System and method for generating steam by directly utilizing sensible heat of high-temperature sintering ore material

A technology of high-temperature sintering and superheated steam, which is used in the fields of cooling high-temperature solid materials and sensible heat recovery and utilization, can solve the problems of high energy consumption, low heat transfer intensity, complicated piping system, etc., so as to improve cycle thermal efficiency and heat transfer intensity. , the effect of reducing the cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

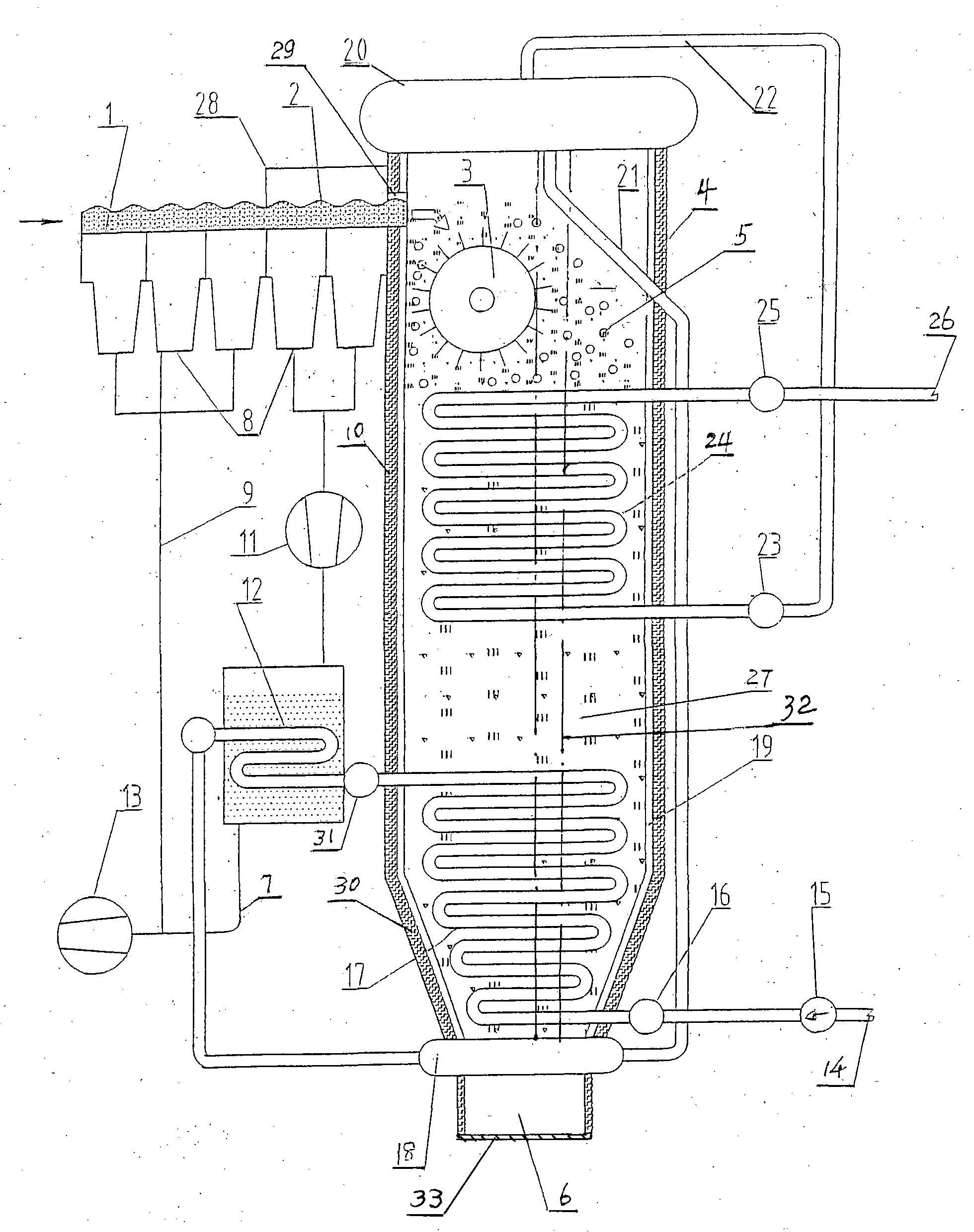

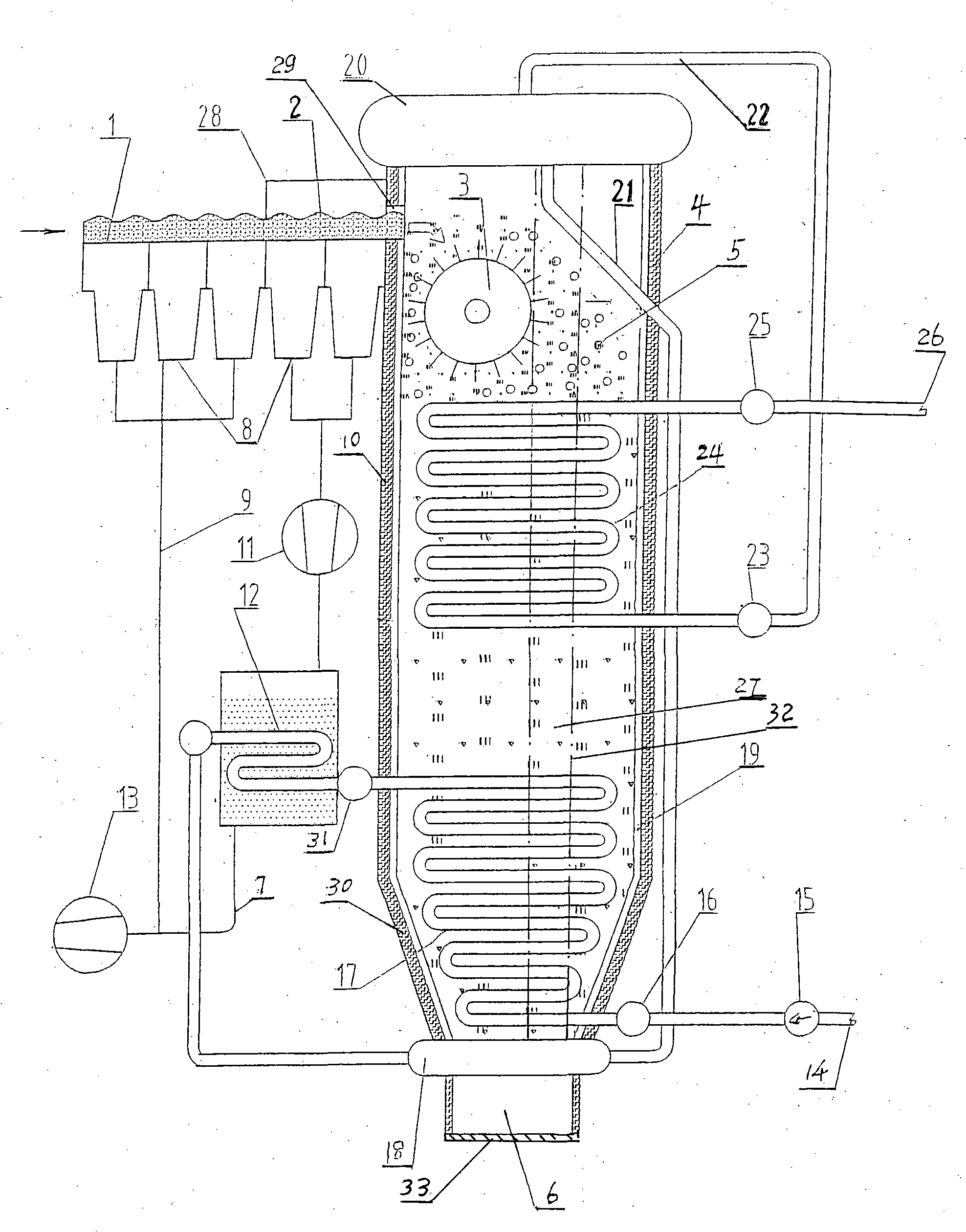

[0022] As shown in the figure, the system mainly includes a sintering machine (1) for transporting mineral materials (2) and a steam generator (4). The steam generator (4) is a three-dimensional hollow body placed in the sintering machine (1) Below the discharging exhaust port (29), the four walls of the steam generator (4) are furnace walls (10), the middle is a furnace (27), and the bottom of the furnace (27) is a funnel that gradually narrows in volume ( 30), the lowermost part is the discharge baffle (33) and the discharge and air inlet (6), the lower part and the upper part of the furnace (27) are respectively equipped with the lower header (18) and the steam drum (20), the furnace (27 ) is equipped with heater water pipe (17), superheated steam pipe (24) and crusher (3) successively from bottom to top, and the bottom furnace (27) of crusher (3) is filled with crushed ore heat source body ( 5), the four walls of the furnace are equipped with water-cooled wall pipes (19) b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com