Patents

Literature

12577results about "Liquid material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

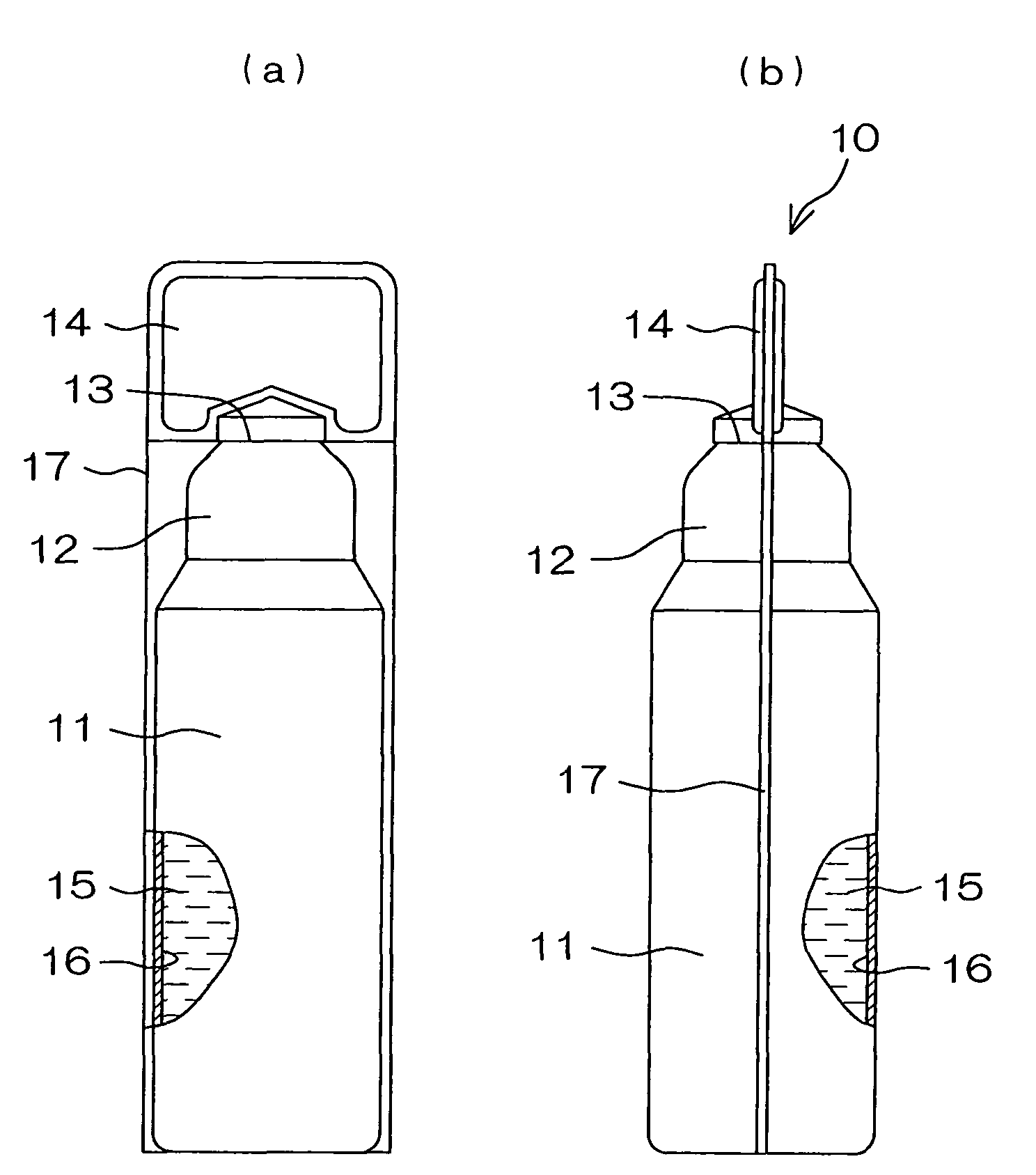

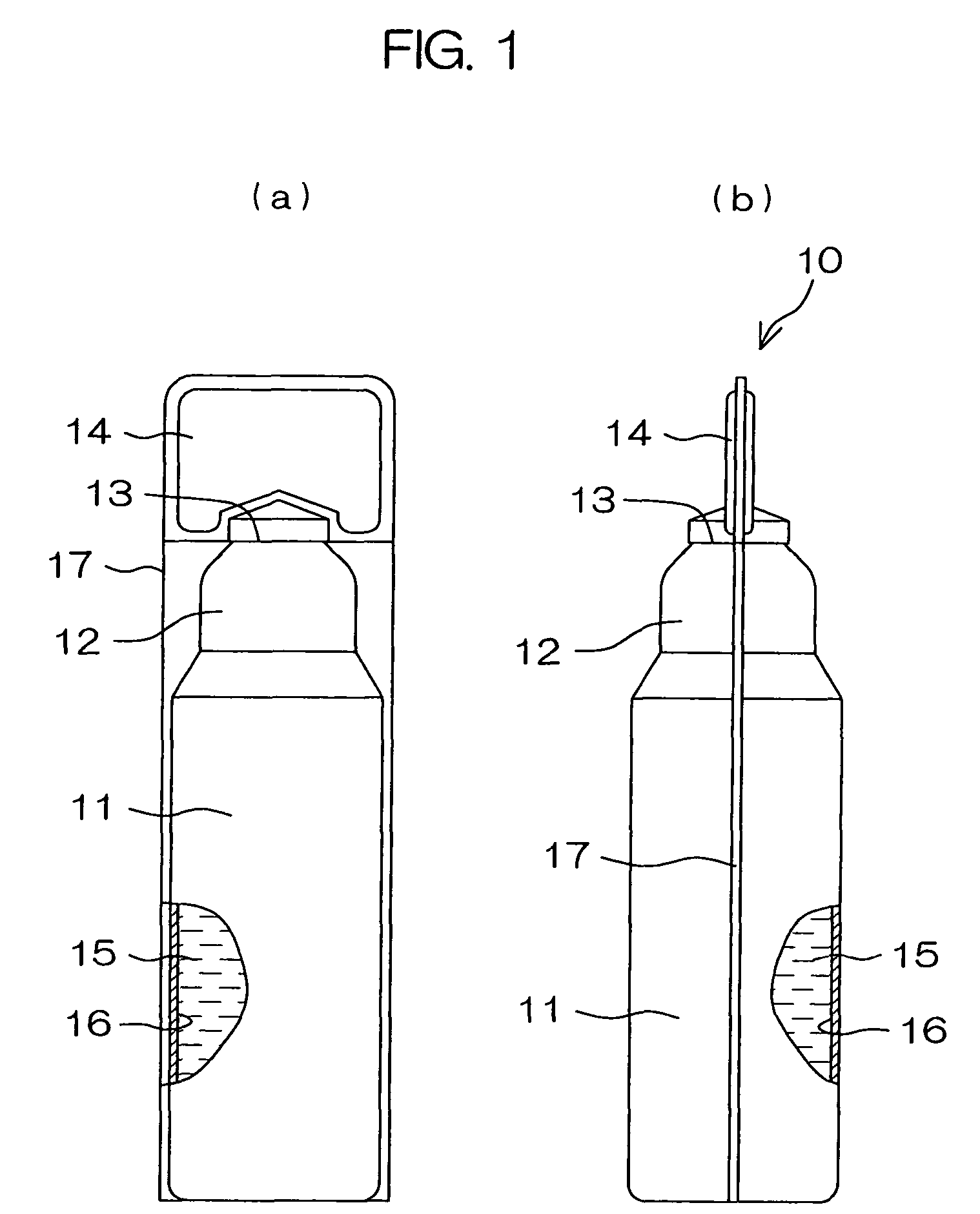

Drug solution filling plastic ampoule and process for producing the same

A drug solution filling plastic ampoule having gas, steam and light ray barrier properties, a drug permeation preventing capability and an absorption / adsorption preventing capability, and a production method for the plastic ampoule. The drug solution filling plastic ampoule includes a container body, a fusion-bonded portion which seals a mouth of the container body, and a wrench-off holder tab connected to the fusion-bonded portion. The ampoule is formed from a parison including two or more layers, at least one of which is a functional layer having at least one characteristic property selected from the group consisting of a gas permeation preventing capability, a steam permeation preventing capability, a light ray permeation preventing capability, a drug permeation preventing capability and a drug absorption / adsorption preventing capability.

Owner:OTSUKA PHARM FAB INC

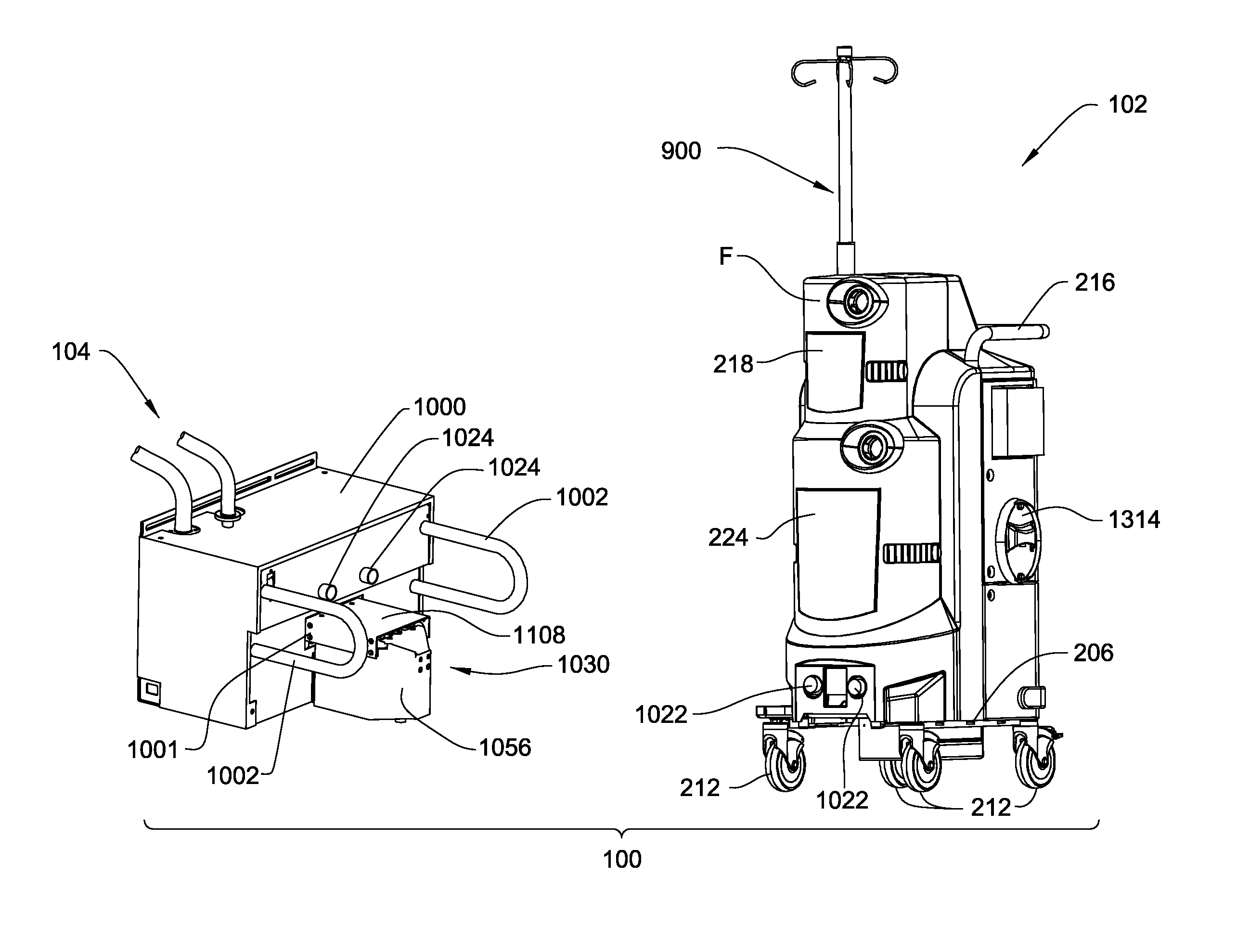

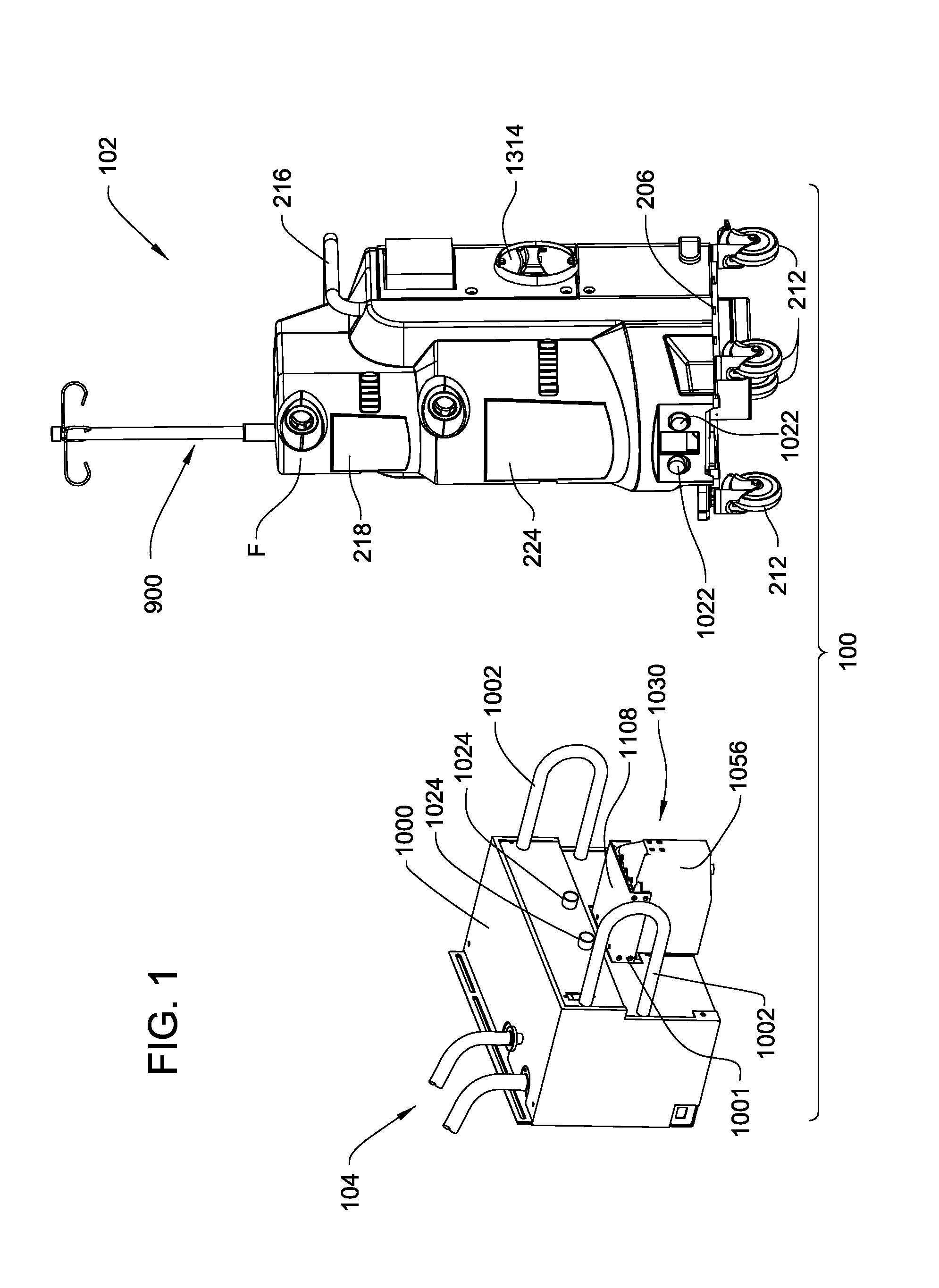

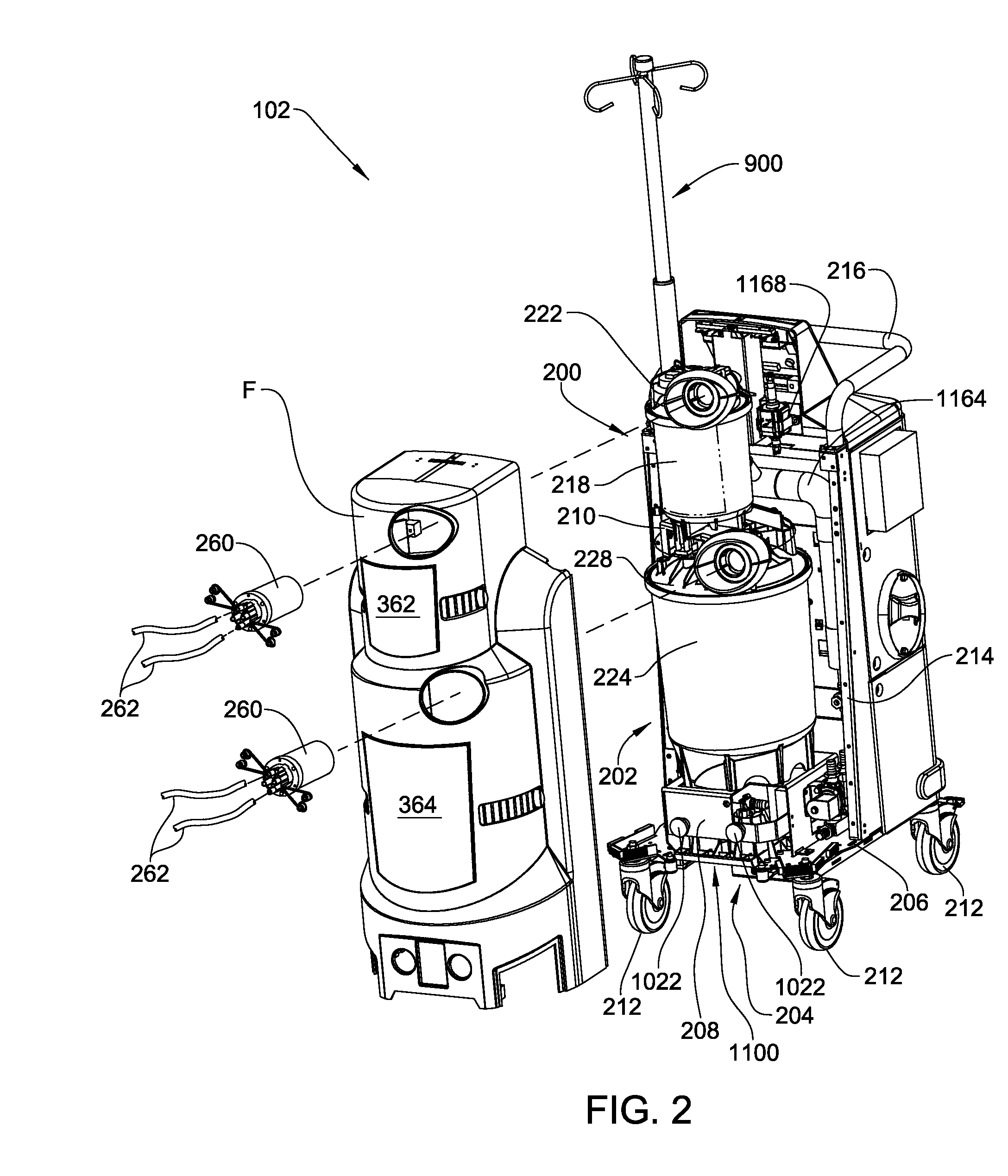

Medical/surgical waste collection unit including waste containers of different storage volumes with inter-container transfer valve and independently controlled vacuum levels

ActiveUS7621898B2Reduce in quantityLarge storage capacityMechanical apparatusDispersed particle filtrationDocking stationVacuum level

Owner:STRYKER CORP

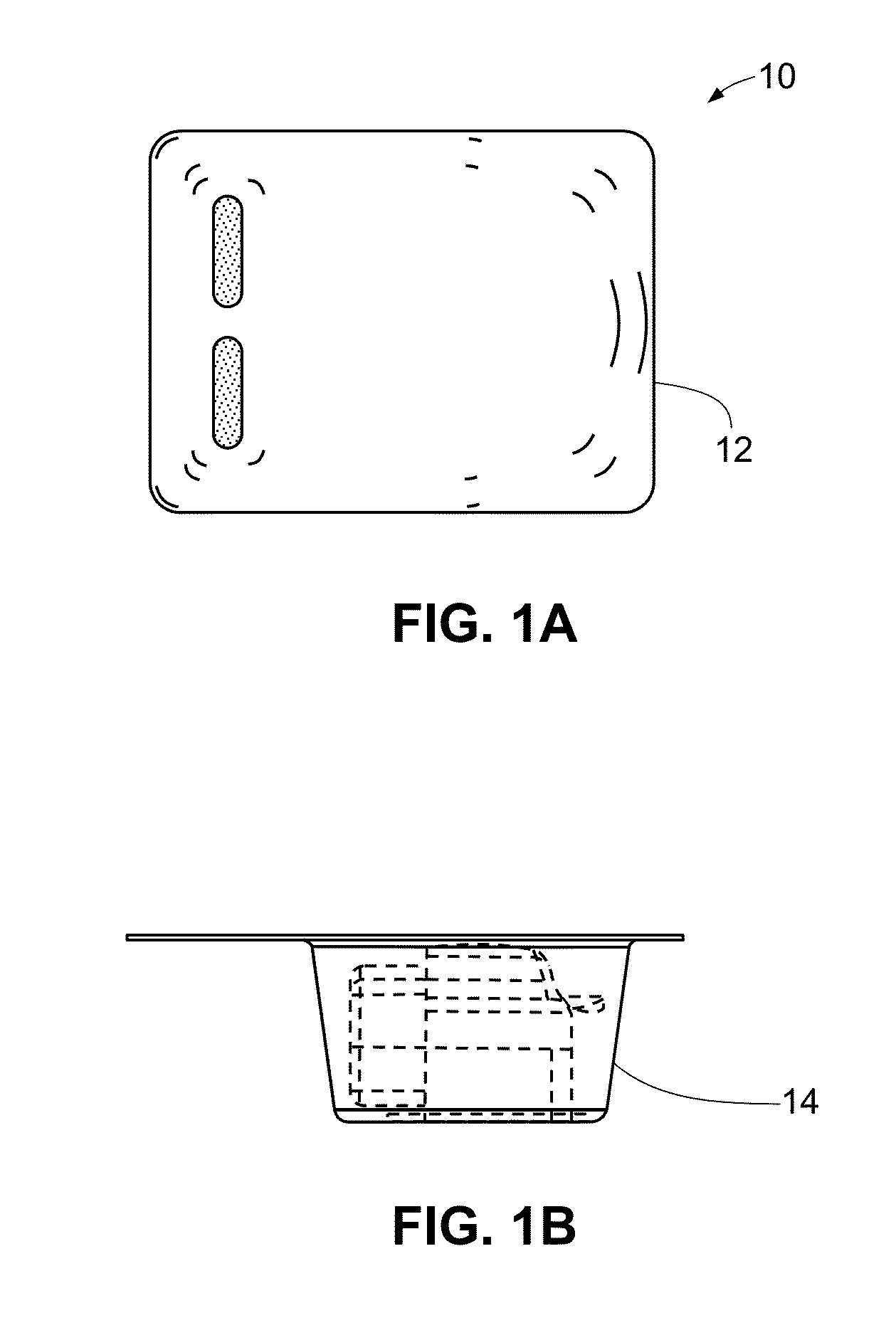

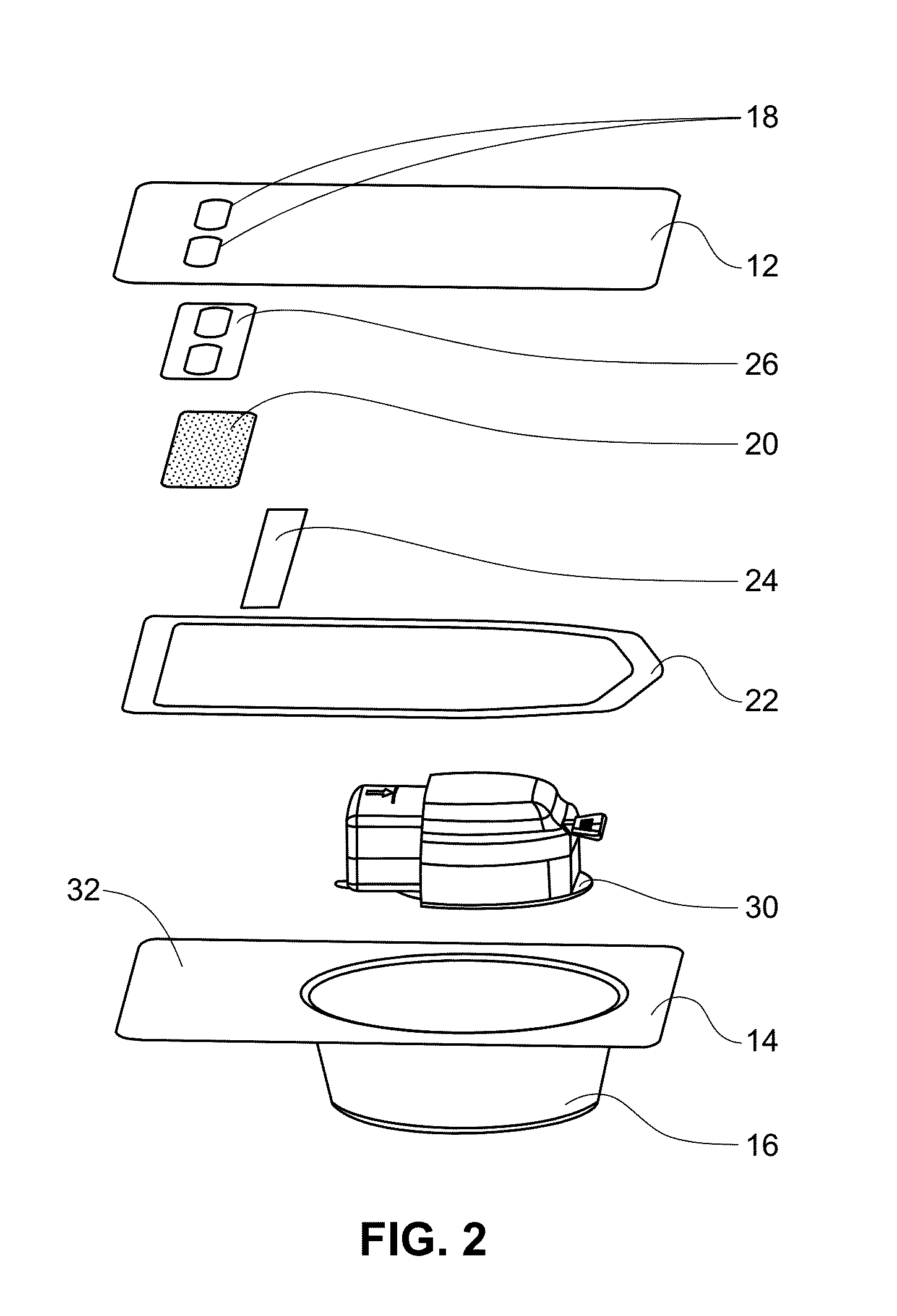

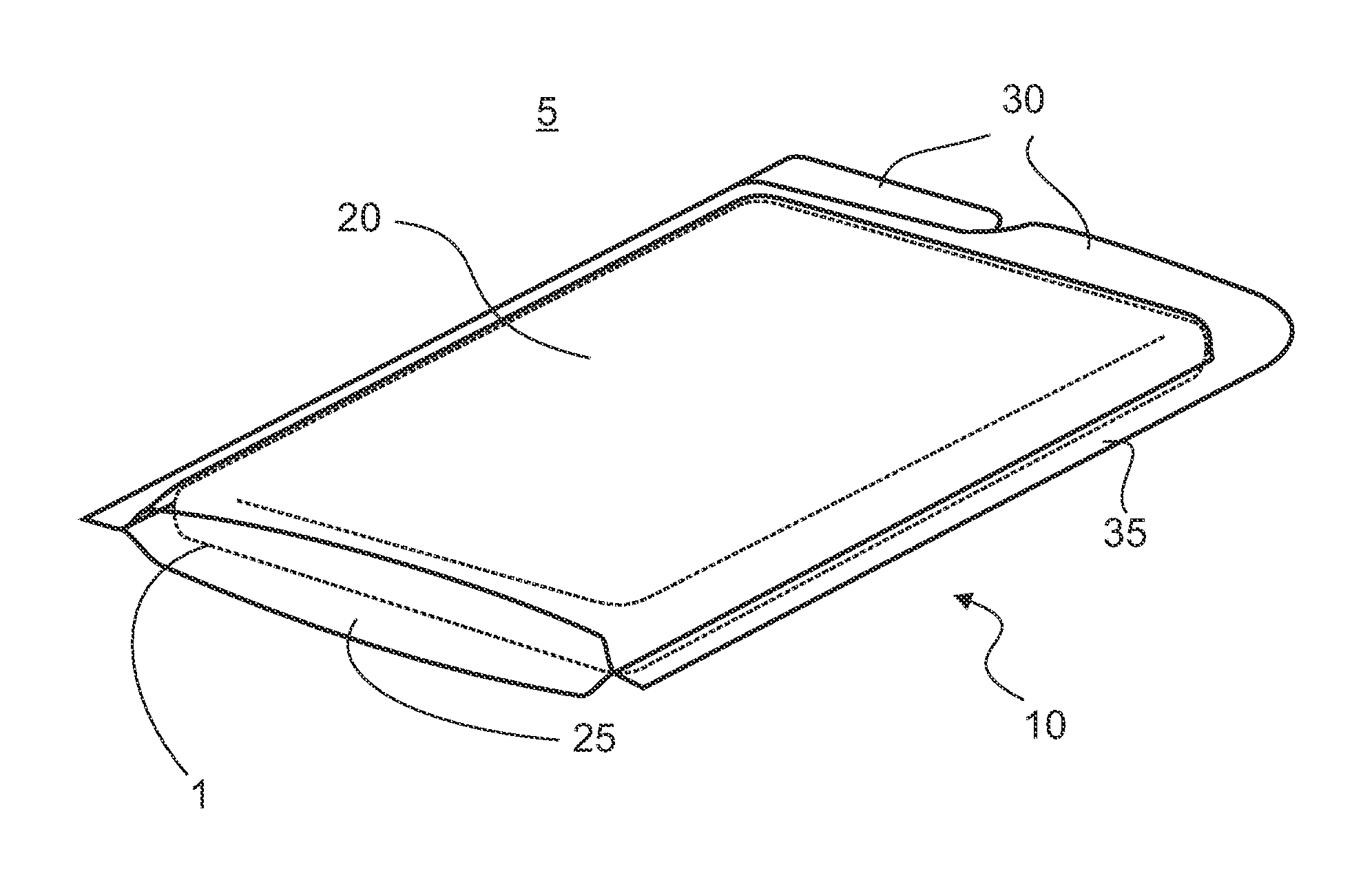

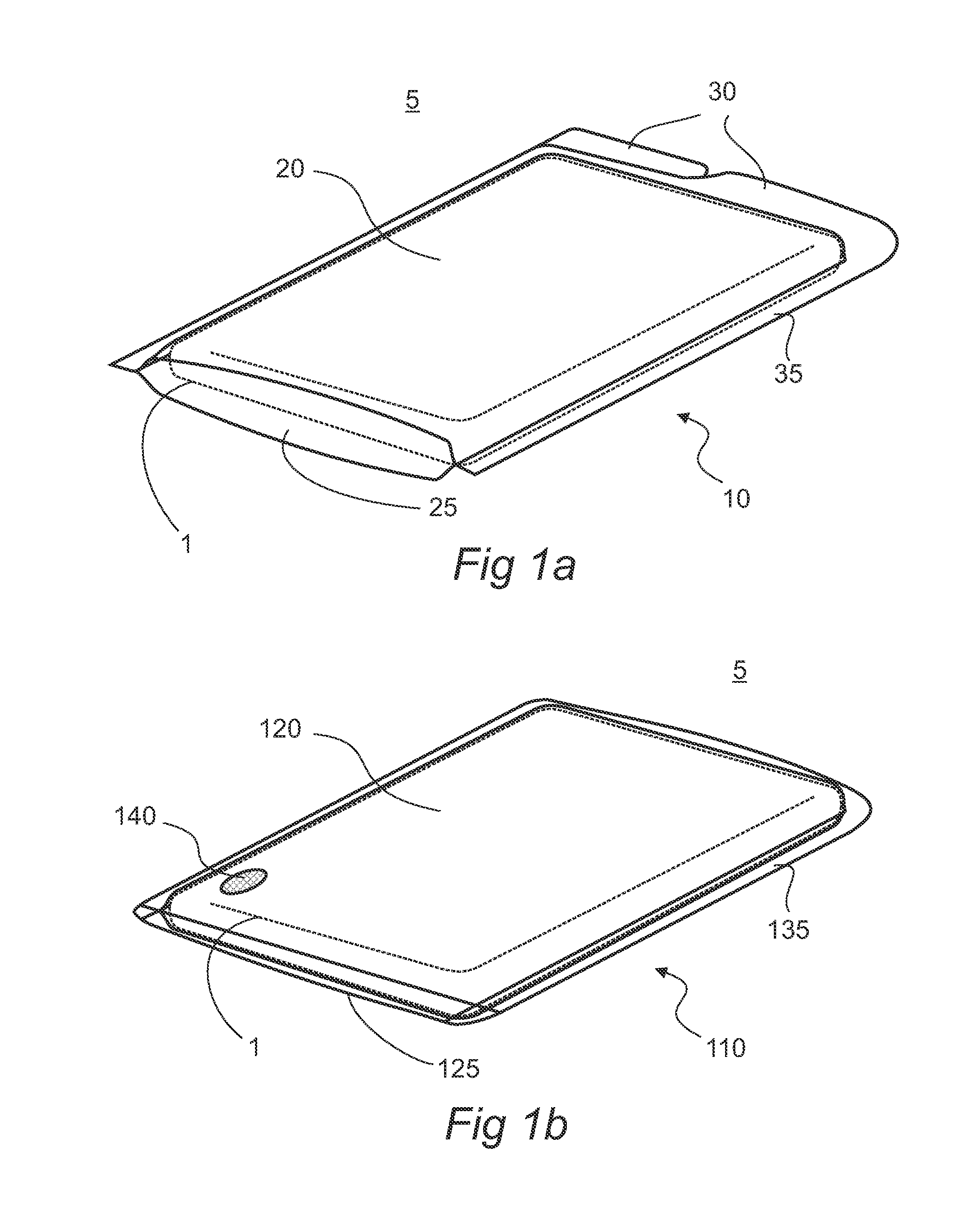

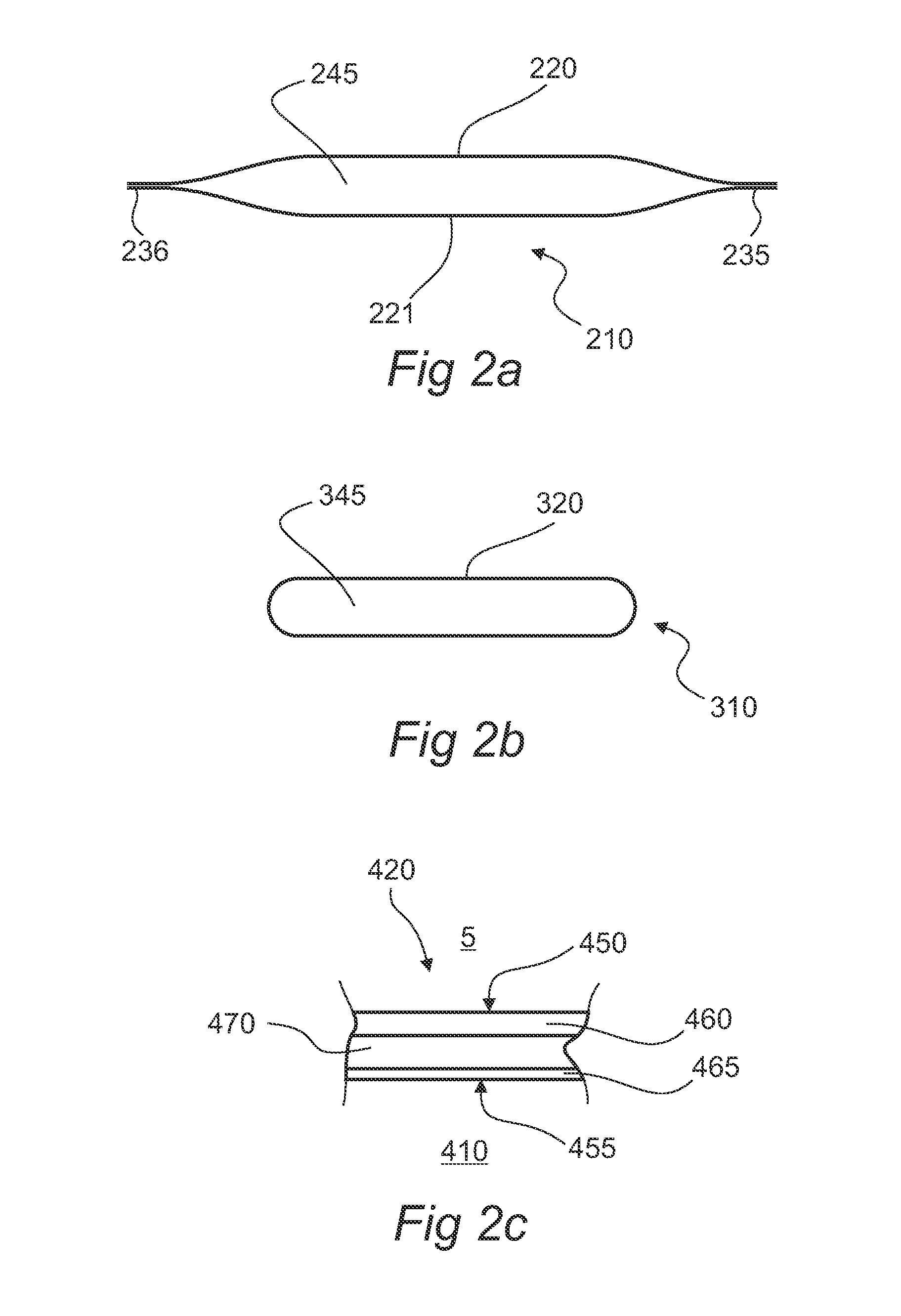

Isolation system for a mobile computing device

InactiveUS20120008880A1Maintaining visual acuityReduce glareSurgical furnitureDiagnosticsEngineeringEmbedded system

An isolation system for isolating a mobile computing device from an environment while retaining the functionality of the mobile computing device that includes at least one sheet and a sealable region. The sheet may include one or more layer to maintain functionality of the enclosed mobile computing device during use. The isolation system may include a sterilizable outer surface for rendering an enclosed mobile computing device usable in a surgical environment. The isolation system may include a pump and channels or valves to allow for fluid removal or addition to the interior of the isolation system. The sheet of the isolation system may further comprise microtextured inner layer so as to maintain functionality of the enclosed mobile computing device in an aqueous environment or in a soiled condition.

Owner:TOTH LANDY

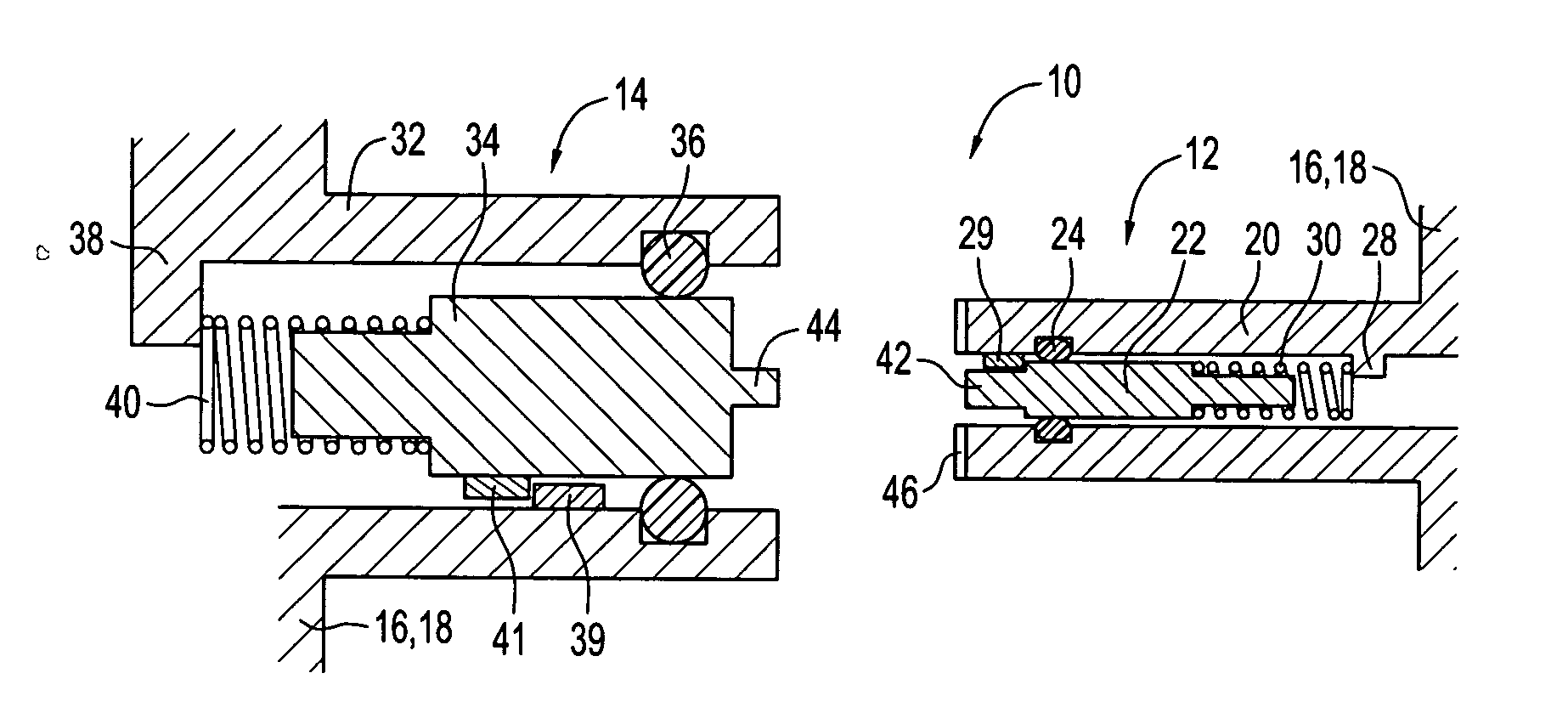

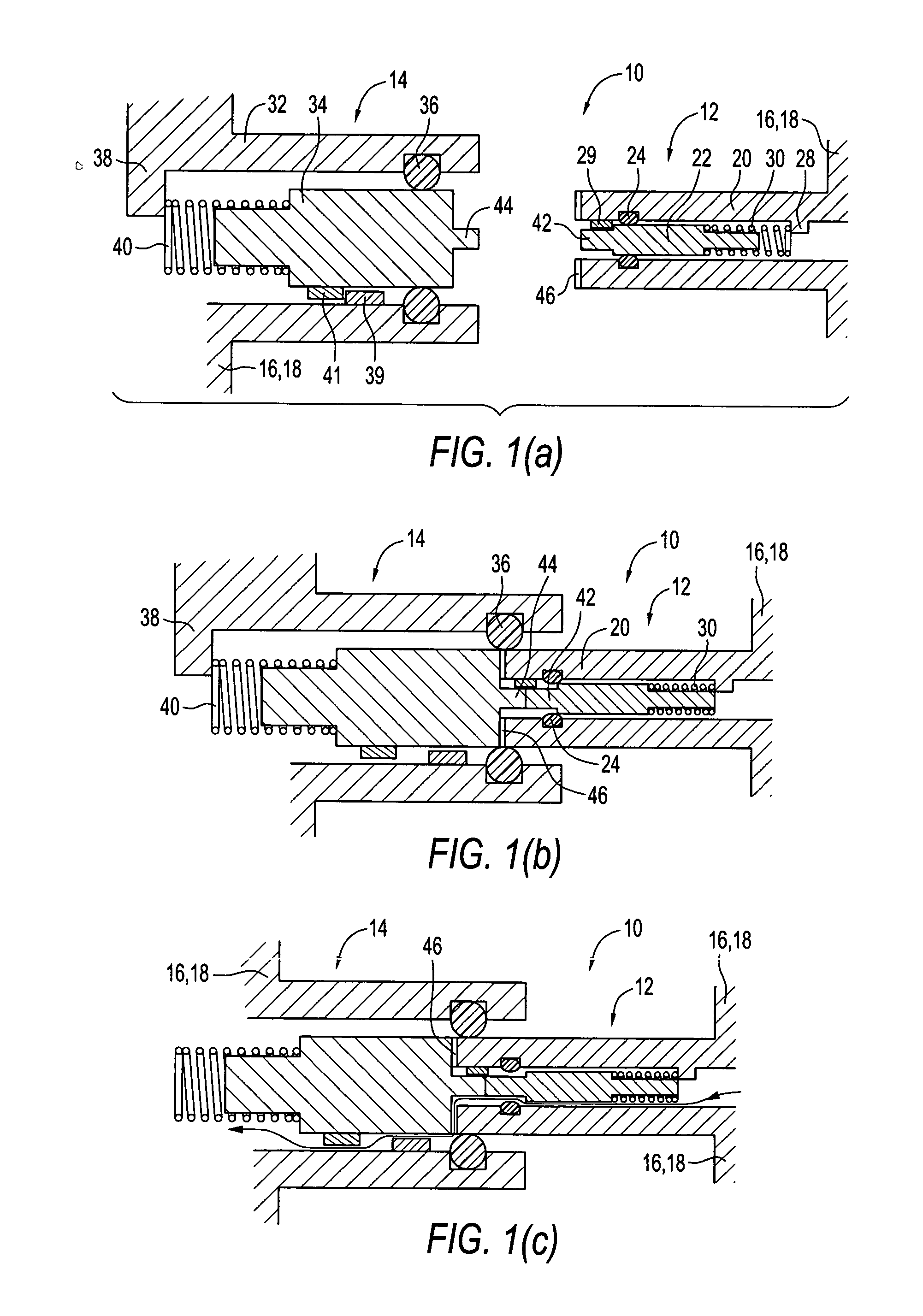

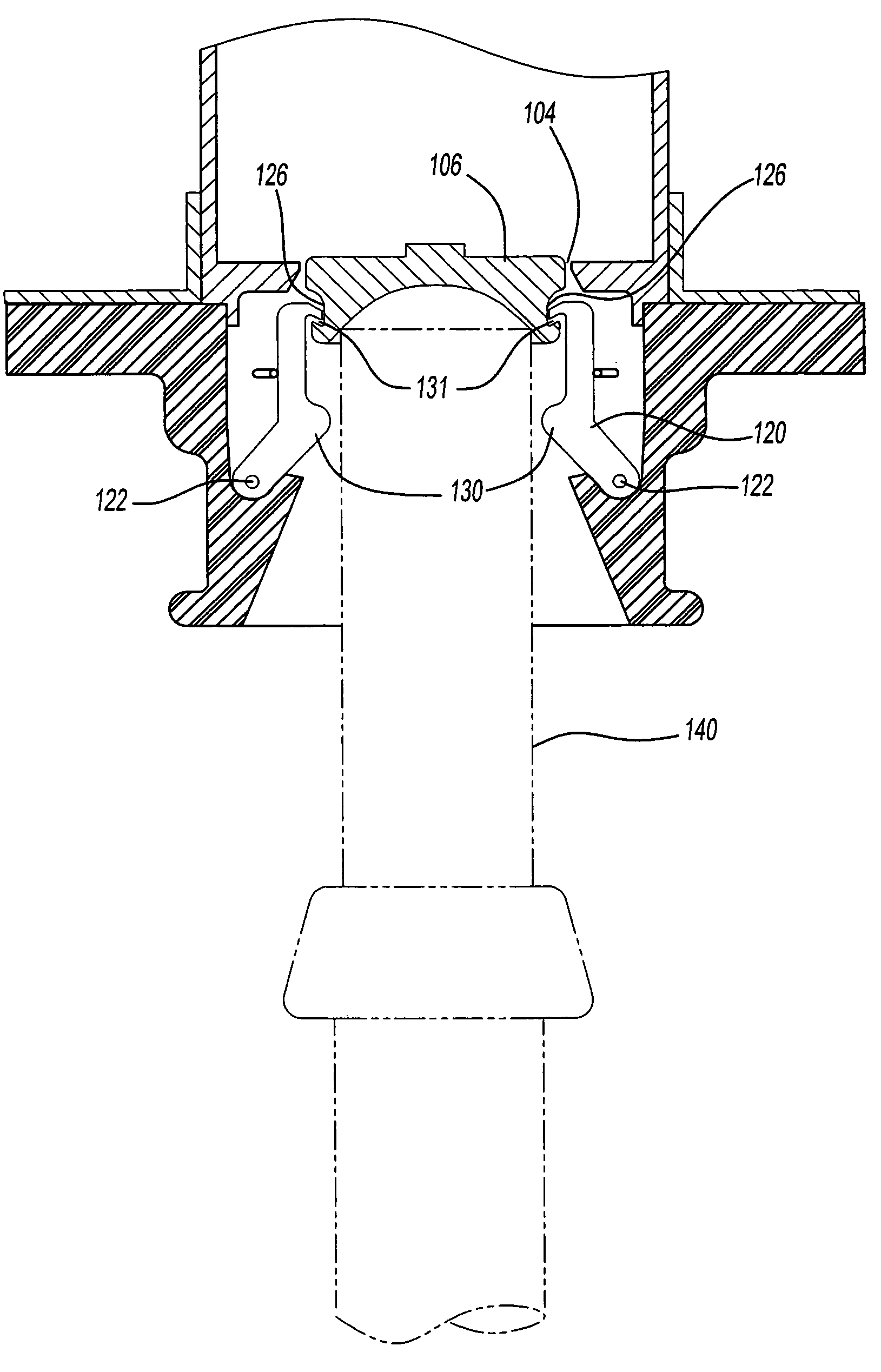

Fuel cartridge with connecting valve

A shut-off valve or connecting valve capable of connecting a fuel supply to a fuel cell is disclosed. The valve comprises a first valve component and a second valve component. Each valve component has an outer housing and a biased slidable member disposed inside the housing forming an internal seal. During the connection process, the two valve components establish an inter-component seal. Afterward, in one suitable embodiment the slidable member moves inward and opens the internal seal in the valve component to establish a flow path. In another embodiment, the slidable member moves inward and exposes a first filler and the first filler abuts a second filler in the other valve component to establish a flow path. In other embodiments, at least one valve component is sized and dimensioned to limit access to the internal seal.

Owner:INTELLIGENT ENERGY LTD

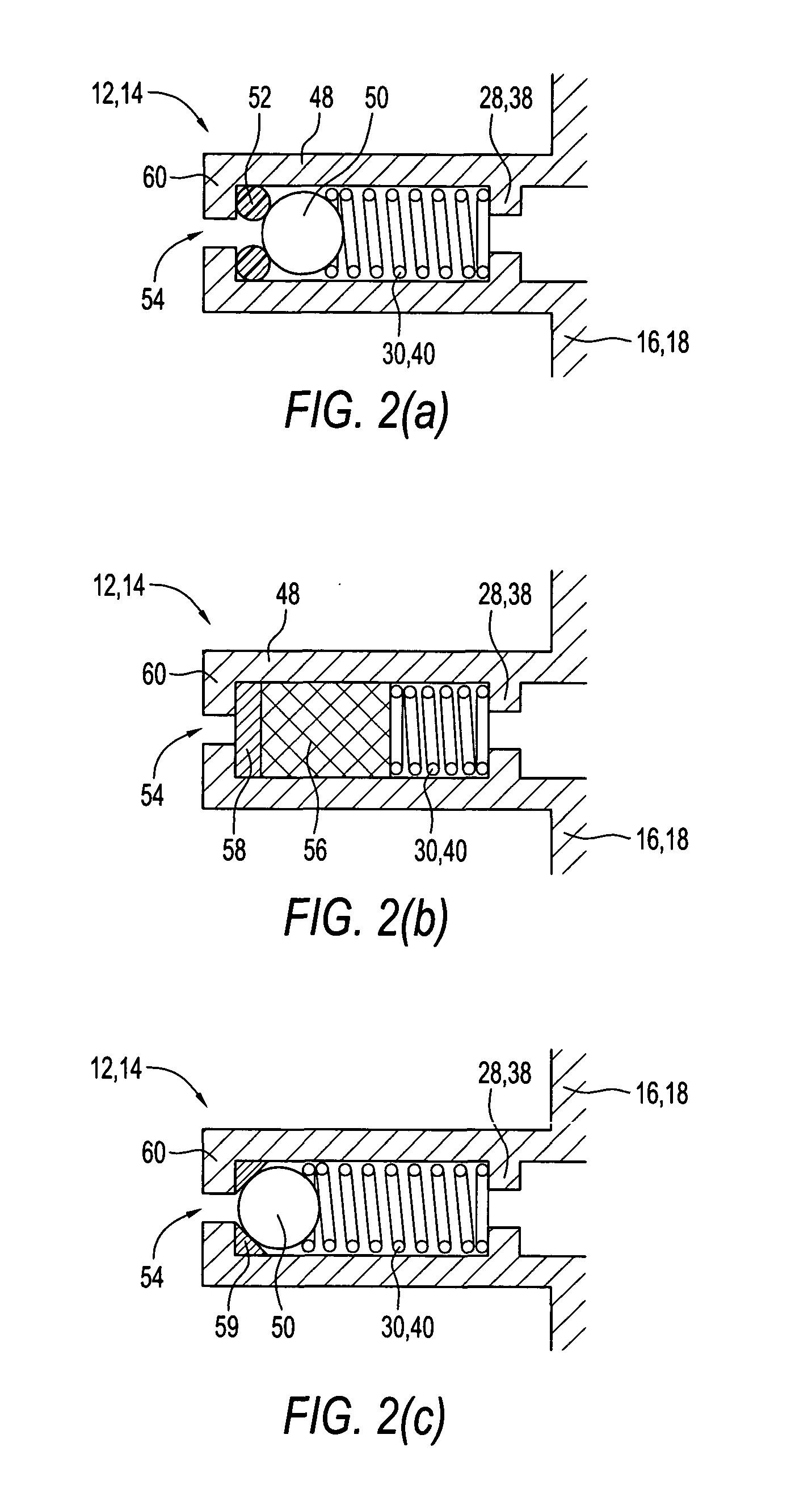

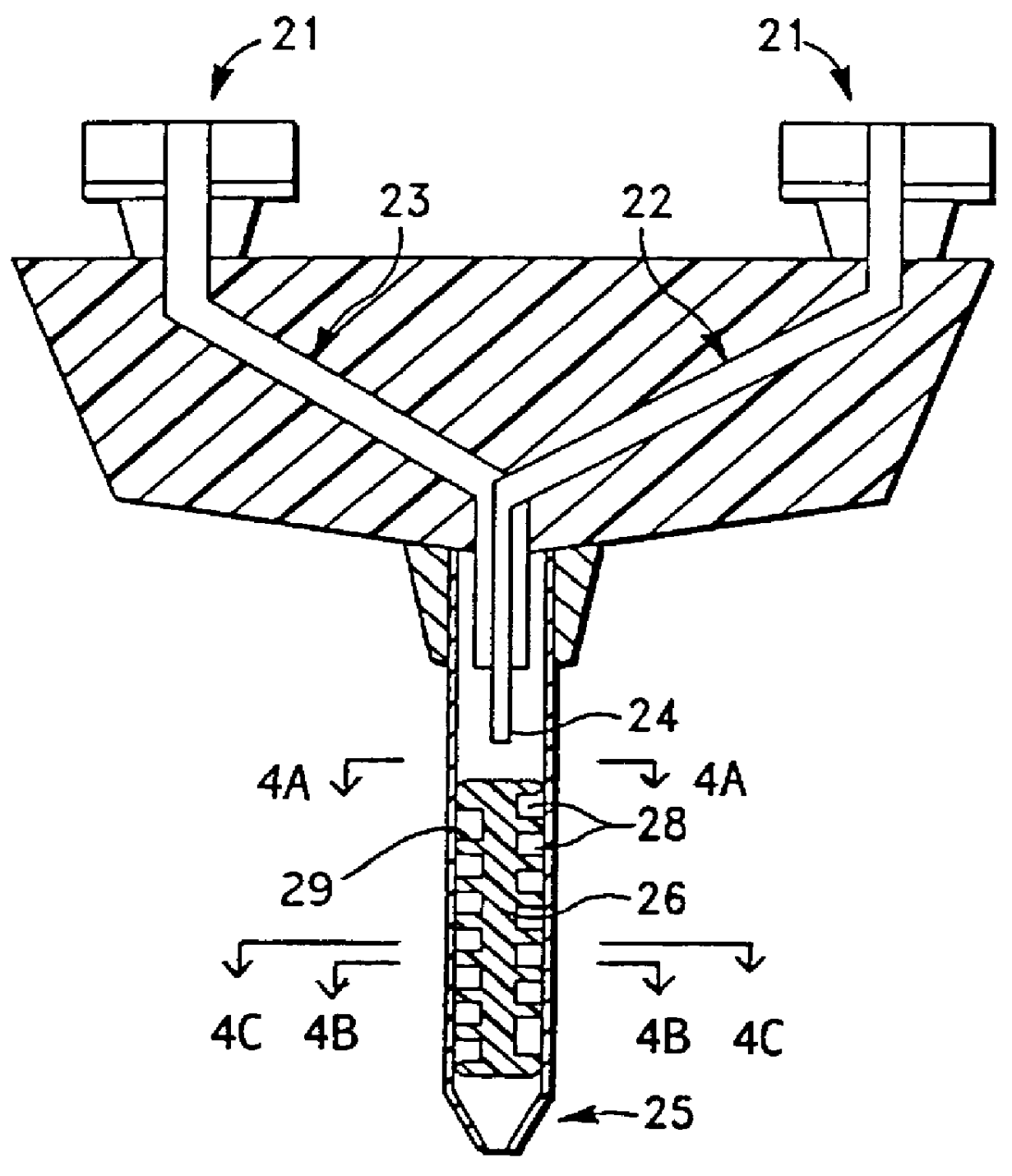

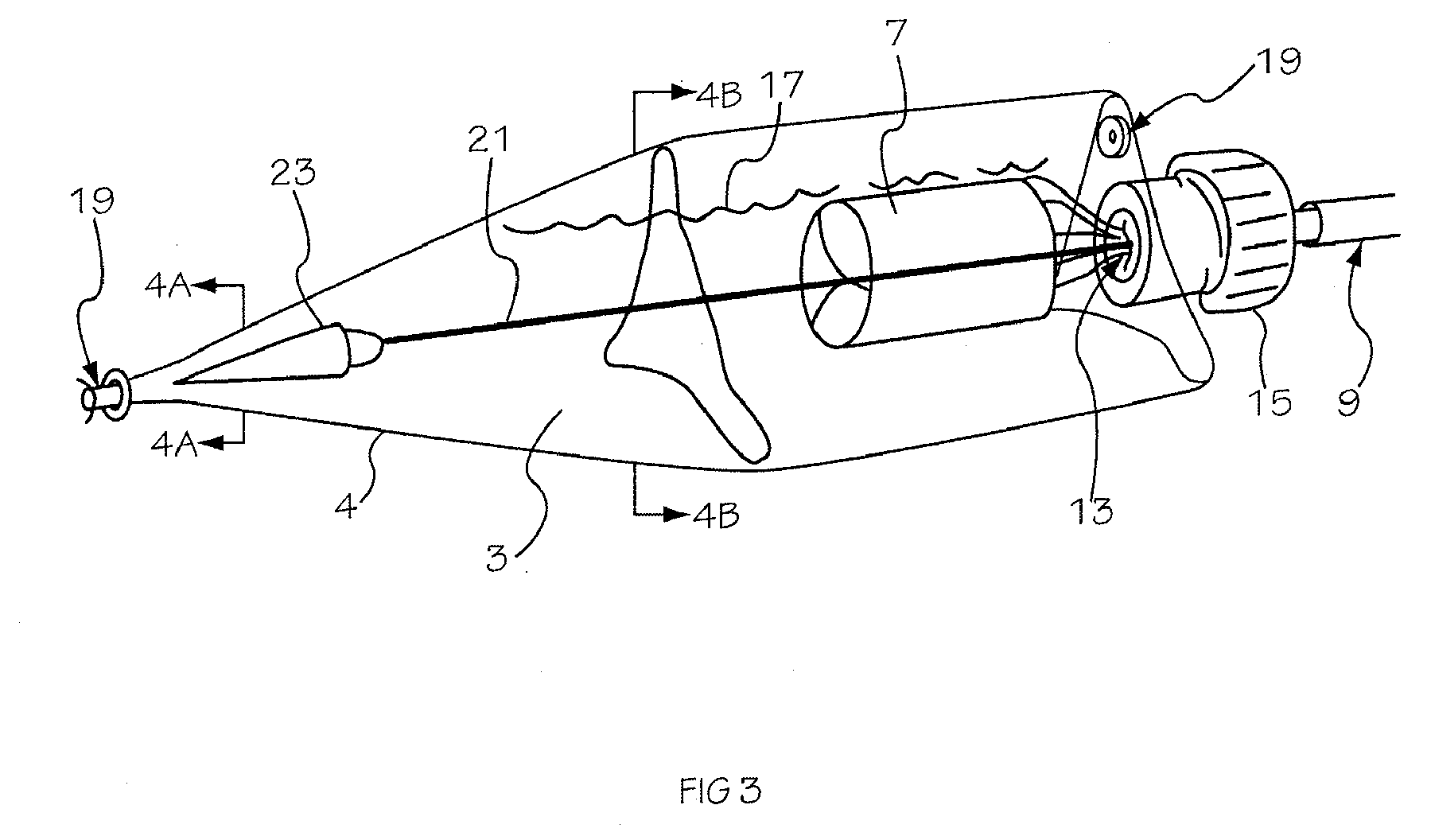

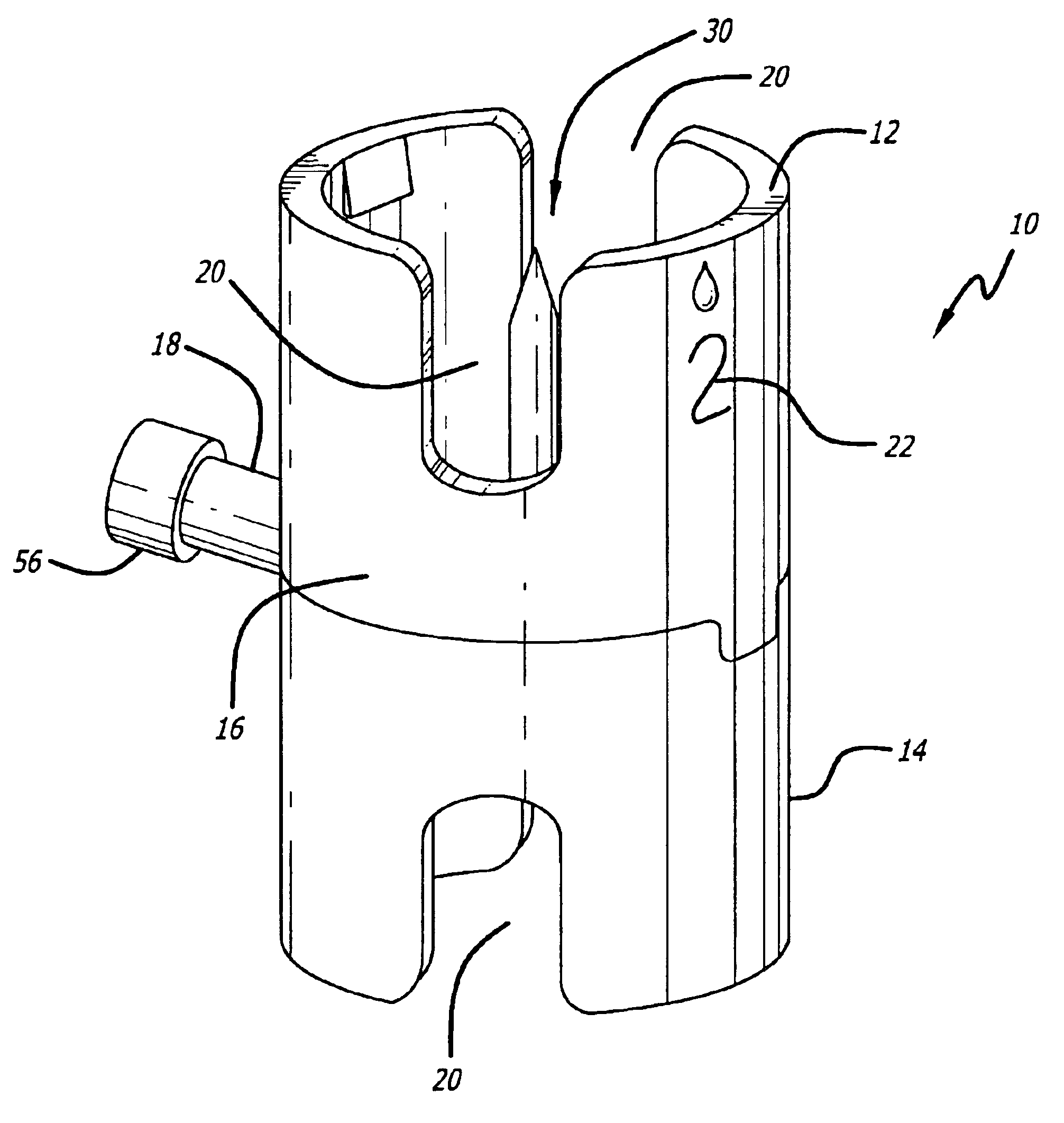

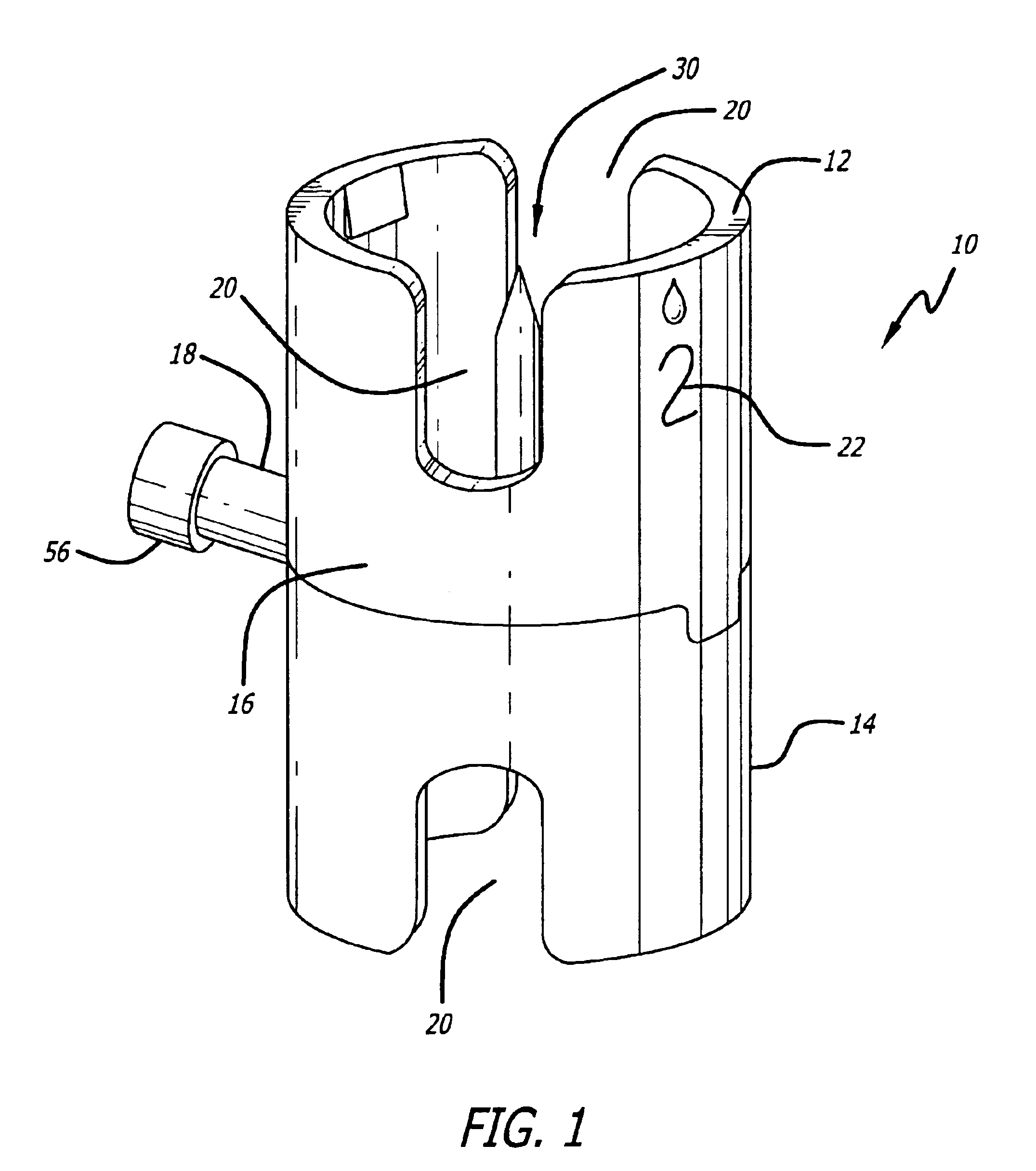

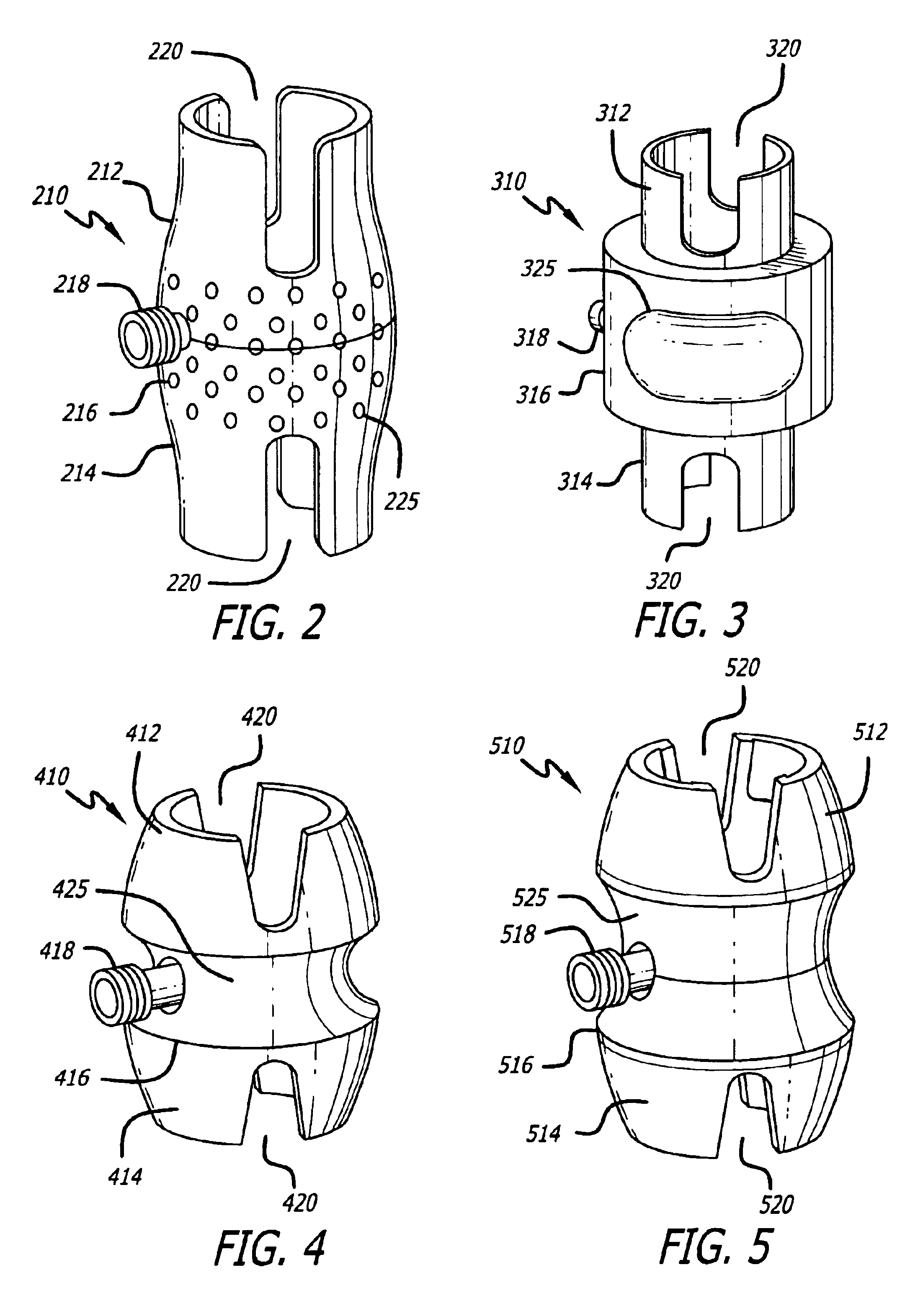

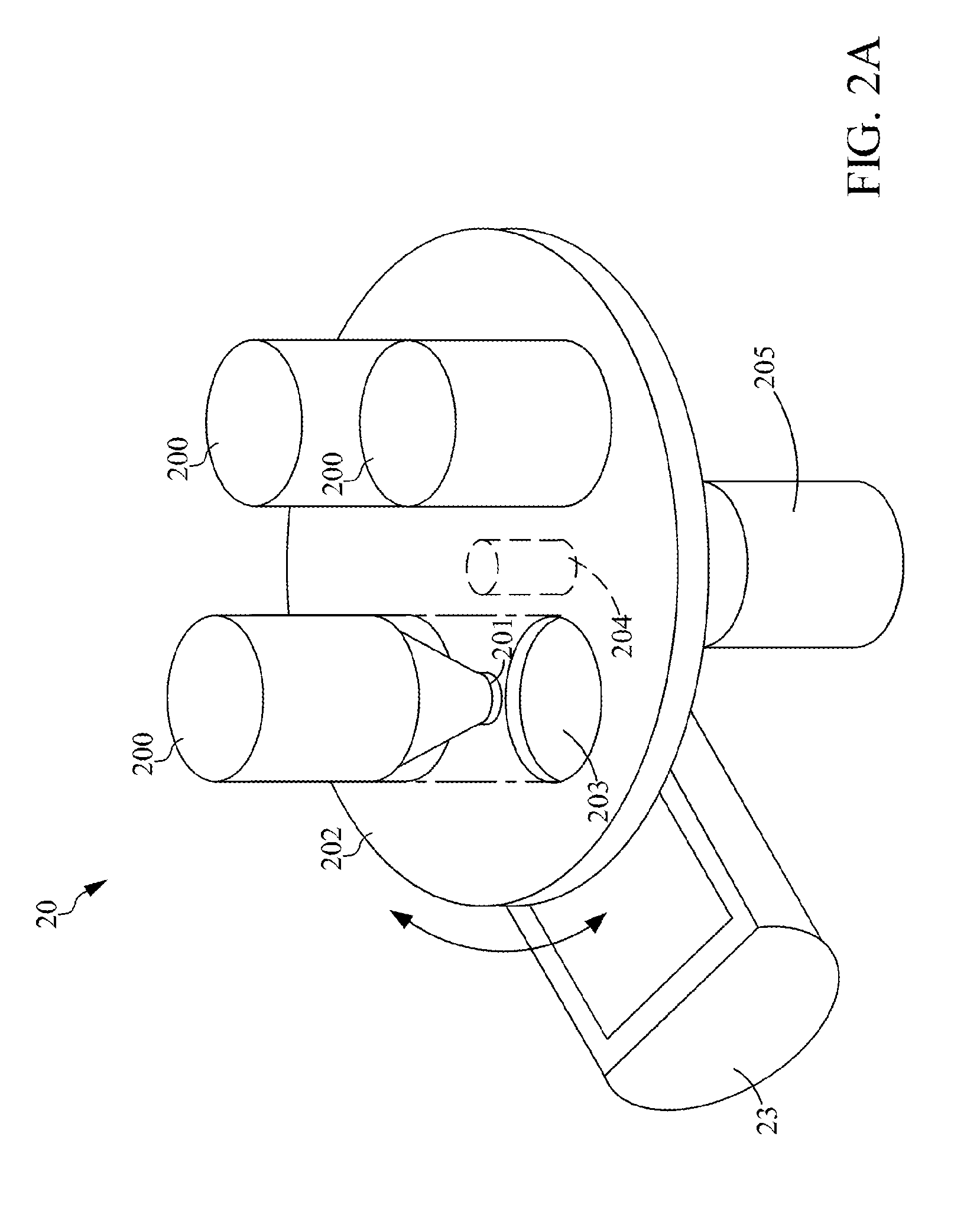

Apparatus for applying tissue sealant

InactiveUS6132396AEasy to fillEasy to assembleLiquid surface applicatorsSurgeryTissue sealantGear wheel

A device and method for applying a fibrinogen-based tissue sealant to seamlessly connect human or animal tissues or organ parts, to seal wounds, stop bleeding and the like by mixing fibrin or fibrinogen with blood clot-promoting coagulation factors are disclosed. The device includes two cylindrical compartments for separately containing the separate fluid components of the sealant preparation, which are simultaneously displaced from the respective compartments by plungers commonly depressable with the same effective strokes. The plungers may be depressed directly or by a common mechanism (e.g., rack and pinion) for accurately controlling the rate of dispensing fluid. The cylindrical compartments are of the same or different cross-sectional area and are arranged either concentrically or side-by-side. The device further includes structure for merging the two fluid components within an outer sleeve housing an inner needle. The sleeve and needle contain conduits for the flow of the two fluid sealant components as they are expressed from the respective compartments. Also disclosed are a convenient device for filling the two compartments, structure for mixing the fluid components, and for atomizing the effluent sealant fluid stream (i.e., spraying).

Owner:PLASMASEAL

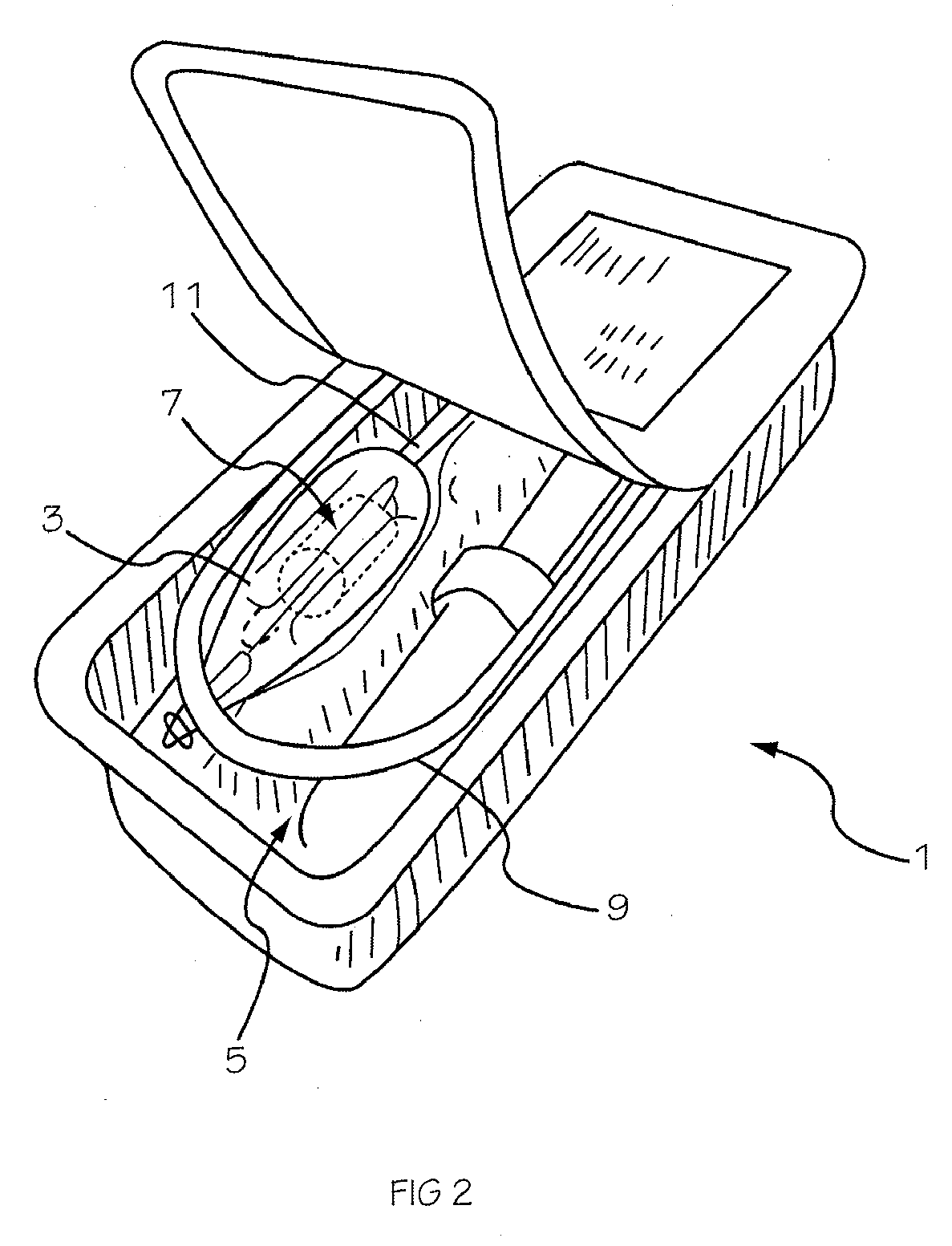

Two-part package for medical implant

ActiveUS7712606B2Low costProcedure be minimizedDispensing apparatusHeart valvesBiomedical engineeringMedical treatment

Owner:BOSTON SCI SCIMED INC

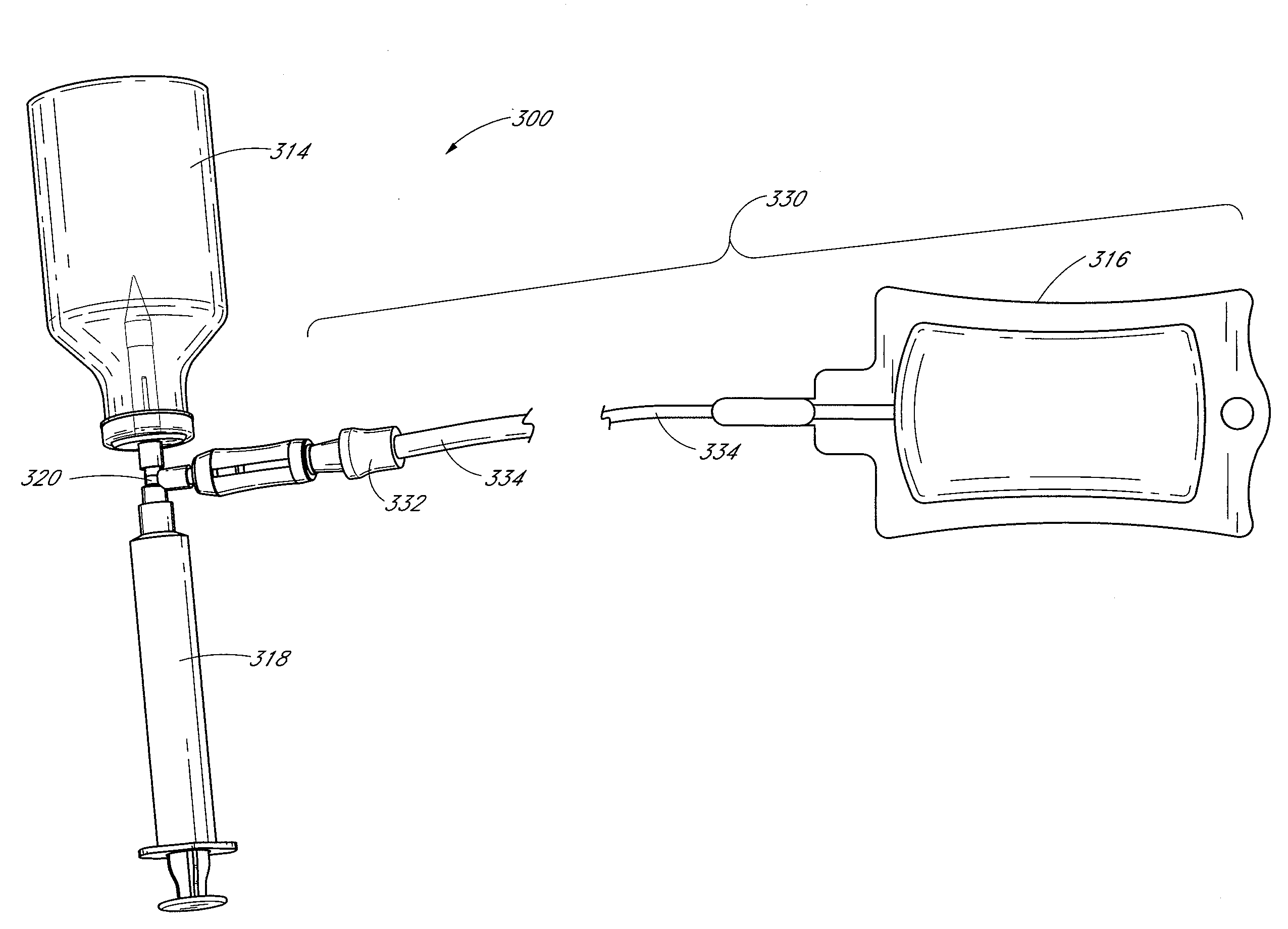

Fluid transfer devices and methods of use

Some embodiments disclosed herein related to a device for transferring precise amounts of fluid from at least one source container to a at least one target container. In some embodiments, the fluid is first transferred from the source container (e.g., a vial) through a connector to an intermediate measuring container (e.g., a syringe). In some embodiments air can pass through an air inlet and enter the vial to compensate for the volume of fluid withdrawn from the vial. An air check valve or a bag or a filter can prevent the fluid from escaping through the air inlet. The precisely measured amount of fluid can then be transferred from the intermediate measuring container to the target container (e.g., an IV bag). In some embodiments the connector can include a source check valve and a target check valve to direct fluid first from the source container to the intermediate measuring container and then from the intermediate measuring container to the target container. Some embodiments of the device can include a motor and a controller for automatically actuating a plunger of the syringe to transfer the desired amount of fluid.

Owner:ICU MEDICAL INC

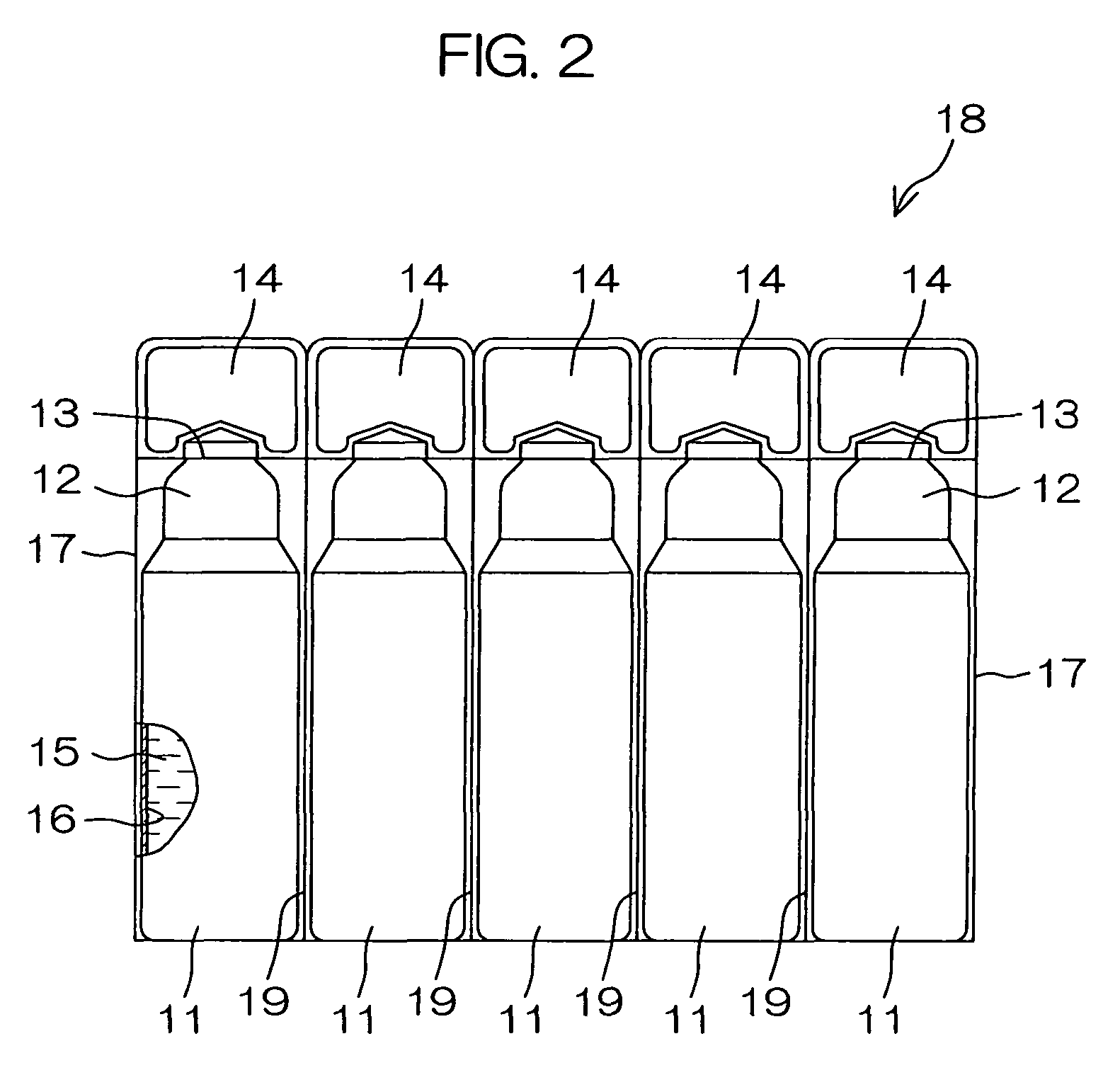

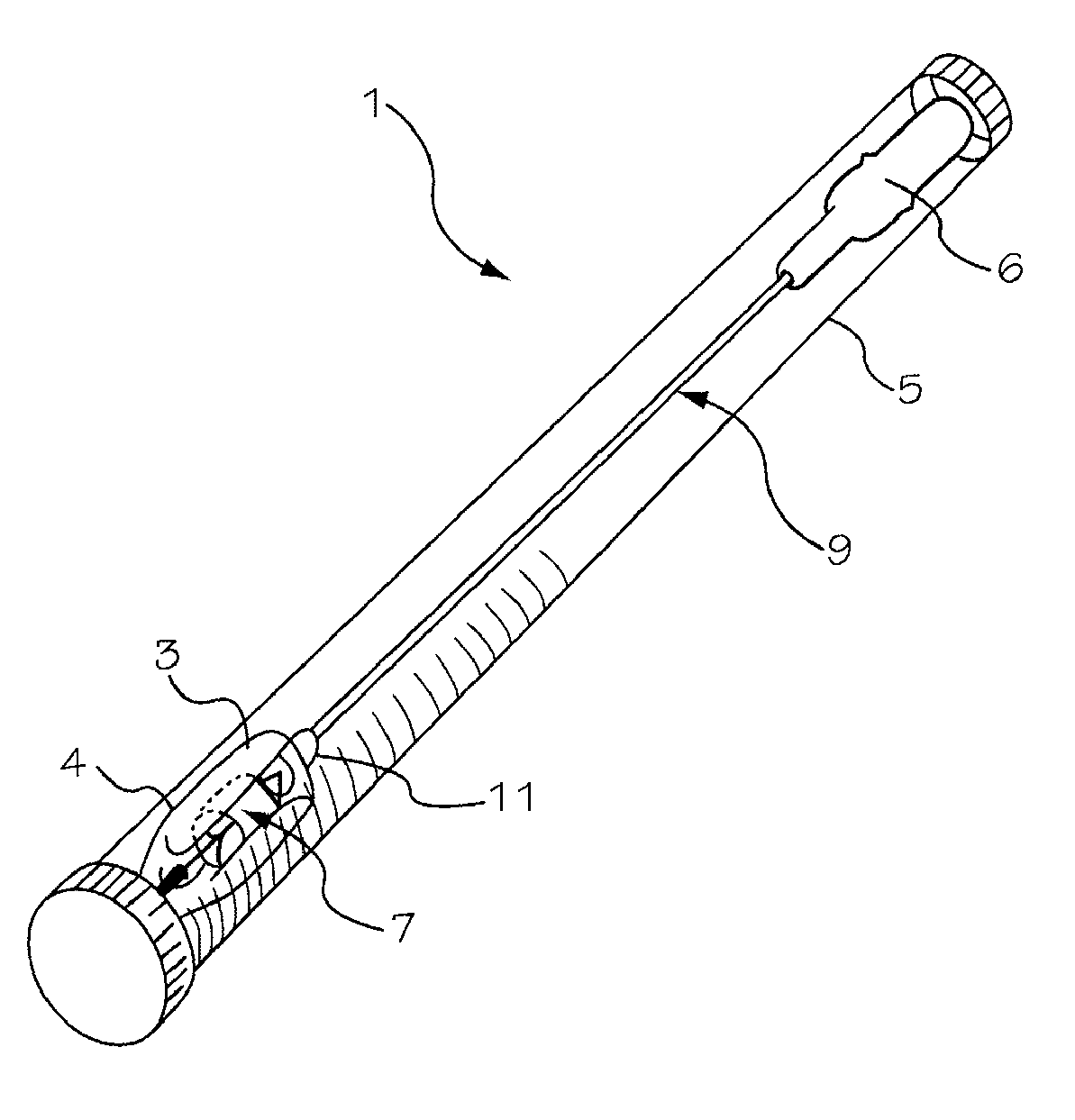

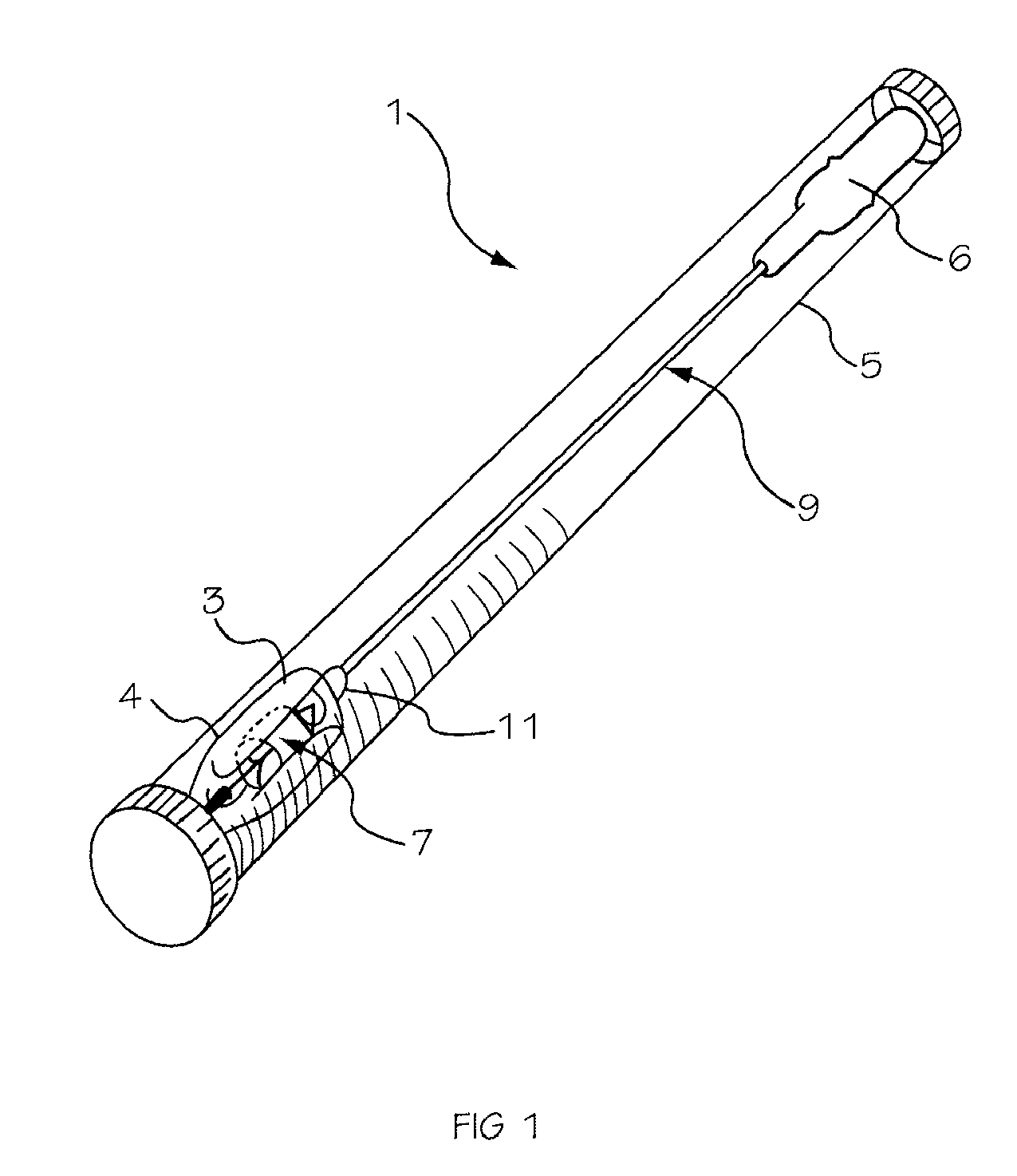

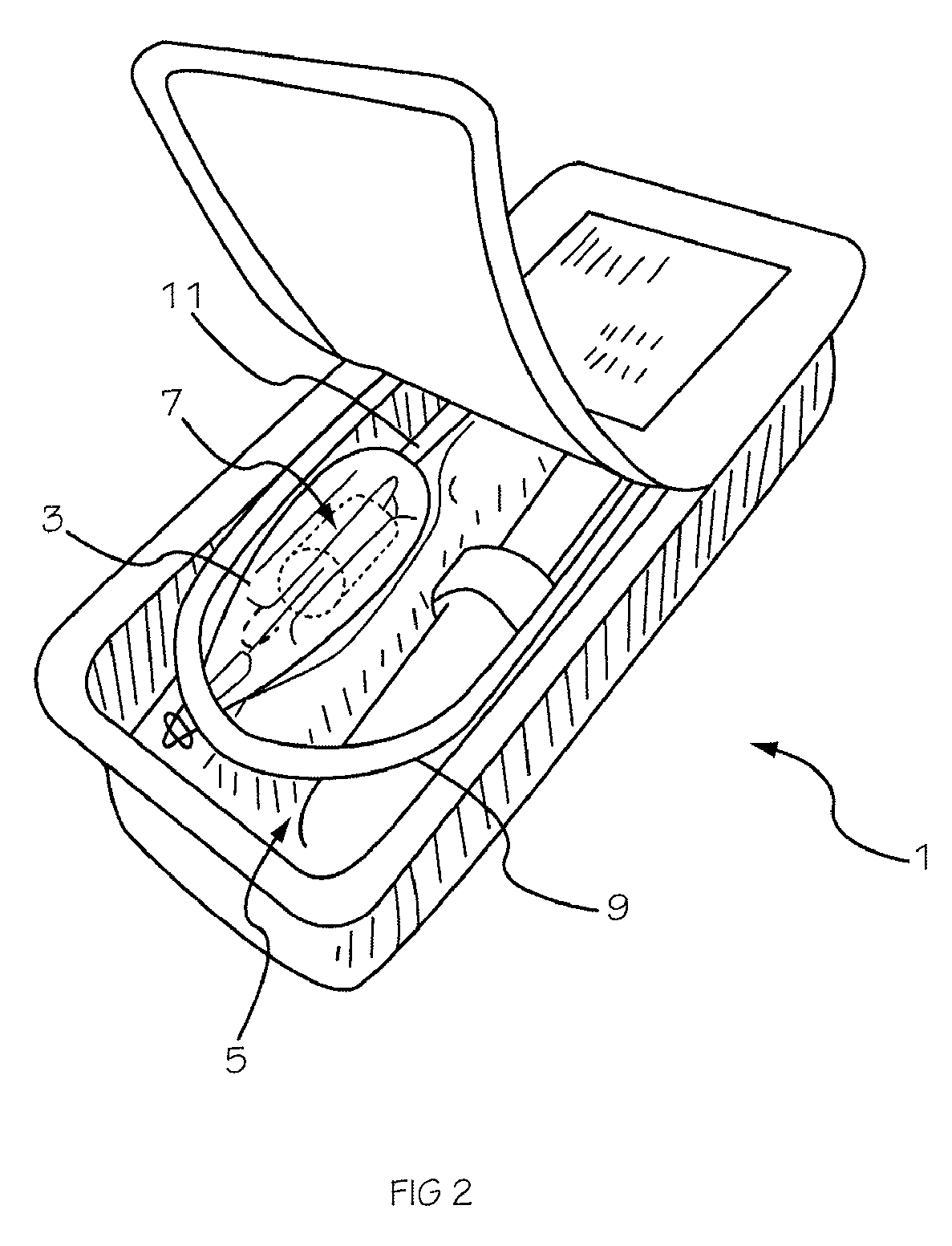

Two-Part Package For Medical Implant

ActiveUS20070061008A1Low costMinimize preparation timeDispensing apparatusHeart valvesBiomedical engineeringMedical treatment

The invention provides a two-part package and method of use for a pre-attached medical implant and delivery tool system. The package includes a wet compartment and a dry compartment and allows a pre-attached implant and delivery tool system to be at least partially stored immersed in a fluid in the wet compartment and at least partially stored in the dry compartment. In one embodiment the implant comprises a replacement heart valve, and the heart valve is stored inside the wet compartment while the heart valve delivery tool remains dry in the dry compartment.

Owner:BOSTON SCI SCIMED INC

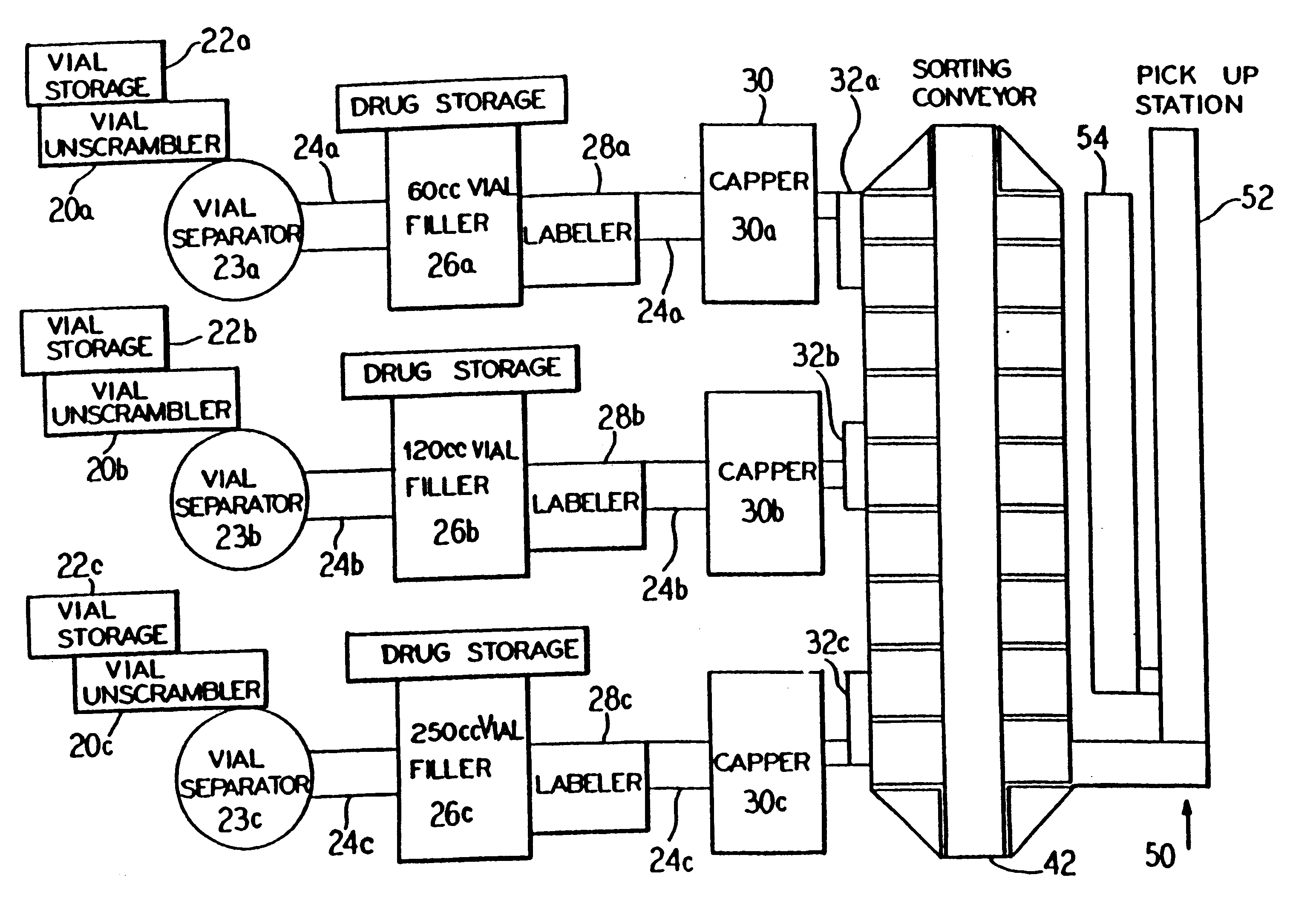

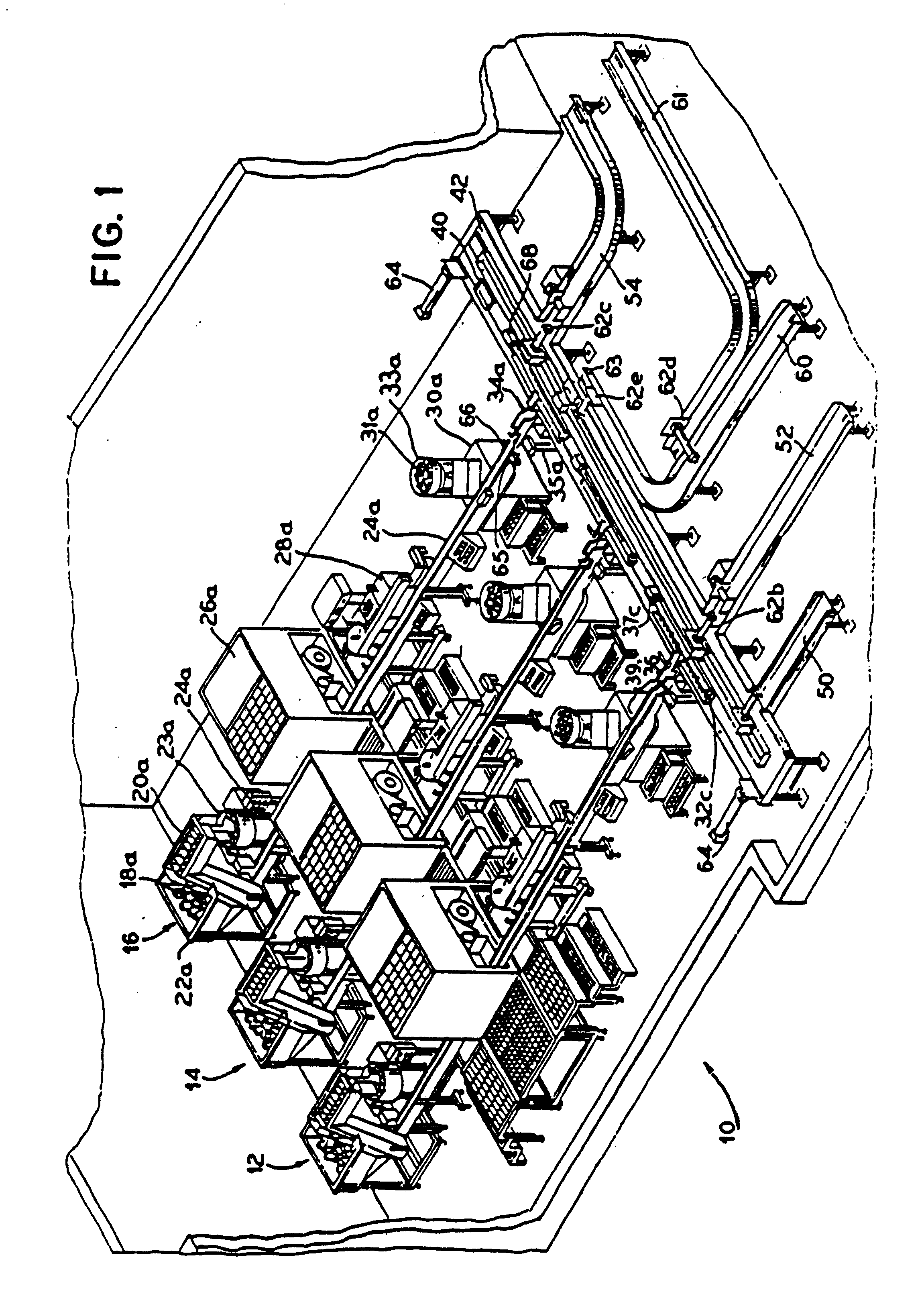

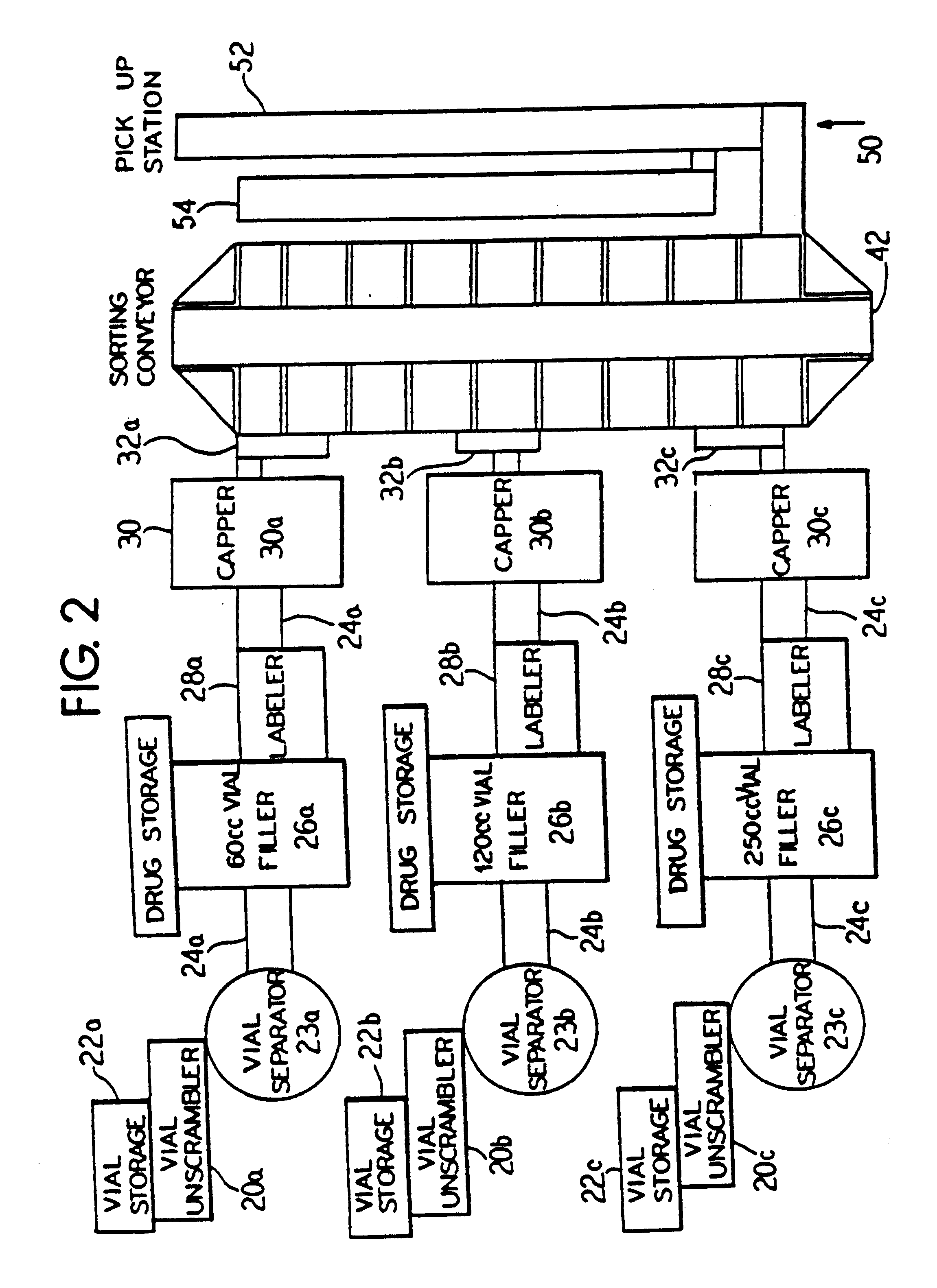

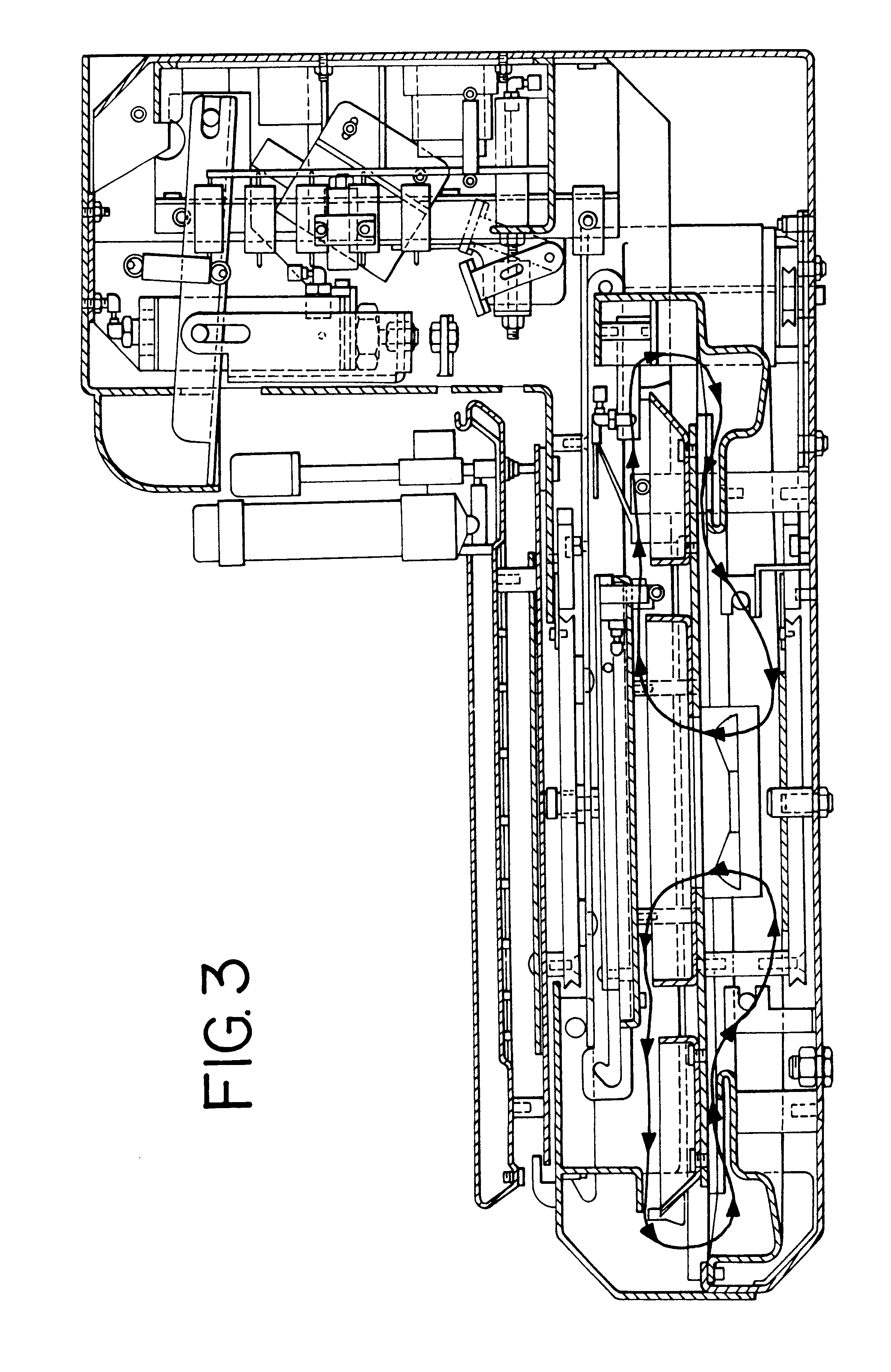

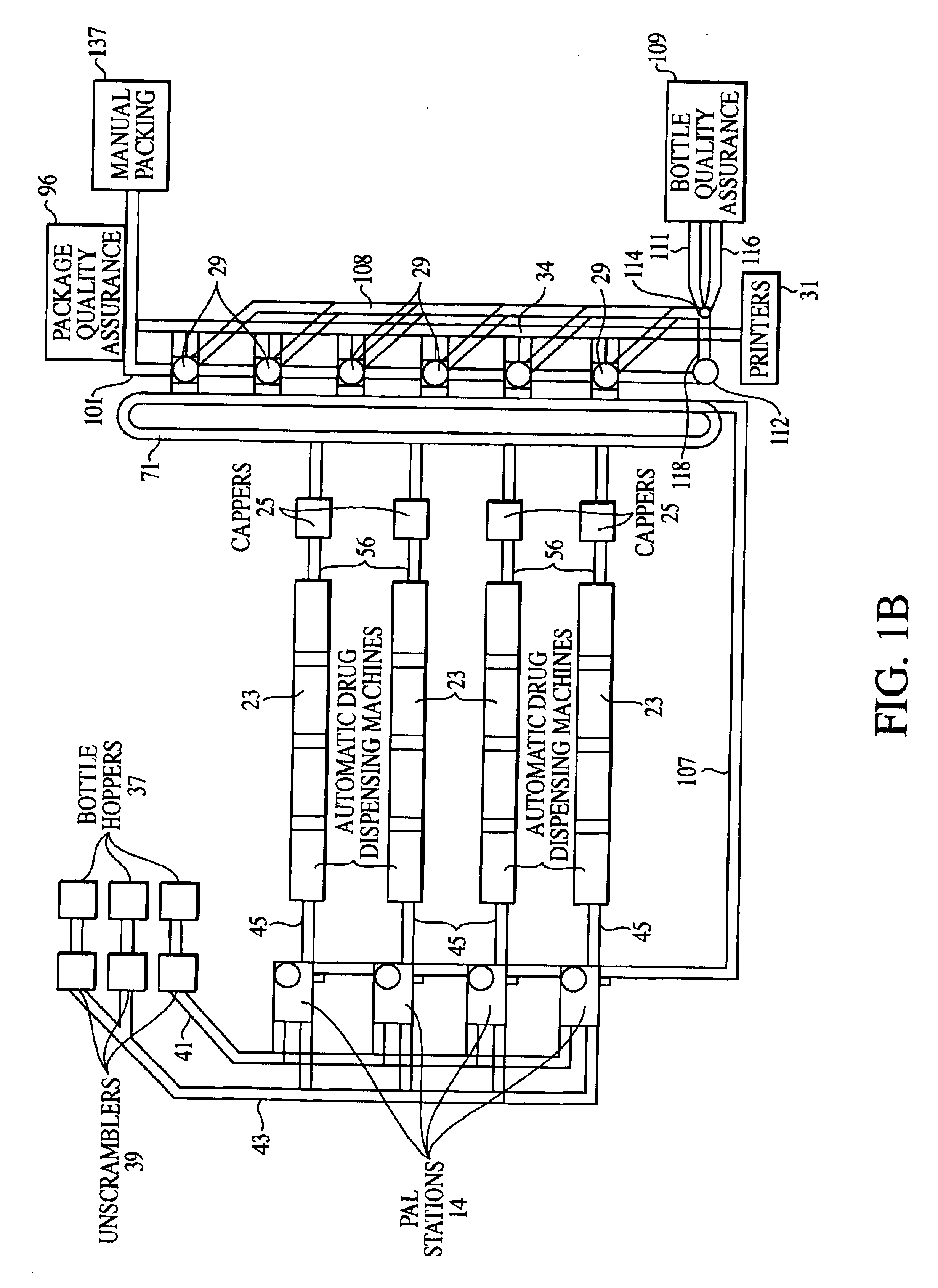

Automated prescription vial filling system

InactiveUSRE37829E1Reduction and inventoryLow costDrug and medicationsDigital data processing detailsMedical prescriptionBiomedical engineering

A method and apparatus for dispensing drugs, wherein a patient's order of one or more prescriptions is automatically filled. Various drugs are stored in three or more filler lines. A vial size is assigned to each line. When a prescription is filled, it is automatically assigned to a line in view of the vial size requirements and processed accordingly. Provisions are made for the inability to fill a prescription or order. Subsequently, all of the patient's prescriptions are collected and made available as a single order.

Owner:AUTOMED TECH

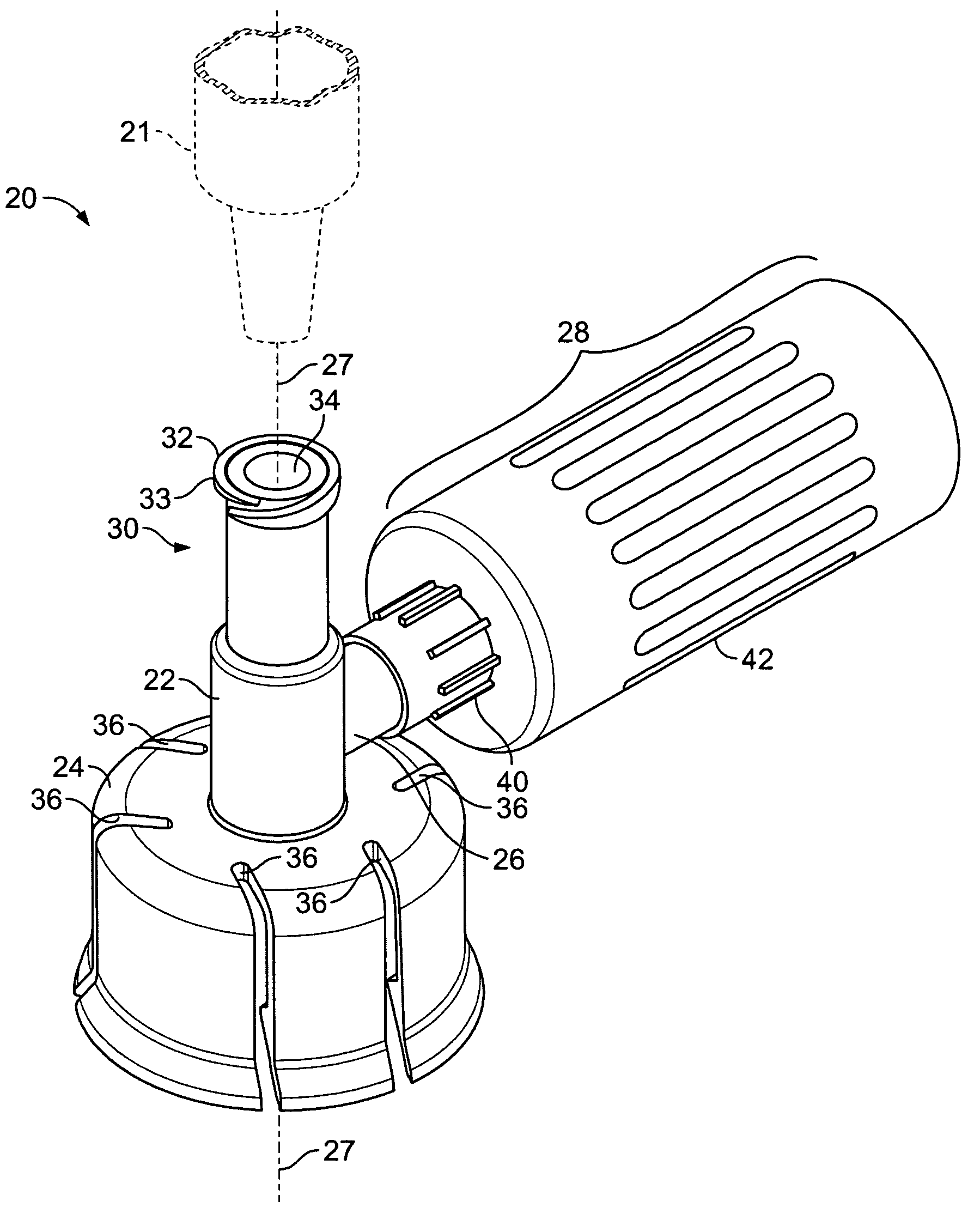

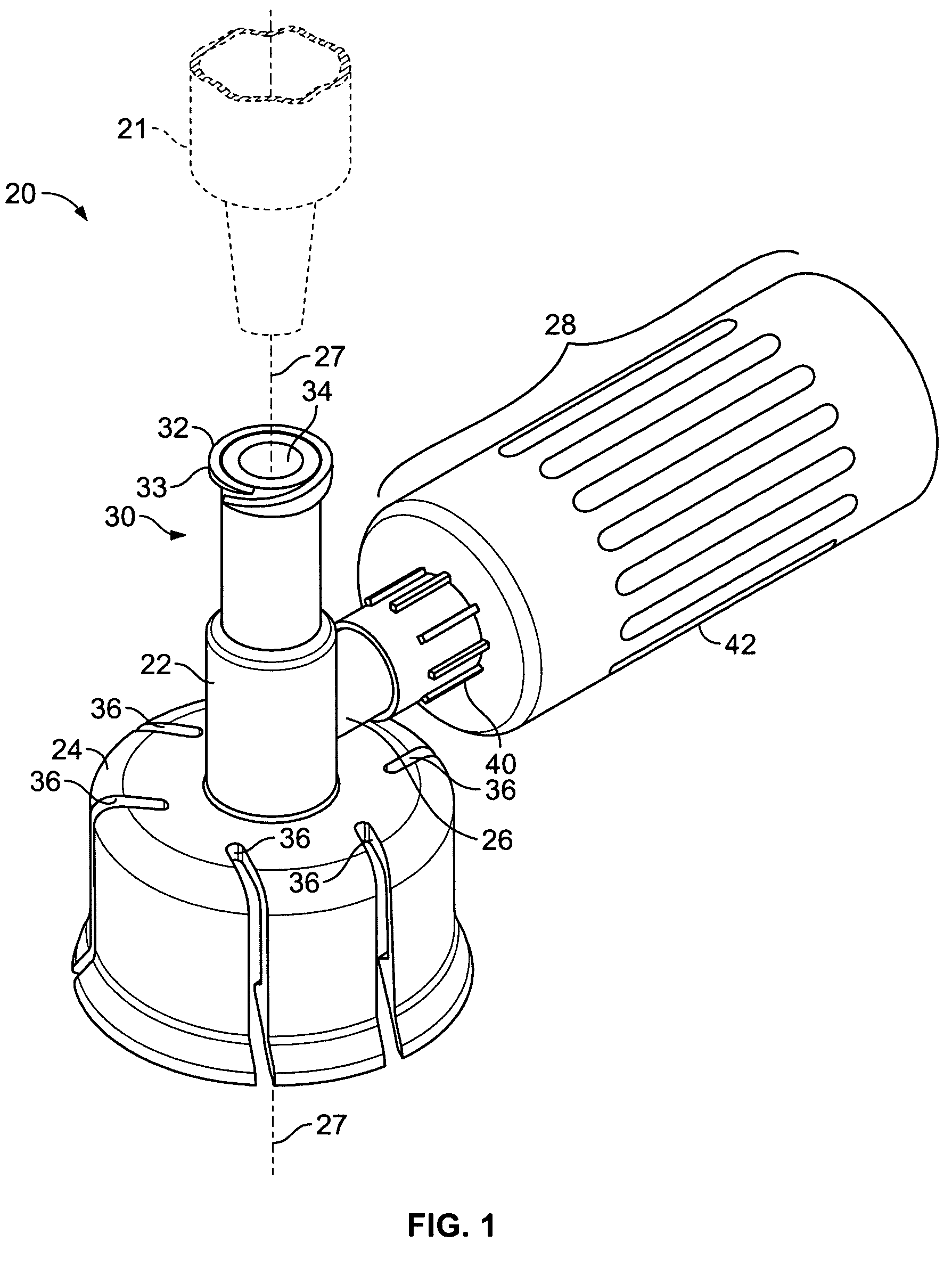

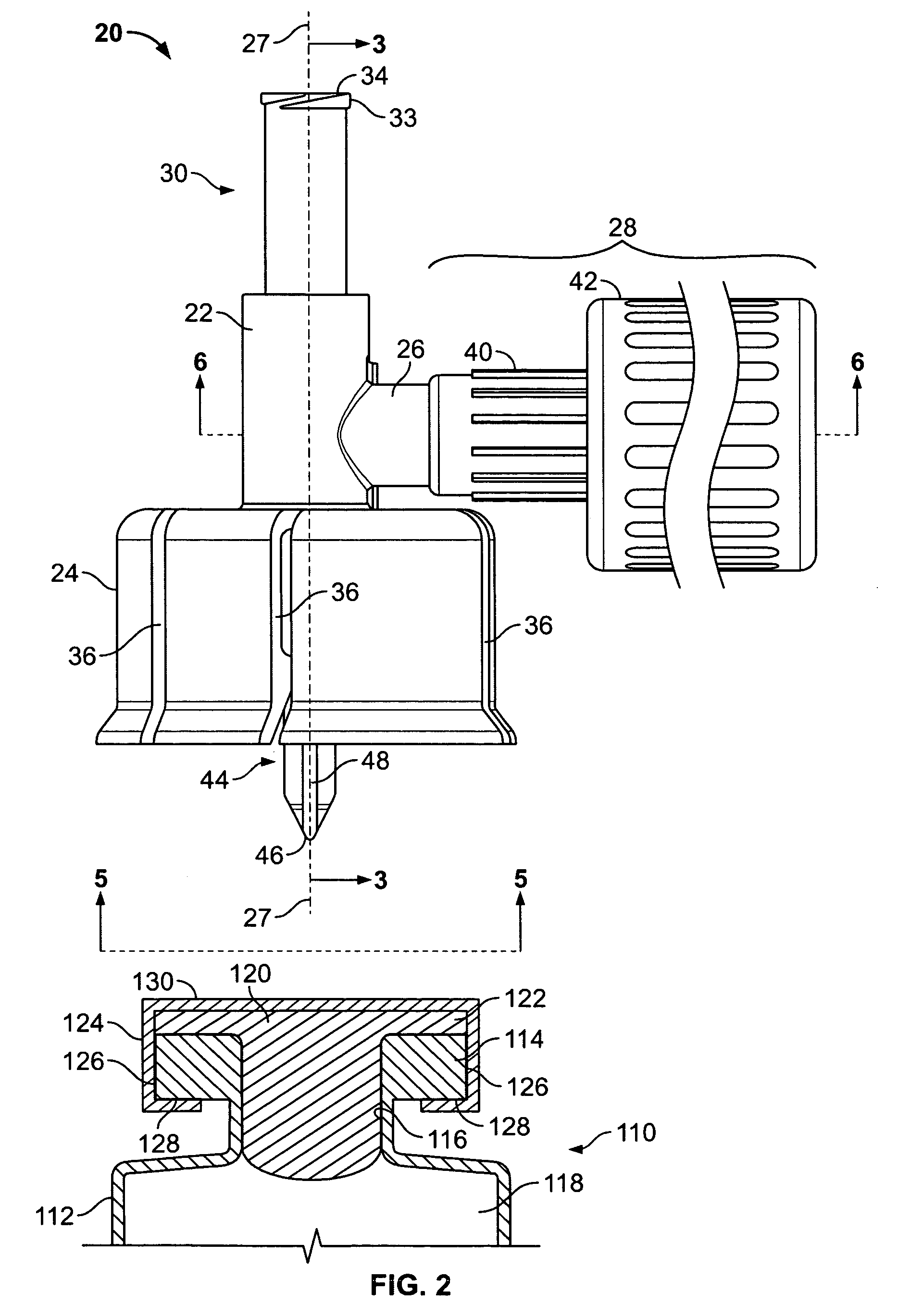

Pressure equalizing device for vial access

ActiveUS7900659B2Prevent buildupPrevent escapeDiagnosticsSurgeryPressure balanceAtmospheric pressure

A pressure-equalizing vial access device and method providing closed and sealed reconstitution of vial contents. A rigid container with a fixed internal volume is connected with a vent lumen extending into the vial. As pressure in the vial increases, the pressure is equalized with atmospheric pressure by varying the volume of a compartment within the rigid container. The compartment is formed with a volume control device that automatically varies the volume of the compartment in the rigid container to accommodate and equalize the pressure in the vial by increasing or decreasing the volume of the compartment. In one case the volume control device comprises a sliding disk and in another, a bladder that compresses with an increase in volume in the container and expands with a decrease.

Owner:CAREFUSION 303 INC

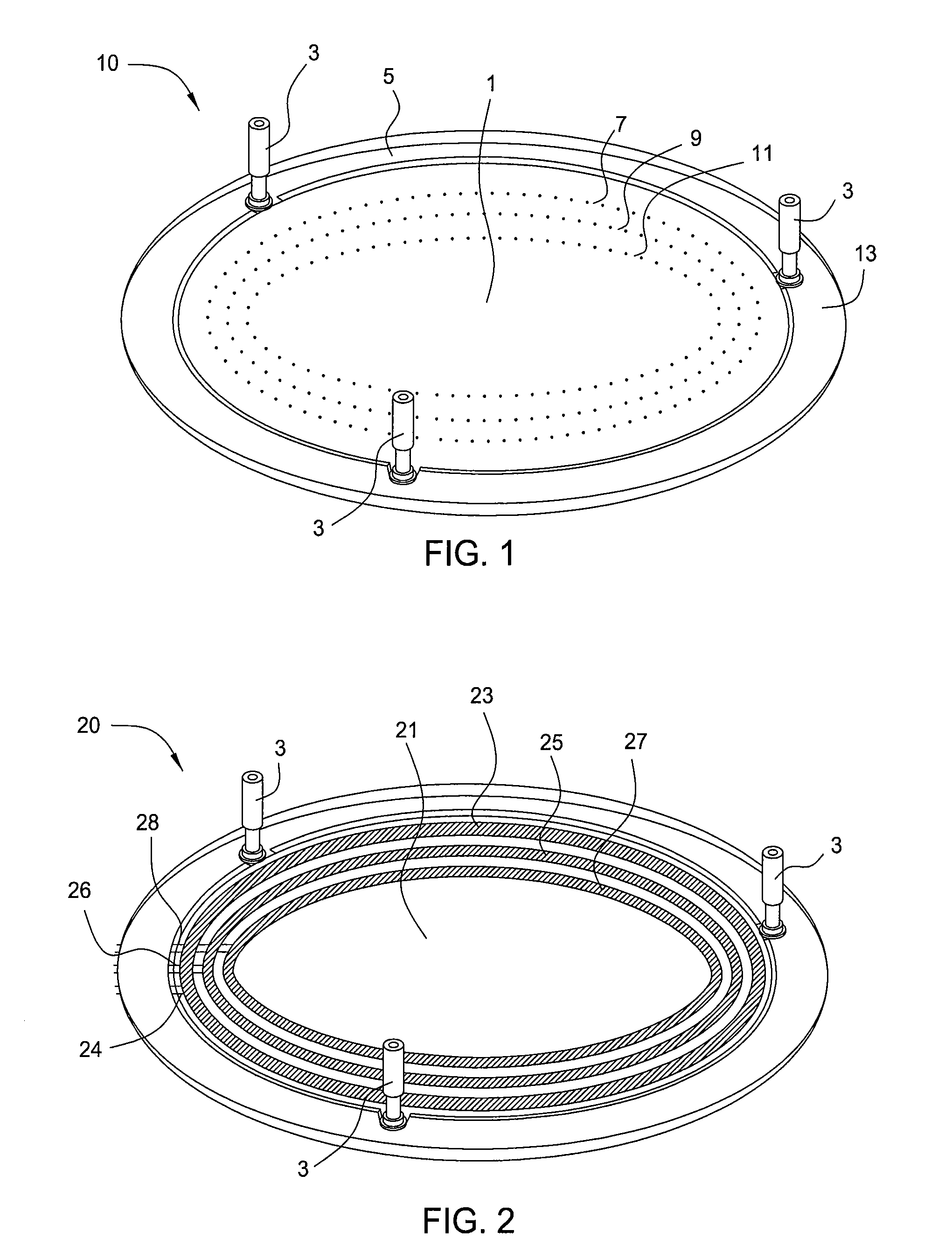

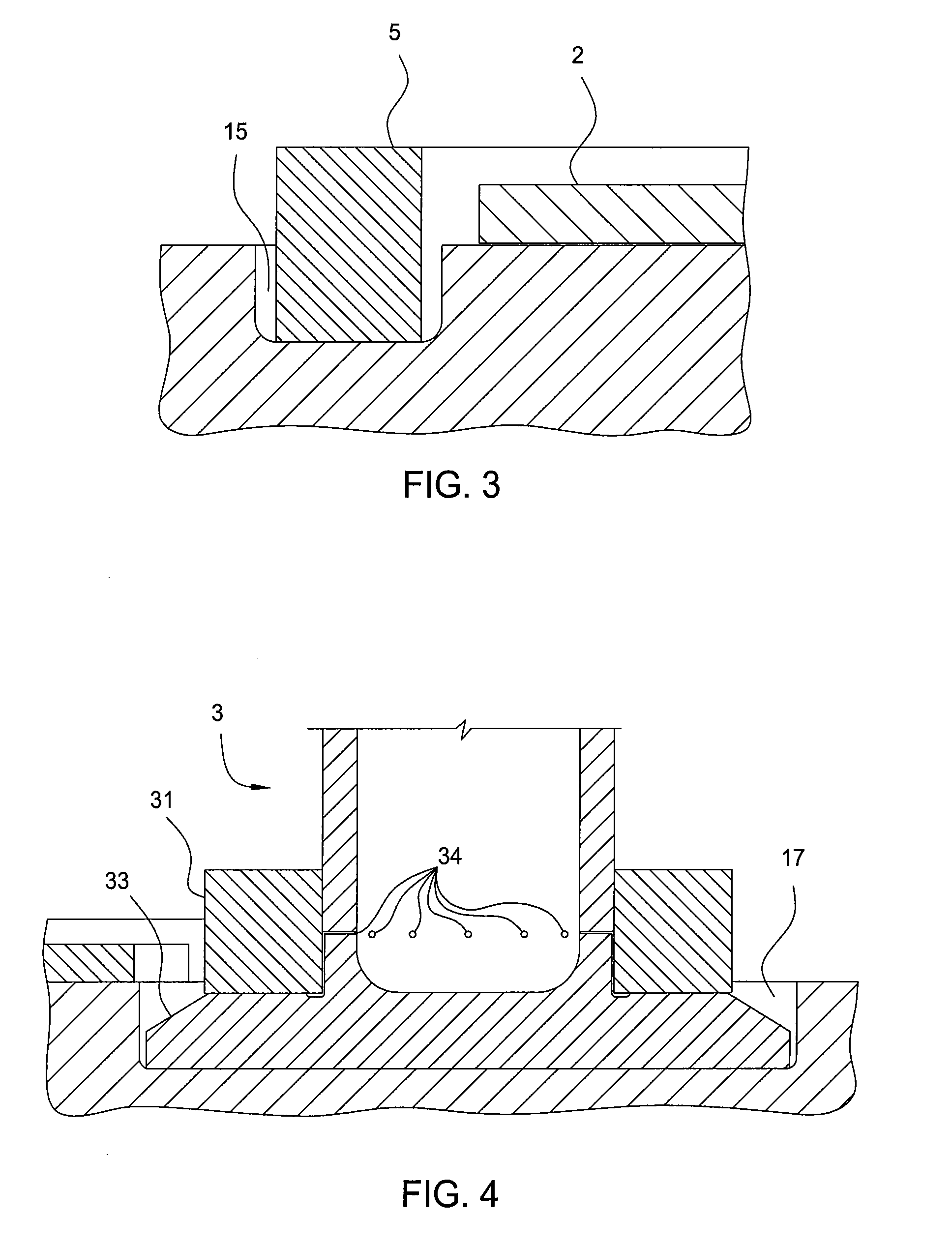

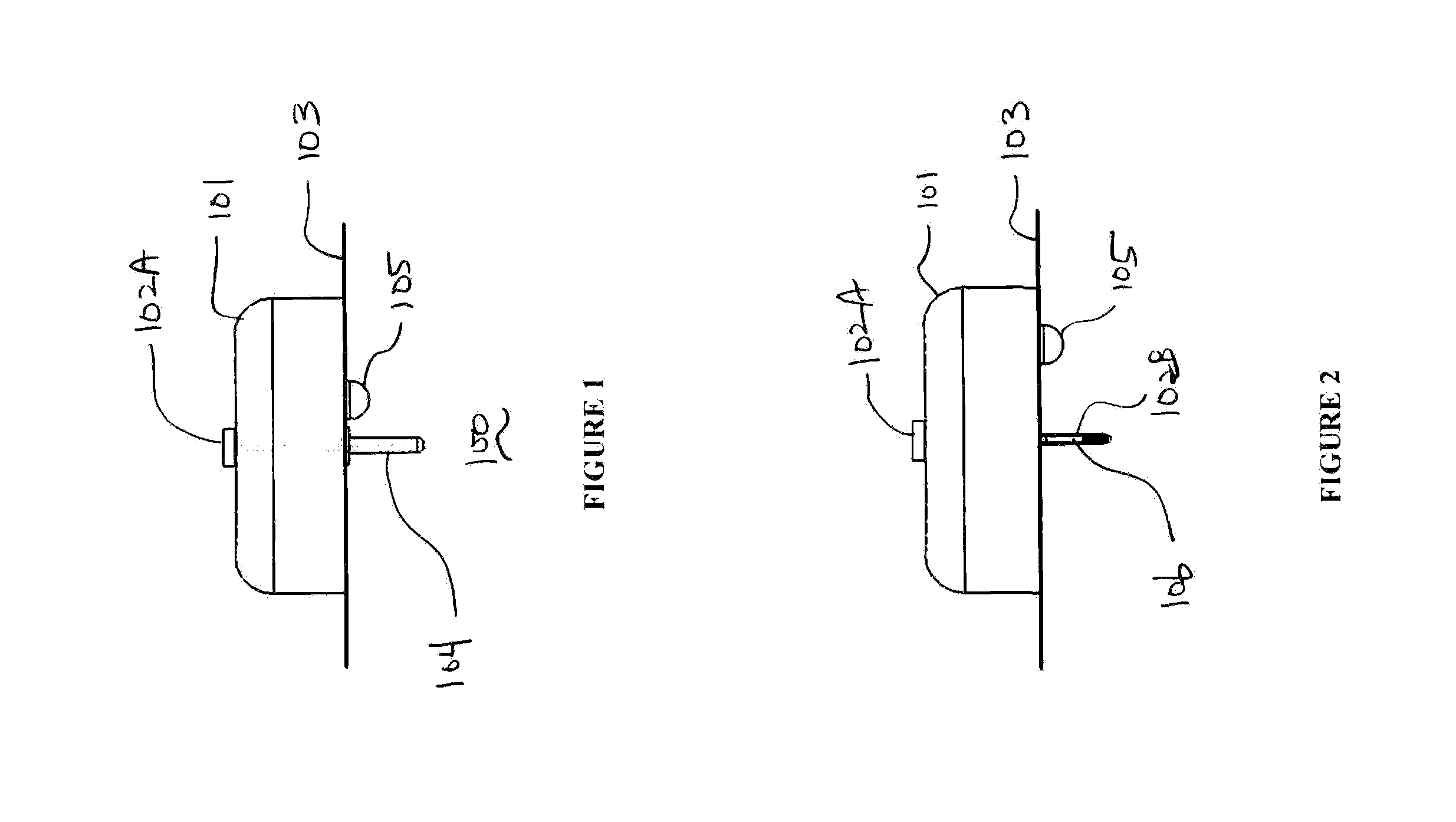

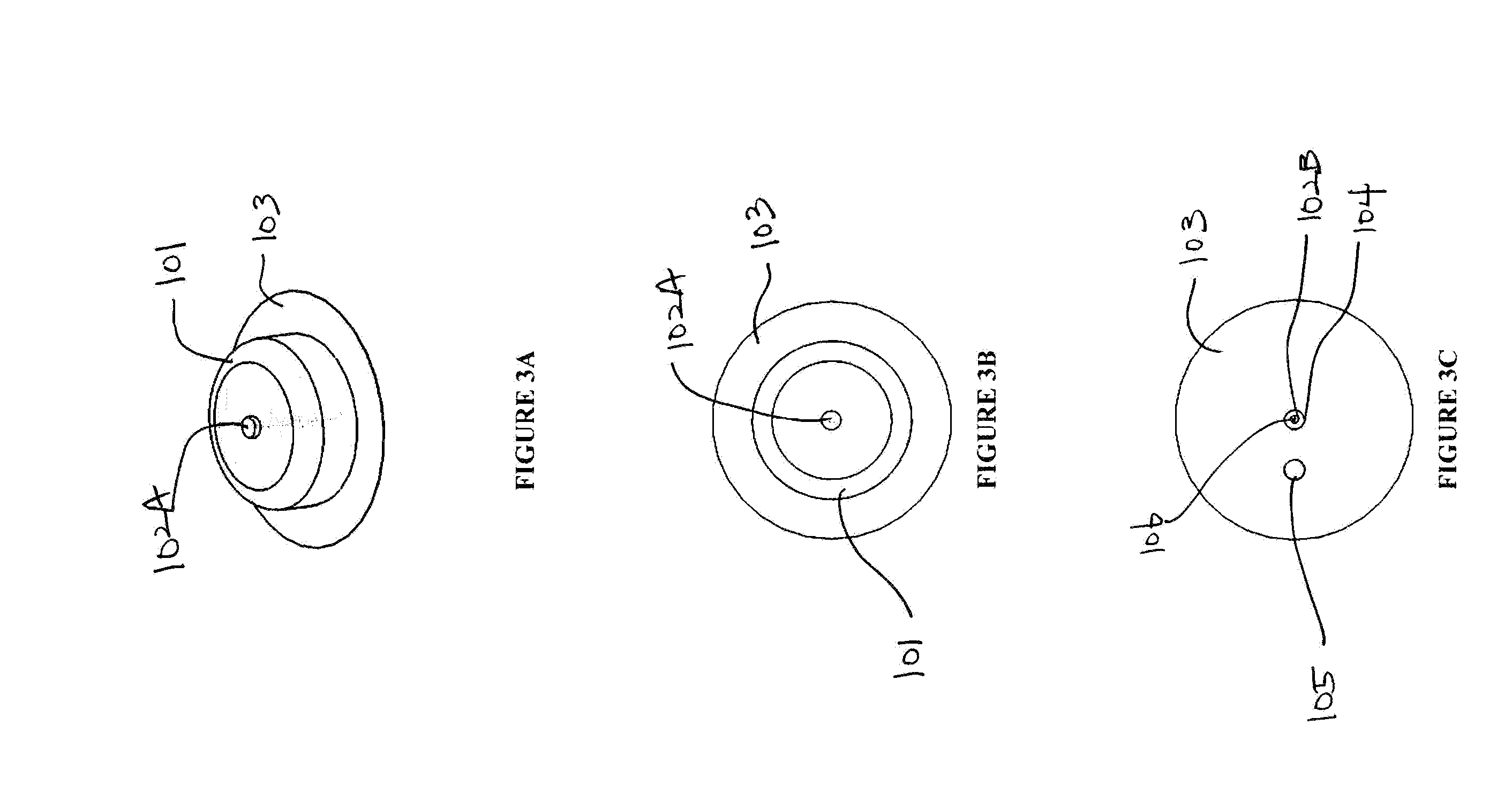

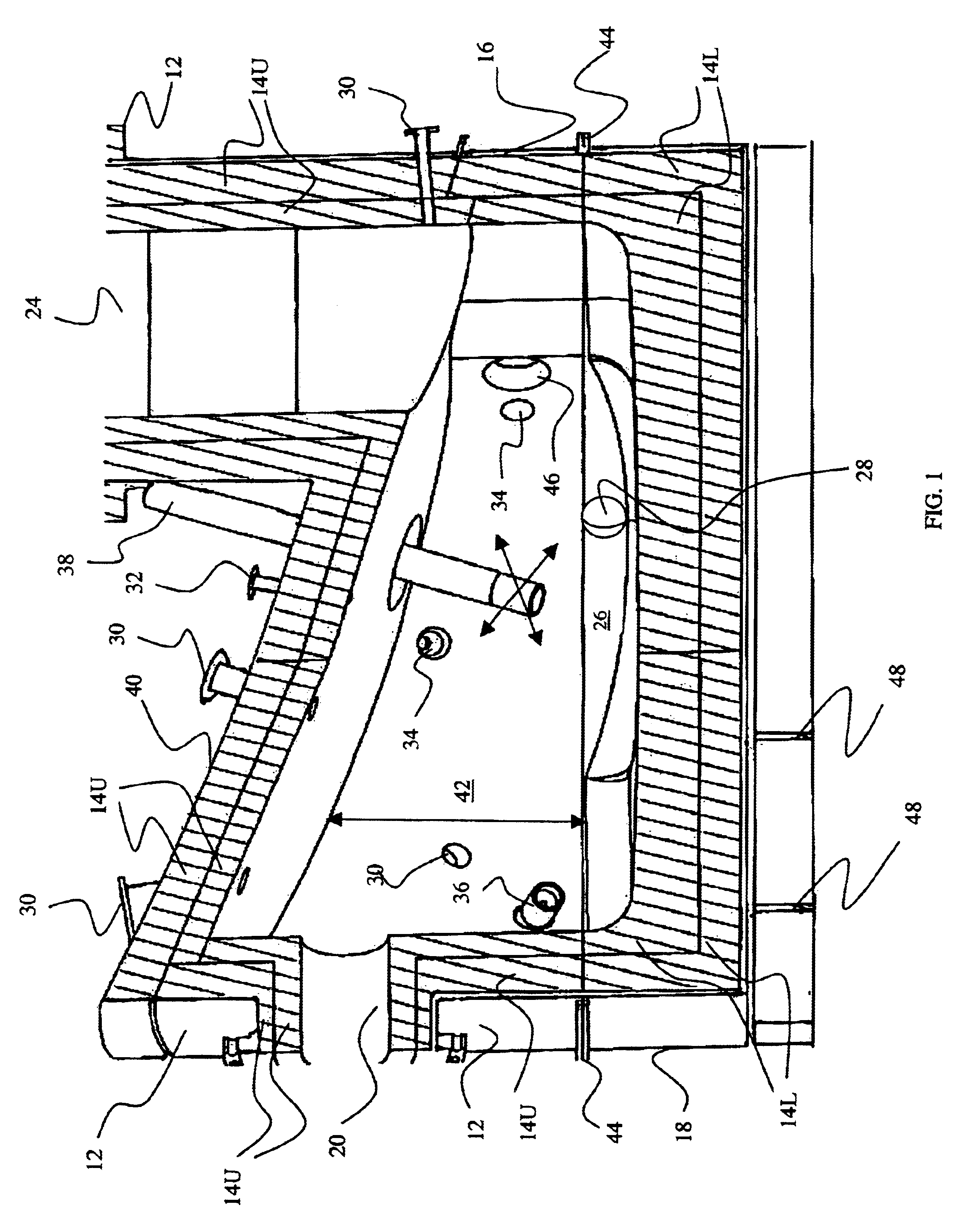

Apparatus and method for supporting, positioning and rotating a substrate in a processing chamber

ActiveUS20080276864A1Increase pressureReduce stressLiquid surface applicatorsSemiconductor/solid-state device manufacturingAir bearingThin layer

An apparatus and method for supporting, positioning and rotating a substrate are provided. In one embodiment, a support assembly for supporting a substrate includes an upper base plate and a lower base plate. The substrate is floated on a thin layer of air over the upper base plate. A positioning assembly includes a plurality of air bearing edge rollers or air flow pockets used to position the substrate in a desired orientation inside above the upper base plate. A plurality of slanted apertures or air flow pockets are configured in the upper base plate for flowing gas therethrough to rotate the substrate to ensure uniform heating during processing.

Owner:APPLIED MATERIALS INC

Method and System for Providing An Integrated Analyte Sensor Insertion Device and Data Processing Unit

ActiveUS20080097246A1Simple and accurate sensor deploymentEasy to operateSurgeryVaccination/ovulation diagnosticsAnalyteComputer science

Method and apparatus for providing an integrated analyte sensor and data processing unit assembly is provided.

Owner:ABBOTT DIABETES CARE INC

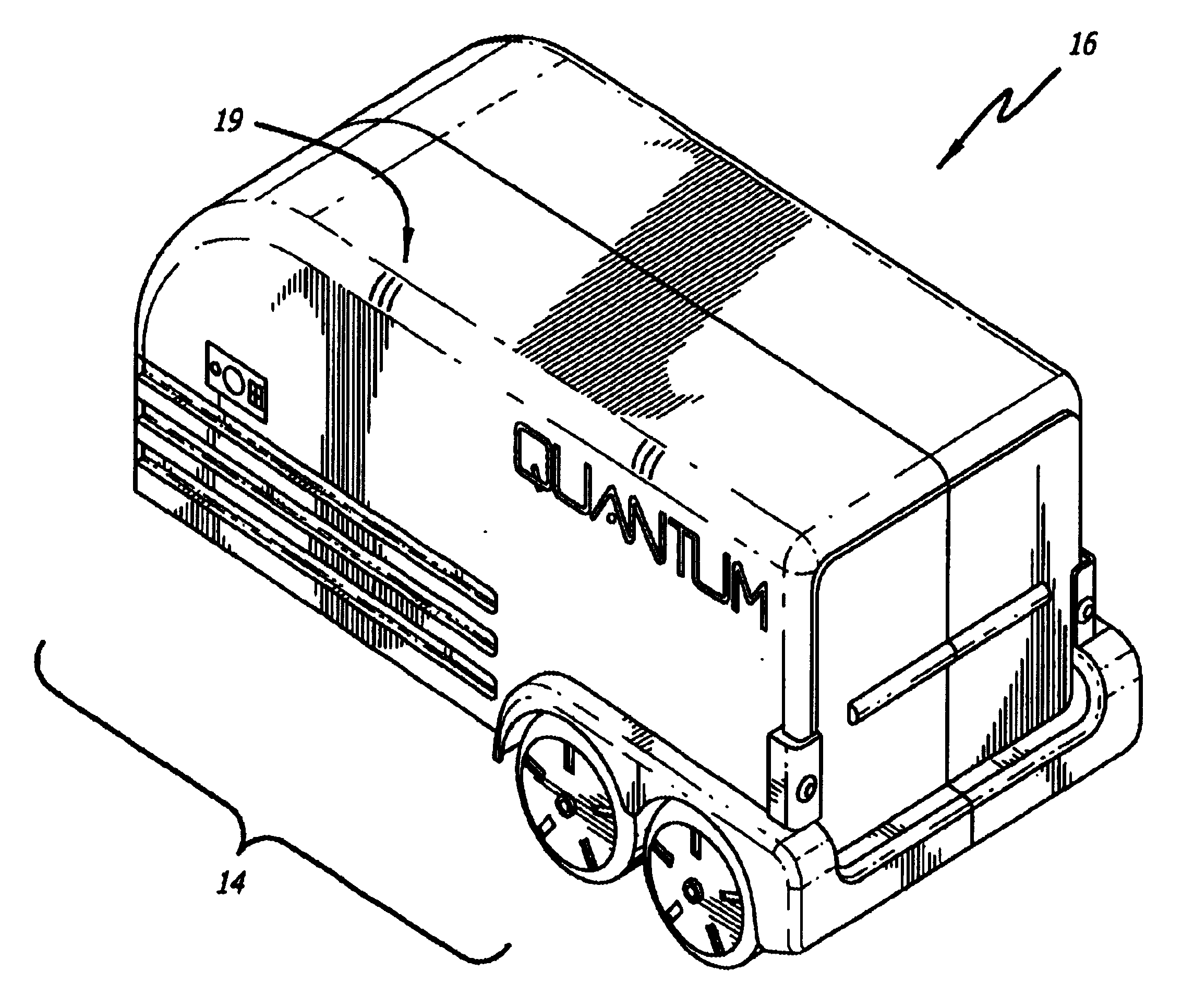

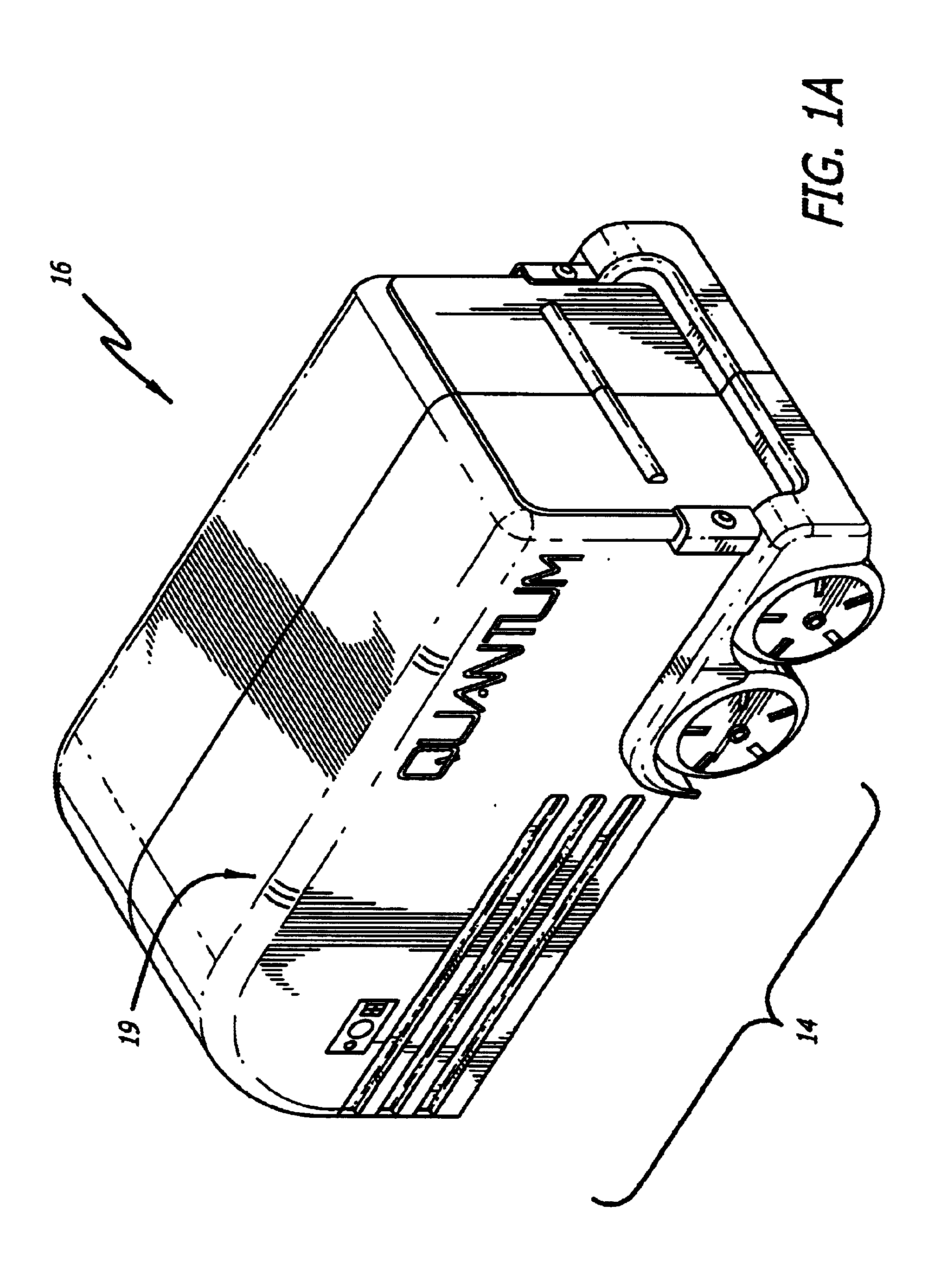

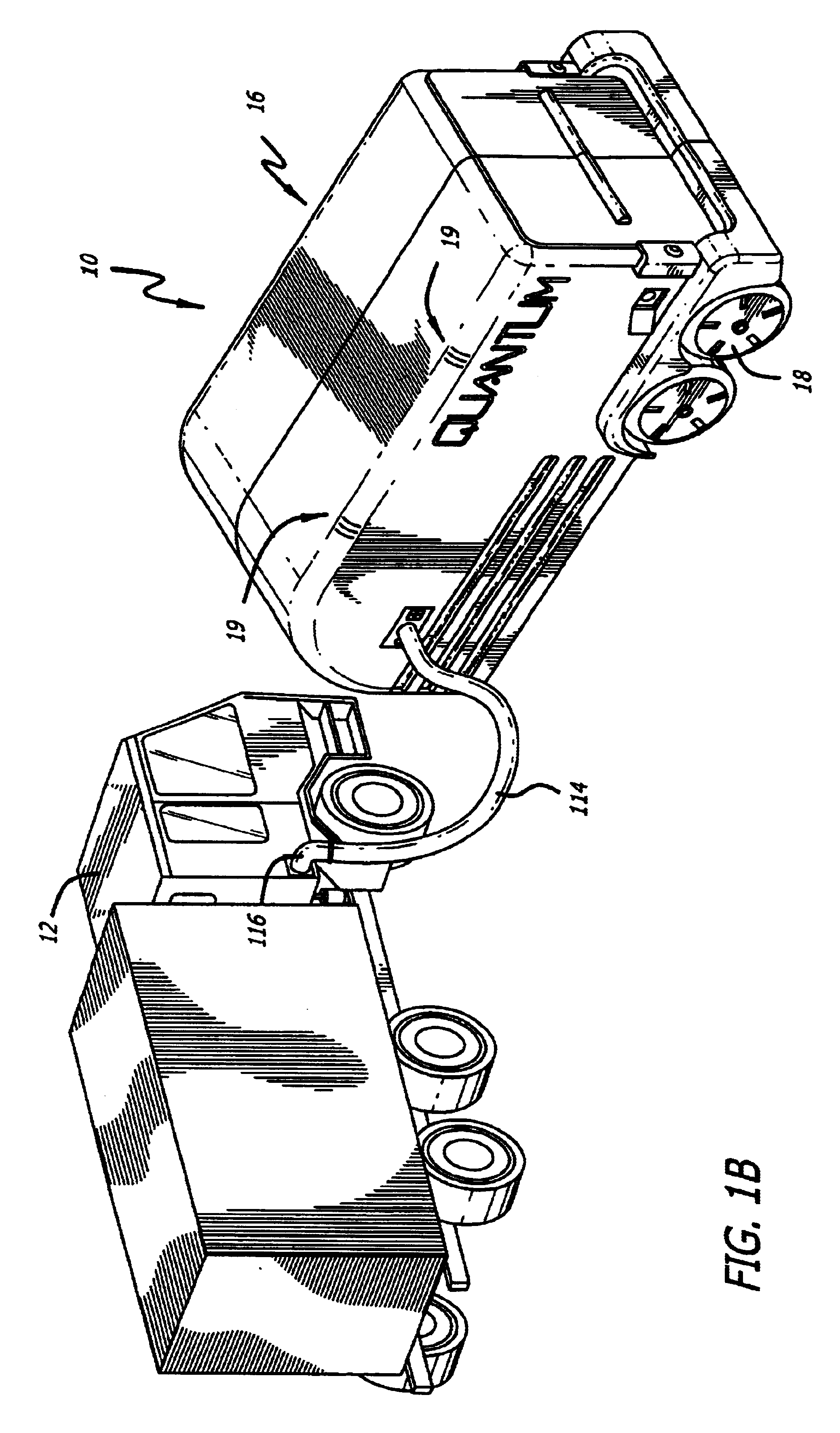

Transportable hydrogen refueling station

InactiveUS6755225B1Easy to monitorReduce riskTank vehiclesGas handling applicationsHigh pressureGaseous hydrogen

A portable hydrogen refueling stations which can dispense gaseous hydrogen from one or more internal high pressure tanks. The refueling station can be refilled with a lower pressure hydrogen gas feed and then compressed for storage within the refueling station.

Owner:QUANTUM FUEL SYST TECH WORLDWIDE INC

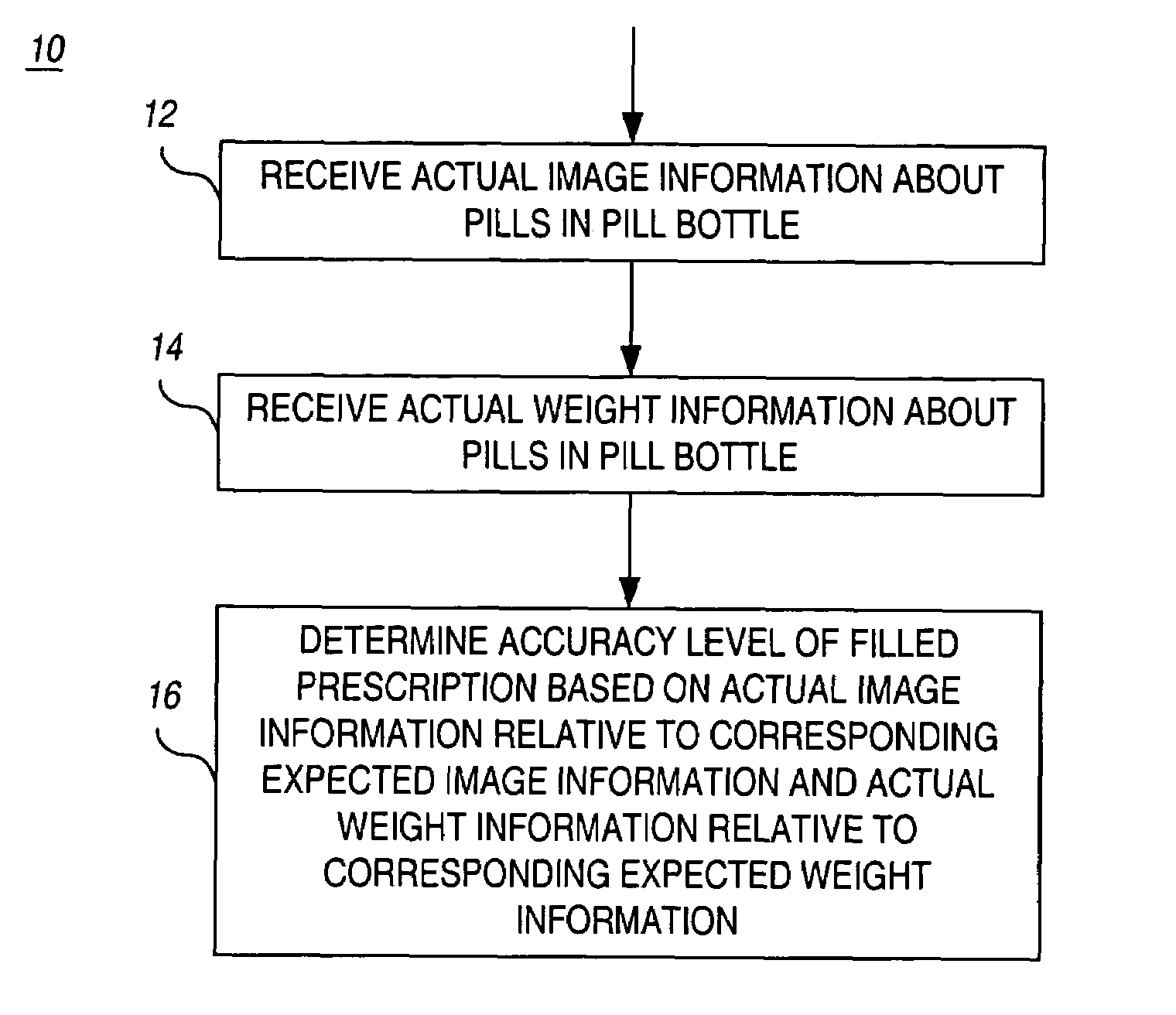

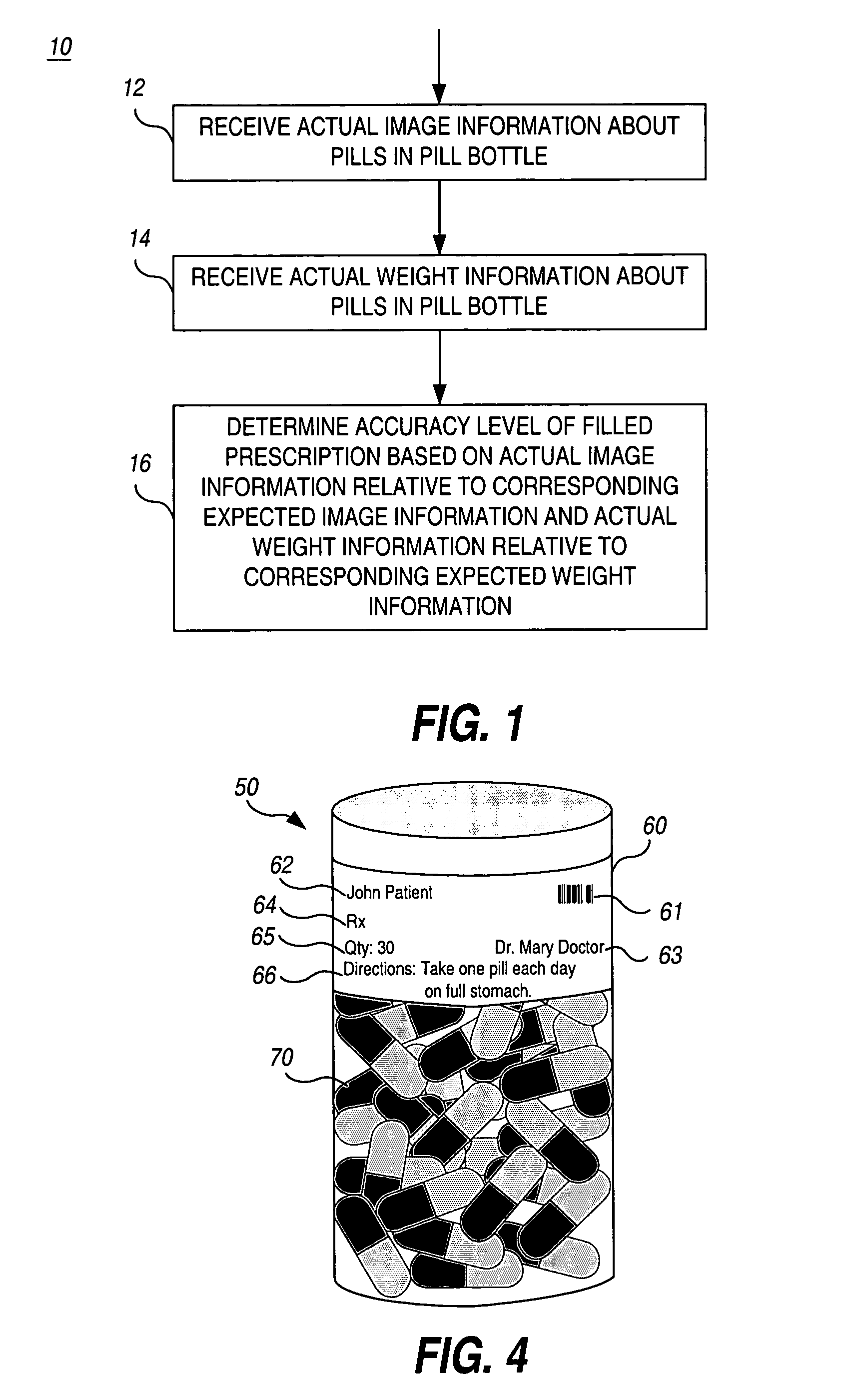

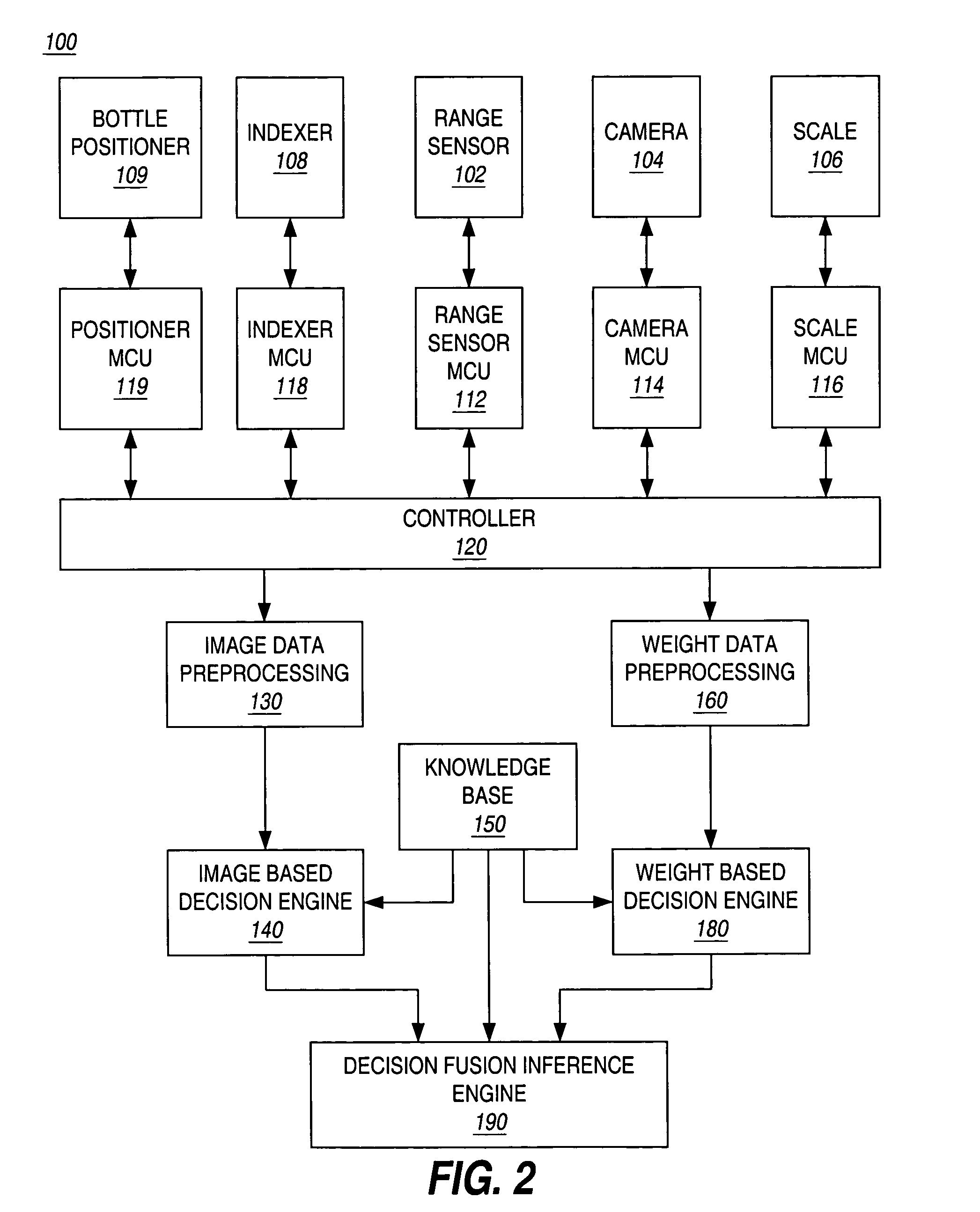

Apparatus and method for automatic prescription verification

InactiveUS7028723B1Eliminate unnecessary idle timeLiquid fillingDrug and medicationsThe InternetOrder form

An apparatus and method are used to perform the verification of a pharmaceutical prescription after it is filled but prior to shipment. Due to the high volume of mail / internet orders, the analysis is to be performed on the whole prescription, not on each individual pill of the prescription. The apparatus automatically gathers information about the pills contained in a pill bottle, including image and weight information, and incorporates a decision-making engine to decide whether the content of the pill bottle matches the prescription order.

Owner:ALOUANI ALI TAHOR +1

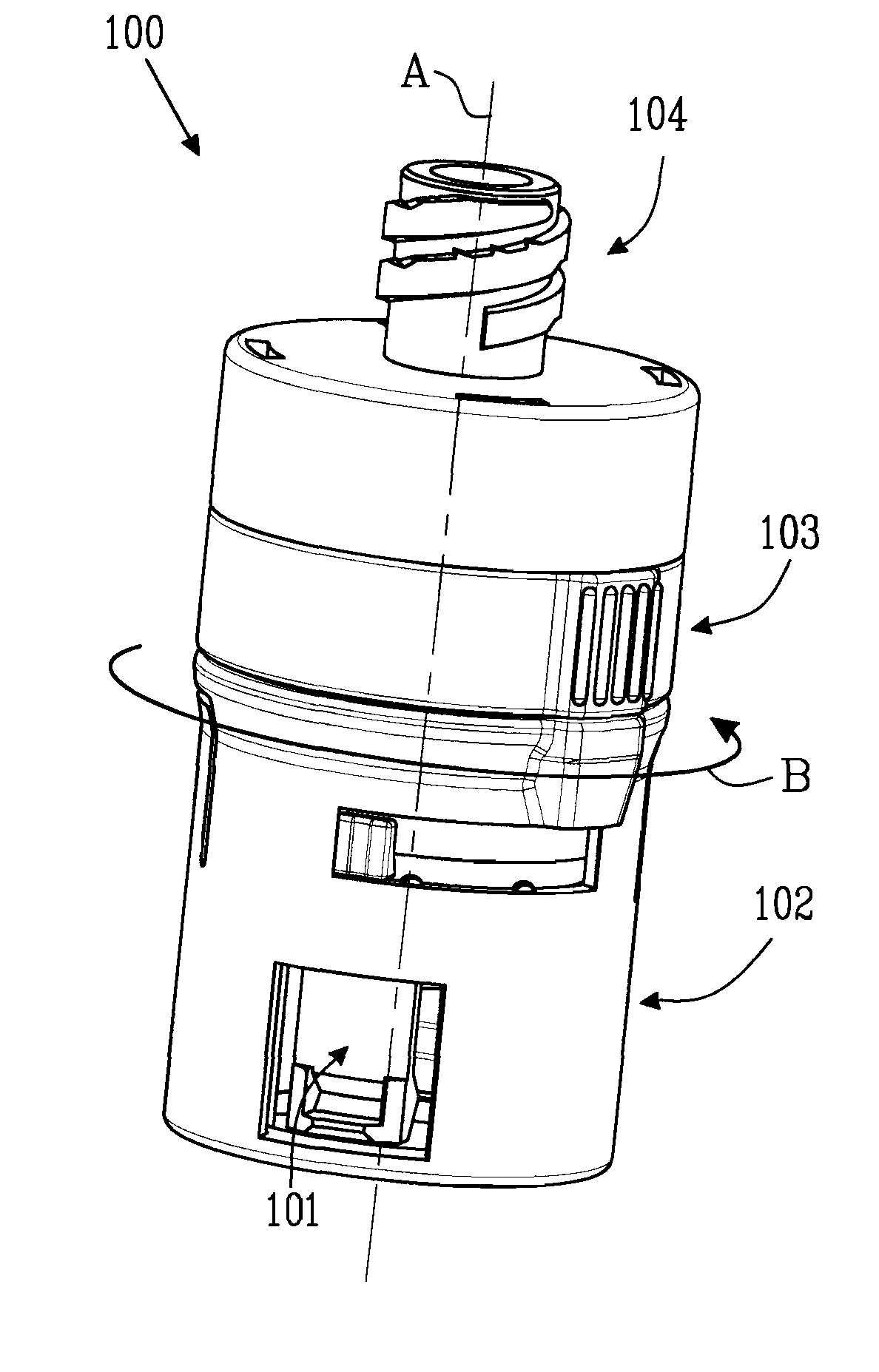

Reconstitution device and method of use

A reconstitution device is disclosed and includes a first container receiver having a first component cannula disposed therein, the first component cannula having a withdrawal port and a first transfer port formed thereon, a second container receiver having a second component cannula disposed thereon, the second component cannula having a vent port and a second transfer port formed thereon, a device body coupling the first container receiver to the second container receiver and having a transfer lumen formed therein, the transfer lumen in fluid communication with the first and second transfer ports, a selectively sealing interface secured to the device body and in fluid communication with the withdrawal port, and a venting member in communication with the vent port through a vent lumen.

Owner:TAKEDA PHARMA CO LTD

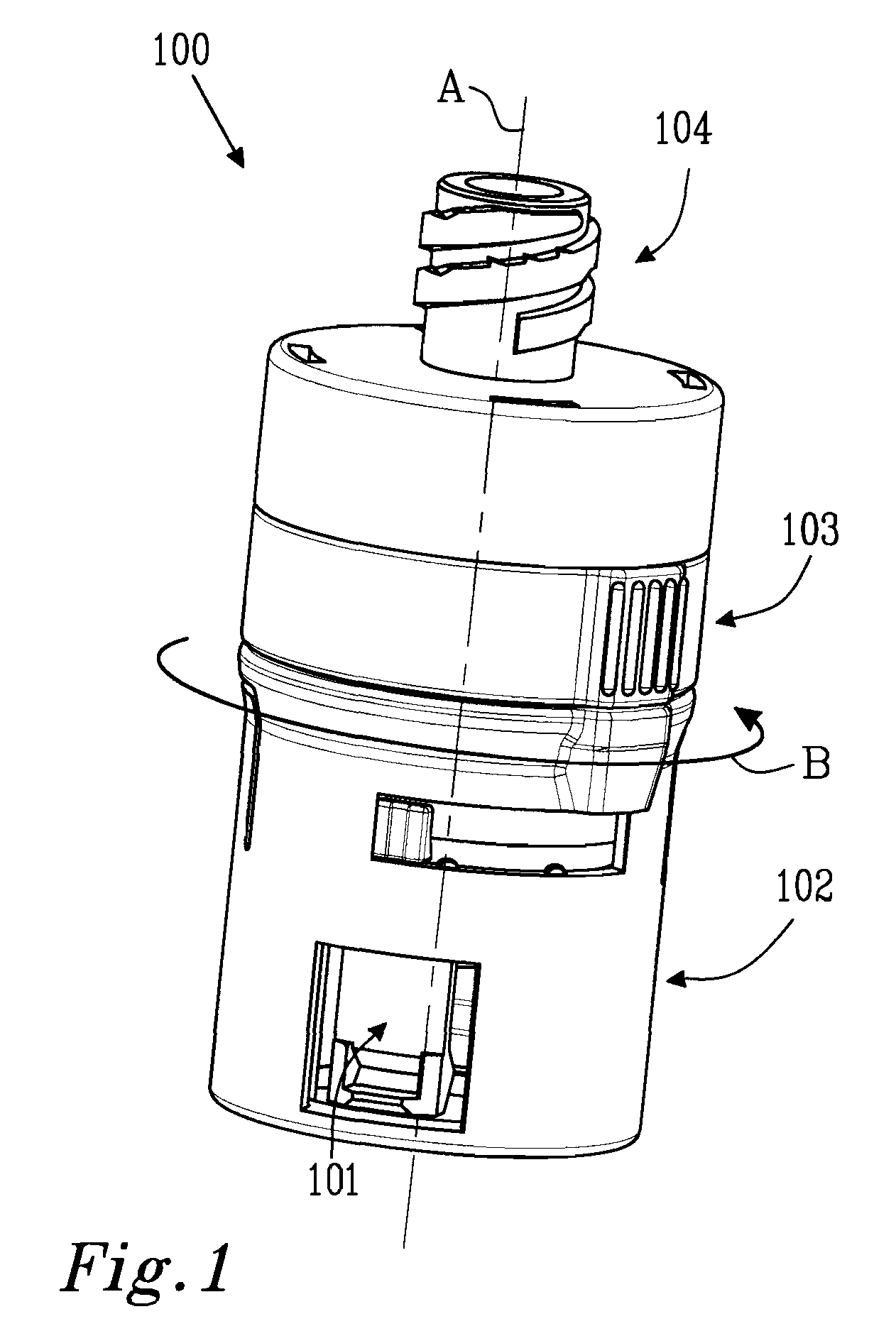

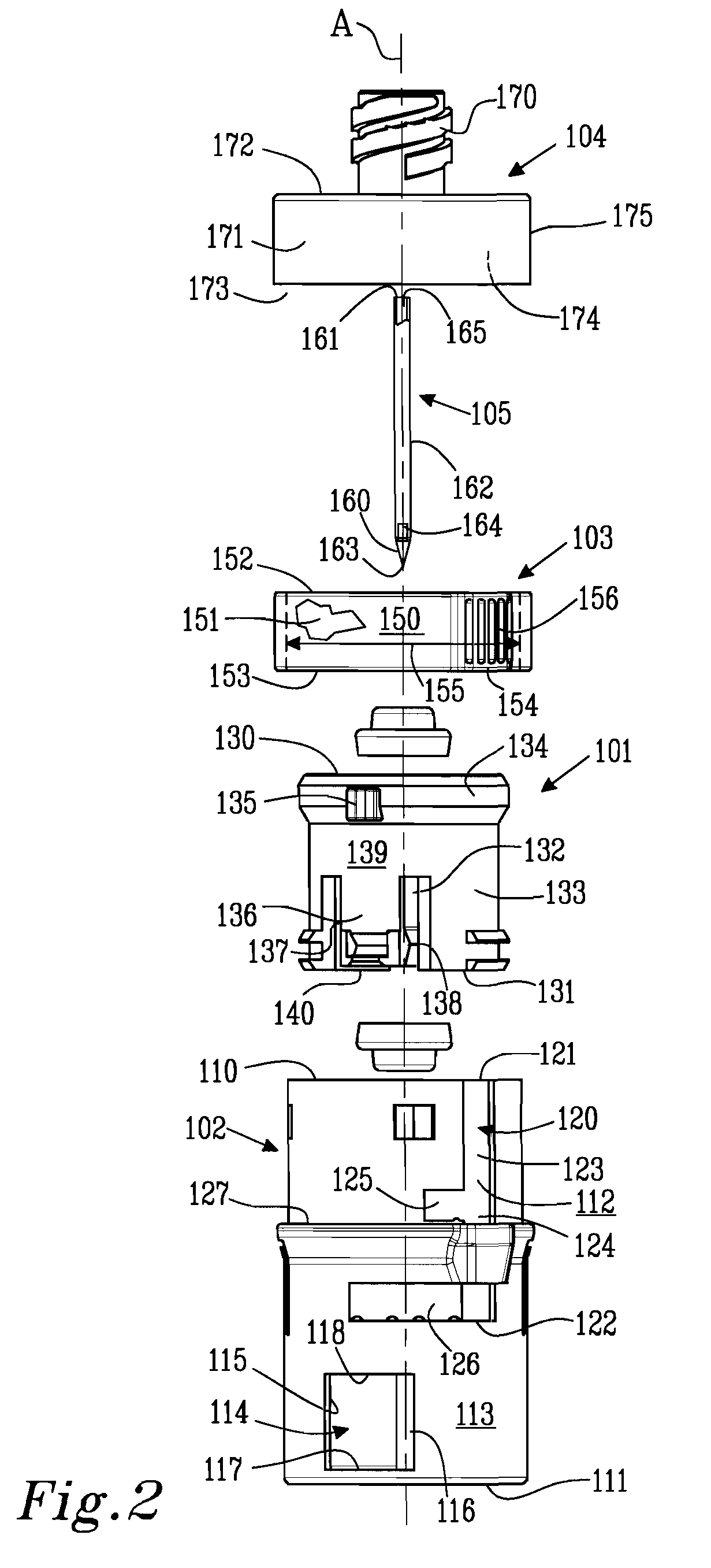

Piercing member protection device

ActiveUS8287513B2Avoid connectionPrevent disengagementCapsLiquid fillingEngineeringElectrical and Electronics engineering

Owner:CARMEL PHARMA

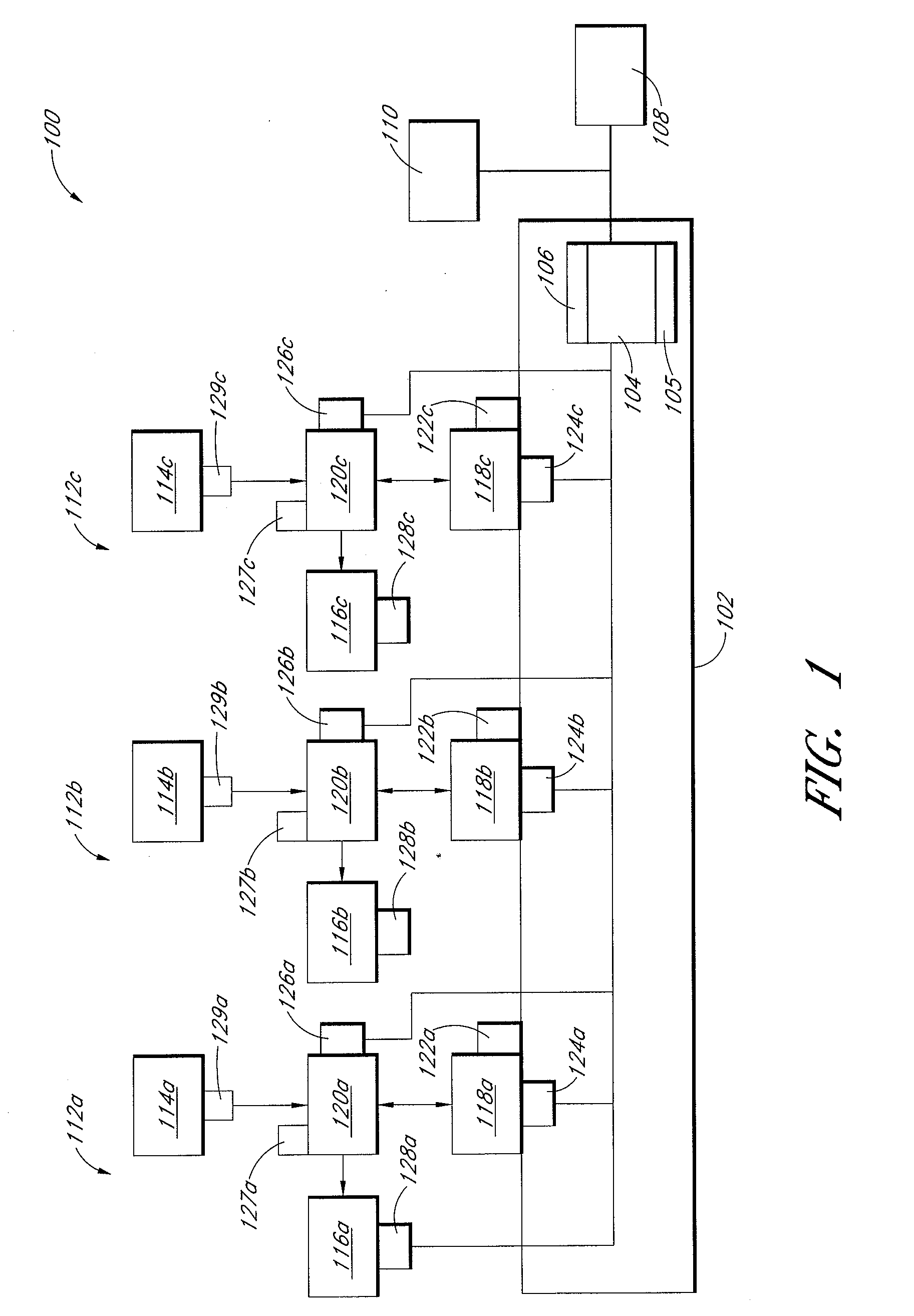

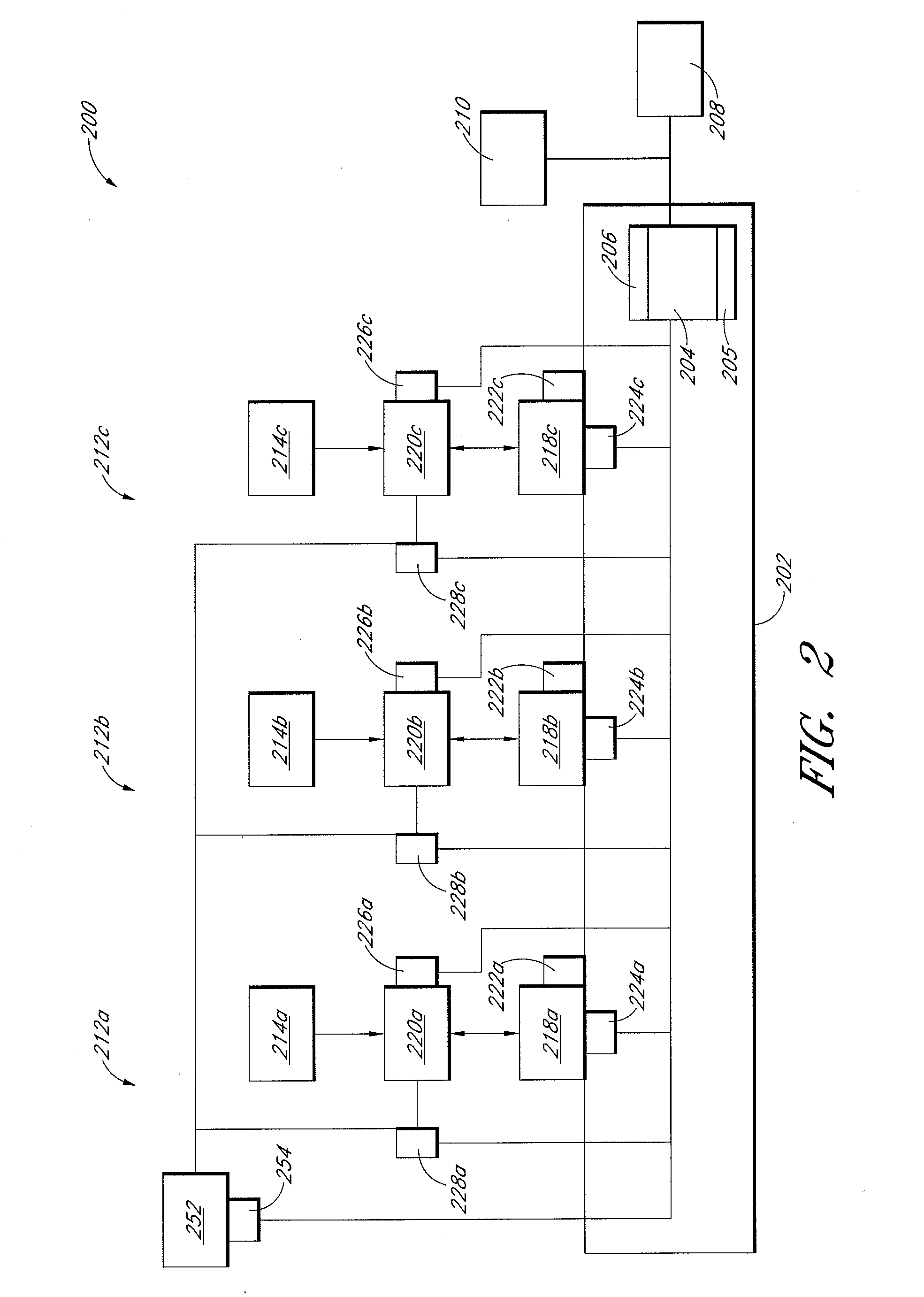

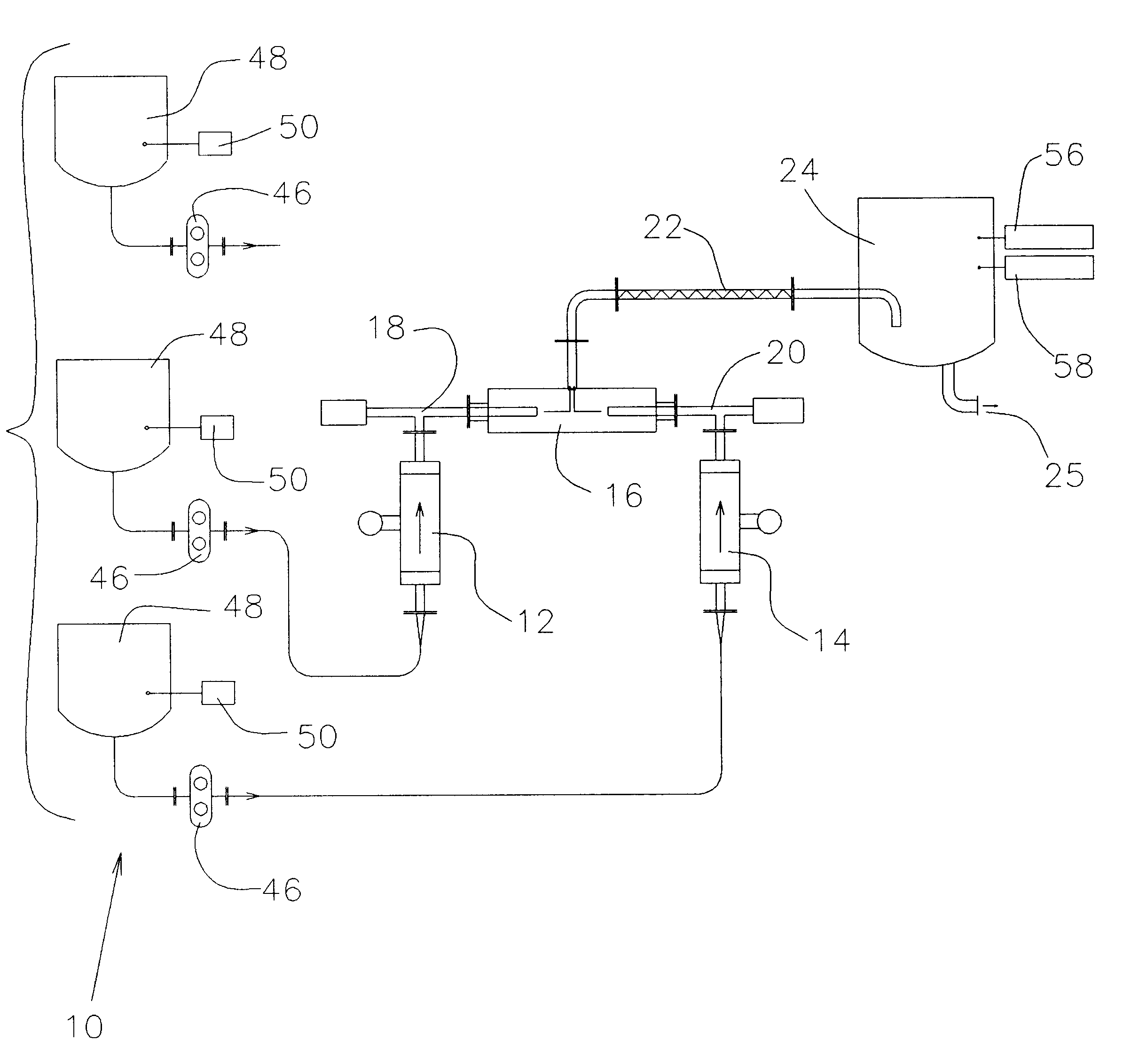

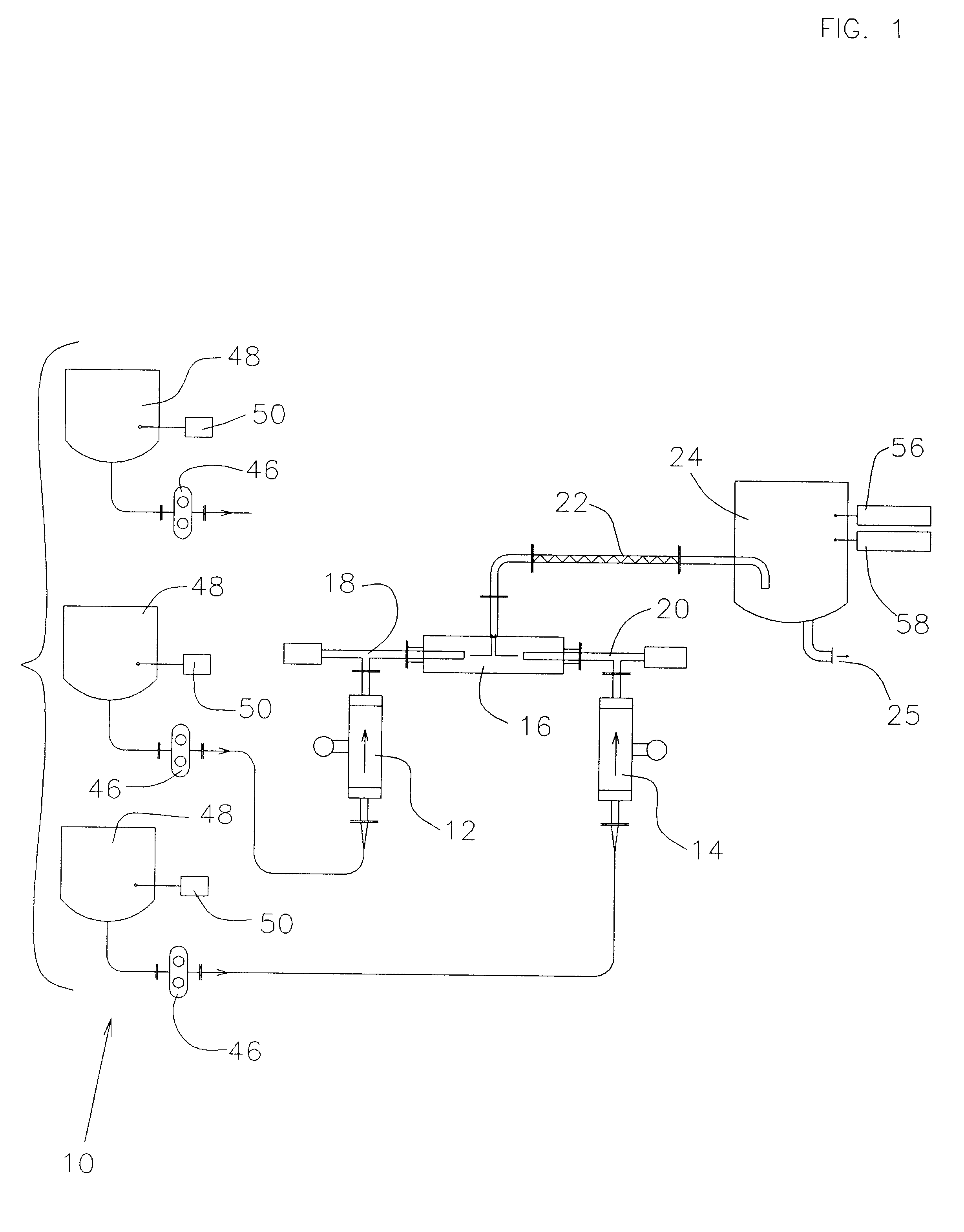

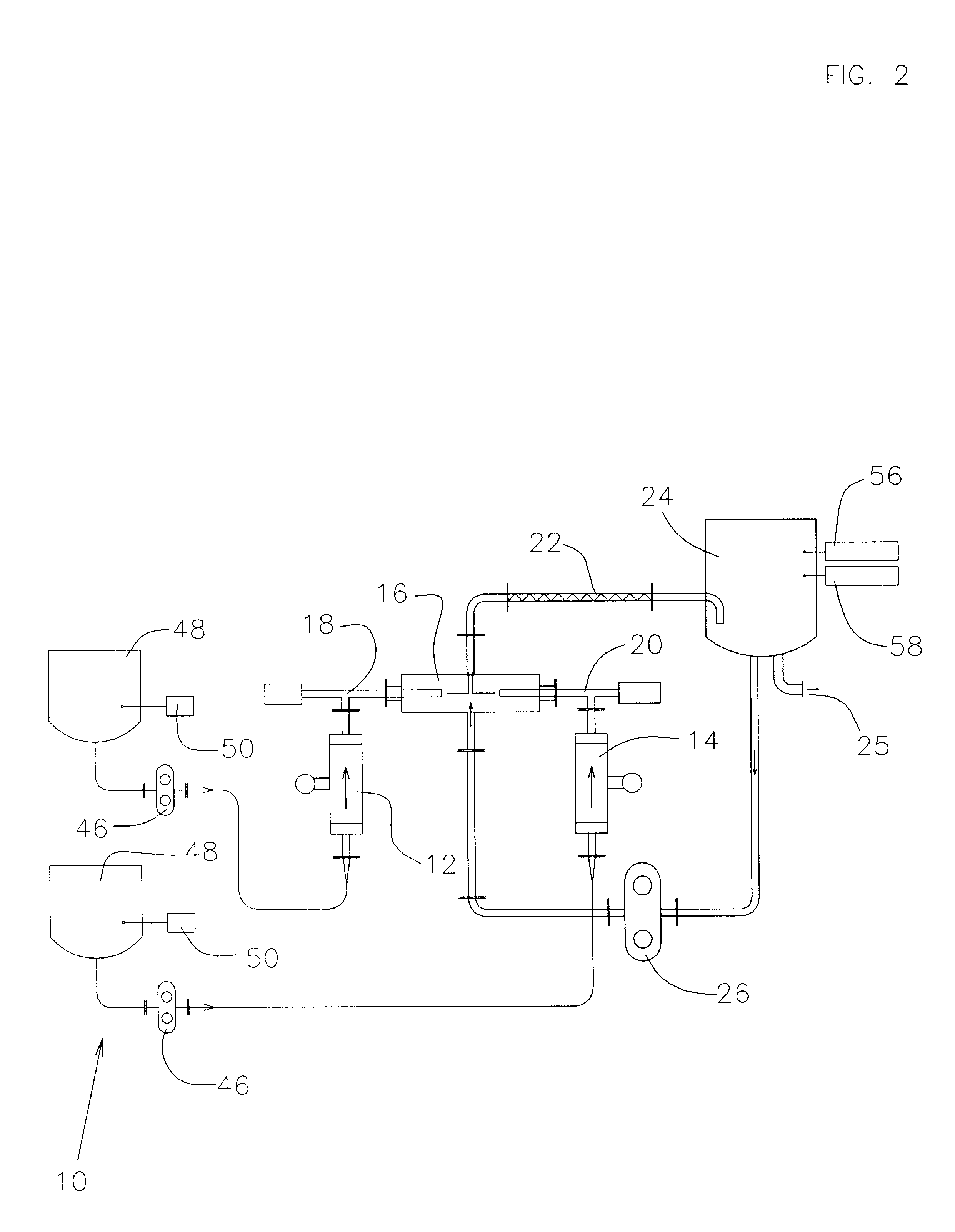

Continuous liquid stream digital blending system

InactiveUS6186193B1More disadvantageSimplifies software and set-up computationLiquid fillingControlling ratio of multiple fluid flowsHybrid systemDigital clock

The present invention consists of a method and apparatus providing for the continuous stream blending, preferably on a mass ratio basis, of two or more liquids. Each individual liquid stream is synchronously dosed in precise mass ratio to a common mixing point. The flow of each stream is on-off or digital. Repeated mass ratio doses of defined and matching flow interval, referred to as synchronous digital flow, interspersed with a defined interval of no flow, constitutes digital flow at a net rate sufficient to meet or exceed some required take-away of the blended liquids. In one preferred embodiment, each dose stream flow is produced and measured by a four element apparatus preferably consisting of a servo motor and controller, a precision positive displacement pump, a Coriolis mass meter and a precision flow stream shut-off device. The servo motor and controller establish and control a periodic and intermittent flow rate necessary to displace a defined mass dose in a precisely defined flow interval. The flow interval is measured against a precision millisecond digital clock. The Coriolis mass meter is used only to totalize mass flow to define the desired mass dose during the defined digital flow interval. The flow stream shut-off device ensures precise delivery of the mass dose to the common mixing point. The flow rate of a stream is automatically adjusted by the control electronics until the required mass dose is delivered in the defined flow interval.

Owner:ODEN MACHINERY

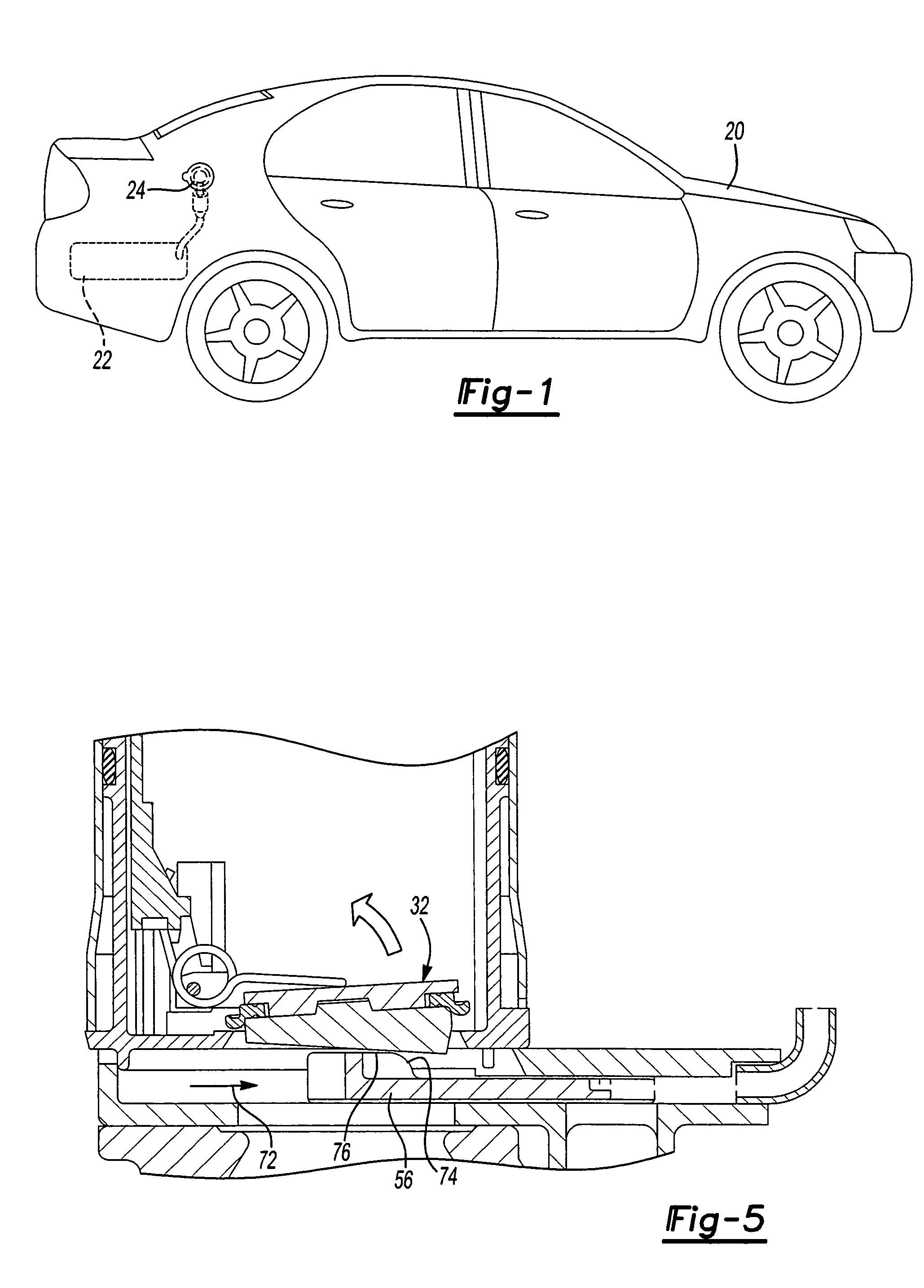

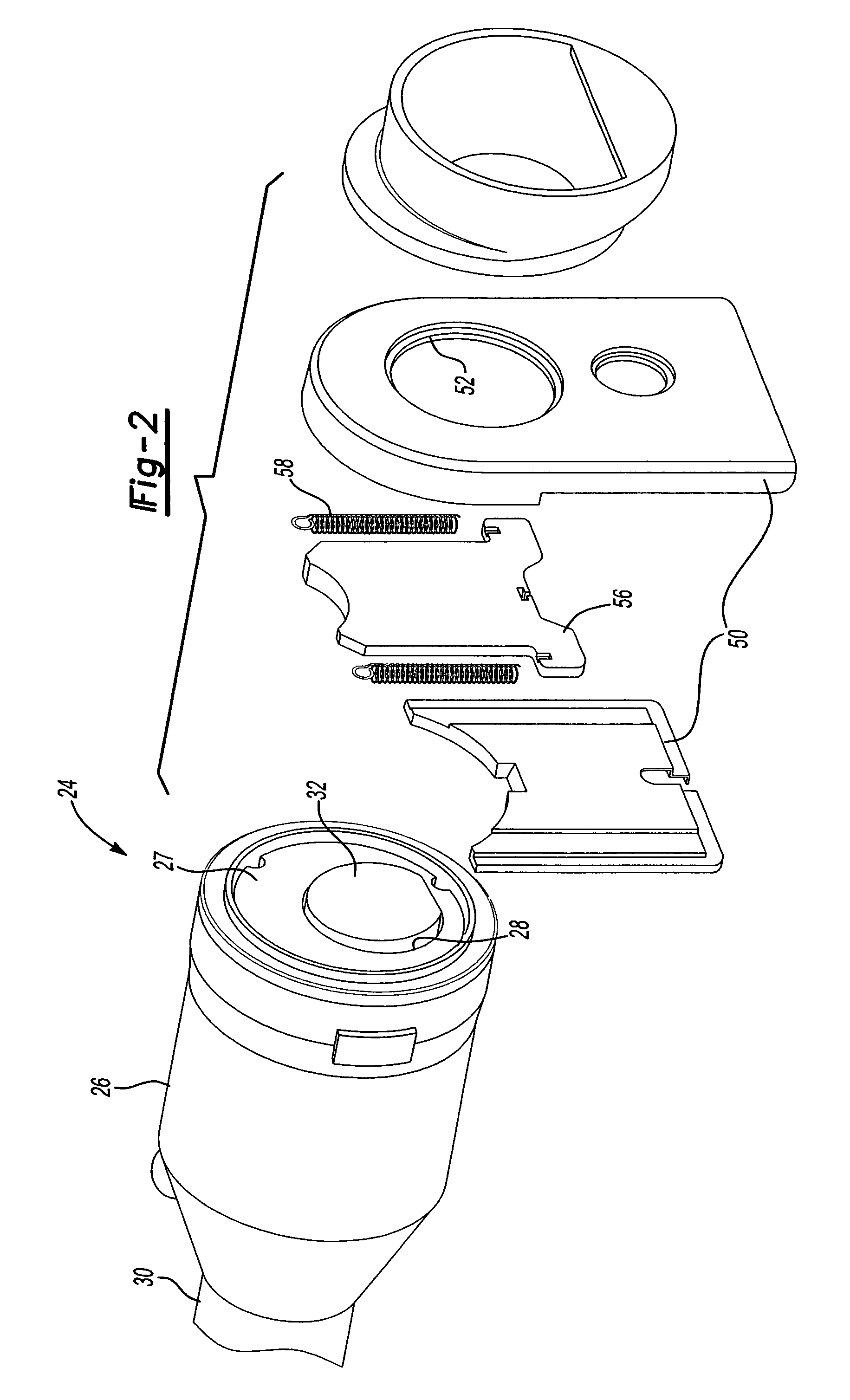

Capless automotive fueling system

A capless automotive fueling system having a funnel with a port open to receive a fuel filling nozzle. A spring loaded valve is movable between an open position in which the port is open and a closed position in which the fuel valve overlies and sealingly covers the port. A shield is movable between a first position in which the shield overlies and covers the valve, and a second position in which the shield is laterally disposed to one side of the valve to permit insertion of the fuel filling nozzle. A motor is drivingly connected to the shield and, on activation, moves the shield from its first and to its second position. Alternatively, two latches engage the valve to retain the valve in a closed position. Upon insertion of a properly sized fuel nozzle, the nozzle engages the latches and pivots them to an open position.

Owner:MARTINREA IND INC

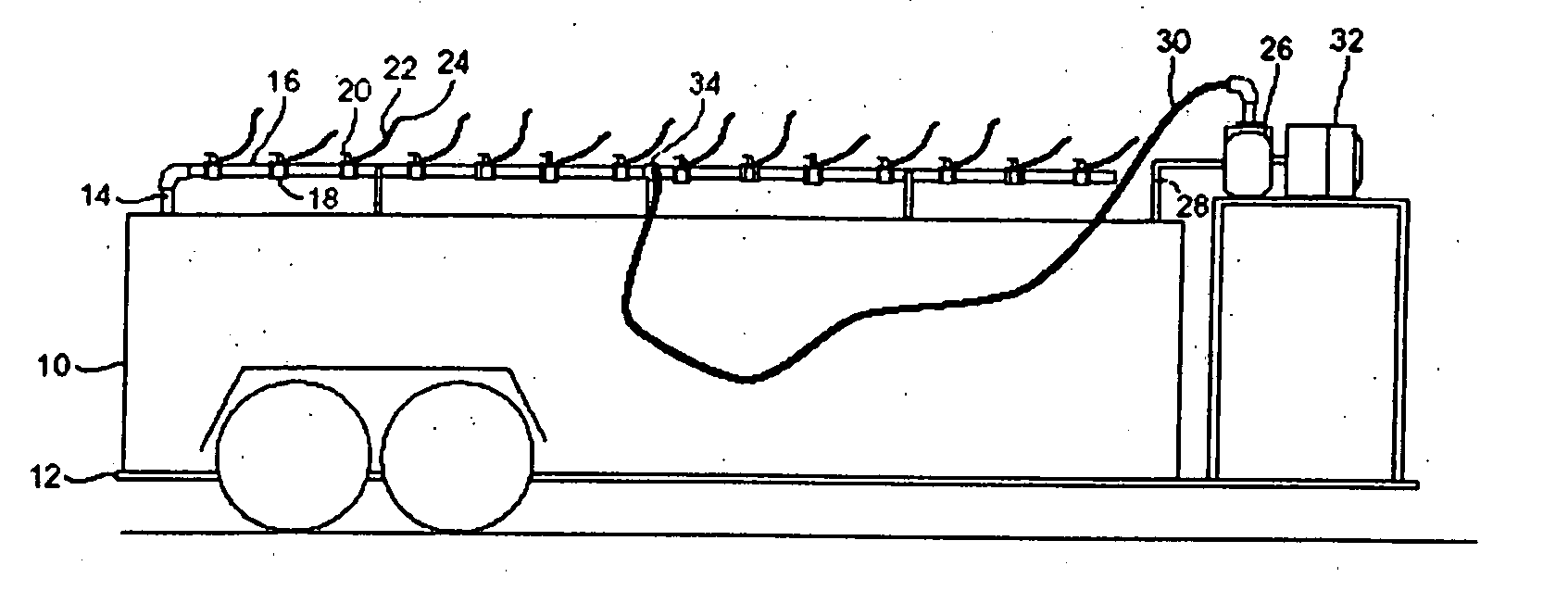

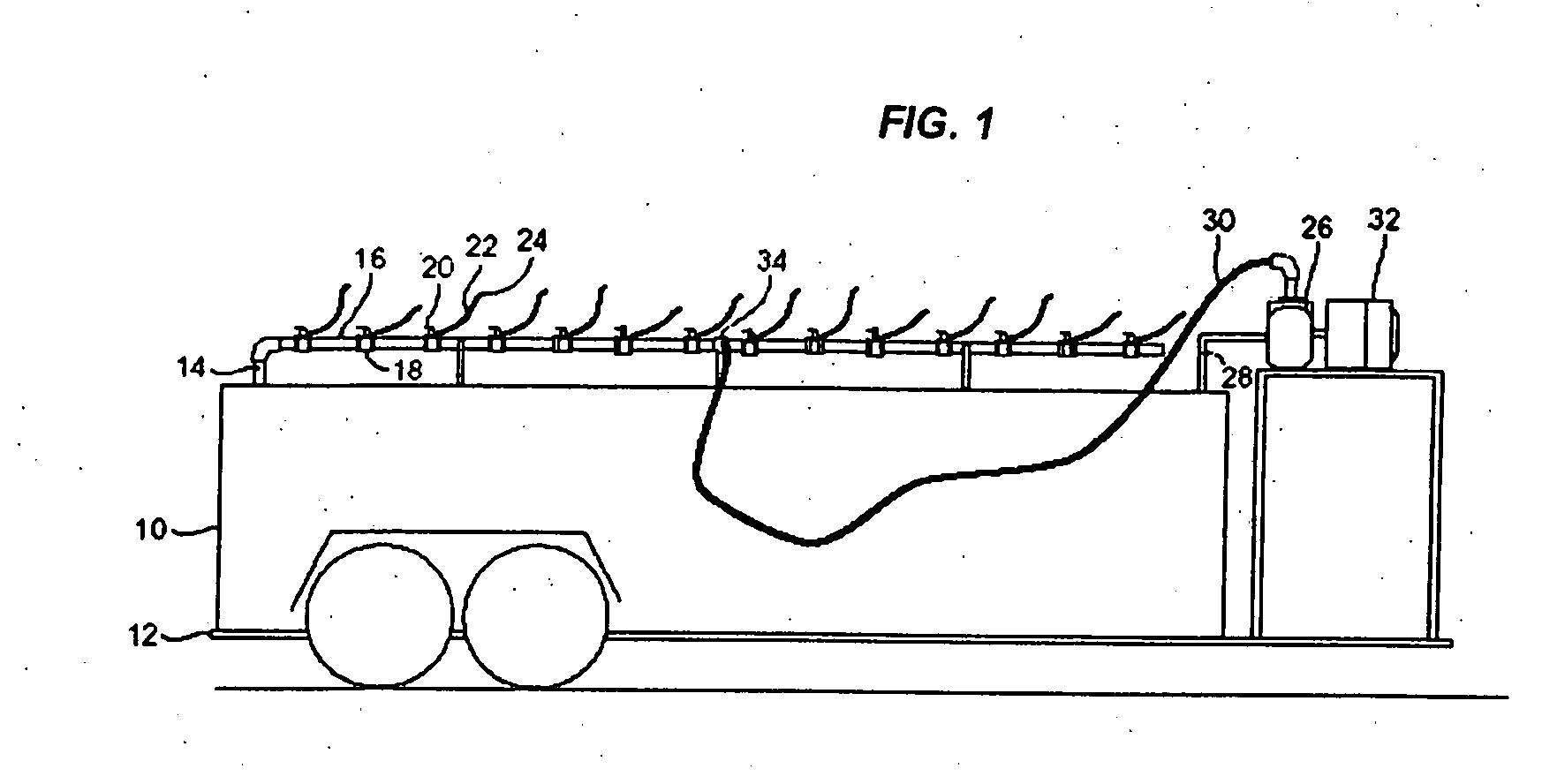

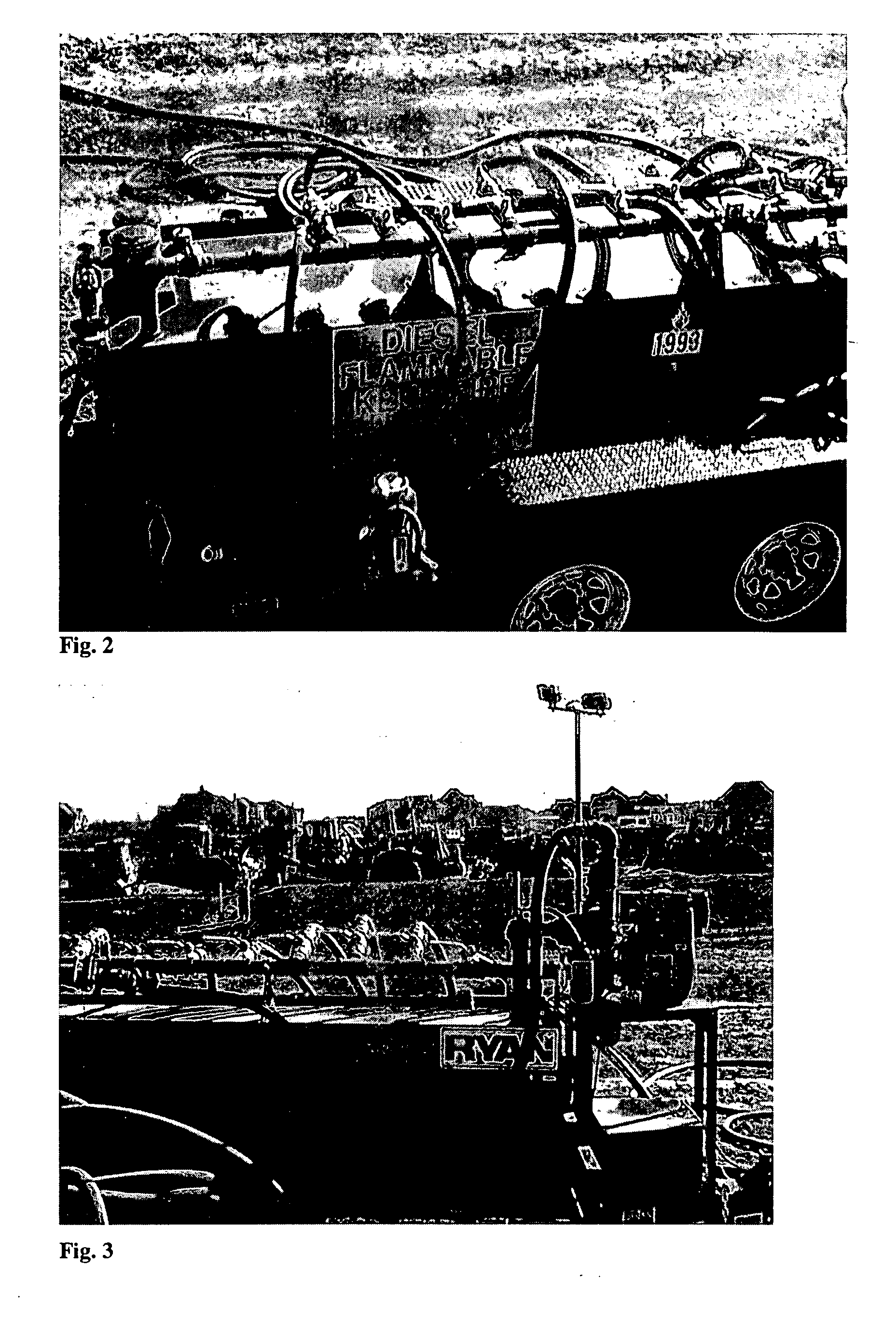

Method and apparatus for refueling multiple vehicles

InactiveUS20070181212A1Easy accessReduces time and expenseSolid materialItem transportation vehiclesFuel tankTruck

A refueling dock for refueling multiple vehicles at one time is disclosed. The dock has a manifold that has an inlet that can be connected to a fuel tanker truck and a plurality of outlet openings. Each outlet opening has a valve that controls the flow of fuel through the hose. A nozzle is fitted to the hose and is located at the end of the hose distant from the outlet opening. Two or more hoses can be simultaneously connected to different equipment in need of refueling. A valved fuel tank inlet line enables fuel to flow from the manifold to a fuel tank on the dock. When needed, fuel from the tank can then be pumped to the manifold through a fuel tank outlet line,.which can be connected to the same inlet on the manifold that is used to receive fuel from the tanker trick.

Owner:RYAN CENT

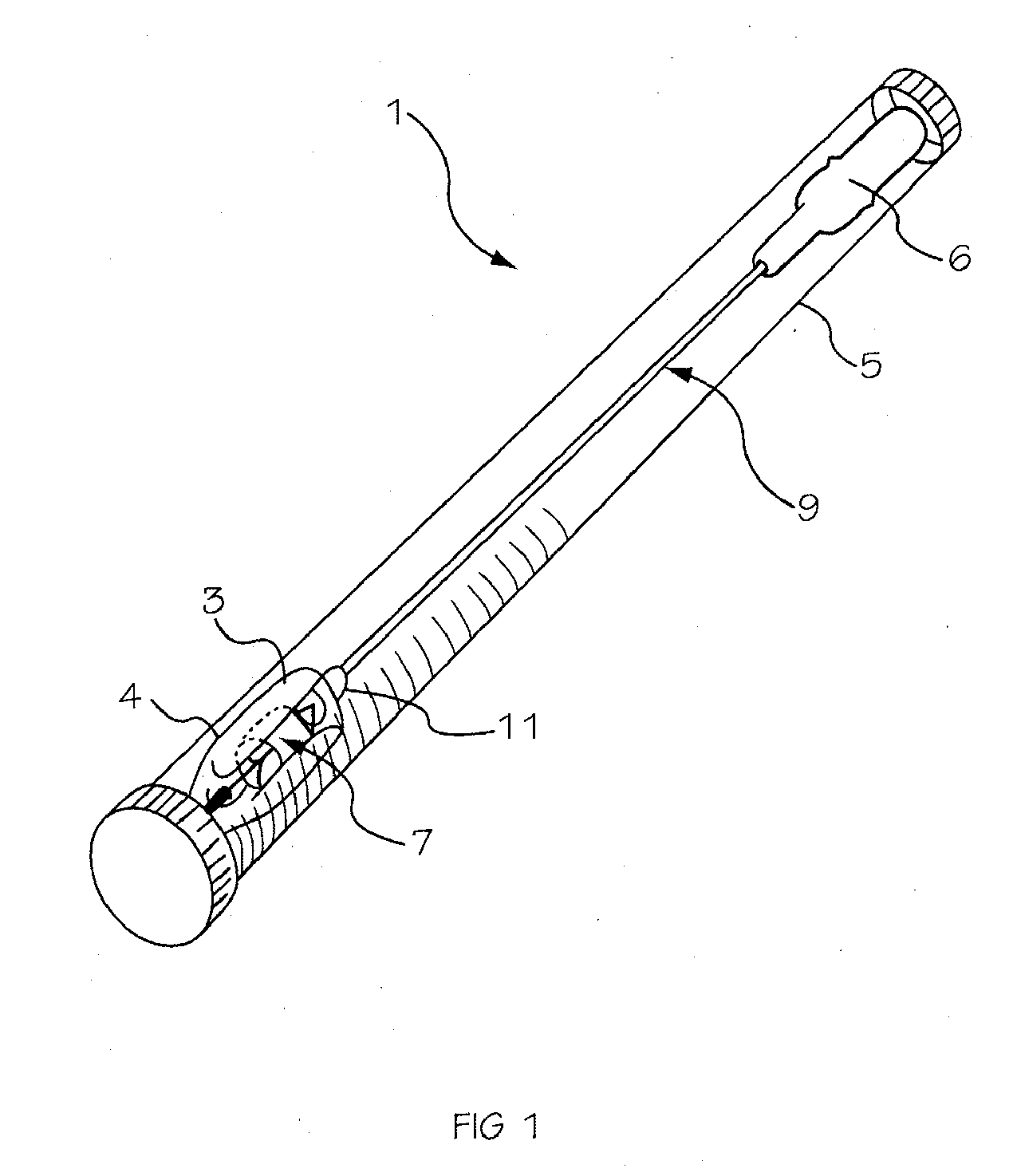

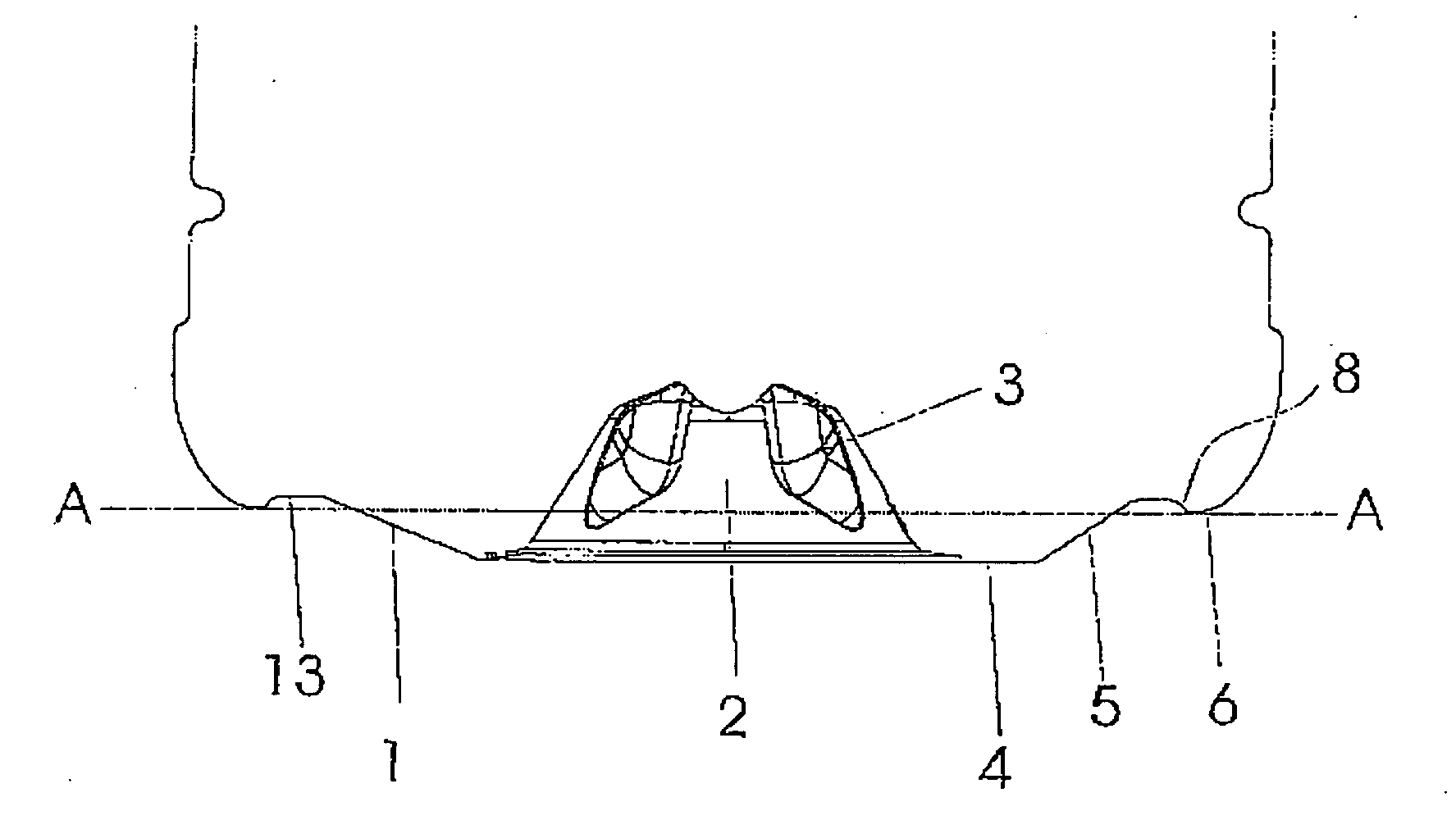

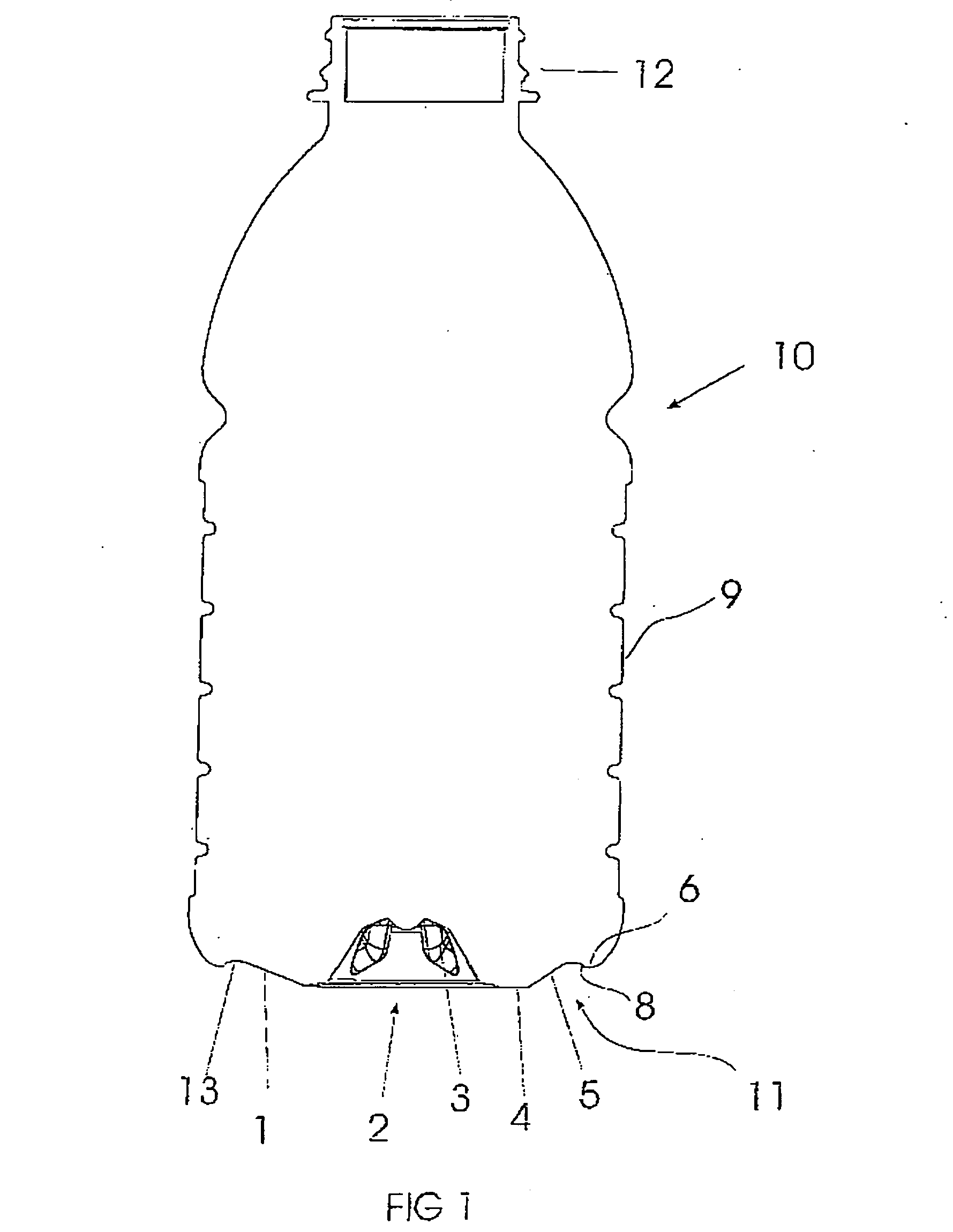

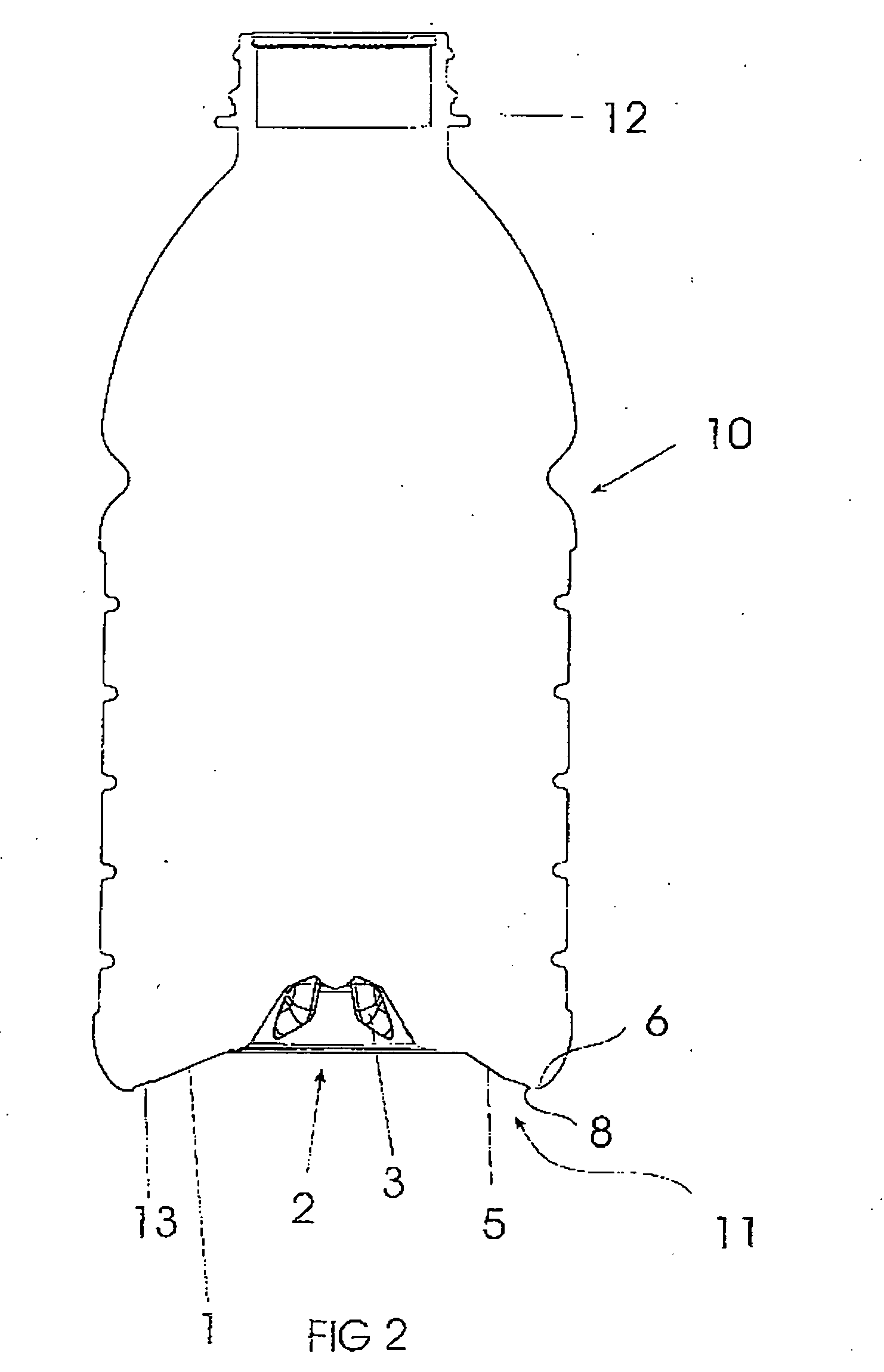

Container structure for removal of vacuum pressure

A hot-fill PET container or bottle (10) filling with a liquid at an elevated temperature has a side wall (9) extending to a lower portion including a pressure panel (11) and a base (21) in its unfolded or pre-fill position. The panel (11) is transversely oriented and has a decoupling or hinge structure (13), an initiator portion (1) and control portion (5) of a steeply angled inverting conical section between 30 and 45 degrees. The control portion enables the inversion of the panel (11) into the container (10) to compensate for vacuum or reduced pressure induced within the container as the liquid cools down. The base (2) can also have a plurality of reinforcing ribs (3).

Owner:CO2 PAC

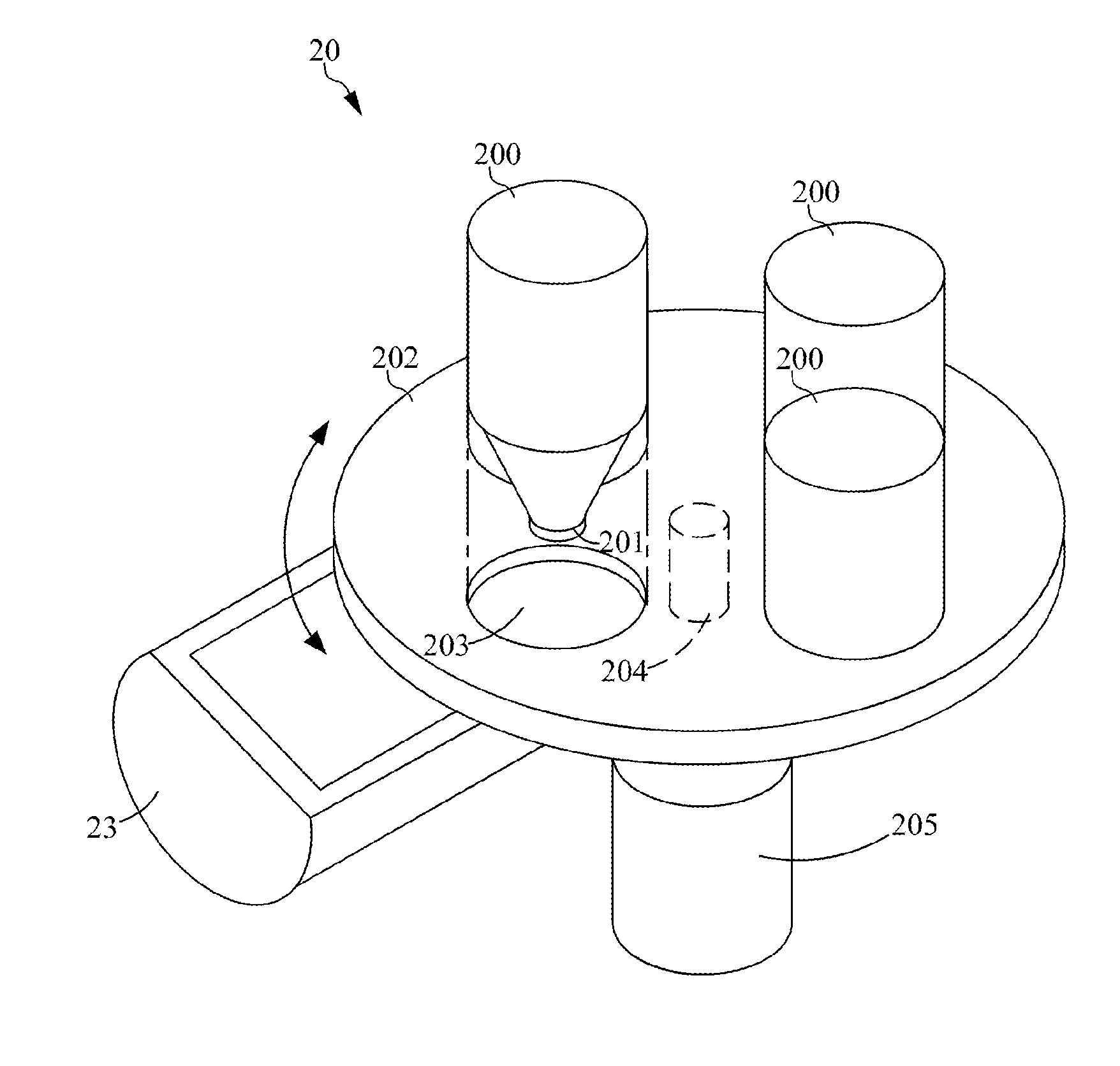

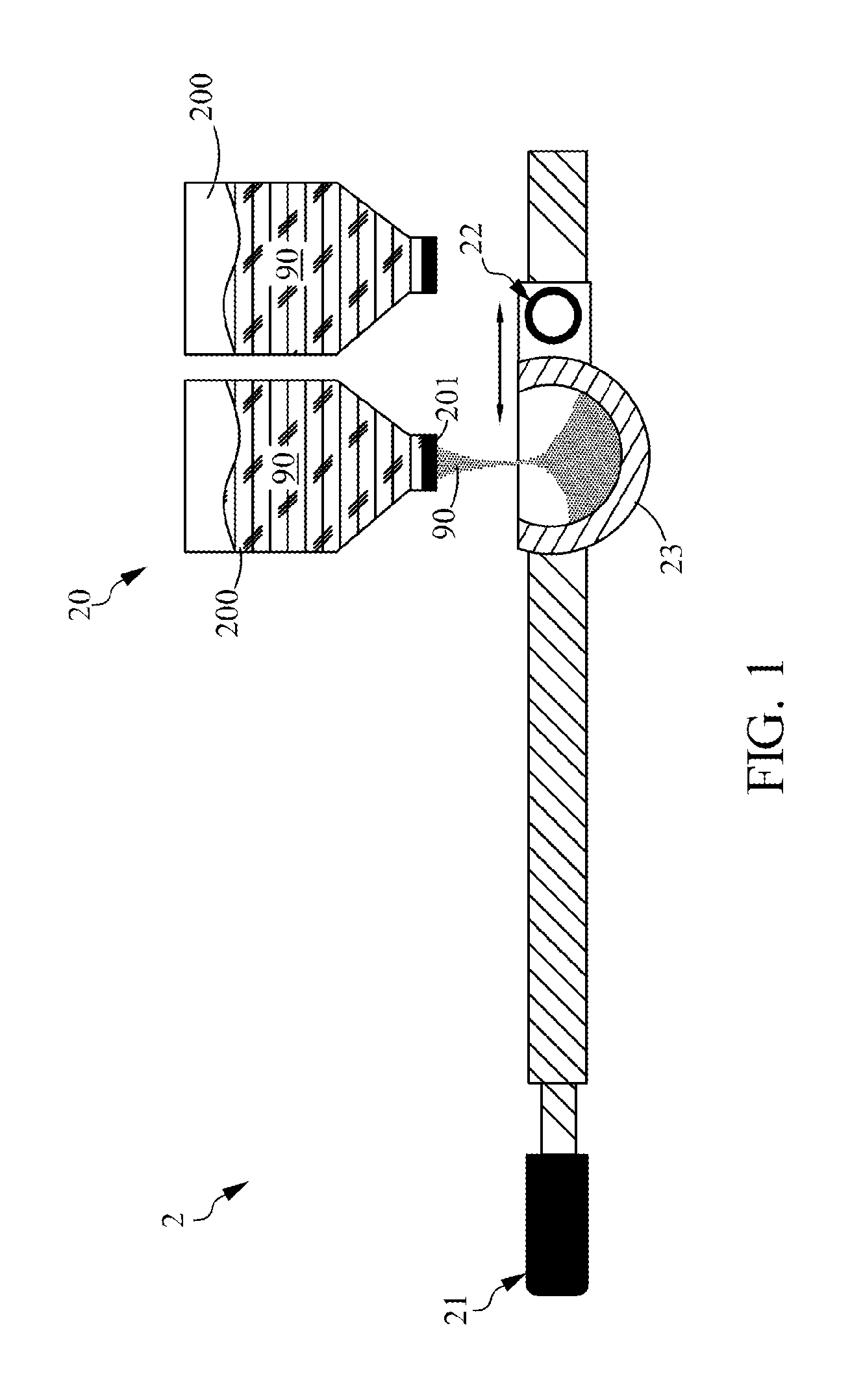

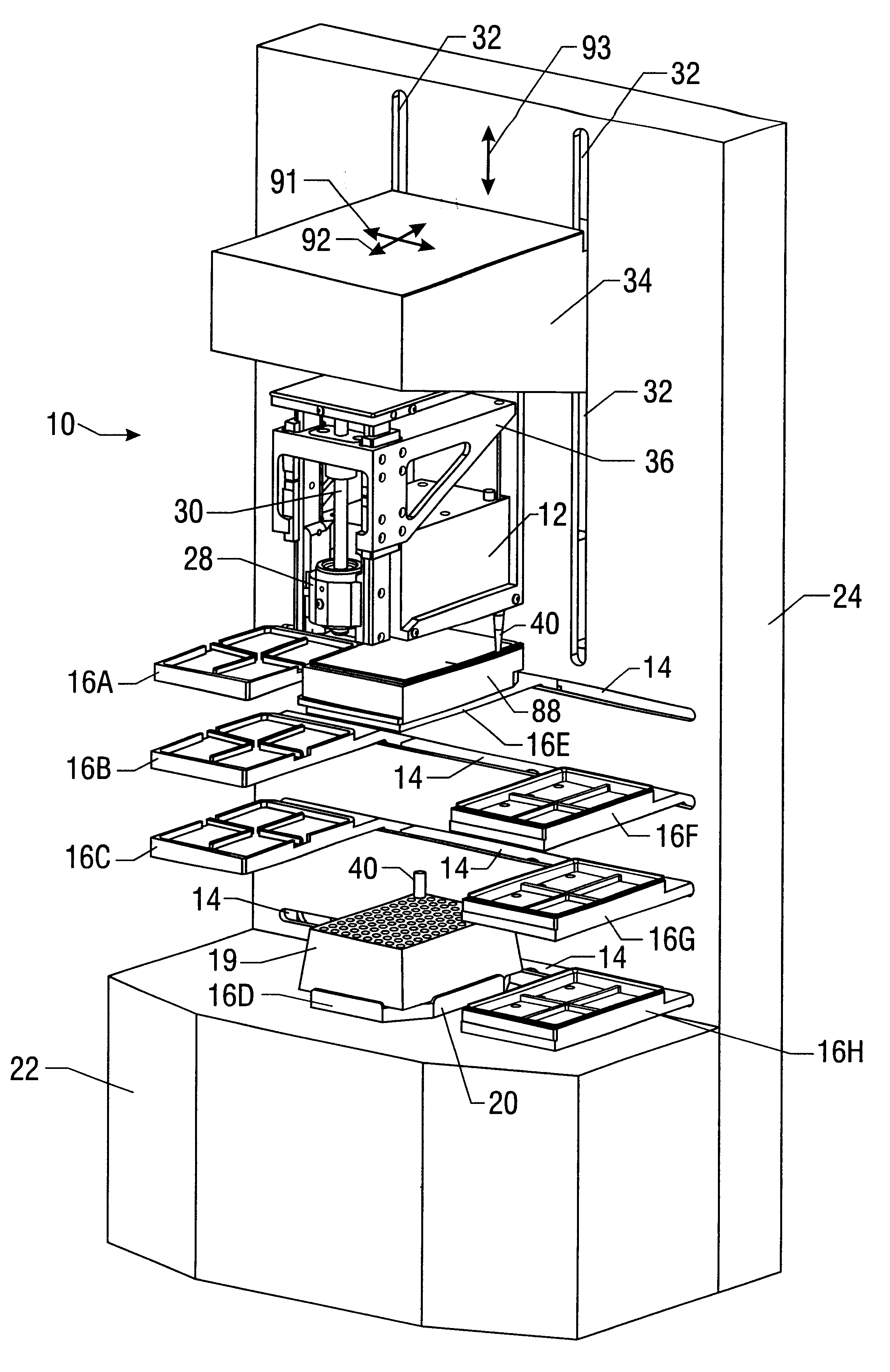

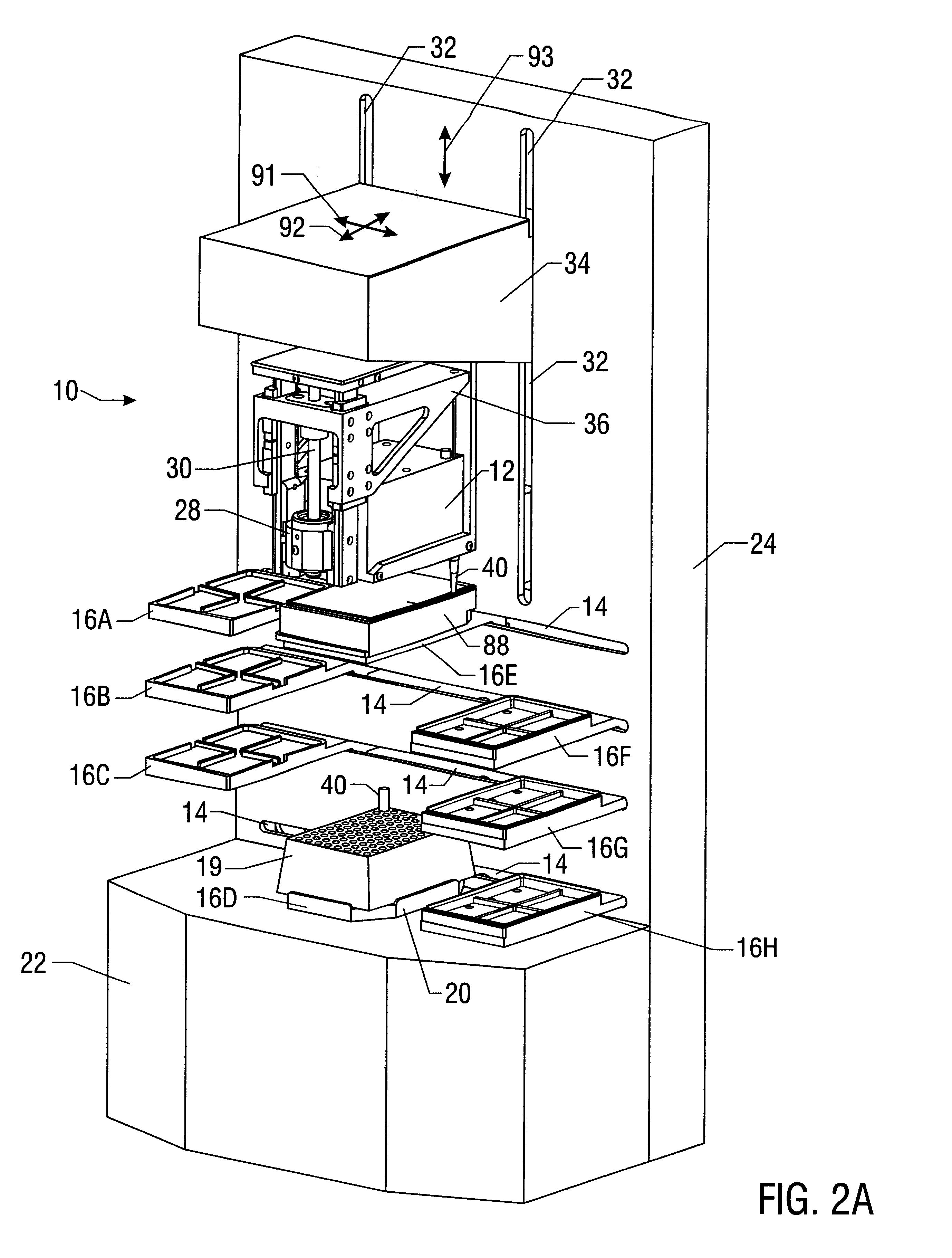

Device and method for powder distribution and additive manufacturing method using the same

ActiveUS20130186514A1Improve compactnessWell mixedLiquid surface applicatorsManufacturing driving meansMetallurgyThermal deformation

The present disclosure provides a device and method for powder distribution and an additive manufacturing method, wherein different size or kind of powders could be chosen to be accommodated within a receptacle. The receptacle can uniformly mix the powder by a rotation movement, pour out the powders by the rotation movement and distribute the powders for forming a layer by a translation movement. In another embodiment, the receptacle further comprises a heating element for preheating the powders. Not only can the present disclosure uniformly mix the powders so as to reduce the thermal deformation and distribute the powder layer compactly, but also can the present disclosure distribute different kinds of powder in different layer so as to increase the diversity in additive manufacturing.

Owner:IND TECH RES INST

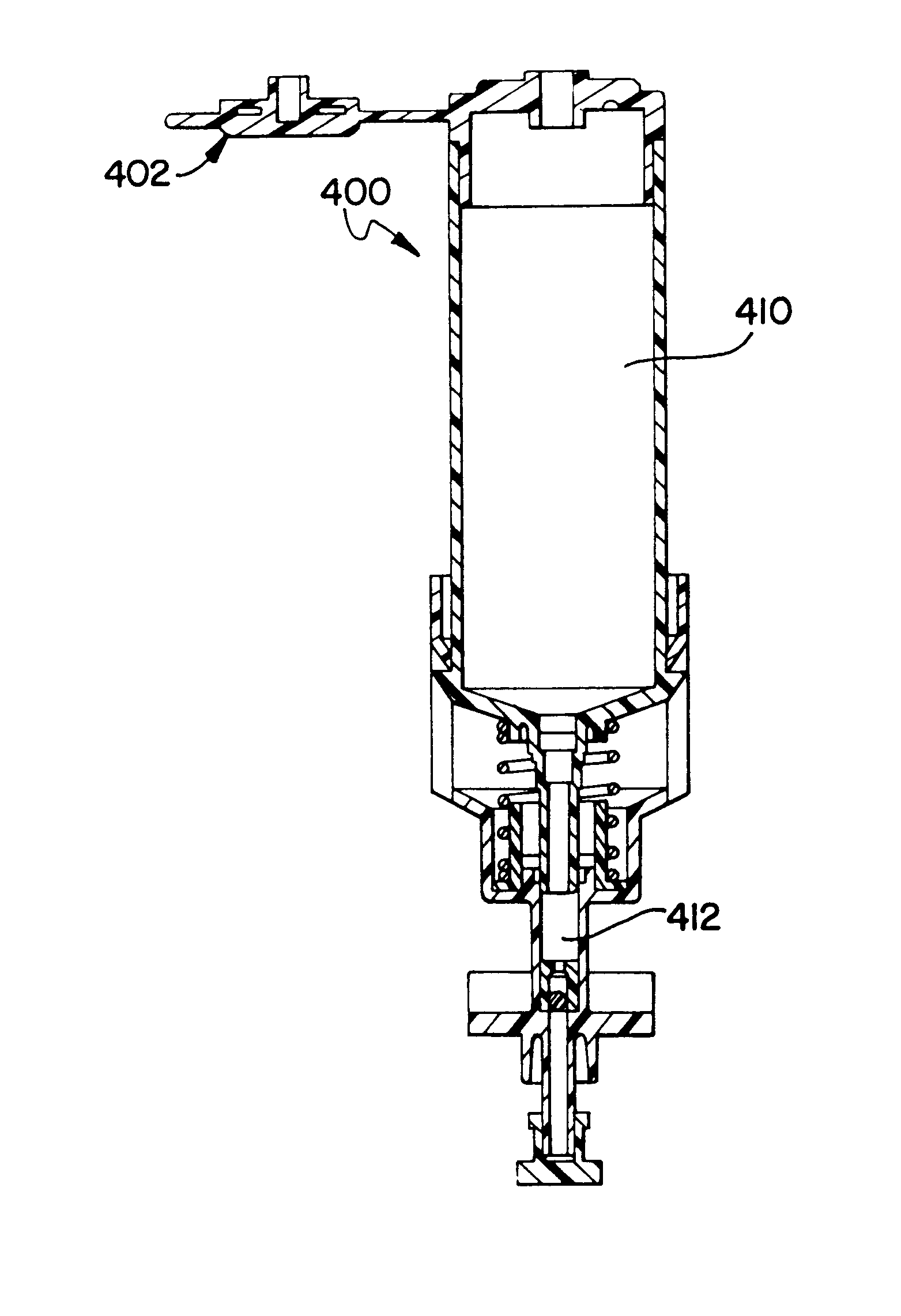

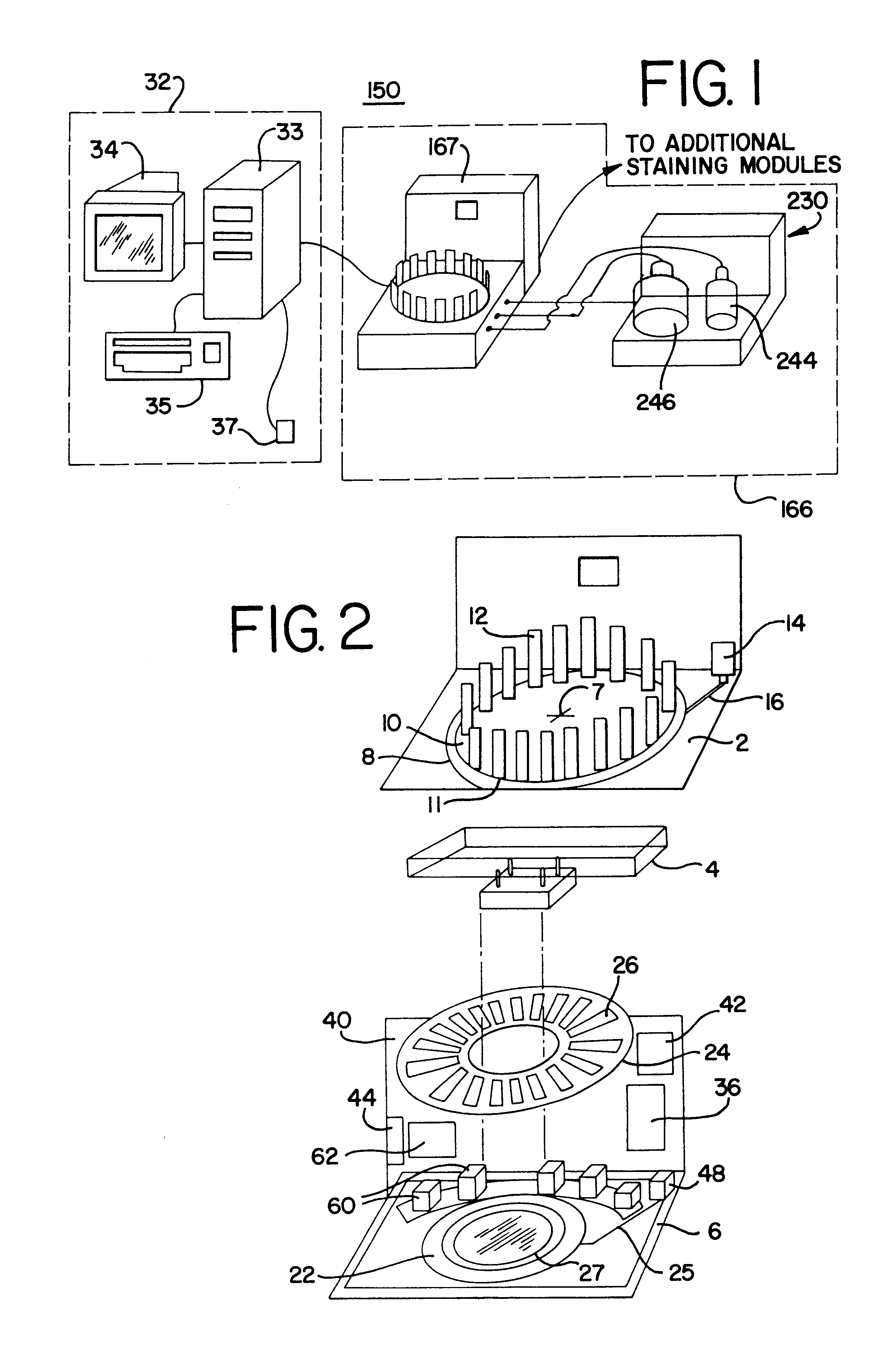

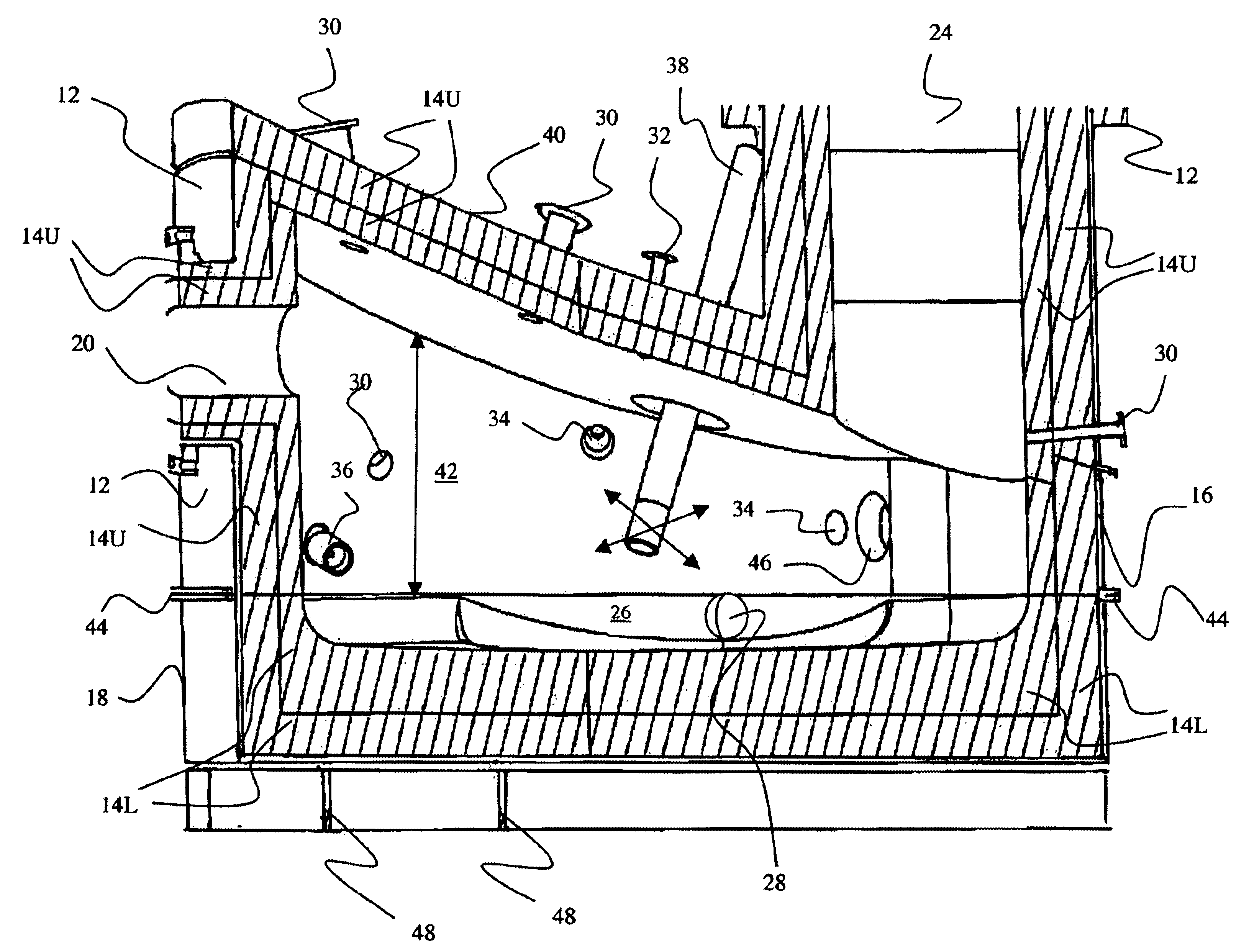

Fluid dispenser

InactiveUS6192945B1Efficient and reliableEasy to manufacturePreparing sample for investigationLiquid flow controllersModularityReactive system

A method and apparatus for an automated biological reaction system is provided. In the processing of a biological reaction system, there is a need for consistently placing an amount of fluid on a slide. In order to accomplish this, several methods are used including a consistency pulse and a volume adjust means. Moreover, in order to reliably operate an automated biological reaction system, the dispenser must be reliable, easy to assemble and accurate. Among other things, in order to accomplish this, the dispense chamber is substantially in line with the reservoir chamber, the reservoir chamber piston is removed, and the flow of fluid through the dispenser is simplified. Further, in order to operate the automated biological reaction system more reliably, the system is designed in modular pieces with higher functions performed by a host device and the execution of the staining operations performed by remote devices. Also, to reliably catalog data which is used by the automated biological reaction system, data is loaded to a memory device, which in turn is used by the operator to update the operator's databases. The generation of the sequence of steps for the automated biological reaction device based on data loaded by the operator, including checks to determine the ability to complete the run, is provided.

Owner:VENTANA MEDICAL SYST INC

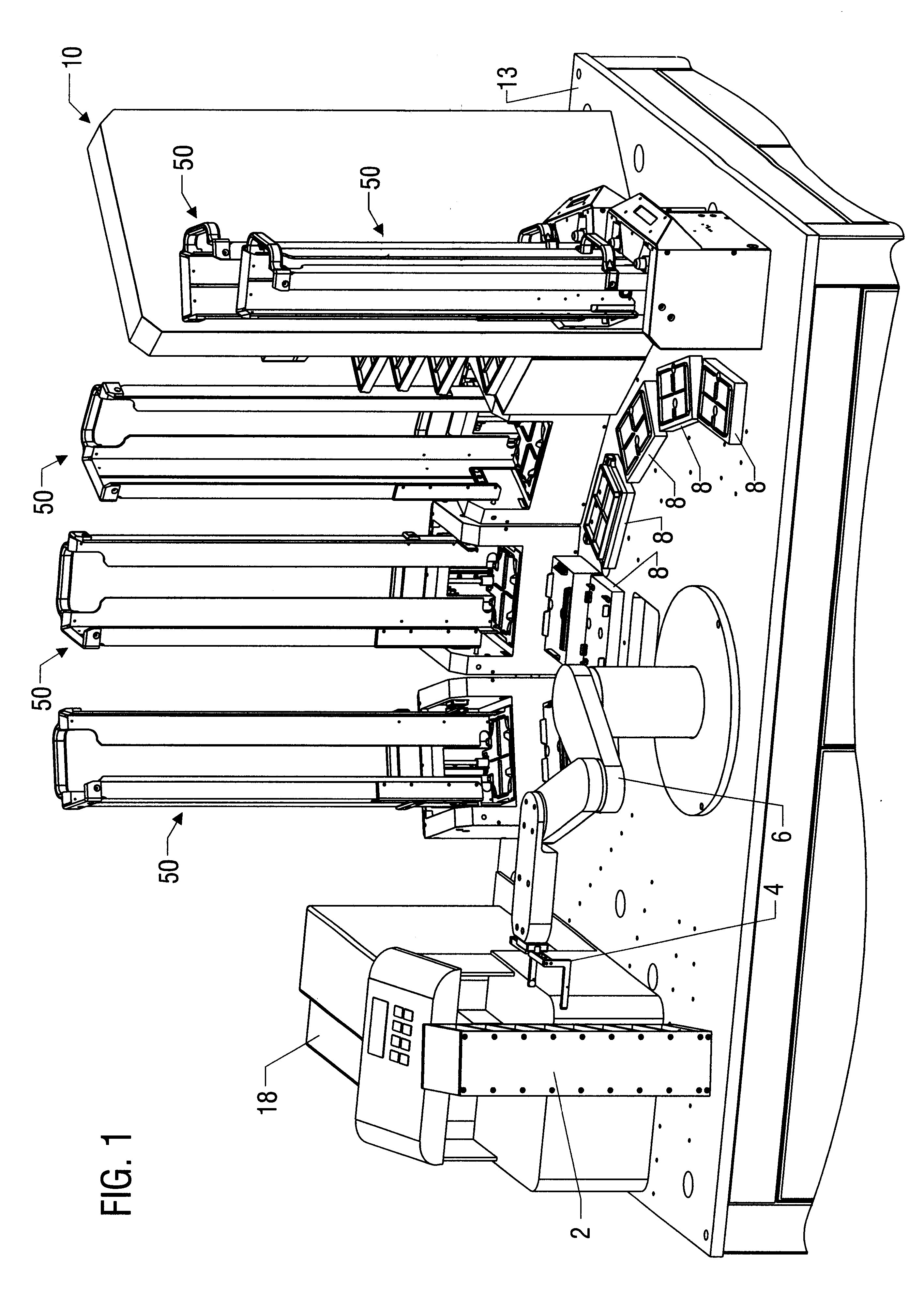

Pipetting station apparatus

InactiveUS6325114B1Withdrawing sample devicesMaterial analysis by optical meansPipetteMicrowell Plate

A pipette station is described for use in the field of sample analysis. The pipette station increases the rate and ease with which a liquid may be manipulated into and out of sample carriers such as microwell plates. The pipette station includes shafts in the X, Y, and Z direction which possess ball screws which are integrated with motor shafts thus improving accuracy and eliminating the need for a coupling apparatus thereby reducing the space required for the pipette station. The pipette station may be interfaced with an automated laboratory system.

Owner:VELOCITY11 +1

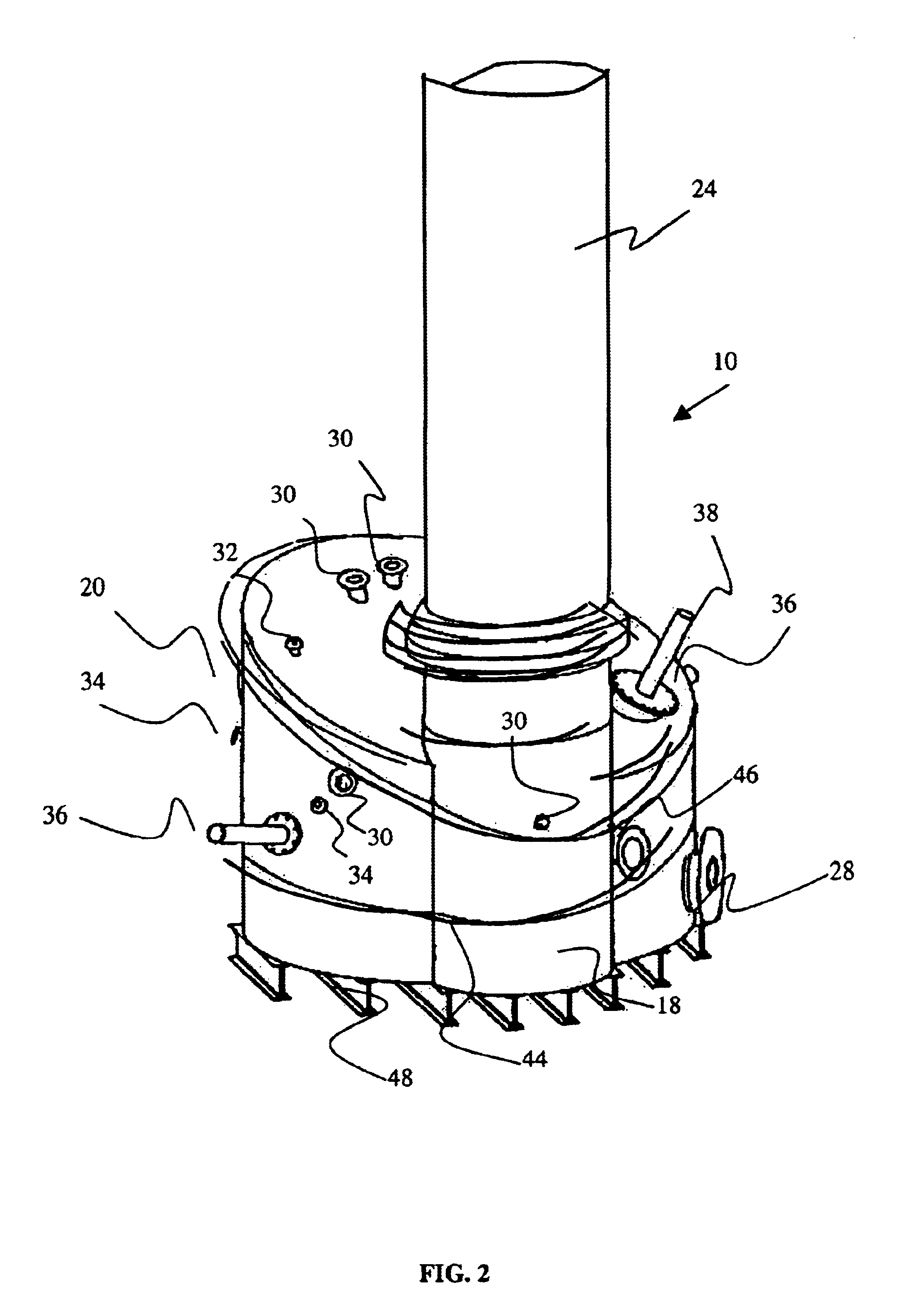

Multiple plasma generator hazardous waste processing system

A waste processing system is provided herein which entails the use of at least one fixed-position plasma arc generator for primary processing and at least one moveable plasma arc generator for secondary processing assistance and / or final conditioning of the slag prior to exit from the reactor vessel. This optimum processing environment is provided by control of reactor vessel configuration and real time control of processing characteristics to ensure maximum processing efficiency.

Owner:PLASCO ENERGY GROUP INC

Method of passivating a gas vessel or component of a gas transfer system using a silicon overlay coating

A method of passivating the interior surface of a gas storage vessel to protect the surface against corrosion. The interior surface of the vessel is first dehydrated and then evacuated. A silicon hydride gas is introduced into the vessel. The vessel and silicon hydride gas contained therein are heated and pressurized to decompose the gase. A layer of silicon is deposited on the interior surface of the vessel. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the vessel. The vessel is then purged with an inert gas to remove the silicon hydride gas. The vessel is cycled through the silicon depositing step until the entire interior surface of the vessel is covered with a layer of silicon. The vessel is then evacuated and cooled to room temperature.

Owner:SILCOTEK CORP

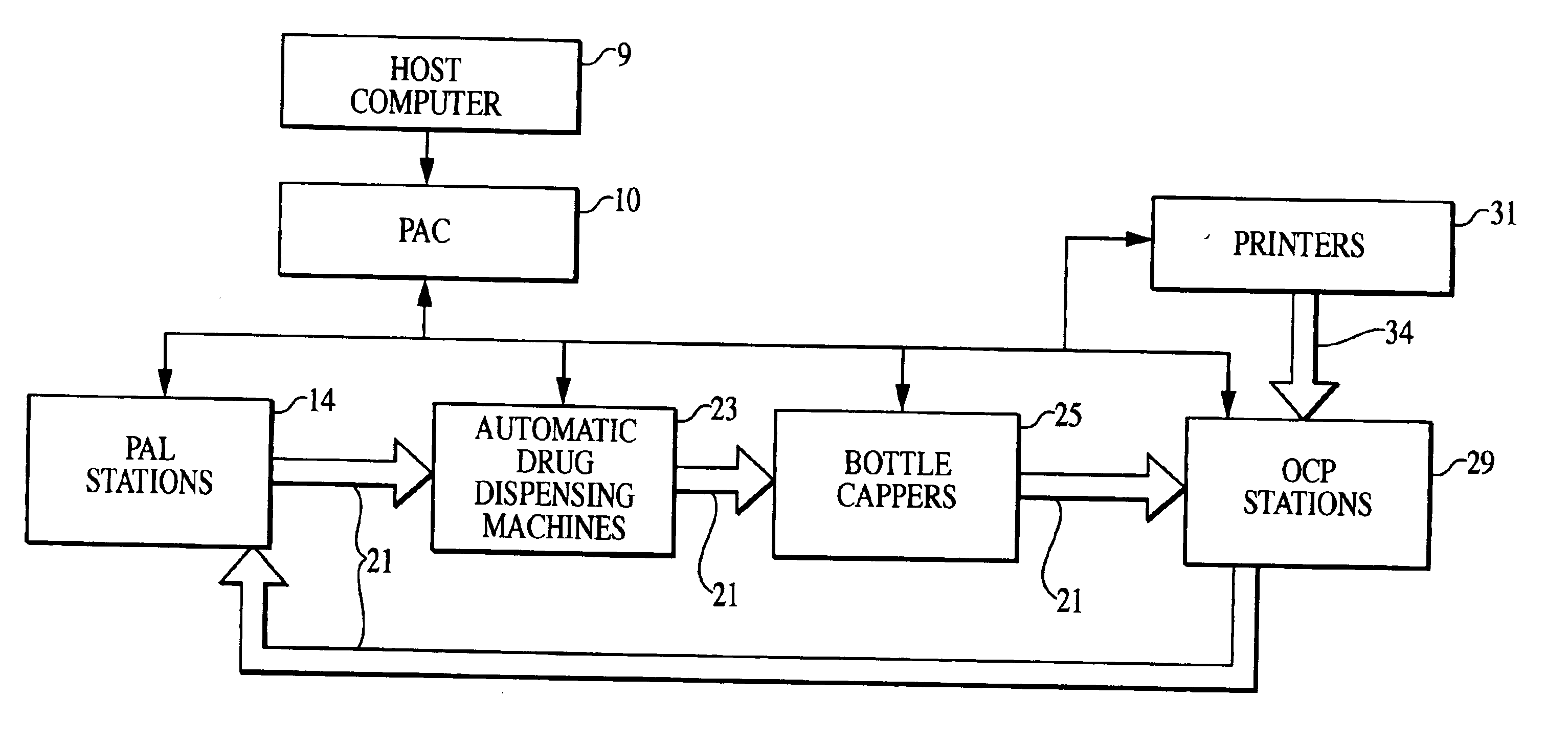

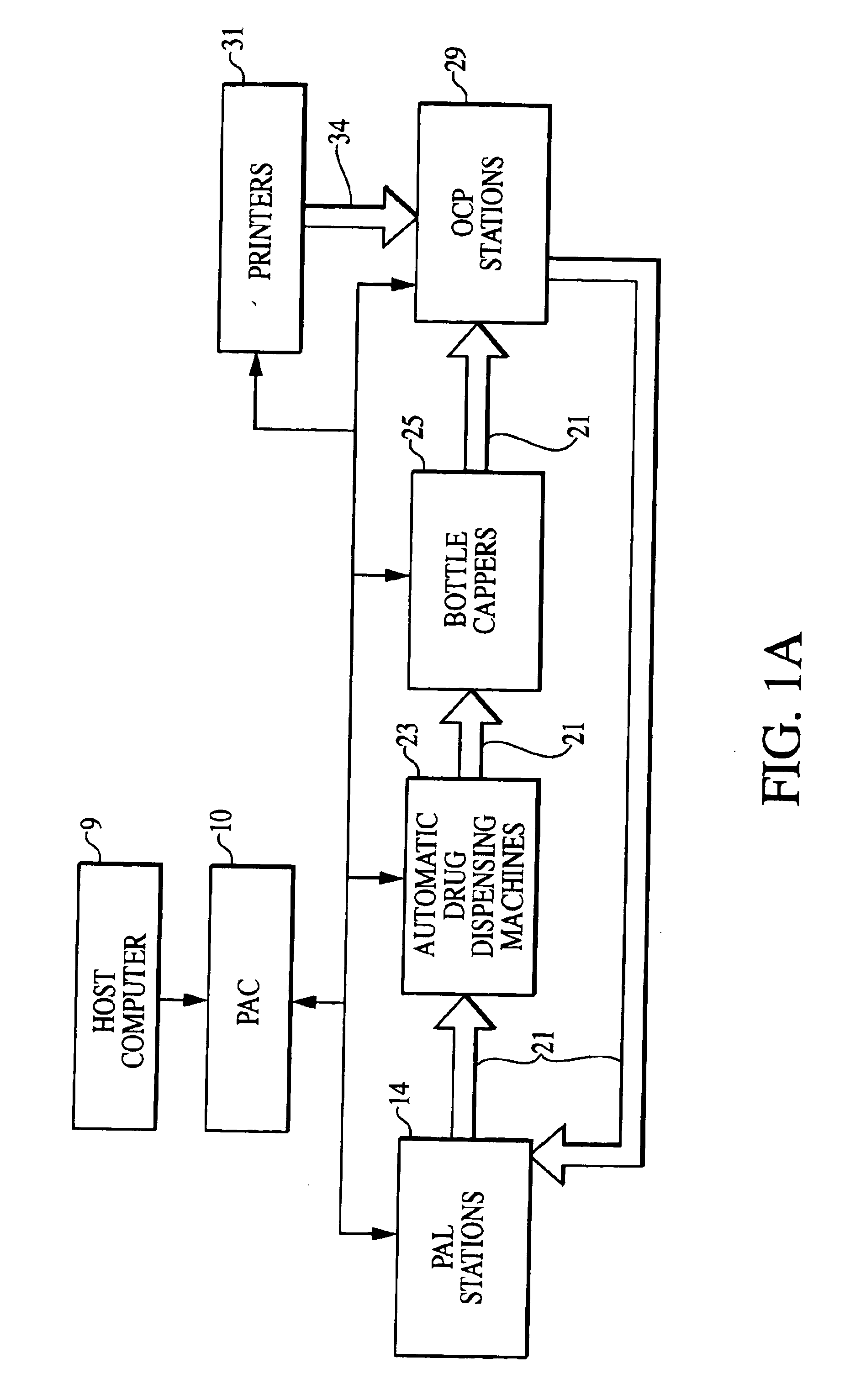

Automated prescription filling system/method with automated labeling and packaging system/method automated order consolidation system/method

Computer assisted systems, methods and mediums for filling one or more orders. One embodiment of the present invention is a system that includes an order consolidation station configured to receive at least one bottle containing pills individually counted and / or at least one package containing pharmaceutical products without having been designated for any of the orders when the package was created and / or at least one literature pack optionally including patient specific information. The order consolidation station is further configured to combine automatically the received bottle and / or package and / or literature pack into a container to be sent to a recipient including, for example, mail order pharmacies, wholesalers and / or central fill dealers for subsequent distribution or sale including retailer distribution or sale. The bottle is specifically designated for the order, and the order generally includes at least one prescription for the package.

Owner:EXPRESS SCRIPTS STRATEGIC DEV INC

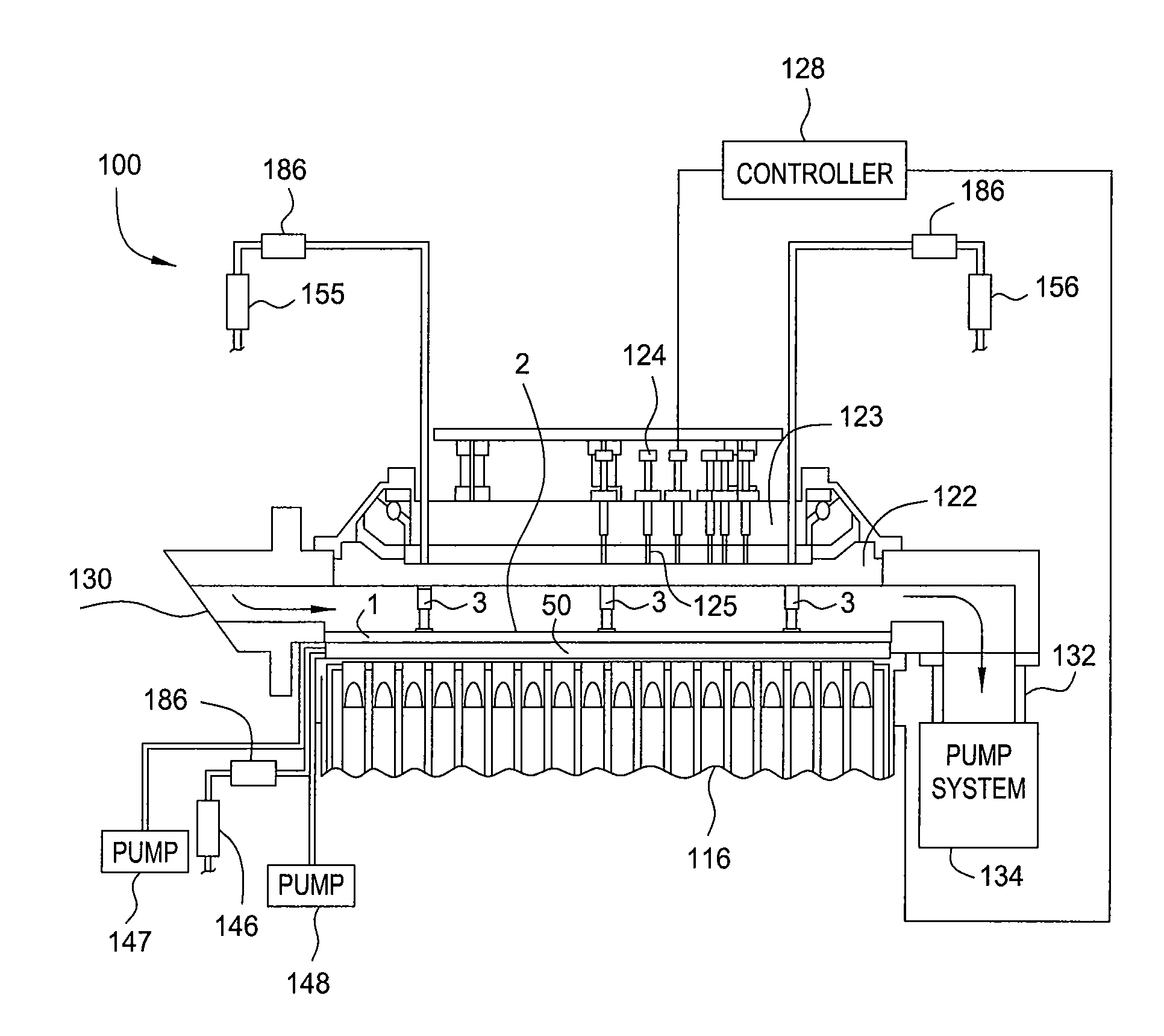

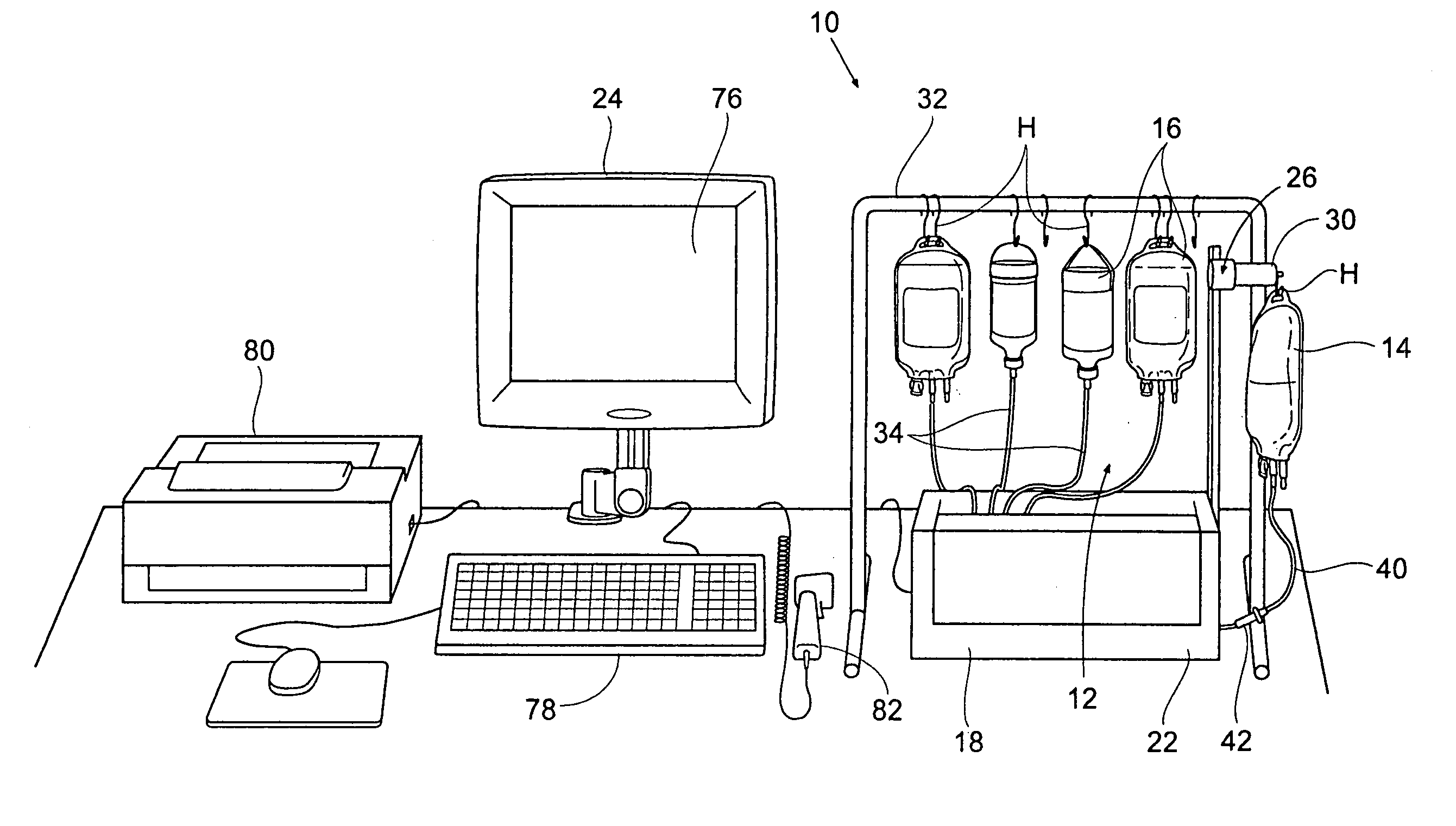

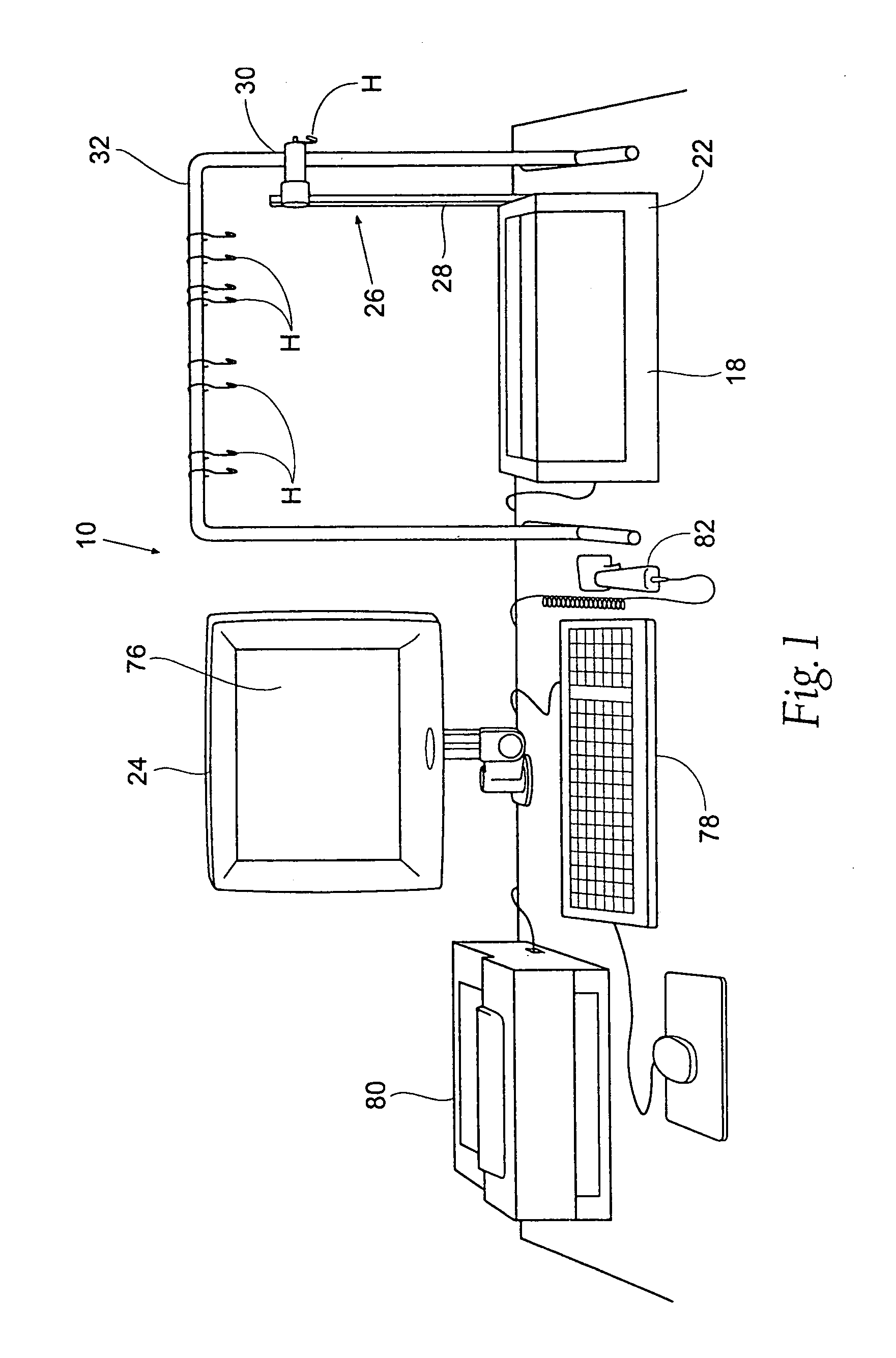

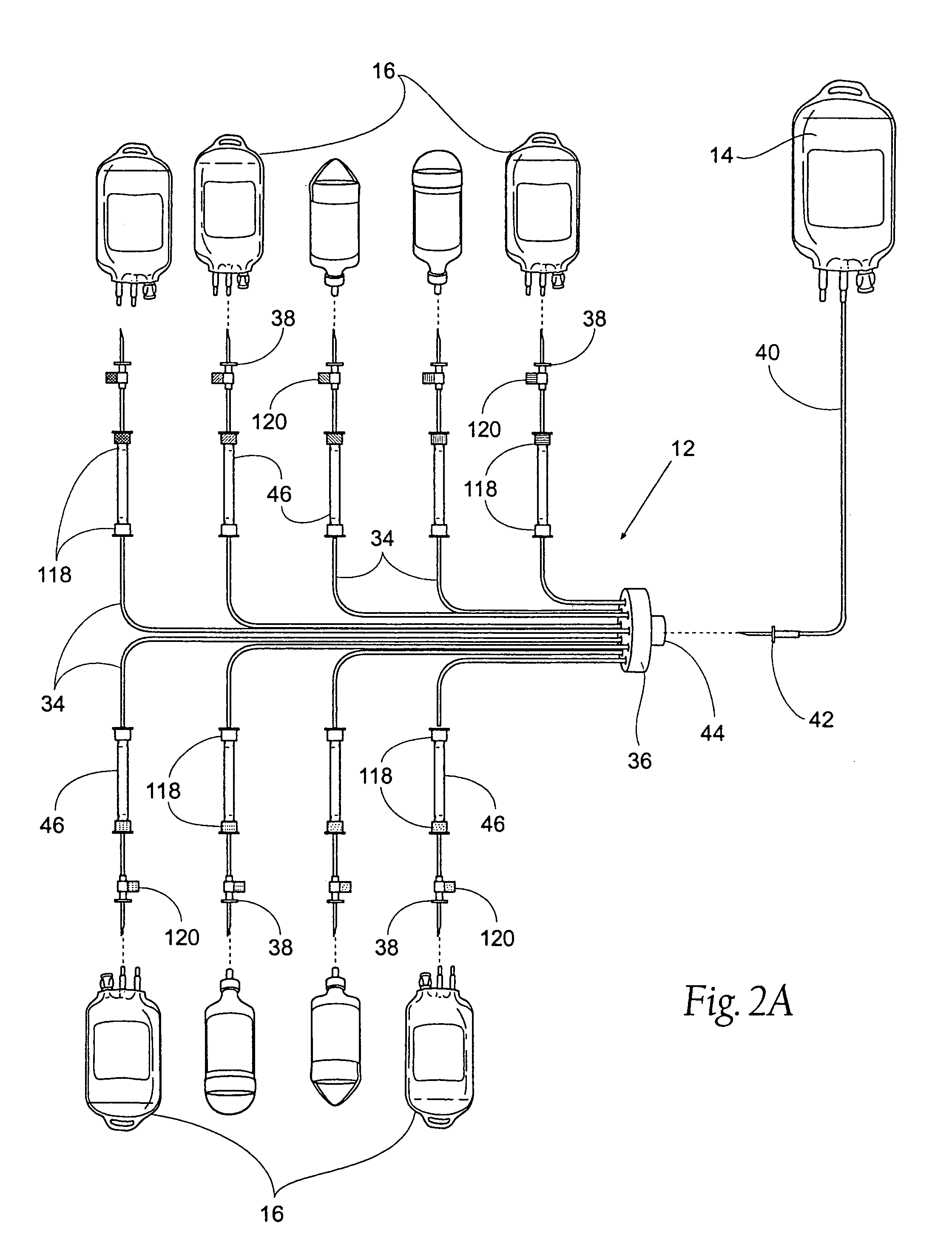

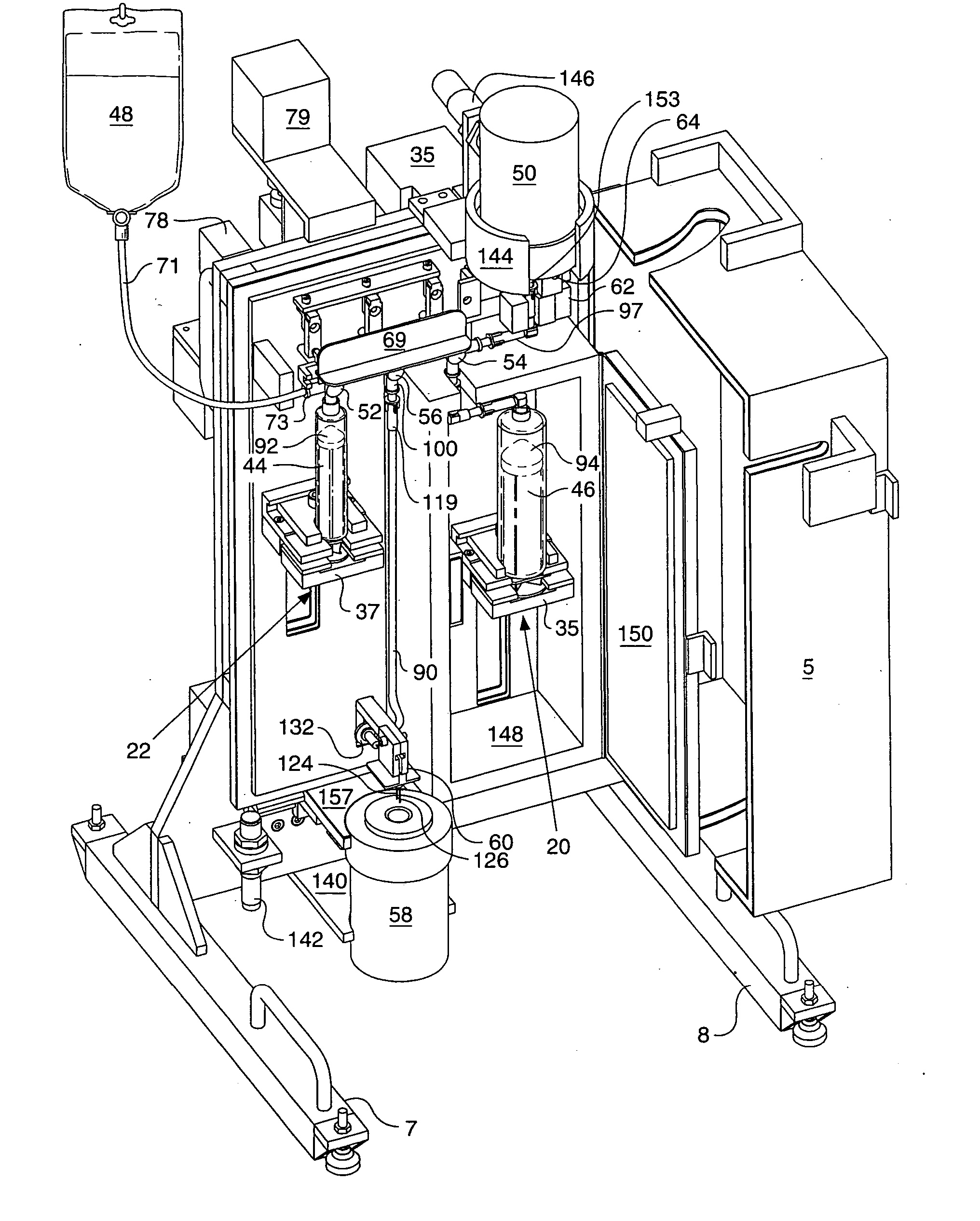

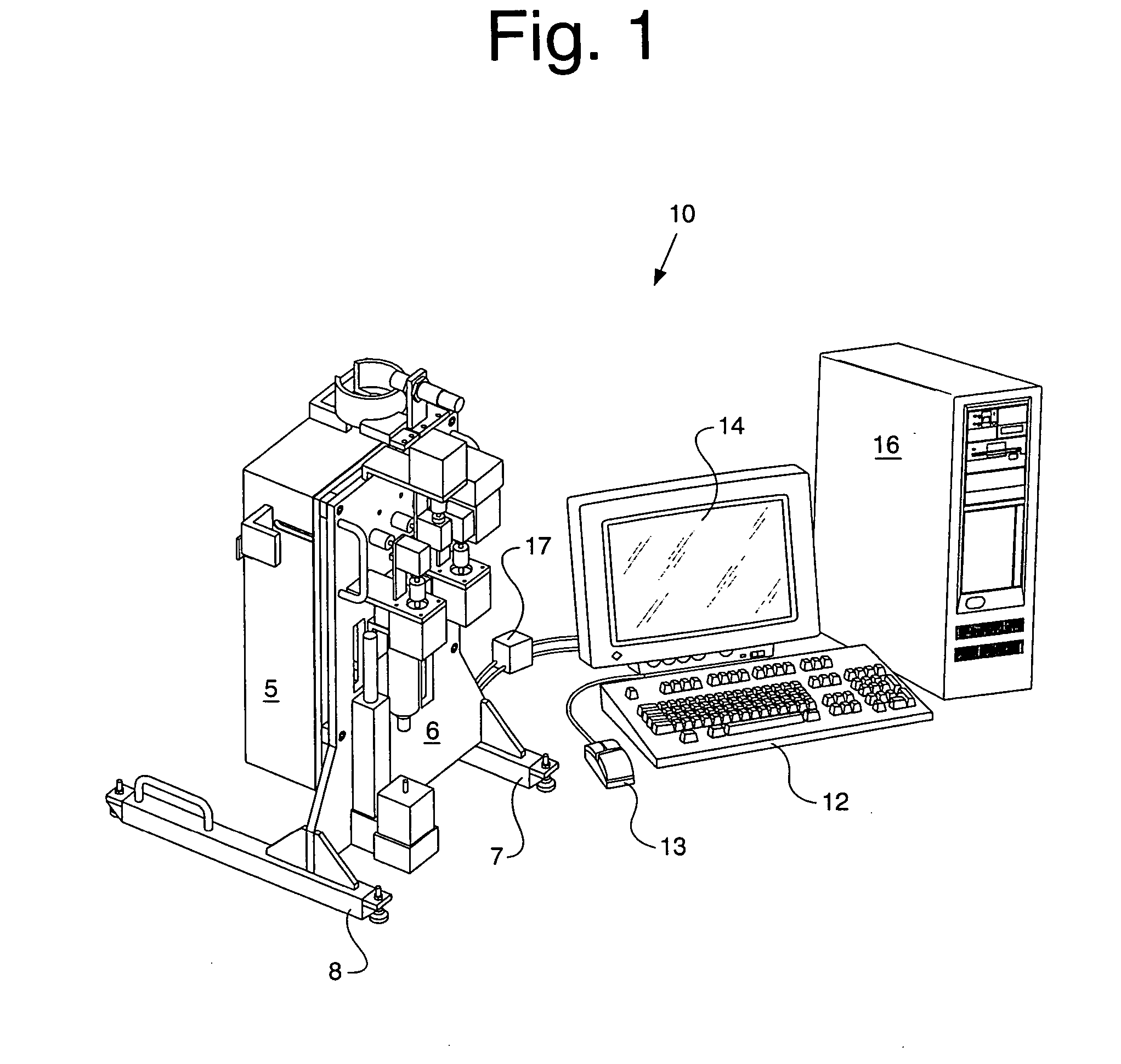

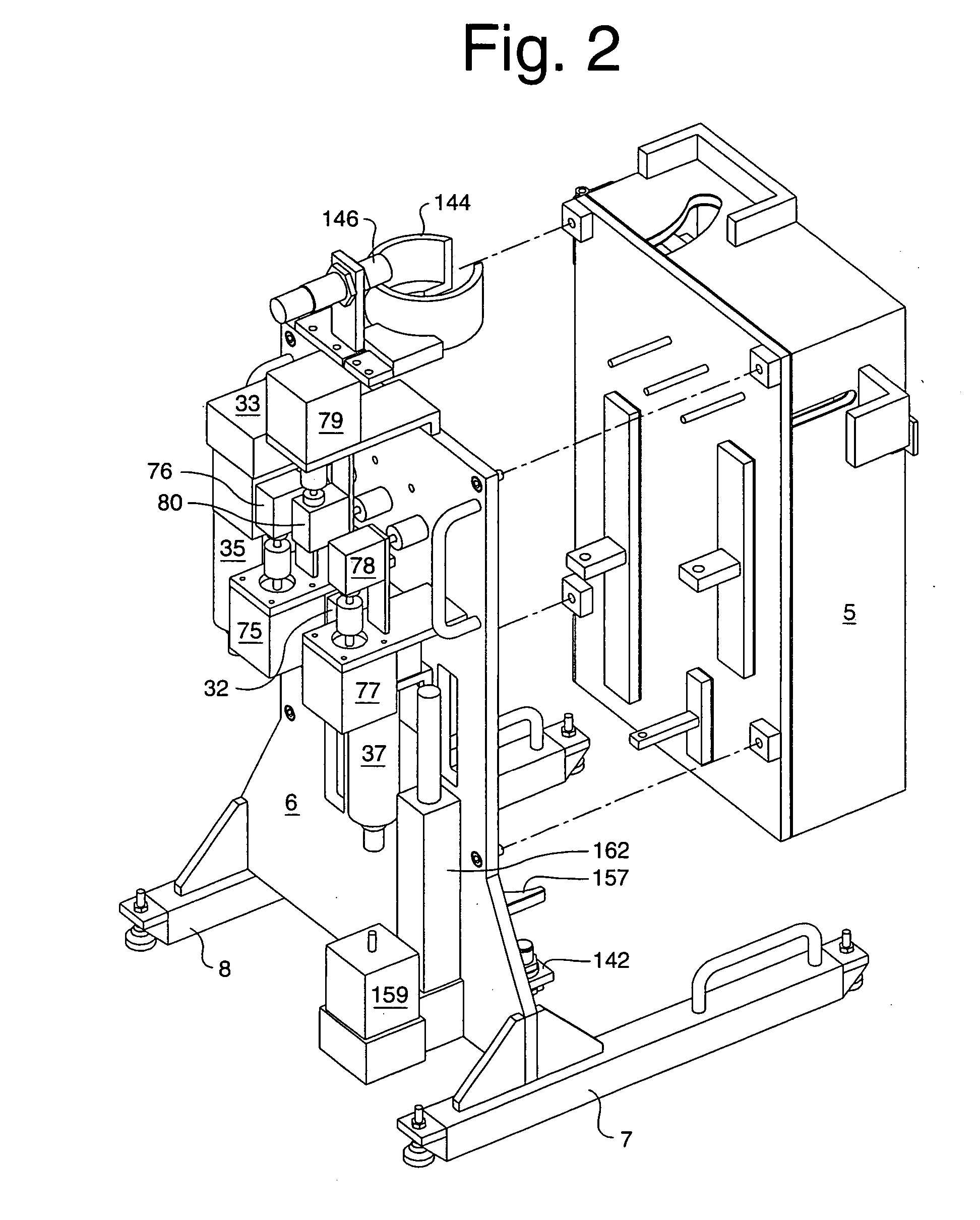

Pharmaceutical compounding systems and methods and information management system for same

Owner:B BRAUN MEDICAL

Automated dispensing system and associated method of use

An automated bulk dispensing system and a method of use including selectively receiving a predetermined amount of radioactive liquid from a second container into a third container, selectively receiving a predetermined amount of nonradioactive liquid from a first container into a fourth container or directly into the third container depending on whether kits or multi-dose containers of medicine are desired. Preferably, this is for nuclear pharmaceuticals. Displacement mechanisms that are connected to the third container and fourth container are for mixing and dispensing liquid. There is at least one control valve, preferably three control valves, which are each controlled by drive mechanisms. The mixed liquid from the third container can be transferred to a recipient container. There is also a gas vent and bubble detector to eliminate bubbles with a processor that is also utilized to control the displacement mechanisms and the drive mechanisms.

Owner:MALLINCKRODT INC

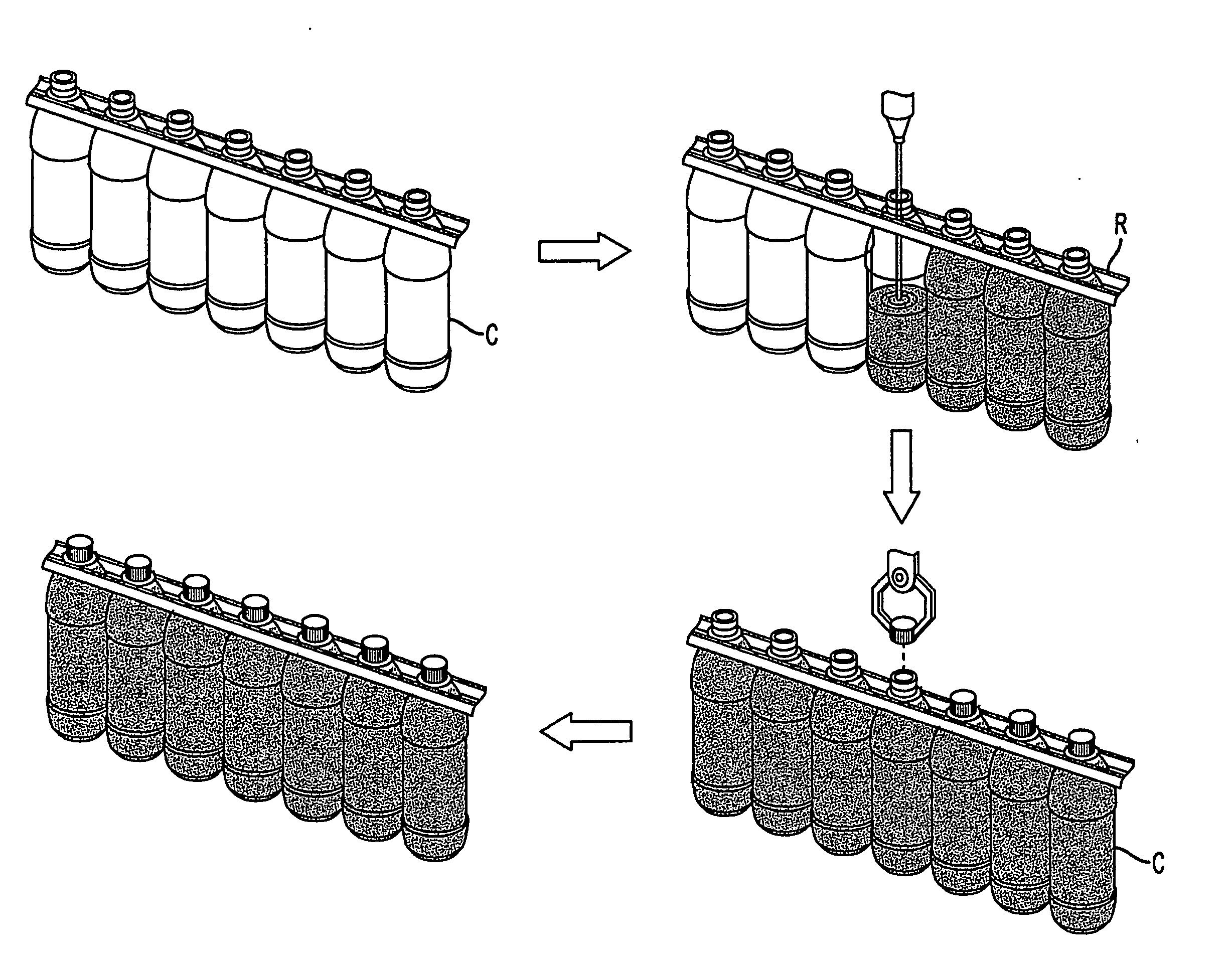

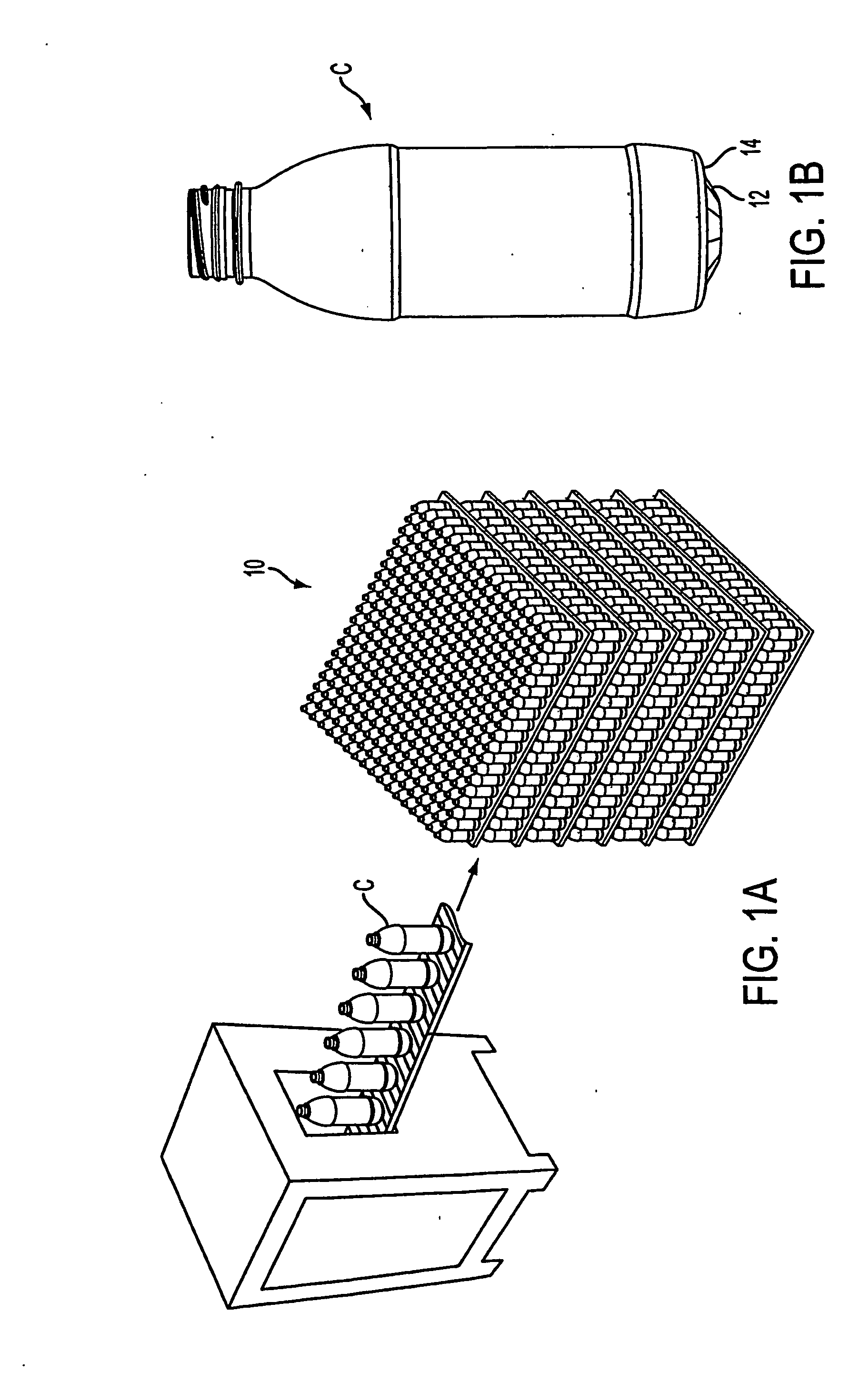

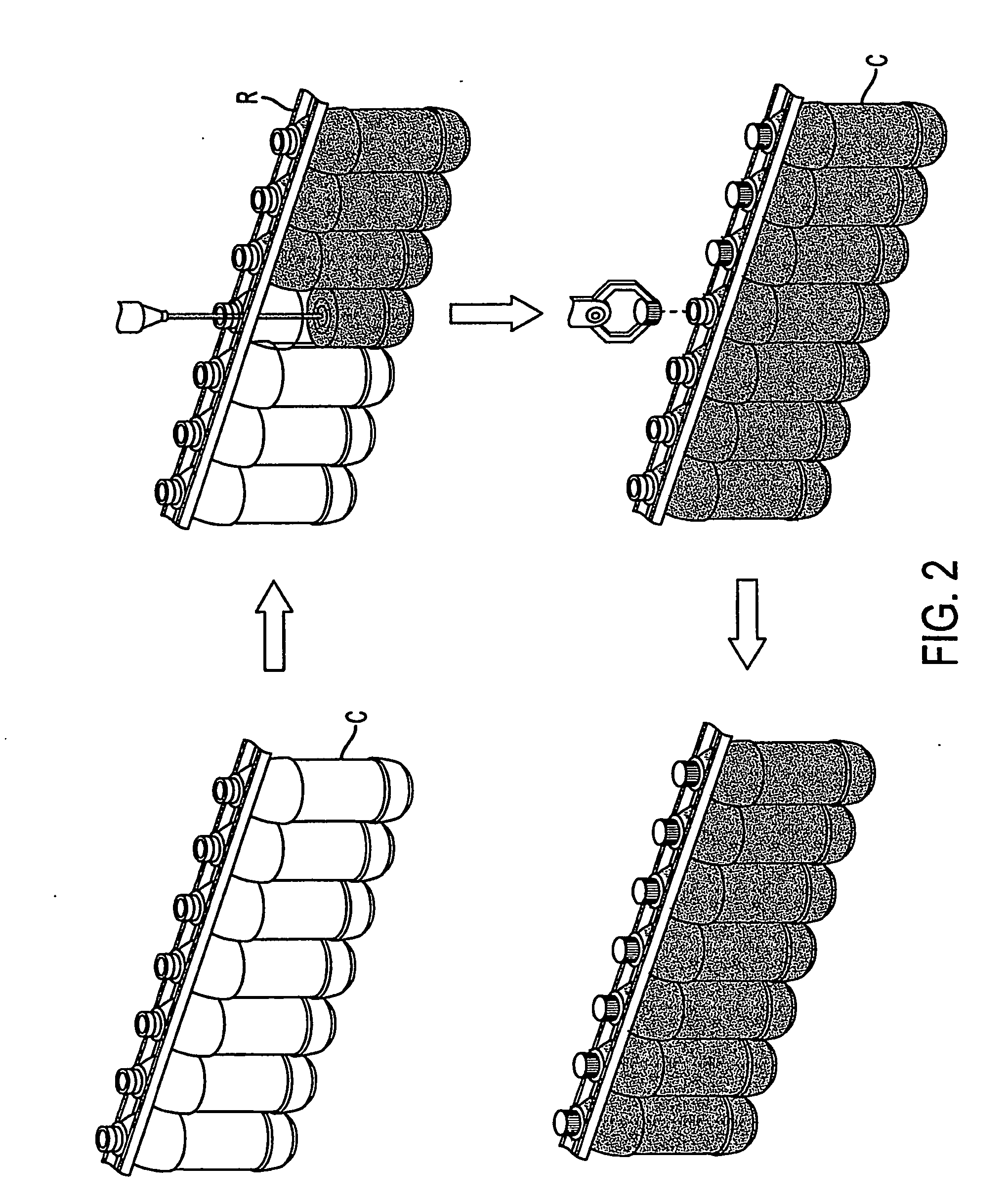

Container handling system

ActiveUS20070051073A1Smooth for label placementThorough removalCapsDecorative coversBlow moldingStructural geometry

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com