Patents

Literature

48 results about "Structural geometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Masonry structures may follow traditional geometry or more structural geometry. Classical geometry is composed of vertical columns and walls, which support arches, vaults and domes that are circular arcs of constant radius.

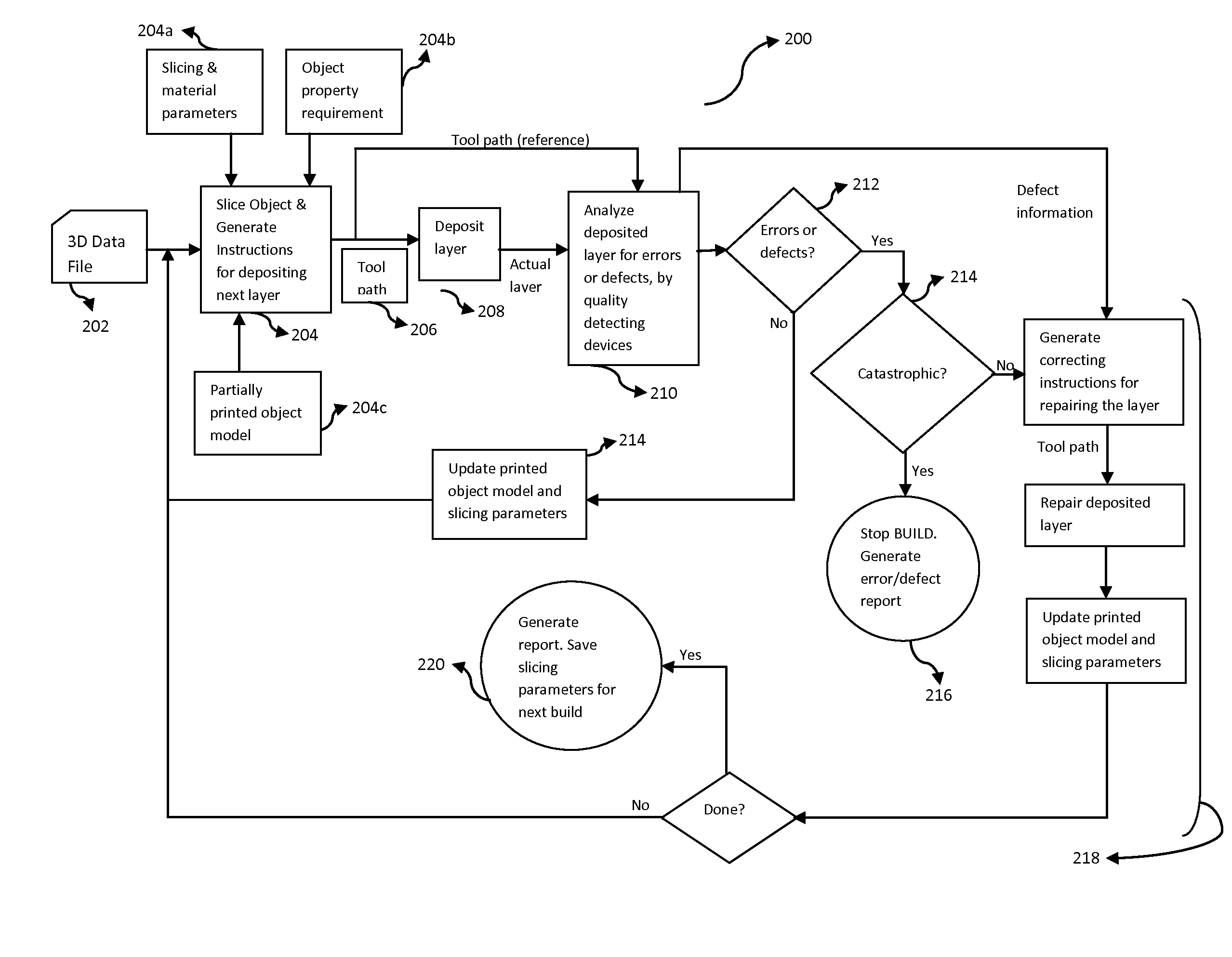

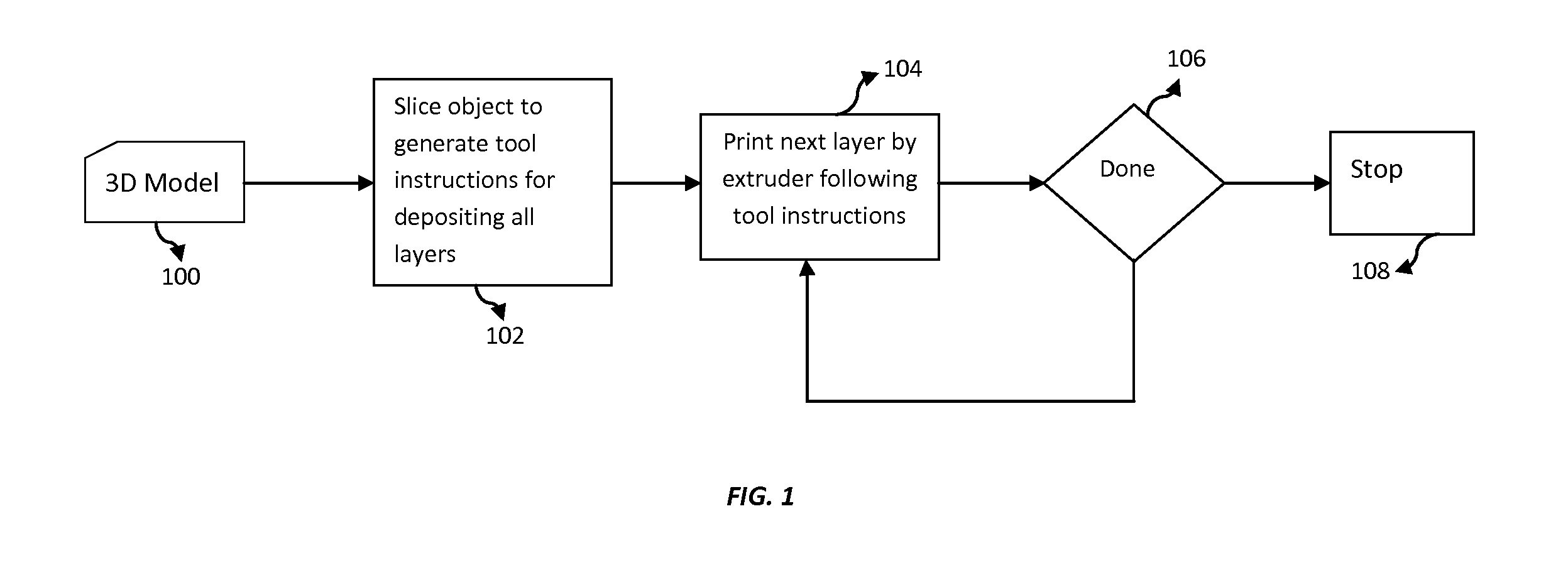

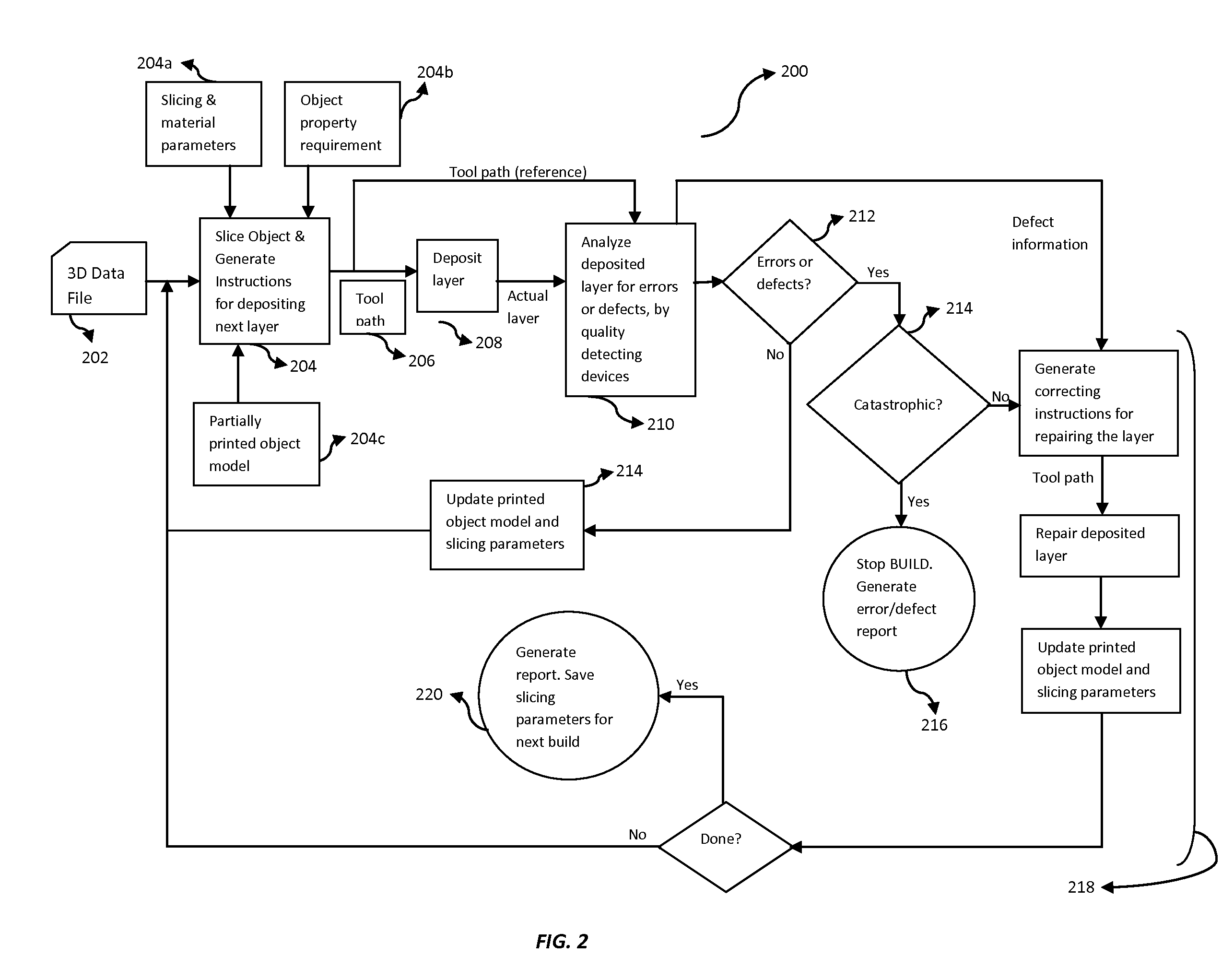

Method to monitor additive manufacturing process for detection and in-situ correction of defects

ActiveUS20160236414A1Minimize presenceProgramme controlAdditive manufacturing apparatusStructural geometryEngineering

The present invention provides a system and a method for real time monitoring and identifying defects occurring in a three dimensional object build via an additive manufacturing process. Further, the present invention provides in-situ correction of such defects by a plurality of functional tool heads possessing freedom of motion in arbitrary planes and approach, where the functional tool heads are automatically and independently controlled based on a feedback analysis from the printing process, implementing analyzing techniques. Furthermore, the present invention provides a mechanism for analyzing defected data collected from detection devices and correcting tool path instructions and object model in-situ during construction of a 3D object. A build report is also generated that displays, in 3D space, the structural geometry and inherent properties of a final build object along with the features of corrected and uncorrected defects. Advantageously, the build report helps in improving 3D printing process for subsequent objects.

Owner:AREVO INC

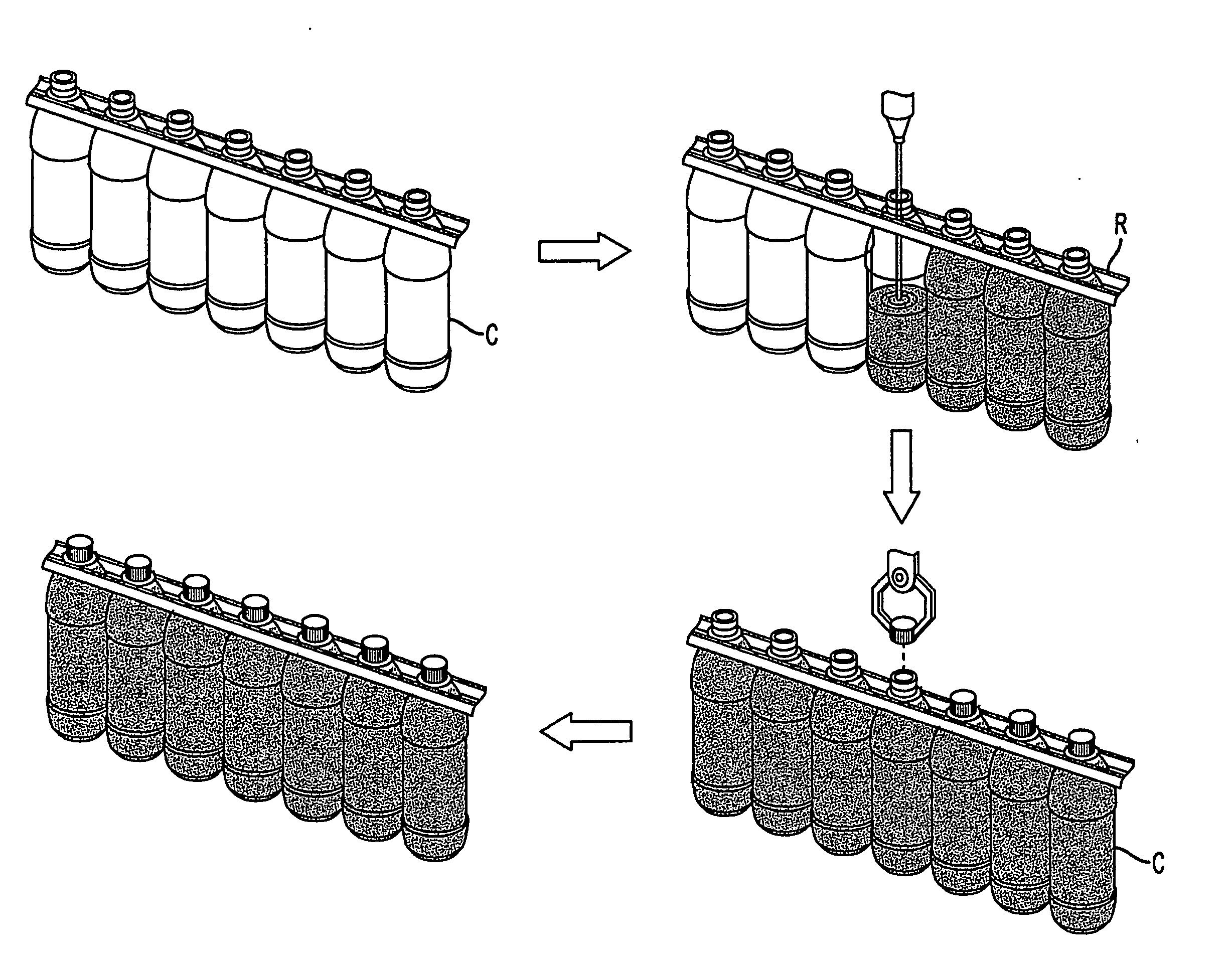

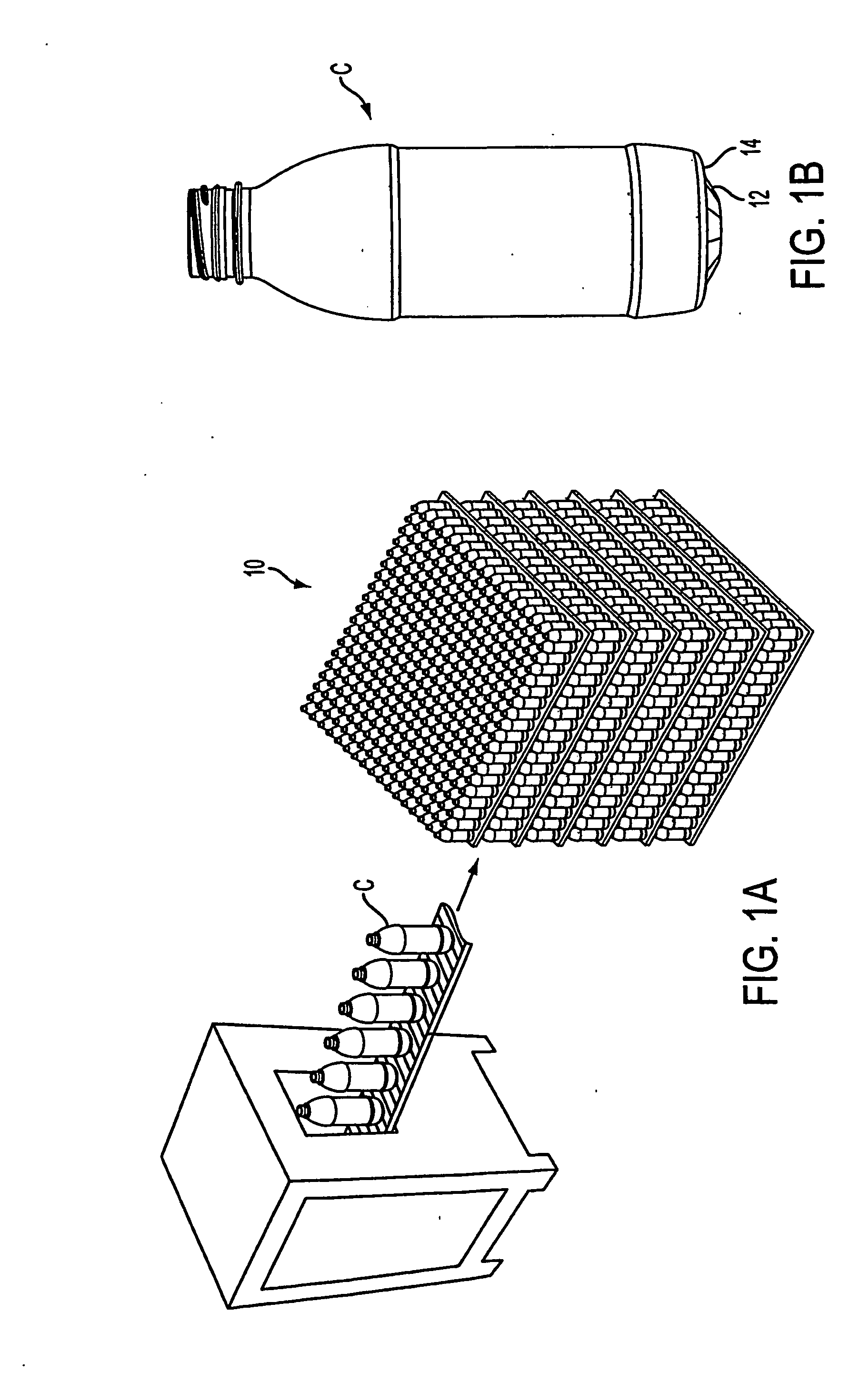

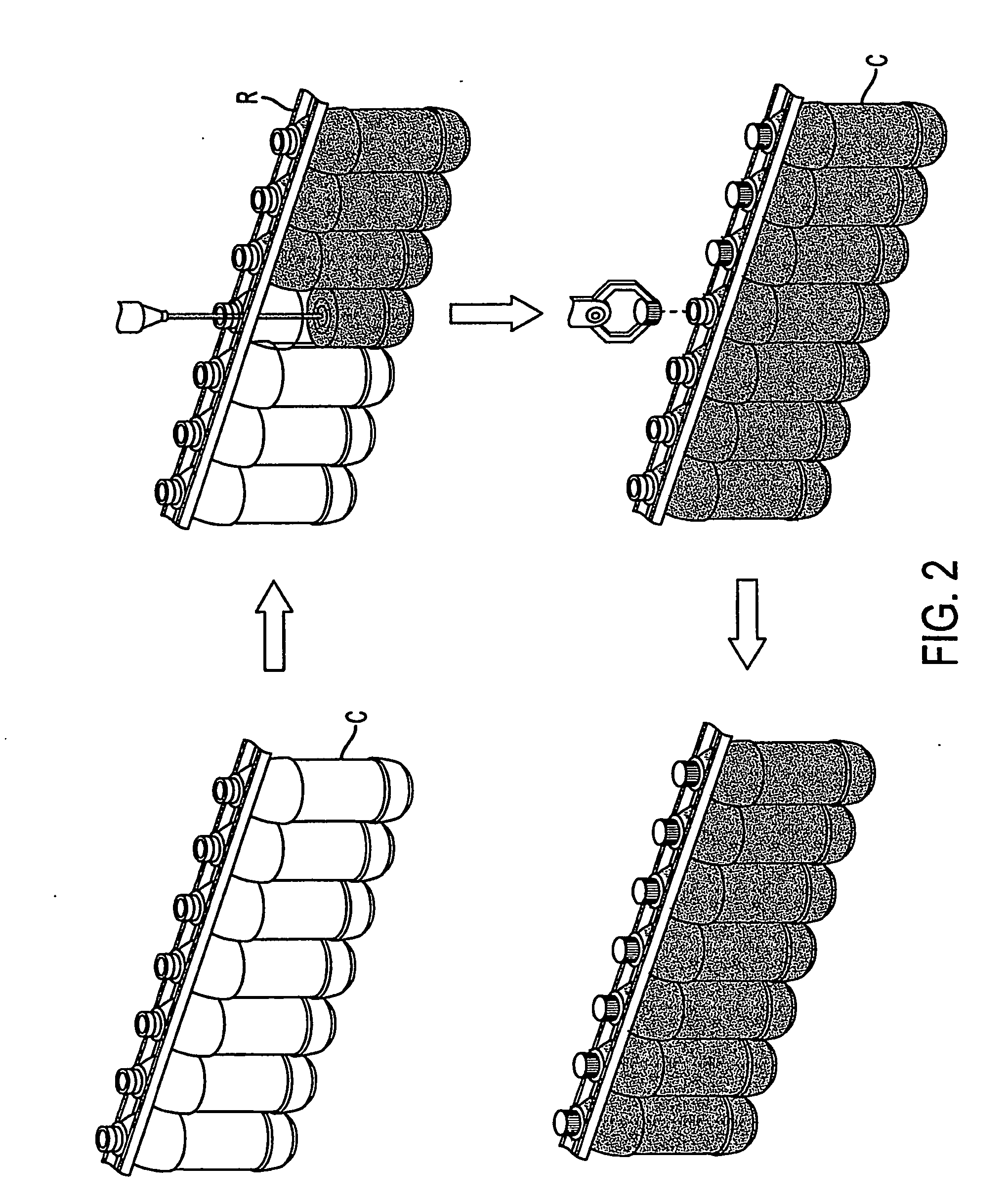

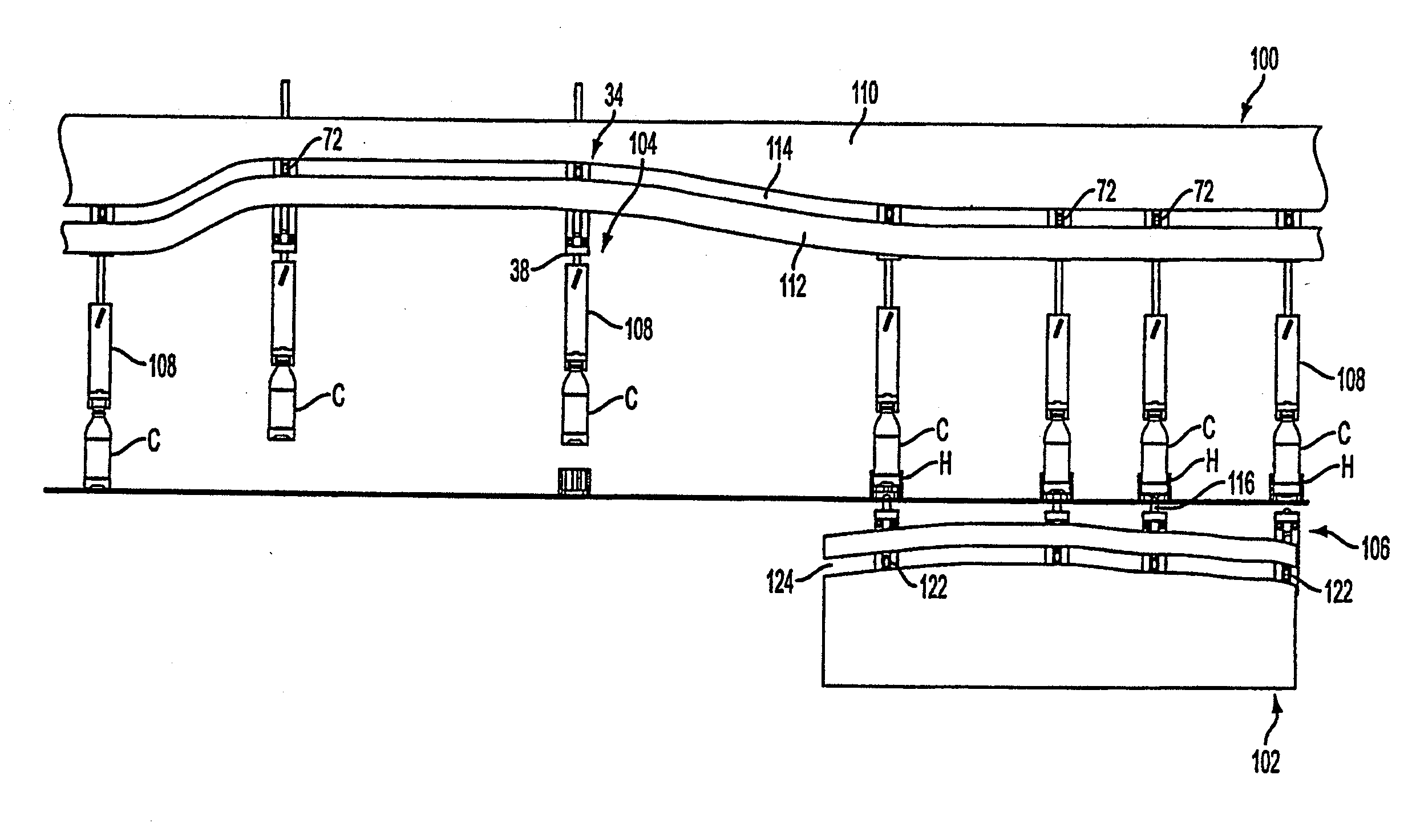

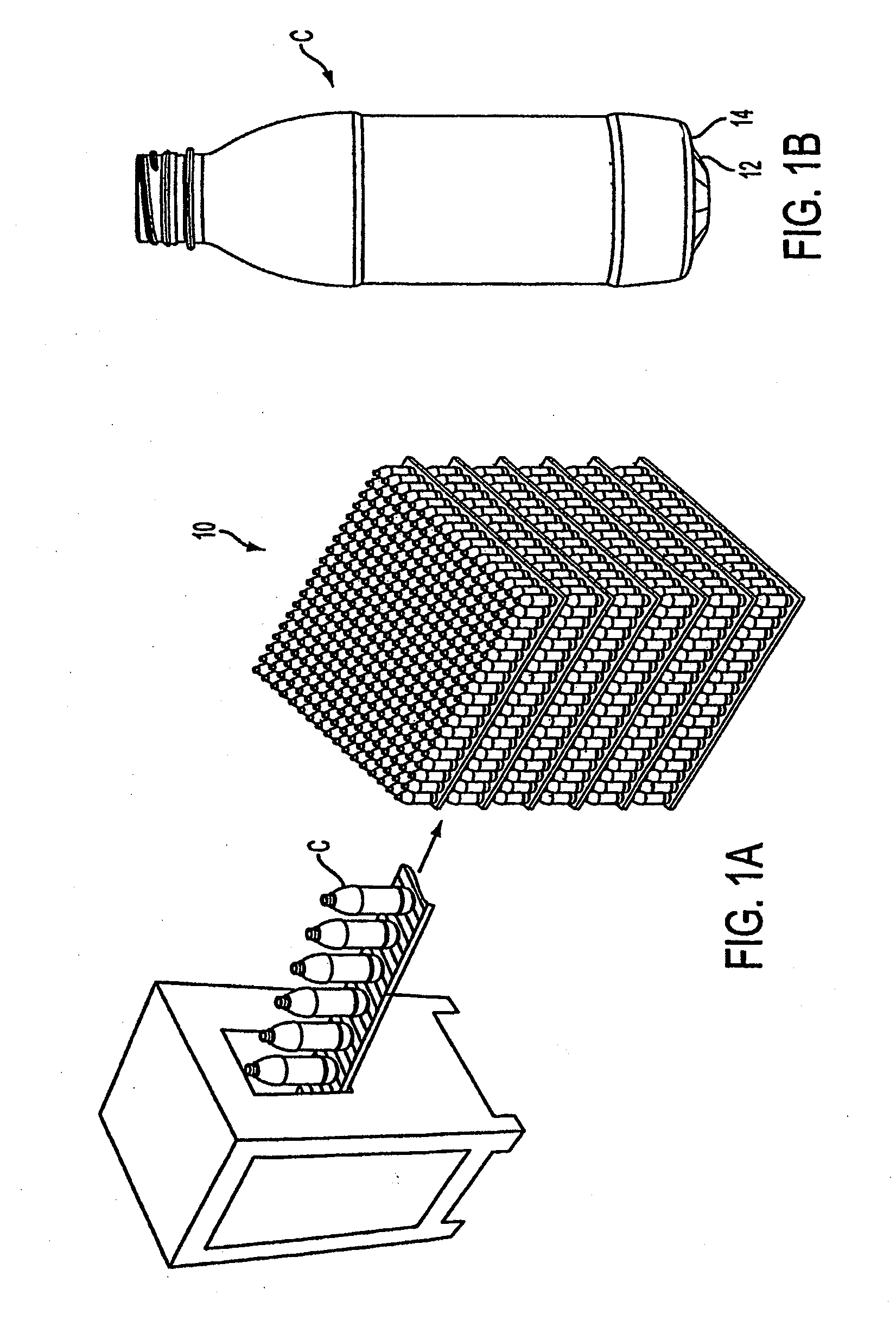

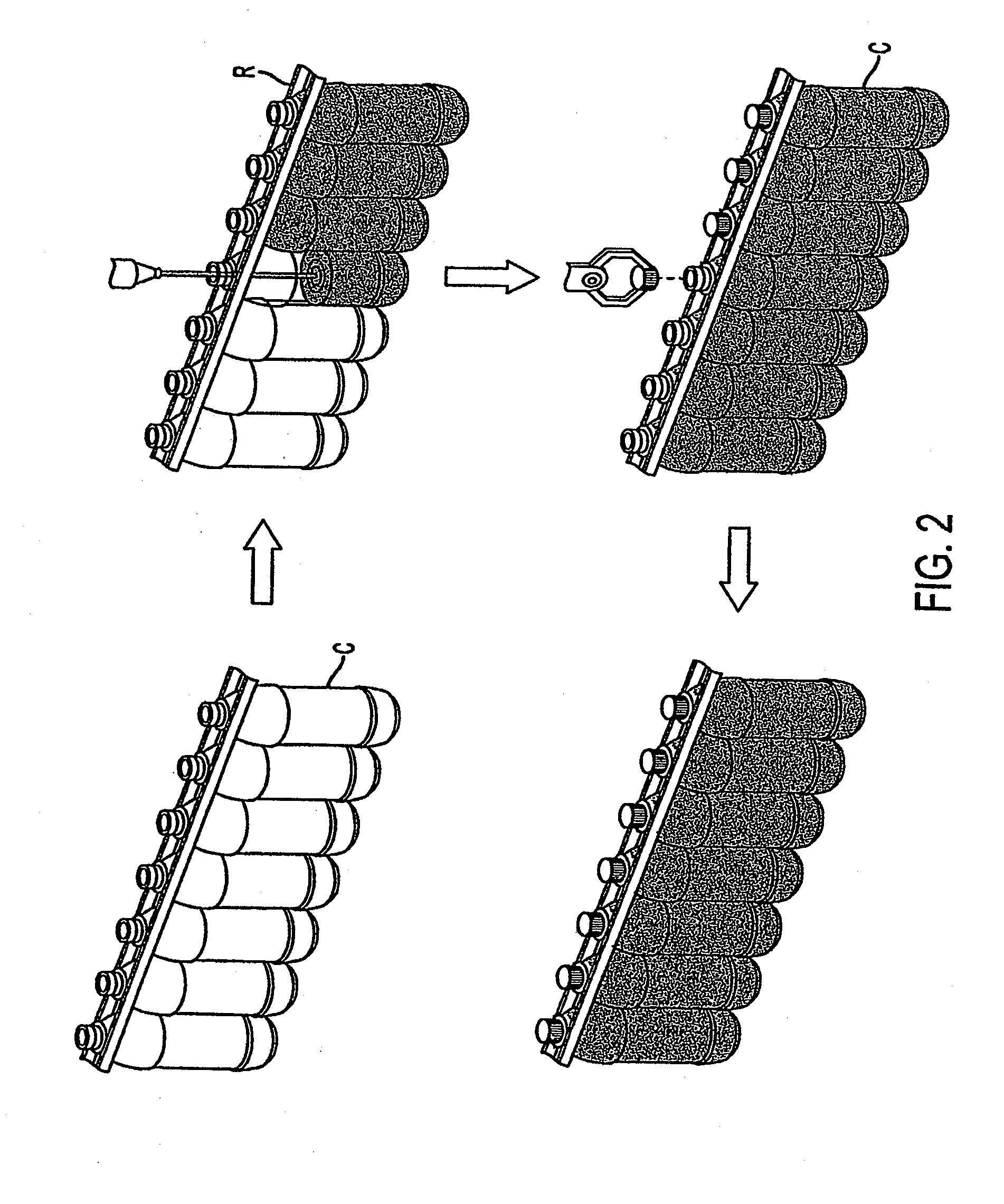

Container handling system

ActiveUS20070051073A1Smooth for label placementThorough removalCapsDecorative coversBlow moldingStructural geometry

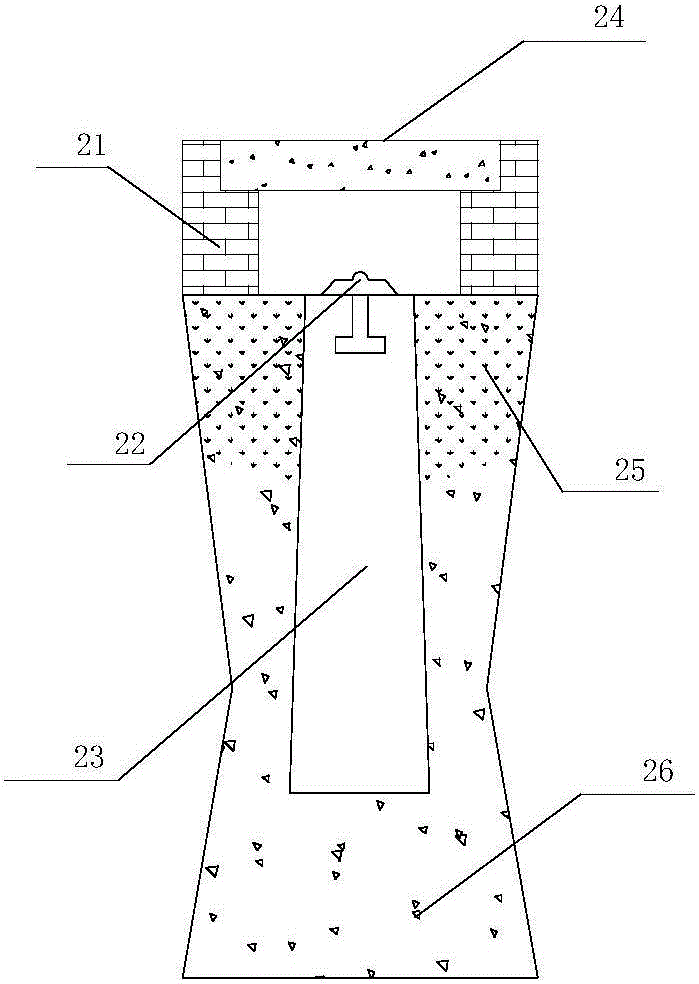

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

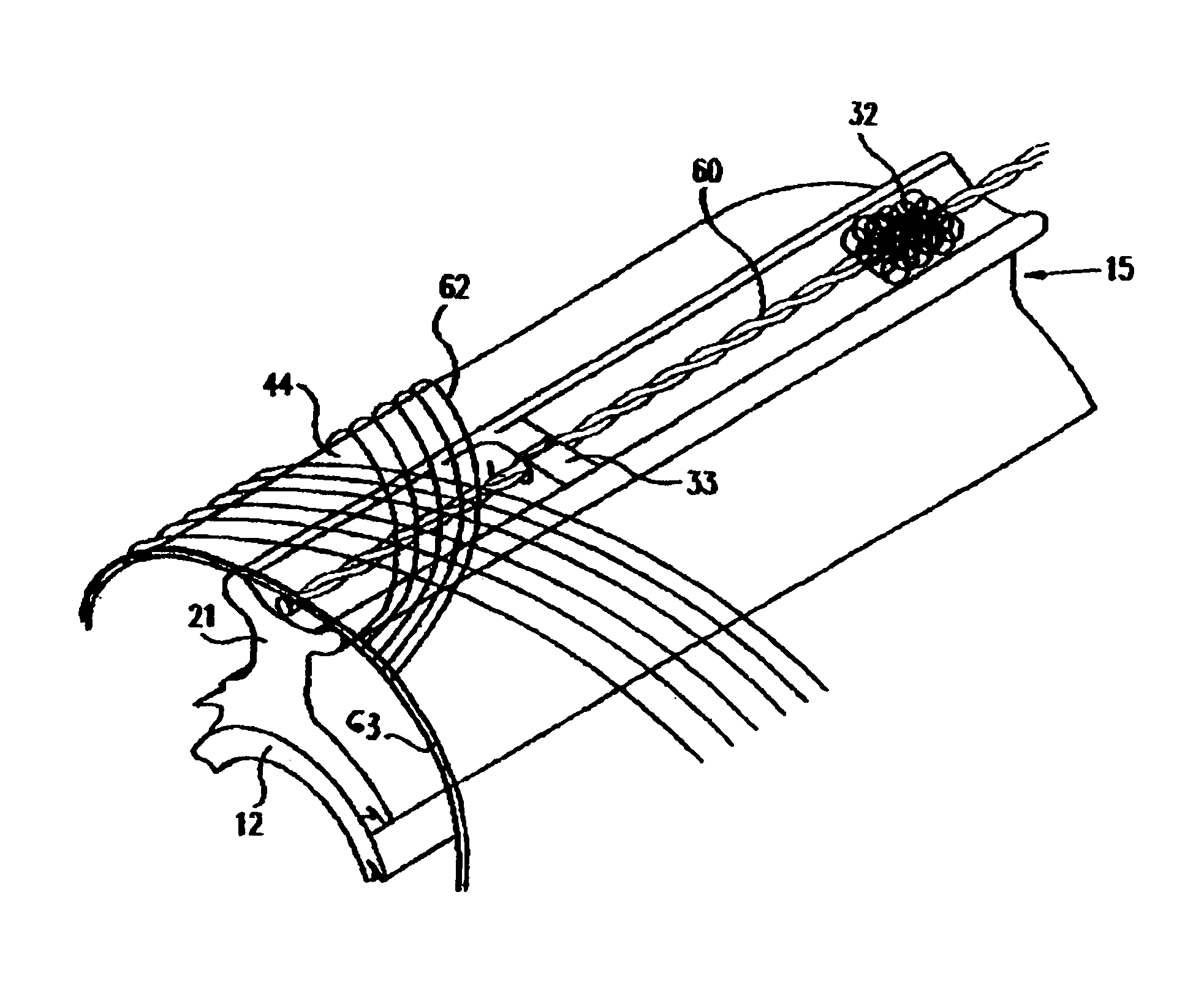

Bone growth promoting implant

InactiveUS7255712B1High of controlHigh degree of flexibilityInternal osteosythesisJoint implantsNatural boneStructural geometry

A stem-like bone implant includes longitudinal structural members and tension cables that provide curvature control and support, and rigidity against bending and buckling. The longitudinal structural members and tension cables may become an integral part of a composite regenerated bone having a substantially increased strength over natural bone. The flexibility of the implant is controlled by specifically varying the structural geometry of certain portions of the implant, and by adjusting the tension in the tension cables before, during and after the implantation operation to thereby adjust the stiffness of the implant. The tension cables may be adjusted to produce asymmetric or non-uniform levels of tension in the longitudinal structural members.

Owner:ACTIVE IMPLANTS LLC +1

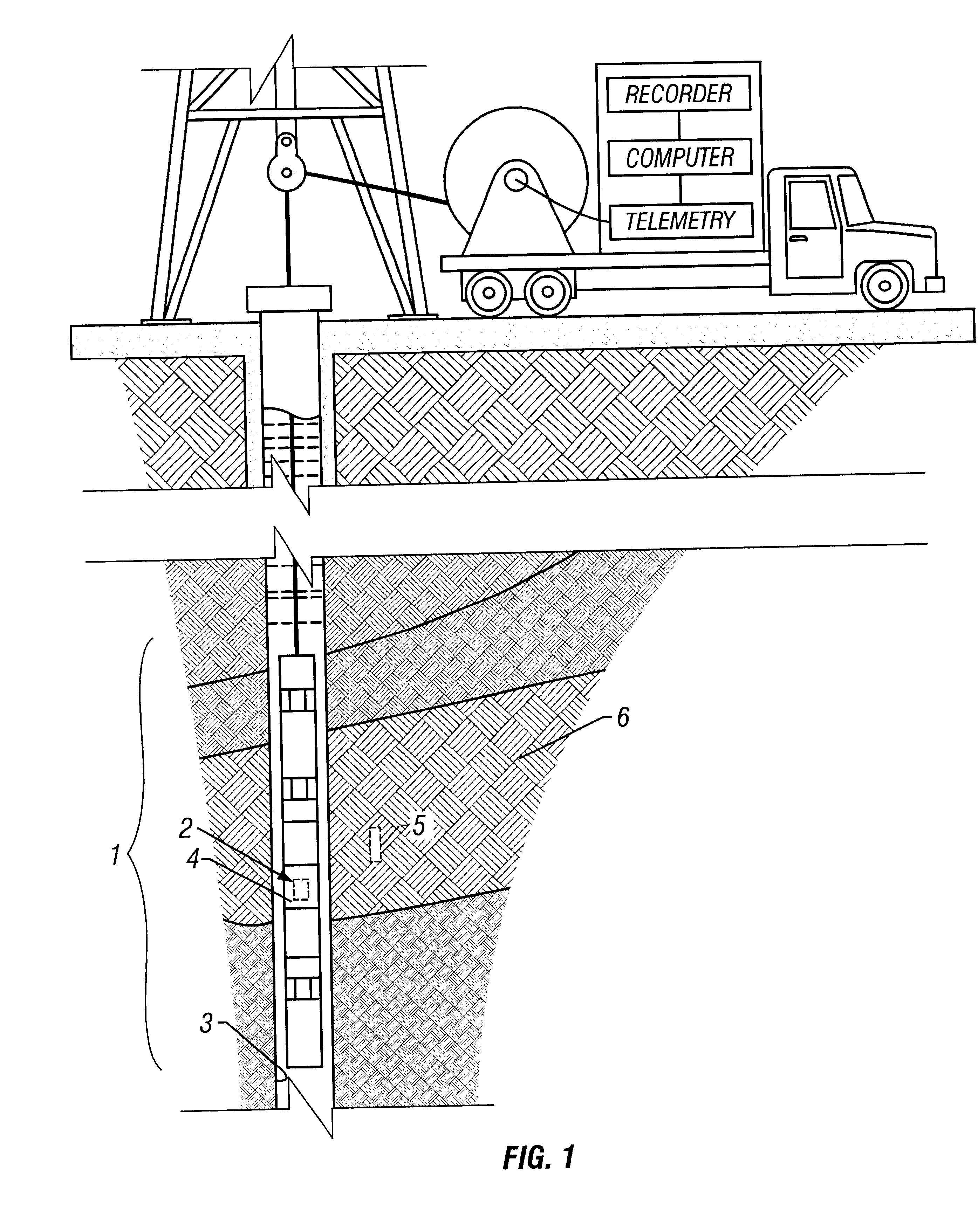

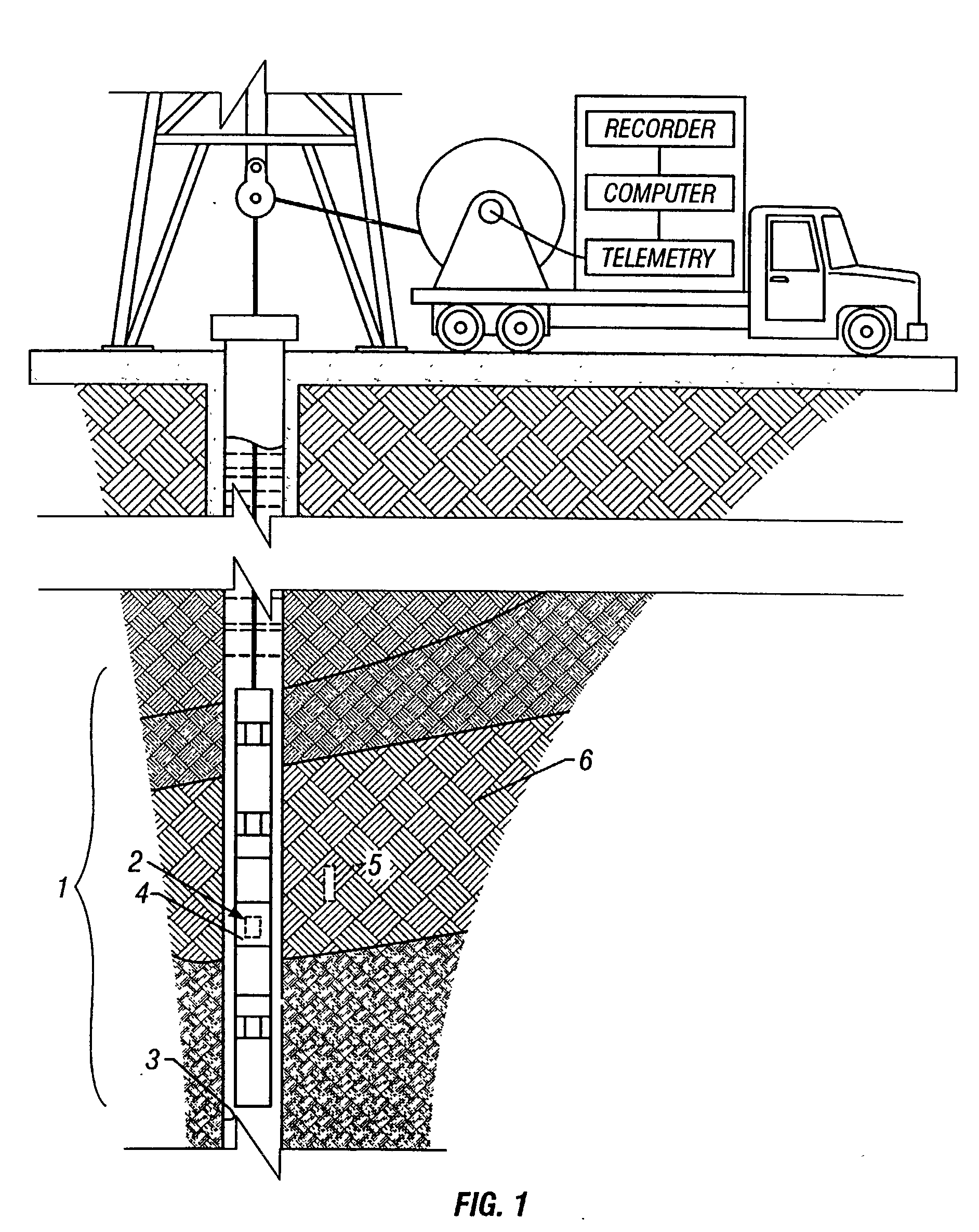

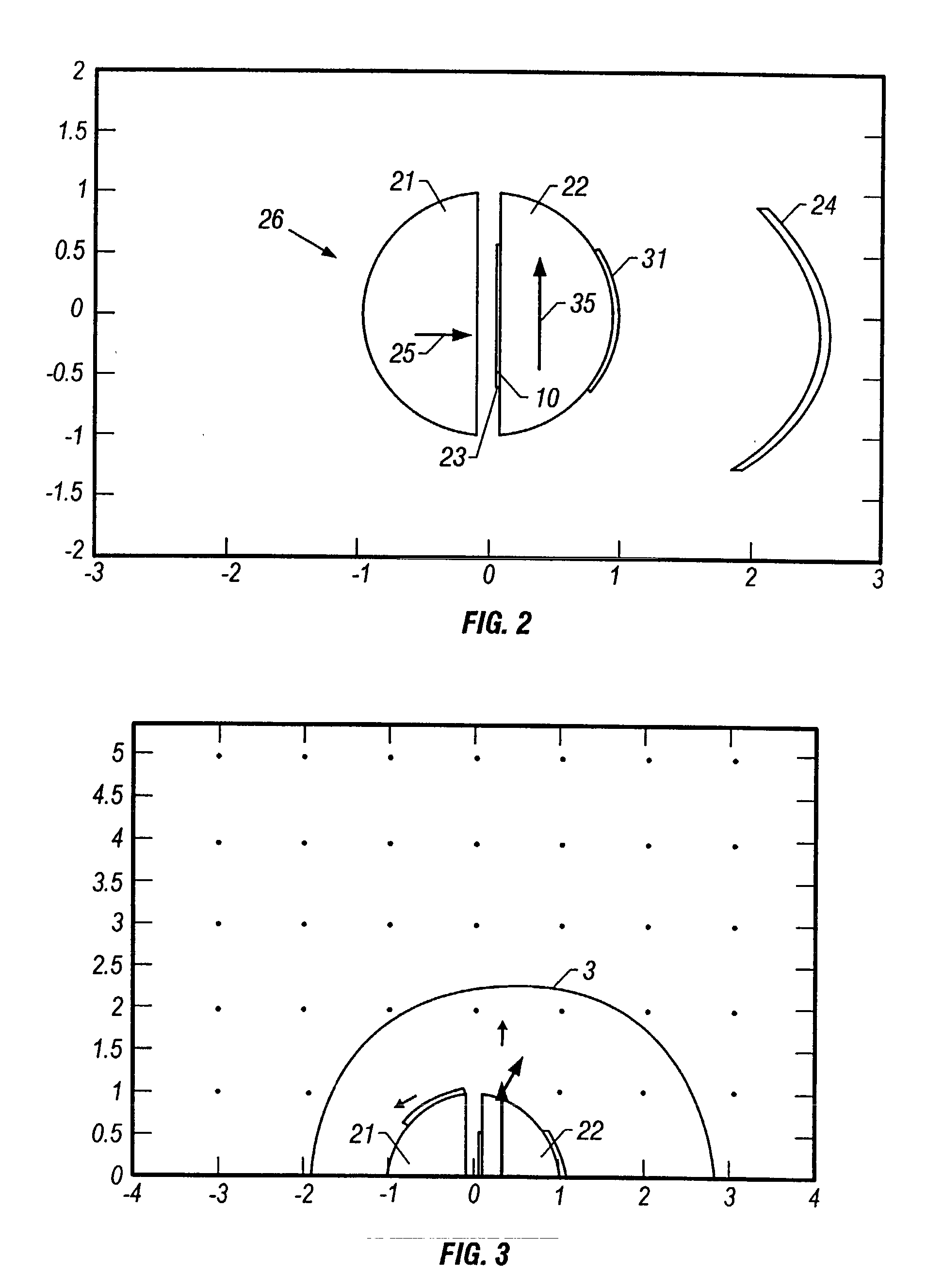

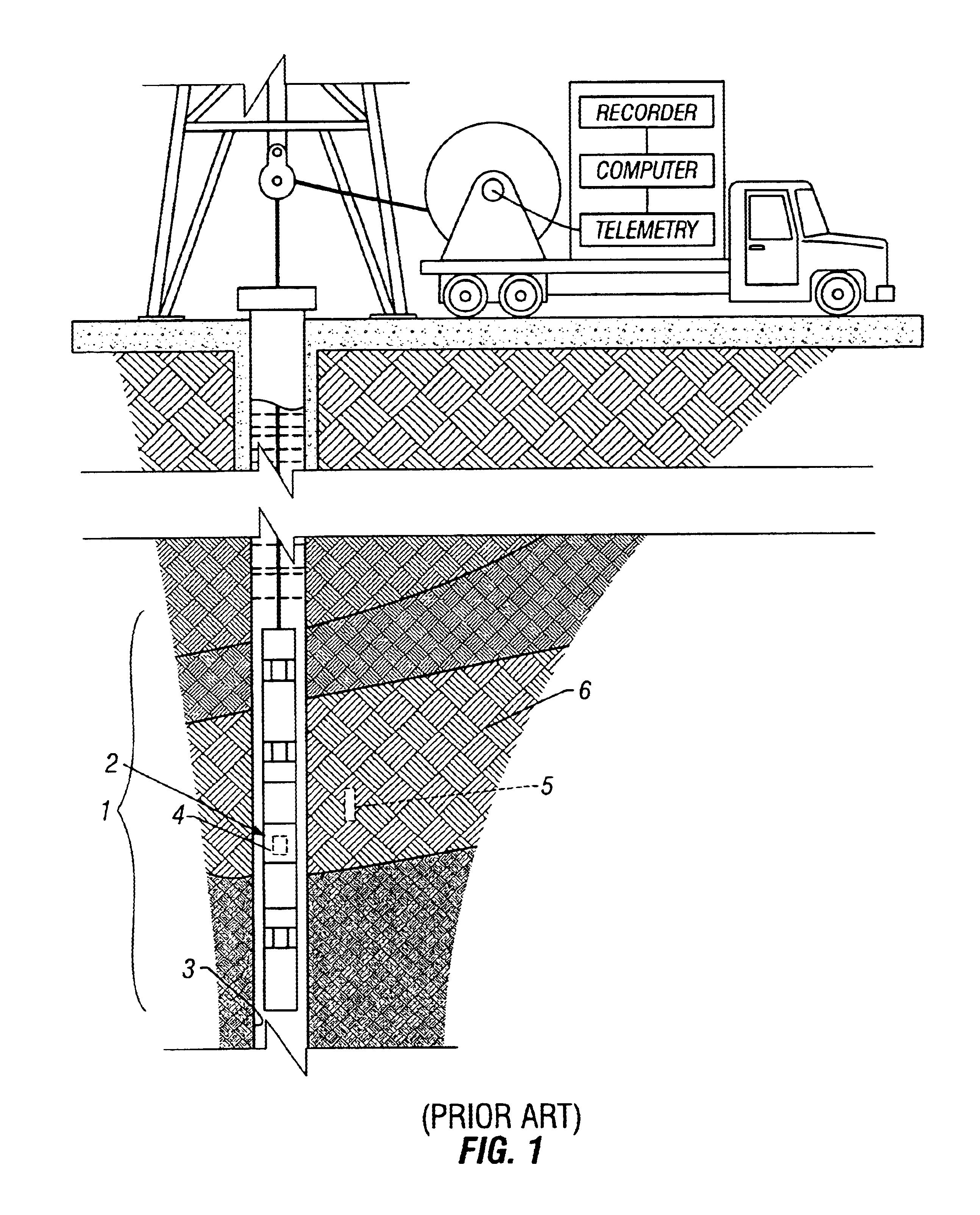

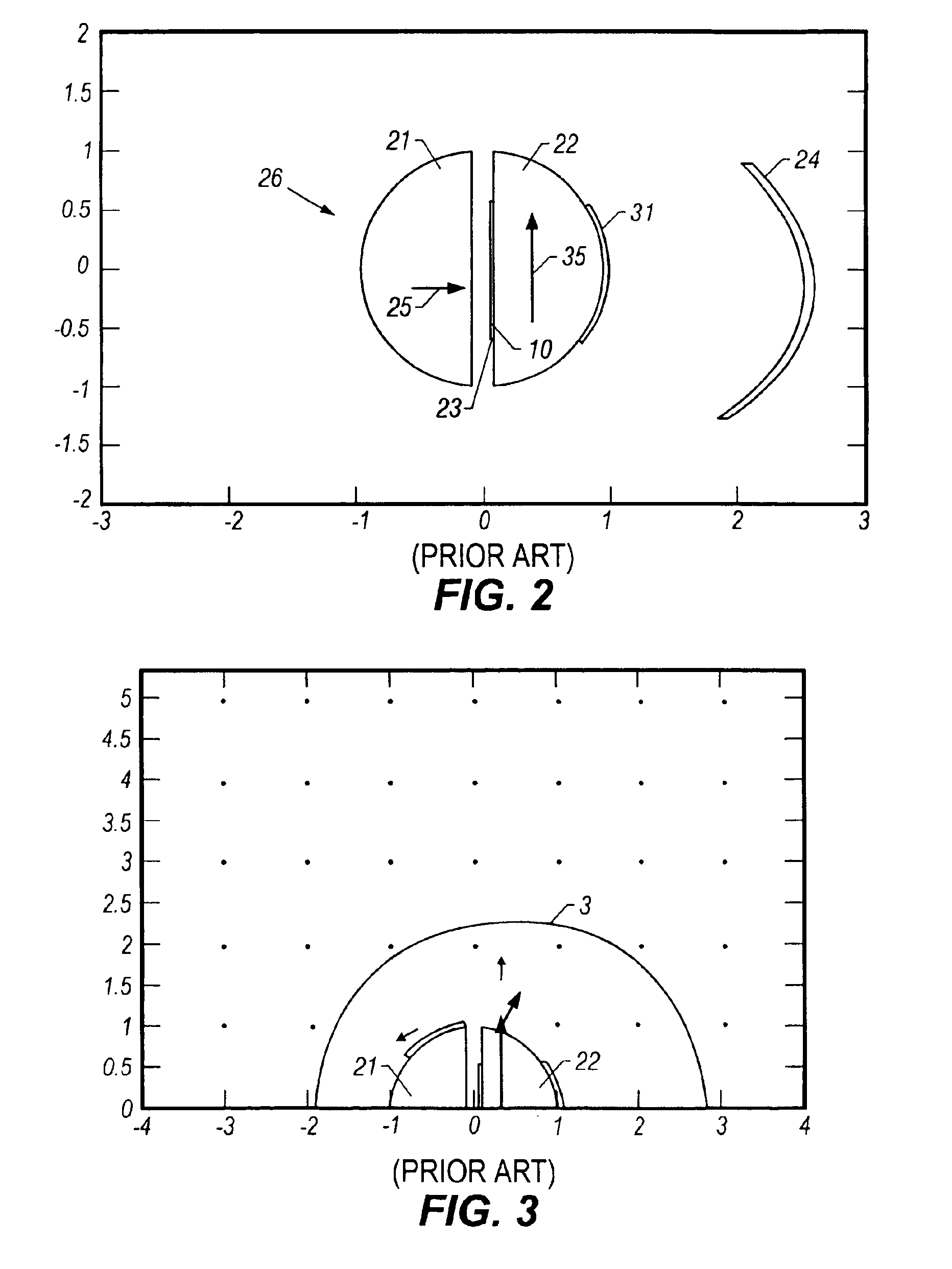

Method and apparatus of using soft non-ferritic magnetic material in a nuclear magnetic resonance probe

InactiveUS6452388B1Optimization of RF antenna efficiencyLow efficiencyElectric/magnetic detection for well-loggingMaterial analysis by using resonanceNMR - Nuclear magnetic resonanceStructural geometry

The present invention provides a novel use of a powdered high saturation flux density soft magnetic material as a NMR probe core material. The probe structural geometry facilitates the use of powdered material, which has a relatively low magnetic permeability.

Owner:BAKER HUGHES INC

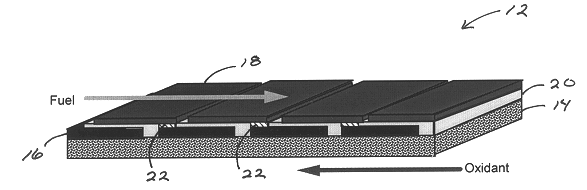

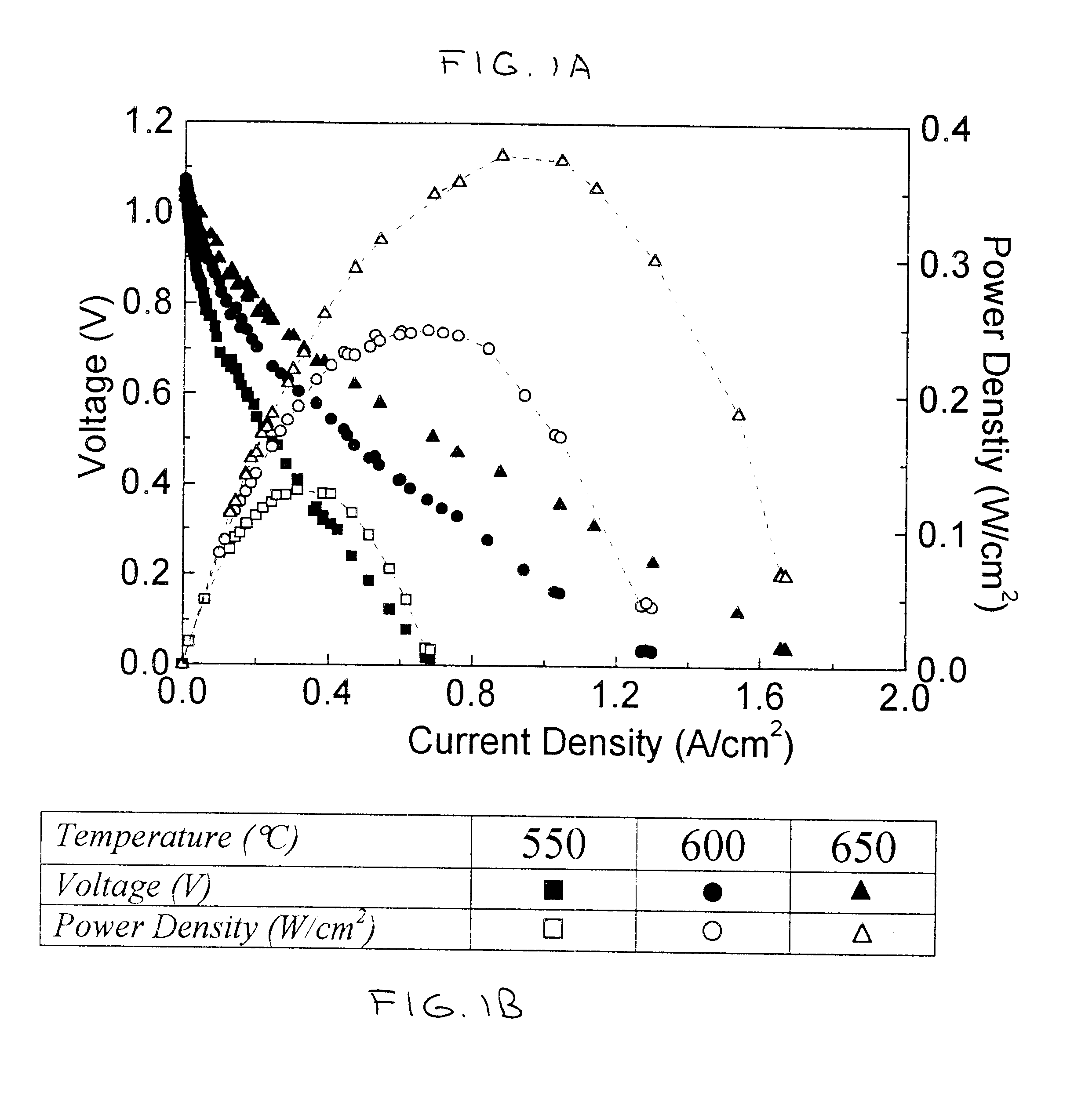

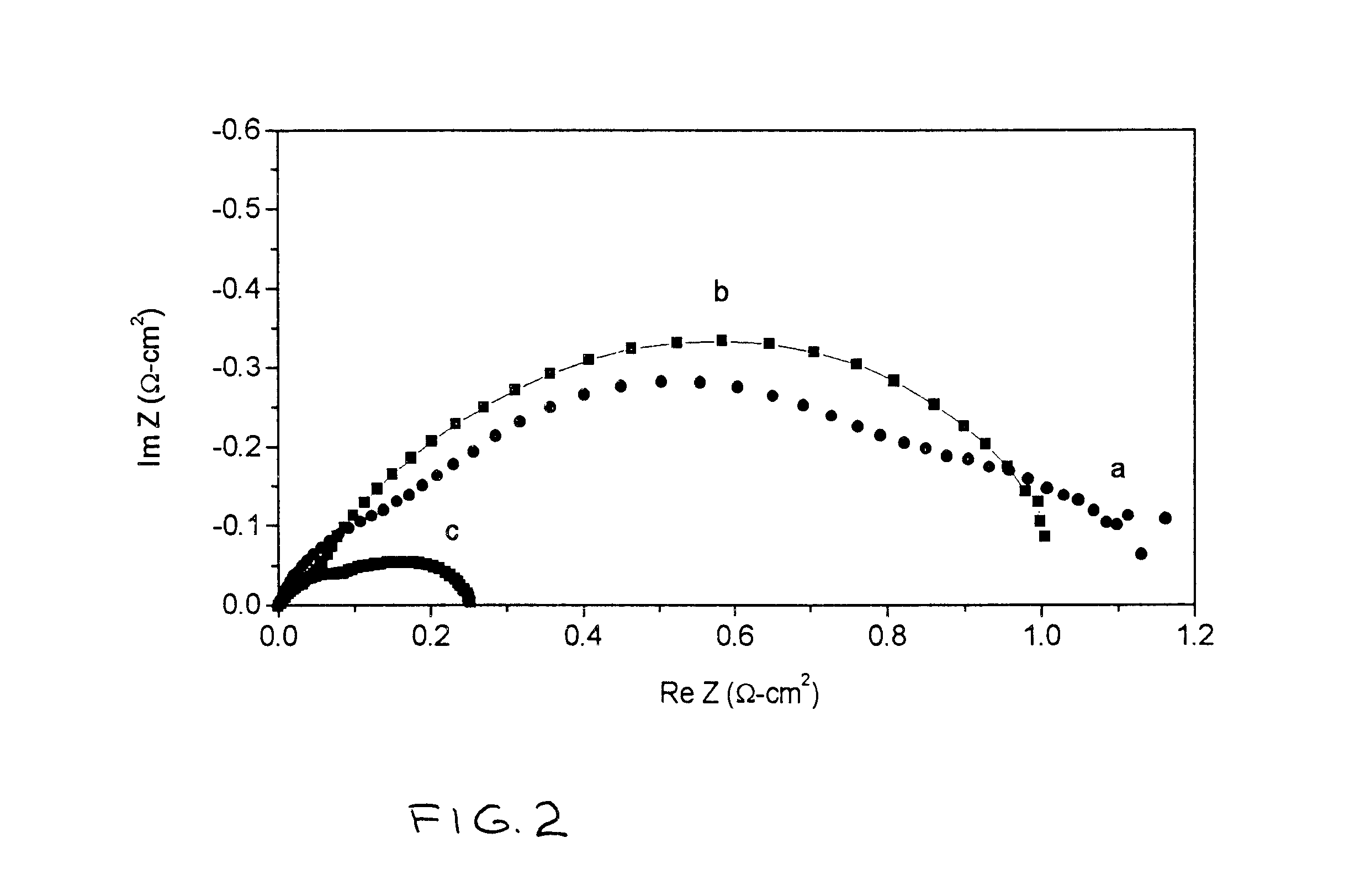

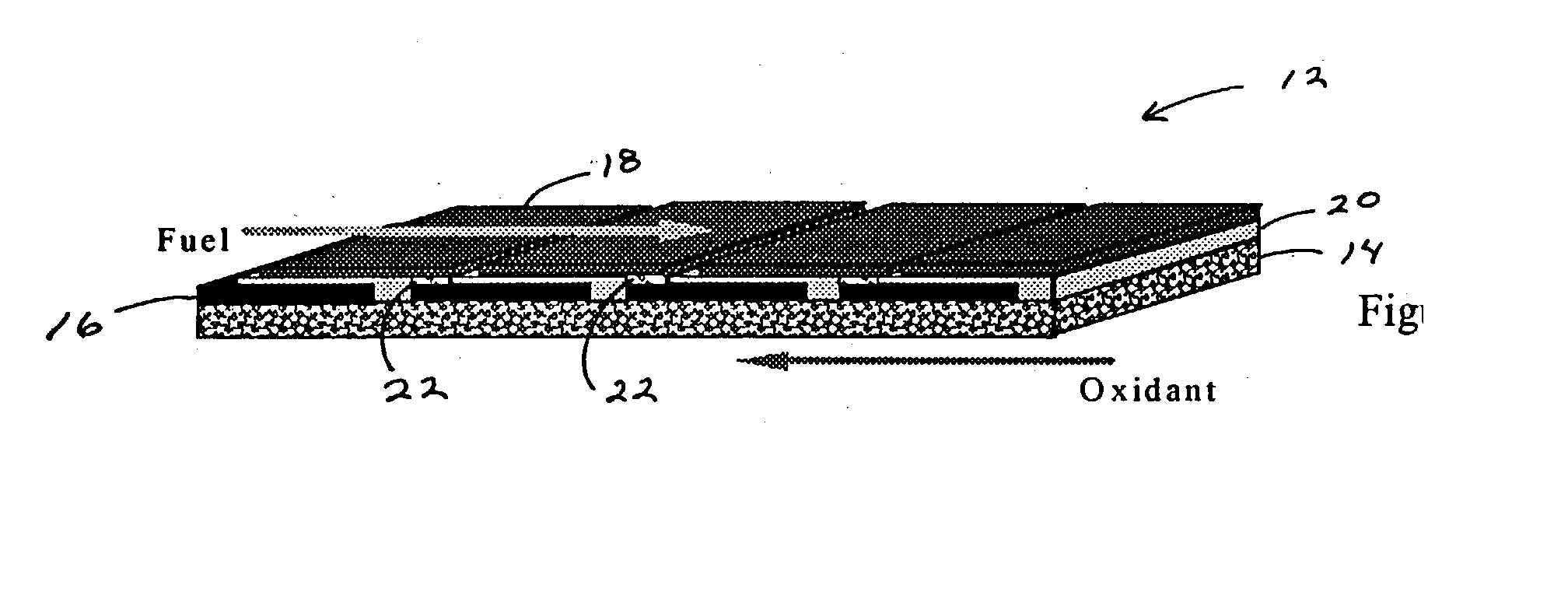

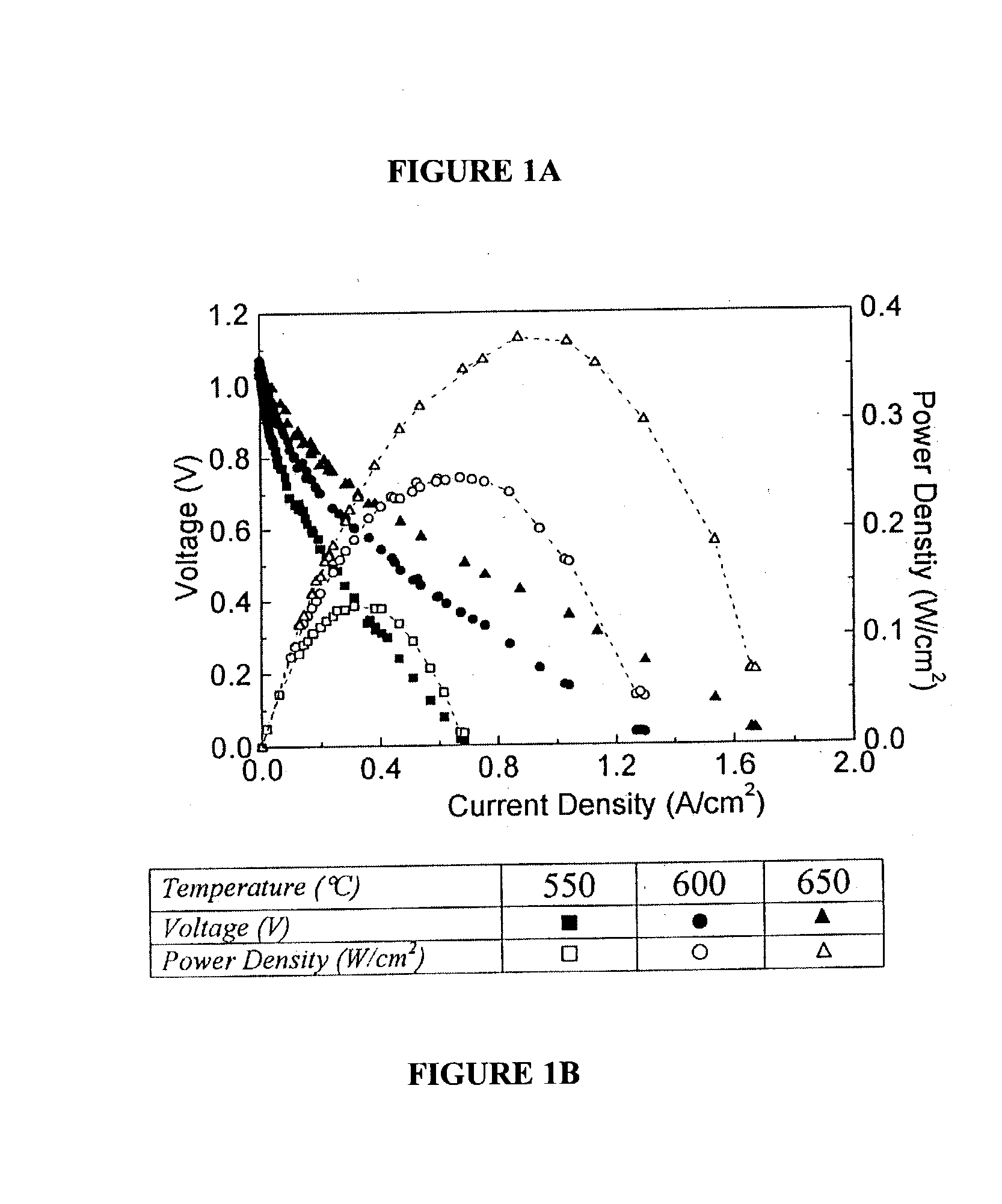

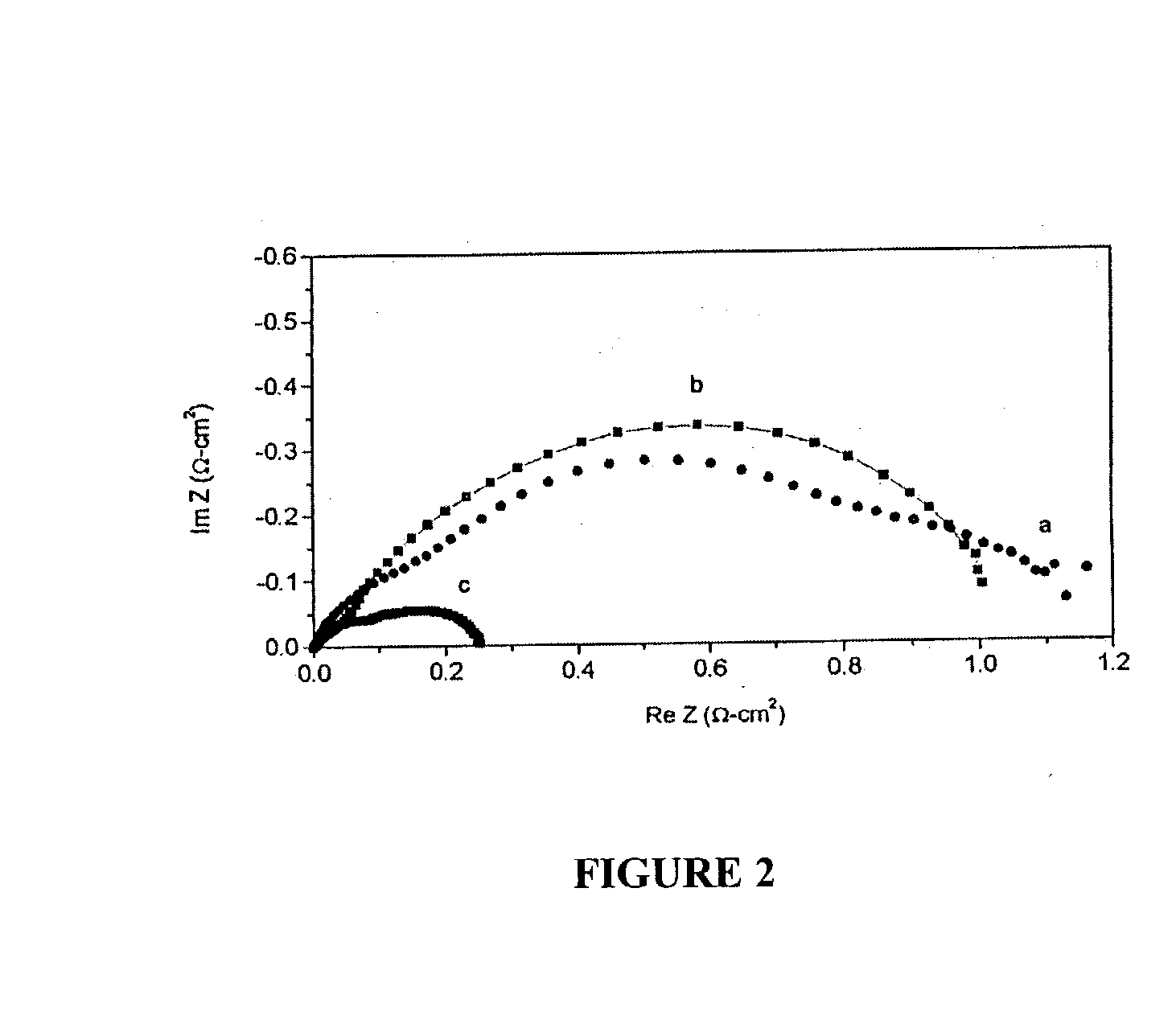

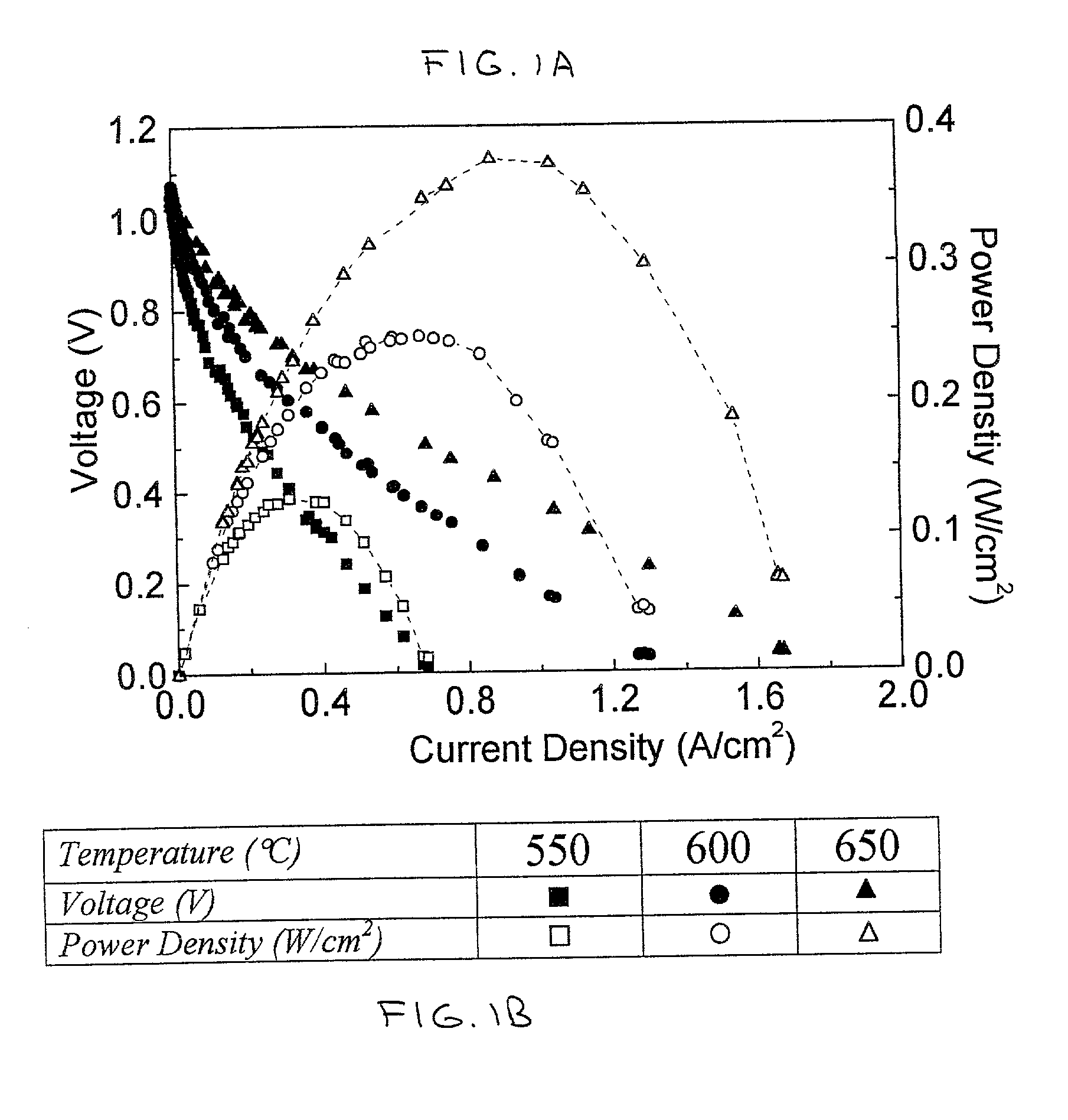

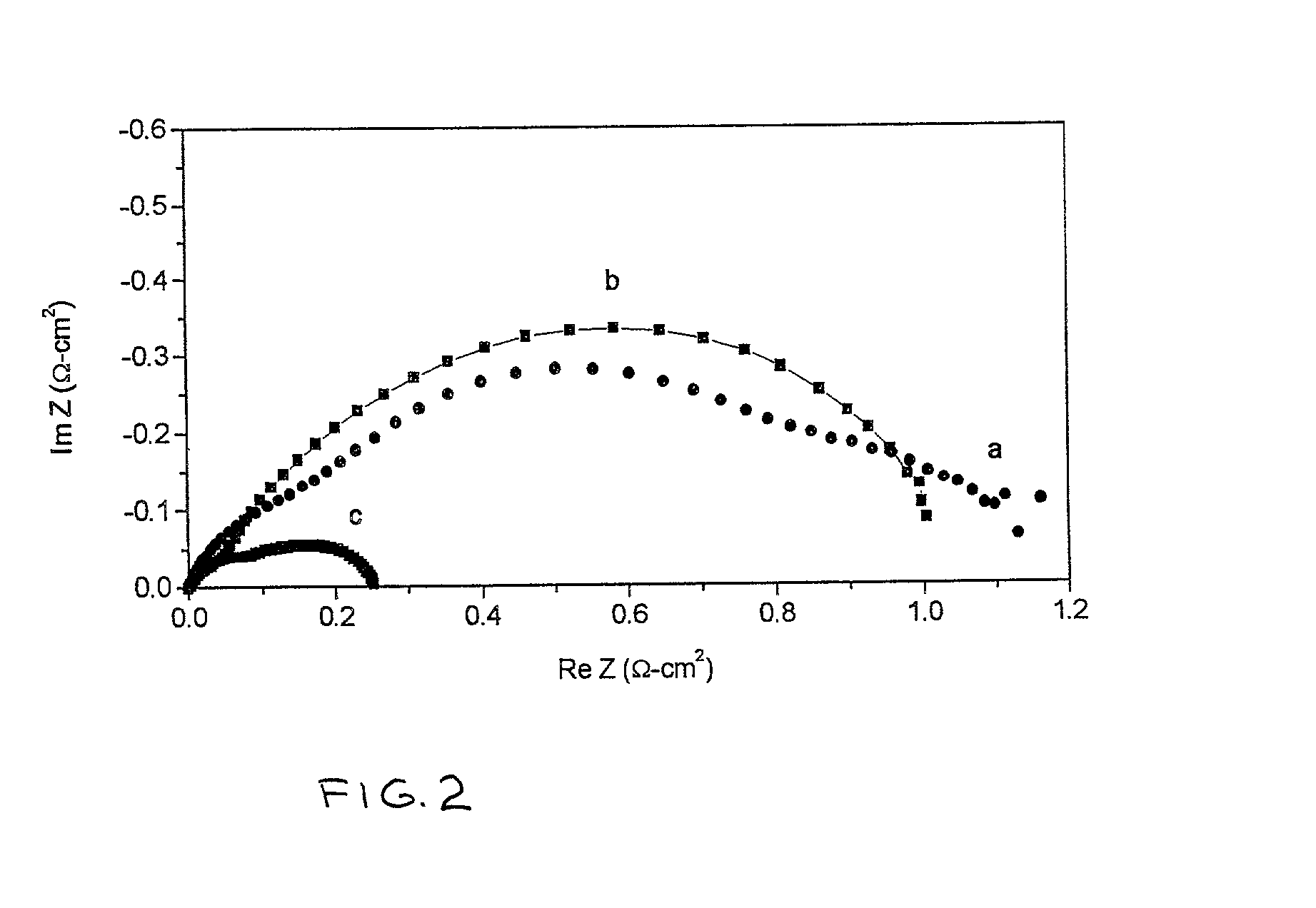

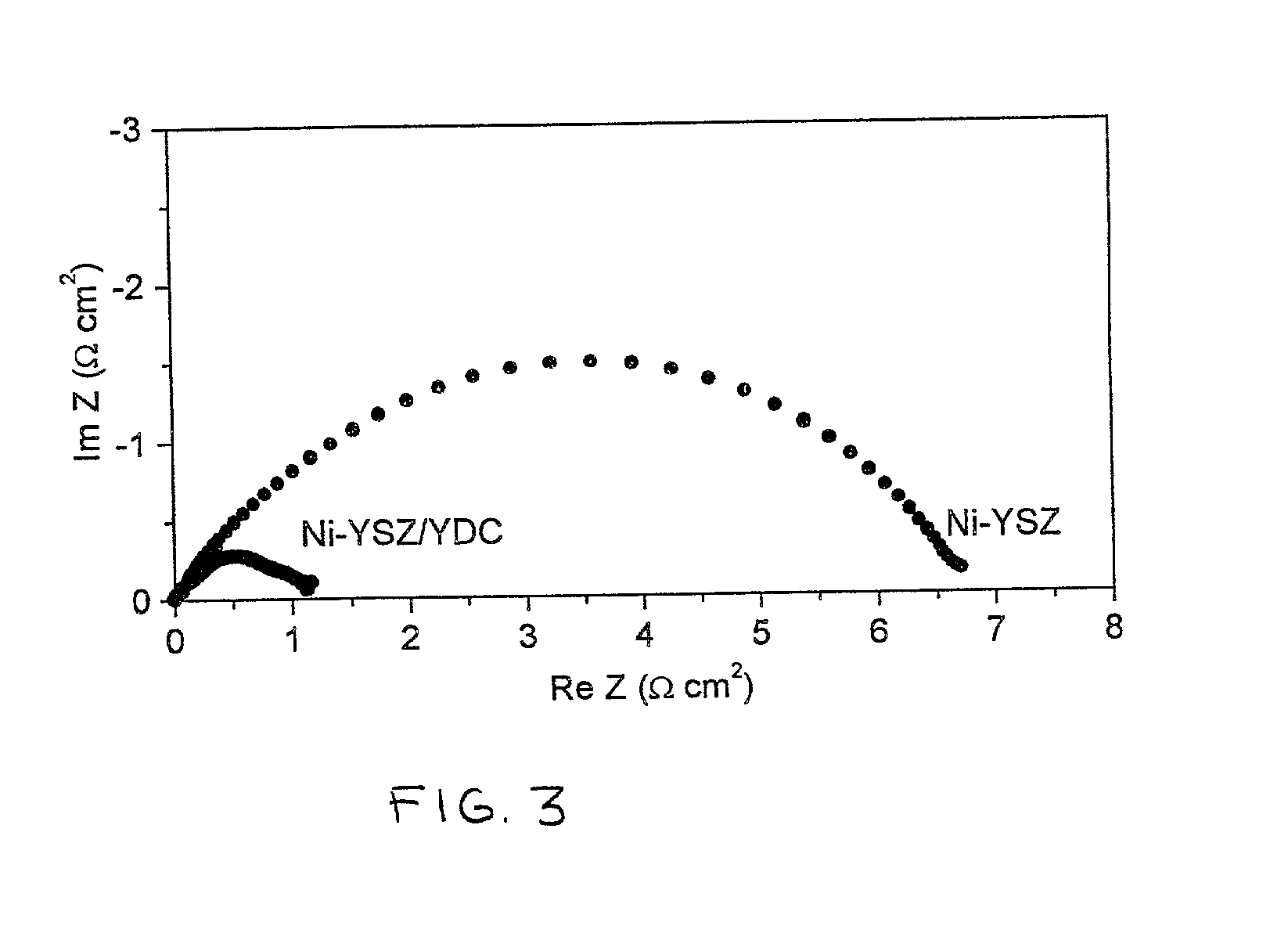

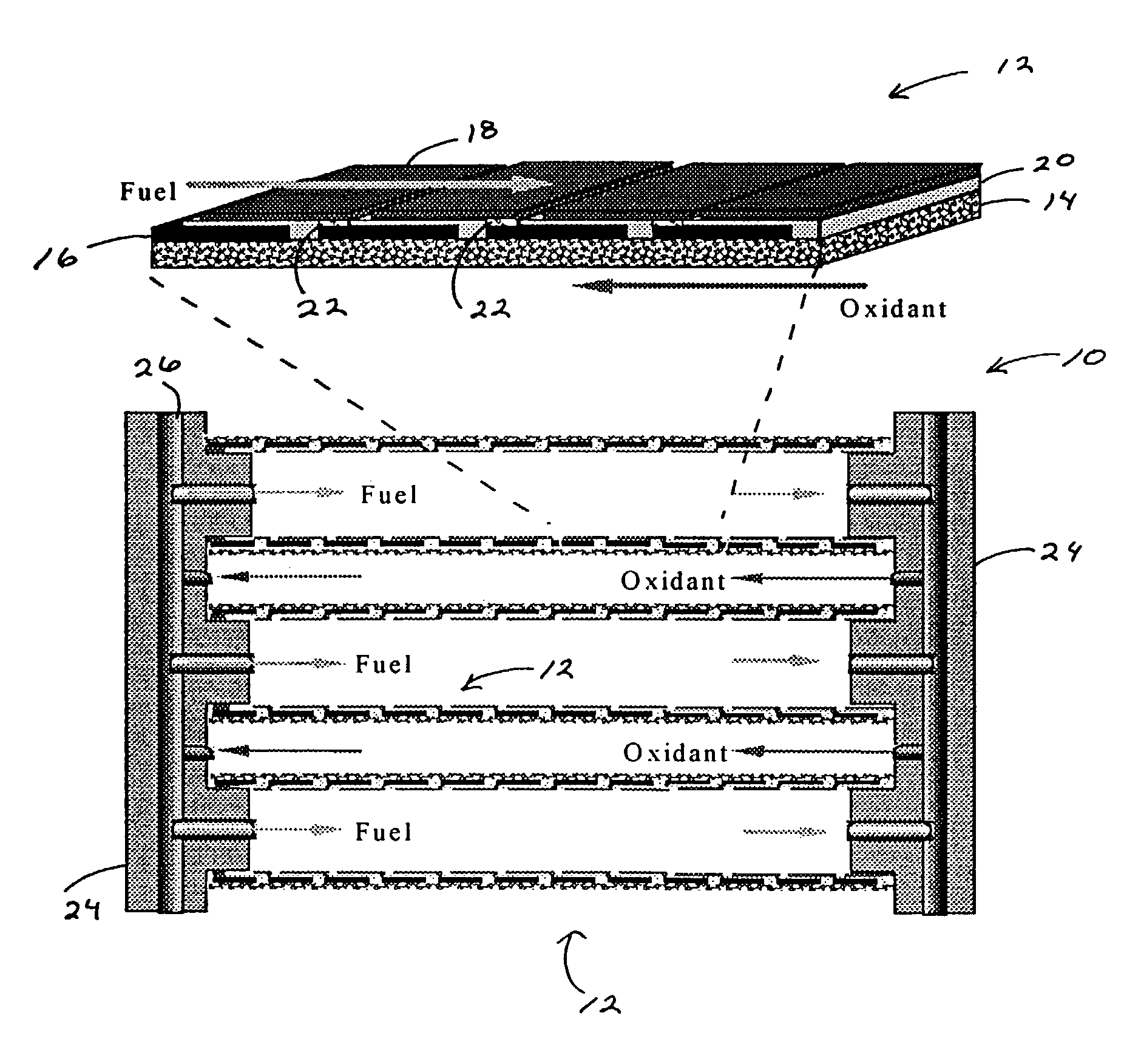

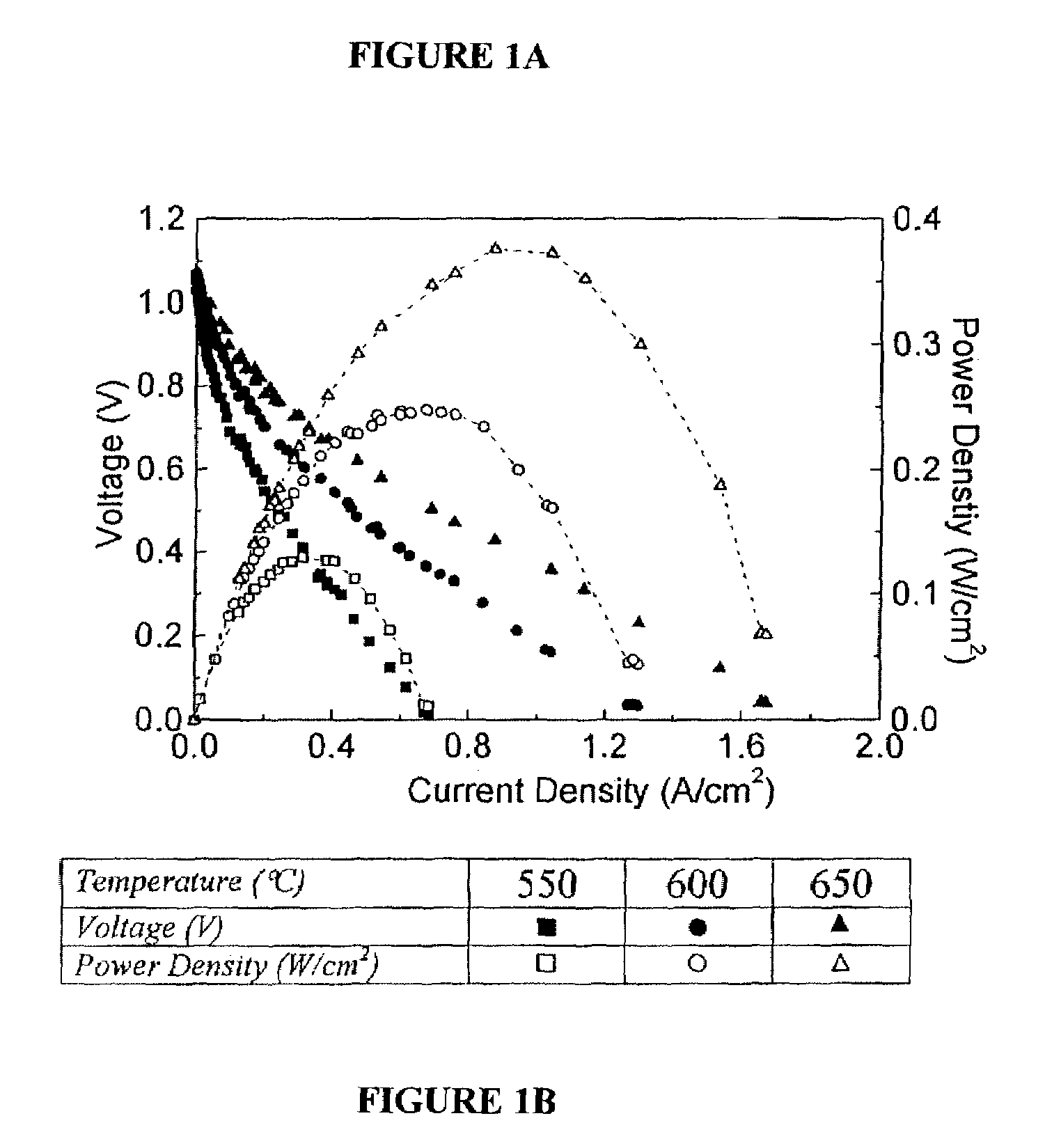

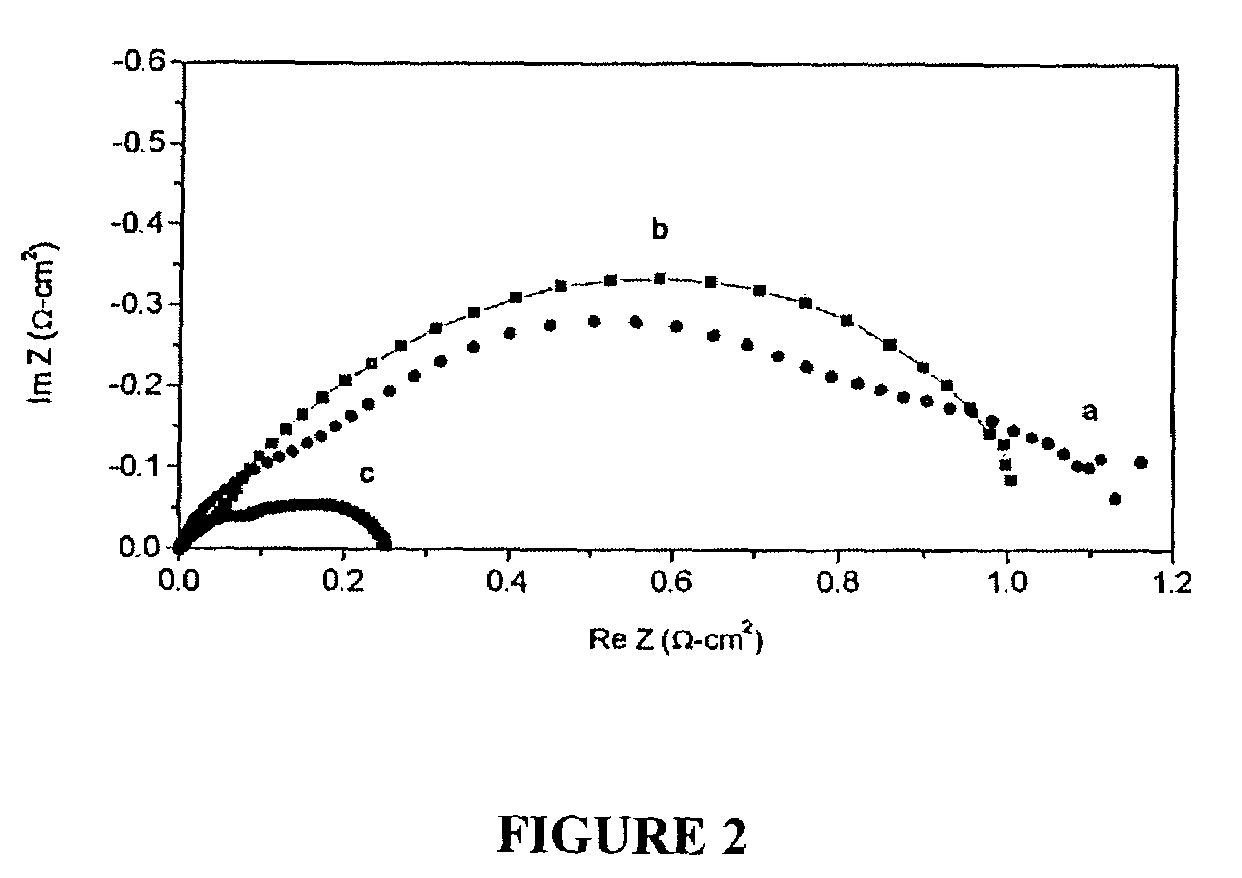

Direct hydrocarbon fuel cells

InactiveUS6479178B2Increase ratingsUseful power densityFuel cells groupingFinal product manufactureHydrogenFuel cells

The direct electrochemical oxidation of hydrocarbons in solid oxide fuel cells, to generate greater power densities at lower temperatures without carbon deposition. The performance obtained is comparable to that of fuel cells used for hydrogen, and is achieved by using novel anode composites at low operating temperatures. Such solid oxide fuel cells, regardless of fuel source or operation, can be configured advantageously using the structural geometries of this invention.

Owner:NORTHWESTERN UNIV

Direct hydrocarbon fuel cells

InactiveUS20040033405A1Increase ratingsUseful power densityFuel cells groupingCell electrodesHydrogenFuel cells

The direct electrochemical oxidation of hydrocarbons in solid oxide fuel cells, to generate greater power densities at lower temperatures without carbon deposition. The performance obtained is comparable to that of fuel cells used for hydrogen, and is achieved by using novel anode composites at low operating temperatures. Such solid oxide fuel cells, regardless of fuel source or operation, can be configured advantageously using the structural geometries of this invention.

Owner:NORTHWESTERN UNIV

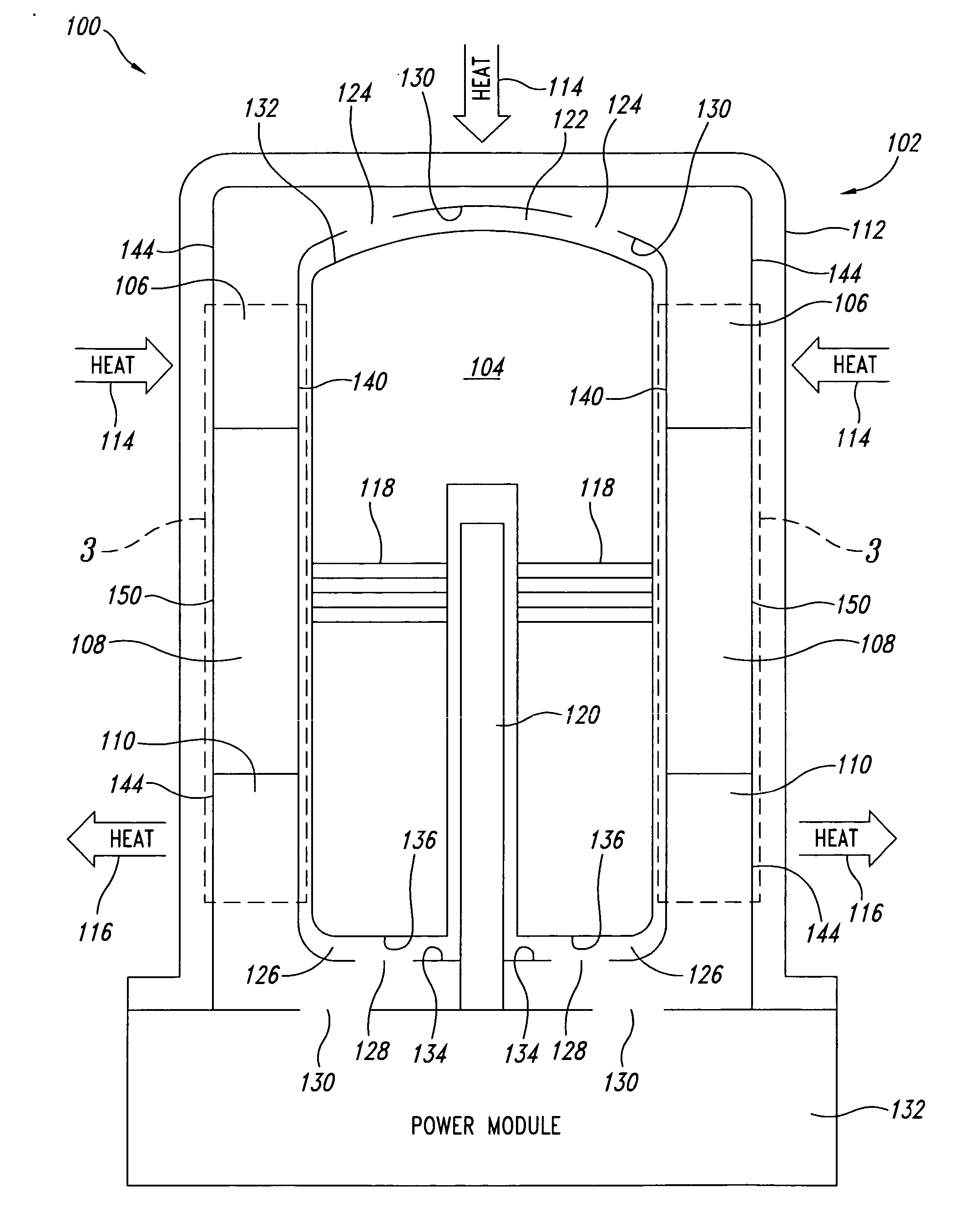

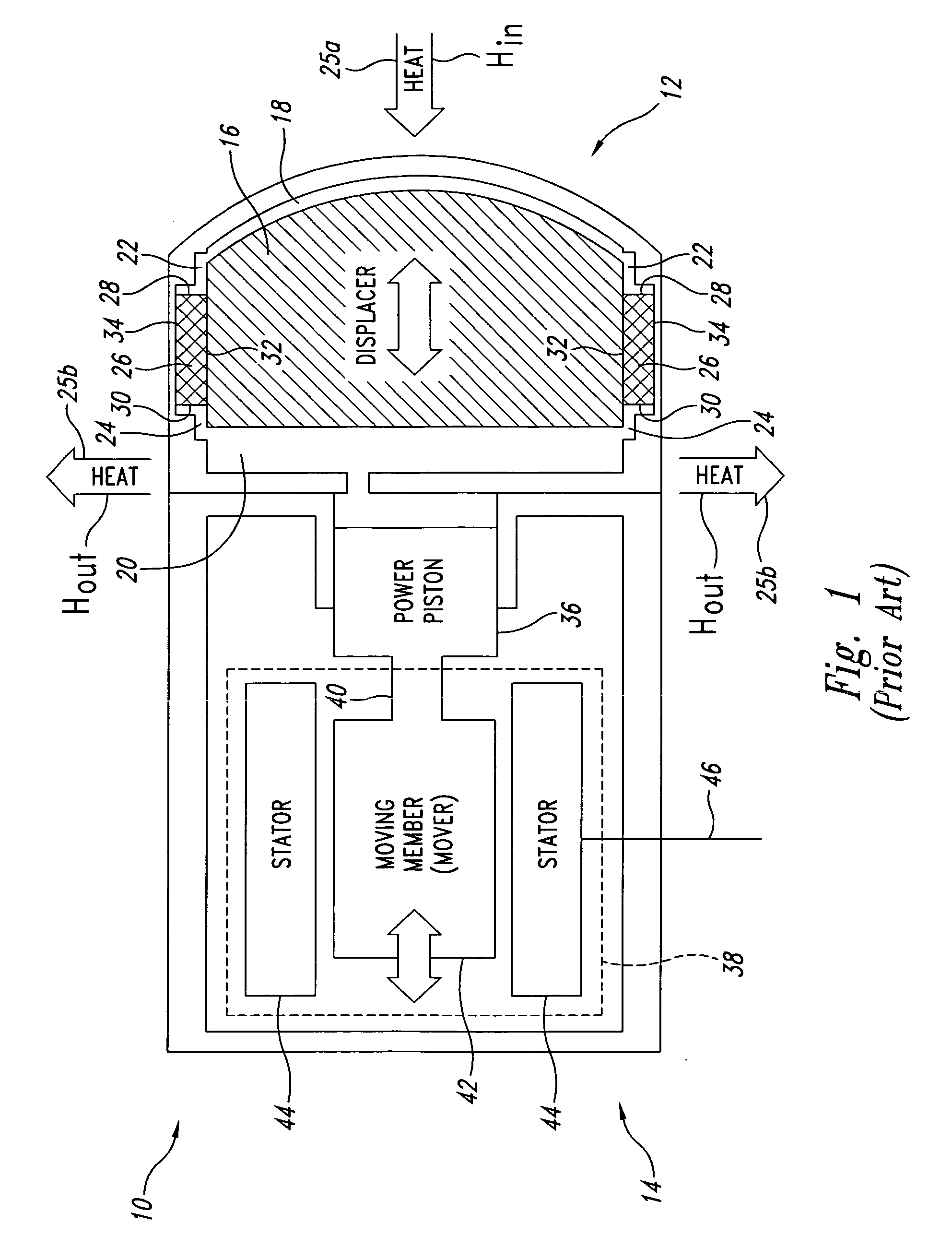

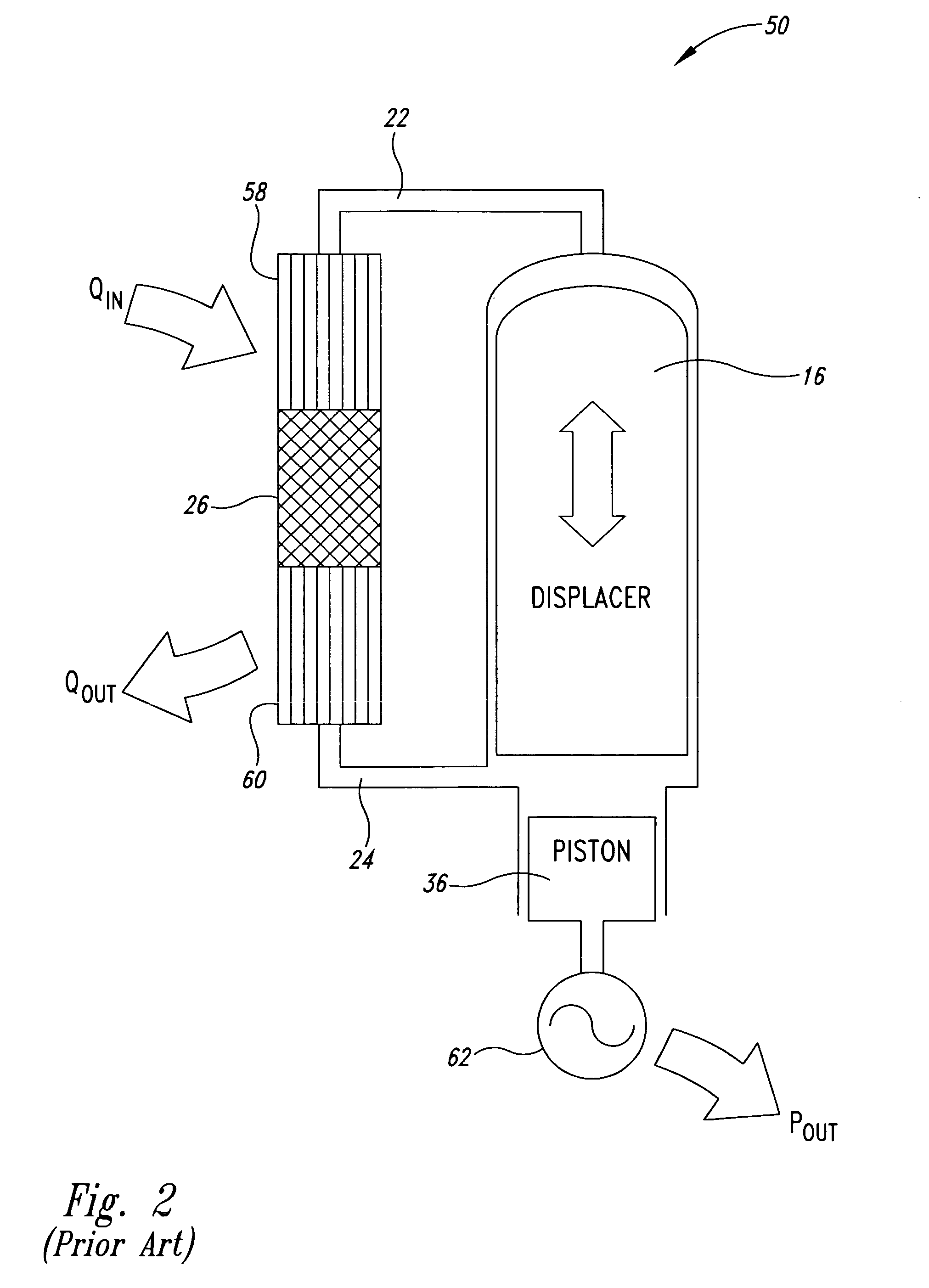

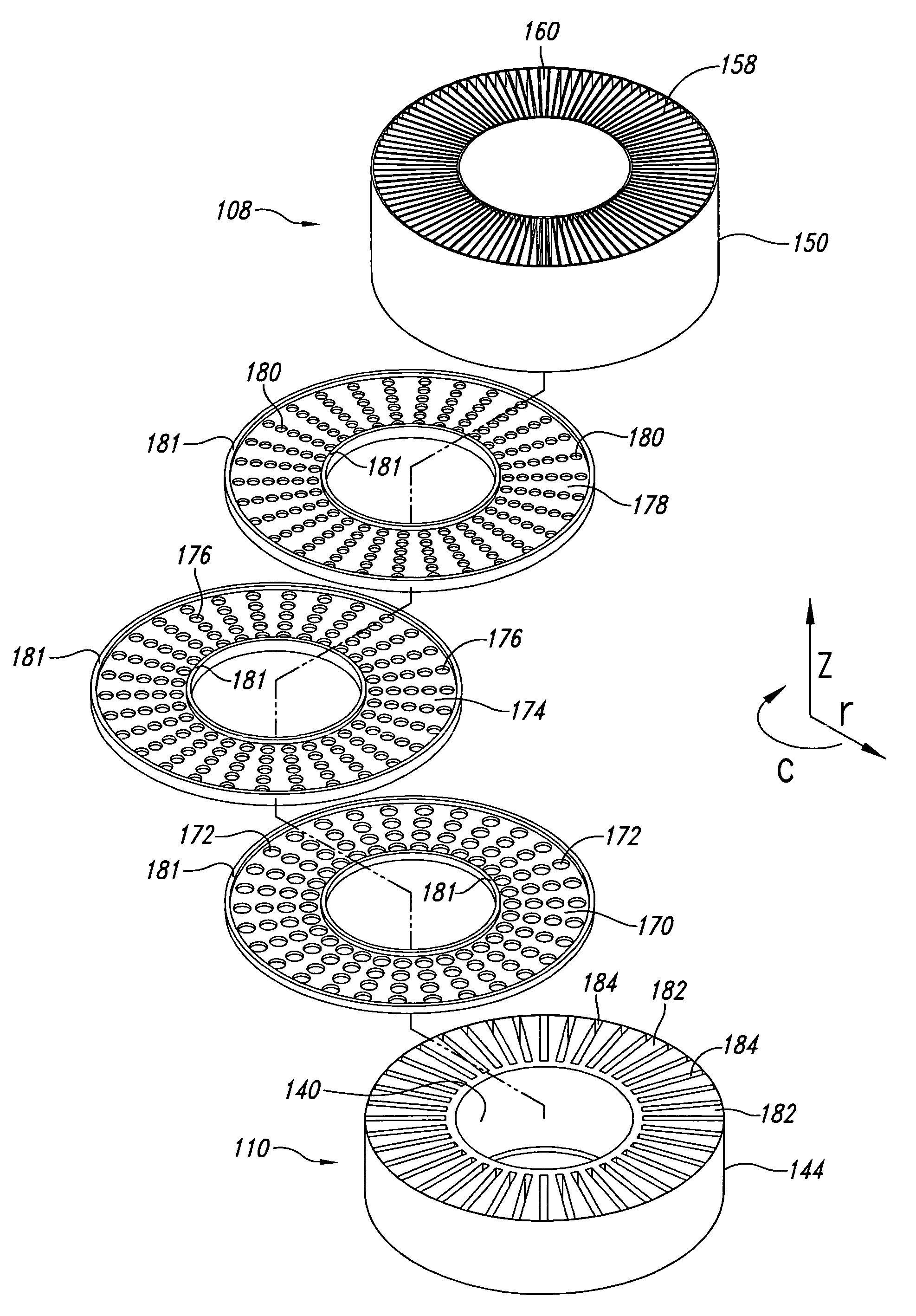

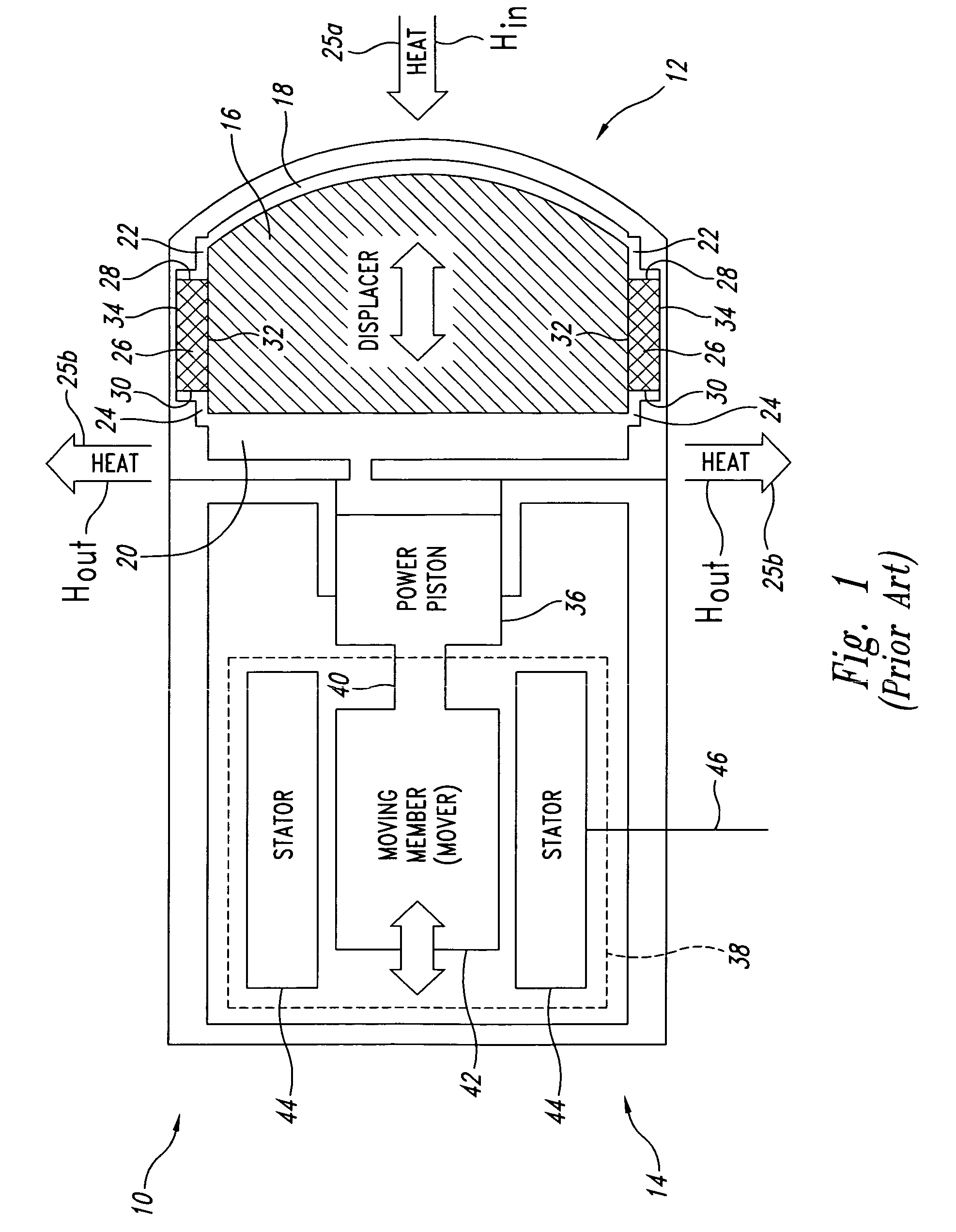

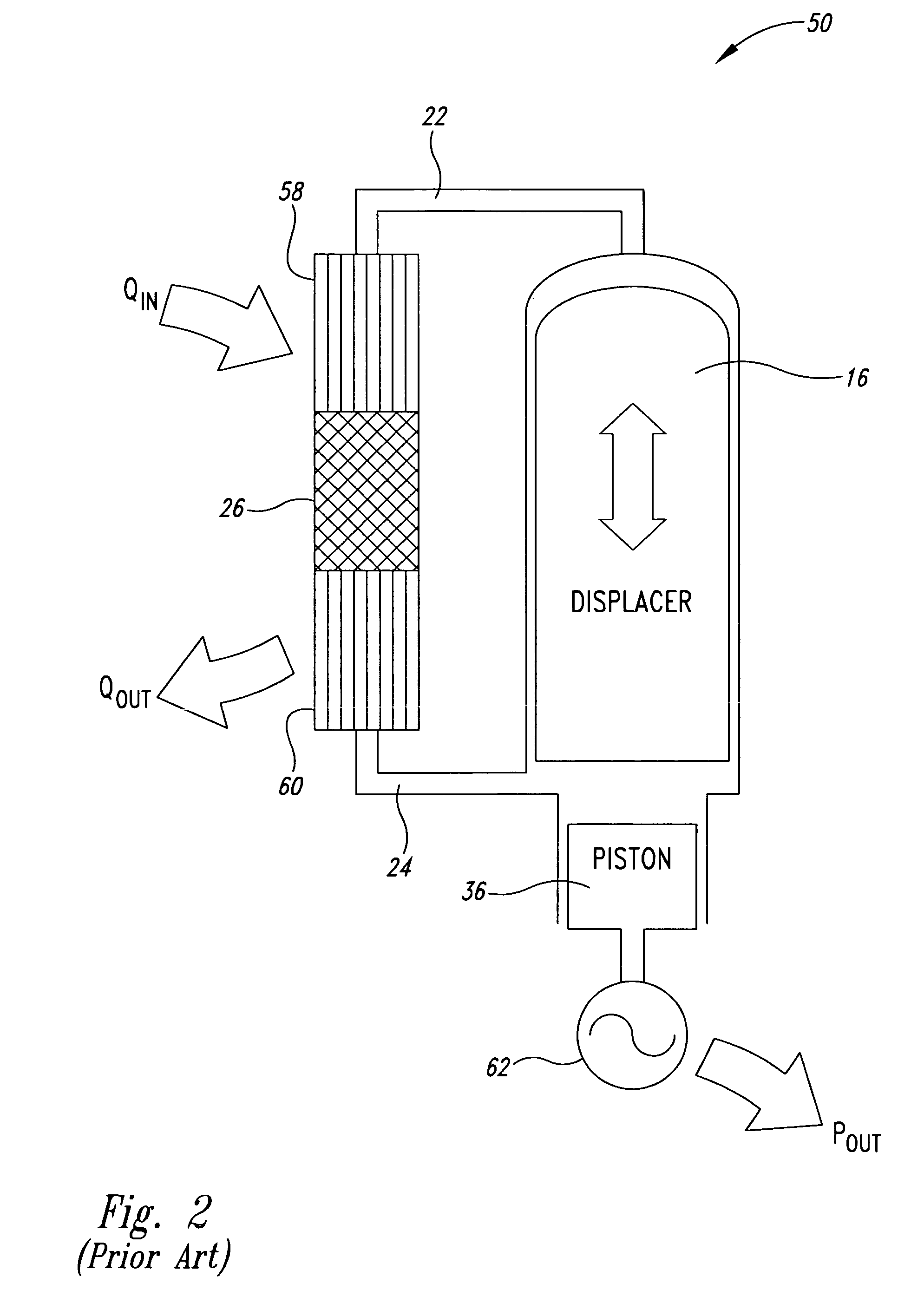

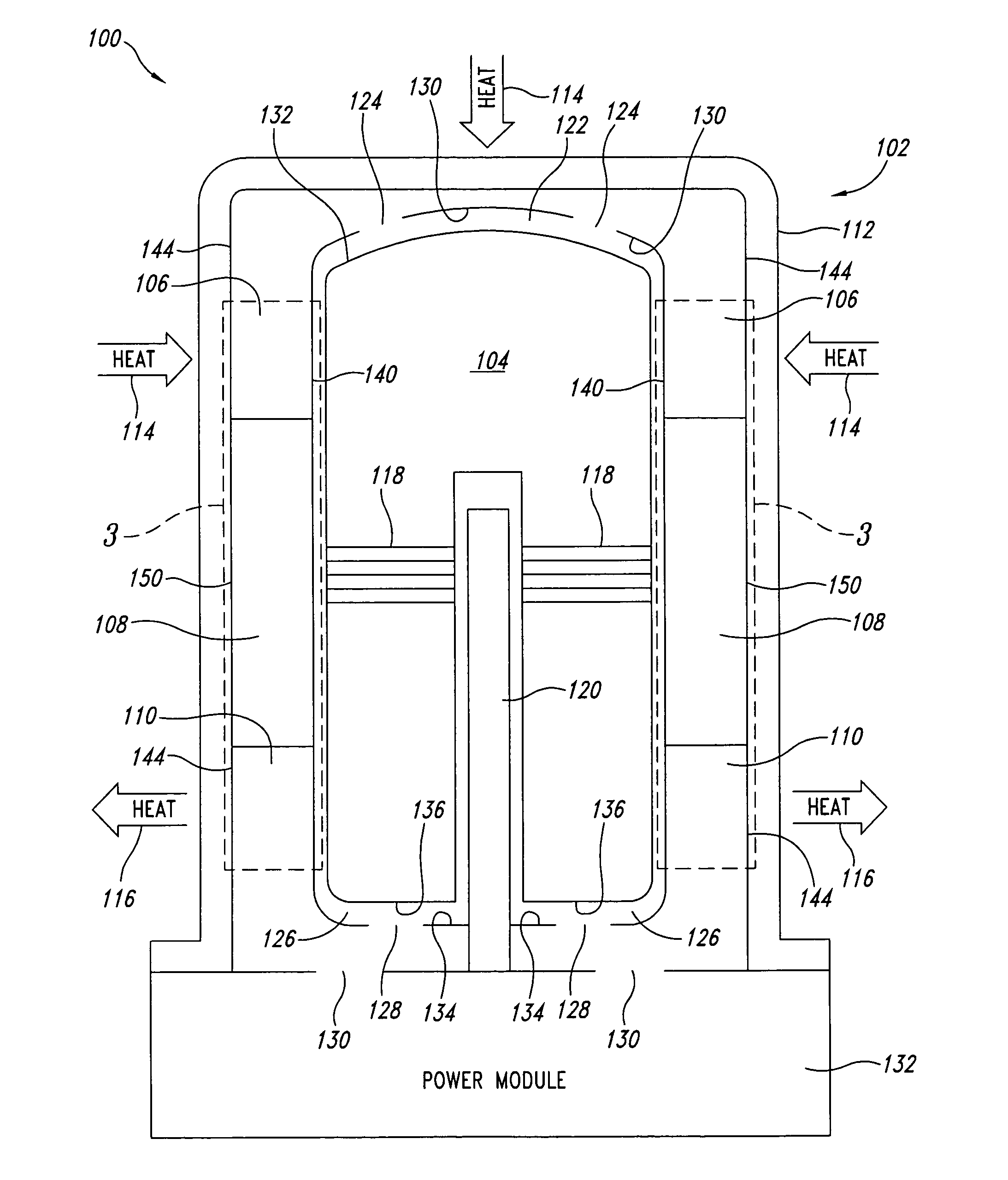

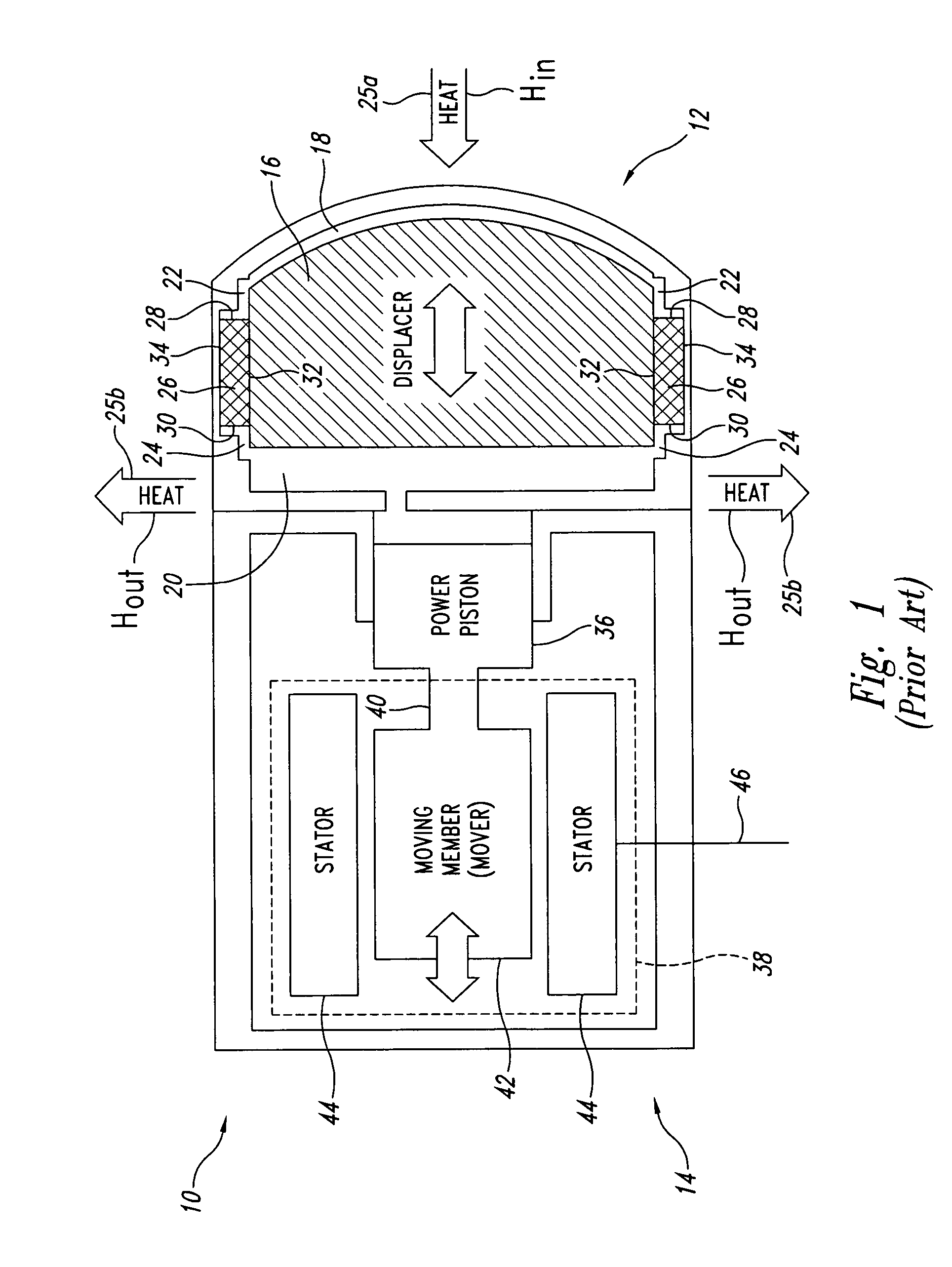

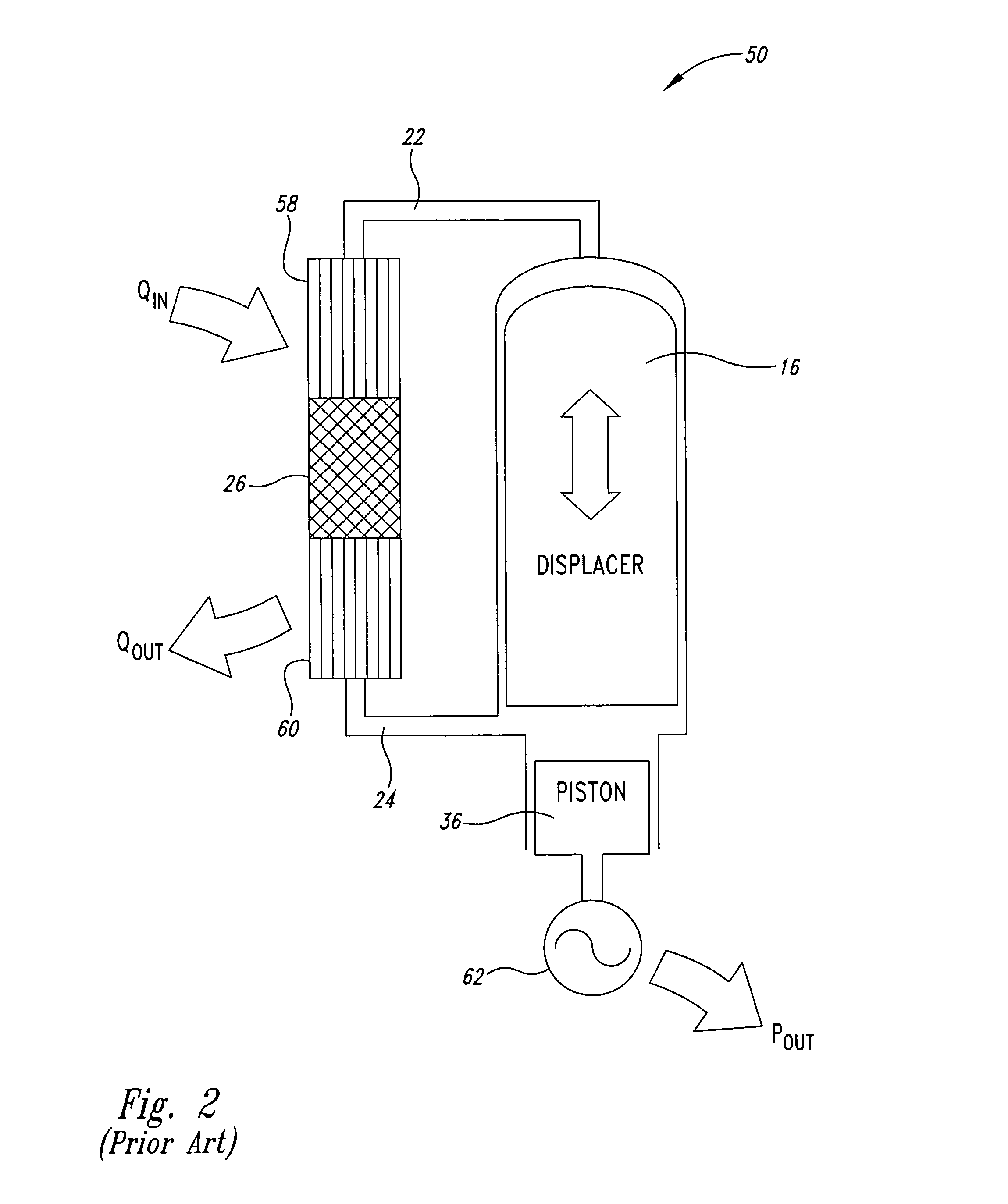

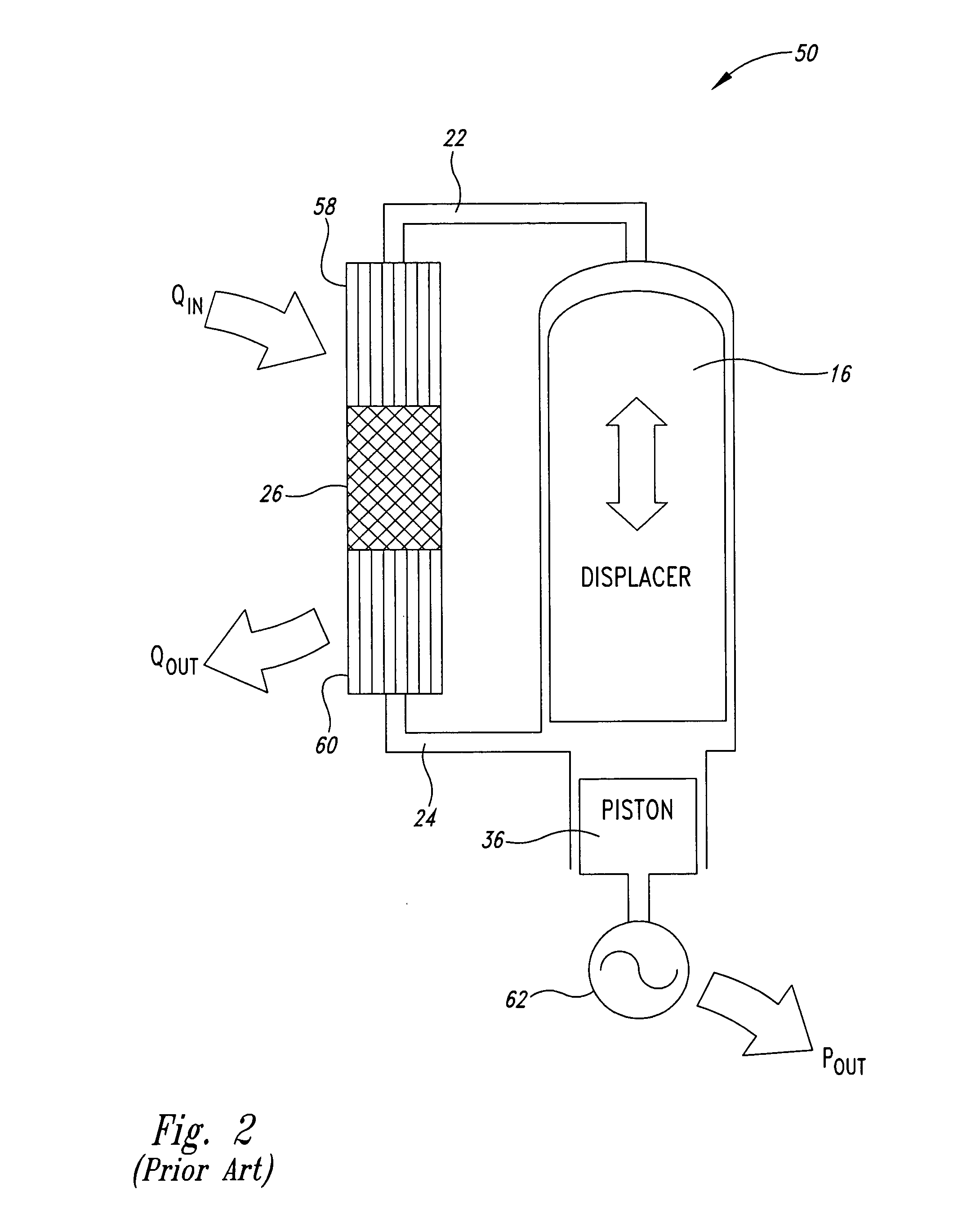

Channelized stratified regenerator with integrated heat exchangers system and method

InactiveUS20060179835A1Avoid short travelRegenerative heat exchangersClosed-cycle gas positive displacement engine plantWorking fluidStructural geometry

A channelized stratified regenerator with integrated heat exchangers are disclosed using micromachining to precisely construct structural geometries, such as fins and axial stratification of material to be used in a Stirling cycle based system. In operation, a working fluid passes through the regenerator when traveling between two heat exchangers. In some implementations, the regenerator and the heat exchangers are formed as a single construction. In other implementations, the regenerator and heat exchangers are formed separately, but are constructed to integrate efficiently with one another.

Owner:QNERGY

Direct hydrocarbon fuel cells

InactiveUS20020098401A1High mechanical strengthImprove toughnessFuel cells groupingFinal product manufactureHydrogenFuel cells

The direct electrochemical oxidation of hydrocarbons in solid oxide fuel cells, to generate greater power densities at lower temperatures without carbon deposition. The performance obtained is comparable to that of fuel cells used for hydrogen, and is achieved by using novel anode composites at low operating temperatures. Such solid oxide fuel cells, regardless of fuel source or operation, can be configured advantageously using the structural geometries of this invention.

Owner:NORTHWESTERN UNIV

Laser hard-surface coating process method of titanium alloy vane of gas turbine

InactiveCN101613860AEasy to adjustImprove physicsMetallic material coating processesLaser processingStructural geometry

The invention belongs to a laser processing technology for enhancing the surface hardness, i.e. the wearing resistance of titanium or titanium alloy, in particular to a laser hard-surface coating process method of a titanium alloy vane of a gas turbine. In the invention, corresponding mantle clamping fixture is adopted according to the geometrical shapes of structure of vane apex or damping convex shoulders of the vane, powder is placed in the mantle clamping fixture in advance, a static powder bed is formed by the mantle clamping fixture and the powder added in the mantle clamping fixture, powder is uniformly placed on the vane apex of the vane or the damping convex shoulders of the vane in advance by the static powder bed, and inert gases or N2 is adopted to protect a laser radiation area and carry out laser radiation on the vane. A hard-surface coating with the hardness of 35 to 62 HRC and the thickness of 0.05 to 2.0mm can be formed on the vane apex or the damping convex shoulder of the titanium alloy vane when the invention is adopted. The invention has the advantages that vacuum is not needed; laser cladding can be carried out only under the protection of inert gases of Ar, He, and the like in atmosphere conditions; the operation is convenient; and the formed hard-surface coating and basal body of the vane have good adapter properties in physics and chemistry.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Container Handling System

ActiveUS20090120530A1Smooth for label placementThorough removalSynchronising machinesFilling using counterpressureBlow moldingStructural geometry

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

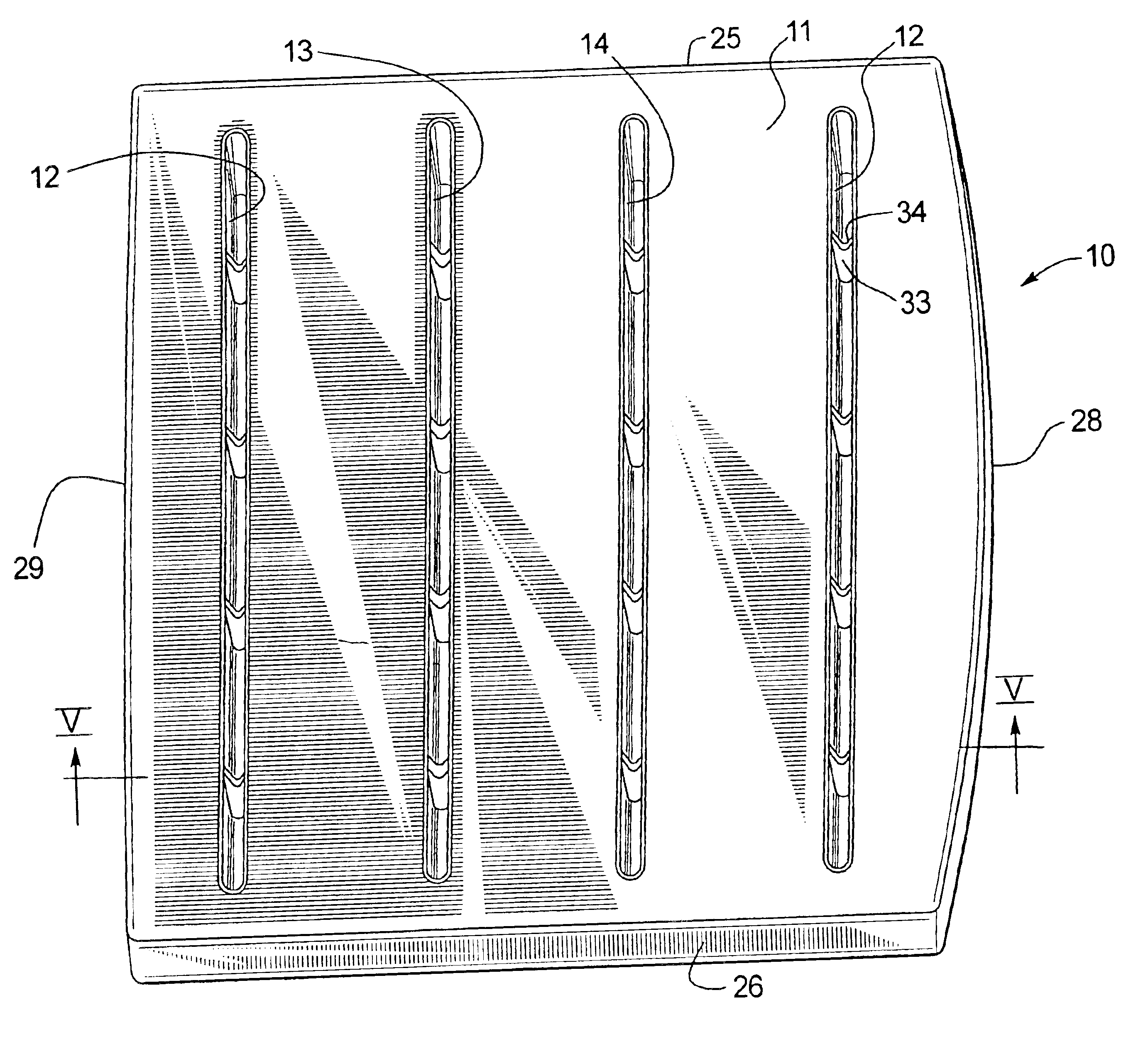

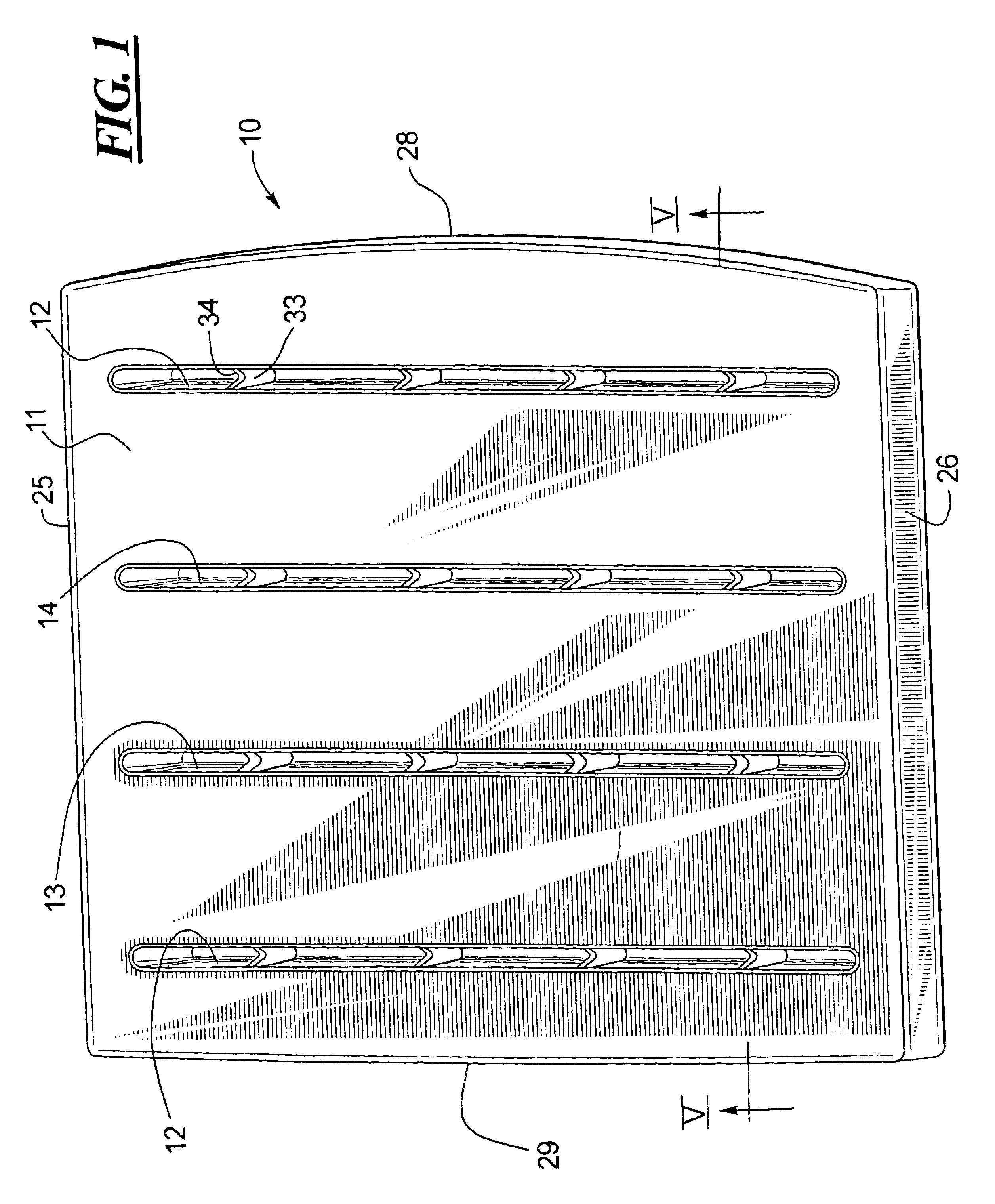

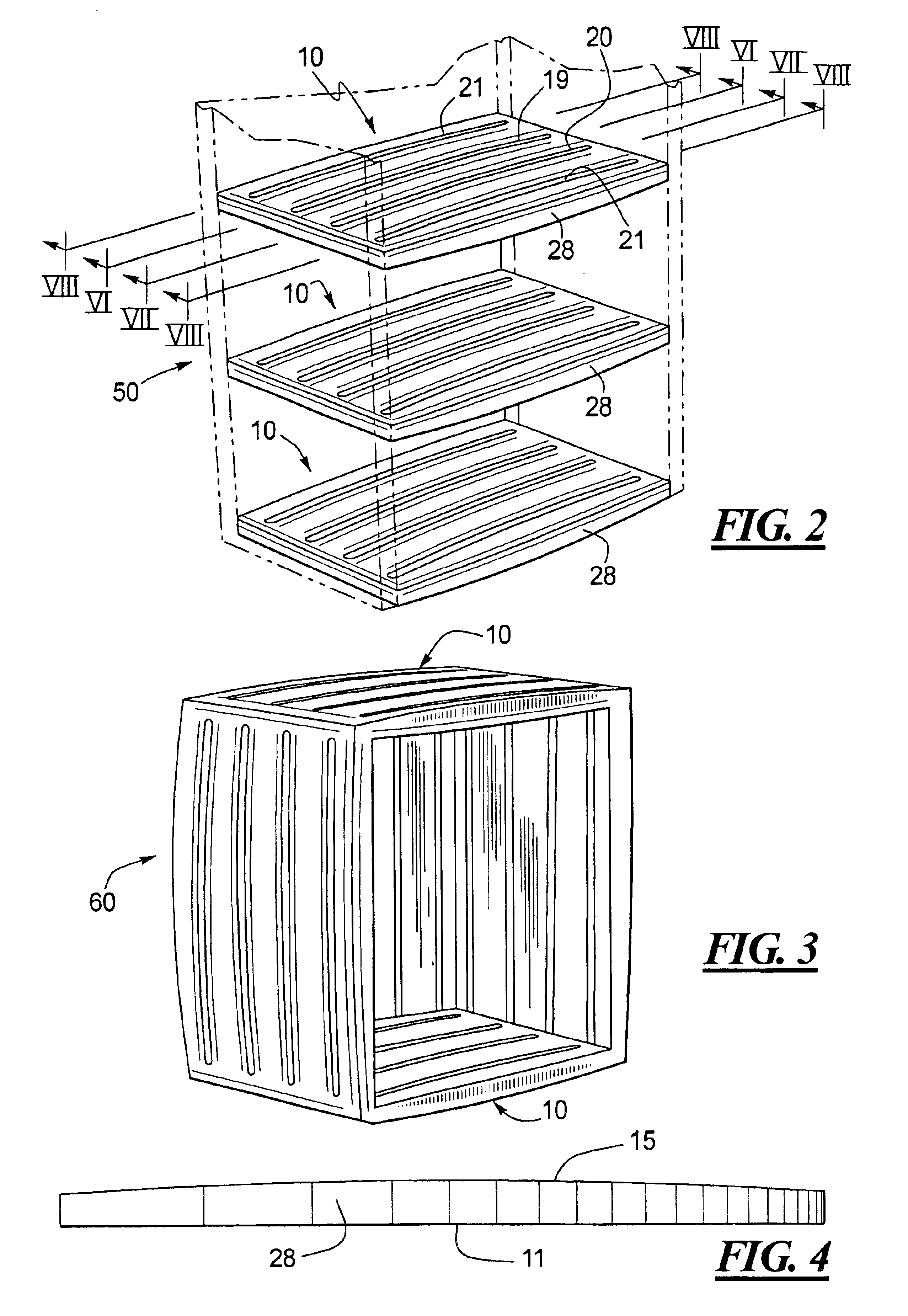

Plastic blow-molded panel with improved structural geometry

An improved plastic blow-molded panel structure is shown and described that is lightweight and provides superior resistance to sagging, warping and creeping under high stress loads, especially when used in a horizontal position. The disclosed panel structure includes a combination of transverse or lateral beams extending from the second panel towards the first panel and, in certain embodiments, a plurality of transverse ribs disposed within the lateral beams. The disclosed shelving units may be fabricated from conventional blow-molding processes.

Owner:RUBBERMAID

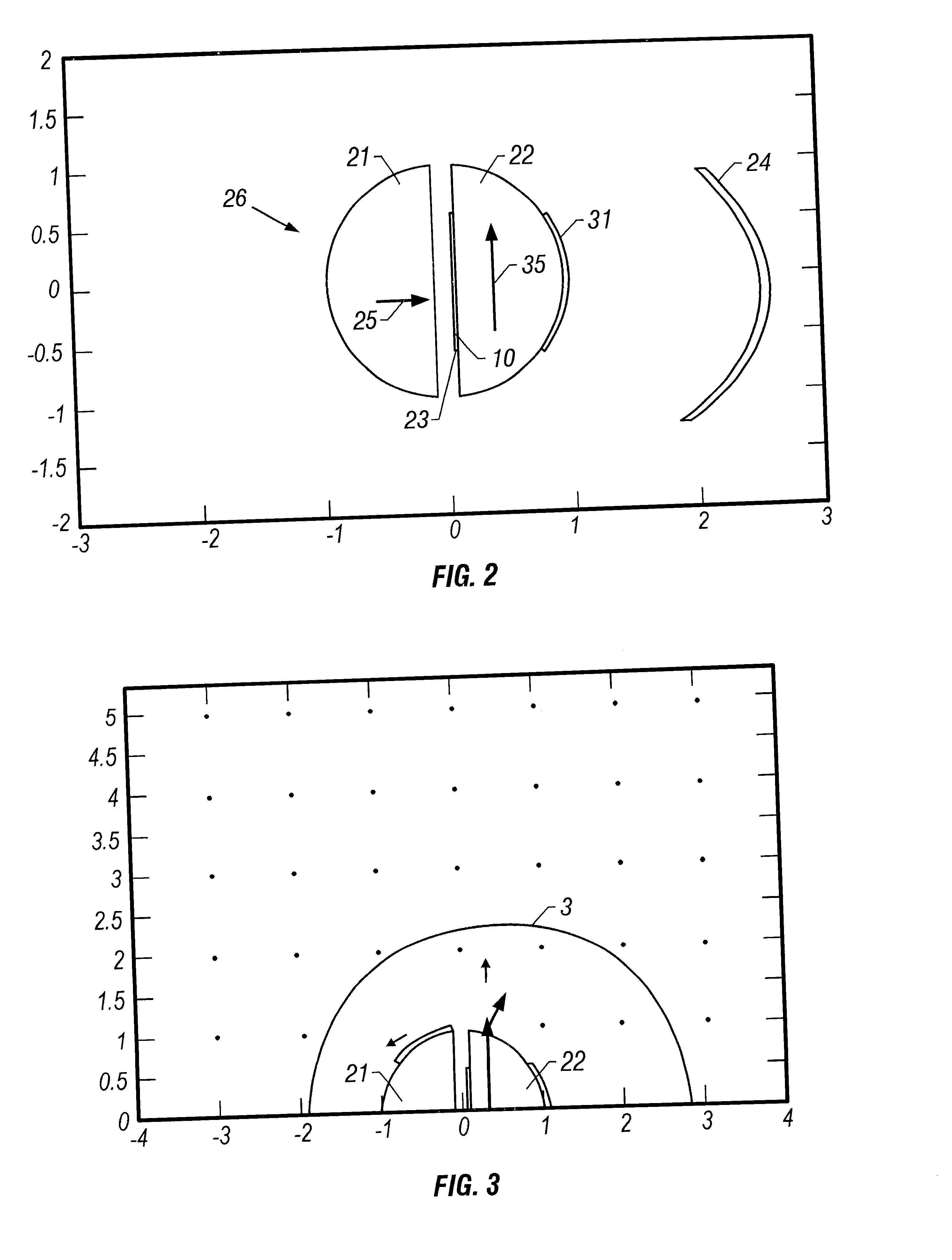

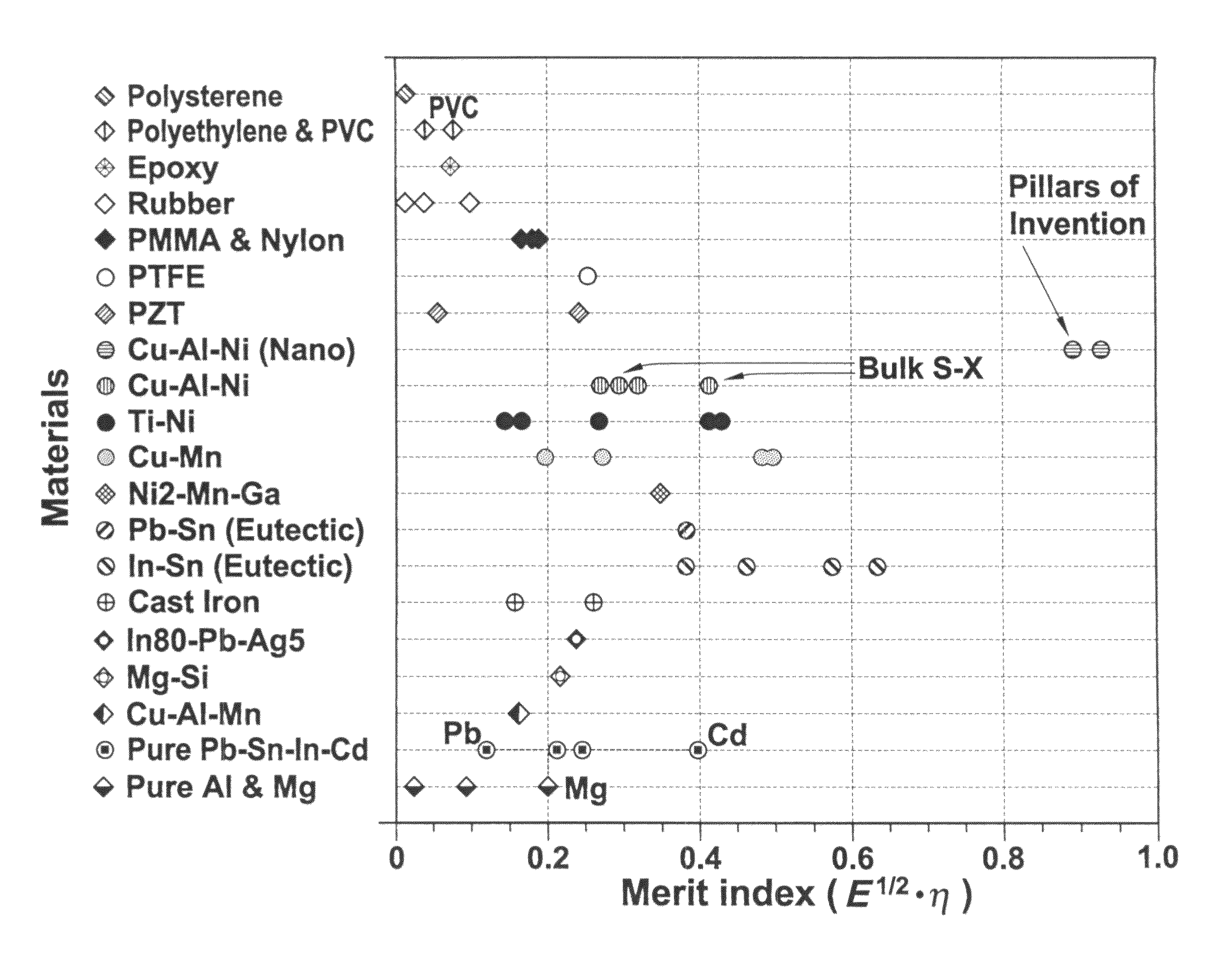

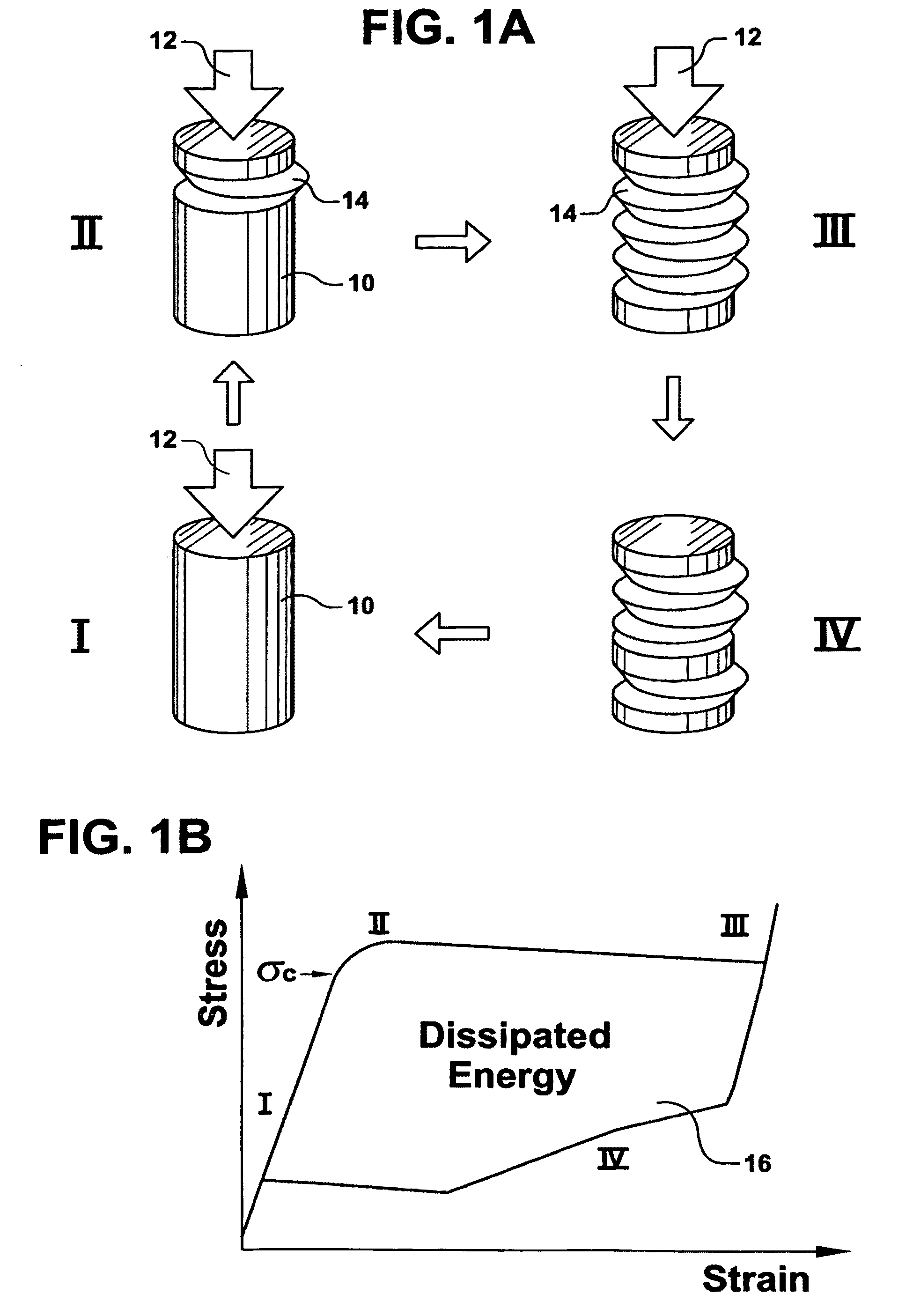

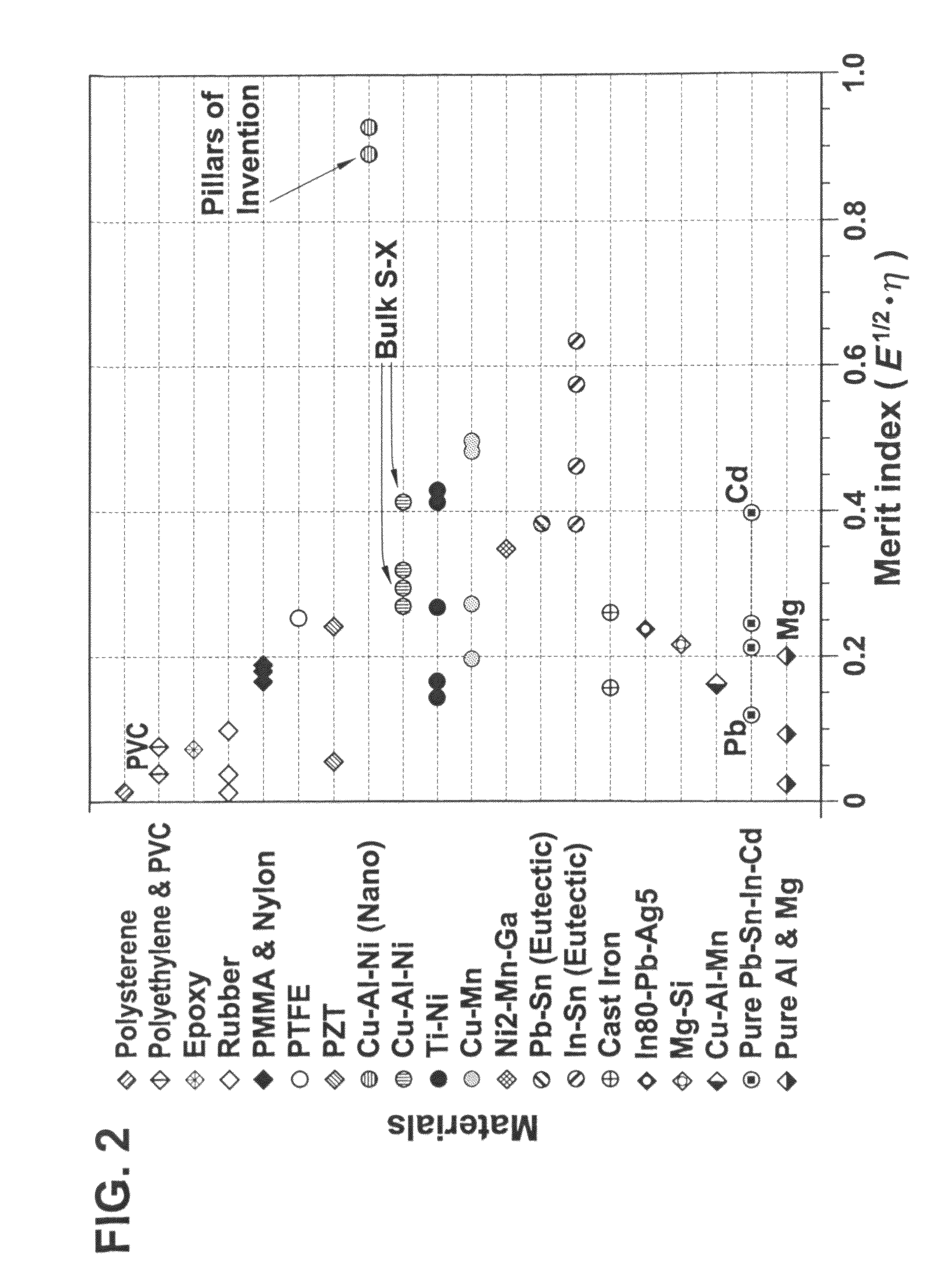

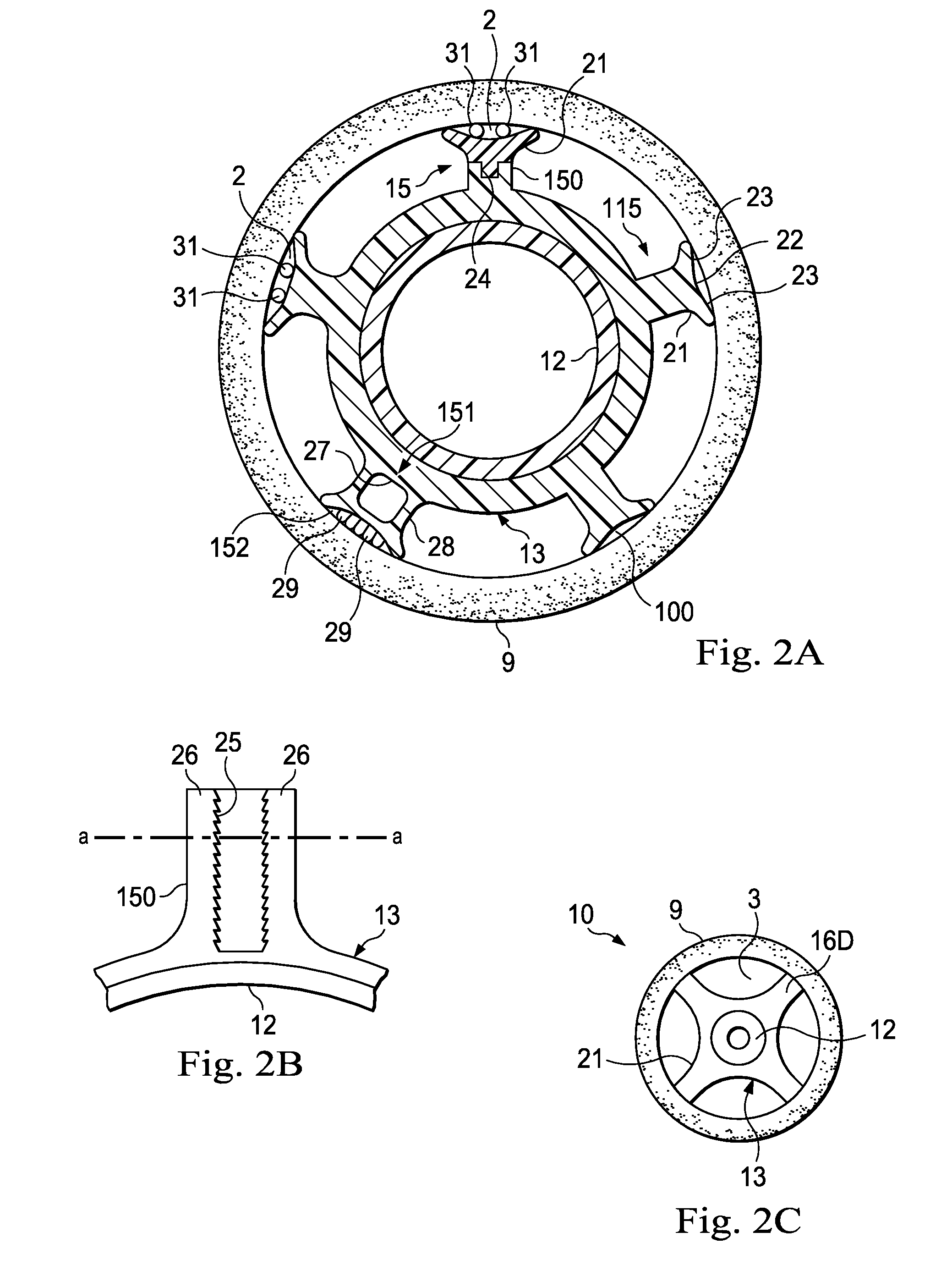

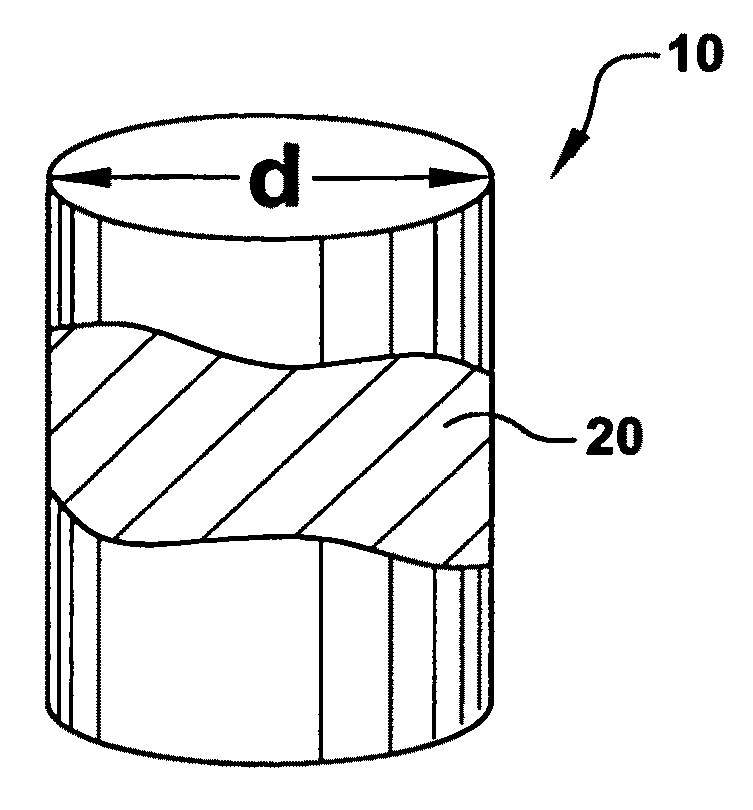

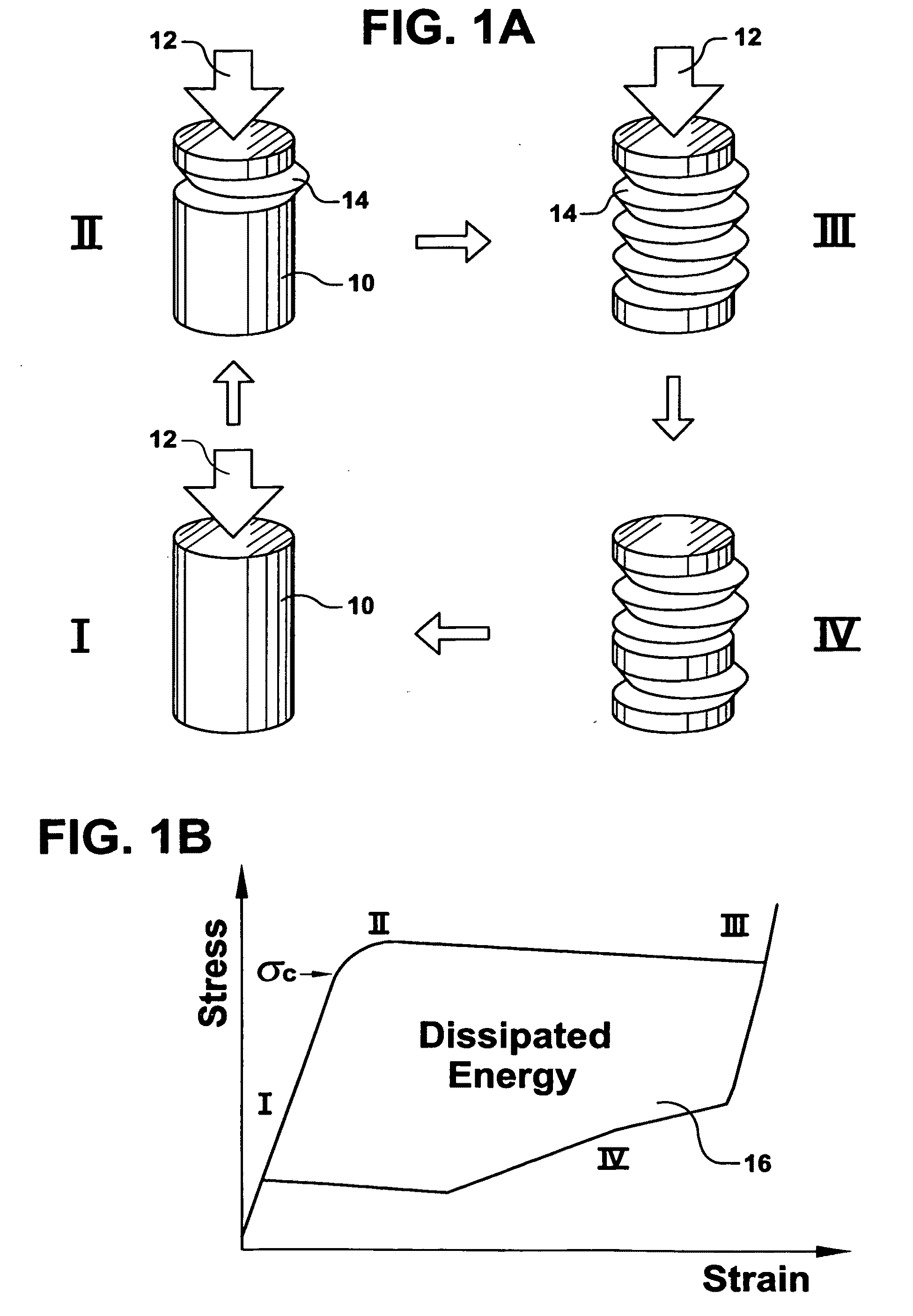

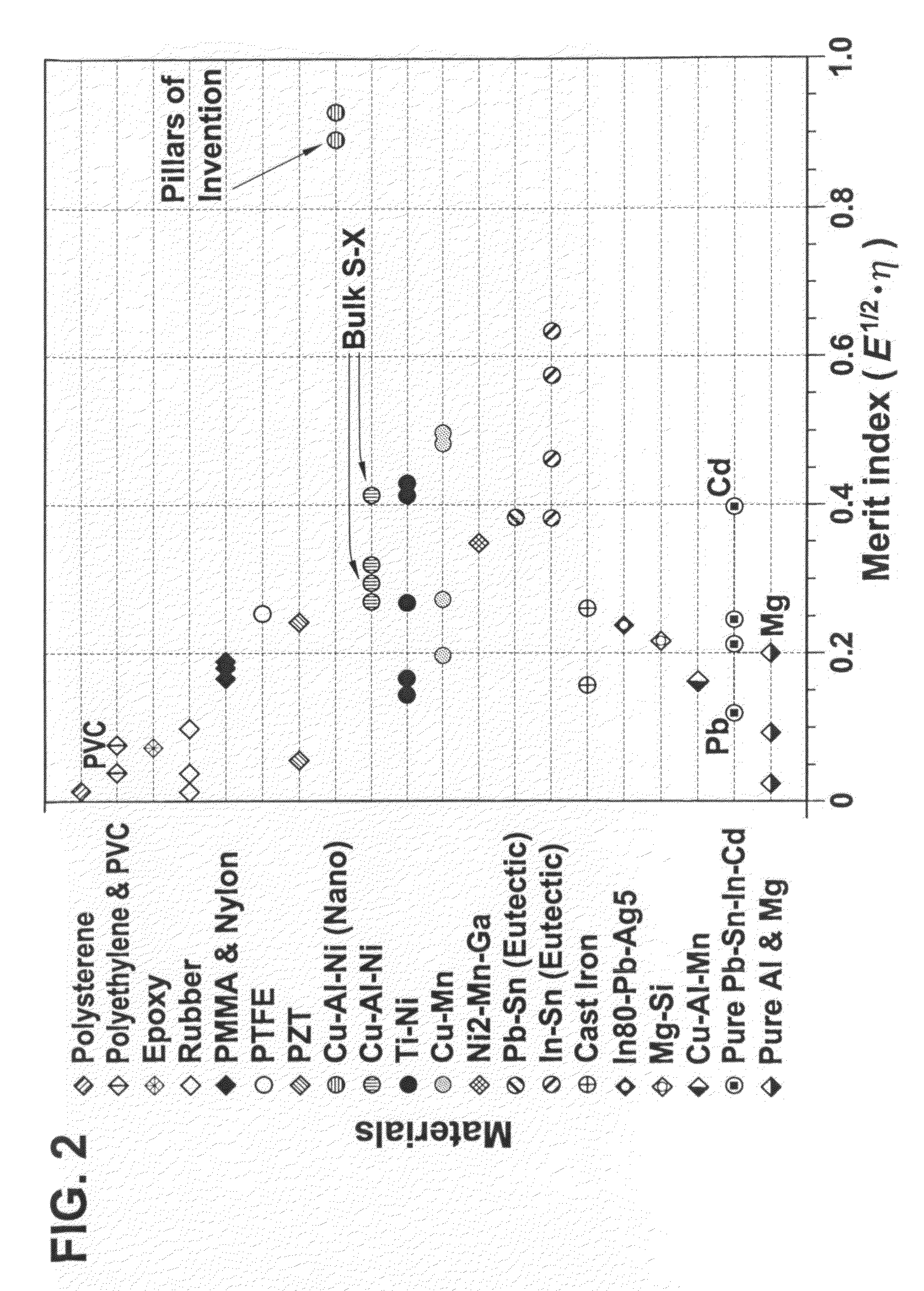

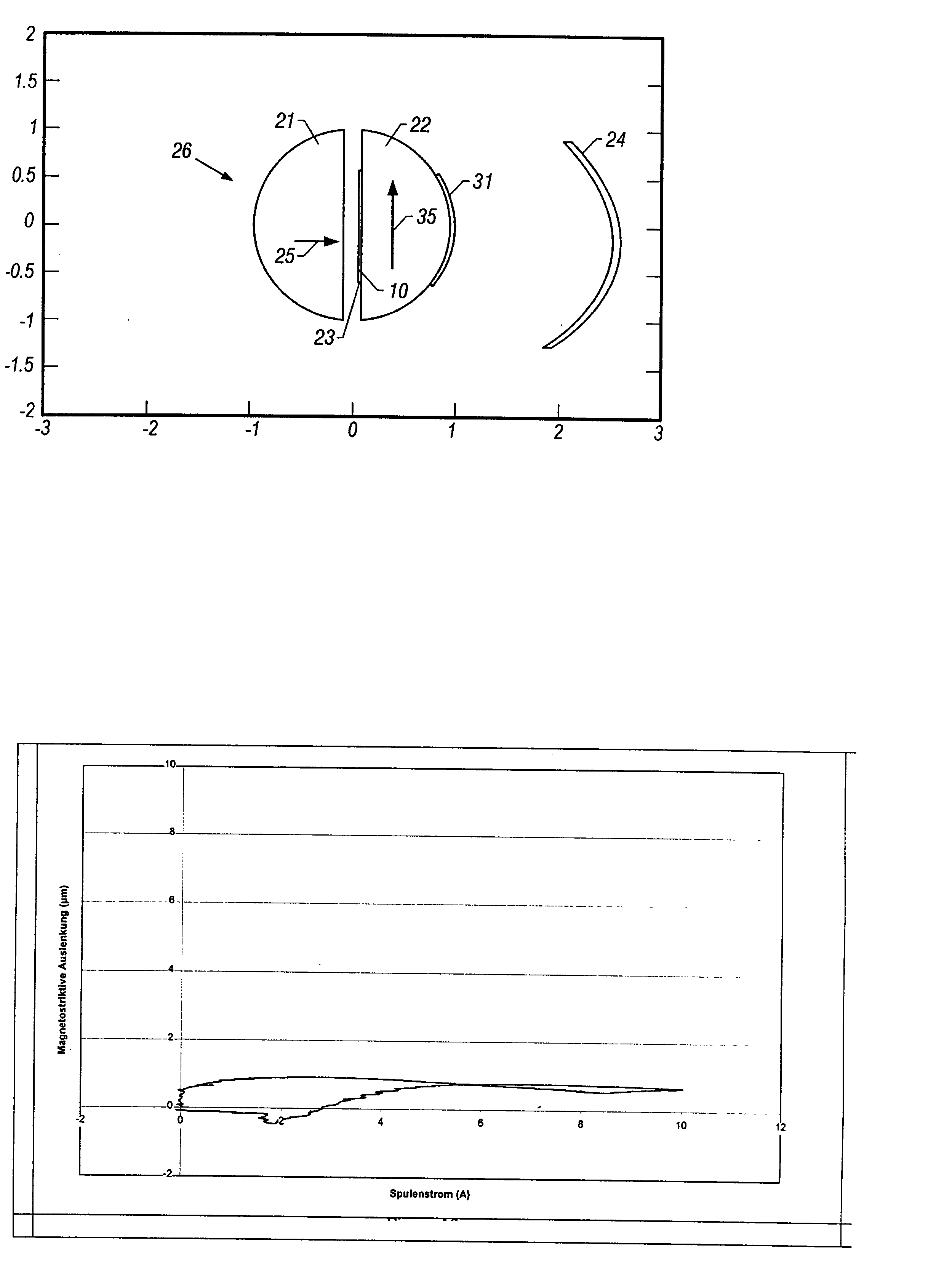

Superelastic alloy structural geometry for ultrahigh mechanical damping

ActiveUS8282746B2Ultra-high-damping performance characteristicsAccurate and reliable processSpringsStands/trestlesMartensite transformationMicrometer

A mechanical structure is provided with a crystalline superelastic alloy that is characterized by an average grain size and that is characterized by a martensitic phase transformation resulting from a mechanical stress input greater than a characteristic first critical stress. A configuration of the superelastic alloy is provided with a geometric structural feature of the alloy that has an extent that is no greater than about 200 micrometers and that is no larger than the average grain size of the alloy. This geometric feature is configured to accept a mechanical stress input.

Owner:MASSACHUSETTS INST OF TECH

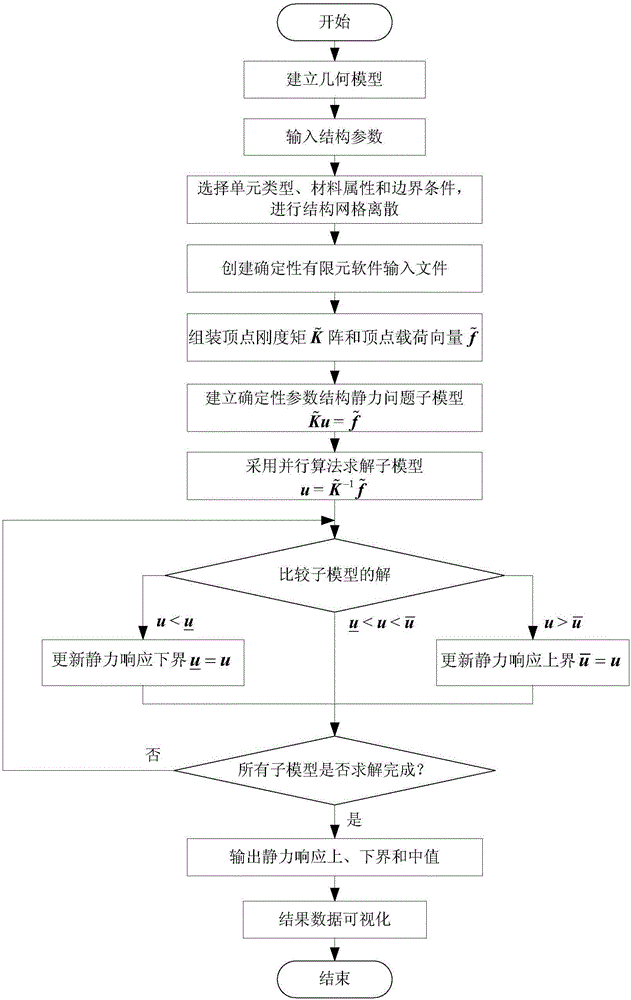

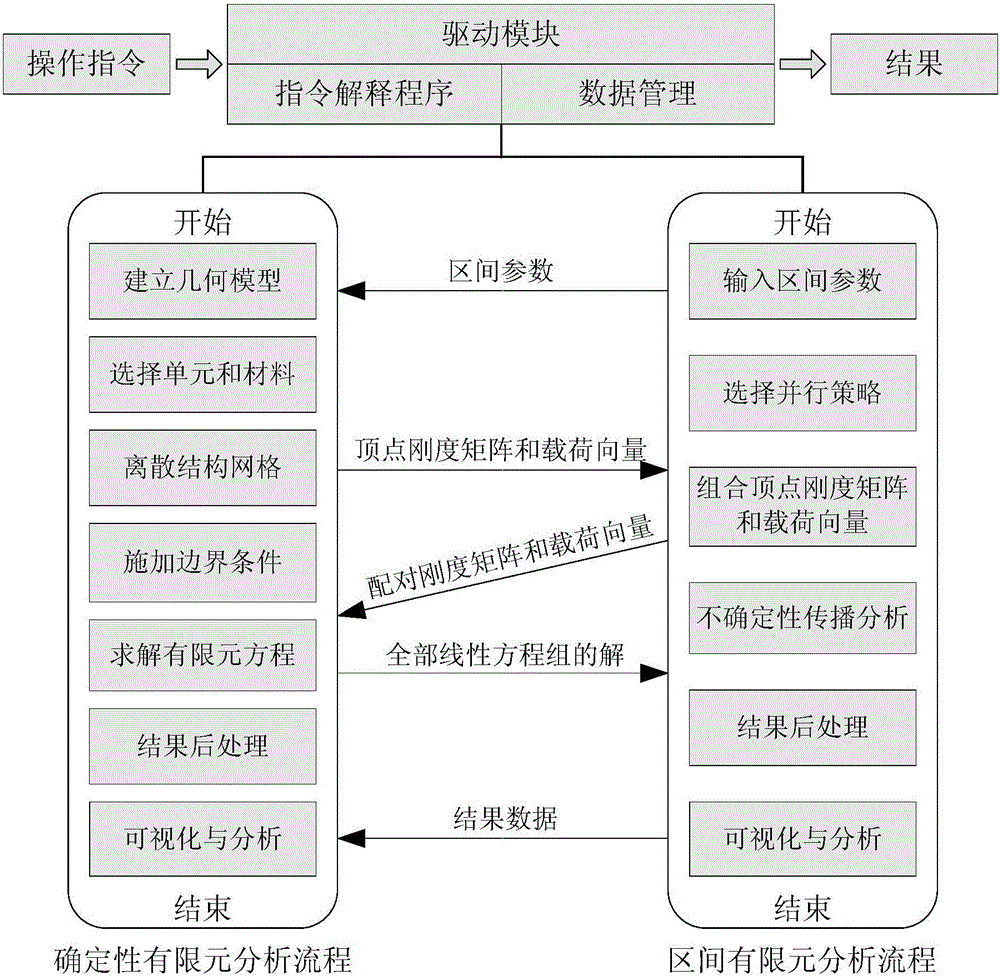

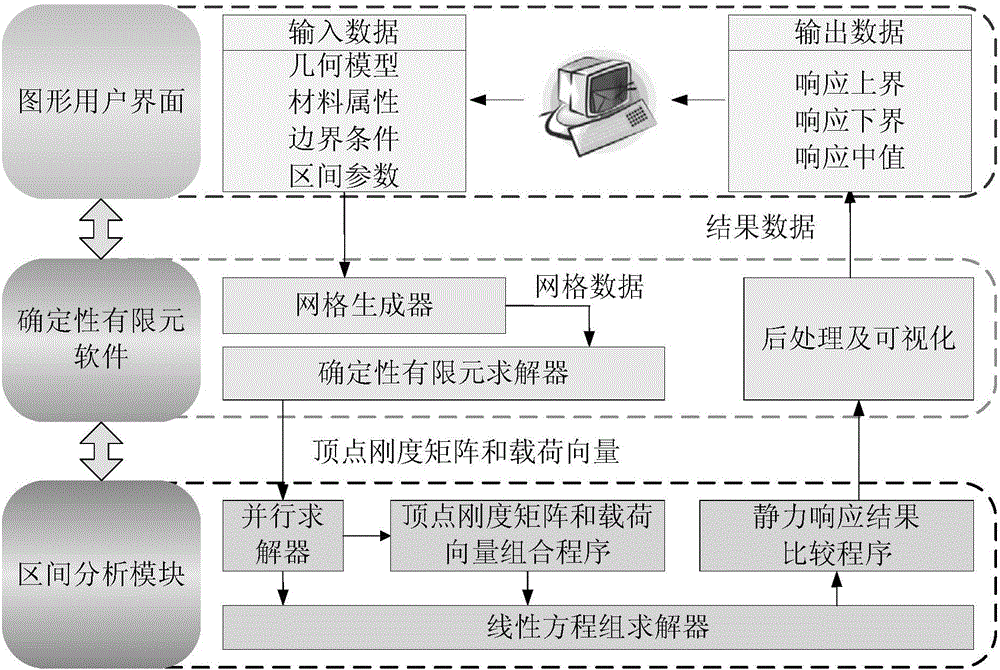

Method for applying deterministic finite element software to analysis of simple or large-size complicated structure containing interval parameters

ActiveCN106021824ASolve problemsMeet the practical needs of uncertainty analysisDesign optimisation/simulationSpecial data processing applicationsStructure analysisStructural geometry

The invention discloses a method for applying deterministic finite element software to the analysis of a simple or large-size complicated structure containing interval parameters. The method for applying the deterministic finite element software to the analysis of the simple or large-size complicated structure containing the interval parameters comprises the following steps of (1), establishing the geometric model of the structure; (2), inputting the interval parameters of the structure; (3), selecting a unit type, a material attribute and a boundary condition, and carrying out grid discretization on the structure; (4), getting back data in steps (2) and (3) to construct an input file of the deterministic finite element software; (5), running the deterministic finite element software to generate a vertex stiffness matrix and a vertex load vector; (6), converting the static problem of the structure containing the interval parameters into a series of sub-models of the static problem of a structure containing deterministic parameters according to a vertex solution theorem; (7), solving the sub-models by adopting a parallel algorithm, so as to obtain structural static responses of all the sub-models; (8), carrying out post processing on a result to obtain the upper bounds, the lower bounds and the mid-values of the structural static responses, and carrying out result visualization as required. By using the method for applying the deterministic finite element software to the analysis of the simple or large-size complicated structure containing the interval parameters, a succinct and effective method is provided for solving the interval analysis of the complicated structure.

Owner:BEIHANG UNIV

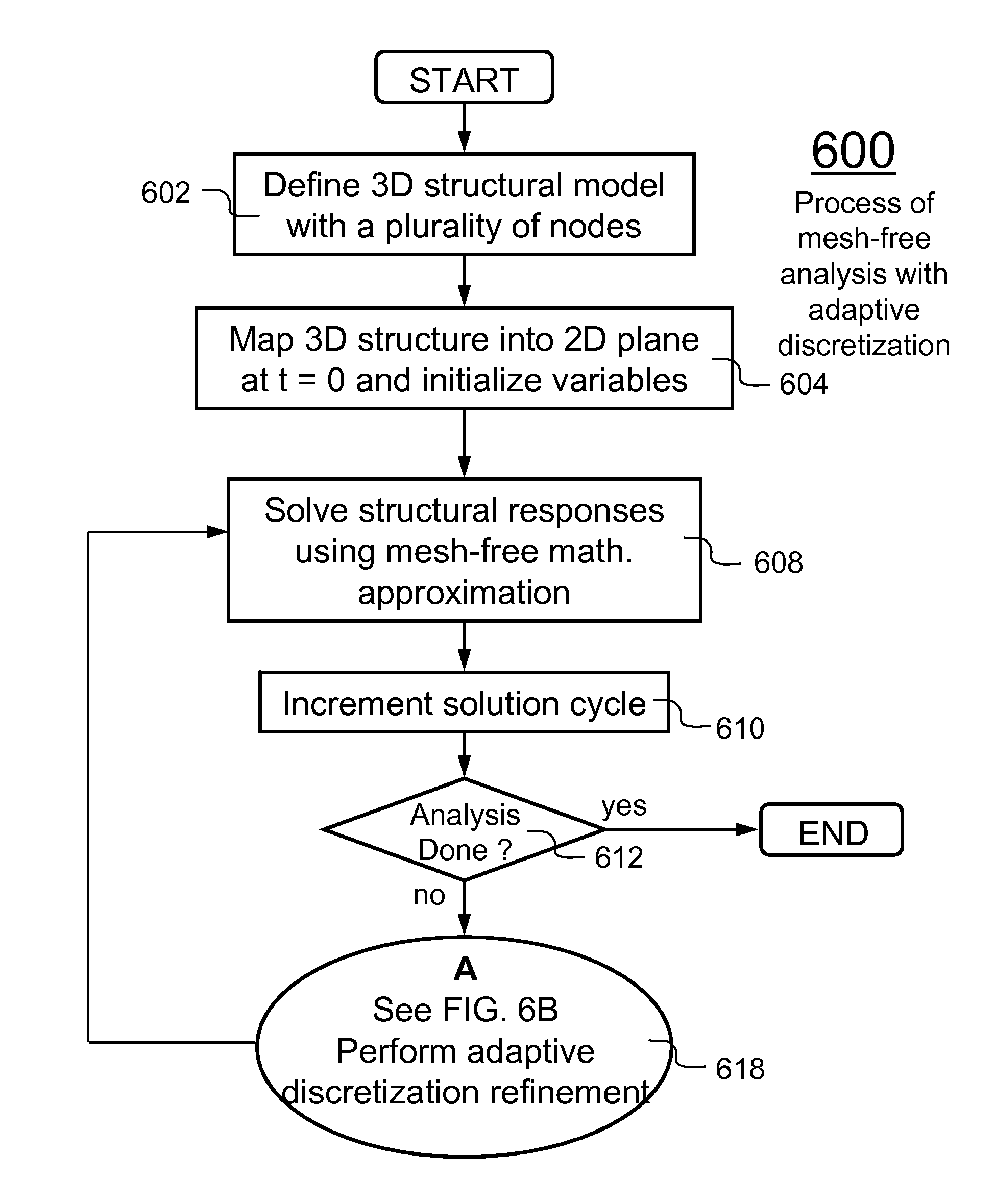

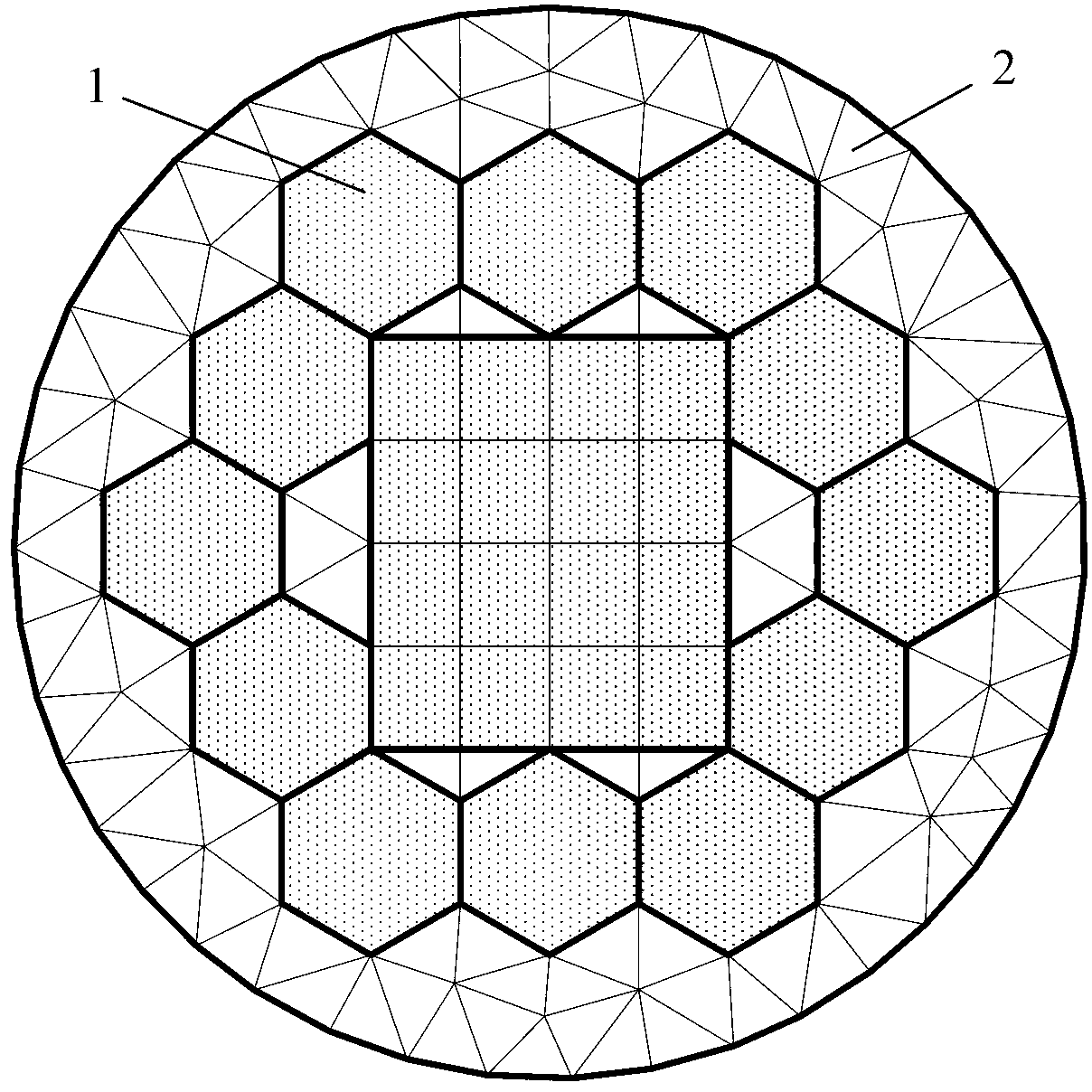

Method and system for adaptive mesh-free shell structures

ActiveUS7702490B1Efficient analysisRealistic analytical resultComputation using non-denominational number representationDesign optimisation/simulationComputational scienceTime domain

A method, system and computer program product pertained to adaptive discretization refinement of shell structure is disclosed. The adaptive mesh-free model is based on a technique for dividing the critical area into a finer model. The present invention is a method for enabling adaptive mesh-free shell structure in a time-domain analysis, the method comprises: defining the mesh-free shell structure by a structural geometry description file including a plurality of nodes and a reference 3-D mesh, which includes a plurality of shell elements, mapping the 3-D reference mesh into a 2-D parametric plane, wherein the 2-D parametric mesh includes a plurality of integration cells corresponding to the plurality of shell elements, solving structural responses at current solution cycle using mesh-free mathematical approximations pertaining to each of the plurality of integration cells, performing adaptive discretization refinement for the plurality of the integration cells.

Owner:ANSYS

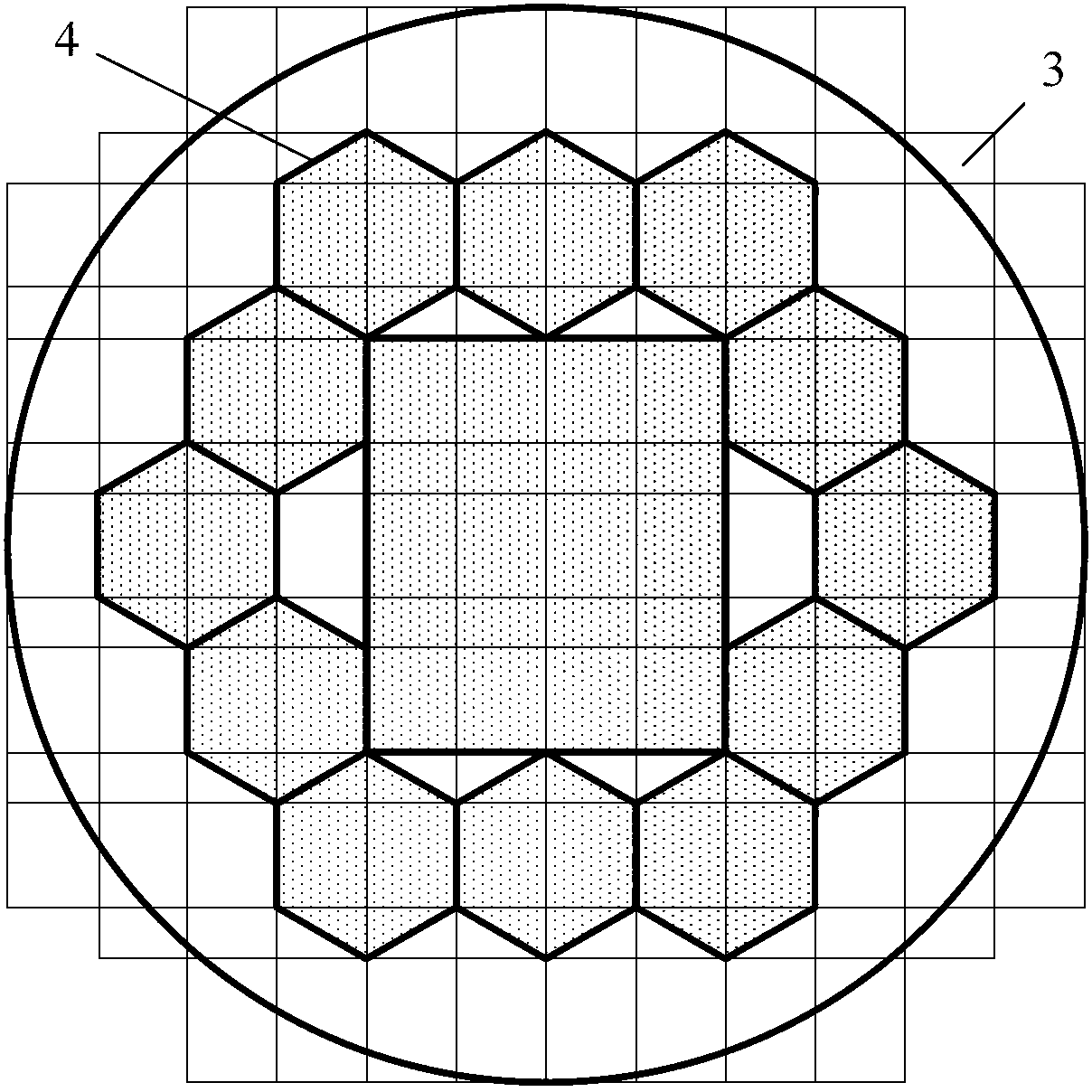

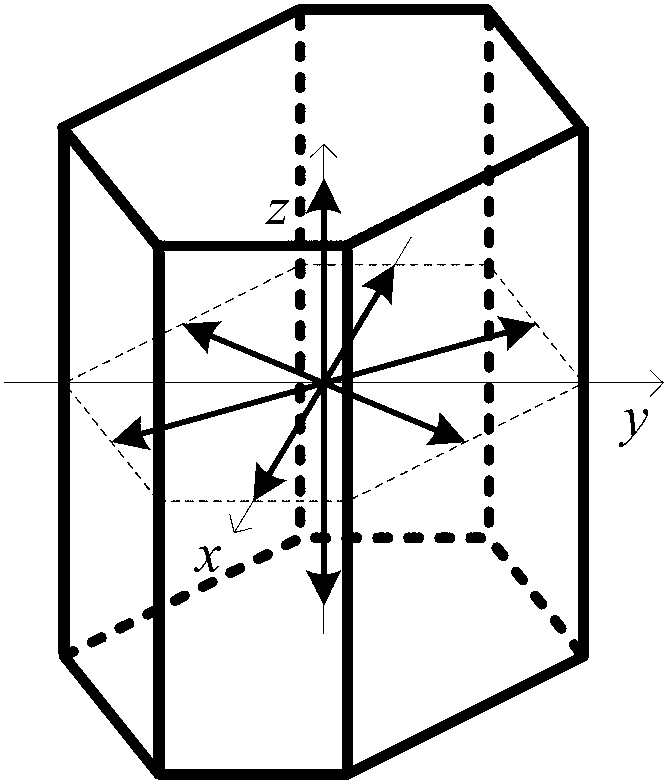

Method for calculating single rod power of overall reactor core

InactiveCN103294898AGuaranteed accuracySpecial data processing applicationsNuclear reactor coreNuclear reactor

Discloses is a method for calculating single rod power of an overall reactor core. The method includes steps of 1), determining geometrical and material parameters of a target nuclear reactor according a reactor core structure thereof; establishing an SP3 equation set of step 0 or step 2 neutron angular flux torque density according to a multigroup neutron transport theory; 2), adopting structural grids to subdivide structural geometry zones with corresponding shapes, and unstructured grids to subdivide unstructured geometry zones; 3), establishing a segment SP3 method, subjecting the SP3 equation set in the step 2) to numerical discretion by adopting approximate processing modes which are mutually compatible under a structural grid and the unstructured grid, and acquiring neutron-flux density on all grids of the nuclear reactor core by utilizing iterative algorithm to solve discrete algebraic equation set; 4), adopting the neutron-flux density acquired in the step 3) to calculate the single rod power of the overall reactor core. By reducing approximation from grid subdivision, approximation from the numerical discretion and iterative calculation process and approximation from component homogenization and component power reconstitution, the high-precision single rod power of the overall reactor core can be calculated.

Owner:XI AN JIAOTONG UNIV

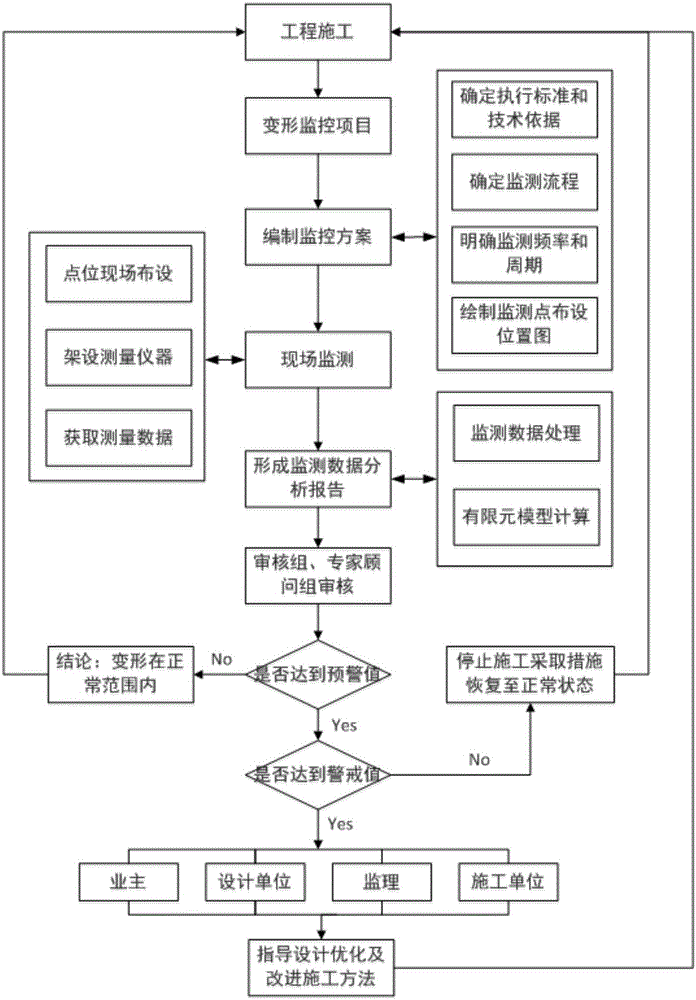

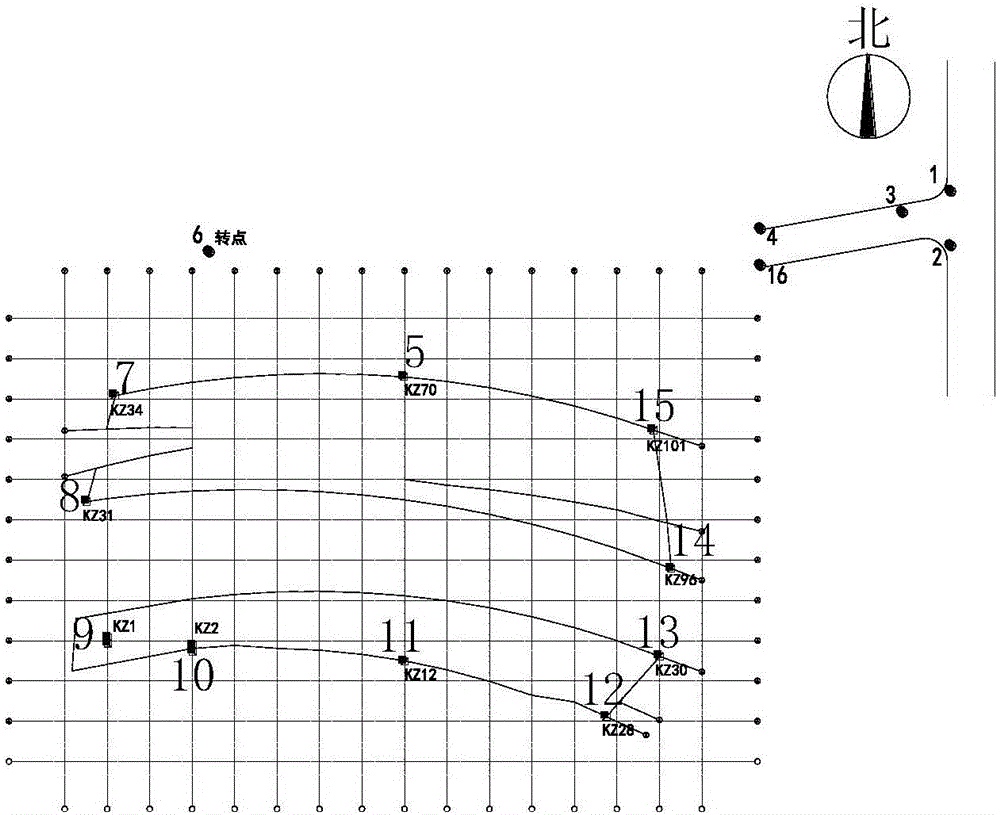

Structural geometric deformation safety monitoring method

The invention provides a structural geometric deformation safety monitoring method. Deformation data of the structure in different working conditions are measured, a formula is used for deducing corresponding structure deformation values in different working conditions, the actual structure deformation value acquired through measurement and a simulated deformation value calculated by a finite element model are compared, and the deformation value is ensured to be in a safety range specified by specifications. As for a building, inter-floor deformation and total floor deformation are included. In a condition in which the structural geometric deformation tends to be unsafe, pre-judgment is made timely, corresponding processing measures are taken, and the monitored structure deformation can still be in the safety range during the building process.

Owner:SHANGHAI CONSTRUCTION GROUP

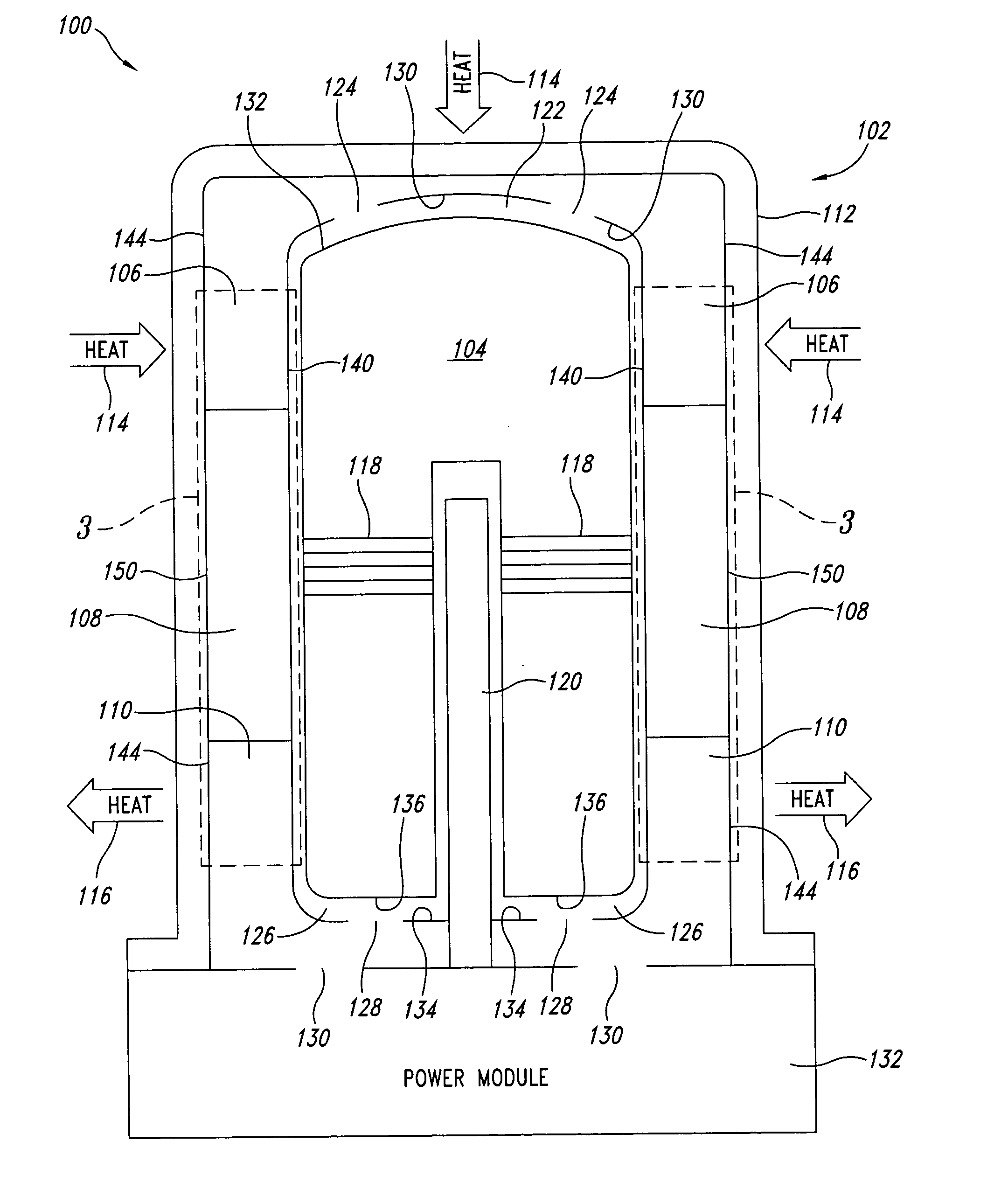

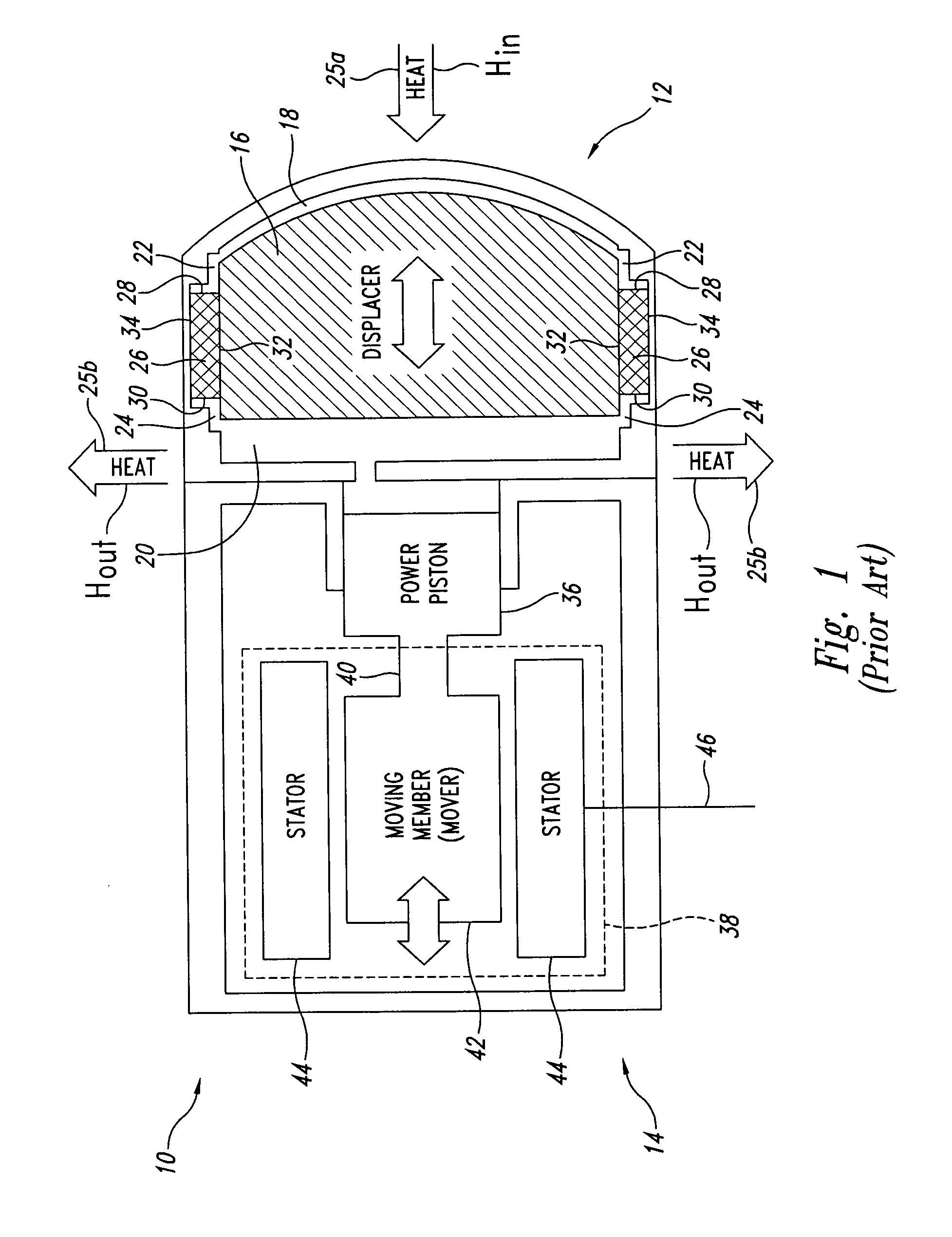

Channelized stratified regenerator system and method

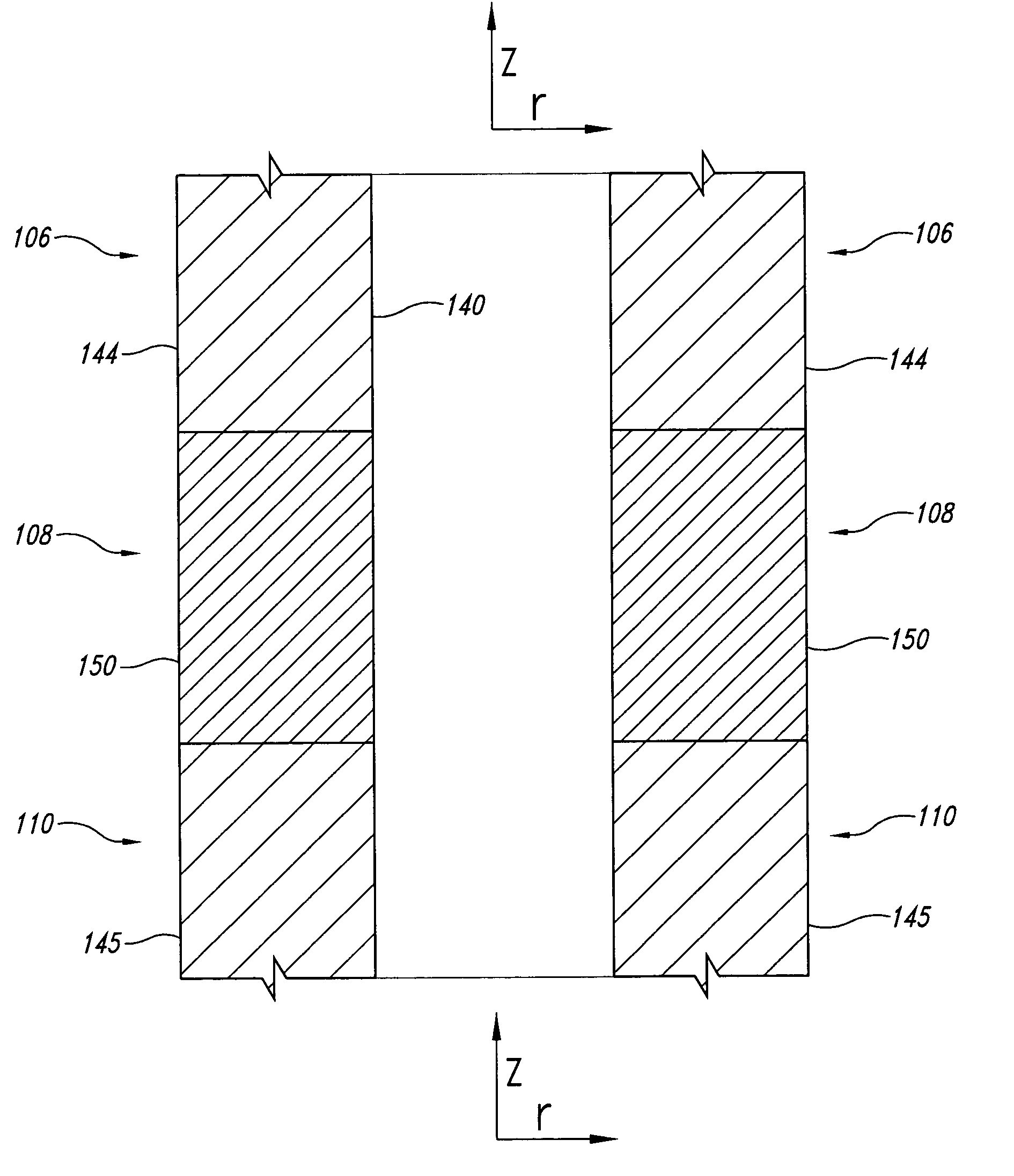

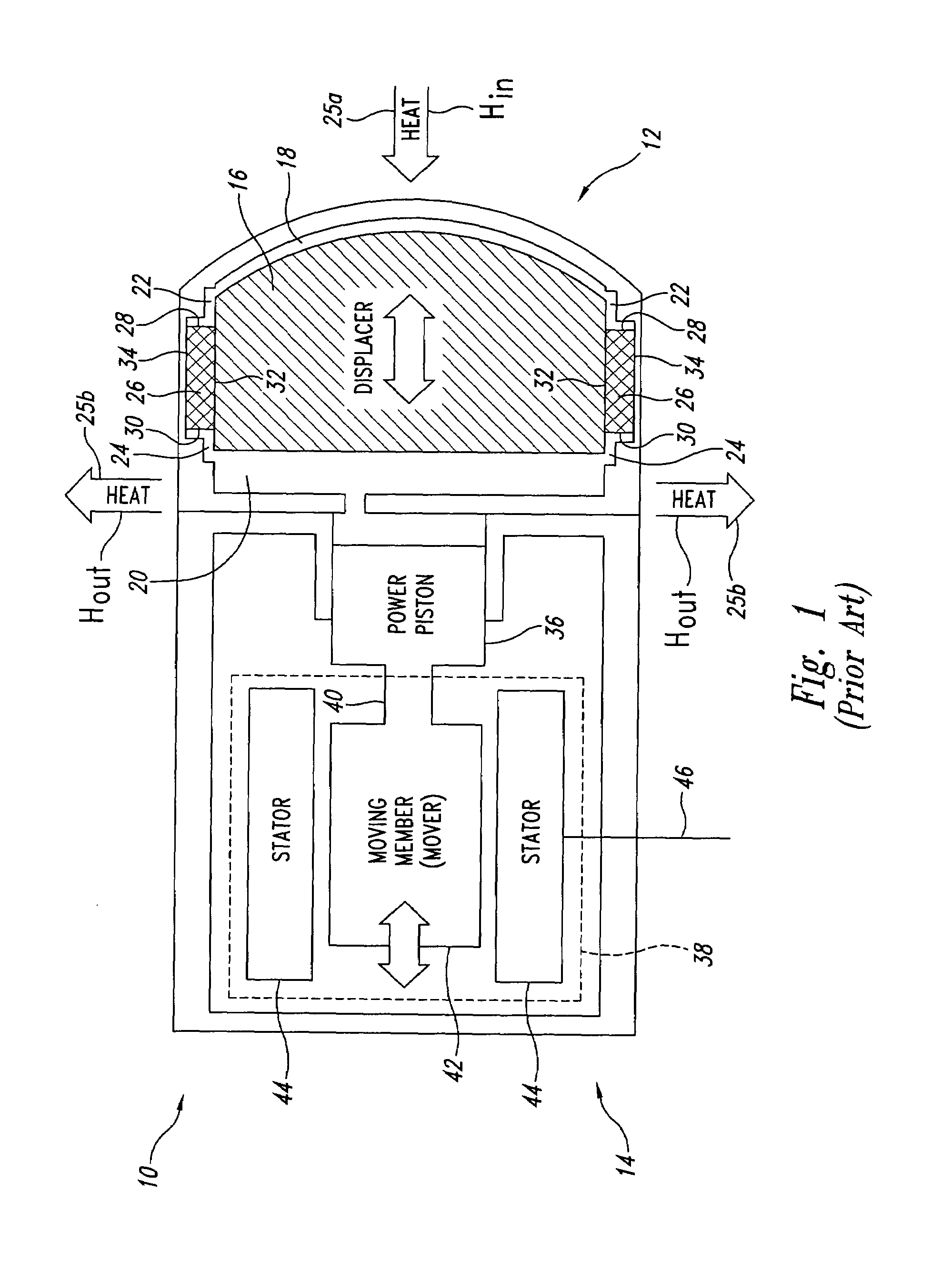

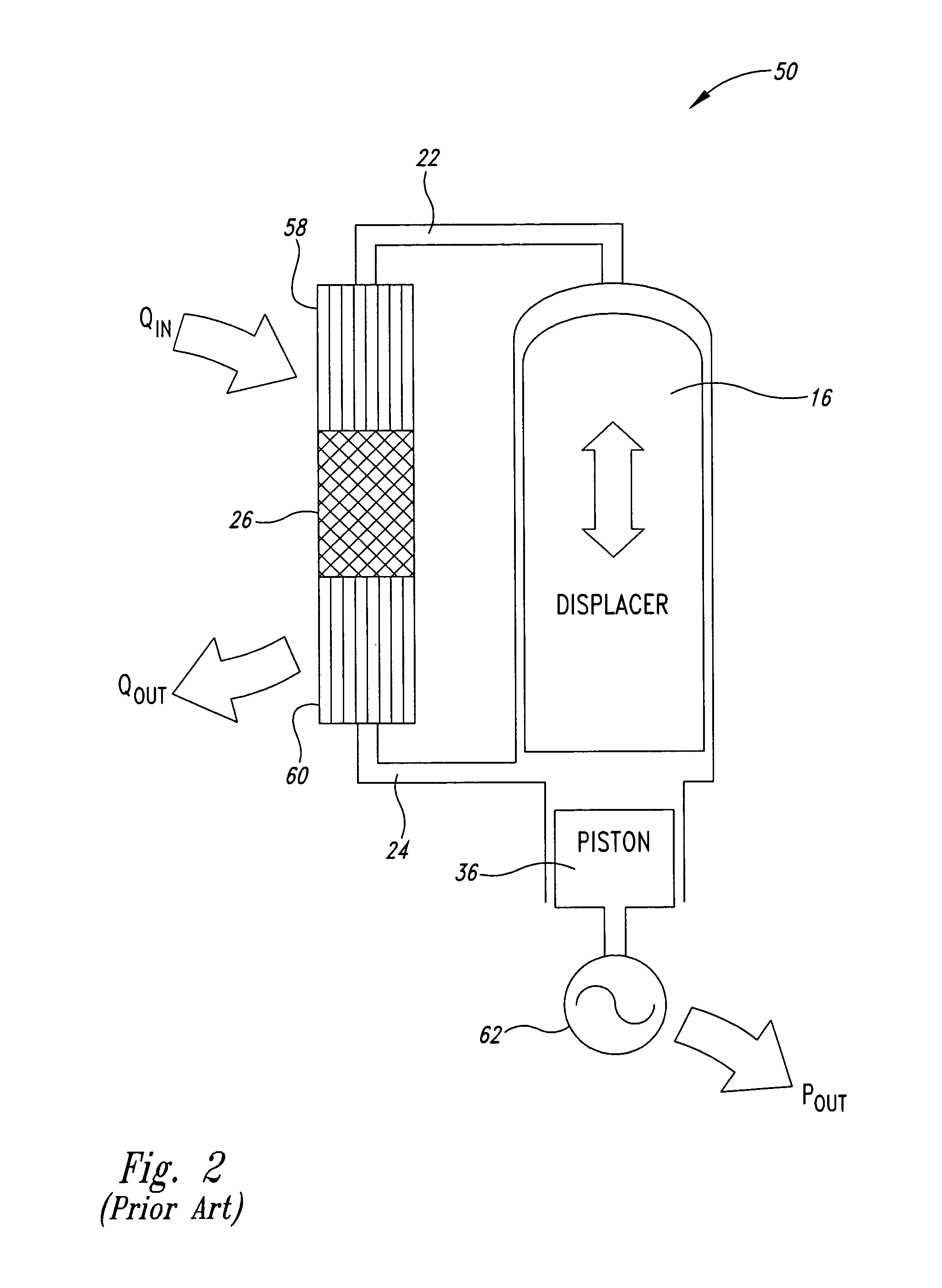

InactiveUS7089735B1Avoid short travelClosed-cycle gas positive displacement engine plantPlate heat exchangerWorking fluid

A channelized stratified regenerator with integrated heat exchangers are disclosed using micromachining to precisely construct structural geometries, such as fins and axial stratification of material to be used in a Stirling cycle based system. In operation, a working fluid passes through the regenerator when traveling between two heat exchangers. In some implementations, the regenerator and the heat exchangers are formed as a single construction. In other implementations, the regenerator and heat exchangers are formed separately, but are constructed to integrate efficiently with one another.

Owner:QNERGY

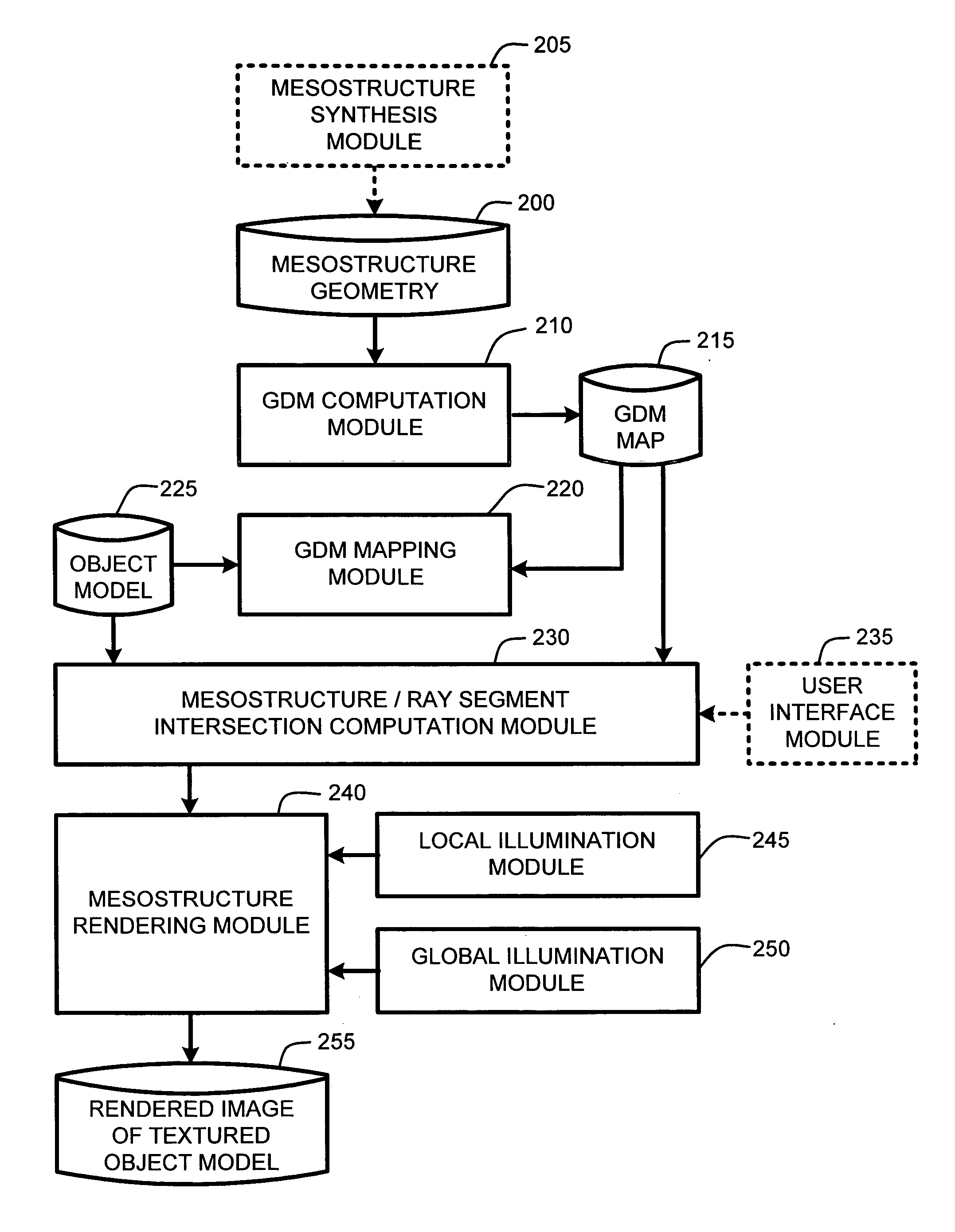

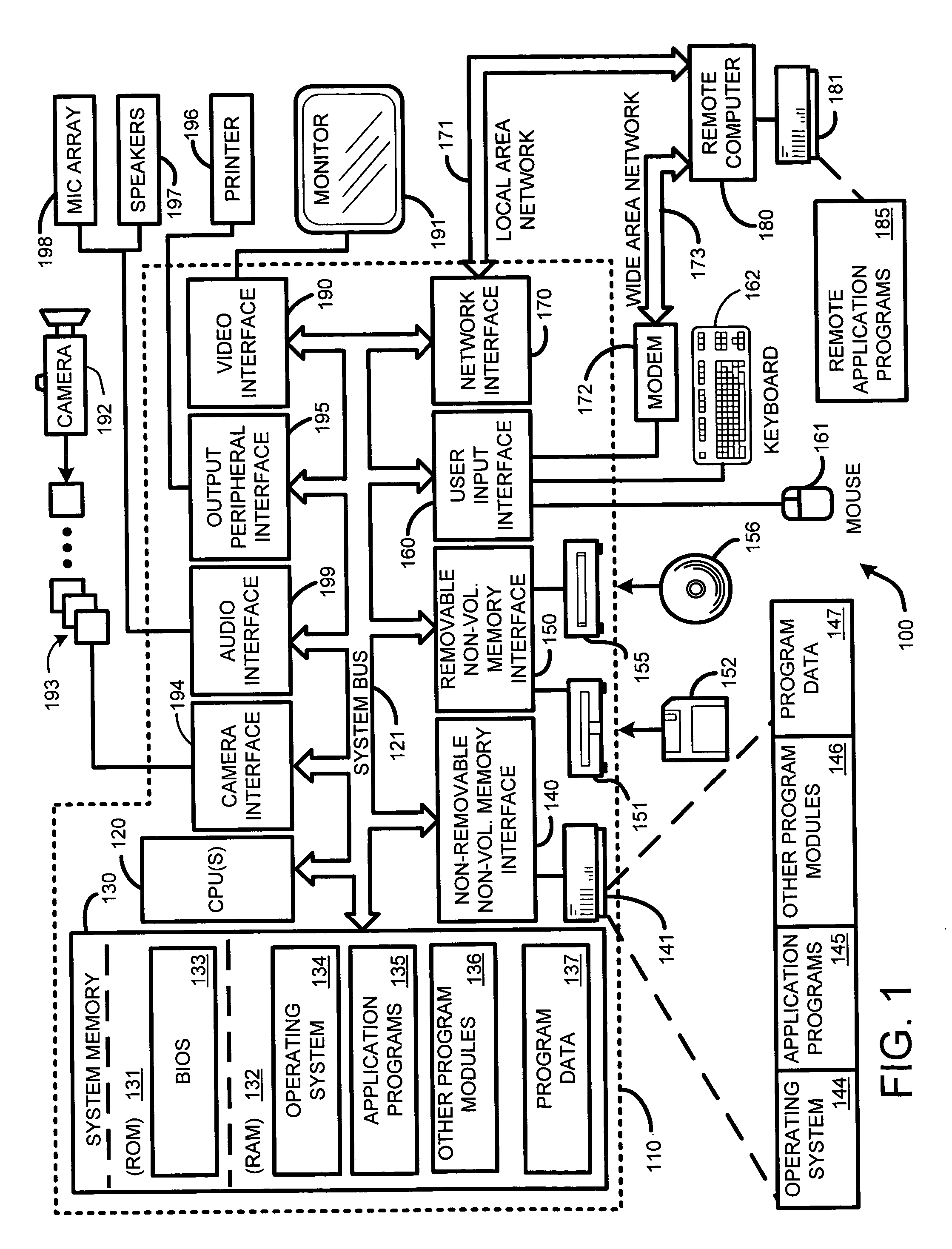

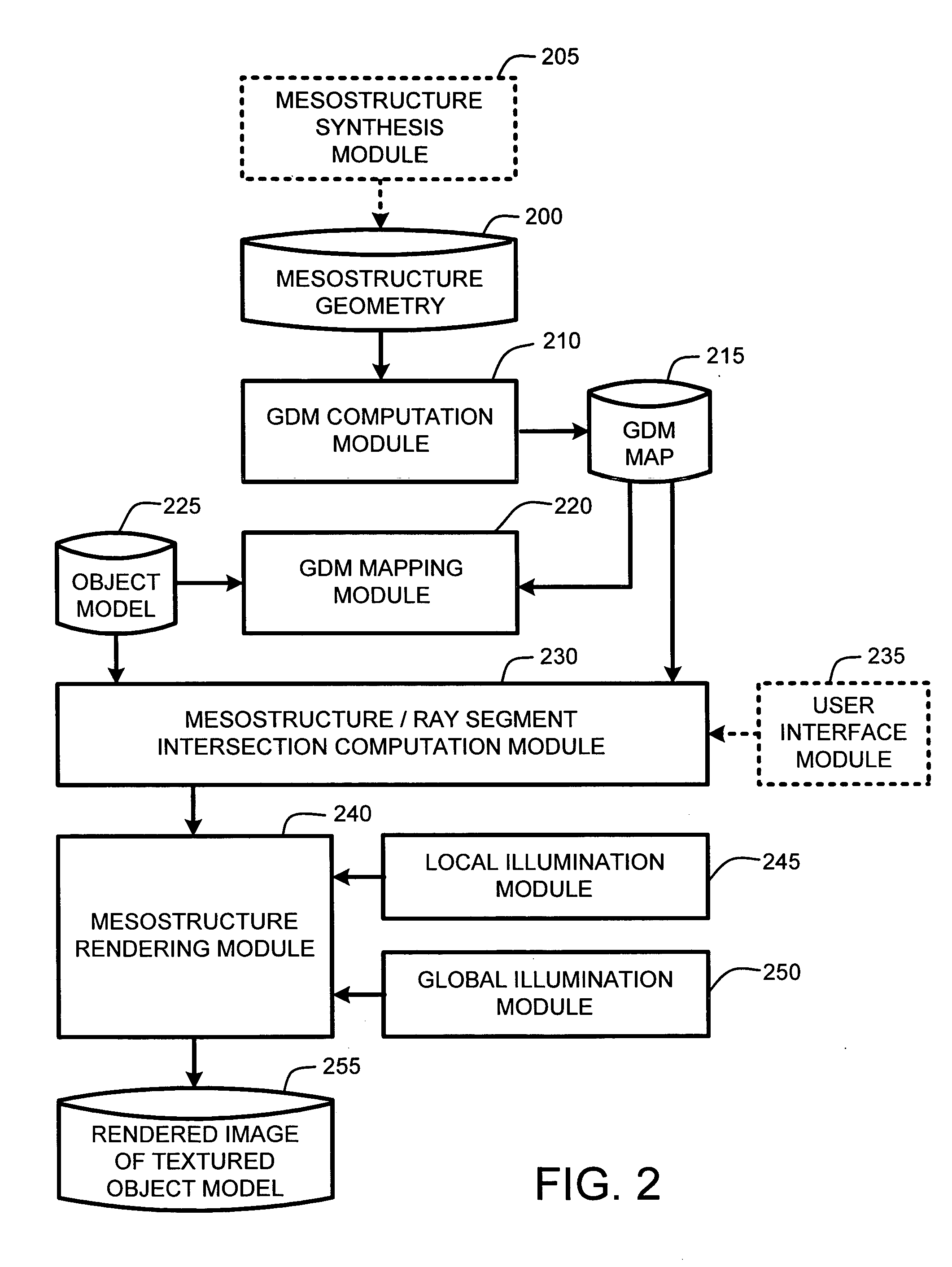

System and method for generating generalized displacement maps from mesostructure geometries

InactiveUS20050280647A1Facilitate texture coordinate computationAccelerate mesostructure renderingCathode-ray tube indicators3D-image renderingVisibilityGraphics

A “mesostructure renderer” uses pre-computed multi-dimensional “generalized displacement maps” (GDM) to provide real-time rendering of general non-height-field mesostructures on both open and closed surfaces of arbitrary geometry. In general, the GDM represents the distance to solid mesostructure along any ray cast from any point within a volumetric sample. Given the pre-computed GDM, the mesostructure renderer then computes mesostructure visibility jointly in object space and texture space, thereby enabling both control of texture distortion and efficient computation of texture coordinates and shadowing. Further, in one embodiment, the mesostructure renderer uses the GDM to render mesostructures with either local or global illumination as a per-pixel process using conventional computer graphics hardware to accelerate the real-time rendering of the mesostructures. Further acceleration of mesostructure rendering is achieved in another embodiment by automatically reducing the number of triangles in the rendering pipeline according to a user-specified threshold for acceptable texture distortion.

Owner:MICROSOFT TECH LICENSING LLC

Direct hydrocarbon fuel cells

InactiveUS7709124B2Increase ratingsUseful power densityFuel cells groupingFinal product manufactureHydrogenFuel cells

Owner:NORTHWESTERN UNIV

Bone growth promoting implant

InactiveUS20080039941A1Promote growthImprove bone strengthInternal osteosythesisJoint implantsNatural boneStructural geometry

Owner:ACTIVE IMPLANTS LLC

Superelastic Alloy Structural Geometry for Ultrahigh Mechanical Damping

ActiveUS20100140439A1Ultra-high-damping performance characteristicsAccurate and reliable processSpringsStands/trestlesMartensite transformationStructural geometry

A mechanical structure is provided with a crystalline superelastic alloy that is characterized by an average grain size and that is characterized by a martensitic phase transformation resulting from a mechanical stress input greater than a characteristic first critical stress. A configuration of the superelastic alloy is provided with a geometric structural feature of the alloy that has an extent that is no greater than about 200 micrometers and that is no larger than the average grain size of the alloy. This geometric feature is configured to accept a mechanical stress input.

Owner:MASSACHUSETTS INST OF TECH

Channelized stratified regenerator with integrated heat exchangers system and method

InactiveUS7137251B2Avoid short travelRegenerative heat exchangersClosed-cycle gas positive displacement engine plantPlate heat exchangerWorking fluid

Owner:QNERGY

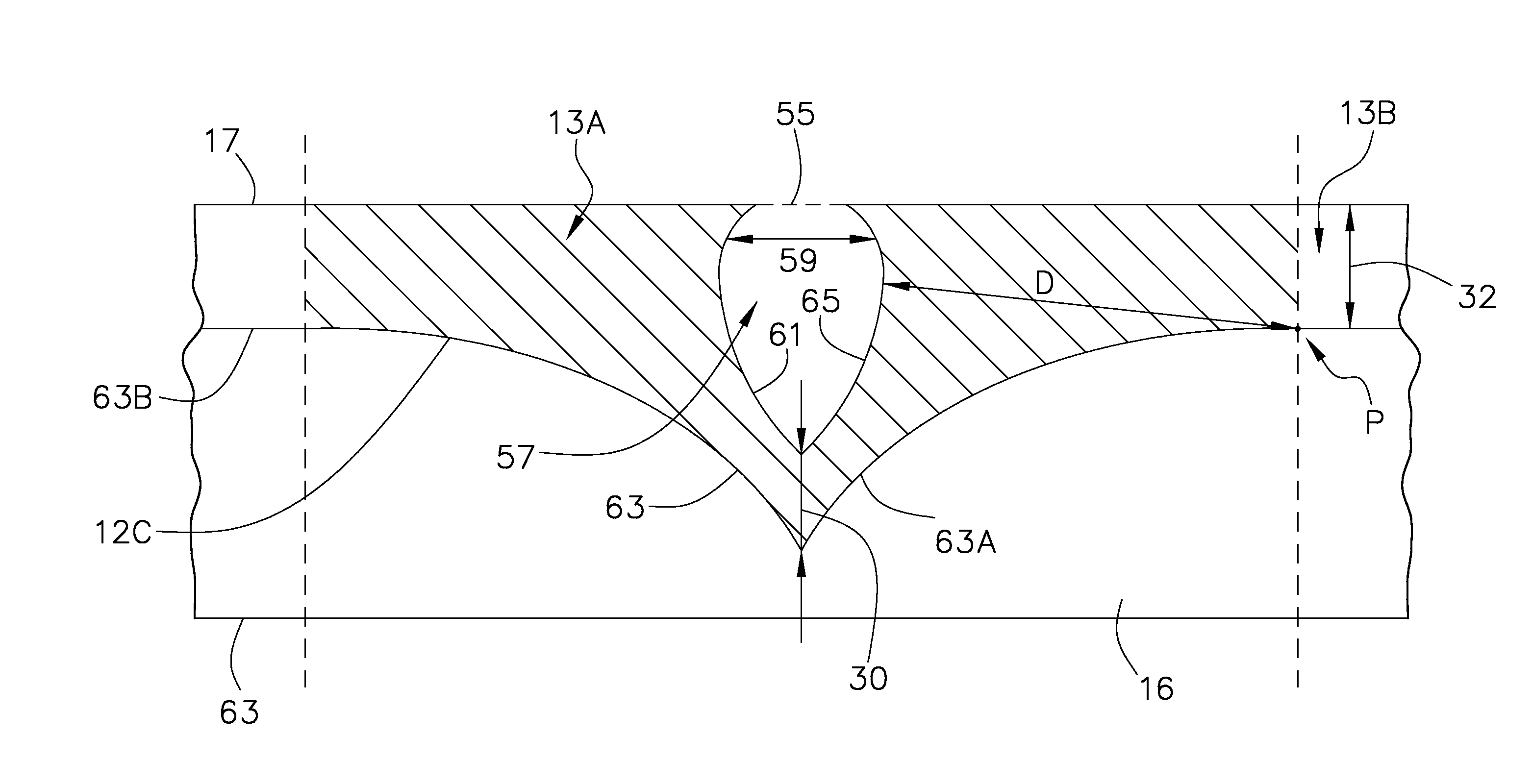

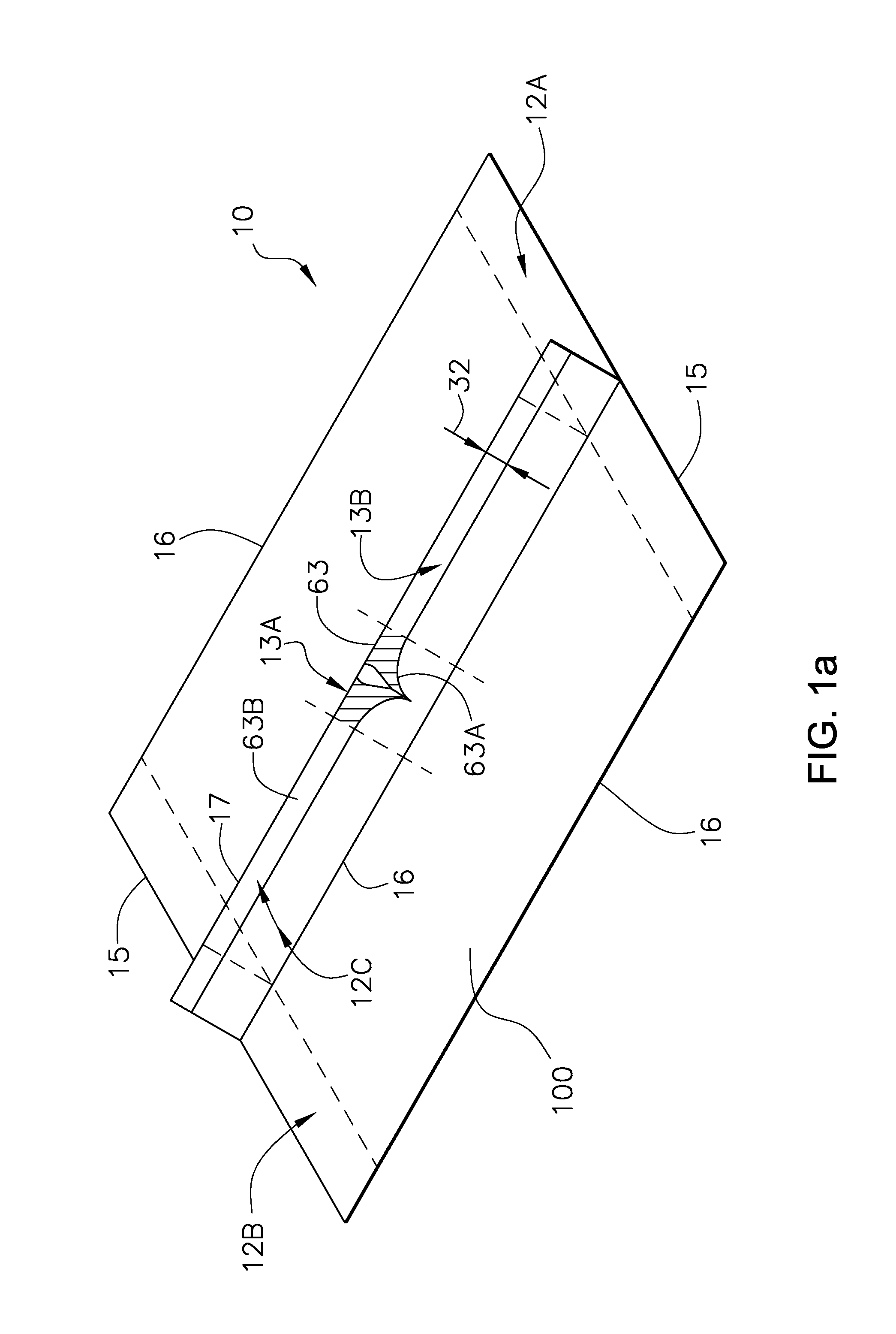

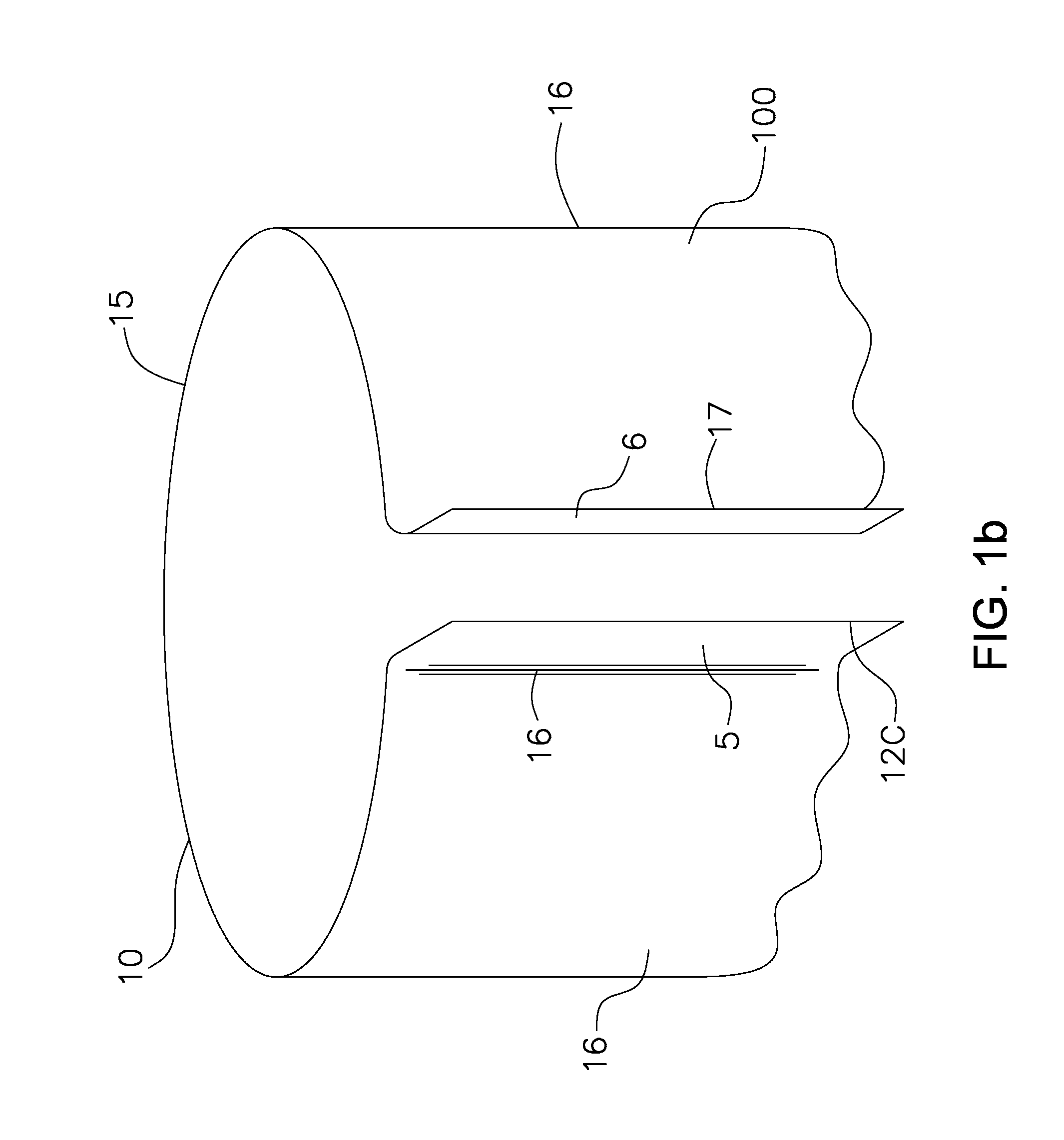

Flexible self-sealing self-venting hot-fill container

InactiveUS20150291342A1Prevent further fluid flow and leakage and spoilageSolve the lack of durabilityReady-for-oven doughsClosuresMicrowaveStructural geometry

Containers are disclosed, as well as multilayer films used in such containers, which advantageously maintain a high seal strength even after being subjected to hot-fill conditions for sterilization. These microwavable / ovenable containers (10) and multilayer films are also beneficially self-venting upon exposure to microwave heating when the internal container pressure exceeds a threshold value. These self-venting containers are also automatically self-sealing after the self-venting feature has ruptured and the container has cooled to room temperature. The self-venting self-sealing nature of these containers arises from particular film and sealing characteristics, in which the seal width differs in defined, self-venting self-sealing seal regions (13A), relative to non-venting seal regions (13B) of a given peripheral seal. Particular film materials and structural geometries of the self-venting self-sealing seal regions can be used to improve the location of venting and control of the vented gases, as well as, the resealability of the containers.

Owner:BEMIS COMPANY INC

Channelized stratified heat exchangers system and method

InactiveUS20060179834A1Avoid short travelClosed-cycle gas positive displacement engine plantRegeneratorsWorking fluidStructural geometry

A channelized stratified regenerator with integrated heat exchangers are disclosed using micromachining to precisely construct structural geometries, such as fins and axial stratification of material to be used in a Stirling cycle based system. In operation, a working fluid passes through the regenerator when traveling between two heat exchangers. In some implementations, the regenerator and the heat exchangers are formed as a single construction. In other implementations, the regenerator and heat exchangers are formed separately, but are constructed to integrate efficiently with one another.

Owner:RICOR GENERATION

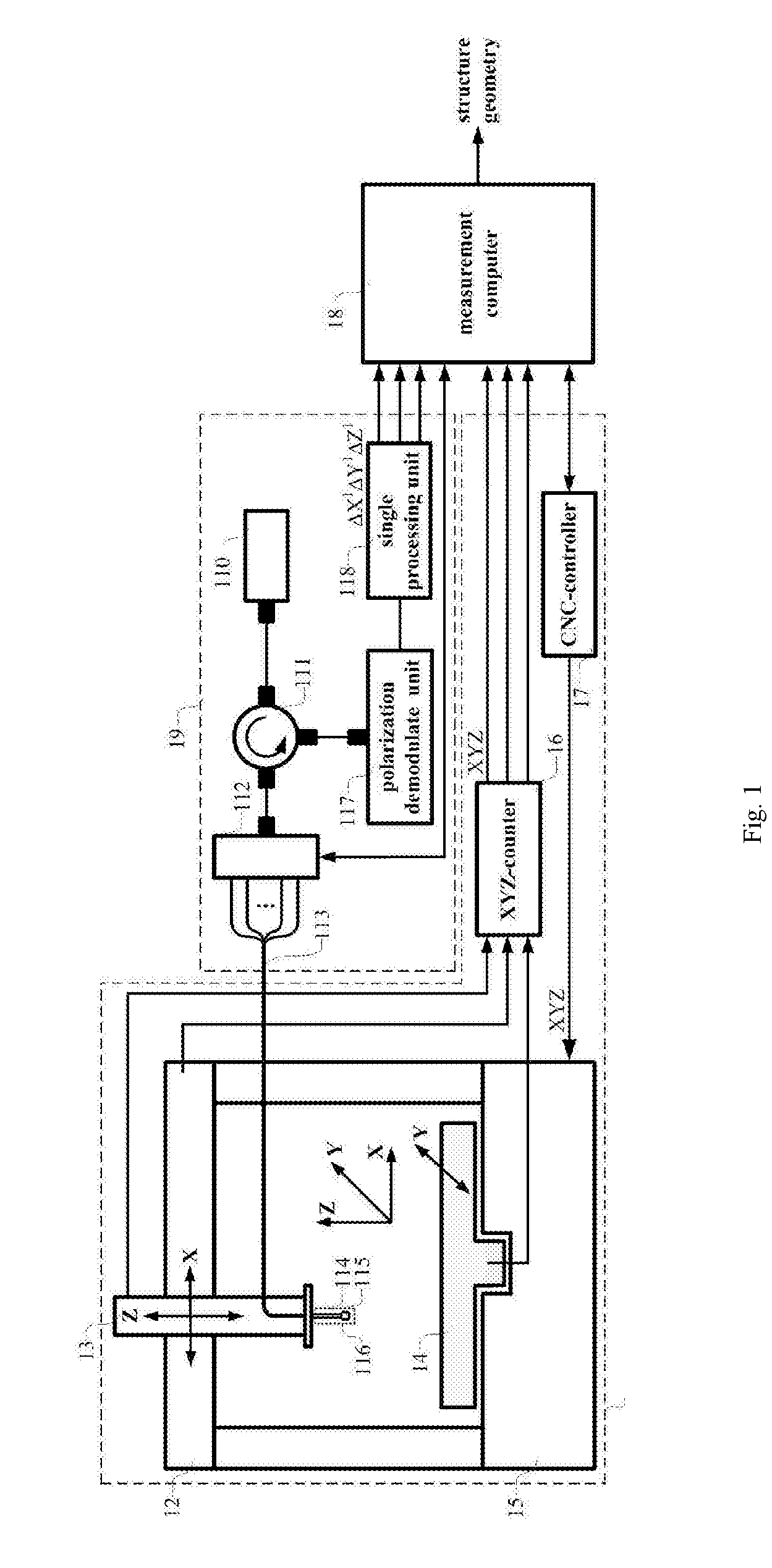

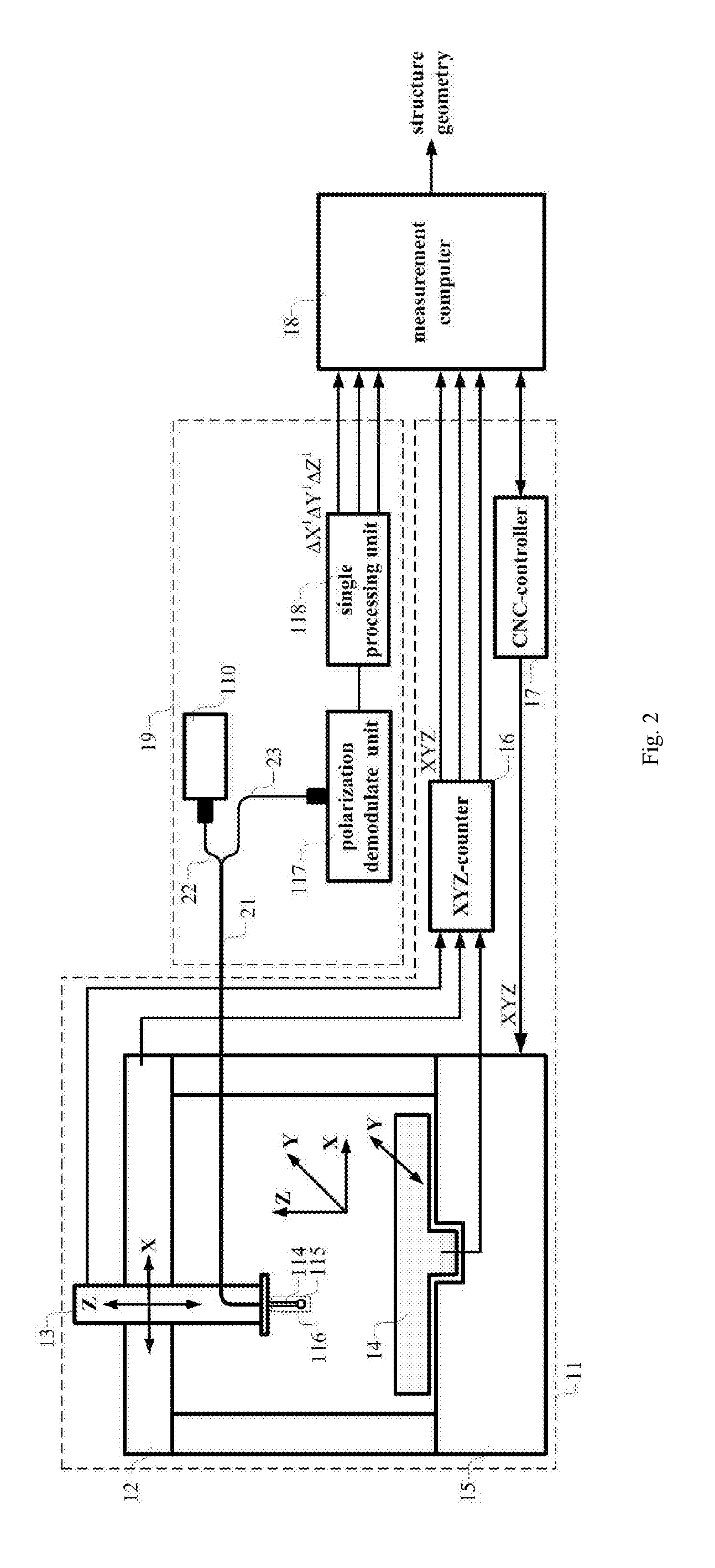

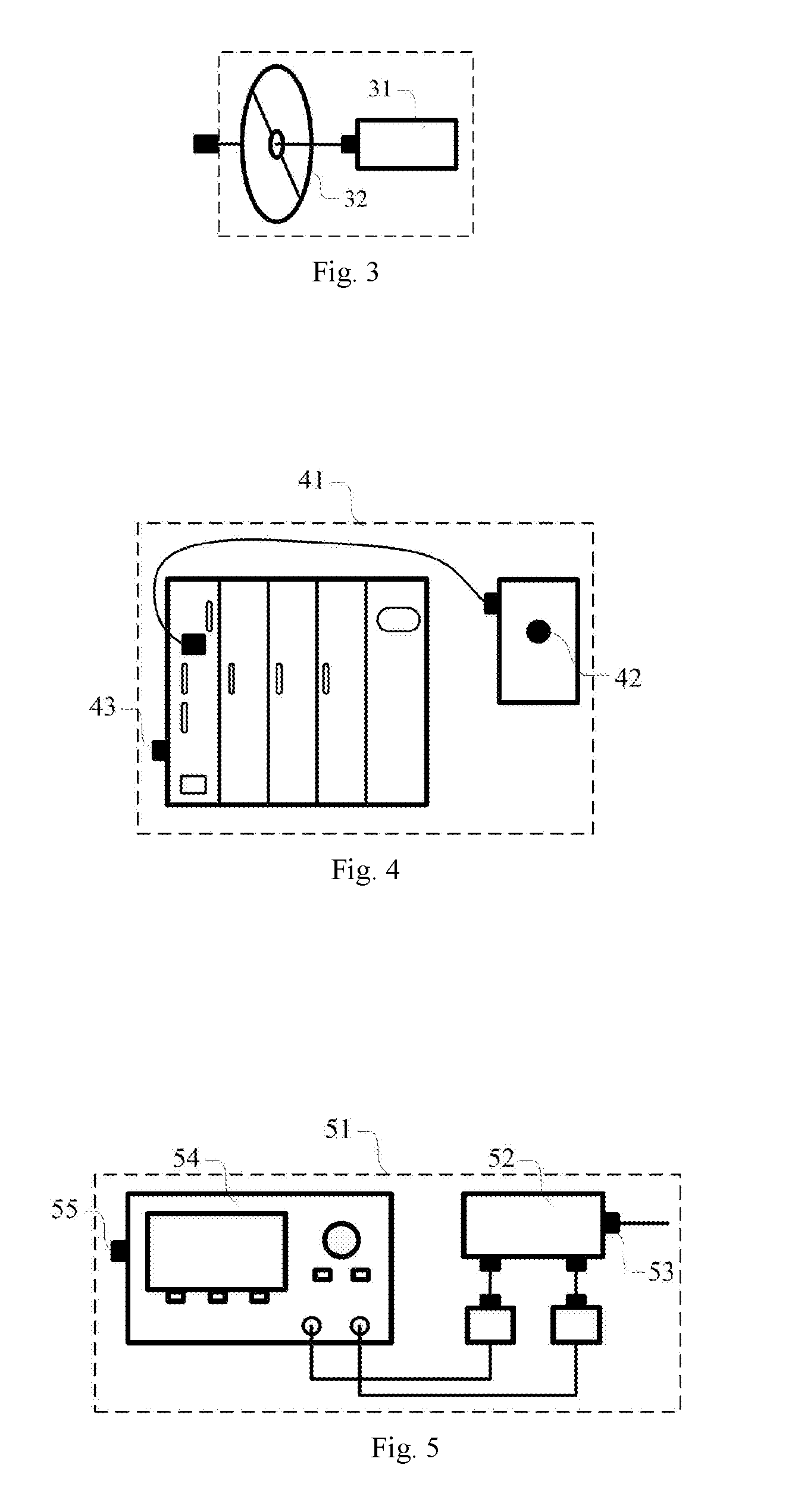

Method And Equipment Based On Detecting The Polarization Property Of A Polarization Maintaining Fiber Probe For Measuring Structures Of A Micro Part

ActiveUS20160305764A1Difficult to resolveReflectometers dealing with polarizationUsing optical meansStructural geometryOptical polarization

A method and equipment based on detecting the polarization property of a polarization maintaining fiber (PMF) probe for measuring structures of a micro part are provided. The provided method relates to how to accomplish measuring structures of a micro part by transforming two or three-dimensional contact displacements into polarization property changes of the PMF probe, and how to reconstruct the structure geometry of a micro part. The provided equipment can be used to bring the spherical tip of the PMF probe into contact with a micro part, to determine coordinates of contact points, and to reconstruct the structure geometry of a micro part. The provided method and equipment feature high sensitivity, low probing force, high inspecting aspect ratio and immunity to environment interference.

Owner:HARBIN INST OF TECH

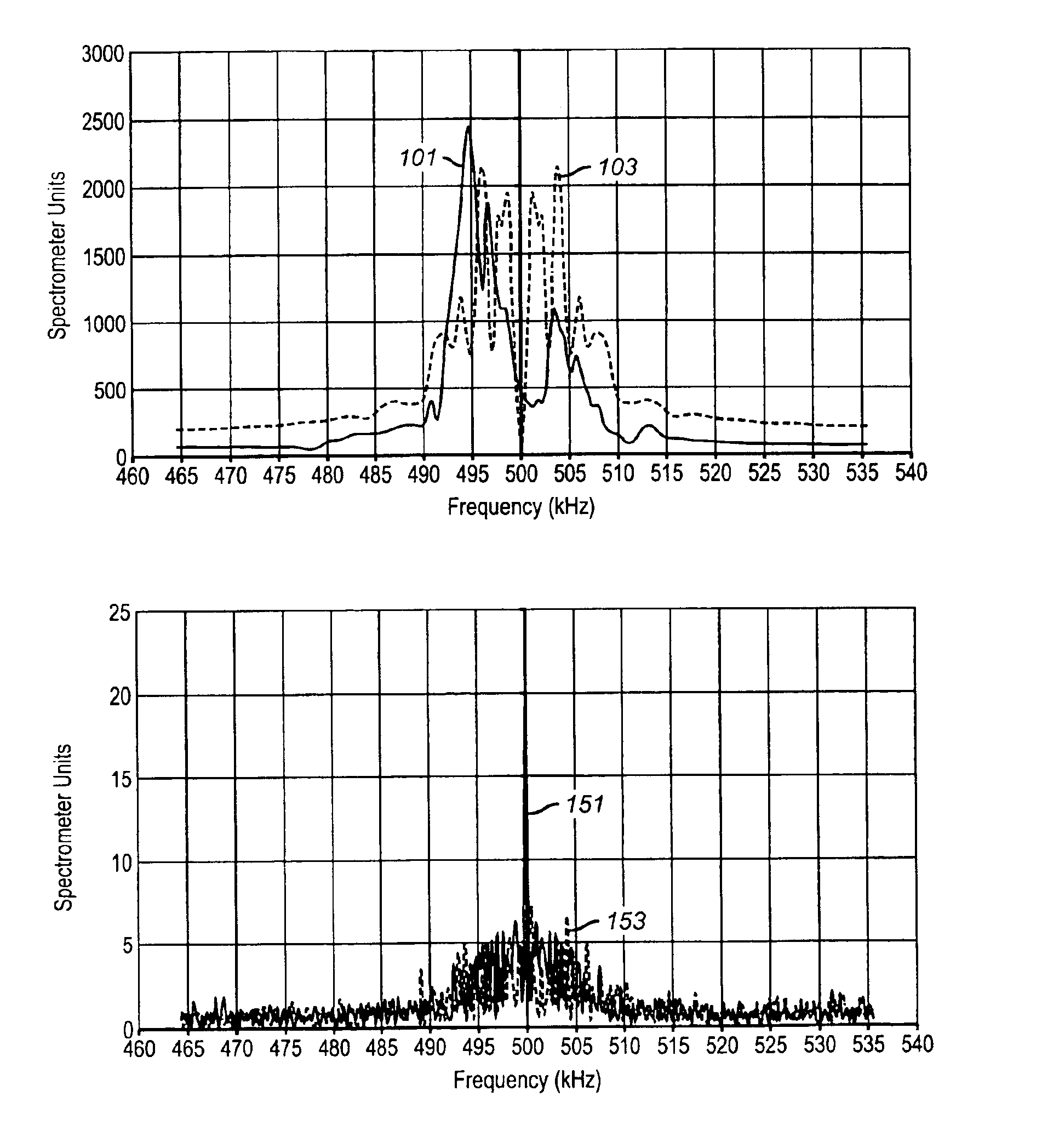

Method and apparatus of reducing ringing in a nuclear magnetic resonance probe

InactiveUS20030038631A1Loop antennas with ferromagnetic coreElectric/magnetic detection for well-loggingRing downNMR - Nuclear magnetic resonance

The present invention provides a novel use of a material having a high internal magnetostrictive damping and / or using material with explicitly low magnetostriction as a NMR probe core material. The probe structural geometry facilitates the use of material, which has a relatively low magnetic permeability.

Owner:BAKER HUGHES INC

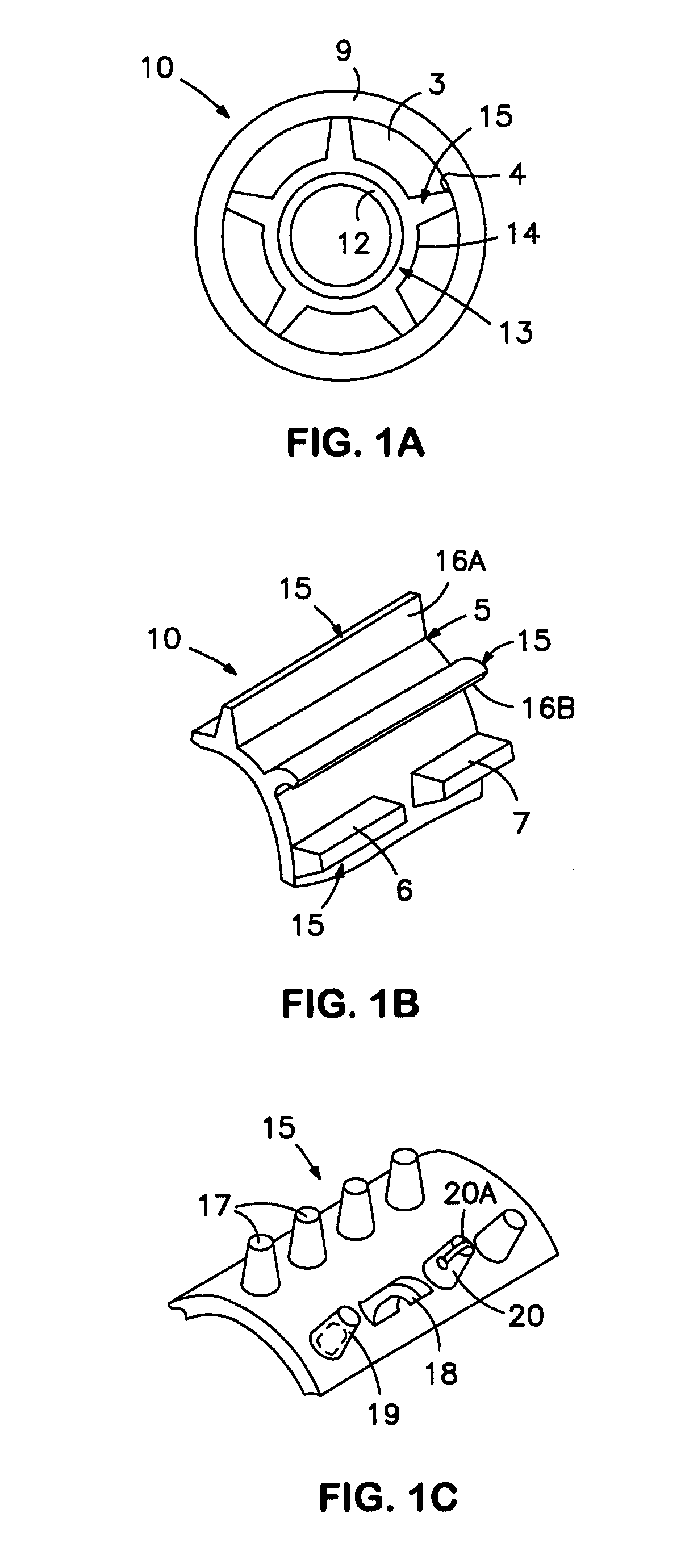

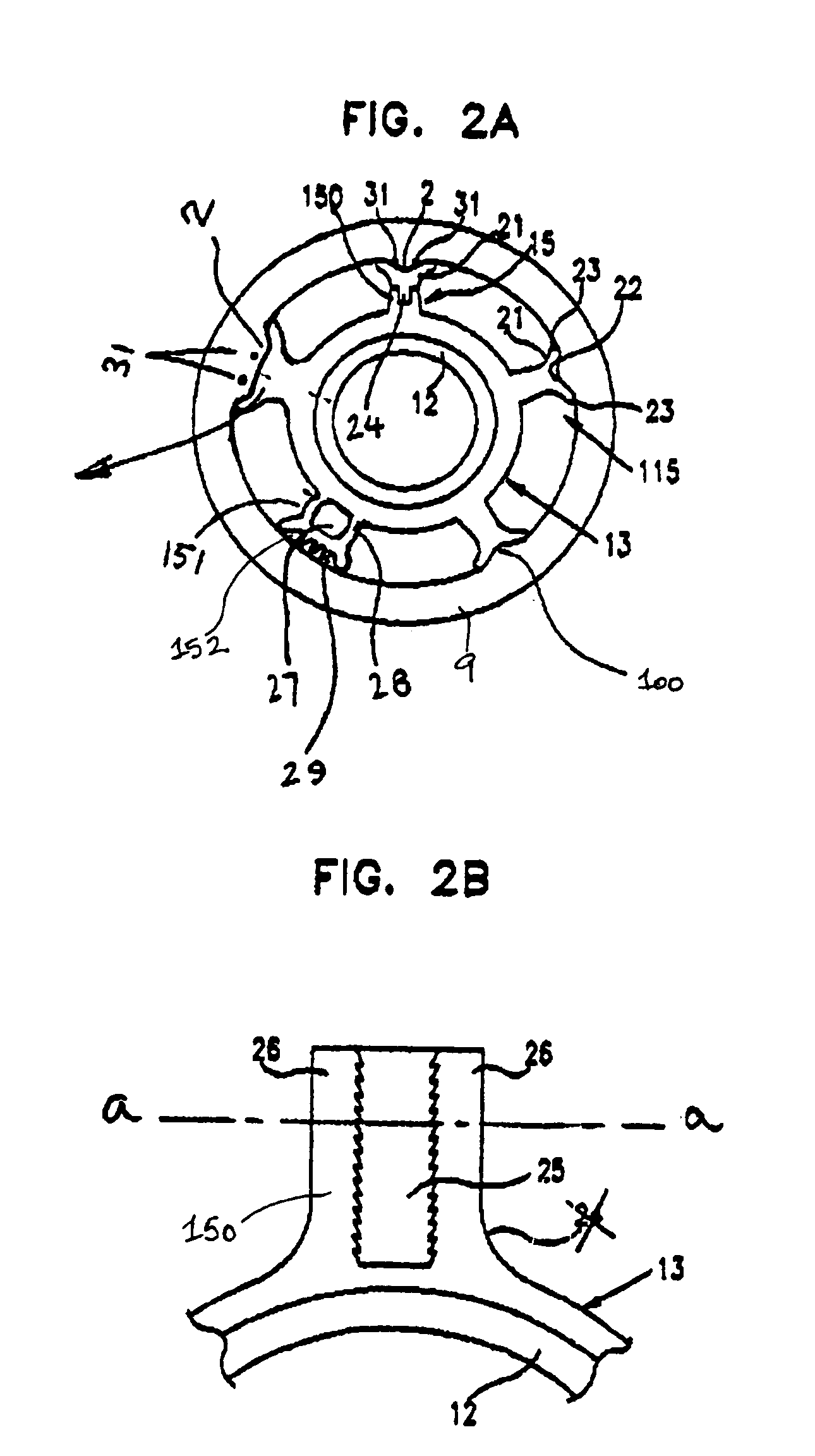

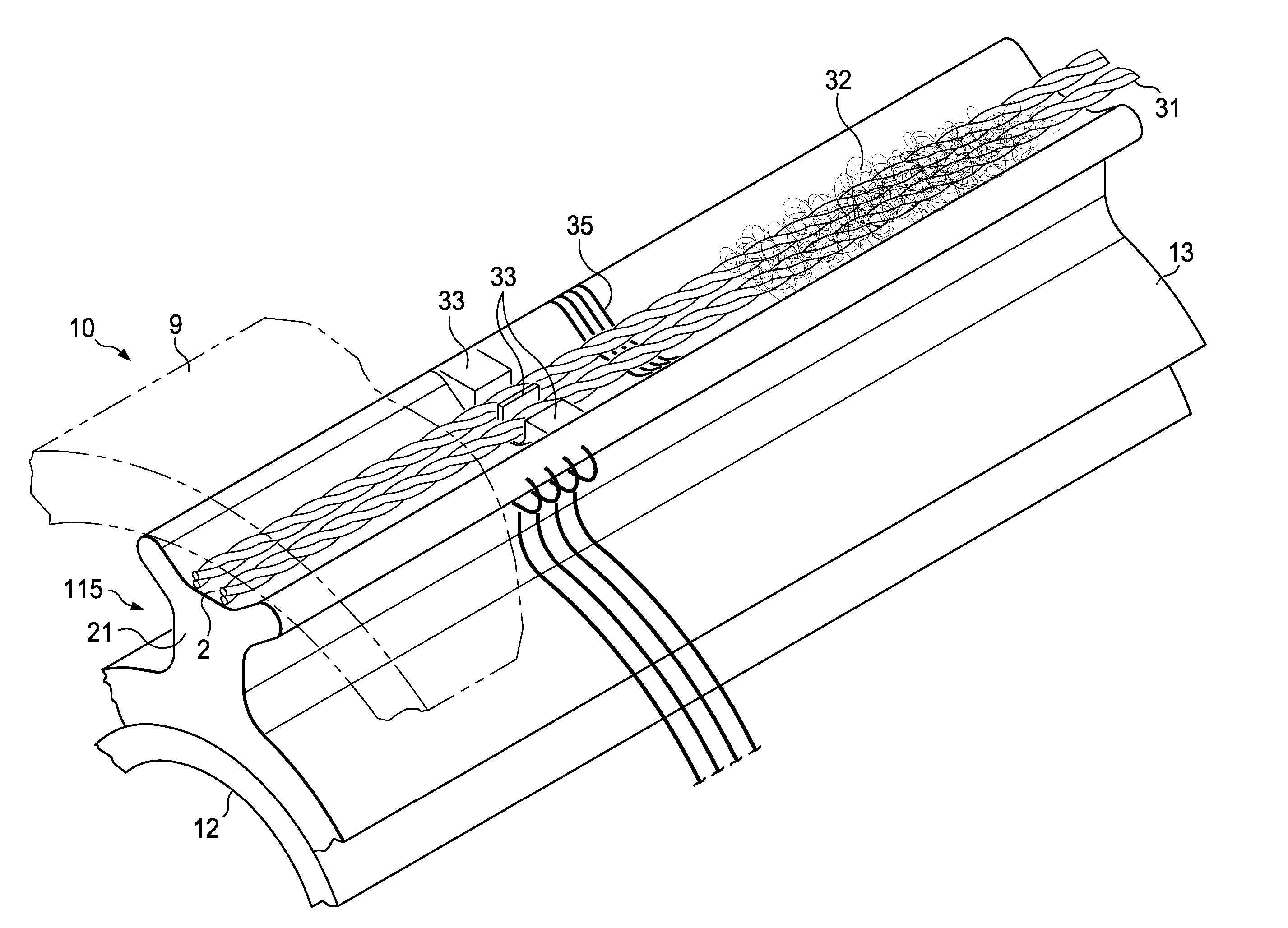

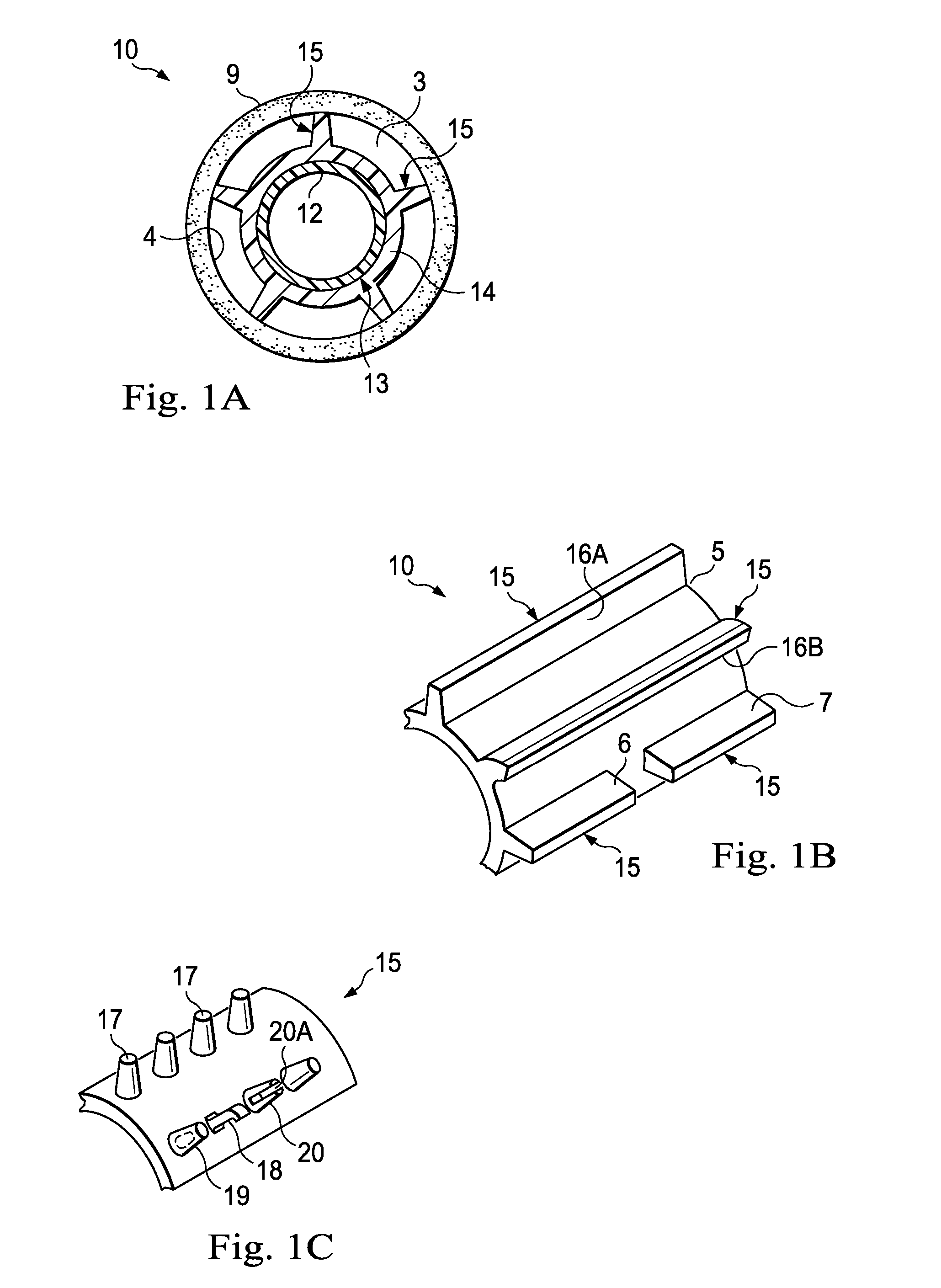

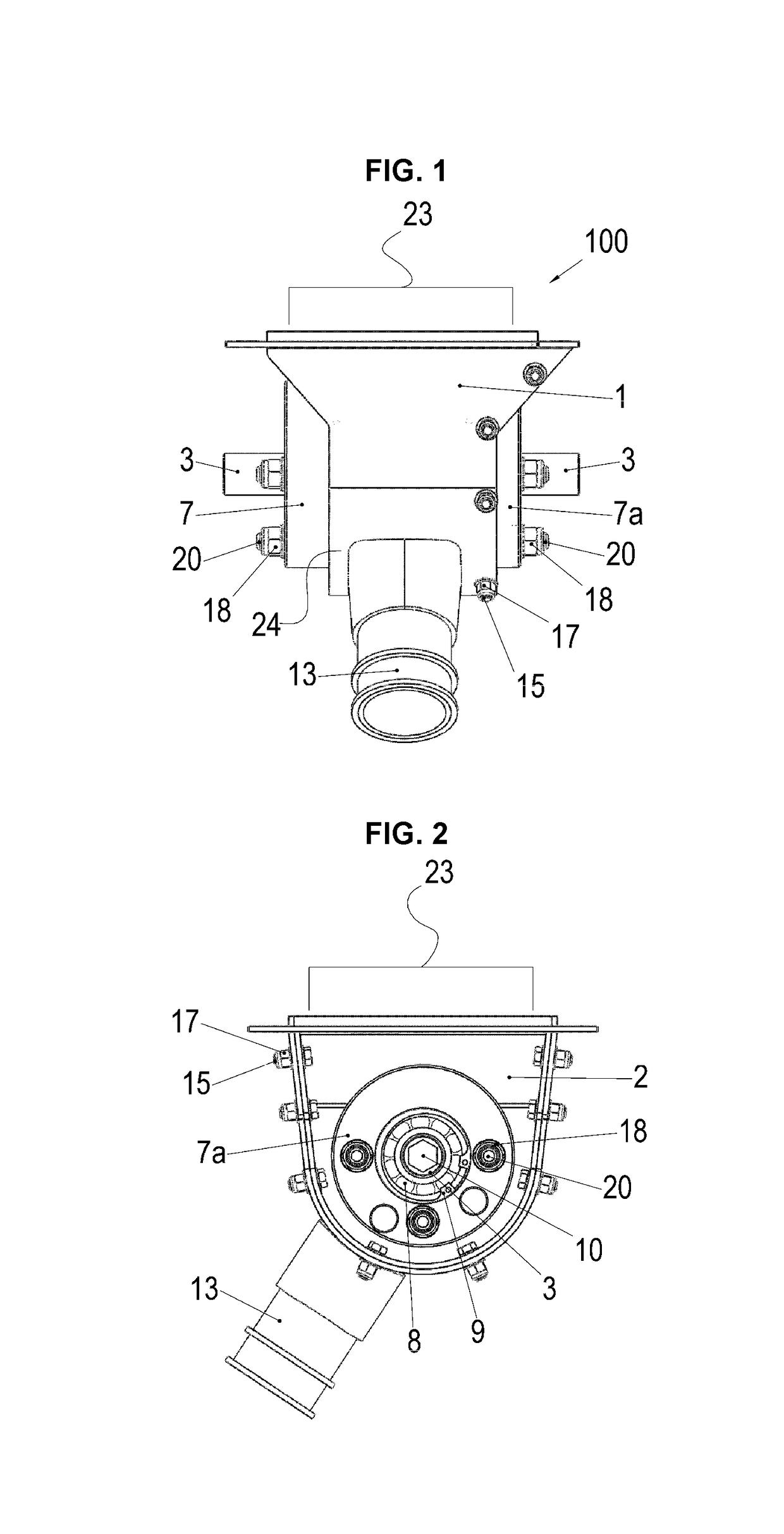

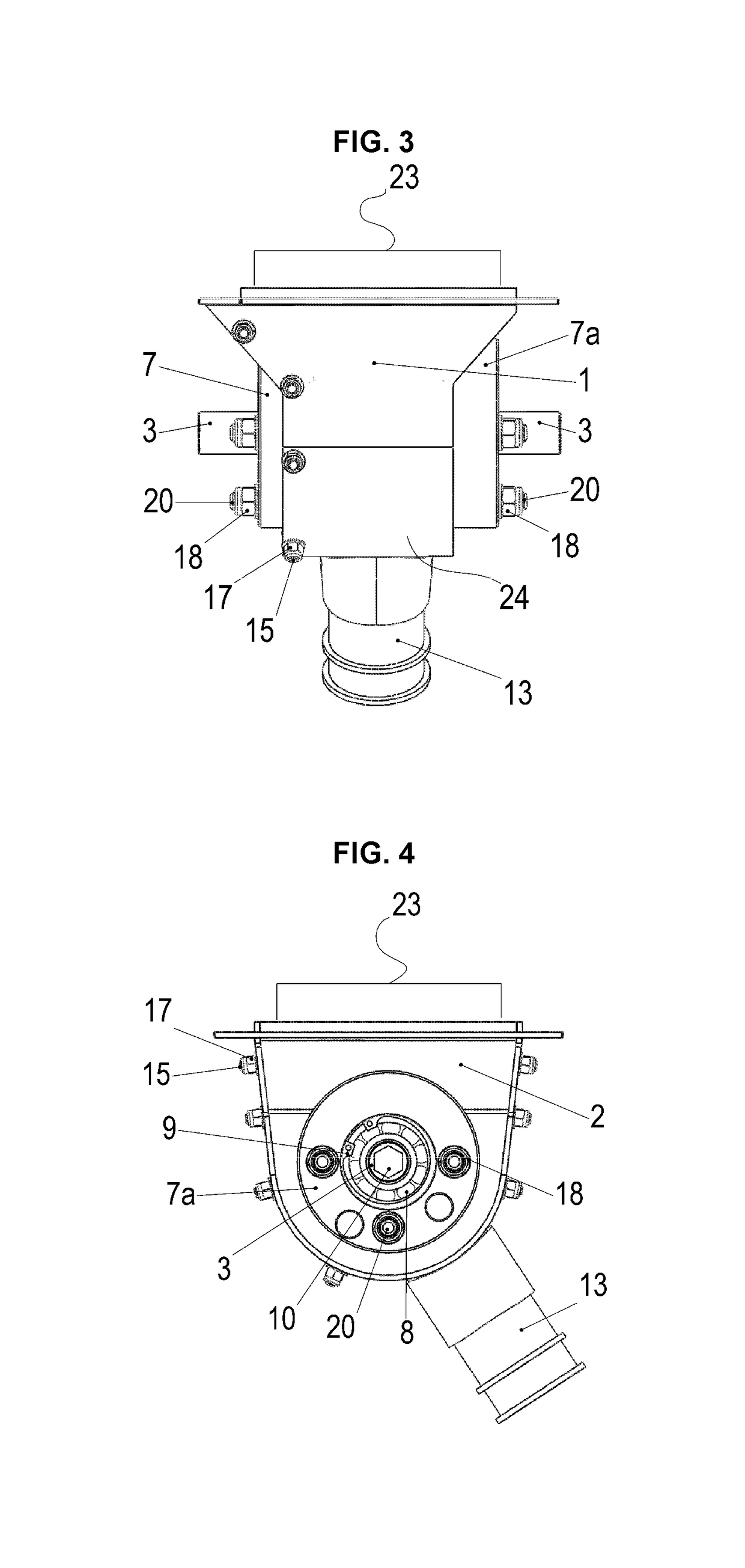

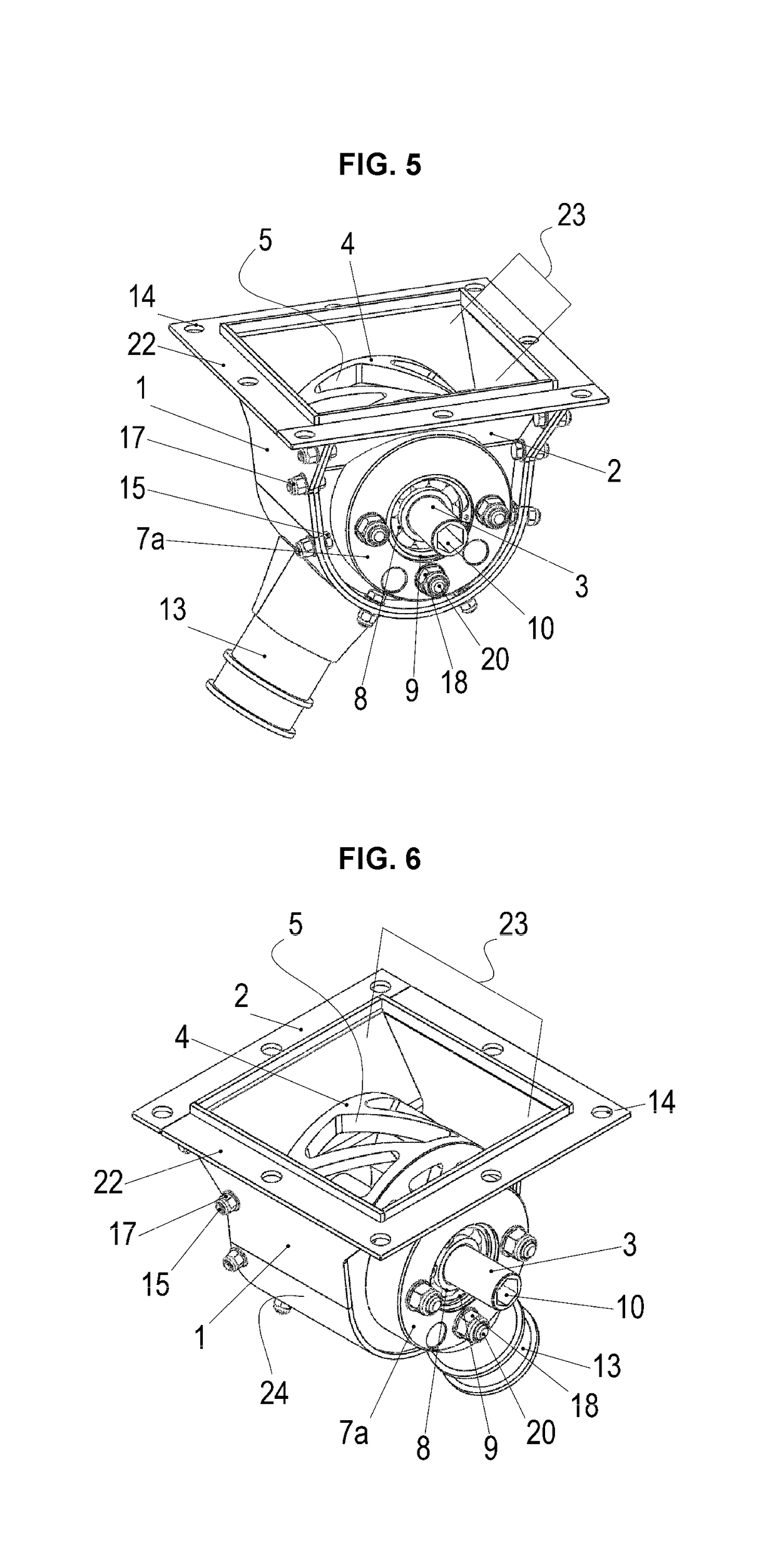

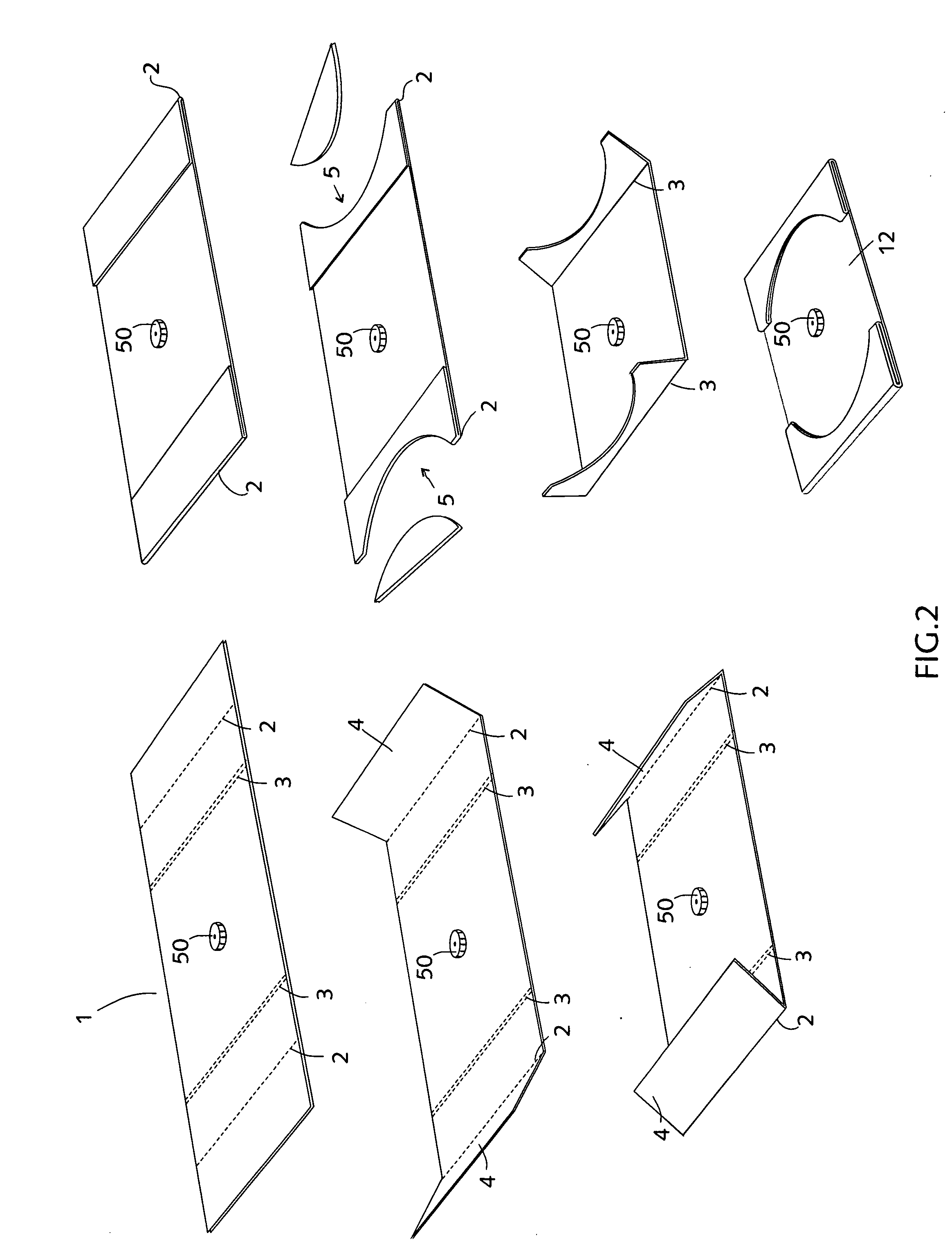

Apparatus For Precision Volumetric Metering And Distribution Of Solid Inputs Used In Agriculture

ActiveUS20180352726A1Improve regularityAvoid both build-ups and lossesFertiliser distributersCentrifugal wheel fertilisersStructural geometryTurbine

An apparatus 100 is described for precision volumetric metering and distribution of solid inputs used in agriculture, the apparatus being coupled to sowing devices and comprising a frame 1 with a through-hole 12 through which an axle 3 radially locked to a turbine 4 extends, the axle 3 driving the metering turbine 4; an opening 21 in the floor of the frame leads the agricultural input 31 to the output nozzle 13. The geometry of the turbine 4 comprises cutouts of various shapes which form chambers 5 for distributing the agricultural input 31 uniformly. A labyrinth 25 is formed by the frame 1, the inner grater 6 and the turbine 4. The structural geometry of the turbine 4 only allows metering of the input 31 while the turbine is rotating, while the agricultural input 31 is retained inside and on the turbine 4 when the turbine does not rotate.

Owner:SILVESTRI +1

Channelized stratified regenerator system and method

InactiveUS20060179833A1Avoid short travelClosed-cycle gas positive displacement engine plantWorking fluidStructural geometry

A channelized stratified regenerator with integrated heat exchangers are disclosed using micromachining to precisely construct structural geometries, such as fins and axial stratification of material to be used in a Stirling cycle based system. In operation, a working fluid passes through the regenerator when traveling between two heat exchangers. In some implementations, the regenerator and the heat exchangers are formed as a single construction. In other implementations, the regenerator and heat exchangers are formed separately, but are constructed to integrate efficiently with one another.

Owner:QNERGY

Method and apparatus of reducing ringing in a nuclear magnetic resonance probe

InactiveUS6844727B2High internal magnetostrictive dampingHigh internal dampingLoop antennas with ferromagnetic coreElectric/magnetic detection for well-loggingRing downNMR - Nuclear magnetic resonance

The present invention provides a novel use of a material having a high internal magnetostrictive damping and / or using material with explicitly low magnetostriction as a NMR probe core material. The probe structural geometry facilitates the use of material, which has a relatively low magnetic permeability.

Owner:BAKER HUGHES HLDG LLC

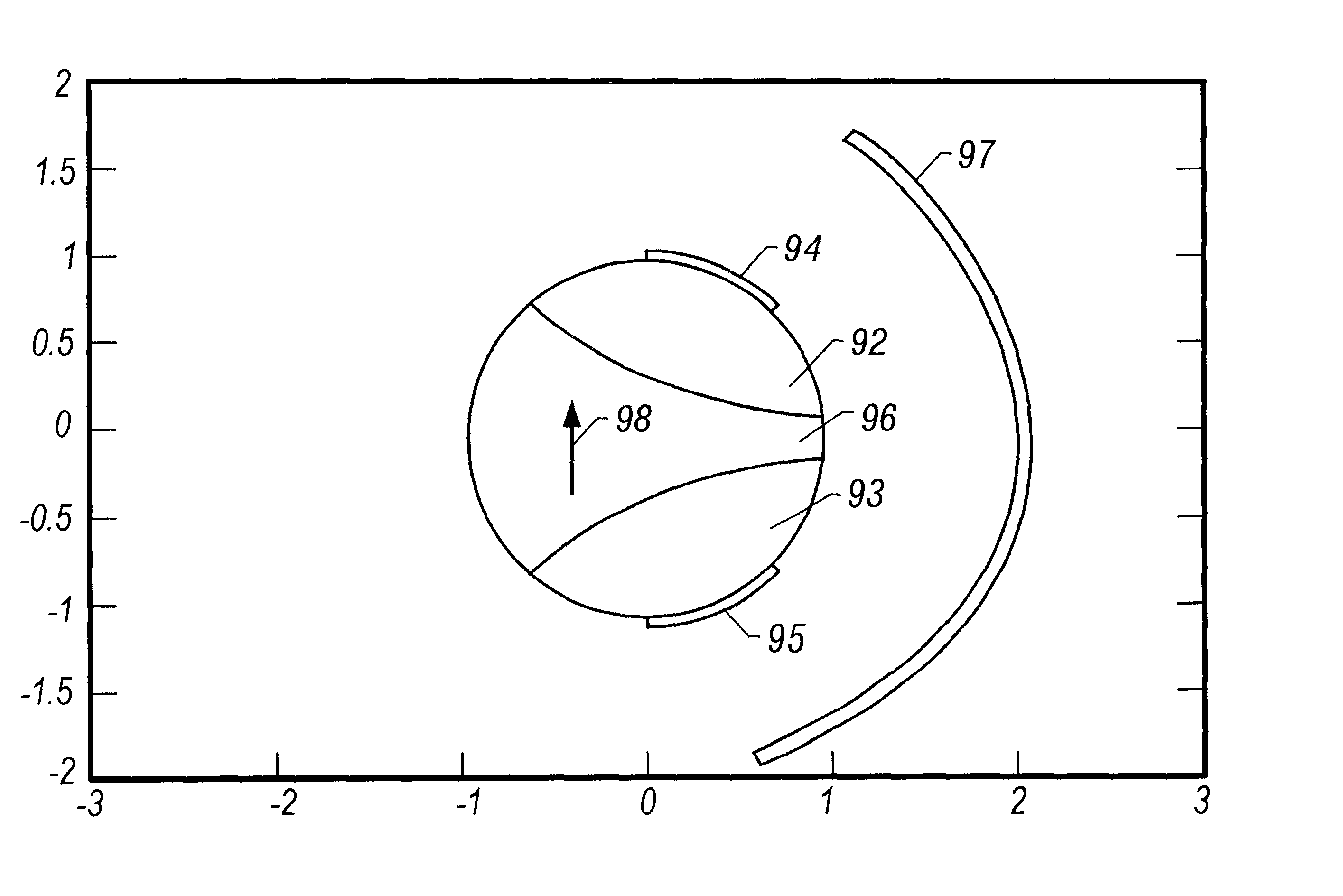

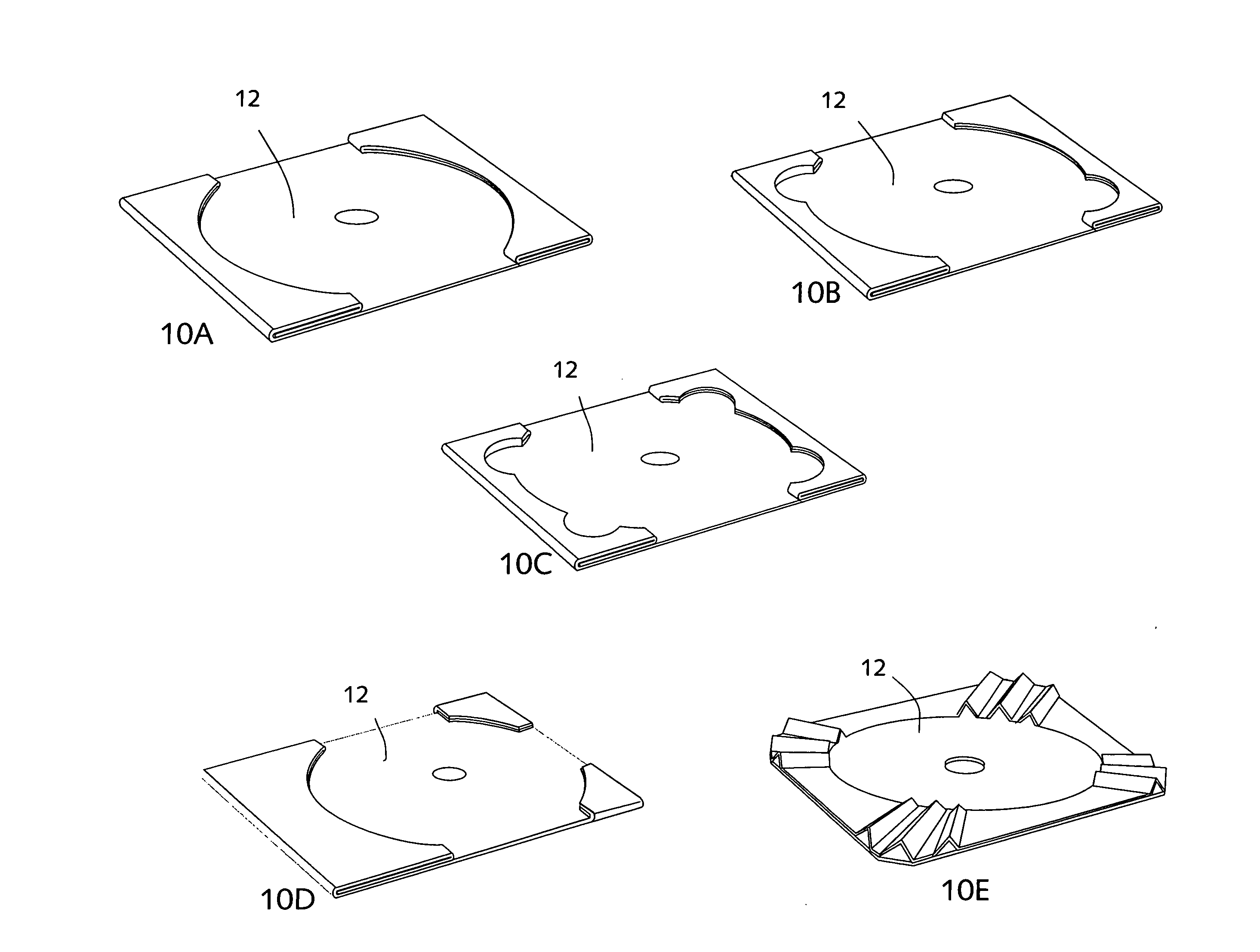

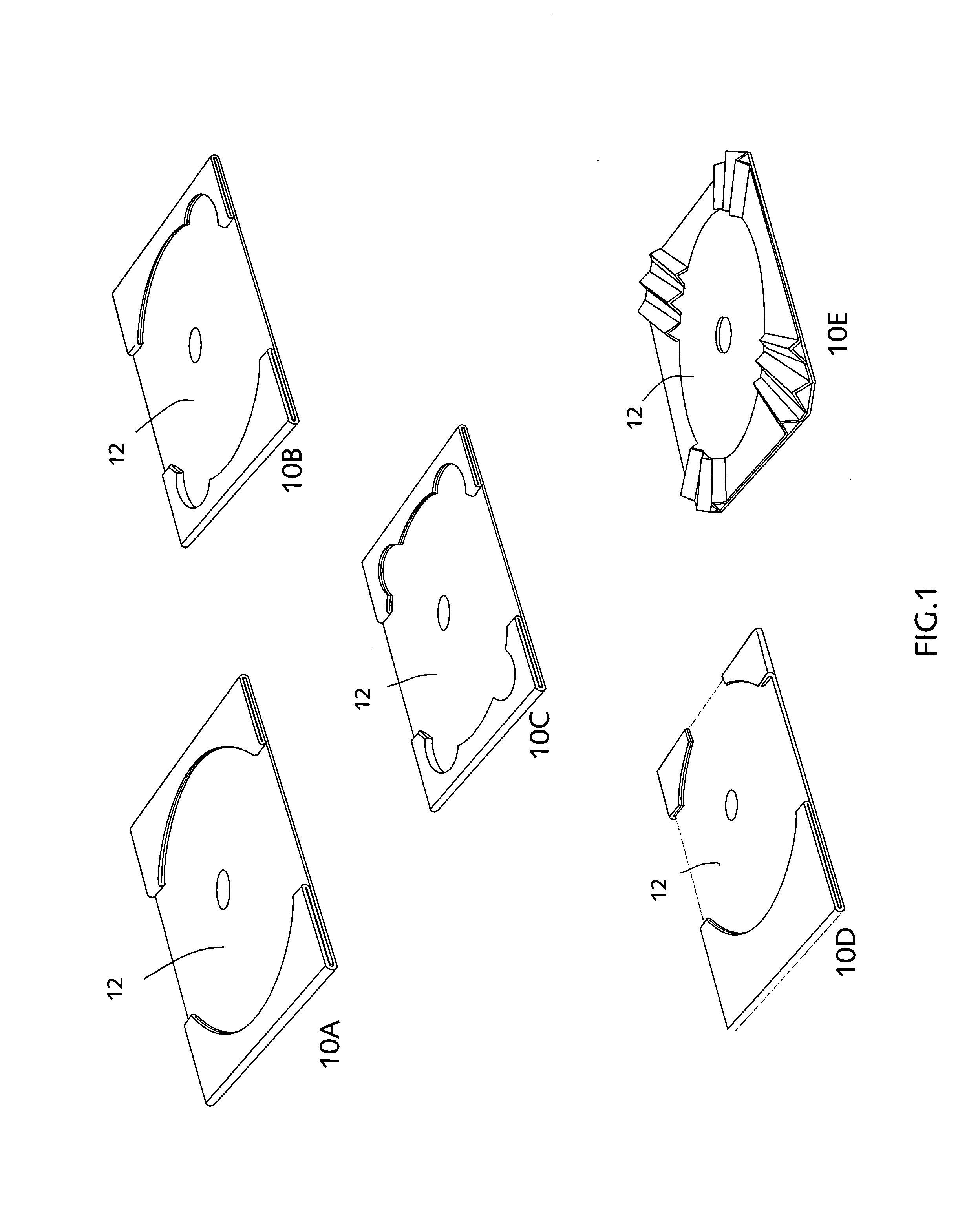

Paperboard CD or DVD tray with paper hub

InactiveUS20080202957A1Duplicates functionalityReduce manufacturing costRecord information storageOther accessoriesDVD-RAMStructural geometry

A CD or DVD tray made from paperboard is provided. The tray may be made from 100% recycled paperboard and can be 100% recyclable. The design of the tray or holder (used interchangeably throughout) uses the structural geometry of facets, central hole and radial slits to form a hub that achieves the function of securing the CD to the tray. Non-structural paper stock is formed into an effective fastening device whereby the fit of the hub is determined by the geometry of the folded paper. The paper tray of the present invention duplicates the functionality of plastic trays and is compatible with industry auto-loading, while providing the environmental benefits of paper.

Owner:LACKO MARK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com