Patents

Literature

6367 results about "Gas compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor. Compressors are similar to pumps: both increase the pressure on a fluid and both can transport the fluid through a pipe. As gases are compressible, the compressor also reduces the volume of a gas. Liquids are relatively incompressible; while some can be compressed, the main action of a pump is to pressurize and transport liquids.

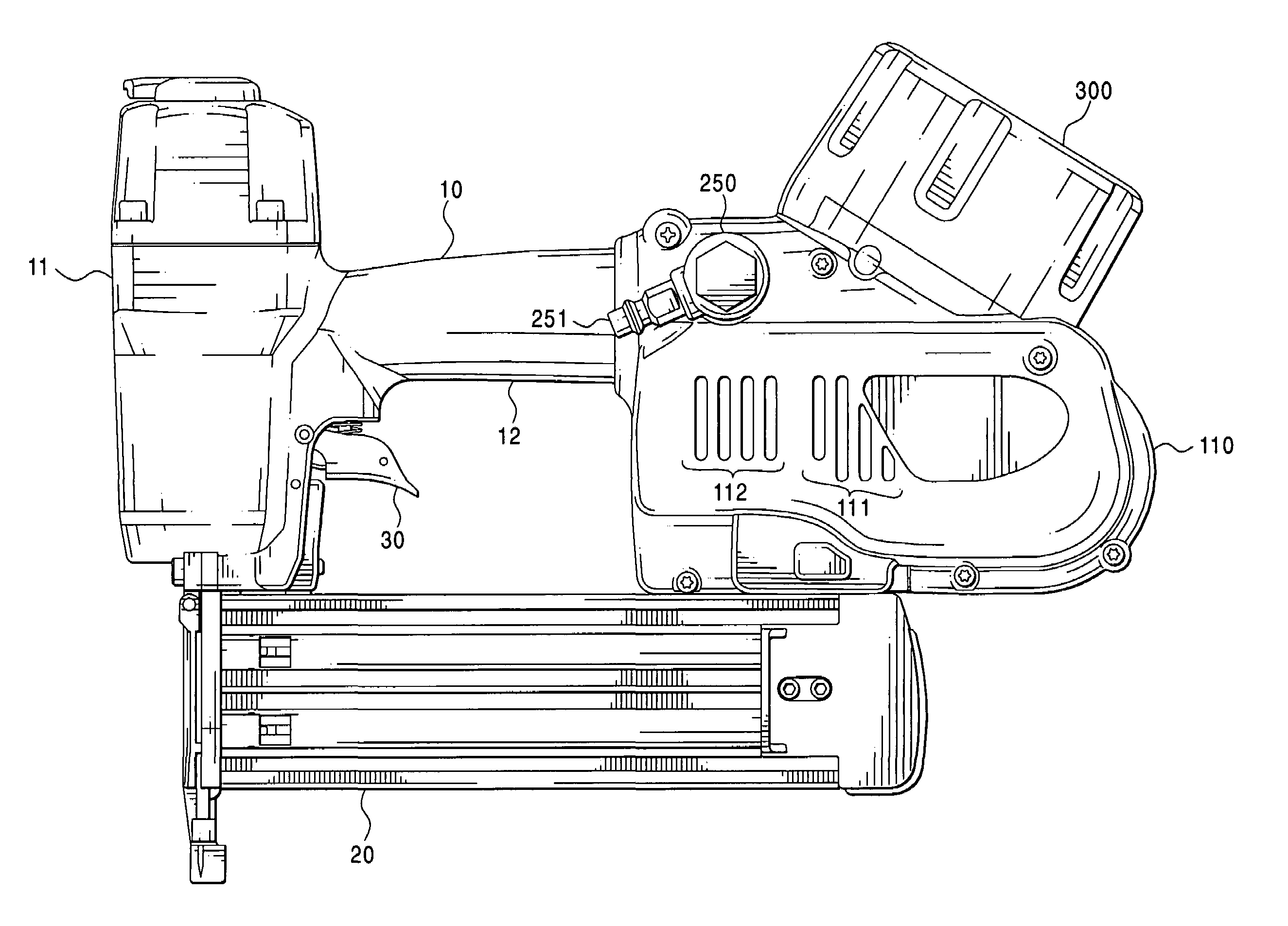

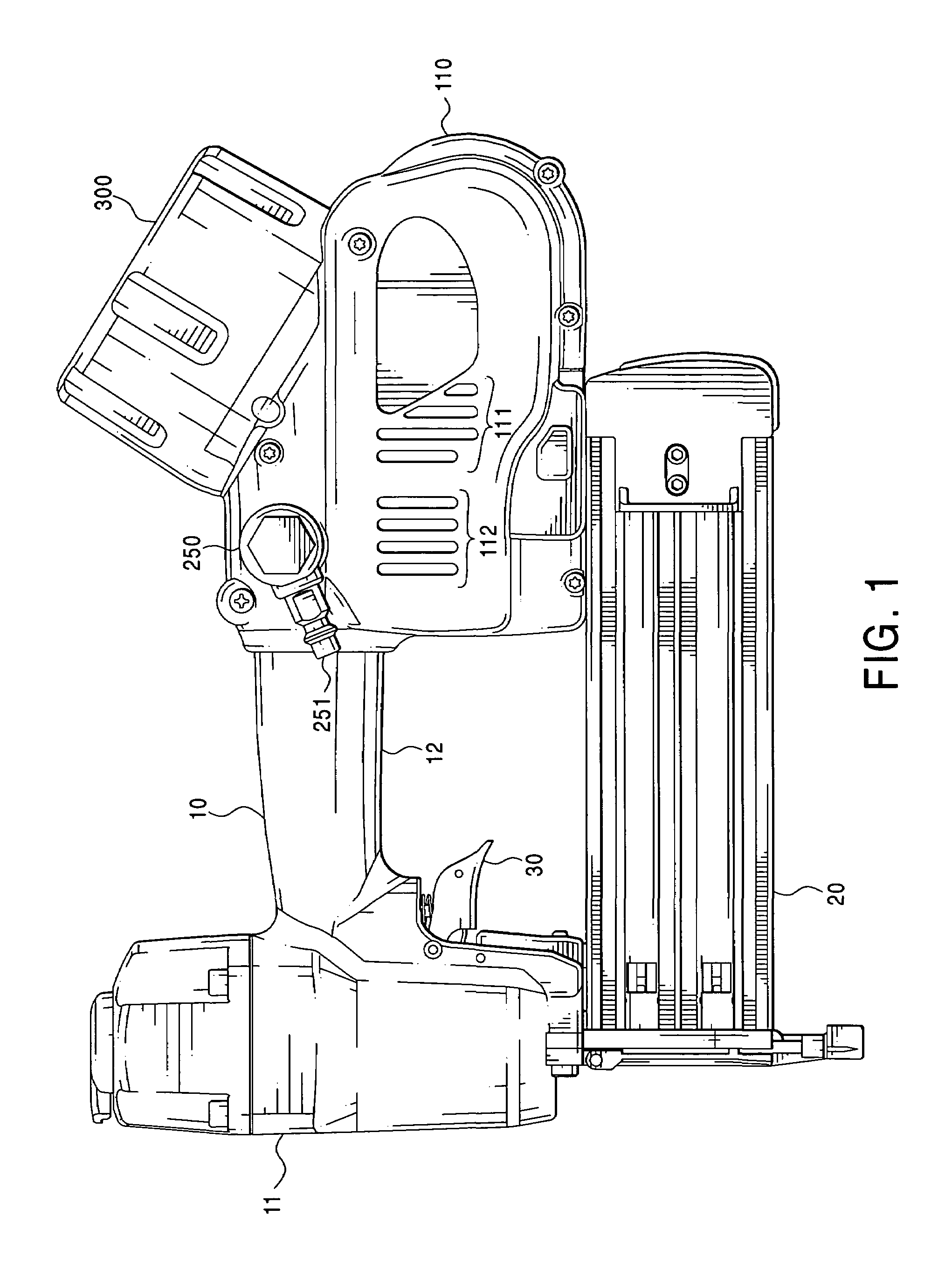

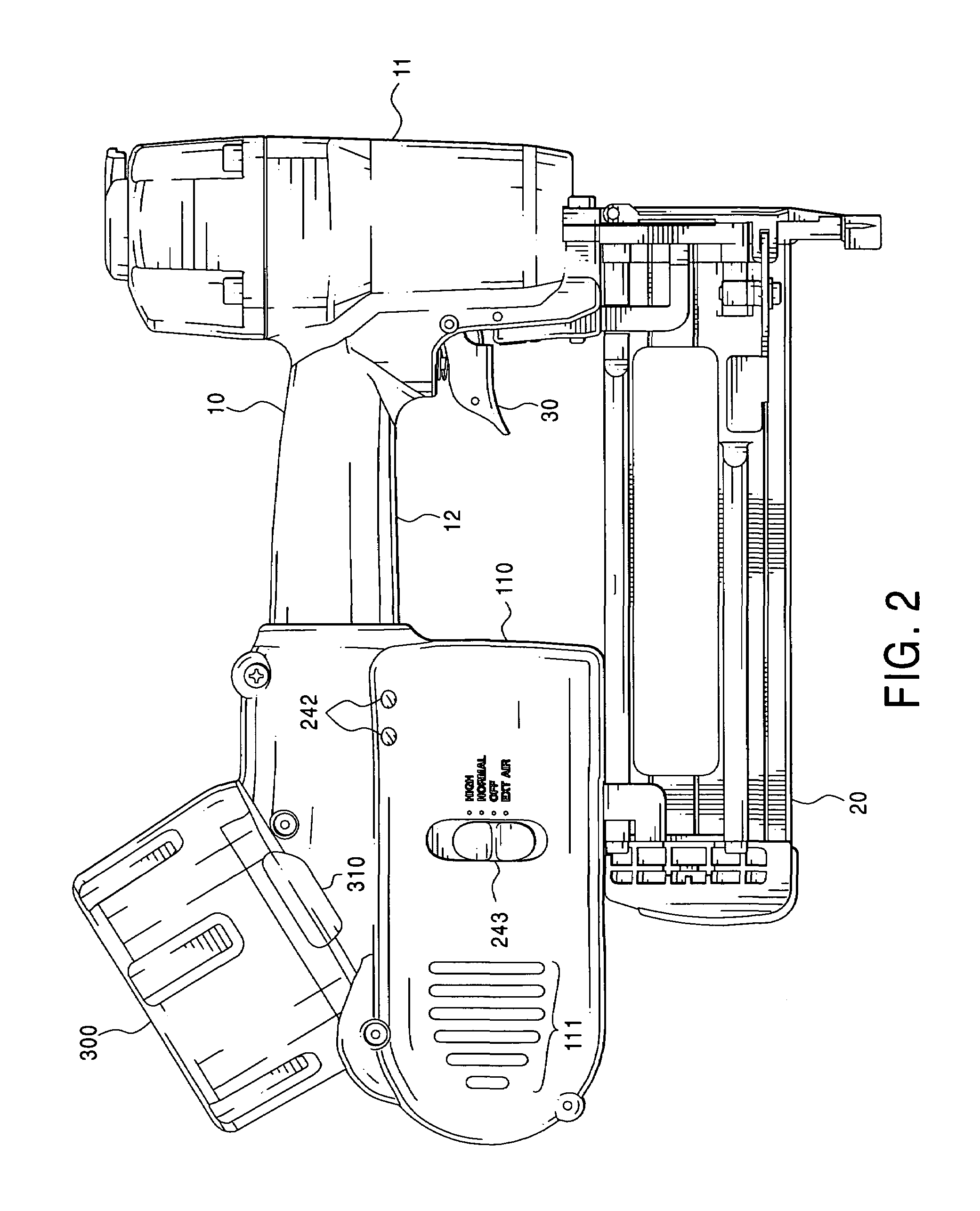

Portable, battery-powered air compressor for a pneumatic tool system

Owner:BLACK & DECKER INC +1

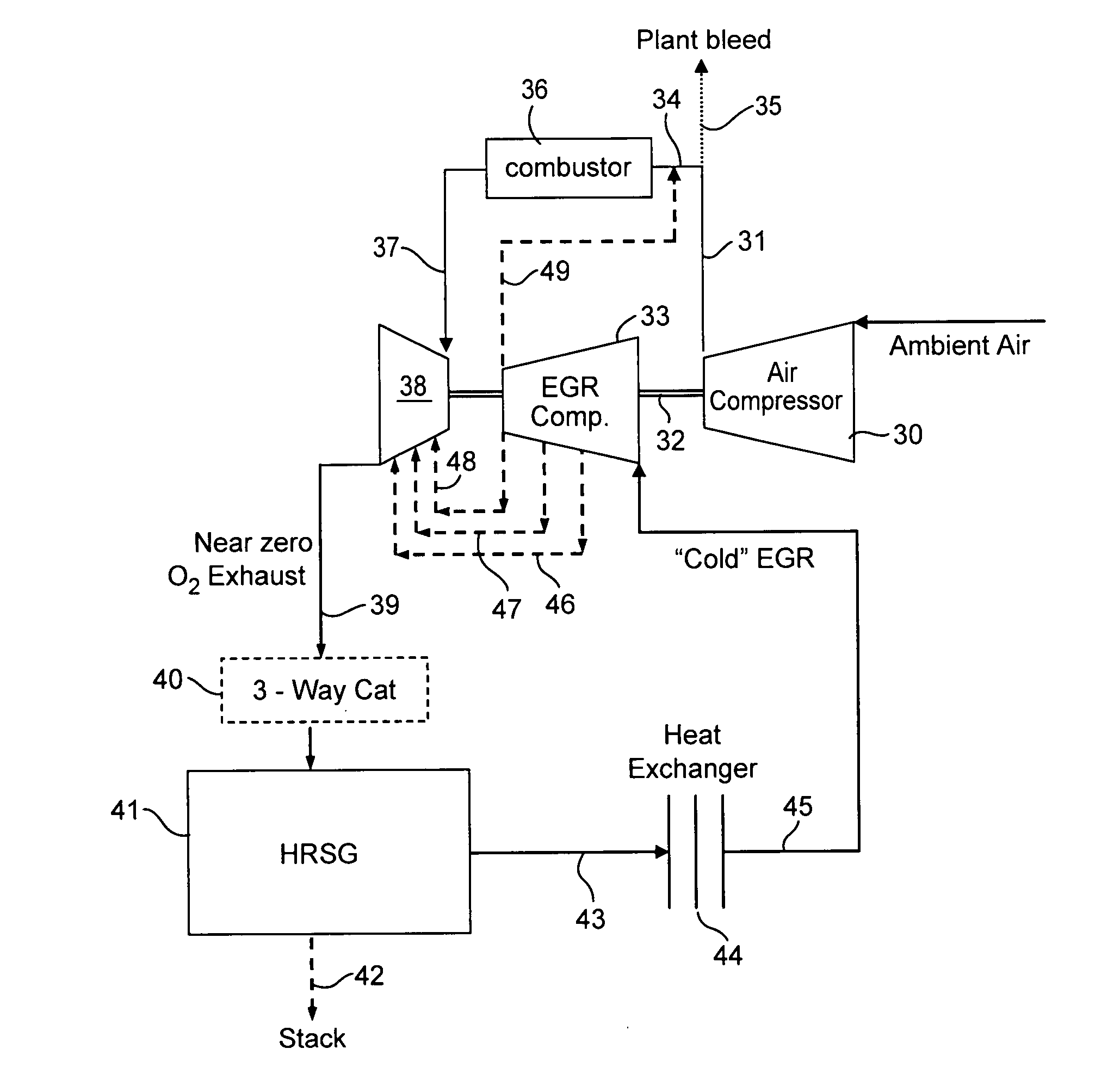

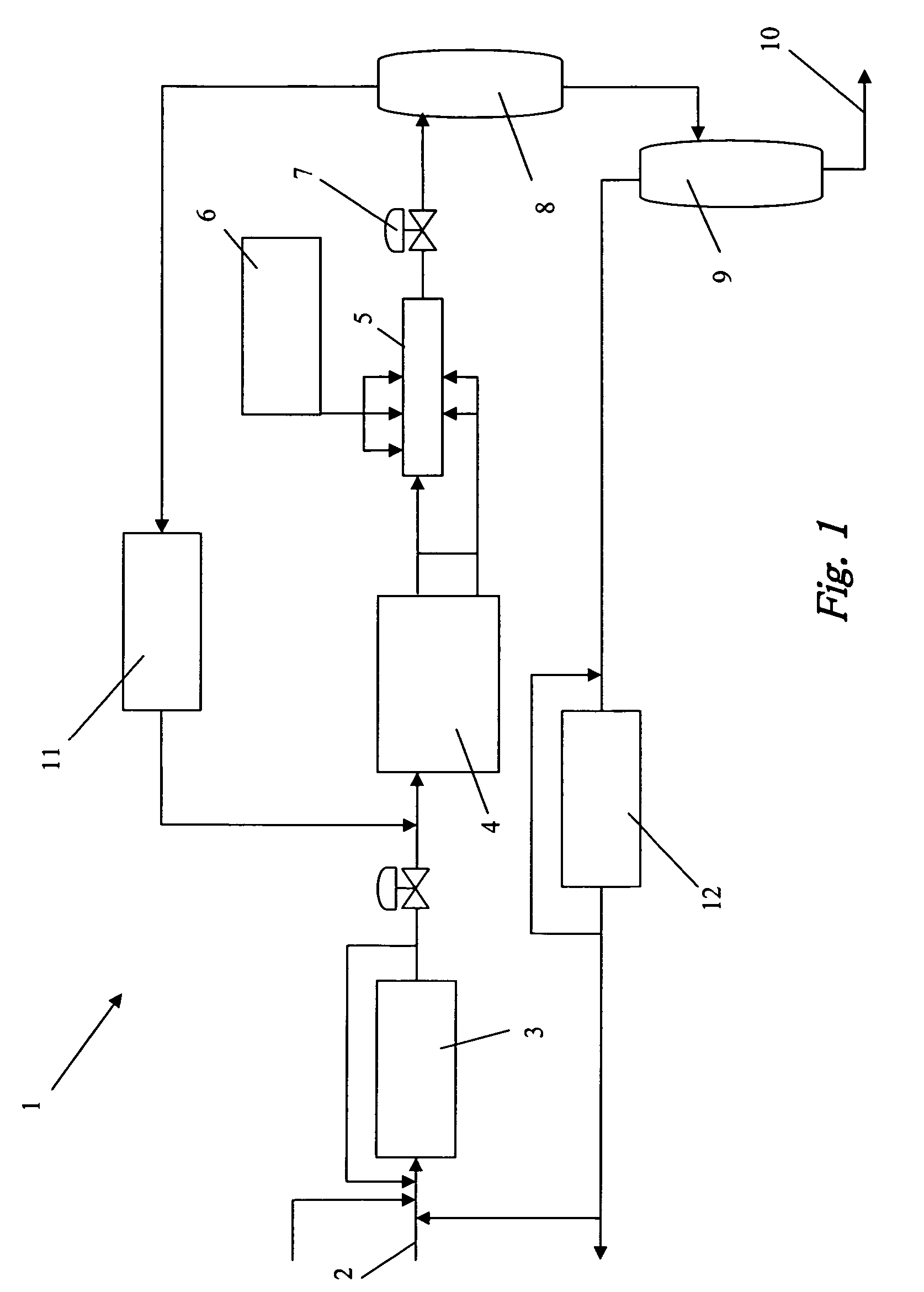

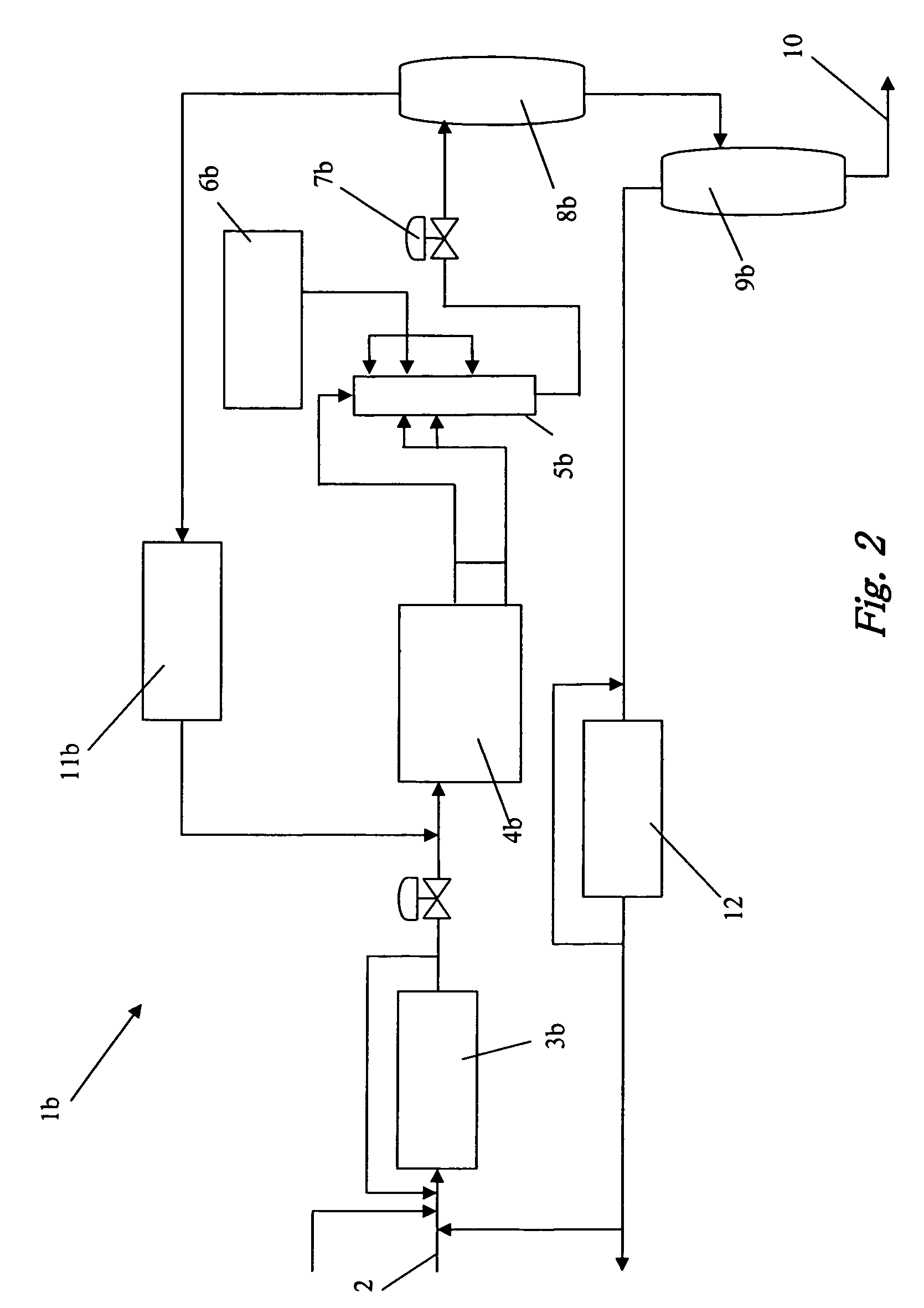

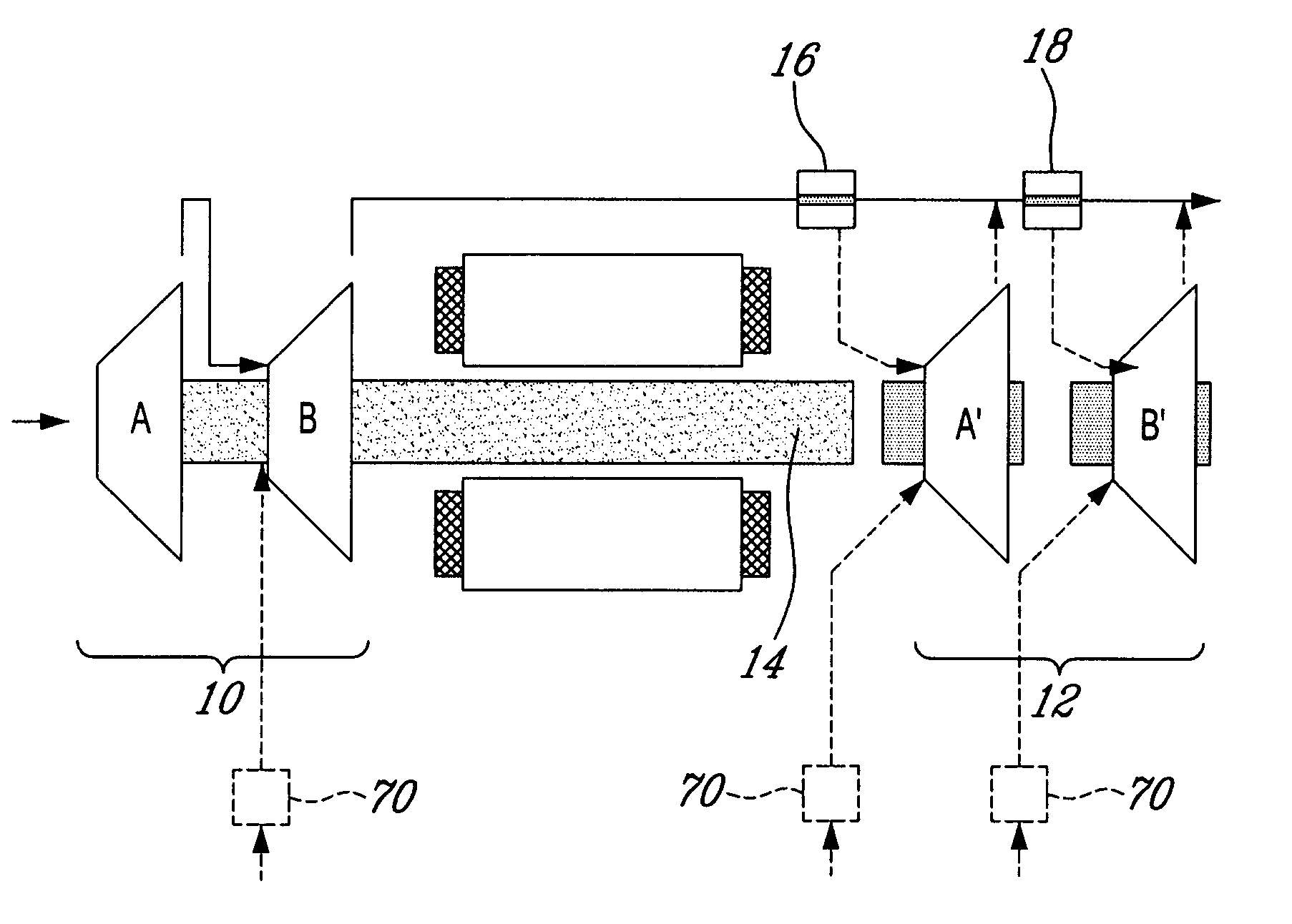

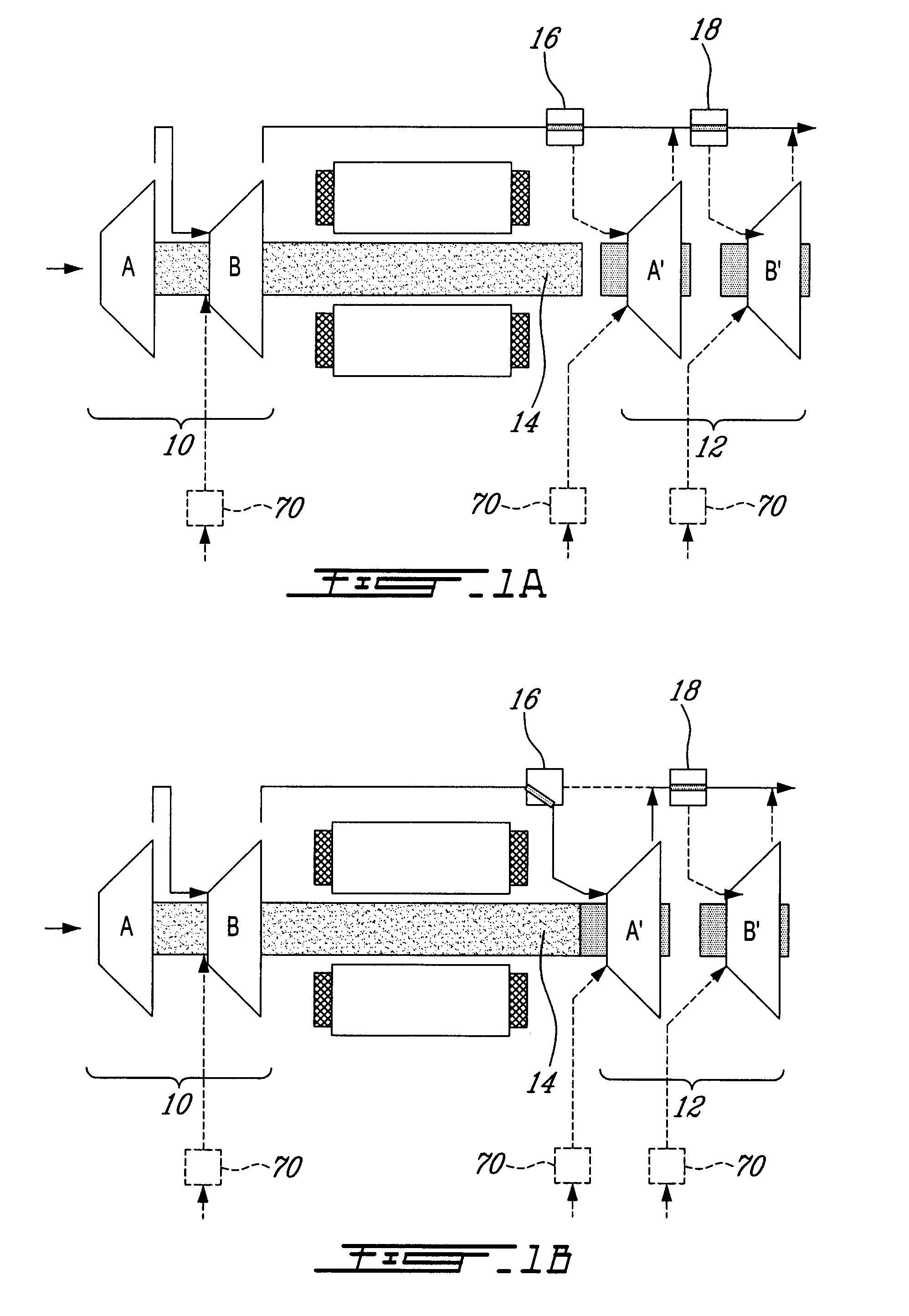

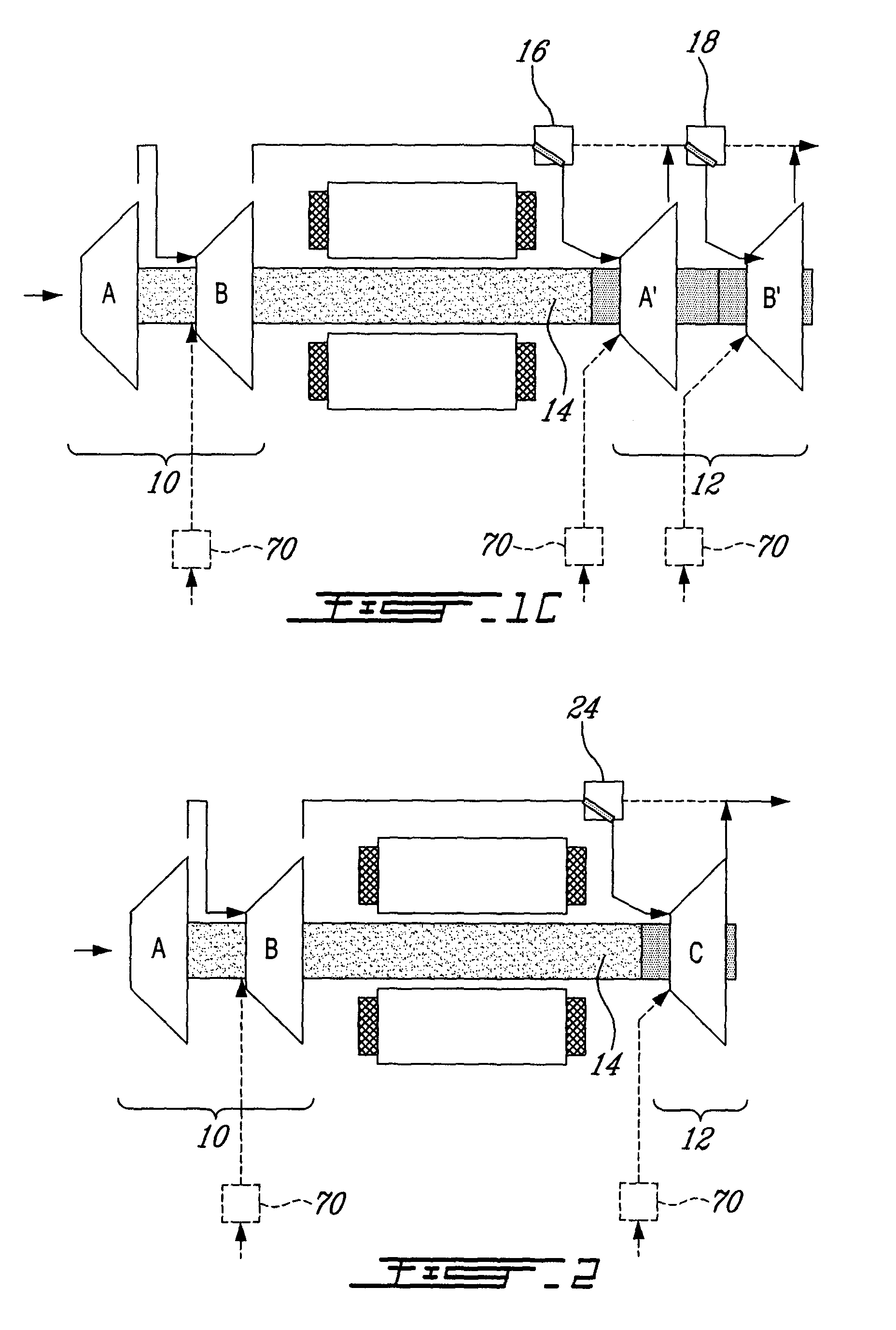

Dry 3-way catalytic reduction of gas turbine NOx

ActiveUS20090284013A1Reduction in amount of NOxIncrease carbon dioxide concentrationInternal combustion piston enginesExhaust apparatusCombustion chamberGas compressor

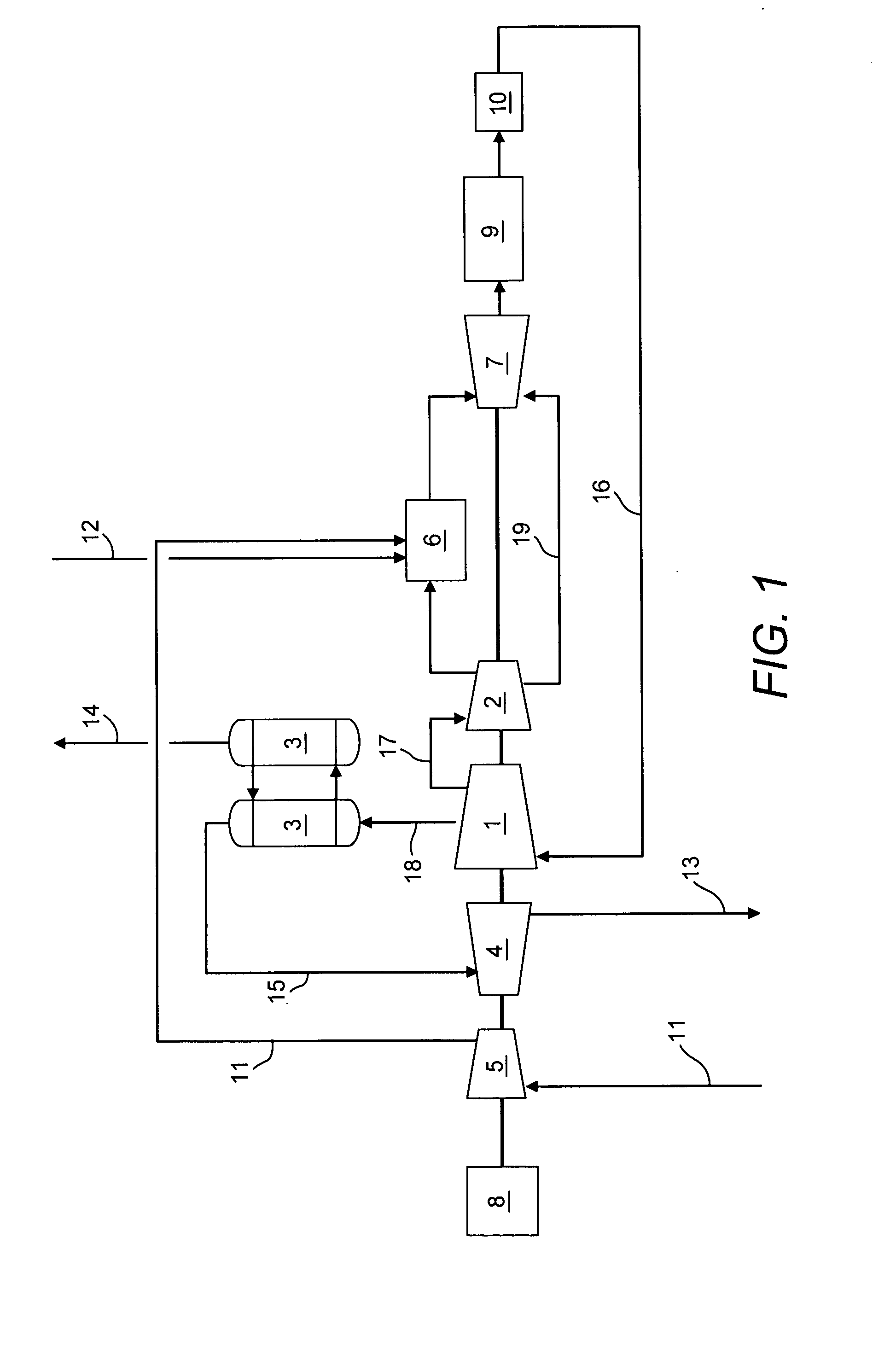

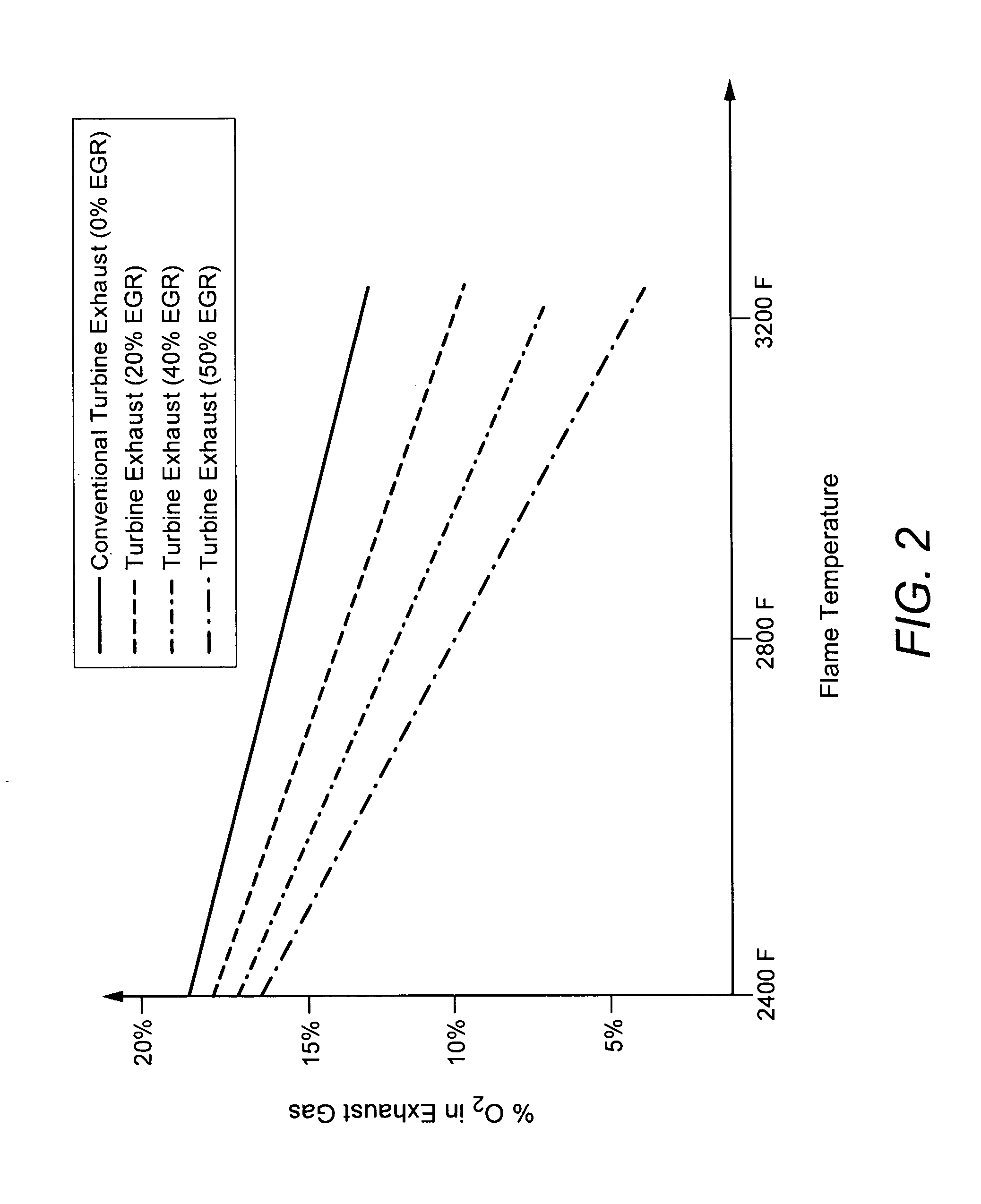

A power generation system capable of eliminating NO, components in the exhaust gas by using a 3-way catalyst, comprising a gas compressor to increase the pressure of ambient air fed to the system; a combustor capable of oxidizing a mixture of fuel and compressed air to generate an expanded, high temperature exhaust gas; a gas turbine engine that uses the force of the high temperature gas; an exhaust gas recycle (EGR) stream back to the combustor; a 3-way catalytic reactor downstream of the gas turbine engine outlet which treats the exhaust gas stream to remove substantially all of the NOx components; a heat recovery steam generator (HRSG); an EGR compressor; and an electrical generator.

Owner:GENERAL ELECTRIC CO

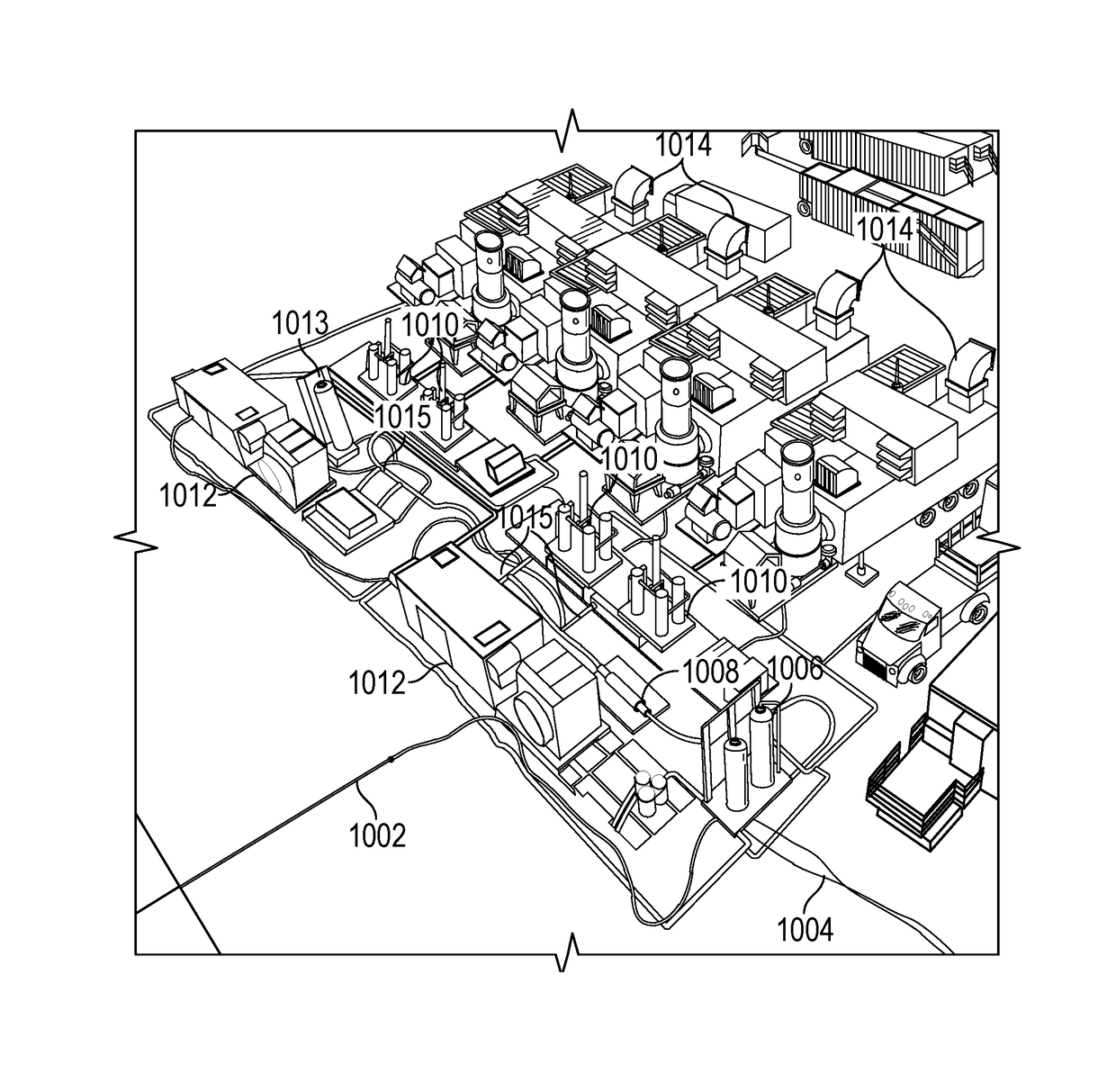

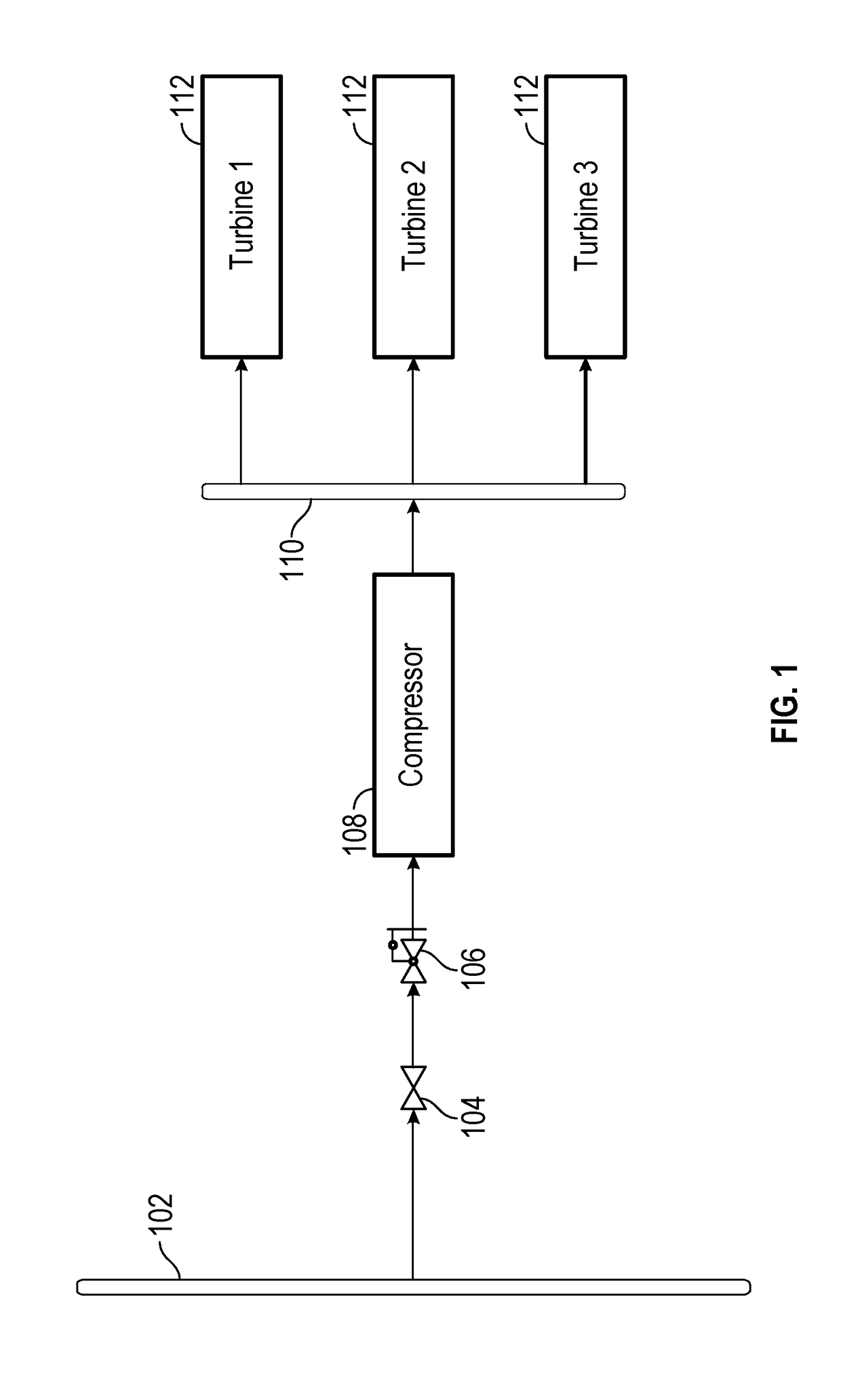

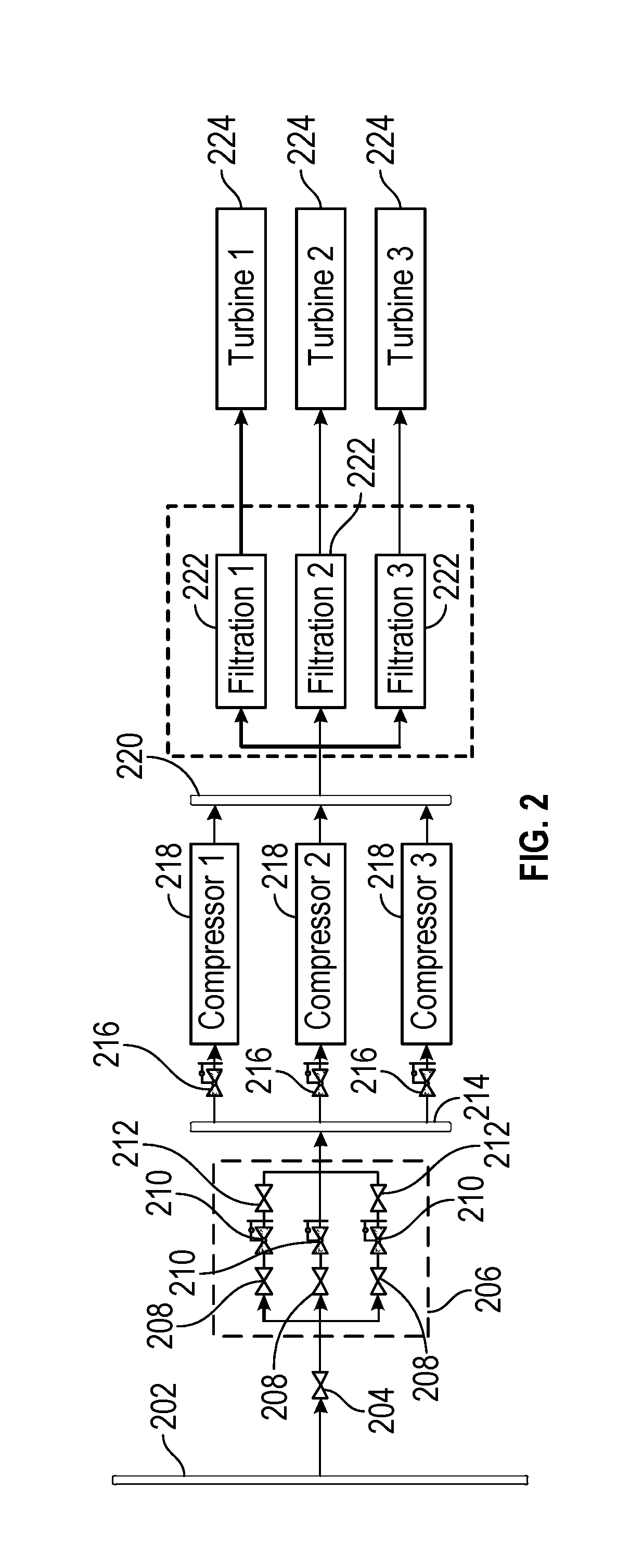

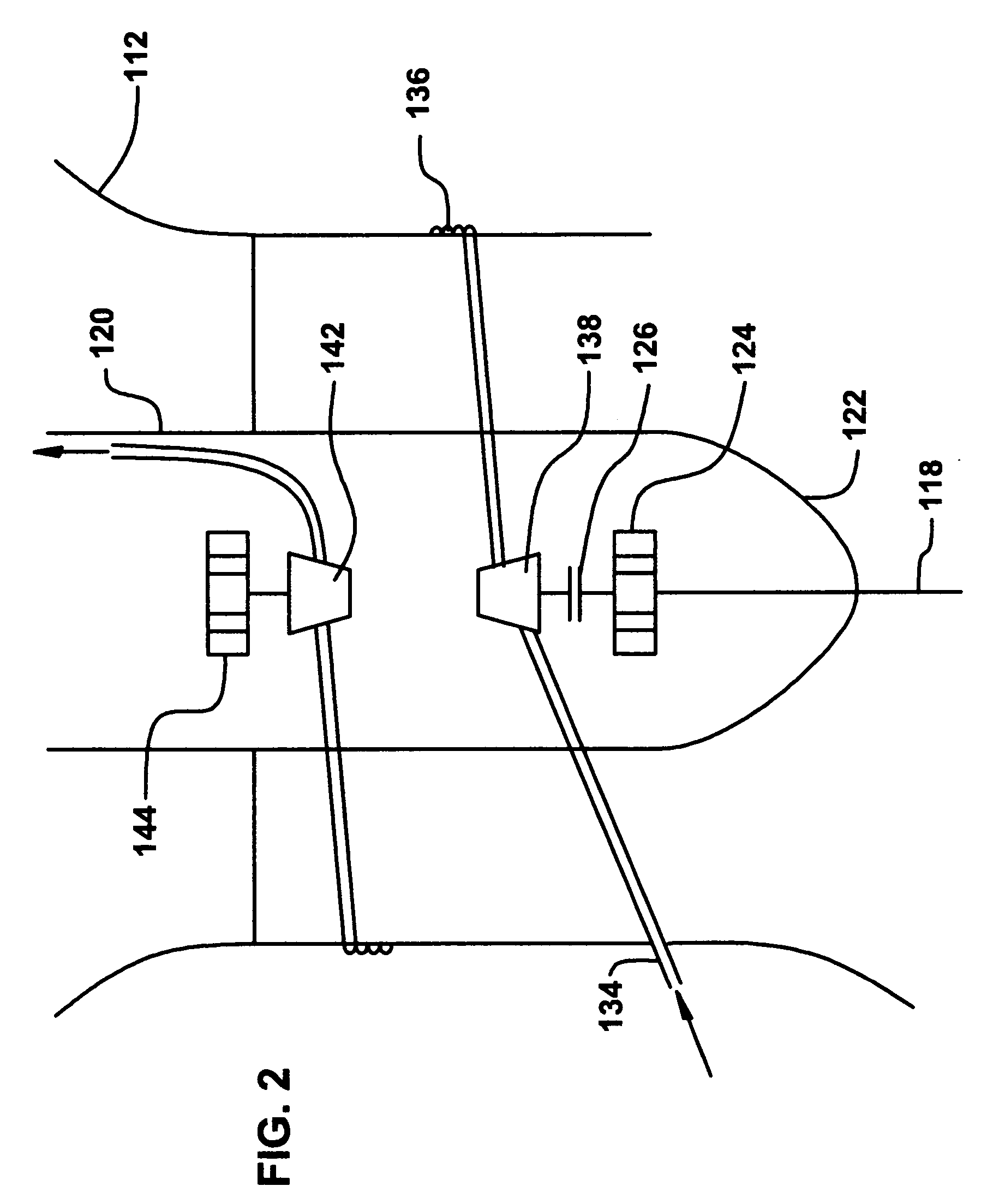

System for gas compression on electric hydraulic fracturing fleets

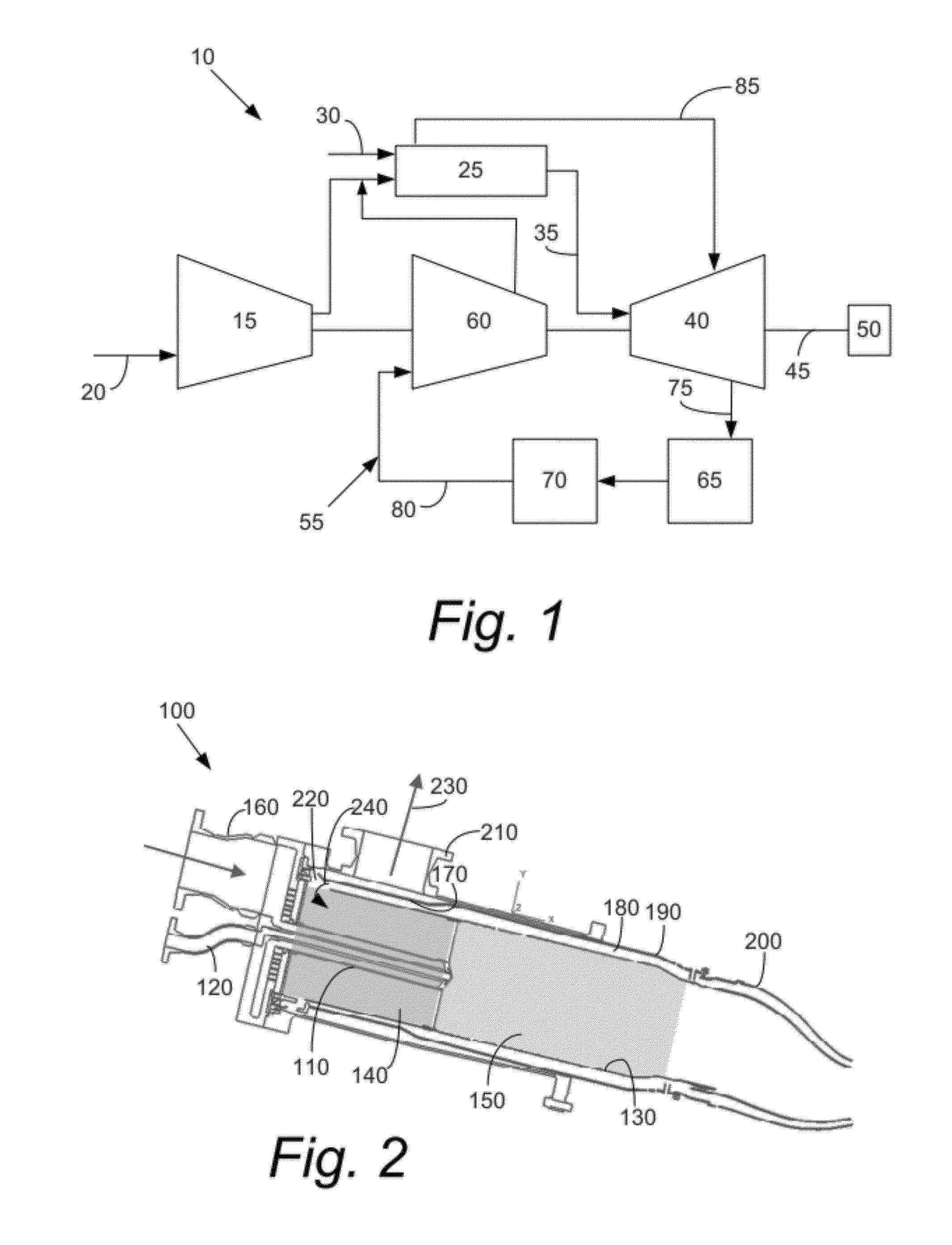

PendingUS20170145918A1Reduce pressureTurbine/propulsion fuel supply systemsGas turbine plantsElectricityGas compressor

Embodiments relate to hydraulic fracturing equipment powered by one or more natural gas turbine generators. Natural gas from a supply line is released via a valve into a turbine gas line. The turbine gas line includes one or more regulators to reduce the pressure of the natural gas stream in the turbine gas line to a pressure or pressure range optimum for one or more gas compressors. The gas compressors increase the pressure of the natural gas stream, which is then directed to one or more natural gas turbine generators. The natural gas turbine generators combust the natural gas to produce electricity, which powers electric hydraulic fracturing equipment.

Owner:US WELL SERVICS LLC

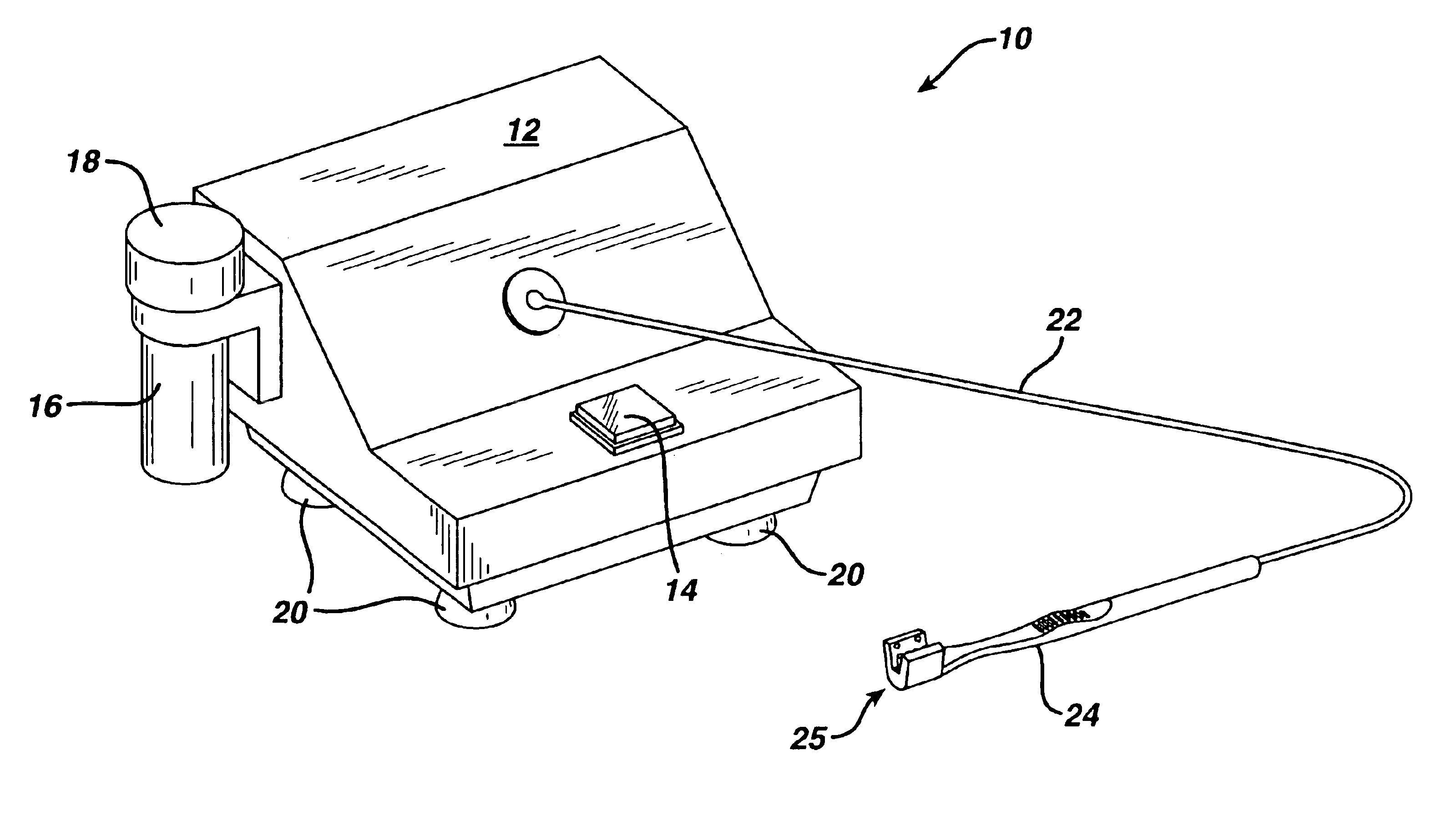

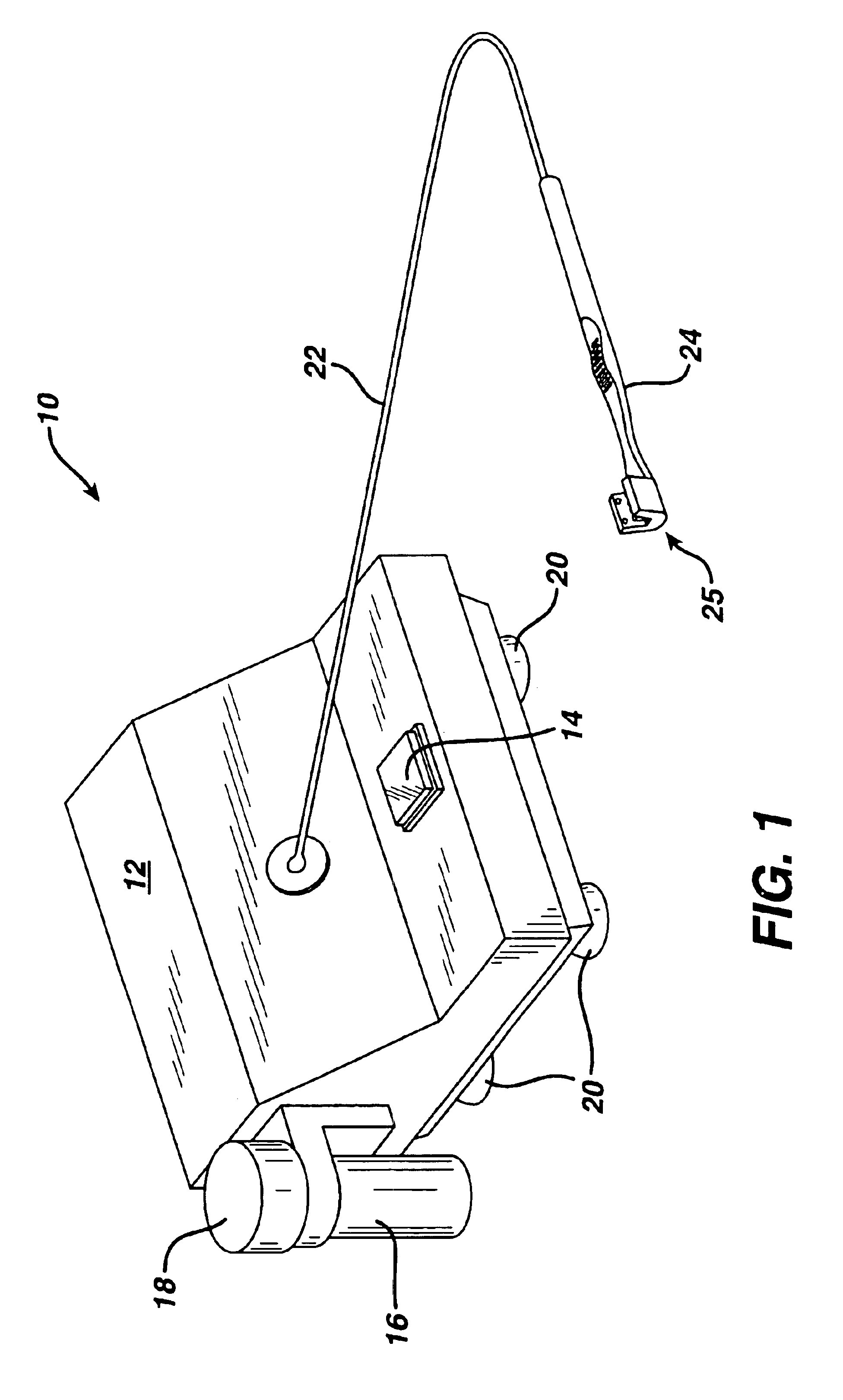

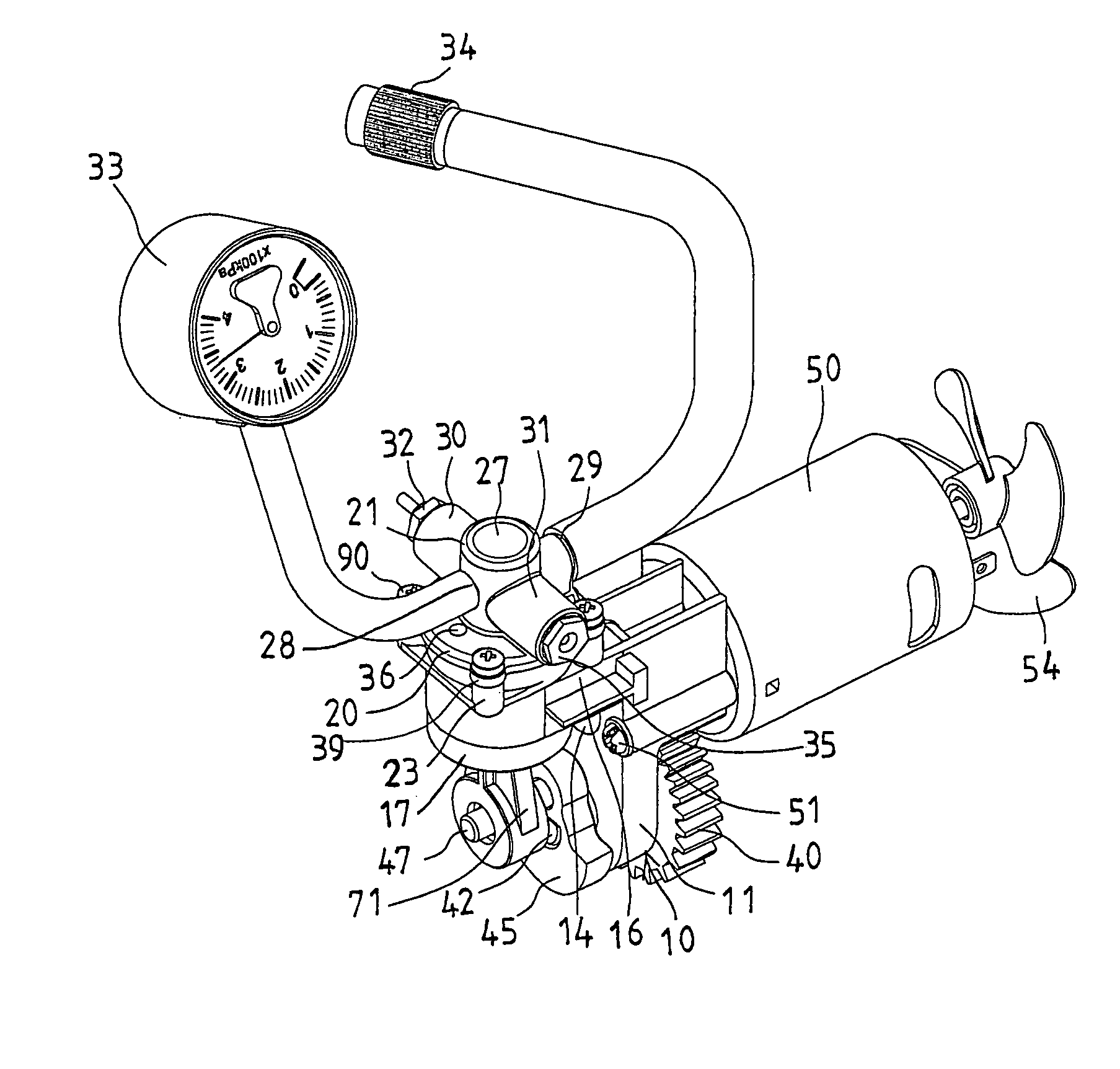

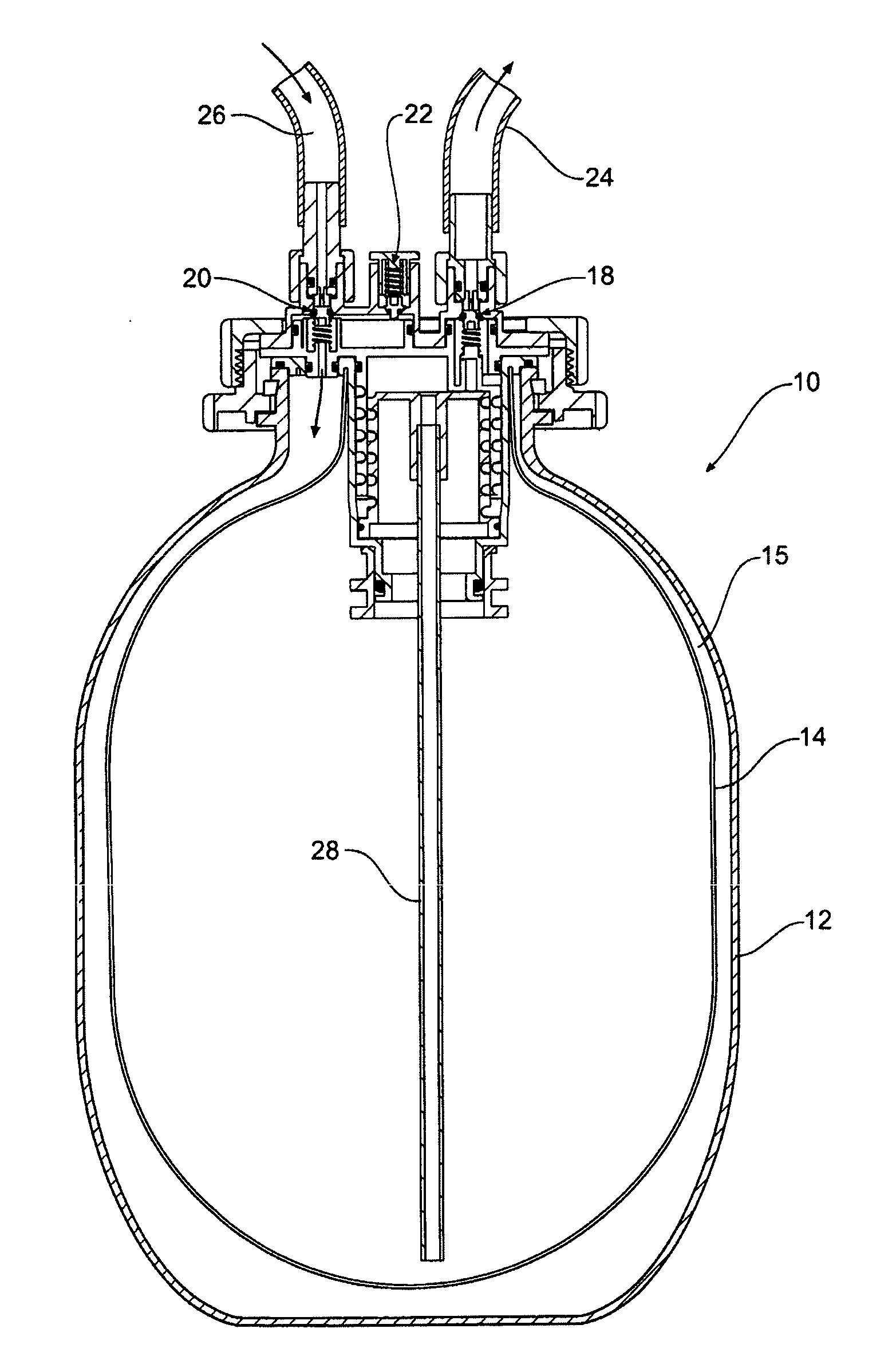

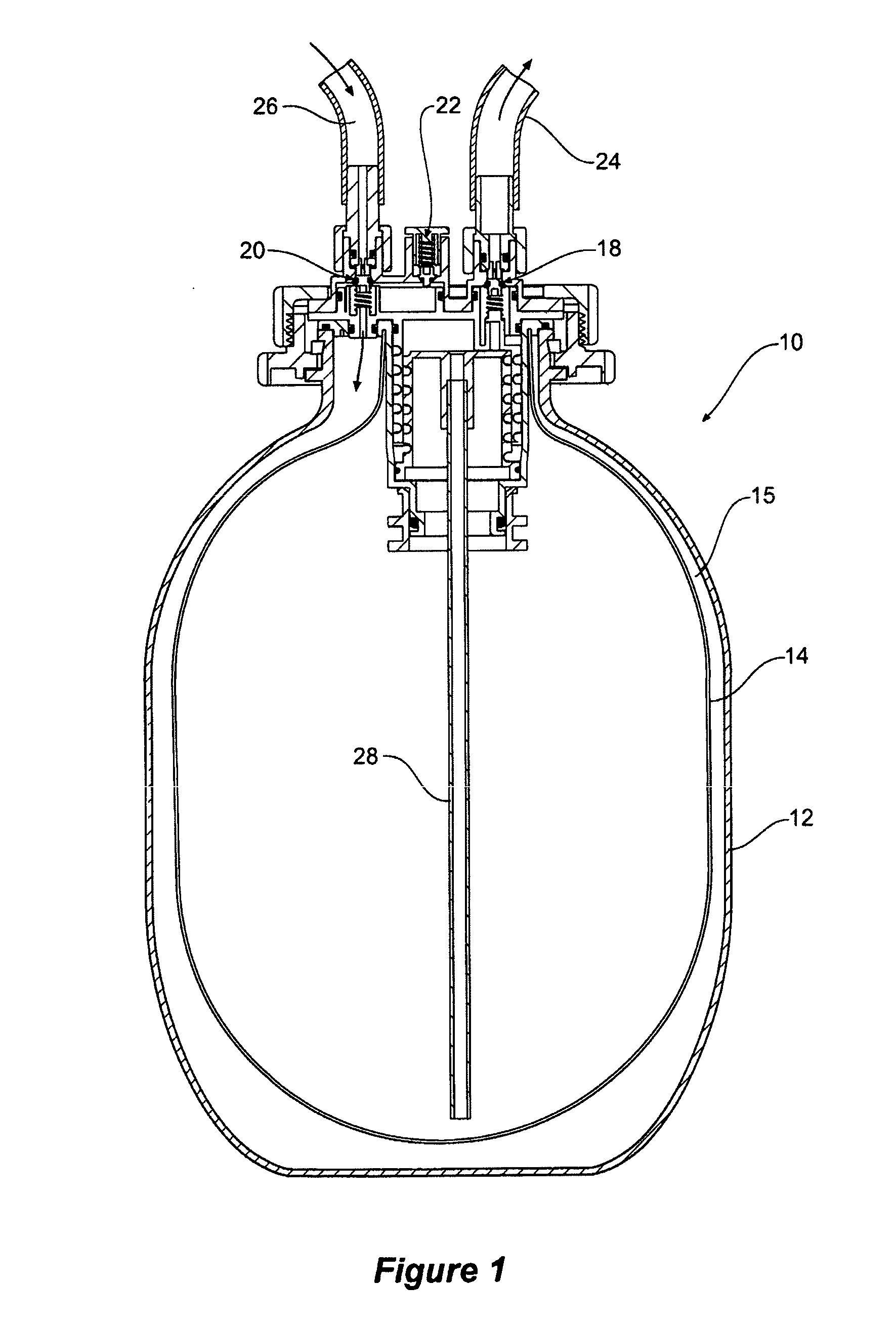

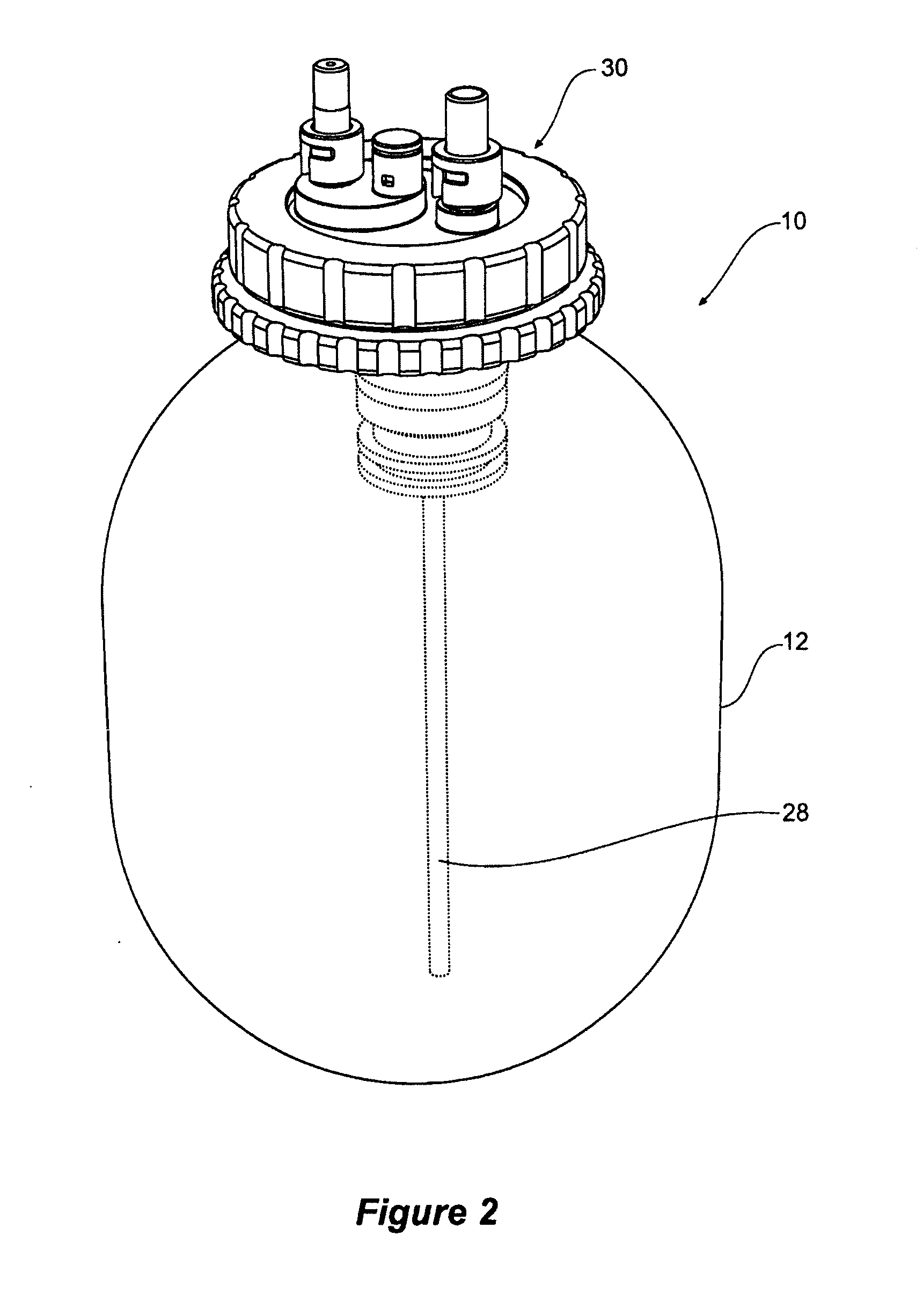

Oral care device

An oral care device includes an electric motor, an air compressor operated by the motor, and an enclosed container for holding a slurry. A first conduit conducts compressed air from the compressor into the container. The compressed air is at a pressure of between about 20 psi to about 50 psi. A second conduit conducts the slurry and air from the container to an applicator from which the slurry and air is sprayed into the oral cavity of a human. The second conduit is at least about 24 inches in length.

Owner:THE GILLETTE CO

Isothermal reciprocating machines

InactiveUS20060248886A1High materialIncrease heating capacityPositive displacement pump componentsMulti-stage pumpsWorking fluidGas compressor

A reciprocating gas compressor is described operating according to an extended cycle of 4,6 or more strokes, wherein the first two strokes are sequential induction and compression strokes using a low pressure gas as working fluid and compressing it to a high pressure gas, and the remaining strokes are pairs of sequential filling and emptying strokes using more of the low pressure gas as heat transfer fluid for transferring heat from inside the gas compressor to outside the gas compressor. The gas compressor also contains an in-cylinder heat regenerator for absorbing heat from the compressed gas and releasing heat to the heat transfer fluid thus achieving near-isothermal compression. Using parallel principles, a reciprocating gas expander is also described for achieving near-isothermal expansion. Also described are reciprocating machines using the near-isothermal gas compressor and near-isothermal gas expander in combination according to the Ericsson heat engine cycle, the Stirling heat engine cycle and the Stirling refrigeration cycle.

Owner:MA THOMAS TSOI HEI

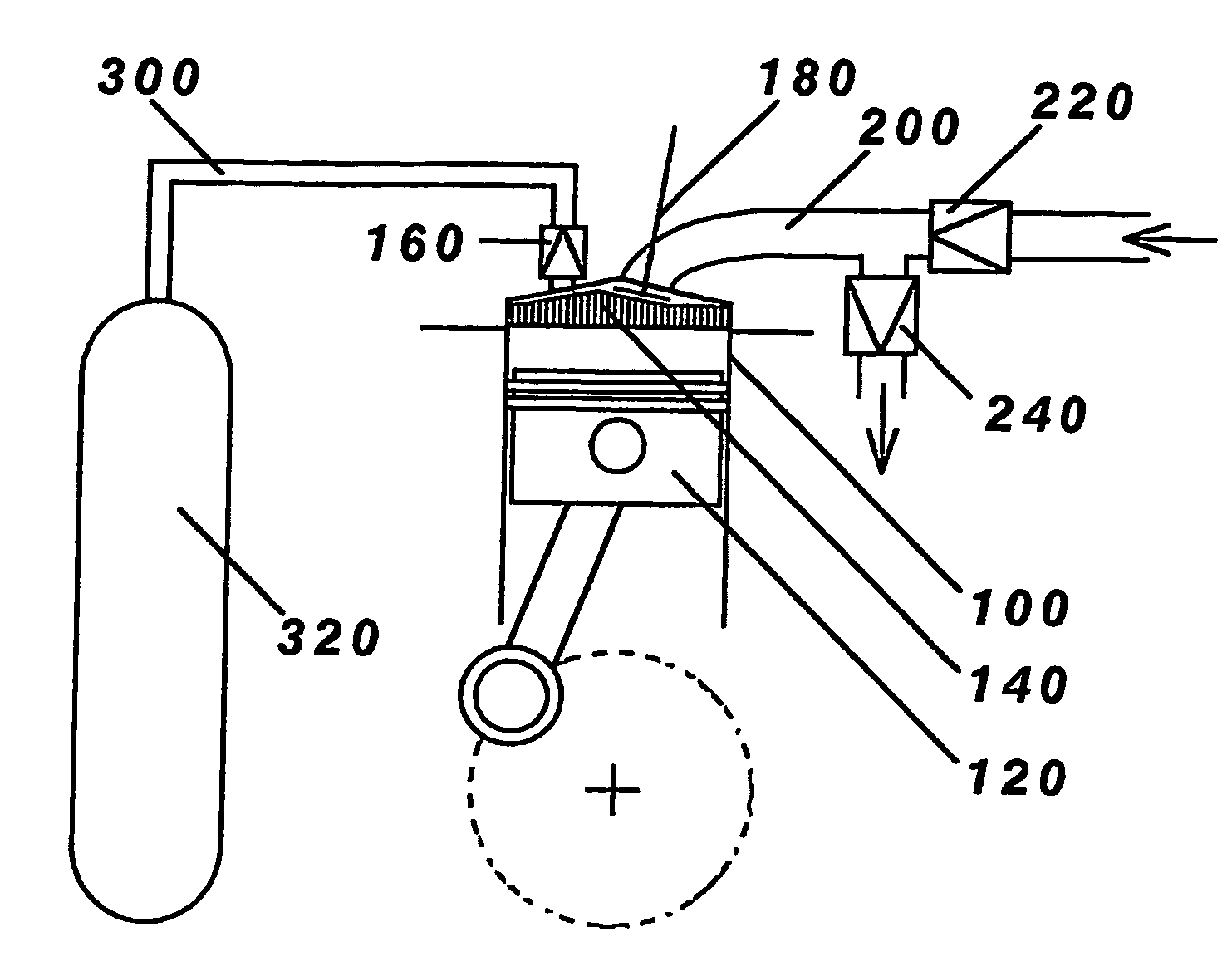

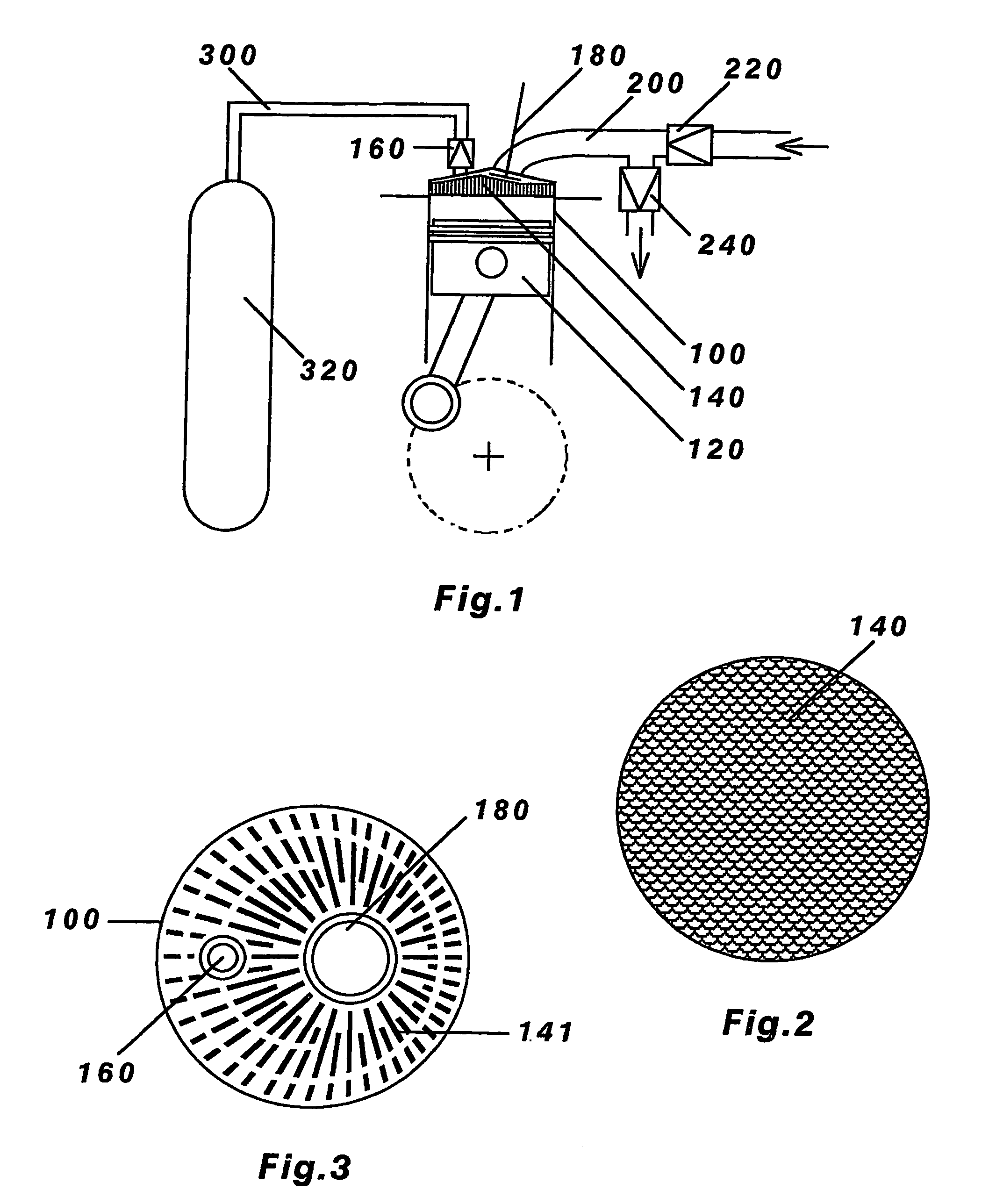

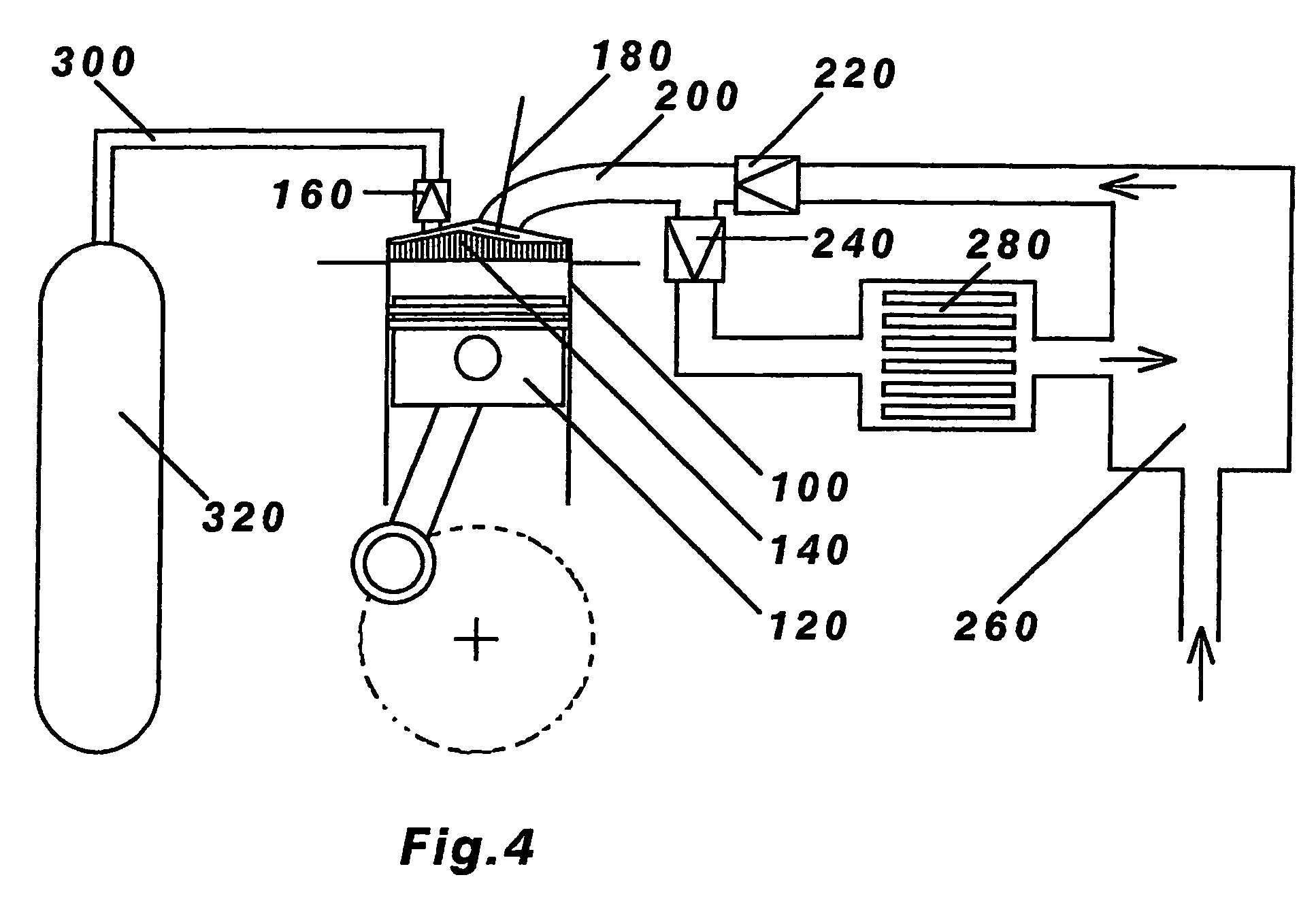

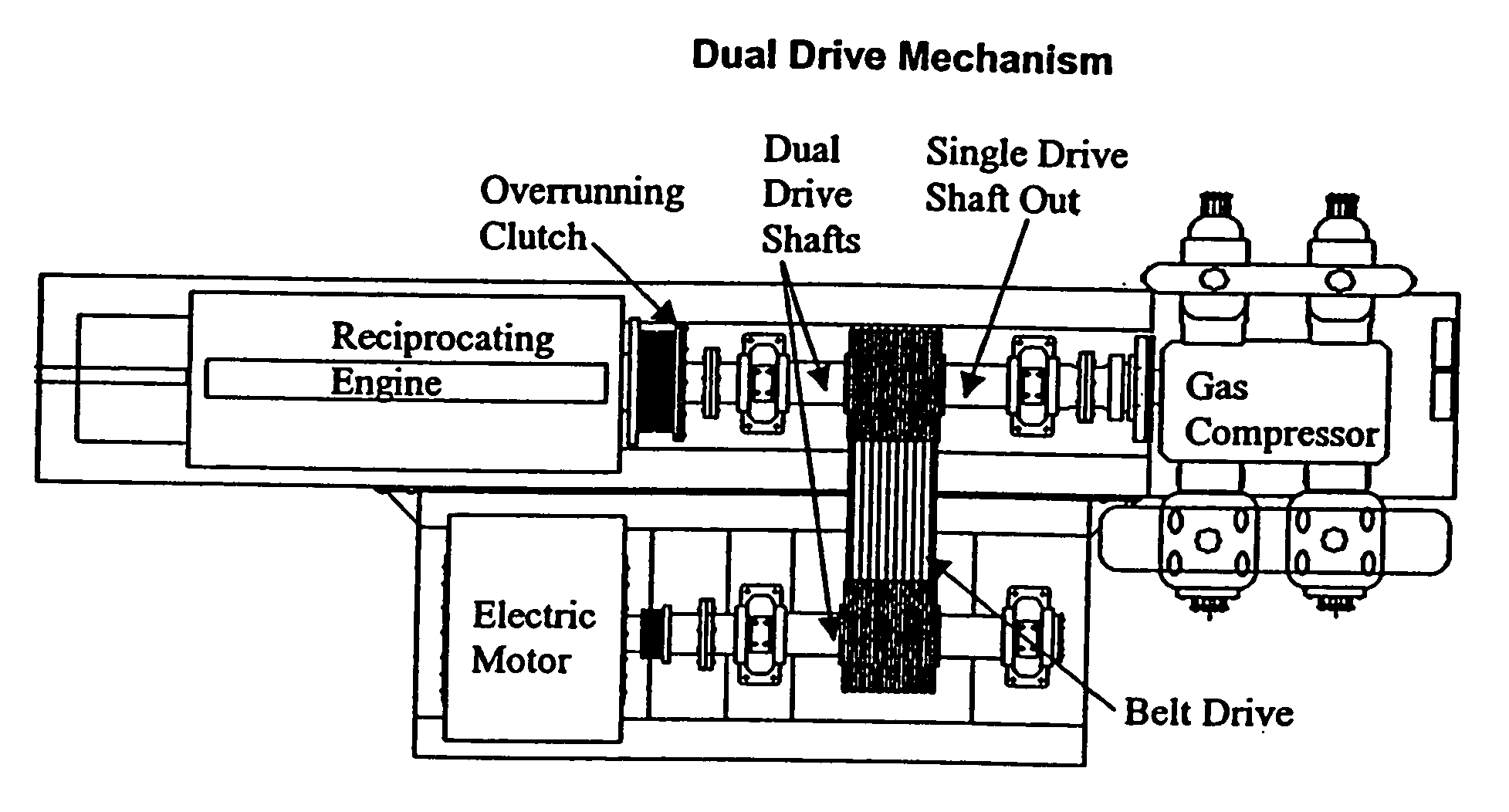

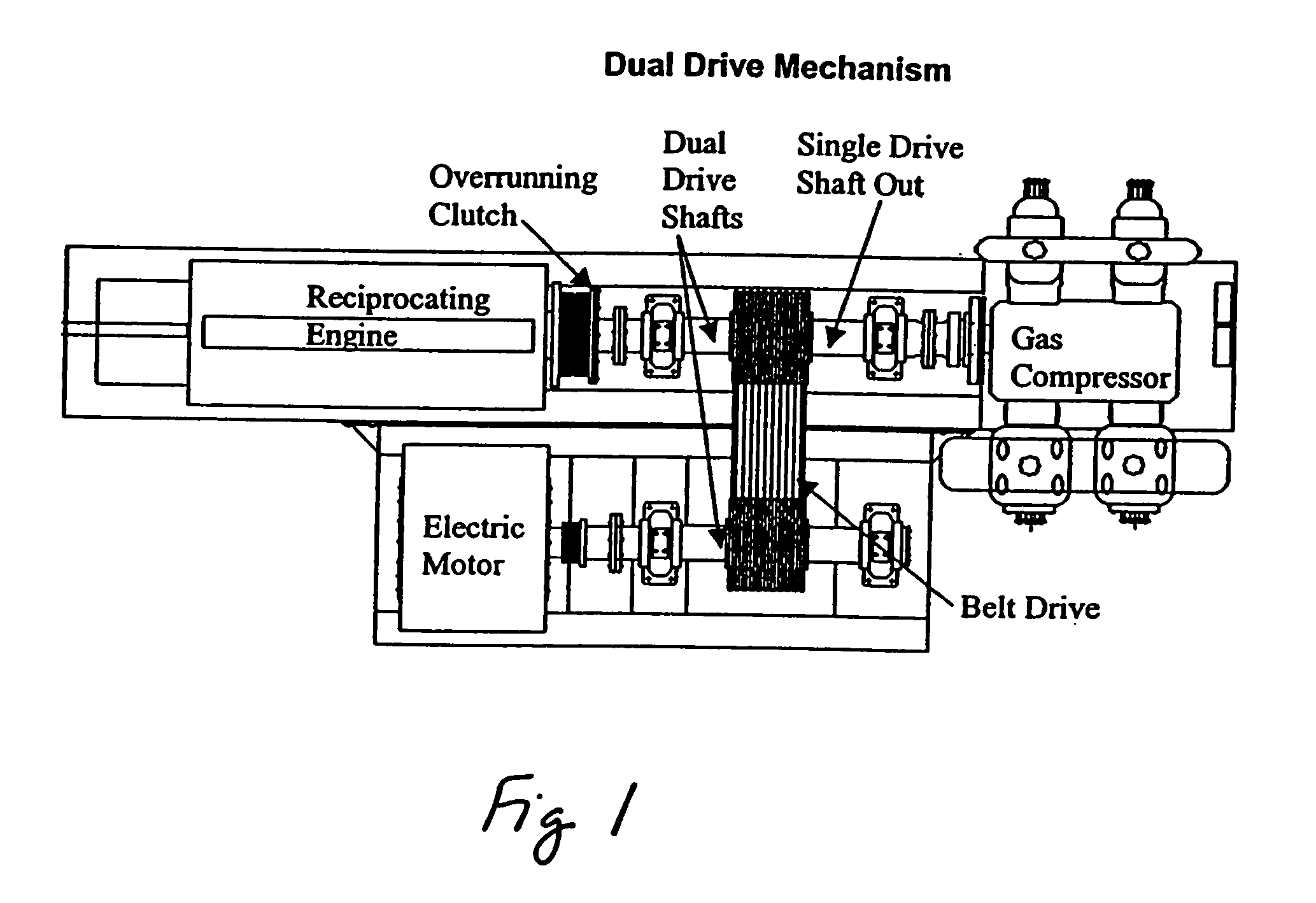

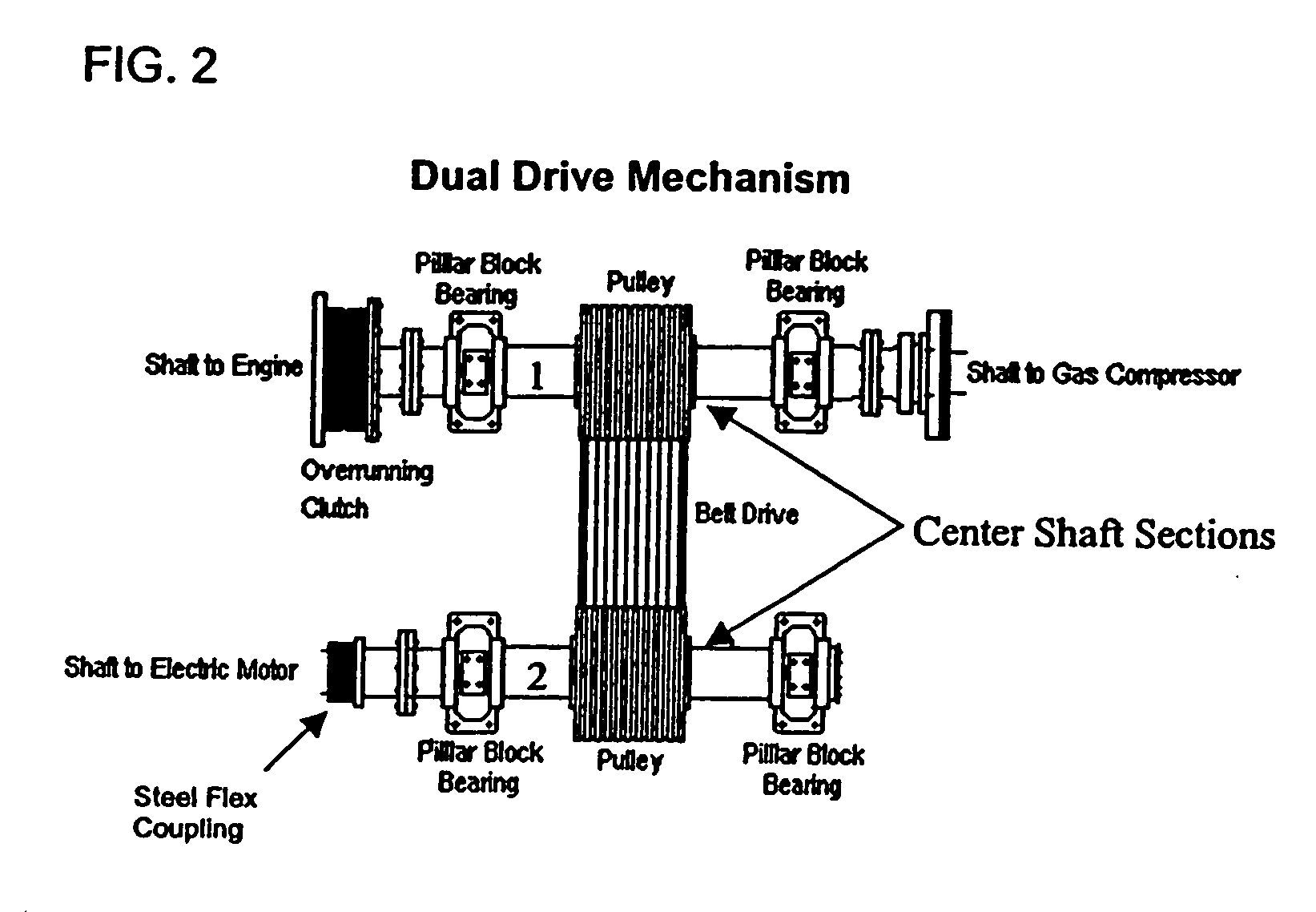

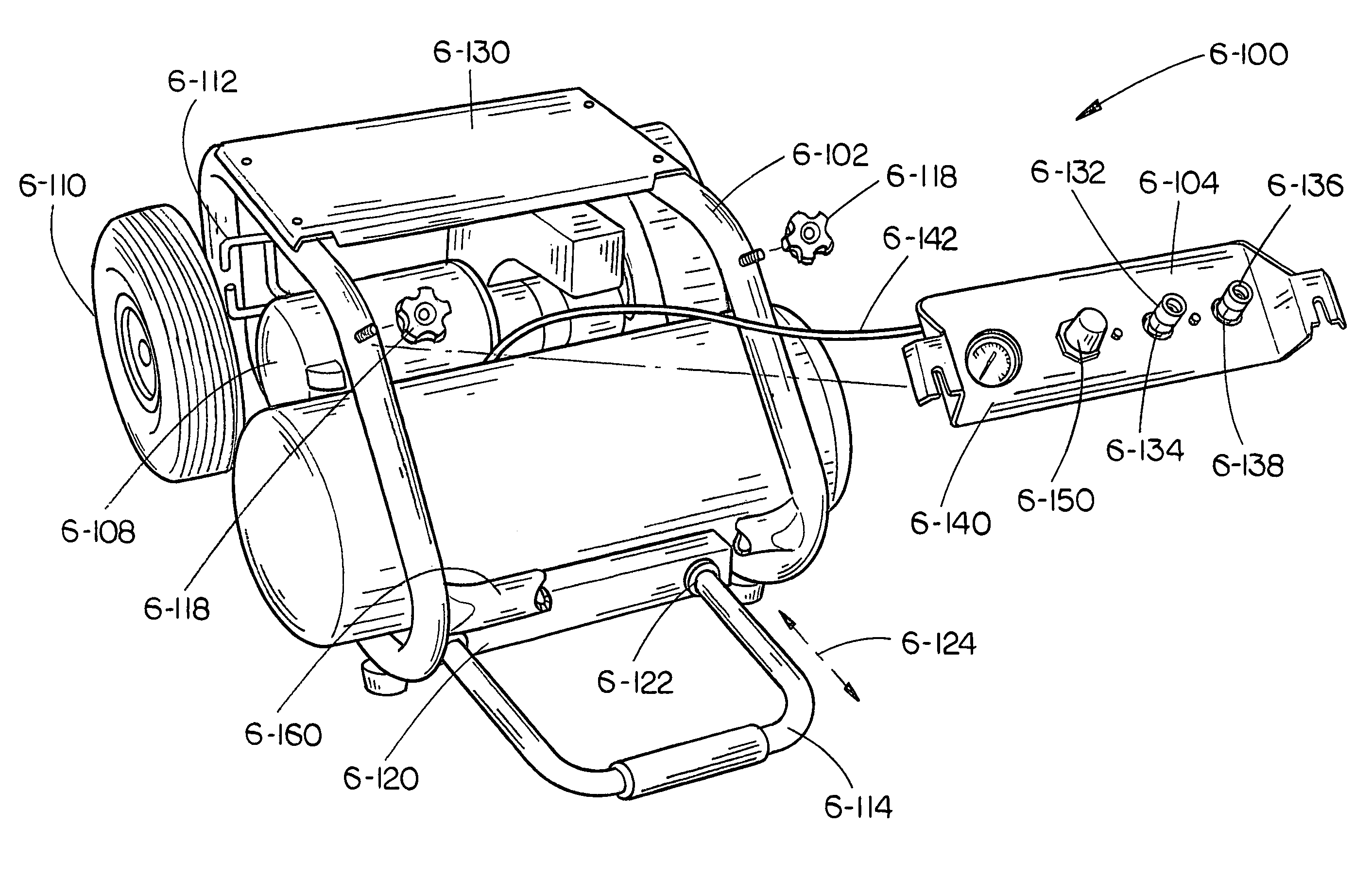

Gas compressor dual drive mechanism

InactiveUS20050196298A1Increase redundancyIncrease productivityPiston pumpsPositive-displacement liquid enginesGas compressorElectric power

A dual drive mechanism for a gas compressor includes a pulley and belt drive system to provide power to a gas compressor using either an electric motor or a reciprocating engine. The source of the power can be chosen by the operator of the system depending on a number of variables, including the cost of electric power.

Owner:MANNING JOHN B

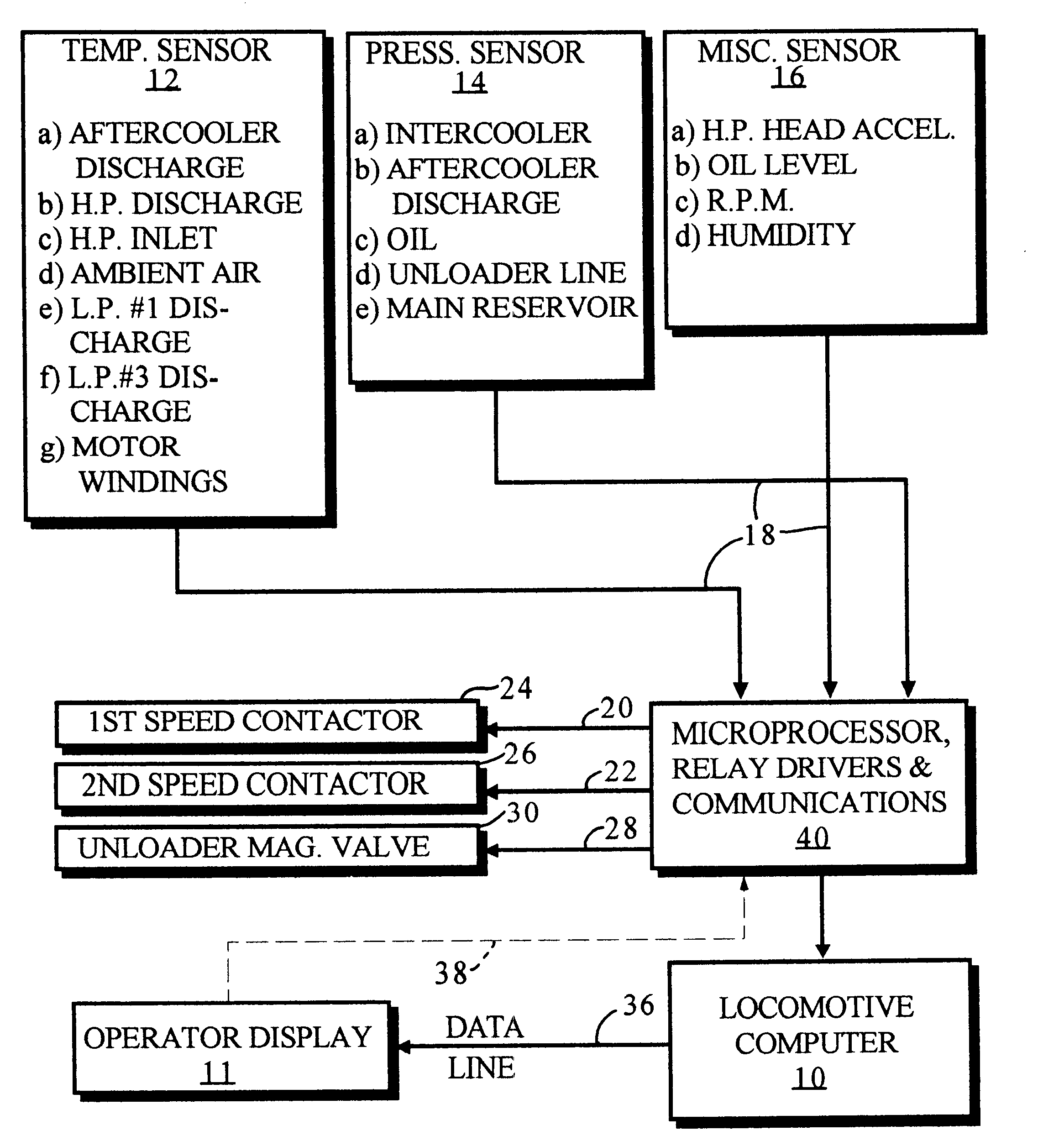

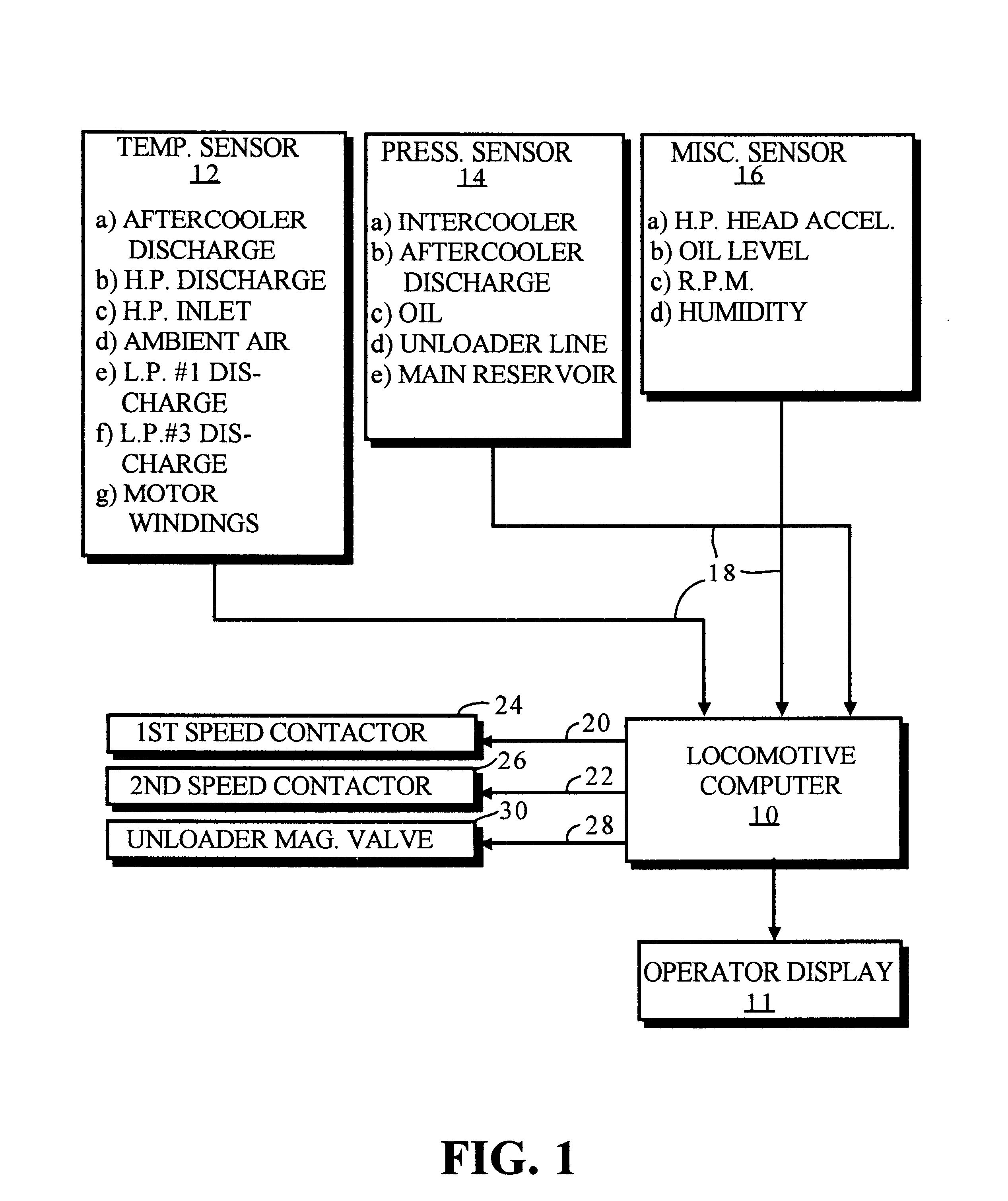

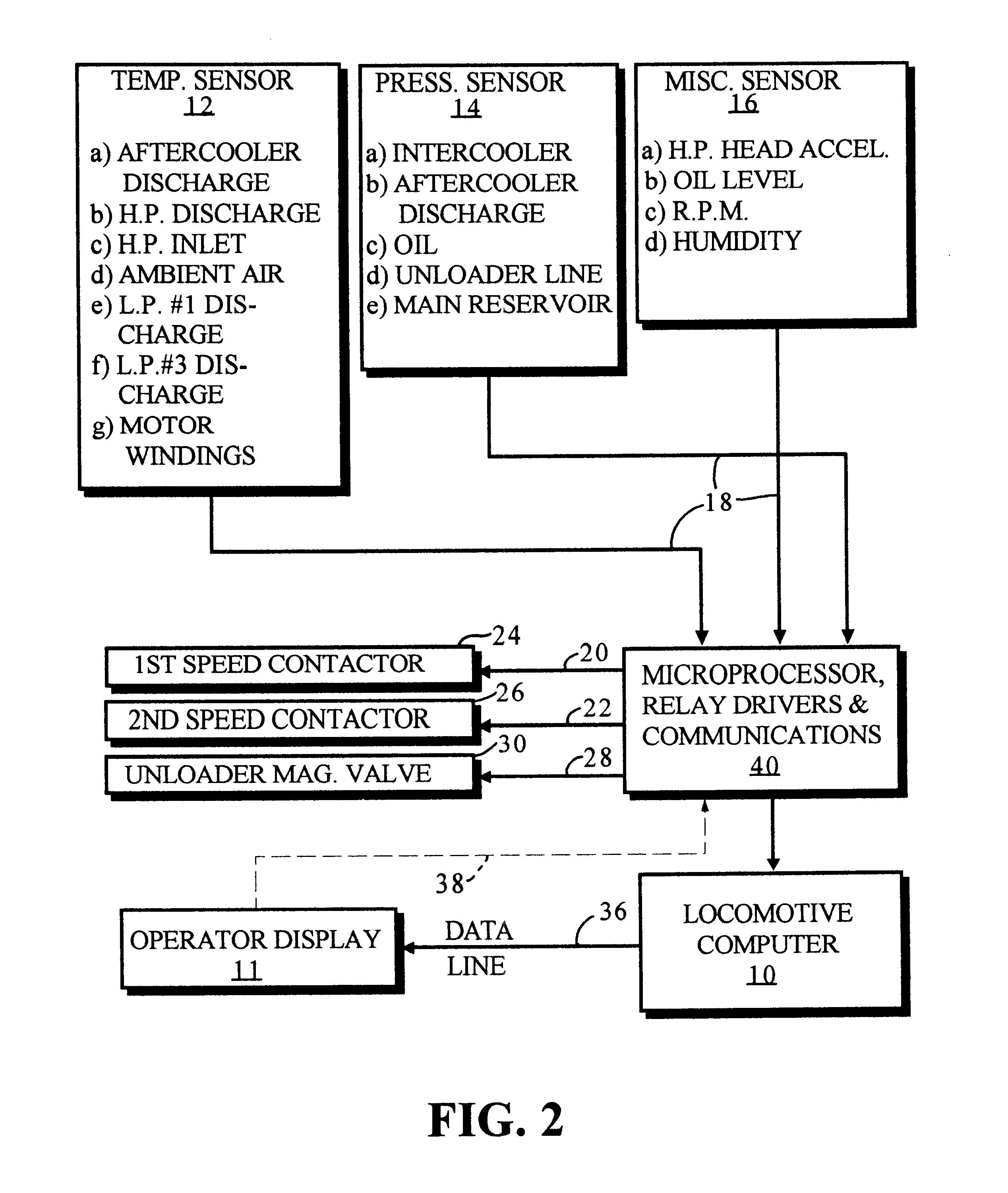

Intelligent air compressor operation

Apparatus for and method of monitoring the condition of an air compressor. The apparatus includes a plurality of appropriately located sensors for sensing operating parameters of the air compressor and for outputting signals indicative of the condition of each of the operating parameters. An information processor is connected to receive the output signals from the sensors and to communicate output control signals in response thereto. The control signals contain information that allows appropriate control and maintenance of the air compressor.

Owner:WESTINGHOUSE AIR BRAKE CO

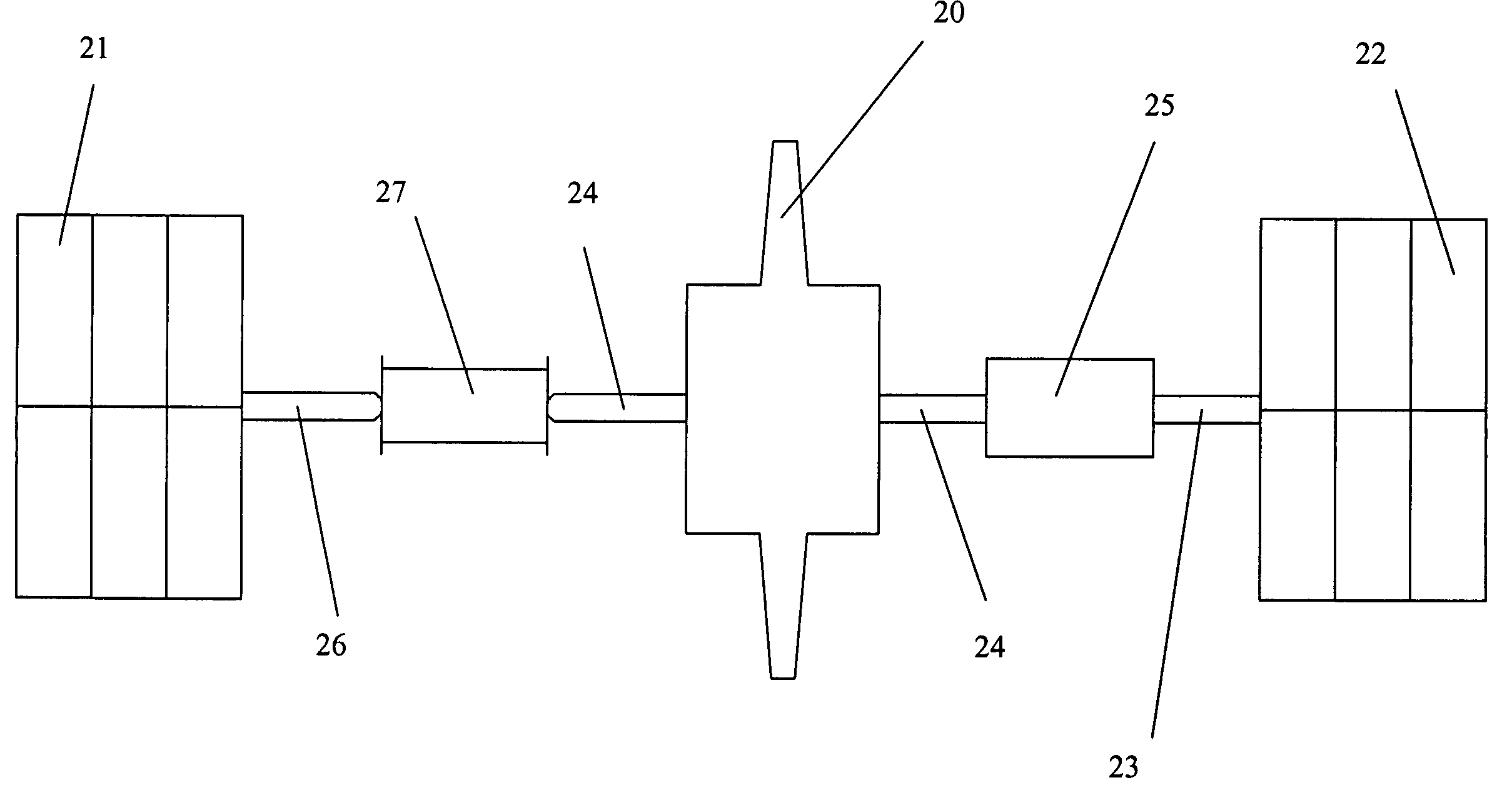

Compressor for high pressure polymerization

ActiveUS7563413B2Accurate predictionImprove reliabilityYielding couplingShaft for rotary movementGas compressorCoupling

Owner:EXXONMOBIL CHEM PAT INC

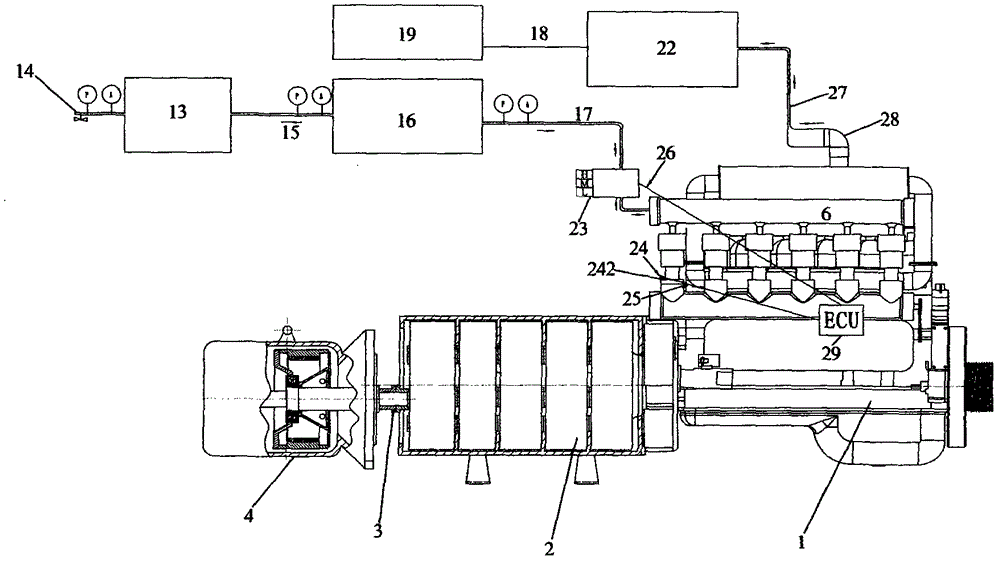

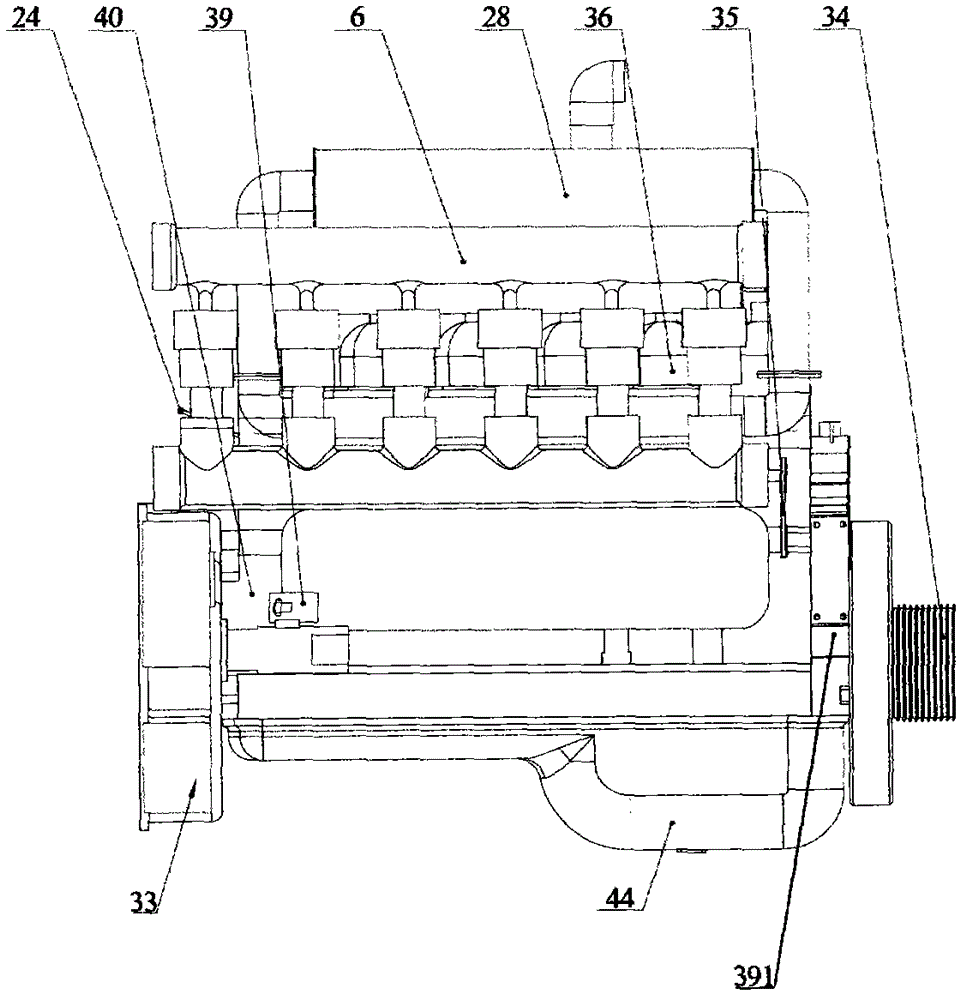

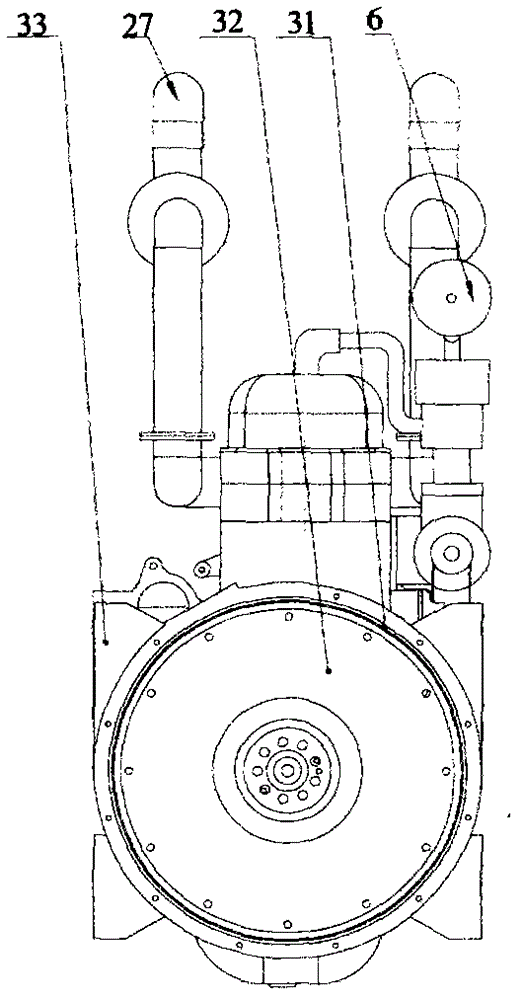

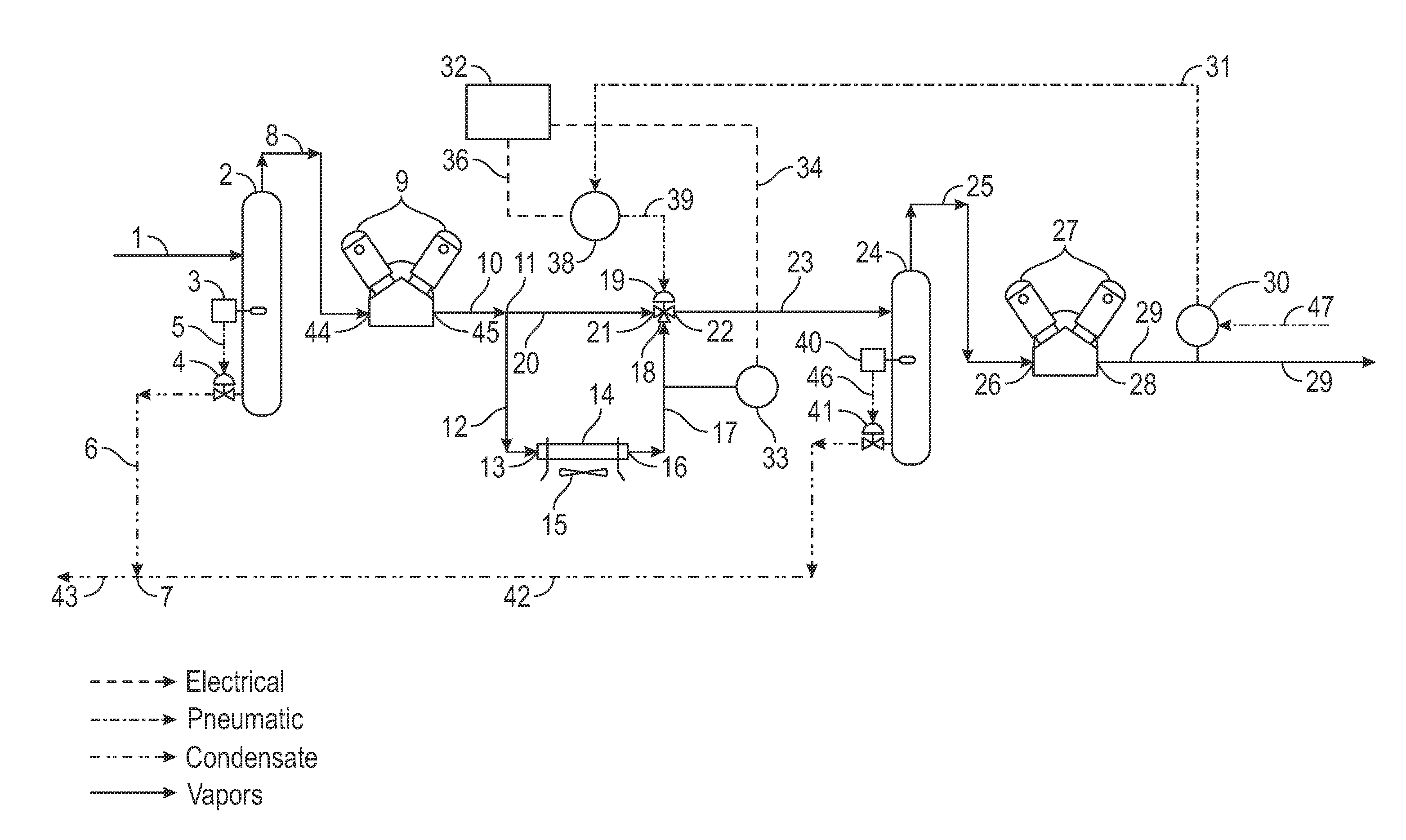

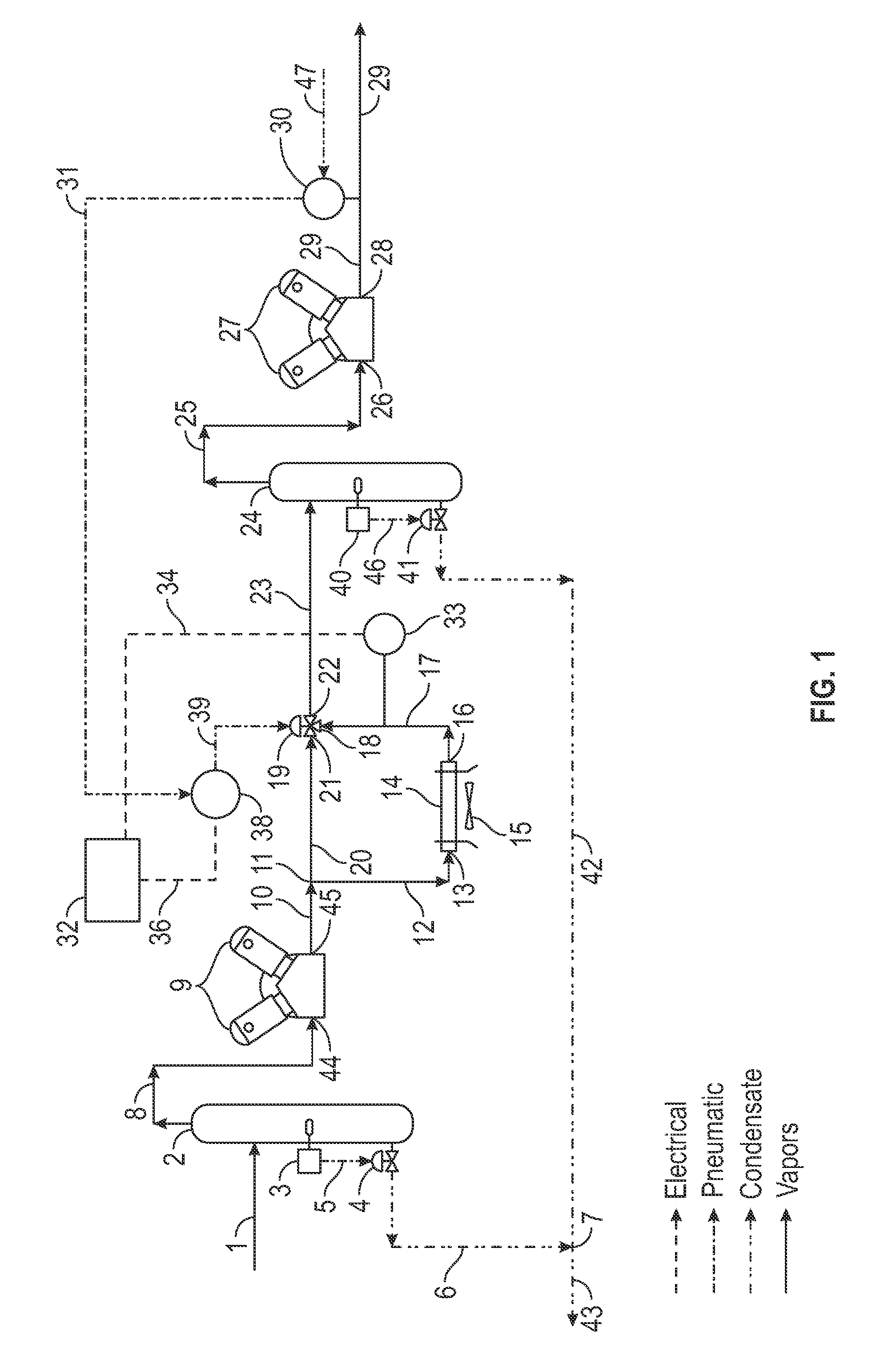

Compressed air engine assembly with tail gas recovery loop

The invention relates to a two-stroke engine, in particular to a two-strike compressed air engine assembly which takes compressed air as a power source. The compressed air engine assembly comprises an engine body (1), a multi-cylinder power divider (2), a power plant (4), a controller system (6), an air inlet control and speed regulation valve (23), a high-pressure gas tank group (13), a constant-pressure tank (16), an electronic control unit (ECU) (29) and a tail gas recovery loop. The tail gas recovery loop comprises an air compressor (7), a condenser (11), a tail gas recovery tank (9), an electric turbine one-way air pump (19) and a tail gas noise deadener (22).

Owner:周登荣 +1

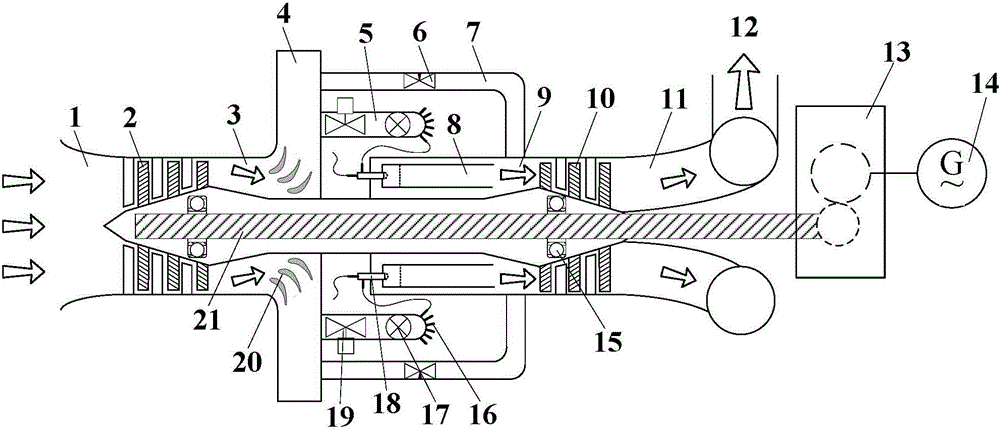

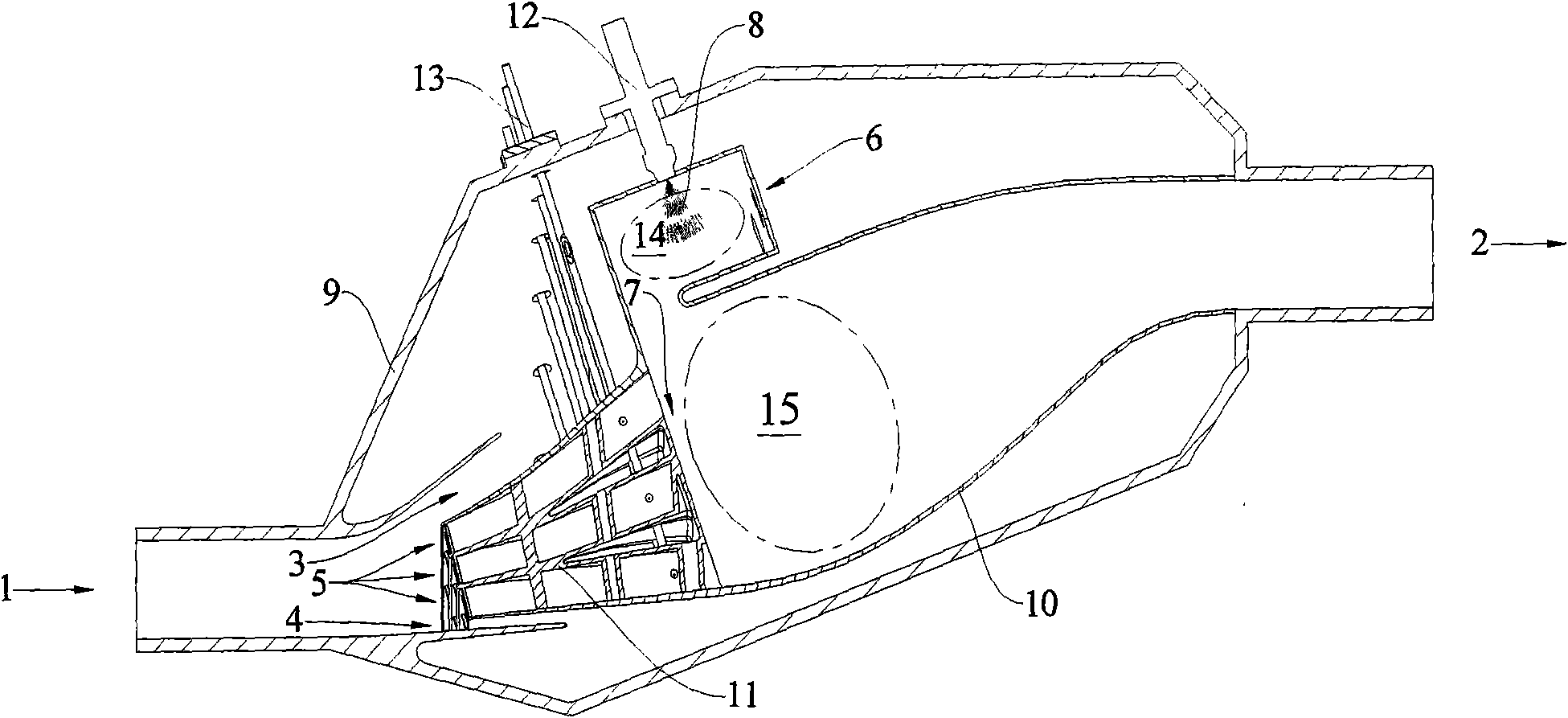

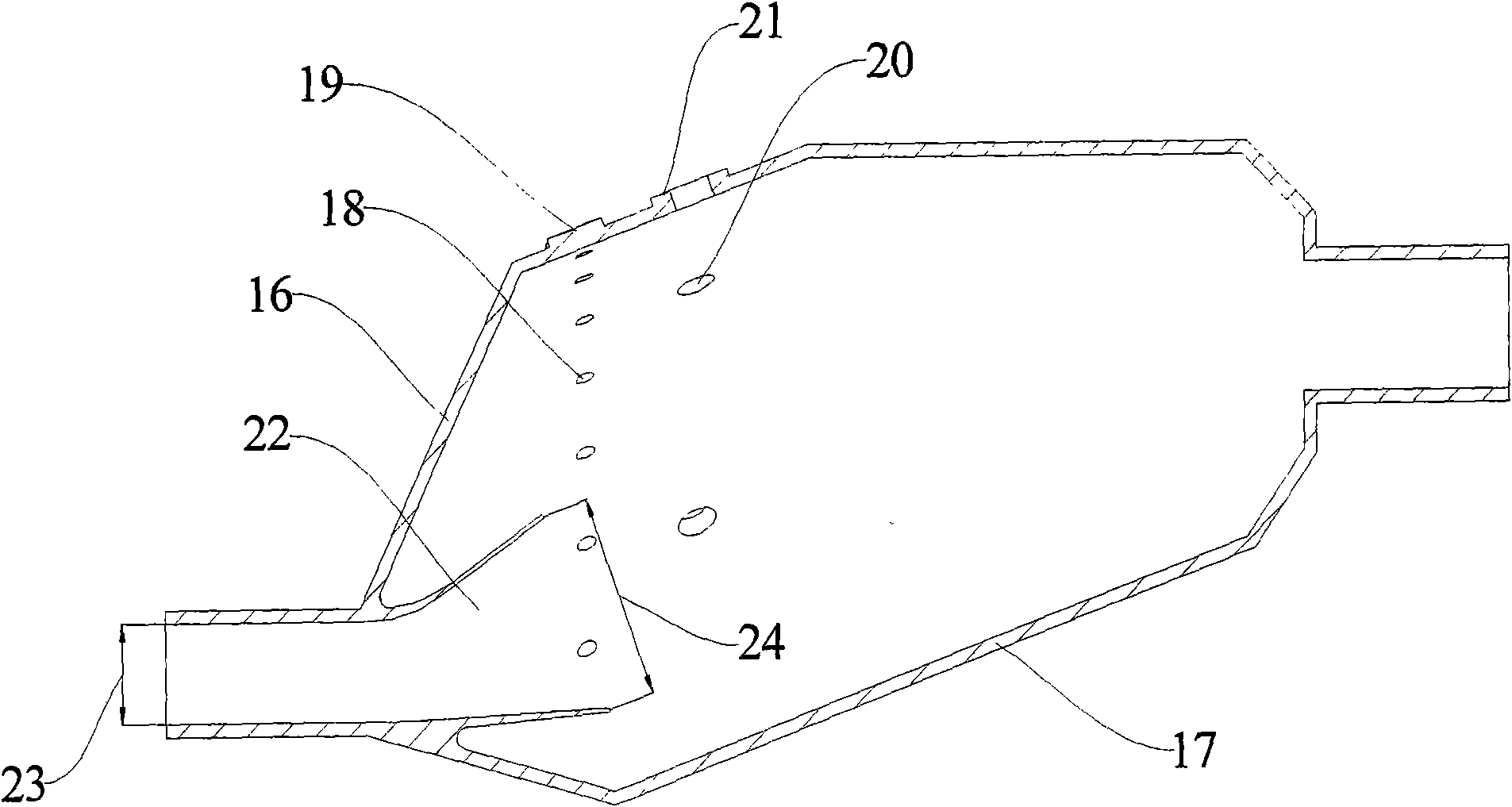

Stoichiometric Exhaust Gas Recirculation Combustor

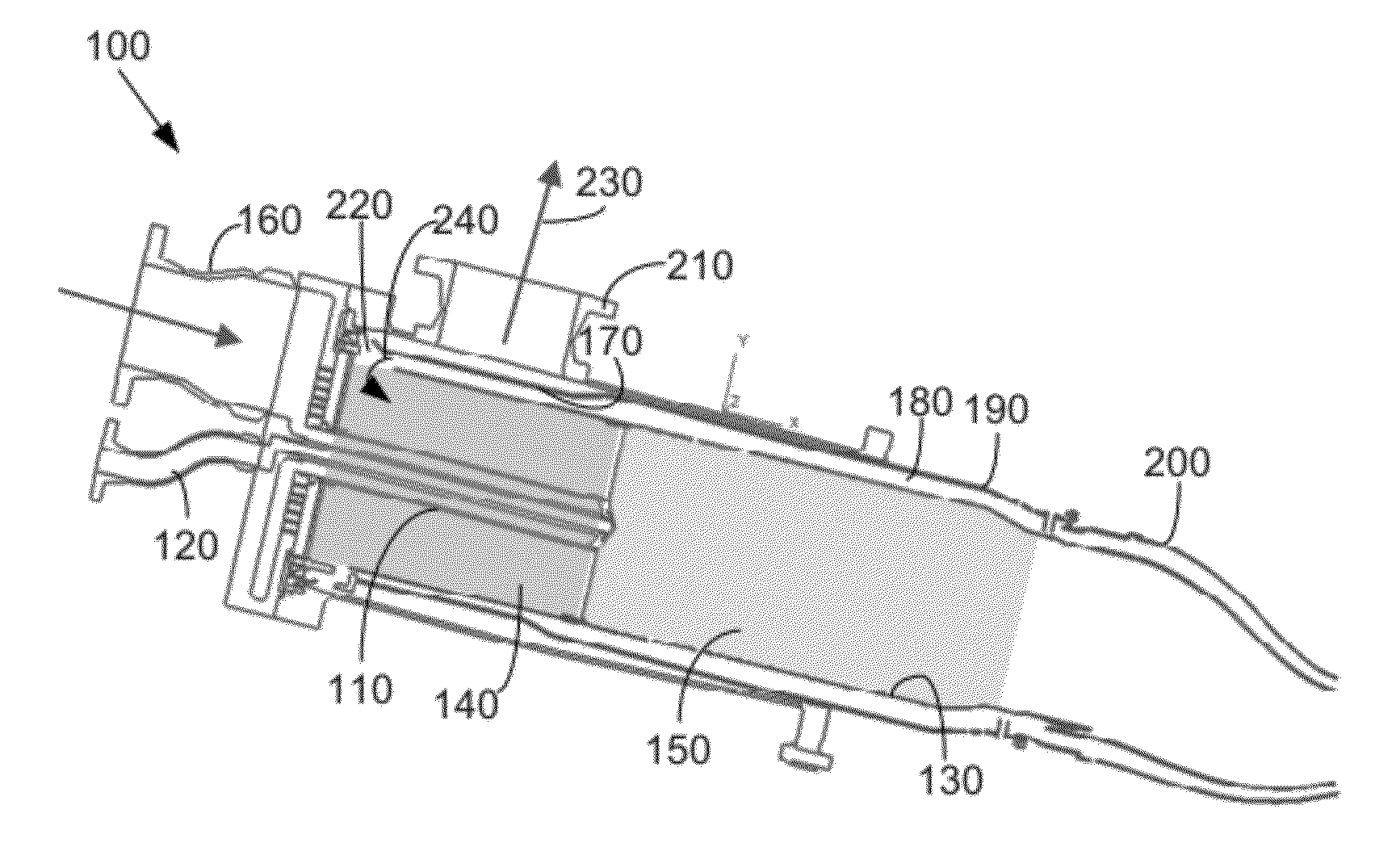

The present application provides a stoichiometric exhaust gas recovery turbine system. The stoichiometric exhaust gas recovery turbine system may include a main compressor for compressing a flow of ambient air, a turbine, and a stoichiometric exhaust gas recovery combustor. The stoichiometric exhaust gas recovery combustor may include a combustion liner, an extended flow sleeve in communication with the main compressor, and an extraction port in communication with the turbine. The extended flow sleeve receives the flow of ambient air from the main compressor so as to cool the combustion liner and then the flow of ambient air splits into an extraction flow to the turbine via the extraction port and a combustion flow within the combustion liner.

Owner:GENERAL ELECTRIC CO

Advanced hybrid coal gasification cycle utilizing a recycled working fluid

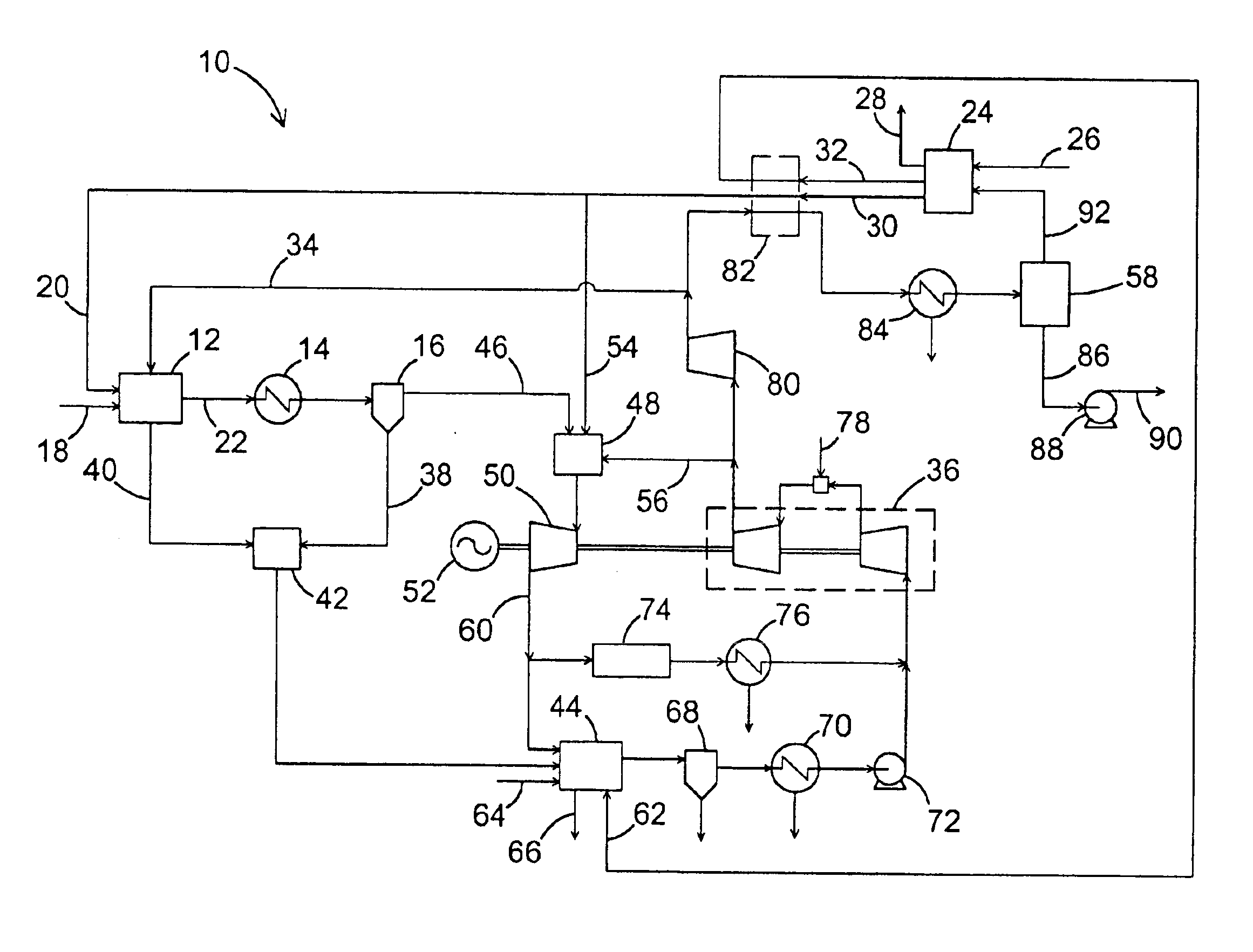

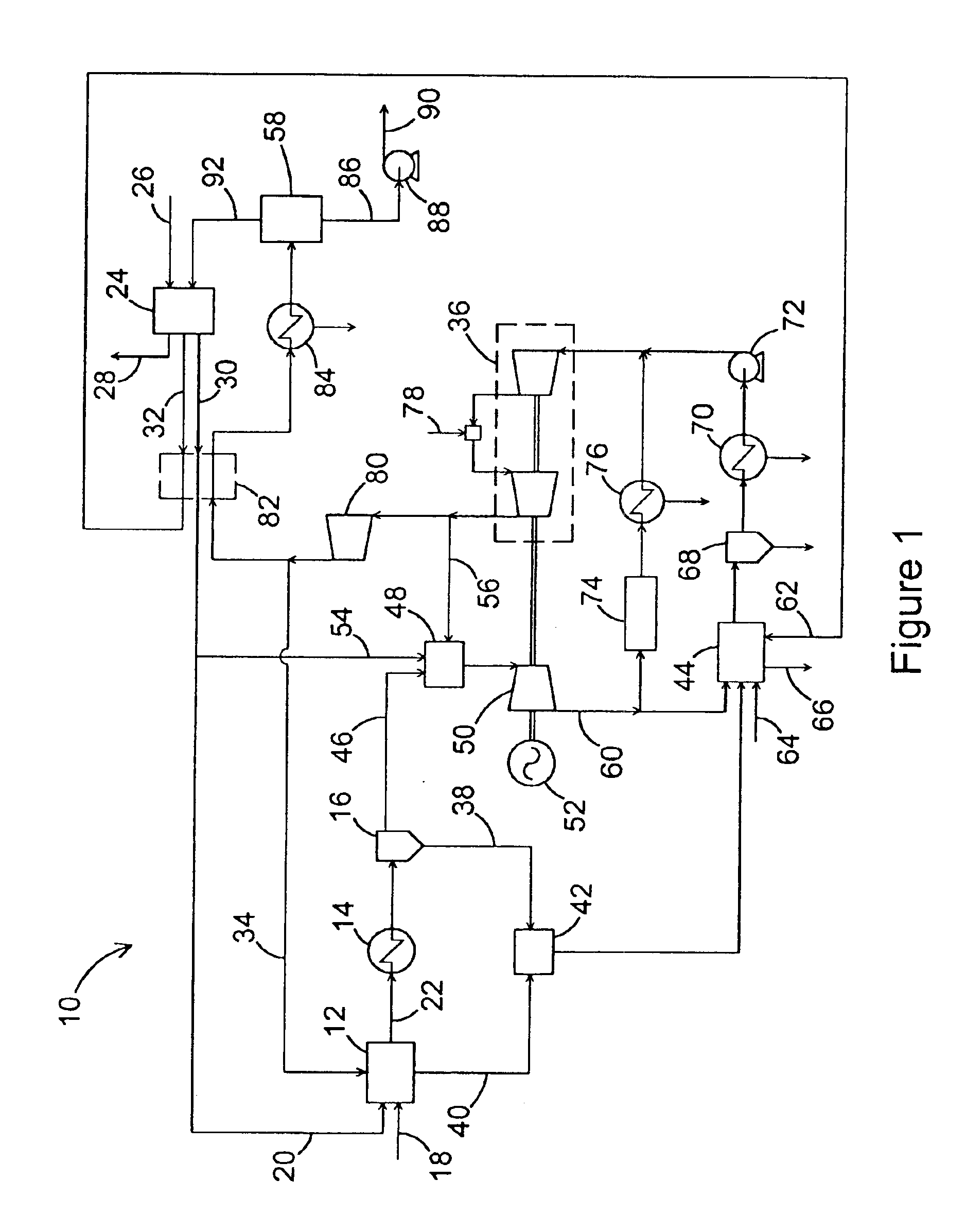

InactiveUS6877322B2Generate efficientlyEliminate and reduce carbon dioxide emissionSolidificationLiquefactionSyngasCombustor

A power generating system having a hybrid gasification cycle, in which CO2 is recycled to a gasifier to be used as a gasification reactant and working fluid. The power generating system includes a source of fresh, pure oxygen, a gasifier, a particle separator arranged in flow connection with the gasifier, a syngas combustor, a gas turbine arranged in flow connection with the syngas combustor, a steam generator arranged in flow connection with the outlet of the gas turbine, and a gas compressor system which discharges a stream of compressed exhaust gas. A first portion of the stream of compressed exhaust gas is conducted to the gasifier to control the temperature in the gasifier, to provide CO2 and steam for gasification, and to decrease the demand for fresh, pure oxygen therein.

Owner:FOSTER WHEELER ENERGY CORP

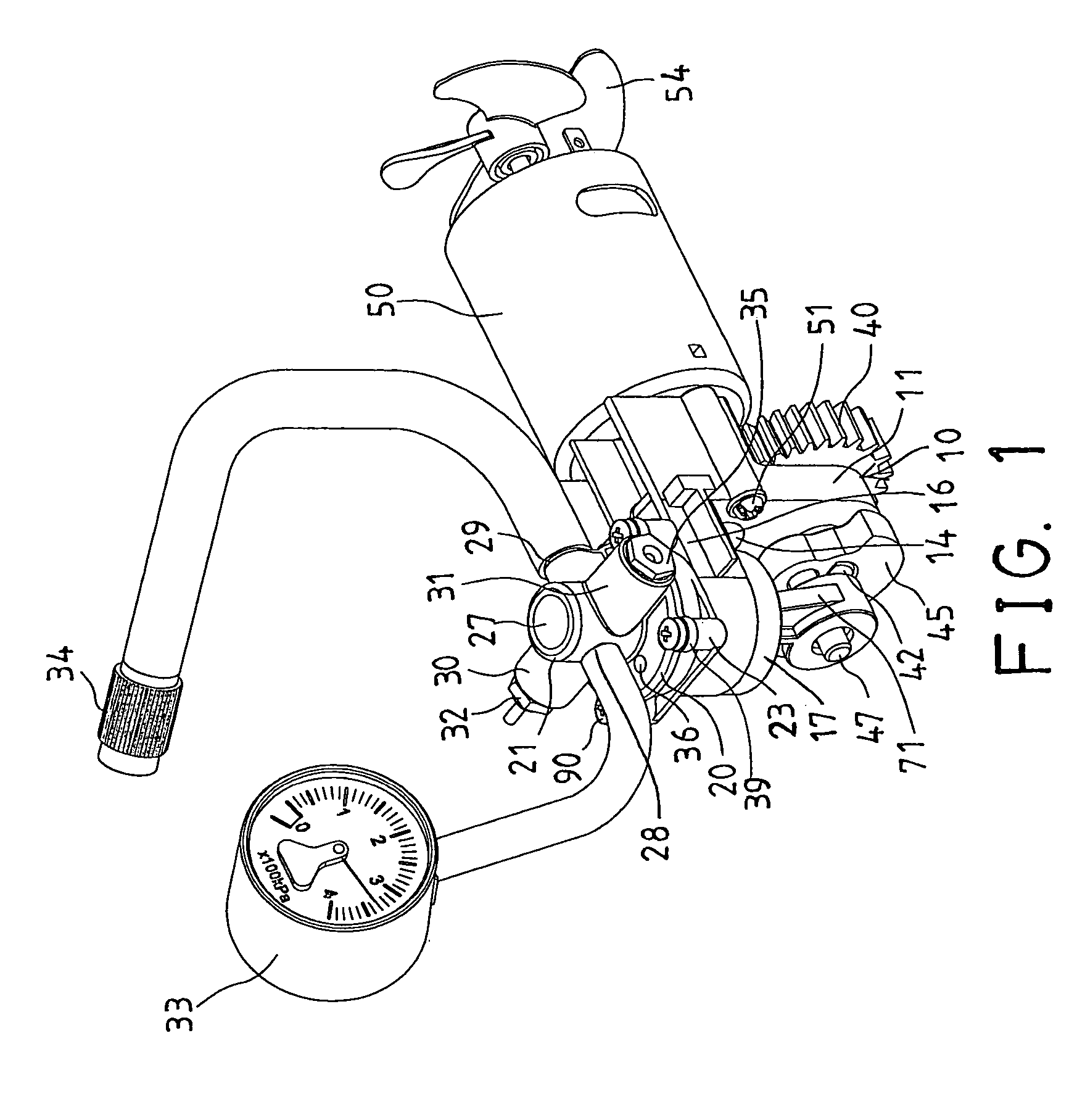

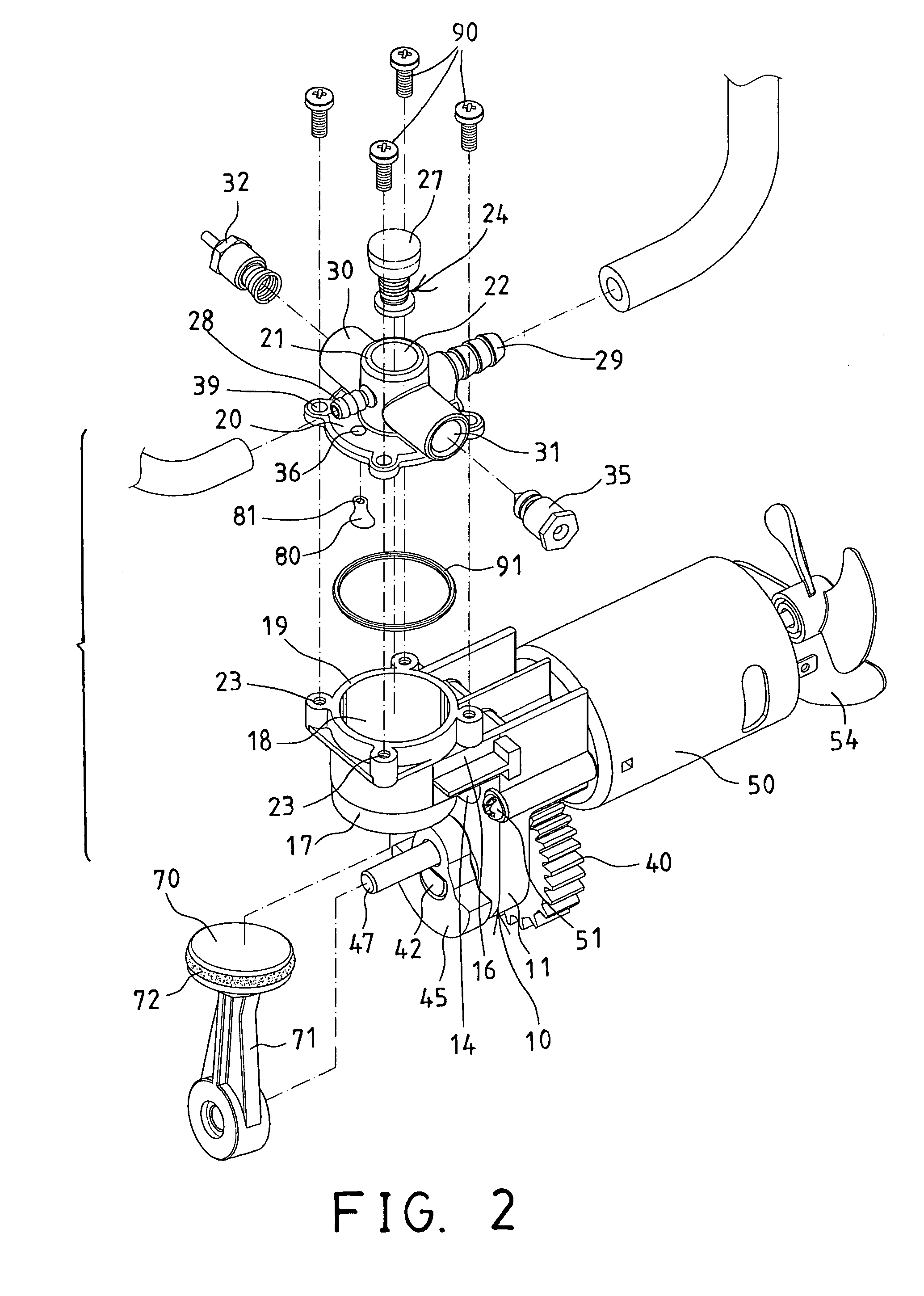

Air compressor having changeable structure

ActiveUS7240642B2Avoid flowPositive displacement pump componentsAir coolingGas compressorReciprocating motion

An air compressor includes a piston slidably received in a cylinder housing, and a motor coupled to the piston for moving the piston relative to the cylinder housing in a reciprocating action, in order to generate pressurized air. A cover is detachably secured on top of the cylinder housing, and includes an outlet tube having a compartment communicating with the cylinder housing, for receiving pressurized air from the cylinder housing, and includes an inlet blocked by a check valve device. The cover may be adjusted and secured to the cylinder housing, to adjust the inlet to different position relative to the cylinder housing, and to prevent the inlet from being blocked by objects.

Owner:CHOU WEN SAN

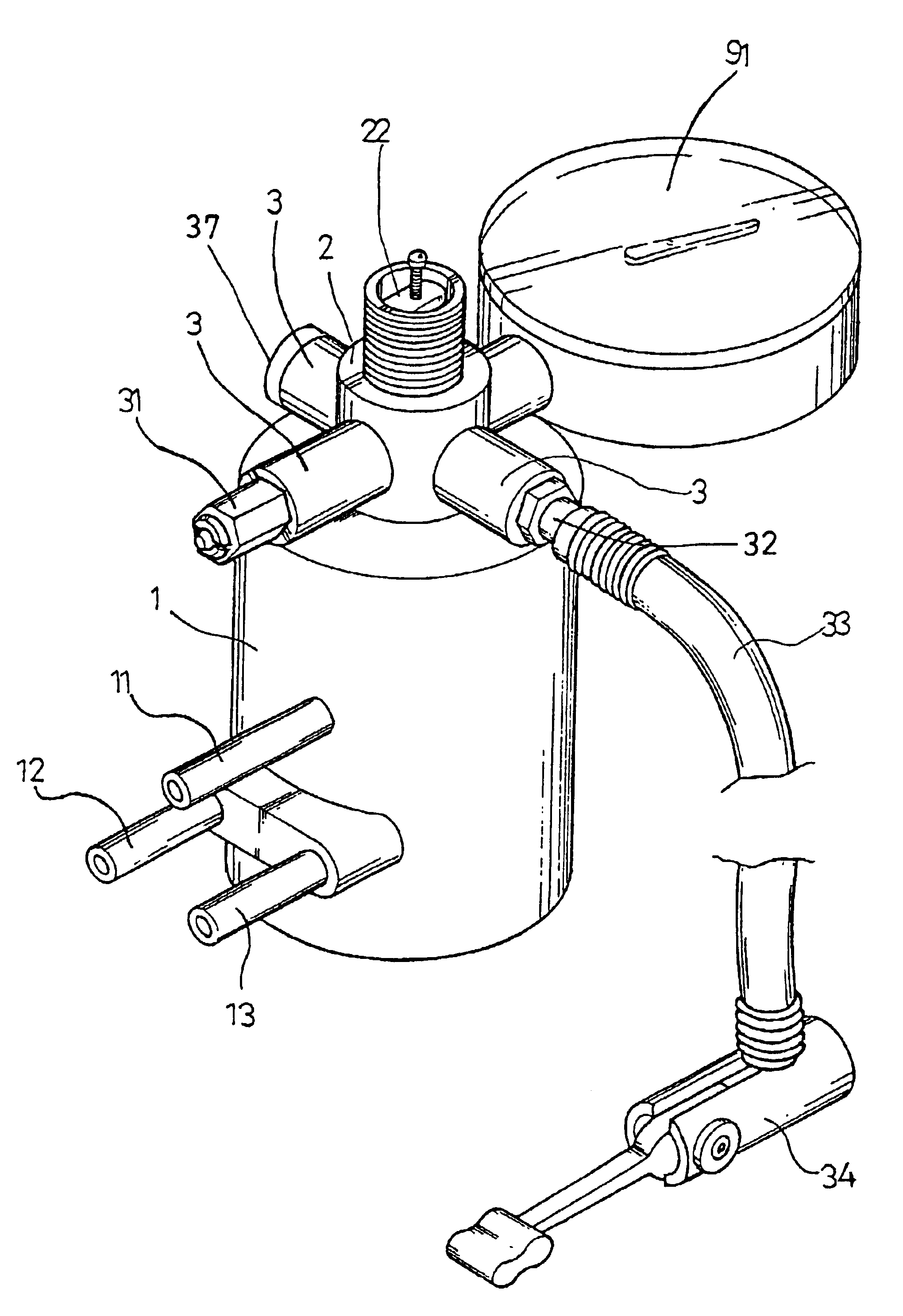

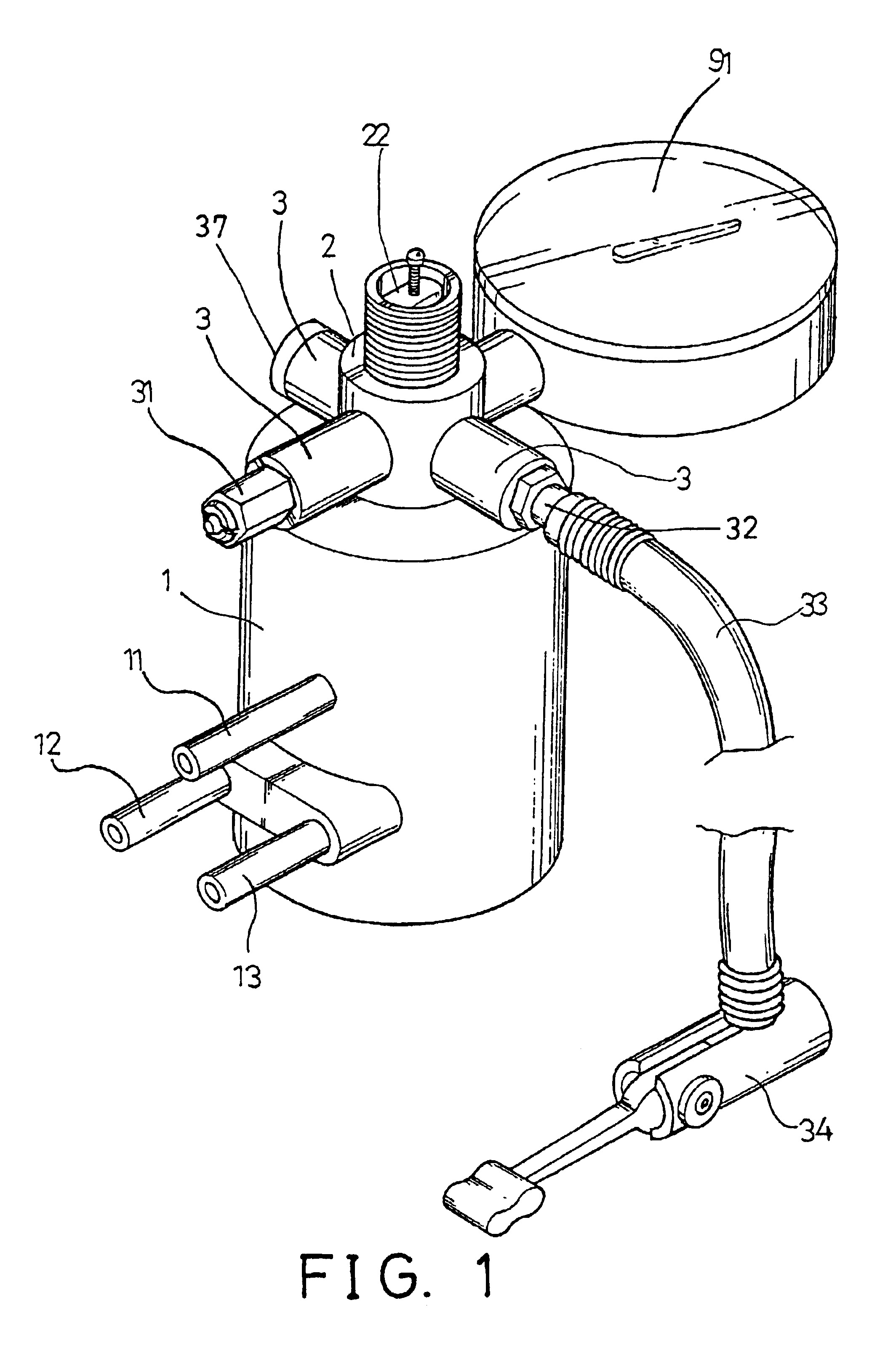

Cylinder housing for air compressor

InactiveUS6846162B2Easy to assembleGood adhesionPositive displacement pump componentsPump controlReciprocating motionGas compressor

An air compressor includes a cylinder housing having a passage formed in one end, a piston slidably received in the cylinder housing and moved relative to the cylinder housing in a reciprocating action to generate a pressurized air out through the passage of the cylinder housing. The cylinder housing includes an outlet tube having a bore communicating with the passage and the chamber of the cylinder housing, and having two or more ducts for readily coupling to and for supplying the pressurized air to the nozzle, the pressure gauge, the safety valve, or the other devices.

Owner:CHOU WEN SAN

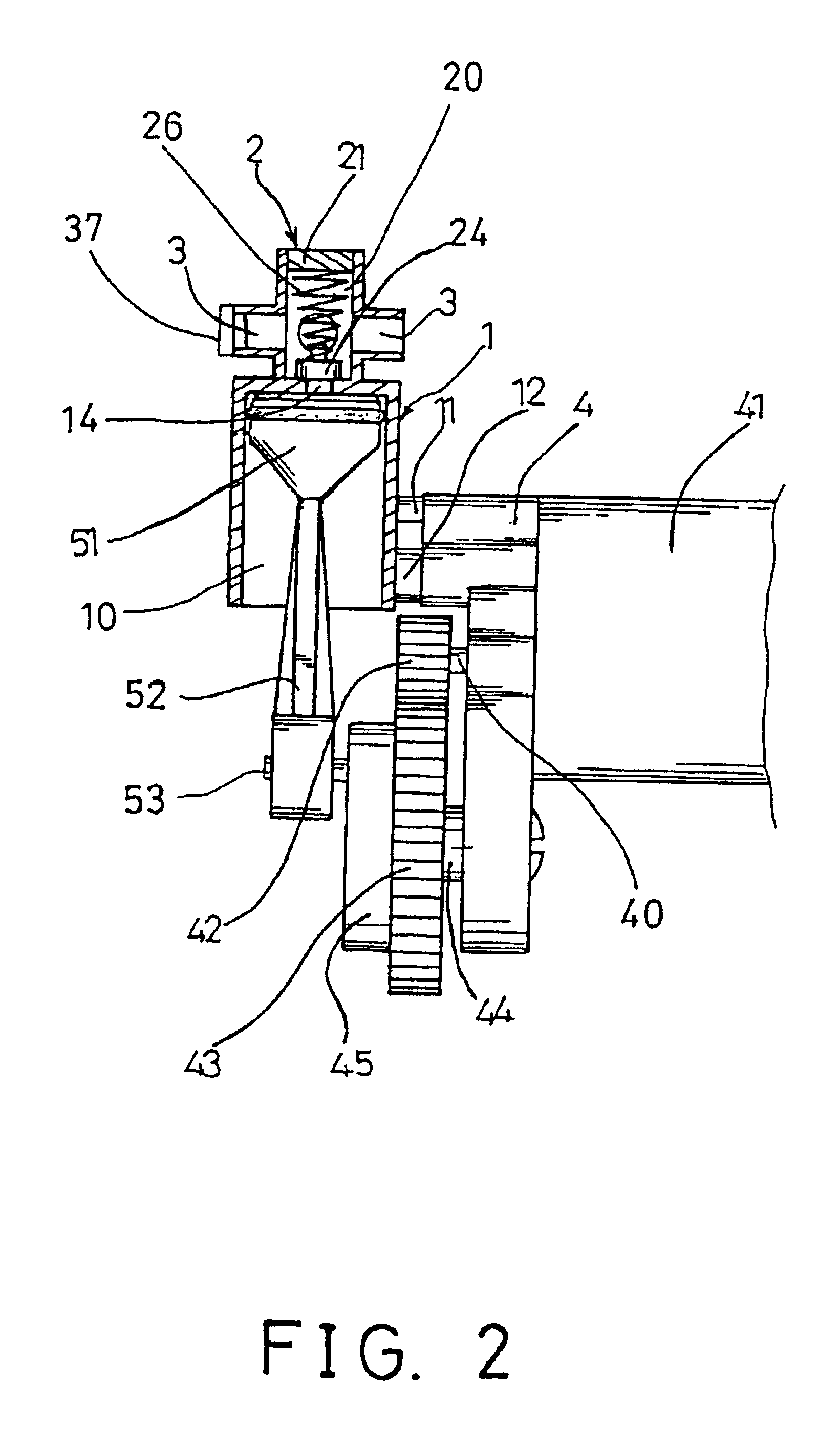

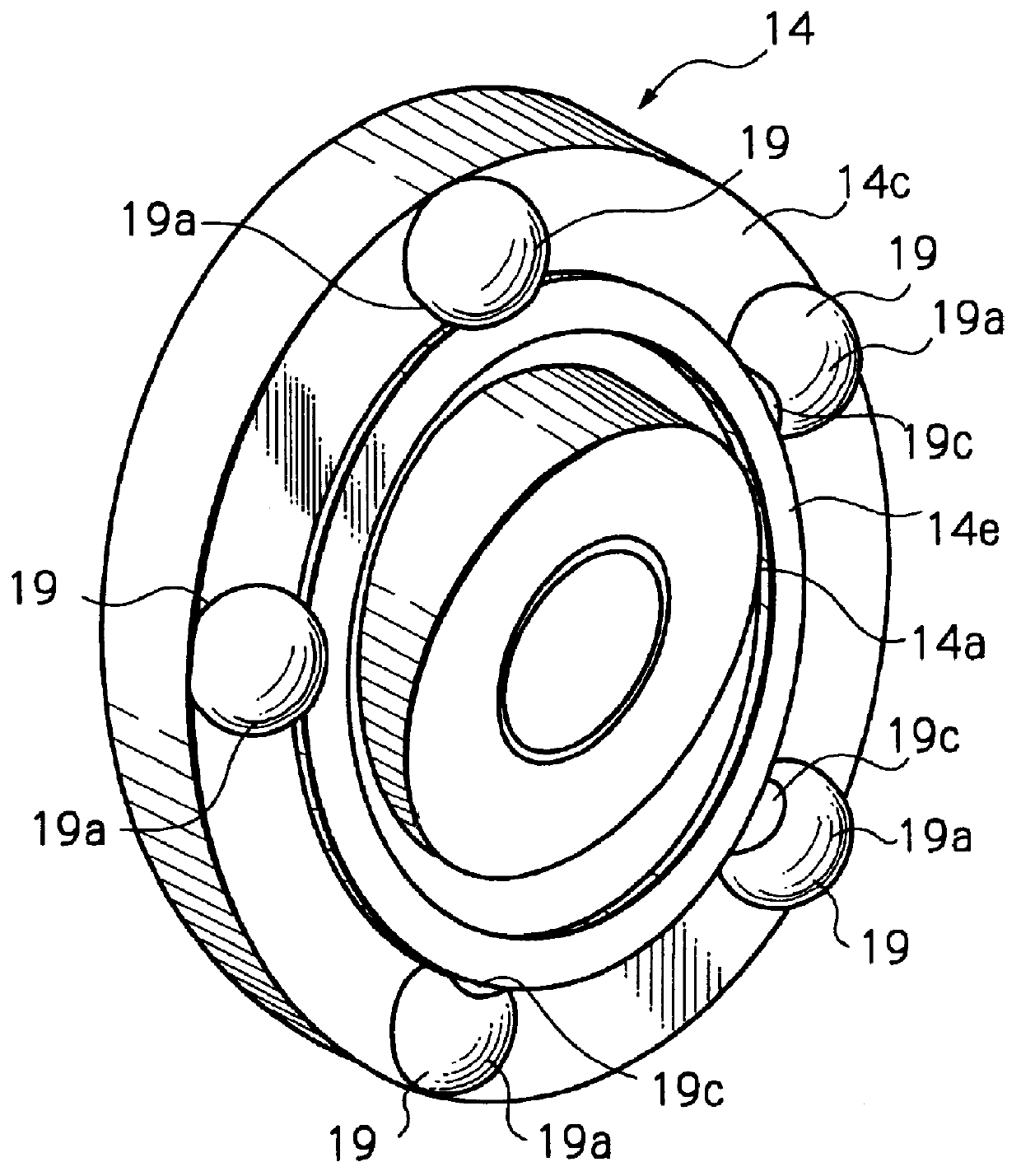

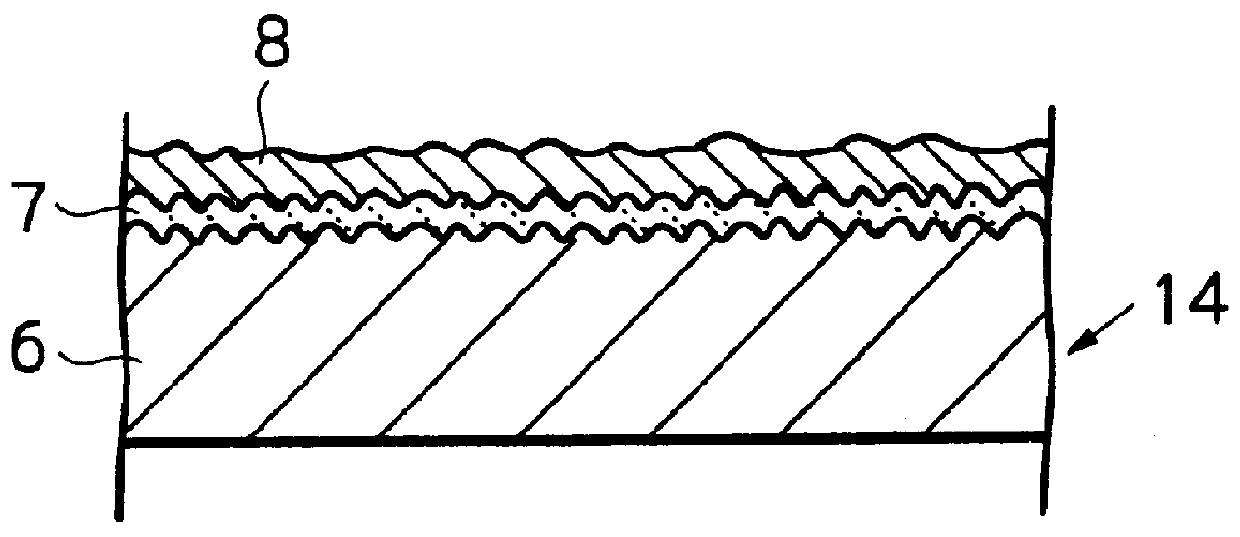

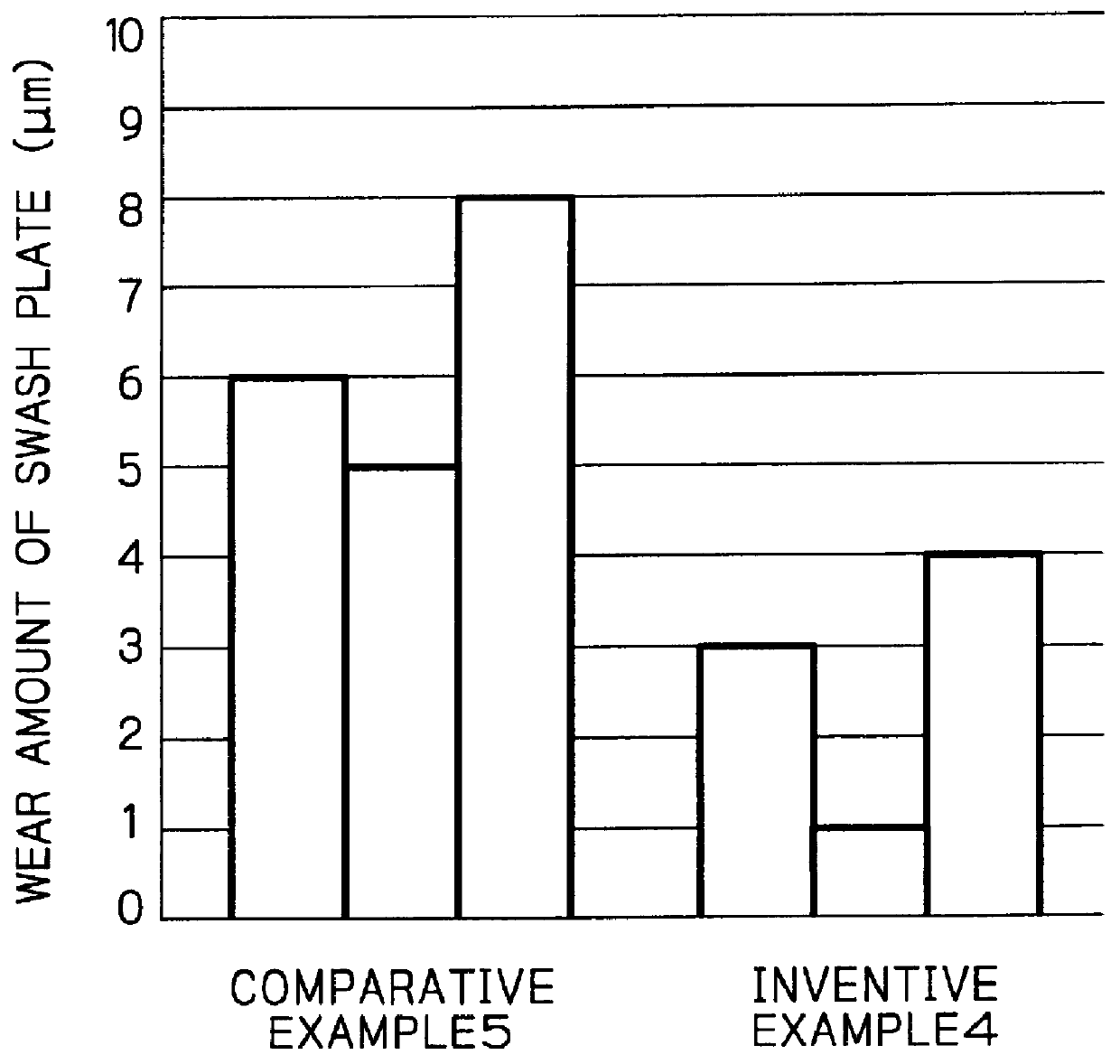

Swash plate of swash-plate compressor

InactiveUS6123009AReduce coating thicknessReduce loadPositive displacement pump componentsAdditivesGas compressorGraphite

A swash plate of a swash-plate compressor is subjected to sliding on shoes and is required to have excellent seizure resistance and wear resistance under the dry lubricating condition. The swash plate according to the present invention is provided with the surface-treated layer, i,e., the intermediate layer consisting of Cu, Sn or metal phosphate, and a sliding contact layer consisting of MoS2 and / or graphite and thermosetting resin.

Owner:TAIHO INDUSTRIES CO LTD +1

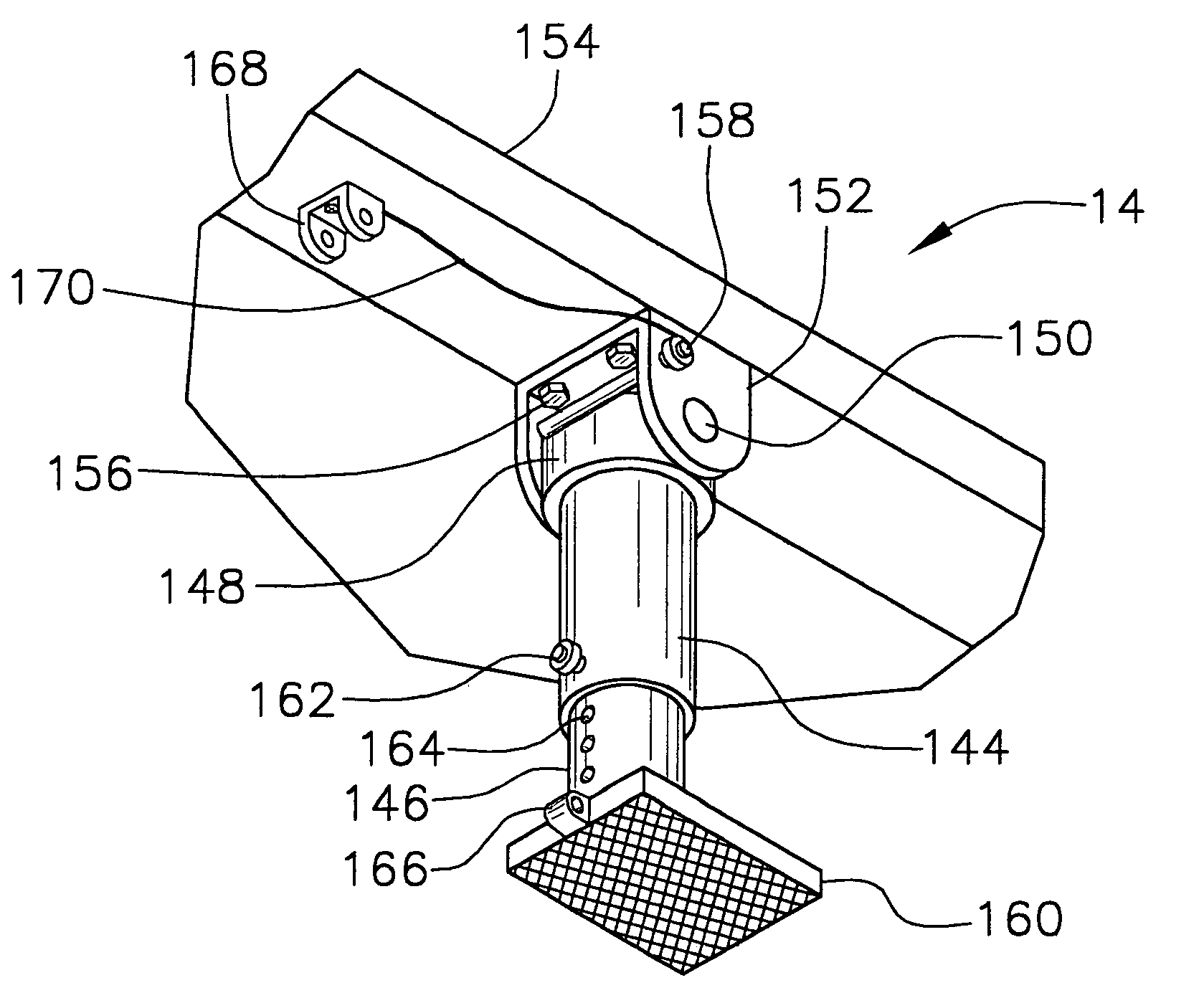

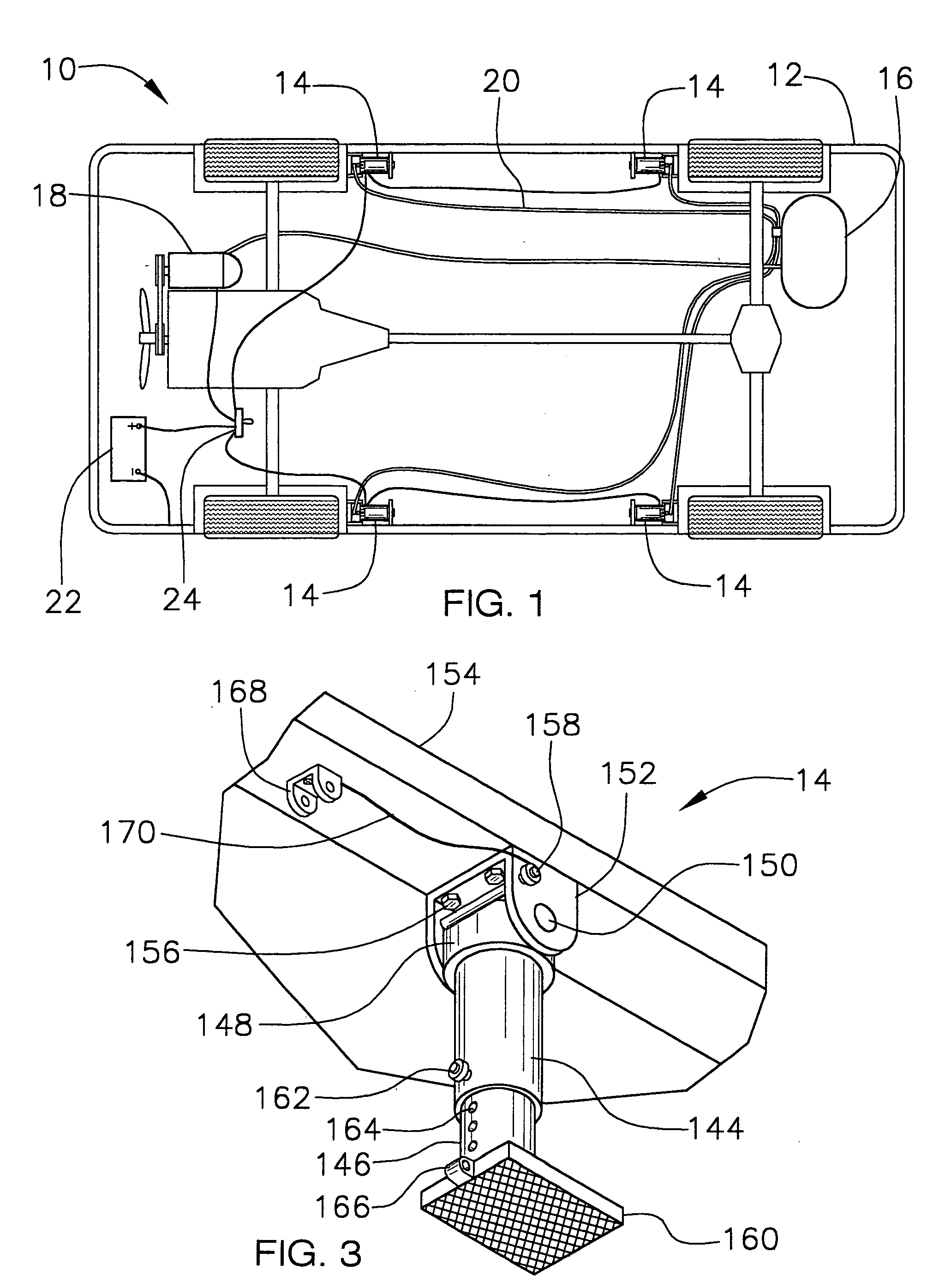

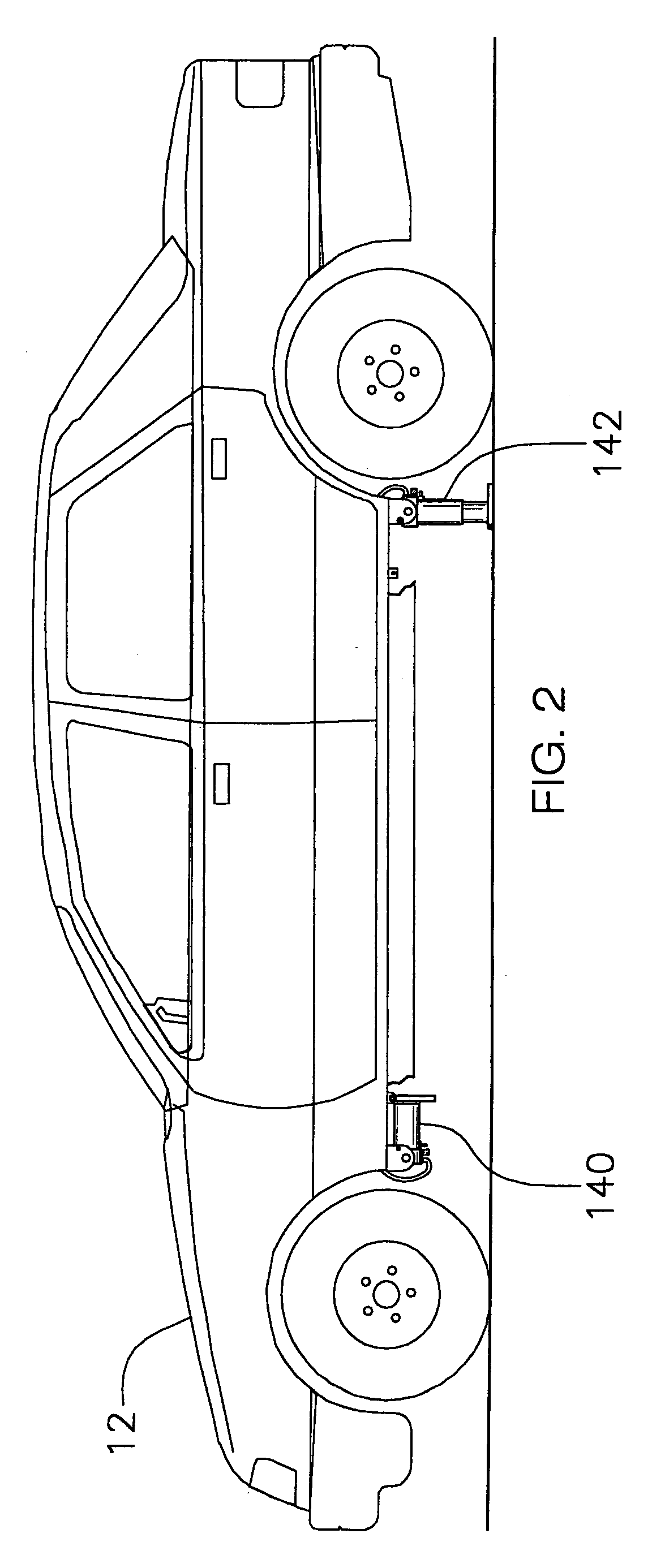

Motor vehicle pneumatic jacklift system

InactiveUS6895648B1Easy to modifyEasy and efficient to manufactureVehicle fittings for liftingVehicle cleaning apparatusSolenoid valveGas compressor

A permanently mounted pneumatic jack (jacklift) system for motor vehicles, as well as an impact wrench for removing and installing lug nuts. The system provides a quick and safe means of lifting one or more tires off the ground for replacement of a spare or rotating the tires on a motor vehicle. The present invention comprises two or more (typically four) pneumatic jacks, a system ON / OFF switch, an air compressor, a 120-psi air tank, air lines (hoses), individual jack extend / retract switches, jack position-locking pins, safety-locking pins, and impact wrench. Each jack can be locked in a horizontal stowaway or vertical operational position. The jack is cylindrical shaped with a telescopic body that can be extended or retracted as needed to raise and lower the vehicle. A solid cylindrical lift rod slides inside a cylindrical outer housing with a high-pressure seal means used to maintain pressure on the support rod. A ground support foot (plate) is mounted on the lower end of the solid cylindrical lift rod to provide sufficient traction with the ground to support the lifting process. A quick release air coupler is included on the pneumatic chamber to support the use of an air hose and impact wrench. An extend / retract toggle switch is included on each jack to control a solenoid valve to allow the air to flow into the jack. A quick release safety-locking pin is used to mechanically pin the solid cylindrical lift rod to the outer housing once the desired height is achieved to assure that the vehicle does not fall down in the event of a high-pressure air loss, thereby providing safety to the person(s) working around the vehicle. An air compressor located in the engine compartment of the vehicle is mechanically belt-driven off the engine. A high-pressure air line carries the air to a high-pressure (at least 120-psi) air tank located in the trunk or other suitable storage area on the vehicle. Separate air lines extend from the air tank to the individual jacks.

Owner:WILLETT MICHAEL J

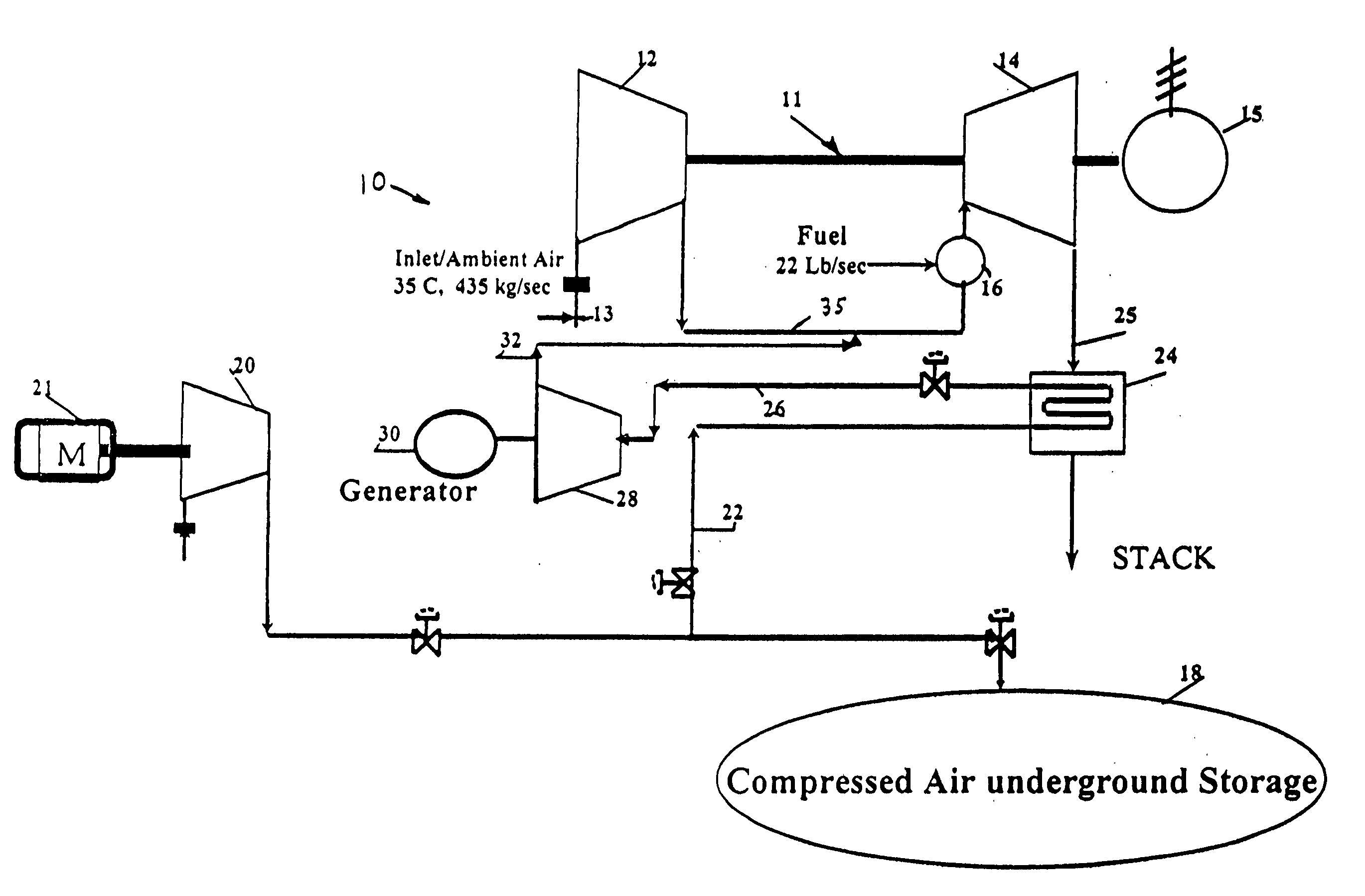

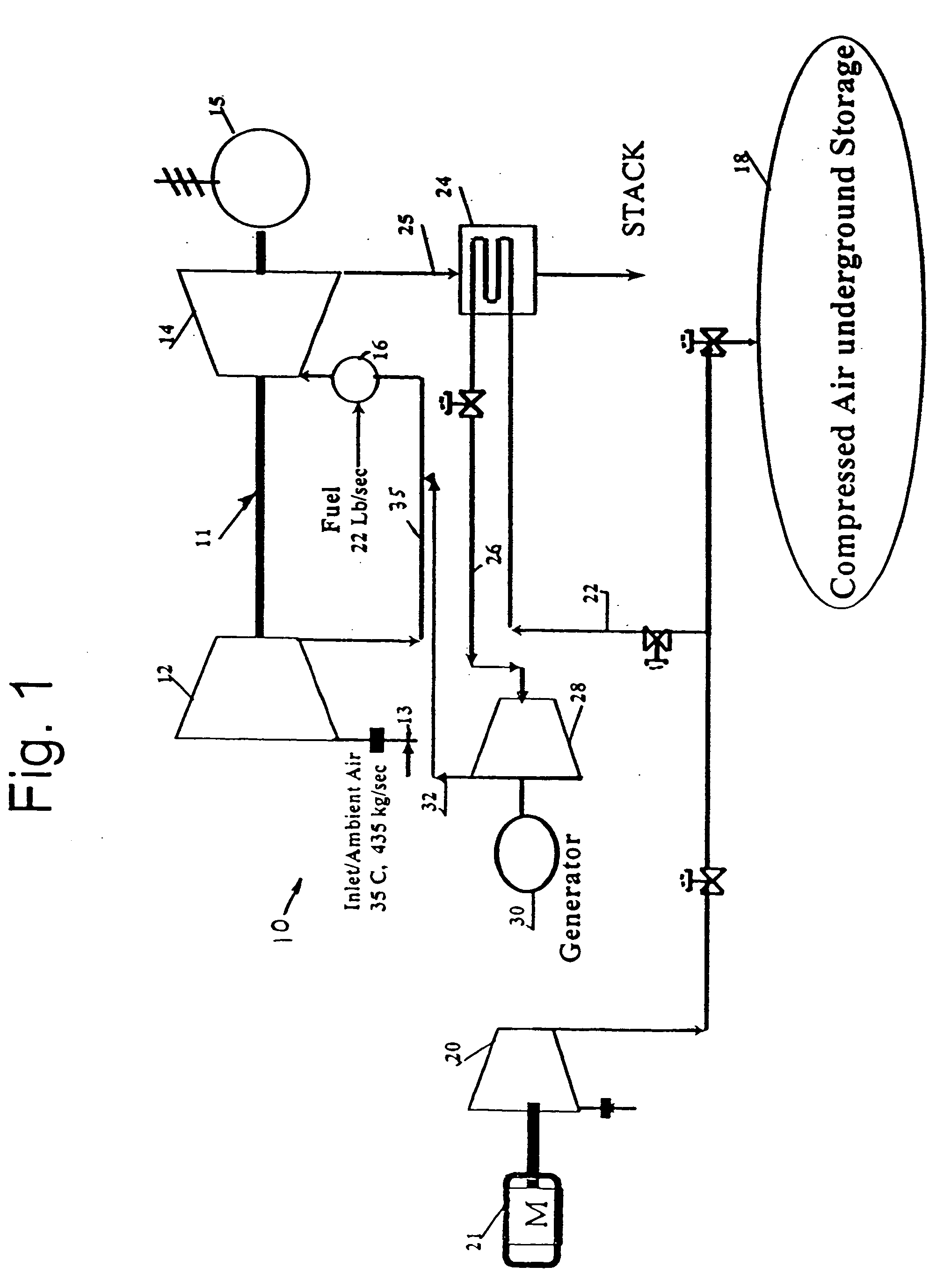

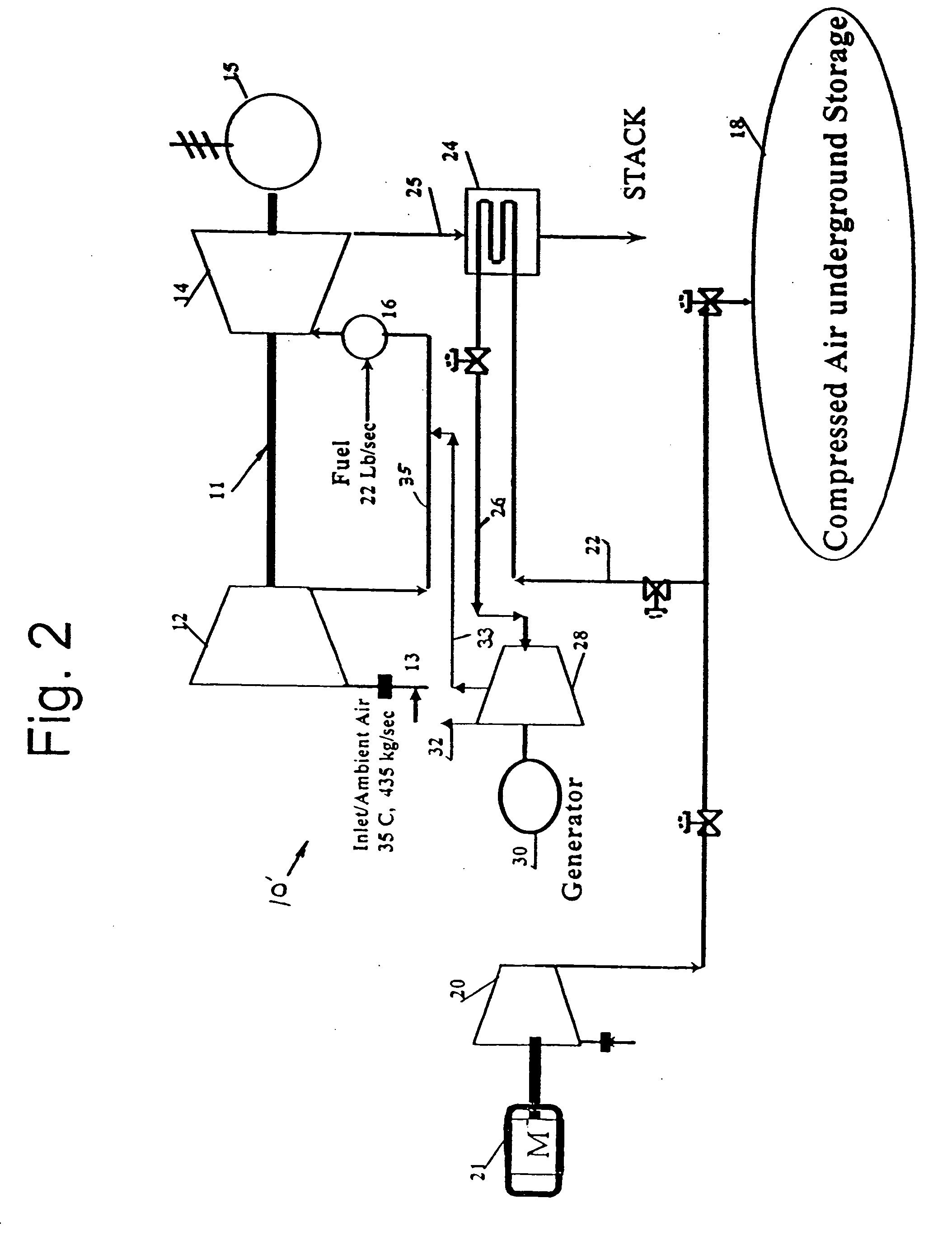

Power augmentation of combustion turbines with compressed air energy storage and additional expander

InactiveUS20080272598A1Gas turbine plantsMechanical energy handlingGas compressorThermal energy storage

A combustion turbine power generation system (10) includes a combustion turbine assembly (11) including a main compressor (12) constructed and arranged to receive ambient inlet air, a main expansion turbine (14) operatively associated with the main compressor, combustors (16) constructed and arranged to receive compressed air from the main compressor and to feed the main expansion turbine, and an electric generator (15) associated with the main expansion turbine for generating electric power. A compressed air storage (18) stores compressed air. A heat exchanger (24) is constructed and arranged to receive a source of heat and to receive compressed air from the storage so as to heat compressed air received from the storage. An air expander (28) is associated with the heat exchanger and is constructed and arranged to expand the heated compressed air to exhausted atmospheric pressure for producing additional electric power via an electric generator associated with the expander and to permit only a portion of airflow expanded by the air expander to be injected, under certain conditions, into the combustion turbine assembly.

Owner:NAKHAMKIN MICHAEL

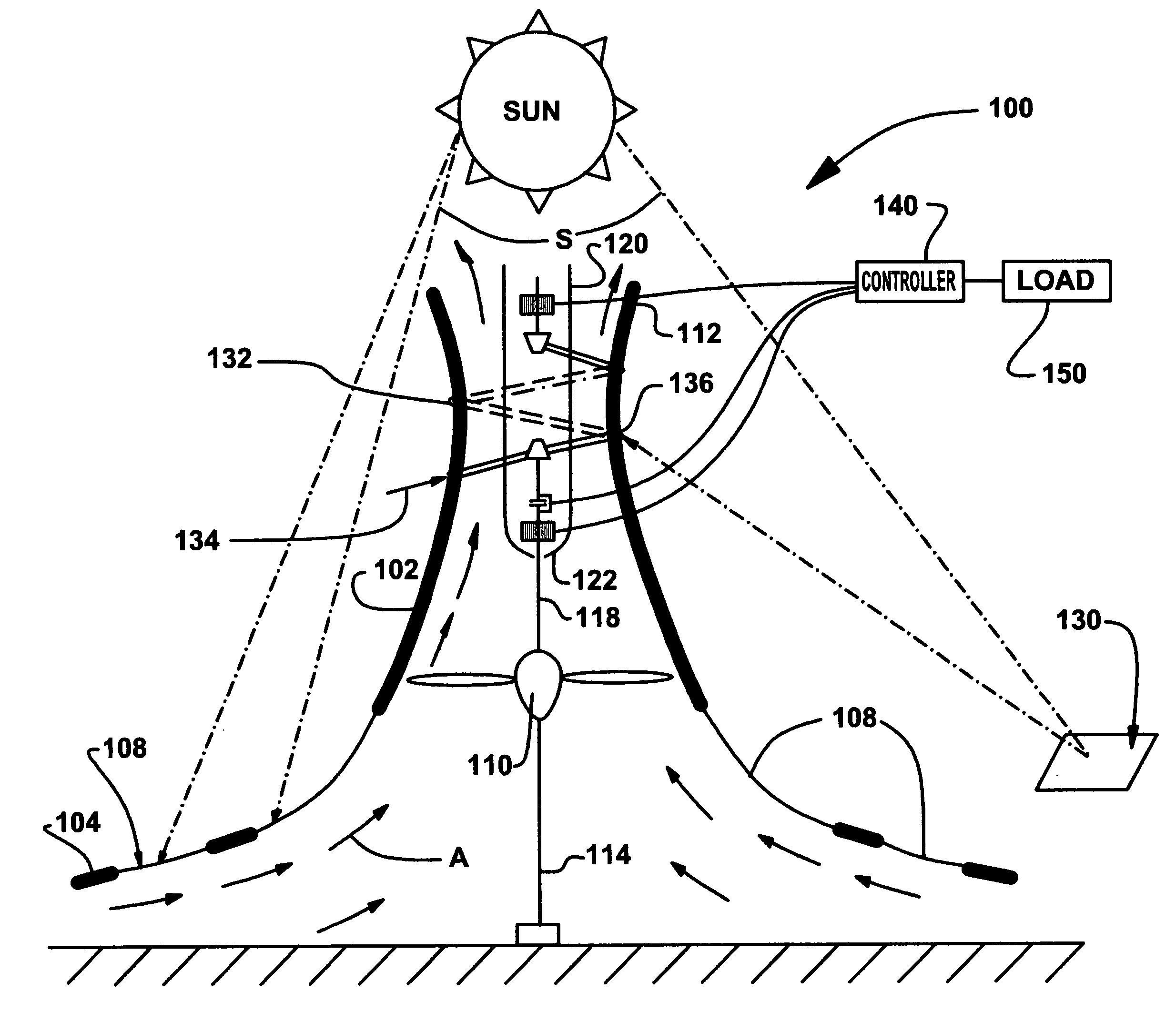

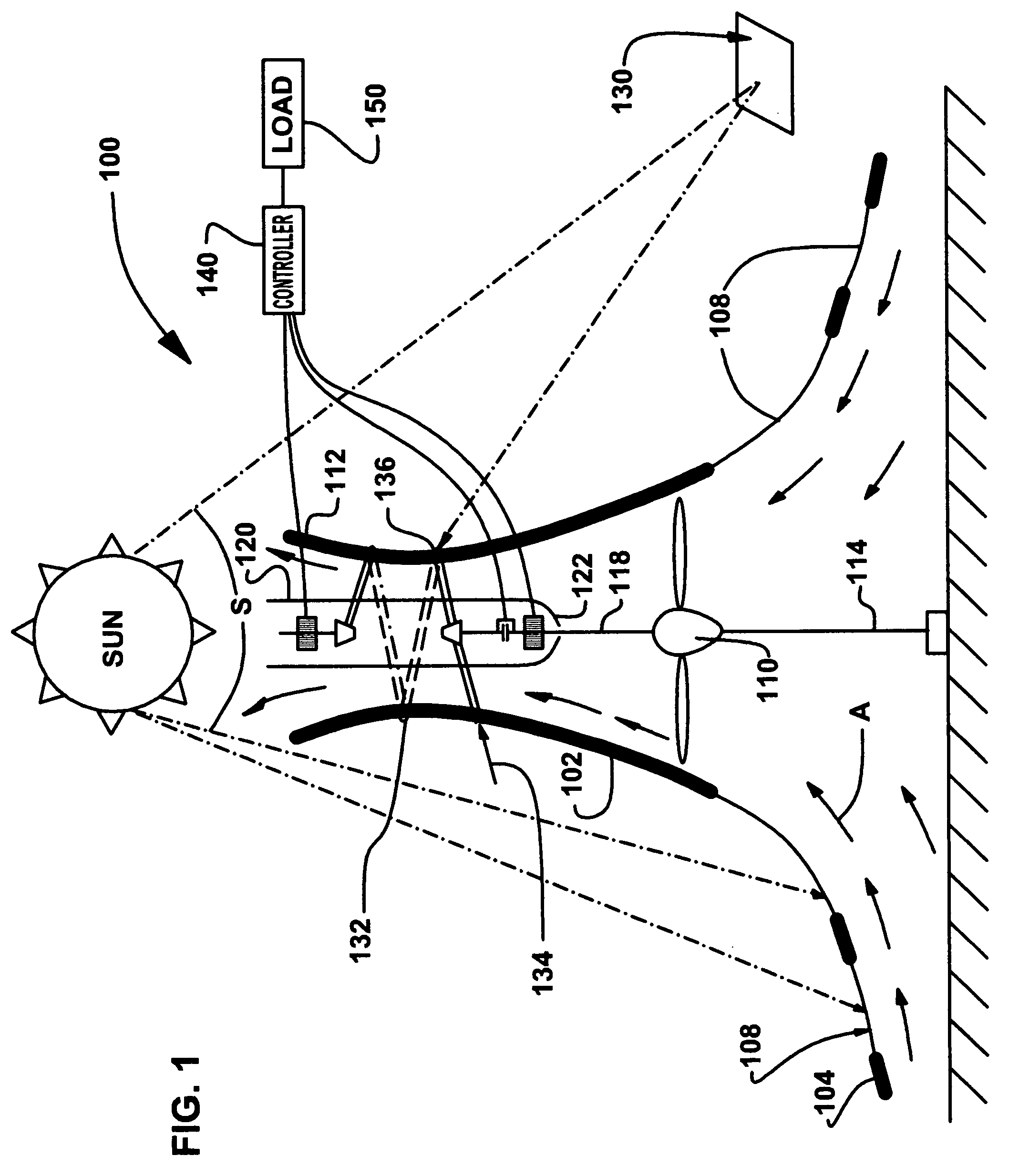

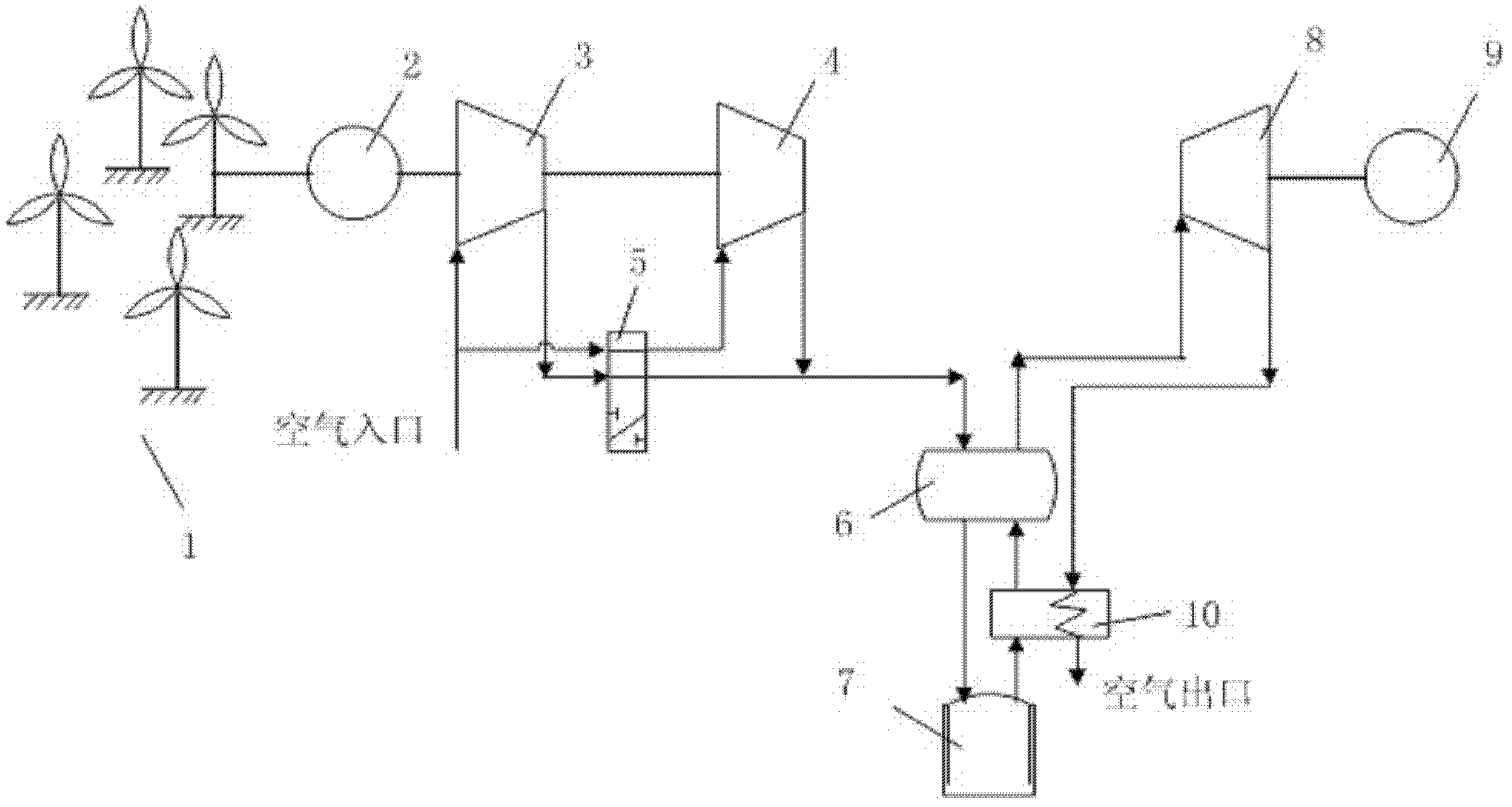

Hybrid solar thermal chimney

A solar power arrangement for converting solar energy into electricity comprising; a solar chimney, the chimney having a flared base spaced from the ground the chimney including a transparent surface to allow solar energy to heat air within the solar chimney. A first air turbine drives a first generator, and the chimney including an exhaust. The first air turbine drives an air compressor and wherein the compressor includes an ambient air intake and a plurality of pipes for receiving compressed attached to the solar chimney. A plurality of heliostats focus solar energy on the pipes to heat the compressed air contained therein and a second turbine driven by expansion of the compressed air wherein the second turbine drives a second generator.

Owner:LE JOHN O +2

Beverage dispensing apparatus

ActiveUS20120187153A1Lower the volumeReduce pressureLiquid flow controllersLiquid transferring devicesGas compressorEngineering

The present invention relates to a refillable keg assembly for use in dispensing beverages, in particular beer. The keg assembly comprises an outer shell, and a collapsible container for holding the beverage, positionable within the outer shell. A sealed cavity is defined between the outer shell and the collapsible container. A beverage outlet from the collapsible container enables beer to be dispensed from the keg assembly, and a gas valve allows gas to enter the cavity. The pressure in the container is maintained above atmospheric pressure, and when dispensing the beverage, pressure in the cavity collapses the collapsible container and forces the beverage out through the beverage outlet. A gas compressor is connected to the gas valve, and is activated by a pressure switch to maintain the pressure within the cavity. To refill the keg assembly, the collapsible container can be replaced, and a new collapsible container filled whilst within the outer shell.

Owner:COOPERS BREWERY

Rotary knocking gas turbine

InactiveCN104153884AImprove cycle thermal efficiencyLower Burn Control SystemGas turbine plantsJet propulsion plantsCombustion chamberGas compressor

The invention discloses a rotary knocking gas turbine. The rotary knocking gas turbine comprises a gas inlet passage, a diffusion section and a gas storage chamber which are connected in sequence from left to right, wherein a gas compressor is arranged at the downstream of the gas inlet passage; a rotary knocking combustion chamber is positioned at the right end of the gas storage chamber, the right end of the rotary knocking combustion chamber is connected with a mixing chamber, a turbine and an exhaust pipe in sequence, a plurality of nozzles are annularly arranged on the left end face of the rotary knocking combustion chamber at equal intervals, and six ignition plugs are uniformly arranged on the circumference of the rotary knocking combustion chamber; an air passage and a combustion passage are arranged on each nozzle, the gas storage chamber is communicated with the rotary knocking combustion chamber through a gas supply passage and the air passages of the nozzles, and the mixing chamber is communicated with the gas storage chamber through a gas escape bypass; a rotor is arranged between the gas compressor and the turbine, the gas compressor of a rotating component of the gas turbine and the turbine are connected with a casing of a static bearing component of the gas turbine through two bearings, and one end of the rotor is led out from the gas exhaust pipe. When the rotary knocking gas turbine is used, the leading-out end of the rotor is connected with a generator assembly through a speed changer.

Owner:XIAN THERMAL POWER RES INST CO LTD

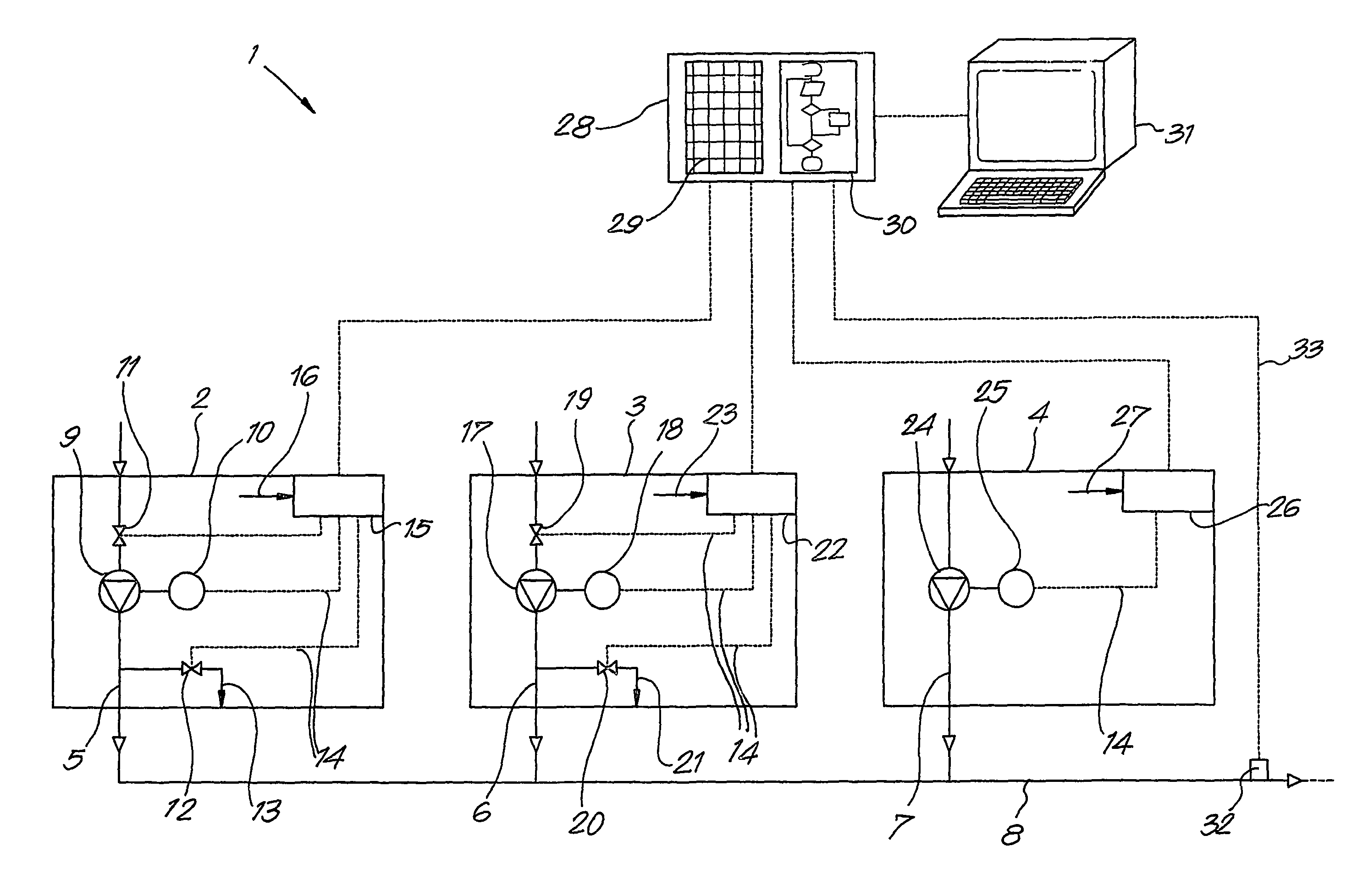

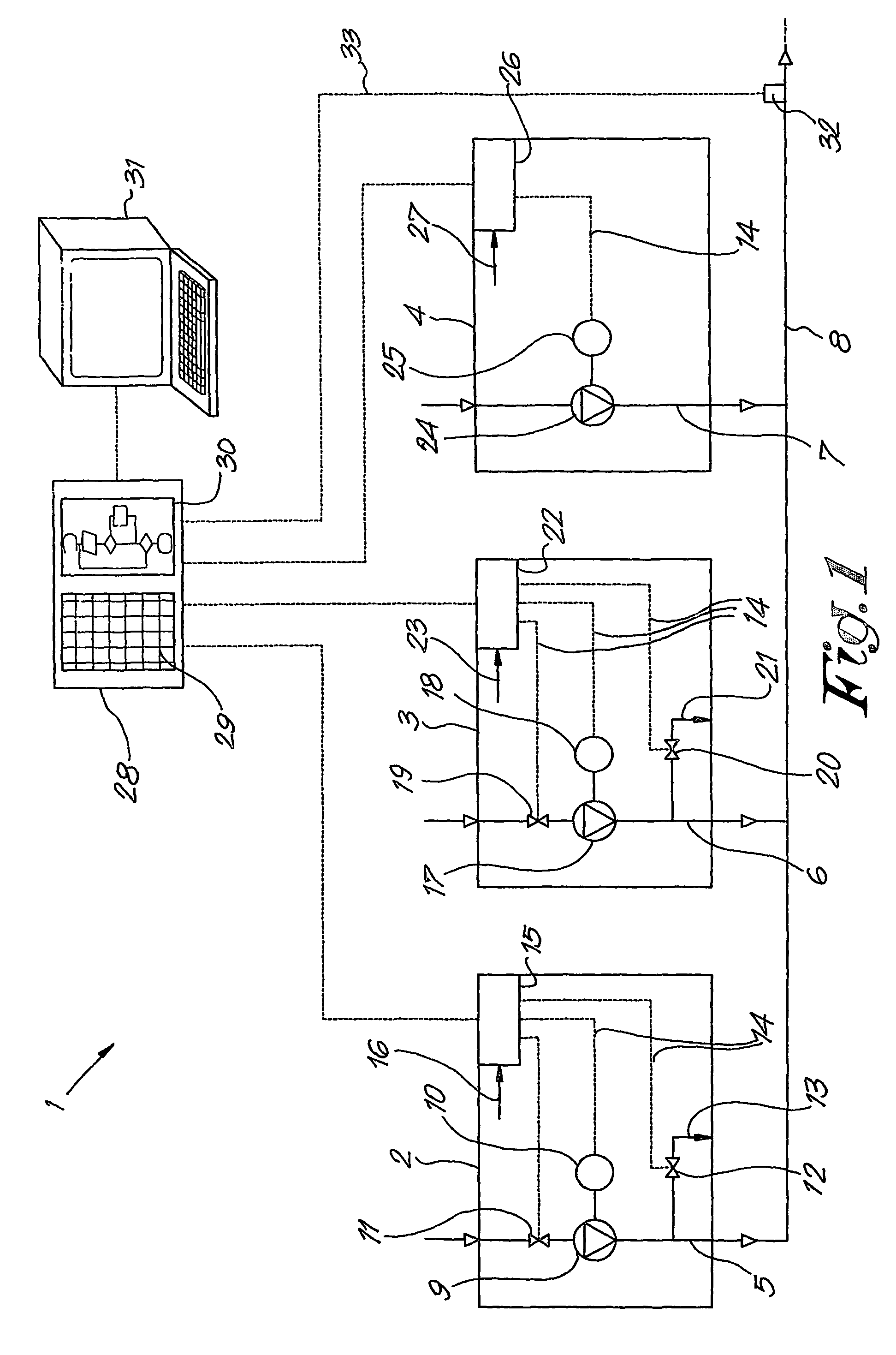

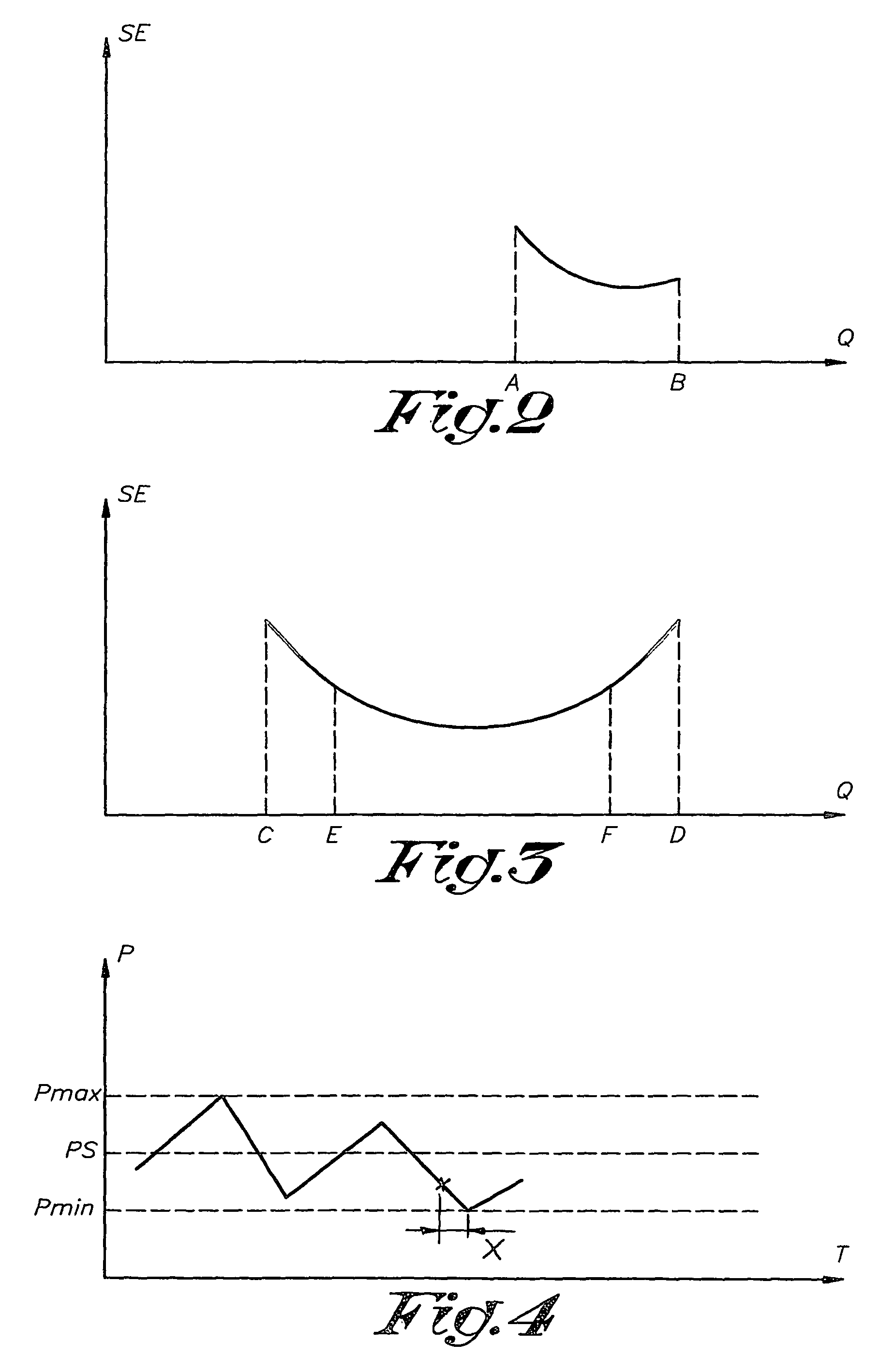

Method for controlling a compressed air installation comprising several compressors, control box applied thereby and compressed air installation applying this method

ActiveUS7955056B2Easy to adjustFlexible member pumpsWorking fluid for enginesGas compressorEngineering

Method for adjusting a compressed air installation using several electrically driven compressors of what is called the “loaded / unloaded” type and / or the turbo compressor type and / or the compressor type with variable rotational speed, wherein these compressors are each connected to a single compressed air network with their outlets, and wherein use is made of a control box which makes it possible to adjust the pressure in the compressed air network around a target pressure to be set. The adjustment takes place by controlling the flow of one or several of the compressors, in particular in order to increase the overall flow supplied by the compressors when the pressure drops too much, and in order to lower the overall supplied flow when the pressure becomes too high.

Owner:ATLAS COPCO AIRPOWER NV

Compressor inter-stage temperature control

InactiveUS20120261092A1Mechanical apparatusCompression machines with non-reversible cycleTemperature controlGas compressor

A method, system and apparatus for providing temperature control of compressed gases between stages of a multiple-stage compressor, by selectively manipulating a valve which can cause at least a portion of the compressed gases to flow through an air-cooled heat exchanger.

Owner:HEATH RODNEY T +2

Compressed-air energy-storage system

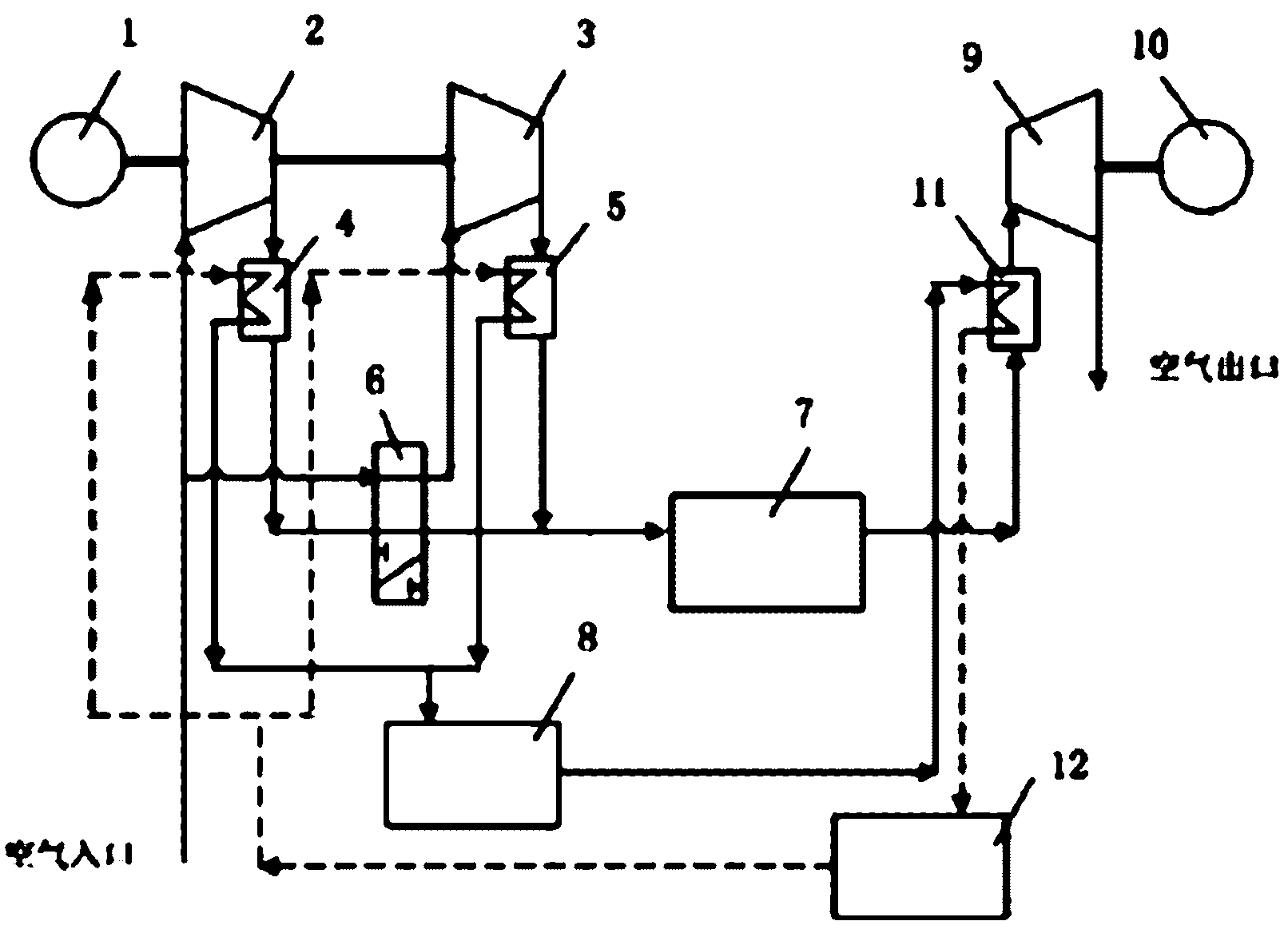

ActiveCN102213113AIncrease flexibilityChange flowFrom solar energyWind energy with garvitational potential energyPower stationFour-way valve

The invention relates to a compressed-air energy-storage system. A three-position four-way valve is arranged in a pipeline of a compression part and an expansion part of the system and the flowing condition of air in the system is changed by utilizing the feature of change of a turn-on state of the three-position four-way valve, thus the variation of the manners of serial-connection and parallel-connection between a gas compressor and a turbine is realized, and the overall working efficiency is increased. With the adoption of the three-position four-way valve, on one hand, the overall flexibility of the compressed-air energy-storage system is improved, so that the operating of the system is more targeted, and the use of the compressed-air energy-storage system matched with various types of power stations is facilitated; and on the other hand, the service condition of turbomachinery is improved, and the optimized configuration of the turbomachinery according to the needs of energy storage and power generation can be realized.

Owner:中科国风科技有限公司

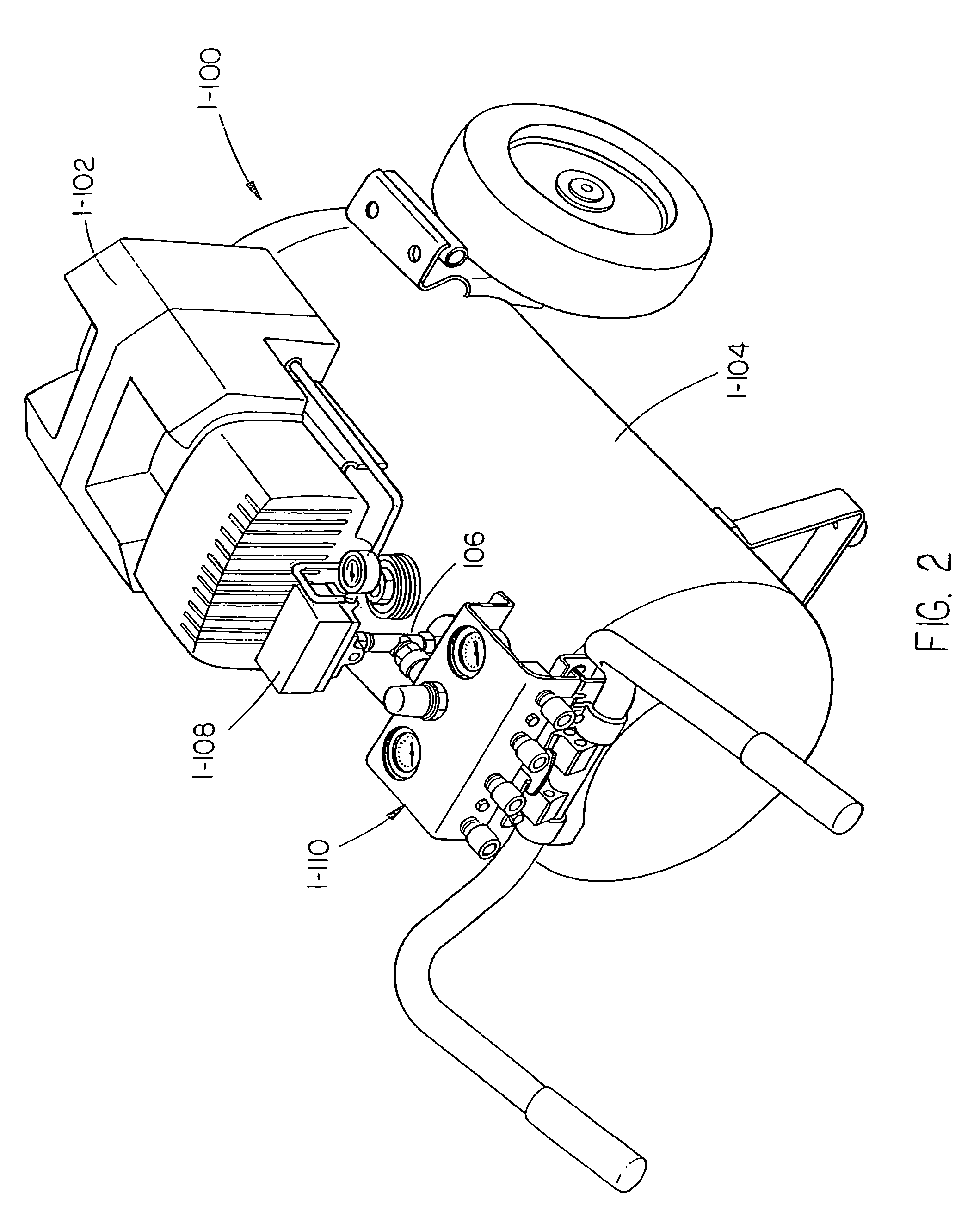

Air compressor with extensible handle bar assembly

InactiveUS6923627B1Damage to contactPrevent removalValve arrangementsPipeline systemsGas compressorPneumatic tool

An air compressor assembly with one or more of the following features: a removable manifold assembly capable of being remotely located from the air compressor assembly for controlling and distributing compressed air from the air compressor assembly to one or more air powered tools, a lifting handle, a handle capable of assuming a plurality of positions, condensate removal devices, and a stable base and tie-down points.

Owner:BLACK & DECKER INC

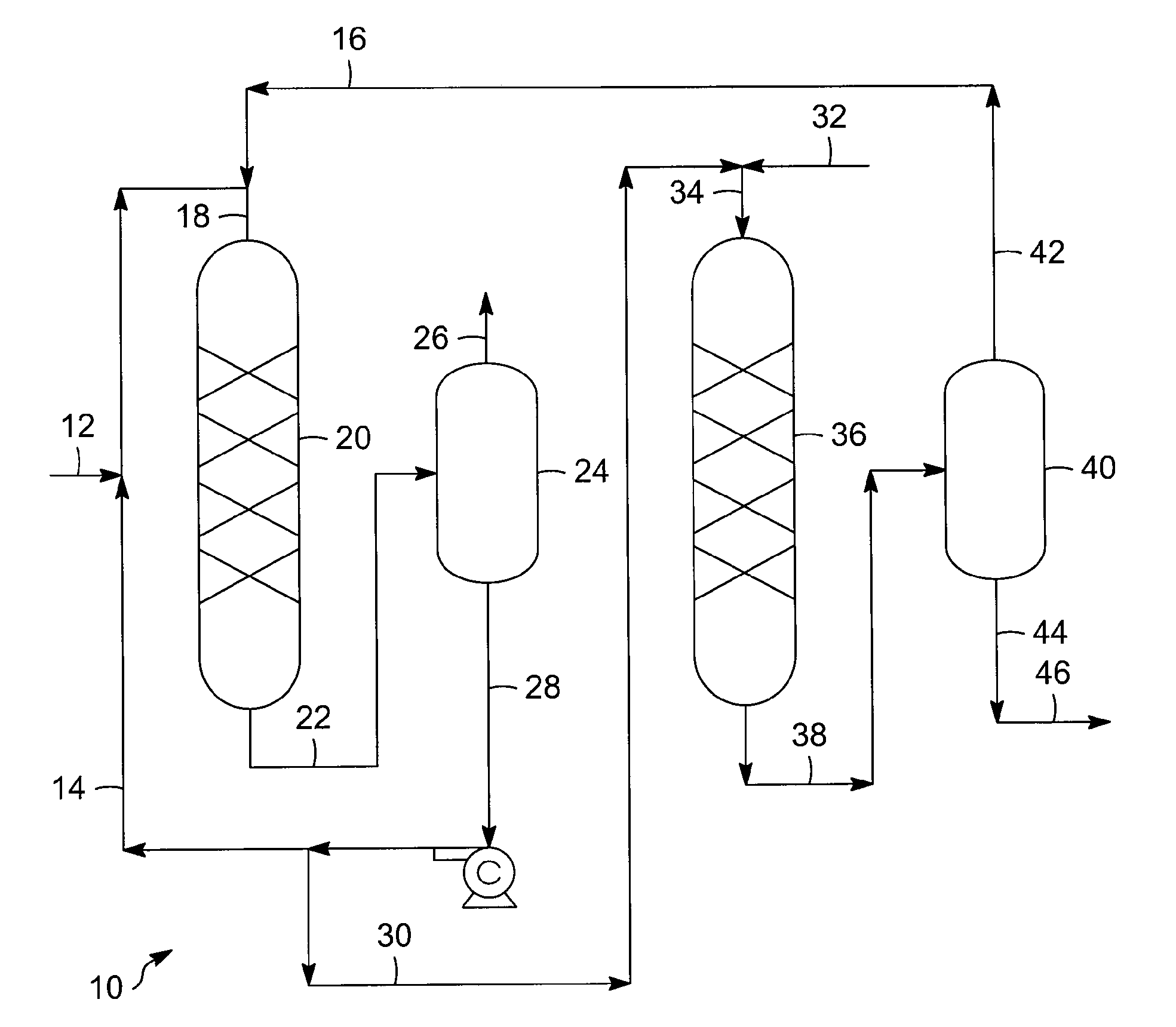

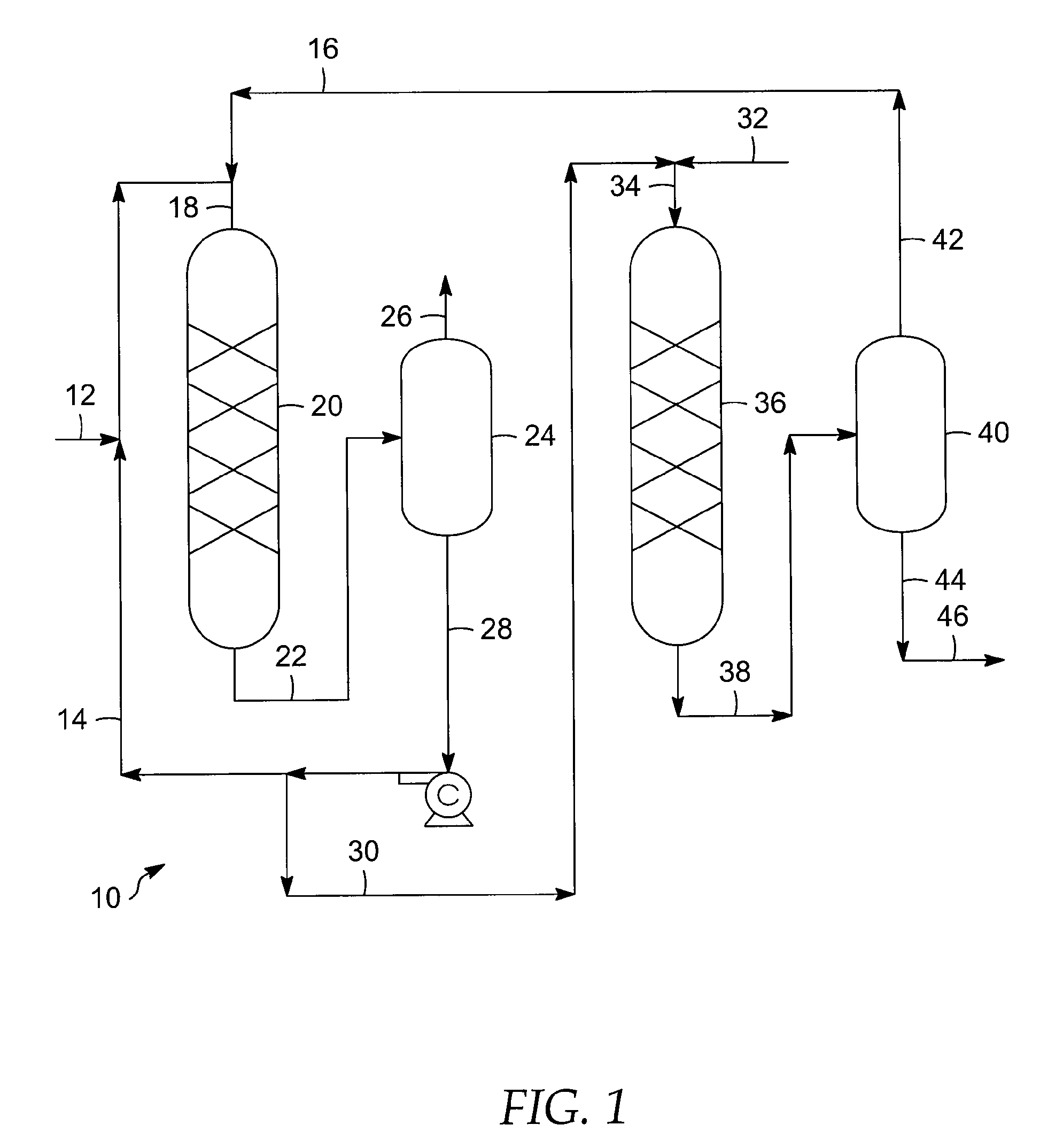

Three-Phase Hydroprocessing Without A Recycle Gas Compressor

ActiveUS20090321310A1Improvement to capital effectivenessReduction in required utilityTreatment with plural serial cracking stages onlyCoke ovensHydrogenGas compressor

In general, methods of hydroprocessing a hydrocarbonaceous feed stock are provided that do not use a costly recycle gas compressor, but are still able to use the more efficient reaction systems provided in a substantially three-phase hydroprocessing zone. The method combines a substantially liquid-phase hydroprocessing zone with the substantially three-phase hydroprocessing zone in a manner so that the hydrogen requirements for both reaction zones can be provided from an external source thereto without the use of a hydrogen recycle or recycle gas compressor to the substantially three-phase reaction zone.

Owner:UOP LLC

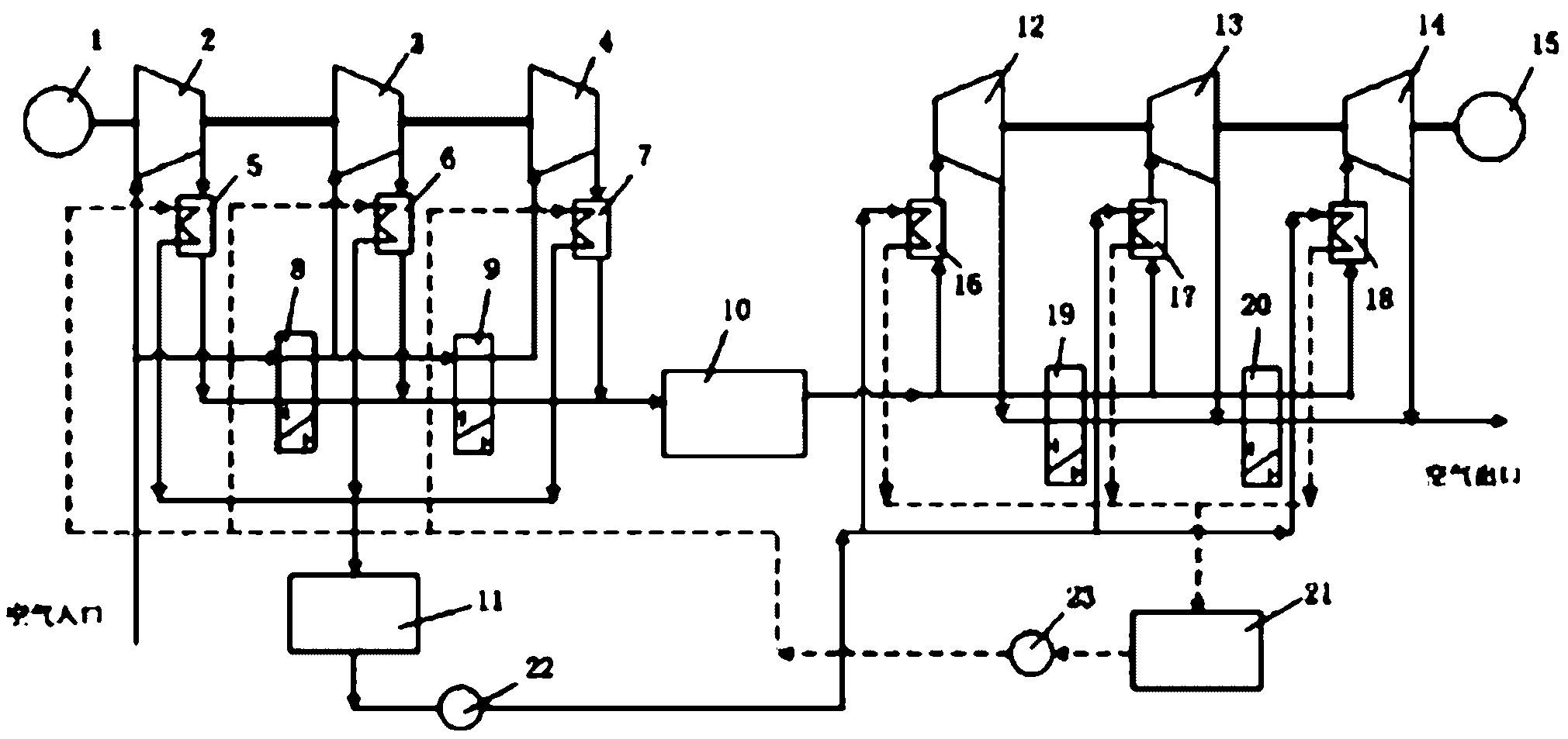

Multi-stage compressor

InactiveUS20110038737A1Increase capacityReduce capacityPump componentsFlexible member pumpsGas compressorEngineering

A system and a method for adding and subtracting stages of compression to a compressor as and when the compressor requires them. If the compressor needs only a low pressure ratio, then the system and method allow the compressor to operate with only a primary pumping circuit spinning, while available additional stages, forming a secondary pumping circuit, and which may be required at other times when the needed pressure ratios increase, are decoupled from the rotating shaft, so that the compressor pumps at its most efficient and flexible point. Further, a system and method for adding and subtracting stages of compression to a compressor in order to increase and decrease the pumping capacity as and when required to satisfy a given load requirement.

Owner:DANFOSS AS

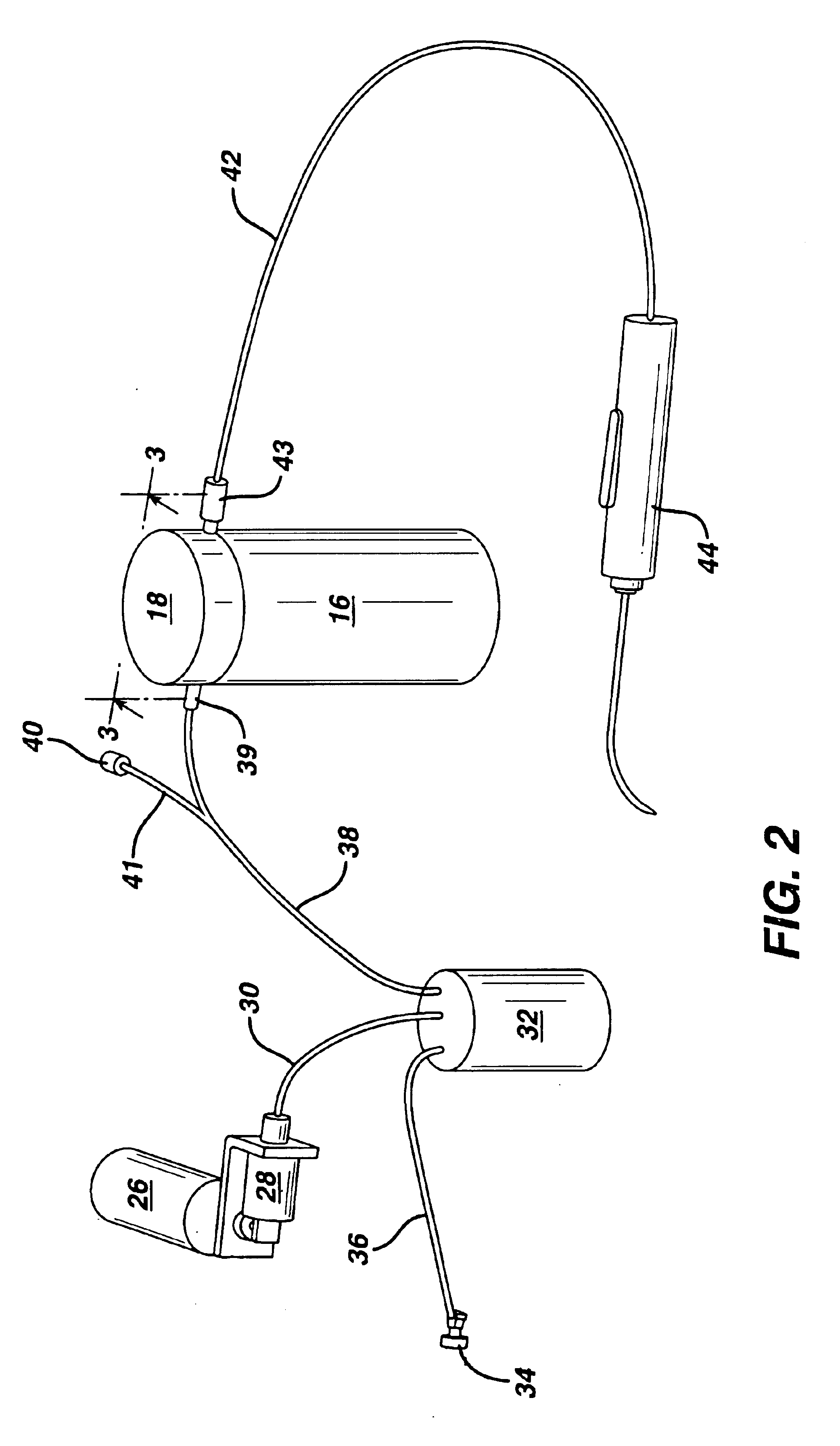

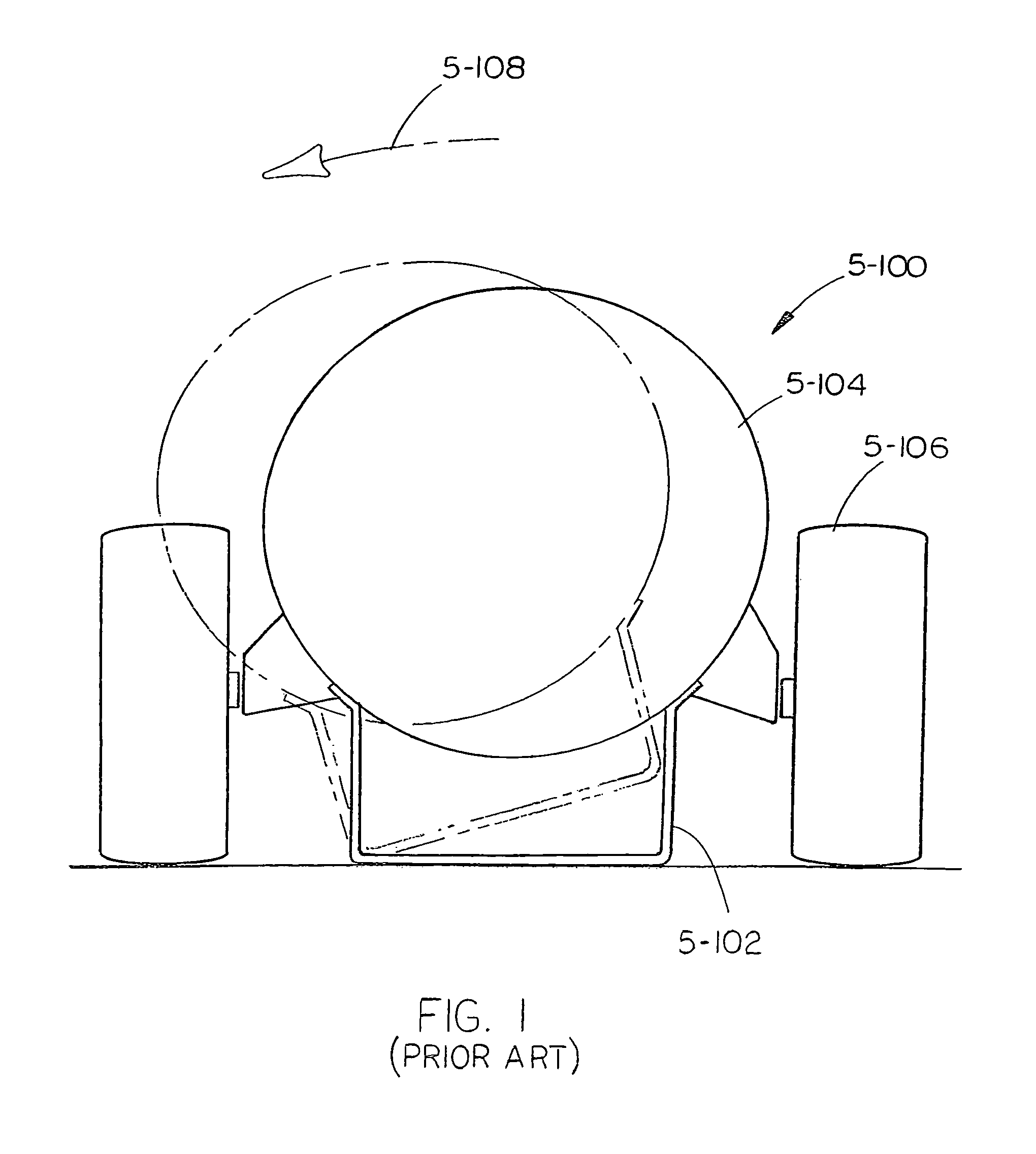

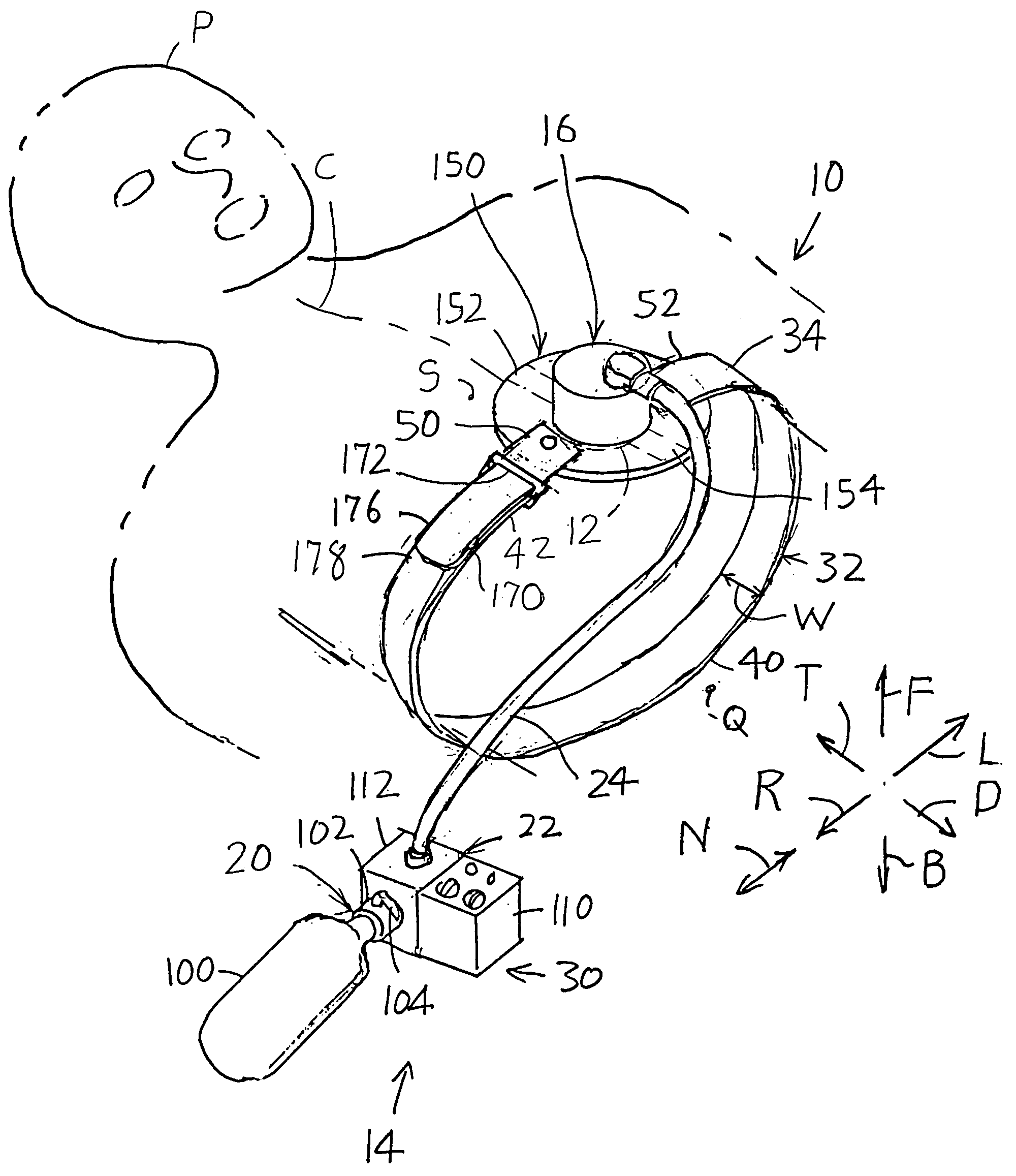

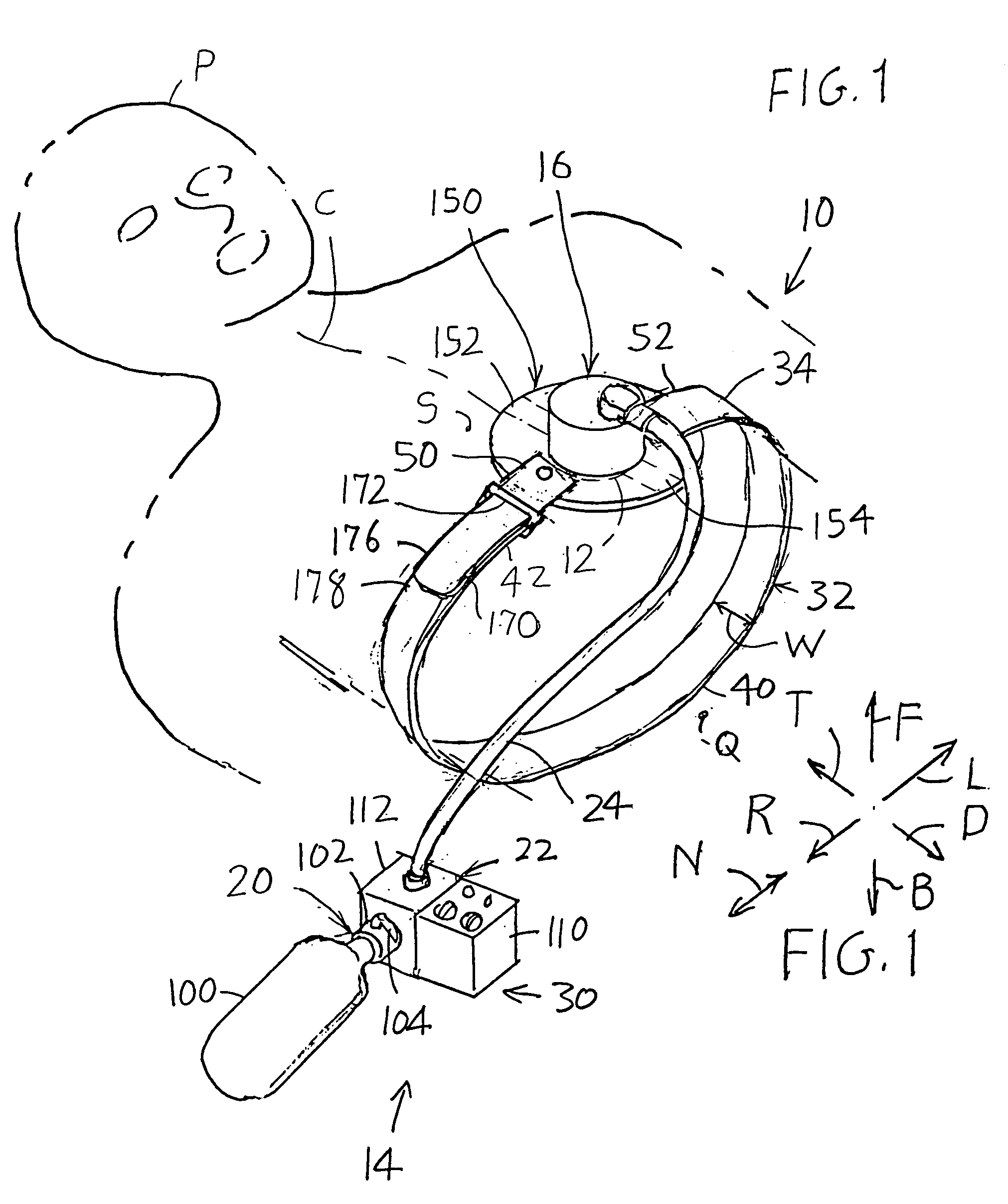

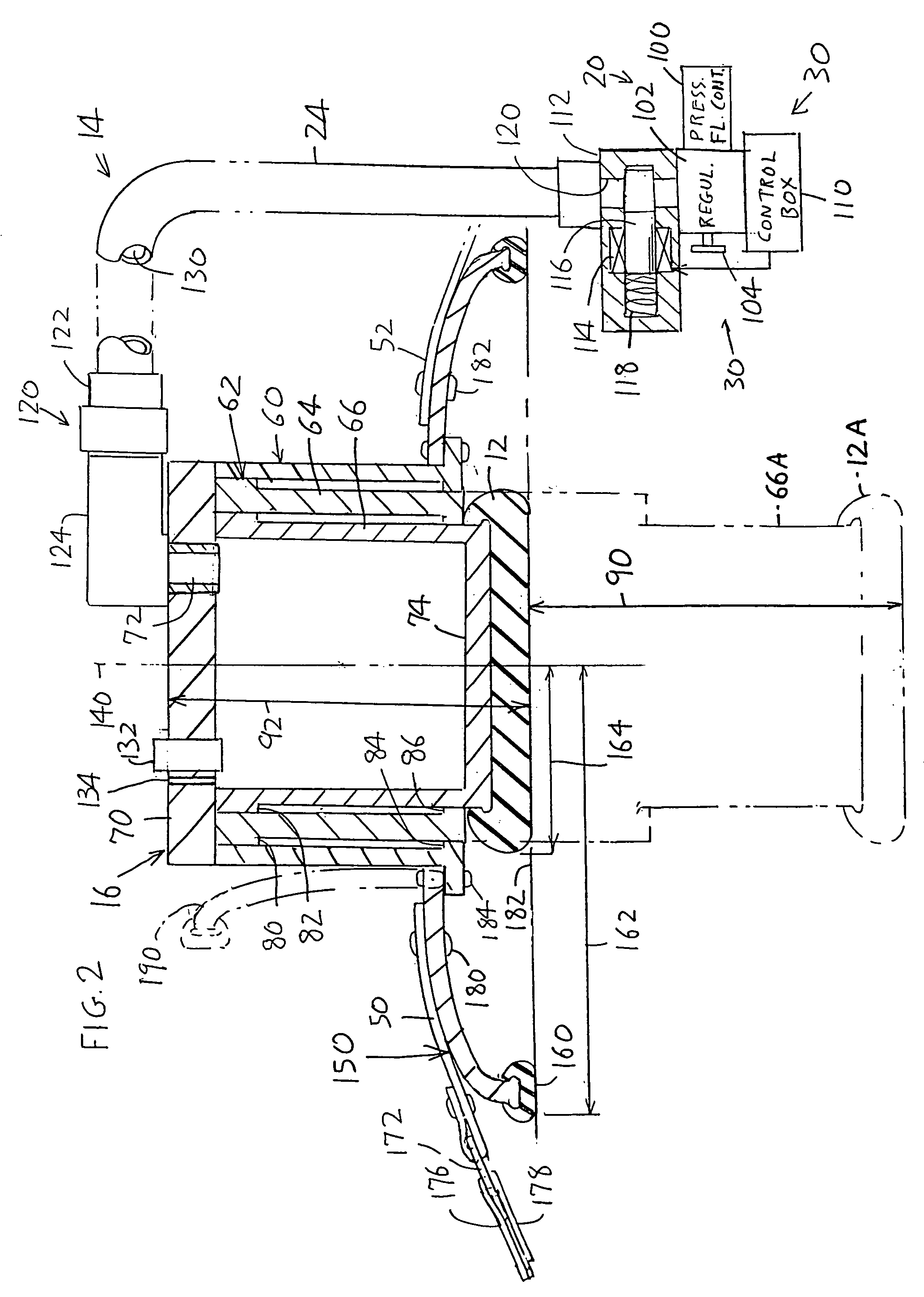

Chest compressor

InactiveUS7060041B1Light weightElectrotherapyChiropractic devicesPhysical medicine and rehabilitationGas compressor

Apparatus for compressing the chest of a patient to stimulate blood circulation, includes a torso wrap (32) that has a back portion (40) lying at the back of the patient's chest and a front portion (42) lying at the front of the patient's chest, and includes a compressor assembly with an actuator (16) having a pressing member (12) that can apply a series of force pulses to the sternum of the patient to stimulate blood circulation. The actuator is energized by pressured fluid, with a controlled pressured fluid source (20) connected by an elongated flexible hose (24) to the actuator so the pressured fluid source and a control (22) can lie on the ground and only the actuator lies on the torso wrap. The actuator includes a cylinder (66) and a plurality of telescoping piston parts (64, 66) to provide a long stroke in an actuator of small height. A stabilizer (150) that limits tilt of the actuator from the vertical, includes a saucer-shaped member that presses against the front of the patient.

Owner:SUNLIFE SCI INC

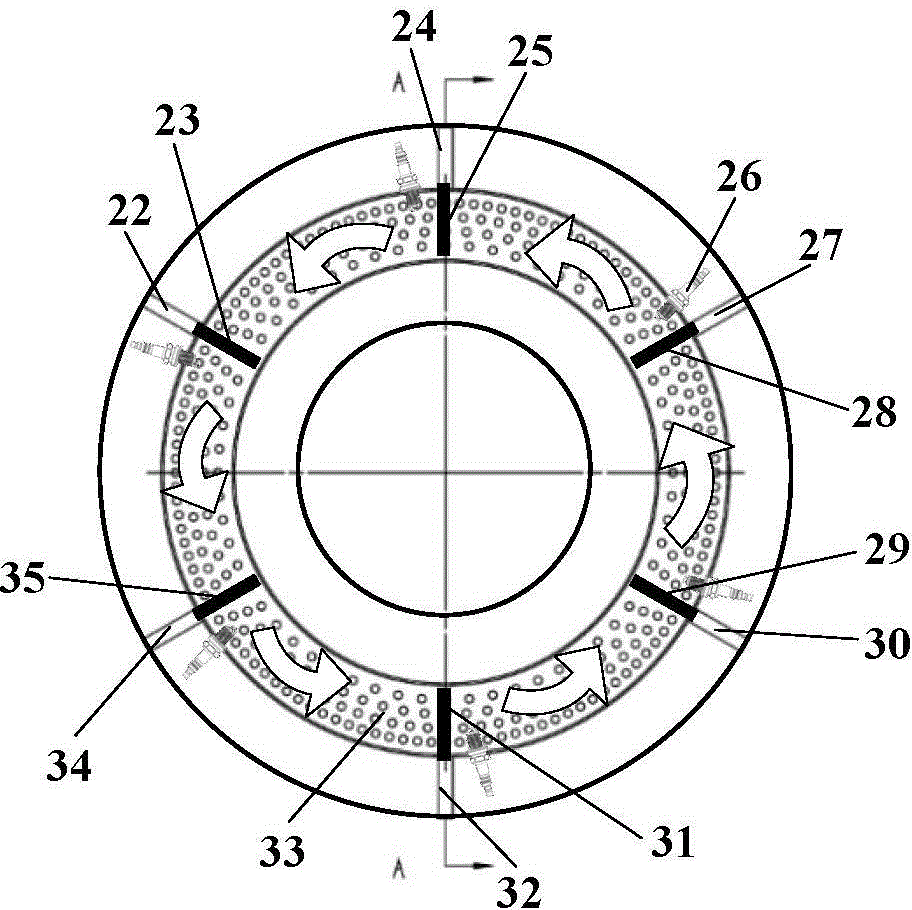

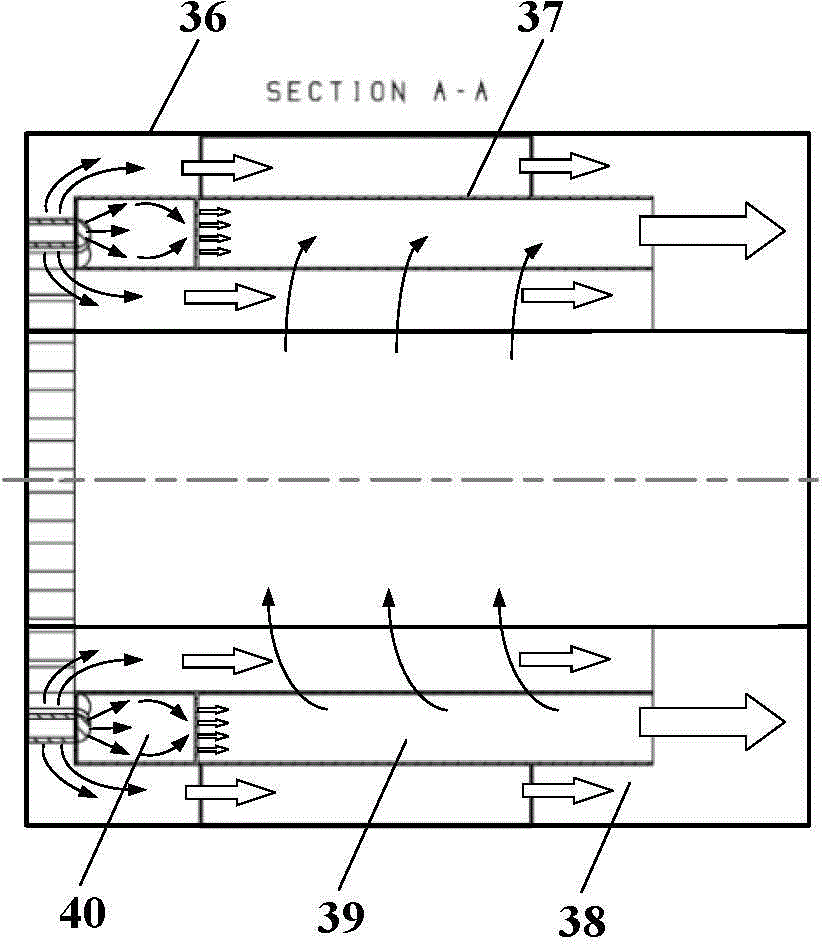

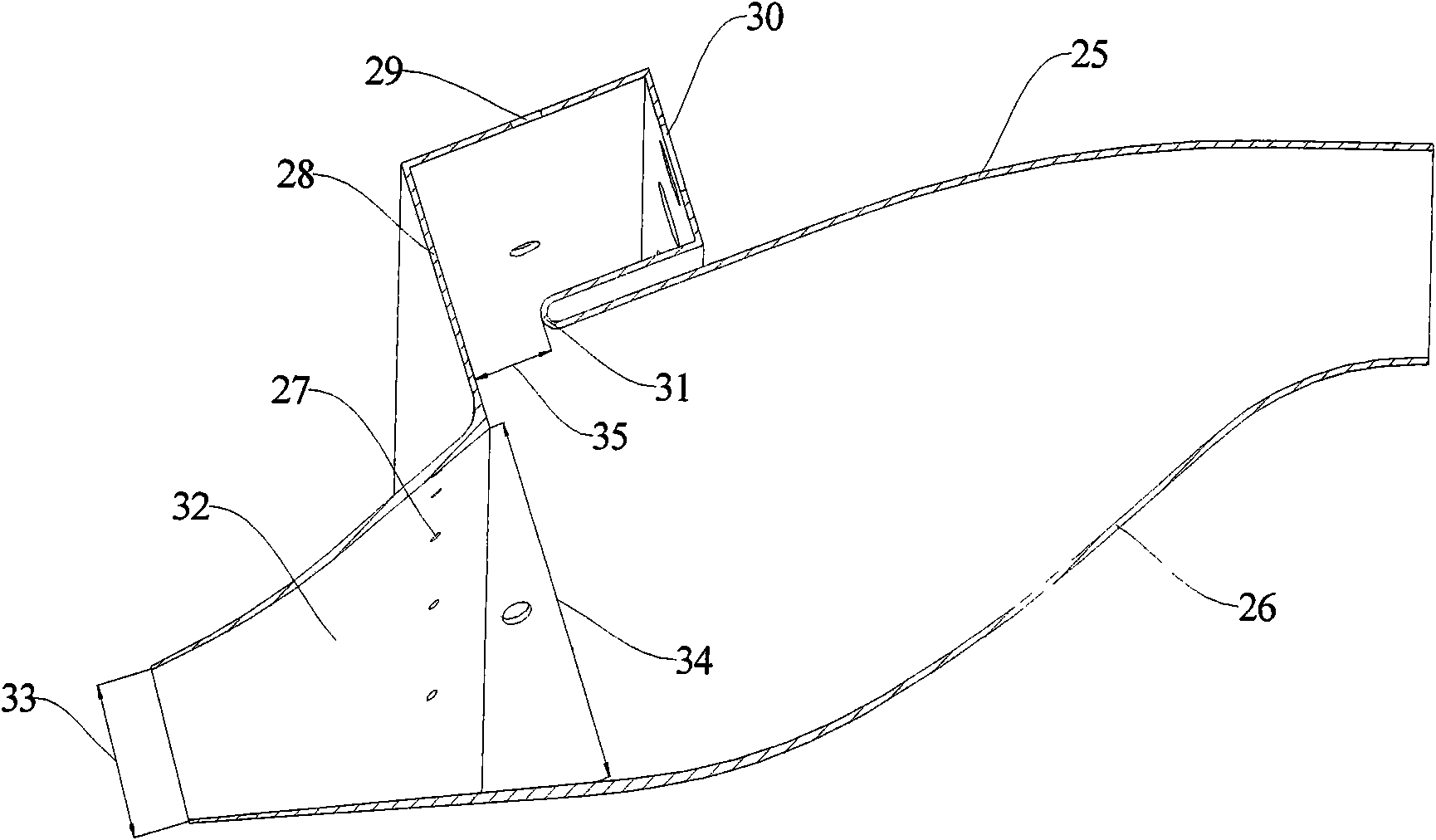

Integrated diffusion oriented combustion chamber

InactiveCN101650038AGuaranteed temperature distributionSimplified matching structureContinuous combustion chamberLow speedCombustion chamber

The invention relates to an integrated diffusion oriented combustion chamber which adopts a full ring combustion chamber structure. The integrated diffusion oriented combustion chamber mainly comprises a crankcase, a combustion liner and an oriented diffuser. The oriented diffuser realizes pneumatic and structural coupling, controls the tangential flow direction and carries out diffusion and speedreduction, and a local return low-speed zone is formed, thereby being good for flame linkage and tangential stable combustion; grading combustion is adopted, and a pre-combustion grade can be selected to work alone and work together with a main pre-combustion grade according to work conditions; the pre-combustion grade utilizes the trapped vortex combustion technology for stable work, goes into amain combustion zone to inflame a main combustion grade through a contraction outlet, and provides a stable ignition source for the main combustion grade; fuel of the main combustion grade is injected to a main combustion grade airflow in the oriented diffuser, atomization evaporation mixing with short distance is realized, and combustible mixture gas with uniform mixing is provided for the maincombustion zone. The invention allows tangential rotational flow of a gas compressor to directly go into the combustion chamber so as to realize tangential highly efficient and stable combustion; in addition, the discharge of pollutants is low, pre-rotation is provided for a turbine, the structure can be simplified, the weight is lightened, and the densification of a gas turbine is realized.

Owner:BEIHANG UNIV

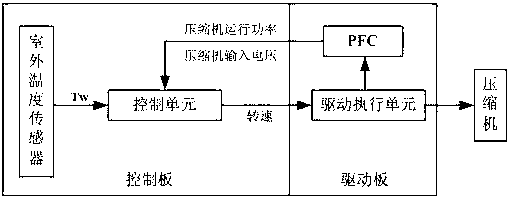

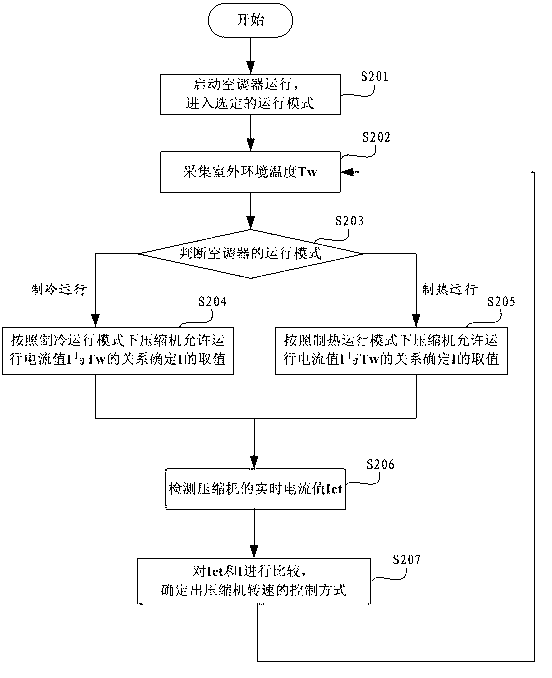

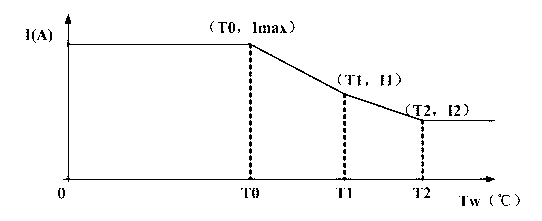

Rotation speed control method of air conditioner compressor and air conditioner

ActiveCN102937322AImprove reliabilityEnsure safetySpace heating and ventilation safety systemsLighting and heating apparatusElectricityGas compressor

The invention discloses a rotation speed control method of an air conditioner compressor and an air conditioner. The method comprises the following steps of: firstly detecting the temperature Tw of an environment in which an outdoor machine of the air conditioner is located; then determining an allowed running current value I of the air conditioner compressor according to the temperature Tw of the outdoor environment as well as a running mode of the air conditioner; and finally, detecting a real-time current value Ict of the air conditioner compressor, comparing the real-time current value Ict with the allowed running current value I, and lowering the rotation speed of the air conditioner compressor if the Ict>1 until meeting the condition that Ict<=1. The air conditioner provided by the invention implements different control strategies on the rotation speed of the compressor through the temperature of the outdoor environment, when the temperature of the outdoor environment is high, current passing through the compressor and a driving board canbe limited by limiting the rotation speed of the compressor, and thus the running current of the air compressor is always restricted within a range in which each electricity load on the driving board can run safely, so that the safety of the operation of the driving board is ensured, and the running reliability of the whole air conditioner is improved.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

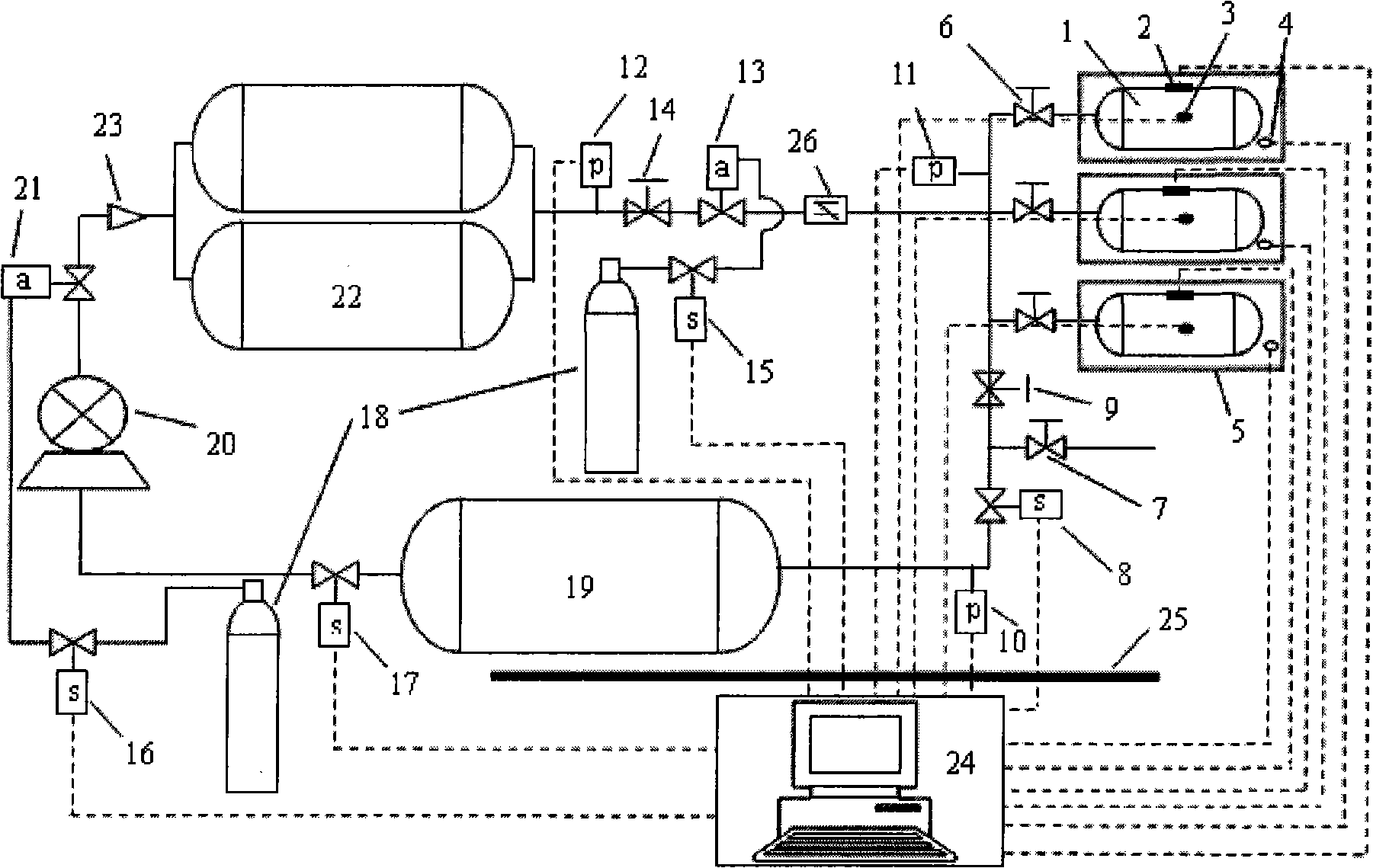

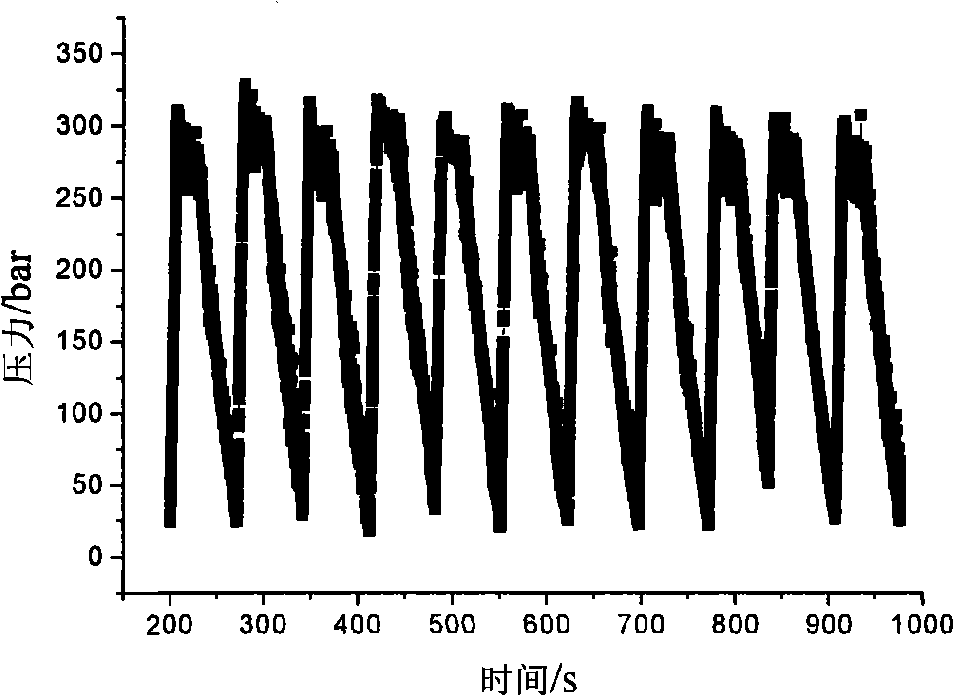

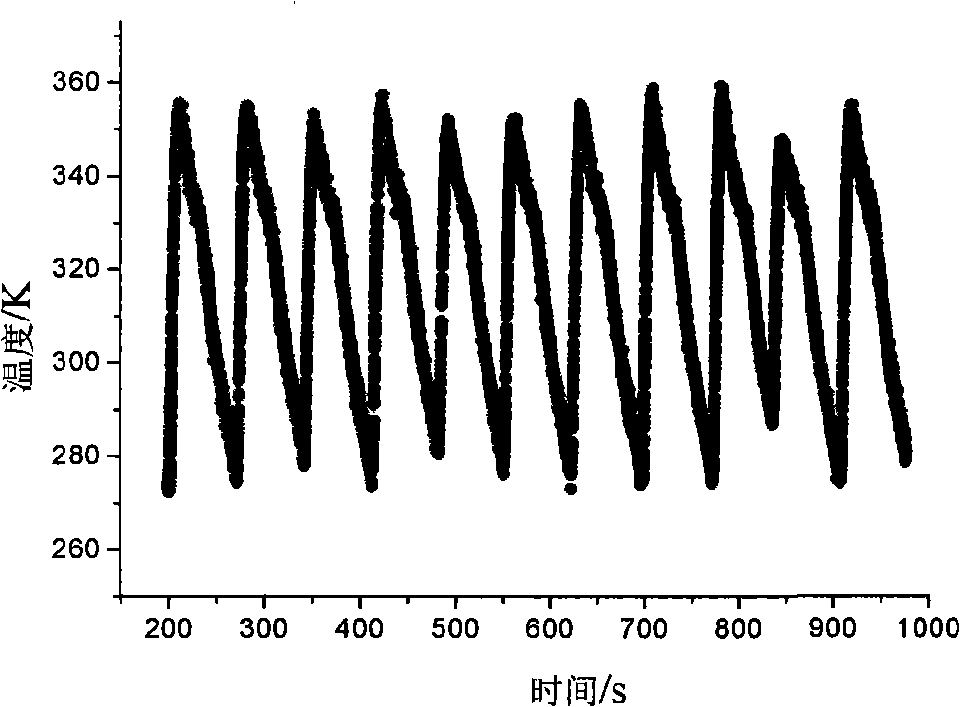

Gas circulation charging/discharging fatigue test system for full-automatic high pressure vessel

InactiveCN101403669ANo wasteNo pollutionMaterial strength using tensile/compressive forcesAutomatic controlSolenoid valve

The invention discloses a full-automatic high-pressure container gas circular charging and discharging fatigue test system which not only can realize the full-automatic control of the high-pressure gas circular charging and discharging fatigue test but also can carry out the on-line automatic detection to the fatigue condition of the high-pressure container. The automatic control of the circular charging and discharging is realized through the dynamic response signals of a temperature sensor arranged inside the tested container, the dynamic response signals of each pressure sensor on the high-pressure pipelines and switching of solenoid valves controlled by the control strategy. The gas medium in the circular charging and discharging process can be recycled after the pressurizing by a pressure-releasing receiving tank and a gas compressor so as to avoid the gas waste and environment contamination. The dynamic fatigue states of the high-pressure container in the circular charging and discharging process are acquired through the changing of response signals of a hydrogen sensor arranged in a sealed bin of the tested container and the response signals of a strain sensor stuck to the surface of the tested container; and when the released hydrogen concentration reaches the set value or the strain of the container material exceeds the set value in the charging and discharging process, the fatigue test system is closed automatically.

Owner:TONGJI UNIV

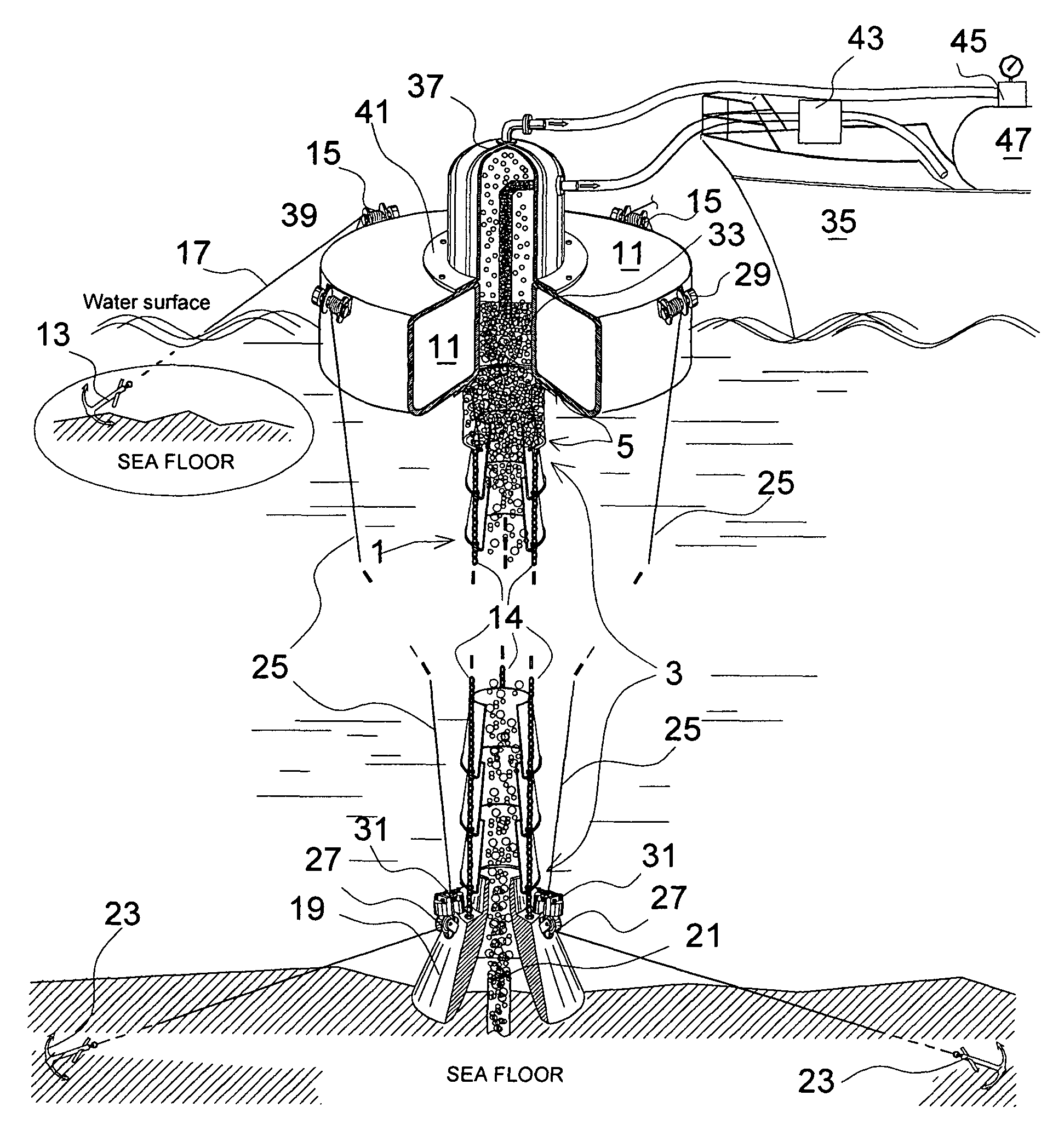

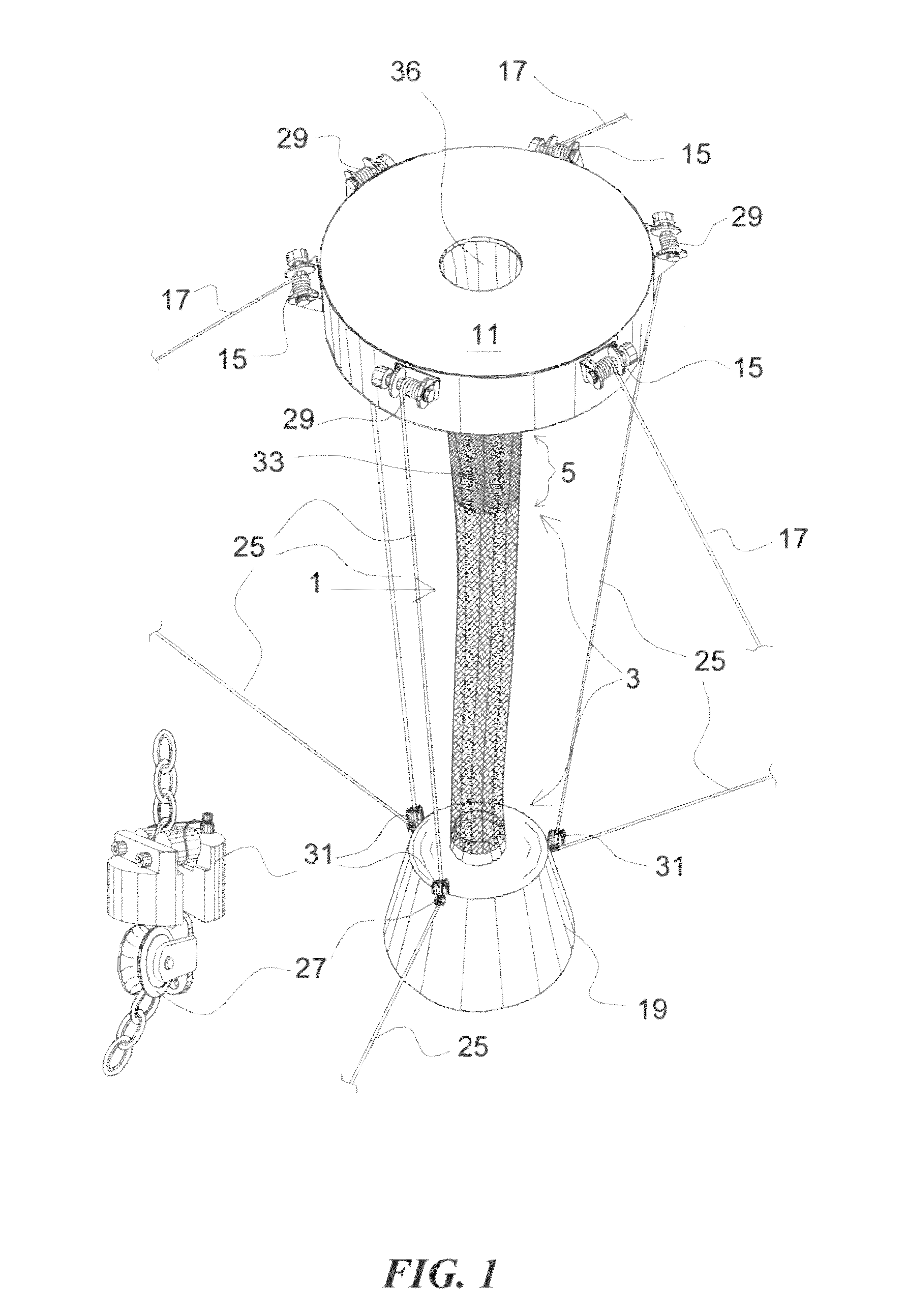

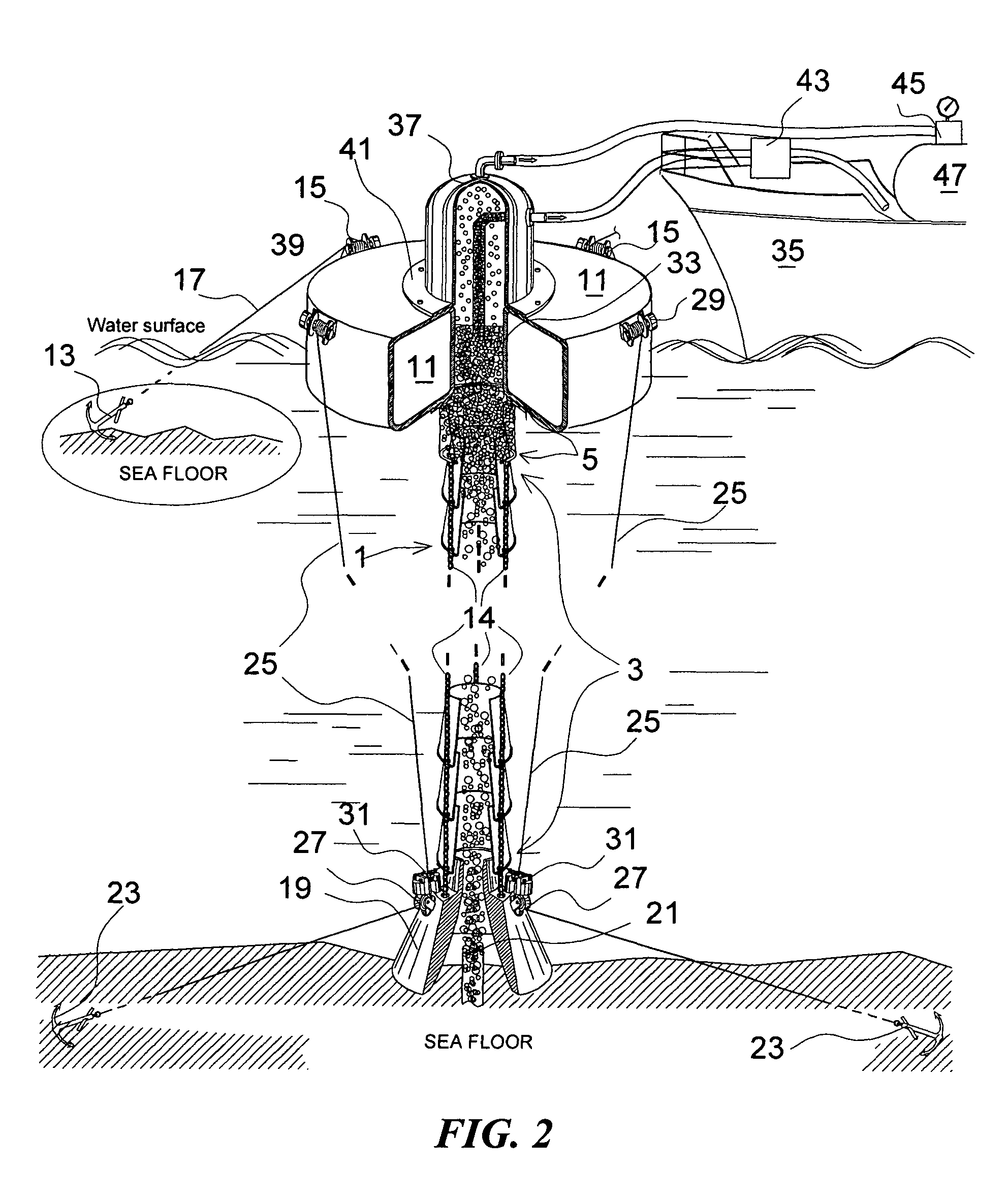

Marine oil leak recovery and marine petroleum mining method

A vertical flexible oil flow director hose is used to recover, to guide, and to filter the spilled oil from its source beneath the sea floor to the surface of water and to accumulate the floating oil therein for being ready to be pumped into an oil tanker. The said hose extends in the sea all the way from the sea floor to the surface of water by connecting its lower end to a circular sinking weight block and its upper end to a hollow doughnut-shaped floating device. The said hose includes two main portions abutting each other, the lower portion is for guiding and displacing water out through the gaps or meshes. The upper portion is for continued guiding and accumulating the oil in its upper section. A gas-tight dome cap having an opening at its bottom may be used to cap the upper opening of the oil accumulator well in the floating object, for holding the gas as necessary. A gas-compressor and gas tank or tanks will be equipped on the oil tanker ready to take and to store the gas.

Owner:CHE HUE NGUYEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com