Power supply semi-trailer of electric drive fracturing equipment

A semi-trailer and fracturing technology, which is applied in the direction of mechanical equipment, vehicles used for freight, tractor-trailer combination, etc., can solve the problems of high fuel consumption per unit power, bulky and heavy rectifier transformers, etc., and achieve saving Rectifier transformer equipment, optimized space layout, the effect of large output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

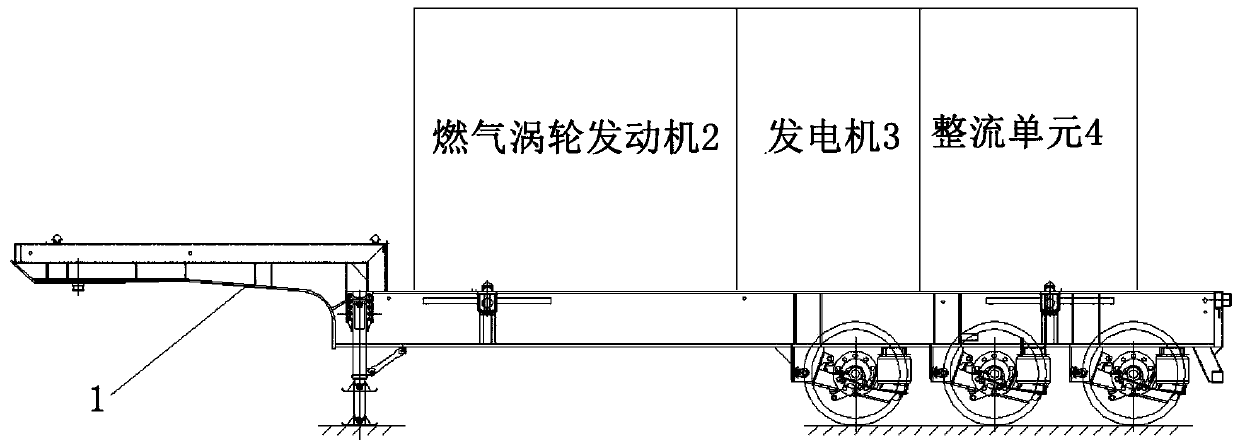

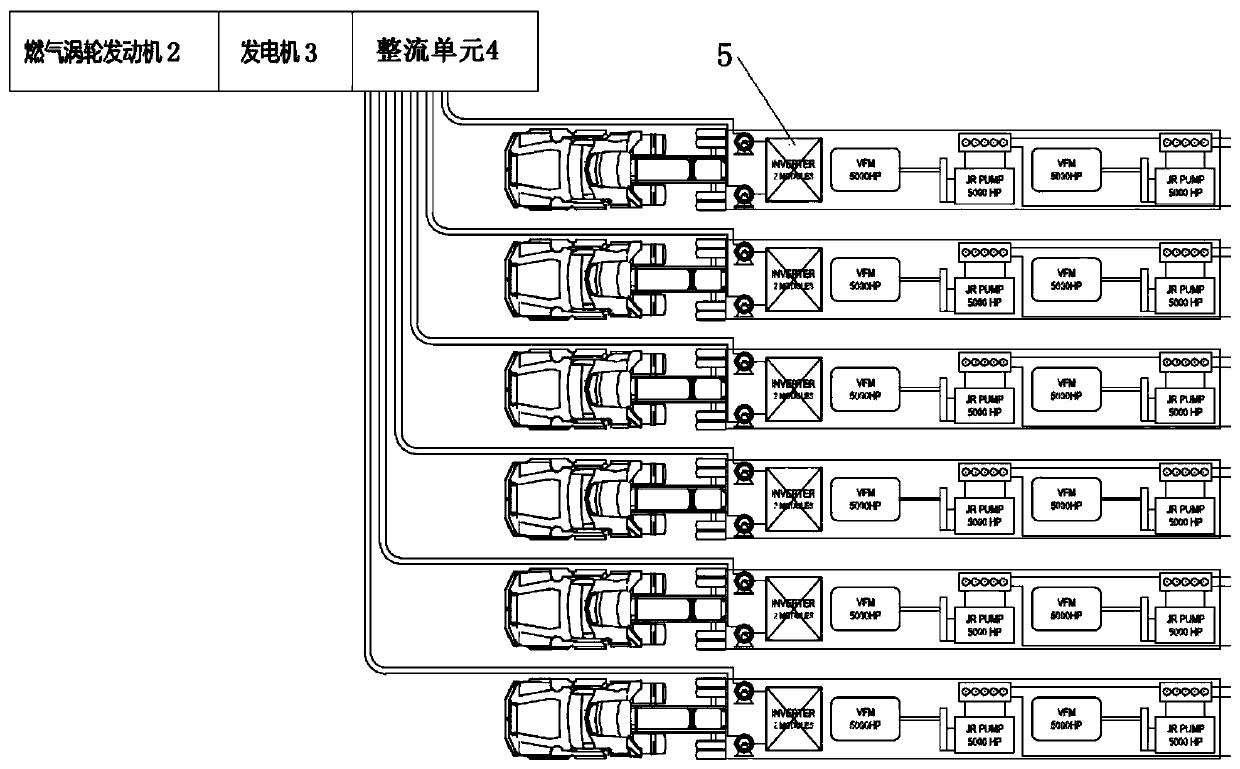

[0023] Examples such as Figures 1 to 2 As shown, a power supply semi-trailer for electric drive fracturing equipment includes a power supply semi-trailer body 1, a gas turbine engine 2, a generator 3, a rectifier unit 4 and an inverter unit, the gas turbine engine 2, generator 3 and The rectification unit 4 is integrated on the power supply semi-trailer body 1. There is one gas turbine engine 2, one generator 3, and multiple sets of rectification units 4. One end of the generator 3 is connected to the gas turbine engine 2, and the other end of the generator 3 One end is connected to the rectification unit 4, multiple sets of rectification units 4 are arranged side by side, and the inverter unit is arranged on the gooseneck of the electric drive semi-trailer body. DC bus connection. The generator 3 is a double-winding generator. The generator 3 directly generates the winding form and voltage required by the rectifying unit 4 . The power supply semi-trailer is a power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com