Rotary knocking gas turbine

A gas turbine and detonation technology, which is applied to gas turbine devices, deflagration combustion chambers, combustion chambers, etc., can solve the problems of easy flameout, complicated combustion control system, and narrow combustion stable area of the combustion chamber, and achieves fast propagation speed and combustion efficiency. High, improve the effect of cycle thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

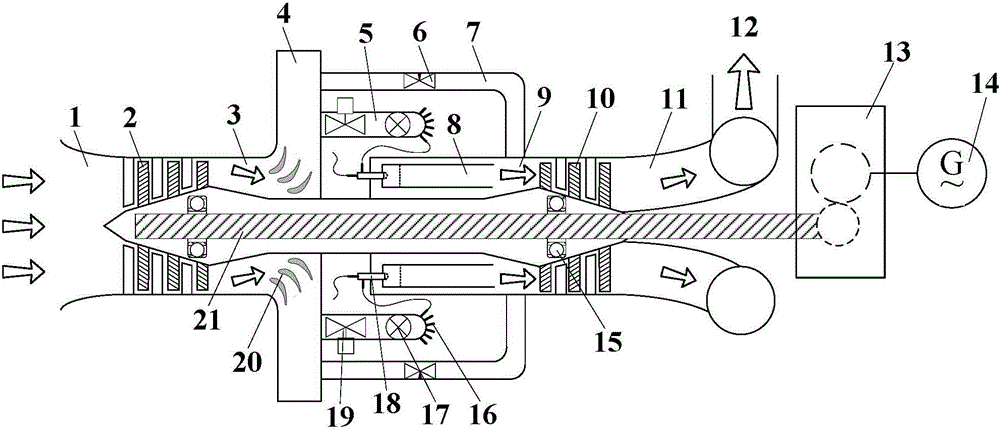

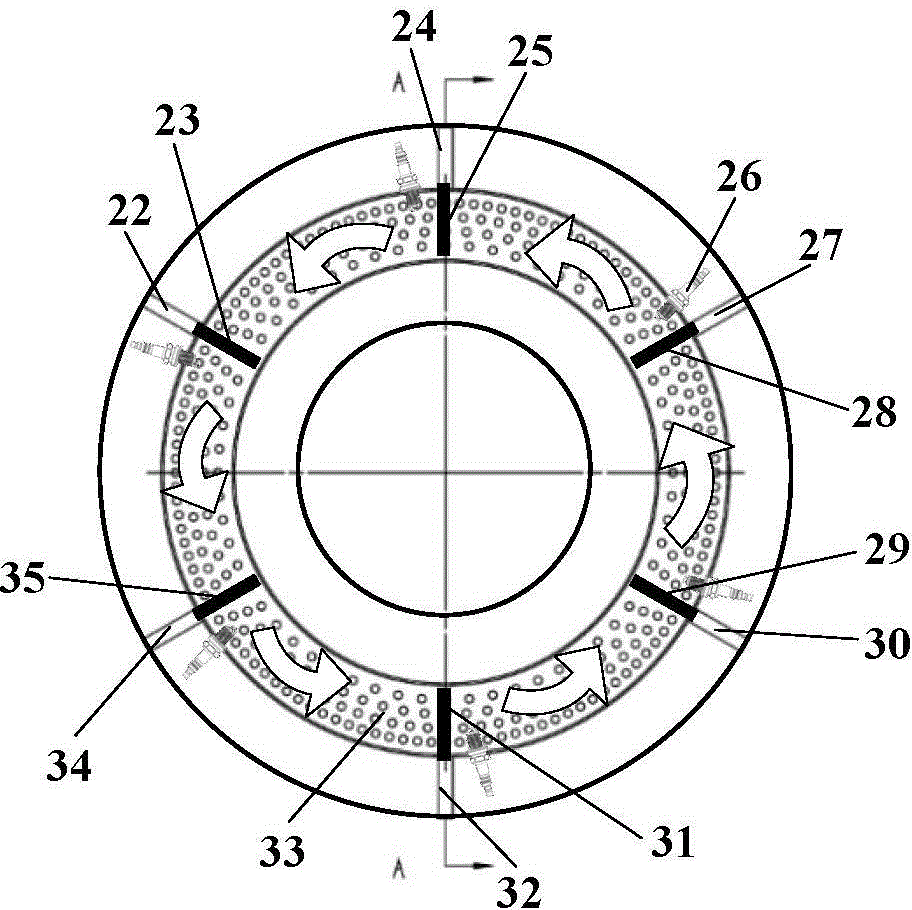

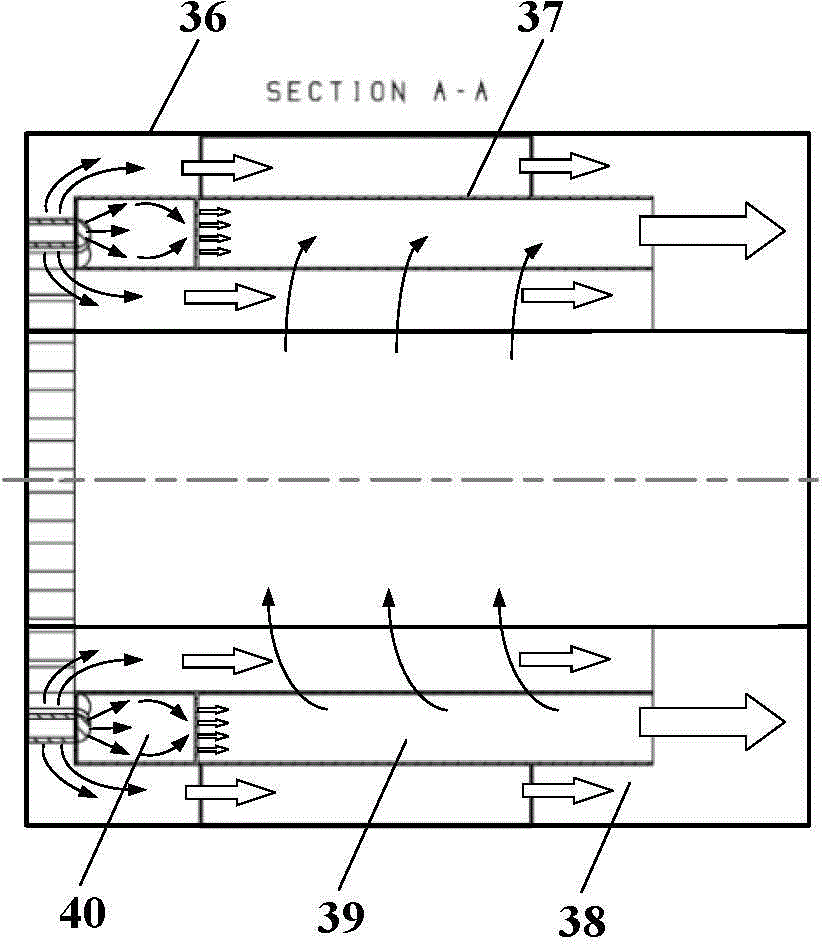

[0028]see figure 1 , a rotary detonation gas turbine of the present invention, comprising an air inlet 1, a diffuser section 3 and a gas storage chamber 4 sequentially connected from left to right, the compressor 2 is arranged downstream of the air inlet 1; the rotary detonation combustor 8 is located at the right end of the gas storage chamber 4, and the right end of the rotary detonation combustion chamber 8 is connected with a mixing chamber 9, a turbine 10 and an exhaust pipe 11 in sequence, and the left end surface of the rotary detonation combustion chamber 8 is provided with a plurality of nozzles in a ring at equal intervals 18. Six spark plugs 26 are evenly arranged in the circumferential direction of the rotary detonation combustion chamber 8; air passages 47 and fuel passages 48 are provided on a single nozzle, and the air storage chamber 4 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com