Patents

Literature

158results about How to "Improve cycle thermal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

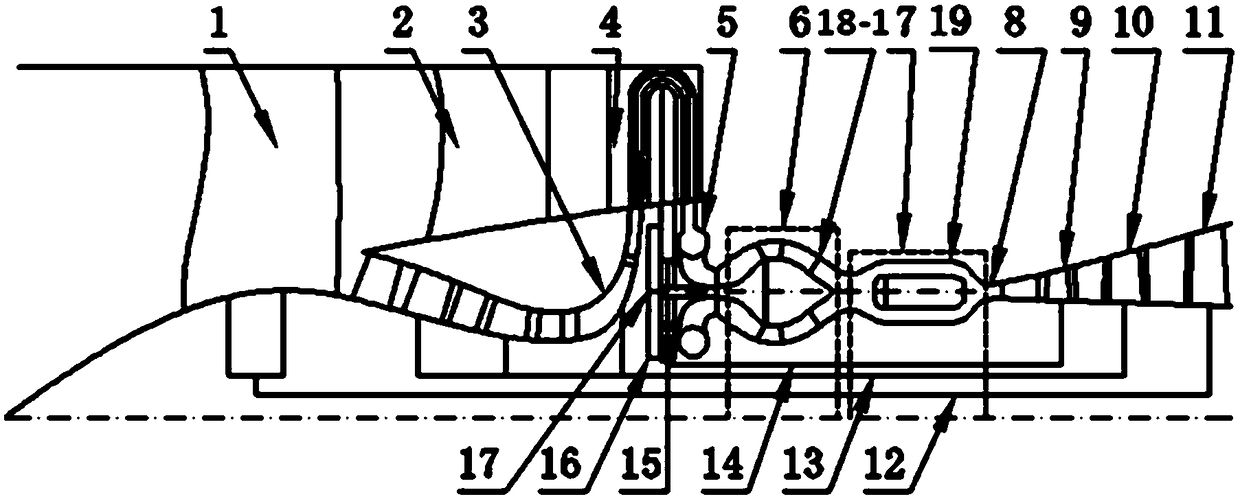

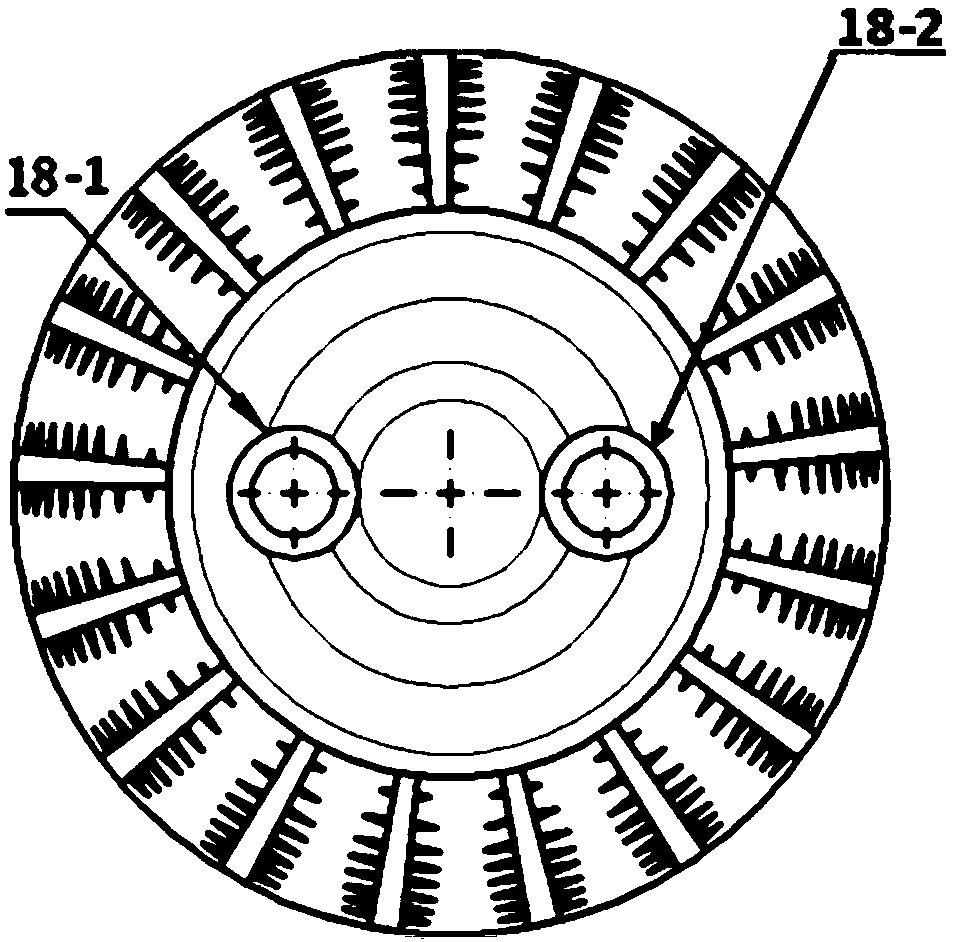

Rotary knocking gas turbine

InactiveCN104153884AImprove cycle thermal efficiencyLower Burn Control SystemGas turbine plantsJet propulsion plantsCombustion chamberGas compressor

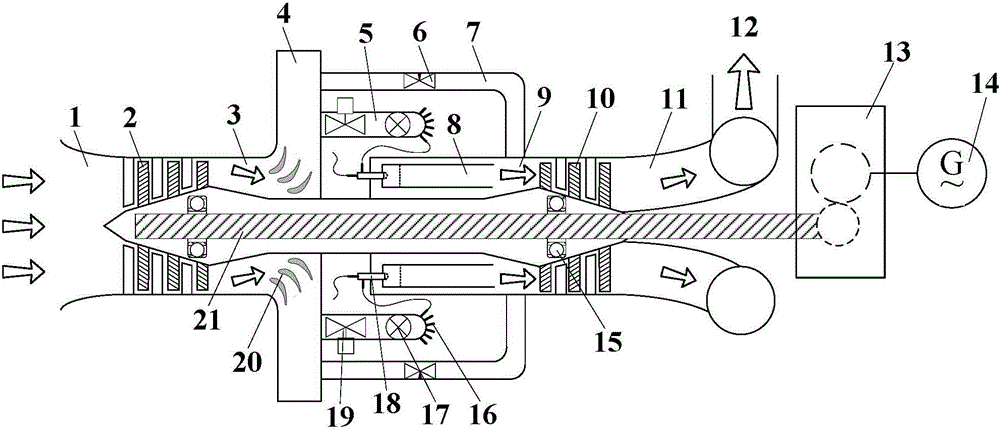

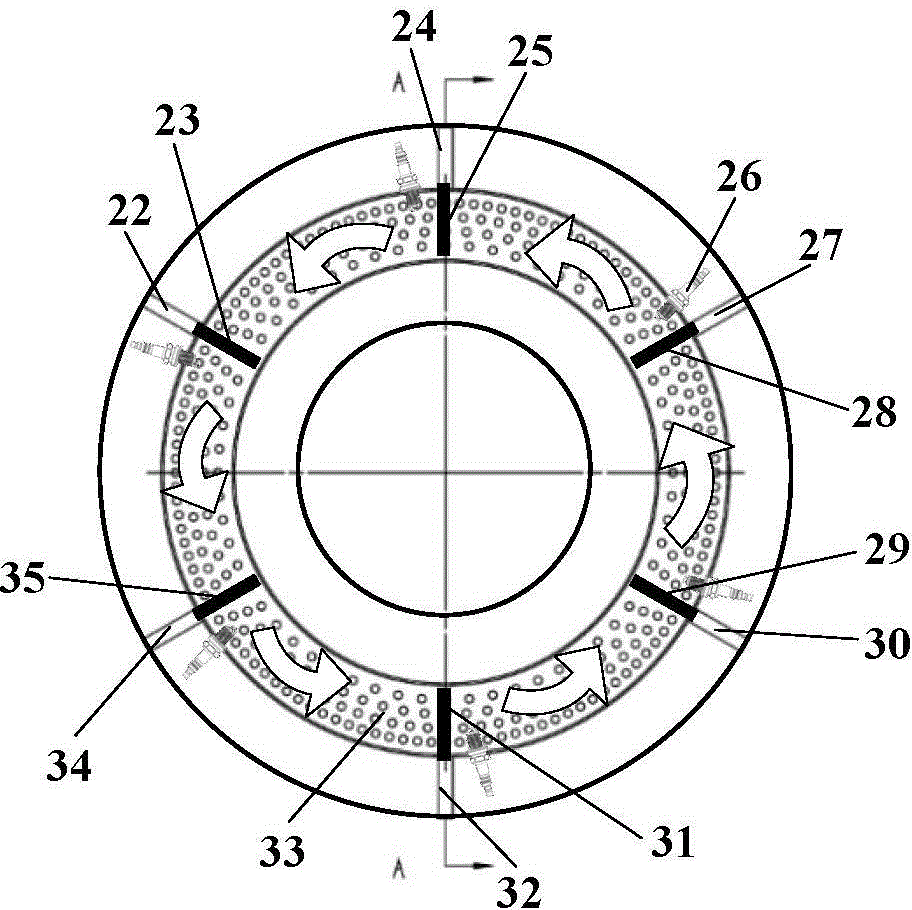

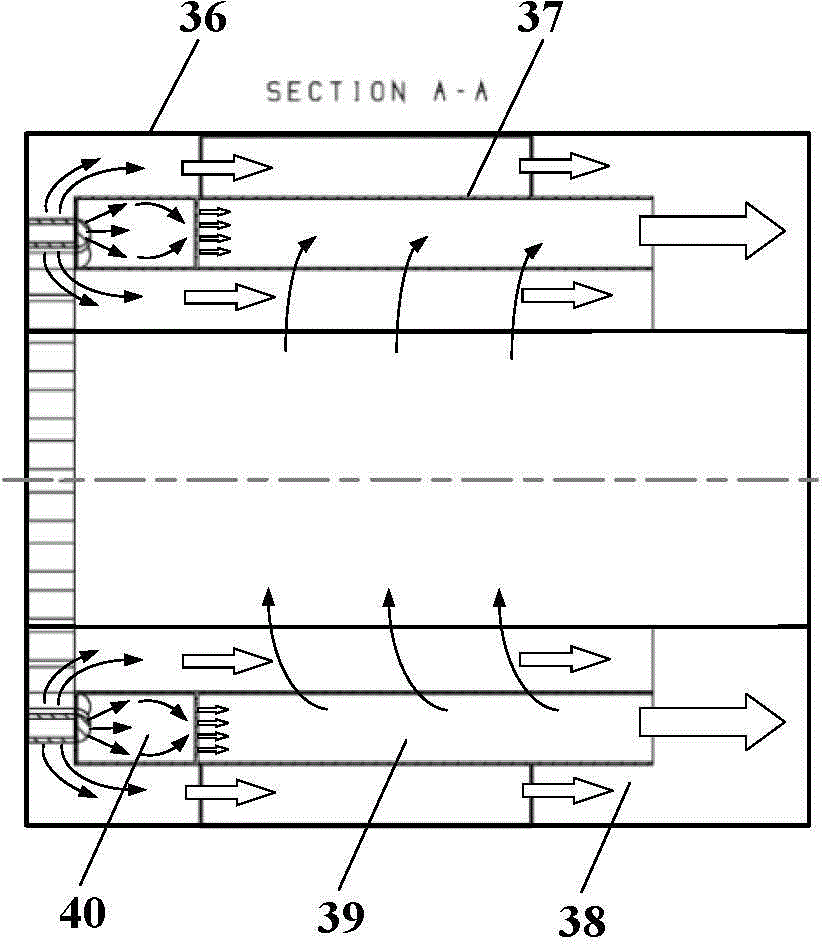

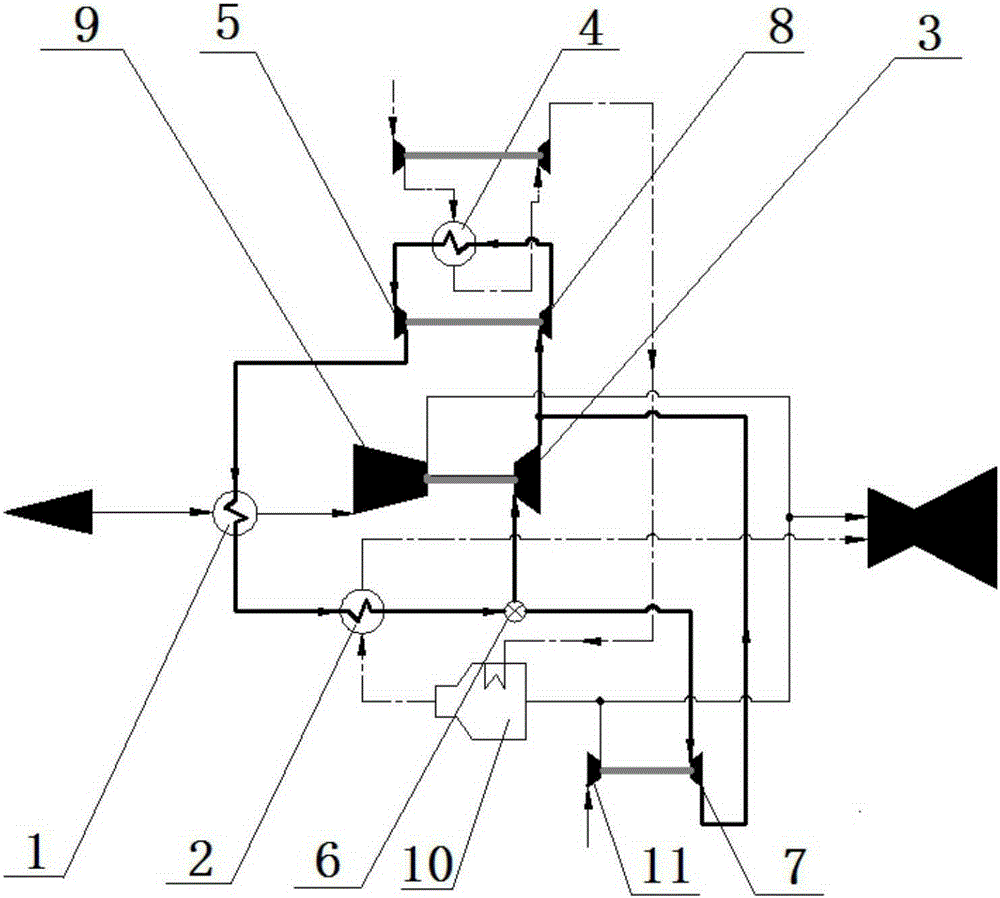

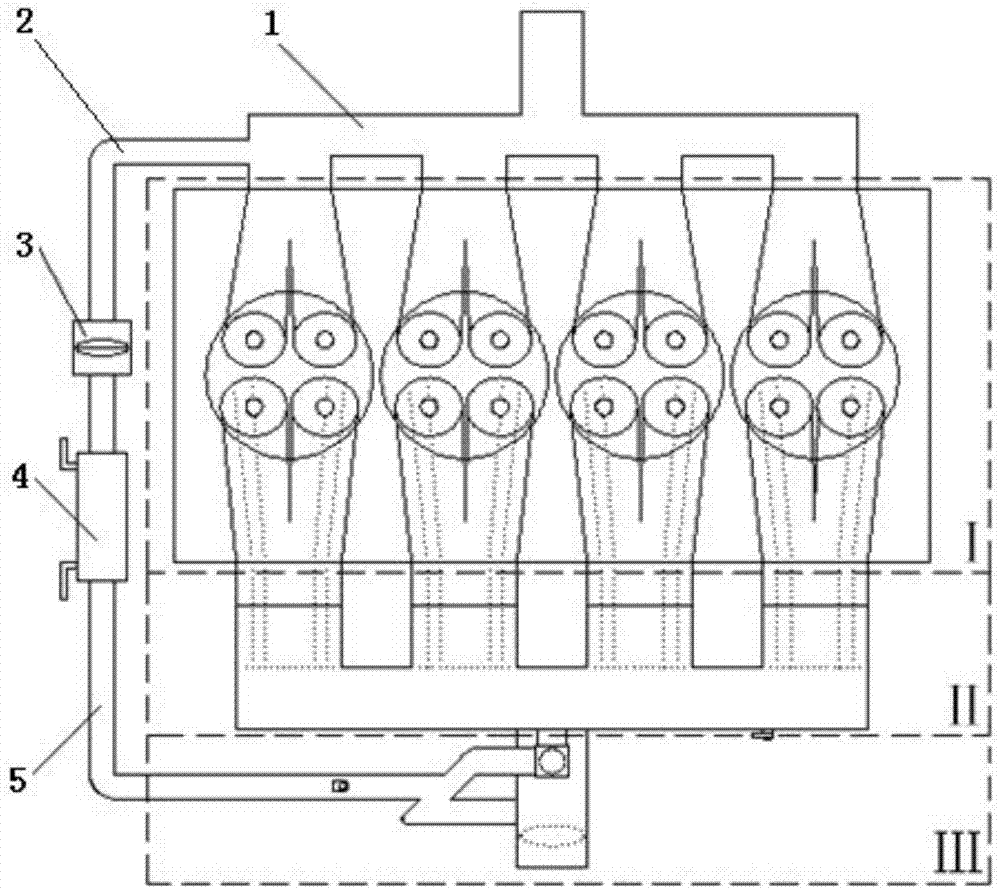

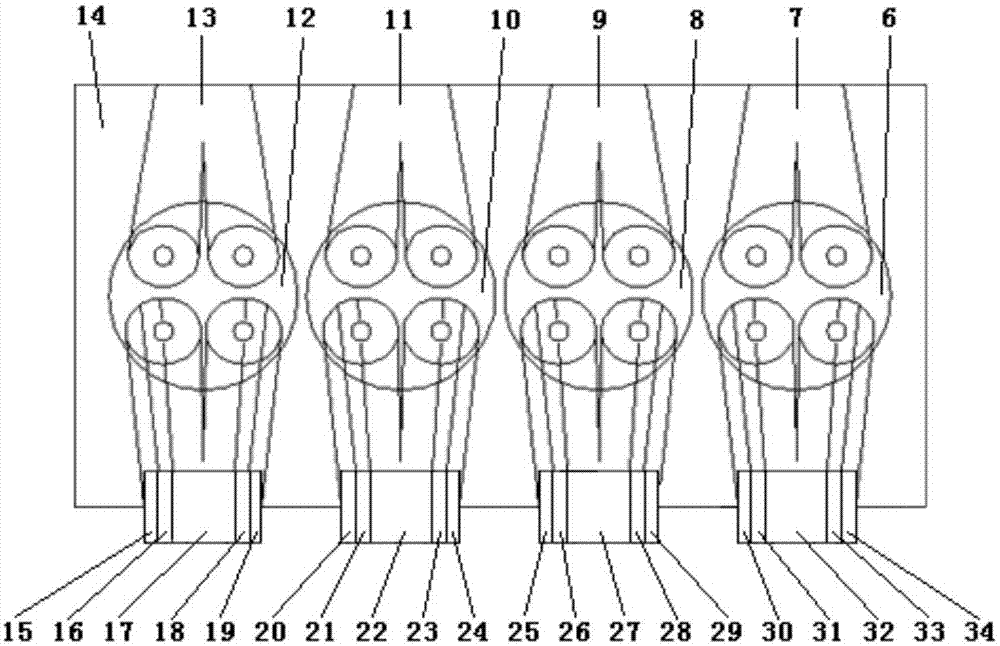

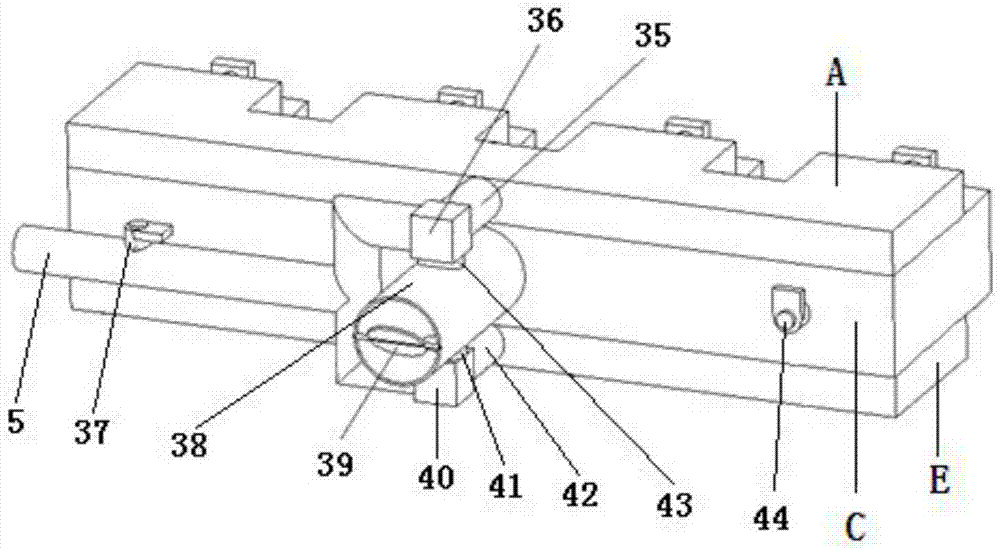

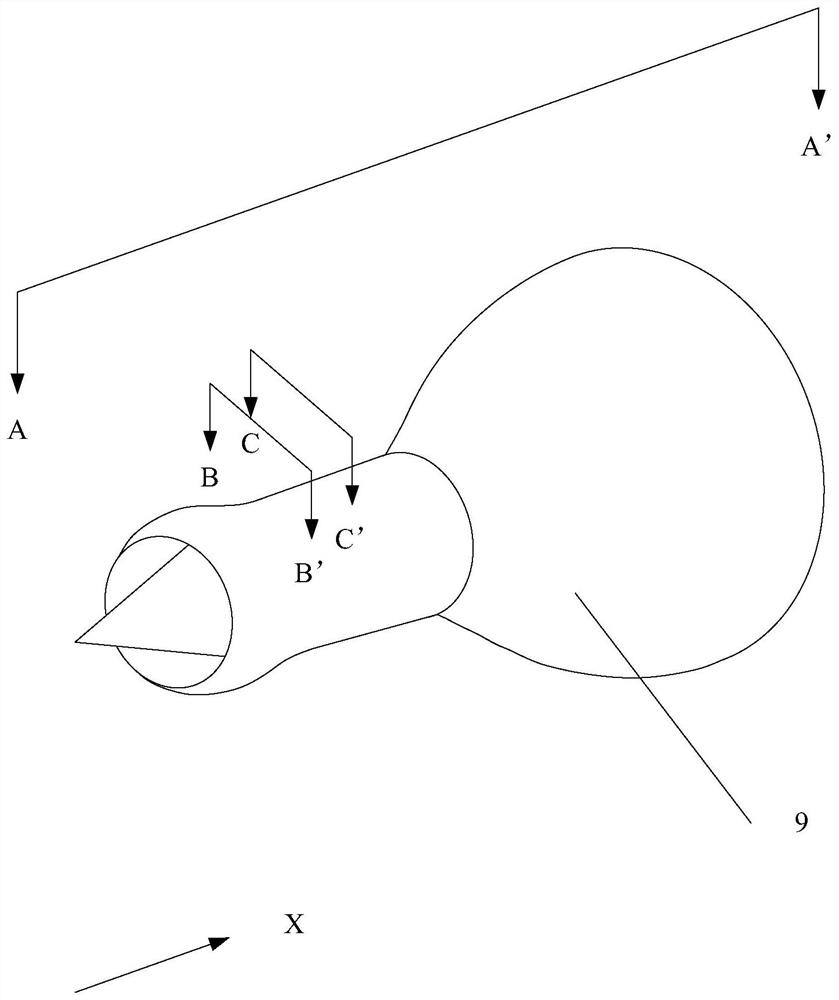

The invention discloses a rotary knocking gas turbine. The rotary knocking gas turbine comprises a gas inlet passage, a diffusion section and a gas storage chamber which are connected in sequence from left to right, wherein a gas compressor is arranged at the downstream of the gas inlet passage; a rotary knocking combustion chamber is positioned at the right end of the gas storage chamber, the right end of the rotary knocking combustion chamber is connected with a mixing chamber, a turbine and an exhaust pipe in sequence, a plurality of nozzles are annularly arranged on the left end face of the rotary knocking combustion chamber at equal intervals, and six ignition plugs are uniformly arranged on the circumference of the rotary knocking combustion chamber; an air passage and a combustion passage are arranged on each nozzle, the gas storage chamber is communicated with the rotary knocking combustion chamber through a gas supply passage and the air passages of the nozzles, and the mixing chamber is communicated with the gas storage chamber through a gas escape bypass; a rotor is arranged between the gas compressor and the turbine, the gas compressor of a rotating component of the gas turbine and the turbine are connected with a casing of a static bearing component of the gas turbine through two bearings, and one end of the rotor is led out from the gas exhaust pipe. When the rotary knocking gas turbine is used, the leading-out end of the rotor is connected with a generator assembly through a speed changer.

Owner:XIAN THERMAL POWER RES INST CO LTD

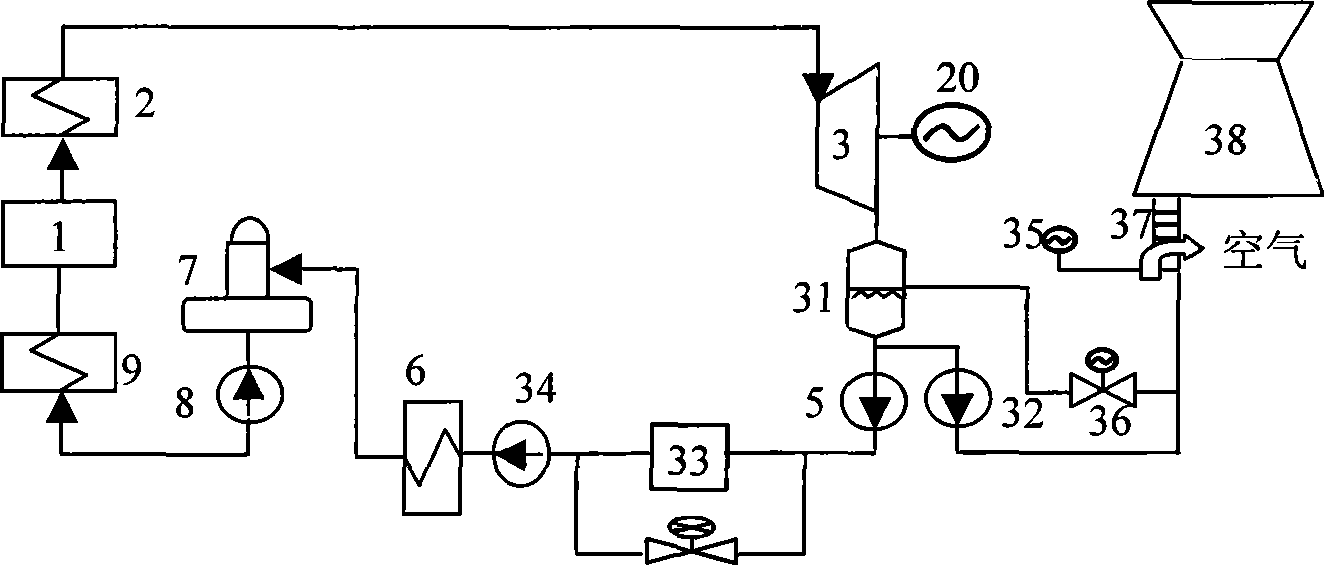

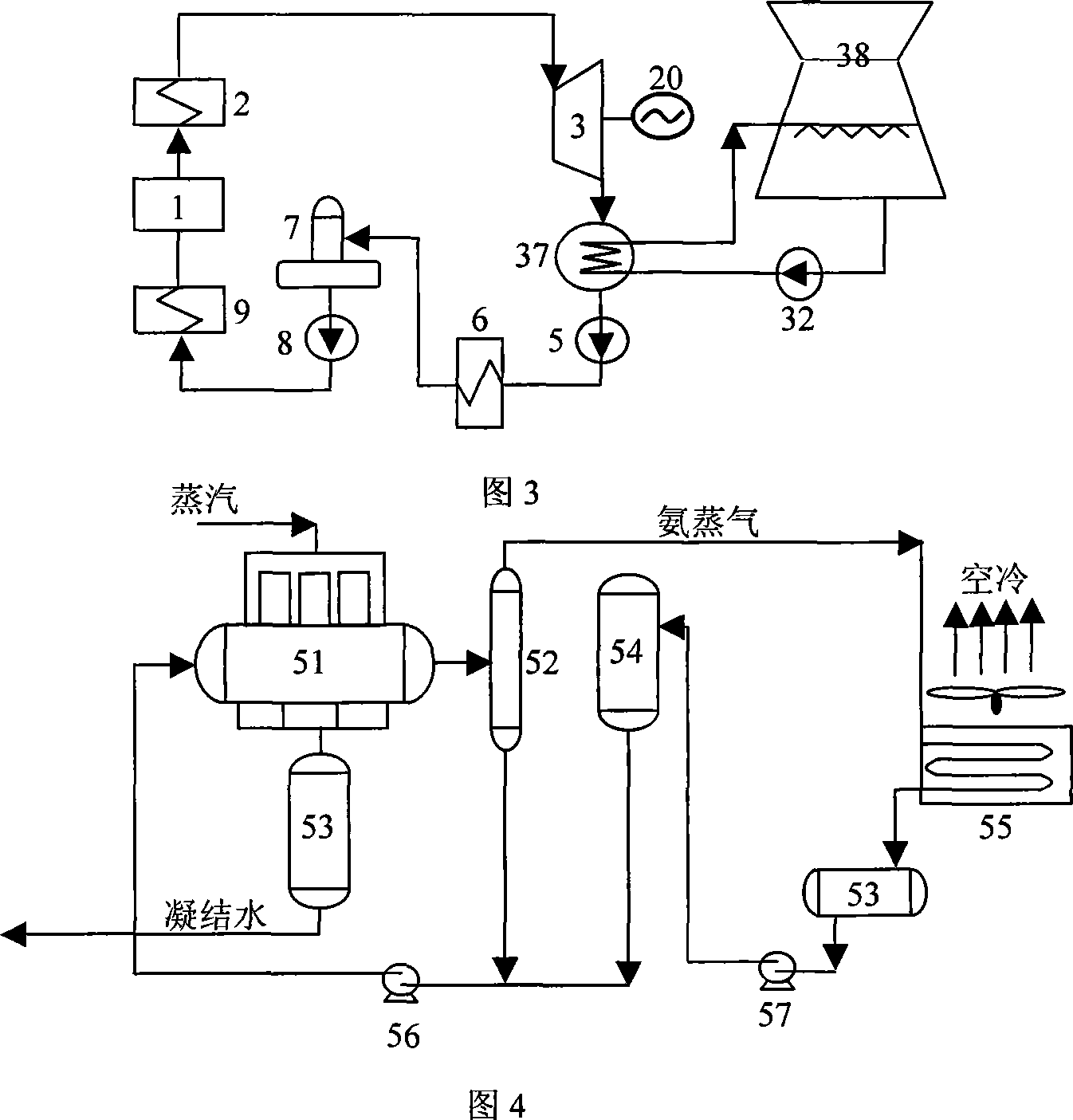

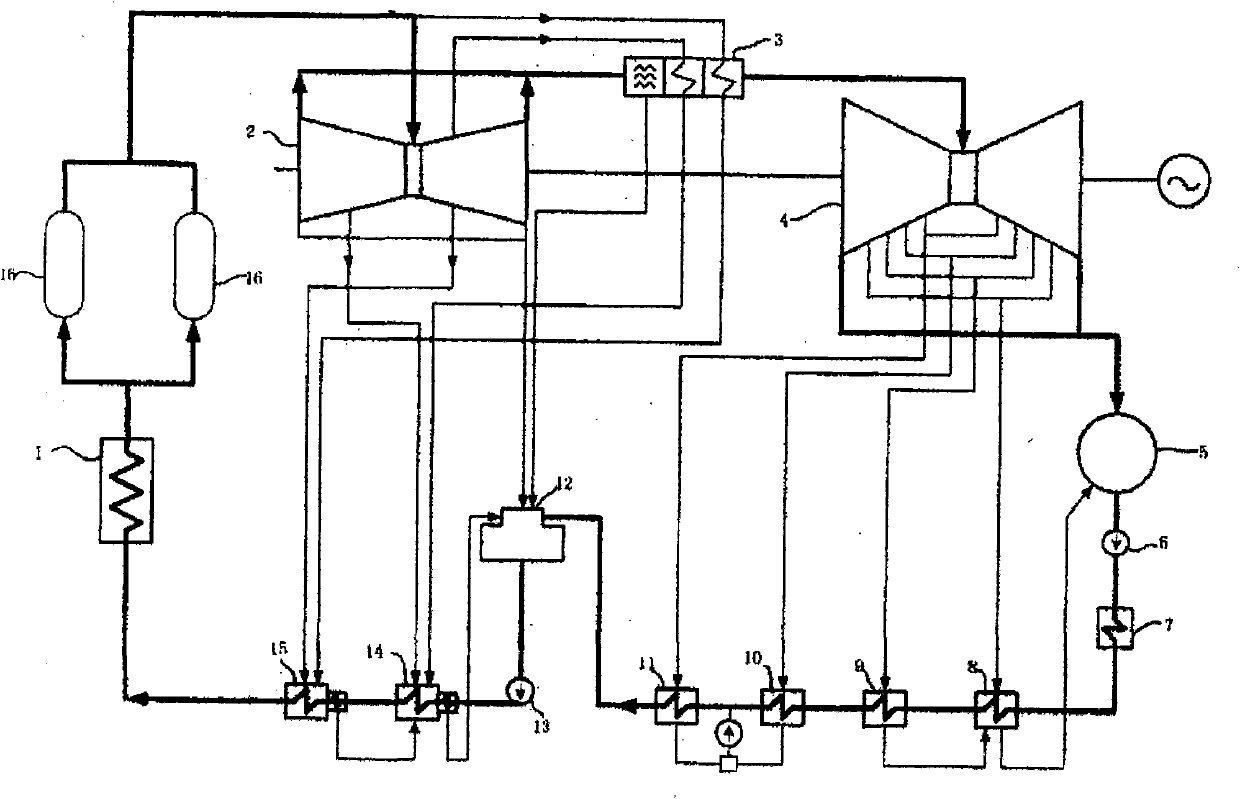

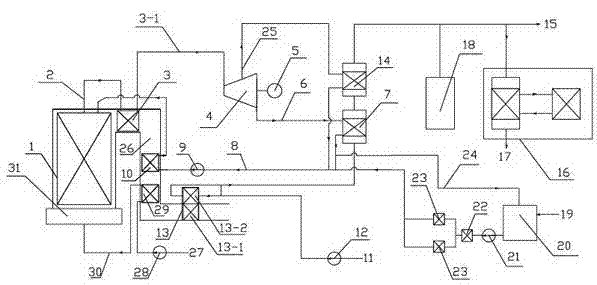

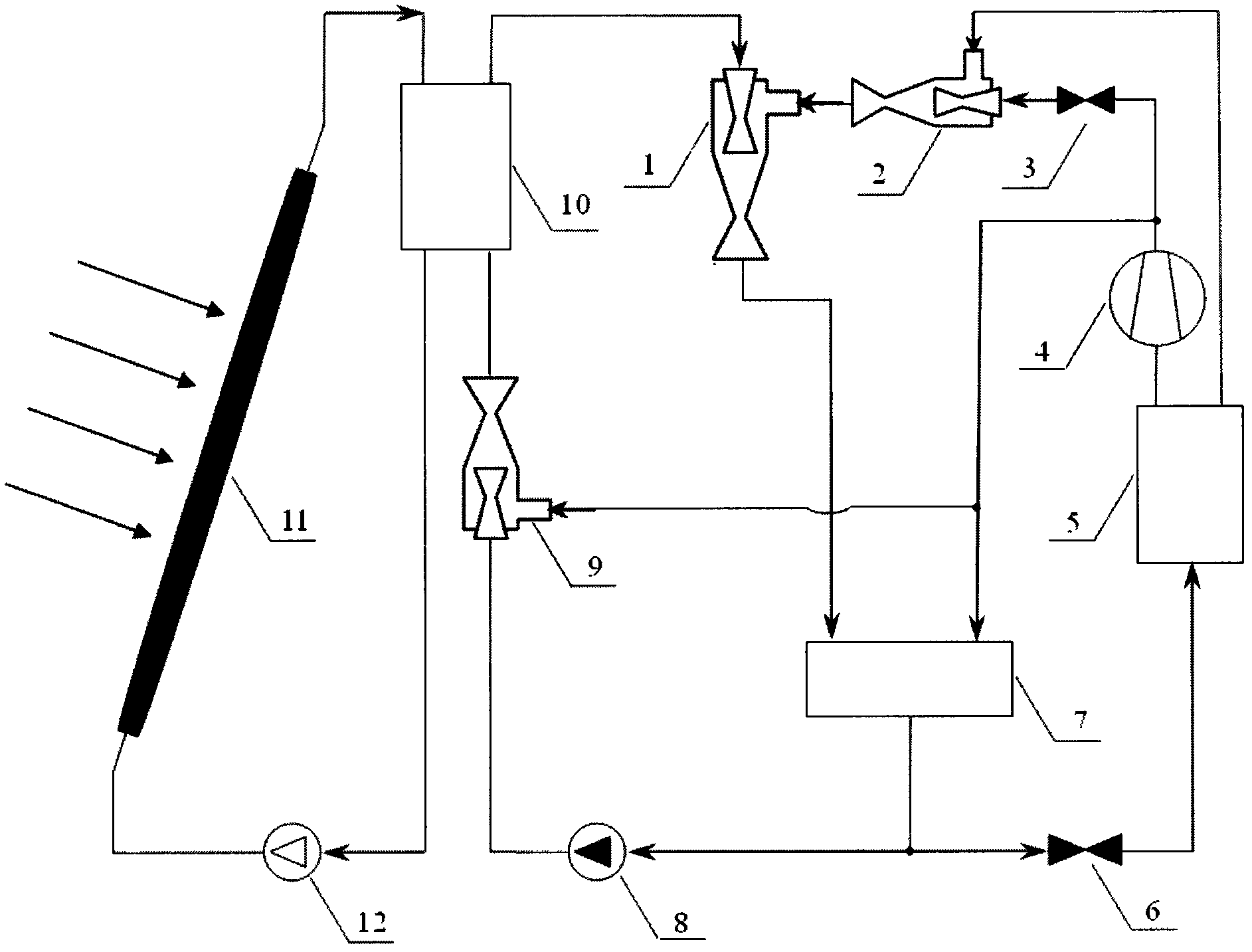

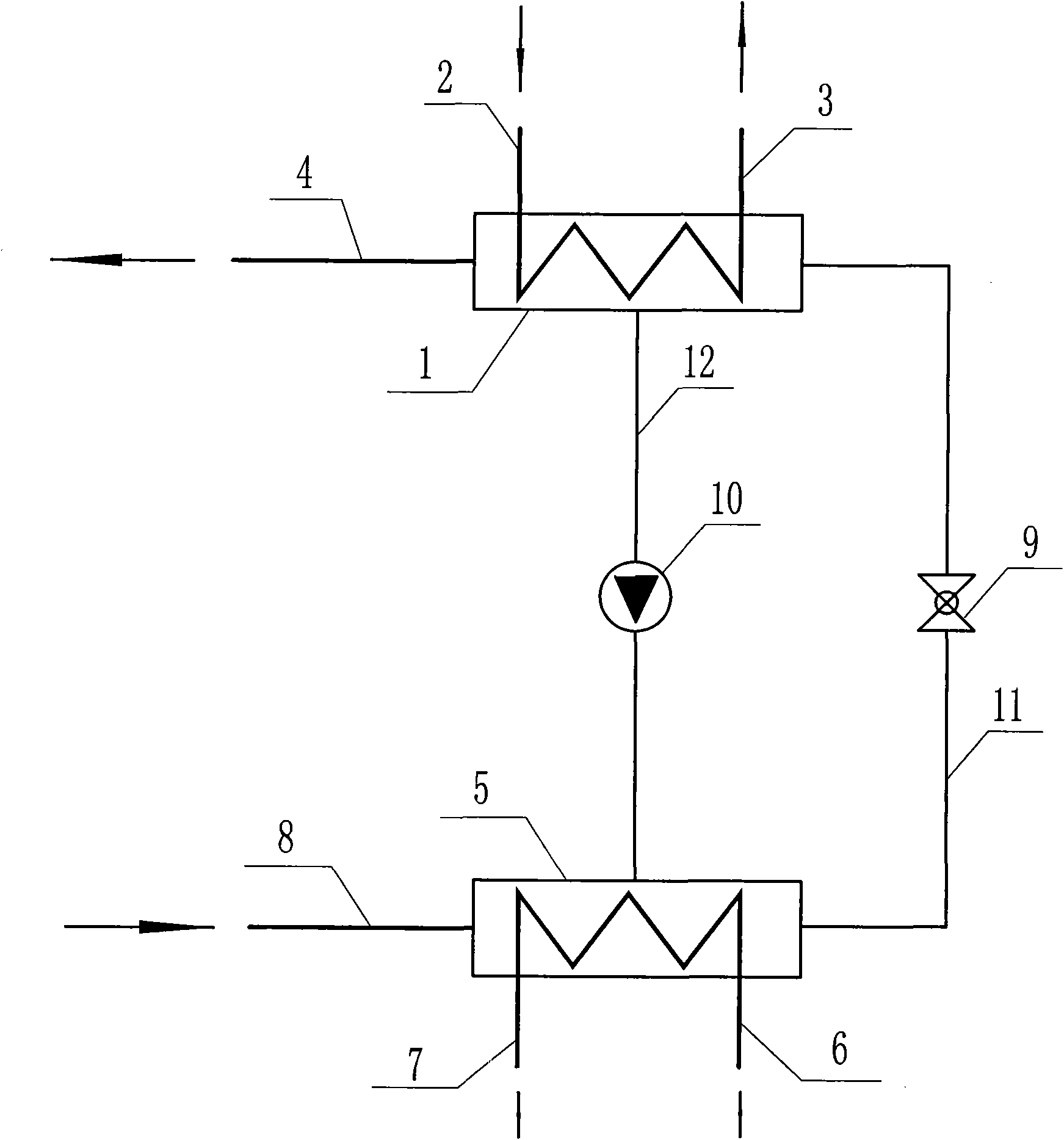

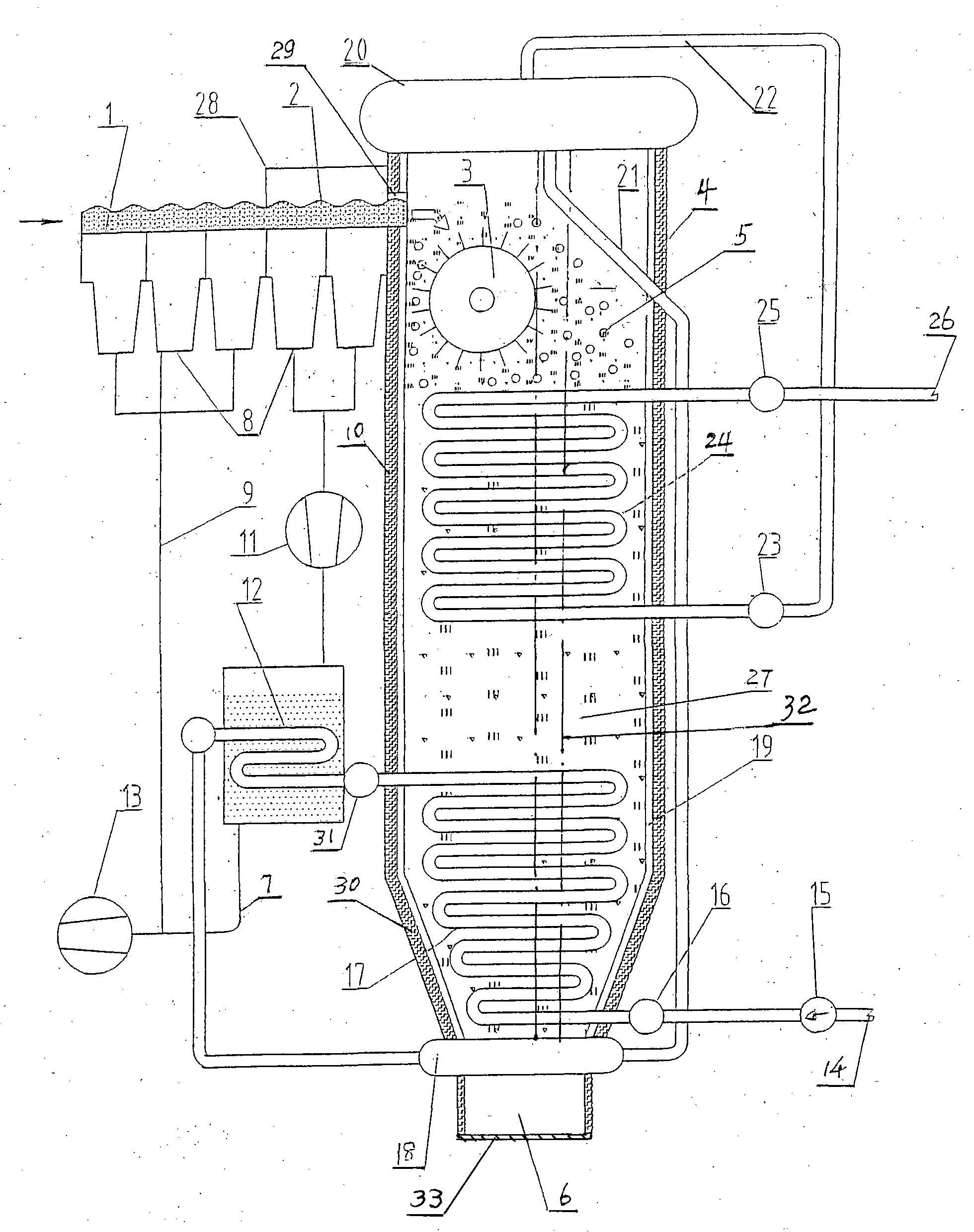

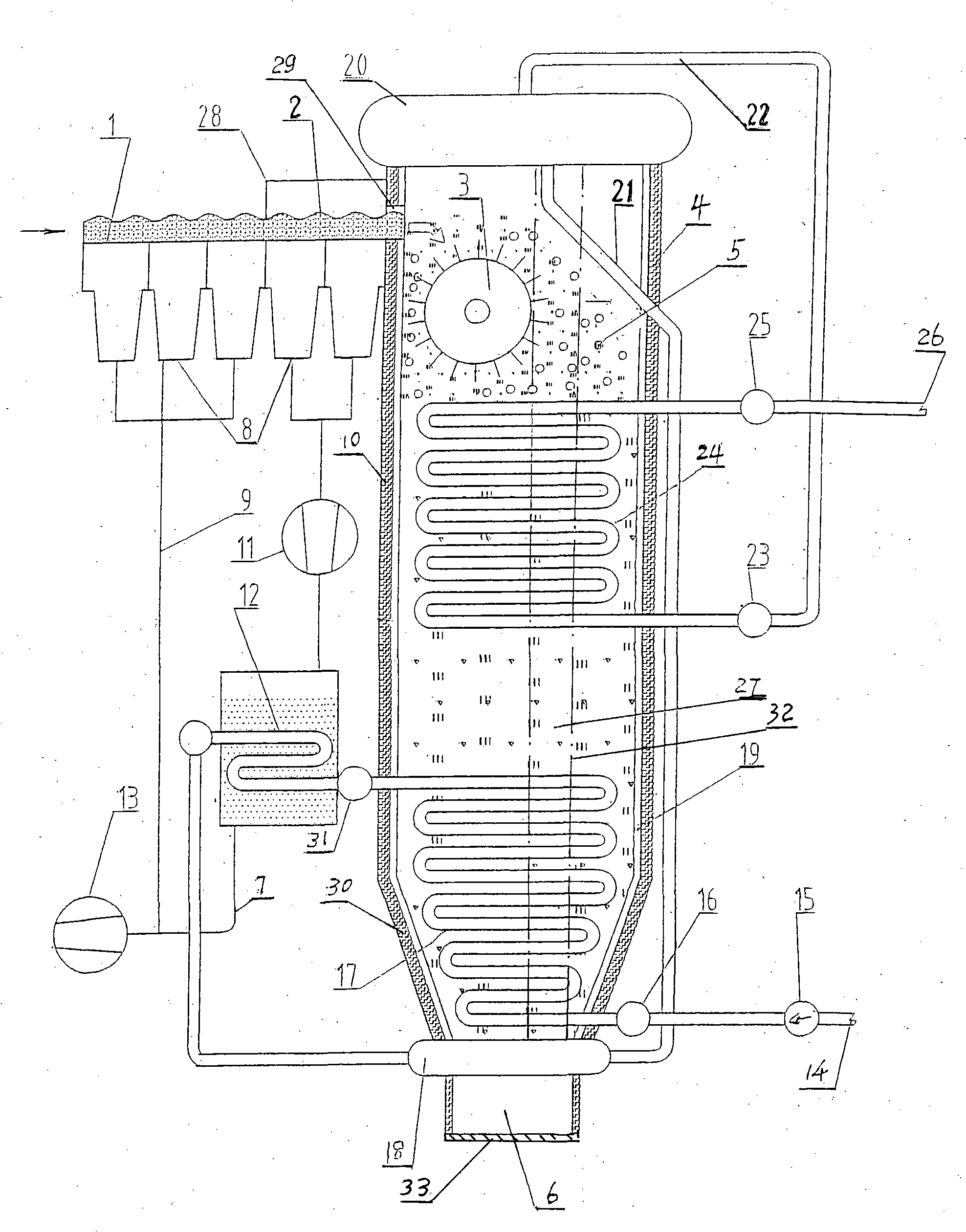

Indirect air cooling method and system for working medium adopting parallel-connection positive and reverse refrigeration cycle

InactiveCN101368767AEasy to implementNovel ideaCompression machines with reversible cycleWorking fluidNuclear power

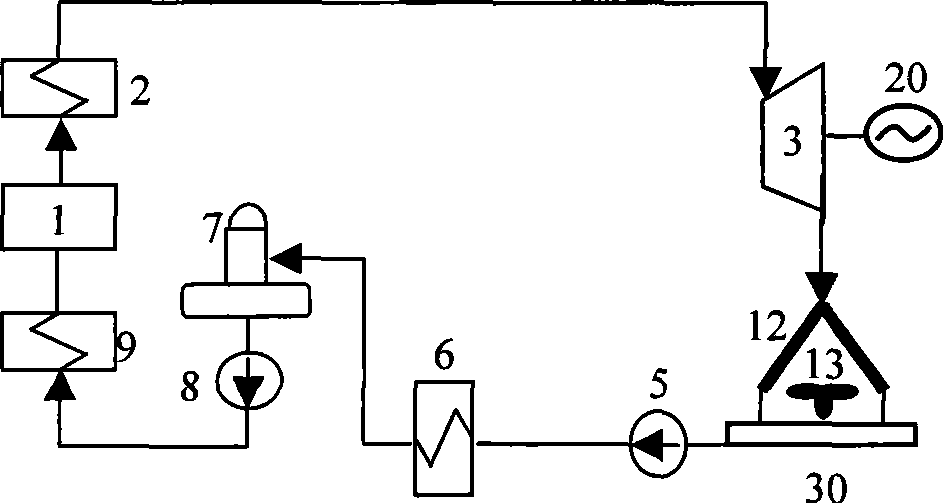

The invention discloses an indirect air cooling method and a system with the working fluid of parallel-connected obverse and inverse refrigeration cycles. Based on the phase transition in the working fluid cooling process, a double-phase transition heat exchanger and a single-phase transition heat exchanger are respectively coupled with an obverse refrigeration cycle and an inverse refrigeration cycle which are connected in parallel; the saturated gaseous refrigerant from the phase-transition heat exchangers is compressed, boosted and then sent to an air-cooled radiator for exothermic condensation, then the condensed refrigerant enters a liquid storage tank and is decompressed through a throttle valve and sent to the phase-transition heat exchangers so as to complete the obverse refrigeration cycle; or the saturated gaseous refrigerant from the phase-transition heat exchangers is throttled and decompressed through a thermal expansion valve and then sent to the air-cooled radiator and the liquid storage tank, pressurized by a booster pump and finally sent back to the phase-transition heat exchangers so as to complete the inverse refrigeration cycle. The method and the system can be widely applied to the cooling systems of the condensers in thermal power, nuclear power and other turbine-generator units or the cooling systems of the intercoolers in petroleum, chemical and other industries to reduce energy consumption, save investments, as well as improve water-saving rate and the adaptability of the cooling system to the environment; therefore, the method and the system are provided with promotional values and can produce larger social environmental benefits and economic benefits after implementation.

Owner:NORTHEAST DIANLI UNIVERSITY

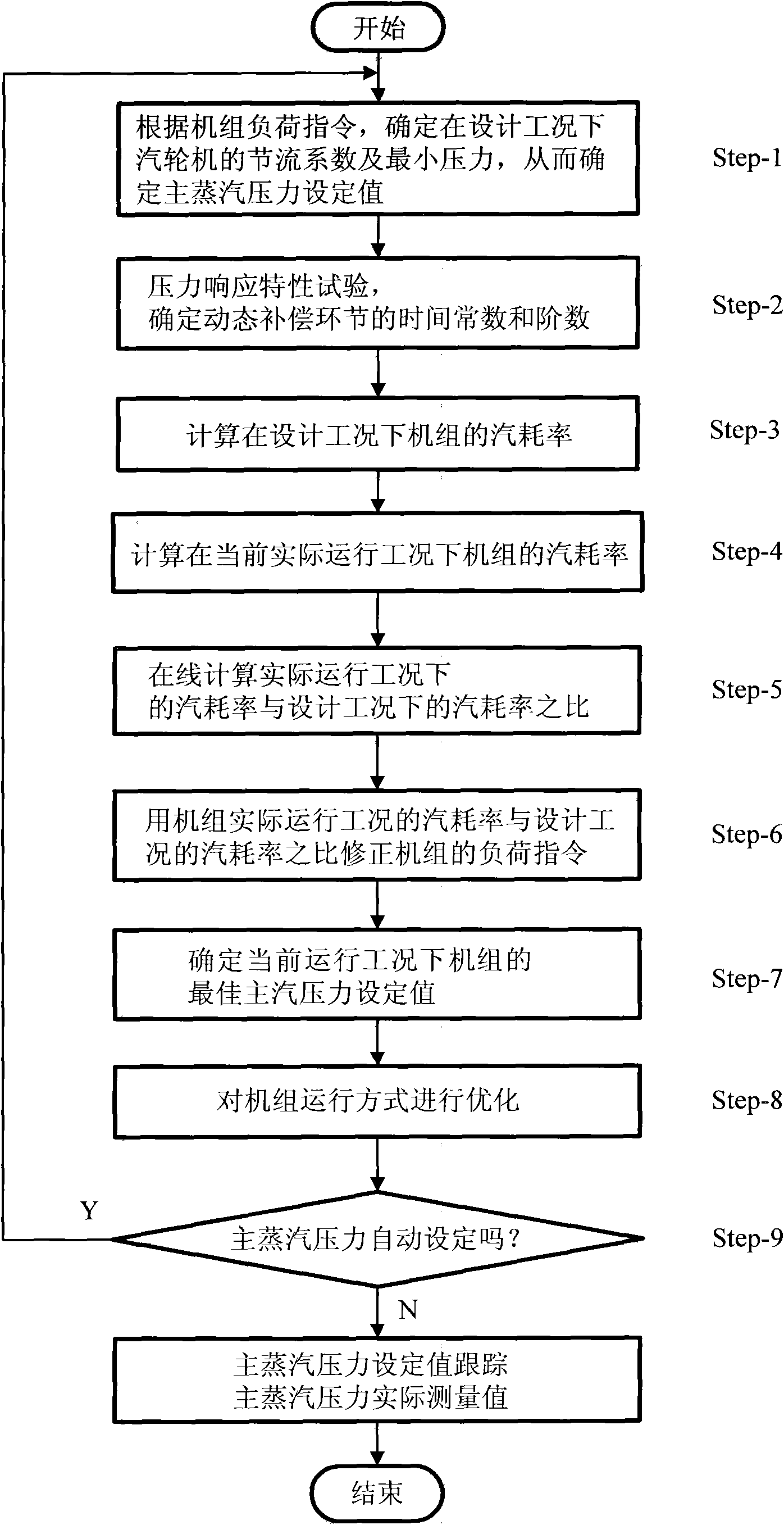

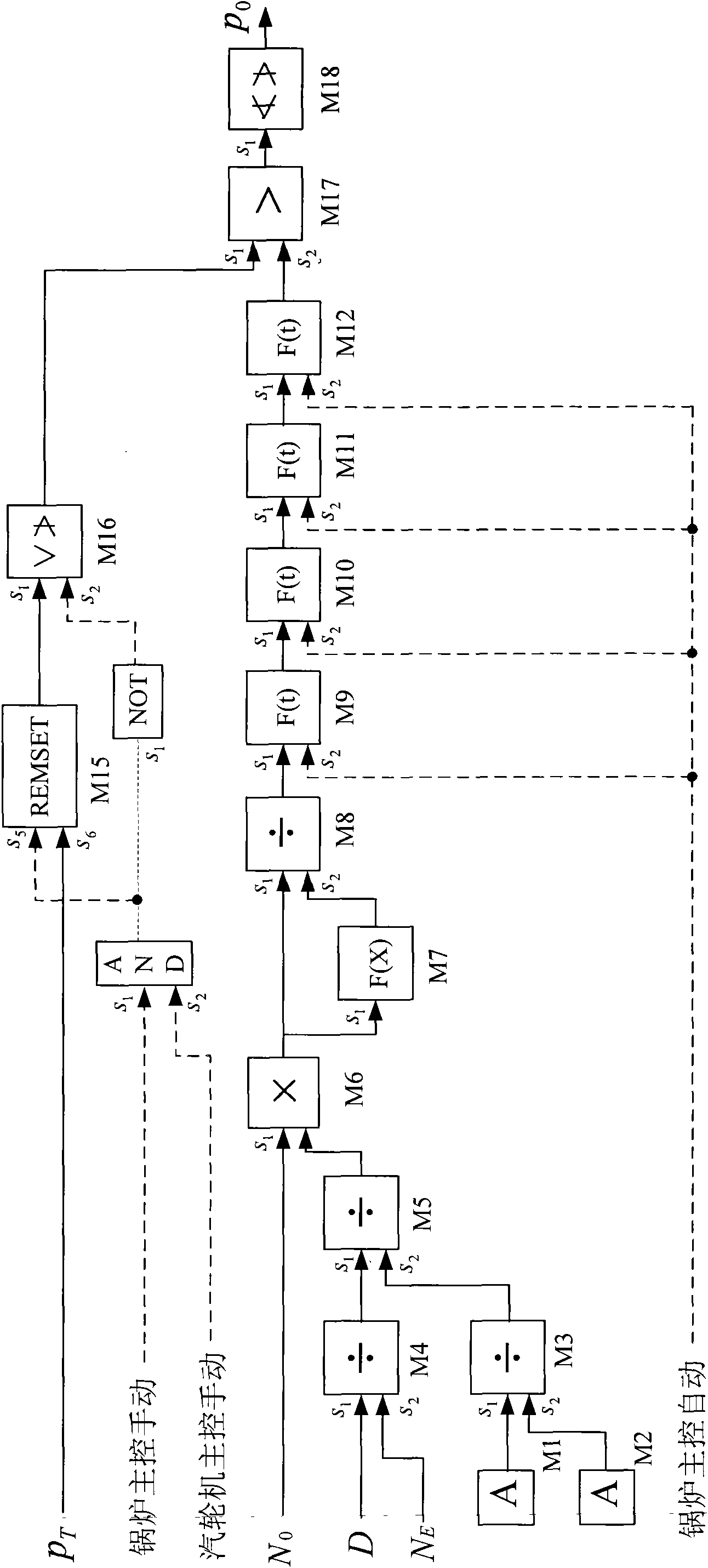

Generating set optimization control method for correcting sliding pressure operation curve by adopting steam consumption rate

ActiveCN101609312AImprove cycle efficiencyBest working pointProgramme control in sequence/logic controllersSteam pressureControl system

The invention discloses a generating set optimization control method for correcting sliding pressure operation curve by adopting steam consumption rate, which comprises the detailed steps of: confirming the throttling coefficients and minimum pressure of a steam turbine under a designed working condition according to the load command of the generating set and confirming the main steam pressure set value; confirming the parameters of dynamic compensation section according to the main steam pressure response characteristics; respectively calculating the steam consumption rate of the generating set under the designed working condition and the actual working condition, working out the steam consumption rate correction coefficients, and implementing online correction on the load command of the generating set; using the corrected load command to divide the throttling coefficients of the steam turbine, then implementing calculation on the dynamic compensation procedure and minimum pressure limitation, and finally obtaining the best main steam pressure set value of the generating set under the current operation condition. The best main steam pressure set value is applied in a cooperation control system of a unit set so as to realize the best cooperation relation between the inlet steam pressure and inlet steam flow of the generating set, thus reducing the throttling loss of the steam turbine and guaranteeing the best thermoeconomic performance of the generating set.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER +1

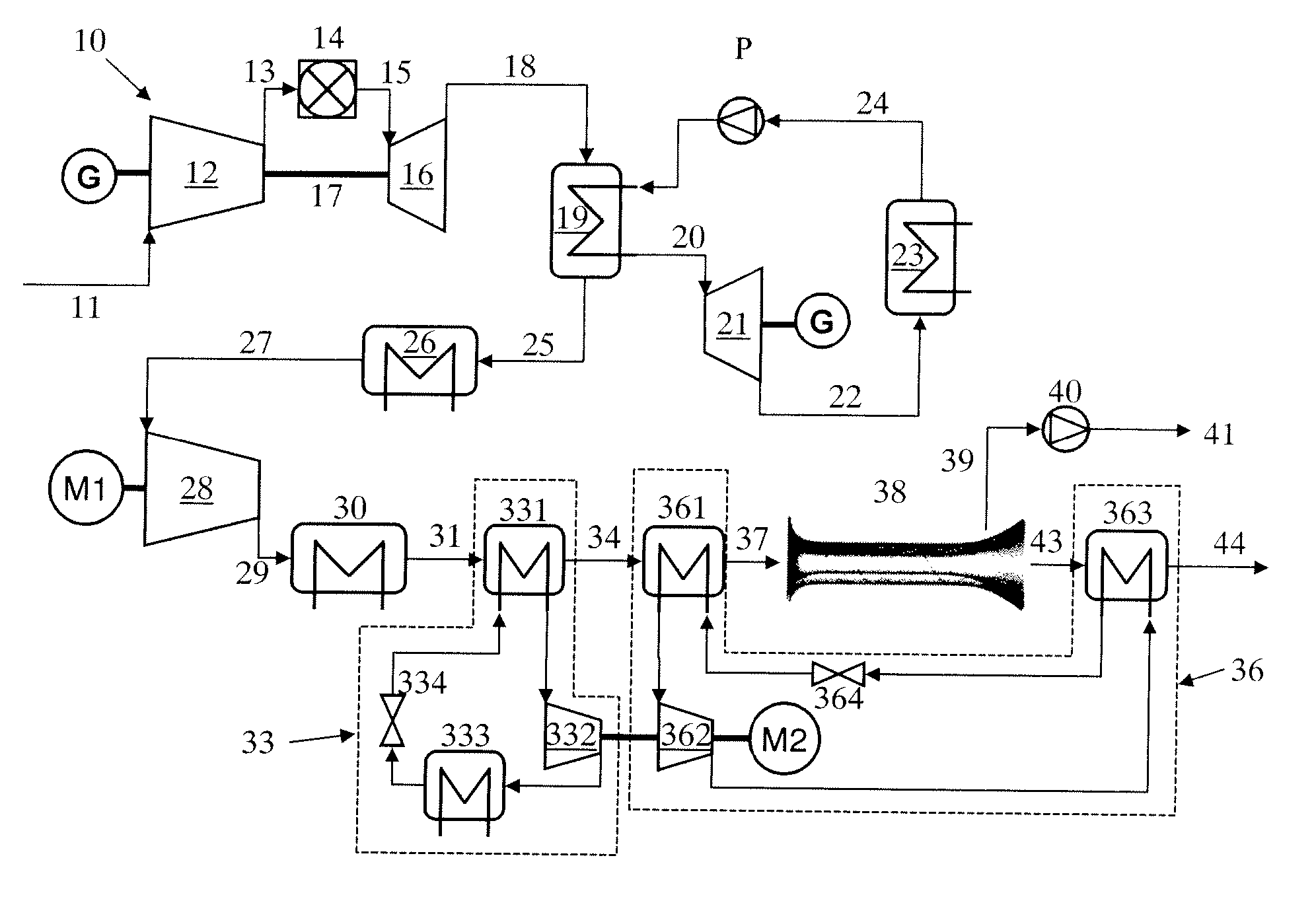

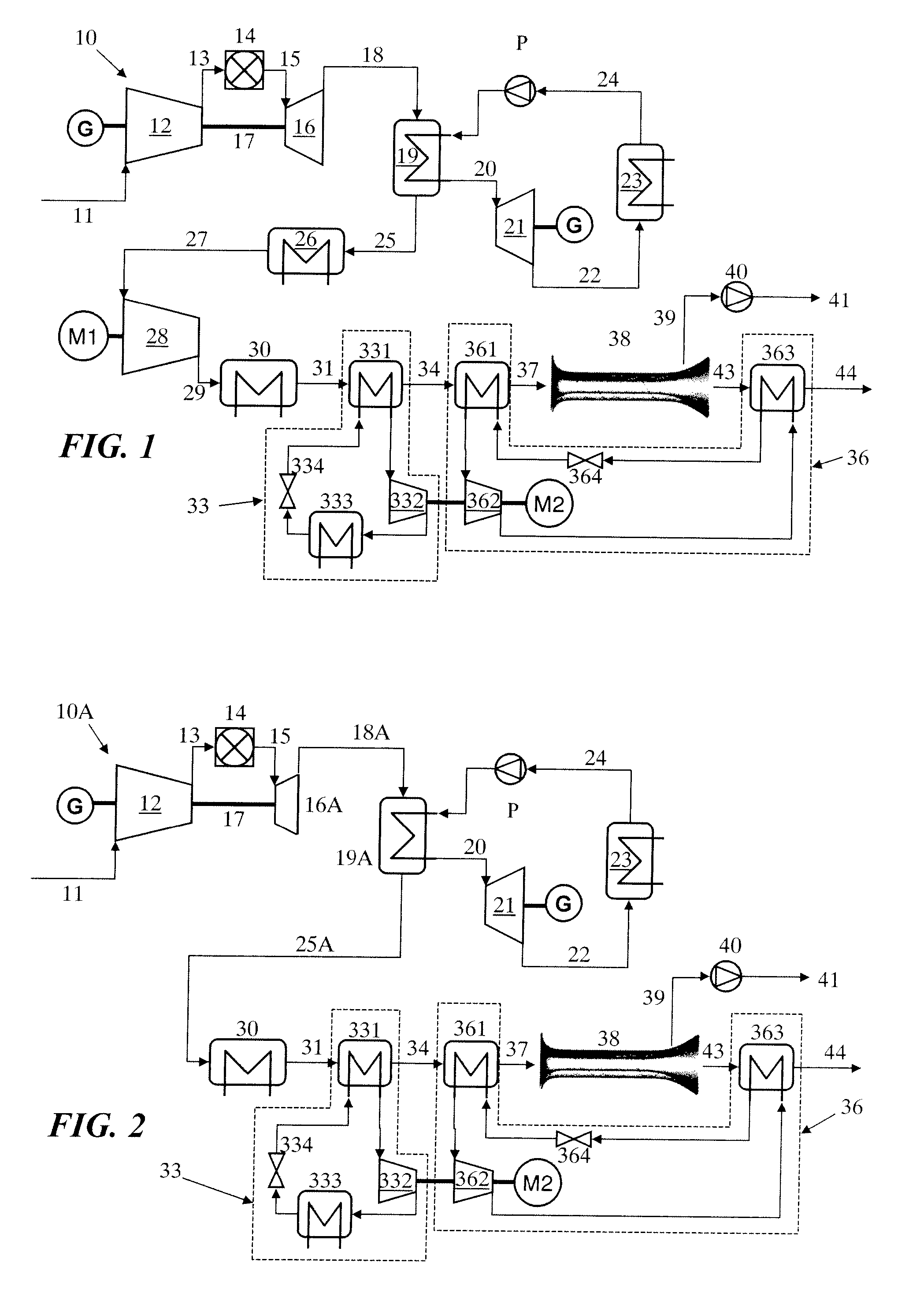

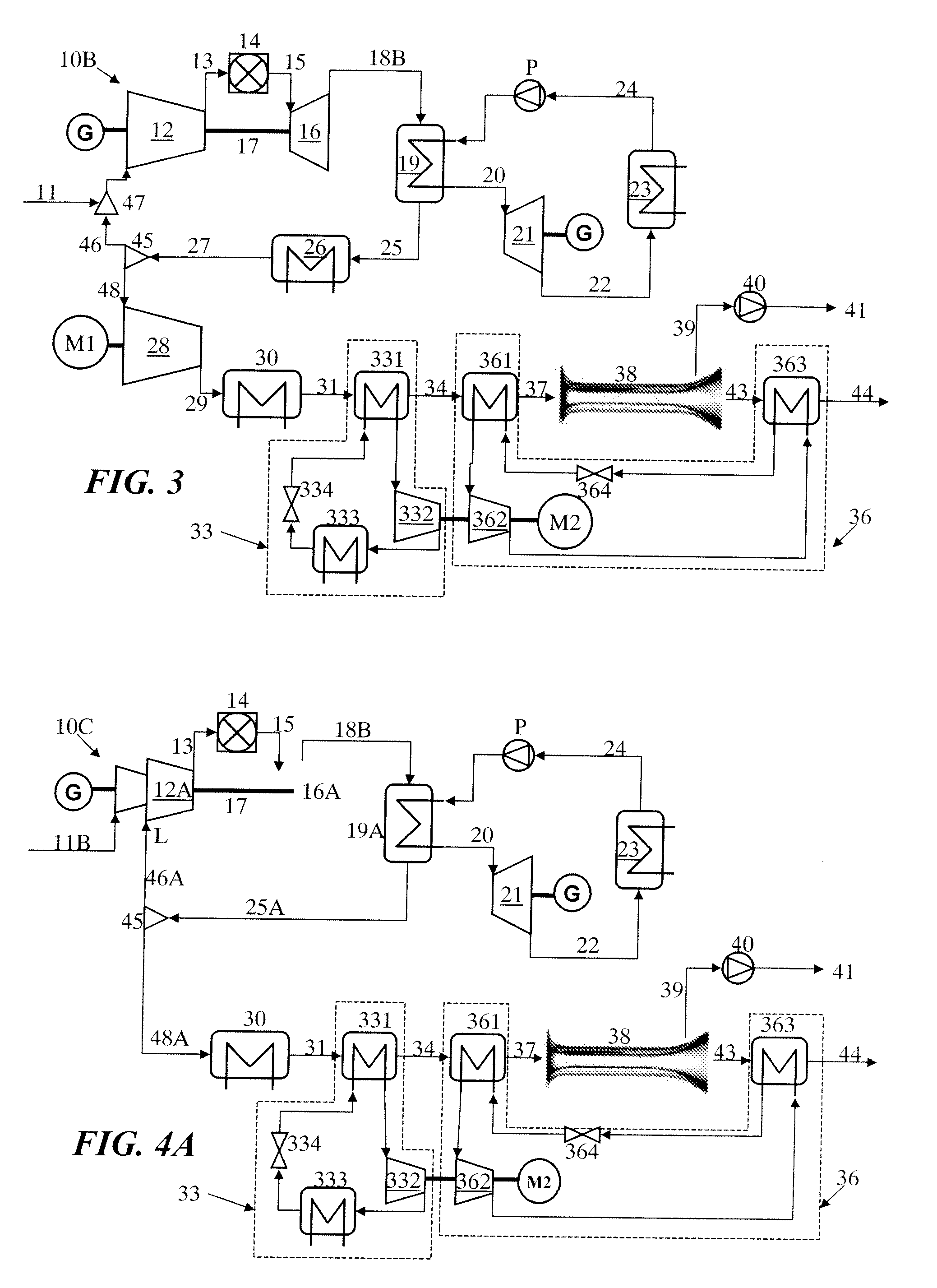

Low carbon emissions combined cycle power plant and process

InactiveUS20100319354A1Increase percentageMinimize mixing lossGas treatmentGas turbine plantsLow-carbon emissionGas cooling

A low carbon emissions, combined cycle power plant utilizes vortex nozzles (38) operative at cryogenic temperatures to separate out carbon dioxide (39) from the flue gases. Complexity of the plant is minimized by operating a gas turbine engine component (10) of the plant at a turbine exhaust pressure of at least 2 bar, so that downstream components of the plant, including a heat recovery steam generator (19A), a gas cooling system (30, 33, 36), and the inlets of the vortex nozzles, all operate at the same pressure of at least two bar. To increase carbon dioxide concentration in the flue gases (37) that pass through the vortex nozzles (38), and thereby increase efficiency of carbon dioxide removal from the flue gases, up to 50% of the flue gases that exit the heat recovery steam generator (19A) may be recirculated to a location (L, FIG. 4)) in the compressor of the gas turbine engine where the pressure of the compressor air matches the flue gas pressure.

Owner:GENERAL ELECTRIC TECH GMBH

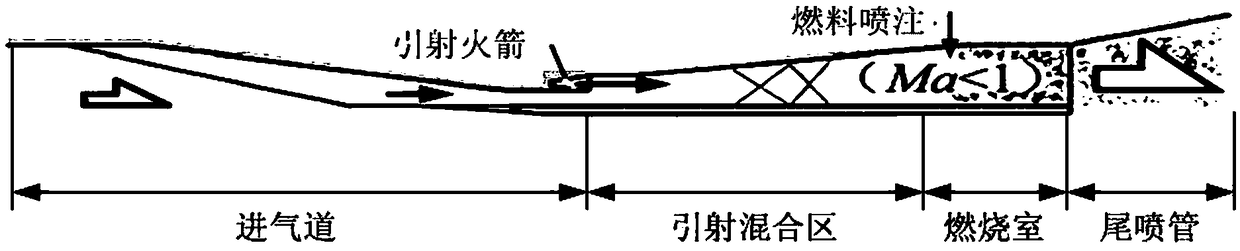

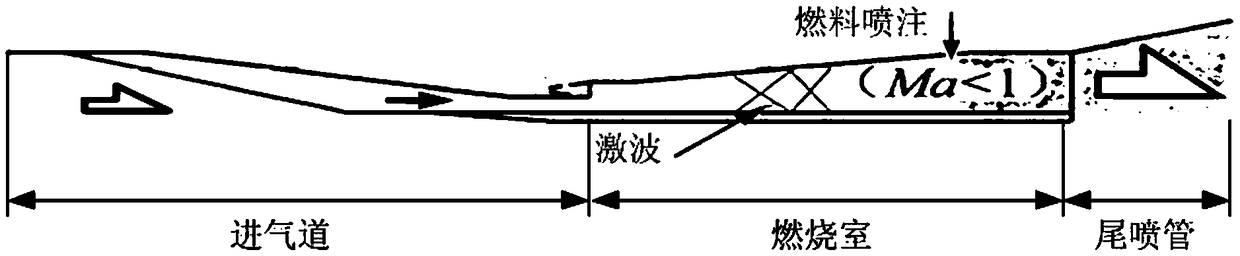

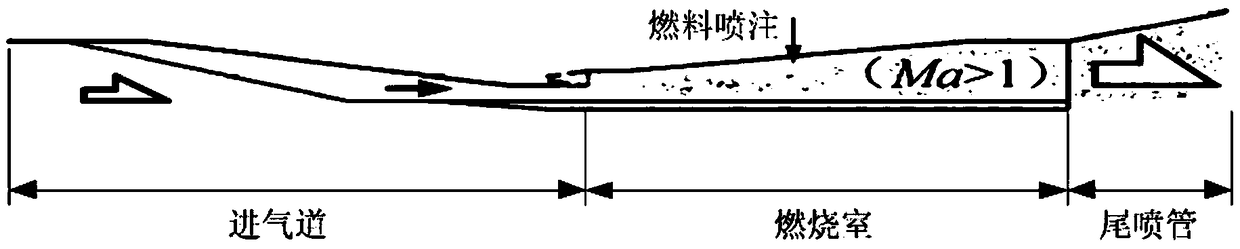

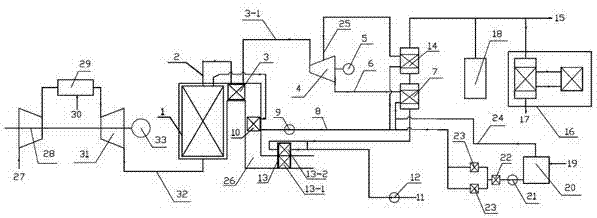

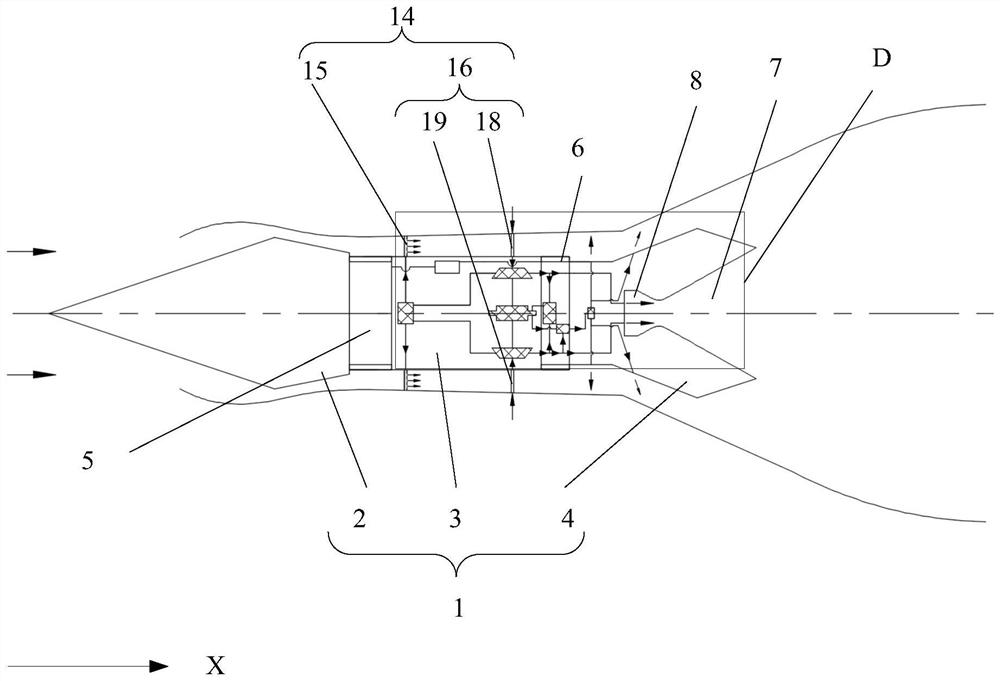

Combined cycle engine and hypersonic aircraft

ActiveCN108757179AThe overall structure is simpleImprove efficiencyTurbine/propulsion engine coolingGas turbine plantsFuel supplyRamjet

The invention discloses a combined cycle engine and a hypersonic aircraft which includes a rotary detonation ramjet engine and a rocket engine arranged therein. The rotary detonation ramjet engine includes a shell and a conical inner body, wherein the shell is in a hollow cylindrical shape and two ends communicate, and the after body of the conical inner body stretches into the shell from an air inlet end of the shell and is connected with the shell. And a gap between the shell and the after body forms a drainage channel for air to be led in the shell. A cavity between the rear end surface ofthe after body and the inner wall of the shell forms a detonation chamber which communicates with the drainage channel, and a first exhaust nozzle communicates with the detonation chamber. The rocketengine includes a combustion chamber arranged in the conical inner body, a second exhaust nozzle communicating with the combustion chamber, and the nozzle of the second exhaust nozzle communicates with the detonation chamber. The outer wall of the shell is machined with an outer nozzle, the two ends of the outer nozzle correspondingly communicates with a fuel supply device and the drainage channel. The outer wall of and / or the after body is machined with multiple internal nozzles, two ends of the internal nozzles correspondingly communicate with the fuel supply device and the drainage channel.

Owner:NAT UNIV OF DEFENSE TECH

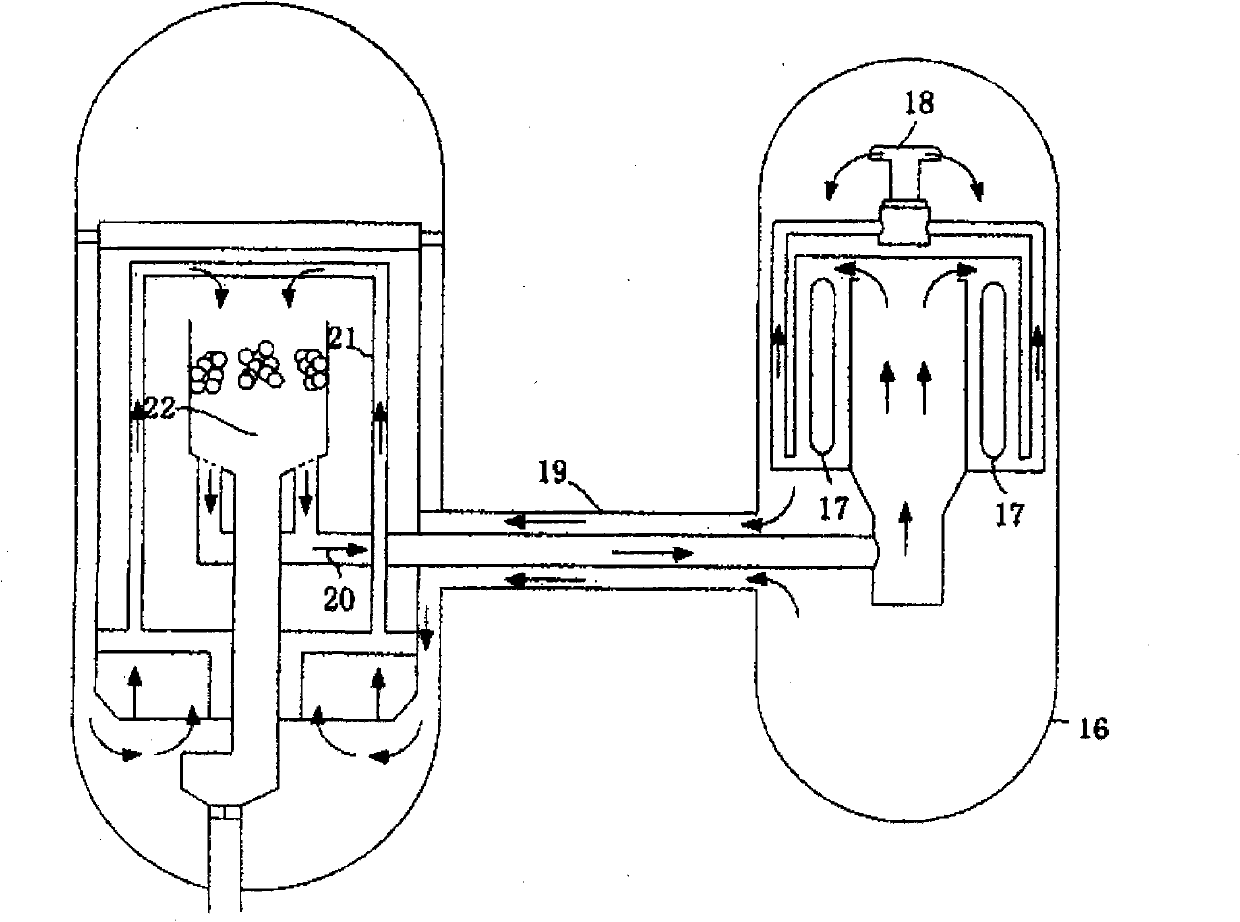

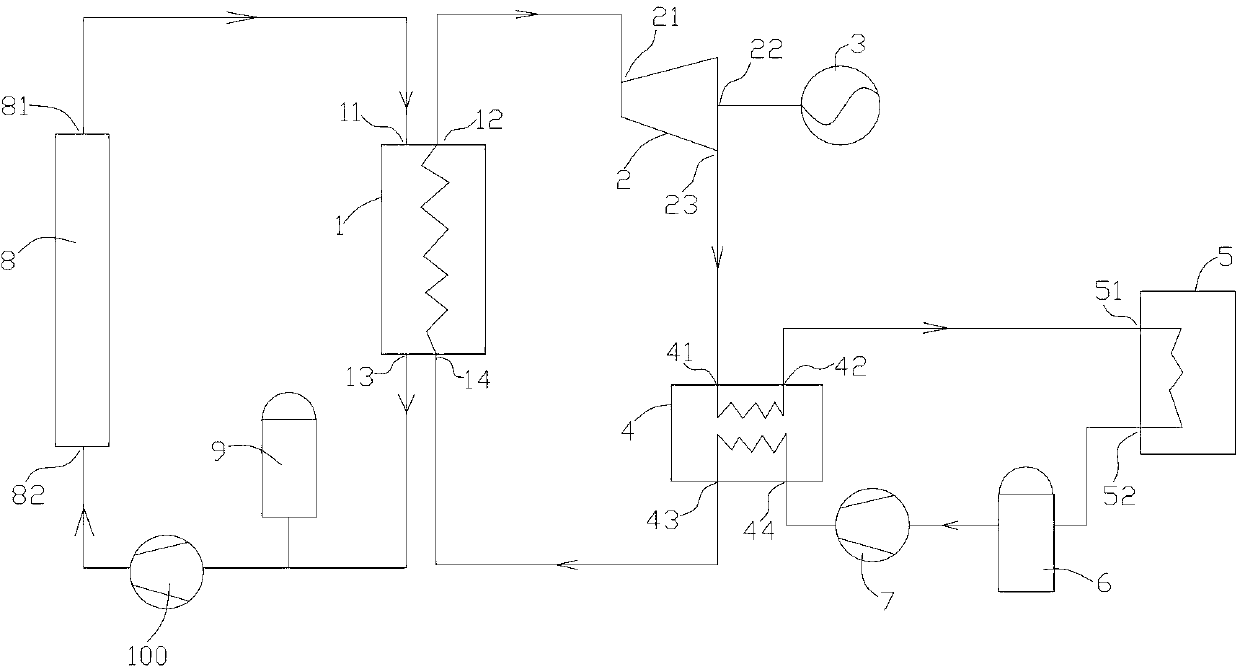

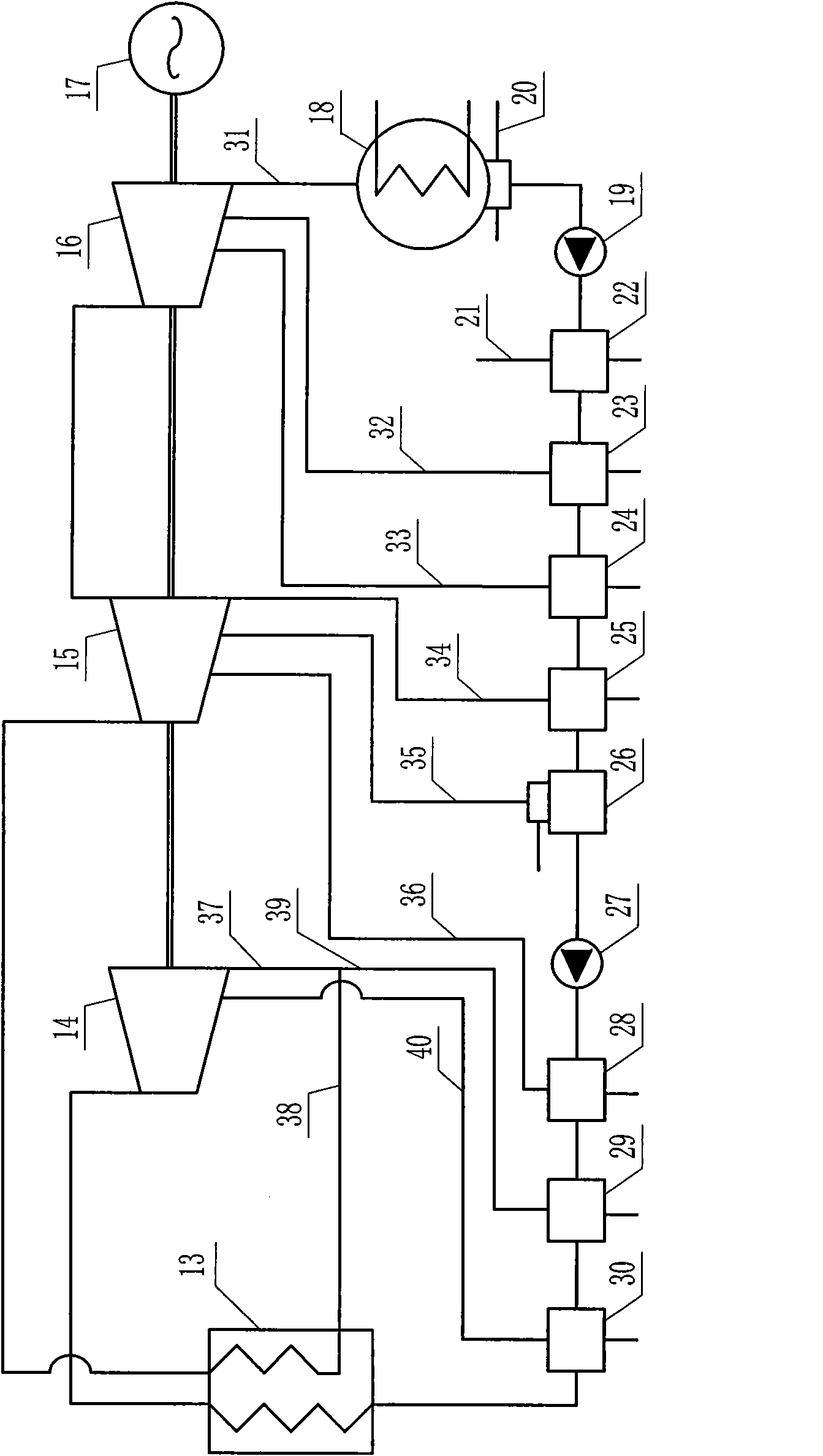

Pressurized water reactor and high-temperature gas cooled reactor-based hybrid thermodynamic cycle system

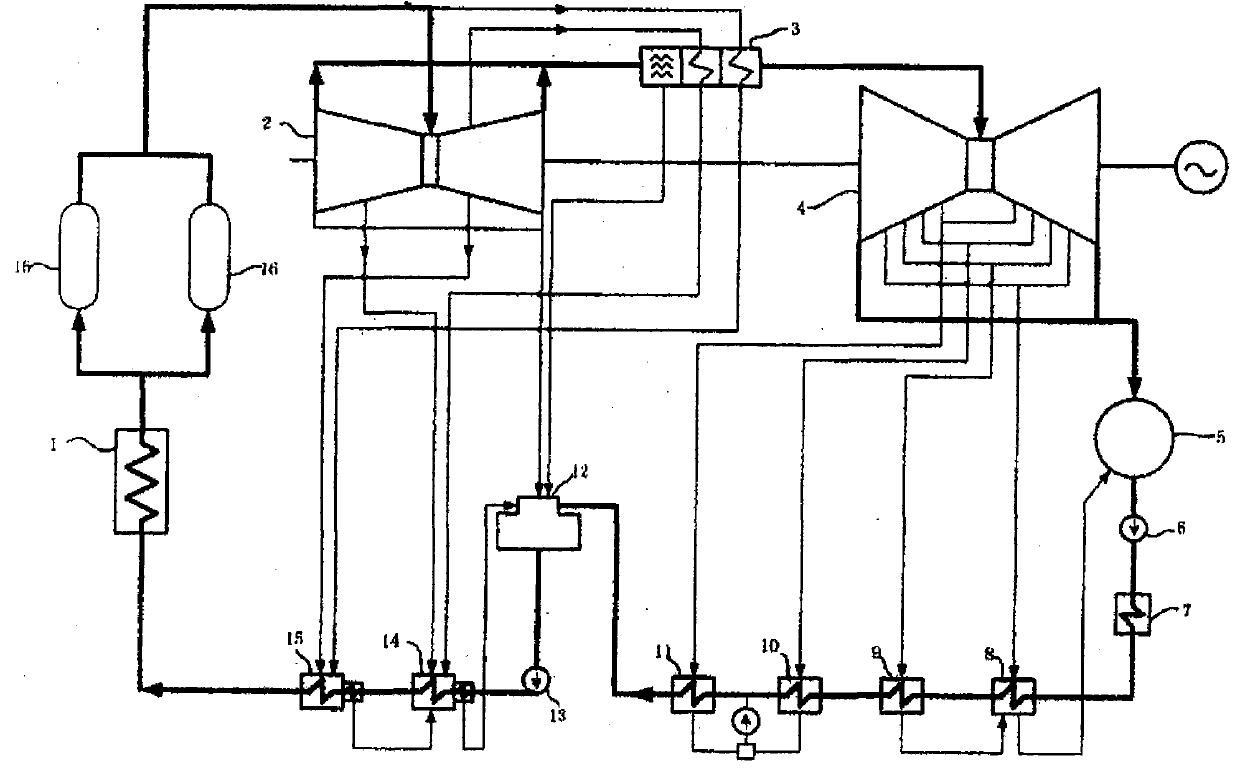

InactiveCN101908386AImprove cycle thermal efficiencyImprove relative internal efficiencyNuclear energy generationReactor heat to mechanical energyPressurized water reactorNuclear power

The invention discloses a pressurized water reactor and high-temperature gas cooled reactor-based hybrid thermodynamic cycle system, which belongs to the technical field of nuclear power energy. The hybrid thermodynamic cycle system comprises a steam generator, a steam turbine, a moisture separator re-heater, a condenser, a condensate pump, a gland steam condenser, low-pressure heaters, a deaerator, a water-feeding pump and high-pressure heaters which are connected according to a thermodynamic cycle process. Steam super-heater pressure shells of two modular high-temperature gas cooled reactors connected in parallel are connected between the steam generator and a high-pressure cylinder in a secondary circuit of a pressurized water reactor nuclear power station. Saturated steam generated by the steam generator performs heat exchange with high-temperature helium in steam super-heaters, and superheated steam flows out of the steam super-heaters and is converged to enter the high-pressure cylinder for working. Therefore, the system is favorable for greatly improving the cycle thermal efficiency of the two loops of the conventional pressurized water reactor, can improve the running security of the steam turbine, and has high economic benefit.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Application of second type absorption type heat pump in heat exchange cycle system of power plant

InactiveCN101806448AReduce consumptionReduce power generationHeat recovery systemsClimate change adaptationAbsorption heat pumpEngineering

The invention discloses application of a second type absorption type heat pump in a heat exchange system of a power plant. The key improvement is that a drive steam inlet of a generator is connected with a first stage steam extraction pipe arranged on a low pressure cylinder of a steam turbine through a pipeline, and a condensate water outlet is connected with a condensate water pipe returning to a boiler through a pipeline; a cooling water inlet of an absorber is connected with the condensate water pipe returning the boiler through a pipeline, and a cooling water outlet is connected with the condensate water pipe returning the boiler through a pipeline; a cooling water inlet of a condensator is connected with a cooling water inlet of a condensor through a pipeline, and a cooling water outlet of the condensator is connected with a cooling water outlet of the condensor through a pipeline; a cooled steam inlet of an evaporator is connected with the first stage steam extraction pipe arranged on the low pressure cylinder of the steam turbine through a pipeline, and a condensed water outlet of the evaporator is connected with the condensate water pipe returning the boiler through a pipeline. The invention has the advantages that the second type absorption type heat pump can reduce the amount of extracting middle-high pressure steam, enhance the energy conversion efficiency and save the resources.

Owner:王利军

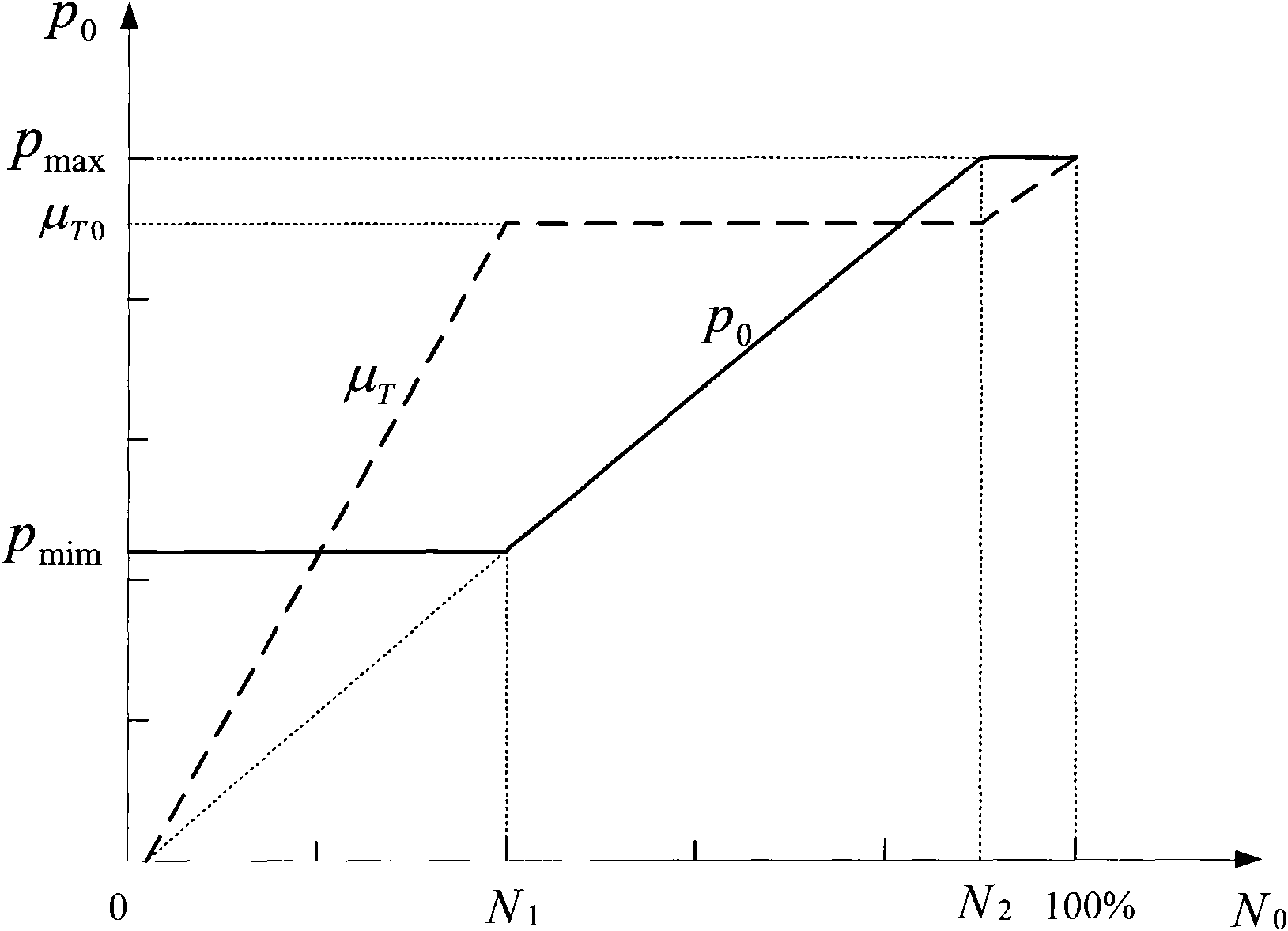

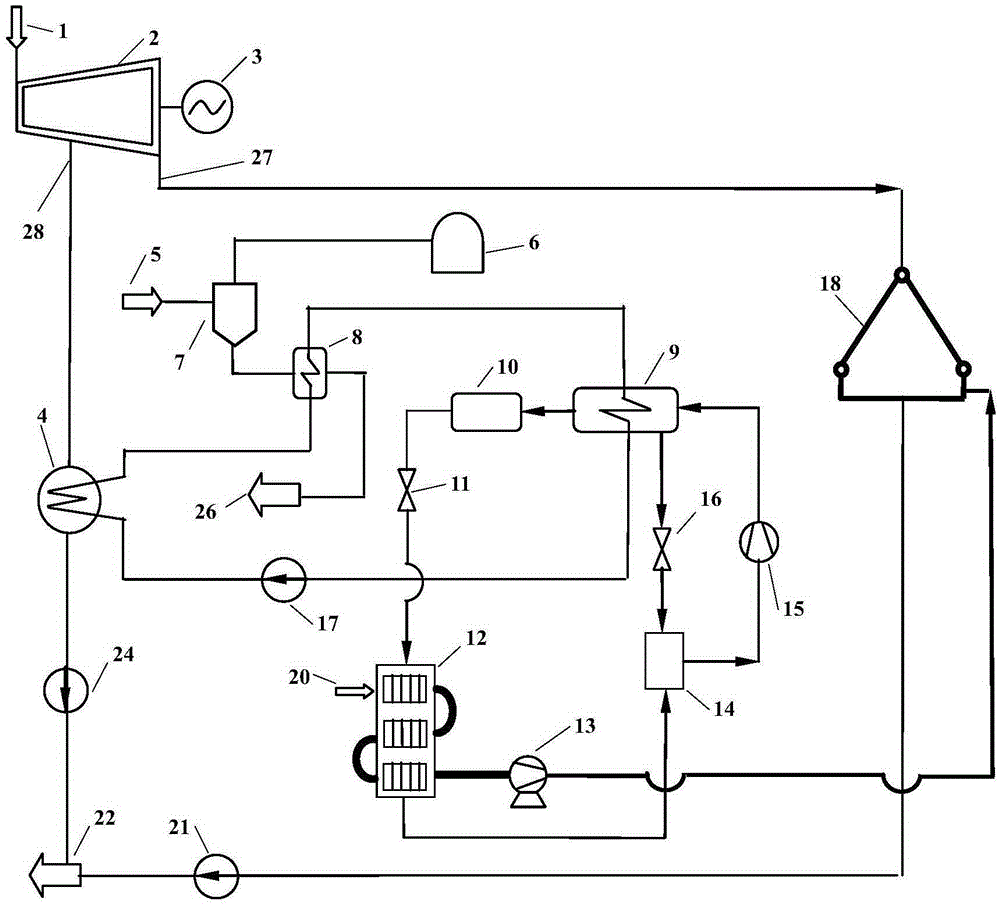

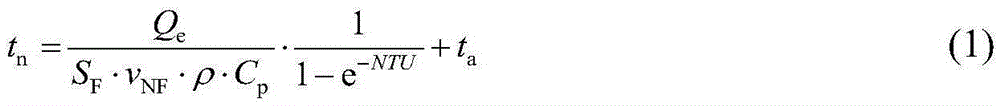

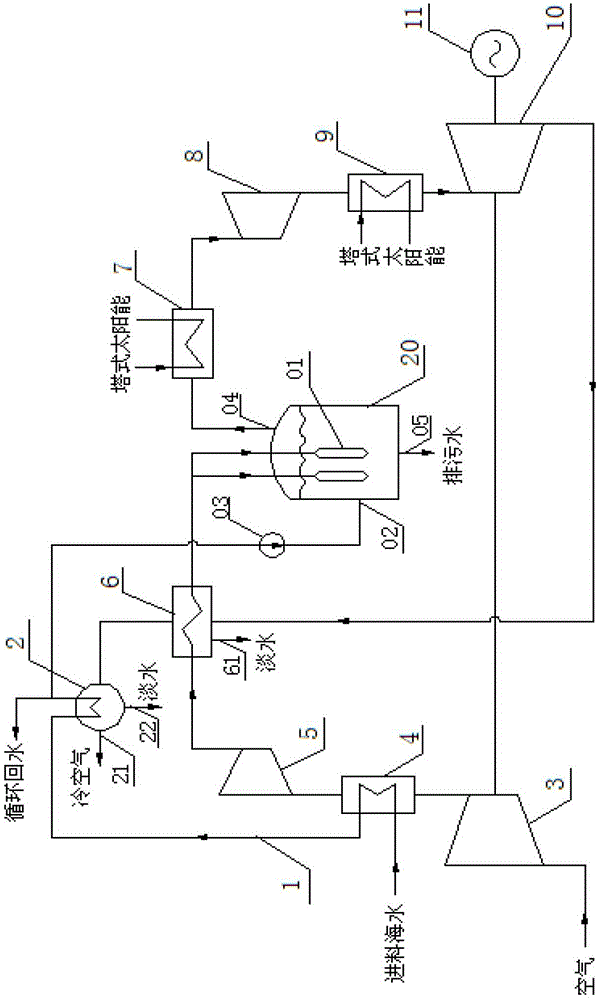

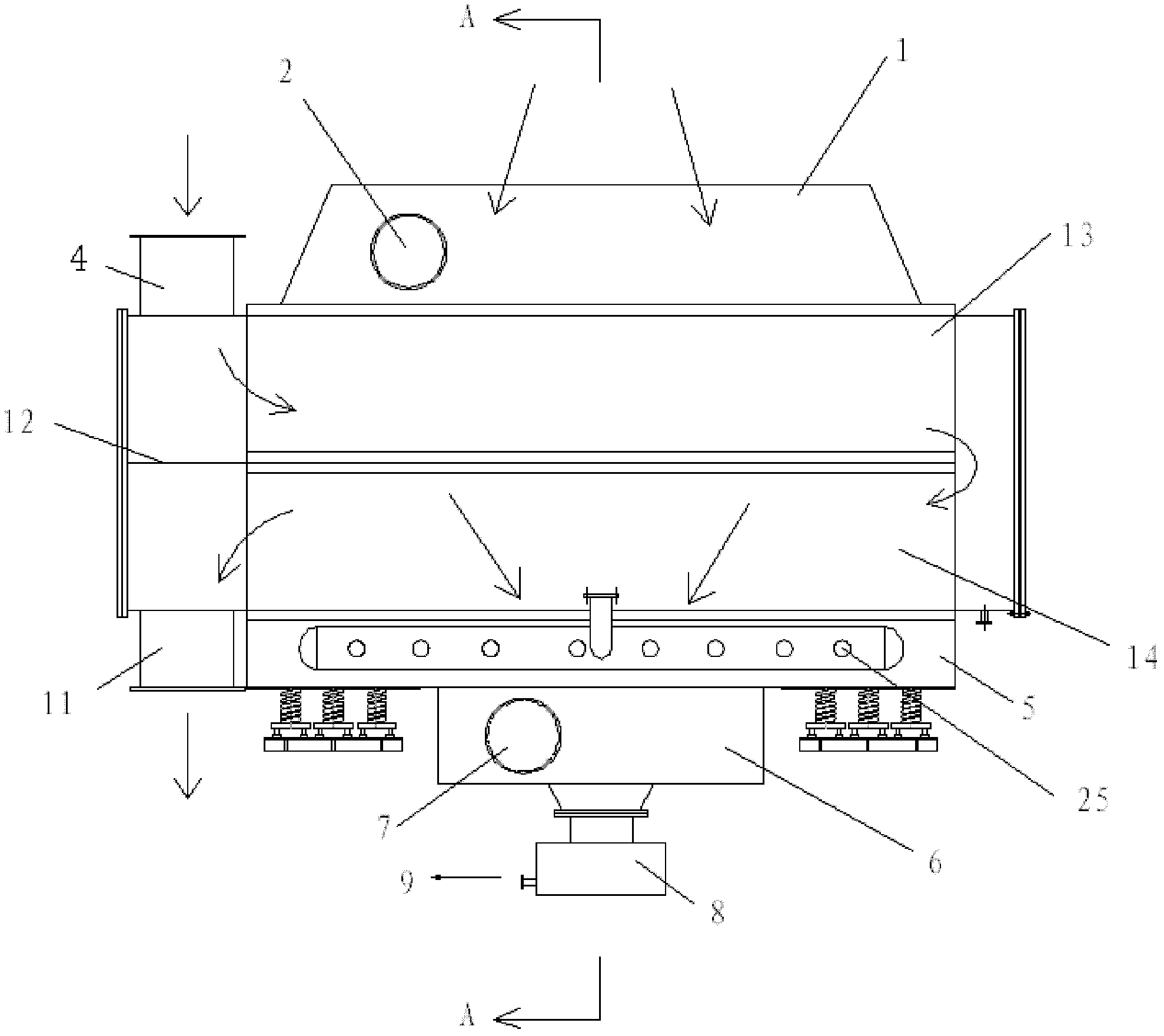

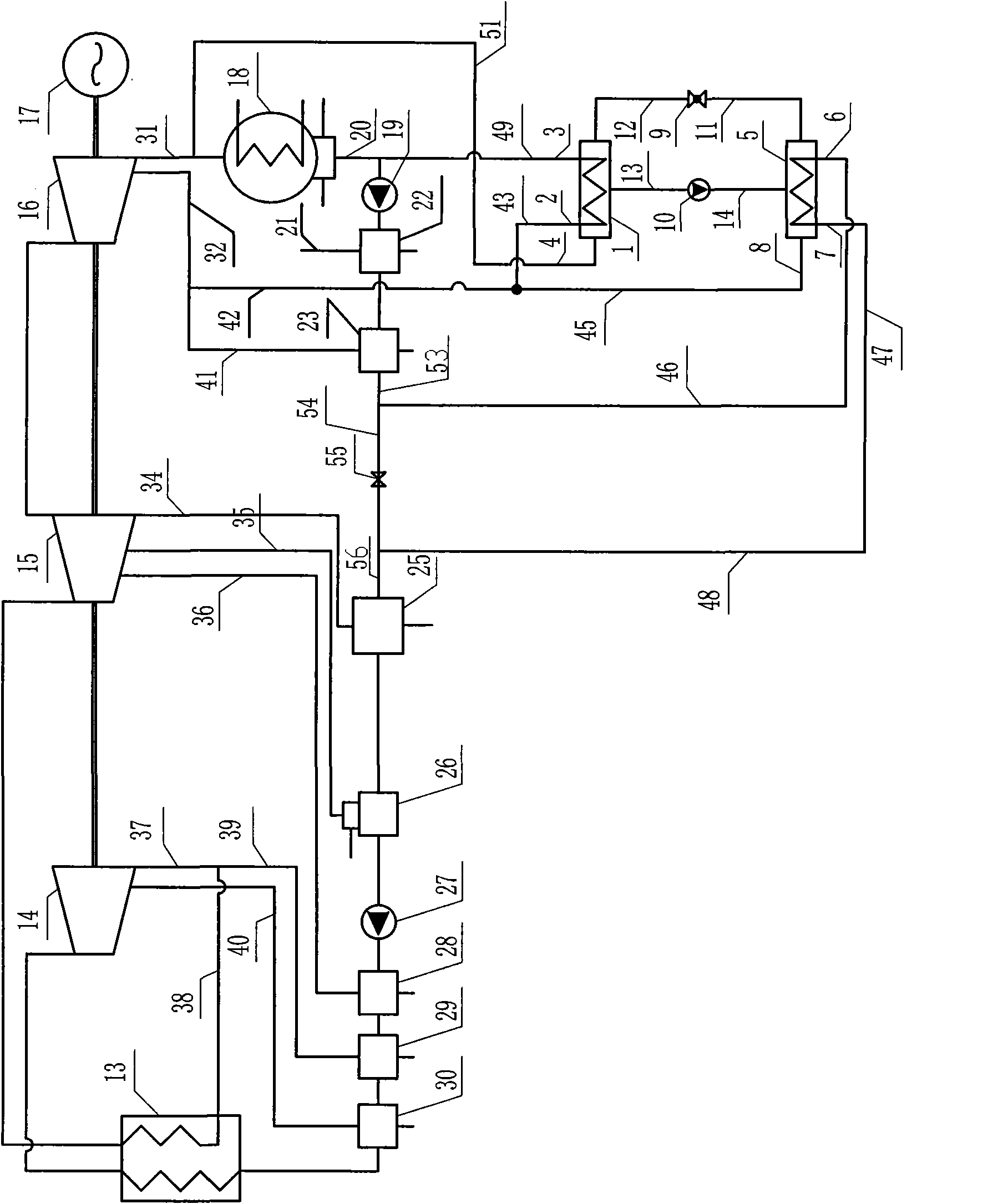

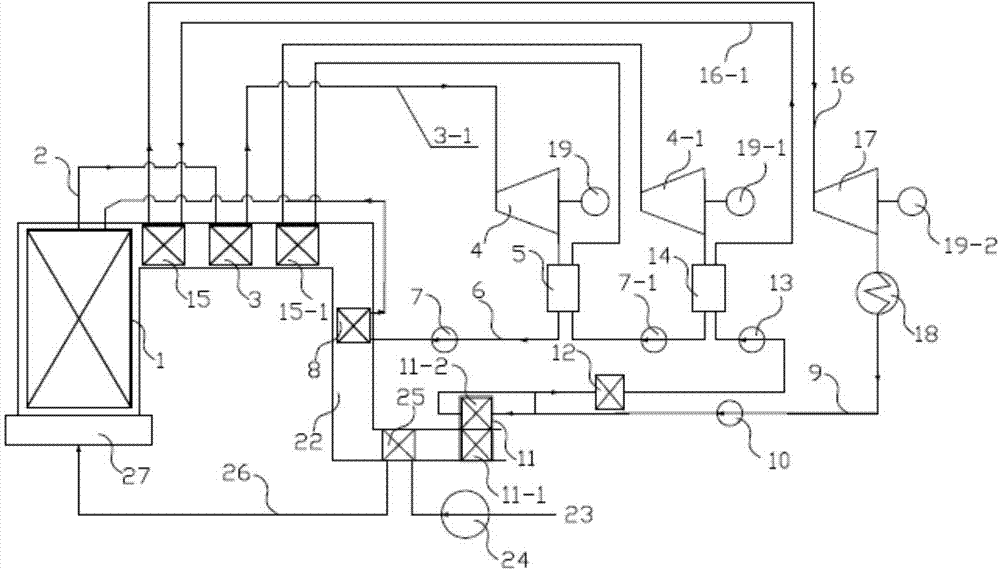

Power station air cooling system adopting combined refrigeration with shaft seal steam leakage of steam turbine and continuous blow-down waste heat of boiler as well as method for predicting heat-transfer coefficient of air-cooling condenser

ActiveCN105423772AReduce dust accumulationLower condensation temperatureHeat pumpsFeed water supplyEngineeringSuperheater

The invention discloses a power station air cooling system adopting combined refrigeration with shaft seal steam leakage of a steam turbine and continuous blow-down waste heat of a boiler. The system is characterized in that the steam turbine is communicated with a steam source, the steam turbine is connected with an electric generator, and the steam turbine is sequentially communicated with an air-cooling condenser, a condensate pump and boiler feedwater; the steam turbine is sequentially communicated with a steam leakage condenser, a steam leakage condensate pump and the boiler feedwater; boiler blow-down water is sequentially communicated with a flash tank, a deaerator, a working medium superheater and a drainage ditch; the steam leakage condenser is sequentially communicated with the working medium superheater, and a generator is communicated with the steam leakage condenser through a working medium circulating pump; the generator is sequentially communicated with a condenser, a first throttling valve and an evaporator, the evaporator is communicated with an absorber, and the generator is sequentially communicated with a second throttling valve, the absorber, a solution pump and a generator; and air is sequentially communicated with the evaporator, an induced draft fan and the air-cooling condenser. A method for predicting a heat-transfer coefficient of the air-cooling condenser is further provided.

Owner:NORTHEAST DIANLI UNIVERSITY

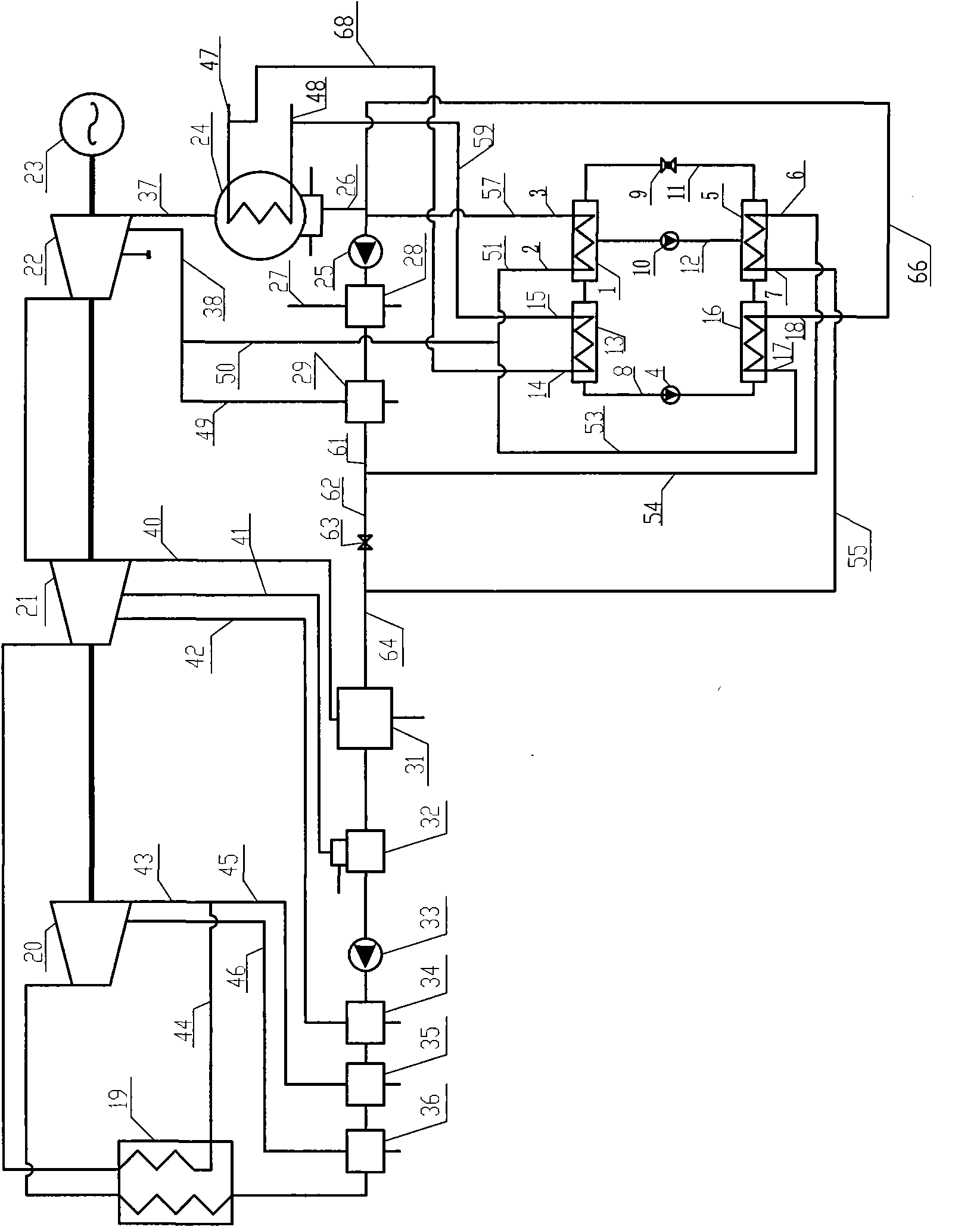

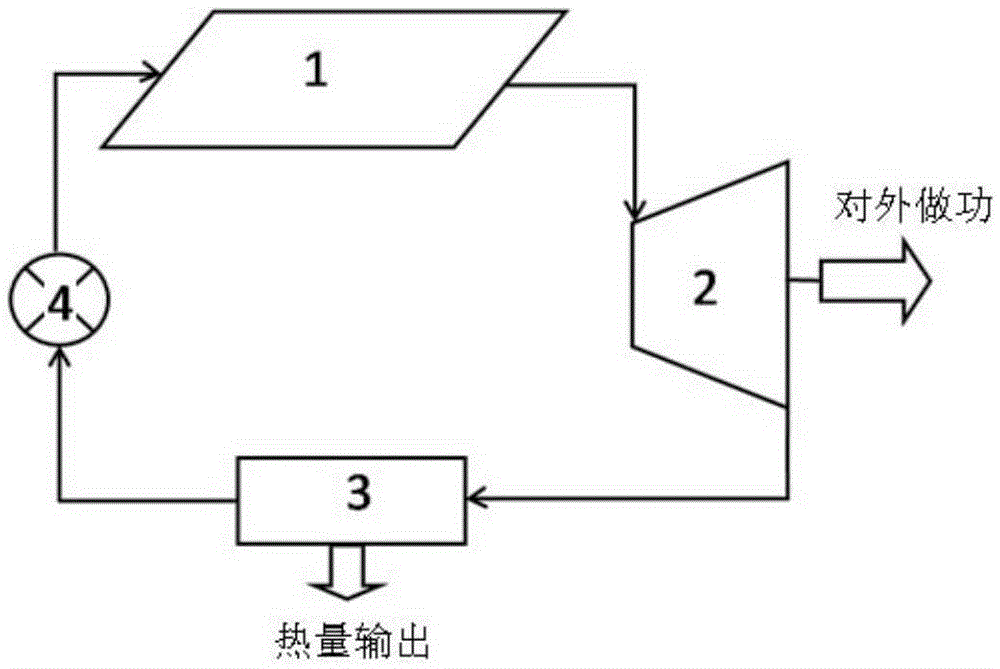

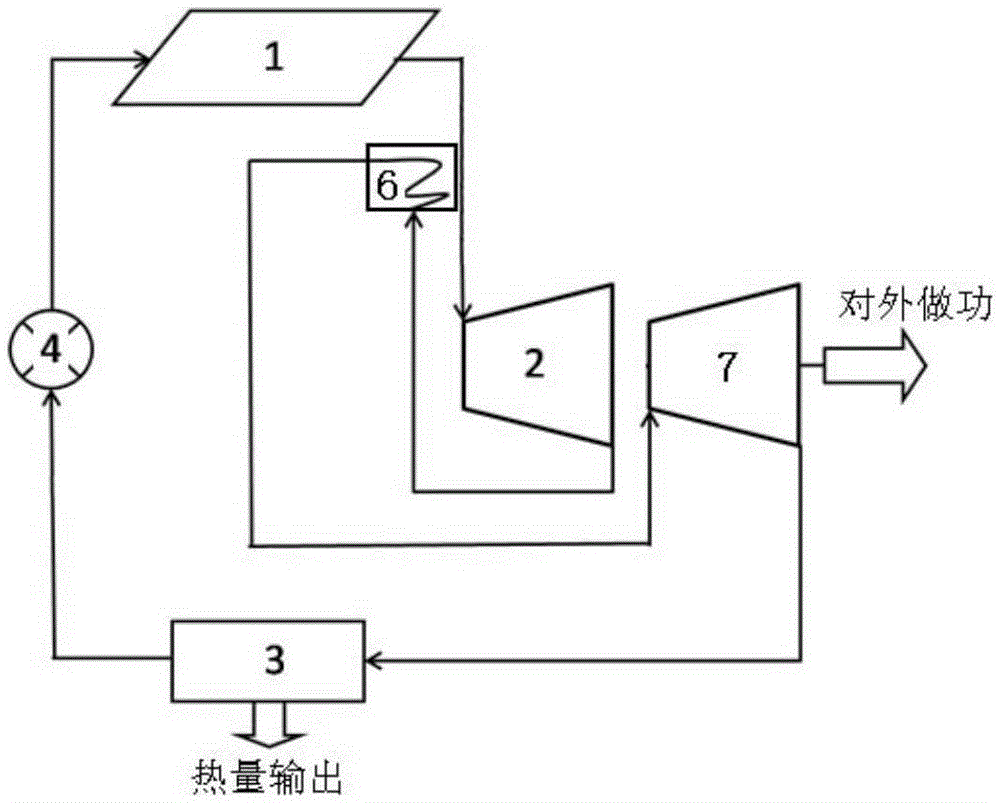

Combined cooling, heating and power device of distributed type industrial boiler

ActiveCN103089349ALow costImprove energy savingSteam engine plantsSteam boilersRefrigerationEnergy source

The invention relates to a combined cooling, heating and power device of a distributed type industrial boiler. A steam Rankine cycle system positive pressure and closed type method is adopted, a condenser of an outlet steam exhaust of a steam turbine serves as heat sources for a heating plant and an absorption refrigeration device, and therefore gradient utilization of energy sources is achieved. High quality energy of fuel is recovered for generating electricity, more than 260 KWh electric quantity can be recovered from per ton evaporation capacity (or 0.7MW heating load), at the same time, cooling and heating combination is achieved, and exhaust gas waste heat can be effectively recovered. According to a steam Rankine cycle system, waste acid and waste alkali are not produced, and the problems of oxygen corrosion and scale formation of the boiler are effectively avoided. Therefore the distributed type industrial boiler is energy-saving, environment-friendly and very remarkable in social benefits.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

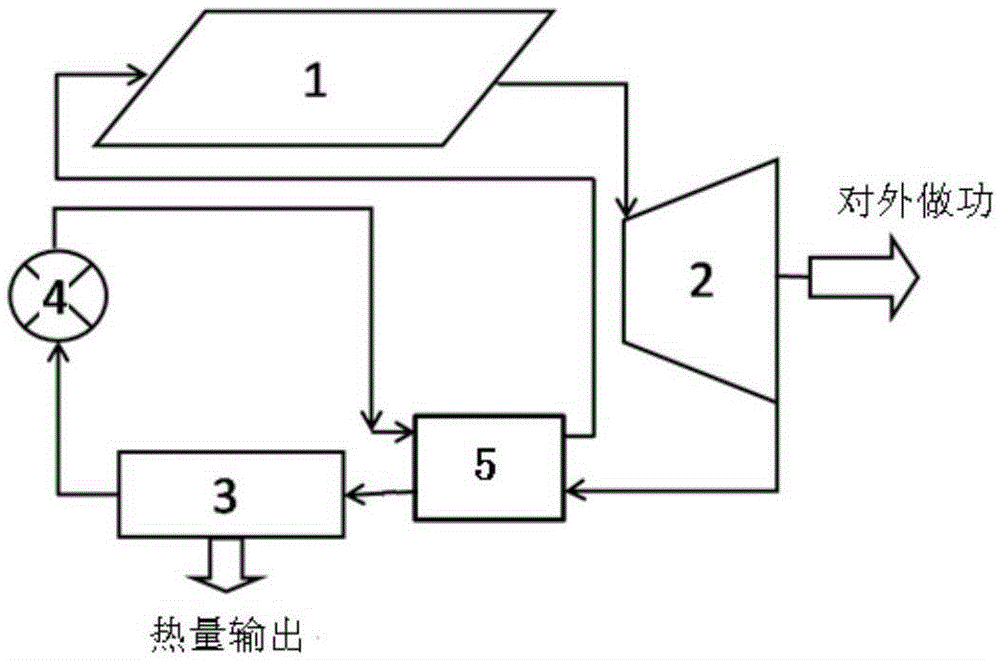

Distributed pneumatic-Rankine combined cycle combined cooling heating and power device

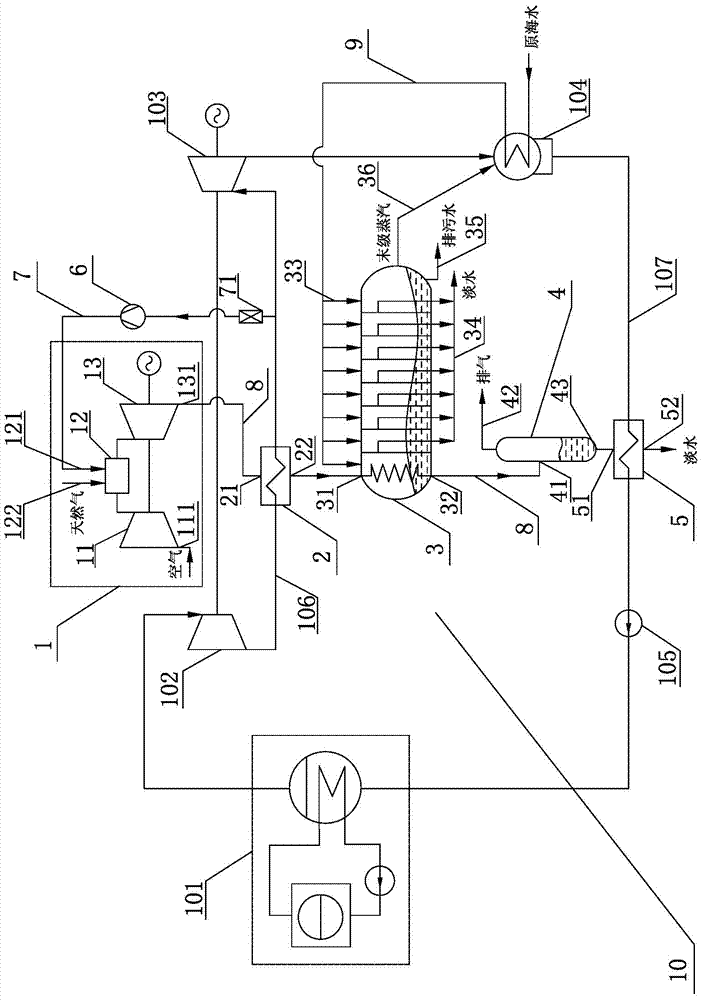

ActiveCN103089441ALow costImprove energy savingSteam useGas turbine plantsWater treatment systemRefrigeration

The invention relates to a distributed pneumatic-Rankine combined cycle combined cooling heating and power device. The distributed pneumatic-Rankine combined cycle combined cooling heating and power device is characterized in that the exhaust of a pneumatic machine is adopted as a heat source of a Rankine cycle waste heat boiler, a steam Rankine cycle system adopts a positive pressure and close type operating mode, a condenser of outlet dead steam of a steam turbine is utilized as a heat source of a heating system and an absorption refrigeration machine, and the cascading use of an energy source is realized; and high grade energy of a recycled fuel is used for generating electricity, evaporative capacity (or the heating load of 0.7 MW) of per ton can recover electric quantity which is more than 340 degrees, meanwhile, the cooling heating combination is realized, and the waste heat of fume is recovered in a high efficiency manner. A water treatment system of the steam Rankine cycle system causes no or only a little of waste acid and waste caustic to generate, and an oxygen corrosion and scaling problem of the boiler is effectively avoided. Therefore, energy conservation, environmental friendliness and social benefits are very notable.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

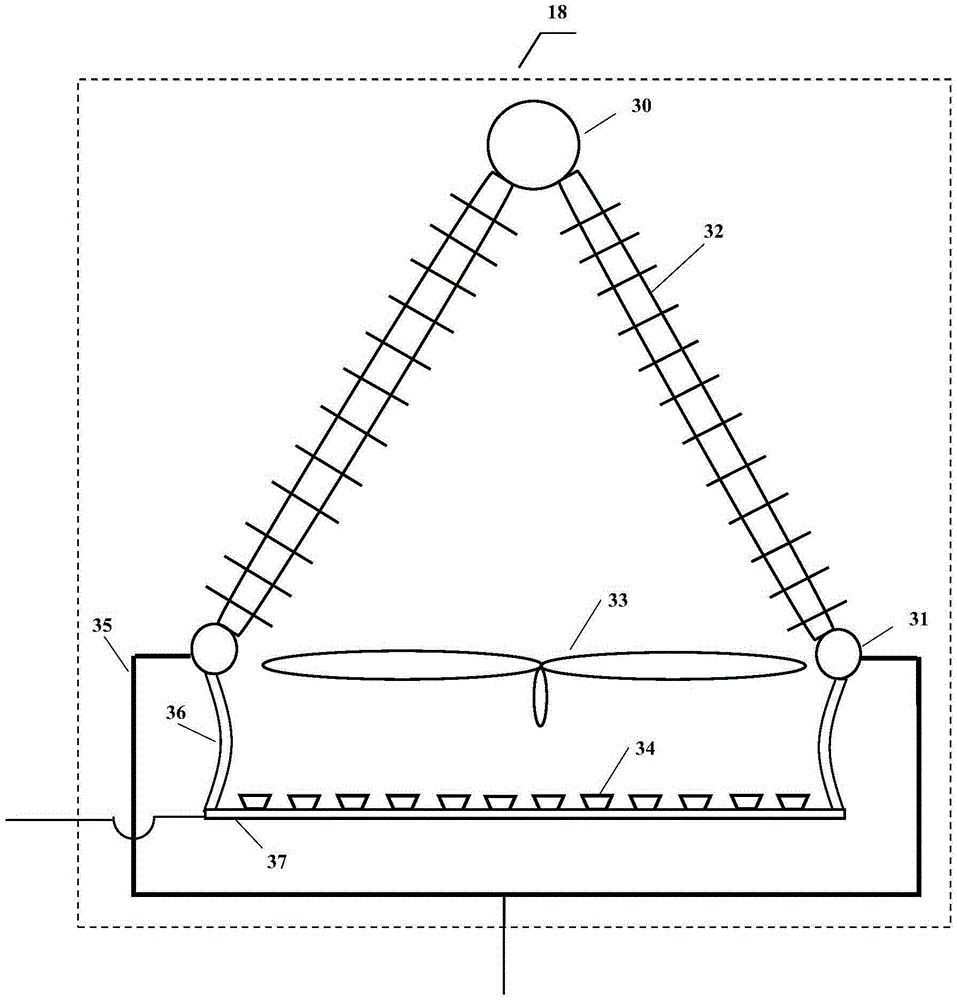

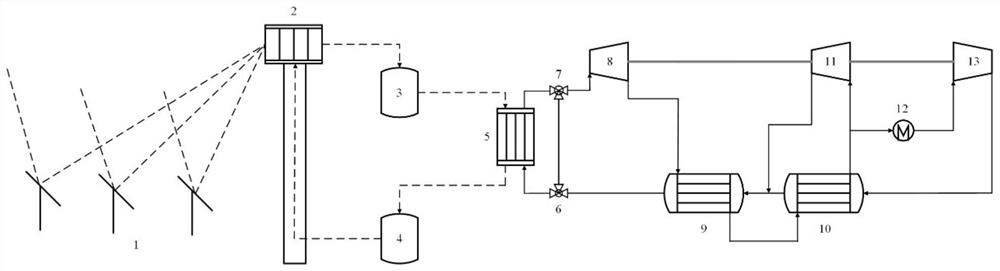

Solar moist air circulating electricity-water cogeneration system

InactiveCN104929709AGood distillationImprove heat transfer efficiencyGeneral water supply conservationSeawater treatmentAir cycleCogeneration

Owner:JIMEI UNIV

Brayton-cascade steam Rankine combined cycle power generation system

ActiveCN103075216AEfficient use ofReduce loadSteam useGas turbine plantsBrayton cycleSteam condensation

The invention relates to a Brayton-cascade steam Rankine combined cycle power generation system. The gas exhaust of a Brayton cycle is adopted as a heat source for a high-temperature end steam Rankine cycle, a steam condenser in a high-pressure end steam Rankine cycle is adopted as one of heat sources for a low-pressure end steam Rankine cycle, the latent heat of vaporization of the steam in the high-pressure end steam Rankine cycle is efficiently recovered to be used for power generation in the low-pressure end steam Rankine cycle, consequently, the load of the steam condenser of the conventional steam Rankine cycle system can be effectively reduced by more than absolute 20 percent, and by adopting a system optimization technique, the absolute thermal efficiency of the cycles of the whole system can be increased by more than 5 percent. The Brayton-cascade steam Rankine combined cycle power generation system not only can be used in the energy-saving alteration of conventional units, but also can be used in the design and construction of new units, and economic, social and environmental protection benefits are remarkable.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

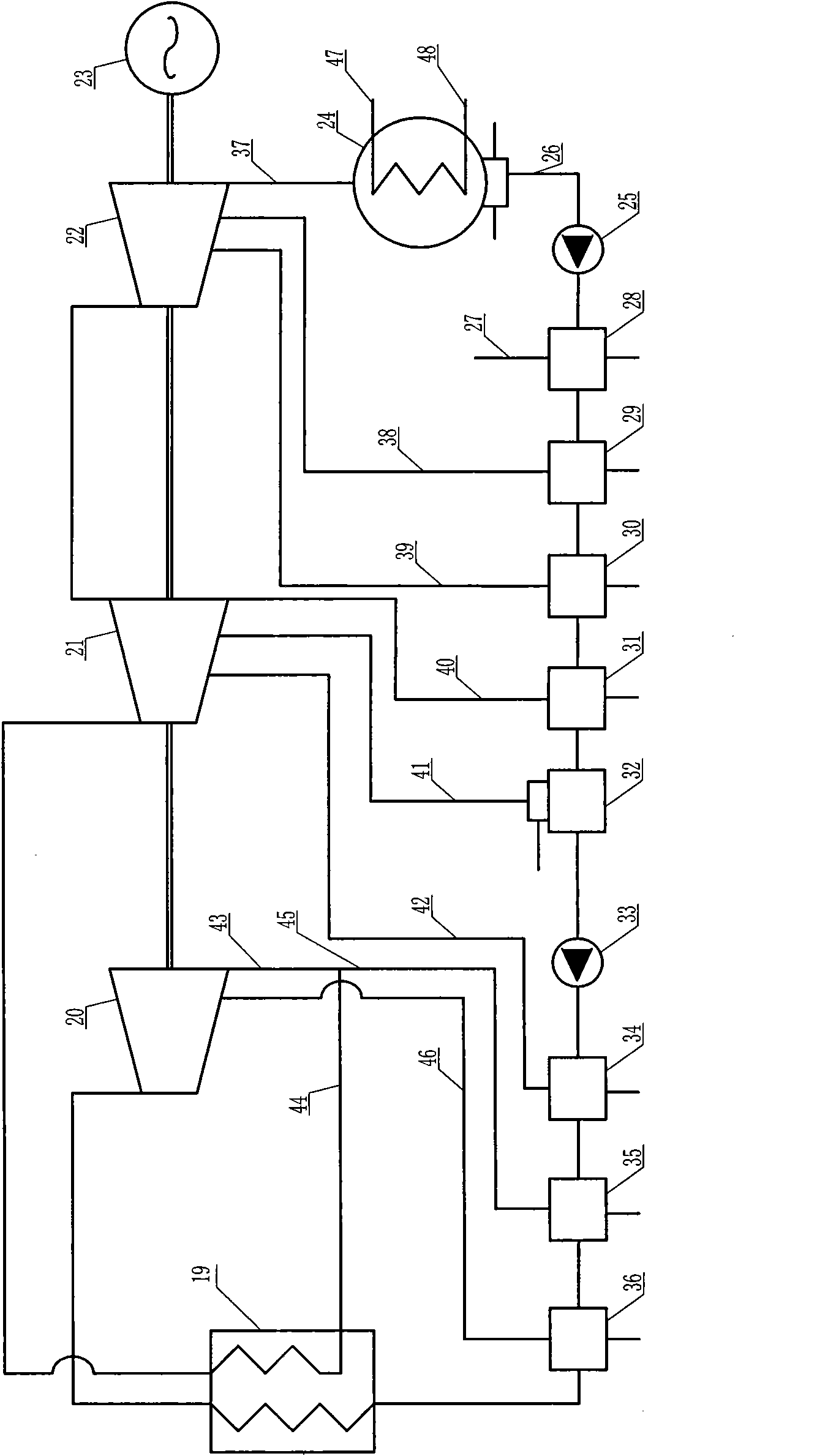

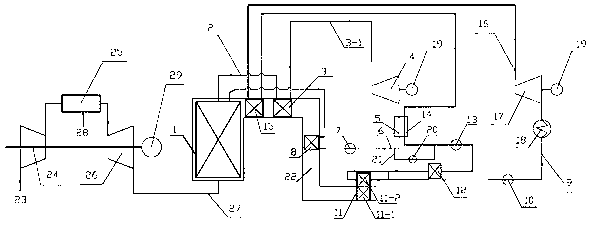

Nuclear power plant and gas turbine combined electricity-water cogeneration system and method

InactiveCN105439233AImprove economyImprove cycle thermal efficiencyGeneral water supply conservationSeawater treatmentCombustion chamberNuclear power

The invention discloses a nuclear power plant and gas turbine combined electricity-water cogeneration system and method. The electricity-water cogeneration system comprises a nuclear power plant secondary circuit system, a gas turbine generator unit, a wet gas reheater, a seawater desalting device, a gas-water separator, a drain cooler, a compressor, a steam injection pipeline, a wet gas pipeline and an original seawater pipeline. A stream of reheated steam from the nuclear power plant secondary circuit system is introduced into a combustion chamber of the gas turbine generator unit, wet exhaust of a gas turbine is used for heating reheated steam of a nuclear power plant through the wet gas reheater so as to increase the temperature of the reheated steam greatly, then the seawater desalting device is driven to produce fresh water, finally fresh water obtained after condensation of wet exhaust and waste heat are recovered through the gas-water separator and the drain cooler in sequence, and final-stage secondary steam of the seawater desalting device is directly introduced into a condenser of the nuclear power plant for condensation recovery so as to serve as make-up water of the nuclear power plant. By the adoption of the electricity-water cogeneration system and method, the heat economical efficiency of the nuclear power plant is improved remarkably, and gas turbine cycle efficiency is quite high.

Owner:JIMEI UNIV

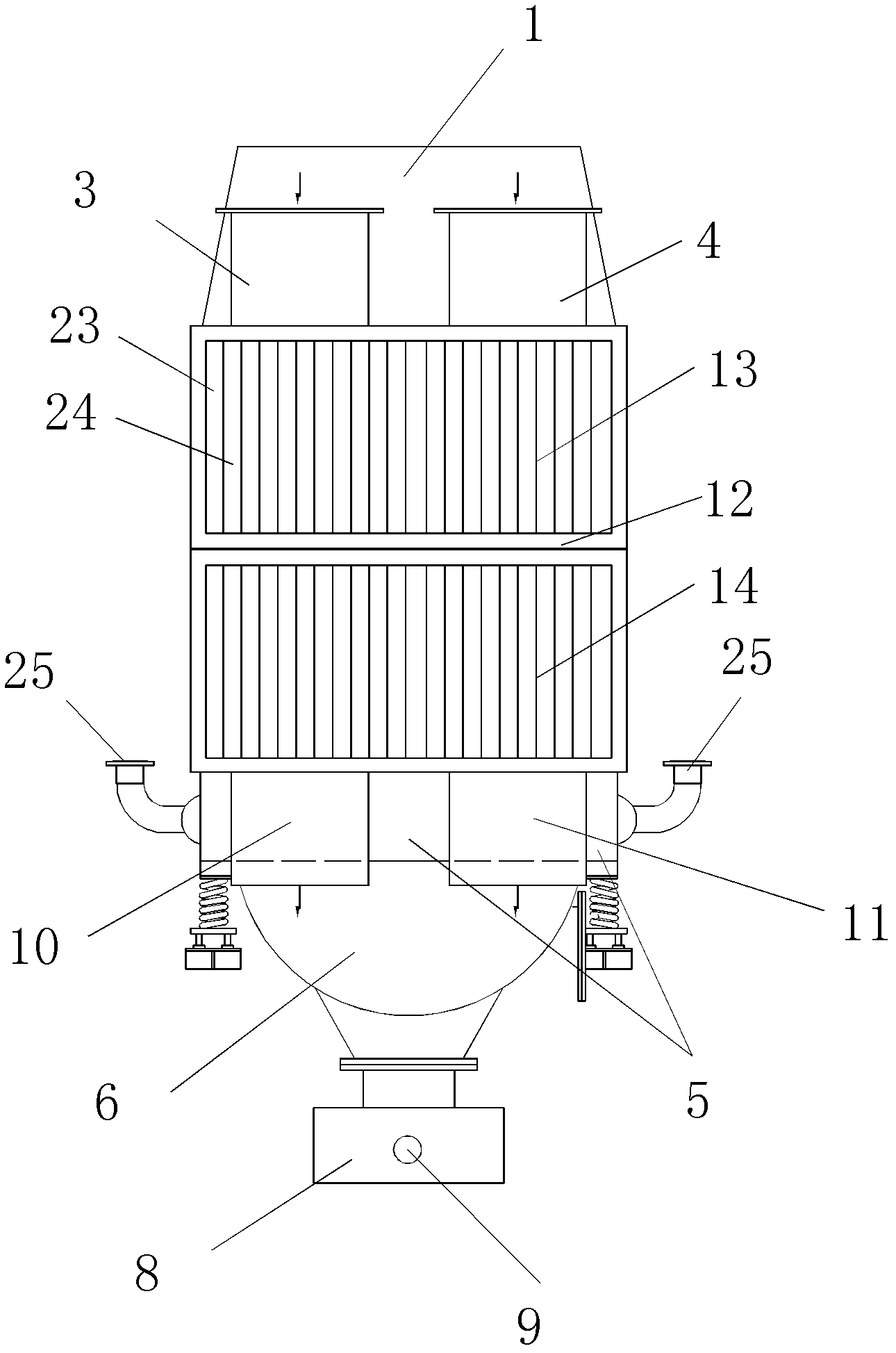

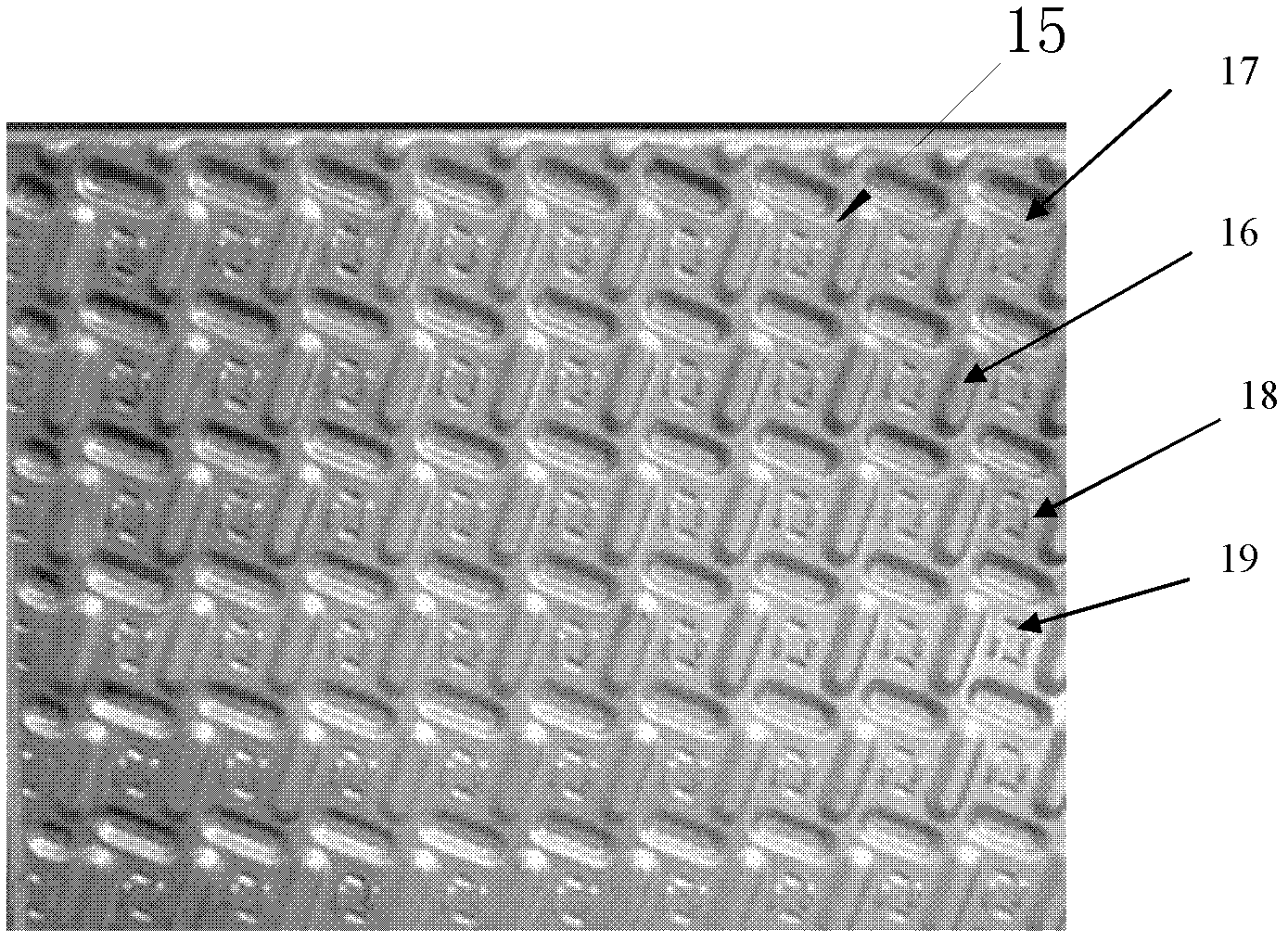

All-welded plate shell type stainless steel condenser and application thereof

ActiveCN102425958AOvercoming Heat Transfer Performance DeteriorationReduce cooling areaSteam/vapor condensersSteam engine plantsPower stationEngineering

The invention provides an all-welded plate shell type stainless steel condenser and application thereof. The all-welded plate shell type stainless steel condenser is a key device in a thermodynamic system of a power plant. Concave-convex multi-point type stainless steel sheets are adopted in a high-vacuum negative-pressure rectangular case at a dead steam part; two sheets are provided with longitudinal welding lines between which tops of convex grooves are opposite to each other, so as to form a dead steam path which is of single flow path type; the other two sheets are provided with transverse welding lines, between which bottoms of concave grooves are opposite to each other, so as to form a circulation cooling water path which is separated into two equal flow paths by a case separator; the height of the convex grooves is equal to the depth of the concave grooves and is not less than 6mm; small convex grooves are arranged among convex grooves and small concave grooves are arranged among concave grooves. The dead steam exchanges heat with the circulation cooling water in a fair flow / cross flow manner from top to bottom by virtue of flow paths at two sides of the sheets, and is condensed into water and flows downwards in a mode of beads, and water gathered in a steam gathering chamber and a water gathering chamber flows out through a heat well condensed water outlet. The condenser has the advantages of compact structure, material saving, light weight, low production cost, short investment return period and is worthy of popularization and application in large scale.

Owner:北京市京海换热设备制造有限责任公司

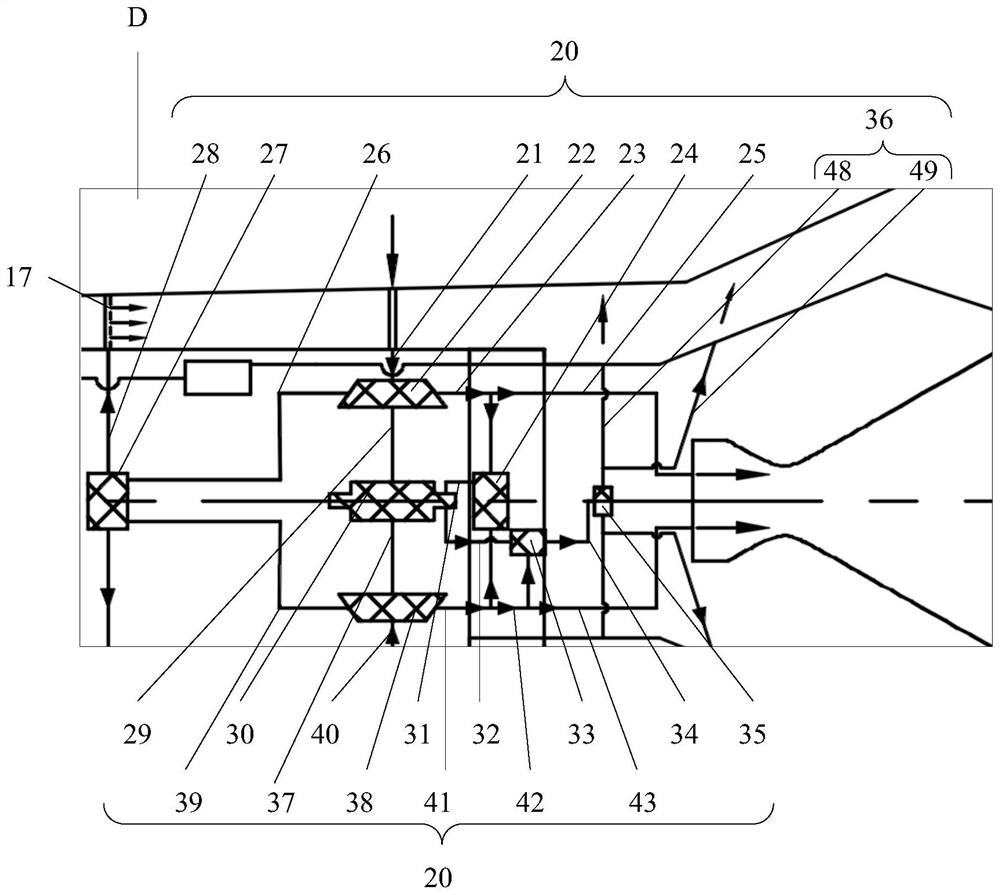

Very-high-pressure intercooling cycle turbofan engine

ActiveCN108661822ACompact structureIncrease stall marginGas turbine plantsJet propulsion plantsSingle stageCombustion chamber

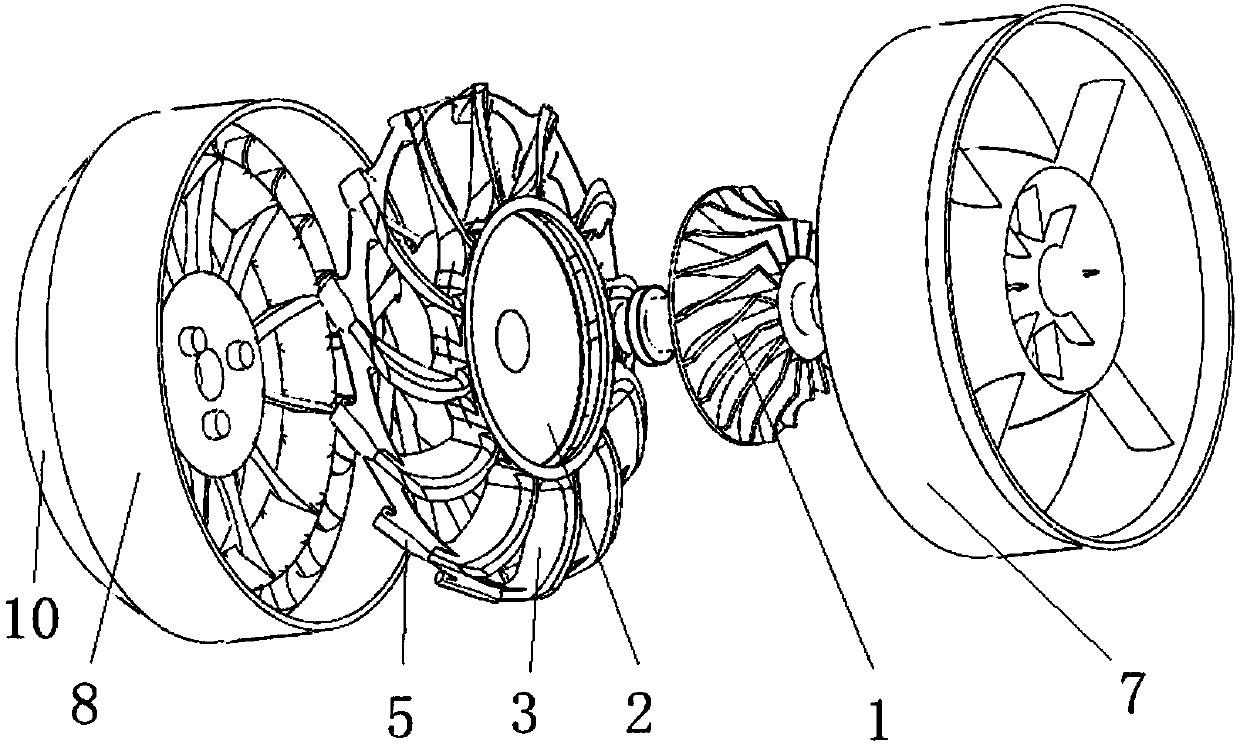

The invention provides a very-high-pressure intercooling cycle turbofan engine. The engine comprises fans, a high-pressure air compressor, an intercooler, a very-high-pressure air compressor, a combustion chamber, a circular rotating fan transition section, a very-high-pressure turbine, a high-pressure turbine, a low-pressure turbine, a low-pressure shaft, a high-pressure shaft and a very-high-pressure shaft. The fans, the high-pressure air compressor, the intercooler, the very-high-pressure air compressor, the combustion chamber, the circular rotating fan transition section, the very-high-pressure turbine, the high-pressure turbine and the low-pressure turbine are connected in sequence. The very-high-pressure turbine drives the very-high-pressure air compressor to operate through the very-high-pressure shaft. The high-pressure turbine drives the high-pressure air compressor to operate through the high-pressure shaft. The low-pressure turbine drives the fans to operate through the low-pressure shaft. The rotation central axis of the very-high-pressure air compressor, and the axis of the combustion chamber are both parallel to the axis of the engine but not coincide with the axis ofthe engine. The high-pressure air compressor is composed of a multi-stage high-load axial flow air compressor and a single-stage high-through-flow centrifugal / oblique flow air compressor.

Owner:AERO ENGINE ACAD OF CHINA

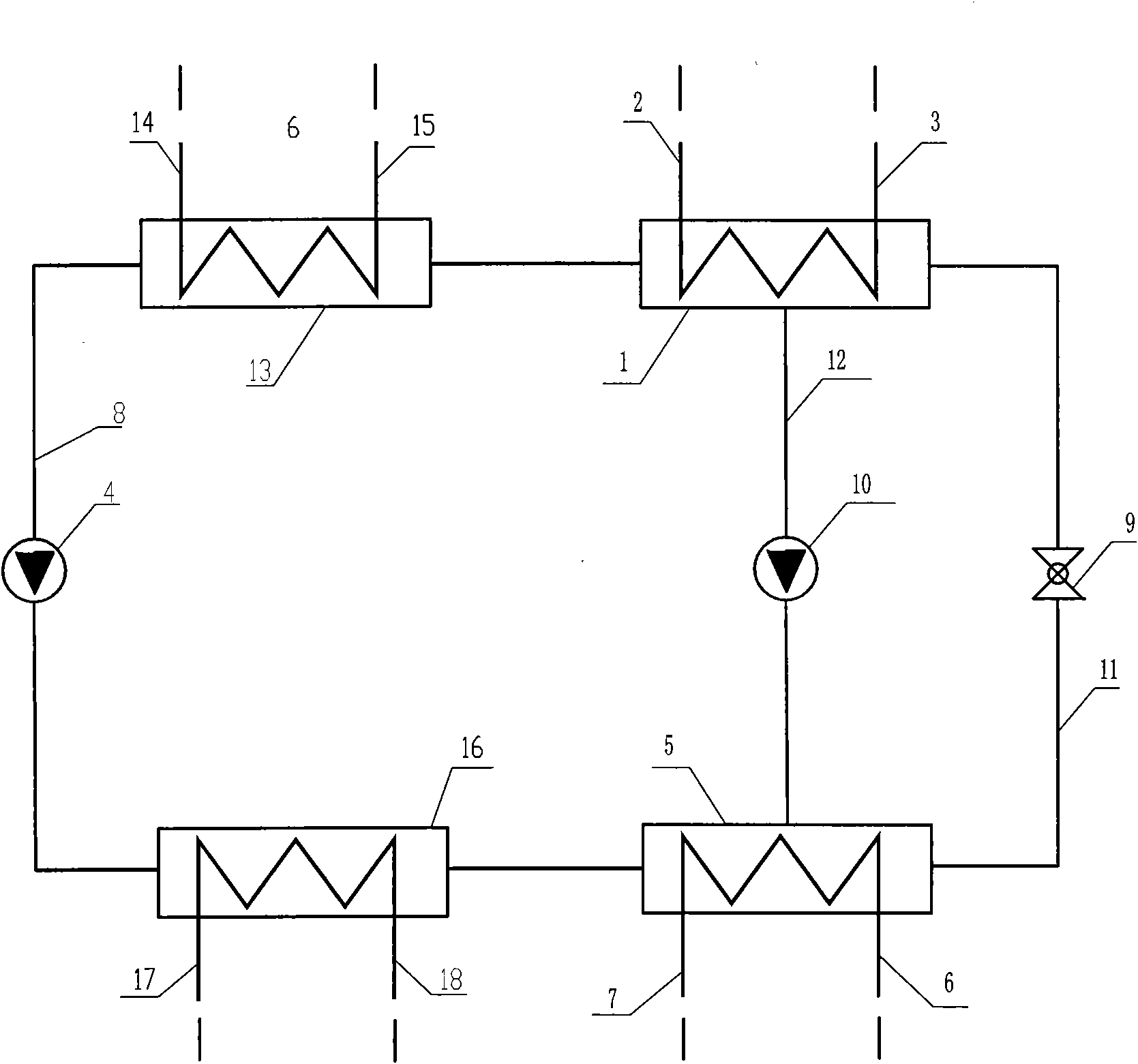

Central air conditioner combining solar energy ejecting cooling system

The invention relates to a central air conditioner combining solar energy ejecting cooling device. The device comprises a main ejector, a pressure adjustment ejector, a preheating ejector, an evaporator, a condenser, a compressor, a throttle valve, a generator, a heat collector, a regulating valve, a freezing medium pump and the like. The system is characterized in that mechanical compressor type cooling is assisted by solar energy ejecting cooling so that the purpose of energy saving is achieved; the two cooling methods share the evaporator and the condenser so that system cost is effectively saved; pressure of driving fluid of the main ejector can be adjusted through the pressure adjustment ejector so that when solar energy radiation waves, the main ejector is still steady in a working condition and efficient in operation; and the preheating ejector is arranged between the generator and the freezing medium pump and lower temperature liquid freezing medium cycle fluid is heated by a gas freezing medium with higher temperature in an outlet of the compressor, namely, waste heat generated by a central air conditioner can be recycled so that energy using rate of the system can be improved.

Owner:广西北联机电科技有限公司

Solar ORC power generation system and power generation method thereof

InactiveCN103277157AImprove heat utilizationImprove cycle thermal efficiencySolar heating energyFrom solar energyEngineeringSolar power

The invention discloses a solar ORC power generation system and a power generation method of the solar ORC power generation system. Solar energy can be utilized to generate power, and therefore the heat energy utilization rate is high. The solar ORC power generation system mainly comprises a heat exchanger which is connected with a solar heat source, a power output device, a generator which is connected with the power output device, a circulating pump and a condenser. The solar heat source comprises solar heat collecting panels, an oil storage tank and a conduction oil circulating pump. The solar heat source further is further provided with a heat regenerator. The heat regenerator is used for conducting heat exchange on an organic working medium discharged by the power output device and an organic working medium discharged by an organic working medium circulating pump, and therefore remaining heat energy of the organic working medium discharged by the power output device can be fully utilized. The solar ORC power generation system is used for power generation, therefore, heat energy can be effectively utilized, energy saving is facilitated, and system device cost is reduced.

Owner:CHENGDU HOT NEW ENERGY TECH

Absorption type heat regenerator and application thereof in regenerative circulation system of power plant

The invention discloses an absorption type heat regenerator and application thereof in a regenerative cycling system of a power plant. The key improvement of the absorption type heat regenerator is as follows: the absorption type heat regenerator comprises a generator, an absorber, an expansion mechanism and a working medium pump. The steam inlet of the generator of the absorption type heat regenerator is connected with the steam pumping pipe of a steam turbine through a pipeline, the condensate outlet of the generator of the absorption type heat regenerator is connected with the return condensate pipeline of a boiler through a pipeline, the steam generation outlet of the generator is connected with the steam exhaust pipe of the steam turbine through a pipeline; and the steam absorption inlet of the absorber is connected with the steam pumping pipe of the steam turbine through a pipeline, the cooling water inlet of the absorber is connected with a condensate pipe, and the cooling water outlet of the absorber is also connected with a condensate pipe. The absorption type heat regenerator has the advantages of reducing the number of regenerative cycles for pumping of high-pressure steam, improving the energy conversion efficiency and generation power, saving the energy, and reducing emissions.

Owner:王利军

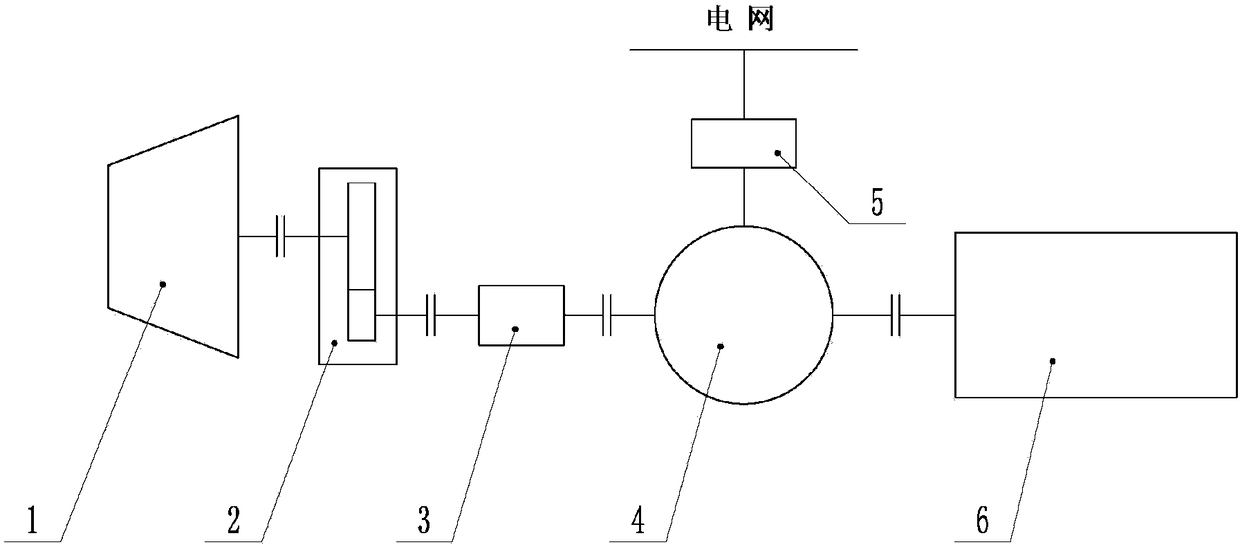

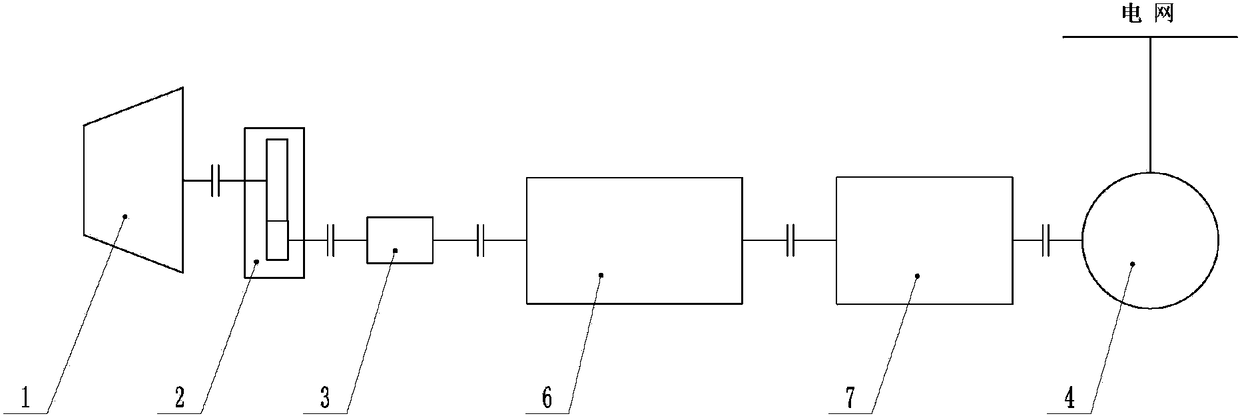

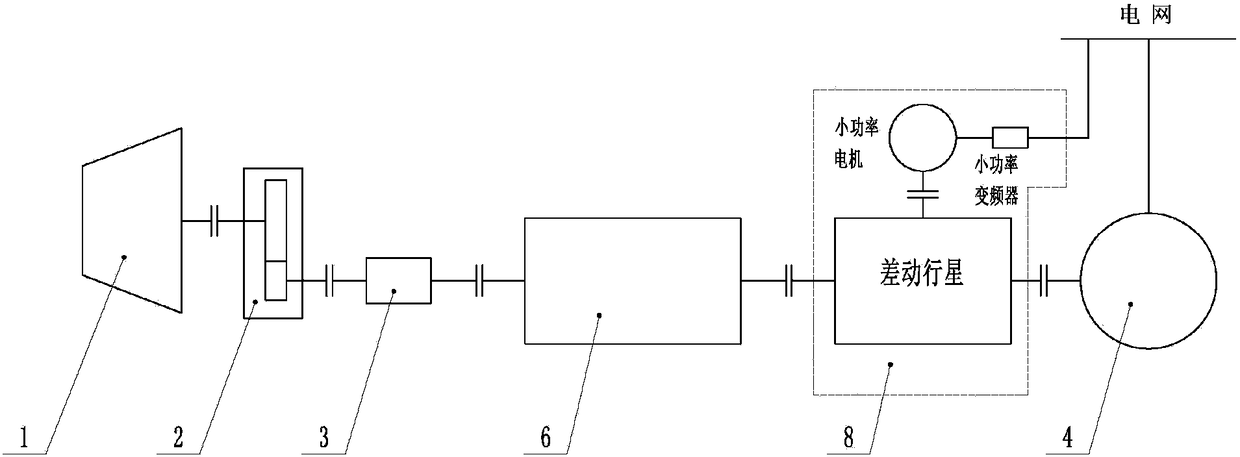

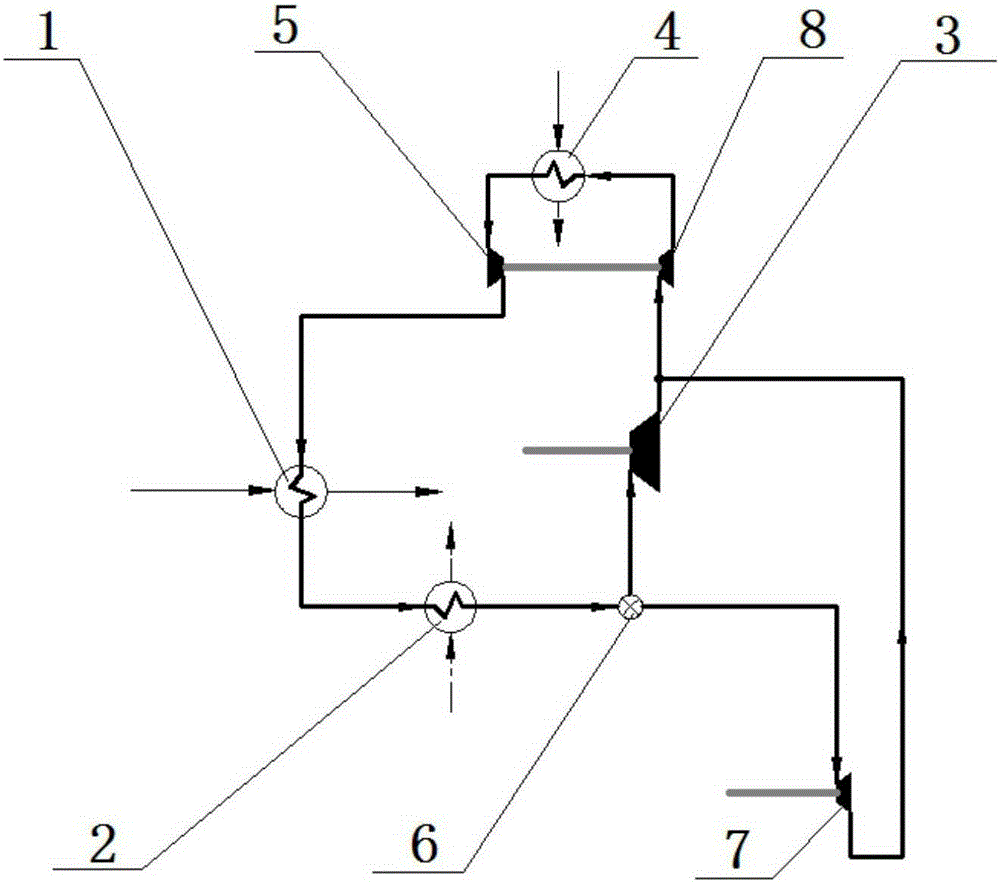

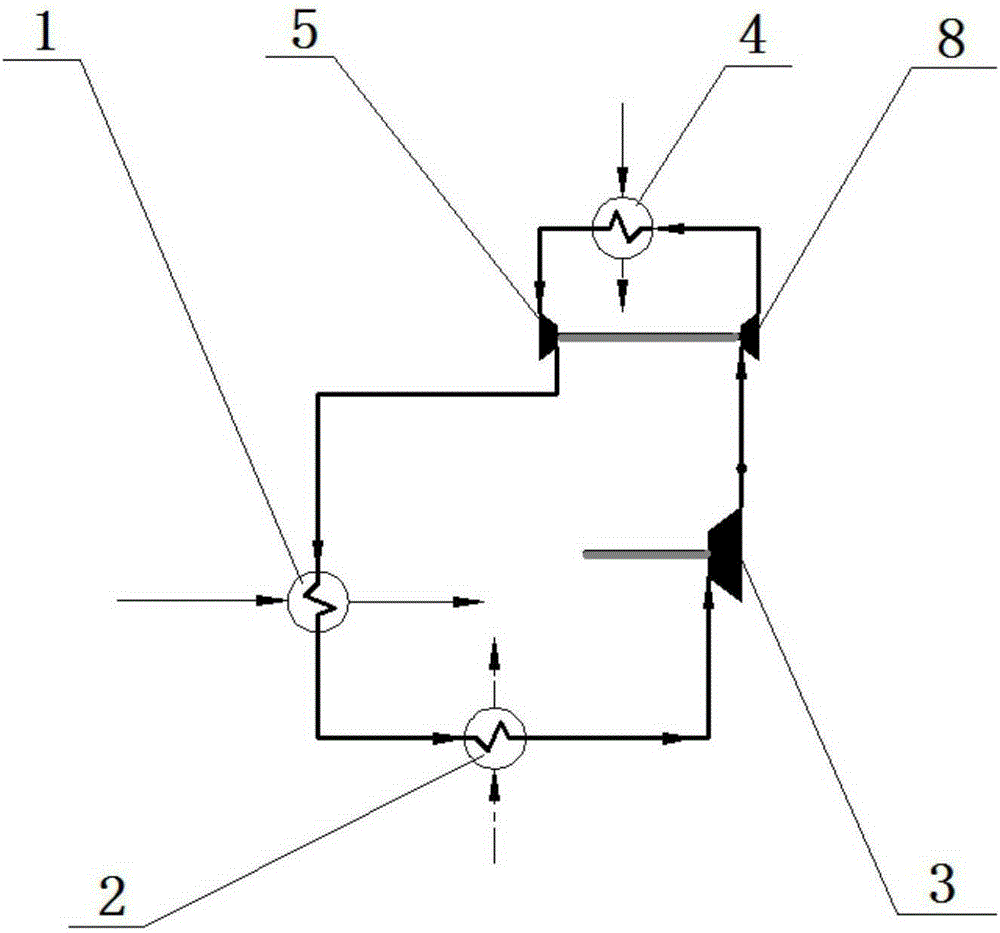

High-efficiency steam-electricity hybrid power speed regulation unit

PendingCN108462316AImprove operational efficiencyIncrease steam productionMechanical energy handlingElectric generator controlElectricityPower station

The invention relates to the field of speed regulation of a power station fan and a water pump unit, in particular to a high-efficiency steam-electricity hybrid power speed regulation unit. The unit includes a steam turbine, a gear box, a synchronous automatic clutch, a motor, a full-power frequency converter, a load, a planetary hydraulic speed regulation / constant speed device, and a planetary variable frequency speed regulation / constant speed device. Through the different arrangements and applications of the device, the hybrid power speed regulation driving unit is realized, the unit integrates the advantages of the steam-driving and electricity-driving parties, has the characteristics of being energy-saving, efficient, high in reliability, saving in investment, and is particularly suitable for actual conditions of peak shaving and future deep peak shaving operation of a current power station.

Owner:中国船舶重工集团公司第七0三研究所

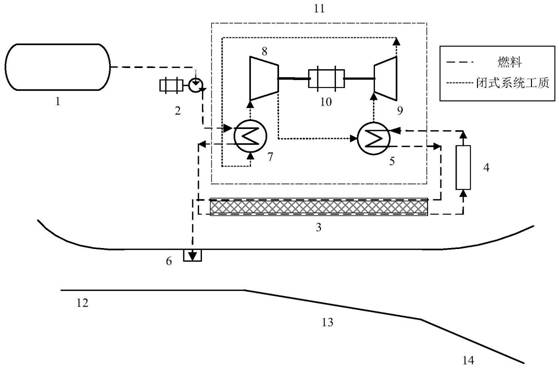

Closed circulating system suitable for aerospace engine

ActiveCN105275662AImprove cycle thermal efficiencyAvoid defectsClosed-cycle gas positive displacement engine plantAviationSingle stage

The invention relates to a closed circulating system suitable for an aerospace engine. Supercritical state fluid serves as a working medium, and the characteristics that the supercritical state fluid is large in heat capacity, extremely high in heat exchange efficiency, quick in response and low in viscosity are fully utilized so that the whole circulating system can be high in energy transmission capacity and small in flow resistance and can well adapt to changes of working conditions. The system can fully use heat released by cooling of high-temperature inflow air, and comprehensive management of engine energy can be achieved. The closed circulating system is used for the aerospace engine and can overcome defects of an existing engine precooling scheme so that the engine can meet the requirements of a hypersonic aircraft and a single-stage-to-orbit aircraft which can be repeatedly used.

Owner:BEIHANG UNIV

Blade tip ejecting self-driven wheeled fan engine

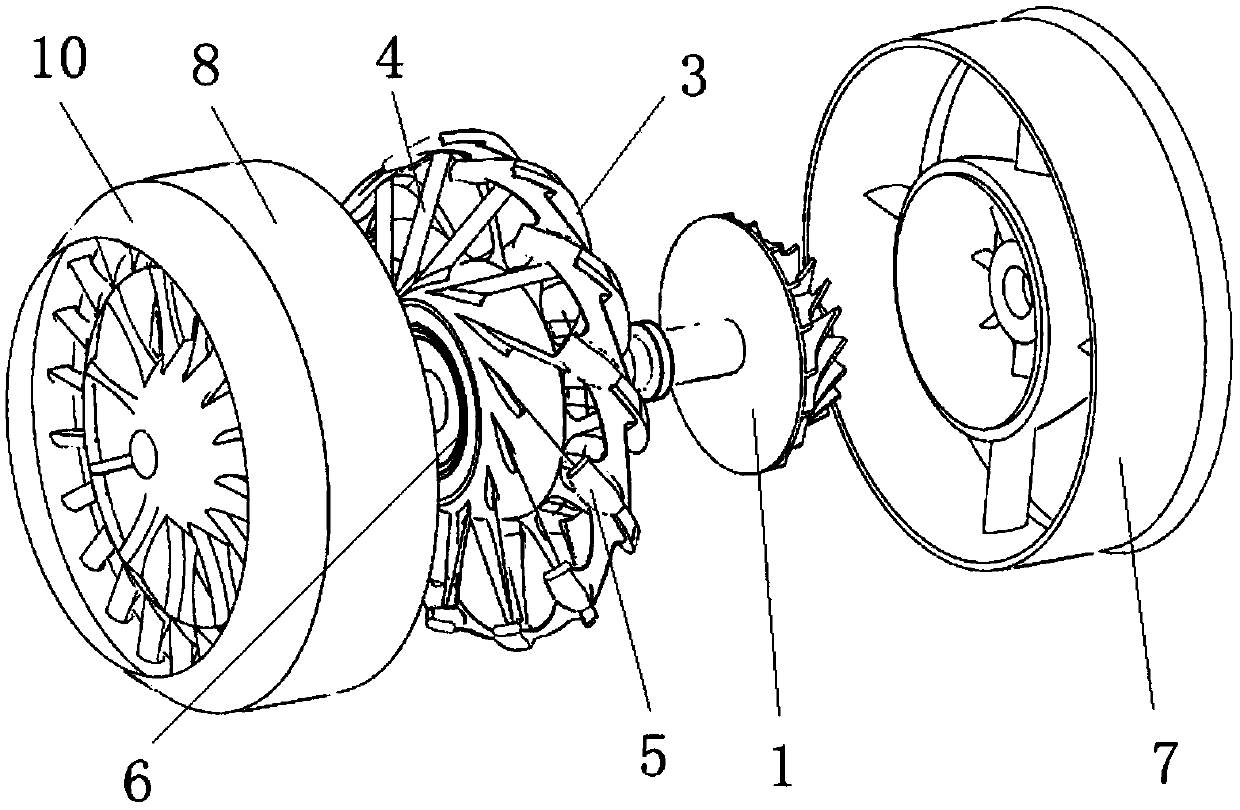

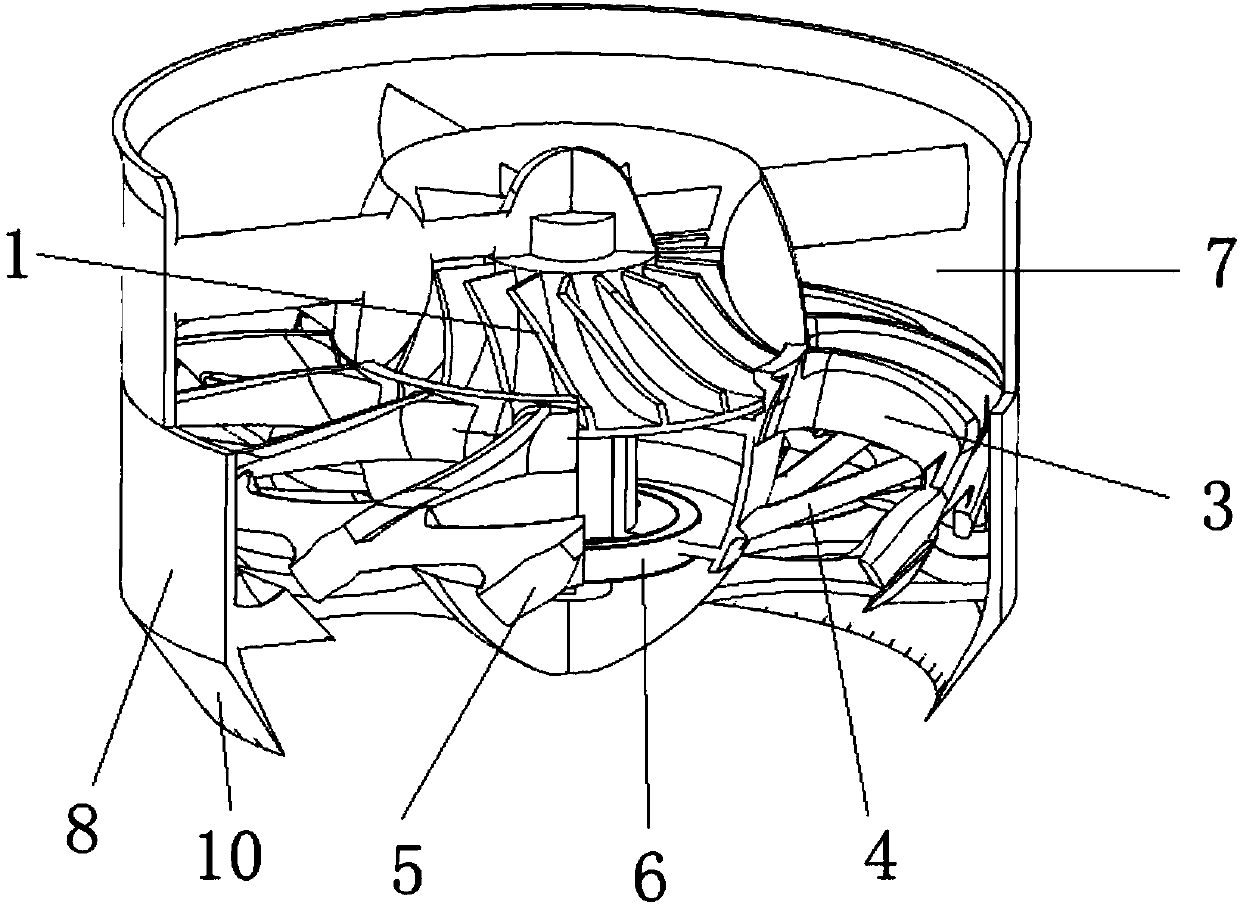

PendingCN108518289AIncrease profitReduce fuel consumptionGas turbine plantsJet propulsion plantsCombustion chamberGas compressor

The invention discloses a blade tip ejecting self-driven wheeled fan engine. The blade tip ejecting self-driven wheeled fan engine comprises a hollow fan with a combustion chamber being arranged at ablade tip. High-pressure gas is provided by a central gas compressor, flows to the blade tip combustion chamber along hollow blades to be combusted and then is ejected out to the lateral rear portion,and the fan is driven by reactive force of jet flow to rotate; and the rotating fan drives the central gas compressor through a planet gear device in a rear casing, and thus circulation operation ofthe whole engine is established. Through the bicycle-wheel-like design that the fan blades, an oil supply pipe and a circumferential band of an outer ring of the fan are combined together, the good stiffness and strength can be maintained under high speed rotation. Compared with existing high-bypass-ratio turbofan engines, a turbine part is omitted, and the structure is lighter and more compact; compared with existing propeller tip ejecting rotor wings of helicopters, the thermal efficiency of the engine is higher; and meanwhile, due to the fact that the turbine is omitted, thermal limiting ofturbine materials is avoided, and the temperature of the combustion chamber of the engine can be further increased compared with that of existing engines.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Gasoline engine EGR stratified charge system based on flow guiding plate

InactiveCN103670815ALarge openingReduce lossesNon-fuel substance addition to fuelExhaust gas recirculationCombustion chamberGasoline

The invention discloses a gasoline engine EGR stratified charge system based on a flow guiding plate, and belongs to the technical field of engines. An exhaust pipe is fixedly connected with an intake manifold through a bypass pipe, an EGR valve, an EGR cooler and an EGR loop. An airflow cavity in the air inlet side of a cylinder cover part is respectively and correspondingly connected with an airflow cavity of an air inlet diverting cavity part, an air inlet of the cylinder cover part corresponds to branch pipes of the air inlet diverting cavity part, a throttle valve is fixedly connected with an intake manifold hole through the intake manifold, and the exhaust branch pipes of the exhaust pipe are correspondingly connected with four exhaust ways of the cylinder cover part respectively. Waste gas and fresh air can be prevented from being early mixed outside a combustion chamber and can also be prevented from being accumulated and mixed when an air inlet door is closed, the equipressure air intake of the fresh air and the pressure can be achieved, the mixed degree of the fresh air and the waste gas can be reduced, the load control of an engine can be achieved, the circulation thermal efficiency of a gasoline engine is improved, high EGR efficiency can be achieved, and the combustion economical efficiency of the gasoline engine is effectively improved.

Owner:JILIN UNIV

Rocket-based combined cycle engine based on detonation and detonation principle and application method

ActiveCN114165357AMeet job requirementsMeet the needs of multi-modal combined propulsionTurbine/propulsion fuel flow conduitsGas turbine plantsRamjetCombustion chamber

The invention discloses a rocket-based combined cycle engine based on the deflagration and detonation principle and an application method. The rocket-based combined cycle engine based on the deflagration and detonation principle comprises a center cone, a shell, a support and a fuel supply system. By forming a double-combustion-chamber and double-spray-pipe structure, the invention provides a non-completely closed circulating propellant supply system, a liquid rocket engine and a ramjet engine based on the detonation and detonation principle are organically combined, and the working requirements of low-speed starting, wide-speed-domain / airspace-range flight and ultra-supersonic-speed cruising can be met; the system has the characteristics of large specific impulse, strong robustness, high circulating thermal efficiency and compact layout.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Rankine cycle system and fluid working medium material construction method thereof

ActiveCN106528900AImprove cycle thermal efficiencyImprove effective utilizationSteam engine plantsSpecial data processing applicationsChemical synthesisEngineering

The invention relates to a Rankine cycle system and a fluid working medium material construction method thereof. The method comprises the steps of selecting out genes with high fluid working medium safety contribution values and low pollution contribution values to establish a gene database; determining a boundary condition of a thermal power generation circulation system and a thermophysical parameter range of a required fluid working medium material, screening out various genes in the gene database, performing combination and replacement on the genes, and forming a compound fluid working medium, wherein various thermophysical parameter values of a compound constructed by the selected genes are higher than or equal to those of CO2; determining a target function of the thermal power generation circulation system; calculating the thermophysical parameters of the compound fluid working medium, and selecting out the compound fluid working medium which meets the target function of the thermal power generation circulation system; and performing chemical synthesis feasibility verification on the compound fluid working medium, and applying the compound fluid working medium which passes the verification to the thermal power generation circulation system engineering. The system and the method can be widely applied to the thermal power generation circulation system.

Owner:CHINA NAT OFFSHORE OIL CORP +2

System and method for generating steam by directly utilizing sensible heat of high-temperature sintering ore material

InactiveCN102588933ASmall footprintHeat transfer between the high-temperature mineral material and the steam generator heating tubeEnergy industryIncreasing energy efficiencyEvaporationConvection heat

The invention discloses a system and a method for generating steam by directly utilizing sensible heat of a high-temperature sintering ore material. The system mainly comprises a steam generator which is placed under a discharge port of the high-temperature sintering ore material of a sintering machine. The method comprises the following steps: the sintering ore material at the temperature of about 1000 DEG C is discharged from the sintering machine and is crushed through a crusher, and the sintering machine falls into a furnace hearth of a steam generator and passes through an overheat steam pipe, a heater water pipe and a vertical evaporation pipe which are arranged in the furnace hearth from top to bottom; the sintering ore material is discharged from the bottom after being cooled to be below 150 DEG C through direct contact heat conduction of the sintering ore material and a be-heated pipe, heat radiation and convection heat transfer of air flow which is sucked by an exhaust fan and is heated through a sintering ore material layer in the furnace hearth from bottom to top; the water and the steam in the pipe are heated to generate overheat steam at the temperature of over 500 DEG C for power generation; and finally, the cooling of the high-temperature sintering ore material is completed in one device and the overheat steam is generated by utilizing sensible heat. The system and the method have compact structure, high utilization ratio of sensible heat and wide energy-saving application prospect in the field of metallurgical industry.

Owner:熊天渝

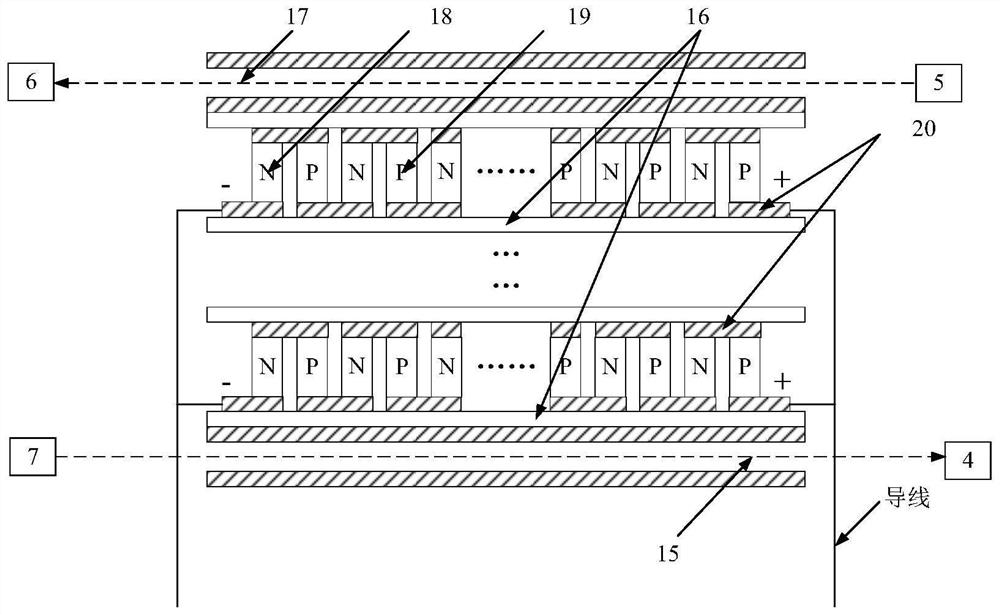

Closed Brayton cycle-semiconductor temperature difference combined power generation system for aircraft

InactiveCN111953232AImprove cycle thermal efficiencyImprove power generation efficiencyAircraft navigation controlTurbine/propulsion engine coolingBrayton cycleCold side

The invention provides a closed Brayton cycle-semiconductor temperature difference combined power generation system for an aircraft. The system comprises a fuel tank, a fuel electric pump, a semiconductor temperature difference power generation device, a fuel heat exchanger, a high-temperature heat exchanger, a cooler, a gas compressor, a turbine and a power generator. The fuel electric pump is connected with the cold side inlet of the cooler, the cold side outlet is connected with the cold side inlet of the semiconductor thermoelectric power generation device, and the cold side outlet is connected with the inlet of the fuel heat exchanger. The outlet of the fuel heat exchanger is connected with a hot side inlet of the high-temperature heat exchanger, the hot-side outlet of the cooler is connected with the compressor, and the compressor is connected with the cold-side inlet of the high-temperature heat exchanger. The cold-side outlet is connected with the turbine, and the turbine is connected with the hot-side inlet of the cooler. The hot side outlet of the high-temperature heat exchanger is connected with the hot side inlet of the semiconductor thermoelectric power generation device, and the hot side outlet of the semiconductor thermoelectric power generation device is connected with the fuel injector. According to the present invention, the high-temperature heat energy of thehypersonic aircraft is fully converted into the electric energy through gradient utilization of energy.

Owner:HARBIN INST OF TECH

Multistage cascaded steam Rankine combined cycle power generation device

PendingCN104727870APromote circulationAbsolute Efficiency Value ImprovementIncreasing energy efficiencySteam engine plantsSteam condensationLoad following power plant

The invention relates to a multifunctional cascaded steam Rankine combined cycle power generation device. A multistage cascaded mode including a high-voltage end Rankine cycle, a middle-voltage end Rankine cycle and a low-voltage end Rankine cycle is adopted, discharged latent heat of vaporization during the vapor condensation of the high-voltage end Rankine cycle and the middle-voltage end Rankine cycle is recycled efficiently and is used for electricity generating of a Rankine cycle system, load of a condenser of a traditional steam Rankine cycle system is efficiently reduced over an absolute value of 20 percent, the system optimization technology is adopted, and the cycled absolute heating efficiency of the whole system can be improved by over 5 percent. The multifunctional cascaded steam Rankine combined cycle power generation device can be used for energy conservation transformation of an existing reheat cycle steam Rankine cycle unit and can also be used for the design and construction of a new-built unit, and the economic benefit, social benefit and environmental protection benefit are remarkable.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

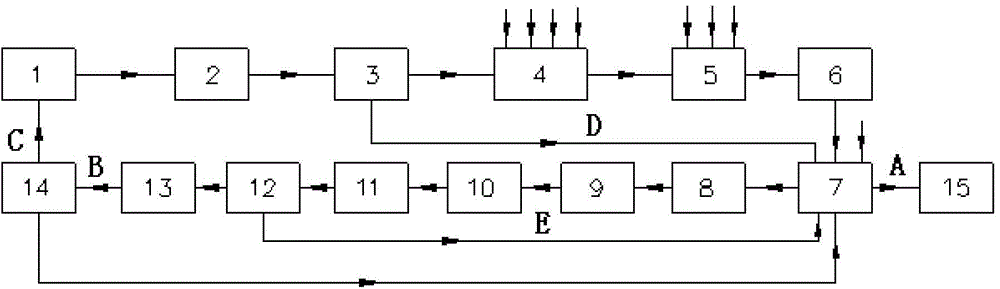

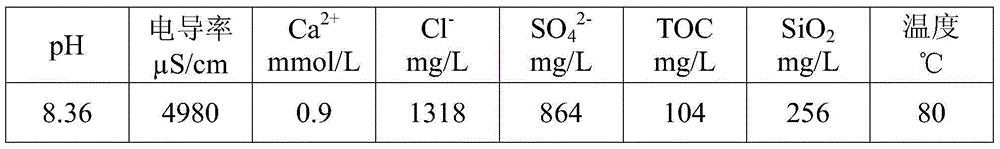

System and method of power station boiler for treating and recycling heavy oil wastewater

ActiveCN104671607AEfficient use ofReuse of waste heatTreatment using aerobic processesScale removal and water softeningEngineeringSuperheated steam

The invention discloses a system and method of a power station boiler for treating and recycling heavy oil wastewater. The system comprises a heavy oil thermal recovery well, a silicon removal reactor and a softening reactor which are connected with one another in sequence, wherein the softening reactor is connected with a liquid inlet of an evaporator, a condensed water outlet of the evaporator is sequentially connected with a biological aerated filter and a desalting device, and a water producing outlet of the desalting device is connected with a power station boiler and steam turbine system; a silicon removal medicament dosing opening is formed in the silicon removal reactor, a softening medicament dosing opening is formed in the softening reactor, and a steam exhaust outlet of a steam turbine in the power station boiler and steam turbine system is connected with a heat source inlet of the evaporator; and a superheated steam outlet of the power station boiler in the power station boiler and steam turbine system is connected to the heavy oil thermal recovery well. By adopting the system disclosed by the invention, co-production of water, heat and electricity can be achieved, the heat energy can be effectively used, and the cycle thermal efficiency can be improved.

Owner:XIAN THERMAL POWER RES INST CO LTD +2

Mixture working medium supercritical Brayton cycle photo-thermal power generation system and power generation method

PendingCN111749862AGuaranteed uptimeIncrease flexibilitySolar heating energyFrom solar energyBrayton cyclePower cycle

The invention discloses a mixture working medium supercritical Brayton cycle photo-thermal power generation system and a power generation method. The system comprises a photo-thermal heat source inputsubsystem and a supercritical CO2 and SF6 mixture working medium power cycle power generation subsystem. According to the system and the method, a supercritical CO2 and SF6 mixture is taken as a working medium, and when the temperature of the working medium at an inlet of a main compressor in the photo-thermal power generation system deviates from the supercritical CO2 critical temperature greatly, the power generation efficiency of the photo-thermal power generation system can be improved remarkably. Besides, in the operation process of a cycle system, the flow of the working medium enteringa particle-sCO2 heat exchanger is adjusted through a flow division control valve, the problem about control of the particle-sCO2 heat exchanger in the system on the temperature of the working mediumat a turbine inlet can be effectively solved, and the operation efficiency and the peak regulation flexibility of the whole photo-thermal power generation system are improved remarkably.

Owner:XIAN THERMAL POWER RES INST CO LTD

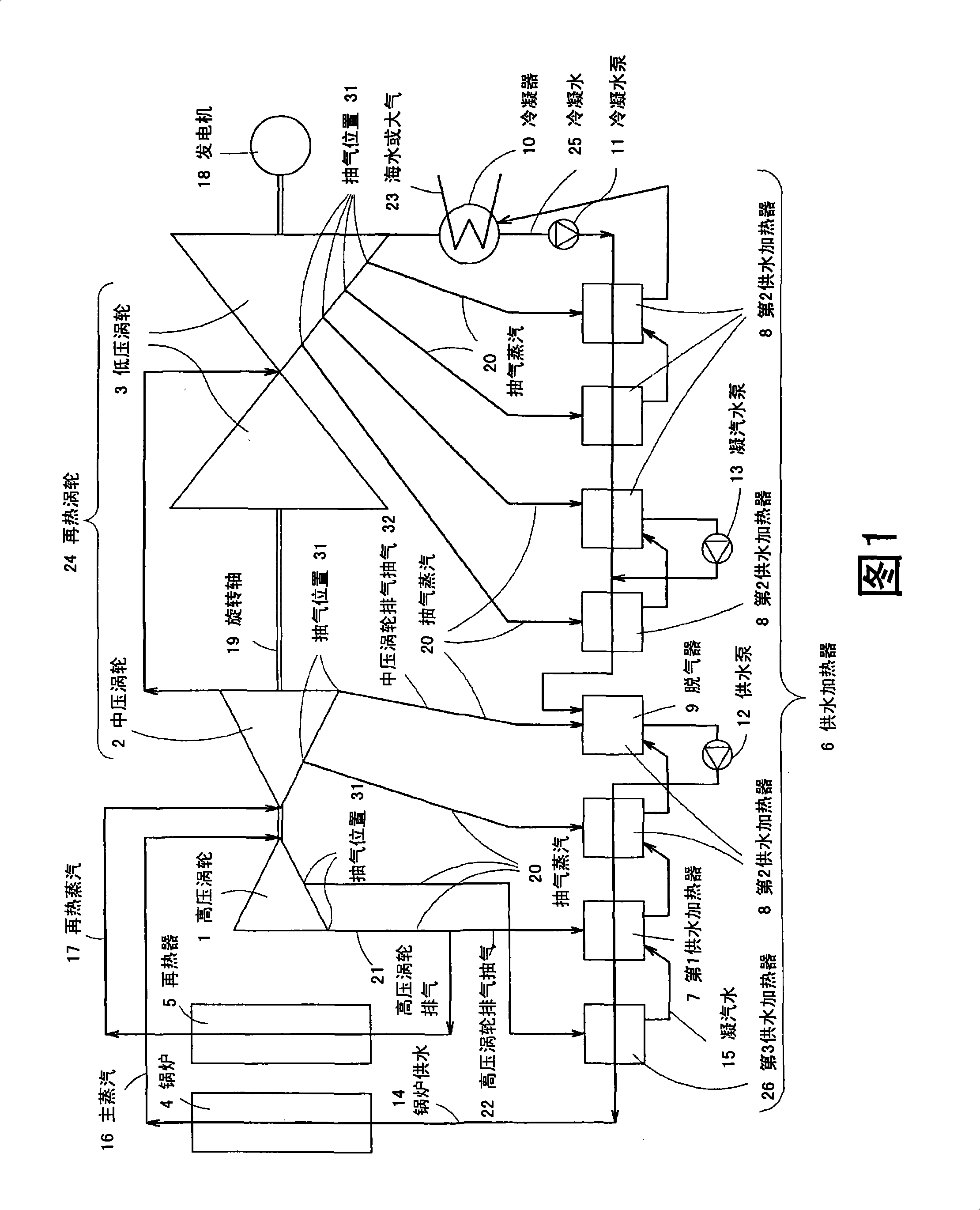

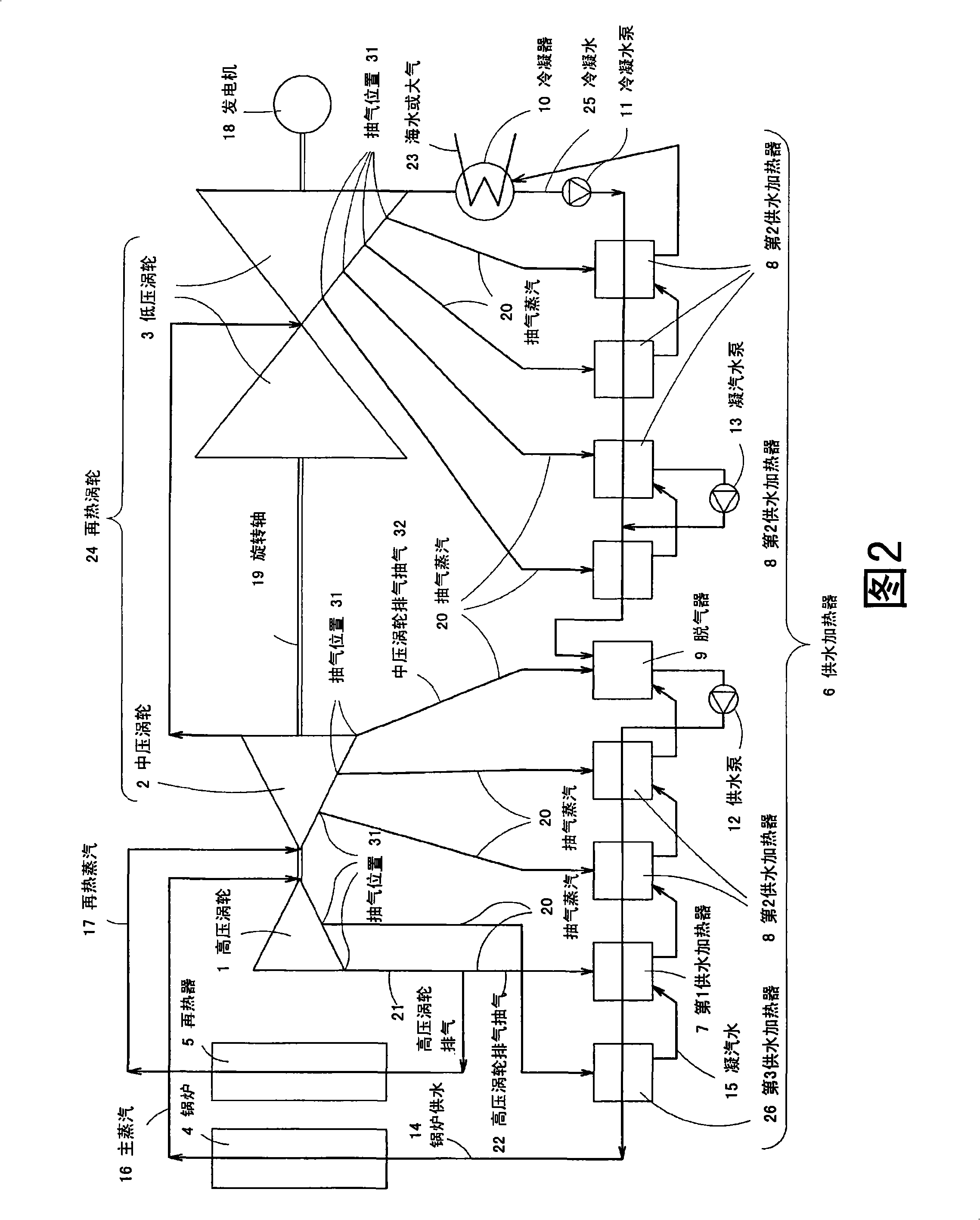

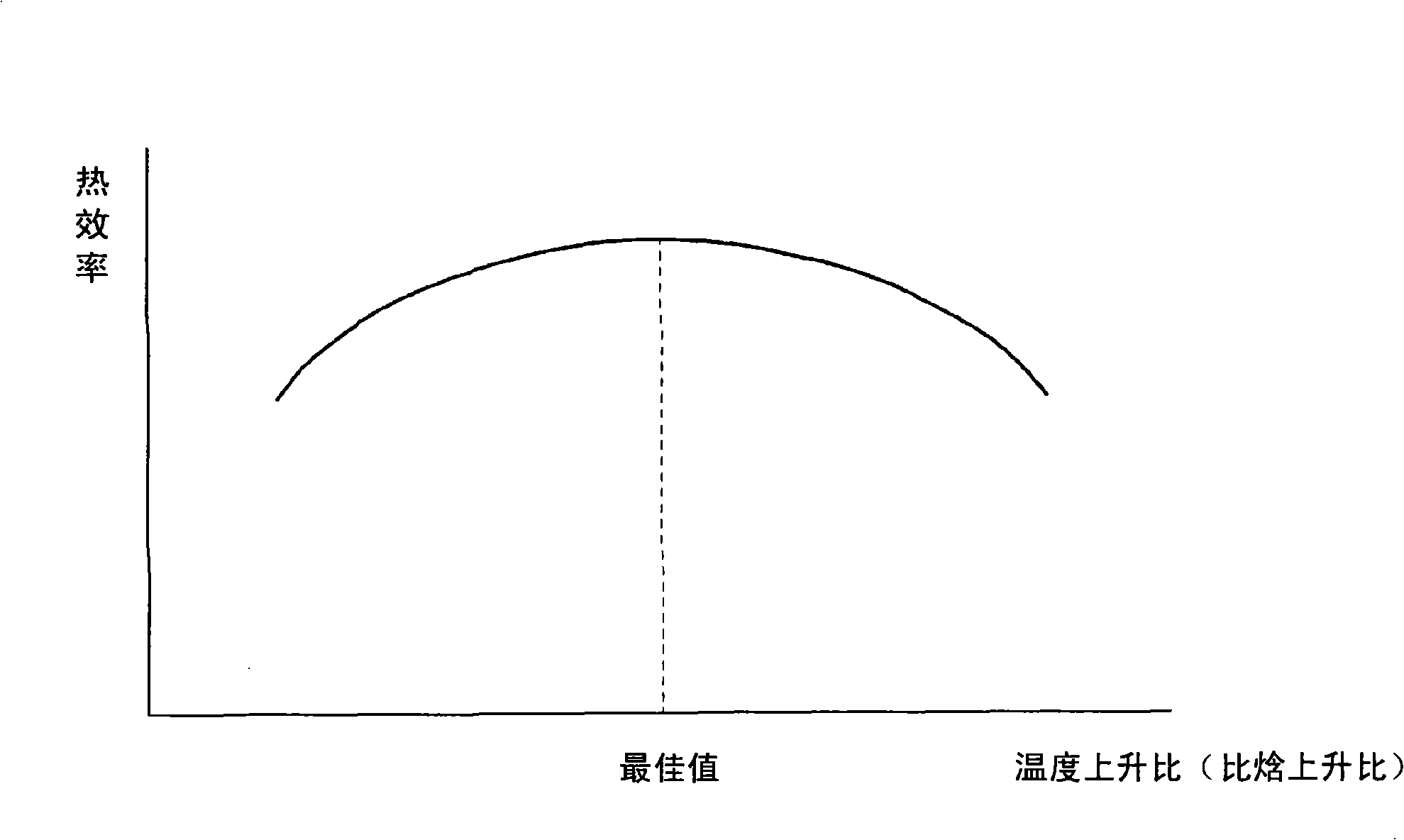

Steam turbine cycle

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com