Patents

Literature

922results about "Closed-cycle gas positive displacement engine plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

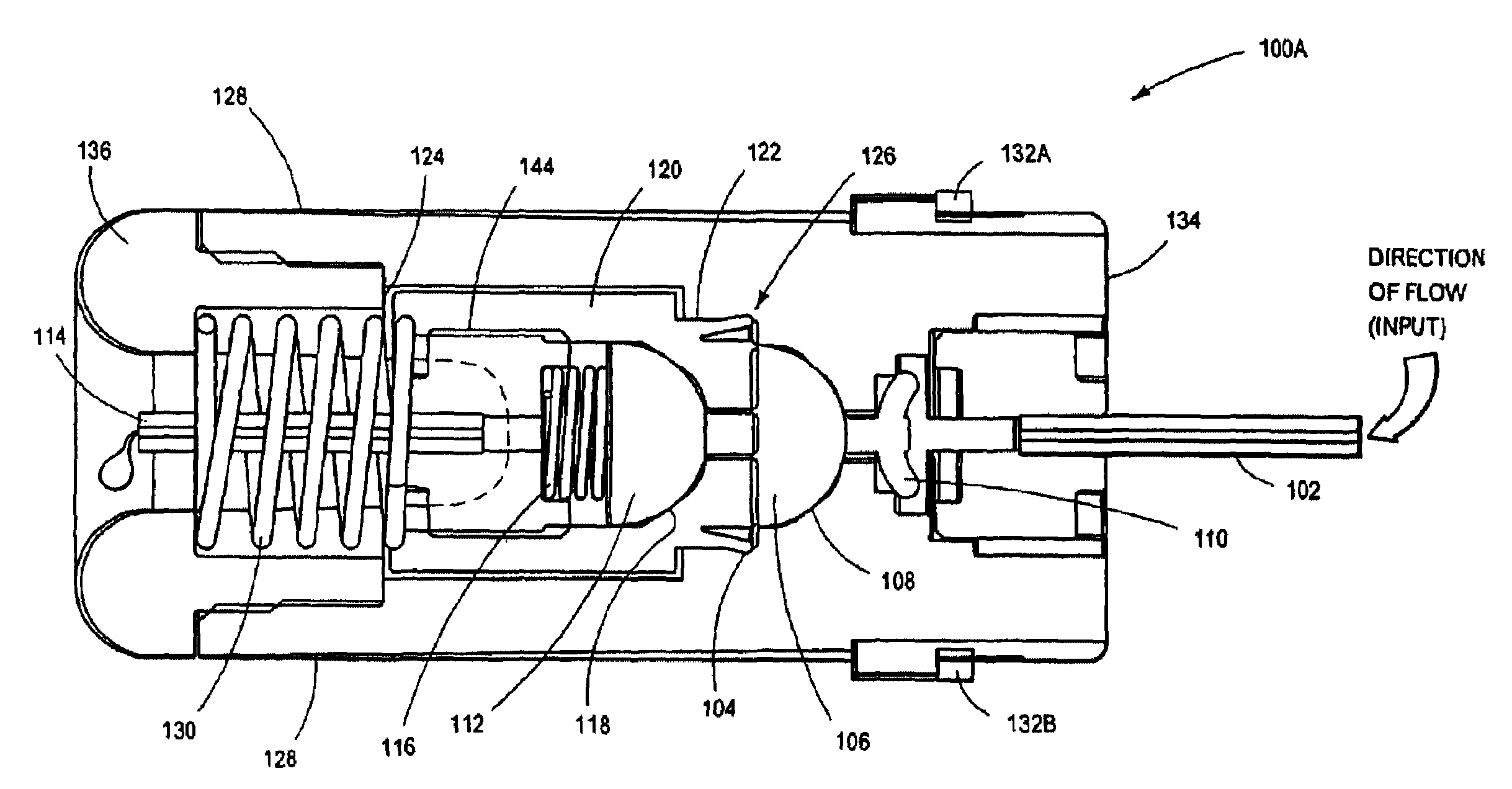

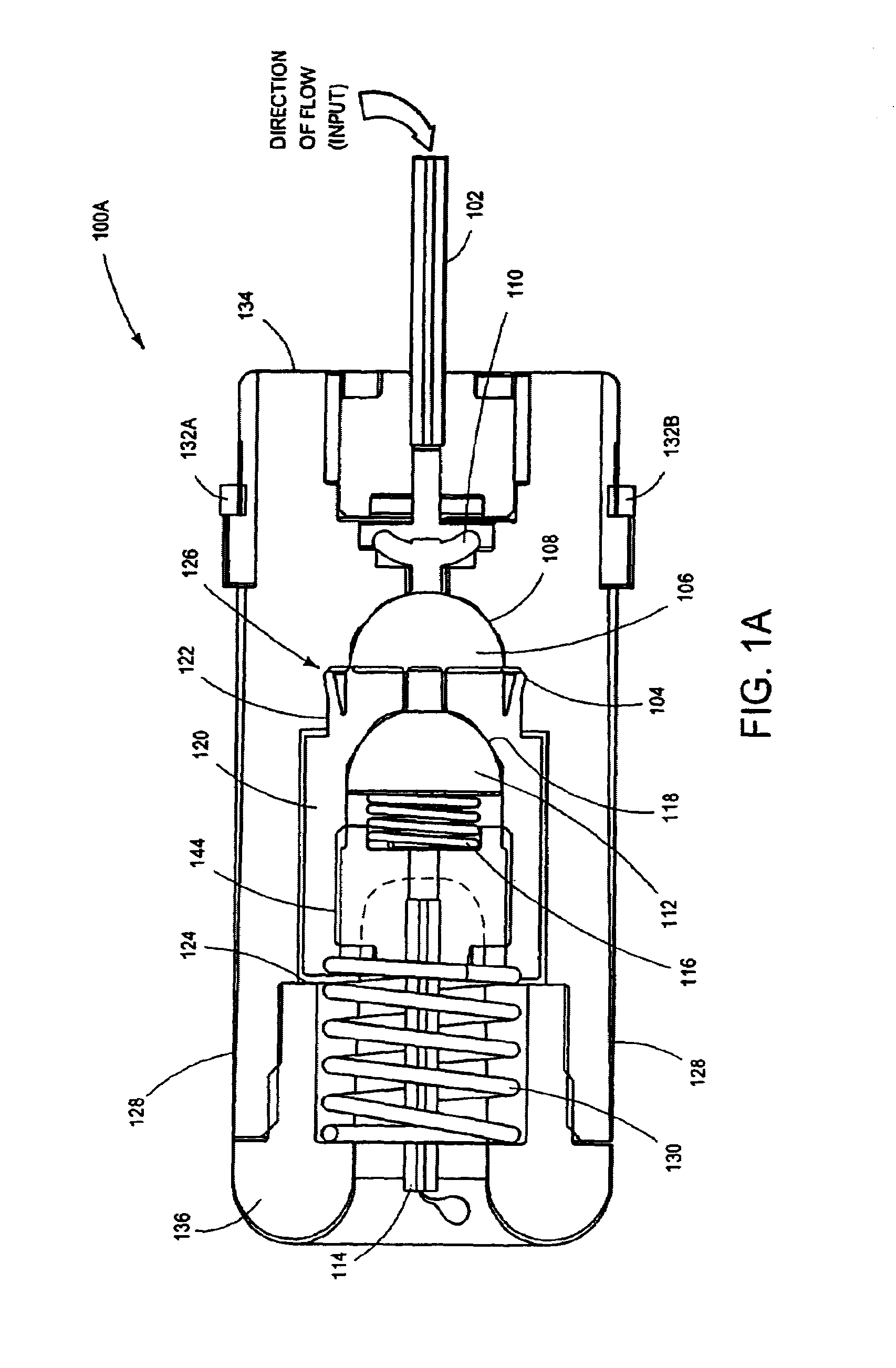

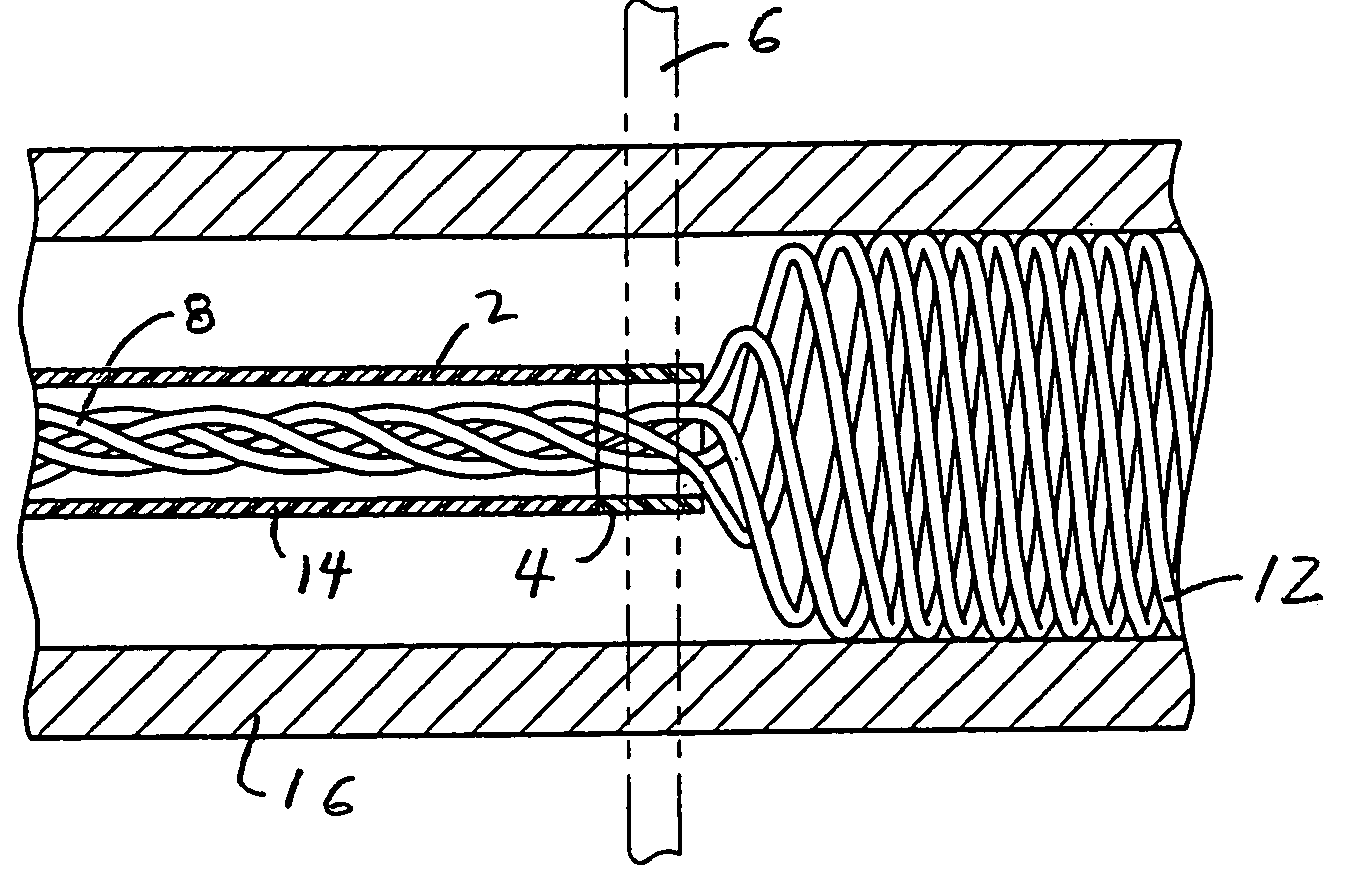

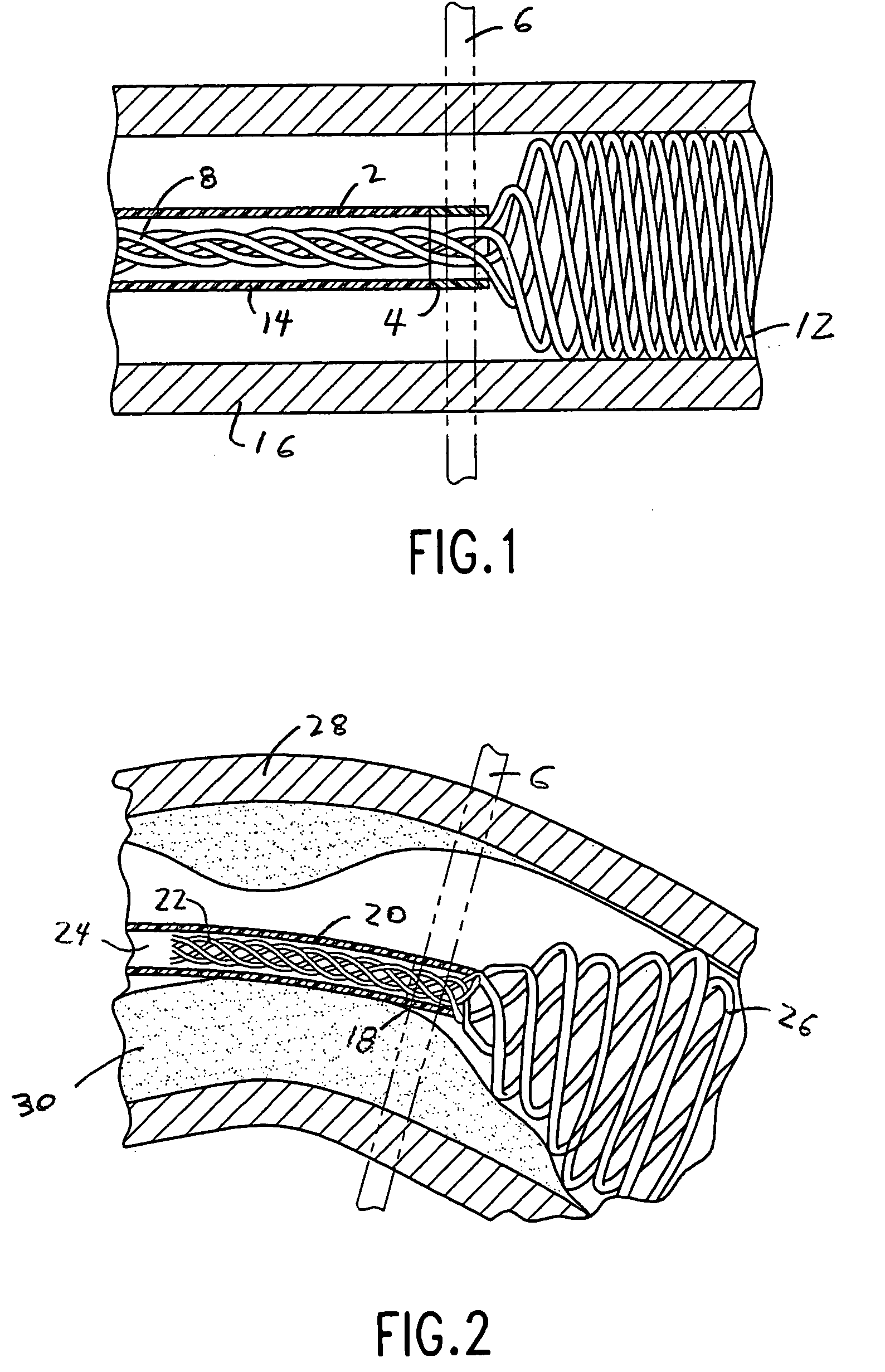

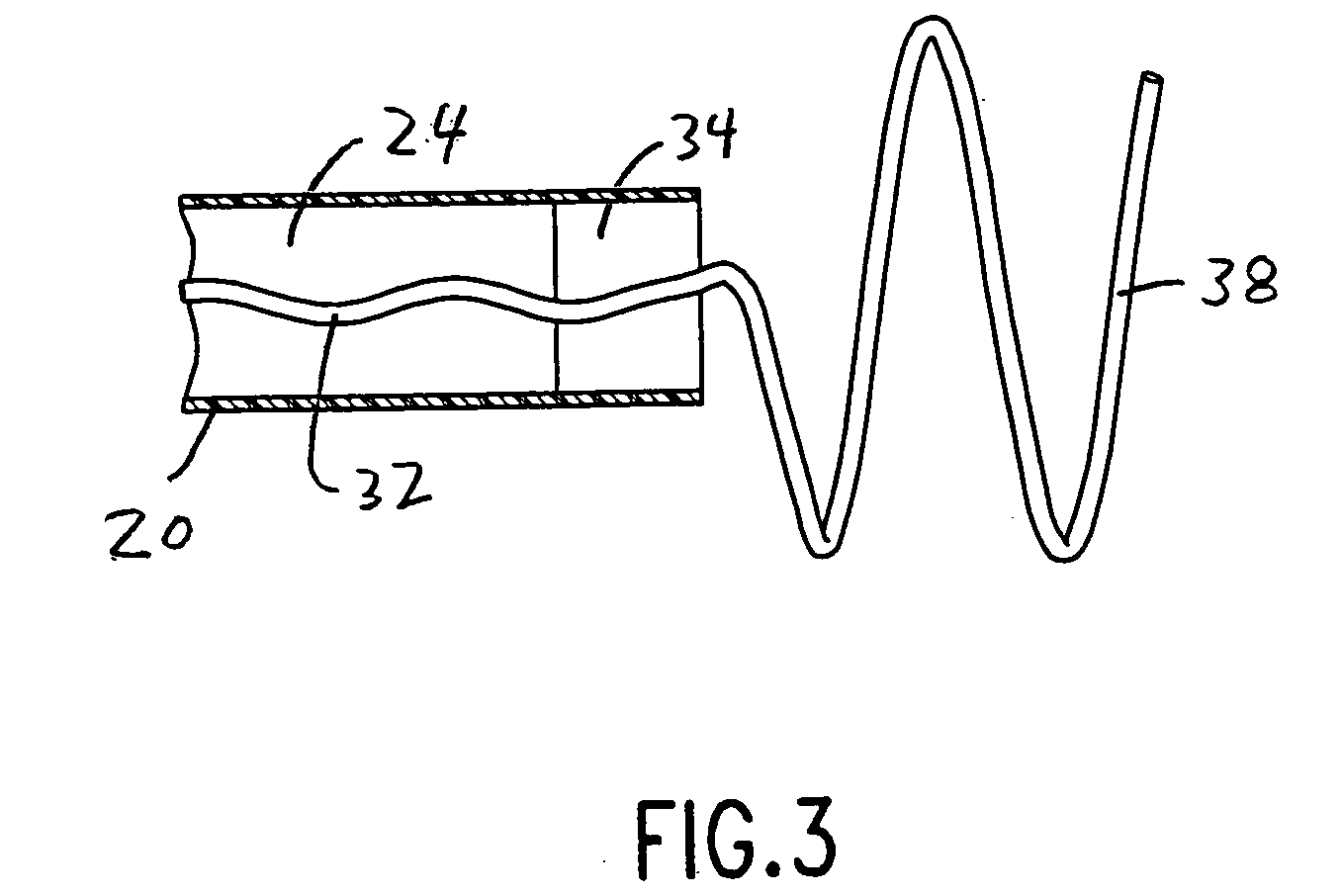

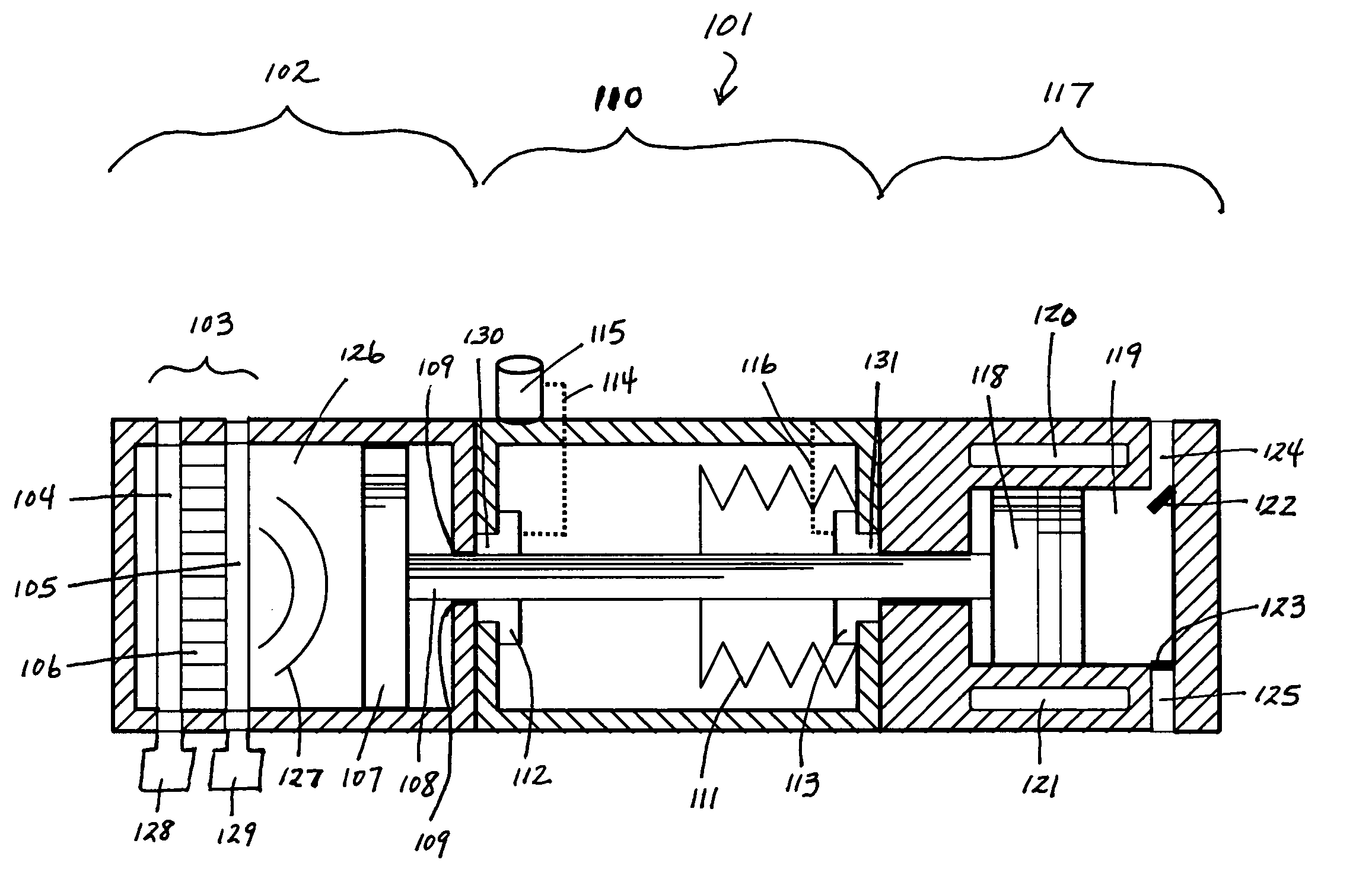

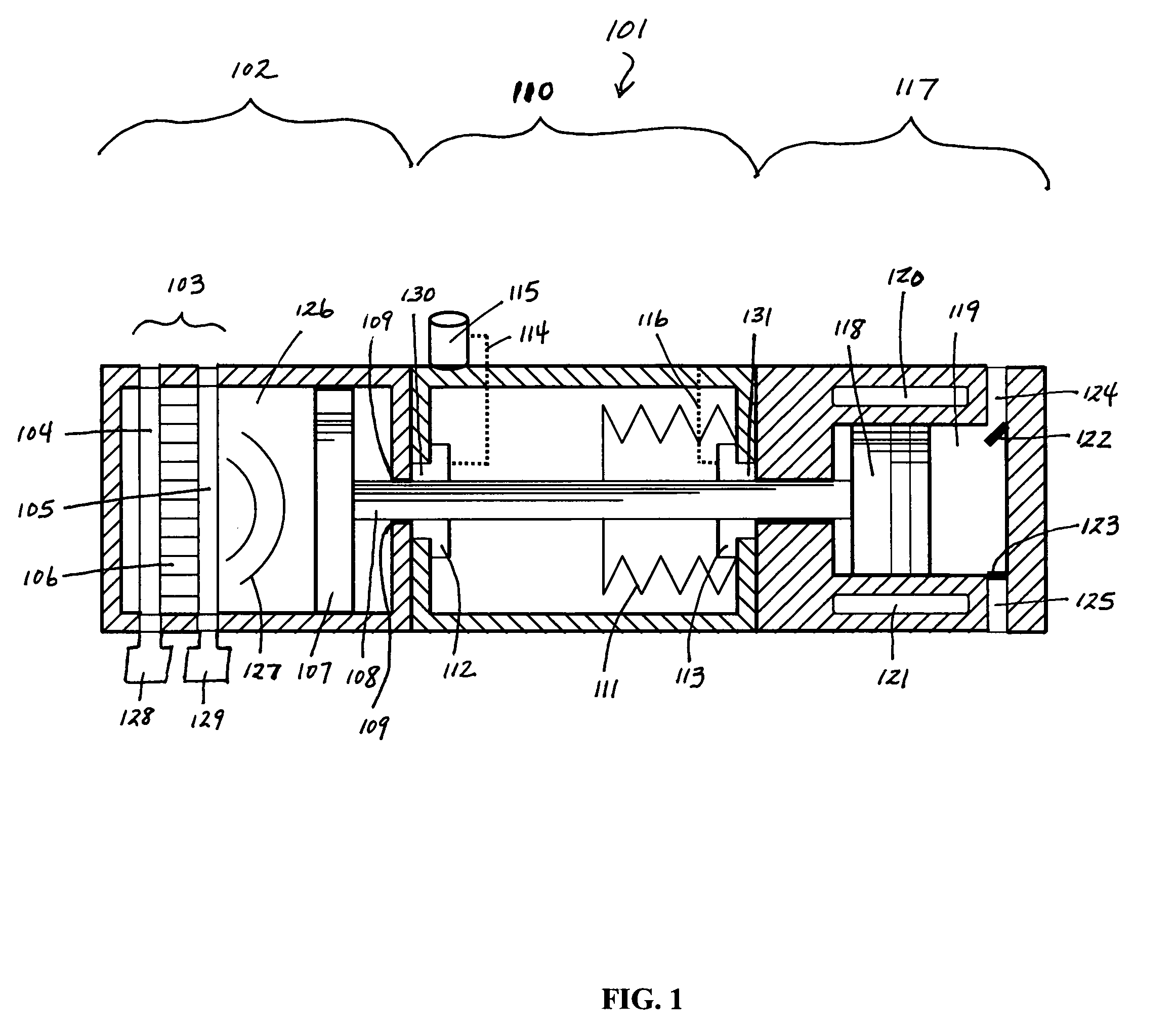

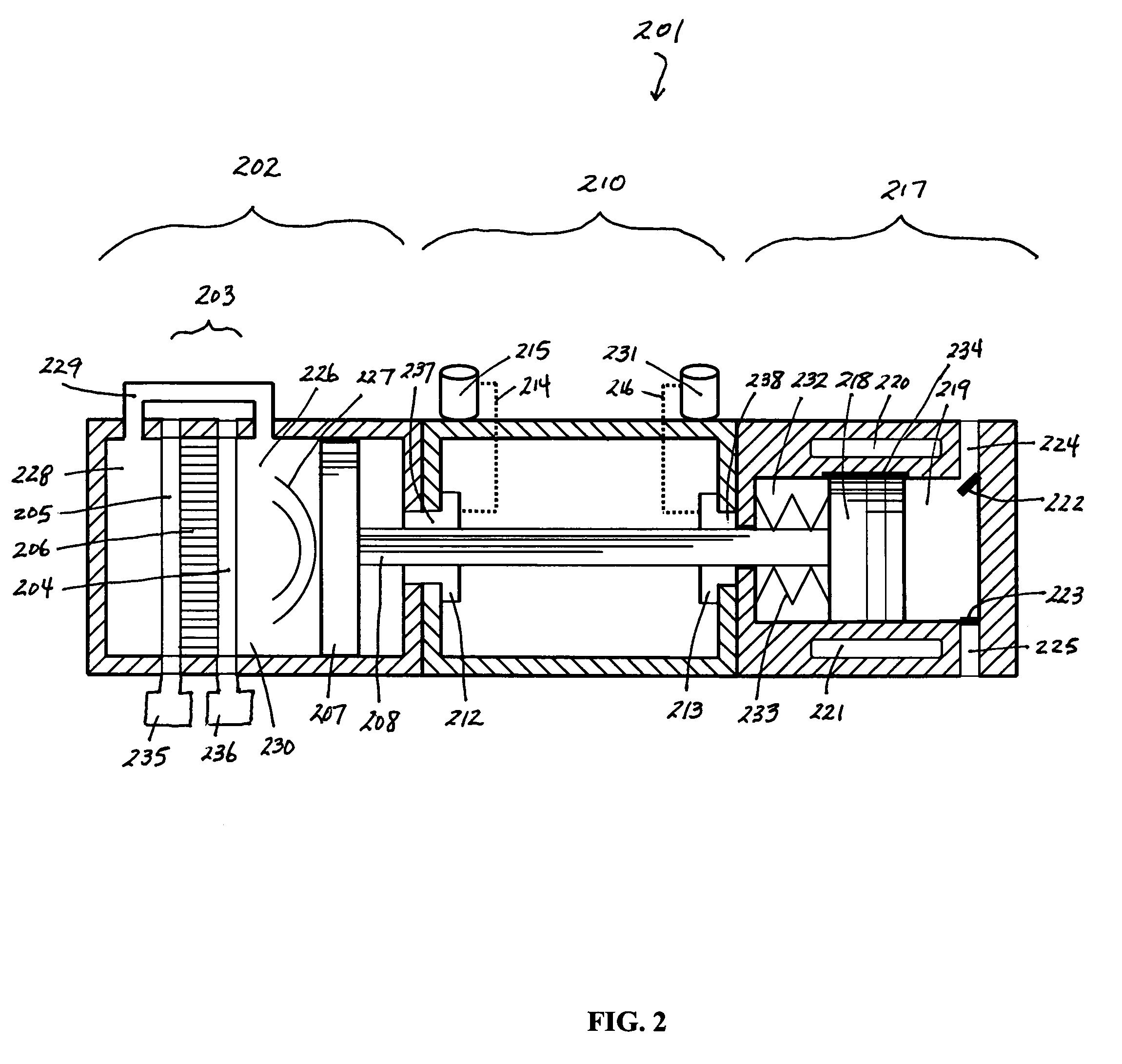

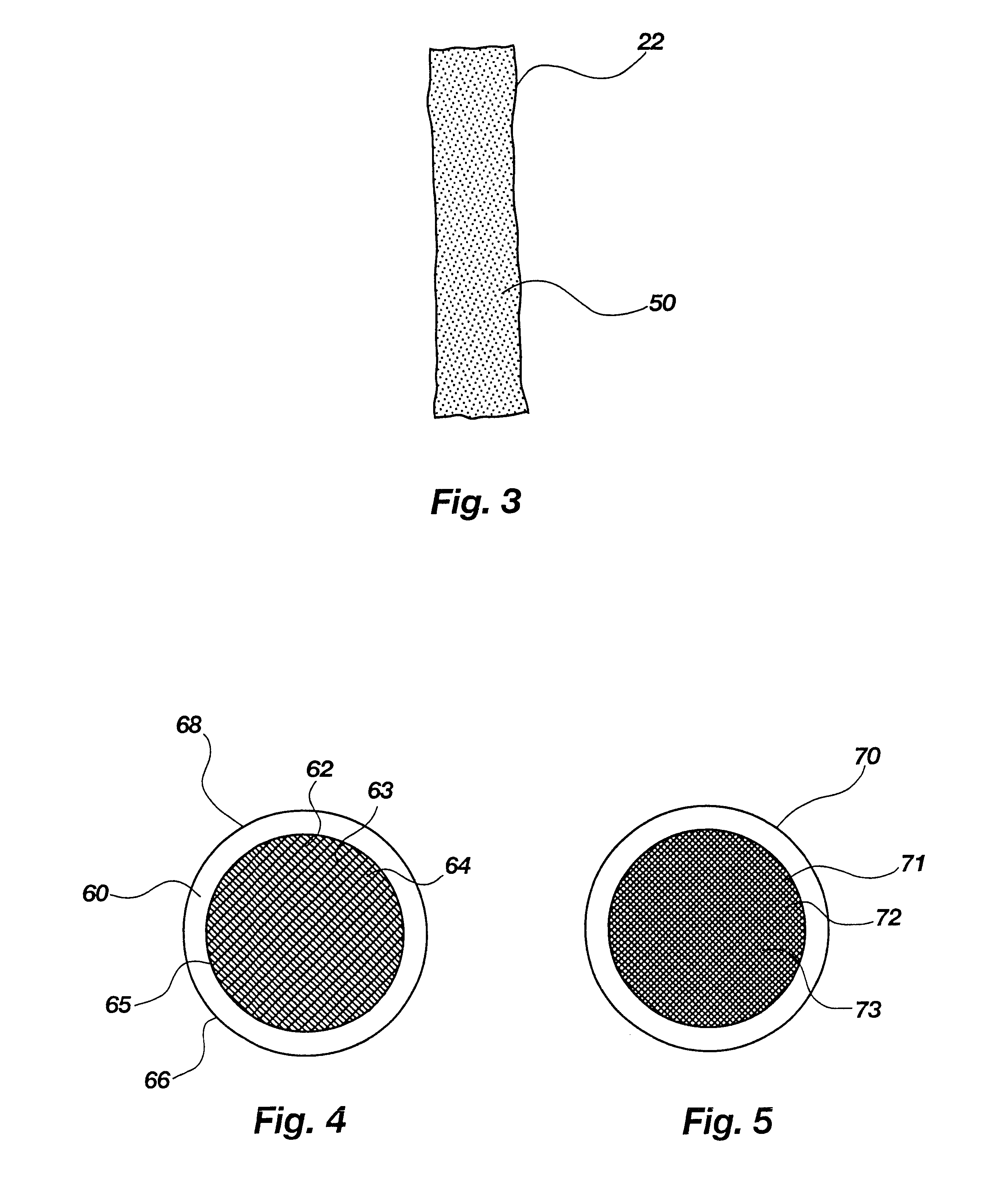

Shape memory alloy wire driven positive displacement micropump with pulsatile output

InactiveUS7052251B2Reliable outputLow costFlexible member pumpsMedical devicesControl electronicsShape-memory alloy

Apparatuses and methods for pumping fluid are disclosed. An exemplary apparatus is a miniature pump that includes a shape memory wire that obtains a plastic condition below a transformation temperature and has a memorized shape such that the shape memory wire produces a work stroke by returning to the memorize shape at least at the transformation temperature. A spring biased against the shape memory wire is deflected by the work stroke to deform the shape memory wire from the memorized shape below the transformation temperature. A fluid pump is coupled to the shape memory wire and driven by the biased spring and shape memory wire to produce a fluid flow. The miniature pump can be incorporated into a self-contained infusion device in the form of a compact self-adhesive patch including a fluid reservoir, control electronics and power supply that is place directly at the infusion site of a user.

Owner:MEDTRONIC MIMIMED INC

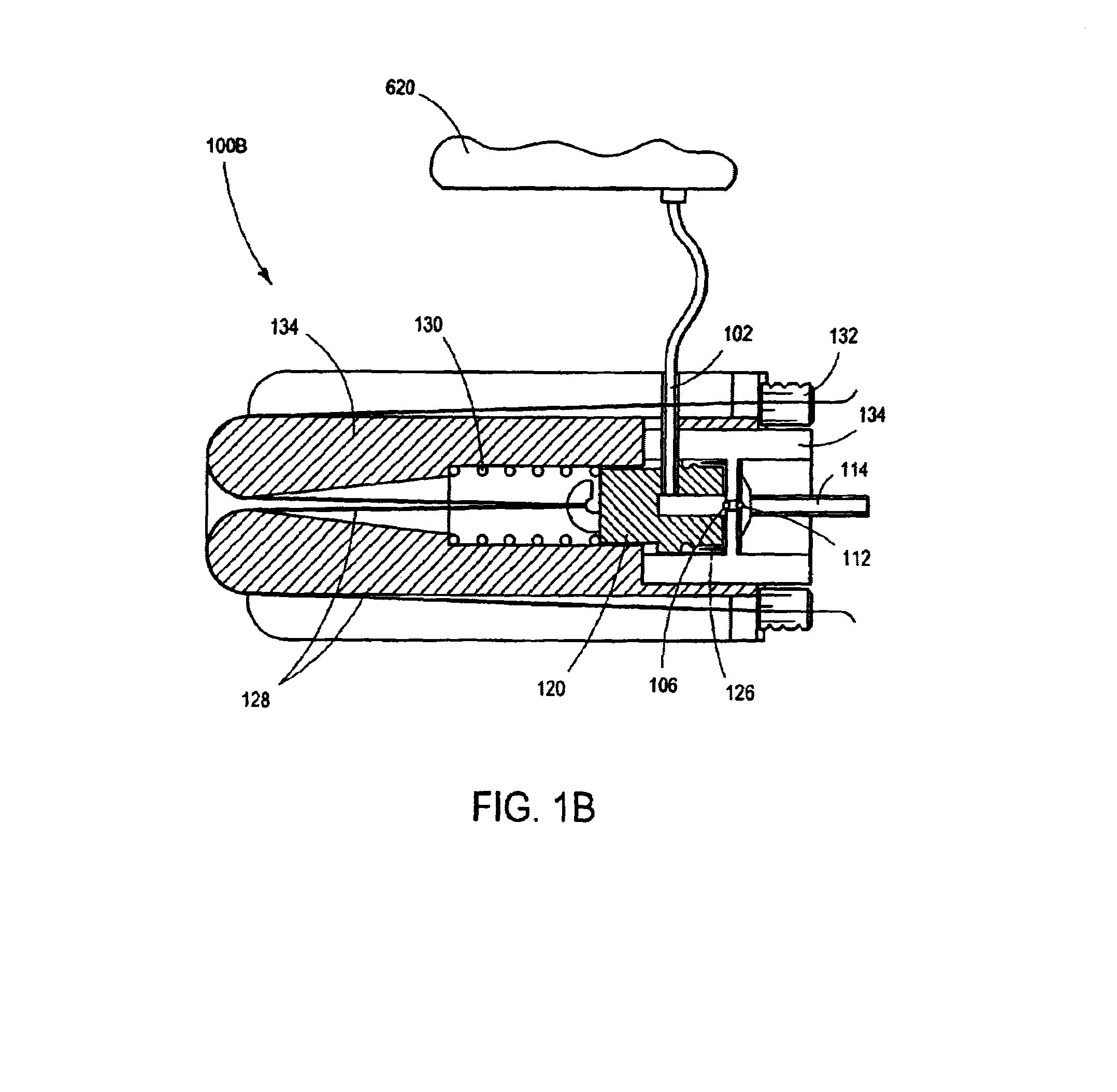

Hydrocarbon combustion power generation system with CO2 sequestration

InactiveUS7043920B2Eliminate needReduce electricity demandReciprocating combination enginesSolidificationAtmospheric airOxygen

A low or no pollution engine is provided for delivering power for vehicles or other power applications. The engine has an air inlet which collects air from a surrounding environment. At least a portion of the nitrogen in the air is removed. The remaining gas is primarily oxygen, which is then routed to a gas generator. The gas generator has inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. The combustion products are then expanded through a power generating device, such as a turbine or piston expander to deliver output power for operation of a vehicle or other power uses. The combustion products are then passed through a condenser where the steam is condensed and the carbon dioxide is collected or discharged. A portion of the water is routed back to the gas generator. The carbon dioxide is compressed and delivered to a terrestrial formation from which return of the CO2 into the atmosphere is inhibited.

Owner:CLEAN ENERGY SYST

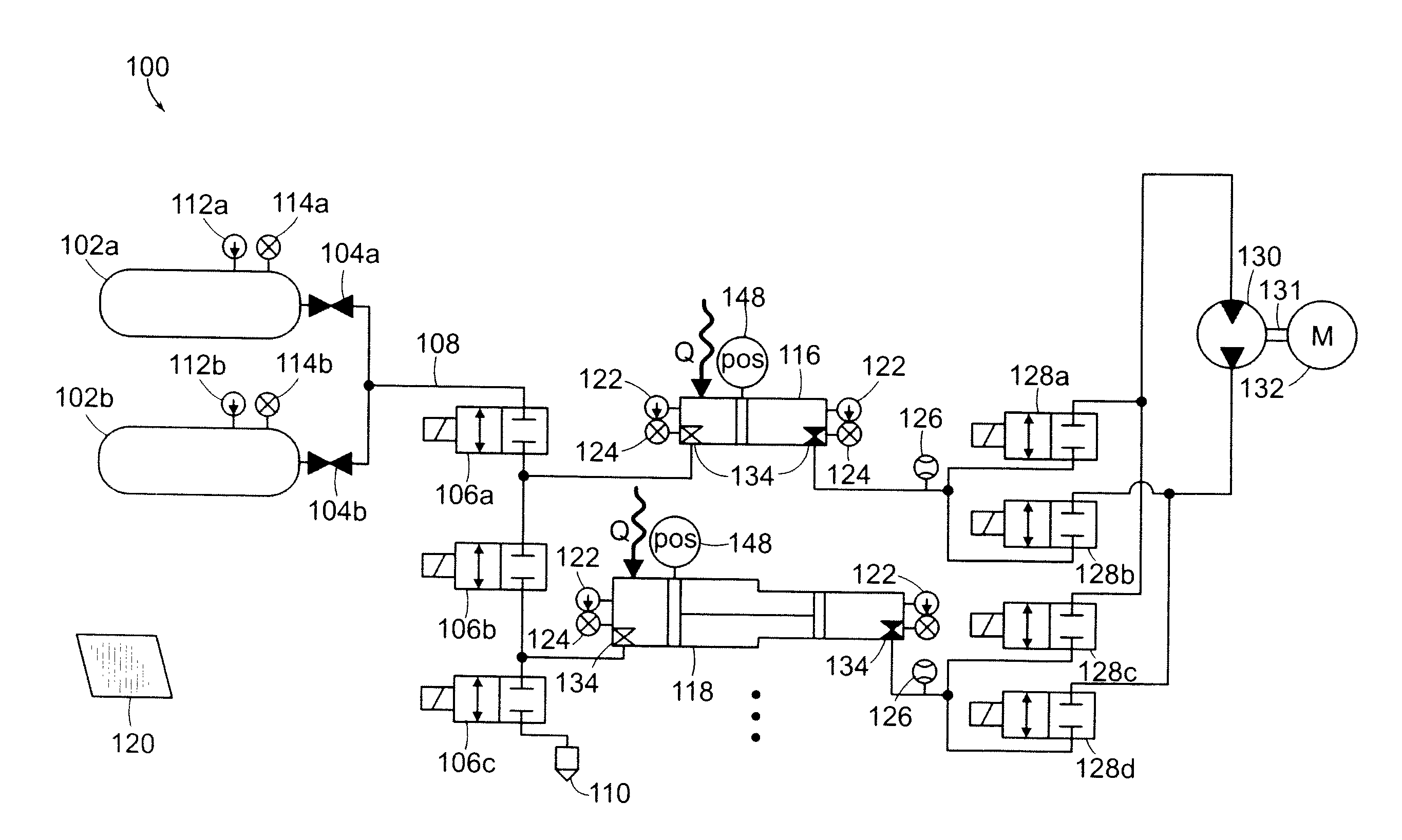

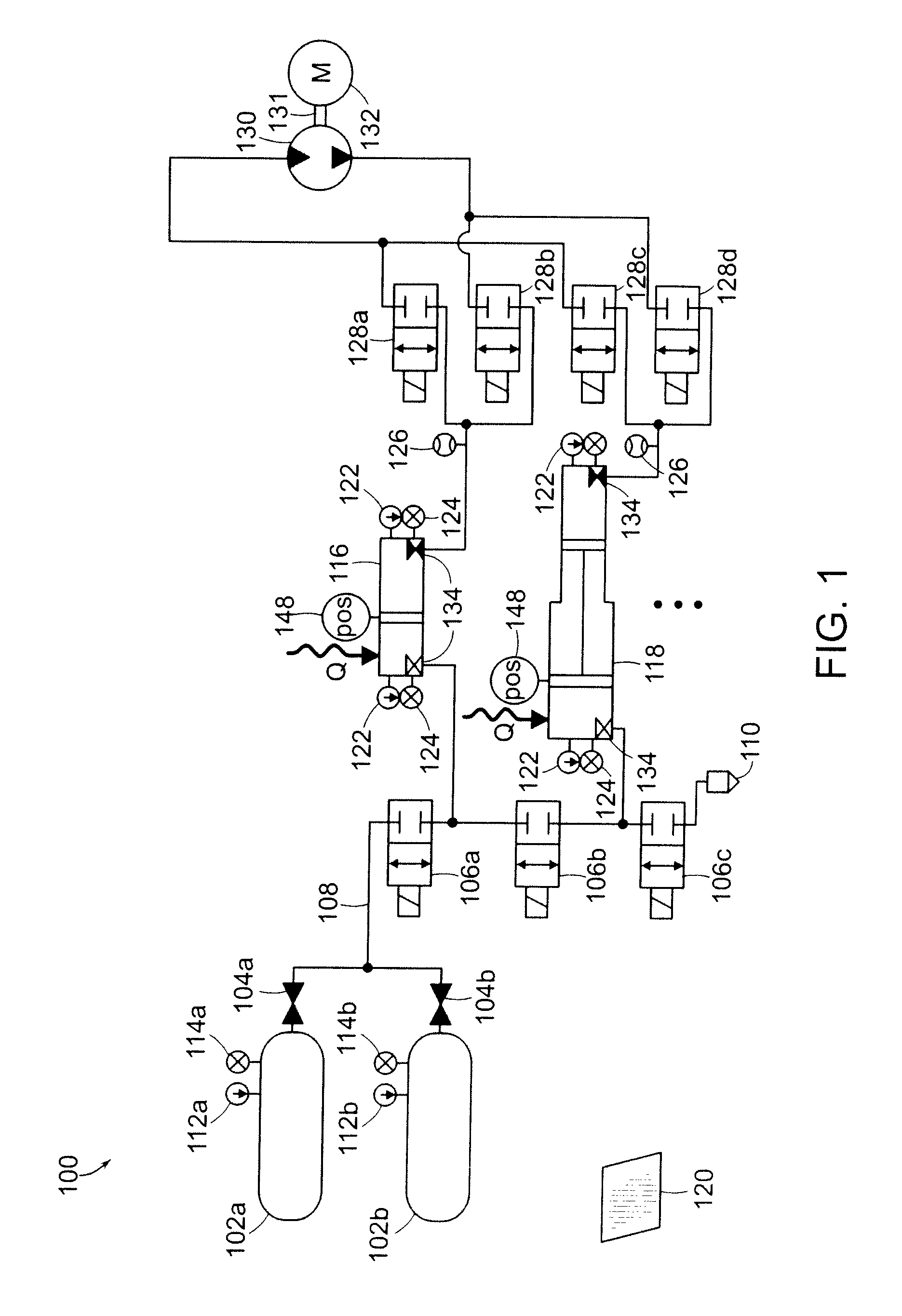

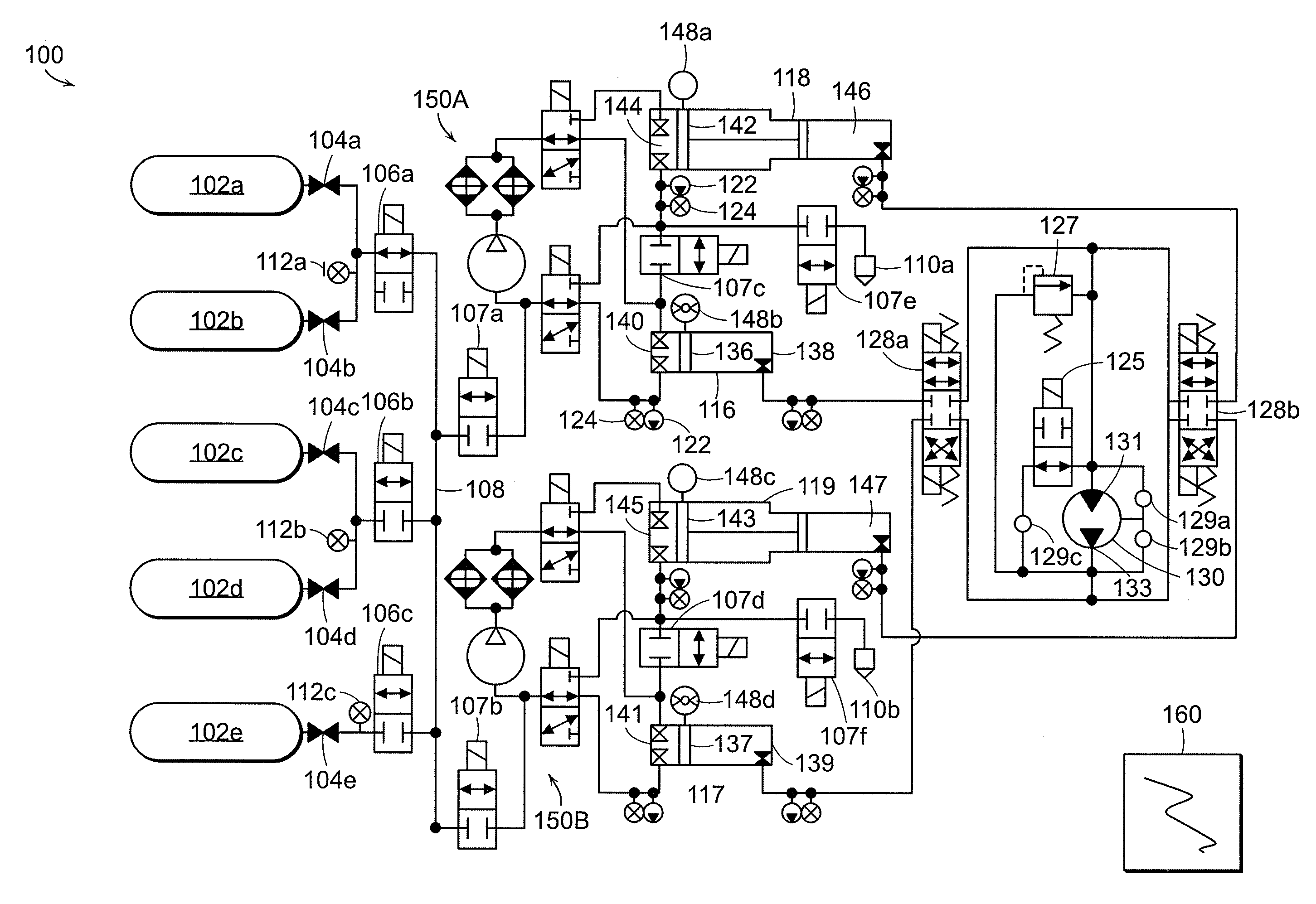

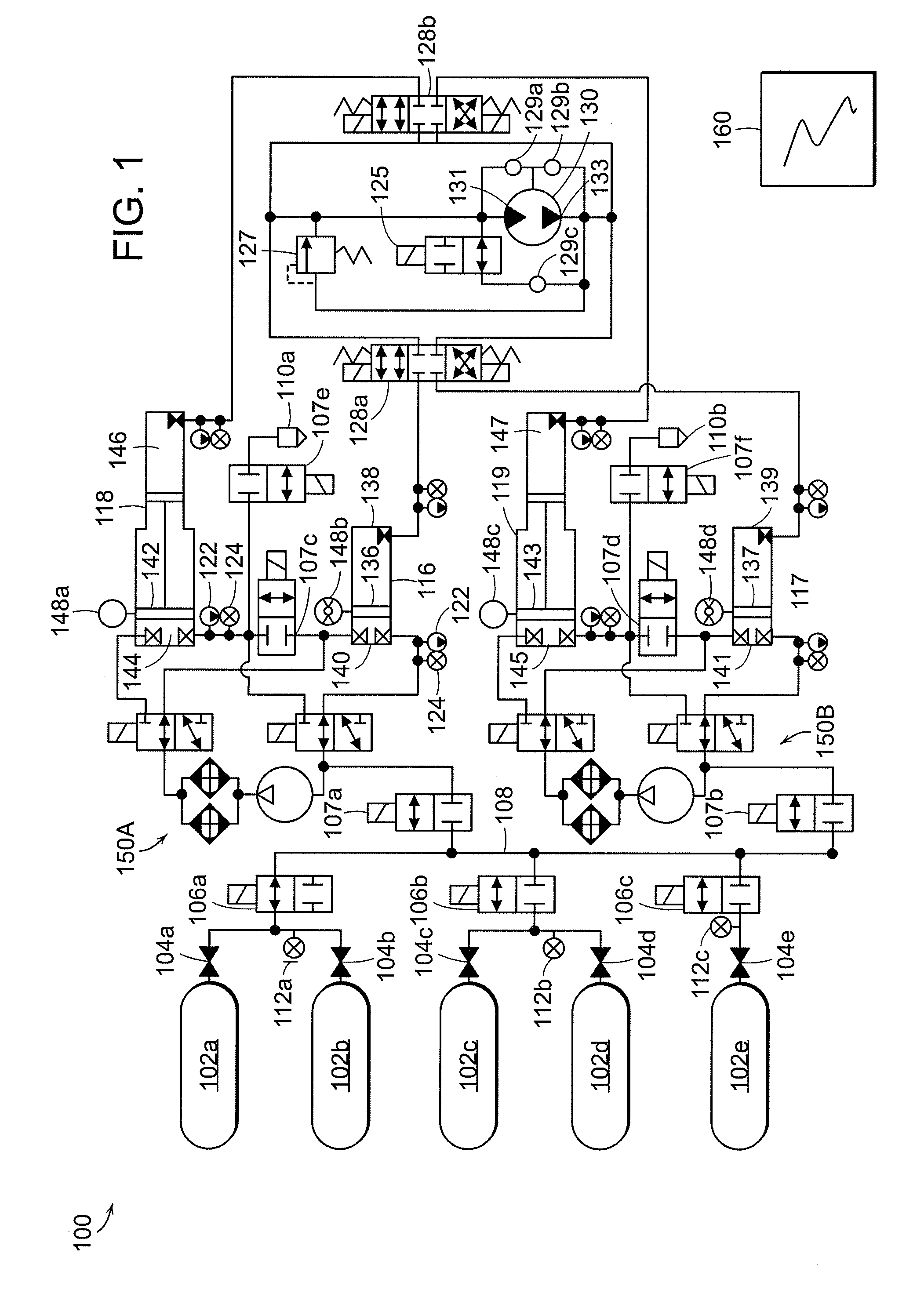

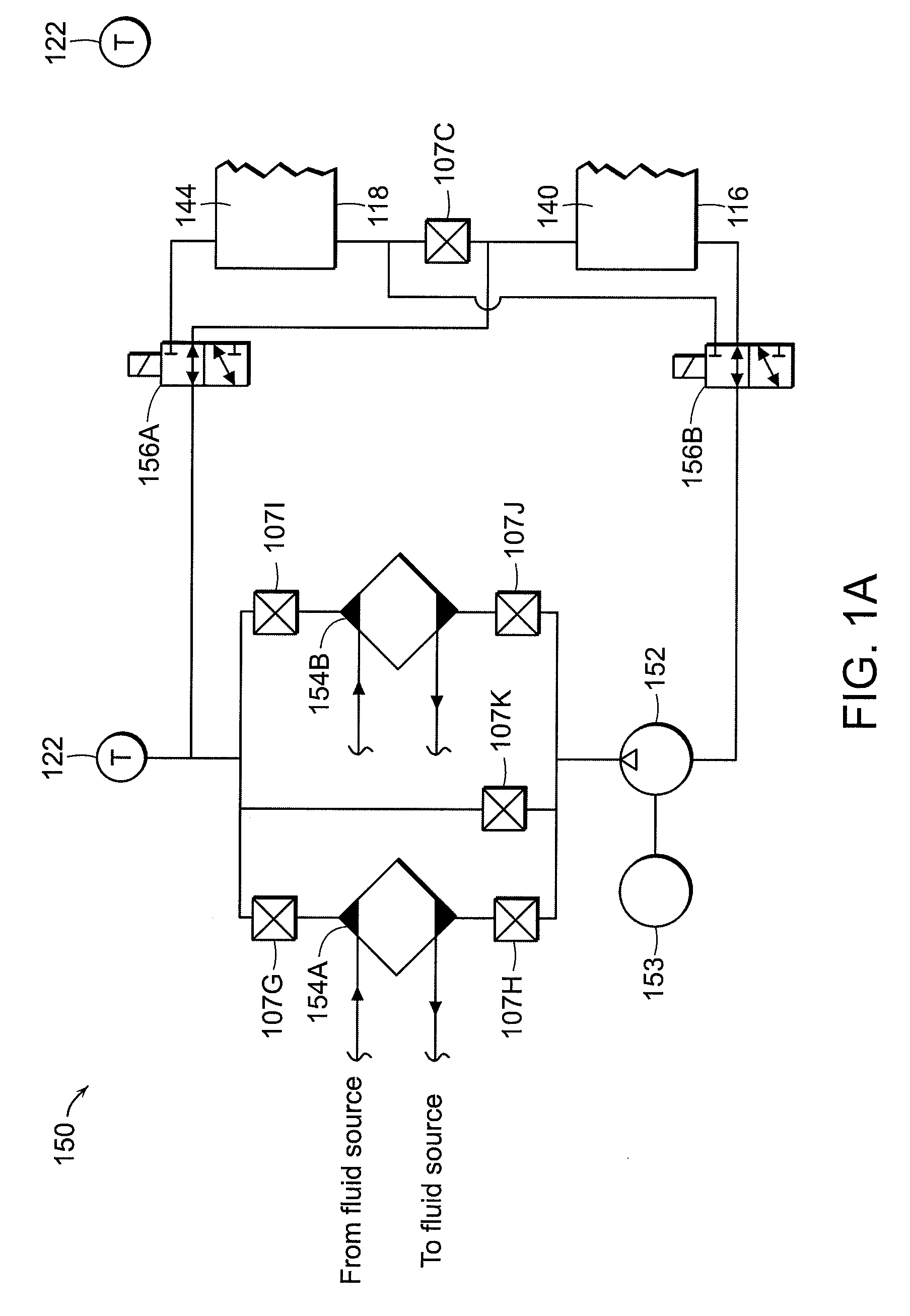

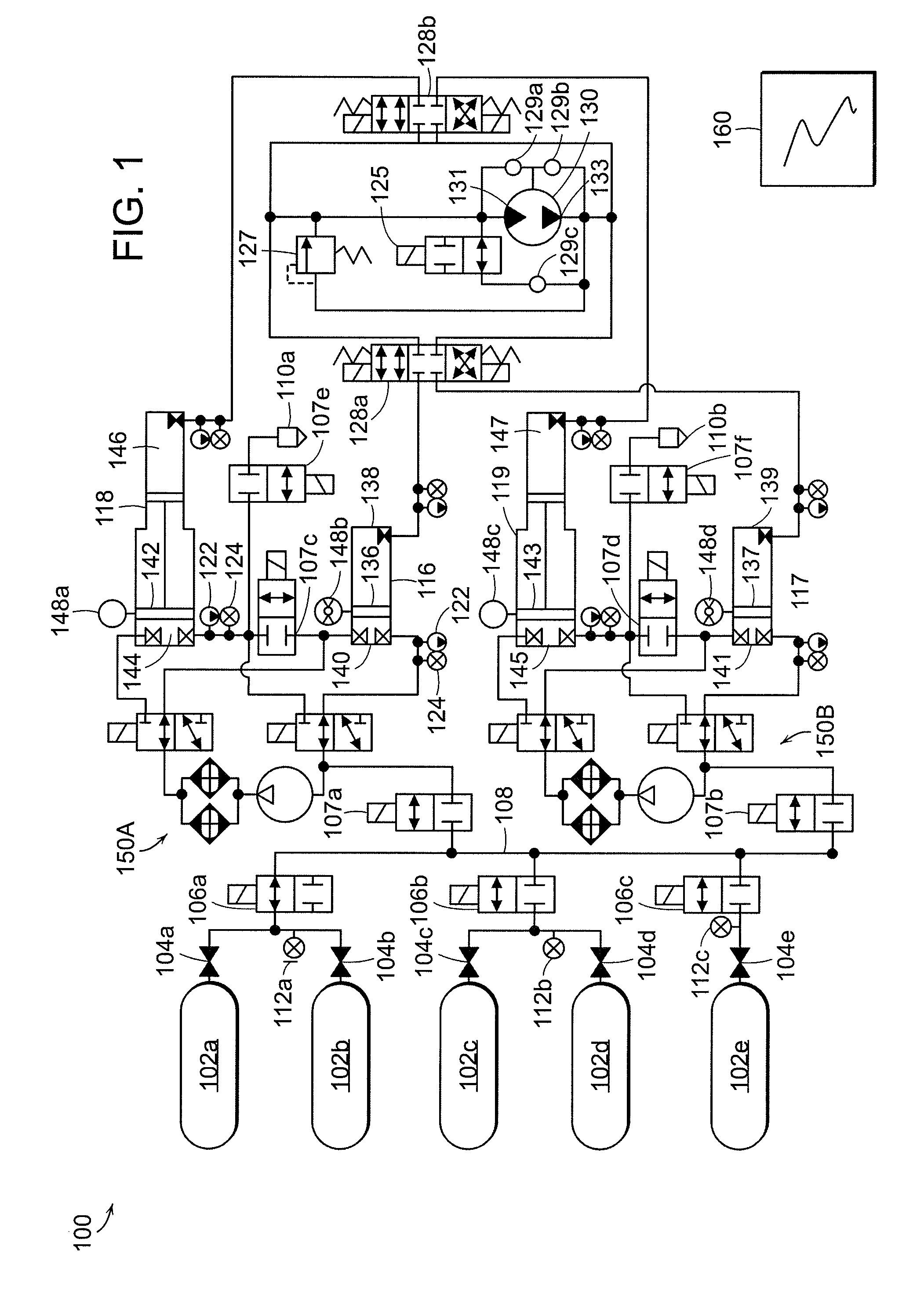

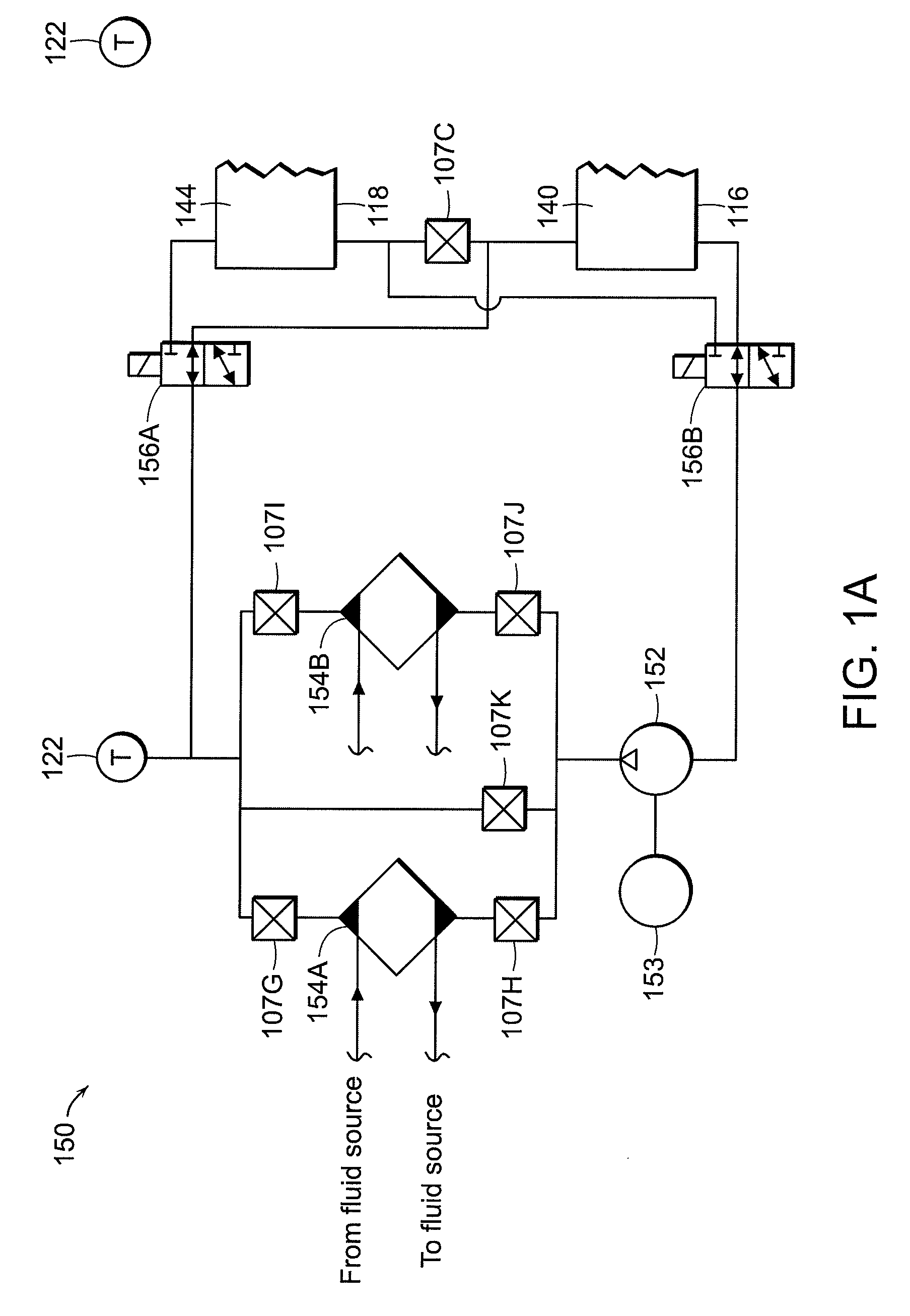

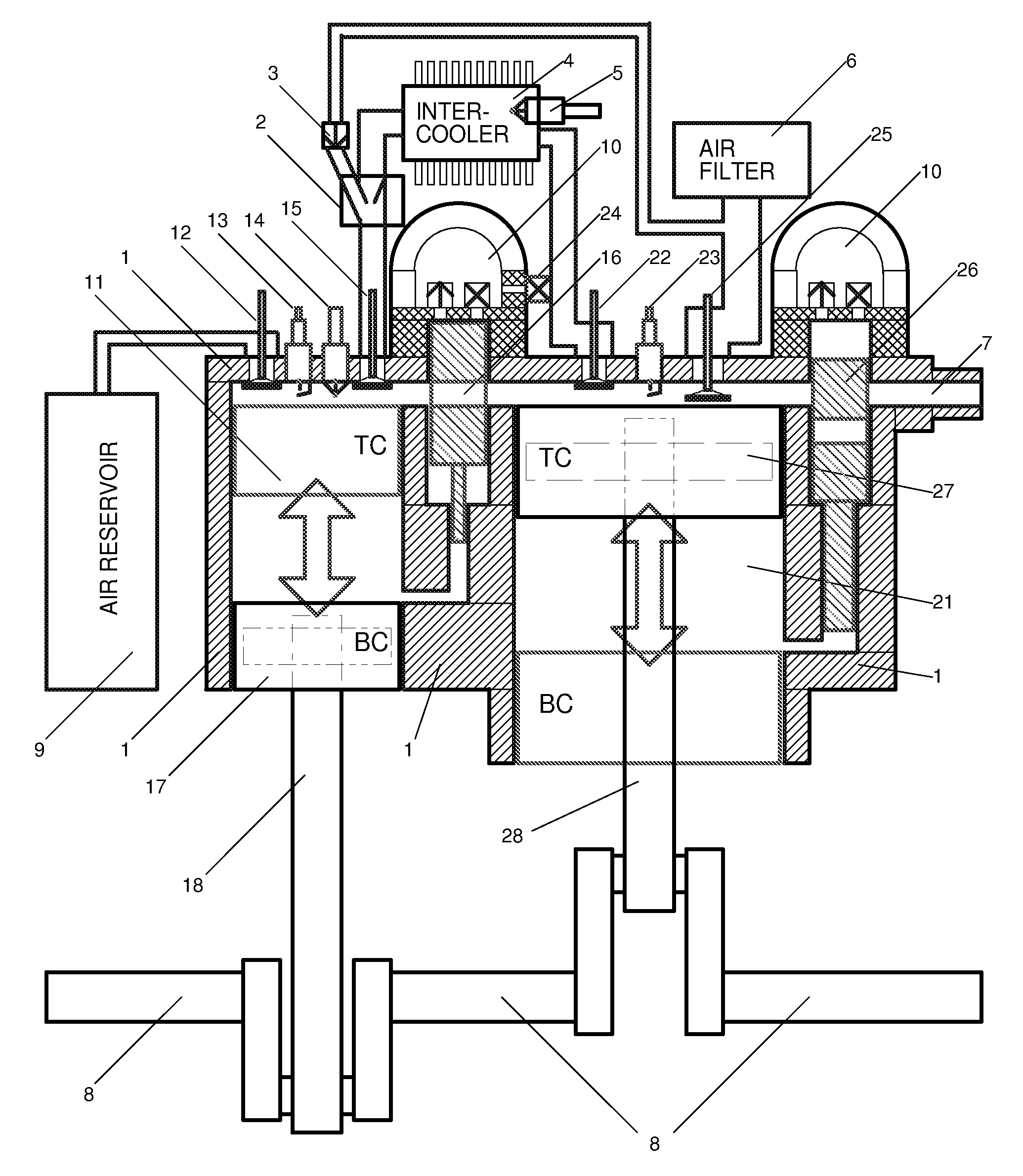

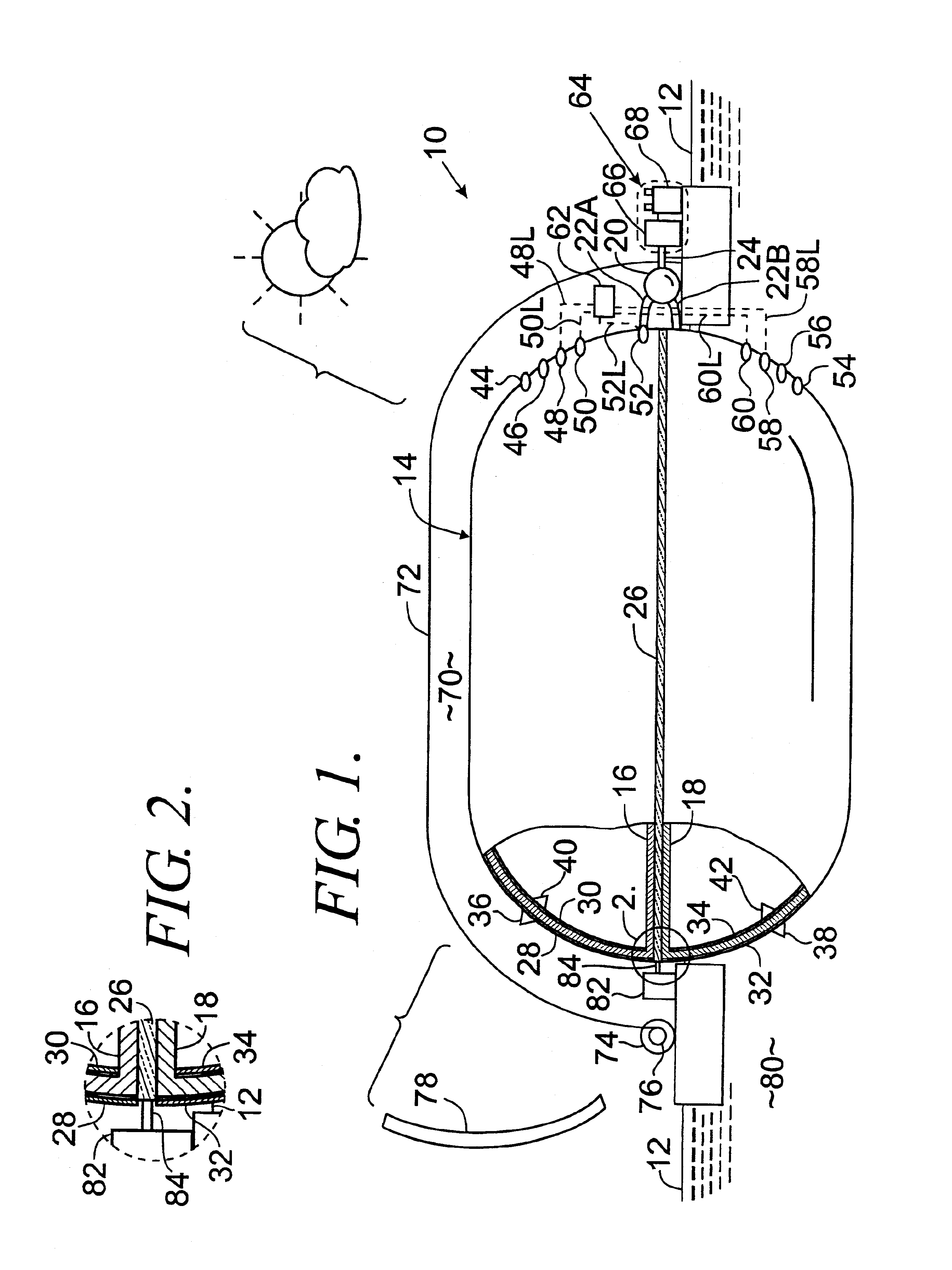

Systems and Methods for Energy Storage and Recovery Using Rapid Isothermal Gas Expansion and Compression

InactiveUS20100089063A1Increase energy densityHigh outputElectrical storage systemInternal combustion piston enginesProduct gasEngineering

The invention relates to systems and methods for rapidly and isothermally expanding and compressing gas in energy storage and recovery systems that use open-air hydraulic-pneumatic cylinder assemblies, such as an accumulator and an intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits. The systems use heat transfer subsystems in communication with at least one of the cylinder assemblies or reservoir to thermally condition the gas being expanded or compressed.

Owner:SUSTAINX

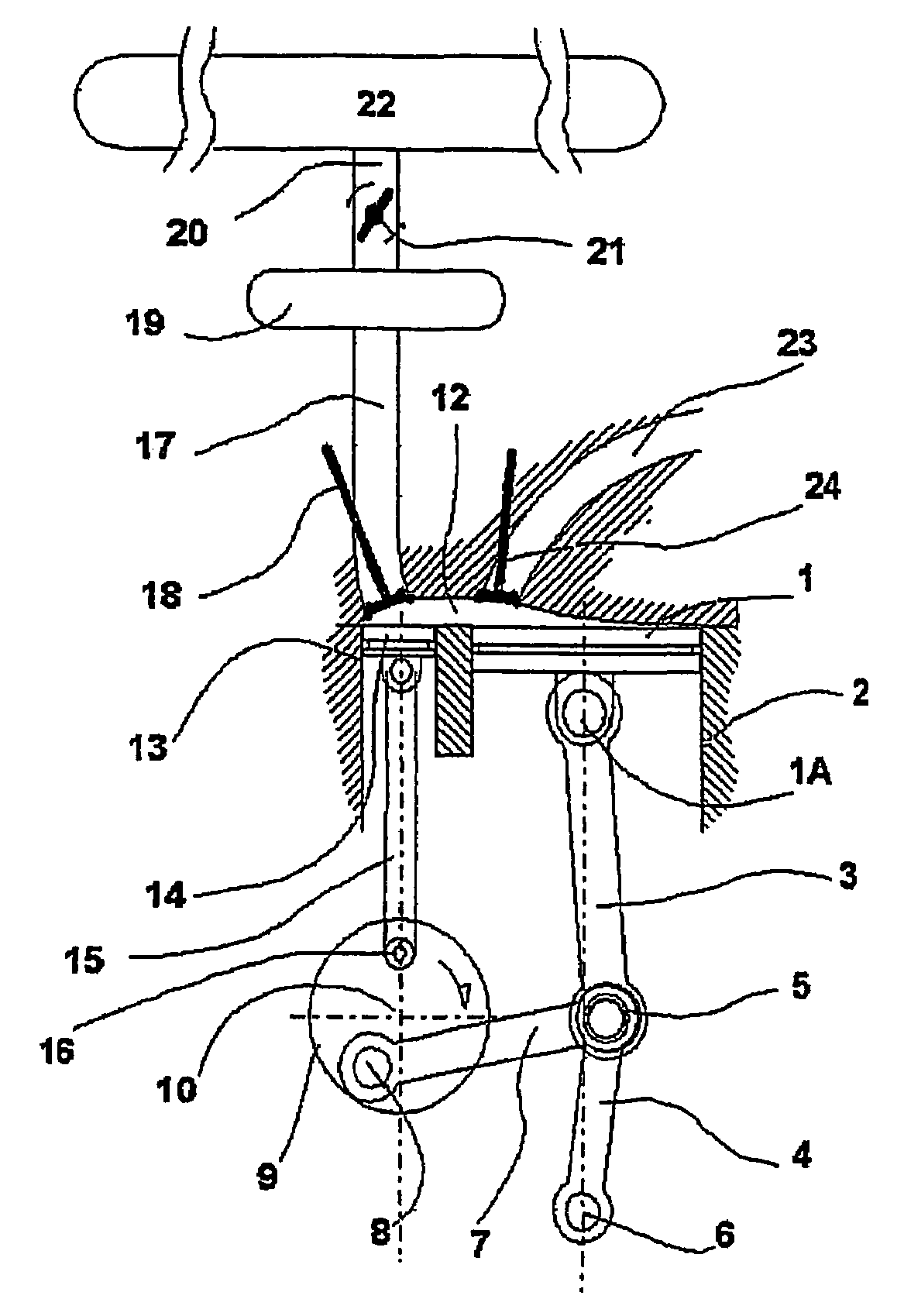

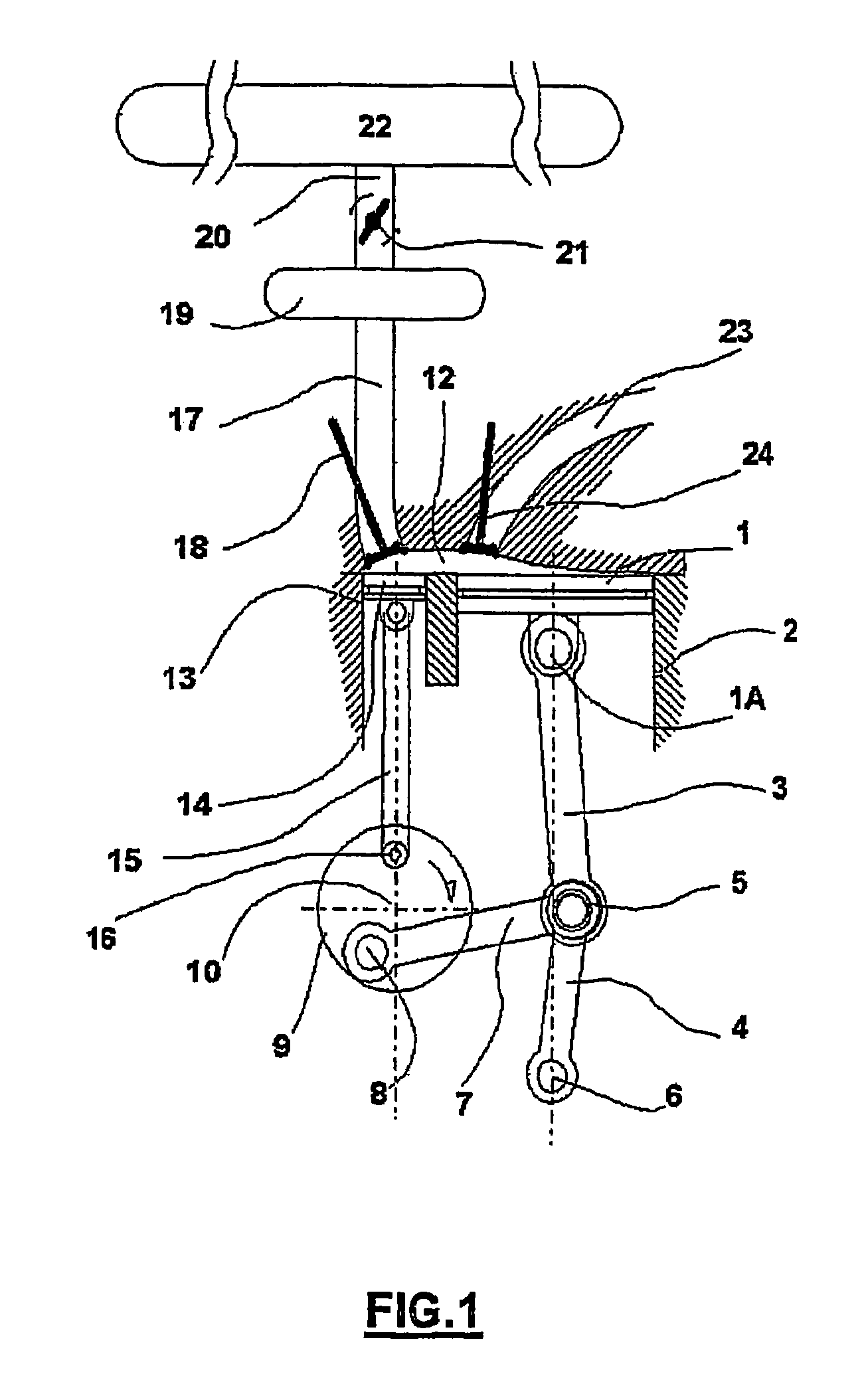

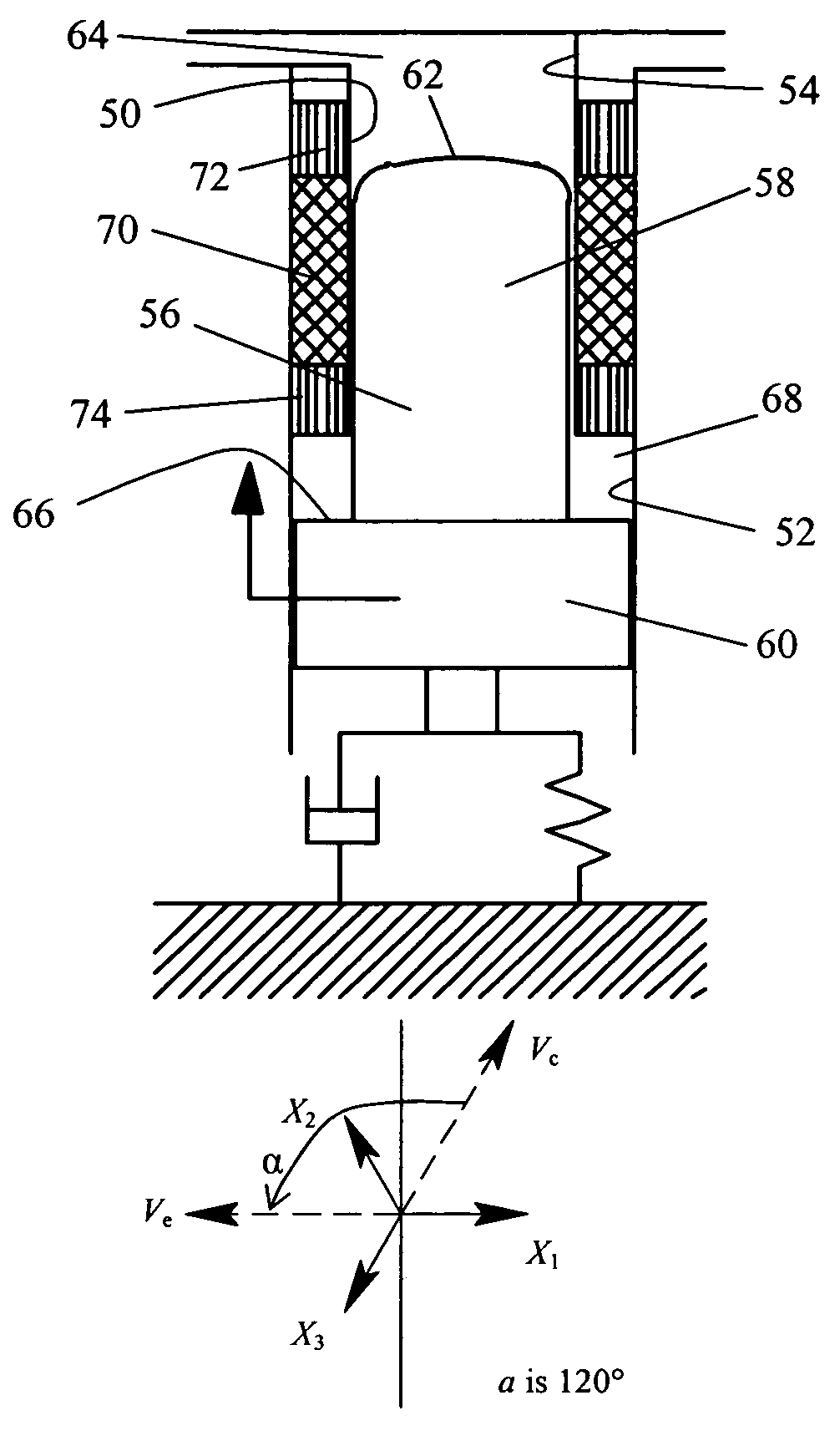

Isothermal reciprocating machines

InactiveUS20060248886A1High materialIncrease heating capacityPositive displacement pump componentsMulti-stage pumpsWorking fluidGas compressor

A reciprocating gas compressor is described operating according to an extended cycle of 4,6 or more strokes, wherein the first two strokes are sequential induction and compression strokes using a low pressure gas as working fluid and compressing it to a high pressure gas, and the remaining strokes are pairs of sequential filling and emptying strokes using more of the low pressure gas as heat transfer fluid for transferring heat from inside the gas compressor to outside the gas compressor. The gas compressor also contains an in-cylinder heat regenerator for absorbing heat from the compressed gas and releasing heat to the heat transfer fluid thus achieving near-isothermal compression. Using parallel principles, a reciprocating gas expander is also described for achieving near-isothermal expansion. Also described are reciprocating machines using the near-isothermal gas compressor and near-isothermal gas expander in combination according to the Ericsson heat engine cycle, the Stirling heat engine cycle and the Stirling refrigeration cycle.

Owner:MA THOMAS TSOI HEI

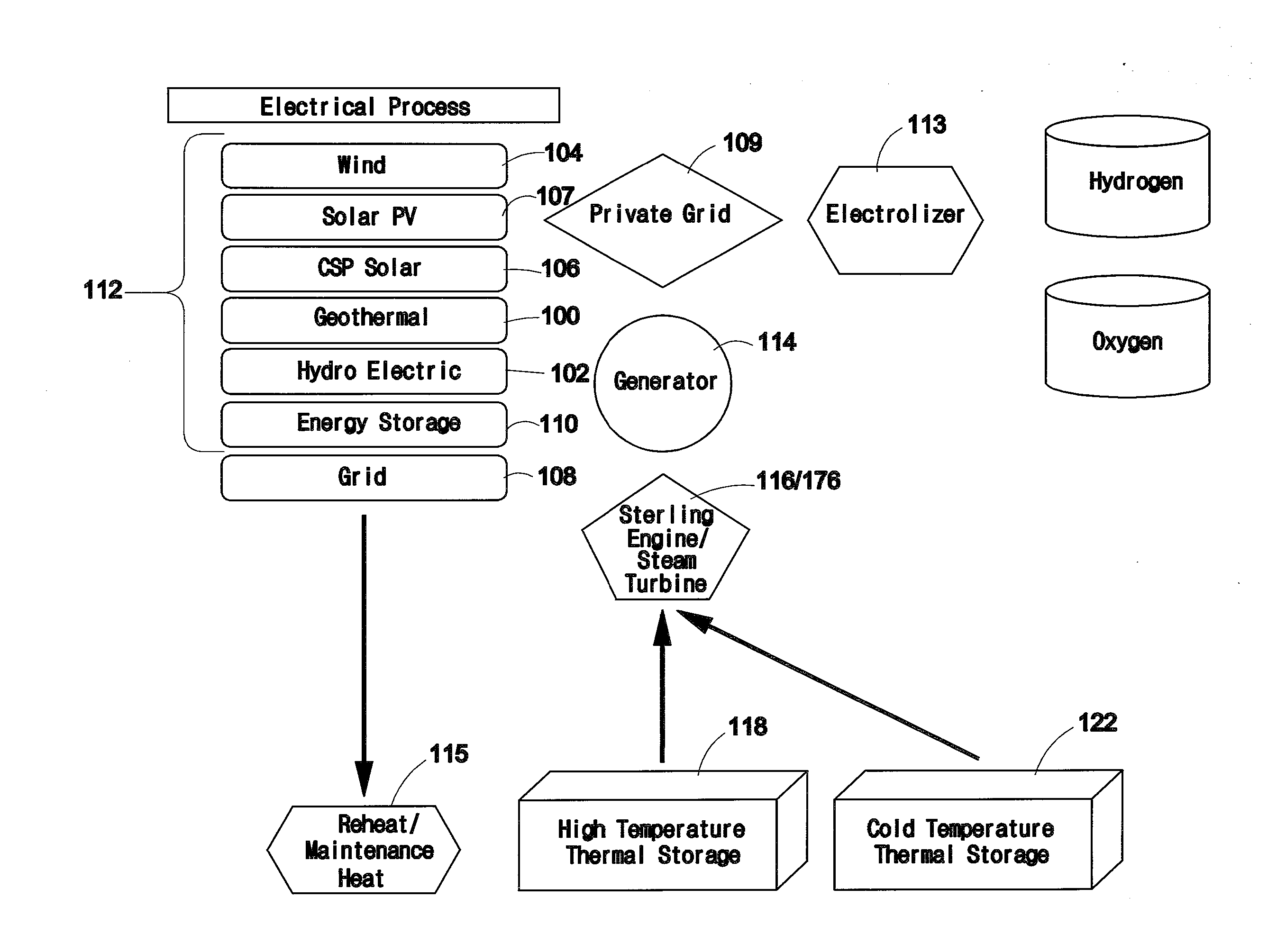

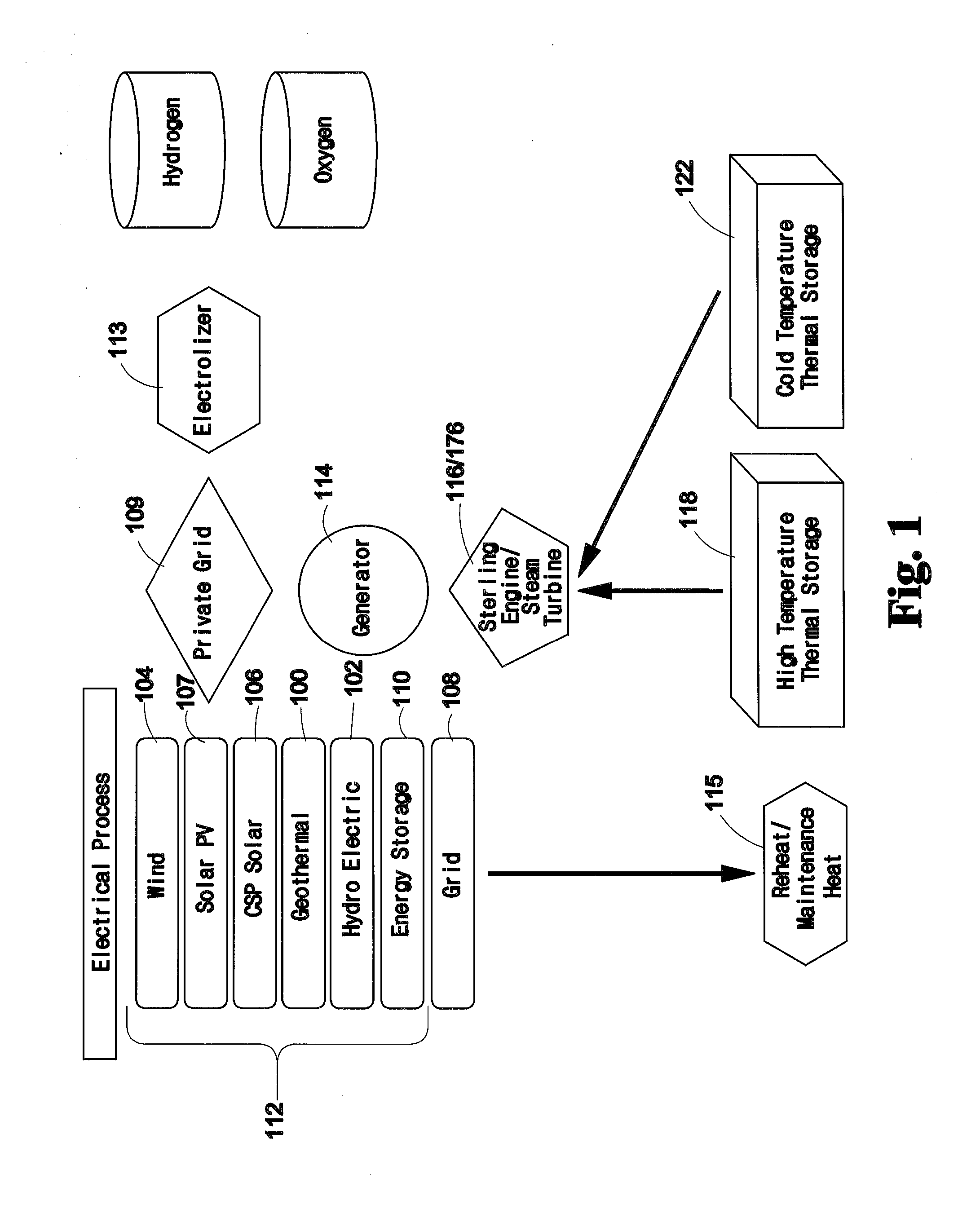

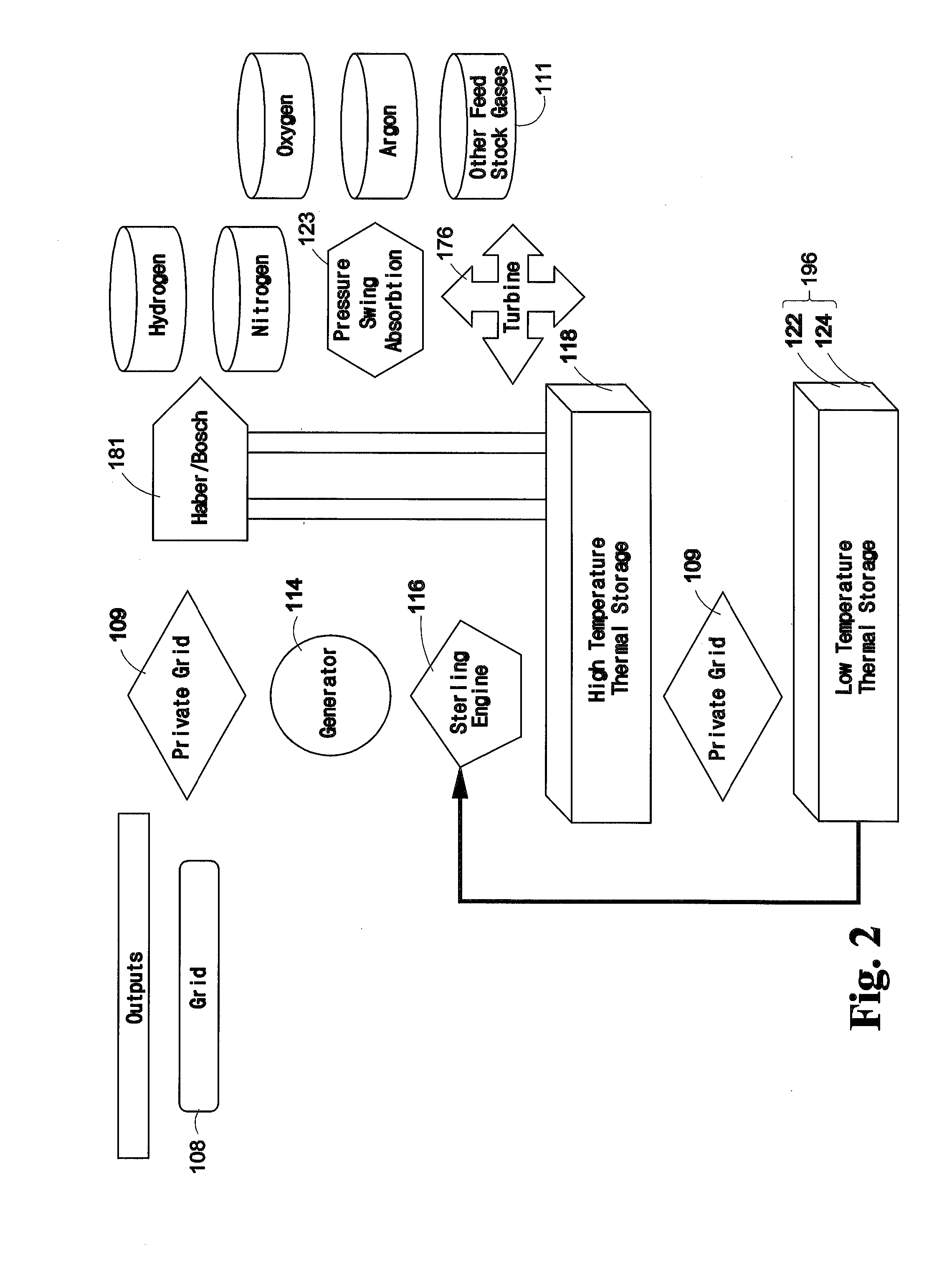

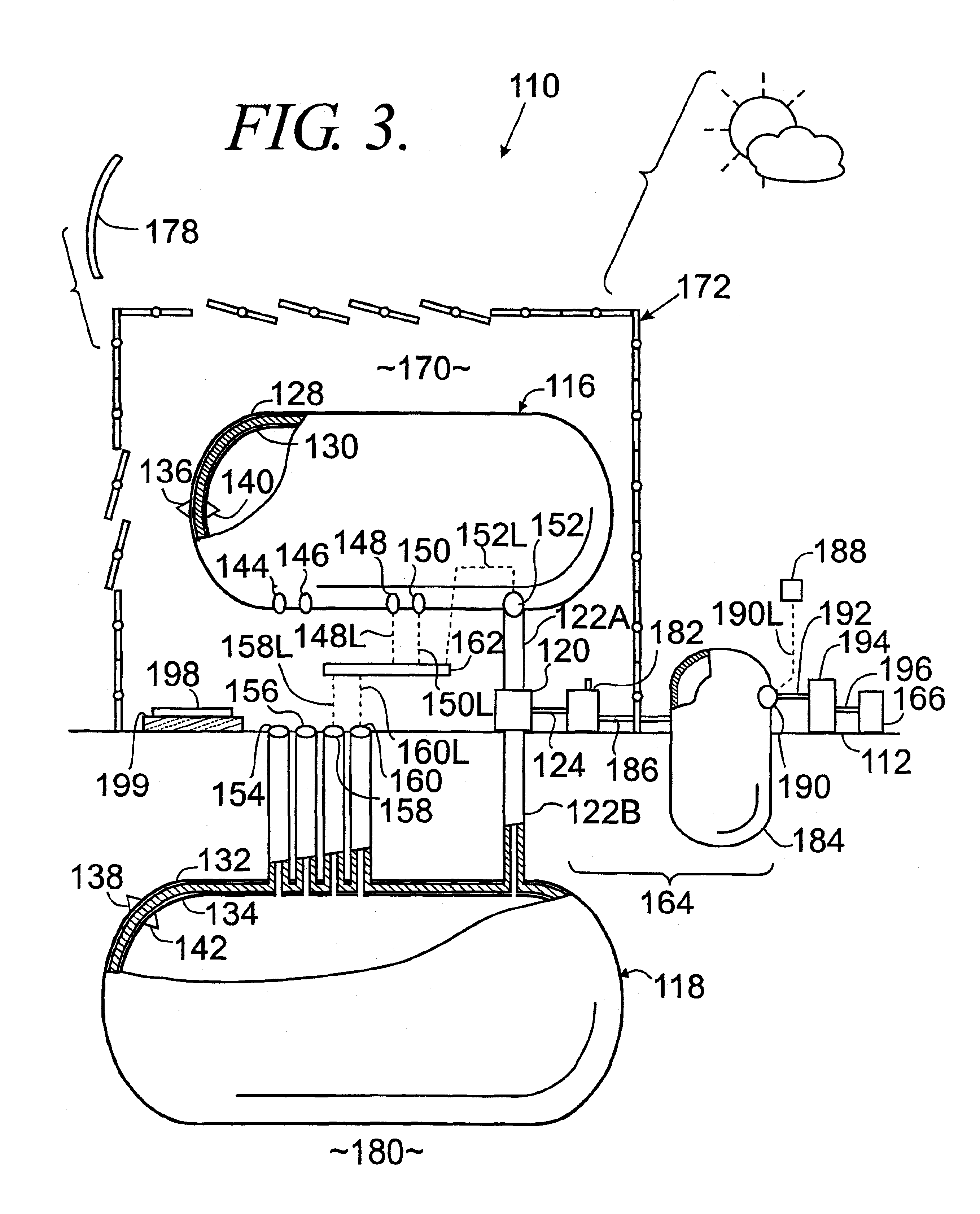

Quintuple-Effect Generation Multi-Cycle Hybrid Renewable Energy System with Integrated Energy Provisioning, Storage Facilities and Amalgamated Control System Cross-Reference to Related Applications

InactiveUS20150143806A1Lowering expensiveIncrease energy generatedSolar heating energyInternal combustion piston enginesEnergy recoveryOpen architecture

Provided is a consumer to industrial scale renewable energy based quintuple-generation systems and energy storage facility. The present invention has both mobile and stationary embodiments. The present invention includes energy recovery, energy production, energy processing, pyrolysis, byproduct process utilization systems, separation process systems and handling and storage systems, as well as an open architecture for integration and development of additional processes, systems and applications. The system of the present invention primarily uses adaptive metrics, biometrics and thermal imaging sensory analysis (including additional input sensors for analysis) for monitoring and control with the utilization of an integrated artificial intelligence and automation control system, thus providing a balanced, environmentally-friendly ecosystem.

Owner:FRIESTH KEVIN LEE

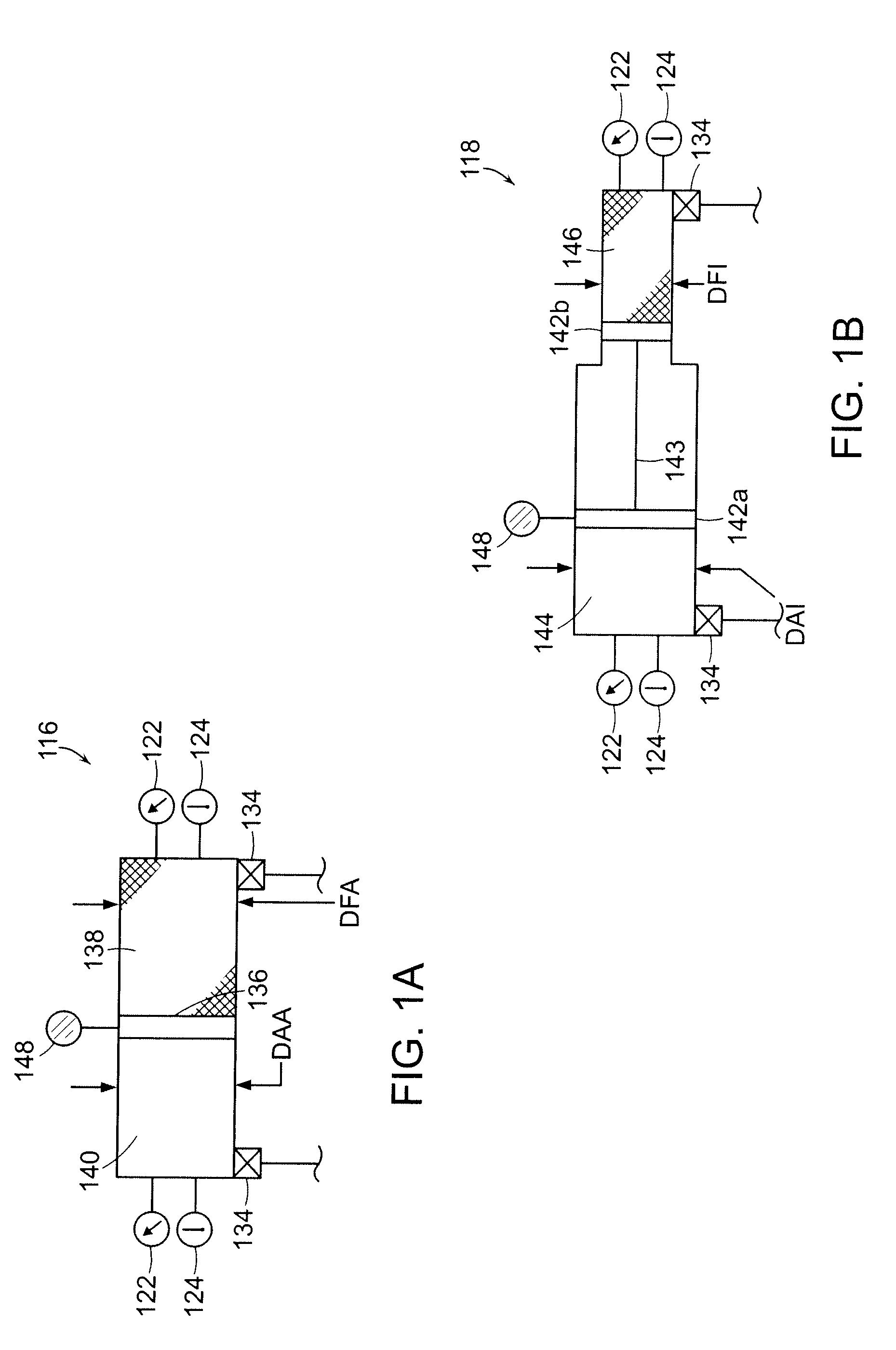

Method of setting and actuating a multi-stable micro valve and adjustable micro valve

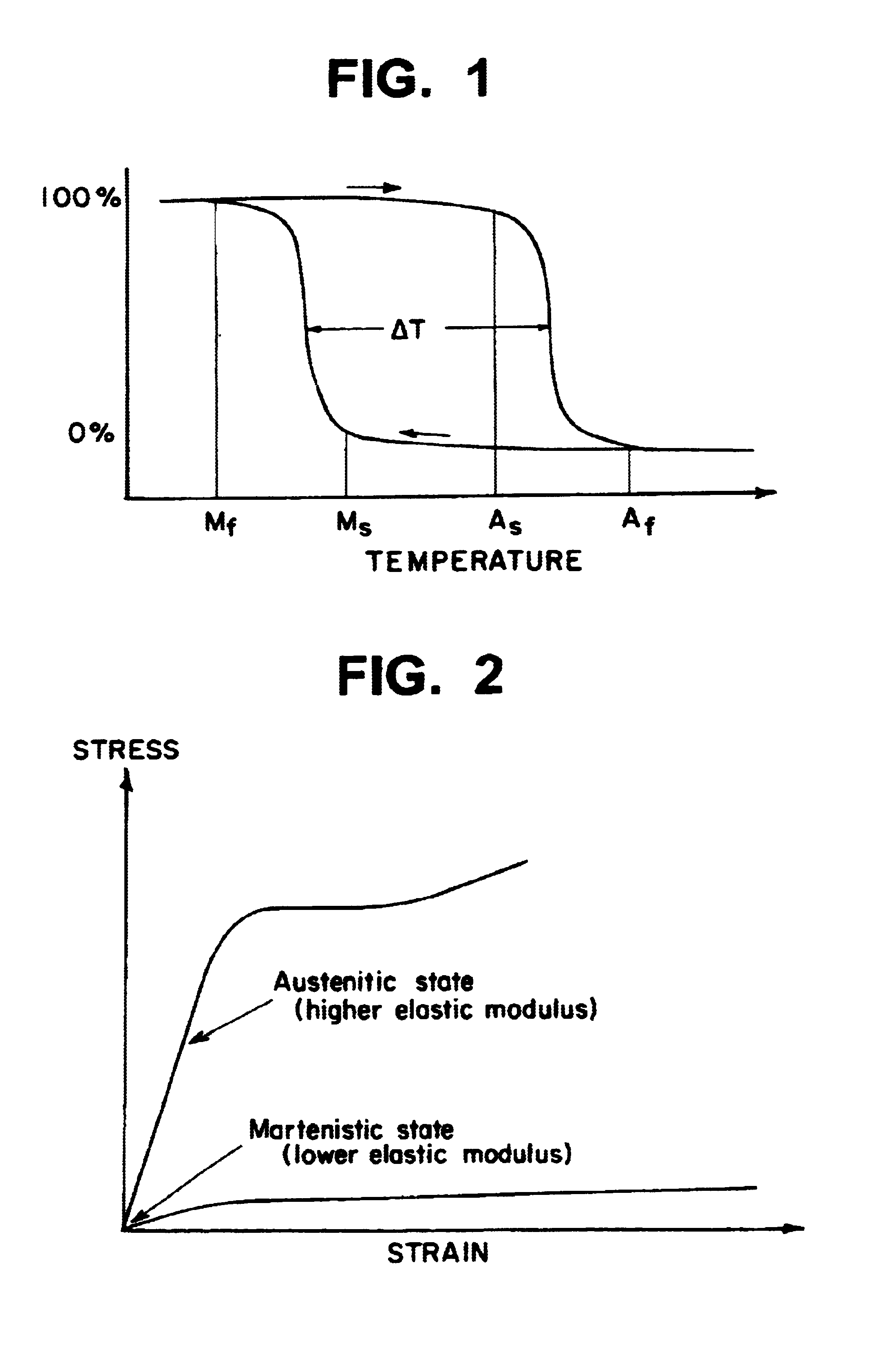

InactiveUS6926246B2Less sensitive to blockageOperating means/releasing devices for valvesCircuit elementsShape-memory alloyEngineering

A micro valve and a method for setting or actuating a micro valve for use in fluidic applications includes cooling an array of actuating members made of Shape Memory Alloy (SMA) material. The SMA material is cooled to a temperature equal to or below the temperature at which a transformation from austenitic to martensitic state occurs so that the entire array of SMA actuating members is either fully or partially in the martensitic state. At least one of the actuating member is selected to correspond to a pre-determined opening pressure or flow resistance. Each of the actuating members are heated individually, except the previously selected one, to a temperature equal to or above the temperature at which a transformation from the martensitic state to the austensitic state occurs.

Owner:MEDOS

System and Method for Rapid Isothermal Gas Expansion and Compression for Energy Storage

InactiveUS20090301089A1Overcome disadvantagesInhibit migrationElectrical storage systemFluid couplingsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

Thermal transition methods and devices

Owner:DELEGGE REBECCA +1

System and method for rapid isothermal gas expansion and compression for energy storage

InactiveUS7802426B2Overcome disadvantagesInhibit migrationElectrical storage systemServomotorsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

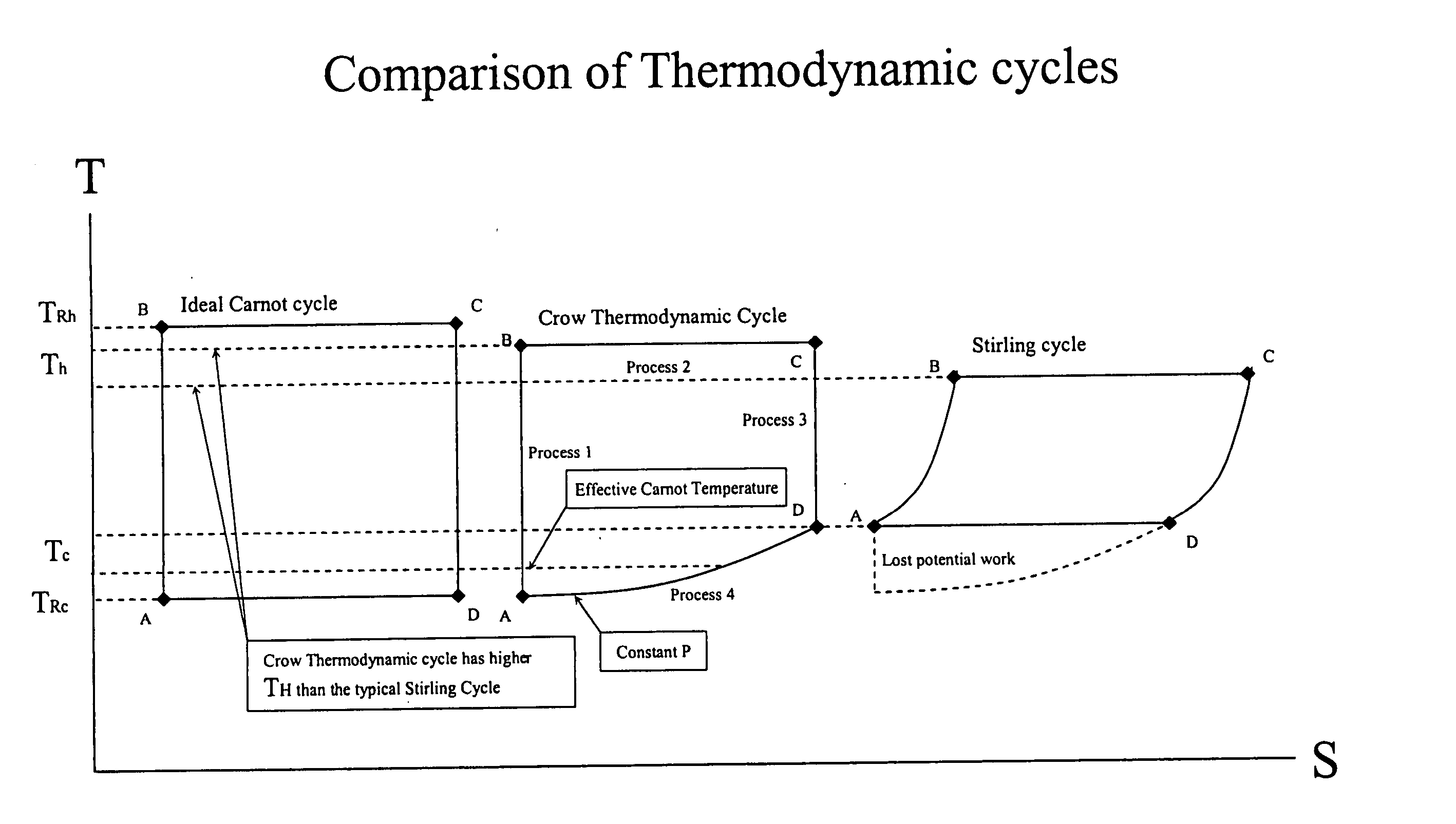

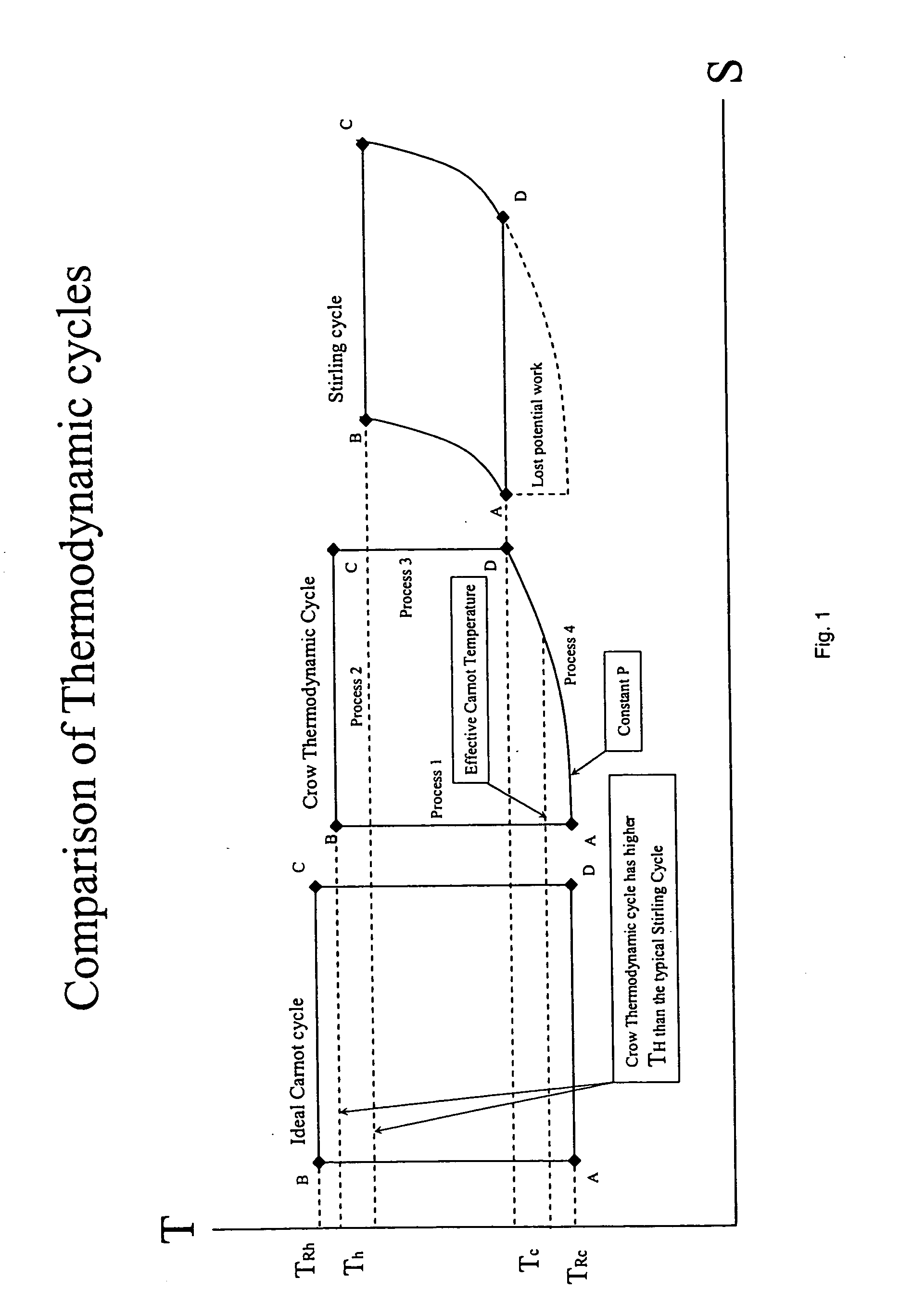

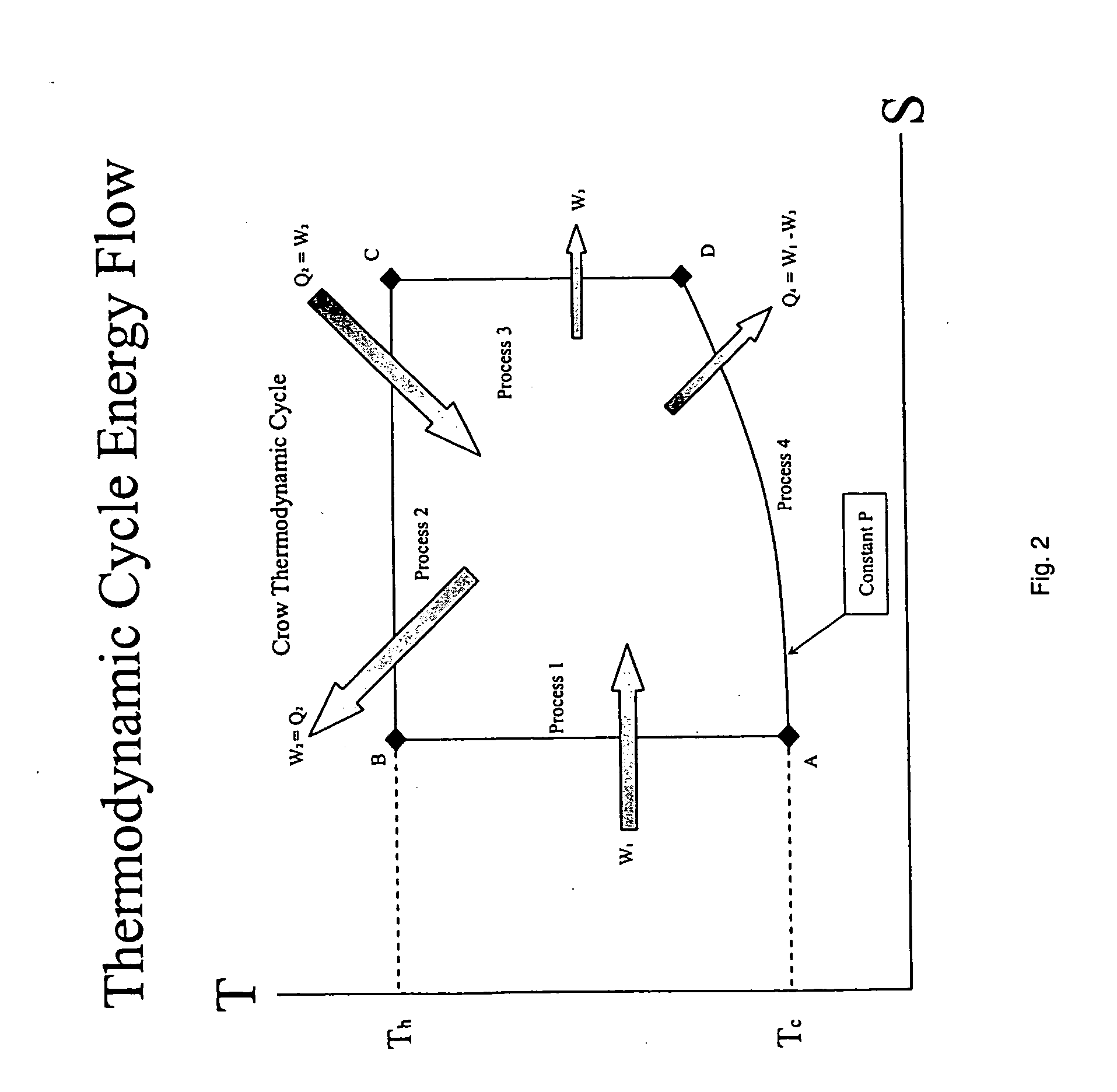

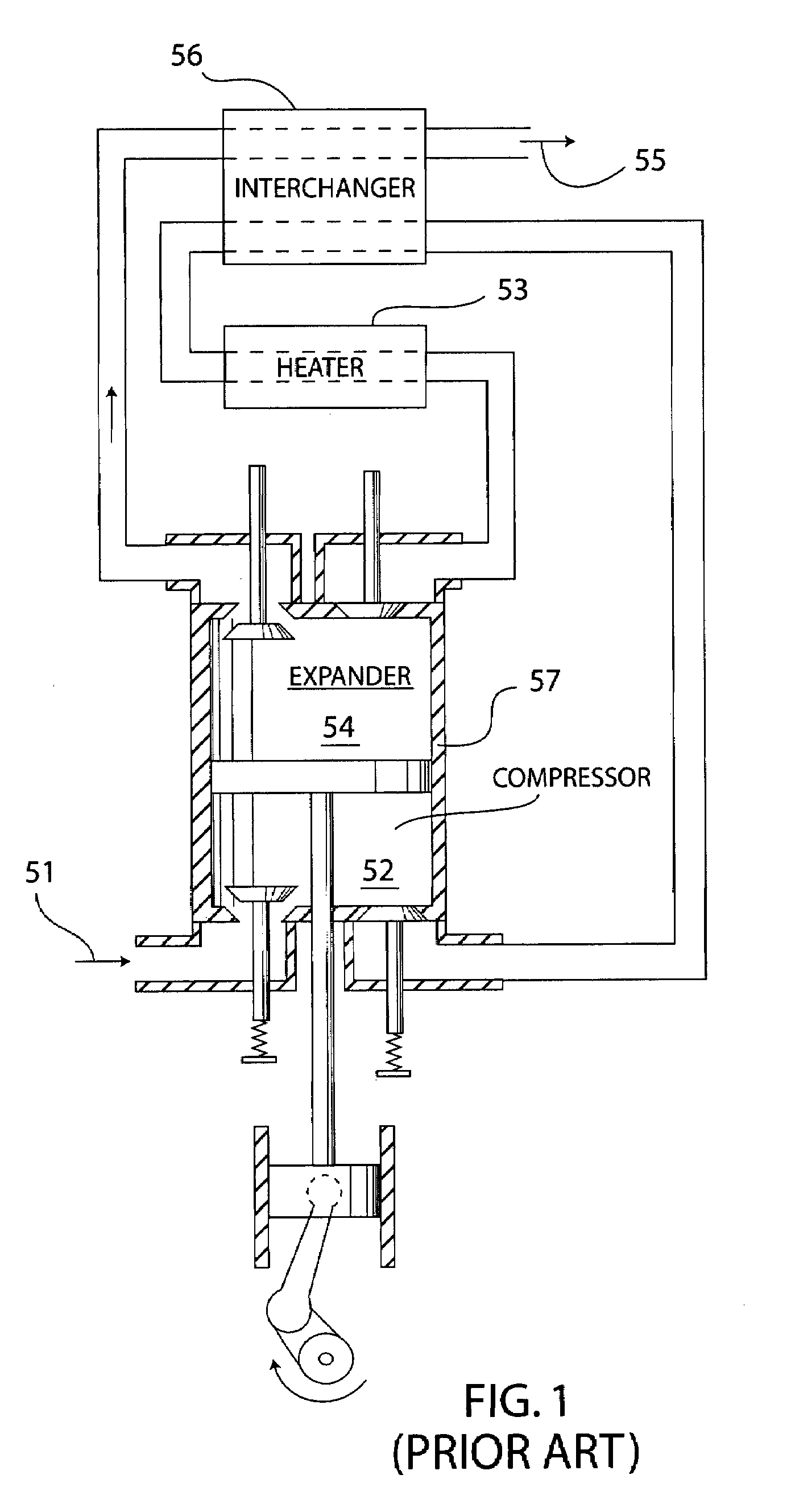

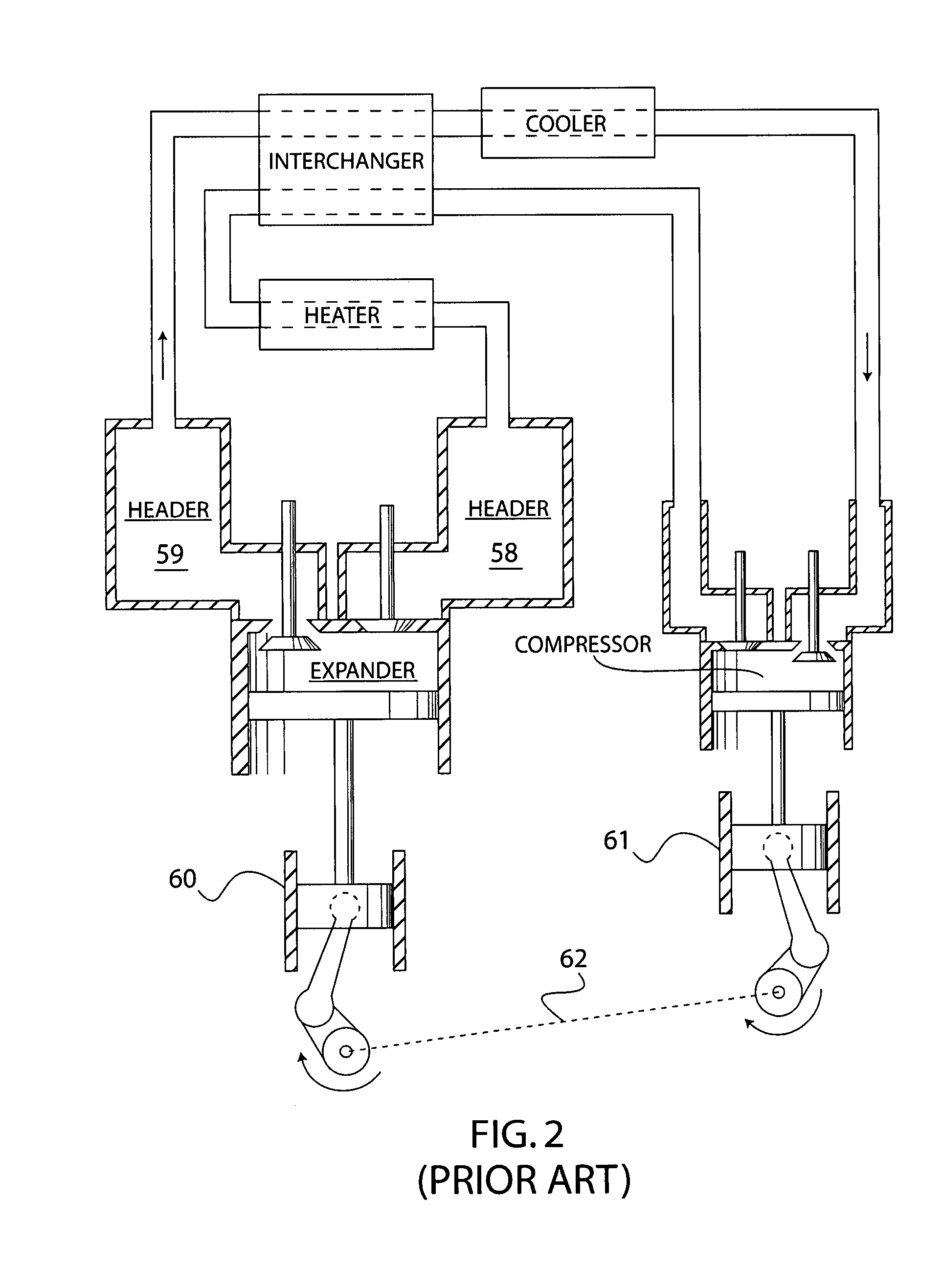

Method and apparatus for converting thermal energy to mechanical energy

InactiveUS20060090467A1Improve efficiencyEfficient regenerationEricsson type enginesSteam engine plantsThermal energyWorking fluid

A method and apparatus for converting thermal energy to mechanical energy which can use a wide range of fuels and perform with a high efficiency. Operating on a little utilized thermodynamic cycle of isentropic compression, isothermal expansion, isentropic expansion and finally constant pressure cooling and contraction. The external heat engine utilizes a heat exchanger carrying heat from the external energy source to the working parts of the engine. Pistons and cylinders are activated by appropriate means to adiabatically compress the working fluid, for example ambient air, to transfer the entire mass of the air through the heat exchanger to accomplish isothermal expansion followed by adiabatic expansion and, finally, exhaust the air to ambient to allow for constant pressure cooling and contraction. Valve pistons in conjunction with the cylinders form valves that allow for the exchange of working fluid with ambient. Energy is added to the engine during isothermal expansion, whereby the energy of compression is added by a flywheel or other appropriate energy storage means, said flywheel stores energy recovered during adiabatic expansion. The thermodynamic cycle described and the engine embodiments disclosed, when run in reverse, perform as a heat pump or refrigeration device.

Owner:CROW DARBY

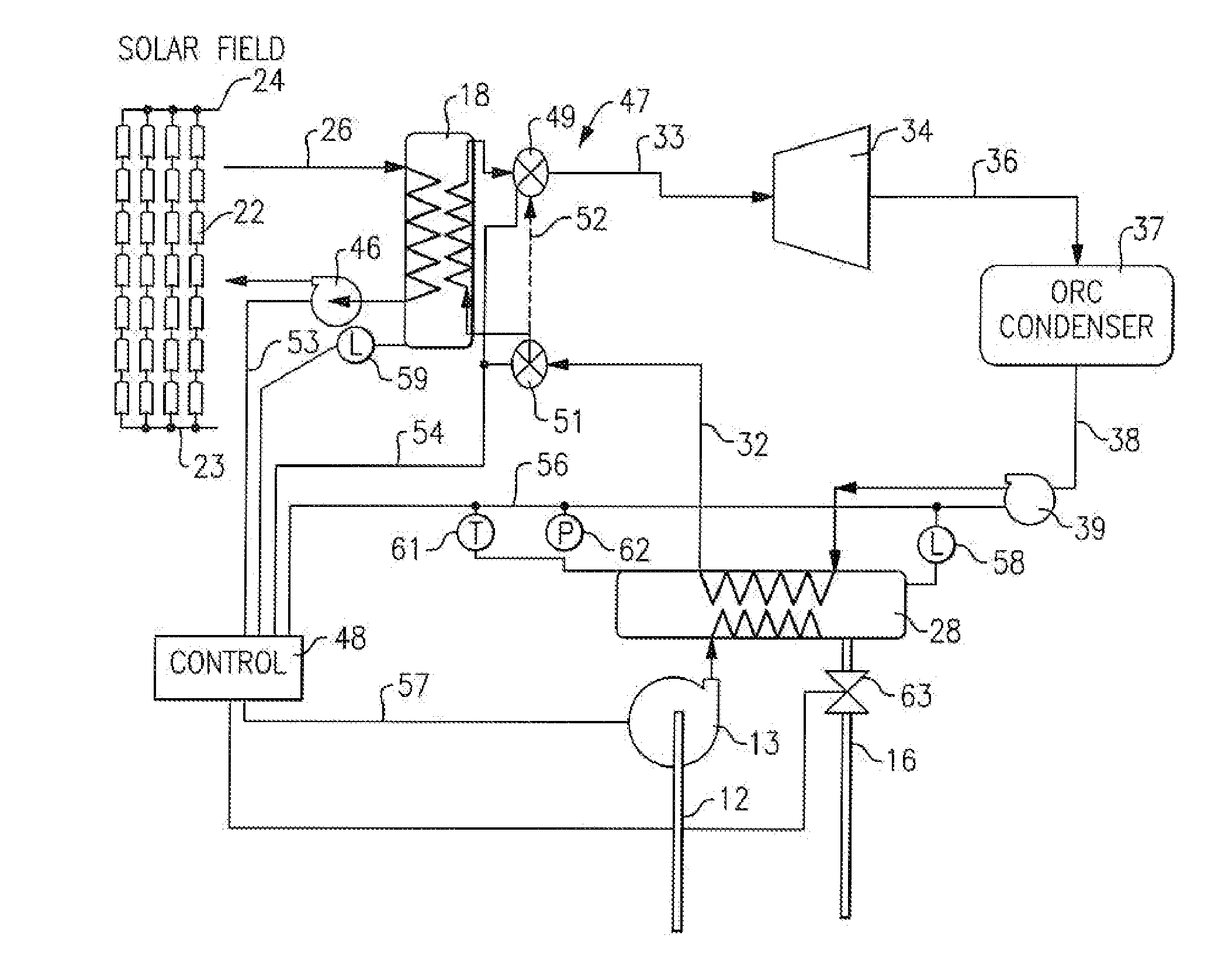

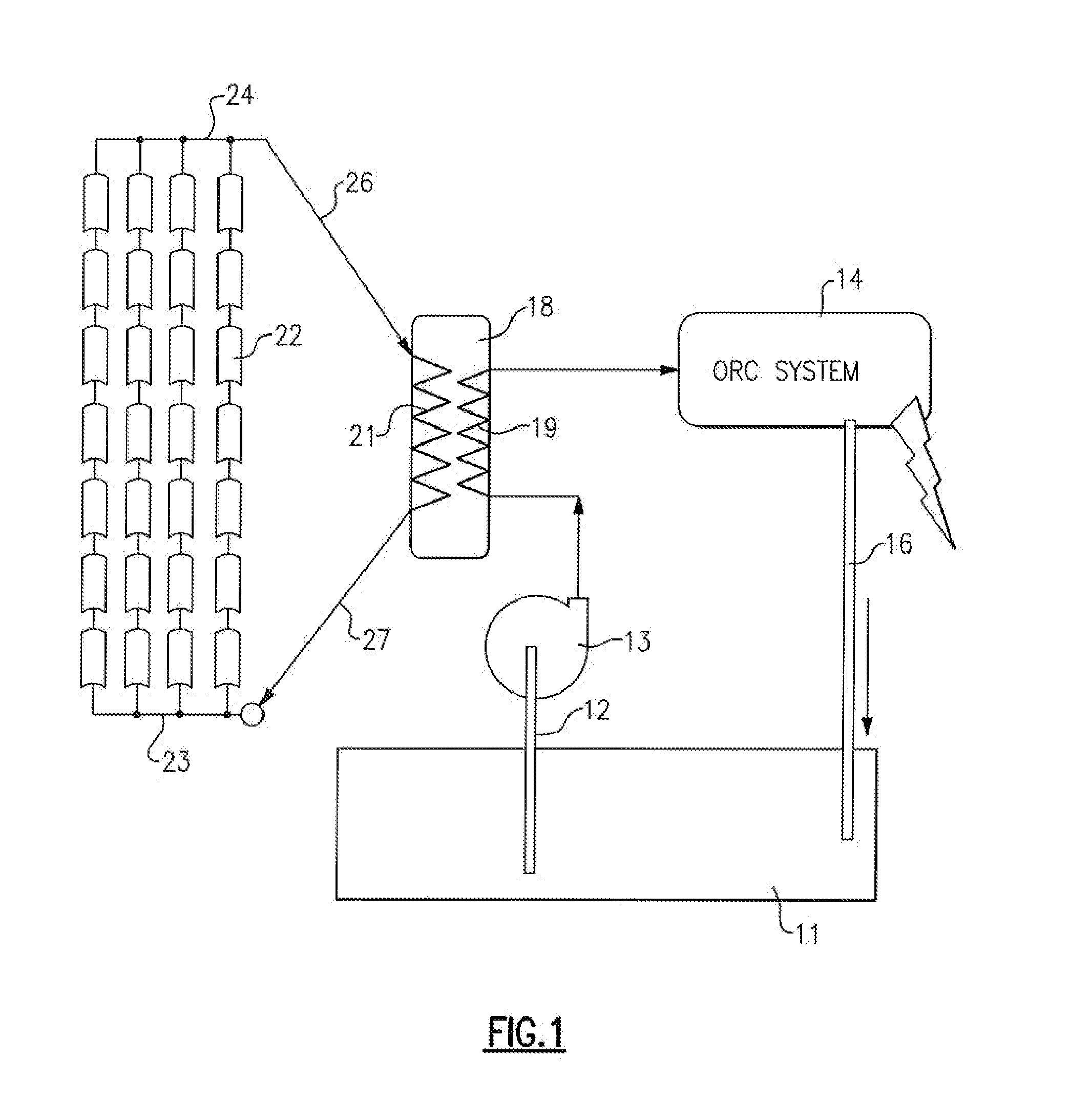

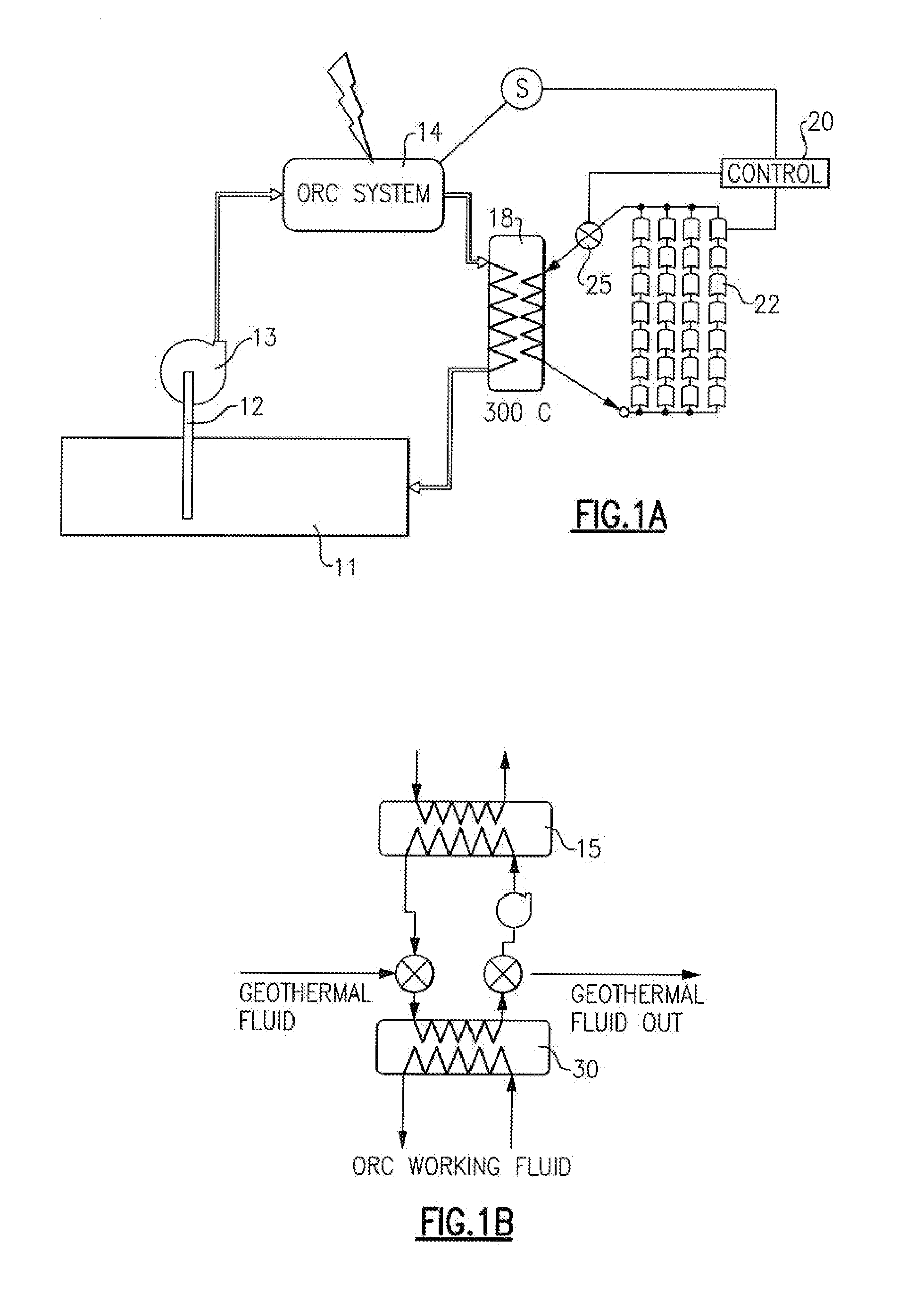

Combined geothermal and solar thermal organic rankine cycle system

In a system where the thermal energy of a geothermal fluid is applied to an ORC system, the energy is enhanced by the use of solar energy to thereby increase the temperature of the fluid being applied by the ORC system. A single heat exchanger version provides for direct heat exchange relationship with the geothermal and solar fluids, whereas a two heat exchanger version provides for each of the geothermal and solar fluids to be in heat exchange relationship with the working medium of the ORC system. Control features are provided to selectively balance the various fluid flows in the system.

Owner:UNITED TECH CORP

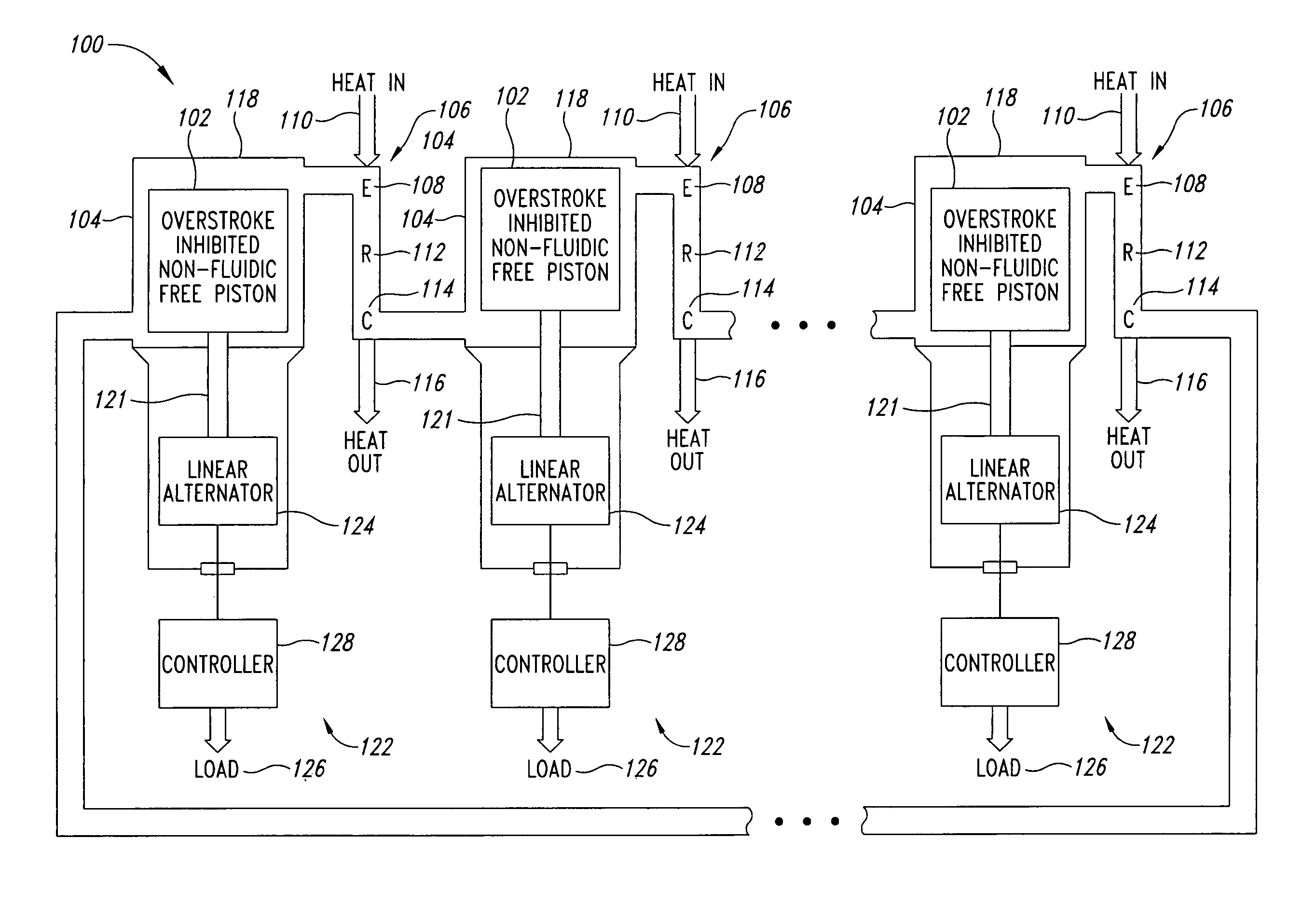

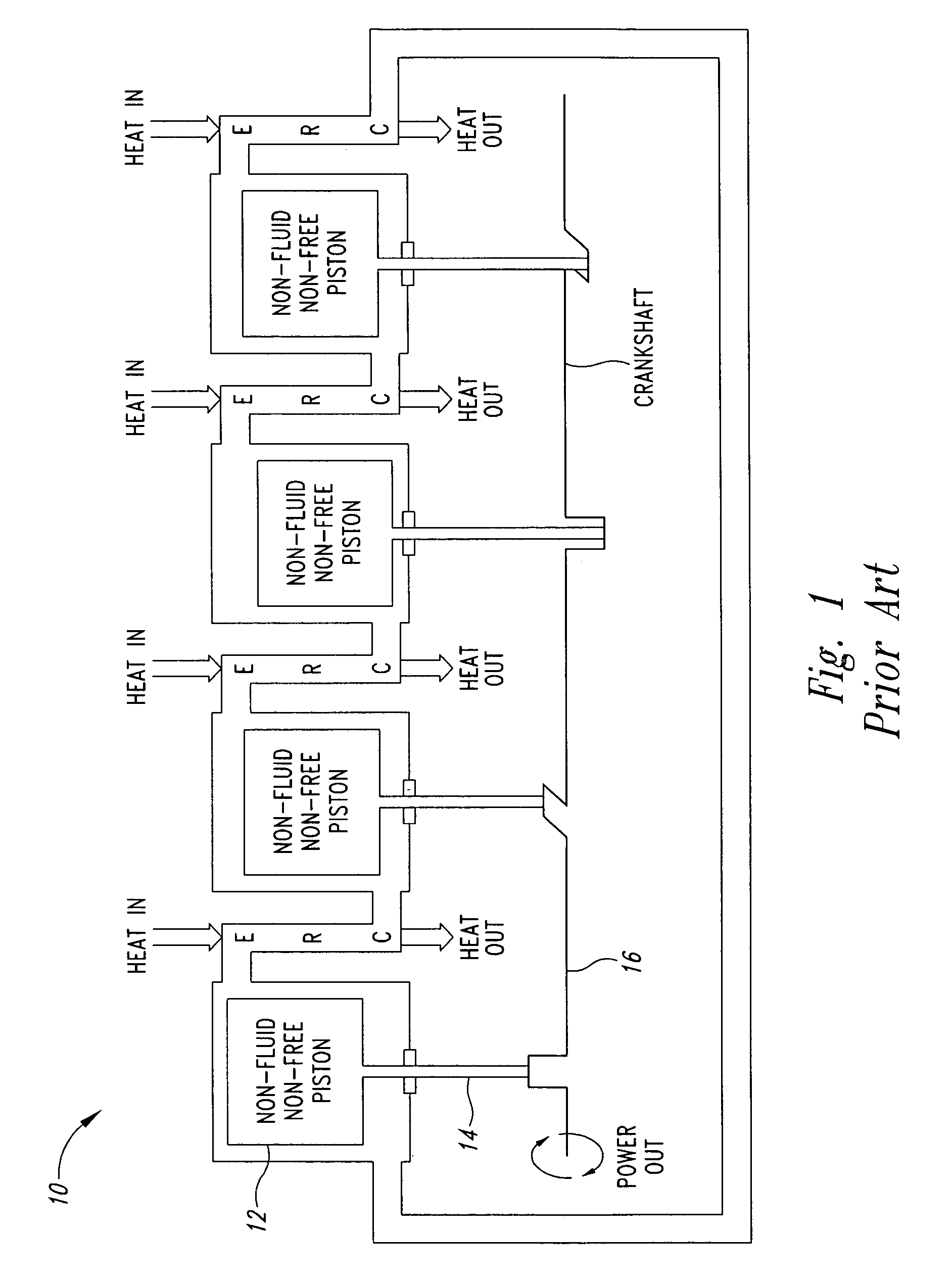

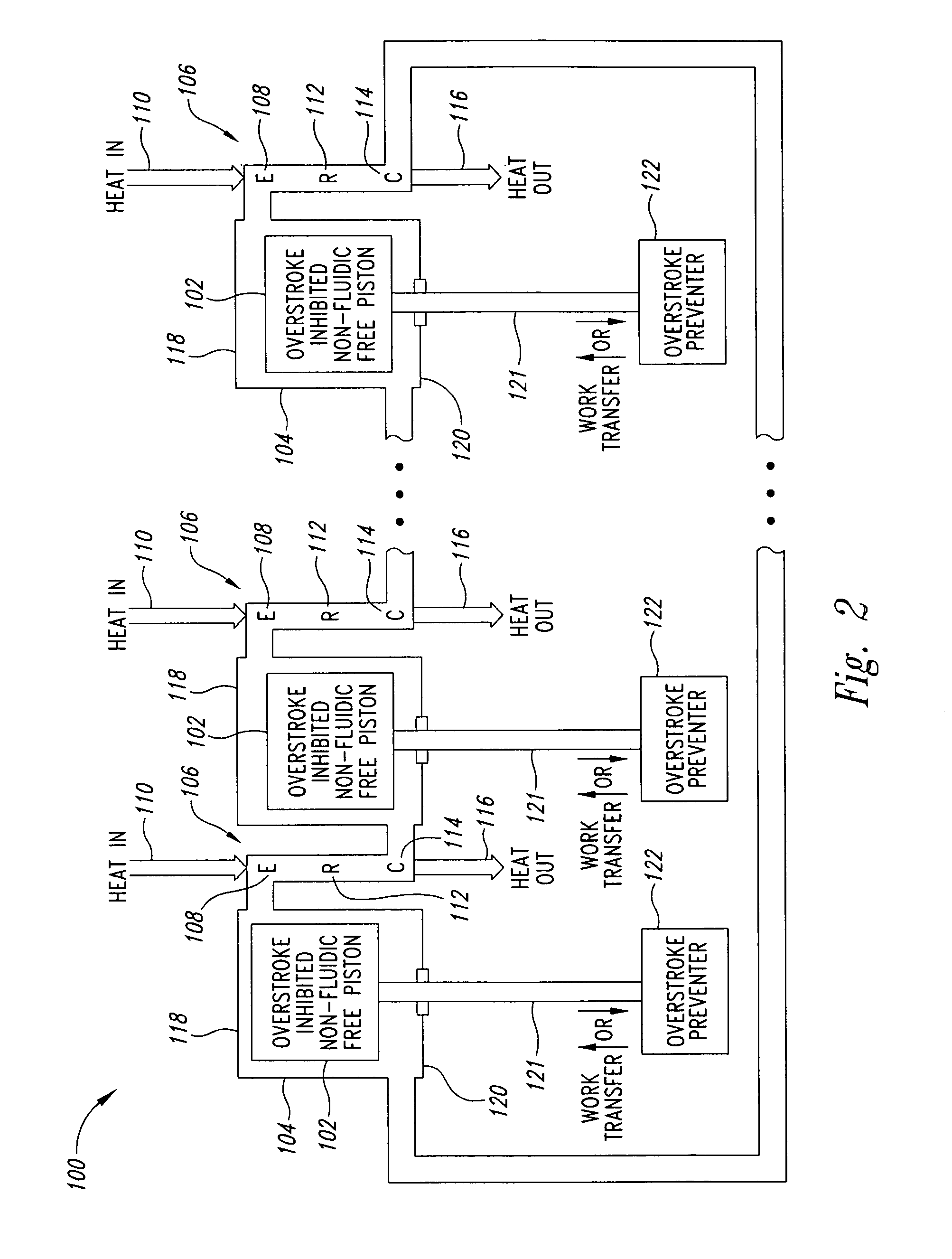

Double acting thermodynamically resonant free-piston multicylinder stirling system and method

Present implementations provide an approach that allows for a double-acting, multi-cylinder, thermodynamically resonant, alpha configuration free-piston Stirling system. The system includes overstroke preventers that control extent of piston travel to prevent undesirable consequences of piston travel beyond predetermined limits. The overstroke preventers involve controlled work extraction out of the system or controlled work input into the system. Implementations can also include duplex linear alternators, and / or frequency tuning systems, and / or vibration balancing configurations.

Owner:QNERGY

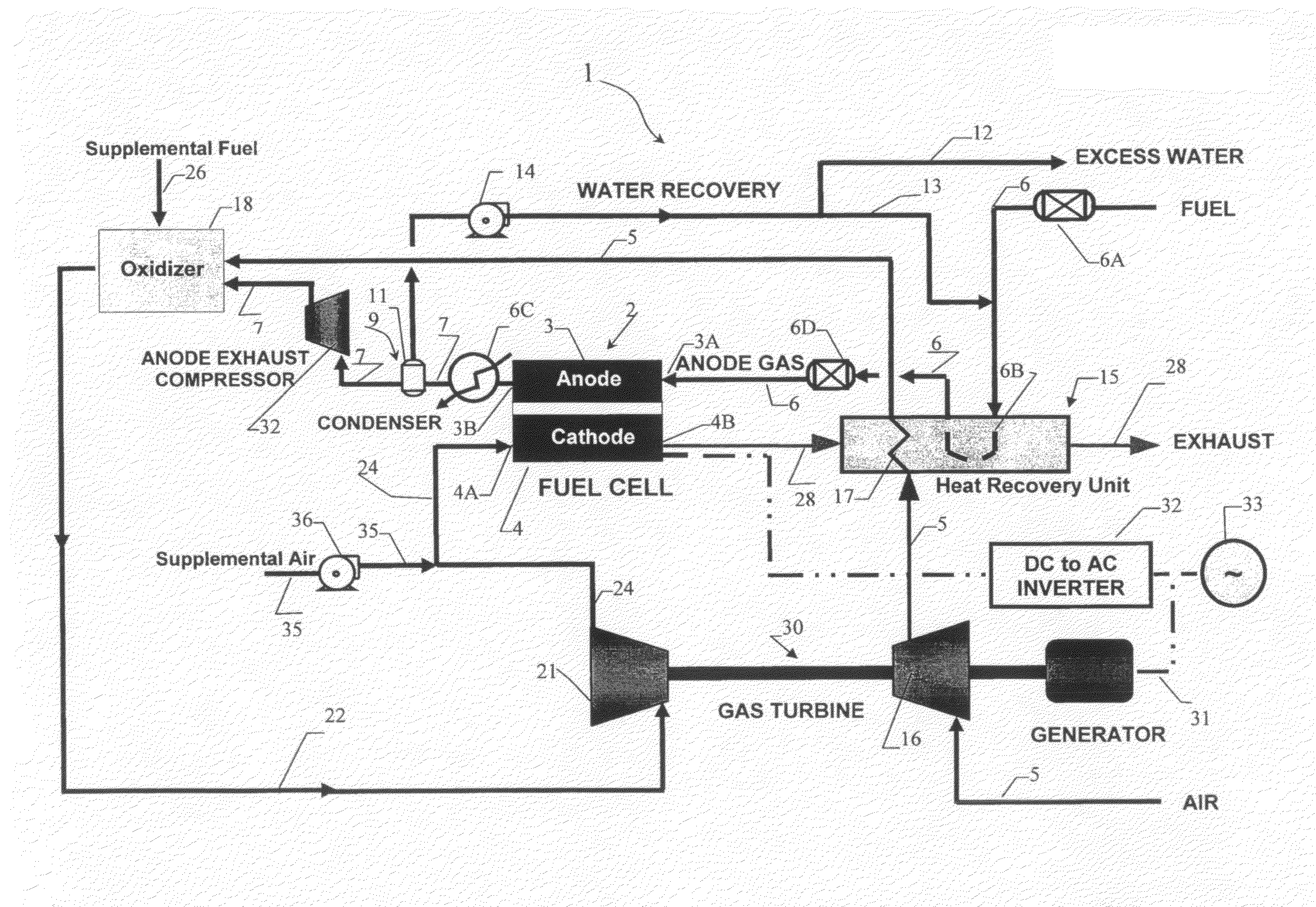

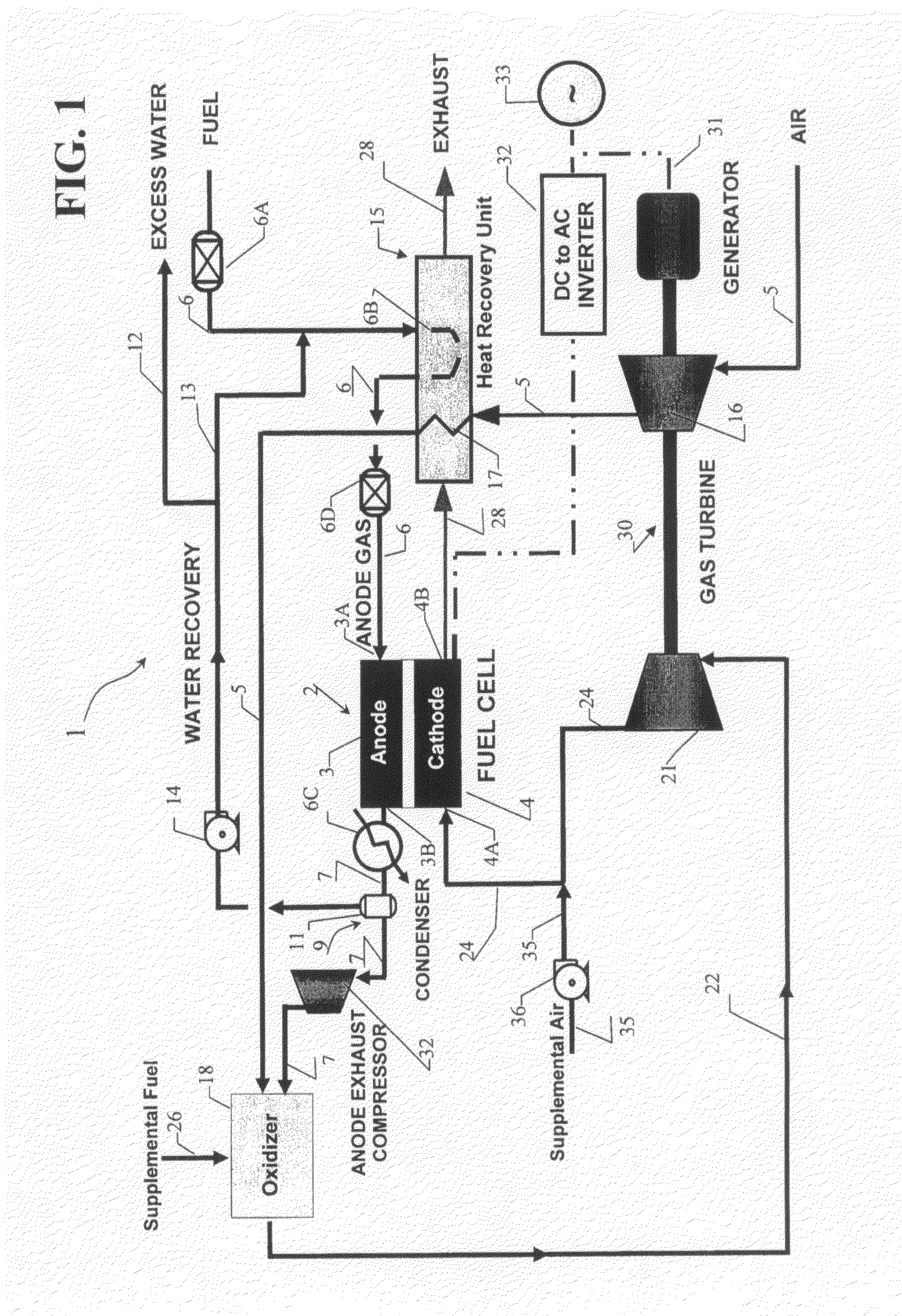

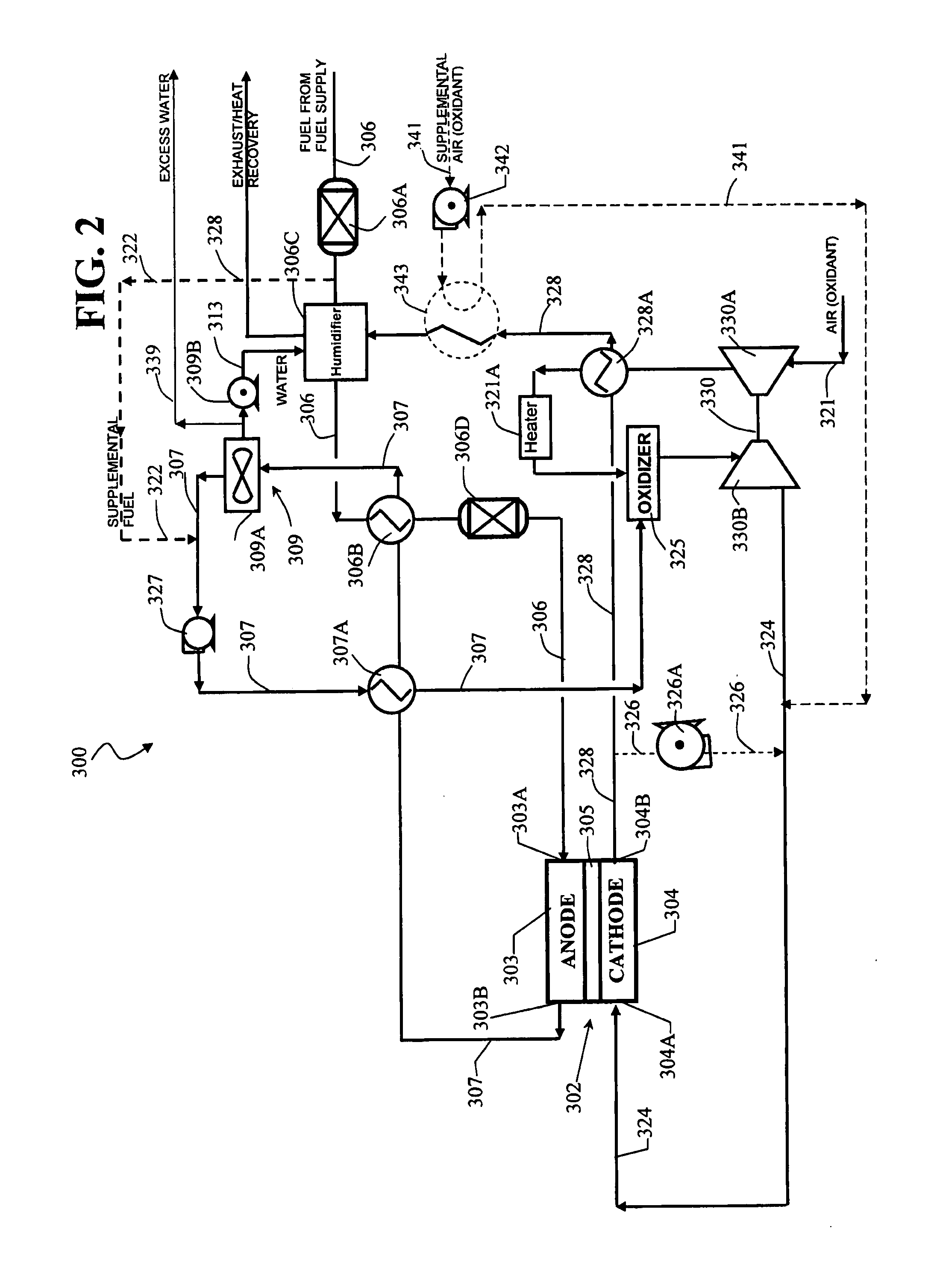

Integrated fuel cell and heat engine hybrid system for high efficiency power generation

ActiveUS20080187789A1Improve system efficiencyImprove efficiencyFuel cell heat exchangeElectricity cogenerationFuel cellsHybrid system

A fuel cell and heat engine hybrid system using a high-temperature fuel cell having an anode compartment adapted to receive fuel from a fuel supply path and to output anode exhaust gas and a cathode compartment adapted to receive oxidant gas and to output cathode exhaust gas. A heat engine assembly is adapted to receive oxidant gas and a further gas comprising one of the anode exhaust gas and a gas derived from the anode exhaust gas and to cause oxidation of the further gas and generate output power, the heat engine also generating heat engine exhaust including oxidant gas. The heat engine exhaust is then used to provide oxidant gas to the cathode compartment of the fuel cell.

Owner:FUELCELL ENERGY INC

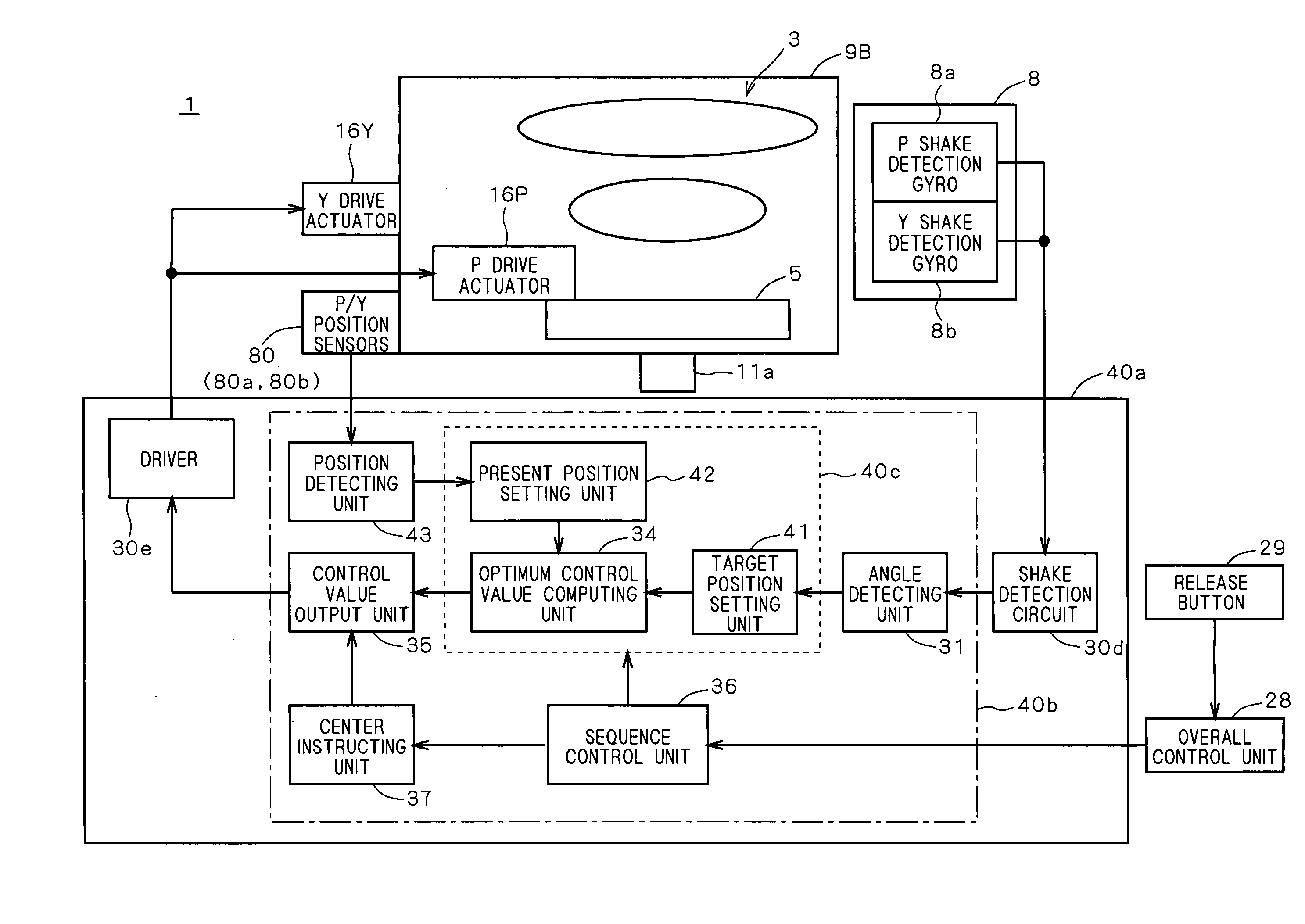

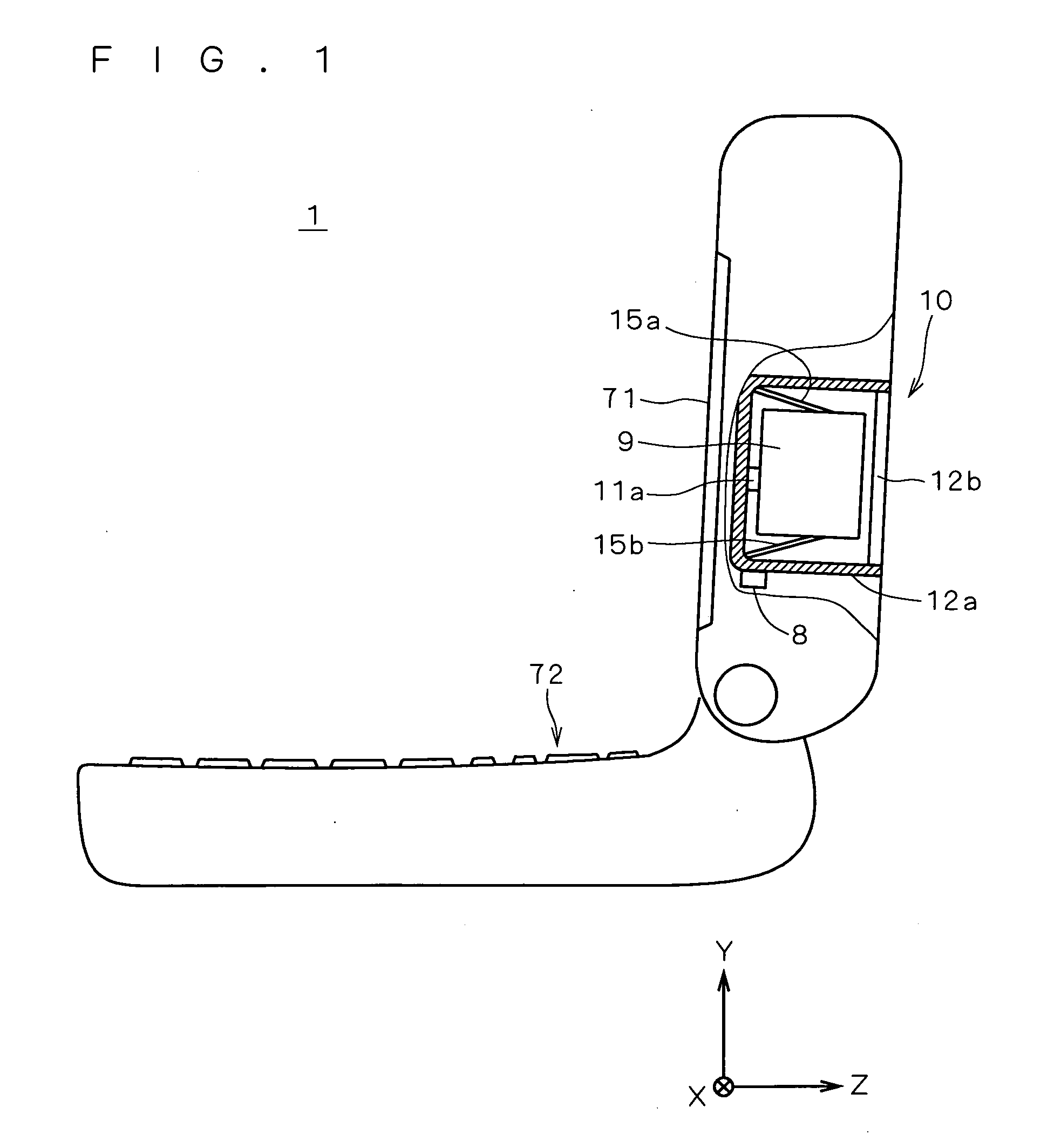

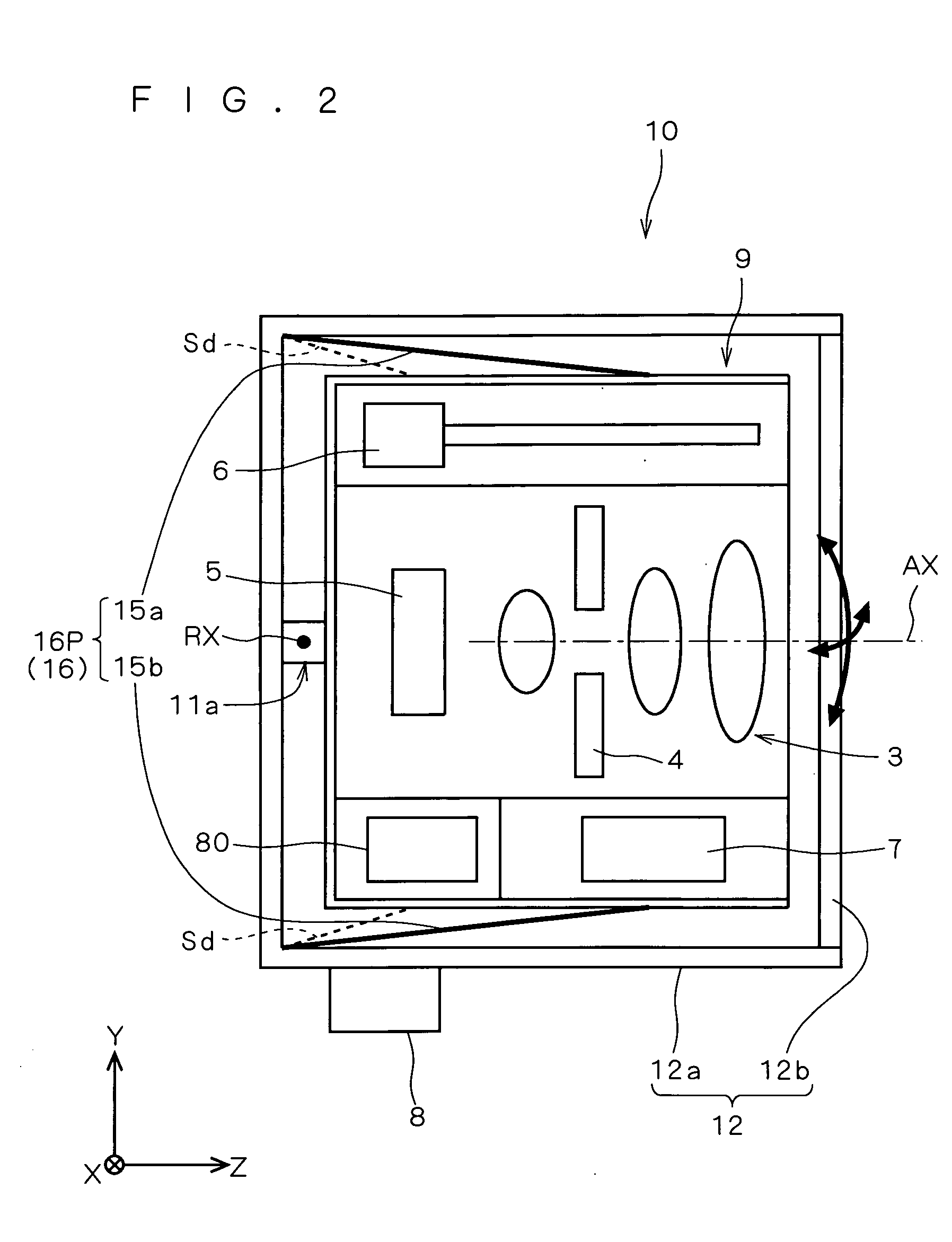

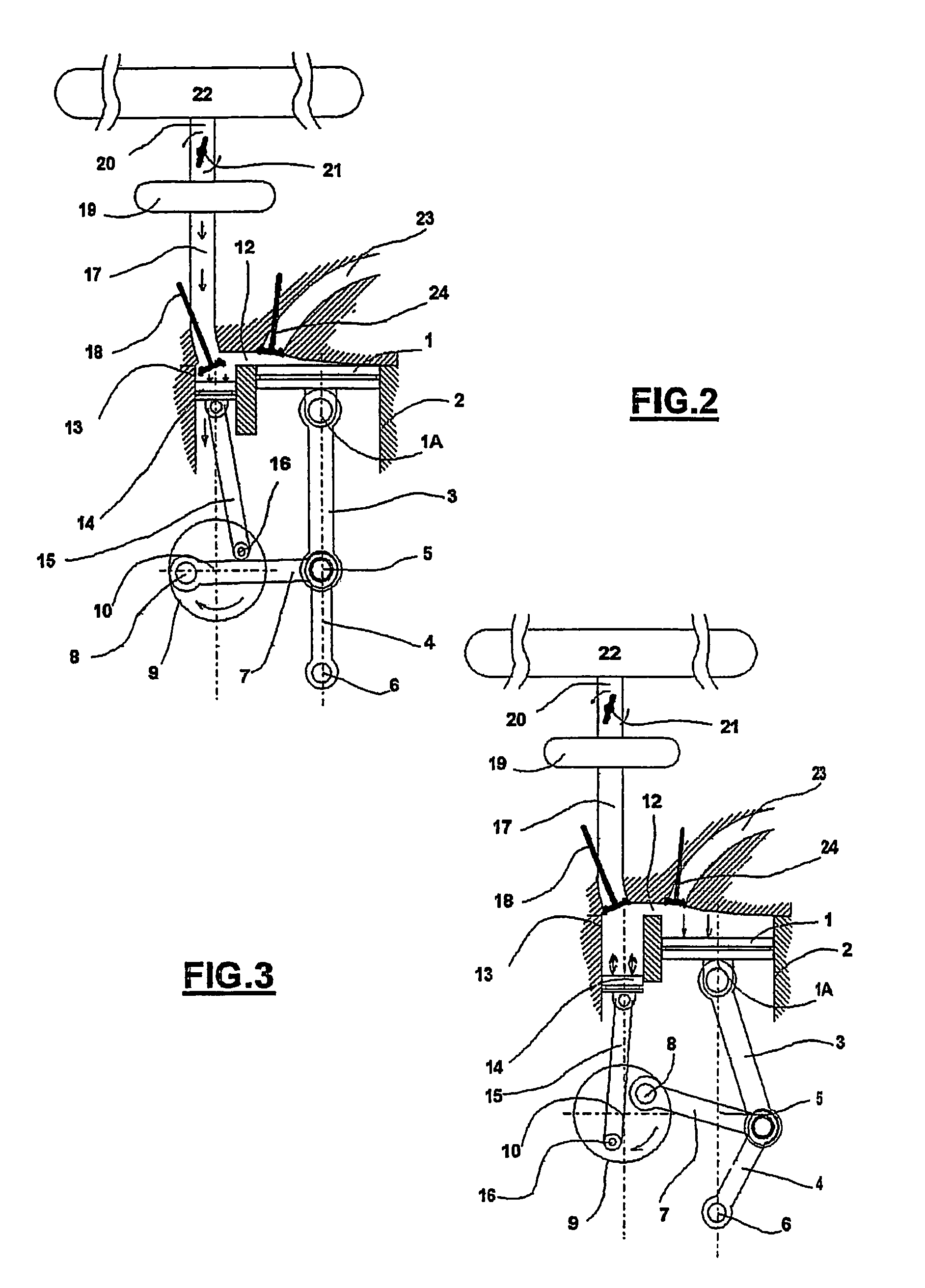

Driving apparatus

InactiveUS20070109412A1Improve responseImprove cooling effectTelevision system detailsOpticsEllipseImage stabilization

In an auto image stabilization system, a driving member formed as a wire of shape memory alloy (SMA) is retained by a projection of an image capturing unit. A distance Lb from the rotation center of an elastic deforming part to center of gravity (point of application) of the image capturing unit is longer than a distance La from the rotation center of the elastic deforming part to the projection (power point). In the configuration, equivalent mass (apparent mass) of the image capturing unit becomes (Lb / La) times, and it causes deterioration in response. Consequently, the driving member having an ellipse-shaped section in which a value obtained by dividing the width in the longer direction of the section by the width in the shorter direction is 1.3 or larger is employed. As a result, heat dissipation of the driving member increases, so that response in the SMA actuator can be properly improved.

Owner:KONICA MINOLTA INC

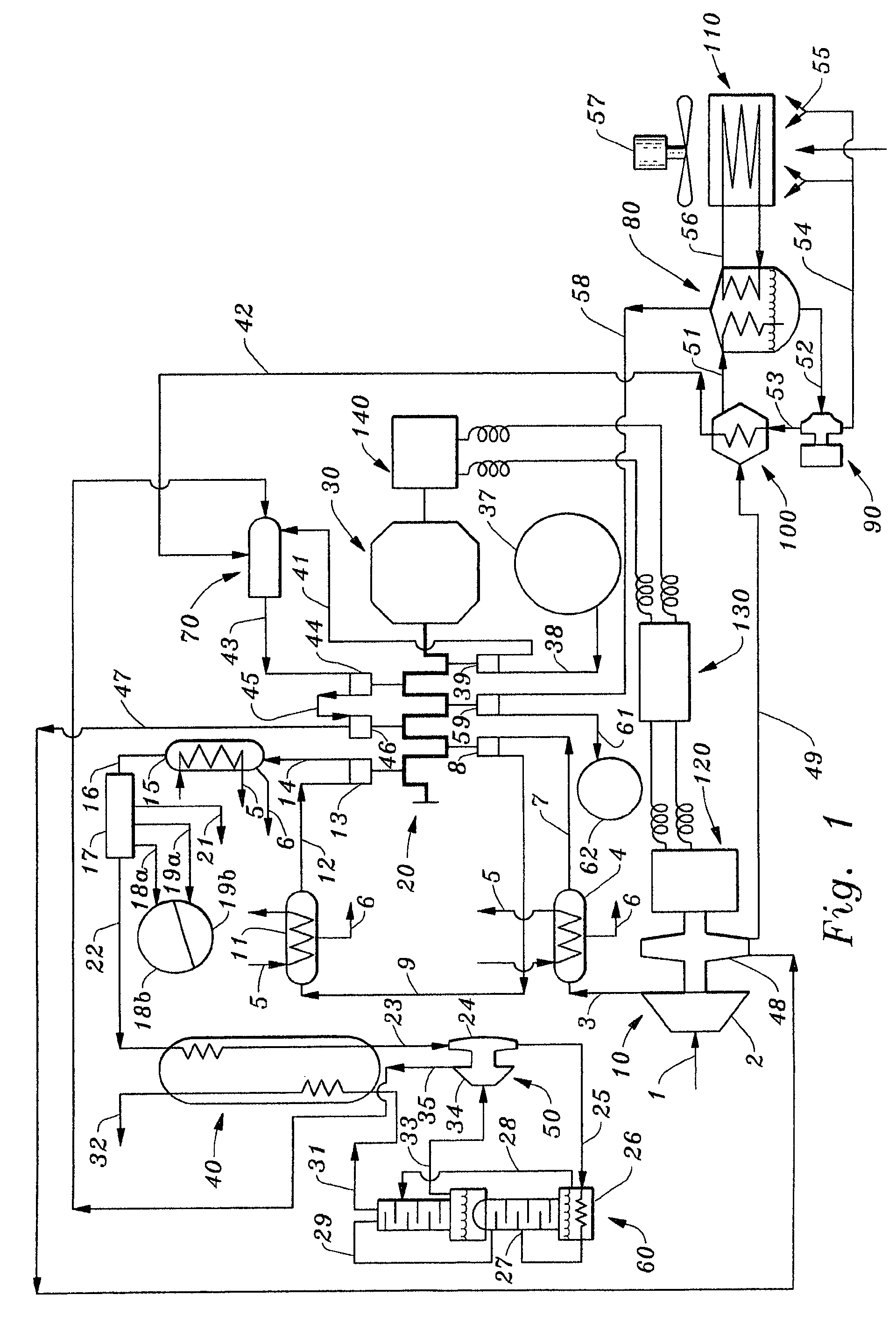

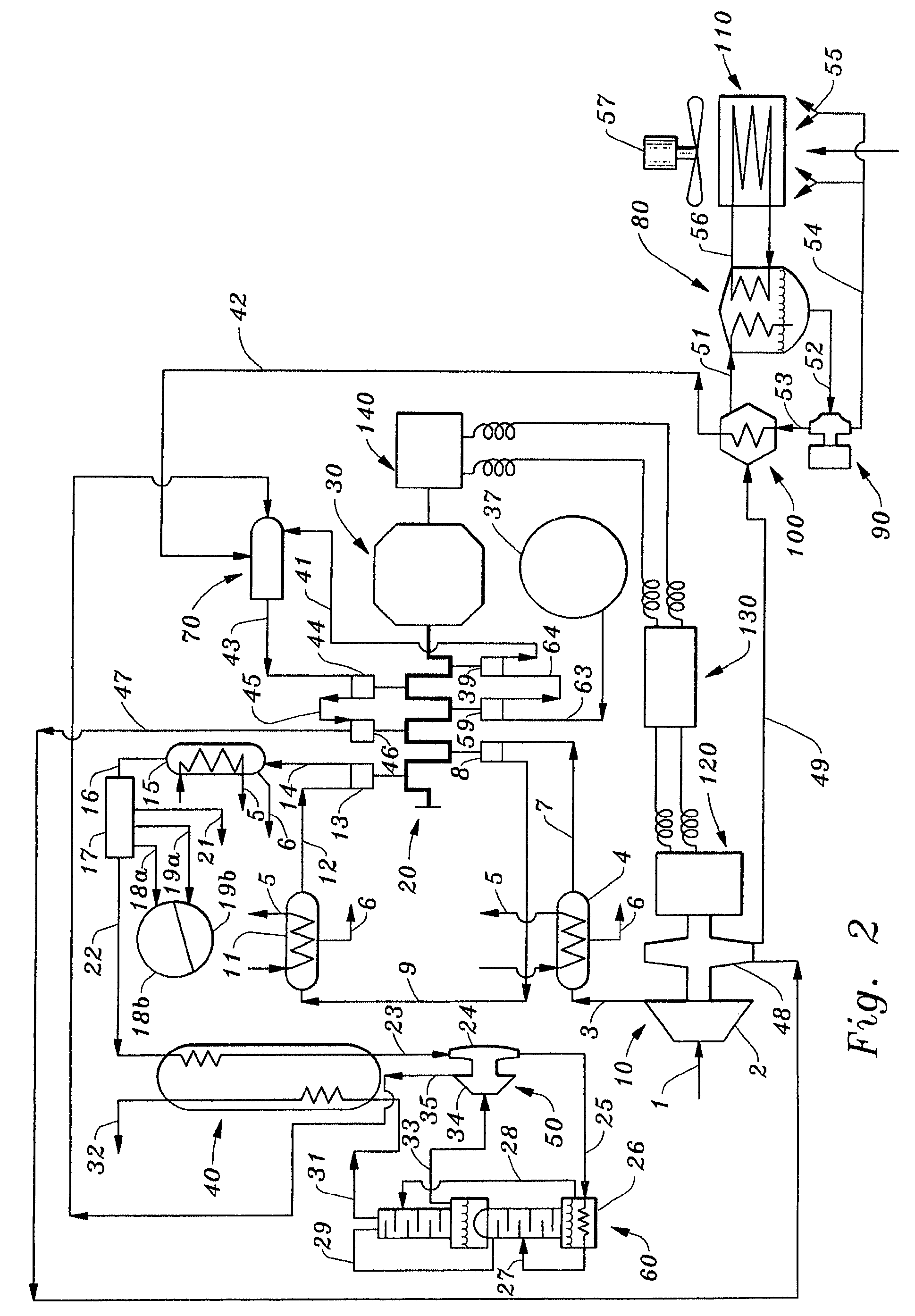

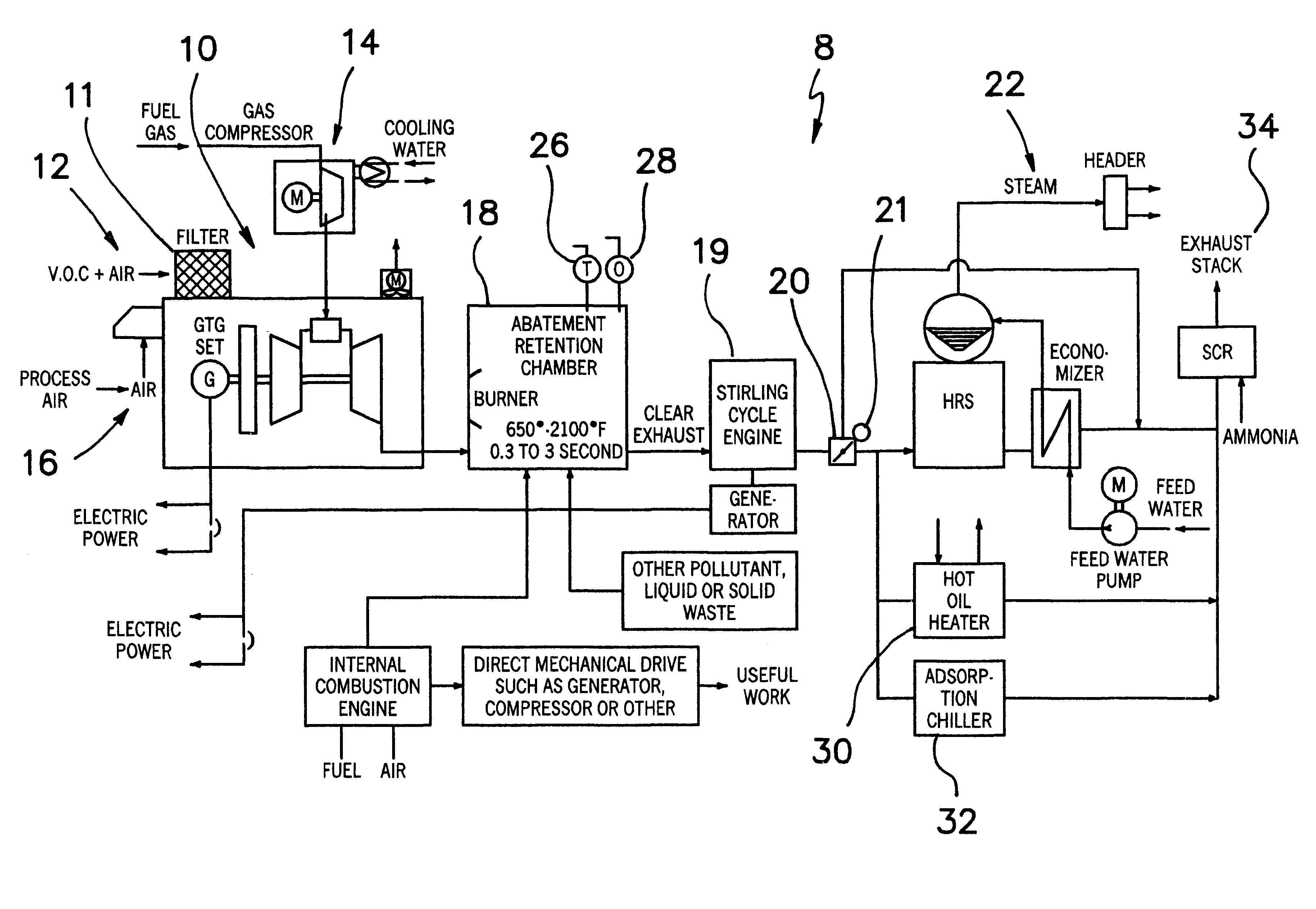

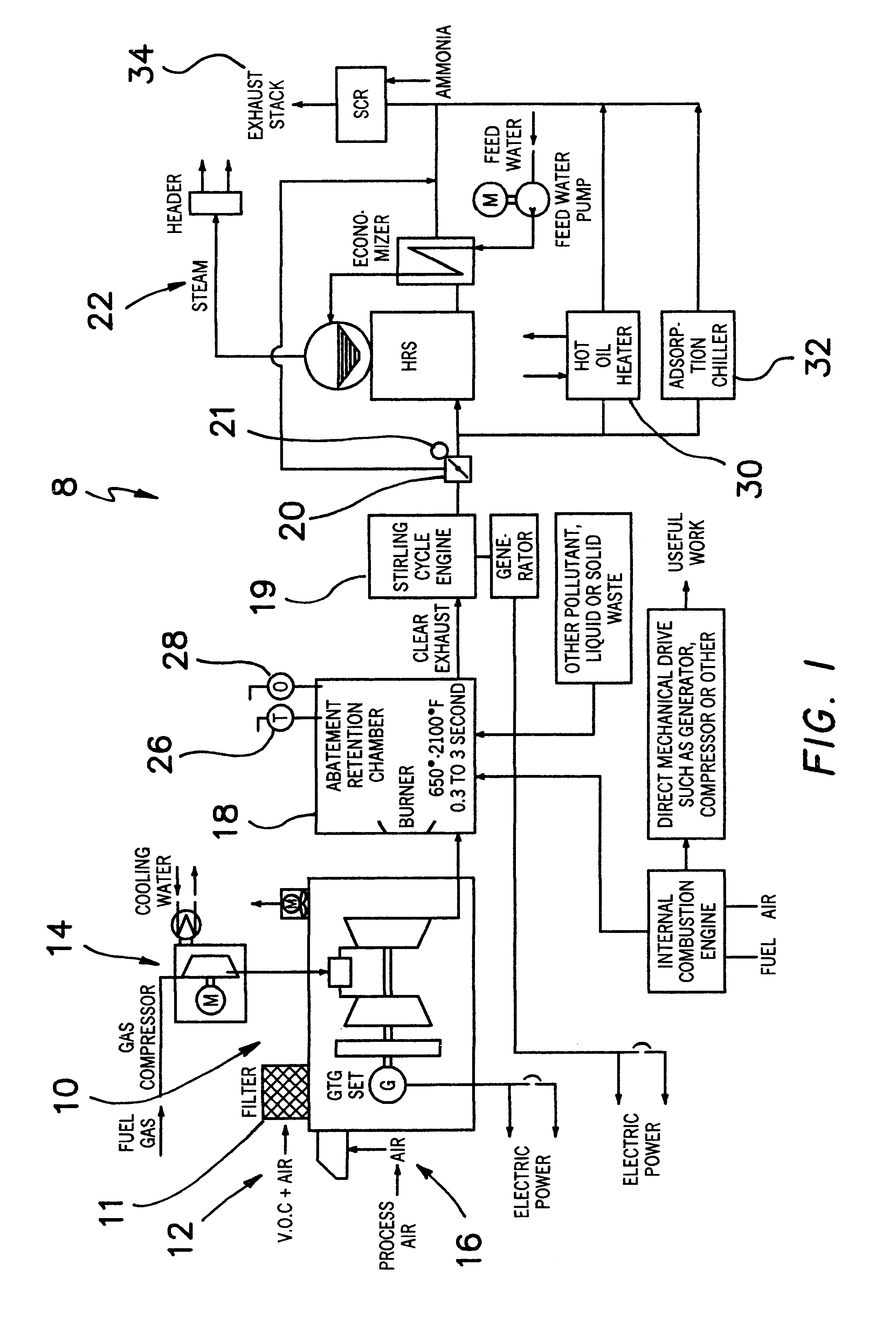

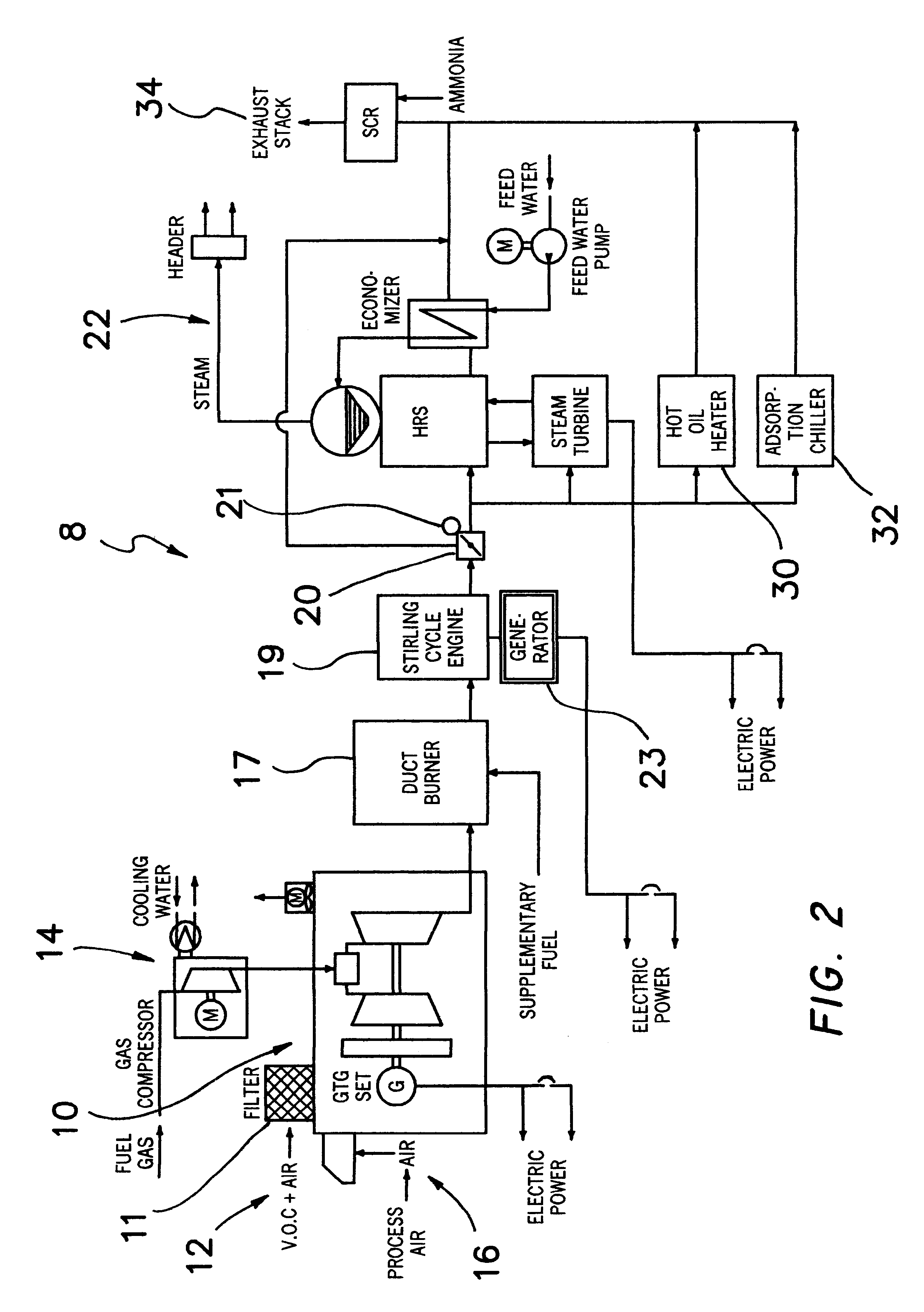

Advanced combined cycle co-generation abatement system

InactiveUS6655137B1Internal combustion piston enginesExhaust apparatusCombustionExternal combustion engine

The present invention is an advanced co-generation system for abating solid wastes, hydrocarbons and other volatile organic compounds (VOC's) produced by various processes utilizing a Stirling cycle engine, turbines or other internal combustion engines doing useful work. The turbine exhaust is directed into an abatement chamber which may include a catalyst that is designed to operate at high temperature and includes supplementary fuel and air inputs which are controlled by a computer that receives sensor inputs to achieve the requisite heat ranges necessary to convert exhaust and VOC's to non-toxic substances. The exhaust generated by the abatement chamber is directed to a Stirling cycle engine for additional heat generation and recovery. The exhaust generated from this process can also be used to perform direct or indirect heating.

Owner:SARDARI AMIR A

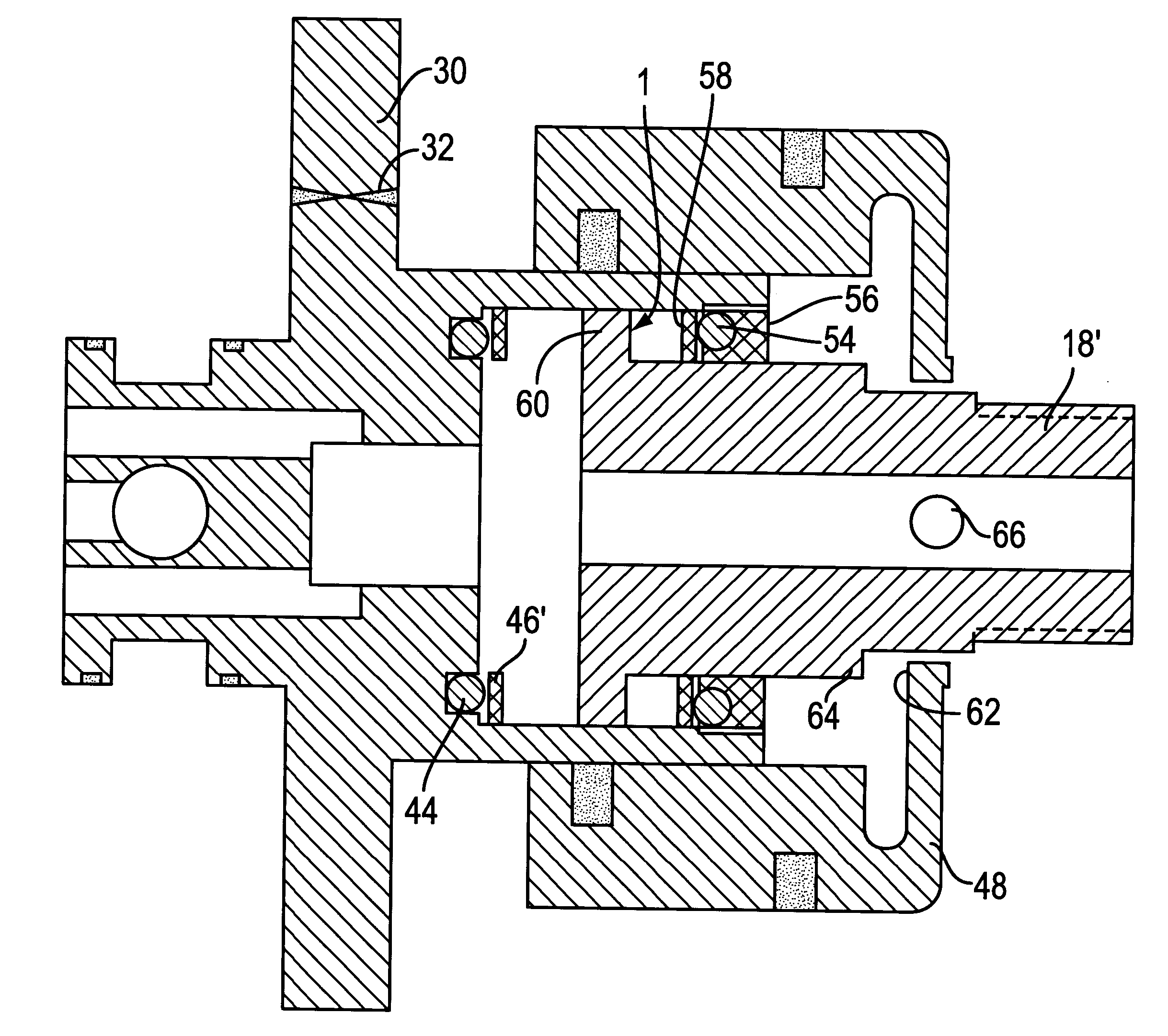

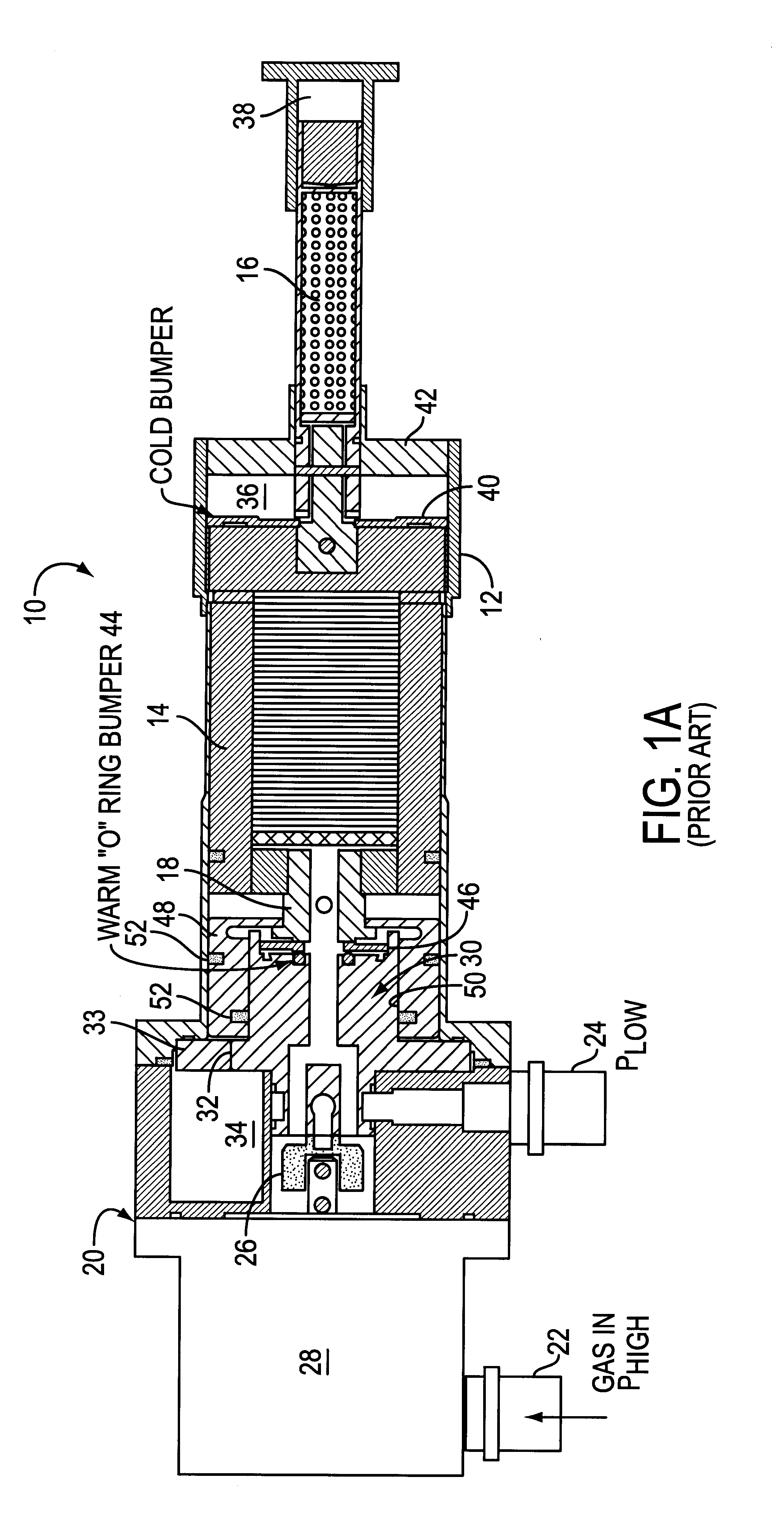

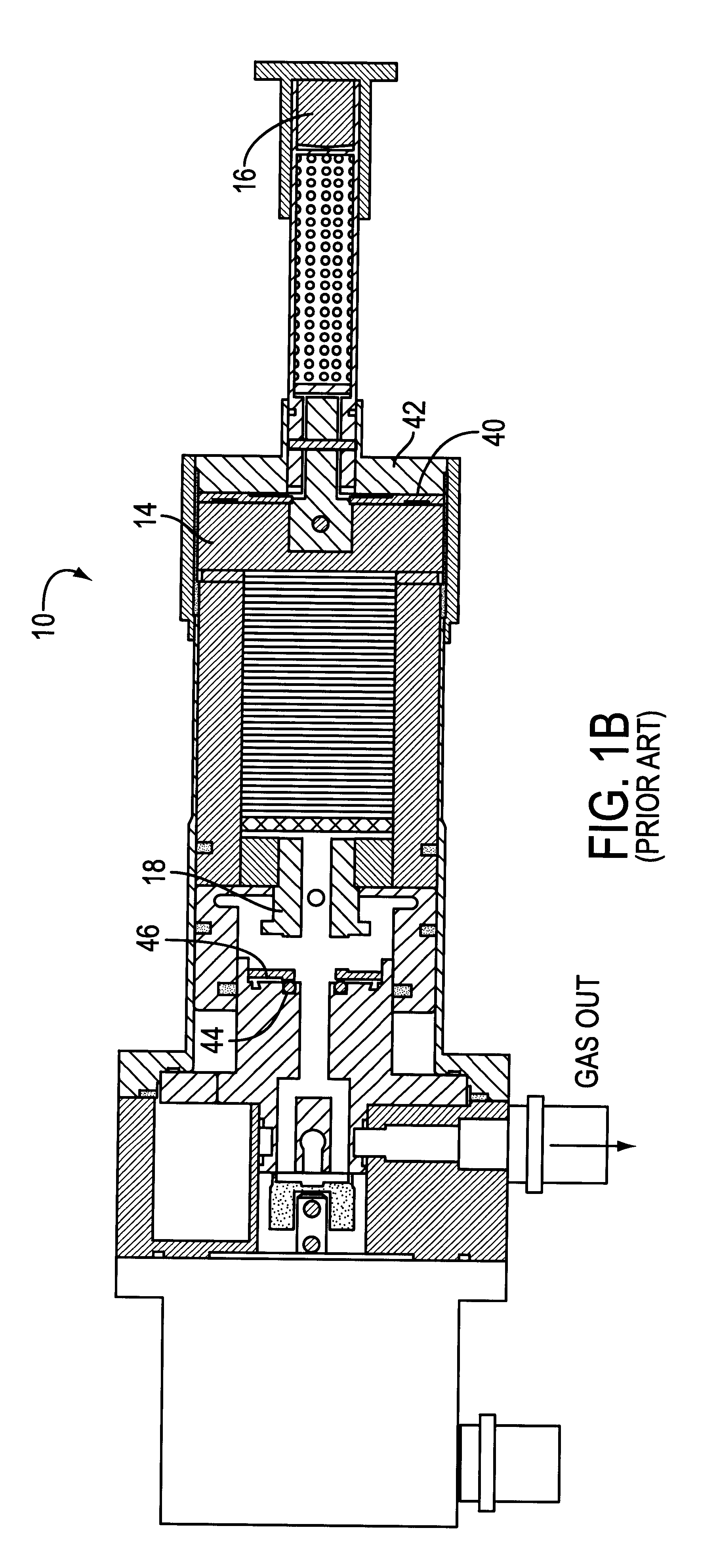

Reduced vibration cooling device having pneumatically-driven GM type displacer

InactiveUS6256997B1Reduce electrical noiseReduce vibrationCompression machinesRefrigeration componentsElastomerEngineering

A GM type displacer has an elastomer "O" ring at the warm end to absorb impact energy when the displacer reaches the bottom of the stroke before it would hit the cylinder end cap. When the displacer reaches the top of its stroke, before the displacer would hit the internal mechanism of the expander, another elastomer "O" ring absorbs the kinetic energy of the displacer. Both absorbers are at or near ambient temperature.

Owner:GENERAL ELECTRIC CO

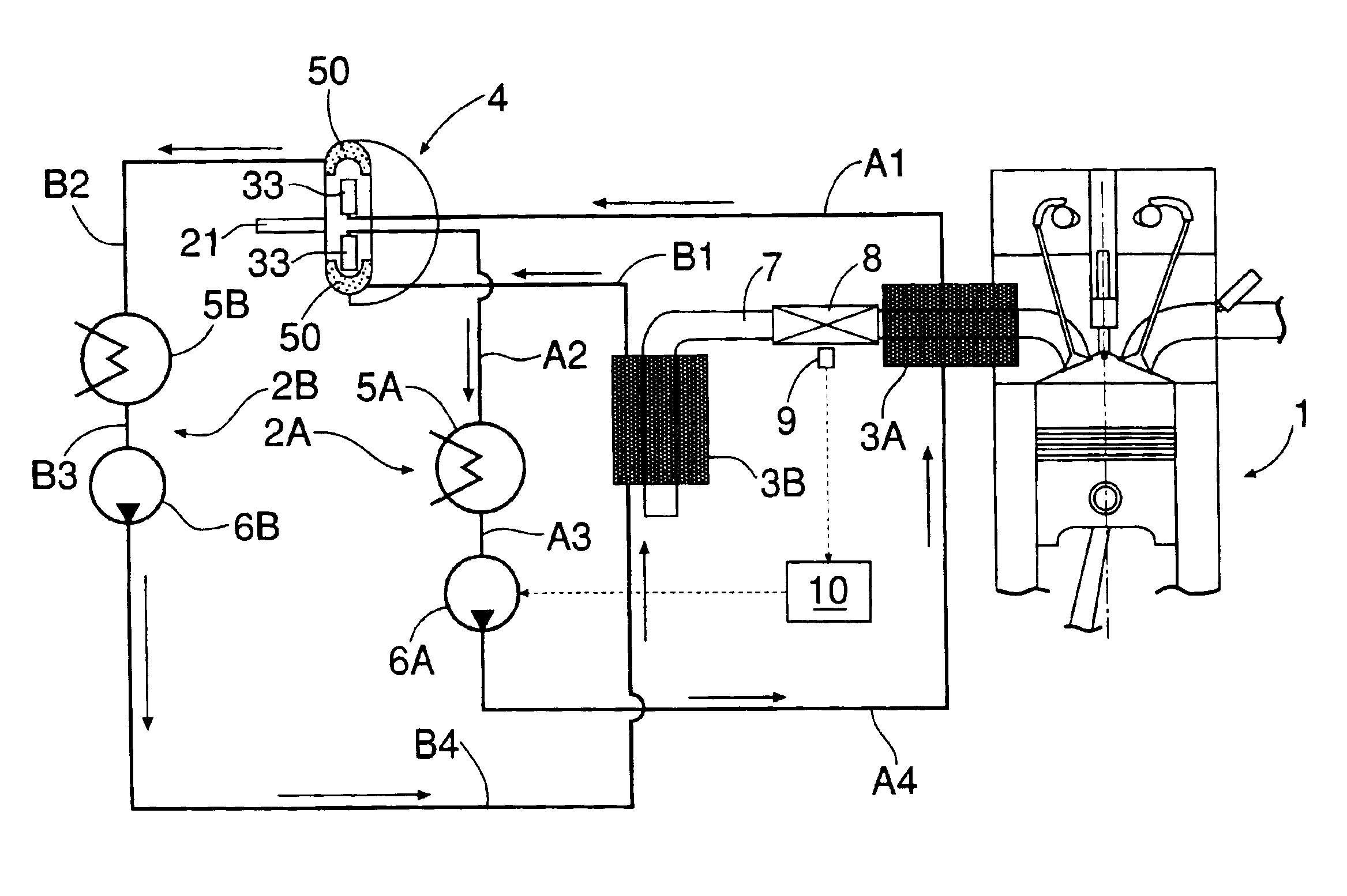

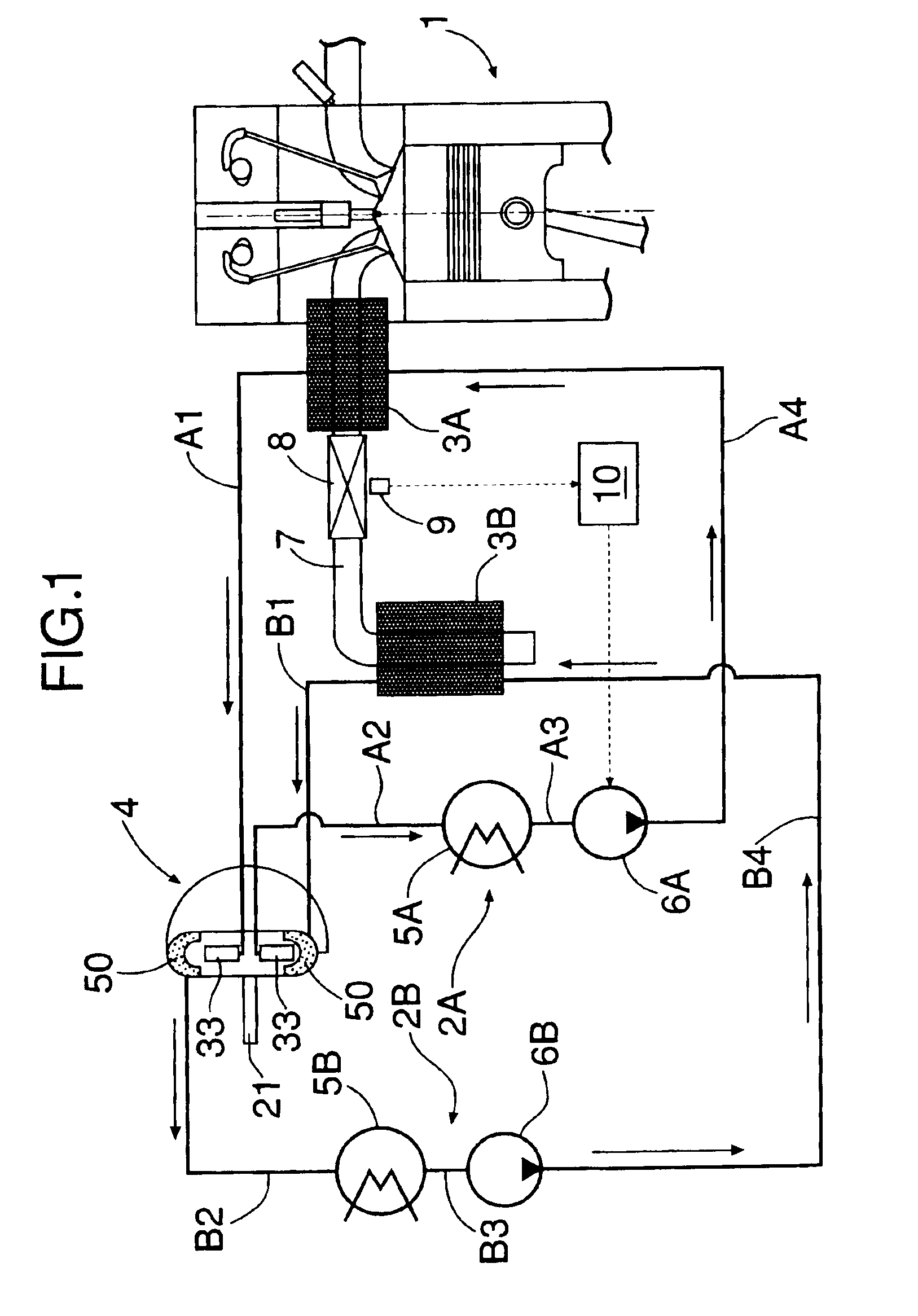

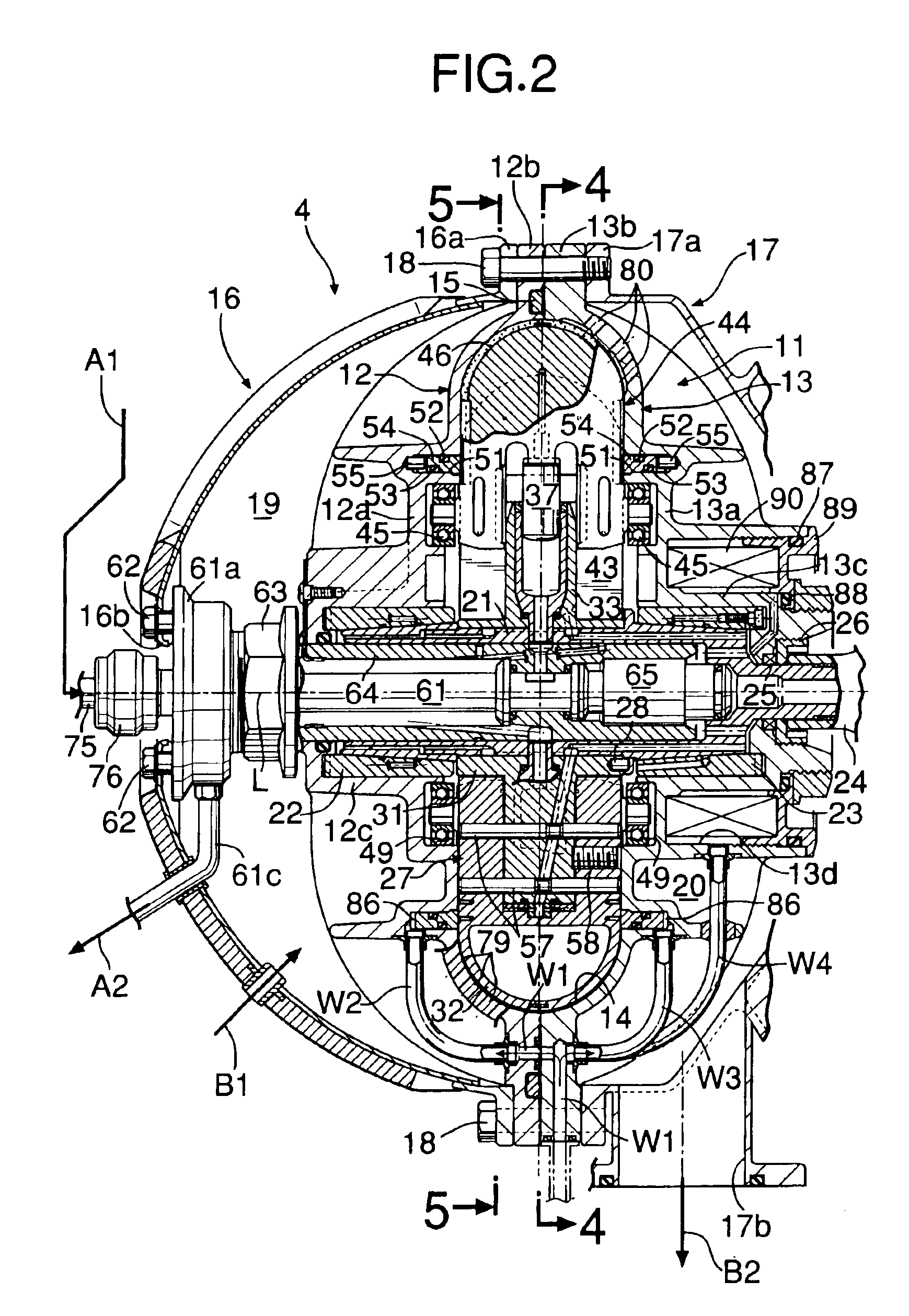

Rankine cycle device of internal combustion engine

InactiveUS6910333B2Efficiency of recovery of wasteImprove efficiencyInternal combustion piston enginesExhaust apparatusExhaust gas emissionsExhaust fumes

A Rankine cycle system includes a first Rankine cycle (2A) operated by a first working medium and a second Rankine cycle (2B) operated by a second working medium. The first Rankine cycle (2A) is constituted from an evaporator (3A), an expander (4), a condenser (5A) and a supply pump (6A), and the second Rankine cycle (2B) is constituted from an evaporator (3B), the expander (4), a condenser (5B) and a supply pump (6c). The evaporator (3A) in the first Rankine cycle (2A) and the evaporator (3B) in the second Rankine cycle (2B) are disposed at locations upstream and downstream of an exhaust emission control device (8) mounted in an exhaust passage (7) for the internal combustion engine (1). The first working medium has a boiling point higher than that of the second working medium, and the capacity of the pump (6A) in at least the first Rankine cycle (2A) is variable. Thus, the efficiency of recovery of a waste heat from the internal combustion engine by the Rankine cycle system can be enhanced to the maximum, and the activation of the exhaust emission control device can be promoted.

Owner:HONDA MOTOR CO LTD

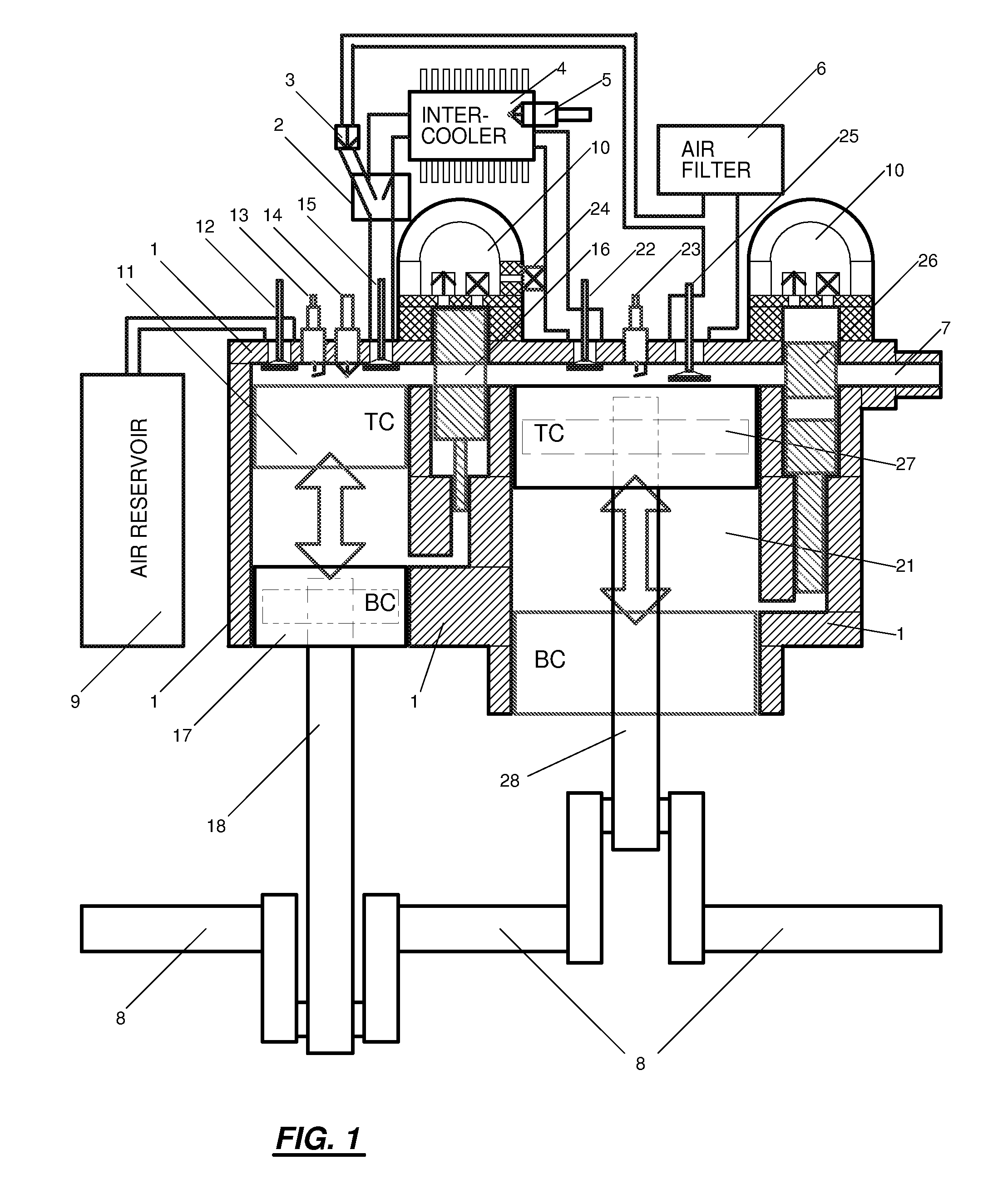

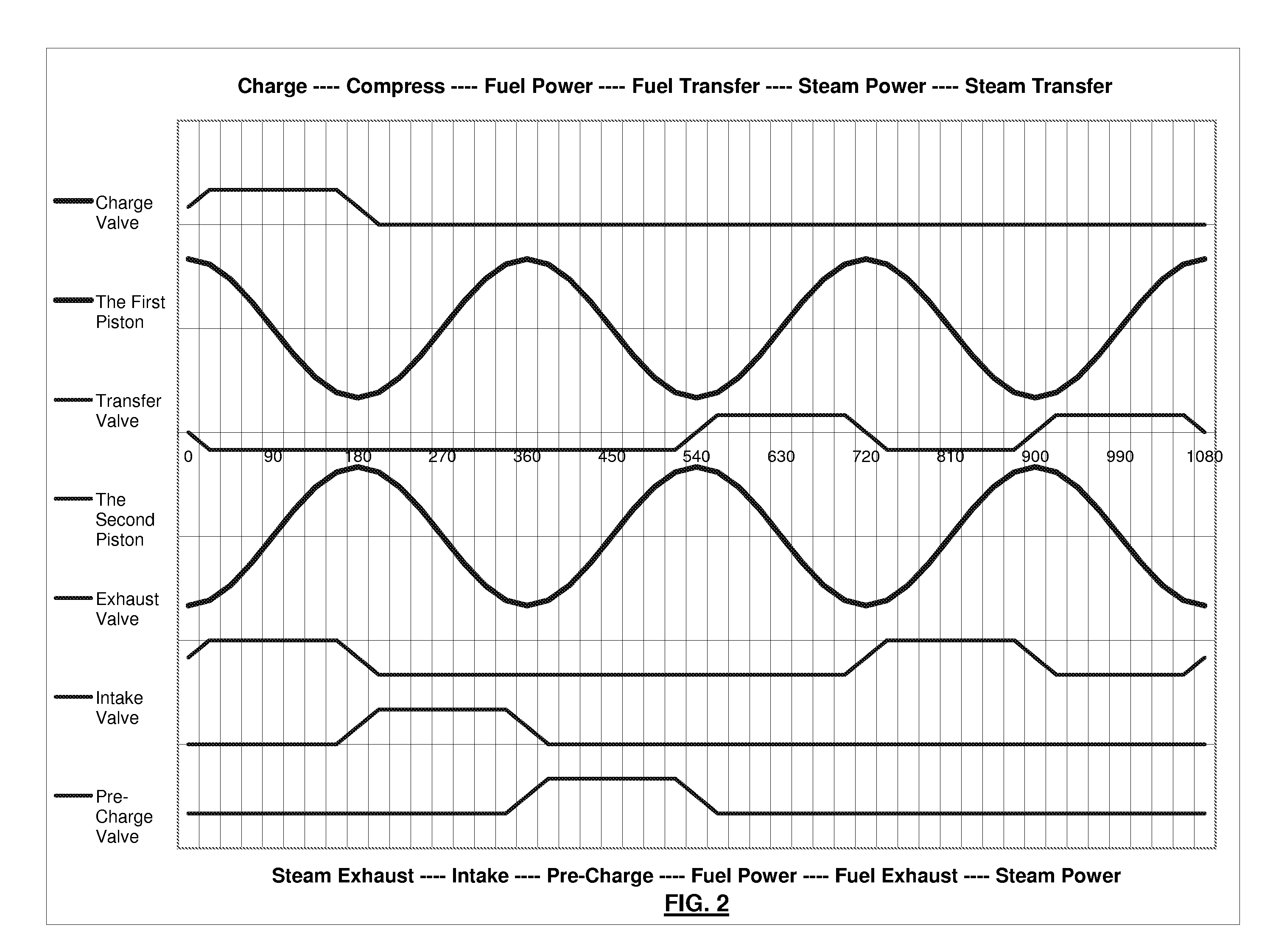

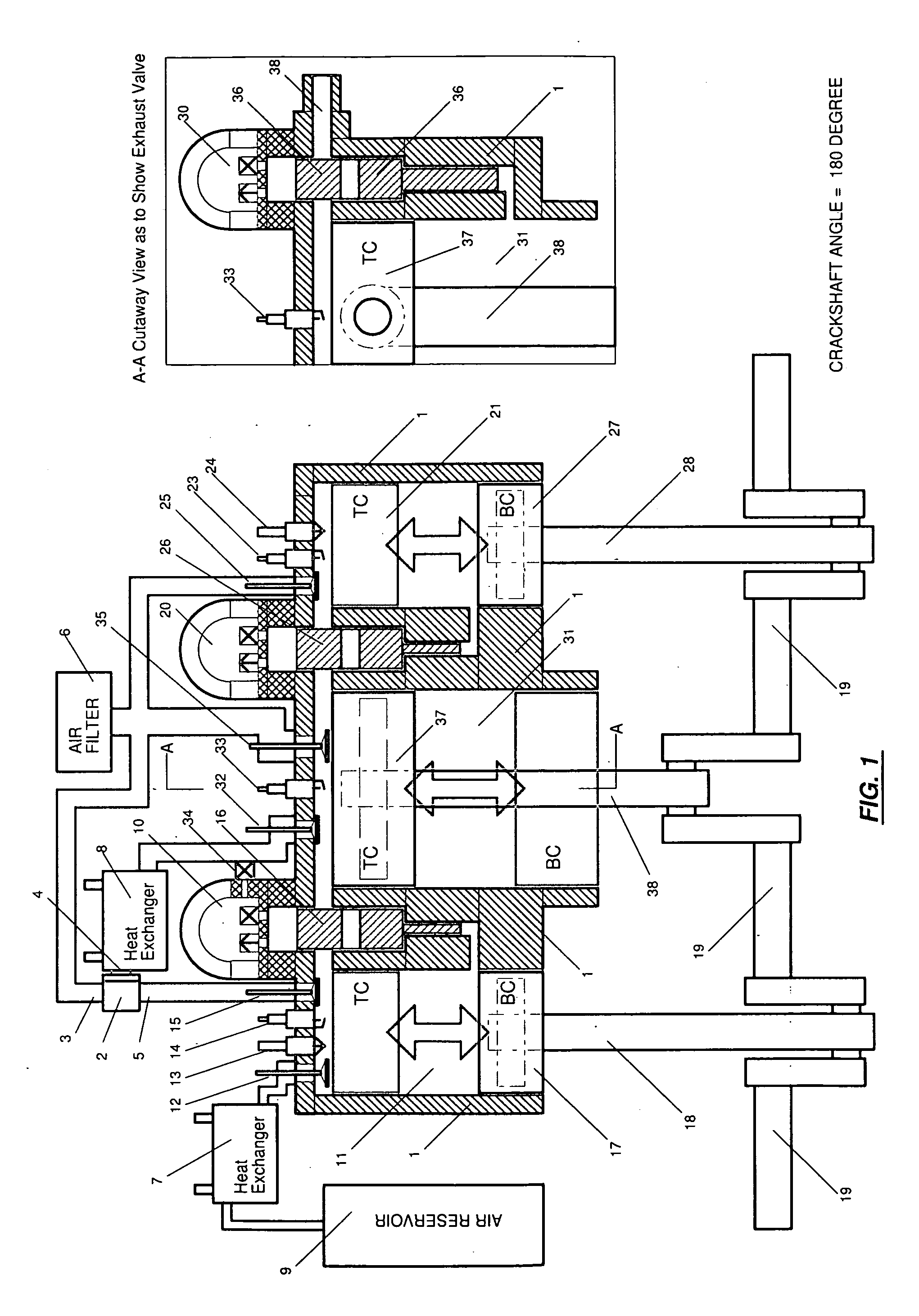

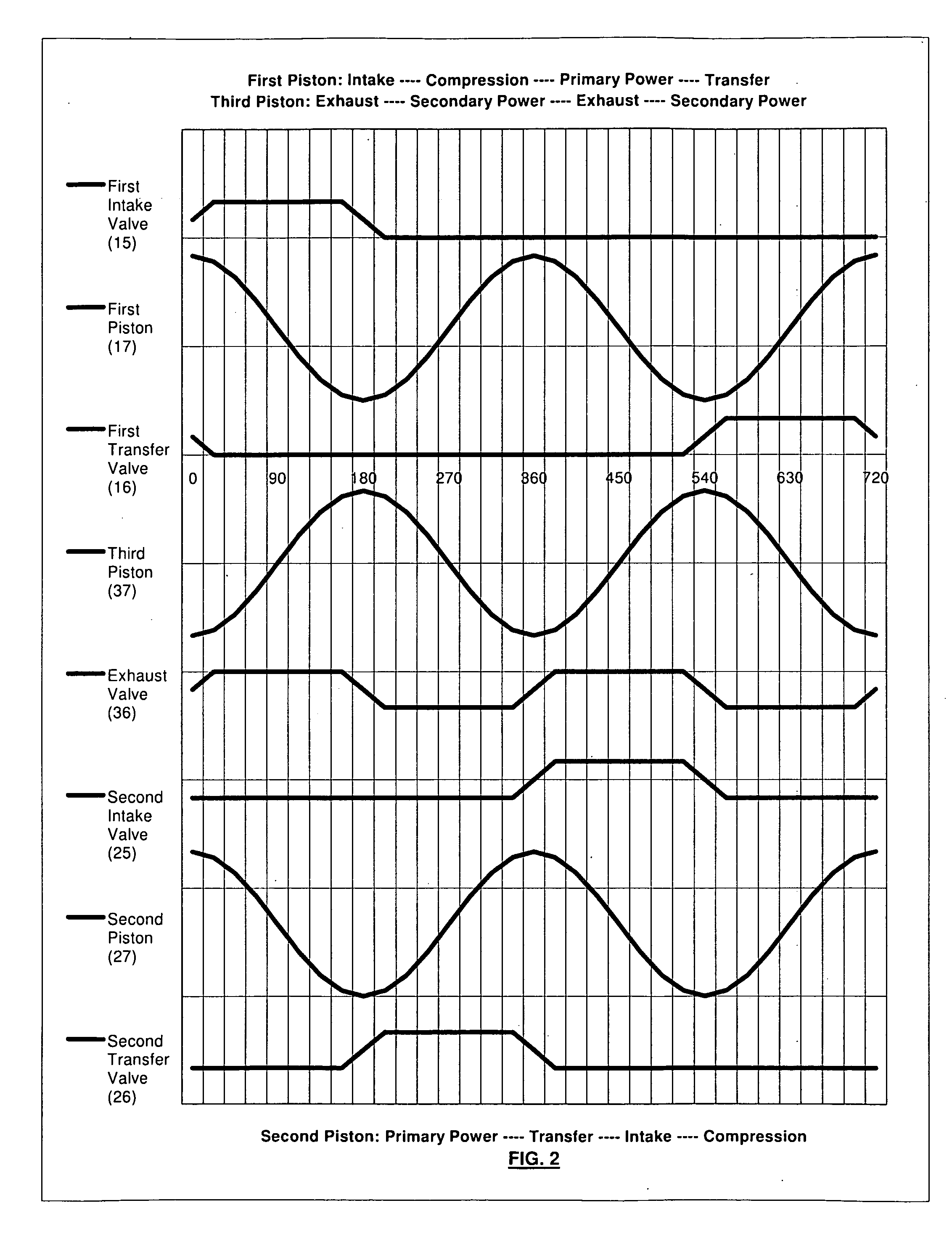

High efficiency integrated heat engine (HEIHE)

InactiveUS20090056331A1Reduce heat lossEfficient heatingInternal combustion piston enginesSteam engine plantsWork periodWorking fluid

The present invention is a High Efficient Integrated Heat Engine, or HEIHE for short. HEIHE is a reciprocal combustion engine integrated with both compound cycle and combined cycle. HEIHE comprises twin compound cylinder structure, with the first cylinder being the primary combustion and / or expansion cylinder; the second cylinder being the secondary combustion and / or expansion cylinder. Power strokes driven by expansions of different working fluids such as air-fuel combustion products, steam and compressed air, are integrated into one engine block. Twin cylinder structure provides compound expansions of three (3) different fluids as to recover the energies that would be lost with the exhaust fluids or during braking. All of these make HEIHE work around six (6) periods with twelve (12) operation strokes. Among six (6) working periods involved, four (4) periods contain four (4) different power strokes but only one of the power strokes consumes the fuel. Thus the fuel conversion efficiency could be greatly increased, or even be doubled comparing with the conventional internal combustion engine (ICE).

Owner:ZHAO YUANPING +1

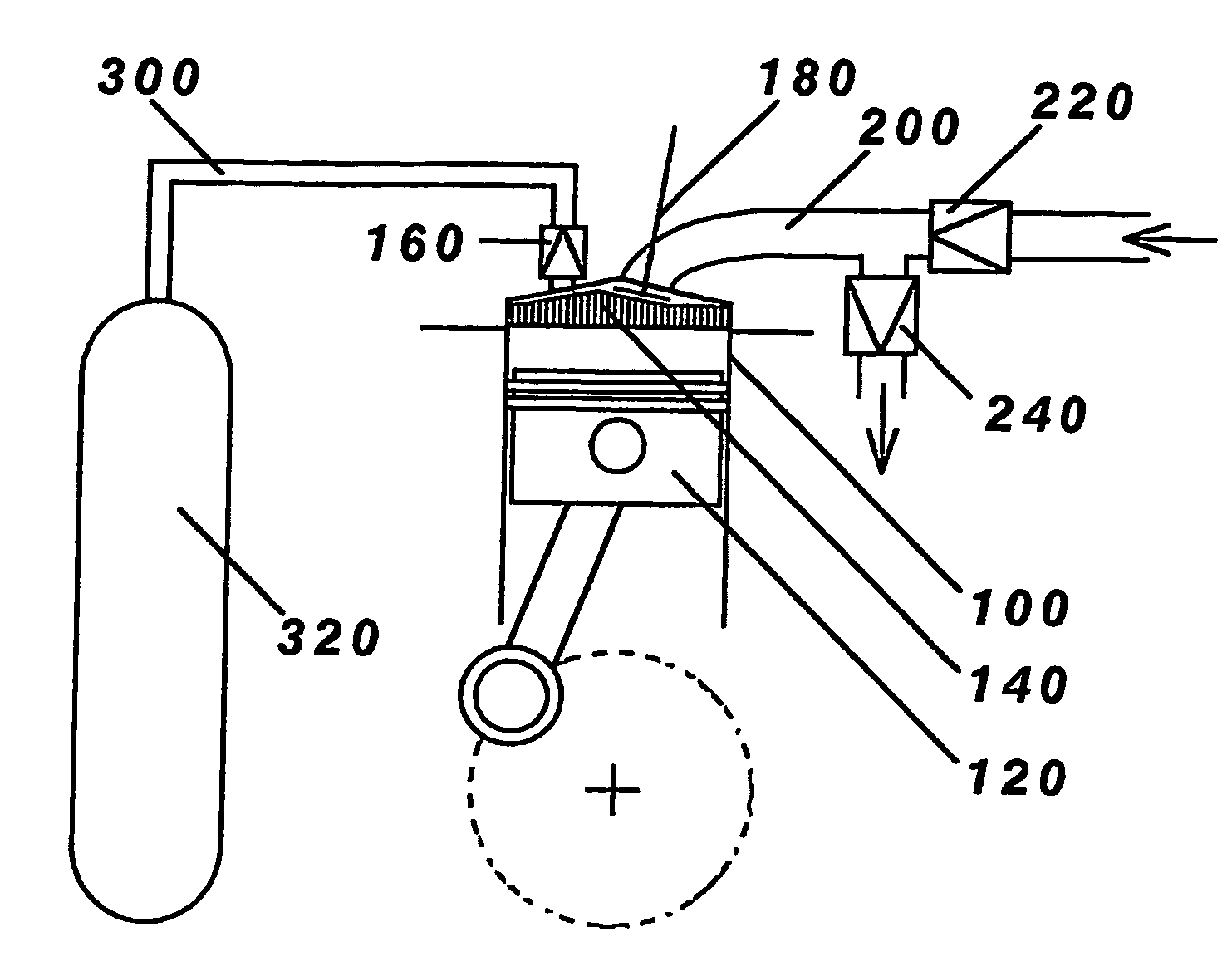

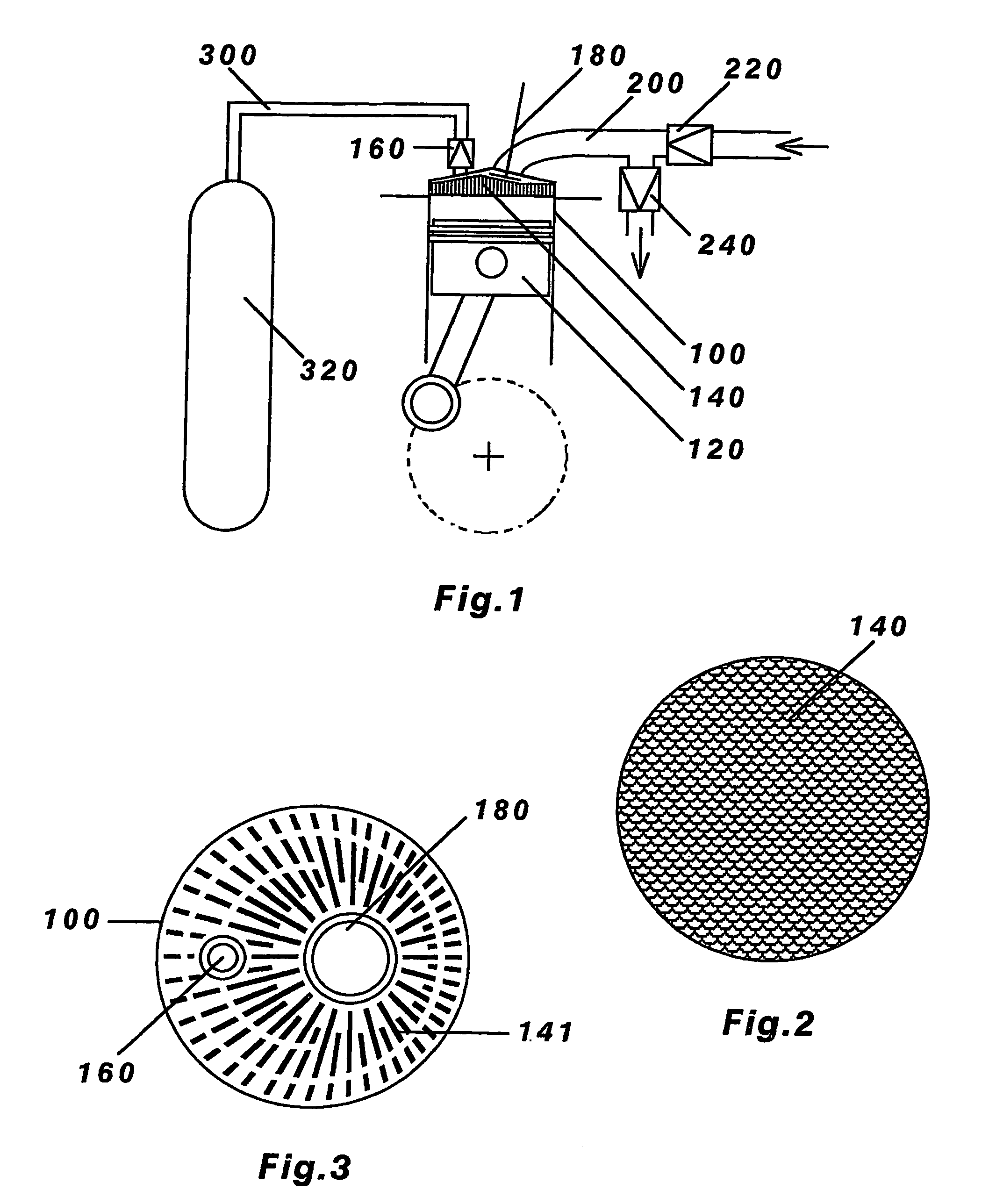

Engine with an active mono-energy and/or bi-energy chamber with compressed air and/or additional energy and thermodynamic cycle thereof

ActiveUS7469527B2Usable and available energyQuantity of usable and availableFlexible wall reciprocating enginesCombustion enginesTop dead centerEngineering

An engine uses a top dead center piston stop device. It is fed by compressed air, via a working capacity, which, in the bi-energy version, includes a device for heating the air supplied by additional energy. The active expansion chamber consists of a variable volume or charge piston sliding in a cylinder, coupled to a space above the engine piston via a passage. When stoped at upper dead center, the pressurized air is admitted into the expansion chamber with the smallest volume thereof and, under the effect of thrust, increases the volume thereof by producing work; the expansion chamber is then kept at a maximum volume during expansion of the engine cylinder driving back the engine piston in its downward stroke, providing work of its own. During exhaust, the two pistons travel in an upward stroke and simultaneously reach top dead center in order to resume a new cycle.

Owner:MDI MOTOR DEV INT SA

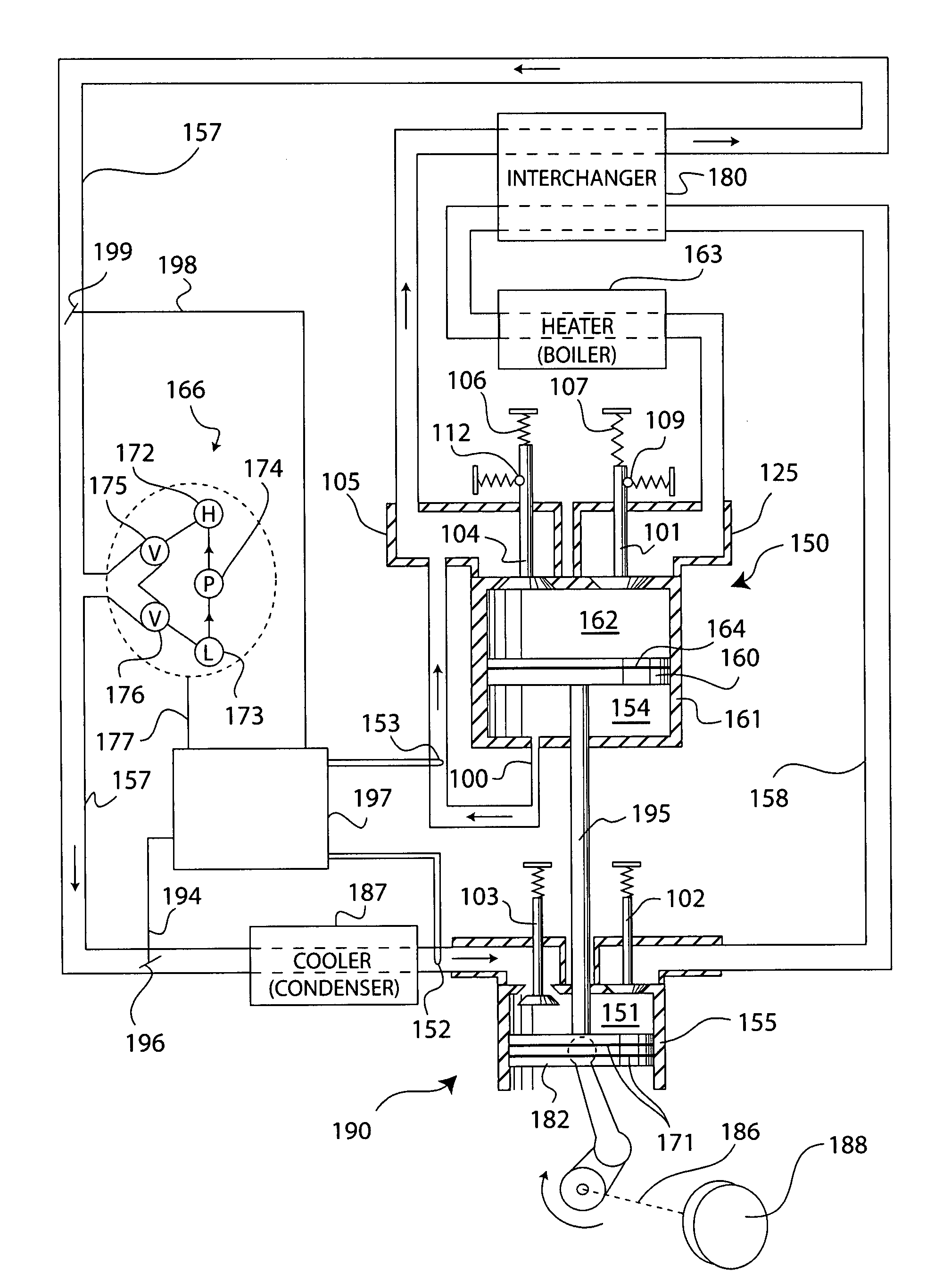

Harmonic engine

A high efficiency harmonic engine based on a resonantly reciprocating piston expander that extracts work from heat and pressurizes working fluid in a reciprocating piston compressor. The engine preferably includes harmonic oscillator valves capable of oscillating at a resonant frequency for controlling the flow of working fluid into and out of the expander, and also preferably includes a shunt line connecting an expansion chamber of the expander to a buffer chamber of the expander for minimizing pressure variations in the fluidic circuit of the engine. The engine is especially designed to operate with very high temperature input to the expander and very low temperature input to the compressor, to produce very high thermal conversion efficiency.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Thermoacoustic driven compressor

The present disclosure details a thermoacoustic driven compressor having a pressurized housing, which contains within a thermoacoustic engine and a working gas, coupled to a positive displacement reciprocating compressor. The thermoacoustic driven compressor generates scalable compressed air from a given heat source.

Owner:ENOVA

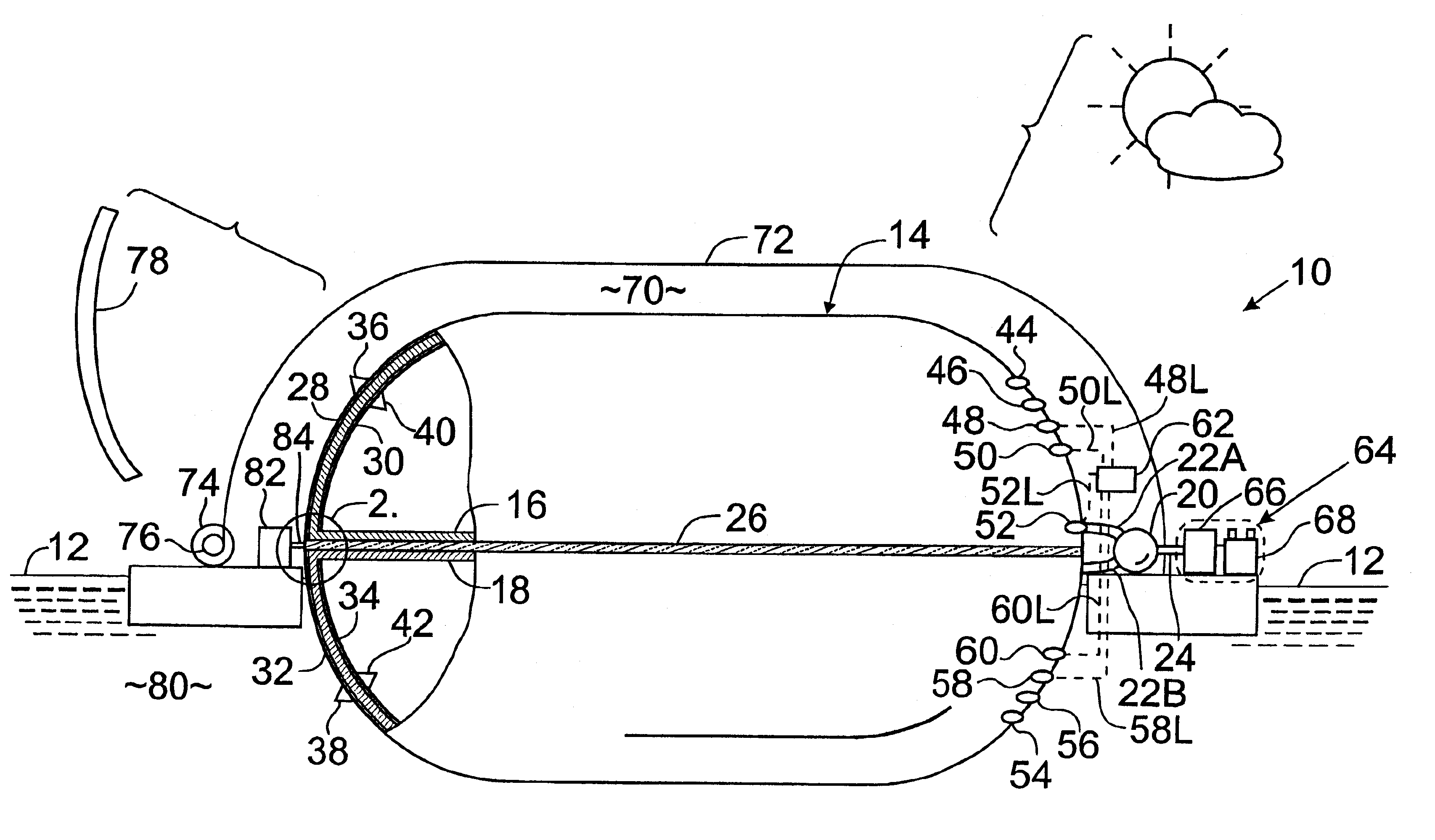

Method and apparatus for energy generation utilizing temperature fluctuation-induced fluid pressure differentials

A method and apparatus for producing energy is provided for generating renewable energy. Captive compressed fluid cycles between two coupled containers through a motive power source. The captive compressed fluid flows between the containers in response to a difference in the pressure of the compressed fluid within the first container compared to the pressure of the compressed fluid within the second container. This pressure differential develops as the compressed fluid within the first container experiences a temperature change of a differing percentage magnitude or direction than the compressed fluid within the second container over the same period of time. The differing percentage temperature fluctuations result as the containers are provided dissimilar exposure to natural renewable or man-made energy sources or are insulated therefrom. A continuous supply of additional compressed fluid is not required, nor is fluid routinely vented to the atmosphere.

Owner:CORCORAN CRAIG C

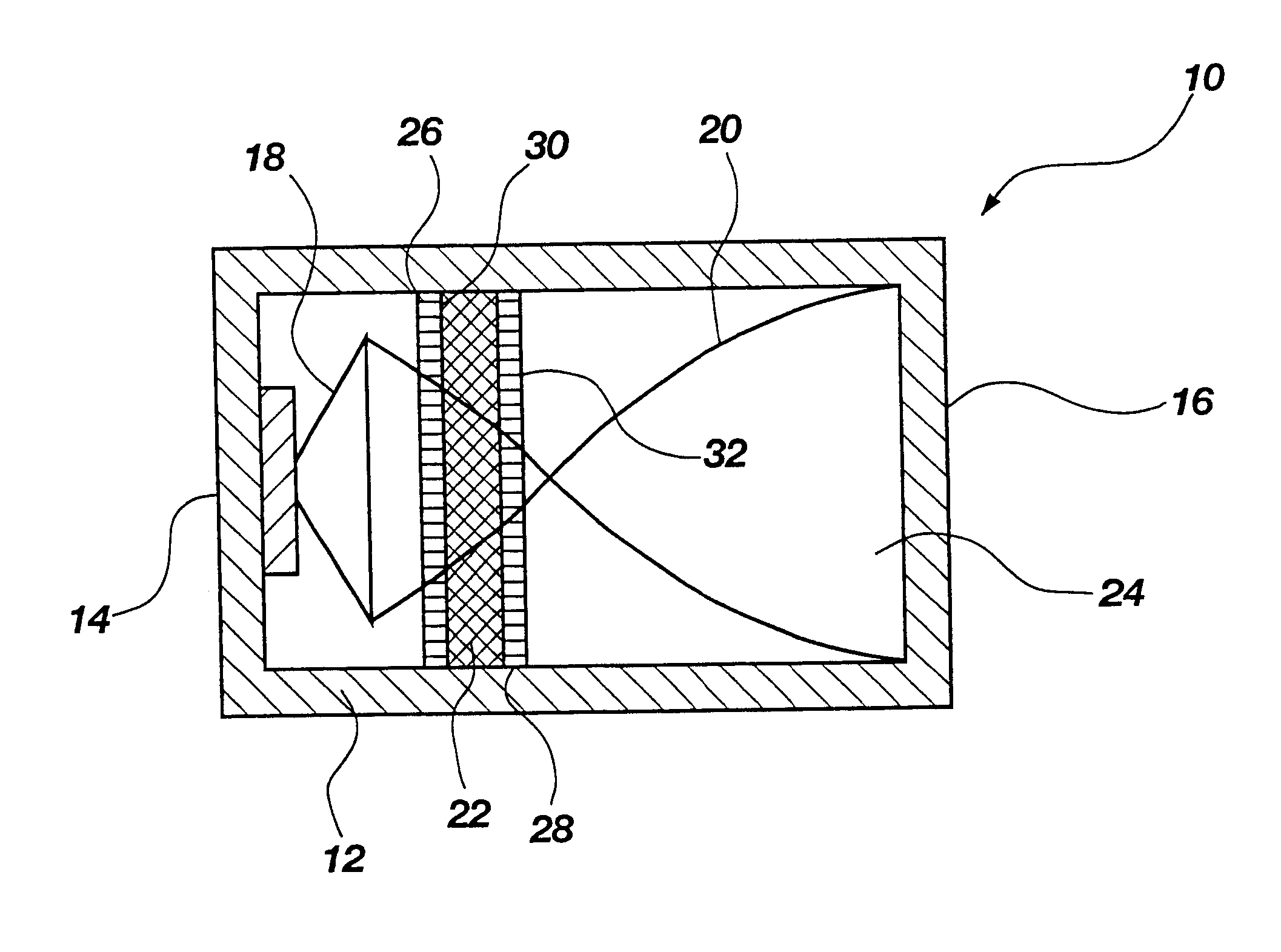

High frequency thermoacoustic refrigerator

InactiveUS6574968B1Simple and inexpensive to manufactureRelatively compactStirling type enginesCompression machinesThermoacousticsResonance

A thermoacoustic refrigerator having a relatively small size which utilizes one or more piezoelectric drivers to generate high frequency sound within a resonator at a frequency of between about 4000 Hz and ultrasonic frequencies. The interaction of the high frequency sound with one or more stacks create a temperature gradient across the stack which is conducted through a pair of heat exchangers located on opposite sides of each stack. The stack is comprised of an open-celled material that allows axial, radial, and azimuthal resonance modes of the resonator within the stack resulting in enhanced cooling power of the thermoacoustic refrigerator.

Owner:UNIV OF UTAH RES FOUND A NON PROFIT ORG

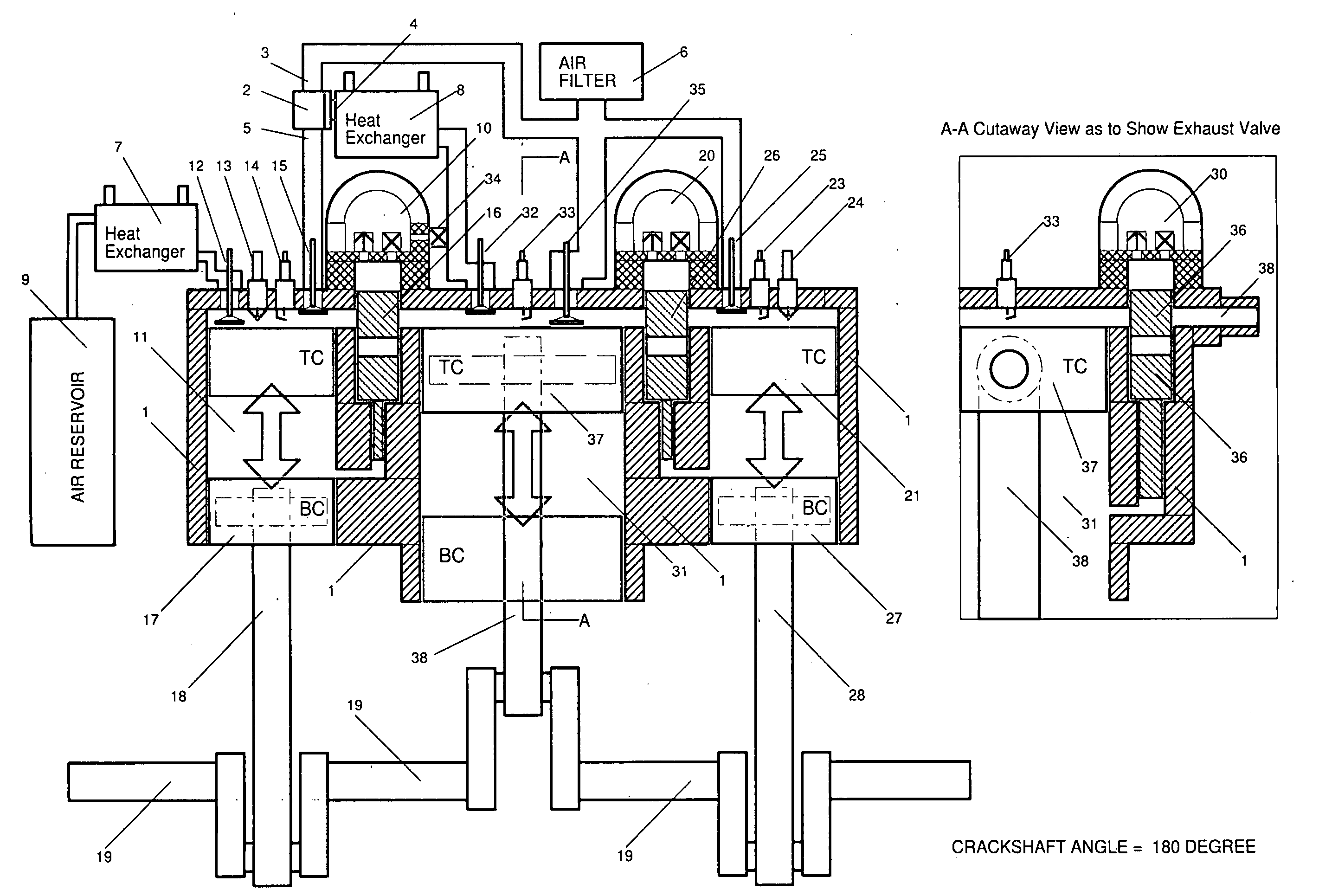

High efficiency integrated heat engine-2 (heihe-2)

InactiveUS20090056670A1Improve efficiencyImprove conversion efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelWork periodWorking fluid

The present invention is a second kind of High Efficiency Integrated Heat Engine, or HEIHE-2 for short. HEIHE-2 is a reciprocal combustion engine integrated with both compound cycle and combined cycle. HEIHE-2 comprises triple compound cylinder structure, with the first cylinder and the second cylinder being the primary combustion and / or expansion cylinders; and the third cylinder being the secondary combustion and / or expansion cylinder. Power strokes driven by expansions of different working fluids such as air-fuel combustion products, steam and compressed air, are integrated into one engine block. Triple cylinder structure provides compound expansions of three (3) different fluids as to recover the energies that would be lost with the exhaust fluids or during braking. All of these make HEIHE-2 work around four (4) periods with six (6) different operation strokes. All four (4) working periods contain four (4) different power strokes but only two (2) of them consume the fuel. Thus the fuel conversion efficiency could be greatly increased, or even be doubled comparing with the conventional internal combustion engine (ICE).

Owner:ZHAO YUANPING +1

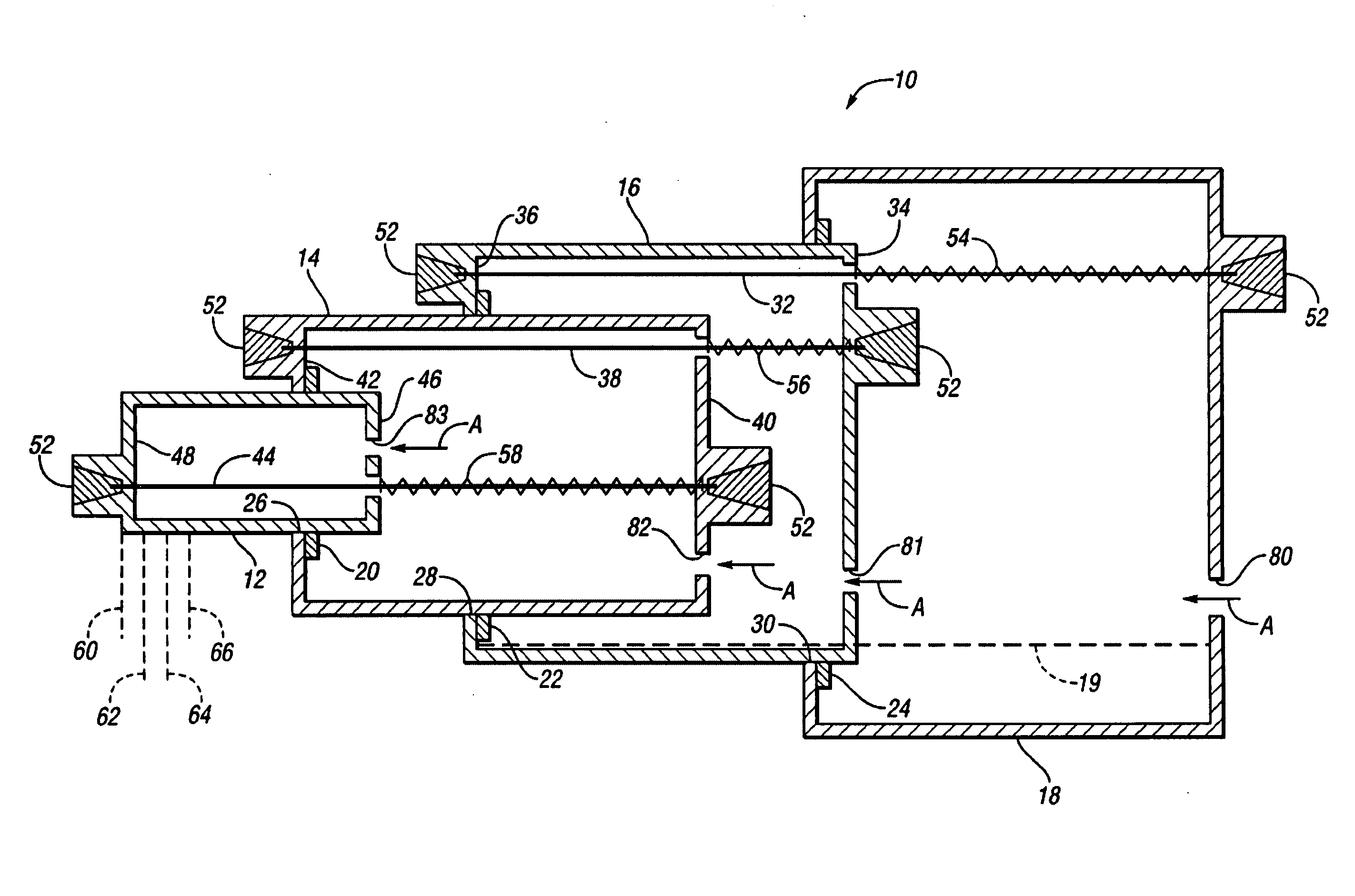

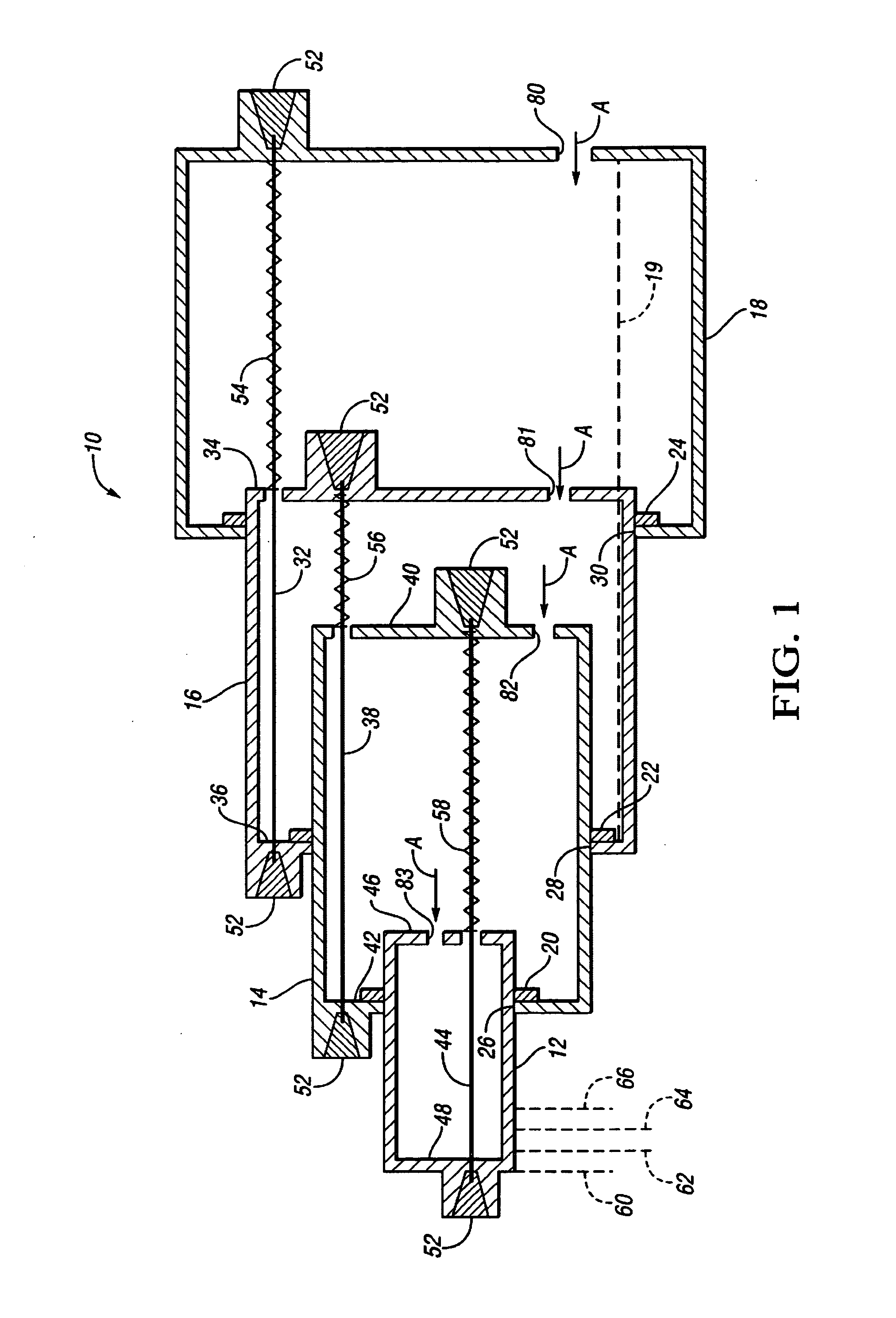

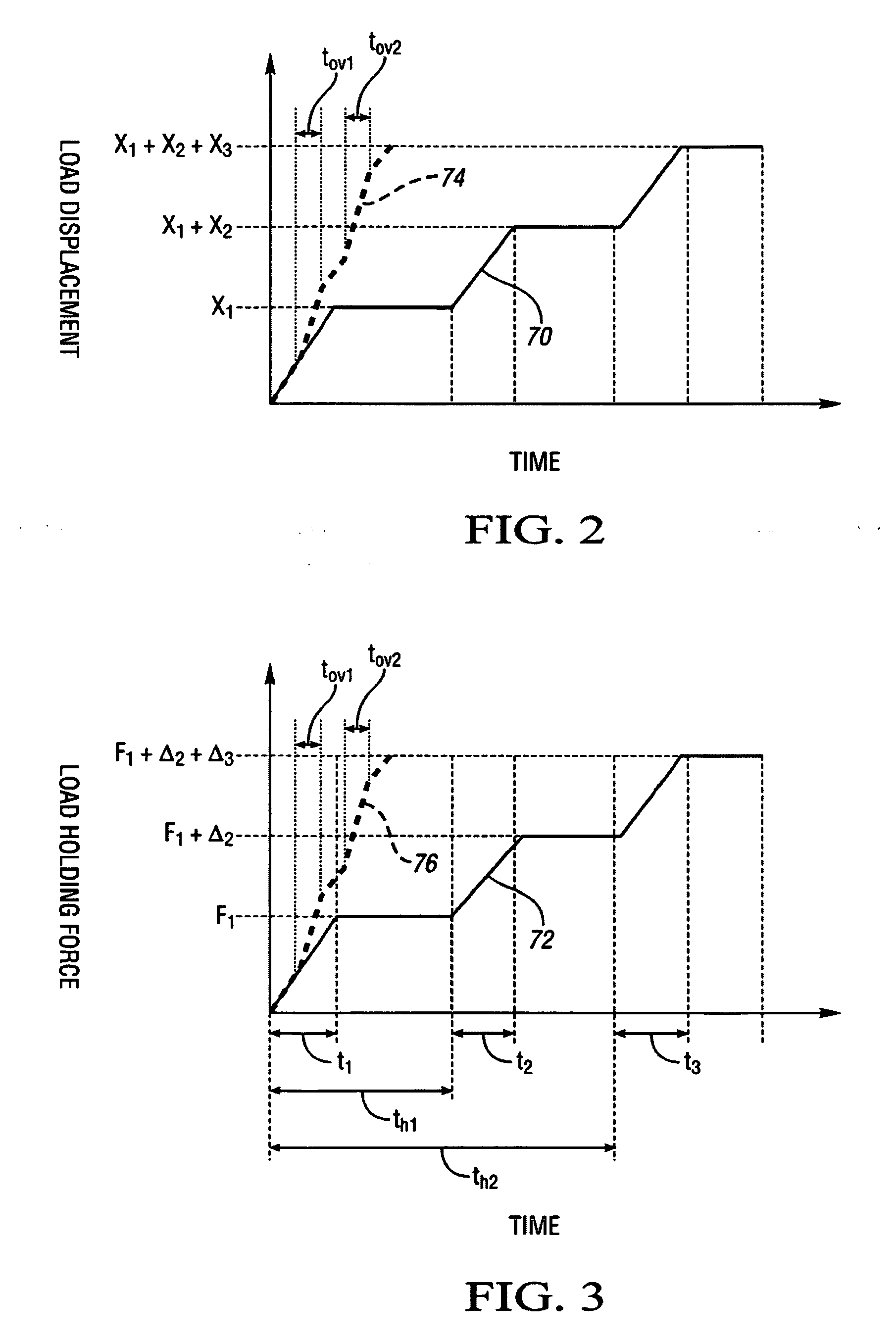

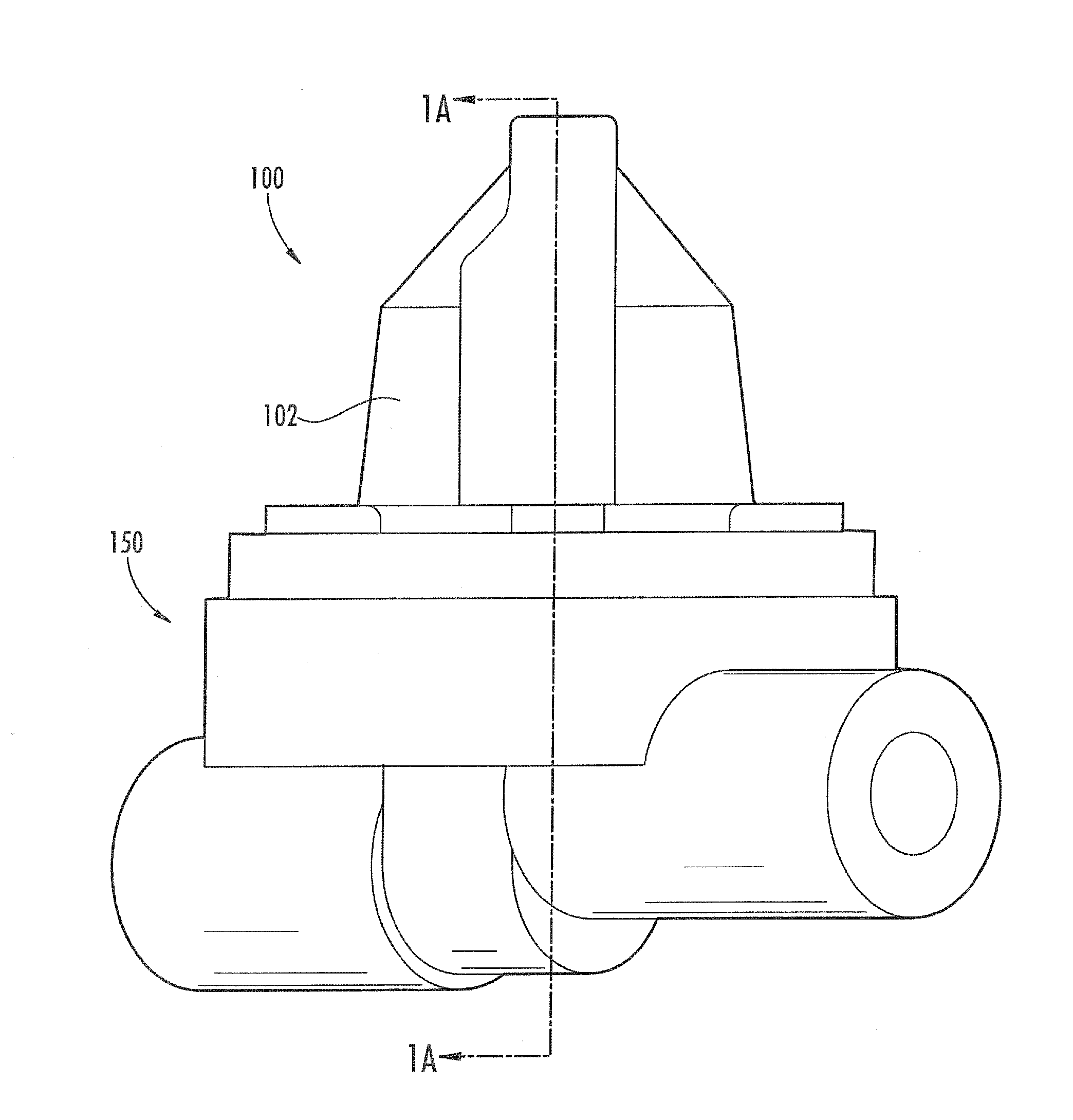

Active material actuator assembly

ActiveUS20080034750A1Simple processFast actuation cycle timePiezoelectric/electrostriction/magnetostriction machinesMechanical power devicesControl systemEngineering

Active material actuator assemblies are provided that enable simplified control systems and faster actuator cycle times. A movable member is provided that has multiple active material components operatively connected to it. The active material components are separately selectively activatable for moving the movable member. Movement of the movable member via activation of a first of the active material components triggers activation of the second active material component to further move the movable member. Alternatively or in addition, previously activated active material components are protected from undesired stretching during activation of another active material component or, when desired, an active material component may be reset via activation of another of the active material components in order to prepare it for subsequent activation.

Owner:GM GLOBAL TECH OPERATIONS LLC

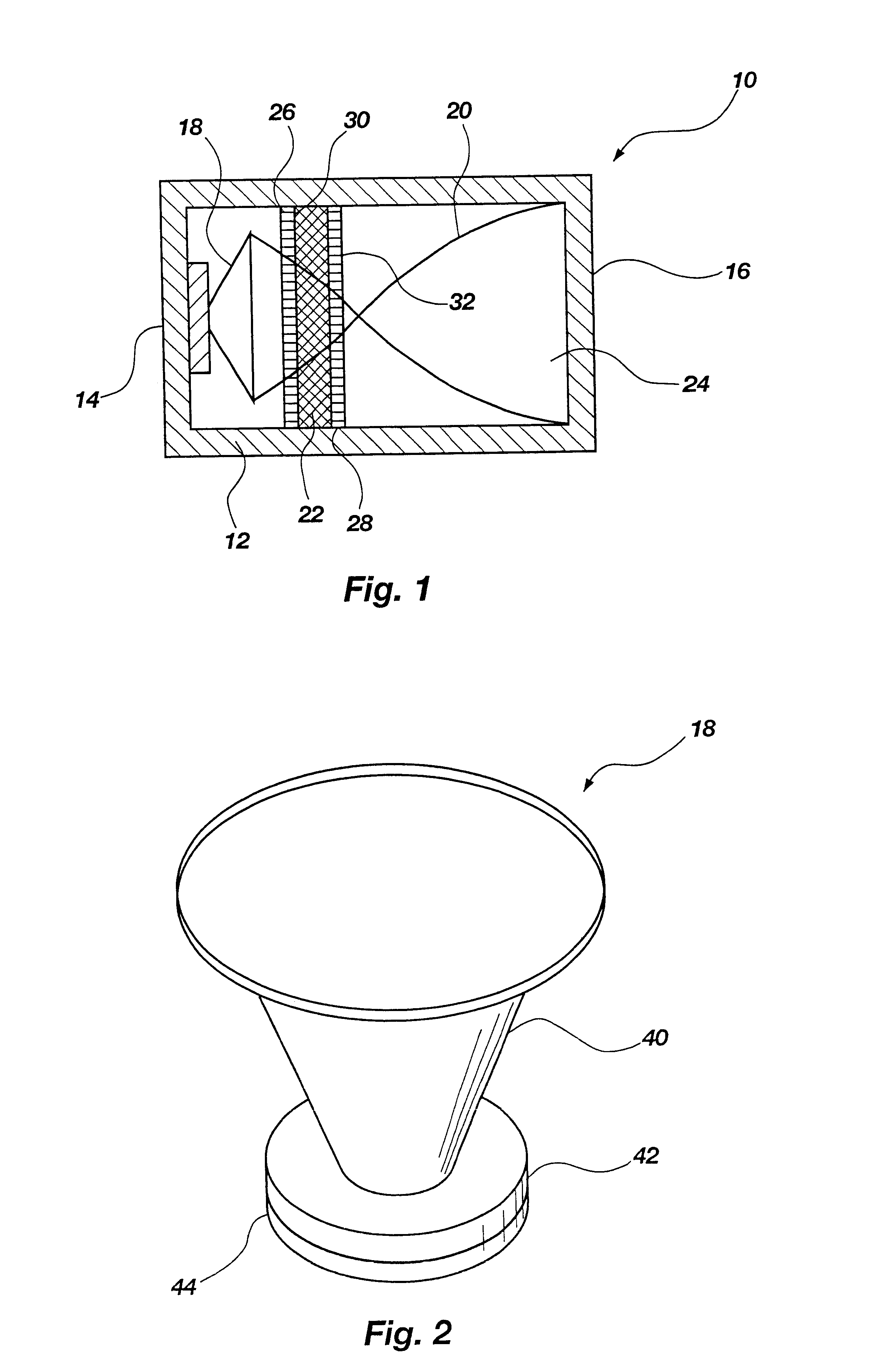

Memory alloy-actuated apparatus and methods for making and using the same

InactiveUS20120151913A1Reduce operating costsLess ecologically damaging wasteOperating means/releasing devices for valvesMechanical power devicesValve actuatorShape-memory alloy

Actuator apparatus having a multi-stable element actuated by memory alloy actuating elements. In one embodiment, the multi-stable actuator comprises a bistable (two-state) diaphragm element adapted to alternate between two stable configurations via forces exerted on the diaphragm by more than one memory alloy filaments in response to thermal activation. The bistable diaphragm element is coupled to a magnetic actuator element resident on a dry portion of a valve fitting, while a plunger actuated by the magnetic actuator element is resident on a wet portion of a valve fitting. Methods for making and using the bistable actuator apparatus are also disclosed.

Owner:AUTOSPLICE SYST

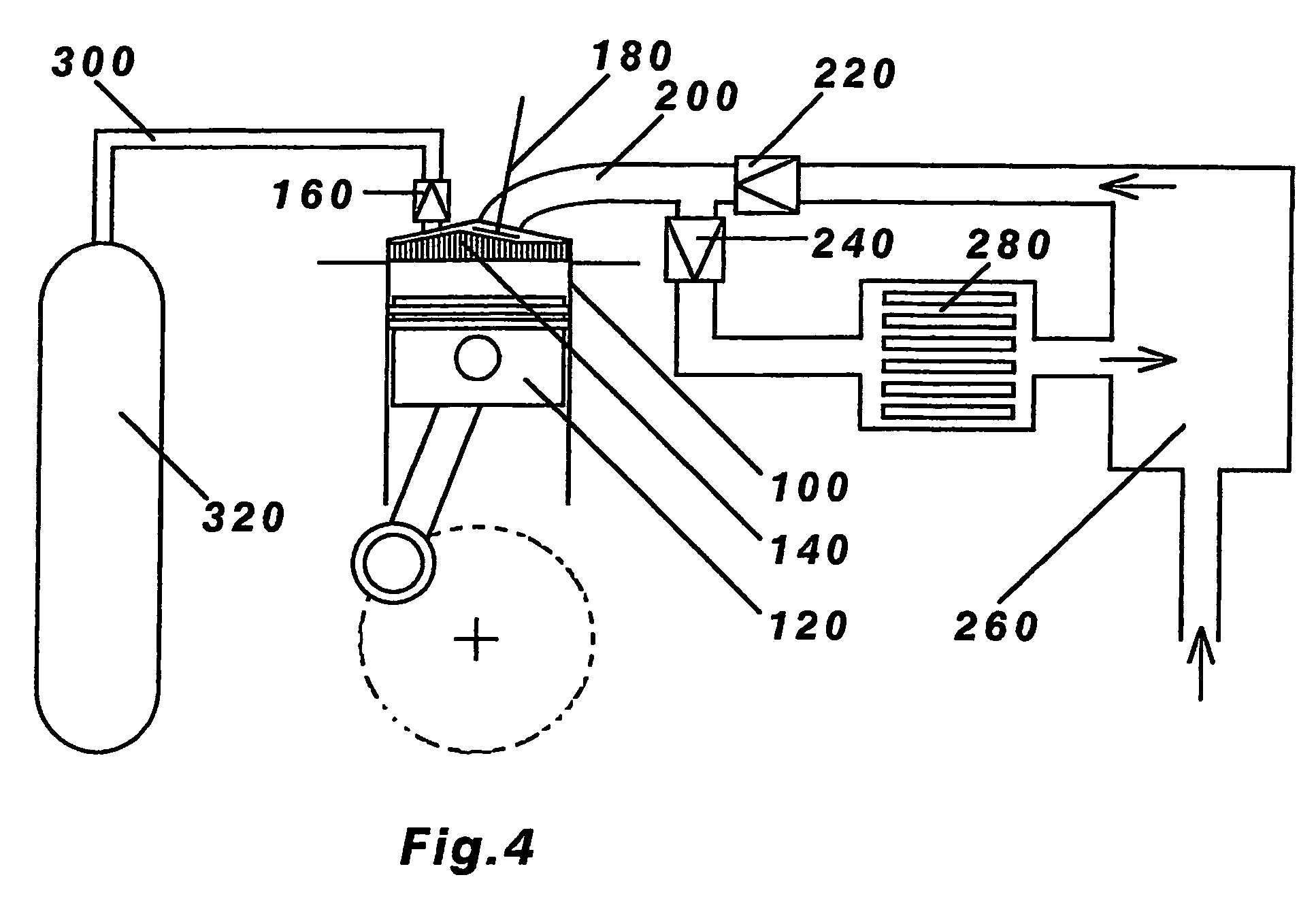

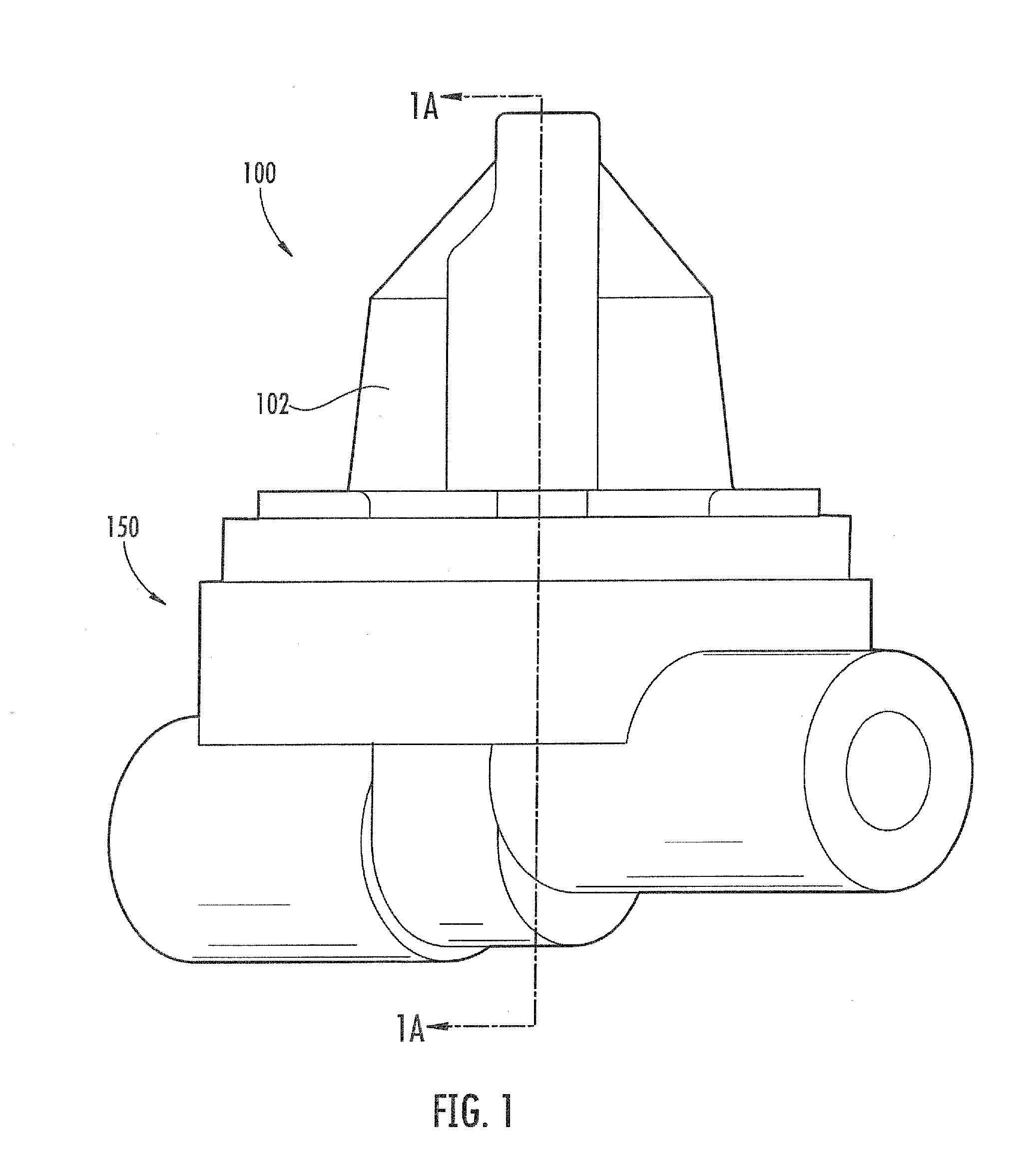

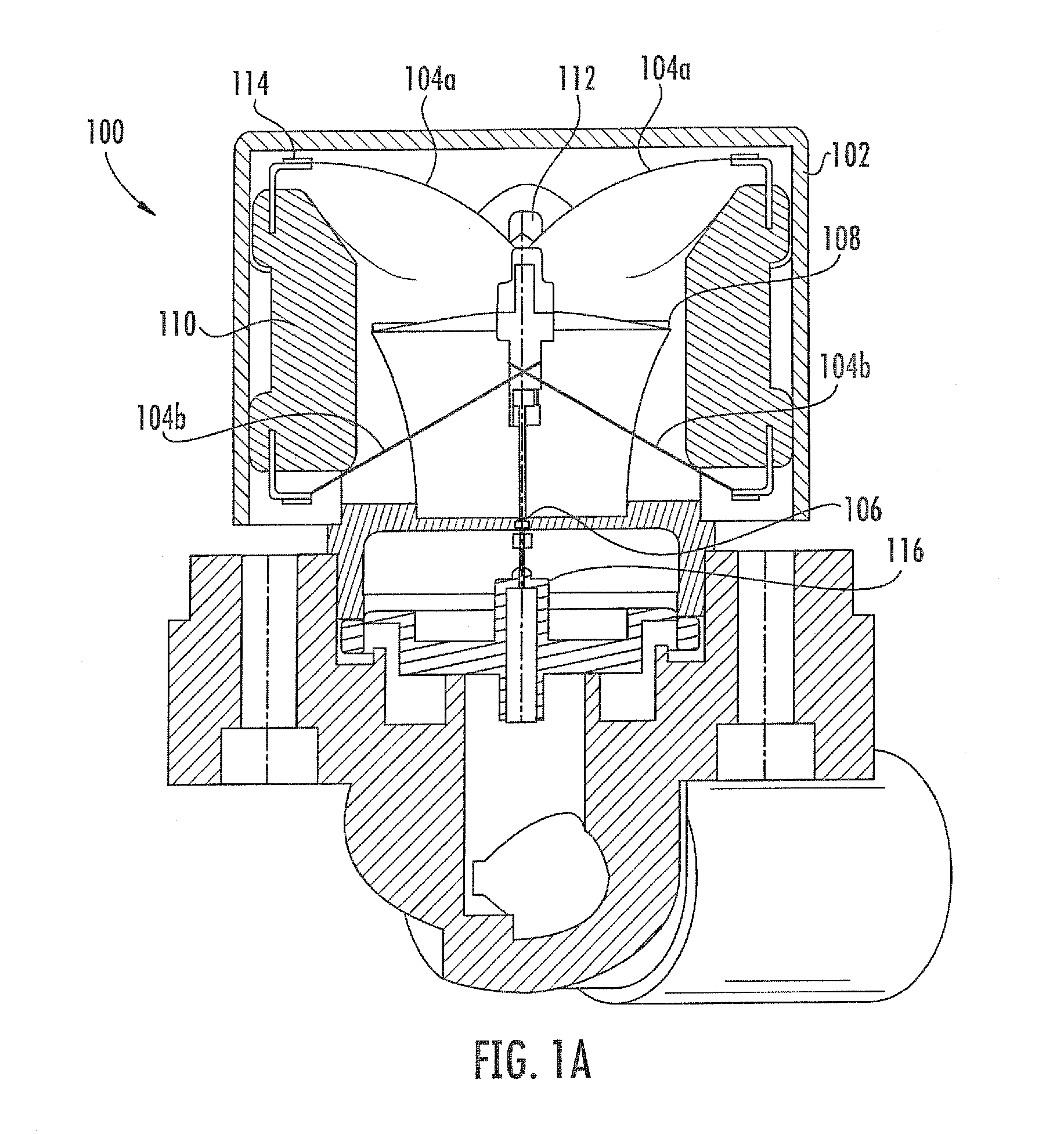

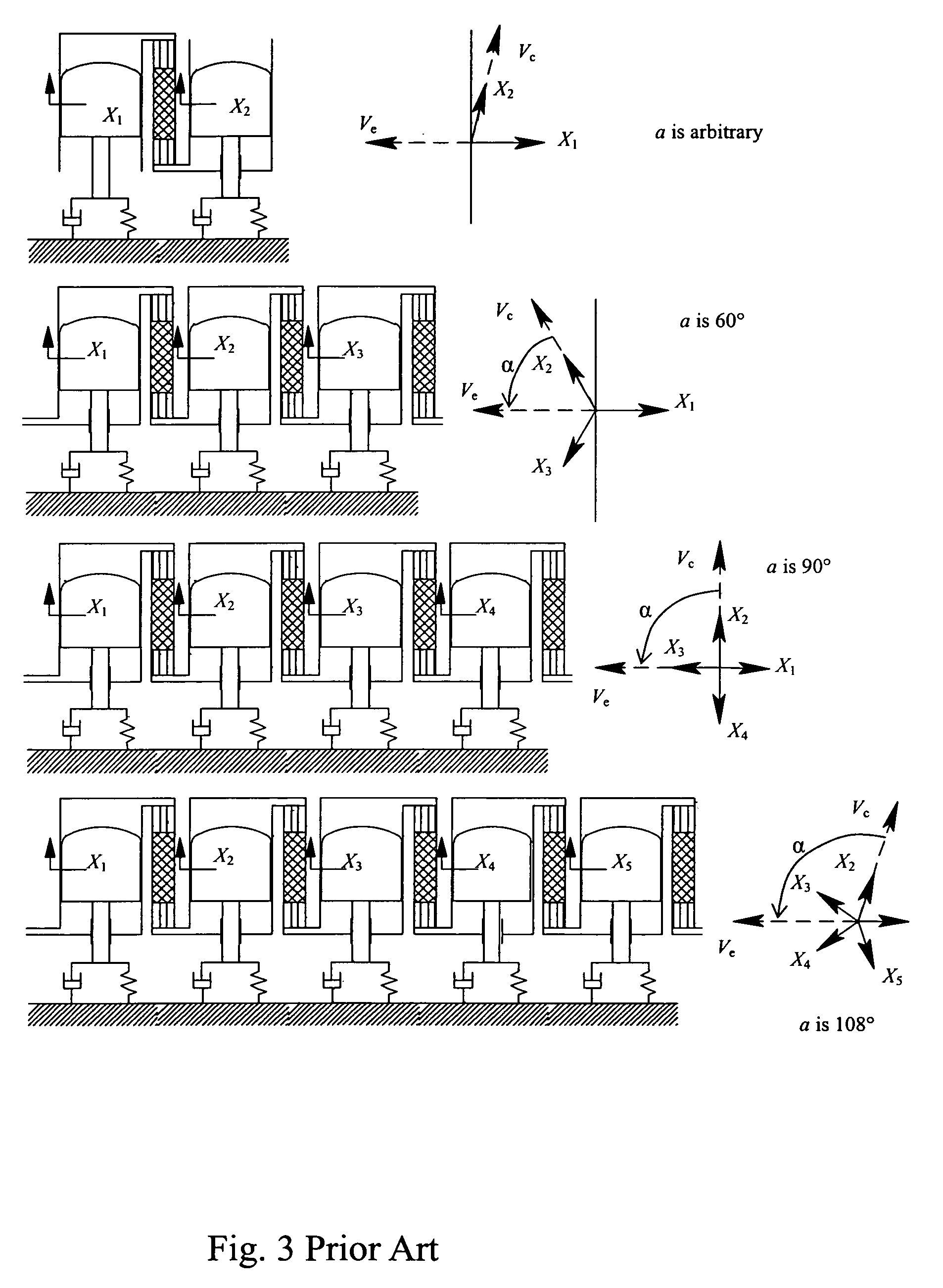

Multiple-cylinder, free-piston, alpha configured stirling engines and heat pumps with stepped pistons

ActiveUS7171811B1Reduce weightReduce in quantityStirling type enginesClosed-cycle gas positive displacement engine plantIsoetes triquetraReciprocating motion

An improved, free-piston, Stirling machine having at least three pistons series connected in an alpha Stirling configuration. Each cylinder is stepped so that it has a relatively larger diameter interior wall and a coaxial, relatively smaller diameter interior wall. Each piston is also stepped so that it has a first component piston having an end face facing in one axial direction and matingly reciprocatable in the smaller diameter cylinder wall and a second component piston having an end face facing in the same axial direction and matingly reciprocatable in the larger diameter, cylinder wall. One of the piston end faces bounds the compression space and the other end face bounds the expansion space. Preferably, each stepped piston has peripheral, cylinder walls that are axially adjacent and joined at a shoulder forming the end face of the larger diameter component piston. Stirling machines with these stepped features are also arranged in various opposed and duplex configurations, including arrangements with only one load or prime mover for each opposed pair of pistons. Improved balancing or vibration reduction is obtained by connecting expansion and compression spaces of a four cylinder in-line arrangement in a 1, 3, 2, 4 series sequence. Three cylinder embodiments provide a highly favorable volume phase angle of 120° and are advantageously physically arranged with three, parallel, longitudinal axes of reciprocation at the apexes of an equilateral triangle.

Owner:GLOBAL COOLING

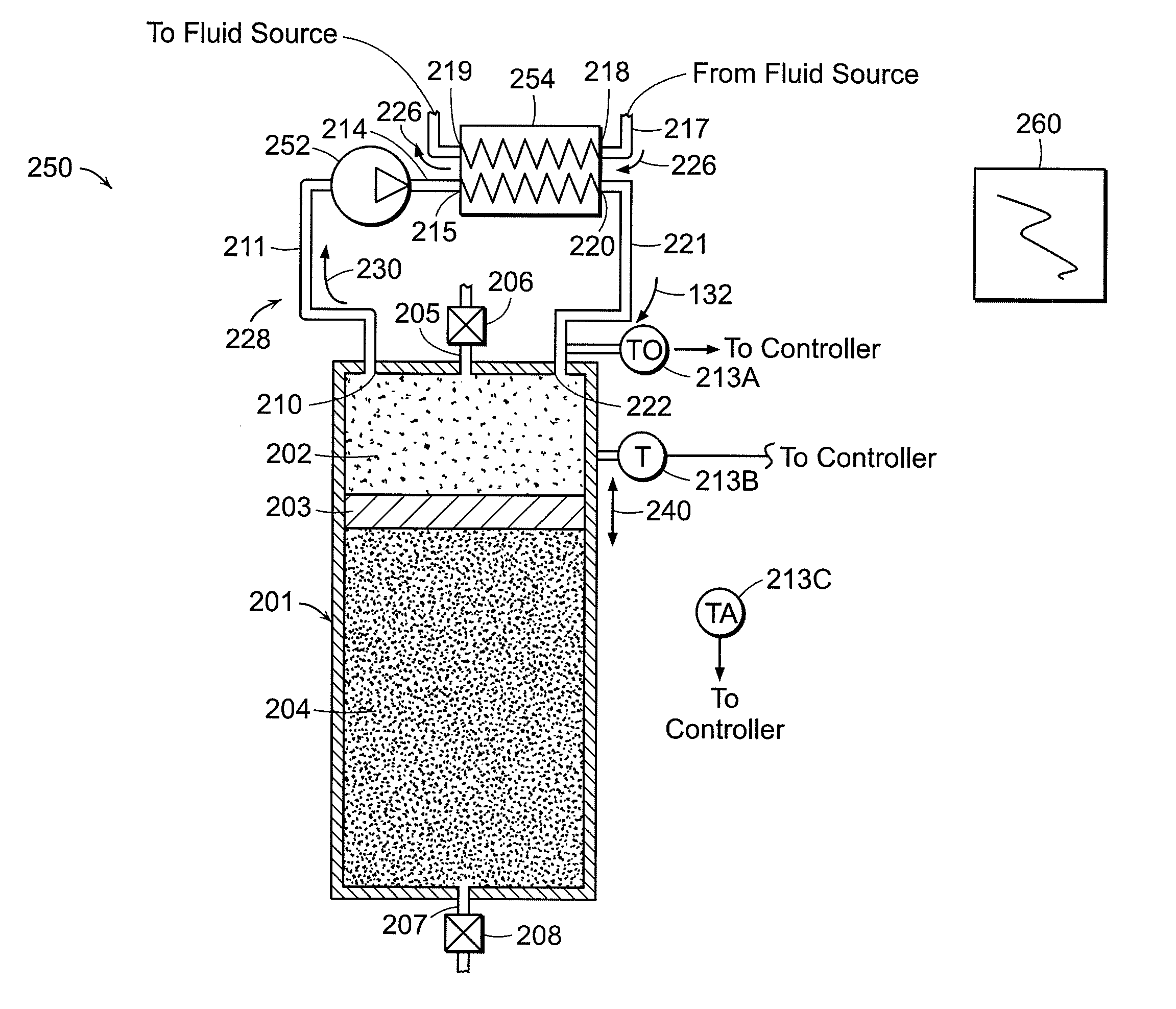

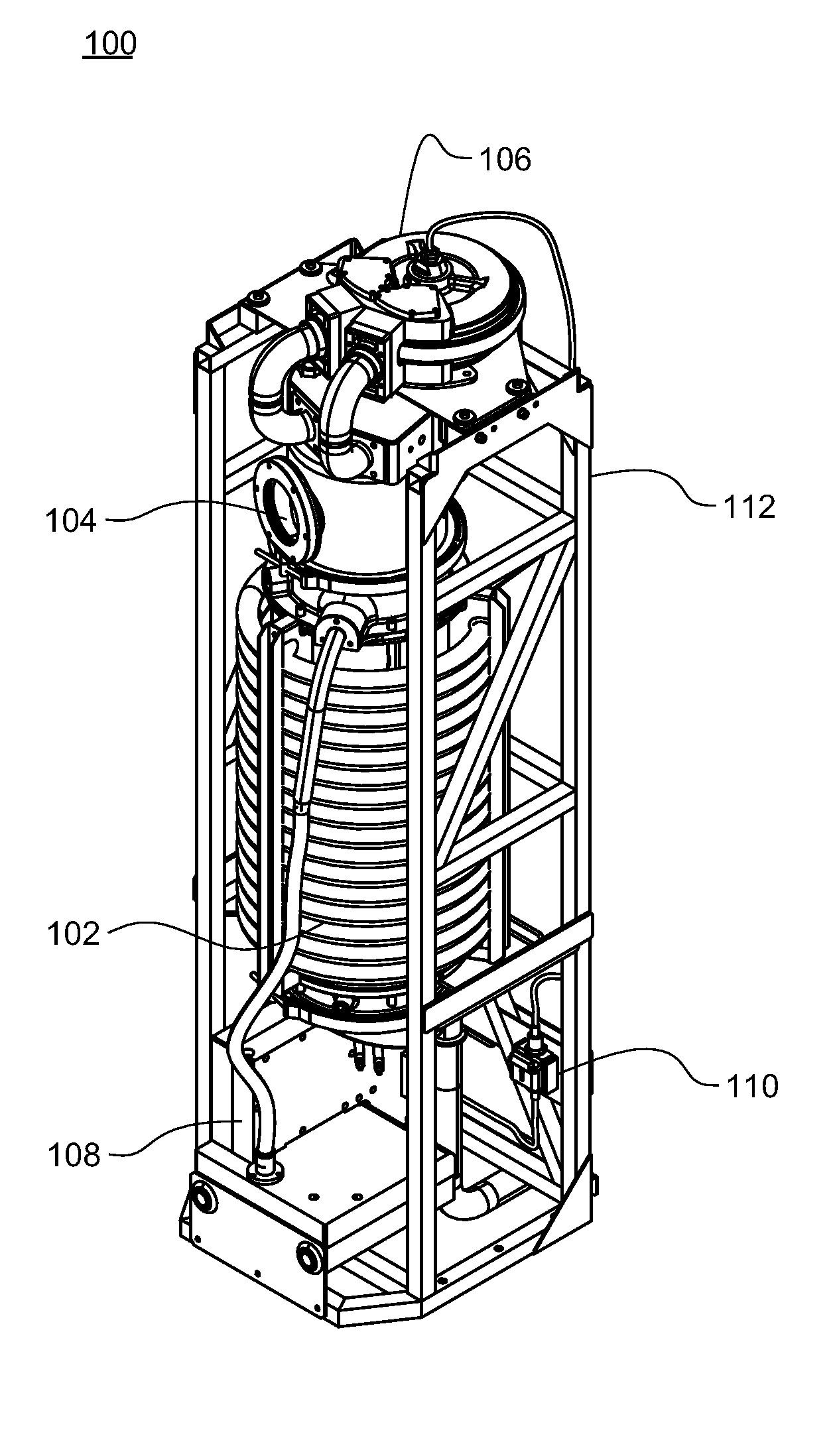

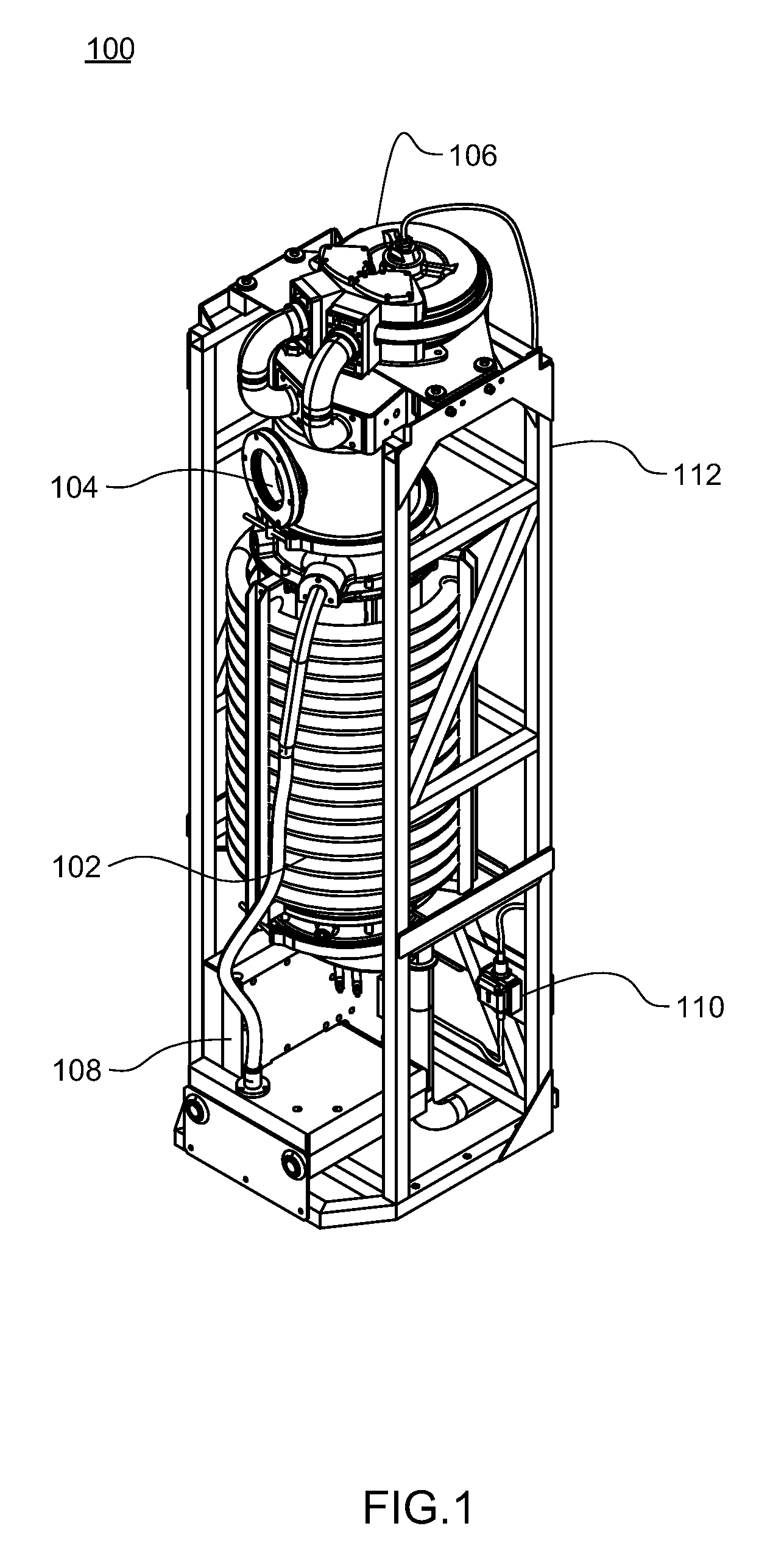

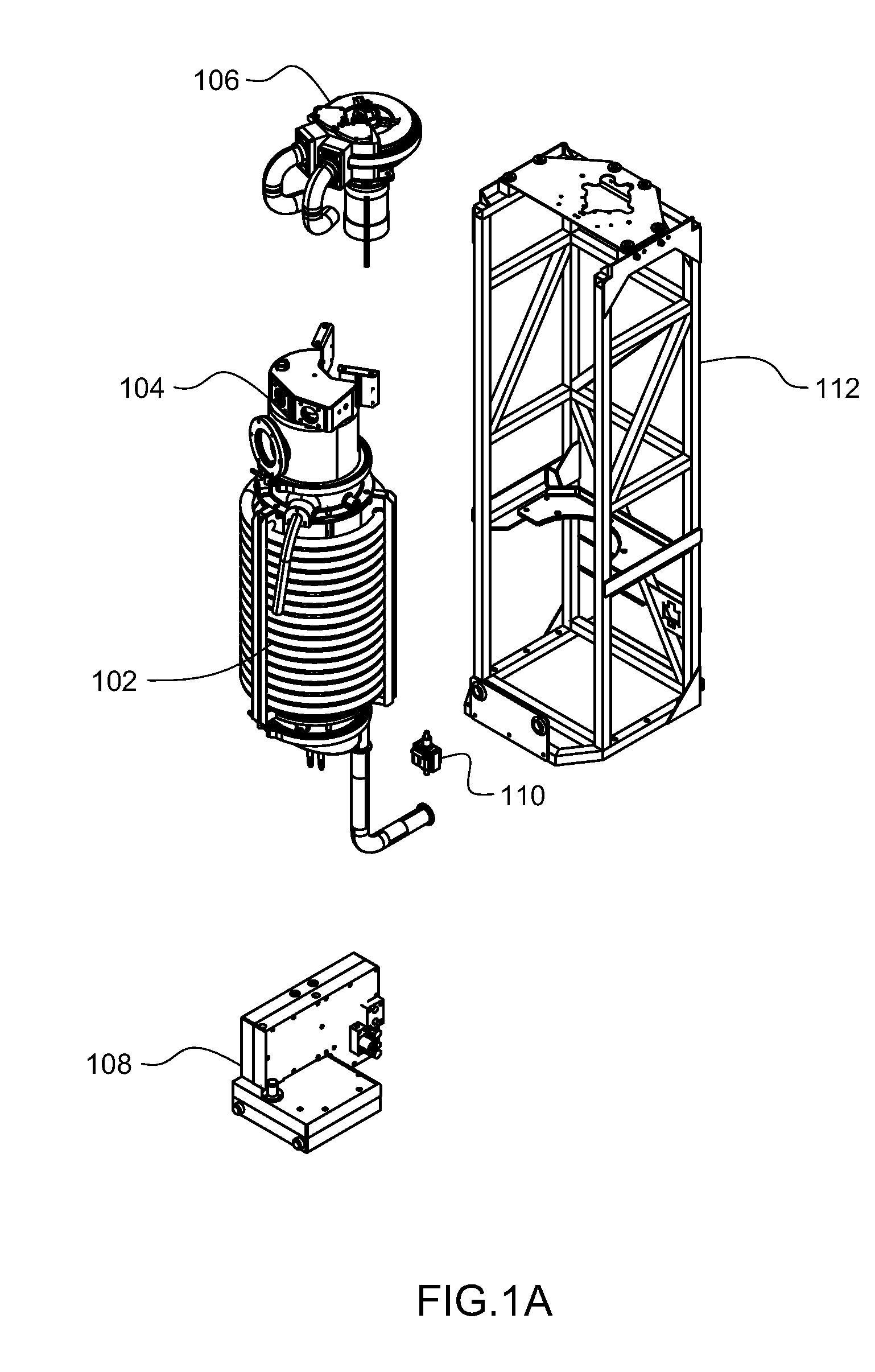

Water Vapor Distillation Apparatus, Method and System

ActiveUS20090025399A1Semiconductor/solid-state device detailsSolid-state devicesWater vaporEngineering

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid.

Owner:DEKA PROD LLP

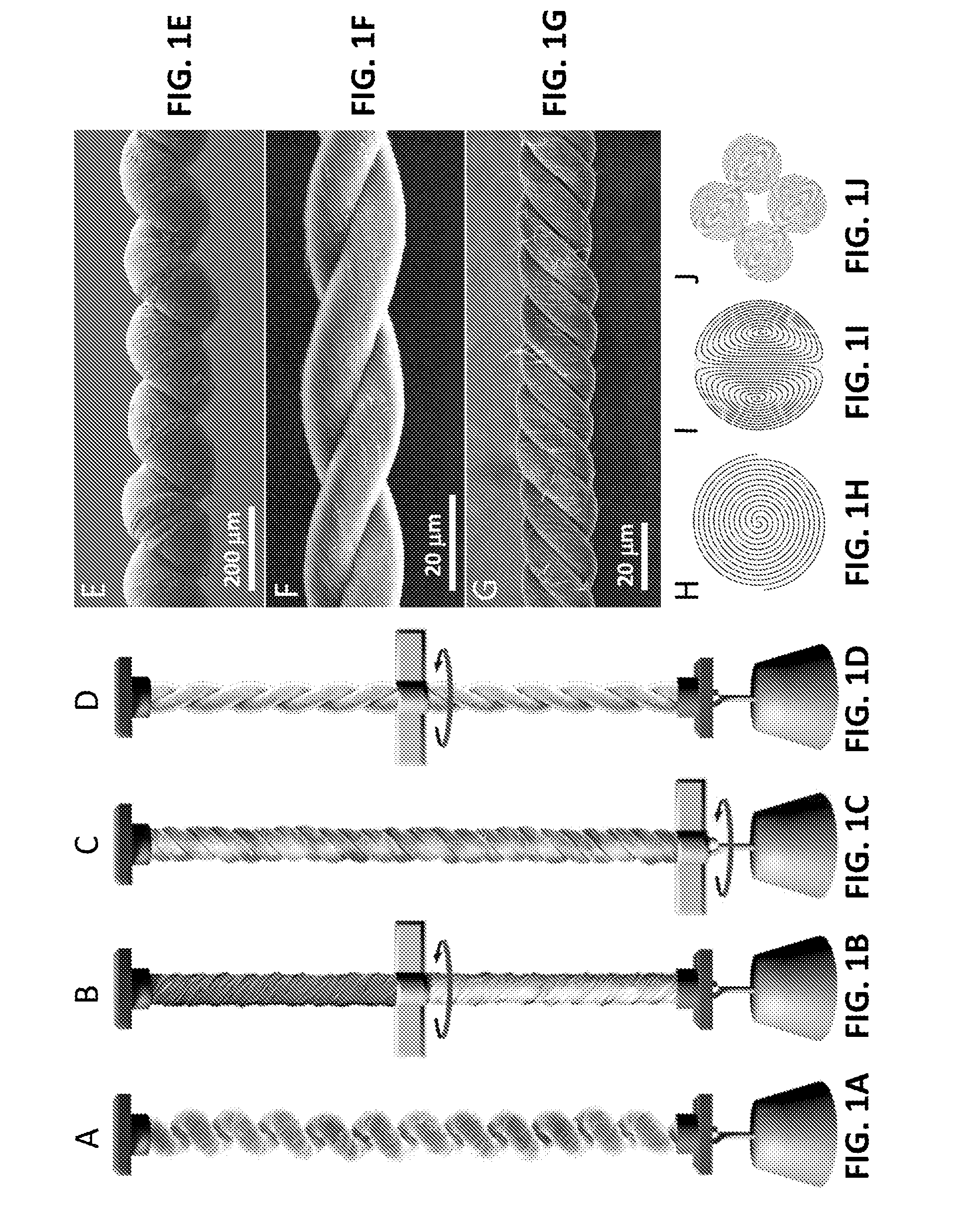

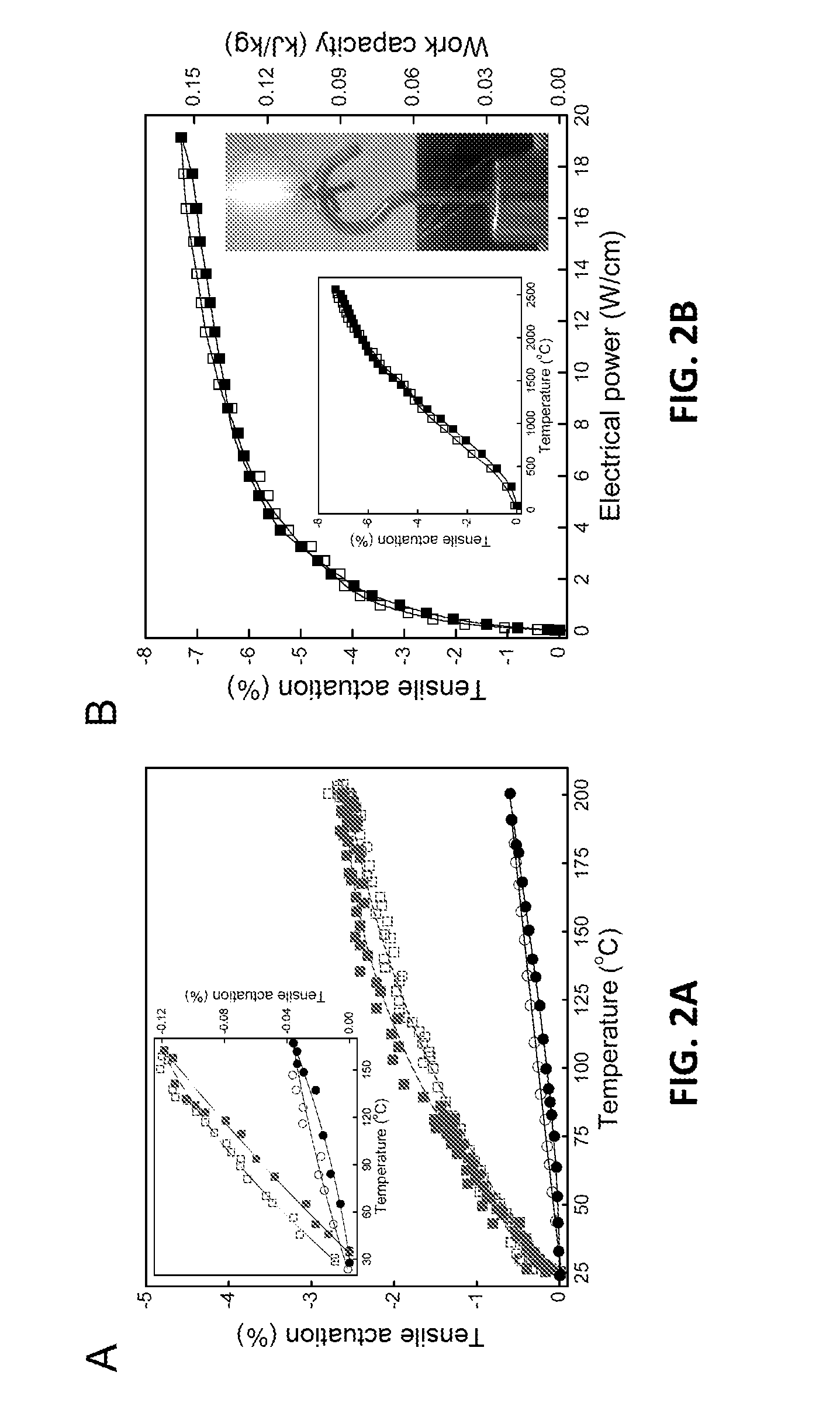

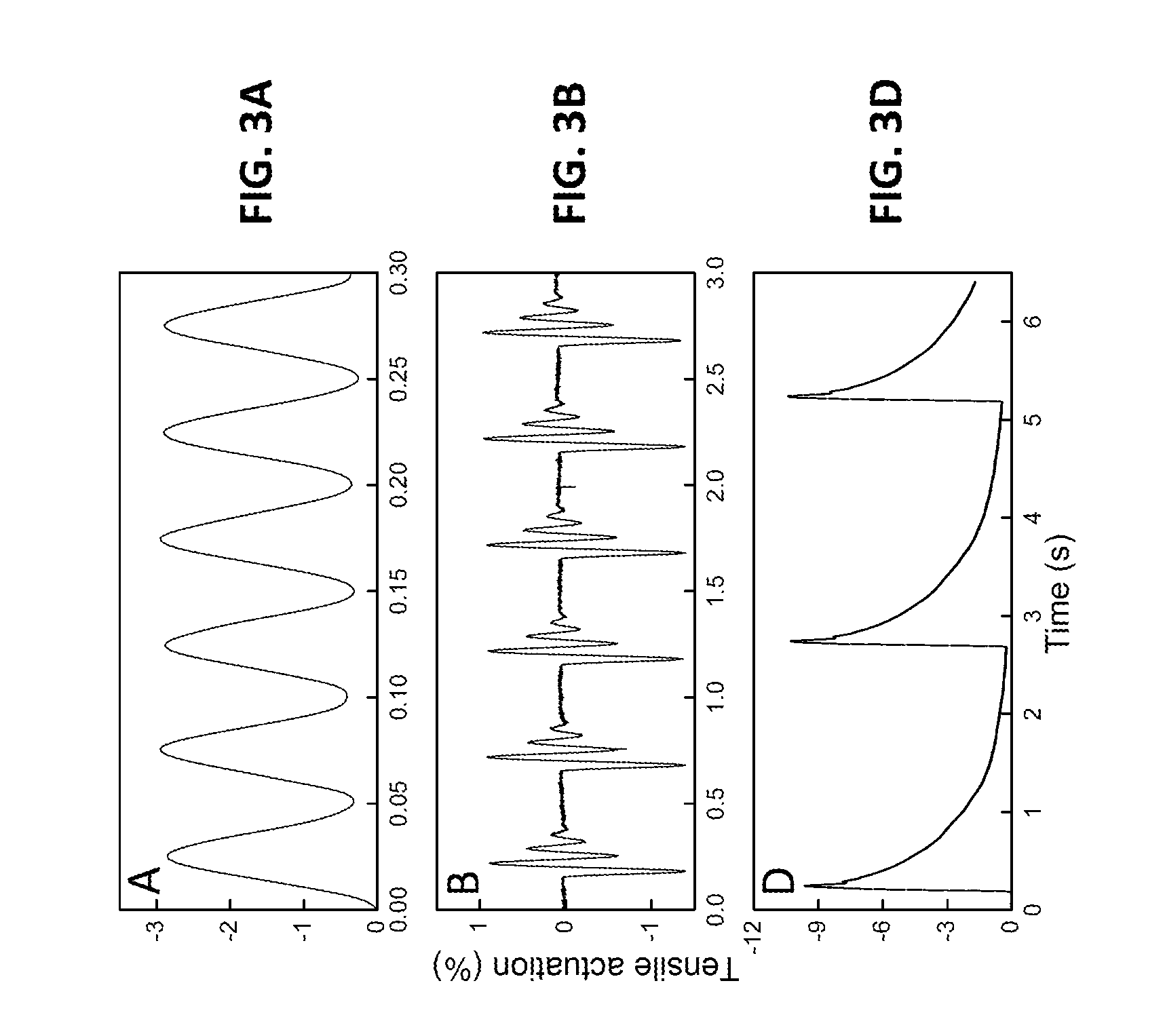

Coiled and non-coiled twisted nanofiber yarn torsional and tensile actuators

Actuators (artificial muscles) comprising twist-spun nanofiber yarn or twist-inserted polymer fibers generate torsional and / or tensile actuation when powered electrically, photonically, chemically, thermally, by absorption, or by other means. These artificial muscles utilize non-coiled or coiled yarns and can be either neat or comprising a guest. Devices comprising these artificial muscles are also described.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

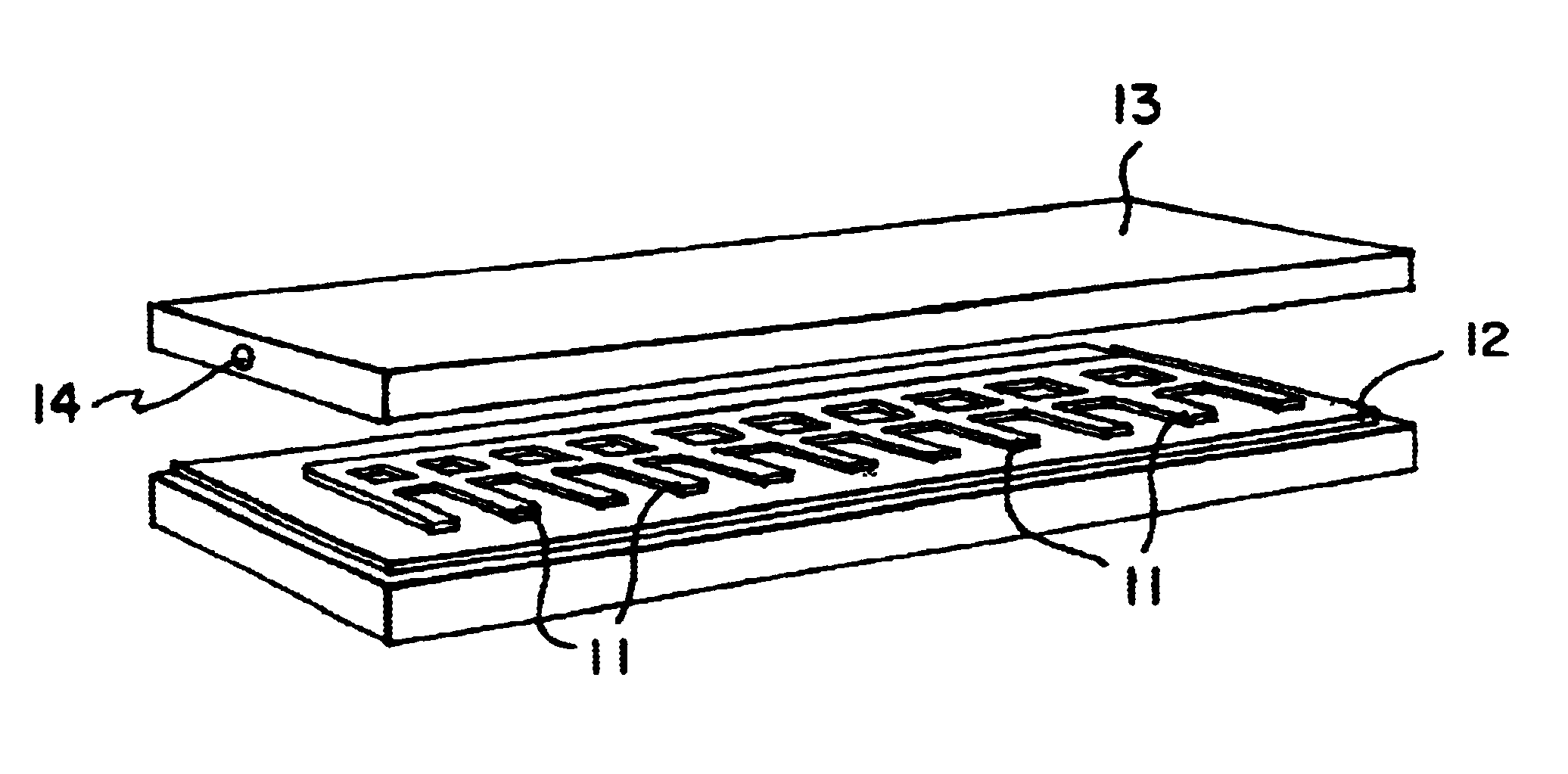

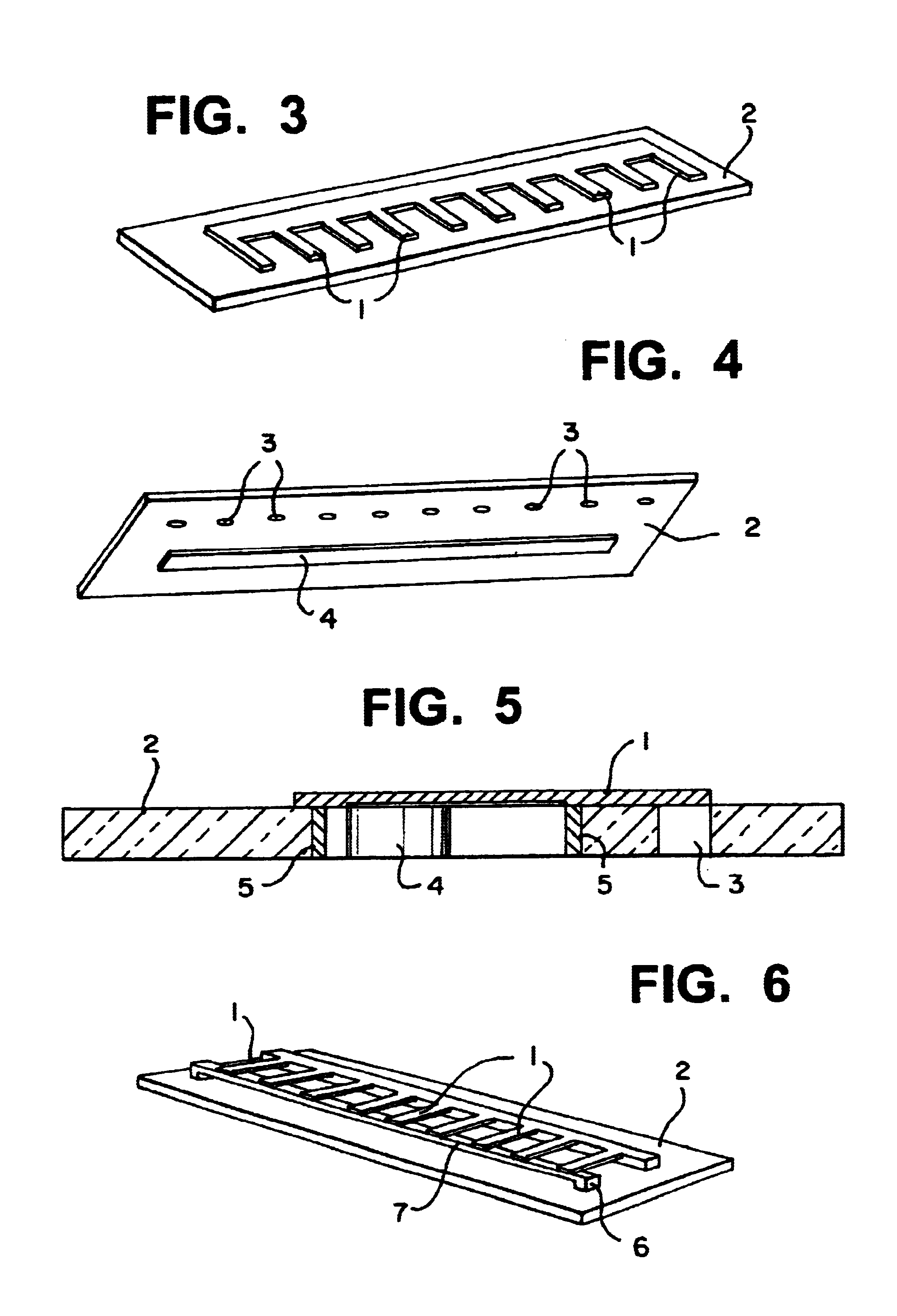

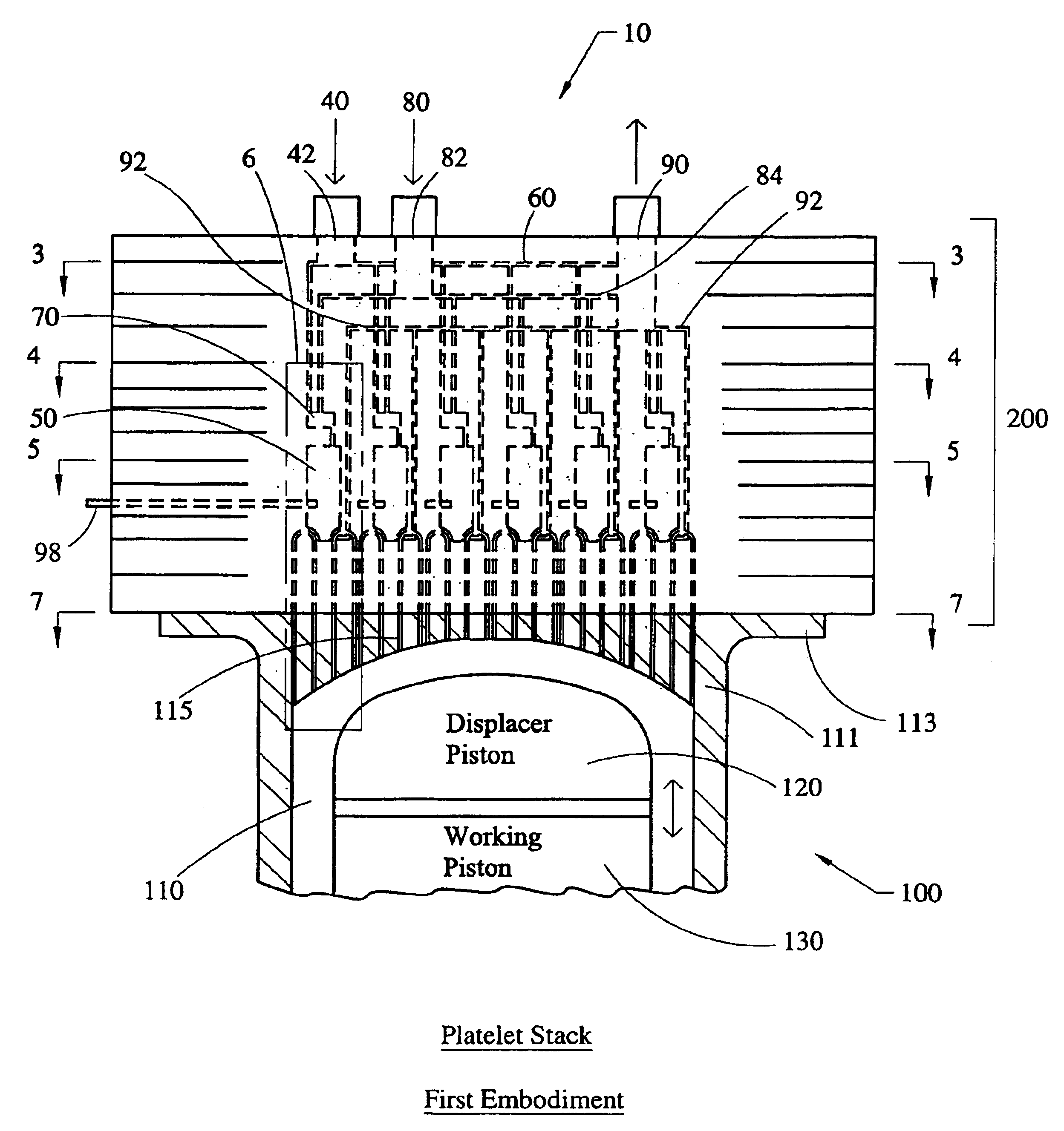

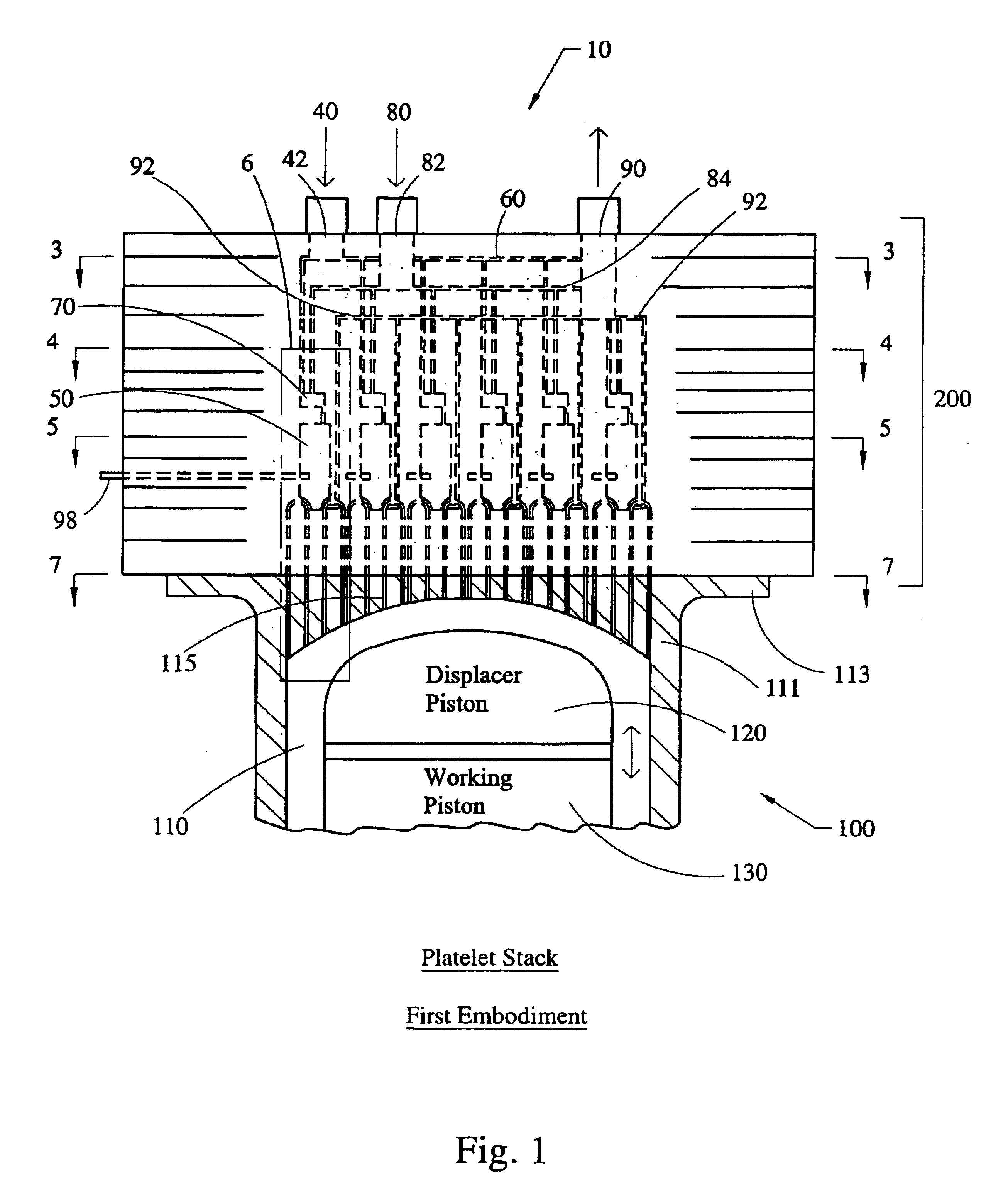

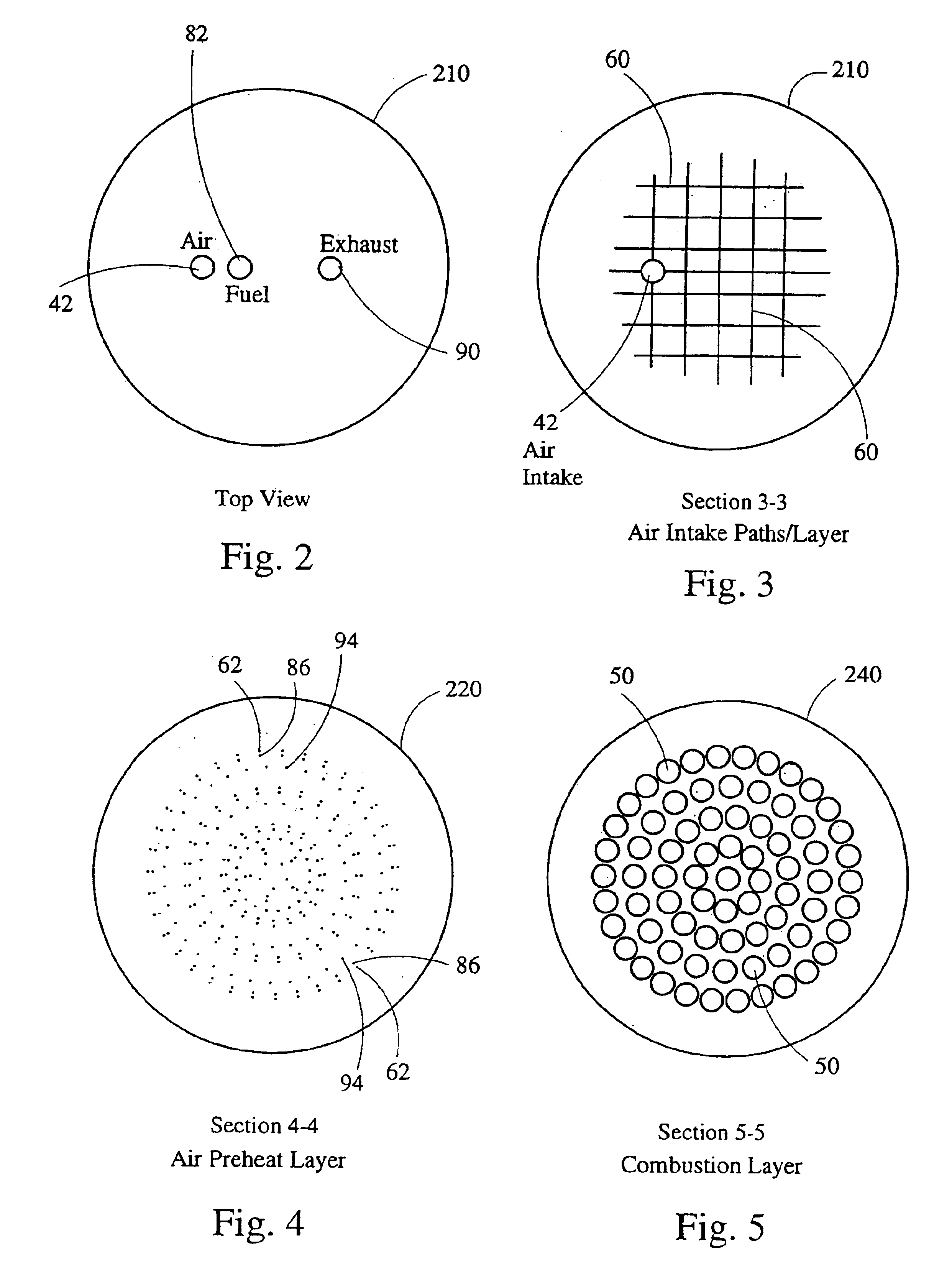

Stirling engine having platelet heat exchanging elements

InactiveUS6931848B2Guaranteed uptimeEfficient heat transferSolar heating energySolar heat devicesEngineeringStaged combustion

The present invention provides heat exchanging elements for use in Stirling engines. According to the present invention, the heat exchanging elements are made from muliple platelets that are stacked and joined together. The use of platelets to make heat exchanging elements permits Stirling engines to run more effiecient because the heat transfer and combustion processes are improved. In one embodiment, multi-stage combustion can be introduced with platlets, along with the flexibility to use different types of fuels. In another embodiment, a single component constructed from platelets can provide the heat transfer rquirements betweeen the combustion gas / working gas, working gas in the regenerator and the working gas / coolant fluid of a Stirling engine. In another embodiment, the platelet heat exchanging element can recieve solar energy to heat the Stirling engine's working gas. Also, this invention provides a heat exchanging method that allows for multiple fluids to flow in opposing or same direction.

Owner:DISENCO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com