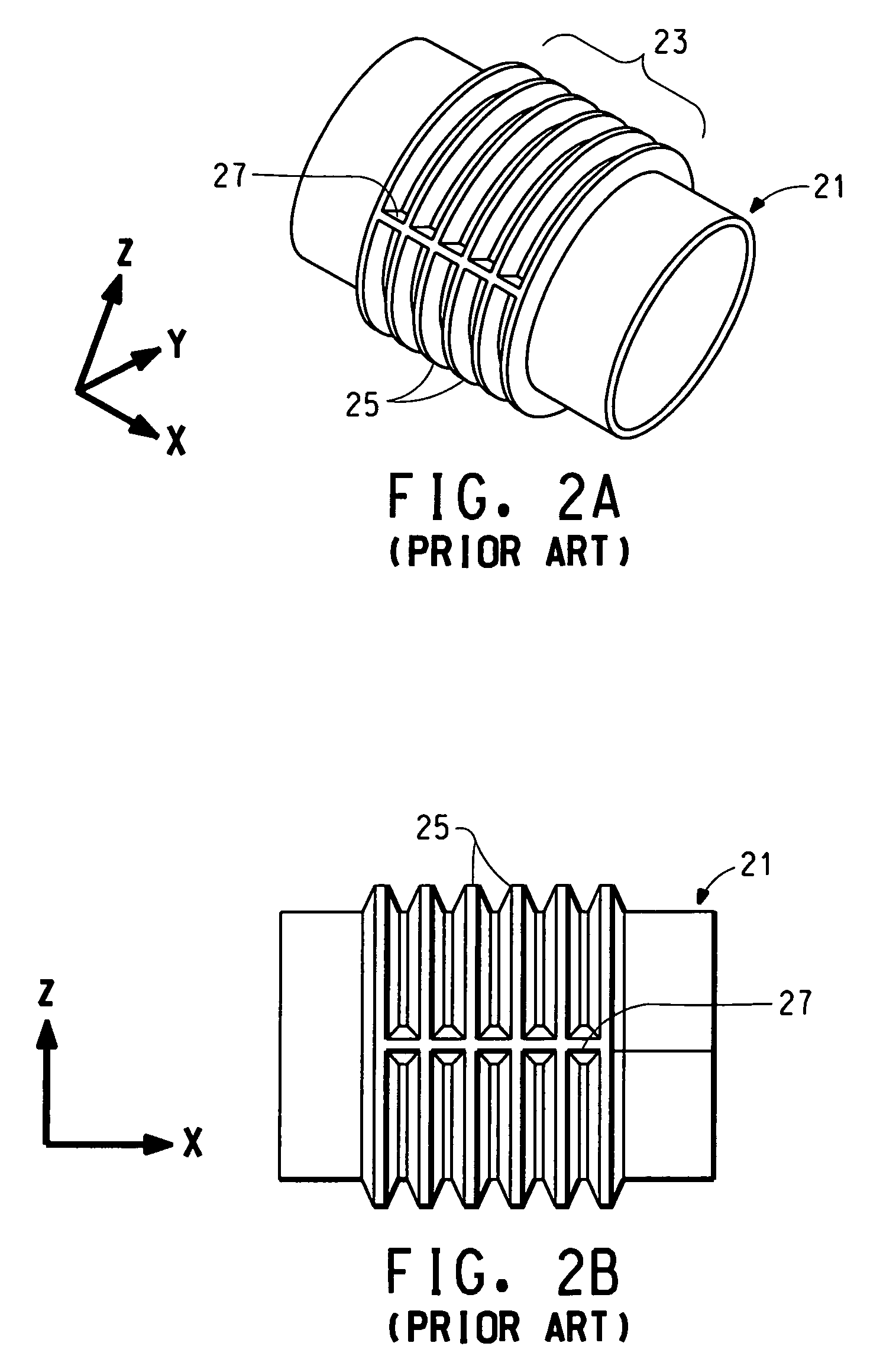

Tubing fitting

ActiveUS7523967B2Engage with obstructionSleeve/socket jointsPipeline expansion-compensationShaft collarBiomedical engineering

A tubing fitting for use in microsurgery including a female tubing fitting and a male tubing fitting. The female tubing fitting has an external surface with a pair of opposing projections disposed thereon and an internal bore. The male tubing fitting has a second internal bore and a collar at least partially surrounding the second internal bore. The collar has an internal surface with two pairs of opposing sloping ramps disposed thereon. The pairs of opposing sloping ramps are arranged so as to create a pair of opposing spaces for removably receiving the pair of opposing projections.

Owner:ALCON INC

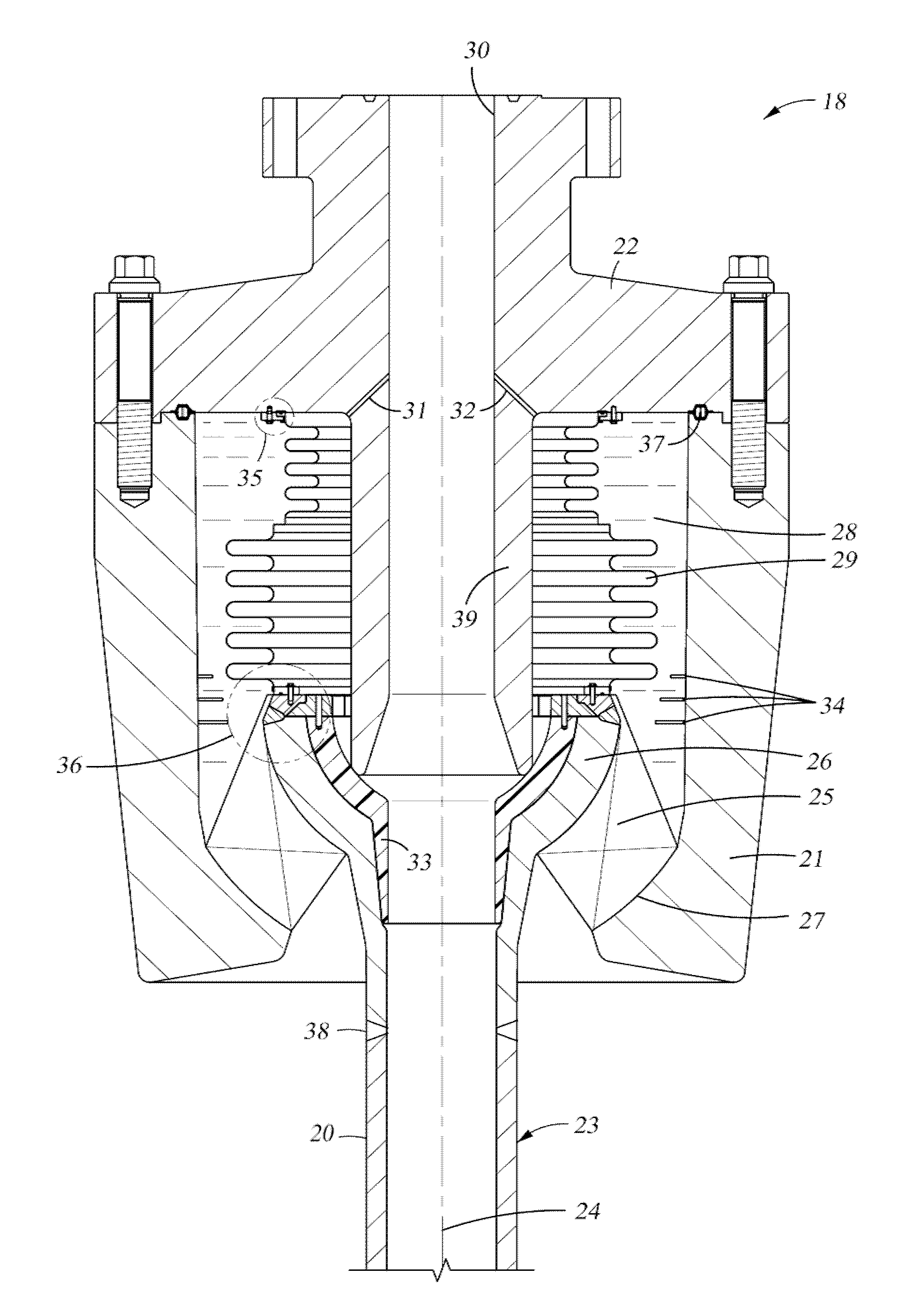

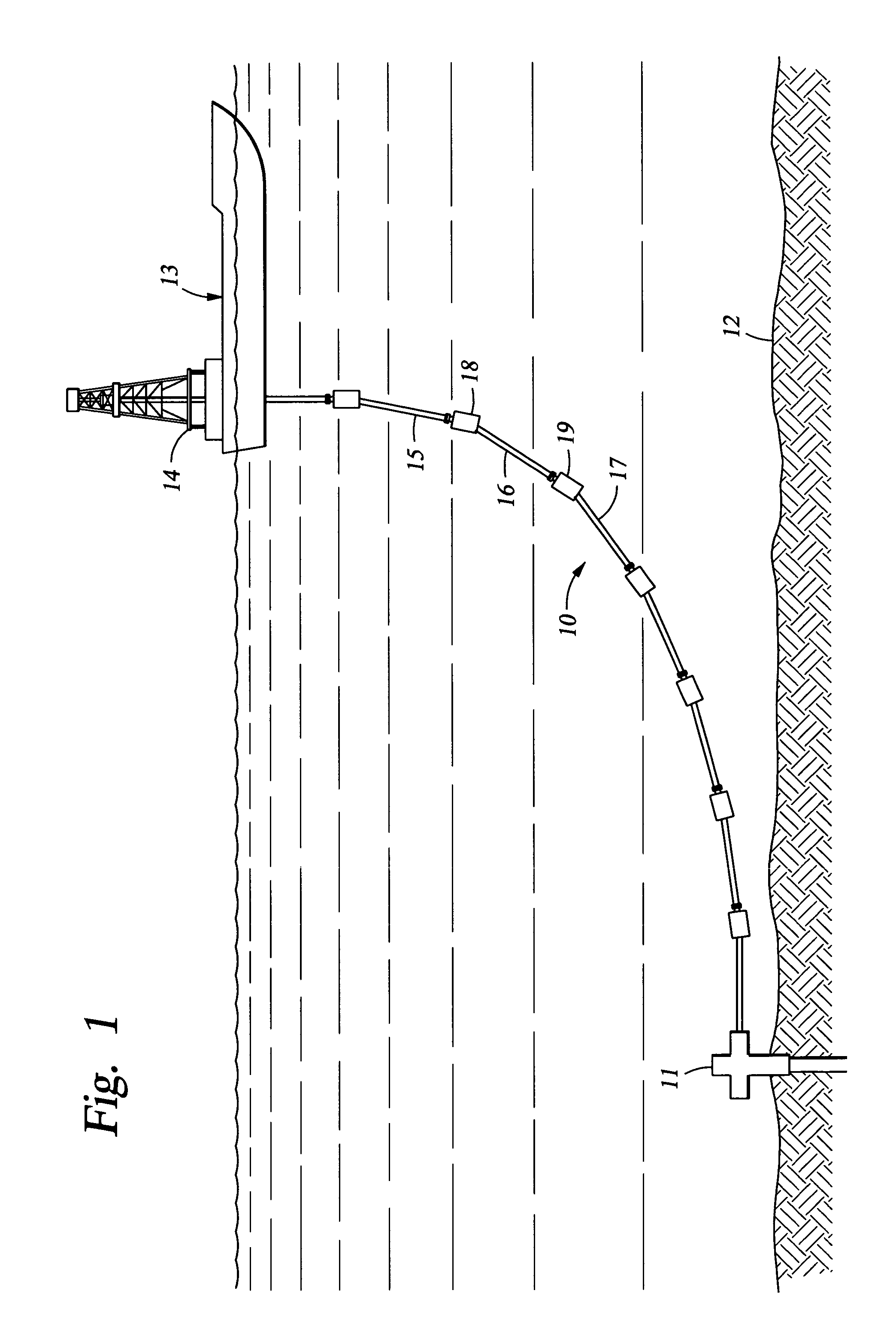

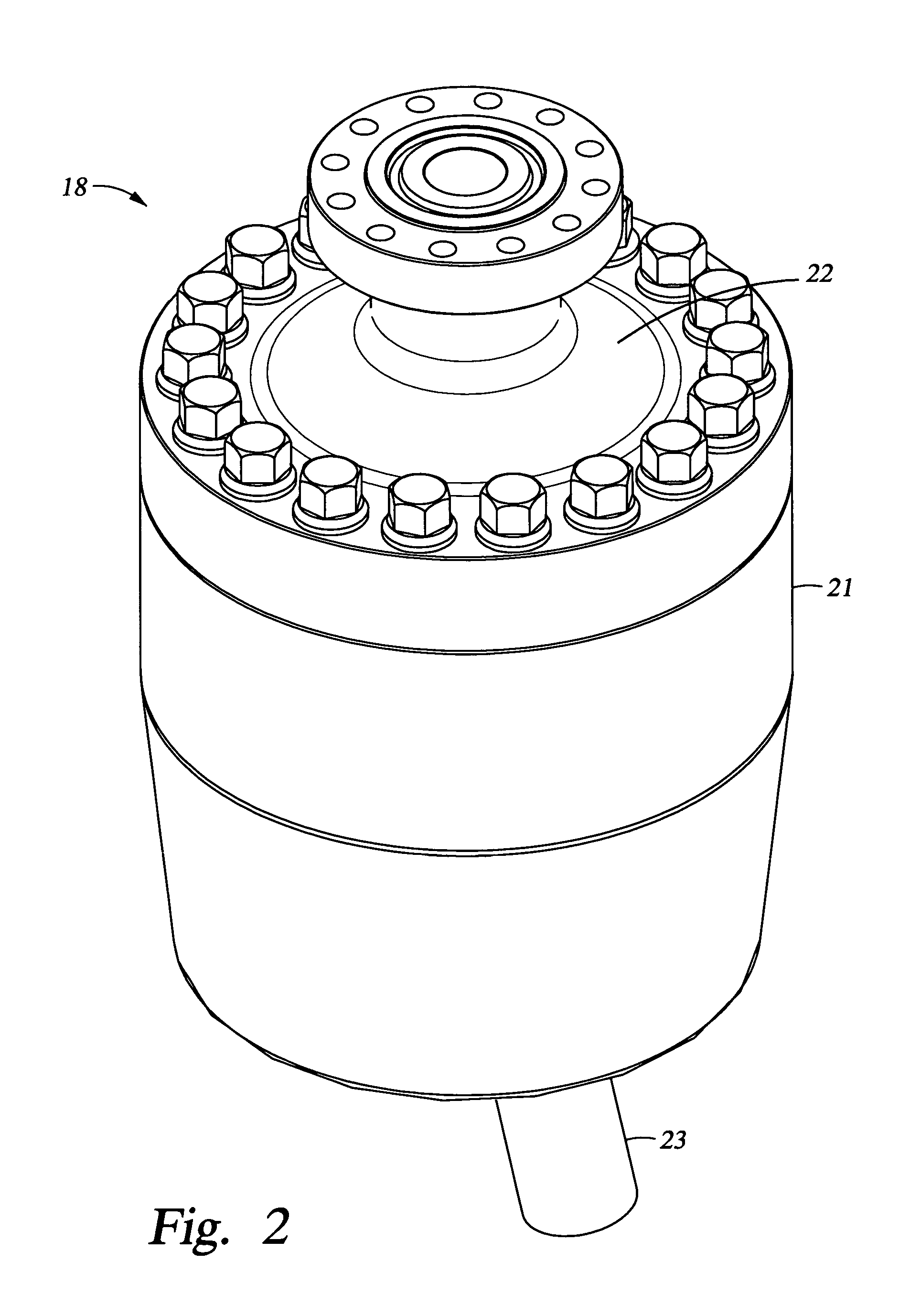

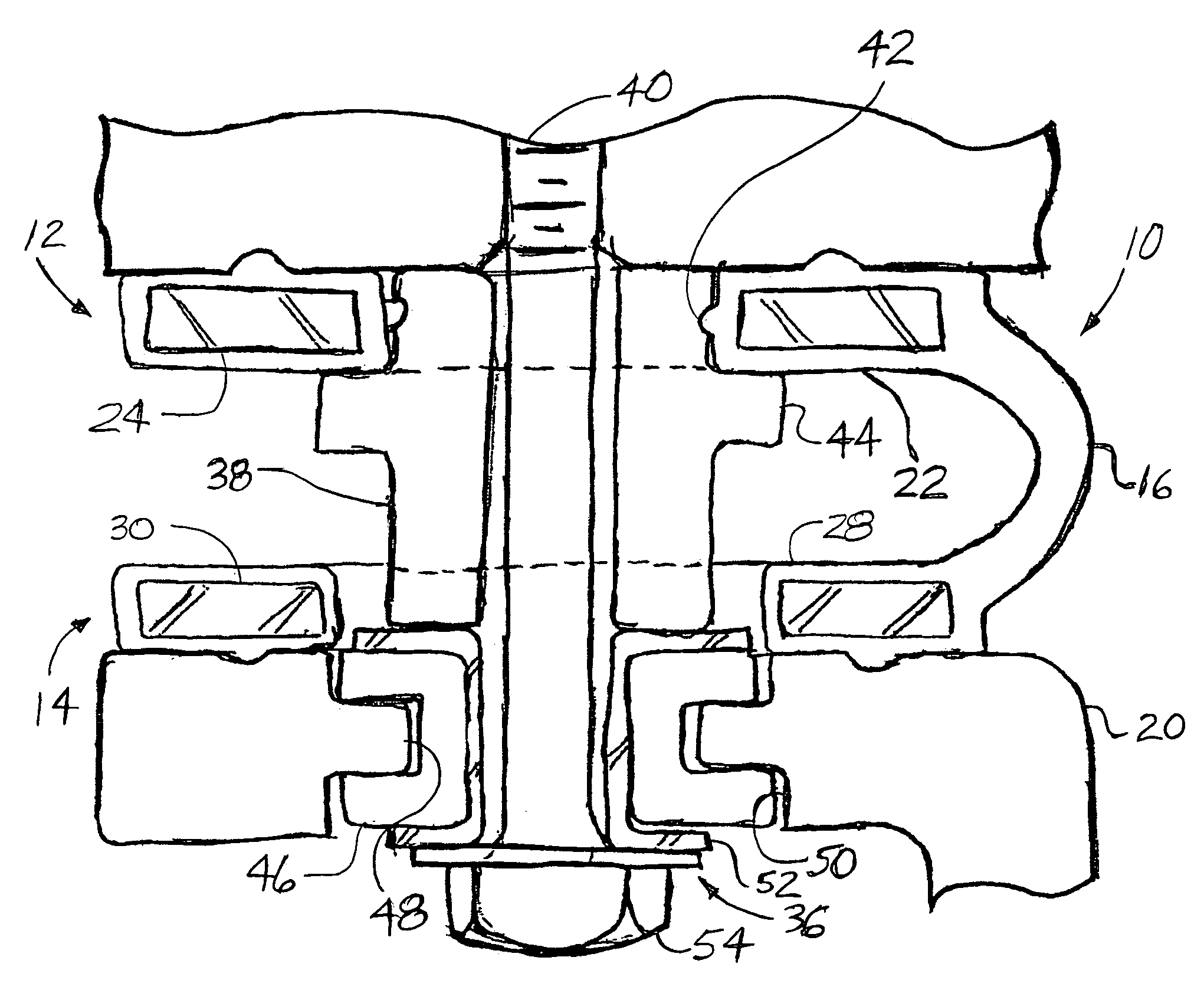

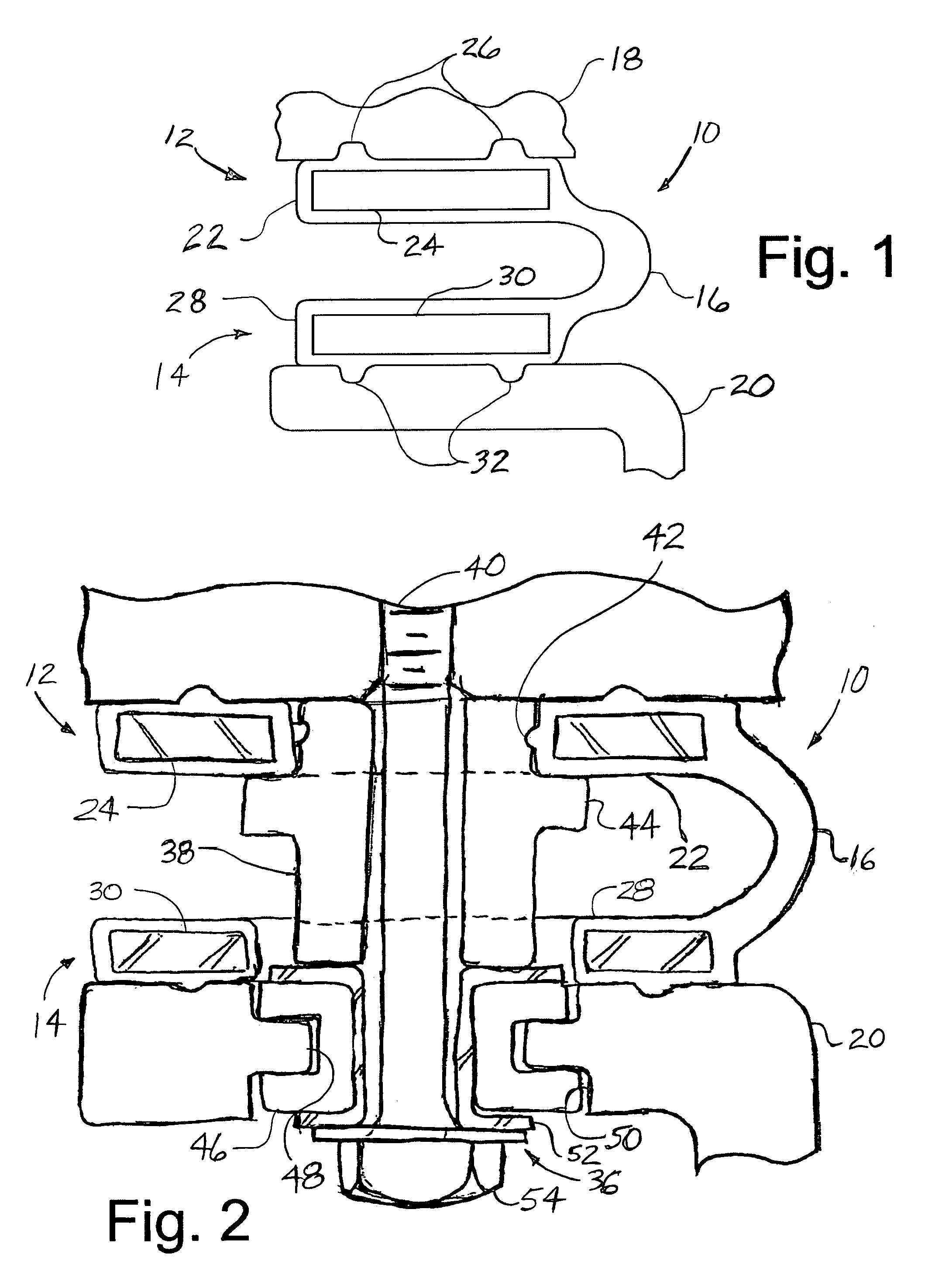

High temperature flexible pipe joint

For continuous high temperature operation over a service life in excess of twenty years, a flexible pipe joint includes various features that tend to reduce the temperature of the load-bearing flex element or reduce strain in the warmer elastomeric layers of the flex element. These features include a heat shield of low heat conductivity material integrated into the inner profile of the pipe extension and interposed between the central bore of the pipe joint and the flex element, low heat conductivity metal alloy components between the hot production fluid and the flex element, high temperature resistant elastomer at least in the warmest inner elastomer layer of the flex element, and a flex element constructed to shift strain from the warmer inner elastomer layers to the colder outer elastomer layers by providing greater shear area, different layer thickness, and / or higher elastic modulus elastomer for the warmer inner elastomer layers.

Owner:WELLS FARGO BANK NAT ASSOC +1

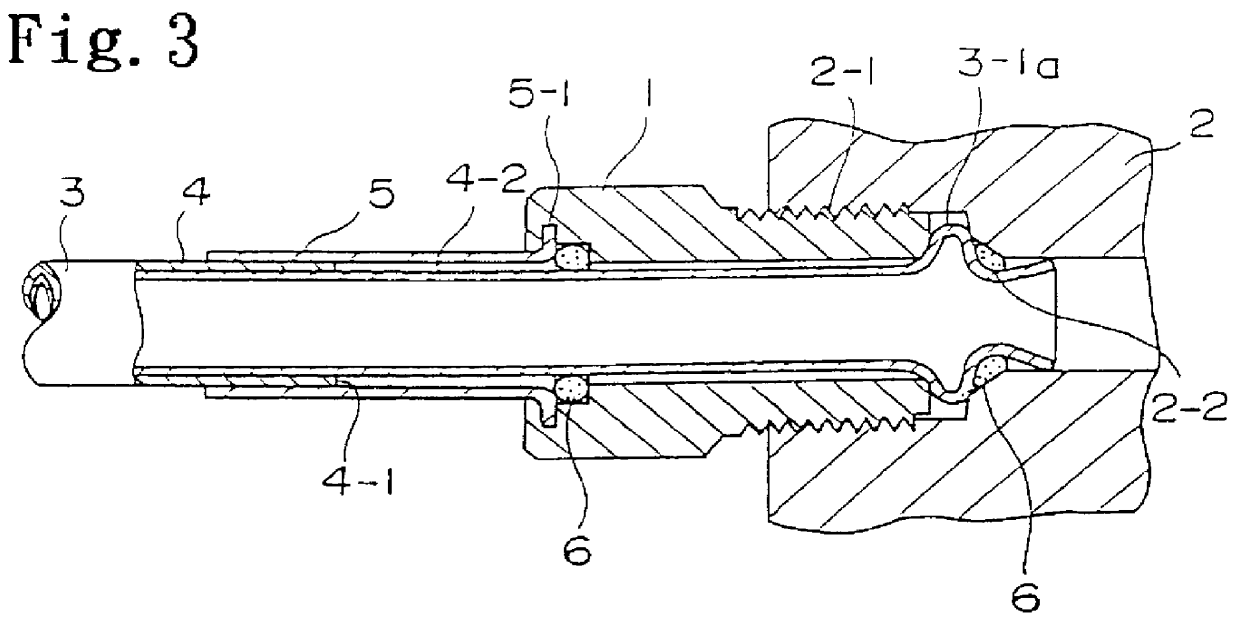

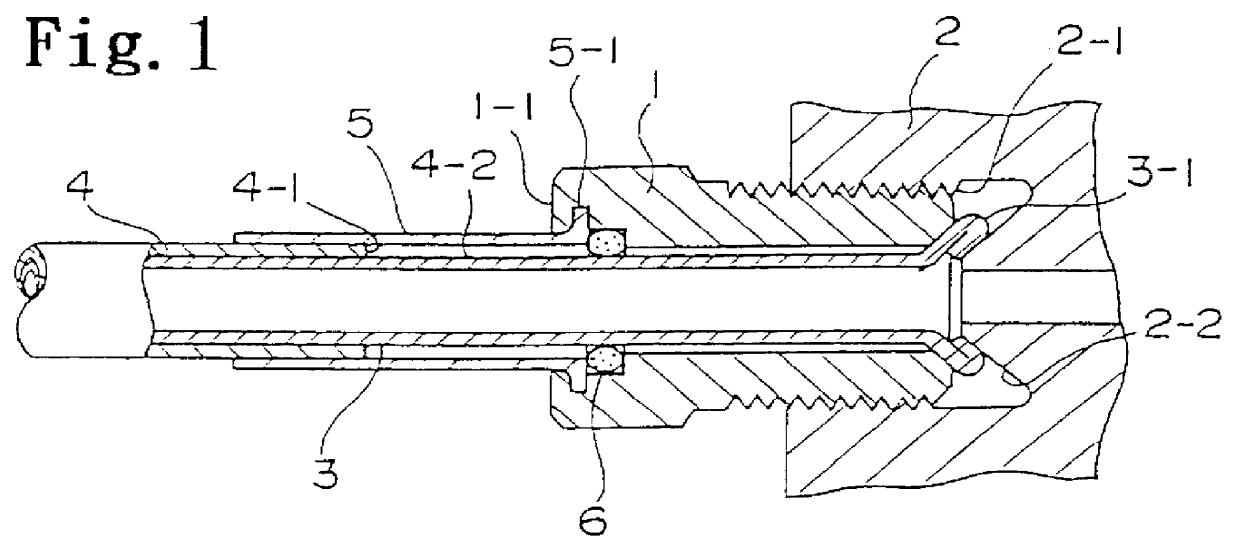

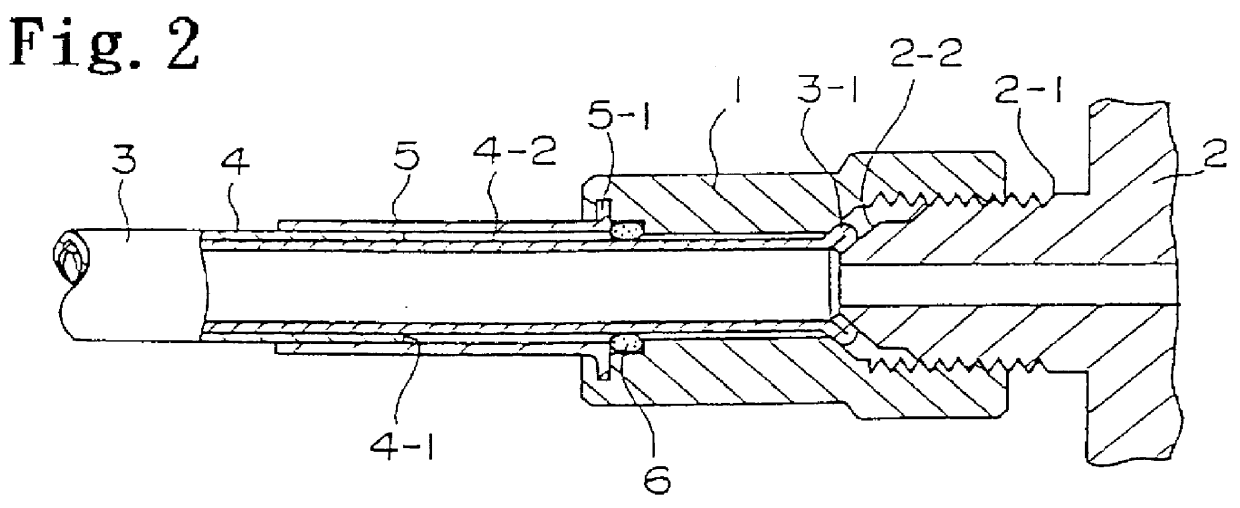

Connecting structure of externally resin-coated small-diameter metallic pipe

A connecting structure of an externally resin-coated small-diameter metallic pipe having an excellent corrosion-resistant property with respect to a mating member is provided. According to the present invention, a resin-uncovered portion of the metallic pipe provided for applying an end processing thereon is completely covered with a protective pipe made of a resin material so that the processed pipe can be connected with the mating member without spoiling its anti-chipping property and an anti-splashing property of the metallic pipe over the entire length thereof. With the exception of the end of the metallic pipe corresponding to the margin at least required for applying an end processing on the pipe, the pipe is covered with an extrusion-moldable thick film-like resin and is connected with a mating member by means of a clamp nut assembled to the pipe end so as to be screw-fitted with the mating member. The connecting structure according to this invention features that one end of a resin pipe is fitted about the above-described resin coated layer on the metallic pipe while the other end of the resin pipe is inserted into, or fitted about, the clamp nut and the resin pipe is fixed to the clamp nut at least at a single portion thereof.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

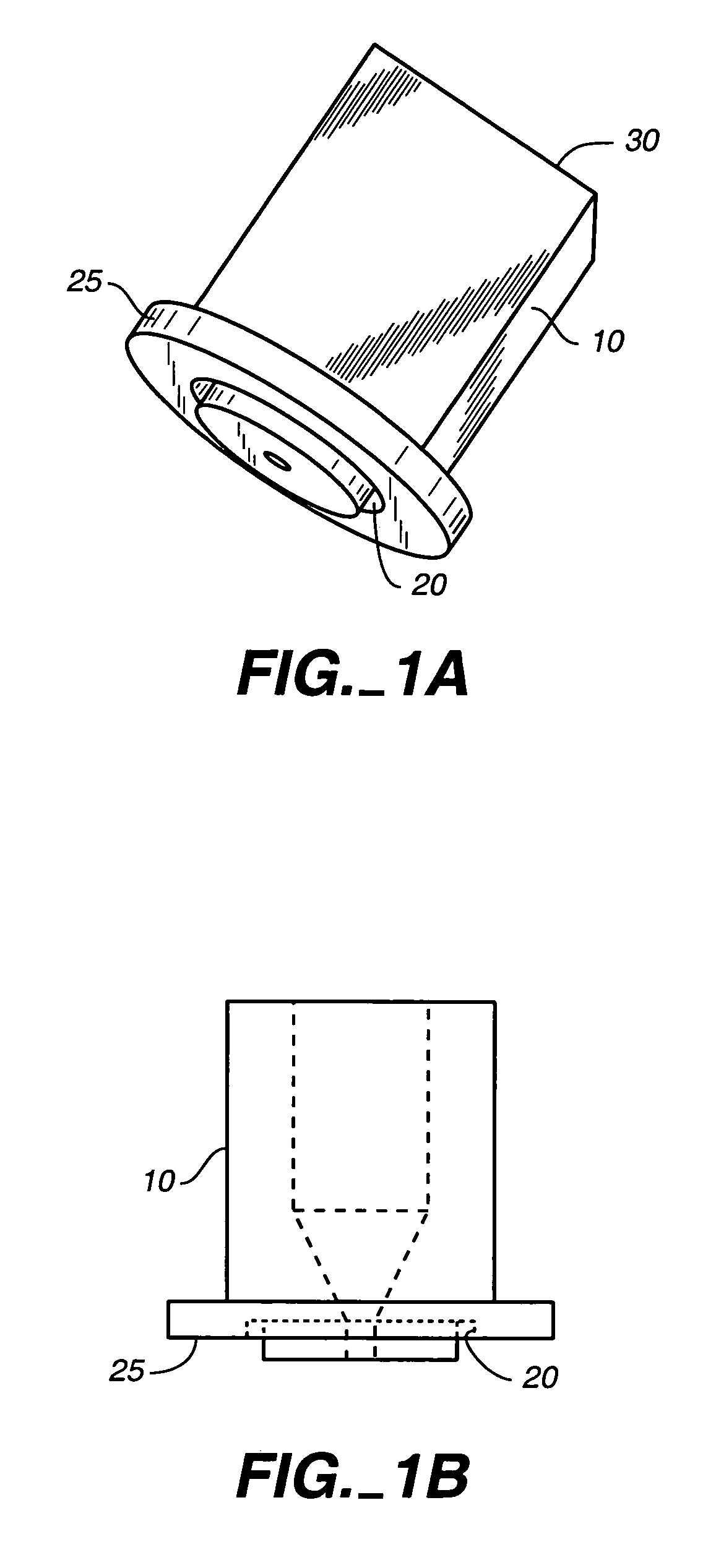

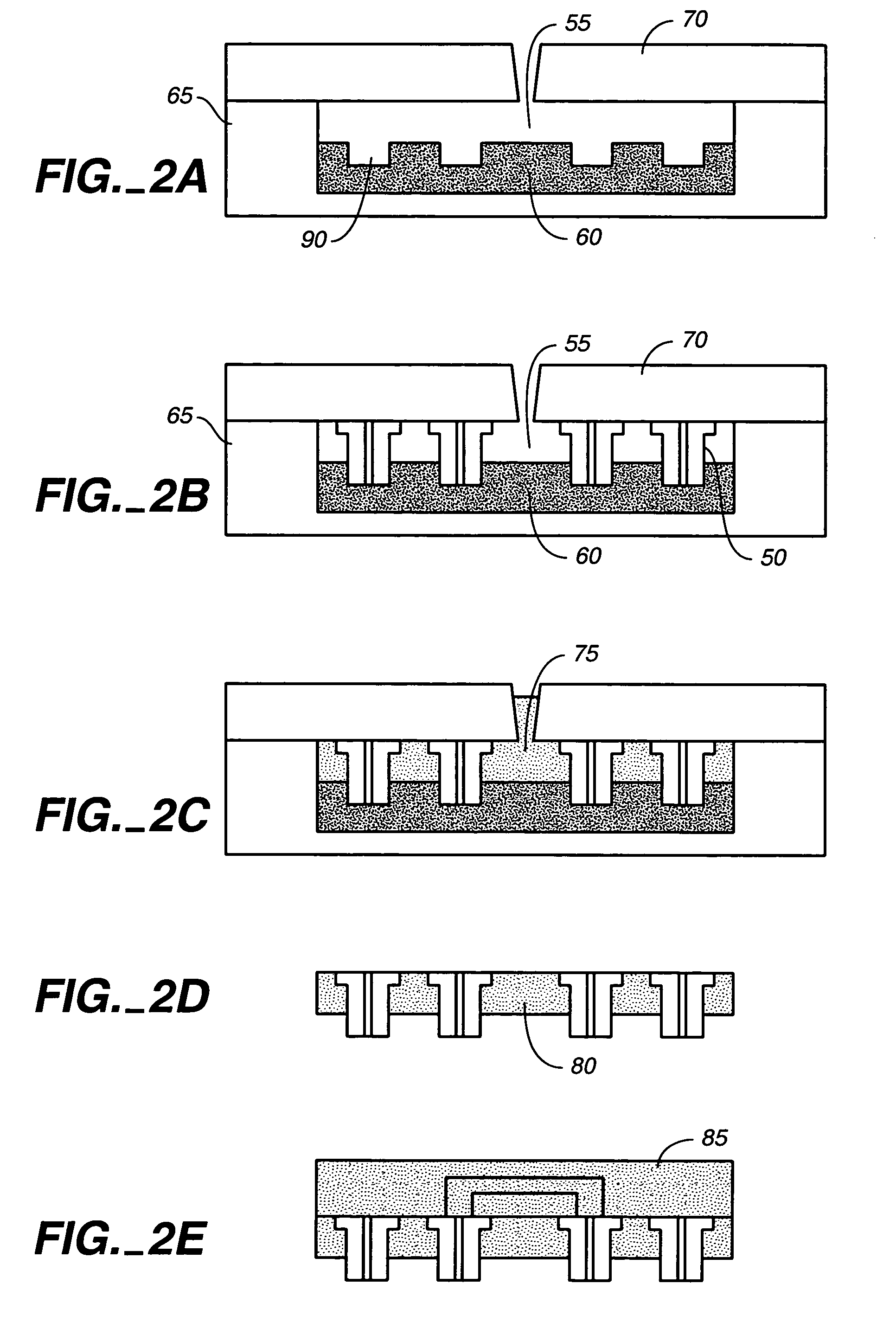

Microfluidic structures and methods for integrating a functional component into a microfluidic device

InactiveUS7351380B2Valve arrangementsPipeline expansion-compensationSolid substrateMaterials science

Owner:SANDIA NAT LAB

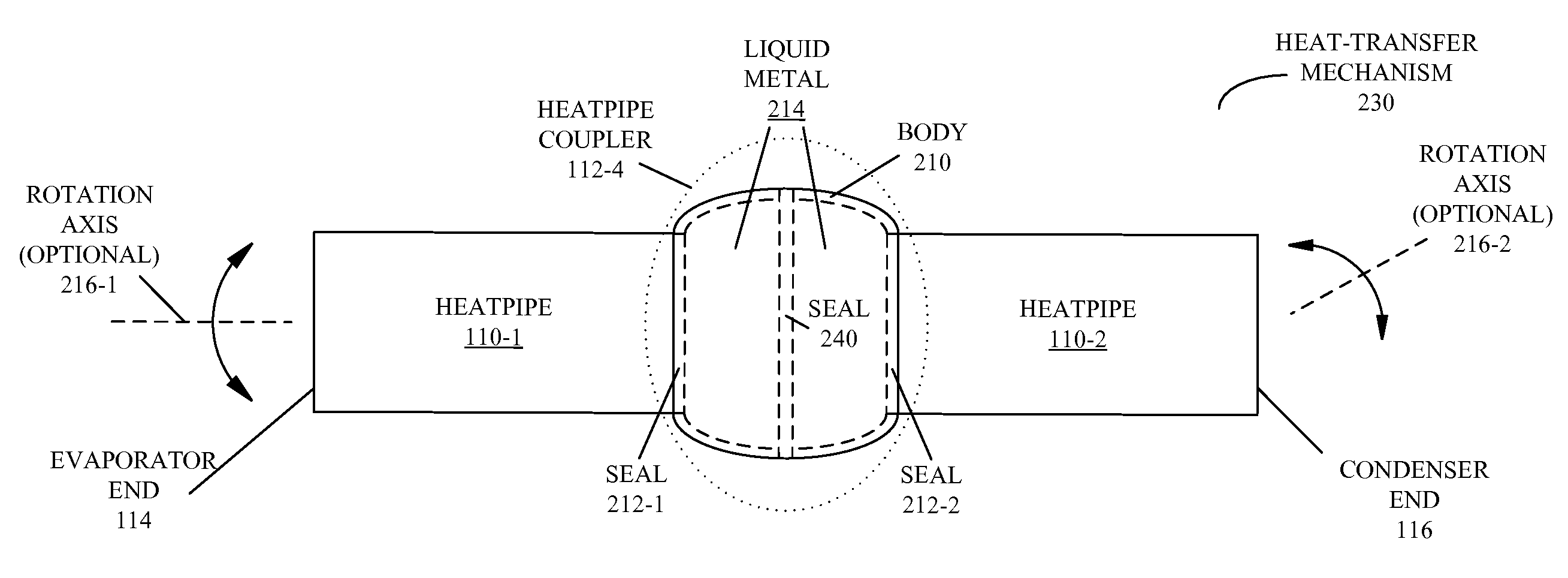

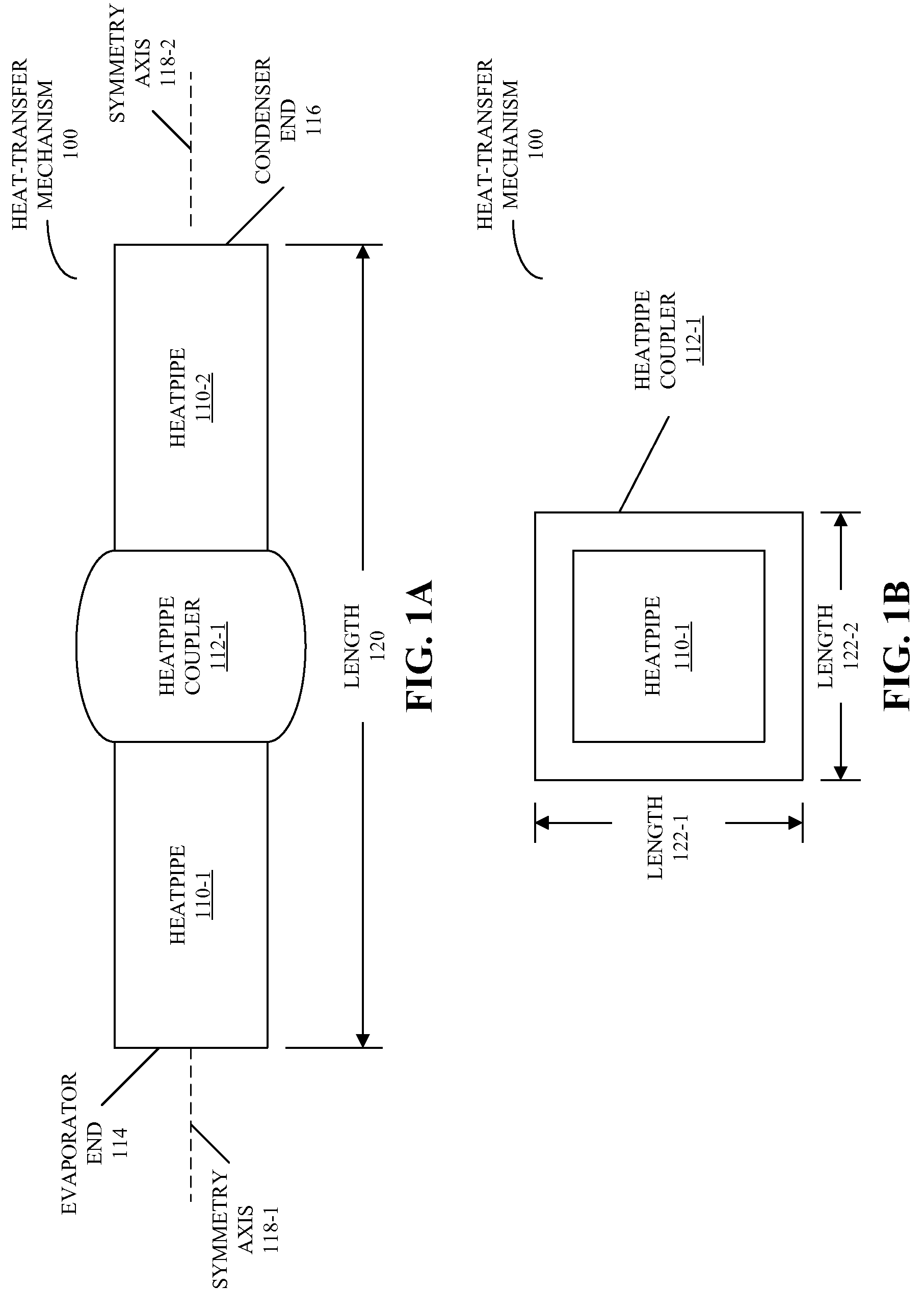

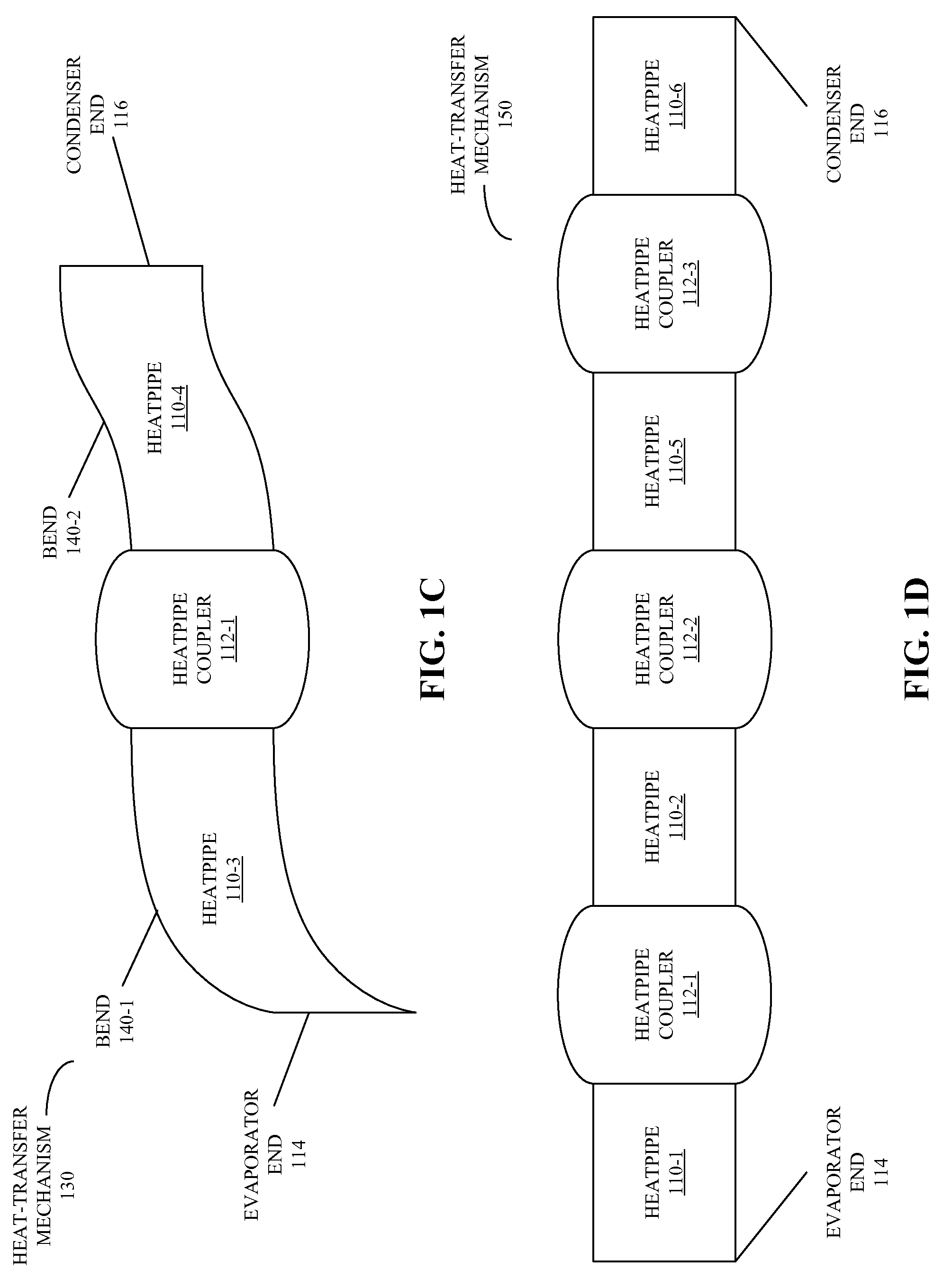

Heat-transfer mechanism including a liquid-metal thermal coupling

Embodiments of a heat-transfer mechanism are described. This heat-transfer mechanism includes a first heatpipe having a first end and a second end, and a second heatpipe having a third end and a fourth end. Moreover, a heatpipe coupler is thermally coupled to the second end of the first heatpipe and the third end of the second heatpipe. This heatpipe coupler includes a housing surrounding a cavity and a liquid metal contained within the cavity, thereby providing a thermal path from the first end of the first heatpipe, which is configured to couple to a condenser, to the fourth end of the second heatpipe, which is configured to couple to an evaporator.

Owner:APPLE INC

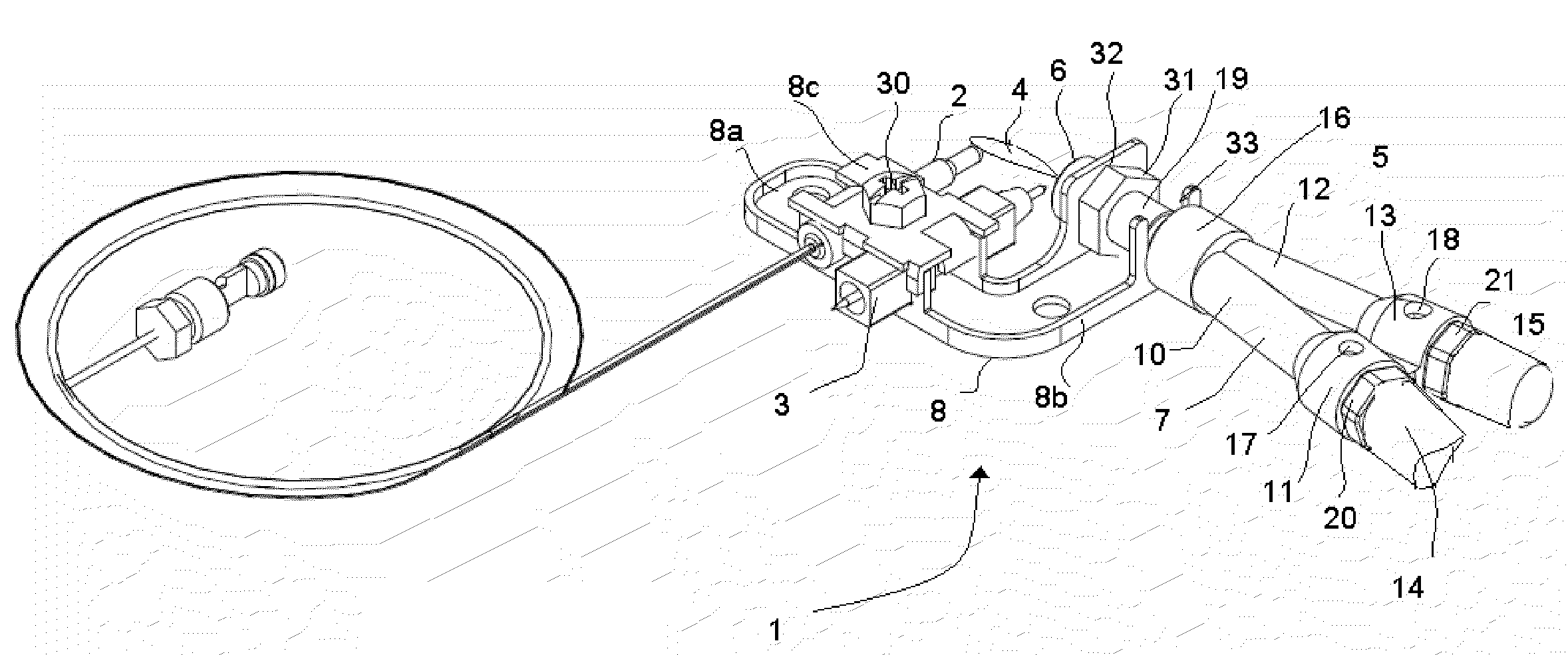

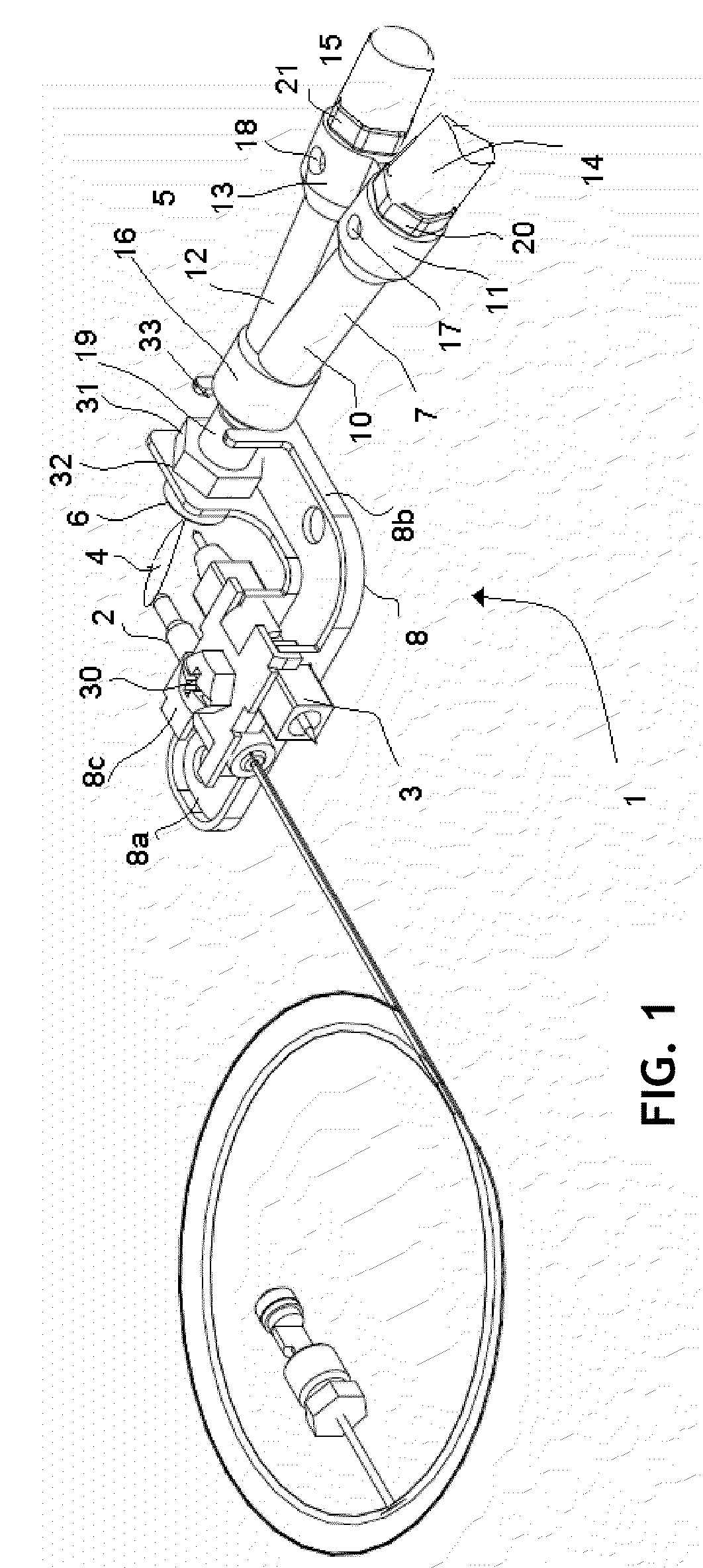

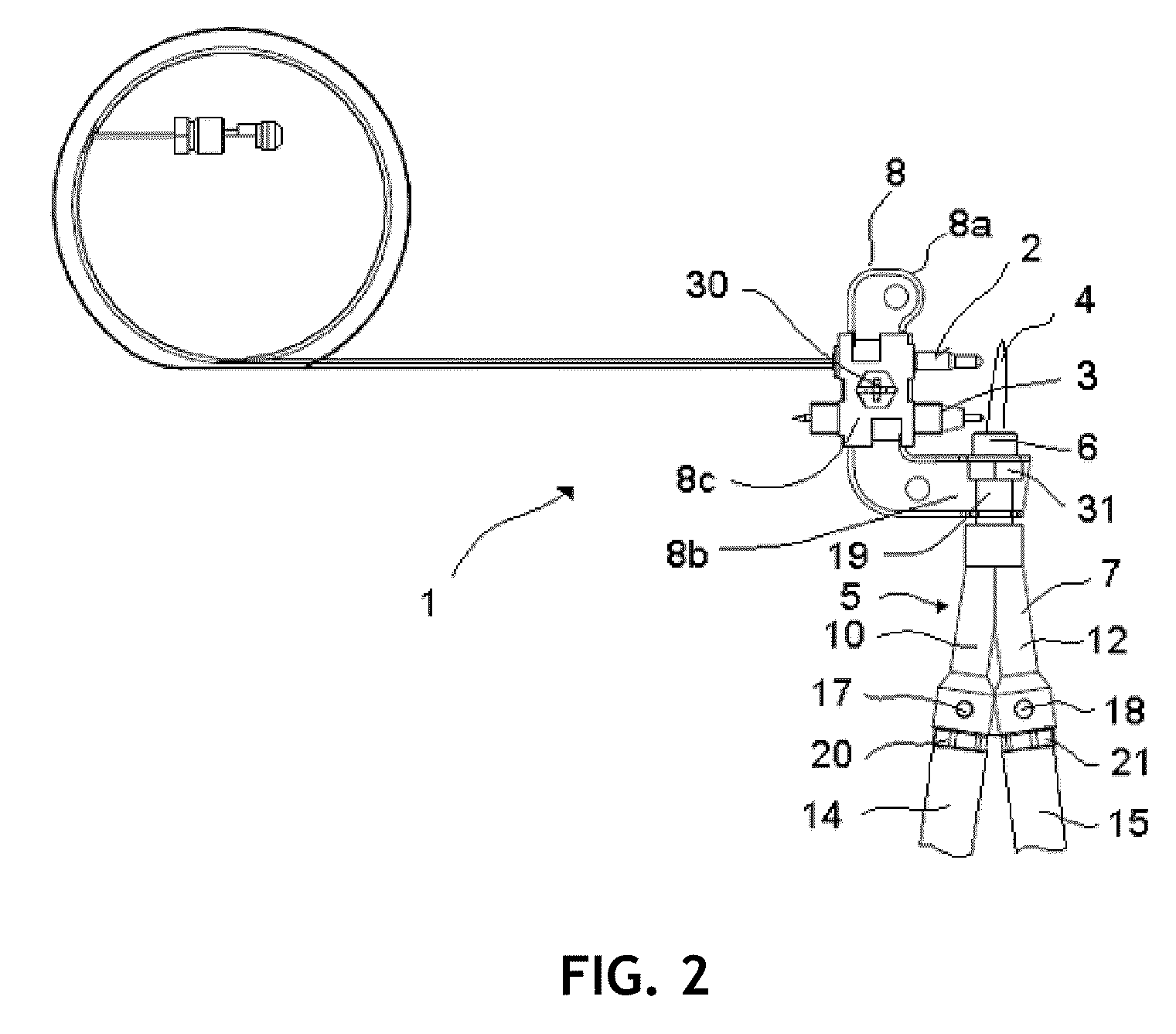

Multiple gas pilot burner

ActiveUS20090280448A1Small sizeLow costIncandescent ignitionPipeline expansion-compensationPower flowThermocouple

A multiple gas pilot burner assembly for a household heating appliance. The pilot burner includes an injector having a first conduit for receiving a flow of a first combustible fluid, a second conduit for receiving a flow of a second combustible fluid and a third conduit connected to and in fluid communication with the first and second conduits which is configured to receive the flow of the first combustible fluid from the first conduit or the flow of the second combustible fluid from the second conduit. A single nozzle at the outlet of the third conduit is provided for supplying a pilot flame. The assembly also includes a single flame igniter positioned to cause an ignition of the pilot flame at the nozzle and also a single thermocouple positioned to be heated by the pilot flame and to generate an electrical current when heated.

Owner:COPRECITEC

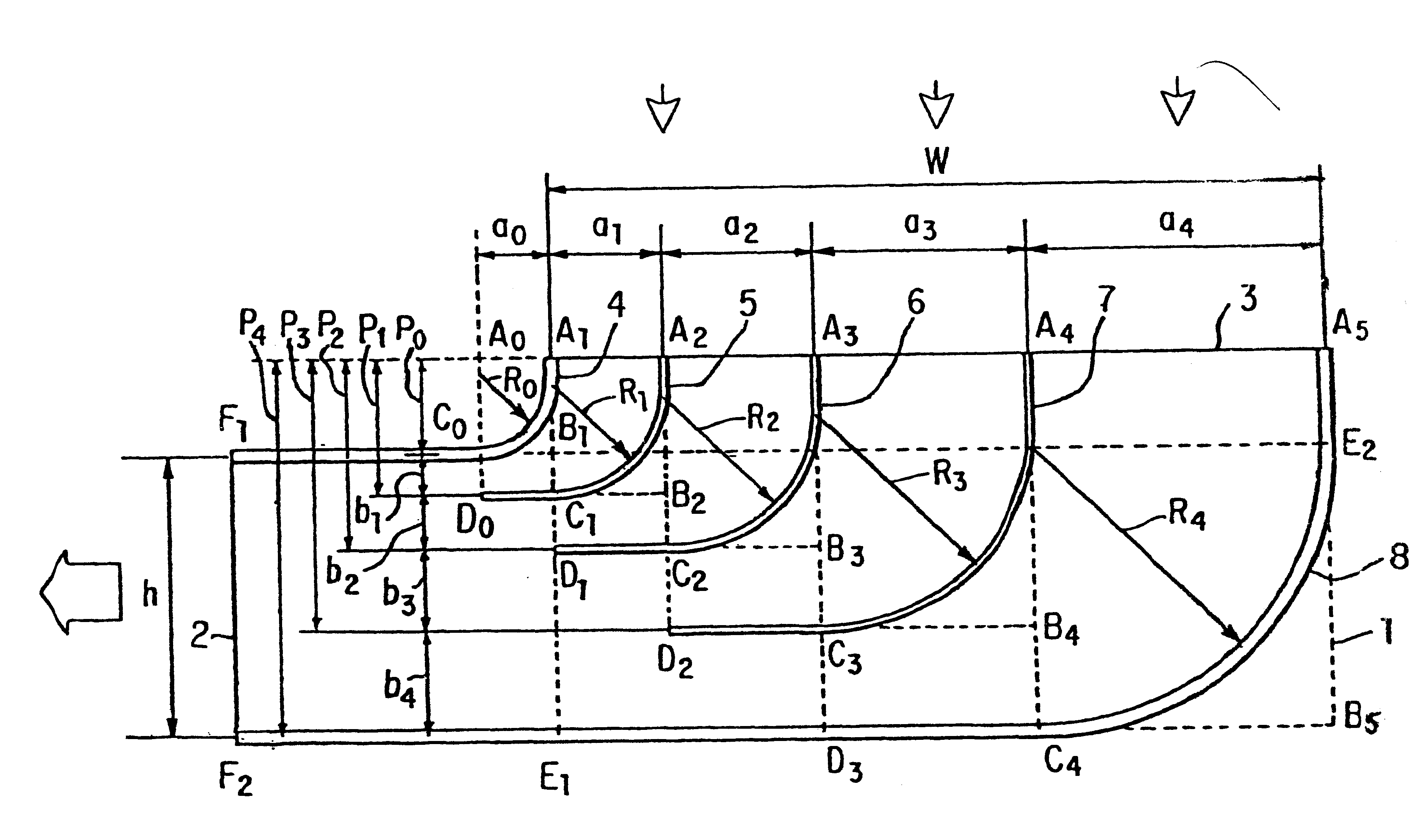

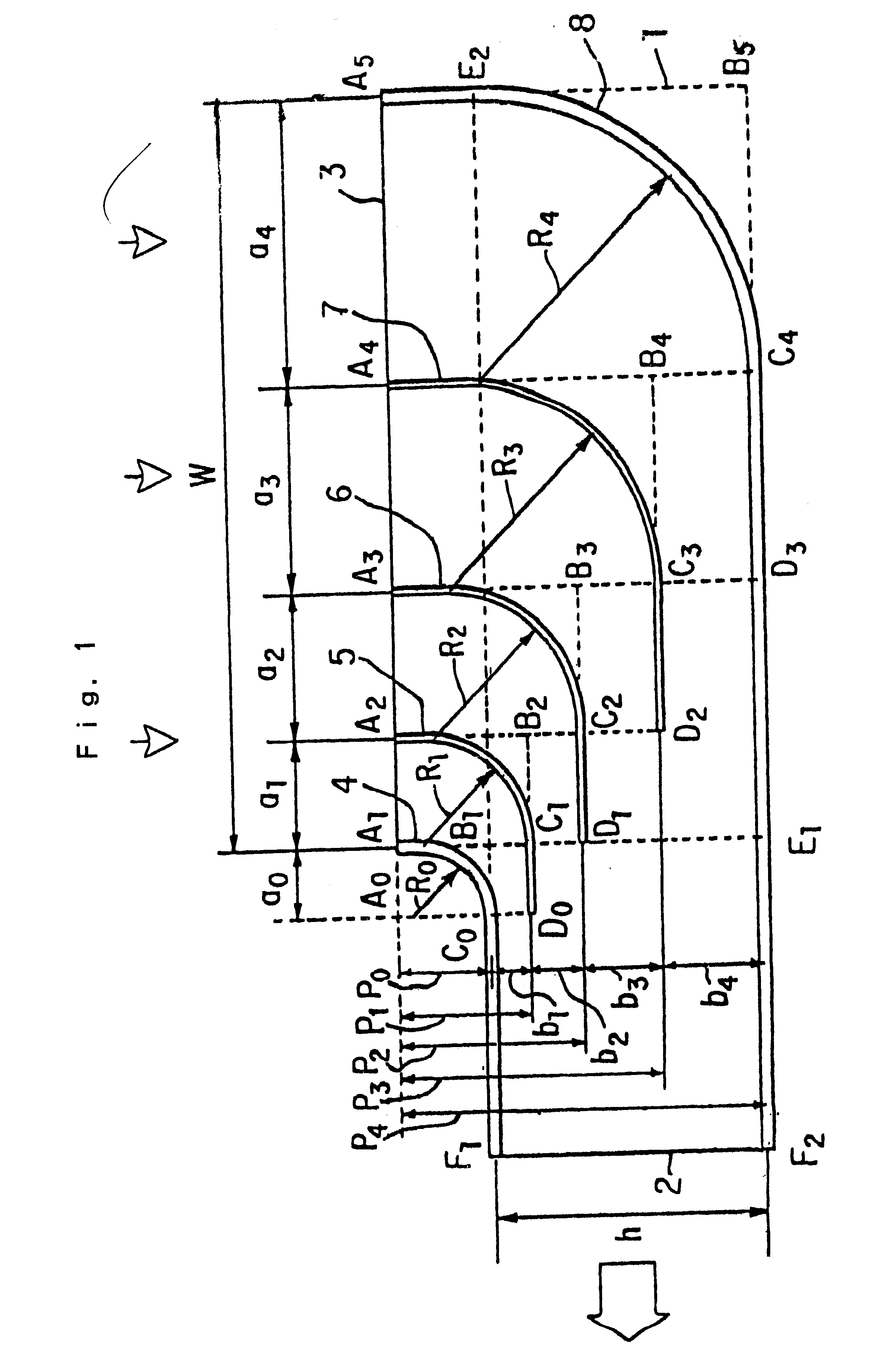

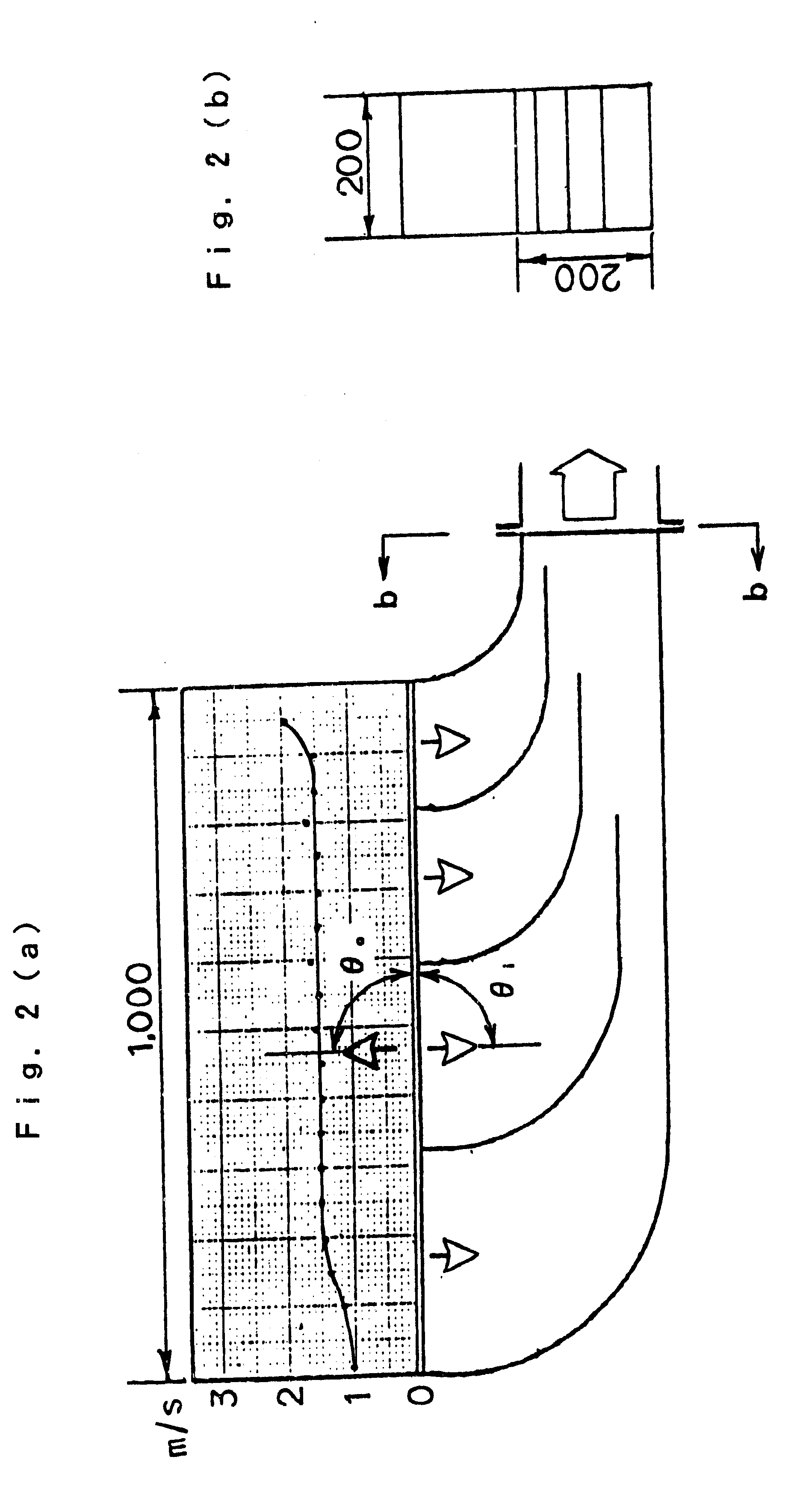

Suction elbow provided with built-in guide blades

InactiveUS6290266B1Evenly distributedSmall pressure lossPipeline expansion-compensationPump componentsEngineeringElbow

A suction elbow is divided in a plurality of sub-channels similar to each other by one or more guide vanes made of a curved plate and flat plates connected to the curved plate based on the following formulas.p0: overhang length at the inlet of the elbowh: outlet breadth of the elbowf: reduction ratio of the elbow (f=W / h)W: inlet breadth of the elbowm: number of sub-channels (m>=2)an: inlet breadth of n-th sub-channel (a0 indicates the radius of curvature of the inner side wall and am indicates the radius of curvature of the outer side wall)r: aspect ratio of the sub-channelsbn: outlet breadth of n-th sub-channel

Owner:KAWANO MICHIHIKO

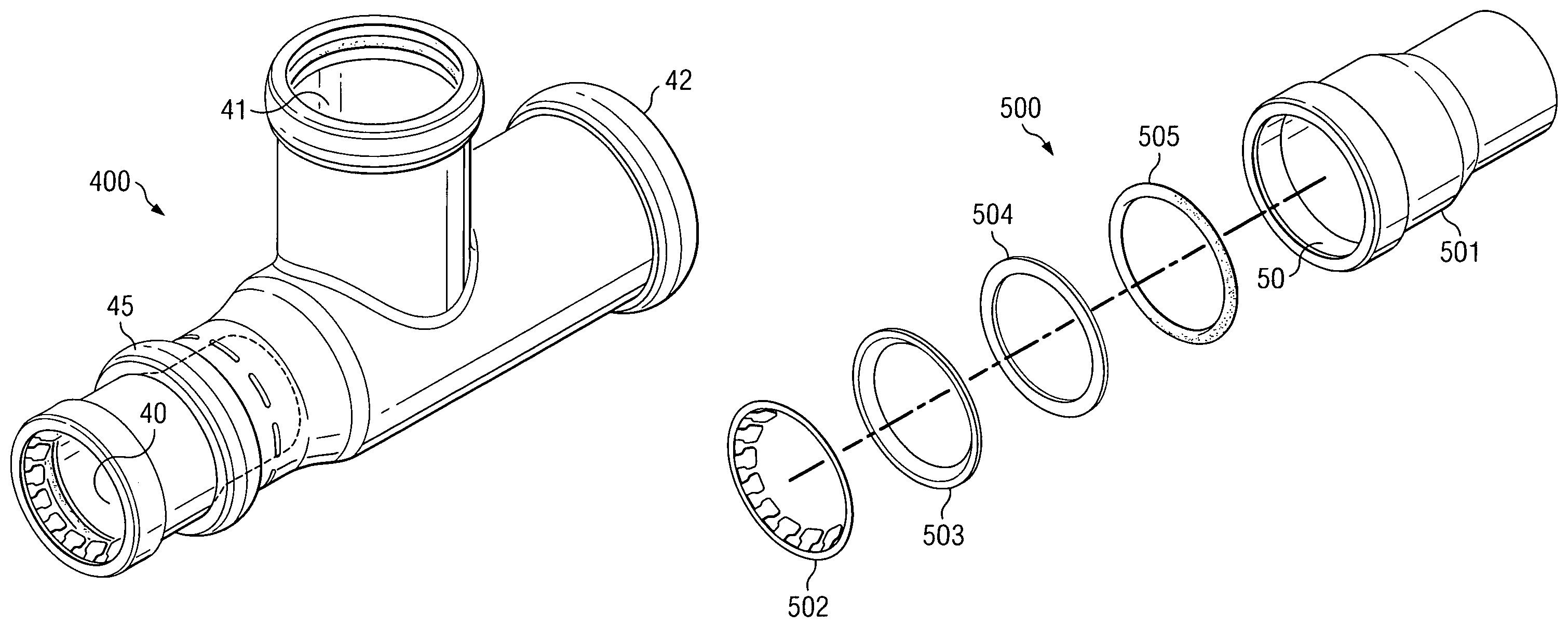

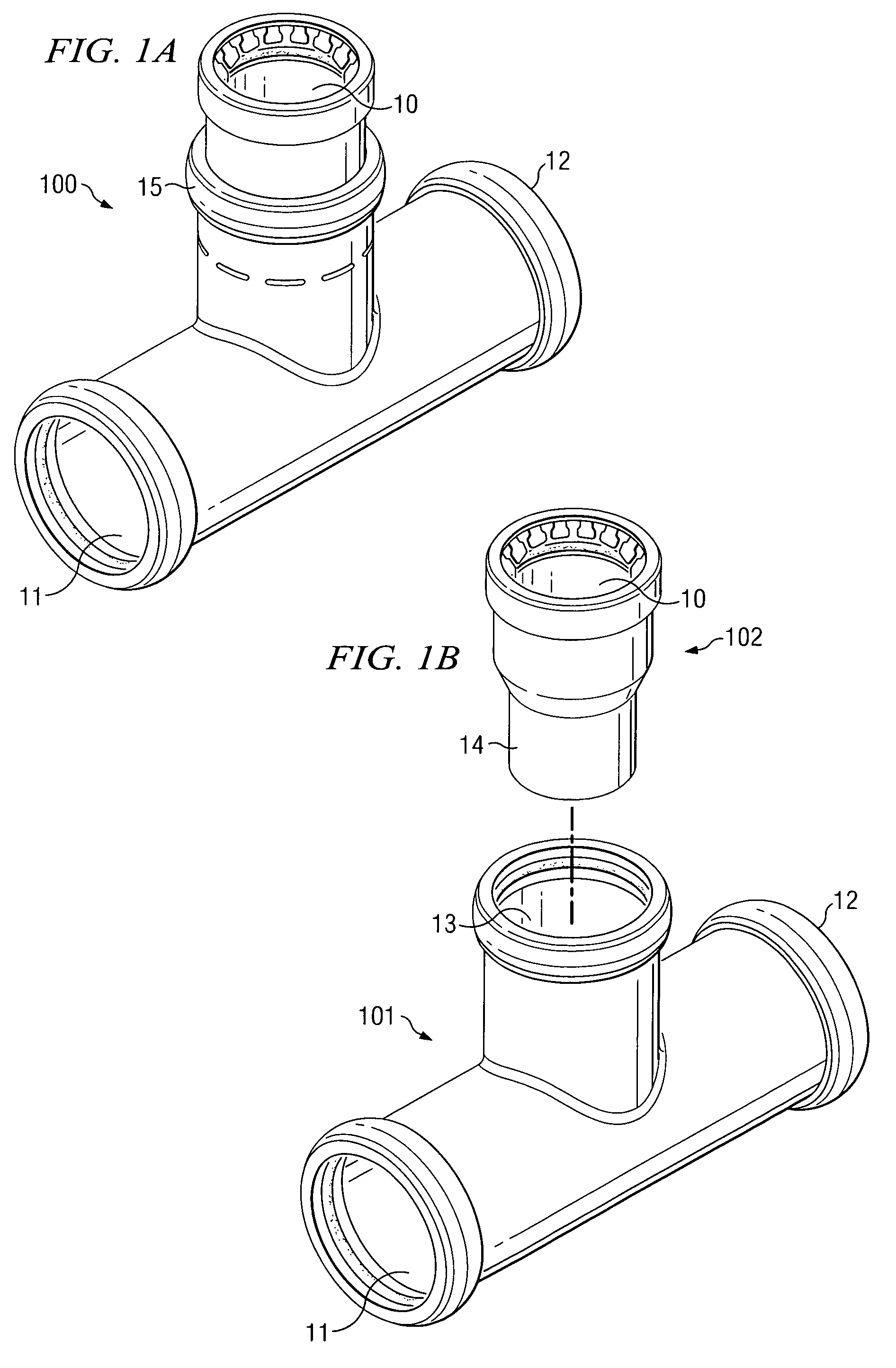

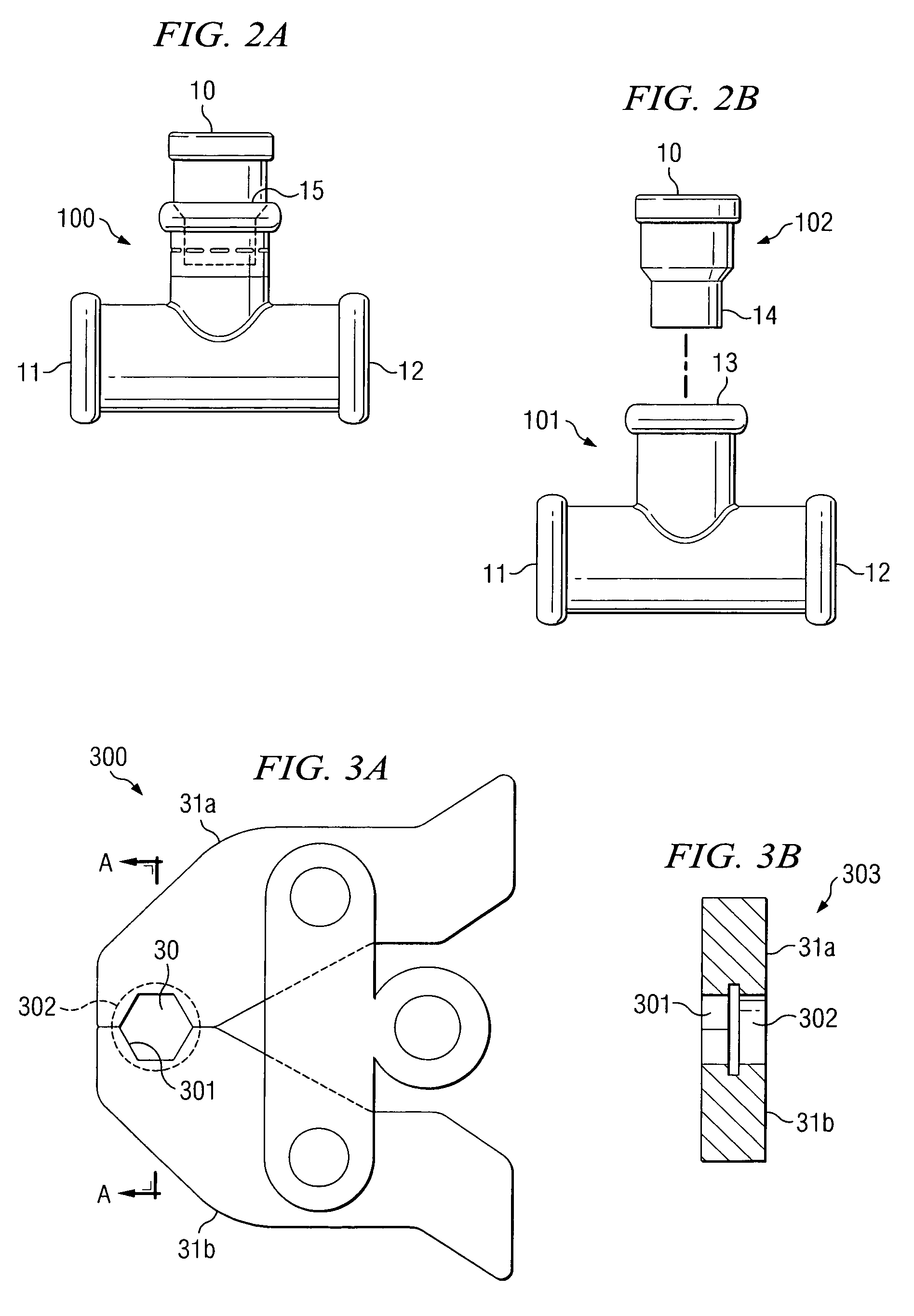

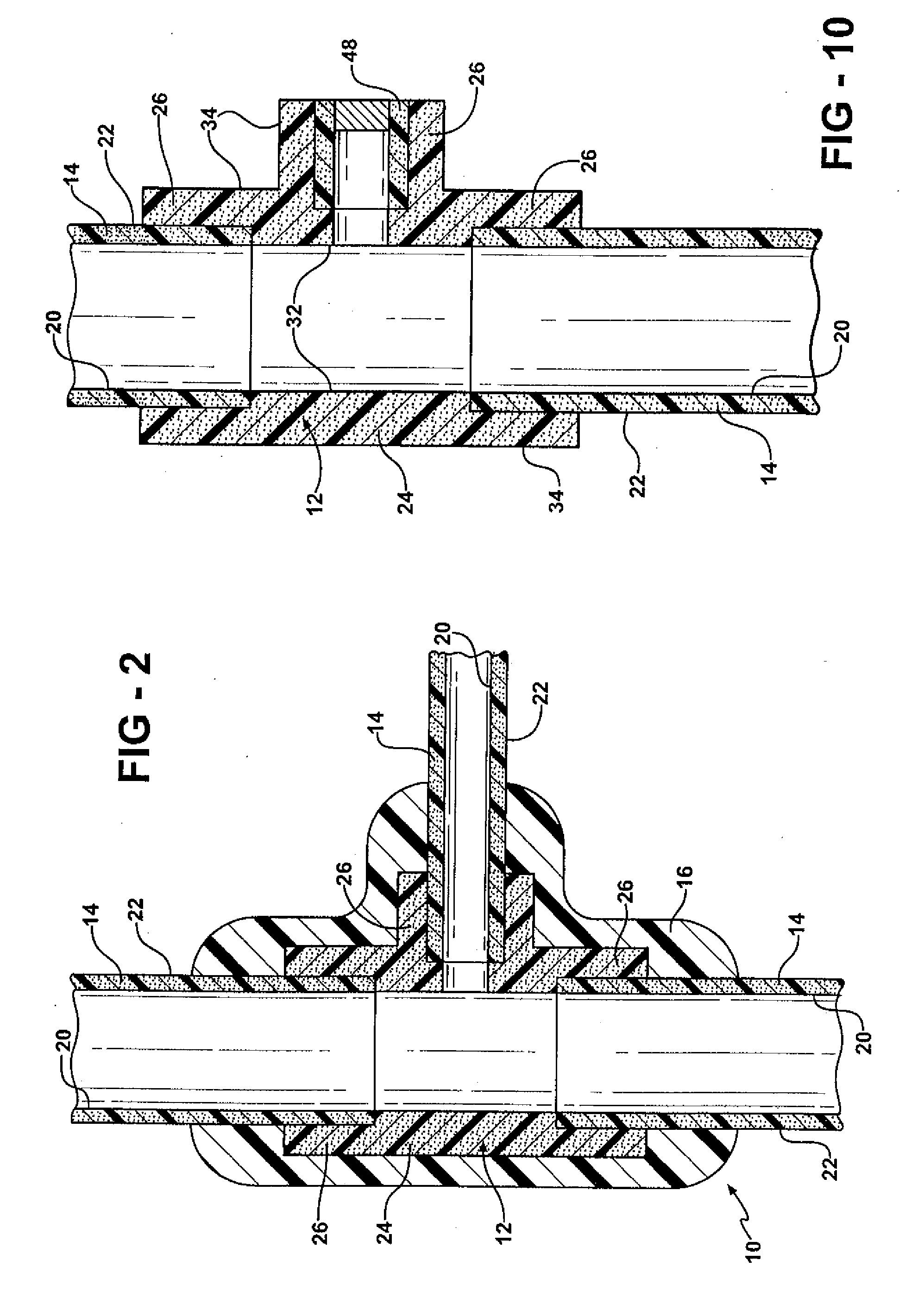

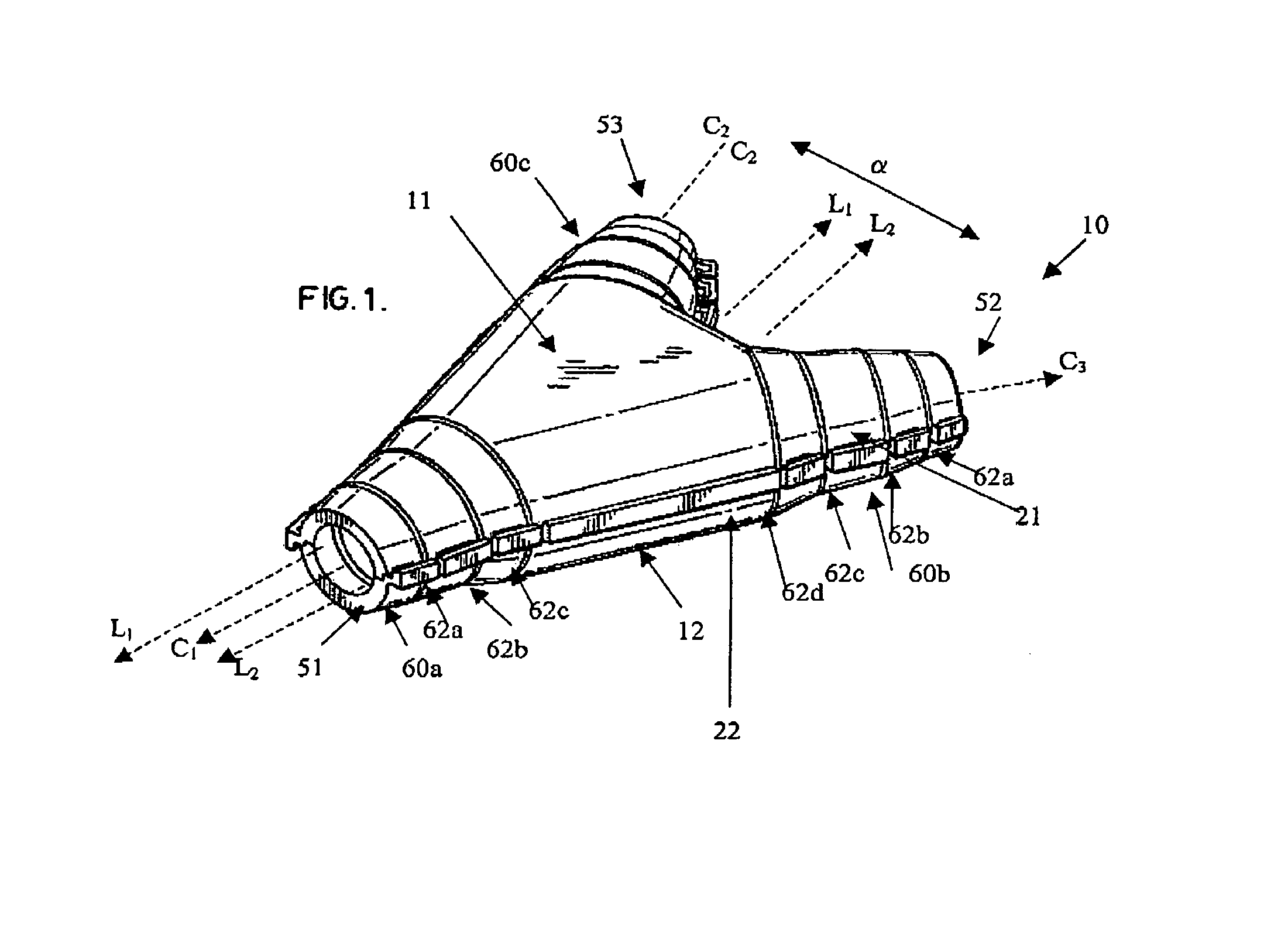

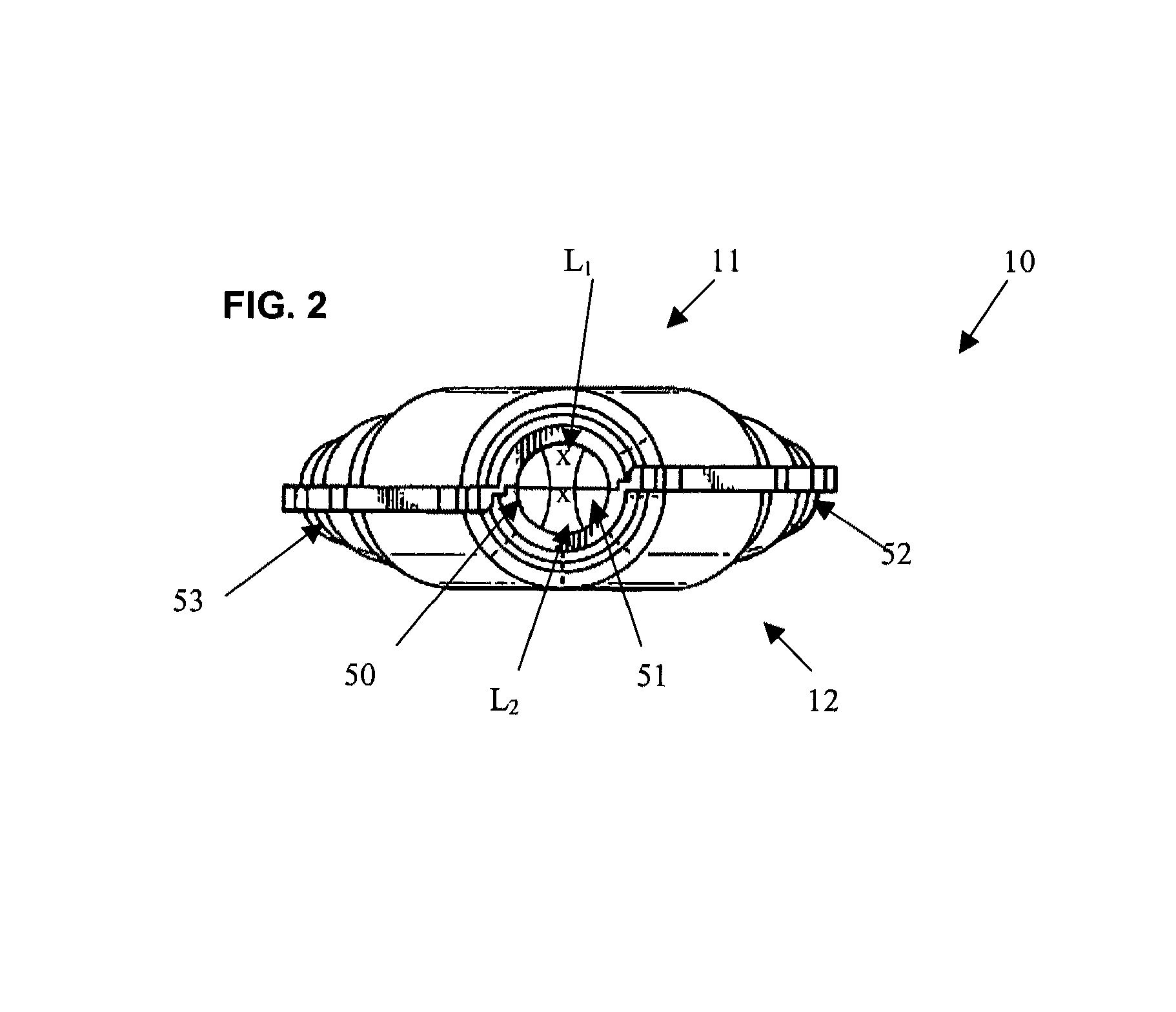

Transition tee coupling

InactiveUS7686346B1Installation time for fittingReduce the time required for installationSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

An improved coupling, such as a transition tee coupling, is described having press-connect fittings on the ends and a push-connect fitting on the outlet. The improved transition tee coupling is formed using a reduced-outlet tee having press-connect fittings on all three sockets. An unfinished end of a tailpiece having a push-connect fitting on the opposite end is inserted into the outlet socket of the press-connect tee. The press-connect fitting of the outlet tee is crimped using a special press tool jaw that does not damage the push fitting on the tailpiece.

Owner:ELKHART PRODS CORP

Flexible downspout connector apparatus

ActiveUS20080023959A1Easy to disassembleSleeve/socket jointsPipeline expansion-compensationDownspoutEngineering

A flexible downspout connector apparatus includes a flexible extension pipe, and a first adapter member and a second adapter member, both nested together at one end of the pipe. The first adapter member includes a connection portion for connecting to a downspout outlet end of a first size, and the second adapter member includes a connection portion for connecting to a downspout outlet of a second size. The second adapter member is releasably telescoped with respect to the first adapter member and may be left in place or easily removed at the option of the user to accommodate for different downspout outlet end sizes.

Owner:TAT ONE SOURCE LLC

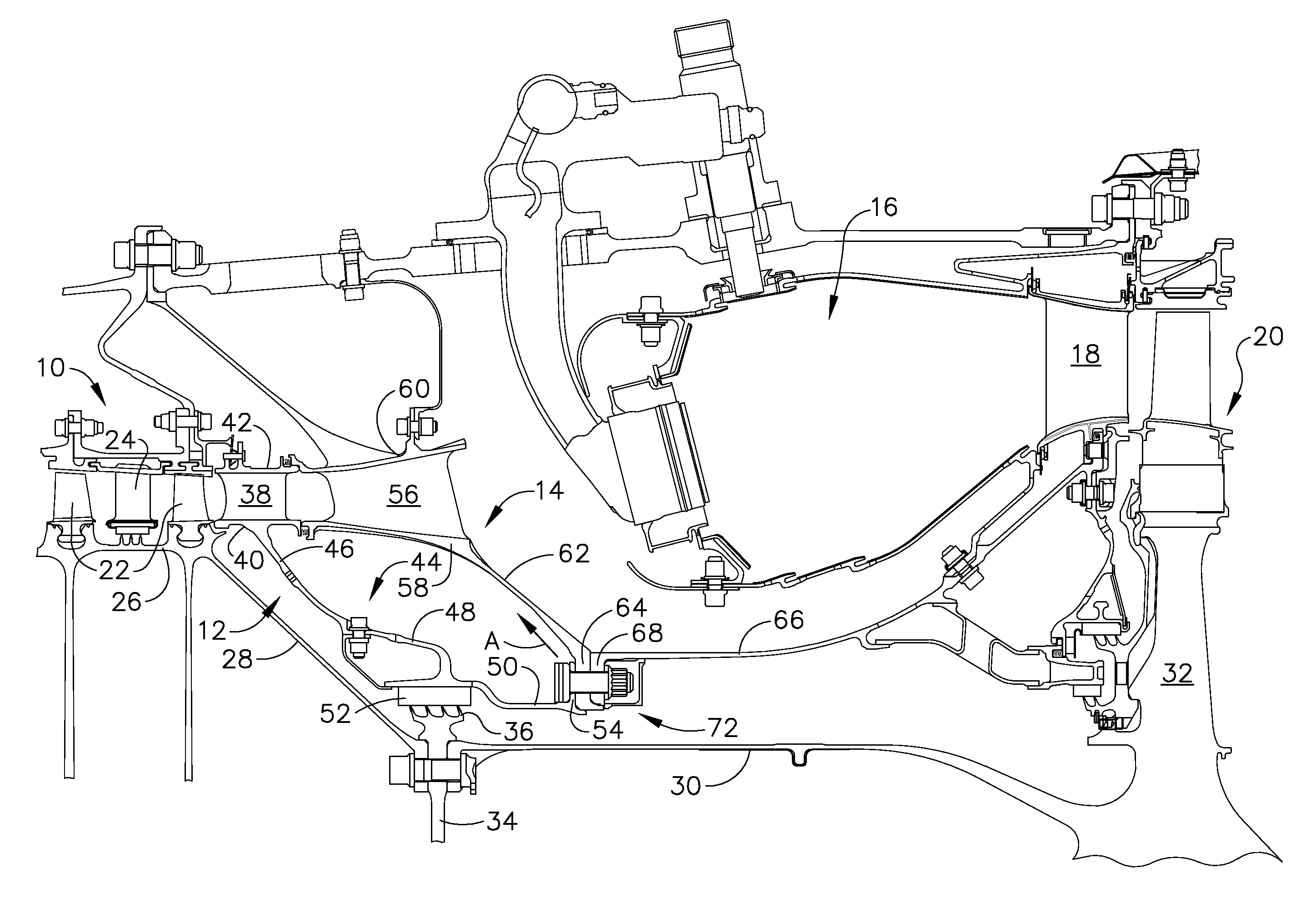

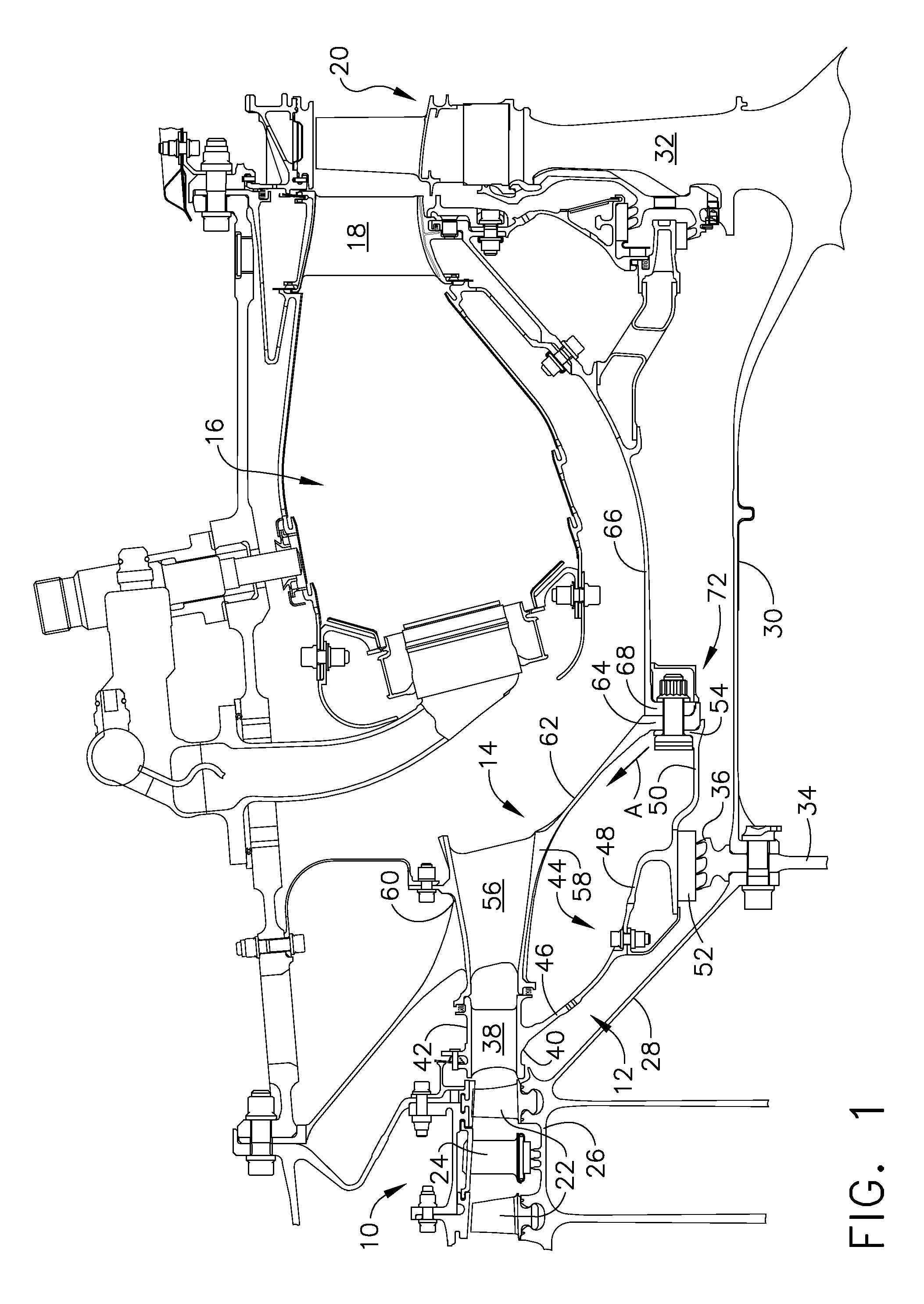

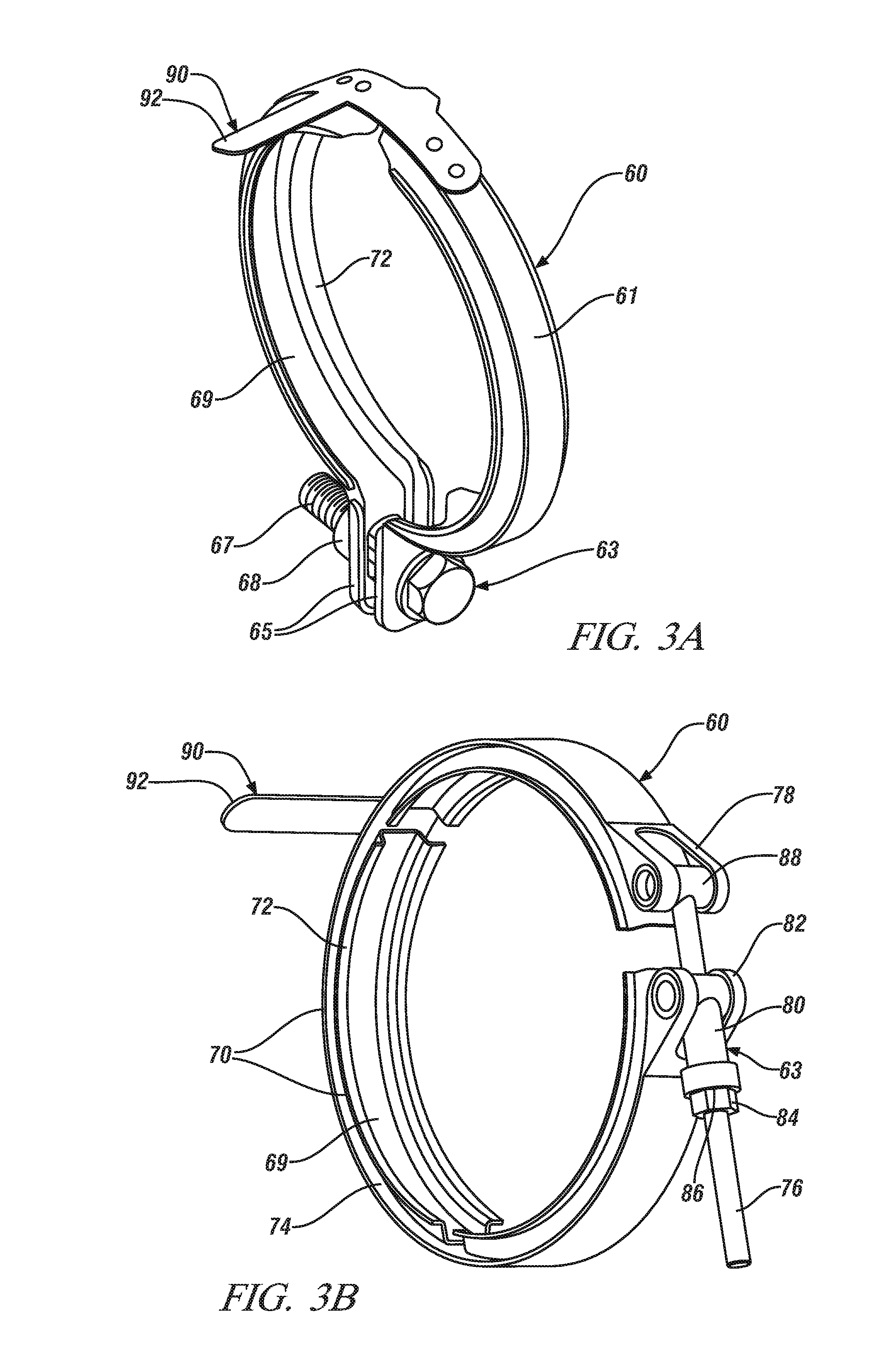

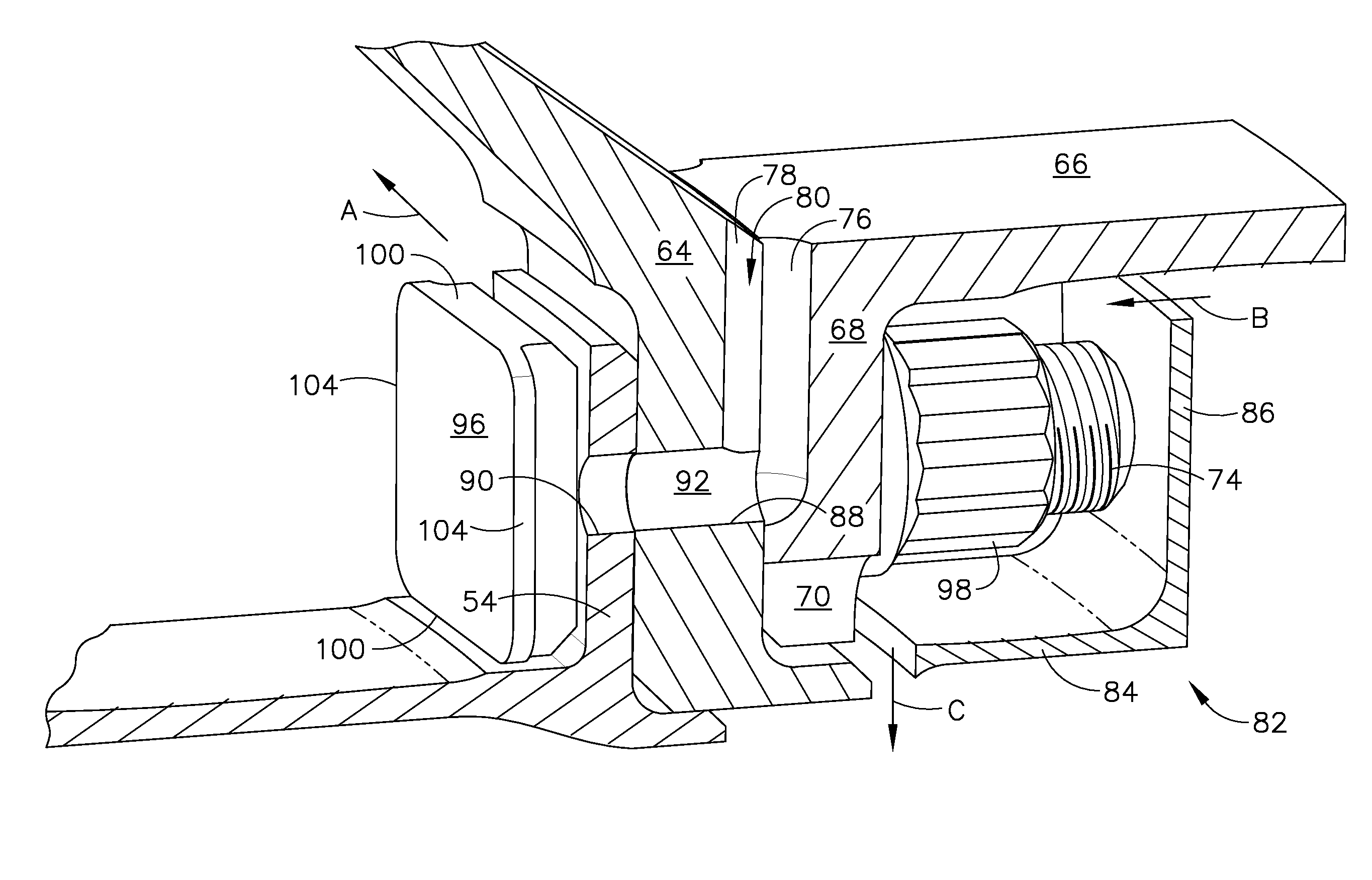

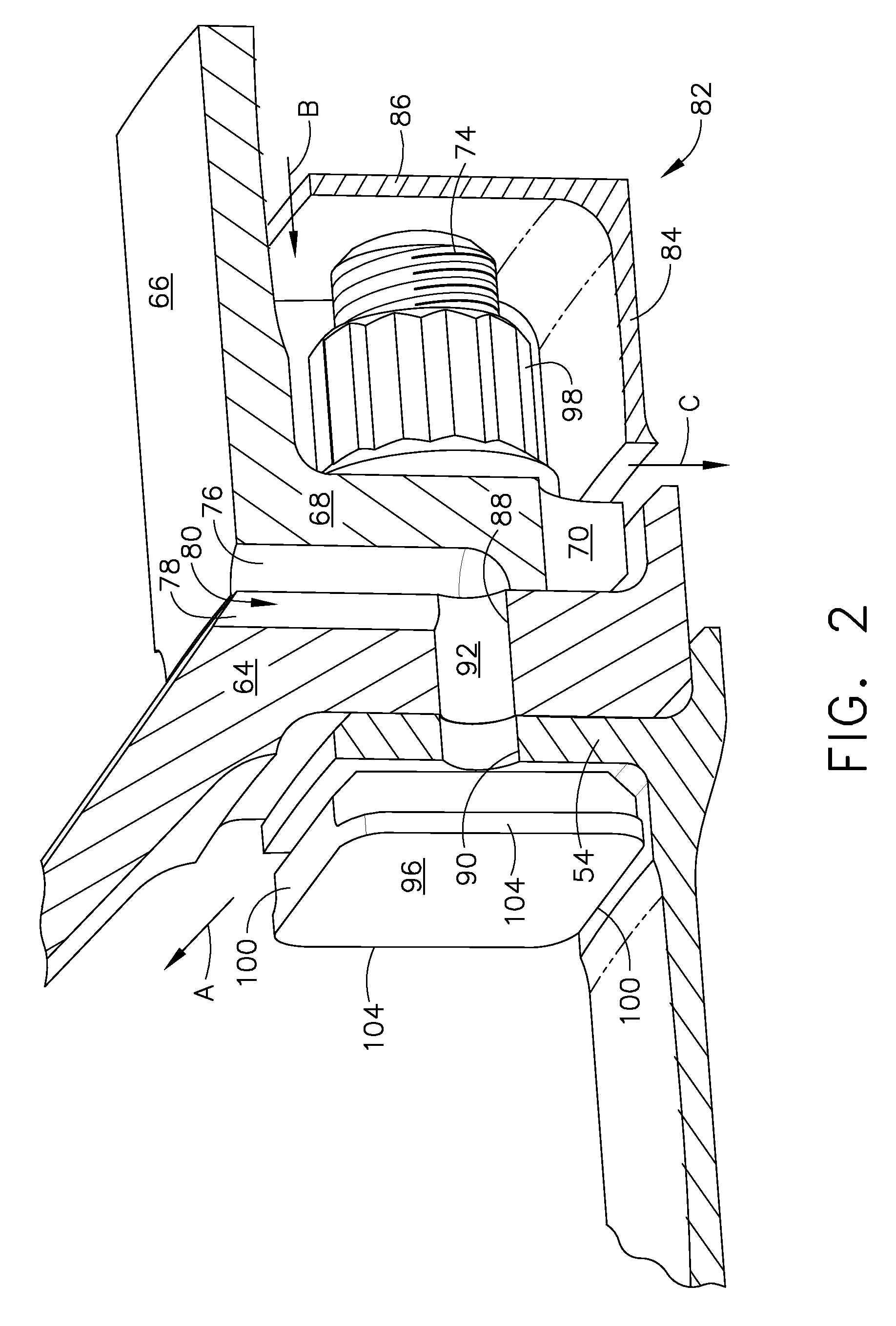

Mechanical joint for a gas turbine engine

ActiveUS20100316484A1Thermal response uniform thermalUniform thermal stressPipeline expansion-compensationPump componentsEngineeringGas turbines

A mechanical joint for a gas turbine engine includes:(a) an annular first component having an annular, radially-extending first flange; (b) an annular second component having an annular, radially-extending second flange abutting the first flange; (c) a plurality of generally radially-extending radial channels passing through at least one of the first and second flanges; (d) a plurality of generally axially-extending channels extending through the first flange and communicating with respective ones of the radial channels; and (e) a plurality of fasteners clamping the first and second flanges together.

Owner:GENERAL ELECTRIC CO

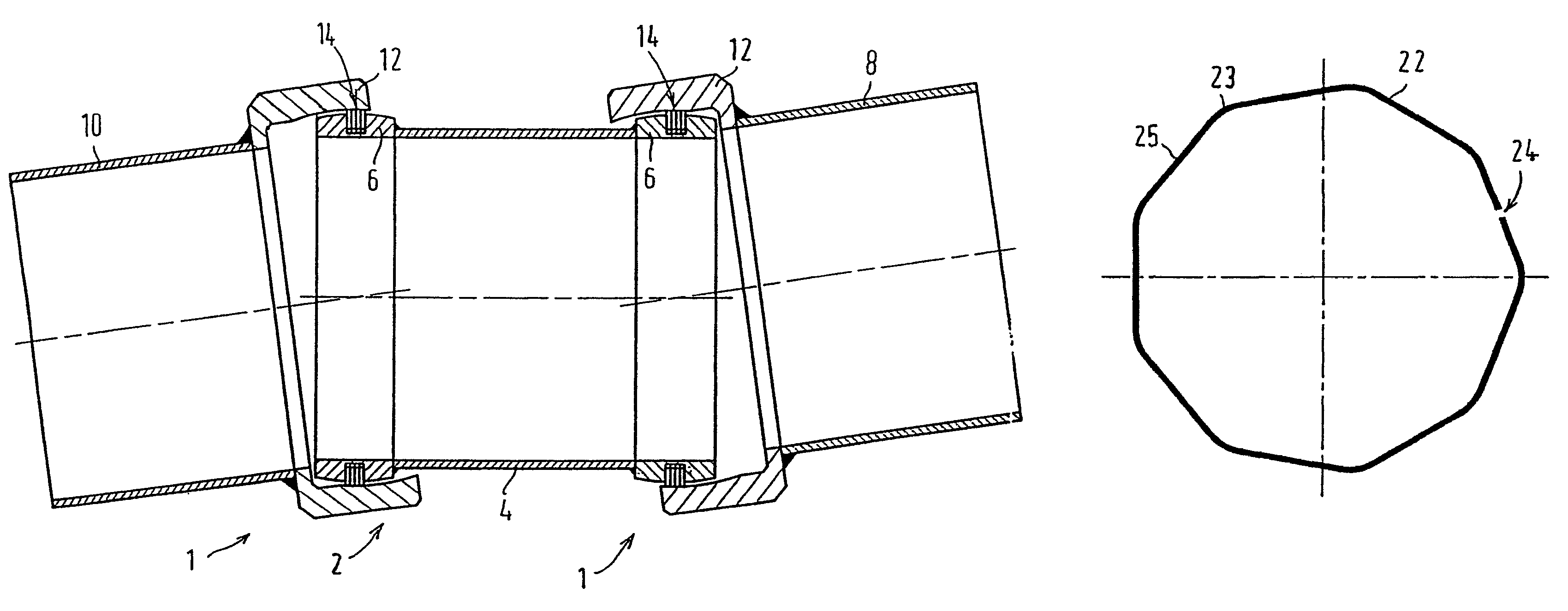

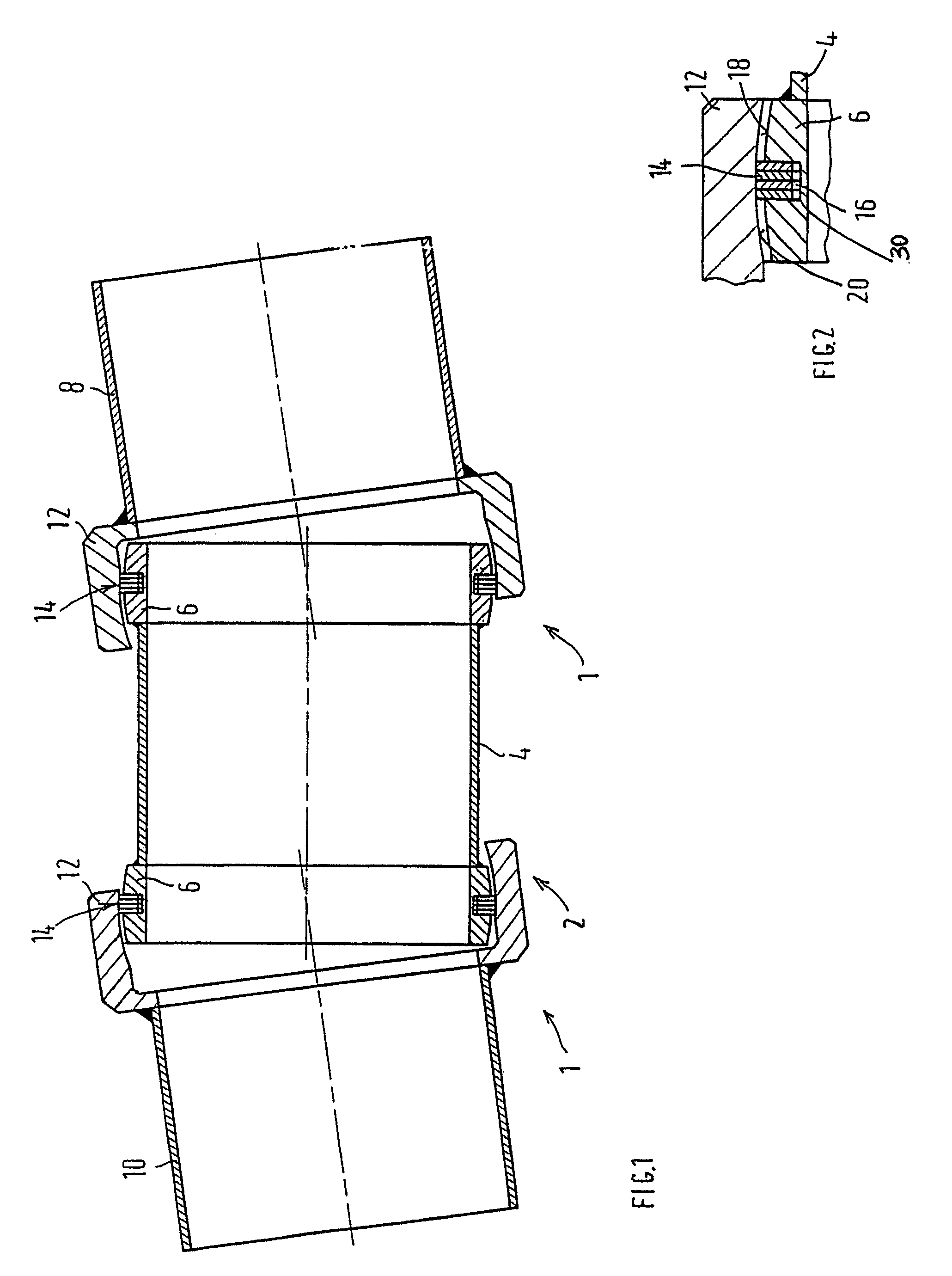

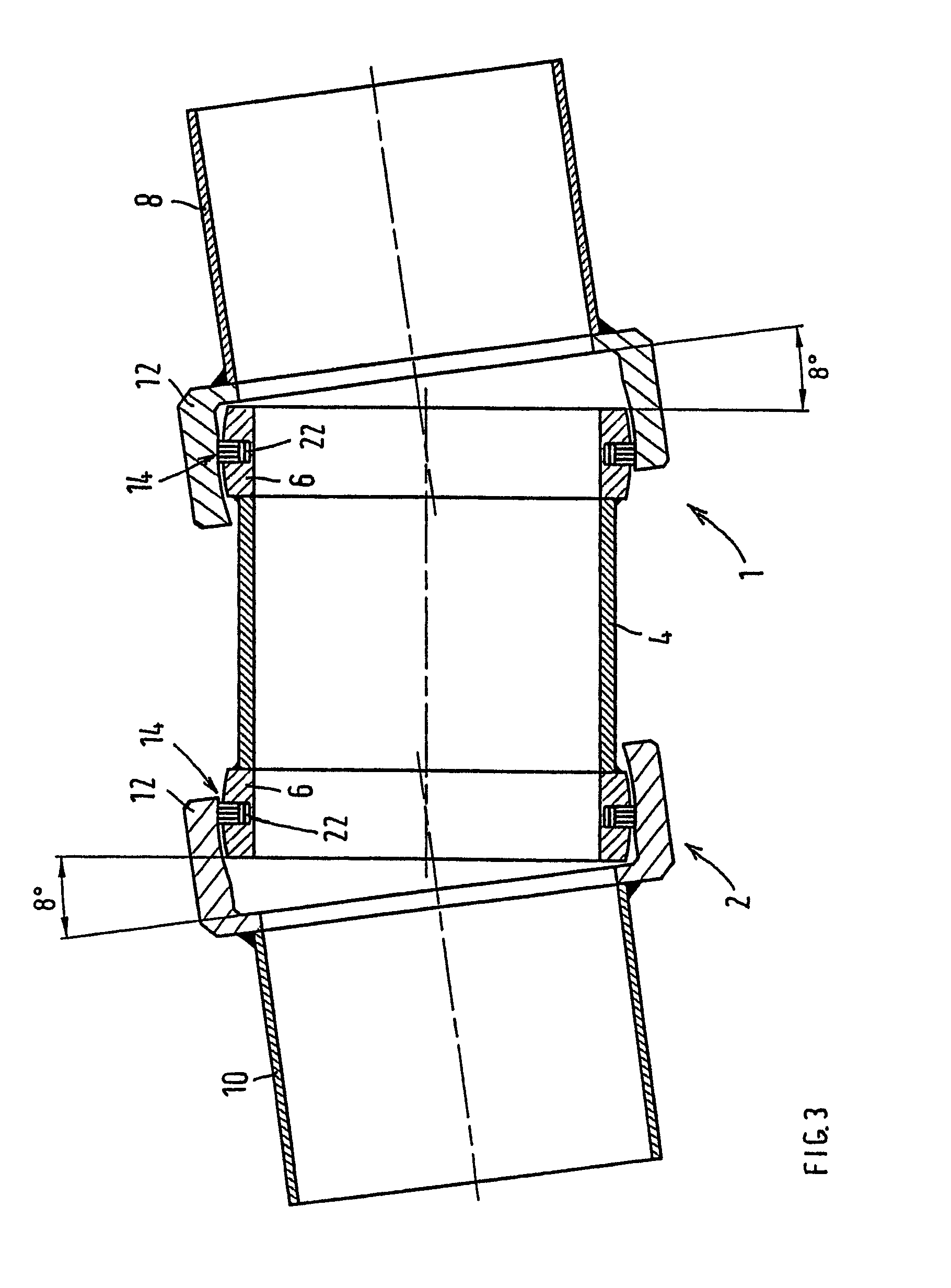

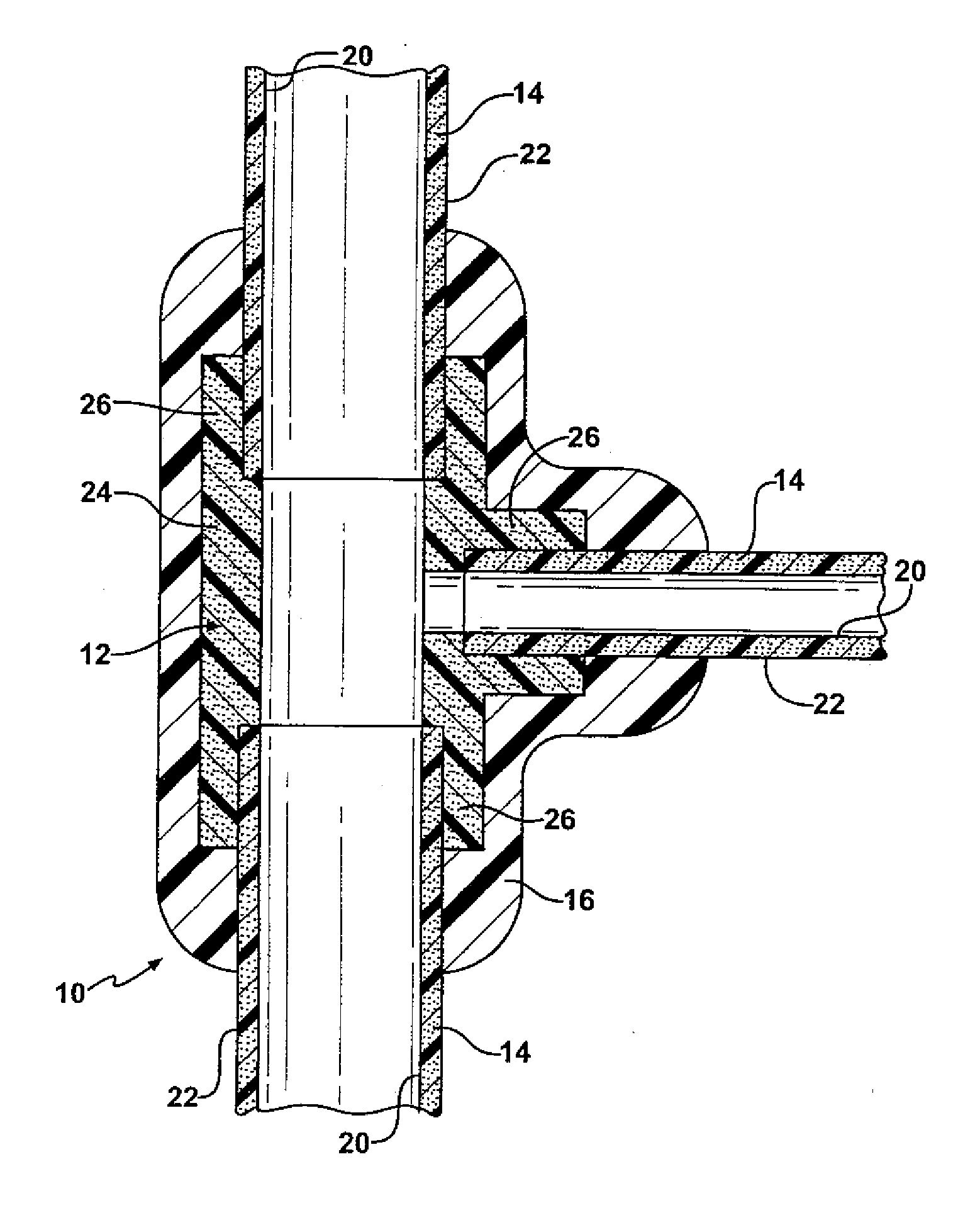

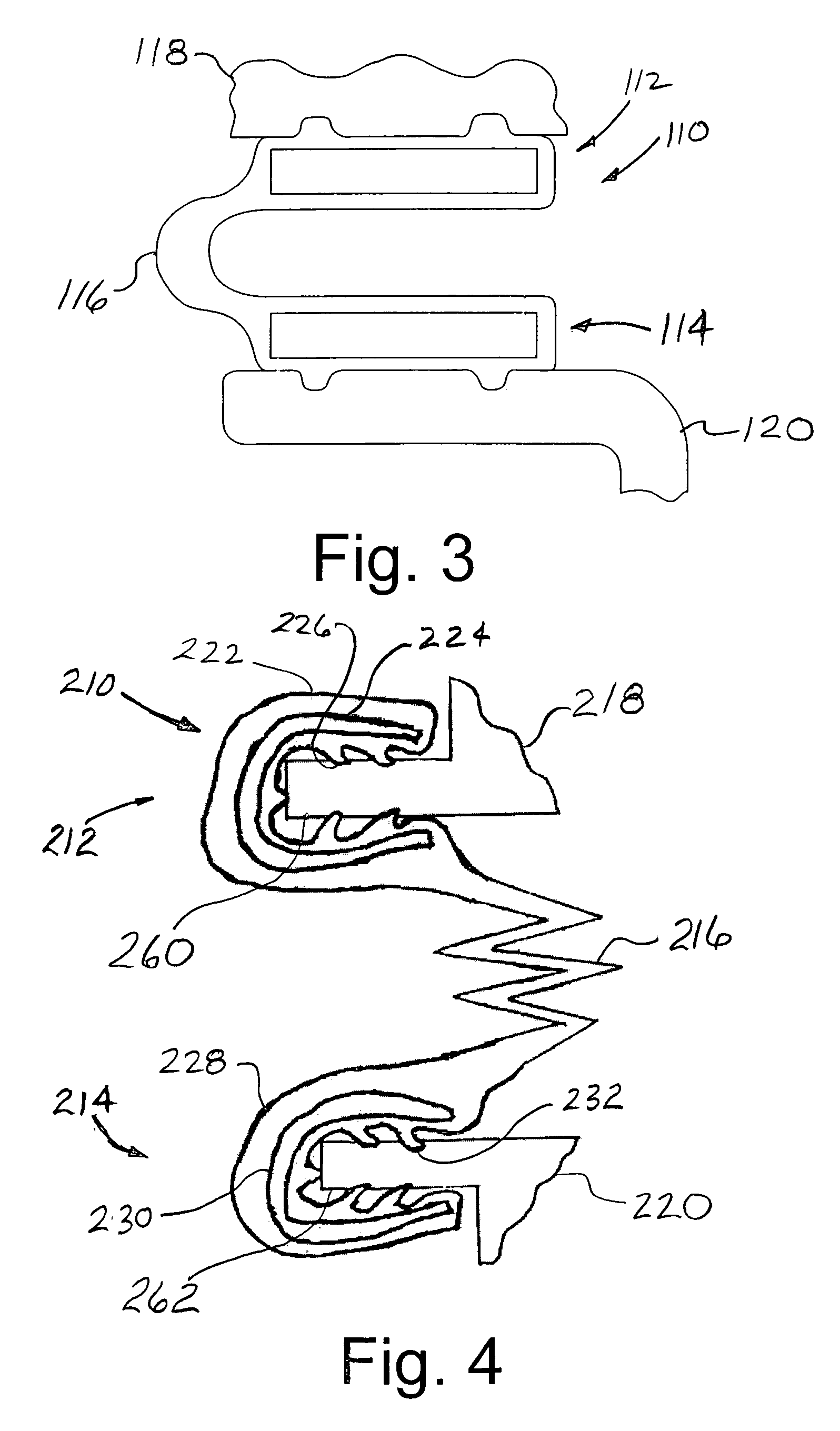

Axial and radial play and angle compensation of a tolerating pipe connection

InactiveUS7556295B2Excellently suitable for sealingSmall spacingSleeve/socket jointsFluid pressure sealed jointsInternal combustion engineExhaust pipe

A pipe connection for exhaust pipes of internal-combustion engines. The pipe connection includes an axial and radial plug and an angle compensation. The pipe connection further includes a first pipe, a second pipe and an interior part at an end of the first pipe. The interior part is enveloped by a bell part at an end of the second pipe. The pipe connection further includes at least one lamellar ring held in an annular groove in either a) a radially outer surface of the interior part or b) a radially inner surface of the bell part. The at least one lameller ring is tensioned against either a) the radially outer surface of the interior part or b) the radially inner surface of the bell part. Either a) the radially outer surface of the interior part or b) the radially inner surface of the bell part is constructed as a concave surface. The at least one lameller ring is tensioned against the concave surface.

Owner:FEY LAMELLENRINGE

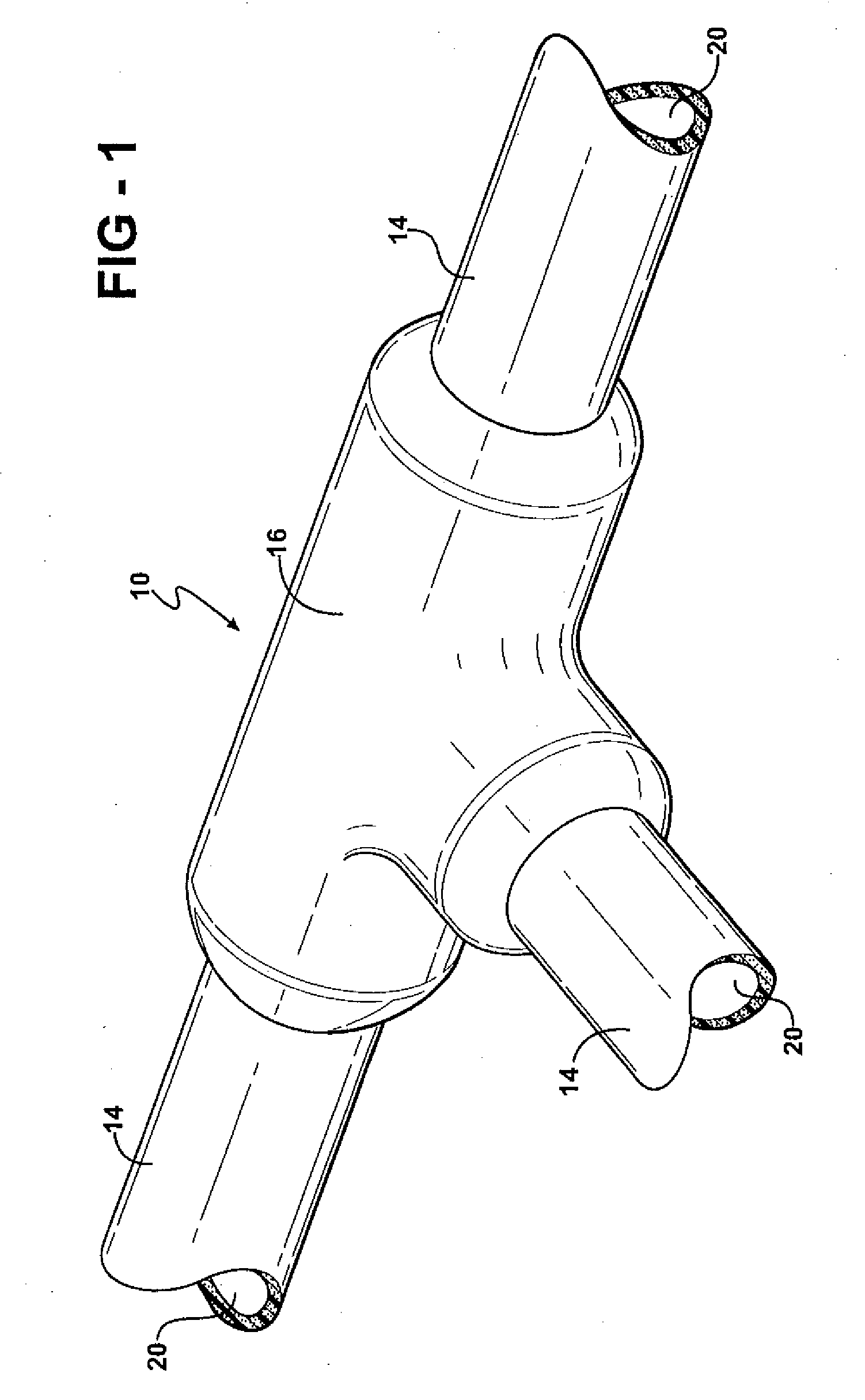

Fluid Transfer Assembly

ActiveUS20080277926A1Easy to assembleEasy to processPipeline expansion-compensationCoatingsContinuous/uninterruptedSilicone

A fluid transfer assembly for transporting medicinal substances. The fluid transfer assembly includes flexible tubes and a manifold each comprising silicone. The manifold has an inner protrusion and connector portions having inner walls. Free ends of the tubes are inserted into complementary configured inner walls of the connector portions until each of the free ends abut the inner protrusion, which creates a continuous uninterrupted passageway between the inner bores of the tubes through the manifold.

Owner:DOW SILICONES CORP

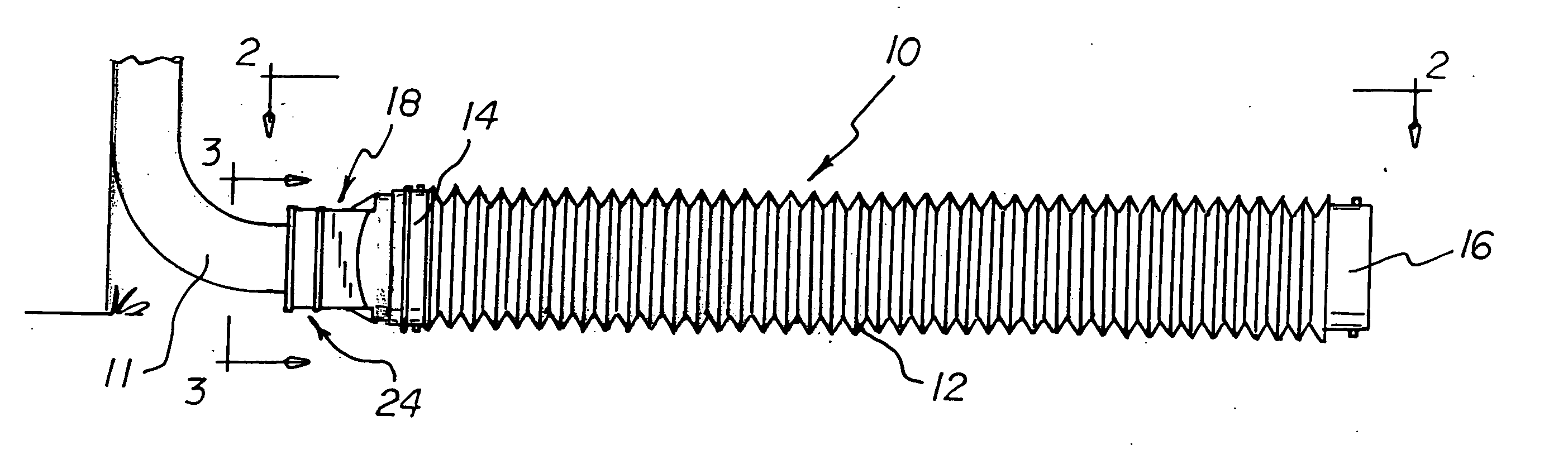

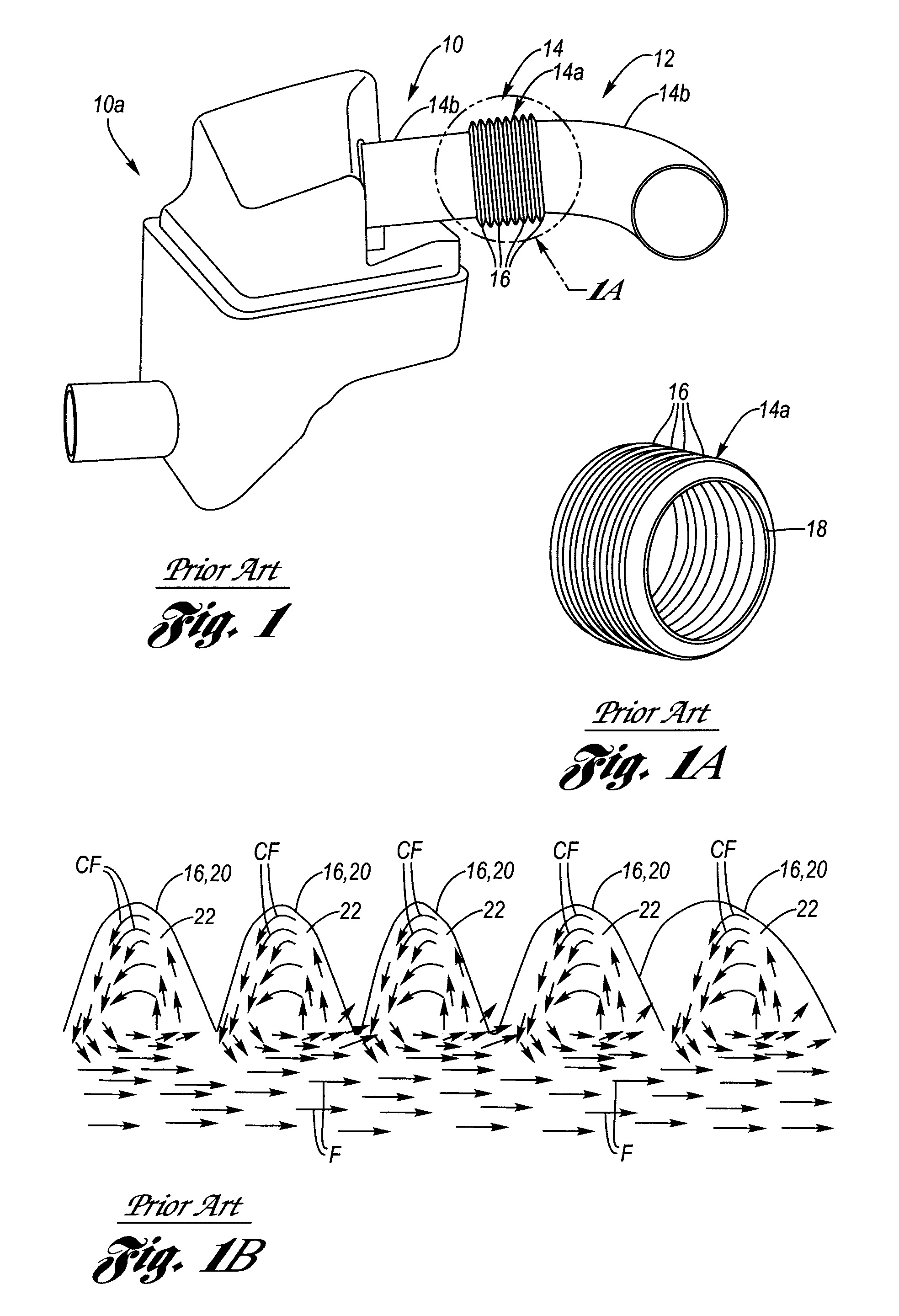

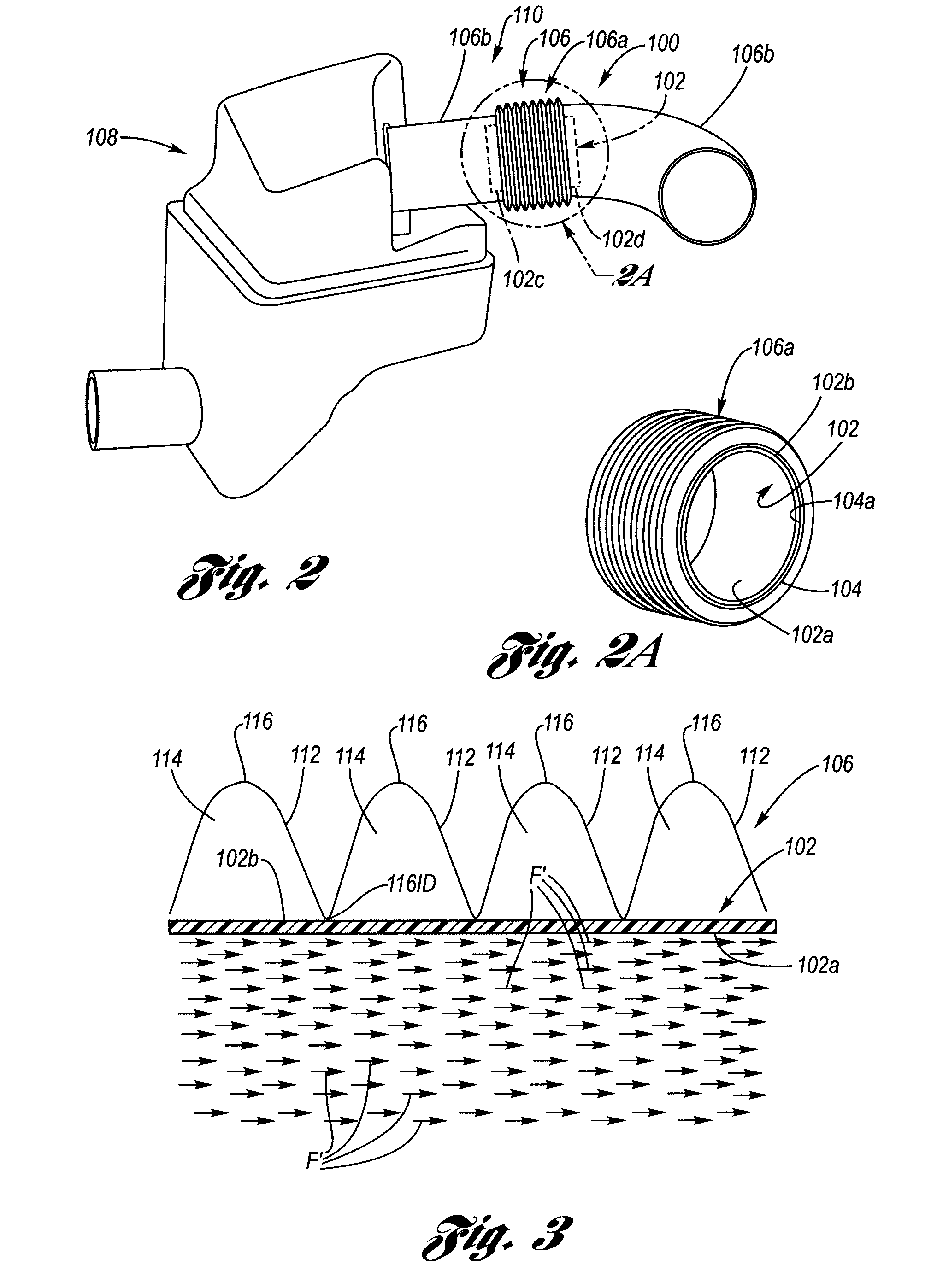

Flexible sleeve liner for a convolute duct

InactiveUS7398798B2Avoids inherent frictional pressure lossSmall pressure lossSleeve/socket jointsInternal combustion piston enginesEngineeringCuff

Owner:GM GLOBAL TECH OPERATIONS LLC

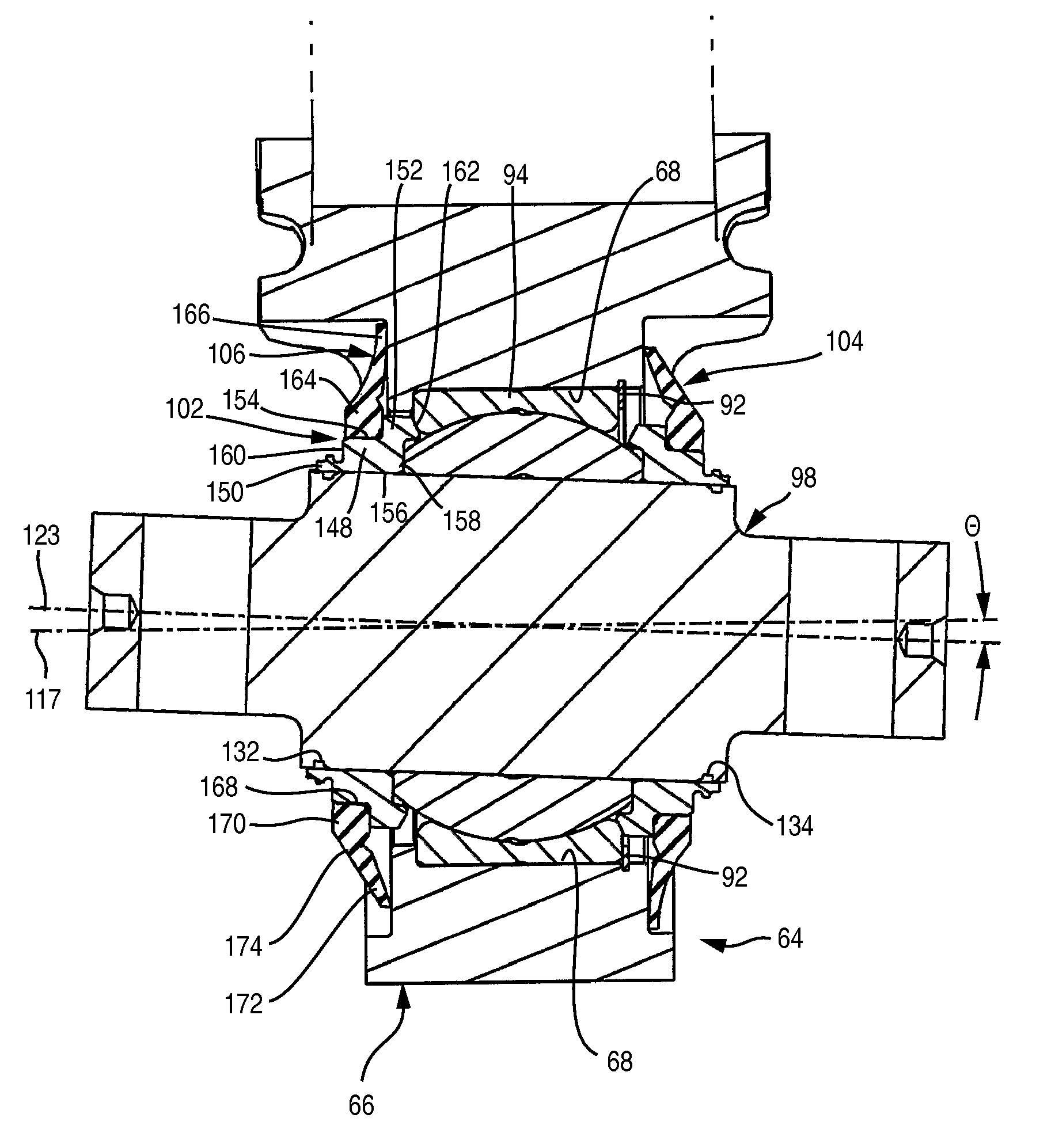

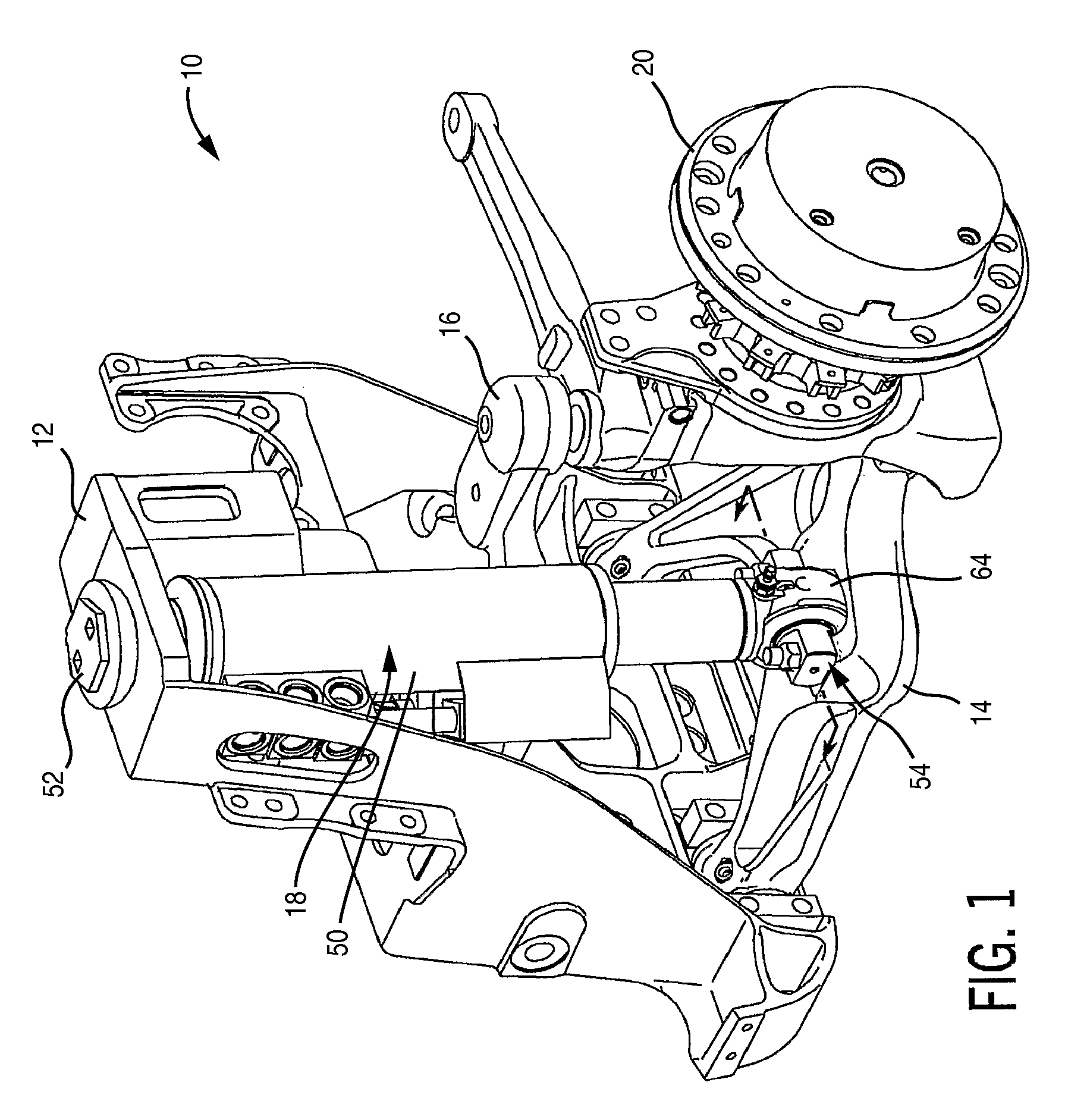

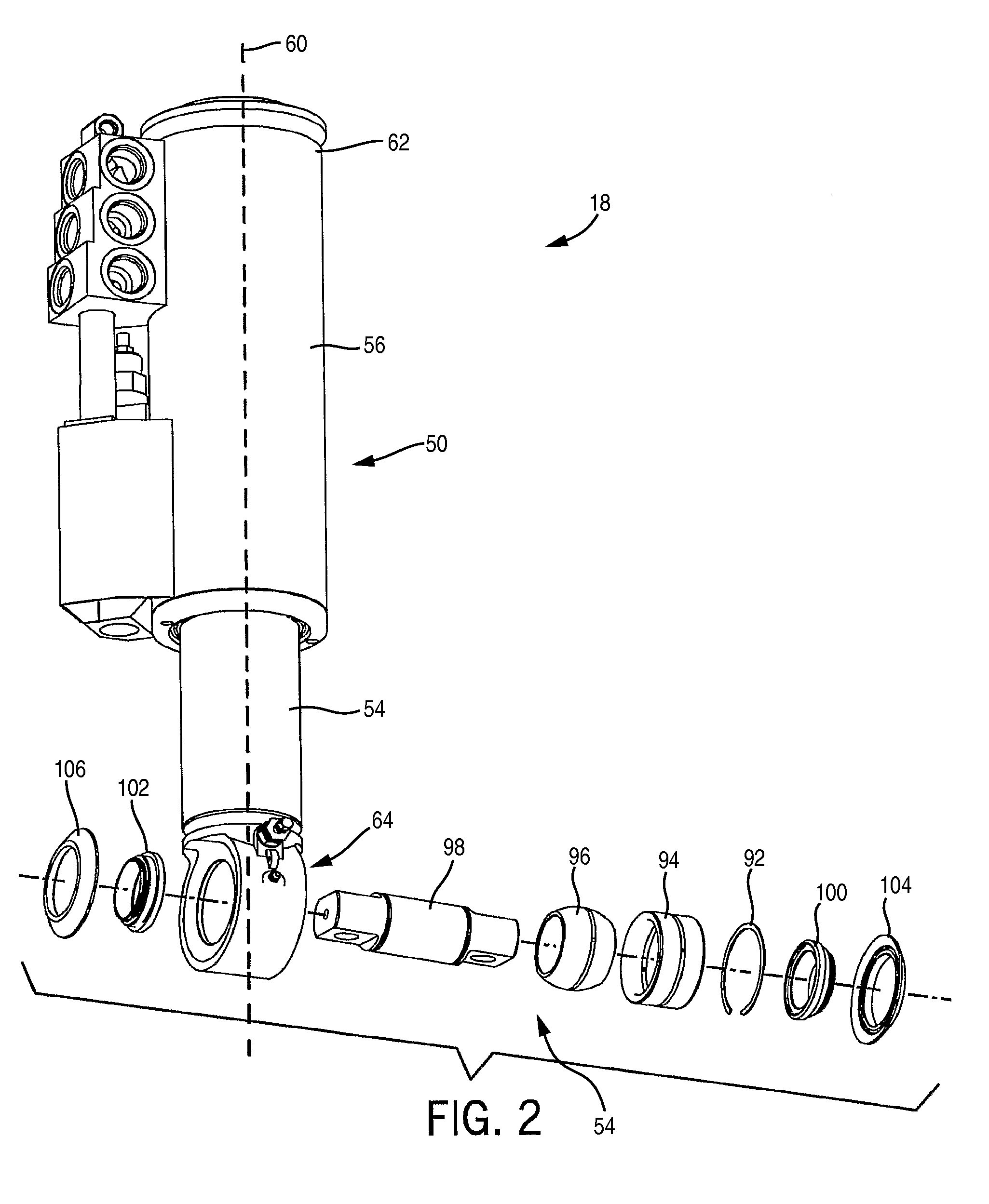

Joint

A joint for use in a suspension system including an elongated suspension member is disclosed. The bearing assembly comprises an outer race, an inner race, a shaft, a collar, and a seal. The outer race is configured to be coupled to the elongated suspension member. The inner race is coupled to the outer race and is moveable relative to the outer race. The shaft is coupled to the inner race. The collar is coupled to the shaft and limits the movement of at least one of the inner race and the shaft relative to the outer race. The seal member is configured to form a seal between one of the shaft and the first collar and one of the outer race and a portion of the elongated suspension member.

Owner:OSHKOSH CORPORATION

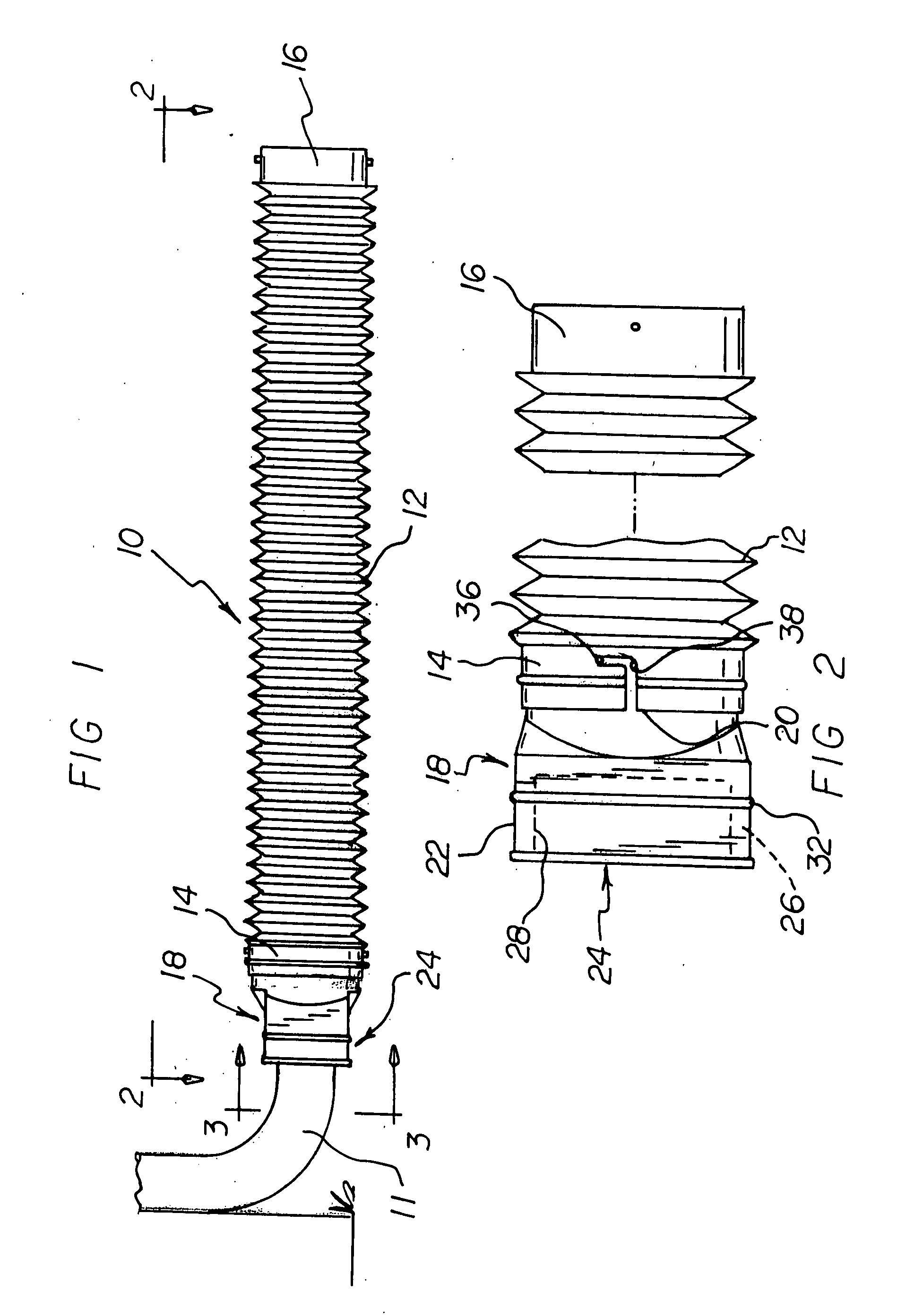

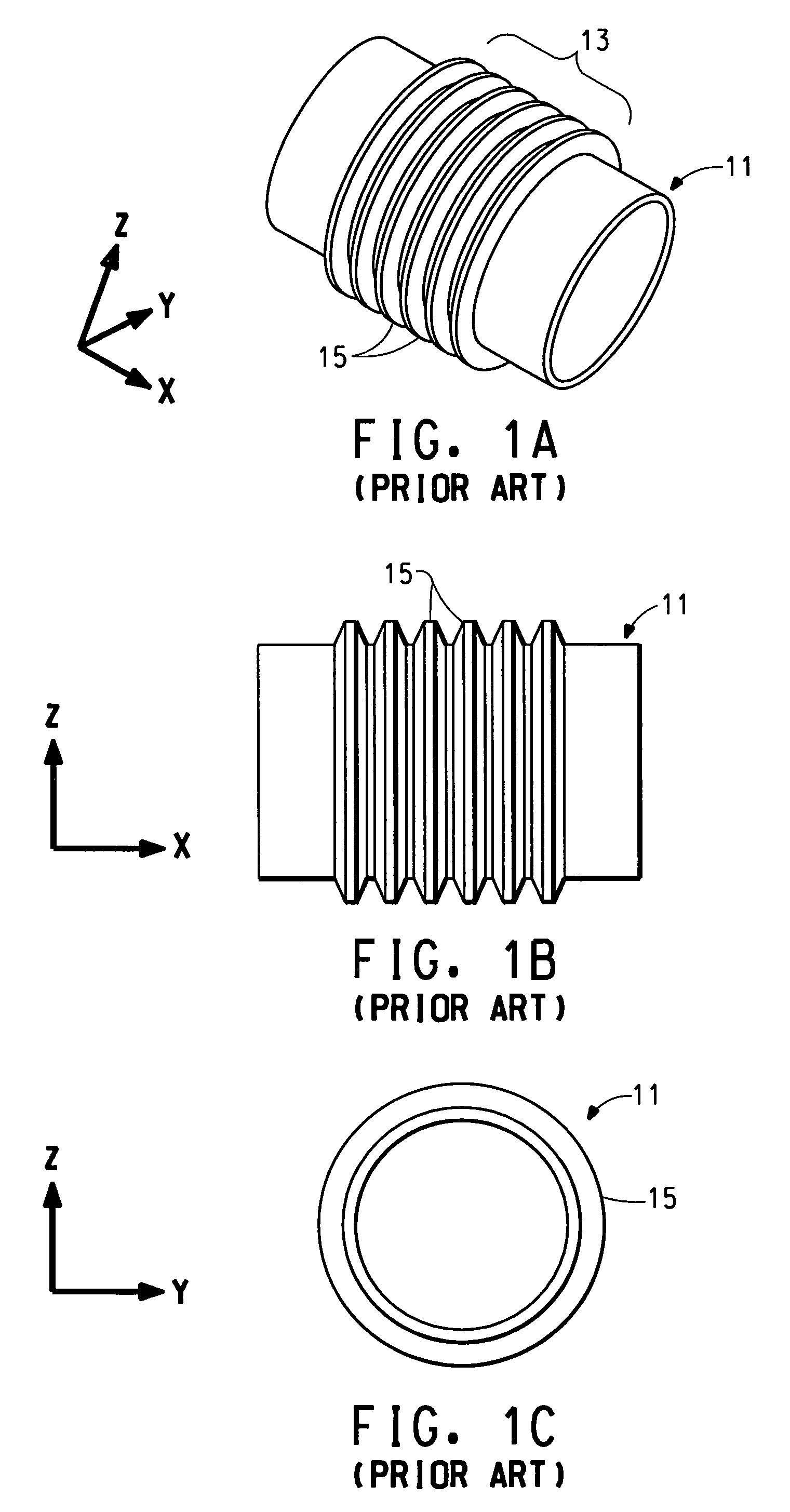

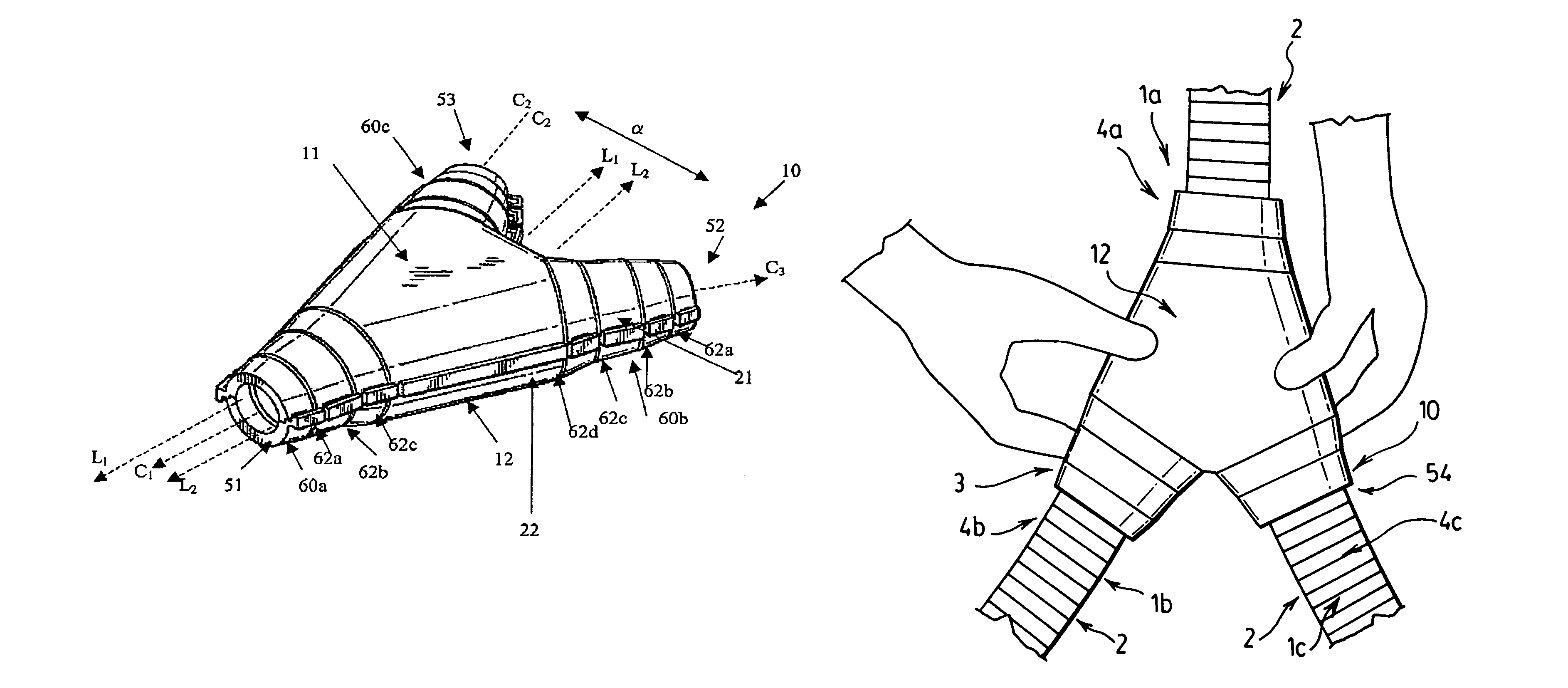

Exhaust pipe decoupler for vehicles

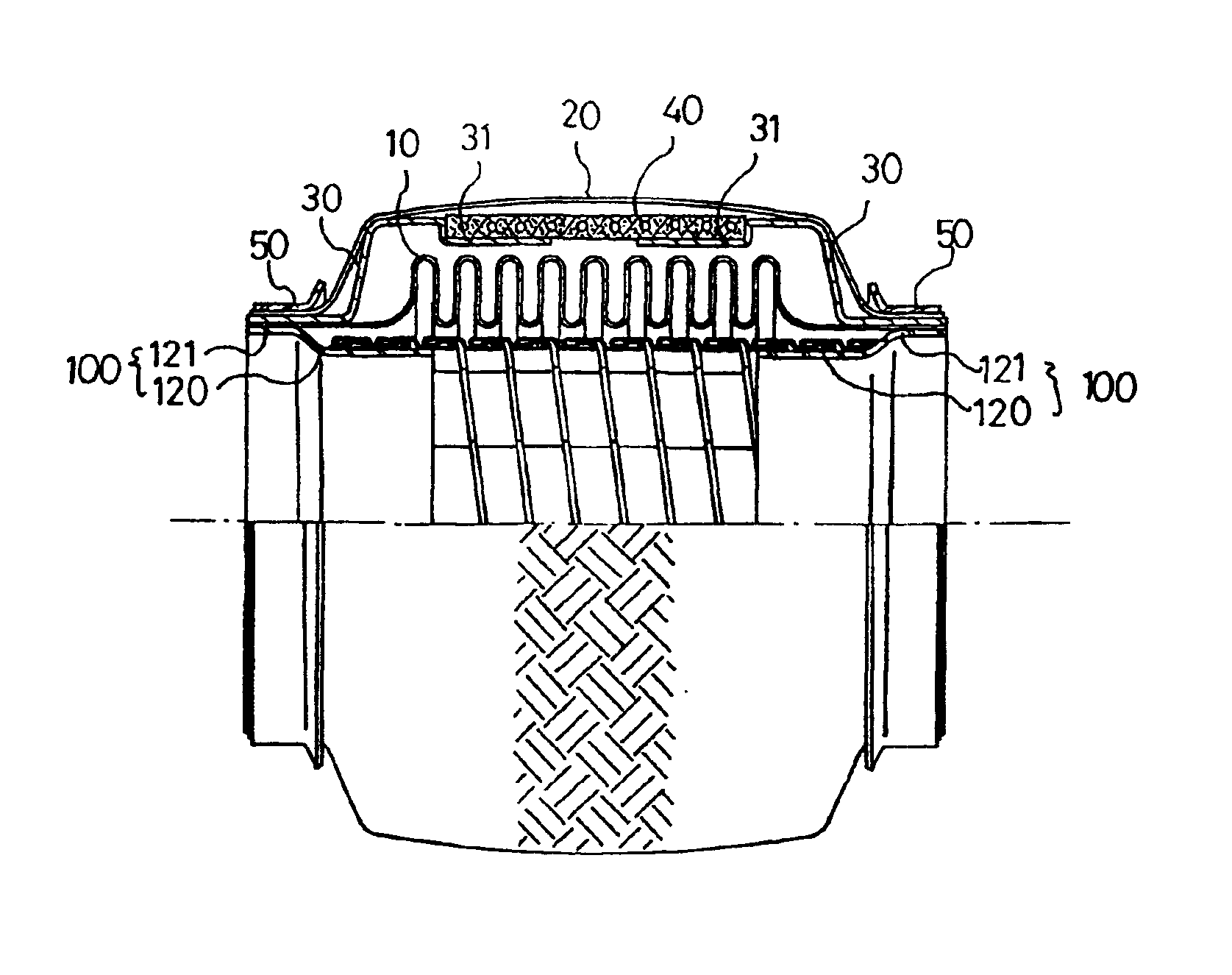

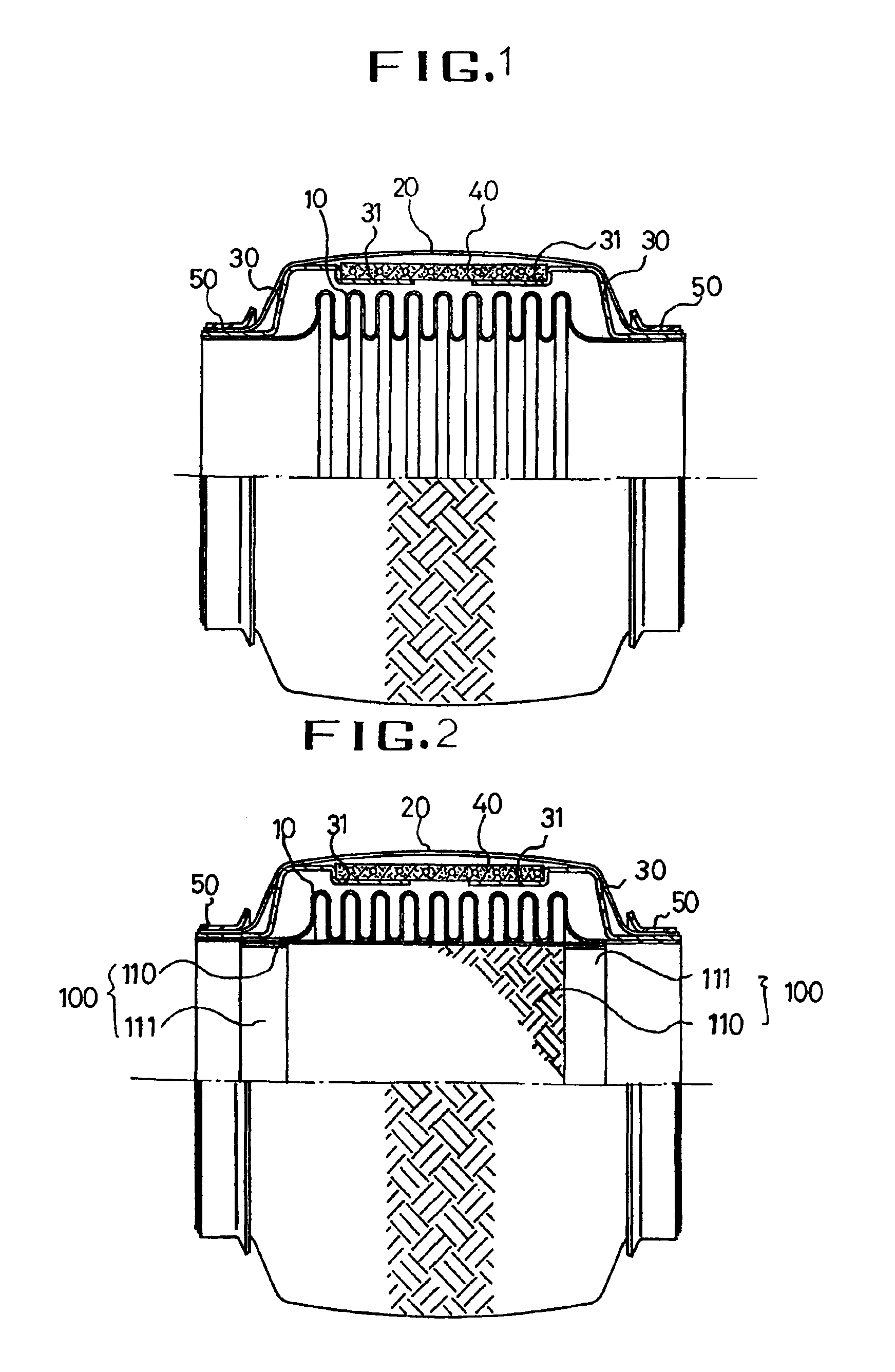

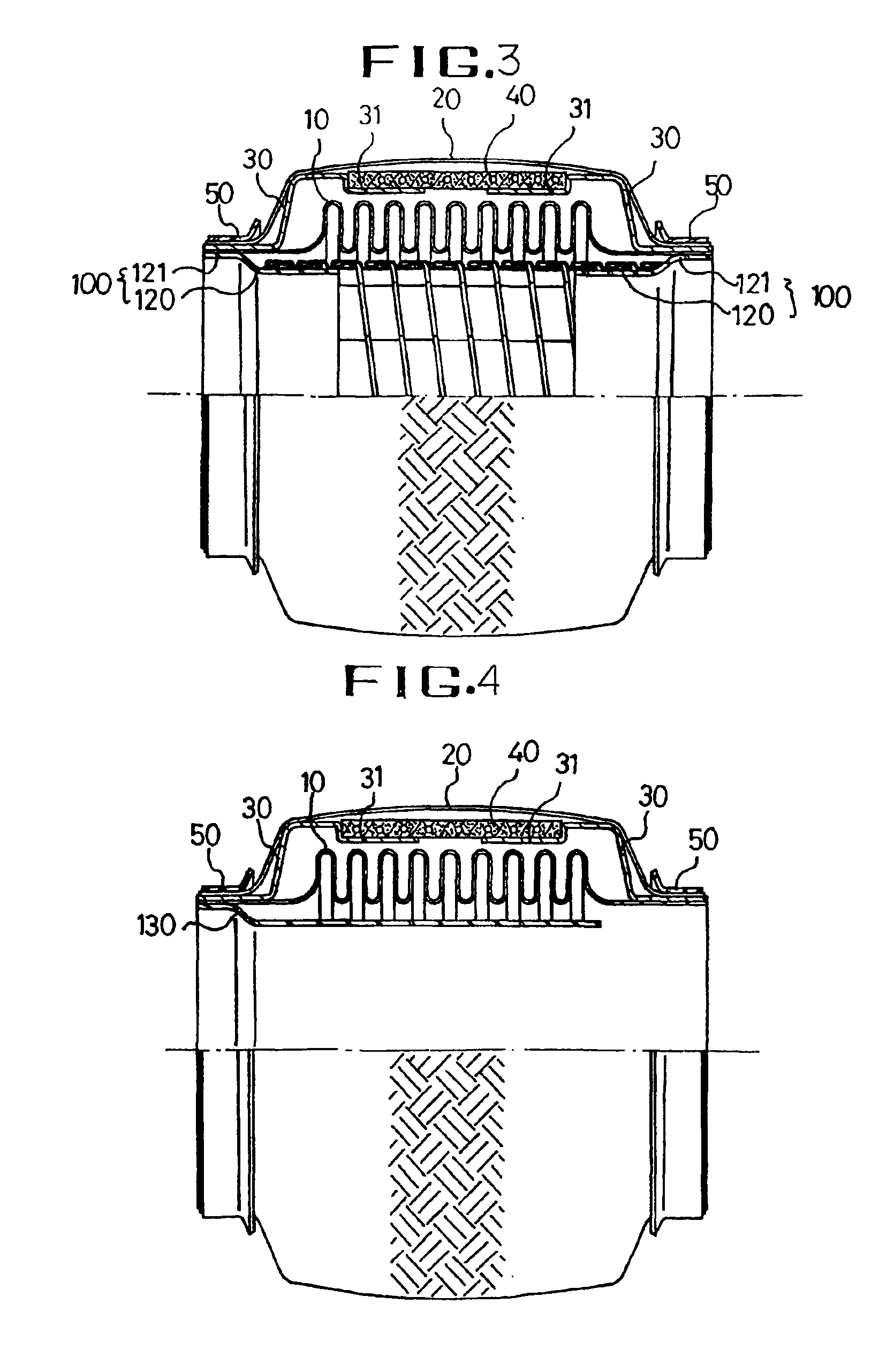

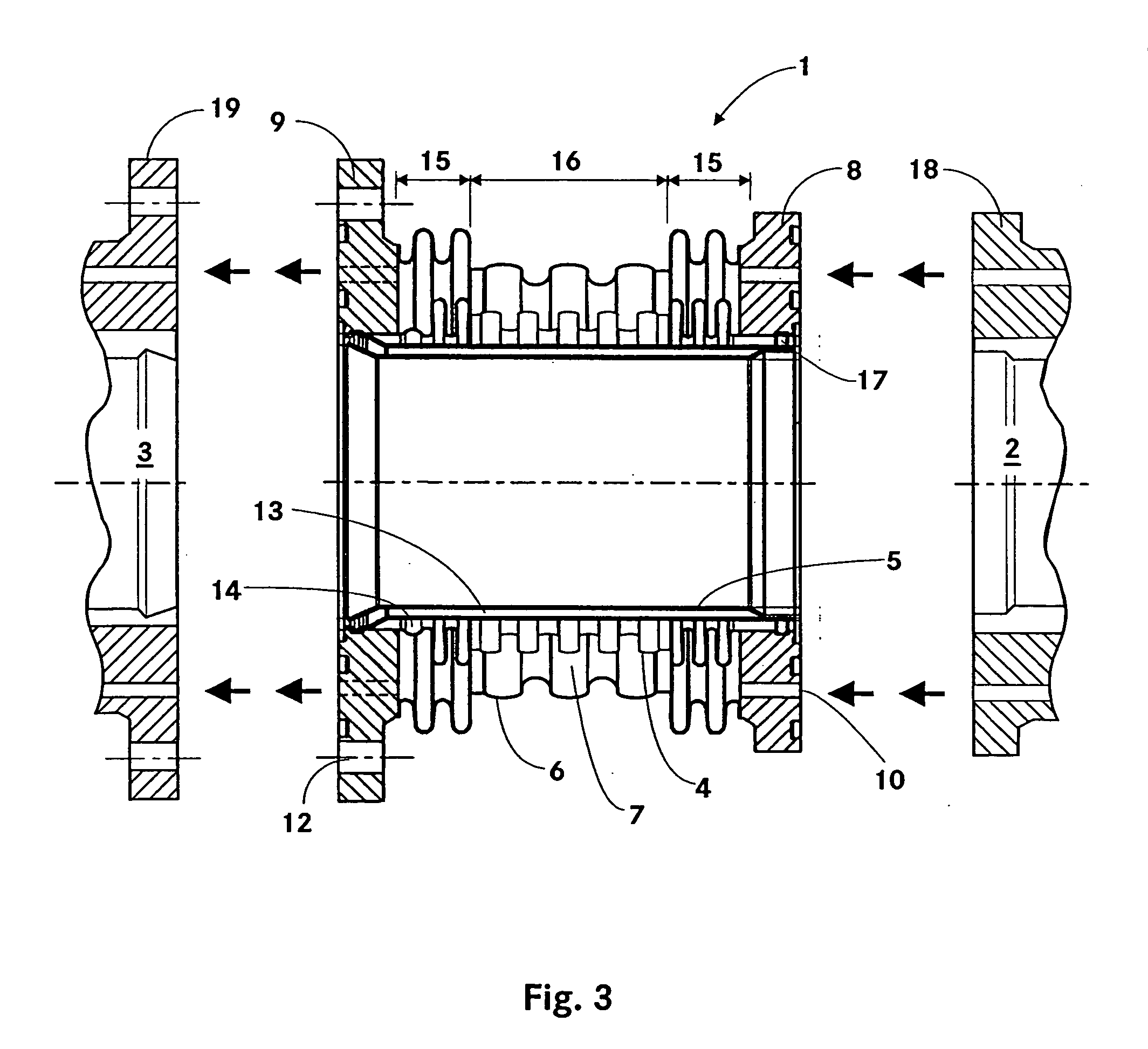

InactiveUS6902203B2Improving durability in deformationIncrease displacementSleeve/socket jointsPipeline expansion-compensationEngineeringExhaust pipe

An exhaust pipe decoupler for vehicles including a bellows (10), an outer braid member (20) spaced from the bellows and braided with a predetermined angle, a retainer (30) having a support (31) inwardly curved at both ends thereof for engaging to a ring damper (40), the retainer being affixed to the ends of the bellows (10) and installed between the outer surface of the bellows (10) and the outer braid member (20) to prevent direct contact thereof, the ring damper (40) located outward the support (31) formed in the retainer (30), a fixing cap (50) coupled to the outer diameter of the outer braid member (20) in order that the outer braid member (20) and the retainer (30) are located outward the bellows (10), wherein the outer braid member (20) absorbs tension in excessive outer forces, i.e., displacement of tension and compression, and the ring damper (40) controls the displacement of compression and shear displacement by the ring damper (40), thereby controlling the bellows within the elastic range.

Owner:SJM

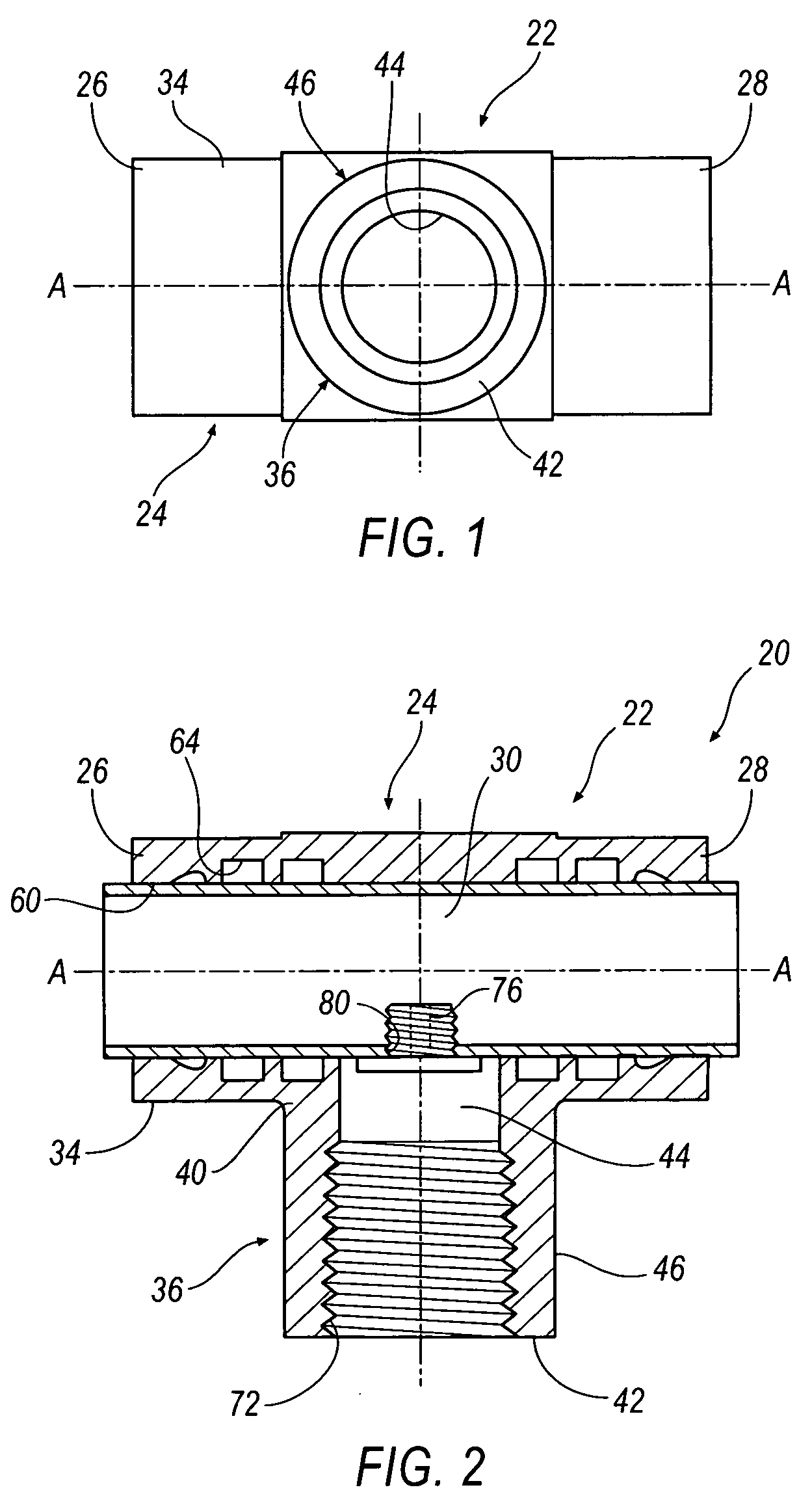

Tapping sleeve

InactiveUS7070209B2More flowSleeve/socket jointsPipeline expansion-compensationRetaining ringElectrical and Electronics engineering

Owner:JCM IND

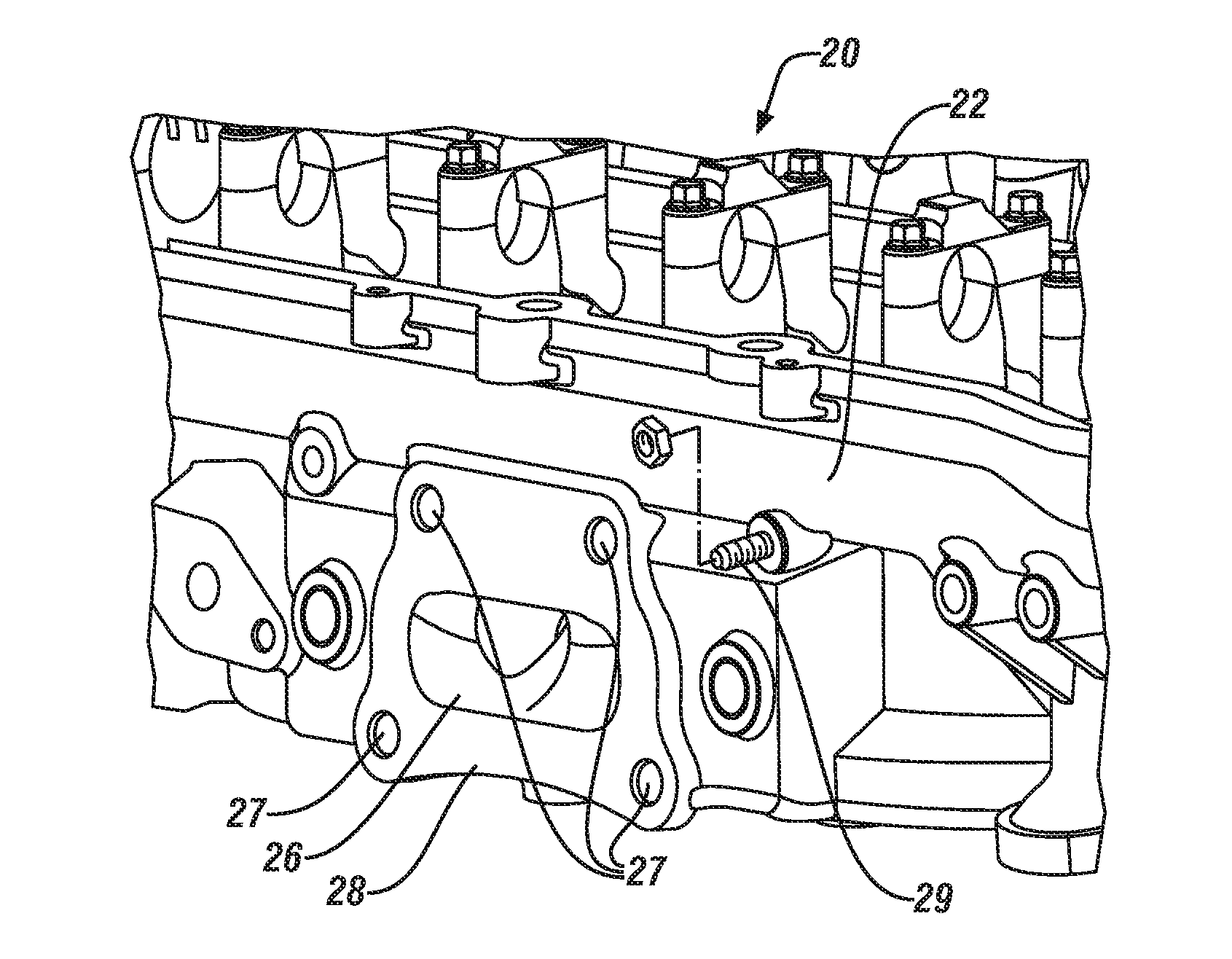

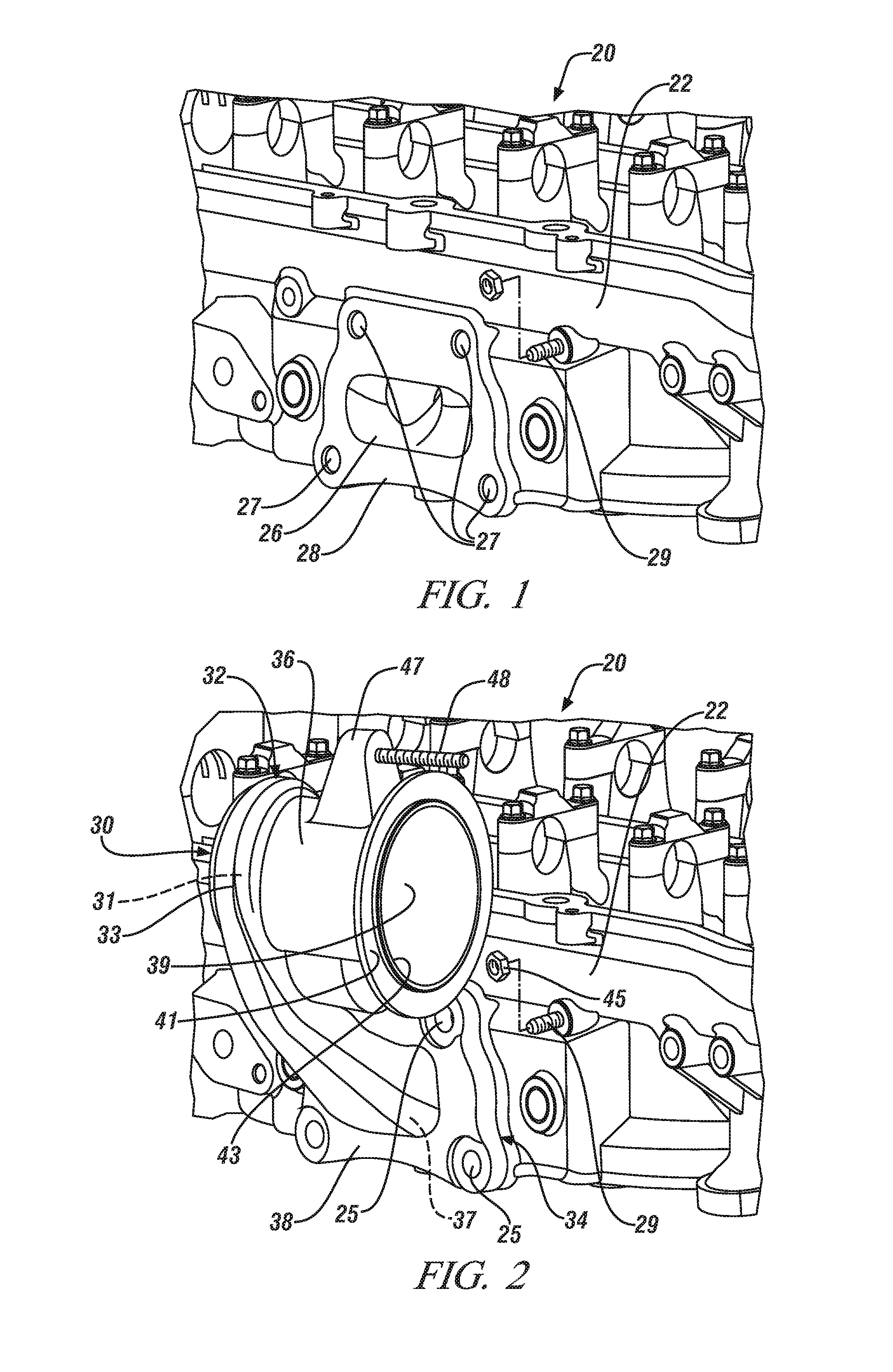

Engine assembly and method of making

An engine assembly comprising a cylinder head, turbocharger in fluid communication with the cylinder head and exhaust conduit in fluid communication with the turbocharger and method of making the assembly using a single human assembler includes: mounting the turbine to the cylinder head; using a first assembly aid to form a slidable joint between the exhaust conduit and head; using a second assembly aid to form a movable joint between the turbine and exhaust conduit and align the turbine outlet flange and exhaust conduit inlet flange; using a third assembly aid to pilotingly engage the flanges; disposing a clamp about the turbine outlet flange and the exhaust conduit inlet flange; tightening the second assembly aid sufficiently to form an immovable joint; tightening the clamp to form a sealed joint between the flanges; and tightening the first assembly aid to form a fixed joint.

Owner:GM GLOBAL TECH OPERATIONS LLC

Vibrationally decoupling gasket

InactiveUS6994354B2Improve sealingIncreased compressive loadSleeve/socket jointsCasingsFistEngineering

A gasket includes a fist sealing portion, a second sealing portion, and an elastic arm sealingly connecting between the two. The first sealing portion sealingly engages a first member and the second sealing portion sealingly engages a second member. The elastic arm is not highly compressed between the members, allowing the gasket to vibrationally decouple the first member from the second member.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

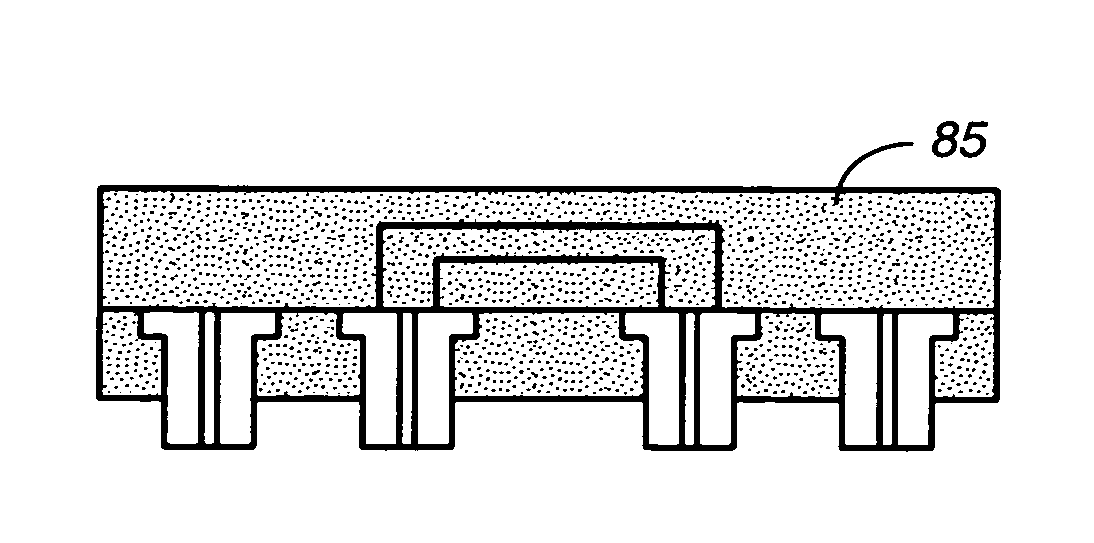

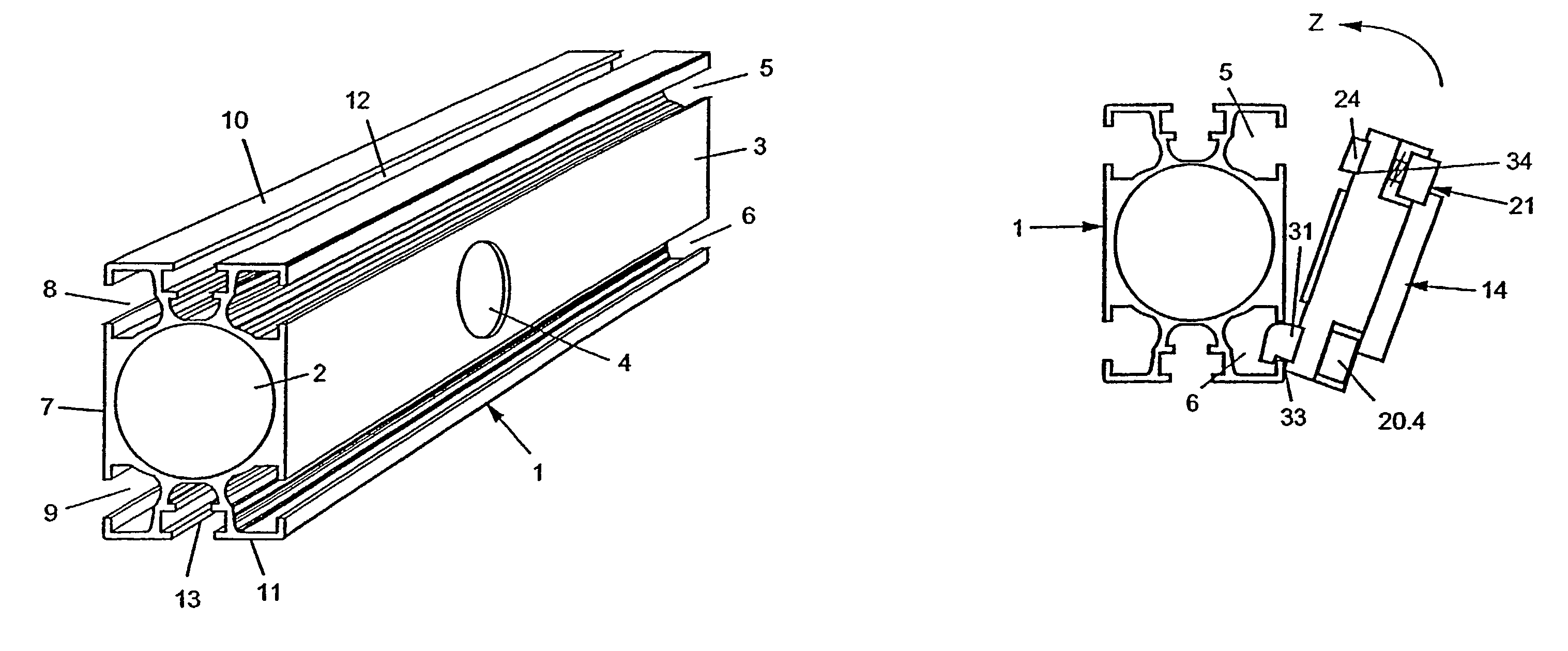

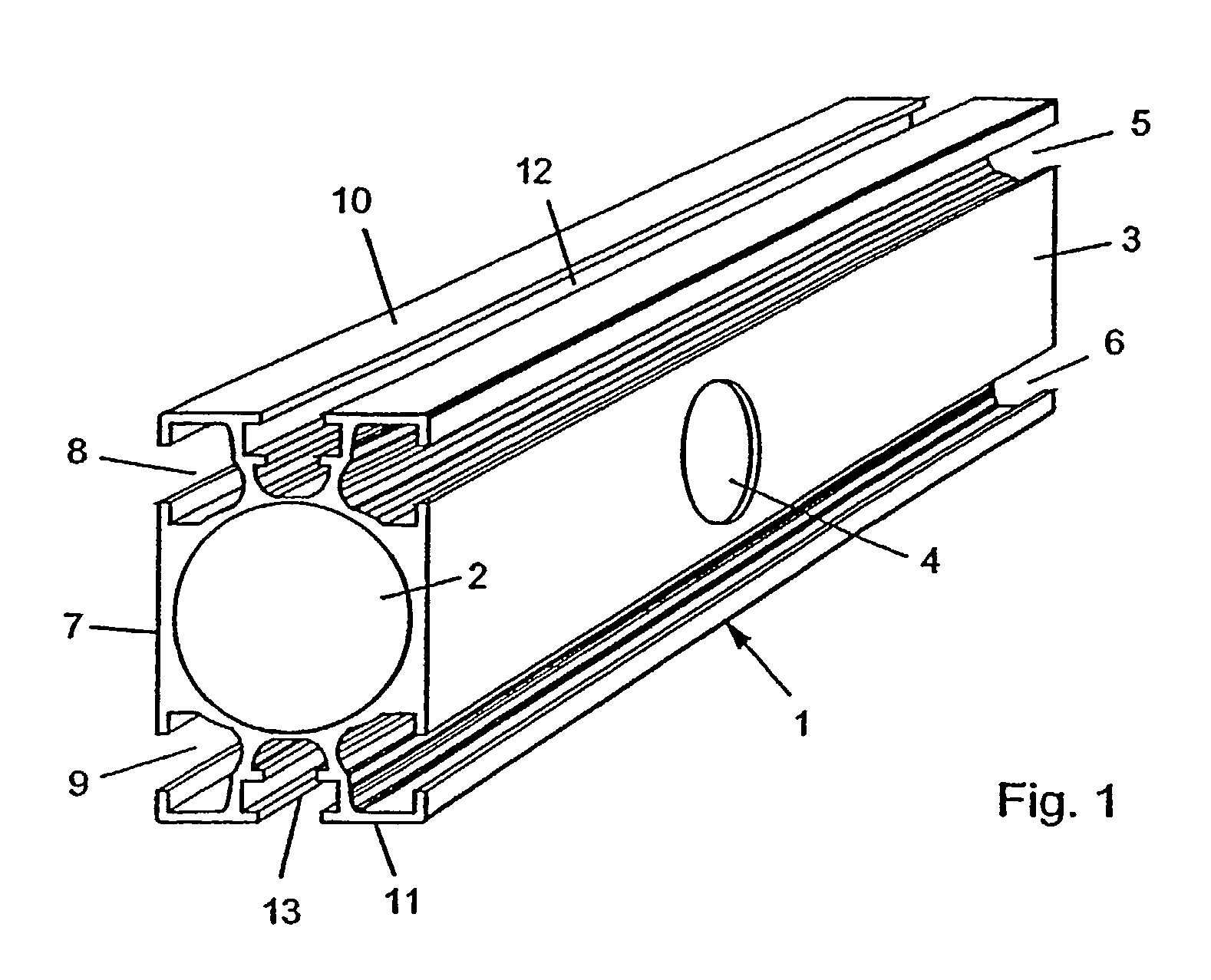

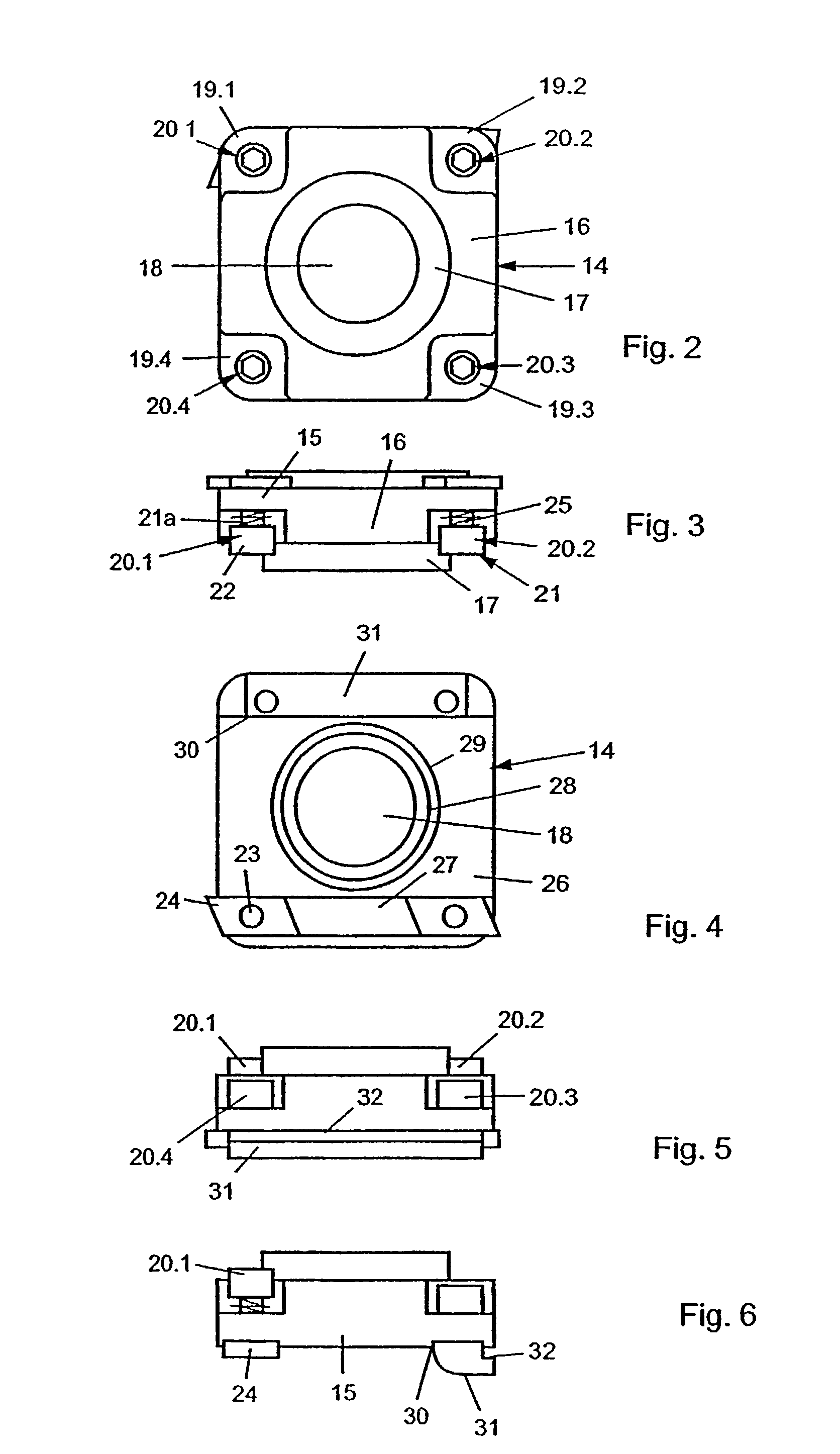

Conduit system

InactiveUS7014213B1Avoid positioningInsertion is complicatedPipeline expansion-compensationJoints with sealing surfacesGuide tubeConduit system

A conduit system for supplying, conducting and distributing fluids, especially air, comprising profiles, which have a longitudinal channel for the fluid and, in at least one outer wall, at least one recess for receiving a fastening element for a connecting element. The fastening element passes through the connecting element and comprises a clamping piece which is inserted into a recess and fixed in the recess by turning.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

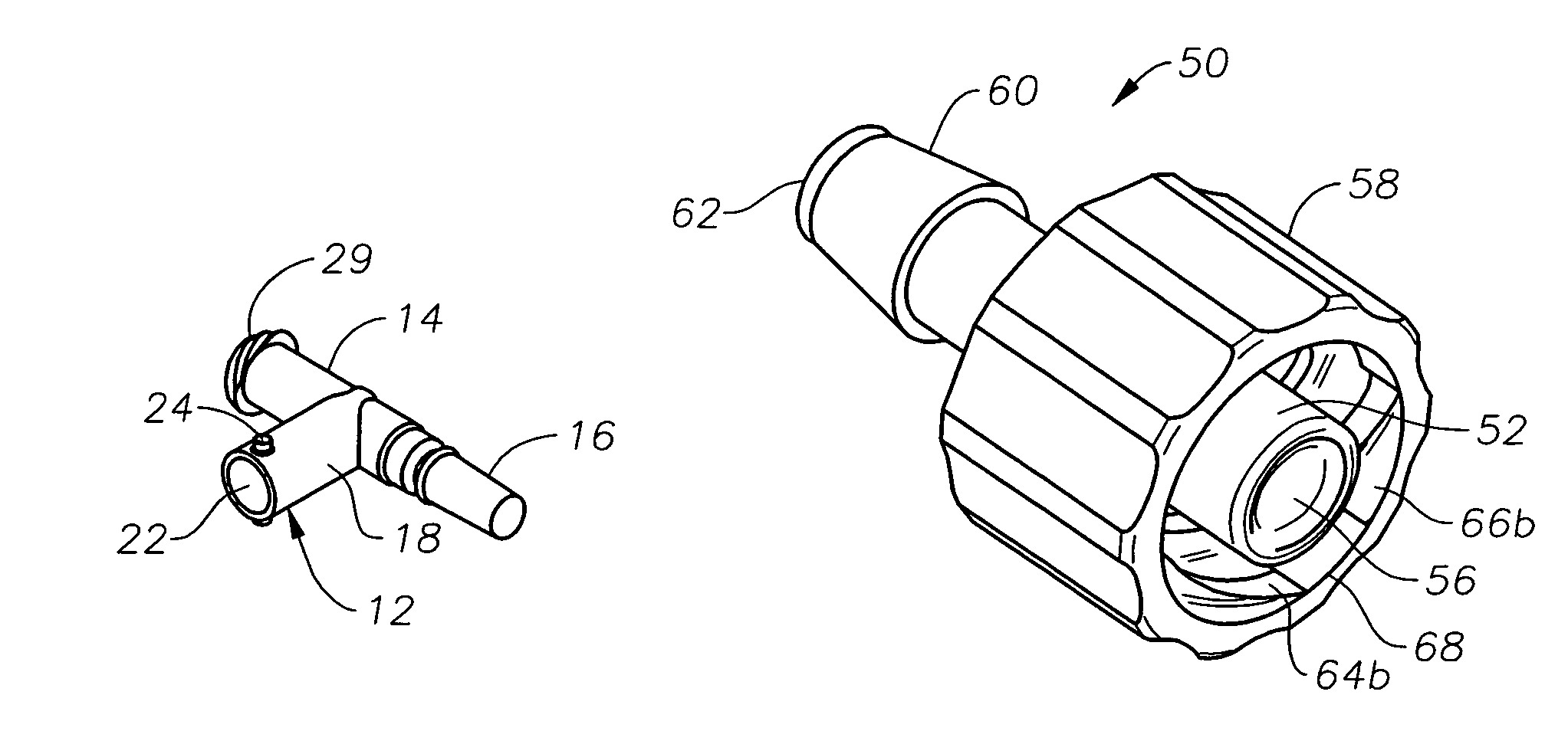

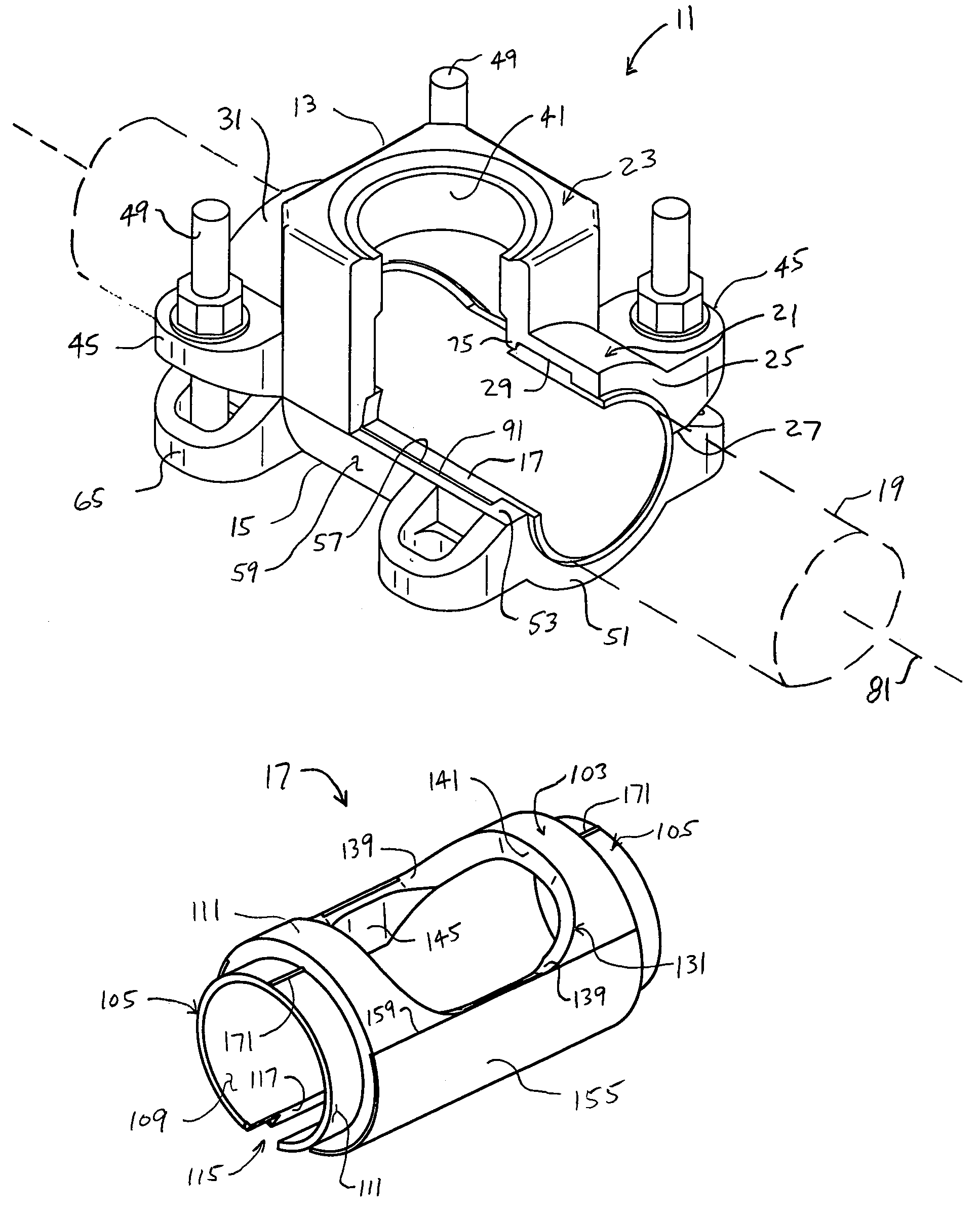

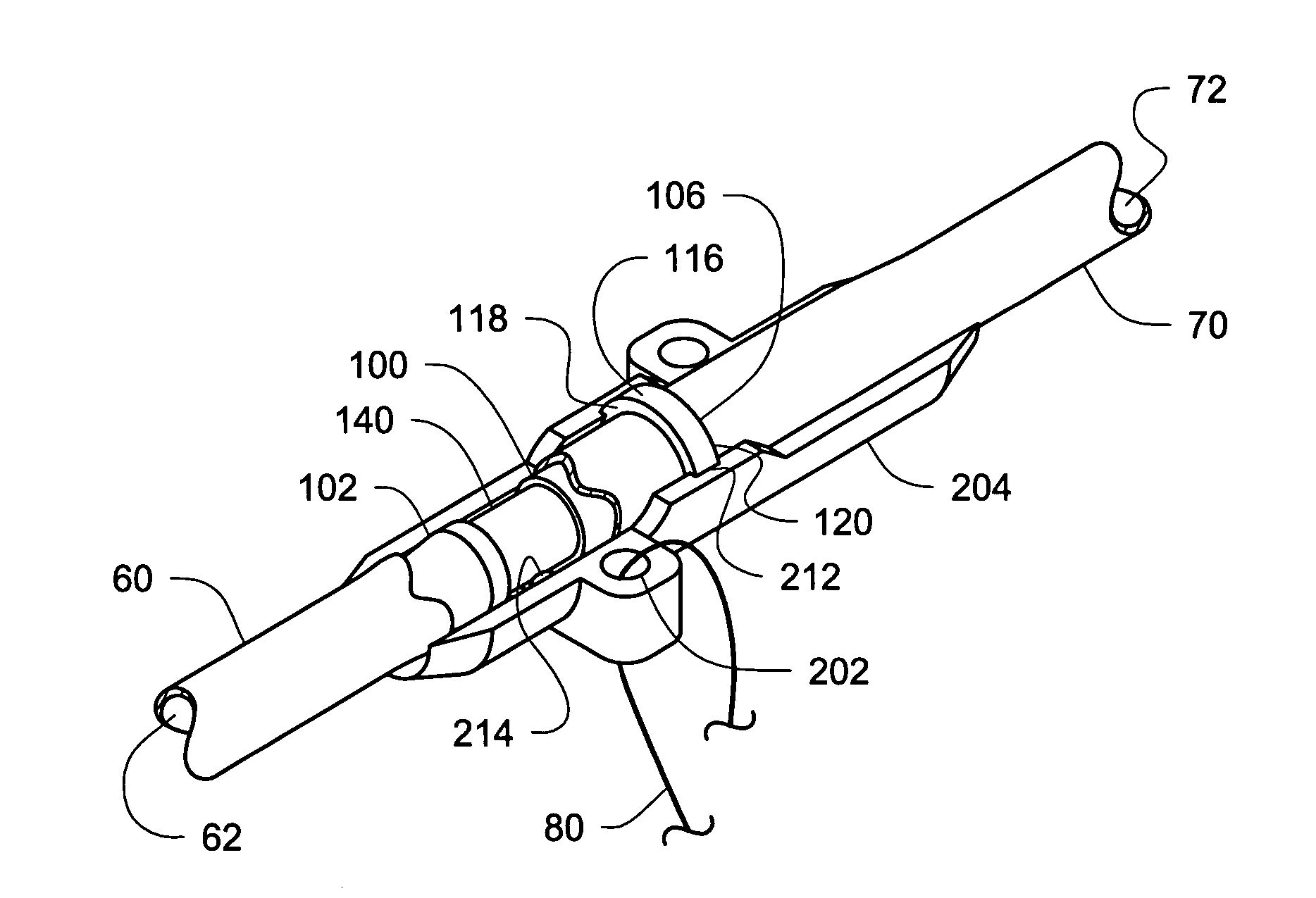

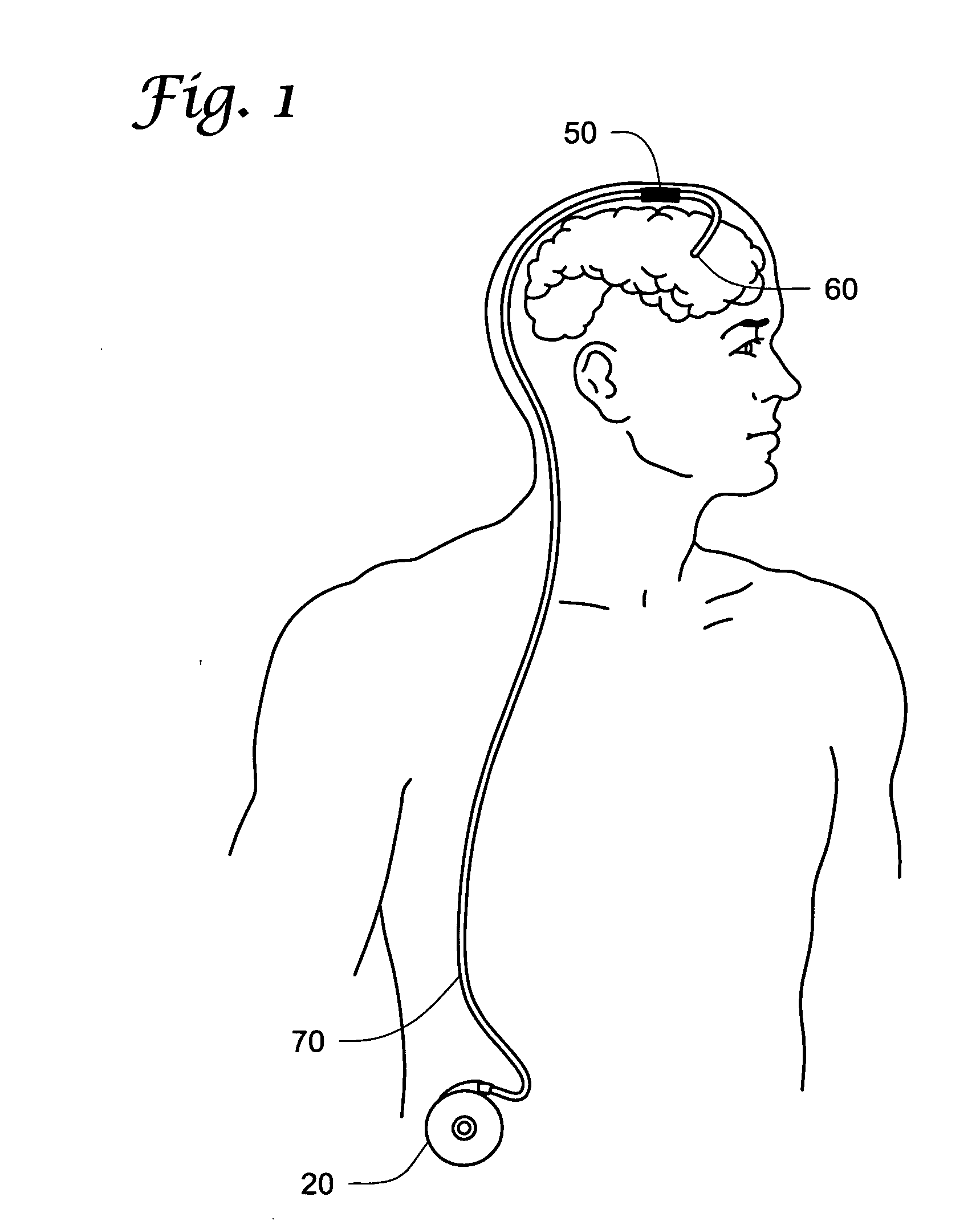

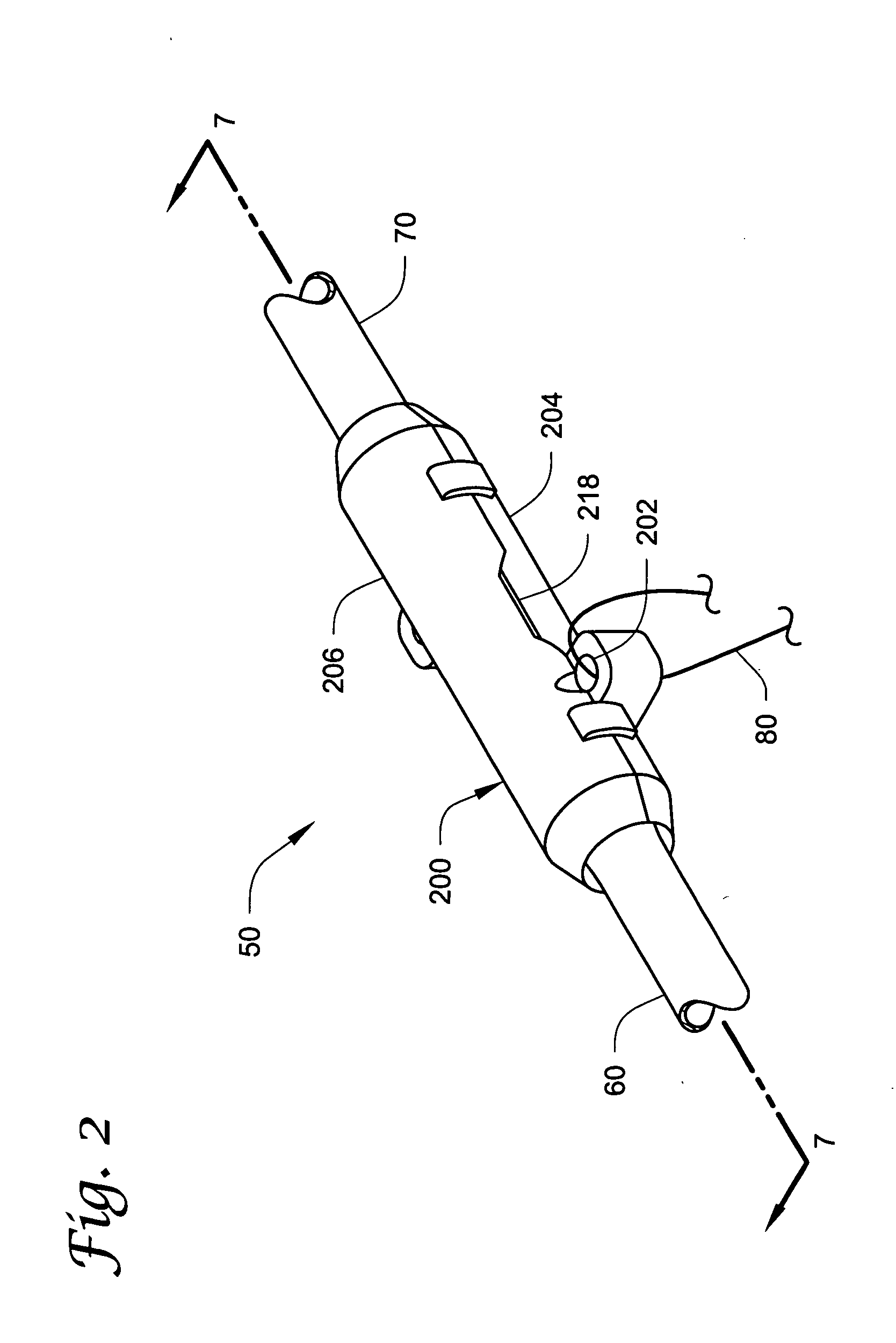

Strain relief device and connector assemblies incorporating same

A connector assembly for interconnecting separate sections of tubing, e.g., catheters, and a method for using the same. Connector assemblies in accordance with embodiments of the present invention may be a two-piece construction having a connector pin and a strain relief device. The strain relief device, in addition to providing secure, substantially leak-free coupling of the tubing sections, may also provide strain relief to the tubing interconnection.

Owner:MEDTRONIC INC

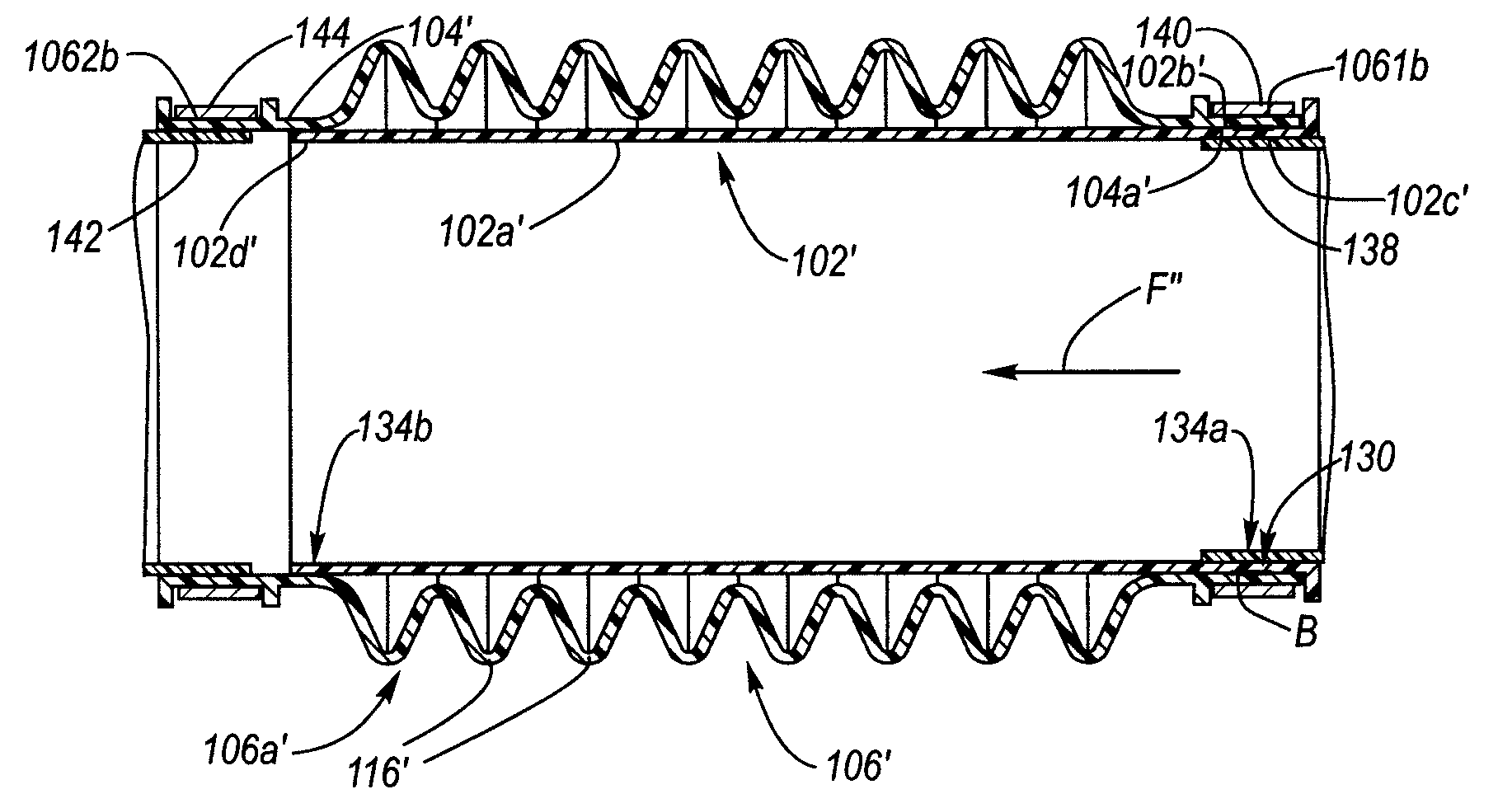

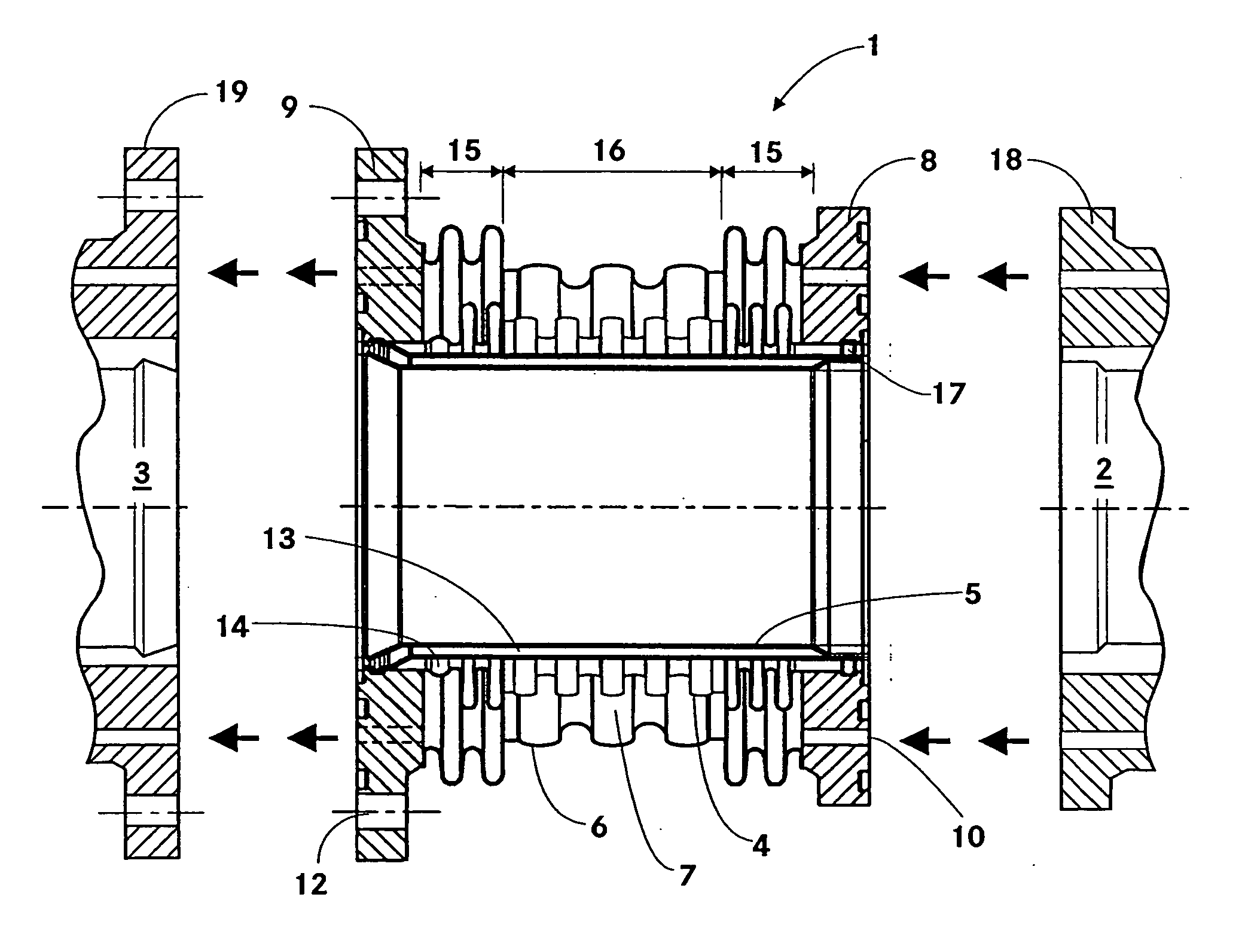

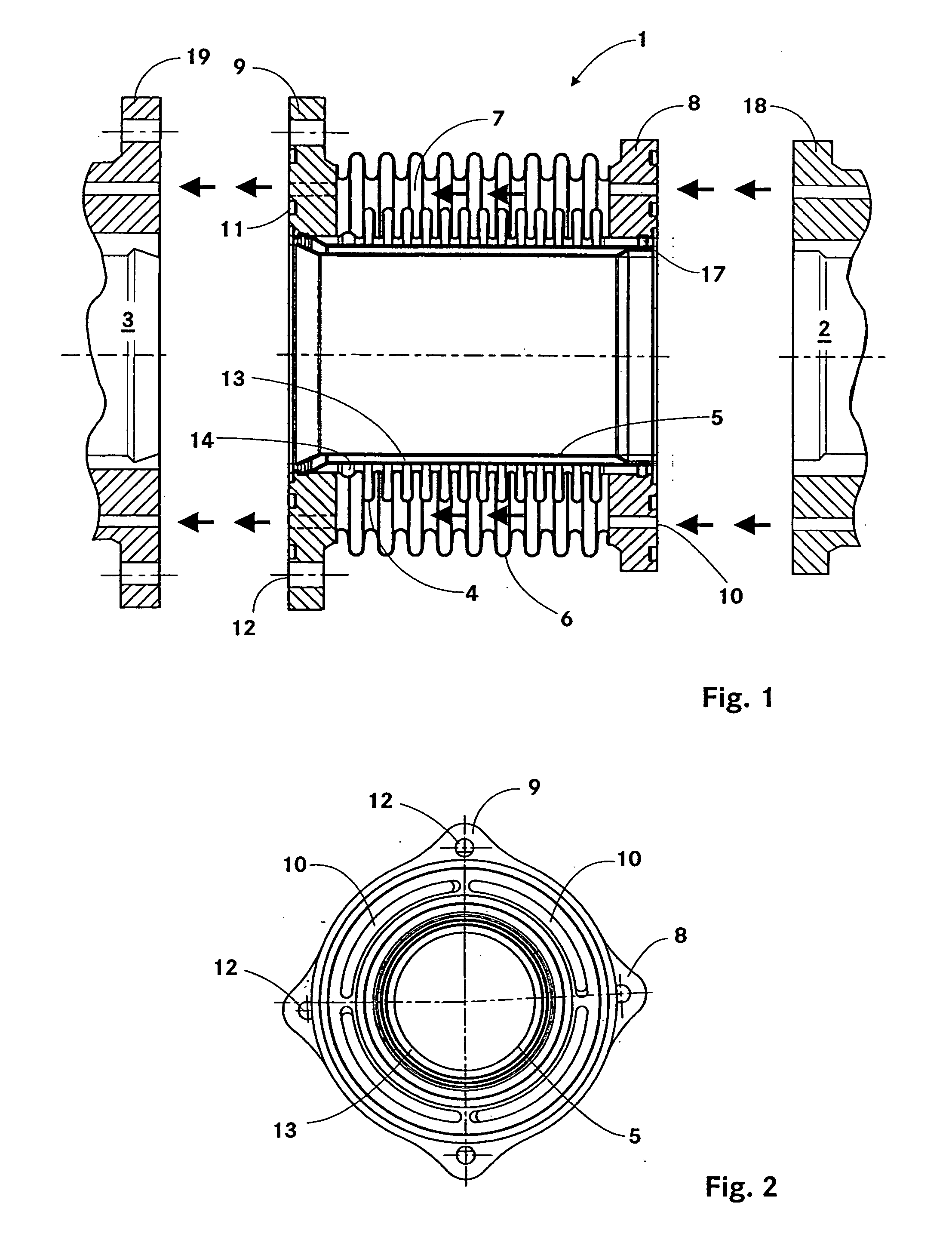

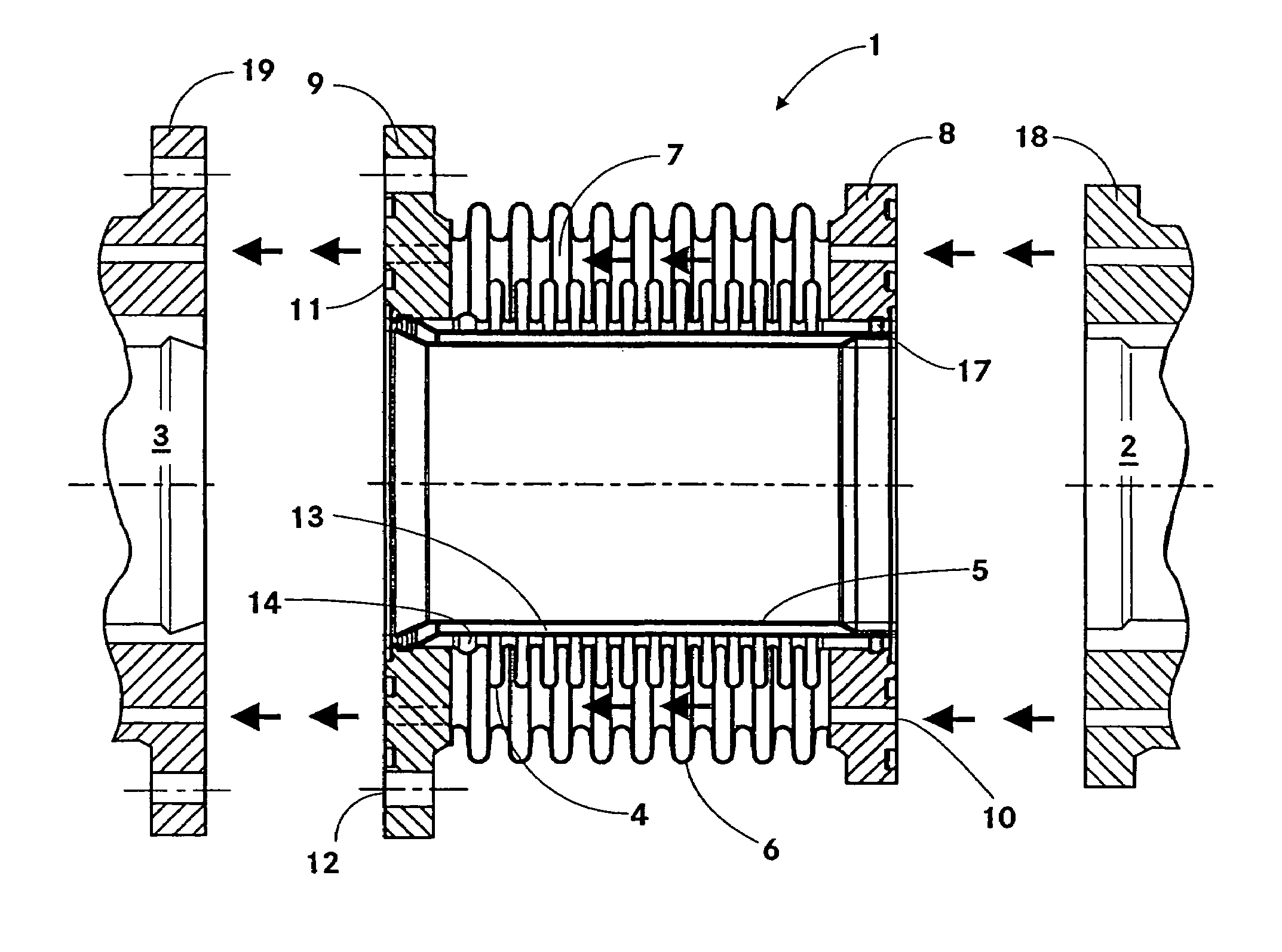

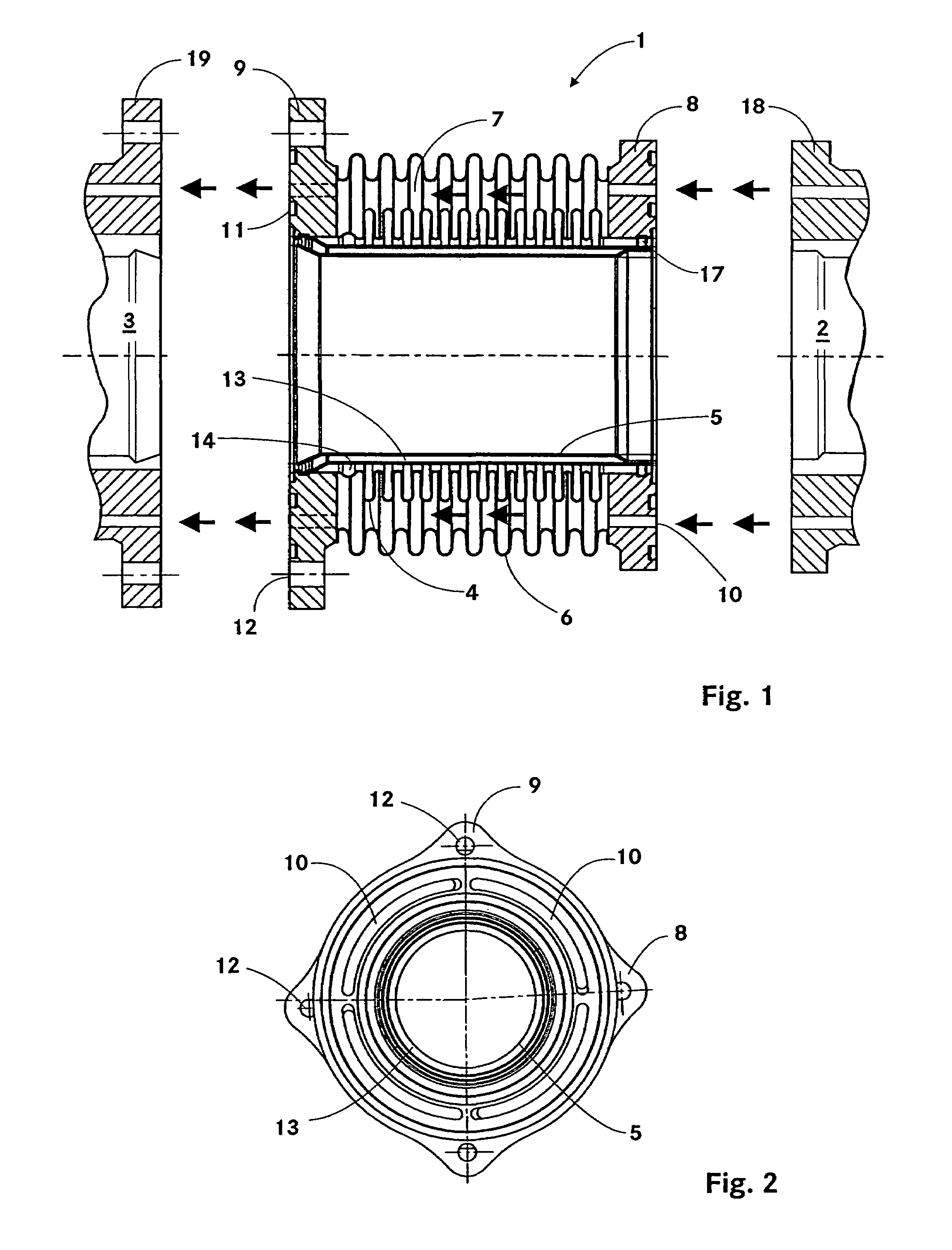

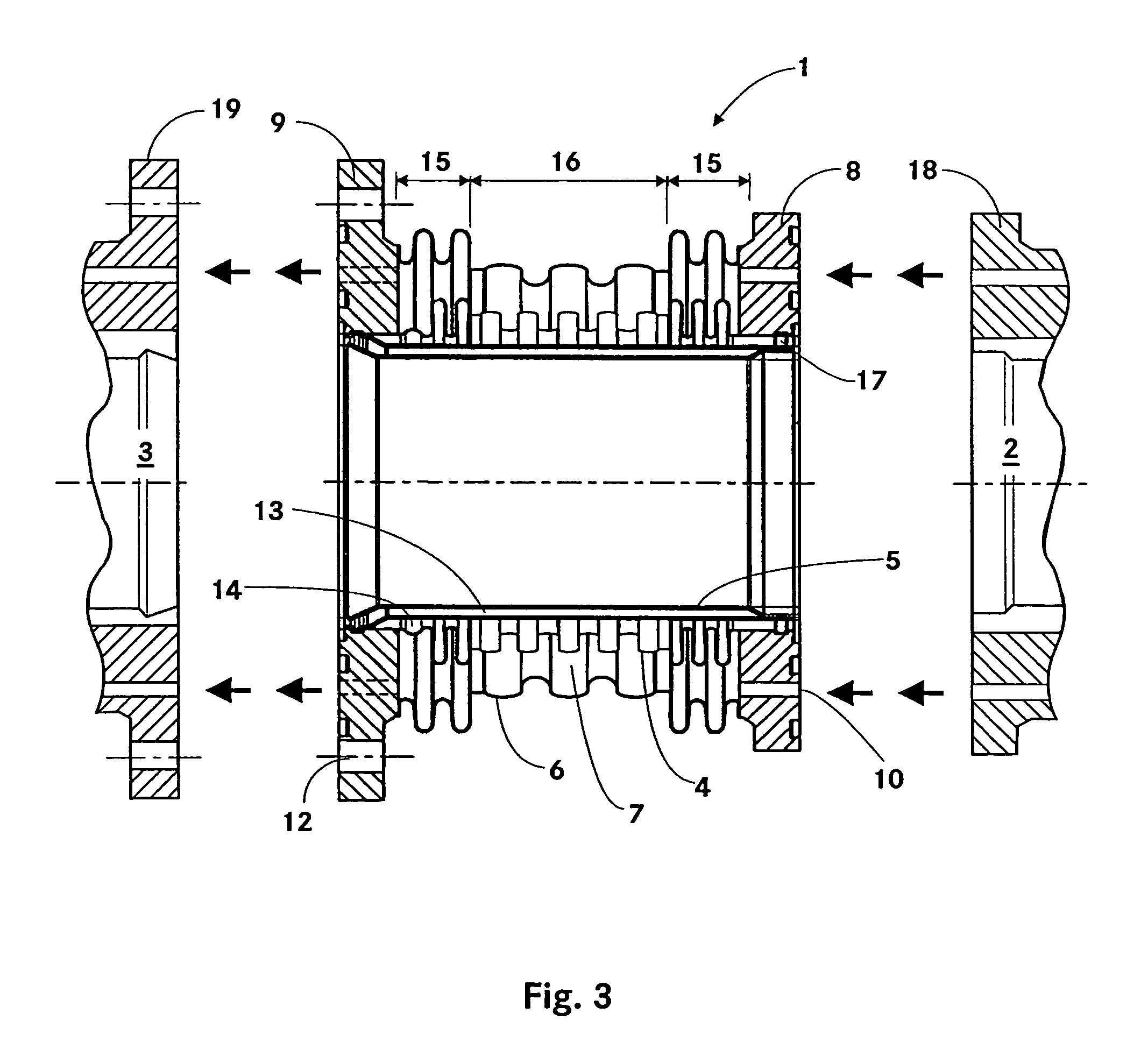

Exhaust gas bellows expansion joint

ActiveUS20050242577A1Simple designReduce manufacturing costSleeve/socket jointsPipe supportsEngineeringExpansion joint

An exhaust gas bellows expansion joint for joining a first section and a second section of an exhaust pipe. The exhaust gas bellows expansion joint including a first corrugated pipe for conveying exhaust gas through the joint, a protective sleeve, which is inserted in the first corrugated pipe, a second corrugated pipe, which coaxially surrounds the first corrugated pipe, and an annular space between the first corrugated pipe and the second corrugated pipe for the passage of liquid through the joint.

Owner:ROLLS ROYCE SOLUTIONS GMBH

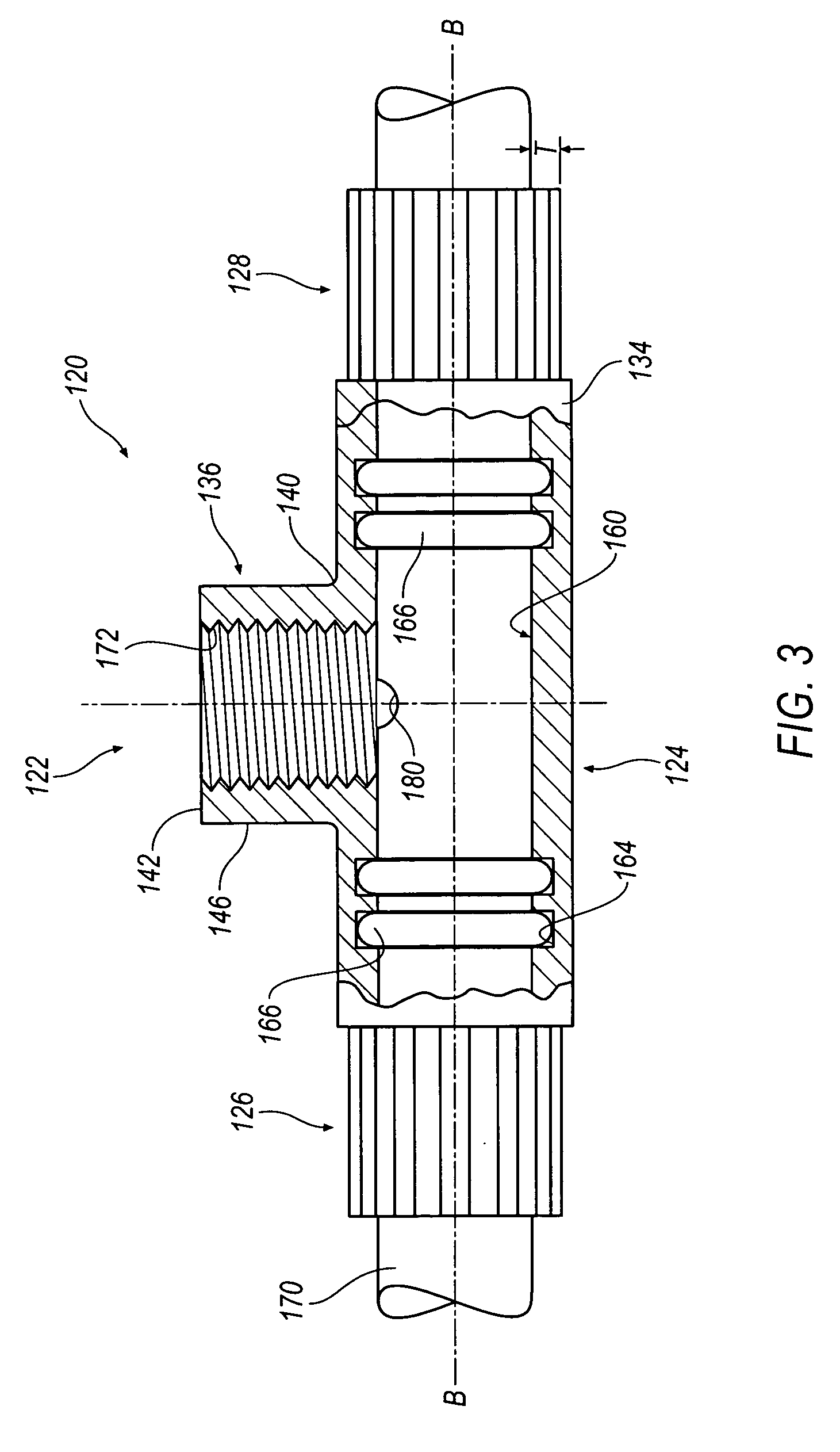

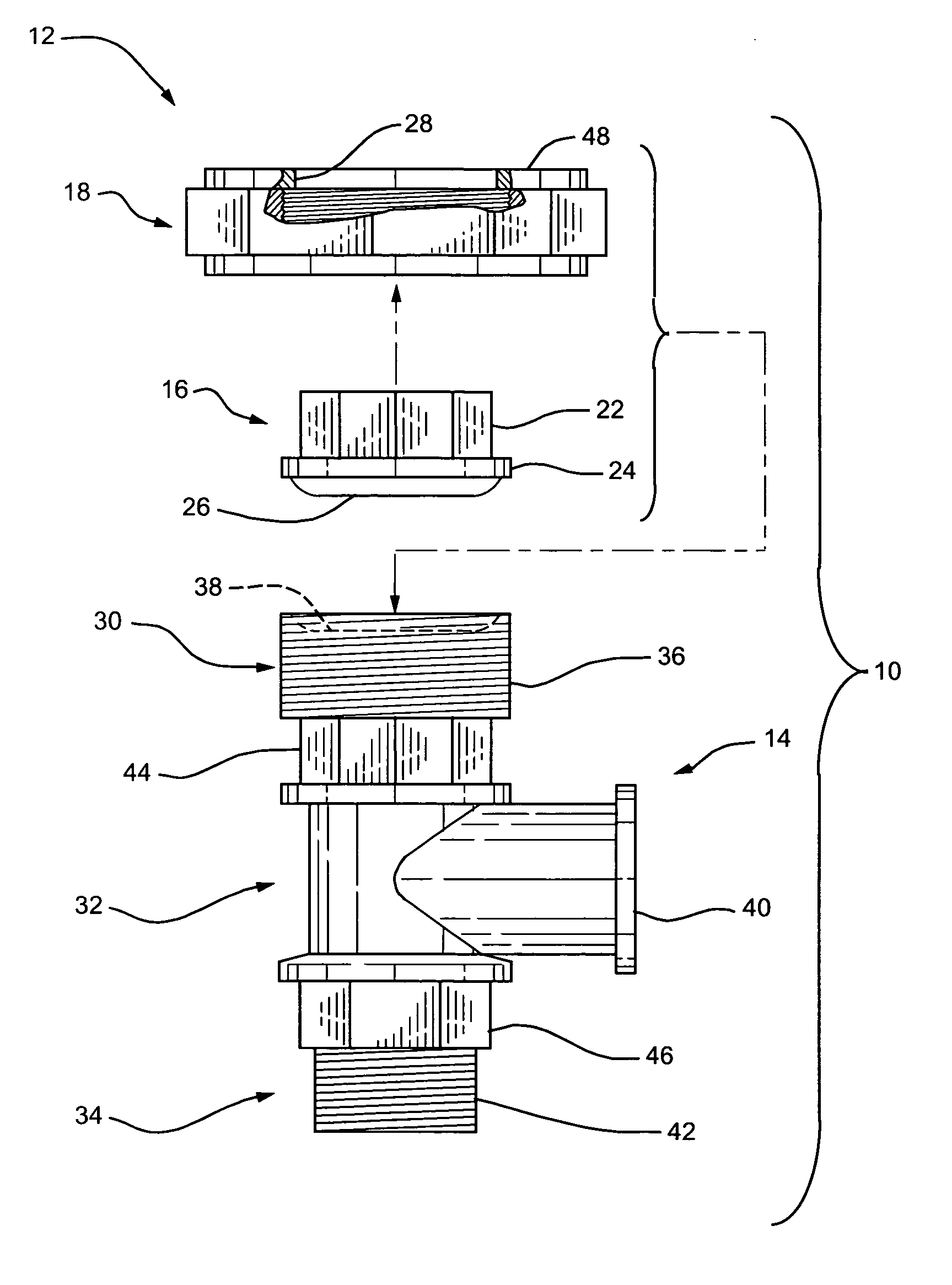

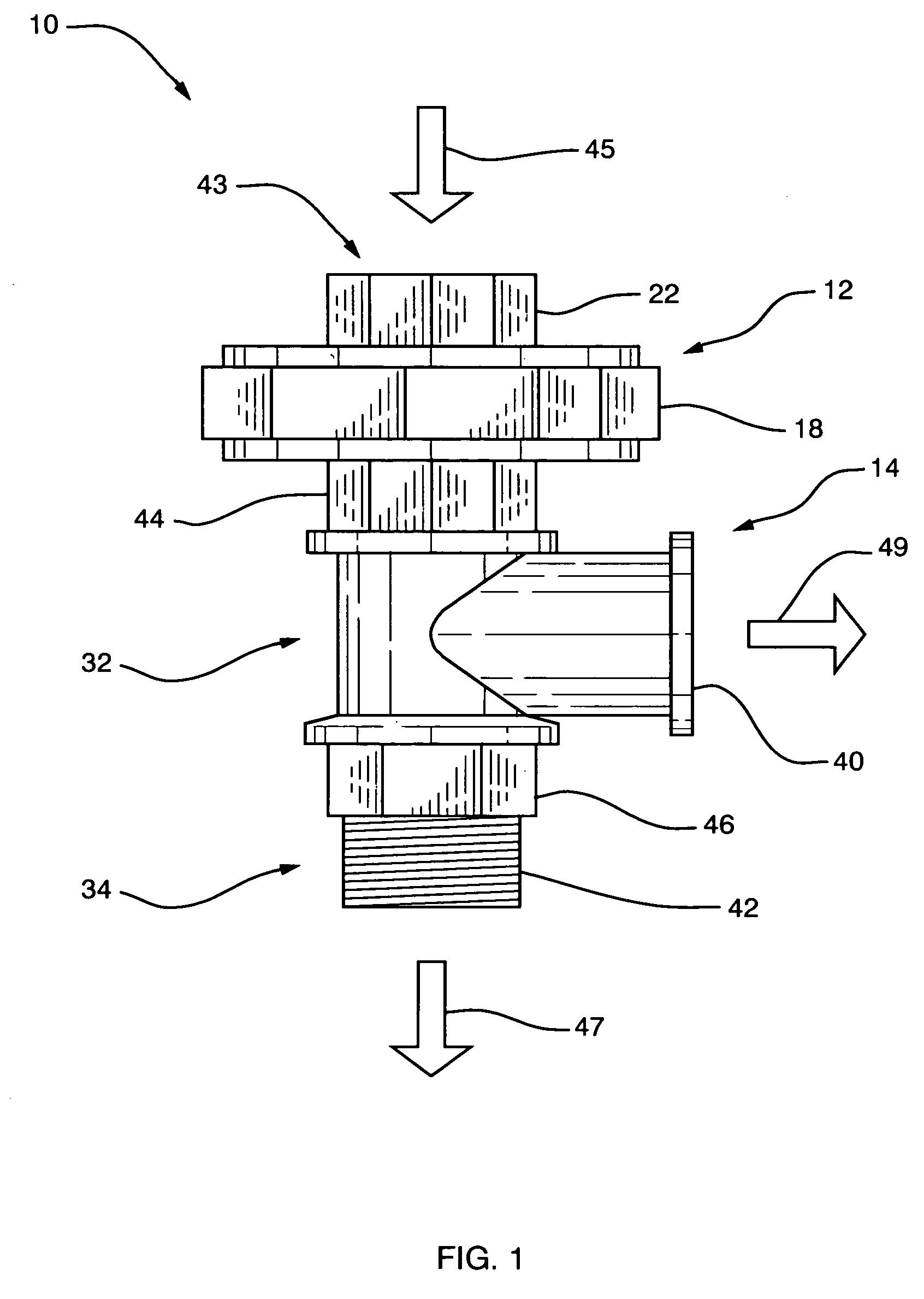

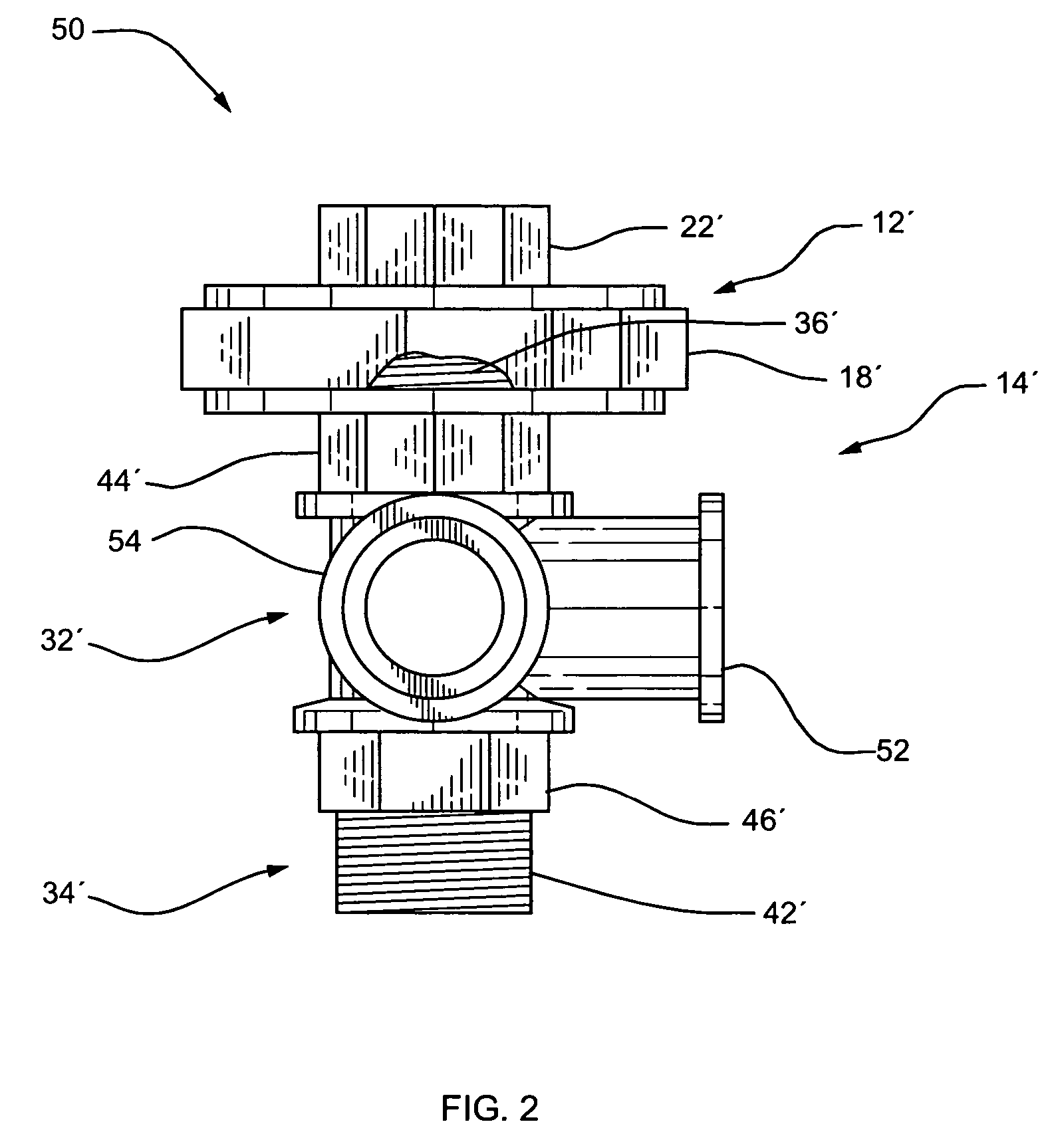

Quick connect and quick disconnect plumbing apparatus

InactiveUS7156425B2Facilitates installation and connectionQuick connectionFluid pressure sealed jointsPipeline expansion-compensationLine tubingThermal water

A plumbing apparatus for connecting a tankless hot water heater to a cold water supply line and a hot water outlet line includes a union and a tee that are interconnected to one another. A first connector at one end of the union is provided for connecting the union to the tankless hot water heater. A second connector at a free end of the tee is provided for connecting the tee to either the cold water supply line or the hot water outlet line. The tee is provided with a branch for connecting the plumbing apparatus to a plumbing device. A passage formed in the union and tee permits fluid to flow there through and through the branch.

Owner:ATKINSON MANUEL DIAZ

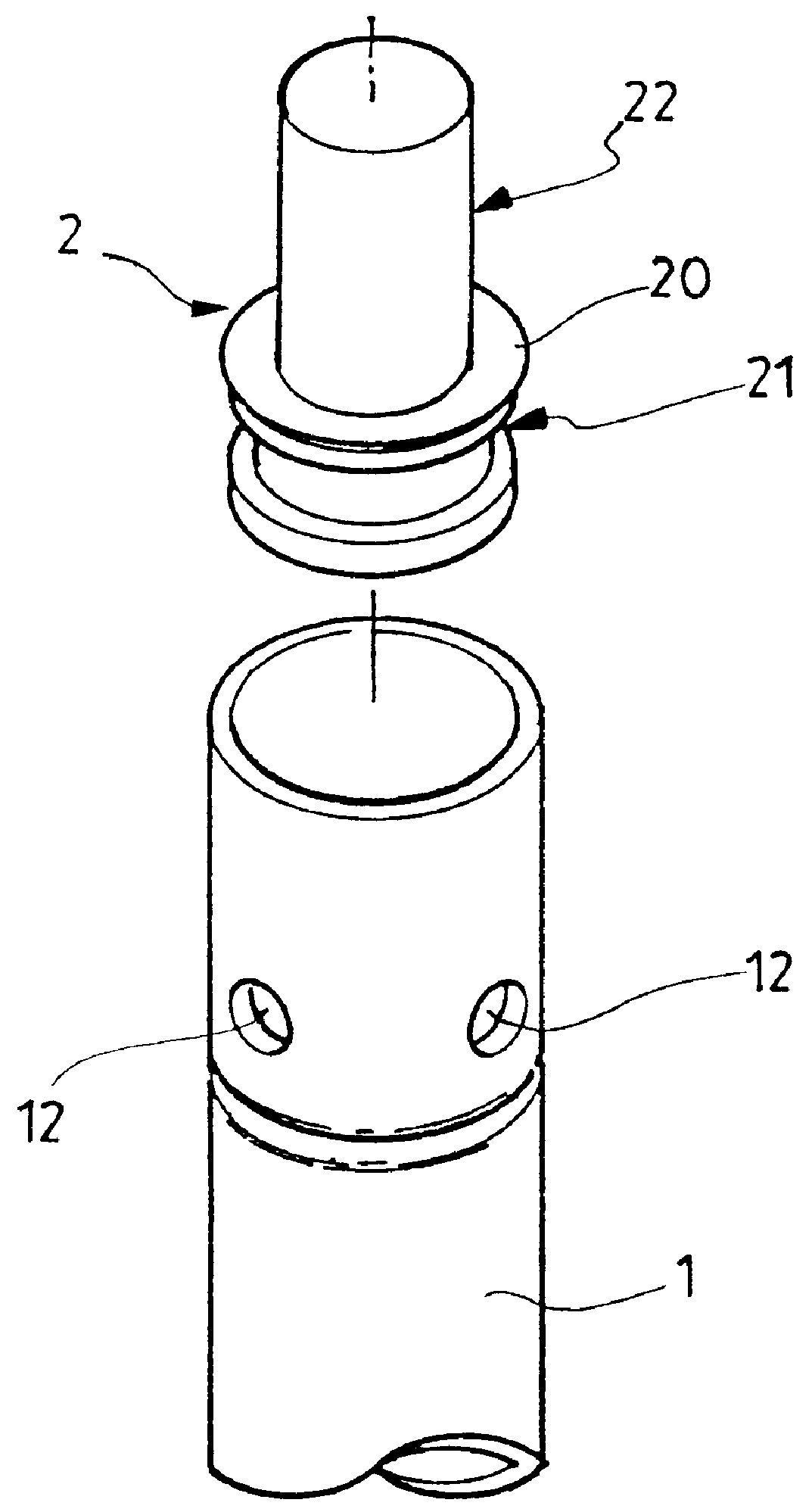

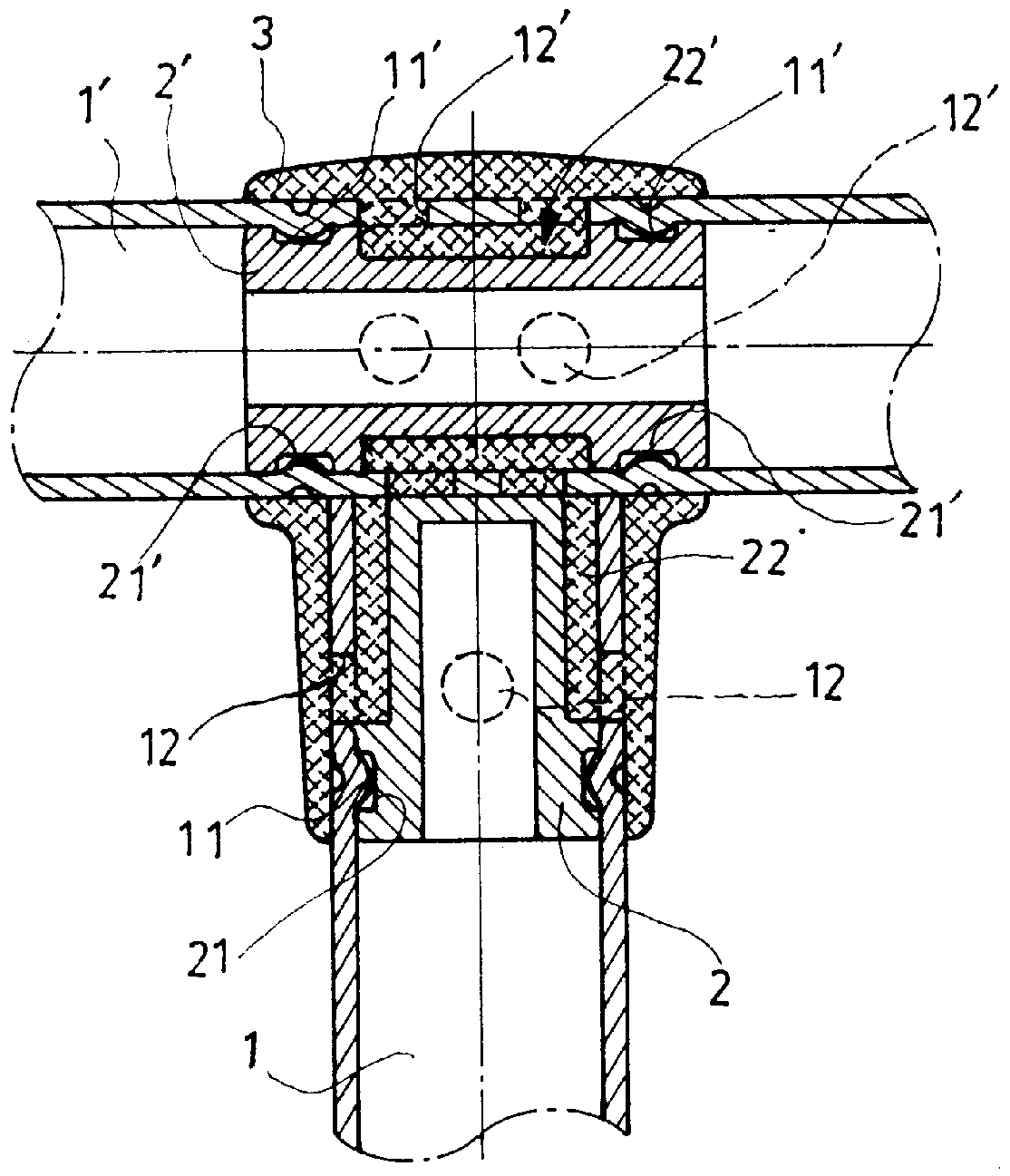

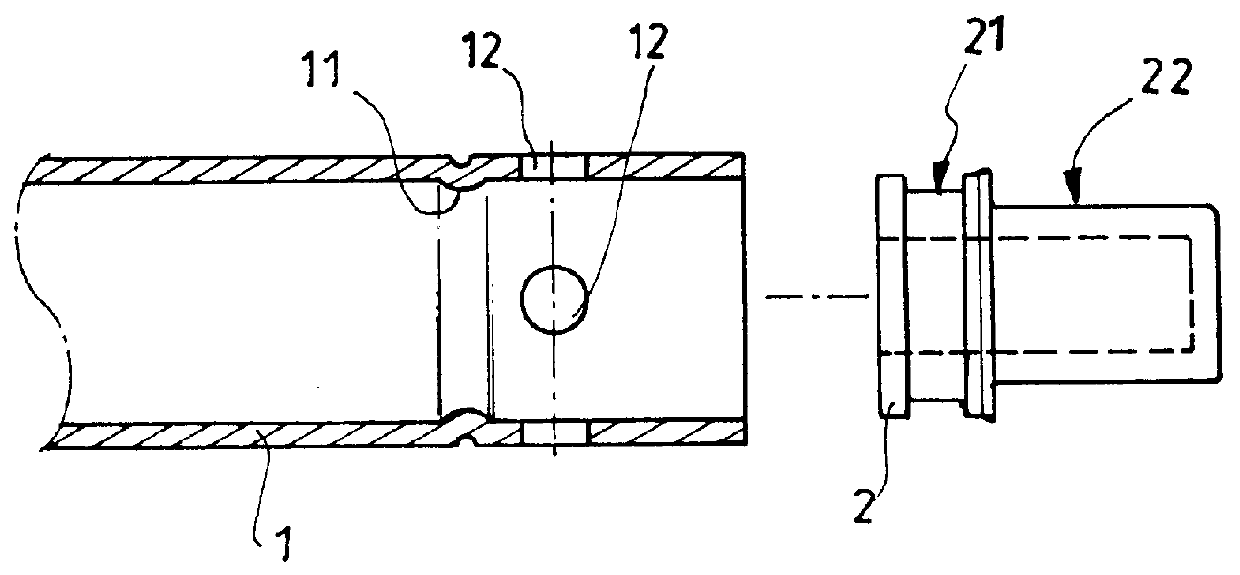

Coupling device for tube

The present invention relates to an improved coupling device for tube and that is configured with a tube and an insert that can be fixedly disposed within the tube. The insert includes at least an enlarged portion that has an annular groove thereof, and a receiving space. The tube is provided with a plurality of through holes at the middle portion or end portions. The insert can be disposed within the tube and the outer of the tube is machined to form an annular recess corresponding to the annular groove in a manner such that the insert is fixedly disposed within the tube. Wherein each of the two tubes is provided with an insert in the position to be connected, and the tubes is arranged side-by-side at the area to be connected. An enclosing element is deployed to the connecting area such that the tubes are fixedly connected.

Owner:LUO CHUNG I

Exhaust gas bellows expansion joint

ActiveUS7284771B2Simple designReduce manufacturing costSleeve/socket jointsPipe supportsEngineeringExpansion joint

Owner:ROLLS ROYCE SOLUTIONS GMBH

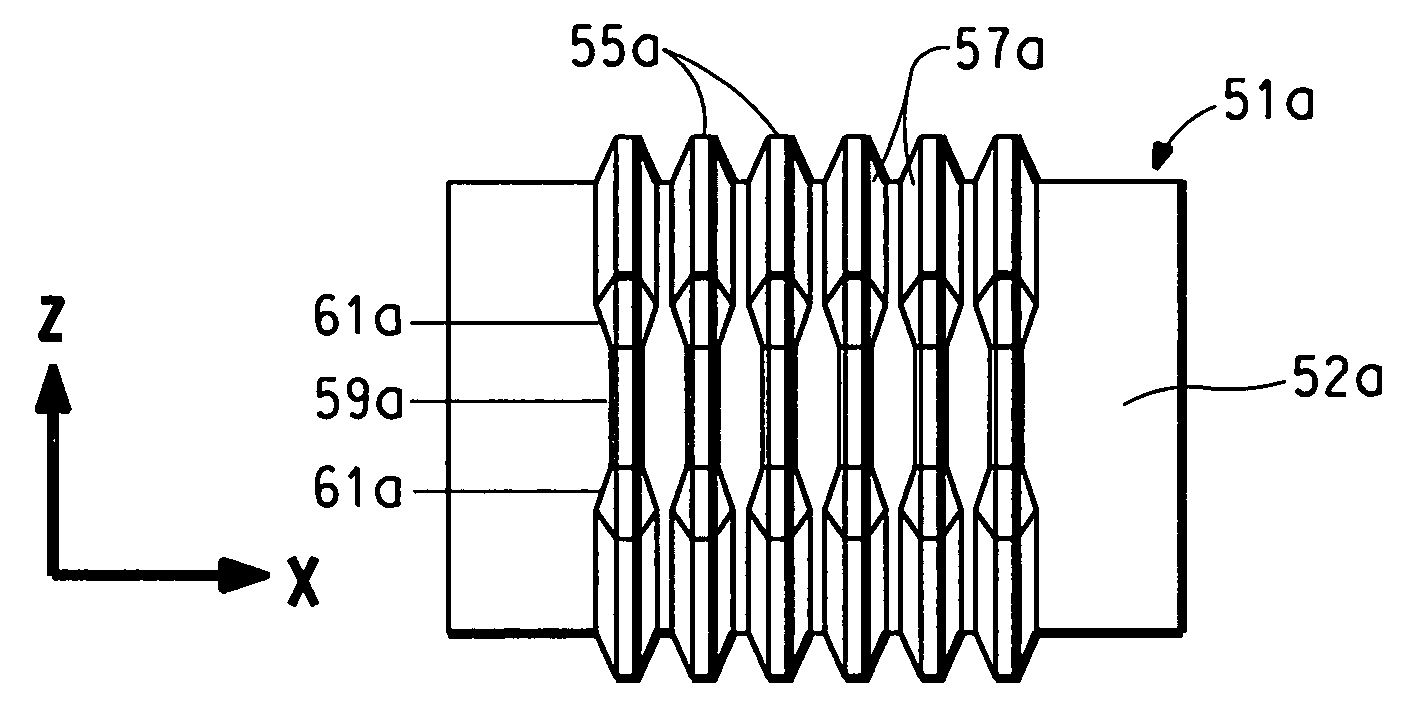

Variable stiffness bellows

Owner:DUPONT POLYMERS INC

Mechanical joint for a gas turbine engine

ActiveUS8459941B2Controls are responsiveUniform thermal stressLocking fastenersReaction enginesEngineeringGas turbines

A mechanical joint for a gas turbine engine includes:(a) an annular first component having an annular, radially-extending first flange; (b) an annular second component having an annular, radially-extending second flange abutting the first flange; (c) a plurality of generally radially-extending radial channels passing through at least one of the first and second flanges; (d) a plurality of generally axially-extending channels extending through the first flange and communicating with respective ones of the radial channels; and (e) a plurality of fasteners clamping the first and second flanges together.

Owner:GENERAL ELECTRIC CO

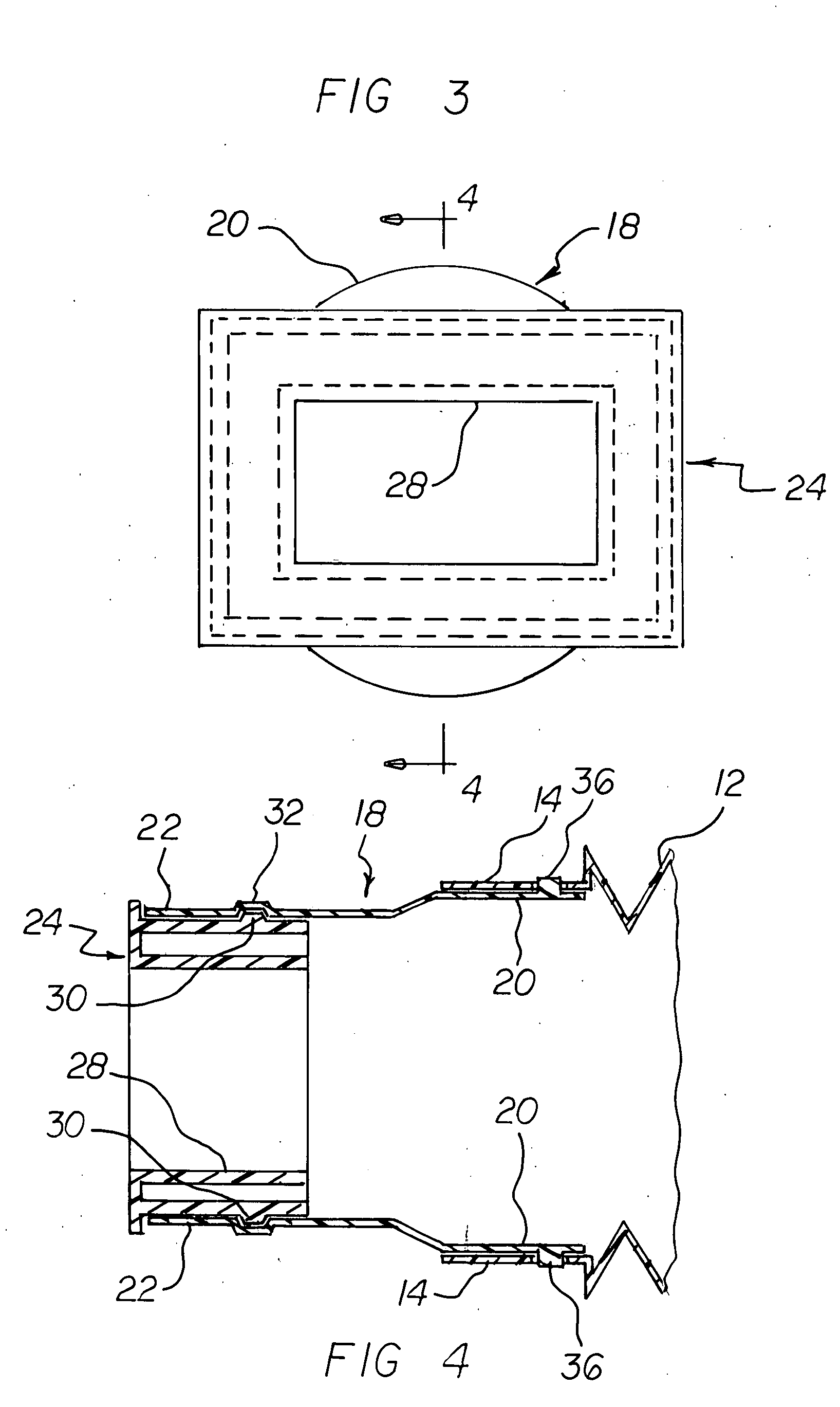

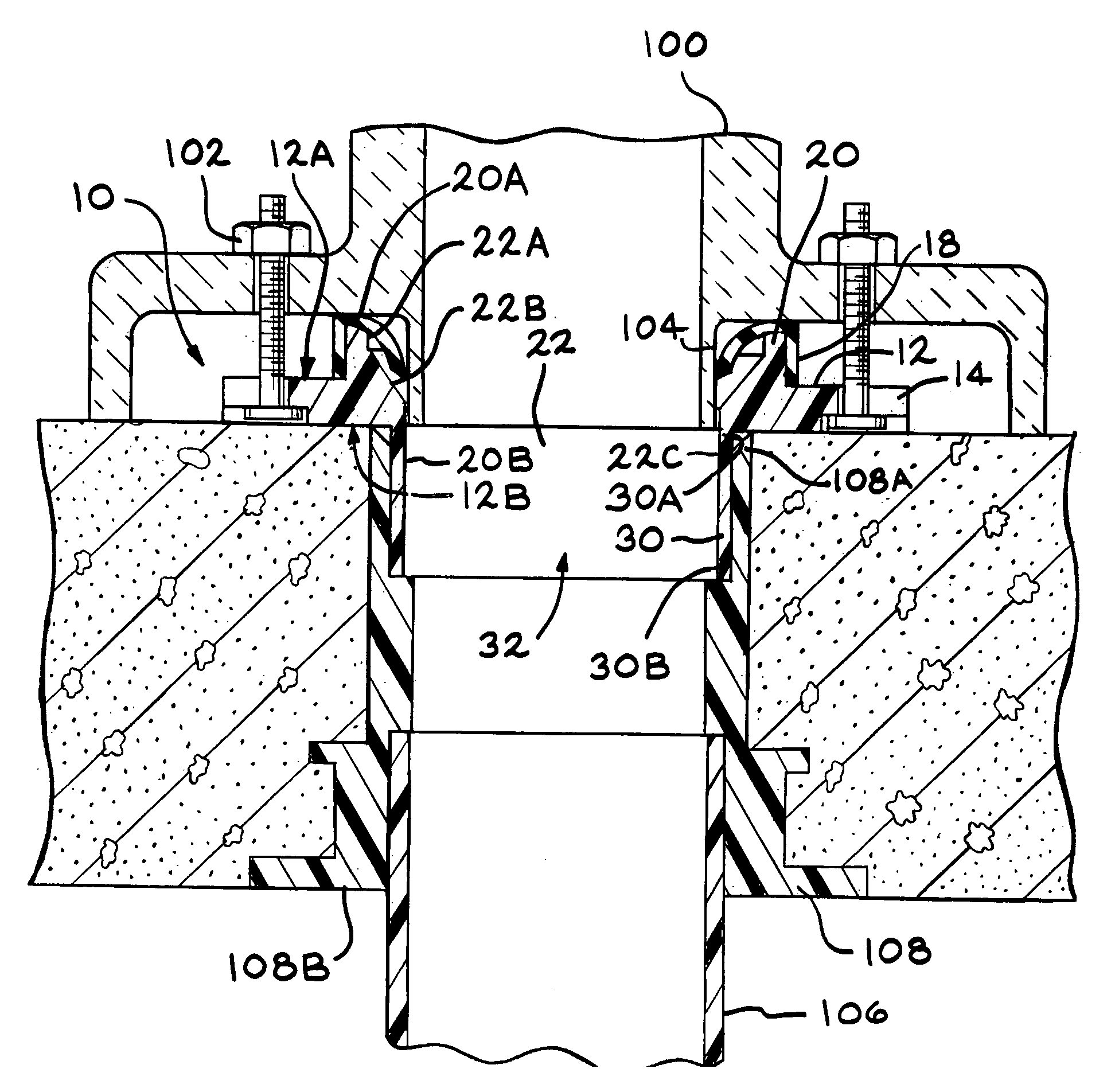

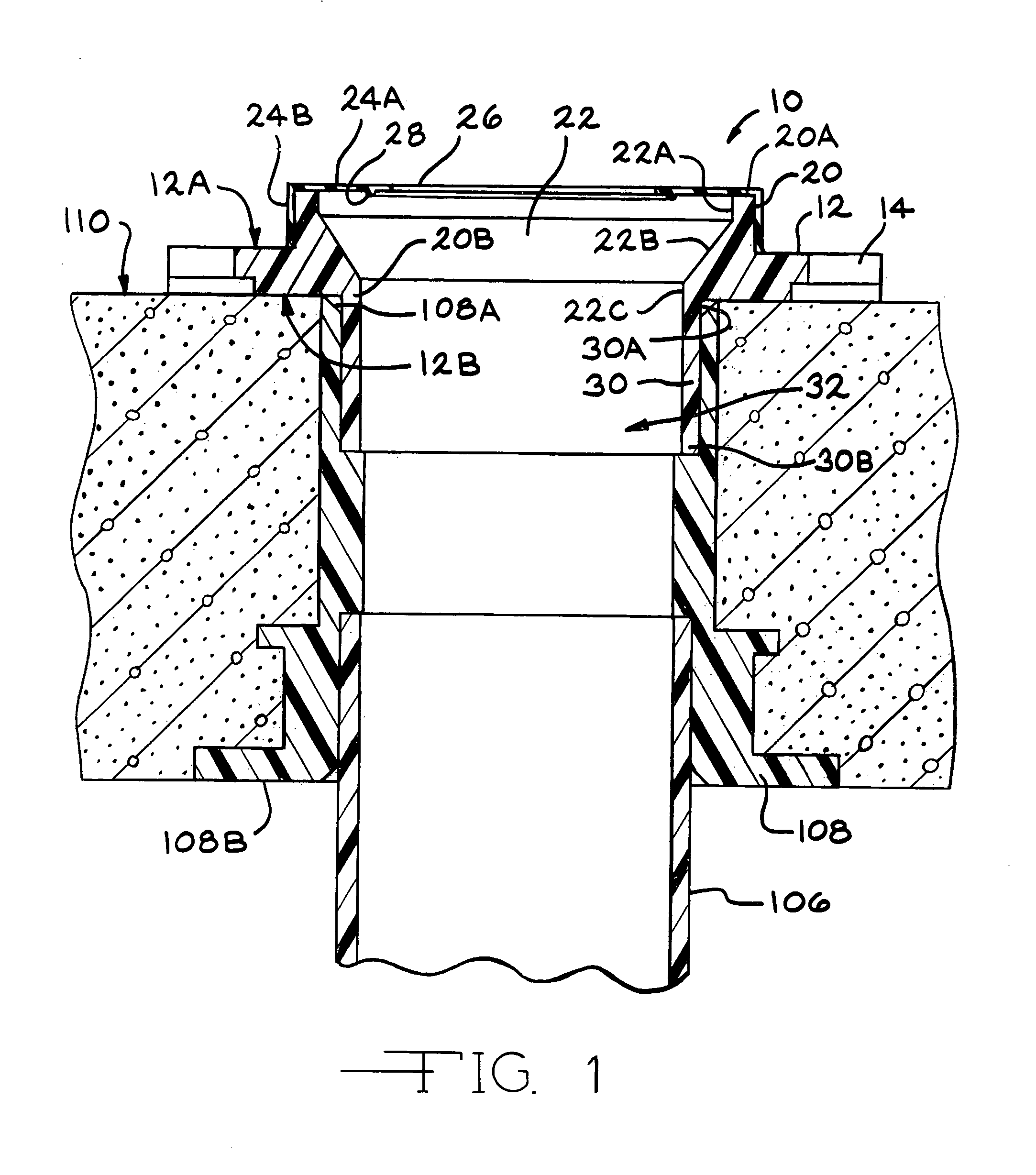

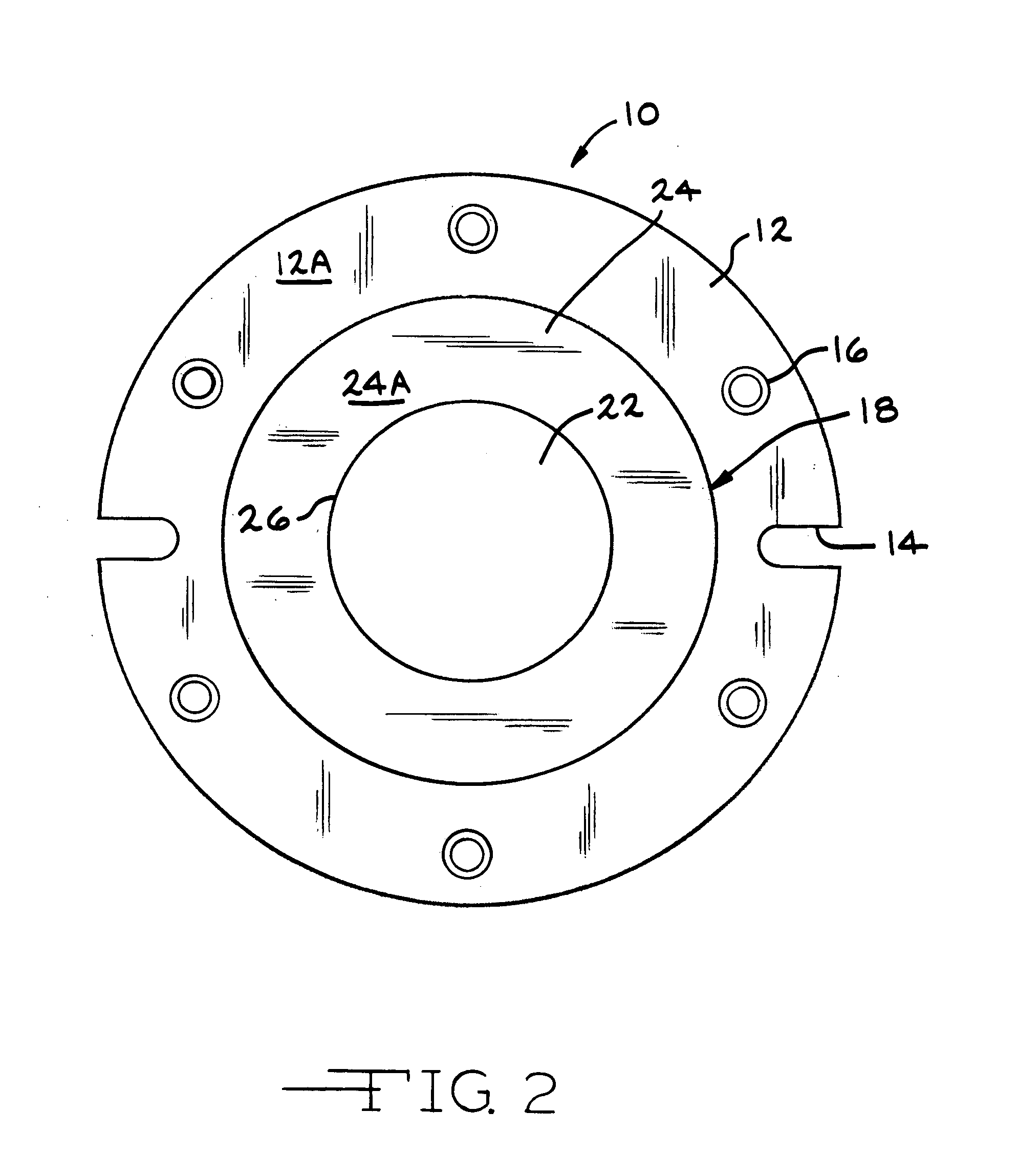

Toilet flange assembly

A flange assembly (10) for connecting a plumbing fixture to a drain pipe (106) in a fluid sealing relationship. The flange assembly includes a ring (12), an extension (20), a gasket (24) and a connector pipe (30). The extension extends outward from the top surface (12A) of the ring and the connector pipe extends outward from the bottom surface (12B) of the ring. The gasket is mounted over the end of the extension opposite the ring. The top wall (24A) of the gasket has an opening (26) which allows access to the center bore (22) of the extension. The waste outlet (104) of the plumbing fixture is inserted through the opening (26) in the top wall of the gasket into the center bore of the extension. When the waste outlet is inserted into the opening in the gasket, the gasket forms a seal between the waste outlet and the extension.

Owner:CORNWALL KENNETH R

Device and method for coupling a conduit

ActiveUS8128126B2Easy to installEasy to modifySleeve/socket jointsFluid pressure sealed jointsDevice formEngineering

A coupling device formed of two identical sides is disclosed. Each of the two sides have a snap fitting mechanism which engage each other to releasably secure the sides together thereby forming the coupling device. The coupling device as formed has a main body communicating with at least two openings. Each opening is sized to engage an end of a corresponding conduit. Generally, the conduits are corrugated such that the openings engage one corrugation to form the friction fit. The openings may be conically shaped with pre-scored cut lines that can be cut at different diameters to engage conduits of different diameters. The openings of the coupling device have pre-score cut lines that may be cut in order to create the friction fit with corrugated conduits having different diameters.

Owner:IPEX TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com